Patents

Literature

496 results about "Film resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Current collector and application thereof, and pole piece and battery using same

ActiveCN108281662ANo fireThere will be no accidents such as explosionsElectrode carriers/collectorsSecondary cellsElectrical resistance and conductanceFilm resistance

The invention specifically relates to a current collector and application thereof, and a pole piece and a battery using the same, belonging to the field of batteries. The current collector of the invention comprises an insulating layer and a conducting layer, wherein the insulating layer is used for bearing the conducting layer; the conducting layer is used for bearing an electrode active materiallayer; and the normal-temperature film resistance Rs of the conducting layer is no less than 0.016 omega / sq and no more than 420 omega / sq. The current collector provided by the invention can greatlyincrease the short-circuit resistance of the battery in cases of abnormal conditions, allows short-circuit current to be greatly reduced, so heat produced by short circuits is greatly lowered, and heat produced at sites where internal short circuits occur can be totally absorbed by the battery; and thus, the influence of short-circuit damage to the battery is limited to certain points, only pointcircuit break occurs, and the normal operation of the battery in a short period of time is not affected.

Owner:CONTEMPORARY AMPEREX TECH CO

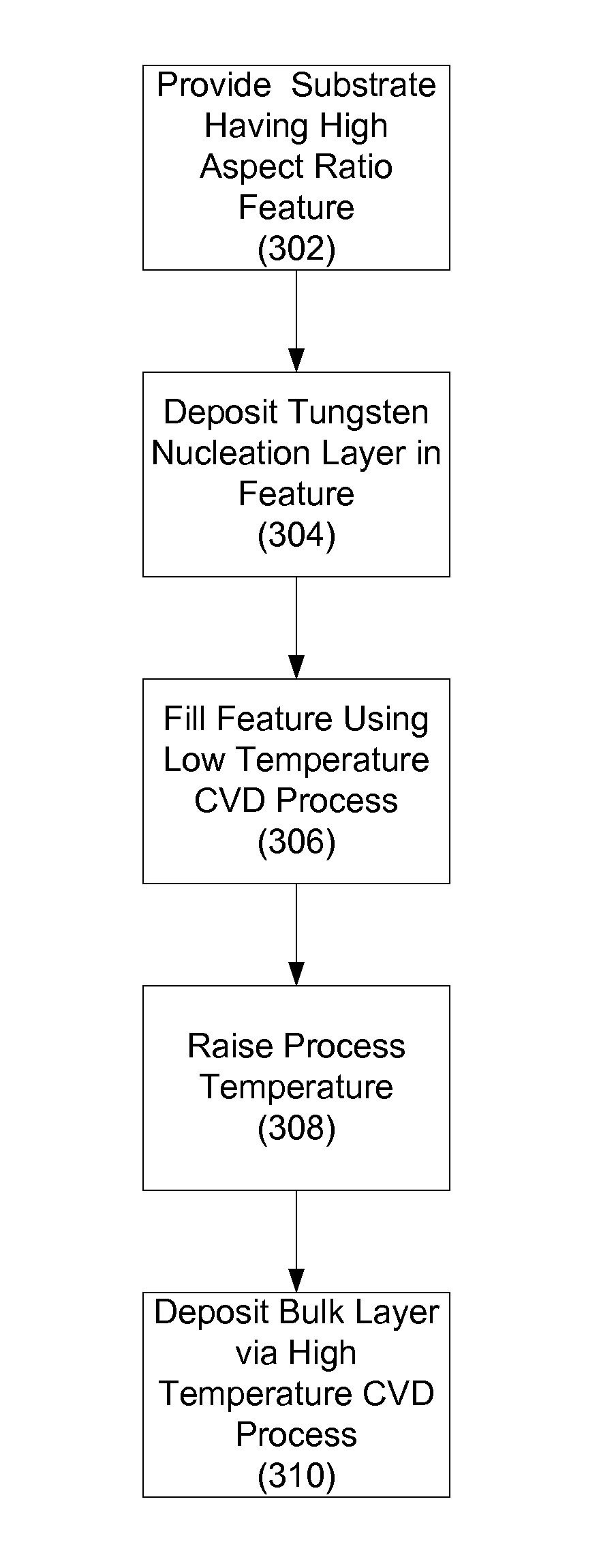

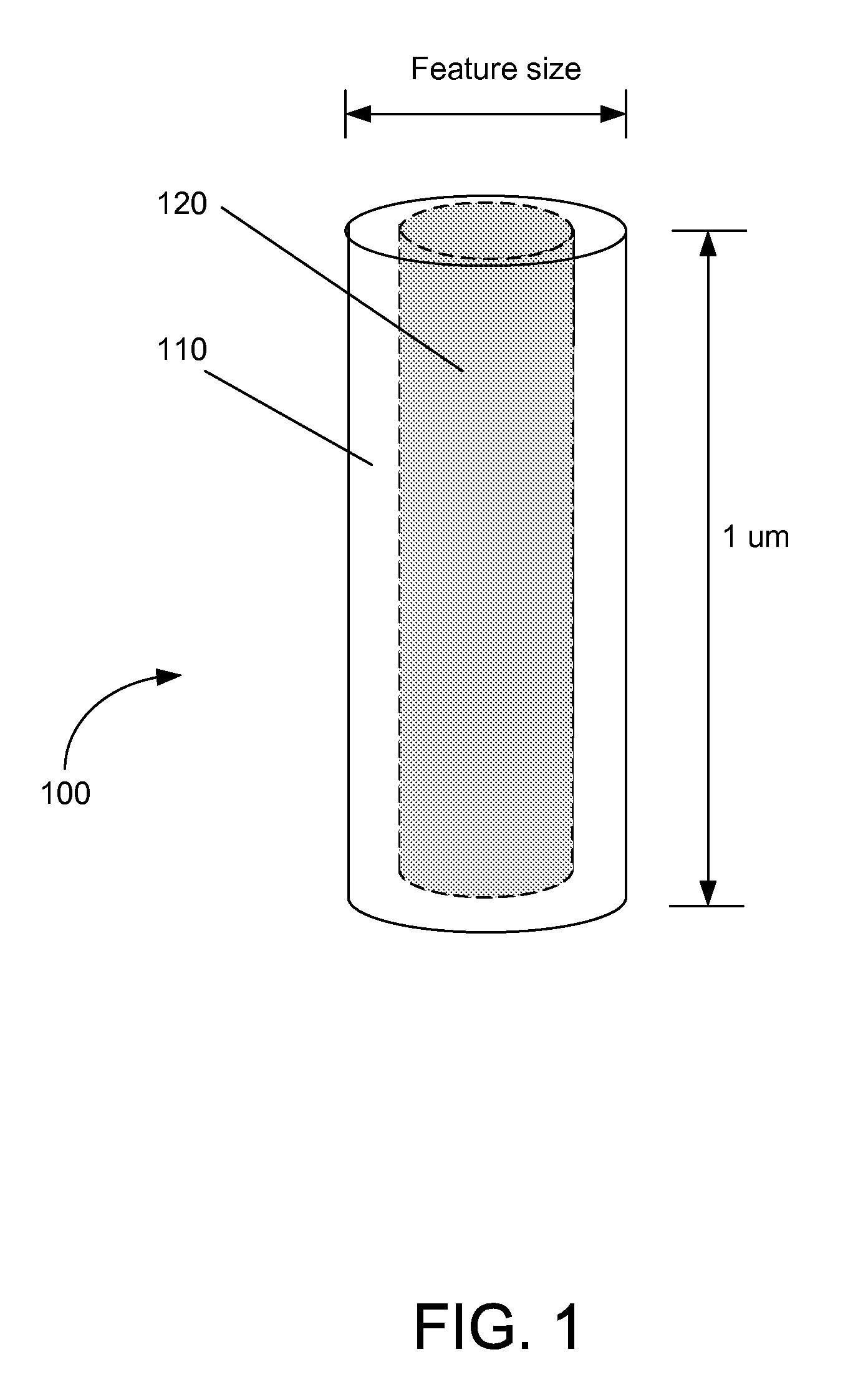

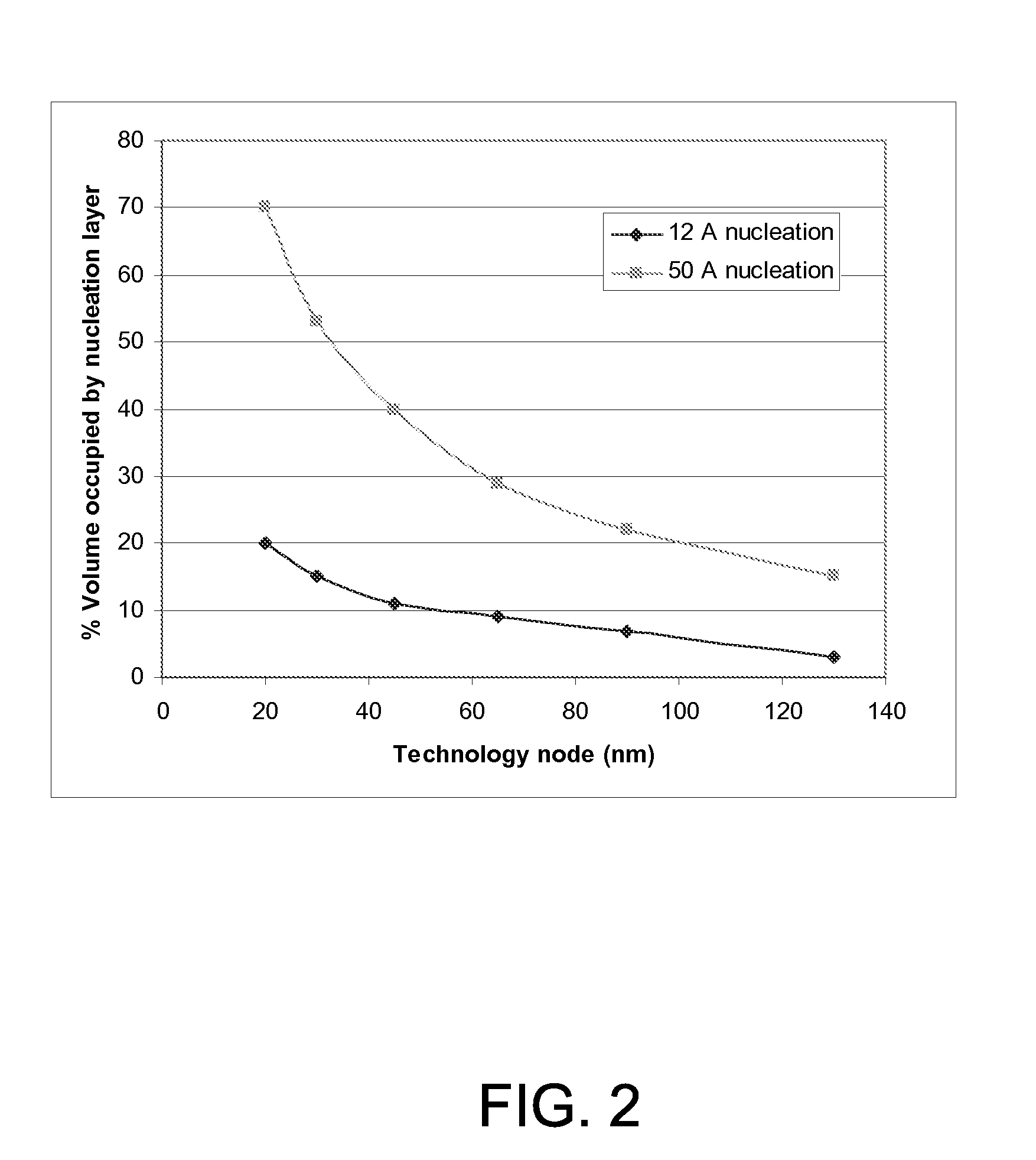

Method for forming tungsten contacts and interconnects with small critical dimensions

InactiveUS20100267230A1High aspect ratio featurePromote migrationLiquid surface applicatorsSemiconductor/solid-state device detailsElectrical resistance and conductanceGas phase

Provided are methods of void-free tungsten fill of high aspect ratio features. According to various embodiments, the methods involve a reduced temperature chemical vapor deposition (CVD) process to fill the features with tungsten. In certain embodiments, the process temperature is maintained at less than about 350° C. during the chemical vapor deposition to fill the feature. The reduced-temperature CVD tungsten fill provides improved tungsten fill in high aspect ratio features, provides improved barriers to fluorine migration into underlying layers, while achieving similar thin film resistivity as standard CVD fill. Also provided are methods of depositing thin tungsten films having low-resistivity. According to various embodiments, the methods involve performing a reduced temperature low resistivity treatment on a deposited nucleation layer prior to depositing a tungsten bulk layer and / or depositing a bulk layer via a reduced temperature CVD process followed by a high temperature CVD process.

Owner:NOVELLUS SYSTEMS

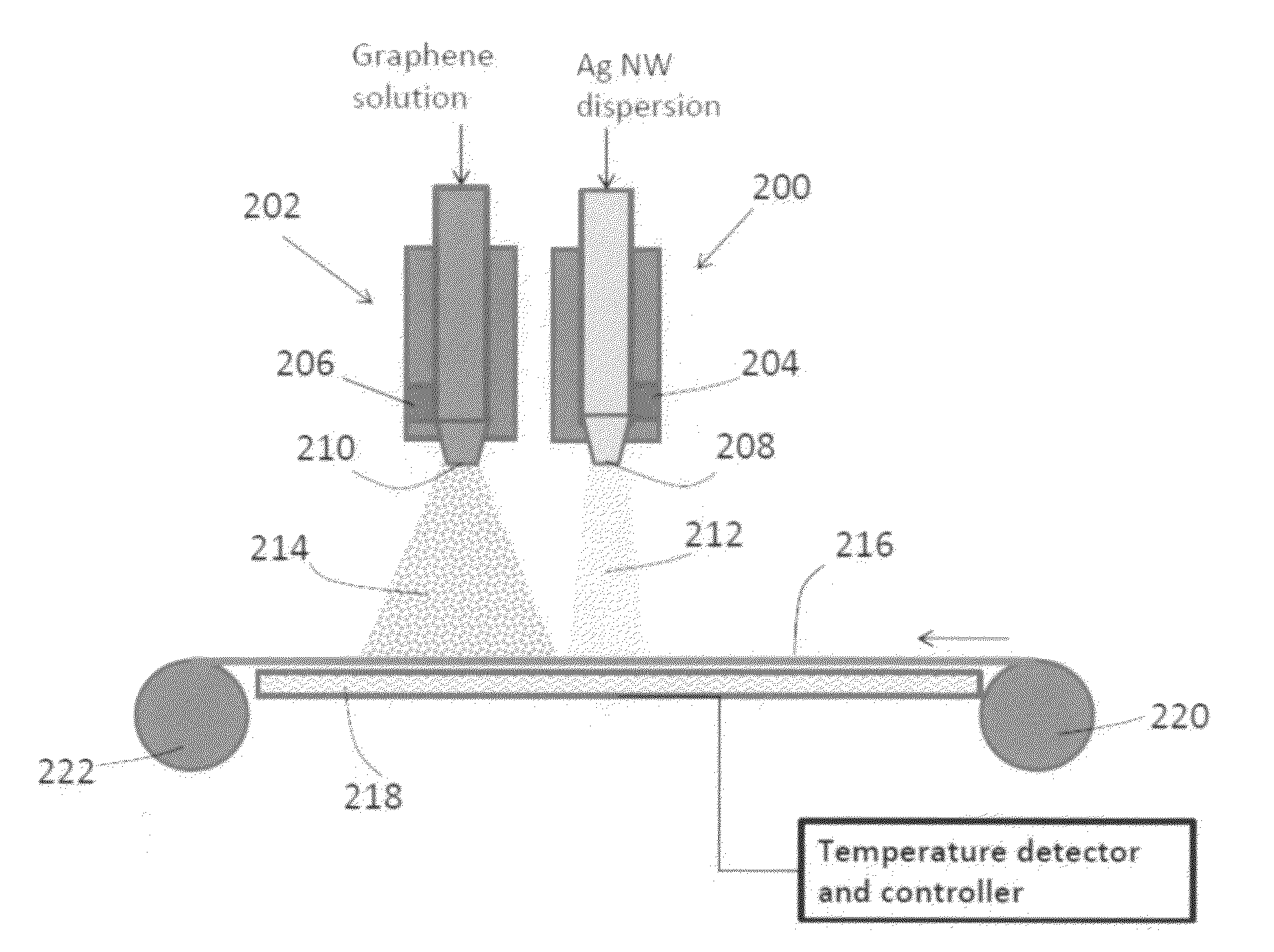

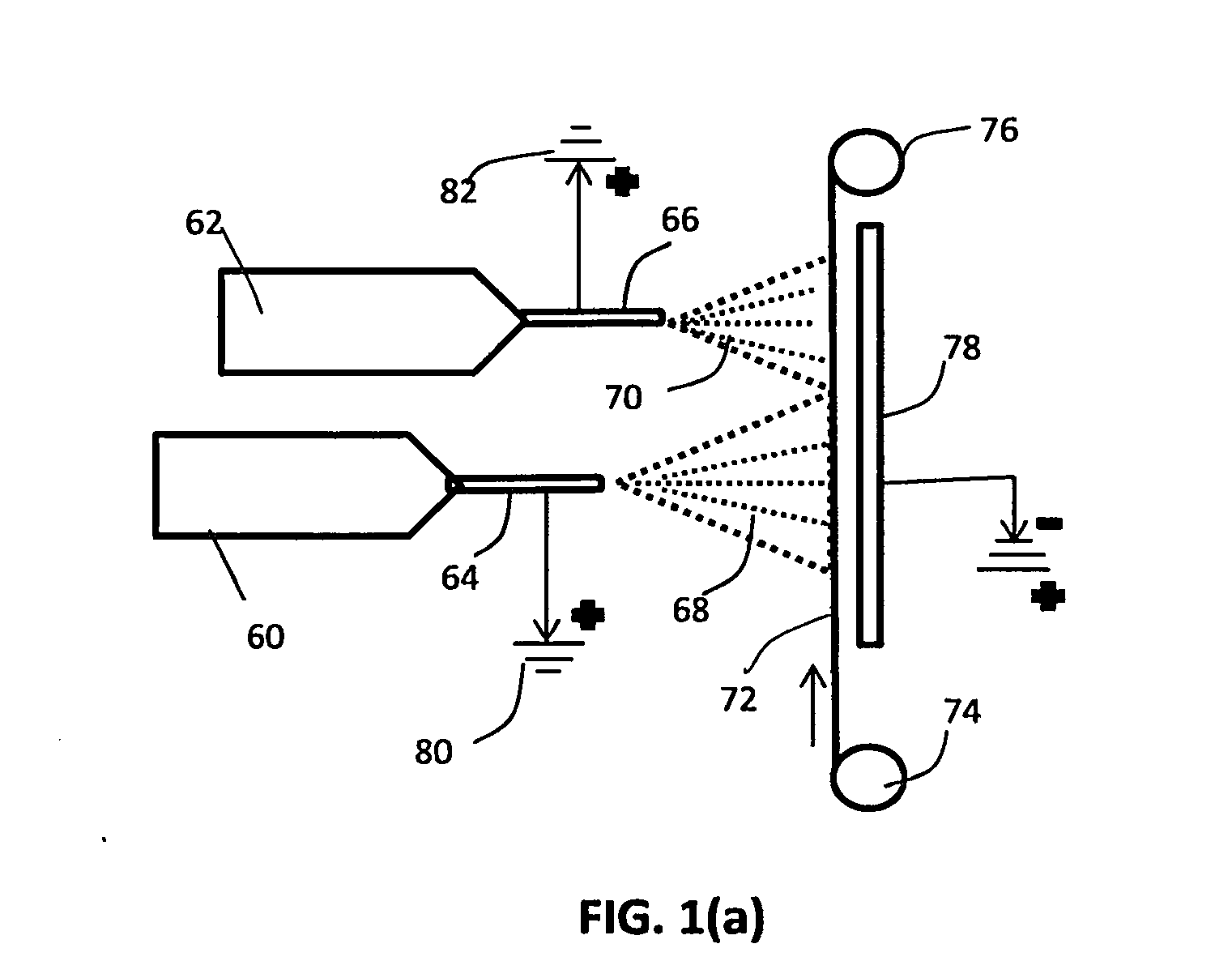

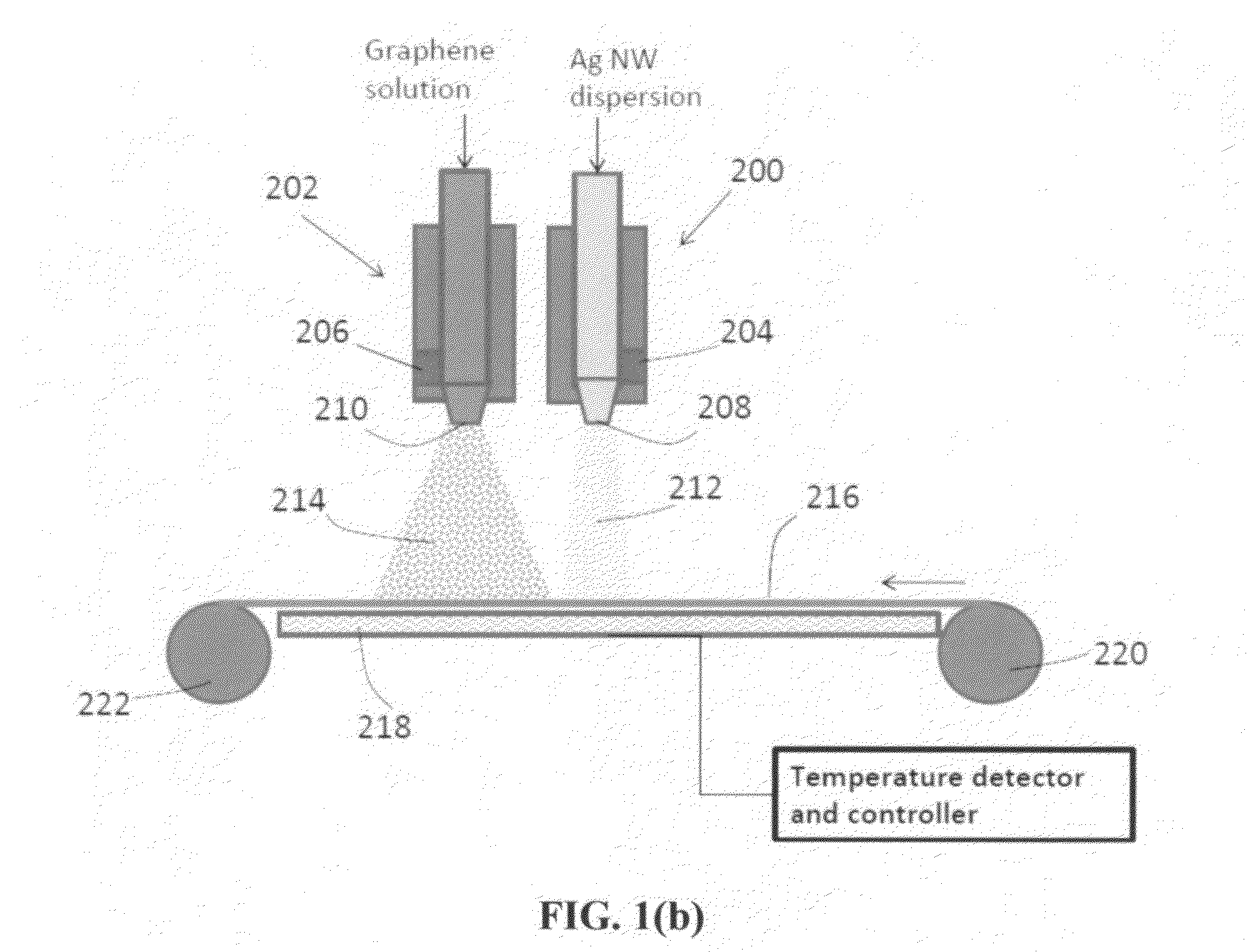

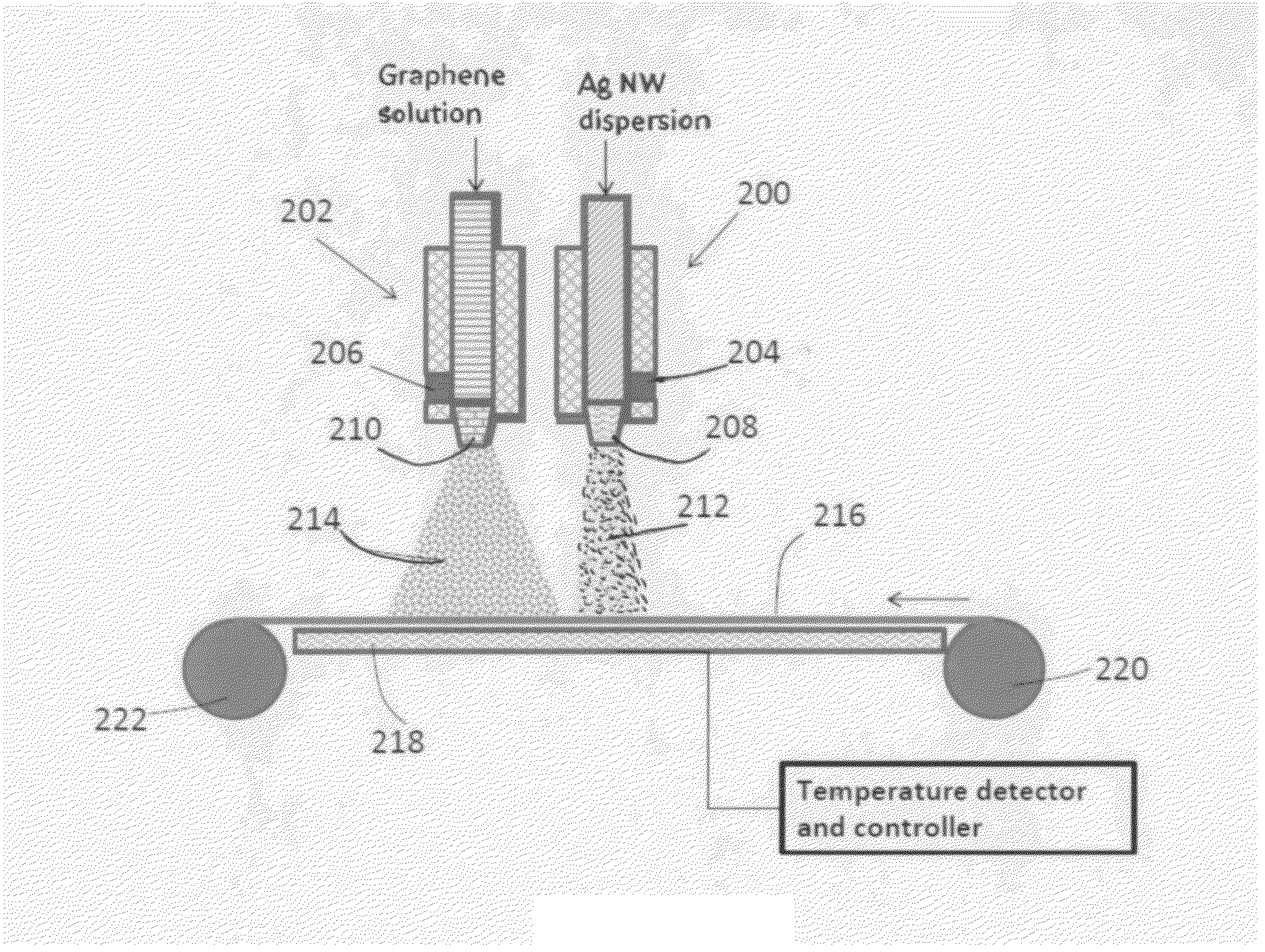

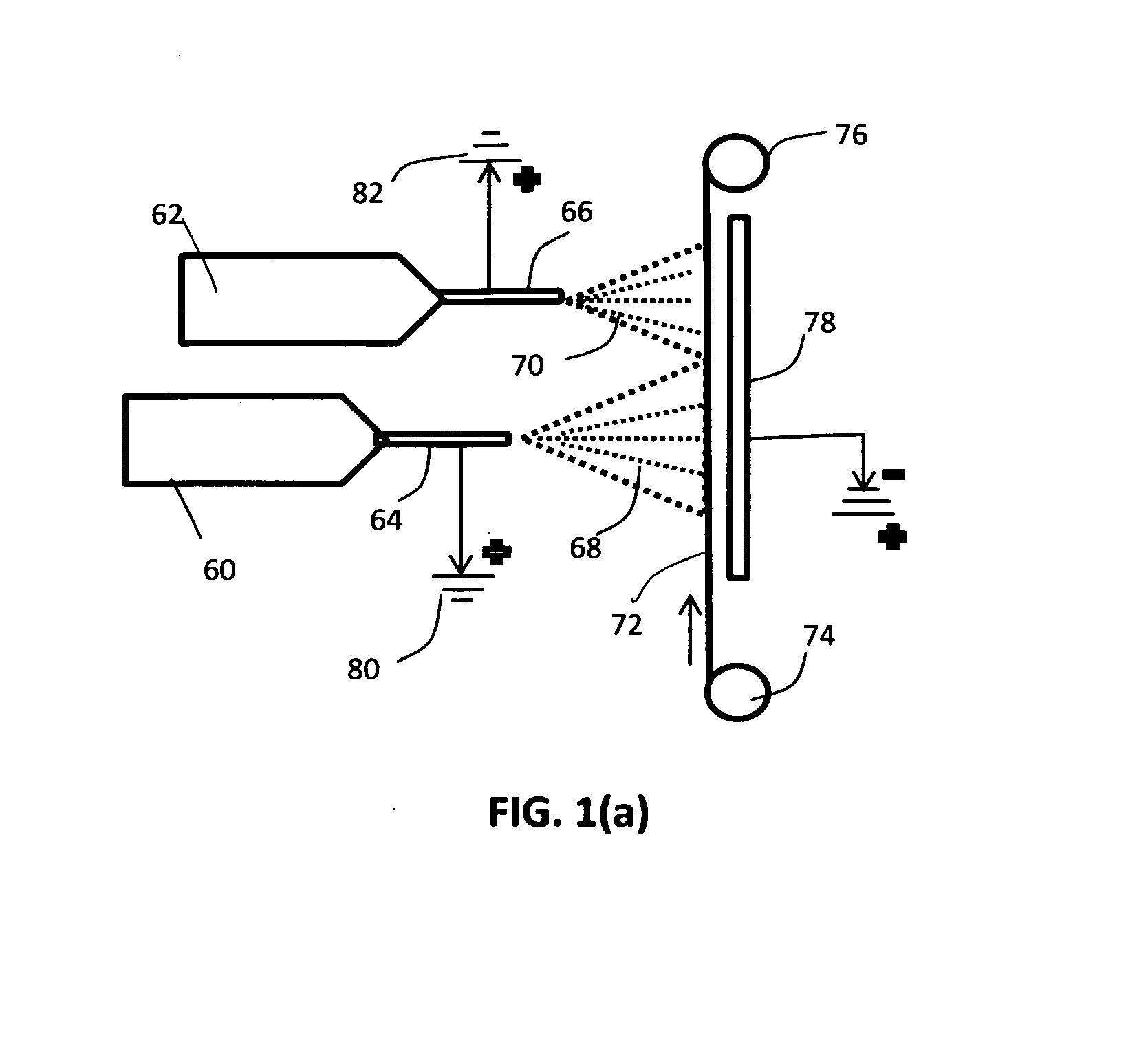

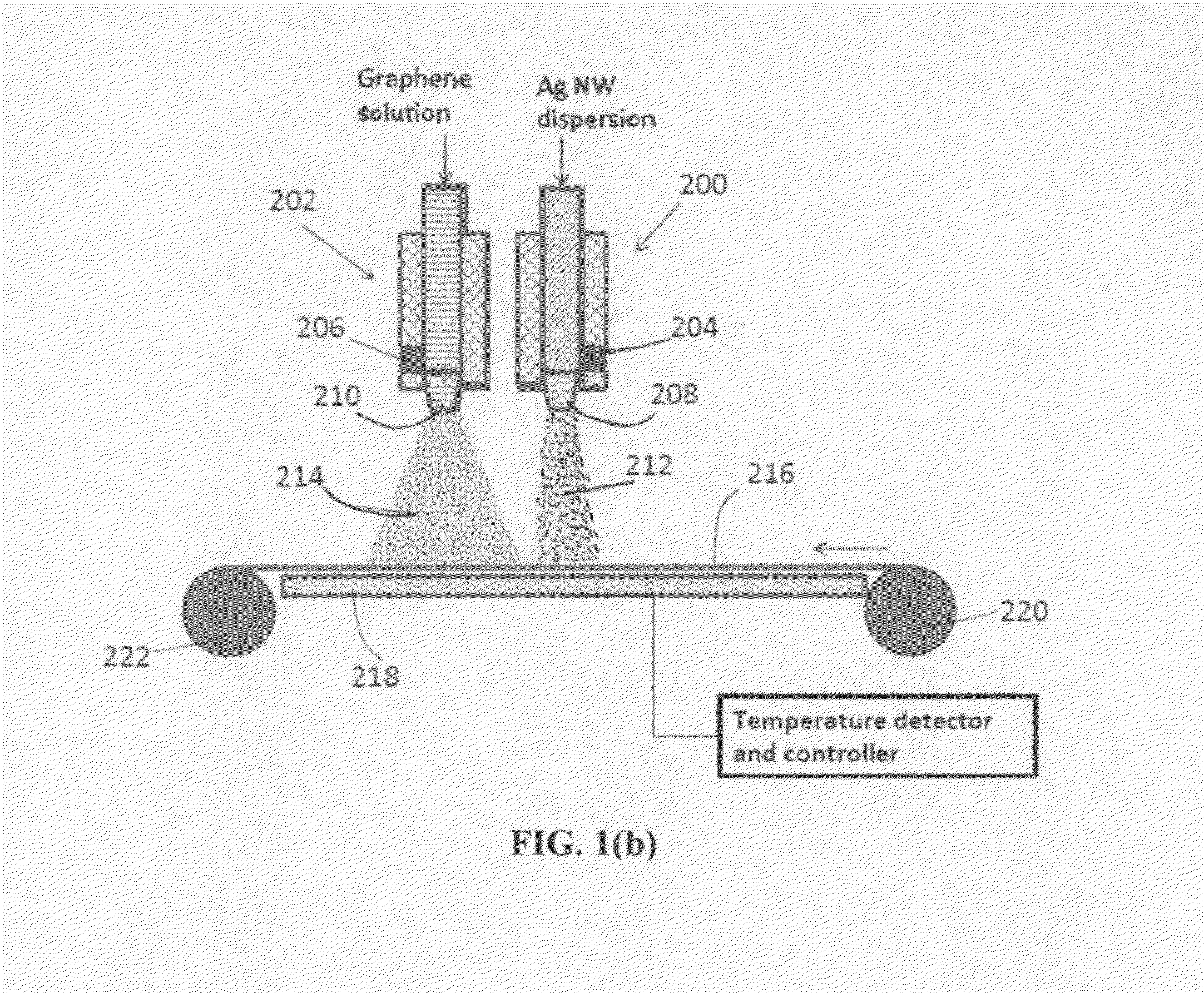

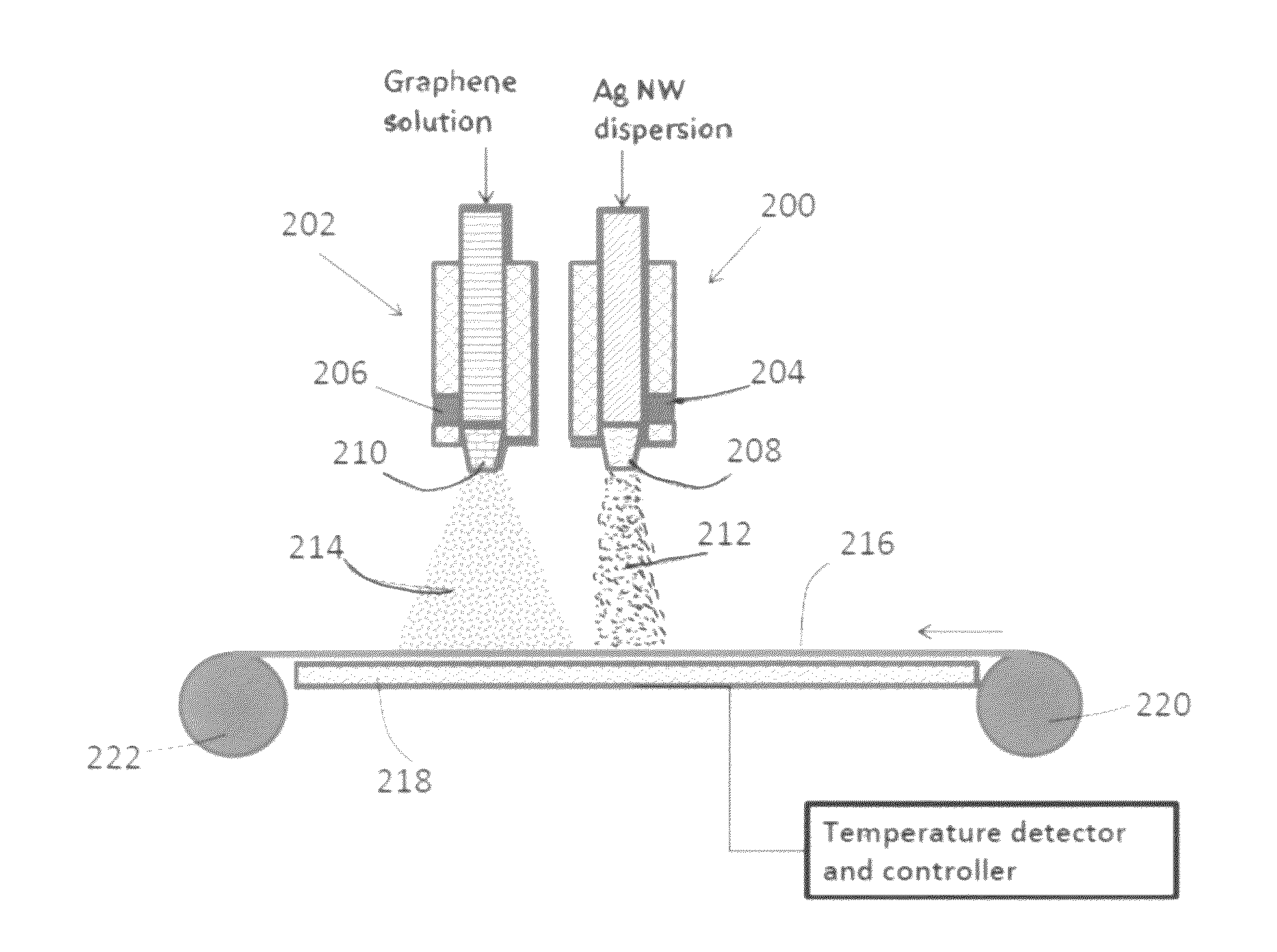

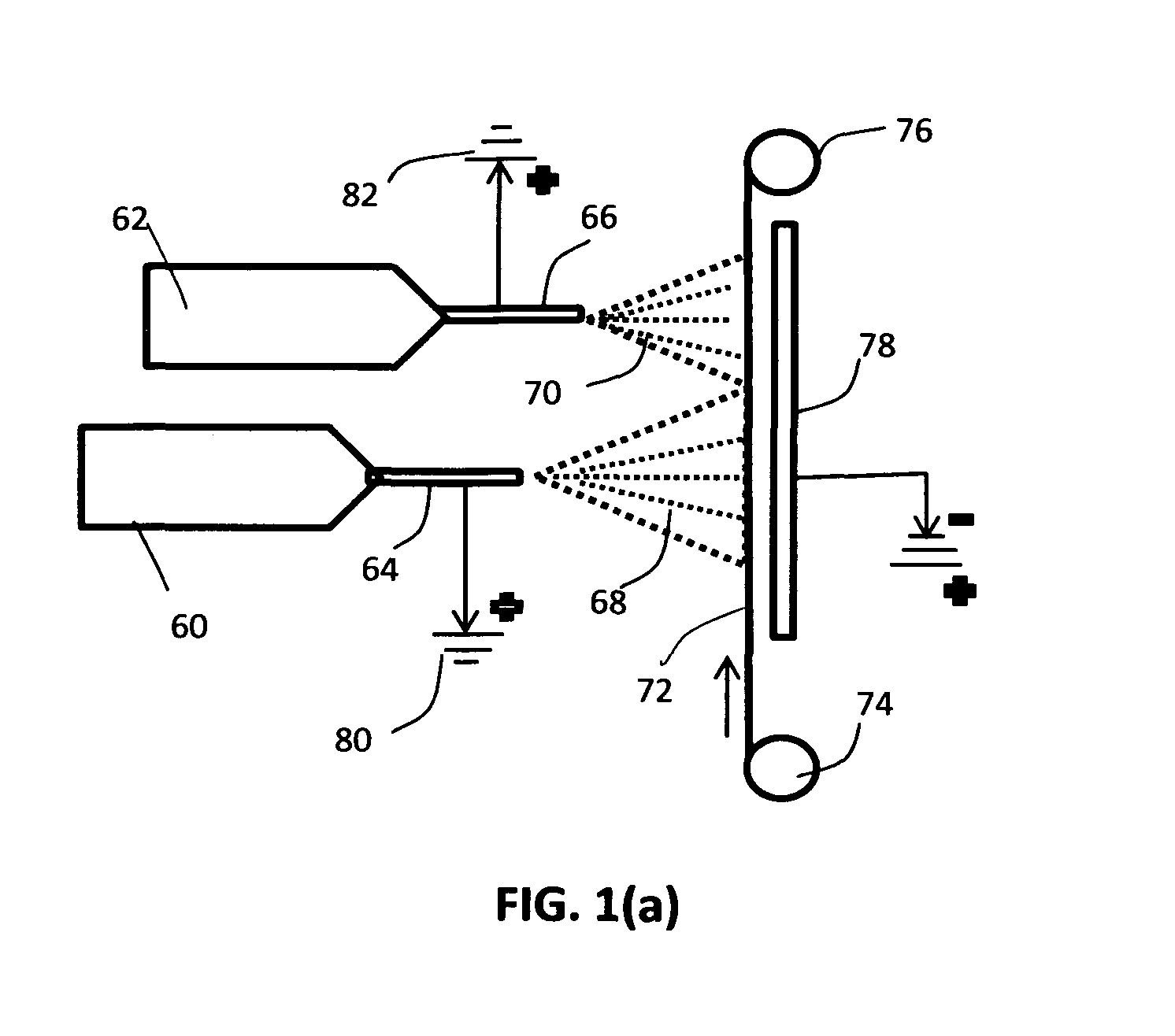

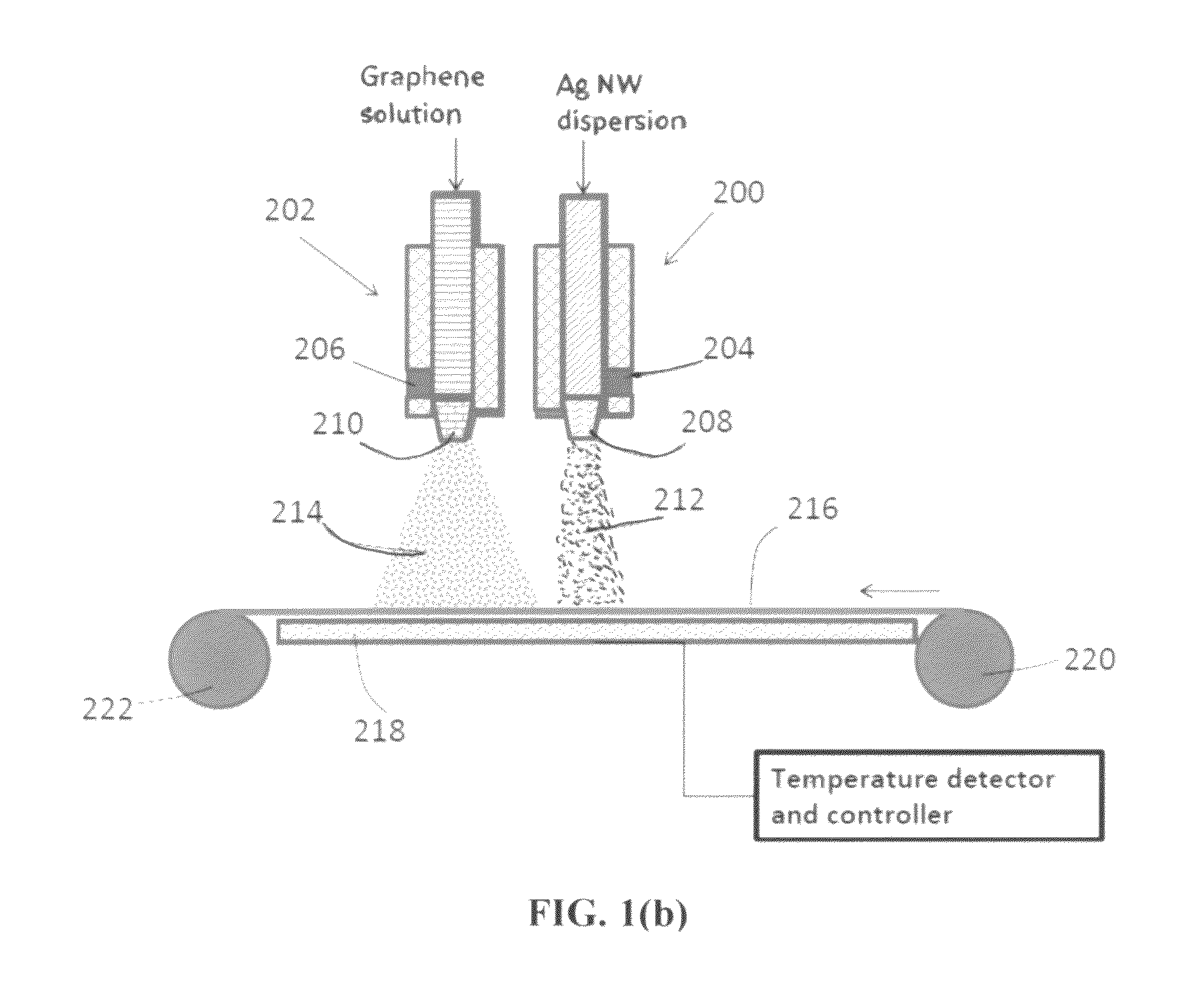

Ultrasonic spray coating of conducting and transparent films from combined graphene and conductive nano filaments

PendingUS20140272199A1Reduce sheet resistanceIncrease speedTransportation and packagingMetal-working apparatusFilm resistanceSpray coating

An ultrasonic spray coating method of producing a transparent and conductive film, comprising (a) operating an ultrasonic spray device to form aerosol droplets of a first dispersion comprising a first conducting nano filaments in a first liquid; (b) forming aerosol droplets of a second dispersion comprising a graphene material in a second liquid; (c) depositing the aerosol droplets of a first dispersion and the aerosol droplets of a second dispersion onto a supporting substrate; and (d) removing the first liquid and the second liquid from the droplets to form the film, which is composed of the first conducting nano filaments and the graphene material having a nano filament-to-graphene weight ratio of from 1 / 99 to 99 / 1, wherein the film exhibits an optical transparence no less than 80% and sheet resistance no higher than 300 ohm / square.

Owner:GLOBAL GRAPHENE GRP INC

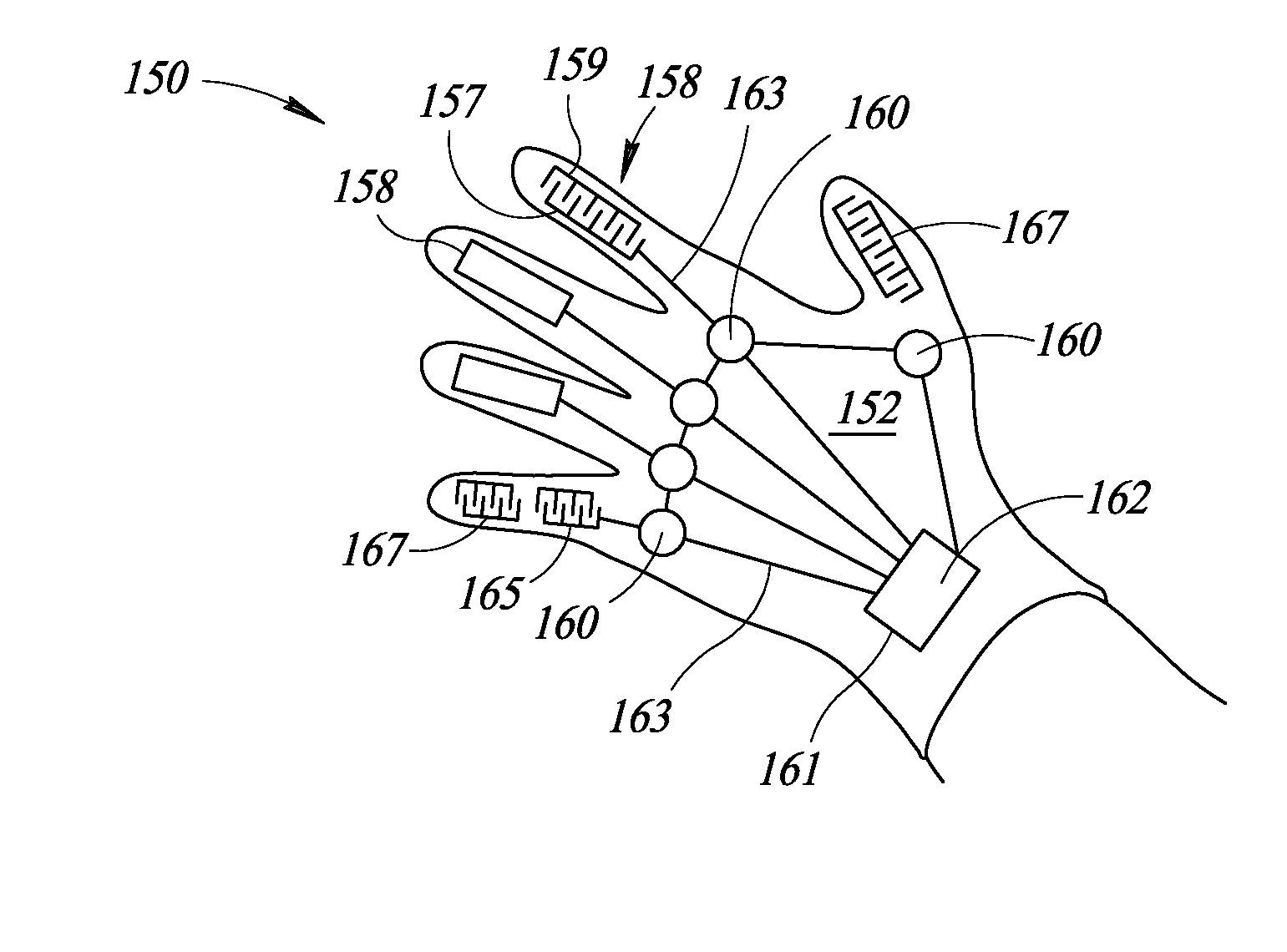

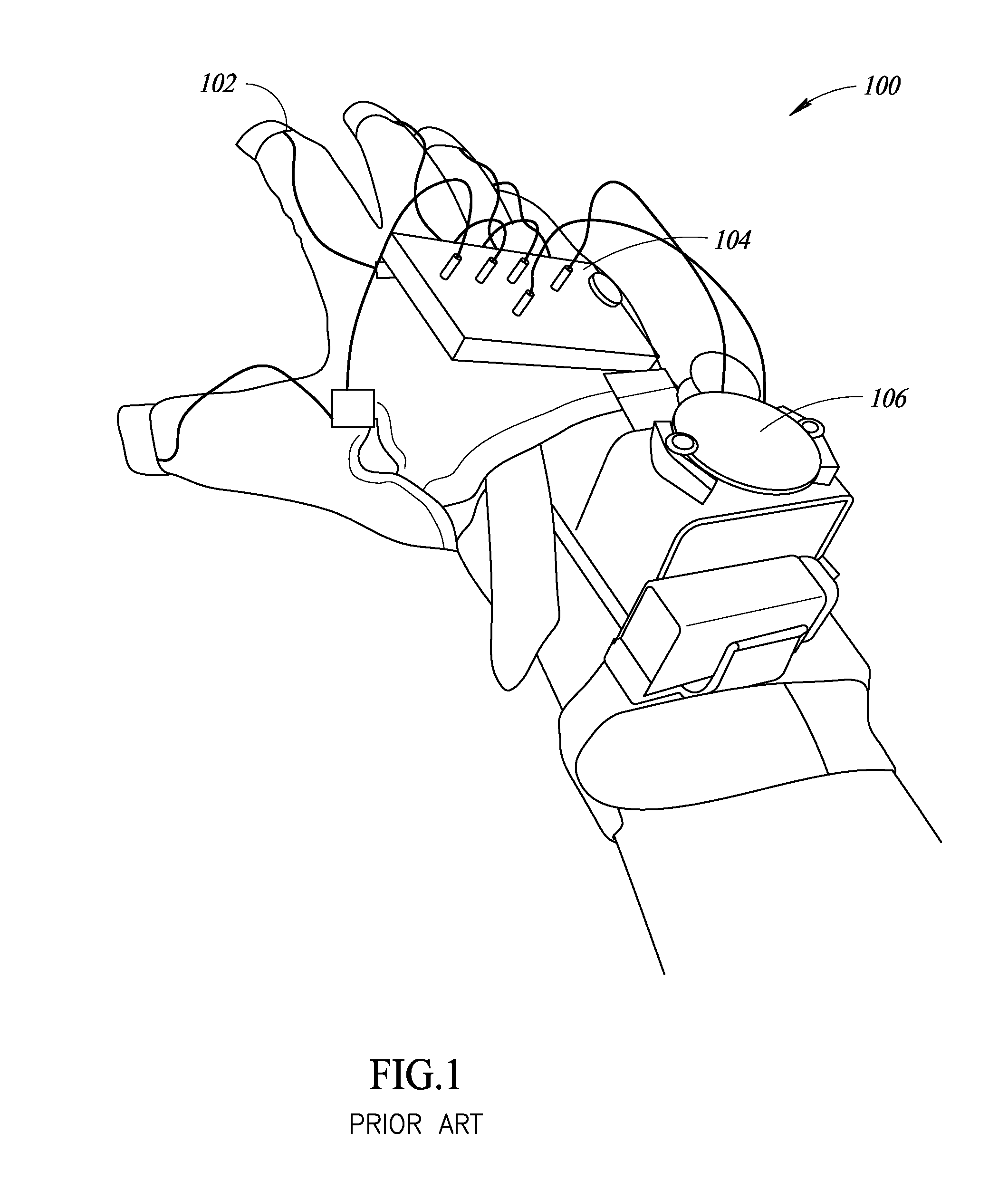

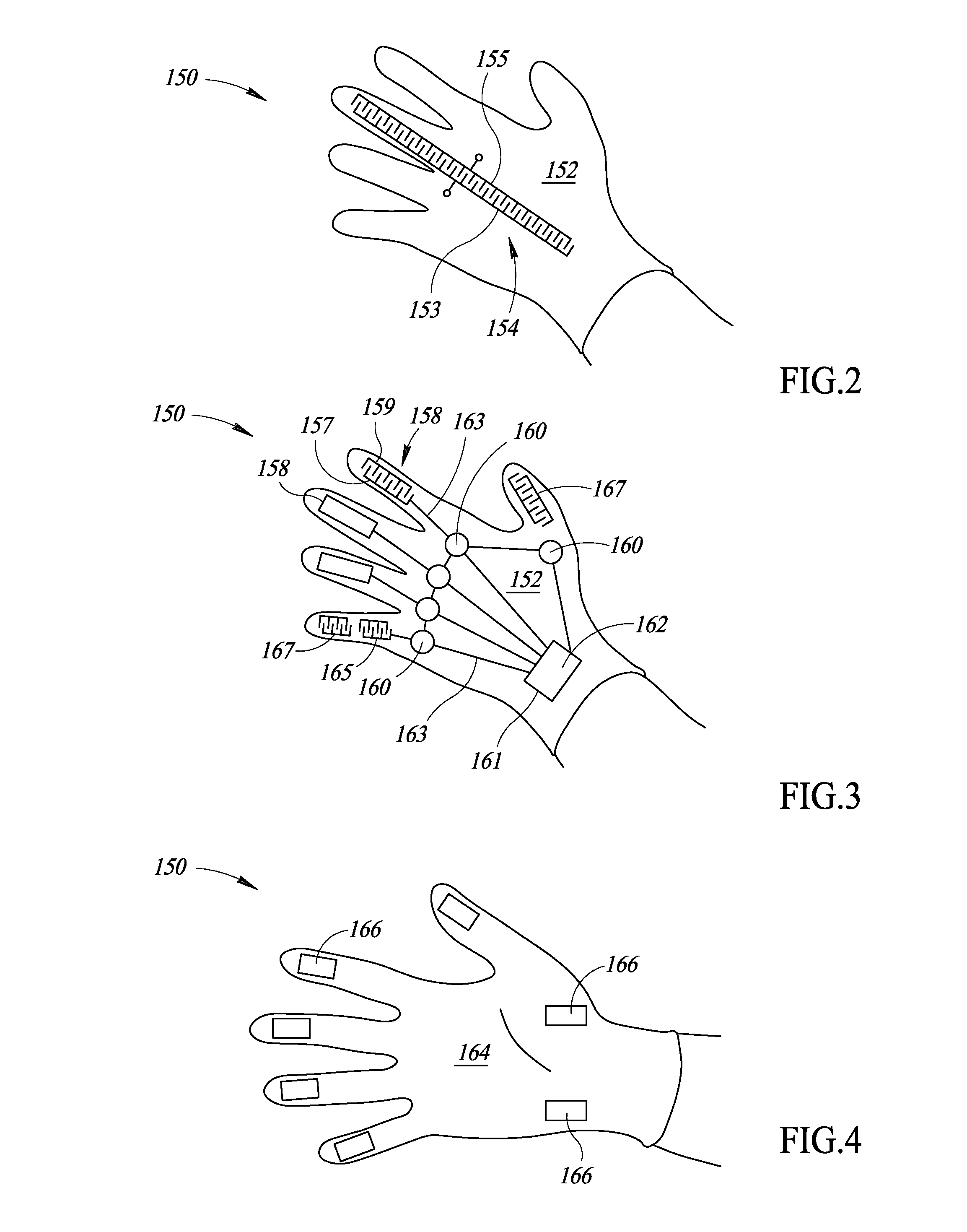

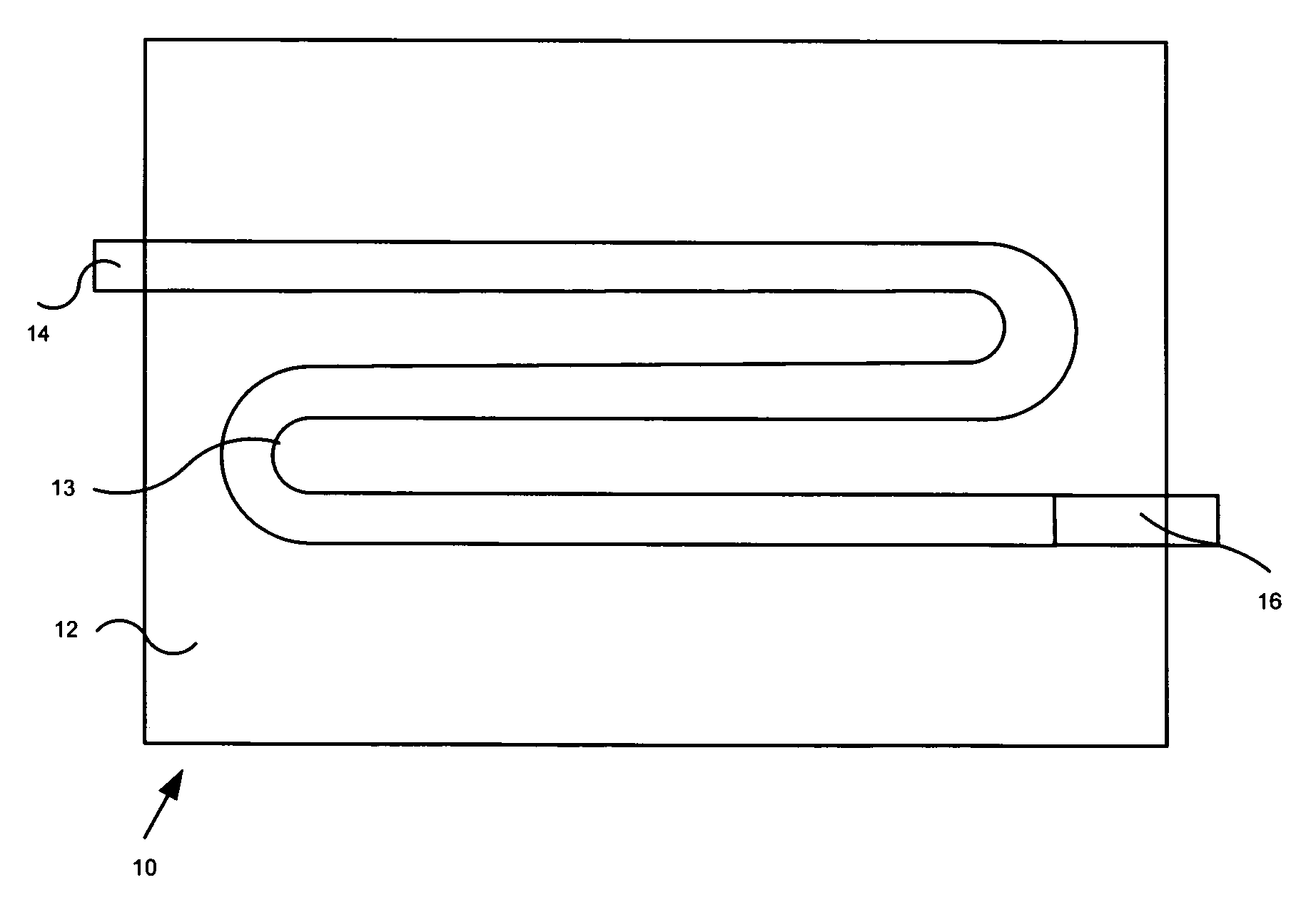

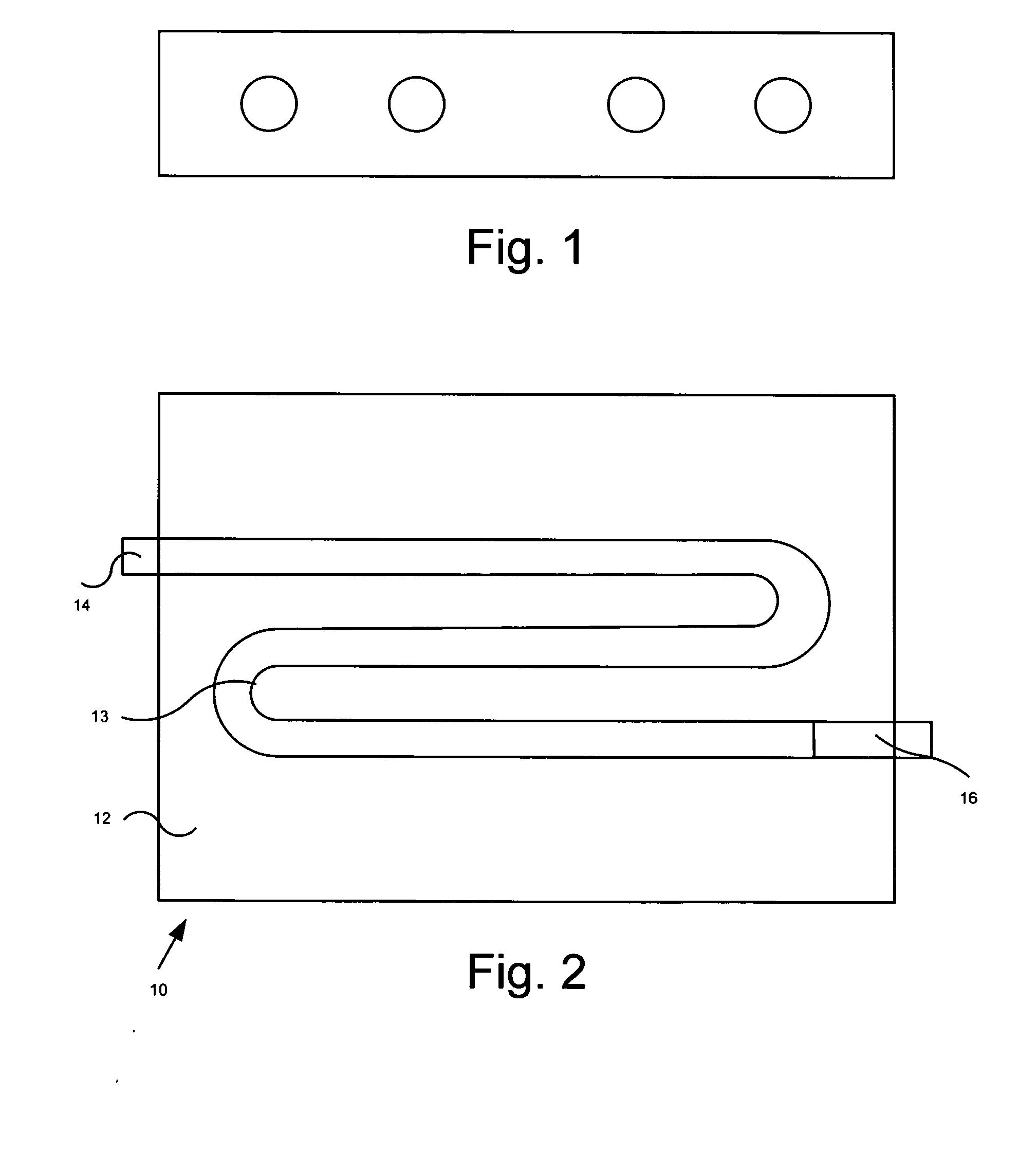

Flexible smart glove

ActiveUS20160187973A1Fine and finger motionMonitor flexion of the back of the handInput/output for user-computer interactionCathode-ray tube indicatorsFilm resistanceContact pressure

A flexible smart glove detects fine hand and finger motions while permitting the wearer to make hand gestures with dexterity. The flexible smart glove has a thickness of less than about 100 μm and incorporates capacitive micro-sensors positioned at finger joint locations. The micro-sensors are thin film devices built on substrates made of a pliable material such as polyimide. Interdigitated serpentine capacitors monitor strain in the back of the hand, while parallel plate capacitors monitor contact pressure on the palm. Thus the smart glove responds electrically to various types of hand motions. Thin film resistors responsive to changes in body temperature are also formed on the flexible substrate. Motion and temperature data is transmitted from the glove to a microprocessor via a passive RFID tag or an active wireless transmitter. An ASIC is embedded in the smart glove to relay real time sensor data to a remote processor.

Owner:STMICROELECTRONICS PTE LTD

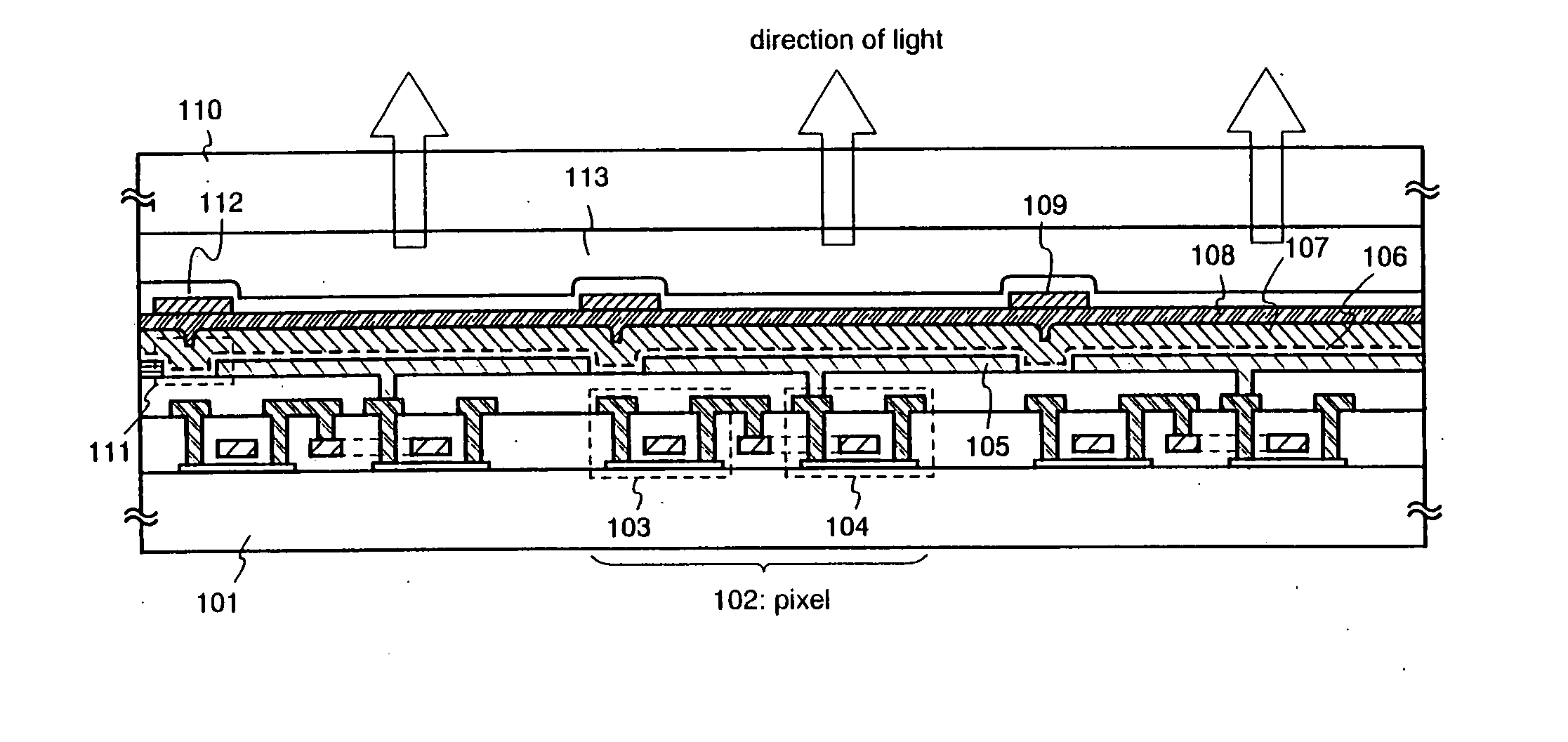

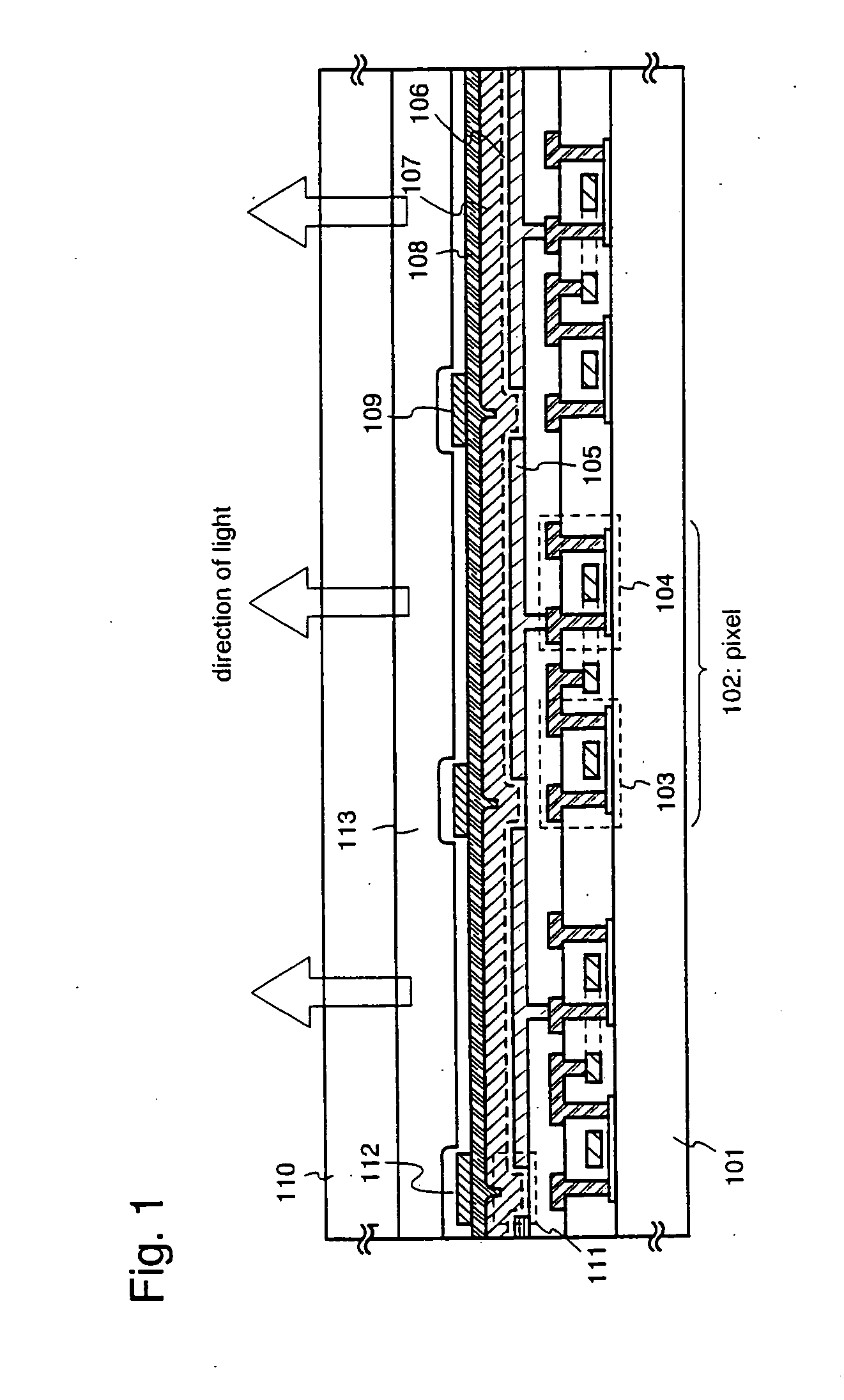

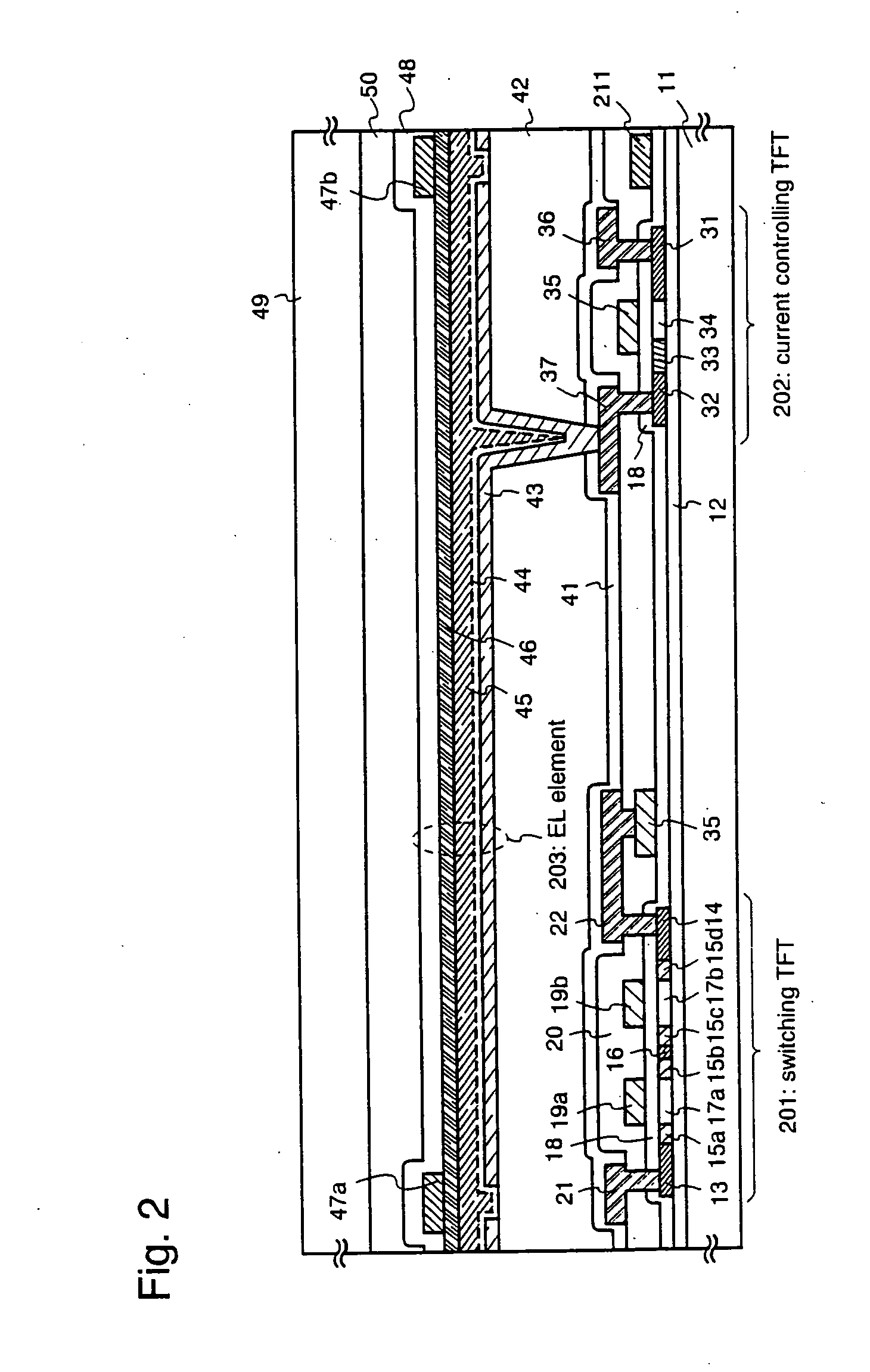

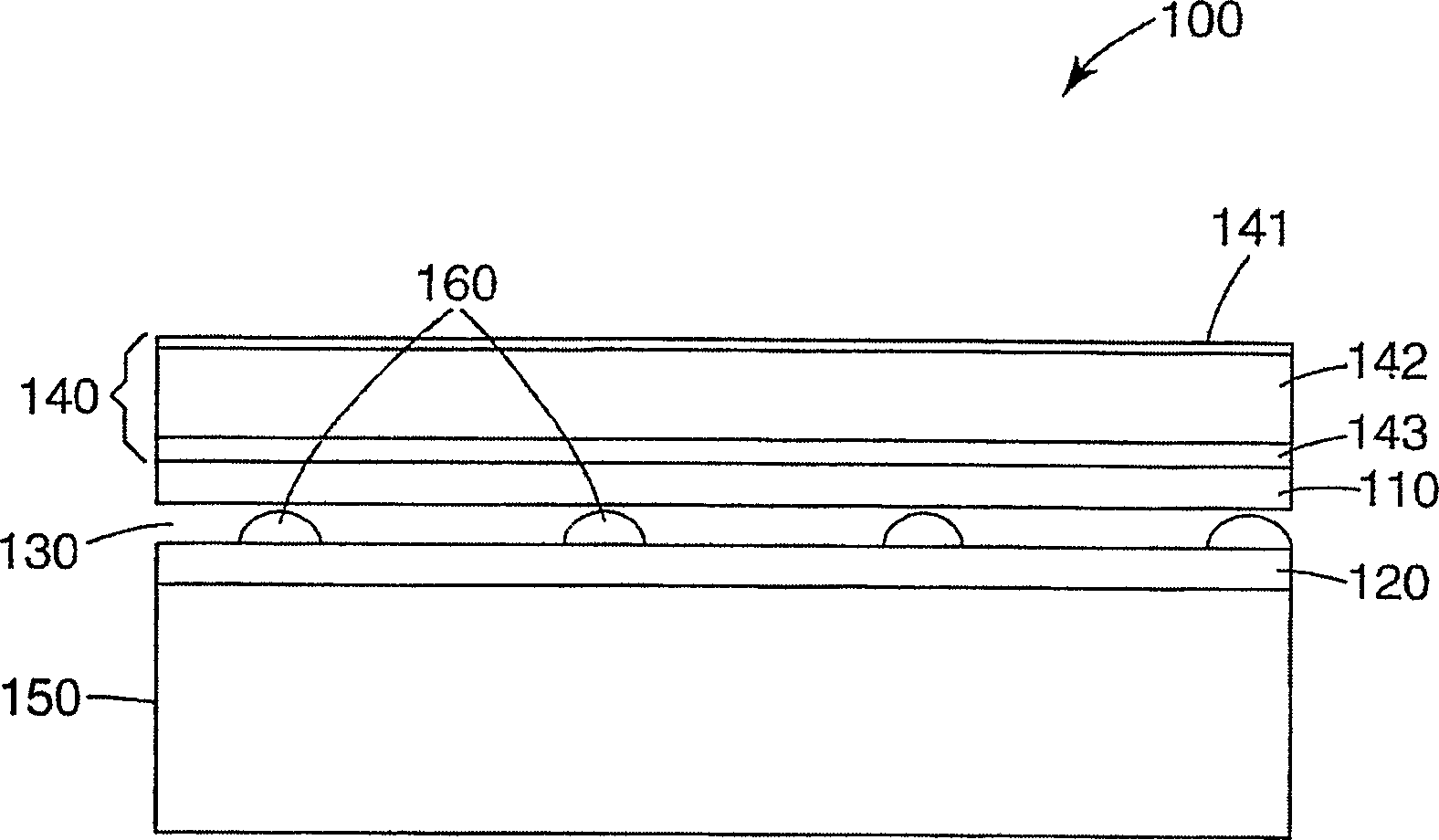

EL display device

InactiveUS20060286889A1Low resistivityReduce sheet resistanceElectroluminescent light sourcesSolid-state devicesFilm resistanceDisplay device

An EL display device capable of reducing an average film resistance of an anode in an EL device as well as displaying an image with high definition, and electrical equipment including such an EL display device are provided. A light-shielding metal film 109 is provided on an anode 108 so as to conceal gaps between the pixels. Thus, an average film resistance of the anode 108 in the EL device is reduced. Furthermore, light leakage from the gaps between the pixels can be prevented, resulting in an image display with high definition.

Owner:SEMICON ENERGY LAB CO LTD

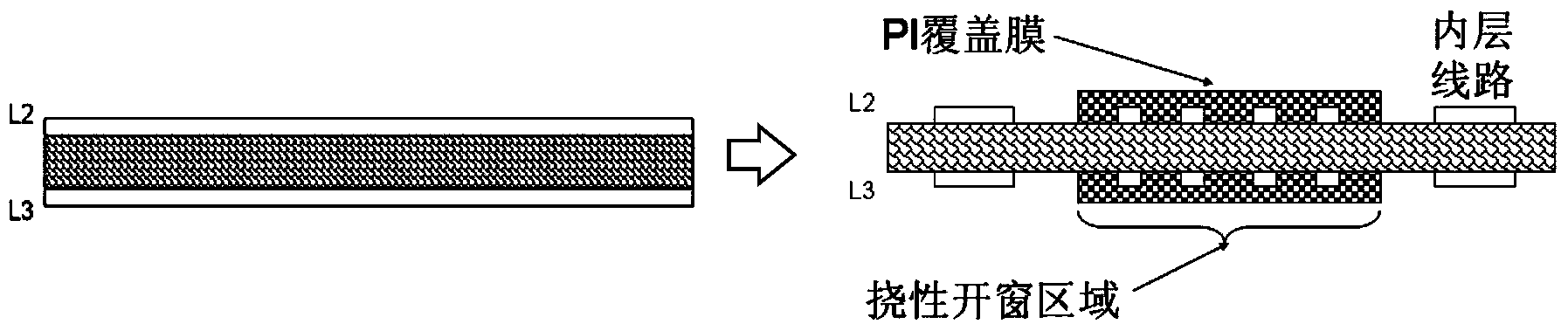

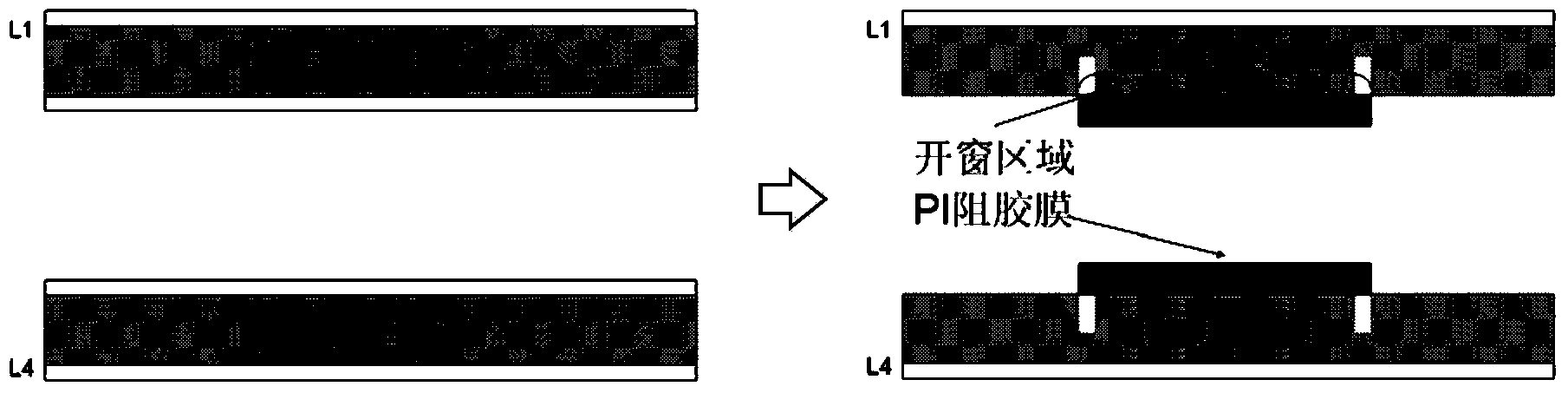

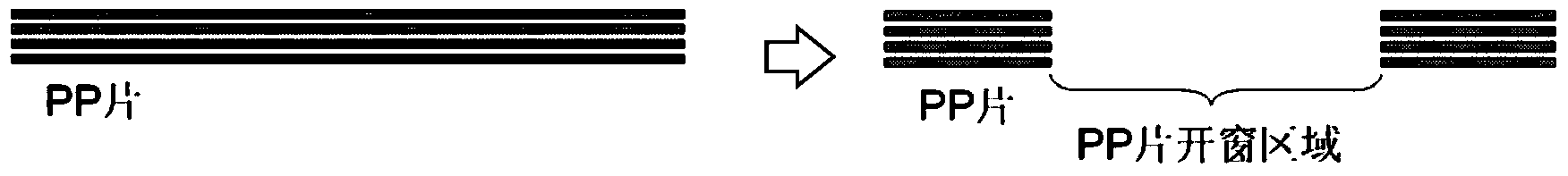

Rigid-flexible combined printed circuit board preparation method

The invention discloses a rigid-flexible combined printed circuit board preparation method. The rigid-flexible combined printed circuit board comprises a rigid sub board, a dielectric layer, a flexible sub board, another dielectric layer, and another rigid sub board which are laminated sequentially. The method comprises the following steps of: flexible board preparation, rigid board preparation, dielectric layer preparation, pressing, cover opening, and post processes. In the invention, a PI film resistance glue is pasted in a rigid board slot area; a flow type prepreg (a PP sheet) windowing area is increased; and the total thickness of the PP sheet is controlled to be less than the total thickness of a polyimide cover film and a polyimide resistance glue film, so that the flow type prepreg can be applied to preparation of the rigid-flexible combined printed circuit board. The excessive glue length of the rigid-flexible connecting point of the pressed printed circuit board is less than 1.0mm, so that the requirements of the IPC-6013B relevant regulation are met.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

Bio-Film Resistant Surfaces

The present invention relates to methods and compositions for rendering a surface resistant to bio-film formation by a combination of an alkanediol and an antimicrobial agent (and, optionally, an organic hydroxy acid). The invention provides for compositions which may be used to render surfaces bio-film resistant, articles having bio-film resistant surfaces, and methods for their preparation. The present invention may be advantageously applied to medical articles as well as articles used in non-medical contexts, such as child care or food preparation.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

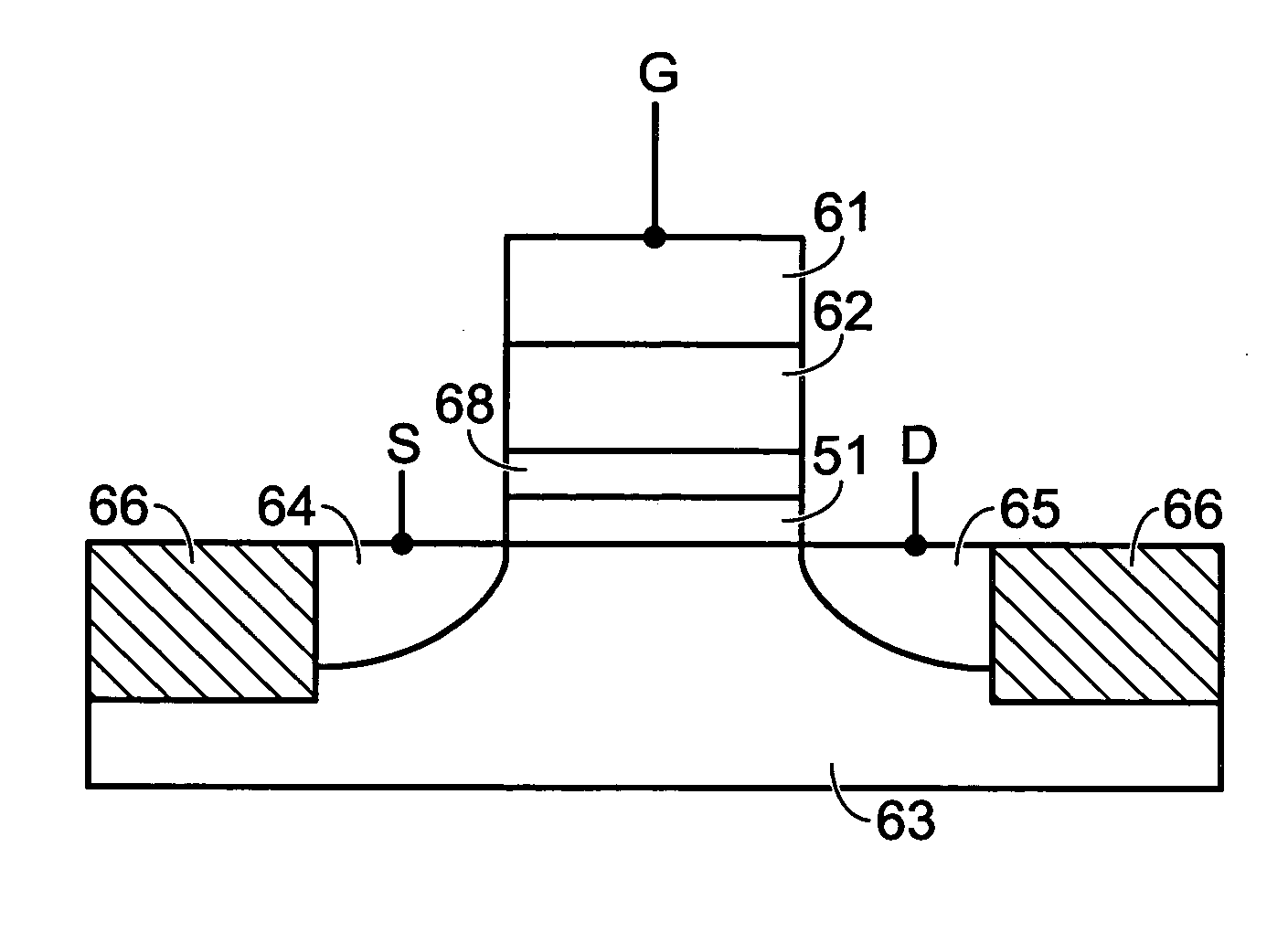

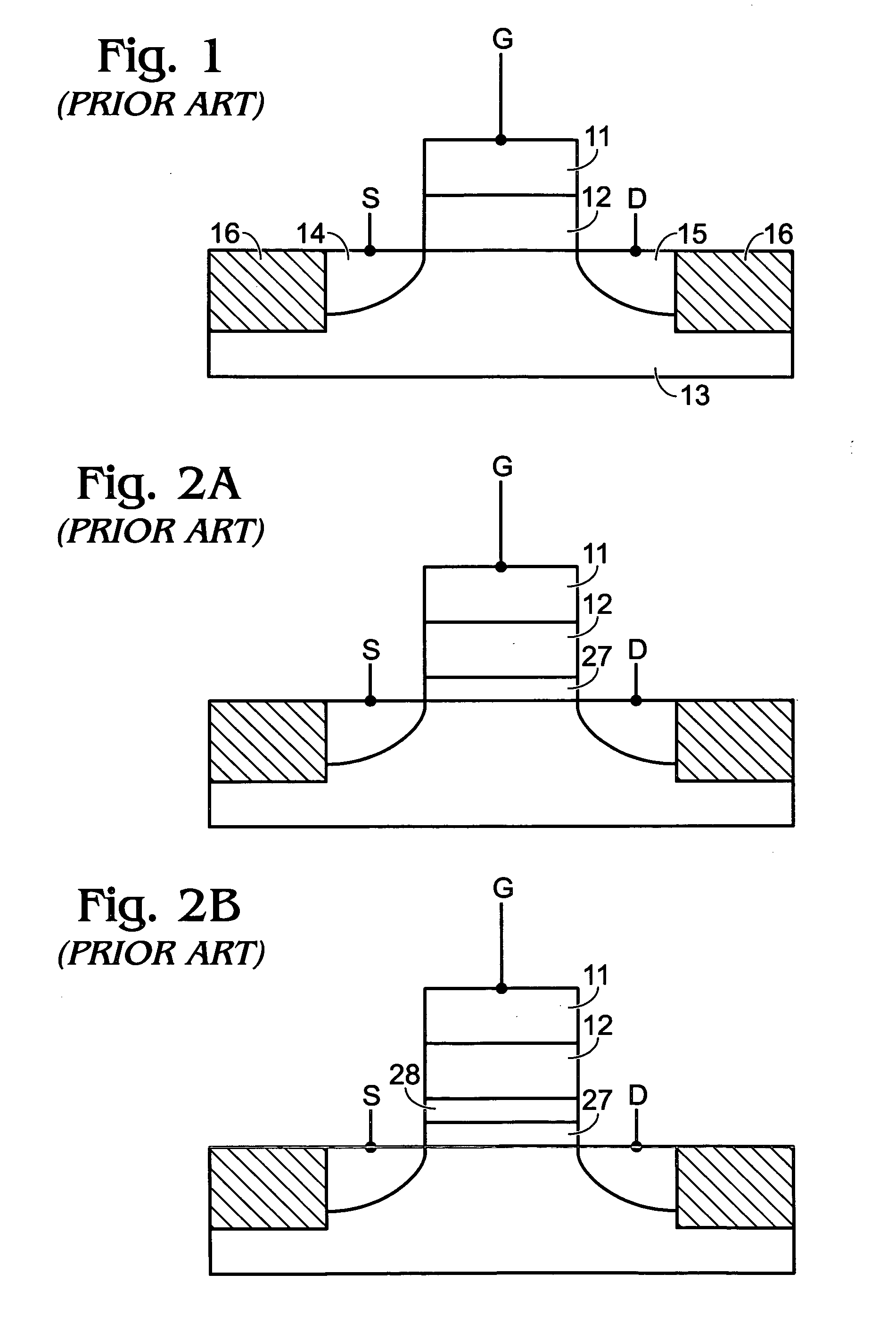

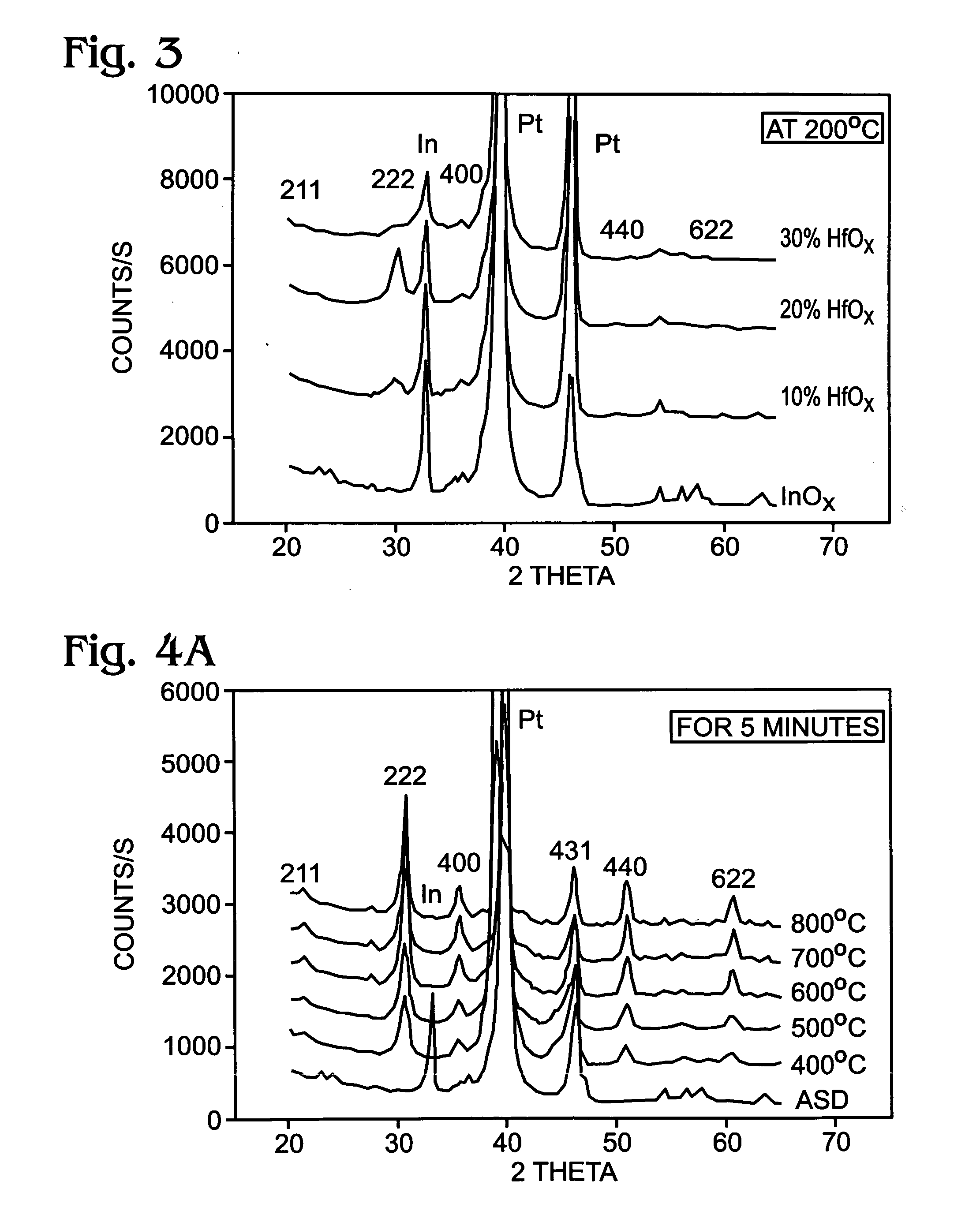

In2O3 thin film resistivity control by doping metal oxide insulator for MFMox device applications

ActiveUS20050151210A1Reduce chargeImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesMemory retentionFilm resistance

The present invention discloses a novel ferroelectric transistor design using a resistive oxide film in place of the gate dielectric. By replacing the gate dielectric with a resistive oxide film, and by optimizing the value of the film resistance, the bottom gate of the ferroelectric layer is electrically connected to the silicon substrate, eliminating the trapped charge effect and resulting in the improvement of the memory retention characteristics. The resistive oxide film is preferably a doped conductive oxide in which a conductive oxide is doped with an impurity species. The doped conductive oxide is most preferred to be In2O3 with the dopant species being hafnium oxide, zirconium oxide, lanthanum oxide, or aluminum oxide.

Owner:SHARP KK

Method for producing conducting and transparent films from combined graphene and conductive nano filaments

ActiveUS20140272172A1Improve conductivityReduce sheet resistanceMetal-working apparatusPretreated surfacesOptical transparencyTransparent conducting film

Owner:GLOBAL GRAPHENE GRP INC

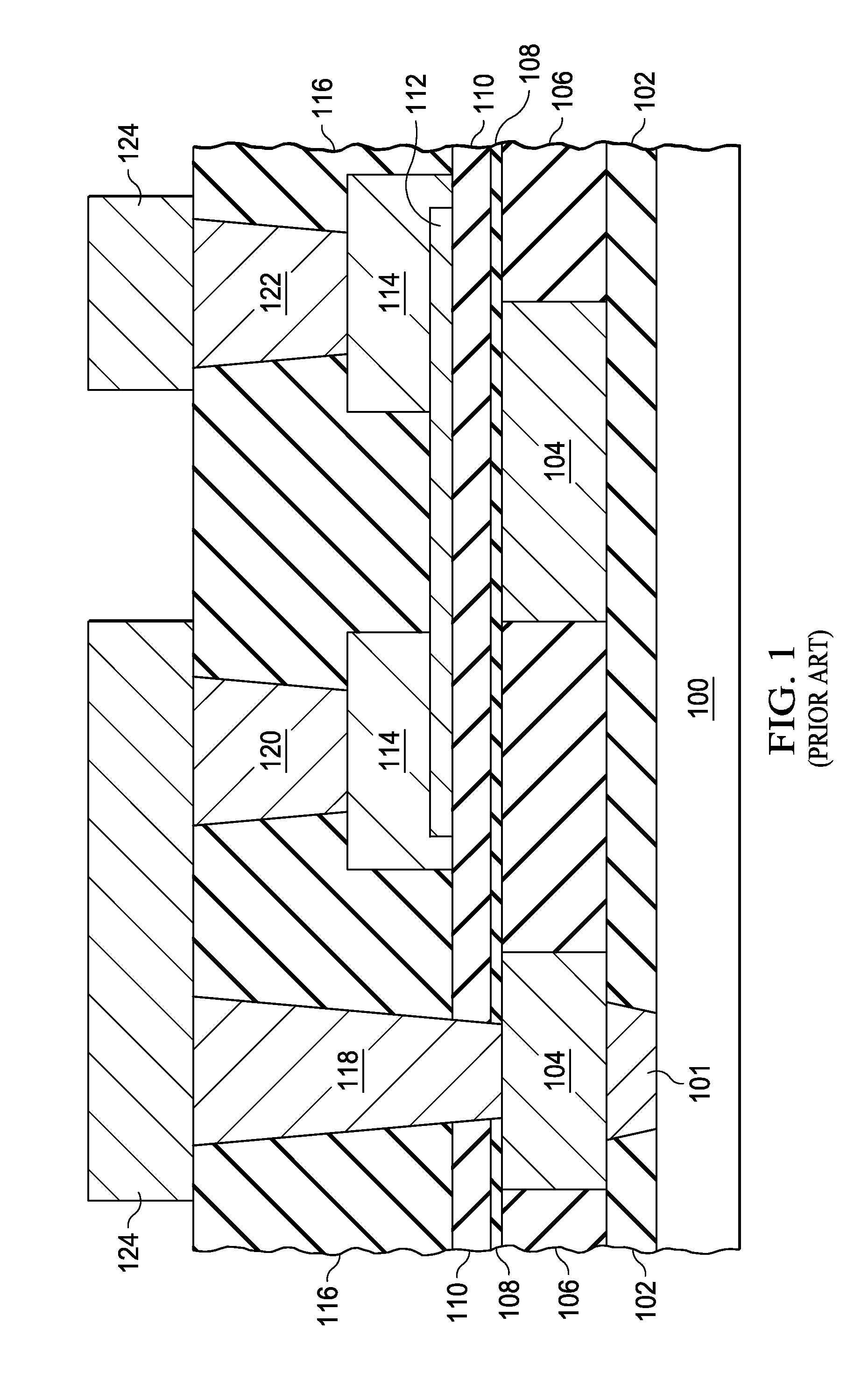

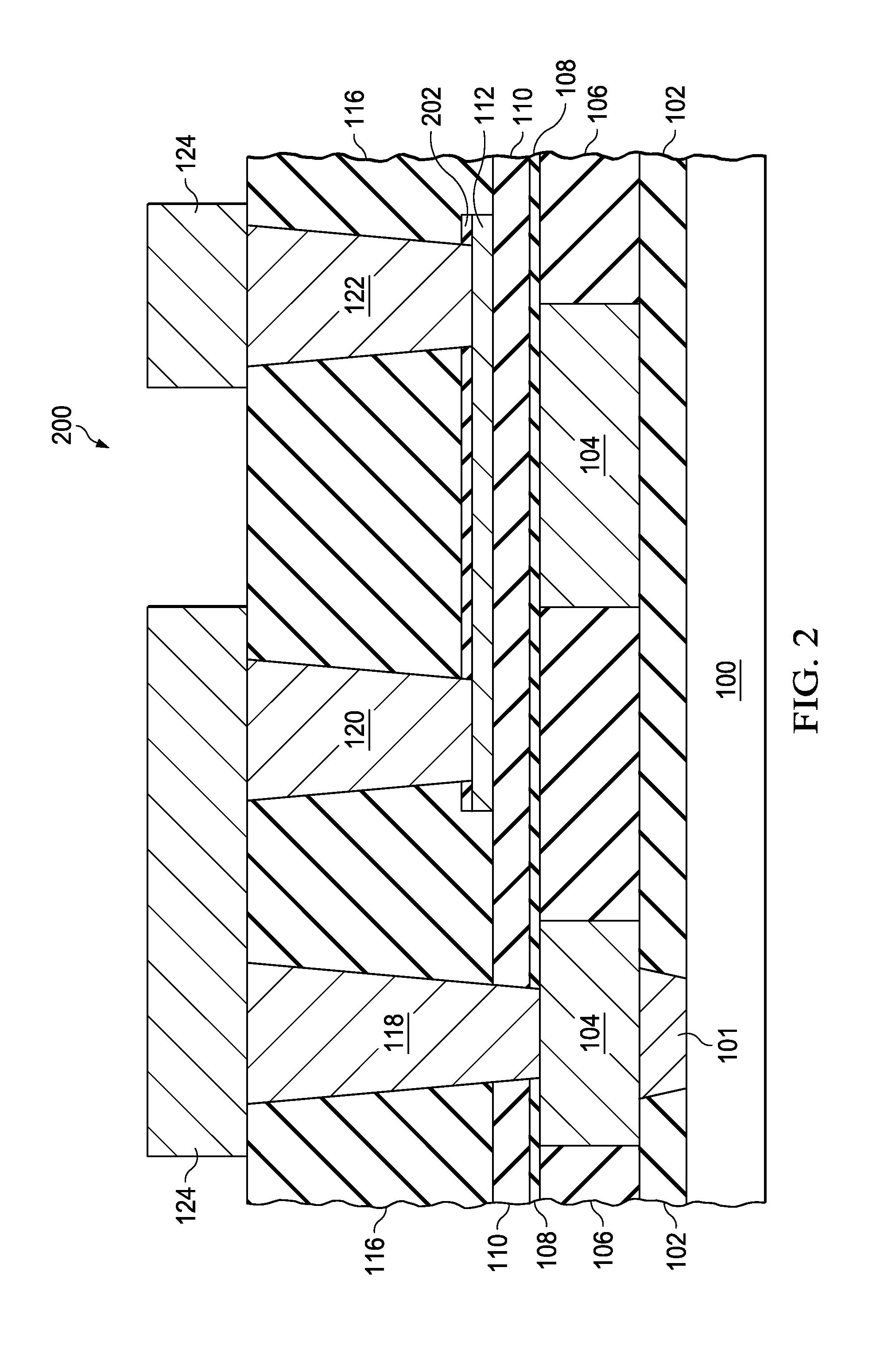

Thin film resistor with current density enhancing layer (CDEL)

ActiveUS20060181388A1Current-carrying capability can be increasedImprove adhesionTransistorElectrostatic/electro-adhesion relaysHigh current densityElectrical conductor

A thin film resistor device and method of manufacture includes a layer of a thin film conductor material and a current density enhancing layer (CDEL). The CDEL is an insulator material adapted to adhere to the thin film conductor material and enables the said thin film resistor to carry higher current densities with reduced shift in resistance. In one embodiment, the thin film resistor device includes a single CDEL layer formed on one side (atop or underneath) the thin film conductor material. In a second embodiment, two CDEL layers are formed on both sides (atop and underneath) of the thin film conductor material. The resistor device may be manufactured as part of both BEOL and FEOL processes.

Owner:GLOBALFOUNDRIES US INC

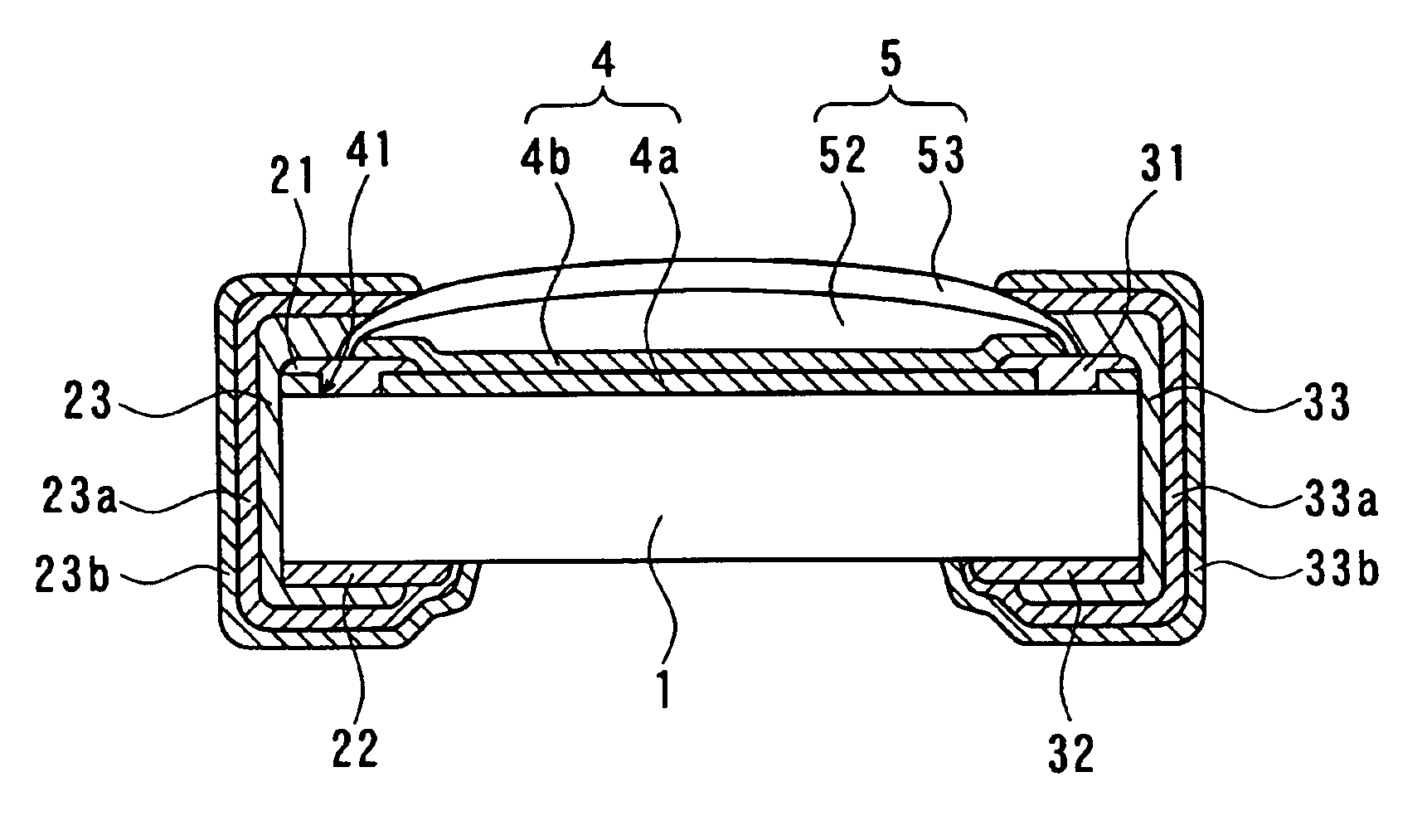

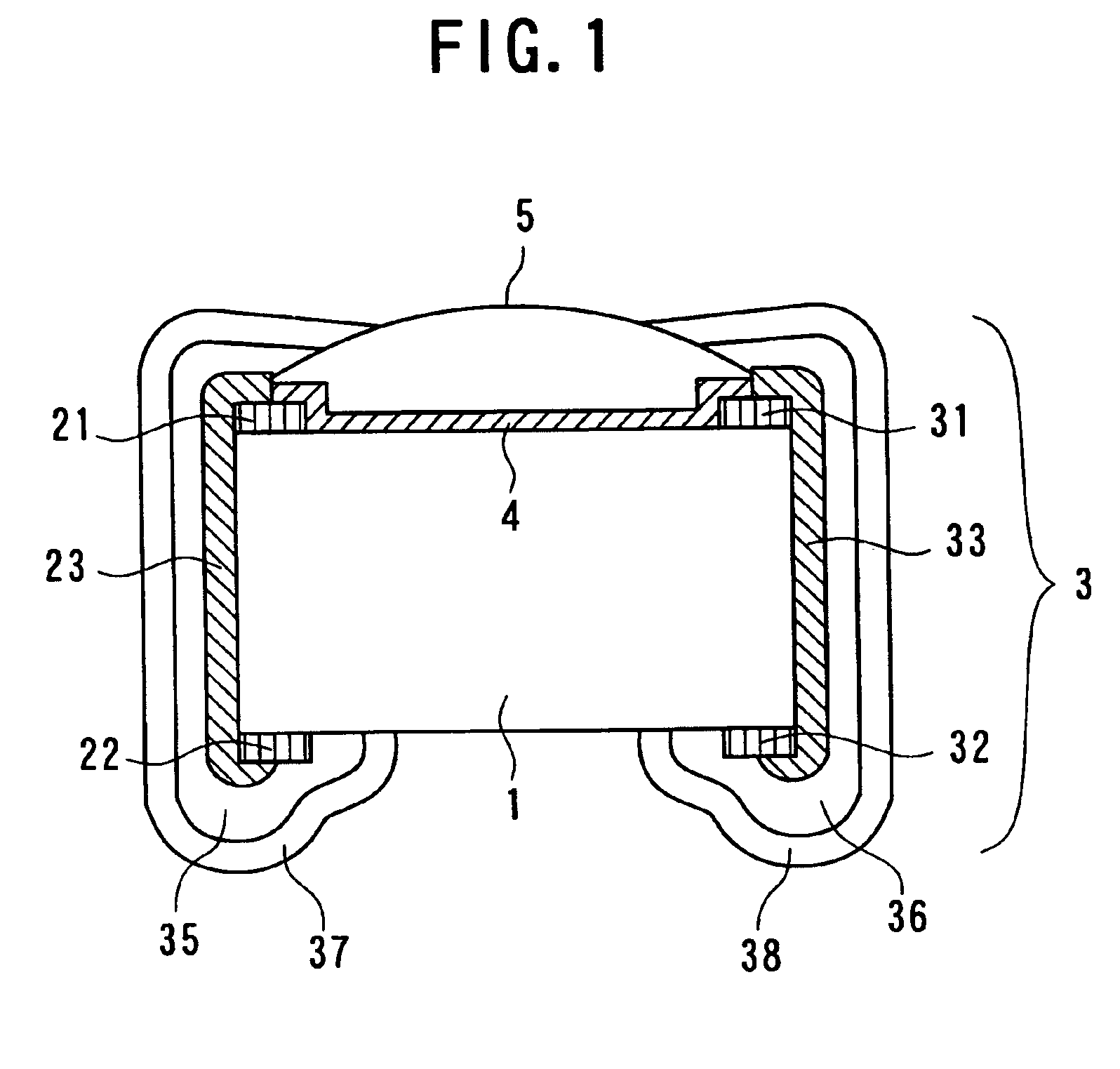

Chip resistor

InactiveUS6943662B2Resistor chip manufactureResistor terminals/electrodesFilm resistanceChemical reaction

Resistance or side electrodes of a chip resistor is prevented from being lost due to chemical reaction with NaCl contained in human sweat and so on when human sweat, seawater, etc. are adhered thereto. The chip resistor comprises an insulating substrate, thick-film upper surface electrodes formed at opposite ends of the top surface of the insulating substrate, a thin-film resistance made of a constituent material not reacting with NaCl, and formed so as to be extended over the upper surface of the insulating substrate and respective portions of the upper surface of the thick-film upper surface electrodes, thick-film back surface electrodes formed at spots on the back surface of the insulating substrate, corresponding to the thick-film upper surface electrodes, respectively, and thick-film side surface electrodes connecting the thick-film back surface electrodes with respective portions of the thick-film upper surface electrodes, exposed out of the thin-film resistance, respectively.

Owner:ROHM CO LTD

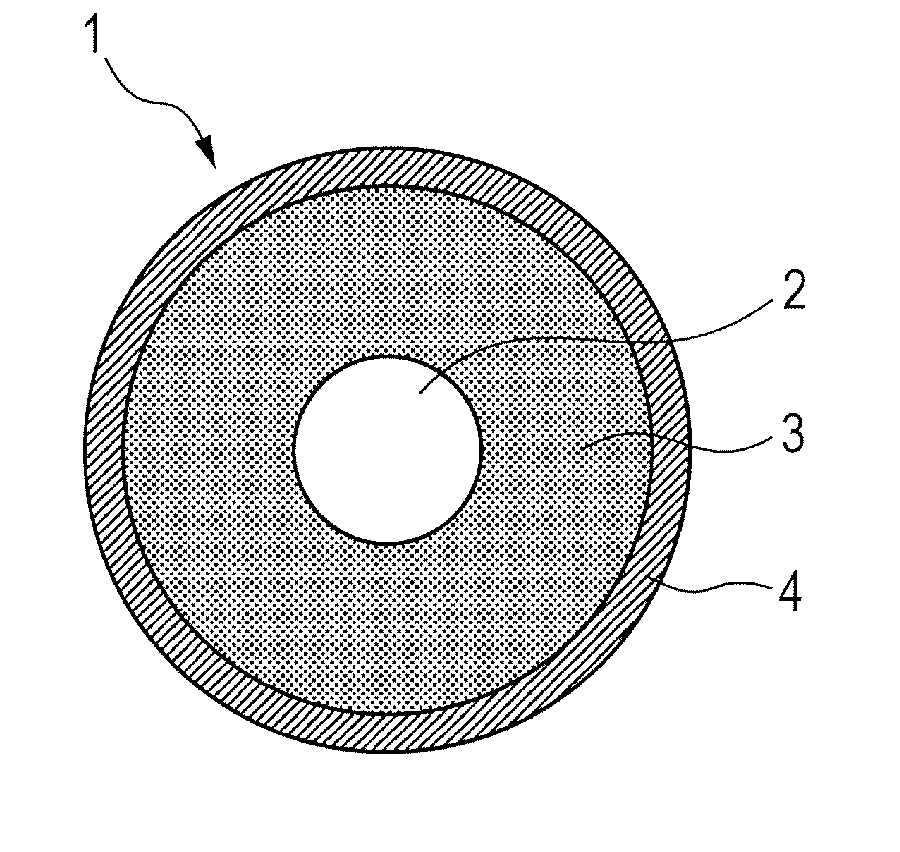

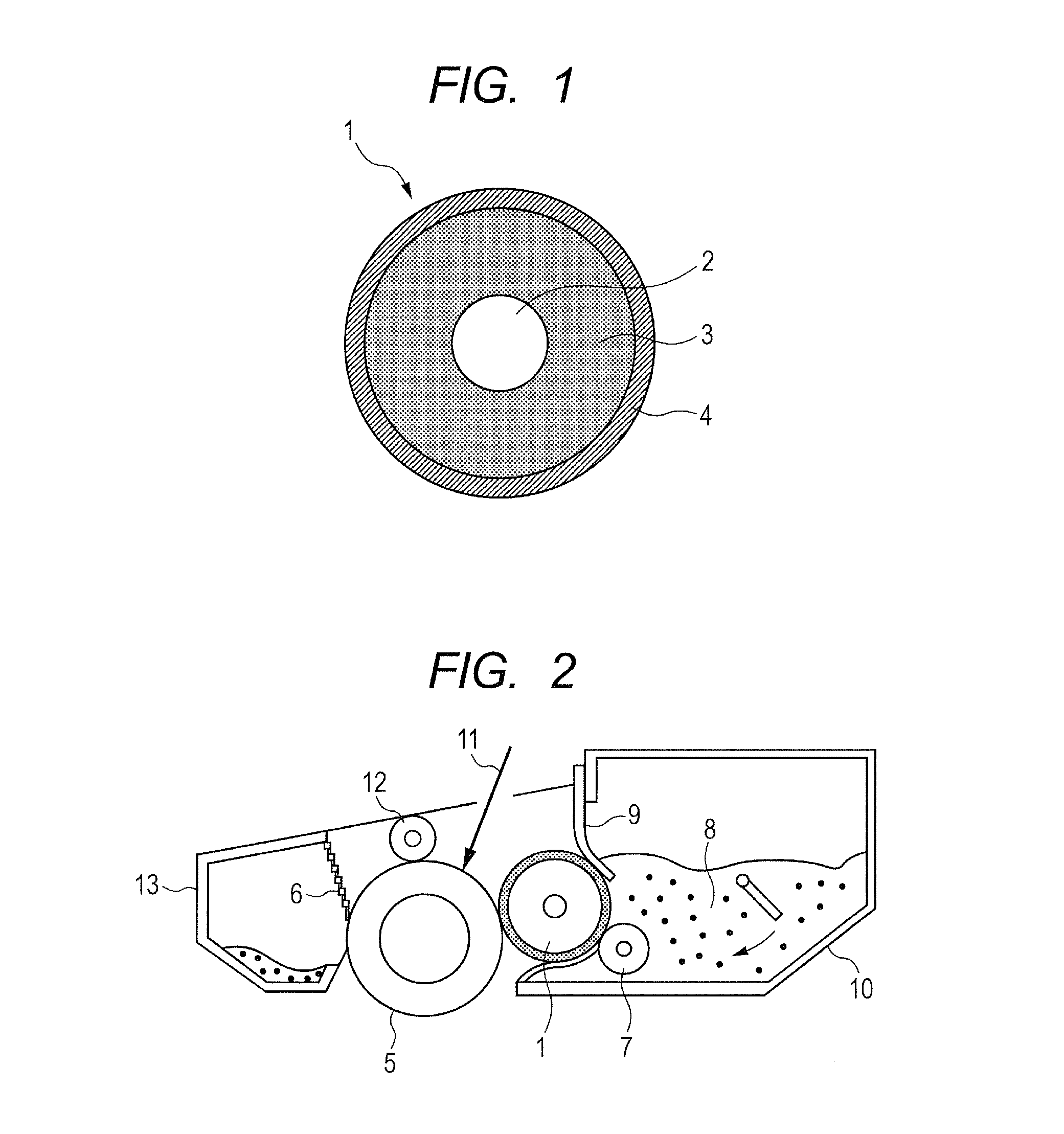

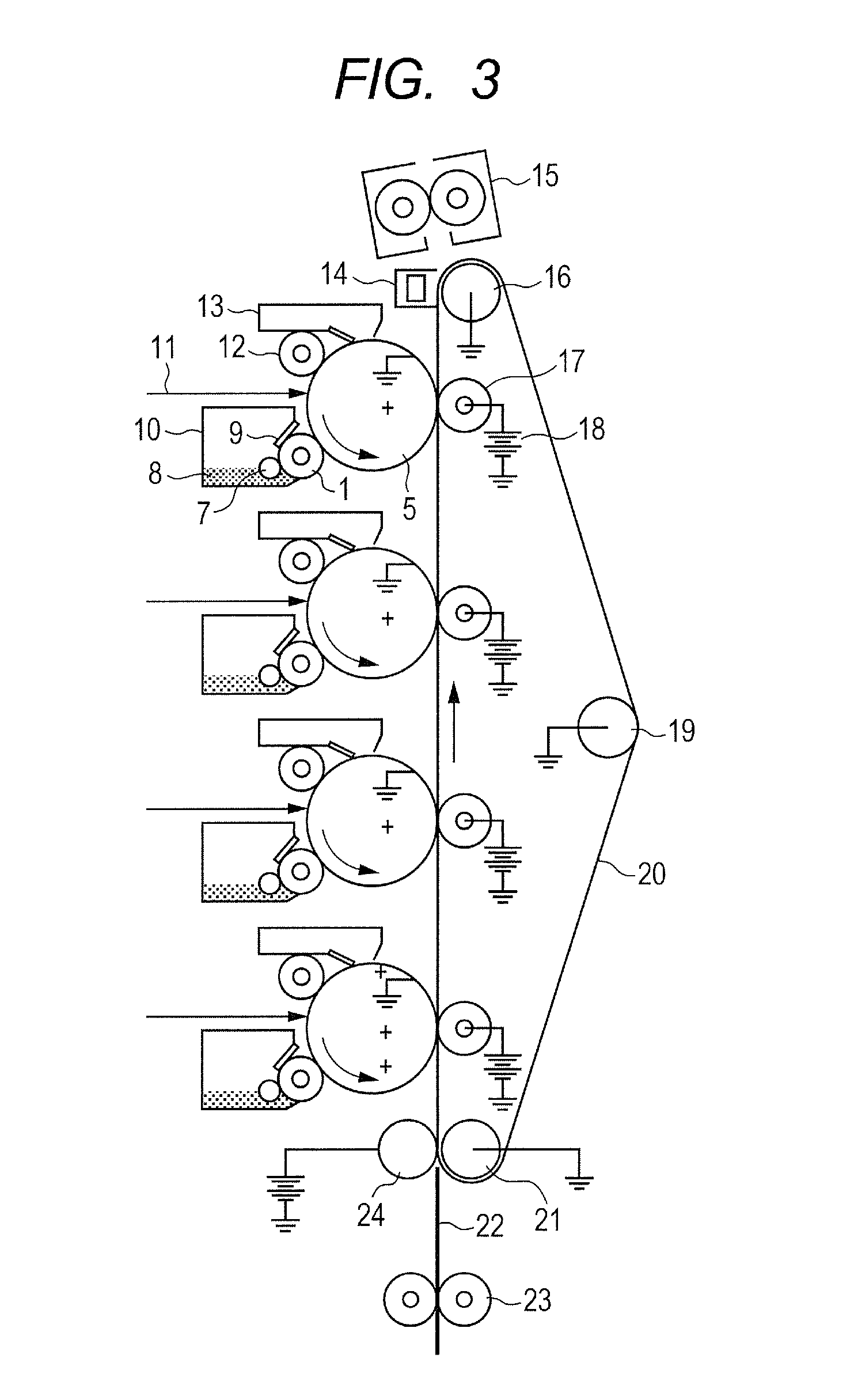

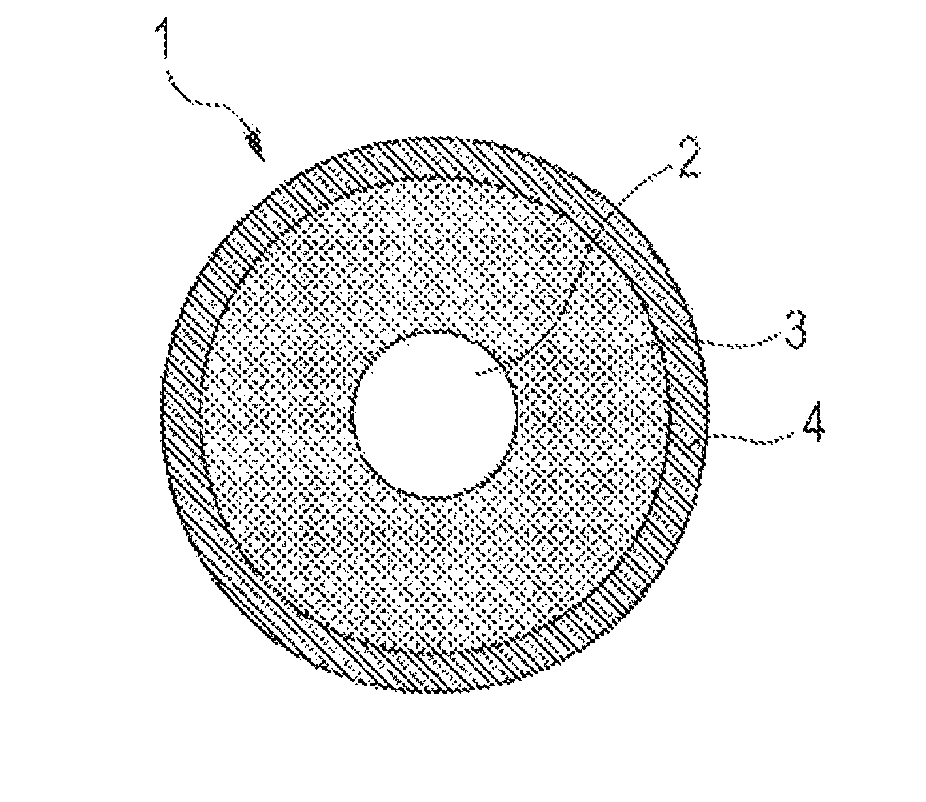

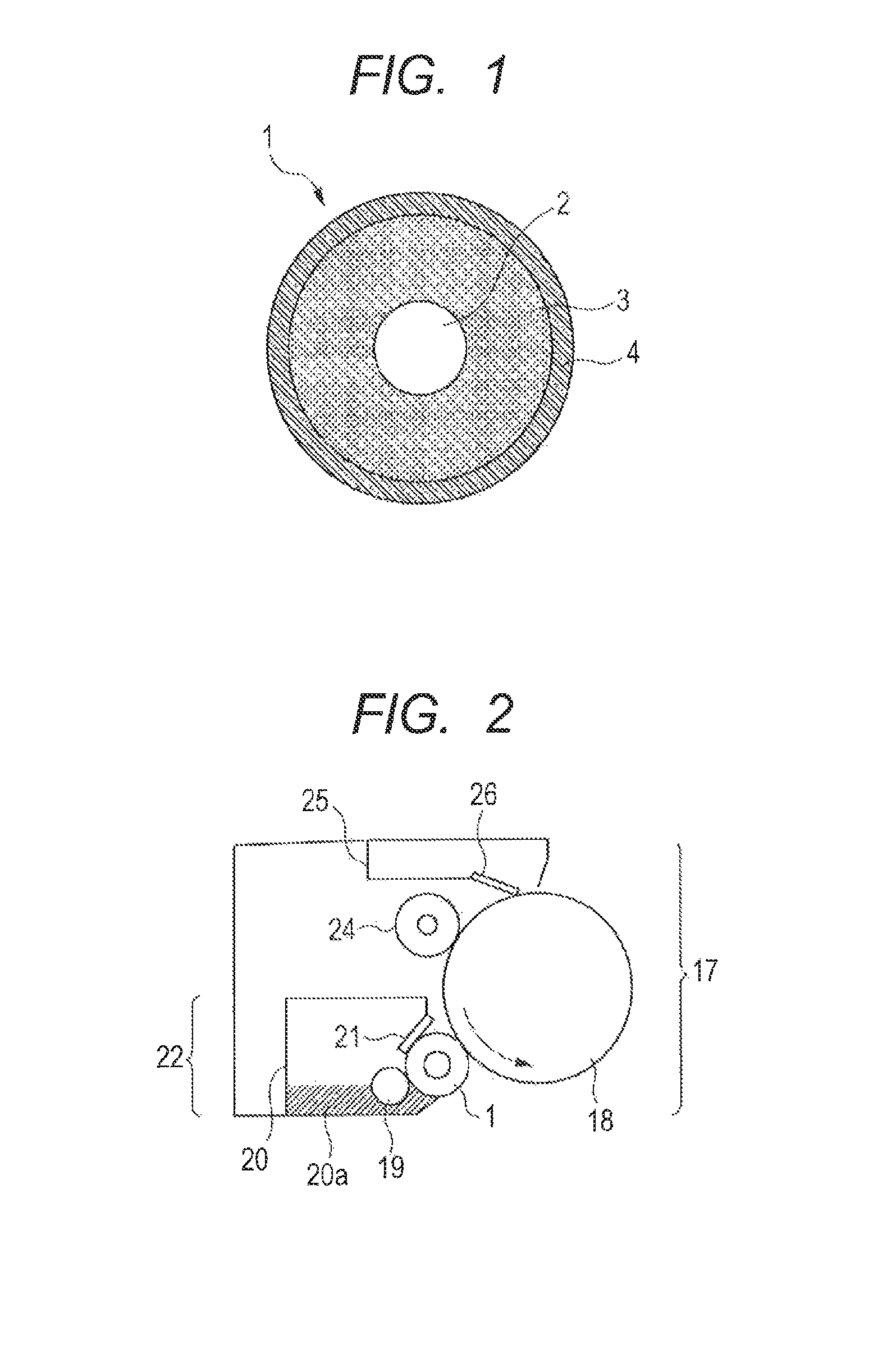

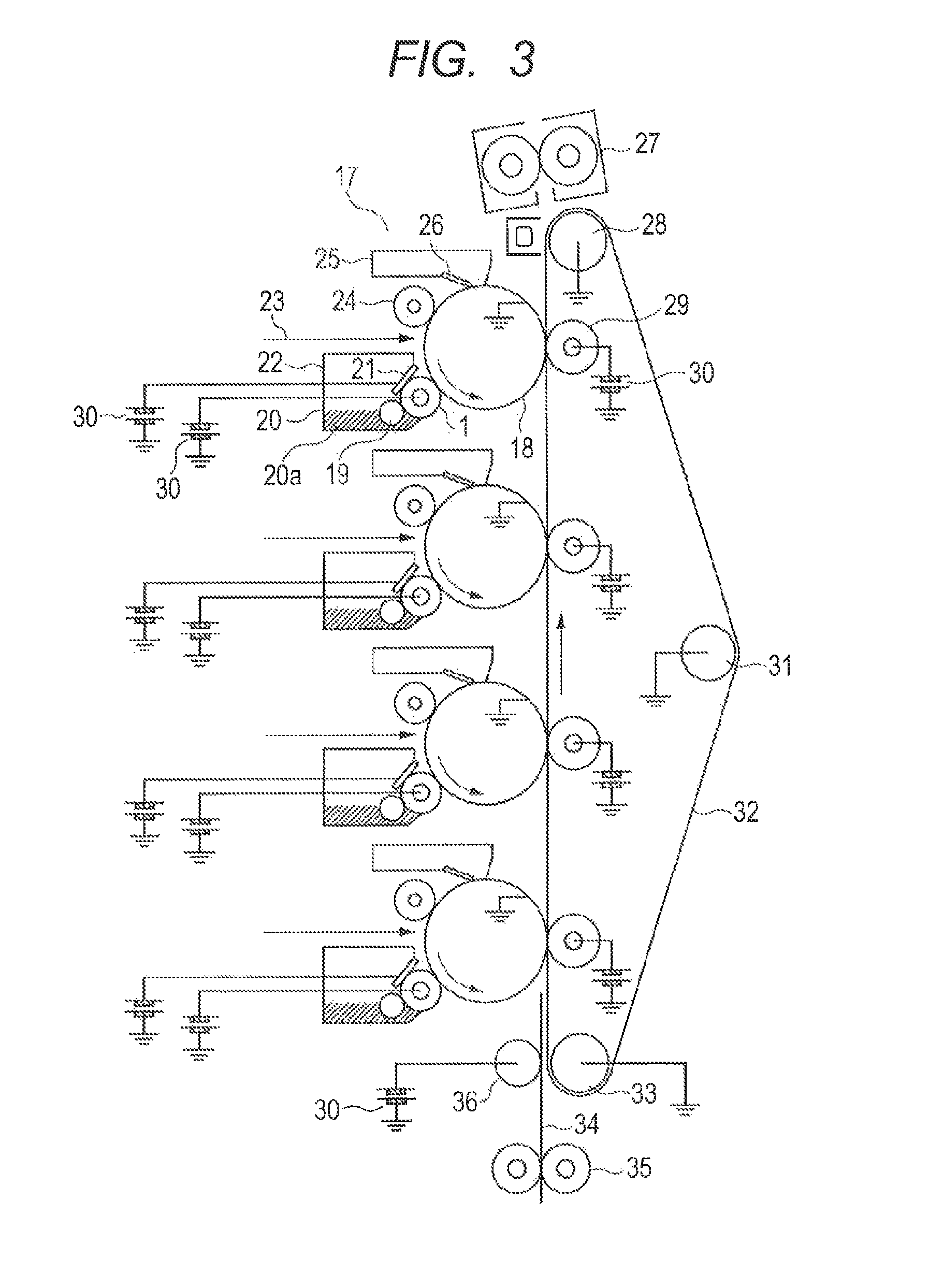

Developing member, process cartridge, and electrophotographic apparatus

ActiveUS8798508B2Quality improvementImprove leak-proof effectSynthetic resin layered productsSpecial tyresSurface layerEngineering

A high-quality developing member which excels in filming resistance and excels in leak resistance despite high electroconductivity is provided. The developing member includes an electroconductive substrate, an elastic layer formed on the substrate, and a surface layer which covers a surface of the elastic layer. The surface layer includes a first resin which has, between two adjacent urethane linkages, a structure represented by the structural formula (1) and one or both of structures selected from the group consisting of a structure represented by the structural formula (2) and a structure represented by the structural formula (3), a second resin which has a structure represented by the structural formula (4) and one or both of structures selected from the group consisting of a structure represented by the structural formula (5) and a structure represented by the structural formula (6), and an electronically conductive filler.

Owner:CANON KK

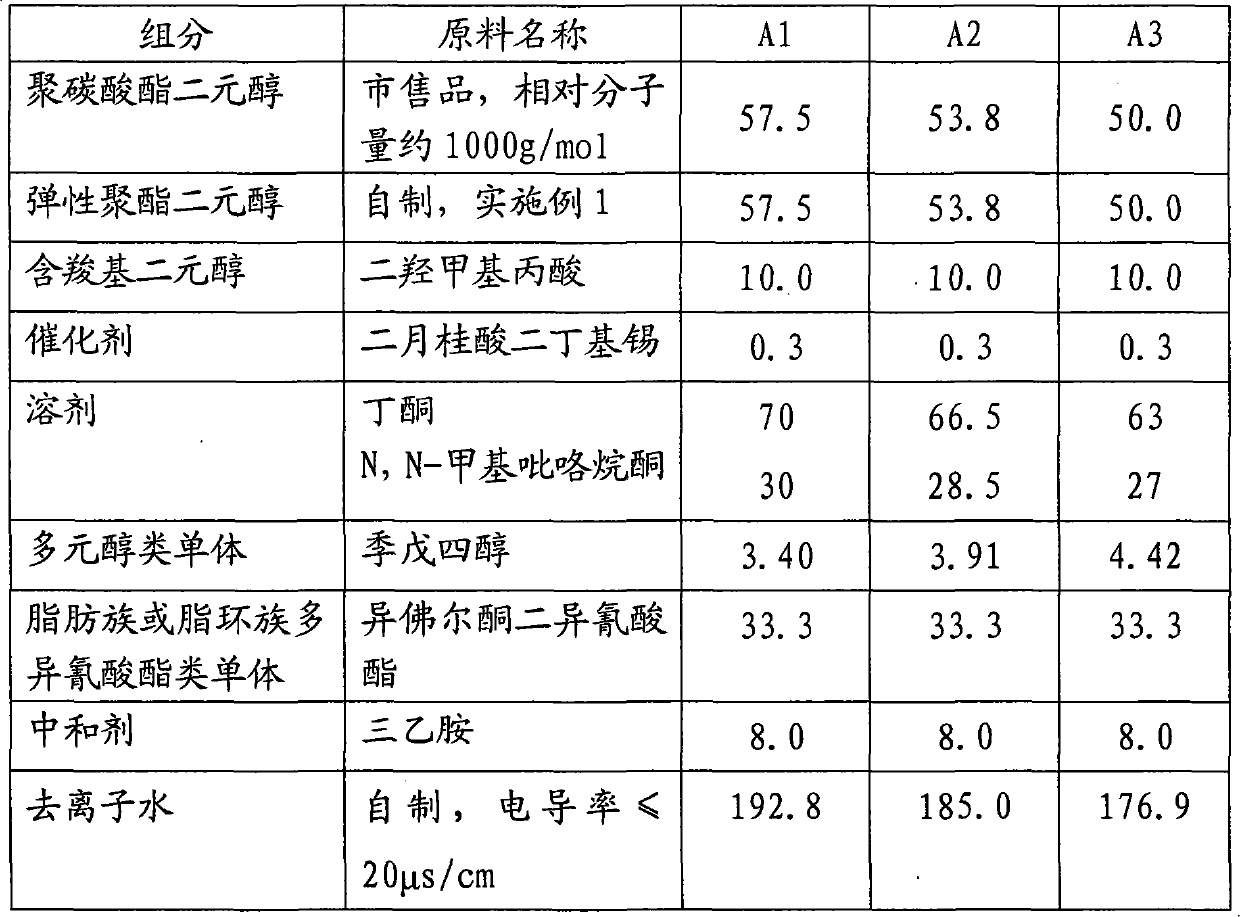

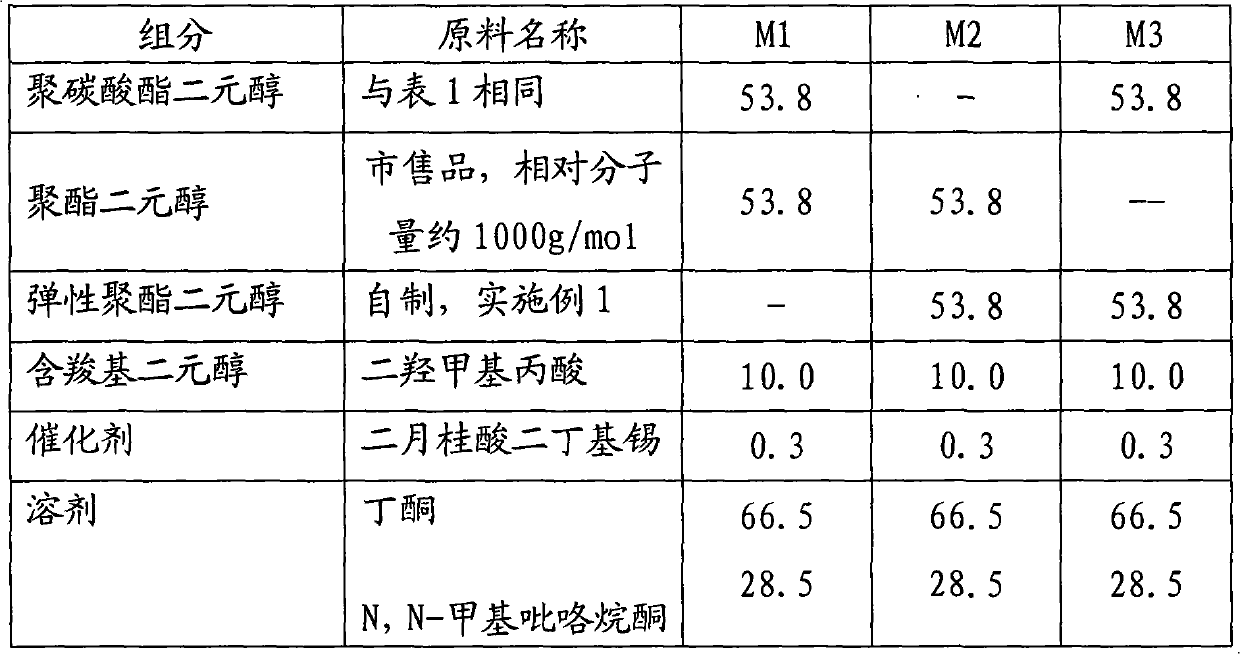

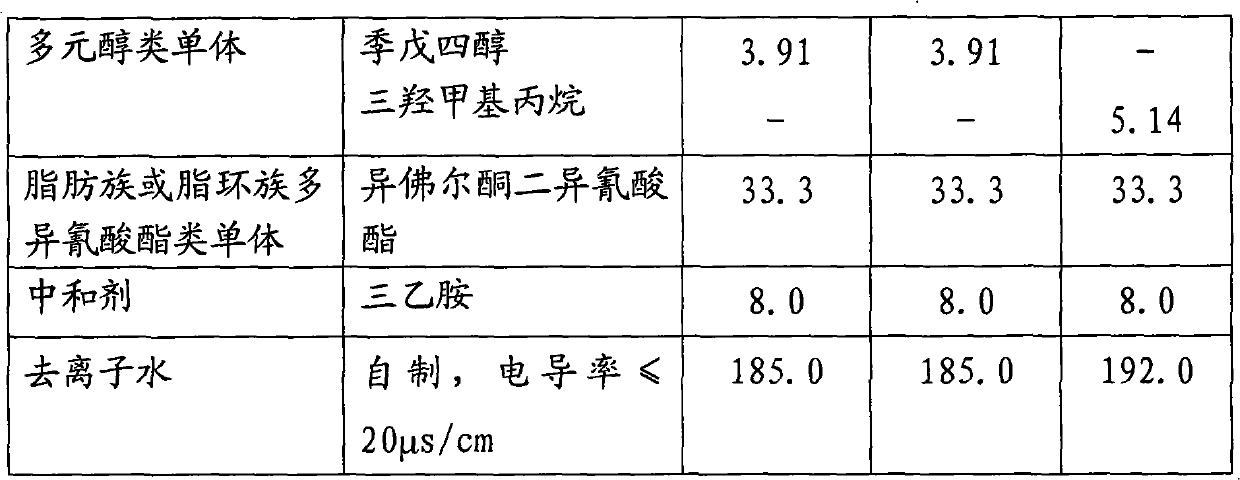

Hydroxylated polyurethane water dispersoid for waterborne soft-feel coating and preparation method thereof

ActiveCN102002166AThe preparation process is simple and controllableEasy to operatePolyurea/polyurethane coatingsPolyesterFilm resistance

The invention relates to a hydroxylated polyurethane water dispersoid for a waterborne soft-feel coating and a preparation method thereof. The hydroxylated polyurethane water dispersoid is the water dispersoid formed by the following steps of: taking the raw materials in parts by weight: 15 to 20 parts of polycarbonate diols, 15 to 25 parts of elastic 4-butanediol, 1 to 5 parts of pentaerythritol, 2 to 5 parts of hydroxylated dimethylolpropionic acid or dihydroxymethyl butyric acid, 10 to 20 parts of fatty group or alicyclic group isocyanates monomers and 0.1 to 1.0 part of catalysts and solvents; carrying out heating polymerization to obtain hydroxylated urethane resin; and then neutralizing a water dispersoid formed after salt forming, self emulsifying and the solvent removing, wherein the coating-4 viscosity change of the coating stored for 6 months is smaller than 5 percent. After the hydroxylated polyurethane water dispersoid prepared by the method is prepared into a double-ingredient waterborne soft-feel coating, better balance is obtained between the coating film soft feel and the coating film resistance on alcohol and contaminants, and the effect of the hydroxylated polyurethane water dispersoid is proved.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Electrophotographic member, process cartridge and electrophotographic apparatus

ActiveUS8846287B2Quality improvementIncreased durabilityElectrographic process apparatusElectrographic processes using charge patternFilm resistanceSurface layer

Owner:CANON KK

Microwave film resistor, microwave film resistor network module and manufacturing method thereof

InactiveCN101533693AReduce microwave lossReduce areaOther resistor networksResistors adapted for applying terminalsFilm resistanceHigh resistance

The invention discloses a microwave film resistor and a manufacturing method thereof, and belongs to the field of circuit elements. The microwave film resistor comprises a ceramic substrate, a film resistance layer which is adhered to the upper surface of the ceramic substrate and an electrode layer which is adhered to the film resistance layer. The film resistor has the advantages of high precision, high using frequency and high resistance stability. In addition, the invention also discloses a microwave film resistor network module and a manufacturing method thereof, wherein the microwave film resistor network module is formed by integrating three or more microwave film resistors on one module.

Owner:广州翔宇微电子有限公司

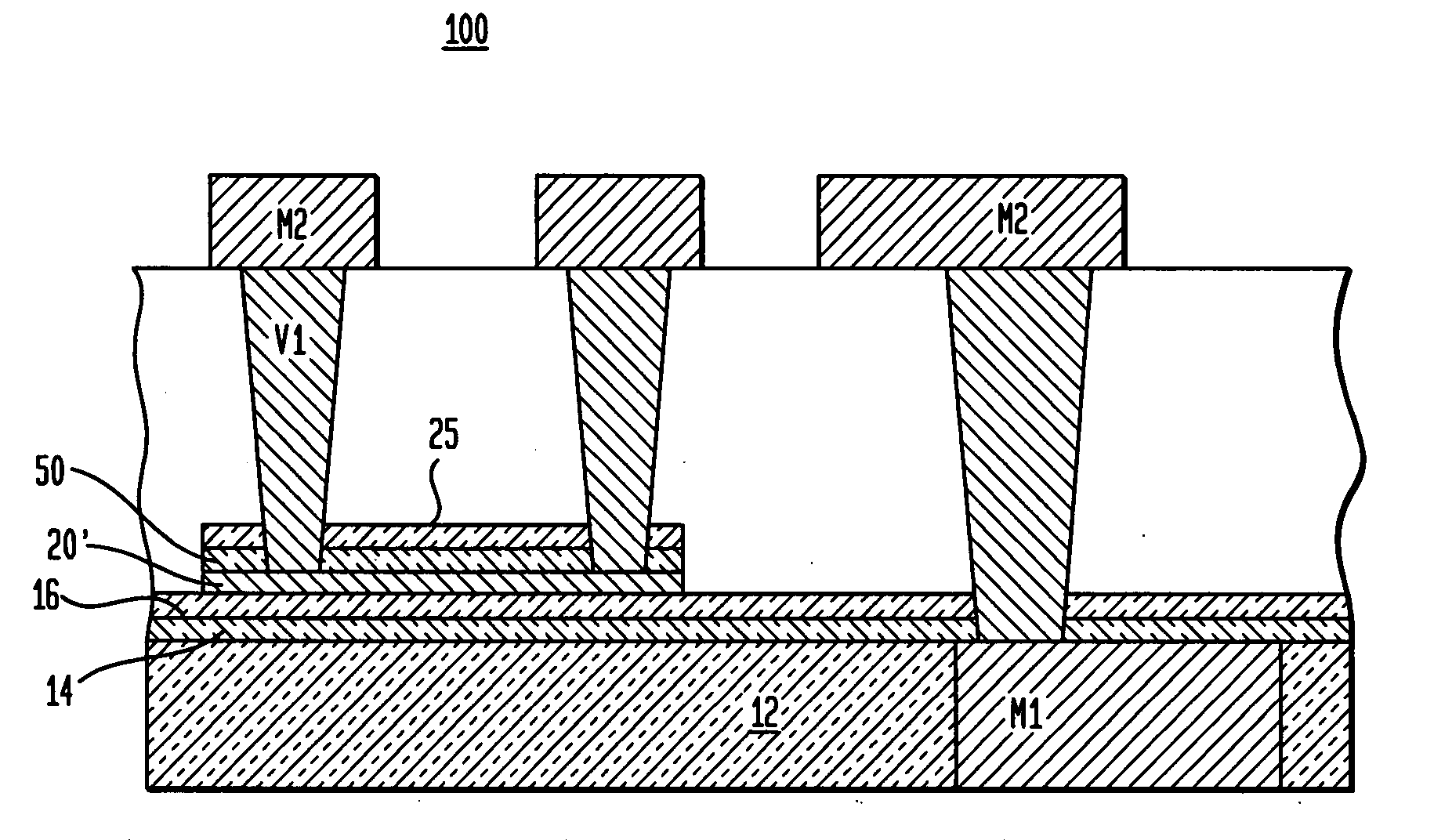

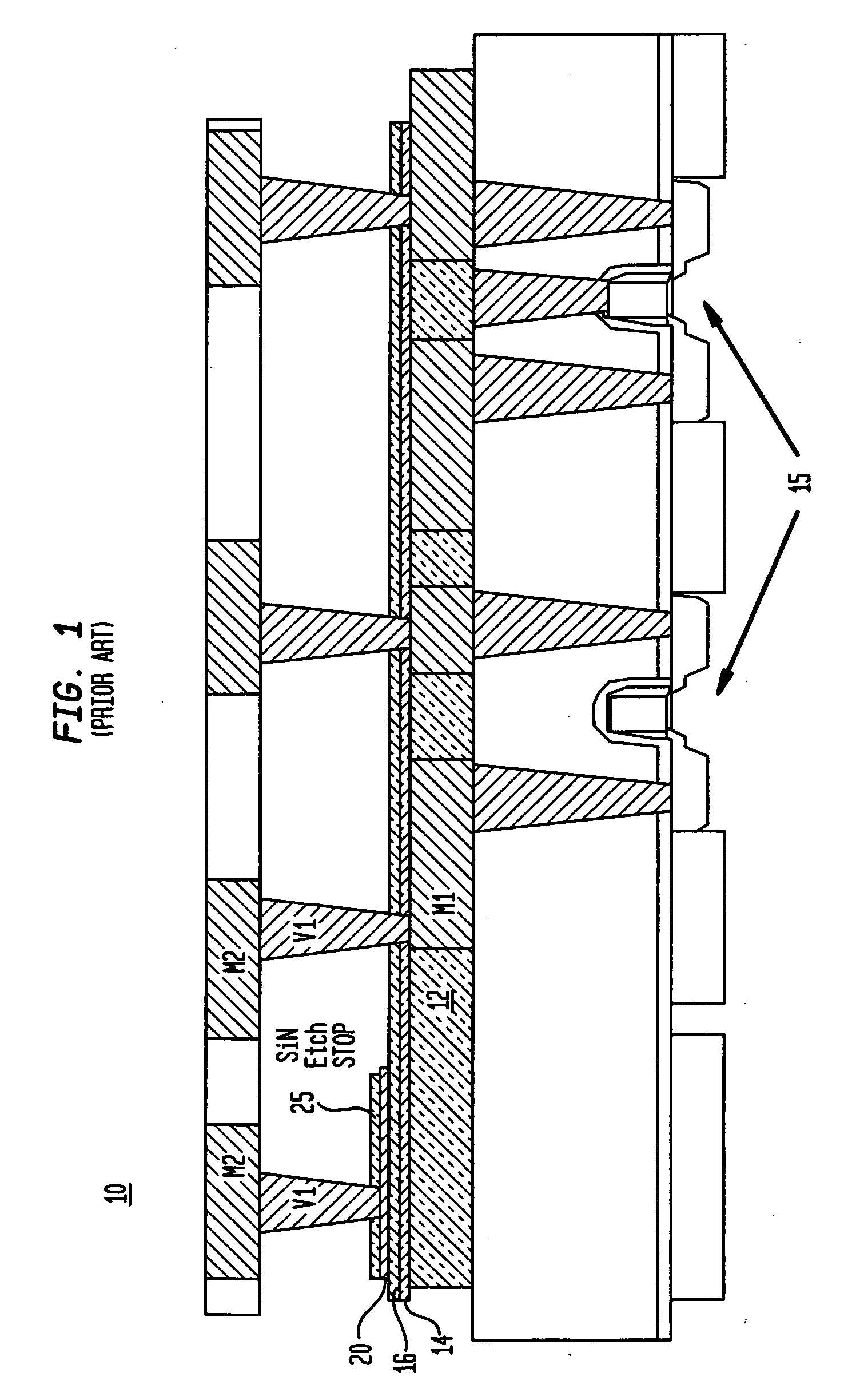

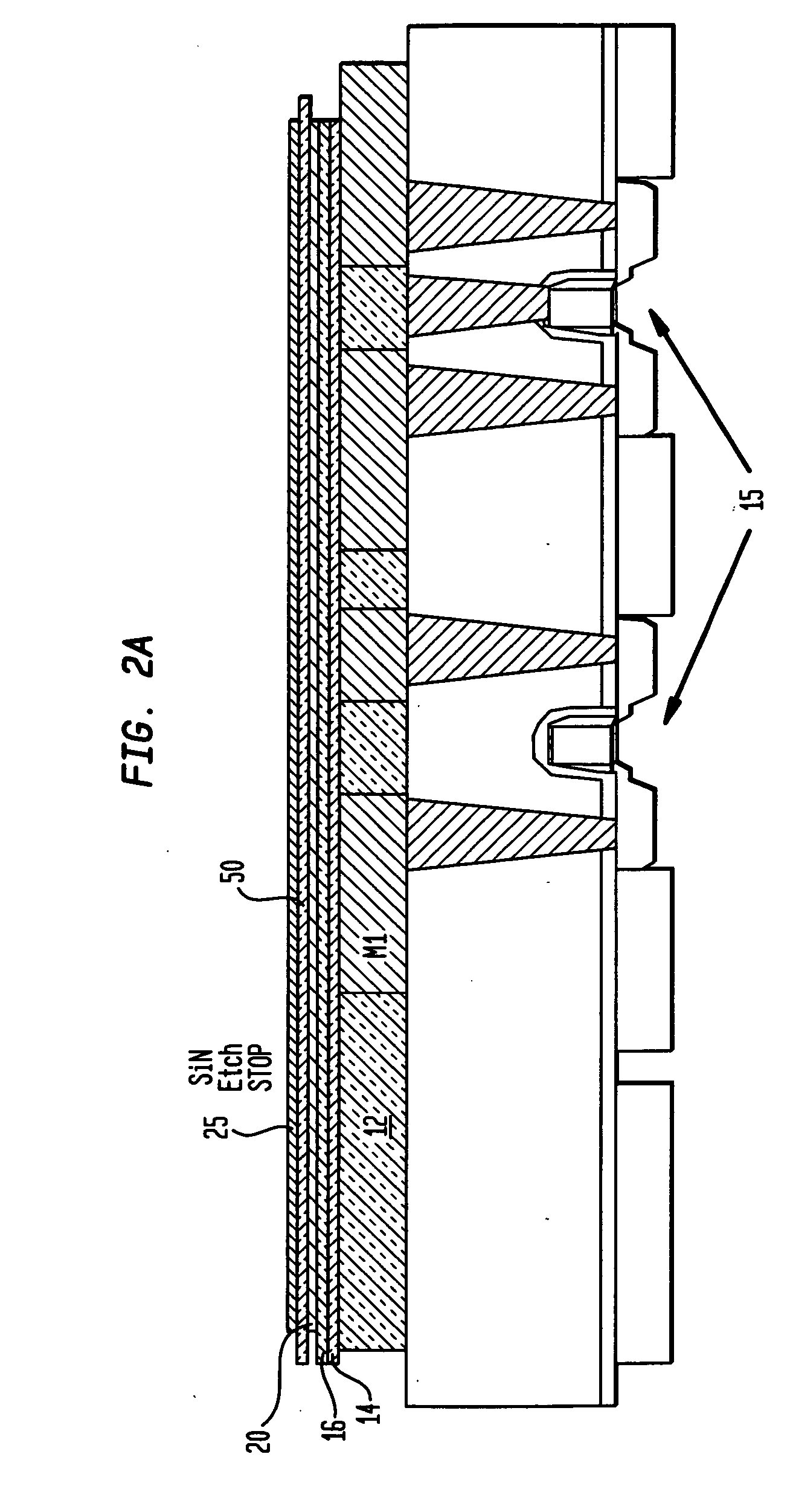

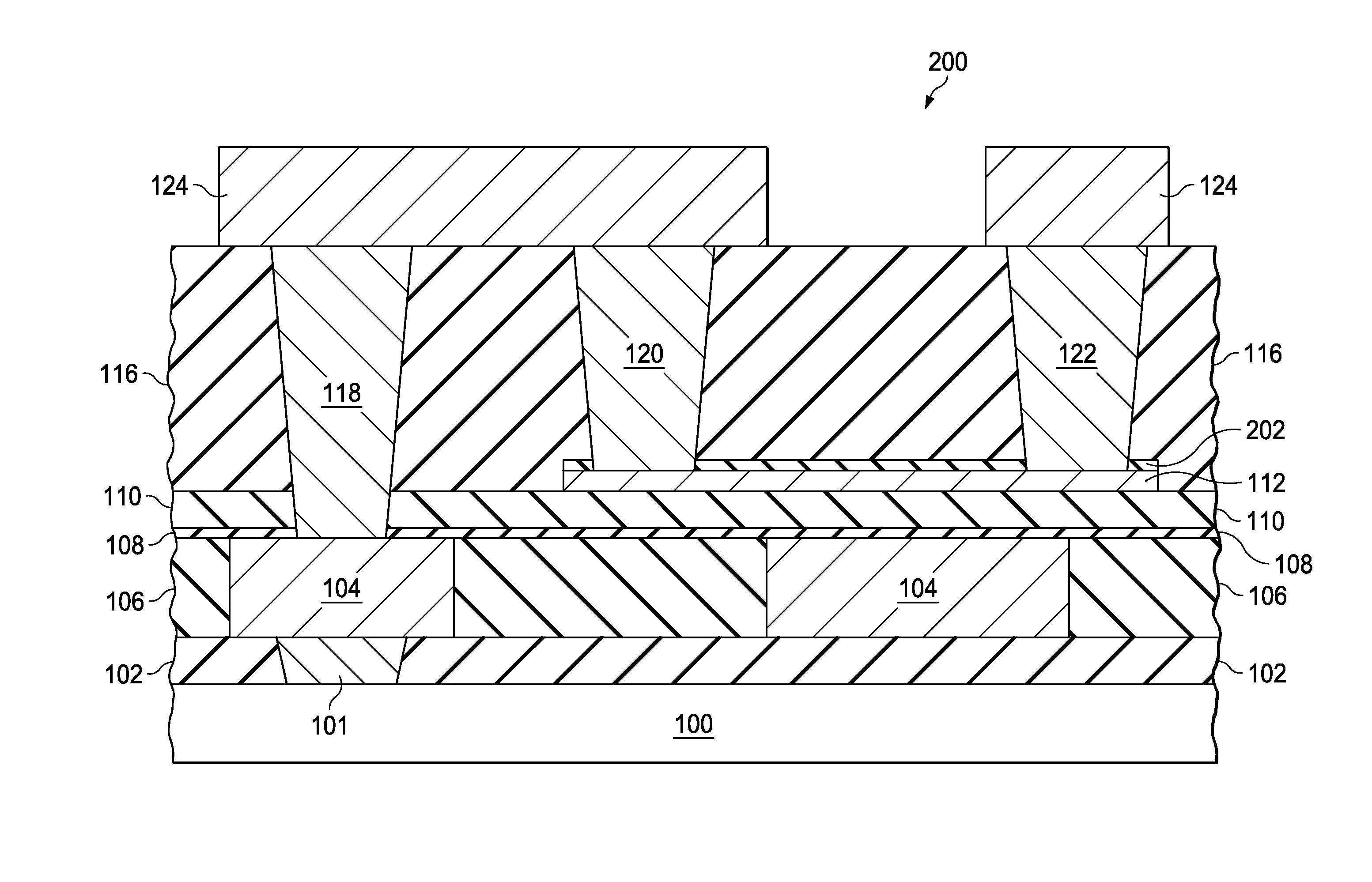

Thin film resistor and dummy fill structure and method to improve stability and reduce self-heating

ActiveUS20060238292A1Improved, inexpensive integrated circuit thin film resistor structureReducing and eliminating inaccuracySemiconductor/solid-state device detailsSolid-state devicesMetal interconnectDielectric layer

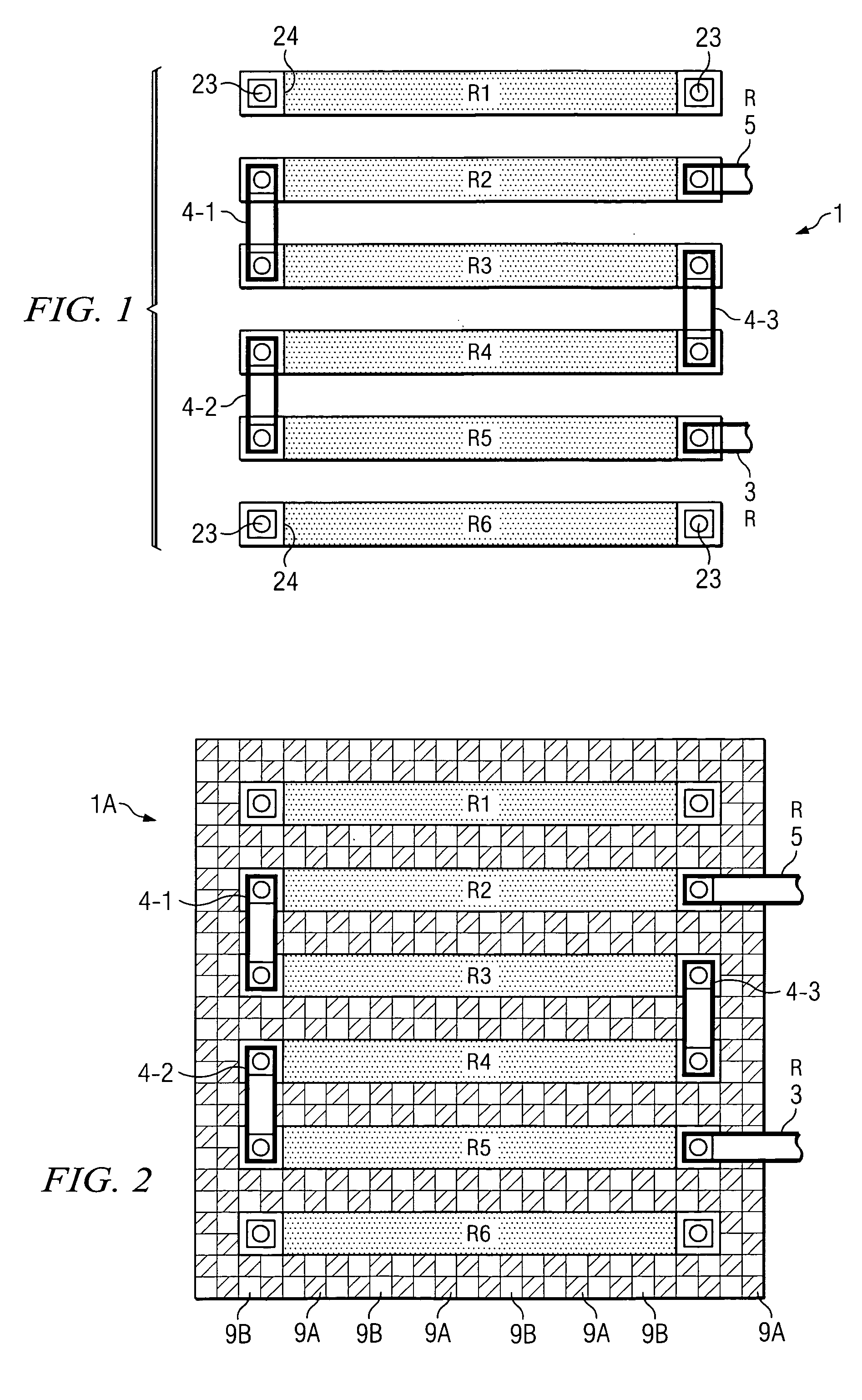

An integrated circuit thin film resistor structure includes a first dielectric layer (18A) disposed on a semiconductor layer (16), a first dummy fill layer (9A) disposed on the first dielectric layer (18B), a second dielectric layer (18C) disposed on the first dummy fill layer (9A), the second dielectric layer (18B) having a first planar surface (18-3), a first thin film resistor (2) disposed on the first planar surface (18-3) over the first dummy fill layer (9A). A first metal interconnect layer (22A,B) includes a first portion (22A) contacting a first head portion of the thin film resistor (2). A third dielectric layer (21) is disposed on the thin film resistor (2) and the first metal interconnect layer (22A,B). Preferably, the first thin film resistor (2) is symmetrically aligned with the first dummy fill layer (9A). In the described embodiments, the first dummy fill layer is composed of metal (integrated circuit metallization).

Owner:TEXAS INSTR INC

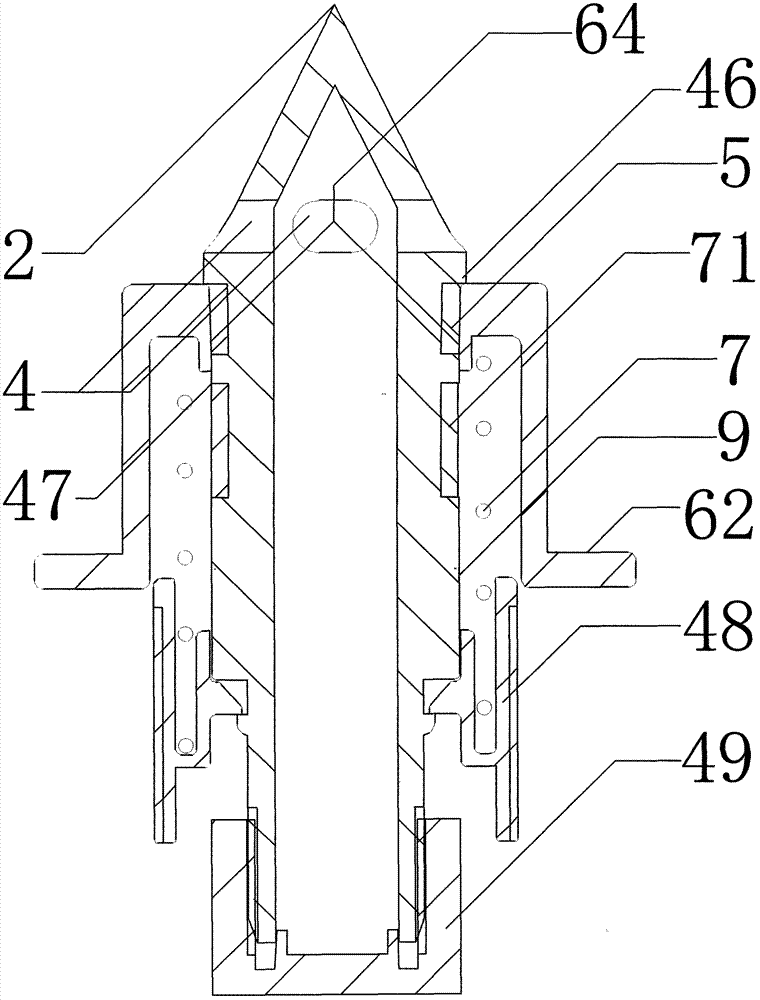

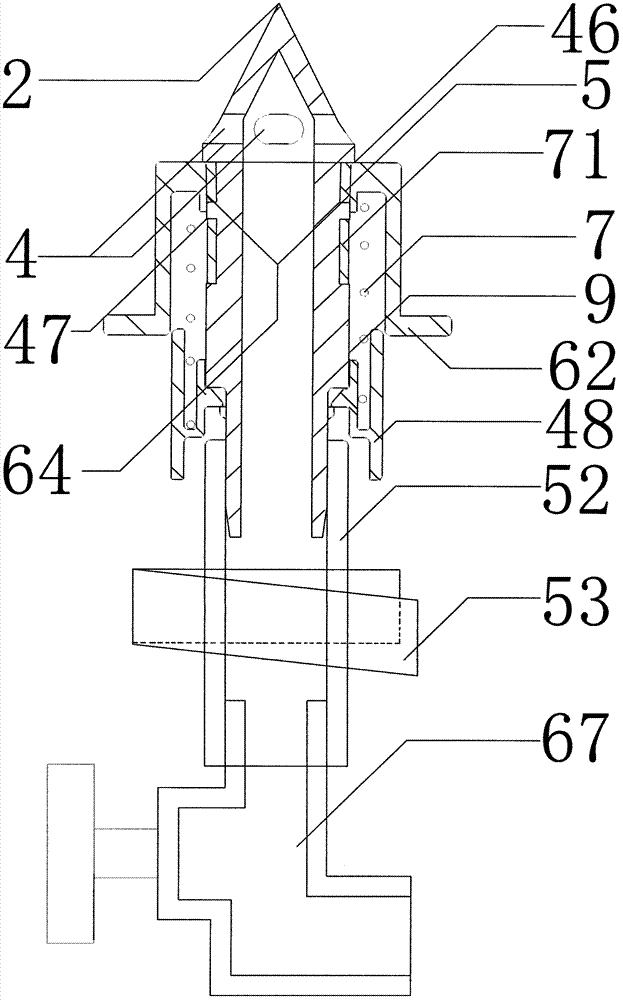

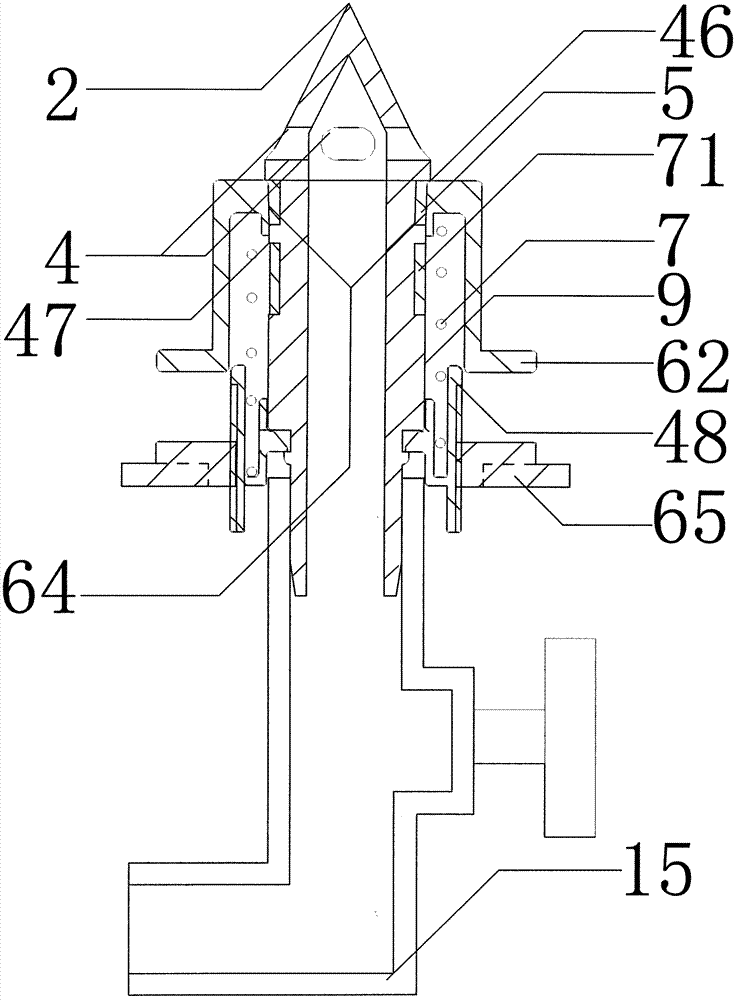

An MEMS heating chip integrating multiple Pt temperature sensors and a manufacture method therefor

ActiveCN108158039ASolution to short lifeWork reliablyTobacco devicesOhmic-resistance heatingElectrical resistance and conductanceEngineering

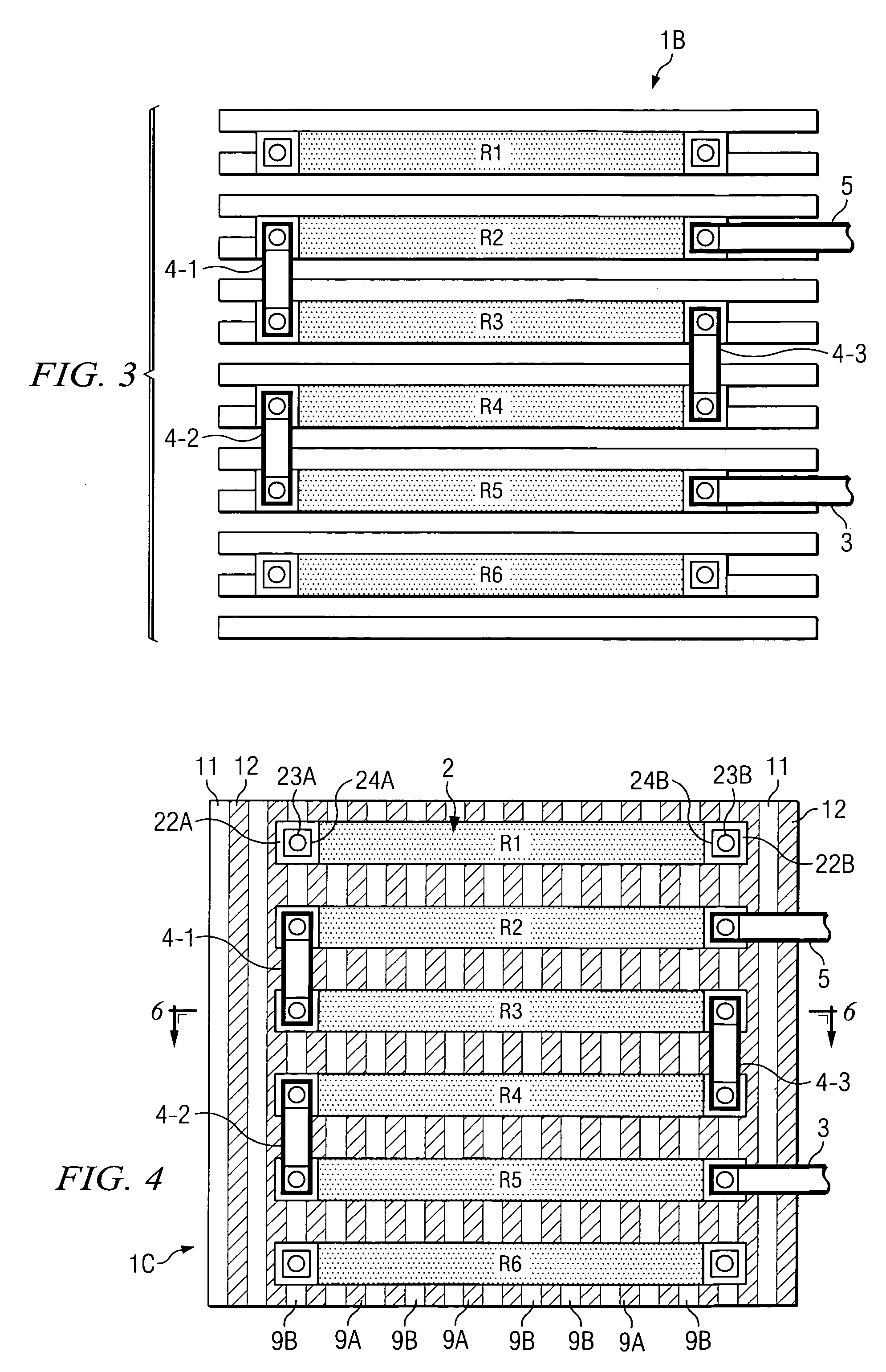

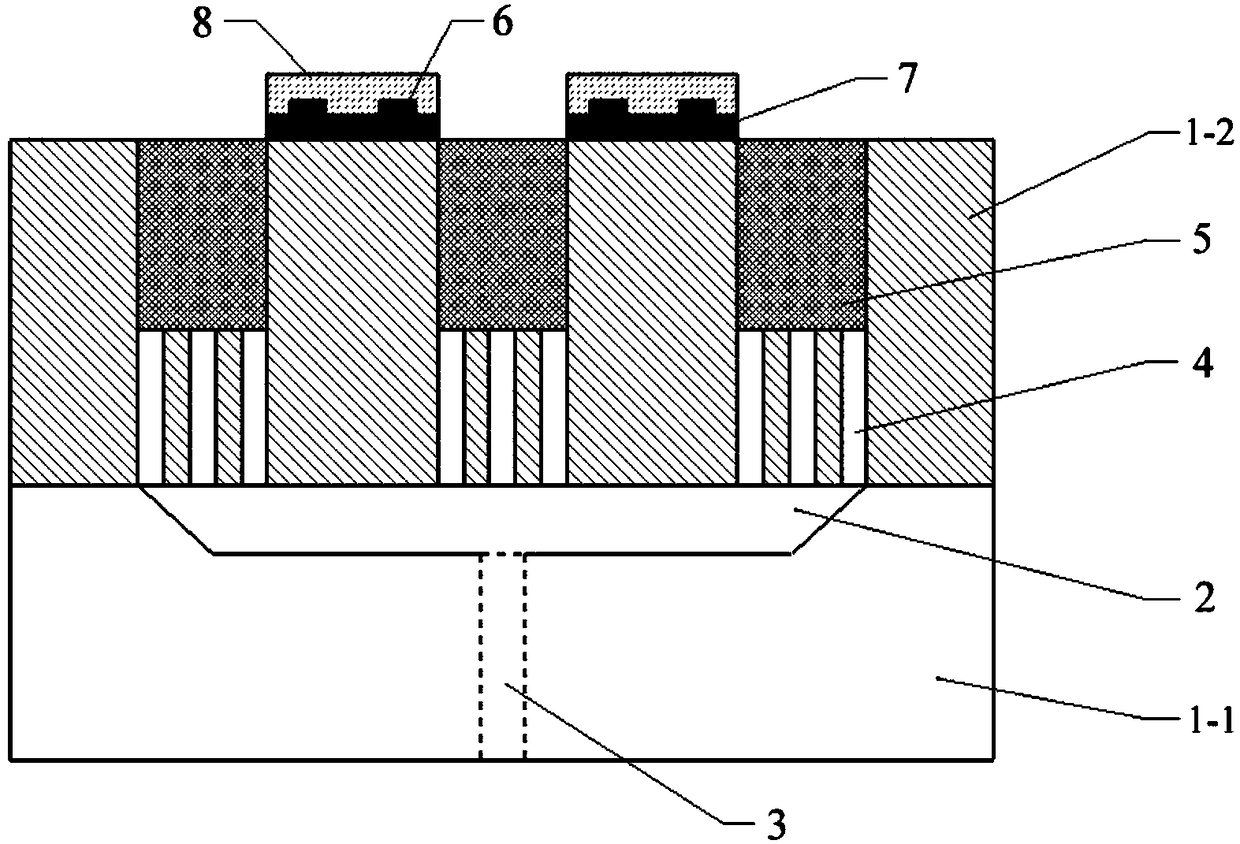

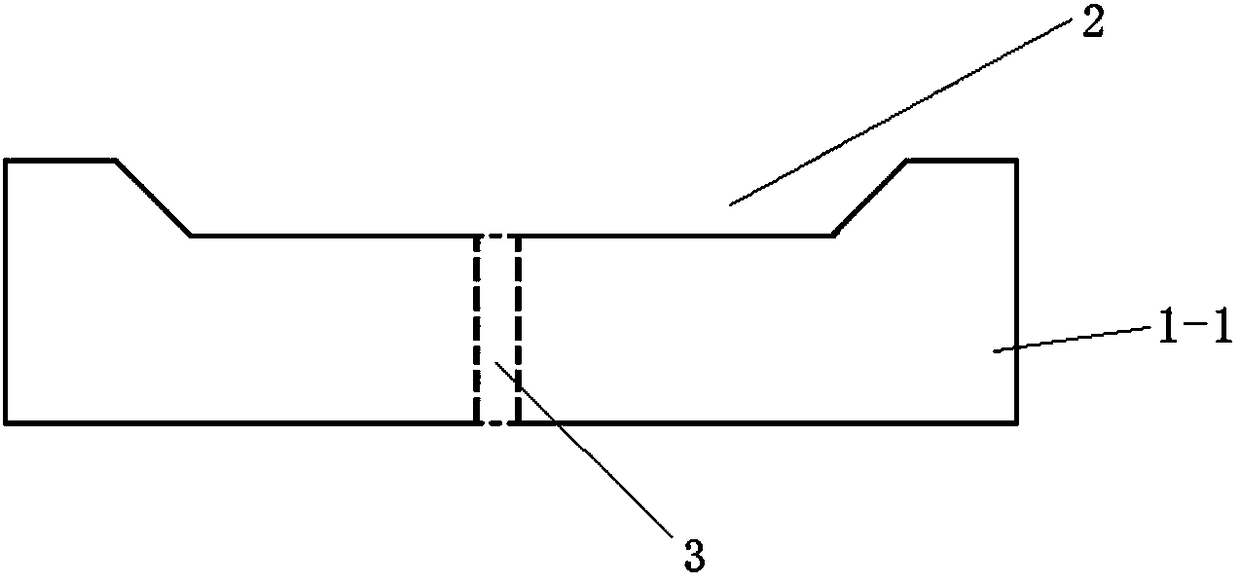

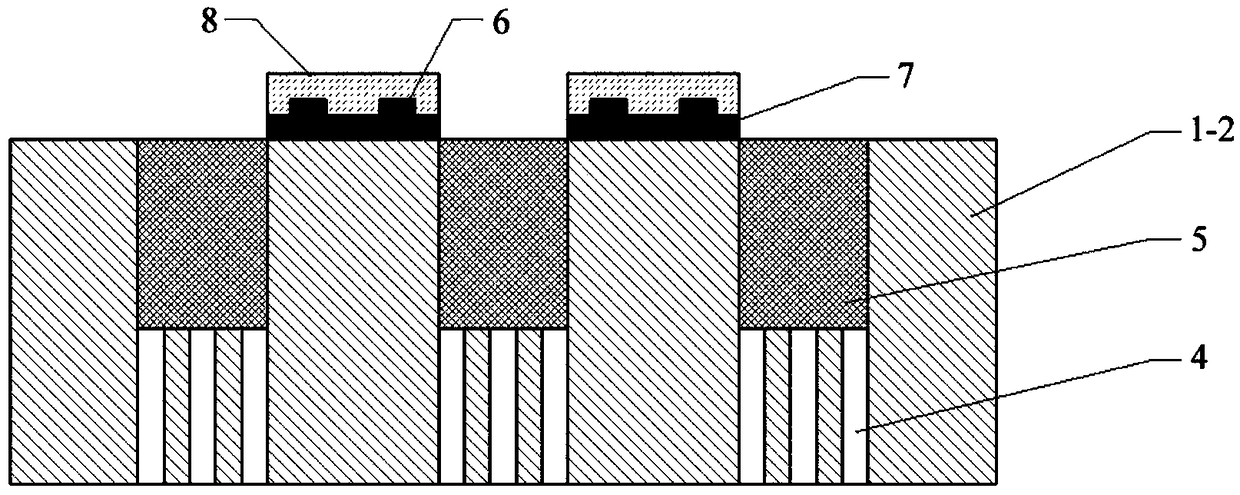

The invention provides an MEMS heating chip integrating multiple Pt thin film resistor temperature sensors. The MEMS heating chip comprises a first substrate (1-1) and a second substrate (1-2). The front side of the first substrate is provided with a concave micro-cavity body (2); a micro-through hole (3) penetrating through the first substrate (1-1) is formed in the micro-cavity body (2); the back side of the second substrate (1-2) is provided with a micro-channel array (4) perpendicular to the back side thereof; the central area of the front side is provided with a multi-hole structure (5) perpendicular to the front side thereof; the micro-channel array (4) communicates with the multi-hole structure (5); the surface of the front side of the second substrate is provided with a plurality of Pt thin film resistor temperature sensors (6); the front side of the first substrate (1-1) and the back side of the second substrate (1-2) are bonded together. The invention also provides a manufacture method for the heating chip. The temperature of the heating chip can be measured in real time and the problem of inaccurate temperature measurement can be effectively avoided.

Owner:CHINA TOBACCO YUNNAN IND

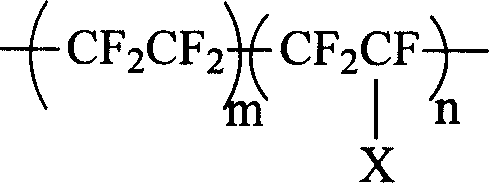

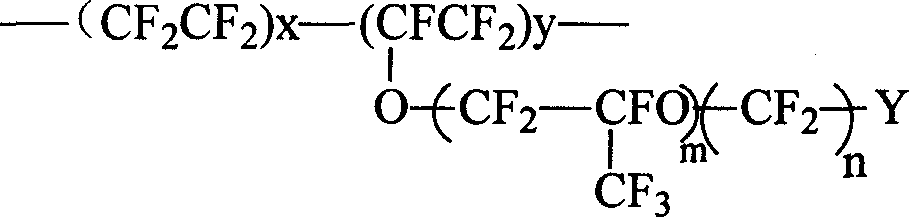

Perfluoro ion exchange solvation reinfercing film and its preparation method

InactiveCN1624202AExtended service lifeImprove bindingOrganic diaphragmsFilm resistancePolymer science

A reinforced perfluoro ion exchange film is composed of at least two layers of ionic film, which prepared from perfluoro ion exchange resin and fused together without interface, at least one layer of perfluoro polymer mesh as reinforcing material and the perfluoro polymer microfibres added to said filming resin. It is prepared through sequential coating. Its advantages are low film resistance, high electric current efficiency, and high mechanical strength and size stability.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

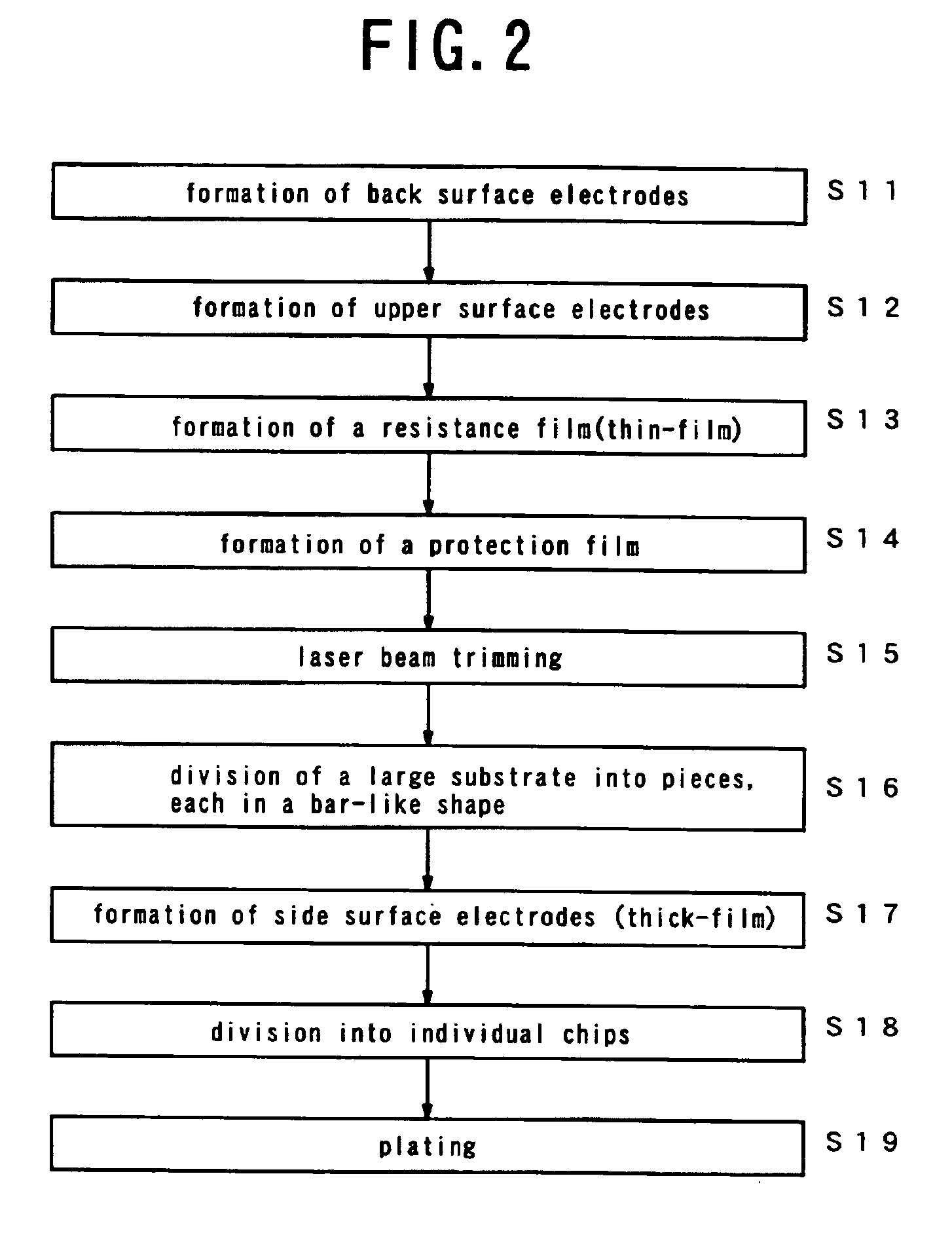

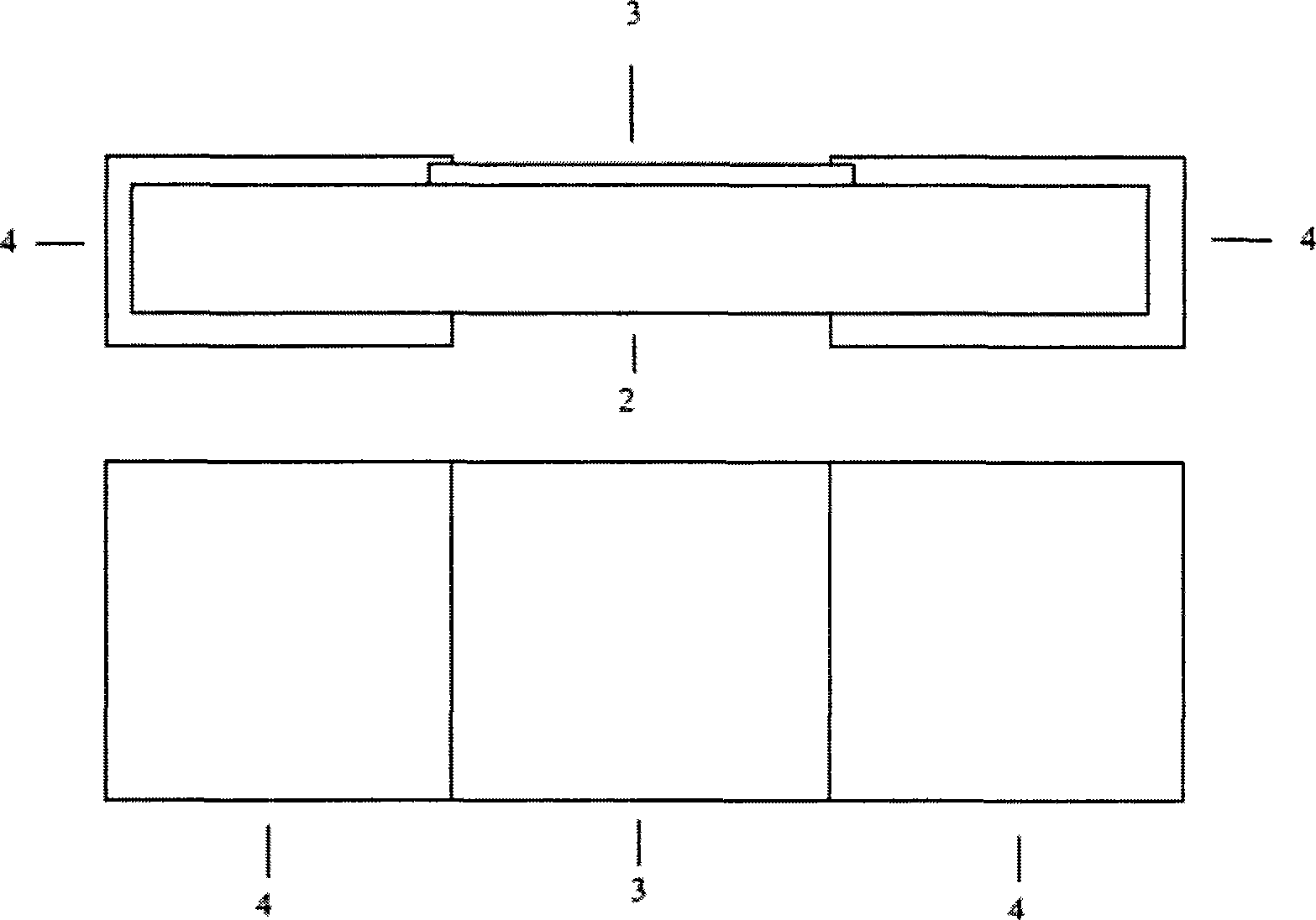

Manufacturing method for plate type thin film resistor

InactiveCN101593588AImprove productivityReduce manufacturing costResistors adapted for applying terminalsResistive material coatingSheet resistanceLaser trimming

The invention discloses a manufacturing method for a plate type thin film resistor, which belongs to a manufacturing method for a plate type resistor. The invention aims to provide a manufacturing method for producing the plate type thin film resistor with high productivity and low cost. The manufacturing method comprises the manufacture of a gauge, a back electrode and a resistor body, encapsulating, trimming, splintering, sintering, end coating and electroplating; and the concrete steps comprise substrate burnishing and cleaning, printing for the gauge and the back electrode, electrode sintering, baffle layer printing, vacuum sputtering, baffler layer removing, thermal treatment, laser trimming, protective layer printing, protective layer curing, primary splintering, end coating for the electrode, end electrode sintering, secondary splintering, nickel plating and tinlead plating. The manufacturing method has the advantages of high productivity, low cost and the like, and is an ideal method for producing the plate type thin film resistors on a large scale.

Owner:CHINA ZHENHUA GRP YUNKE ELECTRONICS

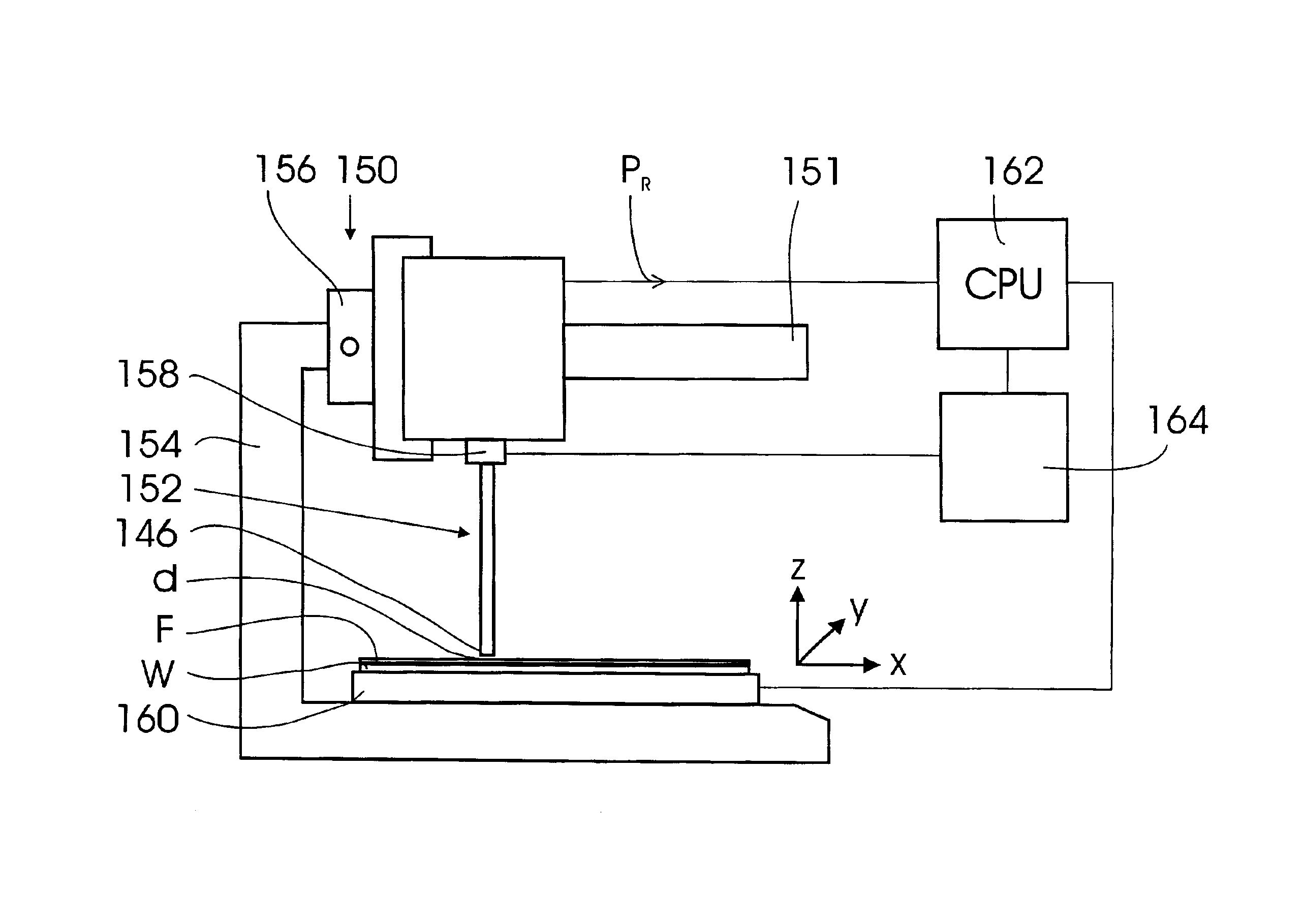

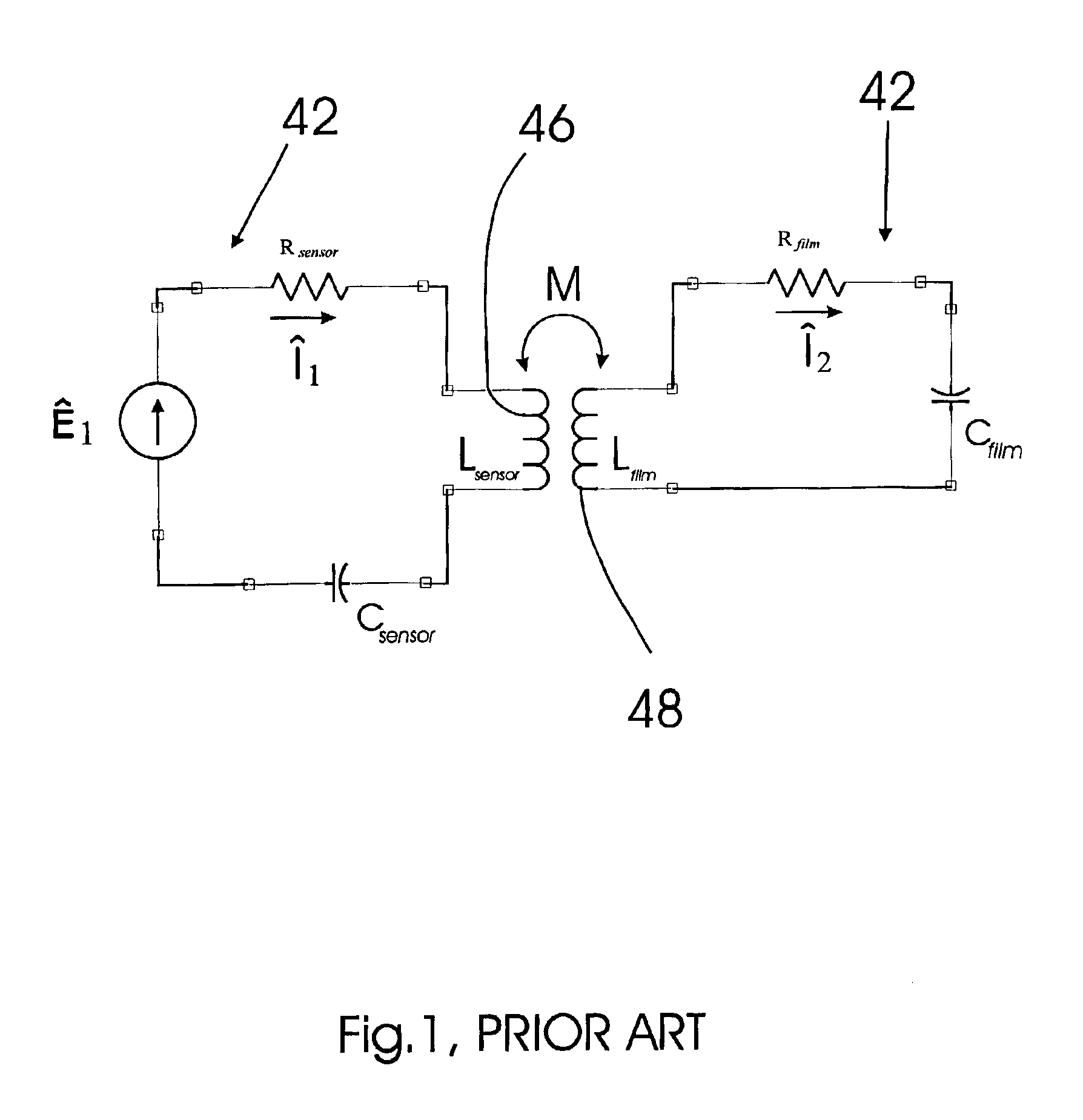

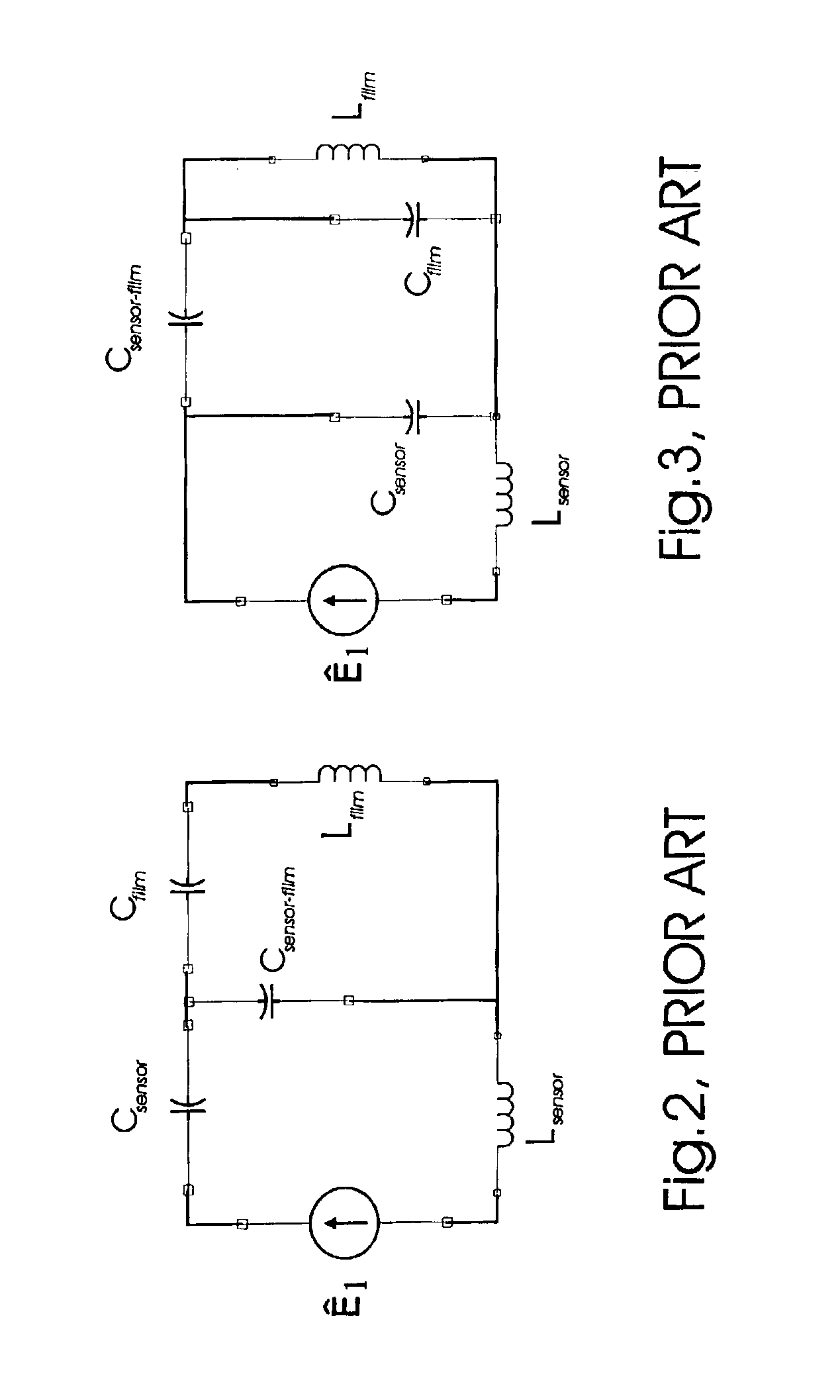

System and method for measuring characteristics of materials with the use of a composite sensor

InactiveUS6891380B2Improve accuracySuitable for useResistance/reactance/impedenceMagnetic property measurementsPhysicsFilm resistance

The system of the invention for measuring characteristics of thin conductive and non-conductive material, such as bulk material or films, is based on the use of a resonance oscillating circuit that incorporates at least two components selected from the group consisting of an inductive coil and a capacitor, which in combination form a sensor that could be approached close to the surface to be measured. The measurement of the film or material characteristics, such as film resistance (film thickness) or a dielectric constant (film thickness) of a non-conductive material, is based on the principle that the sensor is approached to the measured surface at a distance, at which the inductance and capacitance of the sensor generate in the measured material a virtual coil and an additional capacitance, which strongly depend on the characteristics of the measured material. As the sensor approached towards the surface to be measured, the sensor-material system generates a series of resonances having different values of power. One of these resonances can be defined as the so-called full resonance, which is characterized by the maximum value of the power, and hence provides the most accurate measurement and can be used for precisely determining the measurement distance. By comparing the results of measurements with those known from measuring the precalibrated films or materials under the same conditions, it becomes possible to determine the target characteristics of the films or materials.

Owner:MULTIMETRIXS

Radiant heater

InactiveUS20080056694A1Prevent moistureFluid heatersElectric heating systemRadiant heaterPortland cement

A thick film, large area resistance heater including a substrate having an electrically non-conductive surface on which is deposited a film electrical resistor such as a thermally sprayed, photo resist etched foil or sol-gel graphite based material. A combination of an electrically conductive film coated backer board substrate composed of portland cement, sand, cellulose fibers and other selected additives. A mica substrate heater can be cemented to a cement backer board or a vinyl with adhesive backing.

Owner:COOPER RICHARD

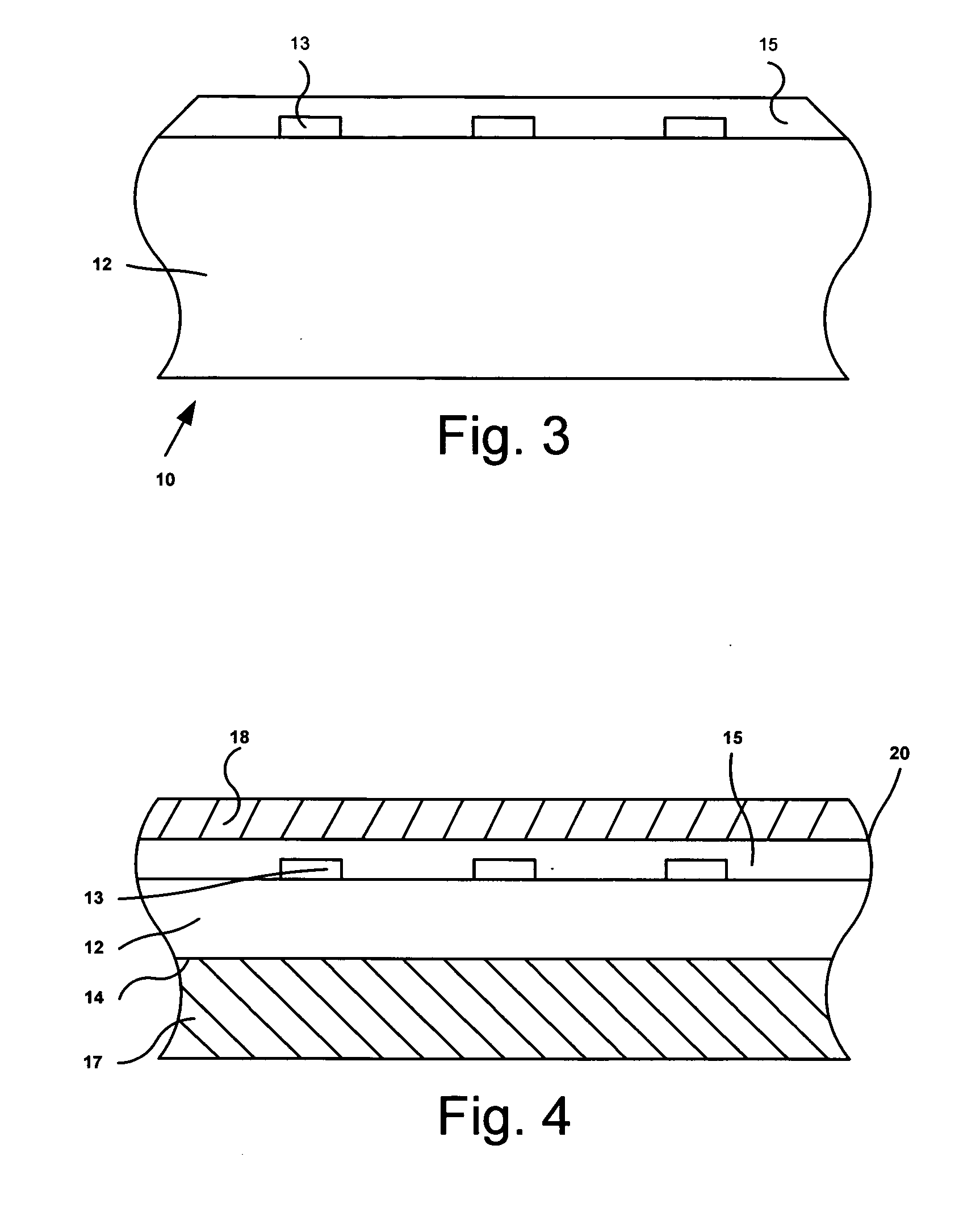

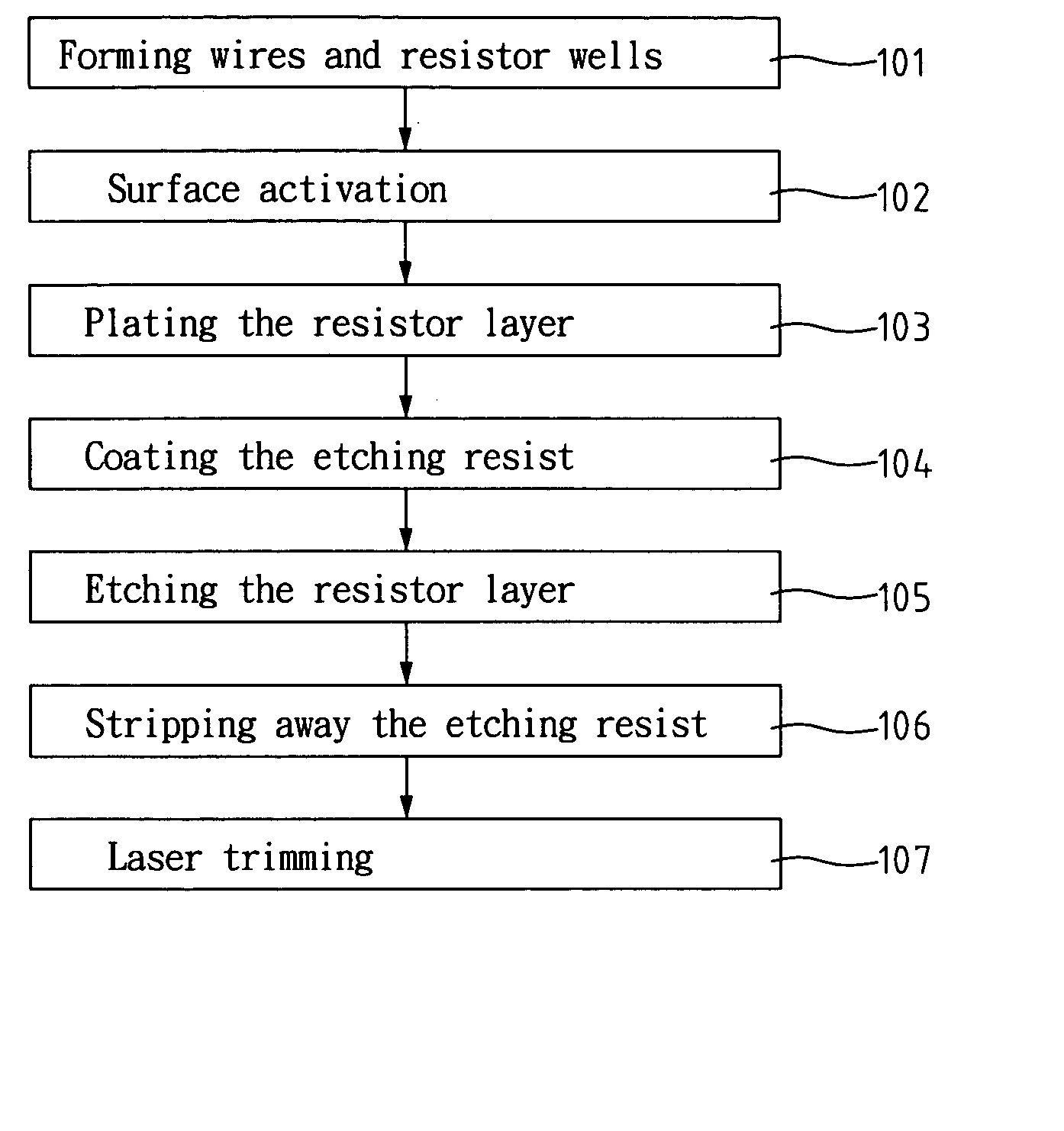

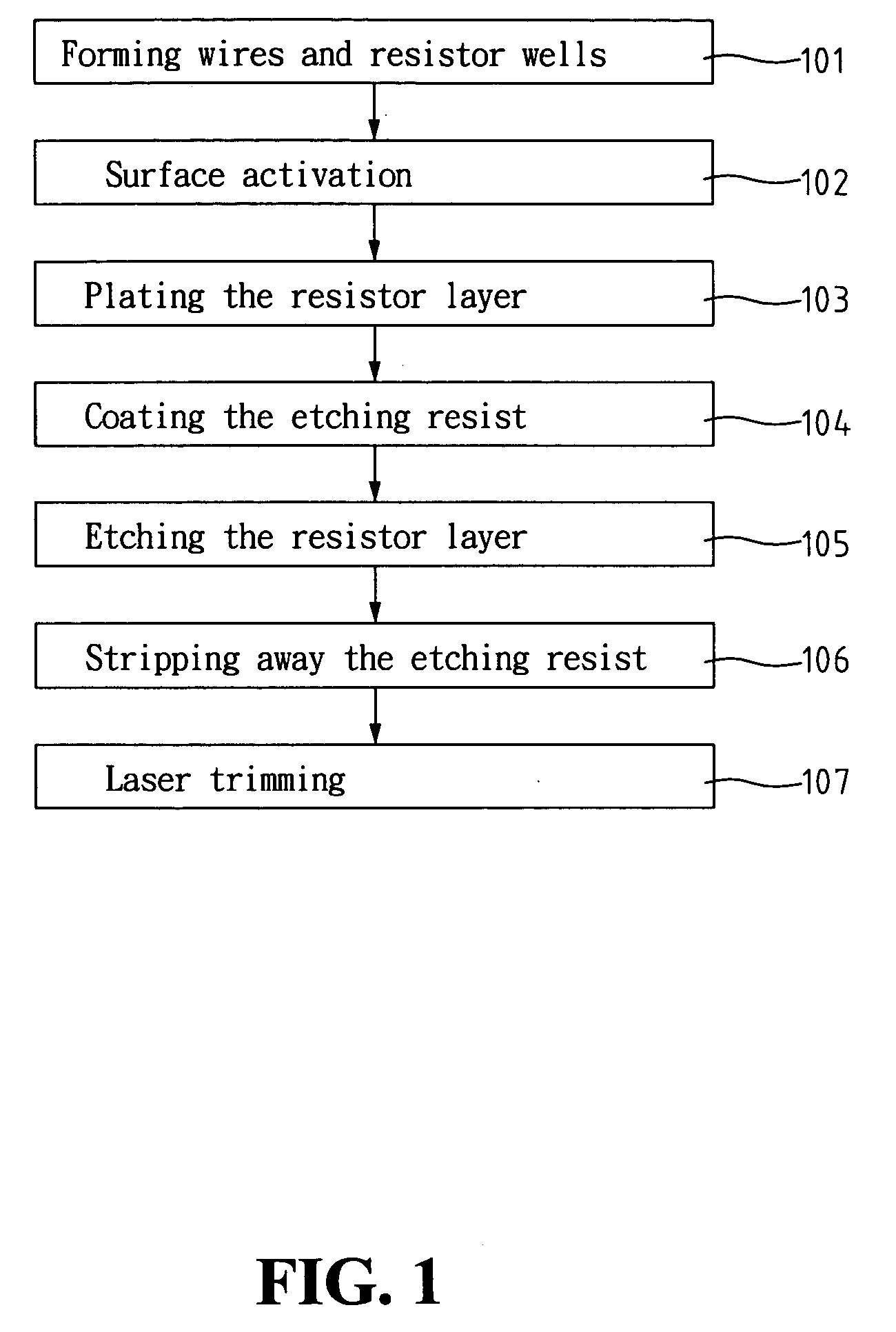

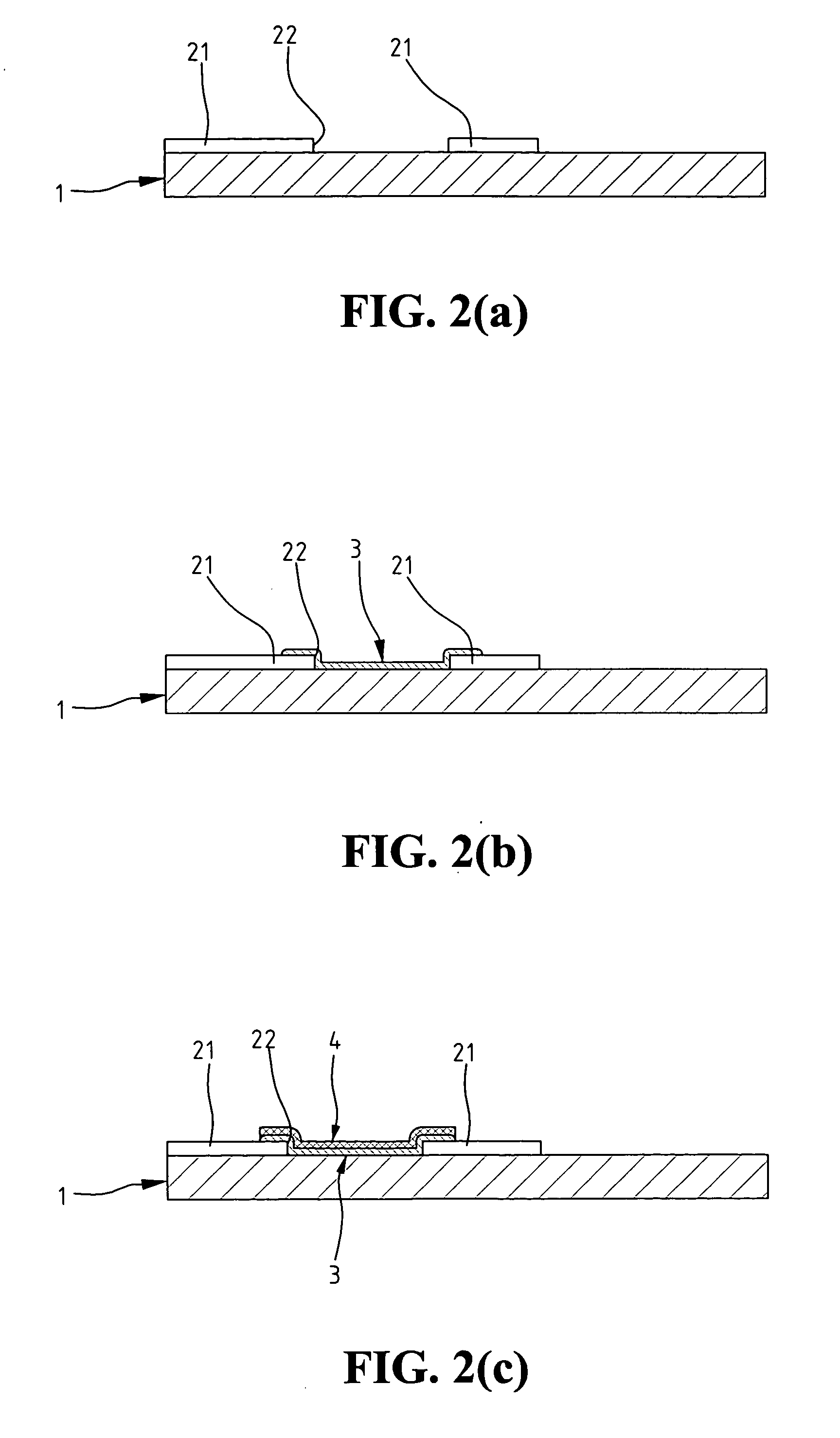

Method for fabricating embedded thin film resistors of printed circuit board

InactiveUS20050196966A1Finer circuit layoutSmall sizePrinted circuit assemblingElectrically conductive connectionsManufacturing cost reductionHigh volume manufacturing

A method for fabricating the embedded thin film resistors of a printed circuit board is provided. The embedded thin film resistors are formed using a resistor layer built in the printed circuit board. Compared with conventional discrete resistors, embedded thin film resistors contribute to a smaller printed circuit board as the space for installing conventional resistors is saved, and better signal transmission speed and quality as the capacitive reactance effect caused by two connectors of the conventional resistors is avoided. The method for fabricating the embedded thin film resistors provided by the invention can be conducted using the process and equipment for conventional printed circuit boards and thereby saving the investment on new types of equipment. The method can be applied in the mass production of printed circuit boards and thereby reduce the manufacturing cost significantly.

Owner:SU SUNG LING

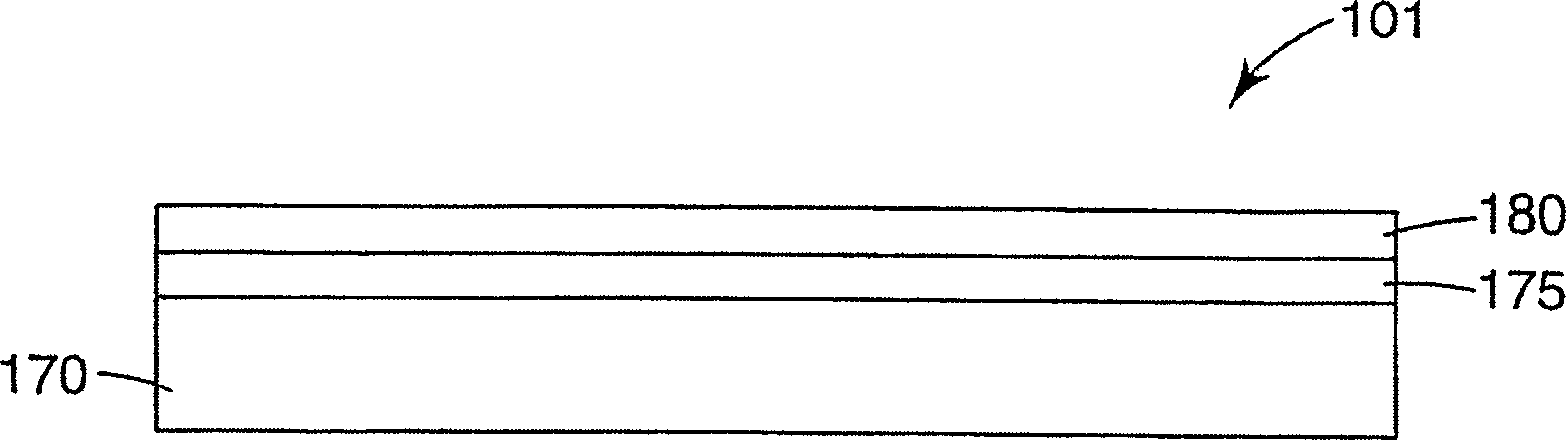

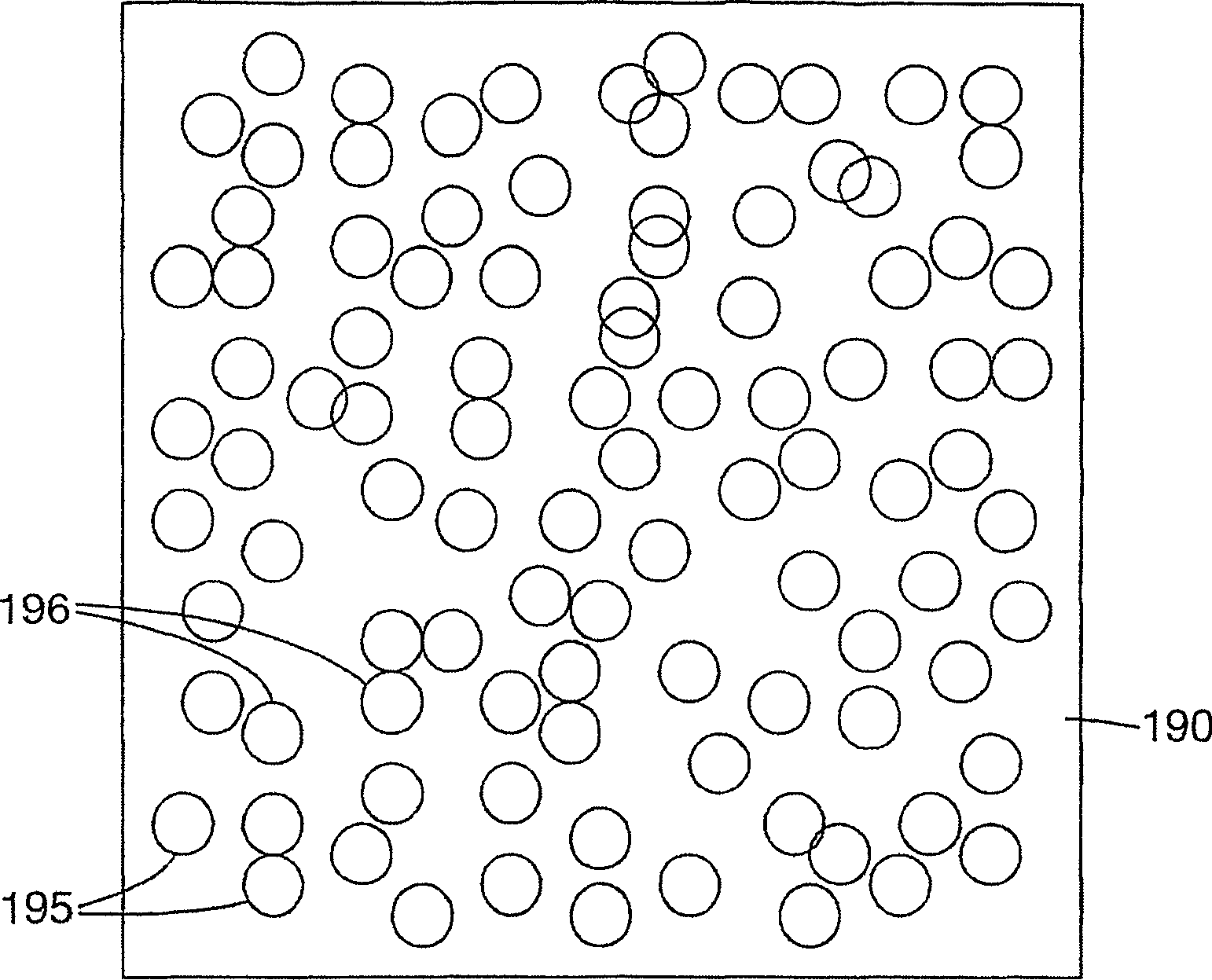

High transparency touch screen

A touch sensor employs one or more transparent conductors including a random pattern of voids. These voids are arranged according to a random pattern that maintains the electrical continuity of the transparent conductive layer. Touch sensors are fabricated by depositing a layer of transparent conductor and forming voids in the transparent conductor. The sheet resistance of selected conductive layers can be obtained by forming voids, as well as increasing light transmission through the touch sensor.

Owner:3M INNOVATIVE PROPERTIES CO

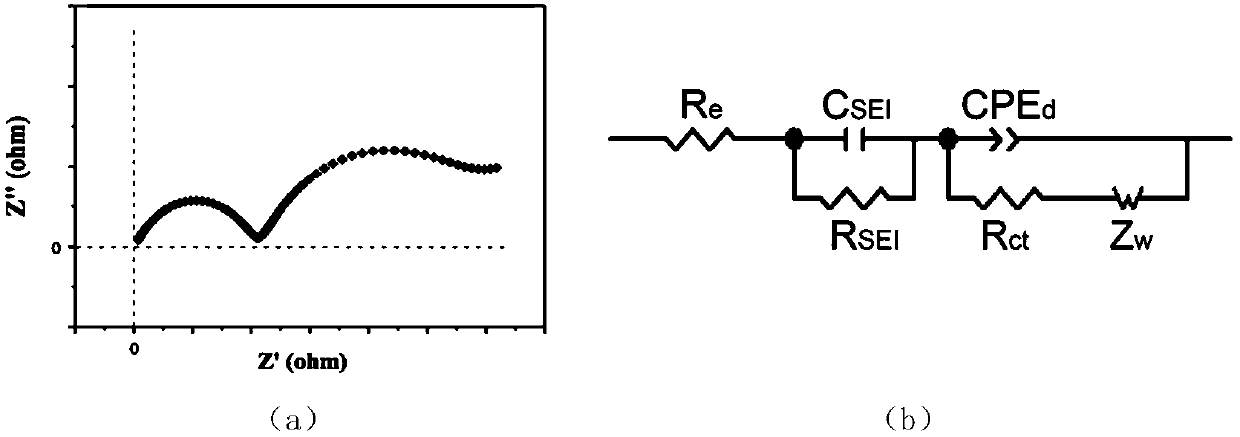

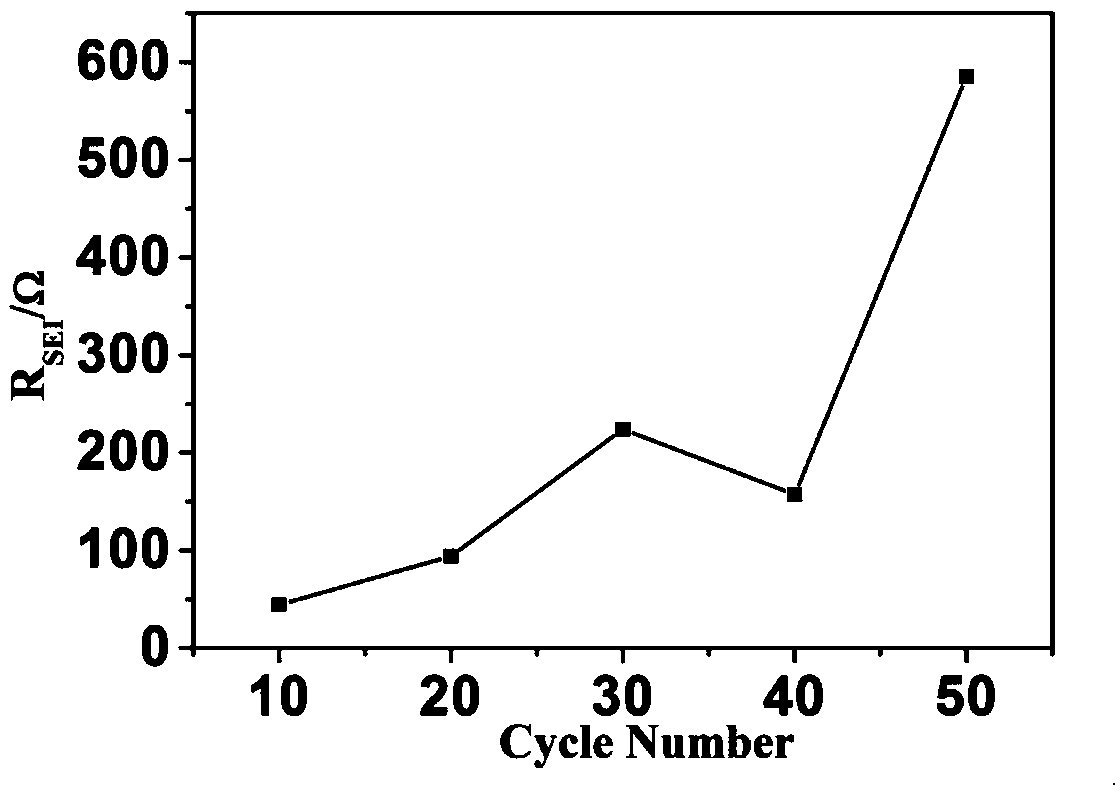

Lithium ion battery failure analysis method based on alternating current impedance method

ActiveCN109581240AAssess lifeAssess securityElectrical testingSecondary cells charging/dischargingFilm resistanceElectrical battery

The invention provides a lithium ion battery failure analysis method based on an alternating current impedance method. The safety performance of a lithium-ion battery has attracted much attention, anda negative electrode of the lithium ion battery is easily subjected to lithium evolution under the abuse condition, so that a lithium dendritic crystal is formed, and thermal runaway or even explosion of the battery is caused. According to the lithium ion battery failure analysis method based on the alternating current impedance method provided by the invention, an electrochemical alternating current impedance testing method is adopted, a relationship between an alternating current impedance spectrum signal and the internal environment of the battery is analyzed, the SEI film resistance change can be analyzed from an alternating current impedance spectrum, and therefore the state of short circuit in the dendritic crystal of the battery can be quickly and accurately predicted without damaging the battery, thereby evaluating the service life and the safety of the battery.

Owner:BEIHANG UNIV

Middle temperature sintering thick-film resistance paste based on high-temperature-resistant flexible substrate and preparation method thereof

InactiveCN105976894AAvoid harmSolve urgent problemsNon-conductive material with dispersed conductive materialCable/conductor manufactureFilm resistanceOrganic solvent

The invention discloses middle temperature sintering thick-film resistance paste based on a high-temperature-resistant flexible substrate and a preparation method thereof. The thick-film resistance paste comprises an inorganic bonding phase, a composite function phase, a TCR regulator and an organic carrier. The inorganic bonding phase is formed by SiO2, Bi2O3, B2O3, P2O5, Al2O3, Li2O and CaF2; the composite function phase is formed by micron flake silver powders, micron spherical silver powders and nanometer silver powders; and the organic carrier is formed by organic solvents, macromolecule thickeners, high-temperature-resistant organic resin, surfactants, plasticizers, dispersants, antifoaming agents and thixotropic agents. The preparation method comprises the steps of preparation of the inorganic bonding phase, preparation of the composite function phase, preparation of the organic carrier and preparation of the resistance paste. The thick-film resistance paste is low in sintering temperature, short in sintering time, large in adhesive force, resistant to aging, high in flexibility, adjustable in square resistance, low and adjustable in resistance temperature coefficient and excellent in printing characteristic and sintering characteristic, and can be matched with the high-temperature-resistant flexible substrate.

Owner:DONGGUAN COREHELM ELECTRONICS MATERIAL TECH CO LTD

Method for producing conducting and transparent films from combined graphene and conductive nano filaments

ActiveUS8871296B2Reduce sheet resistanceIncrease speedTransportation and packagingMetal-working apparatusFilm resistanceOptical transmittance

A method of producing a transparent and conductive film, comprising (a) forming aerosol droplets of a first dispersion comprising a first conducting nano filaments in a first liquid; (b) forming aerosol droplets of a second dispersion comprising a graphene material in a second liquid; (c) depositing the aerosol droplets of a first dispersion and the aerosol droplets of a second dispersion onto a supporting substrate; and (d) removing the first liquid and the second liquid from the droplets to form the film, which is composed of the first conducting nano filaments and the graphene material having a nano filament-to-graphene weight ratio of from 1 / 99 to 99 / 1, wherein the film exhibits an optical transparence no less than 80% and sheet resistance no higher than 300 ohm / square.

Owner:GLOBAL GRAPHENE GRP INC

Glass cream for protective coating and thick film resistance element

ActiveCN1974457AImprove air tightnessImprove acid resistanceNon-metallic protective coating applicationResistive material coatingFilm resistanceAir tightness

The present invention provides a glass paste for protection coating. The glass paste does not contain lead basically, and can be sintered under low temperature specially under the temperatures below 700 DEG C, also the air-tightness and chemistry endurance, especially acid resistance are excellent. Laser trimming can be easily carried out without damaging resistance stability when glass paste is used as precoated layer glass of thick film resistance element. A glass paste for protection coating has a character that said low melting point glass does not contain Pb basically, represented with the mol % of oxide, containing SiO2: 20 to 50 percents, Al2O3: 0.5 to 10 percents, chosen from at least one of BaO and SrO: 5 to 35 percents, ZnO: 5 to 35 percents, TiO2: 1 to 10 percents, chosen from at least one of Li2O, Na2O and K2O: 1 to 13 percents, B2O3: 0 to 20 percents, chosen from at least one of WO3 and MoO3: 0 to 5 percents.

Owner:SHOEI CHEM IND CO LTD

Metal thin film resistor and process

ActiveUS20150187632A1Semiconductor/solid-state device detailsSolid-state devicesFilm resistanceLithographic artist

An integrated circuit with a metal thin film resistor with an overlying etch stop layer. A process for forming a metal thin film resistor in an integrated circuit with the addition of one lithography step.

Owner:TEXAS INSTR INC

Current collector as well as pole piece and battery and application thereof

ActiveCN109873163AImprove job stabilityExtended service lifeFinal product manufactureElectrode carriers/collectorsElectrical batteryCurrent collector

The invention relates to the field of batteries, in particular to a current collector as well as a pole piece and a battery and an application thereof. The current collector comprises an insulation layer with a supporting function and a conductive layer with a conductive and current collection function, wherein a normal-temperature thin-film resistance RS of the conductive layer satisfies: RS is greater than or equal to 0.01 omega and less than or equal to 0.15 omega. By adopting the current collector, the short-circuit resistance when in short circuit under the abnormal condition of a batterycan be greatly increased, so that the short-circuit current is greatly reduced, the short-circuit heat can be greatly reduced, and the safety performance of the battery can be greatly improved; and in addition, due to the small heat yield, the heat produced at a point having the internal short circuit can be completely absorbed by the battery, the temperature increase of the battery is small, sothat the influence of the short-circuit damage for the battery can be limited in a range of the point, and only the point short circuit is formed without influencing the normal work of the battery ina short time.

Owner:CONTEMPORARY AMPEREX TECH CO

Taking machine for liquid or ropy material with better liquidity in high-capacity plastic flexible package

InactiveCN102765518ALow costImprove economyArticle unpackingDischarging meansFilm resistanceStopcock

The invention relates to a taking machine for liquid or ropy material with better liquidity in a high-capacity plastic flexible package. The taking machine comprises a thimble provided with a limit table and a film resistance table, a locking slide bush A or a locking slide bush B or a locking slide bush C or a base provided with a locking face, a locking seal part, a seal element, a spring, a spring slot, a stopcock or a valve or a water suction pump and a cover or a plug. The beneficial effects of the taking machine are as follows: the possibility that the material in the high-capacity plastic flexible package outflows during the package puncturing process or leaks due to imperfect sealing in use process is completely eradicated; the taking machine provided by the invention can be independently or be connected with a clamp, a stopcock and a valve or a water suction pump for being repeatedly applied to the high-capacity plastic flexible package; and based on the taking machine, a novel portable taking machine, or a connecting device or an all-in-one machine in upper material taking pipeline connecting type, an upper material taking floater connecting type, a lower material taking fixing thimble pipeline connecting type, a lower material taking fixing thimble floater connecting type, a lower material taking movable thimble pipeline connecting type and a lower material movable thimble floater connecting type can be assembled.

Owner:欧阳军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com