Perfluoro ion exchange solvation reinfercing film and its preparation method

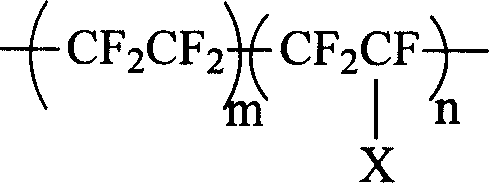

A technology of perfluorinated ions and perfluorosulfonic acid ions, applied in the direction of organic diaphragms, electrolytic processes, electrolytic components, etc., can solve problems such as delamination, affecting service life, and not reaching the molecular level, so as to improve service life and combine perfect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] with tetrafluoroethylene and

[0063] Wherein m=0-3, n=2 or 3 copolymerize to obtain perfluorosulfonic acid resin, the IEC value of this kind of resin is 1.18mmol / g, after resin is converted into Na type, be dissolved in dimethyl sulfoxide, then put The solution is concentrated to 18%, and polytetrafluoroethylene reinforced microfibers with a resin weight of 5% are added, the length of the microfibers is 0.05-30 μm, and the diameter is 0.02-50 μm. Apply the obtained slurry on release paper and dry at 170°C for 1.5 minutes to obtain the first ion exchange layer with a thickness of 45 μm;

[0064] The perfluorosulfonic acid resin with an IEC value of 1.05 mmol / g was converted into Na form and dissolved in dimethyl sulfoxide, and then the solution was concentrated to 18% for the second ion exchange layer.

[0065] Spread polytetrafluoroethylene mesh cloth on the first ion exchange layer, the mesh cloth is interwoven, the warp direction fiber fineness is 200 denier, the ...

Embodiment 2

[0071] with tetrafluoroethylene and

[0072] Wherein m=0-3, n=2 or 3 copolymerize to obtain perfluorosulfonic acid resin, the IEC value of this kind of resin is 0.98mmol / g, after resin is converted into K type, be dissolved in N-methylpyrrolidone, then put The solution was concentrated to 15%, and the obtained solution was coated on the ceramic mold, dried at 160°C for 2 minutes, and repeated to obtain the first ion exchange layer with a thickness of about 60 μm;

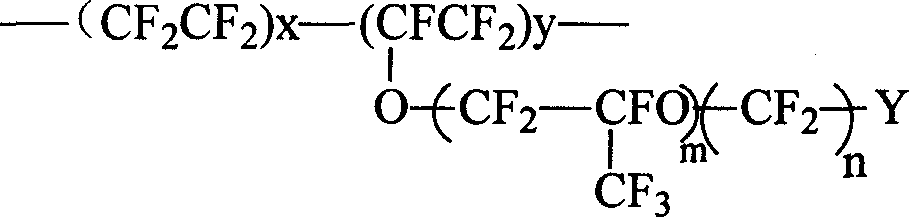

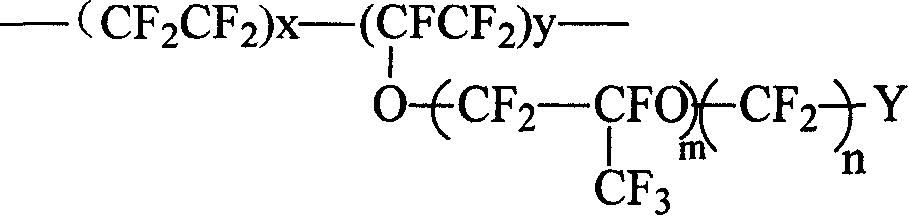

[0073] with tetrafluoroethylene and

[0074]

[0075] m=0~3, n=2~3

[0076] Copolymerize to obtain perfluorocarboxylic acid resin, the IEC value of this kind of resin is 1.22mmol / g, after converting the resin into K type, it is dissolved in N-methylpyrrolidone, and then the solution is concentrated to a concentration of 10%.

[0077] Mix the perfluorosulfonic acid resin solution obtained above with the perfluorocarboxylic acid resin solution at a ratio of 50:50, then add polytetrafluoroethylene reinforced mic...

Embodiment 3

[0081] with tetrafluoroethylene and

[0082] Where m=0-3, n=2 or 3

[0083] Copolymerize to obtain perfluorosulfonic acid resin, the IEC value of this kind of resin is 0.96mmol / g, the resin is converted into acid form and dissolved in propylene glycol, then the solution is concentrated to 16%, and the obtained solution is coated on the glass mold , dried at 150° C. for 1 minute to obtain the first ion exchange layer with a thickness of about 20 μm;

[0084] Copolymerize to obtain the perfluorosulfonic acid resin with IEC value of 0.99mmol / g, dissolve the resin in ethylene glycol after converting the resin into acid form, concentrate the solution to 15%, and then add 10% polytetrafluoroethylene by resin weight to strengthen Microfibers, the length of microfibers is 0.05-30μm, and the diameter is 0.02-50μm. Mix the materials evenly and apply directly on the first ion exchange layer, dry at 170°C for 5 minutes, repeat, and the last drying time is 1.5 minutes. A thickness of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com