Patents

Literature

57results about How to "Improve interface features" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

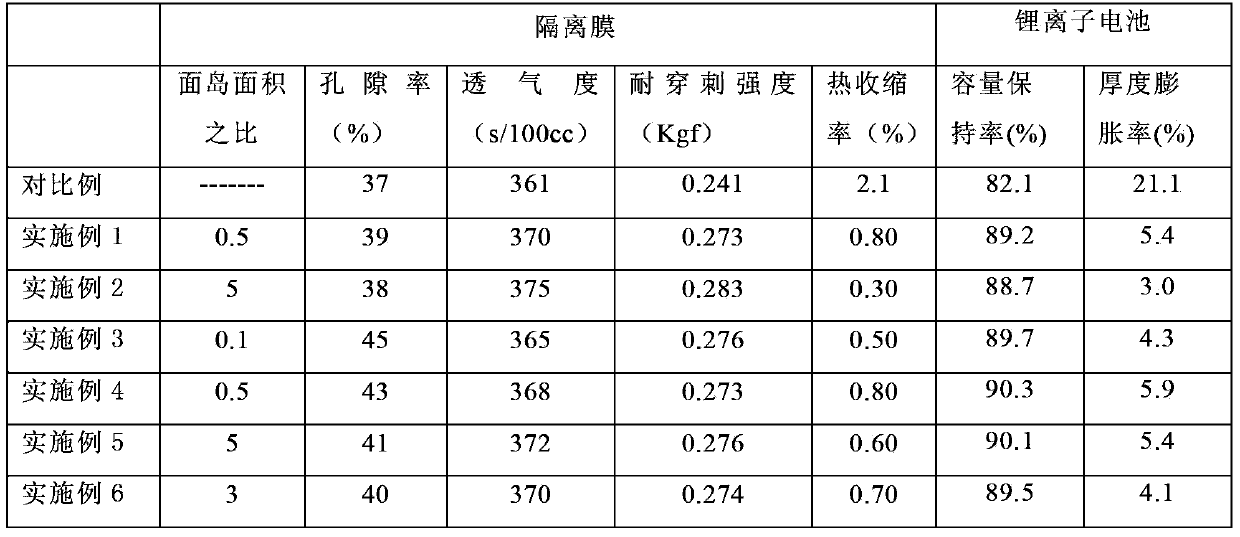

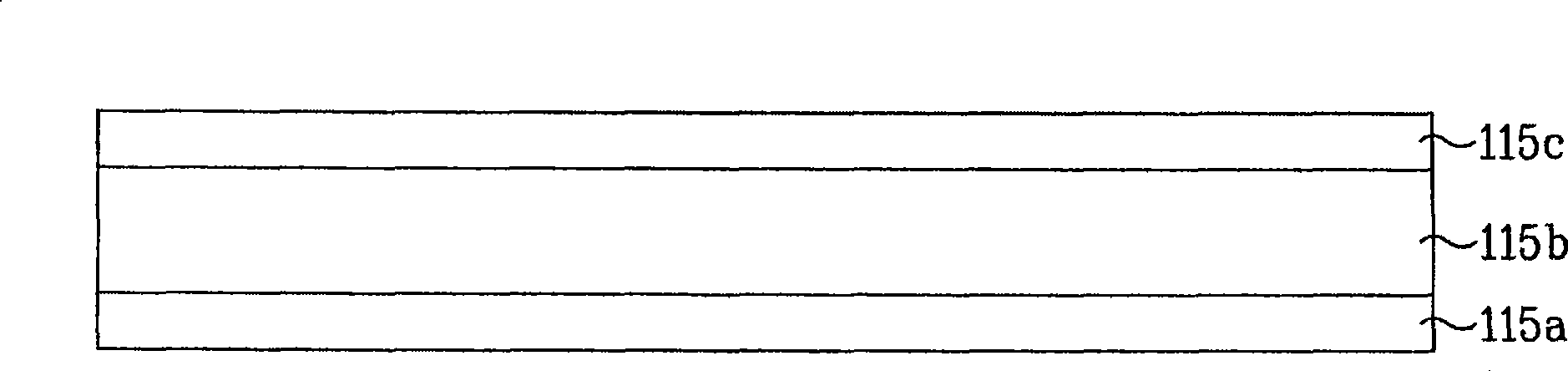

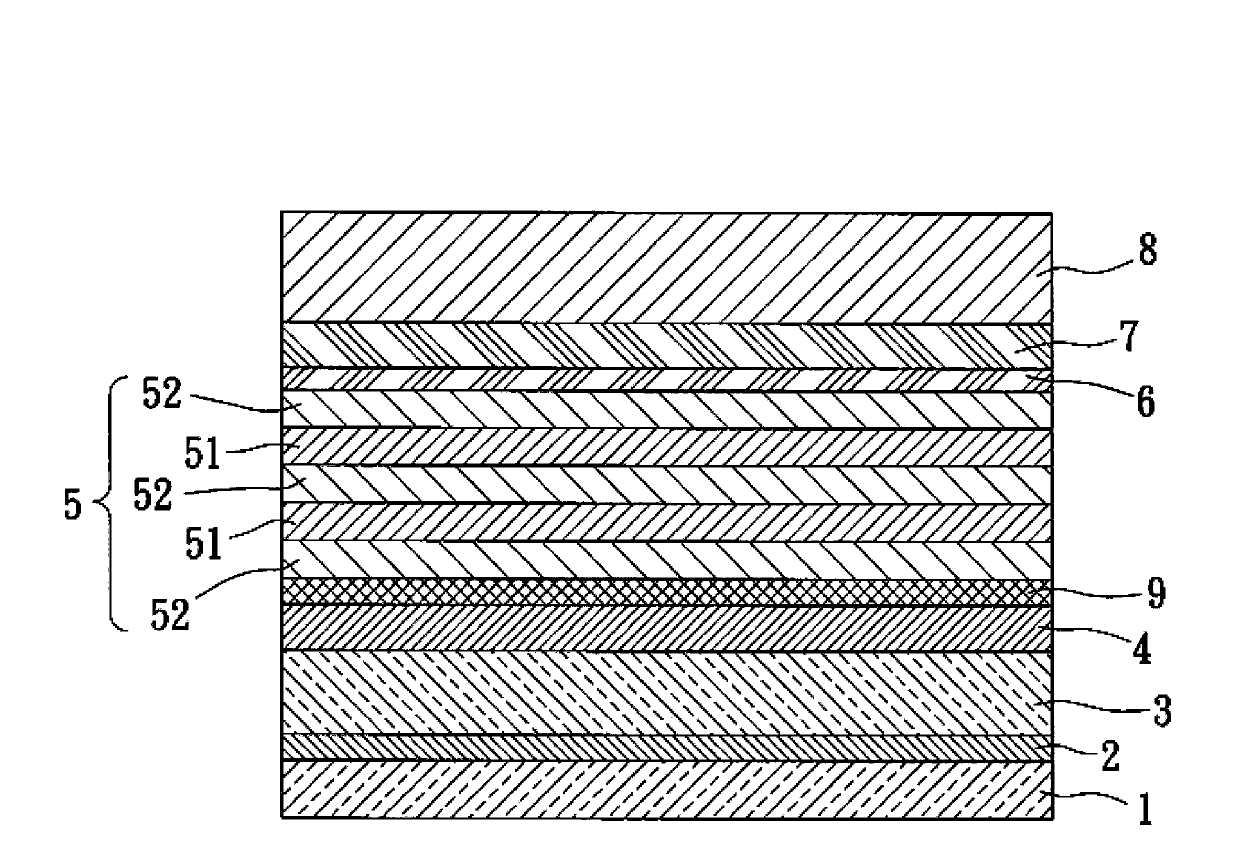

Organic/inorganic composite porous isolating membrane, preparation method thereof and electrochemical device

ActiveCN103441230AImprove breathabilityImprove conductivityHybrid capacitor separatorsCell seperators/membranes/diaphragms/spacersPorous coatingInorganic particle

The invention provides an organic / inorganic composite porous isolating membrane, a preparation method thereof and an electrochemical device. According to the first aspect of the invention, the organic / inorganic composite porous isolating membrane comprises a porous base material and an organic / inorganic composite porous coating coated on at least one surface of the porous base material, wherein the organic / inorganic composite porous coating comprises inorganic particles, a binding agent and organic particles with at least two swelling degrees, and the organic particles are swelled by a plasticizer. The preparation method of the organic / inorganic composite porous isolating membrane is used for preparing the organic / inorganic composite porous isolating membrane described in the first aspect of the invention. According to the third aspect of the invention, the electrochemical device comprises the organic / inorganic composite porous isolating membrane described in the first aspect of the invention. Therefore, the organic / inorganic composite porous isolating membrane can form an excellent interface, so that a risk that the risk of blocking holes by the organic particles is reduced, breathability of the organic / inorganic composite porous isolating membrane is improved, and electrical conductivity of the organic / inorganic composite porous isolating membrane is improved.

Owner:DONGGUAN AMPEREX TECH +1

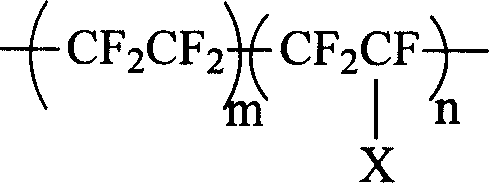

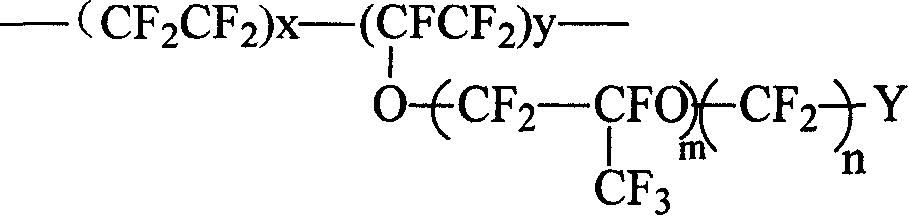

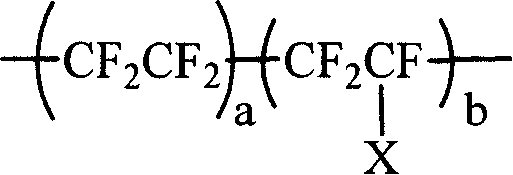

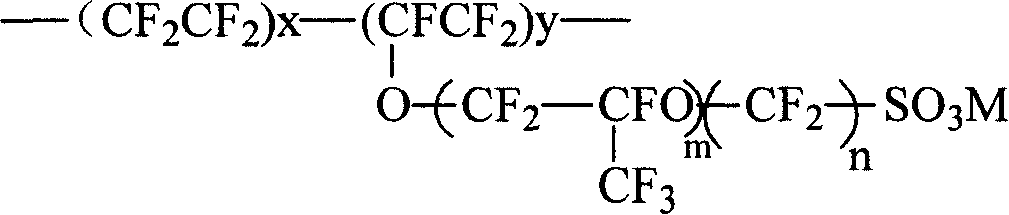

Perfluoro ion exchange solvation reinfercing film and its preparation method

InactiveCN1624202AExtended service lifeImprove bindingOrganic diaphragmsFilm resistancePolymer science

A reinforced perfluoro ion exchange film is composed of at least two layers of ionic film, which prepared from perfluoro ion exchange resin and fused together without interface, at least one layer of perfluoro polymer mesh as reinforcing material and the perfluoro polymer microfibres added to said filming resin. It is prepared through sequential coating. Its advantages are low film resistance, high electric current efficiency, and high mechanical strength and size stability.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

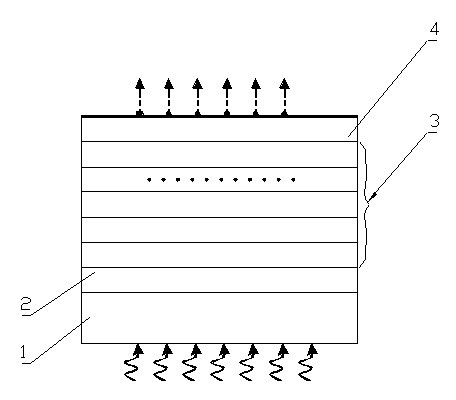

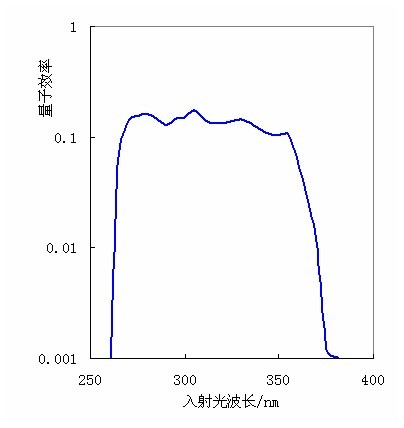

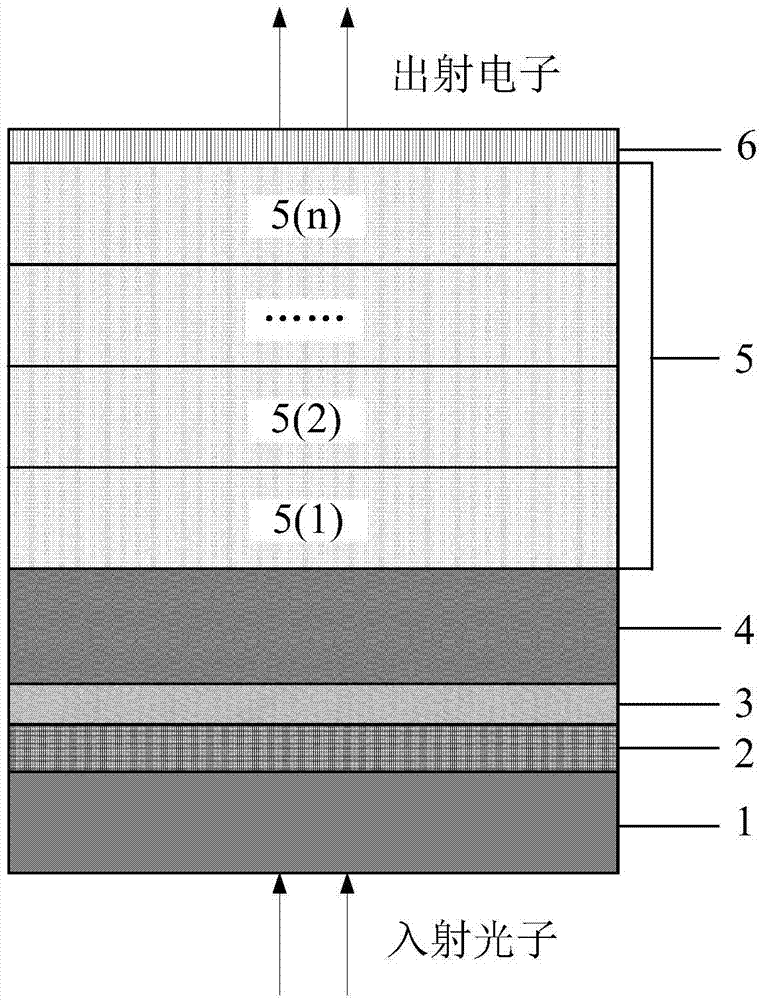

Transmission-type GaN ultraviolet photocathode based on composition graded buffer layer

InactiveCN101866977AImprove interface featuresReduce the interfacial recombination rateFinal product manufactureSemiconductor devicesChemistryQuantum

The invention discloses a transmission-type GaN ultraviolet photocathode based on a composition graded buffer layer, the cathode consists of a double-polished c surface sapphire substrate, an AlxGa1-xN composition graded buffer layer, a p-type GaN emission layer and a Cs or Cs / O active coating from bottom to top; the AlxGa1-xN composition graded buffer layer consists of n unit layers, wherein n is greater than or equal to 3 and is less than or equal to 10; and Al composition in each layer of the n unit layers from bottom to top meets the need that x1)x2)... xn is less than or equal to 1 and is greater than or equal to 0.The buffer layer of the transmission-type GaN ultraviolet photocathode is designed and prepared by adopting the AlxGa1-xN in which the Al component content decreases gradually from 1 to 0, and growth interface stress between buffer a material and an emitting material is reduced by utilizing the composition graded mode, thus improving the interface characteristics of the transmission-type GaN ultraviolet photocathode, reducing the photoelectronic interface recombination rate and finally enhancing the photoemission quantum efficiency of the GaN ultraviolet photocathode.

Owner:CHONGQING UNIV

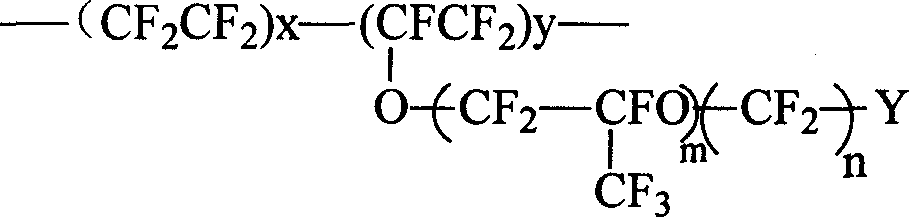

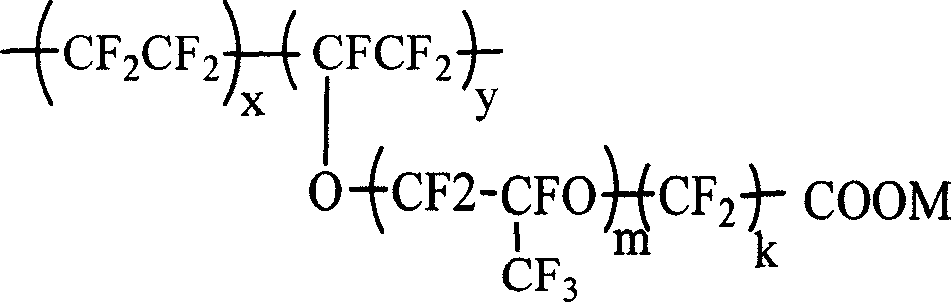

Perfluorinated ion exchange casting enhancement member and preparing method thereof

InactiveCN101054445ALower resistanceHigh peel strengthOrganic diaphragmsExtremely goodCarboxylic acid

A perfluorinated ion exchange membrane fusing-casting reinforced film includes reinforced substrate and ion change layer. Said reinforced substrate is a perfluorinated polymer biaxially oriented film. Said ion change layer is formed by solution casting method, having the perfluorinated ion exchange resin containing sulfonic acid group and / or carboxylic acid group as film forming resin. The film without abrupt interface between the ion exchange layers is formed by the means of solution casting and program coating so as to make the ion exchange group concentration between the ion exchange layers and different ion exchange layers achieve molecule horizontal combination and greatly improve the interface compatibility. The ion exchange membrane has a lower film resistor, a higher current efficiency, a high film planeness, extremely good mechanical strength and dimensional stability. The invention also provides producing method thereof.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

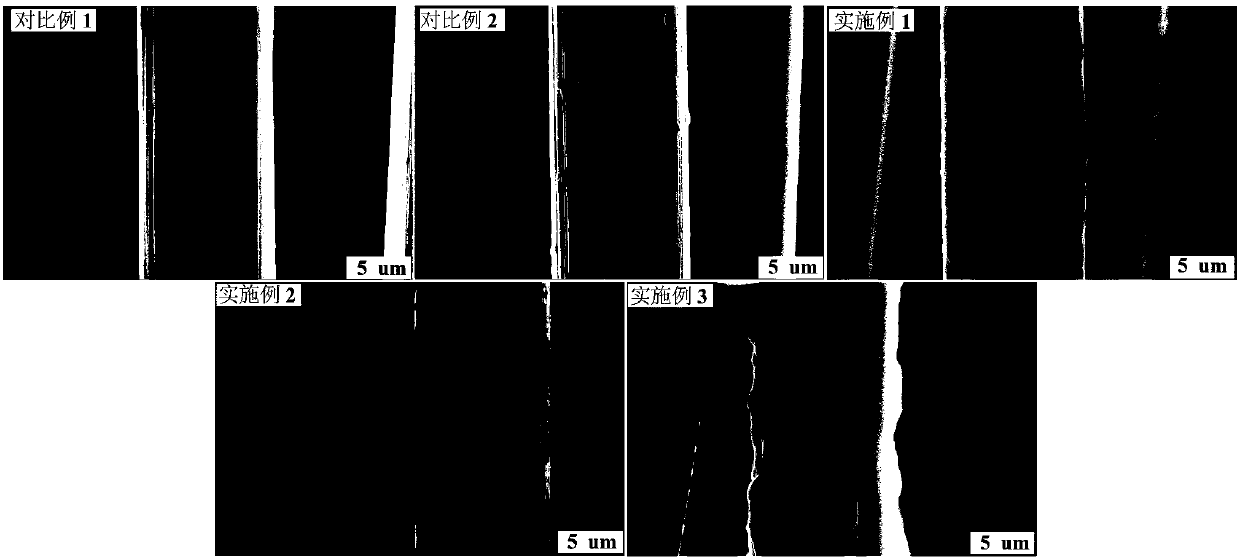

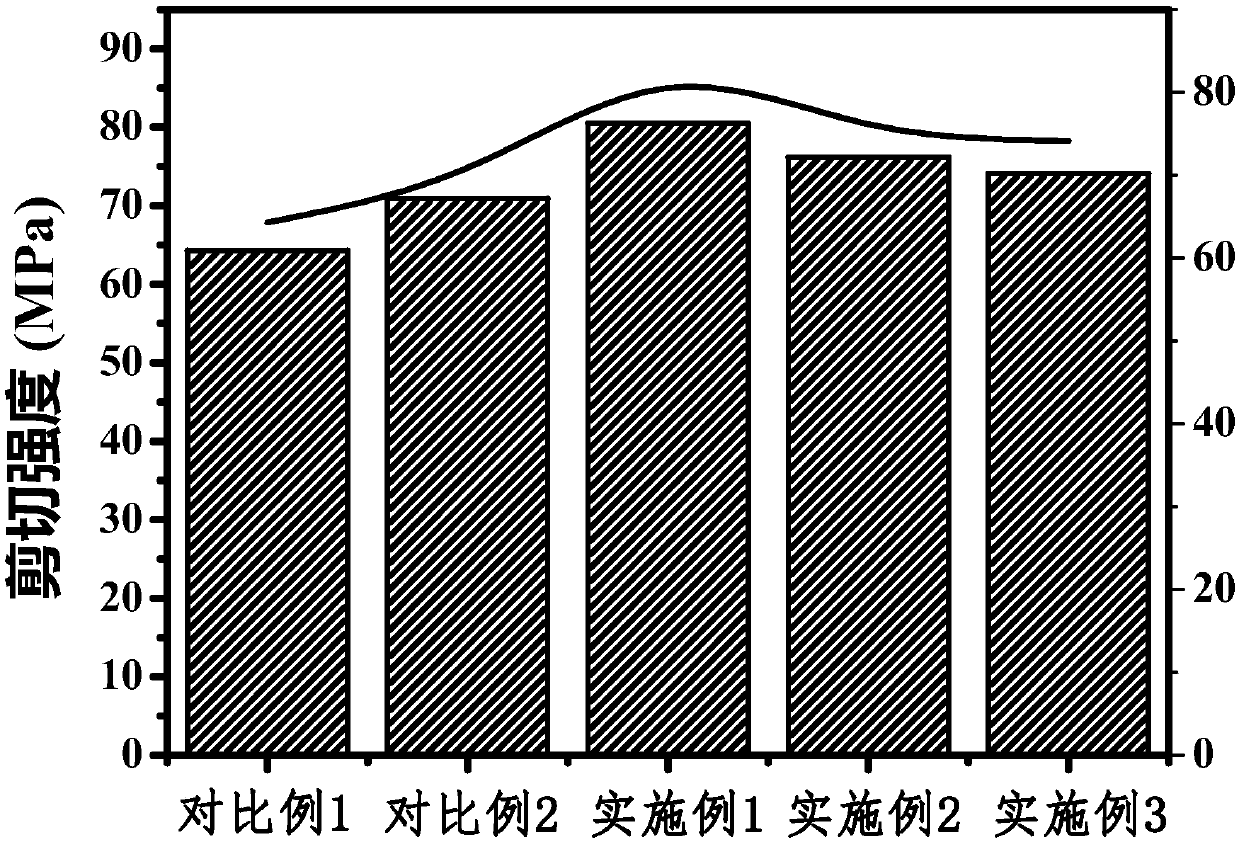

Preparation method of double sizing agent modified carbon fiber reinforced epoxy resin based composite

The invention relates to a preparation method of a double sizing agent modified carbon fiber reinforced epoxy resin based composite. According to the preparation method, through multi-layer modification of an OA-POSS mixed SiO2 sizing agent and a CNT sizing agent, introduction of complicated chemical bonds is avoided, grafting modification is performed on carbon fiber surfaces, and the modified carbon fiber reinforced epoxy resin based composite is obtained through curing at the normal temperature by use of a vacuum assisted forming process. The shearing performance of the composite is improved by 24%, the tensile property of the composite is improved by 29%, which are both higher than the mechanical properties in a thermosetting molding process.

Owner:HEBEI UNIV OF TECH

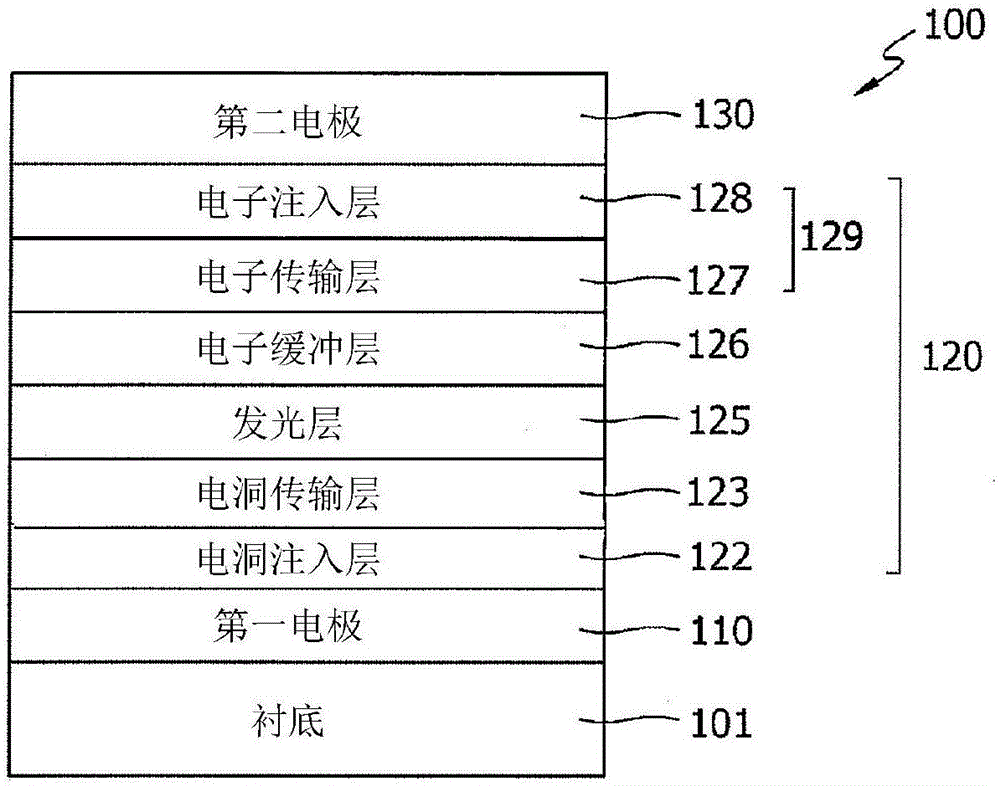

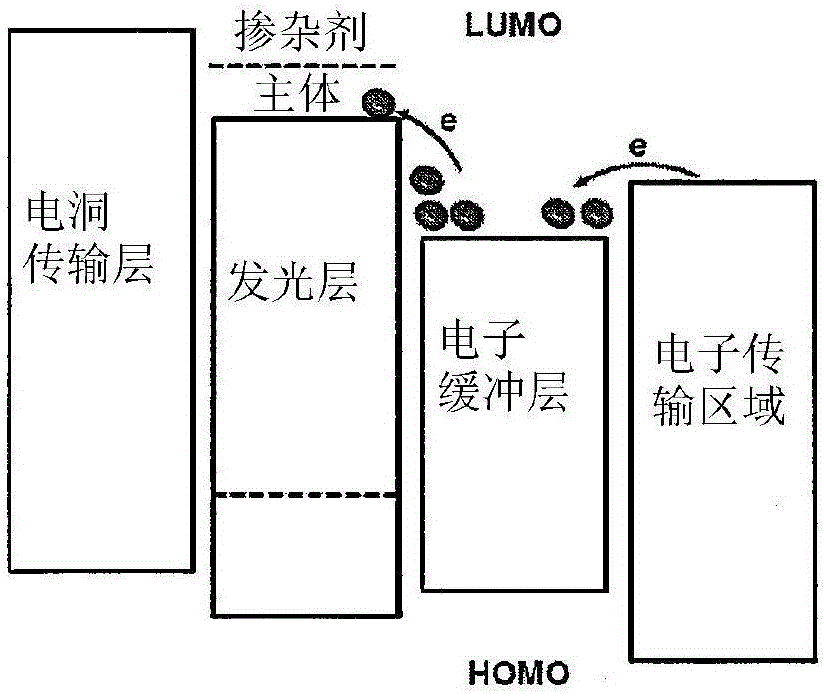

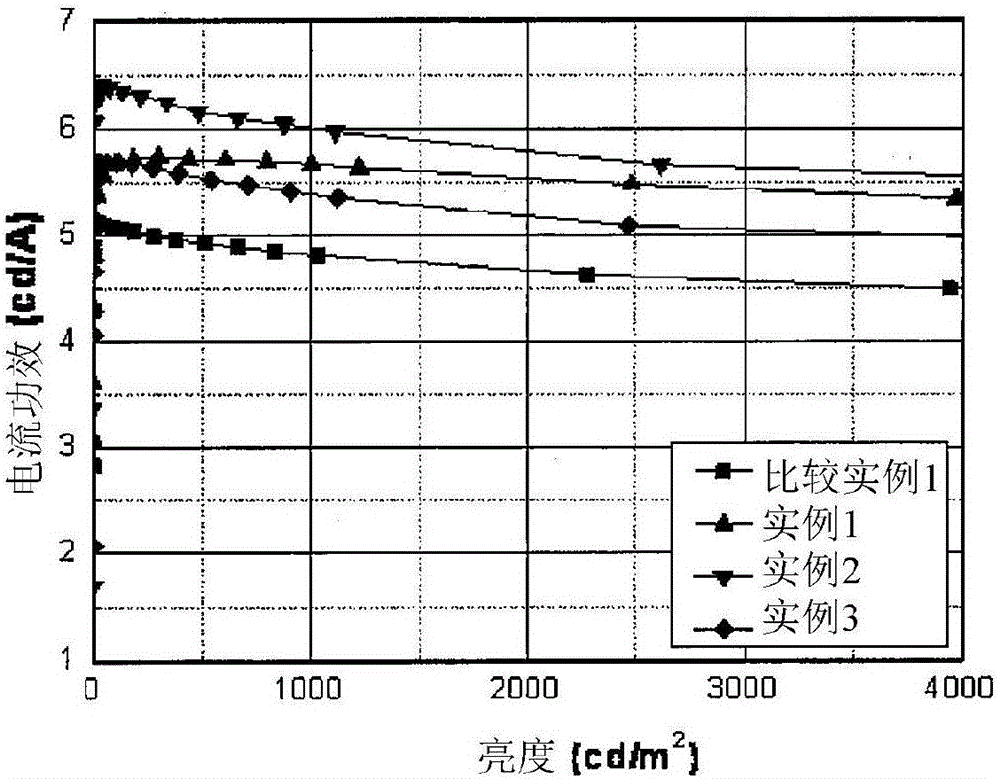

Electron buffering material and organic electroluminescent device comprising the same

ActiveCN106068267AImprove interface featuresImprove overall performanceOrganic chemistrySolid-state devicesOrganic electroluminescenceElectron

The present invention relates to an electron buffering material and an organic electroluminescent device comprising the same in an electron buffer layer. It is possible to provide an organic electroluminescent device having excellent luminous efficiency and lifespan characteristics by using the electron buffering material according to the present invention.

Owner:ROHM & HAAS ELECTRONICS MATERIALS KOREA LTD

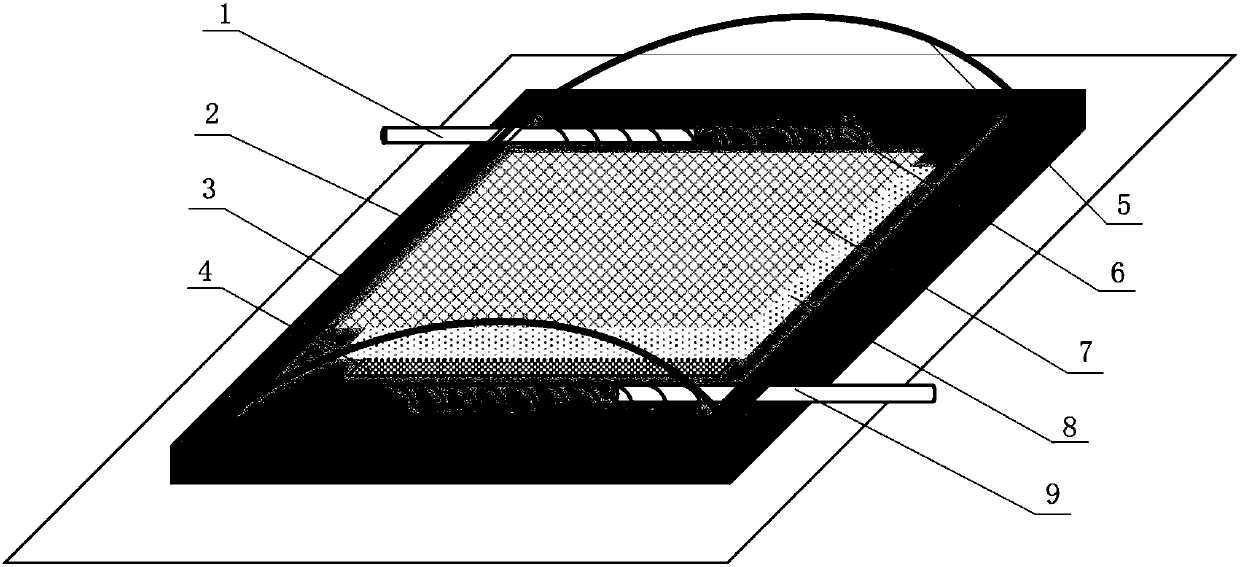

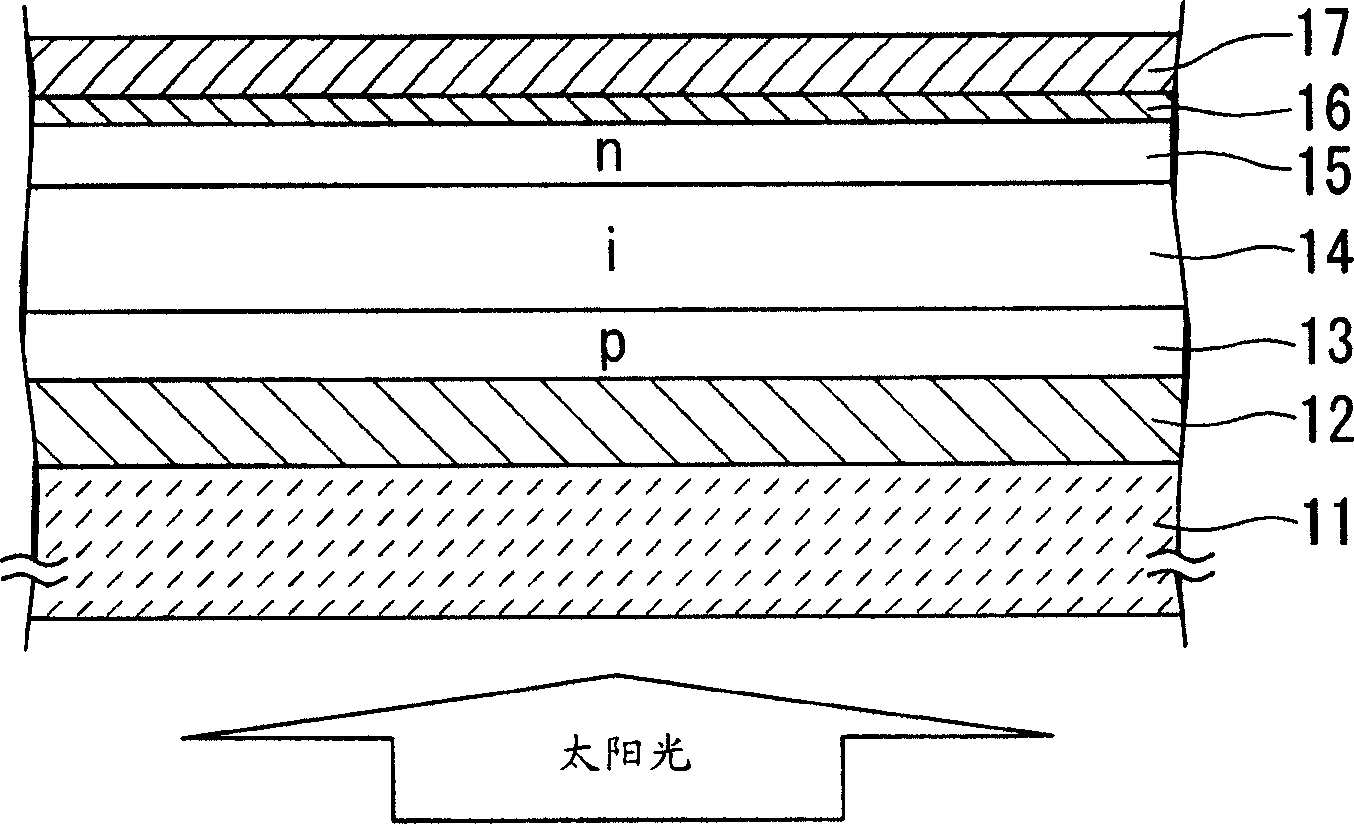

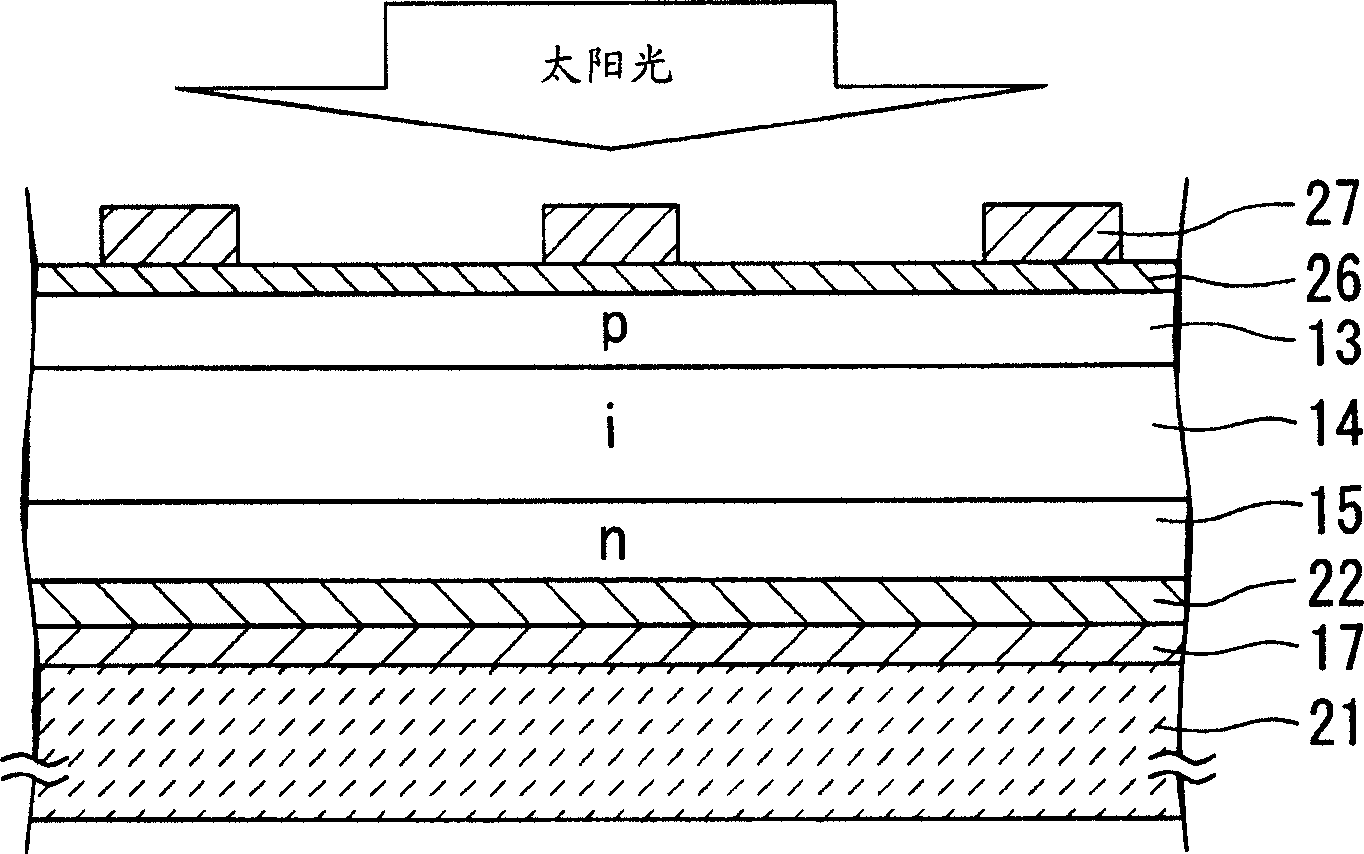

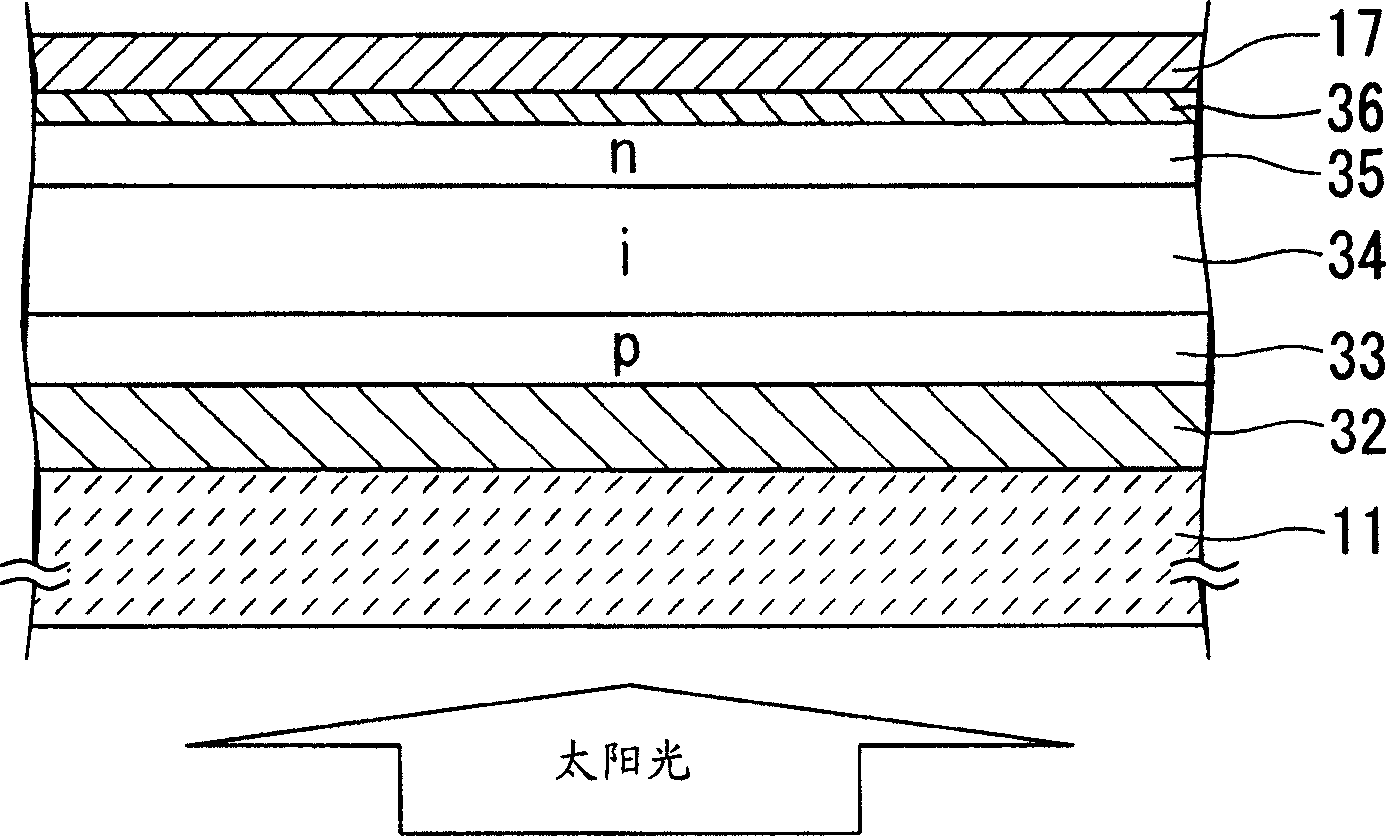

Photovoltaic device

InactiveCN1638153AImprove interface featuresImprove photoelectric conversion efficiencyPhotovoltaic energy generationSemiconductor devicesTransmittanceTransparent conducting film

A photoelectric conversion device that achieves a high photoelectric conversion rate using a transparent electrode or a transparent conductive film having an optimal relationship between resistivity and transmittance. On the transparent insulating substrate, there are at least sequentially stacked: a first transparent electrode, a pin structure or a nip structure microcrystalline silicon layer composed of a p-type silicon layer, an i-type silicon layer and an n-type silicon layer, a second transparent electrode and The backside electrode, wherein at least one of the first transparent electrode and the second transparent electrode is a Ga-added ZnO layer, and the content of Ga is less than or equal to 15 atomic % relative to Zn.

Owner:MITSUBISHI HEAVY IND LTD

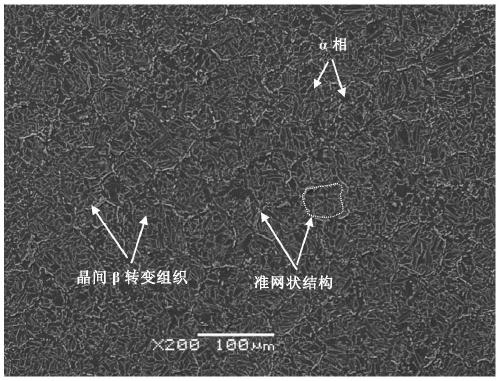

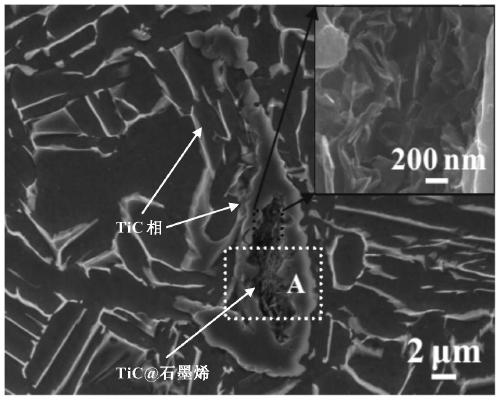

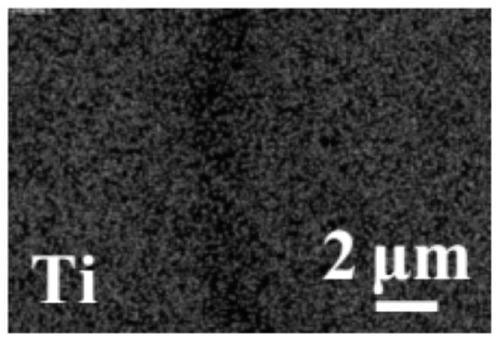

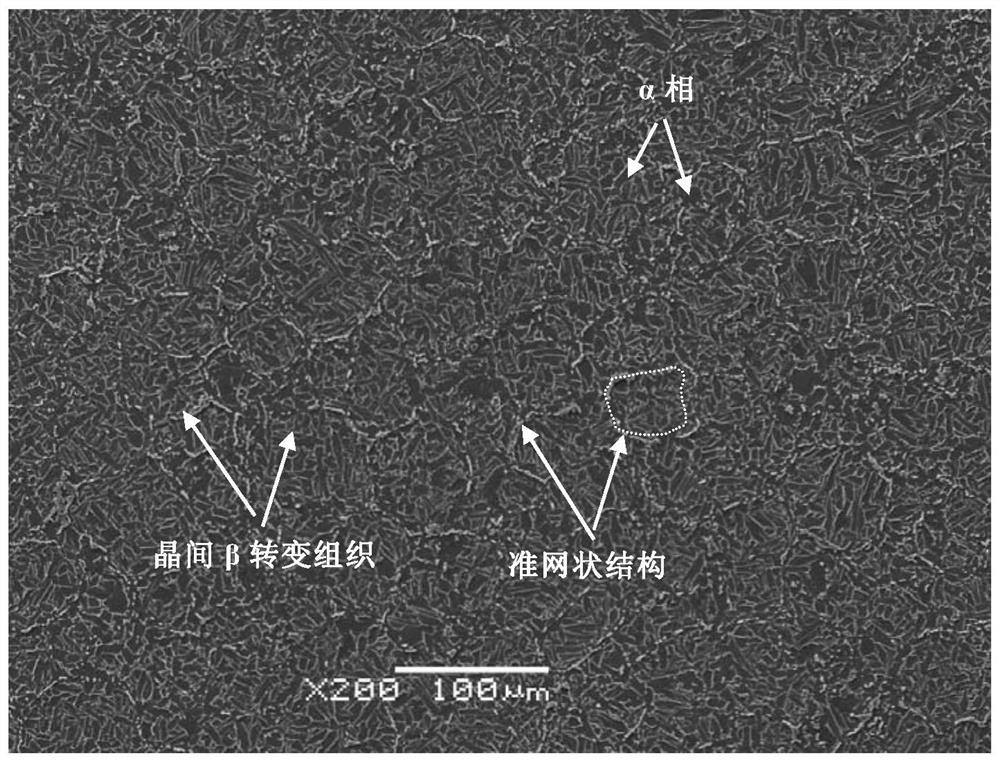

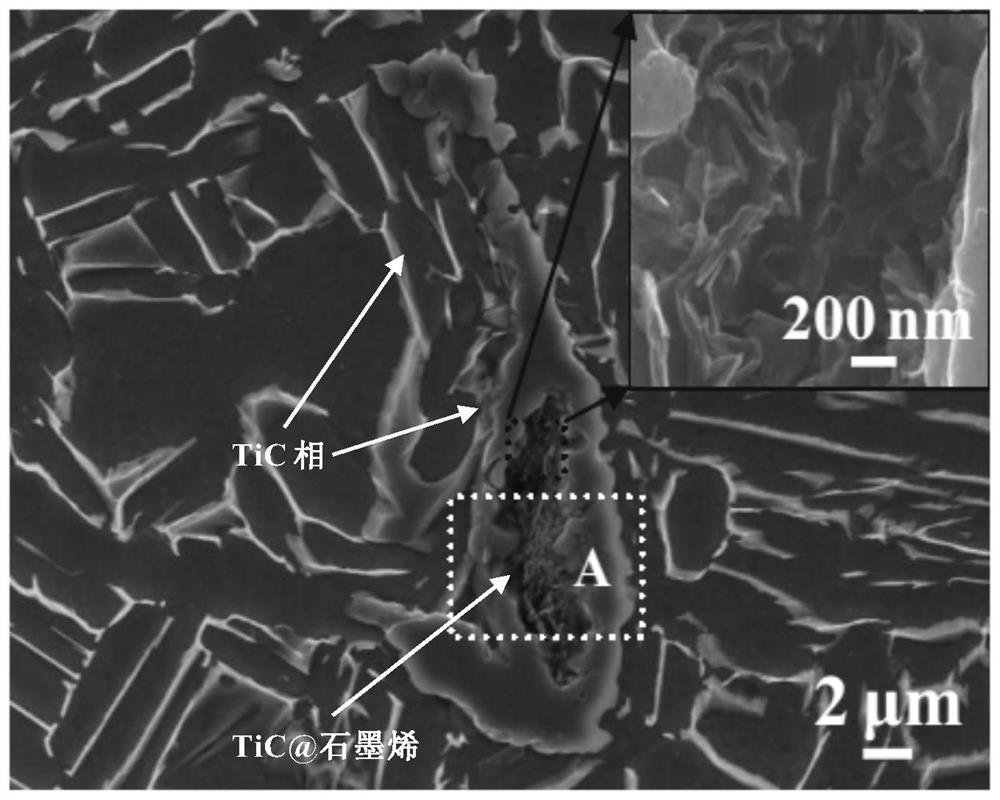

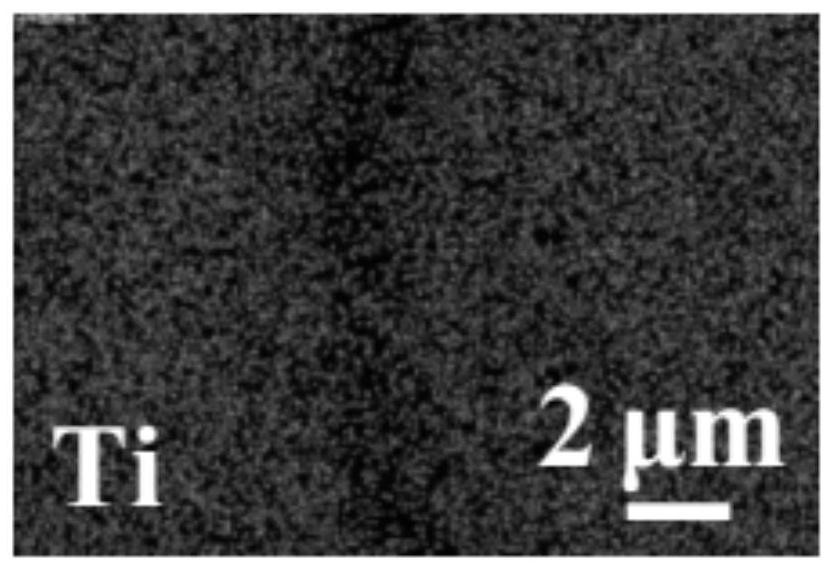

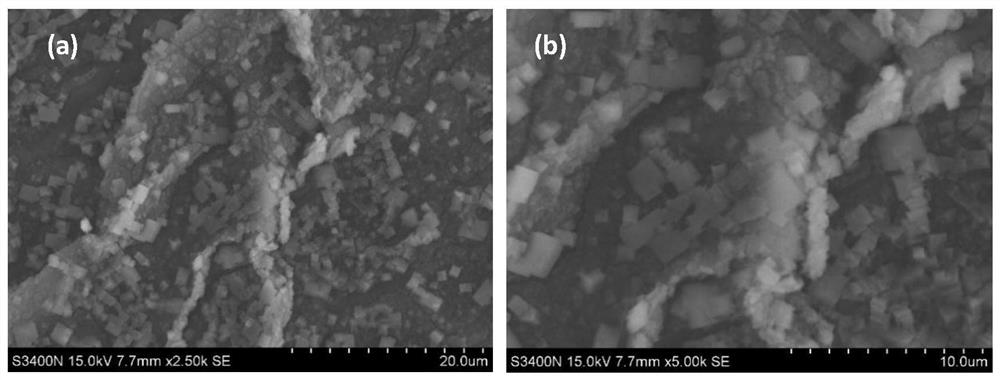

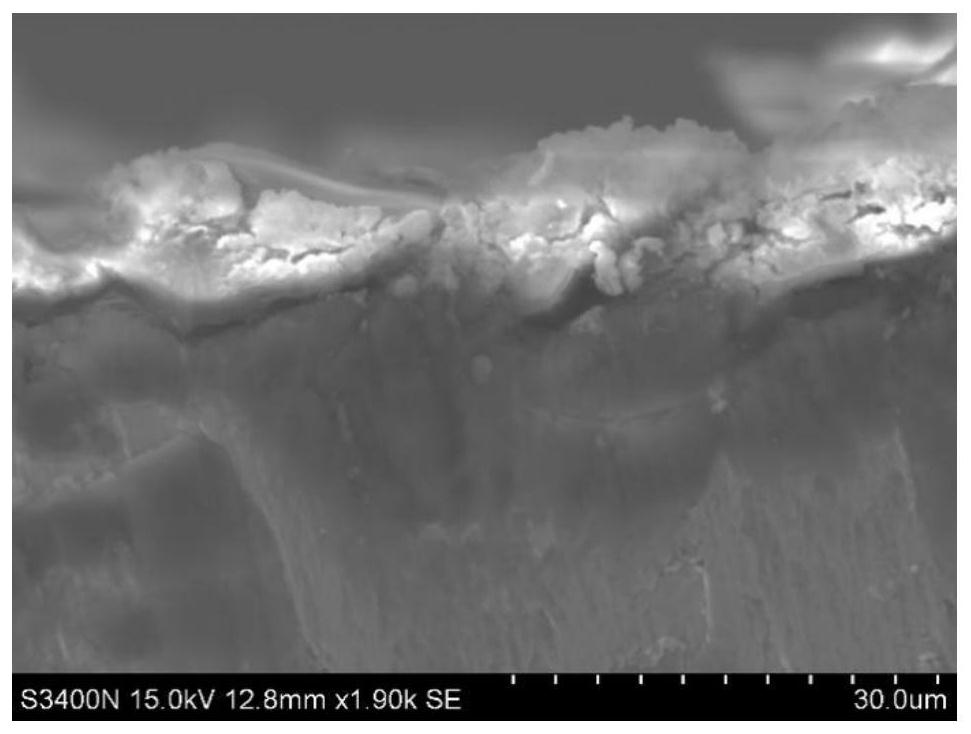

High-plasticity quasi-mesh-shaped structure titanium-based composite material and preparation method thereof

ActiveCN110343904AHigh strengthHigh elongation plasticityTransportation and packagingMetal-working apparatusTitanium matrix compositesRough surface

The invention discloses a high-plasticity quasi-mesh-shaped structure titanium-based composite material. Titanium or a titanium alloy is used as a substrate, the TiC phase synthesized on the Ti substrate in situ and TiC@graphene synthesized on the Ti substrate in situ are used as enhancement bodies, the enhancement bodies are evenly and discontinuously distributed at the position of the original beta grain boundary of the Ti substrate, and a quasi-mesh-shaped structure is formed. The invention further discloses a preparation method of the high-plasticity quasi-mesh-shaped structure titanium-based composite material. According to the method, titanium-based spherical powder particles with rough surfaces are added in a graphene nanosheet suspension solution, mixed powder is prepared, and spark plasma sintering is conducted. By means of distribution states and structures of the enhancement bodies, namely, the TiC phase and the TiC@graphene, in the titanium-based composite material, the enhancement phase surrounded substrate is obtained, strength of the titanium-based composite material is improved, and extension plasticity of the titanium-based composite material is ensured. Accordingto the high-plasticity quasi-mesh-shaped structure titanium-based composite material, by conducting titanium-based powder surface pretreatment and wet method material mixing, the blending degree of the graphene and the titanium substrate is increased, and the defect that the room temperature deformation capacity and extension plasticity of the graphene titanium-based composite material are poor isovercome.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

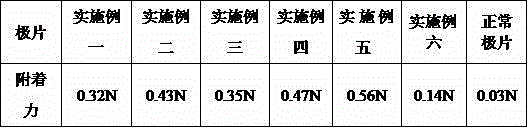

Lithium-ion battery negative pole piece, and preparation method and application thereof

The invention discloses a lithium-ion battery negative pole piece, and a preparation method and the application thereof. The surface of the base of the negative pole piece is coated with a coating which is prepared by a composite coating material; the composite coating material mainly comprises the following components in parts by weight: 20 to 40 parts of inorganic particles, 0.2 to 0.6 part of bonding agent, 4 to 8 parts of organic particles with swelling property, 0.4 to 0.8 part of plasticizer and 60 to 66 parts of solvent. Compared with the prior art, a novel bi-layer electrode material is adopted; an inorganic-organic protective layer is added on the basis of the conventional electrode material, so that the mechanical strength and the thermal stability of the battery are improved; the contact between a negative pole and a positive pole can be avoided under extreme conditions; therefore, a combustion phenomenon is avoided. Compared with the technology of a separation membrane which adopts an organic-inorganic layer, the purpose can be achieved by only coating a layer of coating at one end of the negative pole of the bi-layer electrode; the coating process is simplified; the cost is saved.

Owner:YANCHENG INST OF TECH

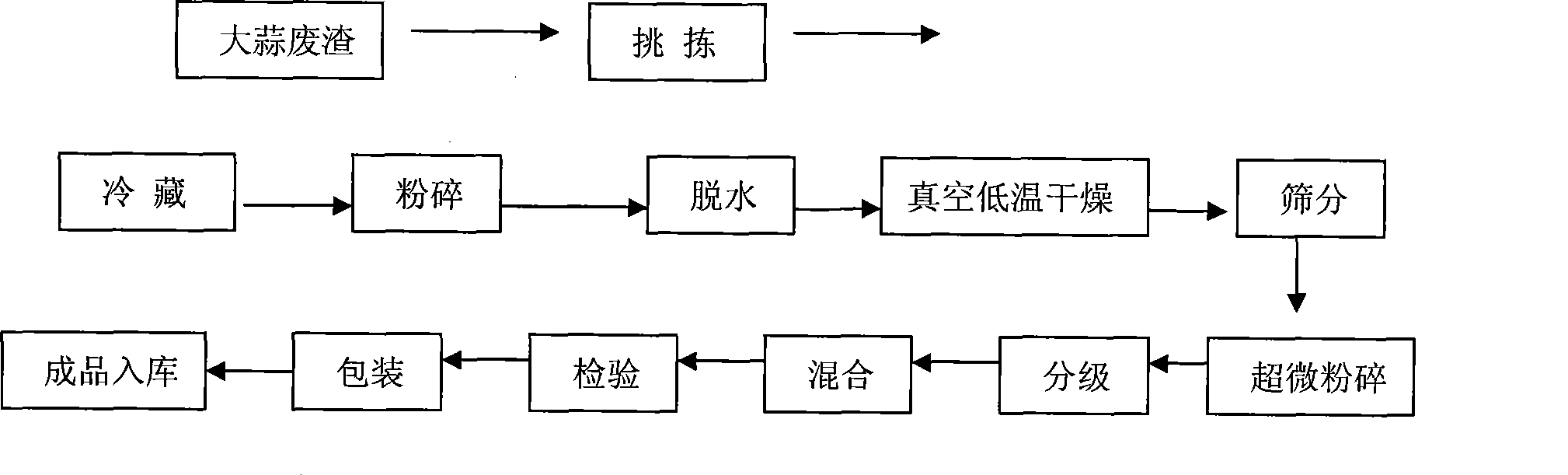

Garlic residues ultramicro powder and preparation method thereof

InactiveCN101361522APromote dissolutionImprove efficacyAnimal feeding stuffWorking-up animal fodderFowlAdditive ingredient

The invention relates to abandoned garlic residues which are chosen, refrigerated, stored, grinded, pulverized, vacuum cold dried and micronized, the effective ingredients are not be destroyed and lost definitely, the obtained submicron powder improves bioavailability, effects and range of application of the product for large superficial area and high tensiometric property, can be widely used in compound feed, feed additive and additive premix of marine products such as fowl and livestock.

Owner:张奎昌

Positive plate of lithium ion battery, and preparation method and application thereof

InactiveCN105226289AHigh strengthSimple processSecondary cellsElectrode collector coatingSodium-ion batterySolvent

The invention discloses a positive plate of a lithium ion battery, and a preparation method and application thereof. A coating layer made of a composite coating material is arranged on the surface of a positive plate substrate, and the composite coating material mainly comprise the following constituents based on weight ratio: 20-40 parts of inorganic particle, 0.2-0.6 part of binder, 4-8 parts of organic particle having swelling property, 0.4-0.8 part of plasticizer and 60-66 parts of solvent. Compared with the prior art, the novel dual-layer electrode material is adopted, an inorganic and organic protection layer is additionally arranged on the basis of the traditional electrode material, the mechanical strength and thermal stability of the battery are improved, a positive electrode and a negative electrode can be prevented from being contacted in an extreme condition, and thus, a combustion phenomenon is avoided. Compared with the a diaphragm technology applying the organic and inorganic layers, the purpose of using the dual-layer electrode can be achieved only by applying a layer to one end of the positive electrode, the coating process is simplified, and the cost is saved.

Owner:YANCHENG INST OF TECH

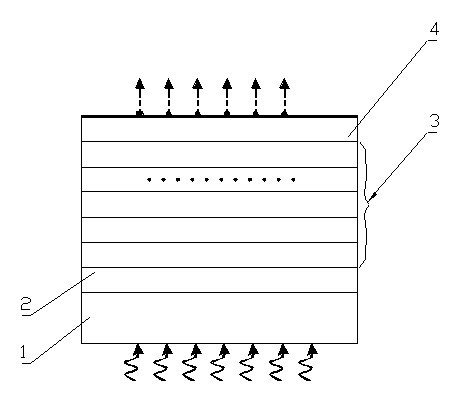

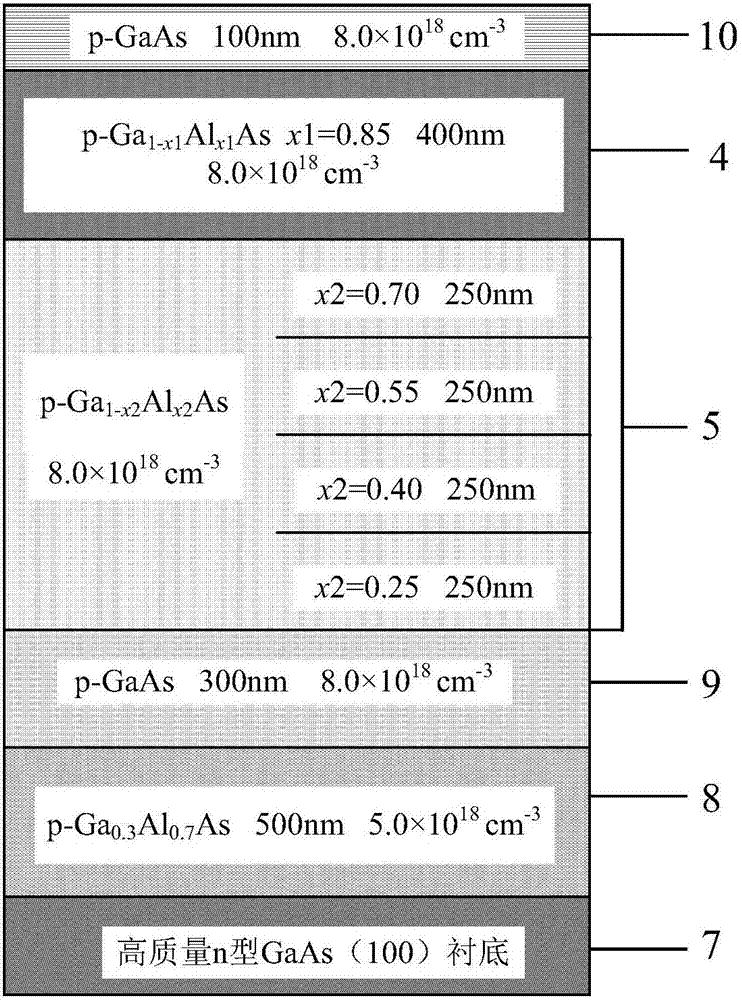

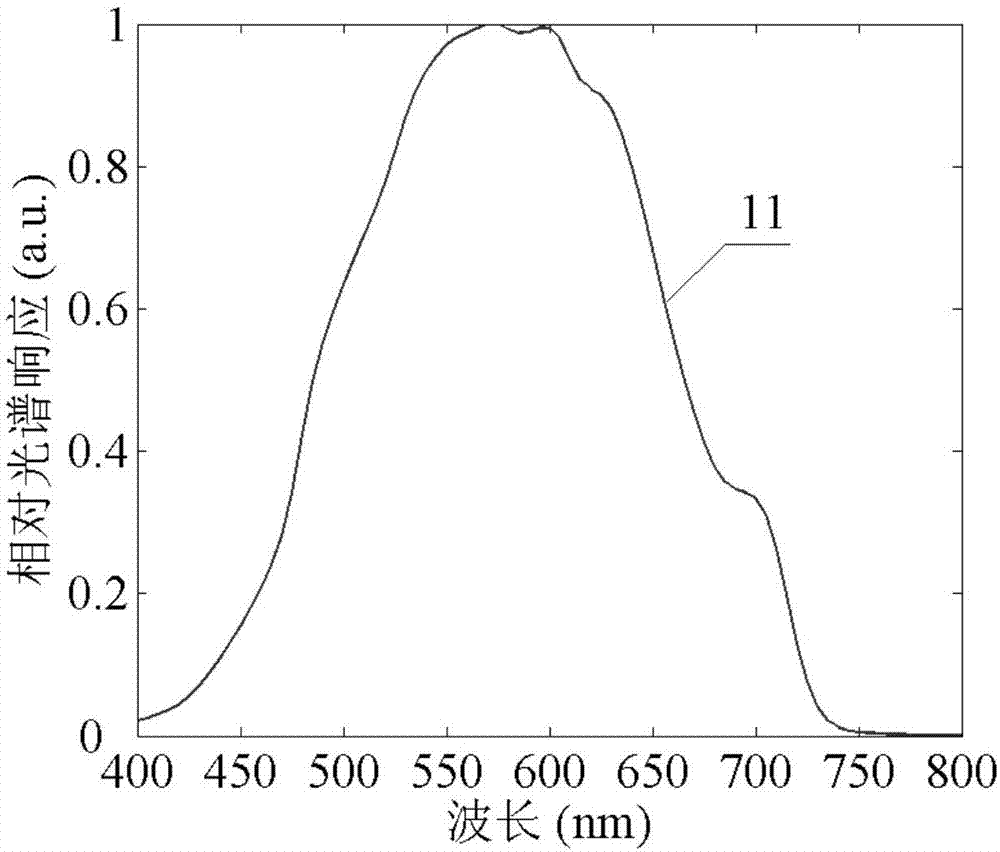

Blue-green sensitive transmission-type GaAlAs cathode of Al compositional gradient gradual change

ActiveCN107393787AImprove interface featuresReduce growth interface stressPhoto-emissive cathodesPhoto-emissive cathodes manufactureLaser technologyConstant composition

The present invention relates to a blue-green sensitive transmission-type GaAlAs cathode of Al compositional gradient gradual change which is sensitive to blue-green light. The cathode is formed by a Corning 7056# glass substrate, a SiO2 protection layer, a Si3N4 anti-reflection layer, a Ga1-x1Alx1As window layer with Al constant composition, a Ga1-x2Alx2As emission layer with Al compositional gradient gradual change and a Cs / O activation layer arranged from down to up. The blue-green sensitive transmission-type GaAlAs cathode of Al compositional gradient gradual change prepares the blue-green sensitive negative electron affinity transmission-type GaAlAs photoelectric cathode based on the Ga1-xAlxAs ternary compound Al / Ga composition control technology, the III-V group compound material epitaxy technology, the photoelectric cathode module preparation technology and the ultrahigh vacuum laser technology, combines an electron multiplier to form a blue-green detector, and can be applied to the fields of sea detection, seabed imaging and the like.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

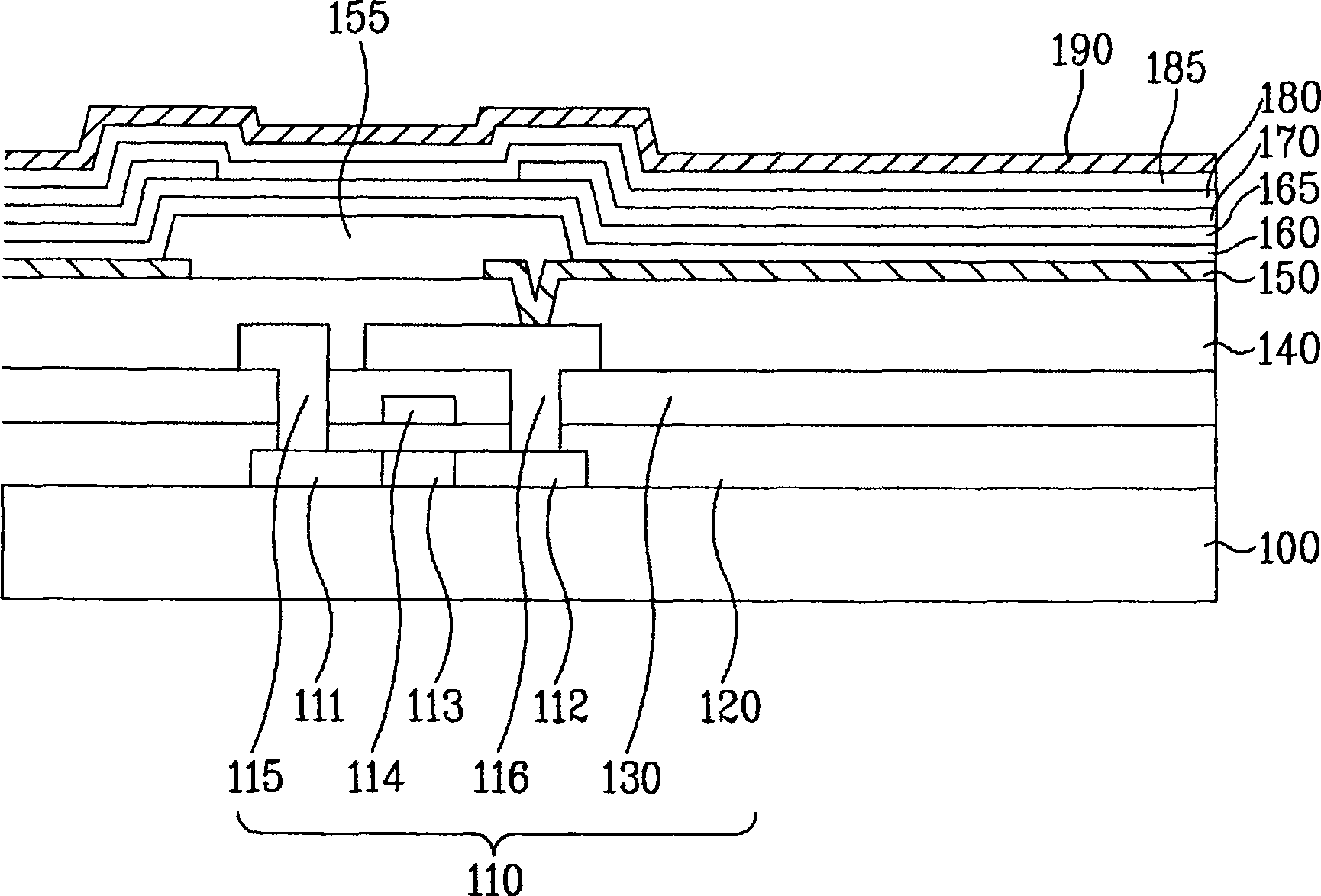

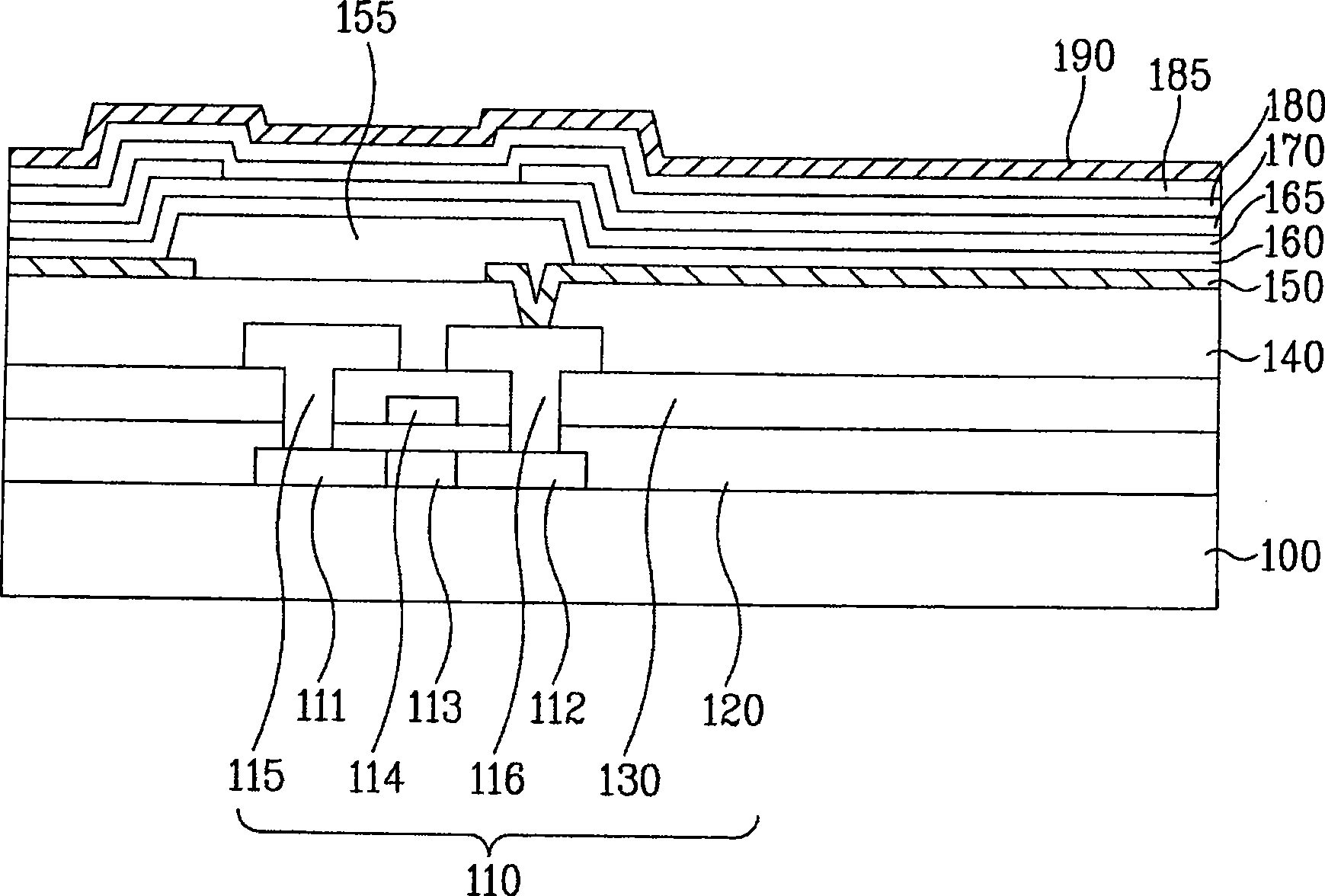

Organic electroluminescence device and method for manufacturing the same

ActiveCN101388404AAvoid damageImprove interface featuresTransistorSolid-state devicesEngineeringOrganic electroluminescence

An organic electroluminescence device and a method for manufacturing the same are disclosed. The organic electroluminescence device includes a transparent substrate, a semiconductor layer including a source region, a channel region and a drain region, a gate insulating film having first contact holes on the source and drain regions and formed on the substrate including the semiconductor layer, a gate electrode formed on the gate insulating film above the channel region, an interlayer insulating film having second contact holes on the source and drain regions and formed on an entire surface of the gate insulating film including the gate electrode, and a source electrode and a drain electrode formed on the interlayer insulating film to be electrically connected to the source and drain regions through the first and second contact holes, wherein at least one of the source electrode and the drain electrode is formed to cover the semiconductor layer.

Owner:LG DISPLAY CO LTD

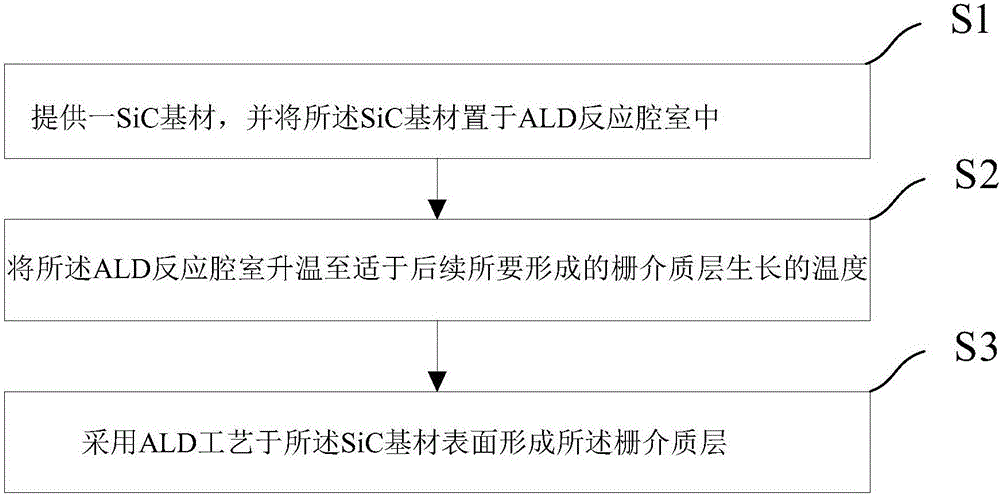

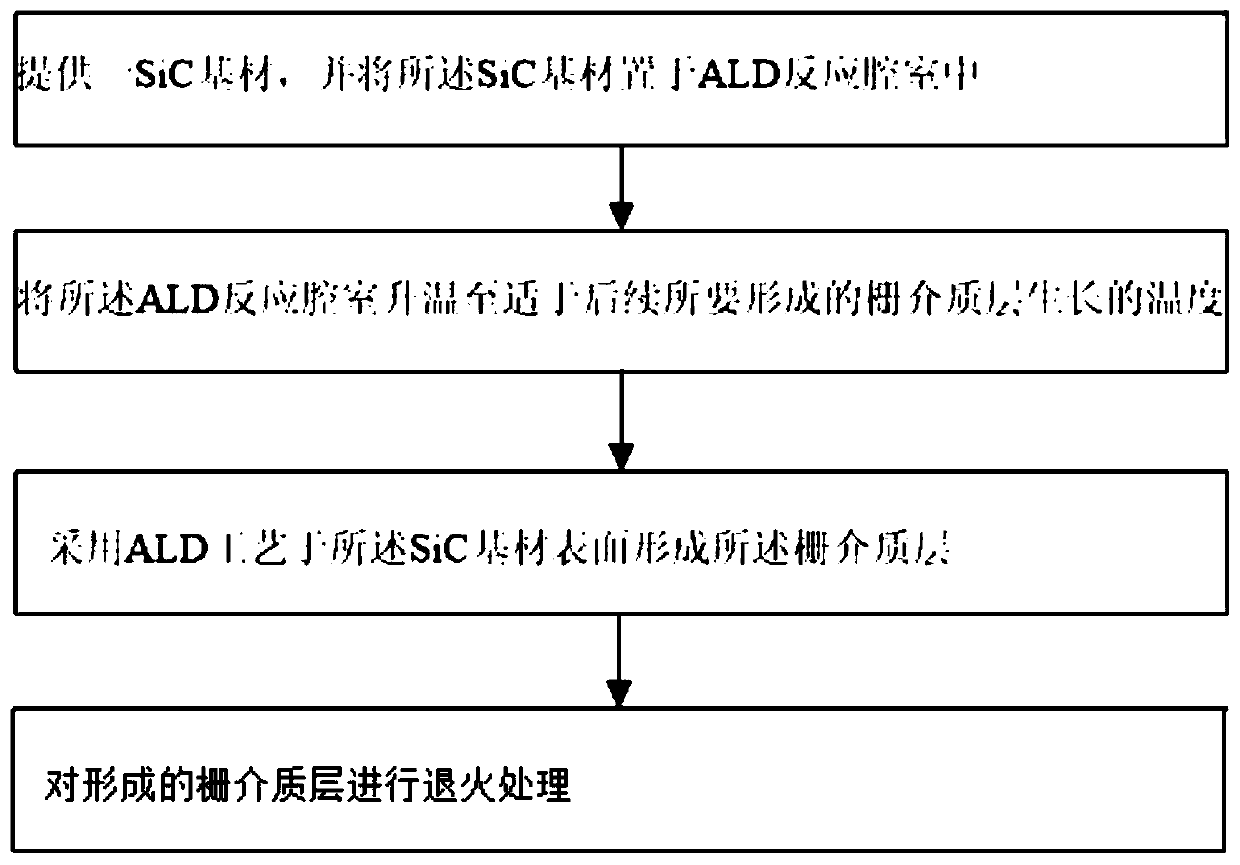

Preparation methods of SiC device gate dielectric layer and SiC device structure

ActiveCN107527803AAvoid cluster CImprove interface featuresSemiconductor/solid-state device manufacturingSemiconductor devicesSic substrateElectric field

The invention provides preparation methods of a SiC device gate dielectric layer and a SiC device structure. The preparation method of a gate dielectric layer includes the following steps: providing a SiC substrate, and placing the SiC substrate in an ALD reaction chamber; heating the ALD reaction chamber to a temperature suitable for the growth of a gate dielectric layer to be formed subsequently; and forming a gate dielectric layer on the surface of the SiC substrate through an ALD process. According to the technical scheme, Si atoms in a SiC epitaxial wafer are not consumed in the growth process of the gate dielectric layer, so that the phenomenon of C group aggregation at the interface of a gate dielectric film and SiC is avoided, and the interface property is improved. The gate dielectric layer is formed through an ALD technology, the thermal budget is low, and the device preparation process is simplified. The gate dielectric layer formed through the ALD technology has the advantages of high critical breakdown strength, low leakage and high dielectric constant. The strength of electric field introduced to the gate dielectric film can be greatly reduced, and breakdown of the gate dielectric can be avoided.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Low-loss, high-temperature and lead-free capacitor material and preparation method thereof

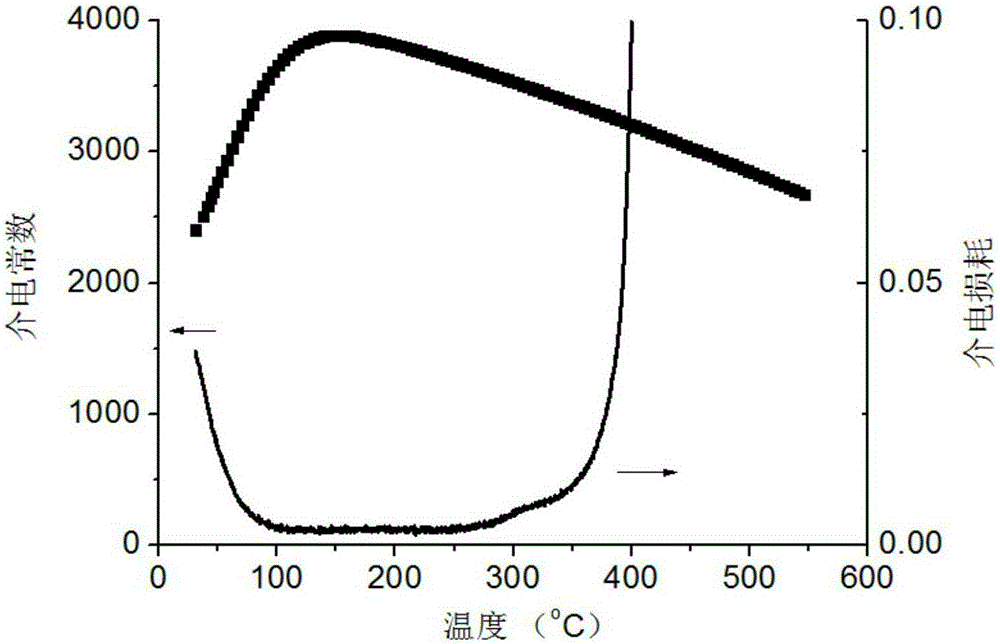

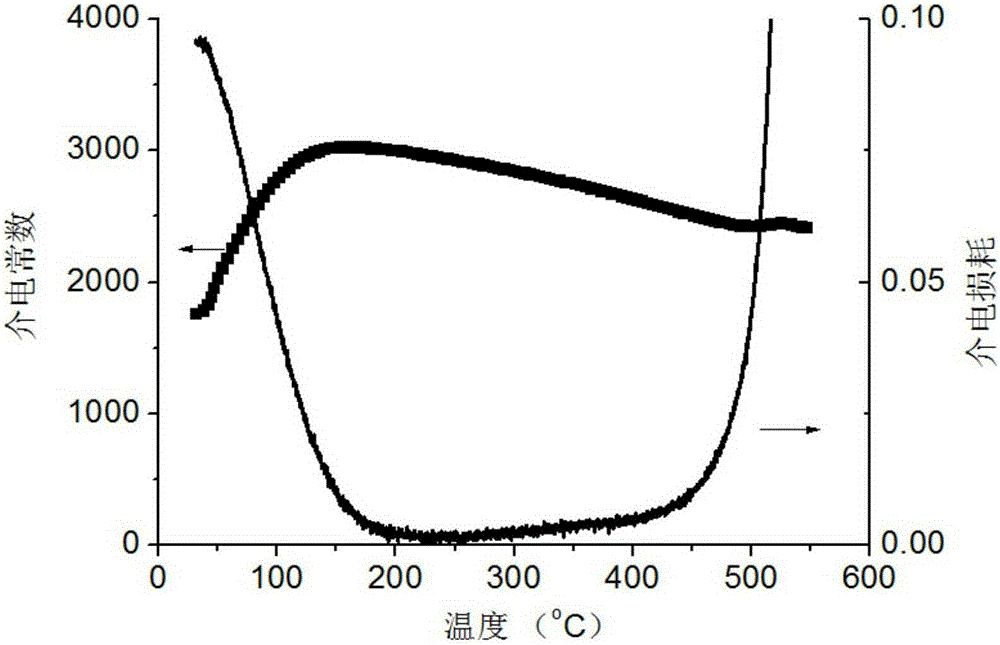

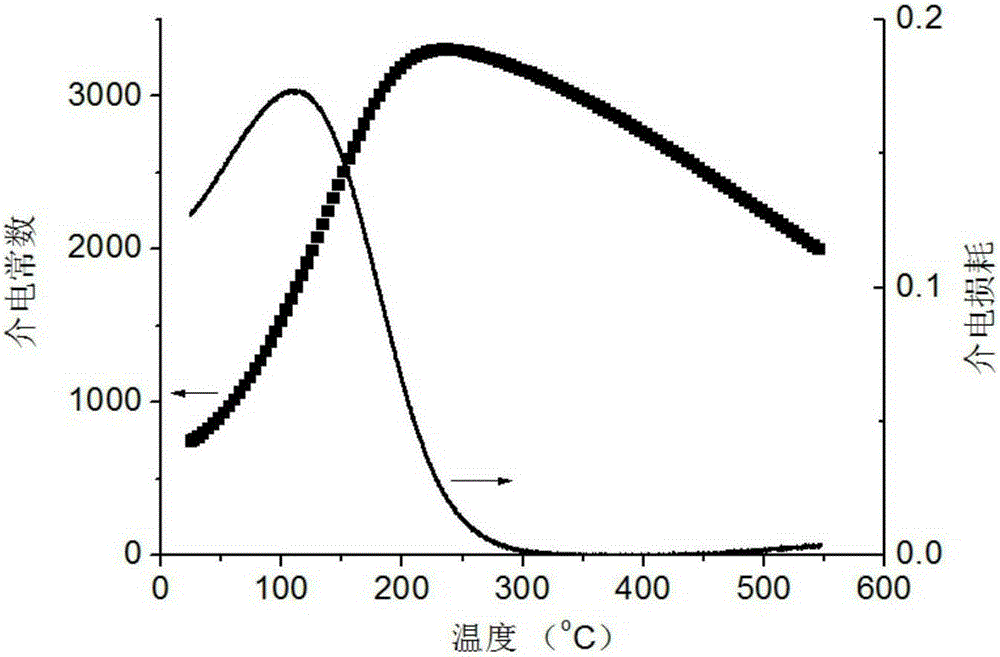

The invention discloses a low-loss, high-temperature and lead-free capacitor material and a preparation method thereof. The material is a two-phase complex formed by Bi(Mg<0.5> Ti<0.5>) O<3> and (Ba<0.8> Sr<0.2>)<(1-x)>Ce<2x / 3>TiO<3>, 0<x<0.4, and x is a mole fraction. (Ba<0.8> Sr<0.2>)<(1-x)>Ce<2x / 3>TiO<3> particles are coated with Bi(Mg<0.5> Ti<0.5>) O<3> powder through the gel process, and the molar ratio of Bi(Mg<0.5> Ti<0.5>) O<3> to (Ba<0.8> Sr<0.2>)<(1-x)>Ce<2x / 3>TiO<3> is 0.5 to 1.5. The low-loss, high-temperature and lead-free capacitor material is good in temperature stability, and has low losses of a wide temperature area and a high dielectric constant.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

Preparation method of lithium titanate negative electrode current collector

ActiveCN104577039AIncrease areal densityImprove wettabilityElectrode manufacturing processesPhysical chemistryCopper foil

The invention belongs to the technical field of a lithium ion battery, and particularly relates to a preparation method of a lithium titanate negative electrode current collector. The preparation method is realized by adopting the following technical scheme: selecting an etching copper foil as a negative electrode current collector, soaking the negative electrode current collector into a modified solution, performing ultrasonic treatment on the surface for 5-30min at the temperature of 20-40DEG C under the ultrasonic frequency of 10-30KHz; drying after the ultrasonic treatment is completed, coating the negative electrode current collector with lithium titanate negative electrode slurry after drying, and the surface density of the coated two sides is 180-220g / m<2>.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

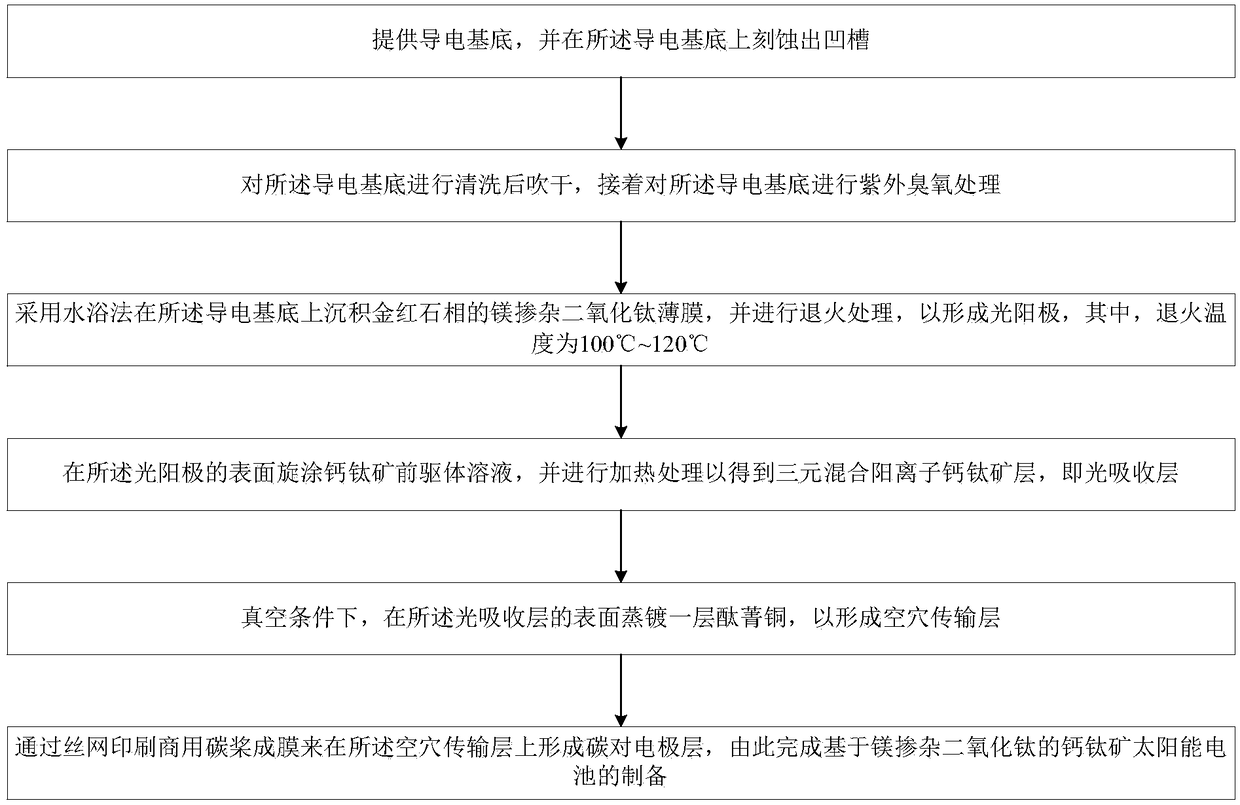

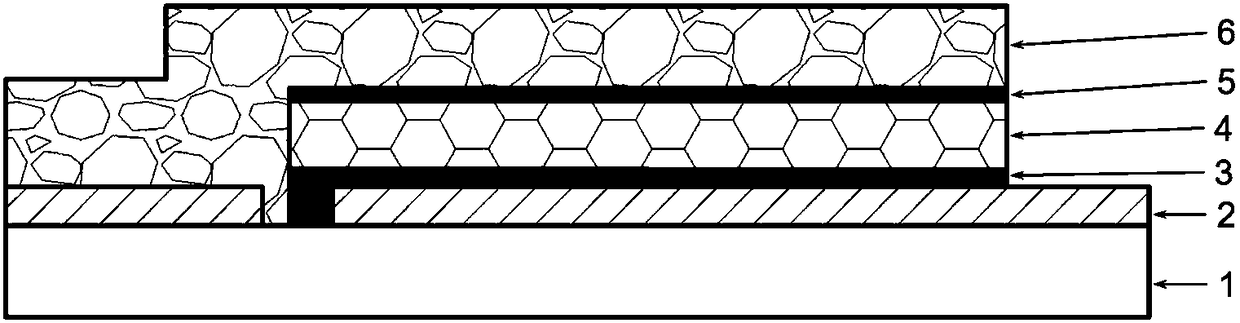

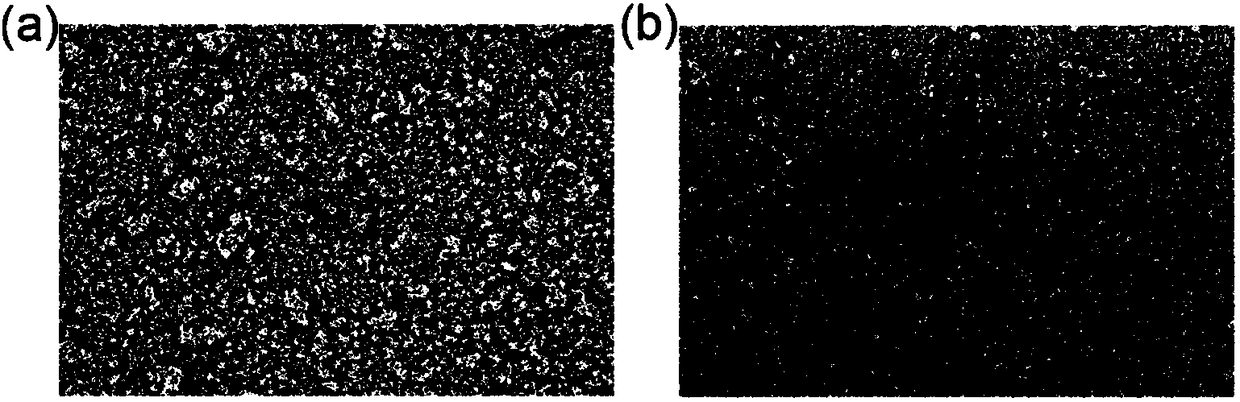

Magnesium-doped titanium dioxide based perovskite solar cell and preparation method thereof

ActiveCN108281550AReduce energy consumptionIncrease surface areaFinal product manufactureSolid-state devicesChemistryMagnesium

The invention belongs to the micro-nano manufacturing related technical fields and discloses a magnesium-doped titanium dioxide based perovskite solar cell and a preparation method thereof. The methodincludes steps: (1) cleaning a conductive substrate; (2) adopting a water bath method for deposition of a rutile-phase magnesium-doped titanium dioxide film on the conductive substrate, and annealingat 100-120 DEG C to form a photo-anode; (4) performing spin coating of perovskite precursor solution on the surface of the photo-anode to obtain a photo-absorption layer; (5) performing evaporation of a copper phthalocyanine layer on the surface of the photo-absorption layer to form a hole transport layer; (6) adopting a silk-screen printing commercial carbon blade for film formation to form a carbon counter electrode layer on the hole transport layer. Production cost is reduced, cell performances and stability are remarkably improved, and large-scale commercial cell production is benefited.

Owner:HUAZHONG UNIV OF SCI & TECH

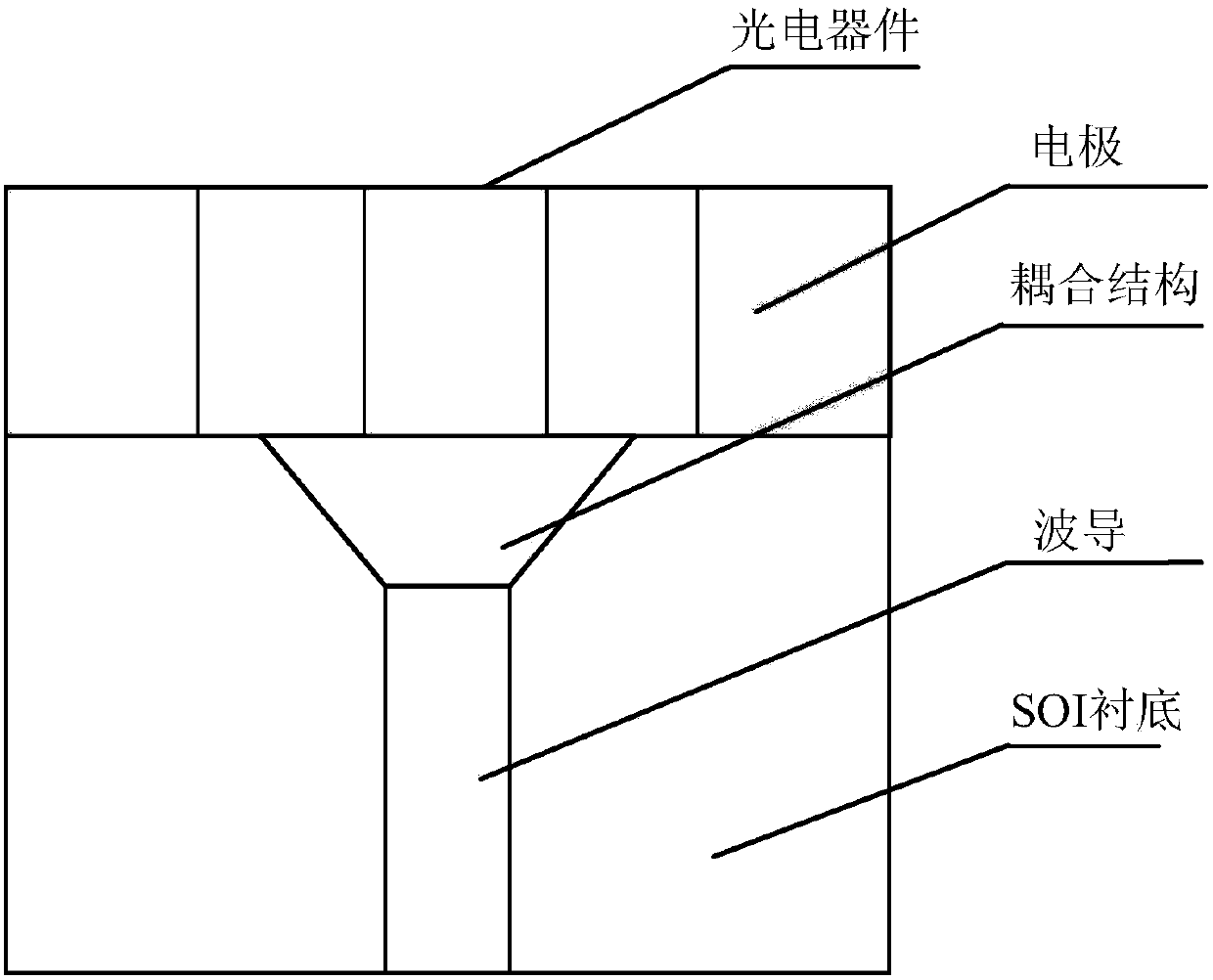

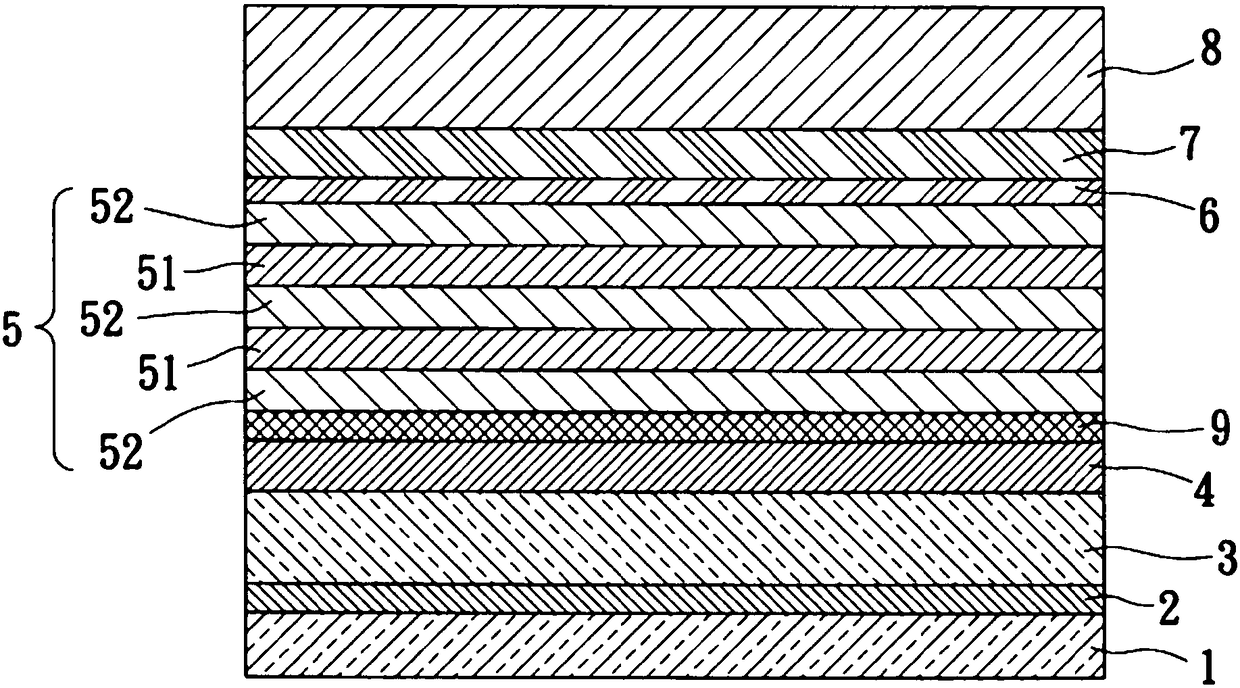

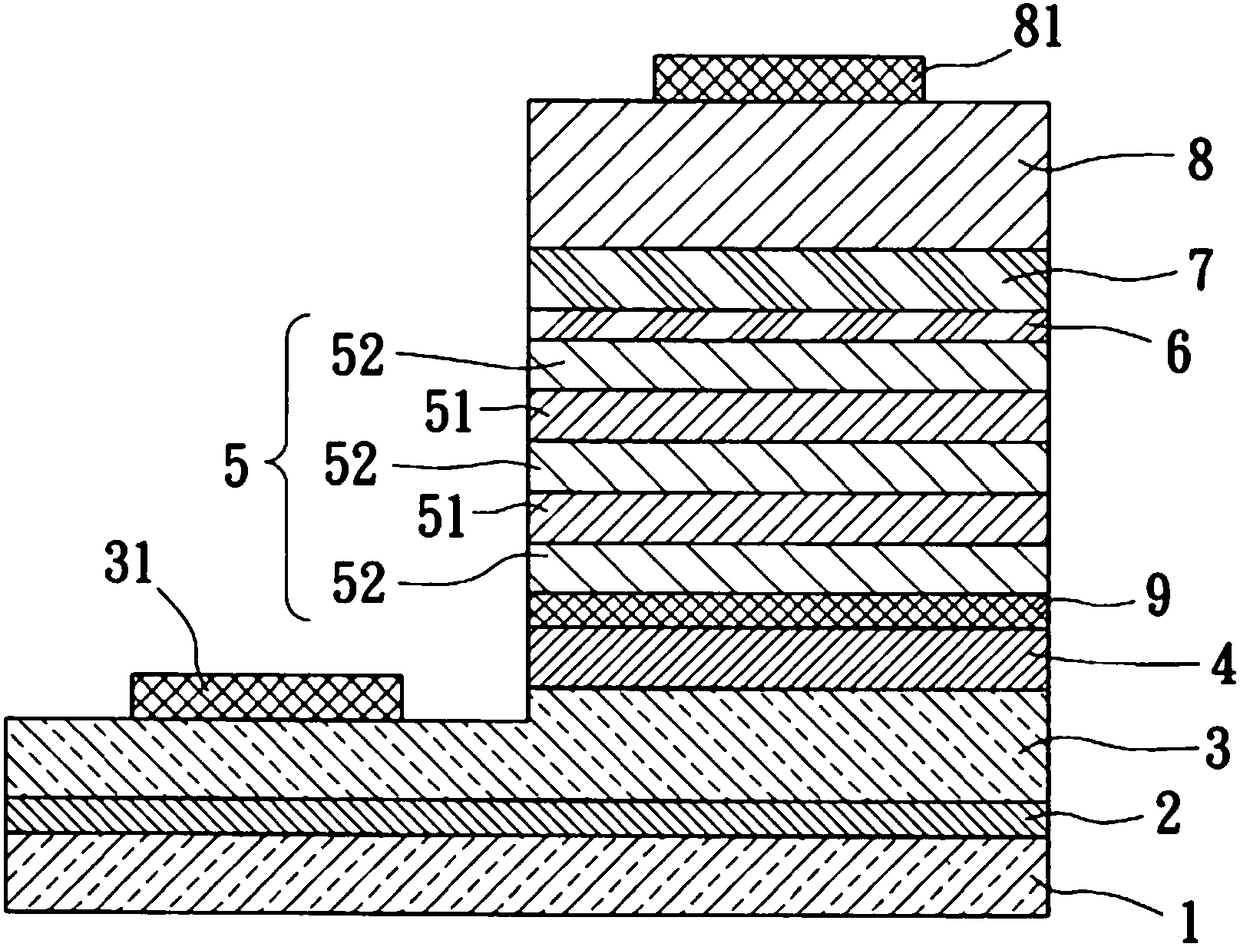

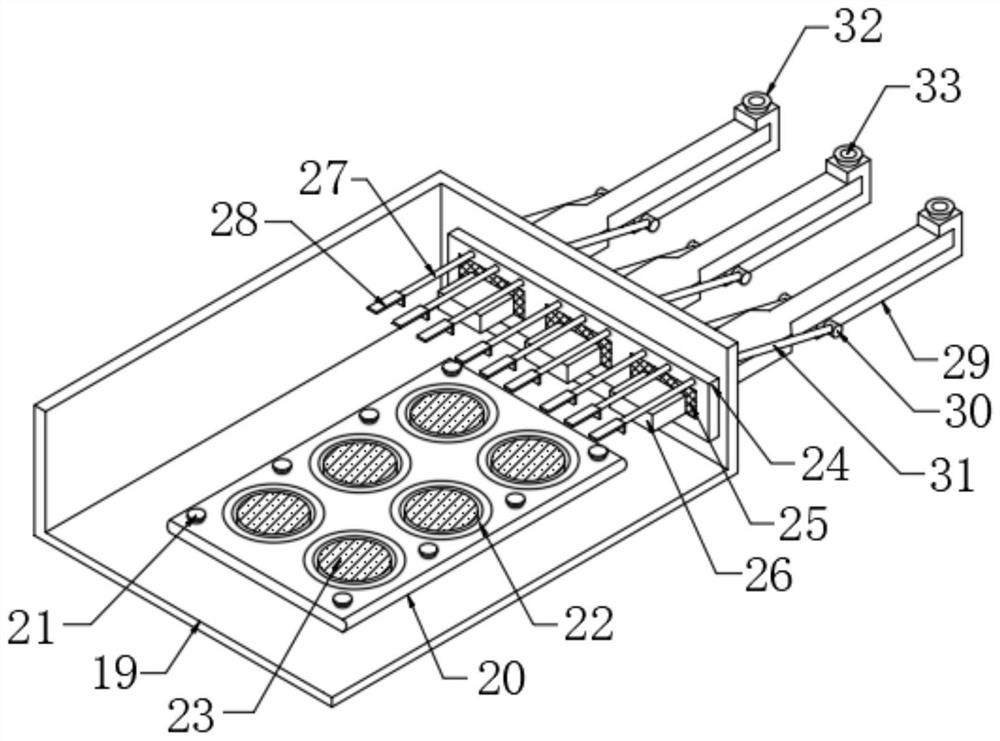

N-Ge-i-Ge-p-Si structural waveguide-type photoelectric detector based on LRC technology and manufacturing method

InactiveCN107863399AImprove crystal qualityThe process steps are simpleFinal product manufactureSemiconductor devicesProtection layerOptical detector

The invention relates to an n-Ge-i-Ge-p-Si structural waveguide-type photoelectric detector based on an LRC technology and a manufacturing method. The method comprises the following steps of manufacturing a SOI substrate; etching and forming a waveguide area, a coupling structure and a device poriton on a top layer Si layer surface respectively; growing a Ge material on a surface of the device portion and manufacturing a protection layer; heating a whole substrate, using a laser technology to crystallize the whole substrate, cooling and making the Ge material form a crystallization Ge layer, and removing the protection layer; growing a first Ge layer and a second Ge layer on a crystallization Ge layer surface; manufacturing a passivation layer on the whole substrate, using a selective etching technology to etch the passivation layer so as to form a P-type contact hole on the top layer Si layer surface and an N-type contact hole on a second Ge layer surface; and depositing metal in theP-type and N-type contact holes and completing interconnection so as to finally form the photoelectric detector. In the invention, by using the photoelectric detector, dark currents can be reduced, aconflict of a high speed response and quantum efficiency in a vertical light-entering-type optical detector is overcome, simultaneously a high speed and high quantum efficiency are guaranteed.

Owner:TIBET UNIVERSITY FOR NATIONALITIES

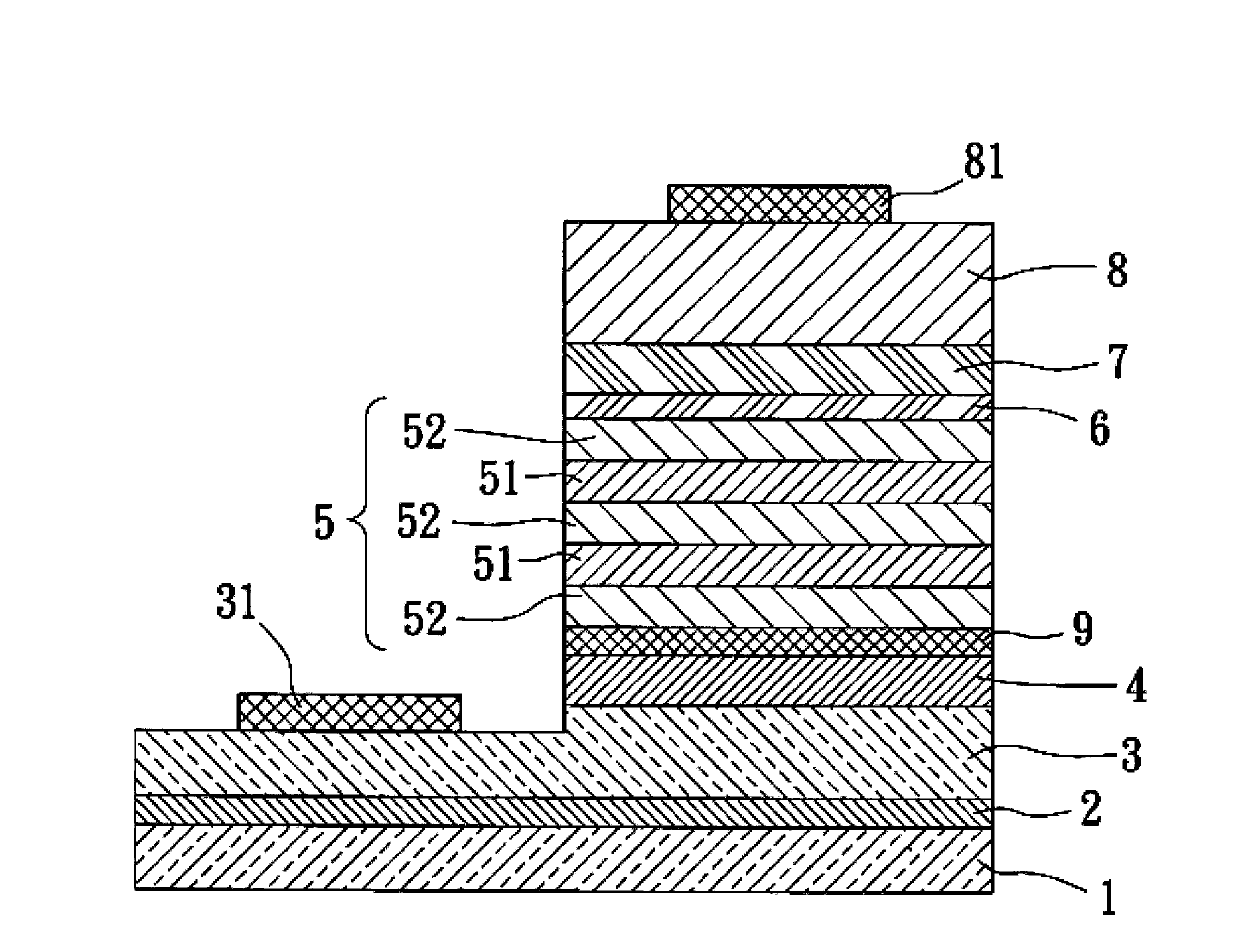

Nitride semiconductor structure and semiconductor light emitting element

InactiveCN108305922AImprove interface featuresImprove luminous efficiencySemiconductor devicesLattice mismatchQuantum well

The invention discloses a nitride semiconductor structure and a semiconductor light emitting element. According to the nitride semiconductor structure, a stress control layer is mainly configured between a light emitting layer and a p type carrier block layer; the p type carrier block layer is formed by a material shown as Al<x>Ga<1-x>N 0<x<1; the stress control layer is formed by a material shownas Al<x>In<y>Ga<1-x-y>N 0<x<1, 0<y<1, 0<(x+y)<1; the light emitting layer has multiple well layers which are alternately stacked, and a multi-quantum-well structure of block layers; and one well layer is formed between every two block layers. The semiconductor light emitting element at least comprises the nitride semiconductor structure, and an n type electrode and a p type electrode which are intwo-phase matching for providing electric energy. Therefore, the stress control layer not only can relieve the problem of crystal quality degradation caused by lattice mismatch between the p type carrier block layer and the light emitting layer, but also can lower compression stress caused by material difference of the well layers.

Owner:GENESIS PHOTONICS INC

Waste tire rubber regeneration concrete and preparation method thereof

The invention discloses waste tire rubber regeneration concrete which is prepared from the following raw materials in parts by weight: 360-400 parts of Portland cement, 500-600 parts of natural crudeaggregate, 200-300 parts of regenerated crude aggregate, 363-379 parts of waste tire rubber powder, 70-90 parts of coal ash, 400-550 parts of chippings, 16.5-18.5 parts of rice hull ash, 13-15 parts of slag powder, 5-10 parts of re-redispersible rubber powder, 13-14 parts of polyacrylamide, 1.8-2.5 parts of a high-strength steel wire imitated fiber, 3.55-4.55 parts of anhydrite, 2.3-3 parts of sulfoaluminate clinker, 1.6-2 parts of nano calcium carbonate, 30-80 parts of a triterpenoid saponins air entraining agent, 50-80 parts of a naphthalenesulfonate formaldehyde condensation compound and 160-190 parts of water. The concrete disclosed by the invention is excellent in bending and impact resistance, and high in overall strength.

Owner:QINGHAI UNIV FOR NATITIES

Nitride semiconductor structure and semiconductor light-emitting component

ActiveCN103972345AImprove the problem of quality deteriorationReduce compressive stressSemiconductor devicesQuantum wellDegradation Problem

The invention relates to a nitride semiconductor structure and a semiconductor light-emitting component. The nitride semiconductor structure is mainly characterized in that a stress control layer is arranged between a light-emitting layer and a p-type carrier barrier layer, the p-type carrier barrier layer is made of materials expressed by AlxGa1-xN, the x is larger than zero and smaller than one, the stress control layer is made of materials expressed by AlxInyGa1-x-yN, the x is larger than zero and smaller than one, the y is larger than zero and smaller than one, a sum of the x and the y is larger than zero and smaller than one, the light-emitting layer is of a multi-quantum-well structure formed by a plurality of alternated and stacked well layers and barrier layers, and one well layer is arranged between every two barrier layers. The semiconductor light-emitting component at least comprises the nitride semiconductor structure, an n-type electrode and a p-type electrode, and the n-type electrode and the p-type electrode supply power energy in a matched mode. In this way, the crystalline quality degradation problem, caused by lattice mismatching, of the p-type carrier barrier layer and the light-emitting layer can be solved through the stress control layer; meanwhile, compression stress caused by material differences and borne by the well layers can be reduced.

Owner:GENESIS PHOTONICS

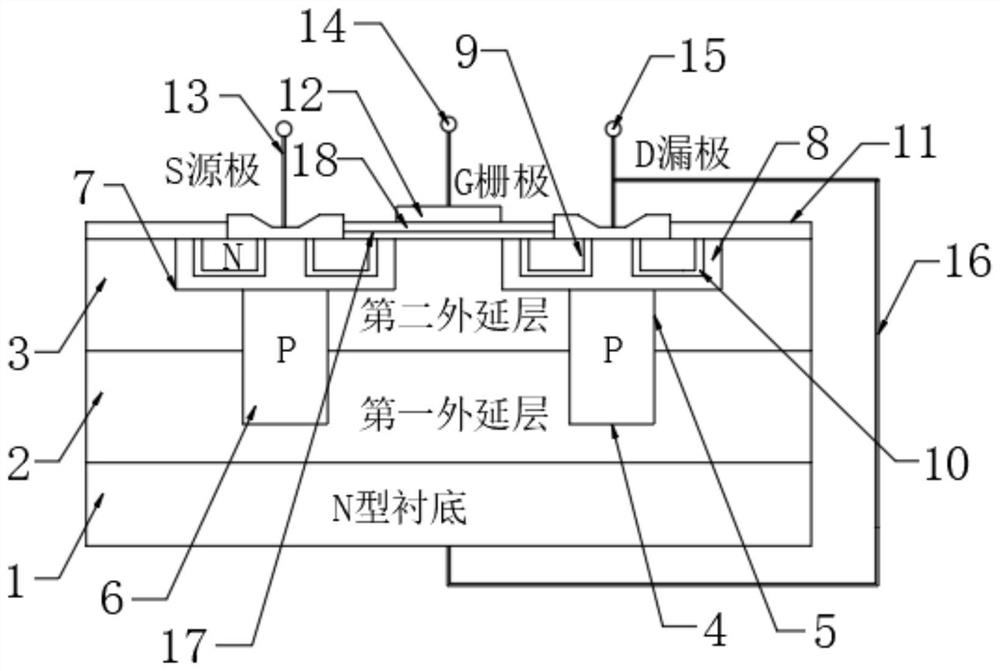

Multi-epitaxy super junction power MOSFET structure and use method

PendingCN113690196AImprove breakdown voltage and performanceImprove interface featuresSemiconductor/solid-state device detailsSolid-state devicesPolycrystalline siliconField-effect transistor

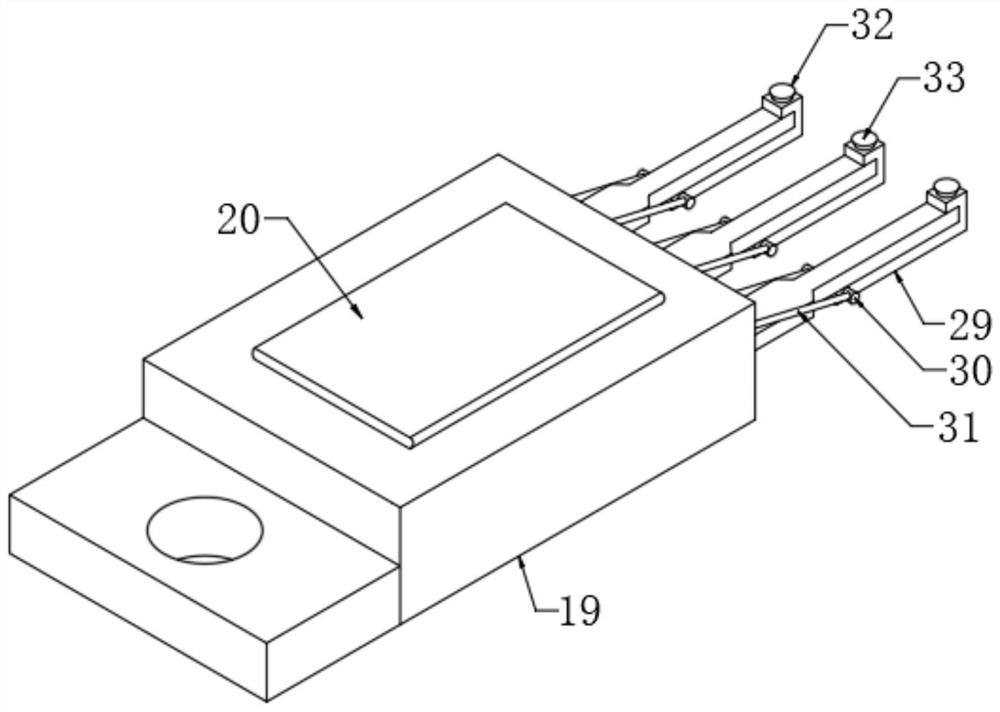

The invention discloses a multi-epitaxy super junction power MOSFET structure and a use method, and relates to the technical field of semiconductor field effect transistors. The multi-epitaxy super junction power MOSFET structure comprises an N-type substrate and a shell, the substrate is arranged in the shell, and the top end of the N-type substrate is fixedly connected with a first epitaxial layer; the top end of the first epitaxial layer is fixedly connected with a second epitaxial layer, two grooves are formed in the top end of the first epitaxial layer, and two through grooves are formed in the middle of the second epitaxial layer. According to the present invention, the N-type substrate is arranged, the first epitaxial layer is formed on the surface of the N-type substrate by means of an epitaxial process, the top end of the first epitaxial layer is etched to form the two grooves, a gate oxide layer is formed in the middle of the surface of the second epitaxial layer, and a polycrystalline silicon grid electrode is formed on the surface of the gate oxide layer, so that the design of double-layer epitaxy or even multi-layer epitaxy can be realized, the breakdown voltage and performance of an MOSFET can be greatly improved, the ideal resistivity matching exists between two layers or multiple layers, and the interface characteristics of the multiple stacked epitaxial layers can be improved.

Owner:厦门芯一代集成电路有限公司

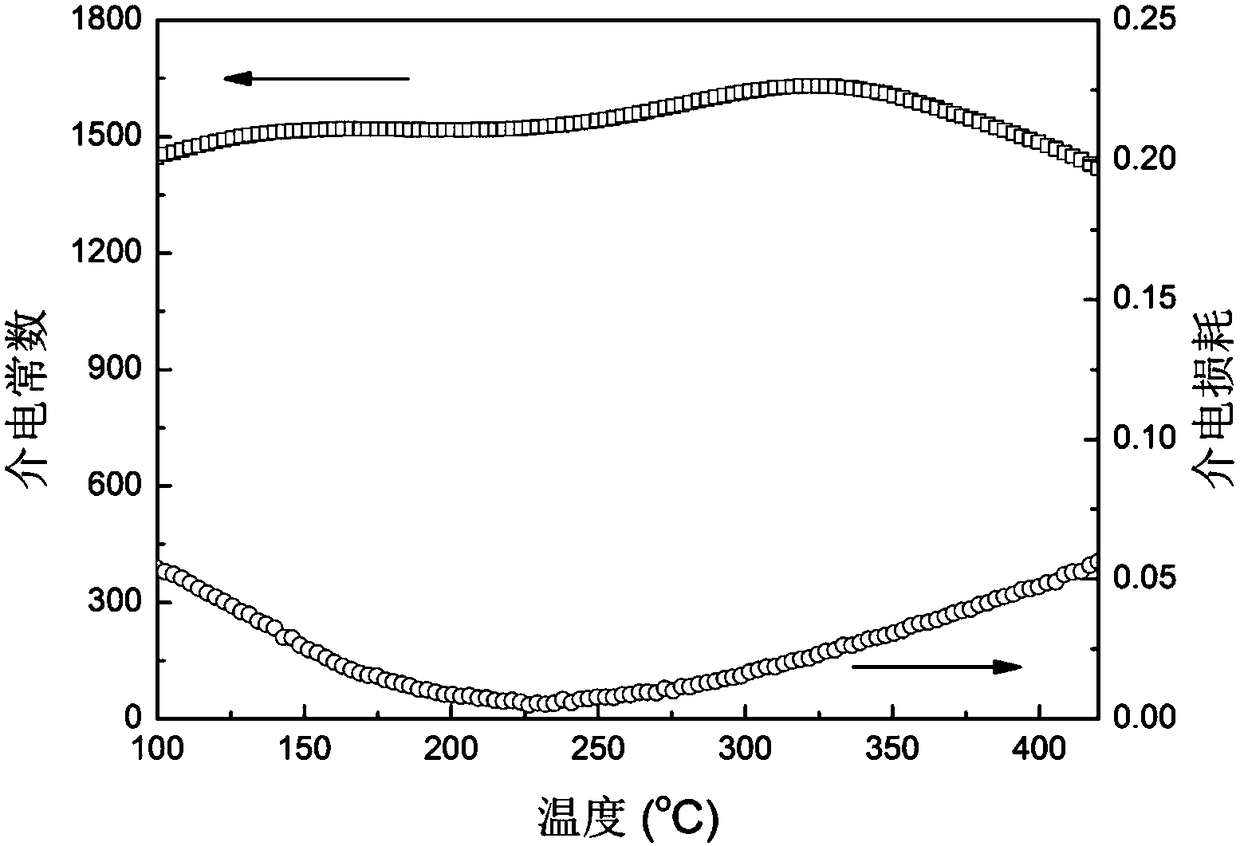

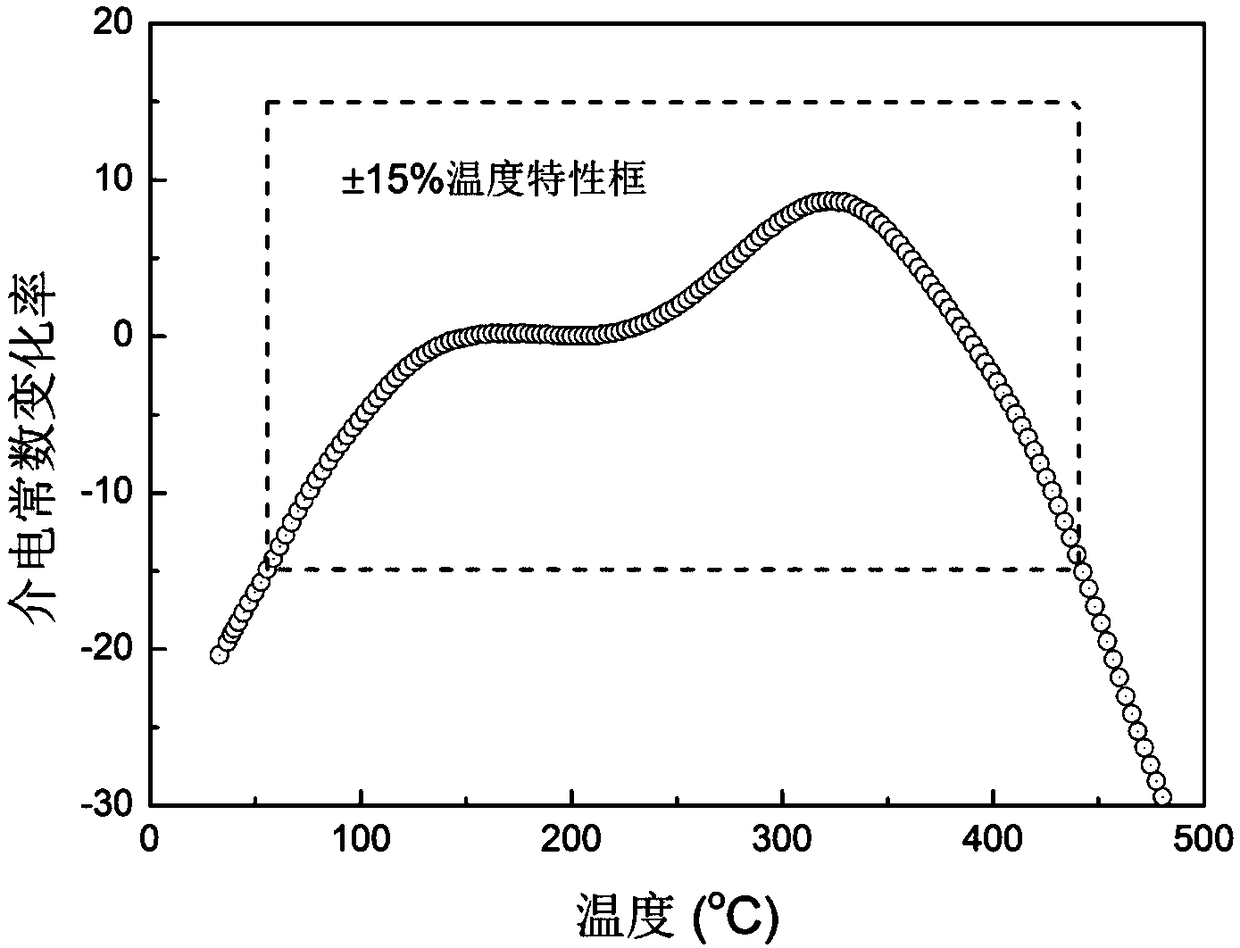

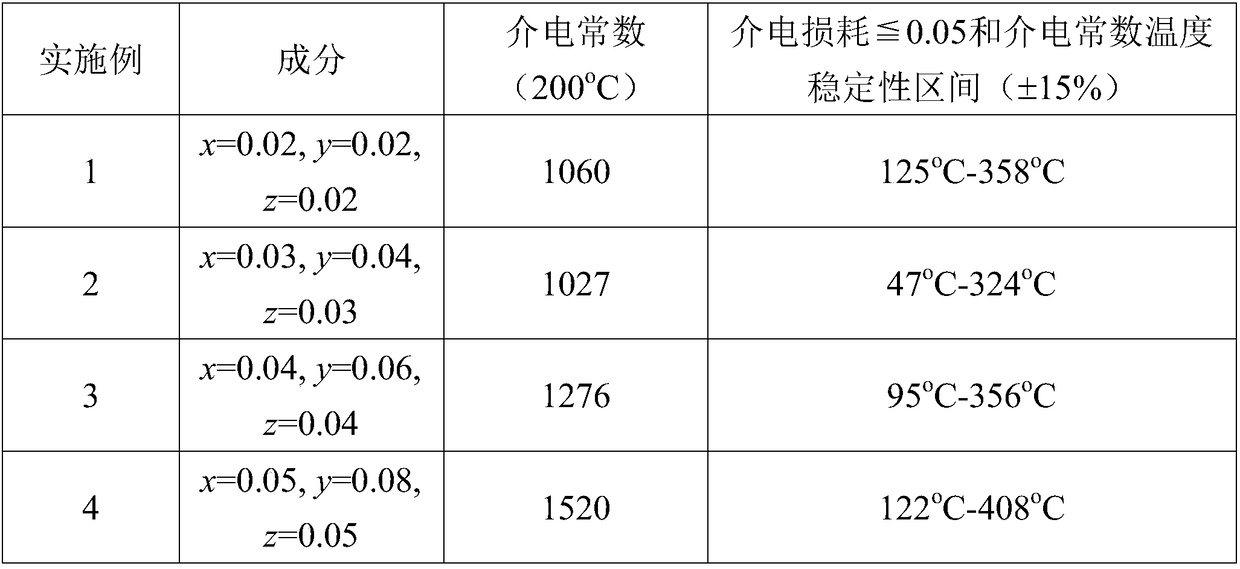

Wide temperature range type high-temperature lead-free ceramic capacitor material and preparation method

InactiveCN108484167ACause harmImprove interface featuresFixed capacitor dielectricCeramic capacitorHot Temperature

The invention discloses a wide temperature range type high-temperature lead-free ceramic capacitor material and a preparation method. The ceramic comprises 0.92(K0.5NaO.5) NbO3-(0.92-x)LiNbO3-xSrTiO3-y(Bi0.5Li0.5)ZrO3-zCuO, wherein x ranges from 0.02 to 0.05; y ranges from 0.02 to 0.08; z ranges from 0.02 to 0.05. The high-temperature lead-free ceramic capacitor material is prepared by a sol-gel technology; the temperature stability in a high temperature range is high; the dielectric constant is high and the loss is low in the wide high temperature range; and the material meets different application demands under high temperature environments.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Method of preparing silicon carbide MOSFET gate dielectric layer

InactiveCN110808282AWide band gapHigh breakdown strengthSemiconductor devicesMOSFETBreakdown strength

The invention provides a method of preparing a silicon carbide MOSFET gate dielectric layer. The method comprises the following steps of: providing a SiC substrate, and placing the SiC substrate in anALD reaction chamber, raising the temperature of the ALD reaction chamber, sequentially and circularly growing a SiO2 film and an Al2O3 film on the surface of the SiC substrate by adopting an ALD process to form a gate dielectric layer, and performing annealing processing on the formed gate dielectric layer in an oxygen atmosphere. In the growth process of the gate dielectric layer, Si atoms in the SiC epitaxial wafer are not consumed, so that the phenomenon of C group aggregation at the interface of the gate dielectric layer and SiC is avoided, and the interface characteristic is improved; the gate dielectric layer is formed by using the ALD technology, the thermal budget is low, and the device preparation process is simplified; the gate dielectric layer formed by the ALD technology hasthe characteristics of high SiO2 breakdown strength, wide forbidden band width, high thermal stability and high Al2O3 dielectric constant at the same time, the electric field intensity introduced intothe gate dielectric film can be greatly reduced, gate dielectric breakdown is avoided, and gate leakage current is inhibited.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

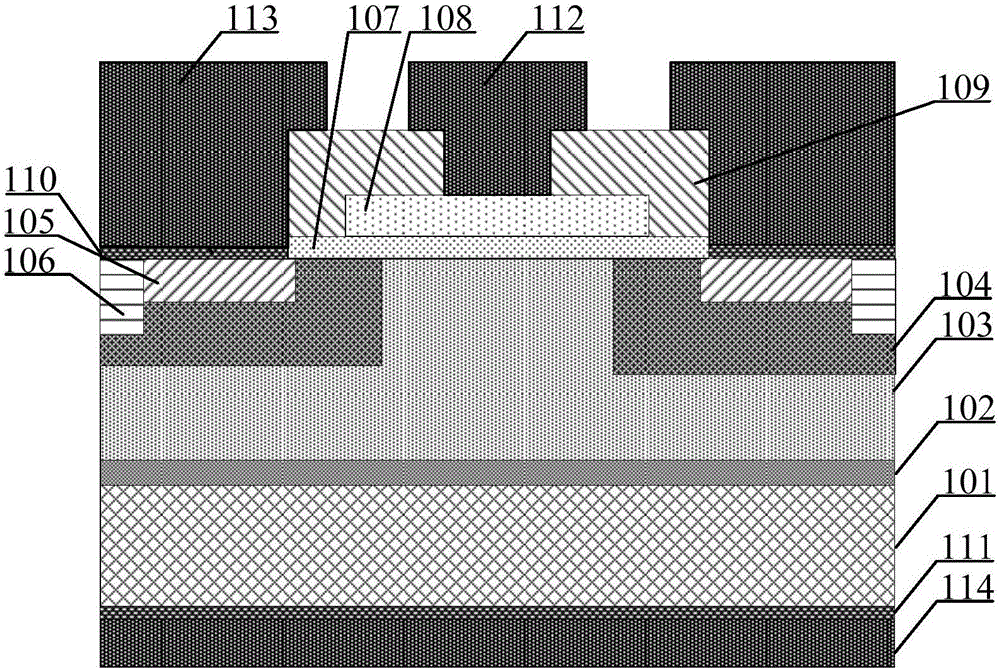

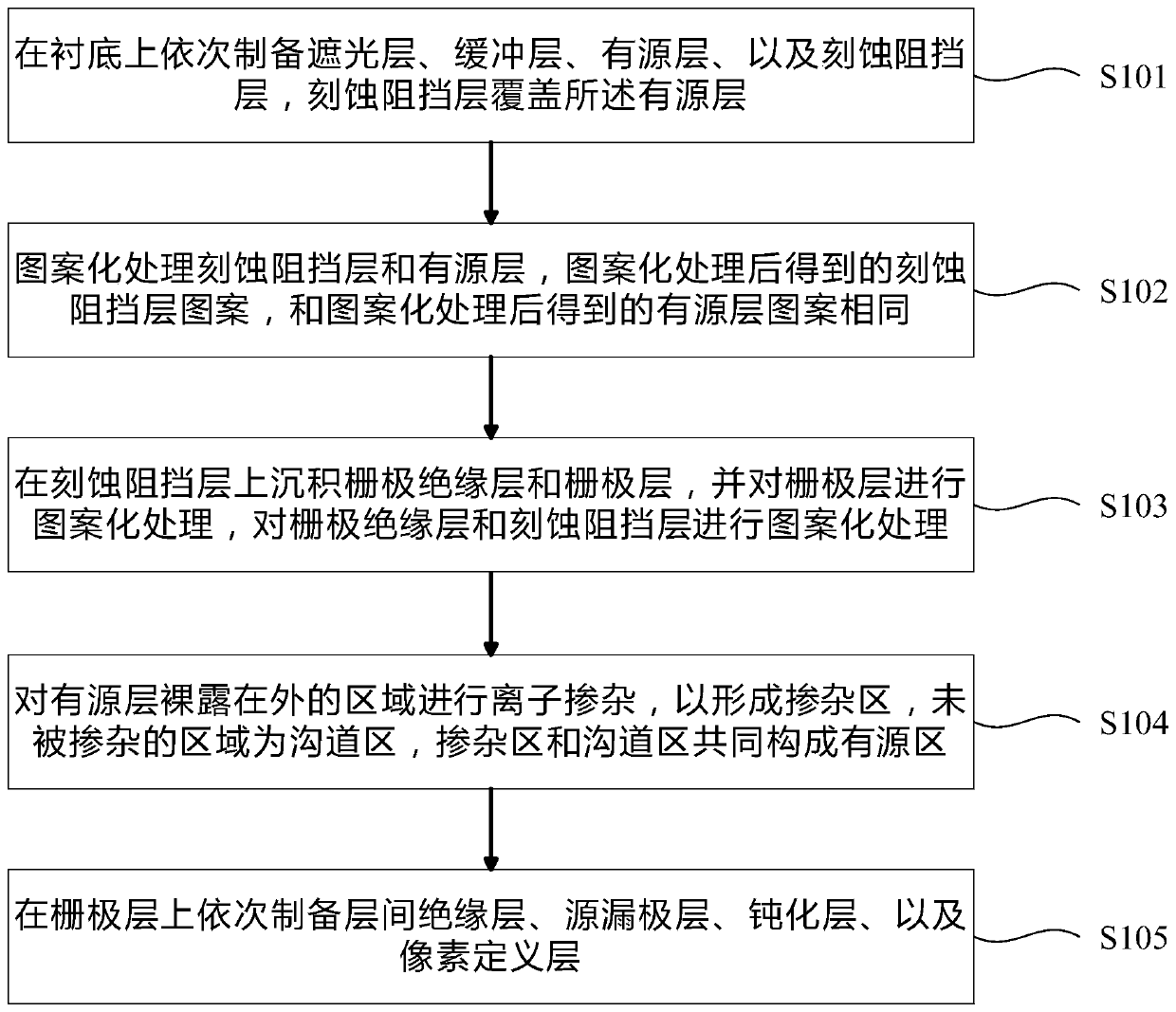

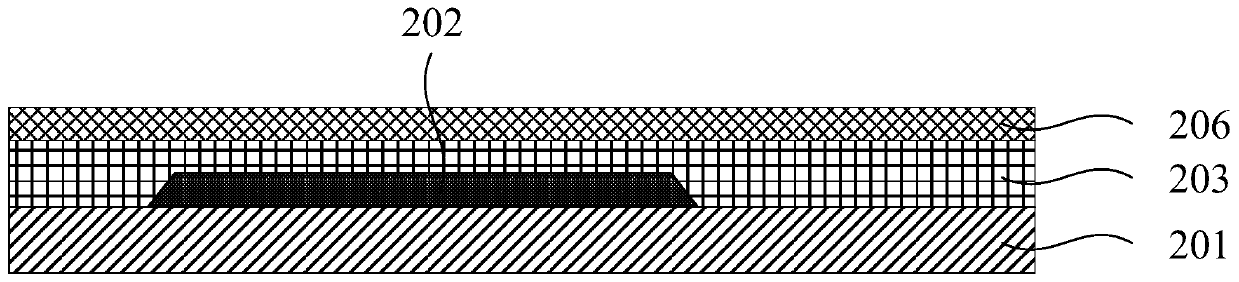

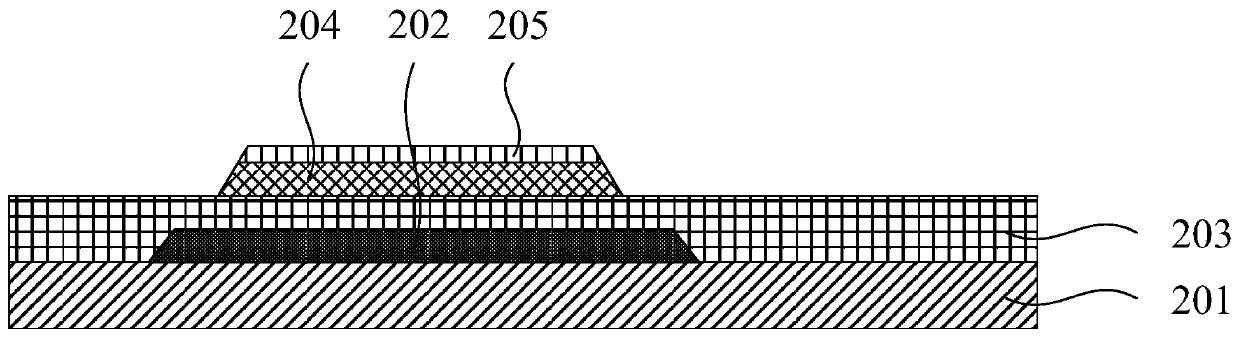

Top gate type oxide array substrate and preparation method thereof

PendingCN110942995AImprove performanceImprove interface featuresTransistorSolid-state devicesPhysicsPhotoresist

The invention provides a top gate type oxide array substrate and a preparation method thereof. The top gate type oxide array substrate comprises a substrate, a shading layer, a buffer layer, an activelayer, an etching barrier layer, a gate insulating layer, a gate layer, an interlayer insulating layer, a source and drain layer, a passivation layer and a pixel electrode layer which are stacked insequence, according to the preparation method, a silicon oxide film layer of which the film quality is close to that of a gate insulating layer is prepared on an active layer to serve as an etching barrier layer, patterning processing is carried out on the etching barrier layer and the active layer together, then the etching barrier layer is etched along with the gate insulating layer, and a parton a channel region of the active layer is reserved; by means of the protection of the etching barrier layer, the active layer is prevented from being eroded or damaged by chemicals in the yellow light and photoresist stripping process, the interface characteristic of the oxide active layer and the gate insulating layer is improved, and then the performance of the top gate type oxide array substrate is improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

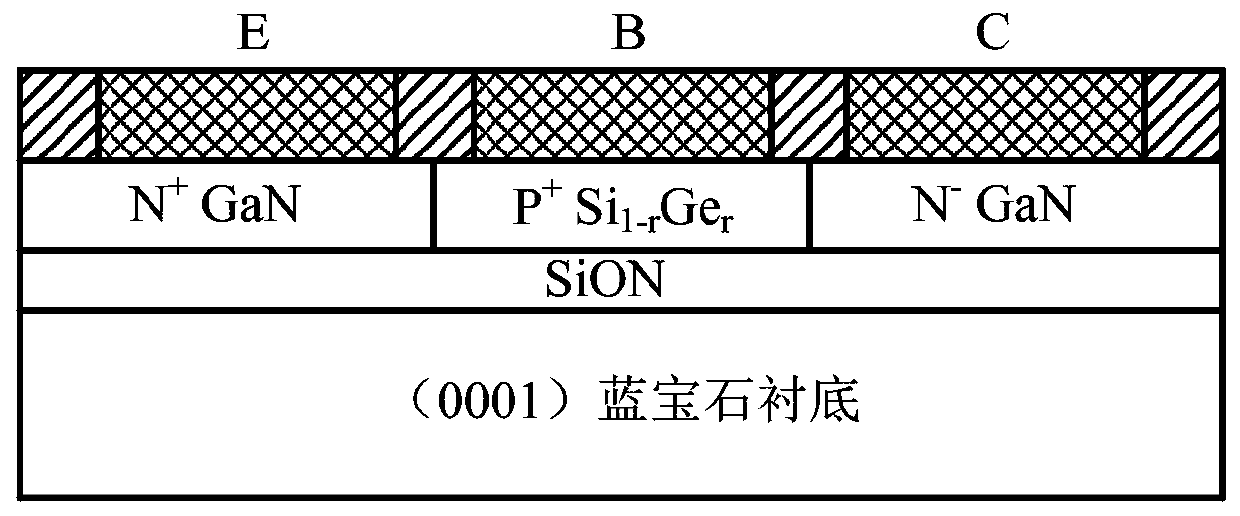

NPN type transverse GaN/SiGe HBT device structure and manufacturing method thereof

PendingCN111129120AReduced transit timeLower breakdown voltageSemiconductor/solid-state device manufacturingSemiconductor devicesMetal silicideElectron mobility

The invention provides an NPN type transverse GaN / SiGe HBT device structure. The structure comprises a sapphire substrate, wherein a SiON oxide layer is formed on a surface of the sapphire substrate;an emitter region, a base region and a collector region which have the same thickness and different widths are formed on the surface of the SiON oxide layer from left to right; N-type doped GaN layersare deposited in the emitter region and the collector region; a P-type doped Si1-rGer layer of which a Ge component is gradually increased from left to right grows in the base region, and r is greater than 0 and less than 1; and electrode leading-out layers of an emitting electrode, a base electrode and a collecting electrode correspondingly grow on the surfaces of the emitting region, the base region and the collector region, all the electrodes are made of the same metal silicide, and the adjacent electrode regions are insulated and isolated through isolation oxide layers. The invention further provides a manufacturing method of the device structure. In the invention, an interface characteristic of a GaN layer and a SiGe layer can be improved, electron mobility of the base region is improved, transition time of the base region is reduced, a frequency of the device is improved, frequency characteristics are more excellent, and meanwhile, a switching speed and a cut-off frequency of the device can be improved by utilizing a metal silicide layer.

Owner:中合博芯(重庆)半导体有限公司

A kind of highly plastic quasi-network structure titanium-based composite material and its preparation method

ActiveCN110343904BHigh strengthHigh elongation plasticityTransportation and packagingMetal-working apparatusTitanium matrix compositesPlastic property

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

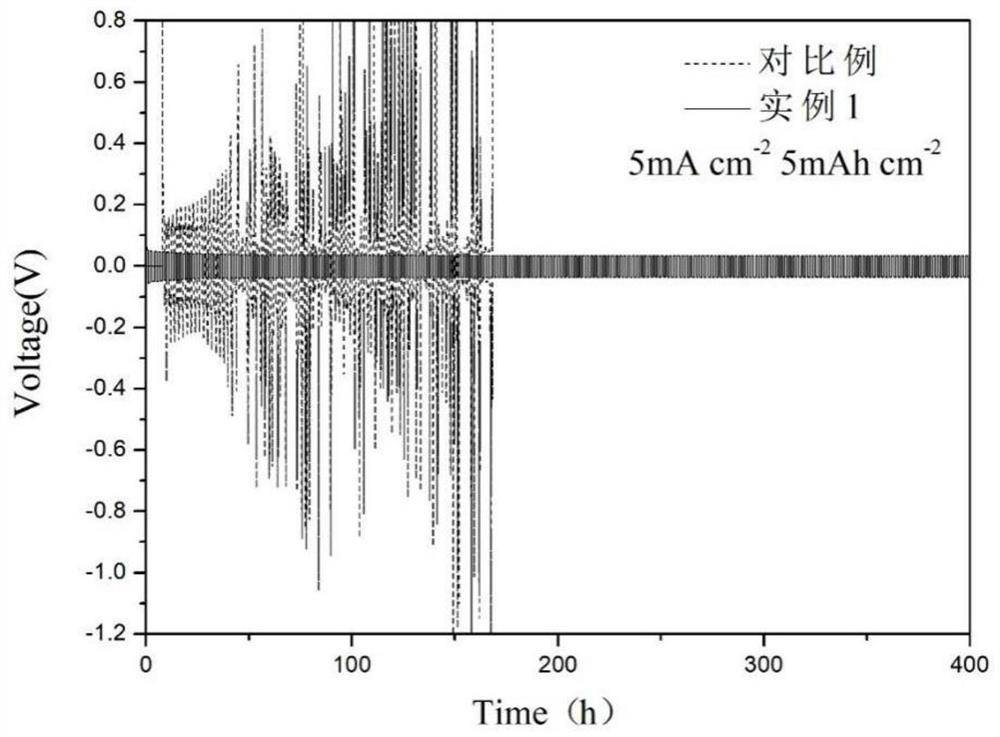

Lithium negative electrode coated with LiF film as well as preparation method and application of lithium negative electrode

InactiveCN112582614AUniform compositionHigh densityCell electrodesLi-accumulatorsLithium dendriteCharge and discharge

The invention belongs to the technical field of lithium metal interface modification, and discloses a lithium negative electrode coated with a LiF film as well as a preparation method and applicationof the lithium negative electrode. The lithium negative electrode coated with the LiF film is prepared by the following steps: dissolving a fluorinating agent in a polar aprotic organic solvent, and preheating at 25-300 DEG C in an inert atmosphere under a sealed condition to prepare a fluorinating agent solution; putting the polished lithium sheet into a fluorinating agent solution, and reactingat 25-300 DEG C in an inert atmosphere; and cleaning with an organic solution, and drying at 50-150 DEG C to obtain the product. The fluorinating agent is used for fluorinating the lithium negative electrode, the LiF film is generated on the surface of the lithium negative electrode in situ, surface impurities are removed by the organic solvent after the reaction is finished to obtain the compactlithium negative electrode coated with the LiF film, and the LiF film effectively improves the interface characteristic of the lithium negative electrode, and inhibits the generation of lithium dendrites. And the coulombic efficiency and the cycling stability of the lithium negative electrode in the charging and discharging process are improved.

Owner:GUANGDONG UNIV OF TECH

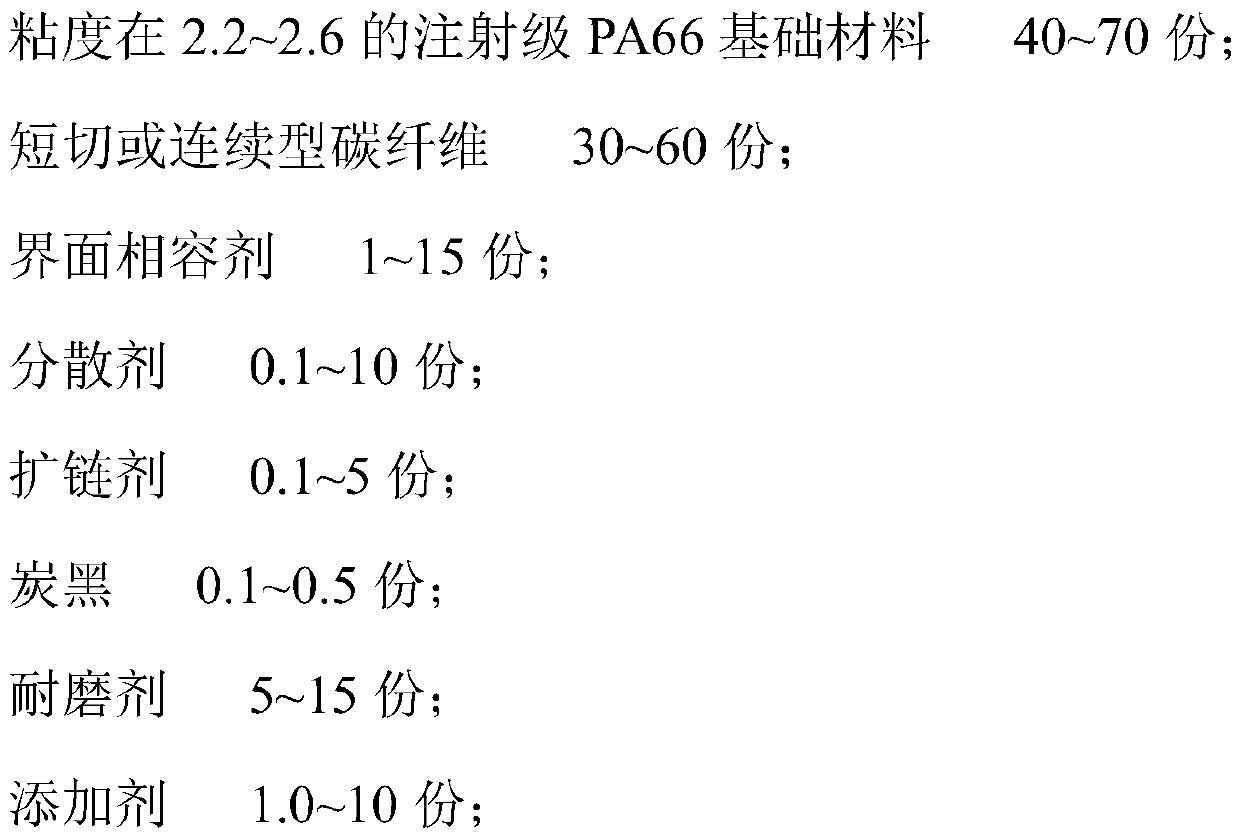

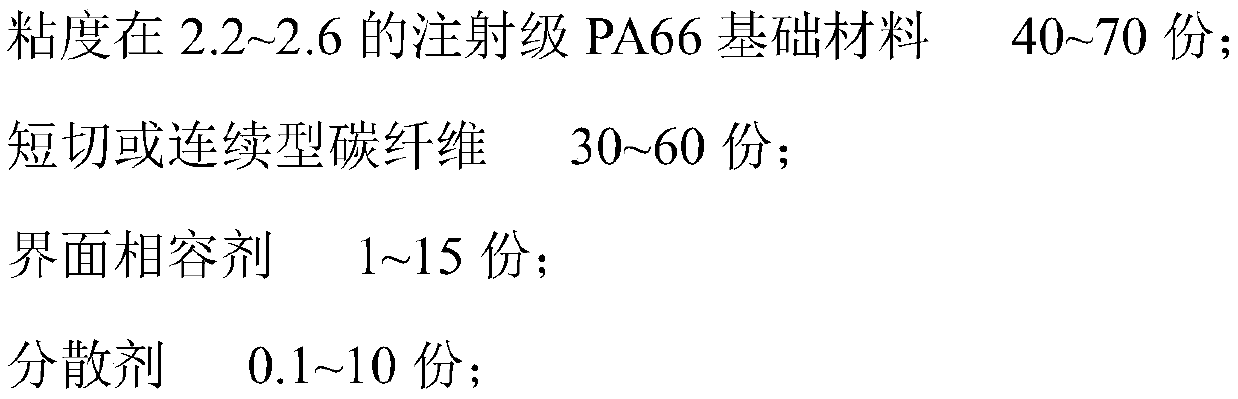

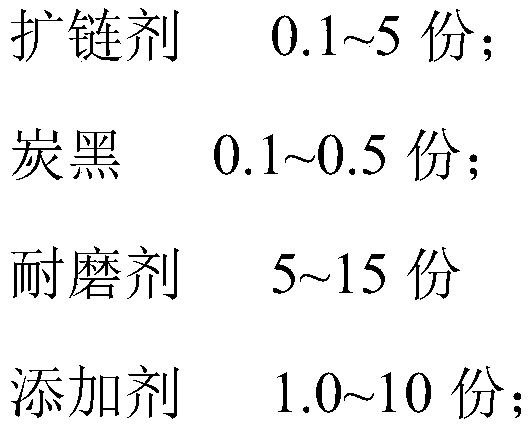

Nylon 66 composite material for connecting rod sleeve and preparation method thereof

The invention discloses a nylon 66 composite material for a connecting rod sleeve. The nylon 66 composite material is prepared from raw material components such as a PA66 base material, carbon fiber,an interfacial compatibilizer, a dispersant, a chain extender, carbon black, an anti-wear agent and an additive; the obtained nylon 66 composite material is light in specific weight, has very strong designability, not only is easy to mould, but also is uniform in material after moulding, and has various significantly improved properties in lubricity, wear resistance, impact resistance, high temperature resistance, corrosion resistance, ageing resistance and the like. In addition, by a preparation method of the nylon 66 composite material, provided by the invention, the raw material mixing sequence is clarified, and especially after the carbon fiber is mixed with the specific interfacial compatibilizer and the matching dispersant in a dry state, melt extrusion is performed through a single-screw extruder and then feeding is performed through a side feed port, so that processing damage such as surface burring and easy tearing and layering due to addition of the carbon fiber is solved, performance advantages of the carbon fiber are fully played, the preparation limitation is broken through, and thus the high strength and the high performance of the nylon 66 composite material are guaranteed.

Owner:烟台恒大聚合体有限公司

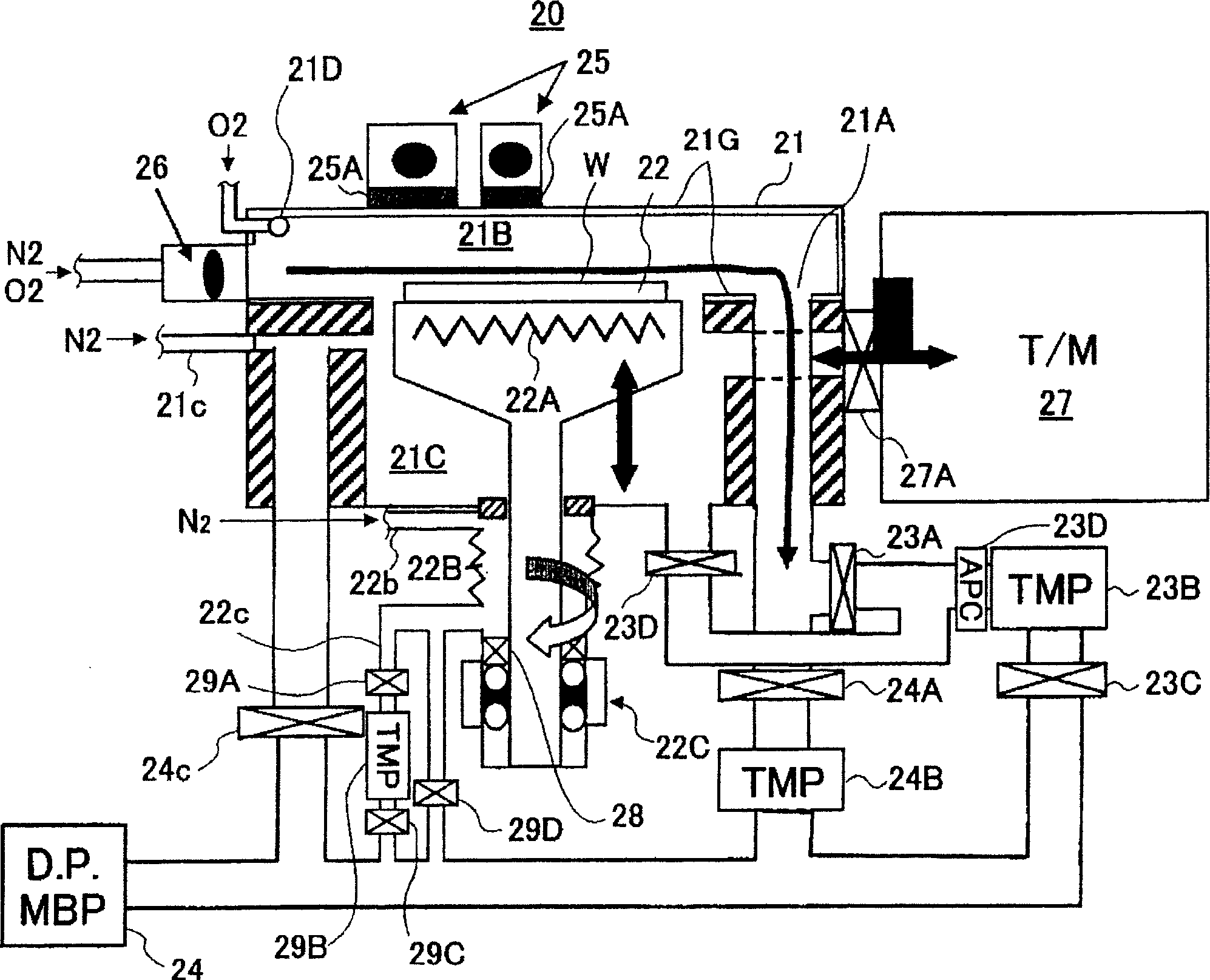

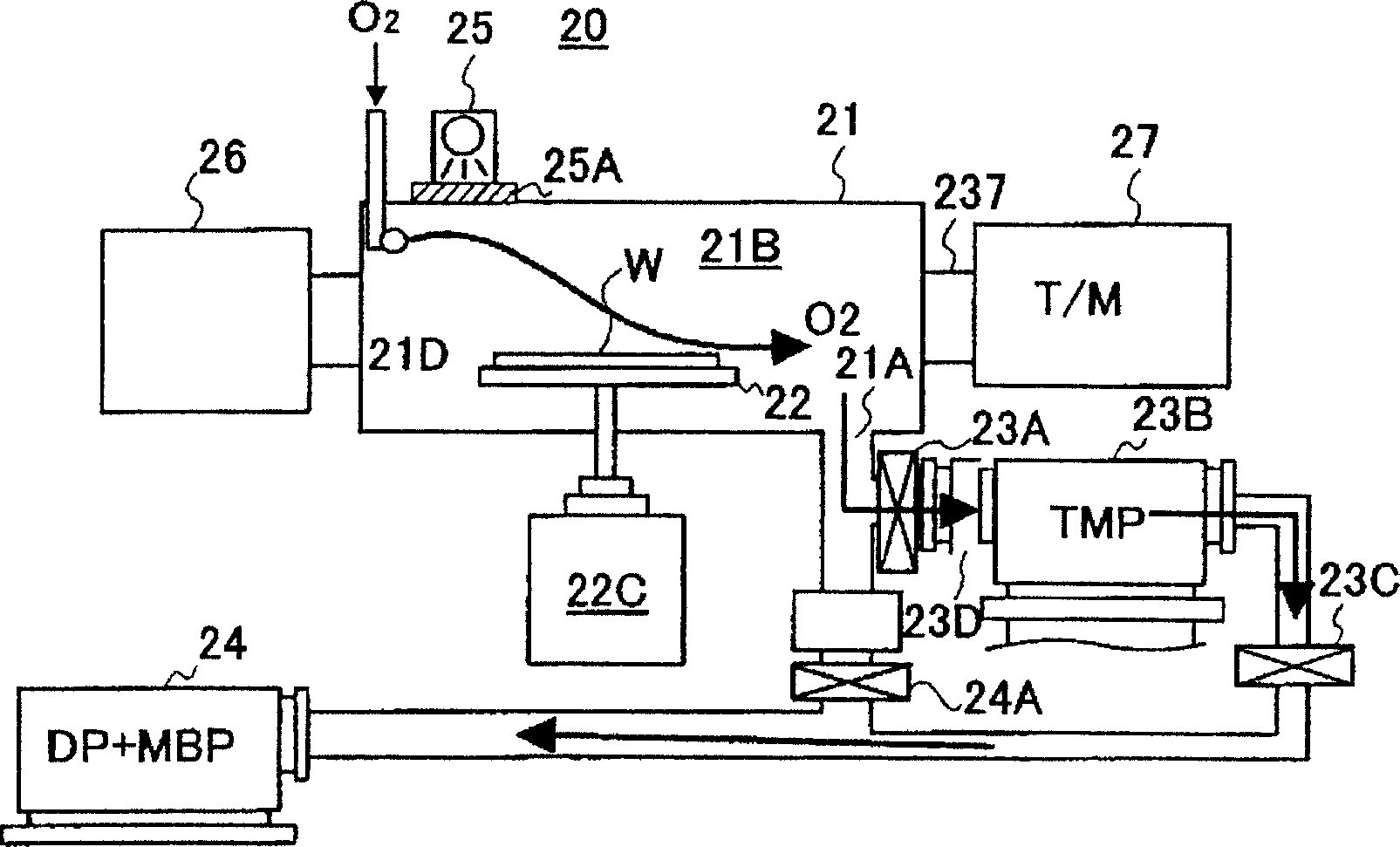

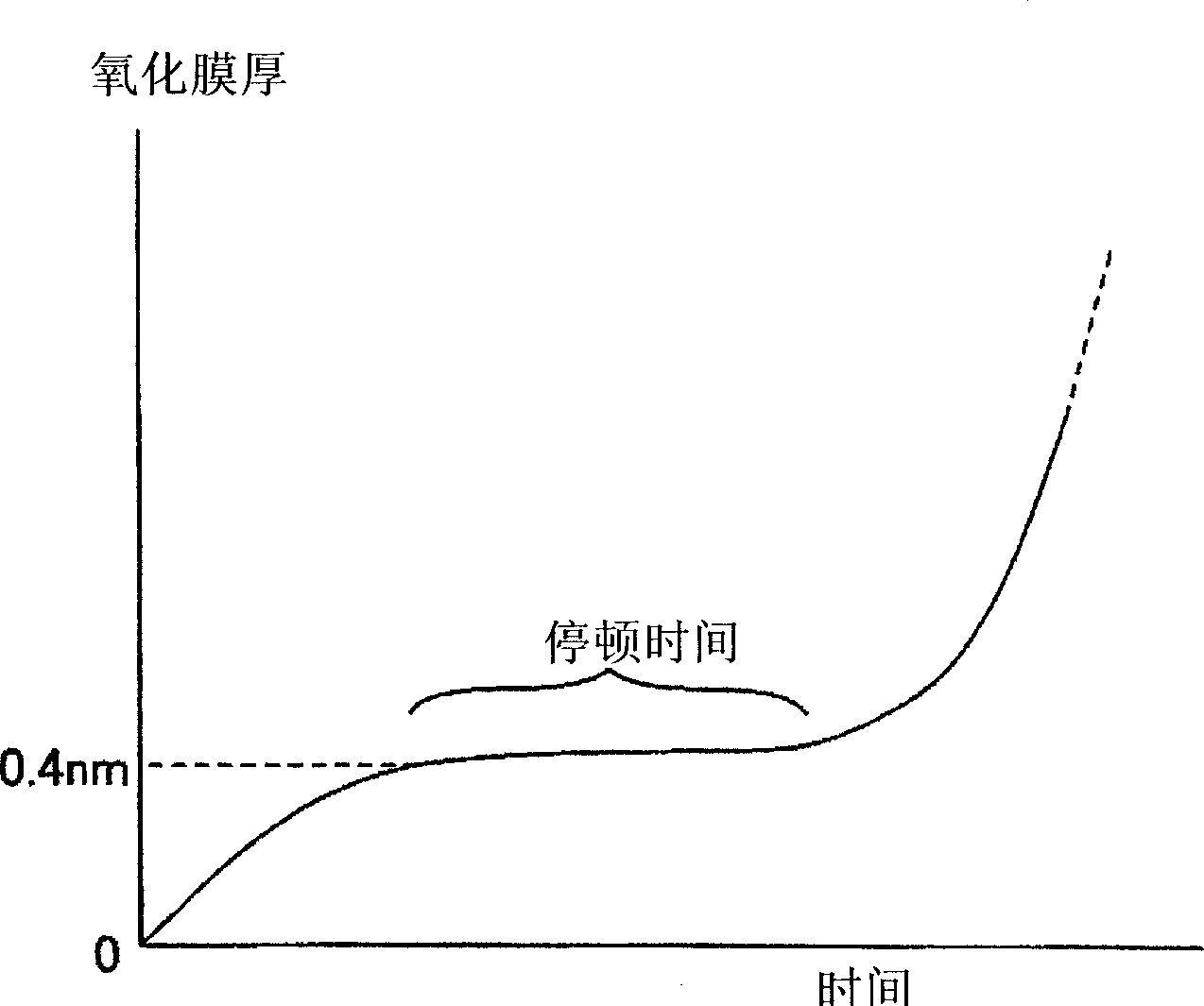

Method for forming film

InactiveCN1856869AInhibition formationReduce partial pressureSemiconductor/solid-state device manufacturingOxygenMaterials science

Disclosed is a method for forming an oxide film on the surface of a substrate to be processed at a certain process temperature in a process chamber. This method comprises a heating step wherein the substrate is heated to the certain process temperature, and this heating step includes a substep wherein the substrate is held in an atmosphere containing oxygen before the temperature of the substrate reaches 450 DEG C.

Owner:TOKYO ELECTRON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com