Patents

Literature

188results about How to "Increase areal density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

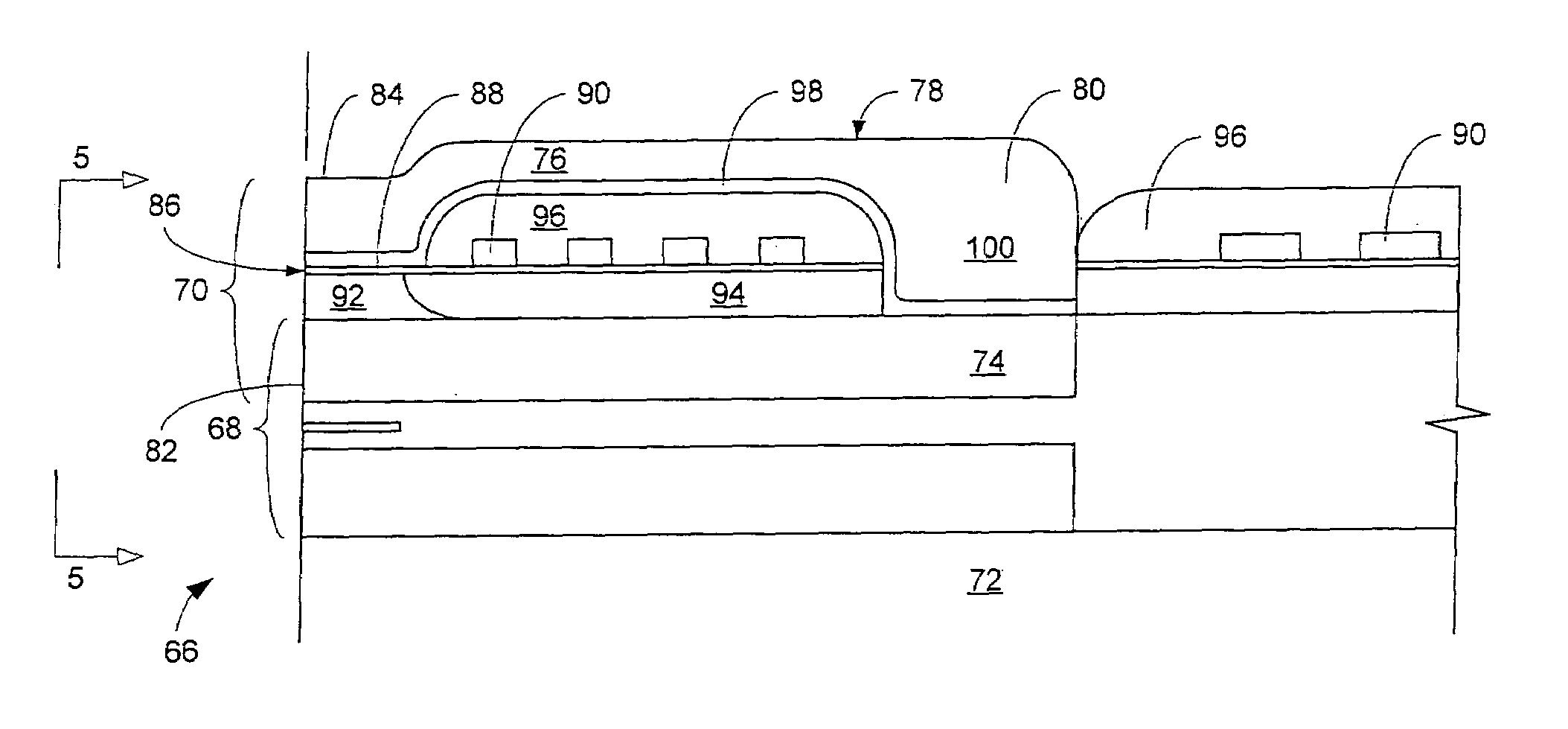

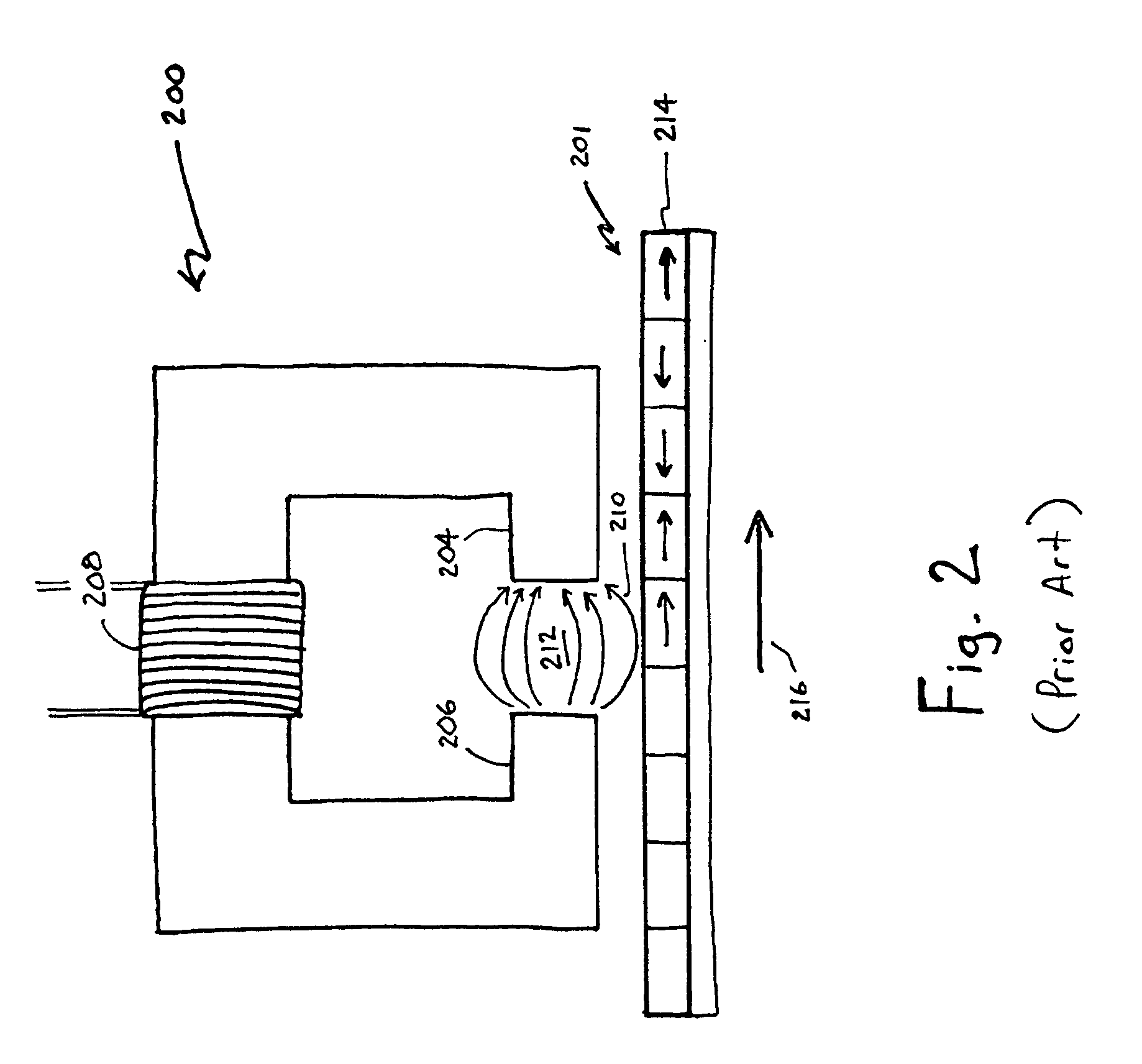

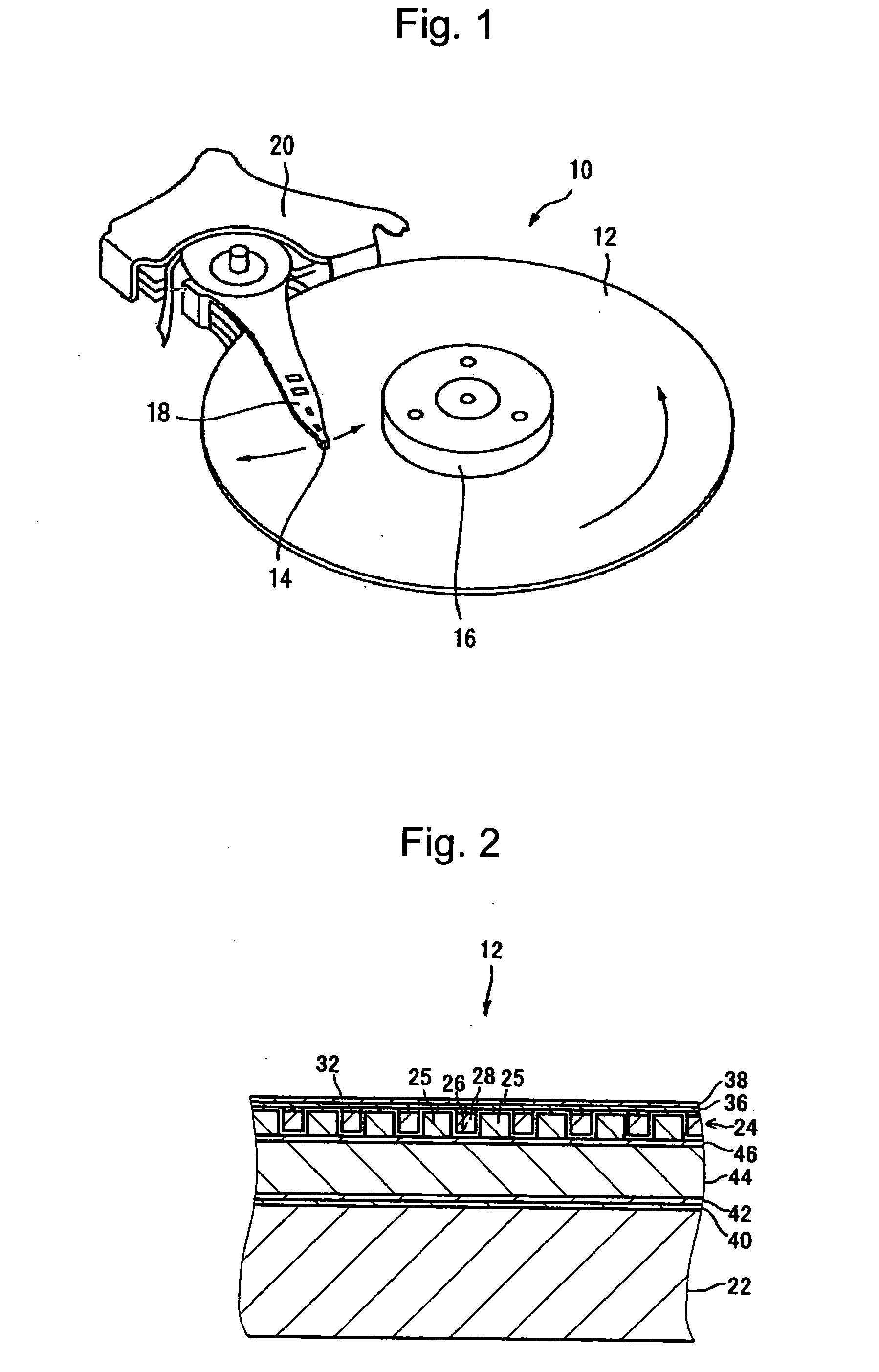

Method for making high speed, high areal density inductive write structure

InactiveUS7007372B1Excellent magnetic propertiesIncrease coverageDecorative surface effectsVacuum evaporation coatingMagnetic mediaMagnetic poles

An inductive write element is disclosed for use in a magnetic data recording system. The write element provides increased data rate and data density capabilities through improved magnetic flux flow through the element. The write element includes a magnetic yoke constructed of first and second magnetic poles. The first pole includes a pedestal constructed of a high magnetic moment (high Bsat) material, which is preferably FeRhN nanocrystalline films with lamination layers of CoZrCr. The second pole includes a thin inner layer of high Bsat material (also preferably FeRhN nanocrystalline films with lamination layers of CoZrCr), the remainder being constructed of a magnetic material capable of being electroplated, such as a Ni—Fe alloy. An electrically conductive coil passes through the yoke between the first and second poles to induce a magnetic flux in the yoke when an electrical current is caused to flow through the coil. Magnetic flux in the yoke produces a fringing field at a write gap whereby a signal can be imparted onto a magnetic medium passing thereby.

Owner:WESTERN DIGITAL TECH INC

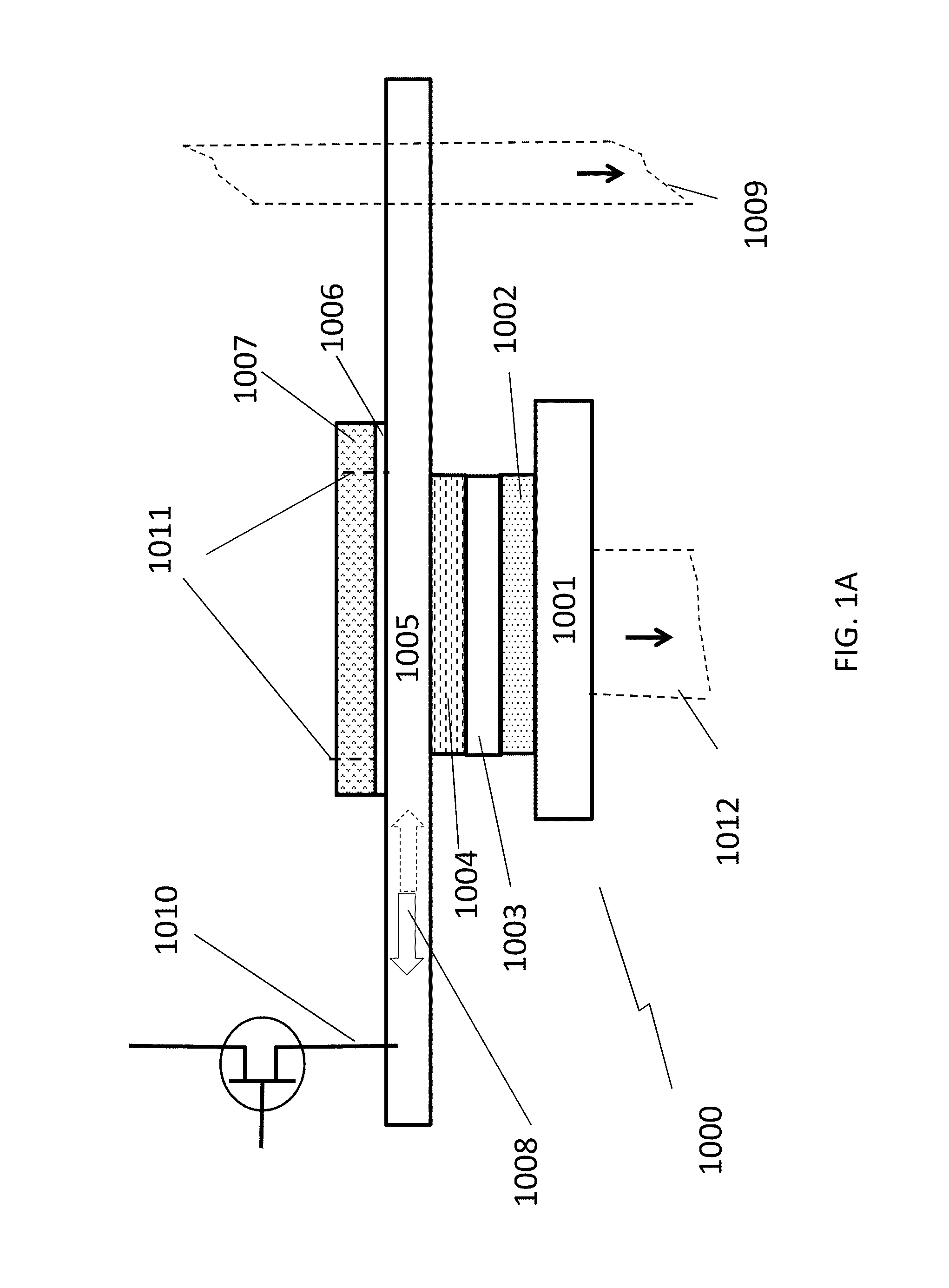

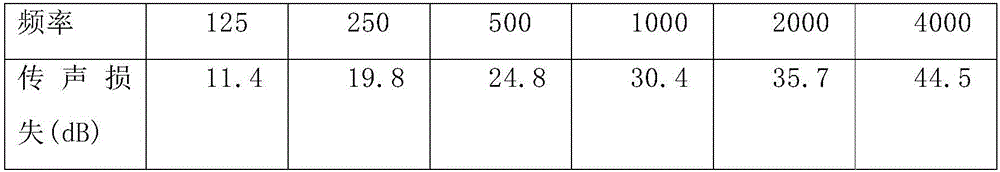

Magnetoresistive random access memory cell and 3D memory cell array

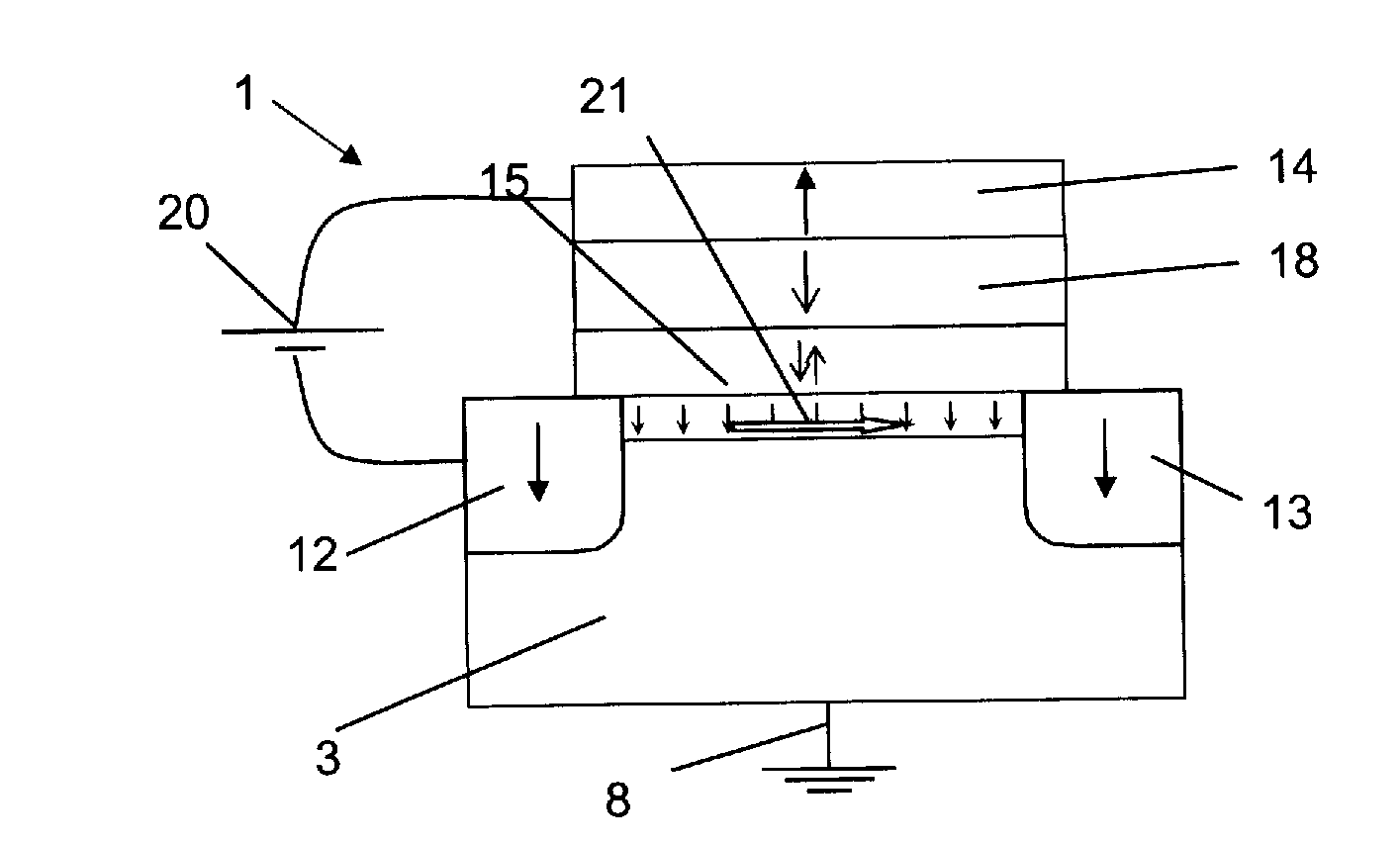

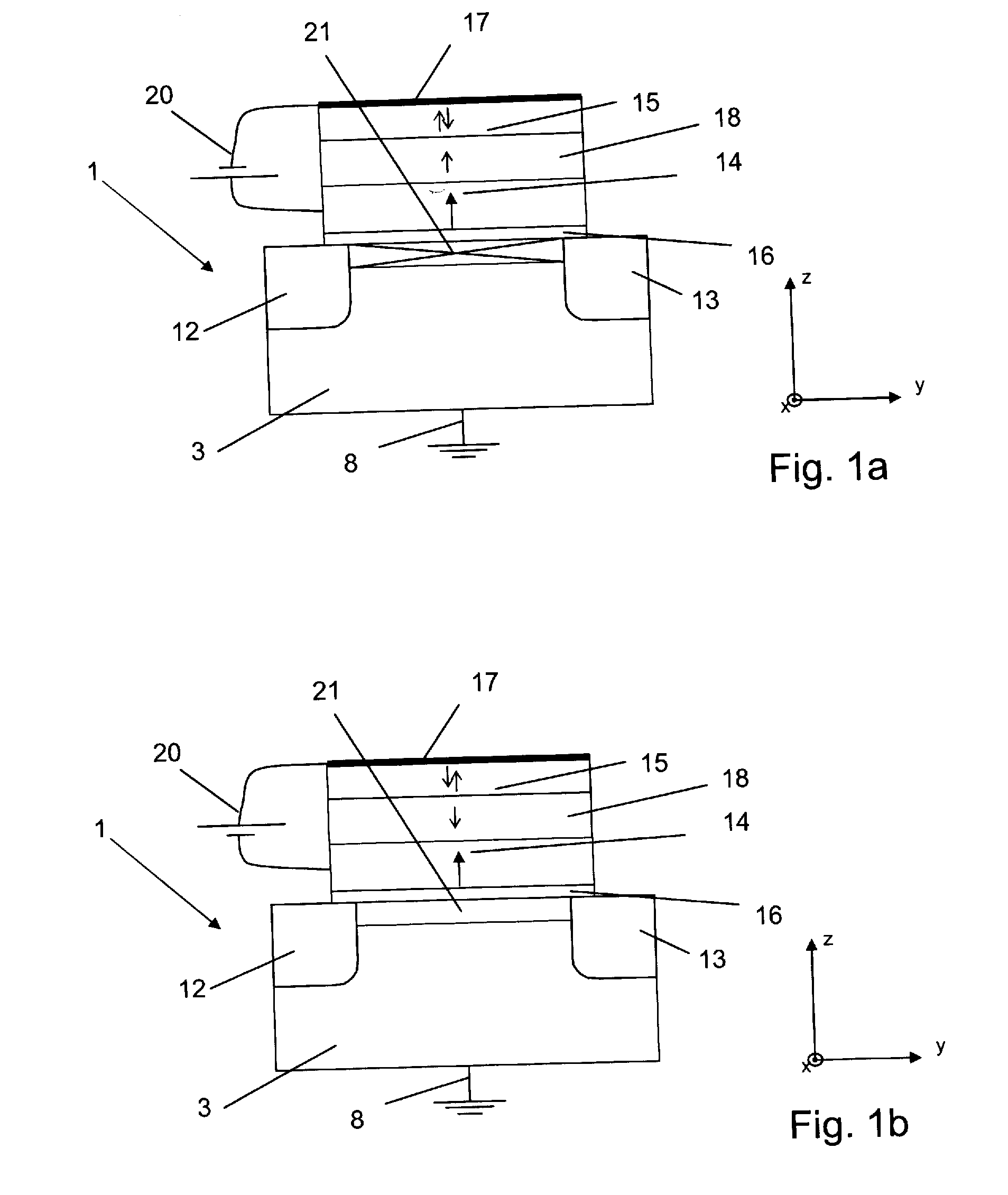

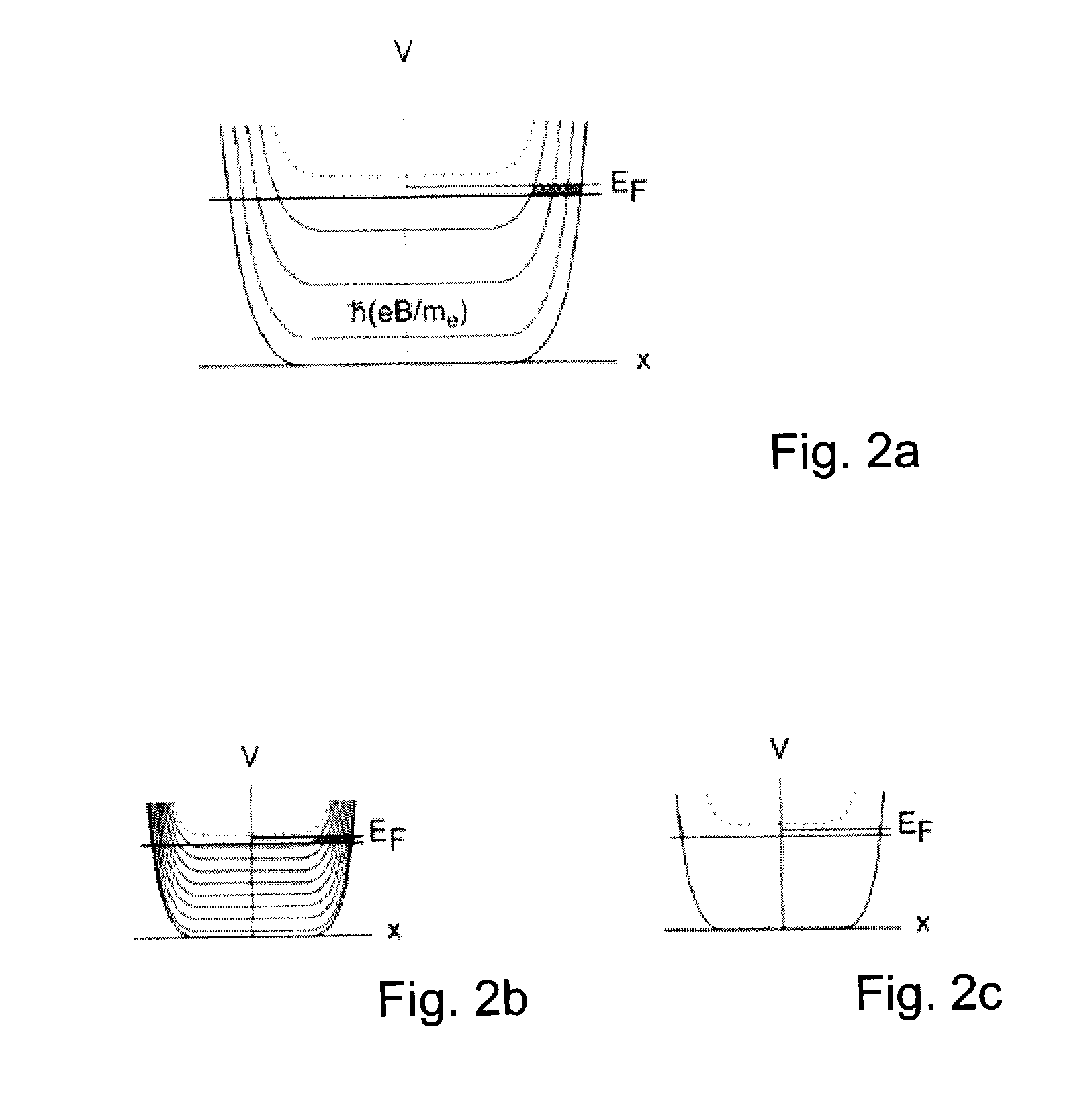

ActiveUS9218864B1Easy to implementImprove thermal stabilityDigital storageMagnetic stabilizationMagnetic reluctance

A novel three-terminal SOT-MRAM memory cell with a unique magnetic stabilization layer or structure is proposed. A complementary magnetic footprint of the data storage layer for the memory cell is able to be created within the magnetic stabilization layer or structure by the magnetic field from the storage layer to enhance the magnetic and thermal stability of the memory cell. Several designs for both perpendicular and in-plane SOT-MRAM memory cell have been invented. With proper wire connection and sensing arrangement, the proposed memory cell is capable of forming not only the 2D array but also 3D array.

Owner:GE YI +1

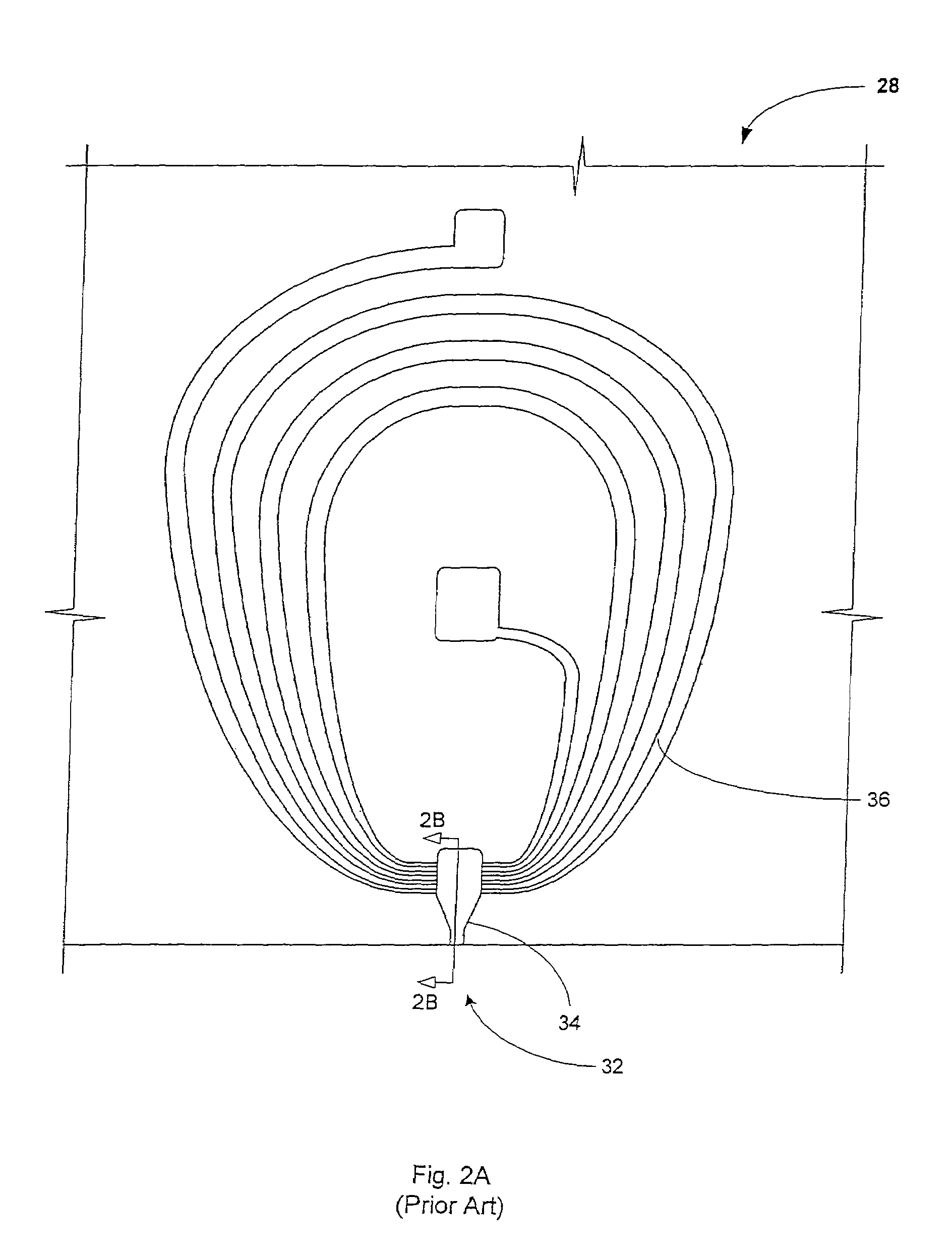

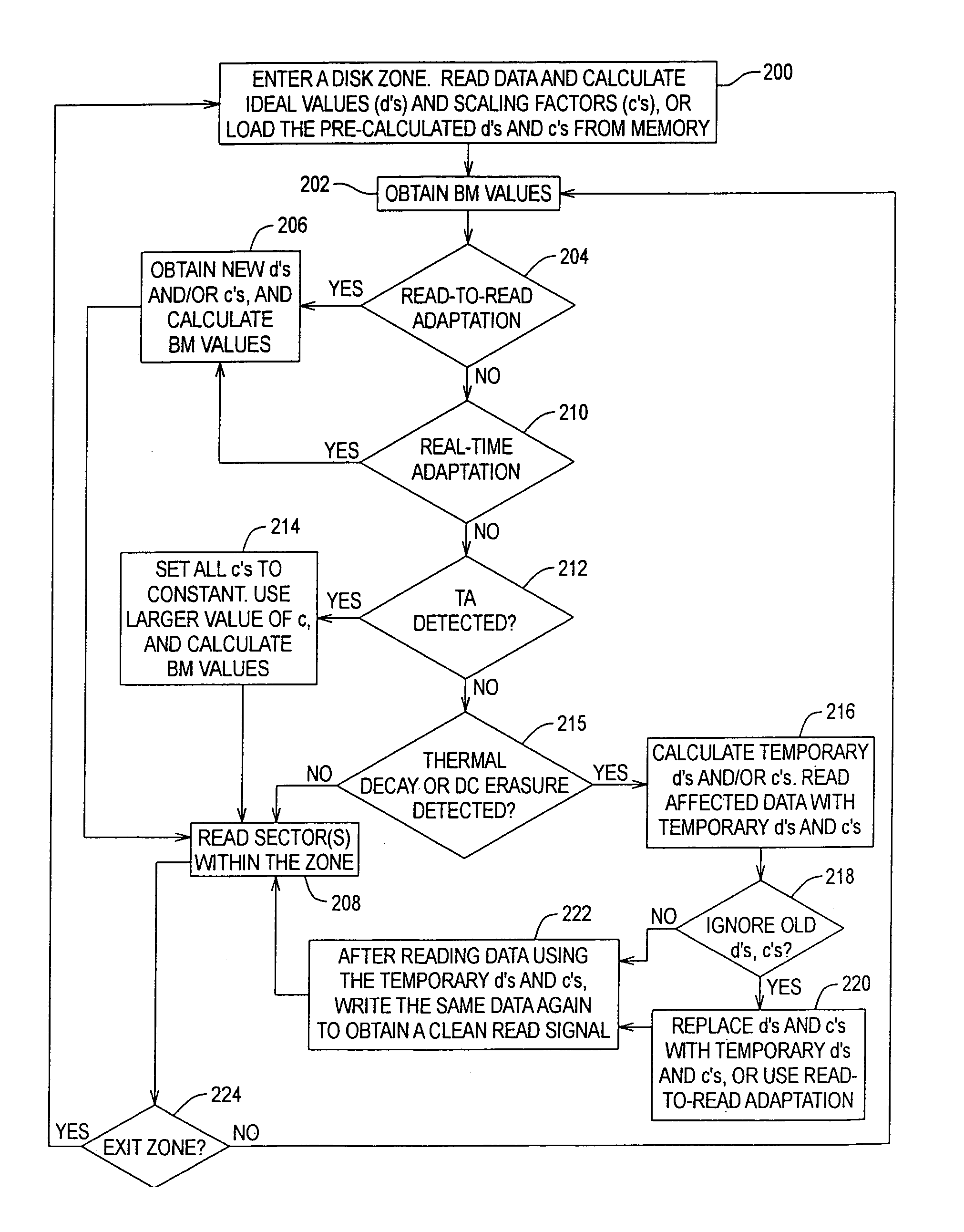

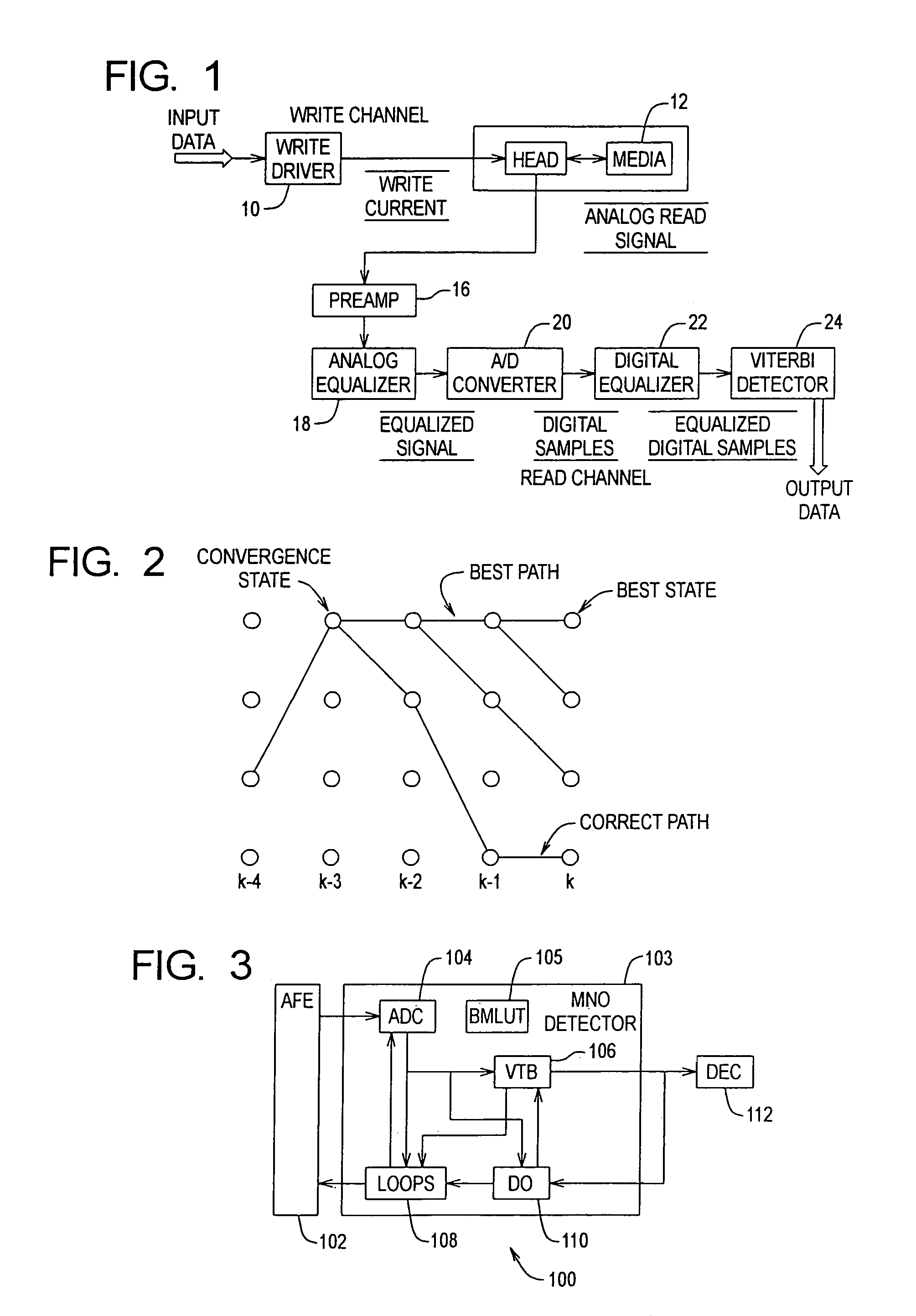

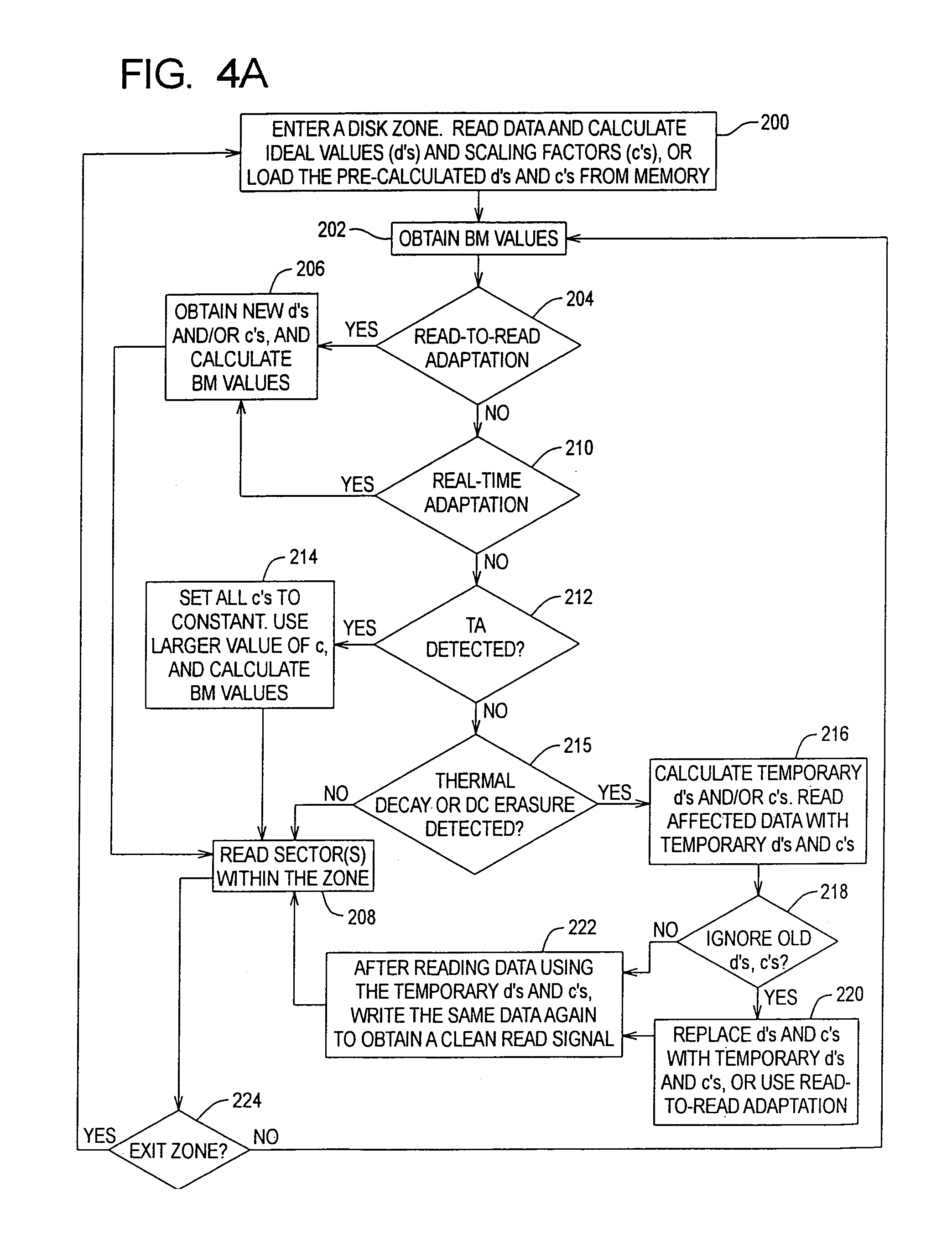

Media noise optimized detector for magnetic recording

InactiveUS7173783B1Significant disk drive yield benefitImprove reliabilityTelevision system detailsModification of read/write signalsPattern recognitionViterbi detector

A media noise optimized (MNO) detector for a read channel compensates for pattern dependent media noise, and compensates for nonlinearities from many sources such as residual MR nonlinearity, residual nonlinear transition shift, partial erasure, write-induced nonlinearity, and steady-state mis-equalization. The MNO detector is implemented by adjusting a conventional Viterbi detector branch metric so that the channel output value (ideal value) can be a nonlinear function of the state / branch bits, and the branch metric scaling factor is a function of the state / branch. For a given state / branch, the ideal value is the mean of analog-to-digital converter samples for the pattern corresponding to the state / branch, and the branch metric scaling factor is proportional to the noise variance for the pattern corresponding to that state / branch.

Owner:MAXTOR

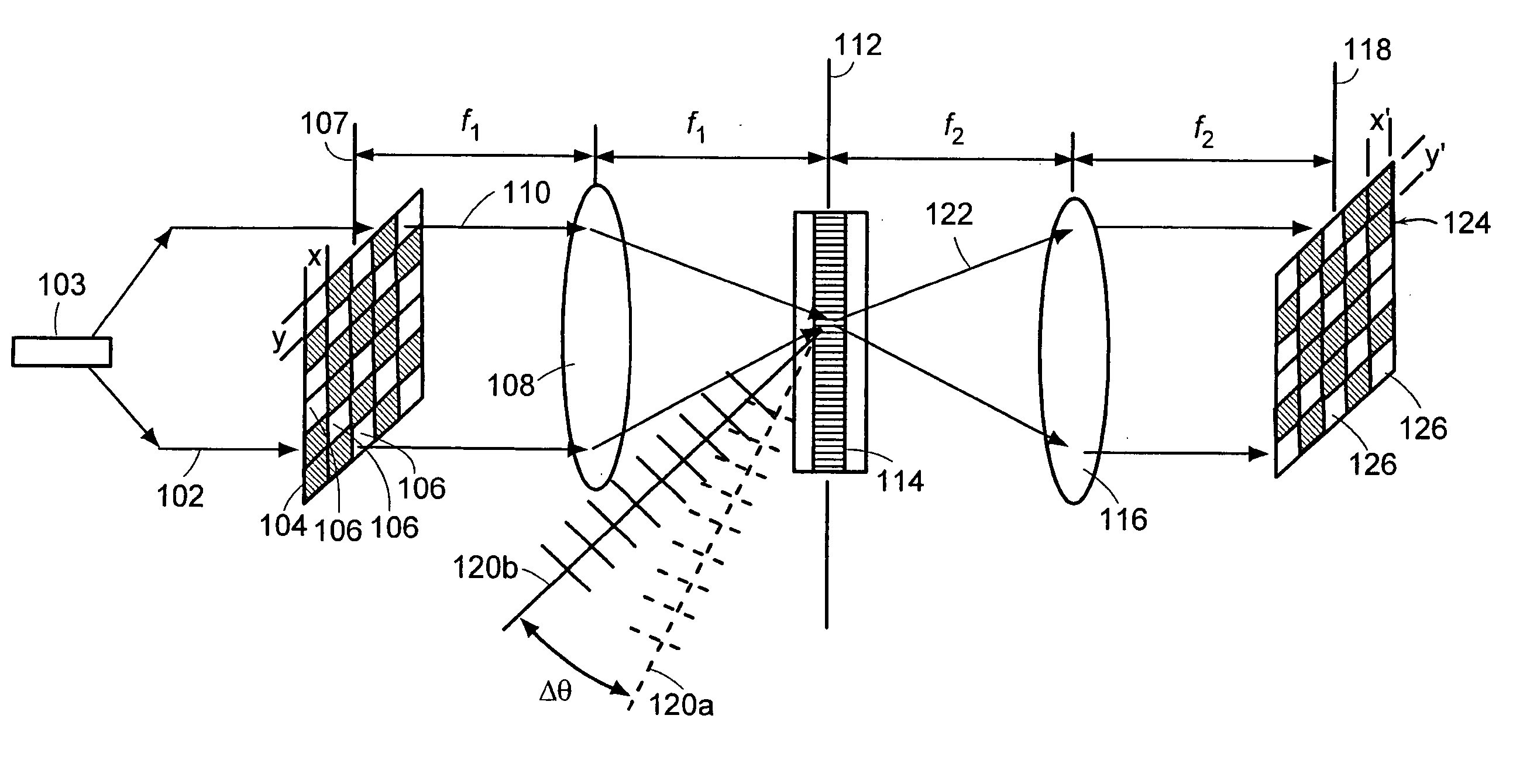

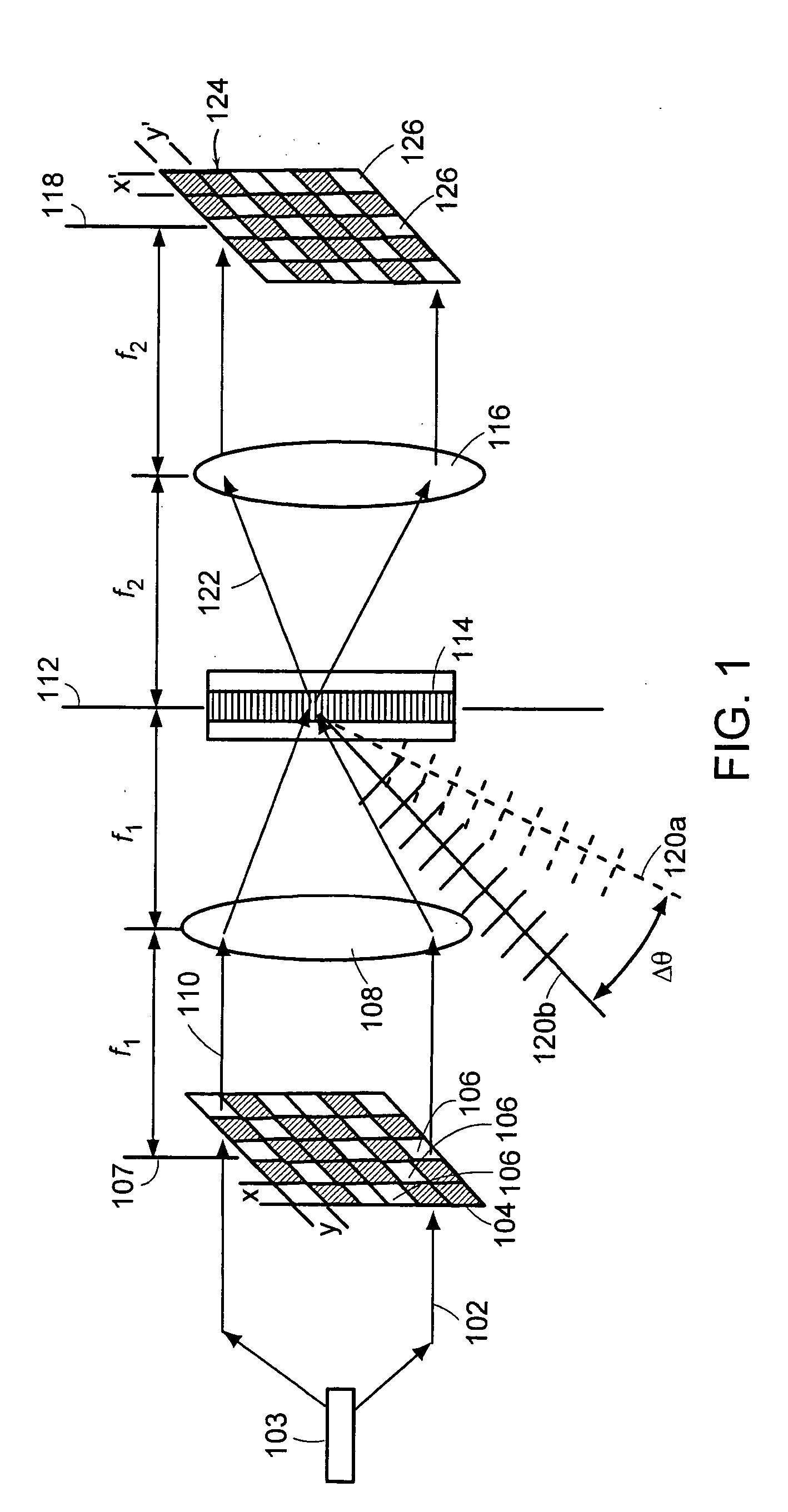

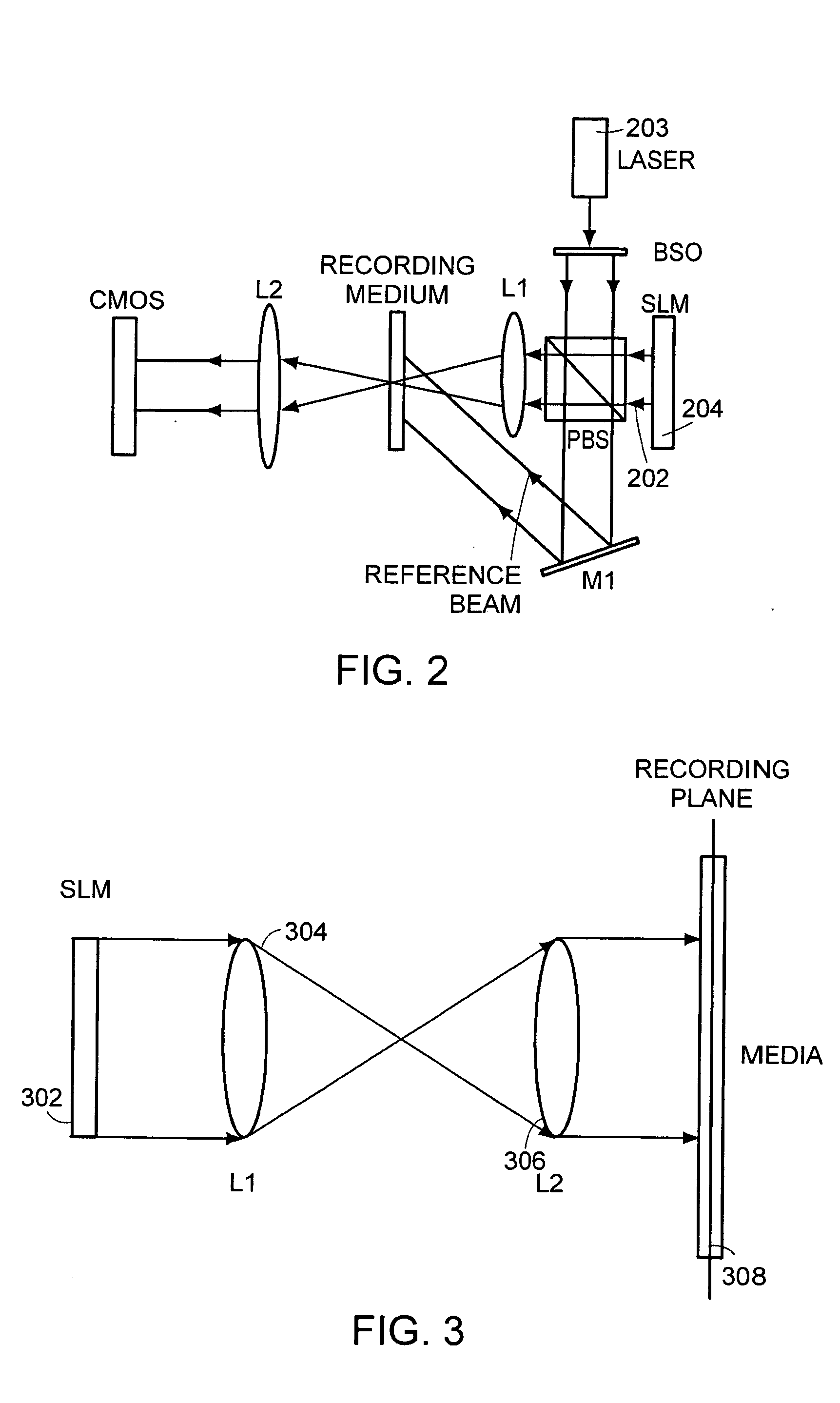

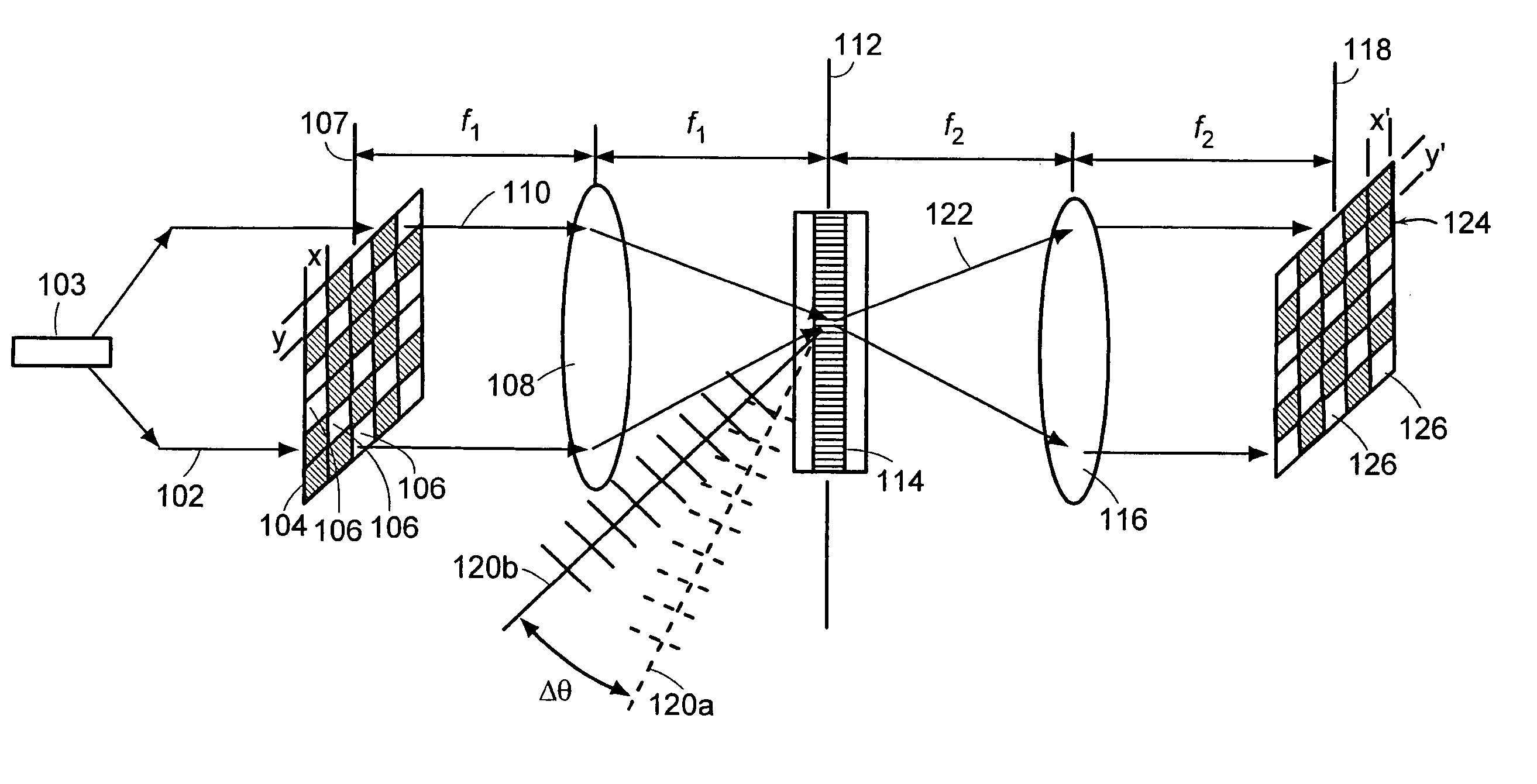

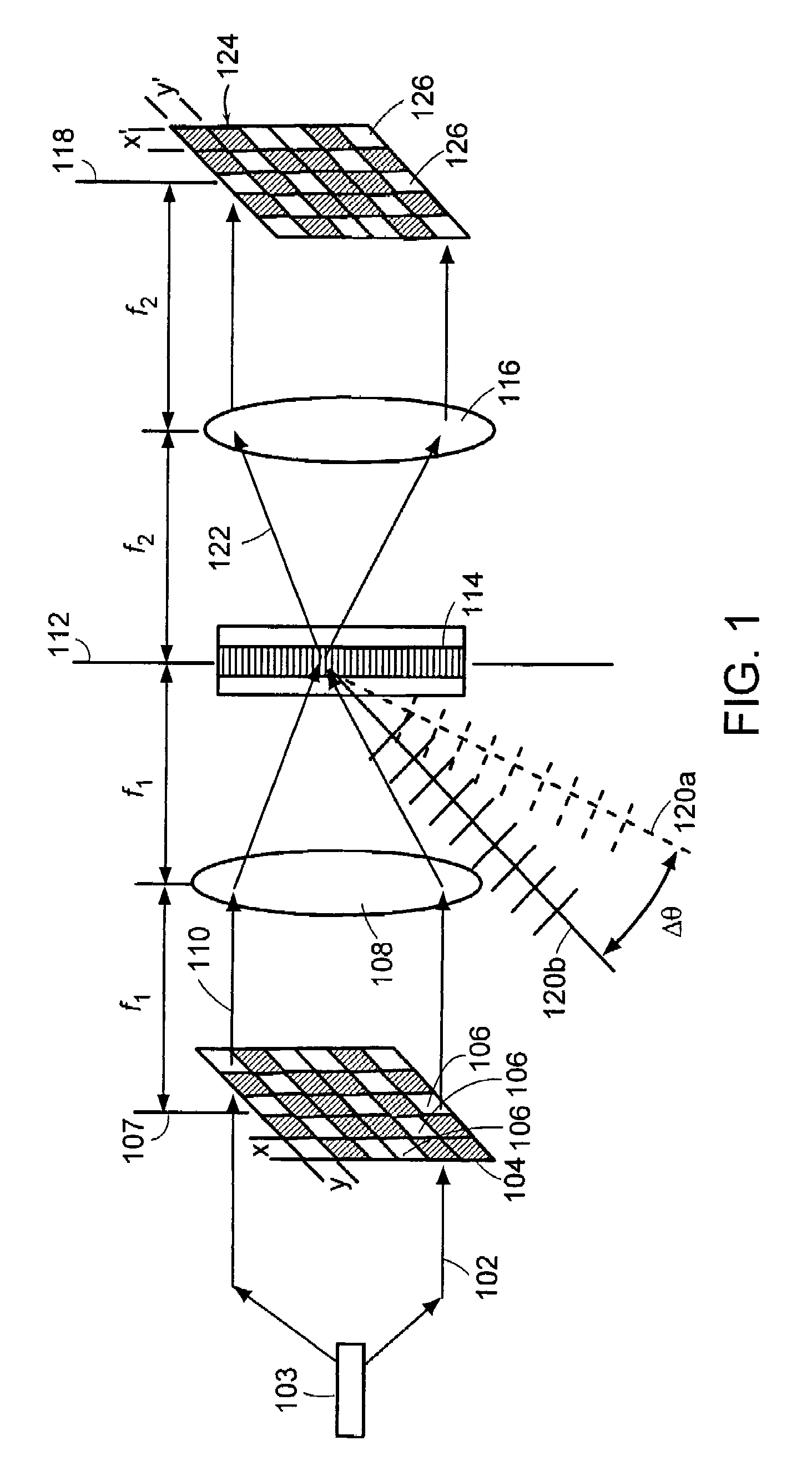

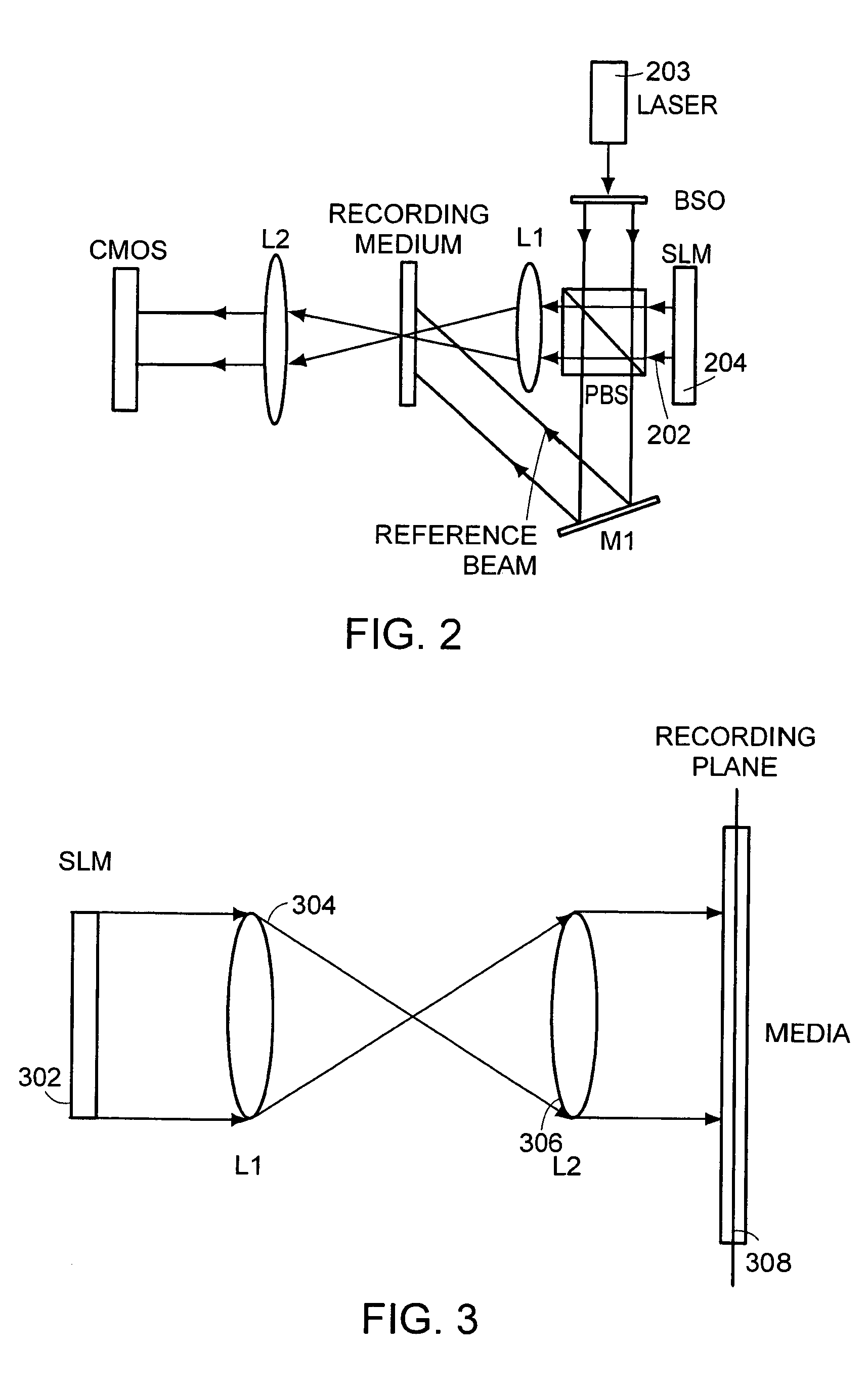

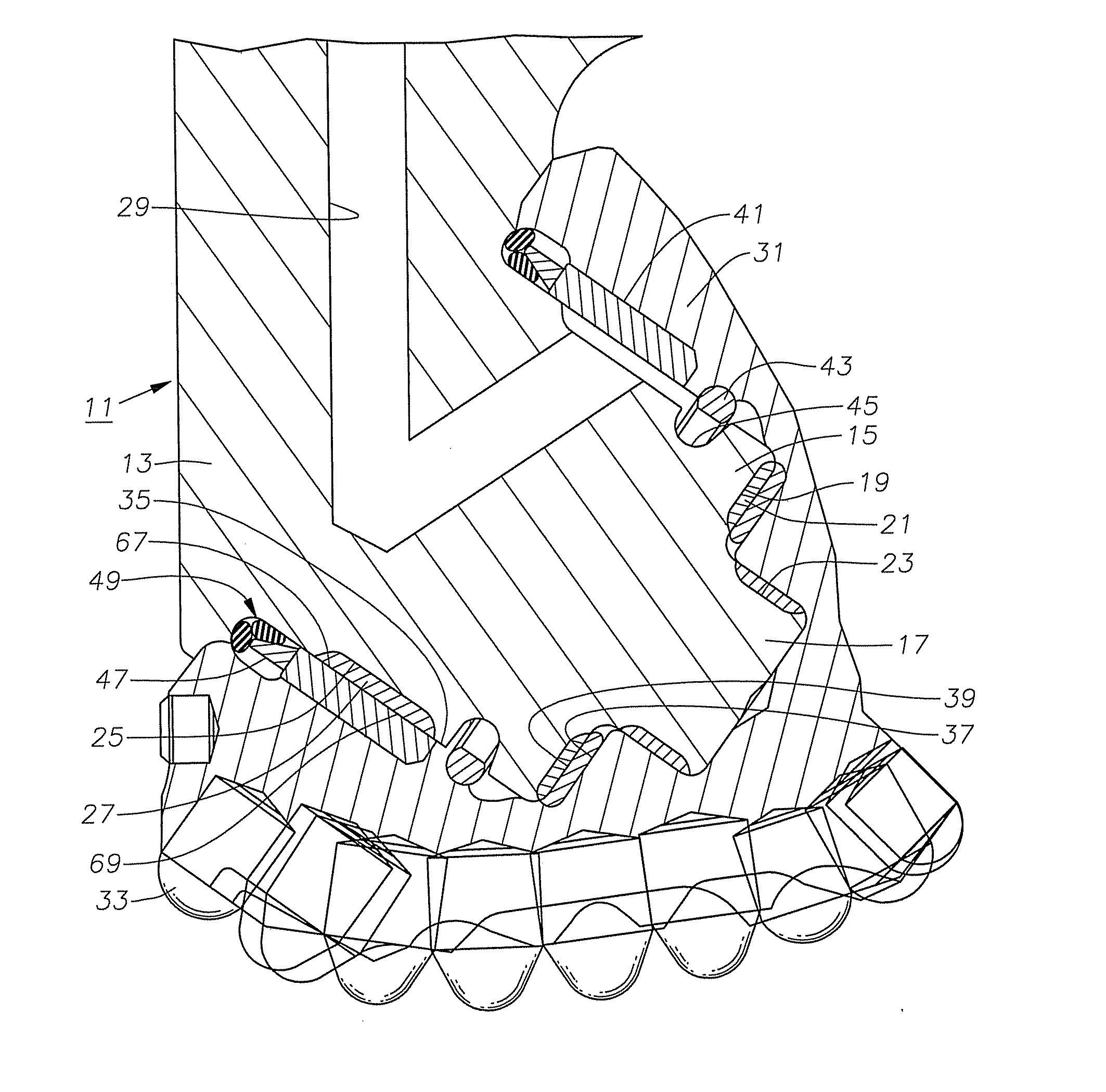

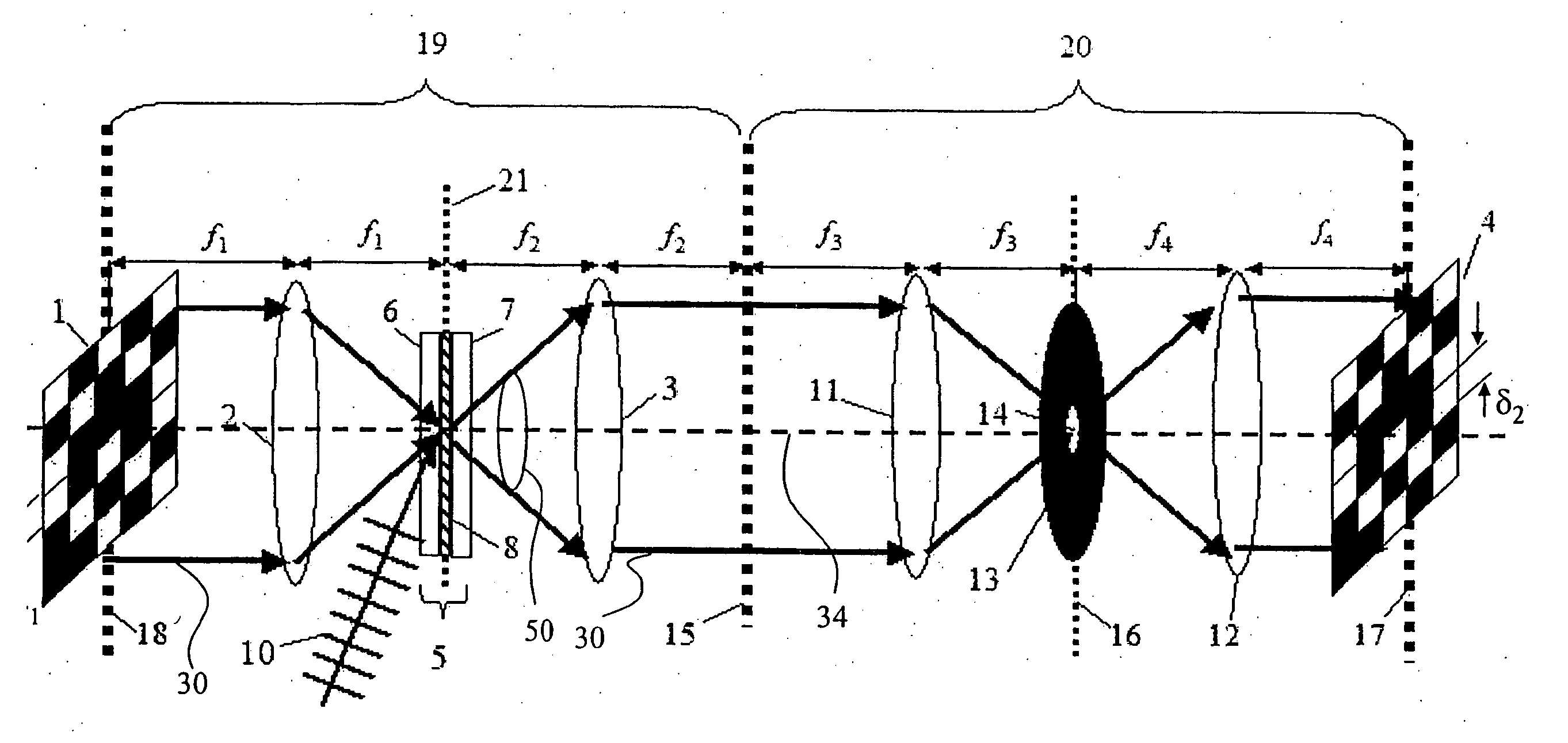

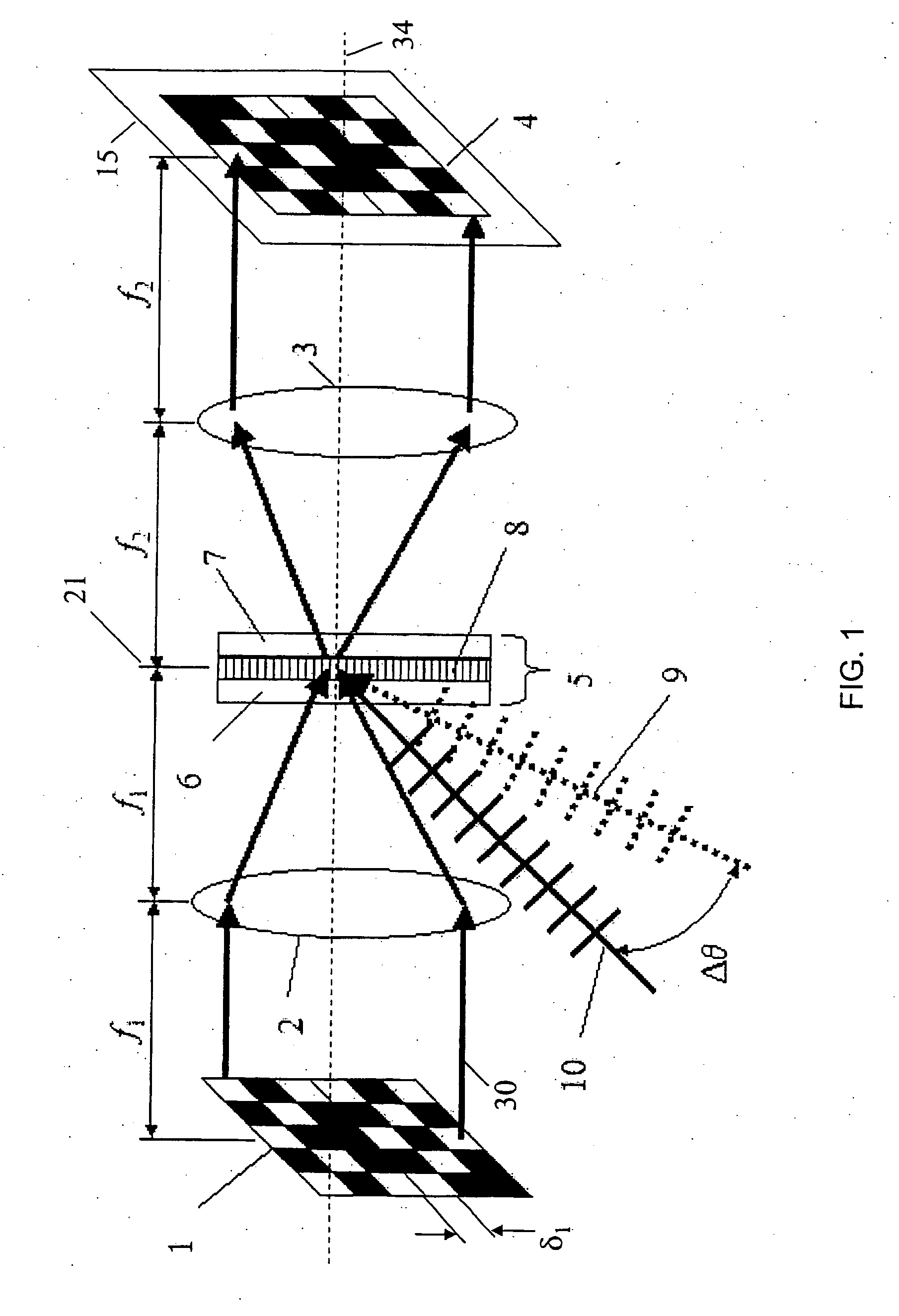

Method and apparatus for phase-encoded homogenized Fourier transform holographic data storage and recovery

InactiveUS20050134948A1Improves fidelity and efficiencyReduce cross-correlationRecord information storageActive addressable light modulatorSpatial light modulatorLight beam

An apparatus for writing and reading holograms, comprising a spatial light modulator (SLM) operable in phase mode, having a plurality of pixels for generating an object beam that overlaps with a reference beam; a holographic recording medium (HRM) in the path of the object beam; and a first lens element disposed in the path of the object beam between the SLM and the HRM; wherein the HRM is disposed at or near the Fourier transform plane of the first lens element.

Owner:POSTECH CO LTD

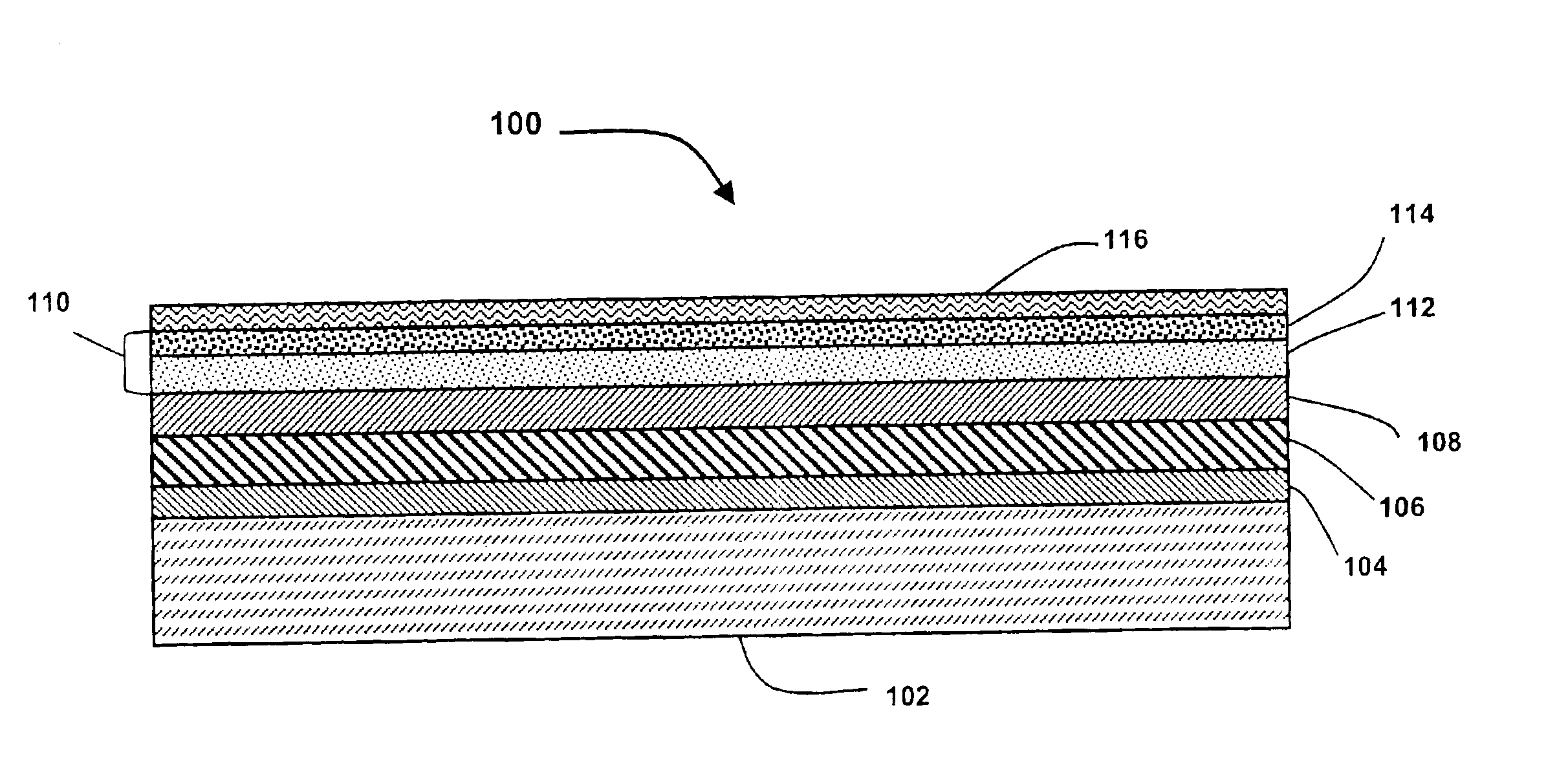

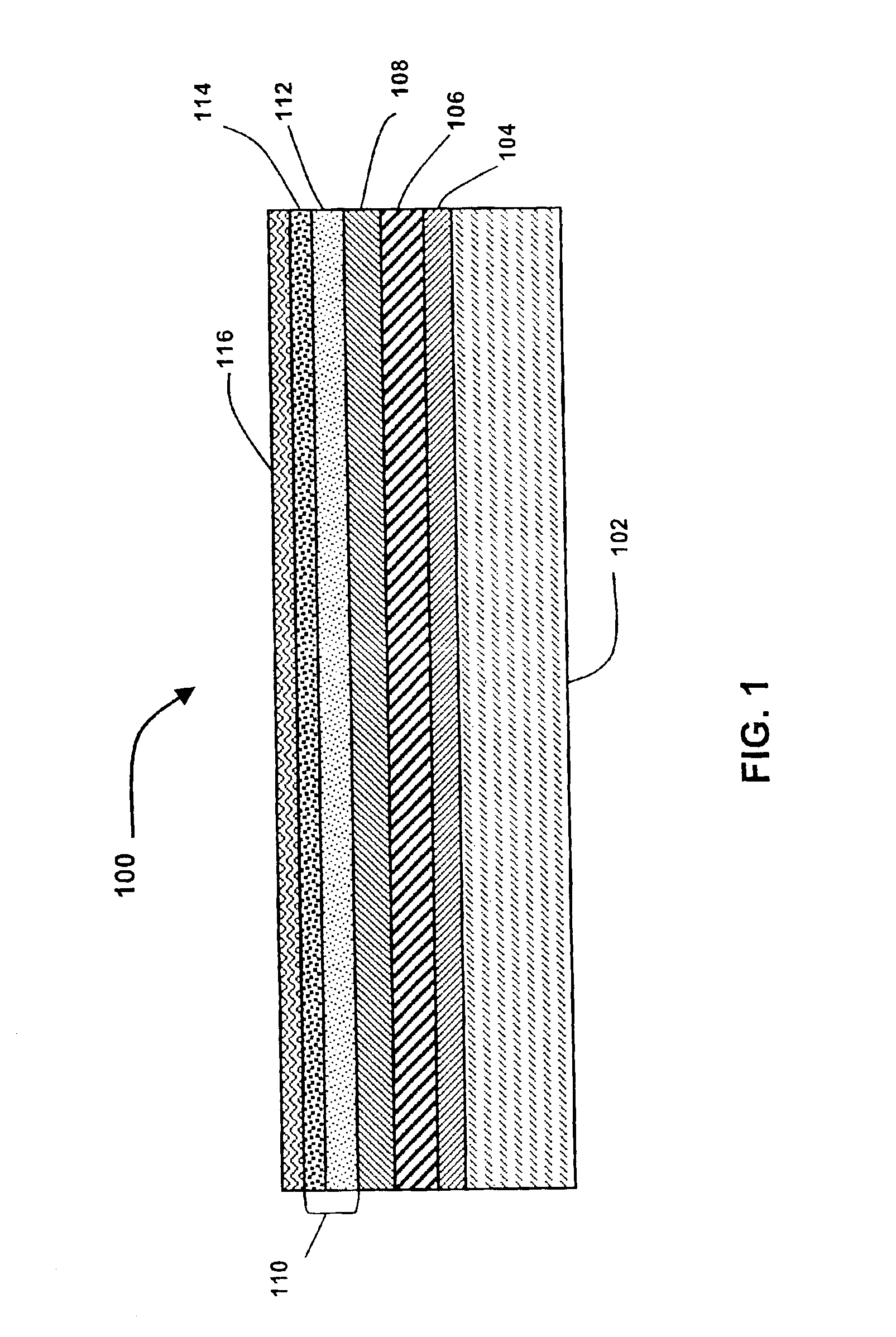

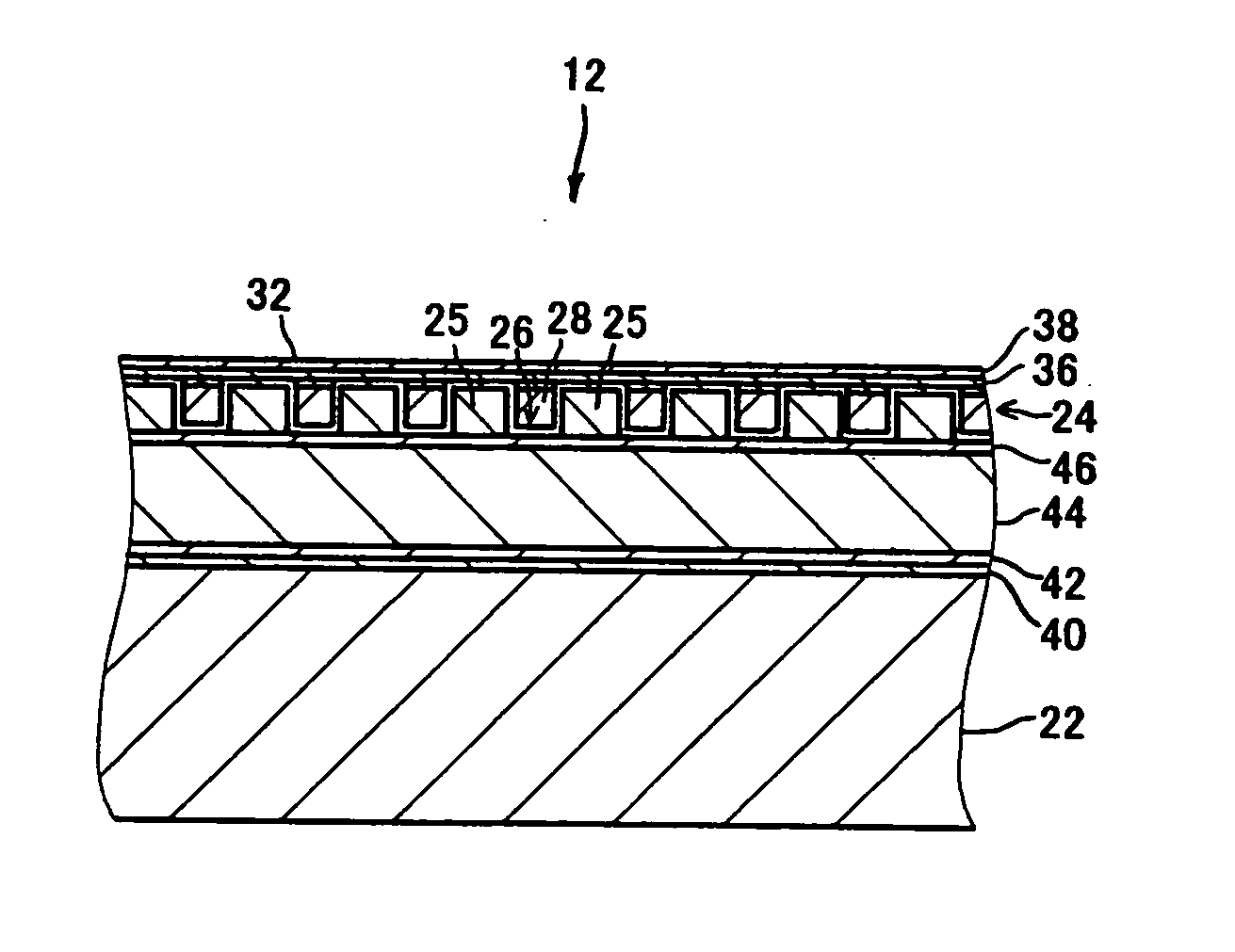

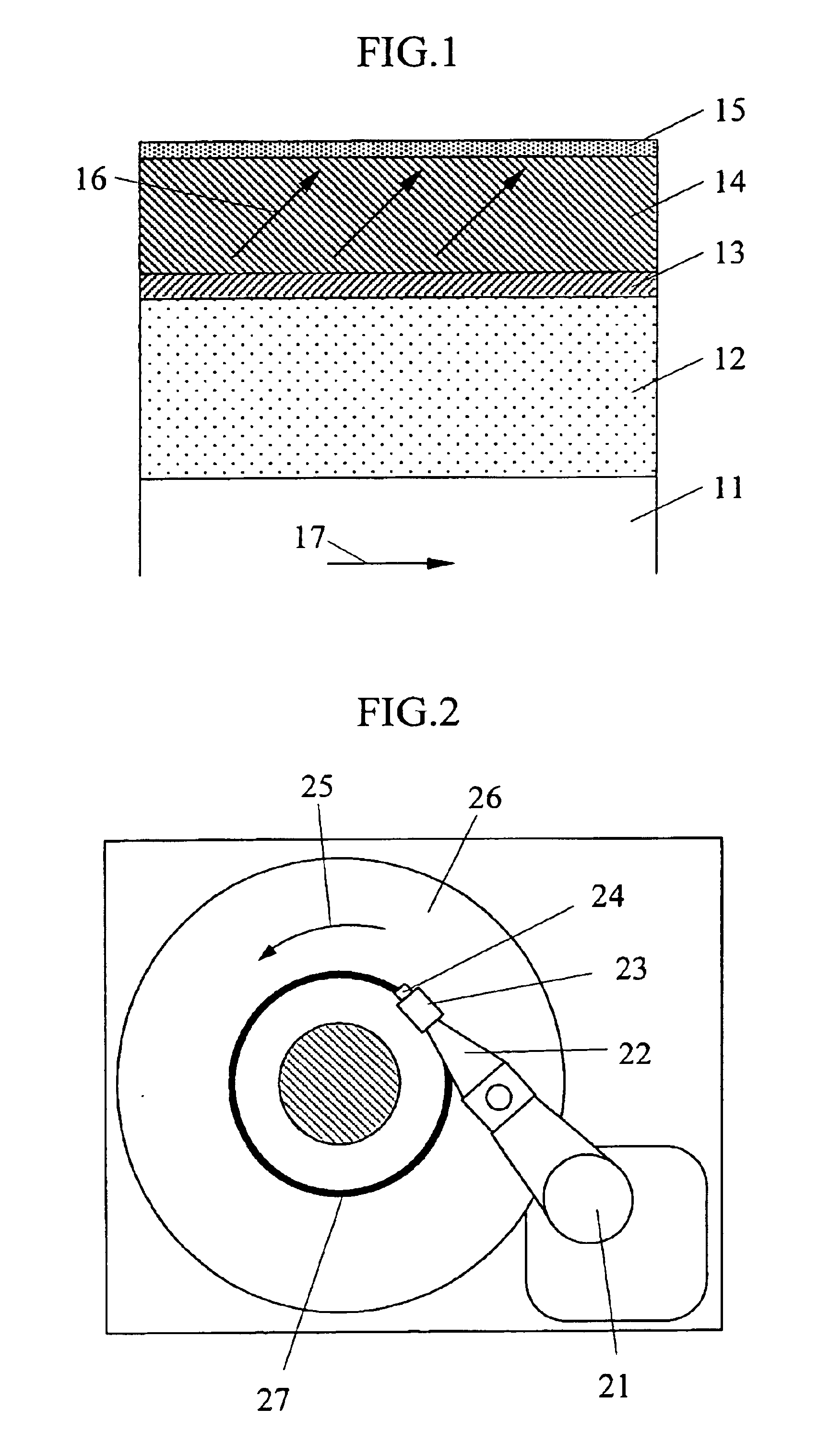

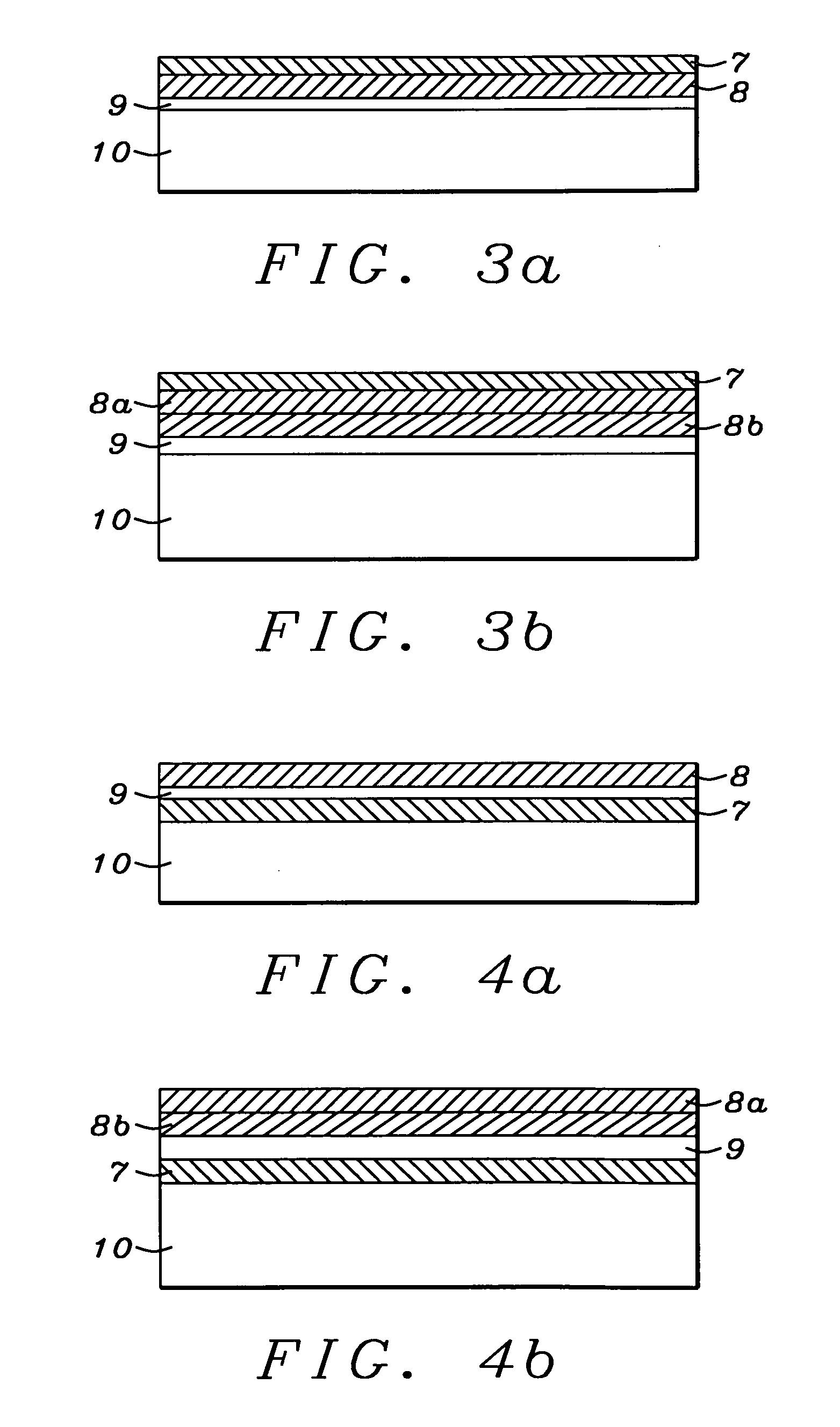

Carbon overcoat for magnetic recording medium

InactiveUS6875492B1Thin carbon overcoatImprove tribological propertiesProtective coatings for layersLayered productsRecording layerMaterials science

Magnetic recording media having a protective carbon overcoat adapted to protect the magnetic recording layer from surface contact events and corrosion. The carbon overcoat includes at least two layers. A first layer is adapted to protect the magnetic recording layer from surface contact events and corrosion. The second layer is disposed on the first layer and is adapted to enhance the bonding of a lubricant to the carbon overcoat and to minimize head degradation. The magnetic recording media of the present invention advantageously enables the use of thin carbon overcoats, enhancing areal density, while maintaining good tribological properties.

Owner:MAXTOR

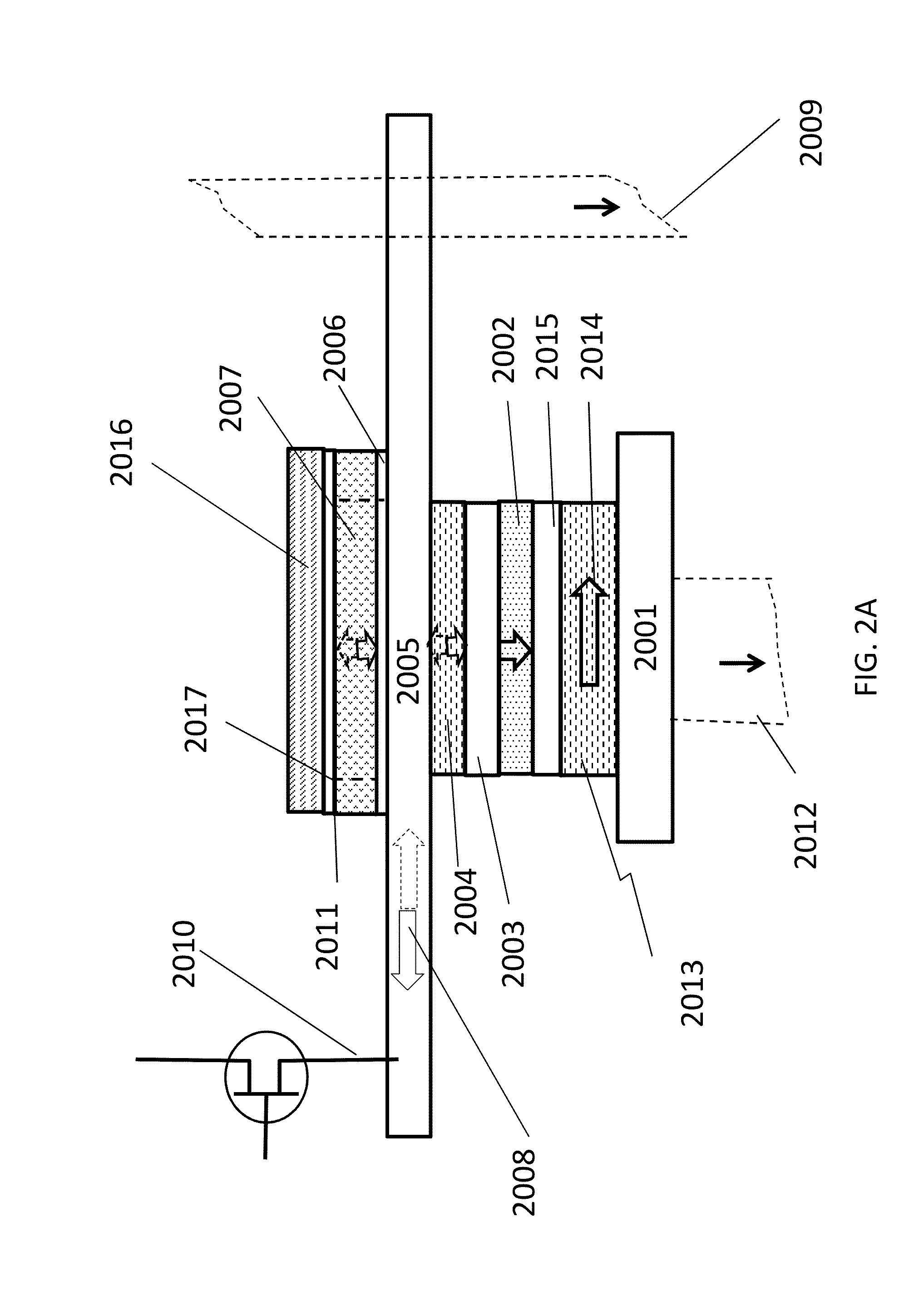

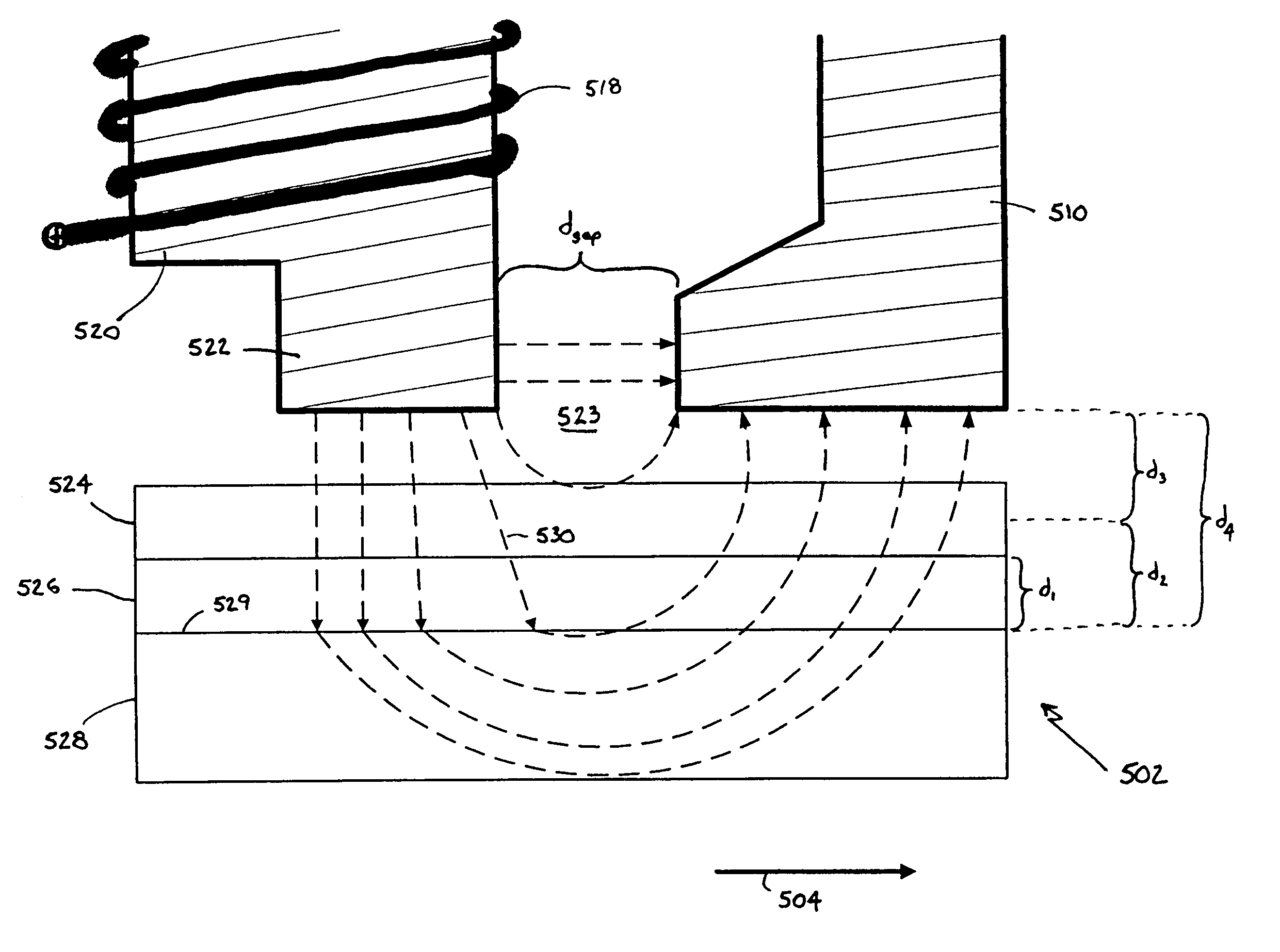

Longitudinal media with soft underlayer and perpendicular write head

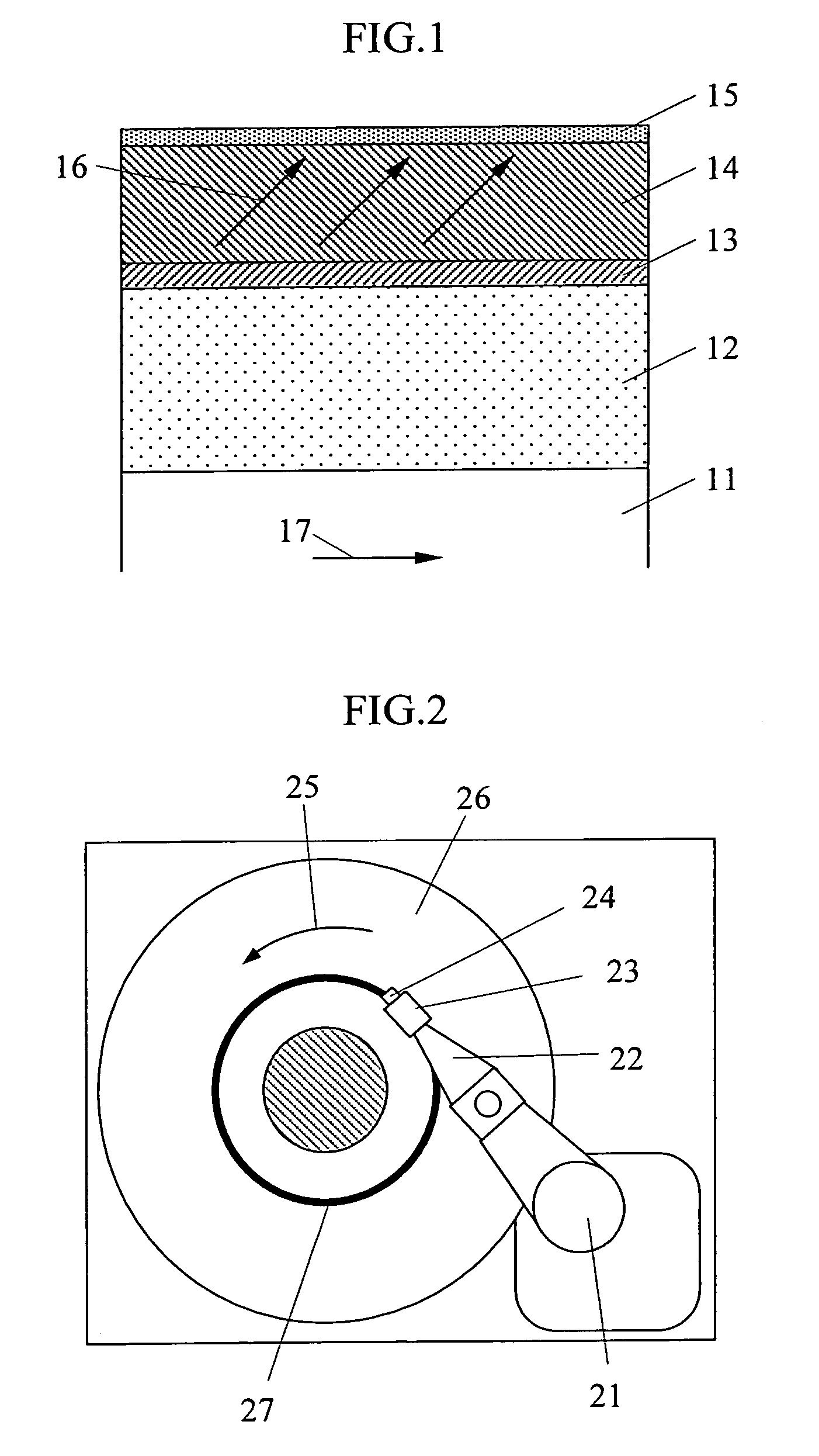

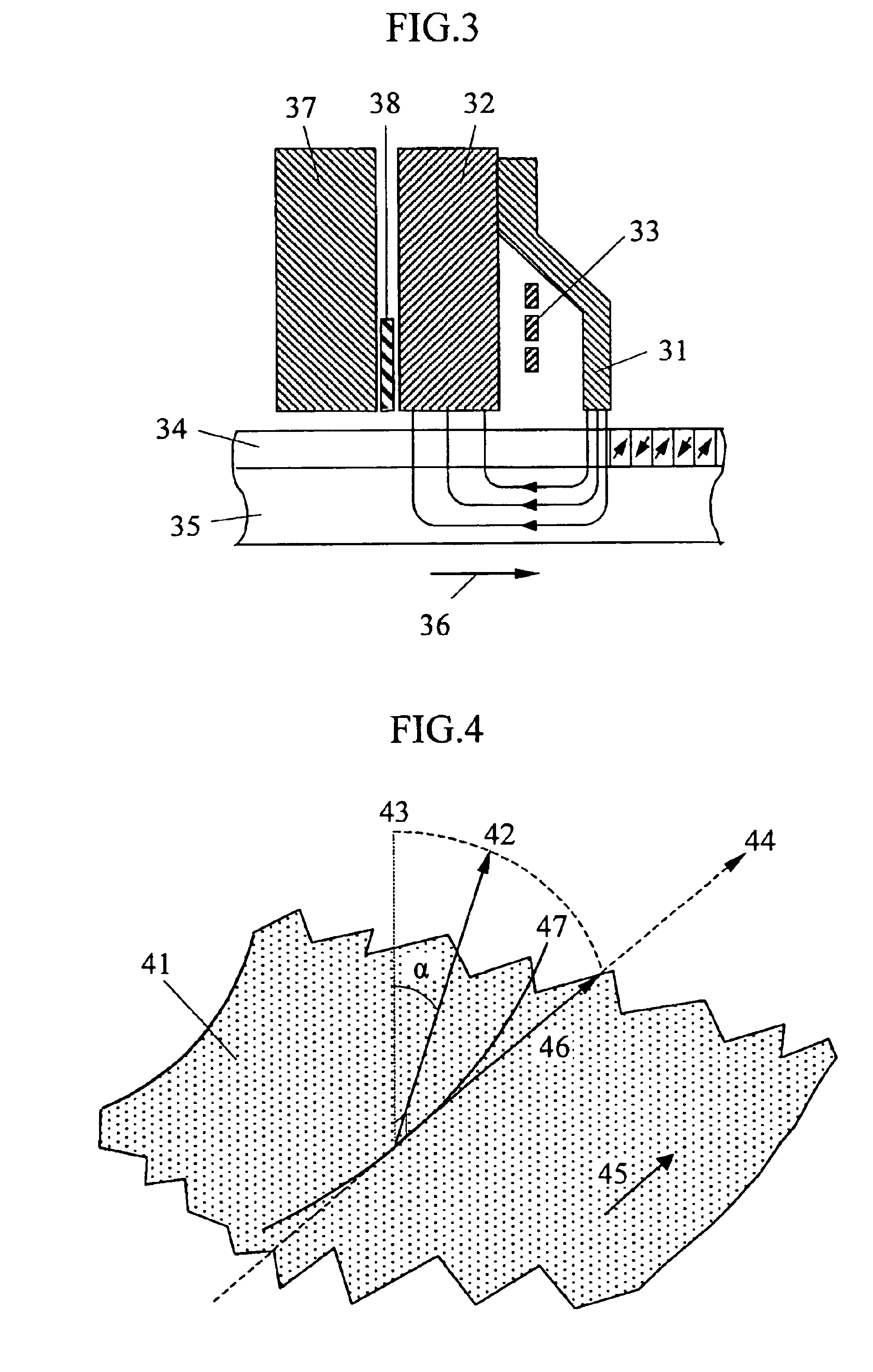

InactiveUS7149045B1High write field gradientReduce width of transitionRecord information storageDigital recordingEngineeringRecording layer

A magnetic recording device including a longitudinal magnetic recording medium. The longitudinal magnetic recording medium includes a magnetically soft underlayer disposed under a longitudinal recording layer. A perpendicular write head is utilized to write data to the longitudinal magnetic recording medium wherein the longitudinal recording layer is disposed within an effective write gap formed by the perpendicular write head and the underlayer. The longitudinal component of the perpendicular write head is sufficient to switch the magnetic grains in the recording layer in the presence of the perpendicular field. The magnetic recording medium can have a high areal density and improved magnetic properties.

Owner:MAXTOR

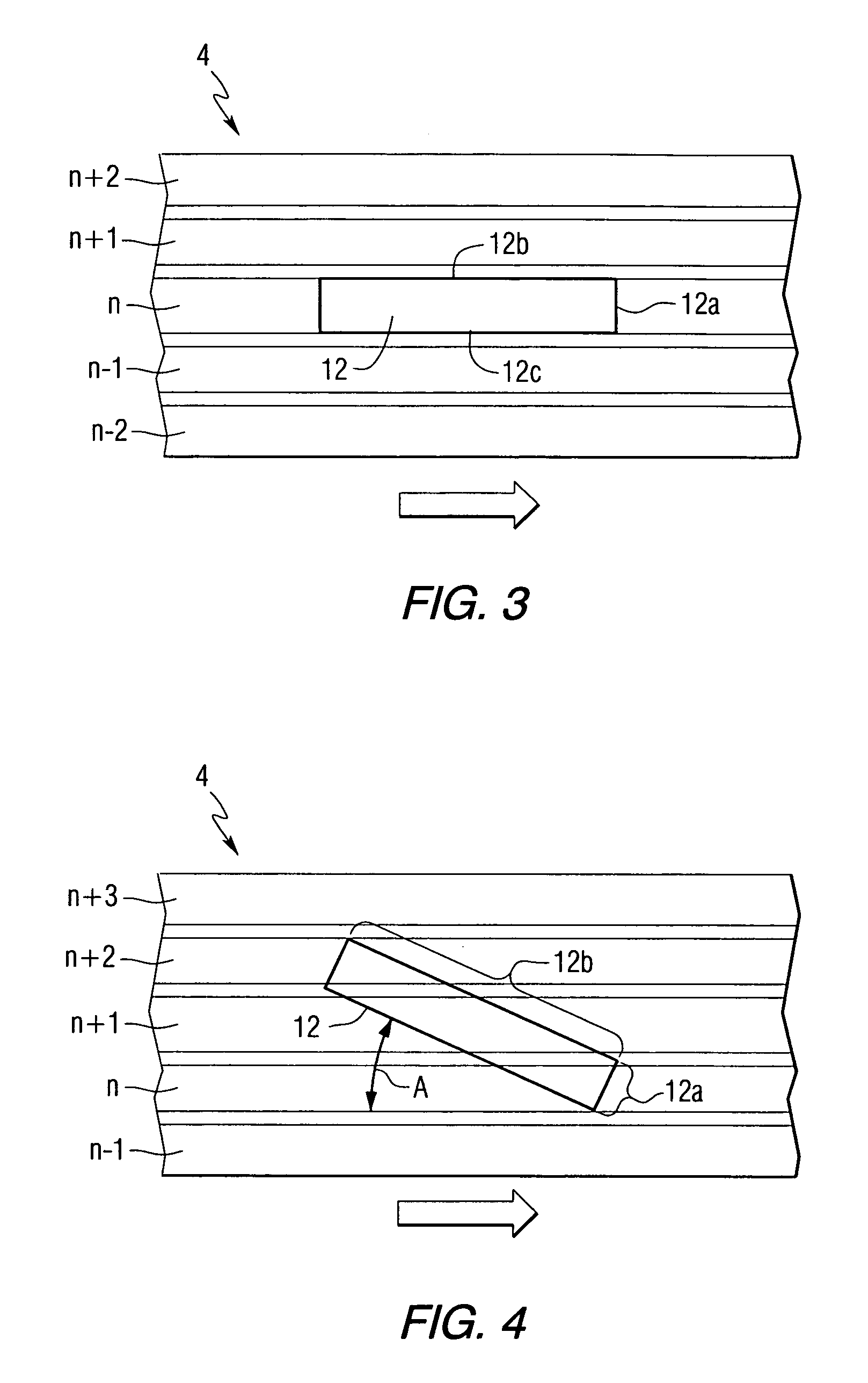

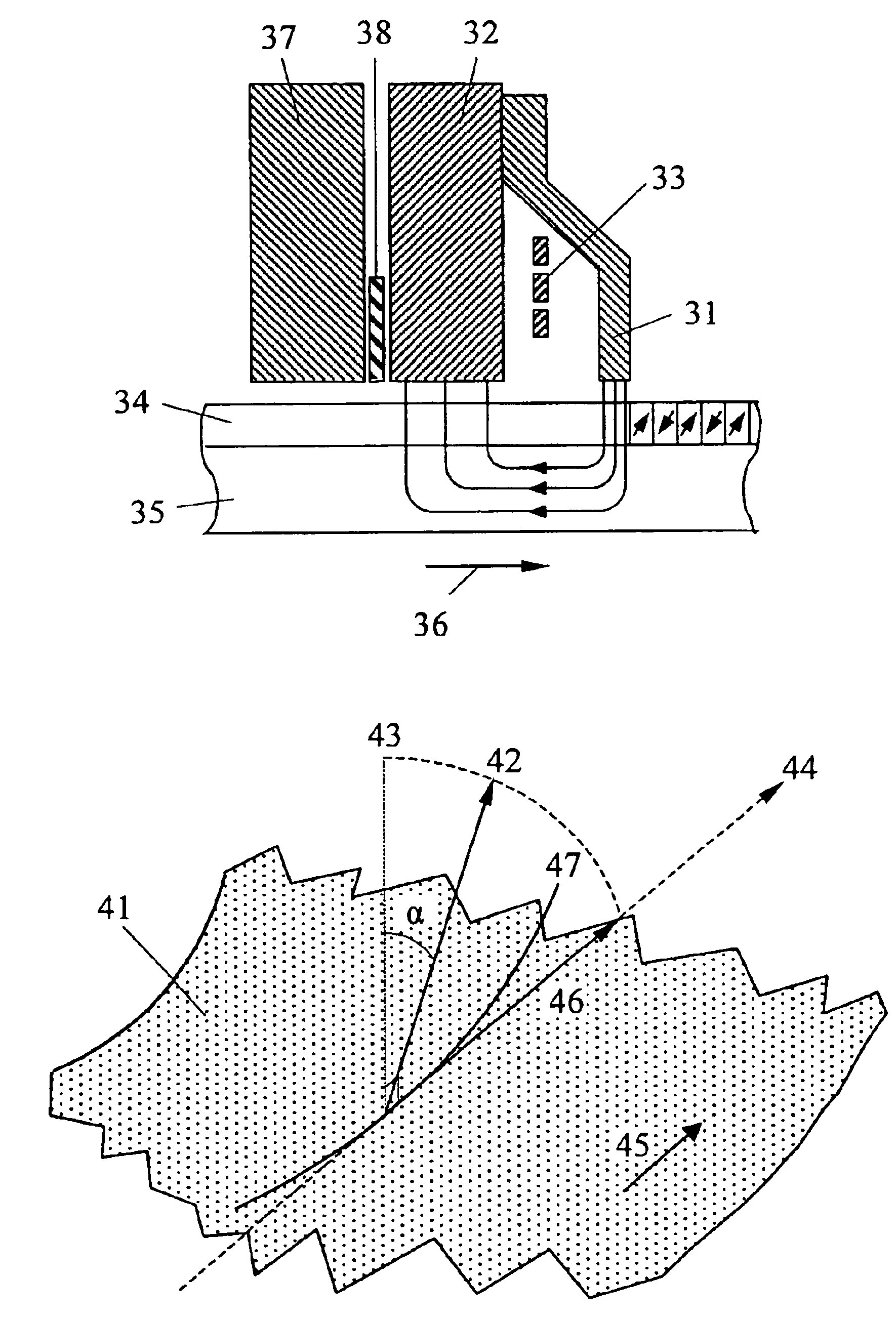

Magnetic recording medium, magnetic recording apparatus using the same, and method and apparatus for manufacturing the magnetic recording medium

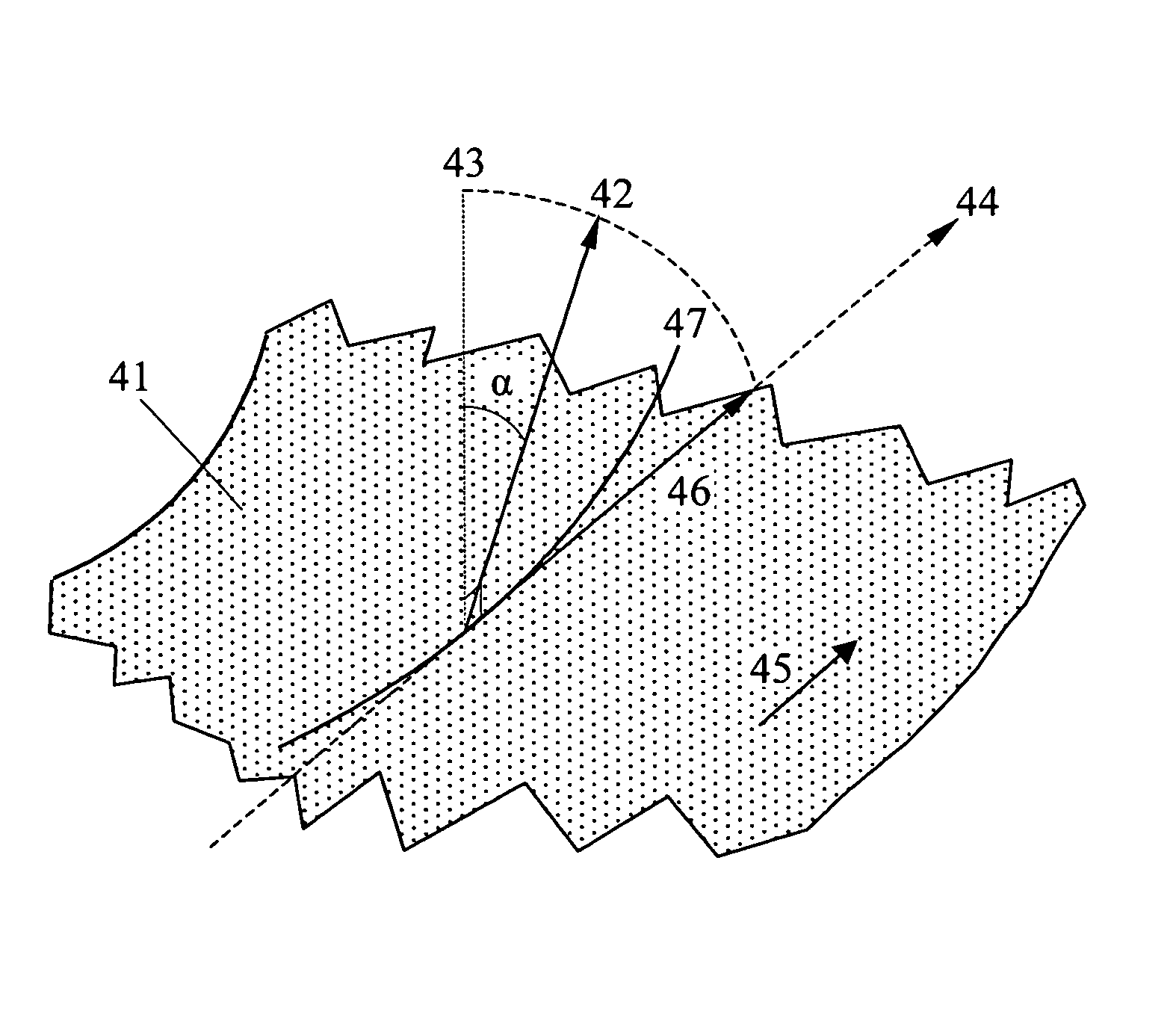

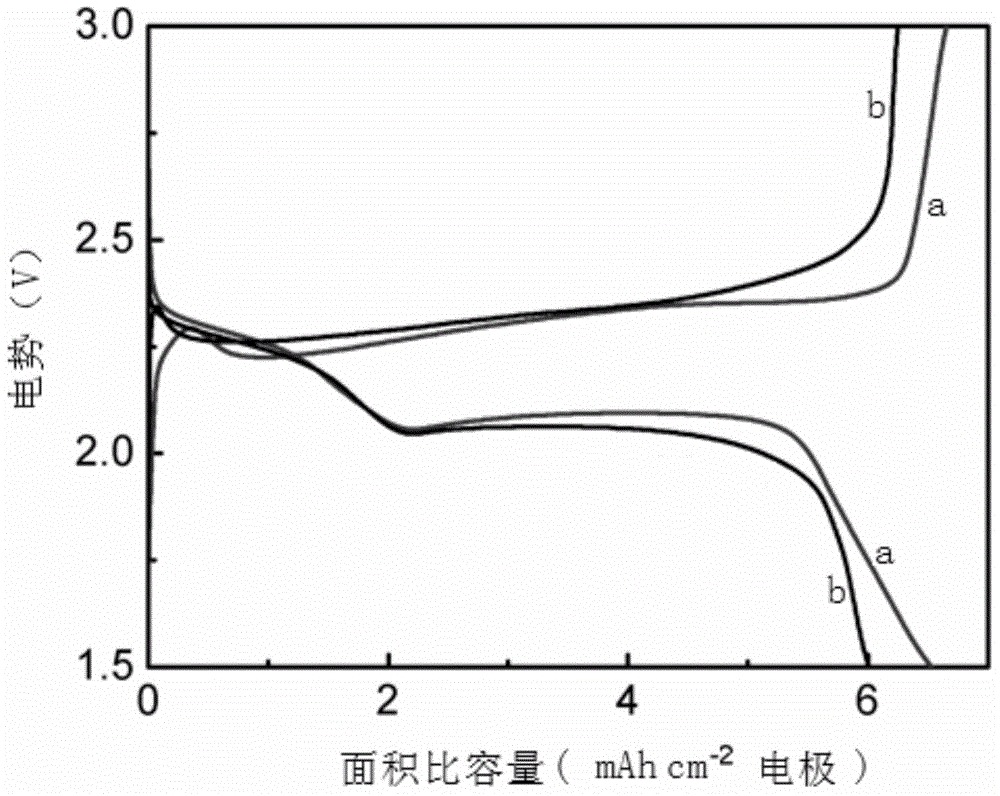

InactiveUS20040106009A1Without adversely affecting the thermal stabilityIncrease areal densityRecord information storageDigital recordingImage resolutionMagnetization

A magnetic recording apparatus provides improved resolution and S / N without adversely affecting thermal stability. An angle formed by the direction of easy magnetization of a recording layer and the direction normal to a magnetic recording medium is in the range between 5° and 55°, the easy magnetization direction is from a back surface of the recording layer toward a front surface thereof, and when a recording track direction is from the upstream of the direction of transportation of the medium toward the downstream thereof, an angle formed by the direction of a projection of the easy magnetization direction on the medium plane and the recording track direction is in the range between 0° and 70°.

Owner:HITACHI GLOBAL STORAGE TECH JAPAN LTD

Method and apparatus for phase-encoded homogenized Fourier transform holographic data storage and recovery

InactiveUS7411708B2Improves fidelity and efficiencyReduce cross-correlationRecord information storageActive addressable light modulatorSpatial light modulatorLight beam

An apparatus for writing and reading holograms, comprising a spatial light modulator (SLM) operable in phase mode, having a plurality of pixels for generating an object beam that overlaps with a reference beam; a holographic recording medium (HRM) in the path of the object beam; and a first lens element disposed in the path of the object beam between the SLM and the HRM; wherein the HRM is disposed at or near the Fourier transform plane of the first lens element.

Owner:POSTECH CO LTD

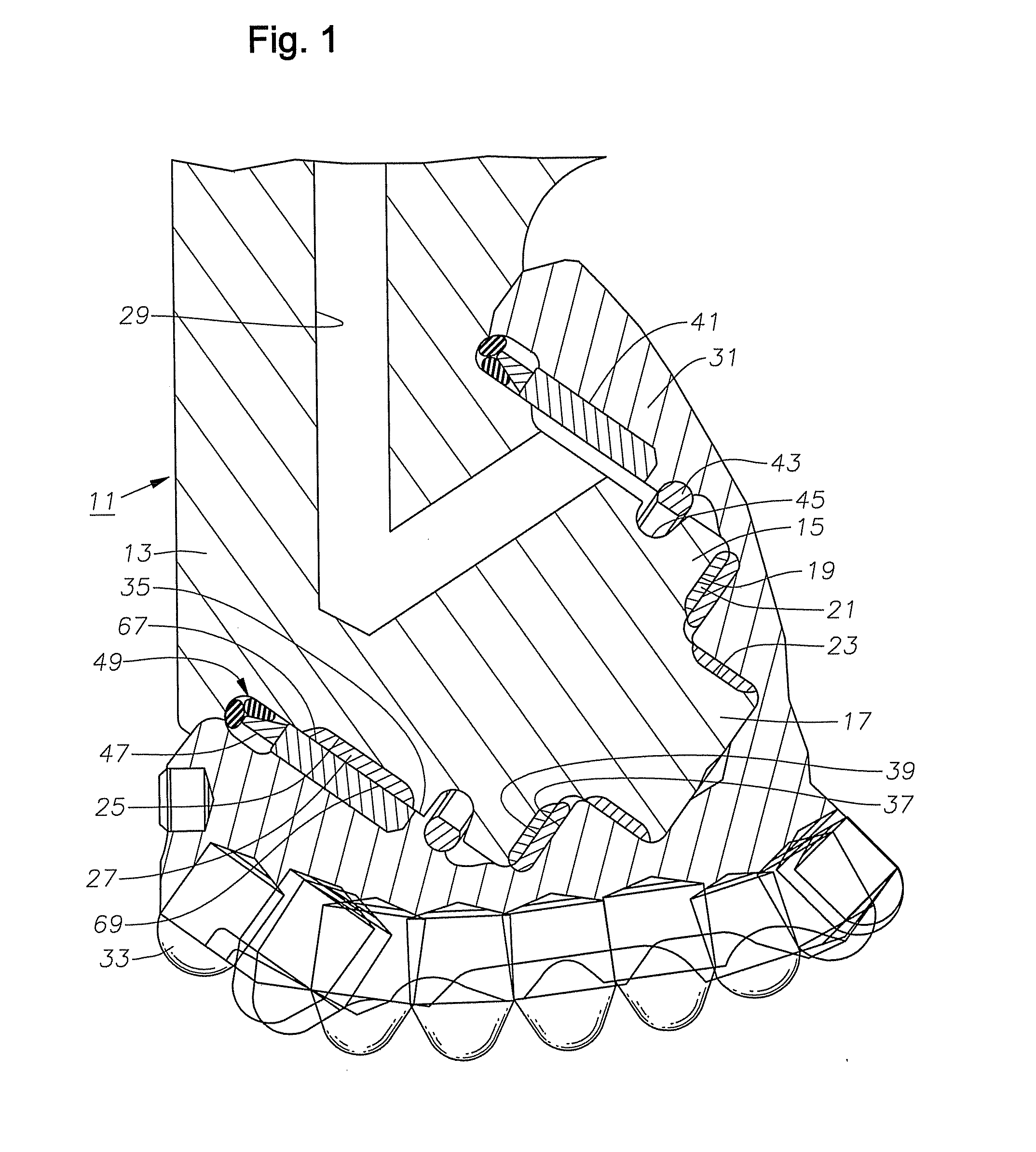

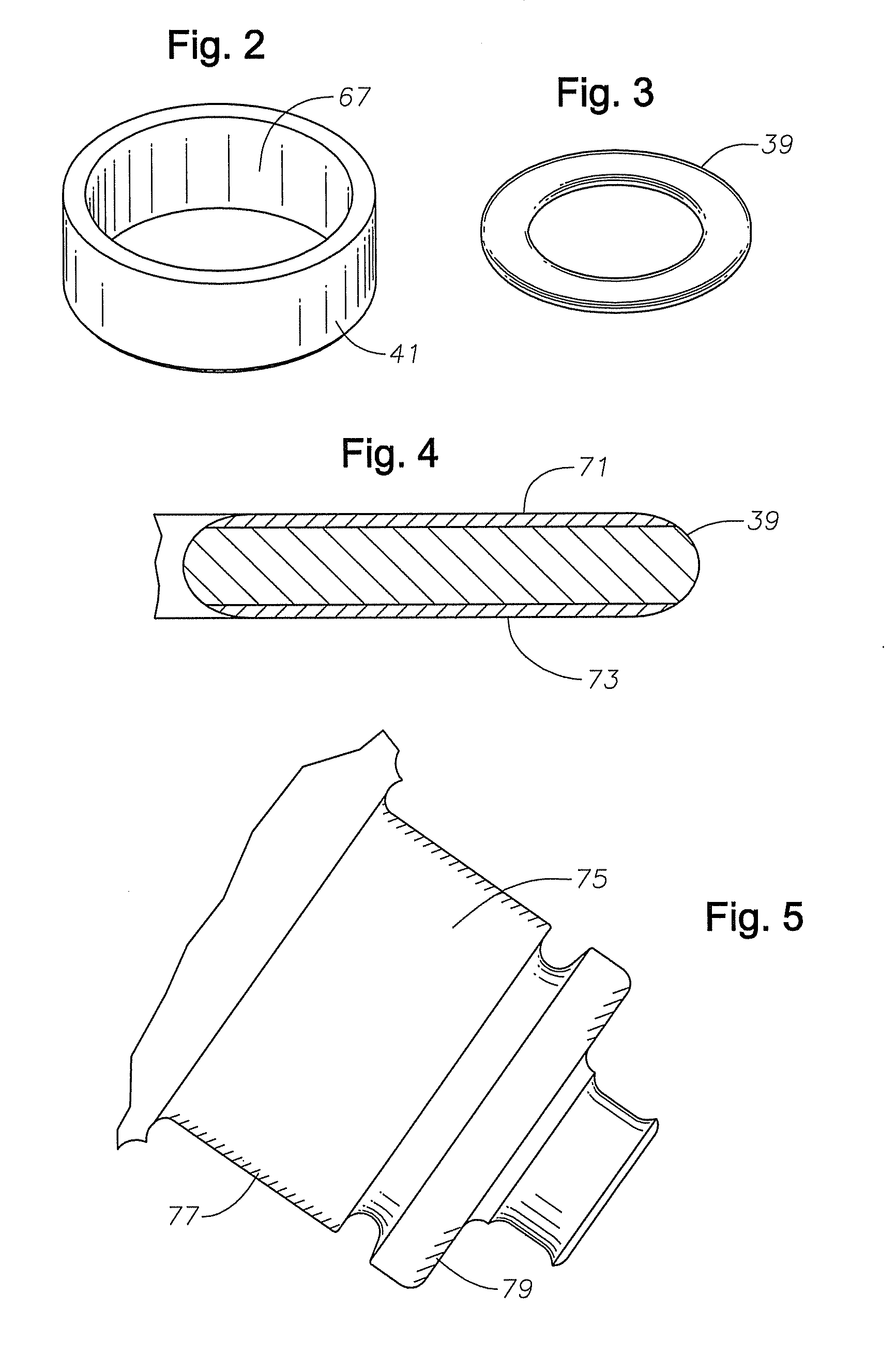

Surface Textures for Earth Boring Bits

ActiveUS20070284150A1Prevent side leakagePromote absorptionDrill bitsBearing componentsEngineeringBearing surface

A texture pattern is applied to bearing surfaces of earth-boring bits, especially the bearings of earth boring bits of the roller cutter variety. The textured surface that may be applied to either or both sides of the thrust washer faces, bearing faces, inlays, or thrust shoulders, or a combination thereof.

Owner:BAKER HUGHES INC

High areal density holographic data storage system

InactiveUS20060152783A1Increase areal densityHigh densityRecord information storageOptical beam guiding meansSignal-to-noise ratio (imaging)Holographic imaging

An apparatus for recording or reading high areal density holographically stored information with high signal-to-noise ratio. The apparatus comprises a holographic imaging system for recording or reconstructing a holographic image, having a first numerical aperture and a first focal length and an additional optical system for filtering the signal beam, having a second numerical aperture and a second focal length, wherein the numerical aperture of the additional optical system is less than the numerical aperture of the holographic imaging system and / or the focal length of the additional optical system is greater than the optical length of the holographic imaging system.

Owner:POSTECH CO LTD

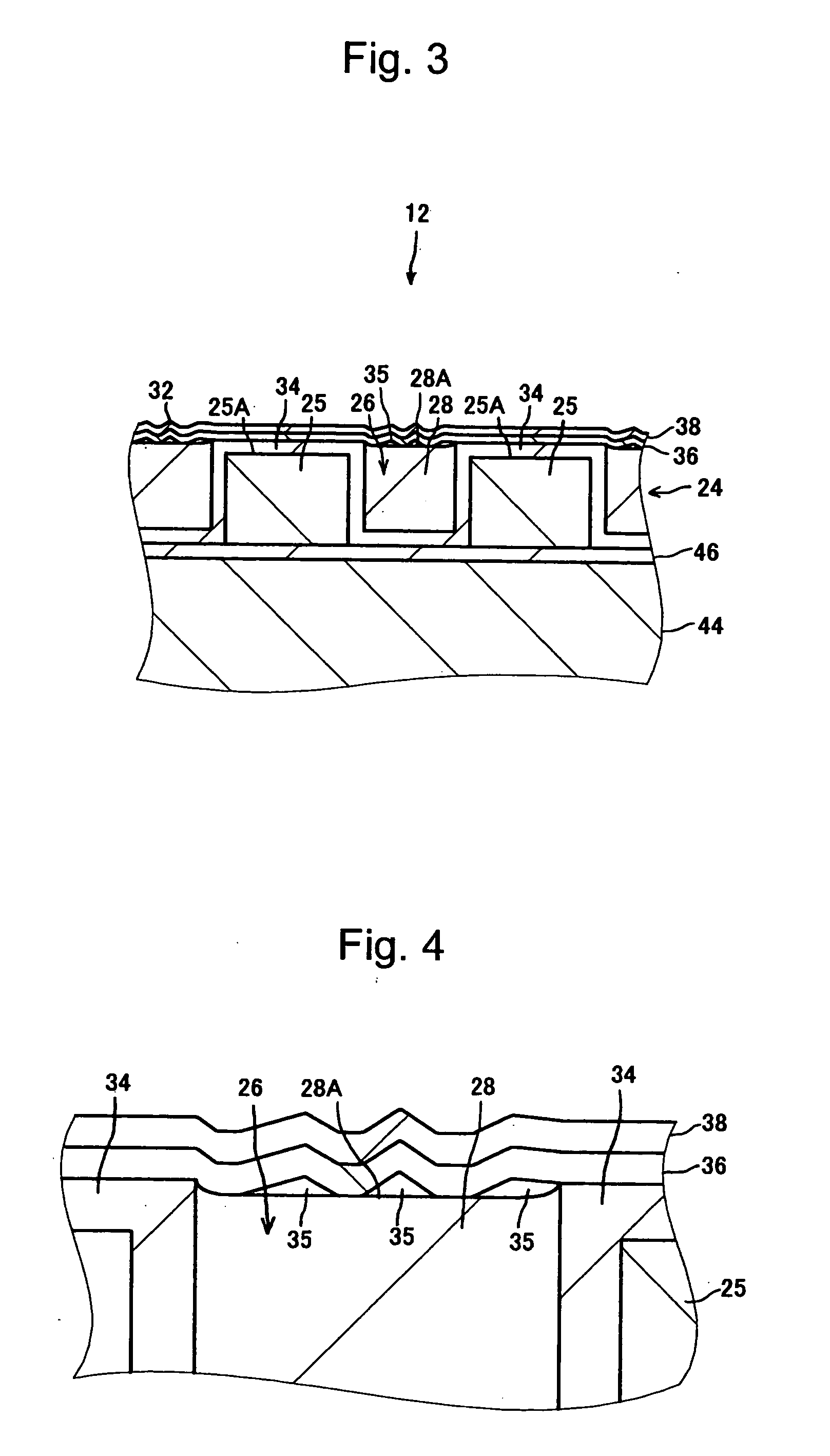

Magnetic recording medium

InactiveUS20050196650A1Increase frictional resistanceIncrease areal densityMagnetic materials for record carriersLayered productsEngineeringNon magnetic

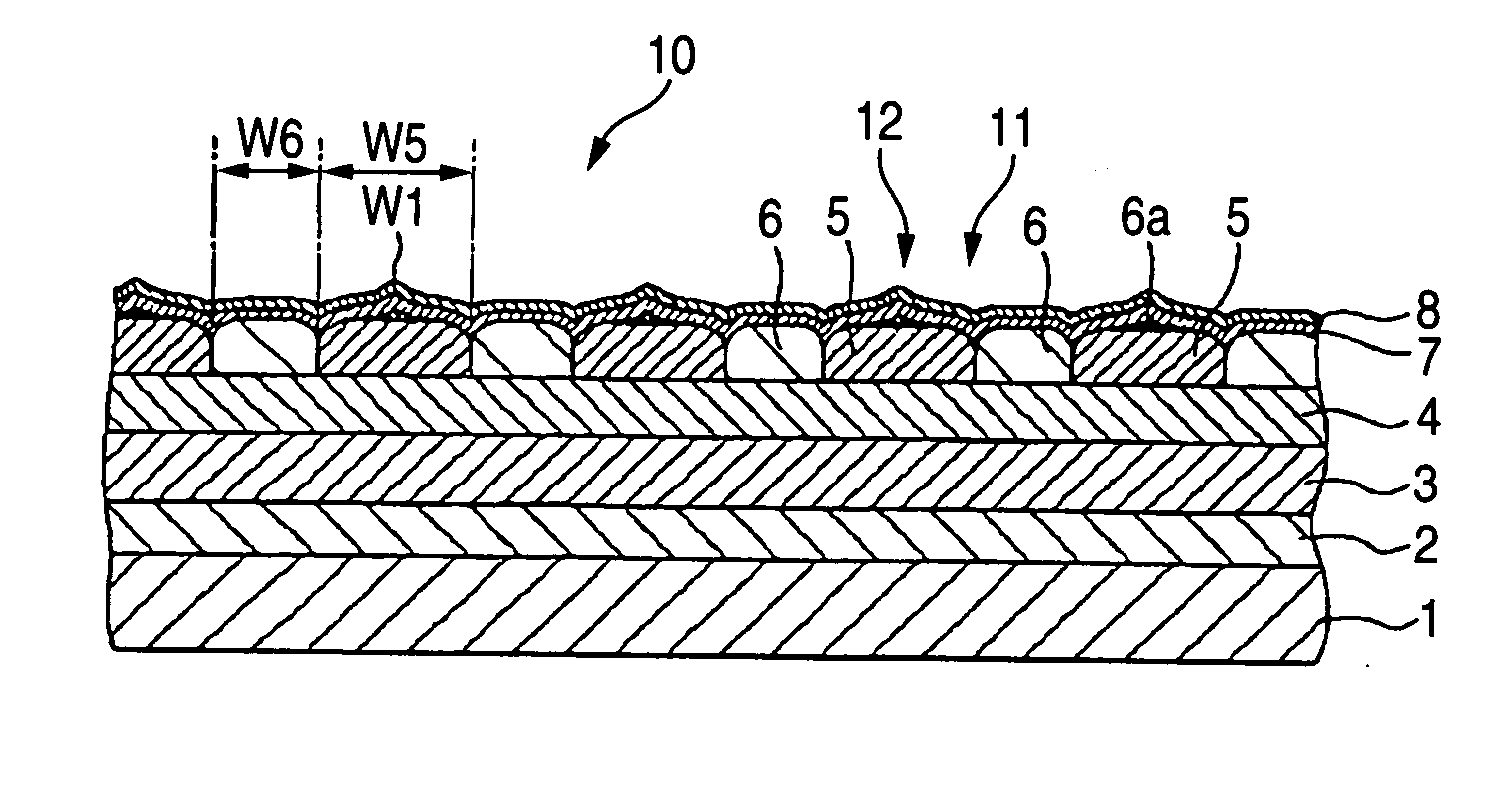

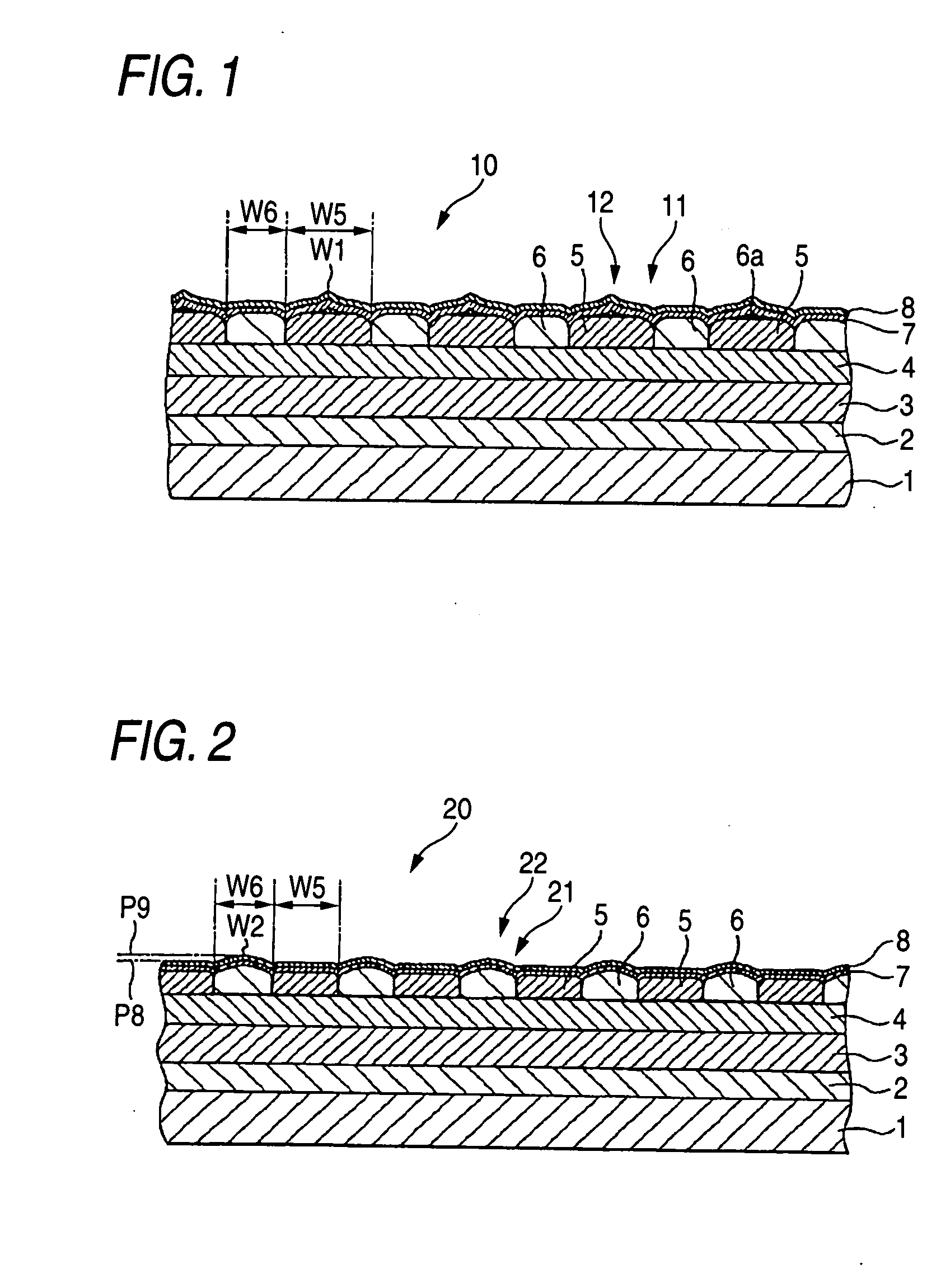

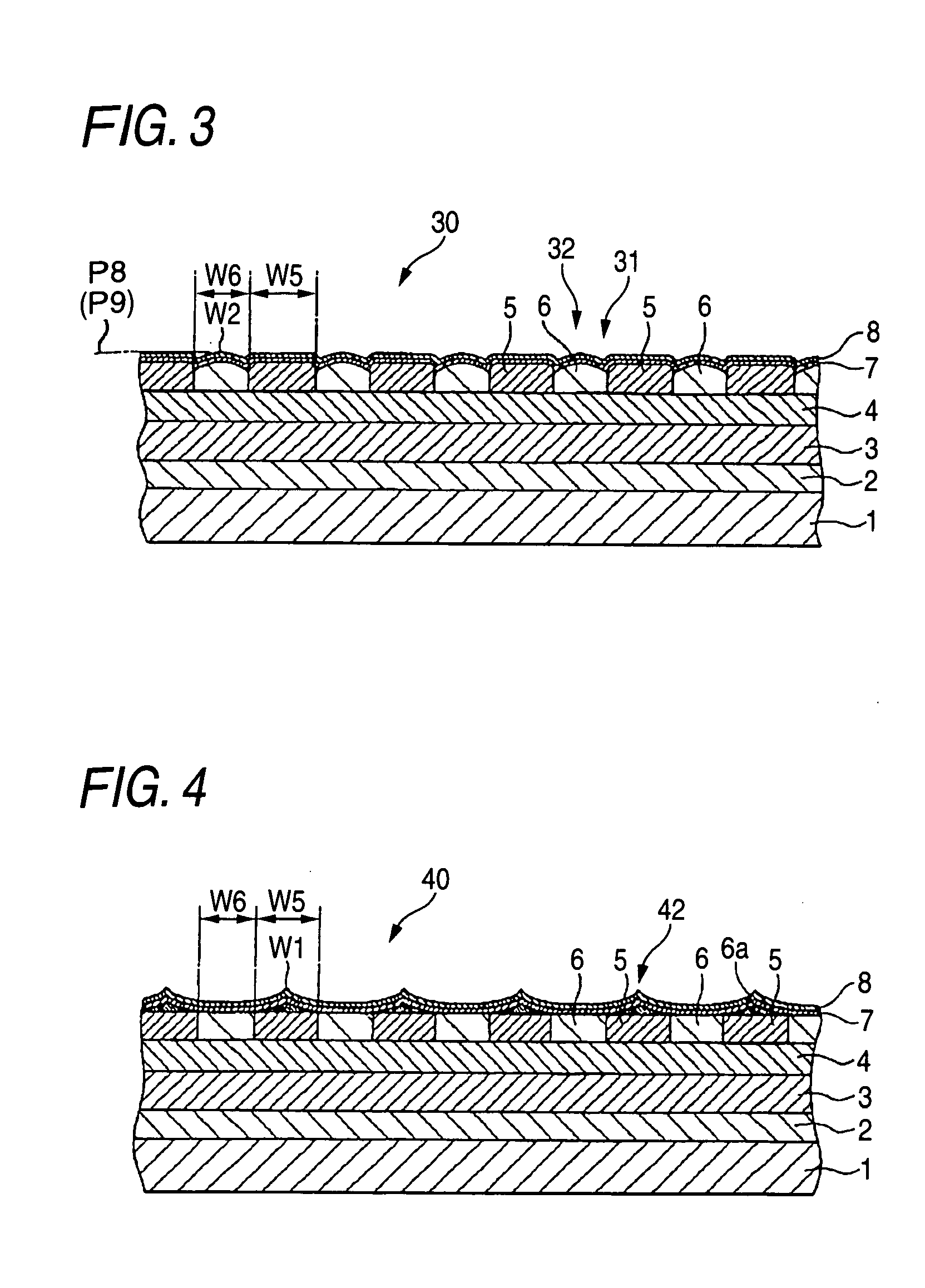

A magnetic recording medium includes at least a disk substrate 1, a magnetic recording layer 5 formed with a predetermined concavo-convex pattern on the disk substrate 1, and a non-magnetic layer 6 formed in concave portions of the concavo-convex pattern. Convex shapes made of a non-magnetic material are formed on the magnetic recording layer 5 or the non-magnetic layer 6. Each convex shape is formed, for example, into a mountain-like shape whose upper surface width (W1 or W2) is made smaller than width W5 of each convex portion of the magnetic recording layer 5 or width W6 of each concave portion where the non-magnetic layer 6 is formed.

Owner:TDK CORPARATION

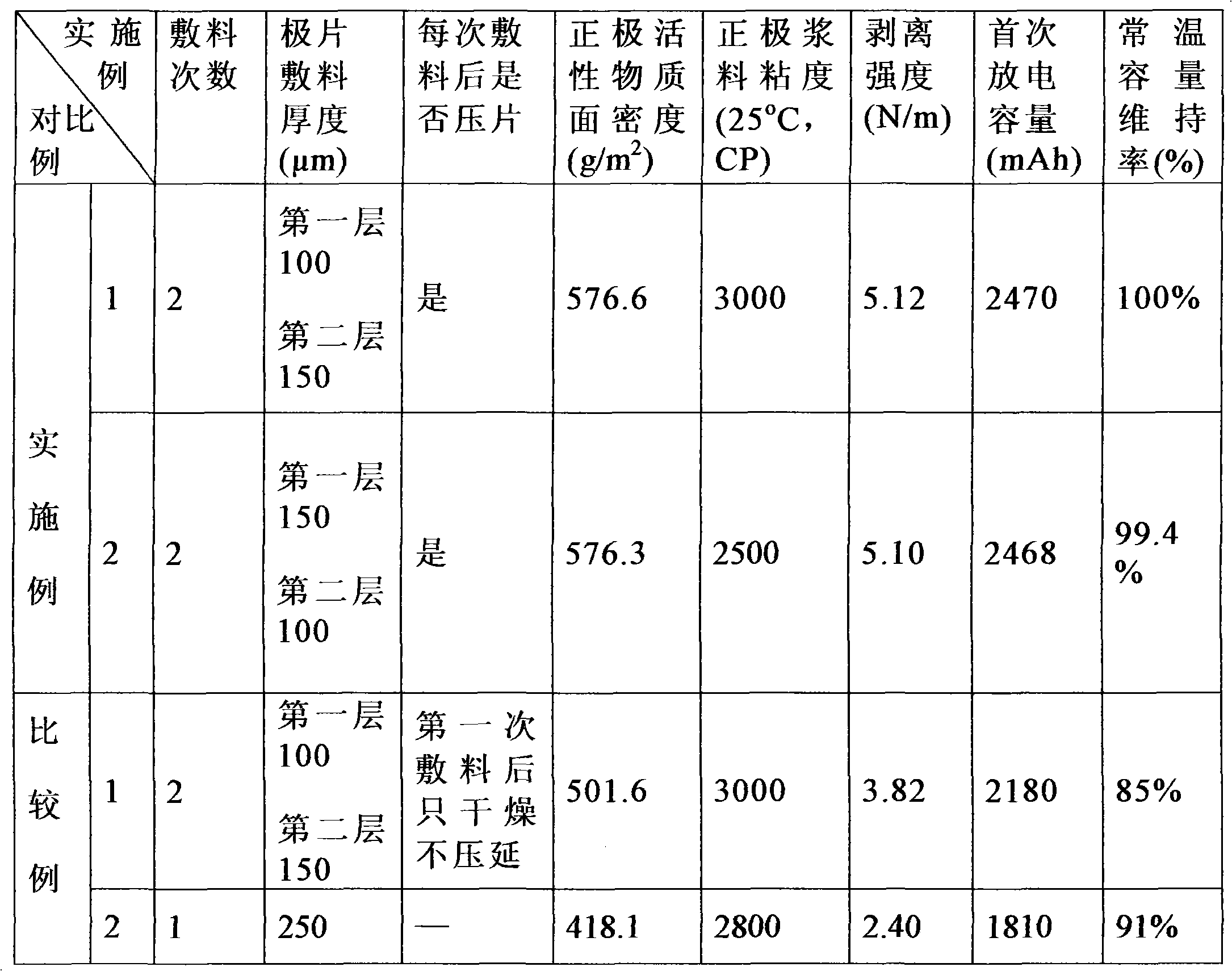

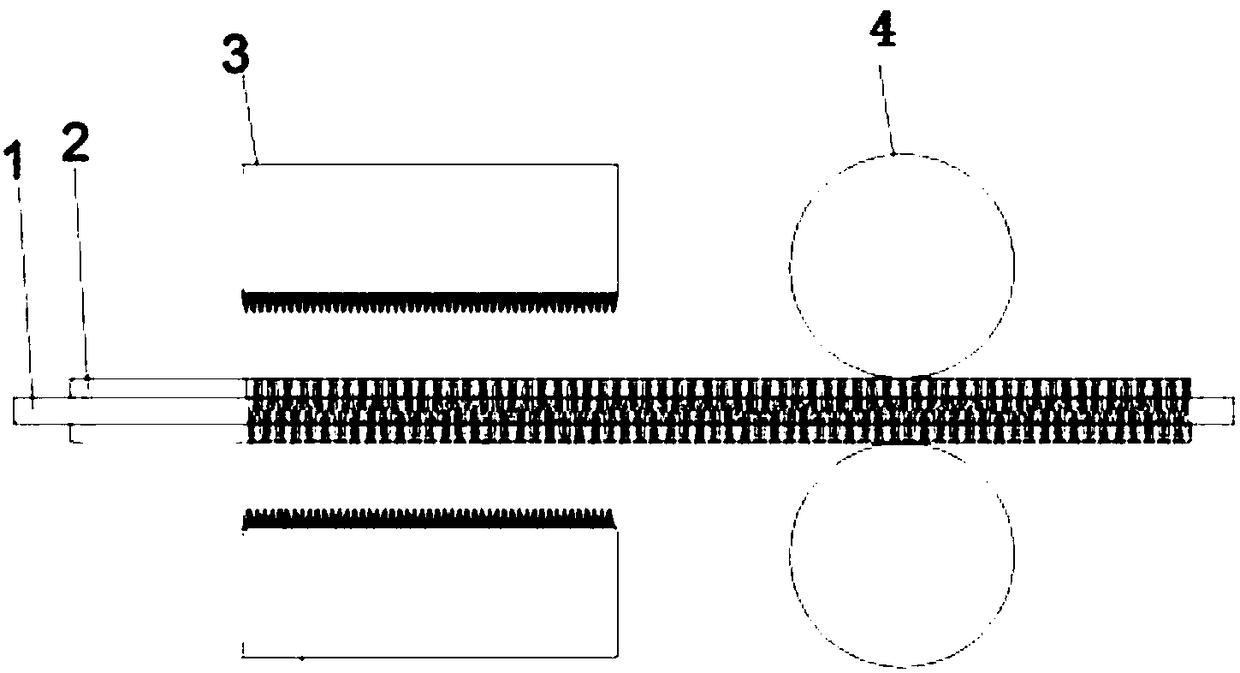

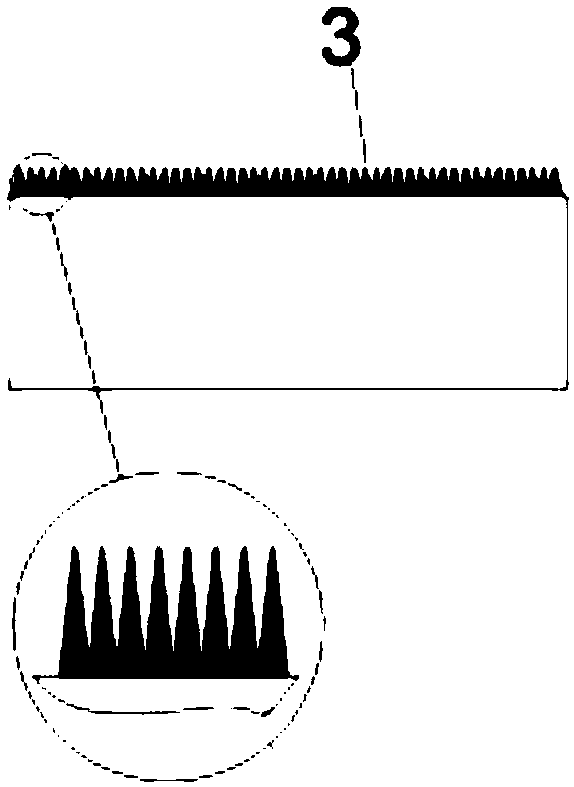

Battery pole piece, preparation method thereof and secondary battery comprising the same

InactiveCN101859885AIncrease capacityImprove cycle performanceElectrode rolling/calenderingNon-aqueous electrolyte accumulatorsHigh surfaceEngineering

The invention provides a preparation method of a battery pole piece, a secondary battery pole piece and a secondary battery. The preparation method of the battery pole piece, which is provided by the invention, comprises the following step of repeatedly carrying out process flows of dressing, drying and calendering at least twice to prepare the battery pole piece, wherein the dressing flow is that size comprising an electrode active material is coated and / or filled on a substrate of a current collector or the current collector comprising an electrode material. Compared with the conventional process, when the dressing thickness is the same, the battery pole piece prepared by adopting the method provided by the invention has higher surface density of the electrode active material, thus, the battery has larger capacity.

Owner:SHANGHAI BYD

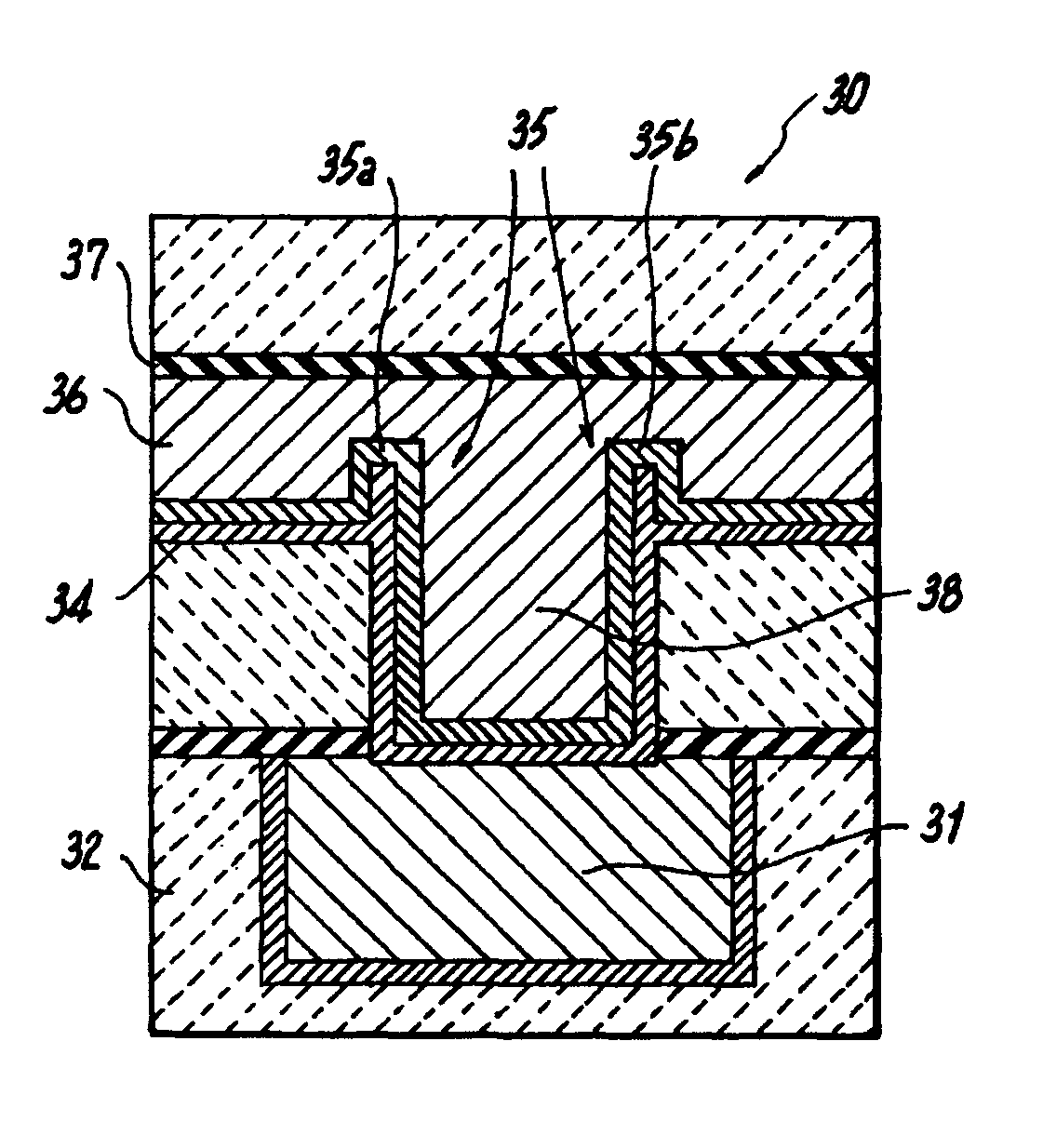

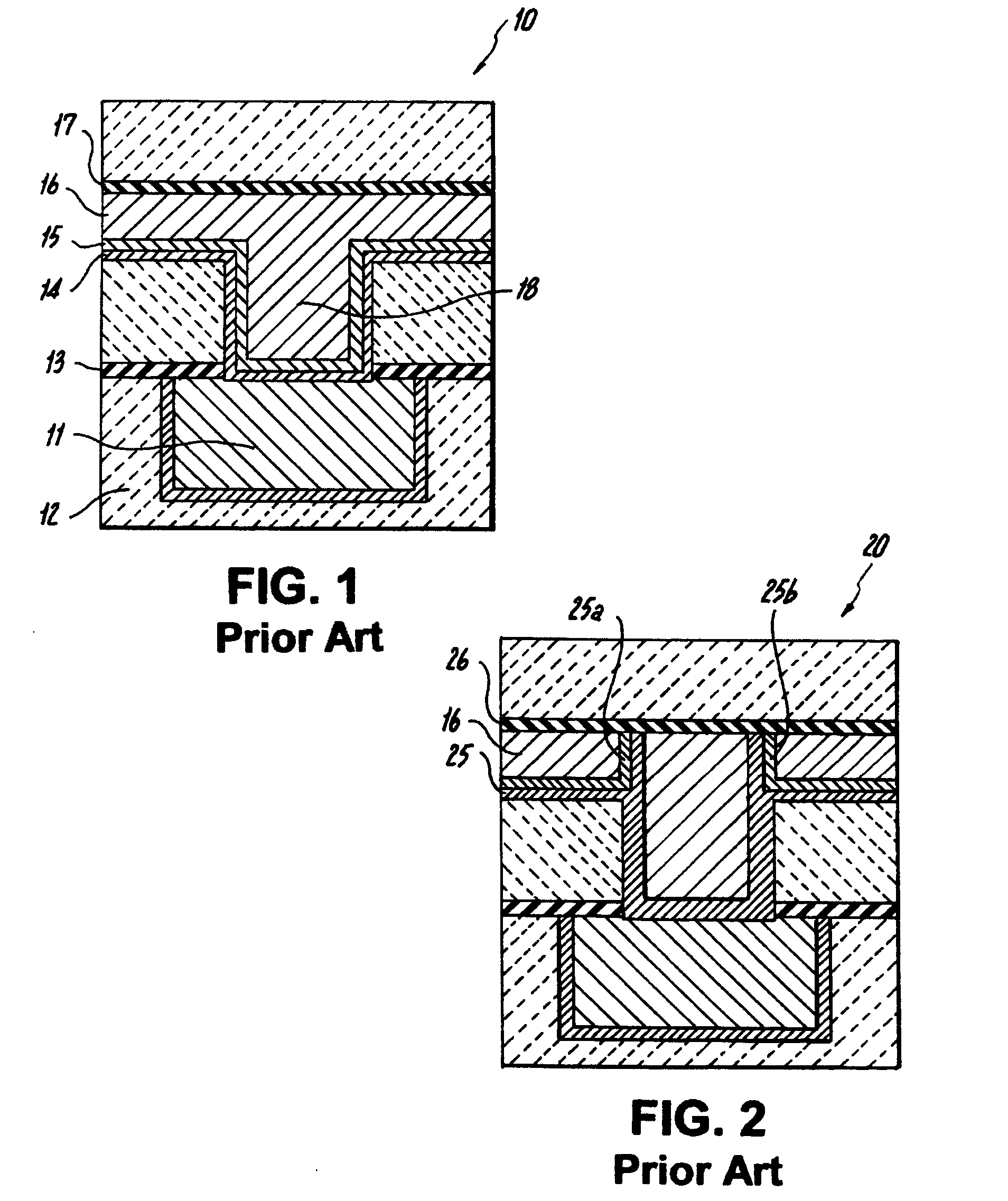

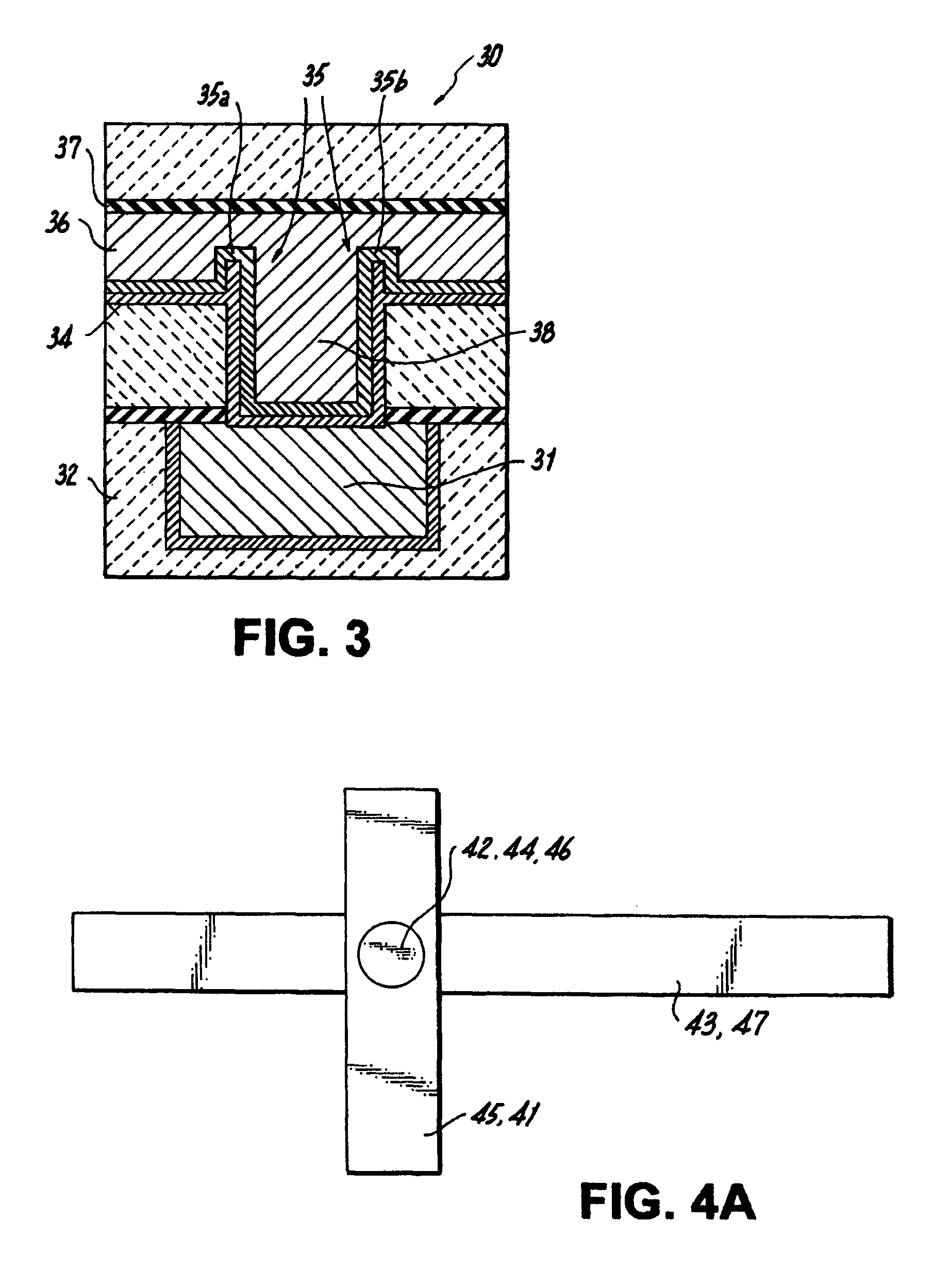

Partial inter-locking metal contact structure for semiconductor devices and method of manufacture

InactiveUS20050112957A1Improves Structural IntegrityHigh wiring densitySemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

A structure and method of fabricating a “Lego”-like interlocking contact for high wiring density semiconductors is characterized in that the barrier liner formed in the contact via extends only partially upwards into the adjacent wire level. As a consequence, current crowding and related reliability problems associated with conventional prior art interconnect structures is avoided and structural integrity of the contact via (metal stud) structure is enhanced. The novel “crown” shape of the Lego-like interlocking contact structure that is fabricated to extend in an upward direction may be employed for other integrated circuit applications including forming capacitor (e.g., MIMCAP) and heat sink structures due to its increased surface area.

Owner:IBM CORP

Magnetic recording medium, magnetic recording and reproducing apparatus, and method for manufacturing magnetic recording medium

InactiveUS20060292400A1Increase areal densityImprove reliabilityRecord information storageSpecial surfacesFilling materialsElectrical and Electronics engineering

A magnetic recording medium that includes a recording layer formed in a predetermined concavo-convex pattern in which recording elements are formed as convex portions, has high areal density, cannot cause crash of a magnetic head easily, and has high reliability, and a magnetic recording and reproducing apparatus including that magnetic recording medium are provided. The magnetic recording medium includes: the recording elements formed as the convex portions of the recording layer formed in a predetermined concavo-convex pattern over a substrate; and a filling material with which a concave portion between the recording elements is filled. The surface roughness of a portion of a surface of the medium above the filling material is larger than that of portions of the surface above the recording elements.

Owner:TDK CORPARATION

Thermal preparation method of solution of self-supported porous graphene-based membrane

ActiveCN104192836AFast oxidation-reduction reactionIncrease specific capacitance valueCvd grapheneElectrochemical energy storage

The invention relates to a thermal preparation method of a solution of a self-supported porous graphene-based membrane, relates to a preparation method of a self-supported porous graphene-based membrane, and aims to solve the technical problems that the size and the thickness of a conventional self-supported porous graphene-based membrane are limited and the electrochemical performance of the conventional self-supported porous graphene-based membrane is poor caused by severe interlay lamination of graphene sheets in the chemical reduction process. The thermal preparation method comprises the following steps: dispersing graphene oxide into water, adding or not adding a doped carbon material, concentrating, and spreading into a membrane, thereby obtaining a graphene oxide membrane; preparing a thermal treatment solution by using acid or alkali solute, putting the graphene oxide membrane into a reaction kettle with a polytetrafluoroethylene lining, adding the thermal treatment solution according to the standard that the membrane is submerged, sealing the reaction kettle, and subsequently performing thermal treatment, thereby obtaining the self-supported porous graphene-based membrane. The self-supported porous graphene-based membrane is prepared by orderly arranging graphene sheets in parallel, and due to the gaps among the graphene sheet layers, the self-supported porous graphene-based membrane can be used in electrochemical energy storage devices such as supercapacitors.

Owner:HARBIN INST OF TECH

Switchable element

InactiveUS20100195381A1Increase areal densityEasy to operateSemiconductor/solid-state device manufacturingDigital storageMagnetic reluctanceEngineering

A switchable element. The element includes a source electrode, a drain electrode, a conducting channel between the source electrode and the drain electrode, and a gate with multiferroic material being switchable, by application of an electrical signal to the gate, between a first switching state with a first spontaneous polarization direction and a second switching state with a second spontaneous polarization direction. The conducting channel is magnetoresistive, and a magnetic field strength at the conducting channel in the first switching state is different than a magnetic field strength in the second switching state, whereby a current-voltage characteristic of the conducting channel is dependent on the switching state of the multiferroic material.

Owner:GLOBALFOUNDRIES INC

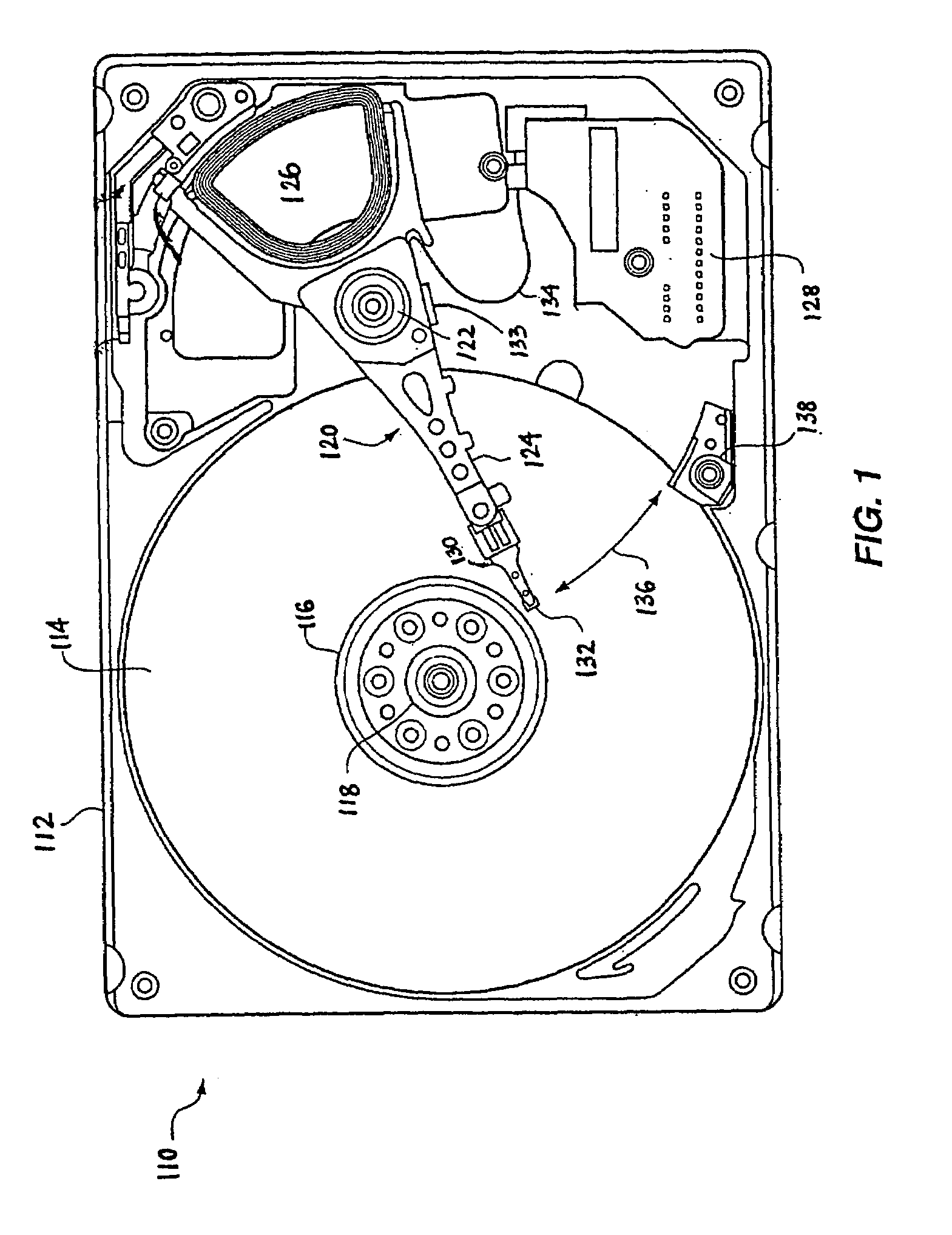

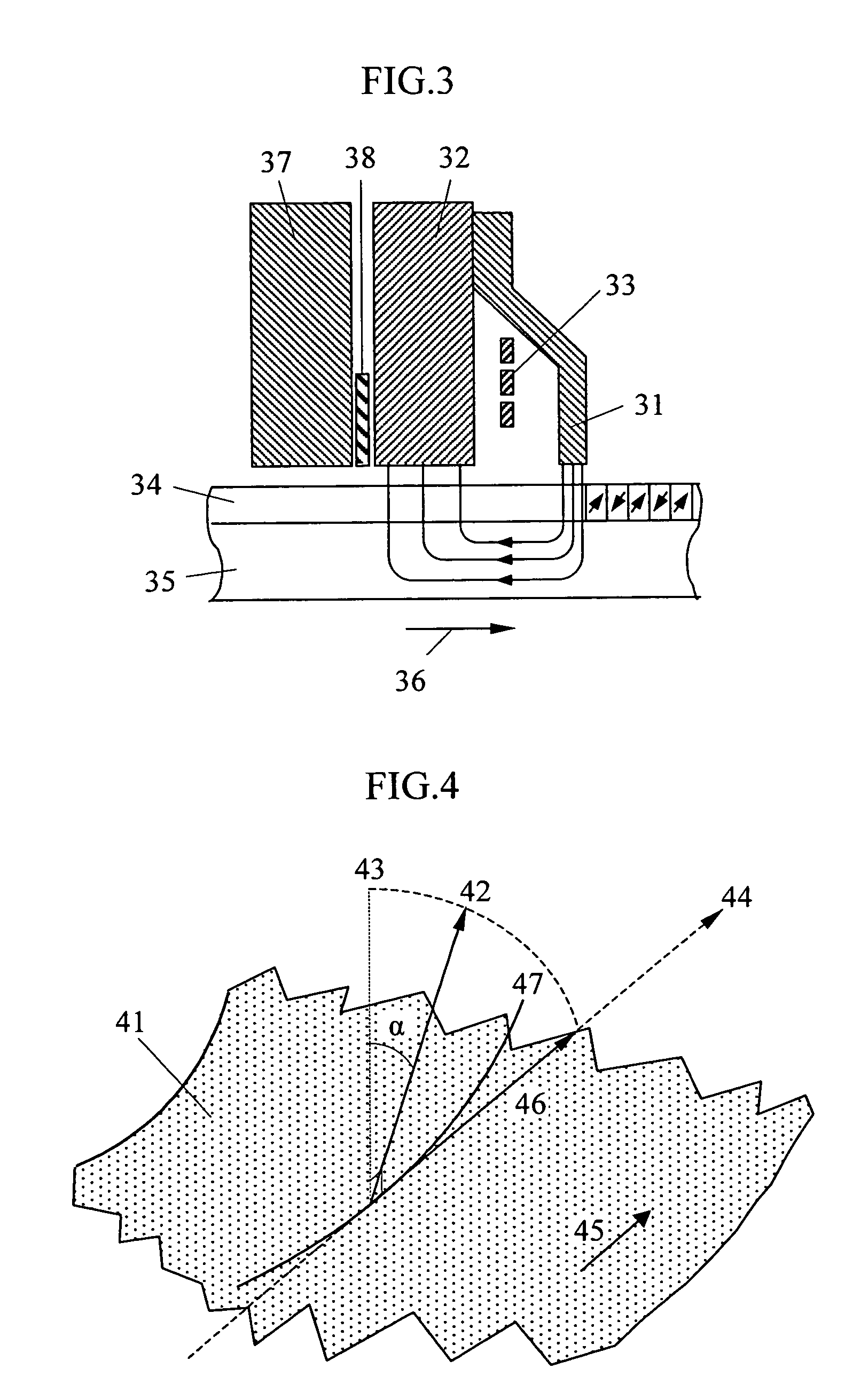

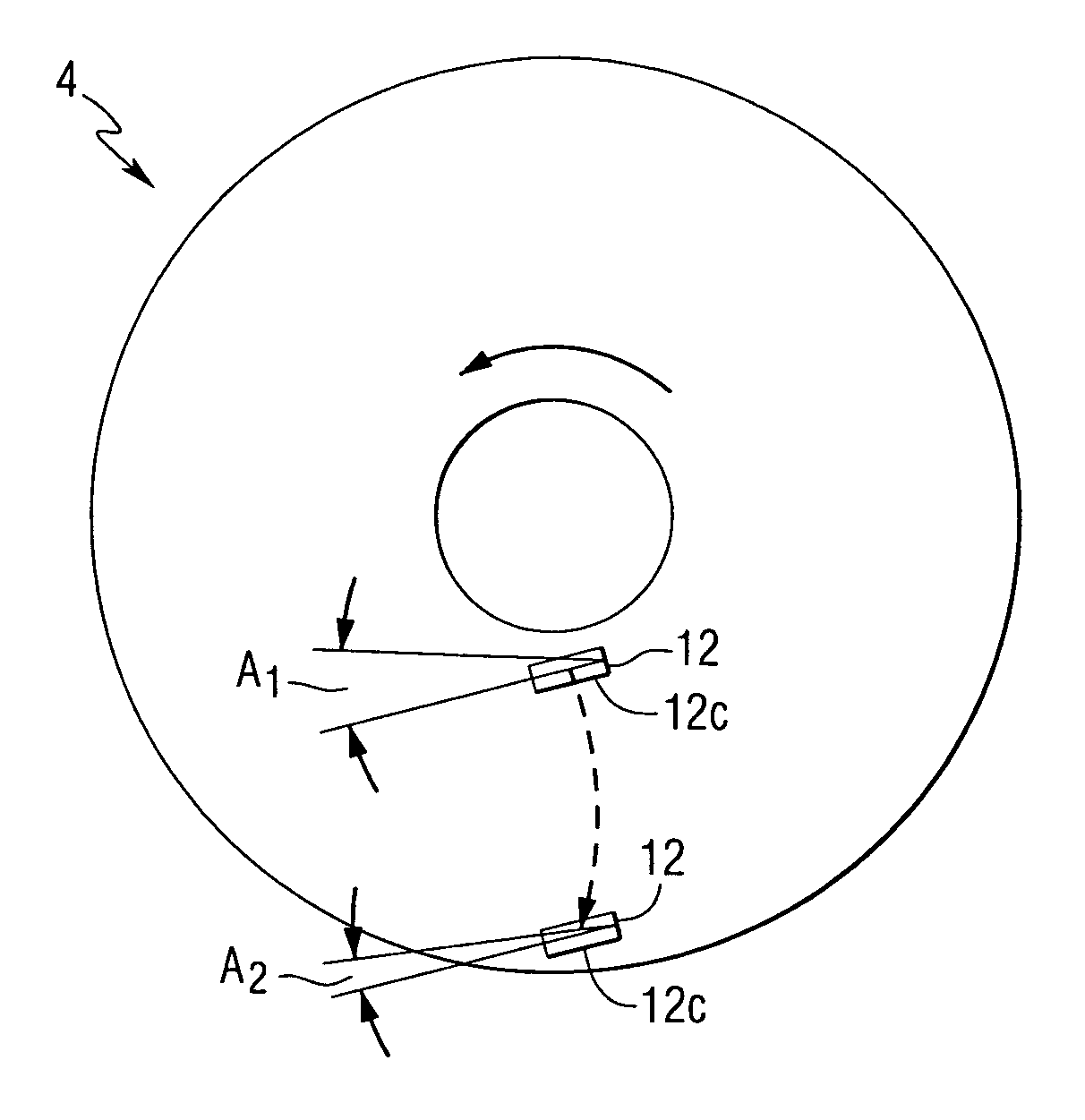

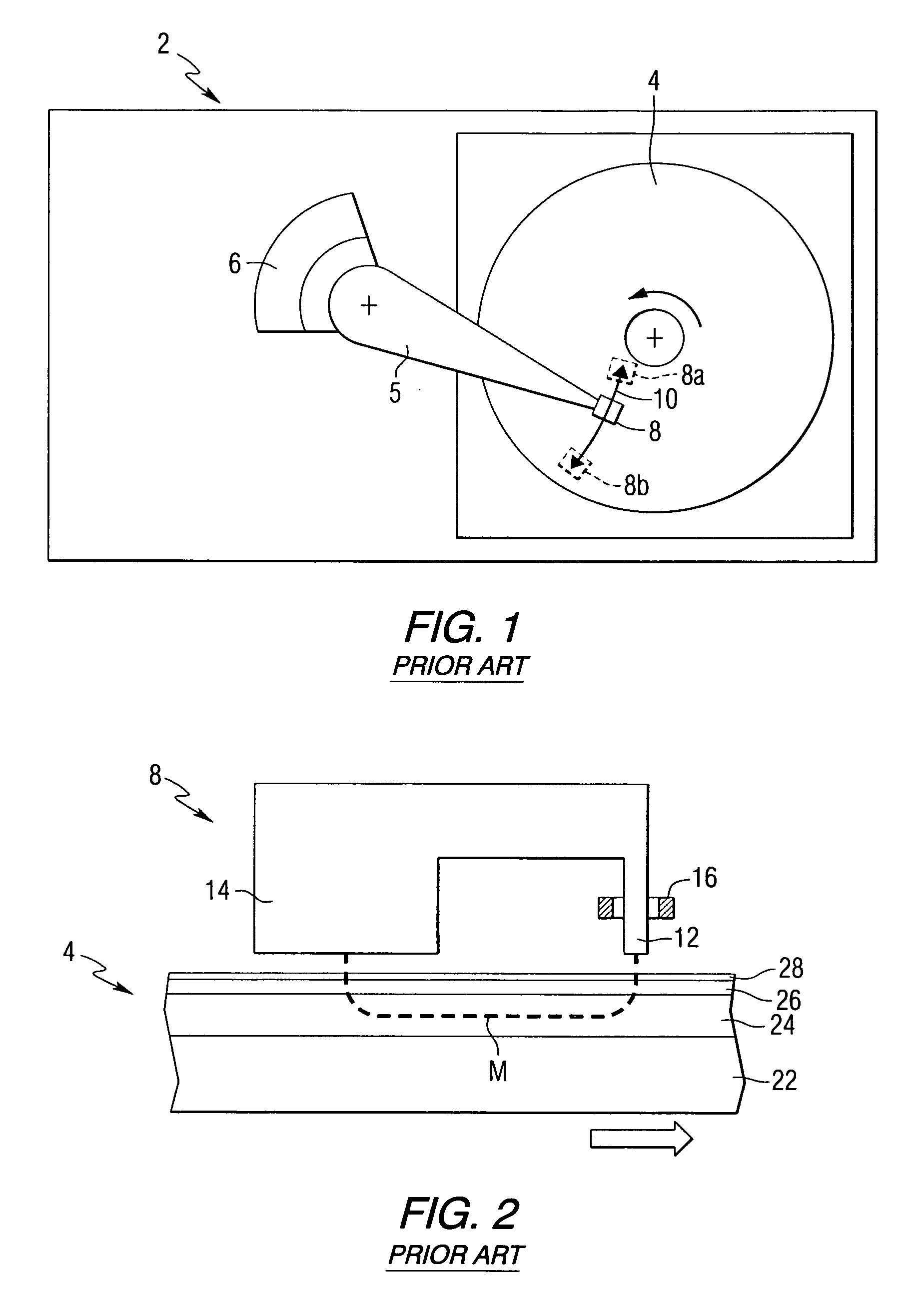

Magnetic recording system which eliminates skew angle effect

InactiveUS6987637B2Reduces and eliminates skew angle effectIncrease areal densityRecord information storageAlignment for track following on disksSkew angleComputer science

A perpendicular magnetic recording system is provided which eliminates unwanted side writing to adjacent recording tracks due to the skew angle effect. The system includes a perpendicular magnetic recording head with a write pole that is used to sequentially write to adjacent tracks of a magnetic recording disk. In one embodiment, the write pole is aligned at a compensation angle with respect to the recording tracks which remains greater than zero as the recording head travels in an arc across the disk. When the recording head moves radially inwardly or outwardly across the tracks of the disk, the compensation angle remains greater than zero. Any side writing by the write pole to adjacent tracks is eliminated as the write pole sequentially writes to the next adjacent track. By eliminating the skew angle effect, smaller spacings may be provided between adjacent tracks, thereby increasing data storage densities.

Owner:SEAGATE TECH LLC

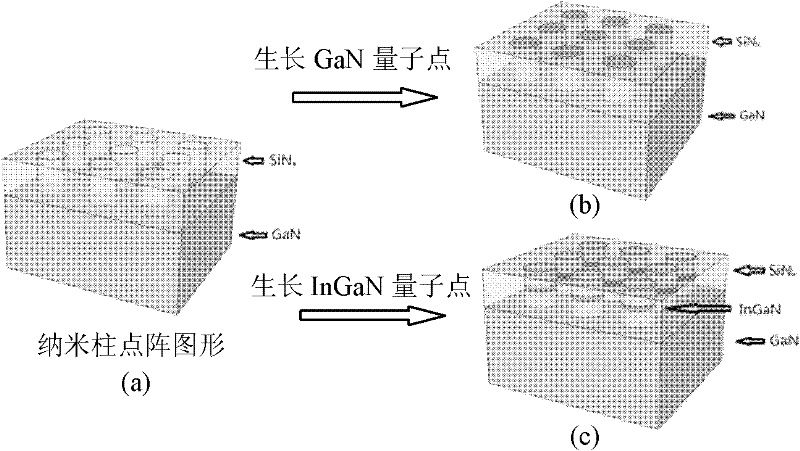

Method for preparing active layer structure with high-density gallium nitride quantum dots

ActiveCN102420277AHigh densityIncrease areal densityLaser detailsSemiconductor lasersMethacrylateNanopillar

The invention relates to a method for preparing an active layer structure with high-density gallium nitride quantum dots; the method comprises the following steps of: (1). depositing a layer of SiO or SiNx dielectric thin film material with the thickness of 10-50nm on a GaN template or surfaces of other semiconductor films, painting a mixing copolymer of PS (Polystyrene) and PMMA (Polymenthyl Methacrylate) on the surface of the dielectric thin film, obtaining a PS nanometer column graph after cleaning the PMMA, transferring the PS nanometer column graph to the dielectric thin film layer by adopting plasma etching, wherein the PS nanometer column graph is prepared according to the following parameters: (1) the surface density reaches 0.8-1.0*1011cm<-2>; (2) the PS nanometer column graph istransferred to the SiNx or SiO2 dielectric thin film layer by adopting reactive ion etching, the PP is removed to obtain a template on which a GaN nanometer point structure grows for the second time through MOCVD (Metal-organic Chemical Vapor Deposition); and (3) a GaN-base quantum dot structure grows, emits strong royal purple light and is used for manufacturing the active layer structure in a light-emitting diode (LED) with high efficiency and a laser device (LD) optoelectronic device.

Owner:NANJING UNIV

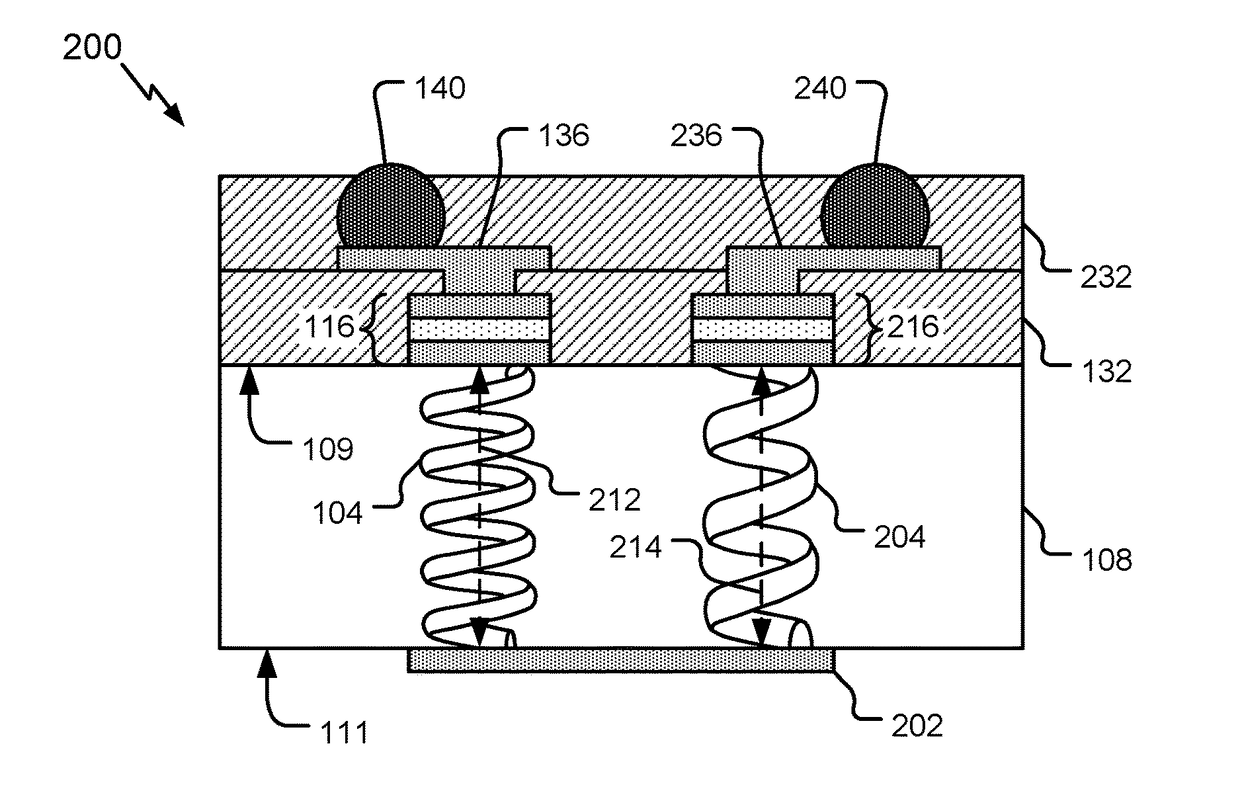

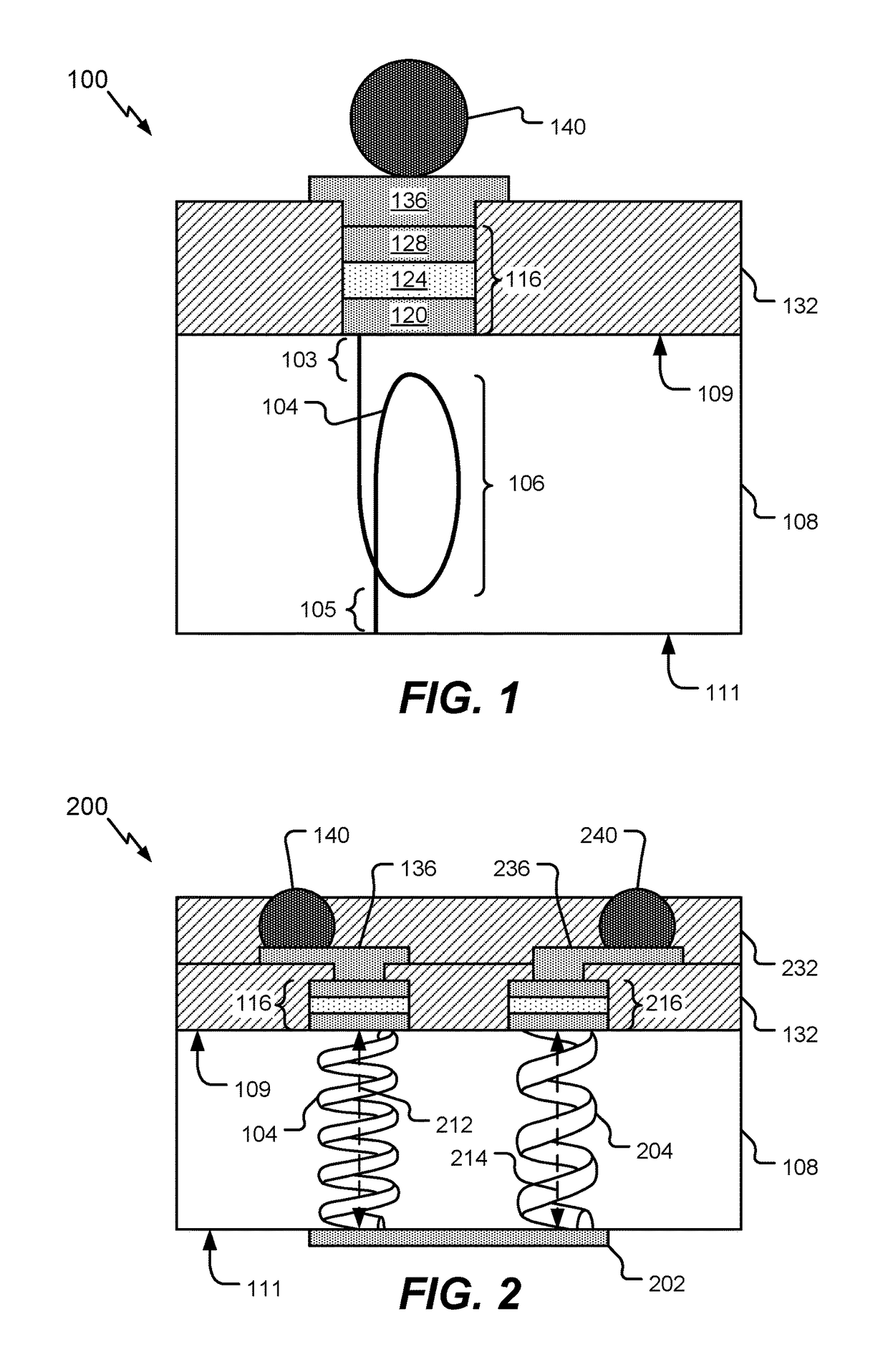

Apparatus with 3D wirewound inductor integrated within a substrate

InactiveUS20170338034A1Increasing circuit area densityImprove device performanceMultiple-port networksSemiconductor/solid-state device detailsInductorEngineering

Owner:QUALCOMM INC

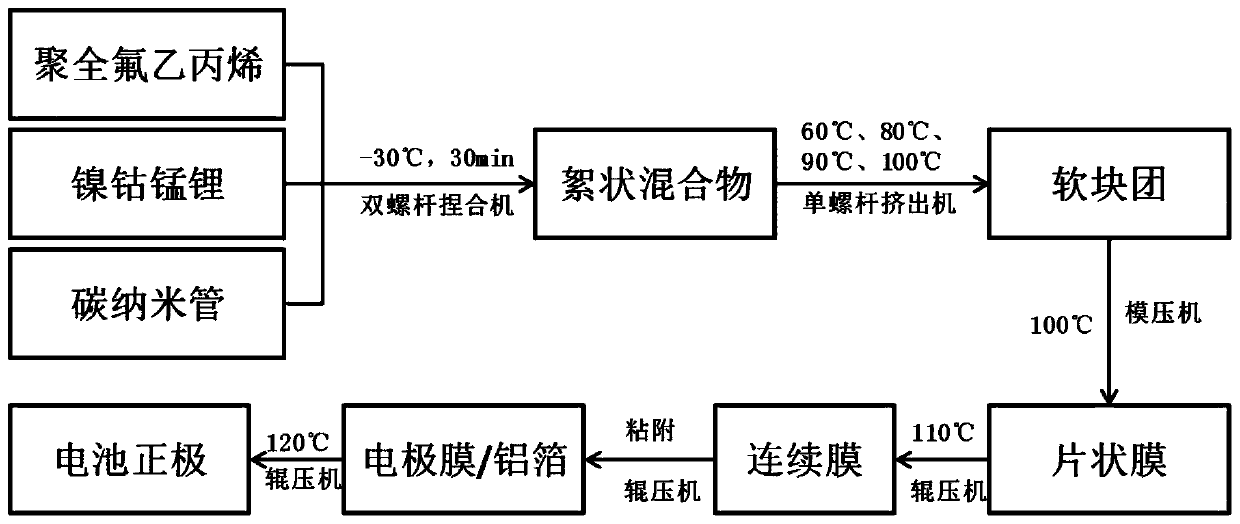

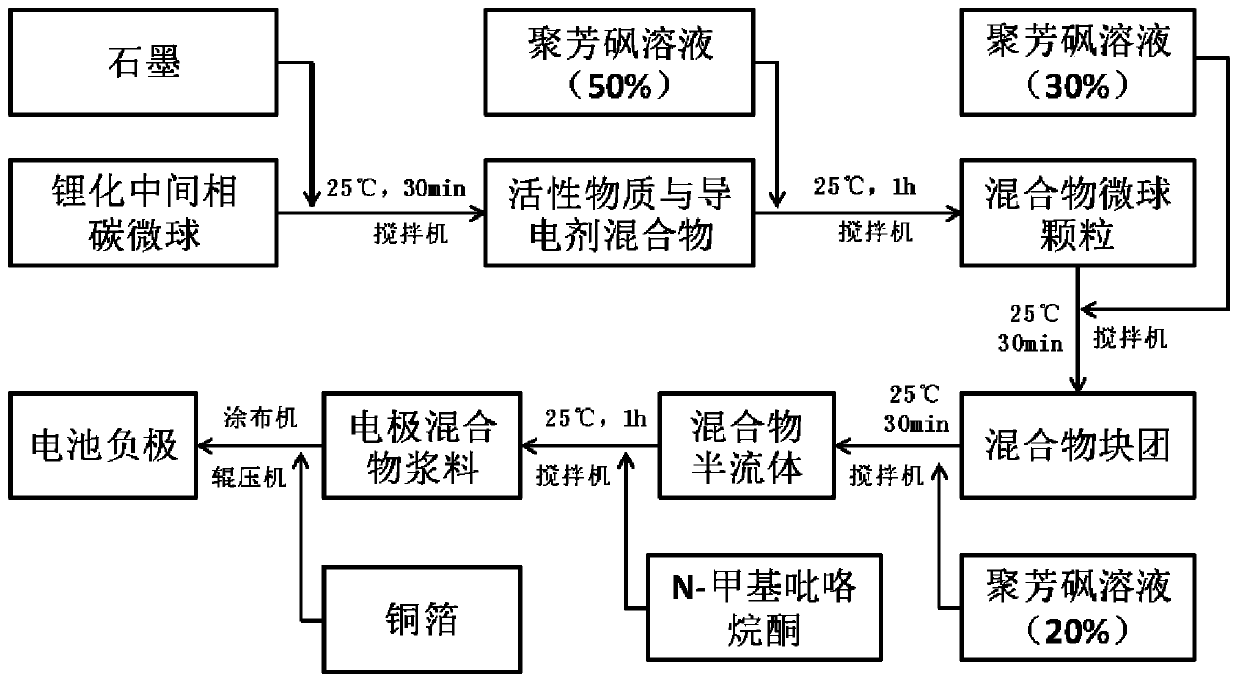

Electrode preparation method and battery

ActiveCN109841796AIncrease areal densityImprove structural stabilityElectrode manufacturing processesSecondary cellsLamellar crystalsInternal resistance

The invention discloses an electrode preparation method and a battery. The battery anode is prepared by pasting an electrode film prepared from an active substrate, a conductive agent and a binder toa current collector, the surface density of a pole piece is improved, the electrode capacity and the pole piece stability are improved, and the internal resistance is reduced. In the preparation process of the electrode film, lamellar crystals of the binder are stretched to paste the active substance and conductive agent, influence of expansion and contraction of the active substance caused by ionembedding and separating is reduced. The battery cathode is prepared by coating a slurry prepared from a pre-lithium active substance, a binder and a conductive agent on the current collector, the active substrate and conductive agent of the cathode are wetted rapidly, dispersed ultra-finely and homogeneous in a binder solution, the amount of the solvent for slurry dispersion is reduced, energy consumption for drying is reduced, the electrode process is shortened, and the load capacity of the cathode active substance is improved. The anode and cathode of the battery can be designed in an integrated way, and energy storage of the battery is improved. The electrode preparation method is simple, production and manufacture are realized by means of existing equipment, and the method is easy topopularize.

Owner:CHINA FIRST AUTOMOBILE

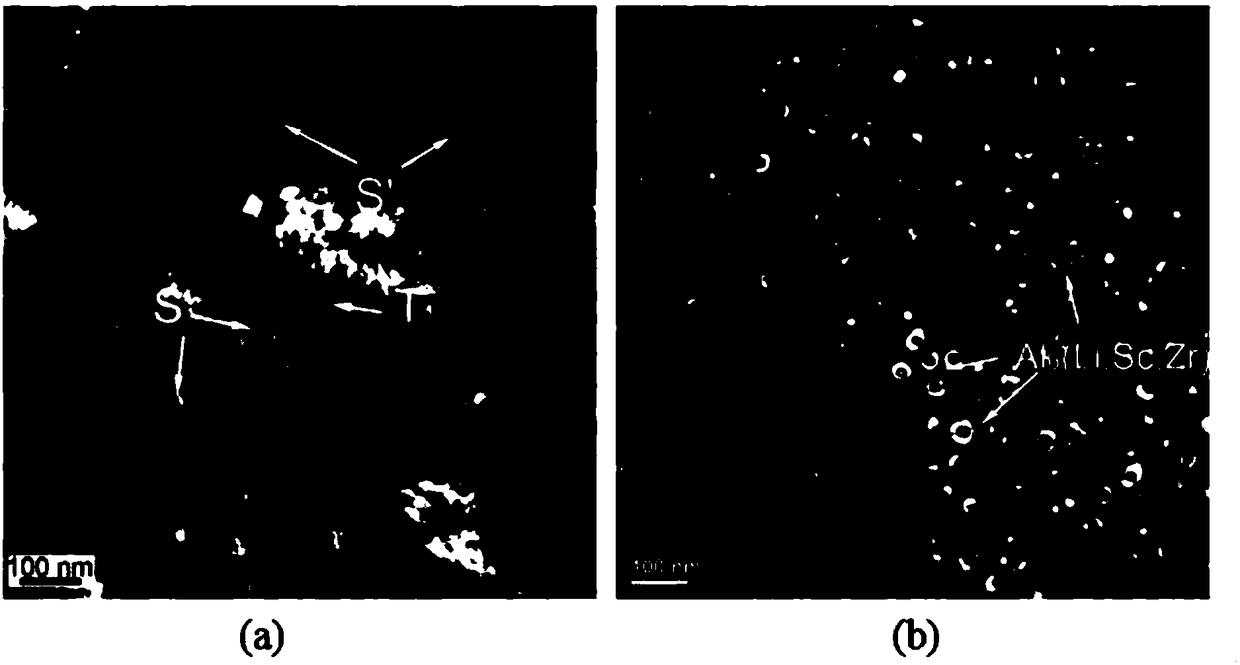

A scandium-containing cast aluminum-lithium alloy and a preparation method thereof

A novel scandium-containing cast aluminum-lithium alloy is disclosed. The alloy includes, by weight, 1.6-1.99% of Li, 0.9-1.9% of Cu, 0.2-0.7% of Mg, 0.1-0.25% of Zr, 0.05-0.35% of Sc, and impurity elements which are Fe, Si, Na, K and P, with the balance being Al, with the Fe content being less than 0.15% and the total content of the impurity elements being less than 0.25%. During preparation, Al-Cu and Al-Zr master alloys, pure aluminum, pure Mg and pure Li are smelted to obtain an aluminum alloy; then three stages of solid solution heat treatment are performed including solid solution heat treatment at 440-460 DEG C for 32 h, solid solution heat treatment at 510-520 DEG C for 24-32 h and solid solution heat treatment at 530-540 DEG C for 1-6 h; and after water quenching, artificial ageing treatment at 150-190 DEG C is performed for 16-48 h to obtain the novel scandium-containing cast aluminum-lithium alloy. The obtained novel scandium-containing cast aluminum-lithium alloy has a uniform microscopic structure, stable performance, density lower than density of traditional aluminum alloys, higher elastic modulus and rigidity, and other mechanical properties, and is low in cost. Theultimate tensile strength of the novel scandium-containing cast aluminum-lithium alloy can be 450-490 MPa and the specific elongation is 4.5-7.0%.

Owner:SHANGHAI JIAO TONG UNIV

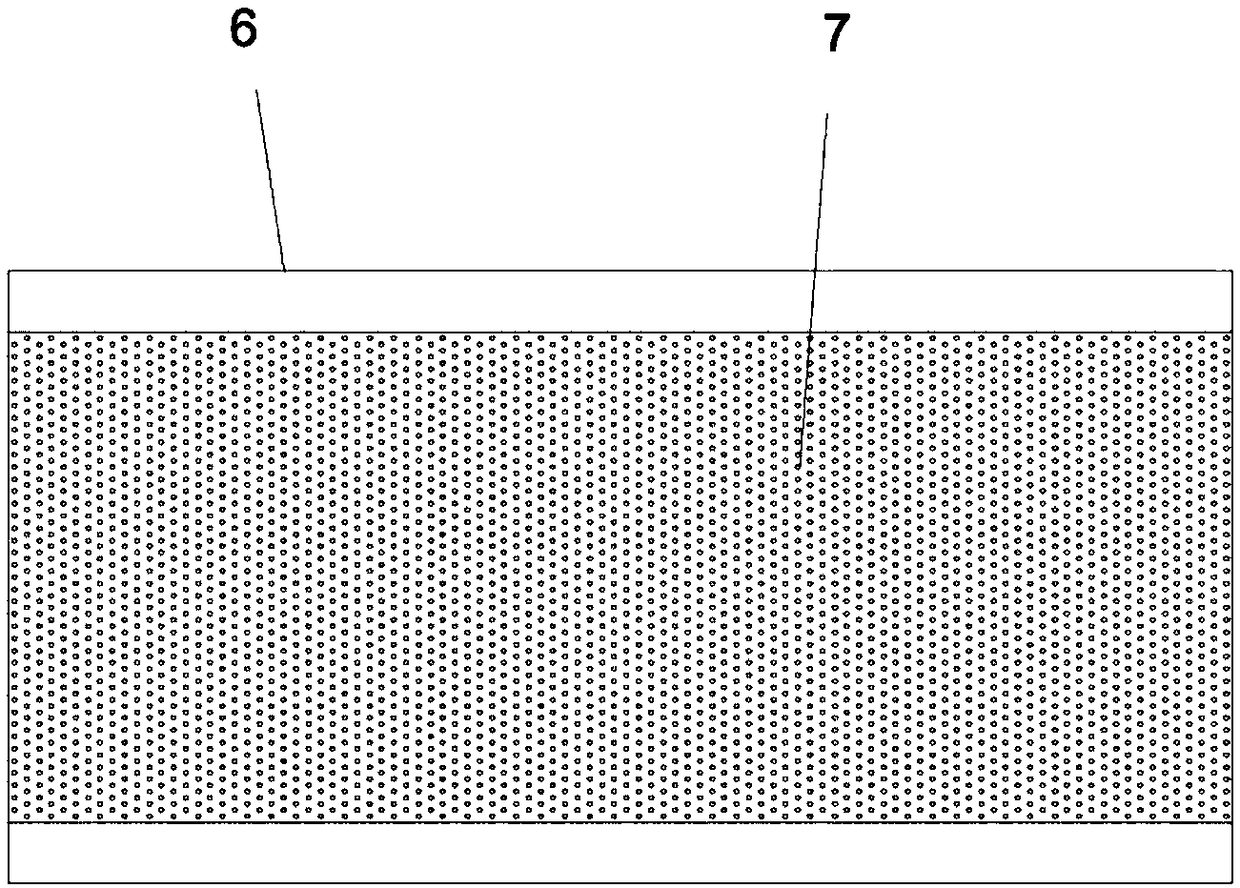

Perforated positive plate of lithium ion battery, and preparation method thereof

ActiveCN108400284AImproved magnification performanceImprove wettabilityElectrode collector coatingElectrical batteryEngineering

The invention discloses a perforated positive plate of a lithium ion battery. The perforated positive plate comprises a current collector coated with a lithium-iron oxide layer, and active substance layers arranged on upper and lower surfaces of the current collector, wherein uniform diffusion through holes are formed on the active substance layers and the current collector. The preparation methodcomprises the following steps: firstly coating a layer of Li5FeO4 on the aluminum foil surface to provide redundant lithium source for the battery, thereby retarding the lithium ion with the negativepole first effect to form irreversible SEI film consumption and enhancing long circulation performance; secondly, increasing the energy density of the battery by using the positive electrode with high compaction and high surface density; and finally forming a perforated pole plate, wherein the electrolyte can sufficiently enter the internal of the active substance to increase the infiltration ofthe electrolyte and retarding the expansion of the active substance, and the perforated positive plate can be applied in the battery industrialization in large scale. The conventional perforated aluminum foil is obtained by coating after perforating, and the perforated positive plate is obtained by perforating after coating, so that the surface density of the active substance is higher, and the energy density of the battery is 30% higher in relative to the conventional perforated pole plate.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

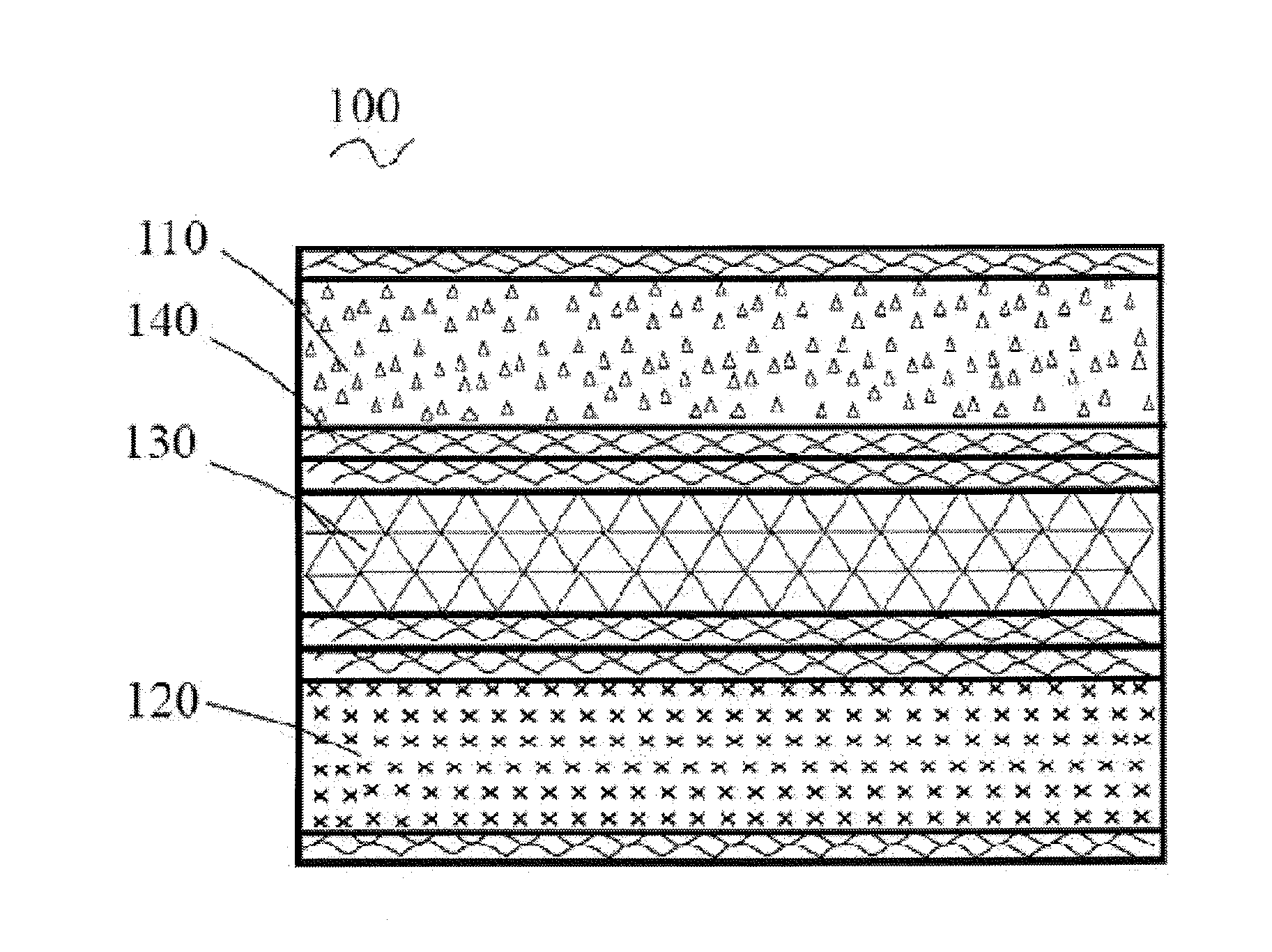

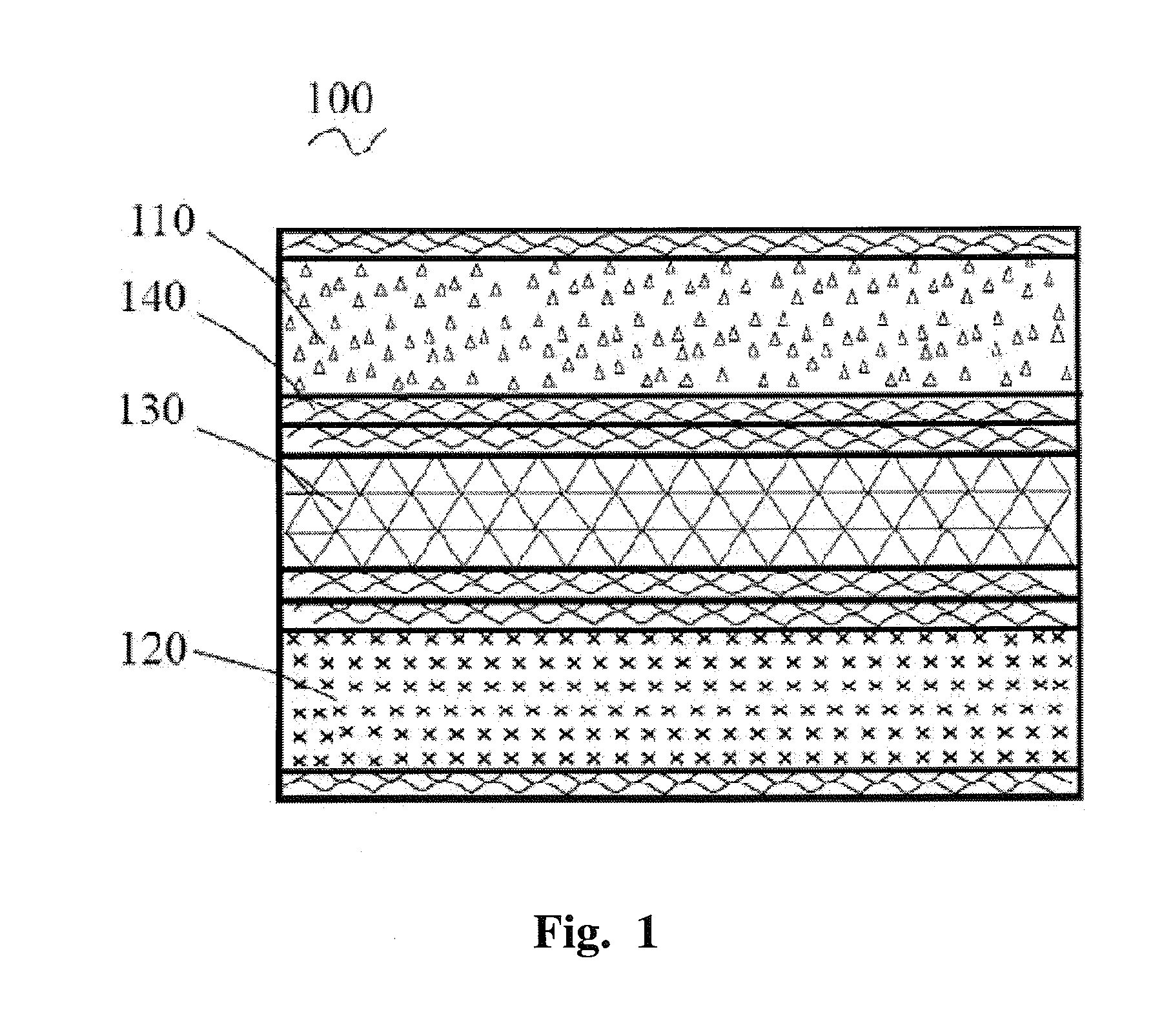

Lithium Ion Battery

InactiveUS20130252092A1Increase areal densityIncrease energy densityElectrode carriers/collectorsActive material electrodesConductive polymerLithium-ion battery

The present invention is related with a novel fabrication technique for a lithium ion battery, consisting of a cathode layer and an anode layer. The cathode and the anode layer are configured through a separator in between. The cathode or the anode layer comprises: a current collector with porous three-dimensional network construction; an electrode active material, filled in the pores and onto the both sides of the abovementioned current collector; and a layer of porous ionic conductive polymer layer, coated on the abovementioned current collector holding the electrode material. In the abovementioned lithium ion battery, the cathode or the anode layer comprises both the current collector and the electrode material. The current collector connects with the electrode material through its porous three-dimensional network and thus improves the active material utilization, capacity and energy density of the lithium ion battery.

Owner:LONG POWER SYST SUZHOU

Magnetic recording medium, magnetic recording apparatus using the same, and method and apparatus for manufacturing the magnetic recording medium

InactiveUS6894856B2Increase areal densityHigh resolutionRecord information storageDigital recordingImage resolutionMagnetization

A magnetic recording apparatus provides improved resolution and S / N without adversely affecting thermal stability. An angle formed by the direction of easy magnetization of a recording layer and the direction normal to a magnetic recording medium is in the range between 5° and 55°, the easy magnetization direction is from a back surface of the recording layer toward a front surface thereof, and when a recording track direction is from the upstream of the direction of transportation of the medium toward the downstream thereof, an angle formed by the direction of a projection of the easy magnetization direction on the medium plane and the recording track direction is in the range between 0° and 70°.

Owner:HITACHI GLOBAL STORAGE TECH JAPAN LTD

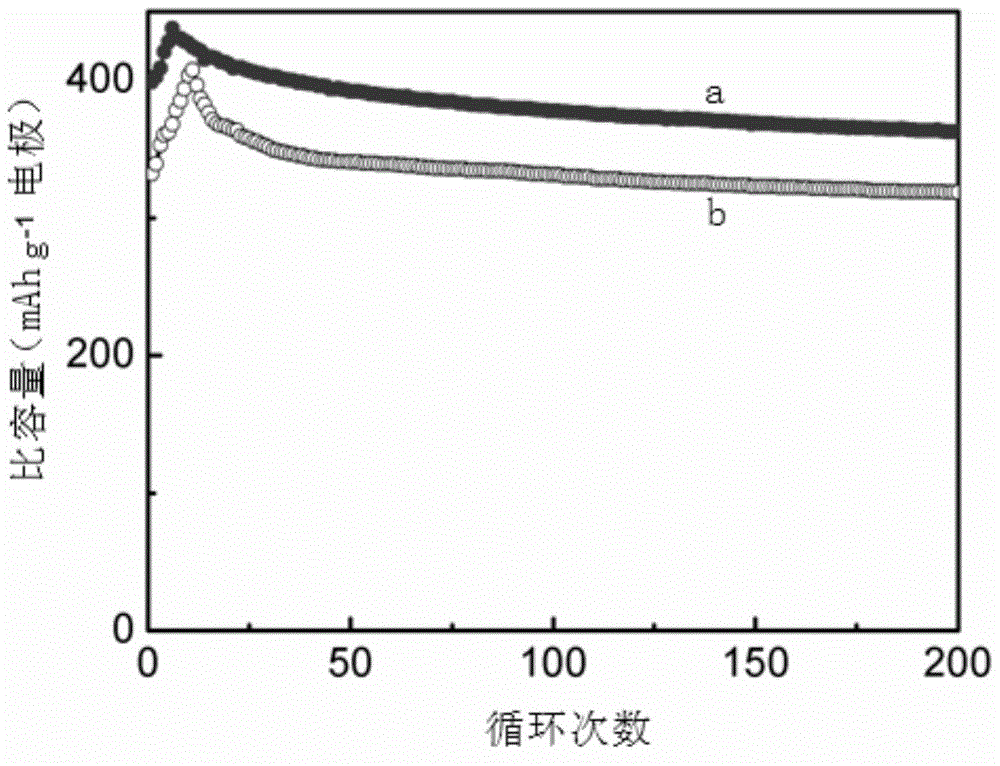

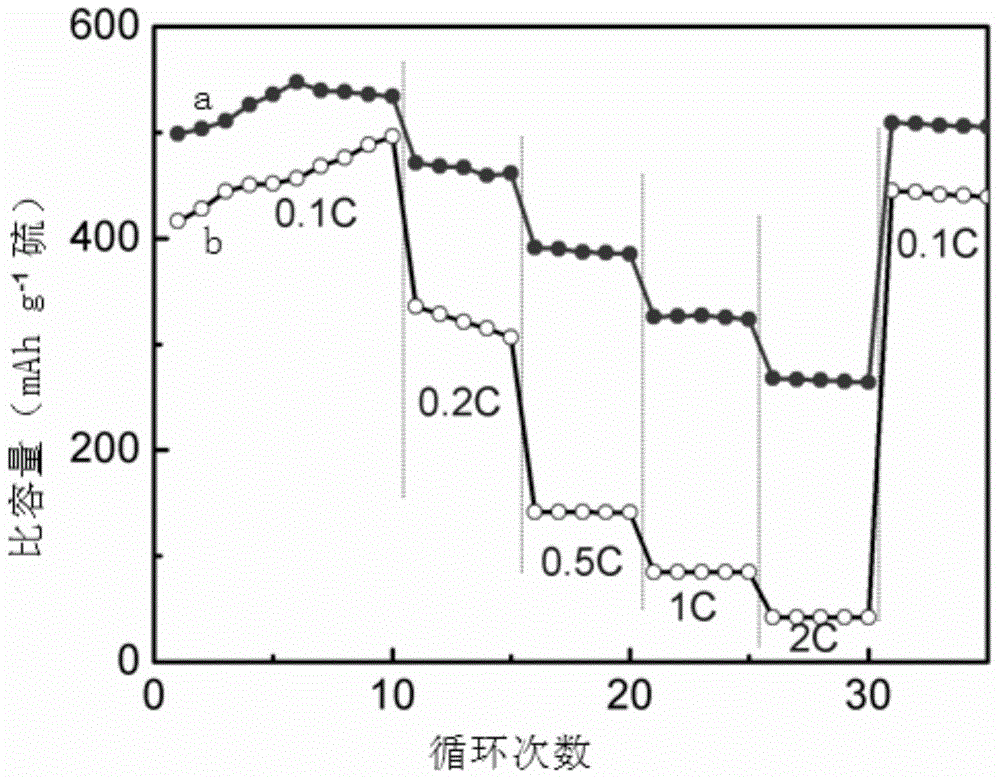

Lithium-sulfur battery carbon fiber reinforced three-dimensional graphene-sulfur positive electrode material, preparation method of material and preparation method of positive electrode

ActiveCN104617283AInhibition of agglomerationImprove conductivityElectrode manufacturing processesFiberCarbon fibers

The invention discloses a lithium-sulfur battery carbon fiber reinforced three-dimensional graphene-sulfur positive electrode material, a preparation method of the positive electrode material and a preparation method of the positive electrode, relates to a lithium-sulfur battery positive electrode material, a preparation method of the positive electrode material and a preparation method of the positive electrode, and can be used for solving the technical problem that the conventional graphene-sulfur electrode is low in area specific capacity and bad in rate capability. The positive electrode material is formed by dispersing elemental sulfur in holes of carbon fiber modified spongy graphene. The preparation method of the positive electrode material comprises the following steps: adding carbon fibers into mixed liquid of graphene oxide dispersion liquid, carrying out hydro-thermal synthesis to obtain hydrogel and carrying out freeze-drying to obtain carbon fiber modified three-dimensional spongy graphene; cutting the carbon fiber modified three-dimensional spongy graphene into slices, sprinkling the elemental sulfur on the surfaces of the slices, placing the slices in a vacuum tank and heating to obtain the lithium-sulfur battery carbon fiber reinforced three-dimensional graphene-sulfur positive electrode material. The positive electrode is prepared by slicing the positive electrode material and then pressing. The area specific capacity of the electrode material is up to 10 mAh / cm<2>, so that the electrode material can be applied to lithium ion batteries.

Owner:HARBIN INST OF TECH

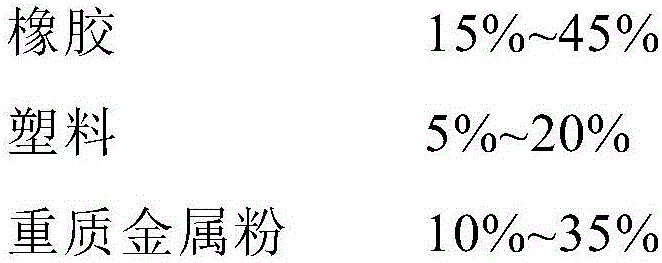

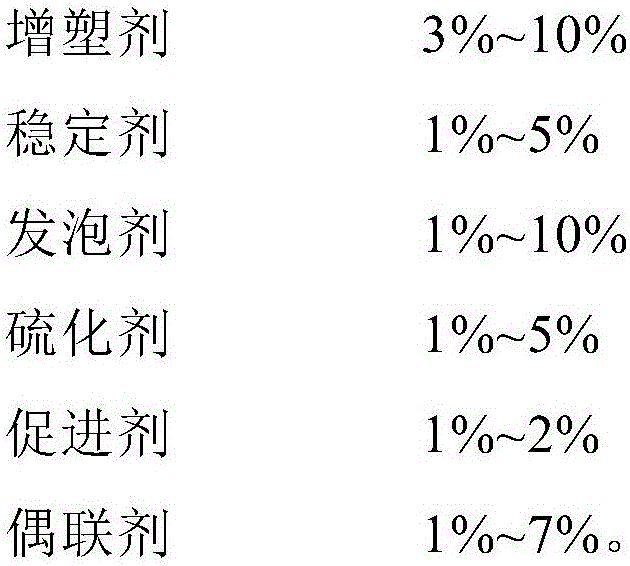

Soft high-specific-gravity rubber-plastic foam material for insulating sound and reducing noise

A related soft high-specific-gravity rubber-plastic foam material for insulating sound and reducing noise consists of the following components in percent by weight: 15%-45% of rubber, 5%-20% of plastic, 10%-30% of a heavy metal powder, 3%-10% of a plasticizer, 1%-5% of a stabilizer, 1%-10% of a foaming agent, 1%-5% of a sulfurizing agent, 1%-2% of an accelerator and 1%-7% of a coupling agent. Compared with the prior art, the soft high-specific-gravity rubber-plastic foam material possesses good elasticity of rubber and good glutinousness of plastic, also possesses relatively high surface density demanded by sound-proof mass action law and additional action of "foam damping", avoids the sound-proof low ebb of a conventional sound-proof material under the effect of resonant frequency and a coincident effect, and is extremely suitable for quality improvement of all kinds of sound environments and noise-controlling places.

Owner:SHANGHAI JIAO TONG UNIV

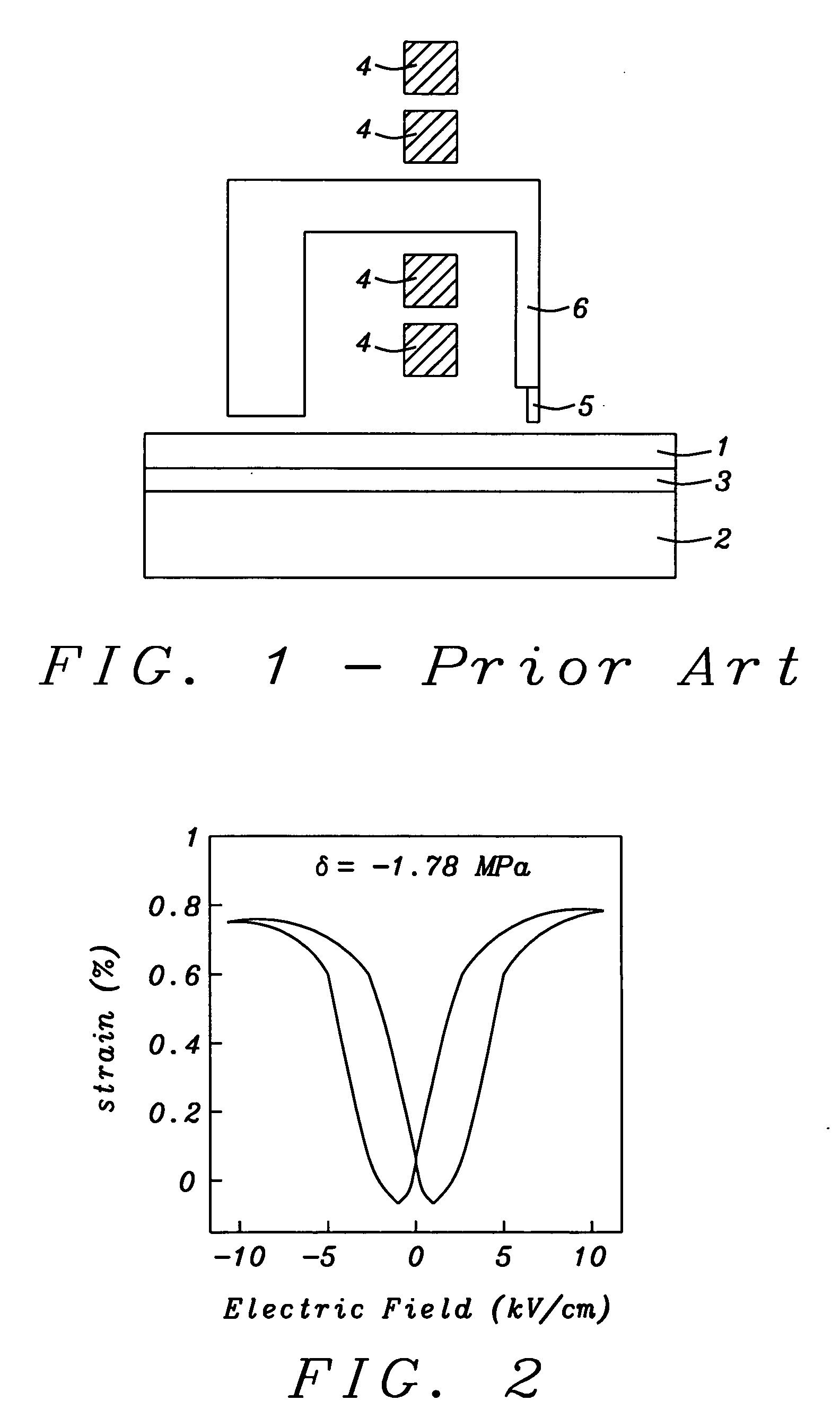

Electric field assisted magnetic recording

InactiveUS20100128377A1Decrease magnetic fieldCoercivity magnetic layerDriving/moving recording headsRecord information storageMagnetic mediaPre stressing

We describe a system for electric field assisted magnetic recording where a recordable magnetic medium includes a magnetic recording layer of high coercivity and vertical magnetic anisotropy that is adjacent to an electrostrictive layer which can be placed in a state of stress by a electric field or which is already pre-stressed and which pre-stress can be turned into strain by an electric field. When the magnetic medium is acted on simultaneously by a magnetic writing field and an electric field, the stress in the elctrostrictive layer is transferred to a magnetostrictive layer which is the magnetic recording layer by itself or is coupled to the magnetic recording layer, whereupon the magnetic recording layer is made more isotropic and more easily written upon. Residual stresses in the electrostrictive layer can then be removed by an additional electric field of opposite sign to the stress-producing field.

Owner:HEADWAY TECH INC

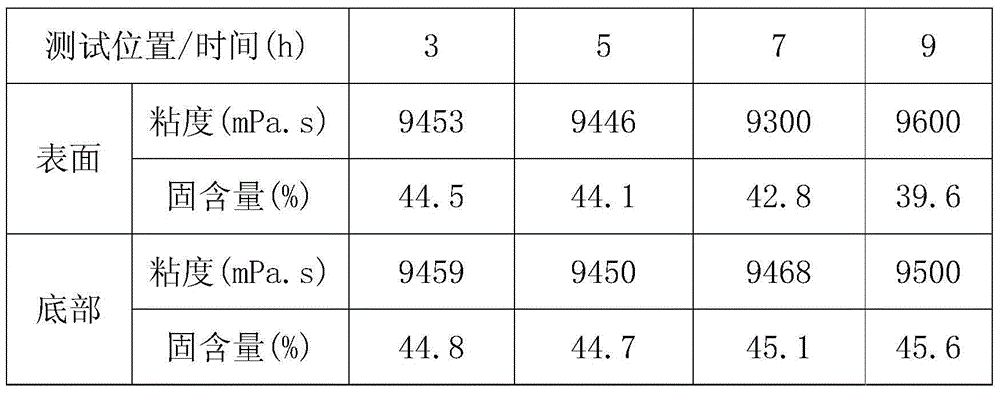

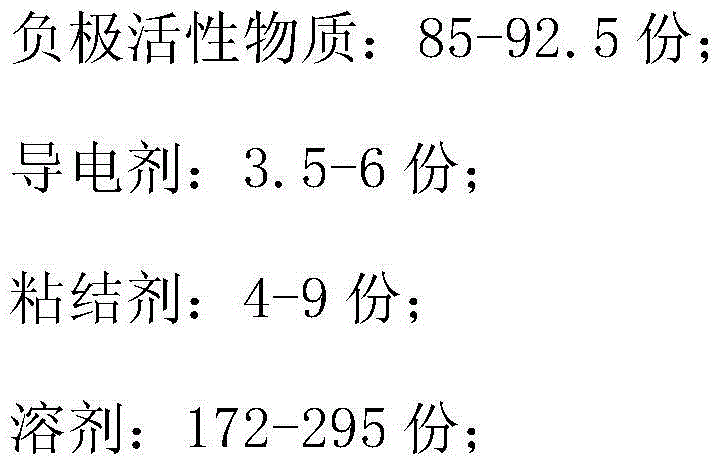

Lithium-ion-battery negative electrode slurry, preparing method thereof and preparing method of negative electrode plate

The invention provides lithium-ion-battery negative electrode slurry, a preparing method thereof and a preparing method of a negative electrode plate. The lithium-ion-battery negative electrode slurry is prepared from, by weight, 85 parts to 92.5 parts of negative-electrode active substances, 3.5 parts to 6 parts of conductive agents, 4 parts to 9 parts of binding agents and 172 parts to 295 parts of solvents. The negative-electrode active substances are prepared from, by weight, 82.5 parts to 92.2 parts of lithium-titanium composite oxide and 0.26 part to 2.78 parts of acidic compound additives. By means of the lithium-ion-battery negative electrode slurry, the surface performance of material particles is improved, the reaction activation energy and the particle granularity of electrode materials are reduced, and the distribution evenness of particles in the slurry is improved; by means of the preparing method of the negative electrode slurry and the preparing method of the negative electrode plate, the prepared negative electrode slurry is good in dispersity and stability; the prepared negative electrode plate is good in softness and processing performance, the surface density and the adhesive force of the coated negative-electrode active materials are increased, and electrochemical performances such as the battery capacity use ratio and cycling performance are effectively improved.

Owner:HENAN KELONG NEW ENERGY CO LTD

Barium sulfate reinforced polypropylene sound insulation composite material

The invention relates to a barium sulfate reinforced polypropylene sound insulation composite material which comprises, by weight, 15-40% of polypropylene, 30-60% of barium sulfate with grain size as 1-100 micrometers, 25-40% of talcum powder with the grain size as 1-100 micrometers, 0.5-2% of coupling reagent, 0.1-1% of lubricant and 0.1-0.3 of stabilizer. The barium sulfate reinforced polypropylene sound insulation composite material is made of polypropylene (PP), barium sulfate, talcum powder, coupling reagent, lubricant and stabilizer and has the advantages of being good in sound insulation effect, non-toxic, lead-free, high in strength, good in processability and low in cost. Barium sulfate is led into material components, surface density of the material is obviously increased, and the barium sulfate reinforced polypropylene sound insulation composite material can be widely used for sound insulation processing in the field of building industry, decorating and the like and can effectively insulate sound and reduce noise.

Owner:HONGSHENG PLASTICS HANGZHOU

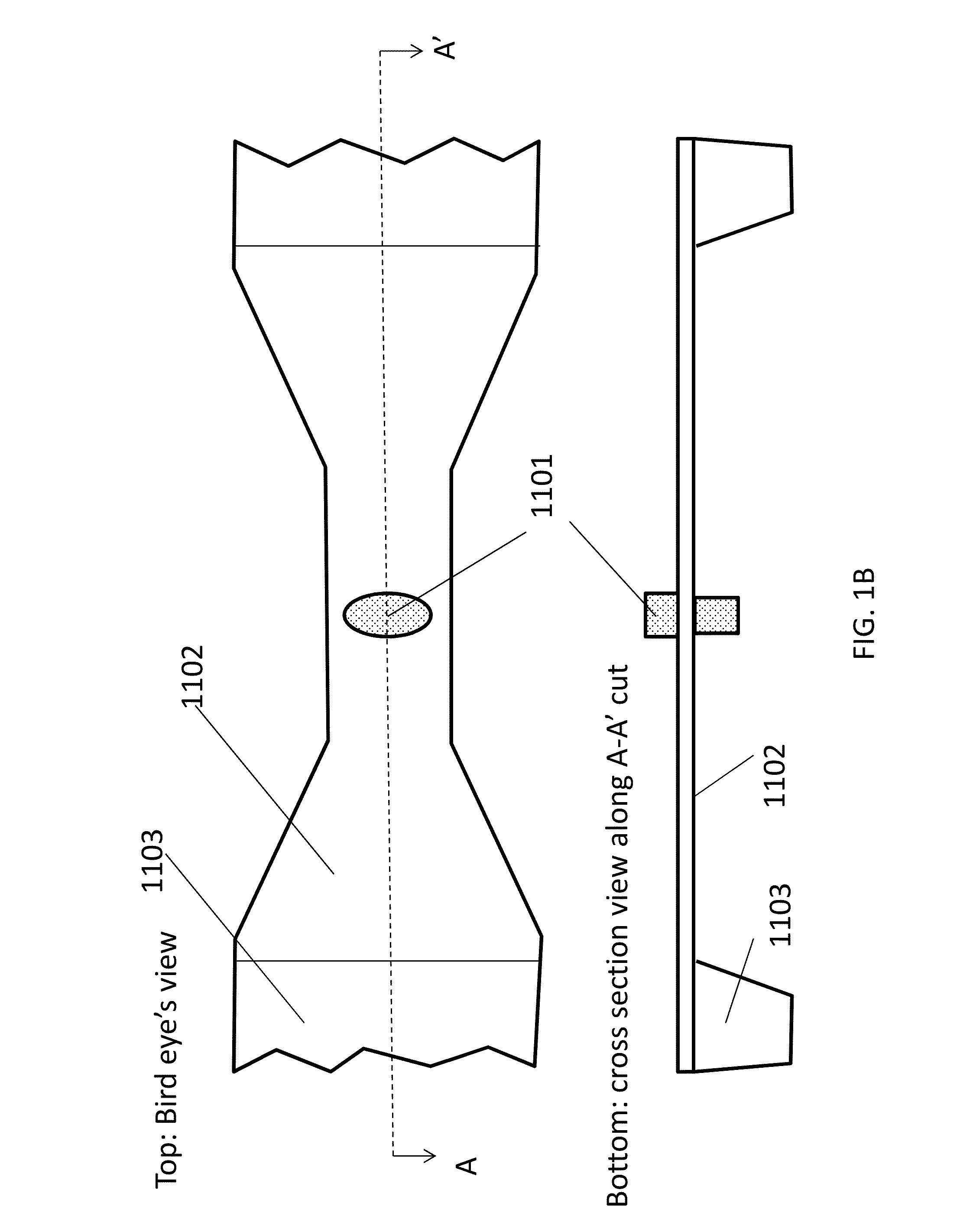

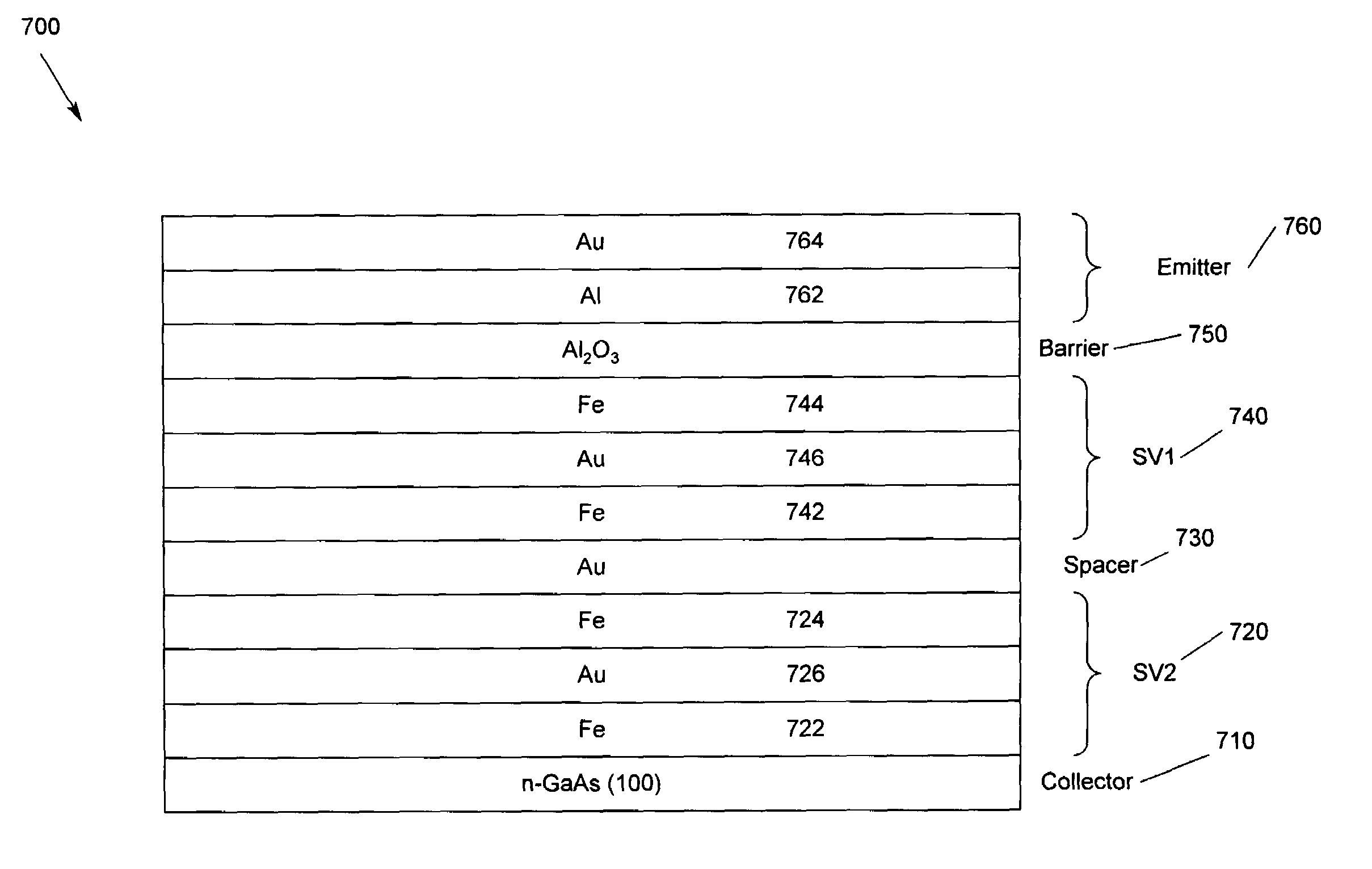

Spin valve transistor with differential detection and method of making

InactiveUS6999285B2High sensitivityDistanceNanoinformaticsRecord information storageSpinsEngineering

A method and apparatus for providing a spin valve transistor with differential detection is disclosed. The present invention provides a structure including spin valves that are (100)-oriented on a (100) substrate to take advantages of the high MR sensitivity of spin valve transistor read heads without the need for shields. This allows the distance between the free layers in the differential sensor to be minimized thereby allowing an increase in the areal density.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com