Patents

Literature

3357 results about "Pre stressing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

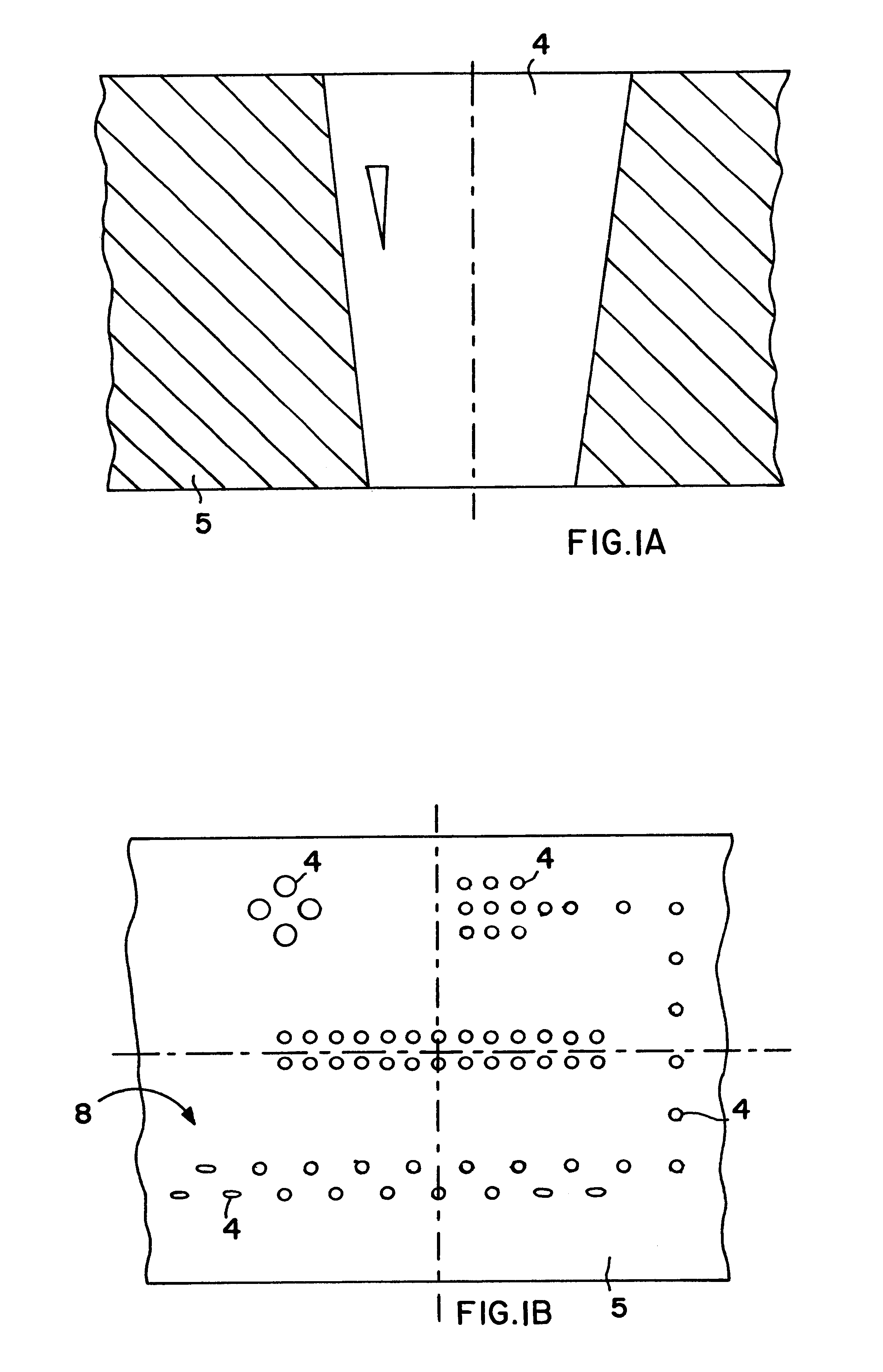

PRE – TENSIONING. A method of prestressing concrete in which the tendons are tensioned before concreting. Pre-tensioning is done by stressing a wire, strand or bar, PRIOR to concreting.

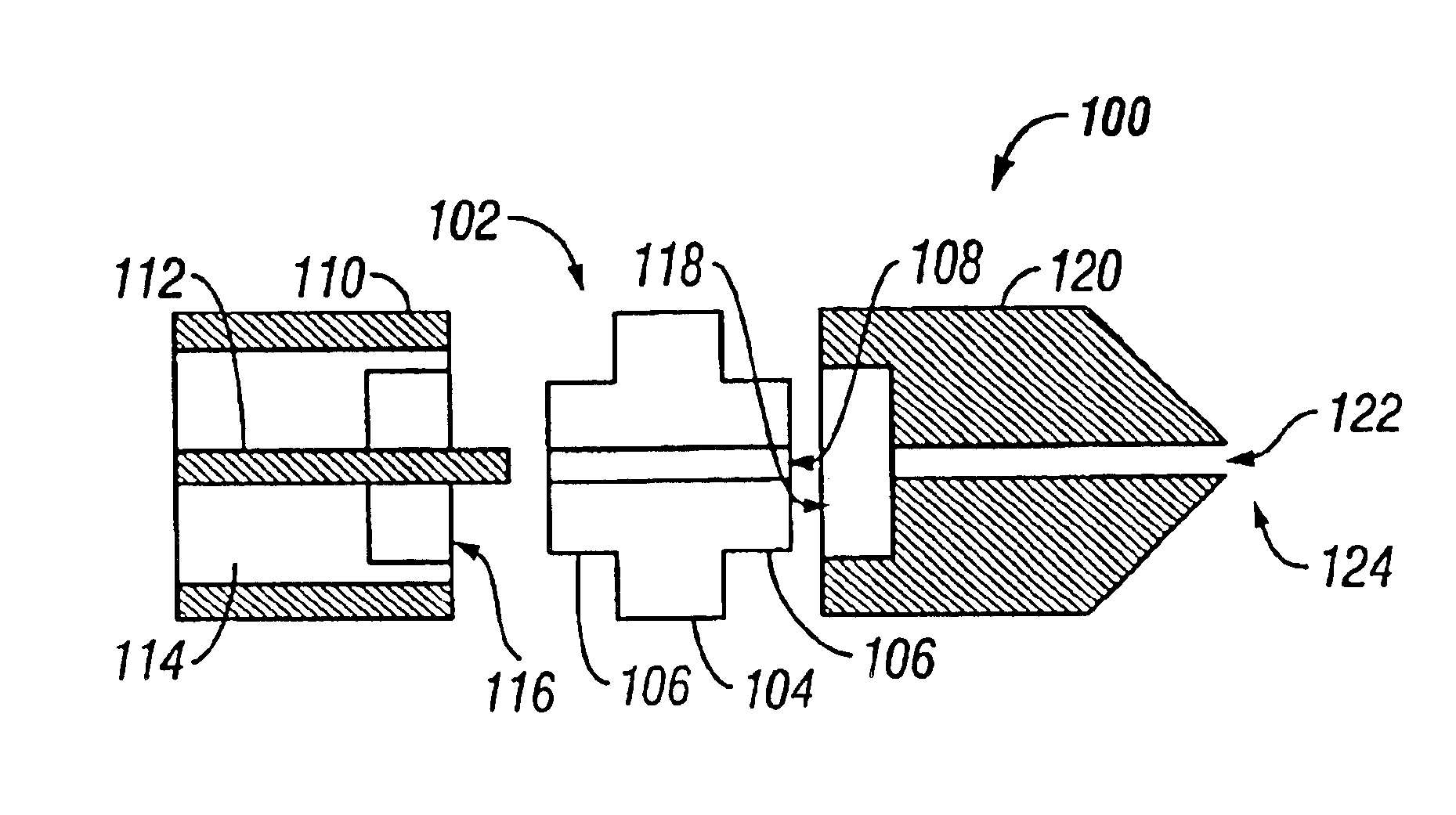

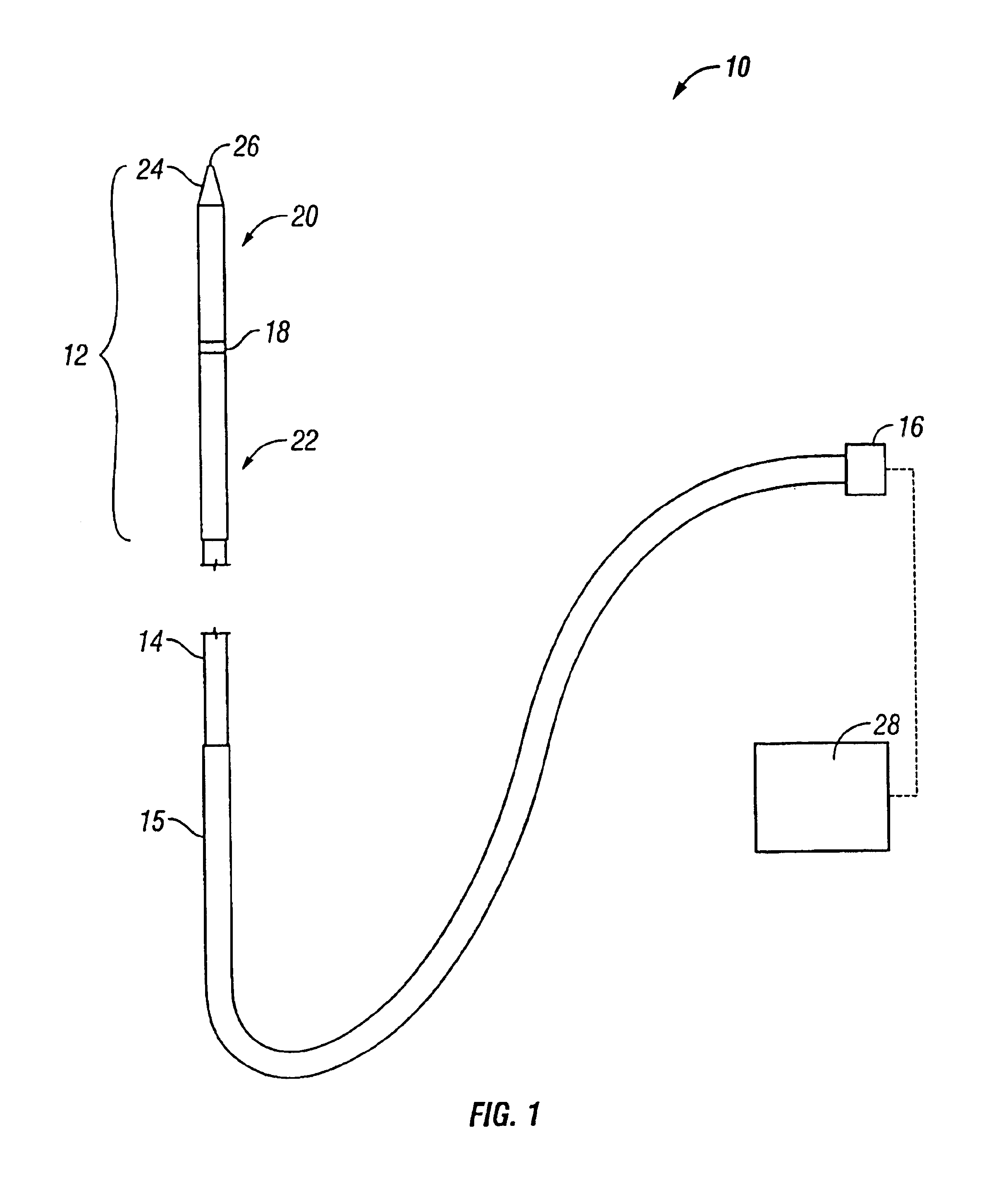

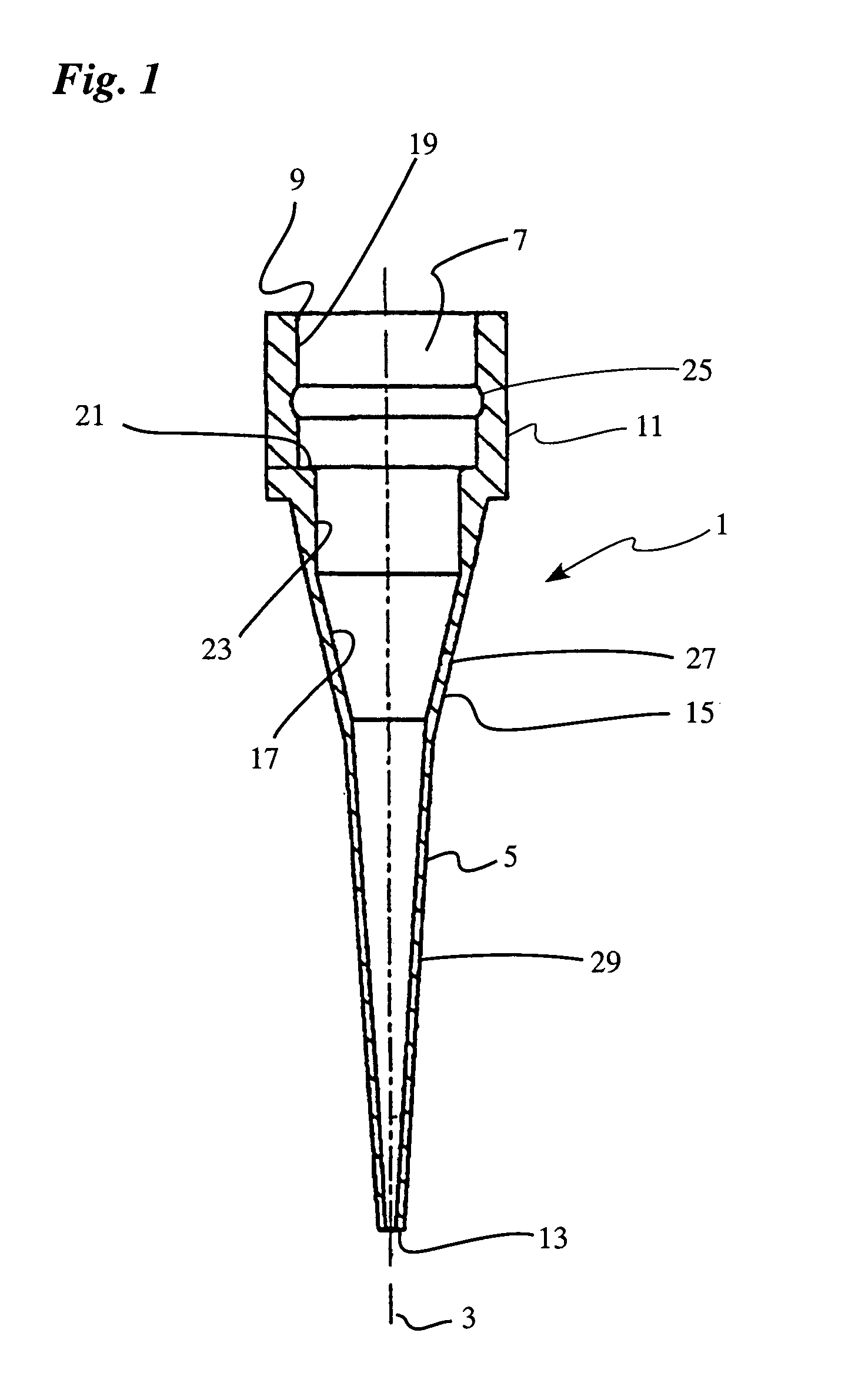

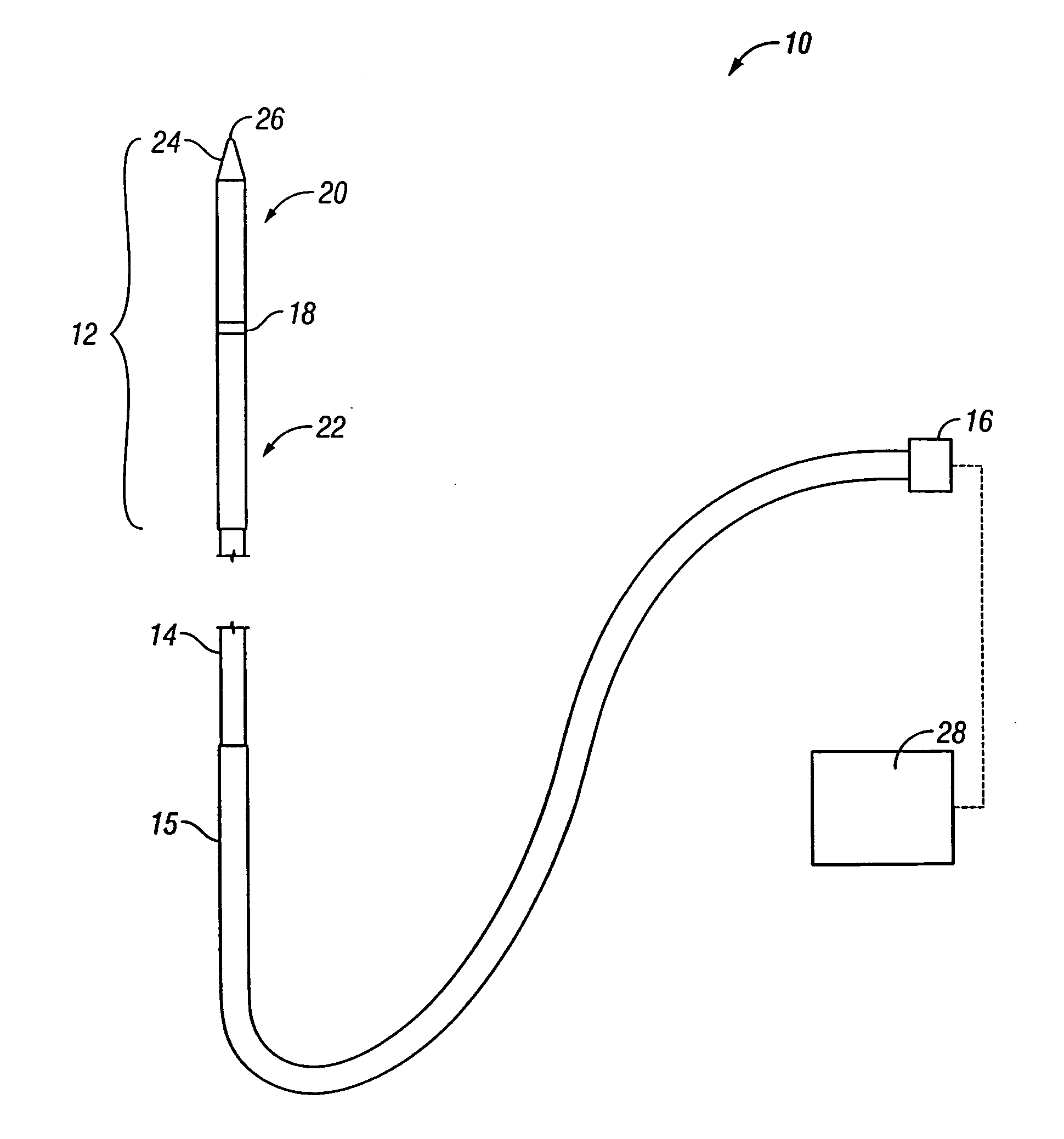

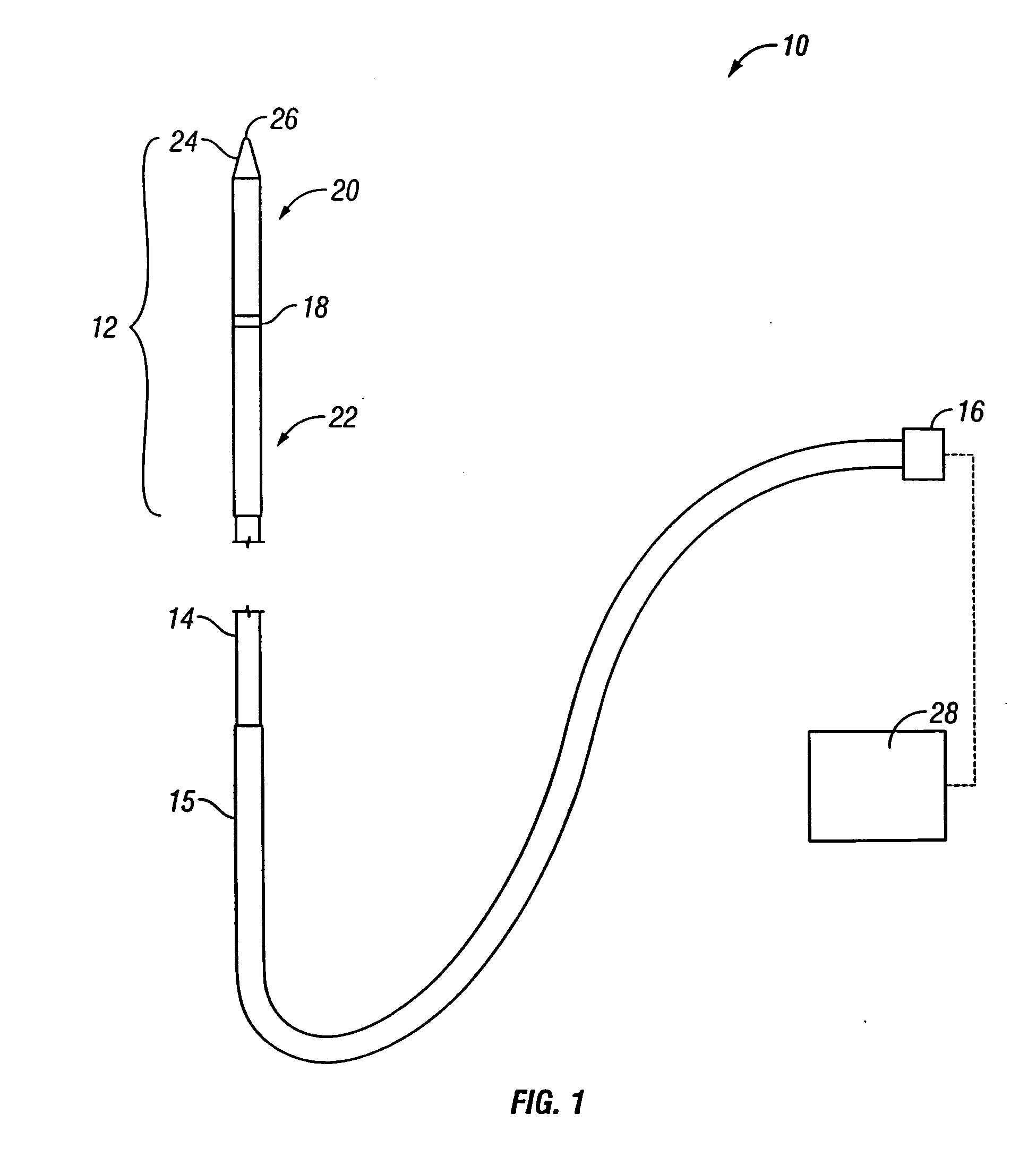

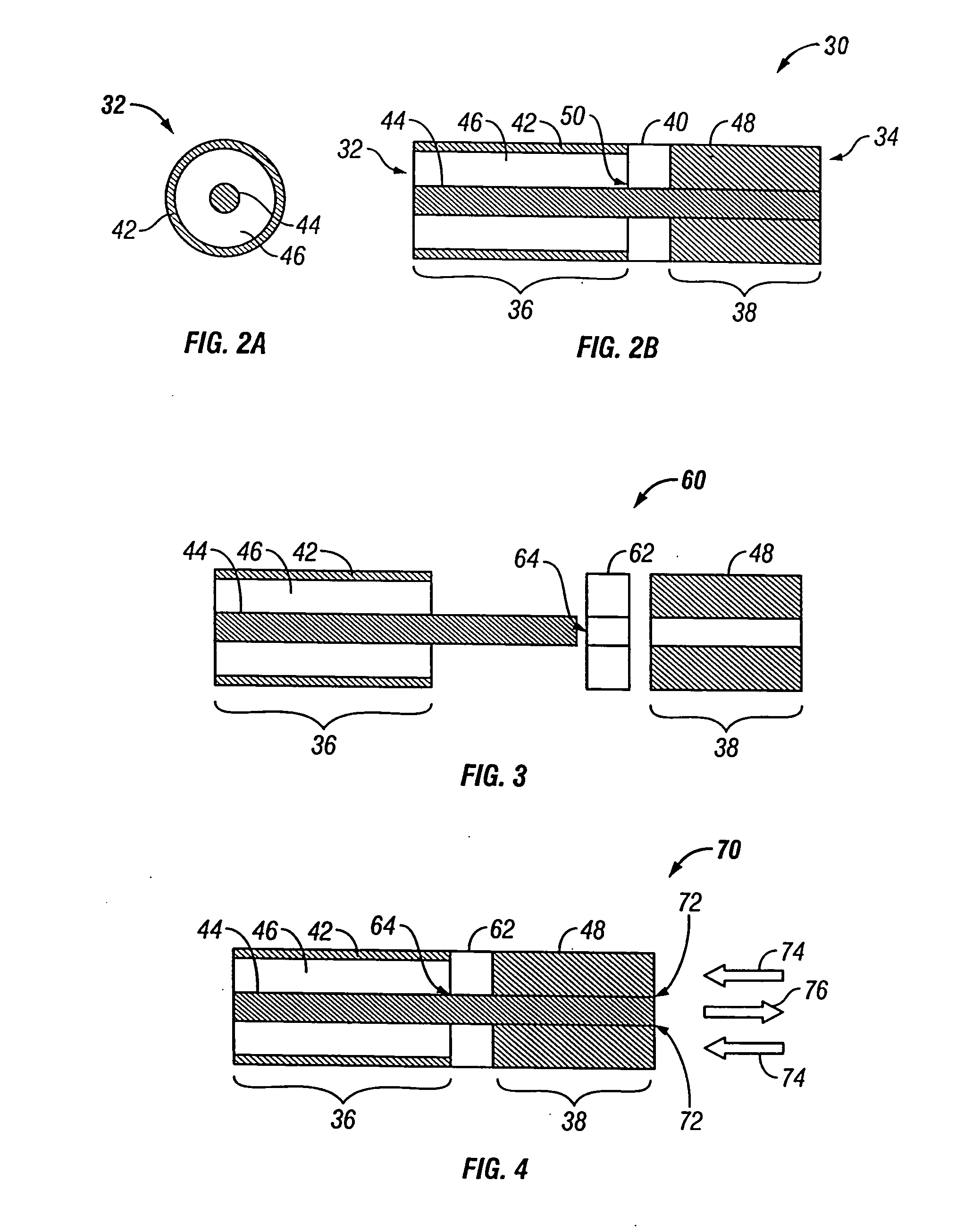

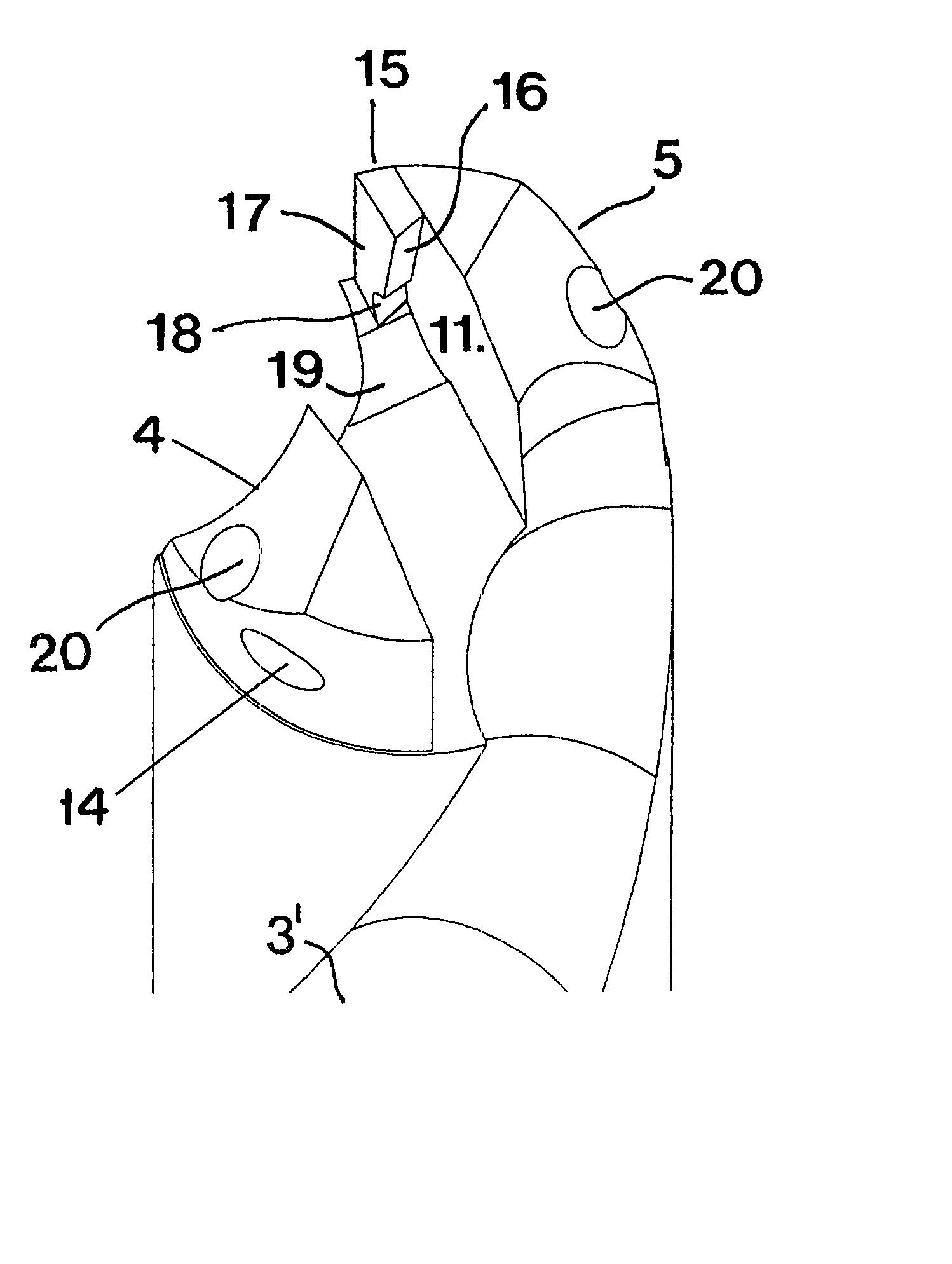

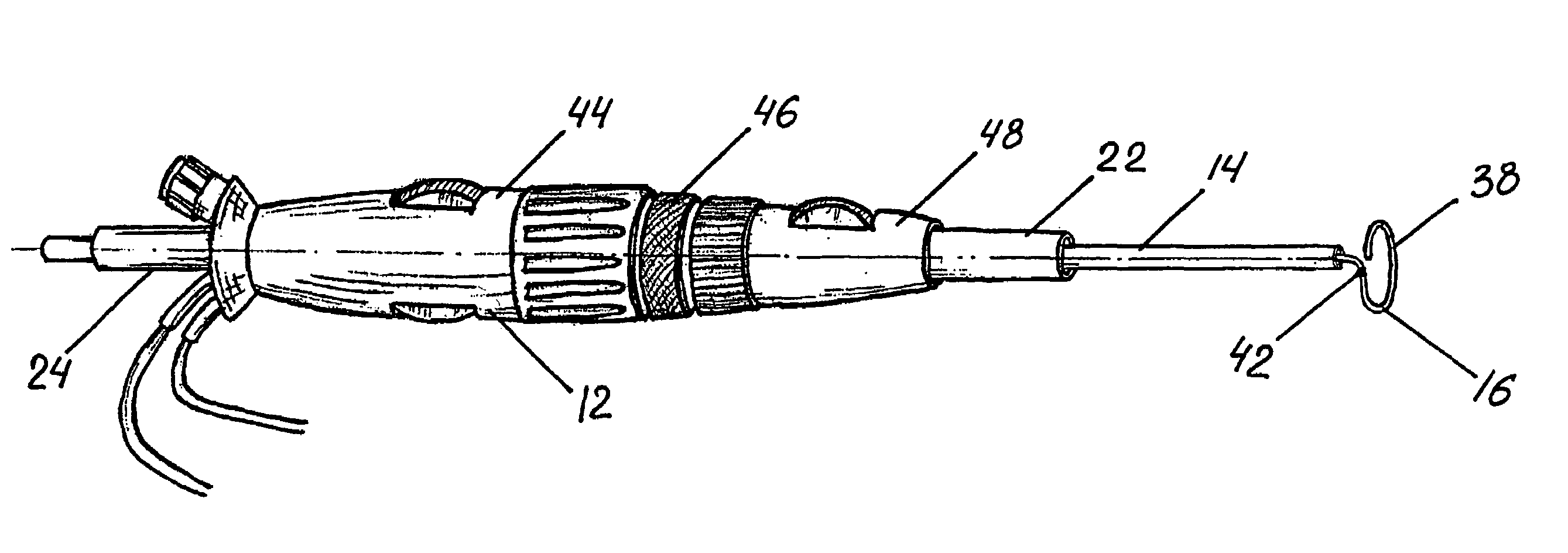

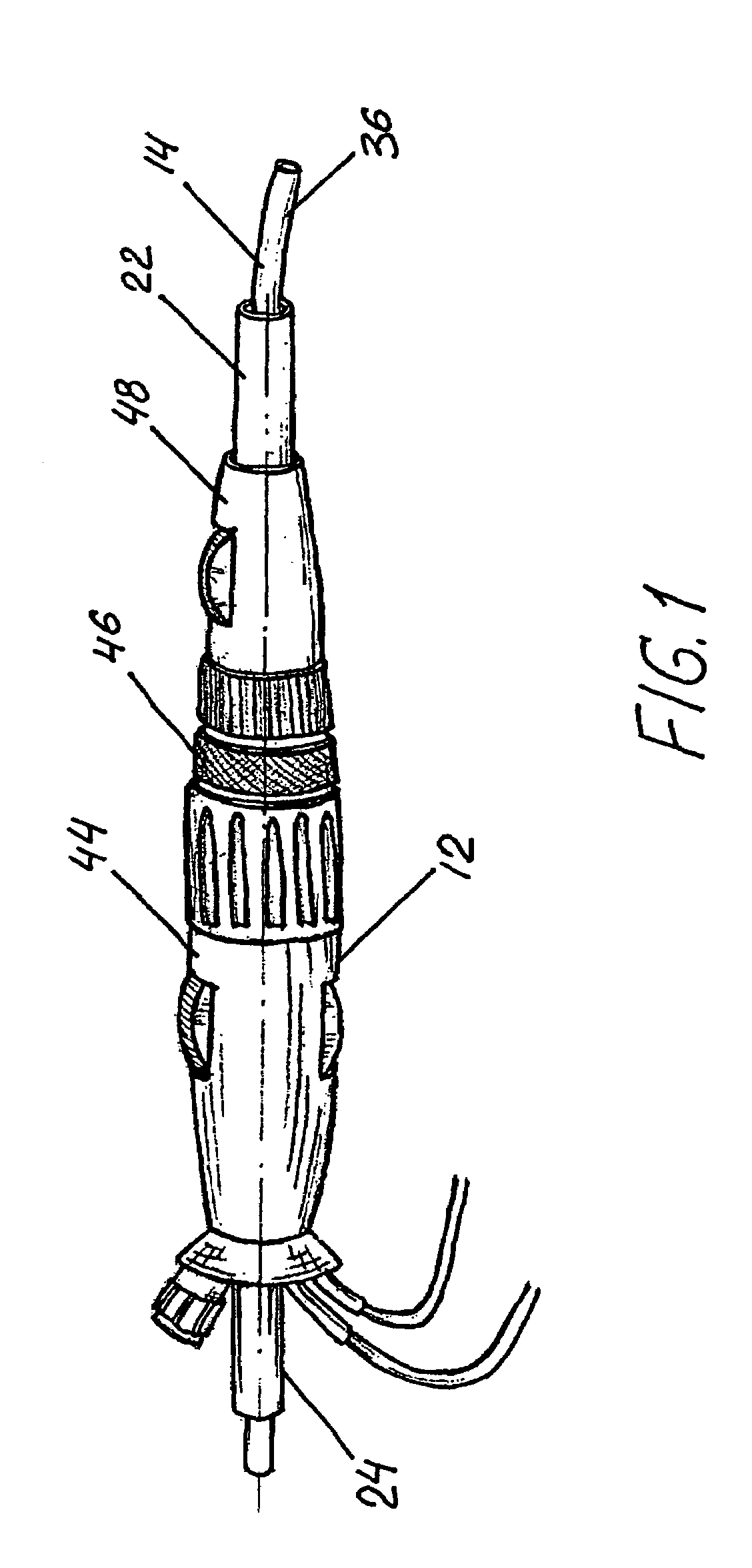

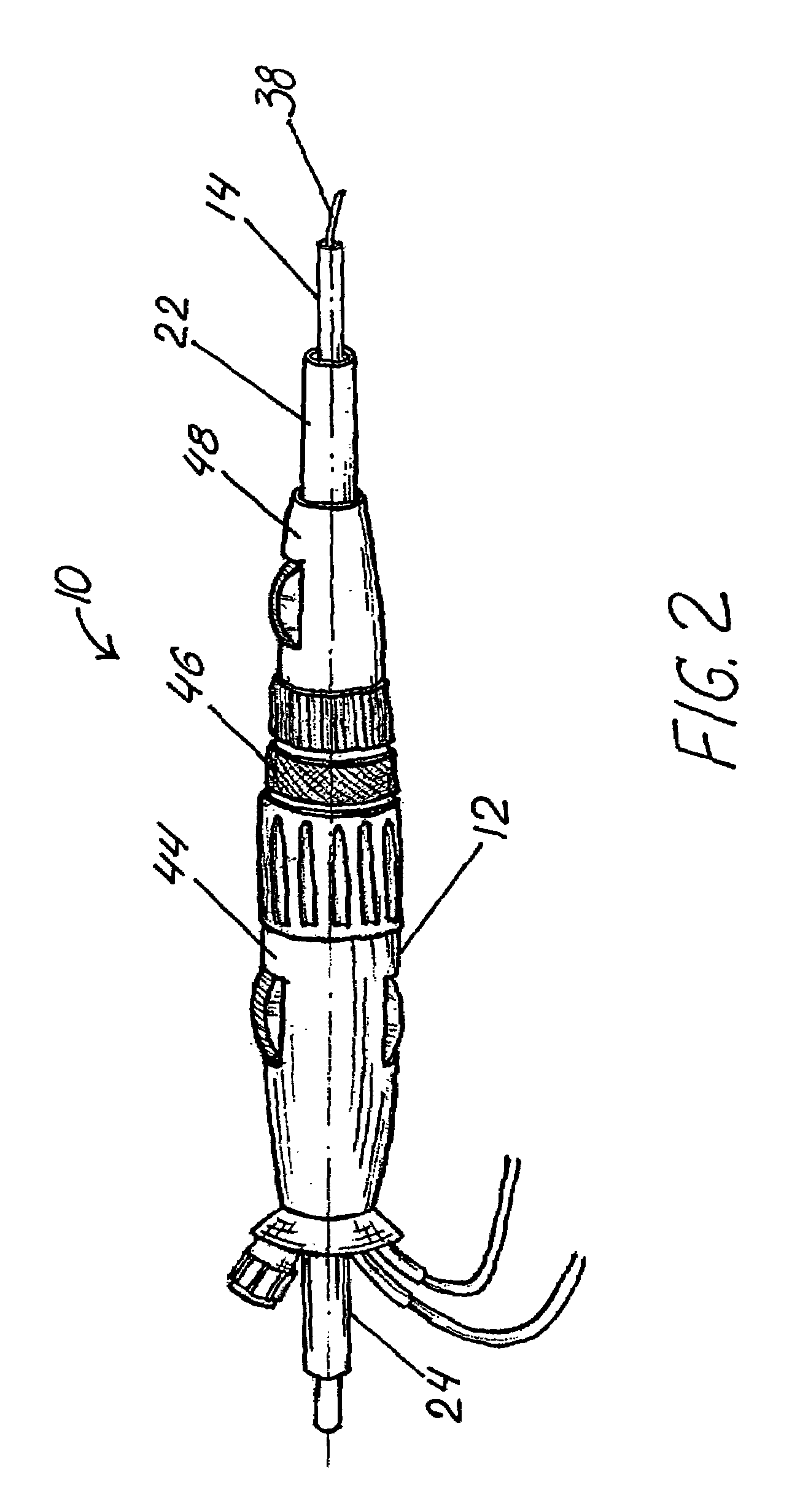

High-strength microwave antenna assemblies

InactiveUS6878147B2Avoid mechanical failureSurgical needlesSurgical instruments for heatingAntenna designElectrical conductor

Various high-strength microwave antenna assemblies are described herein. The microwave antenna has a radiating portion connected by a feedline to a power generating source, e.g., a generator. The antenna is a dipole antenna with the distal end of the radiating portion being tapered and terminating at a tip to allow for direct insertion into tissue. Antenna rigidity comes from placing distal and proximal radiating portions in a pre-stressed state, assembling them via threaded or overlapping joints, or fixedly attaching an inner conductor to the distal portion. The inner conductor is affixed to the distal portion by, e.g., welding, brazing, soldering, or by adhesives. A junction member made from a hard dielectric material, e.g., ceramic, can be placed between the two portions and can have uniform or non-uniform shapes to accommodate varying antenna designs. Electrical chokes may also be used to contain returning currents to the distal end of the antenna.

Owner:COVIDIEN LP

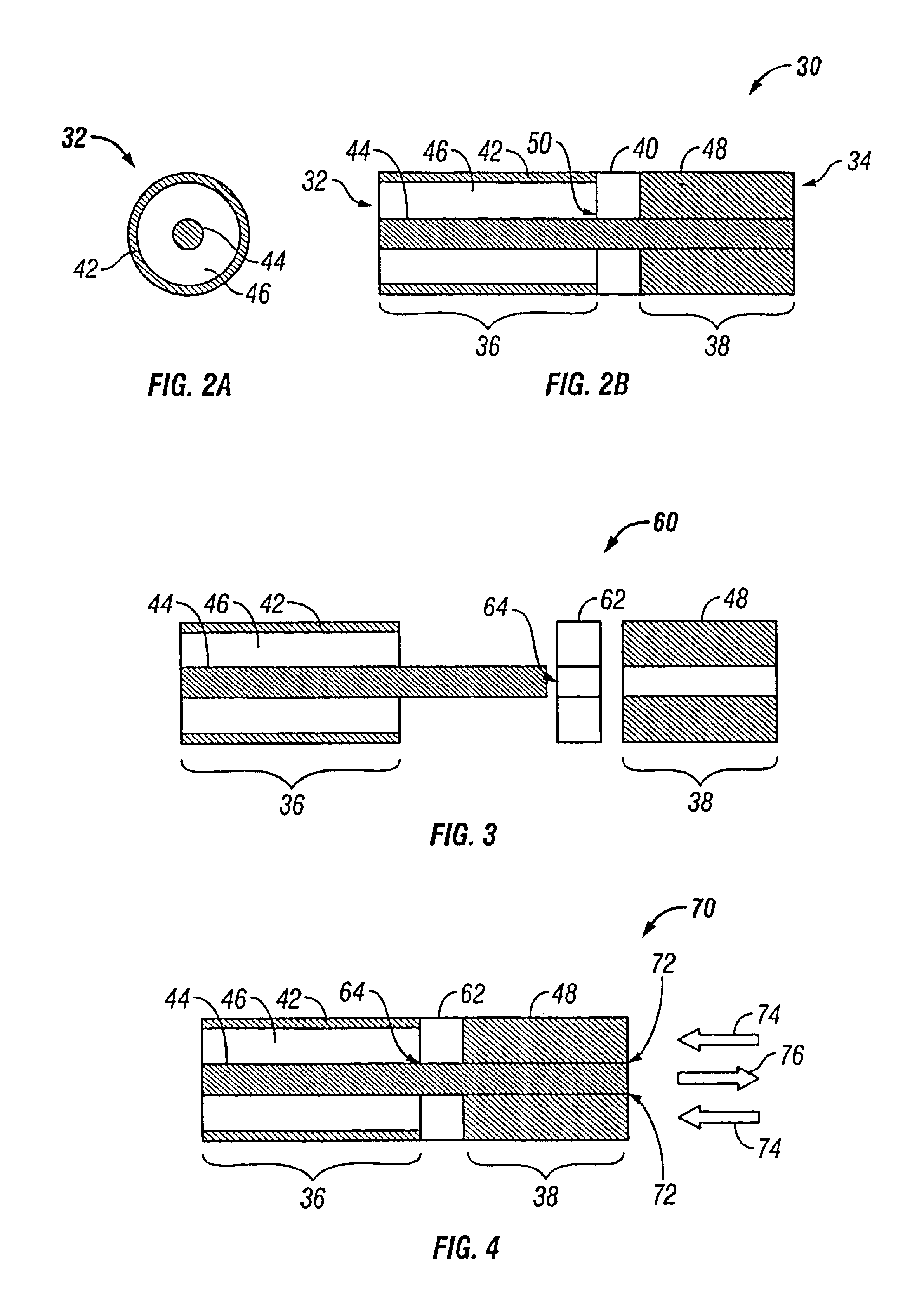

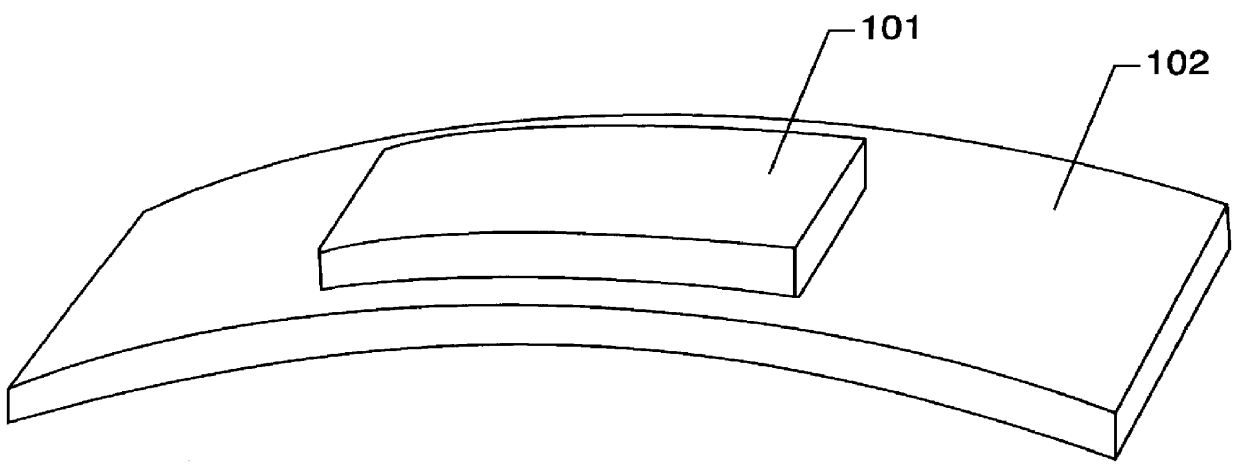

Advanced layered composite polylaminate electroactive actuator and sensor

InactiveUS6060811AImprove efficiencyCancel noisePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesPre stressPre stressing

The present invention relates to the mounting of pre-stressed electroactive material in such a manner that large displacement actuators or sensors result. The invention comprises mounting the pre-stressed electroactive material to a support layer. This combination of a pre-stressed electroactive material and support layer may in turn be attached to a mounting surface. The pre-stressed electroactive material may be a ferroelectric, pyroelectric, piezoelectric, or magnetostrictive material. The size, stiffness, mass, and material of the support layer is selected to result in the electroactive device having dynamic response properties, environmental capability characteristics, and the required resilience optimized for a given application. The capacity to connect the support layer to a surface expands the arenas in which the pre-stressed electroactive device may be used. Application for which the invention may be used include actuators, sensors, or as a component in a pumps, switches, relays, pressure transducers and acoustic devices.

Owner:NASA

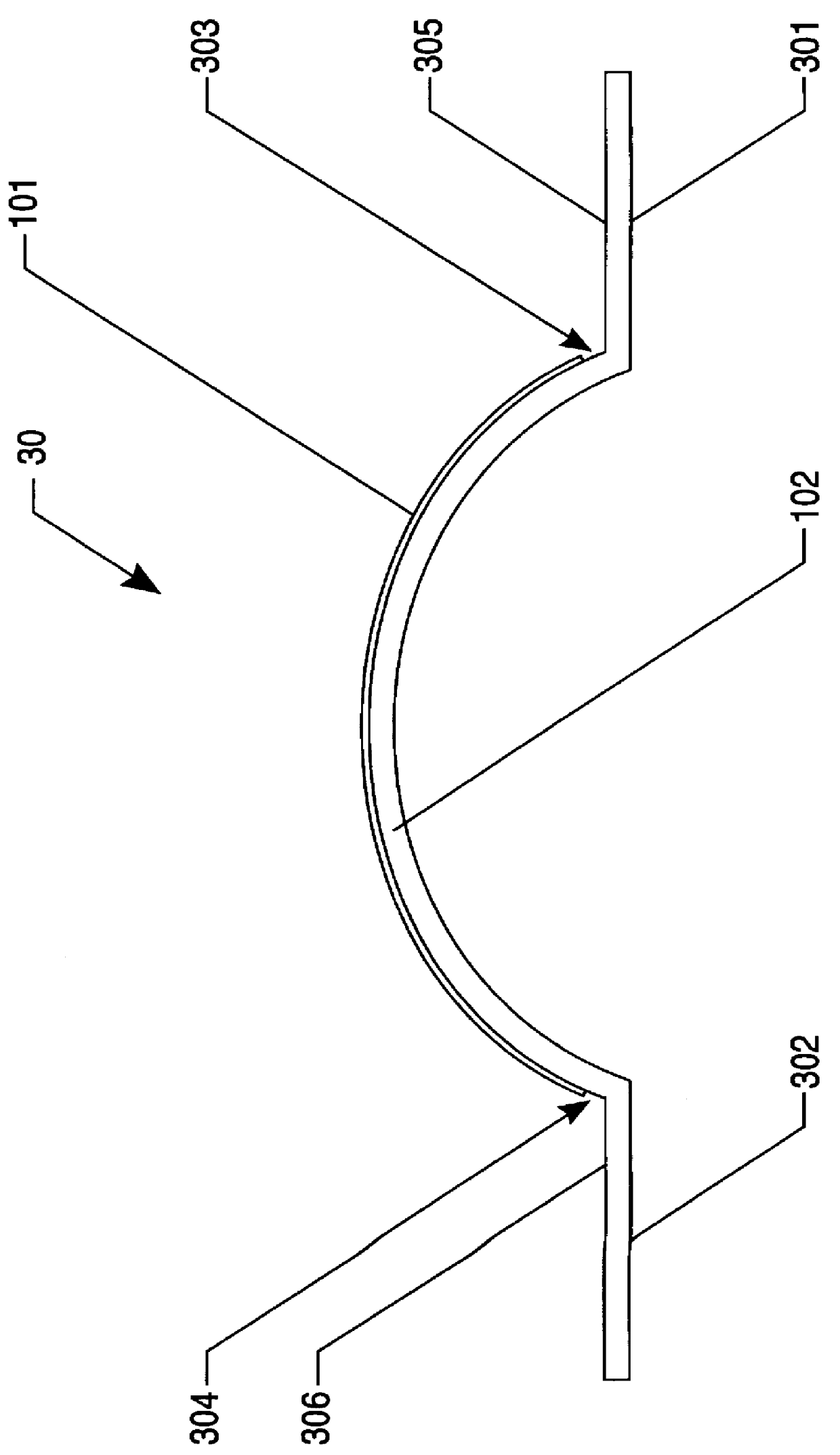

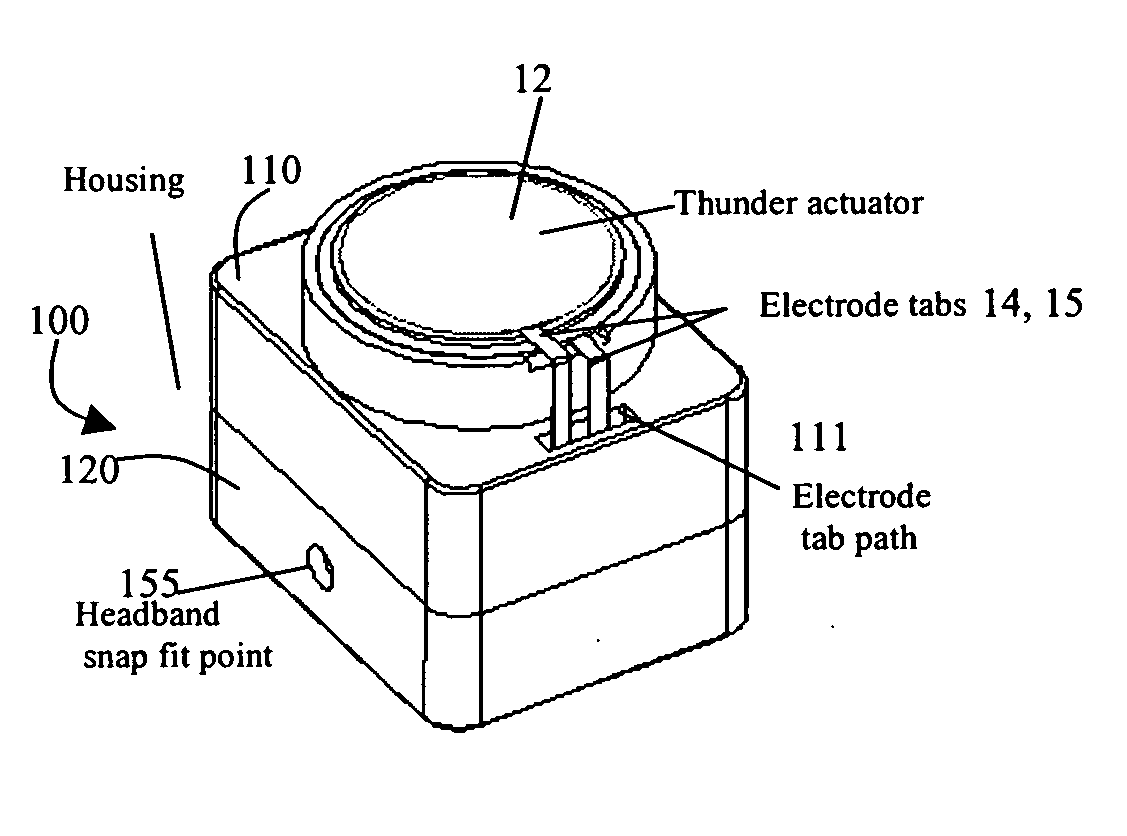

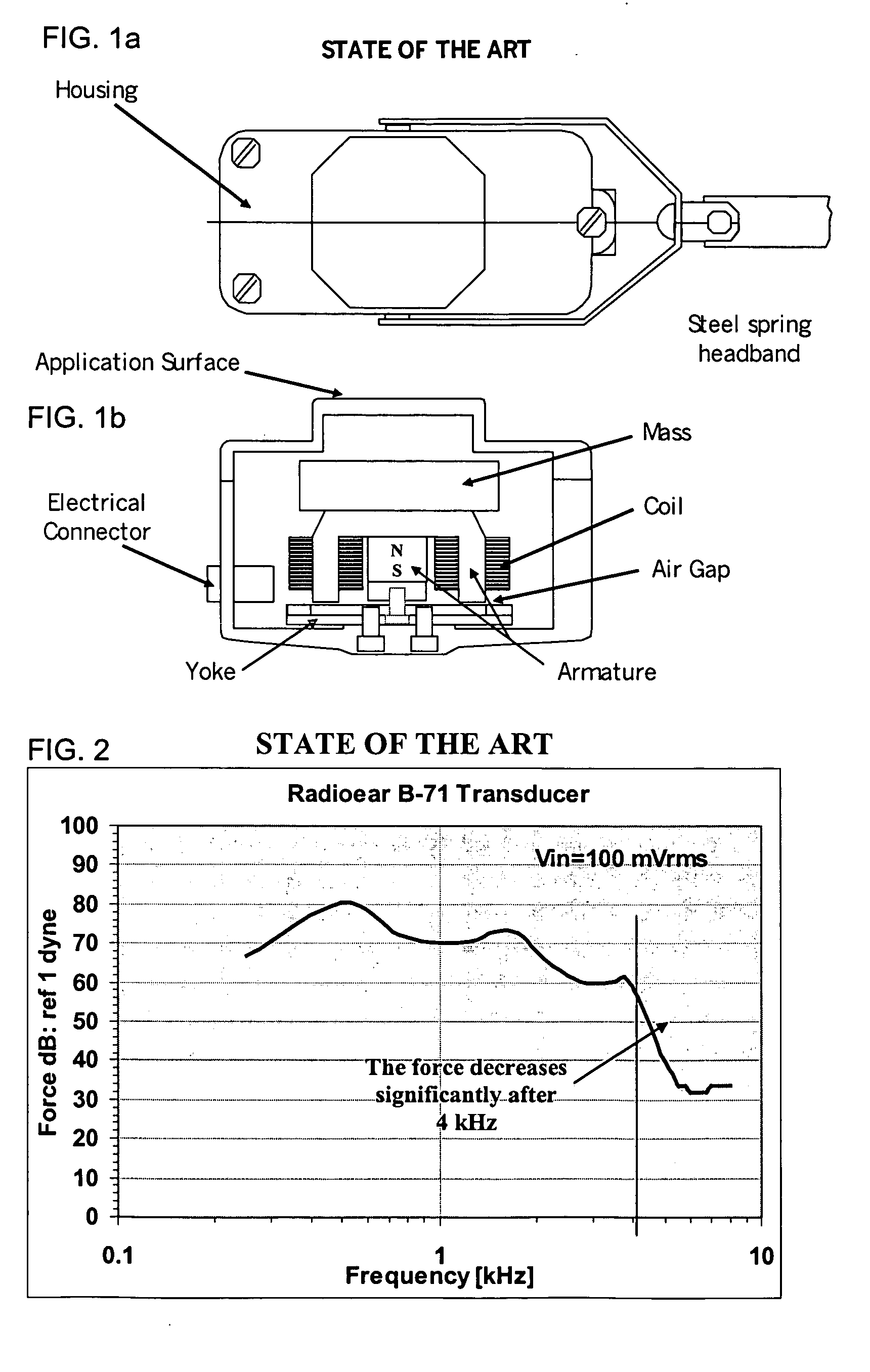

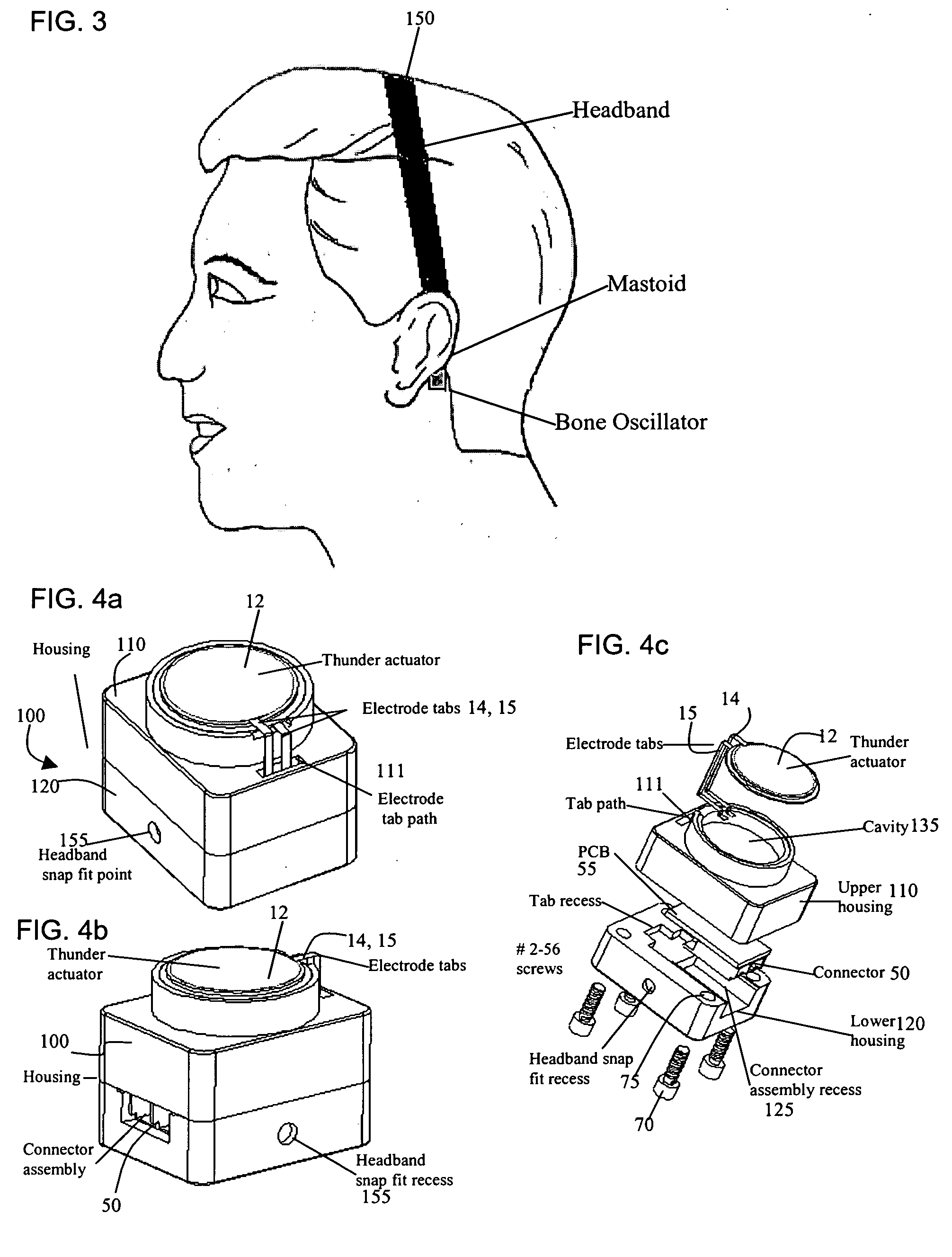

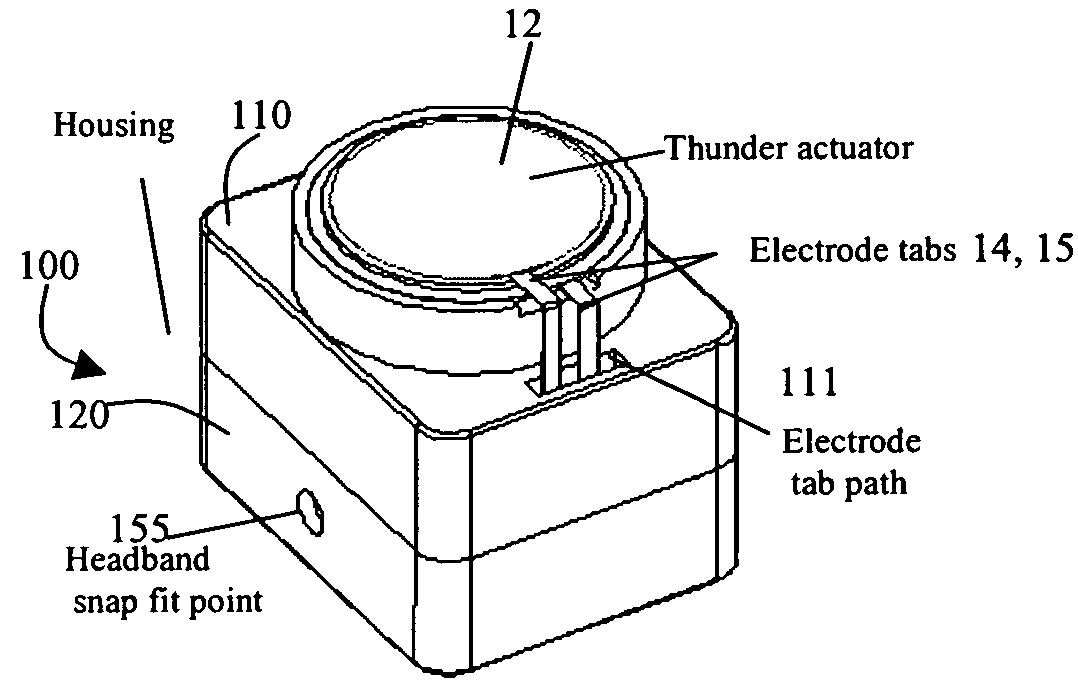

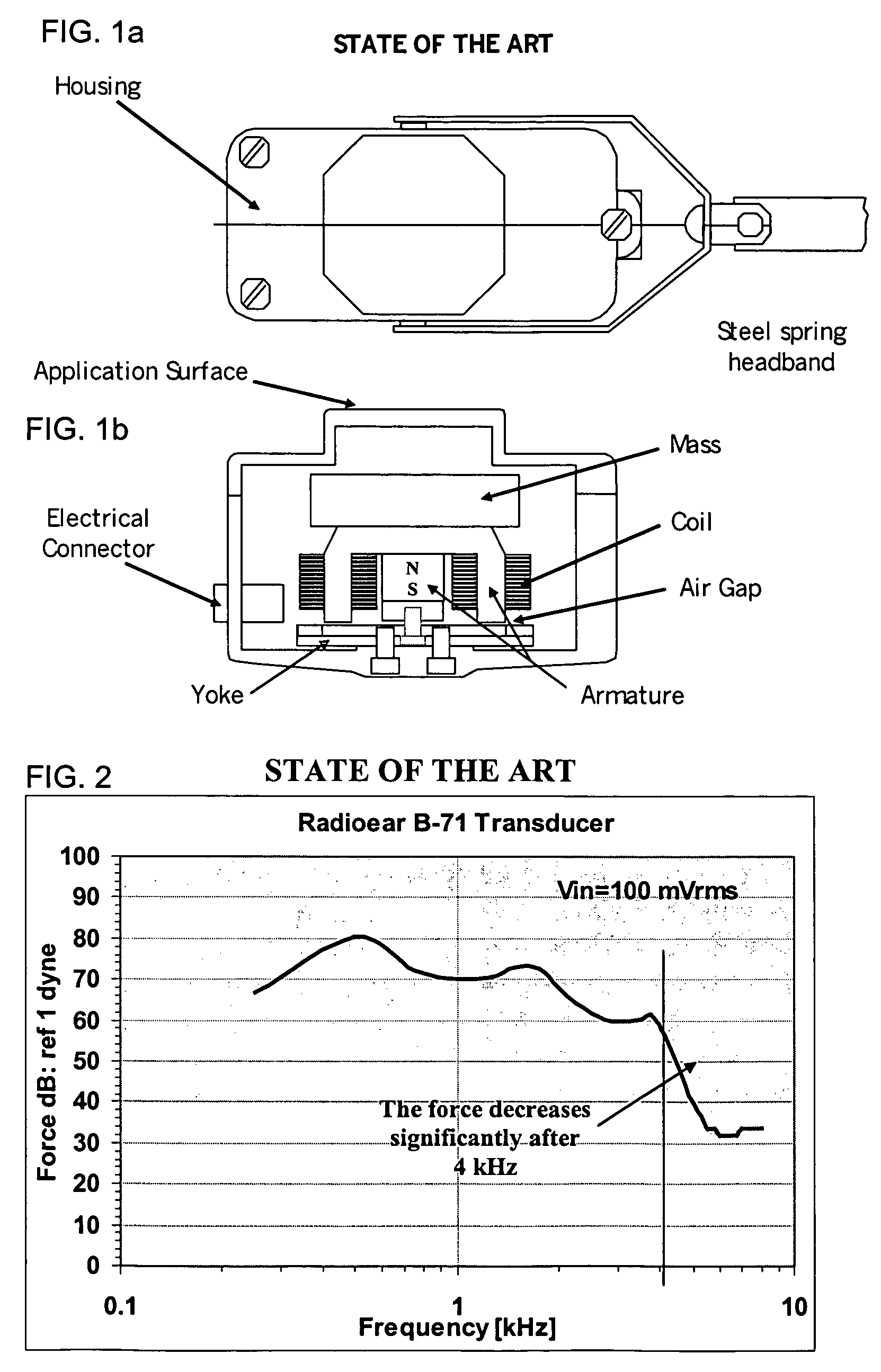

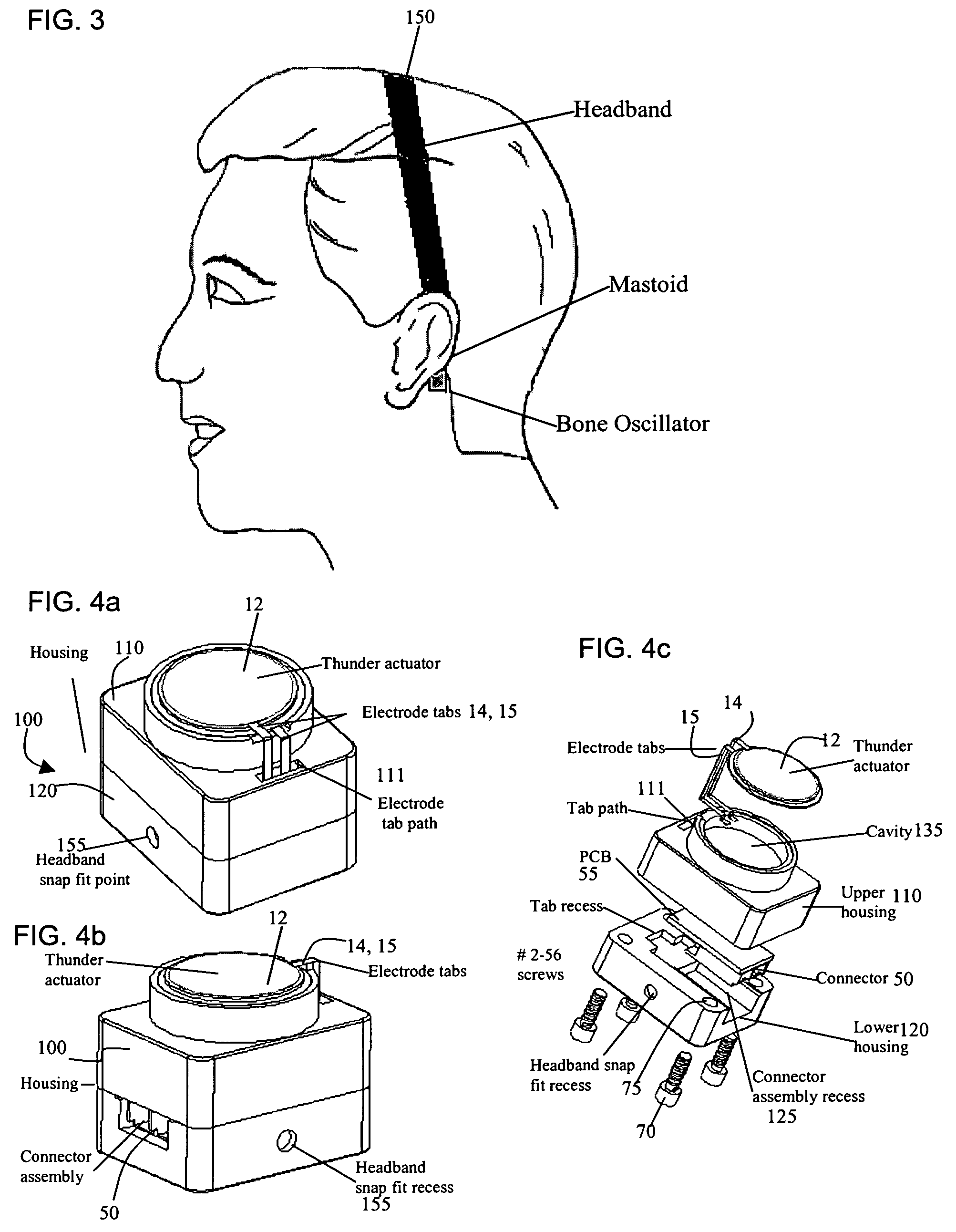

Bone-conduction hearing-aid transducer having improved frequency response

InactiveUS20070041595A1Eliminates soldering wireEliminate useRecord carriersPiezoelectric/electrostrictive transducersFrequency spectrumBone structure

A hearing-aid device and a method for transmitting sound through bone conduction are disclosed. The hearing-aid device comprises a piezoelectric-type actuator, housing and connector. The piezoelectric actuator is preferably a circular flextensional-type actuator mounted along its peripheral edge in a specifically designed circular structure of the housing. During operation, the bone-conduction transducer is placed against the mastoid area behind the ear of the patient. When the device is energized with an alternating electrical voltage, it flexes back and forth like a circular membrane sustained along its periphery and thus, vibrates as a consequence of the inverse piezoelectric effect. Due to the specific and unique designs proposed, these vibrations are directly transferred trough the human skin to the bone structure (the skull) and provide a means for the sound to be transmitted for patients with hearing malfunctions. The housing acts as a holder for the actuators, as a pre-stress application platform, and as a mass which tailors the frequency spectrum of the device. The apparatus exhibits a performance with a very flat response in the frequency spectrum 200 Hz to 10 kHz, which is a greater spectrum range than any other prior art devices disclosed for bone-conduction transduction which are typically limited to less than 4 kHz.

Owner:FACE INT

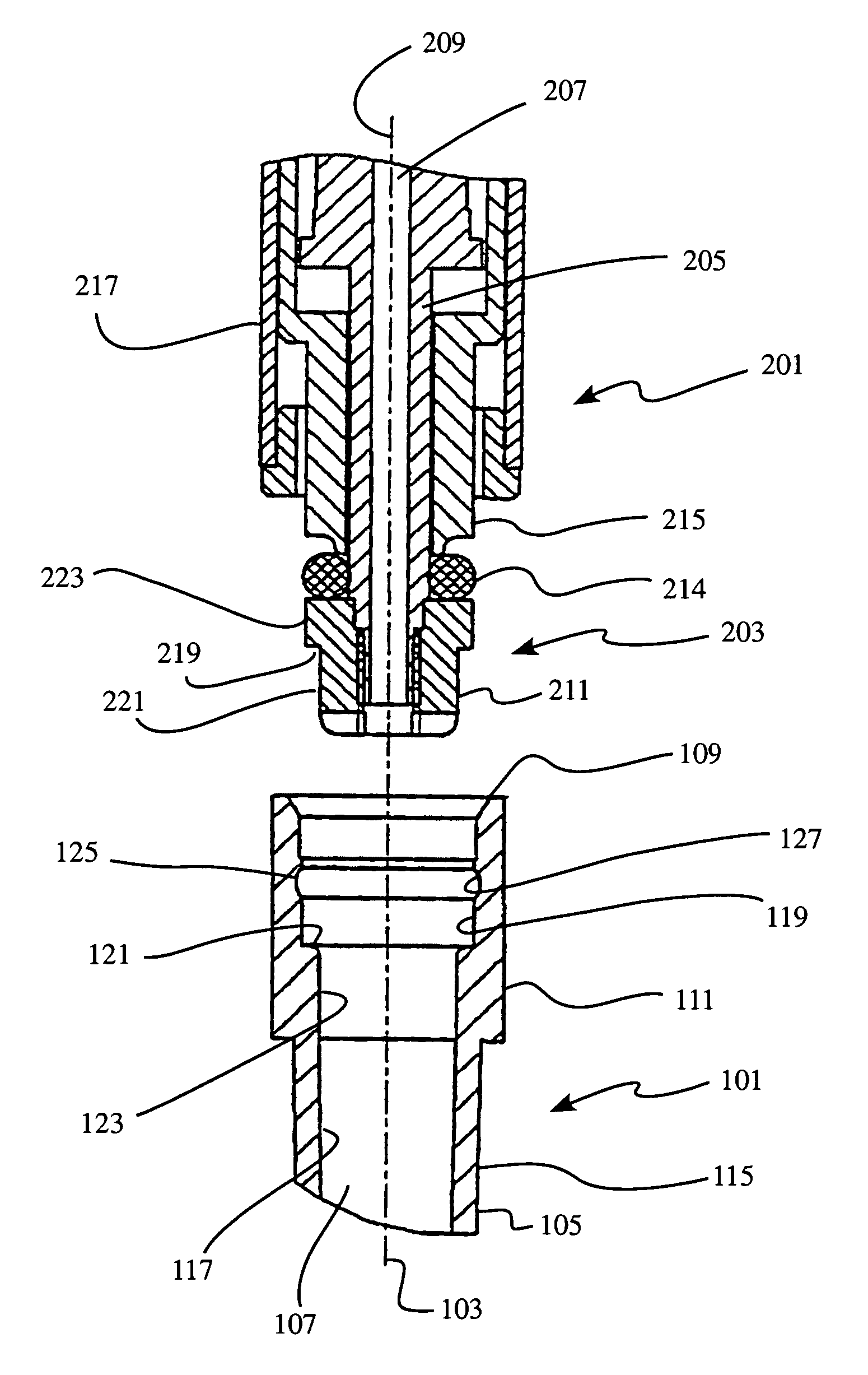

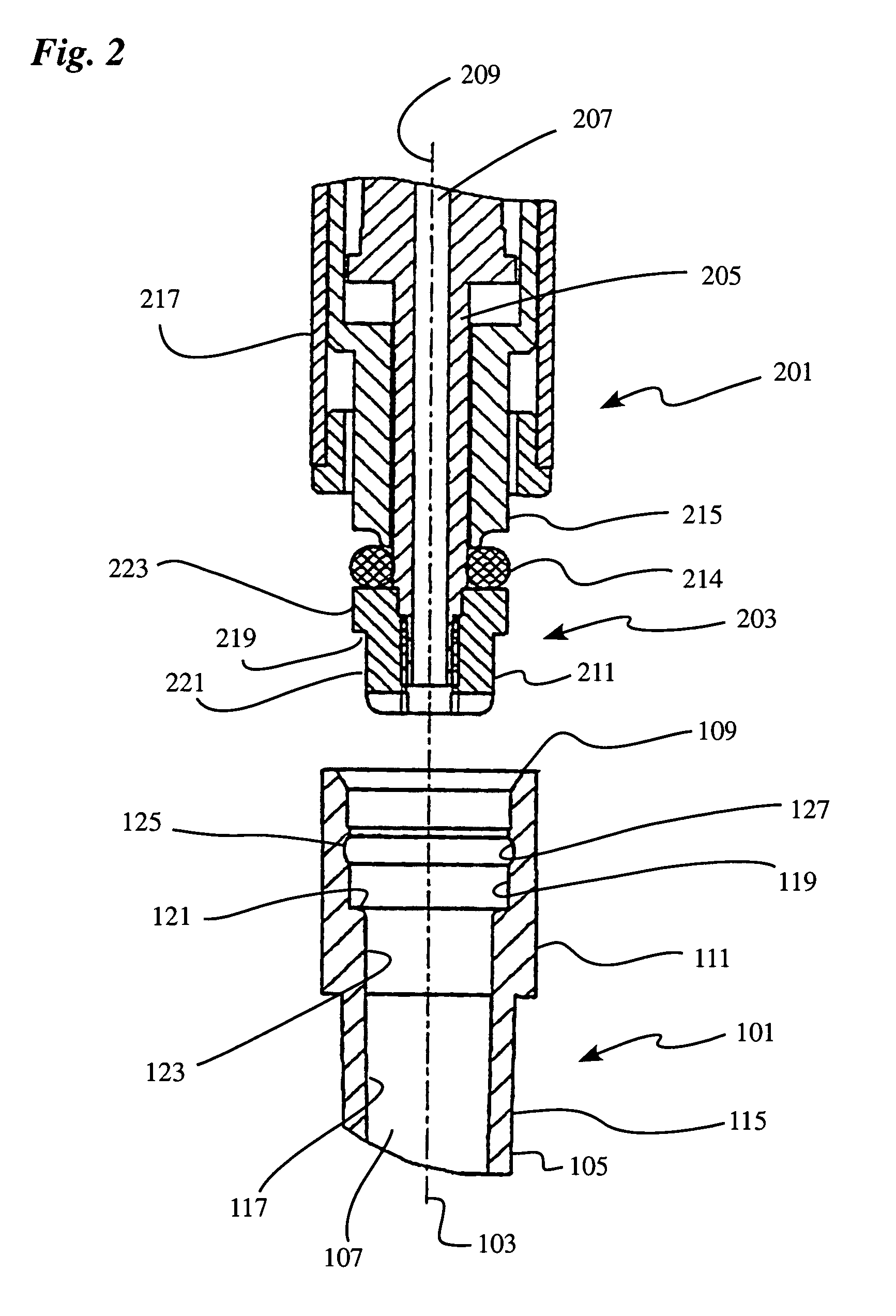

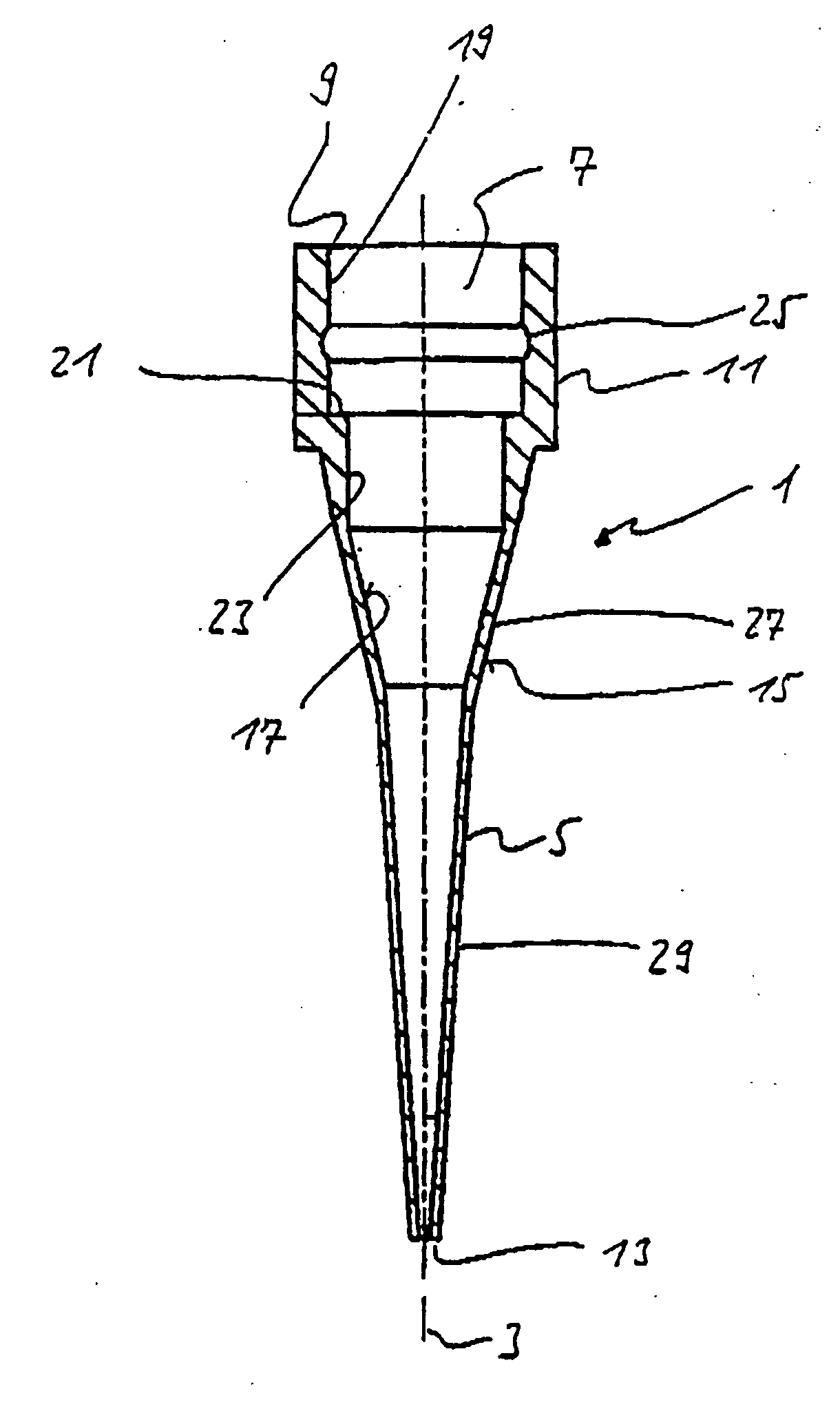

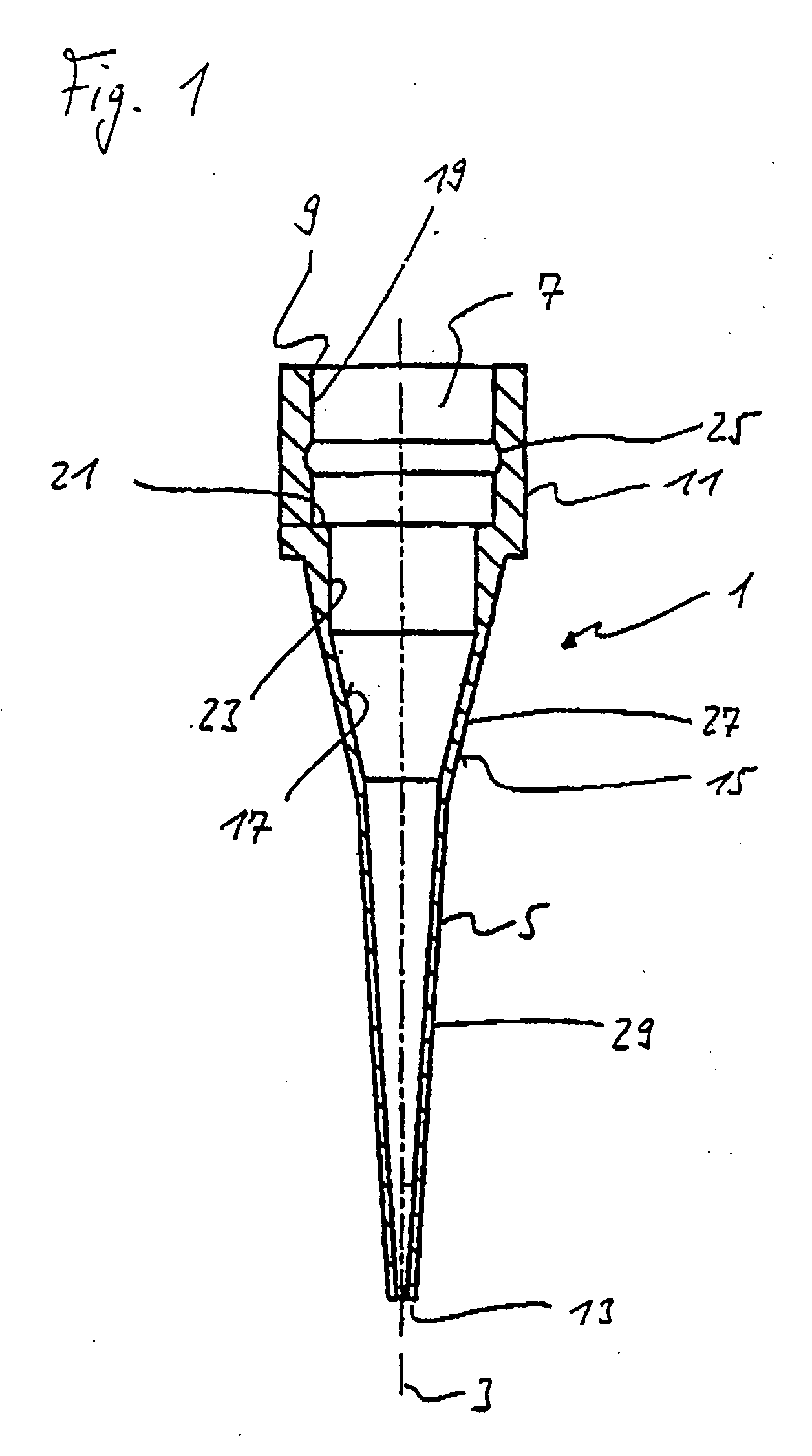

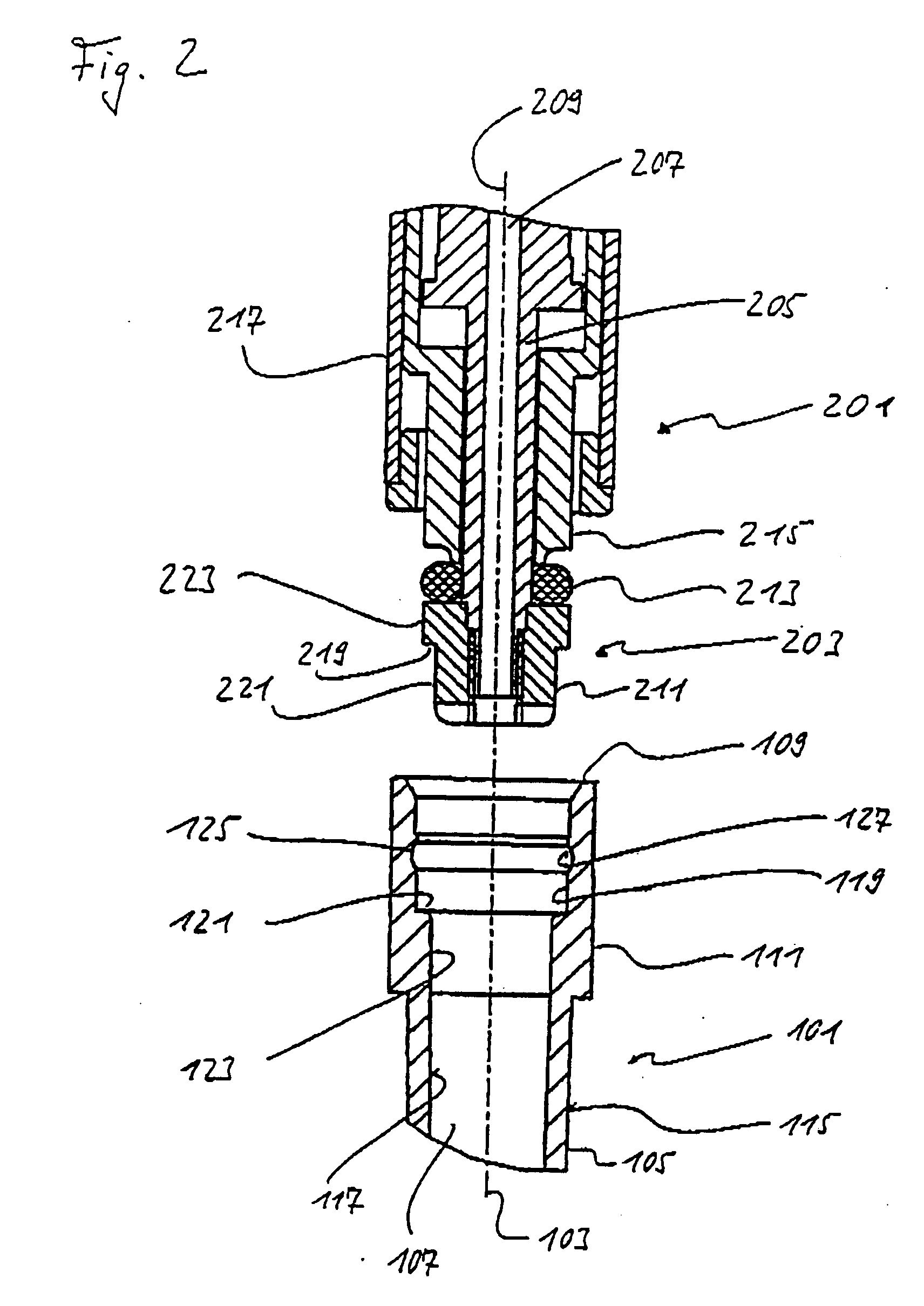

Pipette tip, pipetting device and combination consisting of a pipette tip and pipetting device

InactiveUS7033543B1Extended service lifeStable supportWithdrawing sample devicesBurettes/pipettesPipetteCoupling

A pipette device has a coupling stud on which a pipette tip can be stuck in a slipping-on direction for coupling. The coupling stud has an adjustable pre-stress member that can be adjusted into a prestress state and a release state via an actuation device which is provided in the coupling stud. The pipette tip has an axial stop which interacts with a counter-stop of the coupling stud in an axial coupling position of the pipette tip. The prestress member in its prestress state acts upon a working surface of the stuck-on pipette tip having a surface component of the pipette tip, which extends radially inward, turned away from the stuck on direction, in such a way that it abuts sealingly on the working surface, and prestresses the pipette tip on the pipette unit into the axial coupling position. The prestress member, in its releasing state, substantially releases the working surface of the pipette tip (101).

Owner:HAMILTON BONADUZ AG

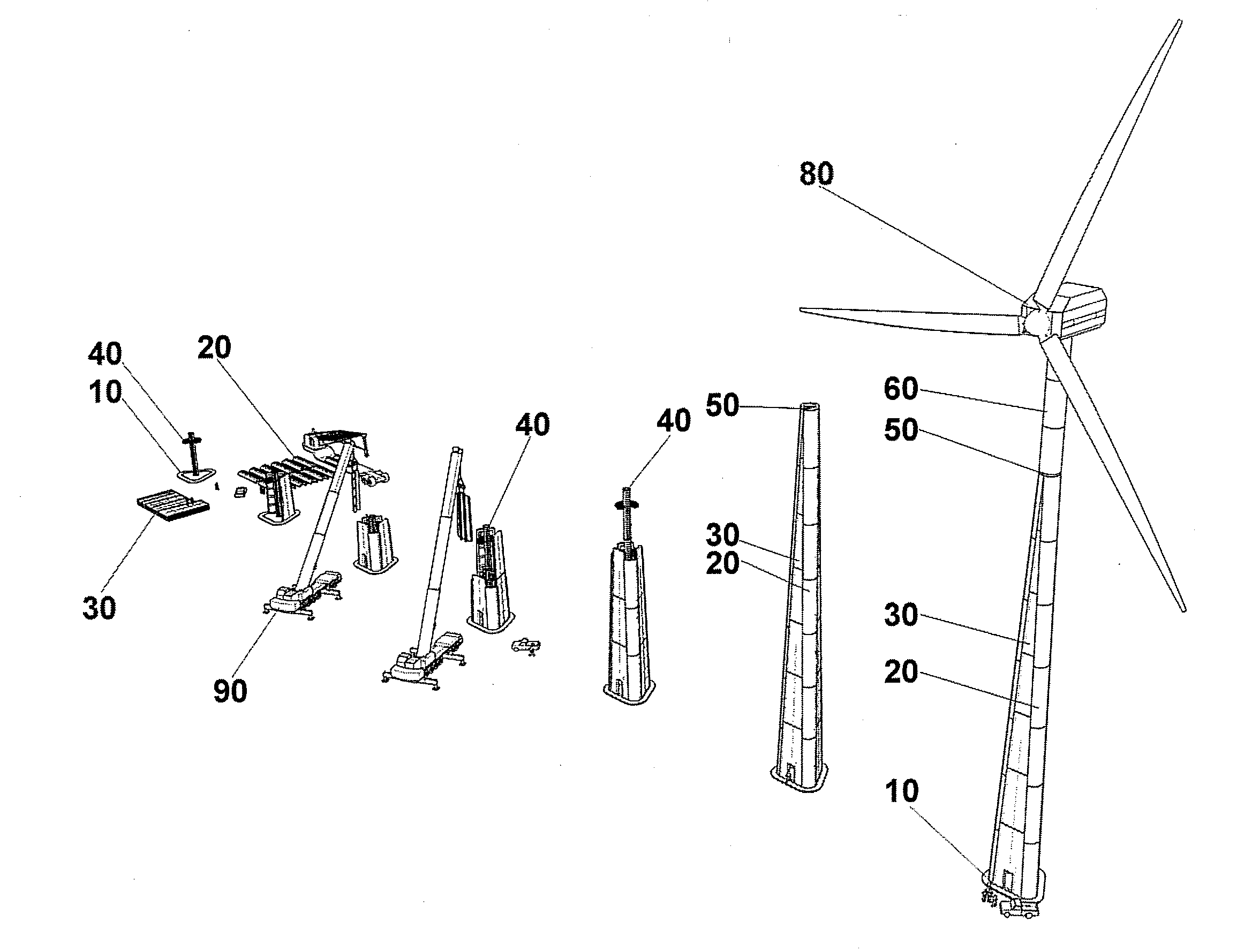

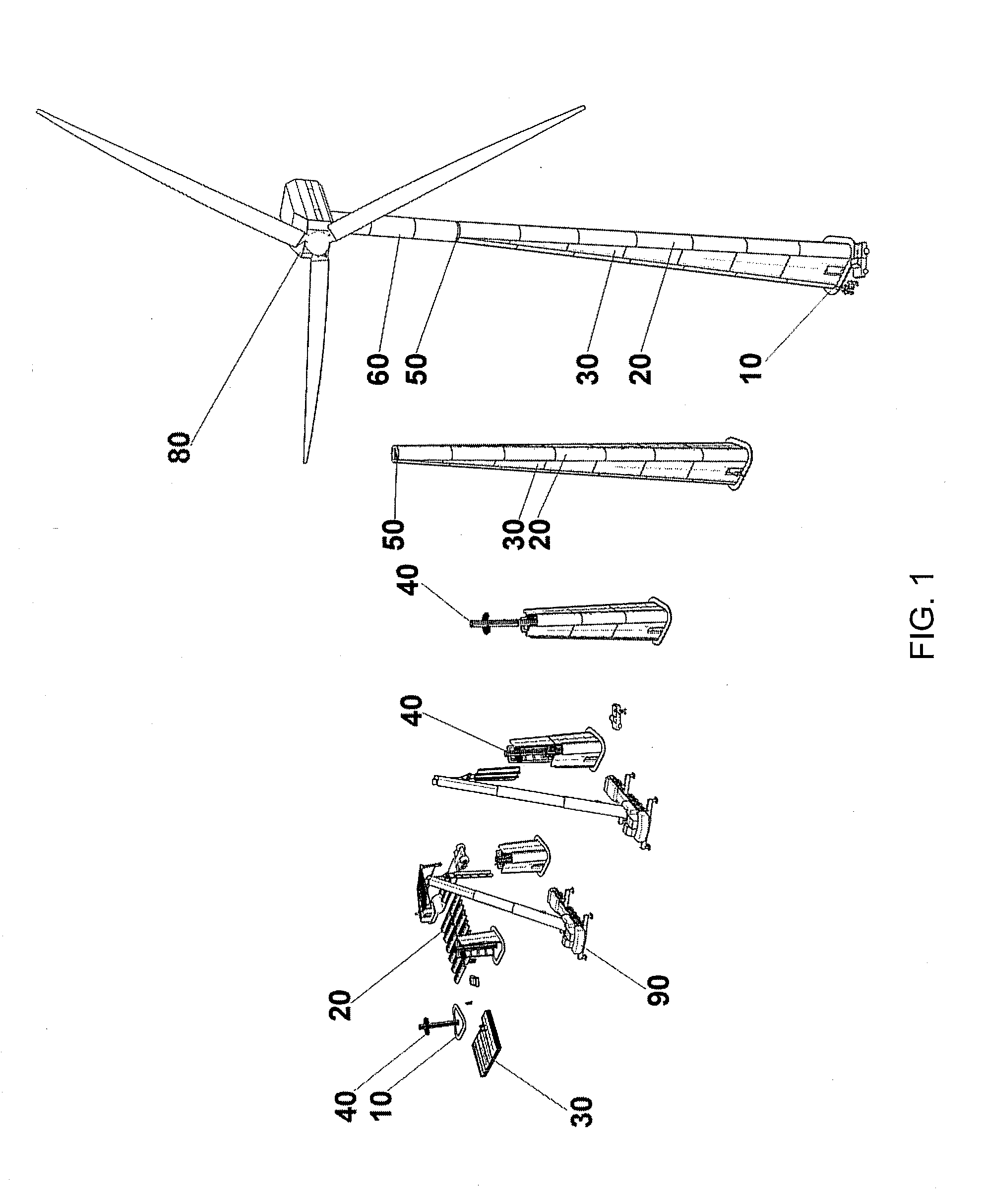

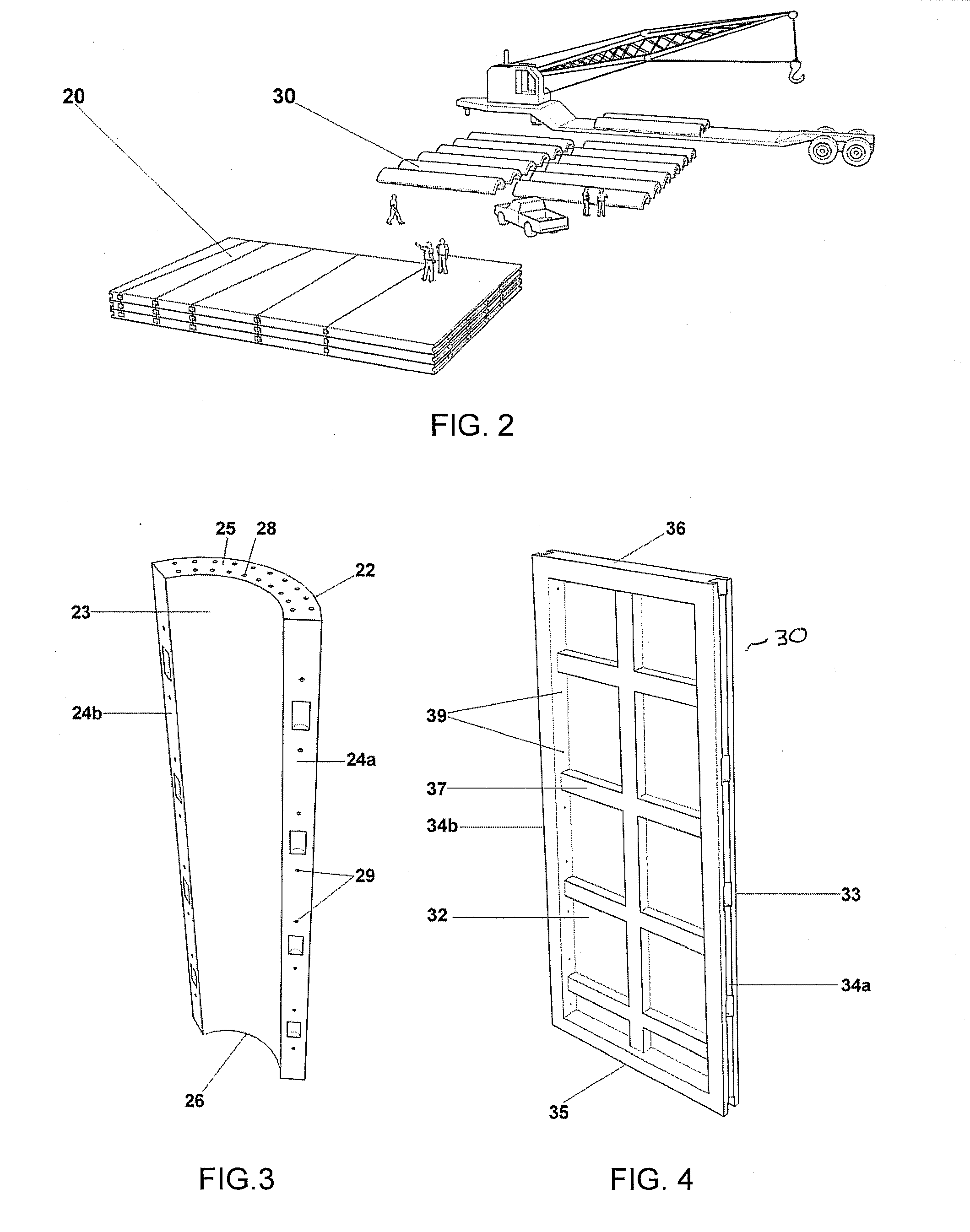

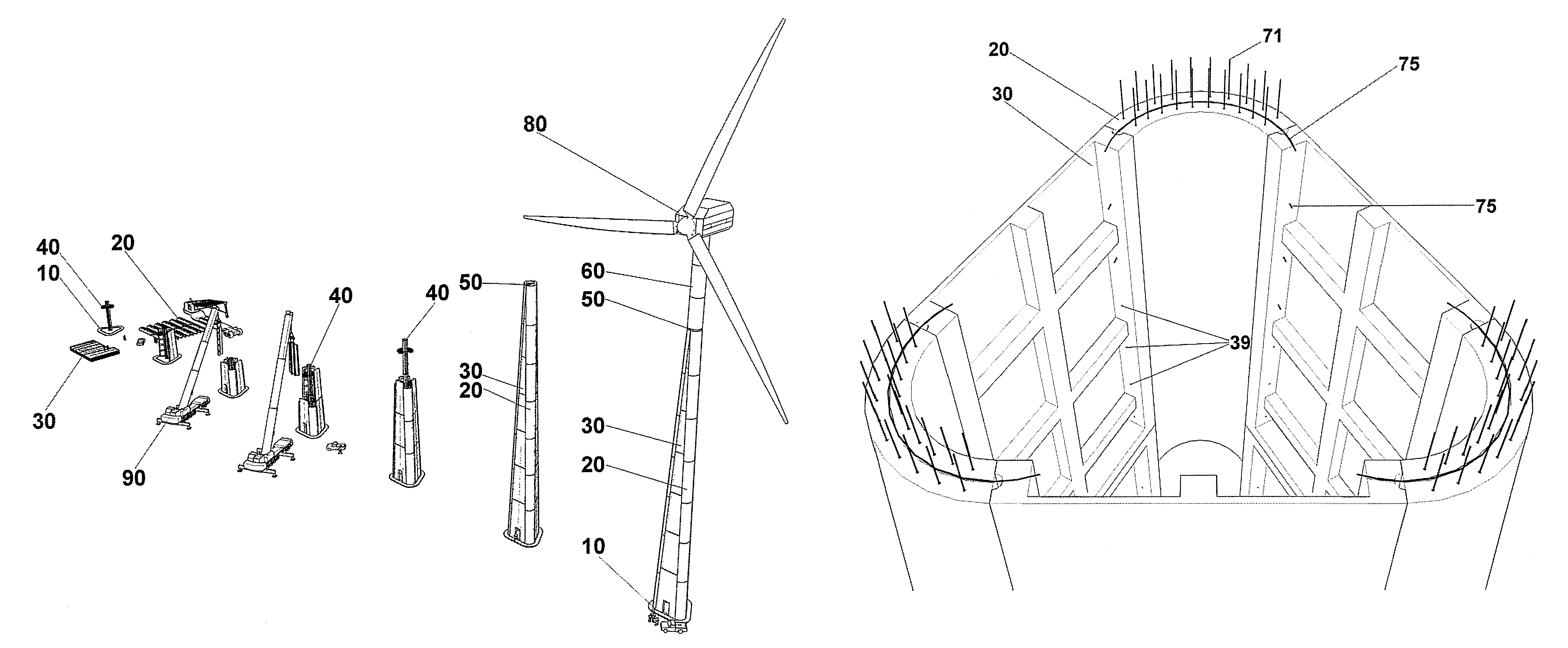

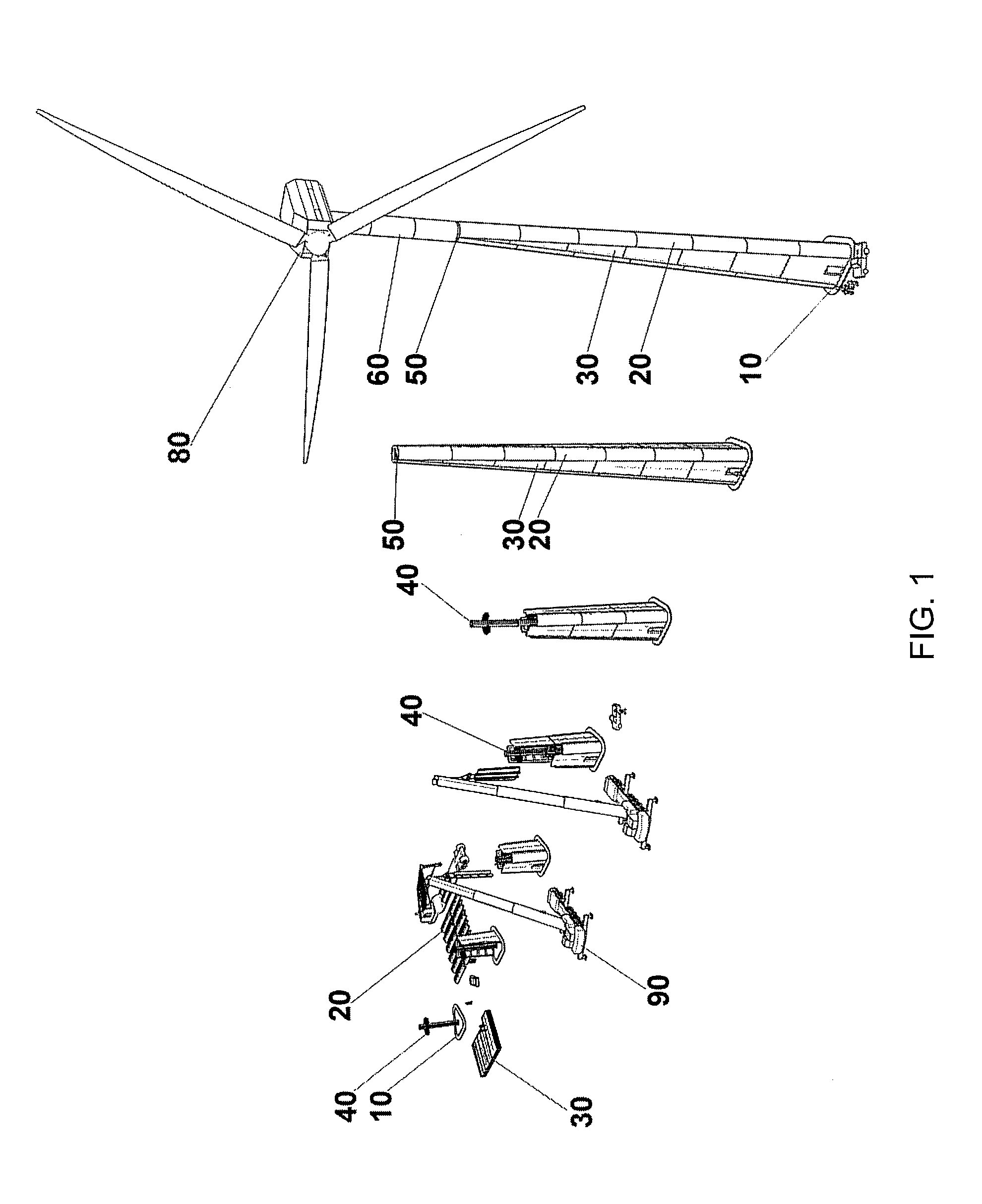

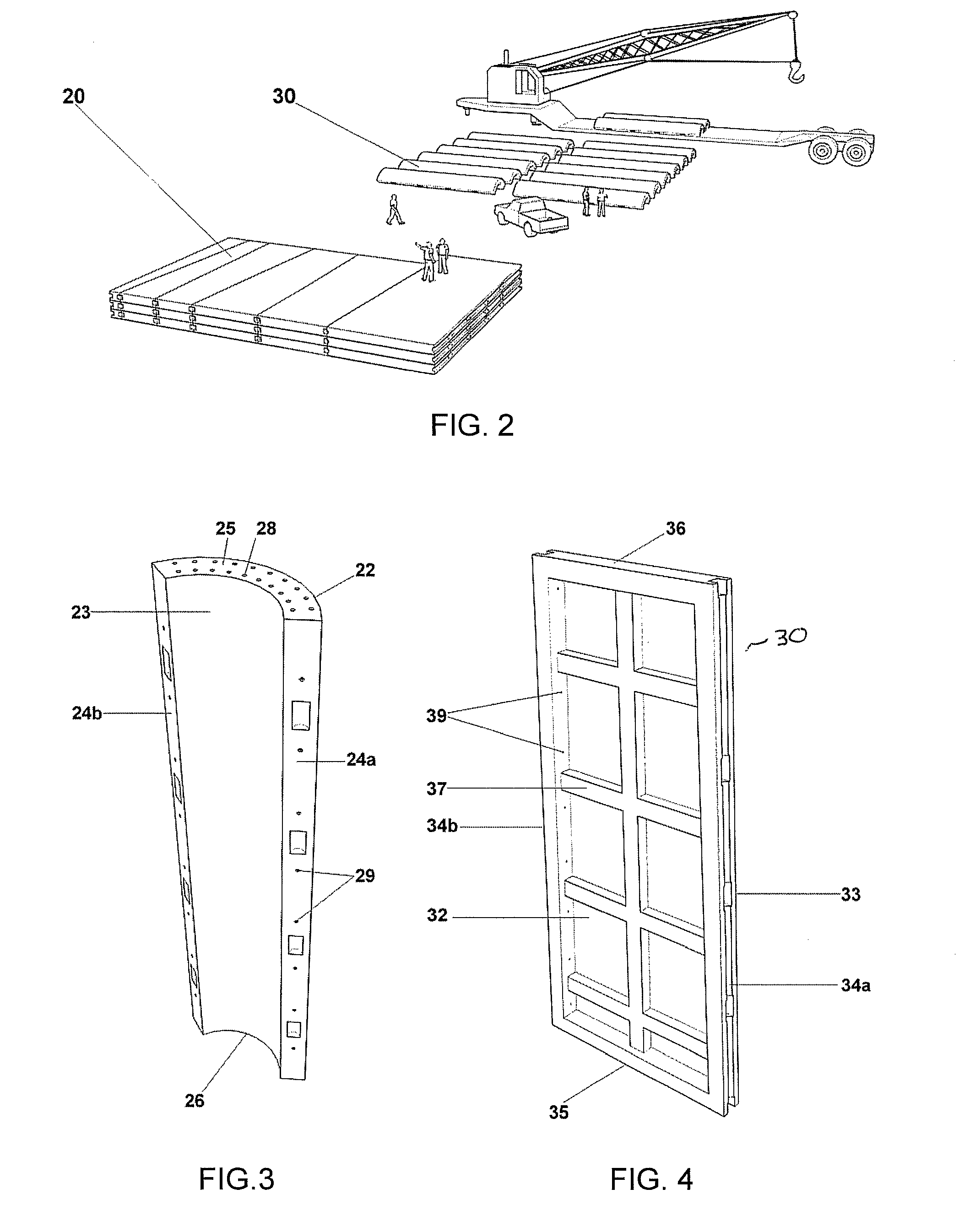

Pre-stressed concrete tower for wind power generators

InactiveUS20090031639A1Simplifying erectionSimplifying fabricationFinal product manufactureWind motor assemblyPre stressPre stressing

A pre-stressed segmented concrete tower for wind power generators is described, and a method for its fabrication, wherein in a pyramidal structure is formed by prefabricated segments, the structure comprising three rounded walls formed with circular segments, and three flat walls, formed with flat segments between the circular walls. One standard curved mold is used for the circular walls, and the flat walls are fabricated horizontally, over templates.

Owner:CORTINA INNOVATIONS DE C V

Pre-stressed concrete tower for wind power generators

InactiveUS7739843B2Simplifying erectionSimplifying fabricationFinal product manufactureWind motor assemblyPre stressPre stressing

A pre-stressed segmented concrete tower for wind power generators is described, and a method for its fabrication, wherein in a pyramidal structure is formed by prefabricated segments, the structure comprising three rounded walls formed with semi-circular segments, and three flat walls, formed with flat segments between the semi-circular walls. One standard curved mold is used for the semi-circular walls, and the flat walls are fabricated horizontally, over templates.

Owner:CORTINA INNOVATIONS DE C V

Method and apparatus for forming a metal sheet under elevated temperature and air pressure

Owner:AIRBUS OPERATIONS GMBH

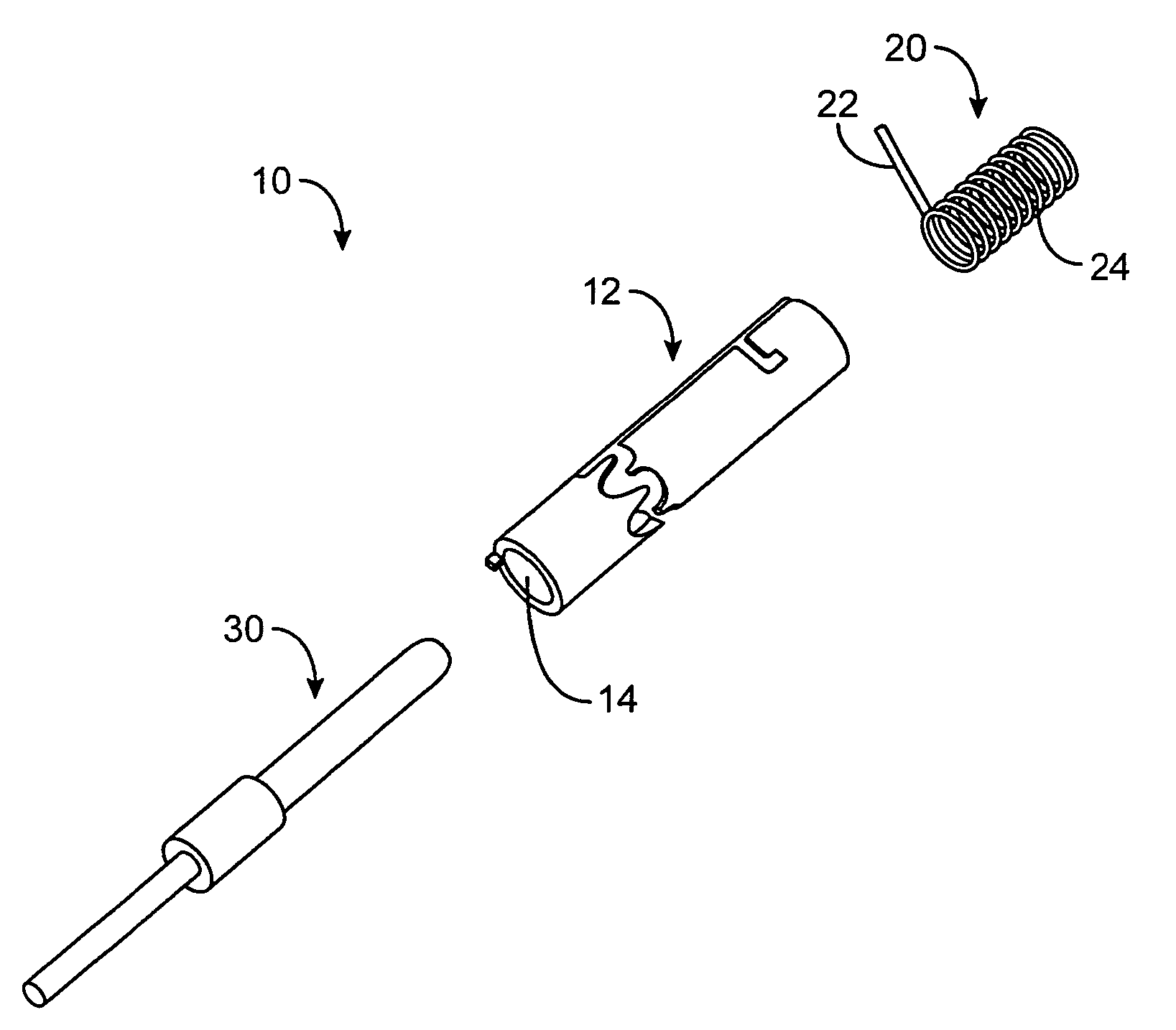

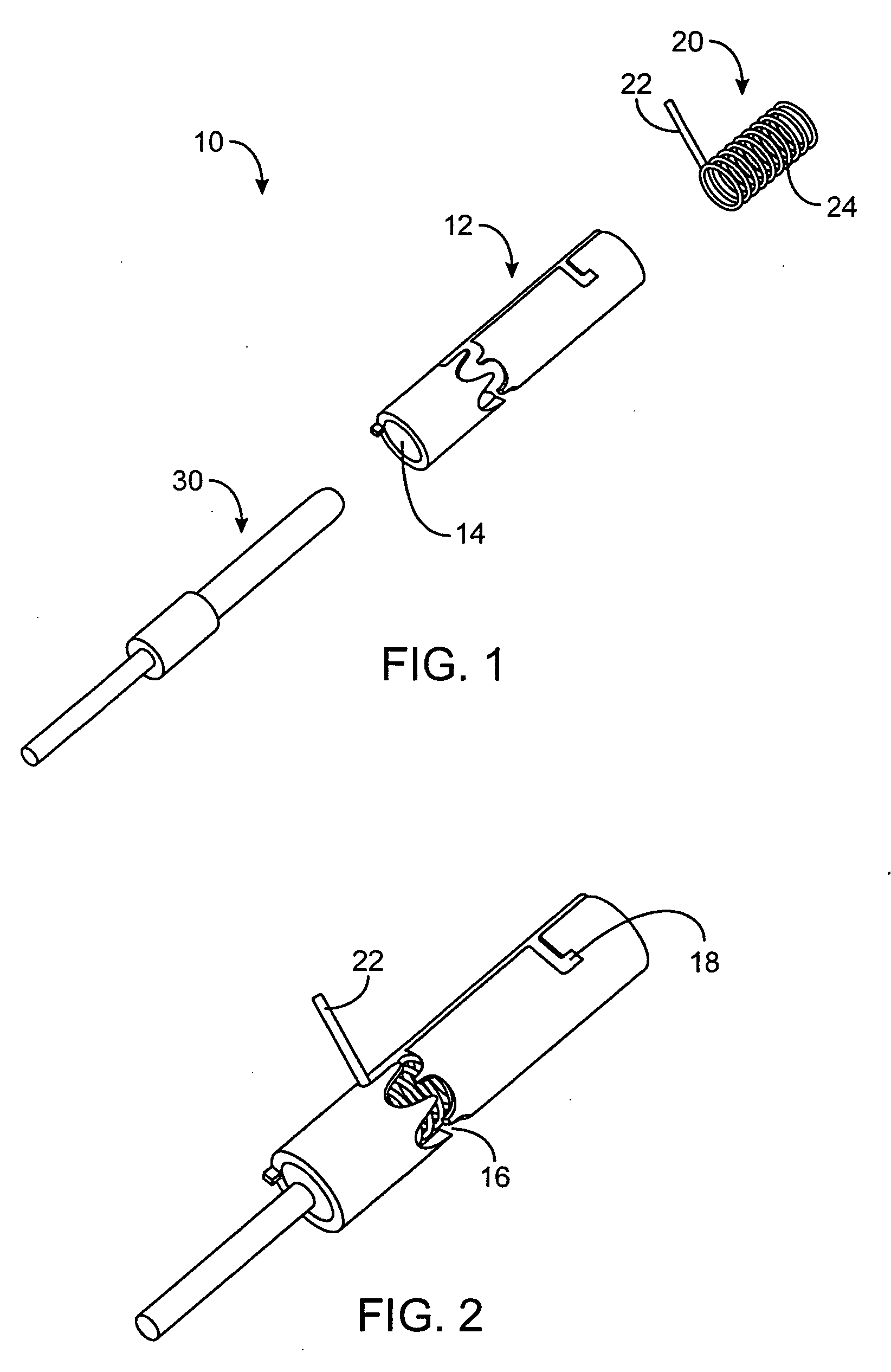

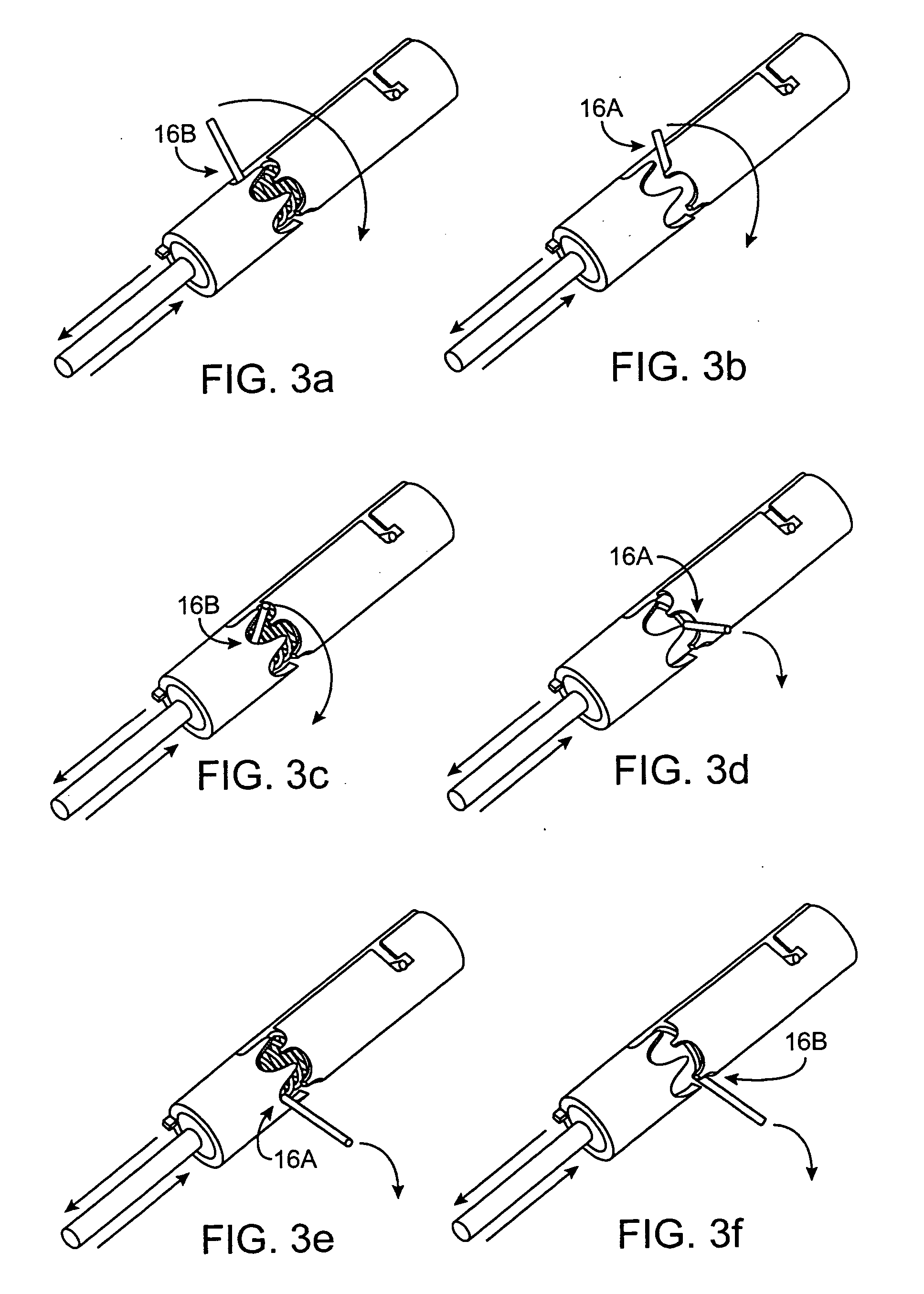

Mechanical limiter switch

A mechanical limiter switch for use in a medical or surgical device has a substantially cylindrically shaped housing with a perimeter and an opening in an axial direction. The housing has a pattern along the perimeter. A spring is mounted in the opening along the axial direction, and is pre-stressed for movement in a radial direction and pre-stressed for movement in the axial direction. The spring has a radial member protruding through the pattern of the housing. A plunger is mounted in the opening along the axial direction, abutting the spring for urging the spring in the axial direction and for moving the member in the pattern along the perimeter. After a pre-determined number of activations of the plunger in the axial direction, the member will come to a terminating position and will either contact a pin to establish electrical continuity or at the terminating position break electrical continuity.

Owner:ATL TECH LLC

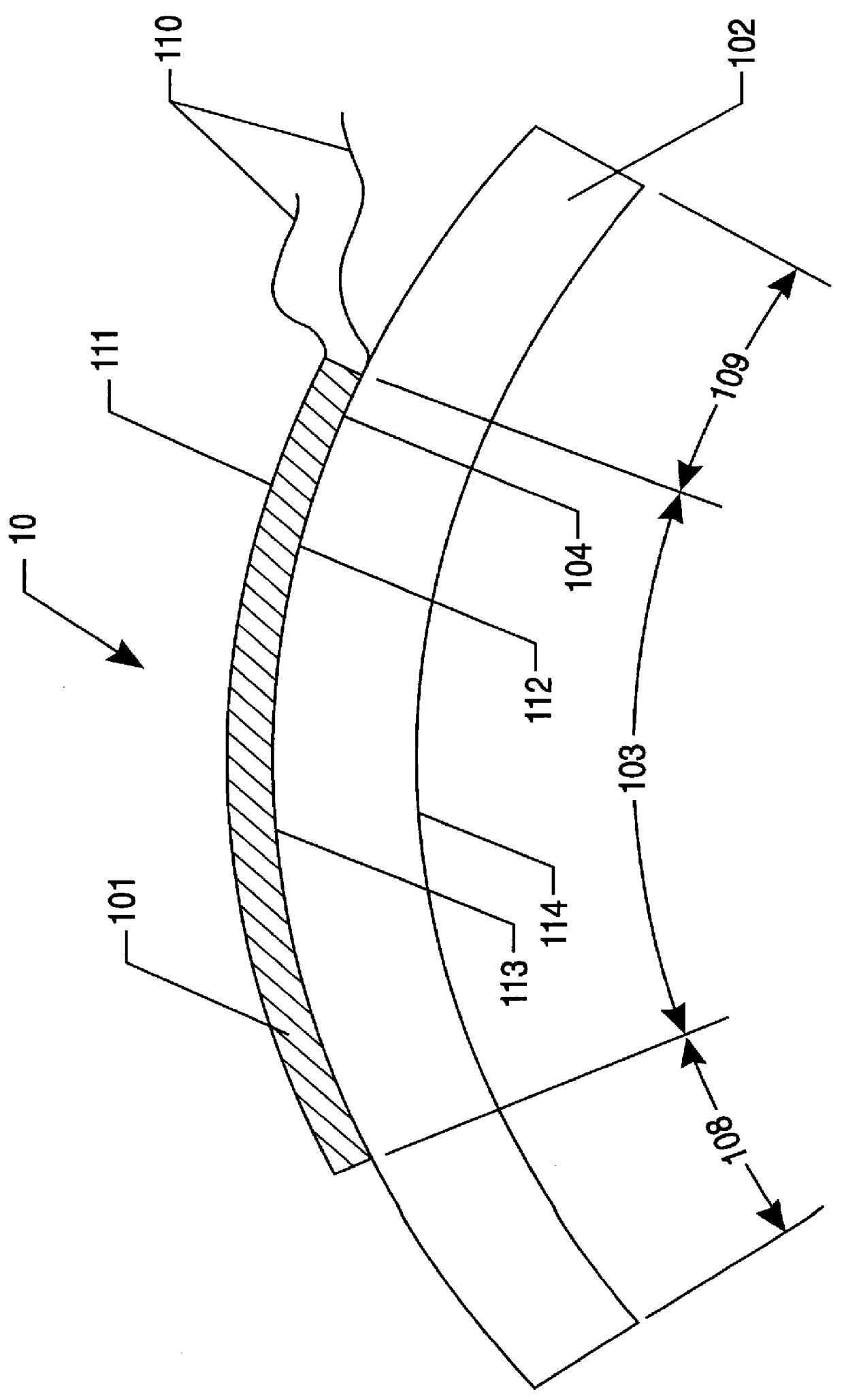

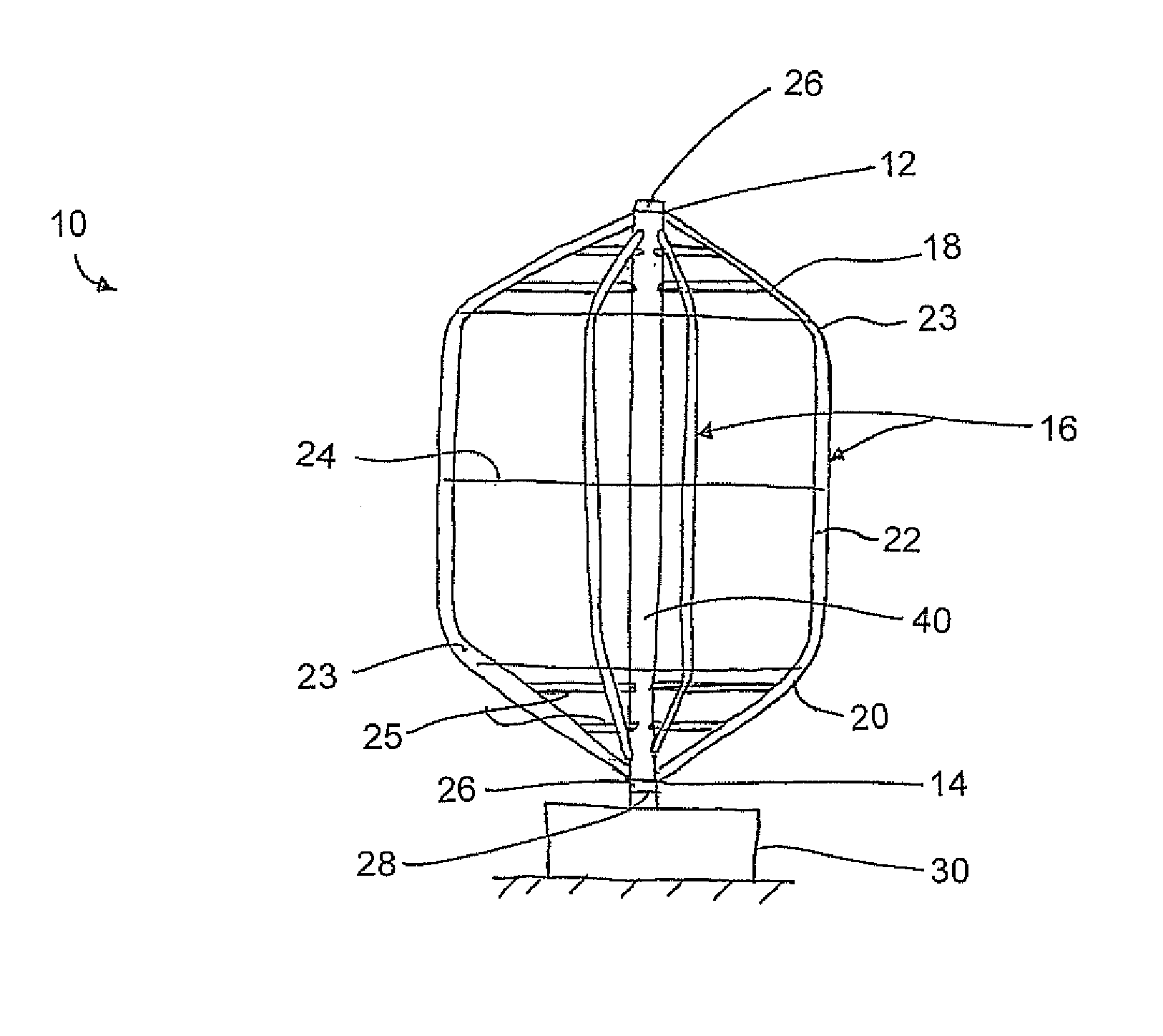

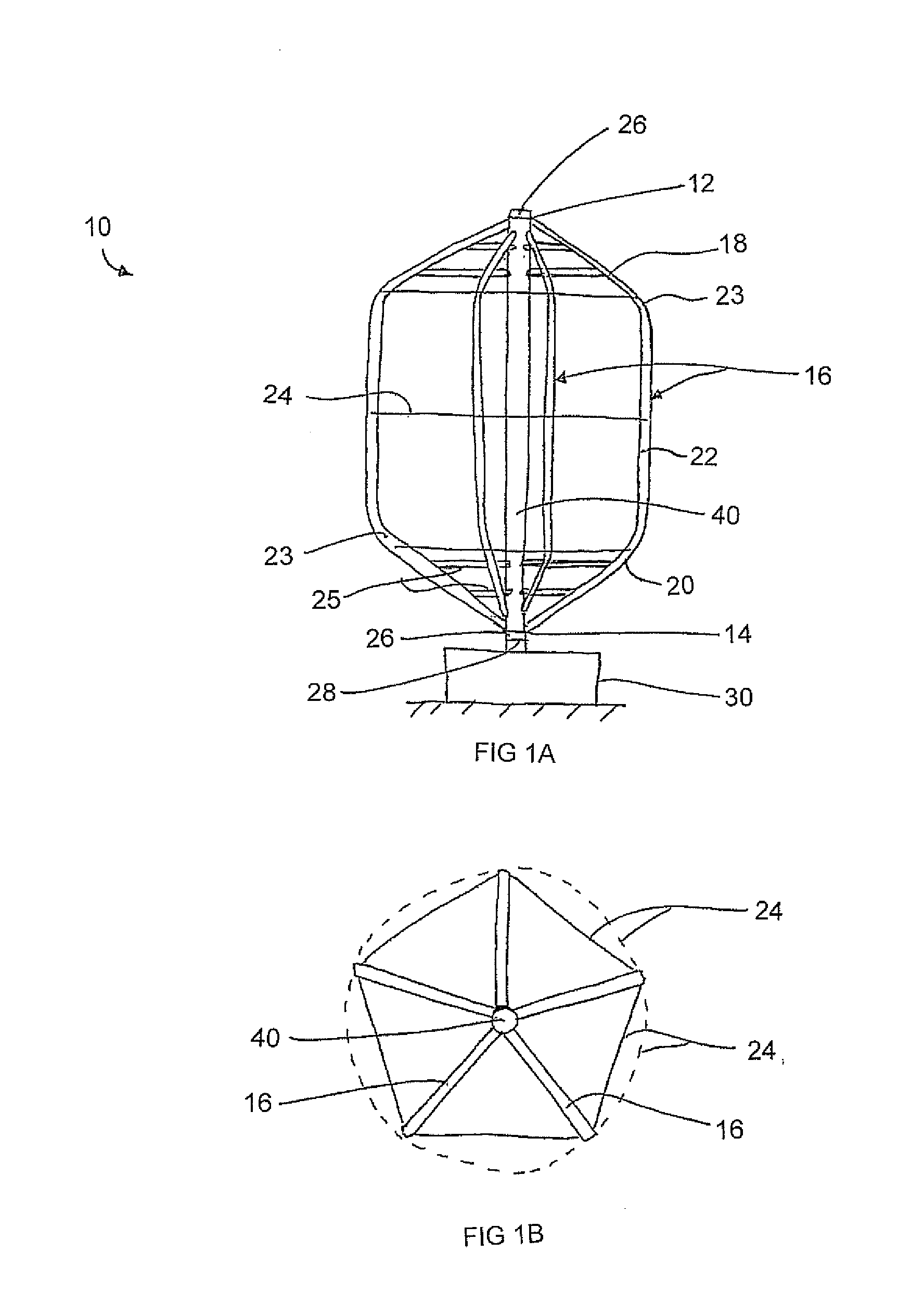

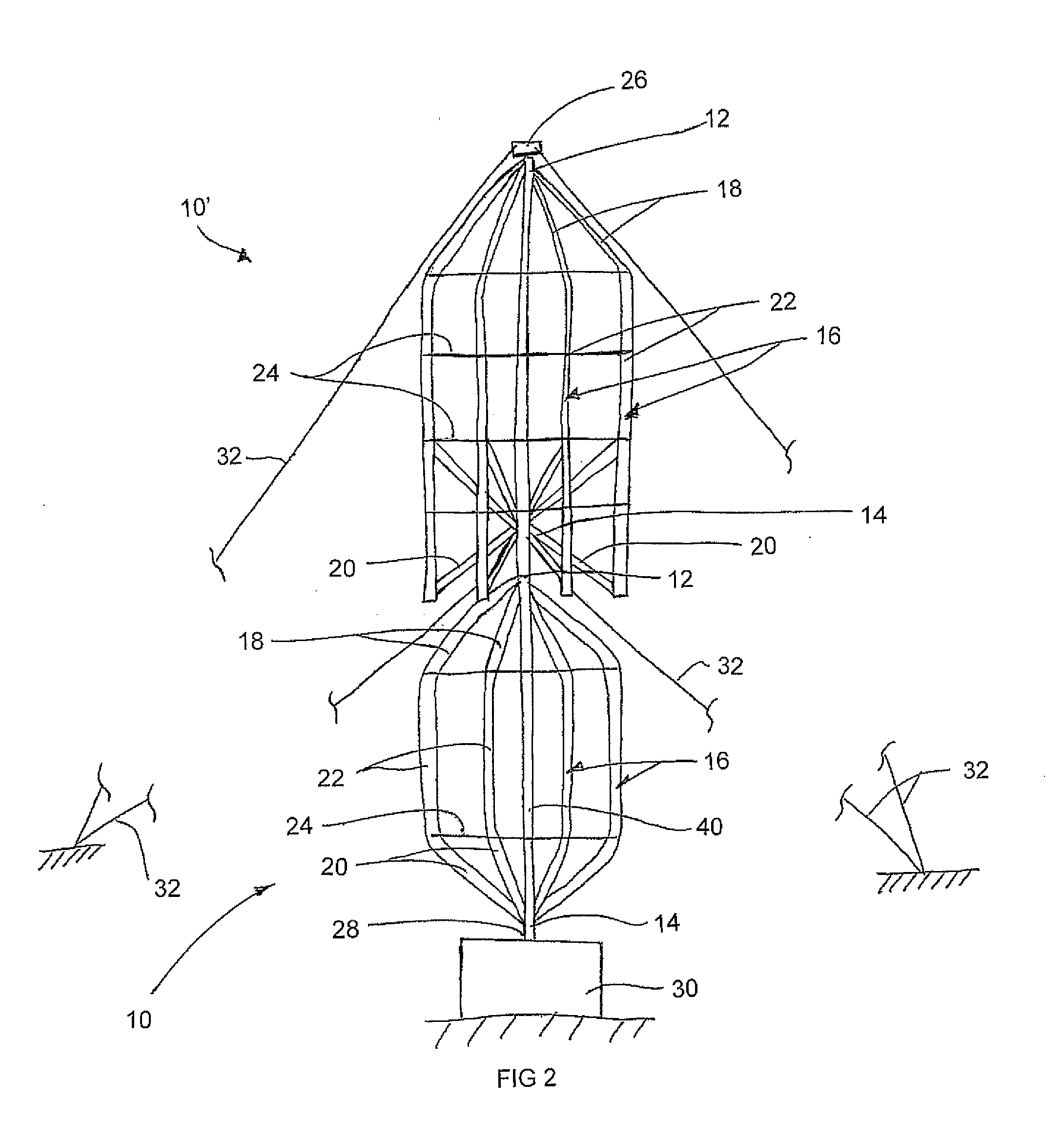

Modified Darrieus Vertical Axis Turbine

A lift-type turbine comprising at least three blades at circumferentially spaced positions is supported for rotation about a vertical axis. Each blade has an airfoil shape to generate a torque about the axis responsive to wind across the blades. A support comprising cables under tension is connected between adjacent ones of the blades to extend generally circumferentially about the turbine. Accordingly a minimum number of parts form the structure of the blades while minimizing the drag produced during rotation thereof due to the support members lying in a common circumferential path. The tension of the support members can support the blades in a pre-stressed condition to optimize the shape and performance thereof.

Owner:LUX

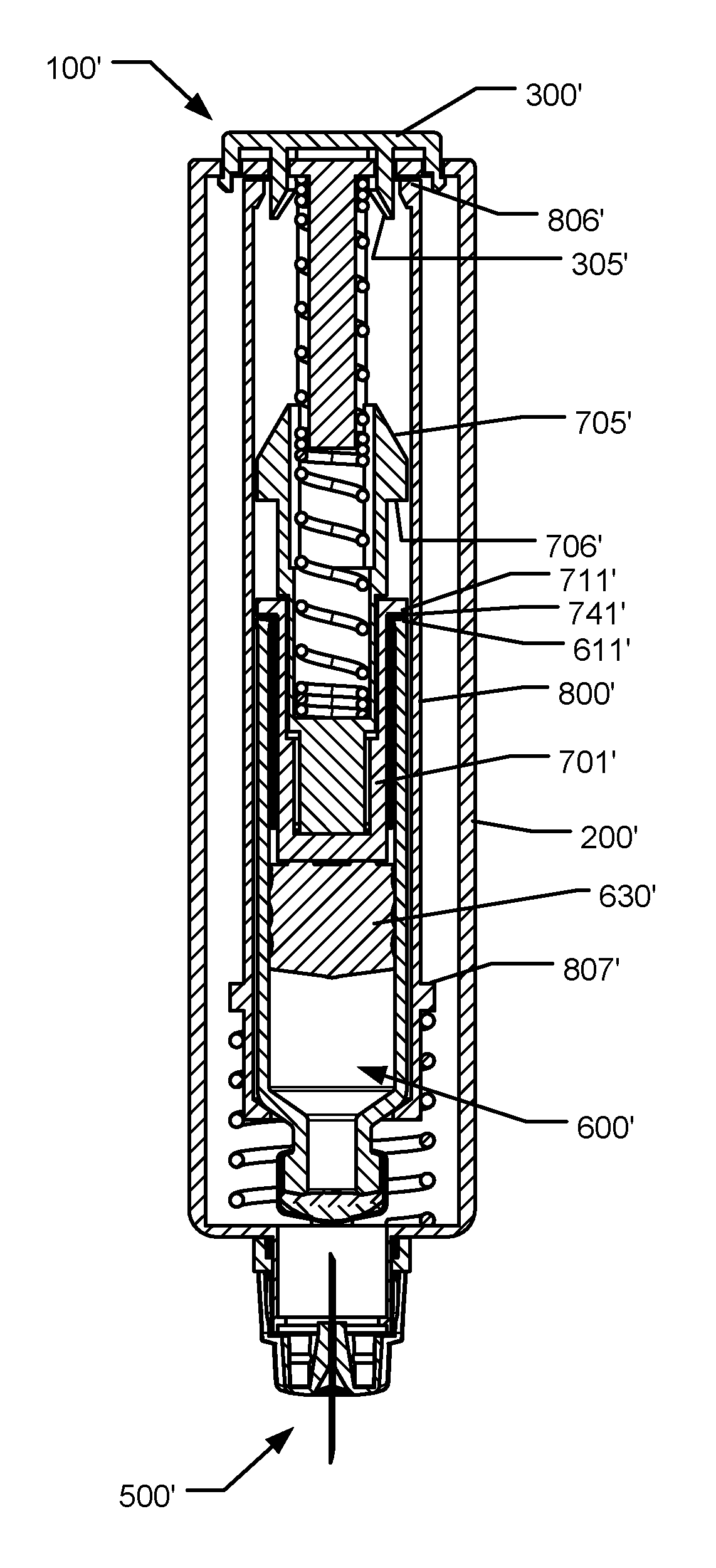

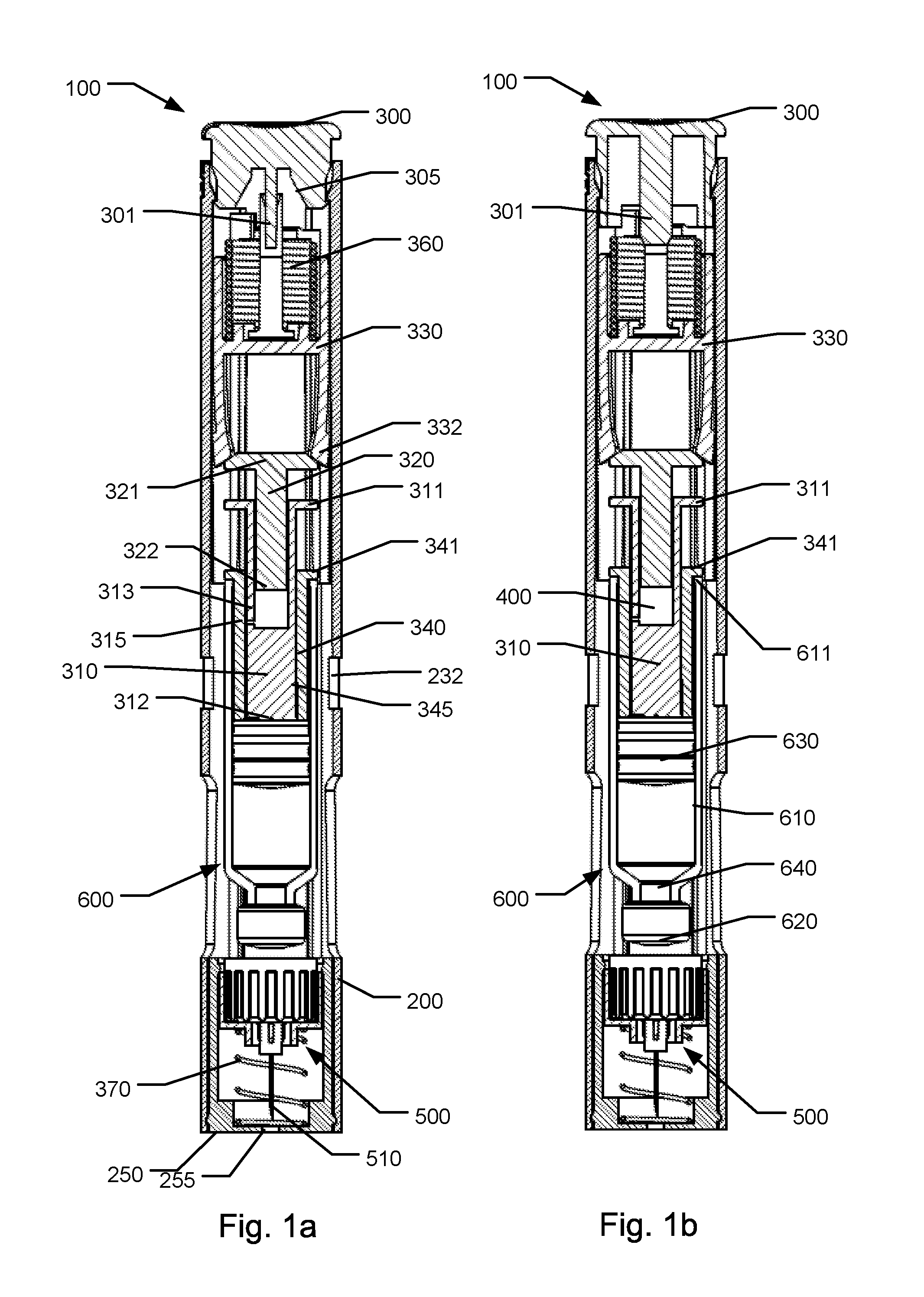

Medical Injection Device

InactiveUS20130218093A1Minimize timeLarge of accuracyAmpoule syringesAutomatic syringesPre stressPre stressing

The present invention relates to injection devices for injecting a medicament from a cartridge (600) through a needle cannula (510). The injection device (100) includes an actuator (330, 360) for driving a piston driver (310) and includes an end of stroke limiter (341, 611). When the piston driver (310) is arrested by the end of stroke limiter (341, 611) a shielding driver (370) is automatically triggered to actively shift the needle cannula (510) into a shielded state. The injection device may include a fluid dispensing interruption mechanism that automatically interrupts fluid flow when the piston driver has moved a predetermined stroke length. The injection device may also include a single pre-stressed spring acting exclusively in a linear compression mode or exclusively in a torsion mode and adapted to sequentially drive the device to enable fully automatic operation. The invention also relates to a method of sterilizing a needle cannula assembly.

Owner:NOVO NORDISK AS

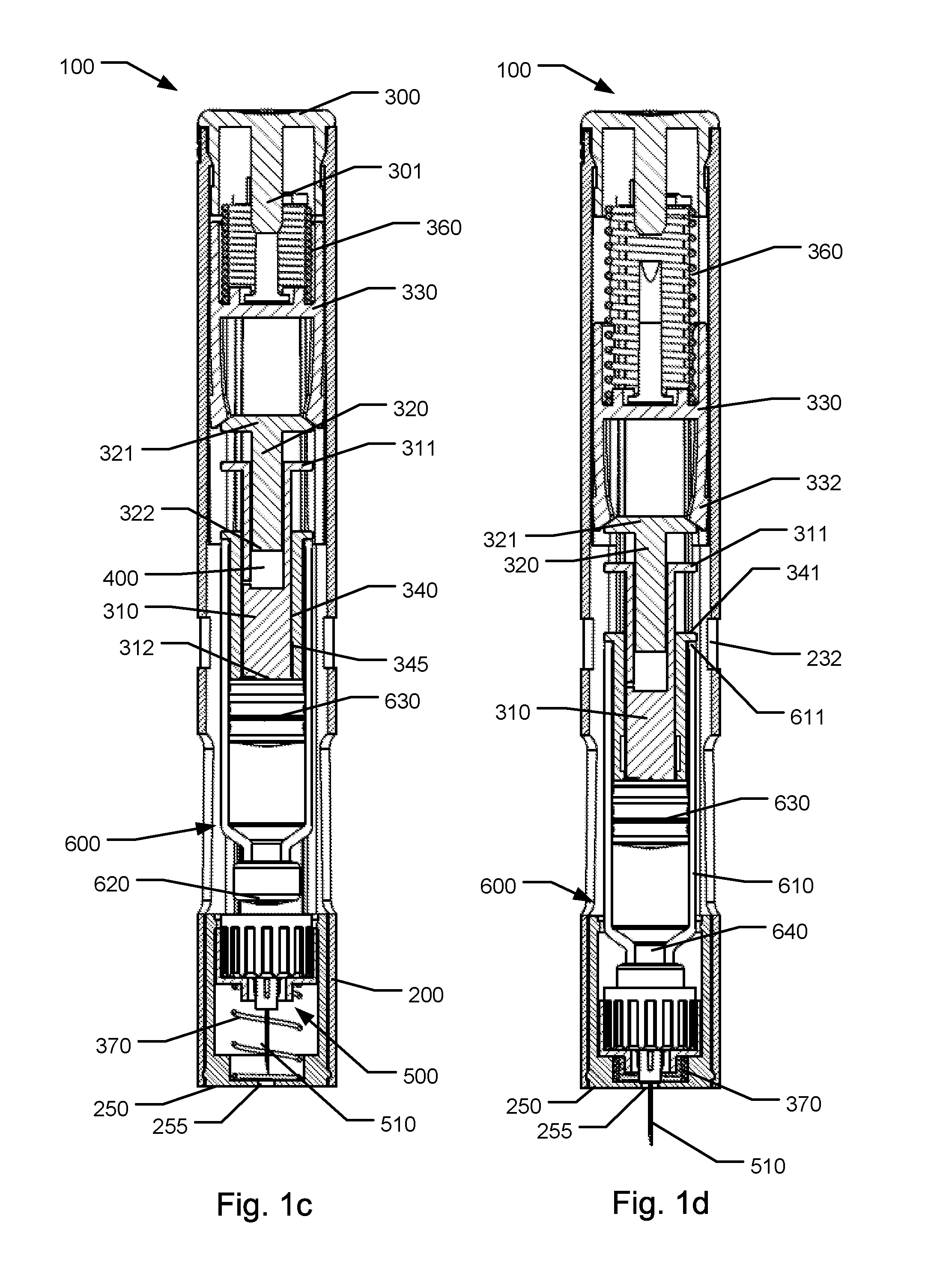

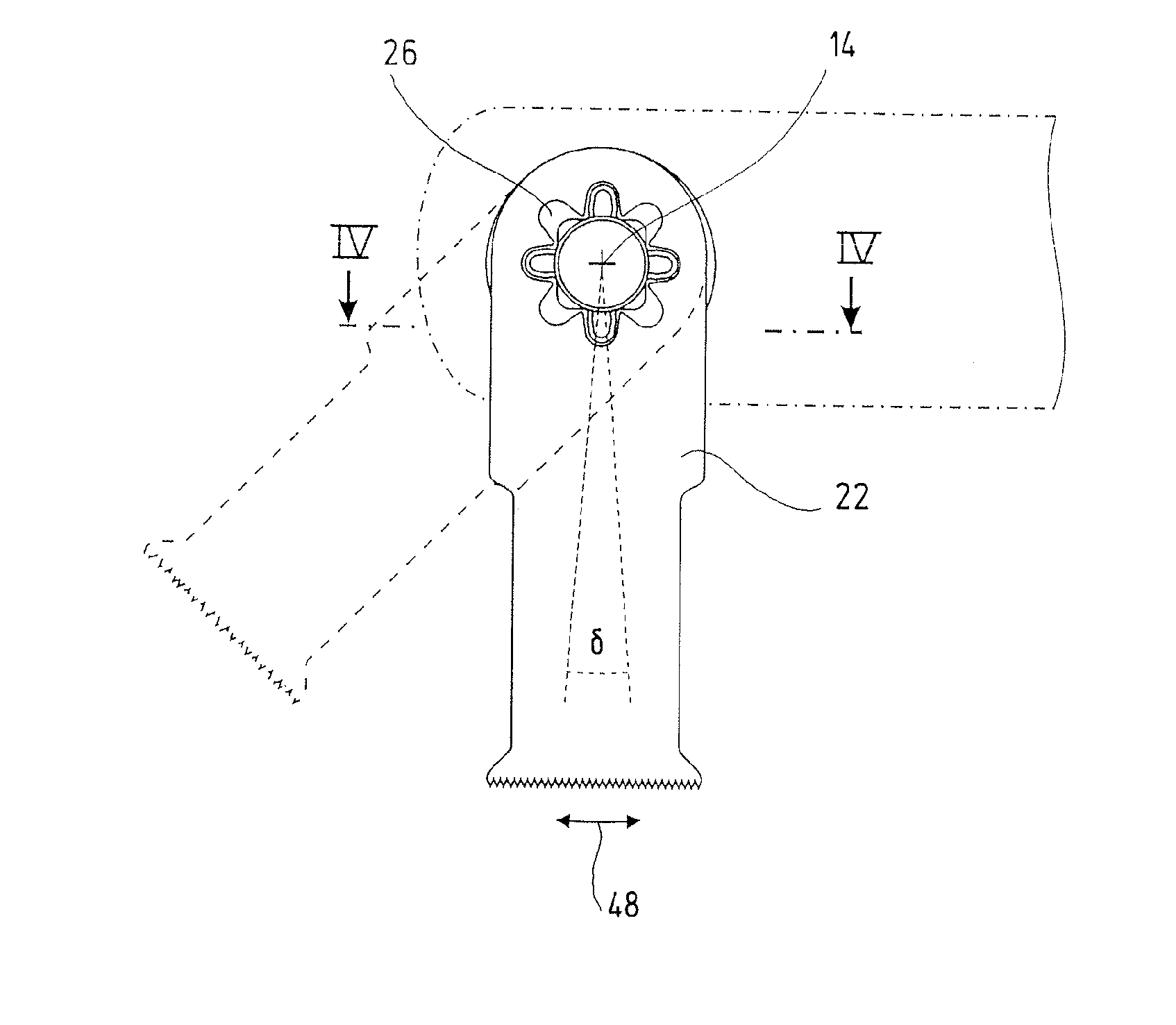

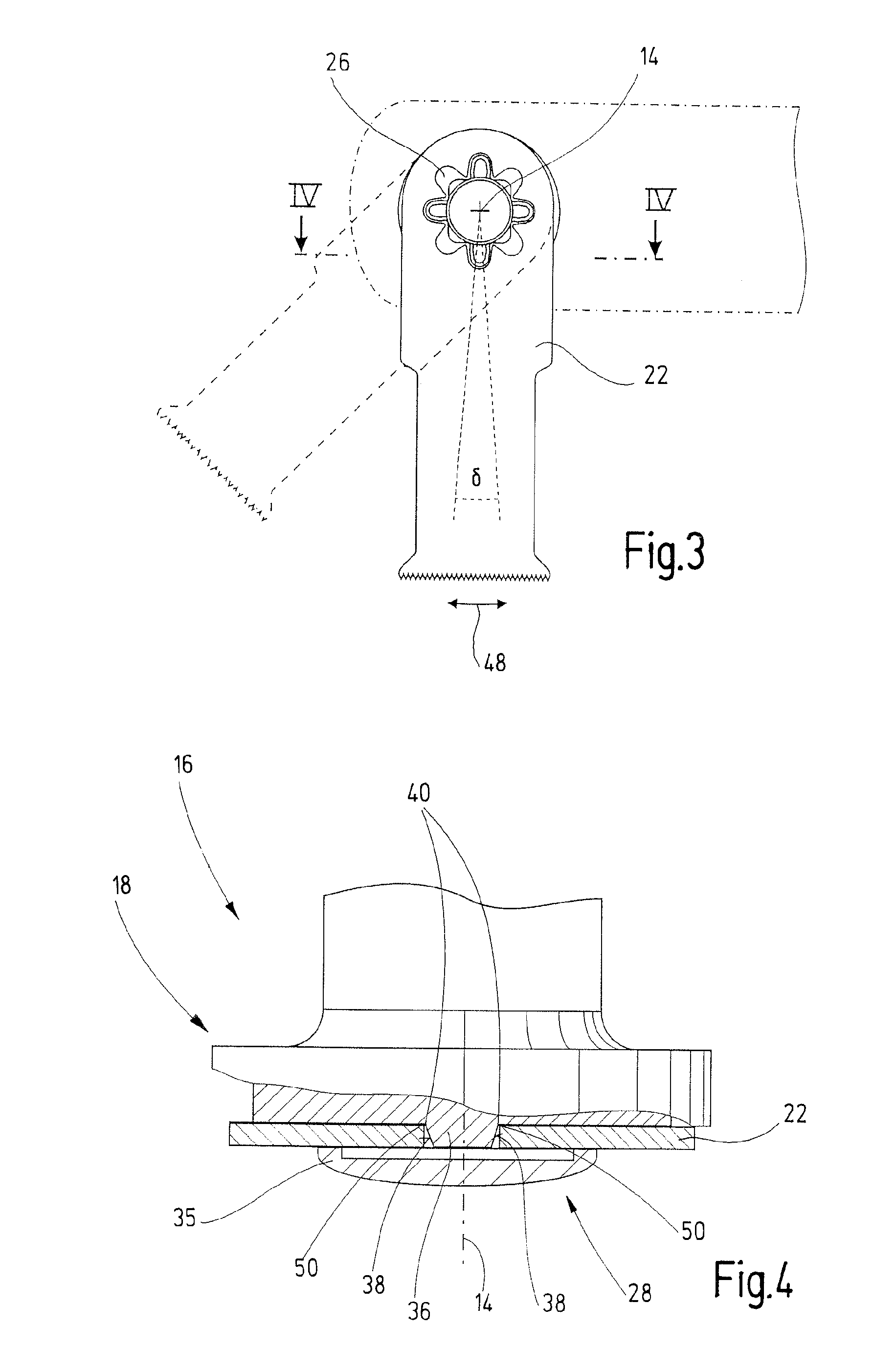

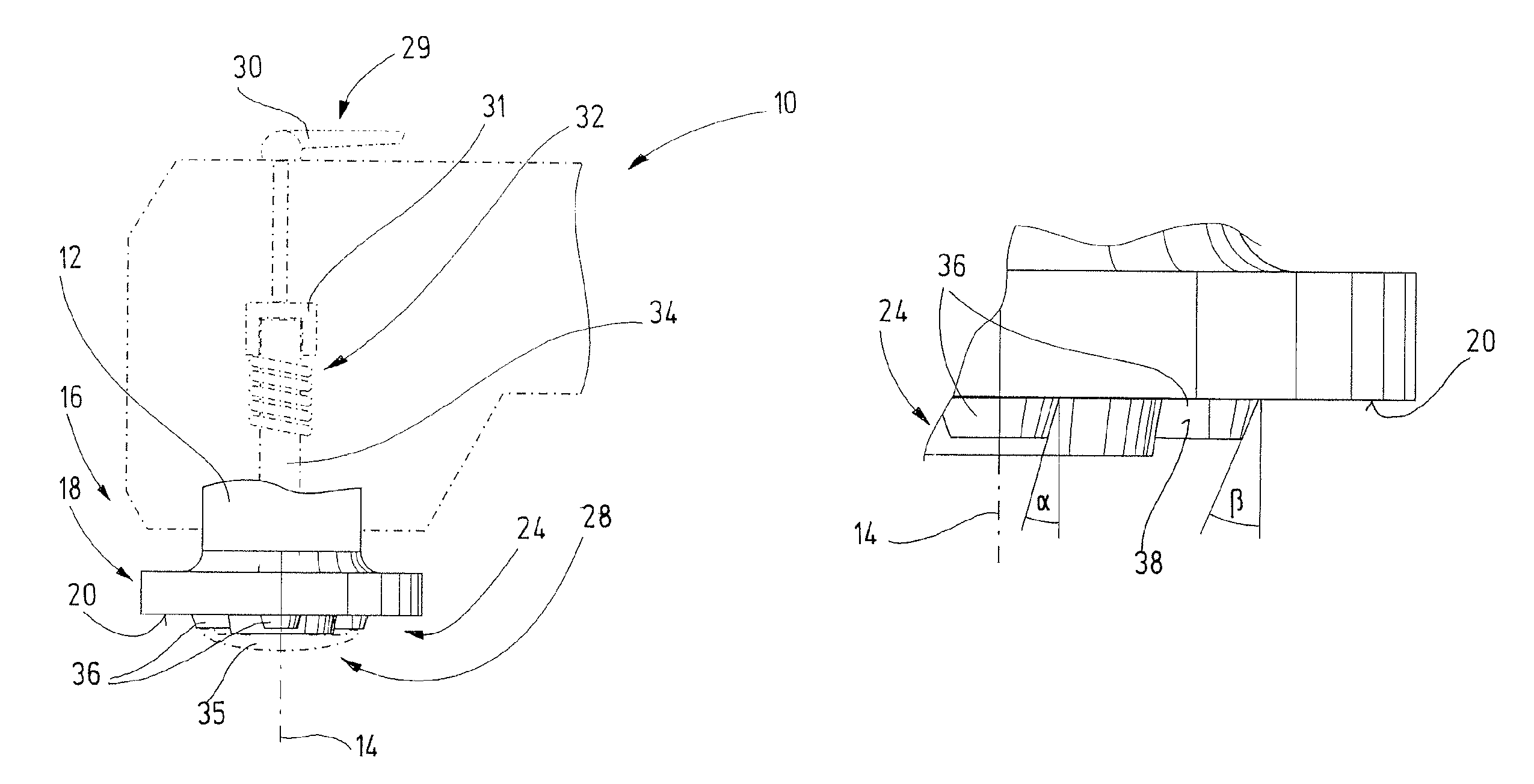

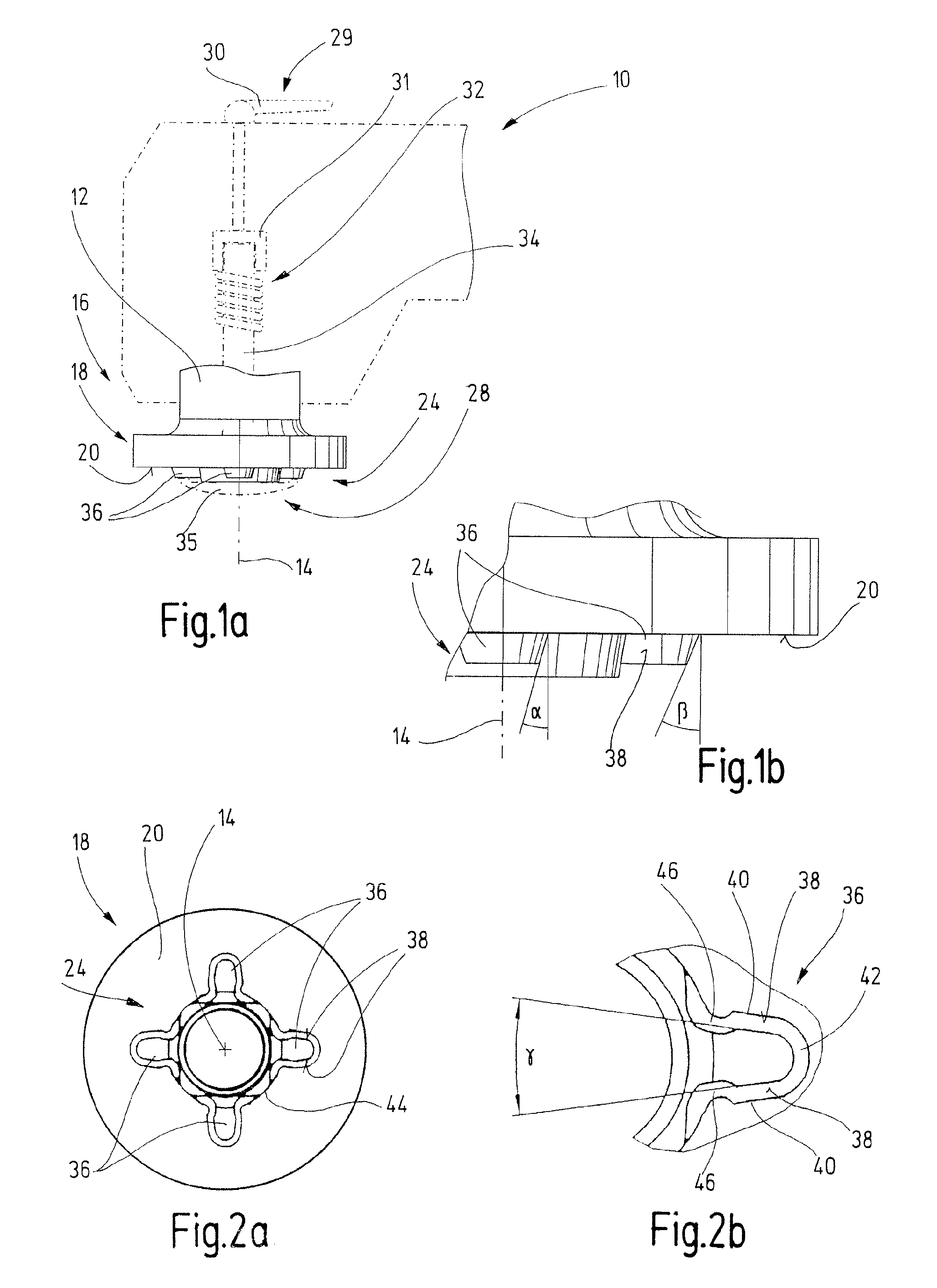

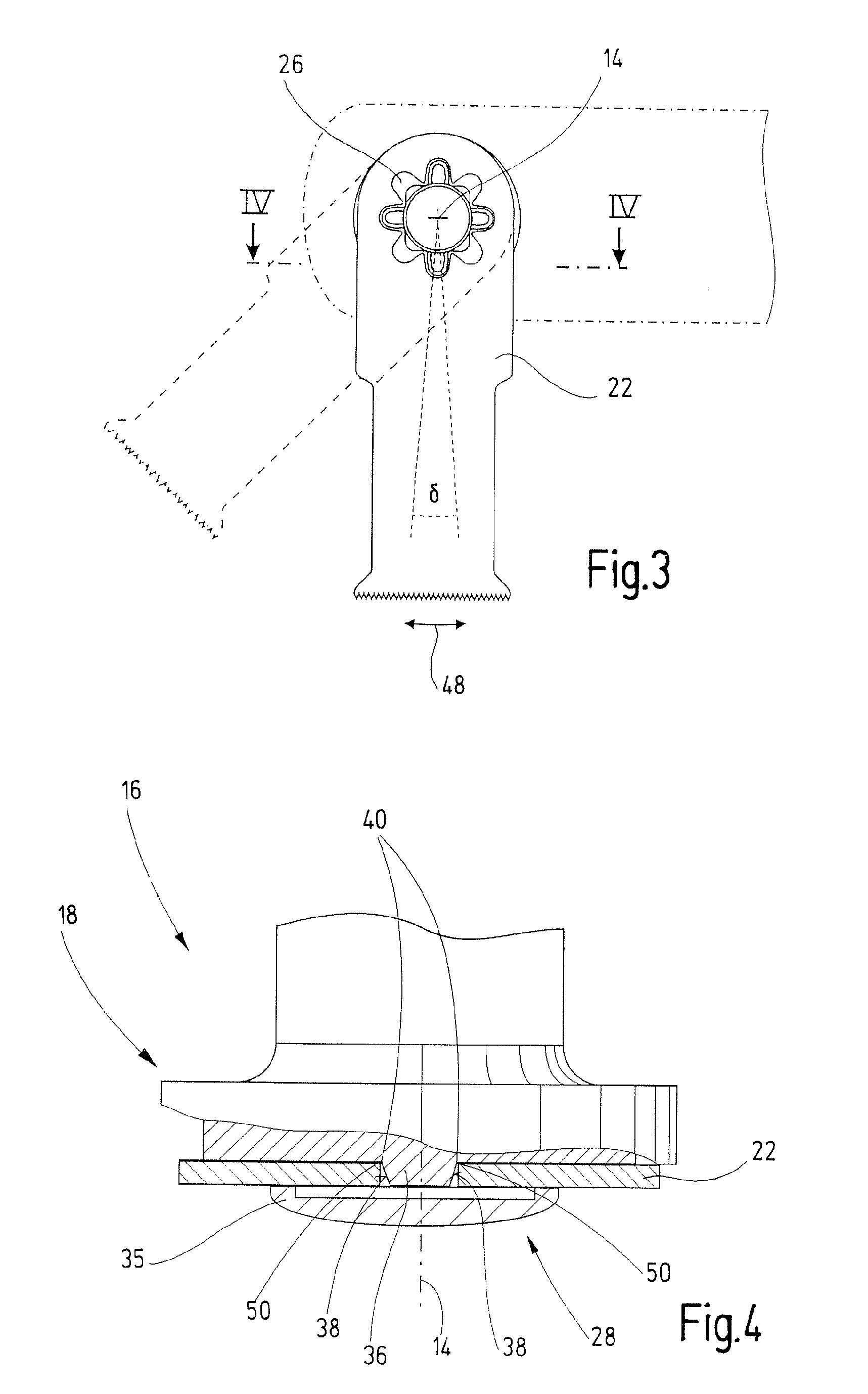

Oscillatory Drive

ActiveUS20070295156A1Reduce disadvantagesImprove transmittanceGrinding wheel securing apparatusTurning machine accessoriesPre stressPre stressing

The invention relates to an oscillatory drive having an output shaft that can be driven to perform a rotationally oscillating movement about its longitudinal axis and that comprises a free end, a holding fixture at the free end of the output shaft comprising a contact surface for attachment of a tool, a mounting section on the holding fixture, raised relative to the contact surface, that projects to the outside in the direction of the longitudinal axis and that is designed for form-locking connection with a mounting opening of a tool placed in contact with the contact surface, and having a securement for fixing the tool with its mounting opening on the holding fixture, the securement permitting the tool to yield in axial direction under the action of a torque, against a pre-stress, and the mounting section permitting the tool to rotate by a certain angle of rotation when the tool gives way axially.

Owner:C & E FEIN

Oscillatory drive

ActiveUS7997586B2Reduce disadvantagesImprove balanceGrinding wheel securing apparatusControlling membersPre stressPre stressing

The invention relates to an oscillatory drive having an output shaft that can be driven to perform a rotationally oscillating movement about its longitudinal axis and that comprises a free end, a holding fixture at the free end of the output shaft comprising a contact surface for attachment of a tool, a mounting section on the holding fixture, raised relative to the contact surface, that projects to the outside in the direction of the longitudinal axis and that is designed for form-locking connection with a mounting opening of a tool placed in contact with the contact surface, and having a securement for fixing the tool with its mounting opening on the holding fixture, the securement permitting the tool to yield in axial direction under the action of a torque, against a pre-stress, and the mounting section permitting the tool to rotate by a certain angle of rotation when the tool gives way axially.

Owner:C & E FEIN GMBH & CO KG

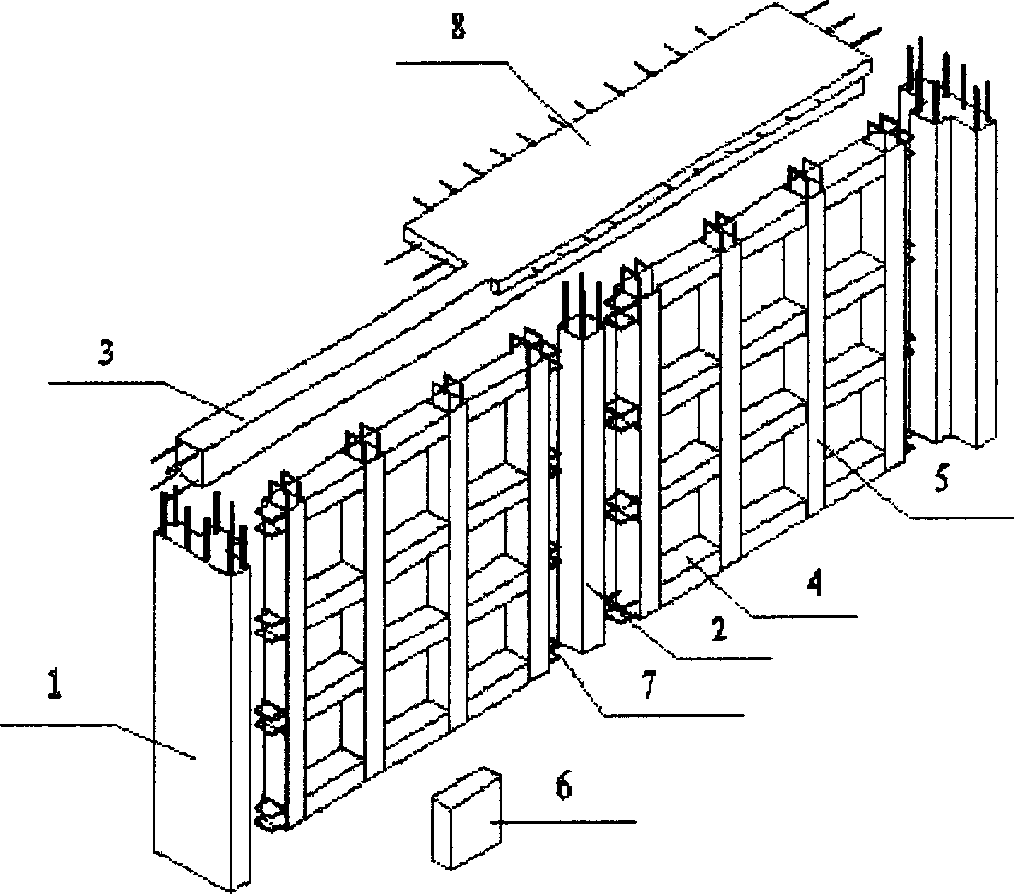

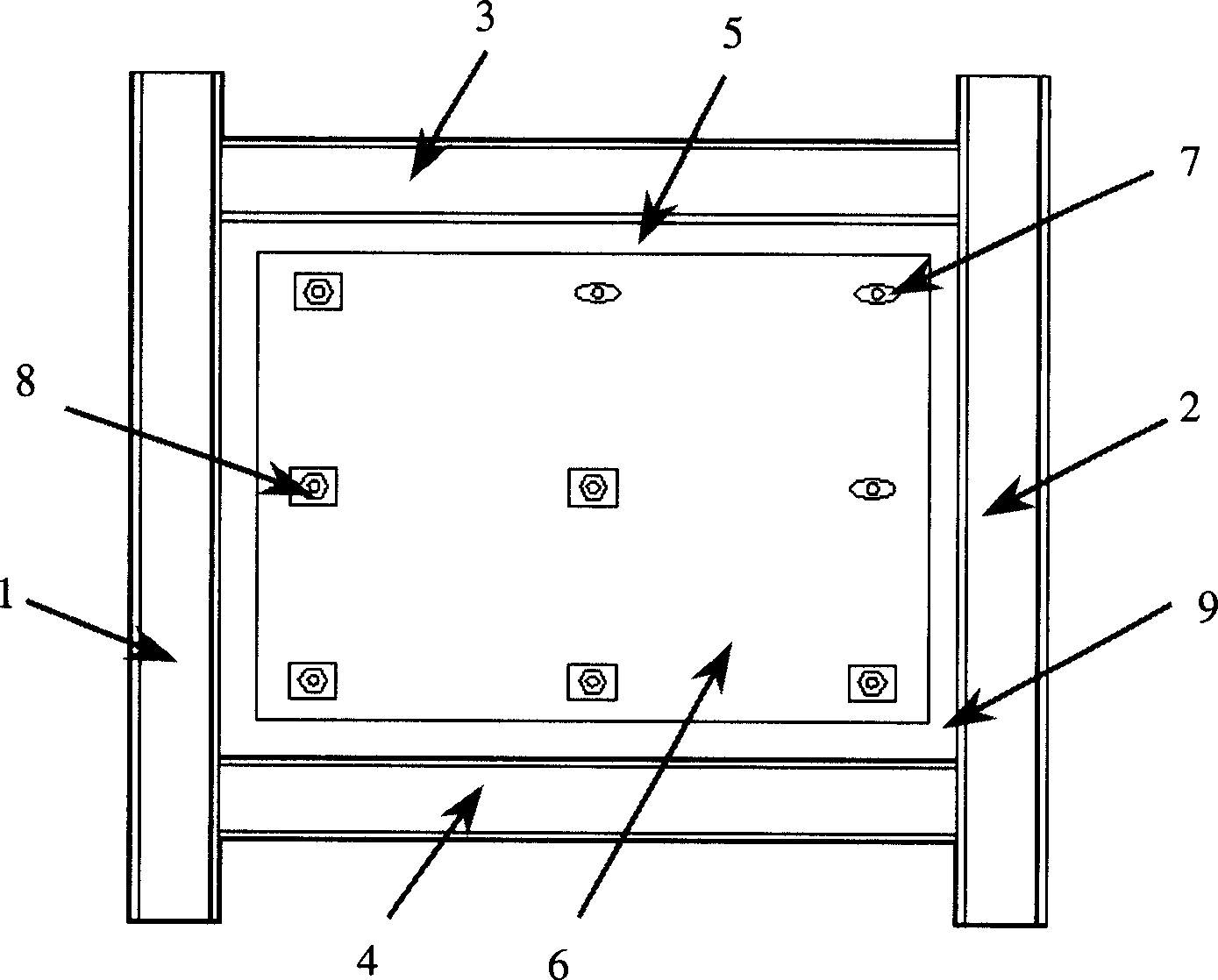

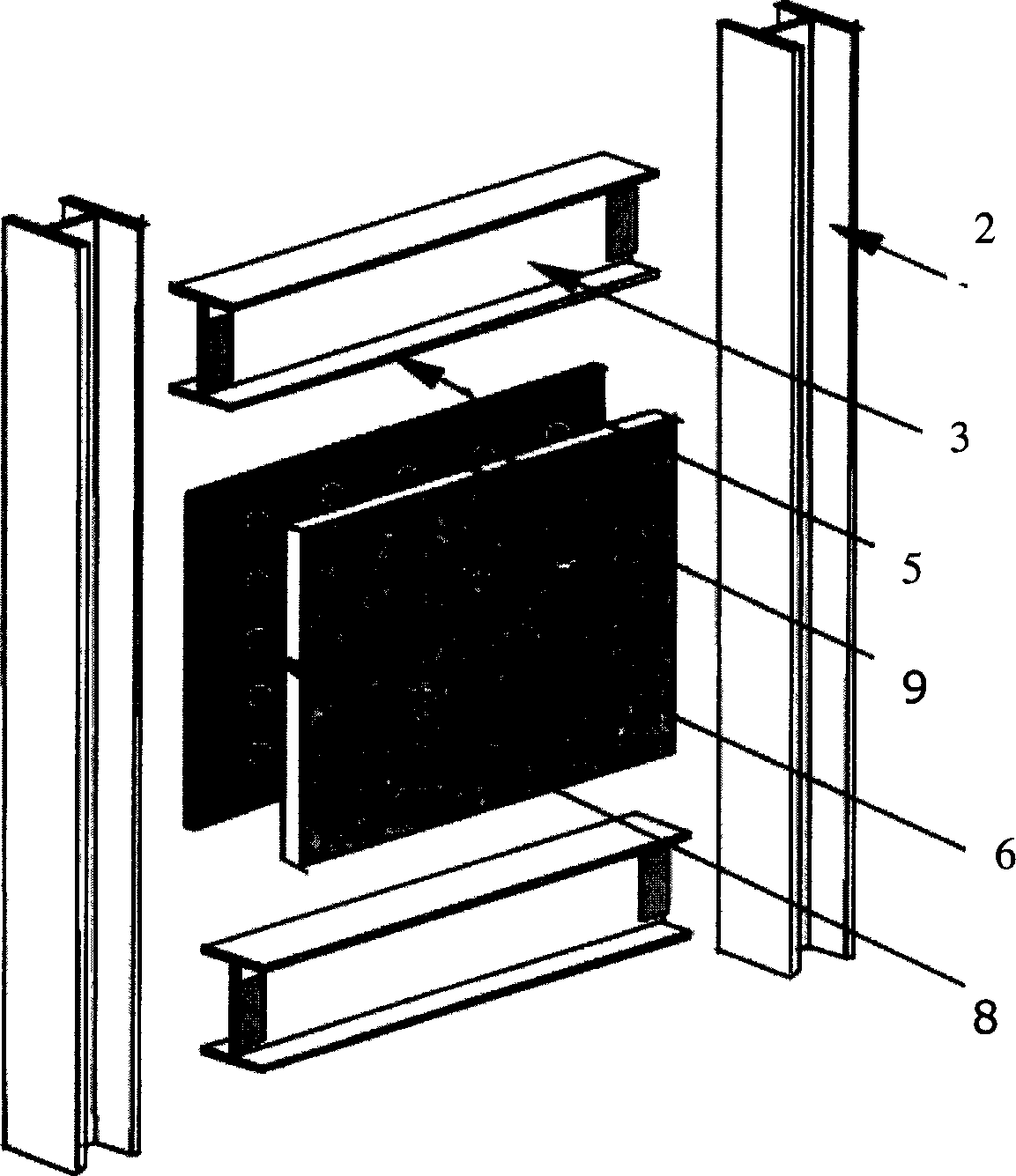

Multi-rib structure system and its connection construction method

InactiveCN1804263AAchieve graded releaseMeet the energy-saving requirements of light buildingsWallsFloor slabPre stressing

The invention relates to a ribbed structure which comprises a ribbed composite wall plate, a hidden frame and a floor. Wherein, the ribbed composite wall plate is a network construction element formed by reinforced steel concrete and light material and divided by the reinforced steel concrete beam as rib beam and rib post in small sections with embedding light material stuffing blocks into the grid; the ribbed composite wall plate also comprises the goatee bar extending from the rib beam and rib post, which is four steel bars with certain anchoring length extending from each rib beam and post and is longitude steel bar whose end is a hook in connection to hook hidden frame; or else the goatee bars are two U-shape closed ring extending from each rob beam an post and is inserted with longitude steel bars in connection; the hidden frame is formed by outer frame post, connection post, and hidden beam which are embedded outside the ribbed composite wall plate while using common concrete, profiled bar concrete or steel structural beam and post; the stuffing material is made from light material with certain strength, volume weight and little elastic modulus; and the floor can select on-situ irrigating concrete, on-sit or prefabricated ribbed composite floor, pre-stress layered floor or special-shaped pre-stress hollow floor.

Owner:姚谦峰

High-strength microwave antenna assemblies

InactiveUS20050062666A1High strengthAvoid mechanical failureSurgical needlesSurgical instruments for heatingAntenna designElectrical conductor

Various high-strength microwave antenna assemblies are described herein. The microwave antenna has a radiating portion connected by a feedline to a power generating source, e.g., a generator. The antenna is a dipole antenna with the distal end of the radiating portion being tapered and terminating at a tip to allow for direct insertion into tissue. Antenna rigidity comes from placing distal and proximal radiating portions in a pre-stressed state, assembling them via threaded or overlapping joints, or fixedly attaching an inner conductor to the distal portion. The inner conductor is affixed to the distal portion by, e.g., welding, brazing, soldering, or by adhesives. A junction member made from a hard dielectric material, e.g., ceramic, can be placed between the two portions and can have uniform or non-uniform shapes to accommodate varying antenna designs. Electrical chokes may also be used to contain returning currents to the distal end of the antenna.

Owner:TYCO HEALTHCARE GRP LP

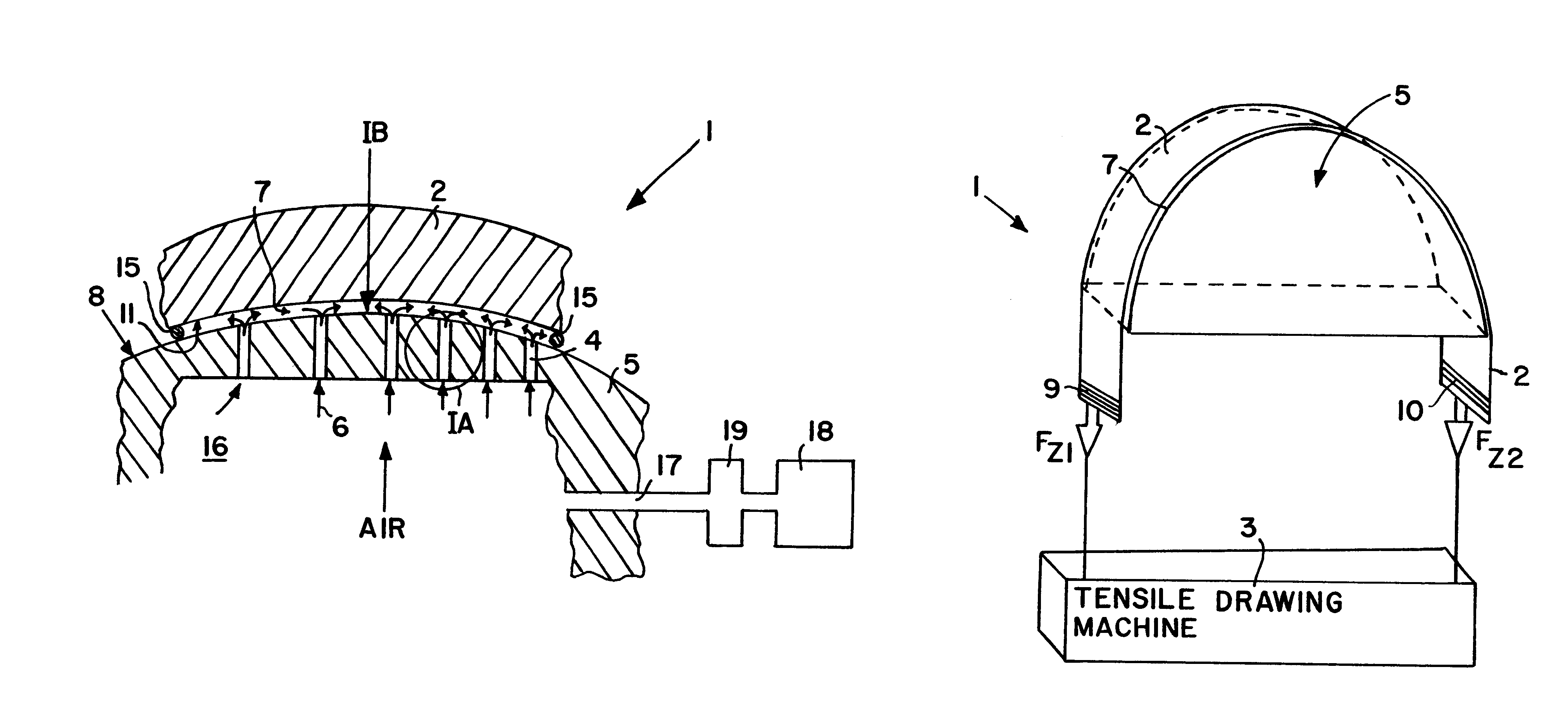

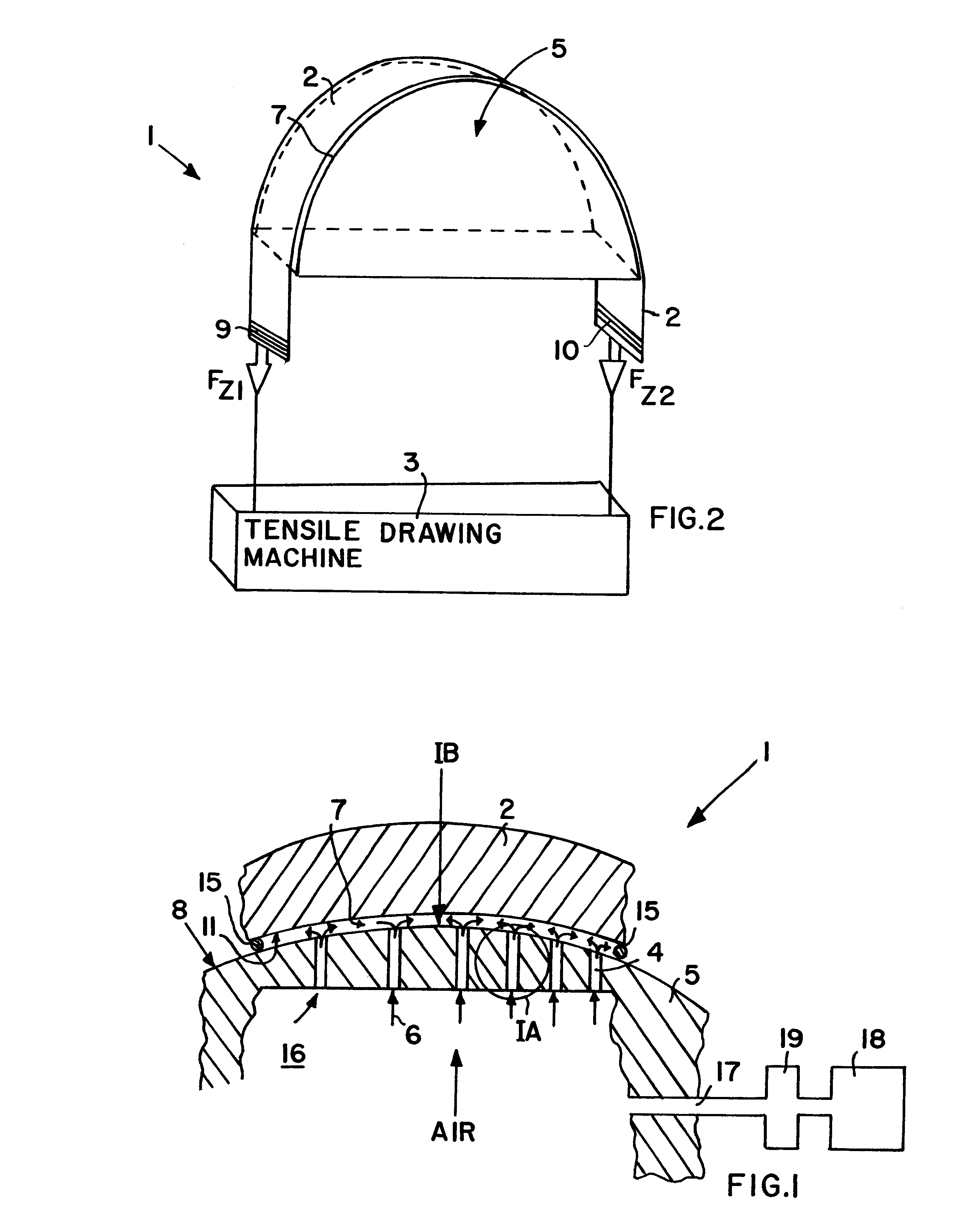

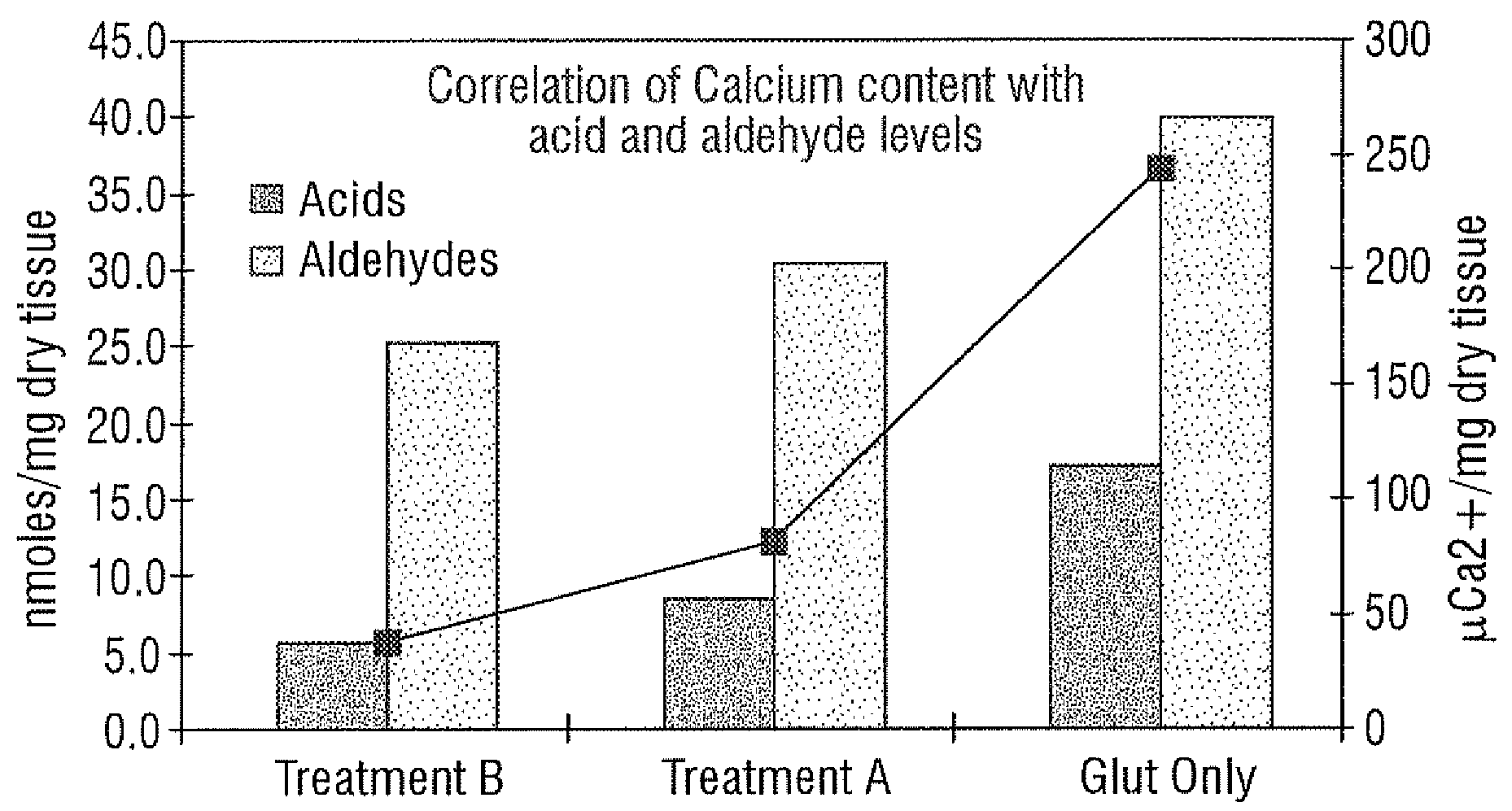

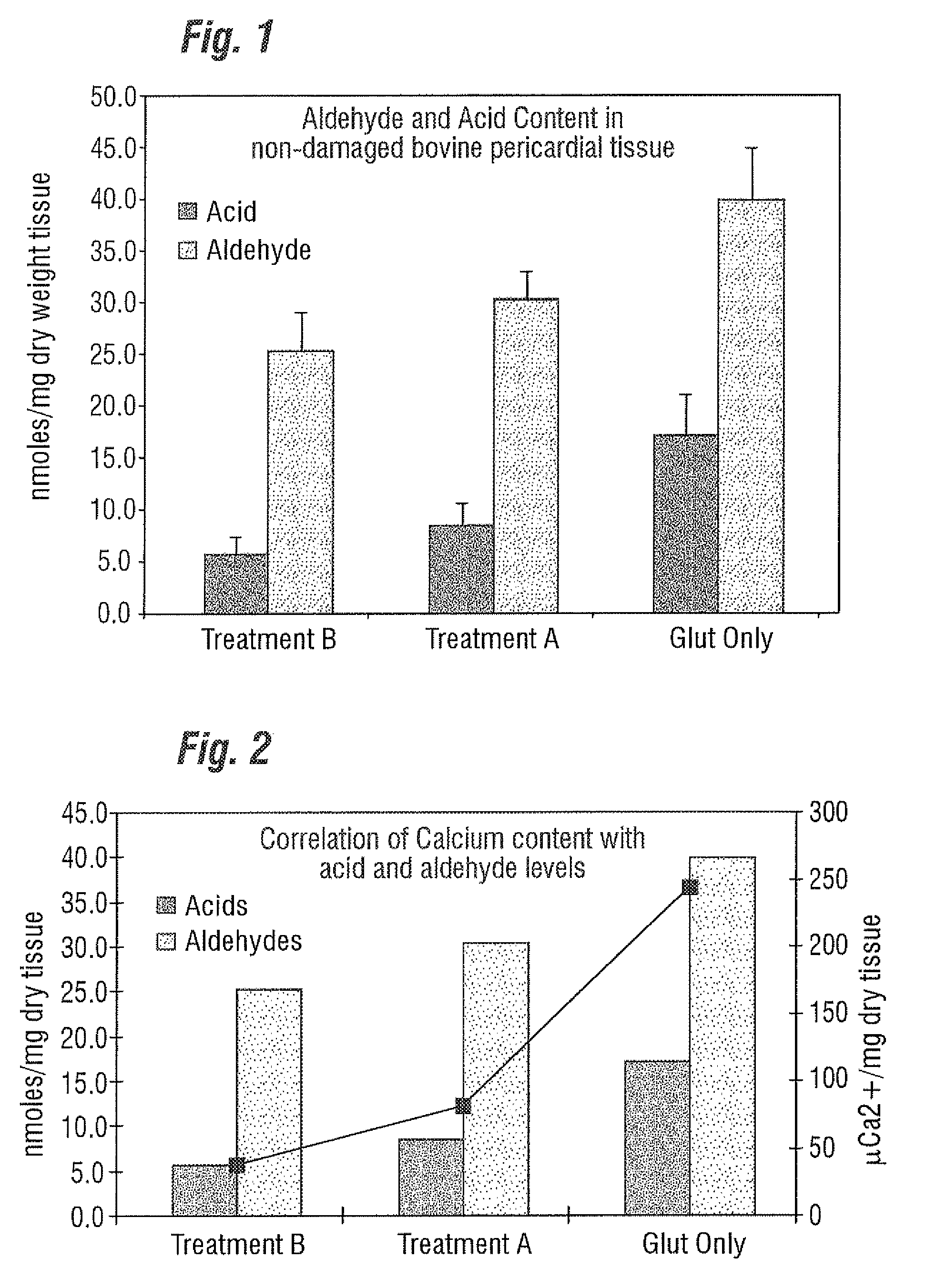

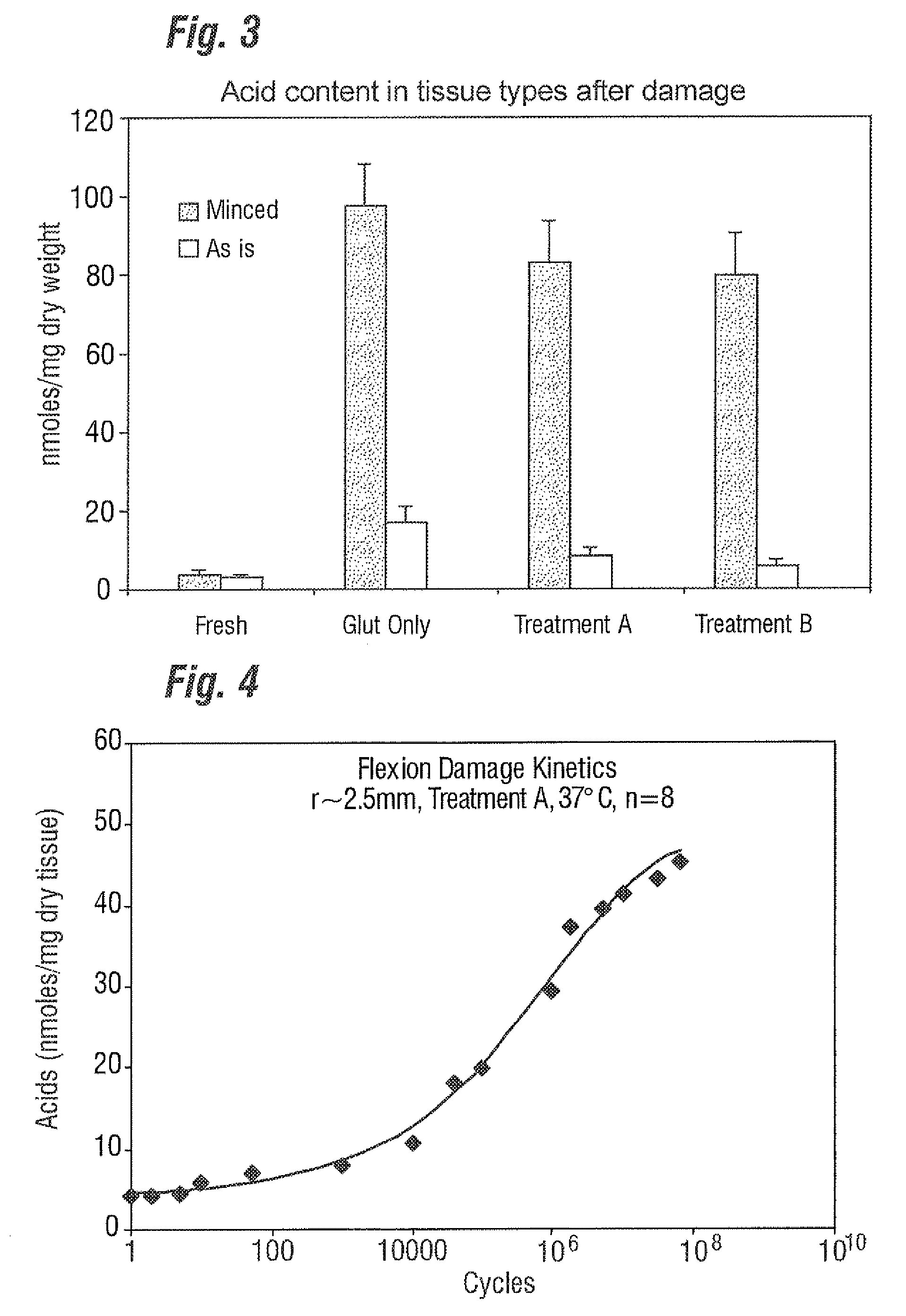

Methods for pre-stressing and capping bioprosthetic tissue

ActiveUS20080302372A1Reduce in vivo calcificationSuture equipmentsHeart valvesDamages tissuePhosphate

A treatment for bioprosthetic tissue used in implants or for assembled bioprosthetic heart valves to reduce in vivo calcification is disclosed. The method includes preconditioning, pre-stressing, or pre-damaging fixed bioprosthetic tissue in a manner that mimics the damage associated with post-implant use, while, and / or subsequently applying a calcification mitigant such as a capping agent or a linking agent to the damaged tissue. The capping agent suppresses the formation of binding sites in the tissue that are exposed or generated by the damage process (service stress) and otherwise would, upon implant, attract calcium, phosphate, immunogenic factors, or other precursors to calcification. The linking agent will act as an elastic reinforcement or shock-absorbing spring element in the tissue structure at the site of damage from the pre-stressing. In one method, tissue leaflets in assembled bioprosthetic heart valves are preconditioned by simulating actual flow conditions for a predetermined number of cycles, during or after which the valve is exposed to the capping agent.

Owner:EDWARDS LIFESCIENCES CORP

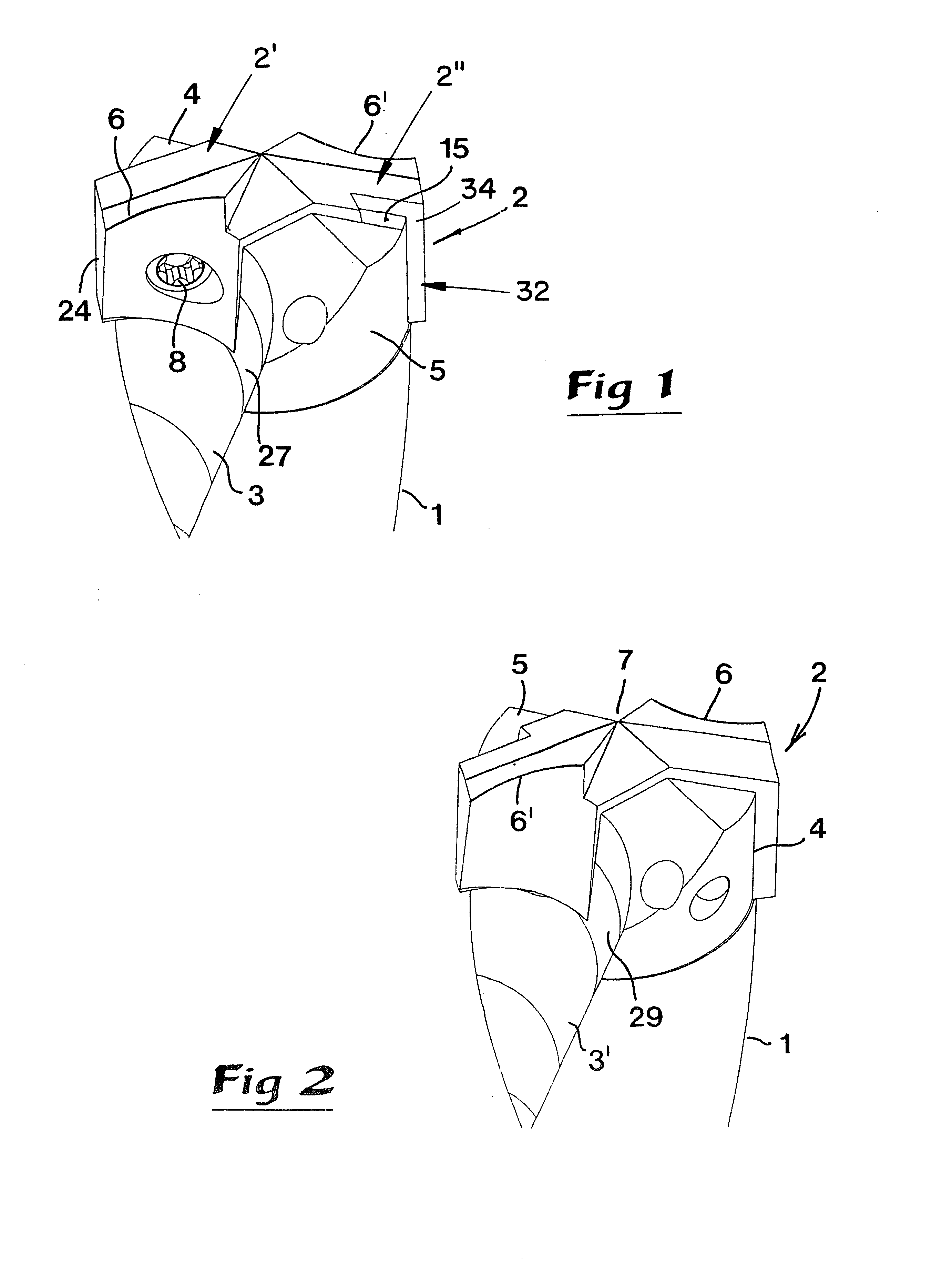

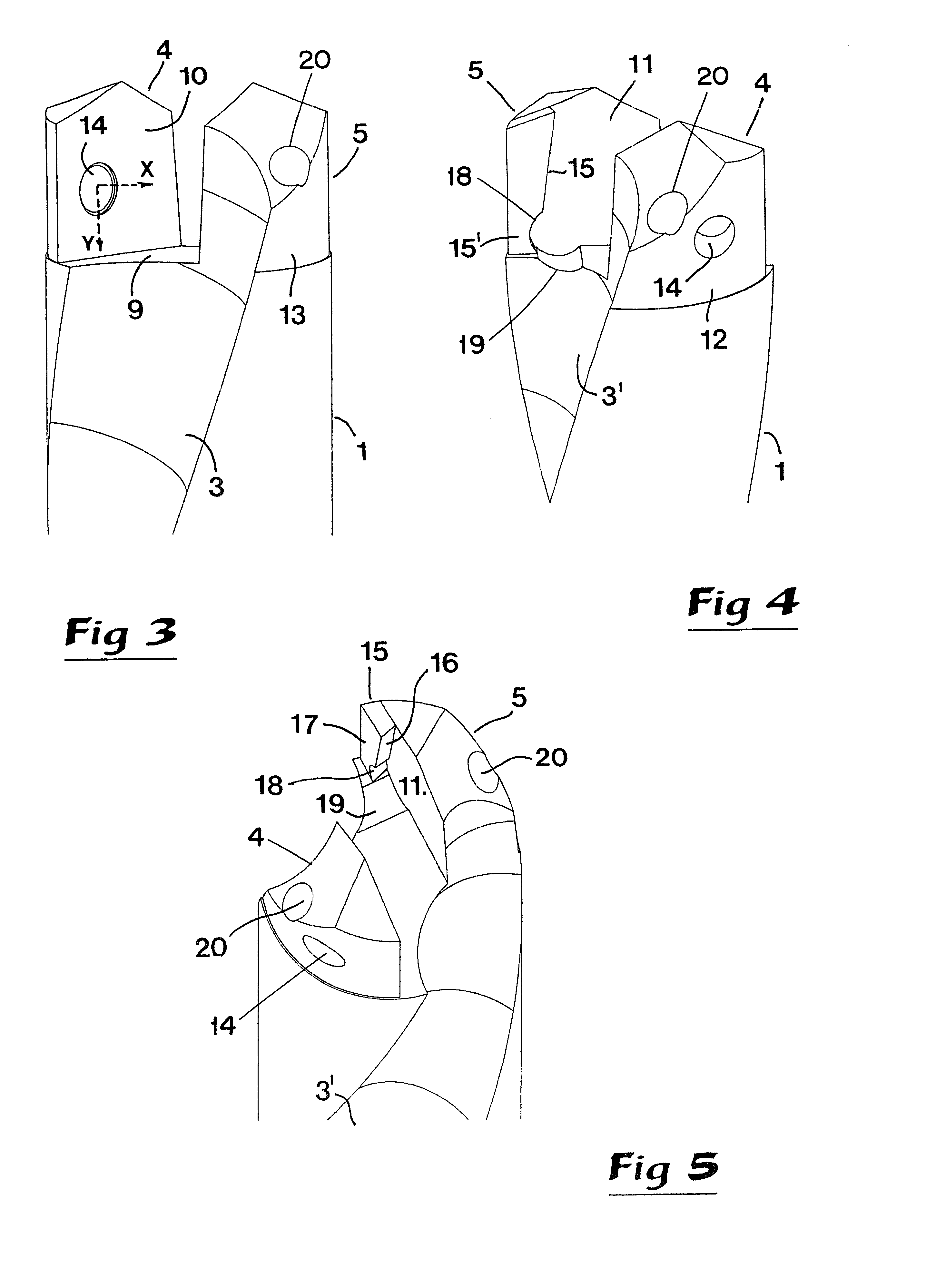

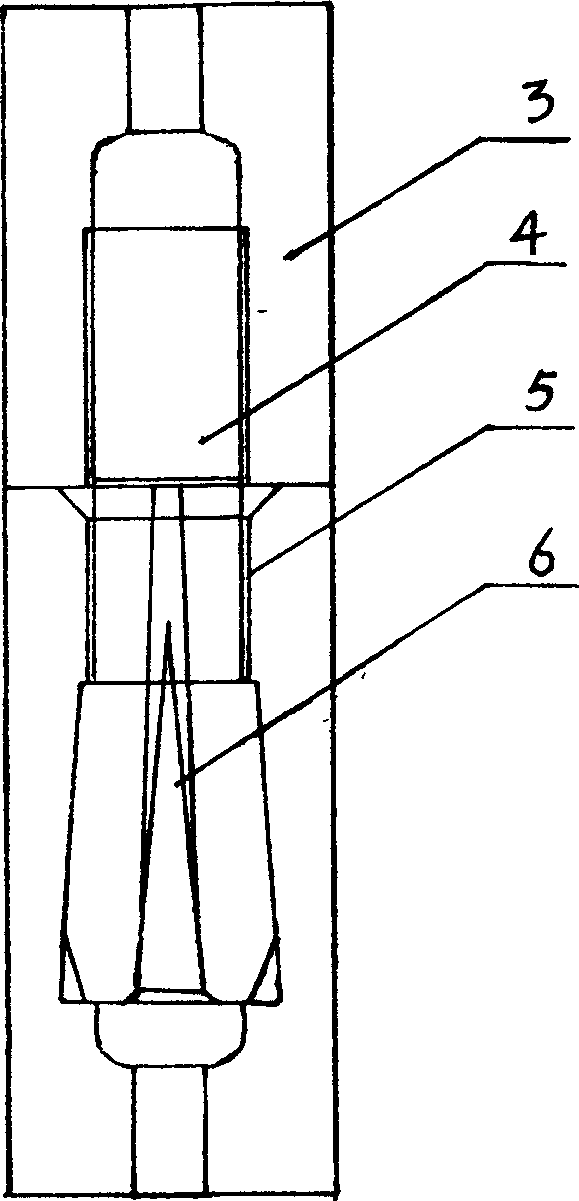

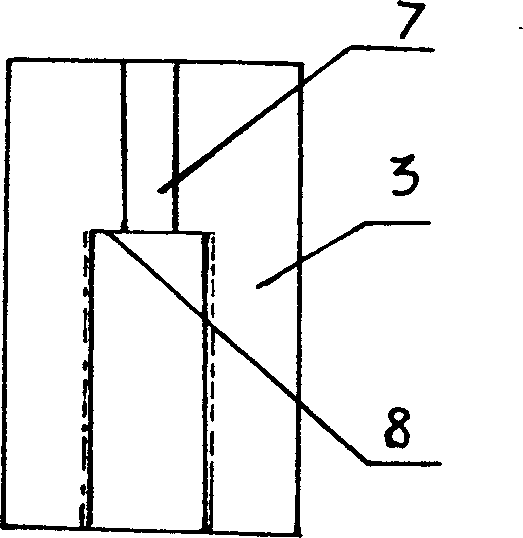

Drilling tool including a shank and a cutting body detachably secured thereto

InactiveUS6481938B2The way is simple and fastImprove cooling effectWood turning toolsTransportation and packagingPre stressPre stressing

A drilling tool includes a shaft having a front end to which a cutting body provided with cutting edges is detachably connected. In the front end of the shaft, a seat is formed which is delimited by spaced-apart protrusions between which there is a bottom surface. In the protrusion, there is a threaded hole for a screw, which when tightened applies pre-stressing forces to the cutting body. On the inside of the opposite protrusion, there is a supporting shoulder against which the cutting body is pressed when the screw is tightened and applies a lateral pre-stressing force to the cutting body. The protrusions are laterally displaced in relation to each other in order to freely expose the screw beside one of the protrusions.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

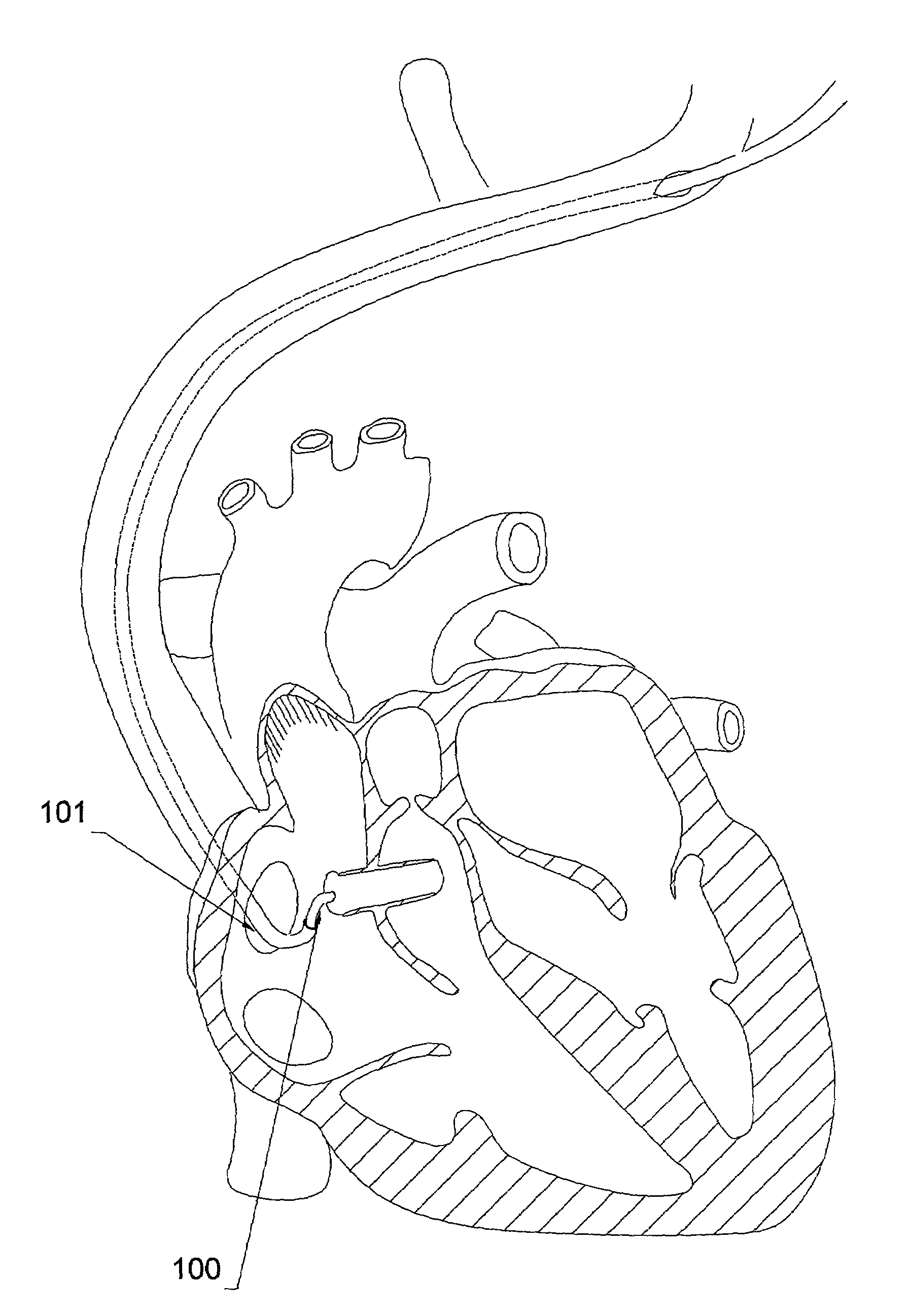

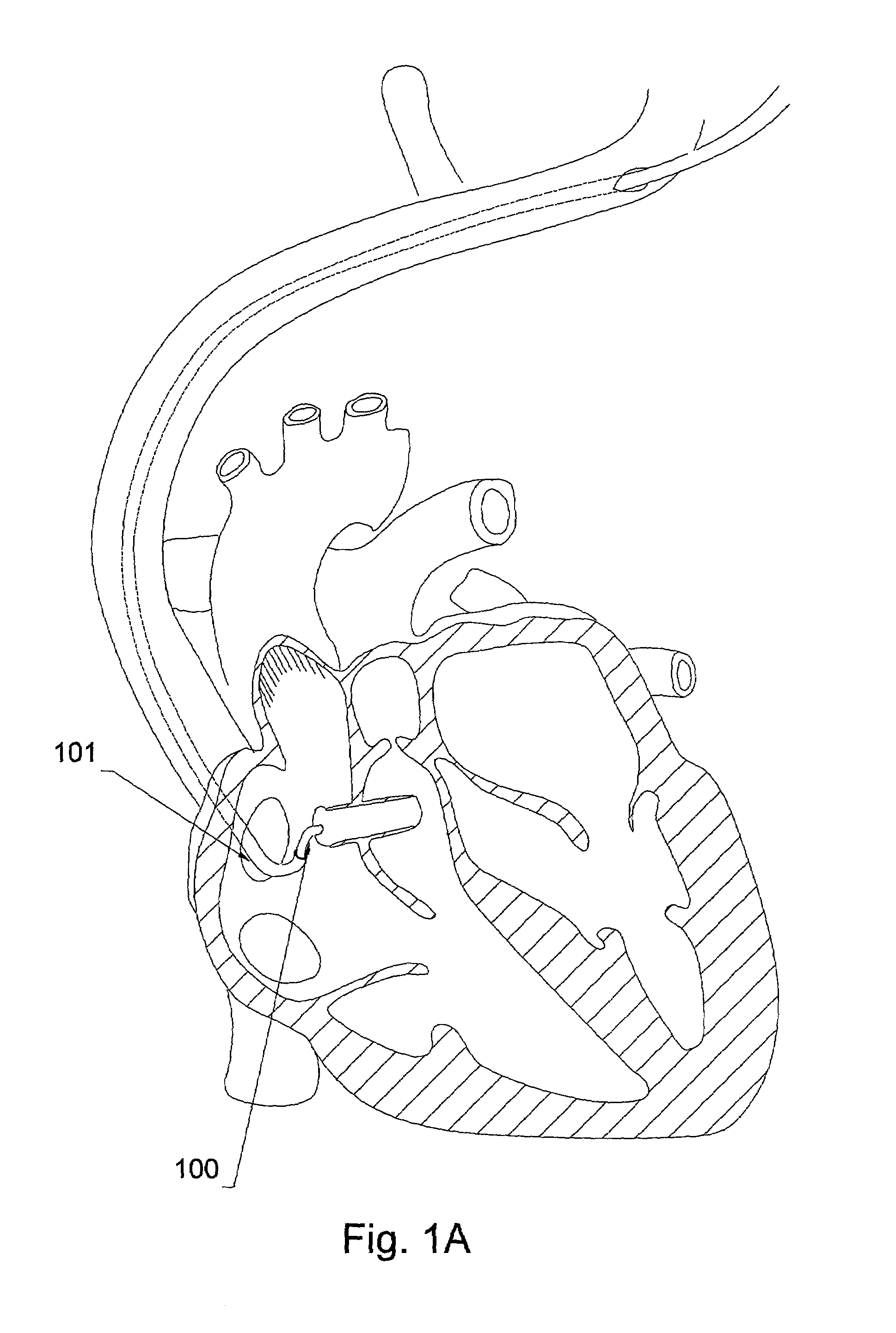

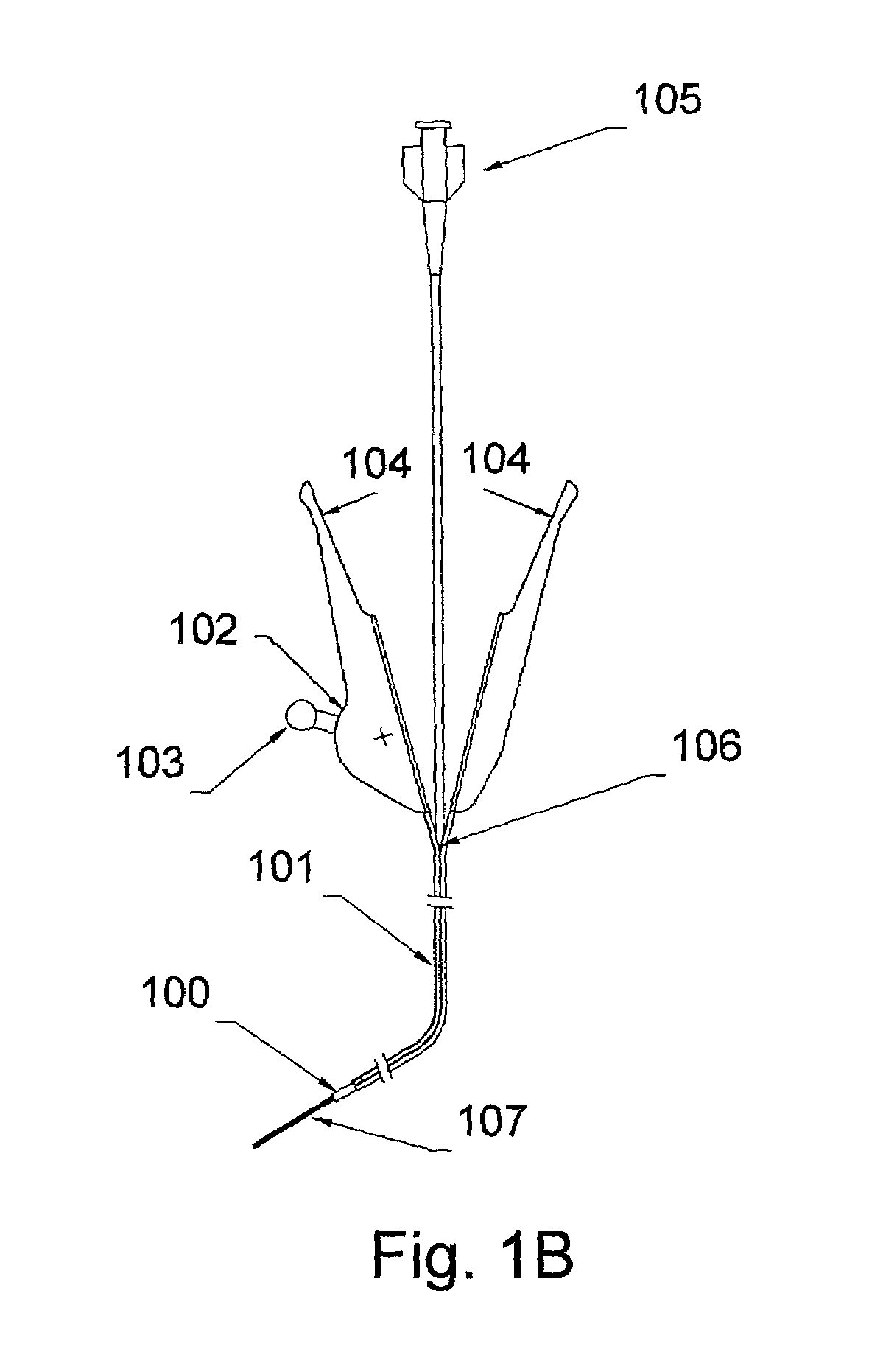

Telescoping guide catheter with peel-away outer sheath

A guide catheter employs a retractable inner guide movably disposed within an open lumen of a splittable outer guide. The outer guide includes a longitudinal pre-stress line extending from distal to proximal ends. The inner guide includes an open lumen adapted to receive a payload. The inner guide is translatable and rotatable relative to the outer guide. The guide catheter further includes a proximally attached guide handle which is separable into at least two sections. Separation of the guide handle splits the proximal end of the outer guide. Proximal outer guide retraction continues the splitting of the outer guide along the longitudinal pre-stress line.

Owner:CARDIAC PACEMAKERS INC

Bone-conduction hearing-aid transducer having improved frequency response

InactiveUS7822215B2Simplified component countRecord carriersBone conduction transducer hearing devicesBone structureFrequency spectrum

A hearing-aid device and a method for transmitting sound through bone conduction are disclosed. The hearing-aid device comprises a piezoelectric-type actuator, housing and connector. The piezoelectric actuator is preferably a circular flextensional-type actuator mounted along its peripheral edge in a specifically designed circular structure of the housing. During operation, the bone-conduction transducer is placed against the mastoid area behind the ear of the patient. When the device is energized with an alternating electrical voltage, it flexes back and forth like a circular membrane sustained along its periphery and thus, vibrates as a consequence of the inverse piezoelectric effect. Due to the specific and unique designs proposed, these vibrations are directly transferred through the human skin to the bone structure (the skull) and provide a means for the sound to be transmitted for patients with hearing malfunctions. The housing acts as a holder for the actuators, as a pre-stress application platform, and as a mass which tailors the frequency spectrum of the device. The apparatus exhibits a performance with a very flat response in the frequency spectrum 200 Hz to 10 kHz, which is a greater spectrum range than any other prior art devices disclosed for bone-conduction transduction which are typically limited to less than 4 kHz.

Owner:FACE INT

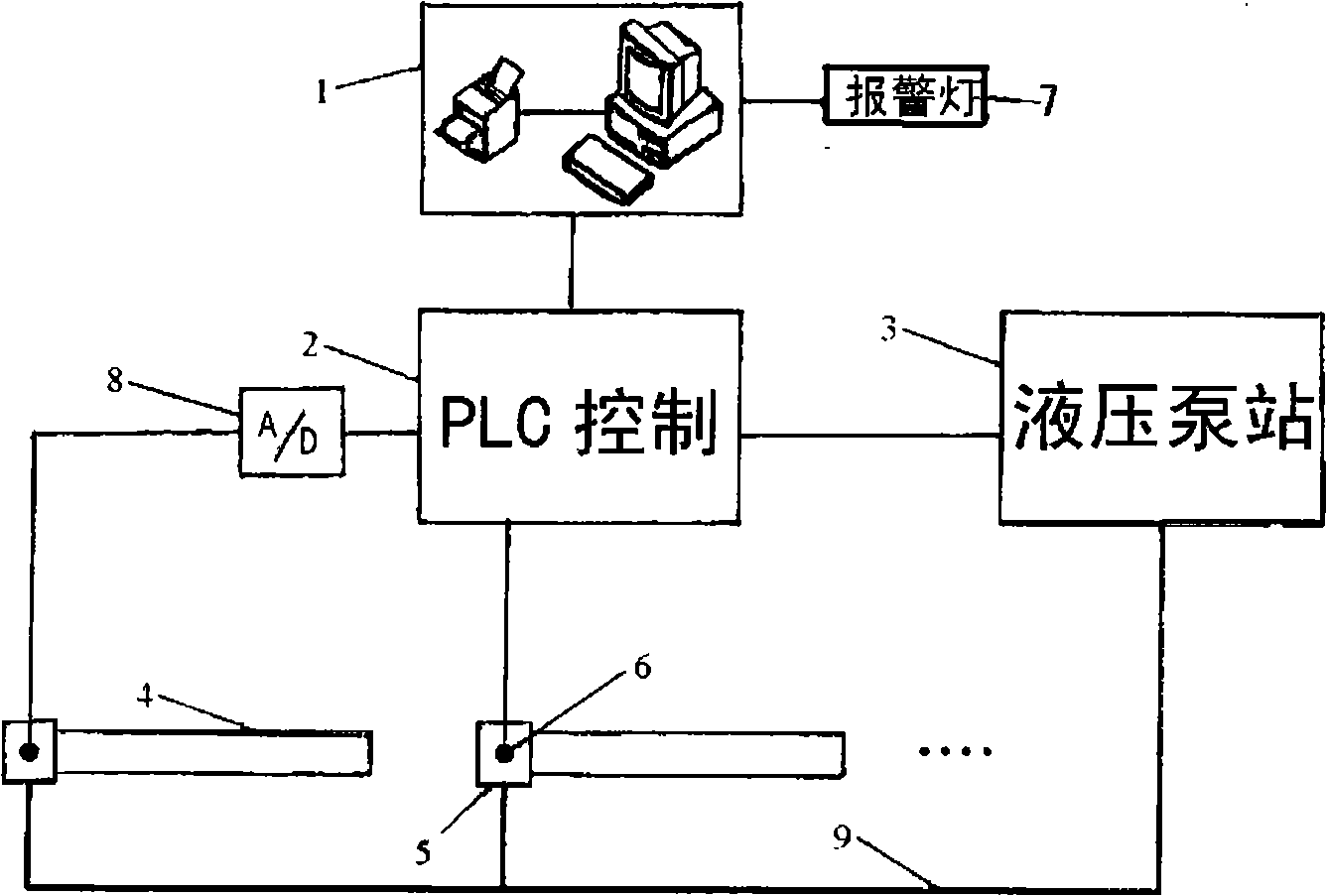

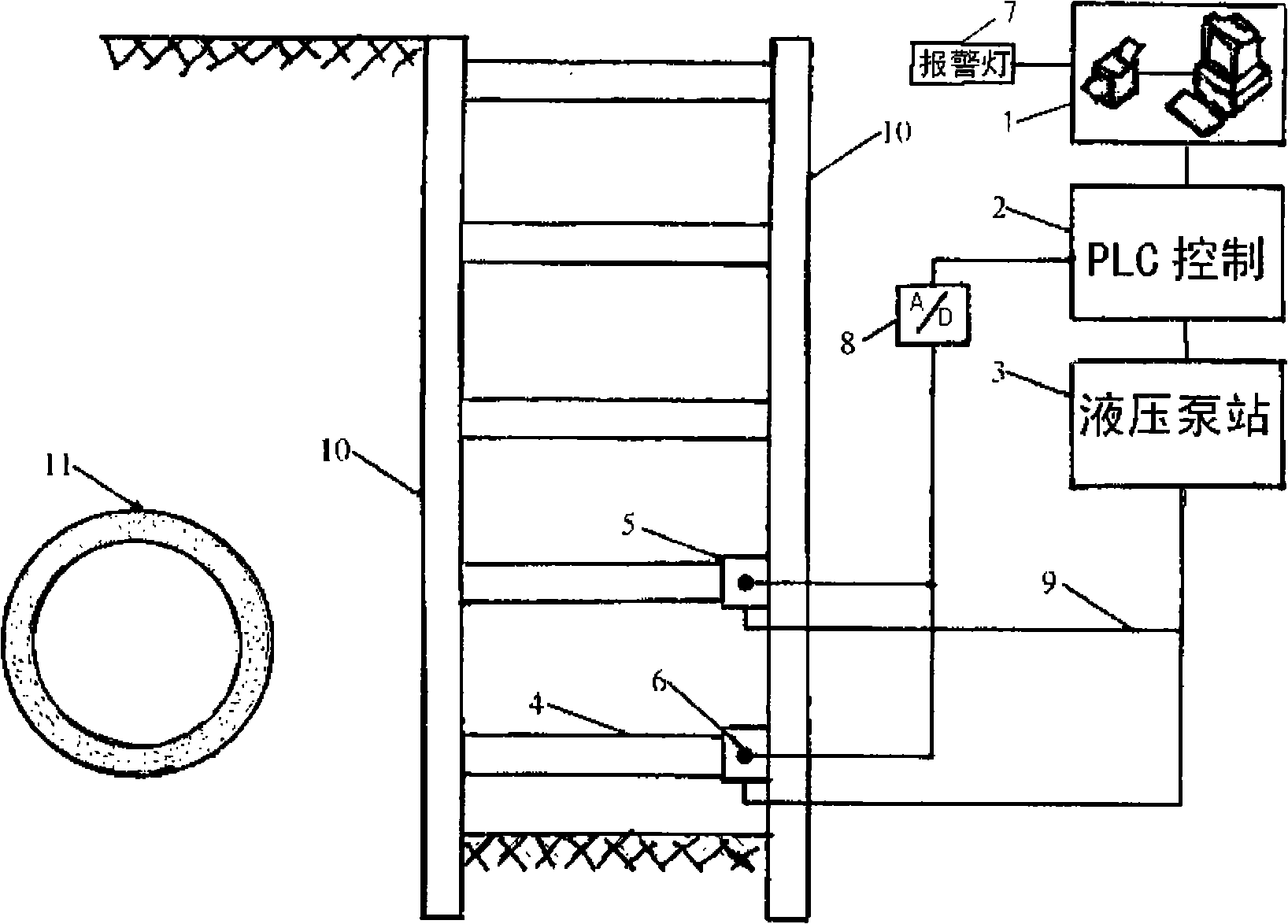

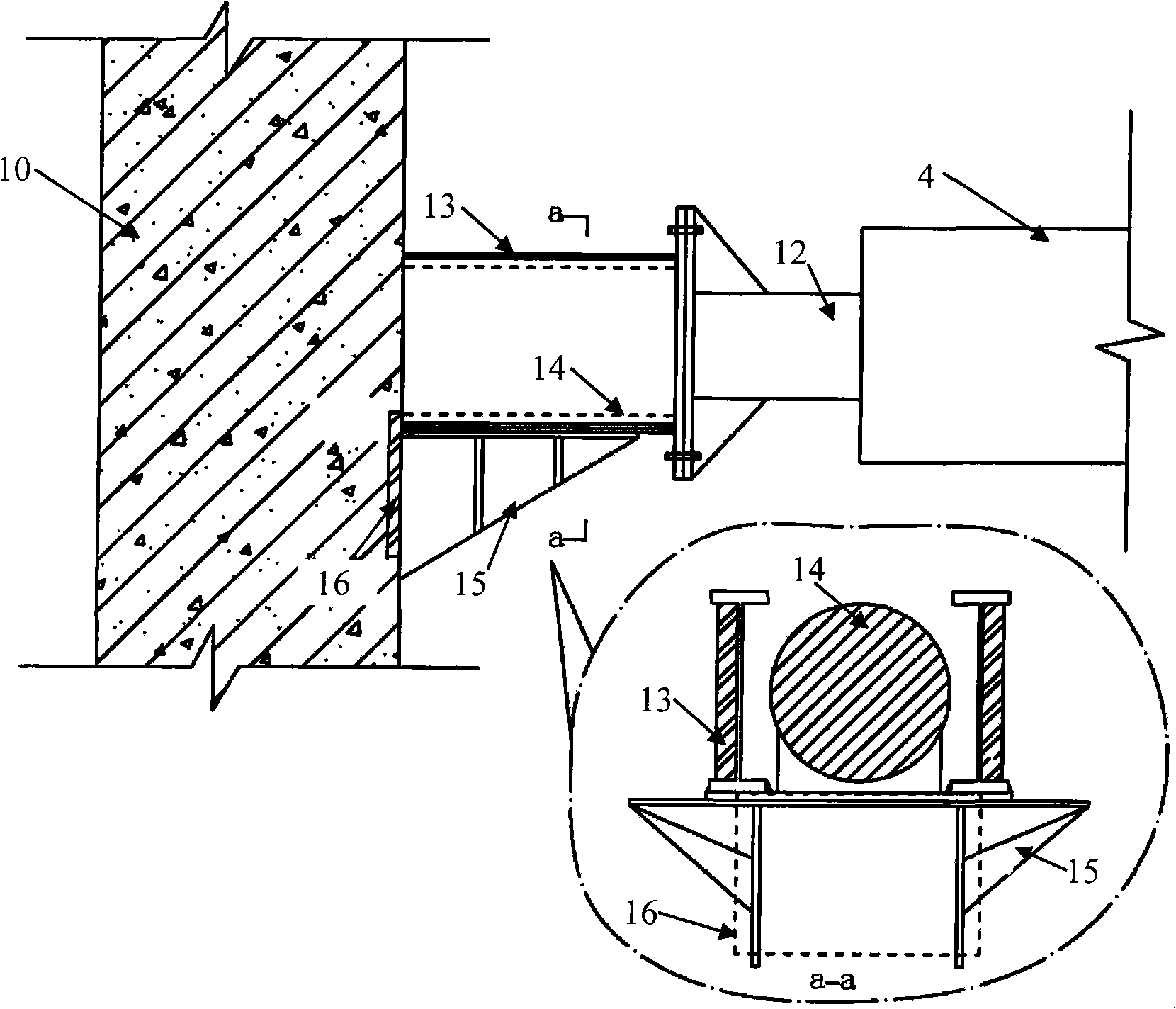

Steel shotcrete support internal force self-compensation, displacement control system and control method

InactiveCN101294389AImprove the force deformation performanceControl deformationExcavationsShotcreteAutomatic control

The invention belongs to the building support component technology field including the stress automatic control and monitoring as well as the structural safety, and relates to a steel tube supporting internal force automatic compensating and displacement controlling system. The system comprises an upper system, a PLC control system module and a field executive system. A steel support is arranged on a reinforced concrete diaphragm wall, a hydraulic jack is arranged on the steel support, and real time pressure monitoring values are fed back through a pressure sensor. The steel support and the hydraulic jack form a pre-stressed steel support structure, the hydraulic jack is connected with a hydraulic pump station through an oil circuit, and is connected with the PLC control system module through the pressure sensor, the hydraulic pump station is connected with the PLC control system module, and a PLC controlling device is connected with the upper system. Through auto-control software and a PLC control system, the automatic control to the axial force of the steel support is realized, thereby controlling the displacement and the settlement of the deep excavation supporting structure and the adjacent basic facilities.

Owner:CSCEC INT CONSTR +1

Pipette tip, pipette device, and combination of pipette tip and pipette device

InactiveUS20060233669A1Metering accuracyHigh measurement accuracyAnalysis using chemical indicatorsAnalysis by subjecting material to chemical reactionPipetteCoupling

A pipette device has a coupling stud on which a pipette tip can be stuck in a slipping-on direction for coupling. The coupling stud has an adjustable pre-stress member that can be adjusted into a prestress state and a release state via an actuation device which is provided in the coupling stud. The pipette tip has an axial stop which interacts with a counter-stop of the coupling stud in an axial coupling position of the pipette tip. The prestress member in its pre-stress state acts upon a working surface of the stuck-on pipette tip having a surface component of the pipette tip, which extends radially inward, turned away from the stuck on direction, in such a way that it abuts sealingly on the working surface, and prestresses the pipette tip on the pipette unit into the axial coupling position. The prestress member, in its releasing state, substantially releases the working surface of the pipette tip (101).

Owner:HAMILTON BONADUZ AG

Upper screw lower connecting pile fastener and precast member

InactiveCN1603523AReduce manufacturing costAchieve consistencyBuilding constructionsBulkheads/pilesNosePre stress

The invention involves a kind of tube column to meet the buckle, as well as uses with the time mouth constitution pre-stressed high strength pre- workpiece and -odd in view of the fact that with the between between connection structure and the connection method, is the pre- workpiece to meet buckles with the pre- workpiece manufacture domain. On under the spiral goes against pile extension buckles by pulls the cap nut, inflates the screw and goes against pulls the cap nut constitution, pulls the cap nut screw together in the spiral which inflates the screw wire shorts, inflates the screw the inflation measure expansion in to go against pulls in the cap nut in the inflation cavity, when pile extension, demands the collection attire two maybe certain to pull the cap nut with the between nose minute to buckle goes against pulls the cap nut mouth which corresponds with the prefabrication, inflates the screw the spiral wire shorts screw together in pulls the cap nut screw thread in, Inflates the screw the inflation to carefully examine like goes against pulls the cap nut the inflation cavity also the inflation sells under the function in its nose to inflate in goes against pulls the cap nut in the inflation cavity, completes docking between the pre- workpiece and pre- workpiece.

Owner:周兆弟

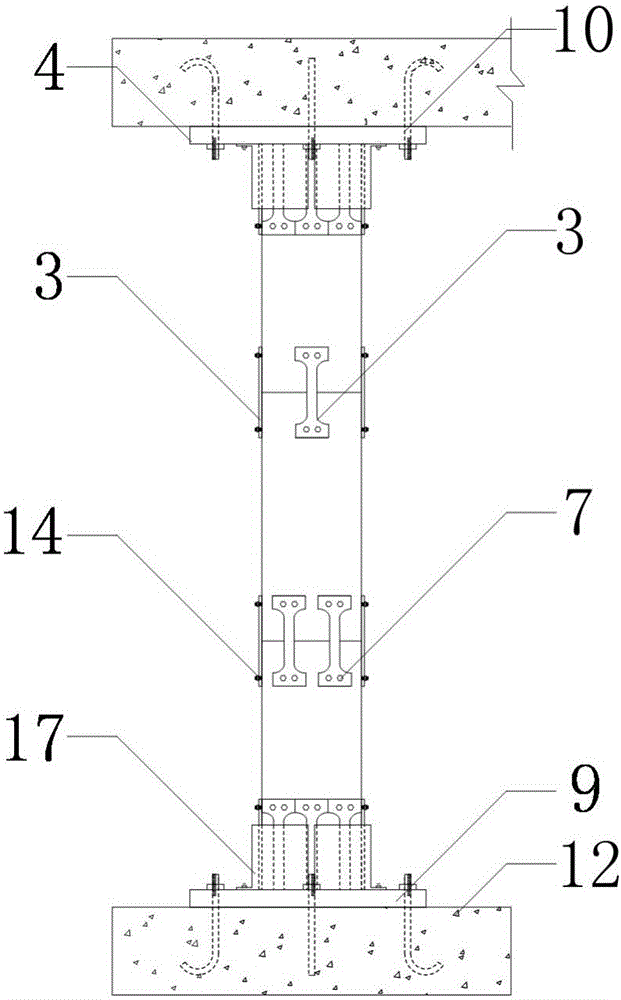

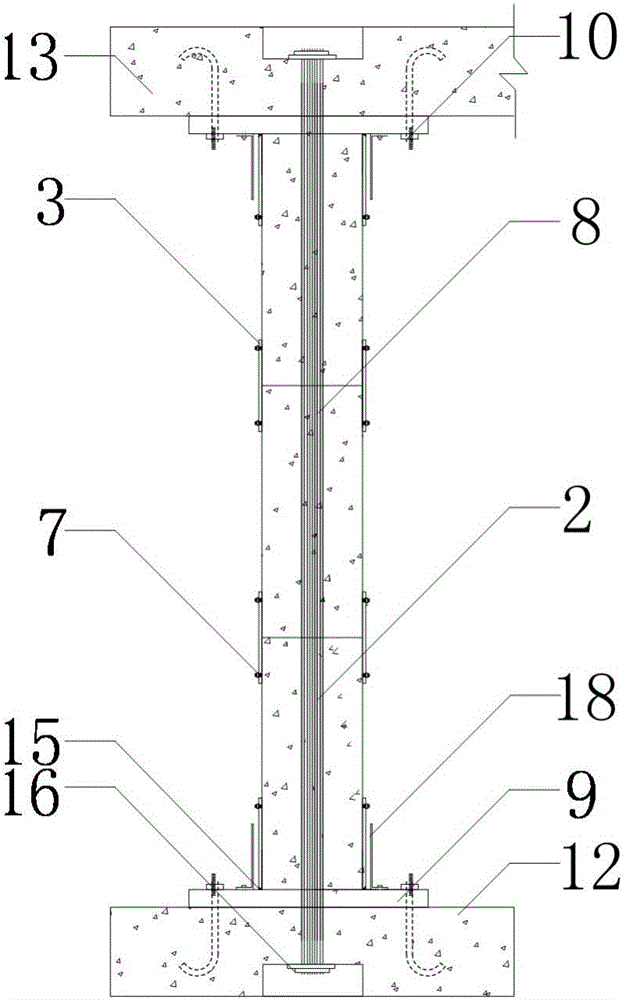

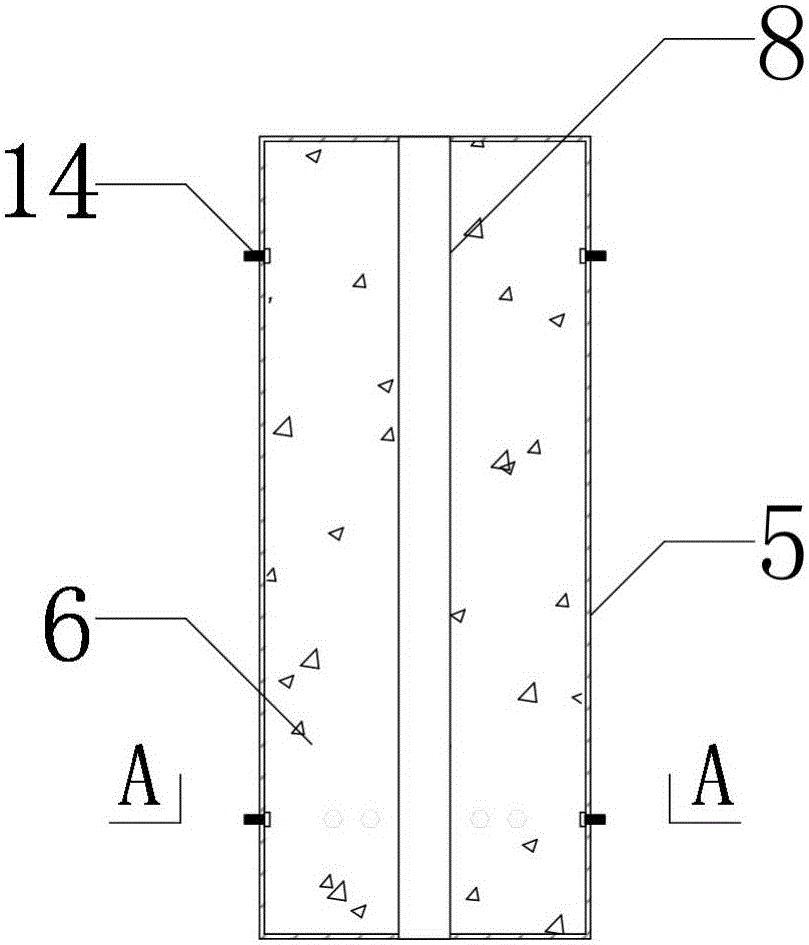

Damage-controllable self-resetting section prefabricated assembled steel pipe concrete bridge pier and manufacturing method thereof

ActiveCN105908621ASmall residual displacement after earthquakeImprove bearing capacityBridge structural detailsBridge erection/assemblyBridge engineeringHigh energy

The invention discloses a damage-controllable self-resetting section prefabricated assembled steel pipe concrete bridge pier and a manufacturing method thereof, and belongs to the field of bridge engineering. An exposed node connecting piece consists of a foot plate, anchor bolts, end connecting plates and buckling restraining sleeves. A connecting plate is mounted between prefabricated steel pipe concrete sections through high-strength bolts; the exposed node connecting piece is connected with each of a cover beam and a bearing platform by utilizing the anchor bolts, and is connected with a prefabricated steel pipe concrete section through the high-strength bolts relying on the end connecting plates. A pre-stressed tendon penetrates through a section prefabricated steel pipe concrete pier; the two ends of the pre-stressed tendon are respectively anchored to the interiors of the bearing platform and the cover beam by using anchorage devices. The energy consumption-controllable self-resetting section prefabricated assembled steel pipe concrete bridge pier disclosed by the invention has the characteristics of small post-seismic residual displacement, high energy consumption capacity, controllable energy consumption, high assembling degree, convenience and quickness in construction process, greenness, high efficiency, energy conservation, environment friendliness, easiness in factory production, convenience and quickness in construction, and the like; the construction period of the pier can be remarkably shortened.

Owner:BEIJING UNIV OF TECH

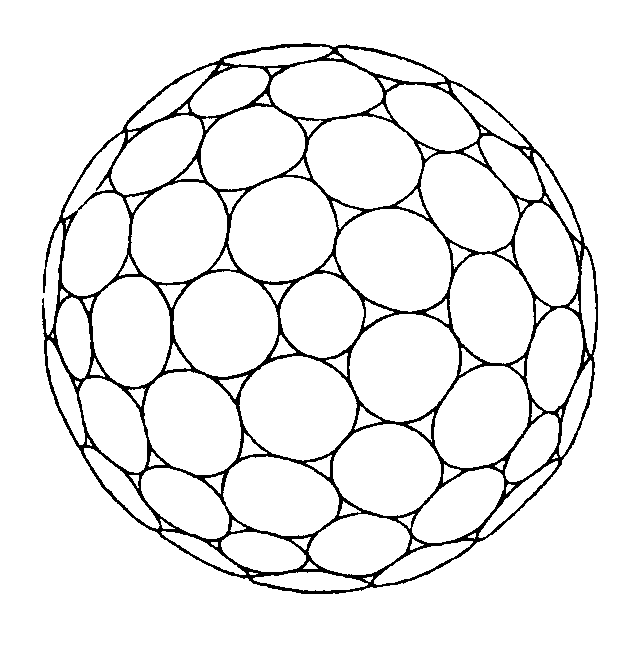

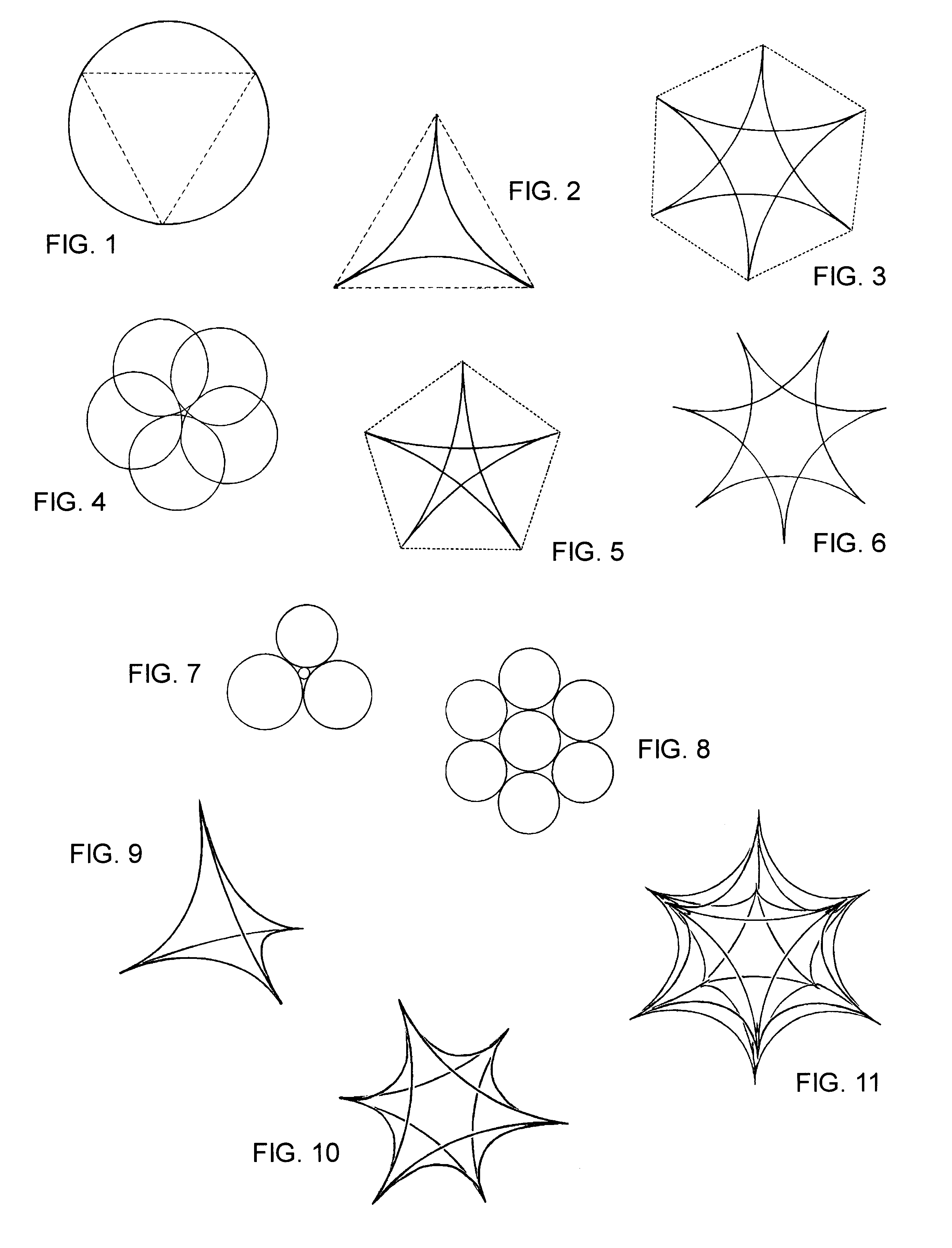

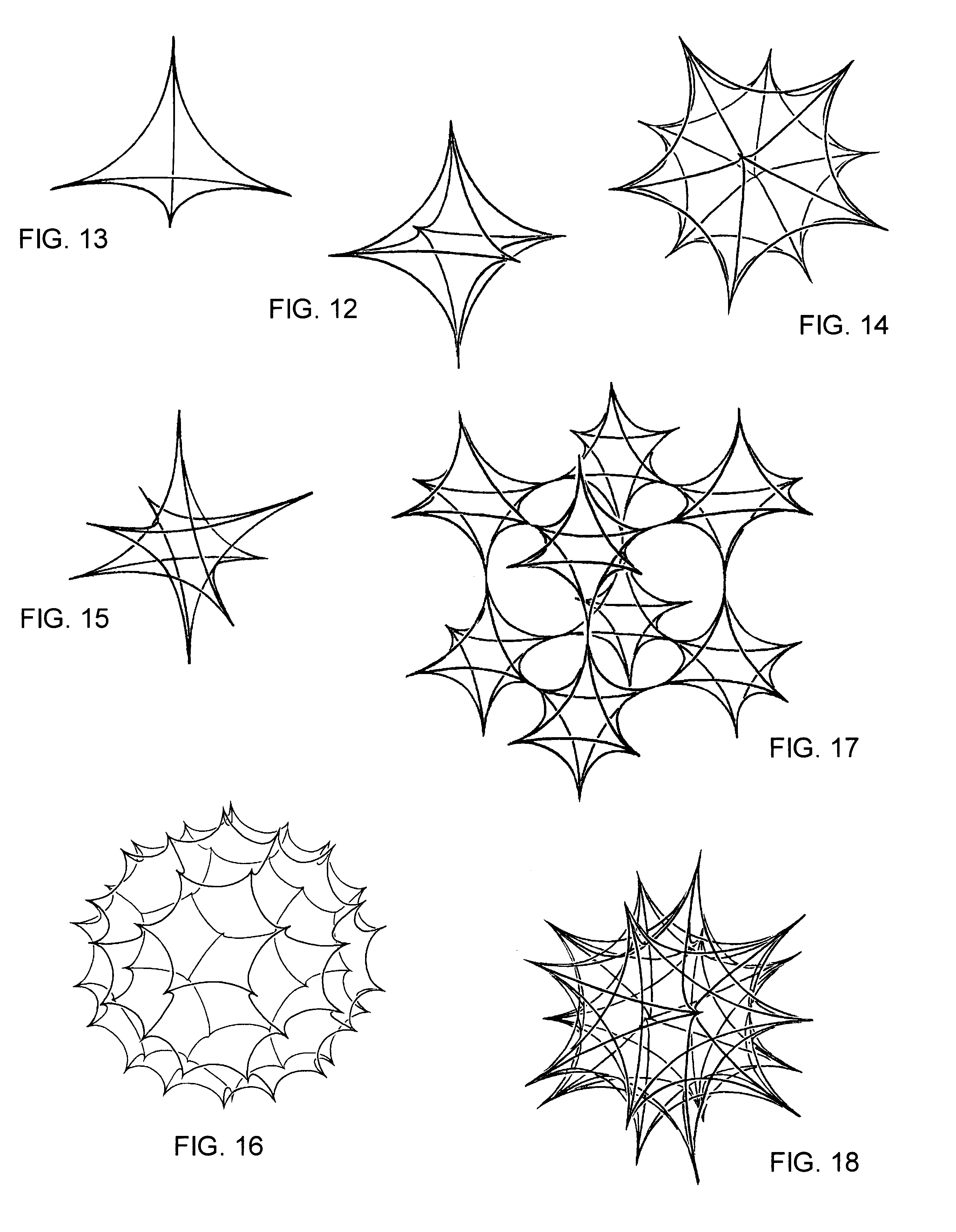

Synetic structural forms and systems comprising same

A strong, lightweight structural system wherein curved structural elements are tangentially joined. Compressive forces are distributed in a near continuous manner throughout the matrix, and tensile forces are present primarily to brace, support and pre-stress the compression net. The system is scalable from molecular through architectural levels, and finds many applications in dome shaped and spherical structures. The structural system also provides a force interaction model that is applicable to a broad array of real and theoretical problems.

Owner:HULTQUIST STEVEN J +1

Methods of using a telescoping guide catheter with peel-away outer sheath

Methods of using a guide catheter employ a retractable inner guide movably disposed within an open lumen of a splittable outer guide. The outer guide includes a longitudinal pre-stress line extending from distal to proximal ends. The inner guide includes an open lumen adapted to receive a payload. The inner guide is translatable and rotatable relative to the outer guide. The guide catheter further includes a proximally attached guide handle which is separable into at least two sections. Separation of the guide handle splits the proximal end of the outer guide. Proximal outer guide retraction continues the splitting of the outer guide along the longitudinal pre-stress line.

Owner:CARDIAC PACEMAKERS INC

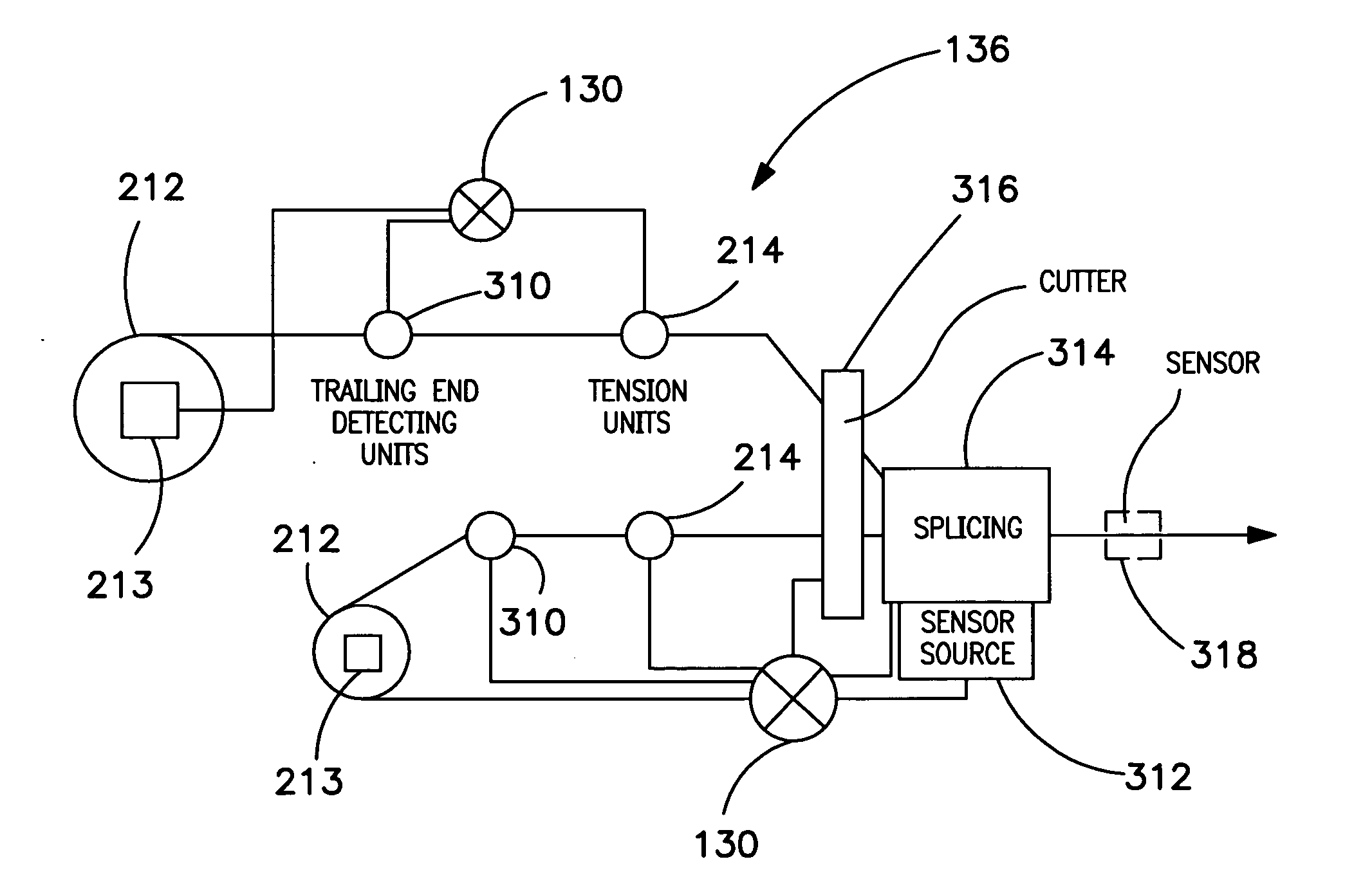

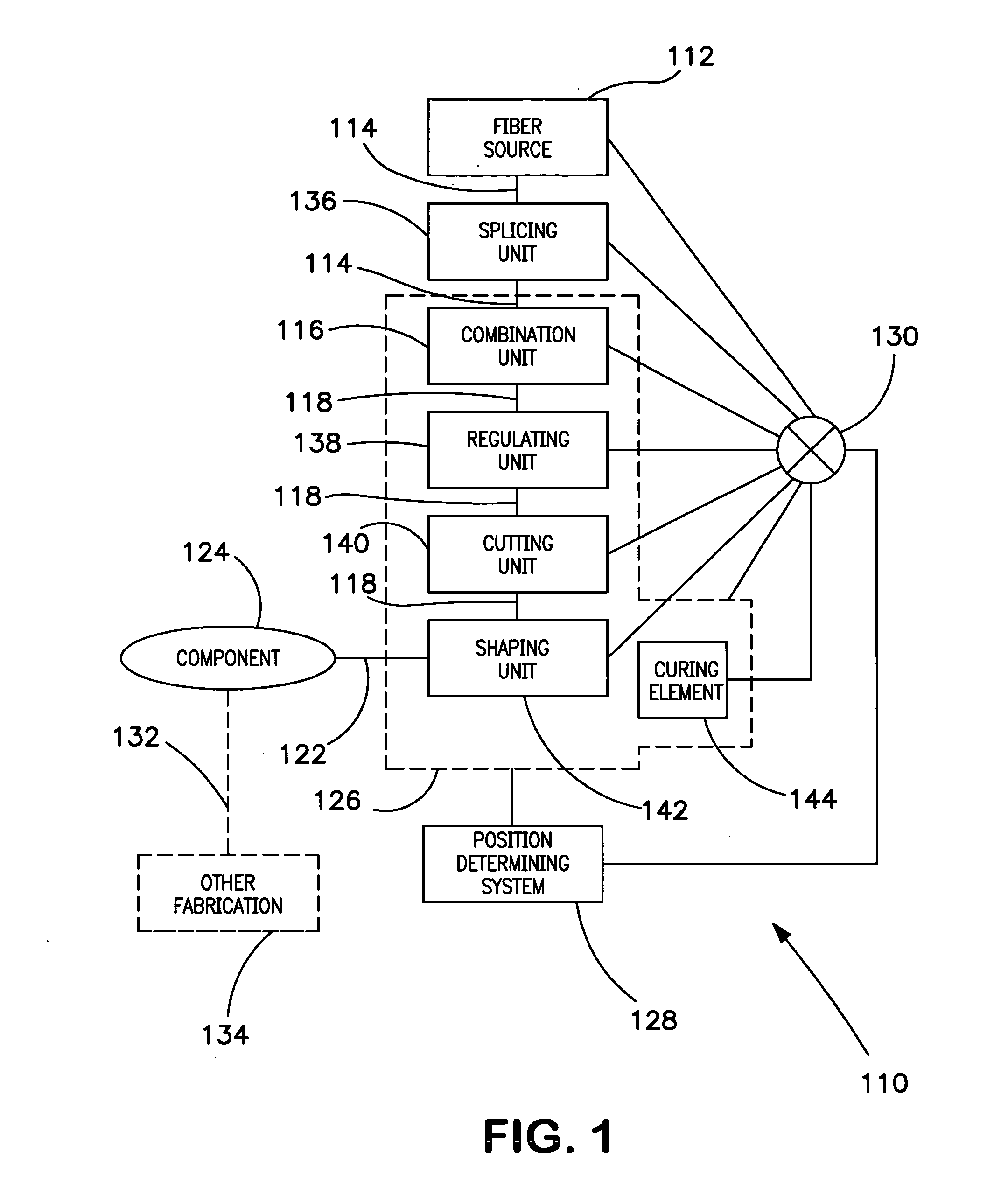

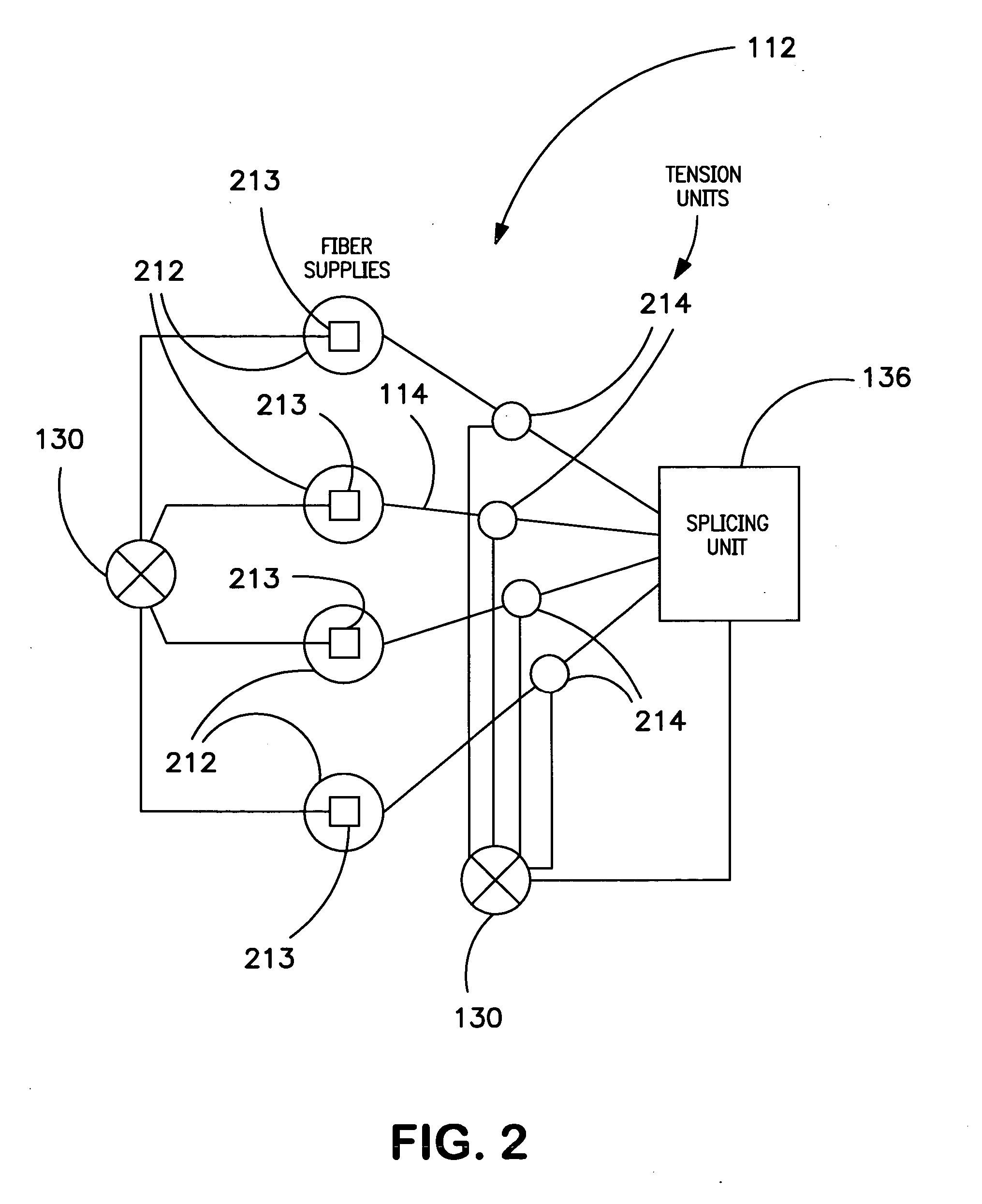

Apparatus and method for manufacture and use of composite fiber components

ActiveUS20050037195A1Add featureEnhance another featureLiquid surface applicatorsCoatingsPre stressPre stressing

A fiber lay-up apparatus and method includes one or more fiber sources from at least one fiber supply wherein a fiber may be fed under tension to provide a pre-stress to the fiber. The fiber lay-up apparatus may include a resin impregnator for impregnating a fiber with a resin. The fiber may be impregnated under pressure to reduce friction, to provide a motive force to move the fiber through the impregnator, or to enhance control over impregnation. The fiber may be shaped by a fiber shaping unit including one or more active or passive shaping members that provide enhanced control over the shape and placement of the fiber as the fiber leaves the fiber lay-up apparatus. A cutting element for cutting a fiber as it is being layed-up may be positioned proximal to the one or more shaping members, and may enable the fiber lay-up apparatus to end the lay-up of one fiber (or set of fibers) and begin the lay-up of a new fiber (or set of fibers) without delay. A UV or other curing element may be provided downstream from the cutting element. A splicing unit may be employed to detect when a fiber supply is exhausted, and may splice a trailing end of an exhausted fiber supply to a leading end of a new fiber supply to provide a continuous (or substantially continuous) fiber feed. The splicing unit may also splice at least one sensor into a fiber being fed from the at least one fiber supply to provide information about the fiber either before, during, or after the fiber is layed-up.

Owner:LIGNUM VITAE

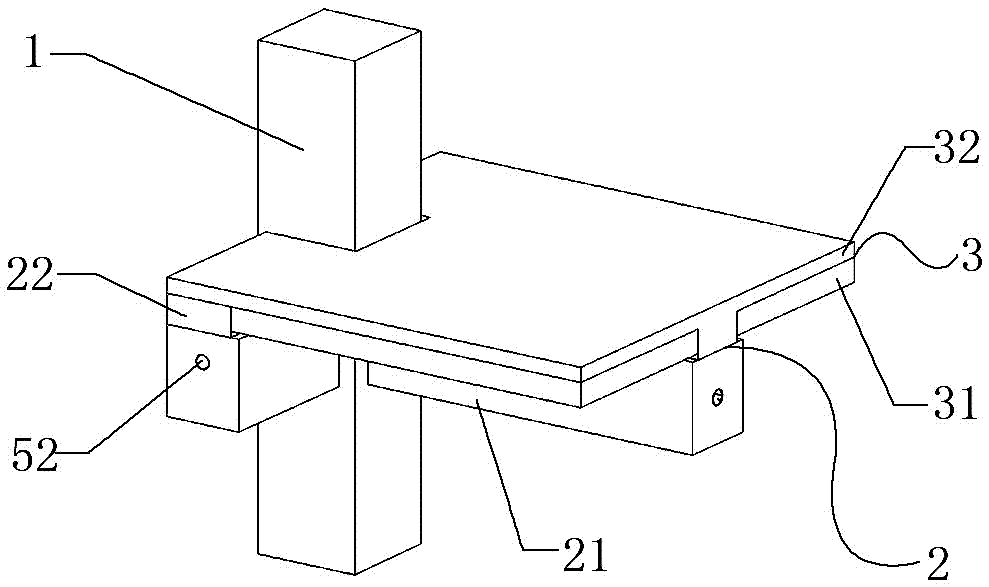

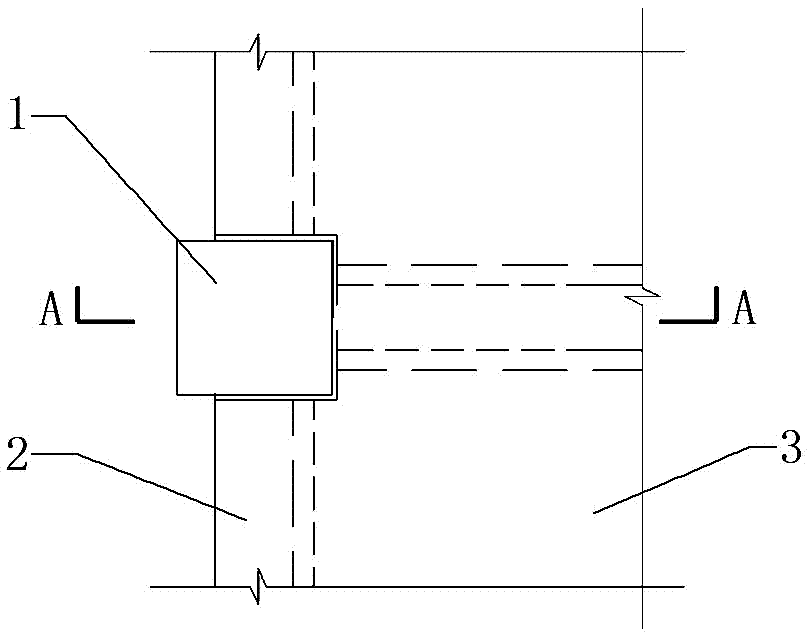

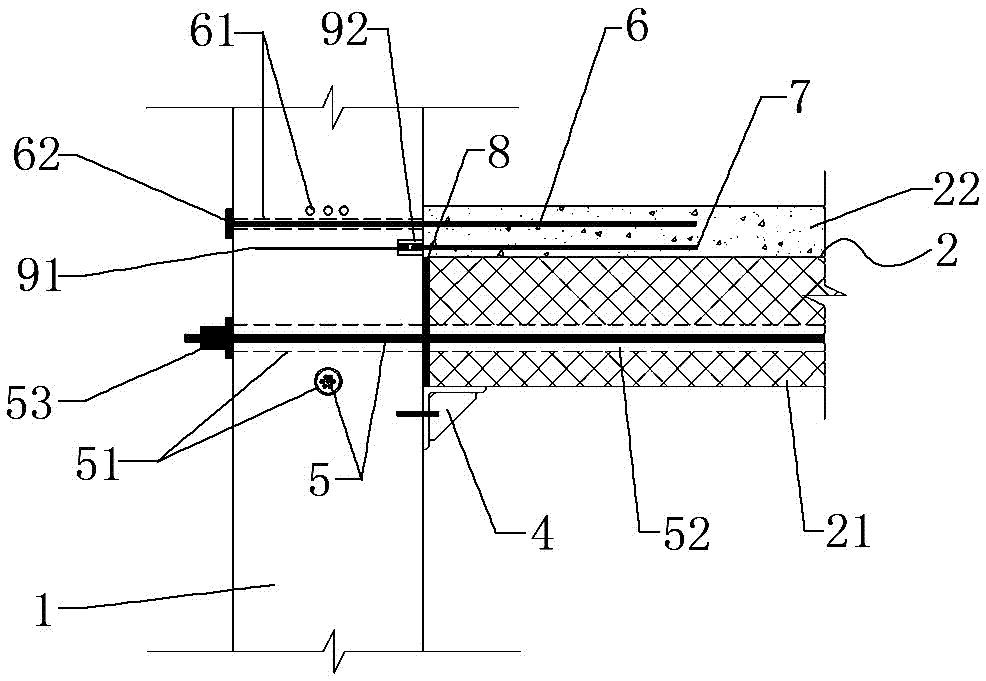

Pre-stressing-force fabricated concrete-frame-joint connecting structure and construction method thereof

PendingCN107165272AImprove integrityImprove energy consumptionGirdersProtective buildings/sheltersFloor slabPre stress

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

Buckling and energy consumption preventing steel plate shear wall

The invention involves a kind of data organization project area of technology to guard against the flexure to consume energy the steel plate shearing force wall. Its characteristic causes to state the shearing force wall to inlay the steel plate and two sides periphery concrete lap by in is composed; In states inlays the steel plate to use the low yield point high ductility steel products or the high strength high ductility steel products; States the periphery concrete lap to use the common concrete slab; States the edge component is composed by the marginal beam and the edge column; In states inlays the steel plate with to state between the concrete lap through to penetrate three blocks the bolts or the pre-stressed bold fastening, in states on the concrete lap to open the ellipse hole in order to the bolt passed through also has the enough slipping space; In states the concrete lap to open the hole site with to bury the trough section to give strengthens. And is strengthening the channel steel the corresponding position to open oval hole. The invention provides guards against the flexure steel plate shearing force wall is the high-rise construction structure or other structures a kind of new anti- lateral force components, it has the earthquake resistance performance well, the ductility is high, consumes energy stagnates winds full and so on the characteristic, is a kind of superior earthquake resistance consumes energy the component.

Owner:TSINGHUA UNIV

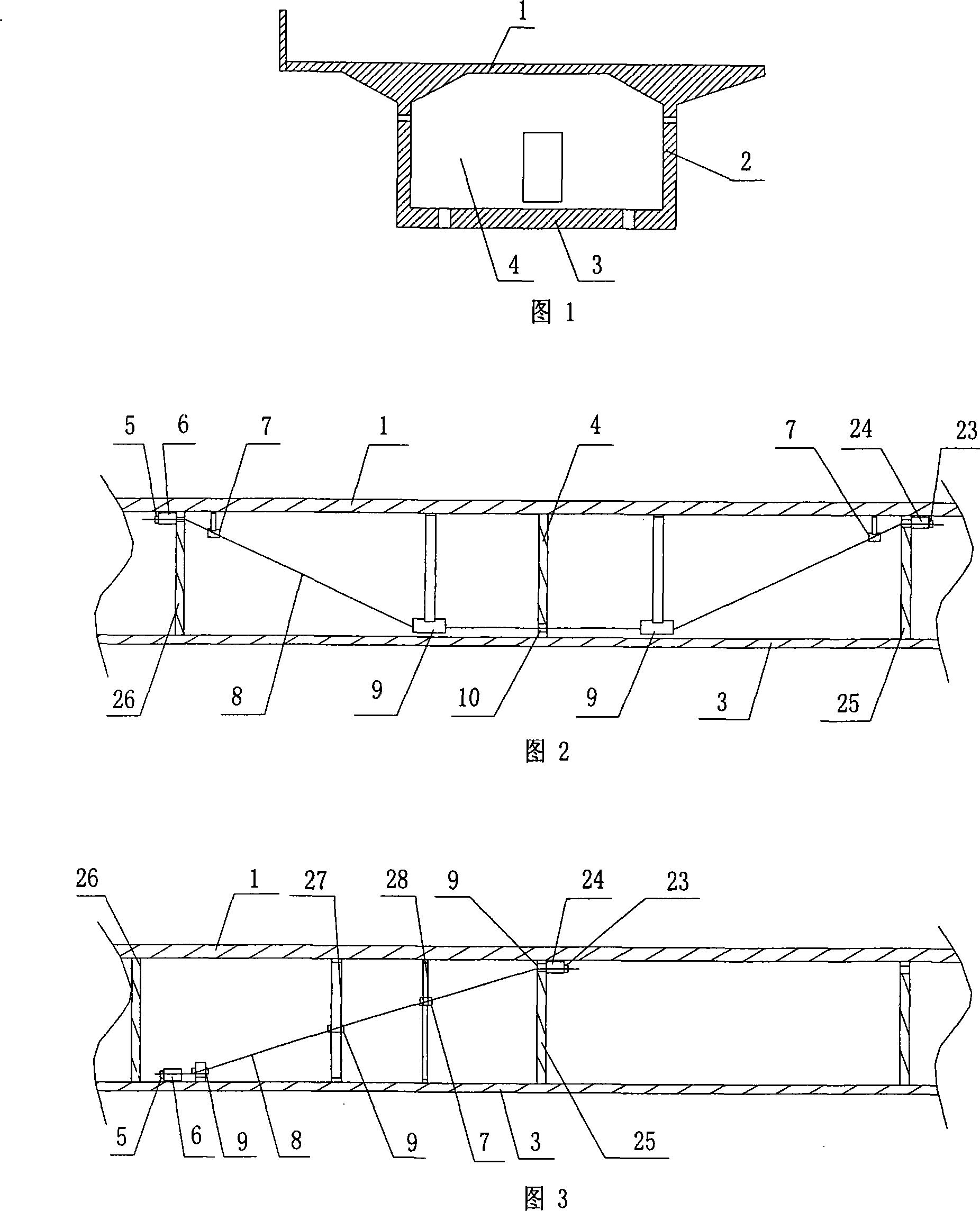

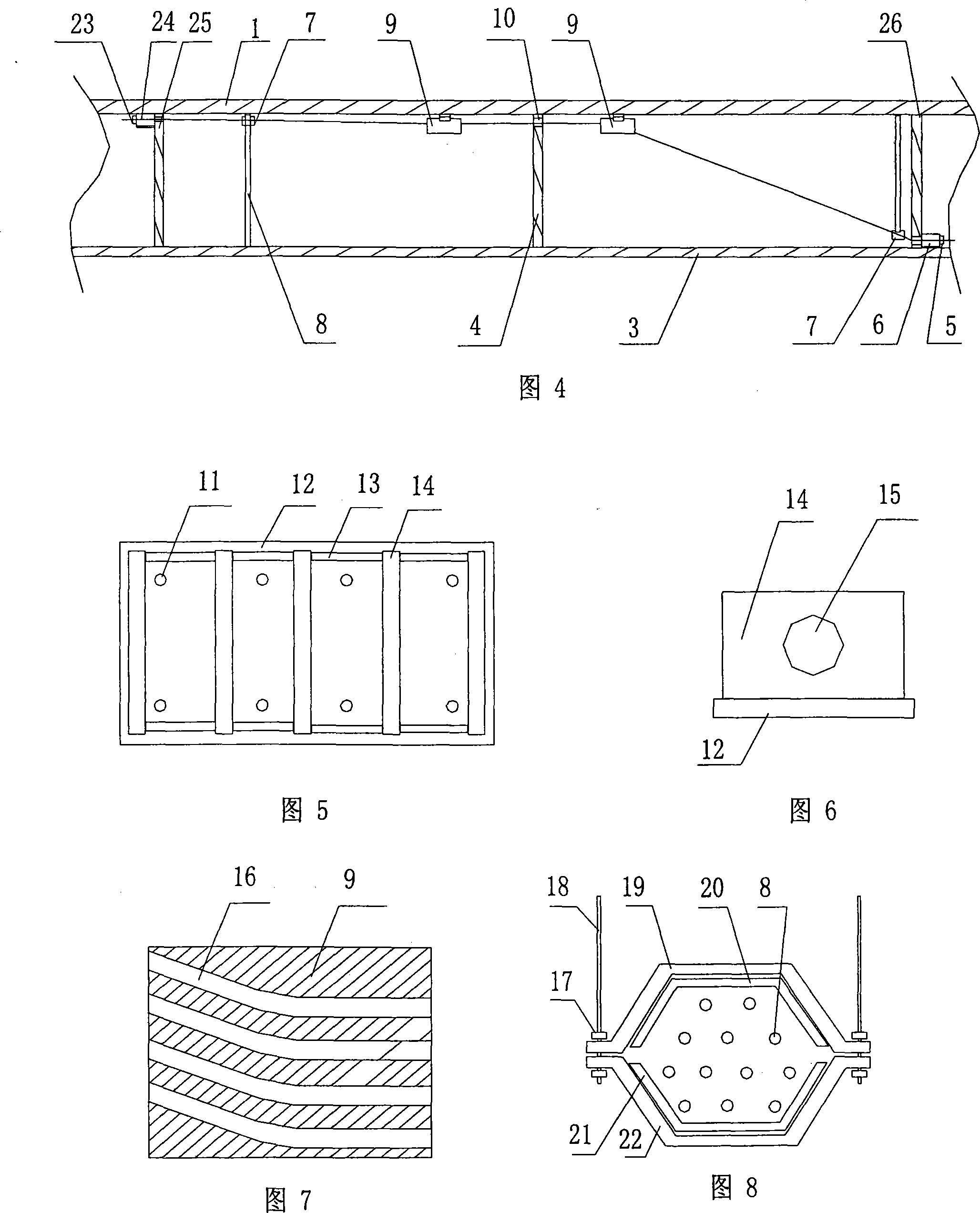

Construction method for chamber type bridge maintaining external pre-stress

InactiveCN101173505AEasy constructionFlexible constructionBridge erection/assemblyBridge strengtheningPre stressPre stressing

The invention discloses an external prestressing construction method for box bridge maintenance, which is characterized in that: 1). The position of an anchor block, a redirector and a shock absorber are decided according to external cable arranging mode for external prestressing; 2). The installation of the anchor block: 2.1). concrete base surface processing; 2.2). hole drilling, hole cleaning and reinforcing bar planting; 2.3). the installation of steel-bonded steel plate: the anchor block comprises a steel-bonded steel plate, a connecting plate and a stiffening plate; all anchor bolts are penetrated through a corresponding fixing hole on the steel-bonded steel plate; 2.4). the installation of other steel plates for the anchor block; the connecting plate is welded with the steel-bonded steel plate, the stiffening plate is welded with the steel-bonded steel plate and is provided with a through hole for external cable; 2.5). glue pouring for the steel-bonded steel plate: glue pouring is made between the steel-bonded steel plate and the concrete base surface for the anchor block; 3). Horizontal partition wall perforation; 4). The installation of a redirecting support and a damping support; 5). The installation of the redirector; 6). Penetrating and tension of prestressing steel strand; 7). The installation of the shock absorber. The invention has the advantages of convenient construction, flexibility and stronger reliability.

Owner:CHINA FIRST METALLURGICAL GROUP

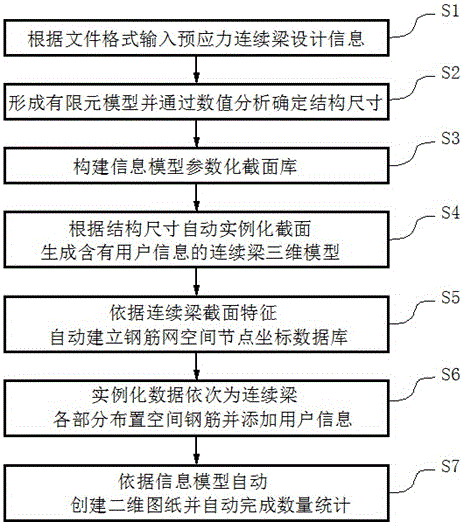

Pre-stressed continuous concrete beam design method based on BIM technology

ActiveCN106354968AAchieve integrationRealize automatic generationGeometric CADDesign optimisation/simulationElement modelContinuous beam

The invention discloses a pre-stressed continuous concrete beam design method based on the BIM technology. The pre-stressed continuous concrete beam design method includes the following steps that according to a file format, pre-stressed continuous beam design information is input; a finite element model is formed, and the structure size is analyzed and determined through the numerical value; an information-model parameterization cross section library is built; according to the structure size, a cross section is automatically instantiated to generate a continuous beam three-dimensional model containing user information; according to the characteristics of the cross section of the continuous beam, a reinforcing-steel-bar-net space node coordinate database is automatically built; instantiation data is sequentially comprises all parts of arrangement space reinforcing steel bars of the continuous beam, and user information is added; according to an information module, two-dimensional drawings are automatically established, quantity statistics is automatically completed. By means of the pre-stressed continuous concrete beam design method based on the BIM technology, rapid forming of universal data, the three-dimensional information model and the reinforcing-steel-bar drawings is achieved, and the pre-stressed continuous concrete beam design method has good popularization value and the good application value.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

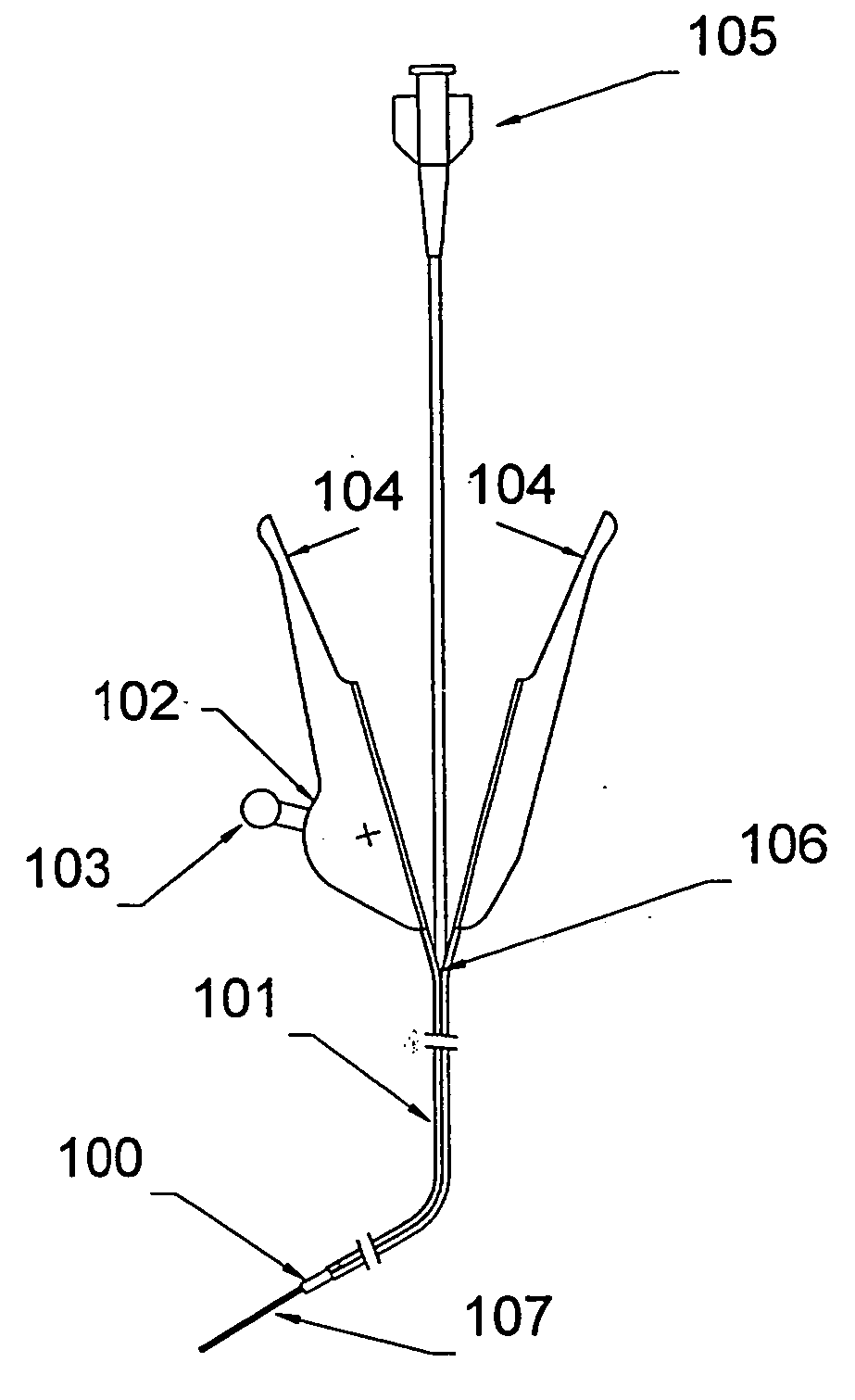

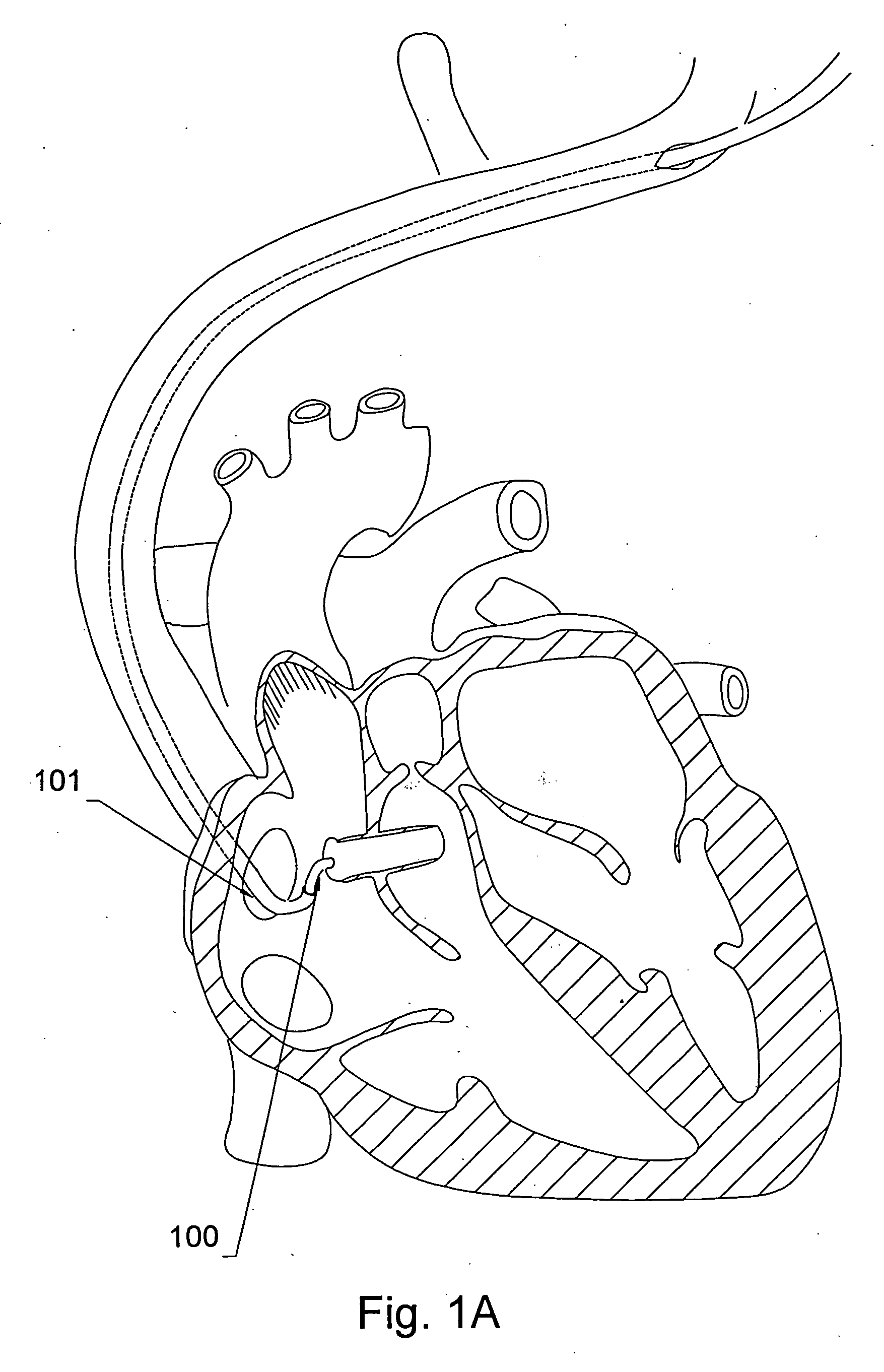

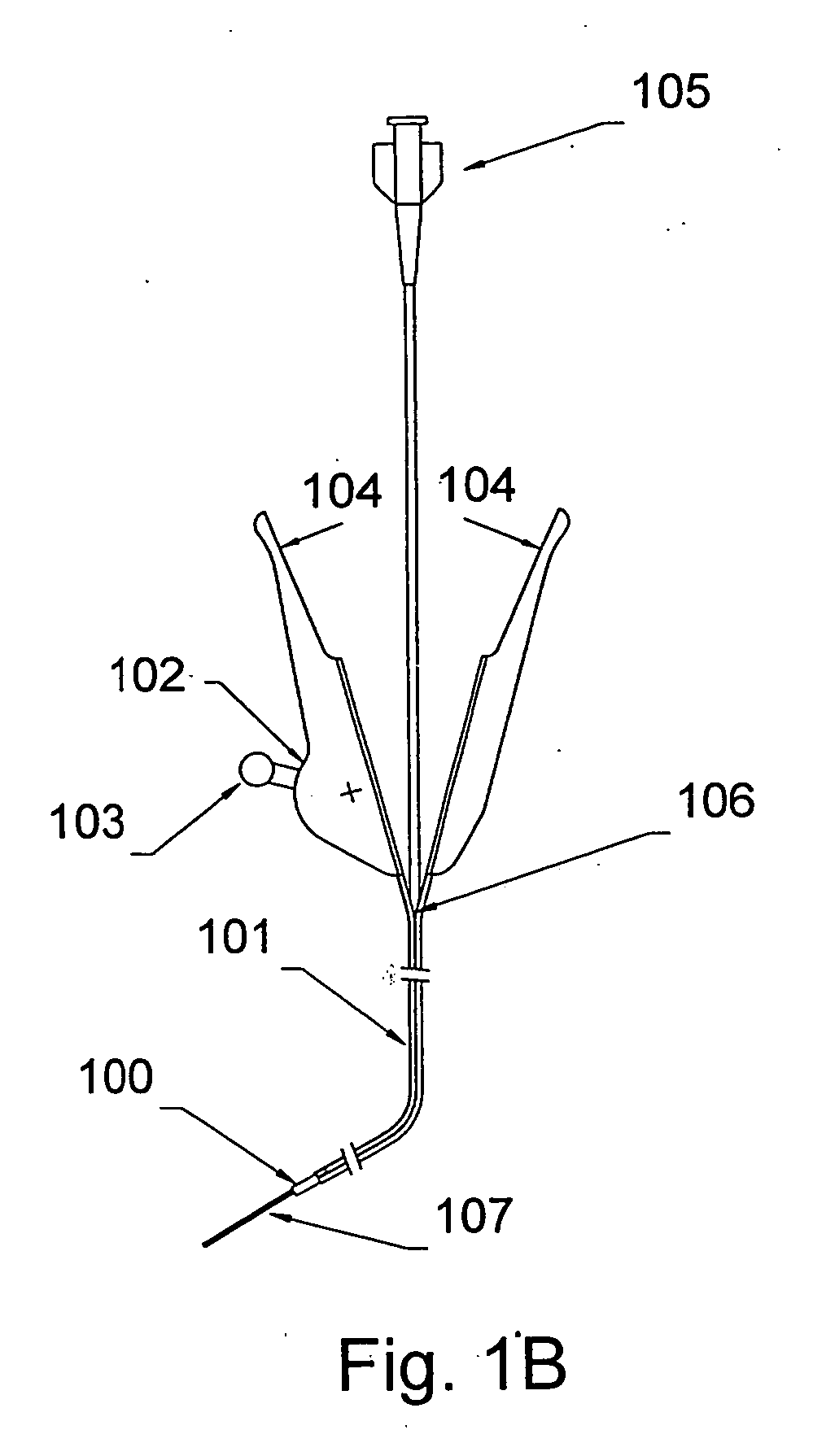

Method and apparatus for epicardial left atrial appendage isolation in patients with atrial fibrillation

A catheter apparatus is provided for isolation of the left atrial appendage (LAA) having a catheter shaft, a probe disposed within the catheter shaft, and a control mechanism coupled to both the catheter shaft and the probe. The catheter shaft includes a main body with a distal tip section. The tip section can be deflected from the shaft's central axis in a controlled manner. The probe can be extended outward from the catheter shaft and has a distal end that is brought into contact with the LAA. The control mechanism controls the catheter shaft's rotational and longitudinal movement, the tip section's degree of deflection, and the probe's axial movement with respect to the catheter shaft. Preferably, the distal end is able to form a pre-stressed loop selected to have a size allowing it to substantially encircle the LAA's base. A method for epicardial isolation of the LAA is also provided.

Owner:MEDTRONIC INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com