Patents

Literature

580 results about "Time pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chess played with a time control, time trouble, time pressure, or its German translation Zeitnot, is the situation where a player has little time to complete the required moves. When forced to play quickly, the probability of making blunders is increased, so handling the clock is an important aspect of chess playing. The last move of the time control (often move 40) is especially prone to blunders if players only have a few seconds to play it, and many games have been lost due to poor time management in time pressure.

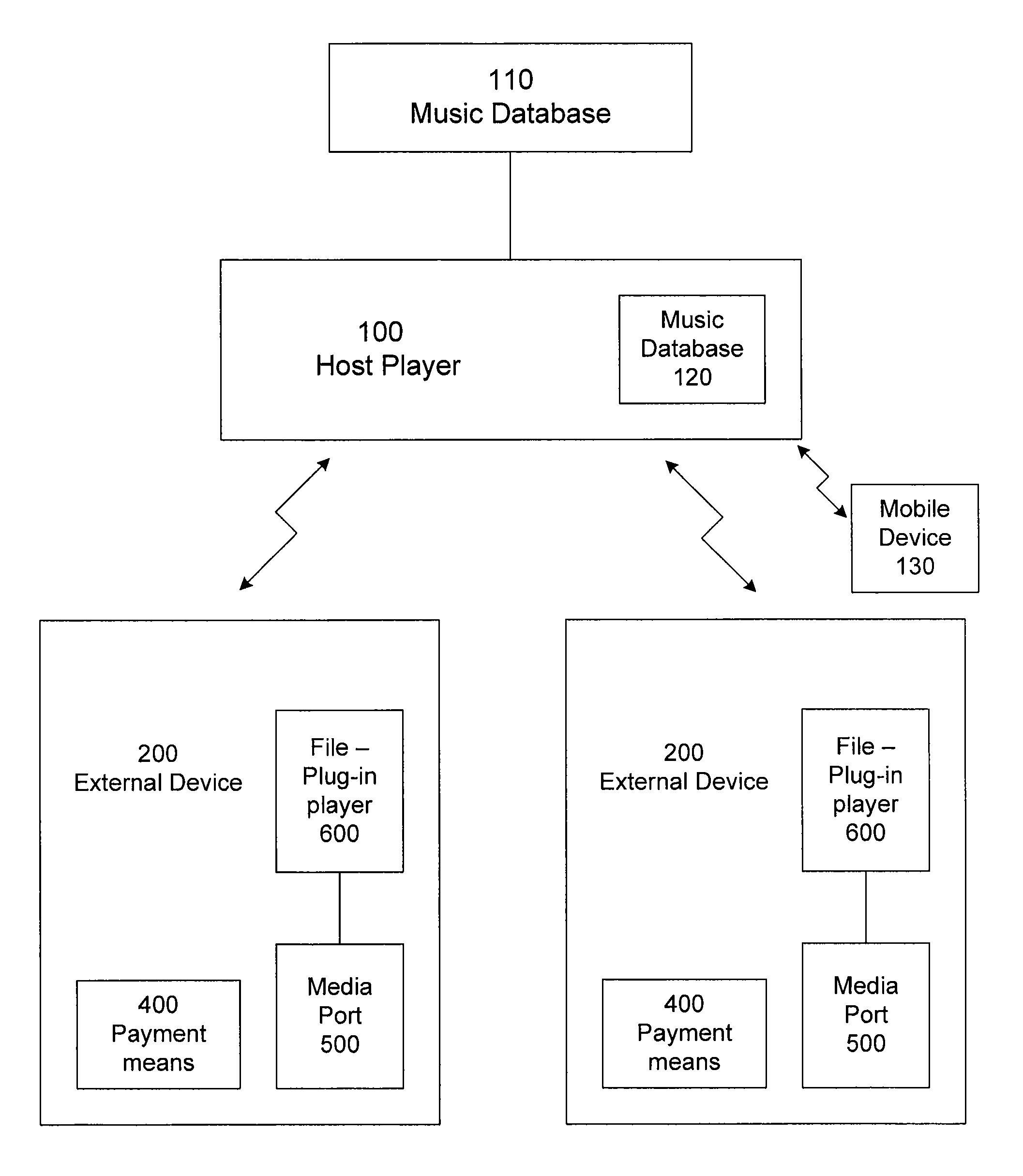

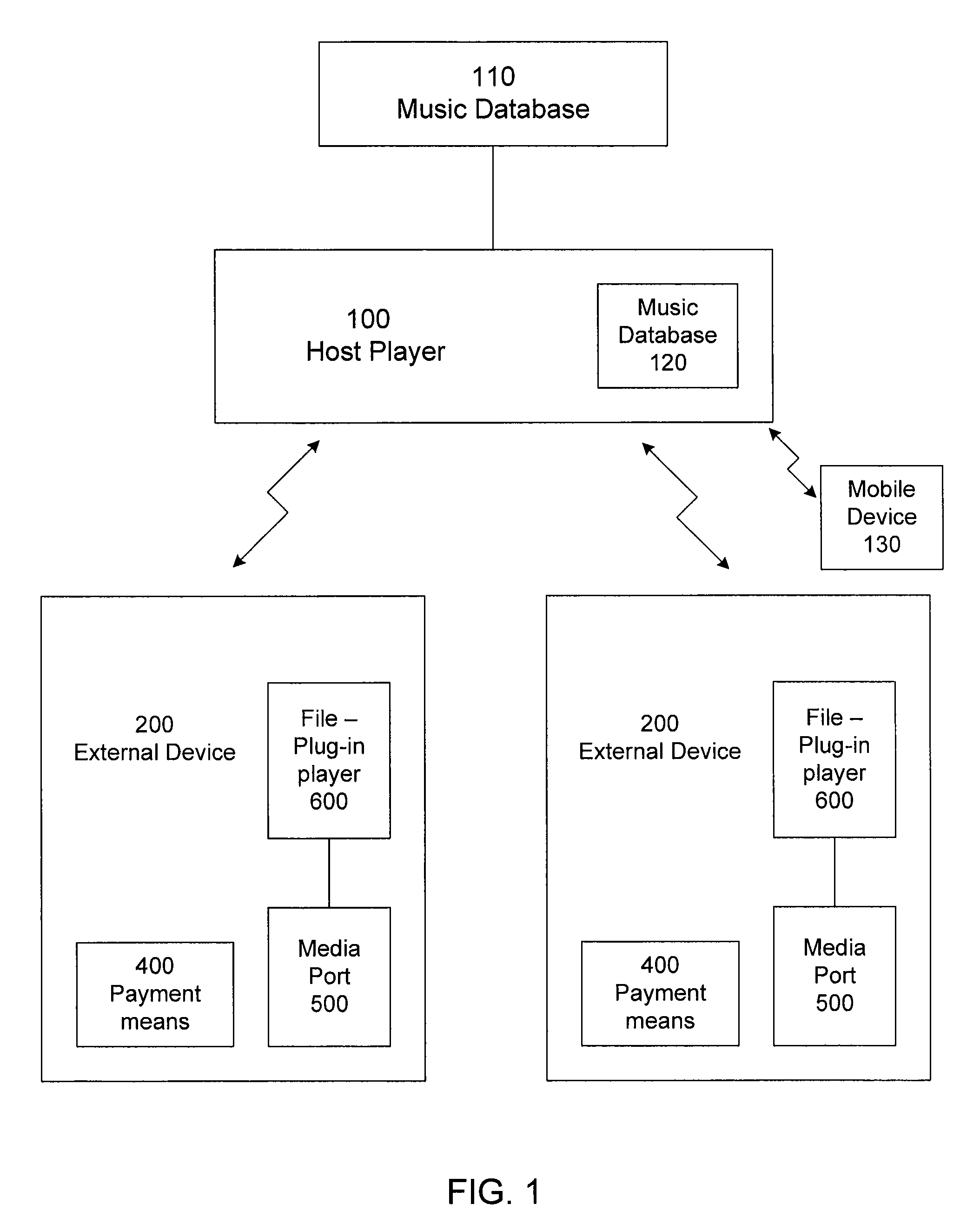

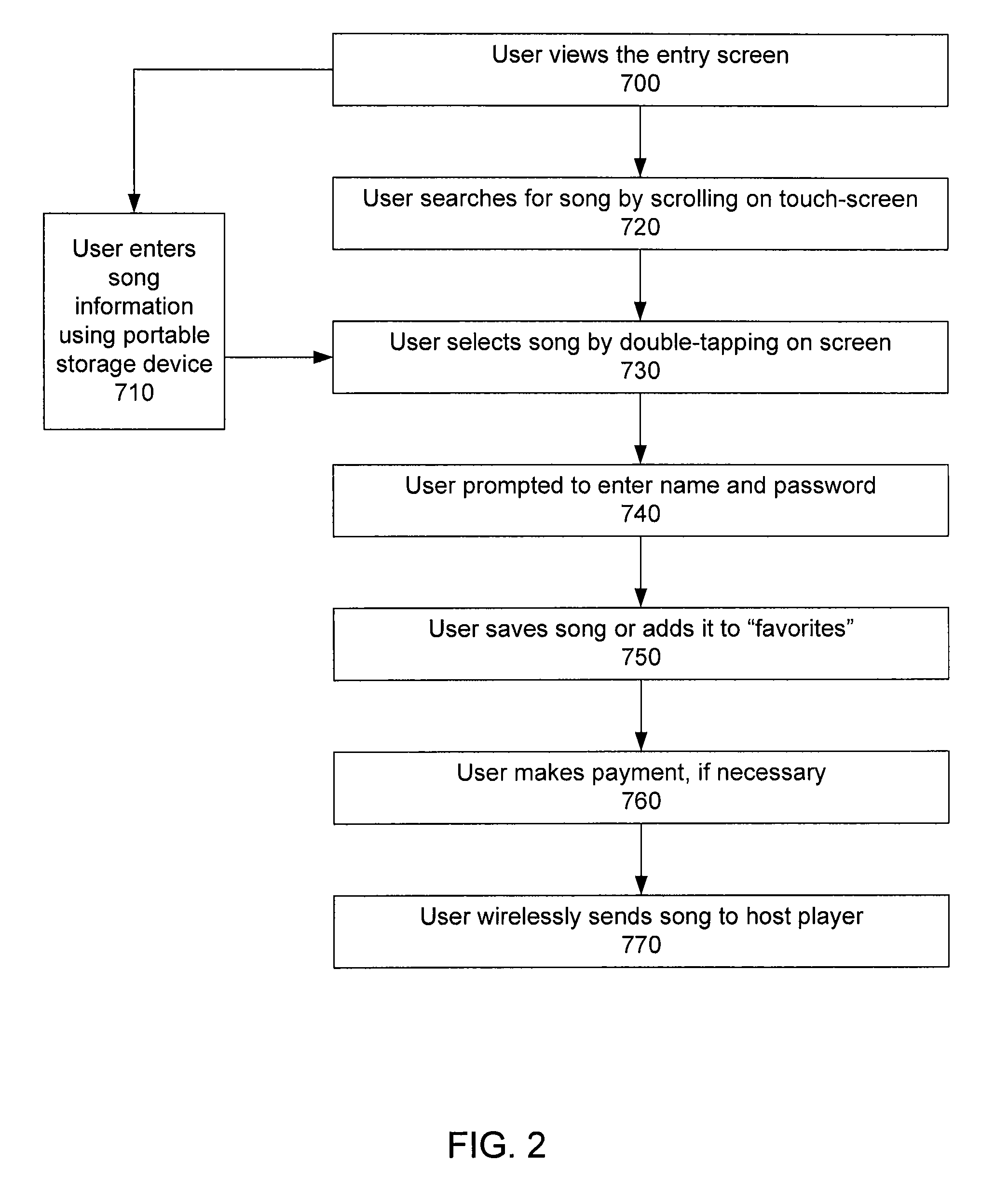

Multimedia platform synchronizer

InactiveUS8015200B2Reduce pressureReduce problemsTelevision system detailsElectrophonic musical instrumentsComputer hardwareComputerized system

Owner:SEIFLEIN PHIL +1

Multimedia platform synchronizer

ActiveUS20090100092A1Streamline karaoke showReduce problemsTelevision system detailsElectrophonic musical instrumentsComputer hardwareComputerized system

A karaoke home entertainment center for streamlining karaoke show; reduce stress, problems and time pressure on the KJ & to prevent piracy. The inventive device includes Ultimate Karaoke Book, Karaoke Rental Systems, ProPlayer, Karaoke Shoppe Download Centre, Karaoke Burning Station, Downloadable Karaoke CD+G Player, Video Library Pro, DRM and Licensing encryption engine, Pre-manufactured CD DRM. The Book eliminates the majority of KJ typing when creating or updating their book. Book with minimal player forms the Karaoke Rental System. ProPlayer incorporates super encryption Dongle or soft encryption, which permits “back-up” copy but can only be used with the original dongle. Karaoke Shoppe Download Center consists of basic computer system that can access our on-line database or come pre-loaded with encrypted songs. Karaoke burning Station Kiosk is either counter-top or stand-alone kiosks that can contain and deliver cds. Downloadable Karaoke CD+G Player is a quality karaoke player that doesn't require a special piece of hardware (other than a personal computer). It can download and play karaoke songs and be given away for free. Video Library Pro is an adaption of the book and player above designed for video professionals. There are two forms of DRM and Licensing encryption engine that perform the function of file protection. Together they form the Karaoke Home Entertainment Center.

Owner:SEIFLEIN PHIL +1

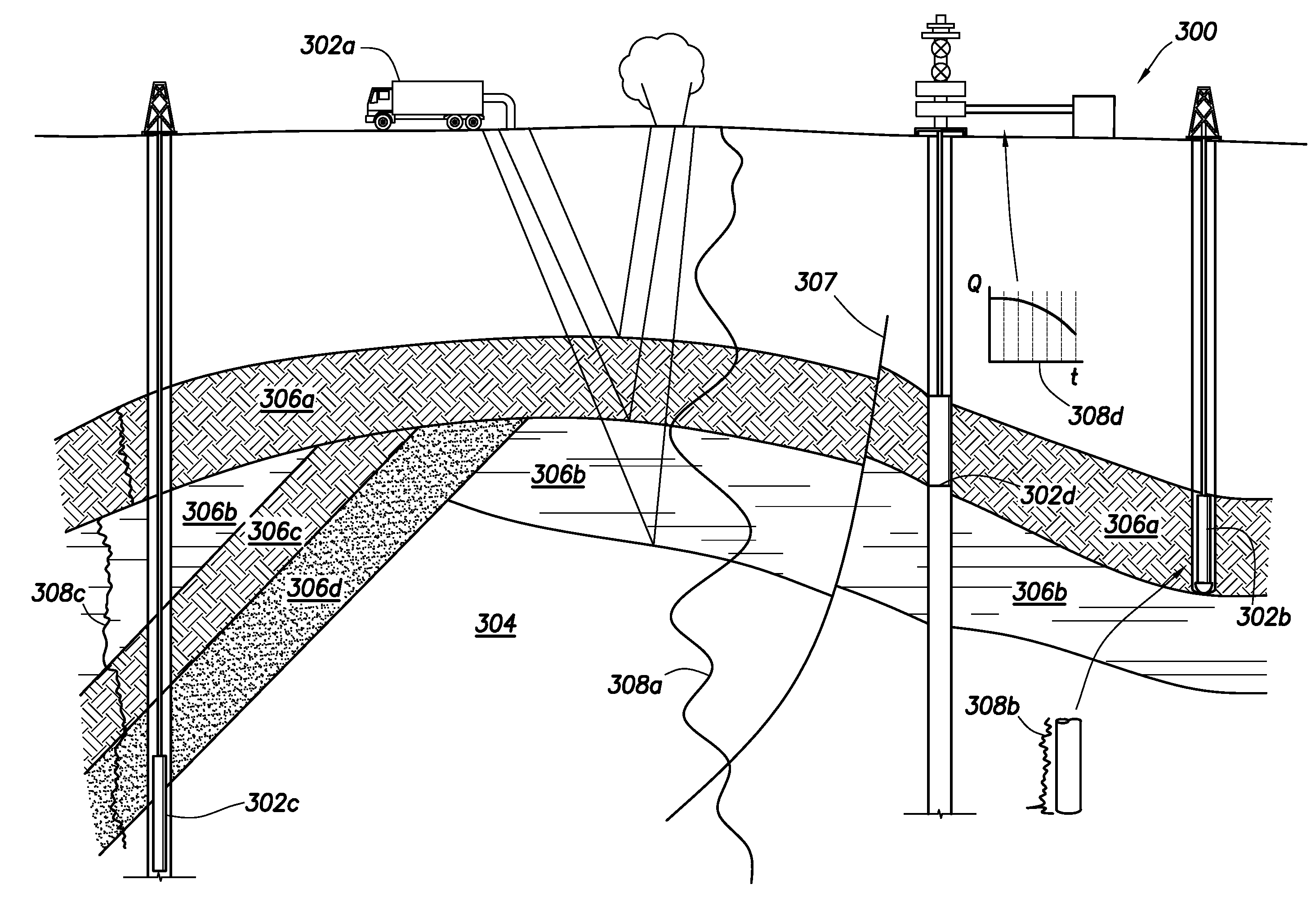

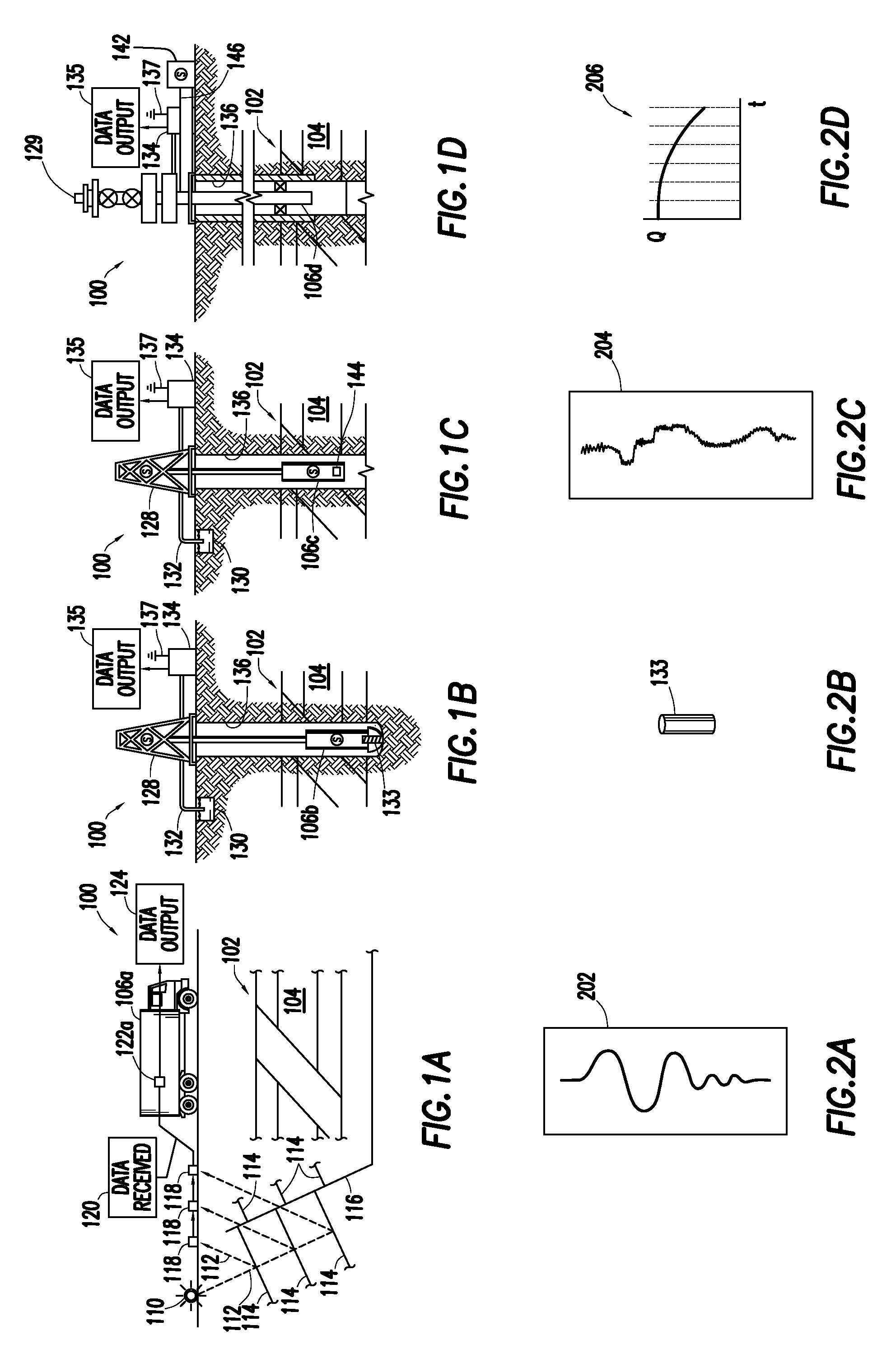

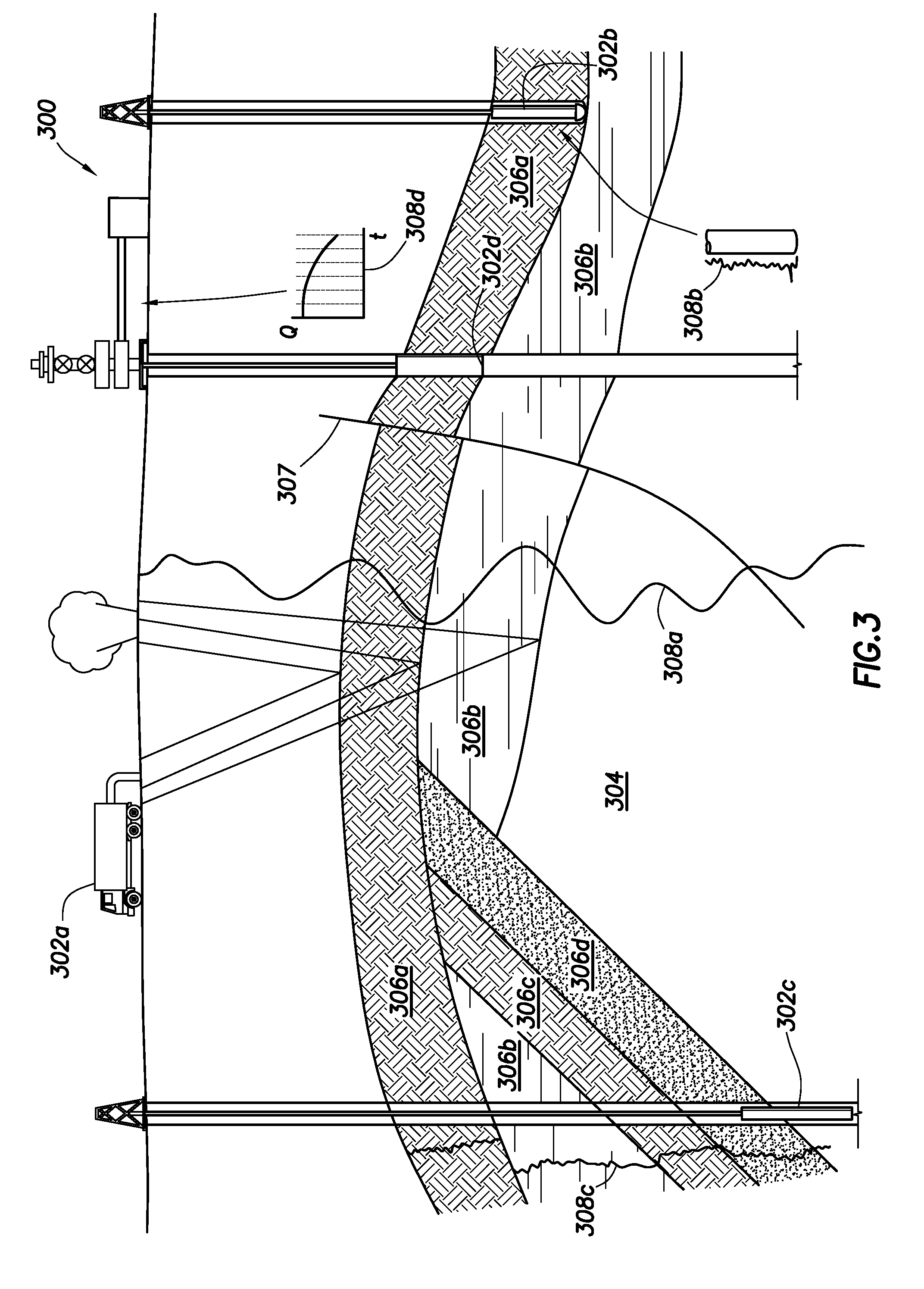

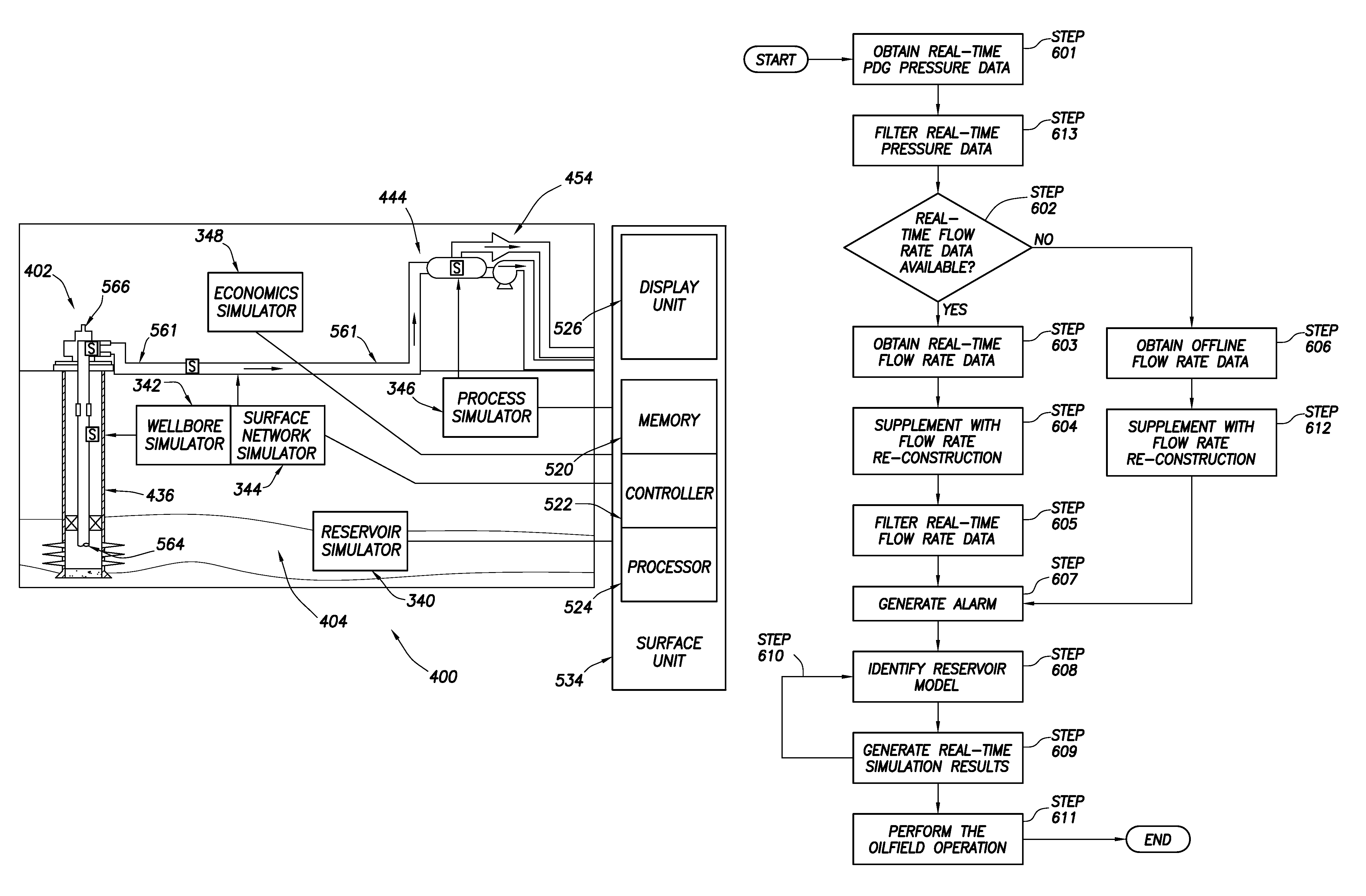

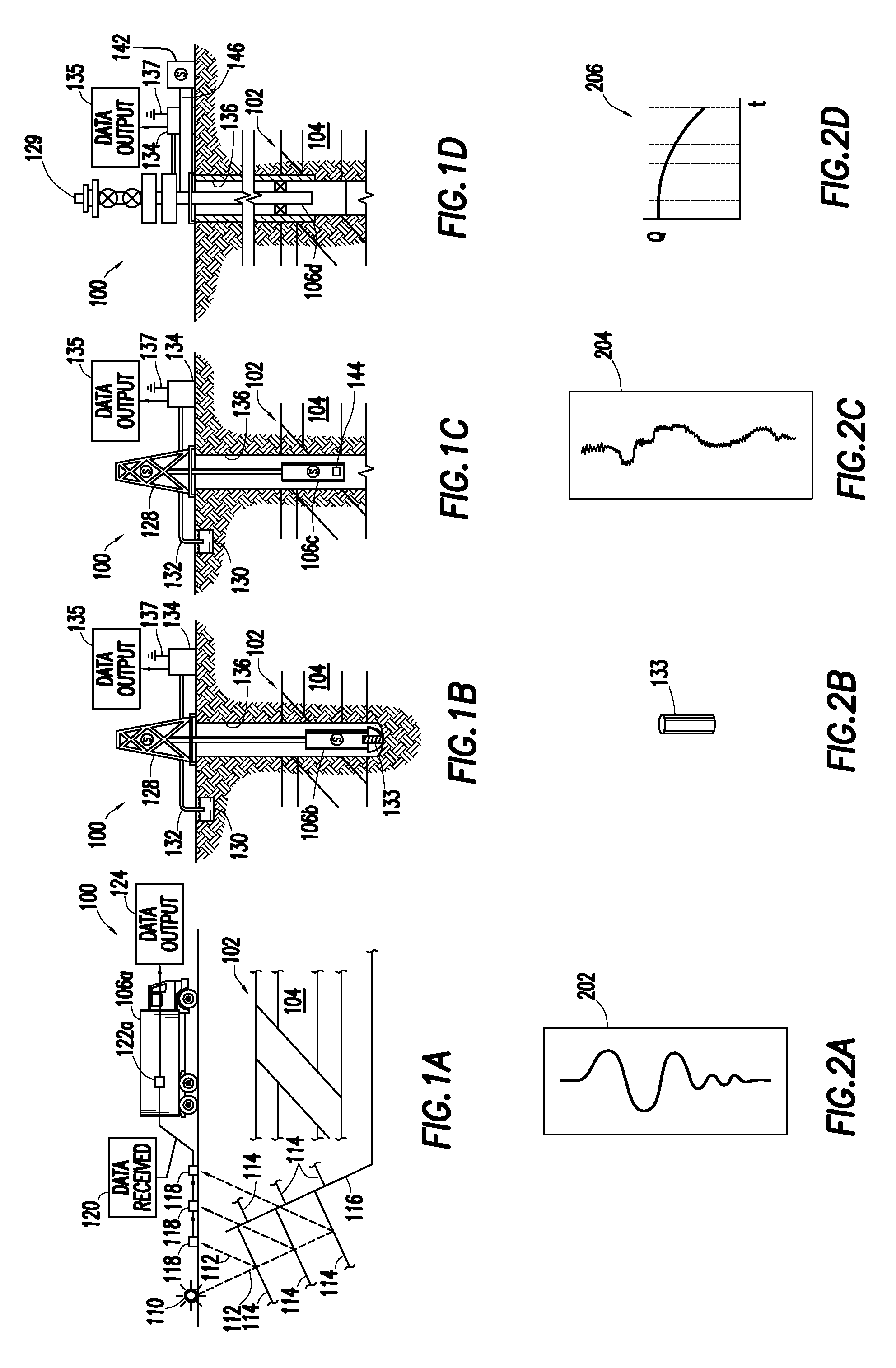

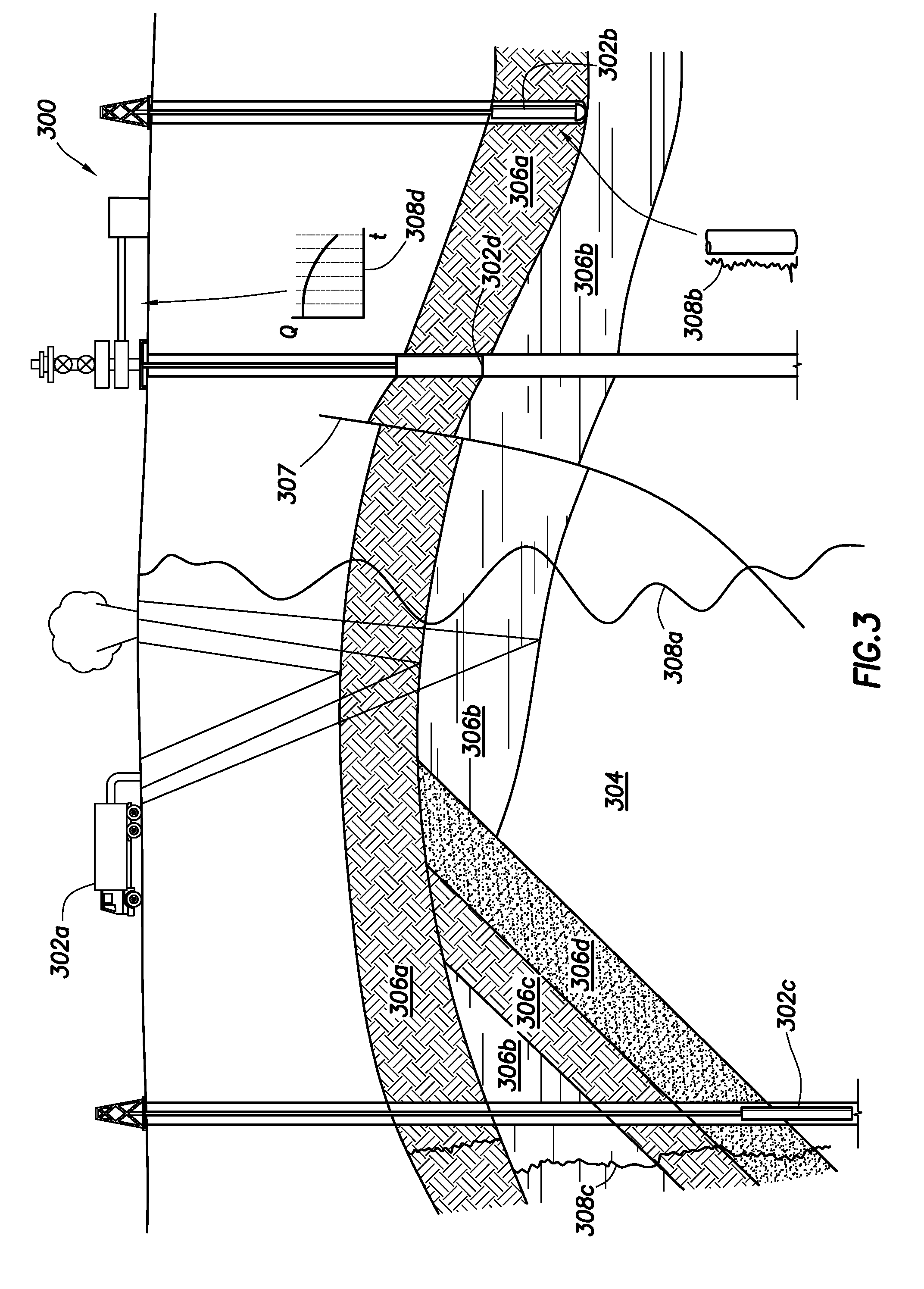

Method for managing production from a hydrocarbon producing reservoir in real-time

ActiveUS20090084545A1Electric/magnetic detection for well-loggingSurveyReal-time simulationStreamflow

The invention relates to a method of performing an oilfield operation of an oilfield having at least one wellsite, each wellsite having a wellbore penetrating a subterranean formation for extracting fluid from an underground reservoir therein. The method steps include obtaining a plurality of real-time parameters from a plurality of sensors disposed about the oilfield, wherein the plurality of real-time parameters comprise at least one selected from a group consisting of real-time flow rate data and real-time pressure data of the wellbore, configuring a gridless analytical simulator for simulating the underground reservoir based on the plurality of real-time parameters, generating real-time simulation results of the underground reservoir and the at least one wellsite in real-time using the gridless analytical simulator, and performing the oilfield operation based on the real-time simulation results

Owner:SCHLUMBERGER TECH CORP

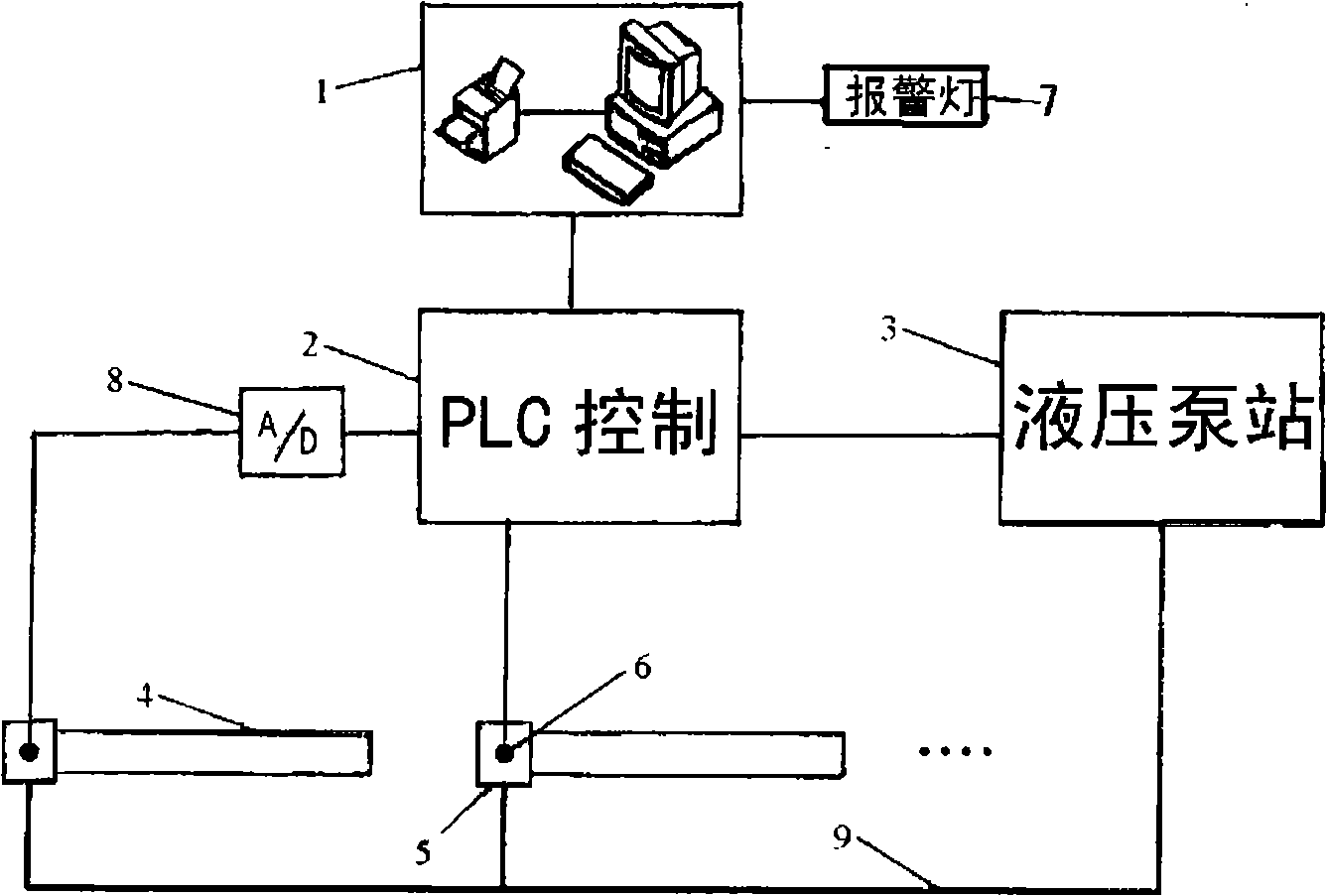

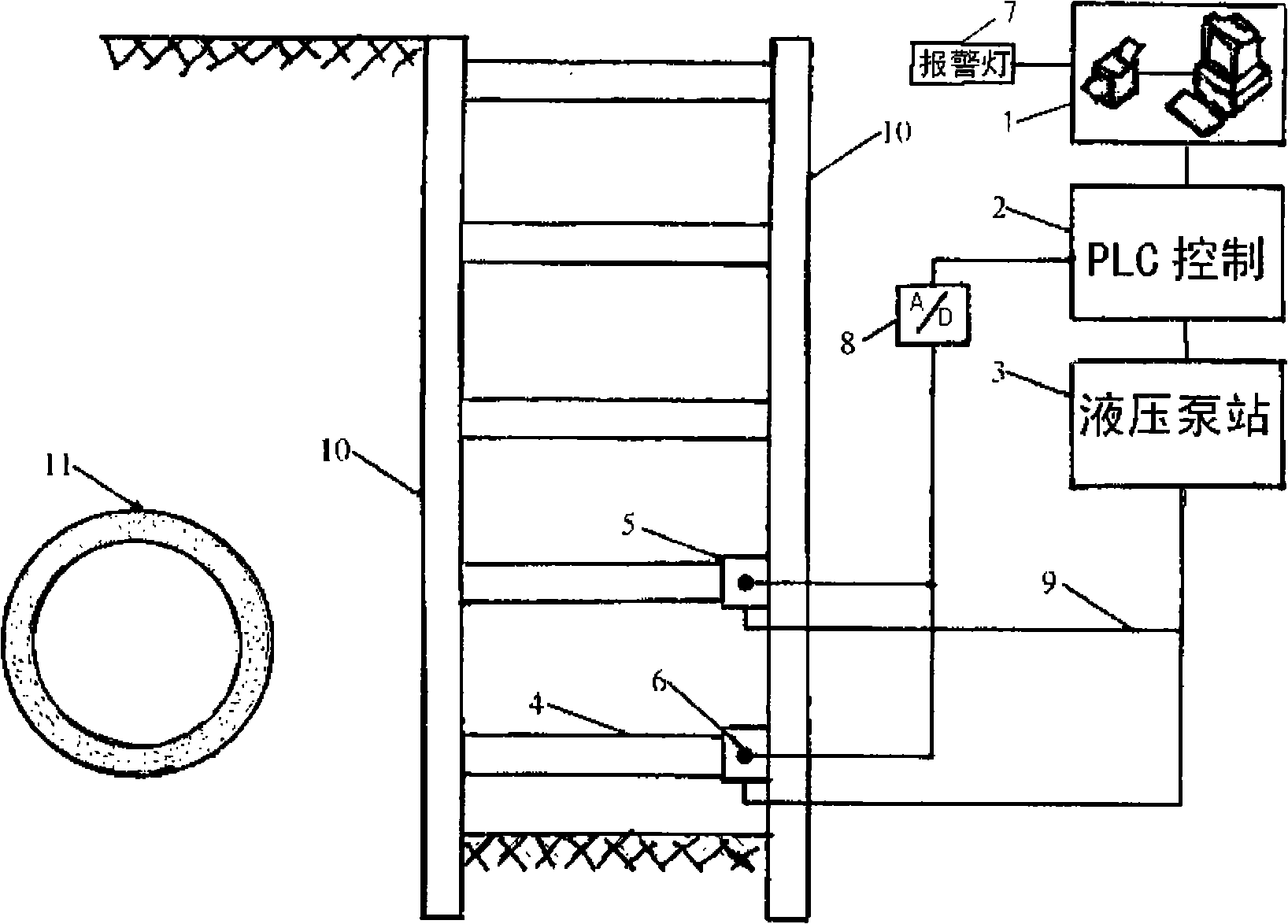

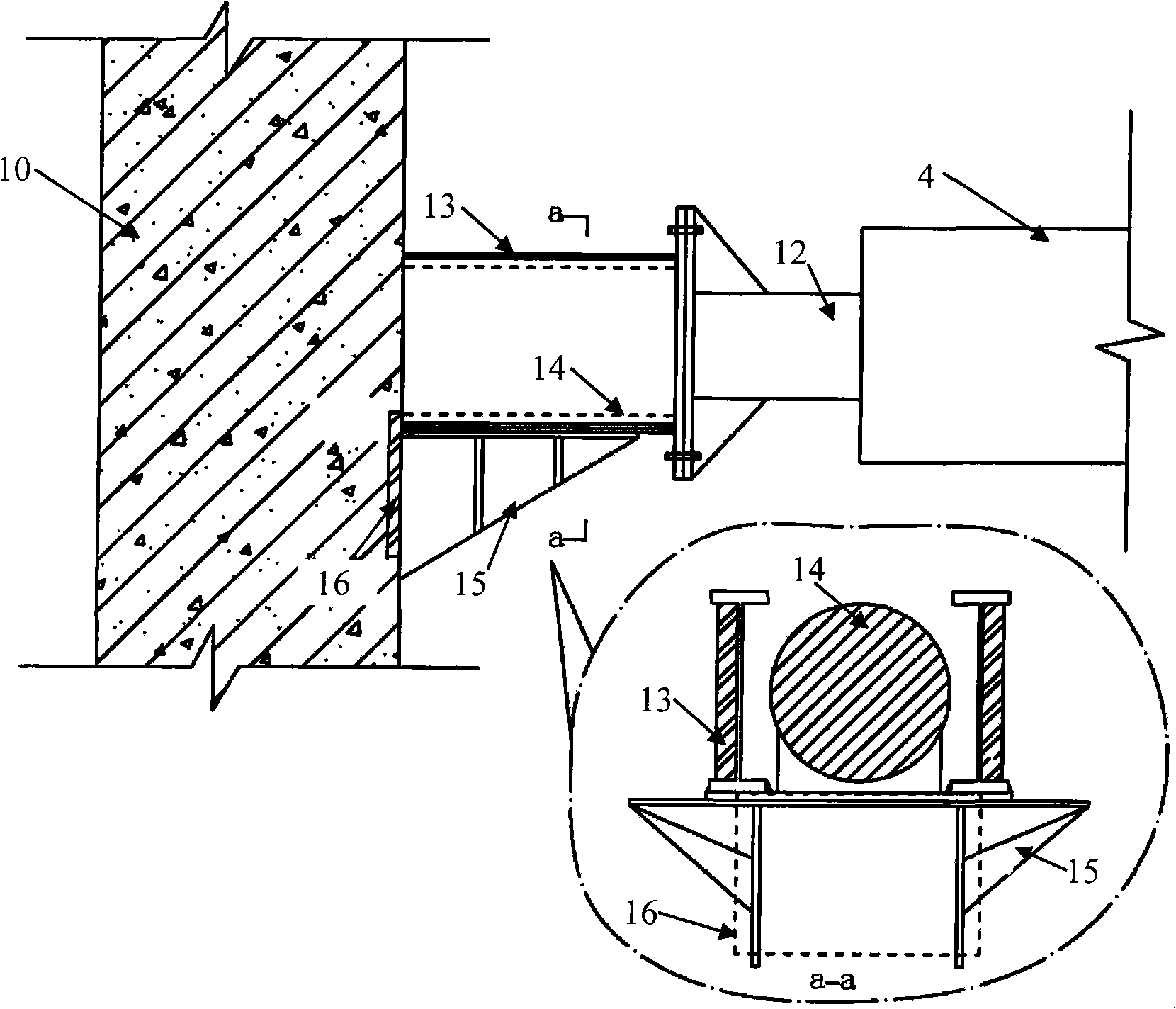

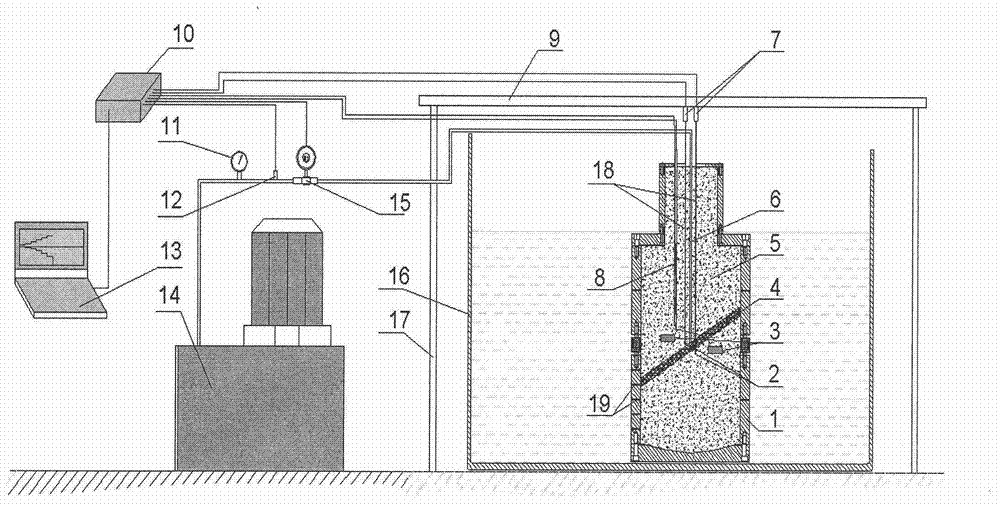

Steel shotcrete support internal force self-compensation, displacement control system and control method

InactiveCN101294389AImprove the force deformation performanceControl deformationExcavationsShotcreteAutomatic control

The invention belongs to the building support component technology field including the stress automatic control and monitoring as well as the structural safety, and relates to a steel tube supporting internal force automatic compensating and displacement controlling system. The system comprises an upper system, a PLC control system module and a field executive system. A steel support is arranged on a reinforced concrete diaphragm wall, a hydraulic jack is arranged on the steel support, and real time pressure monitoring values are fed back through a pressure sensor. The steel support and the hydraulic jack form a pre-stressed steel support structure, the hydraulic jack is connected with a hydraulic pump station through an oil circuit, and is connected with the PLC control system module through the pressure sensor, the hydraulic pump station is connected with the PLC control system module, and a PLC controlling device is connected with the upper system. Through auto-control software and a PLC control system, the automatic control to the axial force of the steel support is realized, thereby controlling the displacement and the settlement of the deep excavation supporting structure and the adjacent basic facilities.

Owner:CSCEC INT CONSTR +1

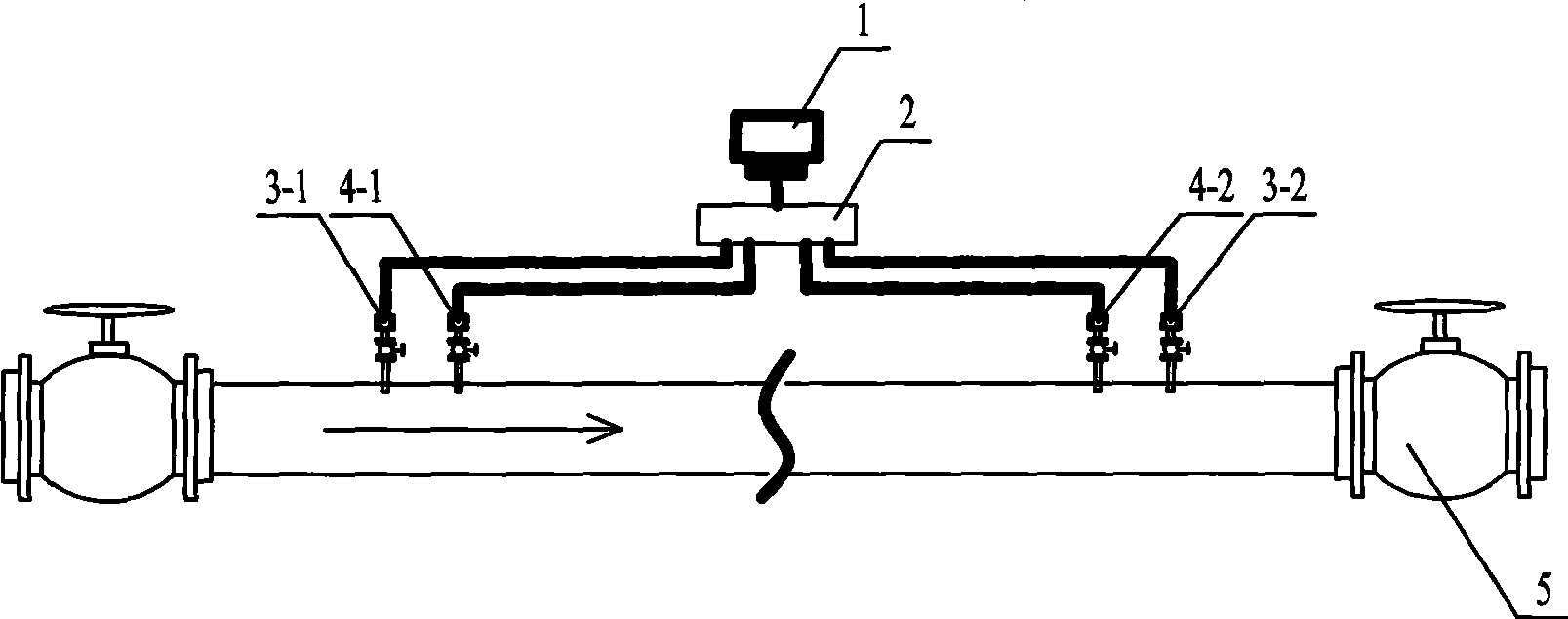

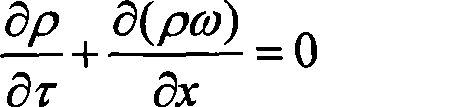

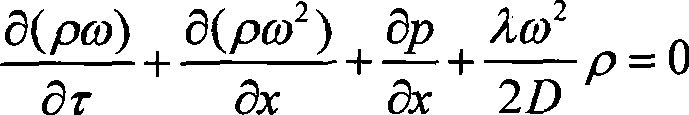

Method for performing gas pipeline leakage position by using instant change on-line diagnosis coupling excitation frequency response

InactiveCN101413628ARealize online real-time detectionReduce false alarm ratePipeline systemsEngineeringPressure response

The invention provides a method which uses transient online diagnosis coupling frequency response to position the leakage of natural gas pipeline, and relates to a natural gas pipeline failure detection and positioning method which can solve the problems that the existing method for detecting and positioning the leakage of the natural gas pipeline can not detect in real time, has long detection period, low positioning precision and high error report rate; real-time pressure value and real-time flux value are respectively collected at the upstream and downstream of the pipeline; the real-time downstream pressure value and the real-time flux value when the pipeline runs stably are reduced by the practical real-time pressure value and the practical real-time flux value at the downstream; if both of the two differences exceed the valve value, the leakage is considered to occur, otherwise the values are collected again; an excitation pressure wave is generated at the downstream end of the pipeline and the wave speed of the response wave of the excitation pressure wave is gained; according to the wave speed of the excitation pressure response wave and the time difference when the excitation pressure response wave is transmitted to the upstream and the downstream, the position of the leakage point is gained. The measurement and collection of the values are completed by normal equipments and the method can be used both in the built pipeline or pipelines under construction.

Owner:HARBIN INST OF TECH

Indoor test system and test method for seepage characteristics of jointed rock mass

InactiveCN103033458AAvoid disturbanceReal-time synchronous display of trafficPermeability/surface area analysisPilot systemData acquisition

The invention discloses an indoor test system and a test method for seepage characteristics of jointed rock mass. Through carrying out seepage, deformation and stress coupling tests of seepage performance for a large scale jointed rock mass test piece under high pressure water to a given jointed rock mass, the test pressure, flow and displacement can be simultaneously displayed and collected in real time, and the test data can be stored. The test method comprises the following steps: a test rock piece with a fissure surface is placed into a mould, the mould is placed into water, and the fissure surface inclination of the rock is adjusted; a water filling pipe is installed on the fissure surface of the rock, the water filling pipe is connected with a high pressure pump, and pressure cells are installed on an upper plate and a lower plate of the fissure surface of the rock; anchorage points are arranged on the upper side and the lower side of the fissure surface, and the anchorage points are connected with a displacement meter; high flow and high pressure hydraulic test is carried out by the high pressure pump to the fissure surface through the water filling pipe, the collected data is transferred to a collector by a pressure sensor on the water filling pipe, a flow sensor, the press cells and the displacement meter respectively and then accesses to a computer, and the real-time pressure, flow, relative displacement of the fissure and coupling relationship are continuously recorded and displayed.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

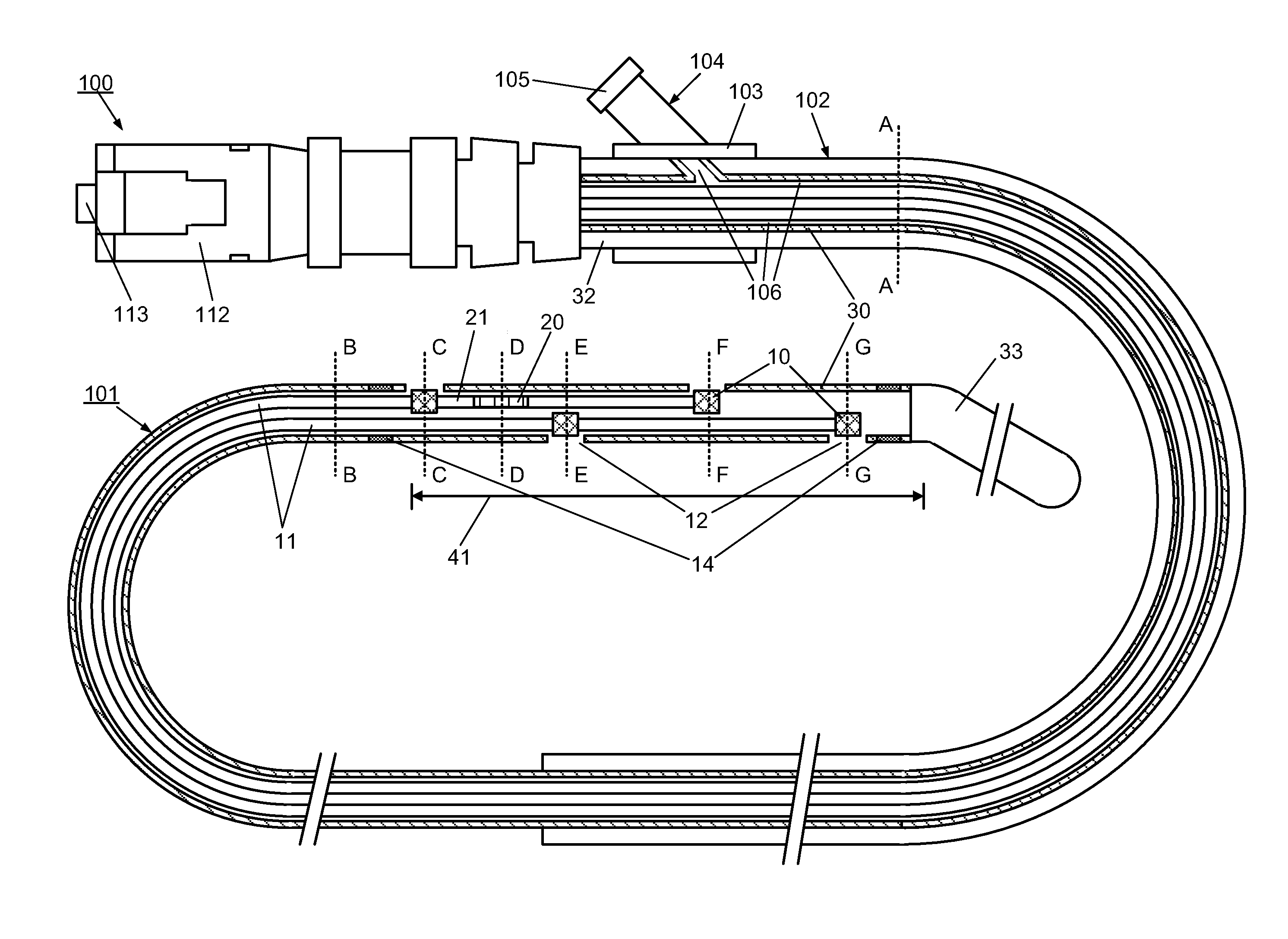

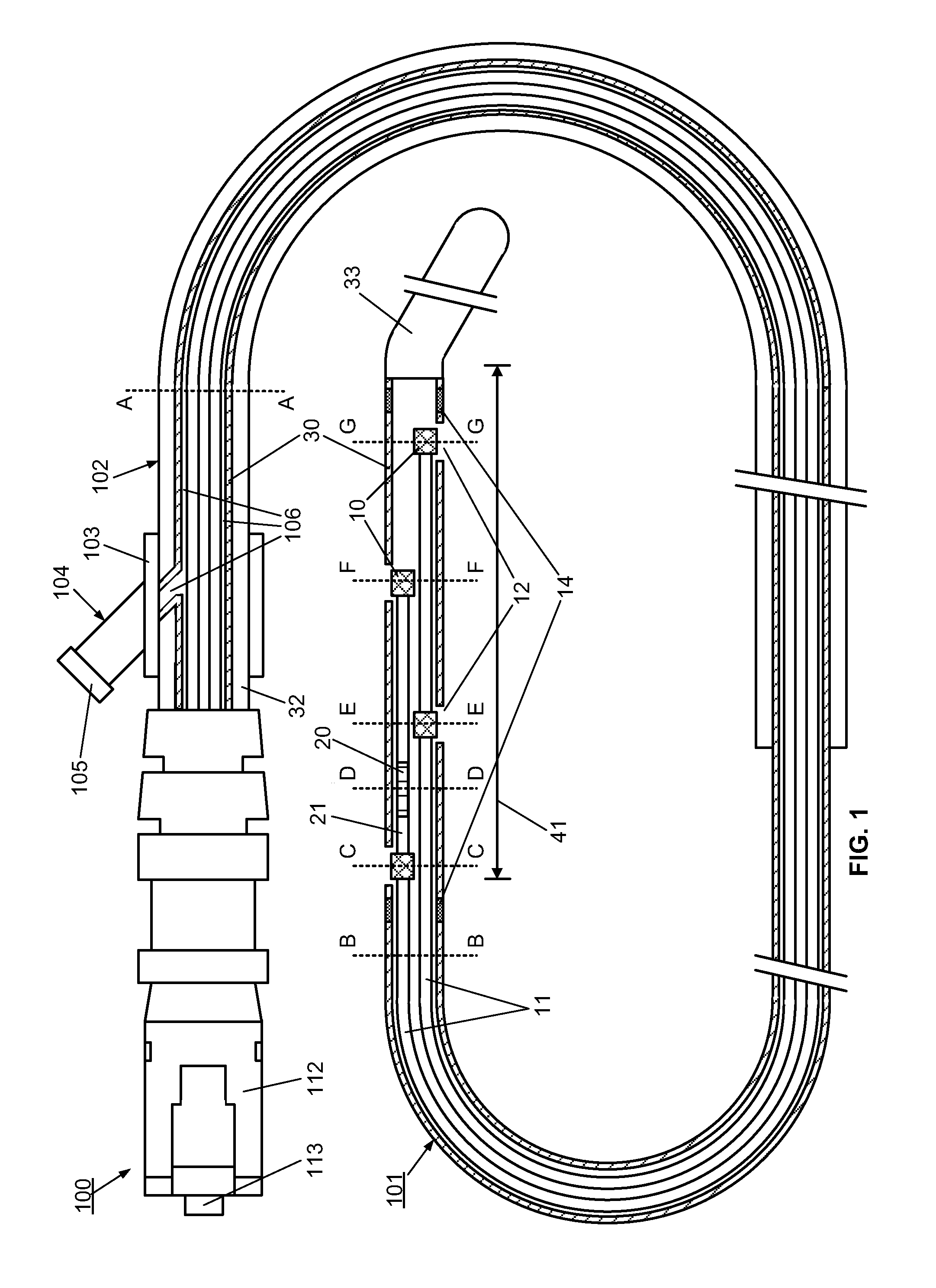

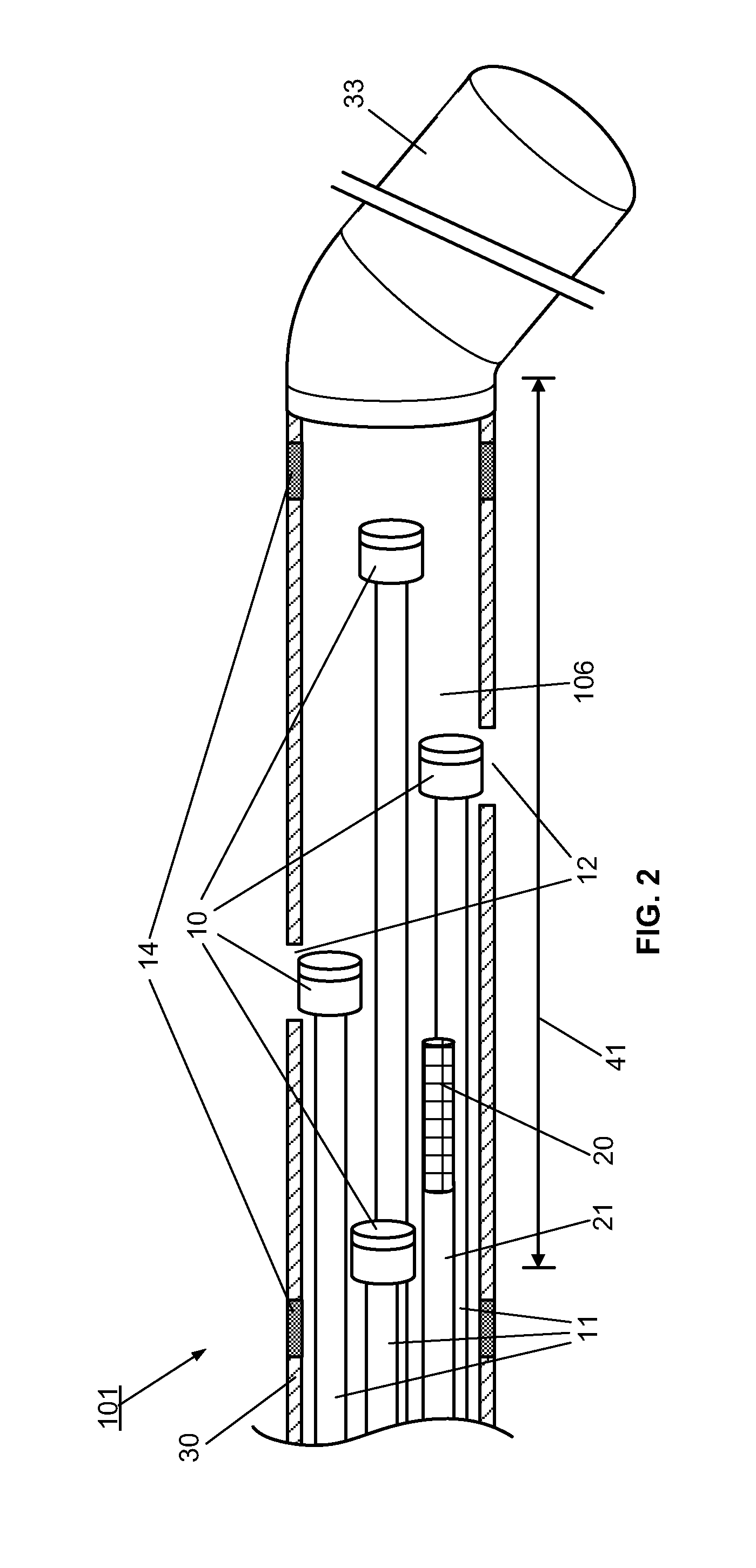

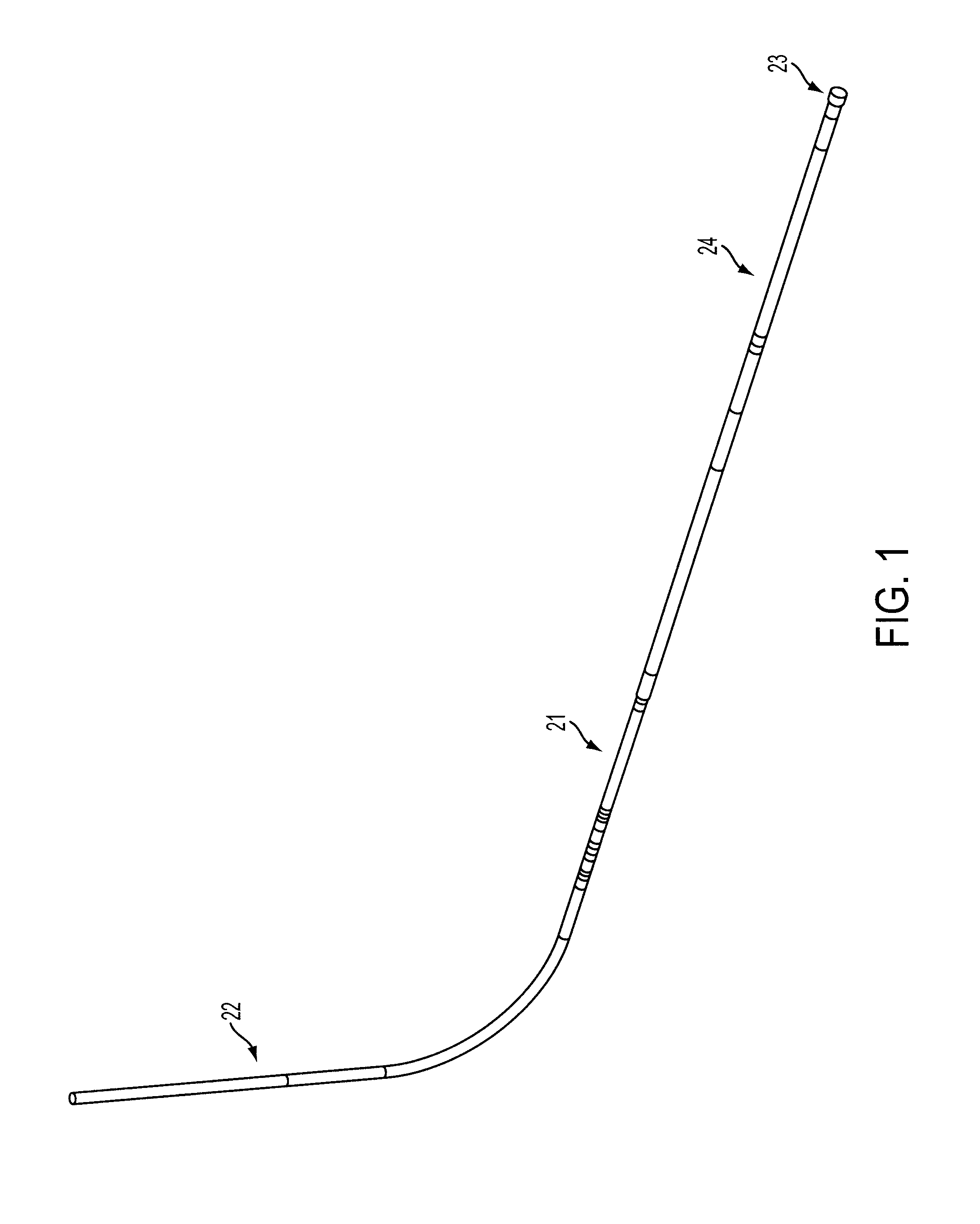

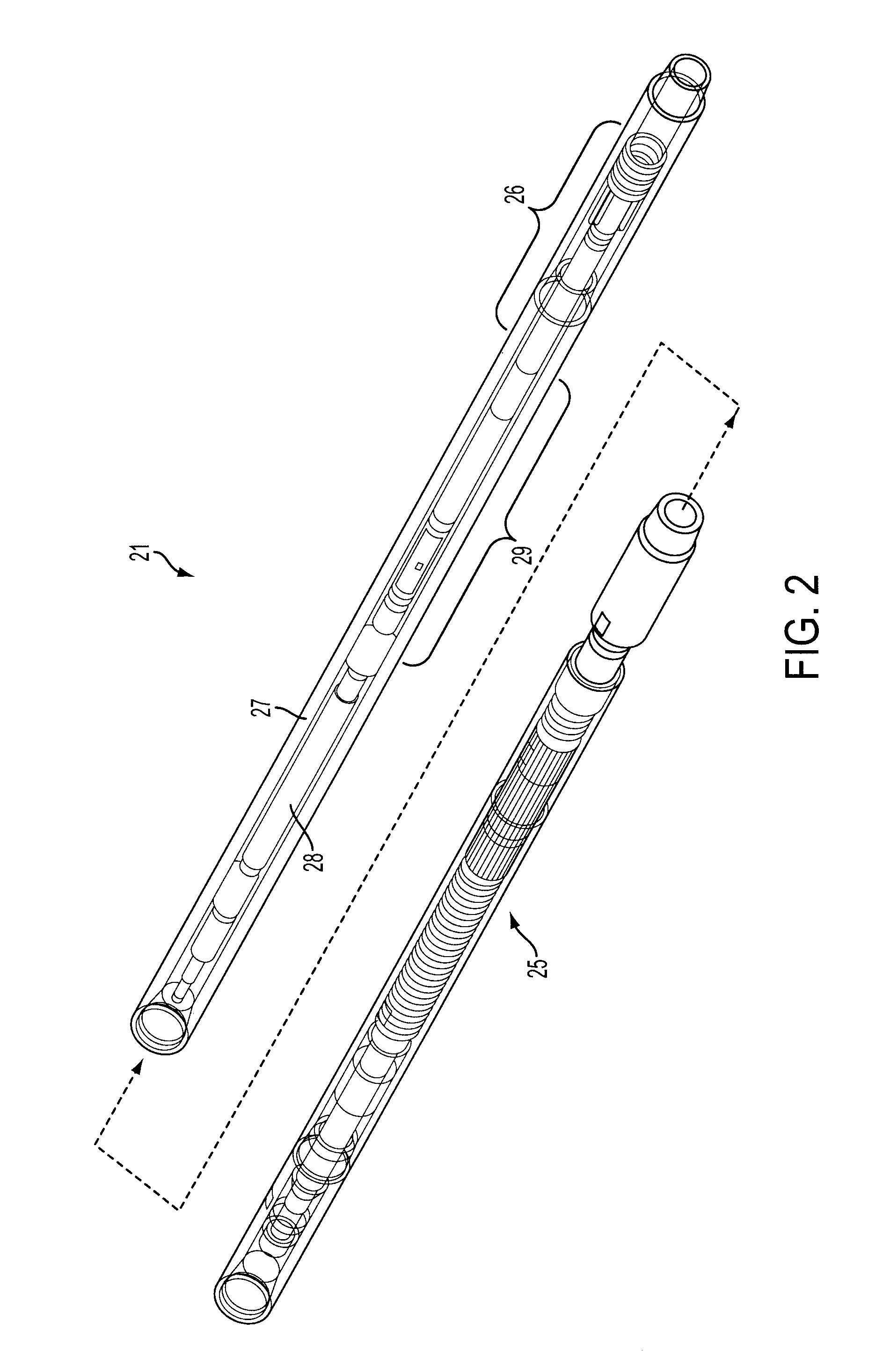

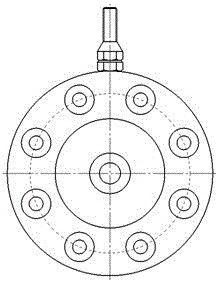

Apparatus, system and methods for measuring a blood pressure gradient

ActiveUS20140249386A1Minimal disruptionMinimal and negligible disruptionMechanical/radiation/invasive therapiesVolume/mass flow measurementElectrical connectionOptical coupler

An apparatus (100), control system (150) and methods are provided for directly measuring a pressure gradient, i.e. by real-time pressure measurements, with particular application for in situ measurement of transvalvular blood pressure gradients for the aortic valve and other heart valves, using minimally-invasive techniques. The apparatus takes the form of a multi-sensor assembly, e.g. enclosed within a micro-catheter or a steerable guidewire, and comprises a plurality of optical pressure sensors (10) is arranged along a length of the distal end portion (101), for measuring pressure simultaneously at each sensor location. For example, four MOMS optical pressure sensors (10), and optionally, a flow sensor (20), are incorporated into a distal end portion (101) having a diameter of 0.89 mm or less, and preferably 0.46 mm or less. Beneficially, all sensors are optically coupled, via respective optical fibers (11), to an optical coupler (112) at the proximal end of the multi-sensor apparatus, without requiring electrical connections.

Owner:HEMOCATH LTD

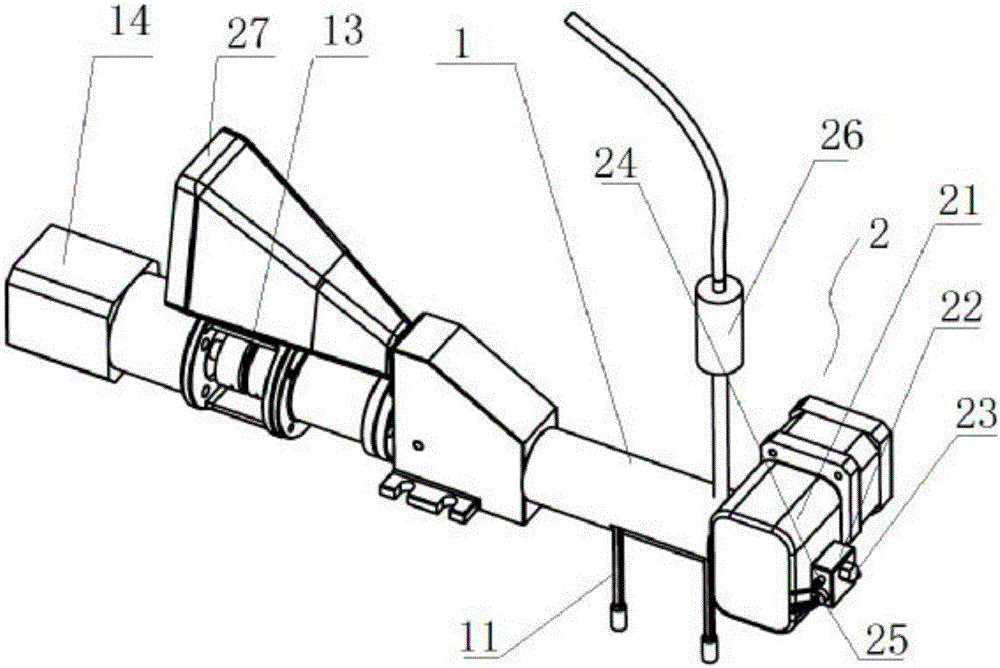

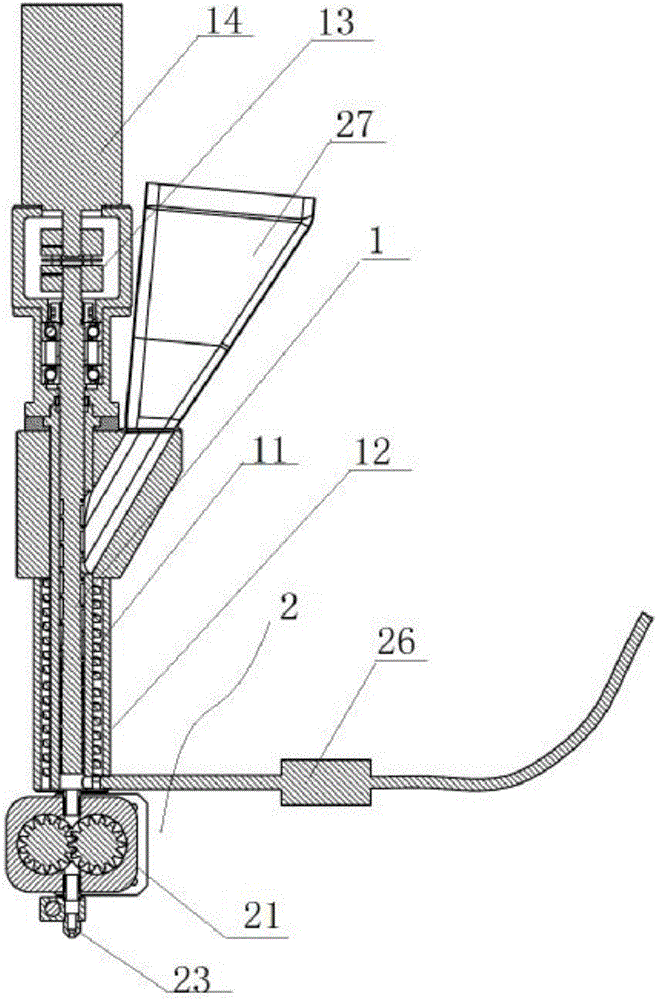

Printing head for 3D printing of powder material

InactiveCN105690762AAvoid the problem of not being able to extrudeGood viscosityAdditive manufacturing apparatusRapid prototypingViscosity

The invention discloses a printing head for 3D printing of a powder material. The printing head for 3D printing of the powder material comprises a melting extrusion mechanism, a printing head body connected with the melting extrusion mechanism, and a driving mechanism. The melting extrusion mechanism is used for conveying the powder material subjected to heating melting to the printing head body. The driving mechanism is used for driving the melting extrusion mechanism. The printing head body comprises a melt pump connected with the melting extrusion mechanism. An outlet of the melt pump is connected with a nozzle mechanism. According to the printing head for 3D printing of the powder material, the temperature of the position of the nozzle is controlled actively so that the optimal viscosity and forming temperature can be provided for powder materials having different properties, and the problem that coagulation is caused due to the fact that the material temperature is decreased in the position of the nozzle, and consequentially the material cannot be extruded is solved; meanwhile, the problem that rapid forming of the materials cannot be achieved easily due to the fact that the temperature is too high is solved; the lower end of a screw is directly connected to the melt pump, a pressure sensor is additionally arranged, the real-time pressure of melt is obtained through the pressure sensor, and the rotating speed of the screw is adjusted; and different rotating speed ranges are adopted according to different materials, and the optimal extrusion pressure range is obtained.

Owner:TRIASTEK INC

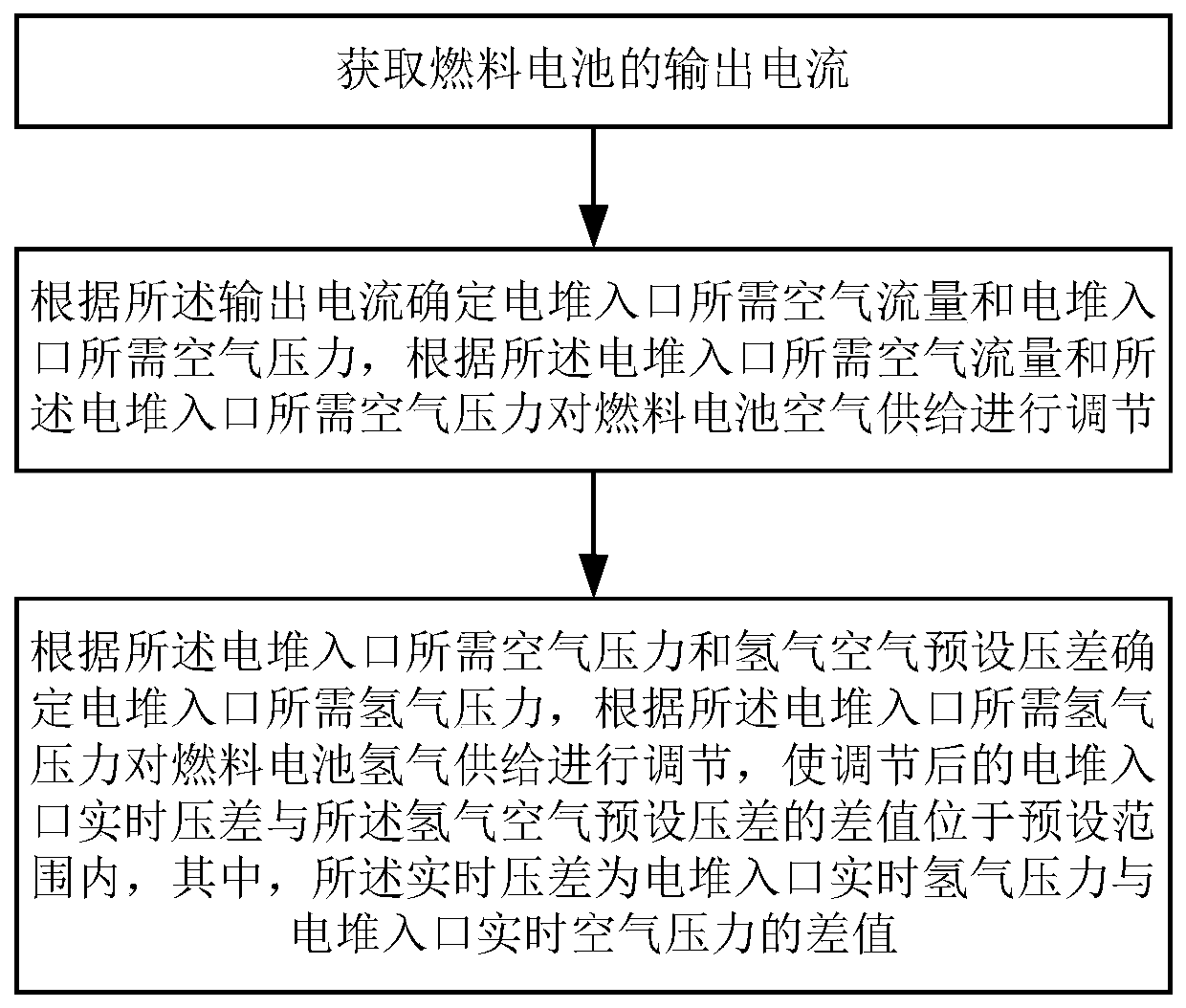

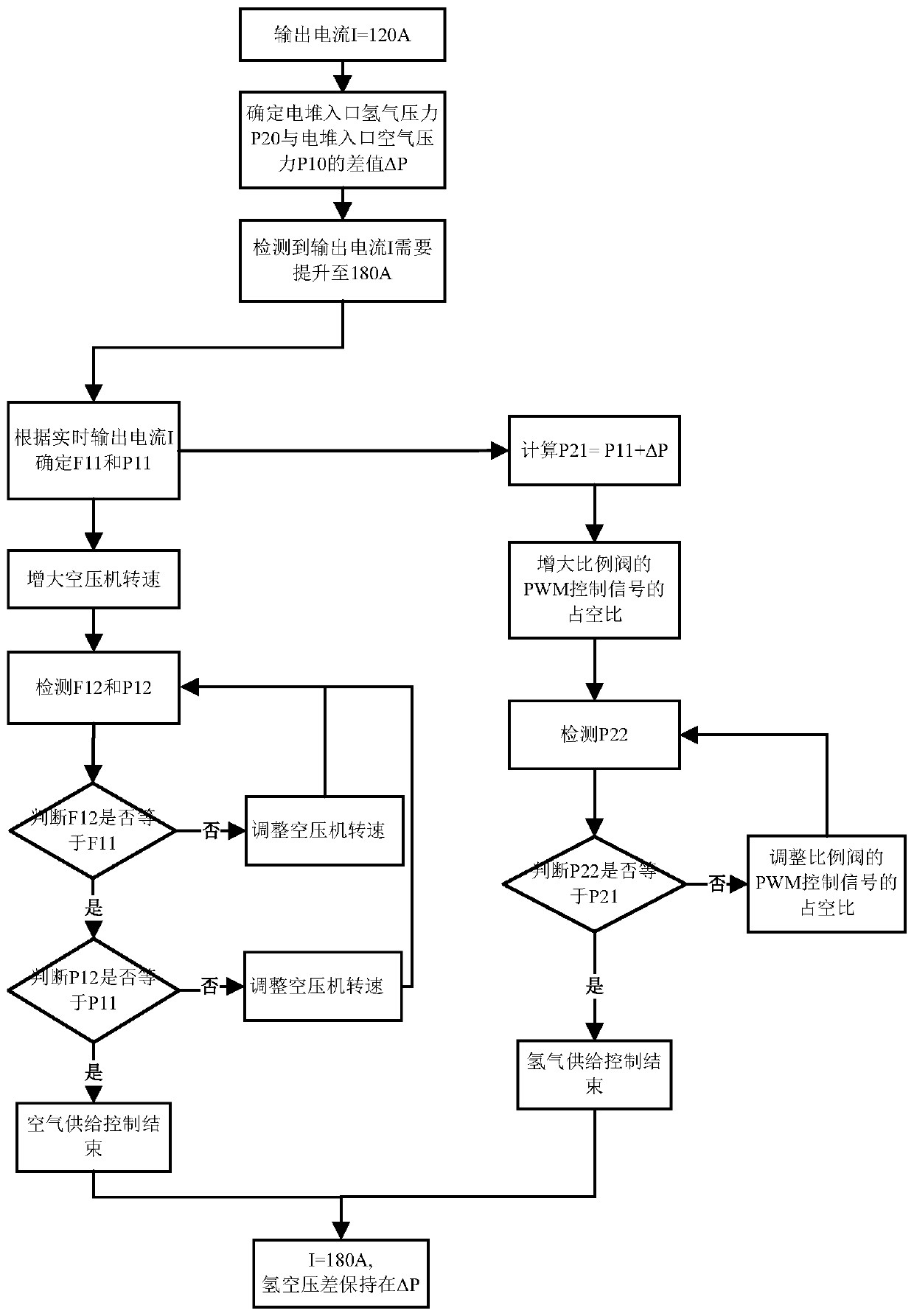

Fuel cell hydrogen and air supply control method, device and system

InactiveCN109980252AGuaranteed durabilityGuaranteed running stabilityFuel cellsHydrogen pressureEngineering

The invention relates to a fuel cell hydrogen and air supply control method, device and system. The method comprises the steps of: obtaining the output current of a fuel cell; determining an air flowand an air pressure required by a galvanic pile inlet according to the output current, and adjusting the fuel cell air supply according to the air flow and the air pressure required by the galvanic pile inlet; determining the hydrogen pressure required by the galvanic pile inlet according to the air pressure required by the galvanic pile inlet and a preset hydrogen-air pressure difference, and adjusting the fuel cell hydrogen supply according to the hydrogen pressure required by the galvanic pile inlet, so that a difference between the real-time pressure difference of the galvanic pile inlet and the preset hydrogen-air pressure difference is within a preset range, wherein the real-time pressure difference is a difference between the real-time hydrogen pressure of the galvanic pile inlet and the real-time air pressure of the galvanic pile inlet. The method can avoid great changes in pressure difference on both sides of a proton exchange membrane of the fuel cell, and ensure the performance and the service life of the fuel cell.

Owner:武汉海亿新能源科技有限公司

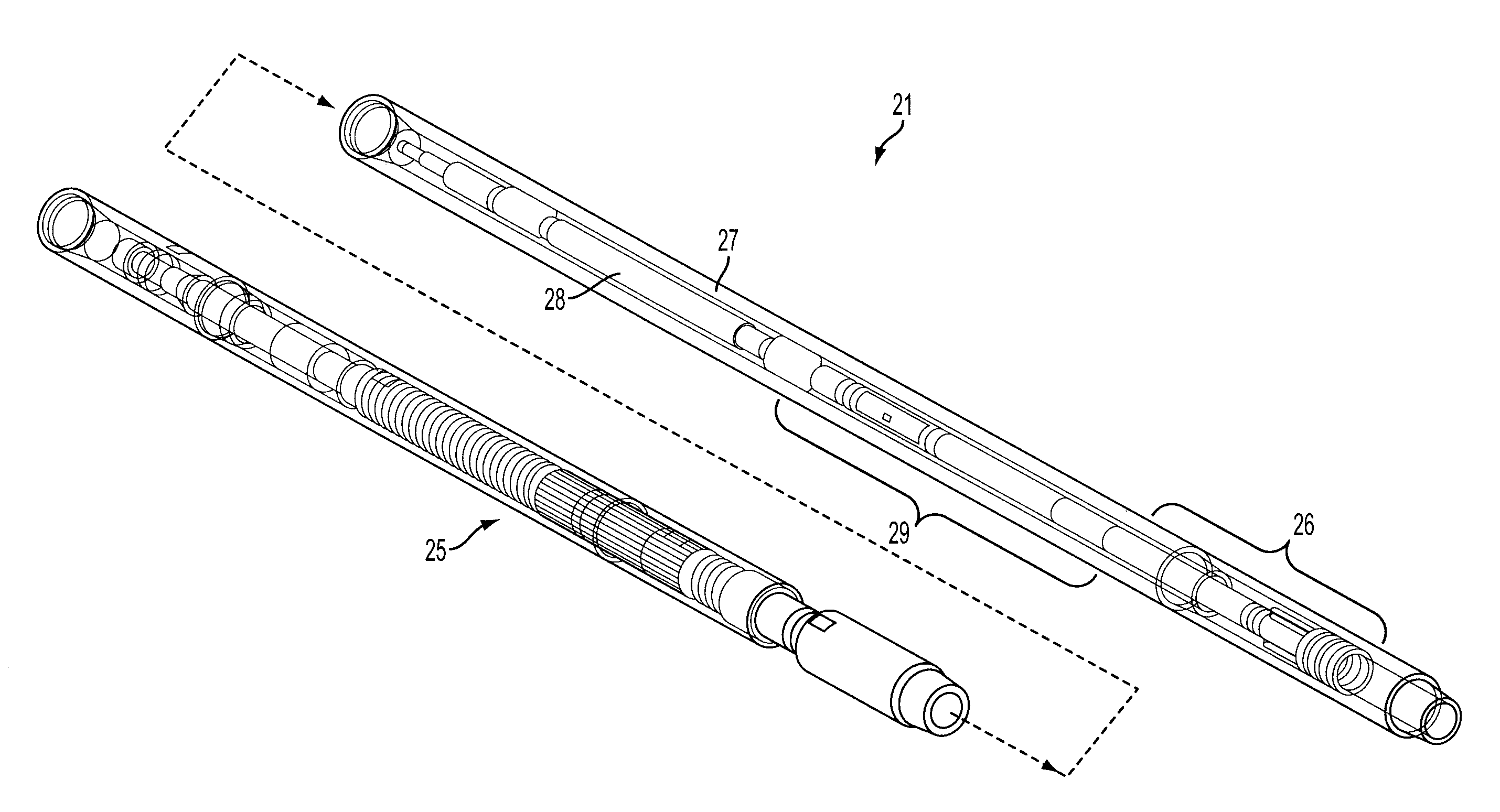

System, method and apparatus for drilling agitator

InactiveUS20120048619A1Promote sportsDrilling rodsReciprocating drilling machinesPressure amplitudeReciprocating motion

A drilling agitator tool, system and method facilitates axial movement of a drill string in a well. The tool has a valve assembly that provides pulses of fluid pressure in the drill string. A valve control assembly controls a frequency and pressure amplitude of the pulses induced by the valve assembly. The valve control assembly monitors real-time pressure and vibration levels of the drill string. An agitator assembly reciprocates in response to the pulses of fluid pressure to provide axial movement of the drill string in the well.

Owner:1473706 ALBERTA

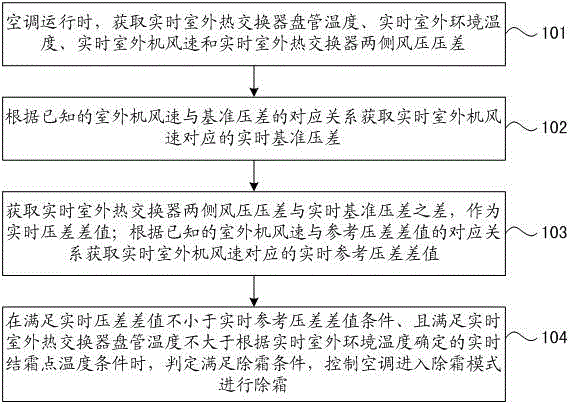

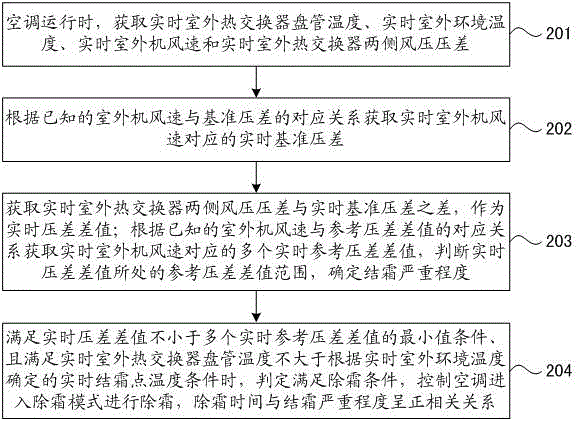

Air conditioner defrosting method

ActiveCN105650821AGood energy saving effectImprove comfort experienceMechanical apparatusSpace heating and ventilation safety systemsPower conditionerEngineering

The invention discloses an air conditioner defrosting method. The method includes the steps that when an air conditioner runs, the real-time temperature of a coil pipe of an outdoor heat exchanger, the real-time outdoor environmental temperature, the real-time air speed of an outdoor unit and the real-time pressure difference of air pressure on the two sides of the outdoor heat exchanger are acquired; according to the corresponding relation between the air speed of the outdoor unit and the reference pressure difference, the real-time reference pressure difference corresponding to the real-time air speed of the outdoor unit is acquired; the difference between the real-time pressure difference of air pressure on the two sides of the outdoor heat exchanger and the real-time reference pressure difference is acquired and serves as a real-time pressure difference value; according to the corresponding relation of the air speed of the outdoor unit and the reference pressure difference value, a real-time reference pressure difference value corresponding to the real-time air speed of the outdoor unit is acquired; and under the conditions that the real-time pressure difference value is not smaller than the real-time reference pressure difference value and the real-time temperature of the coil pipe of the outdoor heat exchanger is not higher than a real-time frosting point temperature, it is judged that the frosting condition is met, and defrosting is performed. By means of the method, the problem that in the prior art, judgment on the frosting condition of the outdoor unit is not accurate, and accordingly energy waste is caused or a user feels uncomfortable can be solved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

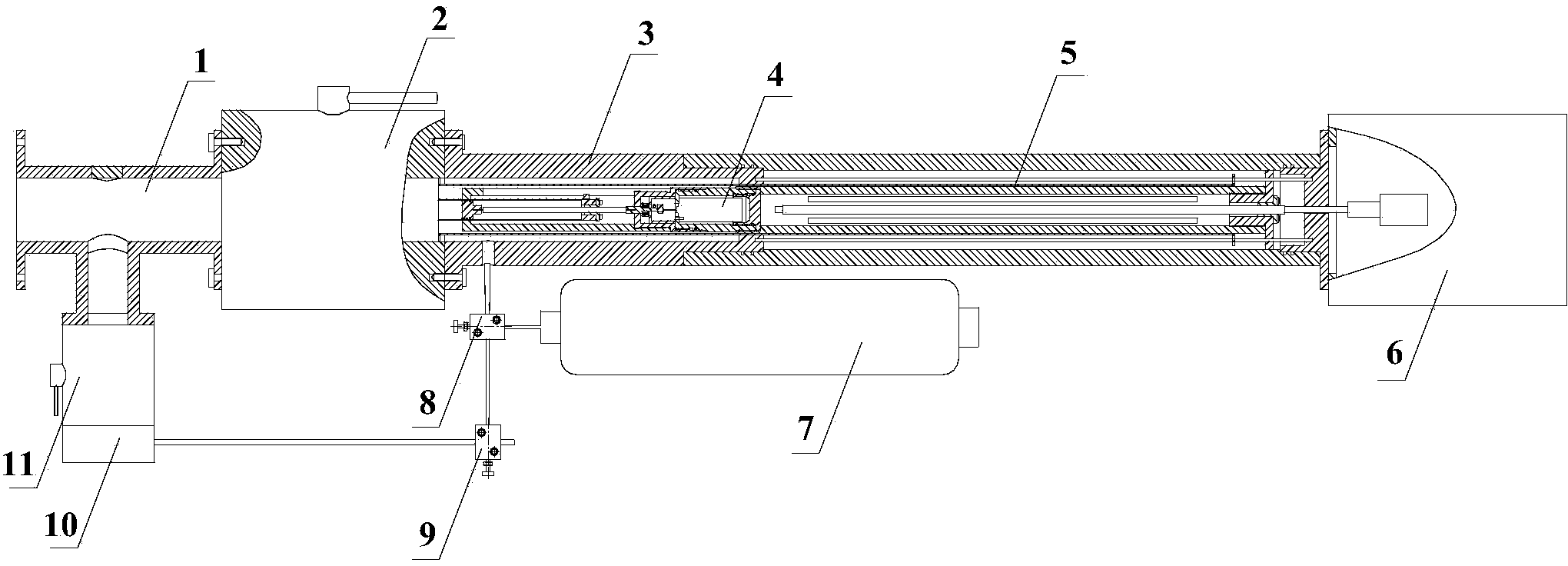

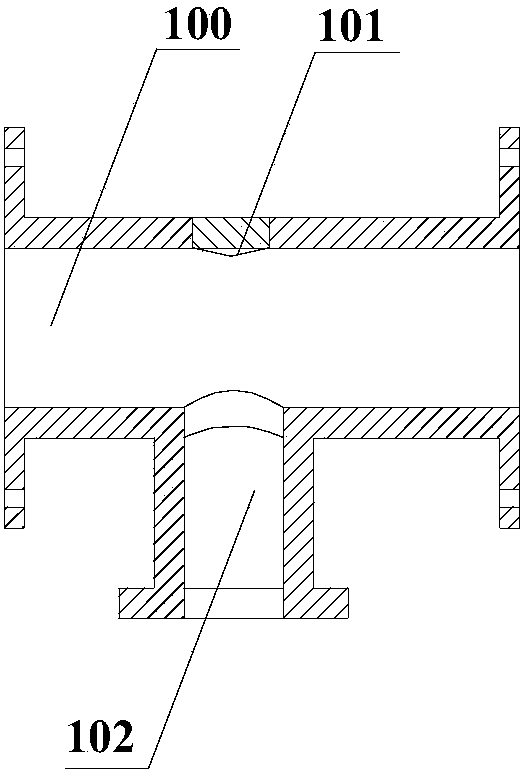

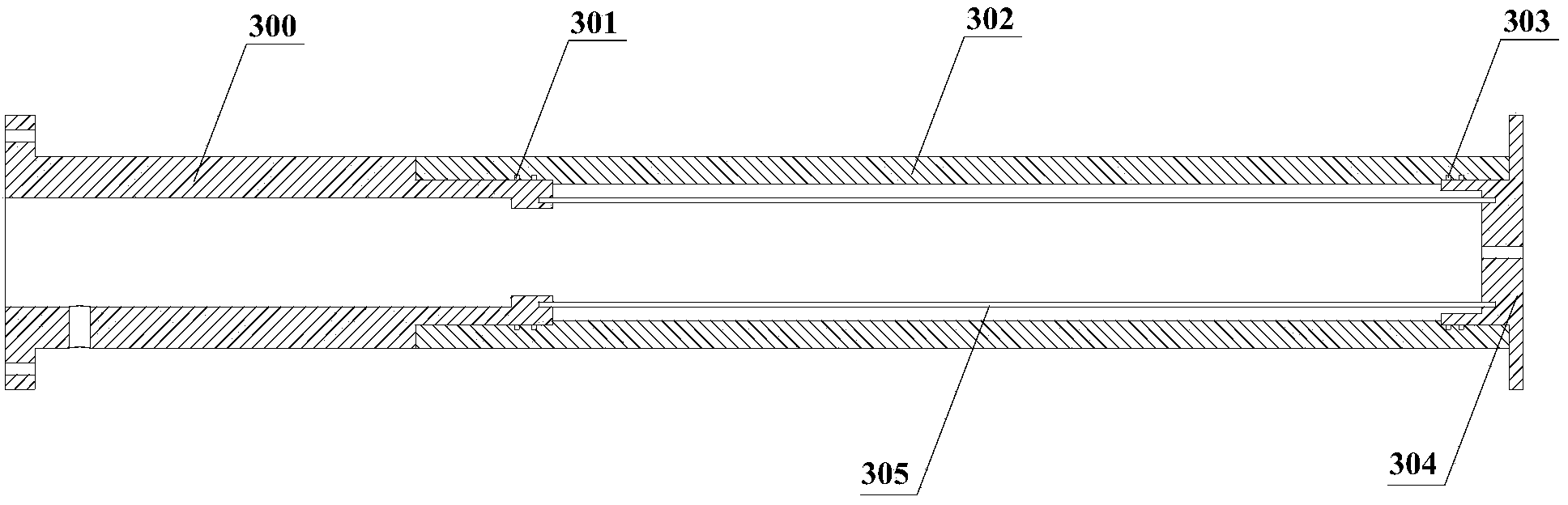

Multi-time pressure maintaining transfer equipment for deep-sea sediments

InactiveCN103913346ASolve the defect of underutilizationSolution volumeWithdrawing sample devicesButt jointEngineering

The invention discloses multi-time pressure maintaining transfer equipment for deep-sea sediments. The multi-time pressure maintaining transfer equipment comprises a pressure maintaining barrel and a sampling device and is further provided with a connector and a main ball valve, wherein the connector is internally provided with a sampling channel and a sample discharging channel which are communicated with each other; the pressure maintaining barrel is in butt joint with the sampling channel by the main ball valve; the sampling device comprises a sampling barrel located in the pressure maintaining barrel, a multi-grade retracting mechanism for driving the sampling barrel and a piston located in the sampling barrel, wherein the sampling barrel is provided with a sampling working position which extends out of the sampling channel via the main ball valve and a sample discharging working position located in the connector; the piston is used for pushing away a sample from the sampling barrel to enter the sample discharging channel when the sampling barrel is located at the sample discharging working position. The multi-time pressure maintaining transfer equipment adopts a brand-new sub-sampling scheme, namely the retracting mechanism is used for a plurality of times so as to realize sub-sampling and transferring of the sample in a pressure cavity; the defects in the prior art that the volume is large and the utilization rate of the sample is not high are overcome.

Owner:ZHEJIANG UNIV

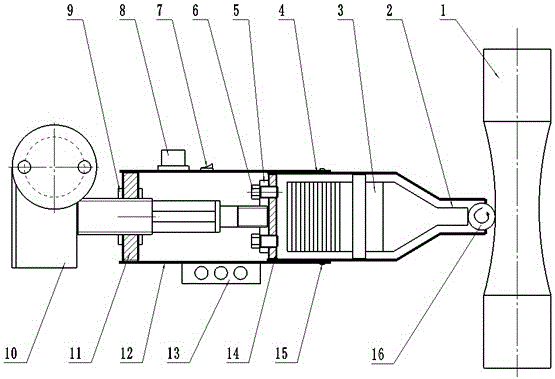

Ultrasonic surface rolling finishing feedback system capable of automatically regulating and controlling static pressure

The invention relates to an ultrasonic surface rolling finishing feedback system capable of automatically regulating and controlling static pressure, and belongs to the field of metal surface treatment. The ultrasonic surface rolling finishing feedback system comprises an ultrasonic transducer, an ultrasonic amplitude transformer, a rolling head, an electric push rod, a pressure sensor and the like, wherein the pressure sensor is fixed to the rear end of an inner sleeve through fastening bolts; a shaft head with a thread is fixed to the pressure sensor; the electric push rod is fastened to a rear cover of an outer sleeve; an ultrasonic vibration system can perform axial motion by extension and retraction of the push rod to generate static pressure. When a load is changed, a signal from the pressure sensor is sent to a PLC (programmable logic controller), the PLC compares real-time pressure value with preset value, and then extension and retraction control over the electric push rod is performed, accordingly, constant static pressure in a machining process is maintained. The ultrasonic surface rolling finishing feedback system has the advantages that the operation is simple, the precision is high, the running is stable, and synchronous automatic control can be achieved.

Owner:JILIN UNIV

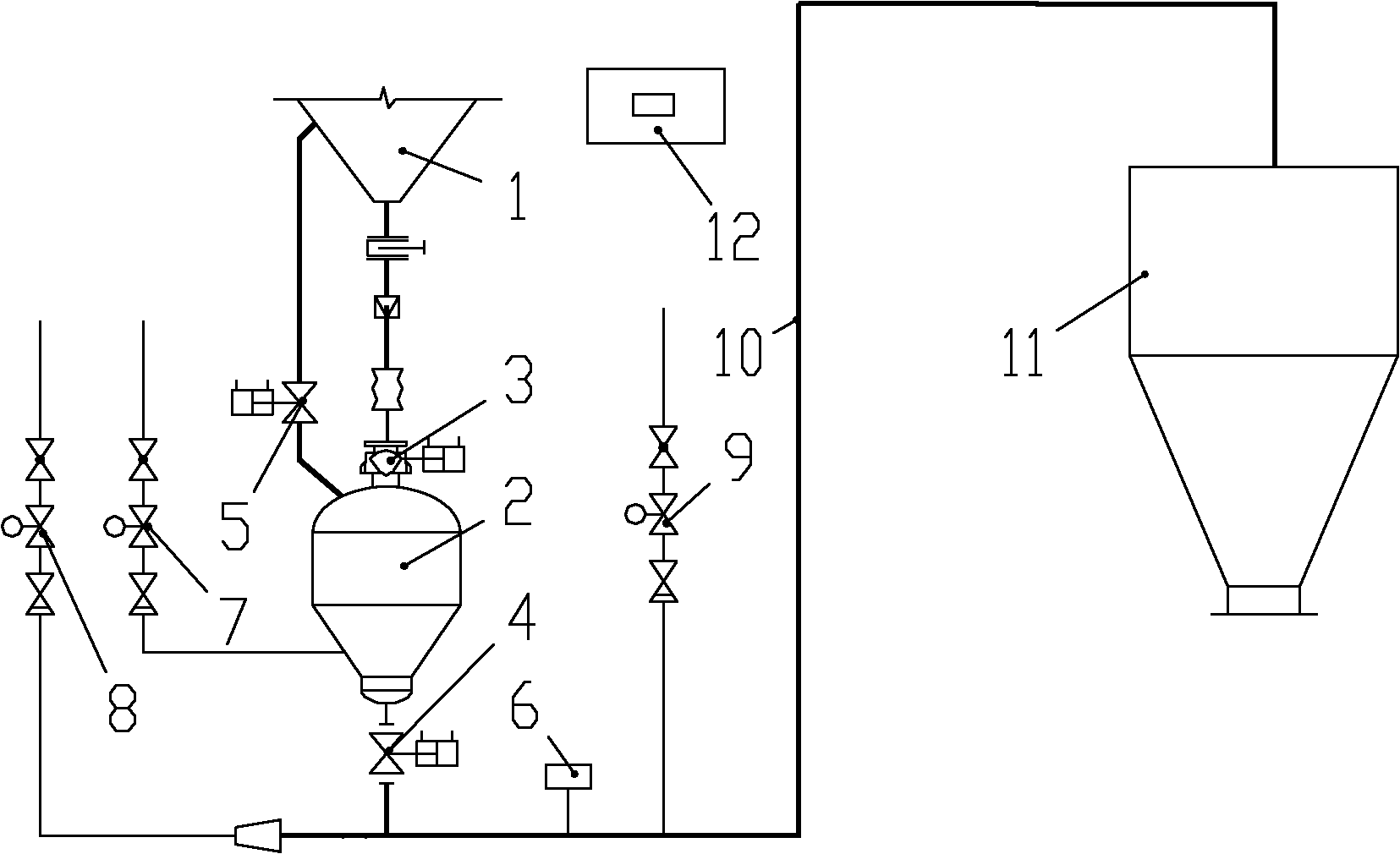

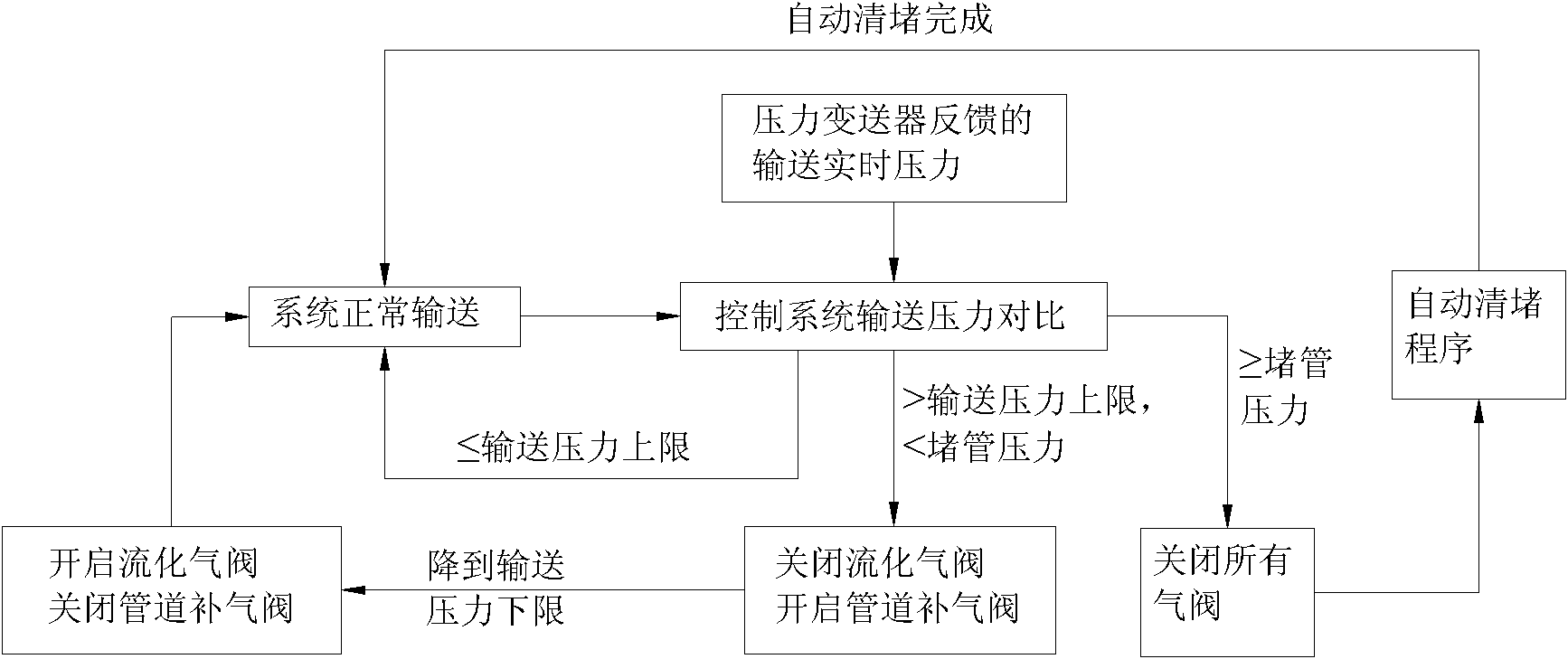

Conveying control method for pneumatic conveying system

The invention provides a conveying control method for a pneumatic conveying system. The conveying control method comprises the following steps of: 1) opening a fluidifying air valve, closing a pipeline air supply valve, comparing conveying real-time pressure with a conveying pressure upper limit, and normally conveying when the conveying real-time pressure is less than or equal to the conveying pressure upper limit, transferring to step 2) when the conveying real-time pressure is more than the conveying pressure upper limit and less than a blockage pressure set value, and transferring to step3) when the conveying real-time pressure is more than or equal to the blockage pressure set value; 2) closing the fluidifying air valve, opening the pipeline air supply valve, and transferring to thestep 1) when the conveying real-time pressure is reduced to a conveying pressure lower limit; and 3) closing all the air valves, transferring to an automatic blockage clearing program, and transferring to the step 1) after the blockage clearing is completed. In the conveying control method, the logic judgment is added on a control system, corresponding air valves are controlled to be opened and closed according to judgment results, the blockage phenomenon is effectively avoided, the time for blockage clearing of the system is shortened, the abrasion and the energy consumption of the system are reduced, and the reliability of the pneumatic conveying system is improved.

Owner:FUJIAN LONGKING

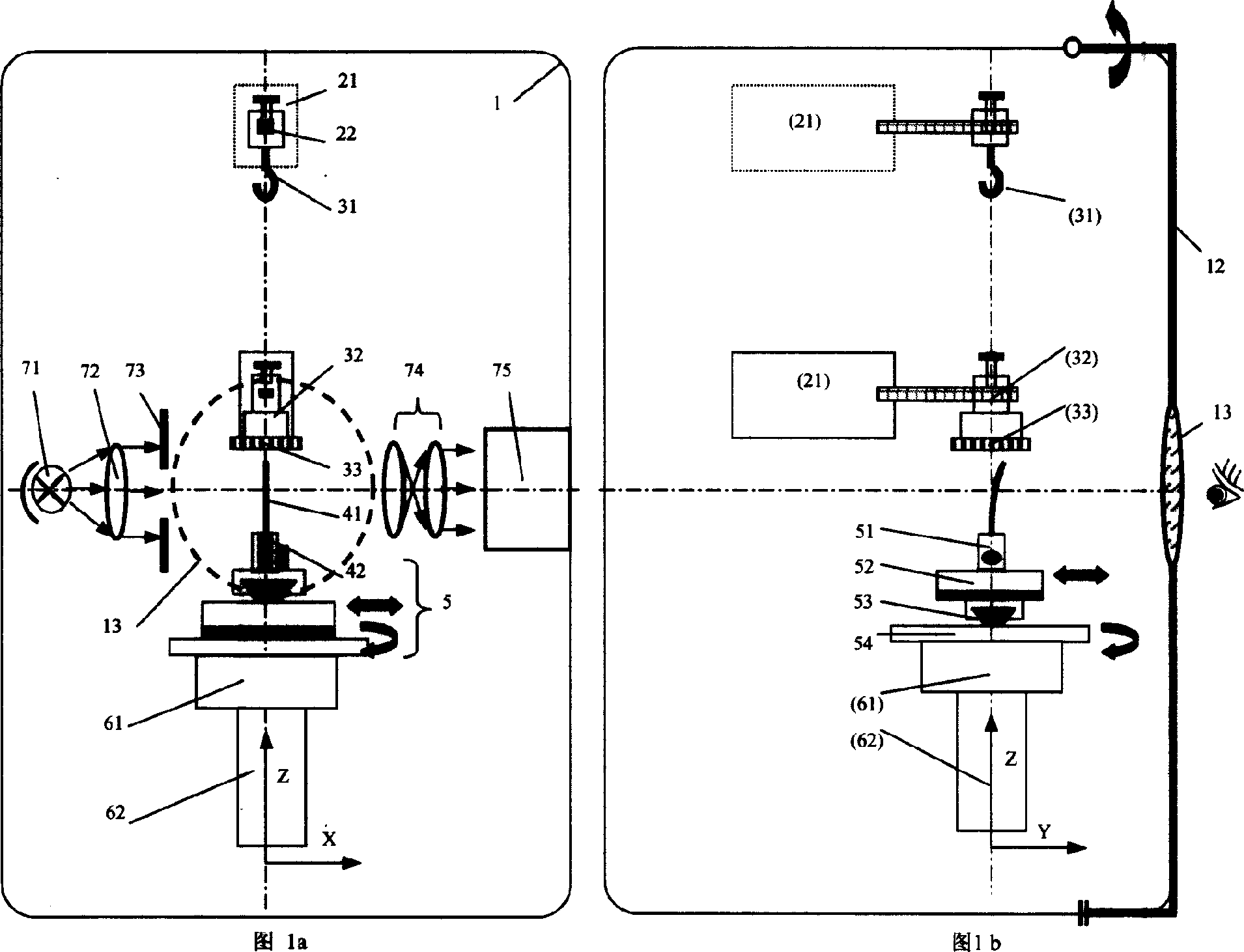

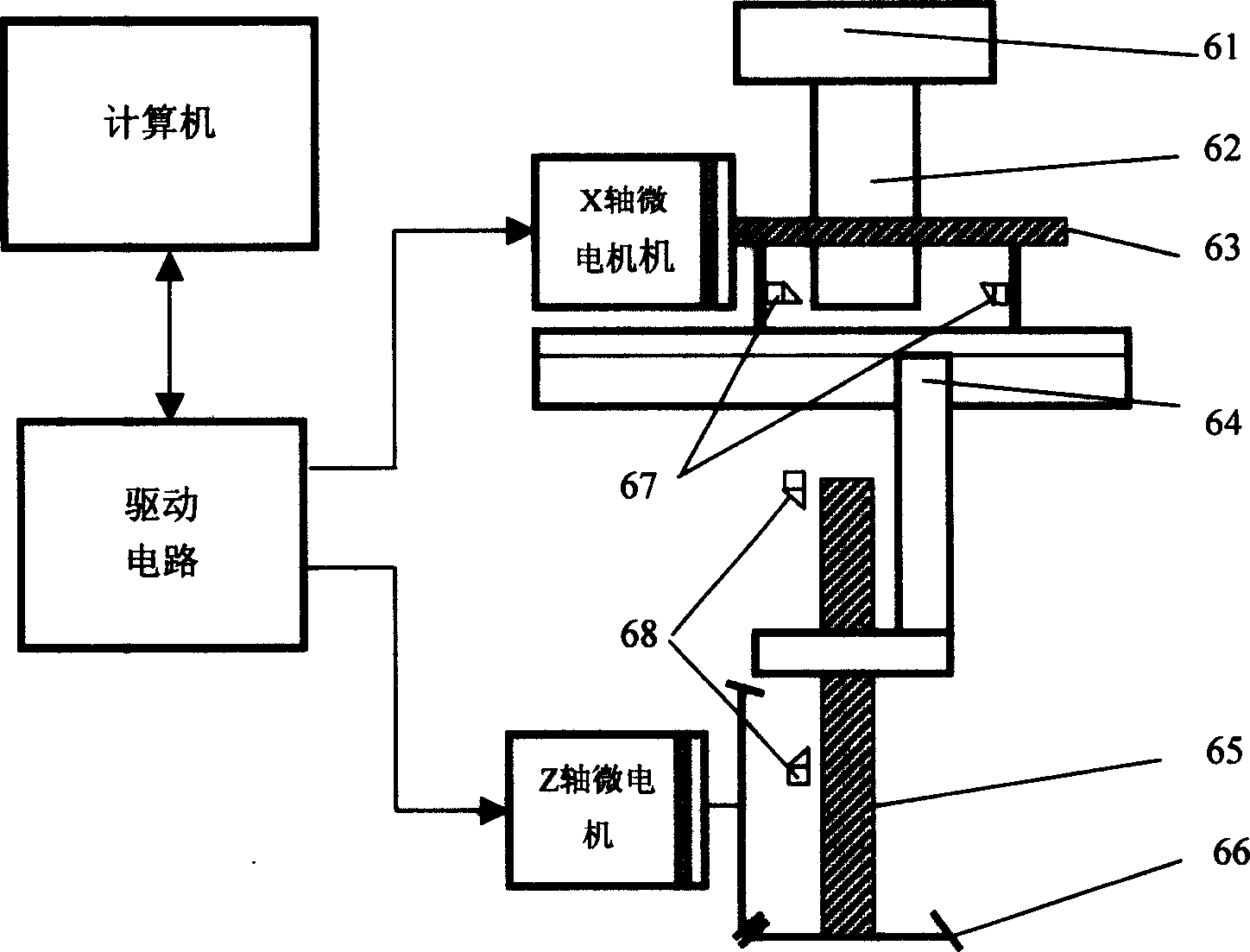

Fiber compressive and flexural property measuring method and device

The invention is a method and device for measuring fiber compression flexural performance, refers to the measurement for cotton, fur, silk, hemp and chemical fiber, and other high performance fiber or fiber type material. The invention includes a force-shift measuring mechanism made up of high precision micro force sensor, multifunctional upper grip holder and the subjacent holder which can move in parallel and vertically, it can acquire the head end stress of fiber and fiber axial deformation data and simulate the puncture effect of human skin. The invention uses optical system to realize the synchronization, changes the deformation under pressure of fiber axial into digital image to be processed, acquires the fiber fineness, holding length, flexibility and curvature of each point and shift, and controls the measured parameter through the computer real-time collected data, measures the real-time pressure, flexibility, fiber bending shape and so on deformation curve and relative character parameter through theory model and algorithm software. It especially applies to axial compressing and bending performance measurement of convex fiber with diameter of 5-200ª–m and length of 1-25mm, and the stretching measurement of fiber with length of 0-150mm.

Owner:DONGHUA UNIV

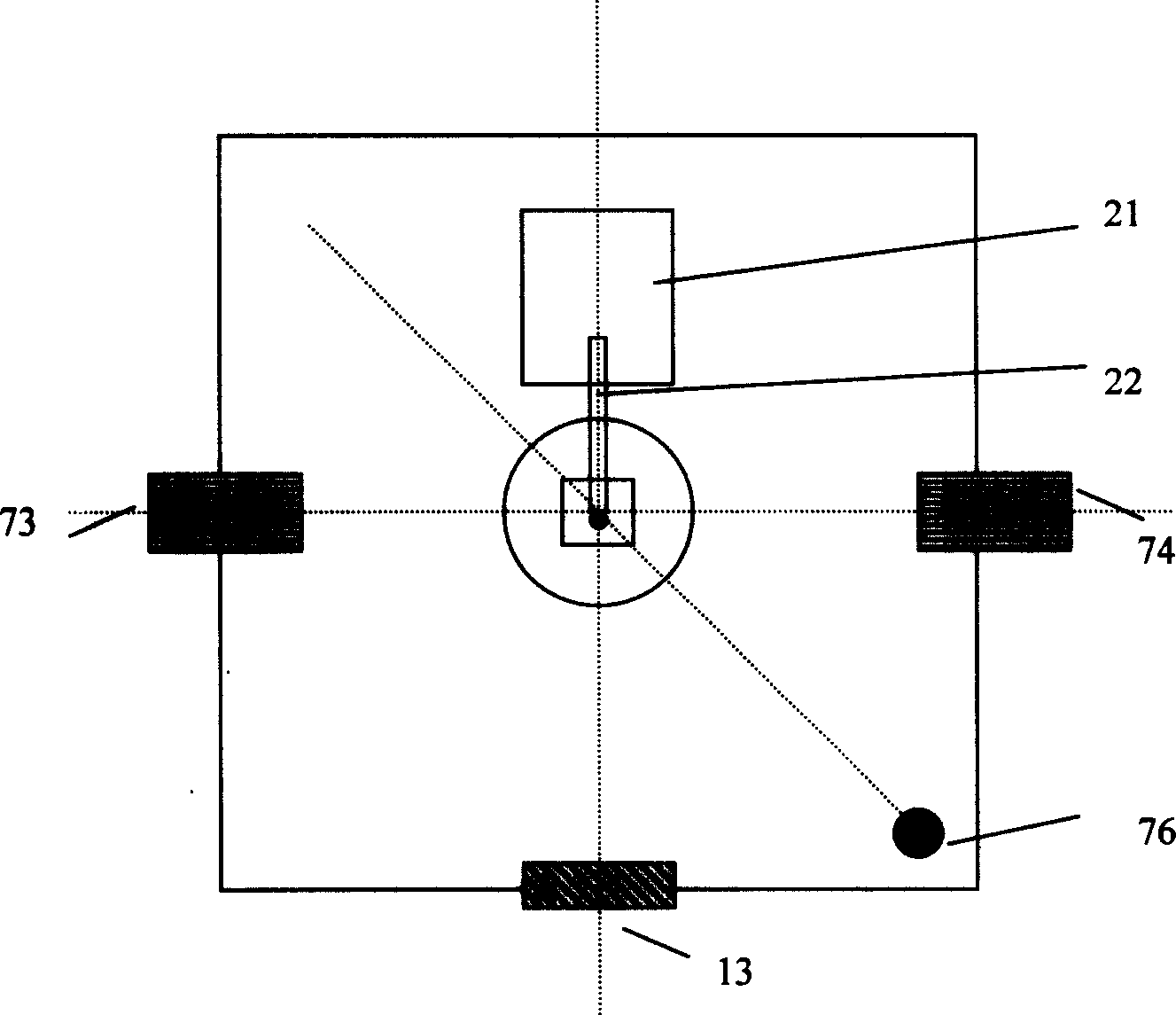

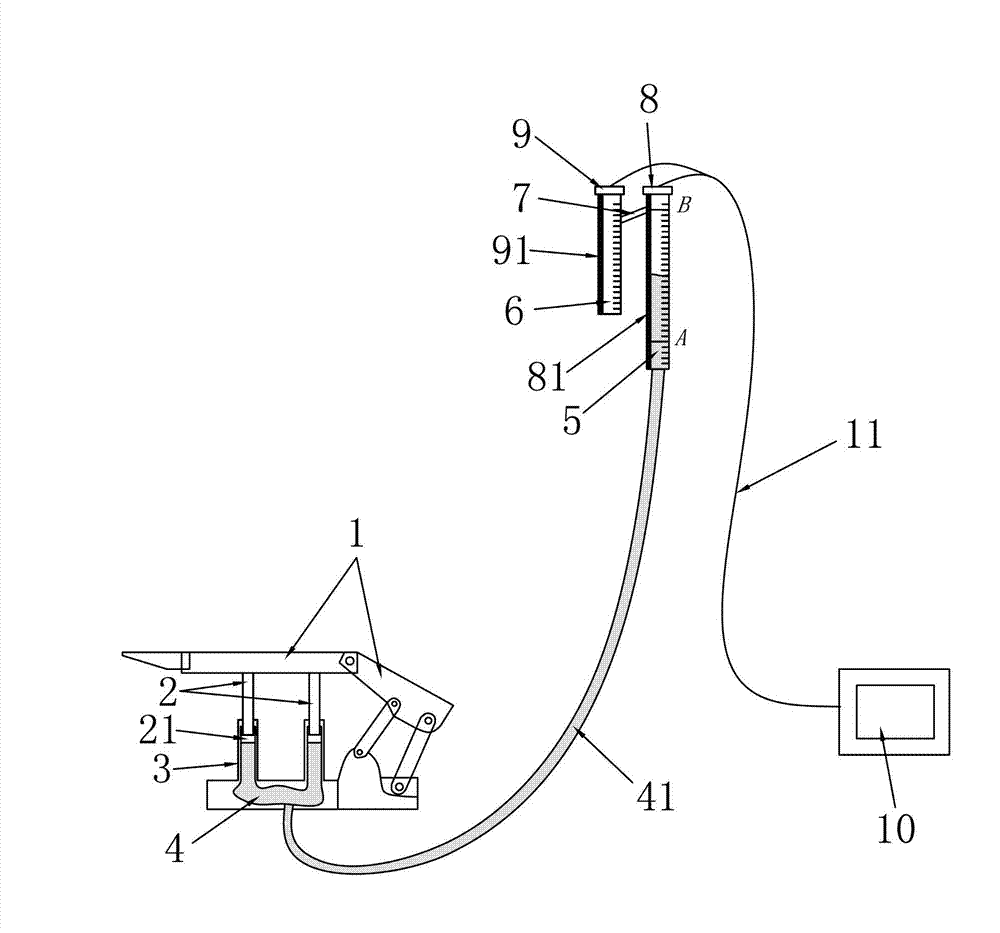

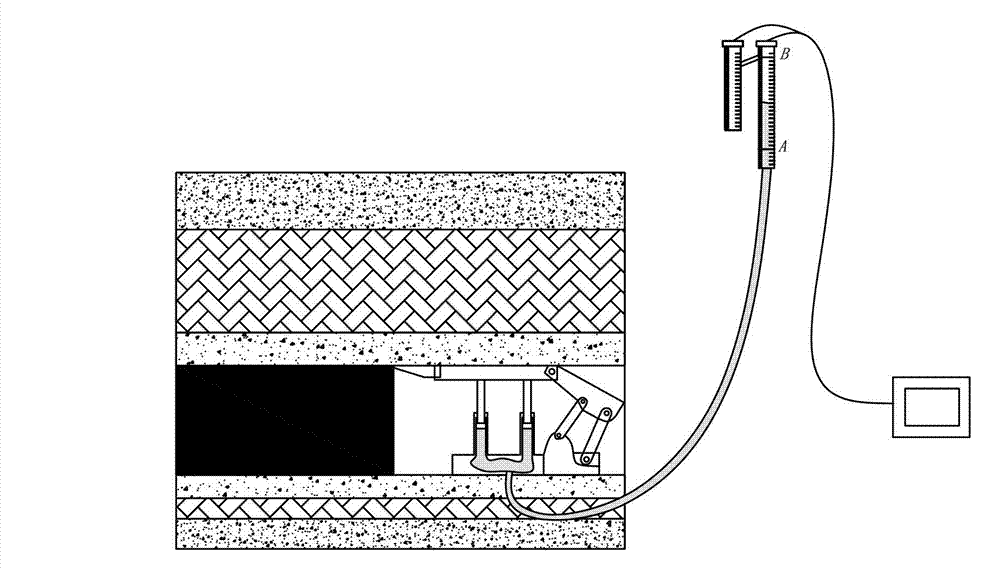

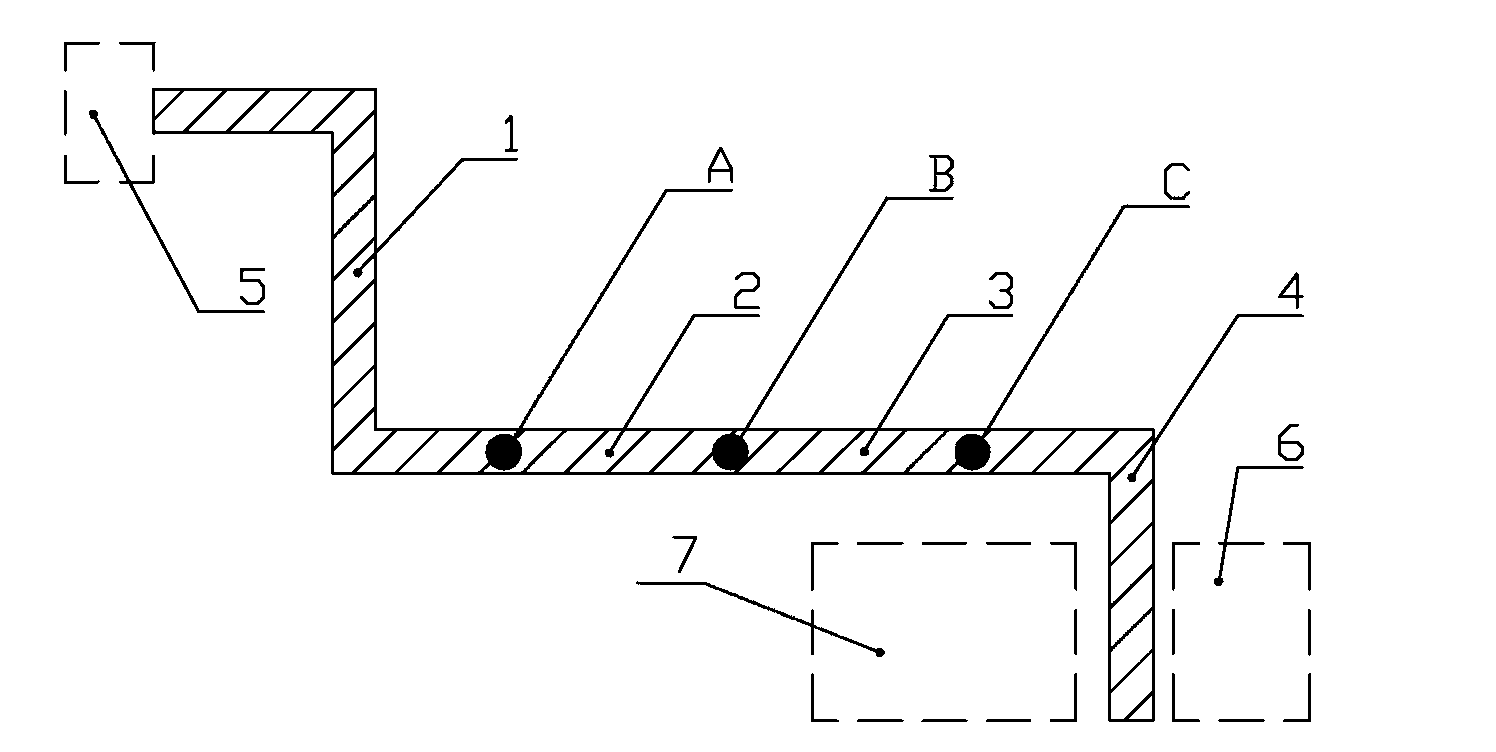

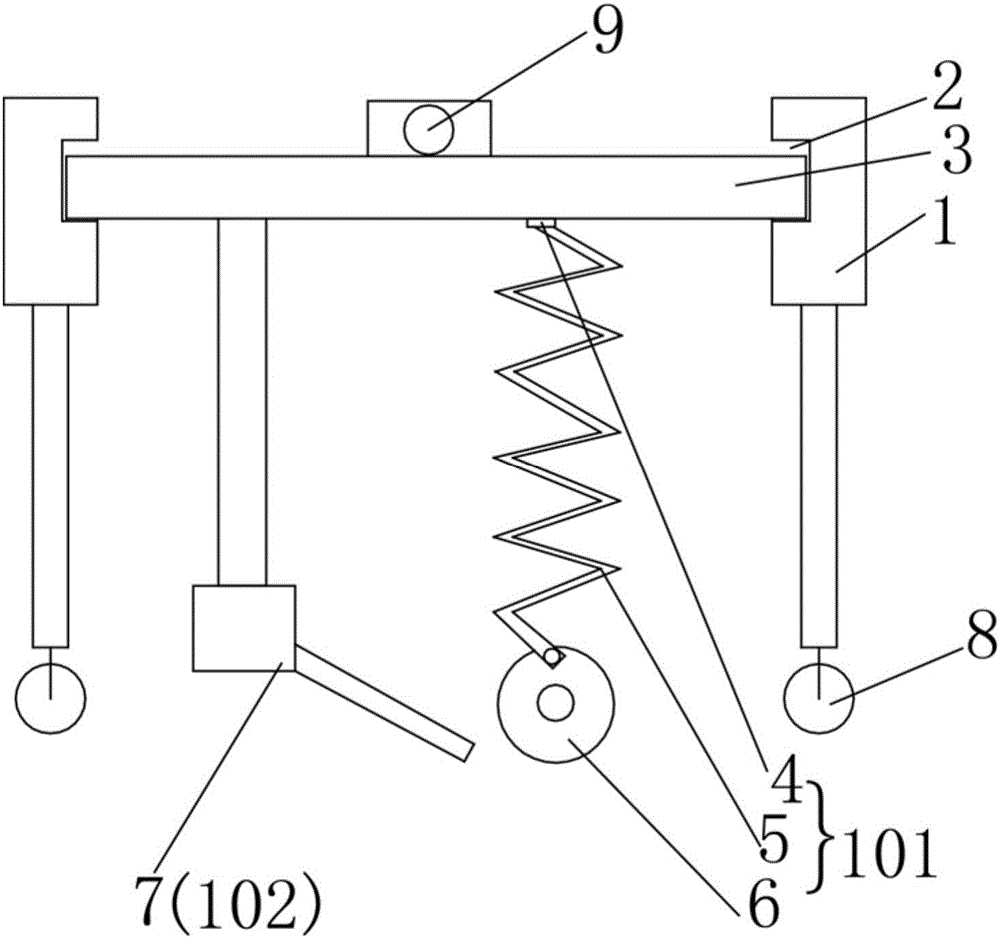

Similar material simulation test system

The invention discloses a similar material simulation test system and relates to an apparatus for measuring or testing force, stress and displacement, in particular to a test system for laboratories to simulate and monitor support load and displacement changes by the aid of similar materials during coal bed excavation. The similar material simulation test system is capable of obtaining real-time pressure and displacement of a support when the support interacts with surrounding rocks. The similar material simulation test system comprises a model support 1, at least one movable column 2, pistons 21, vertical columns 3, a first measuring cylinder 5, a second measuring cylinder 6, a radio-frequency capacitive liquid level transmitter 8 and a radio-frequency capacitive liquid level transmitter 9. The insides of the vertical columns 3 are mutually communicated to form a liquid accommodating cavity 4, liquid is arranged in the liquid accommodating cavity, the first measuring cylinder and the second measuring cylinder are higher than the pistons, a connecting tube 7 is communicated between the first measuring cylinder and the second measuring cylinder through side walls of the first measuring cylinder and the second measuring cylinder, the lower end of the first measuring cylinder is communicated with the liquid accommodating cavity 4 through a hose 41, and the two radio-frequency capacitive liquid level transmitter 8 and 9 are used for measuring the liquid level inside the two measuring cylinders.

Owner:ANHUI UNIV OF SCI & TECH

Solution preparation method of electrolytic manganese metal

InactiveCN103451423AReduce manufacturing costLow impurity contentPhotography auxillary processesElectrolysisFiltration

The invention relates to a solution preparation method of electrolytic manganese metal, and relates to improvement of a preparation process of an electrolytic stock solution in a process of producing manganese metal through a wet method. The method is characterized in that the preparation process comprises the following steps: (1) adding returned anode liquor to manganese ore raw material mineral powder, and adding sulfuric acid for leaching reaction; (2) carrying out primary pressure filtration on leaching reaction slurry, carrying out solid-liquid separation to obtain leaching filter liquor; (3) neutralizing the separated leaching filter liquor, and then oxidizing to remove iron; (4) regulating the PH value, and then sulfurizing to remove heavy metal; (5) carrying out secondary pressure filtration; (6) standing for separating; (7) carrying out third-time pressure filtration to complete a solution preparation process. The method disclosed by the invention can be used for effectively reducing the impurity content of liquid, reducing the consumption of a sulfurizing agent SDD (Sodium Dimethyl Dithiocarbamate) and reducing the production cost of electrolytic manganese, is obvious in impurity removing effect, and can be used for reducing the sulfur content of a product, enhancing the quality of the product and achieving the effect of removing the heavy metal through sulfurization.

Owner:NINGXIA TIANYUAN MANGANESE LIMITED

Method for managing production from a hydrocarbon producing reservoir in real-time

The invention relates to a method of performing an oilfield operation of an oilfield having at least one wellsite, each wellsite having a wellbore penetrating a subterranean formation for extracting fluid from an underground reservoir therein. The method steps include obtaining a plurality of real-time parameters from a plurality of sensors disposed about the oilfield, wherein the plurality of real-time parameters comprise at least one selected from a group consisting of real-time flow rate data and real-time pressure data of the wellbore, configuring a gridless analytical simulator for simulating the underground reservoir based on the plurality of real-time parameters, generating real-time simulation results of the underground reservoir and the at least one wellsite in real-time using the gridless analytical simulator, and performing the oilfield operation based on the real-time simulation results.

Owner:SCHLUMBERGER TECH CORP

Pressure detecting method for preventing clogging of filling pipeline

ActiveCN103216266AAvoid cloggingAccurate fault informationMining devicesMaterial fill-upProgrammable logic controllerDifferential pressure

The invention relates to a pressure detecting method for preventing the clogging of a filling pipeline, which is characterized in that pressure sensors are arranged on at least three pressure detecting points on the main pipe of the filling pipeline, wherein the first pressure detecting point is arranged at the front part of a laneway filling pipe, the second pressure detecting point is arranged in the middle of the laneway filling pipe, the third pressure detecting point is arranged on the filling pipe at the inflection point of a working face and a gate, the pressure sensors are used for transmitting real-time pressure values of the pressure detecting points into a PLC (programmable logic controller), whether pipeline clogging occurs or not is judged and measures needing to be taken when pipeline clogging occurs are judged through a control program preset in the PLC. With the adoption of the pressure detecting method, whether the filling pipeline is clogged or not and the filling pipeline is clogged at which position can be accurately judged and the clogging condition is processed in time according to the pressure difference change of the pressure detecting points and the rapid pressure change of each single pressure detecting point.

Owner:FENY

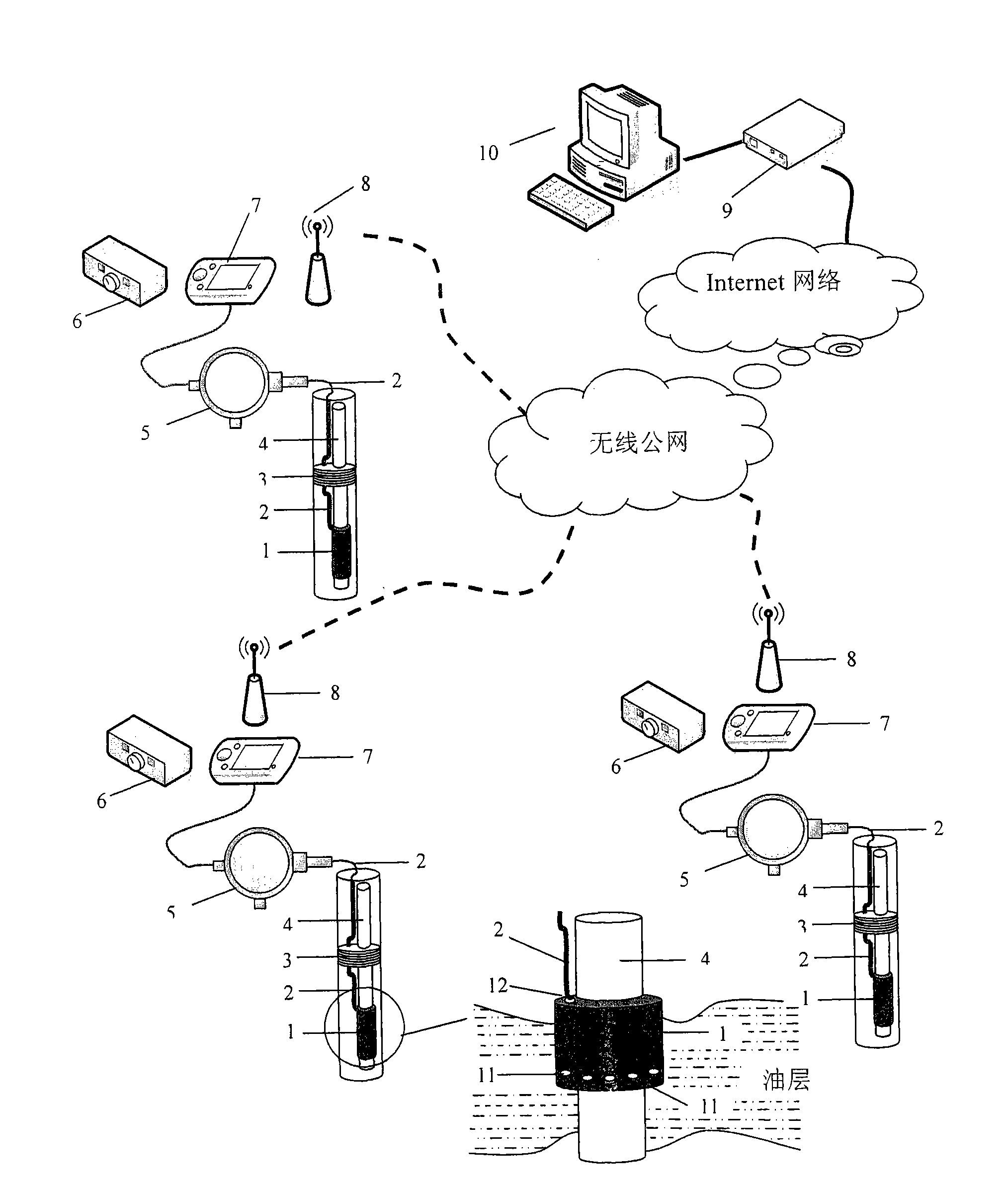

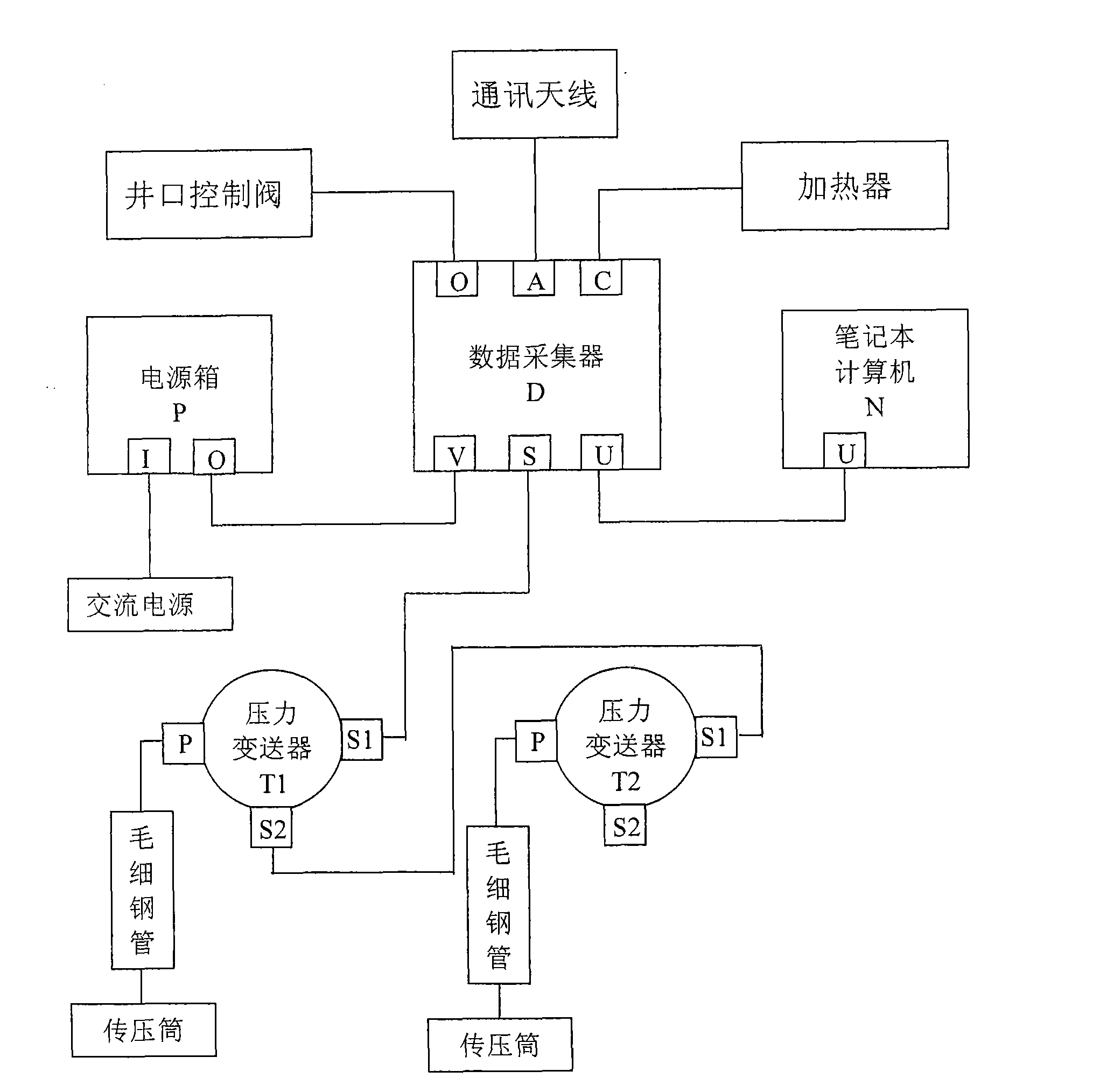

Remote monitoring system for oil well pressure by capillary steel pipes

InactiveCN101514627AIncrease capacityImprove dynamic performanceSurveyInformation processingWell logging

The invention discloses a remote monitoring system for oil well pressure by capillary steel pipes, and relates to the technical field of automation information processing, in particular to an oil well pressure networking monitoring system consisting of distributed monitoring technology. The system consists of a capillary steel pipe pressure measuring device, a ground pressure acquisition terminal and a monitoring center server. Oil well underground pressure is propagated by the capillary steel pipe pressure measuring device to the ground, changed into digital signals by the ground pressure acquisition terminal, and compensated to form an underground actual pressure value, and data are transmitted to a monitoring central station by a wireless communication network to realize remote monitoring of the oil well pressure. At the same time, the monitoring central station can remotely control the parameters and the states of the acquisition device through the wireless communication network. The monitoring system is suitable for oil well platforms with inconvenient transportation such as oceans and deserts, can realize remote monitoring of real-time pressure data and remote control of the oil well, improve the real-time characteristics of the well logging process, save manpower and materials, and improve working benefits of oil exploration and safety production.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

Wind driven generator blade surface defect detection method and detection apparatus

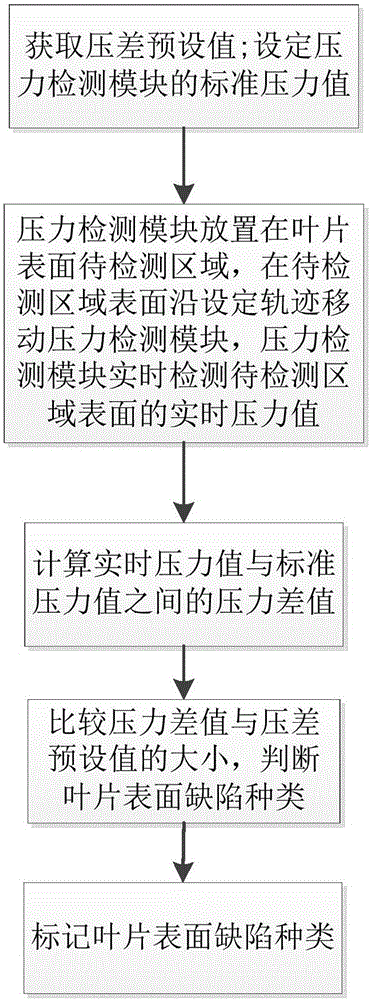

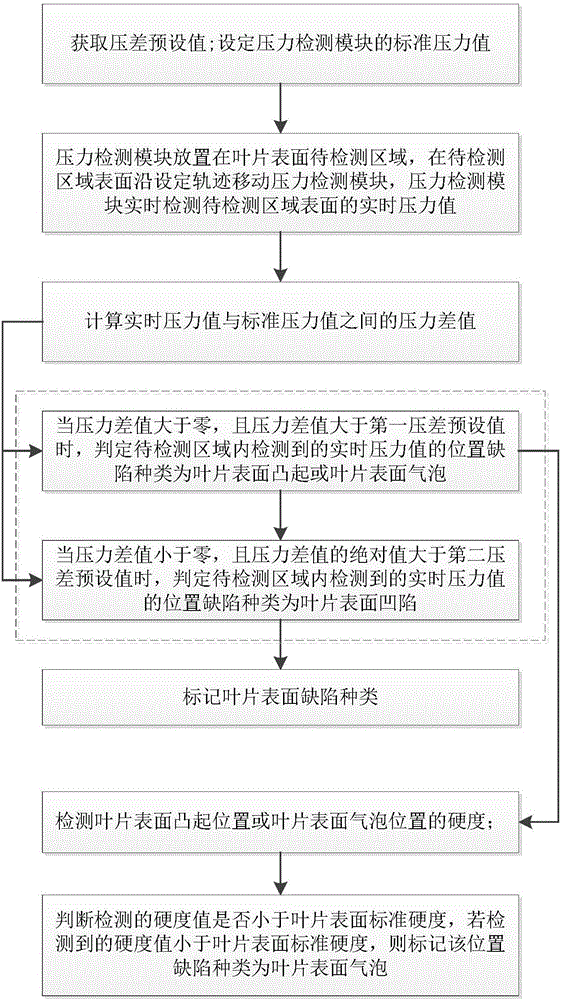

ActiveCN106645570AReduce productionEasy to handleMaterial analysisDifferential pressureComputer module

The invention relates to the technical field of the detection of wind driven generator blades, and in particular to a wind driven generator blade surface defect detection method and detection apparatus. The wind driven generator blade surface defect detection method comprises the following steps: acquiring a pressure difference preset value; setting a standard pressure value of a pressure detection module; placing the pressure detection module at an area to be detected of the blade surface, moving the pressure detection module along a set track at the area surface to be detected, and detecting a real-time pressure value of the area surface to be detected by virtue of the pressure detection module; calculating a pressure difference between the real-time pressure value and the standard pressure value; comparing the pressure difference with the pressure difference preset value, and judging a blade surface defect type; and marking the blade surface defect type. The detection method is low in cost, simple in operation, accurate and rapid in detection, and capable of preventing the long detection time of the surface defect from reducing the production of the wind driven generator blade.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

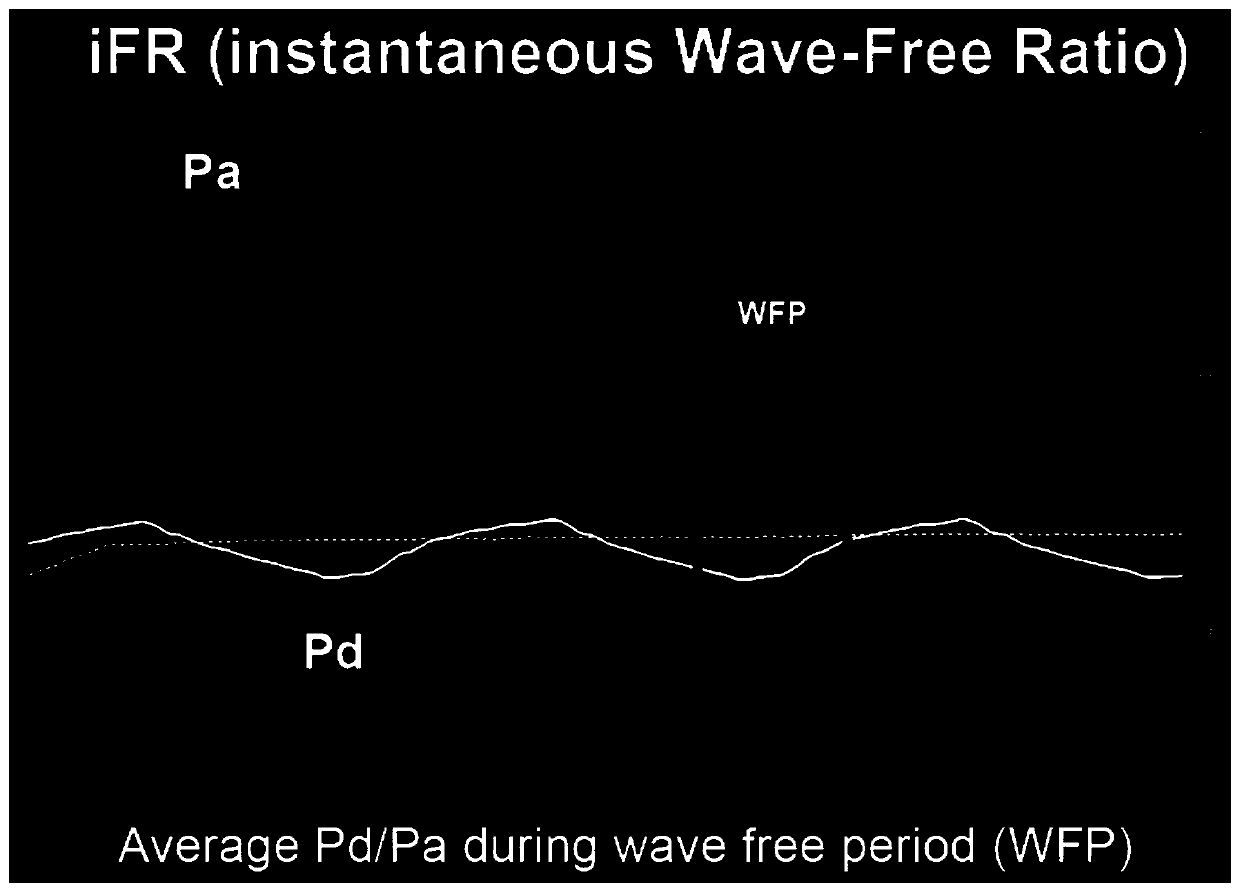

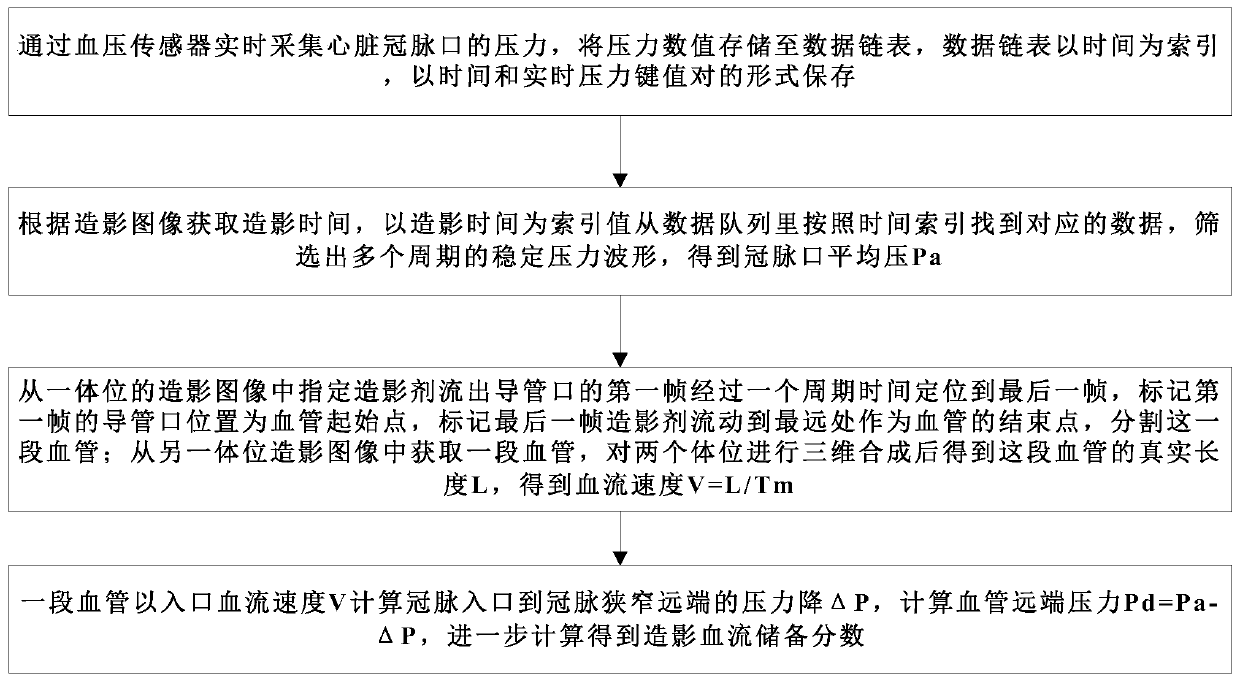

Method for calculating instantaneous waveform-free ratio based on pressure sensor and contrast image

InactiveCN109770888AImprove accuracyStable pressure valueImage enhancementImage analysisCoronary arteriesCardiac cycle

The invention discloses a method for calculating an instantaneous waveform-free ratio based on a pressure sensor and a contrast image, which comprises the following steps of: acquiring pressure of a coronary artery port of a heart in real time through a blood pressure sensor, and storing a pressure numerical value into a data link table, wherein the data link table is stored in the form time and real-time pressure key value pairs by using time as an index; finding corresponding data from a data queue according to the time index by using the contrast time as an index value, and using an averagevalue of four waveform-free pressure values as a waveform-free pressure value Pa; acquiring a time Tn of the end of a diastolic period, namely a waveform-free period, a blood flow velocity V is obtained by obtaining the length L of a section of blood vessel from the imaging images of two positions, pressure drop delta P is calculated, the far-end vessel pressure Pd=Pa-delta P, and the instantaneous waveform-free ratio is further obtained. The pressure value can be accurately obtained, the blood flow velocity of one cardiac cycle can be accurately obtained, and the accuracy of the FFR is greatly improved.

Owner:SUZHOU RAINMED MEDICAL TECH CO LTD

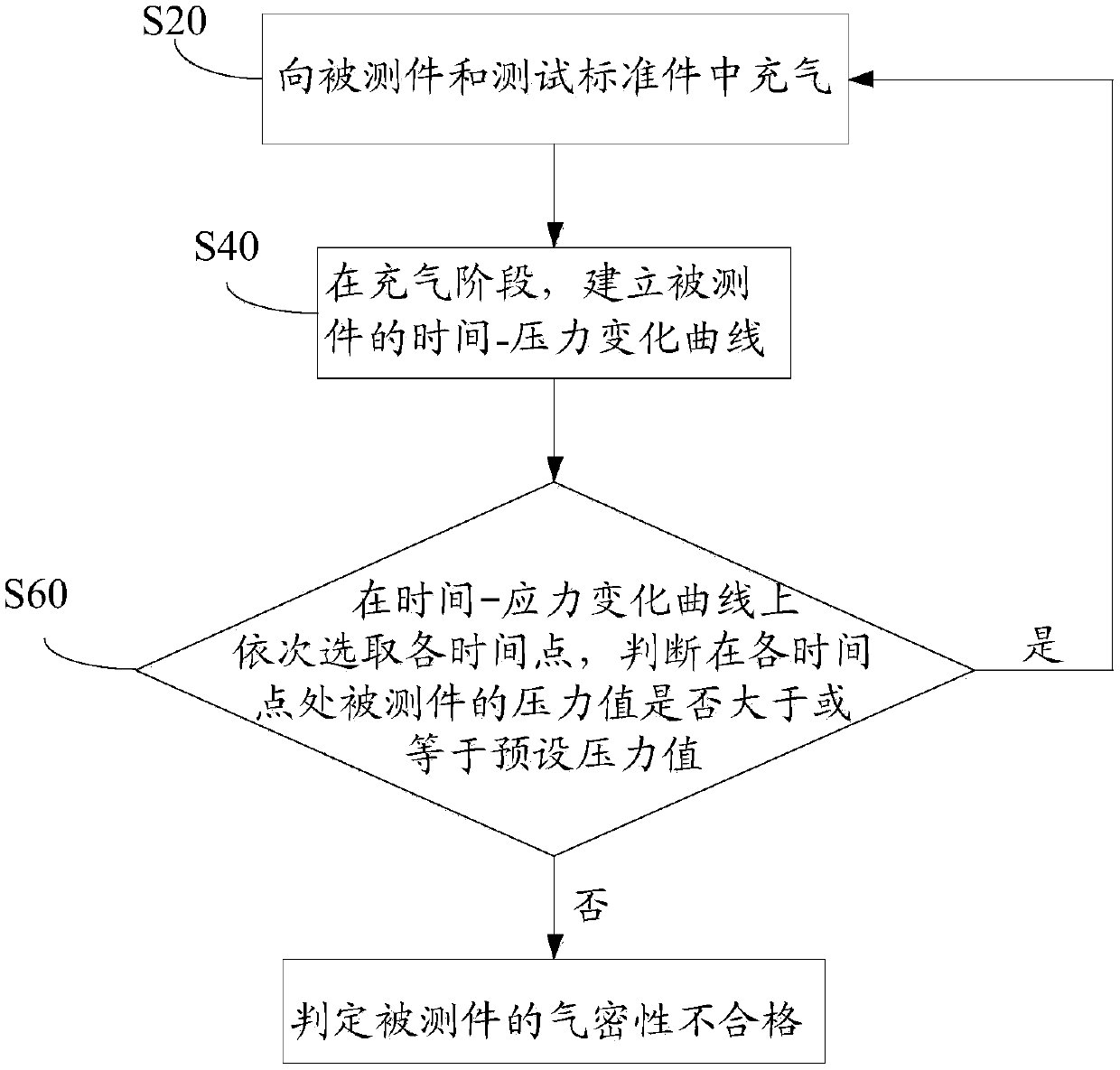

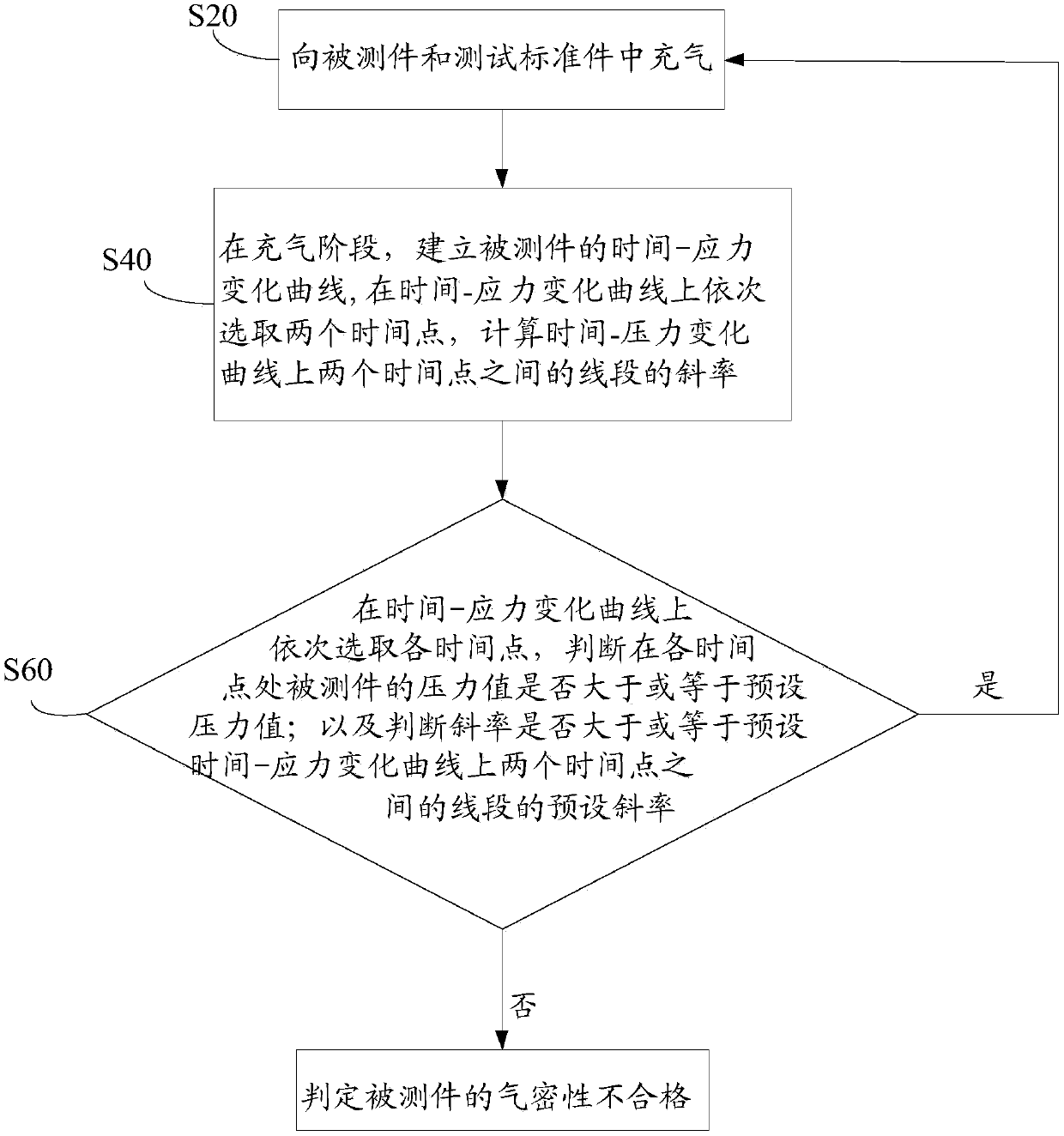

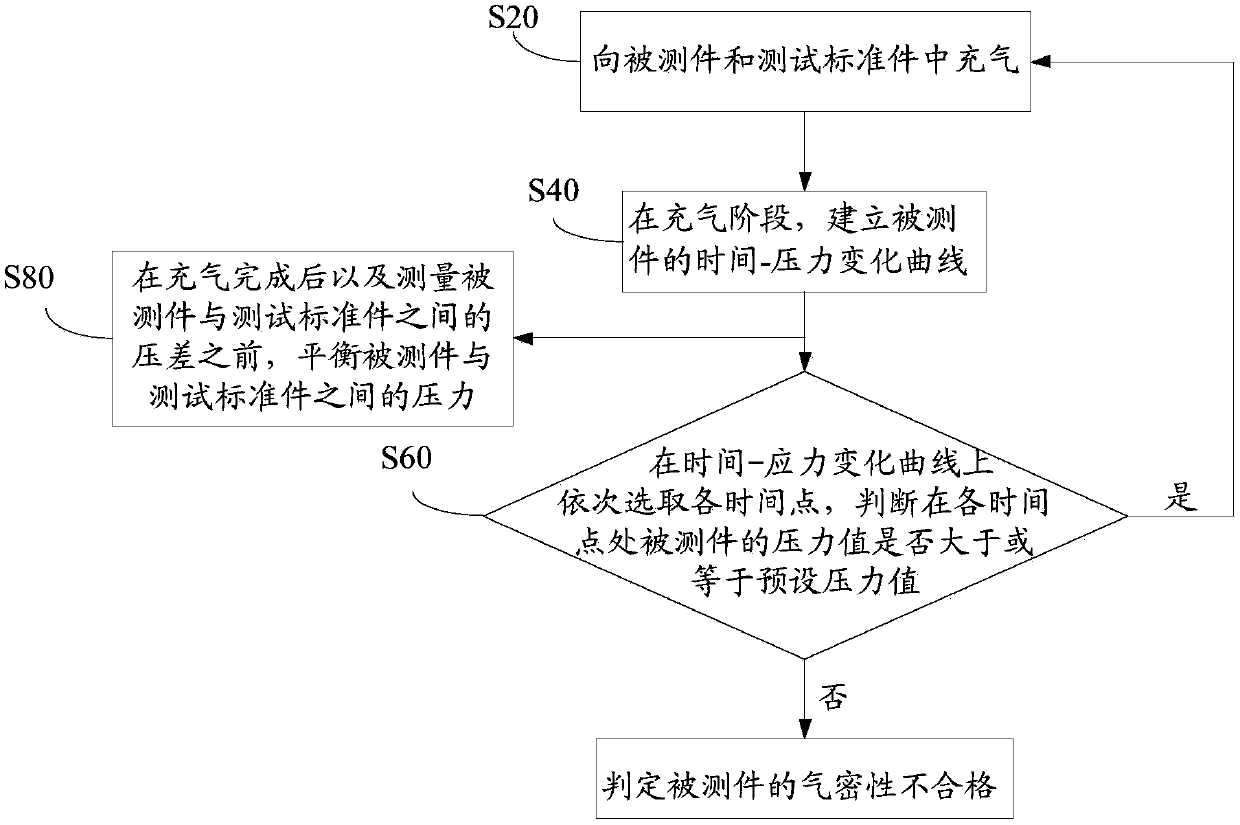

Airtightness detection method and device

InactiveCN109540408AShorten detection timeImprove detection efficiencyMeasurement of fluid loss/gain rateEngineeringAir tightness

Owner:QINGHAI CONTEMPORARY AMPEREX TECH +1

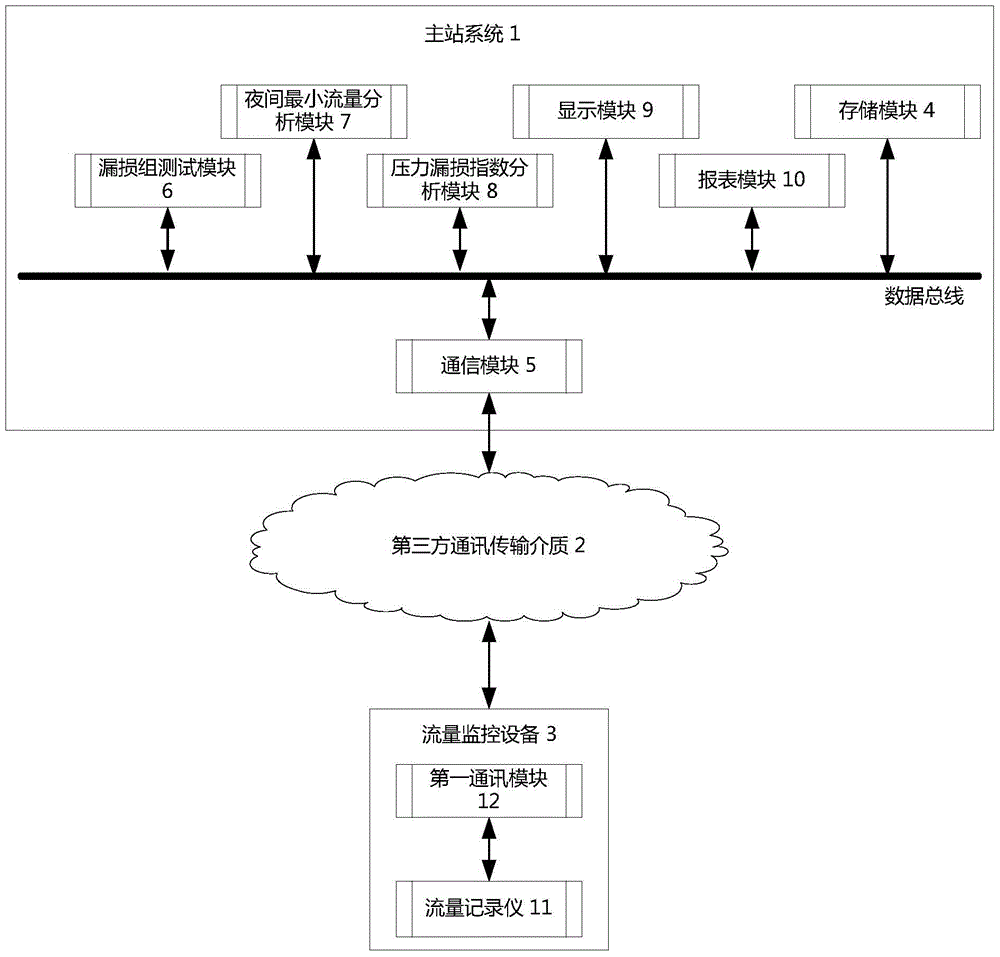

Integrated analysis device for leakage monitoring of water supply pipe network and method of analysis device

ActiveCN105716803ADetect early signs in timeReduce basic cost inputMeasurement of fluid loss/gain rateTransmission protocolThird party

The invention relates to an integrated analysis device for leakage monitoring of water supply pipe network and a method of the analysis device. The device comprises a flow monitoring device with a flow recorder, a third-party communication transmission medium and a main station system; the main station system communicates with the flow monitoring device via the third-party communication transmission medium in transmission protocols; and the flow monitoring device also comprises a first communication module. The installation manner is simple, the integrated degree is high, and the caliber testing range is wide. The method of the analysis device comprises the steps that a water supply pipe network system is divided into blocks, zero pressure test is carried out, the water inlet flow and pressure of a water inlet end of the pipe network block area are monitored in real time and uploaded to the main station system, and the main station system receives the real-time pressure and flow data, and displays, stores, analyzes and reports the data. Early indication of leakage of the water supply pipe network can be discovered timely, the identification range is wide, leakage points are located rapidly and effectively, an analysis result is verified rapidly and effectively, basic cost of the water supply system is reduced, and comprehensive benefits including the economical, cost, resource, management and service aspects of the water supply system are improved.

Owner:SHENZHEN JASON DIGITAL TECH CO LTD

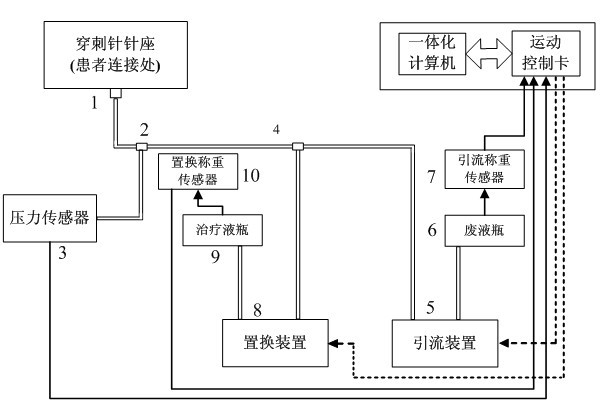

Treatment instrument for intracranial pressure monitoring and drainage and replacement of cerebrospinal fluid

InactiveCN102133096AReal-time monitoring of intracranial pressureAvoid the problem that the replacement speed is difficult to controlDiagnostic recording/measuringSensorsPatient needNeurology department

The invention discloses a treatment instrument for intracranial pressure monitoring and drainage and replacement of cerebrospinal fluid. The treatment instrument combines the drainage treatment technology of a cerebrospinal fluid waist penetrating pipe with the computer virtual instrument technology. The treatment instrument comprises an outer connecting pipe, a pressure monitoring branch, a drainage loop and a replacement loop, wherein the pressure sensor transfers real-time pressure of the cranial cavity to a control system; and the drainage loop and the replacement loop feed back drainage amount and replacement amount to the control system which controls a drainage device / replacement device to work or stop so as to drain / replace the cerebrospinal fluid. The instrument can be widely applicable to places where the intracranial pressure of a patient needs to be continuously monitored and drainage and replacement needs to be carried out on the cerebrospinal fluid in the neurology department and the neurosurgery department, replaces the current manual drainage and replacement operations carried out according to experience, realizes automation of the sections such as pressure monitoring, drainage and replacement in treatment and can continuously acquire and store real-time data in treatment.

Owner:深圳市德普施科技有限公司 +1

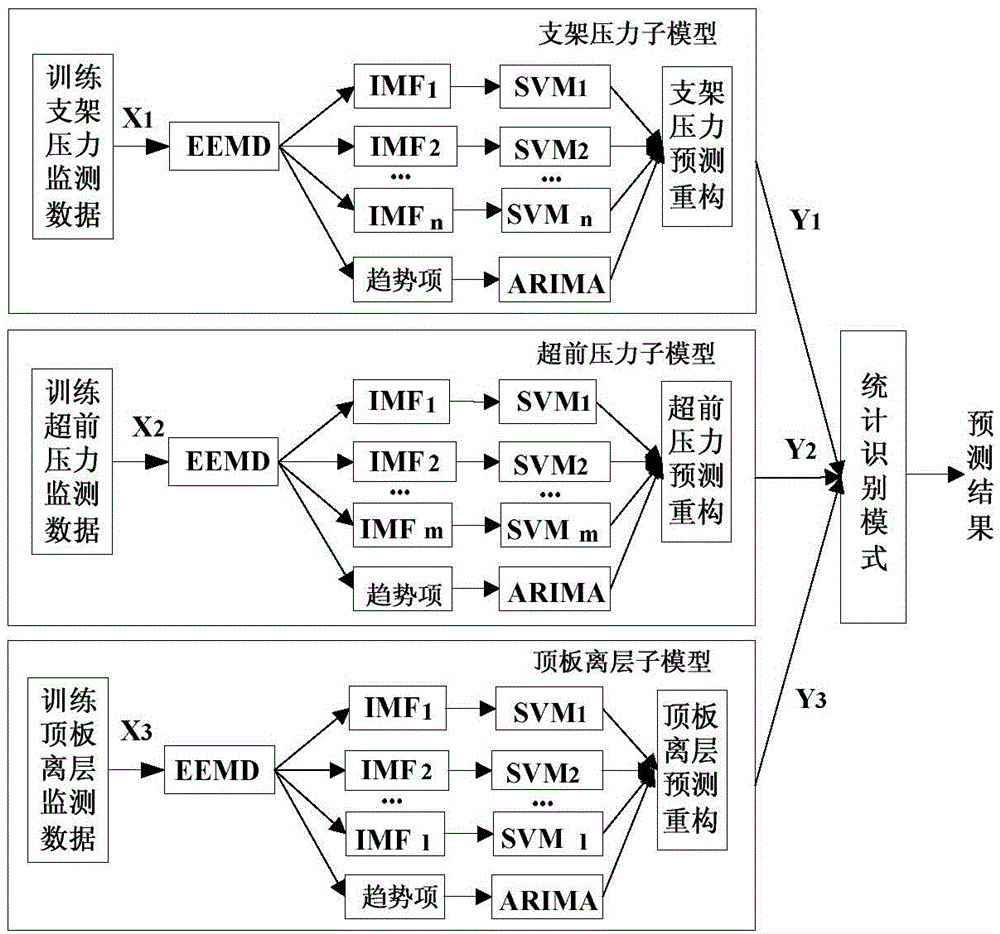

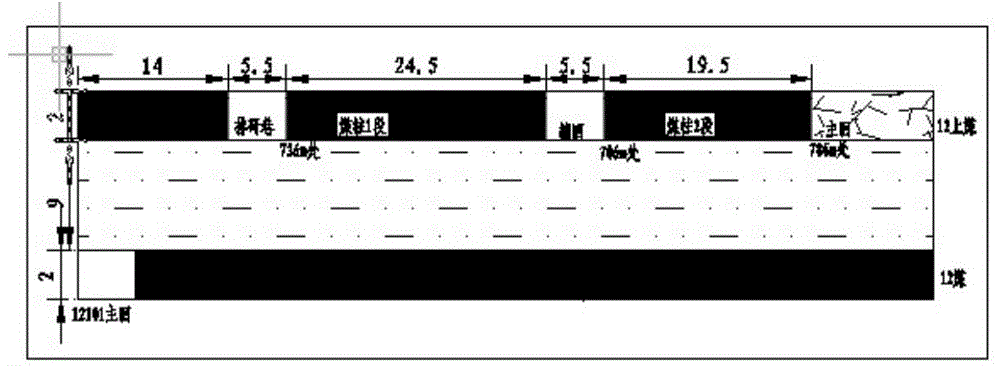

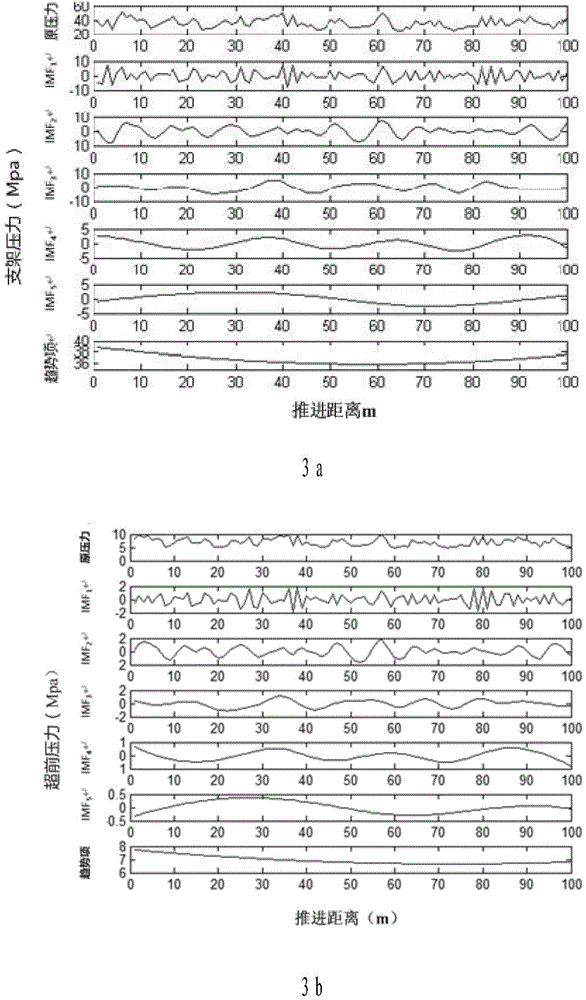

Multi-model mine roof safety early warning model based on decision fusion

The invention discloses a multi-model mine roof safety early warning model based on decision fusion. Real-time pressure monitoring data are collected through sensors, and an average value is selected as a training support pressure monitoring datum X1 to be used for establishing a support pressure submodel; stress distribution information of a coal bed or a rock stratum is collected through a leading pressure sensor to obtain a training leading pressure detection datum X2, and a leading pressure submodel is established; a separation layer indicator collects the separation layer situation of rock in a roof rock pillar near a working face and conducts processing to obtain a training roof separation layer monitoring datum X3, and a roof separation layer submodel is established; the data in the submodels are reconstructed to form corresponding prediction values, namely, Y1, Y2 and Y3, normalized decision fusion is conducted on the prediction values in a statistical recognition mode, and fused information is obtained. The multi-model mine roof safety early warning model is high in prediction and generalization capacity.

Owner:XIAN UNIV OF SCI & TECH

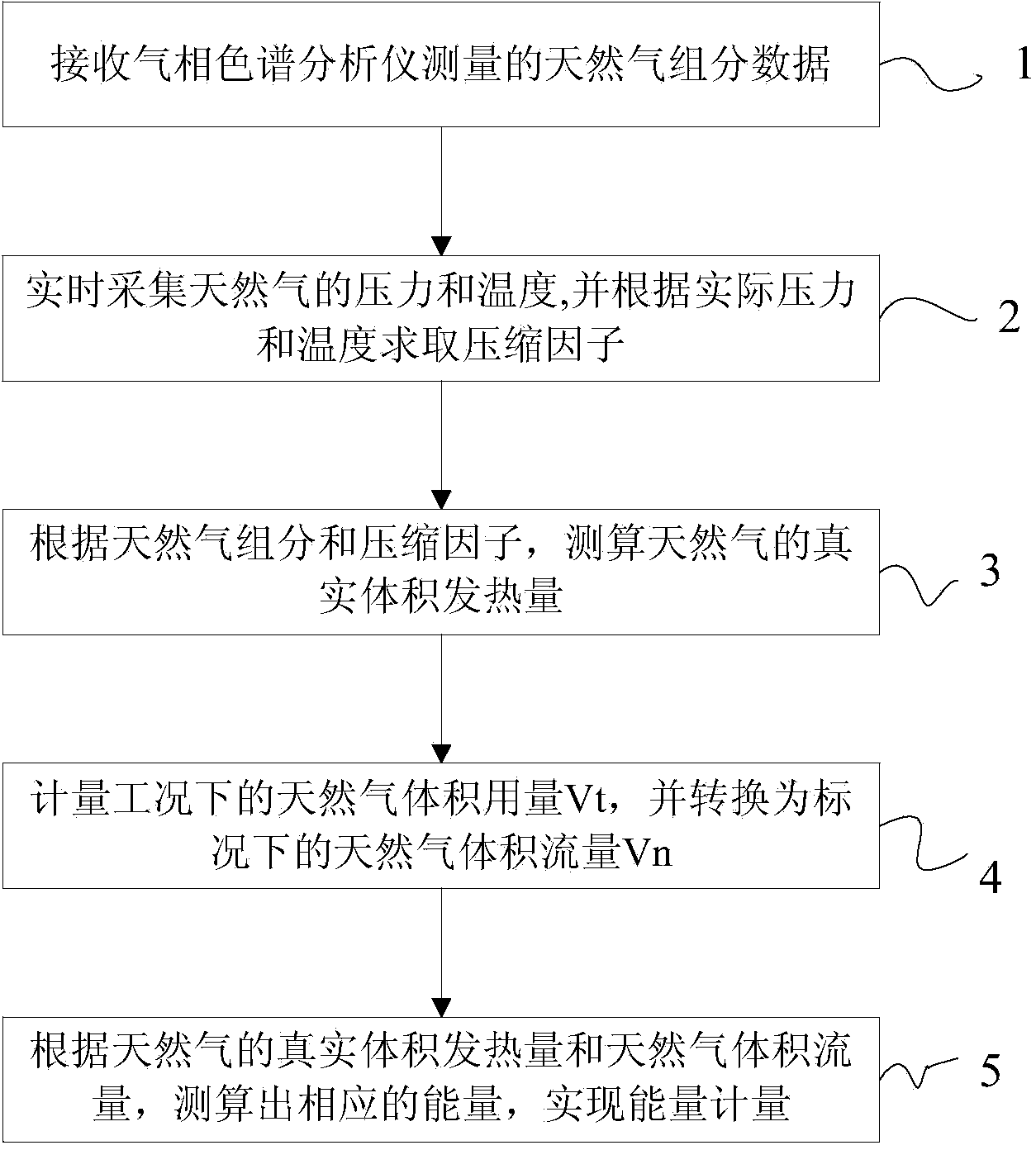

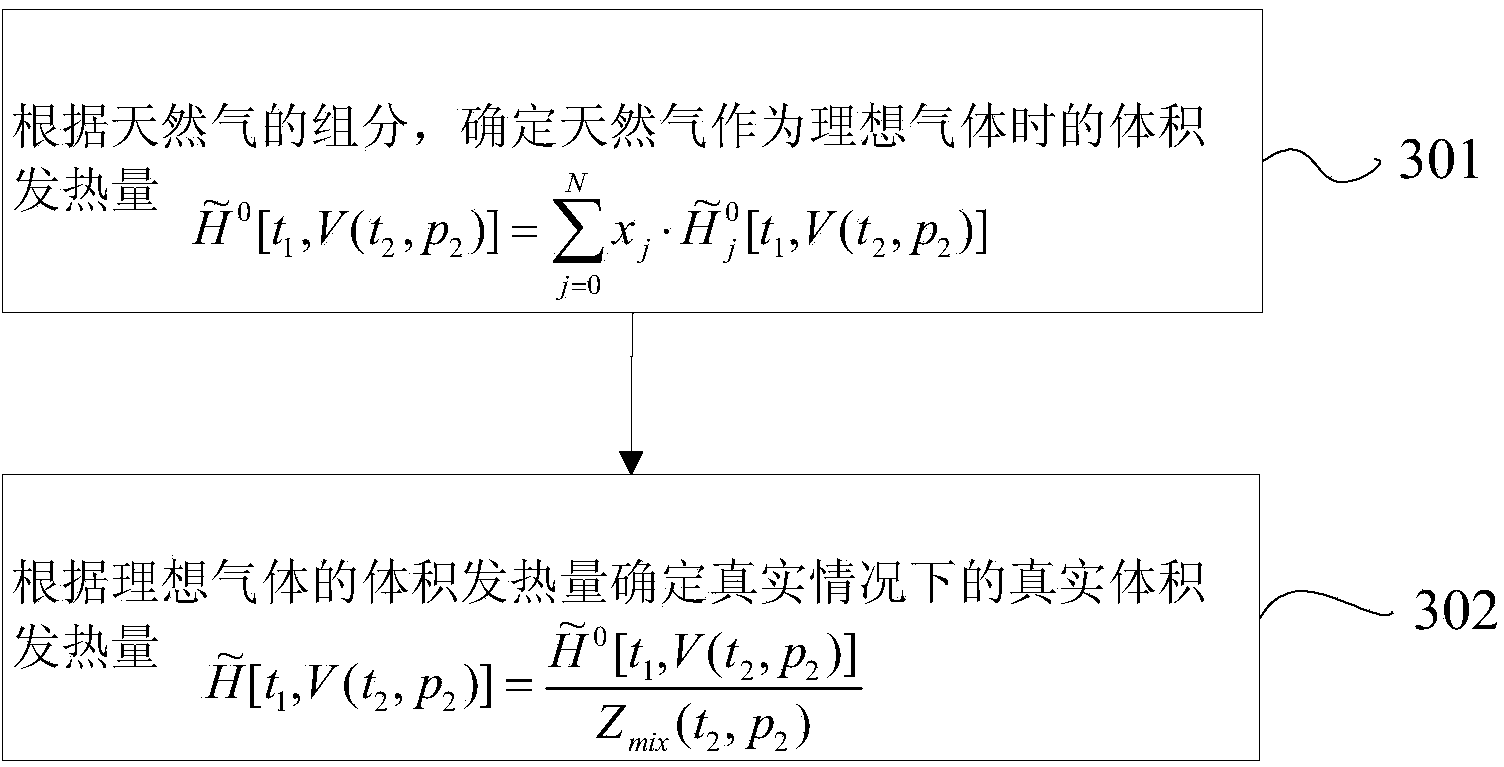

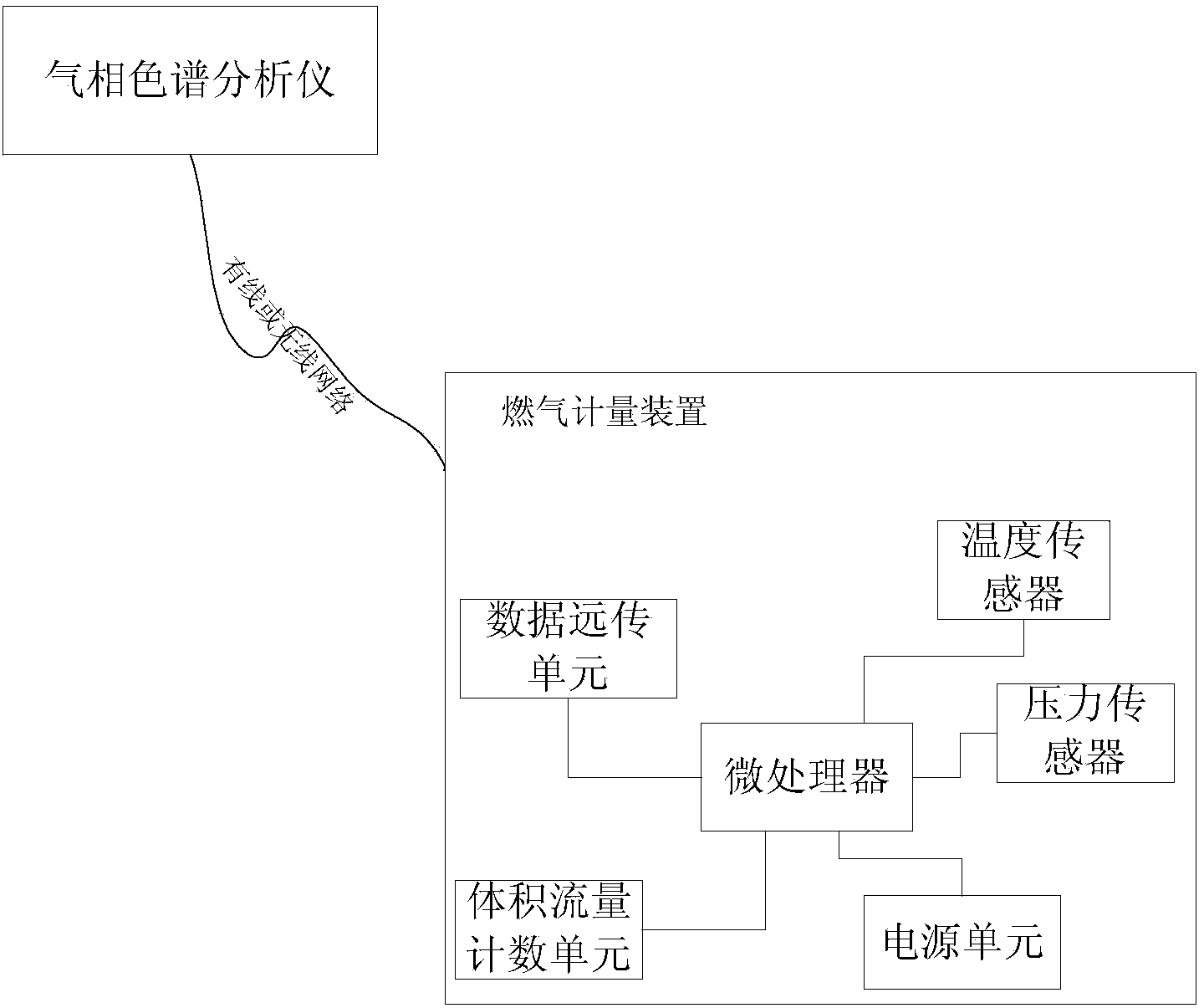

Fuel gas metering method and device based on energy metering

ActiveCN103542904AReasonable measurement method of gas consumptionIndirect mass flowmetersEnergy meteringEnergy based

The invention discloses a fuel gas metering method based on energy metering. The fuel gas metering device receives natural gas component data transmitted by a gas chromatography analyzer and determines real volume heating quantity of natural gas according to the natural gas components, real-time pressure and real-time temperature; then the natural gas use amount Vt under the actual temperature and pressure is metered and converted into fuel gas flow Vn under standard condition; finally, according to Vn, the energy E of the natural gas is determined, and energy metering is finished. The invention further provides a fuel gas metering device based on the energy metering and used for achieving the method. The fuel gas metering device receives the natural gas component data transmitted by the gas chromatography analyzer, the real volume heating quantity of the natural gas is calculated according to the natural gas components and the real-time temperature and pressure, the energy of the natural gas is calculated by combining natural gas volume flow, and energy metering is achieved. The method and device provides a novel metering mode which is reasonable and accurate.

Owner:CHENGDU QIANJIA TECH CO LTD

Protein mixture analysis by mass spectrometry

ActiveUS7070949B2Overcomes time pressureReduce measurementElectrolysis componentsPeptide/protein ingredientsEnzymatic digestionChromatographic separation

The invention relates to the analysis of complex protein mixtures such as entire proteomes, and in particular the rapid detection of previously unknown or unusually expressed proteins by common enzymatic digestion, subsequent chromatographic separation and analysis of the digestion peptides by mass spectrometry. The invention consists in subjecting fractions of the digestion peptides separated by liquid chromatography to analysis by mass spectrometry, at a time other than that of the chromatography, in a tandem time-of-flight mass spectrometer with ionization by matrix assisted laser desorption (MALDI). This method finds many times more proteins than are found through the procedures predominantly used until now of two-dimensional gel electrophoresis with subsequent time-of-flight mass spectrometry. It also removes the time pressure that dominates the real-time analysis of coupled LC-MS processes, and it allows measurements to be reduced to the interesting proteins by intermediate analysis.

Owner:BRUKER DALTONIK GMBH & CO KG

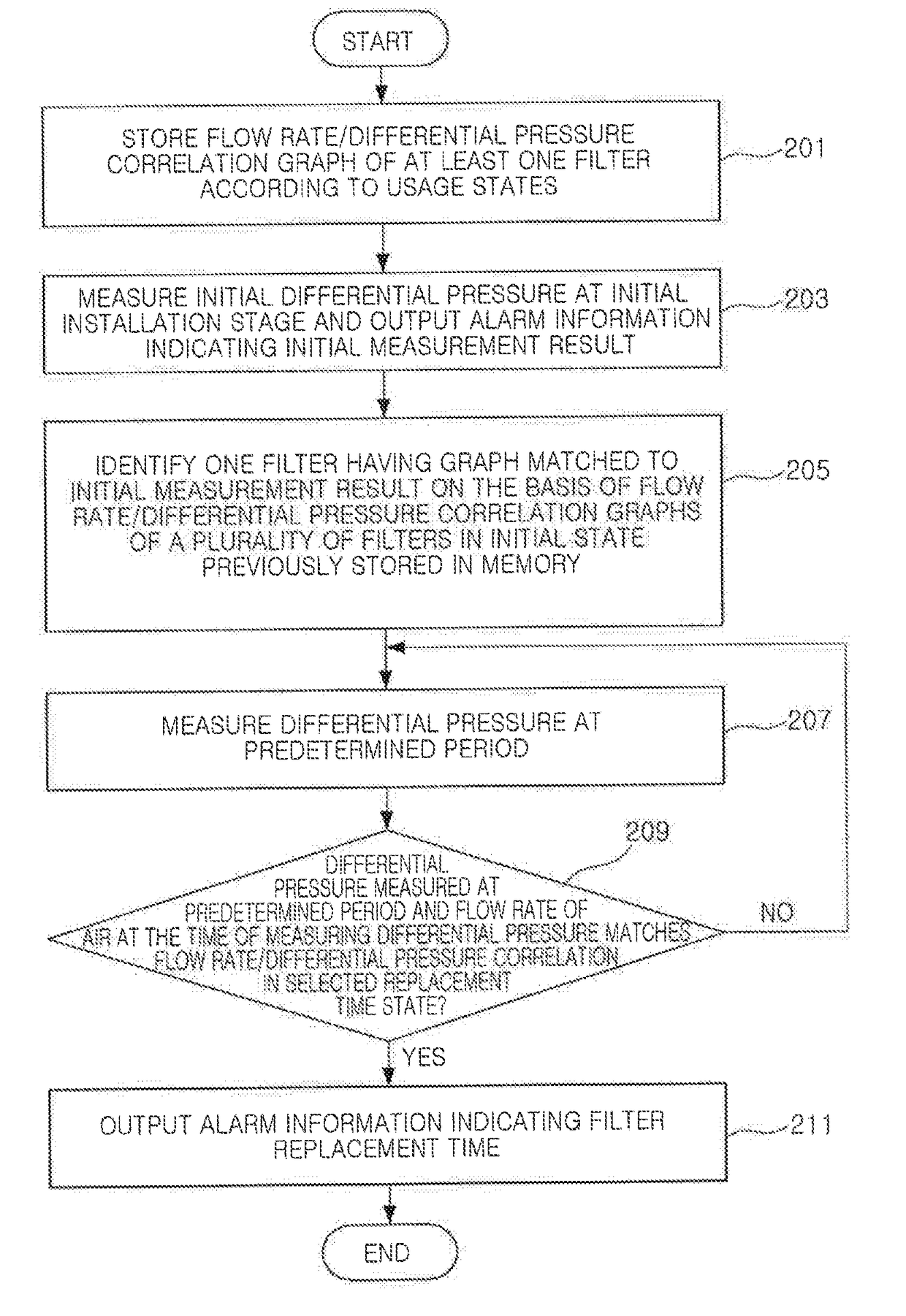

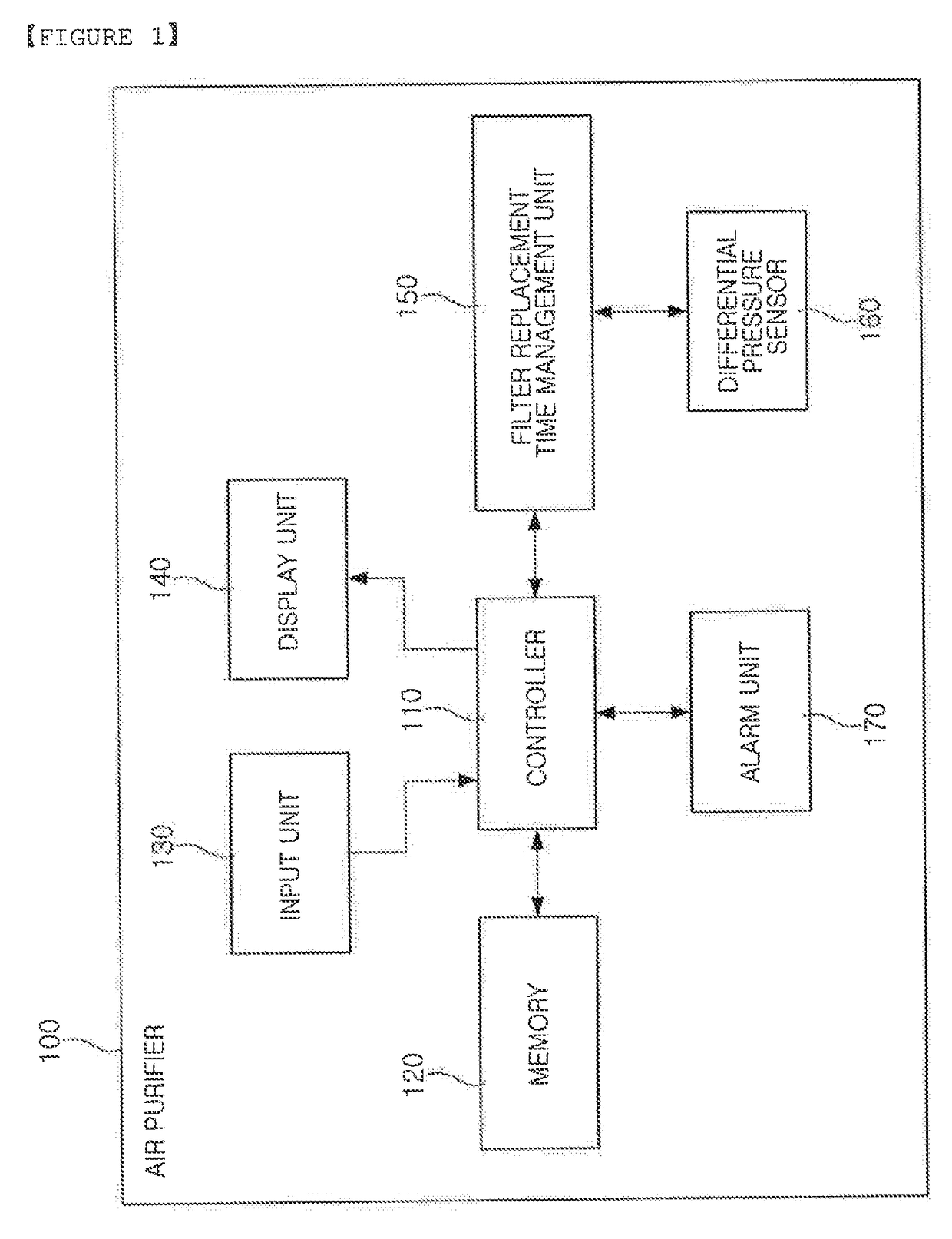

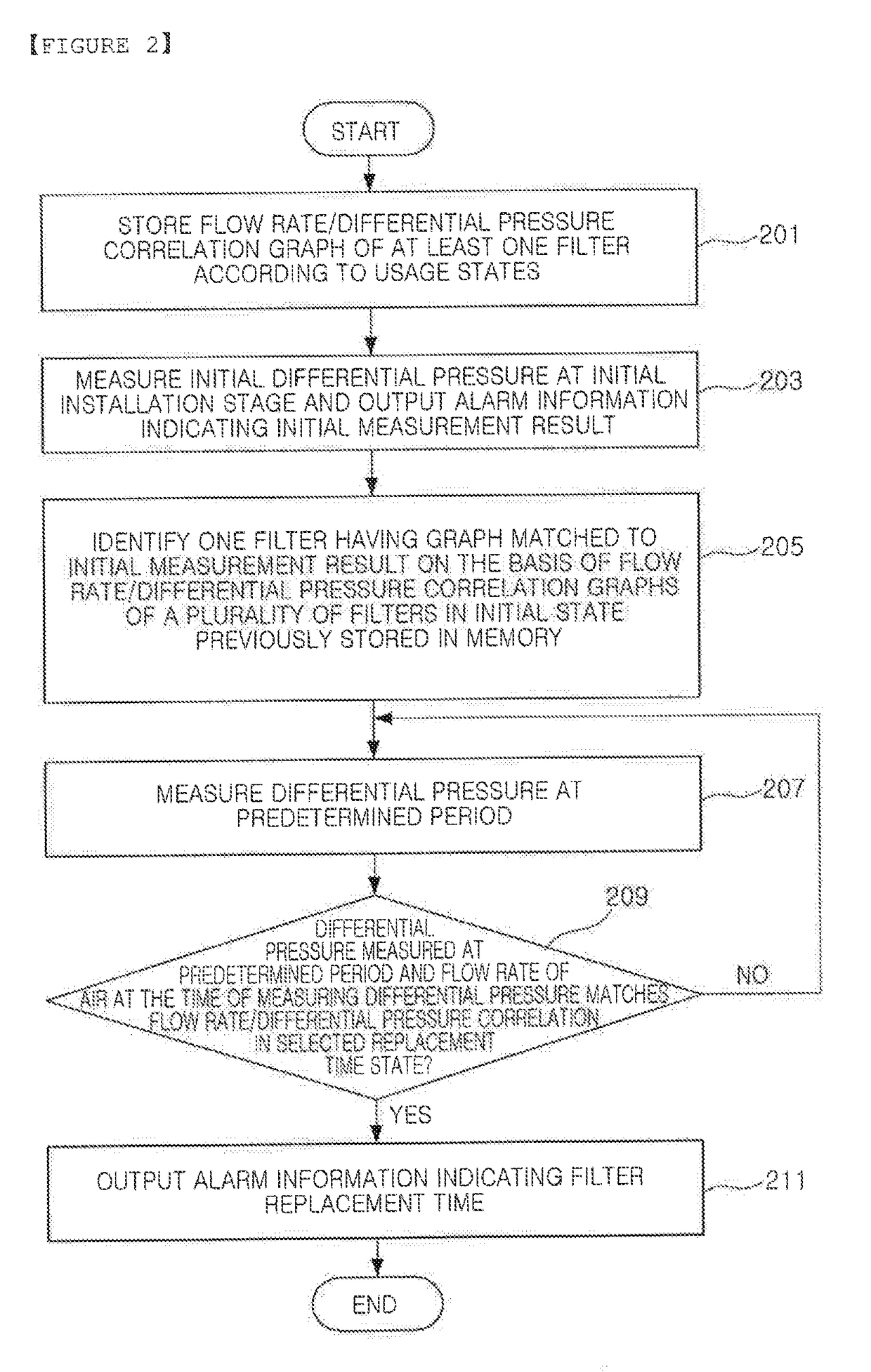

Air Purifier, Method for Determining Time to Replace Filter Thereof, and Device and Method for Determining Filer Replacement Time Pressure Differential Therefor

ActiveUS20170189846A1Exact replacement timeDispersed particle filtrationSpecial data processing applicationsTime managementEngineering

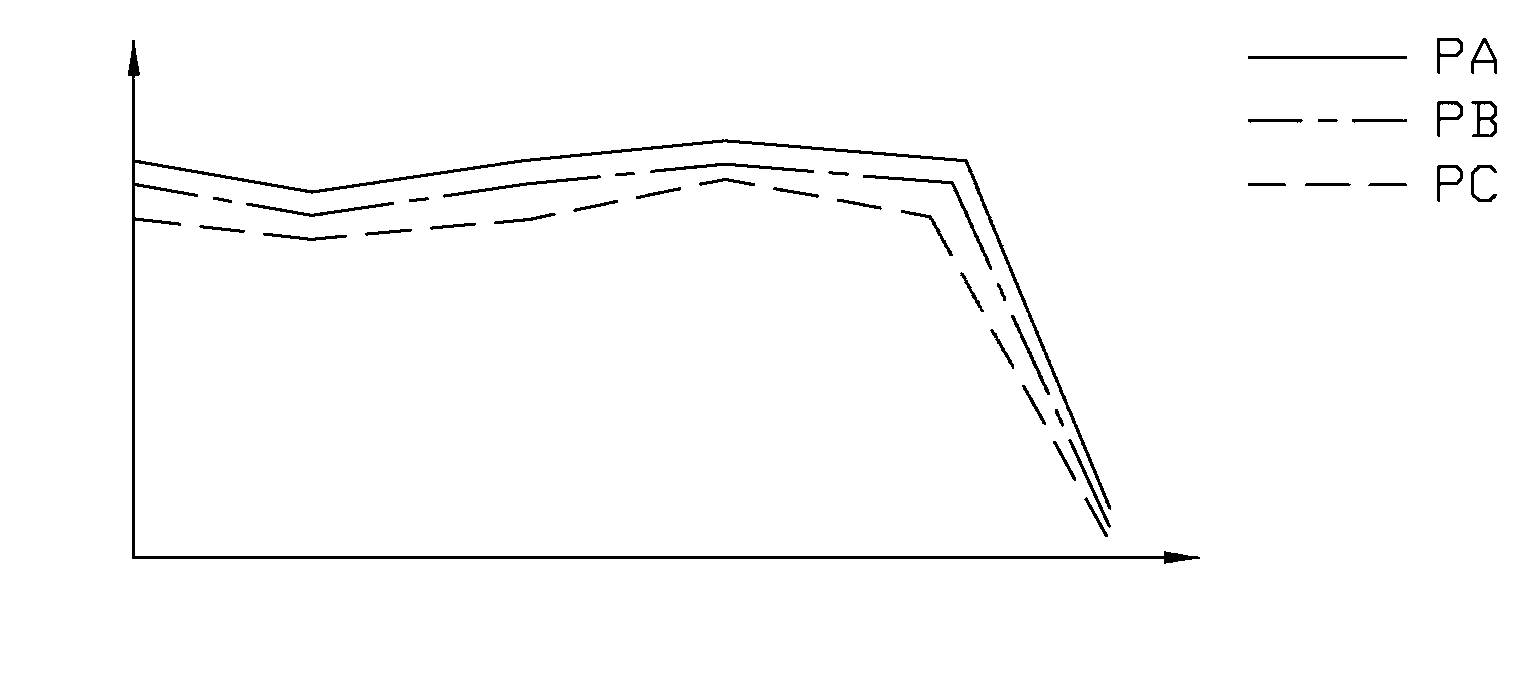

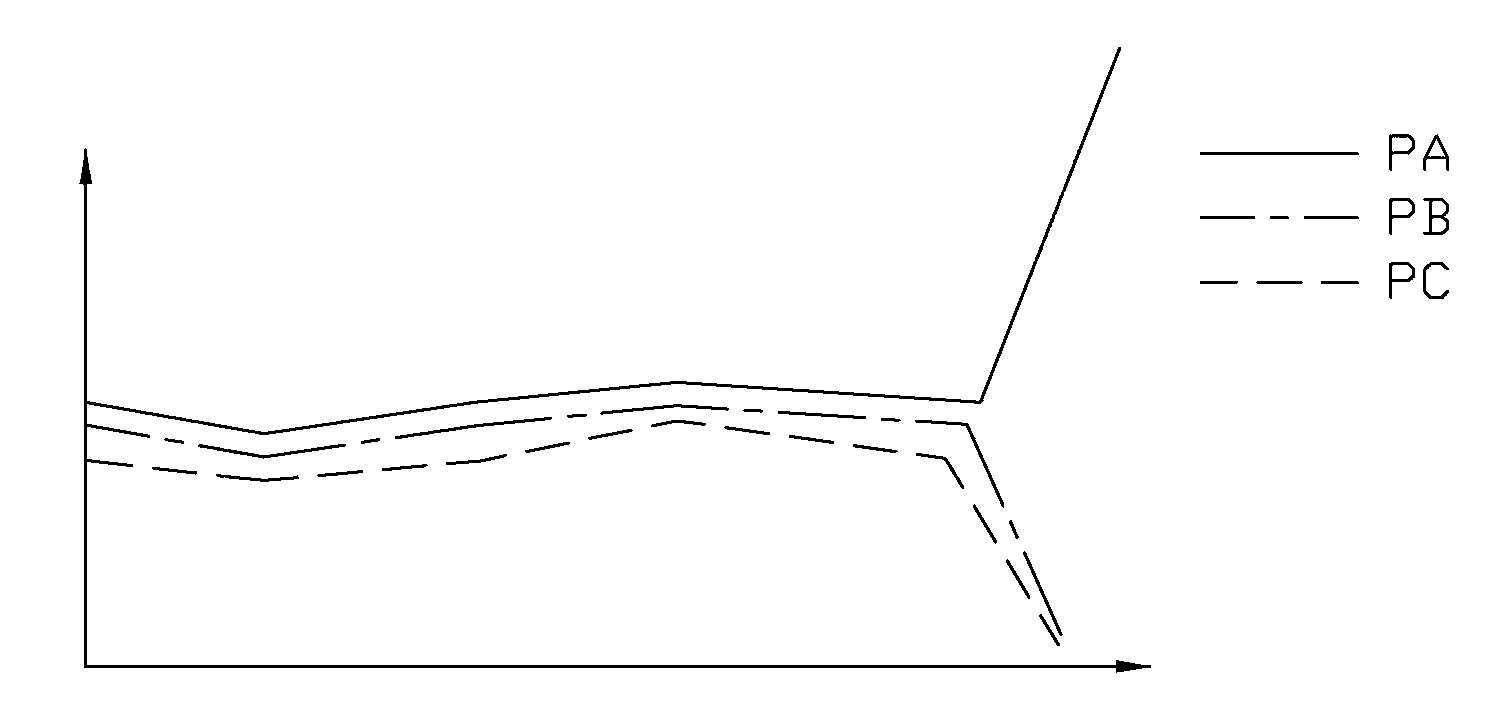

An air purifier according to an embodiment of the present invention may comprise: a memory for storing a flow rate / pressure differential correlation graph with regard to each filter utilization state; a pressure differential sensor for measuring a pressure differential, which is a difference in pressure between the front and rear ends of the filter; and a filter replacement time management unit for determining the time to replace the filter according to a result of matching a pressure differential of the filter, which is measured by the pressure differential sensor at a preset cycle, and the flow rate of air flowing into the filter during pressure differential measurement with the flow rate / pressure differential correlation graph for each utilization state.

Owner:COWAY CO LTD

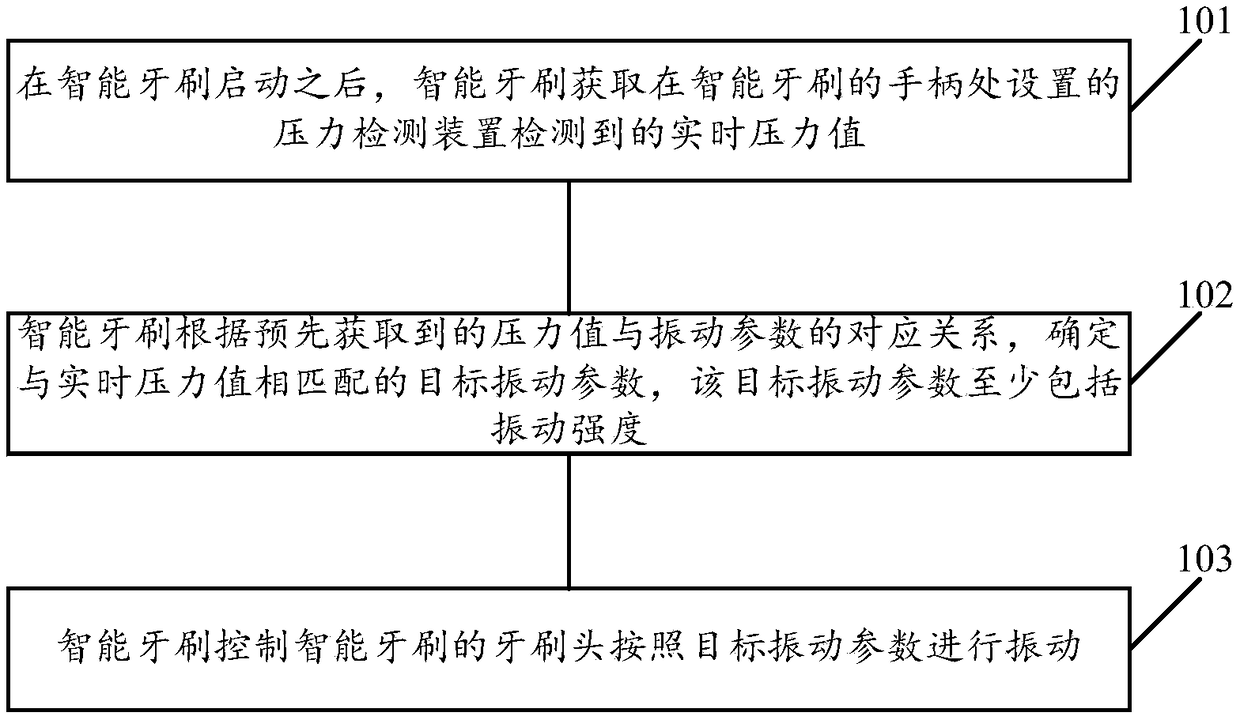

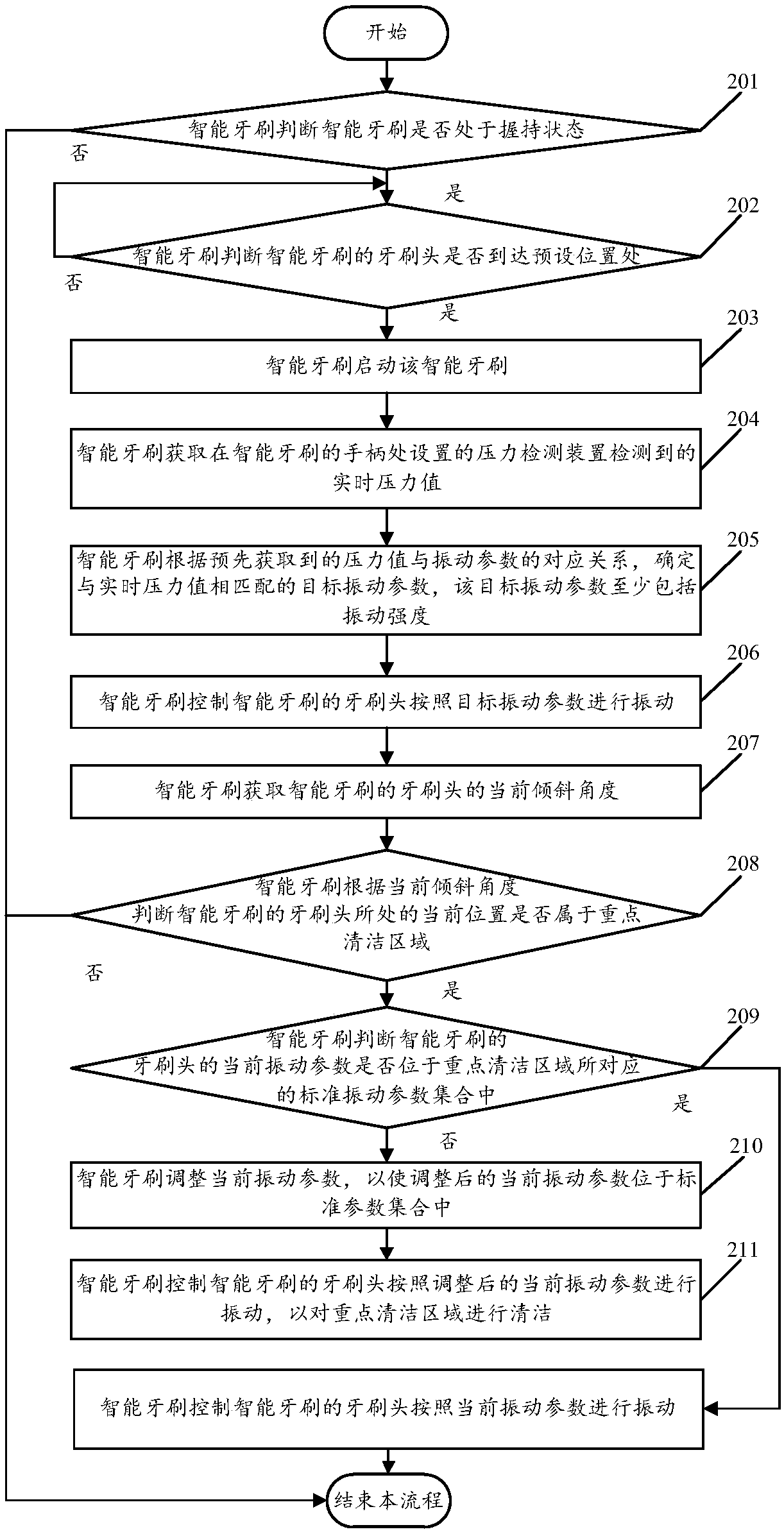

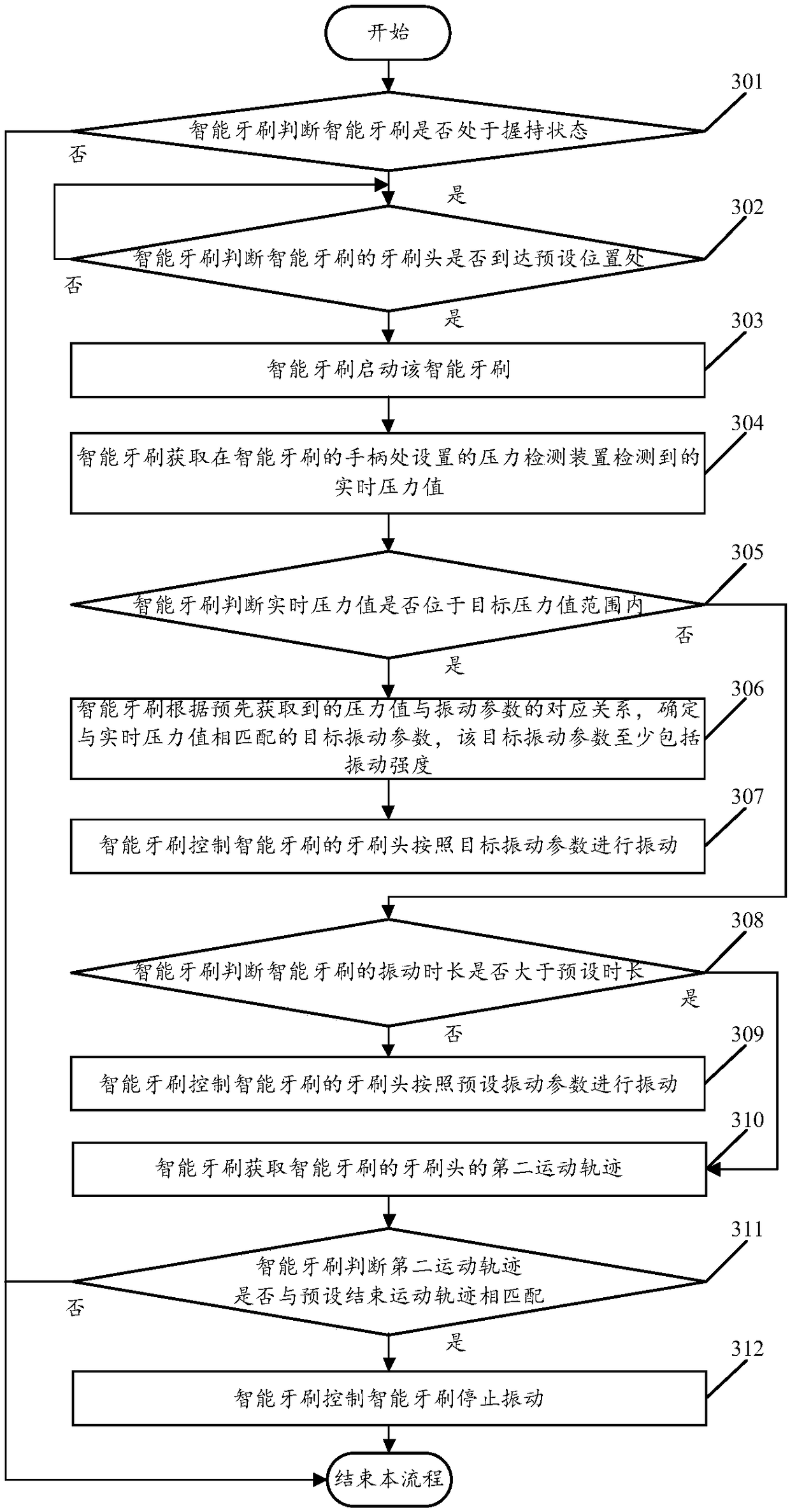

Intelligent toothbrush and control method thereof

ActiveCN108652772AHigh degree of intelligenceImprove user experienceTooth cleaningEngineeringUltimate tensile strength

The invention relates to an intelligent toothbrush and a control method thereof. The control method comprises the following steps of after the intelligent toothbrush is started, obtaining a real-timepressure value detected by a pressure detection device at a handle part of the intelligent toothbrush; according to the pre-obtained corresponding relationship of pressure value and vibration parameters, determining the target vibration parameter matched with the real-time pressure value, wherein the target vibration parameter at least comprises vibration intensity; controlling a toothbrush head of the intelligent toothbrush to vibrate according to the target vibration parameter. The control method provided by the embodiment of the invention has the advantage that the intelligence degree in tooth brushing is improved, so that the tooth brushing efficiency of a user is further improved.

Owner:GUANGDONG XIAOTIANCAI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com