Pressure detecting method for preventing clogging of filling pipeline

A technology for filling pipelines and detection methods, which is applied to filling materials, earth cube drilling, mining equipment, etc., to achieve the effects of preventing the expansion of faults, saving maintenance costs, and shortening maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

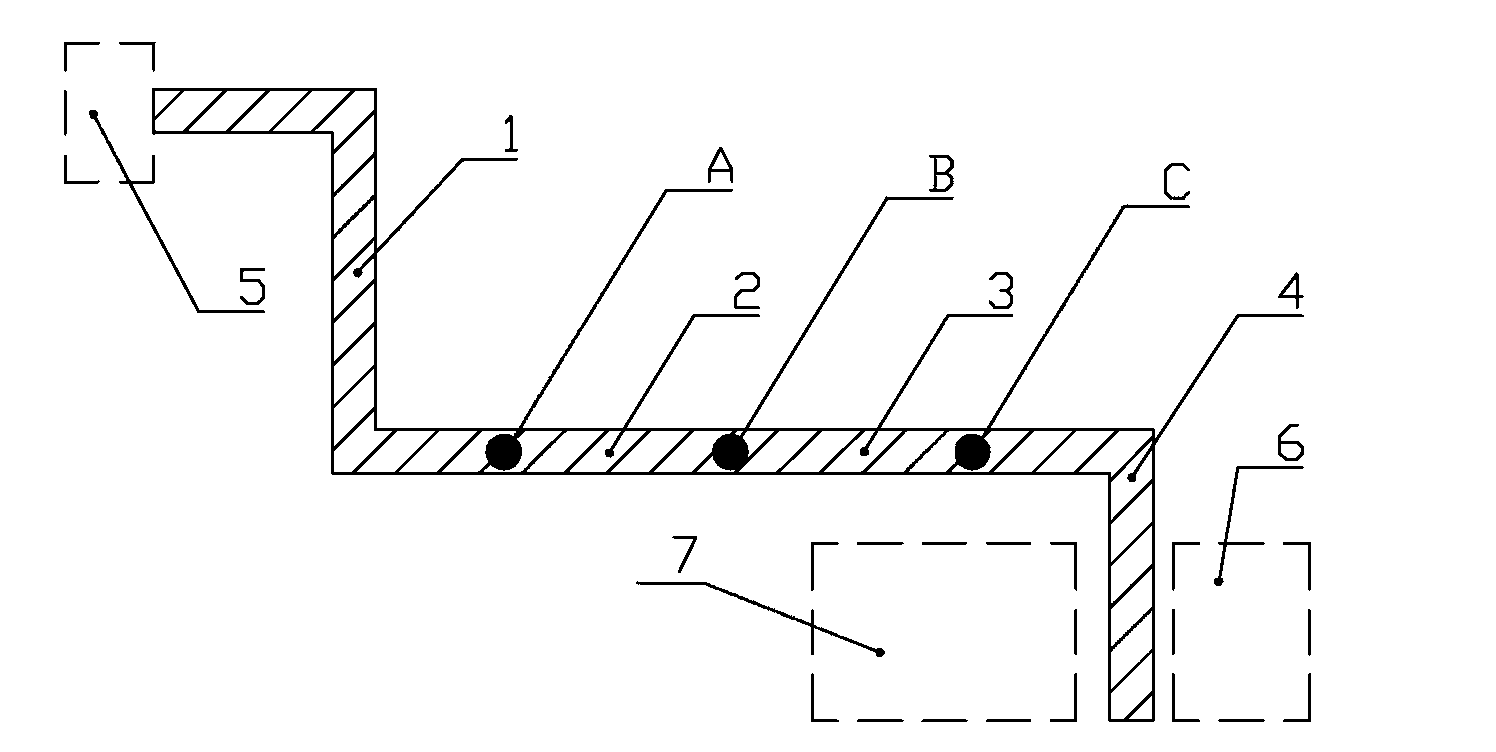

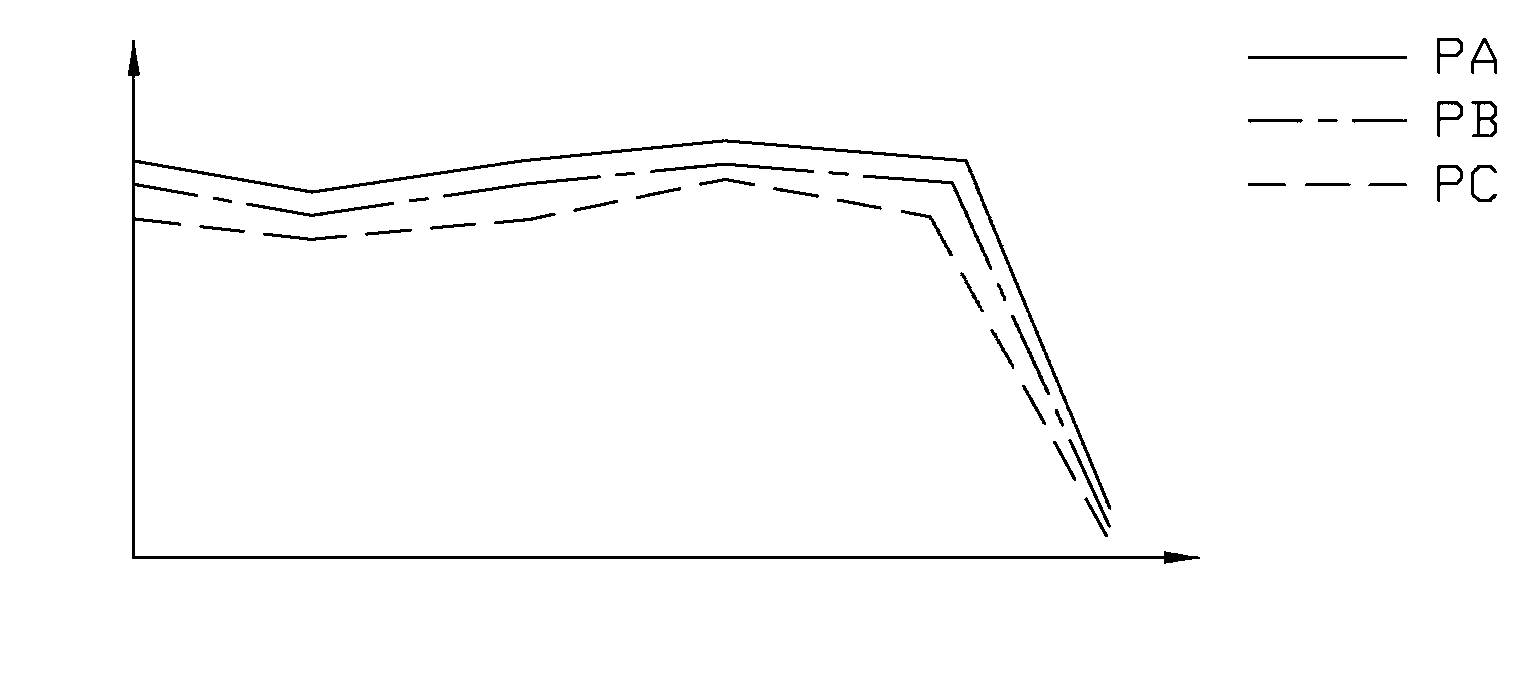

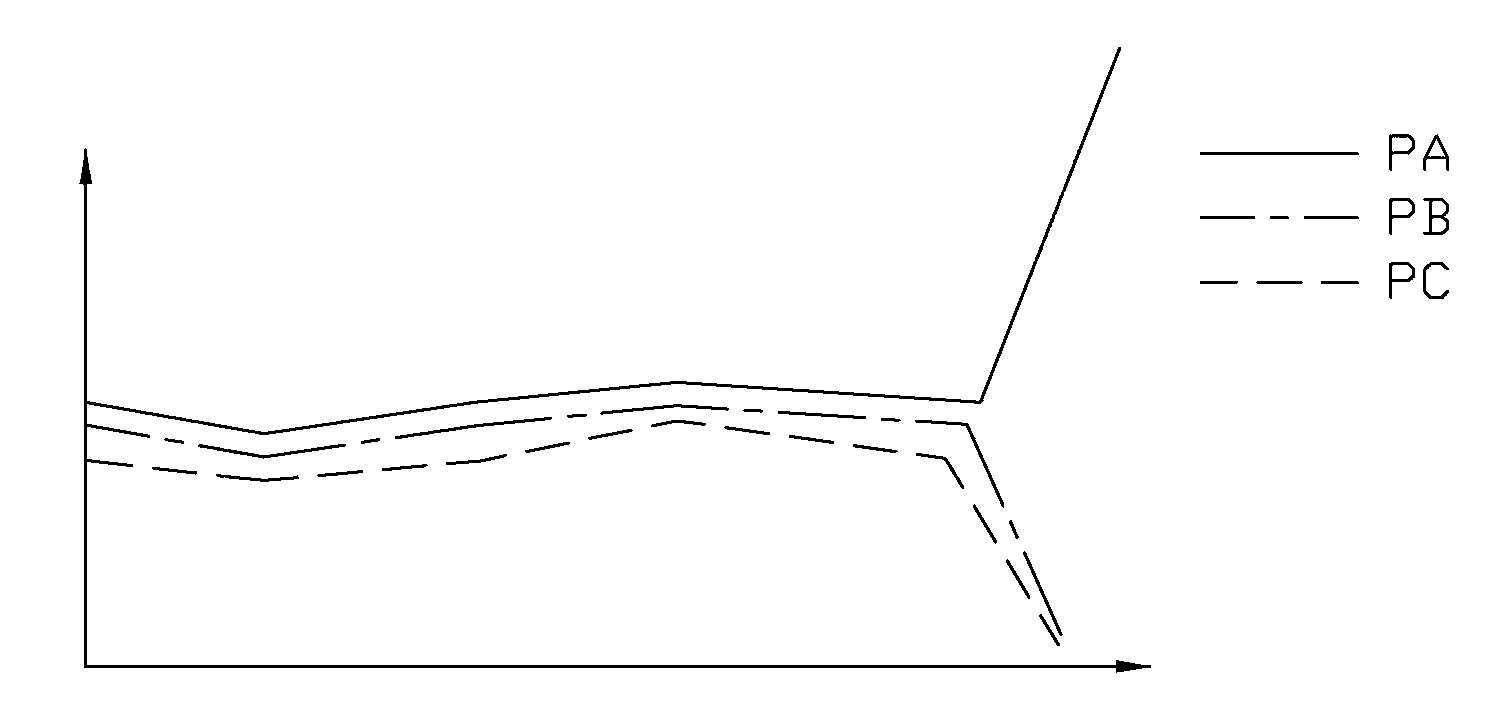

[0023] Select three pressure measurement points on the main pipeline of the filling pipeline and set up pressure sensors with flat ceramic contact surfaces ( figure 1 ), wherein: the first pressure measurement point A is set at the front of the roadway filling pipe to monitor whether the filling pipe, standpipe and two elbows on the ground are blocked. (Note: In actual application, the probability of pipe blockage of elbows is much higher than that of straight pipes) and compare the pressure difference with the other two points.

[0024] The second pressure measurement point B is set in the middle of the roadway filling pipe to monitor whether the filling pipe is blocked, and compare the pressure difference with the other two points.

[0025] The third pressure measurement point C is set on the filling pipe at the inflection point of the working face a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com