Patents

Literature

1250 results about "Main duct" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

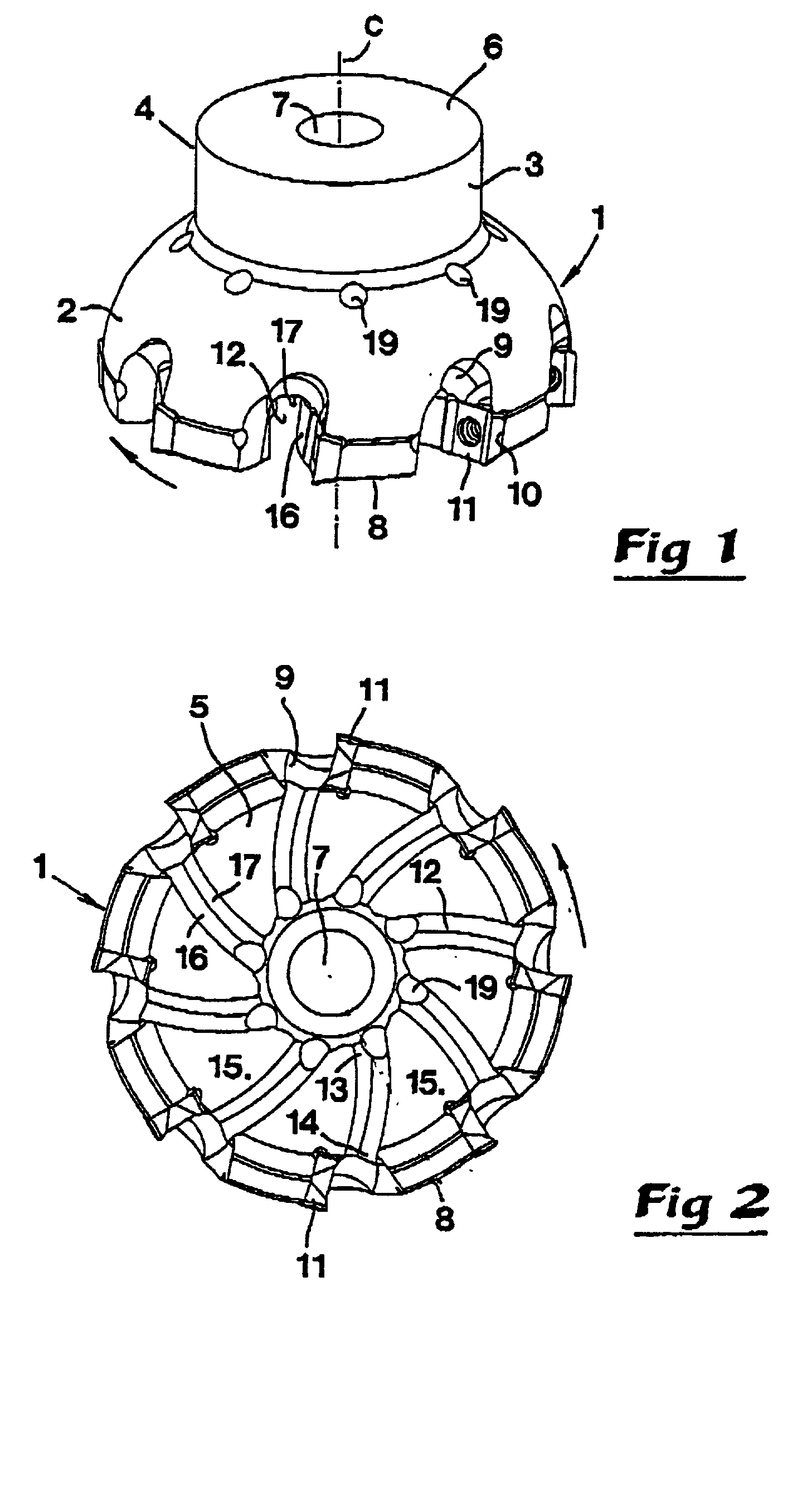

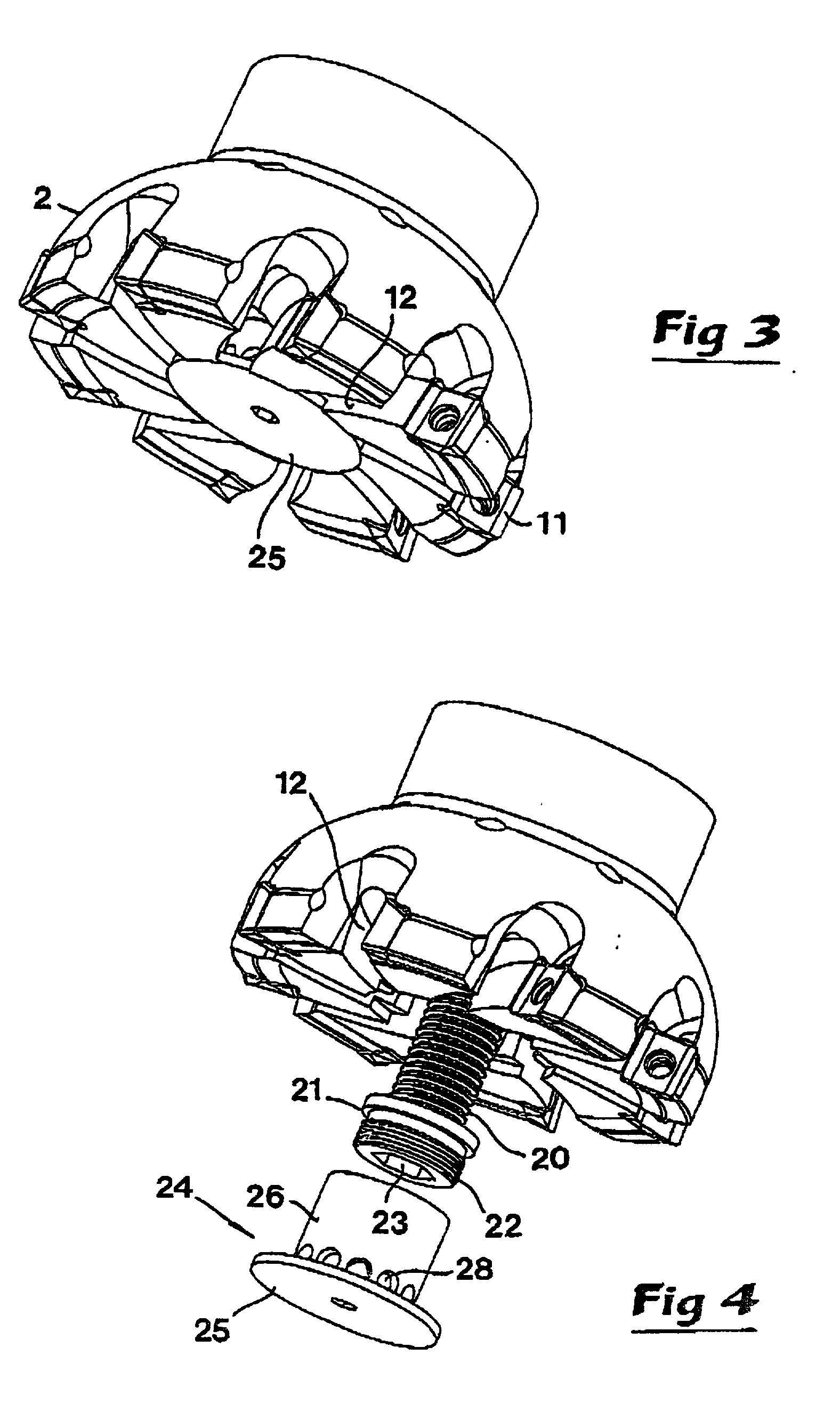

Tool for chip removing machining and having fluid-conducting branch ducts

InactiveUS6595727B2The effect is outstandingManufactured in simple and inexpensiveMilling cuttersTurning toolsEngineeringBranch Duct

Owner:SANDVIK INTELLECTUAL PROPERTY AB

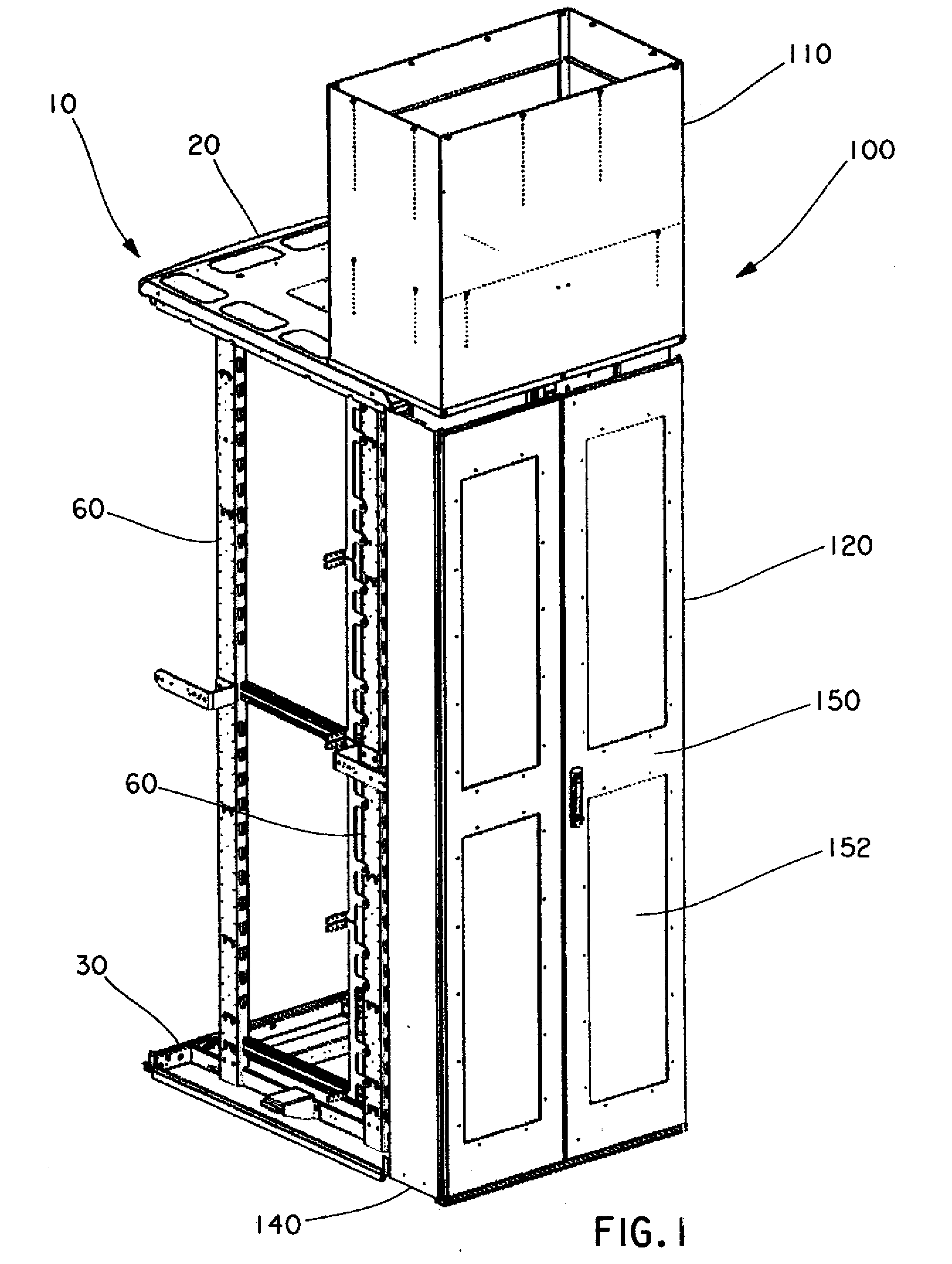

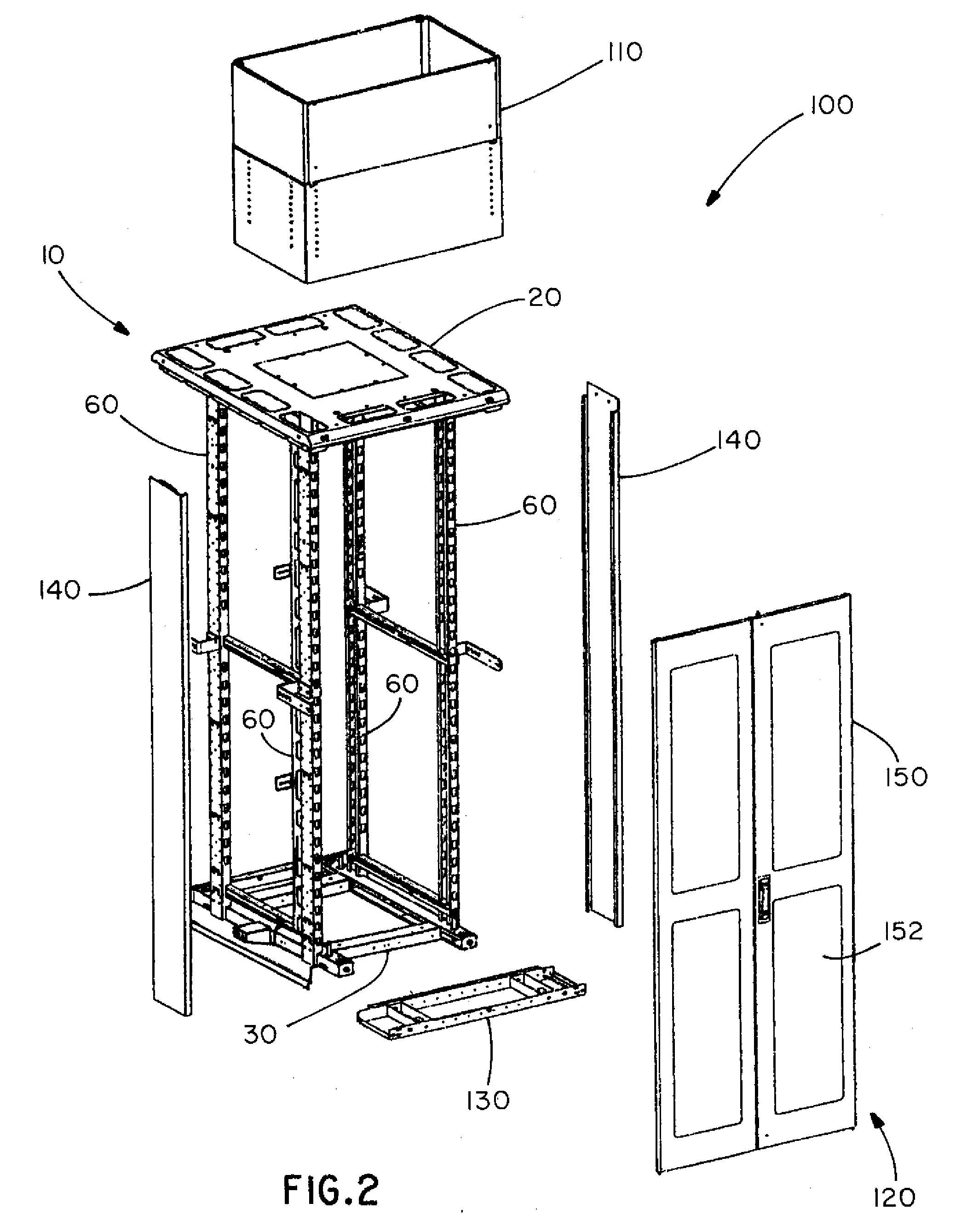

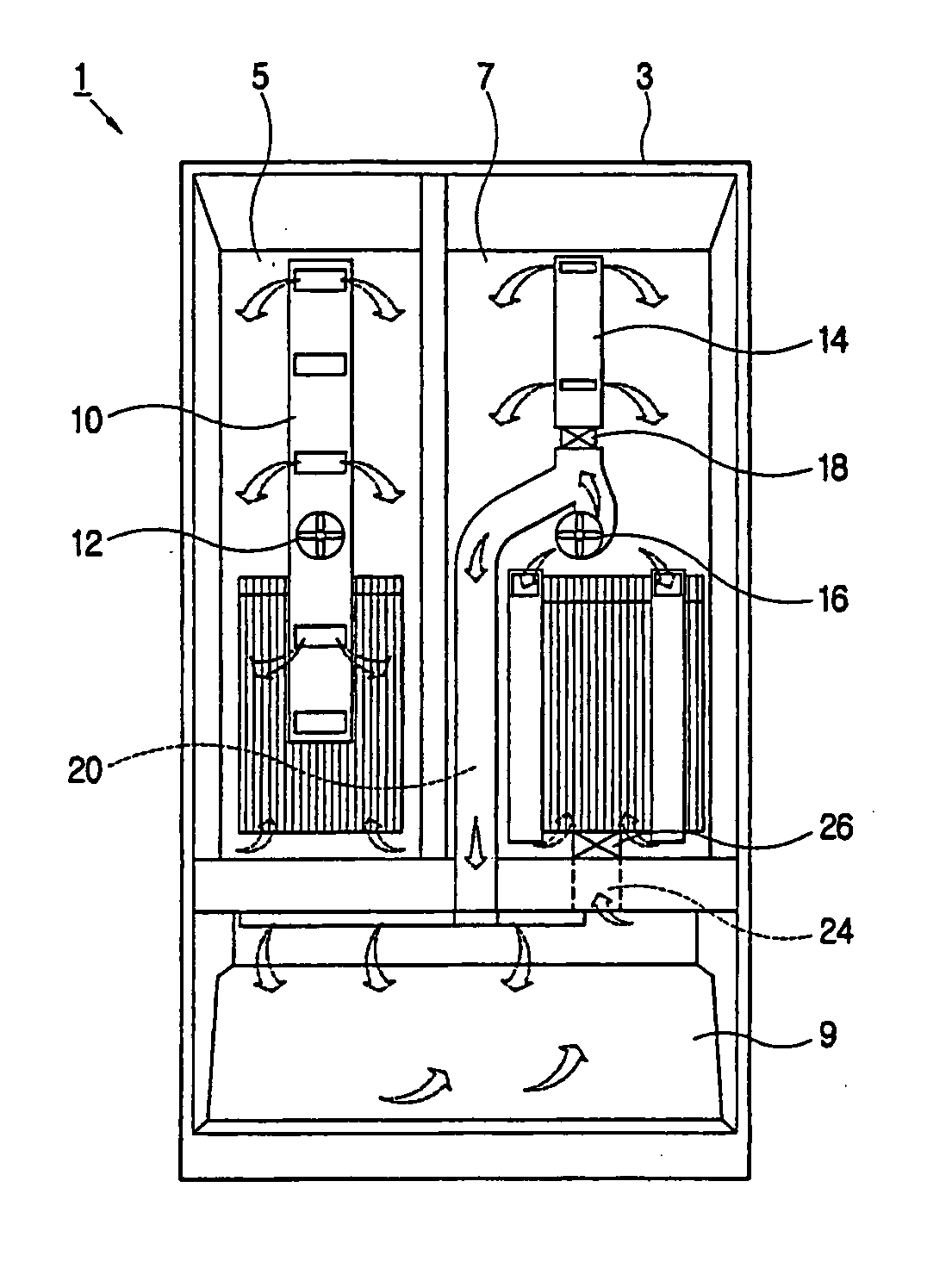

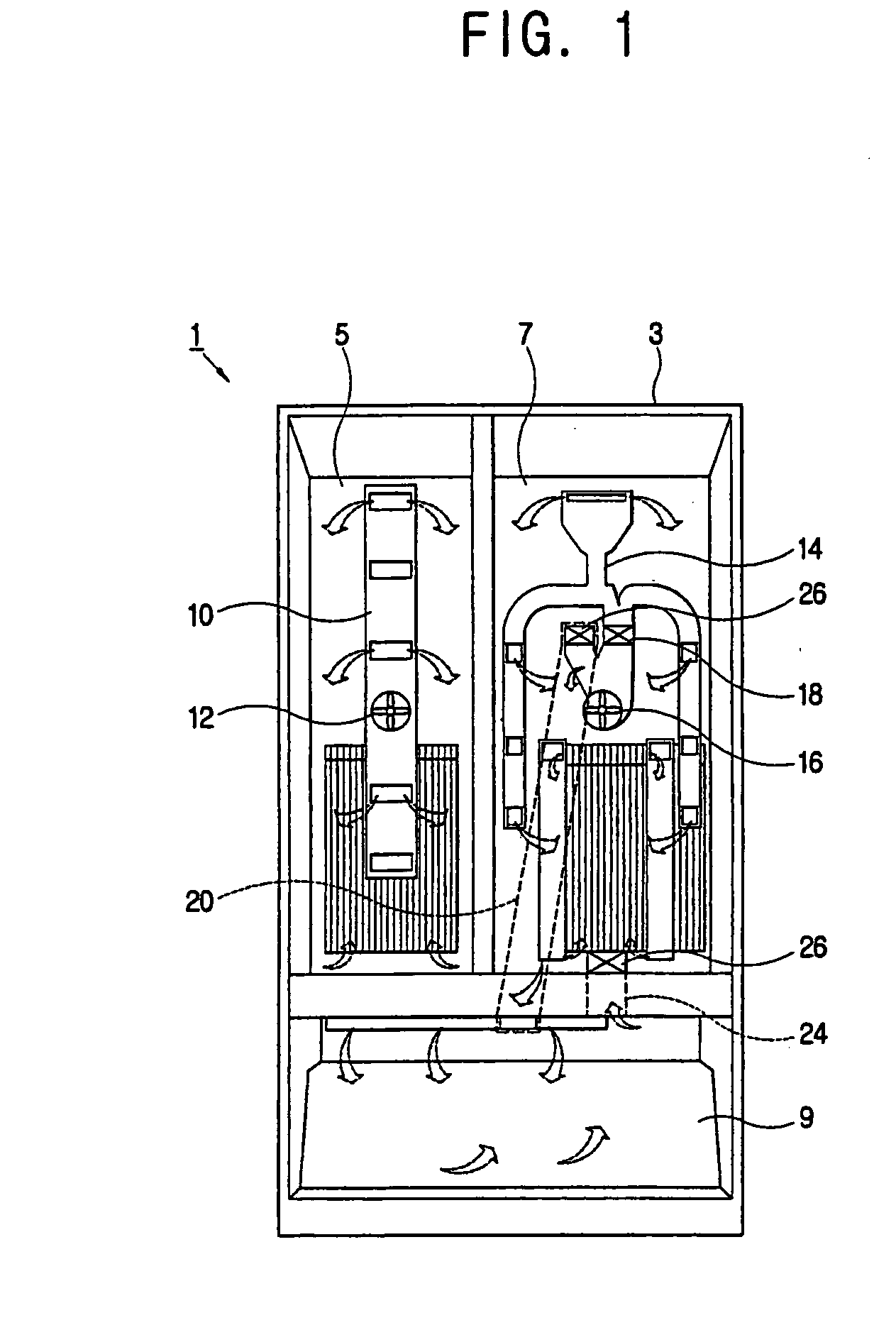

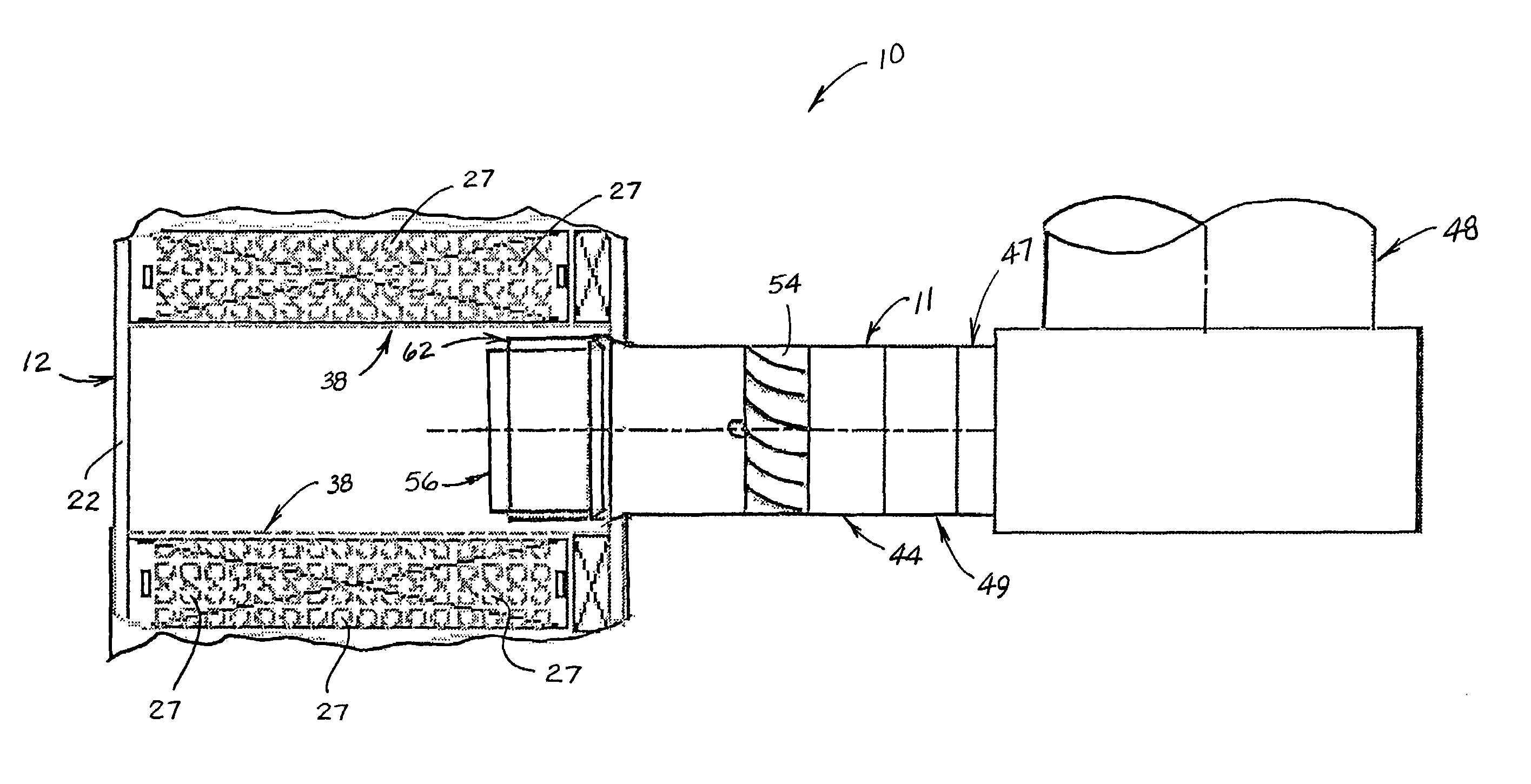

Passive Cooling Systems for Network Cabinet

ActiveUS20100003911A1Easy to installEasy to shareDucting arrangementsLighting and heating apparatusCold airEngineering

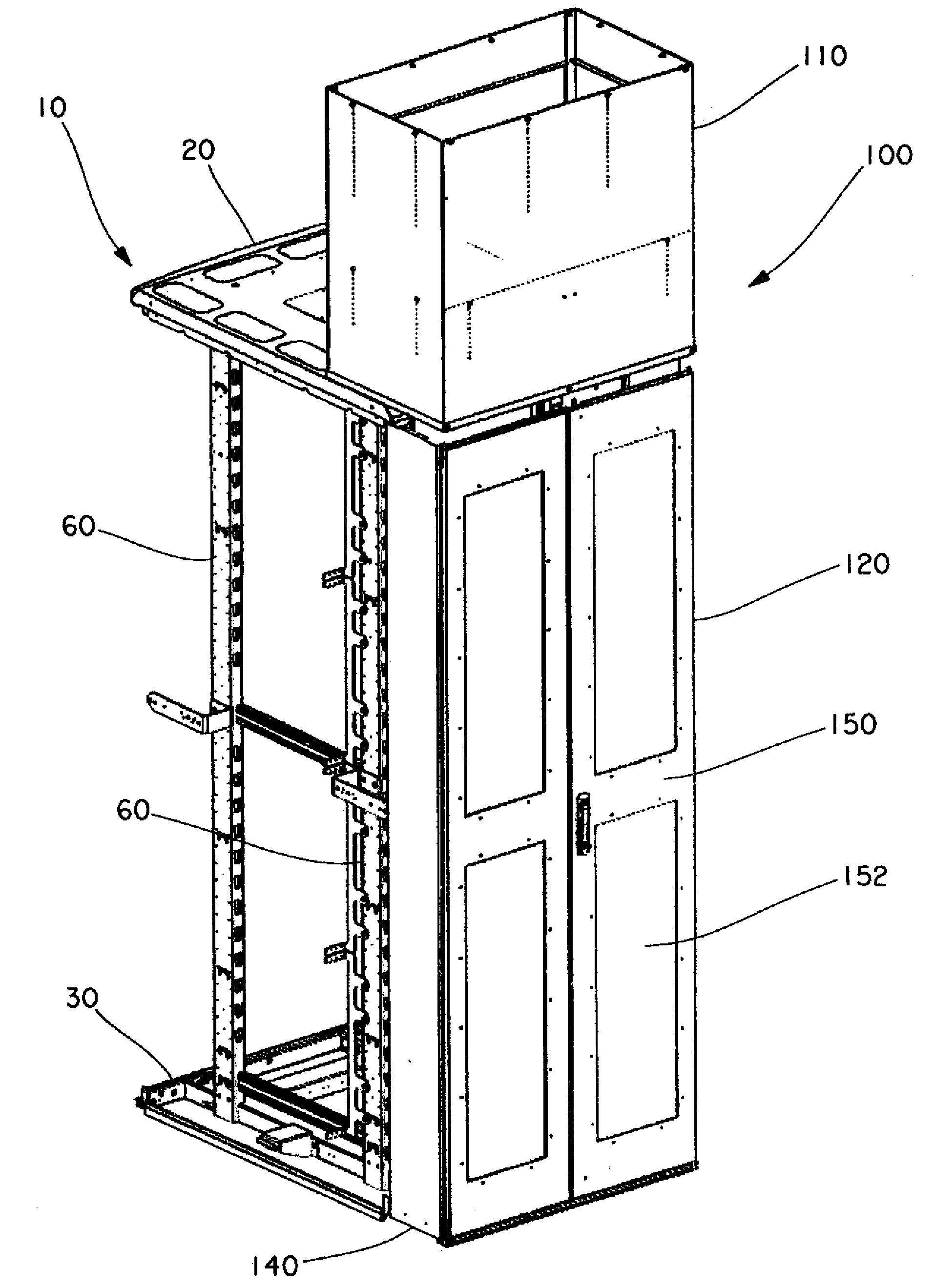

Certain embodiments of the present invention provide a cooling duct assembly for electronic equipment installed in a cabinet. The cooling duct assembly comprises at least one main duct in fluid communication with a front portion of the cabinet. The at least one main duct receives cold air from the front portion of the cabinet and routes the cold air toward a back portion of the cabinet. Additionally, the cooling duct assembly comprises at least one side duct in fluid communication with the at least one main duct. The at least one side duct receives the cold air from the at least one main duct and routes the cold air to at least one side air intake opening on the electronic equipment.

Owner:PANDUIT

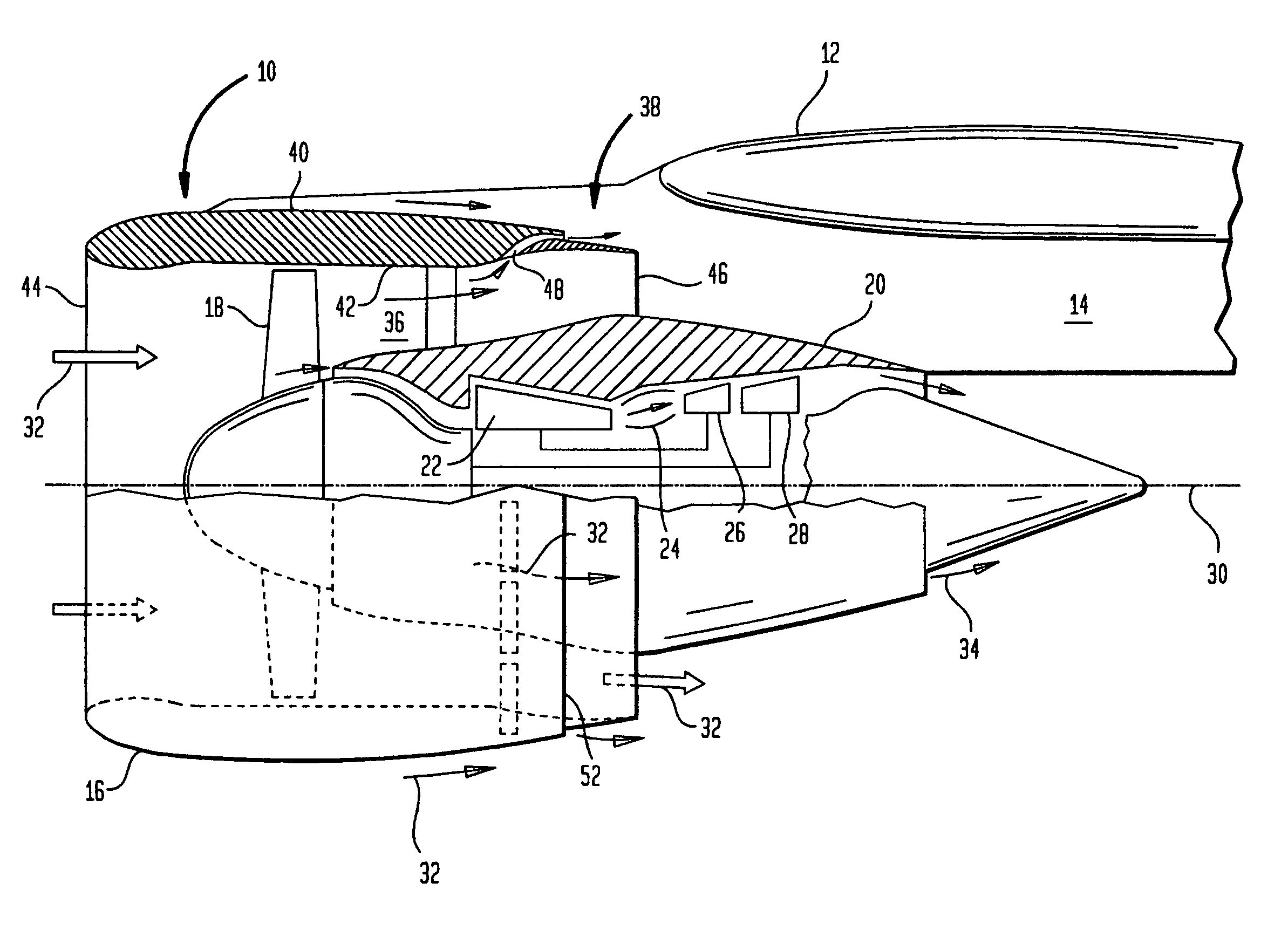

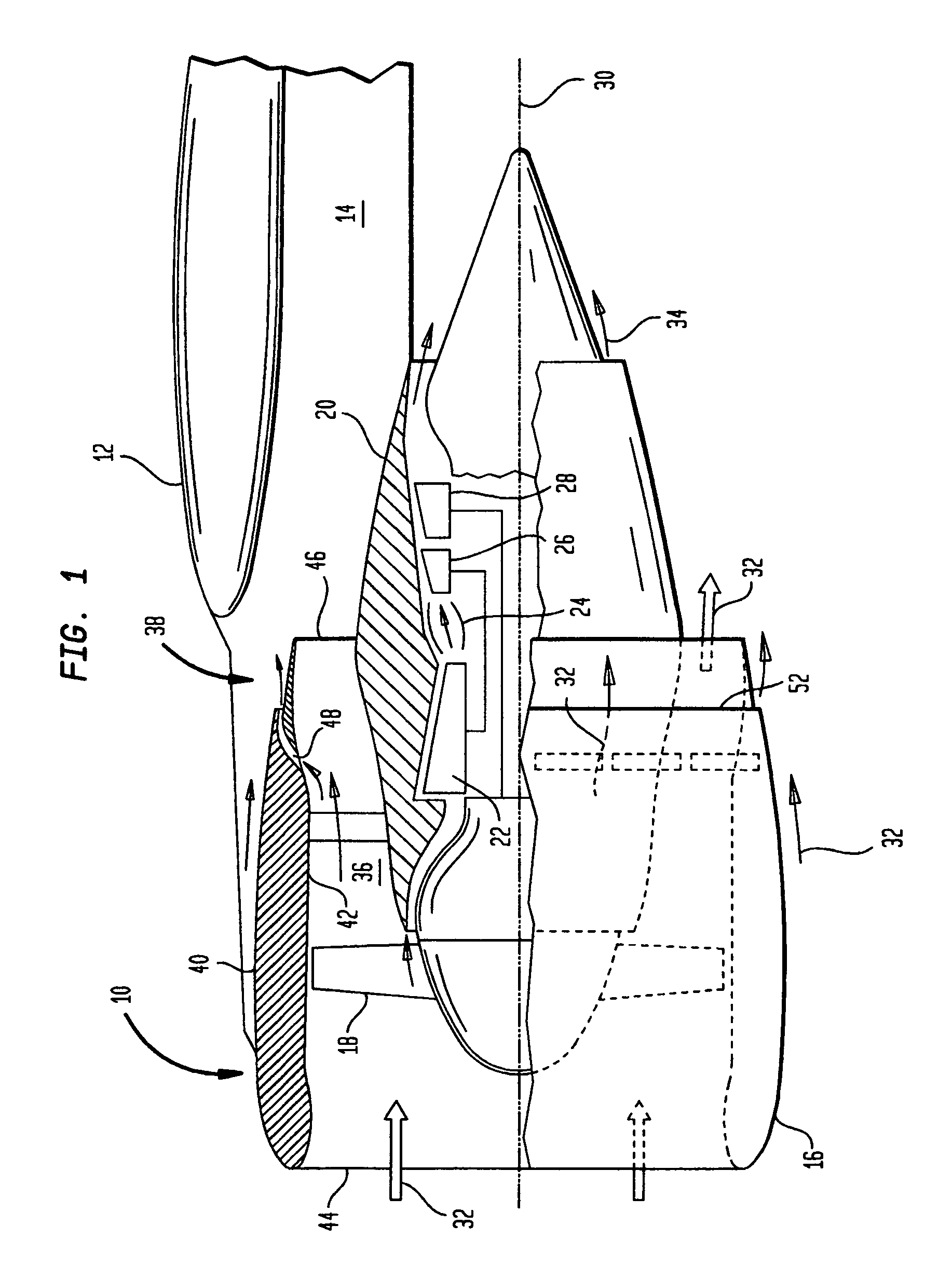

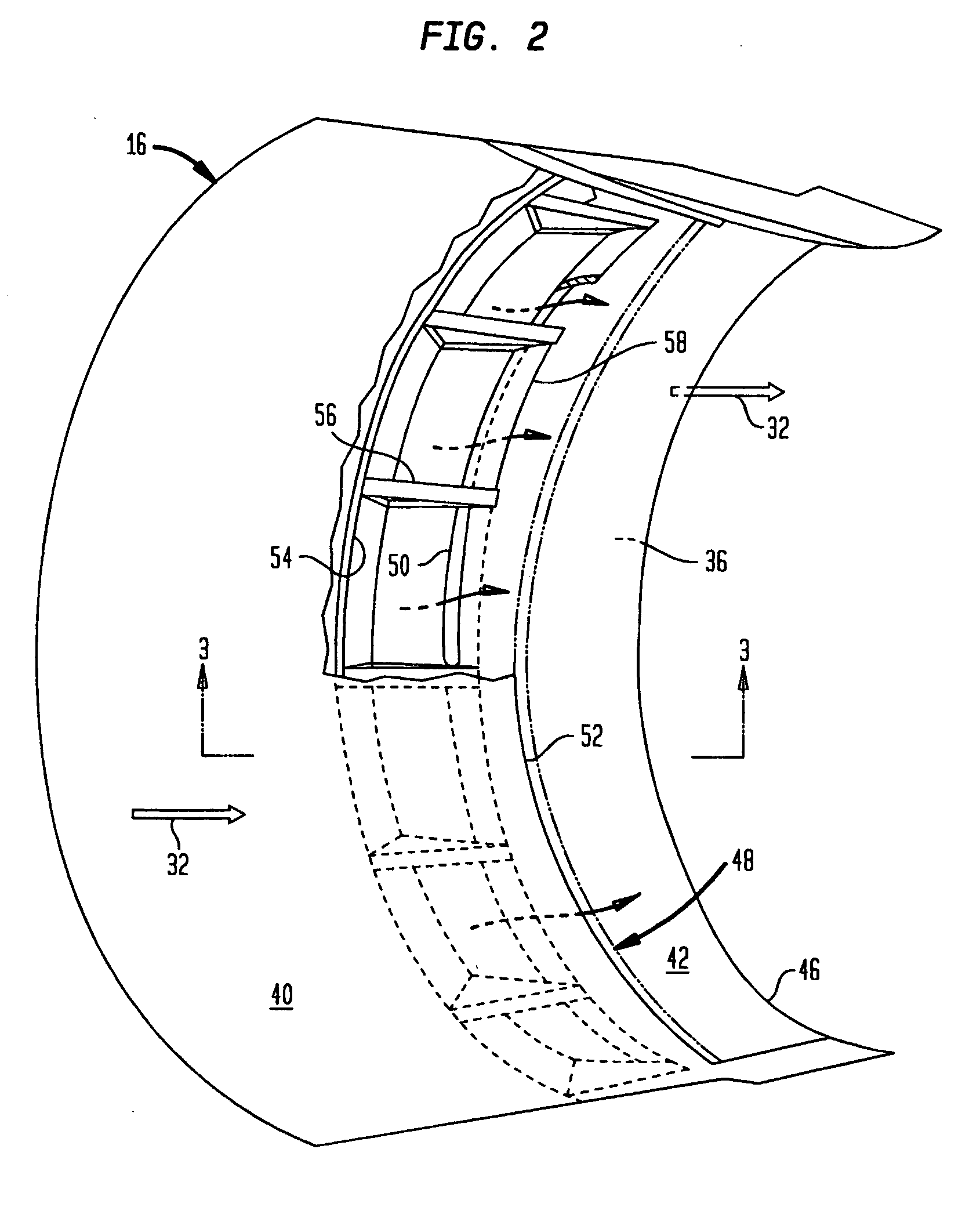

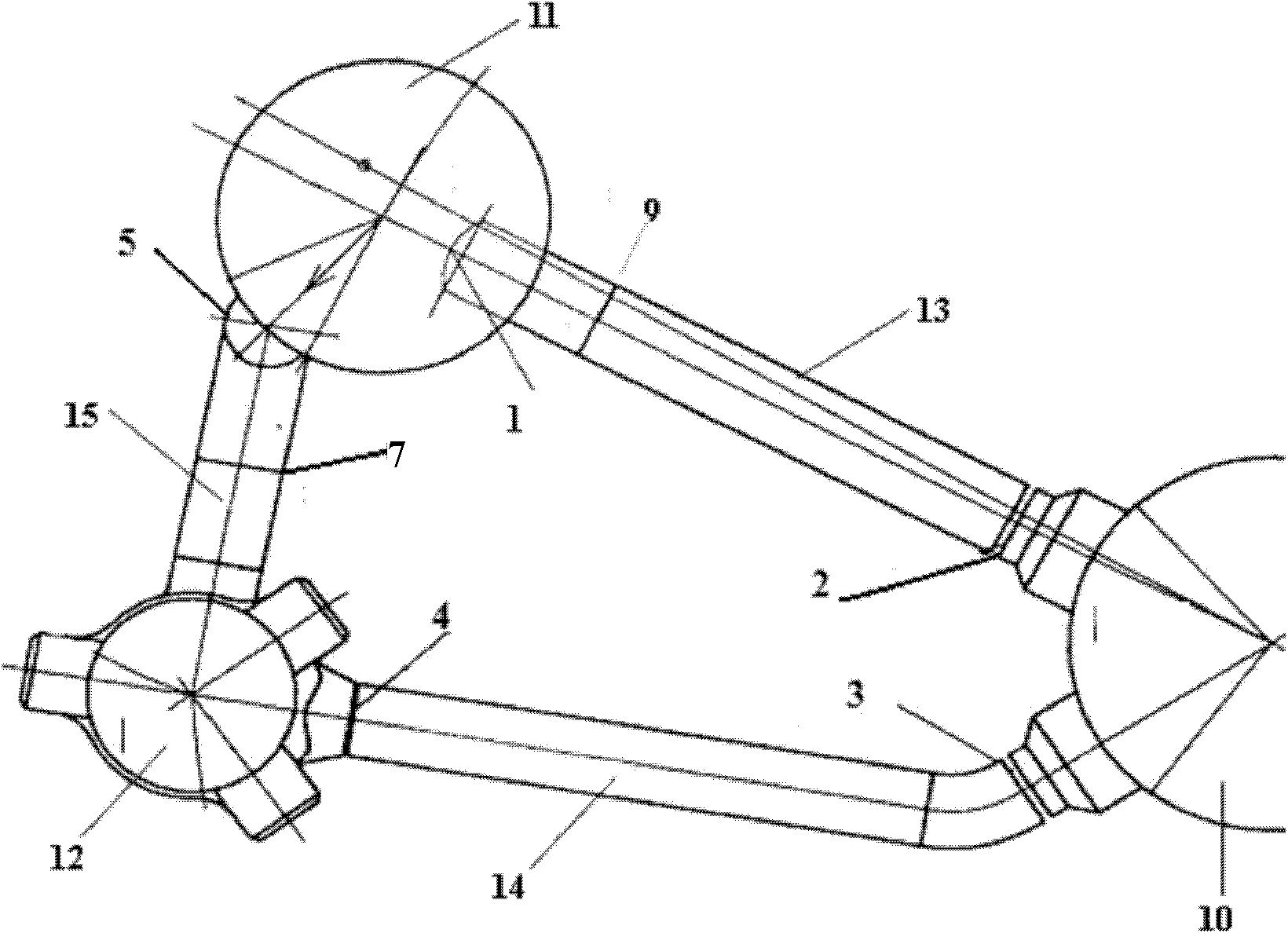

Confluent exhaust nozzle

A gas turbine engine exhaust nozzle includes a nacelle having an inlet and main outlet at opposite ends, and a main duct extending therebetween. A secondary bypass duct extends radially through the nacelle upstream of the main outlet and includes an unobstructed secondary inlet joined to the main duct, and a secondary outlet surrounding the main outlet for collectively discharging exhaust flow in confluent streams.

Owner:THE NORDAM GRP

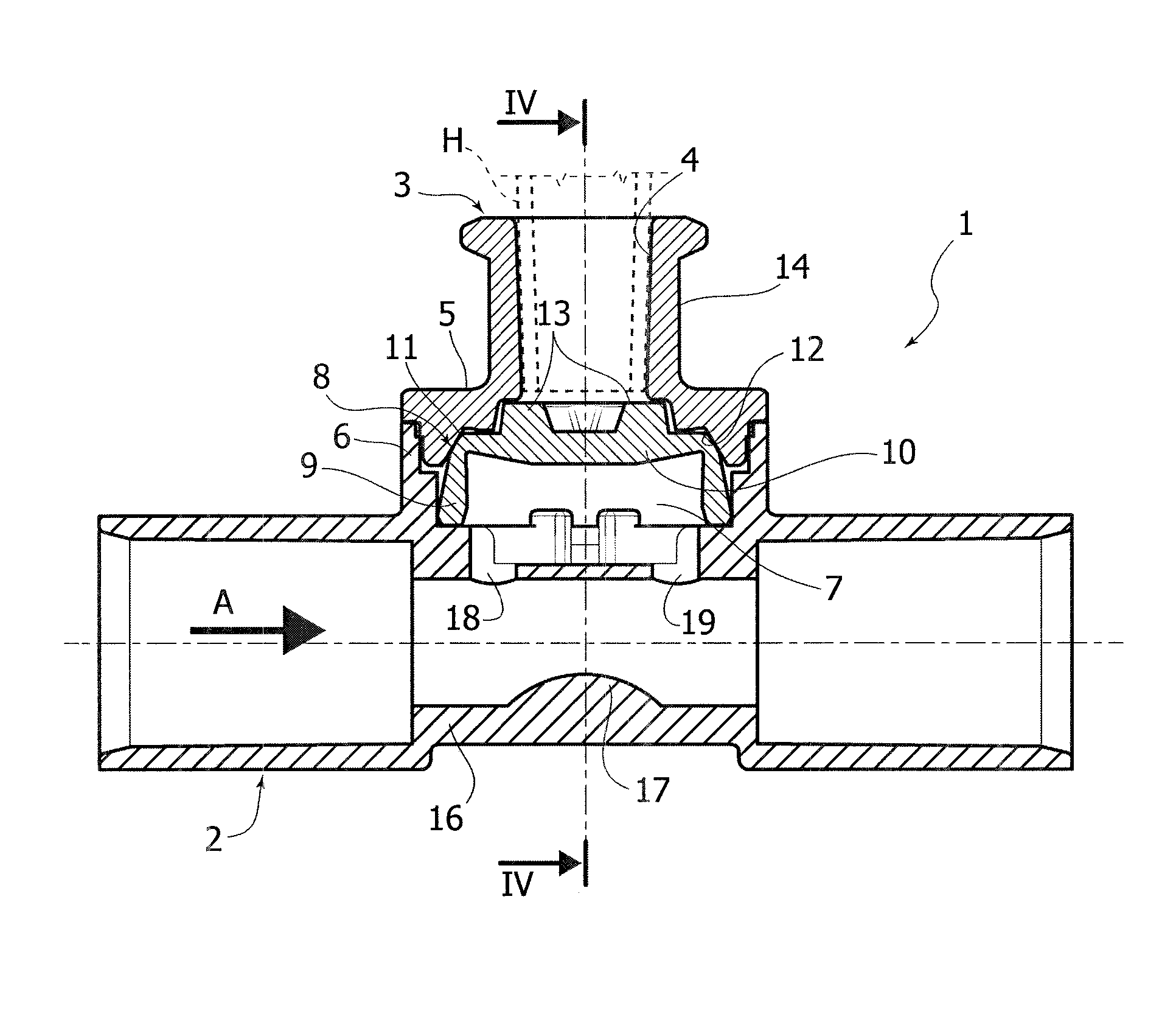

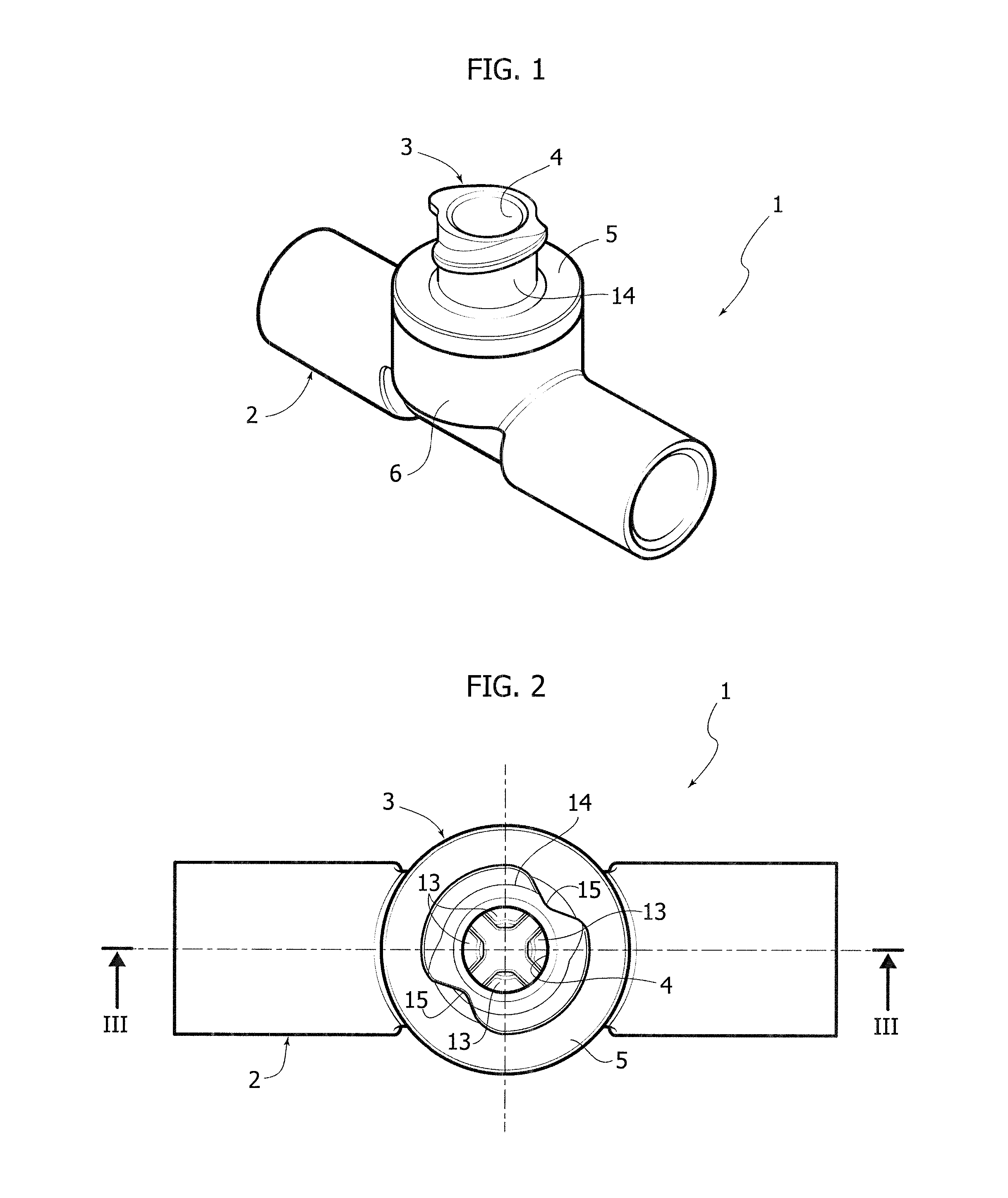

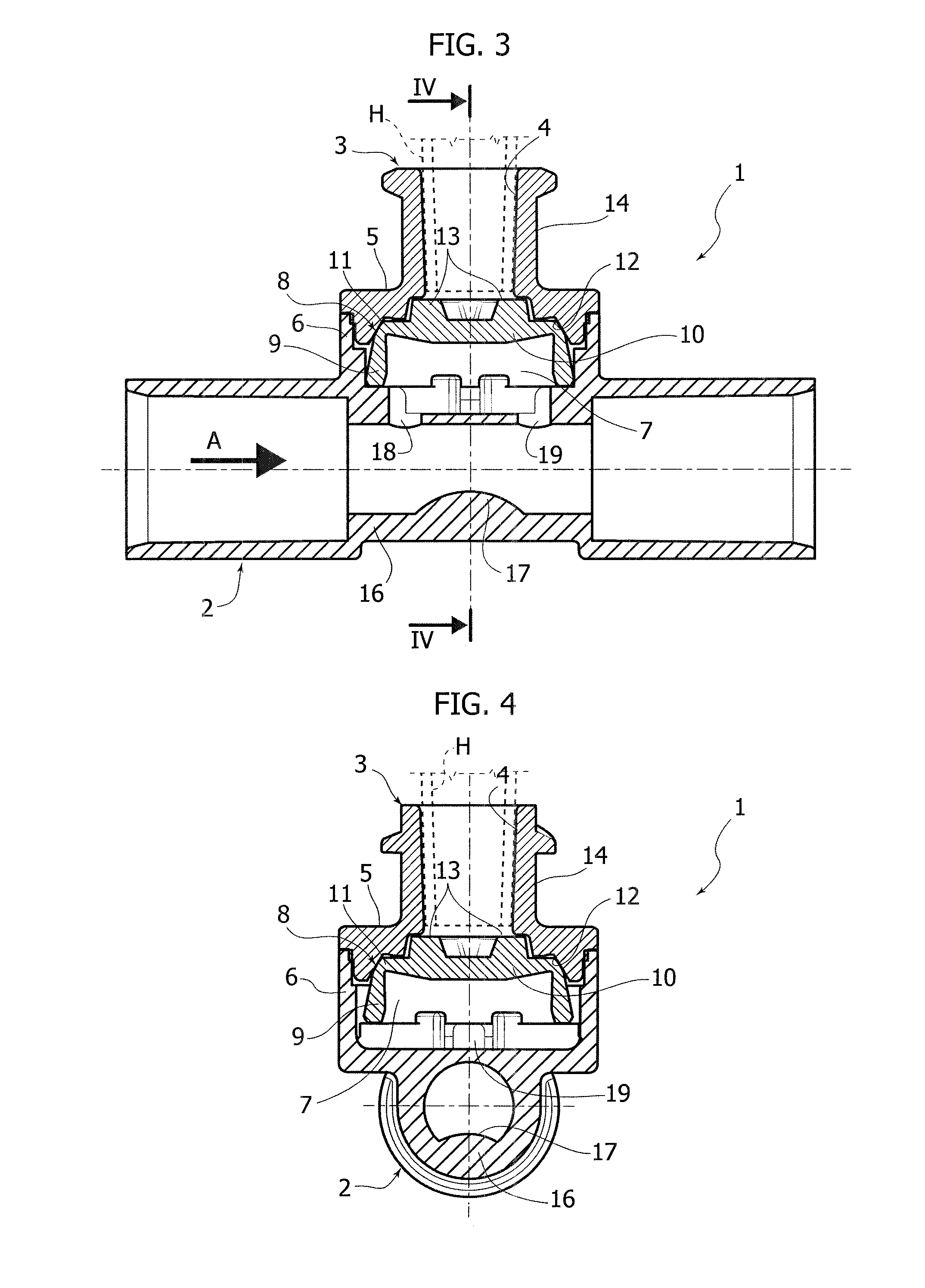

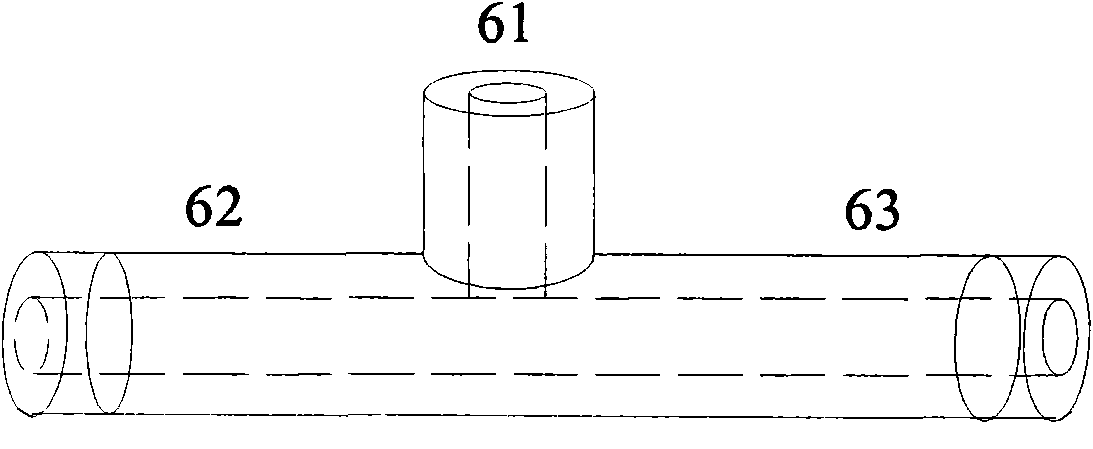

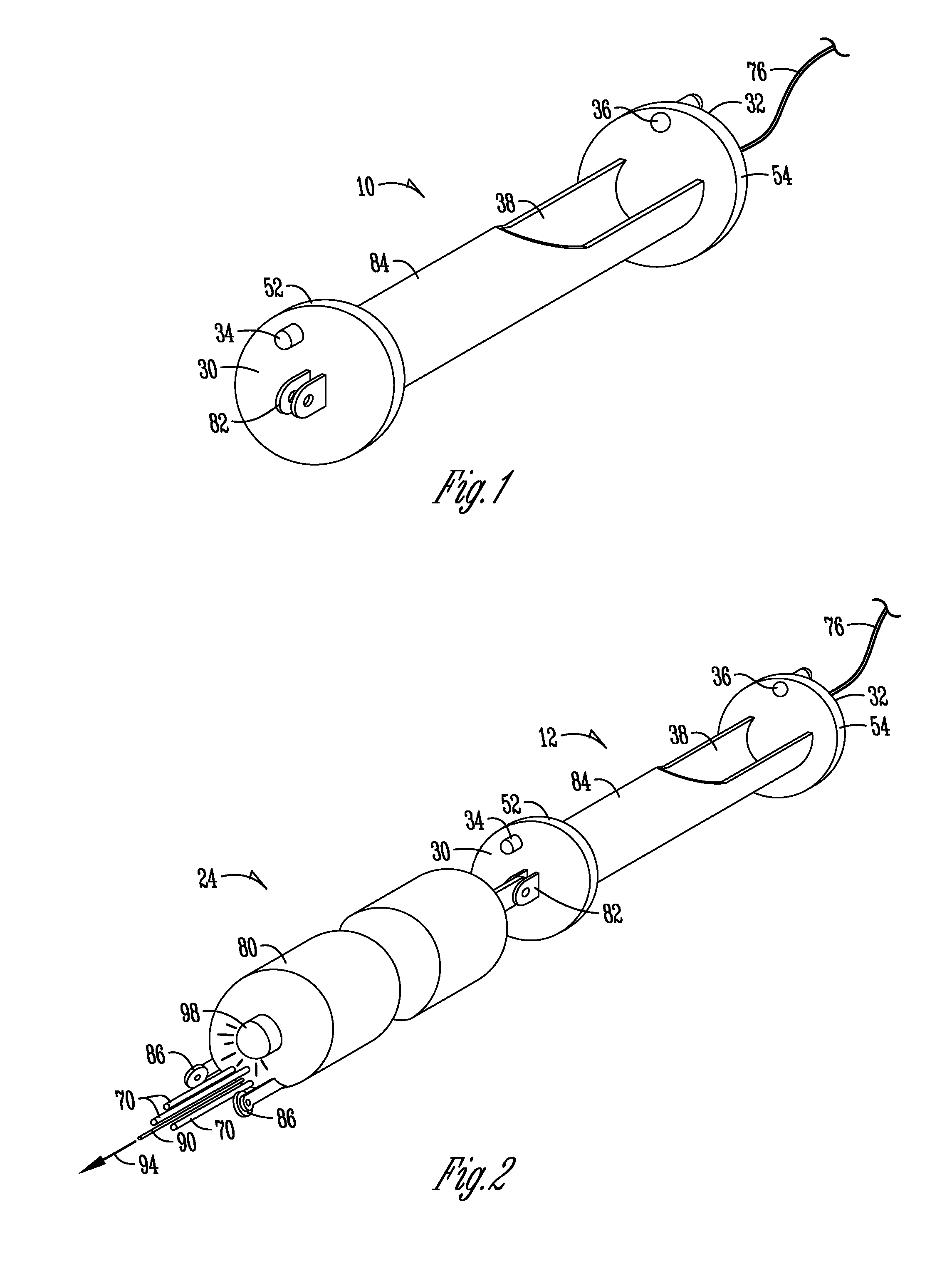

Flow system for medical lines

ActiveUS20150297817A1No risk of contaminationOther blood circulation devicesInfusion devicesEngineeringMain duct

A flow system for medical lines includes a flow component having a main duct and at least one lateral tubular fitting with a female luer cone communicating with the main duct) through a valve. The valve includes a transverse diaphragm normally kept in fluid-tight contact against an annular valve seat of the lateral tubular fitting, which can be moved away from this into an opening position following upon insertion of a male luer-cone introducer of fluid into the lateral tubular fitting. The diaphragm is prearranged for being pushed into the opening position directly by the introducer, and the lateral tubular fitting is configured to couple in a fluid-tight way with the introducer before the latter comes into contact of thrust with the diaphragm.

Owner:IND BORLA

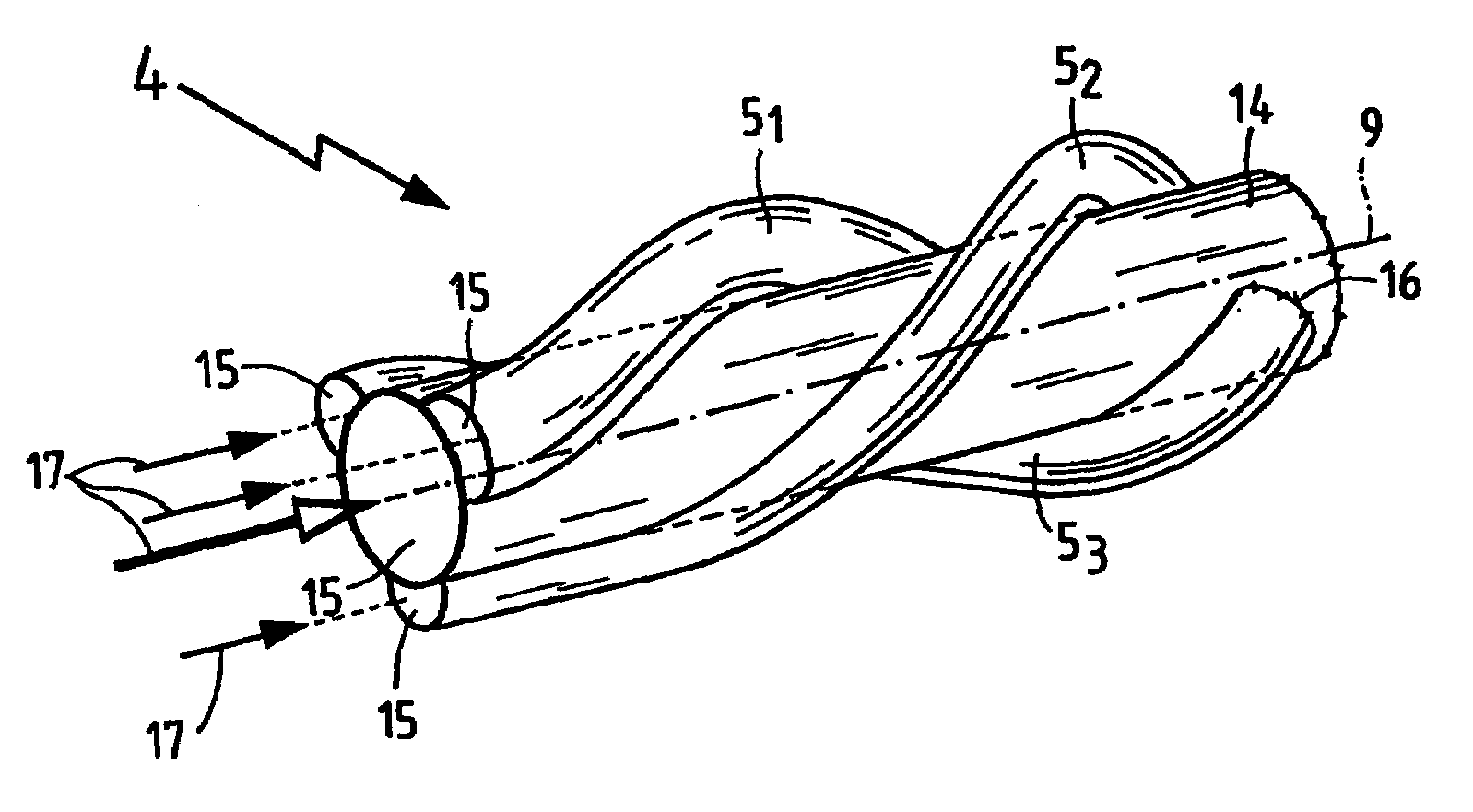

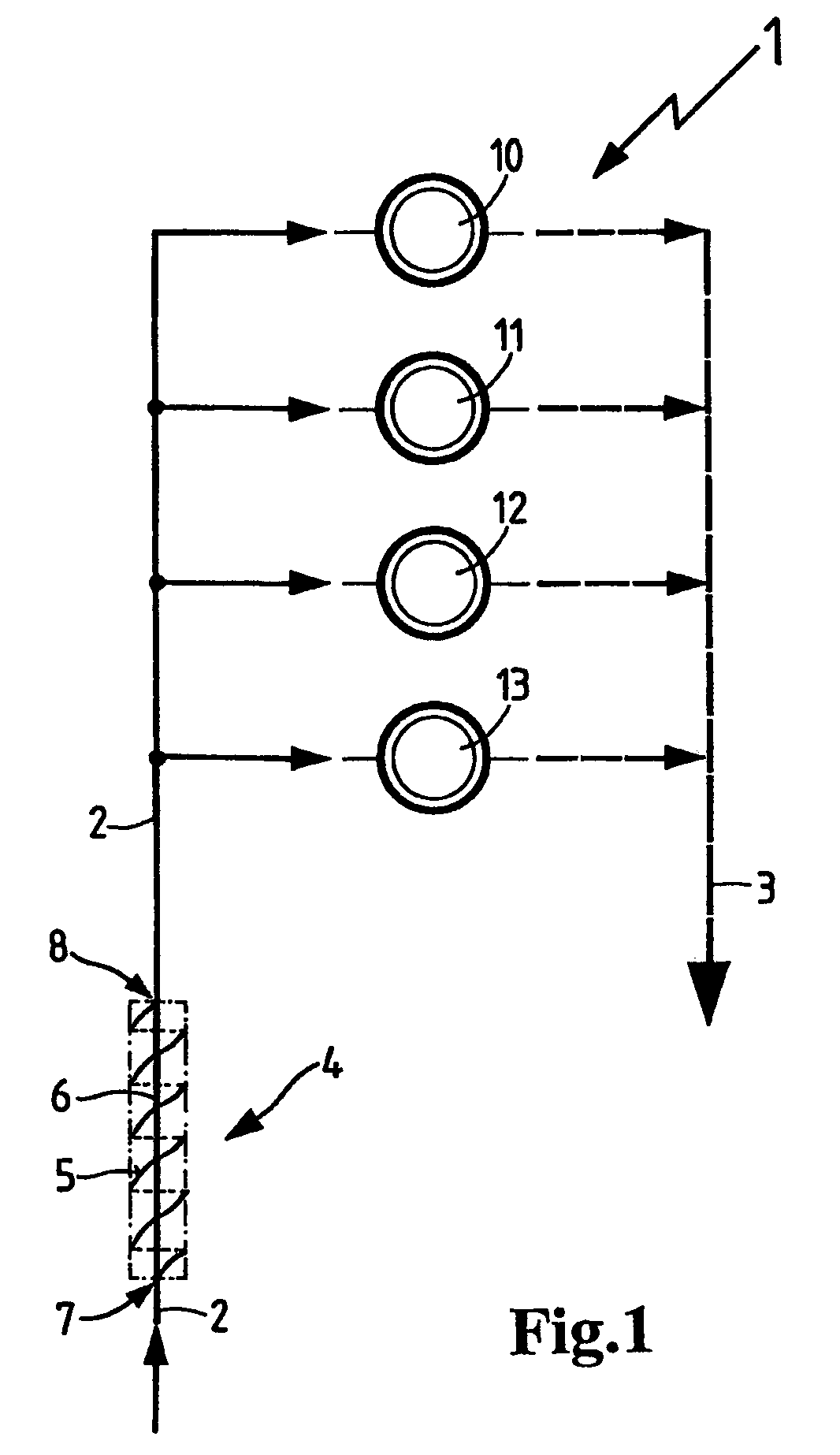

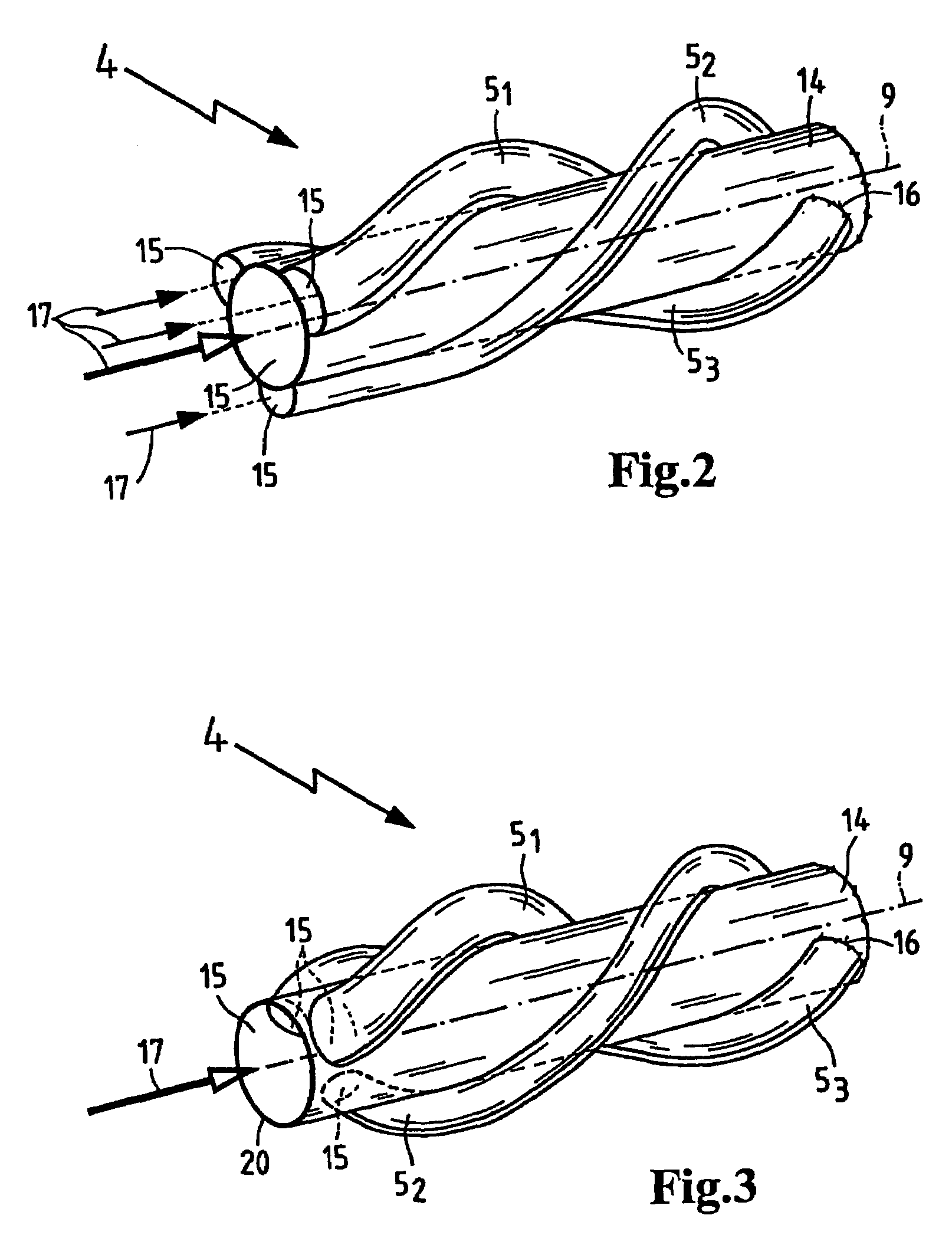

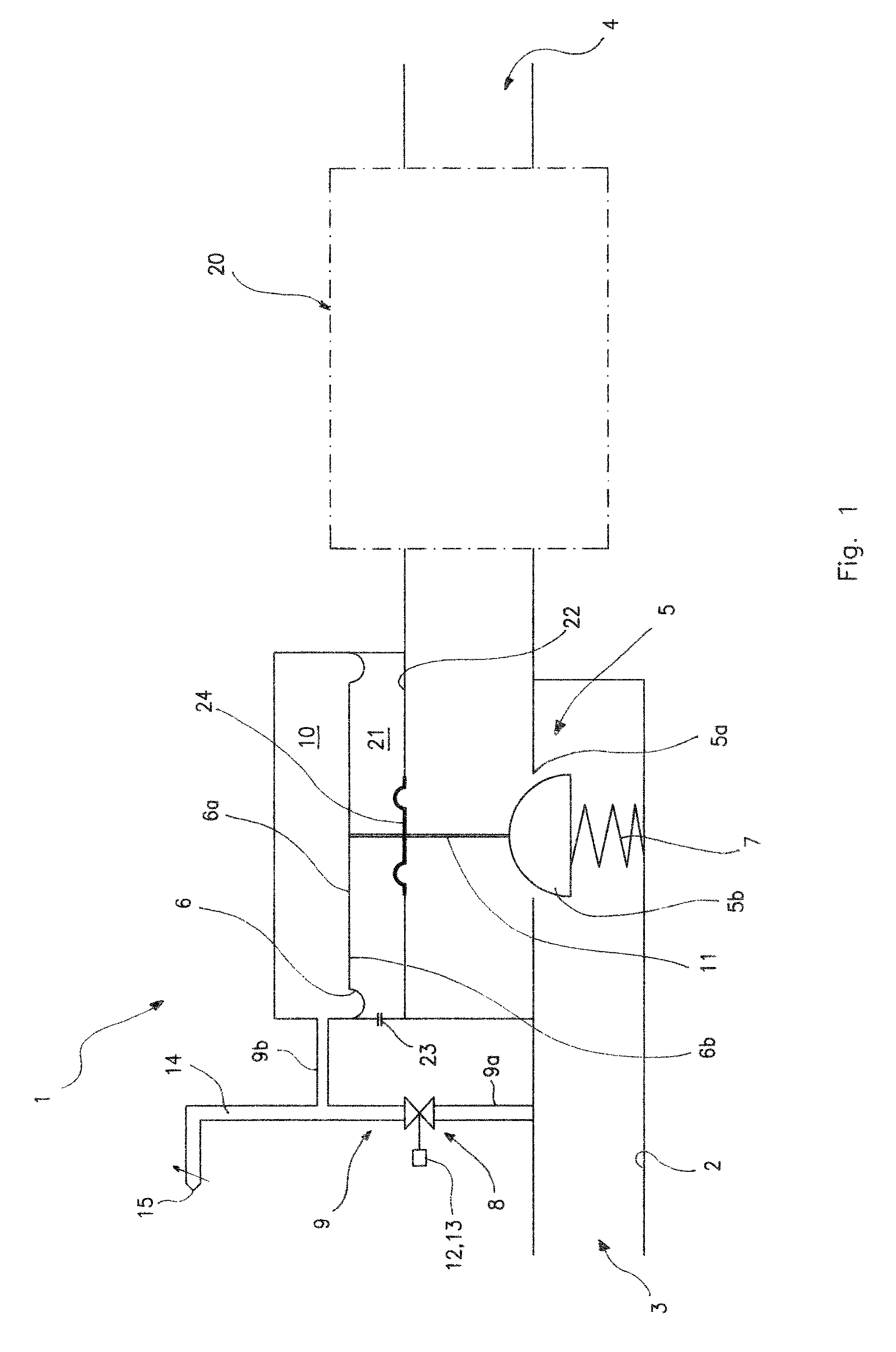

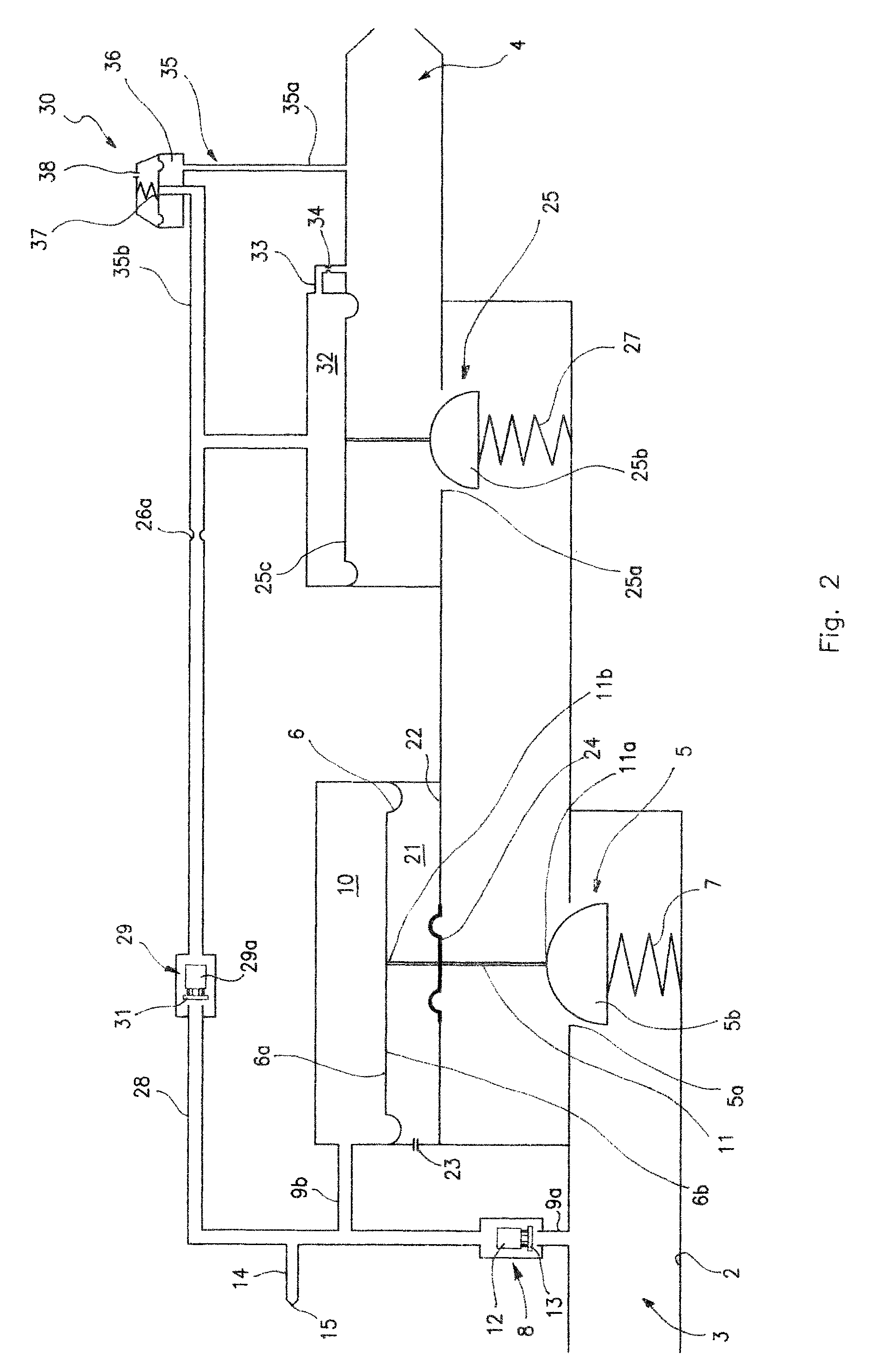

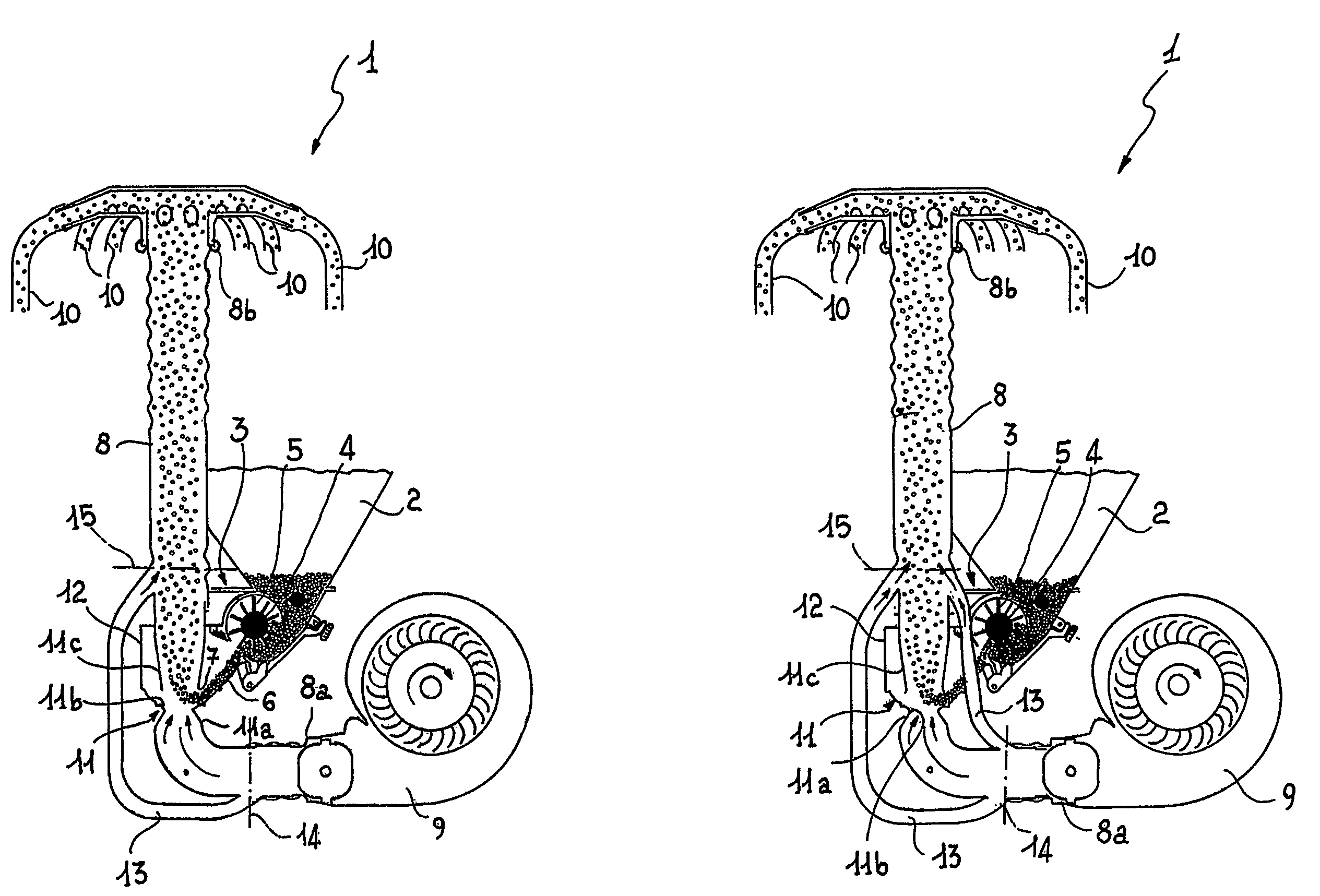

Noise suppressor apparatus for a gas duct

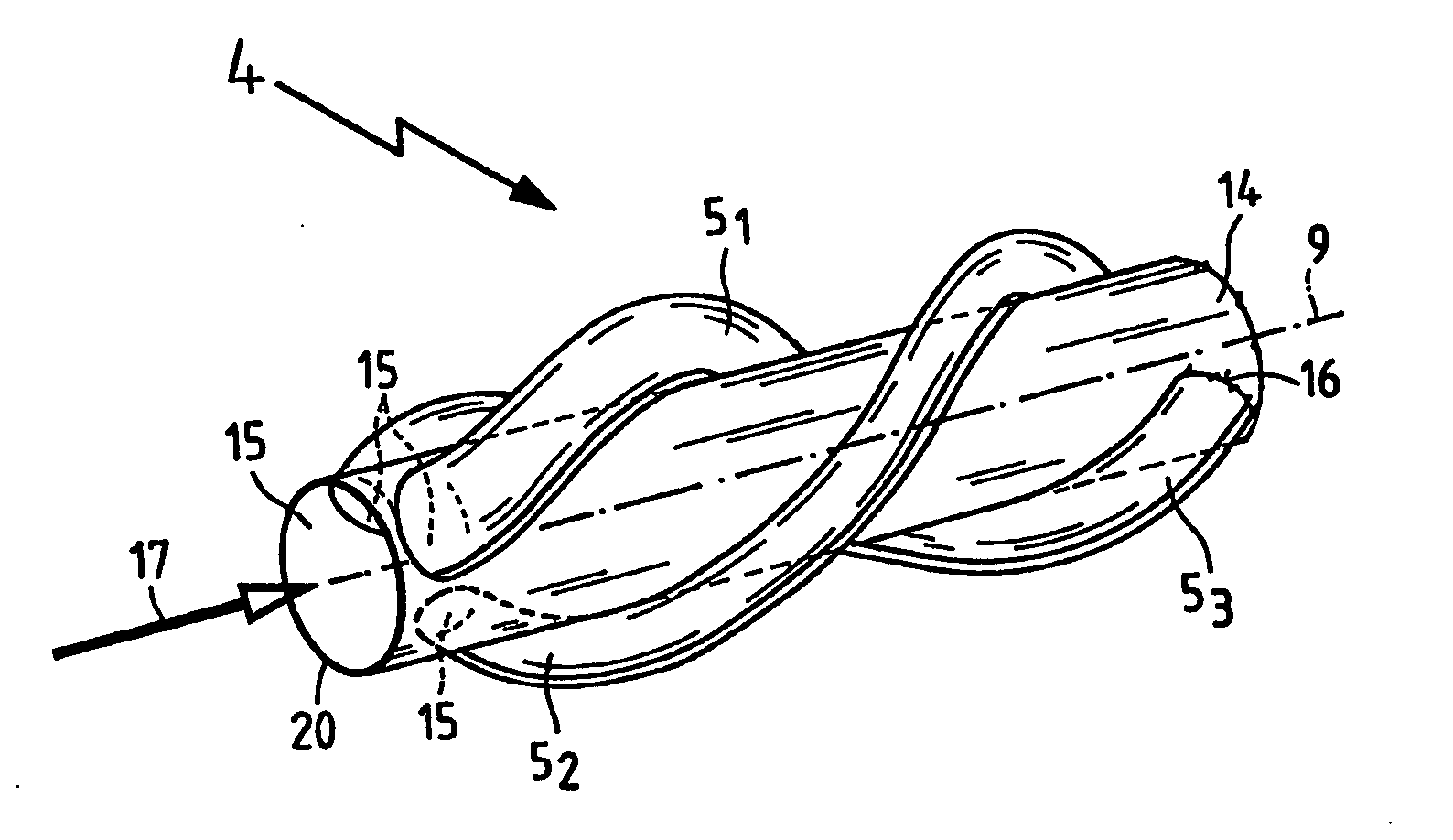

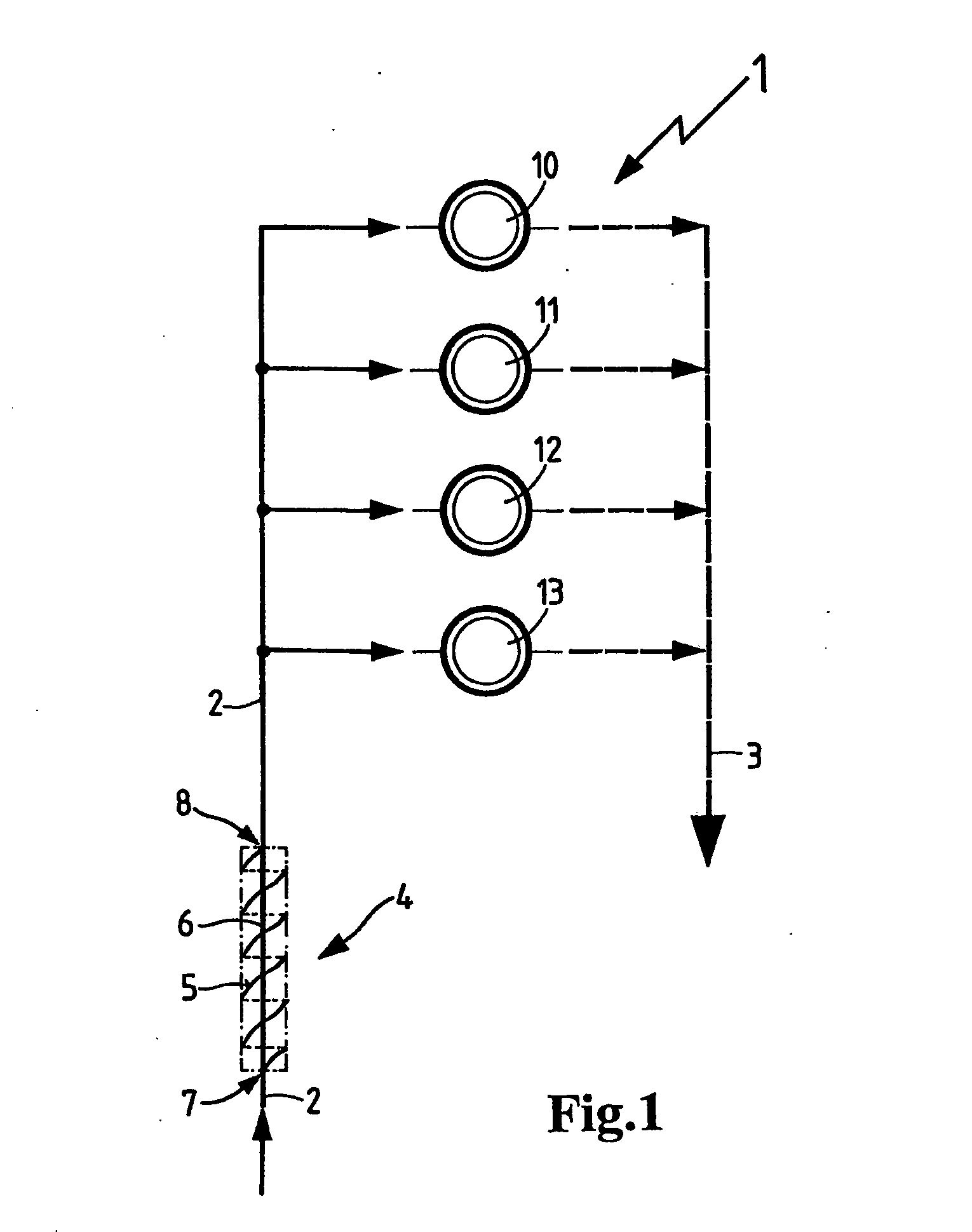

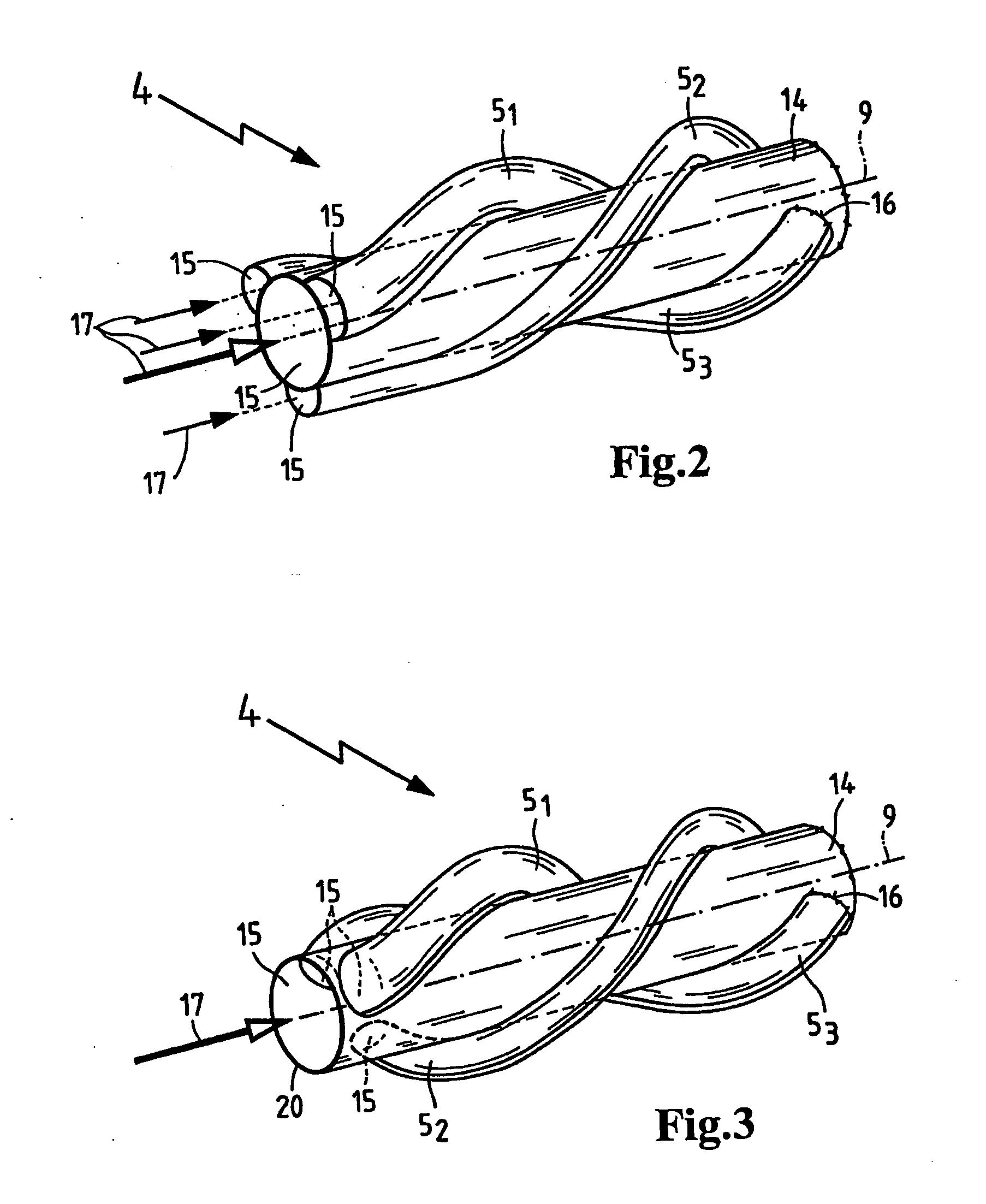

A sound damping device (4) for a tubular duct (2), particularly a gas transporting tract of an internal combustion engine (1) having a least one bypass channel (5) running parallel to a main duct (6) in a section of the duct (2). The bypass channel (5) is longer than the main duct (6) between a branching off point (7) and a re-entry inlet (8). The bypass duct according to the invention is configured as a spiral duct (5) which winds around the centrally disposed main duct (6) in order to decrease the installation space requirements for the noise suppressor (4).

Owner:MANN HUMMEL GMBH

Device for controlling the delivery of a combustible gas to a burner apparatus

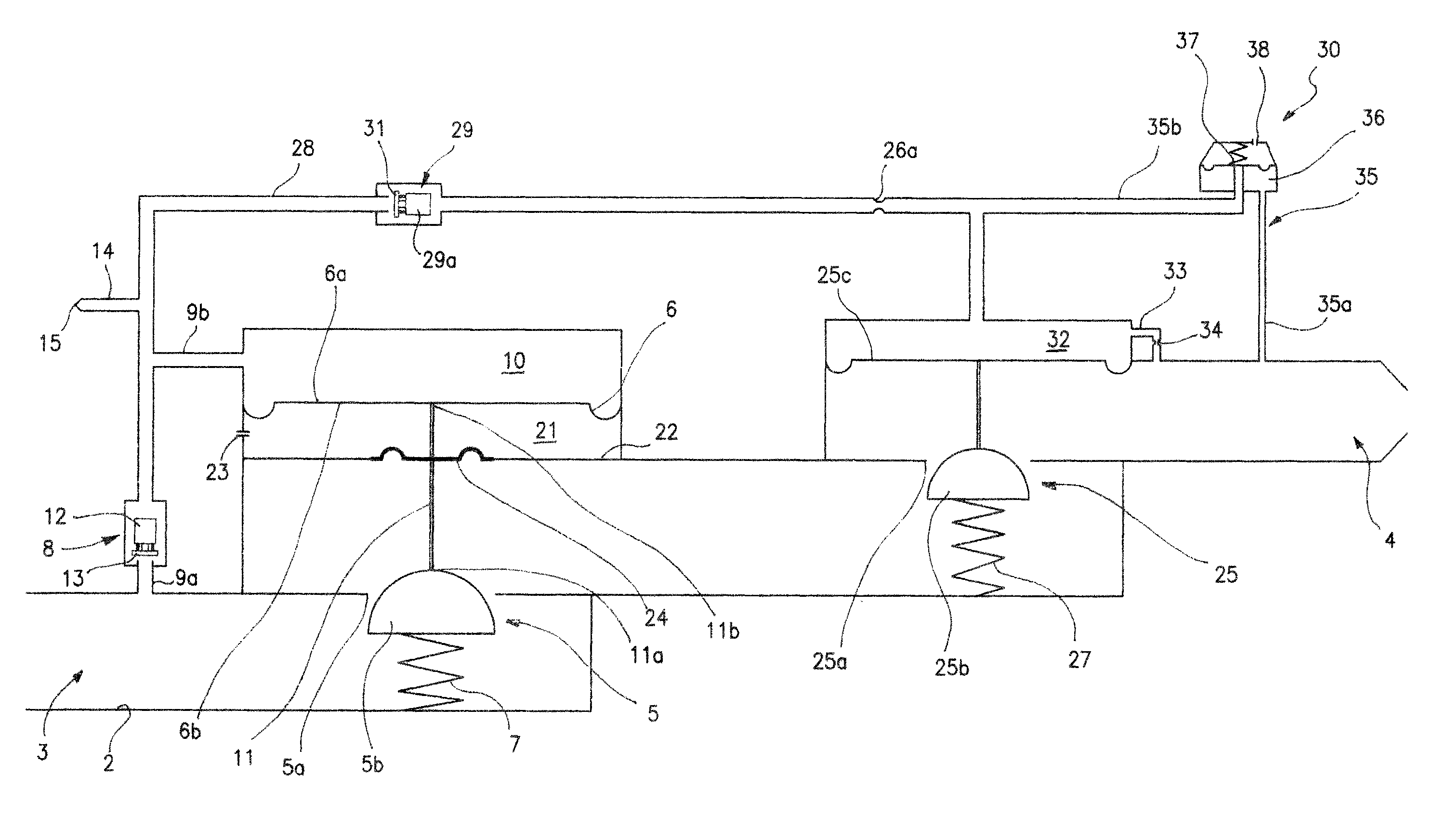

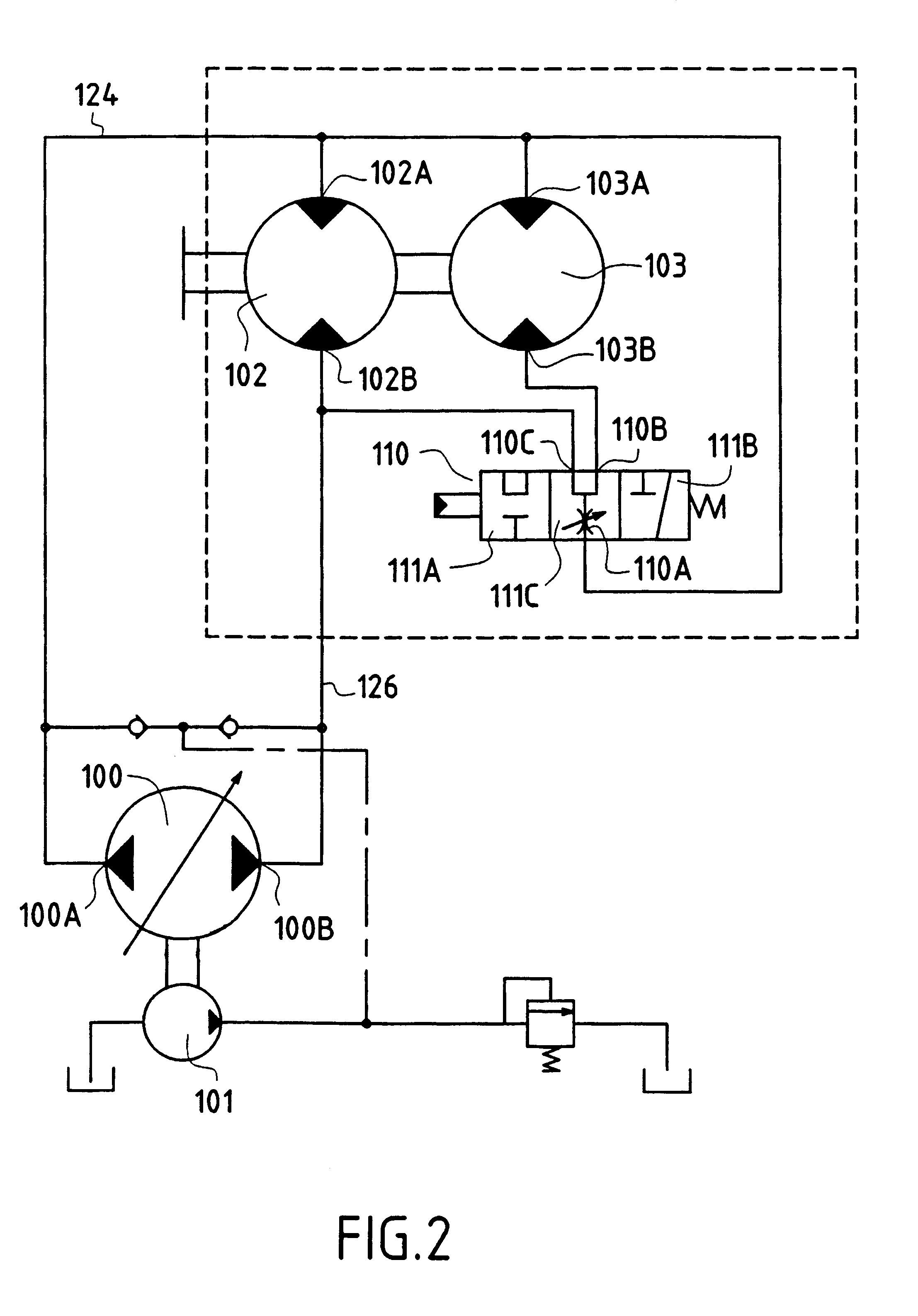

ActiveUS8162002B2Fuel supply regulationOperating means/releasing devices for valvesCombustorSolenoid valve

A device for controlling the delivery of a combustible gas to a burner apparatus is provided including a main gas-delivery duct in which there is at least one servo-assisted diaphragm valve including a valve seat associated with a corresponding closure member with diaphragm control for opening the seat against the action of a resilient biasing member. The diaphragm valve includes a respective control solenoid valve with an electromagnetic operator for controlling the corresponding valve, the solenoid valve being arranged to bring about the opening / closure of a duct of a respective servo-assisted control circuit so as to operate the closure member of the valve indirectly, by the diaphragm control. The duct of the control circuit putting a portion of the main duct that is disposed upstream of the valve seat with respect to the direction of the gas-flow into flow communication with a respective control chamber of the diaphragm valve.

Owner:SOC ITALANA TECNOMECCANICA

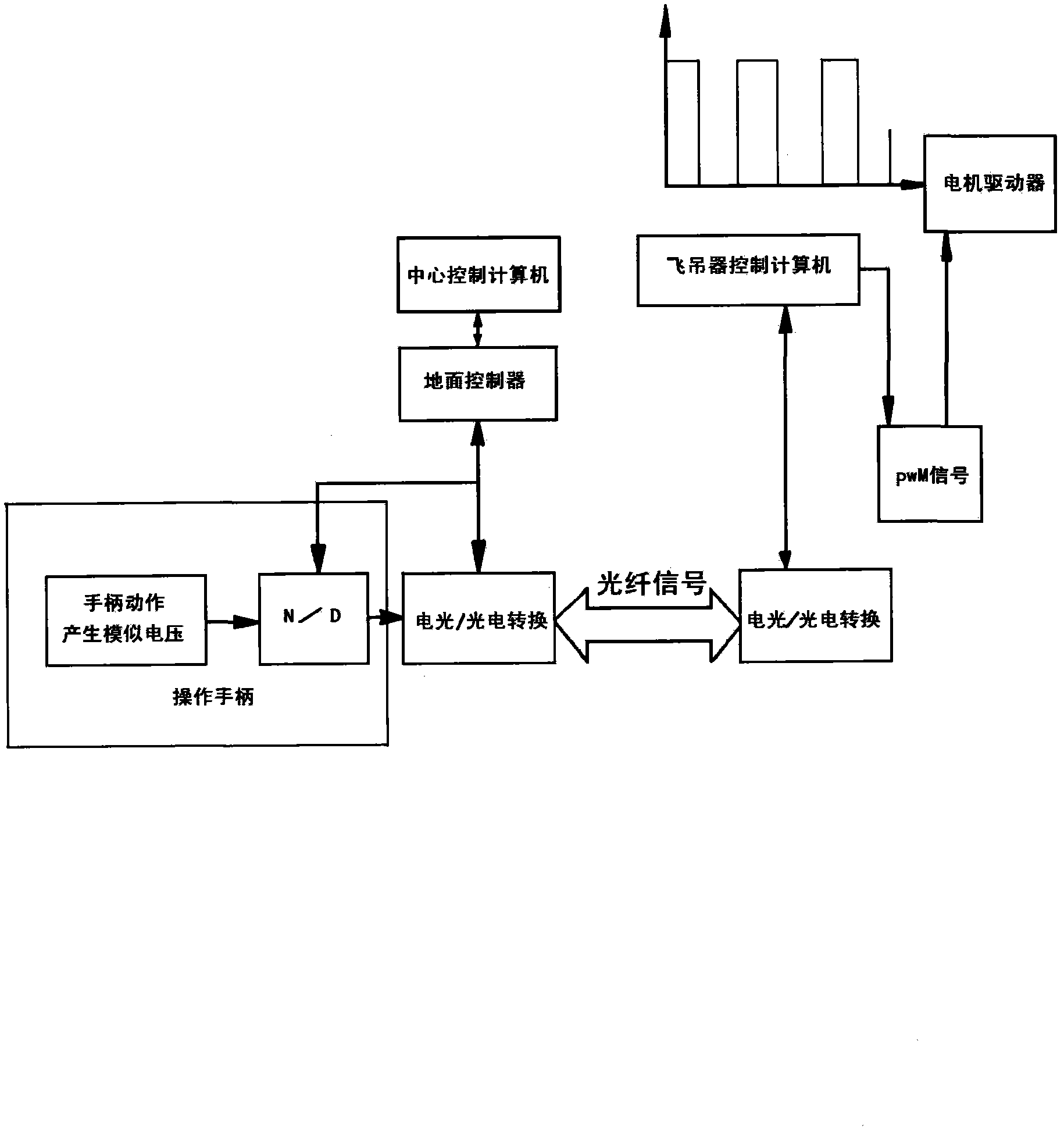

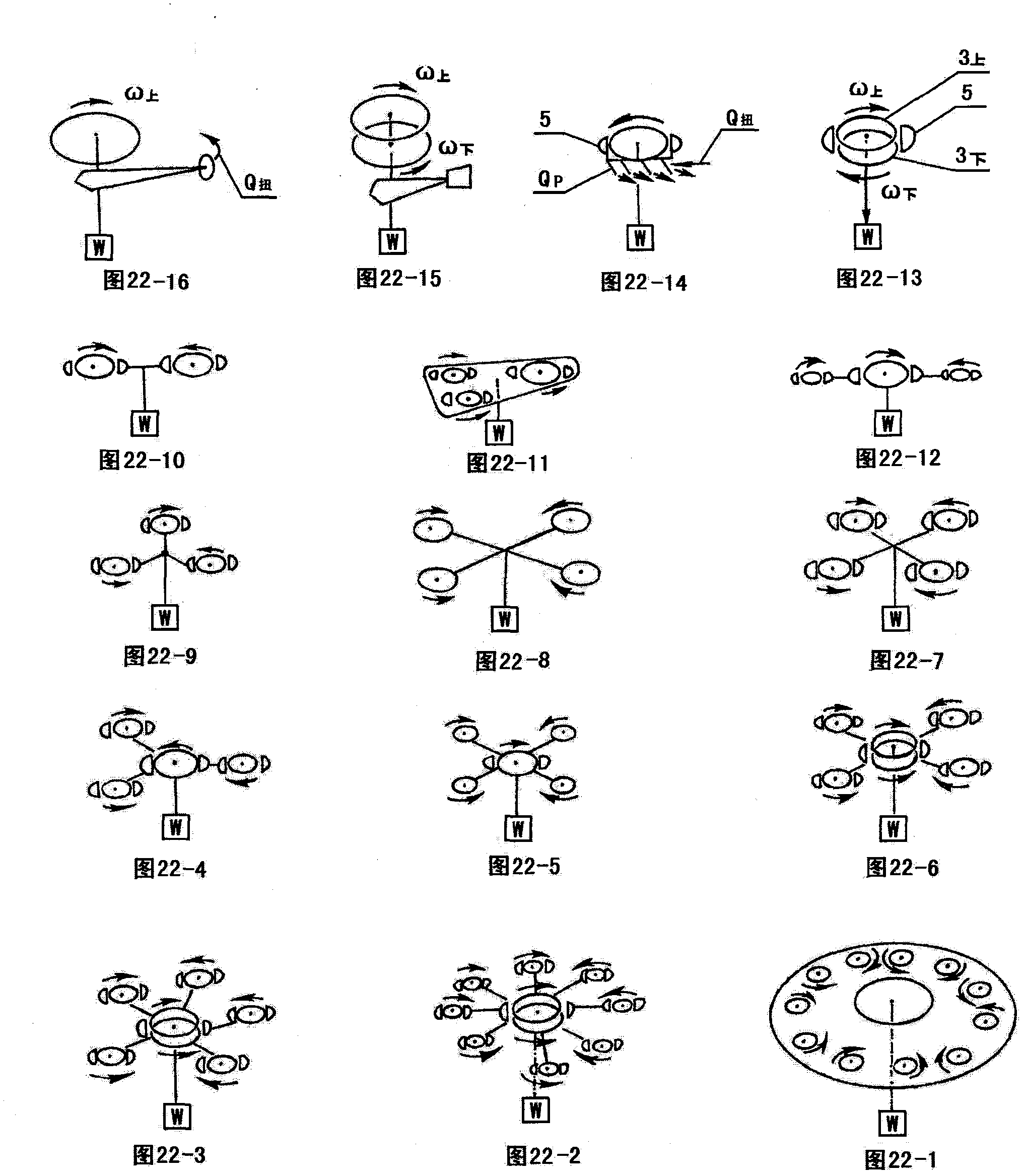

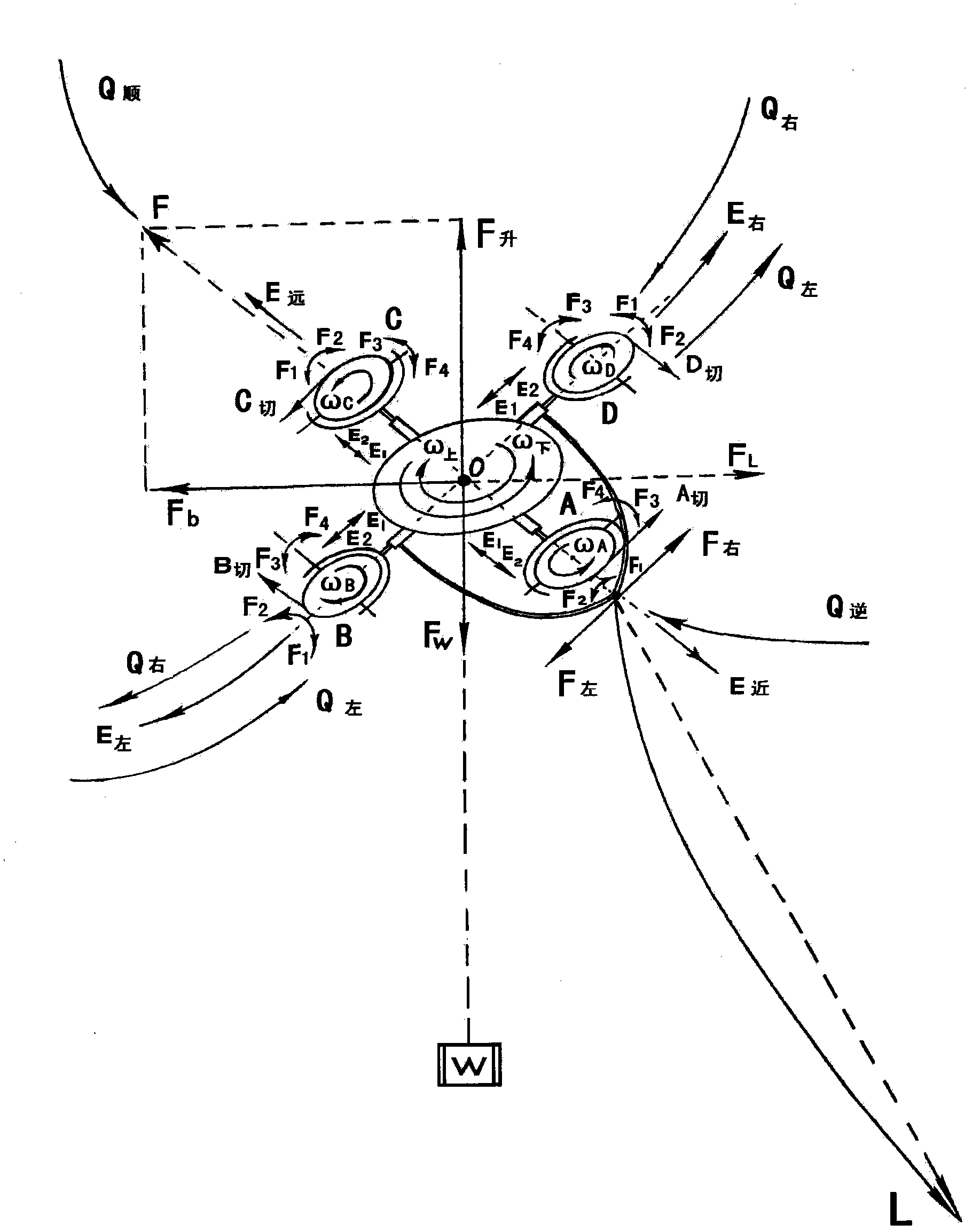

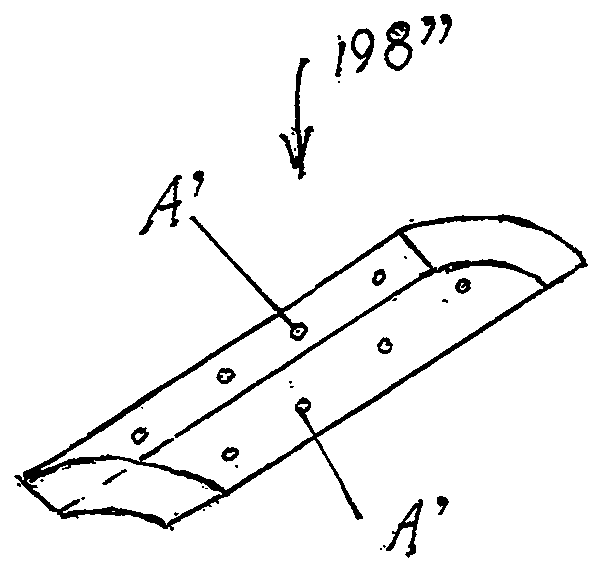

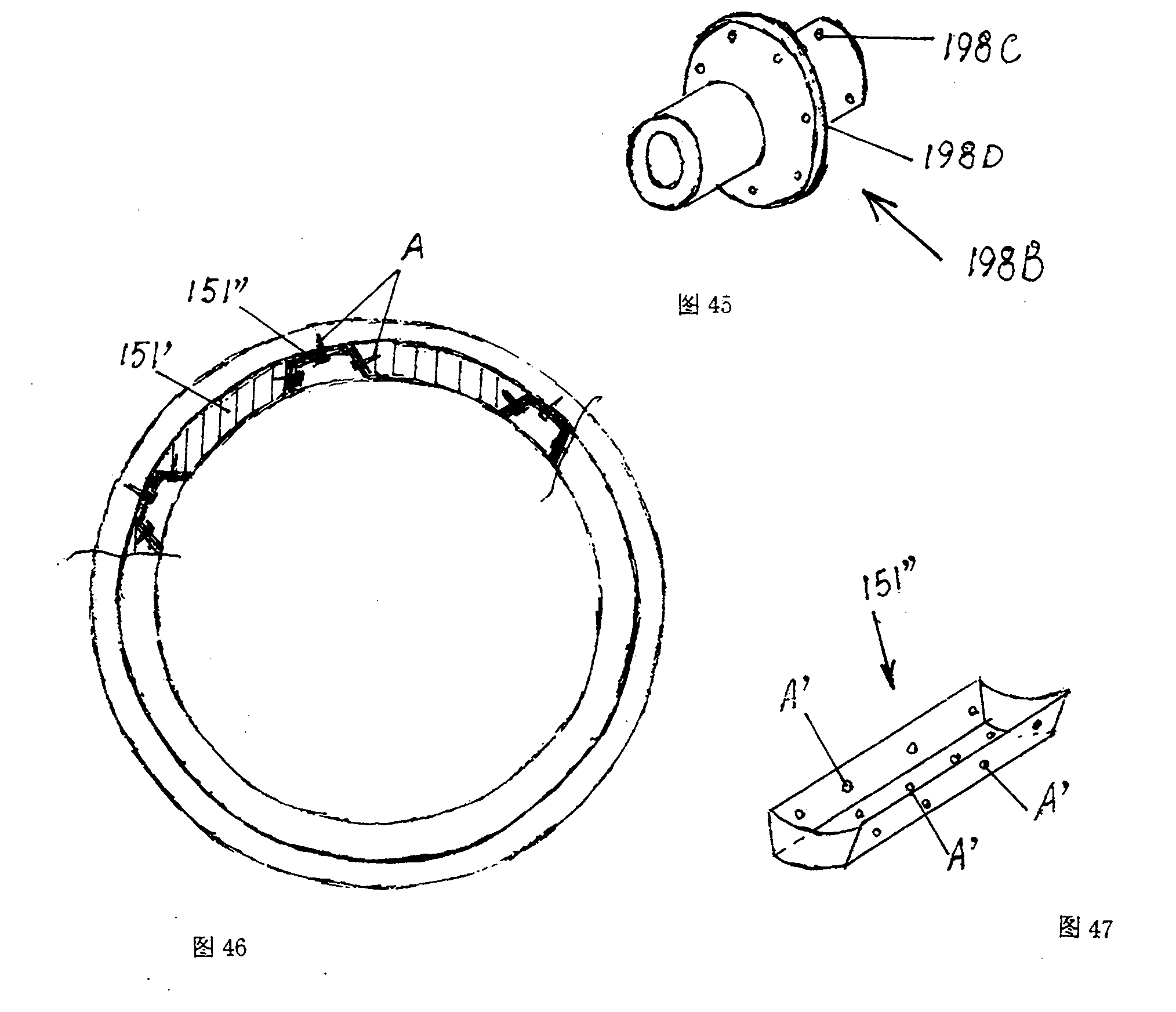

Traction energy transmission type duct rotor wing fly lifter

The invention relates to a fly lifter, in particular to a duct rotor wing fly lifter mainly used for lifting heavy articles. A pneumatic structure bears the main lifting force by taking a large-diameter main duct coaxial positive and negative rotation dual rotor wing as a center; a variable inertia device is arranged in a rotor wing system, so that the rotor wing system generates differential variable inertia, induces to generate the rigidity of gyroscopic effect and has the capability of resisting turbulence transition wind; a plurality of small-diameter duct rotor wings are arranged outside a multi-ring-layer duct; a connecting arm can do telescopic torsional swing to do four-degree-of-freedom action and bear the auxiliary lifting force, direction and posture control and vortex ring prevention; a main nozzle is arranged at the lower end of the main duct; side nozzles are arranged at the periphery of lower end of the main duct; a swing wind guide plate is inbuilt and used for regulating and controlling direction and performing active type vortex ring prevention; and a plasma energy wave generator is provided and used for performing active type vortex ring prevention and improving Reynolds number. The fly lifter transmits power or fuel in a wireless traction mode and is driven by a power machine with energy to perform wireless remote control, so that the fly lifter has dead wind resistance and high suspended load capacity and can perform durable operation under severe environment and weather conditions.

Owner:郑鹏

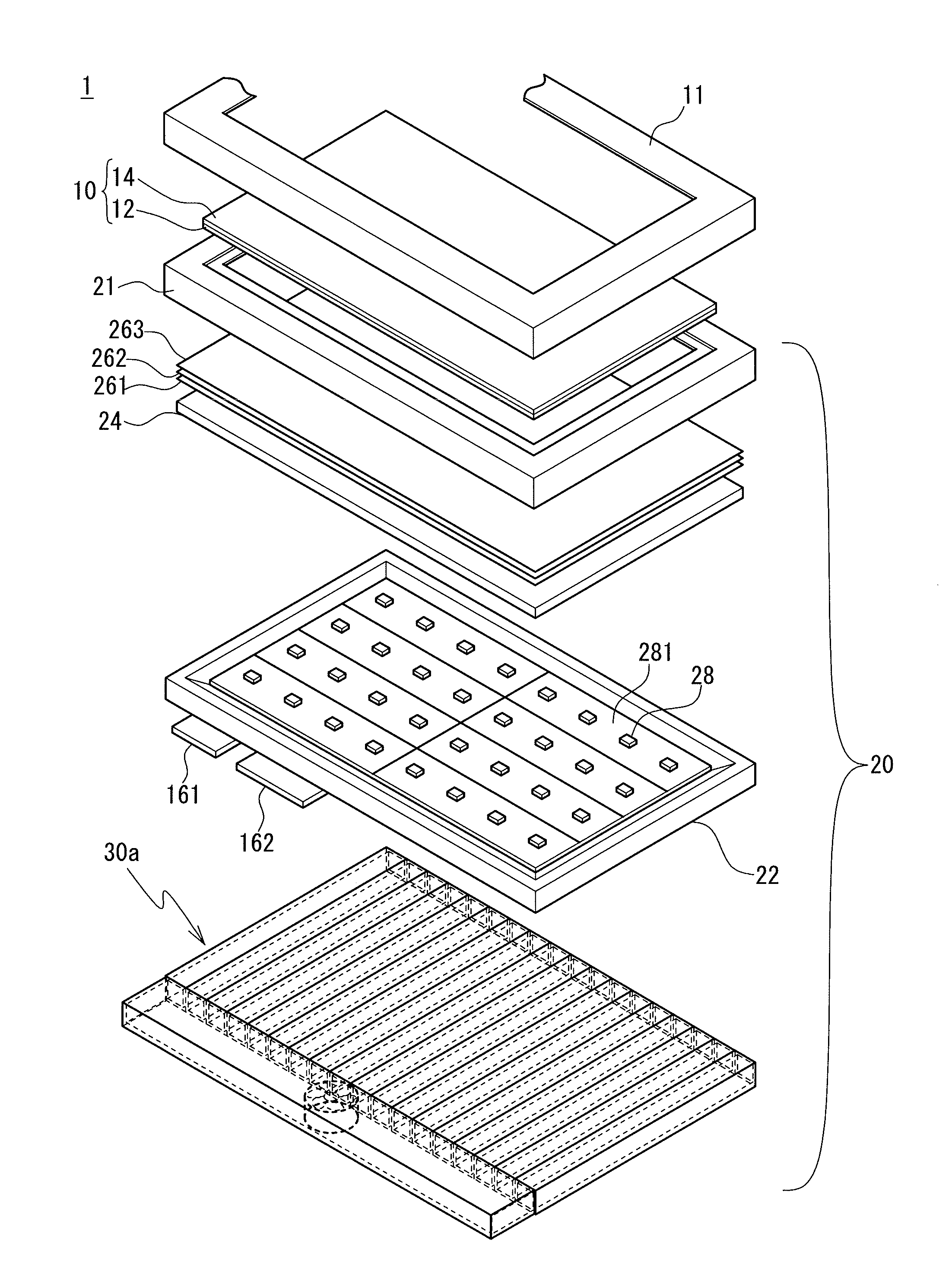

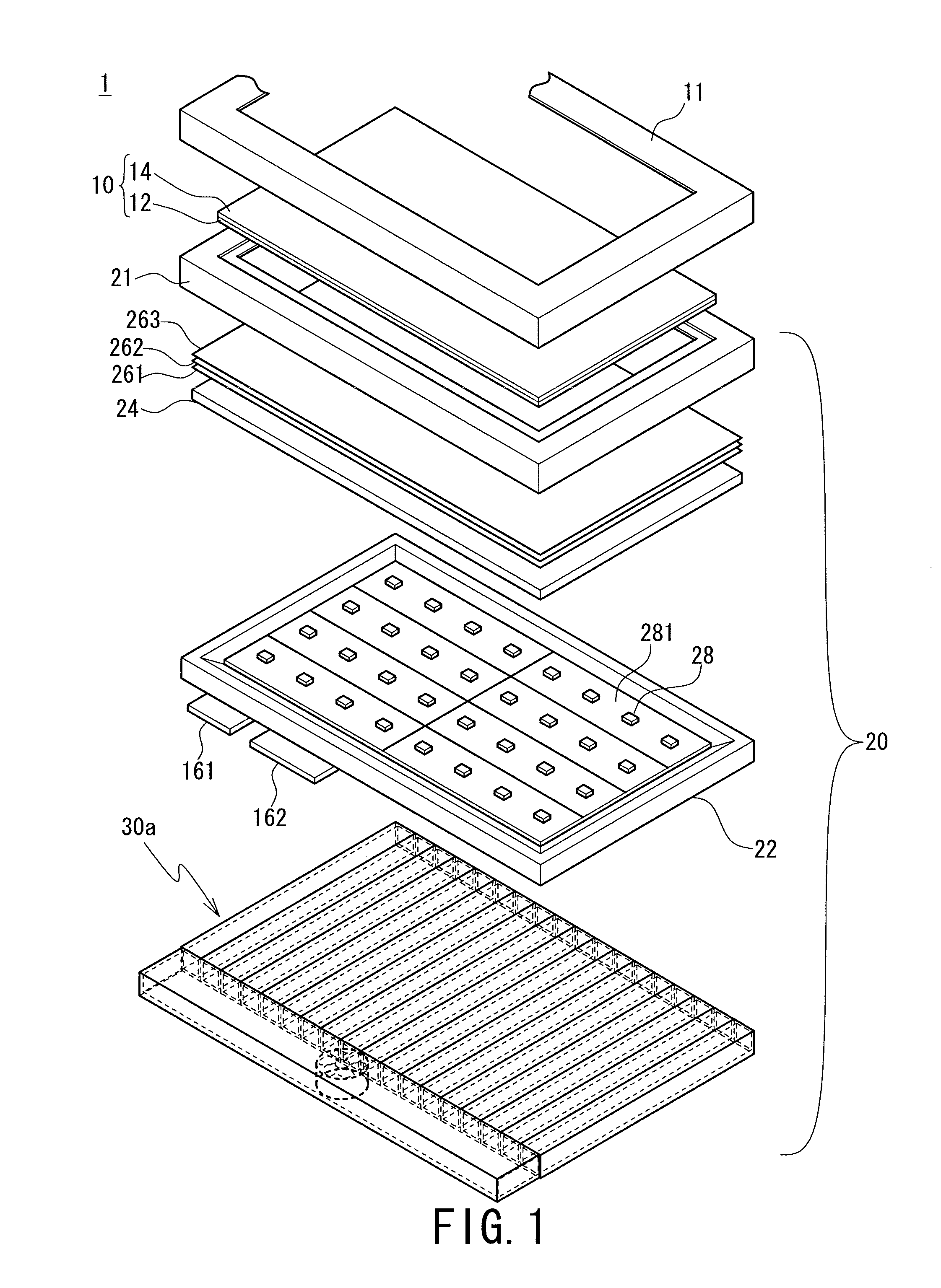

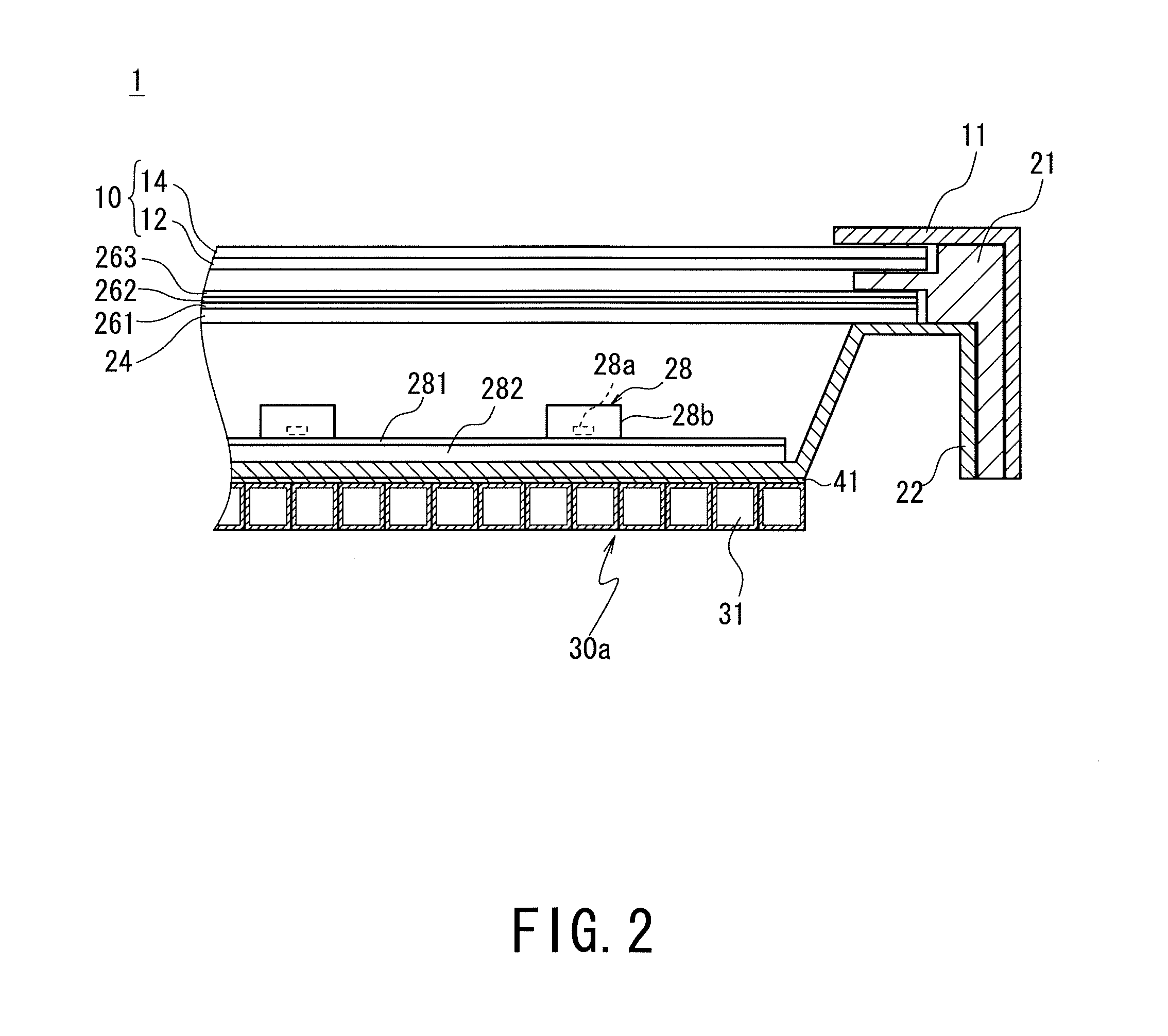

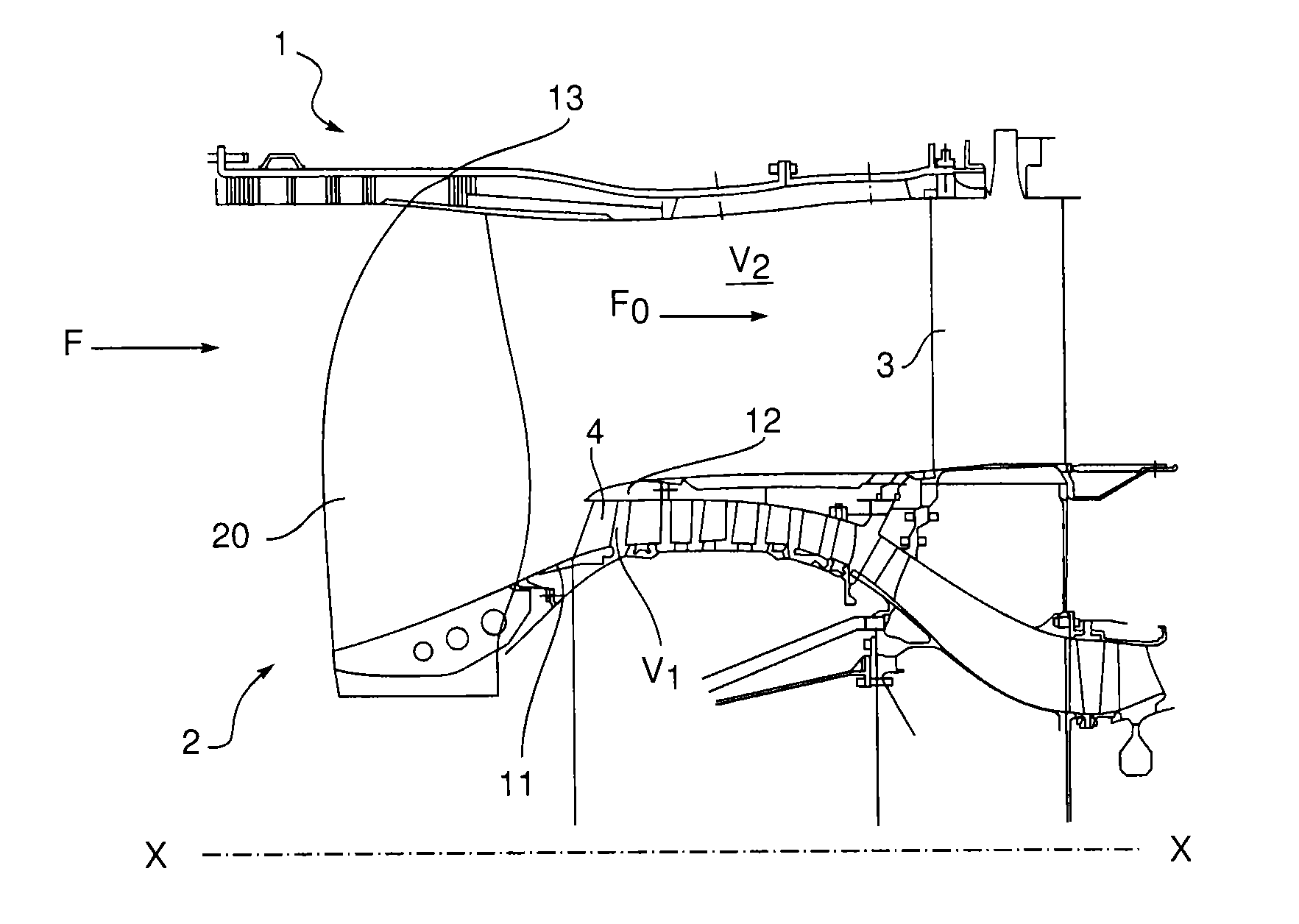

Liquid crystal display device, and LED backlight unit

InactiveUS20120320566A1Improve cooling effectUnnecessary to provideLighting heating/cooling arrangementsIlluminated signsLiquid-crystal displayEngineering

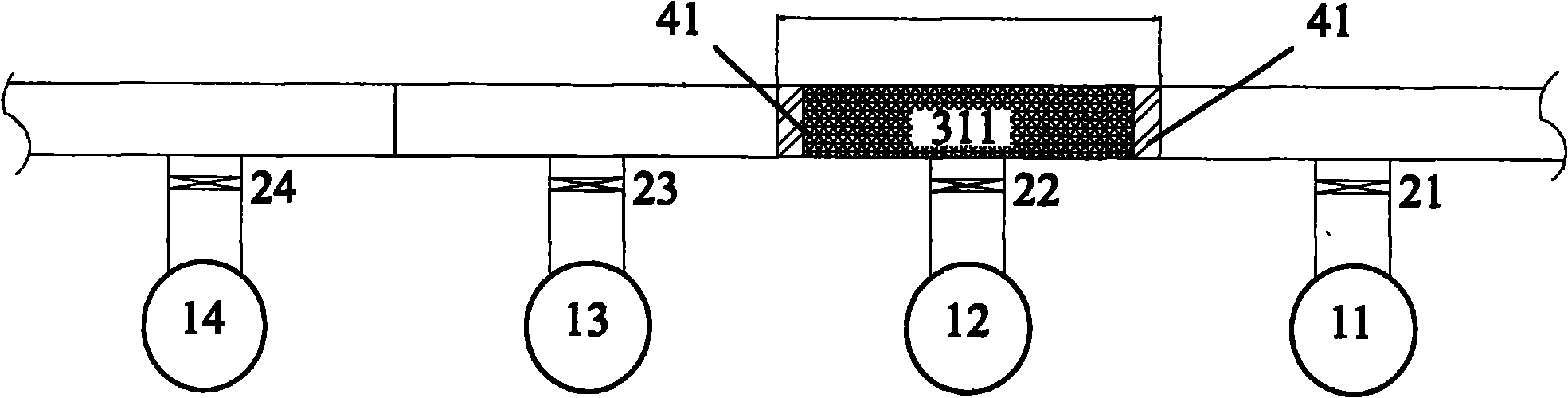

Provided is a liquid crystal display device and a backlight unit that are of high quality and have a simple configuration that a mechanism cooling a cooling medium is not included. Included are a liquid crystal display panel and an LED backlight unit including an LED light source emitting light toward the panel, and a chassis plate on which the light source is disposed, the plate including a through flow path for cooling air dissipating heat from the light source, wherein the path includes a main duct introducing the cooling air and disposed along one side of the panel, and a branch duct branching off from the main duct, aligned along a disposed direction of the light source, and including an exhaust port disposed at an end of the branch duct and discharging the cooling air to outside of the device.

Owner:SHARP KK

Noise suppressor apparatus for a gas duct

A sound damping device (4) for a tubular duct (2), particularly a gas transporting tract of an internal combustion engine (1) having a least one bypass channel (5) running parallel to a main duct (6) in a section of the duct (2). The bypass channel (5) is longer than the main duct (6) between a branching off point (7) and a re-entry inlet (8). The bypass duct according to the invention is configured as a spiral duct (5) which winds around the centrally disposed main duct (6) in order to decrease the installation space requirements for the noise suppressor (4).

Owner:MANN HUMMEL GMBH

Air leakage rate measuring method of sintering machine system

InactiveCN101435711ASolve the large measurement errorReduce contentFurnace typesIndirect mass flowmetersObservational errorGas analysis

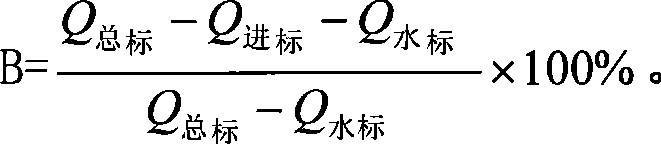

The invention relates to a method for measuring system air leakage rate of a sintering machine in metallurgy. The invention discloses a method for measuring the system air leakage rate of the sintering machine. The method comprises the following steps: firstly, by measuring charge level air speeds at different parts of a machine pallet of the sintering machine, the effective air quantity(Q[inlet]) entering a sinter layer is worked out, by measuring the air speed in a main duct in front of an electrostatic dust collector, the total air quality(Q[total]) pumped in the main duct by an air exhauster is worked out, and by the water content in mixing material, the content of the air converted into vapor is worked out; secondly, the air qualities(Q[total standard], Q[inlet standard] and Q[water standard]) at the standard state are converted all together; and finally, the air leakage rate(B) is worked out according to the formula. The measuring method has strong operability and can overcome the defects of inconvenient measurement, big measurement error and complex air analysis existing in daily production and the defect existing in prior art that the local air leakage rate can only be measured by the air leakage point air speed measuring method. In a word, the method has the advantages of easy operation, accurate measurement and good use effect.

Owner:武钢集团有限公司

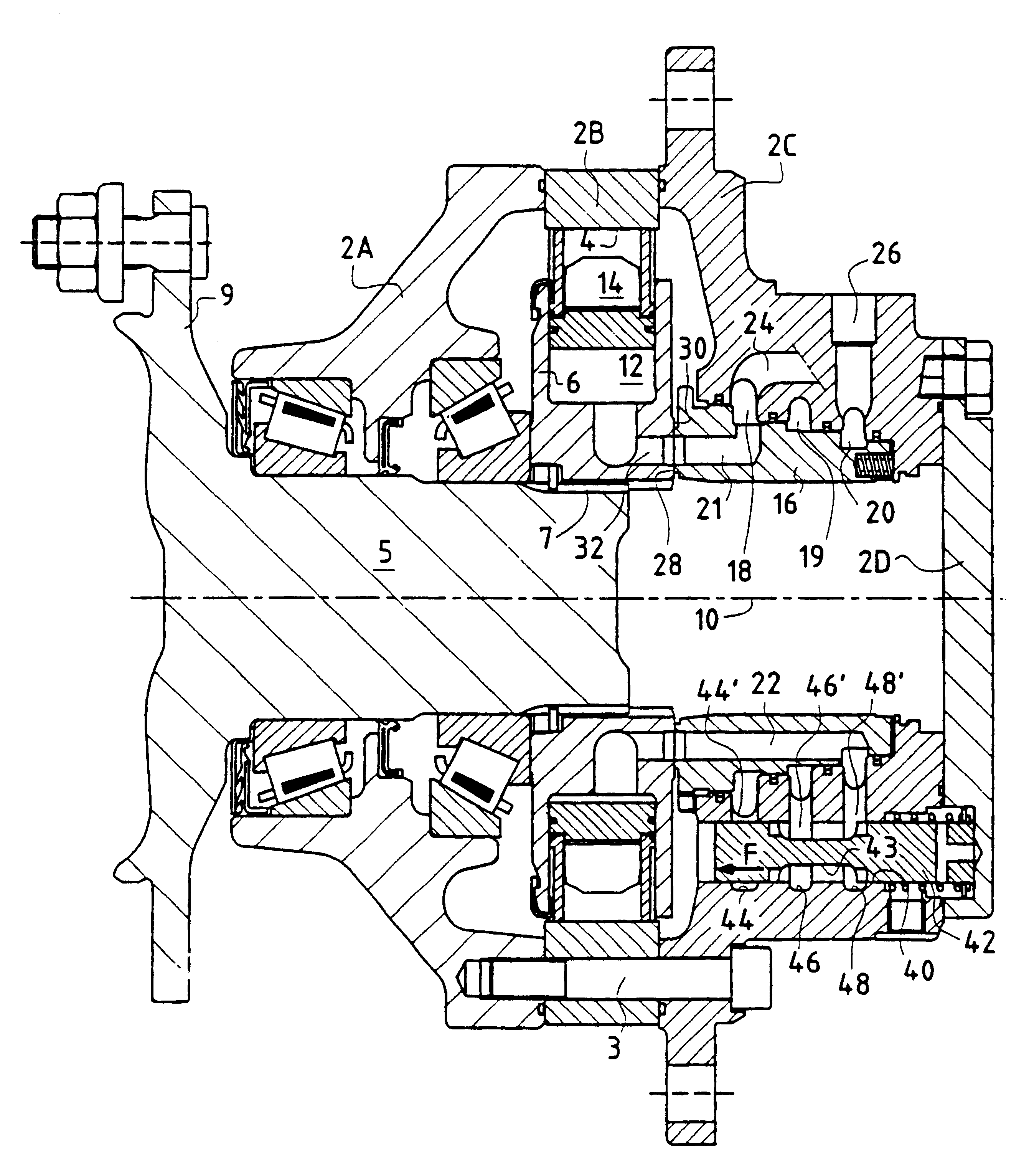

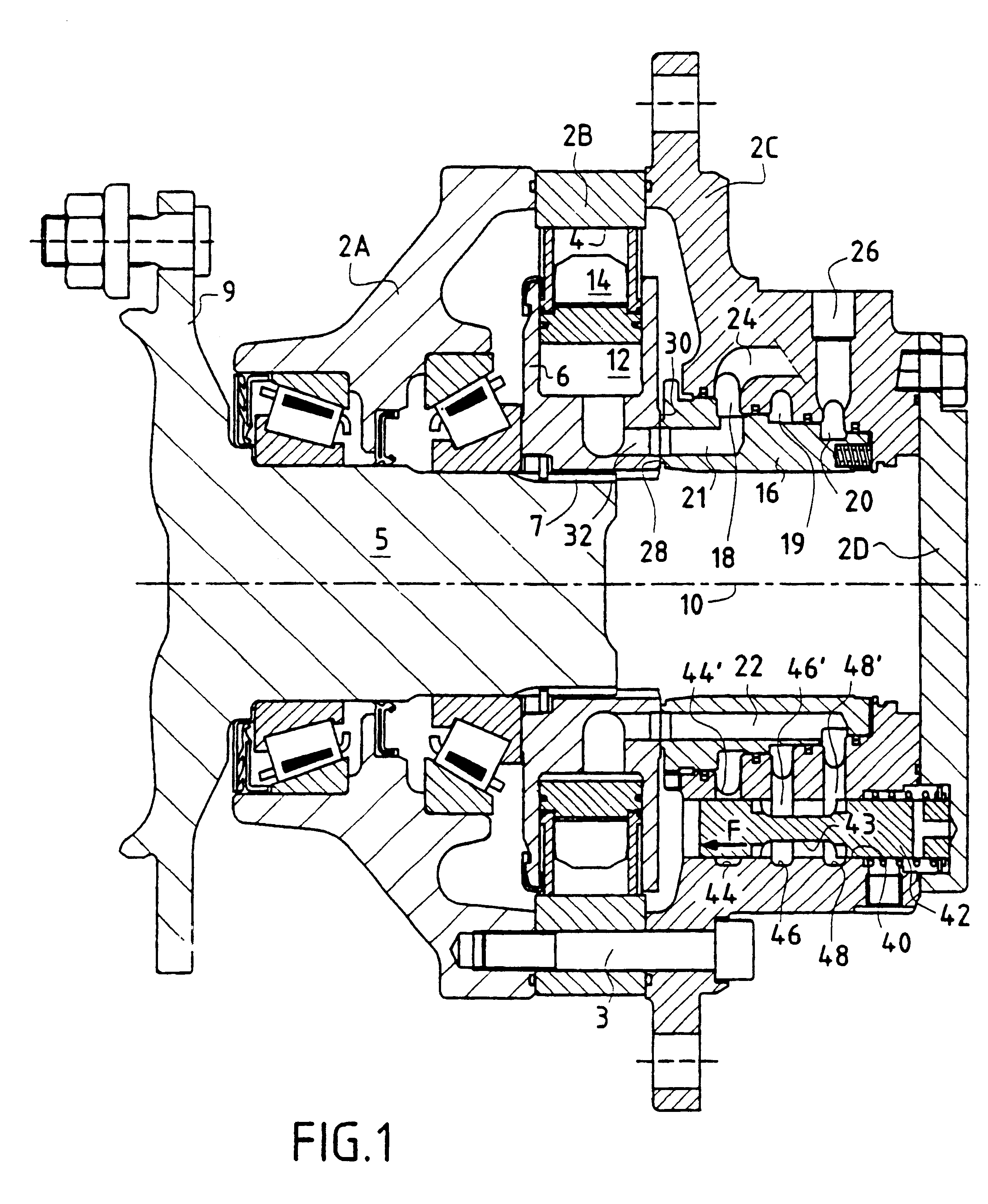

Hydraulic motor cylinder-capacity selector for avoiding jarring when switching from one cylinder capacity to another

InactiveUS6318235B1Reduce vibration effectsReduce impactFluid couplingsServomotor componentsHydraulic motorHydraulic cylinder

A cylinder-capacity selector for a hydraulic motor having at least two active operating cylinder capacities and comprising having at least two main ducts. The selector includes three ports and distribution ducts of the motor to establish selective communication between the main ducts and the cylinders of the motor. When the selector passes between its first and second stable positions, in at least one displacement direction, an intermediate stage exists that is maintained for a lapse of time, during which all three ports are in communication and the section of at least one of the passages between the first and second ports and between the second and third ports of the selector is constricted.

Owner:POCLAIN HYDRAULICS IND

Gas turbine stator

InactiveUS7048497B2Extended service lifeReduce manufacturing costPump componentsEngine fuctionsEngineeringGas turbines

A gas turbine stator including at least a first injector providing a passage for a main cooling air stream into a pressurized chamber. An evacuation mechanism discharges air coming from an internal labyrinth gland of a first cavity towards a lower-pressure second cavity. A second injector evacuates the air contained in the second cavity towards a main duct. The stator further includes a third injector designed to generate an overpressure close to the internal labyrinth gland in the pressurized chamber.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

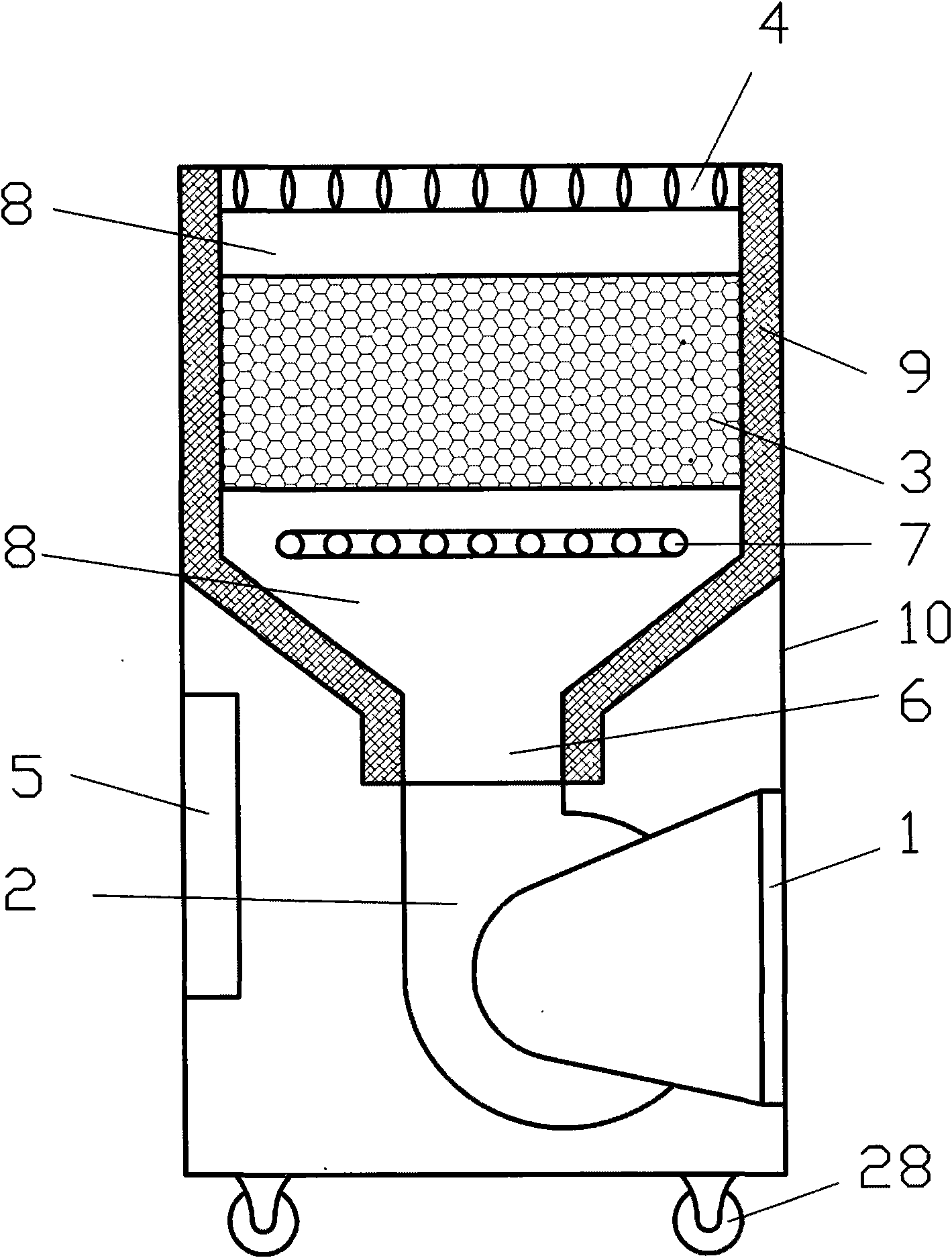

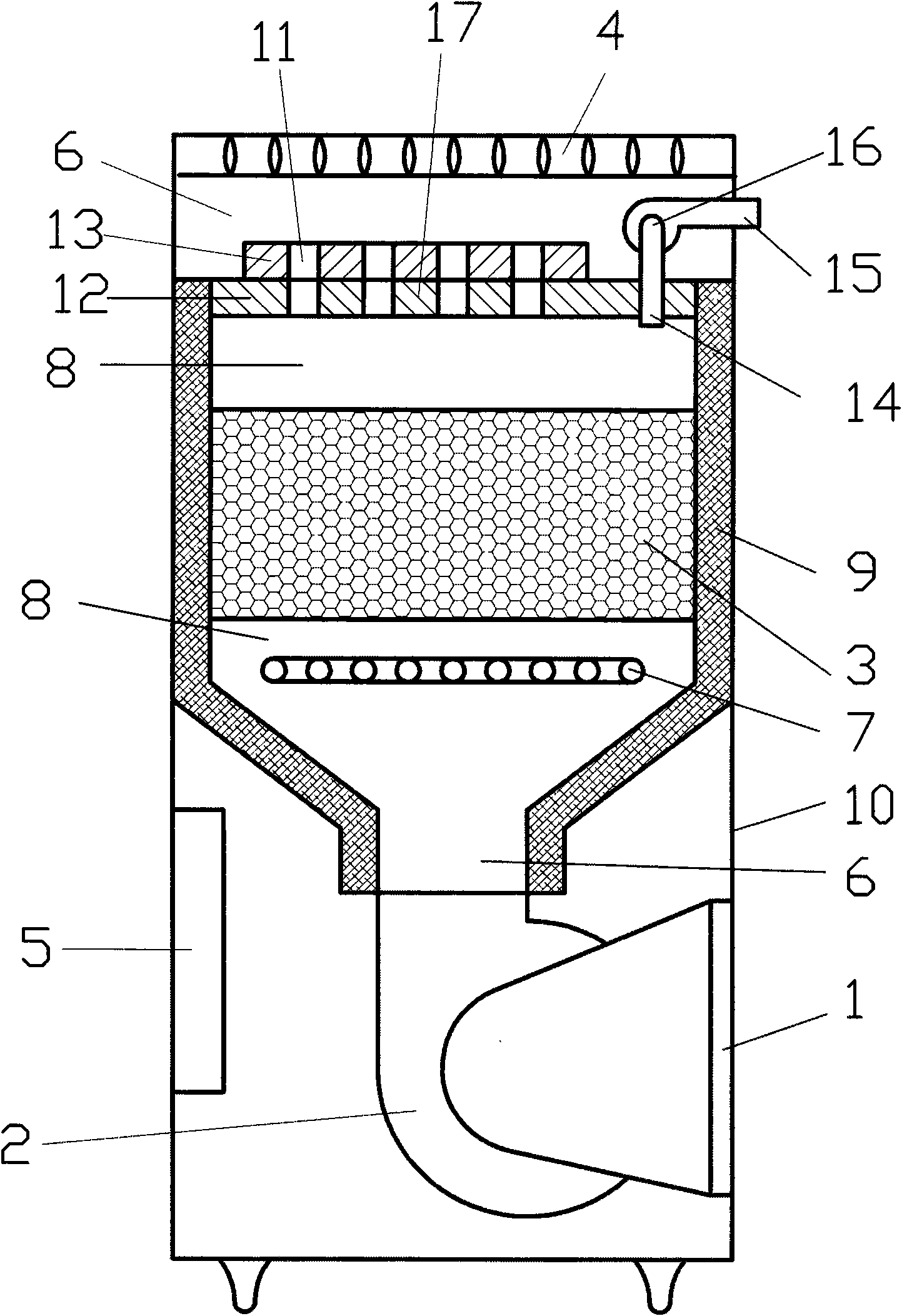

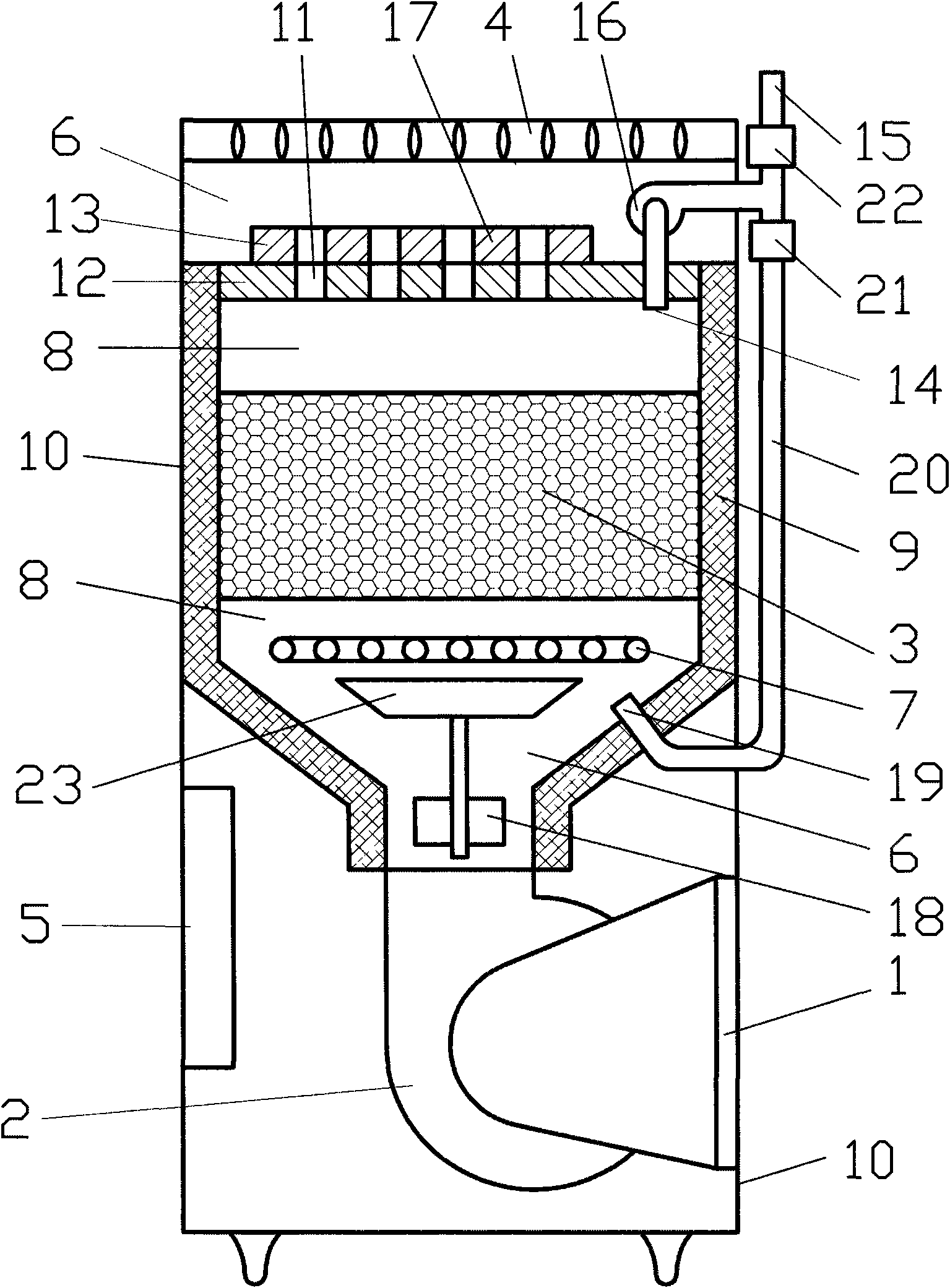

Air purification device

InactiveCN101596390ASolve the problem of desorptionAdsorption continuesDispersed particle separationCombustible gas purificationThermal insulationDesorption

The invention relates to an air purification device, particularly used for removing harmful gas in the air and aiming to solve the desorption problem of adsorbent in the air purification device, thereby renewable adsorbent can be utilized to continuously adsorb the harmful gas in the air. The invention adopts the technical means as follows: a heating element is arranged in a main duct near the adsorption unit part and forms a high-temperature region in the main duct; a thermal insulation layer is arranged on the side wall of the high-temperature region; an air door is respectively arranged at both ends of the high-temperature region; an adsorption unit and the heating element are at least arranged in the high-temperature region; a polluted air exhaust port and a circulating air port are respectively arranged at both sides of the adsorption unit; the circulating air port is arranged at the side provided with the heating element; the air inlet end of a pollution discharge fan is communicated with the polluted air exhaust port; the exhaust end is divided into two ways, one way is led to the circulating air port through a circulating air door and a circulating air tube, and the other way is communicated with the outdoors through a pollution discharge air door and a pollution discharge air tube.

Owner:唐忠联

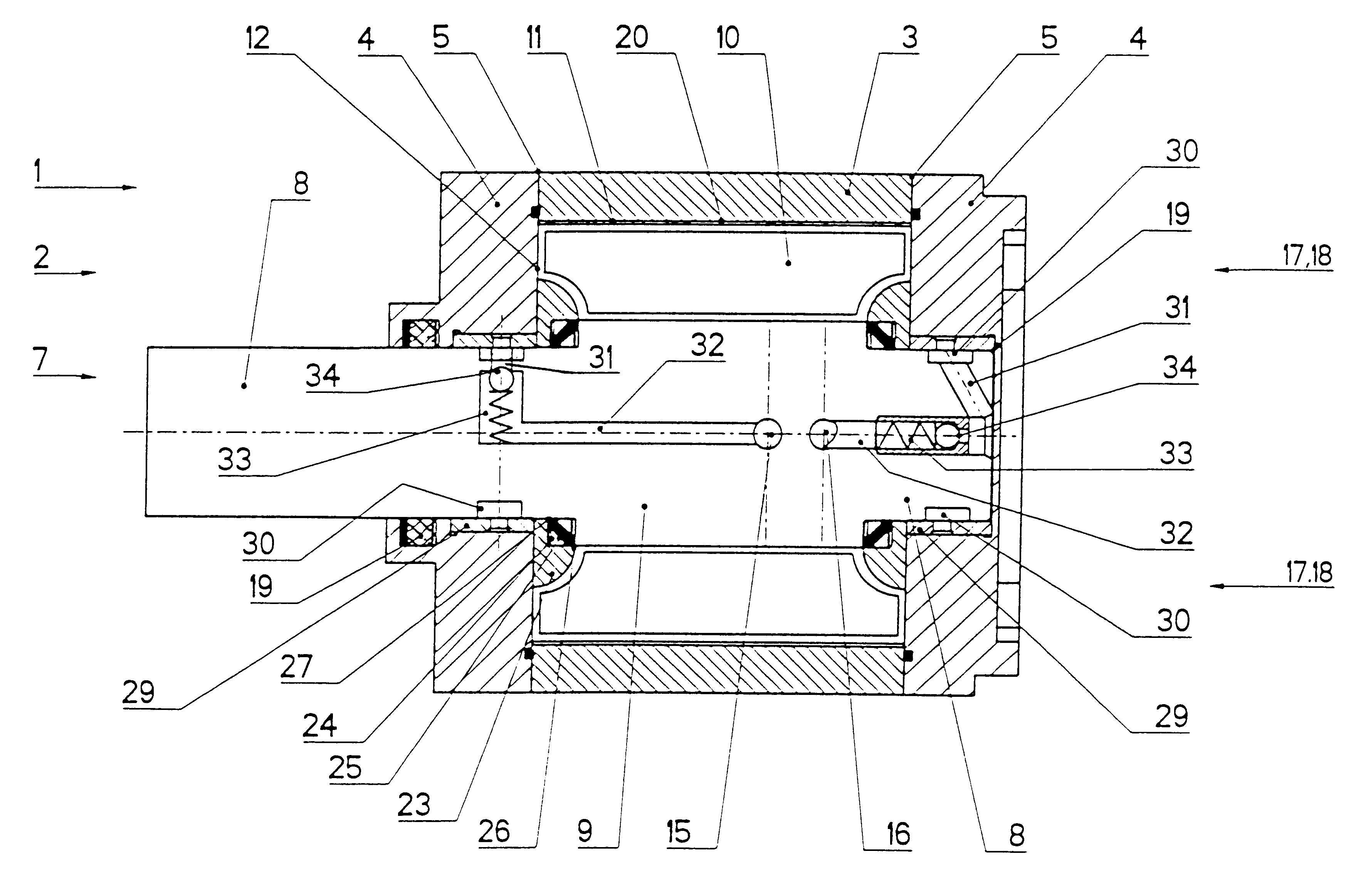

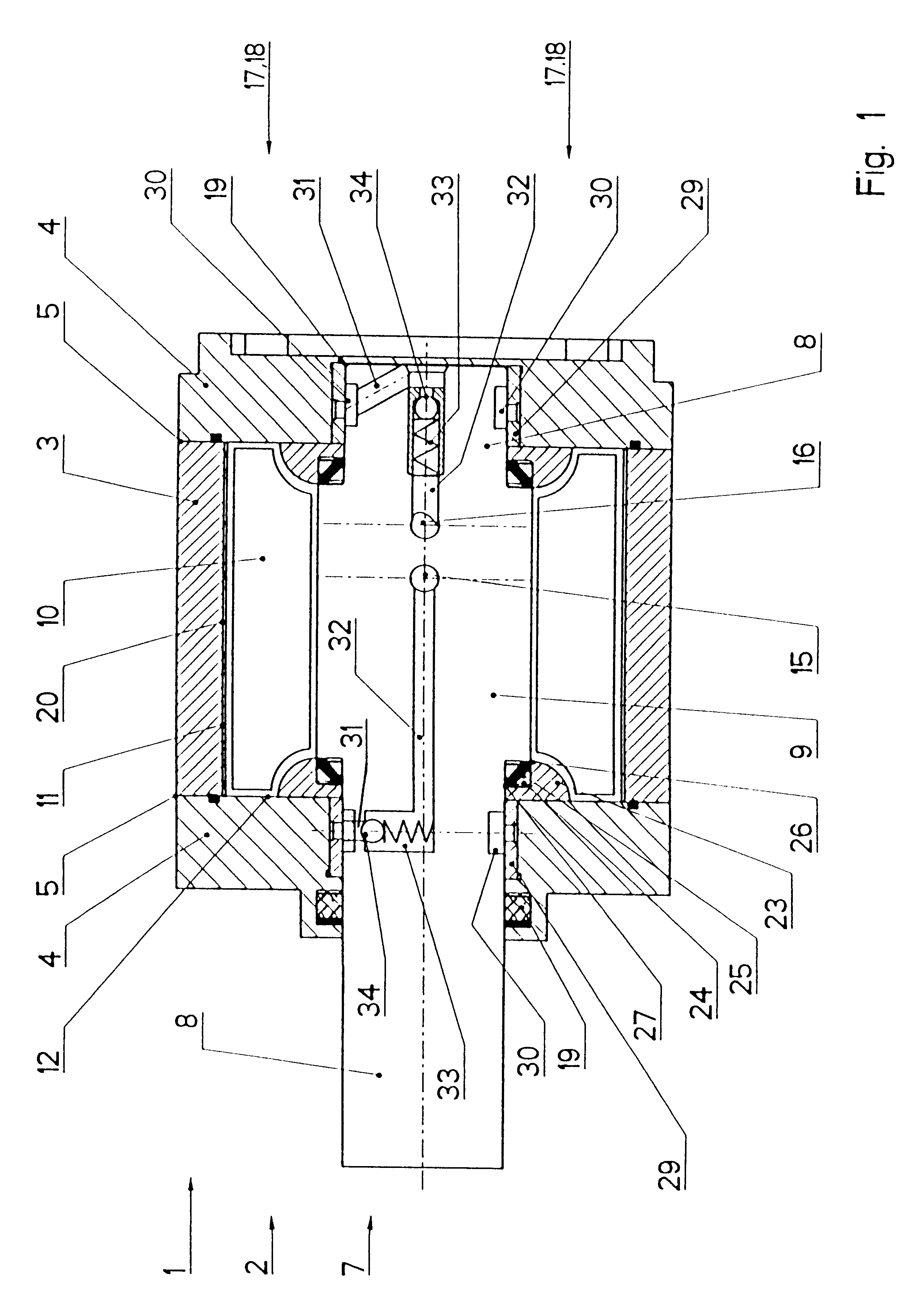

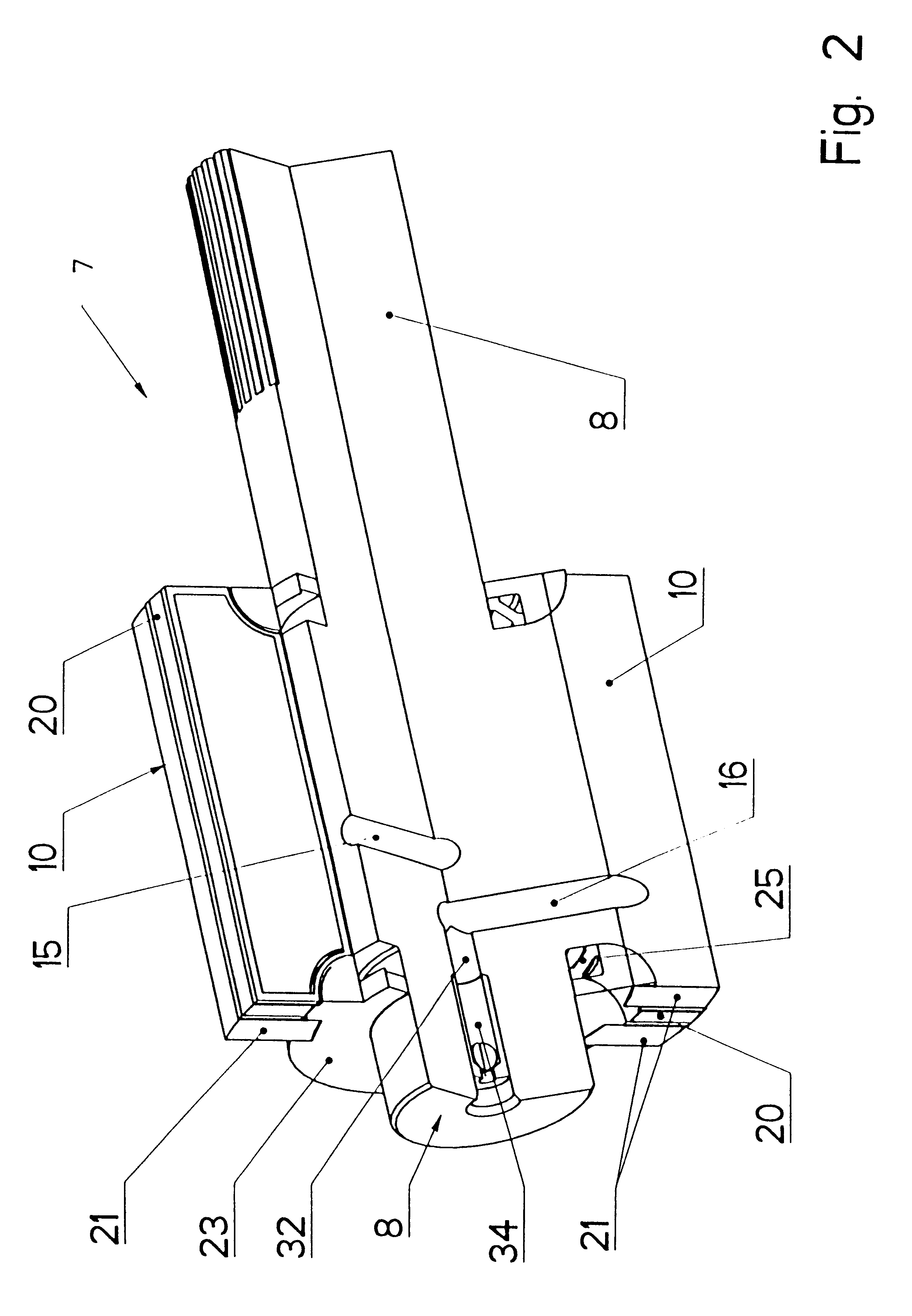

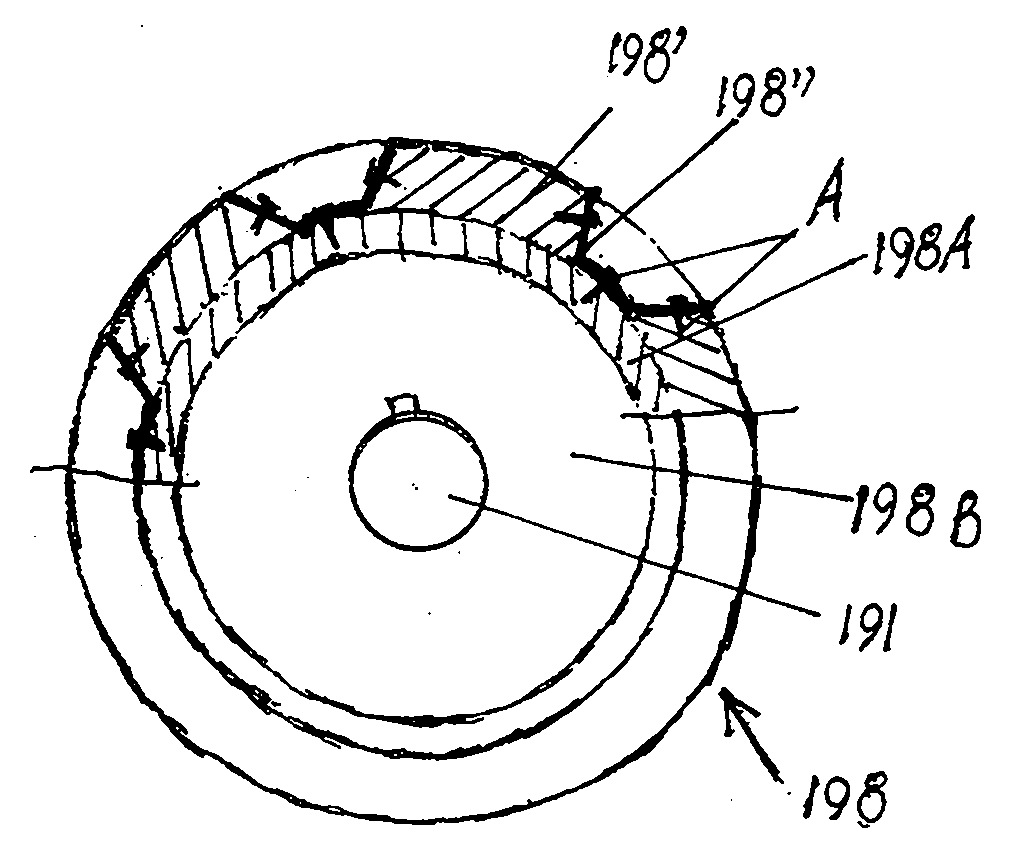

Radial oscillating motor

Radial oscillating motors are generally fitted with an outer overflow oil line in order to protect sealing elements. This requires an over large amount of devices and system expenditure. Large amounts of installation space are also required for oscillating motors of this kind. The invention provides a radial oscillating motor wherein each bearing (29) is hydraulically connected to a discharge chamber (14) via a main duct (30) in addition to radial ducts (31, 15, 16, 35, 37, 38) and axial ducts (32, 36) in a driven shaft (7). A non-return valve opening out in the direction of the discharge chamber (14) is inserted into the ducts (31, 32, 37, 38).

Owner:ZF LEMFOEDER METALLWARE

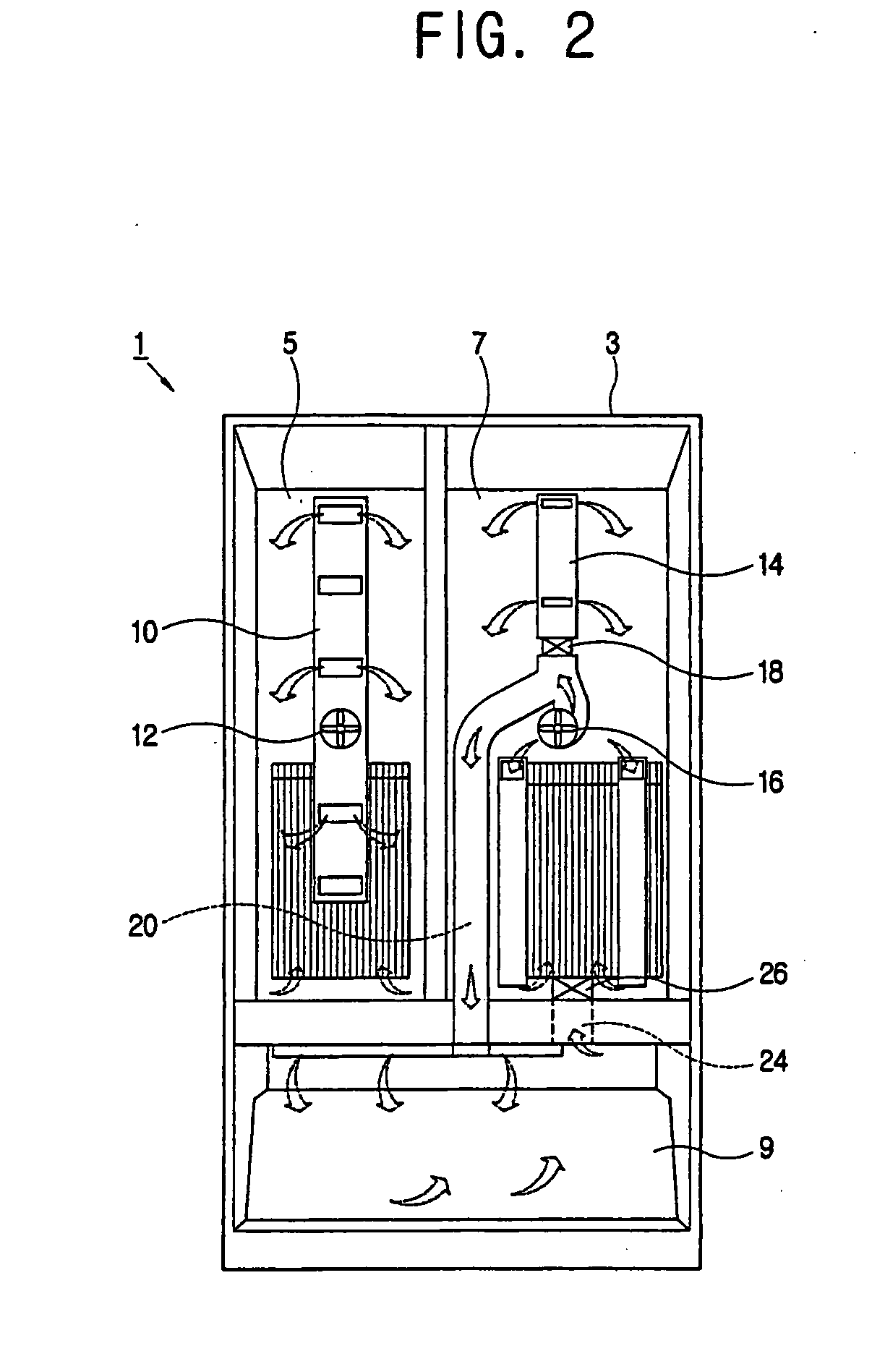

Refrigerator and method of controlling the same

InactiveUS20050126207A1Improve cooling effectDomestic refrigeratorsRefrigeration componentsEngineeringCold store

A refrigerator including [comprising a main body forming a refrigerator compartment and a freezer compartment, each of a freezer compartment main duct and a refrigerator compartment main duct comprising at least one exiting hole and one returning hole communicating respectively with the freezer compartment and the refrigerator compartment, a freezer compartment evaporator and a refrigerator compartment evaporator provided in the freezer compartment main duct and the refrigerator compartment main duct, respectively, and generating cooling air, and a freezer compartment fan and a refrigerator compartment fan provided in the freezer compartment main duct and the refrigerator compartment main duct, respectively, to let out the cooling air generated in the freezer compartment evaporator and the refrigerator compartment evaporator, respectively, through the exiting hole and to return the cooling air in the freezer compartment and the refrigerator compartment through the returning hole, comprising:] an auxiliary storage provided in a main body; an auxiliary supply duct, branched off from one of a freezer compartment main duct and a refrigerator compartment main duct, to supply the cooling air transferred by a corresponding fan to a auxiliary storage; an auxiliary returning duct returning the cooling air in the auxiliary storage to a corresponding main duct; and an auxiliary damper in at least one of the auxiliary supply duct and the auxiliary returning duct, to open and close to respectively supply and block the cooling air to the auxiliary storage.

Owner:SAMSUNG ELECTRONICS CO LTD

Pneumatic distributor of granular and/or powdery materials, in particular for sowing machines

A pneumatic distributor of granular and / or powdery materials includes a main distribution duct having a first end in the region of which an air-flow is injected into the duct under pressure, and a second end. The main duct includes respective adjacent converging-diverging portions, with reference to the direction of the air-flow, defining a Venturi duct. A dosing device is provided for delivering a metered quantity of material into the main duct in the region of the narrow cross-section of the Venturi duct, for the mixing of the material into the air-flow and the entrainment of the mixture obtained towards the second end. The distributor includes at least one auxiliary duct, bypassing the Venturi duct, in order to connect a section of the main duct disposed upstream of the Venturi duct to a section of the main duct disposed downstream of the Venturi duct.

Owner:GASPARDO SEMINATRICI

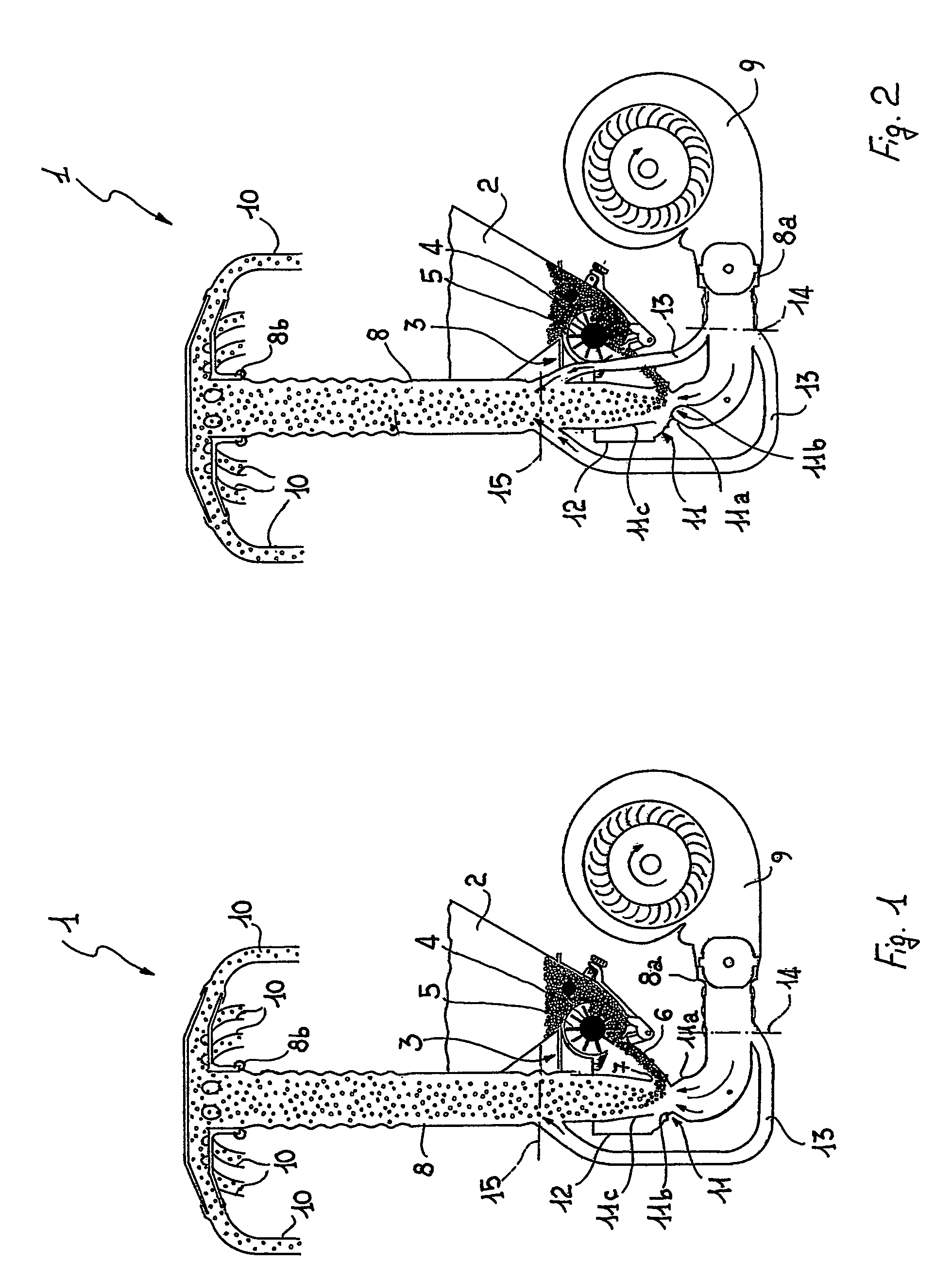

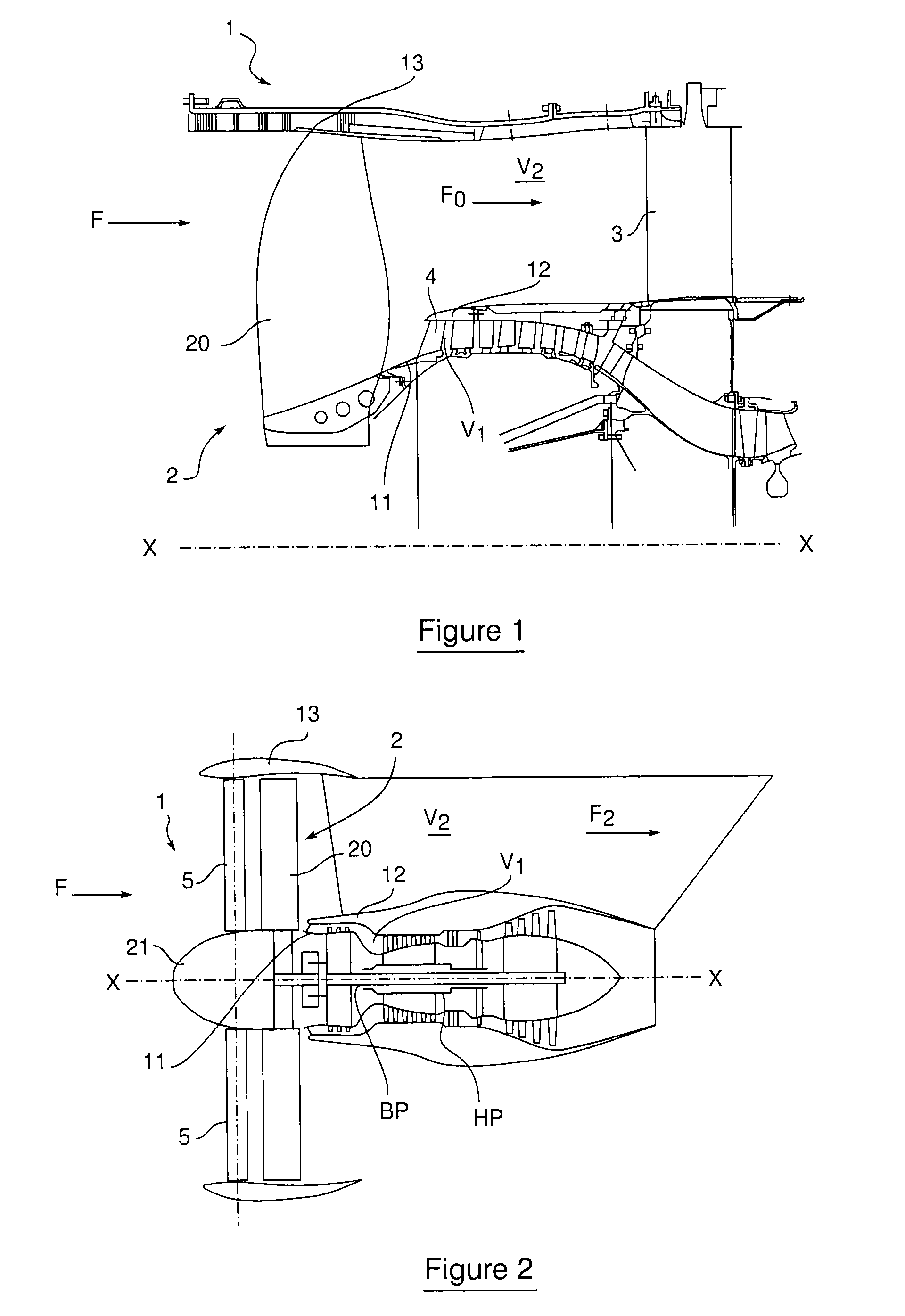

Turbomachine comprising a plurality of fixed radial blades mounted upstream of the fan

Bypass turbine engine, in particular for an aircraft, in which air flows circulate from upstream to downstream, the turbine engine extending axially and comprising:an inner casing, an inter-duct casing and an outer casing (13) so as to define a primary duct between the inter-duct casing and the inner casing, and a secondary duct between the inter-duct casing and the outer casing (13),a rotary shaft comprising, at the upstream end, a movable fan comprising radial blades of which the free ends face the outer casing (13) of the turbine engine so as to compress an air flow at least in the secondary duct,a plurality of variable-pitch radial stator vanes (5) mounted upstream of the movable fan so as to deflect the incident axial air prior to it being axially rectified by the movable fan in the secondary duct,means for individually regulating the pitch of the variable-pitch radial vanes (5) if heterogeneity of the air flow in the secondary duct is detected.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Method for mounting main pipeline and main loop of pressurized water reactor nuclear power station steam generator

ActiveCN101839467AAvoid inconvenienceEasy to controlNuclear energy generationContainmentNuclear engineeringPressurized water reactor

The invention discloses a method for mounting a main return loop of a nuclear power station pressurized water reactor coolant system, which is characterized in that: a main pipeline heat section bend (16) and a main pipeline transition section bend (17) are welded at a loop nozzle of a lower seal end of the used steam generator (1); during mounting, a welding line (9) between a main pipeline heat section (13) and the main pipeline heat section bend (16) on the lower part of the steam generator (11) and a welding line (2) between the main pipeline heat section (13) and a reactor pressure container (10) can be assembled and welded simultaneously. In addition, the working amount for a welding line (5) is reduced during mounting. The mounting method can better control and guarantee the assembling and welding quality, improve the working efficiency, reduce the mounting time, and shorten the construction period.

Owner:CHINA NUCLEAR POWER ENG CO LTD

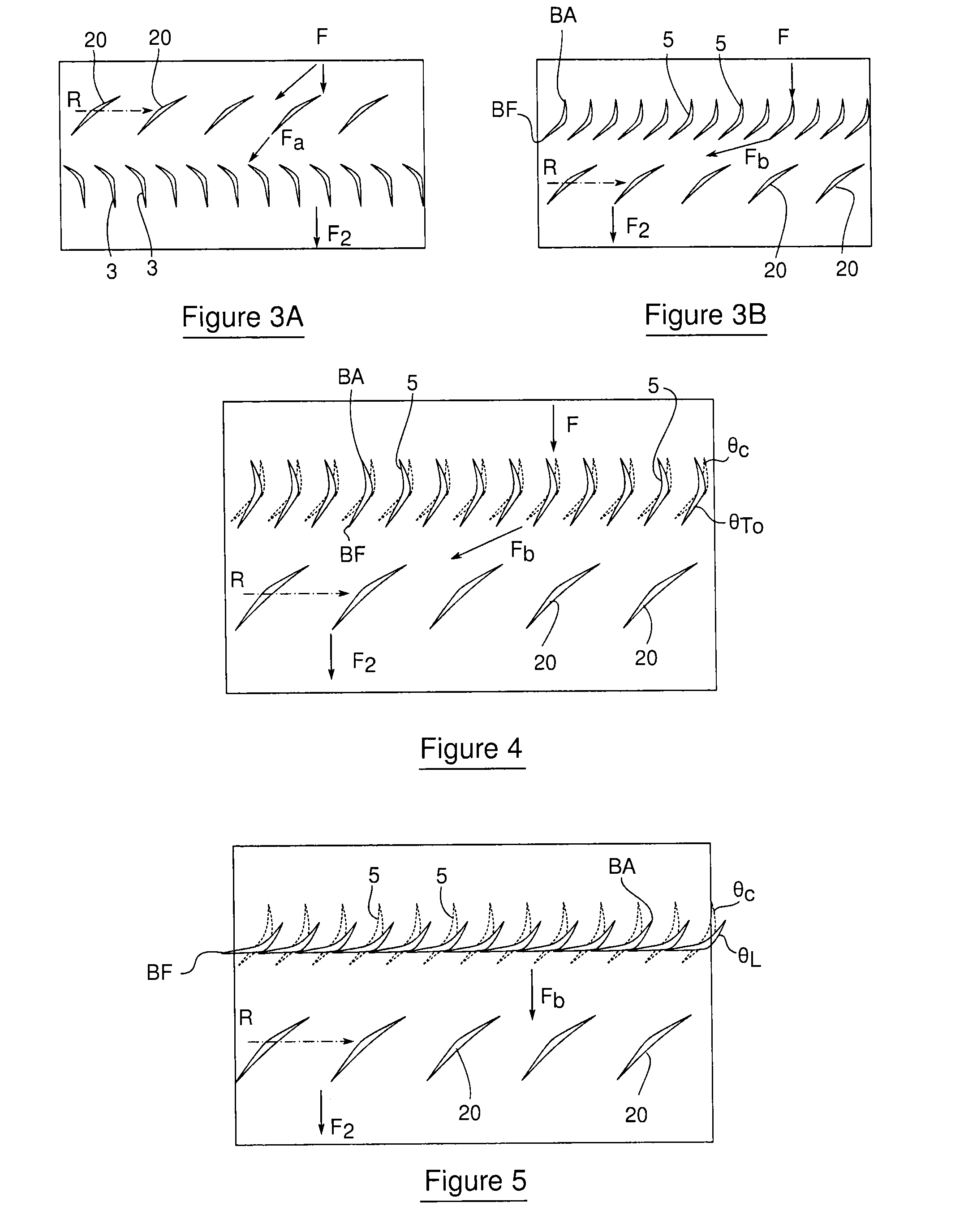

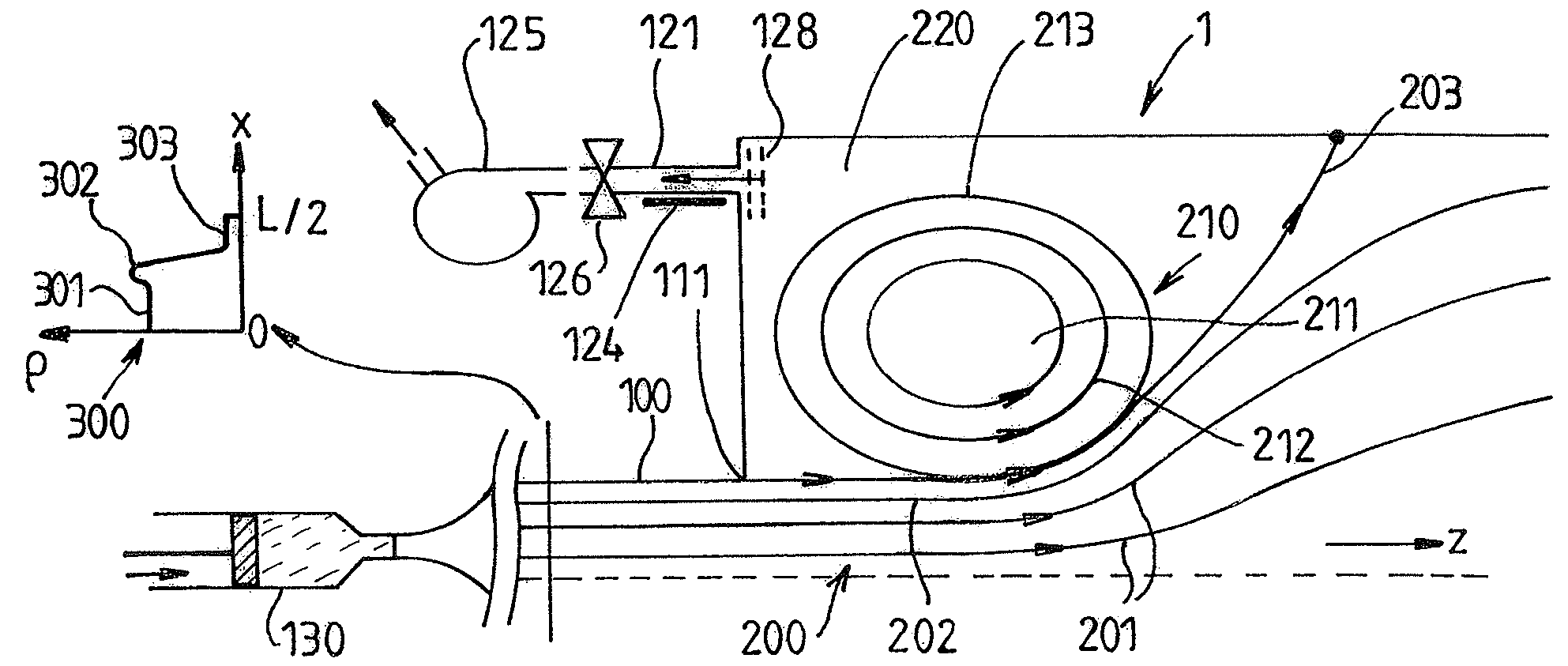

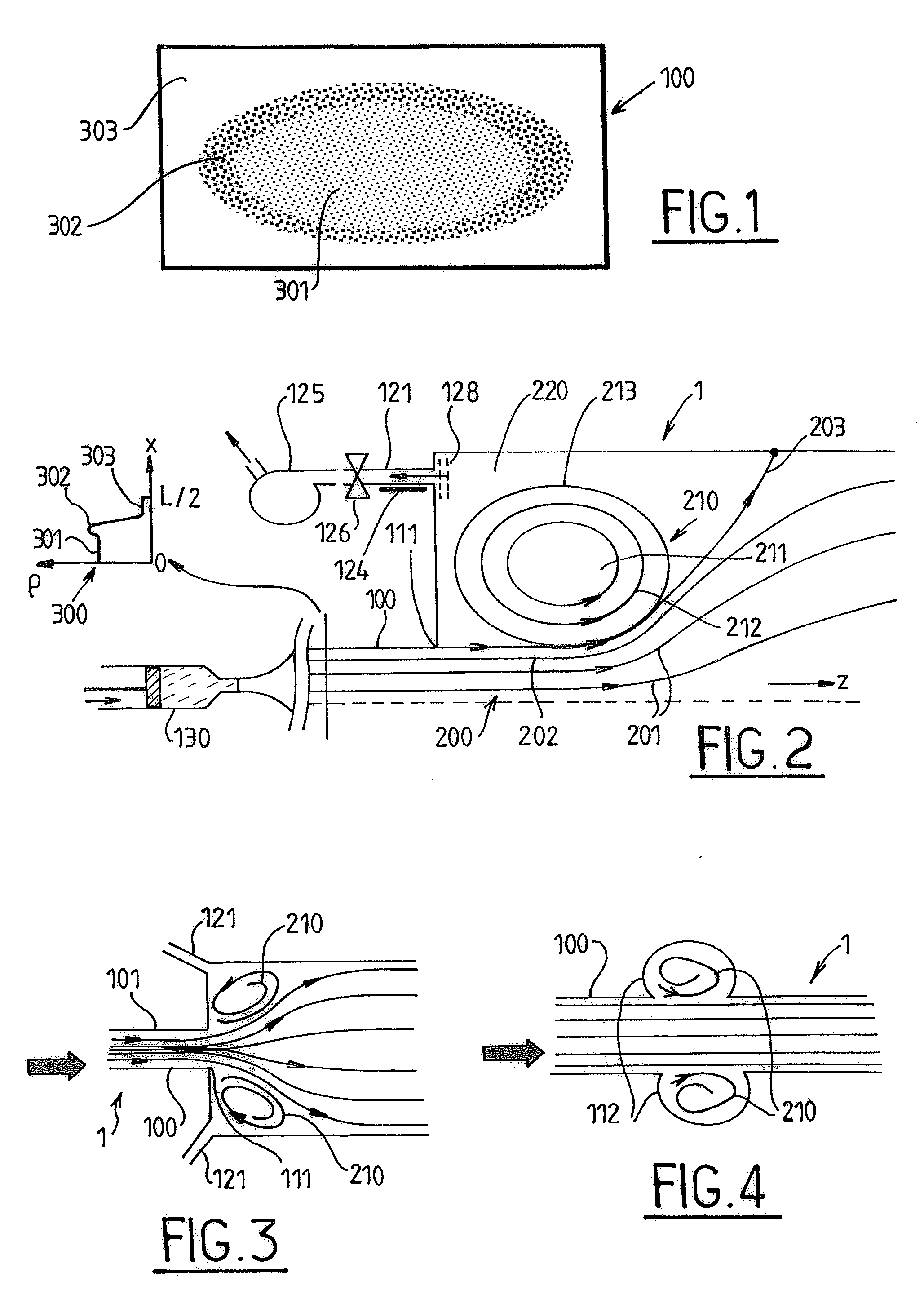

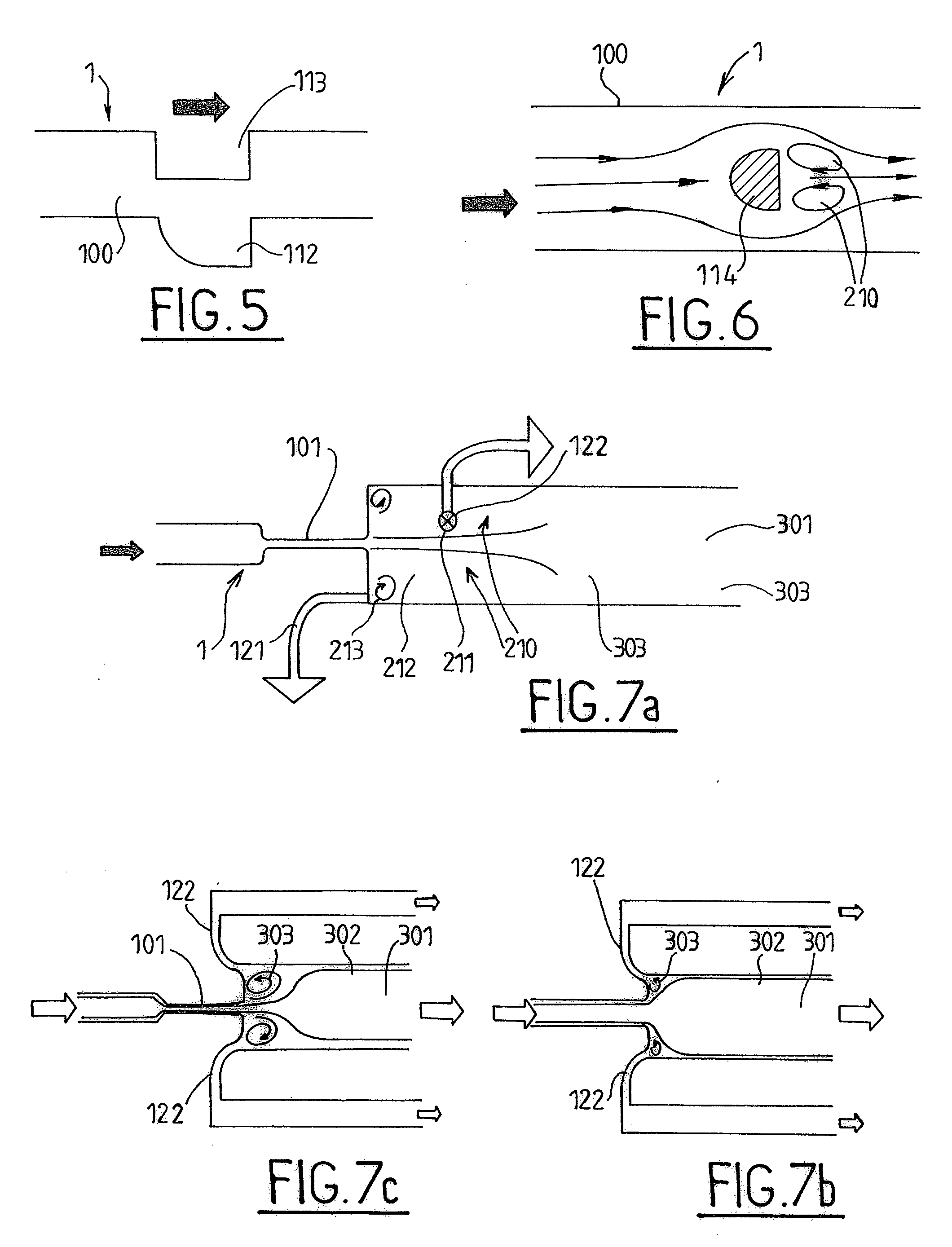

Device and a method for separating a suspension

ActiveUS20090283474A1High extraction rateIncreasing the thicknessSeparation devicesLaboratory glasswaresLiquid layerEngineering

A device for extracting a liquid phase from a suspension, the device being characterized in that it comprises: a main duct for conveying a flow of said suspension, the duct being of a length that is sufficient to enable a layer of said suspension to develop that is depleted in solid phase; flow disturbance means for disturbing the flow of said suspension, said means being provided in the main duct and being adapted to cause at least one recirculation vortex to form so as to increase locally the thickness of said depleted layer; and liquid extraction means disposed in a region of the device where said suspension is enriched in liquid phase as a result of said recirculation vortex.A method of extracting a liquid phase from a suspension, the method comprising injecting said suspension into such a device at a flow rate suitable for causing at least one recirculation vortex to be formed, and extracting a fraction of said suspension that is enriched in liquid as a result of said vortex.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

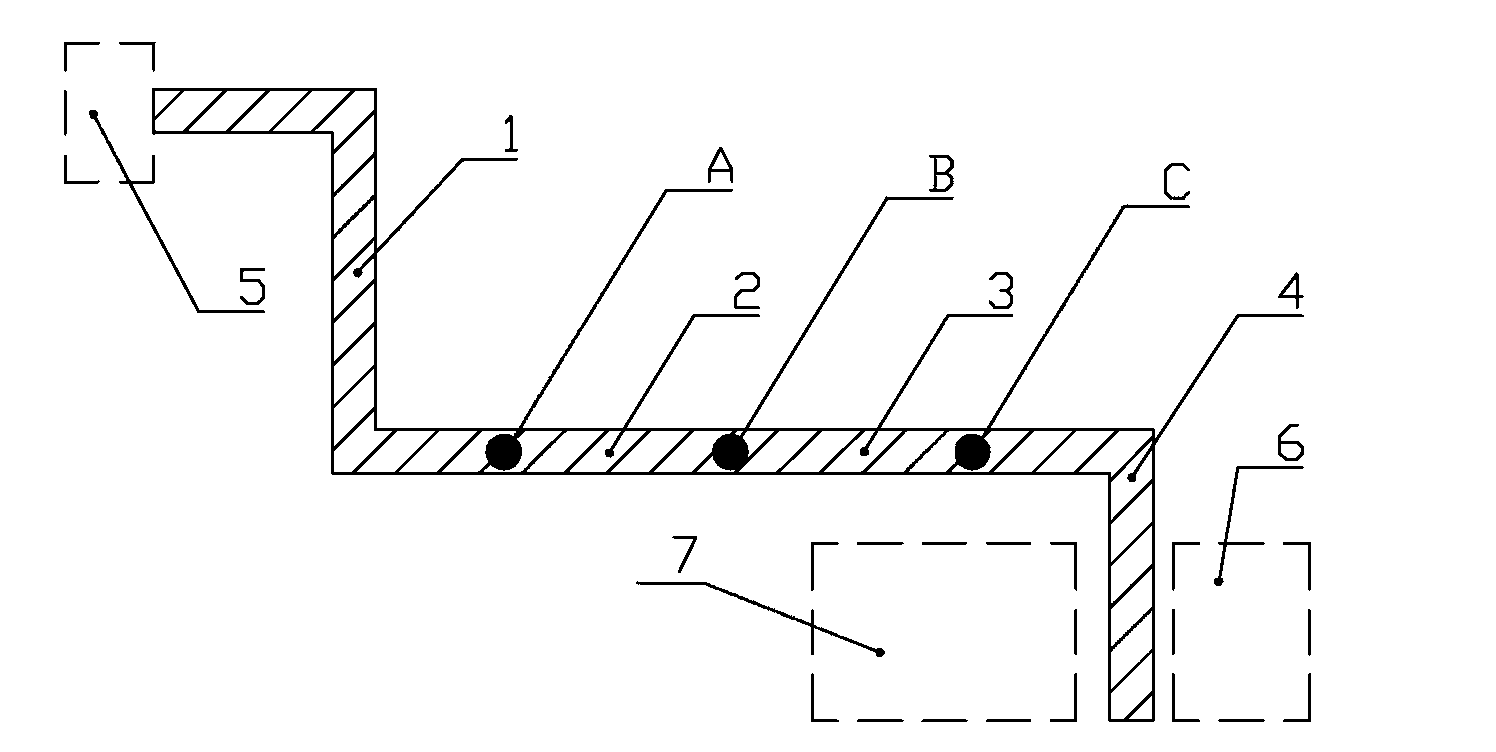

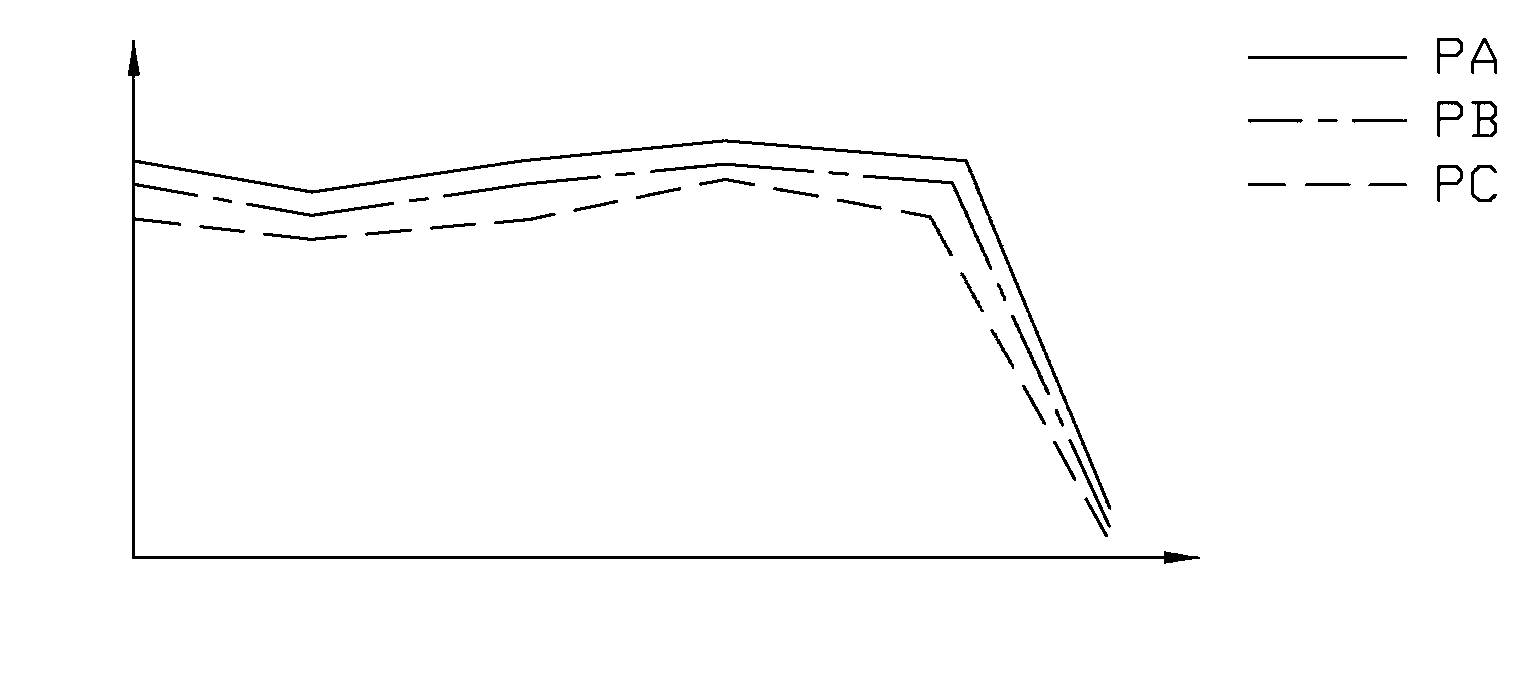

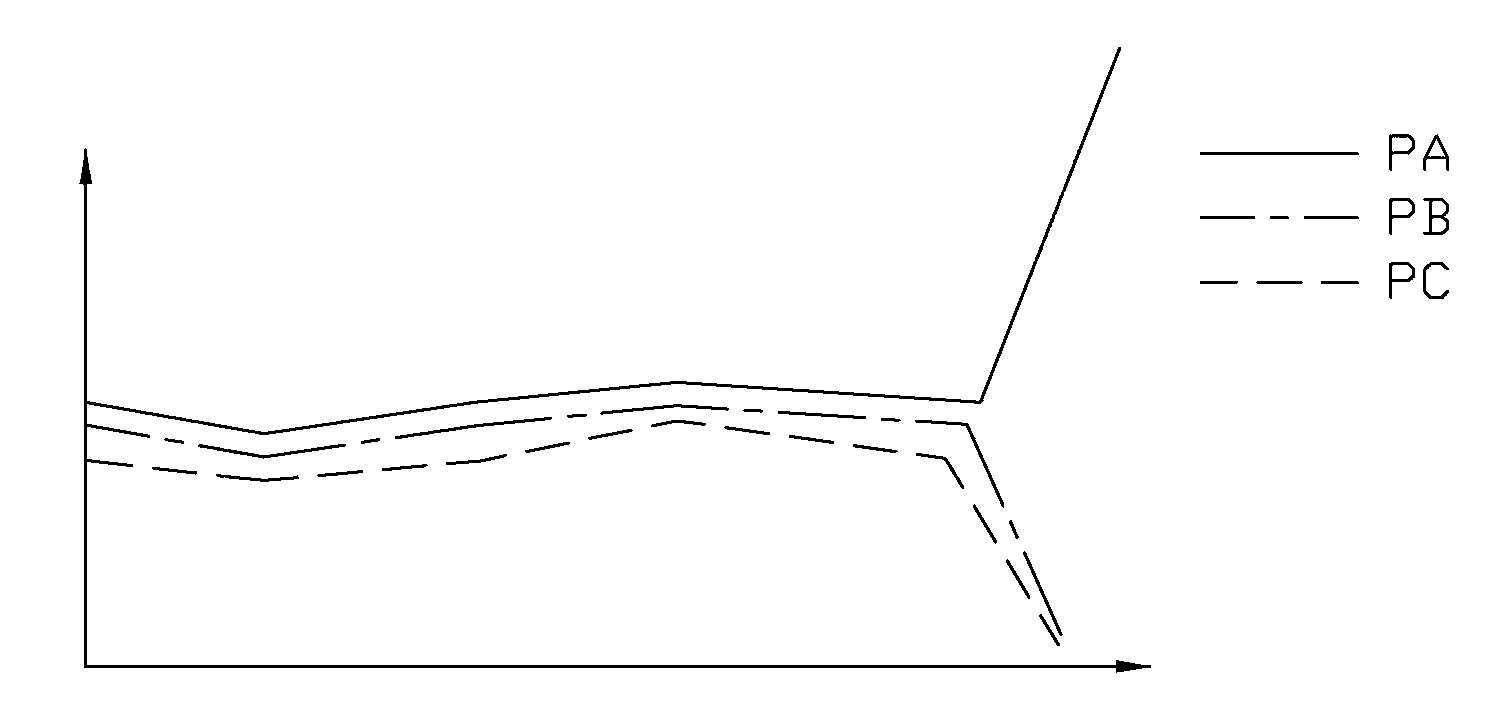

Pressure detecting method for preventing clogging of filling pipeline

ActiveCN103216266AAvoid cloggingAccurate fault informationMining devicesMaterial fill-upProgrammable logic controllerDifferential pressure

The invention relates to a pressure detecting method for preventing the clogging of a filling pipeline, which is characterized in that pressure sensors are arranged on at least three pressure detecting points on the main pipe of the filling pipeline, wherein the first pressure detecting point is arranged at the front part of a laneway filling pipe, the second pressure detecting point is arranged in the middle of the laneway filling pipe, the third pressure detecting point is arranged on the filling pipe at the inflection point of a working face and a gate, the pressure sensors are used for transmitting real-time pressure values of the pressure detecting points into a PLC (programmable logic controller), whether pipeline clogging occurs or not is judged and measures needing to be taken when pipeline clogging occurs are judged through a control program preset in the PLC. With the adoption of the pressure detecting method, whether the filling pipeline is clogged or not and the filling pipeline is clogged at which position can be accurately judged and the clogging condition is processed in time according to the pressure difference change of the pressure detecting points and the rapid pressure change of each single pressure detecting point.

Owner:FENY

Novel ventilating pipeline wind power generation system and generator

InactiveCN102312790ASimple structureEasy to manufactureDucting arrangementsWallsWind drivenEngineering

The invention relates to a novel ventilating pipeline wind power generation system and a generator. With the help of air convection and upward draft of wind in a ventilating pipeline, fresh air naturally flows into a fresh air collecting channel chamber from a fresh air inlet of a second floor equipment room on the ground, enters into an air-supplying stand pipe 3 in a basement by virtue of an air-supplying pipeline 2 in an empty space of the basement, and then enters rooms on each floor by virtue of a main vertical air-supplying pipeline 41 on an outdoor south warming wall and lateral air-supplying branched pipelines 42 and 42' on each floor. An electric wind driven generator is used for solving the problem that the natural wind power in an air flue can not achieve the wind power level for delivering and exhausting air and starting the wind driven generator to generate, thereby providing a system which is free from wind field influence and completely utilizes a novel ventilating pipeline system for construction and a wind generating set system arranged in a pipeline of the novel ventilating pipeline system and composed of multiple minitype wind generating sets to generate electricity while performing ventilating air conditioning, so as to greatly lower the costs of ventilating air conditioning and wind power generation.

Owner:冯刚克

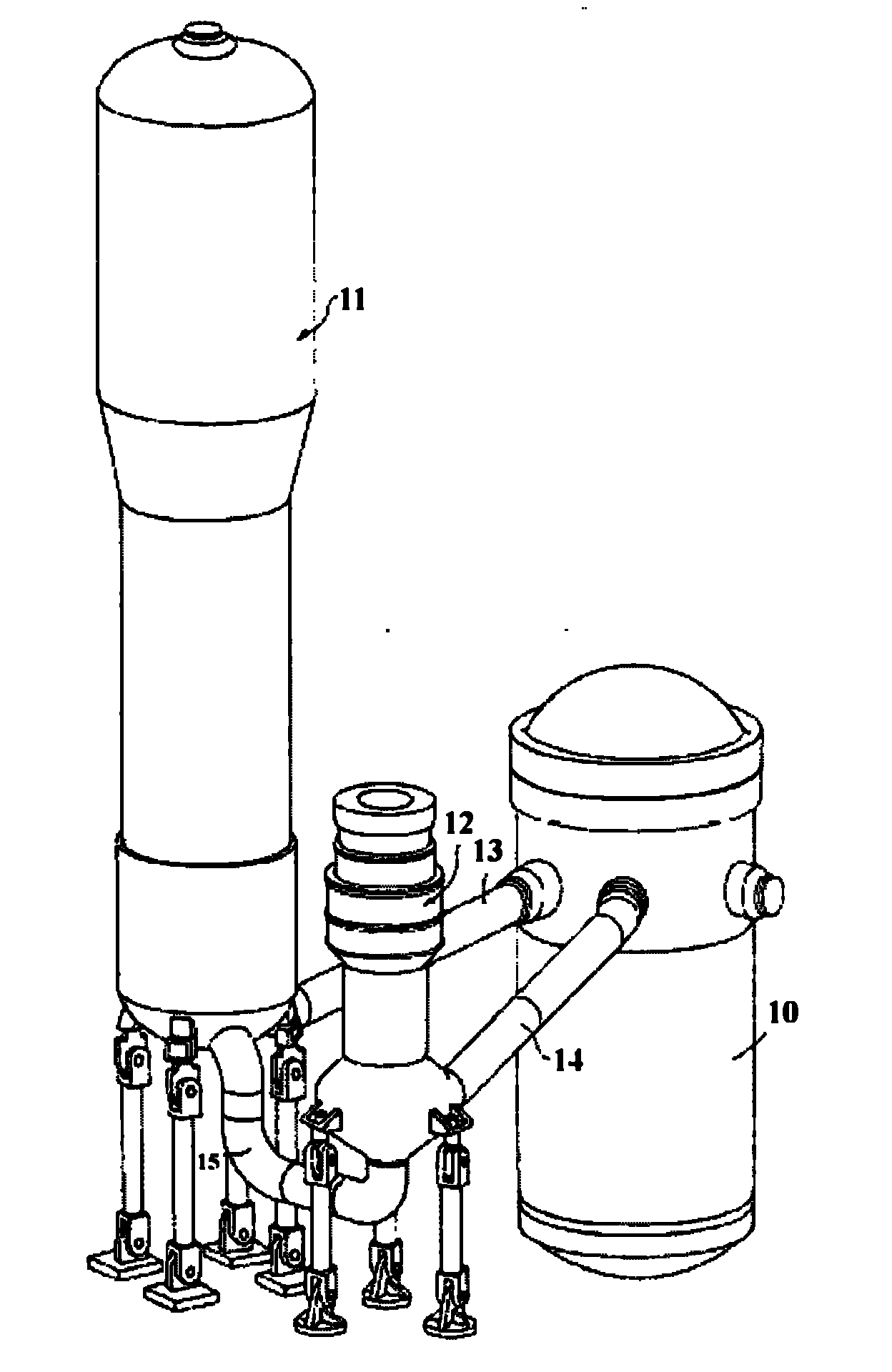

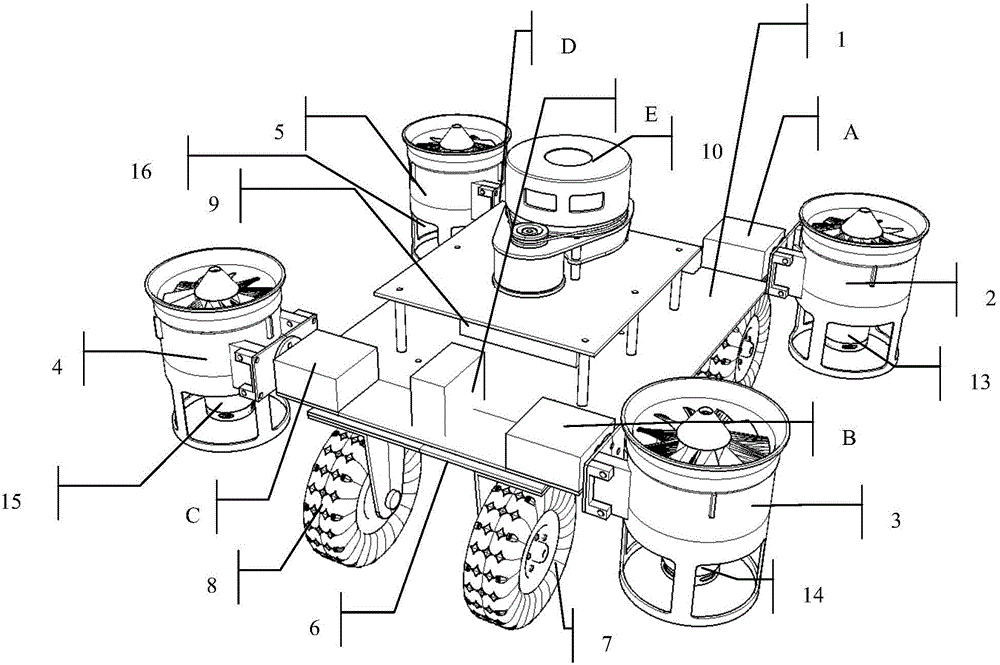

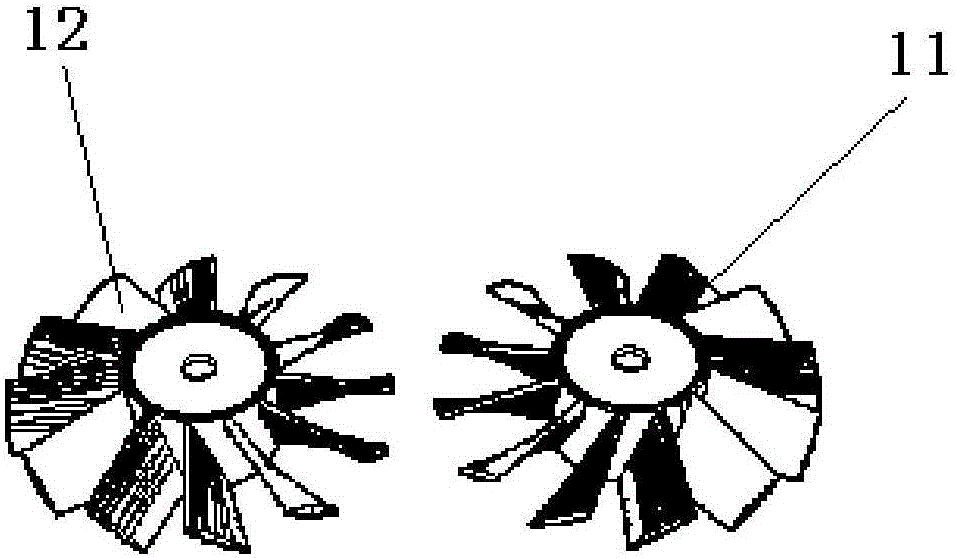

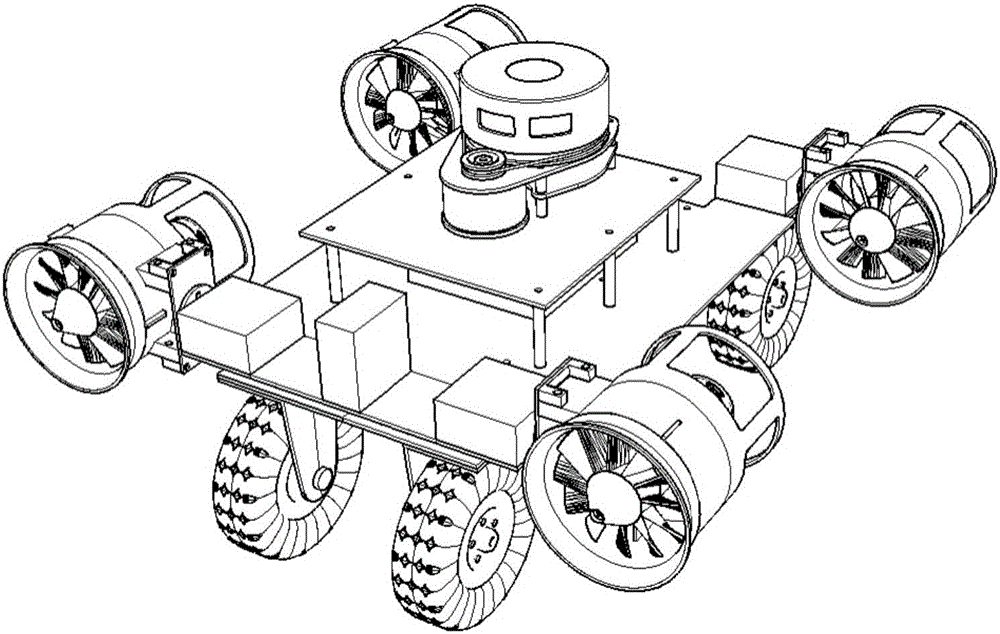

Duct type unmanned aerial vehicle and control method thereof

InactiveCN105752320AIncrease carrying capacityImprove efficiencyPropellersAircraft controlMultiple formsUncrewed vehicle

The invention discloses a duct type unmanned aerial vehicle and a control method thereof.The unmanned aerial vehicle comprises a main vehicle body (1), a first main duct (2), a second main duct (3), a third main duct (4) and a fourth main duct (5).The first main duct (2) and the second main duct (3) are connected with the first side of the main vehicle body (1).The third main duct (4) and the fourth main duct (5) are connected with the second side of the main vehicle body (1).The first main duct (2) and the fourth main duct (5) are arranged symmetric about the tail of the main vehicle body (1).The second main duct (3) and the third main duct (4) are arranged symmetric about the head of the main vehicle body (1).The unmanned aerial vehicle can run amphibiously on land and in air, so that the unmanned aerial vehicle stably flies in multiple forms to pass through multiple barriers, space of a power system is greatly saved through a duct type structure, large space is vacated for carrying of the unmanned aerial vehicle, and compared with a traditional multi-rotor-wing unmanned aerial vehicle, the duct type unmanned aerial vehicle is safer and more reliable.

Owner:陈方平

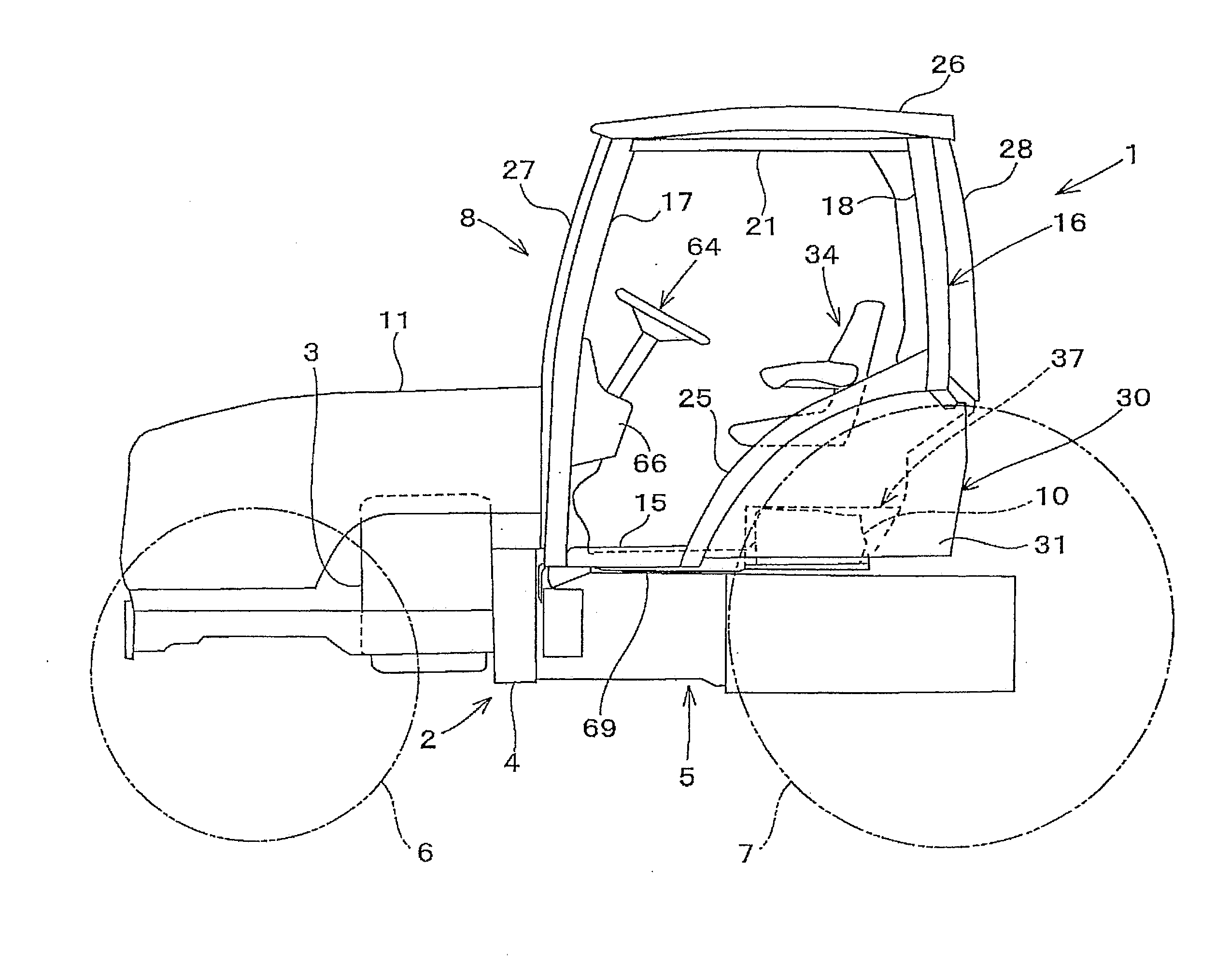

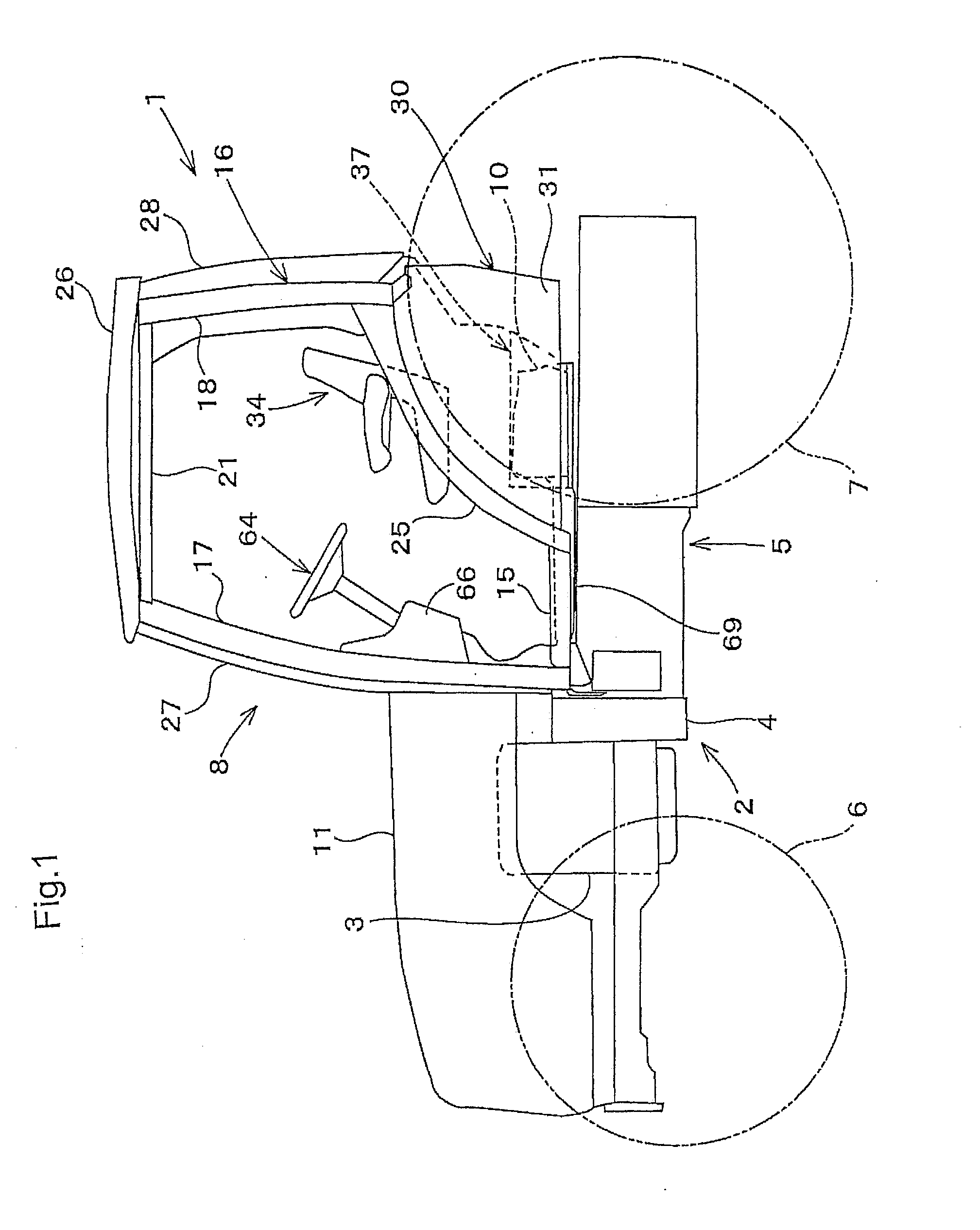

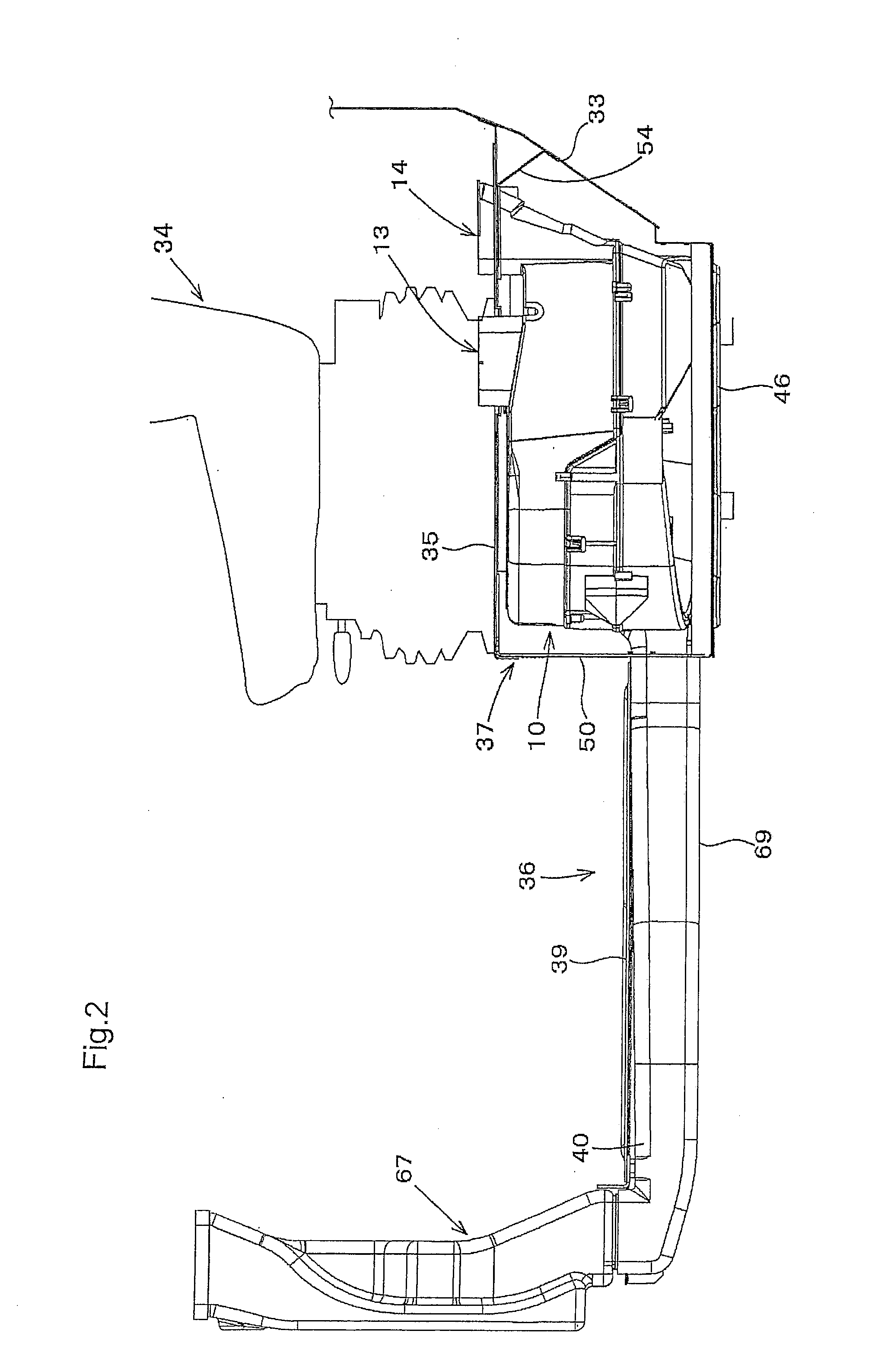

Cabin System

ActiveUS20110241379A1Area minimizationIncrease heightVehicle seatsSoil-shifting machines/dredgersNacelleEngineering

A cabin system to be mounted on a vehicle body is disclosed. The cabin system includes a driver's seat, an air conditioner body for indoor air conditioning disposed downwardly of the drive's seat, a plurality of support pillars constituting a cabin framework, a ceiling portion, and a main duct having a hollow tubular construction, the main duct forming therein an air passageway for the indoor air conditioning. The main duct includes, at a lower portion thereof, a duct connecting opening to be connected to the air conditioner body and also includes, at a lateral portion thereof, a support pillar engaging face. The main duct is attached through the support pillar engaging face to one of the support pillars along an indoor side peripheral face of the one support pillar. The support pillar engaging face of the main duct and the indoor side peripheral face of the one support pillar have profiles complementary with each other.

Owner:KUBOTA LTD

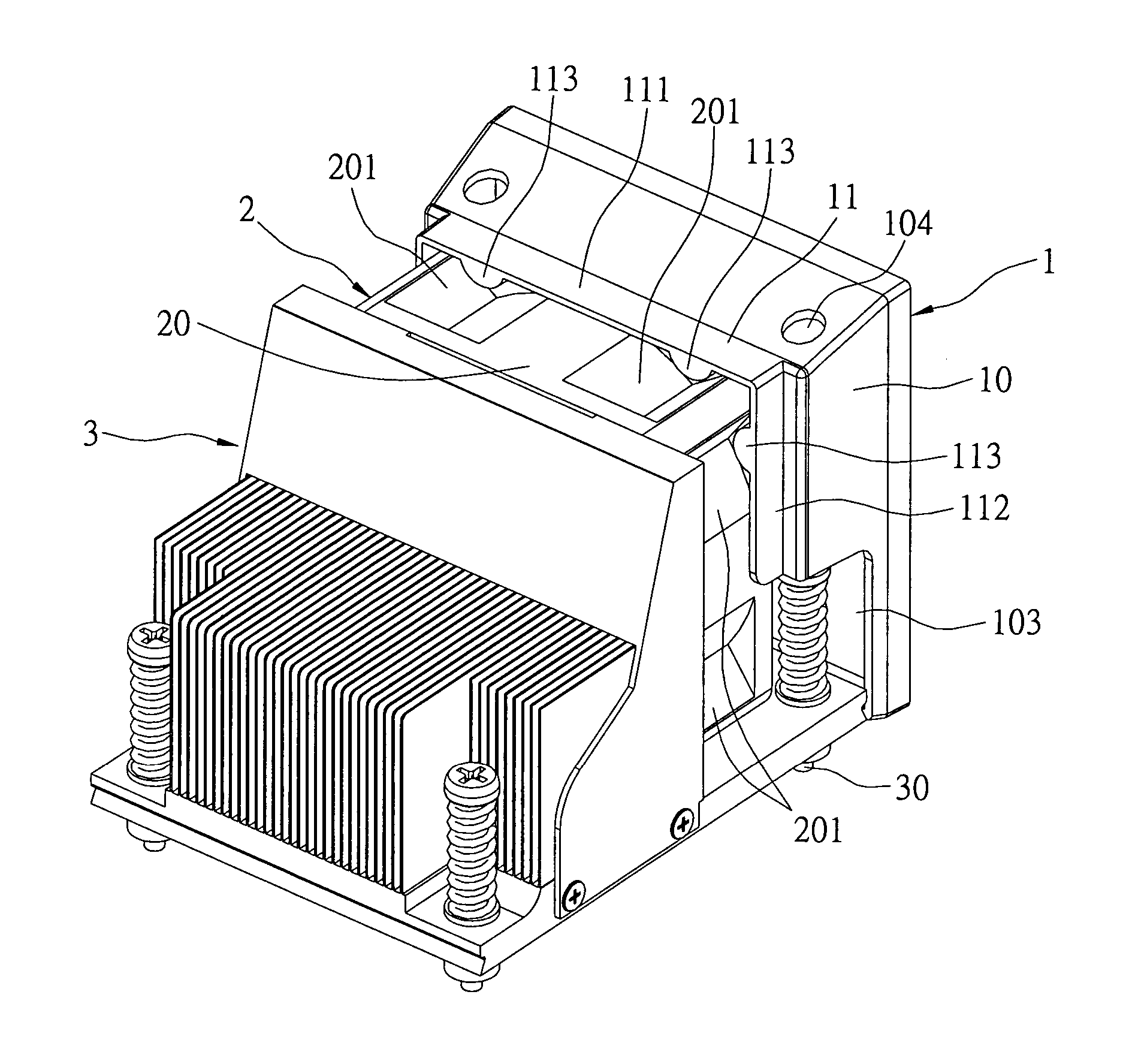

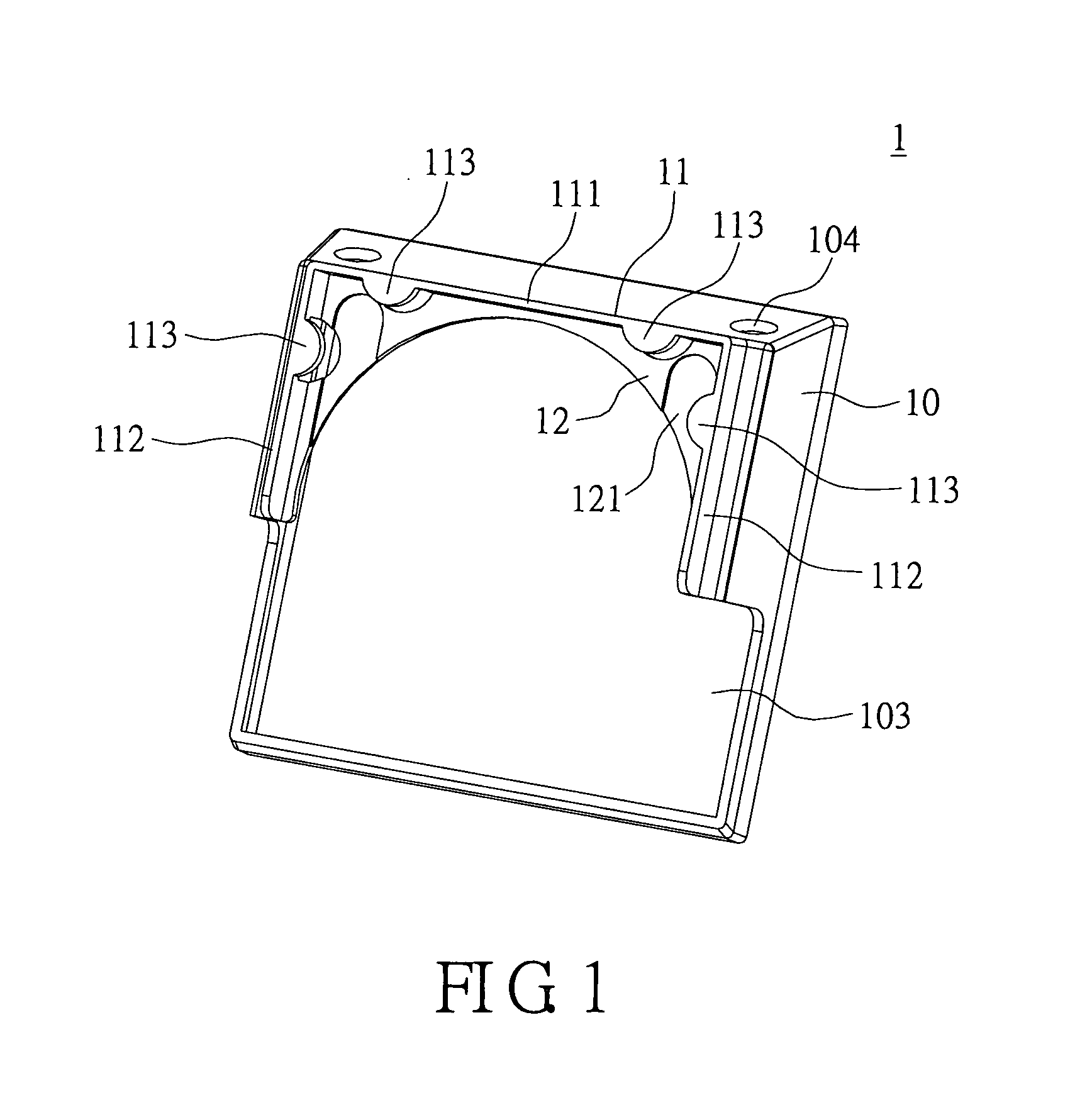

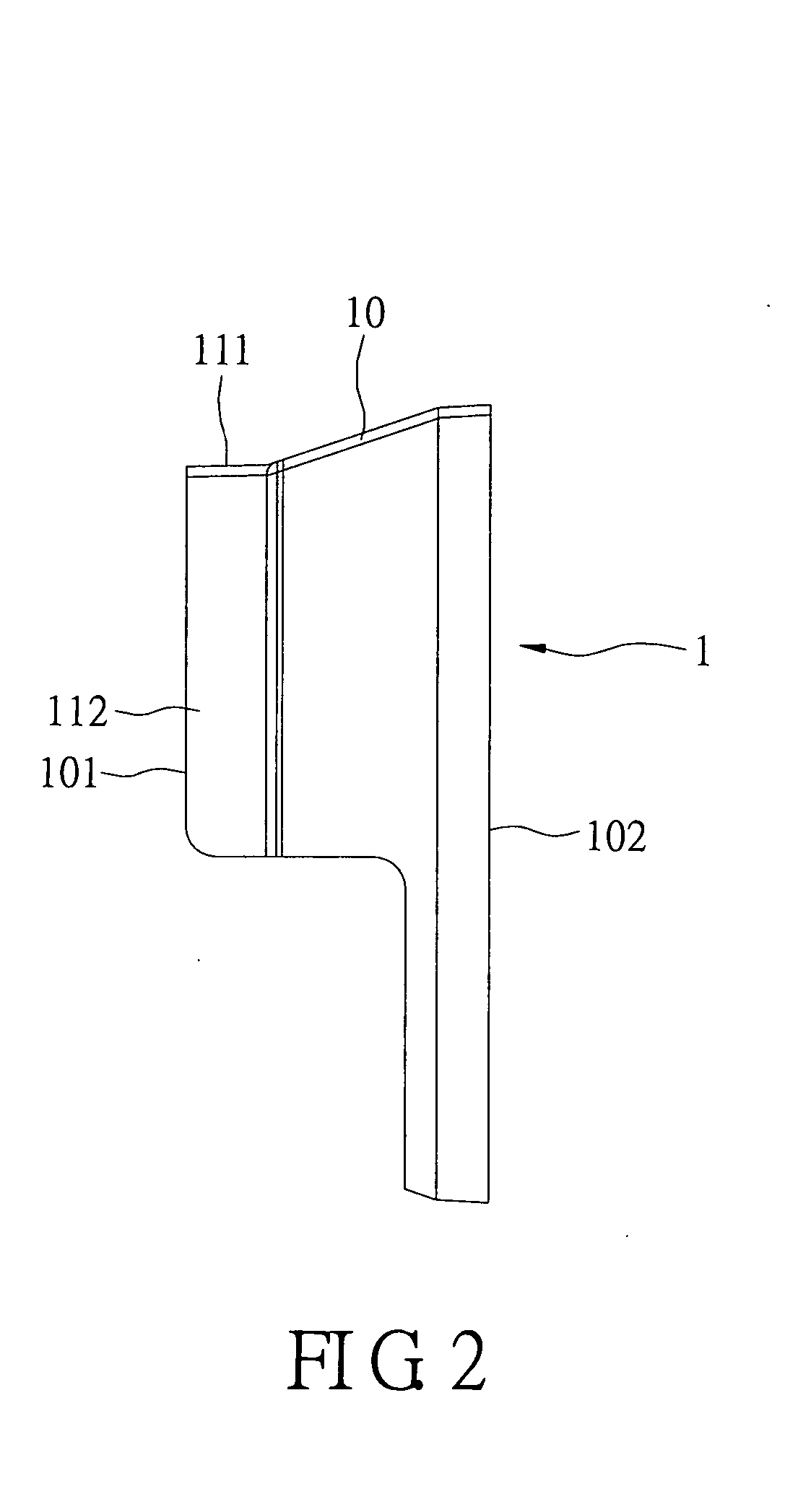

Fan duct

InactiveUS20070058341A1Good lookingDigital data processing detailsSemiconductor/solid-state device detailsEngineeringMain duct

A fan duct is retained on a fan. The fan has an outer frame. The outer frame forms a plurality of cavities in an outer circumferential surface thereof. The fan duct has a main duct wall and a connecting wall. The main duct wall has a fan-end opening. The connecting wall extends outwardly from the fan-end opening of the main duct wall and has at least two hooks. An edge of the outer circumferential surface of the outer frame of the fan matches an inside of the connecting wall, and each of the hooks locks into a corresponding one of the cavities. As a result, the fan duct of the present invention is capable of being easily hung onto the fan, so that the fan duct can be mounted on and detached from the fan without requiring the use of tools.

Owner:UNIVERSAL SCI IND CO LTD

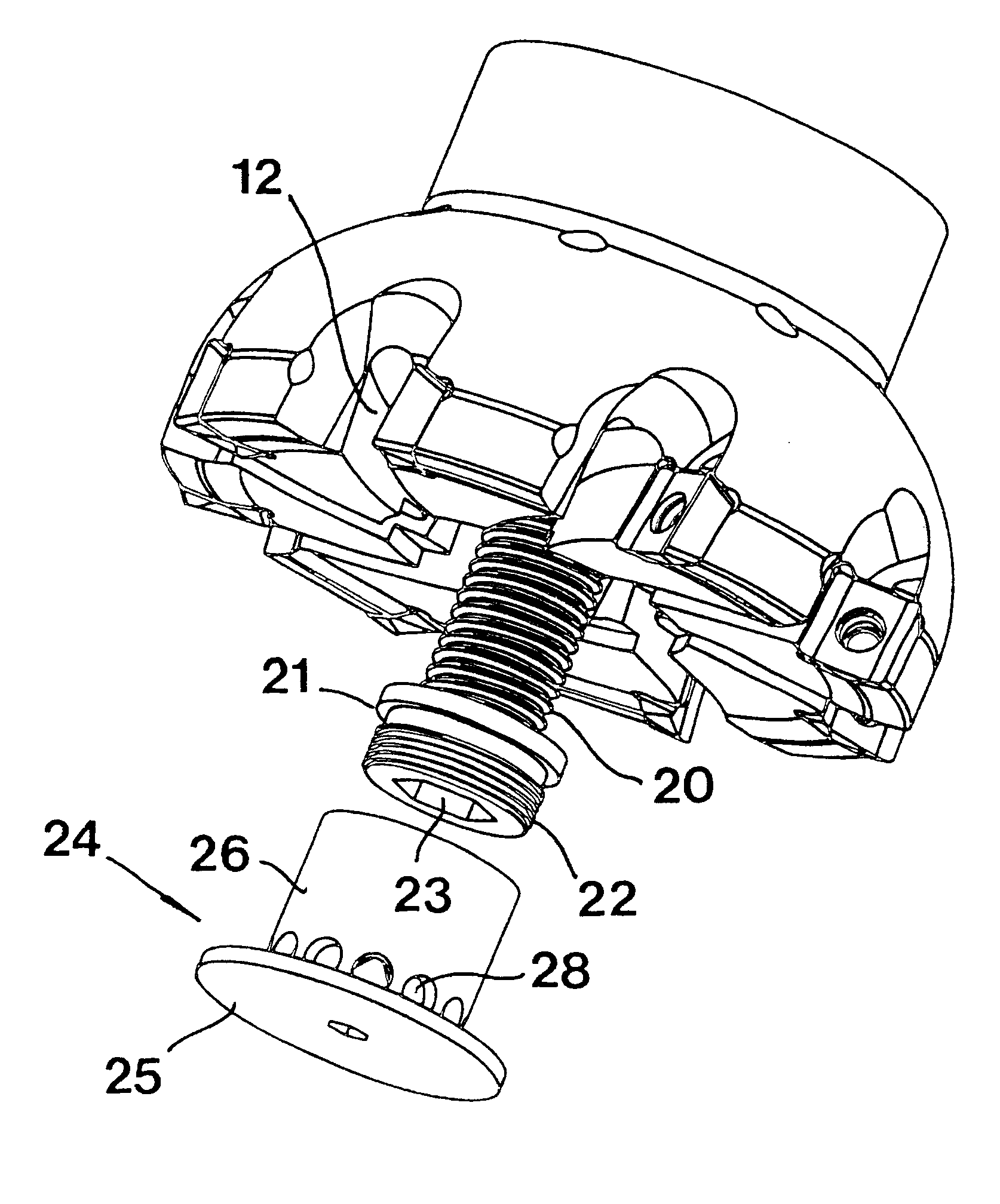

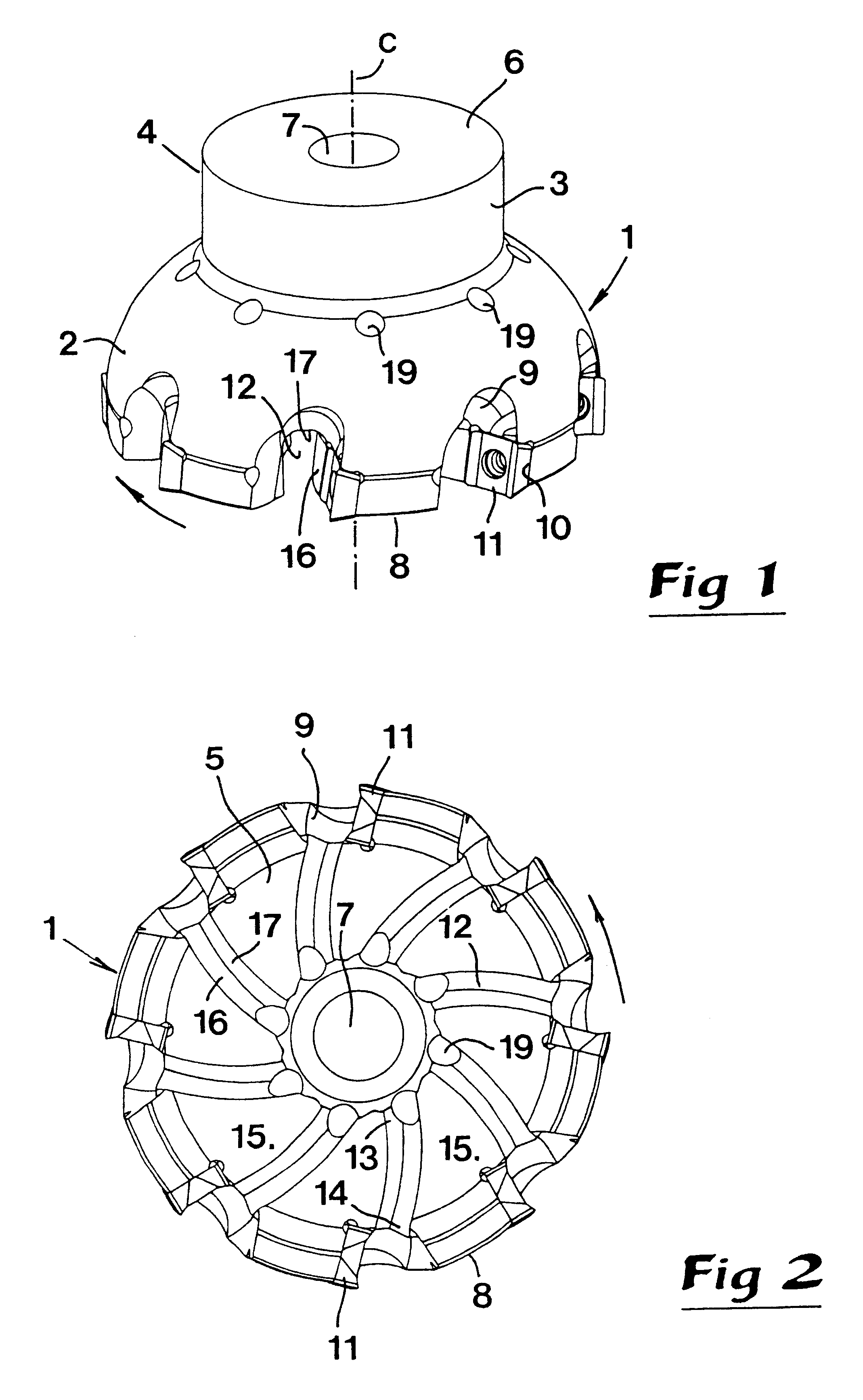

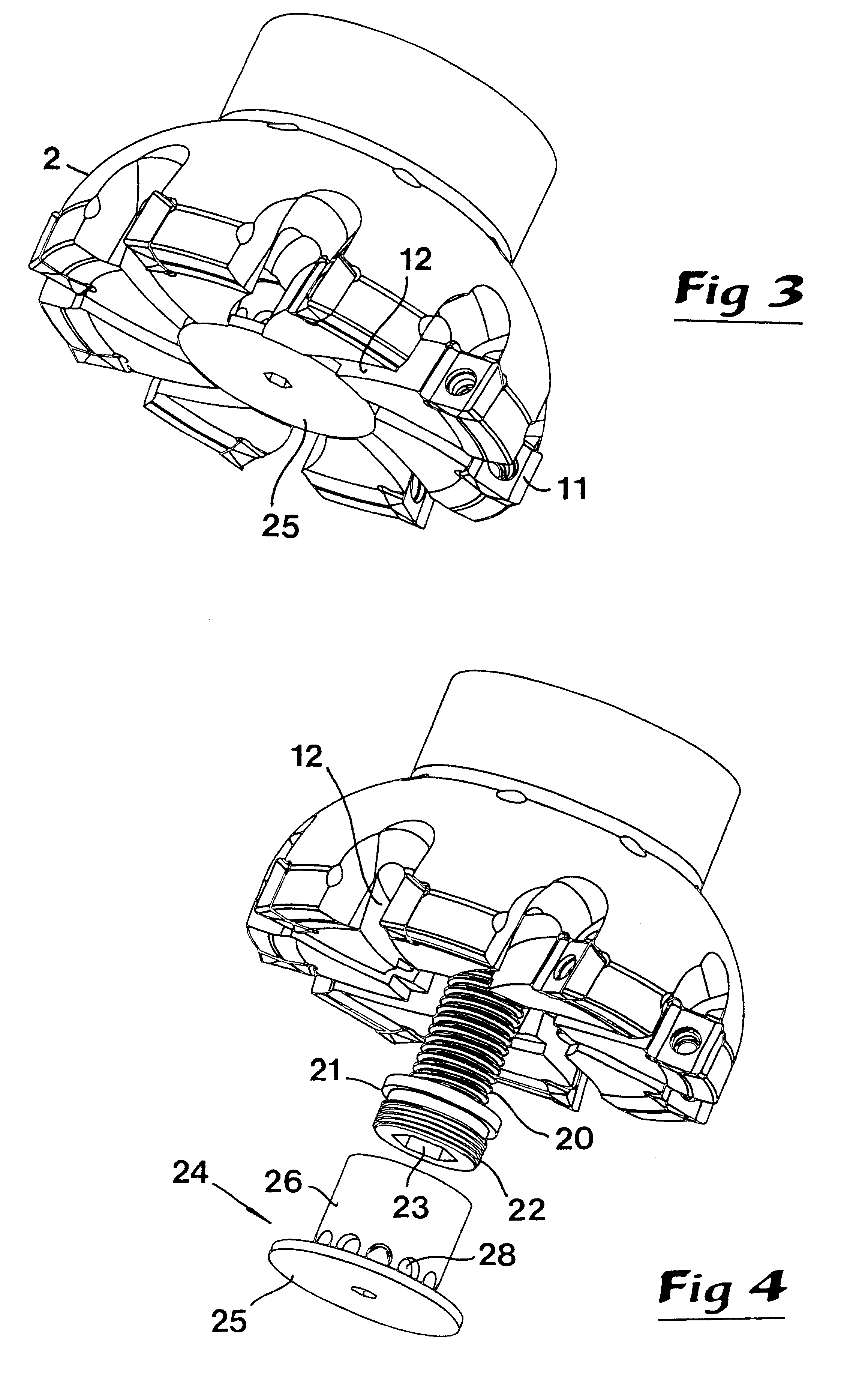

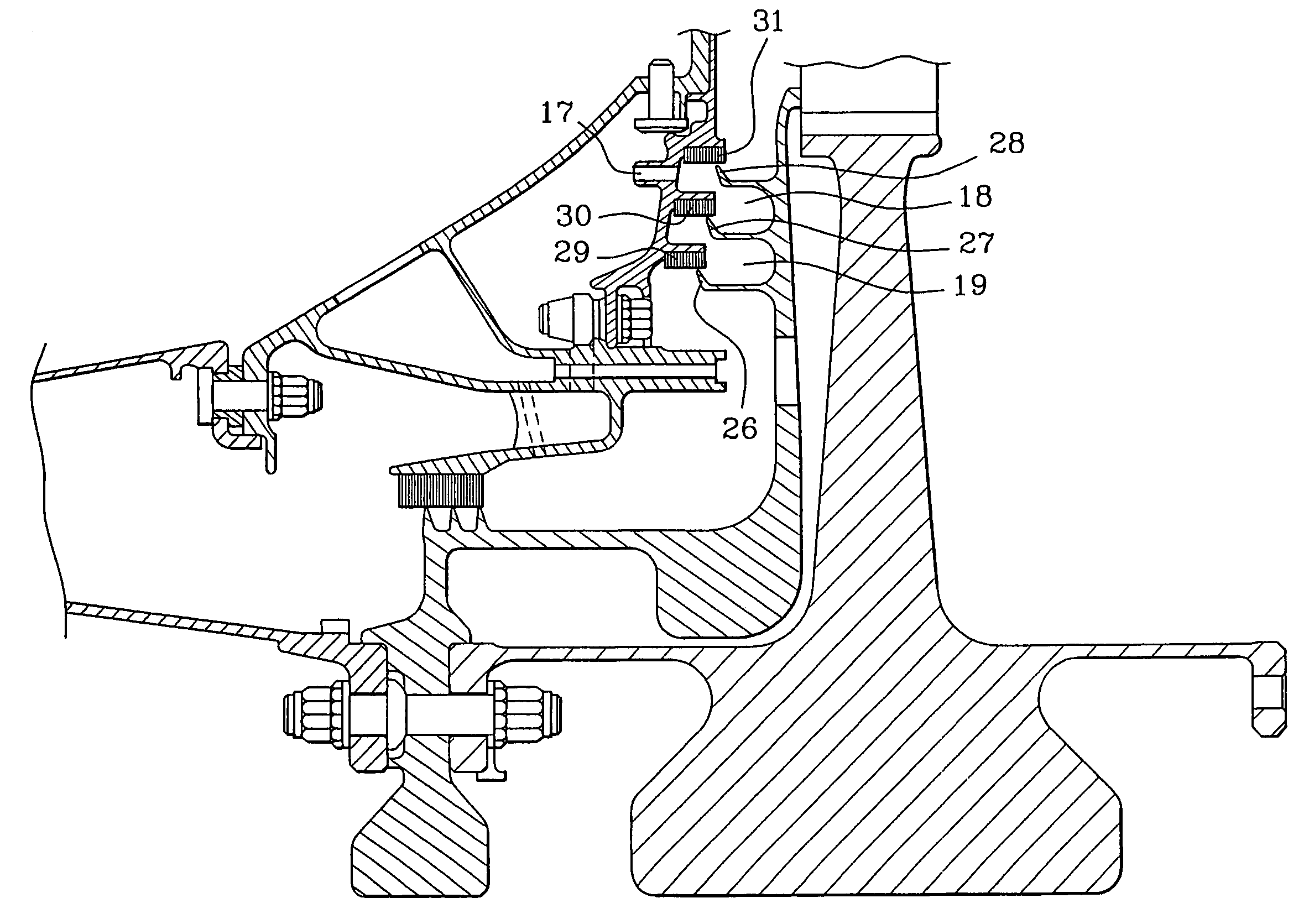

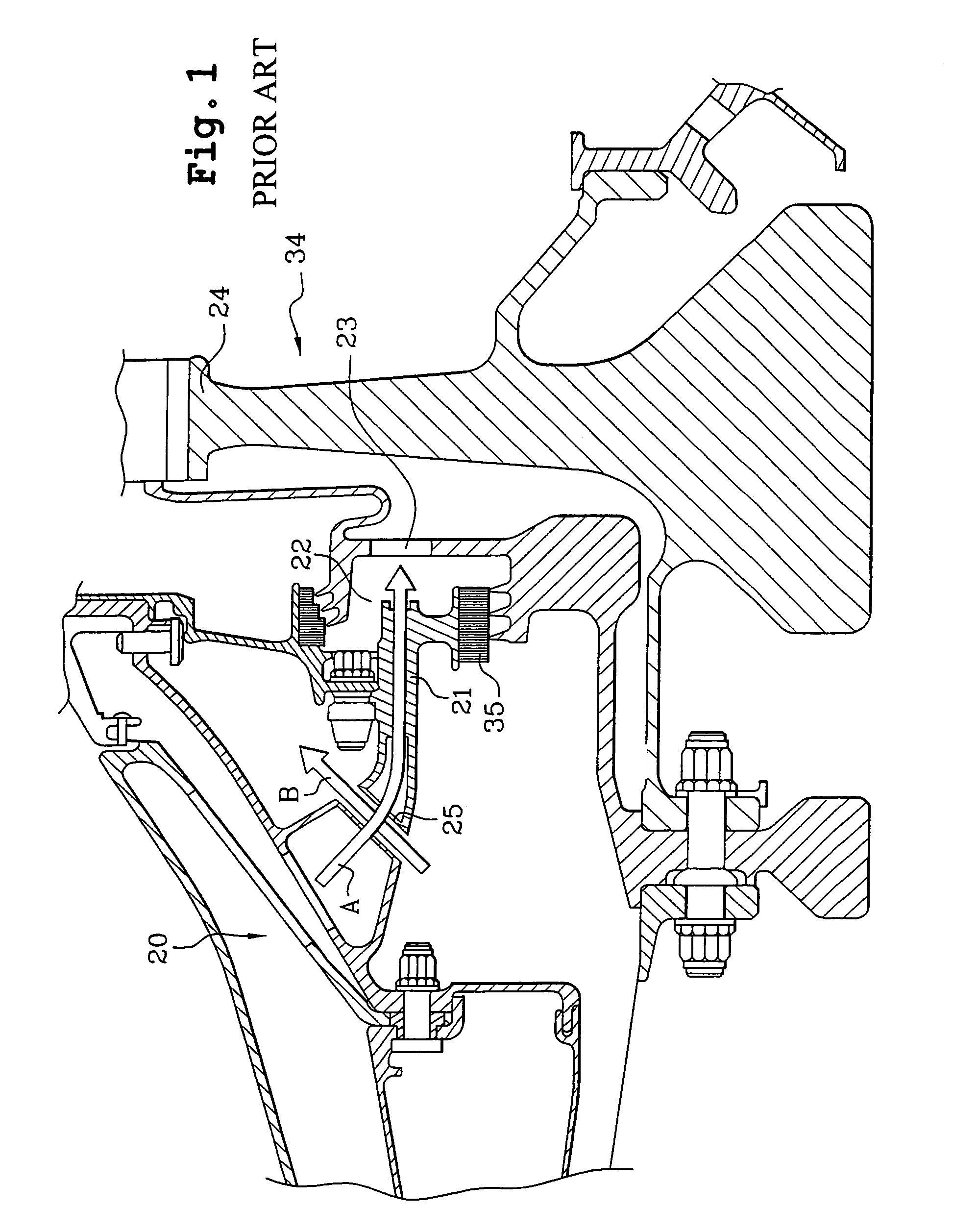

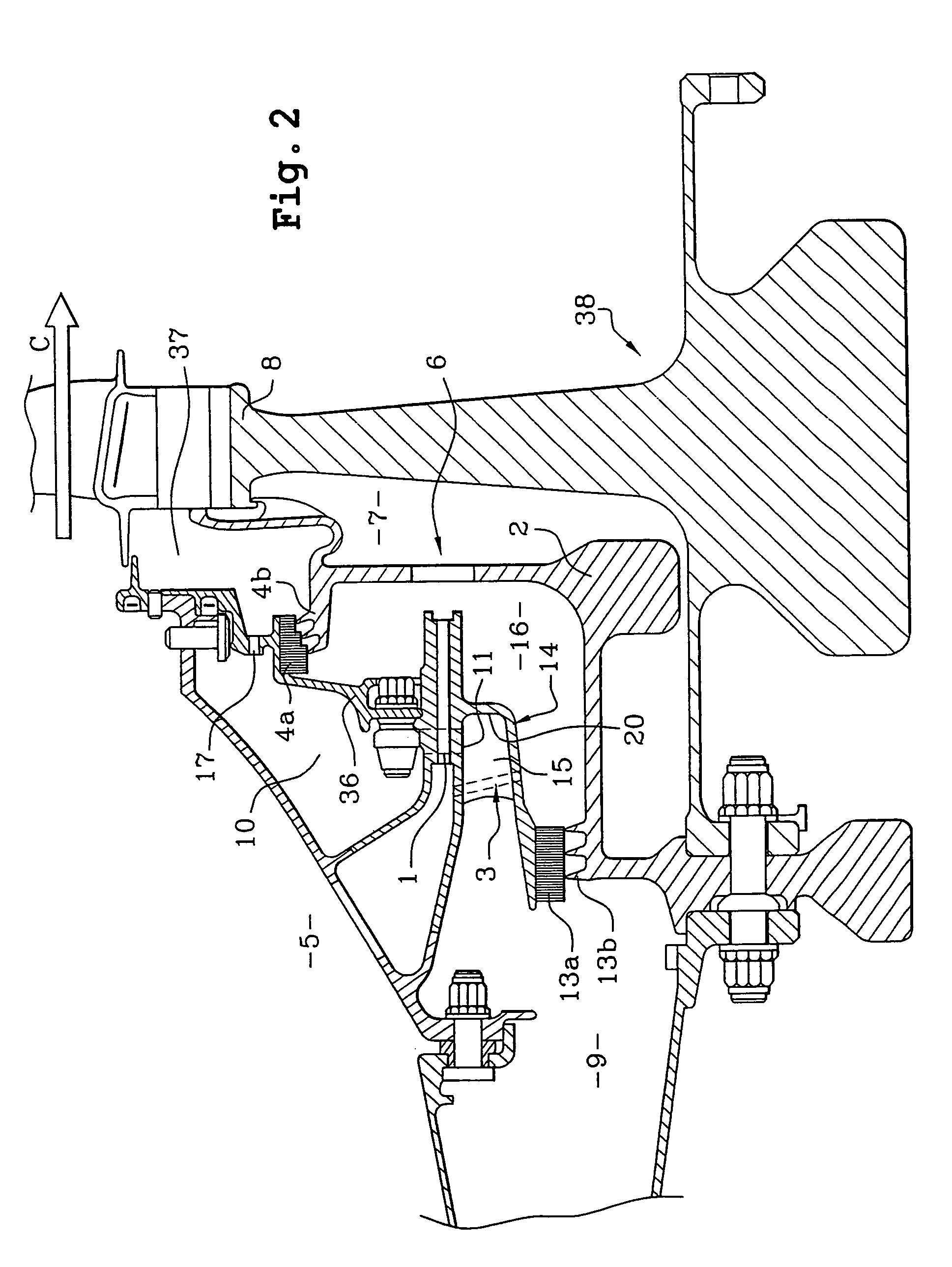

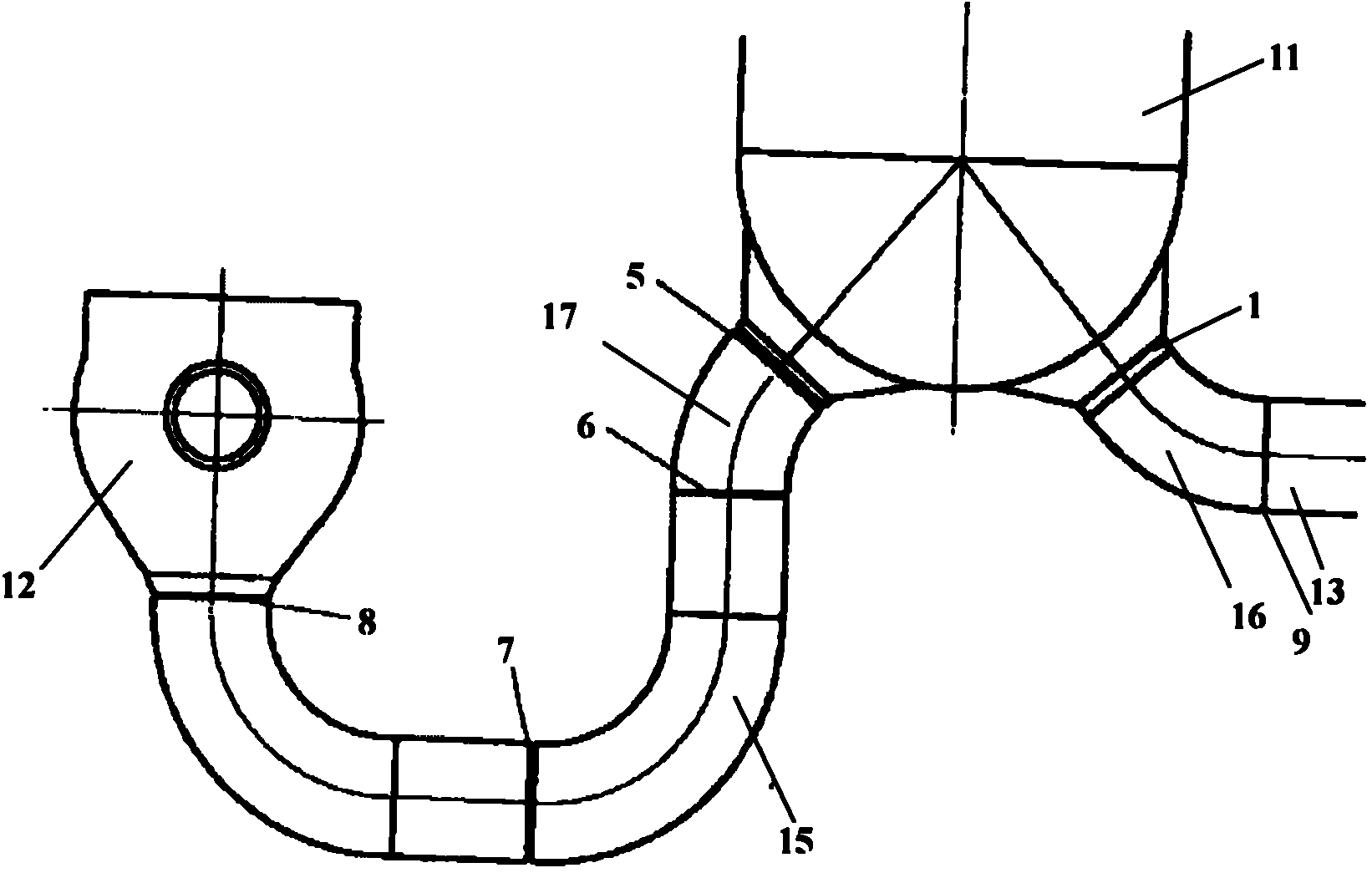

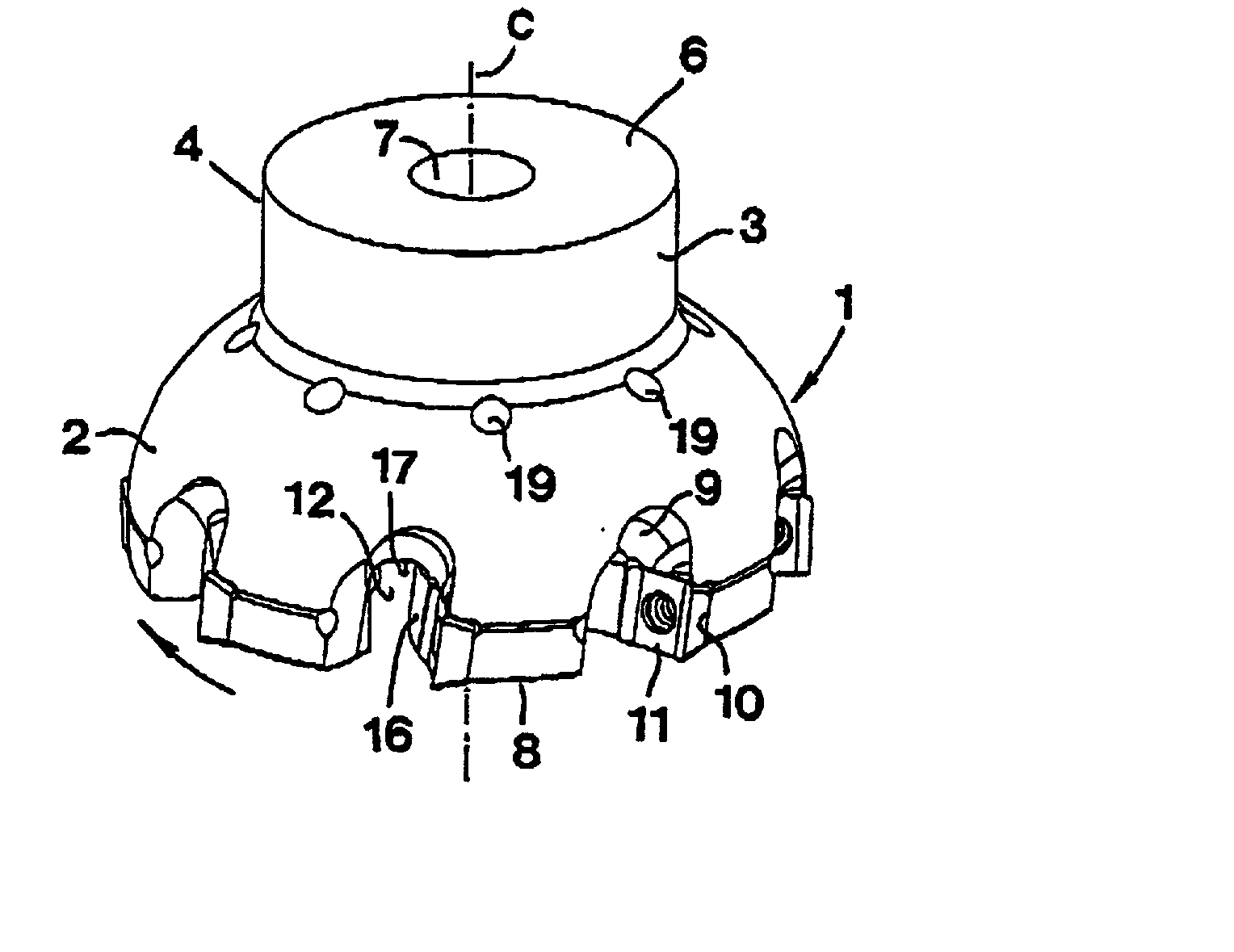

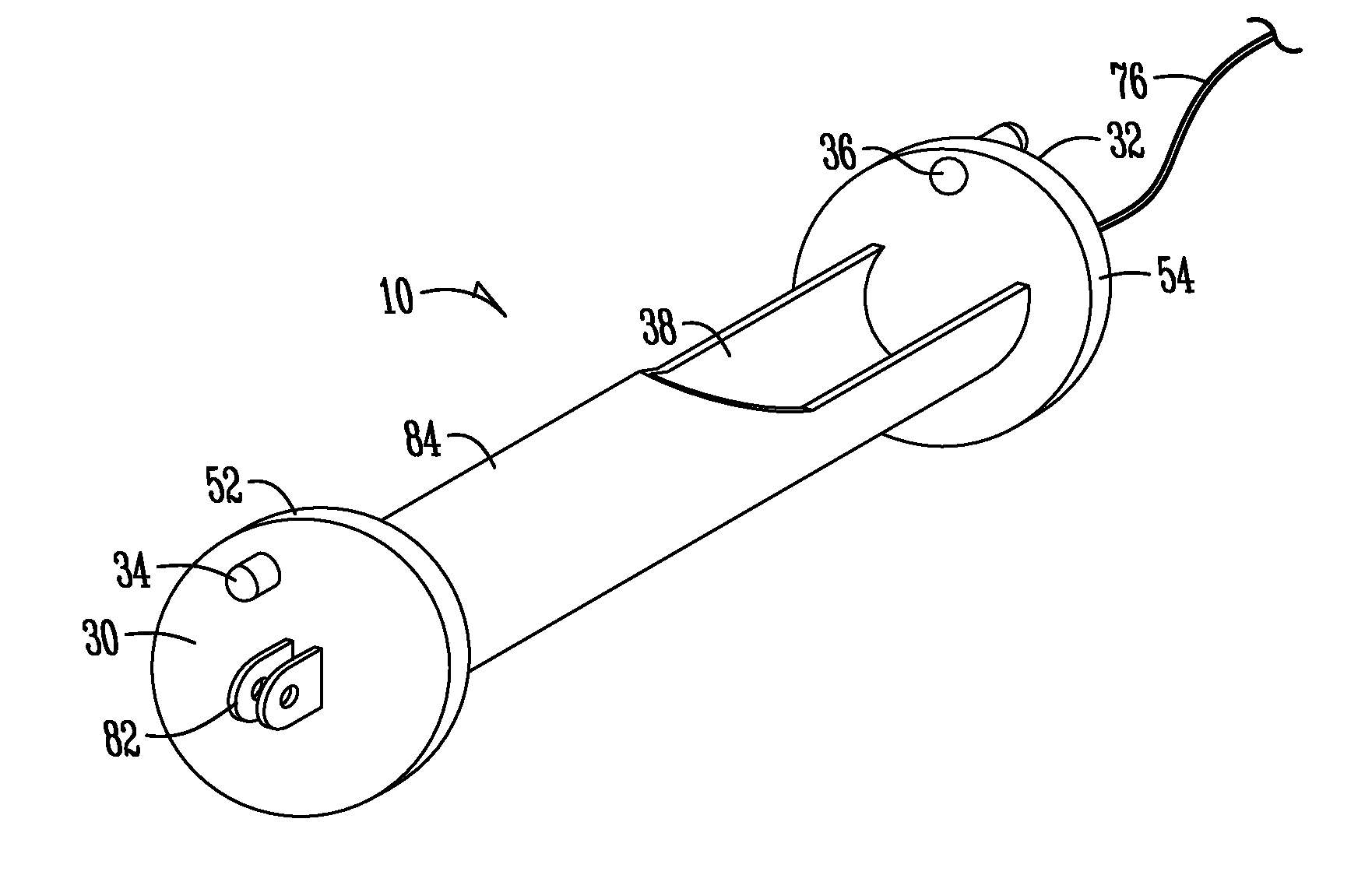

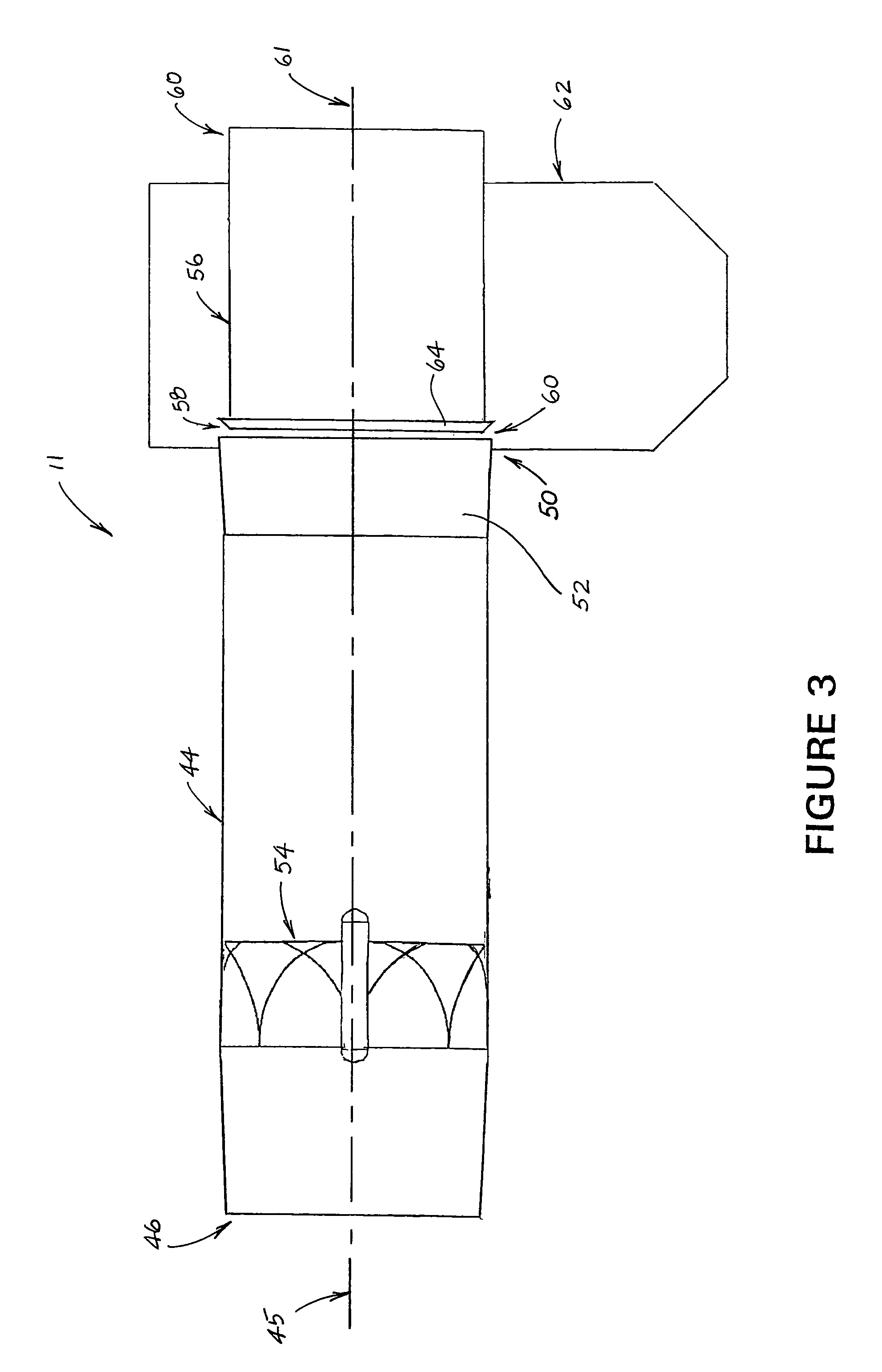

Tool for chip removing machining and having fluid-conducting branch ducts

InactiveUS20020009339A1The effect is outstandingManufactured in simple and inexpensiveMilling cuttersTurning toolsEngineeringBranch Duct

A milling tool includes a rotary cutting head having an end surface in which grooves are formed. The grooves communicate with a duct extending coaxially completely through the center of the cutting head to conduct cooling / lubricating fluid to cutting inserts mounted at outer ends of the grooves. The grooves induce a flow of fluid from inner ends of the grooves to the outer ends in response to rotation of the cutting head. A removable deflector can be attached to the end surface to deflect fluid from the main duct to the grooves.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

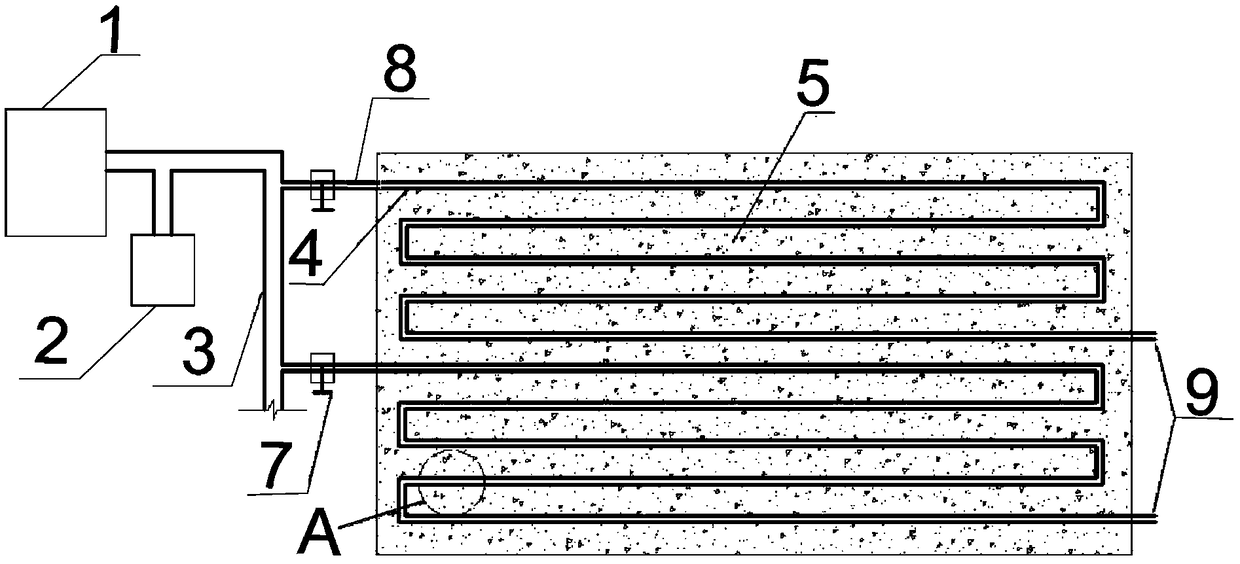

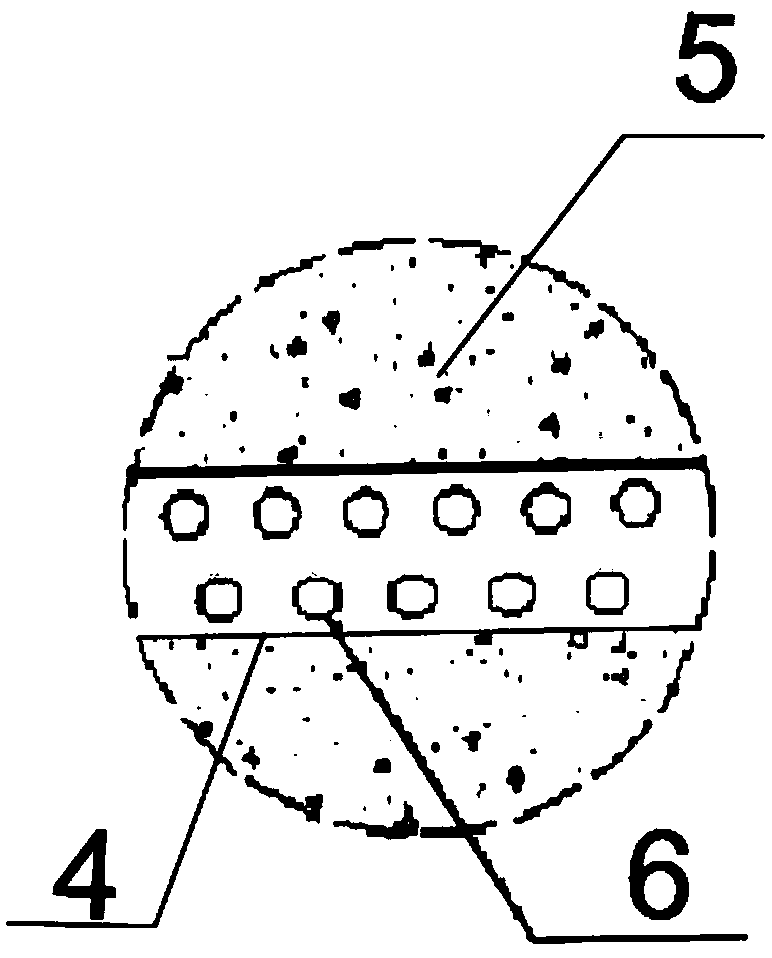

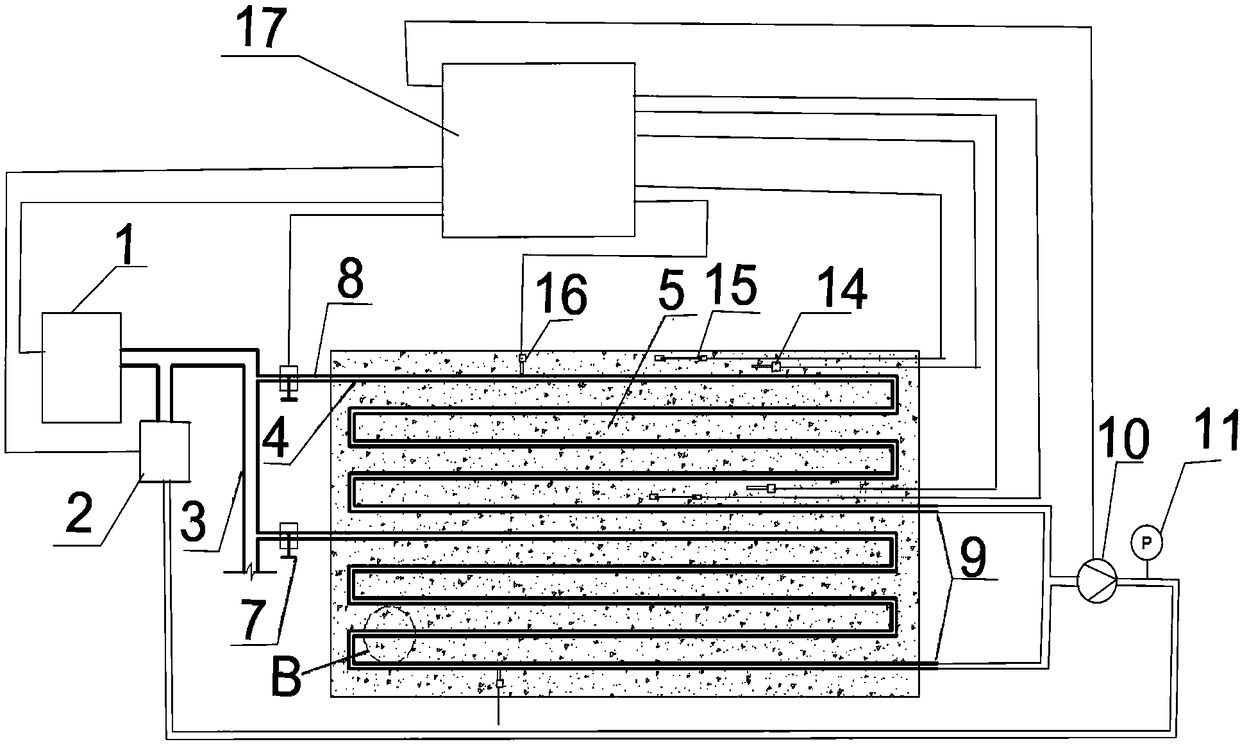

Curing device and method for internal cooling and humidification of mass concrete

ActiveCN109372263AReduce internal stressReduce drynessBuilding material handlingCrack resistanceWater vapor

The invention relates to a curing device and method for internal cooling and humidification of mass concrete. The curing device comprises an air refrigerating machine, an atomizer and a cold air pipeline; the cold air pipeline comprises a cold air main pipeline and a plurality of roundabout cold air buried pipes evenly pre-buried in the concrete; an air outlet of the air refrigerating machine anda mist exhaust opening of the atomizer are connected with the cold air main pipeline, the cold air main pipeline is simultaneously connected with the multiple cold air buried pipes, and control valvesare arranged at inlets of the cold air buried pipes; and a plurality of vent holes are formed in the pipe walls of the cold air buried pipes. The curing device adopts low-temperature atomized water vapor instead of refrigerated water as a refrigerant, thus the double effects of internal cooling and wet curing are achieved, drying shrinkage and temperature shrinkage can be reduced simultaneously,and crack resistance is effectively realized; large-scale engineering facilities for storage of cooling water are not needed on site; refrigerating air preparation is high in efficiency and low in cost; the pipe burst risk is avoided in the period of construction cooling; and after the cooling period is finished after concrete setting, water can be directly poured into a cooling pipe, and wet curing is further continued through water seepage.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

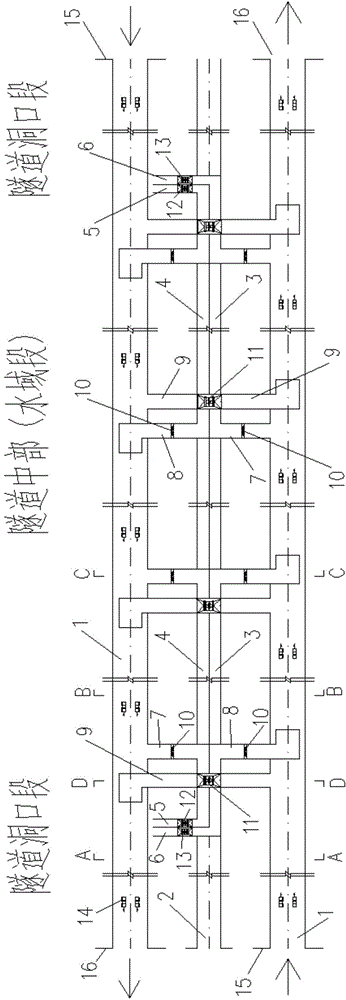

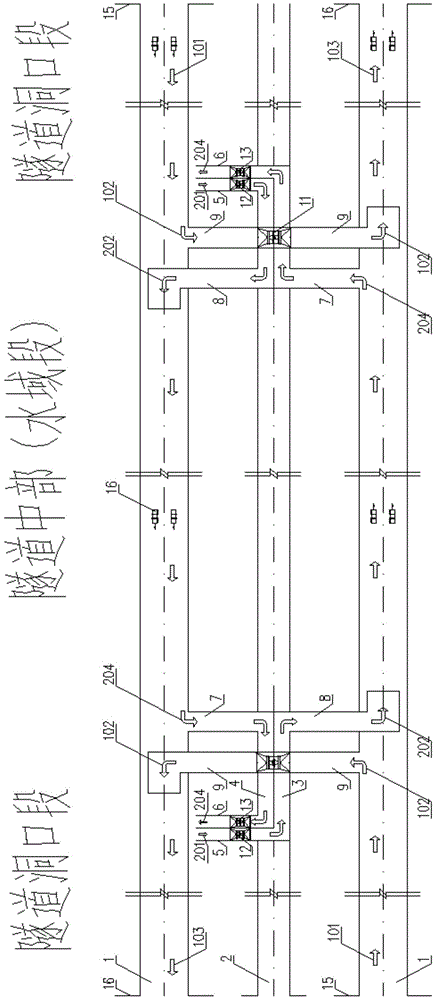

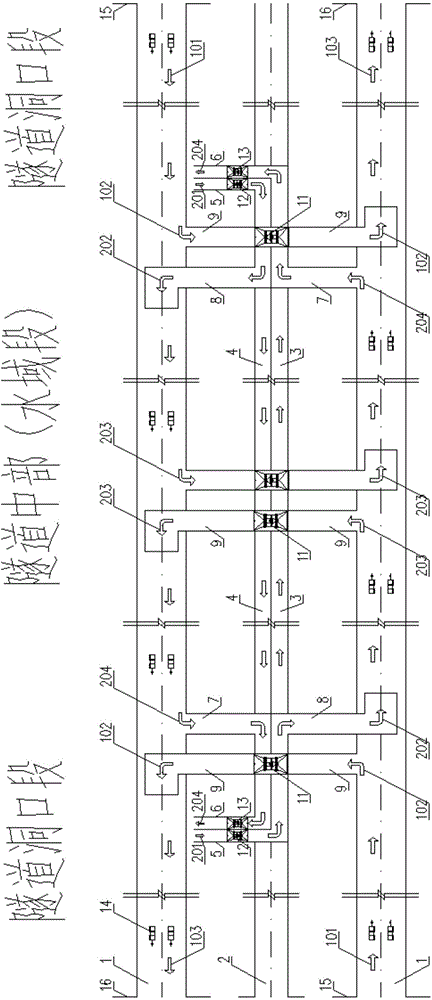

Underwater tunnel ventilation system and ventilation method

ActiveCN104675424ASimple structureLow costArtificial islandsTunnel/mines ventillationFresh airAgricultural engineering

The invention discloses an underwater tunnel ventilation system and ventilation method. Two ends of a service tunnel are provided with ventilation shaft exhaust ducts and ventilation shaft air delivery ducts and are connected with the exhaust ducts and the air delivery ducts; each exhaust duct is communicated with one main tunnel via an exhaust connection duct; each air deliver duct is communicated with the other main tunnel by an air delivery connection duct; a replacement ventilation connection duct is arranged between the two main tunnels to communicate the two main ducts; fresh air enters the air delivery duct from the ventilation shaft air delivery ducts on two ends of the service tunnel, and enters one main tunnel via the air delivery connection duct; replacement axial fans are started to cause air flow in one main tunnel to enter the other main tunnel via the replacement ventilation connection duct, and polluted air is discharged from the ventilation shaft exhaust ducts via the exhaust connection duct and the exhaust ducts. According to the ventilation system, the service tunnel is used as an air duct to import fresh air into the tunnel and discharge the polluted air, and the difficulty that an artificial island ventilation shaft needs to be arranged in every multiple kilometres for a part, which passes through a water area, of the tunnel for a long distance is solved.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

On-line changing method of hot blast main duct of blast furnace

ActiveCN101899545ASolve the technical problems of online partial replacementShort construction periodBlast furnace detailsHeating stovesBrickMaterials science

The invention relates to an on-line changing method of a hot blast main duct of a blast furnace, belonging to the field of construction of a pipeline system used for gas distribution in a brick-built hot blast furnace. The on-line changing method of the hot blast main duct of the blast furnace sequentially comprises the following steps after the hot blast furnace stops producing and each energy medium pipeline is closed: disassembling the hot blast main duct; plugging pipeline openings positioned on both ends of a section which is not disassembled; building the three-way part of the hot blast main duct on the ground; lifting the hot blast main duct; building the hot blast main duct on line; and disassembling a heat-insulation plugging wall. The invention has short construction period, low cost and little influence on production.

Owner:MCC5 GROUP CORP SHANGHAI

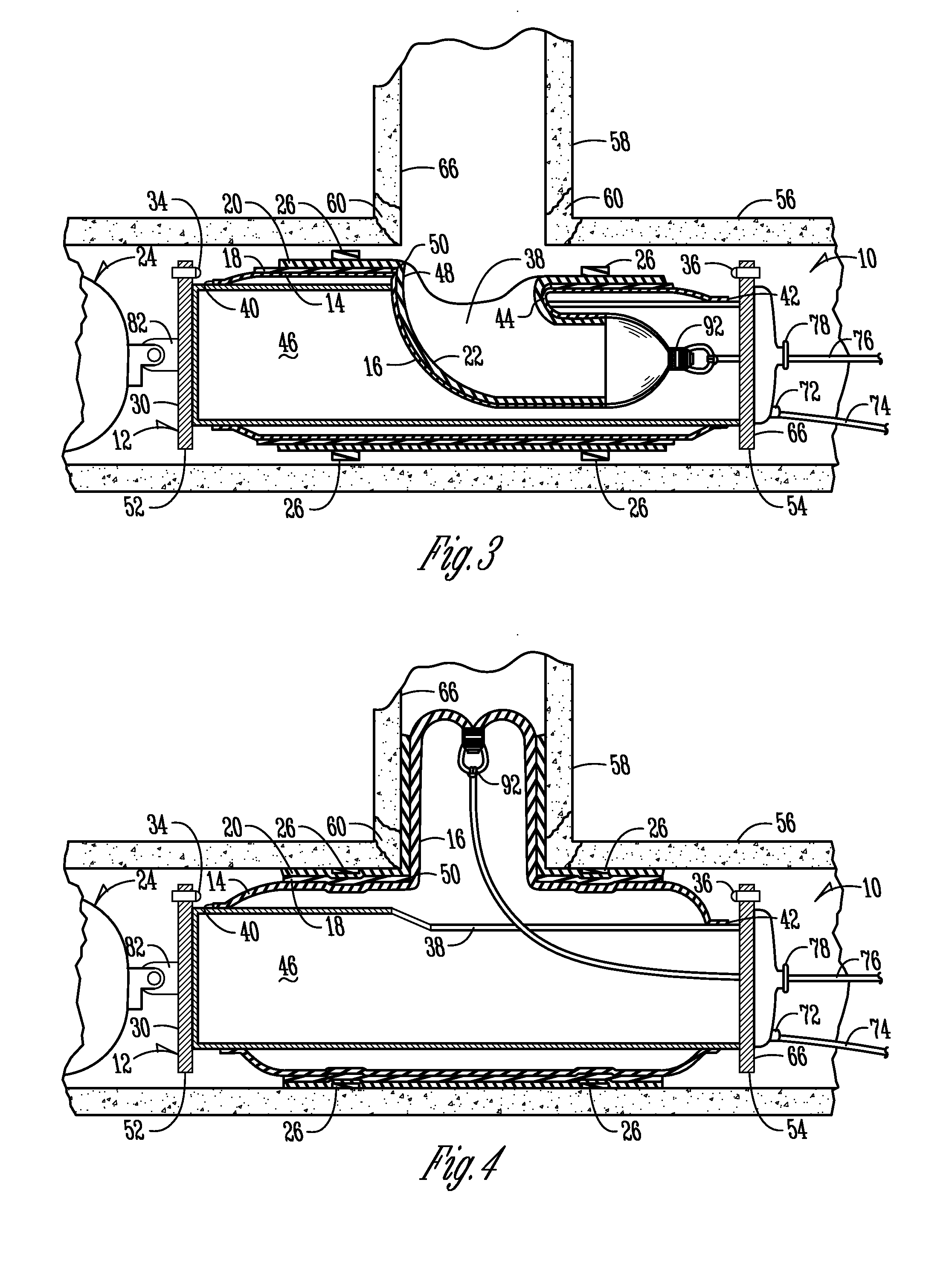

Apparatus and method for lining a pipe junction

A liner assembly is provided for repairing a pipe junction. The liner assembly includes a first and second camera and a containment bladder all operably connected to a launcher device, and which are used in combination by a user in a remote location to position and align the liner assembly in a main pipe, adjacent a lateral pipe, wherein no external access to the lateral pipe is available. The user will use images from the cameras to send control information to a positioning device, which positions and aligns a liner assembly with a lateral pipe. The liner assembly is then used to repair damage to the lateral pipe and the juncture between the main and lateral pipes.

Owner:LMK TECH LLC

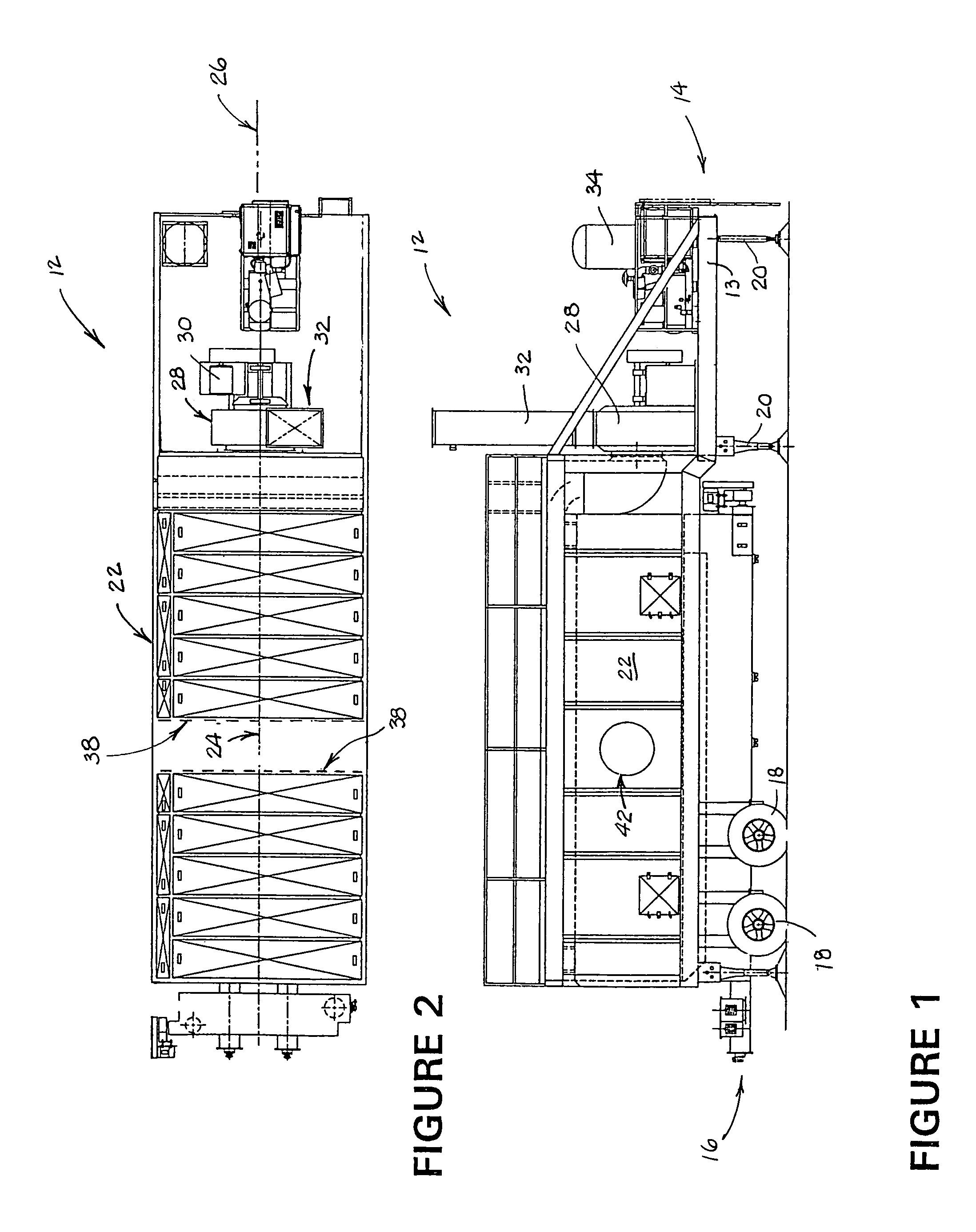

Assembly for removing dust from gas stream

A dust collection assembly includes a primary collection assembly and a secondary collection assembly and may be connected to a source of gas having dust entrained therein. The primary collection assembly includes a primary duct having an inlet end and an outlet end. A first apparatus is mounted within the primary duct imparts a swirling motion to the gas which enters through the inlet end of the duct. A second apparatus is located downstream of the first apparatus for removing a portion of the dust entrained in the gas. The secondary collection assembly is in fluid communication with the outlet end of the primary collection assembly, and it includes a plurality of filter bags. The dust collection assembly also includes a fan that is in fluid communication with the secondary collection assembly.

Owner:ASTEC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com