Patents

Literature

44results about How to "The effect is outstanding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

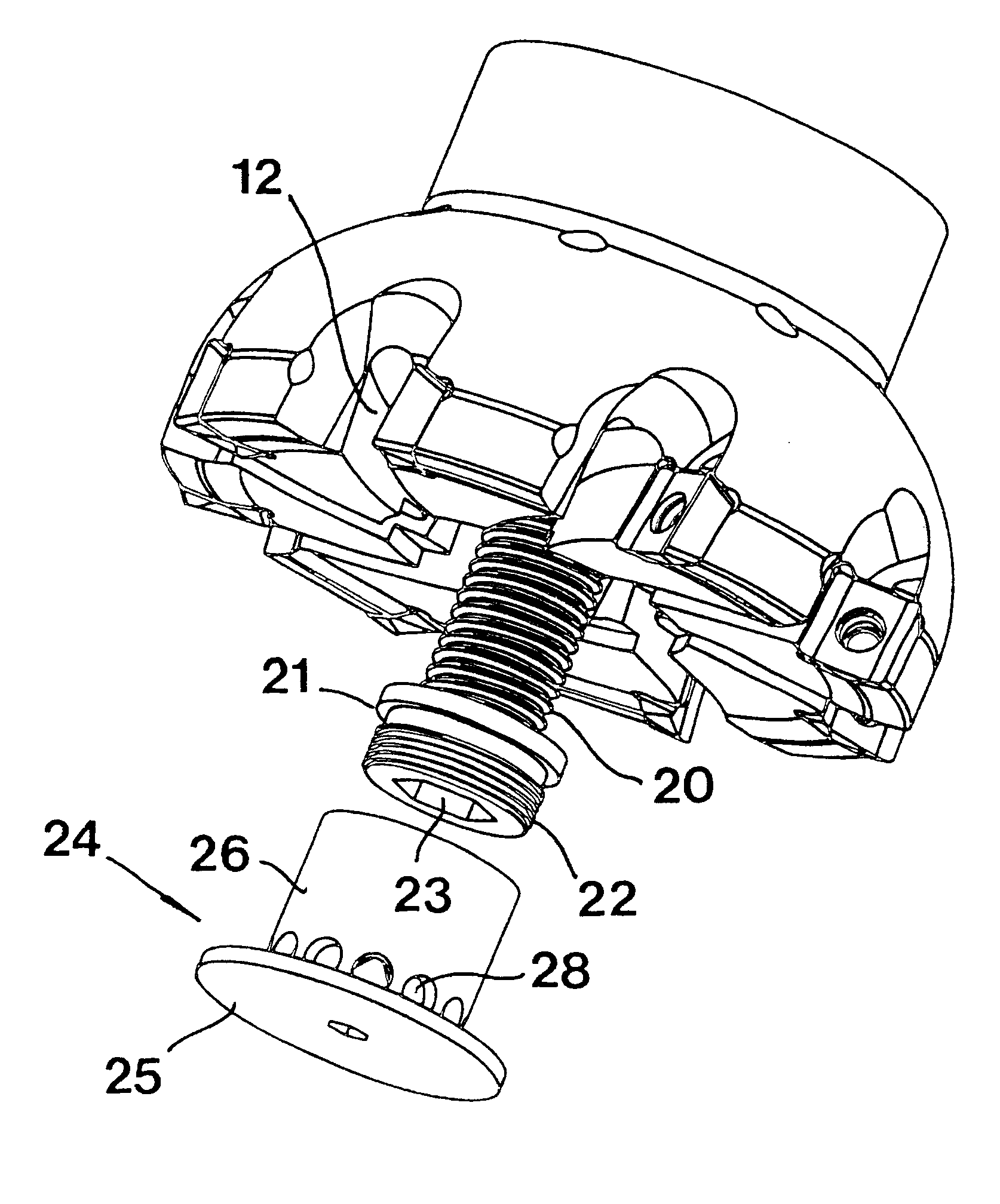

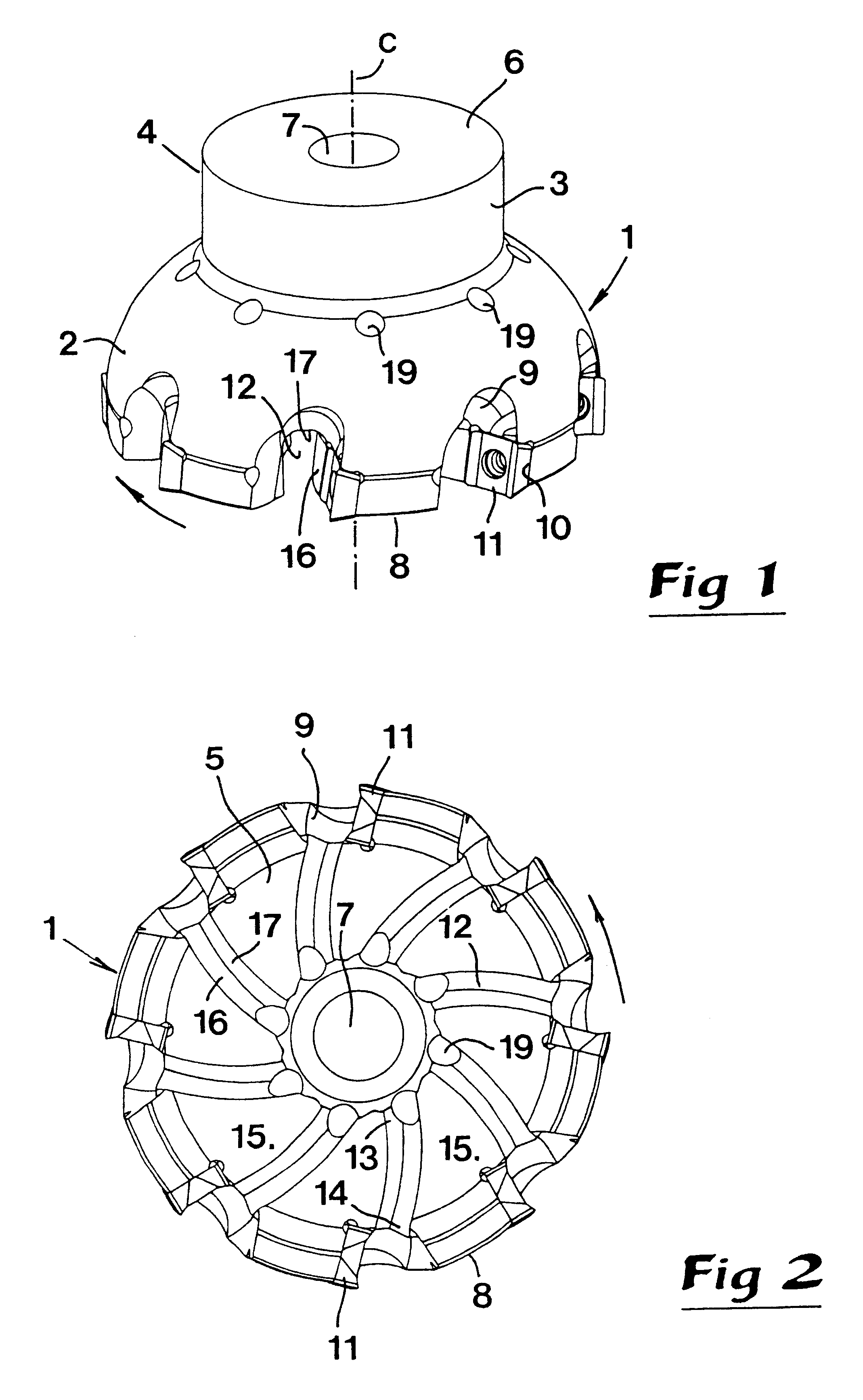

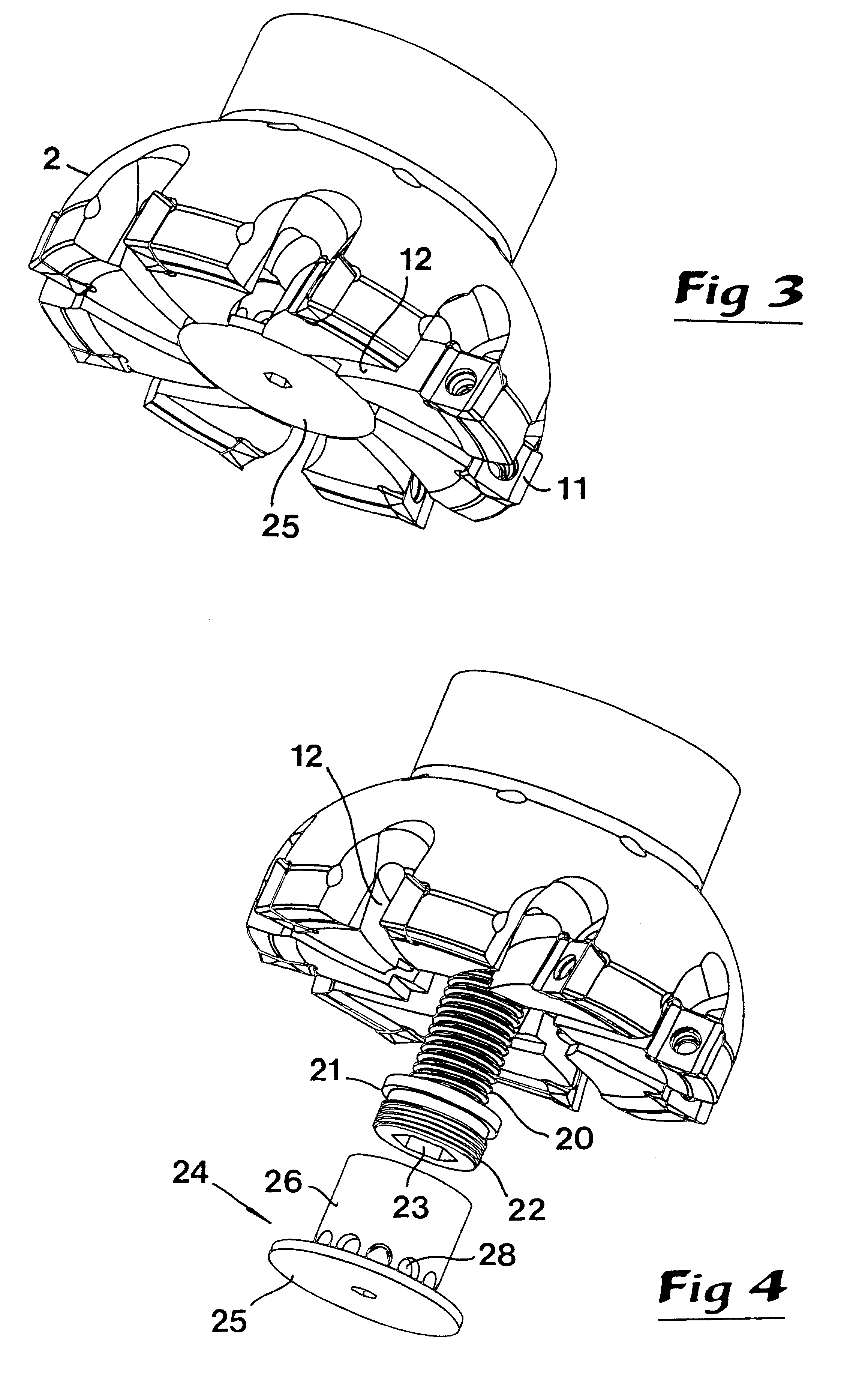

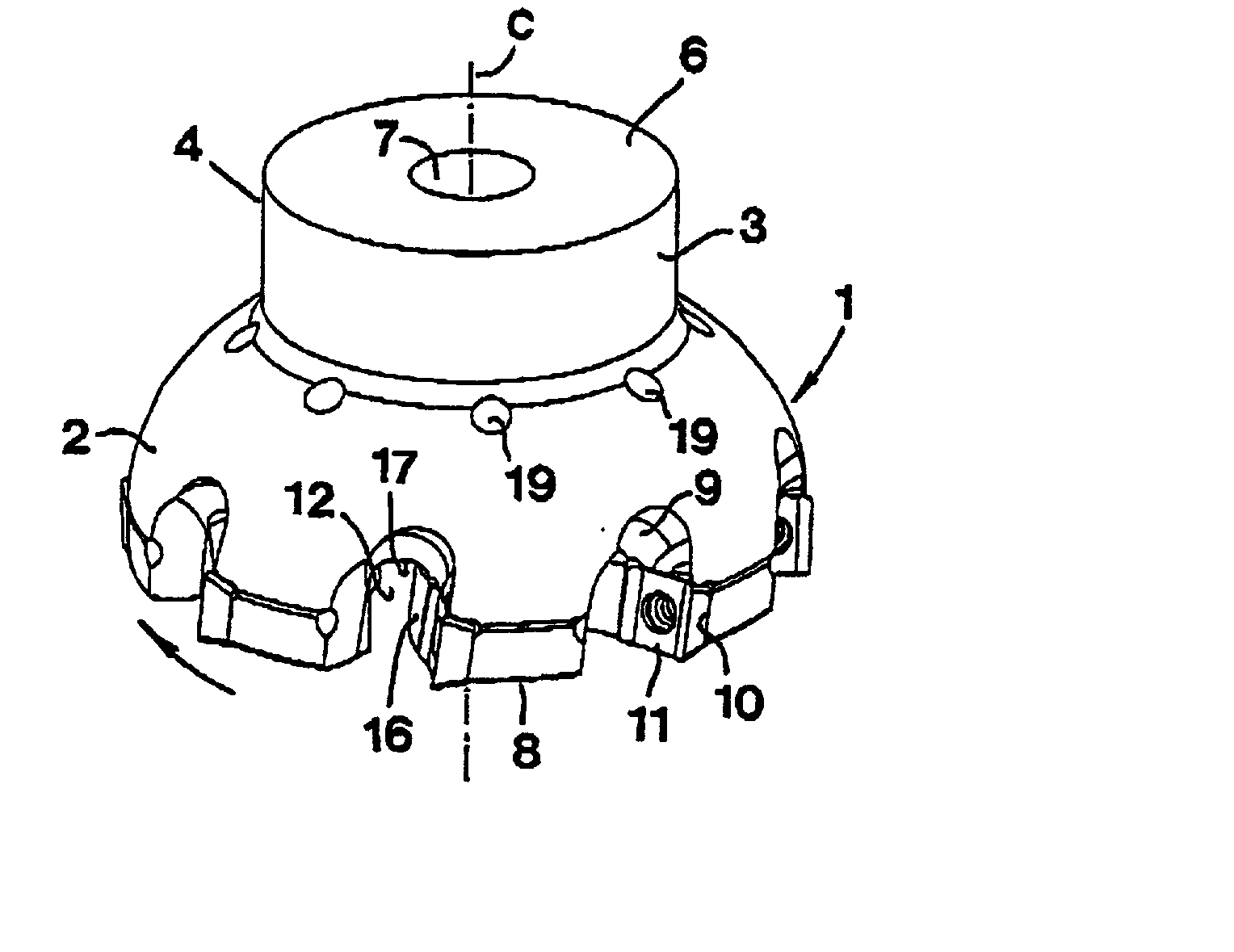

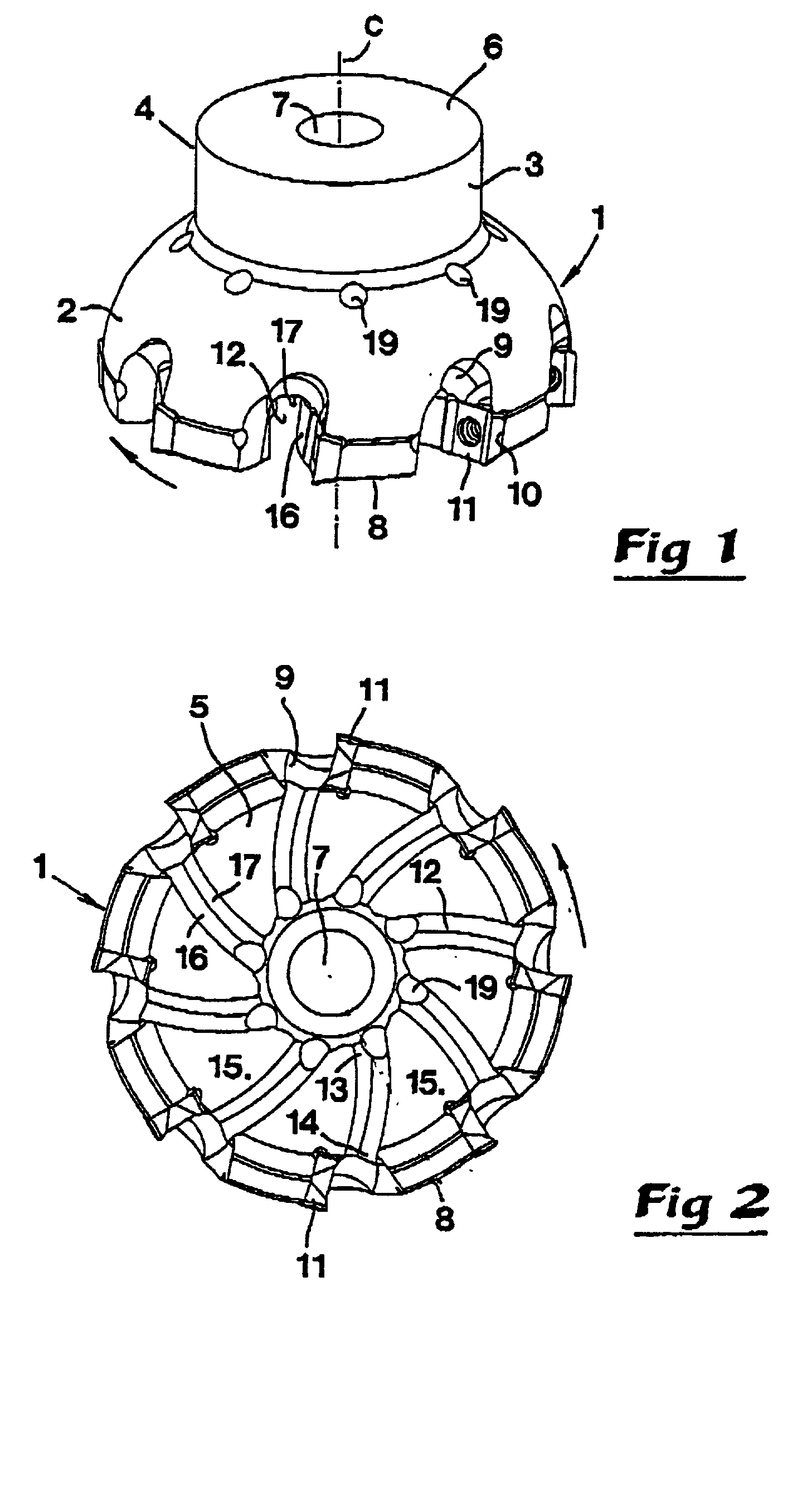

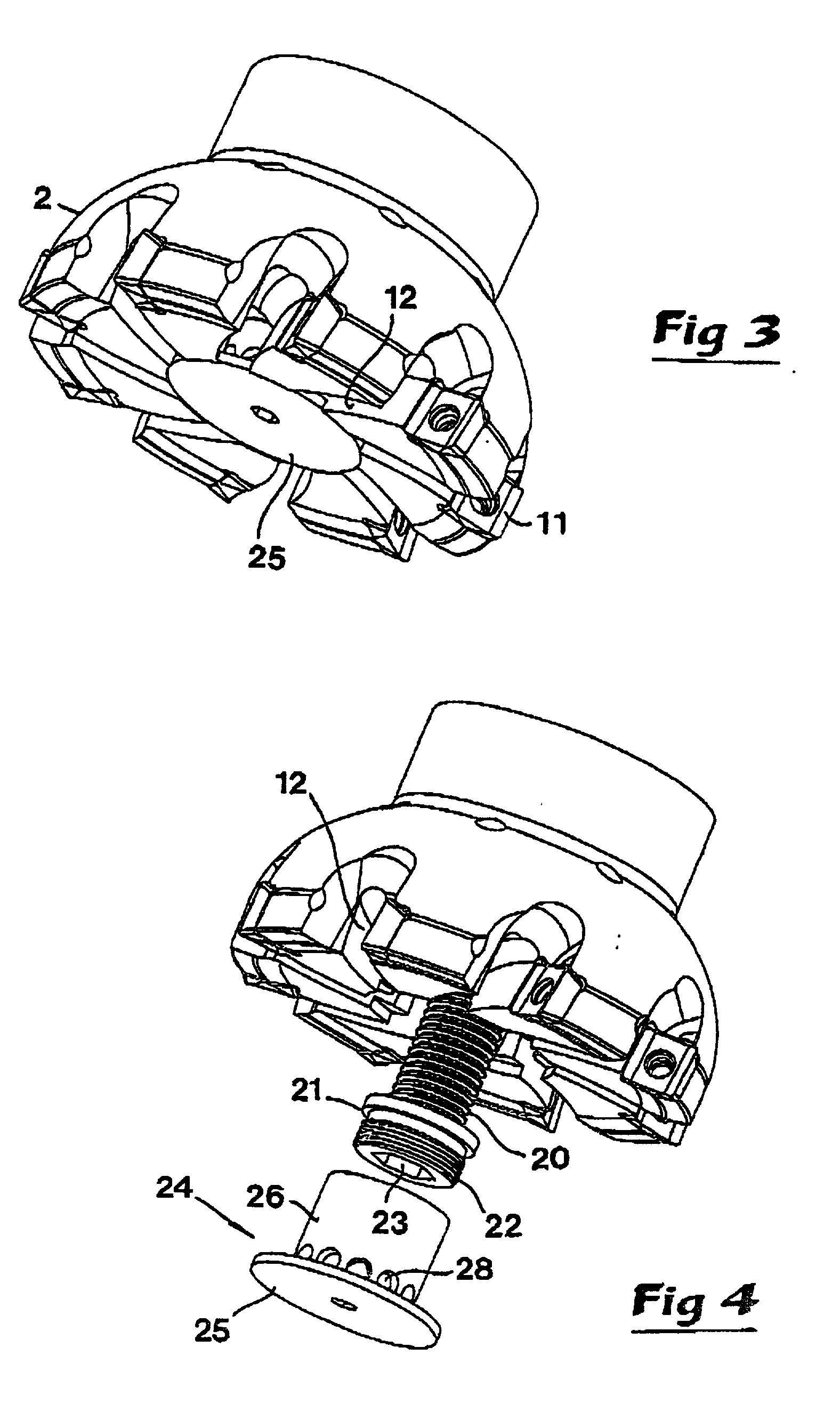

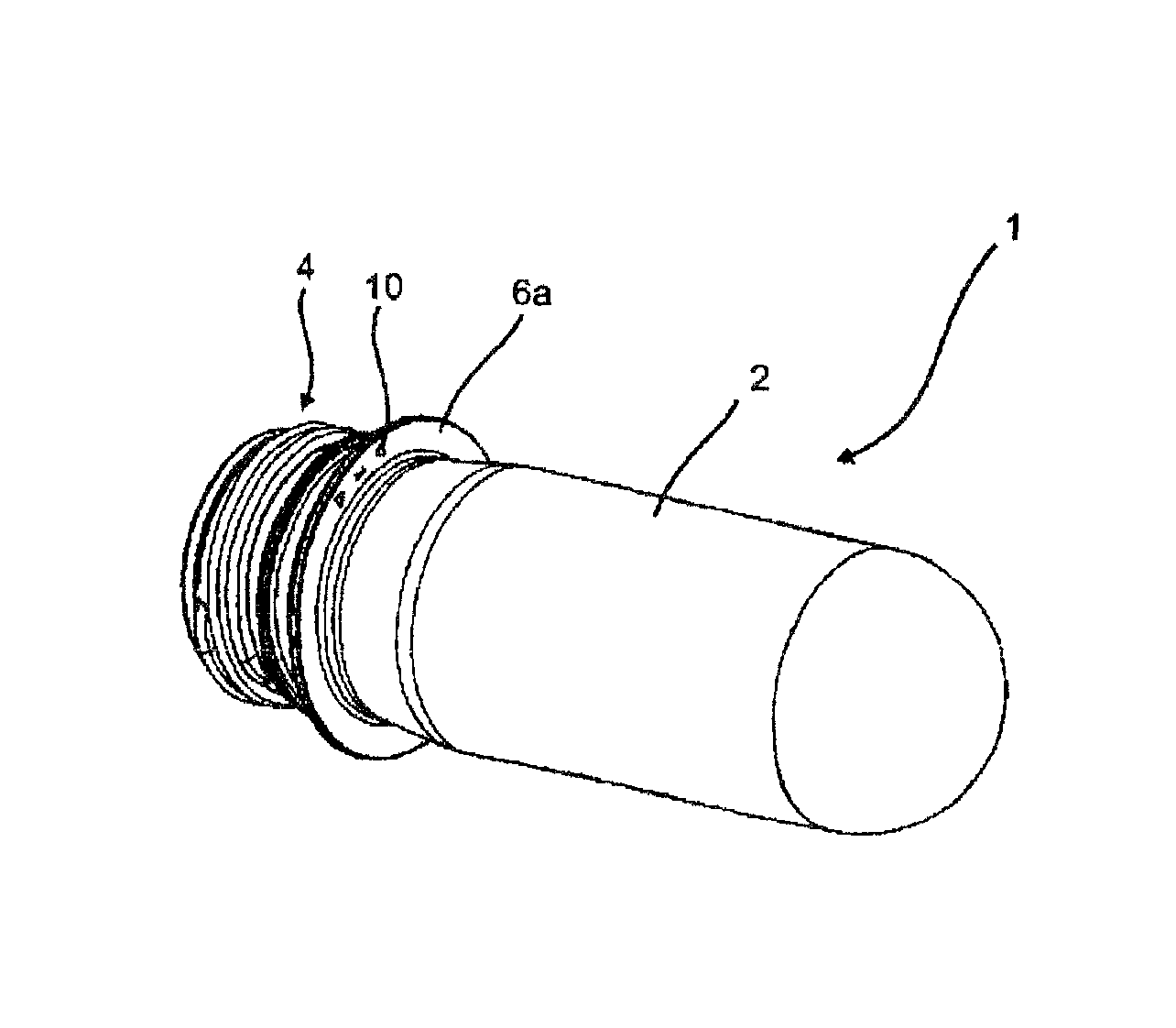

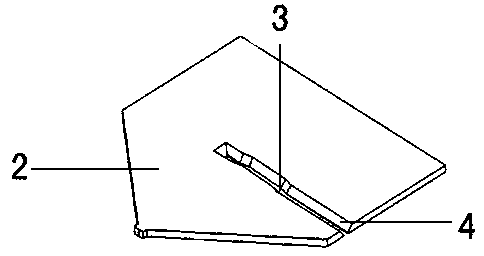

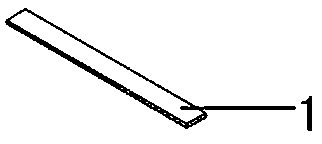

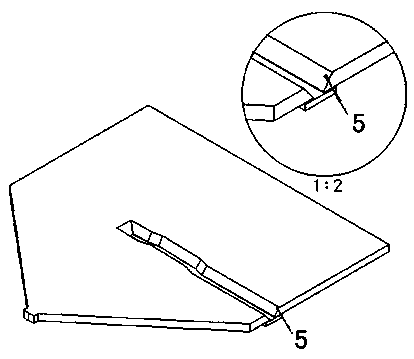

Tool for chip removing machining and having fluid-conducting branch ducts

InactiveUS6595727B2The effect is outstandingManufactured in simple and inexpensiveMilling cuttersTurning toolsEngineeringBranch Duct

Owner:SANDVIK INTELLECTUAL PROPERTY AB

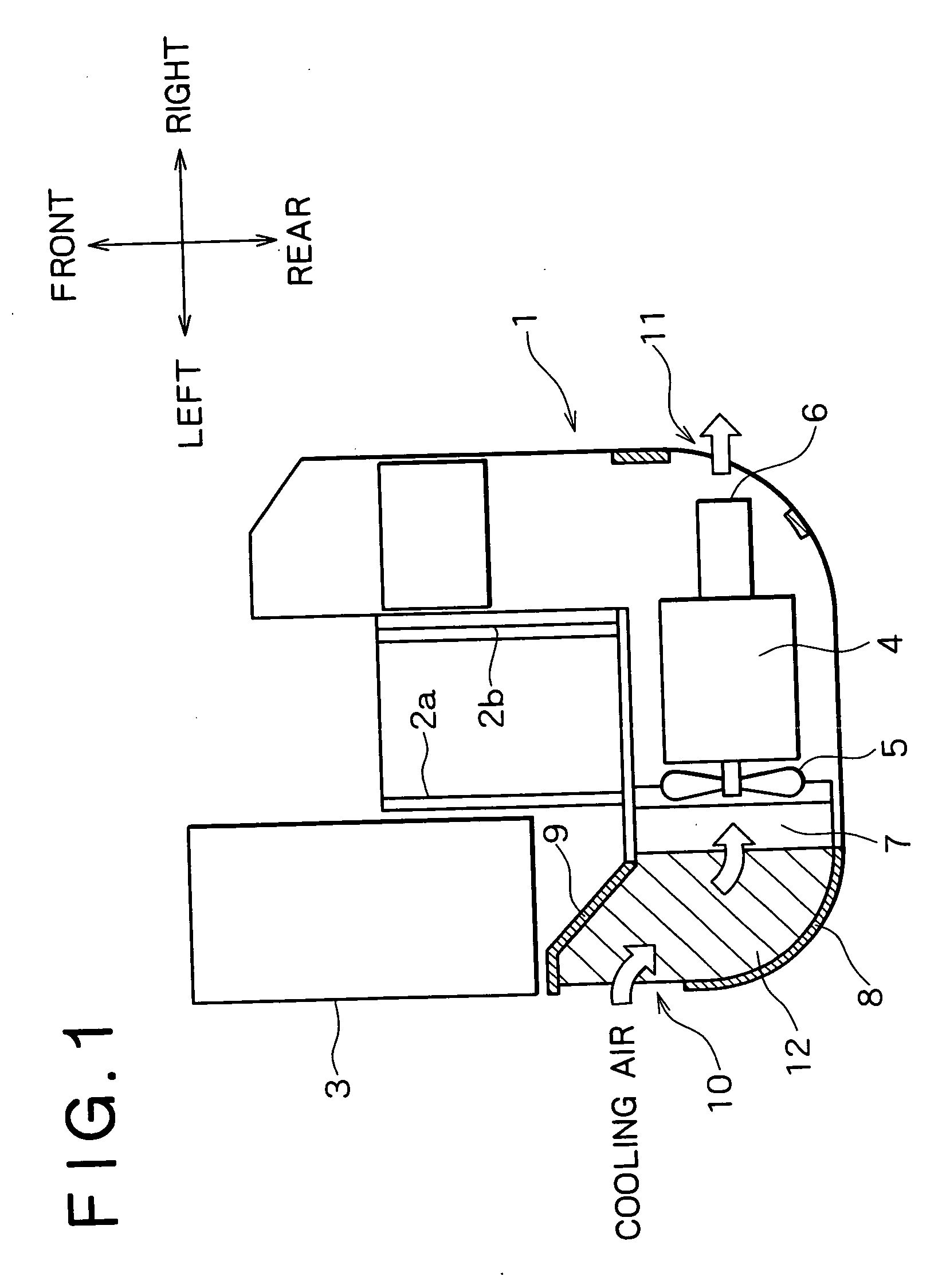

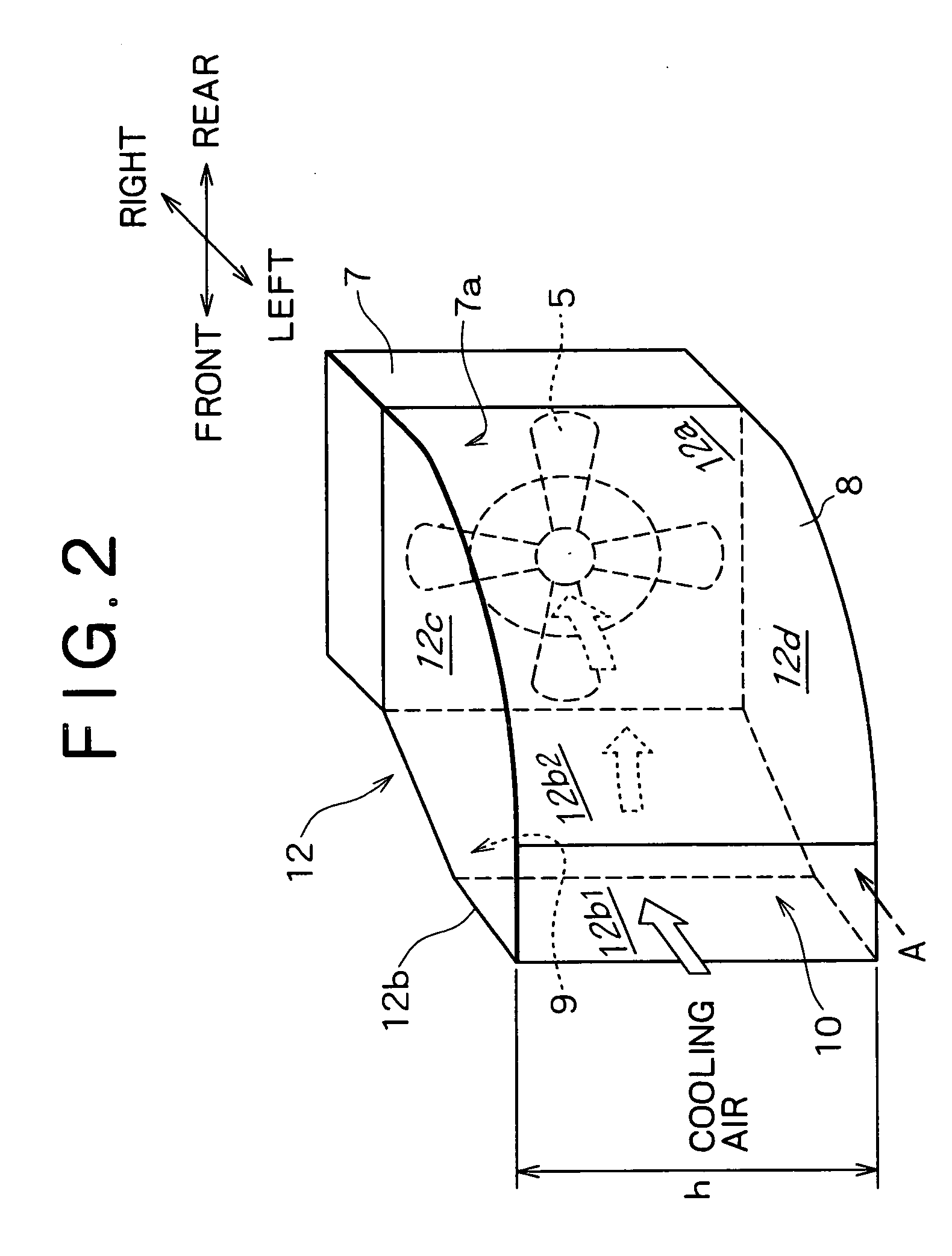

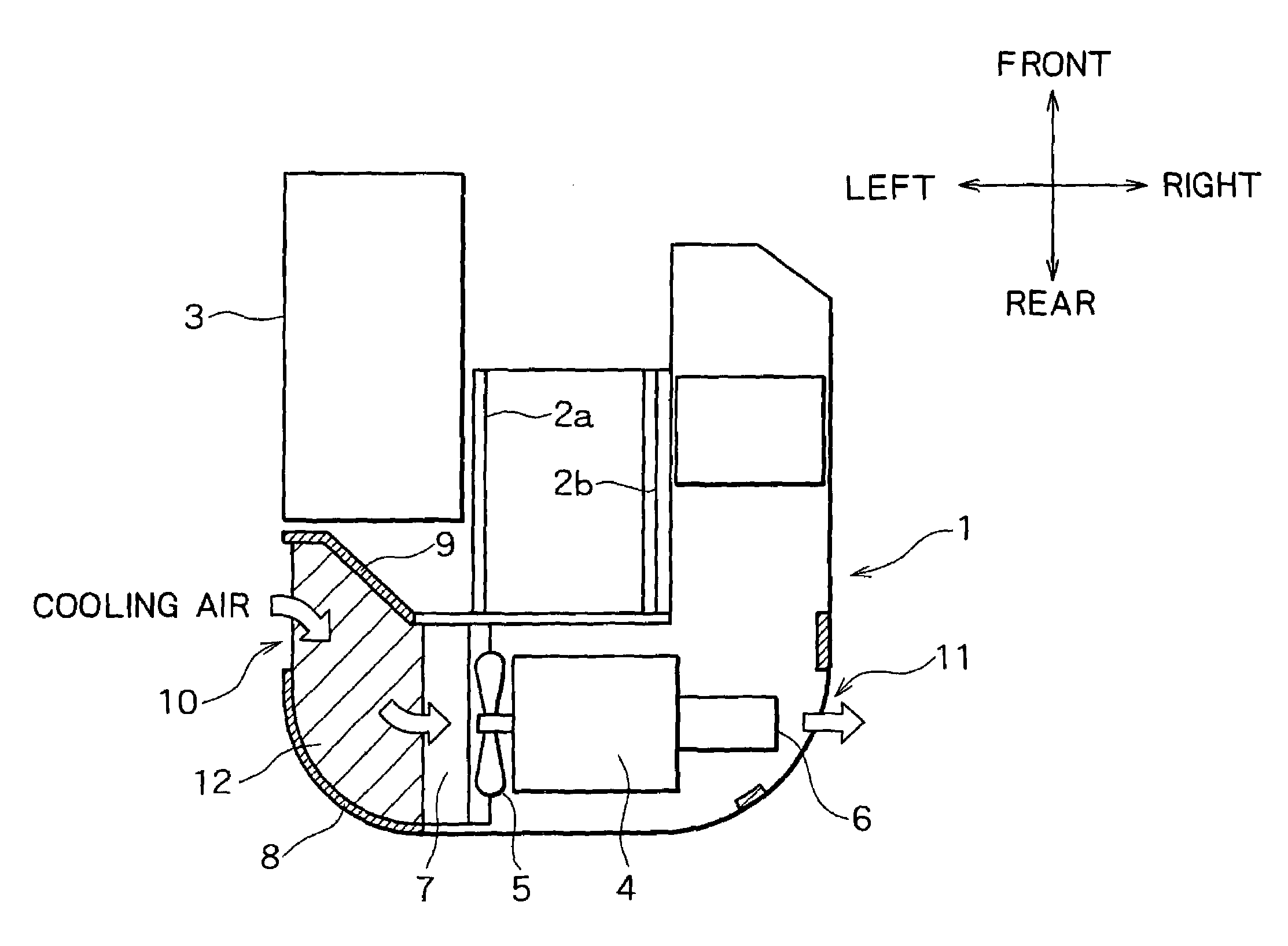

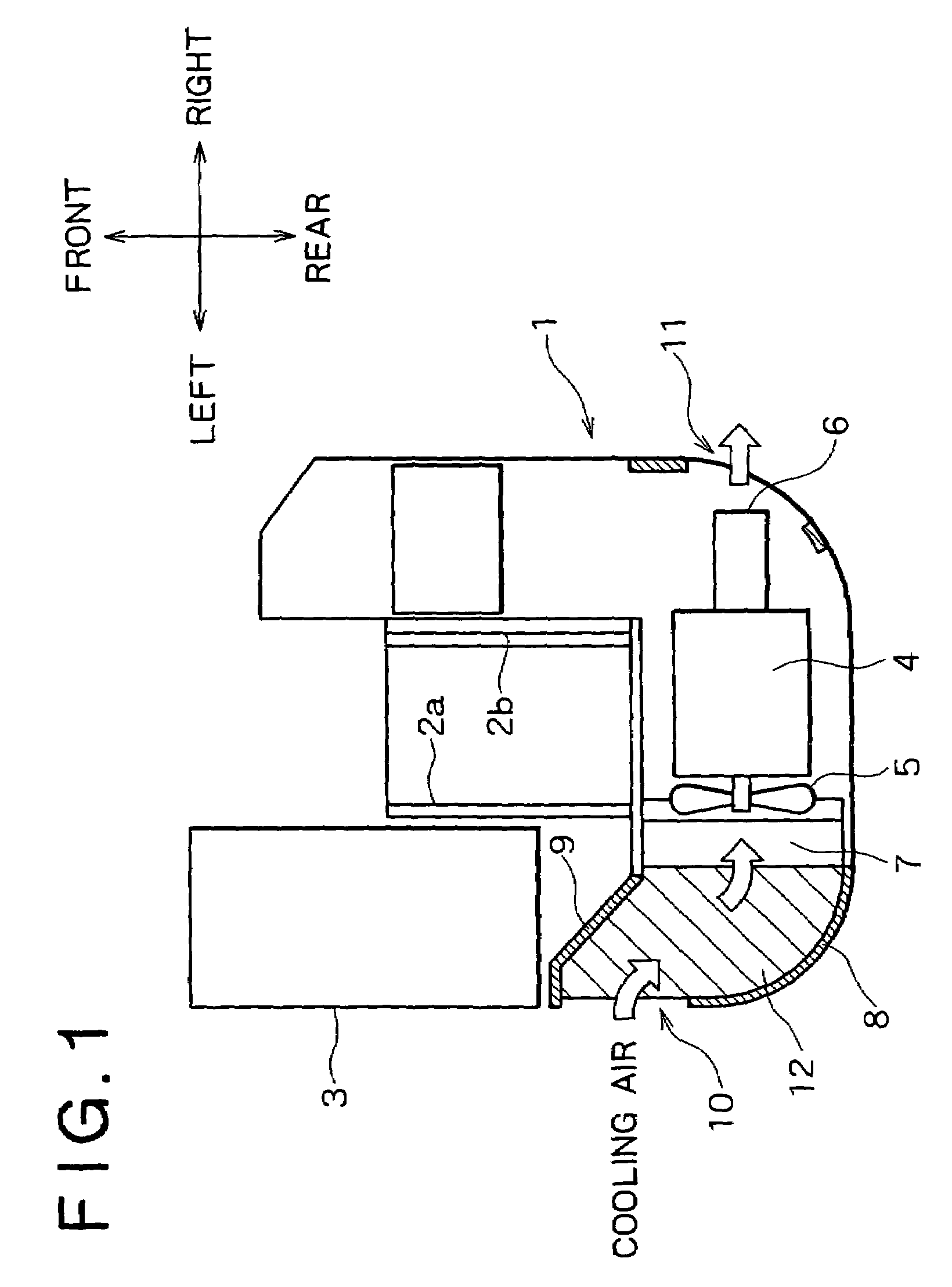

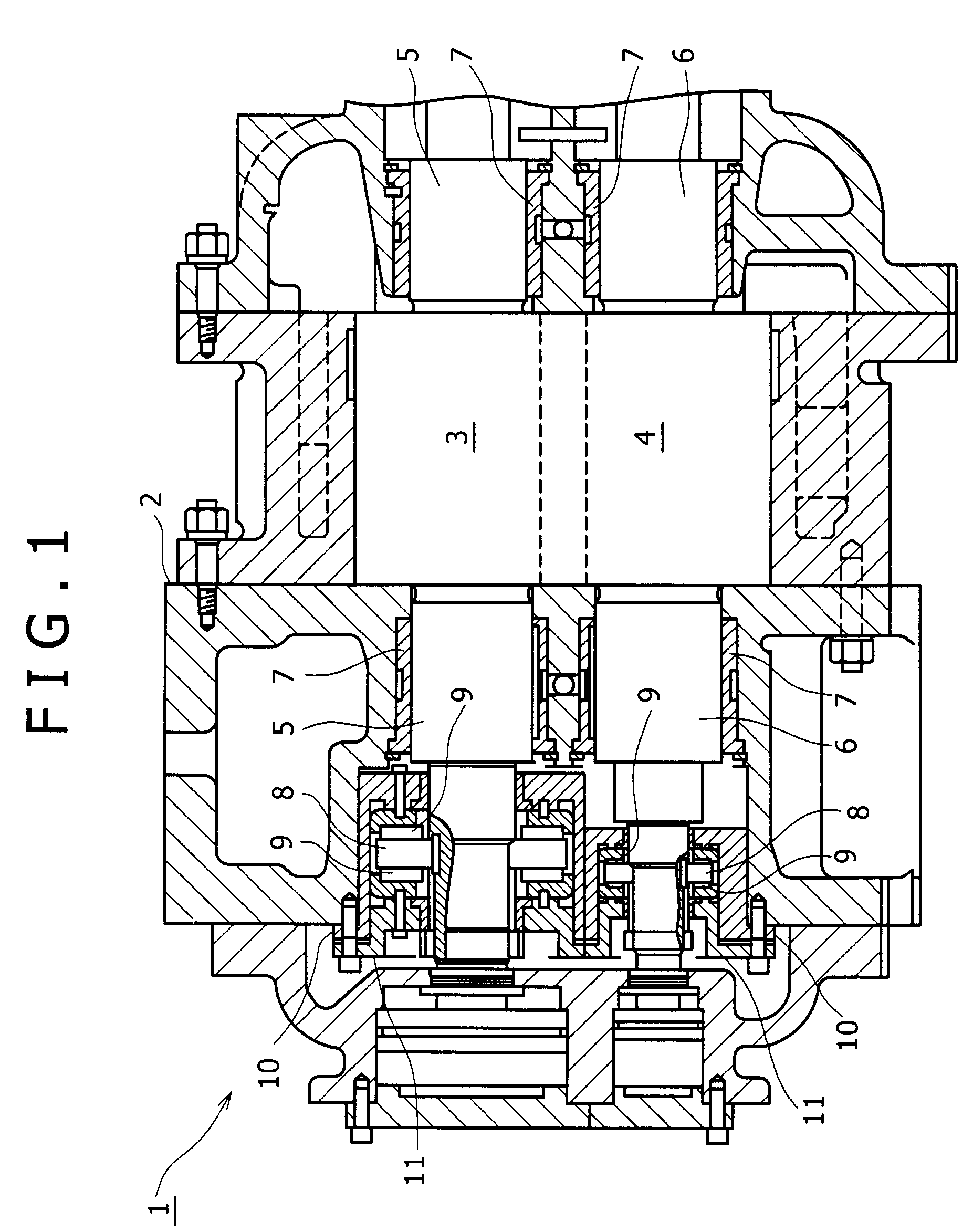

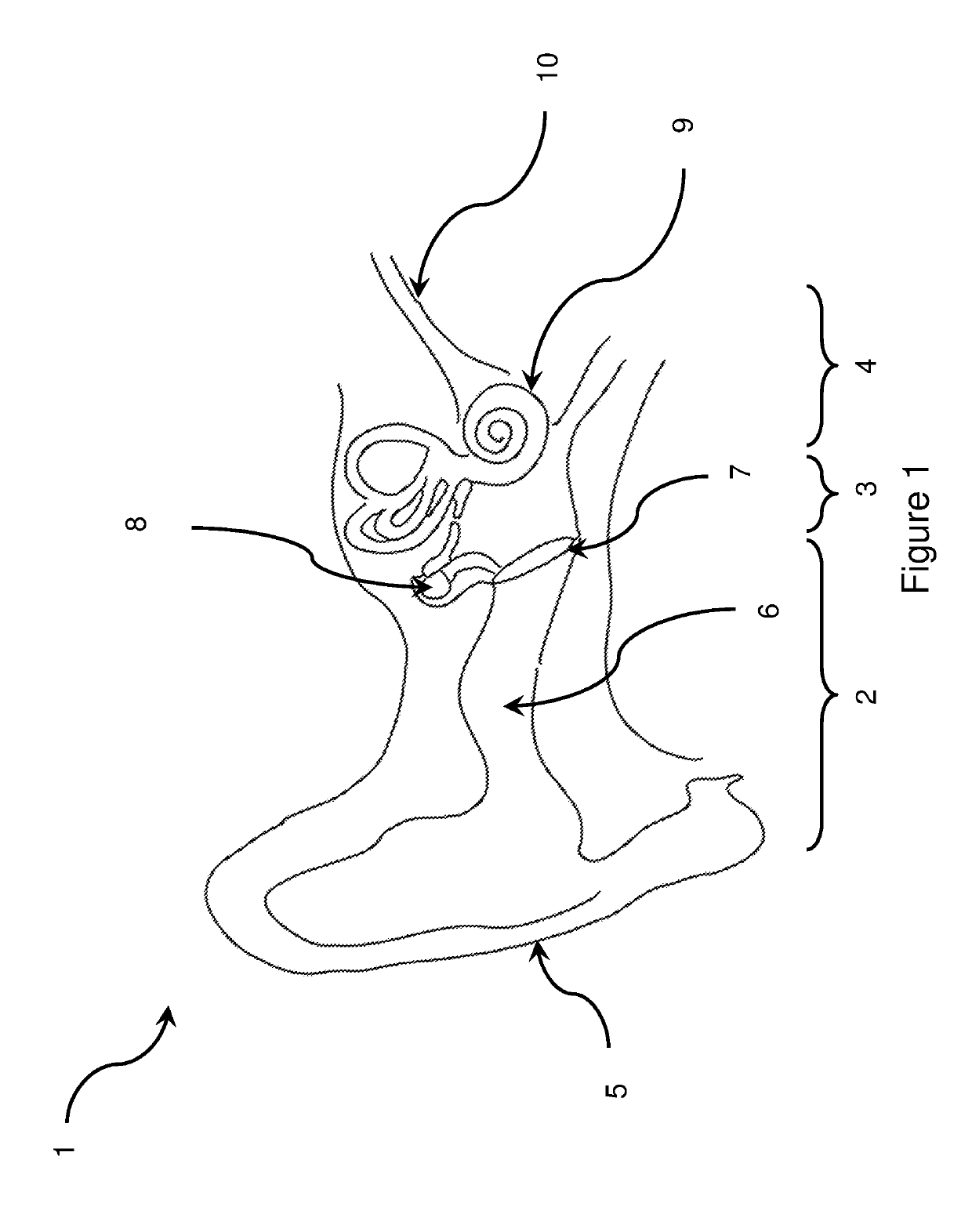

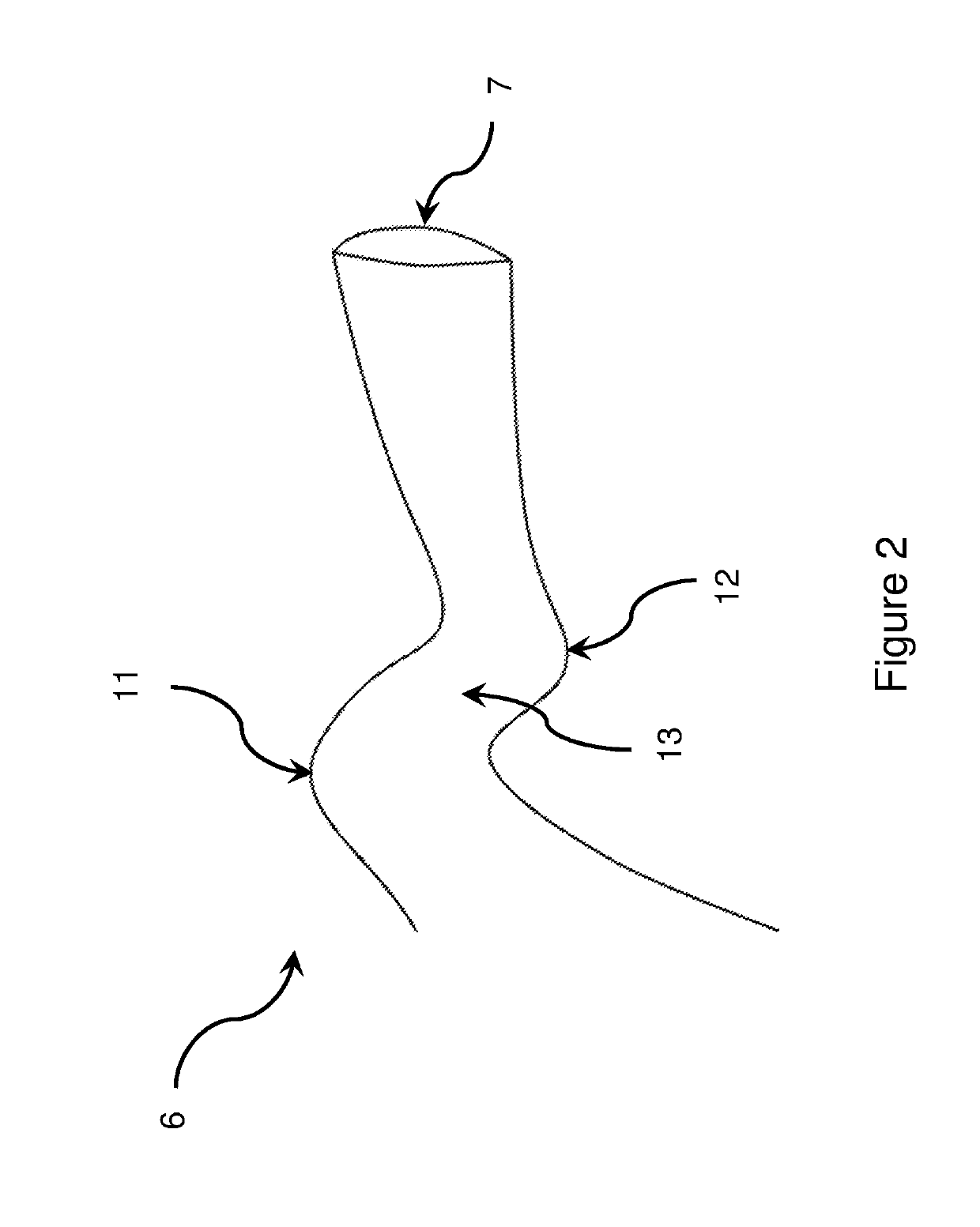

Construction machine

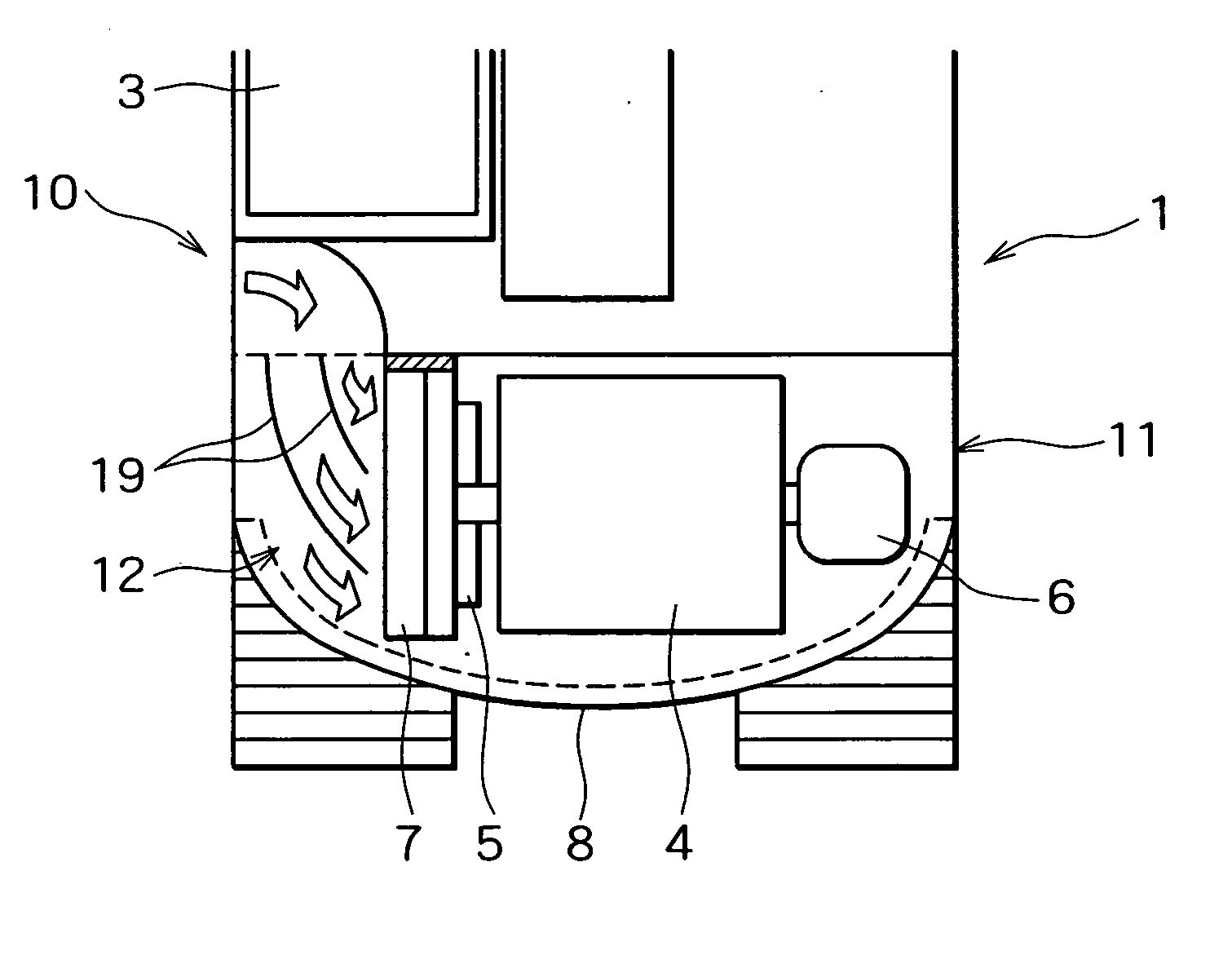

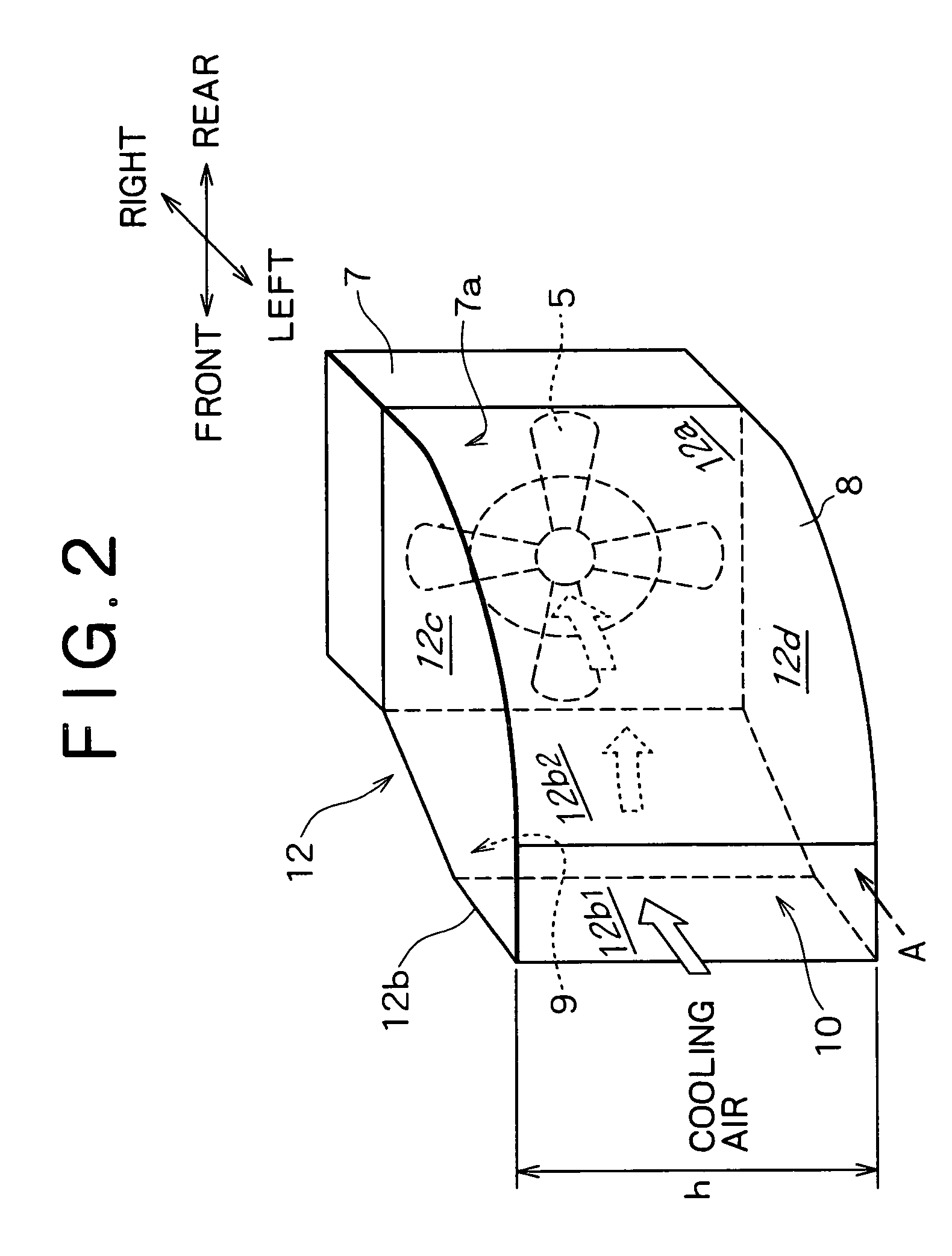

ActiveUS20060144350A1Outstanding engine noise reducing effectImprove noiseCoolant flow controlAir coolingEngineeringHeat exchanger

Engine noise of a construction machine is effectively reduced without reducing cooling performance and with an increase in the height of a body cover kept minimum. To achieve the above, an air-intake opening portion (10) and an air discharge opening portion (11) are arranged in a body cover (8) of an upper rotating body (1), and a cooling fan (5) in an engine room covered by the body cover (8) is driven, taking cooling air in from the air-intake opening portion (10) to cool a heat exchanger (7) in the body cover (8) and discharging the air from the air discharge opening portion (11). The air-intake opening portion (10) is laterally offset from a position facing to a ventilation surface of the heat exchanger (7). Alternatively, plural air-intake opening portions are located in a scattered manner such that the plural air-intake opening portions include the offset air-intake opening portion offset from the ventilation surface of the heat exchanger (7).

Owner:KOBELCO CONSTR MASCH CO LTD

Electrode additive

InactiveUS7282528B2The effect is outstandingStabilizing fluoropolymer dispersionFilm/foil adhesivesFibre treatmentPolymer scienceFluoropolymer

An electrode additive comprising an aqueous fluoropolymer dispersion, wherein the aqueous fluoropolymer dispersion is stabilized by the use of a surfactant that does not substantially remain in an electrode coating film after a drying step during electrode production.

Owner:DAIKIN IND LTD

Construction machine

ActiveUS7451843B2Improve noiseLoud noiseAir coolingSoil-shifting machines/dredgersEngineeringEngine room

Engine noise of a construction machine is effectively reduced without reducing cooling performance and with an increase in the height of a body cover kept minimum. To achieve the above, an air-intake opening portion (10) and an air discharge opening portion (11) are arranged in a body cover (8) of an upper rotating body (1), and a cooling fan (5) in an engine room covered by the body cover (8) is driven, taking cooling air in from the air-intake opening portion (10) to cool a heat exchanger (7) in the body cover (8) and discharging the air from the air discharge opening portion (11). The air-intake opening portion (10) is laterally offset from a position facing to a ventilation surface of the heat exchanger (7). Alternatively, plural air-intake opening portions are located in a scattered manner such that the plural air-intake opening portions include the offset air-intake opening portion offset from the ventilation surface of the heat exchanger (7).

Owner:KOBELCO CONSTR MASCH CO LTD

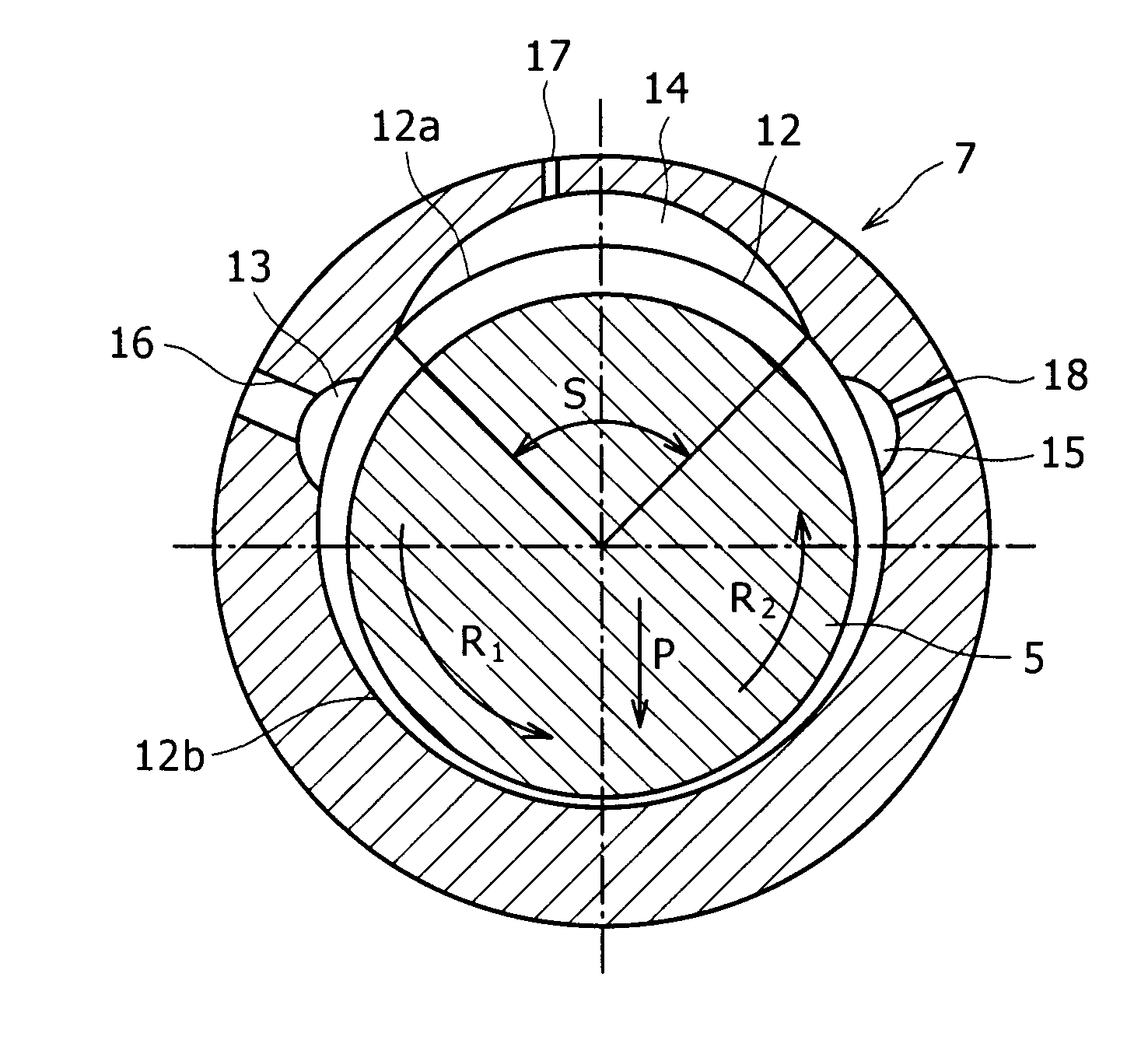

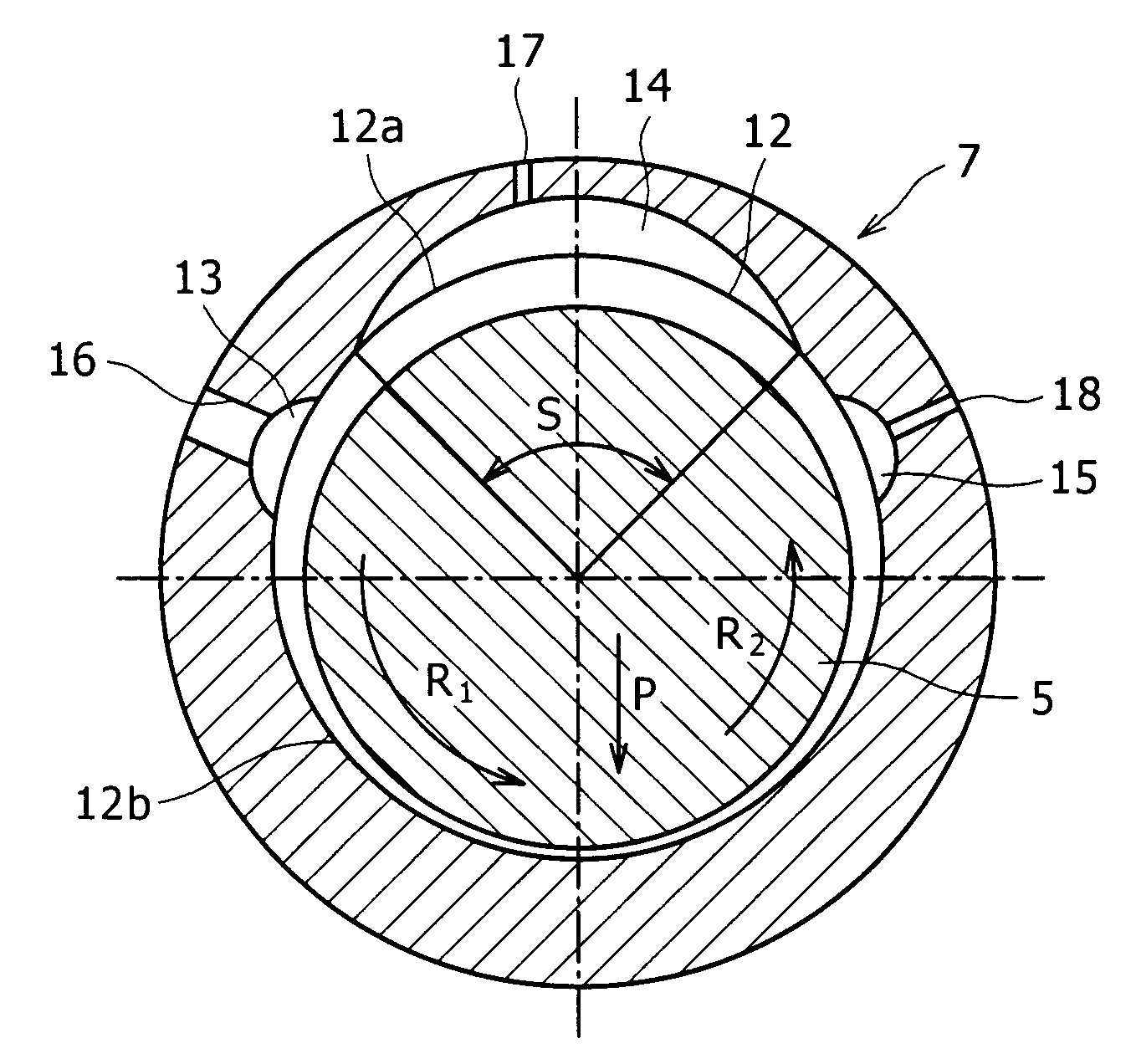

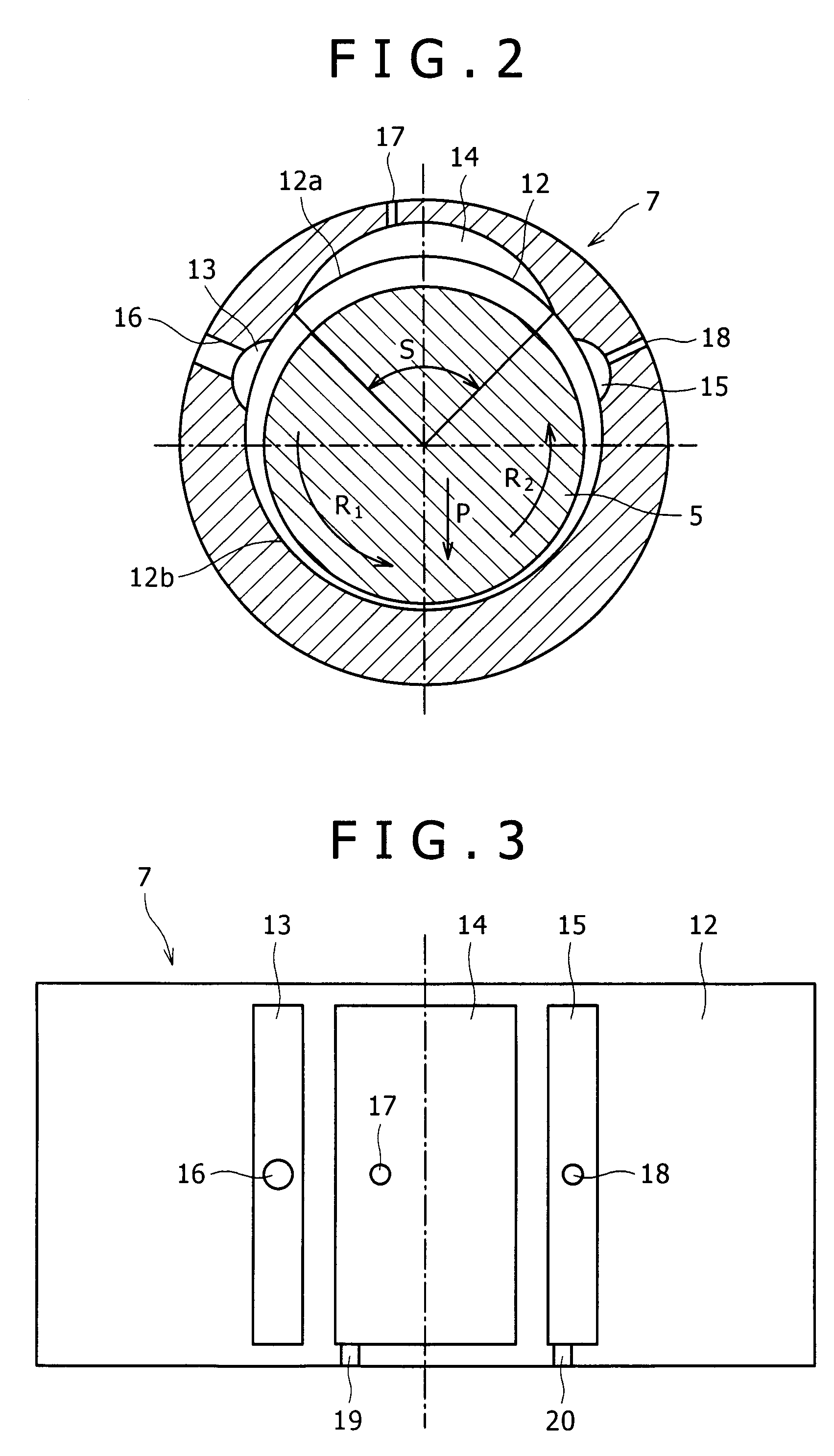

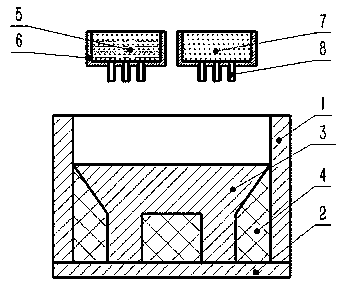

Compressor bearing

ActiveUS20080056632A1Reduce loadOutstanding rotor shaft cooling effectCrankshaftsCrossheadsBearing surfaceOil pressure

In a compressor bearing for supporting a rotor shaft of a compressor, a first oil groove is formed in a bearing surface on the side opposite to a bearing load acting direction, a second oil groove is formed in a position adjacent to the first oil groove in an anti-rotational direction, a first oil channel and a second oil channel communicating with the first oil groove and the second oil groove, respectively, to supply oil to the first and second oil grooves from an exterior, common oil supply source are provided, a circumferential length of the second oil groove is set larger than that of the first oil groove, and a minimum value of a sectional area perpendicular to the longitudinal direction of the second oil channel is set smaller than that of a sectional area perpendicular to the longitudinal direction of the first oil channel. The compressor bearing of such a configuration is small in load induced by oil pressure and exhibits an outstanding rotor shaft cooling effect.

Owner:KOBE STEEL LTD

Tool for chip removing machining and having fluid-conducting branch ducts

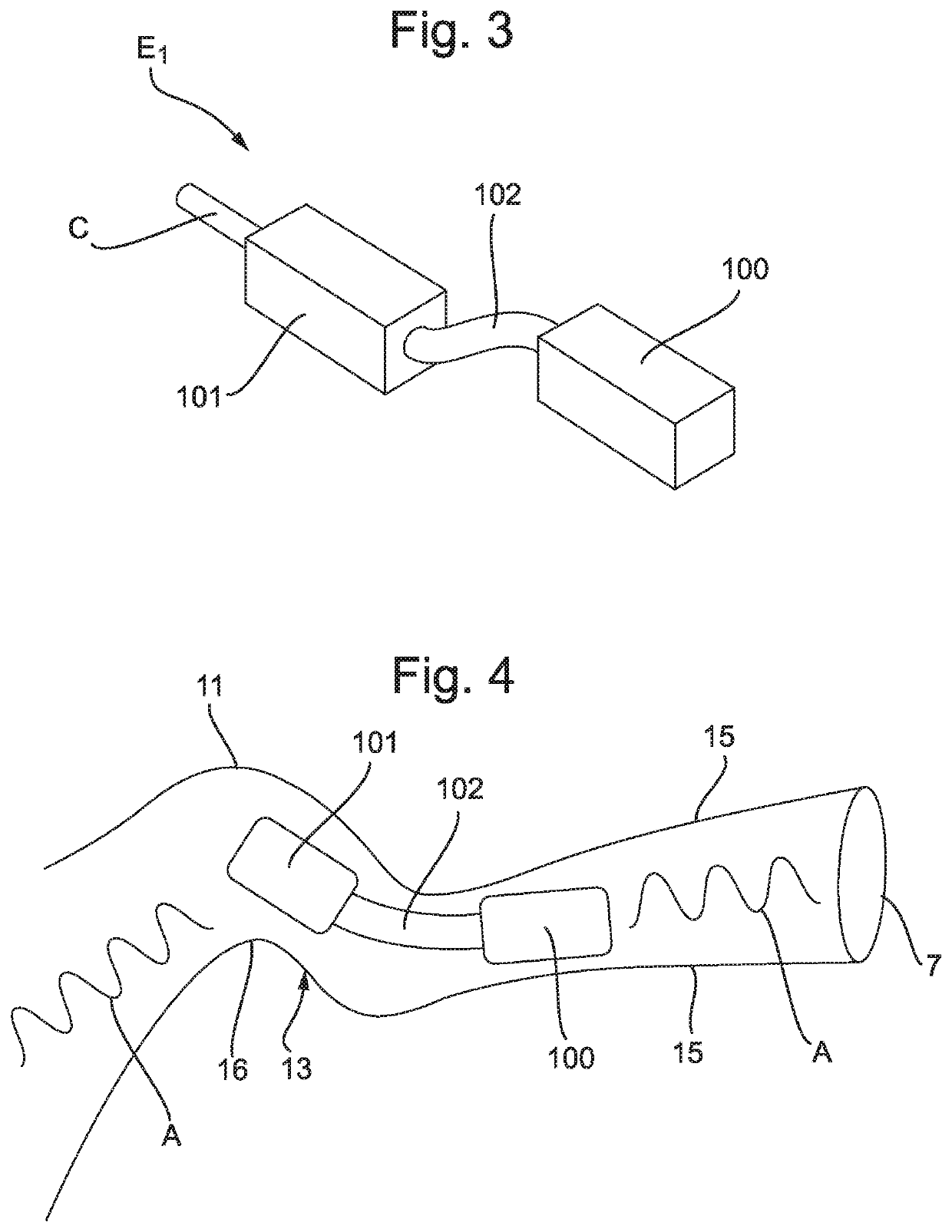

InactiveUS20020009339A1The effect is outstandingManufactured in simple and inexpensiveMilling cuttersTurning toolsEngineeringBranch Duct

A milling tool includes a rotary cutting head having an end surface in which grooves are formed. The grooves communicate with a duct extending coaxially completely through the center of the cutting head to conduct cooling / lubricating fluid to cutting inserts mounted at outer ends of the grooves. The grooves induce a flow of fluid from inner ends of the grooves to the outer ends in response to rotation of the cutting head. A removable deflector can be attached to the end surface to deflect fluid from the main duct to the grooves.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

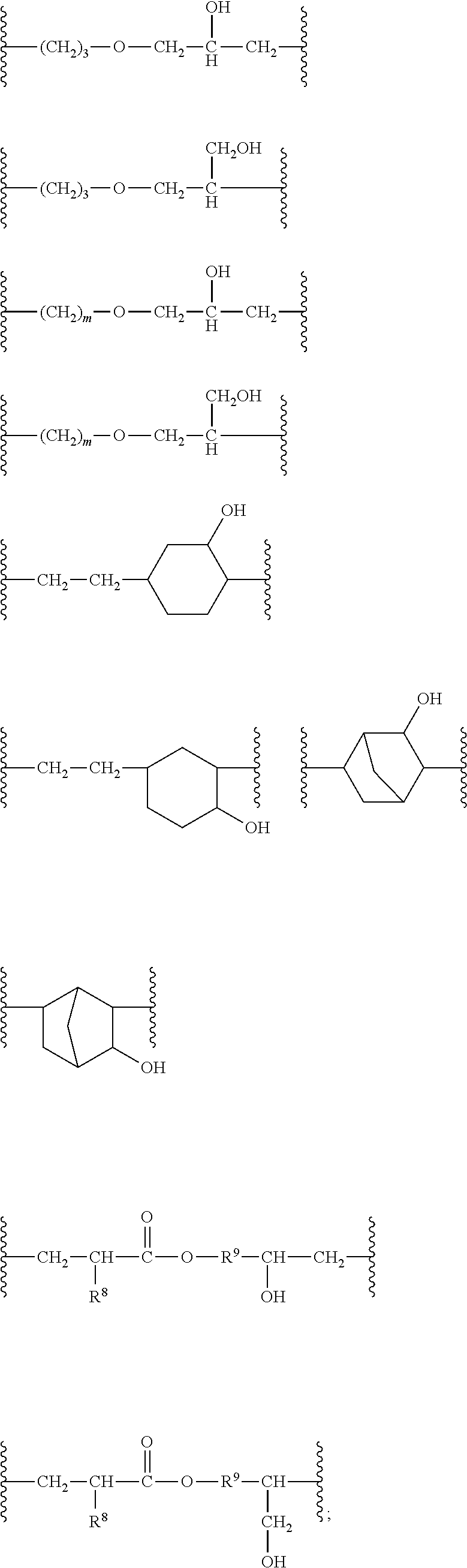

Novel polysiloxanes having quaternary ammonium groups, method for producing same and use thereof in formulations for cleansing and care

InactiveUS20120294819A1Outstanding condition effectIncrease of volume of foamBiocideSilicon organic compoundsAmmoniumPolymer

The invention relates to novel polysiloxanes having quaternary ammonium groups, and to a method for producing same. The invention further relates to the use of said polymers as an active care ingredient in formulations for the care and cleansing of skin and skin appendages, for example, as conditioning agents for hair.

Owner:EVONIK DEGUSSA GMBH

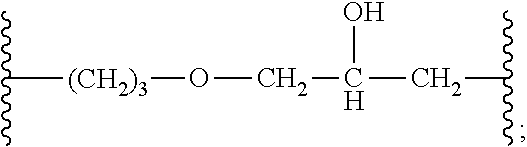

Method for preparing beancurd preserved flavour product

InactiveCN101181039AProsperous lifeEasy to adjustCheese manufactureFood preparationFlavouring agentFood flavor

The invention provides a preparation method of preserved bean curd flavor product, which relates to the technical field of food production. The operation steps are that: the preserved bean curd is mixed with albumen that is separated from preserved bean curd catsup and soybean / enzymolysis albumen produced from the enzymolysis of soybean powder to obtain mixture; (1) water is added into the mixture that is then sprayed and dried to get powder material, sweetening agent and filling agent is added to the powder material that is then pressed, sterilized and packed into slice-shaped preserved beancurd flavor product; (2) quality improver and flavouring agent are added into the mixture that is then heated, dropped in temperature, packed and cooled to be juice / cream-shaped preserved bean curd flavor product; (3) quality improver, flavouring agent and solidifying salt are added into the mixture that is then heated, dropped in temperature, packed and cooled to be block-shaped preserved beancurd flavor product. The invention is applied to the development and production of new food that is similar to 'cheese' with the flavor of the preserved bean curd and takes plant albumen as raw material, so as to research a series of preserved bean curd flavor new products with plant albumen and production method to enrich the life of people and promote industrial technological progress with the health keeping novel products with compound nutrition.

Owner:北京首农味业集团有限公司

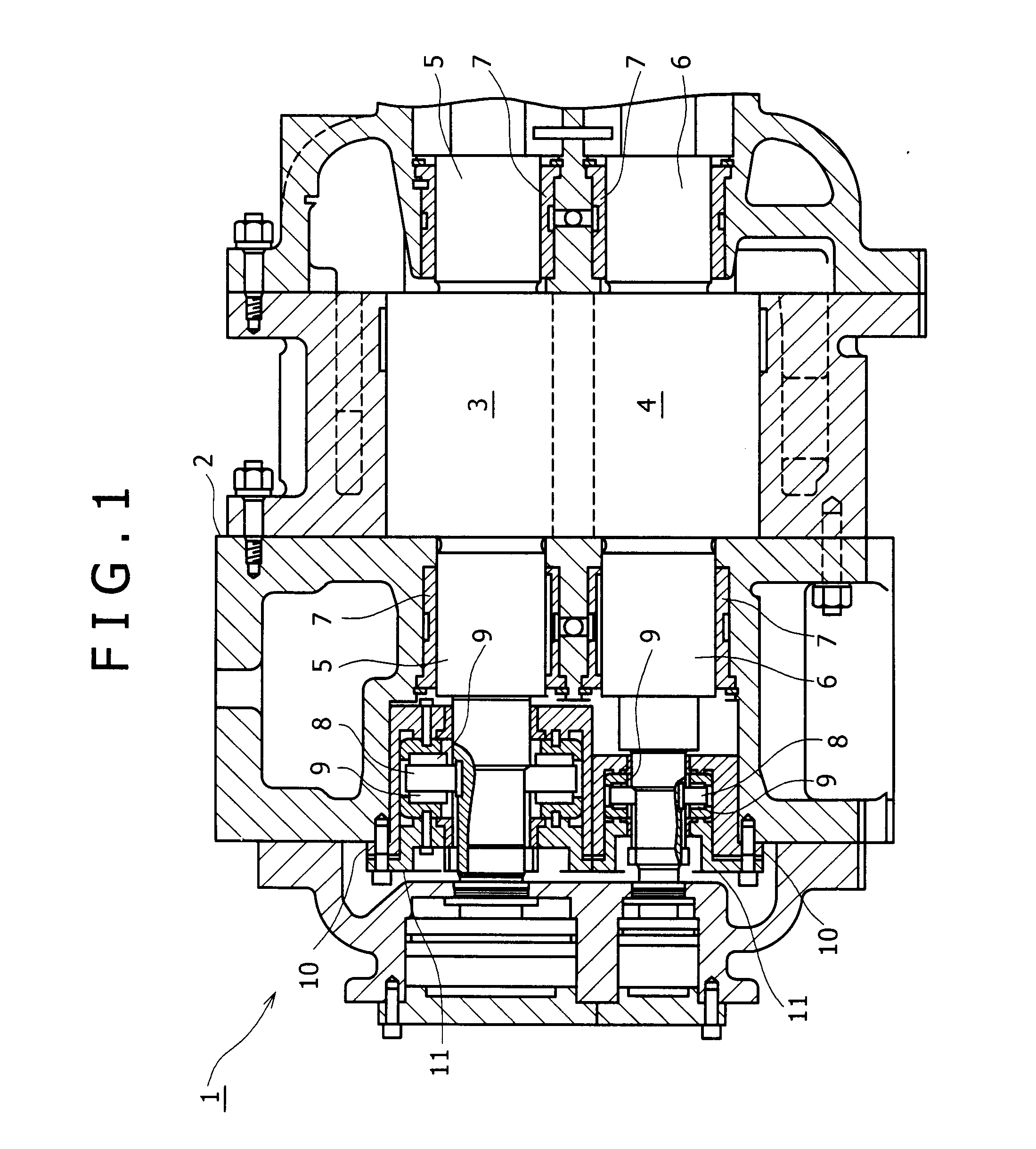

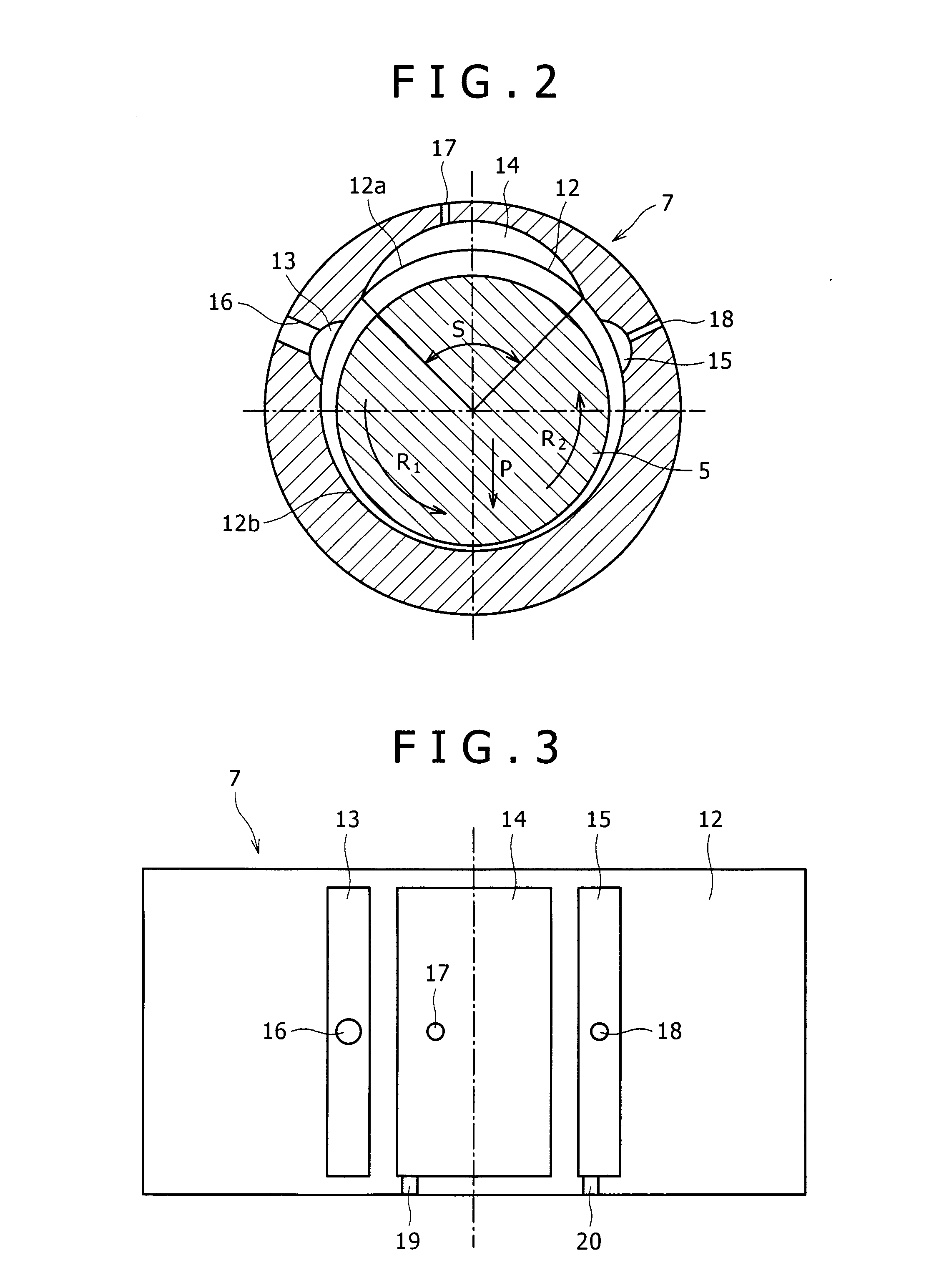

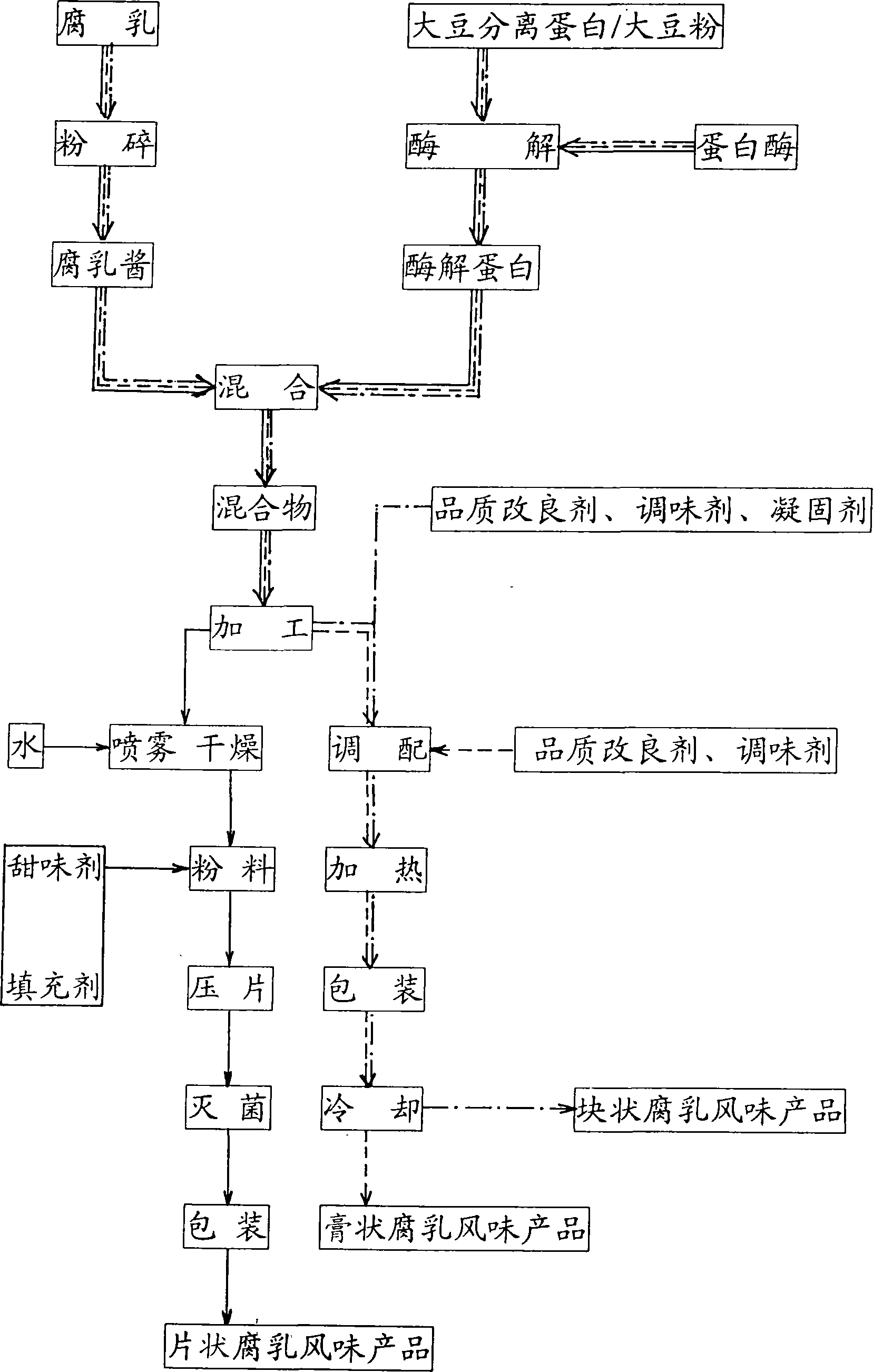

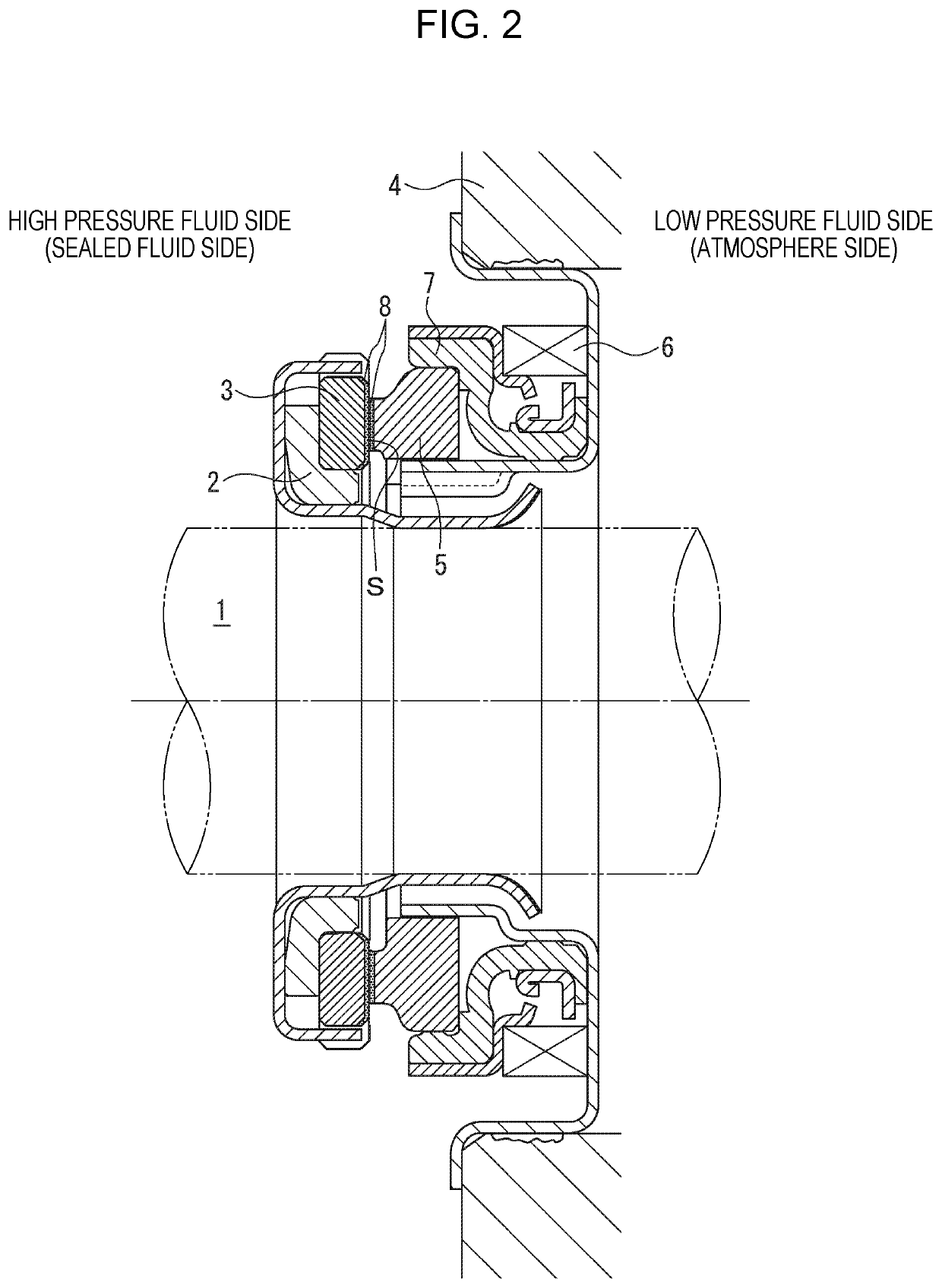

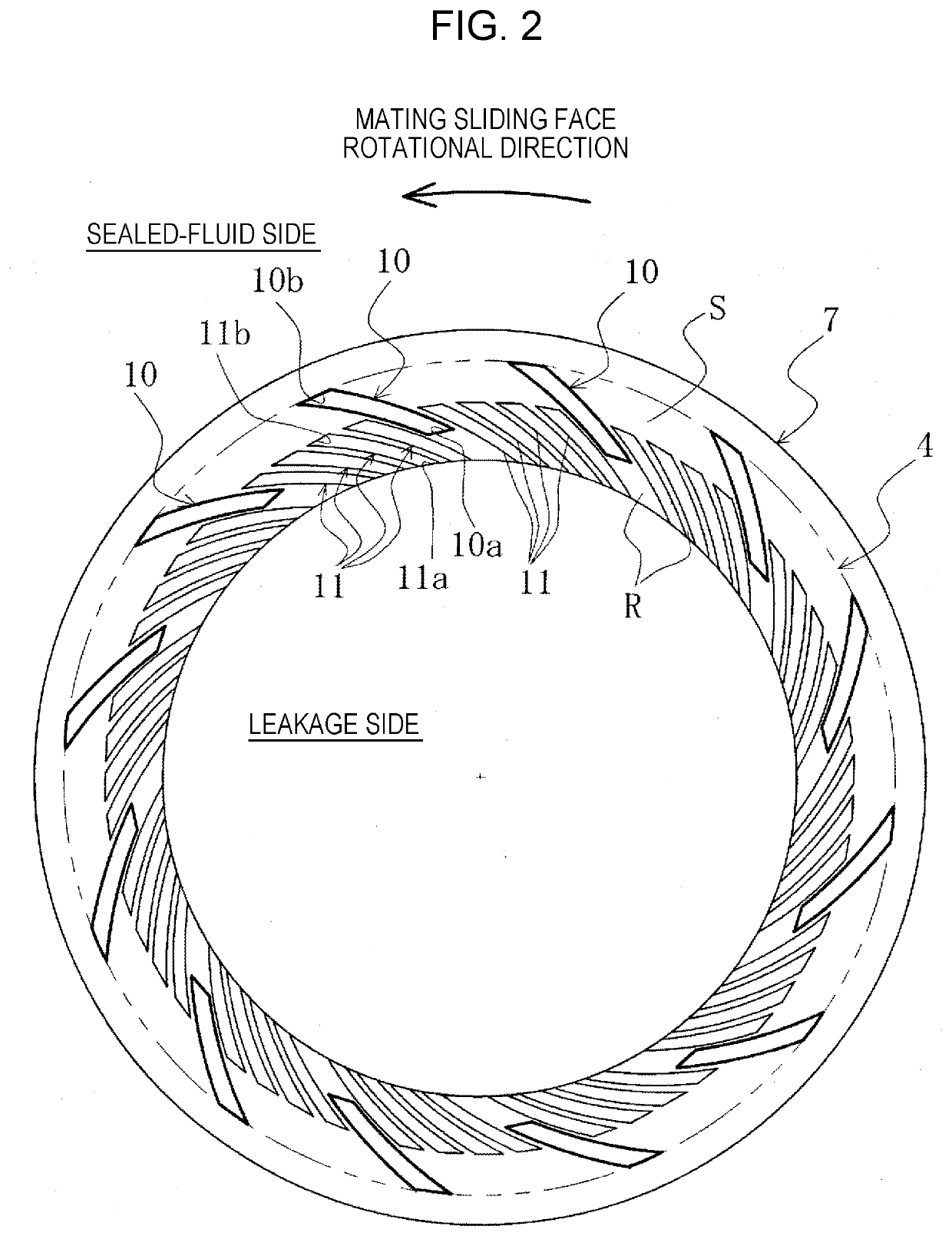

Sliding component

ActiveUS20200182356A1The effect is outstandingAvoid depositionEngine sealsBearing componentsCarbon filmRotational axis

In an exemplary embodiment, a sliding component includes an annular stationary side seal ring 5 fixed to the stationary side and an annular rotating side seal ring 3 to be rotated together with a rotating shaft, in which by relatively rotating opposing sealing faces S of the stationary side seal ring 5 and the rotating side seal ring 3, a silicate-containing sealed fluid present on one side in the radial direction of the relatively rotating sealing faces S is sealed, wherein an amorphous carbon film 8 formed by using a hydrocarbon gas containing no silicon compound is provided on at least any one of the sealing faces S of the stationary side seal ring 5 and the rotating side seal ring 3, and content of silicon of the amorphous carbon film 8 is 1.5 at % or less.

Owner:EAGLE INDS +1

Bi-color Illuminated Emblem

InactiveUS20140184068A1Improved weatherability against ultraviolet lightSatisfies designOptical signallingElectricityLight intensity

A bi-color illuminated decorative device for an automobile includes a metal-look portion having a metal look layer, a substrate layer that supports the metal look layer, and a plurality of illuminating elements; and a controller that is electrically connected to the illuminating elements and that controls the light intensity of the illuminating elements. The illuminating elements are arranged to conform to the shape of the metal-look portion. The metal look layer and the substrate layer pass light from the illuminating elements. The controller controls the light intensity of the illuminating elements depending on ambient light and braking status.

Owner:KWON YOUNG CHUL

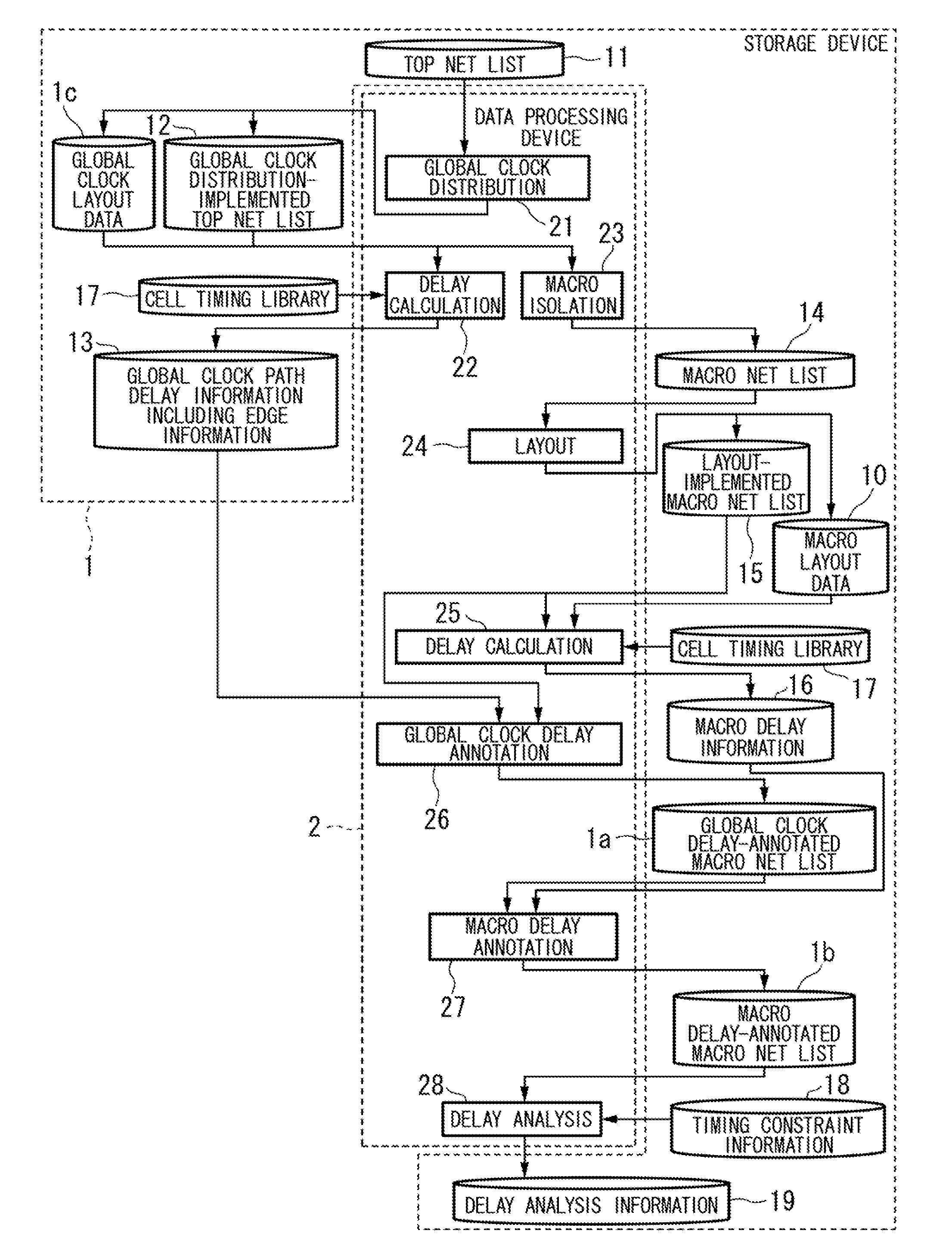

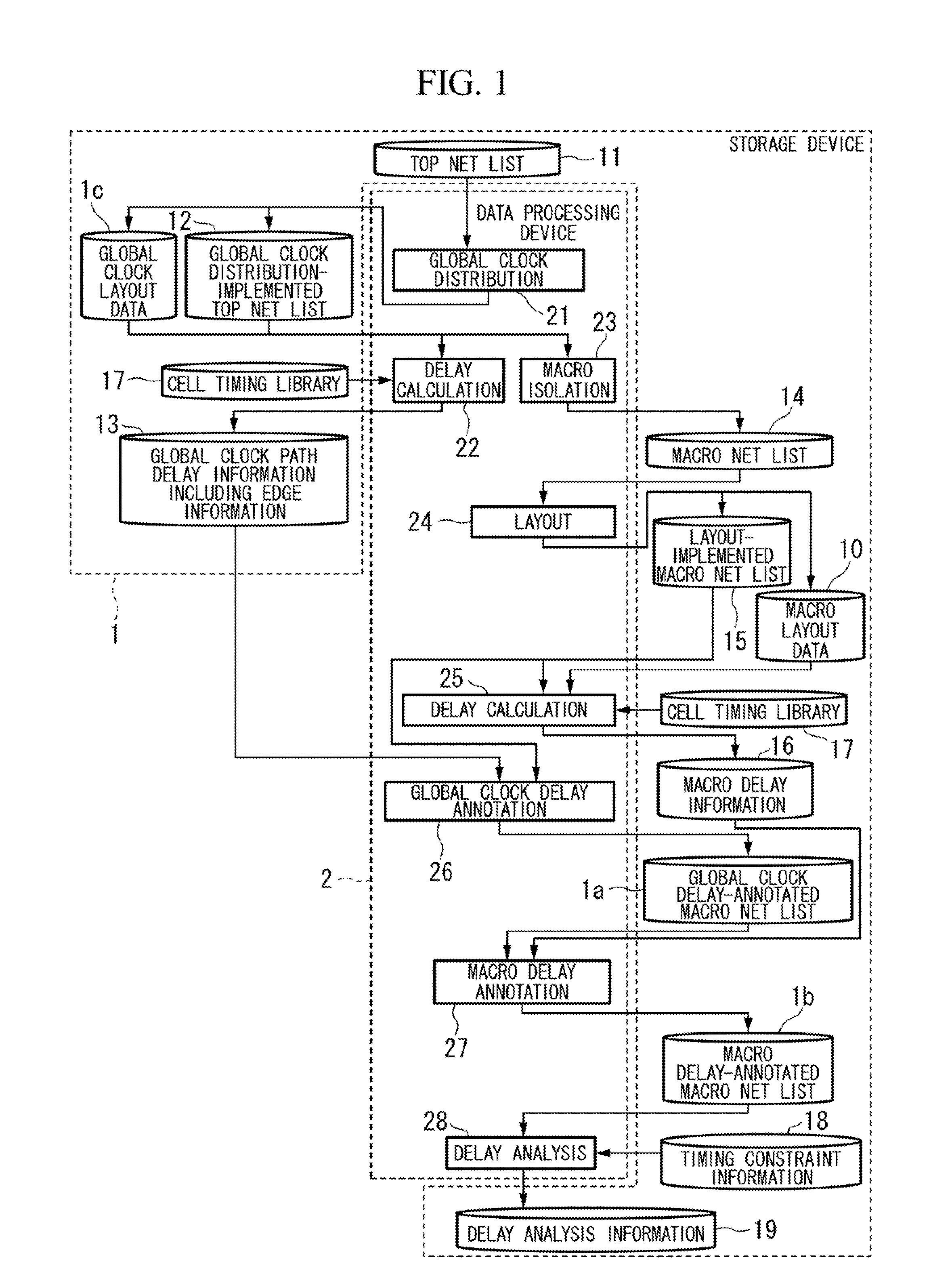

Delay analysis processing of semiconductor integrated circuit

InactiveUS20110046937A1The effect is outstandingOutstanding featuresComputer aided designSpecial data processing applicationsComputer scienceDelay analysis

A delay analysis device composed of a storage device and a data processing device analyzes a chip fabricating a semiconductor integrated circuit. Delay calculation is performed via an RC simulation with reference to a layout-implemented macro net list, macro layout data, and a cell timing library, thus producing macro delay information. An initial stage of a macro is annotated by the global clock path delay information including the edge information so as to produce a global clock delay-annotated macro net list, which is then converted into a macro delay-annotated net list. Based on the macro delay-annotated net list and timing constraint, the delay analysis device calculates delay times of signal paths and clock paths as well as clock skews with a high precision. It checks whether or not the relationship between the delay times of signal paths and clock paths meets the timing constraint, thus producing delay analysis information.

Owner:NEC CORP

External preparation for treating painful skin wound

ActiveUS20070197483A1Less side effectsExcels in inhibitory effectBiocideSalicyclic acid active ingredientsSalicylic acidPainful skin

External preparations for treatment of painful skin wound having an analgesic activity which comprises acetylsalicylic acid or its pharmacologically acceptable salt as an active ingredient.

Owner:TEIKOKU SEIYAKU KK TEIKOKU SEIYAKU CO LTD

Compressor bearing

ActiveUS7762724B2Reduce loadThe effect is outstandingCrankshaftsCrossheadsCooling effectBearing surface

In a compressor bearing for supporting a rotor shaft of a compressor, a first oil groove is formed in a bearing surface on the side opposite to a bearing load acting direction, a second oil groove is formed in a position adjacent to the first oil groove in an anti-rotational direction, a first oil channel and a second oil channel communicating with the first oil groove and the second oil groove, respectively, to supply oil to the first and second oil grooves from an exterior, common oil supply source are provided, a circumferential length of the second oil groove is set larger than that of the first oil groove, and a minimum value of a sectional area perpendicular to the longitudinal direction of the second oil channel is set smaller than that of a sectional area perpendicular to the longitudinal direction of the first oil channel. The compressor bearing of such a configuration is small in load induced by oil pressure and exhibits an outstanding rotor shaft cooling effect.

Owner:KOBE STEEL LTD

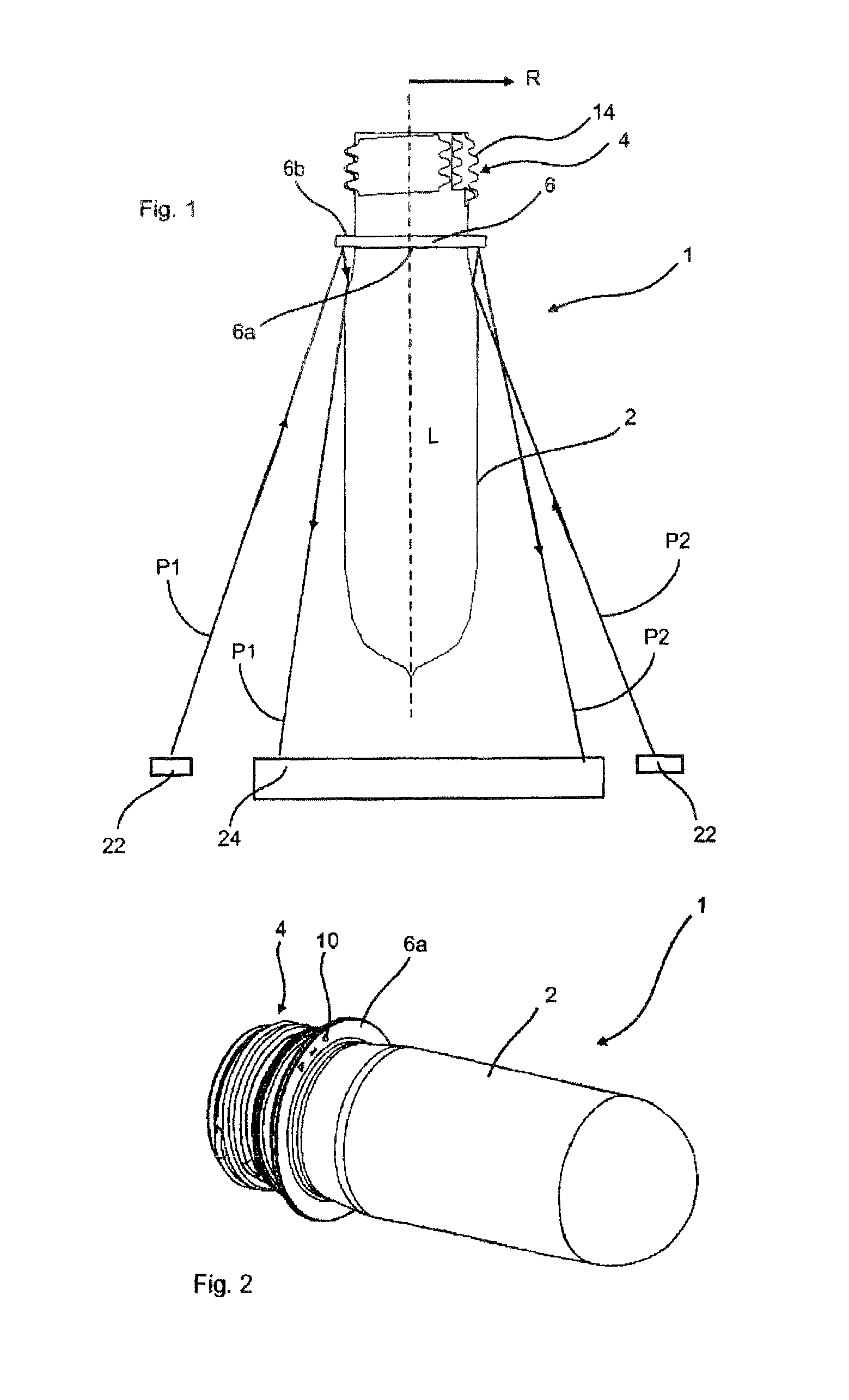

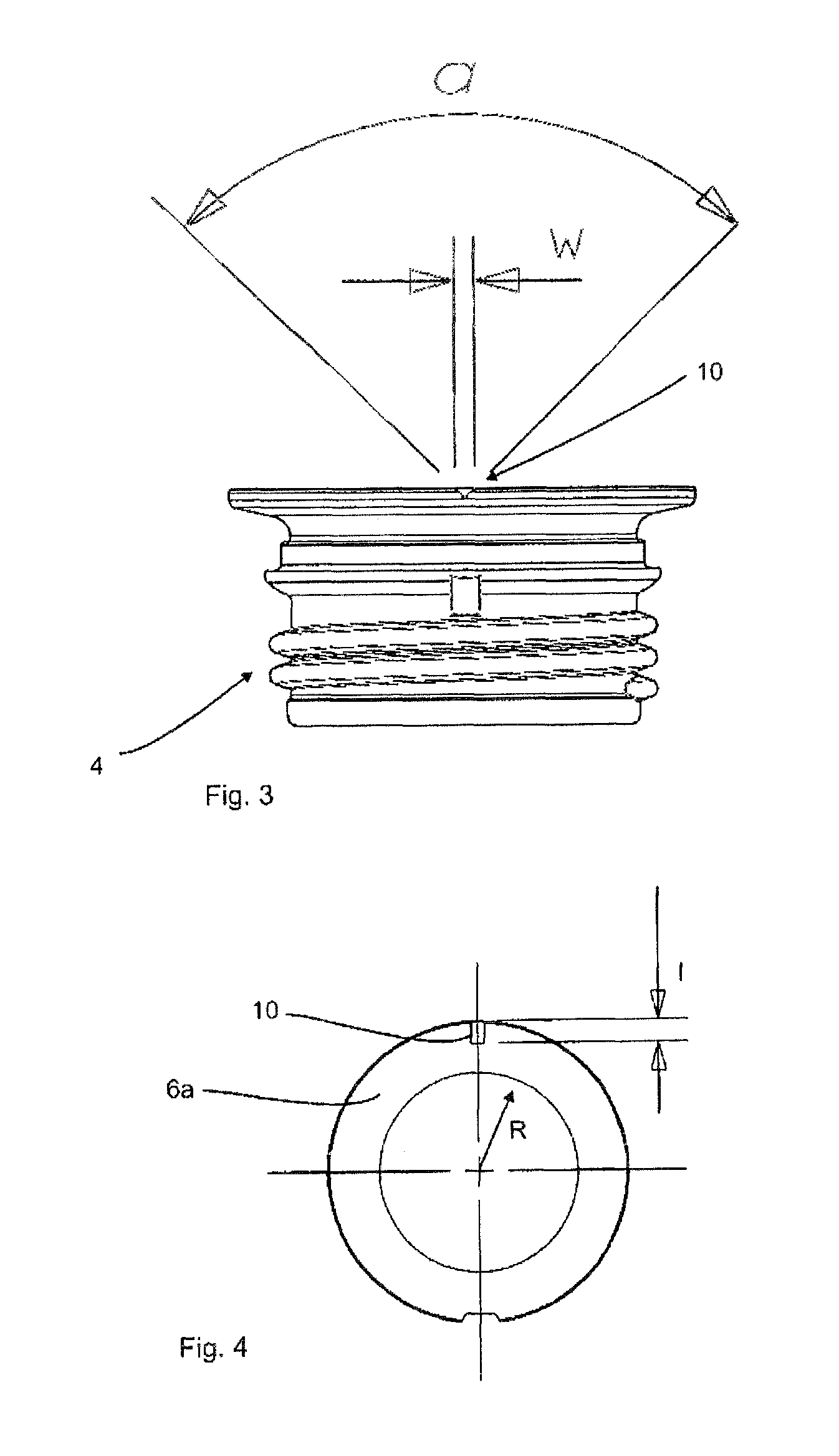

Plastic preforms with marking for position detection

ActiveUS8663761B2Blowability is simplifiedDisturbances due to the light passing through are minimisedBottlesSynthetic resin layered productsEngineeringMechanical engineering

Owner:KRONES AG

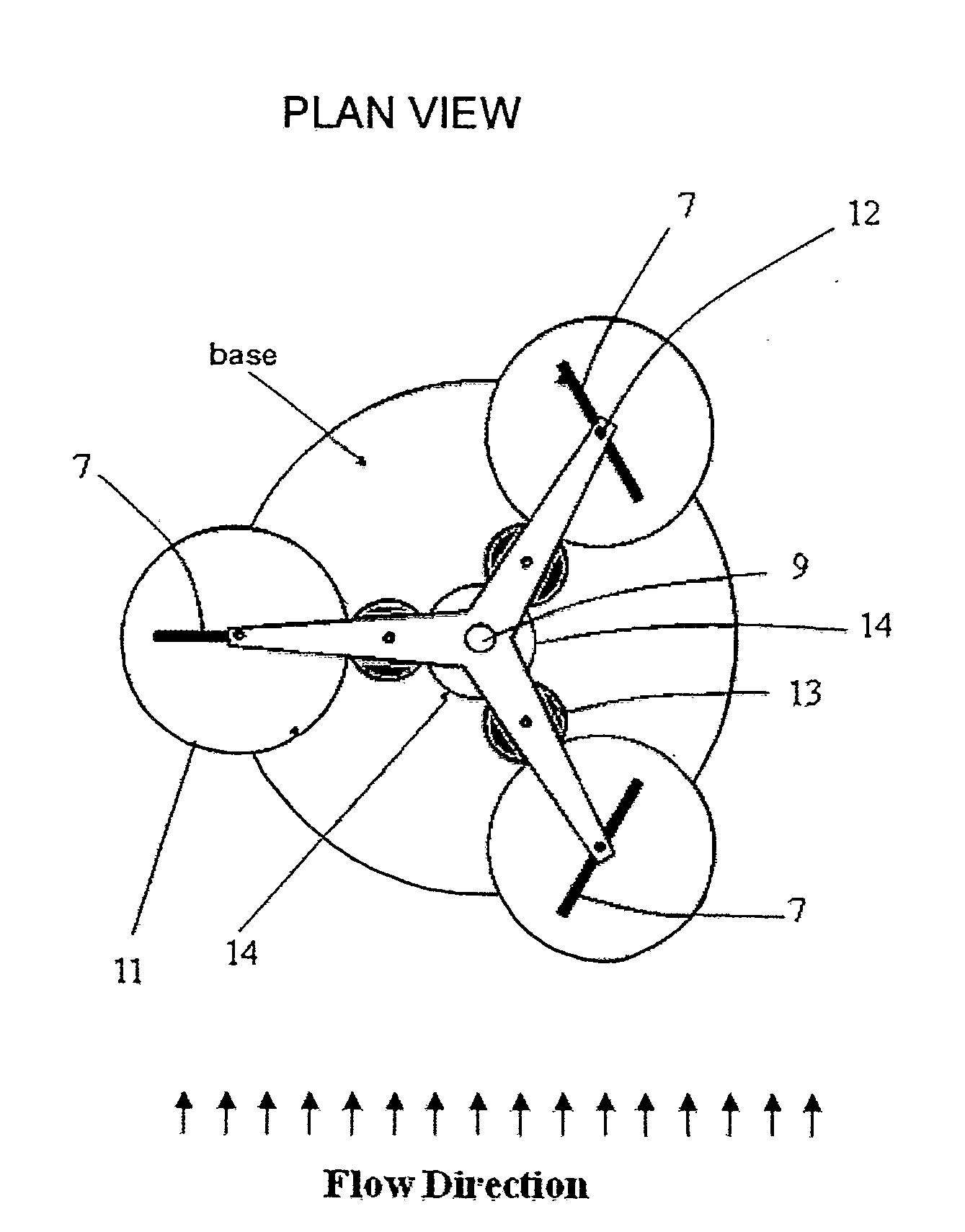

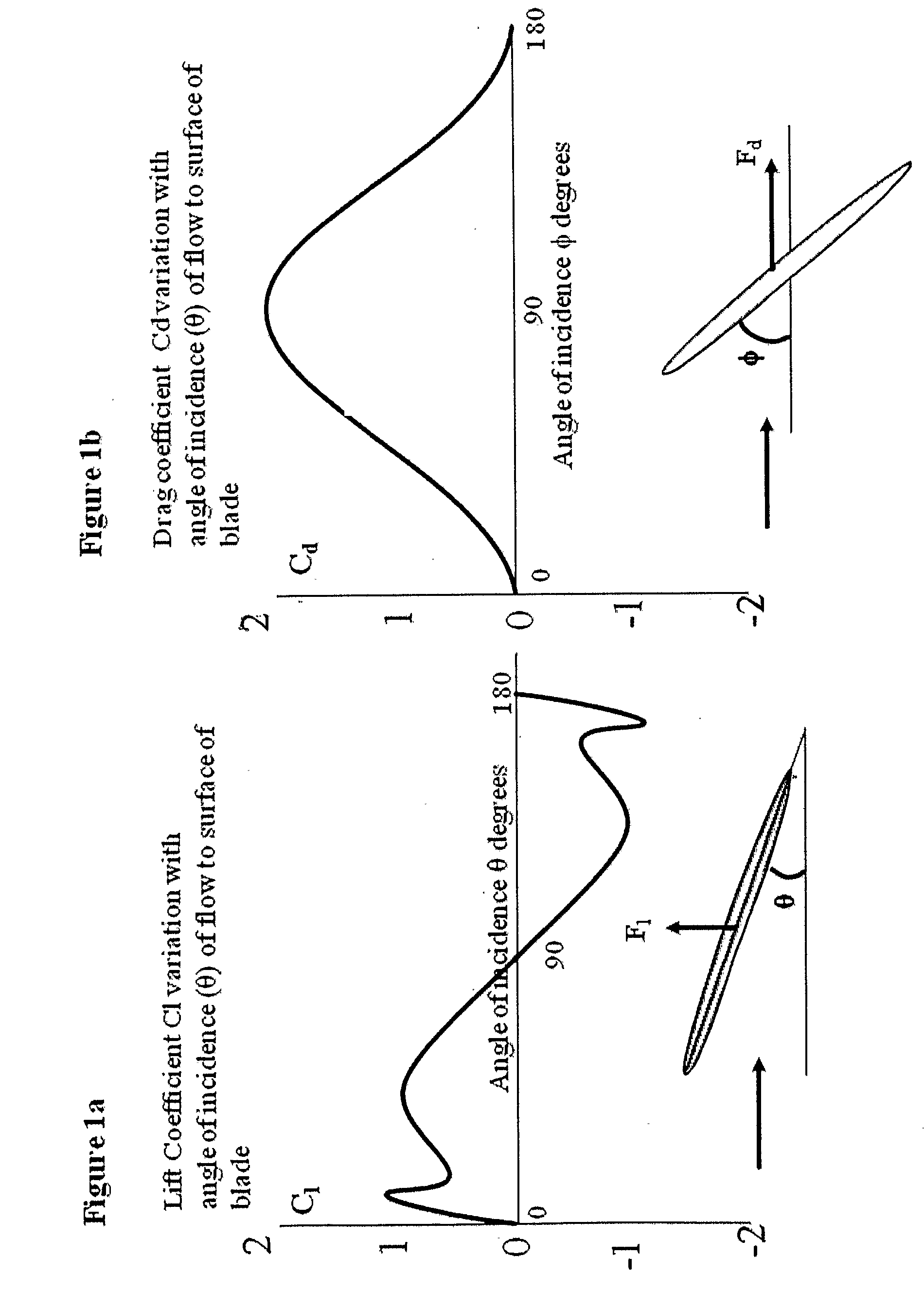

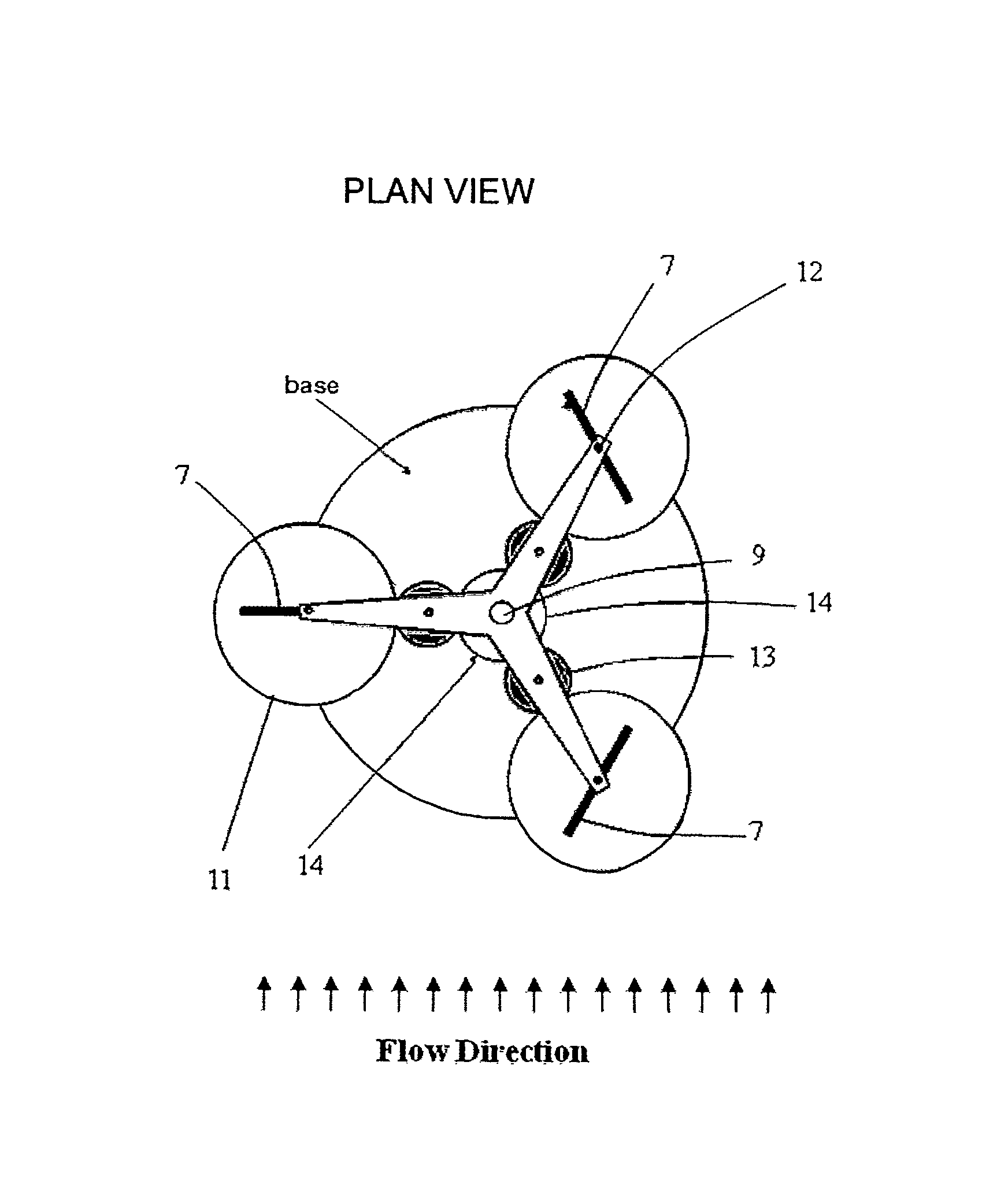

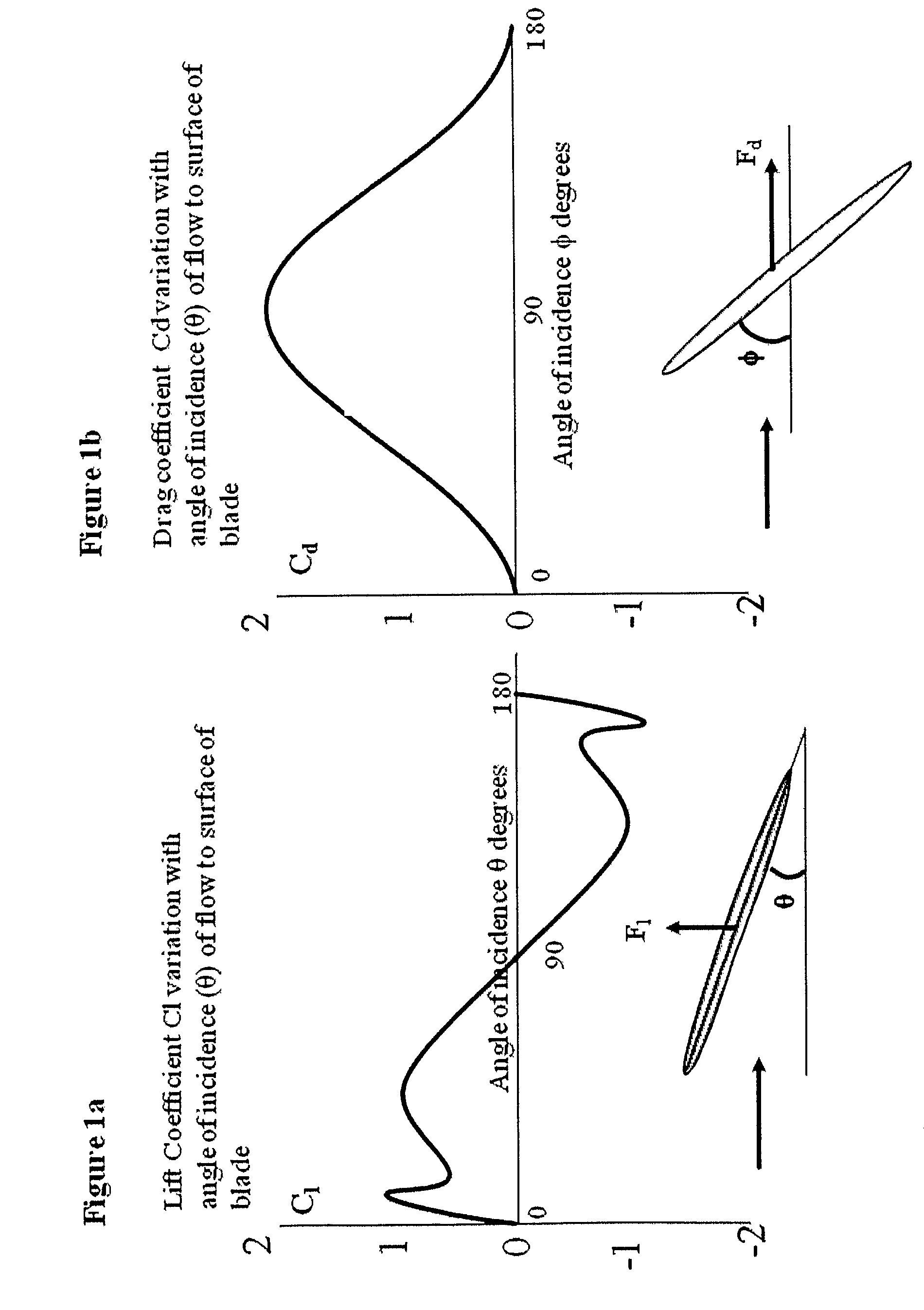

Fluid turbine

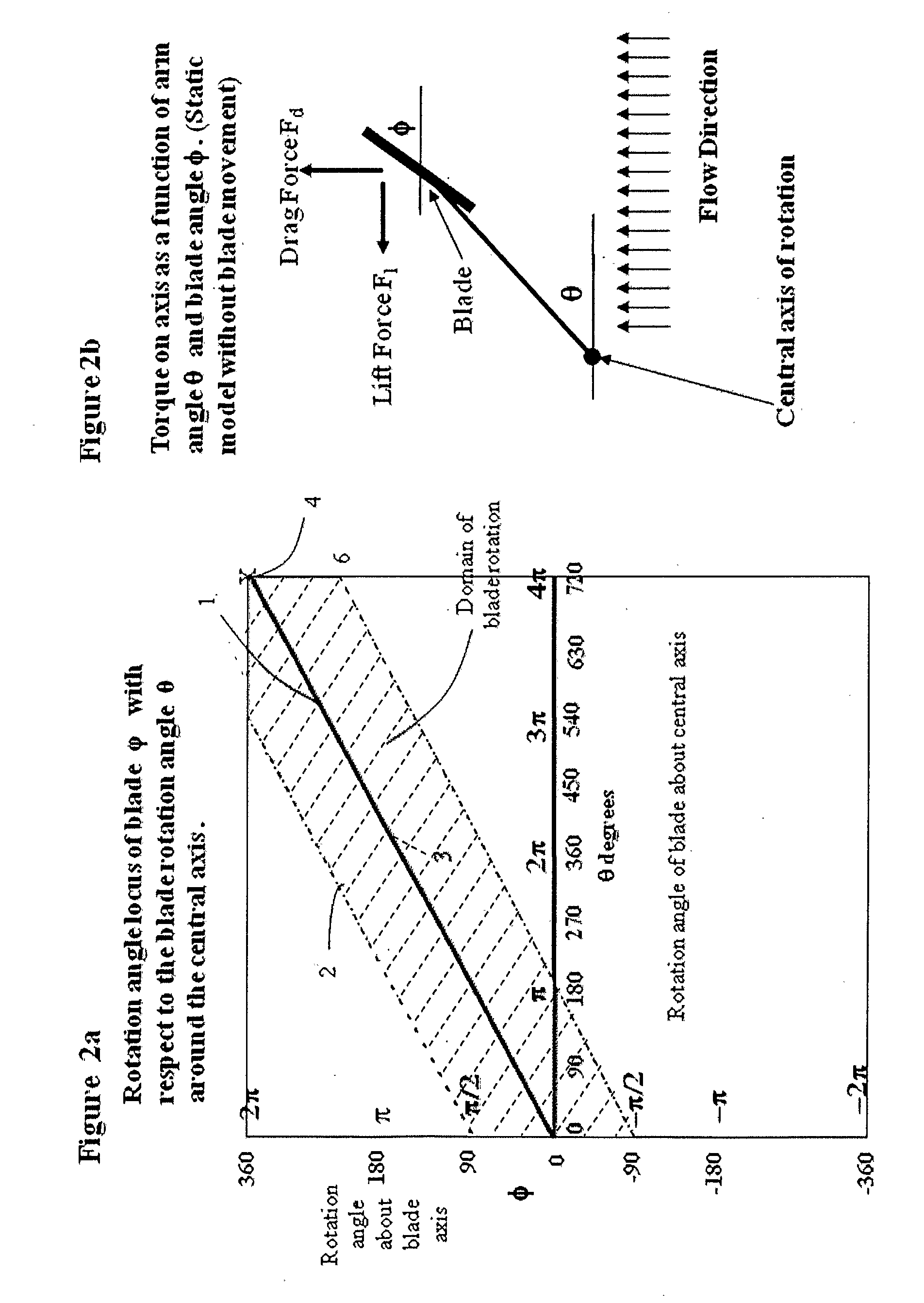

A turbine for extracting power from a flowing fluid comprises a blade for interaction with the fluid, the blade being rotatable both about a primary axis and a blade axis. The blade axis is proximate to the blade, substantially parallel to the primary axis and spaced therefrom. Rotation actuating means is provided to rotate the blade about the blade axis in dependence upon the rotation of the blade about the primary axis such that the rotation angle of the blade about the blade axis is a function of the rotation angle of the blade about the primary axis. The rotation of the blade about the blade axis is in the same direction of rotation as the blade axis about the primary axis.

Owner:SUN YI +1

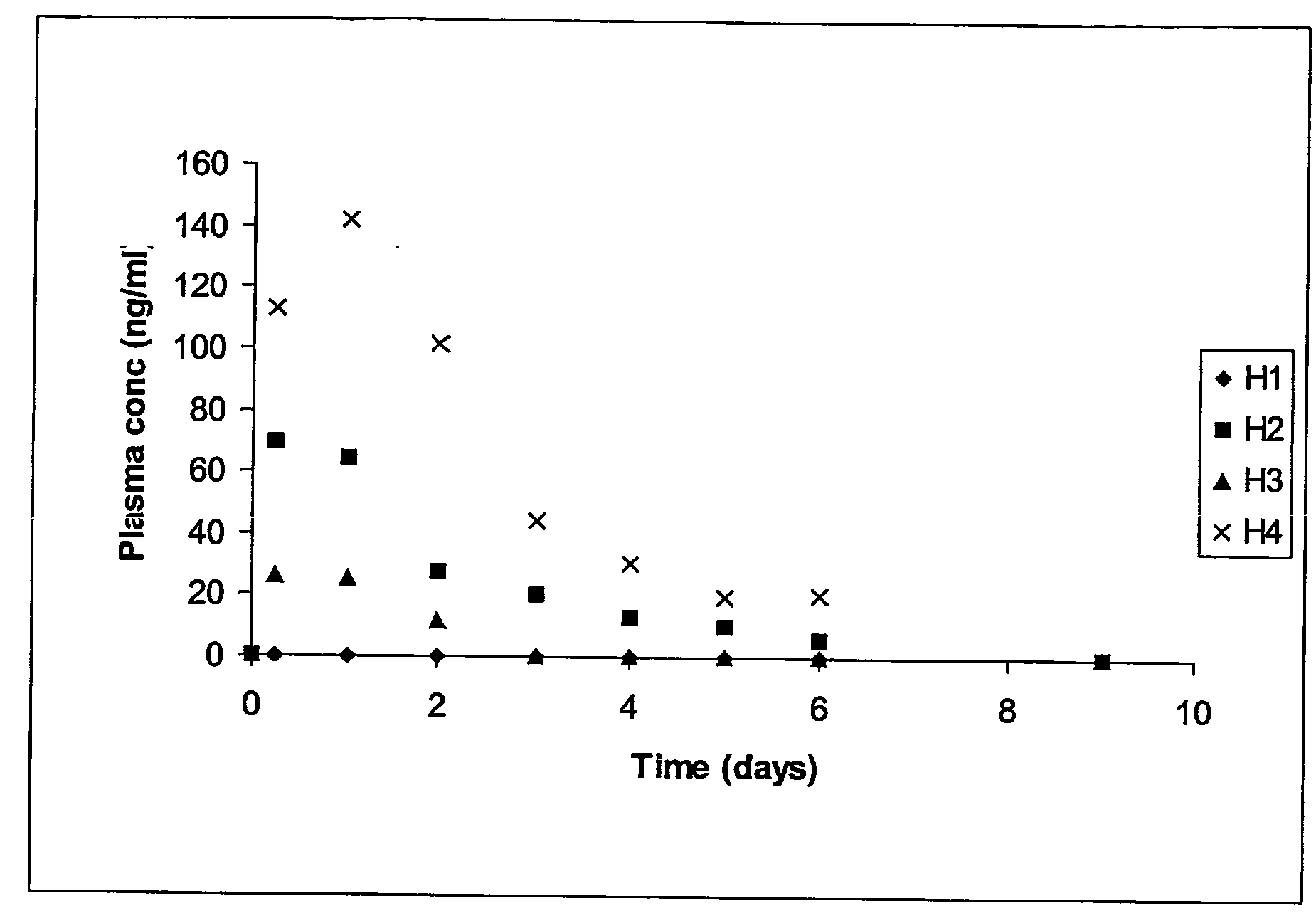

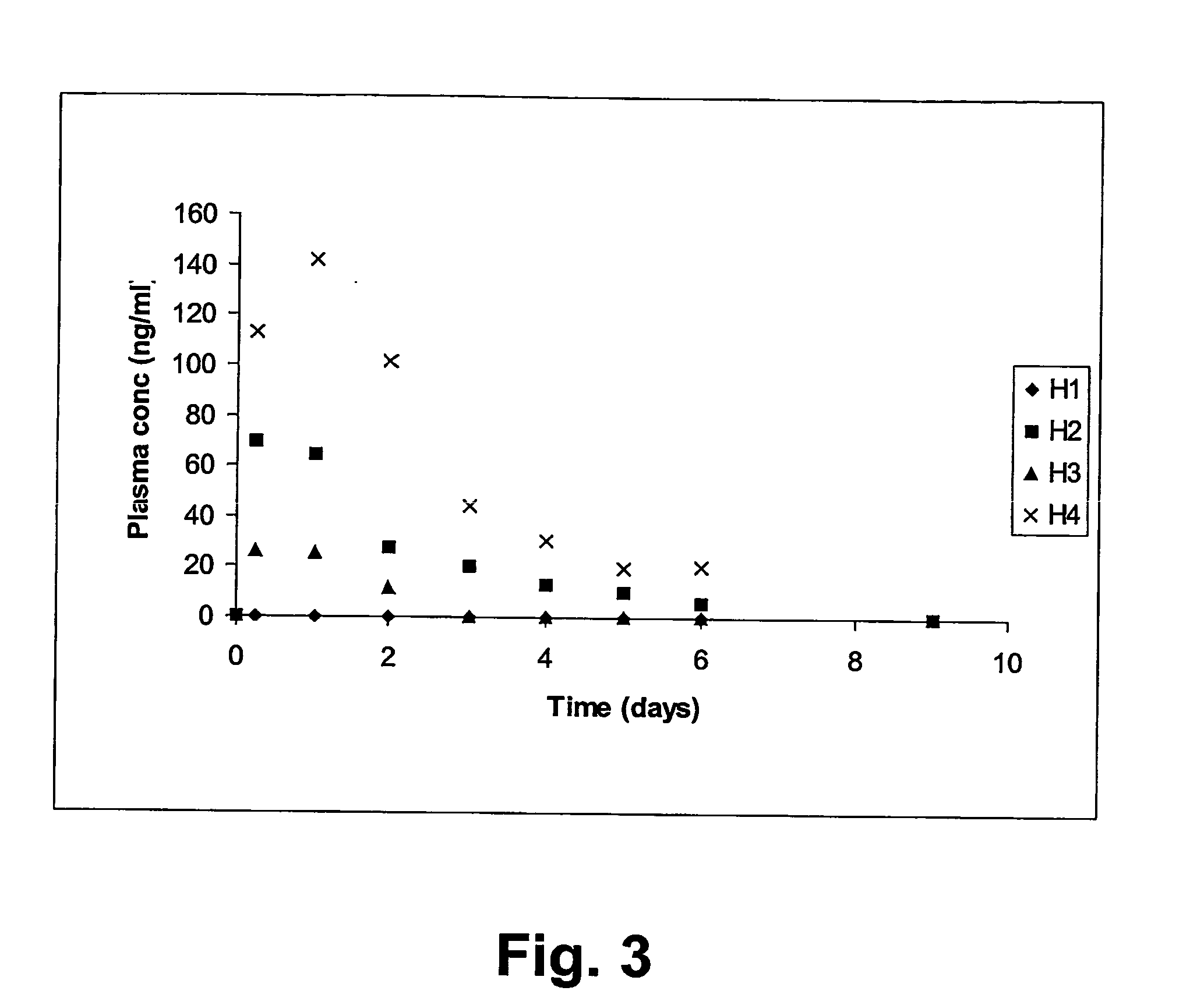

Composition comprising biodegradable hydrating ceramics for controlled drug delivery

ActiveUS20090036392A1The effect is outstandingMinimise spectrumOrganic active ingredientsGenetic material ingredientsDrugCeramic

The present invention relates to a drug carrier composition comprising i) one or more biodegradable hydrating ceramics ii) one or more expandable agents, and iii) sorbed aqueous medium which in solid form has a ruptured structure. The function of the expandable agent is to create a ruptured structure in the solidified composition, either a foam-like structure or a disintegrated structure where it is split into a large number of parts, particles, units, granules or pieces, so as to obtain an enlarged apparent surface area that is exposed to degradation or erosion upon administration. Suitable substances to obtain this surface enlarging effect are gas-forming agents or swelling agents, gelling agents or disintegrants, here referred to as expandable agents. The expandable agents may be bioresorbable or non-bioresorbable.

Owner:LIDDS AB

Fluid turbine

InactiveUS8858177B2Increase the horizontal lengthMinimize impactPropellersPump componentsTurbineMotive power

Owner:SUN YI +1

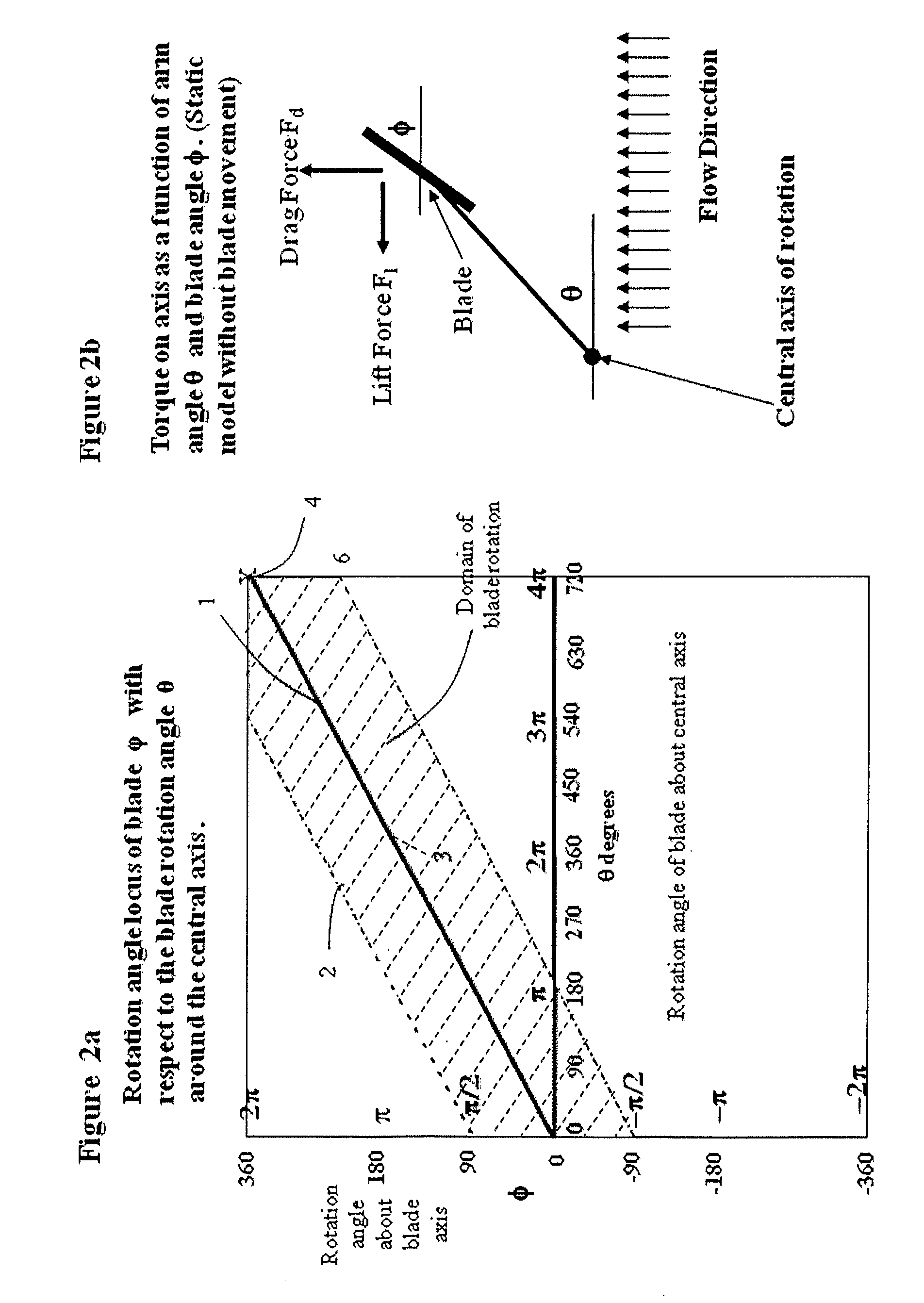

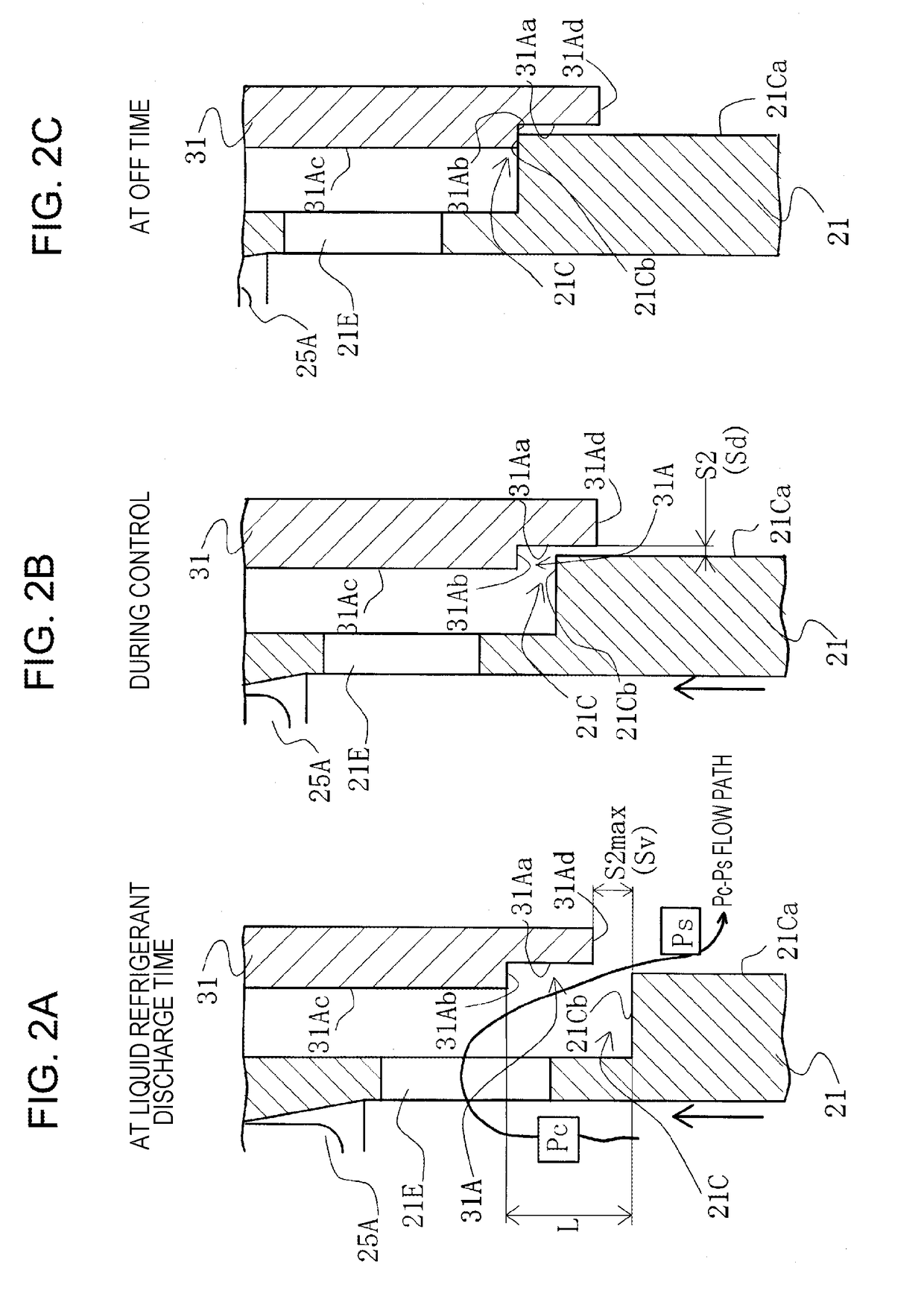

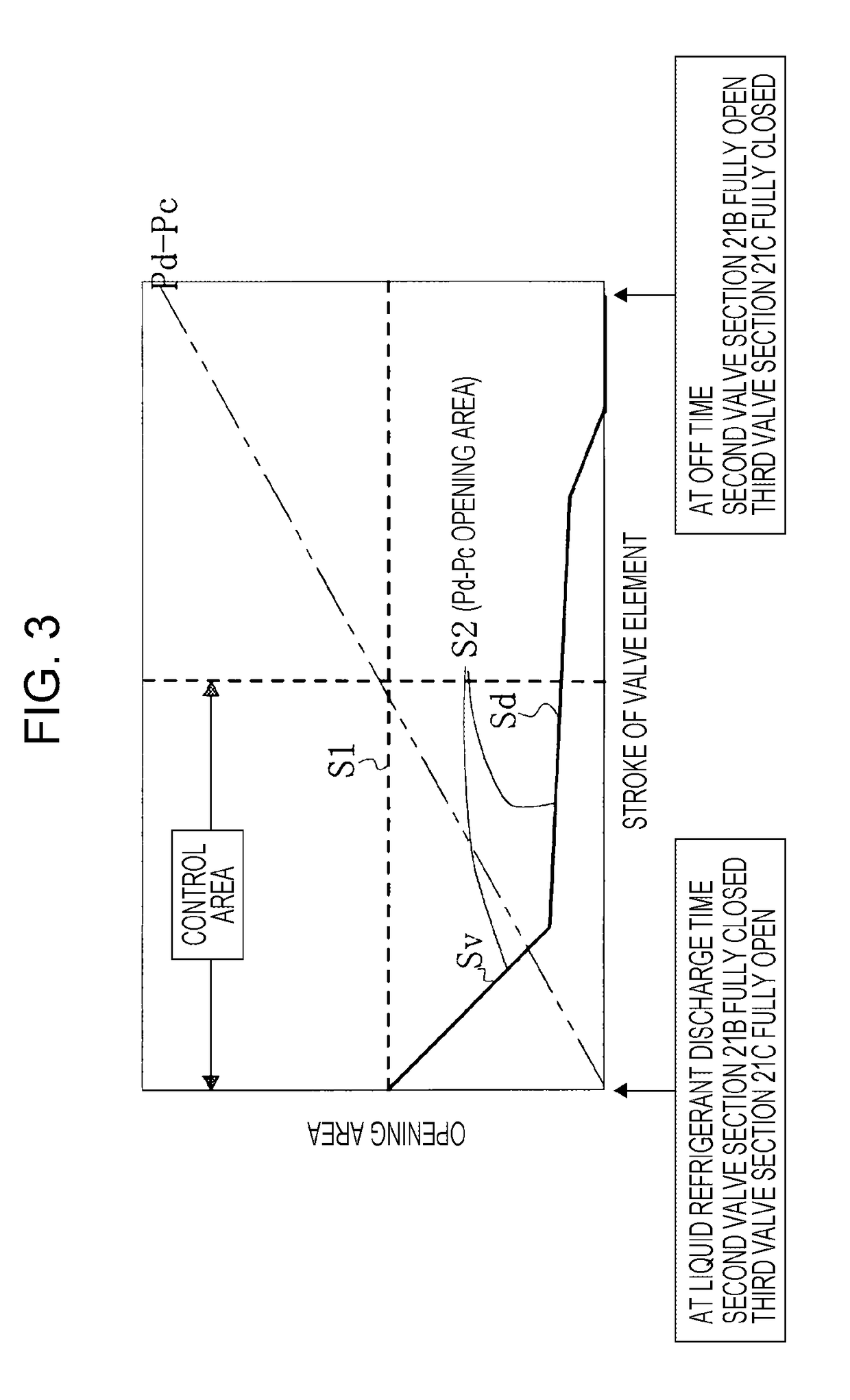

Displacement control valve

ActiveUS20190078562A1The effect is outstandingFunction increaseMultiple way valvesPump parameterDisplacement controlControl room

A displacement control valve improved in the function of discharging a liquid refrigerant in a control chamber at startup achieves a reduction in startup time and an improvement in operating efficiency during control of a variable displacement compressor simultaneously. An opening area between a third valve section and a third valve seat surface in a control area to control the flow rate or pressure in a working control chamber is set smaller than an area of an auxiliary communicating passage, thereby reducing the minimum area of a Pc-Ps flow path in the control area.

Owner:EAGLE INDS

Preparation method of nano titanium dioxide ultraviolet light catalytic purification coating layer

InactiveCN112646447AHigh activityGood antibacterial and disinfecting functionAntifouling/underwater paintsPaints with biocidesEmulsionPhoto catalytic

The invention relates to the technical field of purification, and in particular, relates to a preparation method of a nano titanium dioxide ultraviolet light catalytic purification coating layer, wherein the preparation method comprises the following steps: proportionally putting carrier dispersion slurry into a high-speed dispersion machine, and stirring at low speed by using the high-speed dispersion machine; respectively adding a nano titanium dioxide dispersion liquid, a fluorine-acrylic emulsion and water glass while stirring, uniformly stirring, and continuously and slowly adding a cosolvent and a coalescing agent with the same amount; adjusting the rotating speed of the high-speed dispersion machine, then continuously and slowly adding a high-shear rheological additive, mixing and stirring for 5-10 min, then carrying out the next step of operation, and properly adjusting the rotating speed of the high-speed dispersion machine along with the increase of the viscosity; and diluting a low-shear rheological additive by using two times of deionized water, and then slowly adding the low-shear rheological additive into the high-speed dispersion machine for many times until the viscosity of the low-shear rheological additive is 85-90. The nano titanium dioxide ultraviolet light catalytic purification coating layer has the functions of purifying air and resisting bacteria.

Owner:瑞康诺(深圳)创新发展有限公司

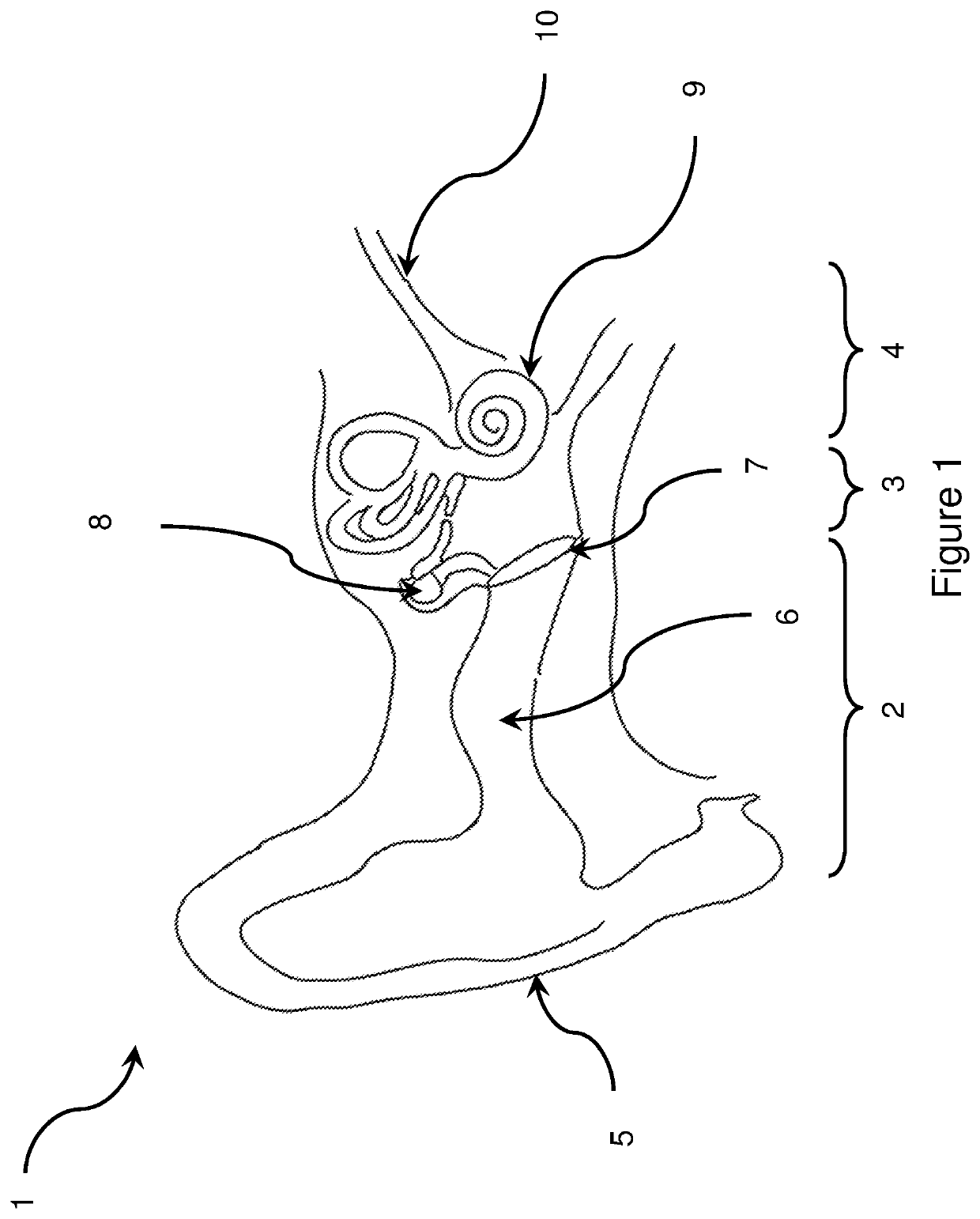

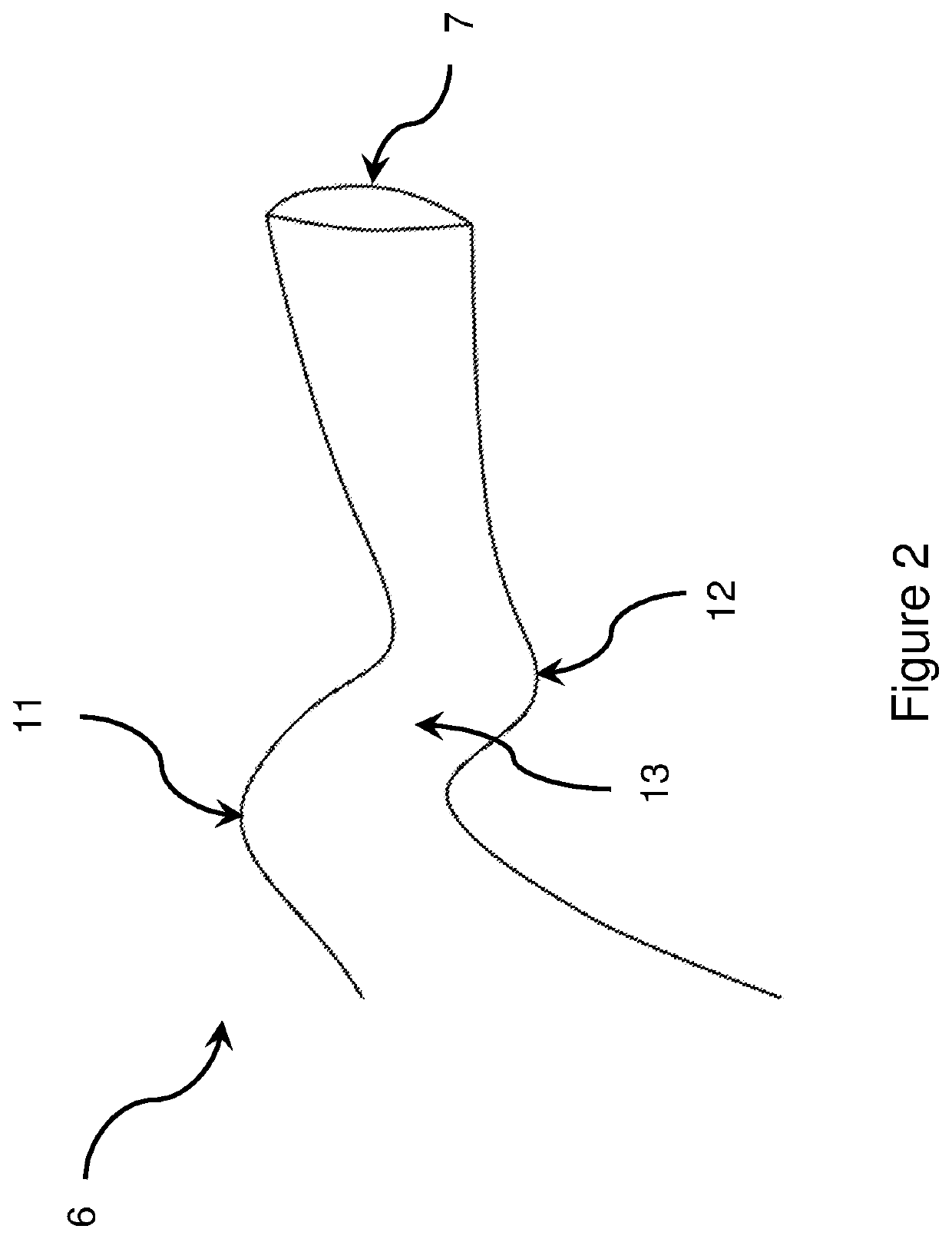

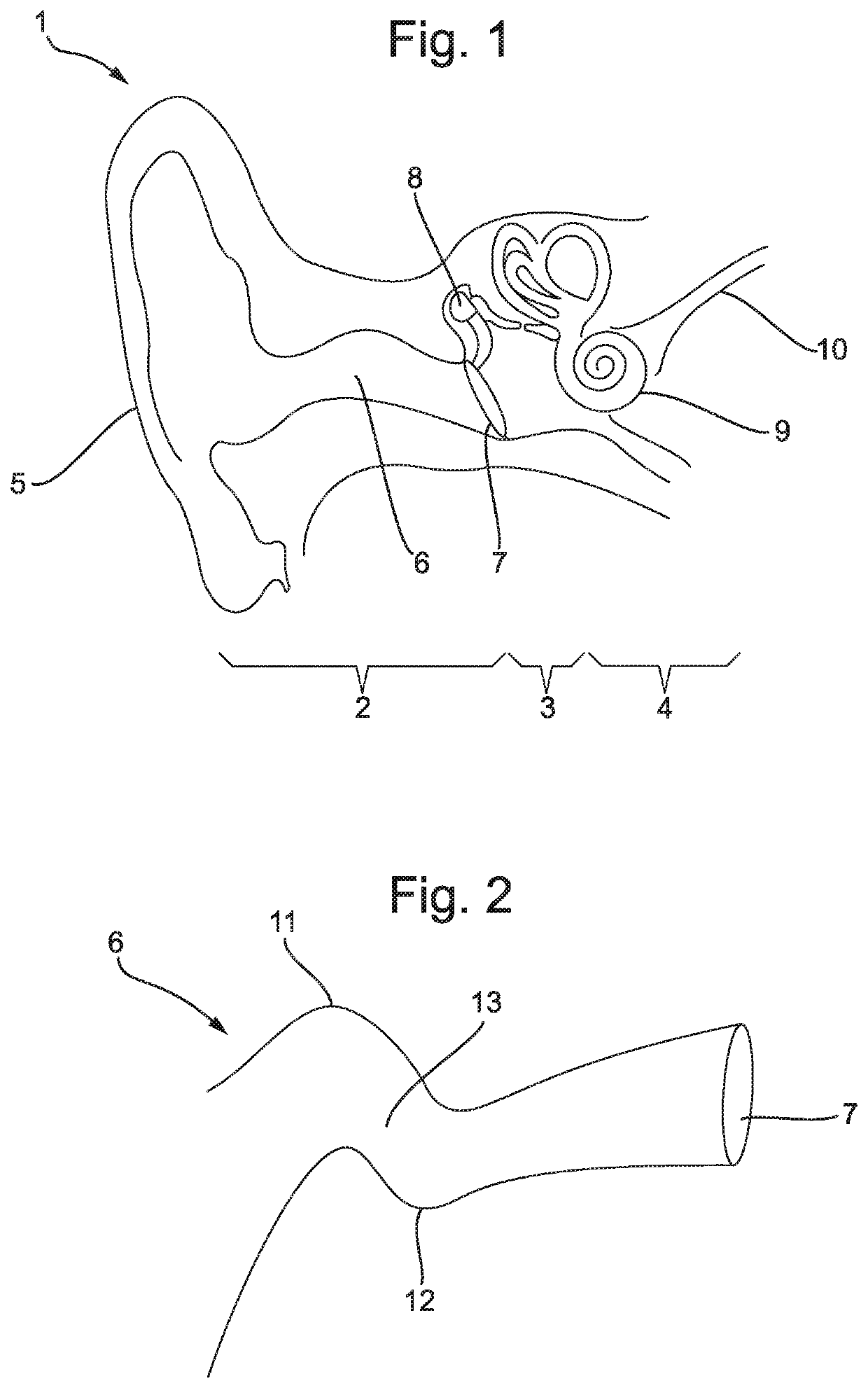

An earpiece

ActiveUS20190230428A1Maintain positionReduce lossesCompletely in canal hearing aidsIn the ear hearing aidsMedicineHeadphones

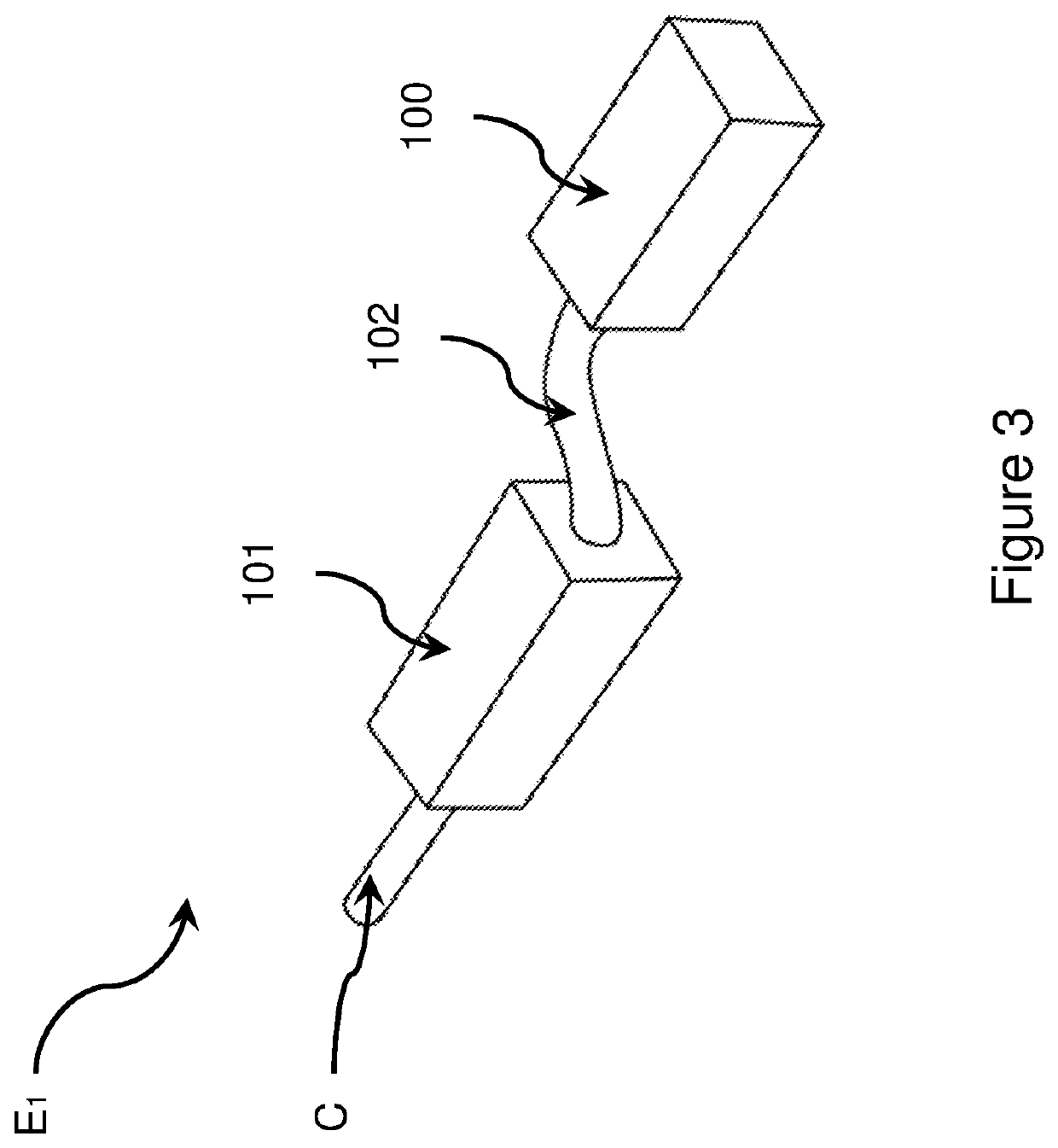

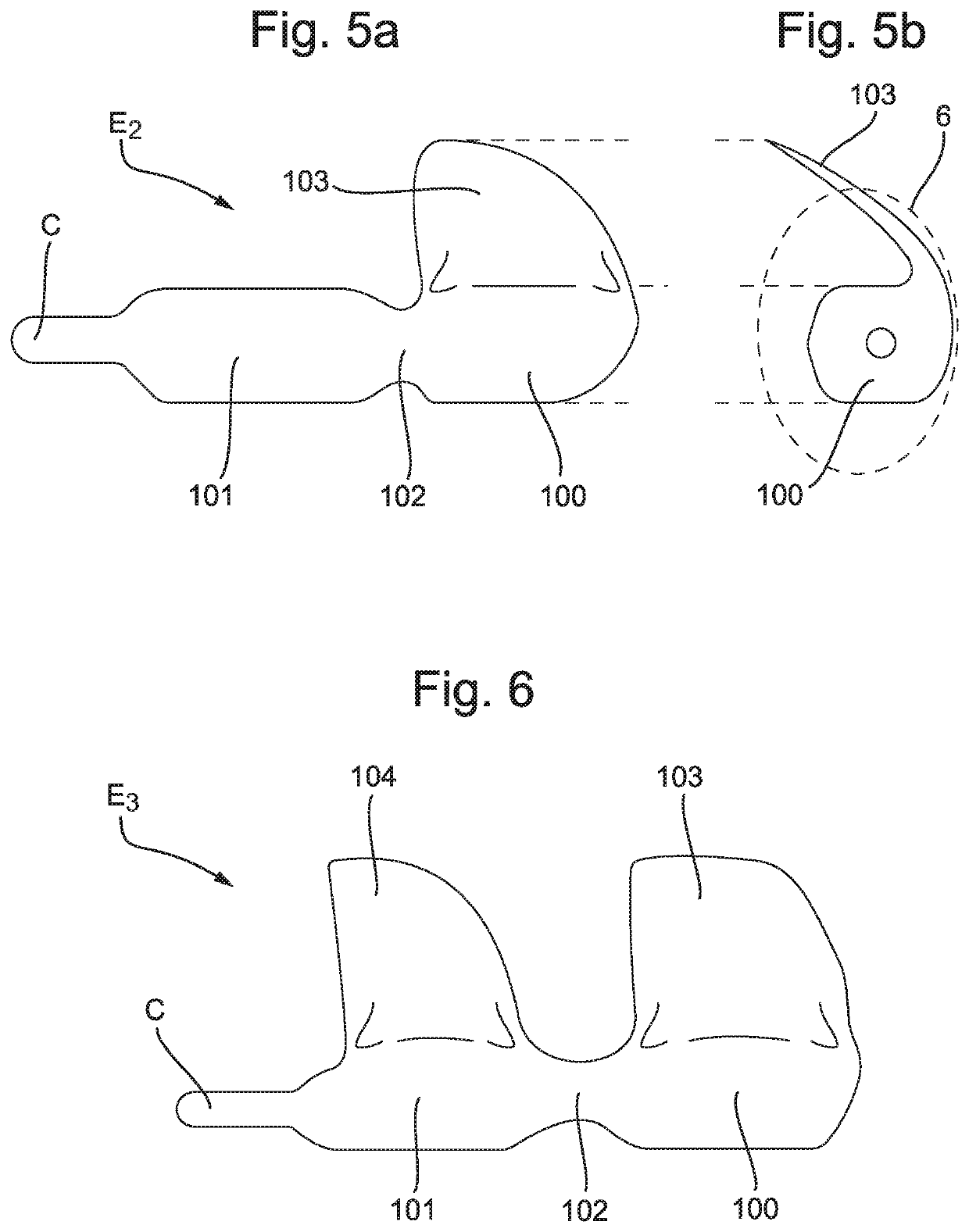

An earpiece for an earphone comprising a first portion (100), a second portion (101), and a resilient bridge (102) interconnecting the first portion (100) and second portion (101), wherein the resilient bridge (102) is configured to flex so that the earpiece can conform to ear canal geometry as it is received in a user ear canal and thereby be at least substantially locatable within the ear canal. The resilient bridge (102) may be configured to provide a biasing effect so that the first portion (100) and / or second portion (101) can bias against the ear canal wall (15).

Owner:ZOKU LTD

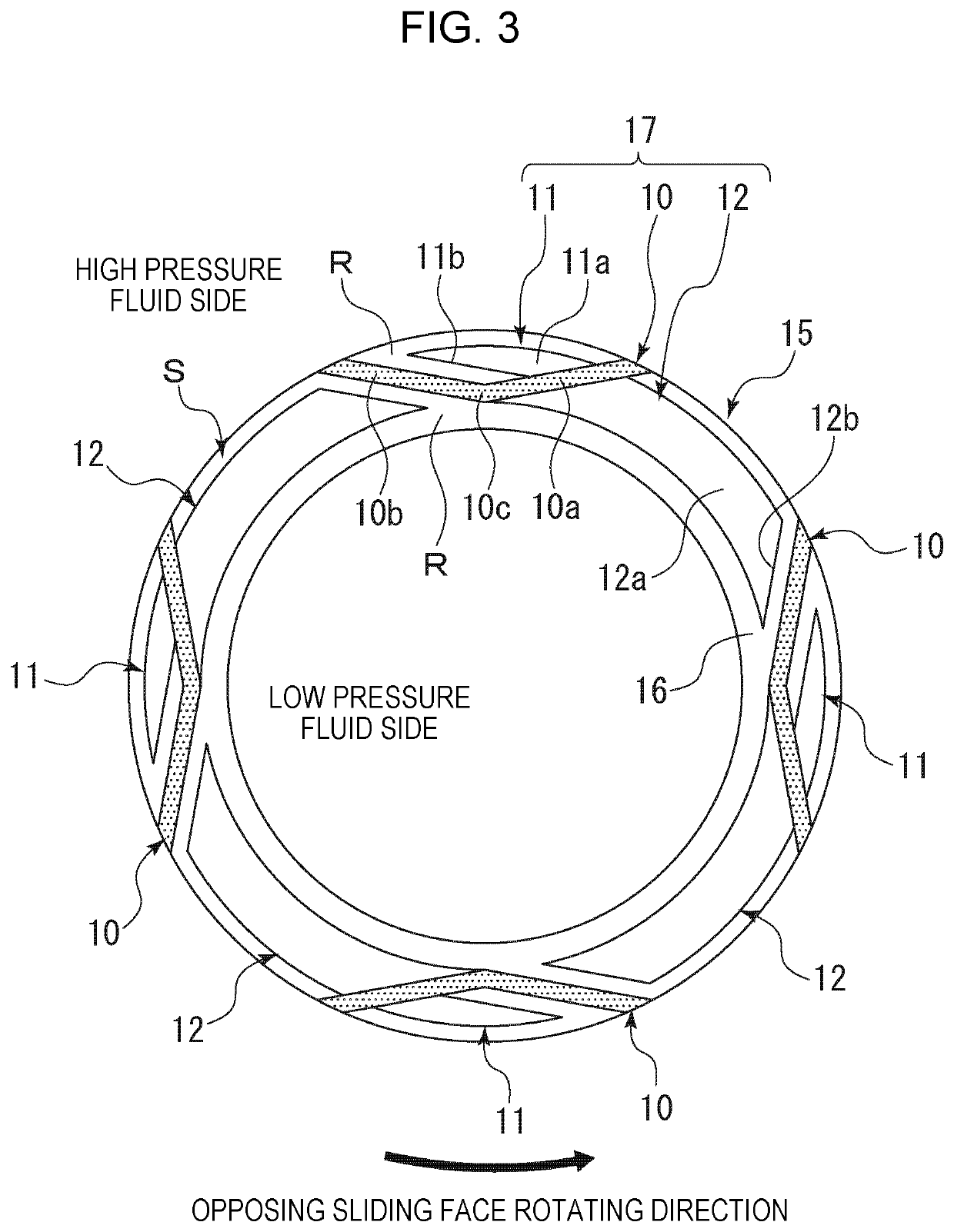

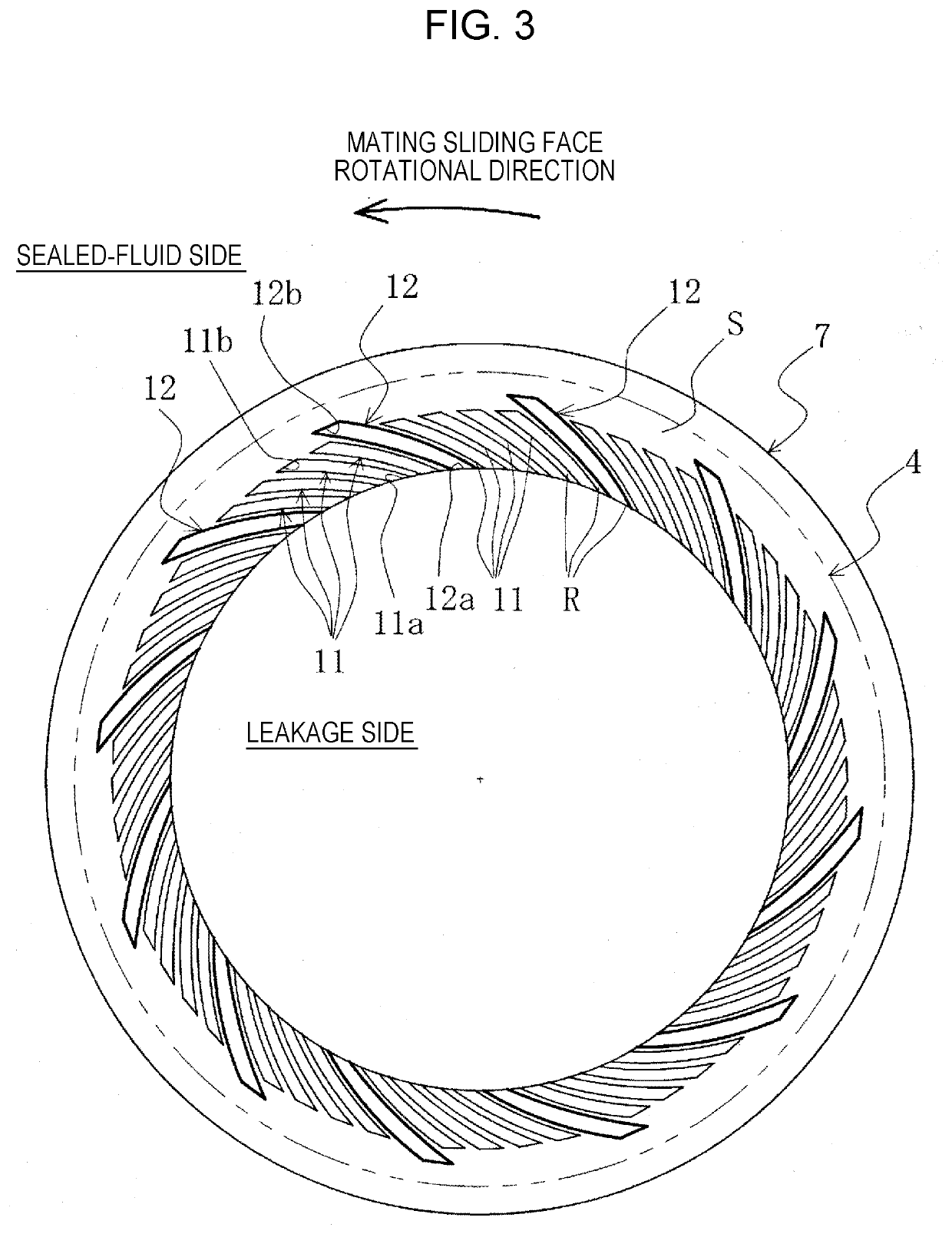

Sliding component

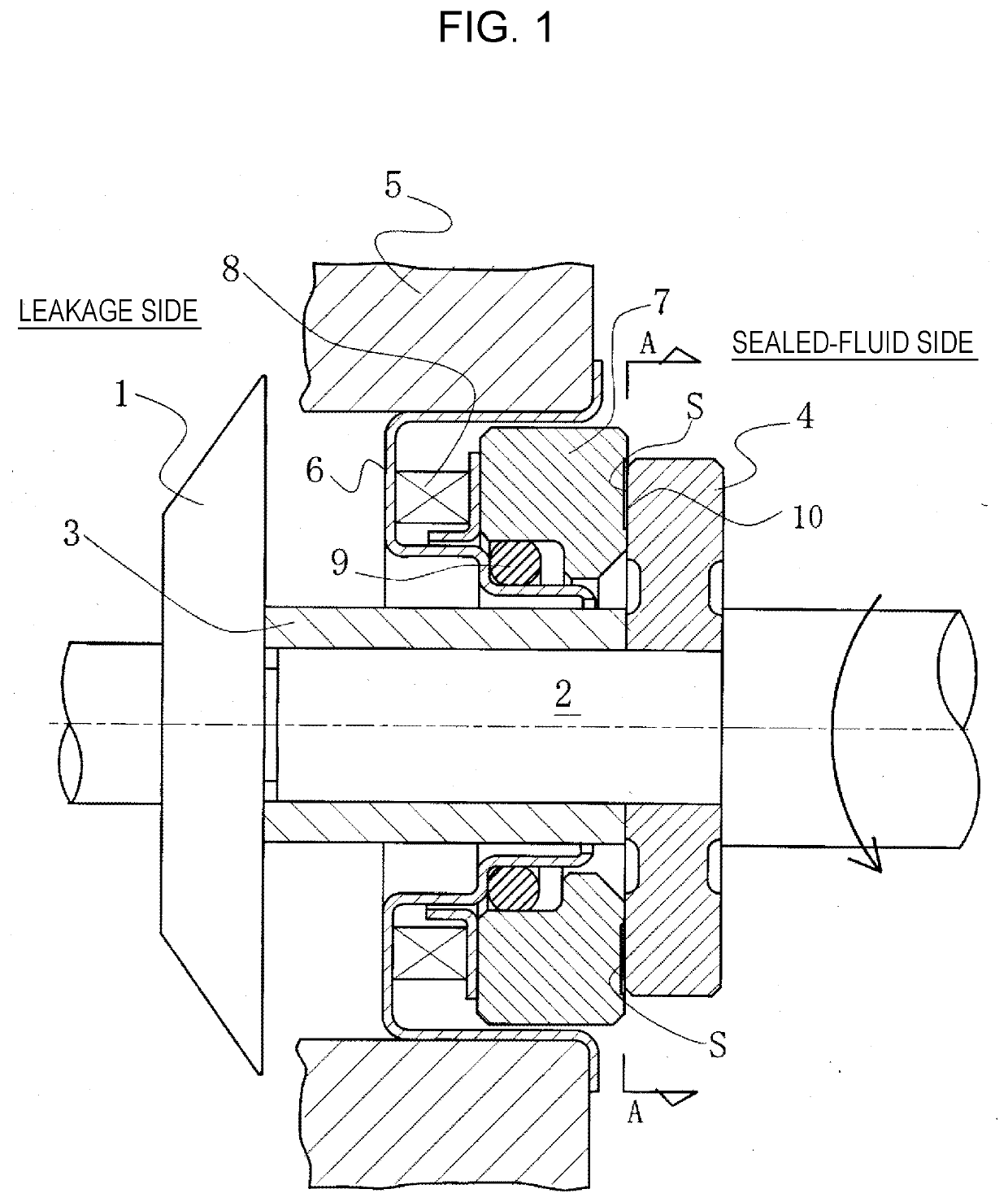

ActiveUS20210054935A1The effect is outstandingInhibit wearEngine sealsShaftsEngineeringMechanical engineering

In an exemplary embodiment, a sliding component includes a pair of sliding parts sliding relatively to each other. One sliding part is a stationary-side seal ring 7, and the other sliding part is a rotating-side seal ring 4, wherein the seal rings have sliding faces S formed radially for sealing a liquid or a misty fluid as a sealed fluid against leakage. At least one of the sliding faces S is provided with: spiral grooves 11 which have upstream ends 11a connected to a leakage side, and downstream ends 11b not connected to a circumferential edge on a sealed-fluid side, and are disposed at an angle from upstream to downstream; and discharge grooves 10 disposed at an angle such that their upstream ends 10a are located on the leakage side and their downstream ends 10b are located on the sealed-fluid side.

Owner:EAGLE INDS

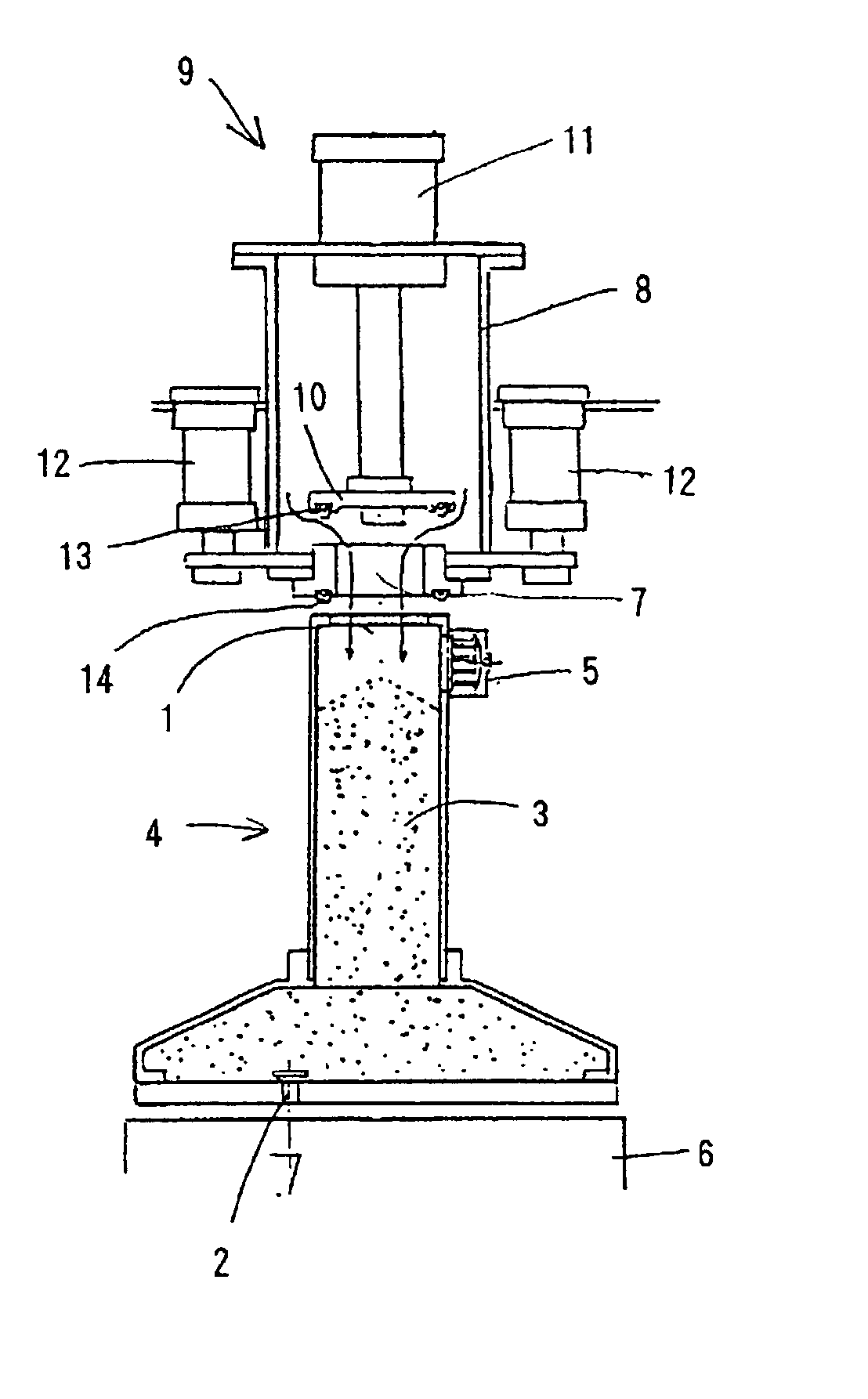

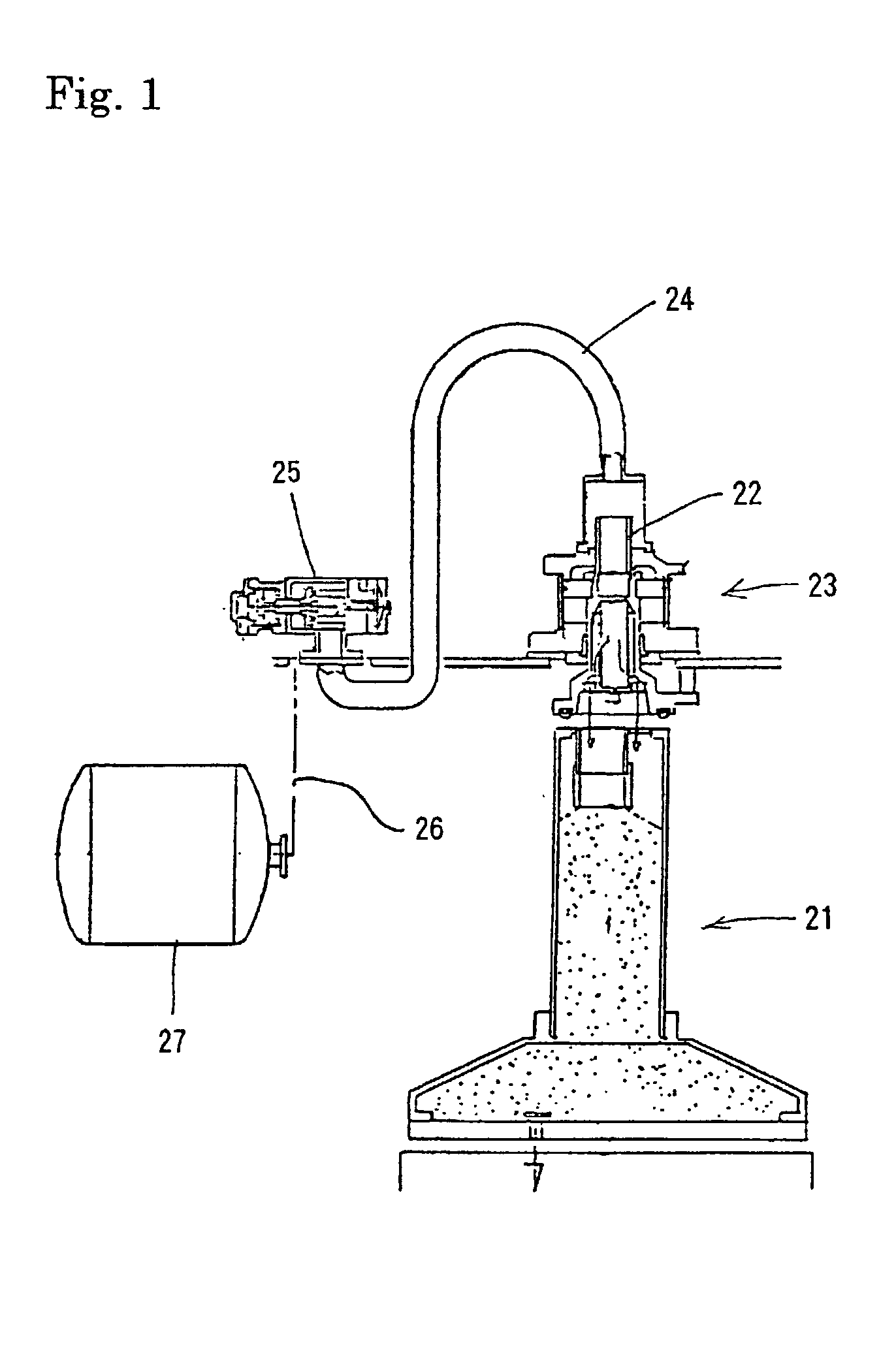

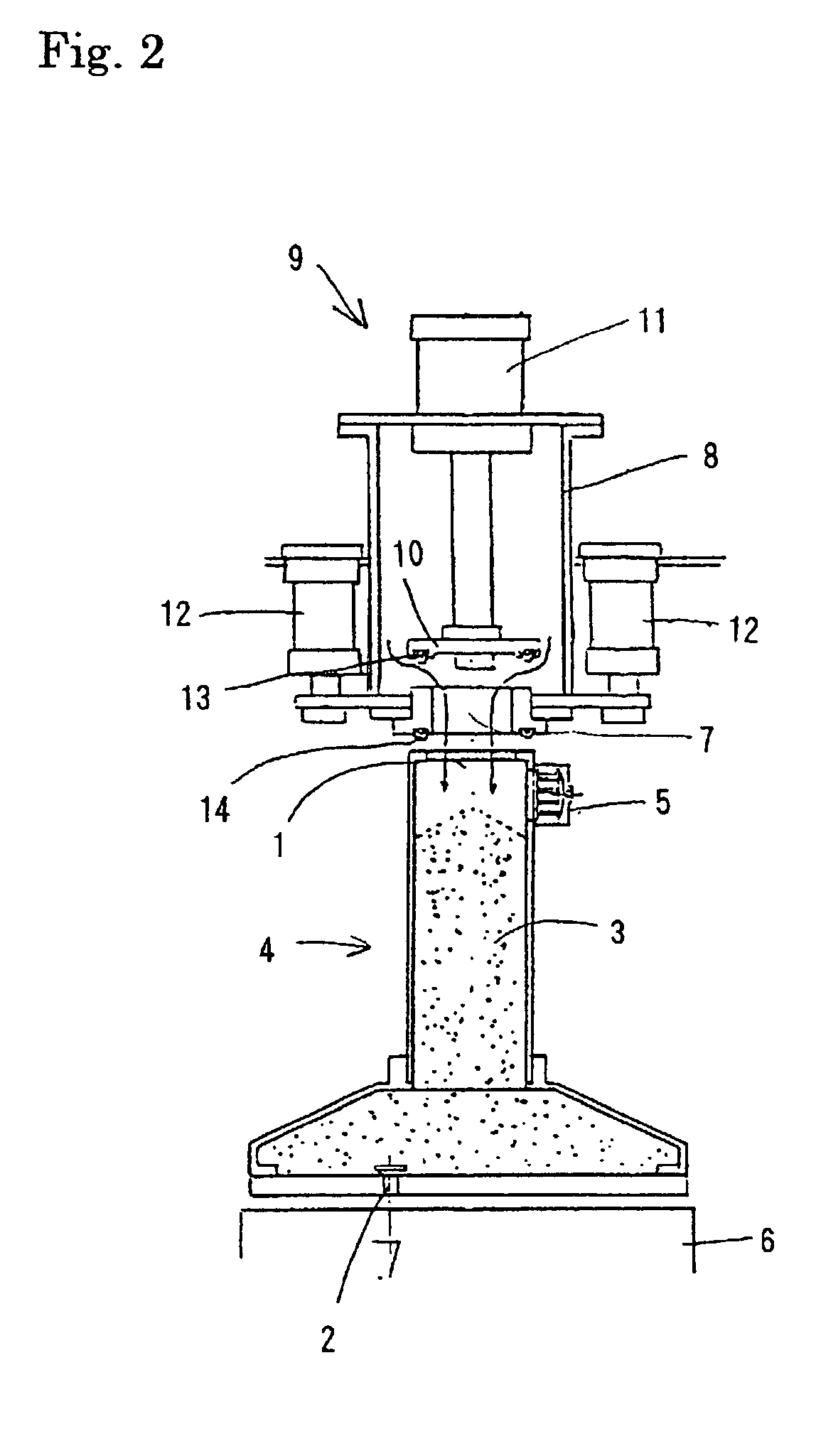

Casting sand blowing device for molding machines

InactiveUS20020157804A1Simple structureEasy to changeFoundry mouldsAuxillary shaping apparatusExhaust valveMolding machine

A blow-squeeze molding apparatus equipped with a compact and cheap gas treating apparatus wherein the loss of pressure in the compressed air is small and the position at which sand is blown into the mold can be easily changed. The apparatus comprises a sand-storing tank equipped with a sand-discharging nozzle and an exhaust valve, a compressed air-storing tank equipped with a compressed air-discharging opening, and means for opening and closing the compressed air-discharging opening. The blow squeeze machine comprises a stationary member for fixing a stationary piece of mold (mold half) and a sliding member for sliding a movable piece of mold. The gas treating apparatus comprises a hood surrounding the shell machine, means for treating gases with a smell, and a guide tube for guiding gases with a smell.

Owner:SINTOKOGIO LTD

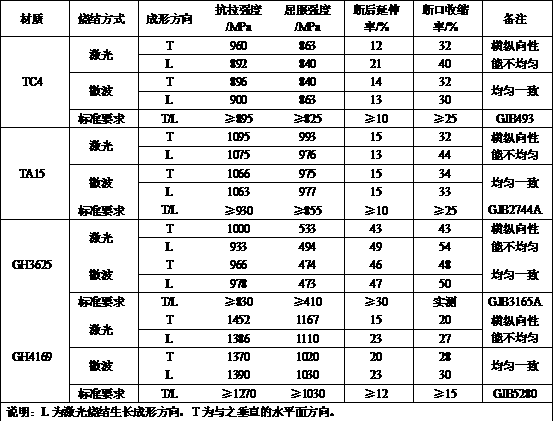

Spraying and microwave sintering-forming method for superfine particle carrier liquid

InactiveCN108655407AGuaranteed uniformityEasy to implementAdditive manufacturing apparatusProcess supportMicrowave shielding

The invention relates to a spraying and microwave sintering-forming method for superfine particle carrier liquid. The spraying and microwave sintering-forming method comprises the following steps of:establishing a solid three-dimensional model of a to-be-printed part and a three-dimensional model of a process supporting structure through three-dimensional software; slicing the three-dimensional model by slicing software, setting manufacturing parameters, and compiling process control program; uniformly mixing metal powder with a dispersing agent in proportion to form metal spraying fluid, andputting the metal spraying fluid into a metal spraying tank; putting a supporting material into a supporting and spraying tank; enabling a plurality of spraying heads to separately spray the metal spraying fluid and the supporting material to a base plate of a forming region layer by layer according to set process control program, thereby manufacturing a formed part; putting the formed part at atemperature higher than a melting point of the supporting material, and melting to remove support; heating the part to a temperature being 900-1300 DEG C through microwaves, and sintering-forming theprocessed printed part; and performing post-treatment on the sintered and formed part to obtain a final finished product part. The spraying and microwave shielding and forming method is safe in cleaning, and can guarantee uniformity of the part.

Owner:沈阳精合数控科技开发有限公司

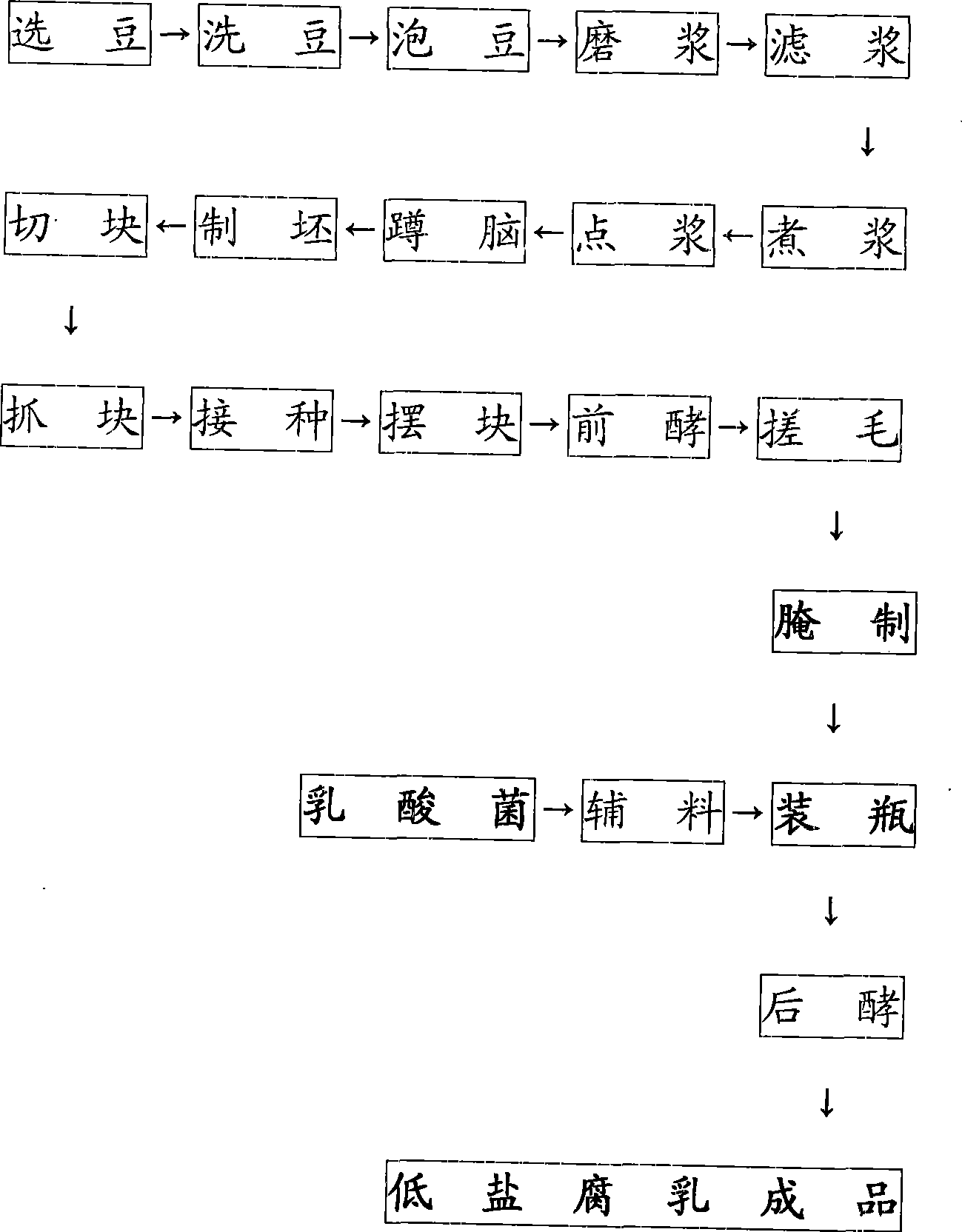

Method for reducing salt content in preserved beancurd

The invention discloses a method for reducing the salt content of fermented bean curd, relating to the technical field of food production. The invention reduces the salt content in the fermented bean curd production and provides a new low-salt fermented bean curd product with a lactic acid bacteria technology; the method goes through the procedures of bean selecting, bean washing, bean soaking, bean refining, pulp screening, pulp boiling, pulp coagulating, jellied bean curd forming, blank making, cake cutting, cake grasping, inoculating, cake laying, pre-fermentation, hair rubbing, preserving, bottling, accessory material adding and post-fermentation to obtain the low-salt fermented bean curd finished product; the method is technically characterized in that the amount of the salt added in the preserving process is controlled less than three-quarters of the conventional amount; during bottling and accessory material adding process, 100-400 fermentative activities / 1000 liters of lactic acid bacteria are added into the accessory material; the preserved blanks and the accessory material with lactic acid bacteria are bottled and evenly shaken; and the salt content of the low-salt fermented bean curd finished product is less than or equal to 4.8%. The method is applied to the fermented bean curd production. The invention provides a new low-salt fermented bean curd product through a new method so as to enrich the life of people, ensure the healthy diet, improve the intake of fermented bean curd, enhance the production and sales, as well as promote the progress of the industry.

Owner:北京首农味业集团有限公司

Earpiece having V-shaped interconnection between two portions of the earpiece when inserted into the ear canal

ActiveUS10757497B2Change shapeChange sizeCompletely in canal hearing aidsIn the ear hearing aidsEngineeringHeadphones

An earpiece for an earphone comprising a first portion (100), a second portion (101), and a resilient bridge (102) interconnecting the first portion (100) and second portion (101), wherein the resilient bridge (102) is configured to flex so that the earpiece can conform to ear canal geometry as it is received in a user ear canal and thereby be at least substantially locatable within the ear canal. The resilient bridge (102) may be configured to provide a biasing effect so that the first portion (100) and / or second portion (101) can bias against the ear canal wall (15).

Owner:ZOKU LTD

External preparation for treating painful skin wound

ActiveUS8658625B2The effect is outstandingNot cause retardationSalicyclic acid active ingredientsBiocideSalicylic acidTreatment pain

External preparations for treatment of painful skin wound having an analgesic activity which comprises acetylsalicylic acid or its pharmacologically acceptable salt as an active ingredient.

Owner:TEIKOKU SEIYAKU KK TEIKOKU SEIYAKU CO LTD

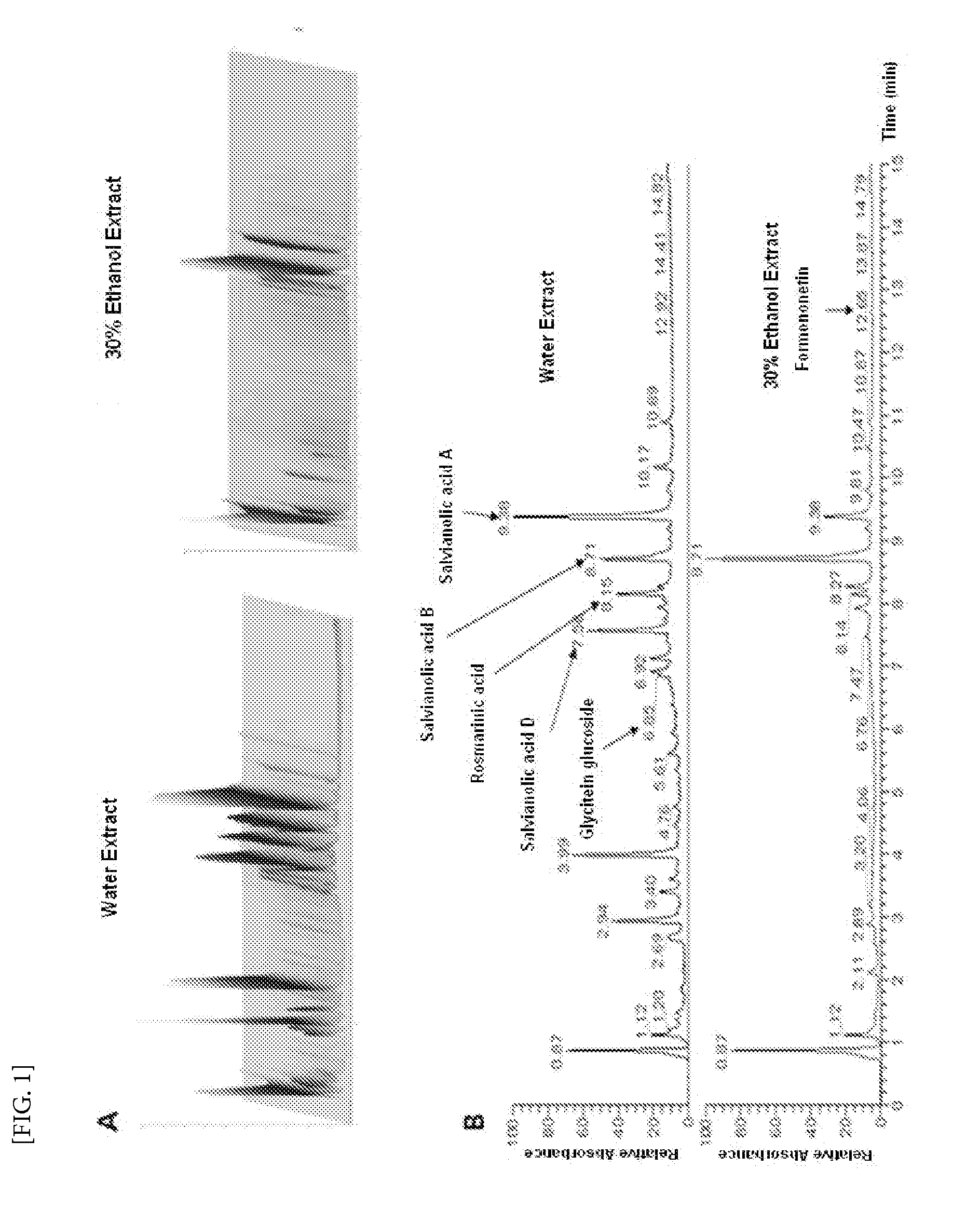

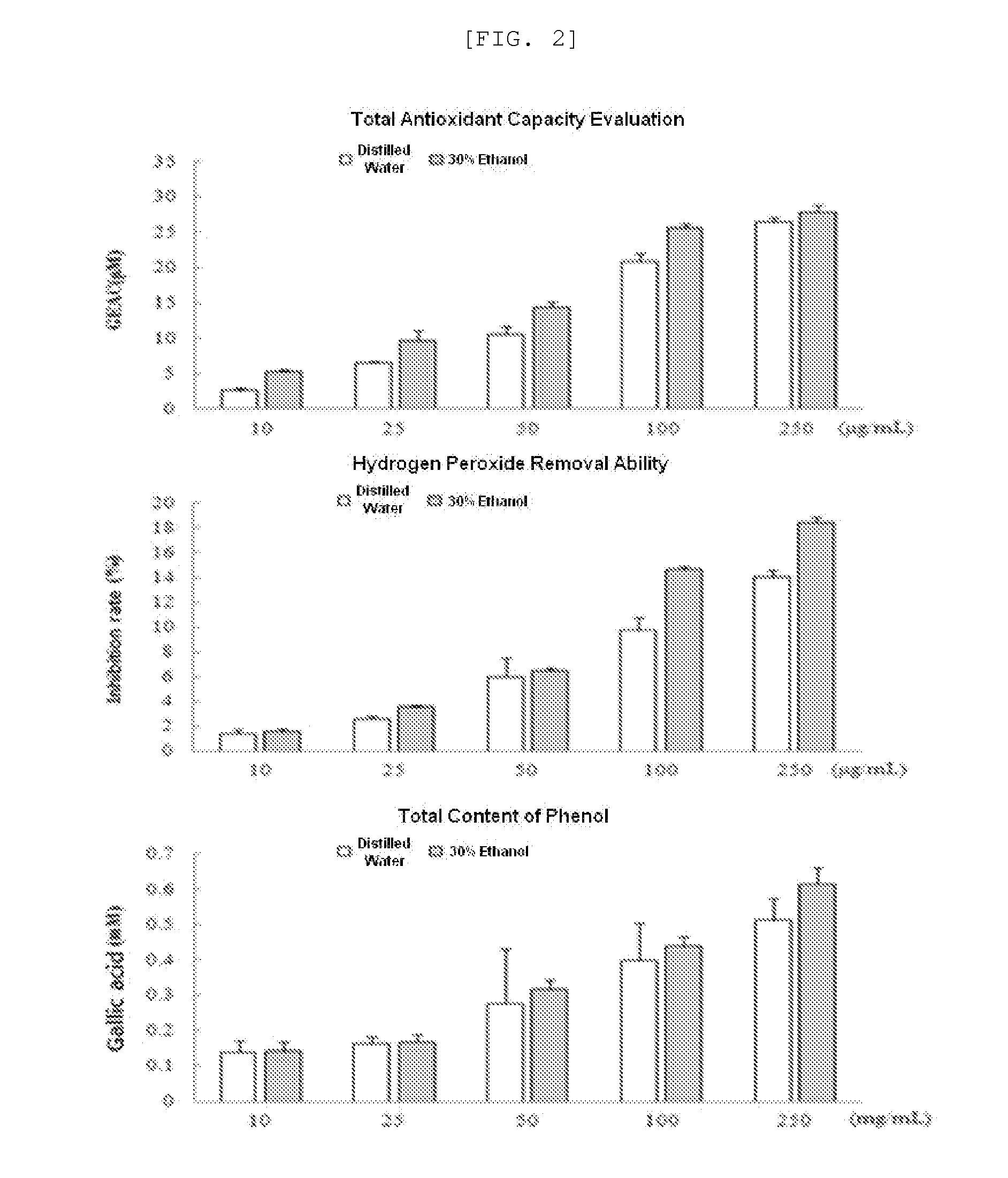

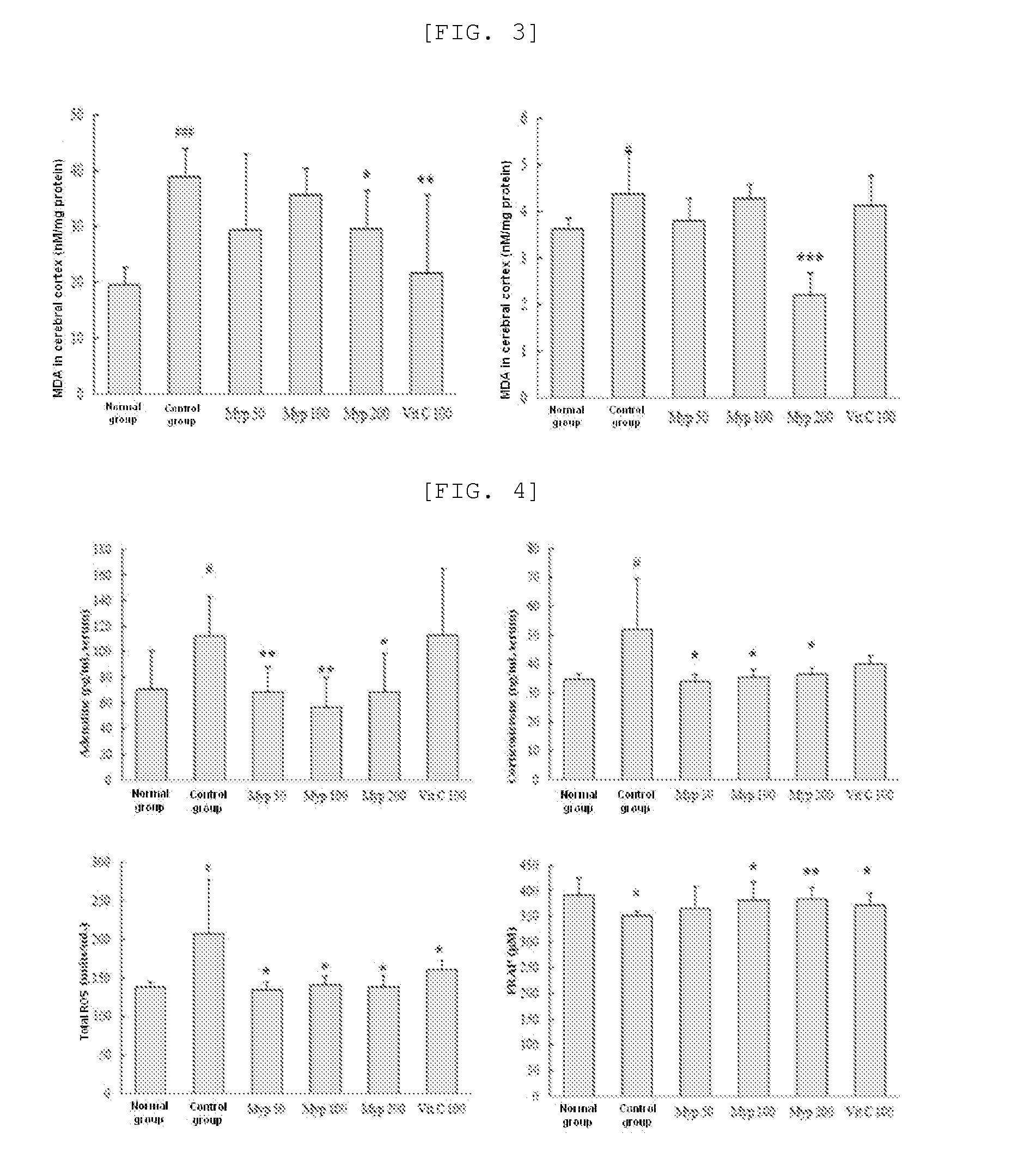

Composition for Preventing or Treating Oxidative Brain Damage and Brain Dysfunction, and Production Method for Same

ActiveUS20150328271A1Outstanding preventive effectOutstanding therapeutic effectBiocideNervous disorderSalvia miltiorrhizaInjury brain

Provided is a composition for preventing or treating oxidative brain injury and brain dysfunction including an extract of Astragali Radix and Salvia Miltiorrhizae Radix as an active ingredient, the composition having a highly outstanding preventive or therapeutic effect in animal models simulating brain-tissue damage and brain dysfunction induced by acute and long-term excessive stress generated in actual clinical practice, which is effectively usable as a therapeutic agent thereof.

Owner:DAEJEON UNIV IND UNIV COOPERATION FOUND

Three-dimensional printing joint method and structure

InactiveCN111251605AEnsure complete removalPrevent unfused defectsAdditive manufacturing apparatusAdditive manufacturing with solids3 dimensional printingIndustrial engineering

The invention discloses a three-dimensional printing joint method and structure. The three-dimensional printing joint method comprises the steps that in the step 101, a to-be-jointed position of a component is machined into a groove structure, and the groove structure and a technology cushion plate are machined; in the step 102, the technology cushion plate and the component are fixed, and a specific interval is reserved between the technology cushion plate and the component; in the step 103, the three-dimensional printing technology is adopted for conducting three-dimensional printing at thegroove structure, and accordingly an integral component is subjected to joint connection through the groove connection and / or a cracked component is subjected to joint repairing through the groove structure; and in the step 104, the component obtained after three-dimensional printing in the step 103 is subjected to technology cushion plate removal. The space of 2mm-3mm is reserved on the upper surface of the technology cushion plate and the lower surface of a component additional material connecting area, the enough allowance is reserved for technology cushion plate deformation in the preventing connection and repairing process, the aftertreatment procedures are simplified, and the aftertreatment procedure cost is saved. The invention further relates to the three-dimensional printing jointstructure.

Owner:TSC LASER TECH DEV BEIJING CO LTD

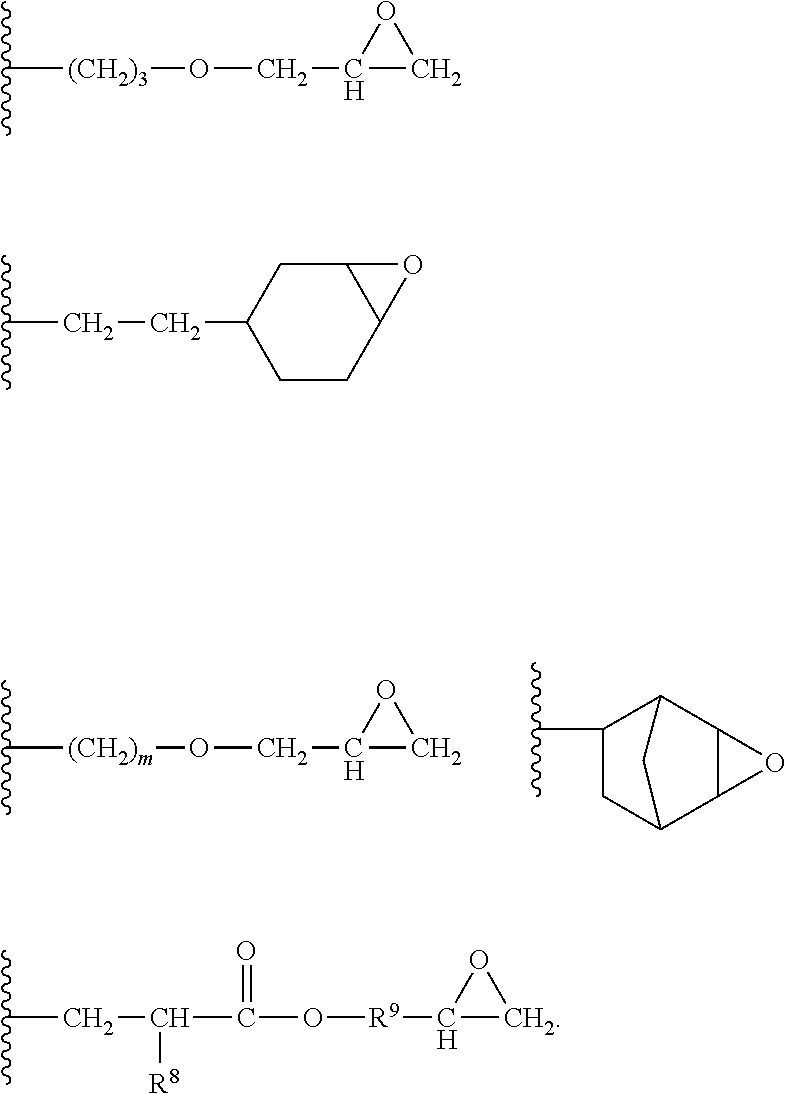

Coating material, process for preparing it, and its use for producing firmly adhering color and/or effect coatings

ActiveUS20090281208A1Improve interlayer adhesionThe effect is outstandingImpression capsPaper coatingPolyesterAryl

Disclosed herein is a liquid coating material curable with actinic radiation, substantially or entirely free from organic solvents, comprising (A) at least two compounds of general formula X—O—Y(—OH)-Z-Gr wherein X is a C6-C14 aromatic radical, C5-C20 heterocyclic aromatic radical or C6-C30 alkyl radical, Y is a trivalent organic radical, Z is a linking functional group, and Gr is an organic radical comprising one group which can be activated with actinic radiation; with the proviso that at least one of the two compounds (A) comprises aromatic or heterocyclic aromatic radical X and at least one comprises alkyl radical X; (B) oligo- and polyurethanes and / or oligo- and polyesters comprising two or three groups which can be activated with actinic radiation; (C) color and / or effect pigments; (D) waxes; (E) matting agents; and (F) polysiloxane additives comprising groups which can be activated with actinic radiation, a process for preparing it, and use thereof.

Owner:BASF COATINGS AG +1

Earpiece

ActiveUS20210006885A1Maintain positionReduce lossesBone conduction transducer hearing devicesPiezoelectric/electrostrictive transducersEngineeringHeadphones

An earpiece for an earphone comprising a leading portion, a trailing portion, and a resilient bridge interconnecting the leading portion and trailing portion. The resilient bridge is configured to flex so that the earpiece can conform to ear canal geometry as it is received in a user ear canal and to provide a biasing effect so that the leading portion and / or trailing portion contact the ear canal wall. An actuator to augment low frequency sound is provided on the leading portion.

Owner:ZOKU LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com