Patents

Literature

1836results about "Crankshafts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

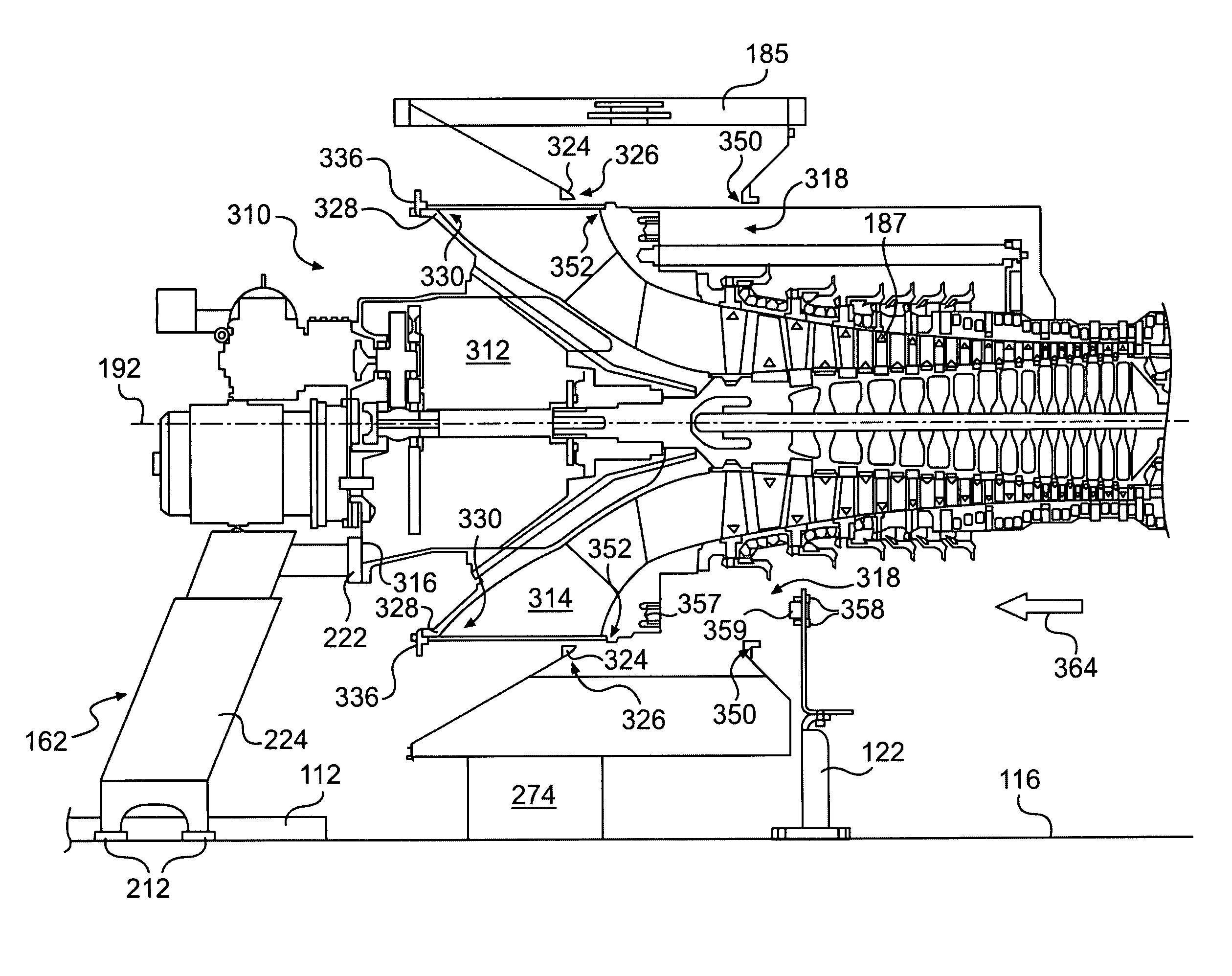

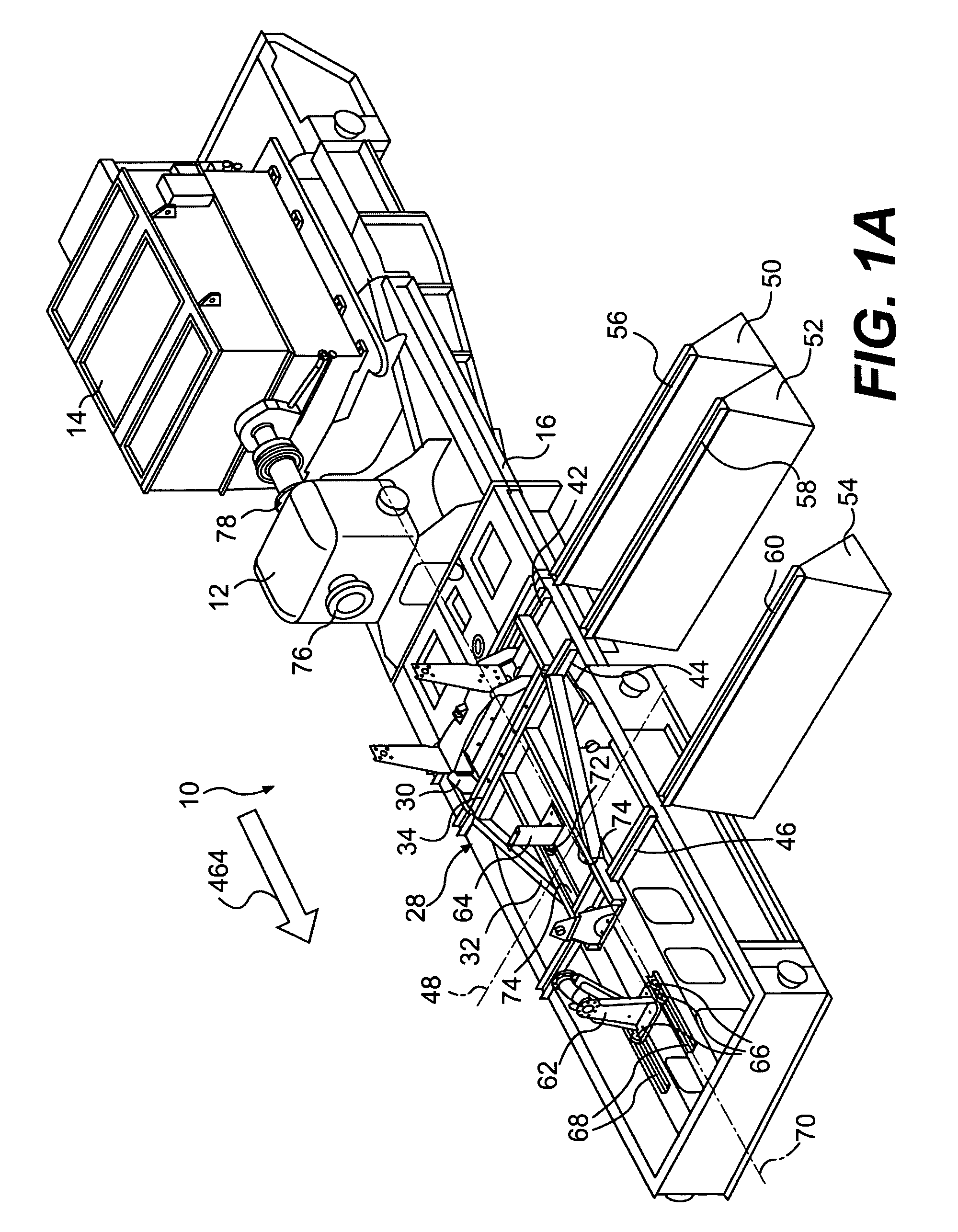

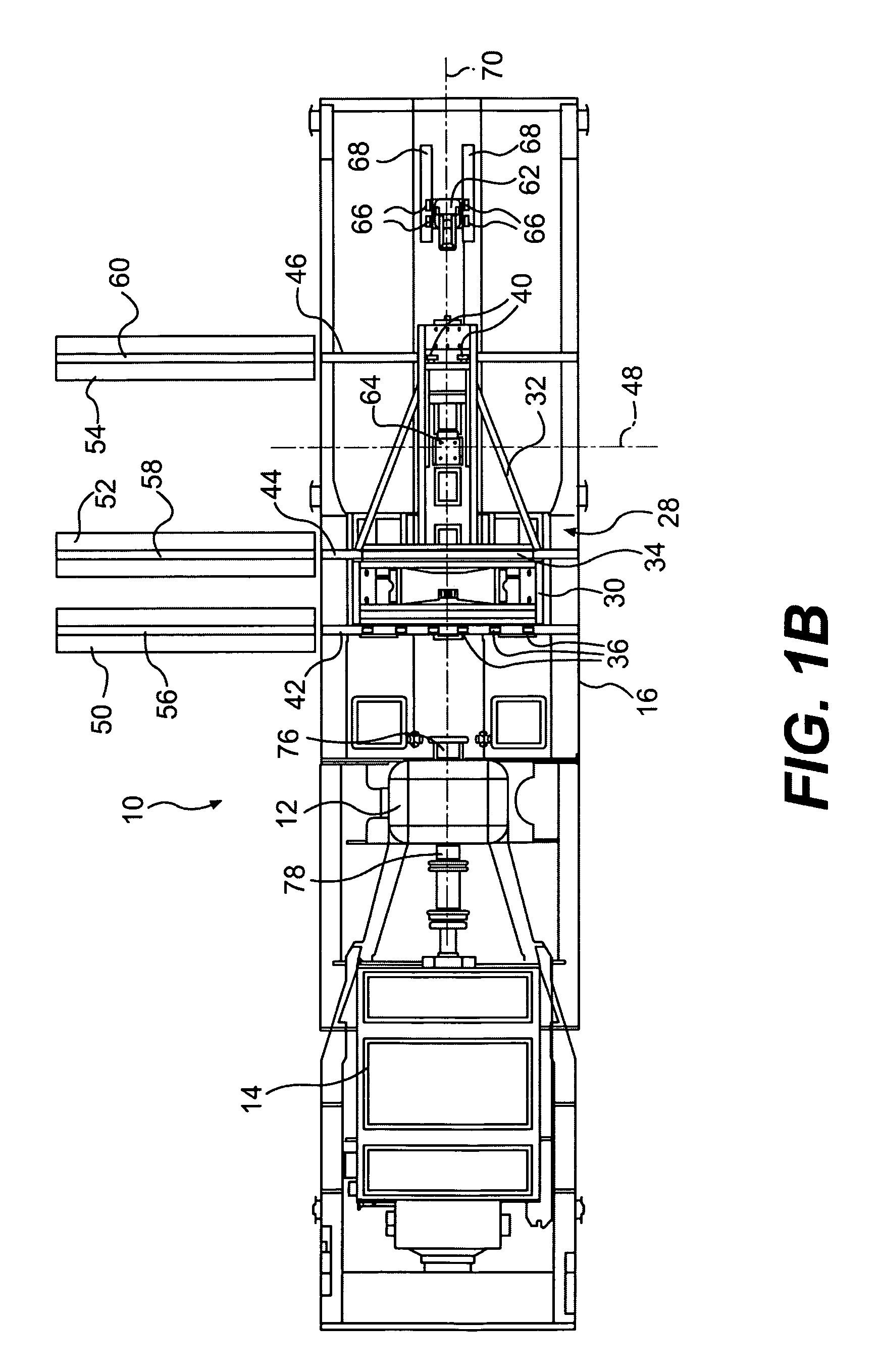

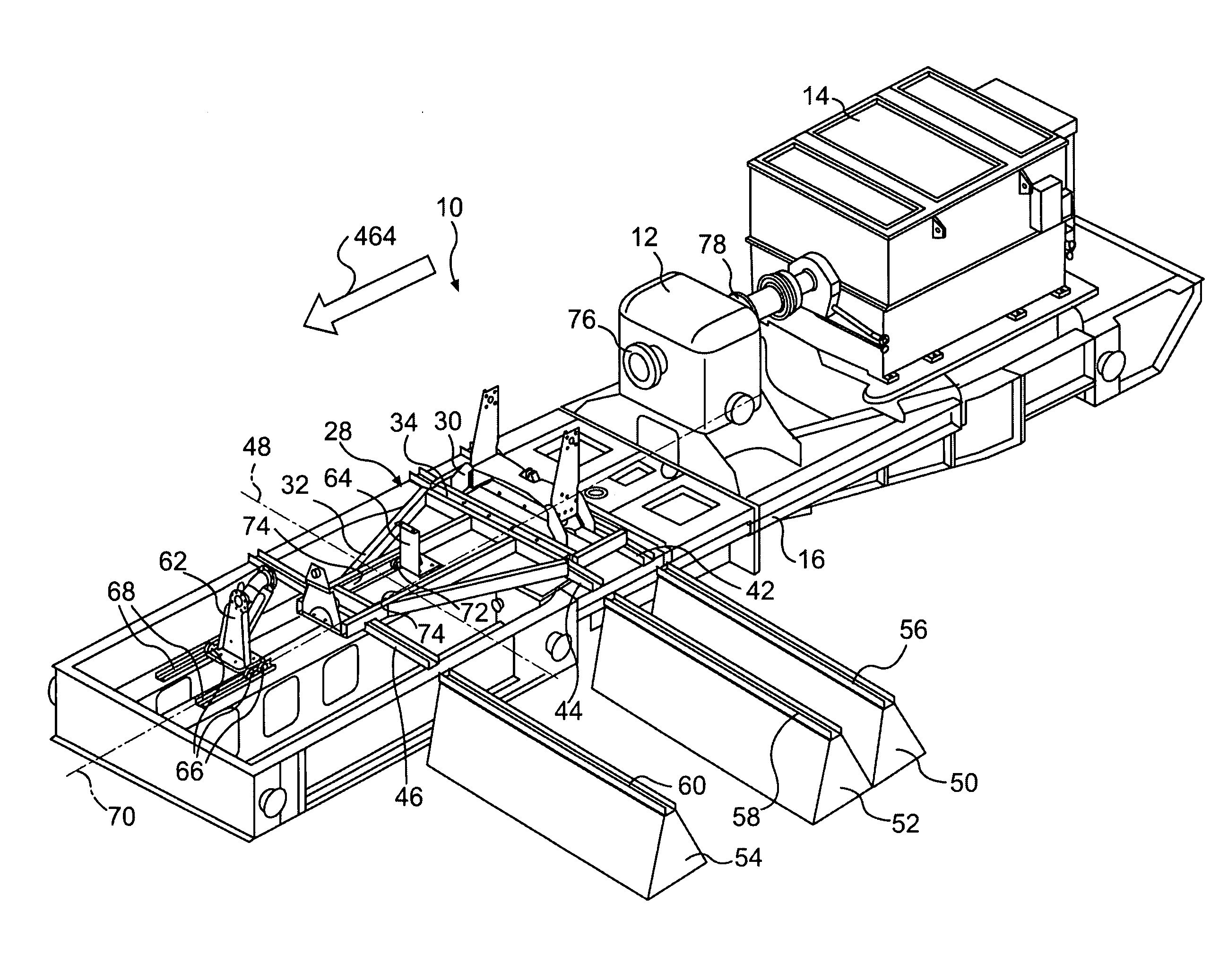

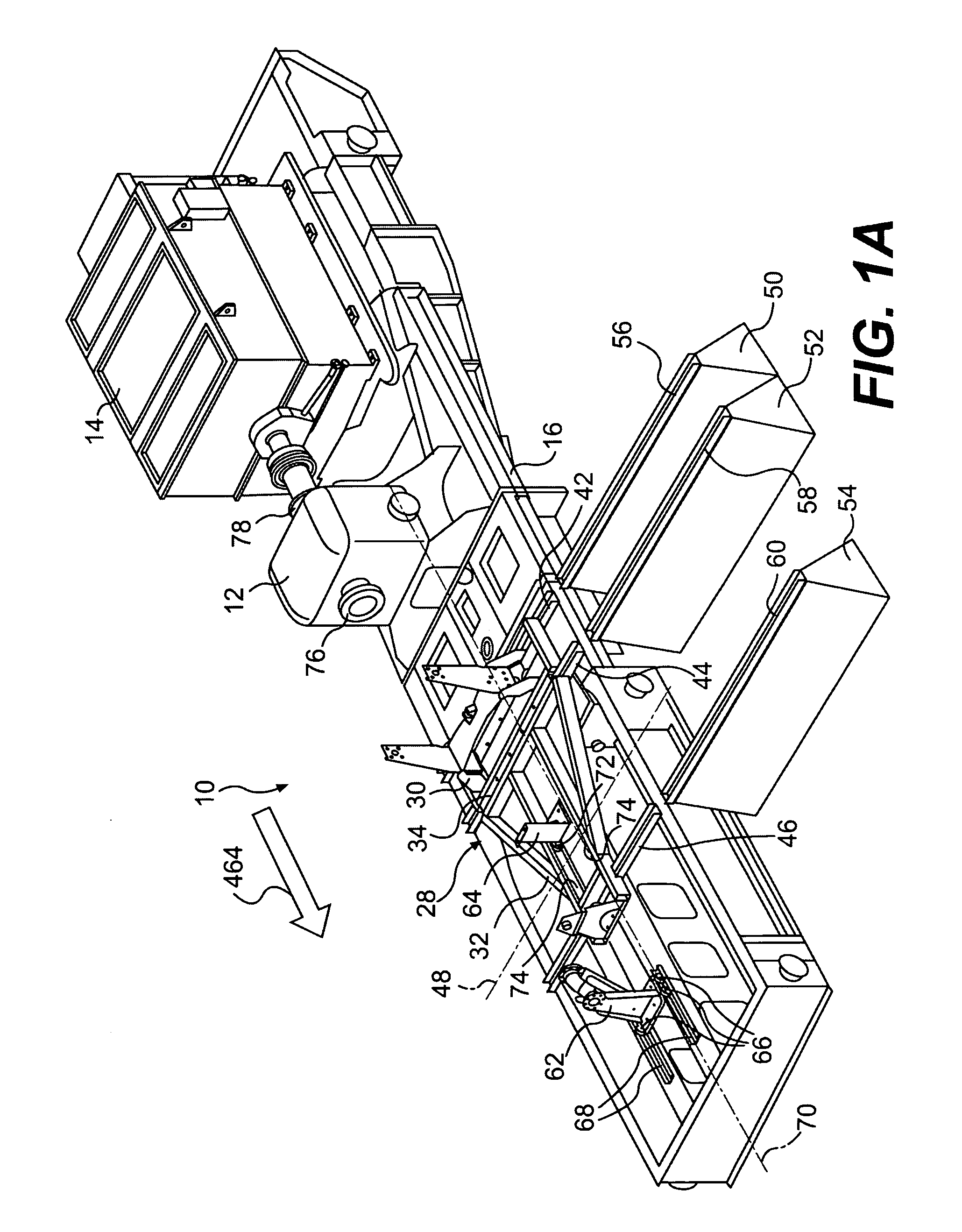

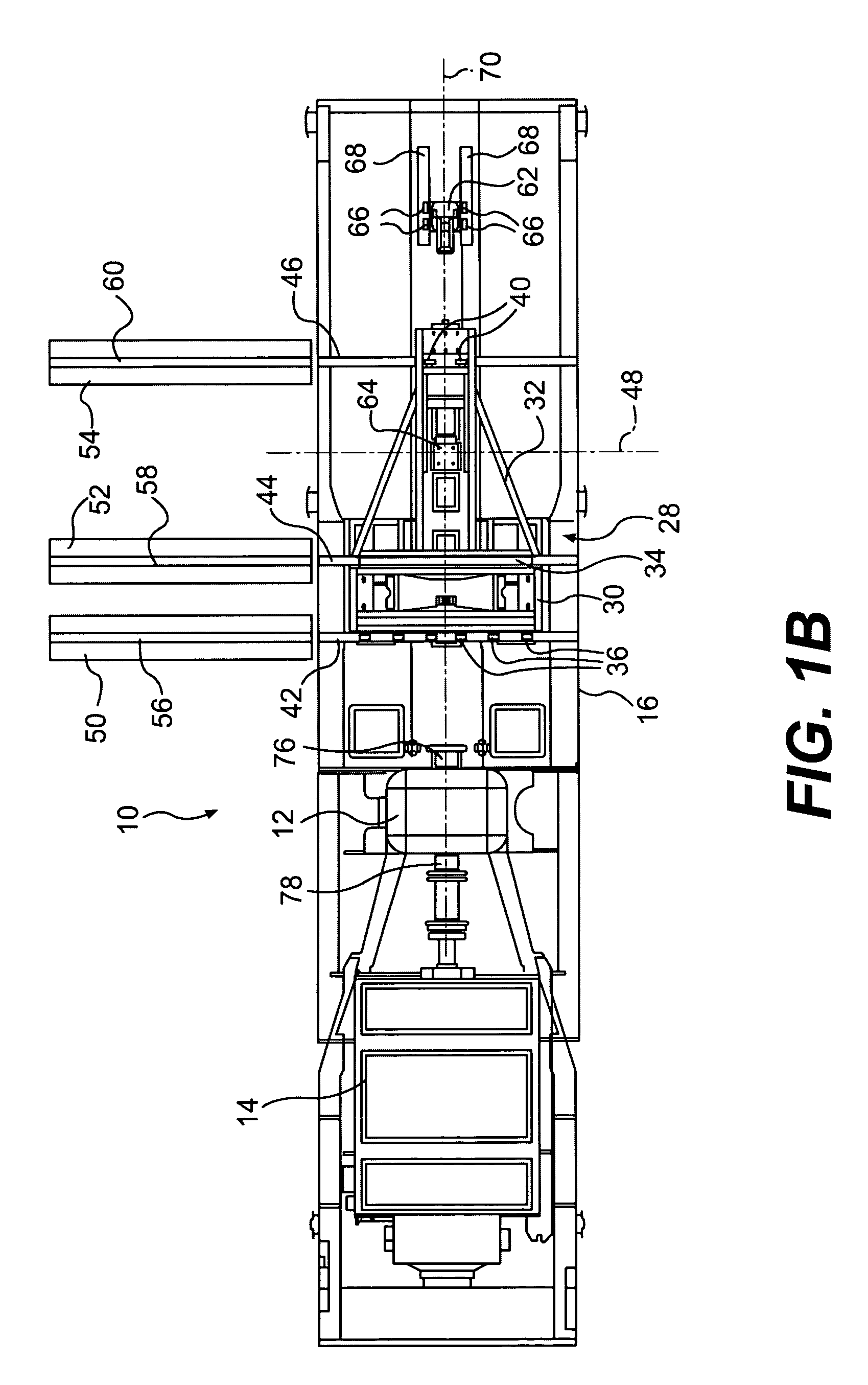

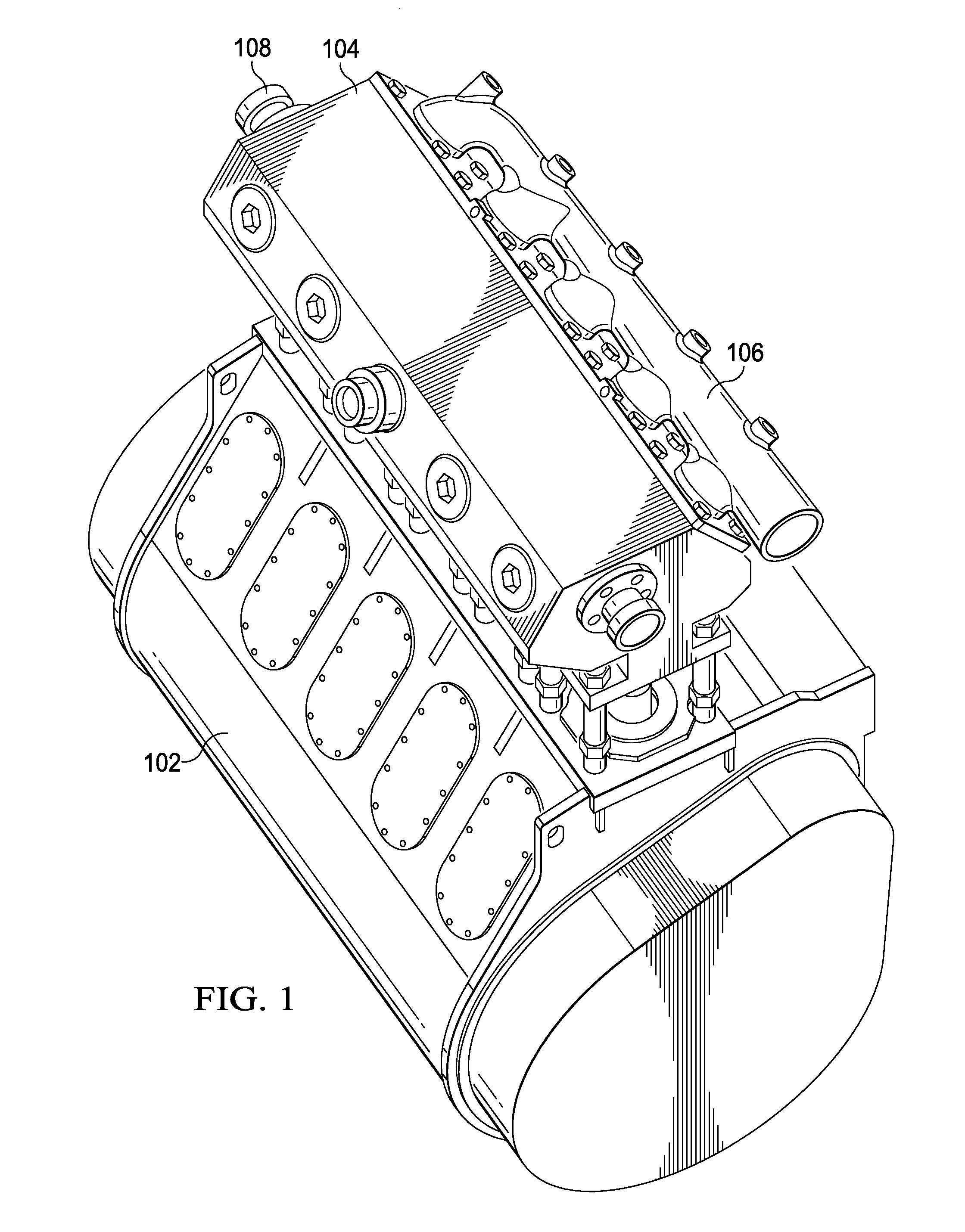

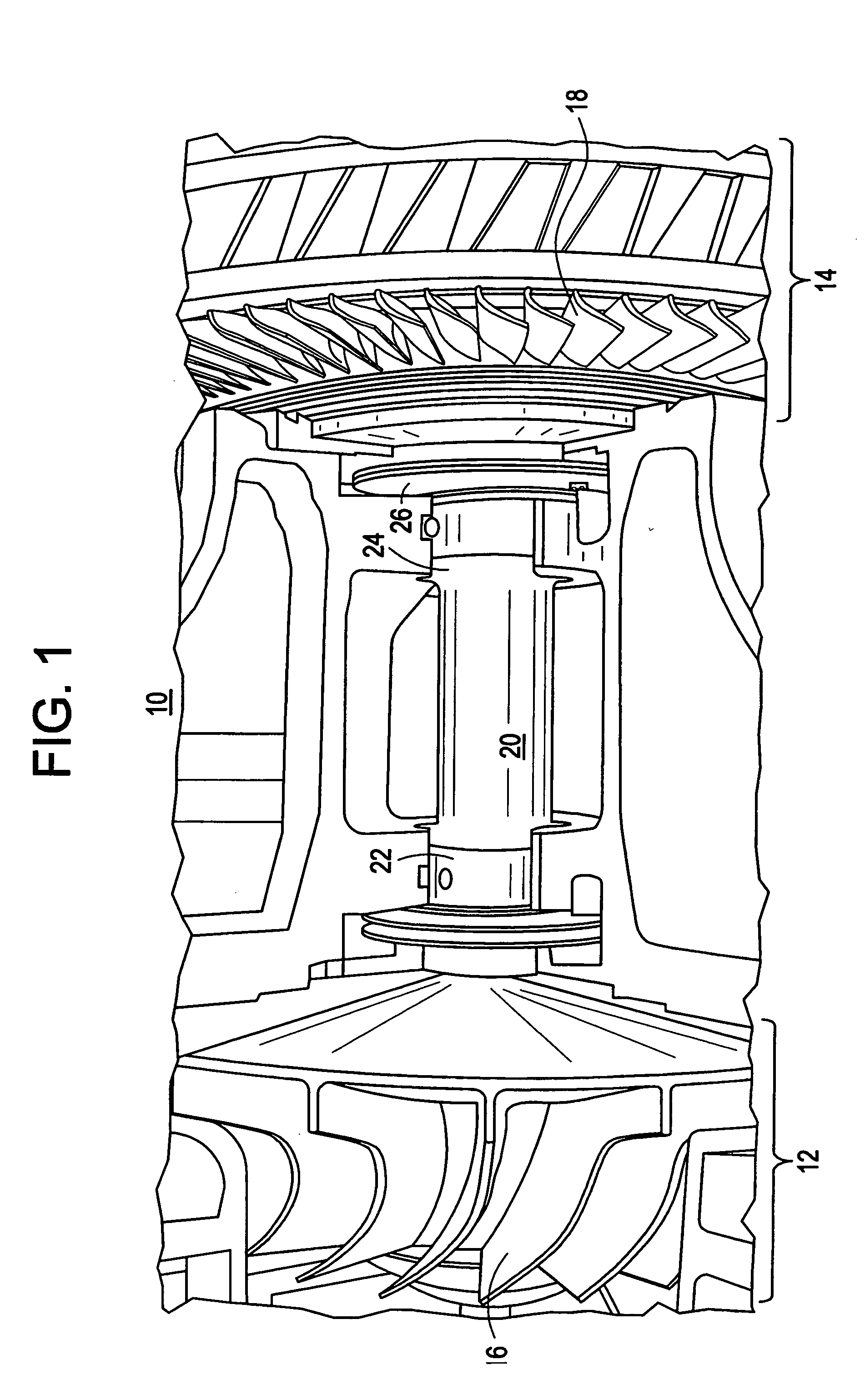

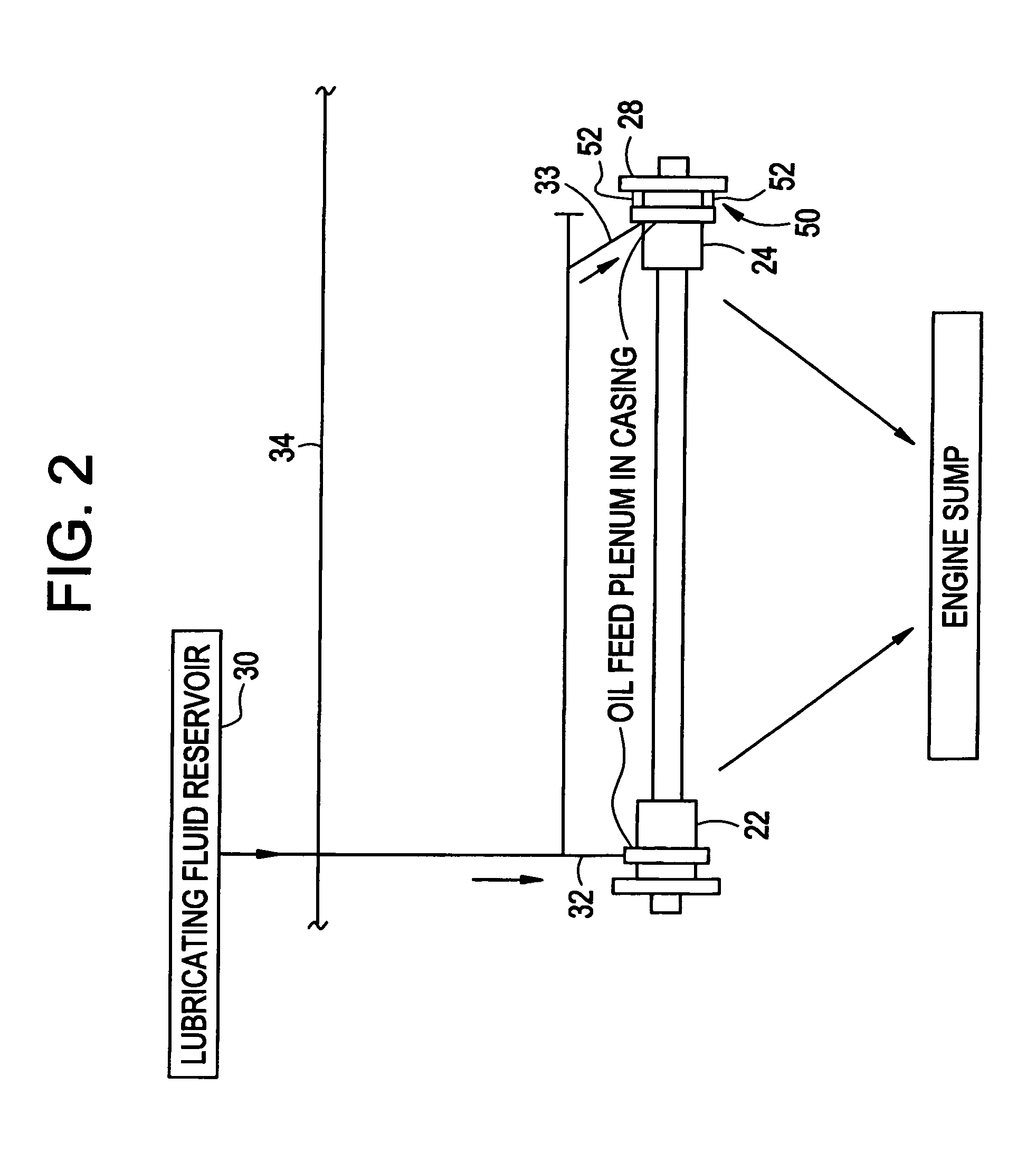

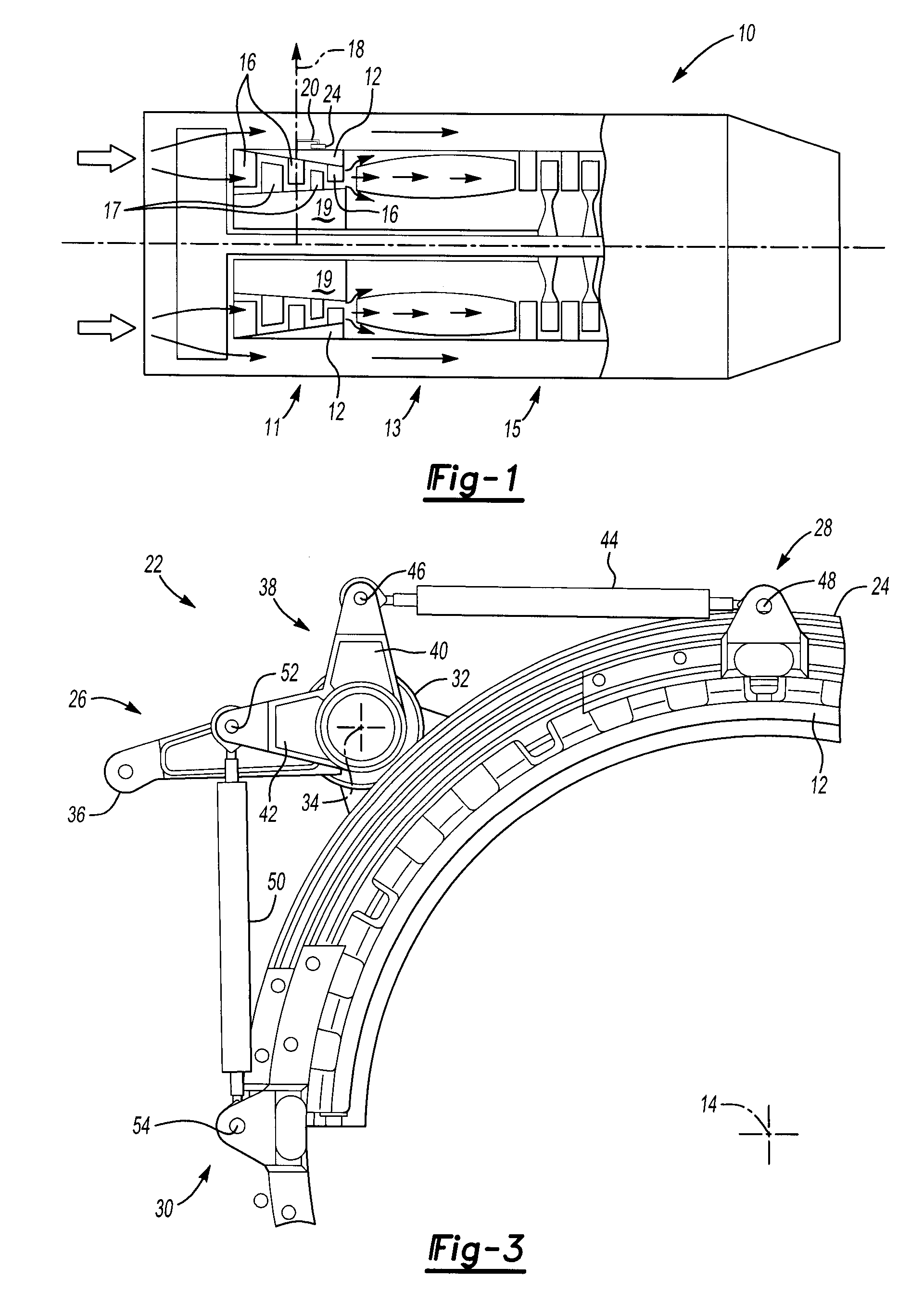

Gas turbine engine and system for servicing a gas turbine engine

A gas turbine engine includes a compressor having first annular connection structure at a forward end portion of an air inlet housing of the compressor. The gas turbine engine may also include intake ducting having second annular connection structure adjacent a central passage of the intake ducting. The first annular connection structure and the second annular connection structure may form at least part of an interface between the air inlet housing and the intake ducting during operation of the gas turbine engine. The first and second annular connection structures may have shapes allowing the first annular connection structure to be moved through and beyond the second annular connection structure in a forward direction, the forward direction being opposite a direction of compressed air flow in the compressor during operation.

Owner:SOLAR TURBINES

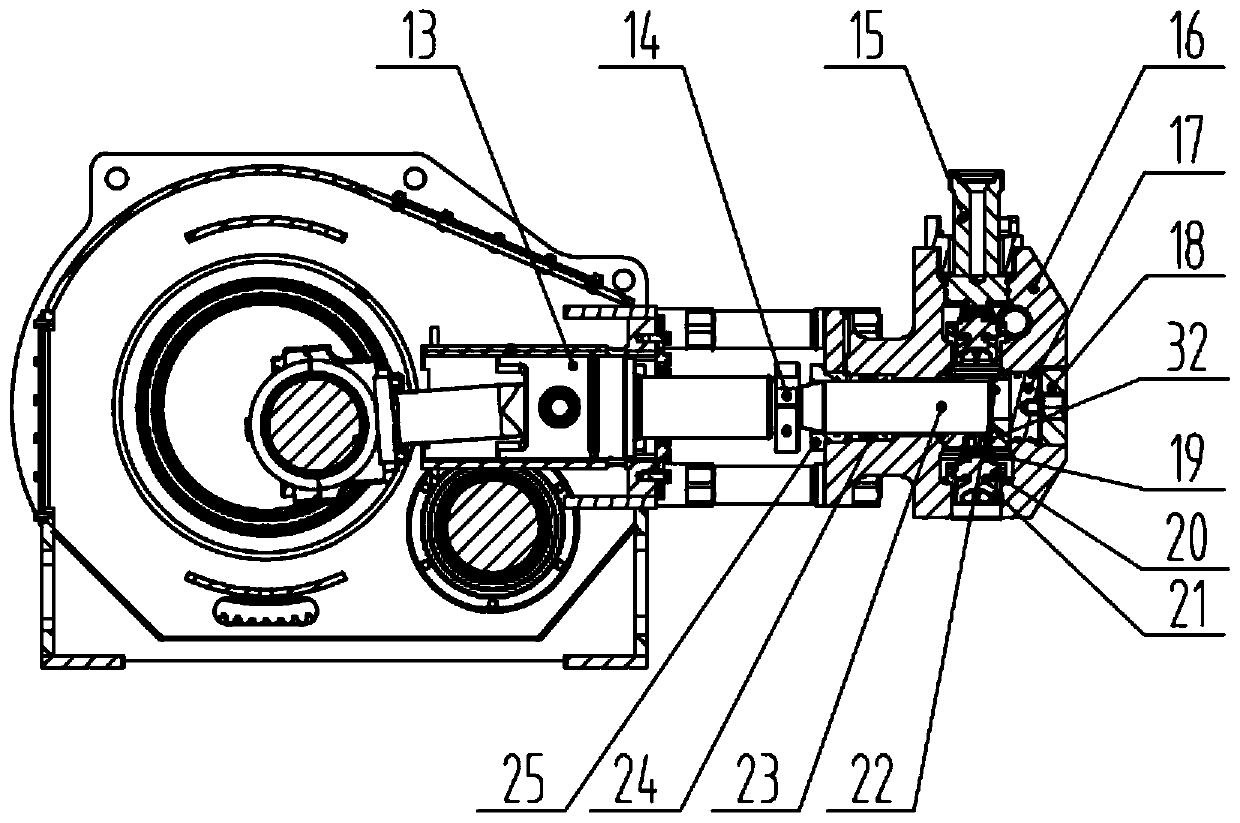

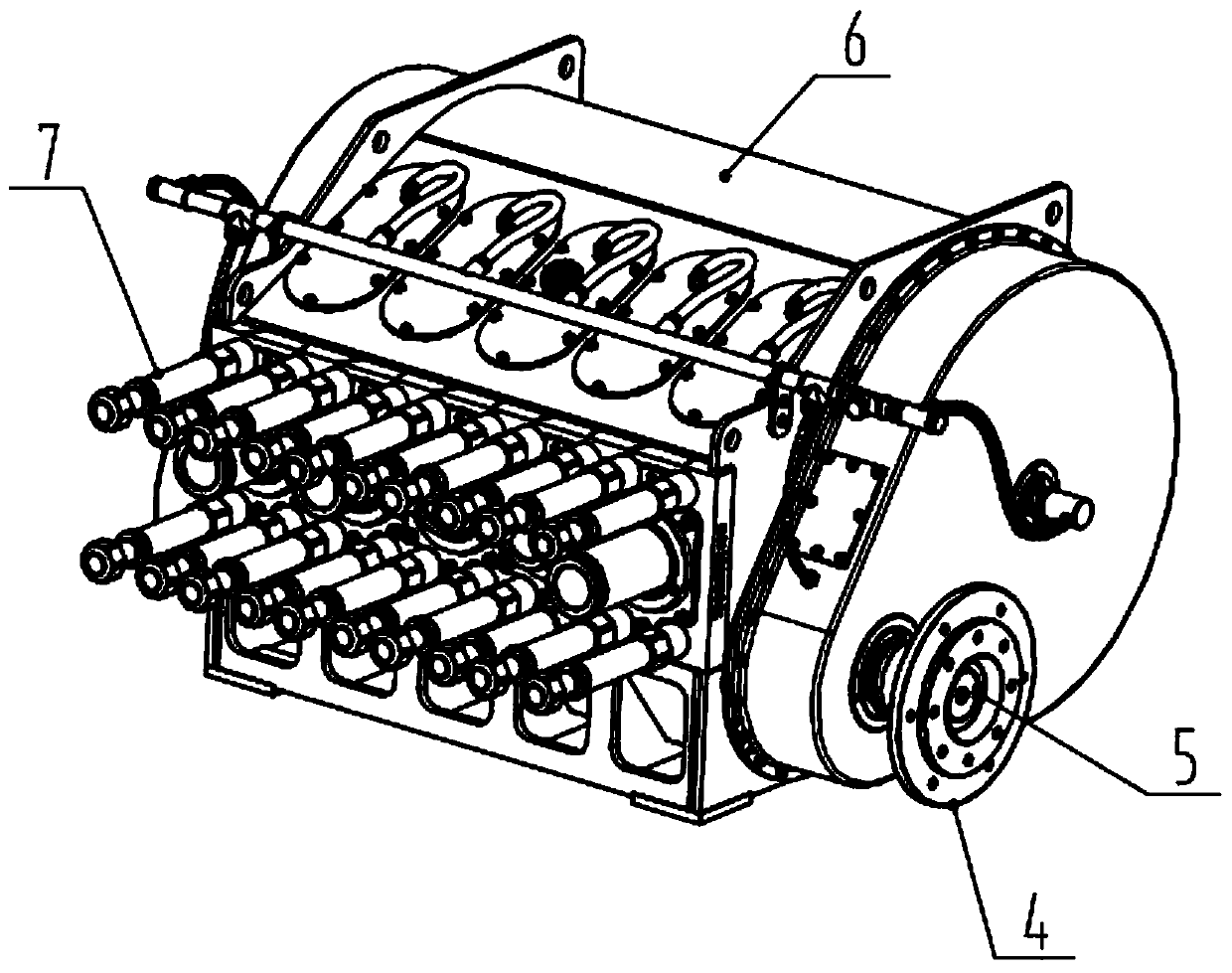

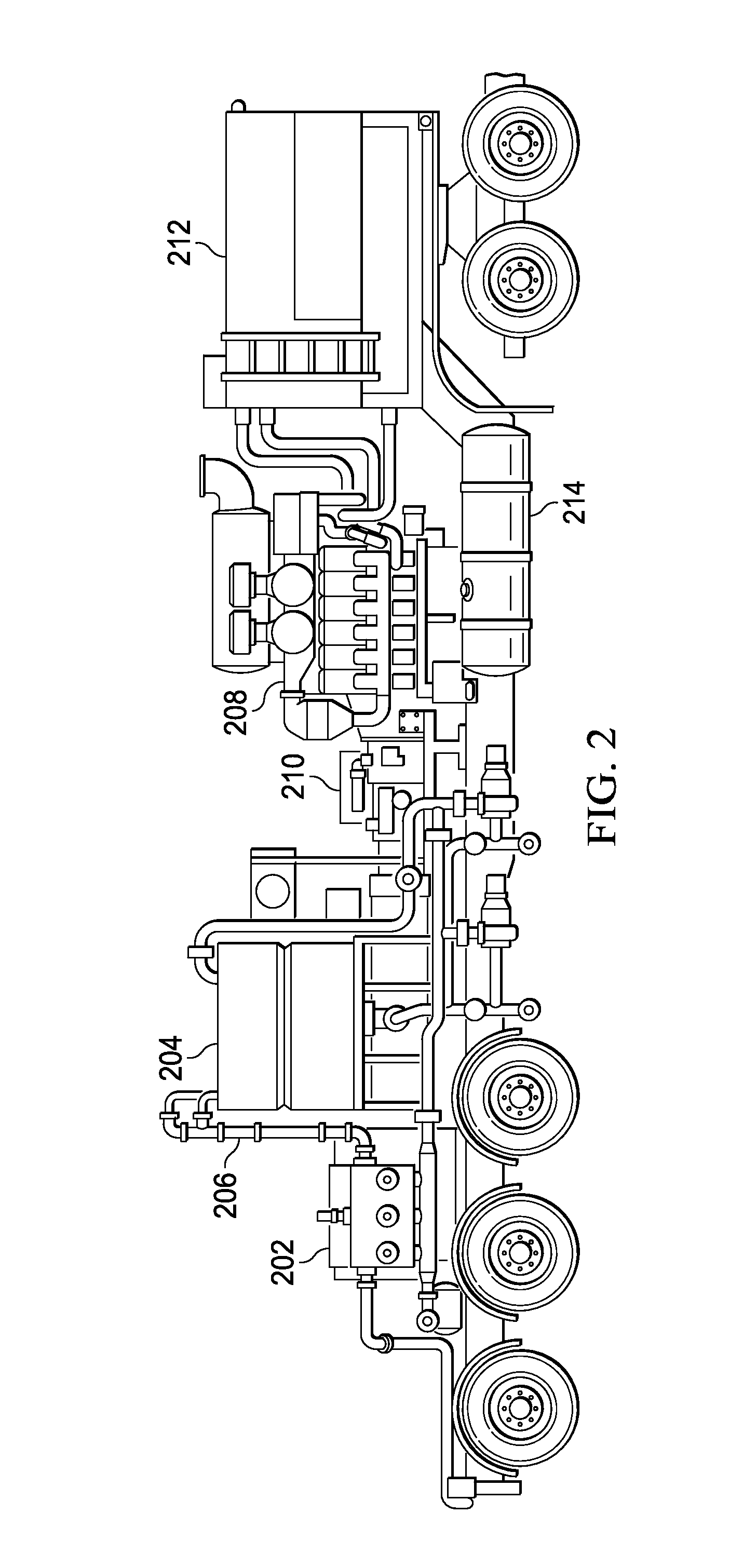

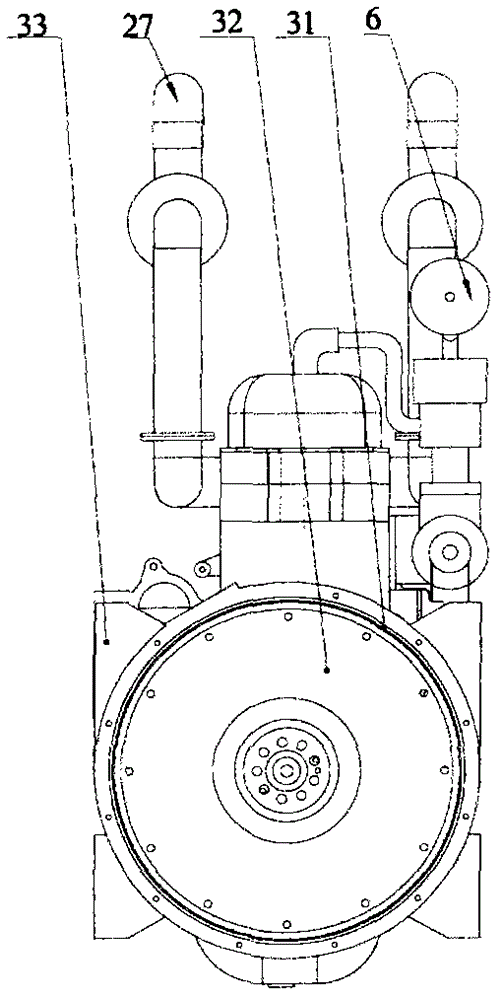

Light five-cylinder plunger pump

PendingCN111441925AIncreased stroke distanceIncrease rated input powerCrankshaftsPositive displacement pump componentsCrankGear wheel

The invention discloses a light five-cylinder plunger pump. The light five-cylinder plunger pump comprises a power end assembly and a hydraulic end assembly, wherein the power end assembly is connected with the hydraulic end assembly; the cylinder spacing of the light five-cylinder plunger pump is 9in; the power end assembly comprises a crank shaft, the crank shaft comprises six crank necks and five crank throws, the crank necks and the crank throws are fixedly connected, the distance between rotating centers of the crank necks and the crank throws is 101.6 mm, and the stroke distance of the light five-cylinder plunger pump is 203.2 mm. According to the light five-cylinder plunger pump, power is increased by increasing stroke, reducing transmission ratio and improving bearing capacity, andmeanwhile, dead weight is reduced by reducing the cylinder spacing, the tooth number of a big gear and the tooth thickness of the big gear and a pinion. The light five-cylinder plunger pump meets conditions of working in the area with severe well cementing operation conditions in aspects of weight and power simultaneously, and working efficiency is increased.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

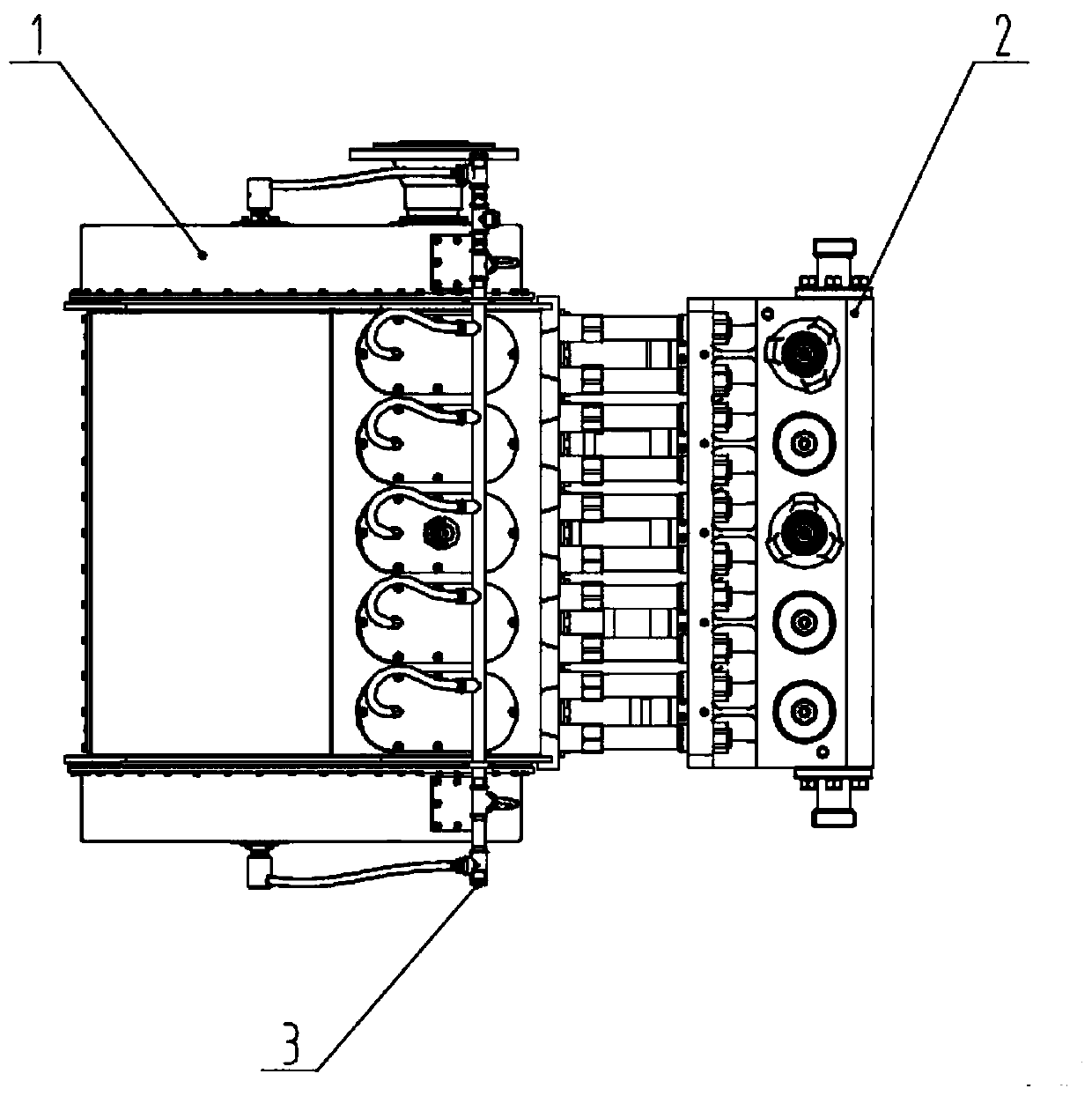

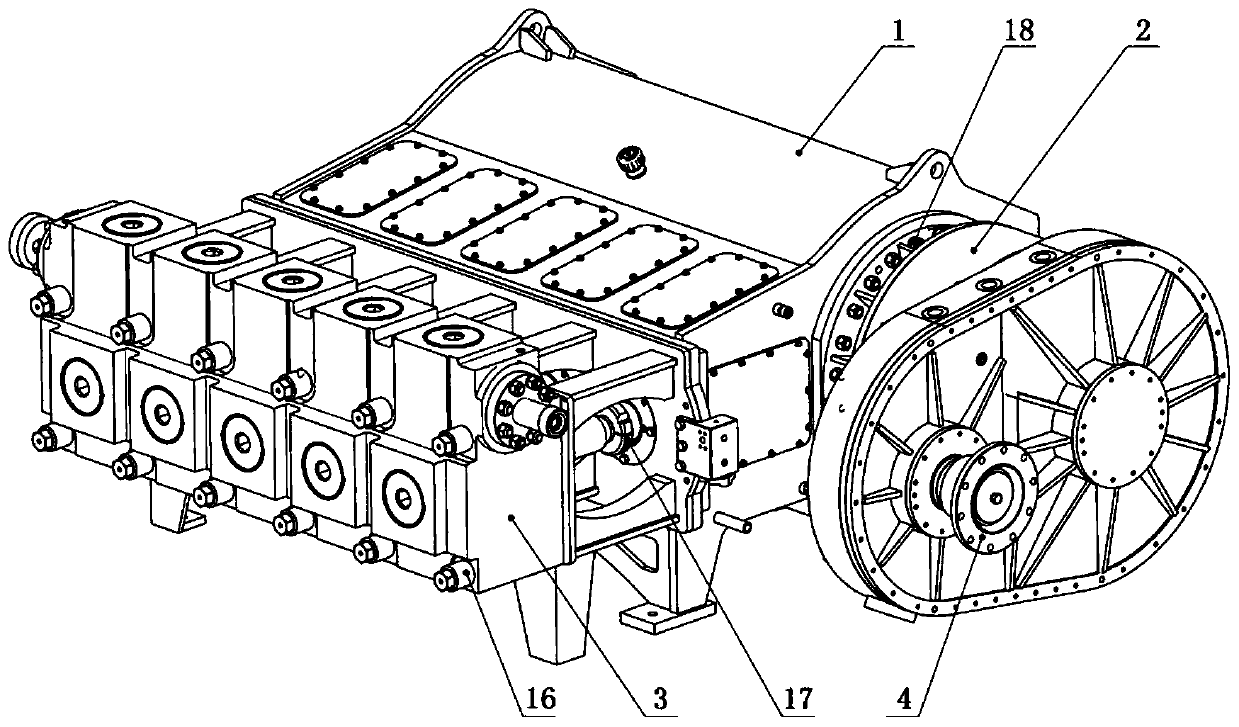

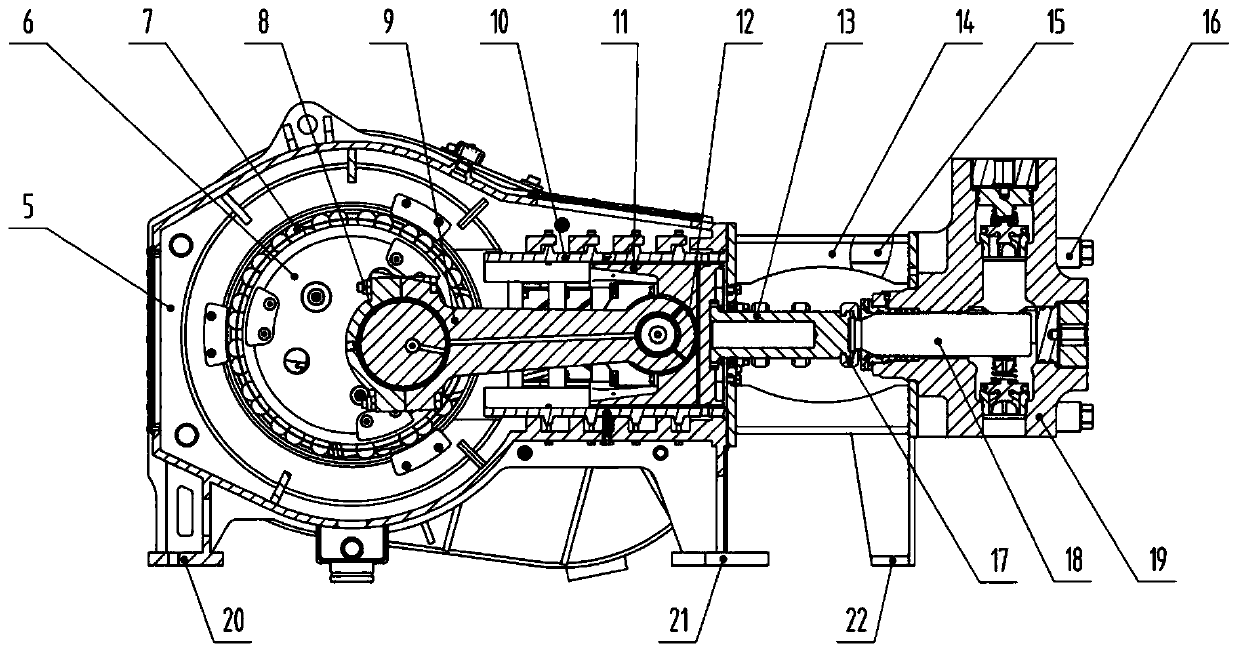

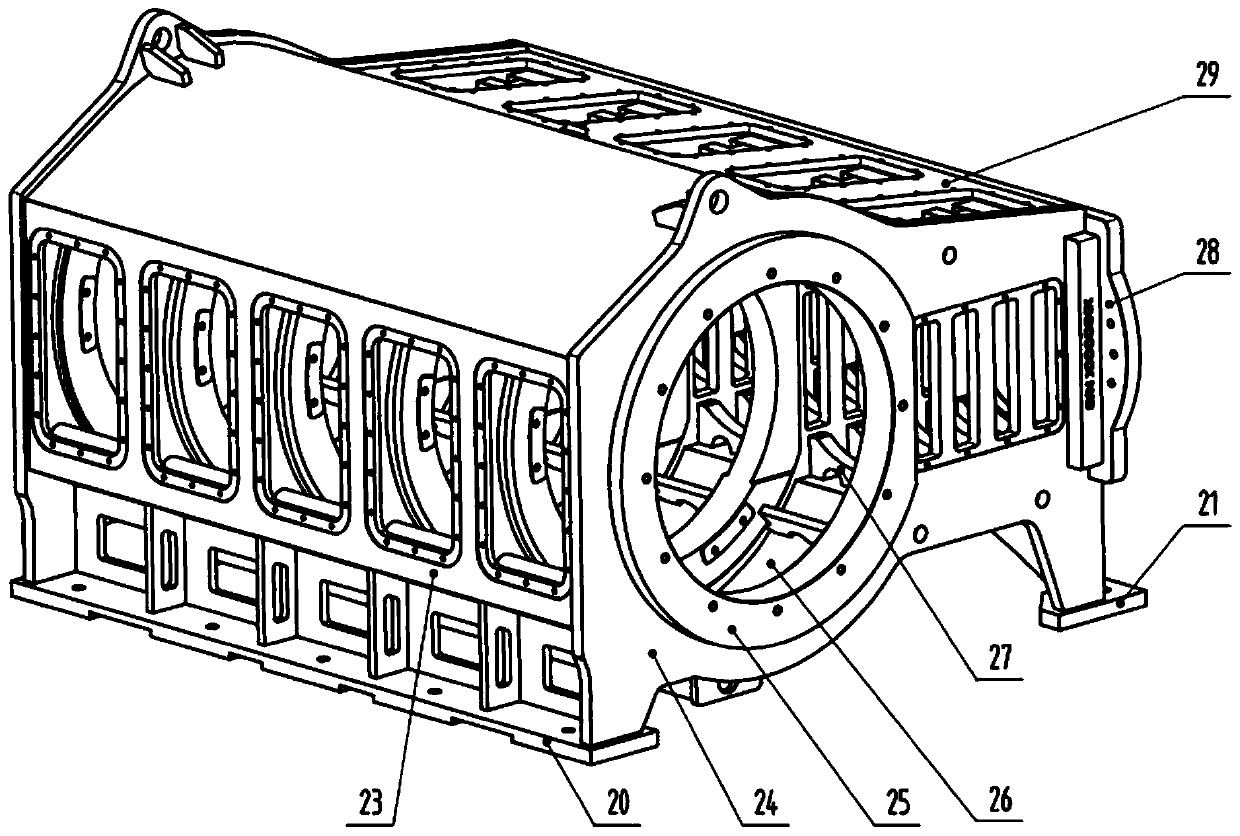

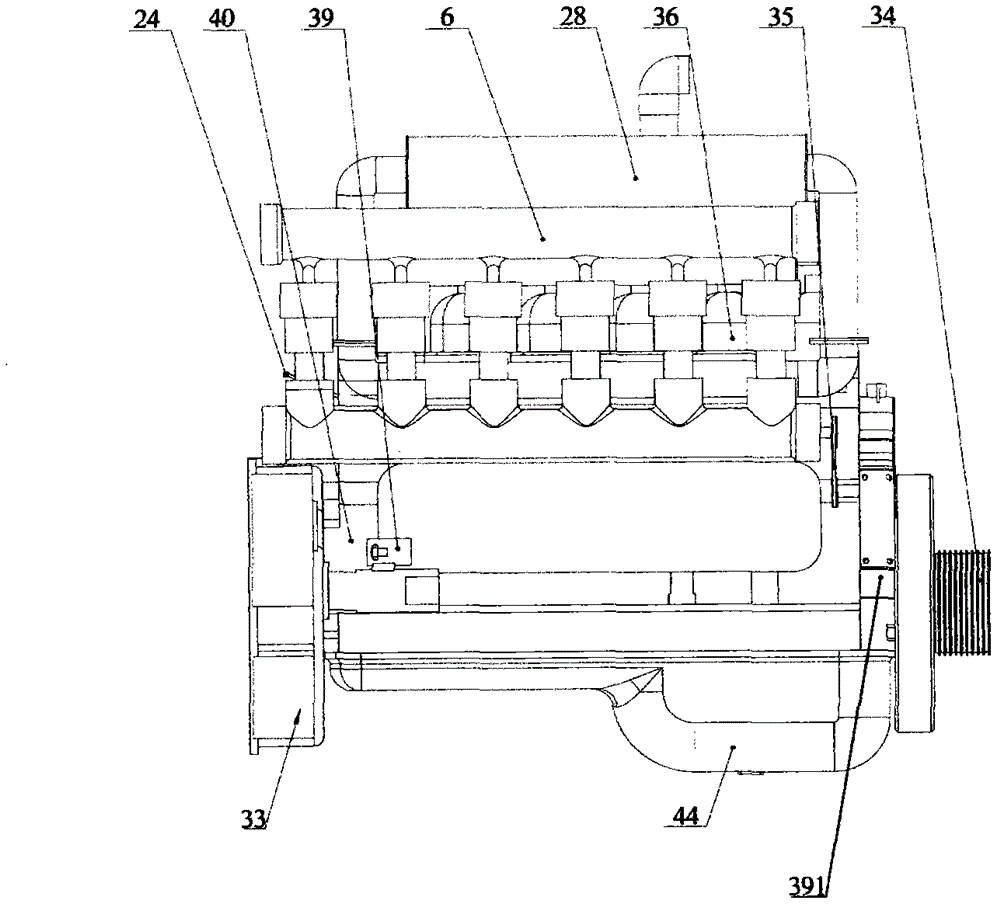

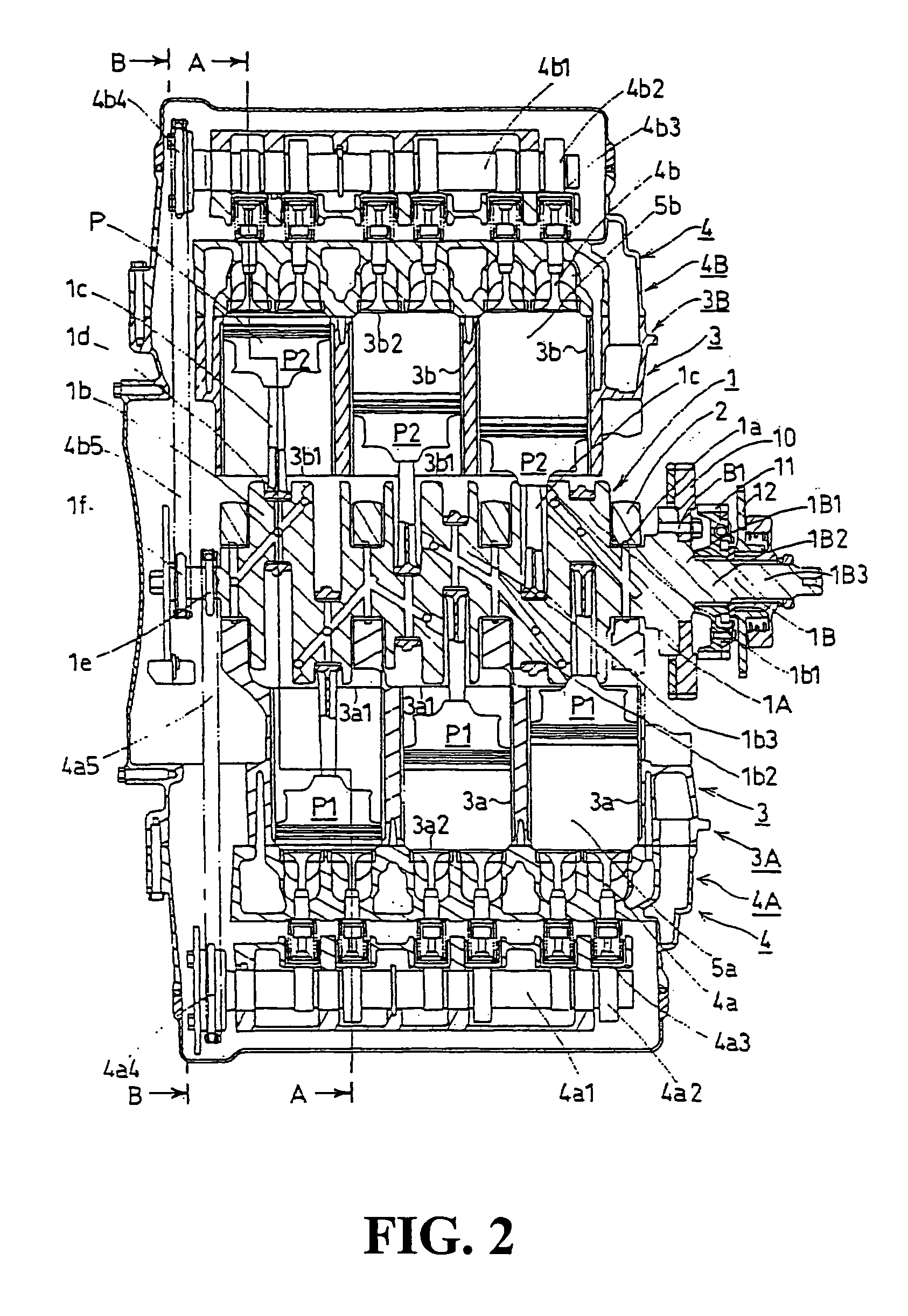

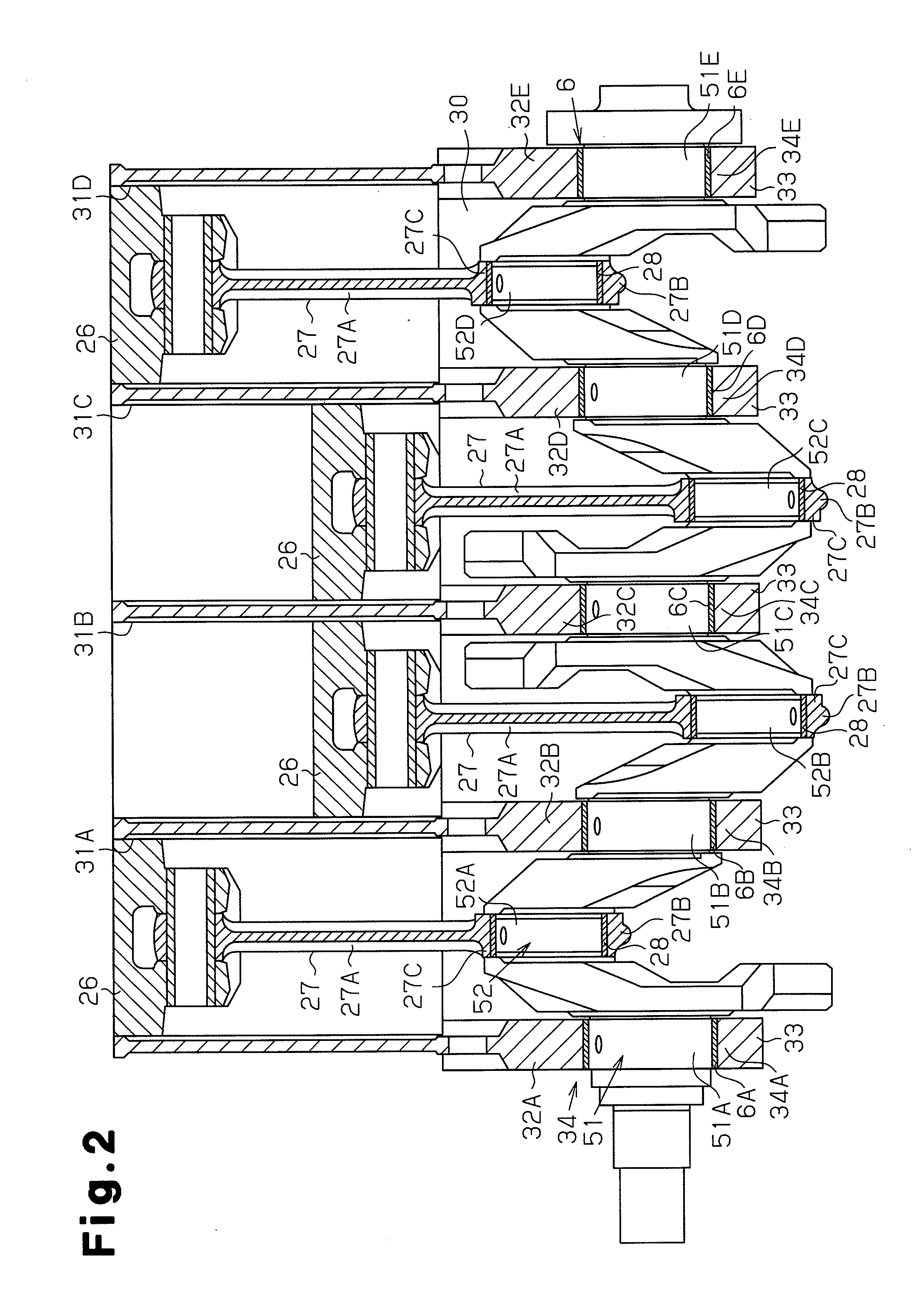

Five-cylinder plunger pump with integral power end structure

PendingCN110617318AExtended service lifeLow strokeCrankshaftsConnecting rod bearingsCrankcaseHigh load

The invention discloses a five-cylinder plunger pump with an integral power end structure. According to the five-cylinder plunger pump, an integral welding structure is adopted for a crankshaft box body and a crosshead box body in a five-cylinder plunger pump power end assembly, so that the structural strength of the power end assembly is higher, the supporting stability is better, and the whole pump vibration can be reduced; the cylinder spacing is 13-14 inches, the bearing area of connecting rods, crossheads and bearing bushes is increased, a guarantee is provided for the output of the high-power of the five-cylinder plunger pump, the high-power five-cylinder plunger pump can effectively solve the problem that the shale gas fracturing well site area is narrow and the required fracturingequipment is relatively large, the use of equipment can be reduced, and the wellsite arrangement is facilitated; the 11-inches long-stroke design can better realize large-displacement operation requirements and improve the operation efficiency; and according to the multi-point supporting design of crankcase bodies, crosshead box bodies and the hydraulic end assembly, the supporting strength of thefive-cylinder plunger pump can be improved, the vibration is reduced, the high-load operation is better guaranteed, and the operation is more stable.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

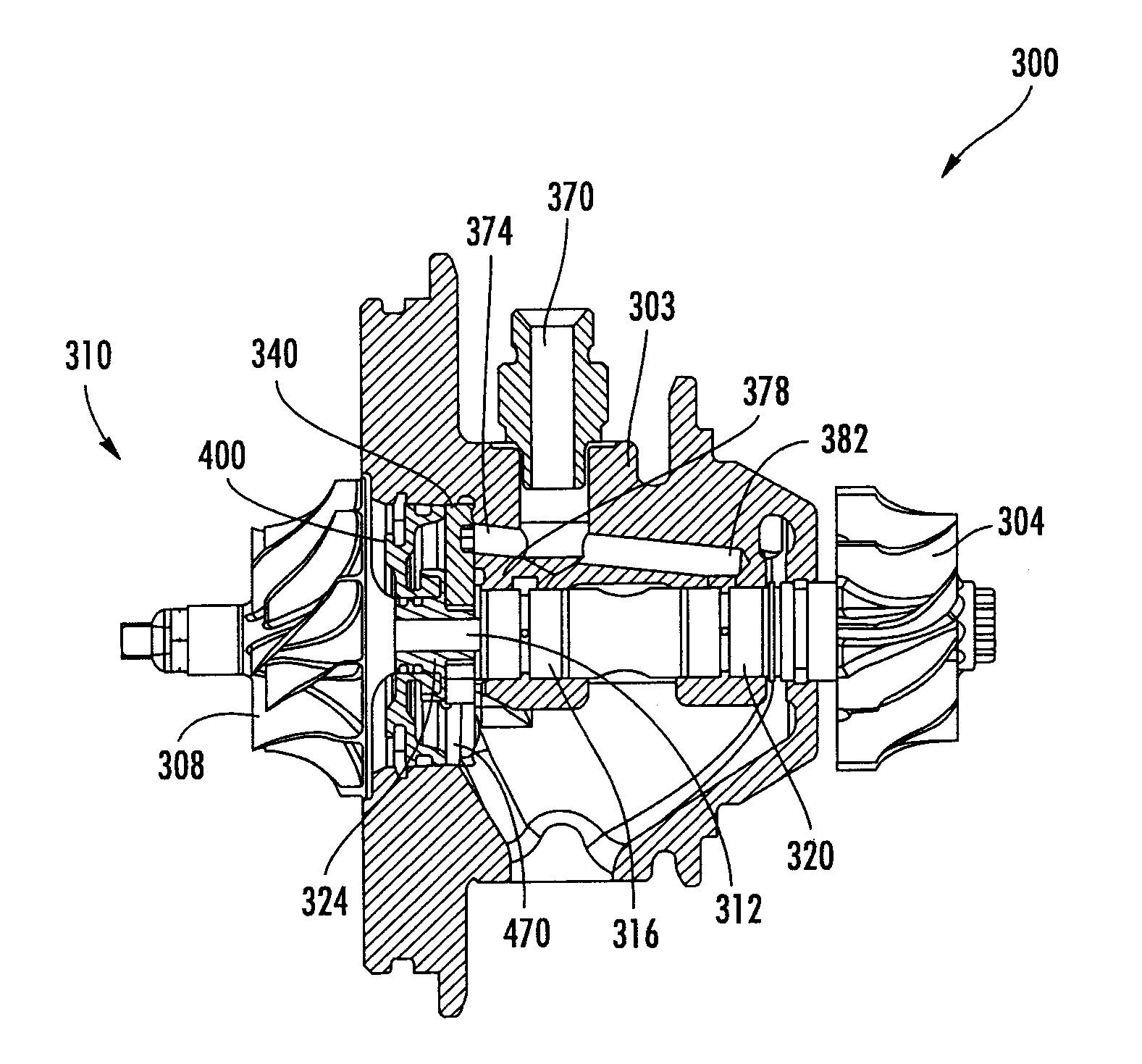

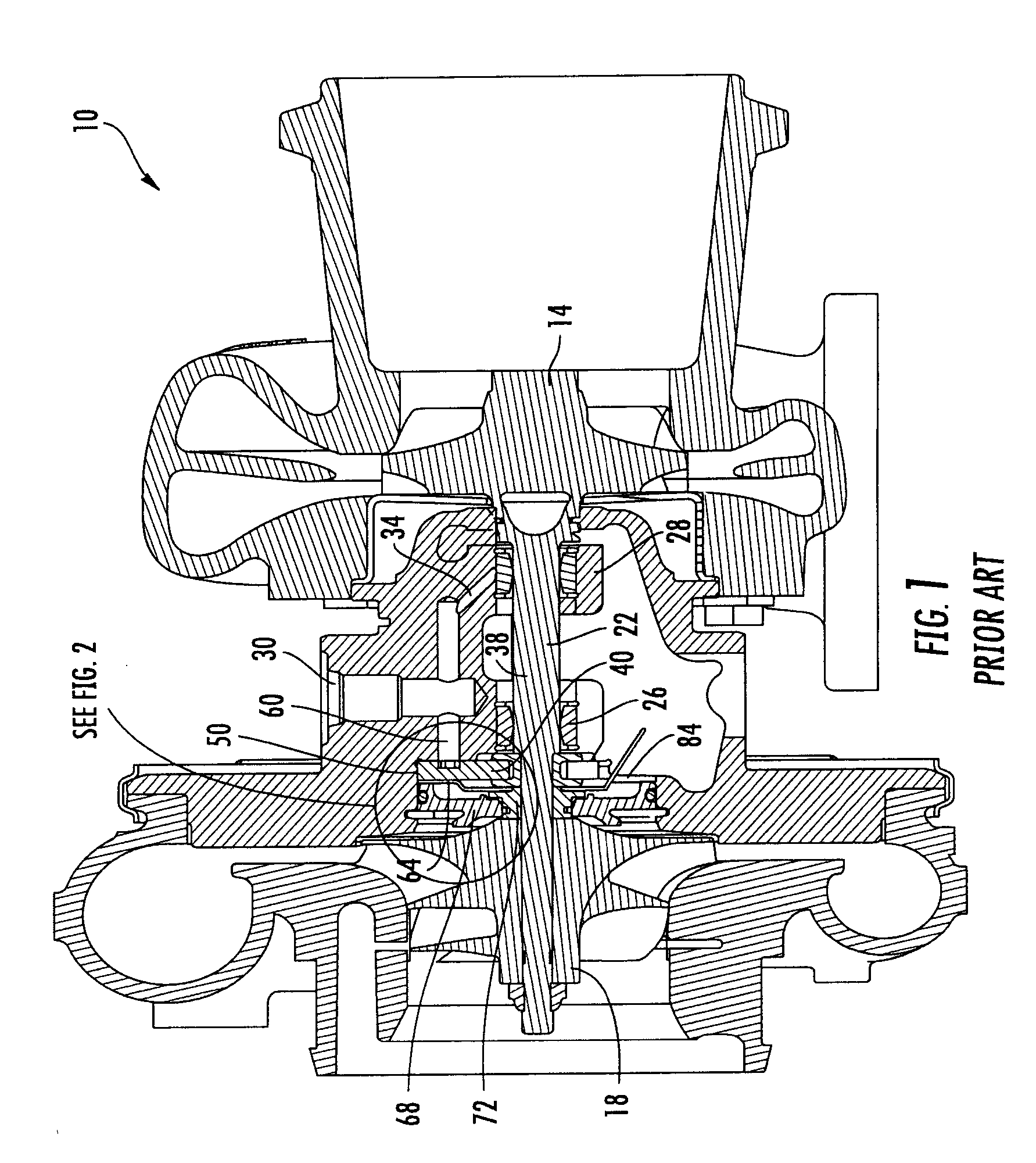

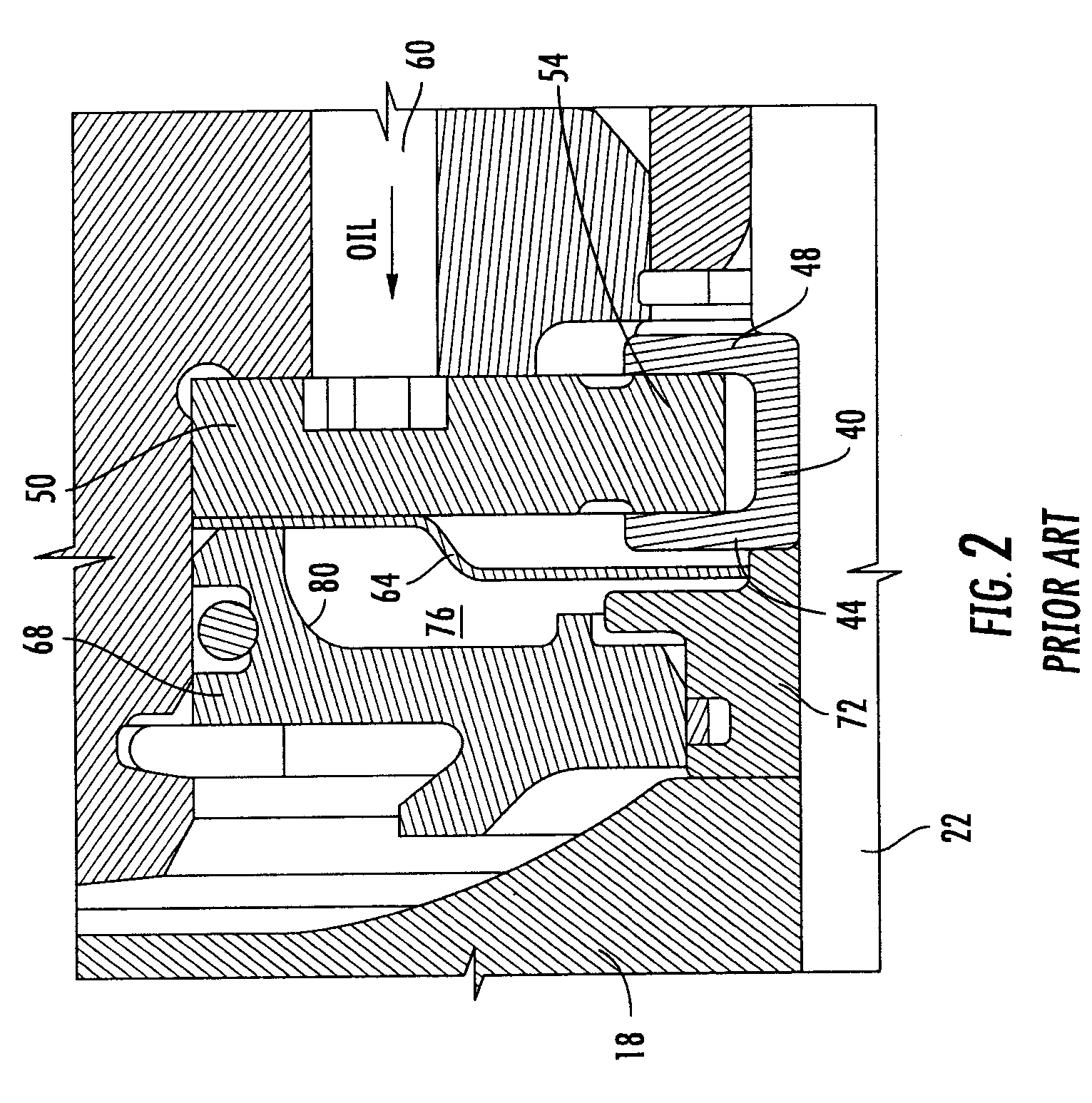

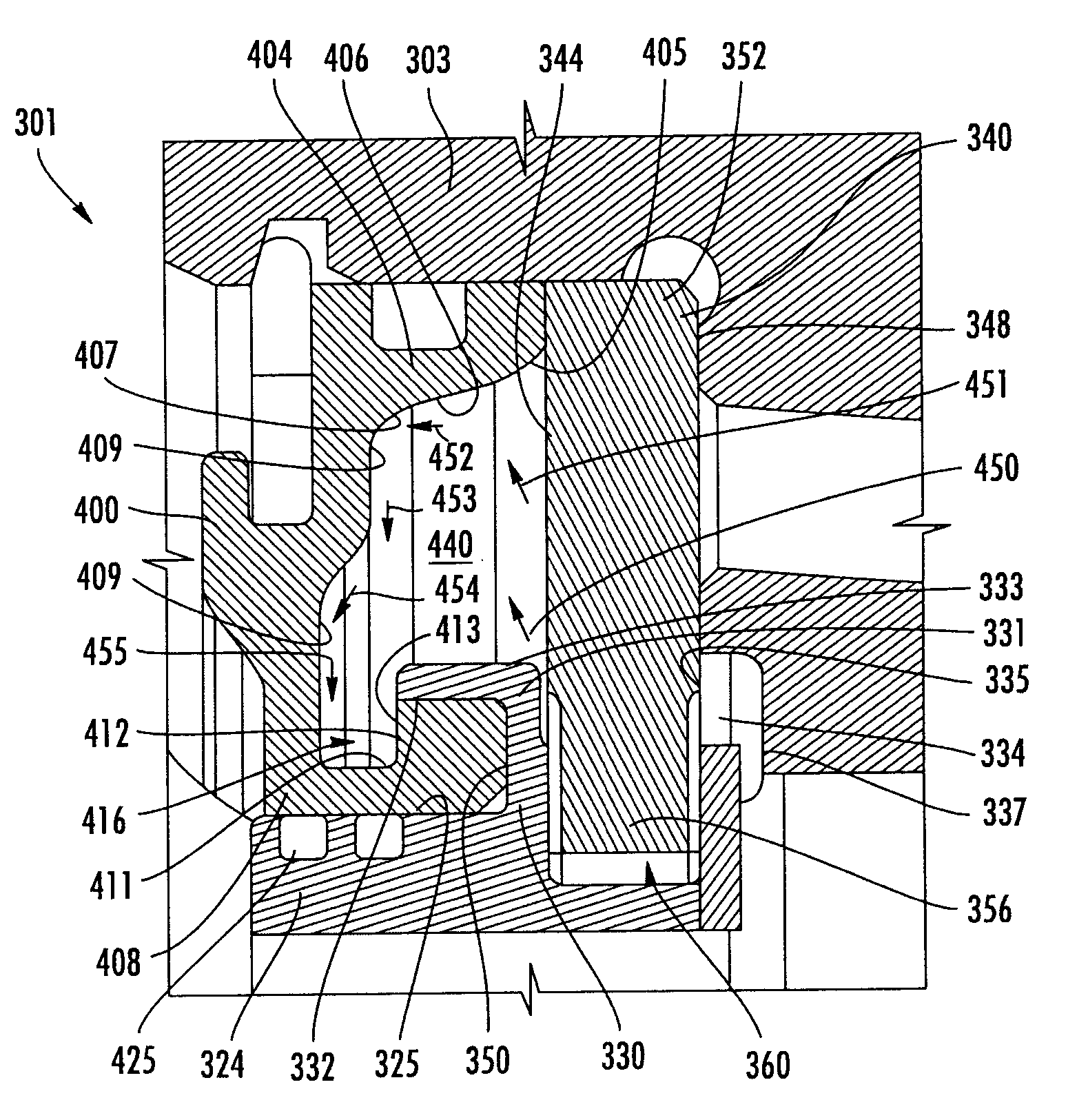

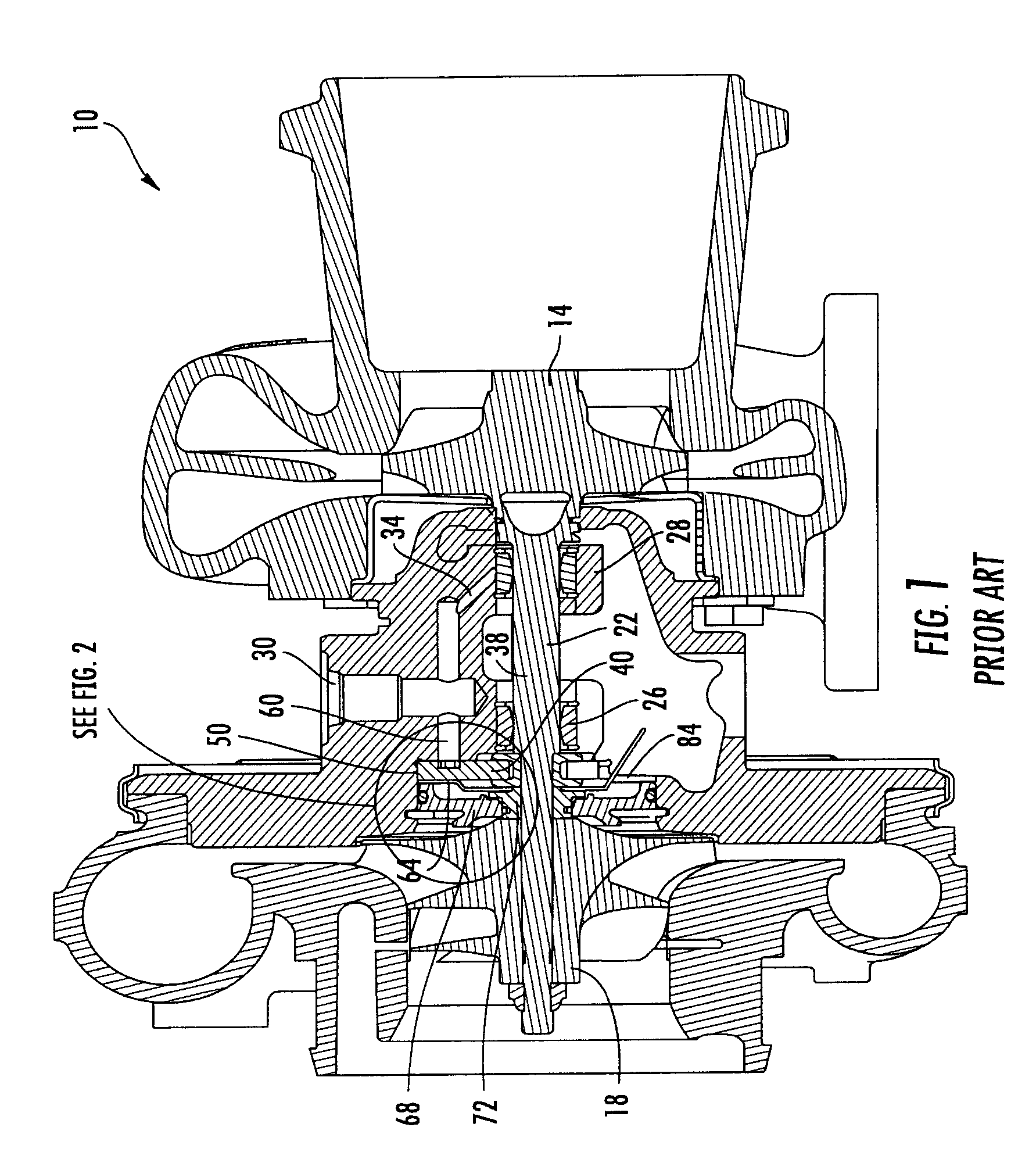

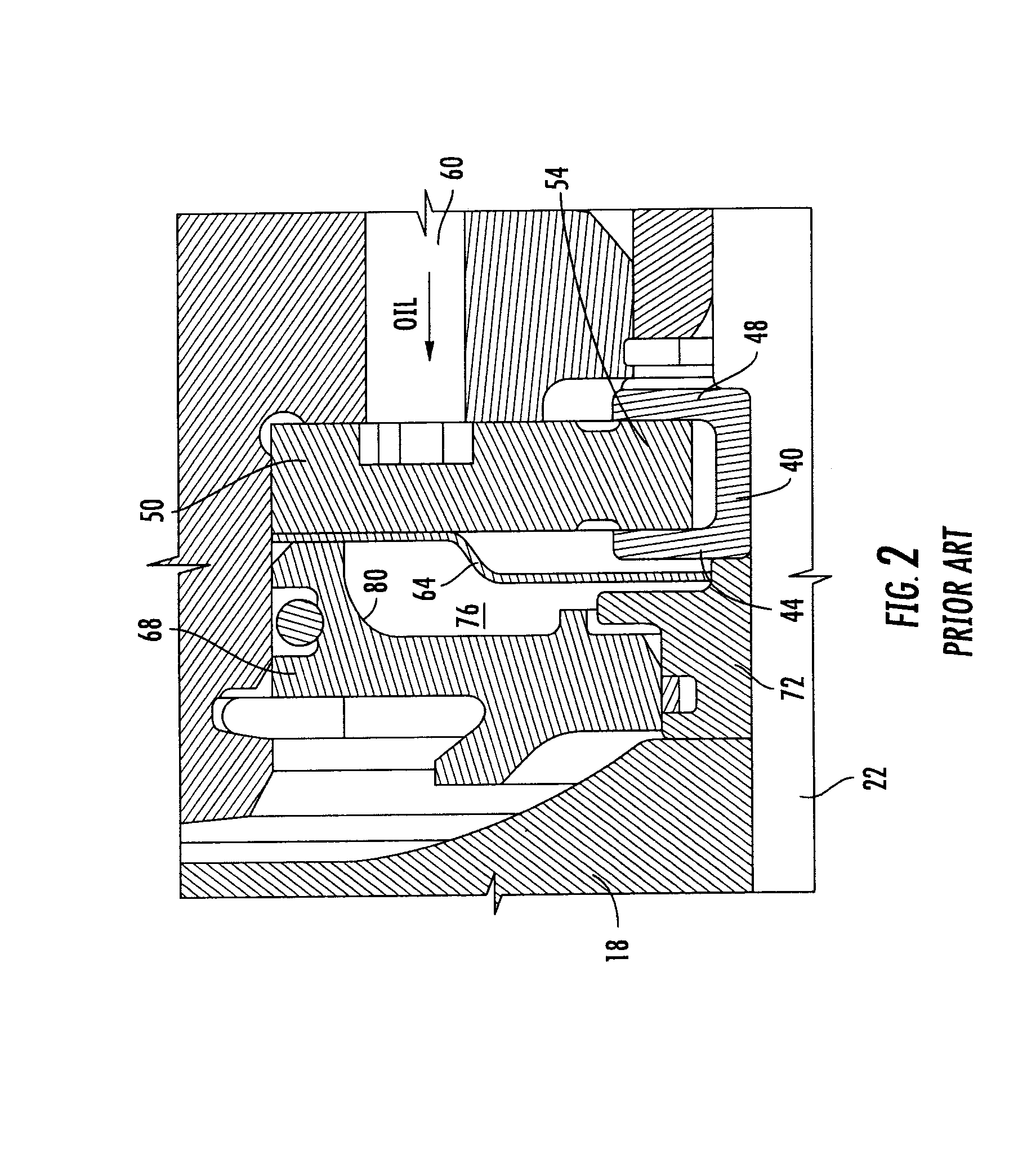

Sealing system between bearing and compressor housing

ActiveUS20100139270A1Efficient and cost-effectiveExtend your lifeCrankshaftsPump componentsTurbochargerThrust bearing

A turbocharger oil discharge assembly (301, 501, 701, 901) can have a thrust collar (324, 524, 724, 924) with a first radially outwardly extending wall and a second radially outwardly extending wall to define a first annular channel. The first radially outwardly extending wall can have an annular flange that at least in part defines a second annular channel. The assembly can also have a thrust bearing (340, 540, 740, 940) having a radially inner end received in the first annular channel, and an insert (400, 600, 800, 1000). An oil collection chamber (440, 640, 840, 1040) can be defined at least in part by a drainage channel of the insert (400, 600, 800, 1000), the annular flange of the thrust collar (324, 524, 724, 924) and the thrust bearing (340, 540, 740, 940). Pressurized oil discharged from an oil release interface can be directed towards a radially outer region of the oil collection chamber (440, 640, 840, 1040) and can be collected in the oil collection chamber (440, 640, 840, 1040) for subsequent exhaust.

Owner:BORGWARNER INC

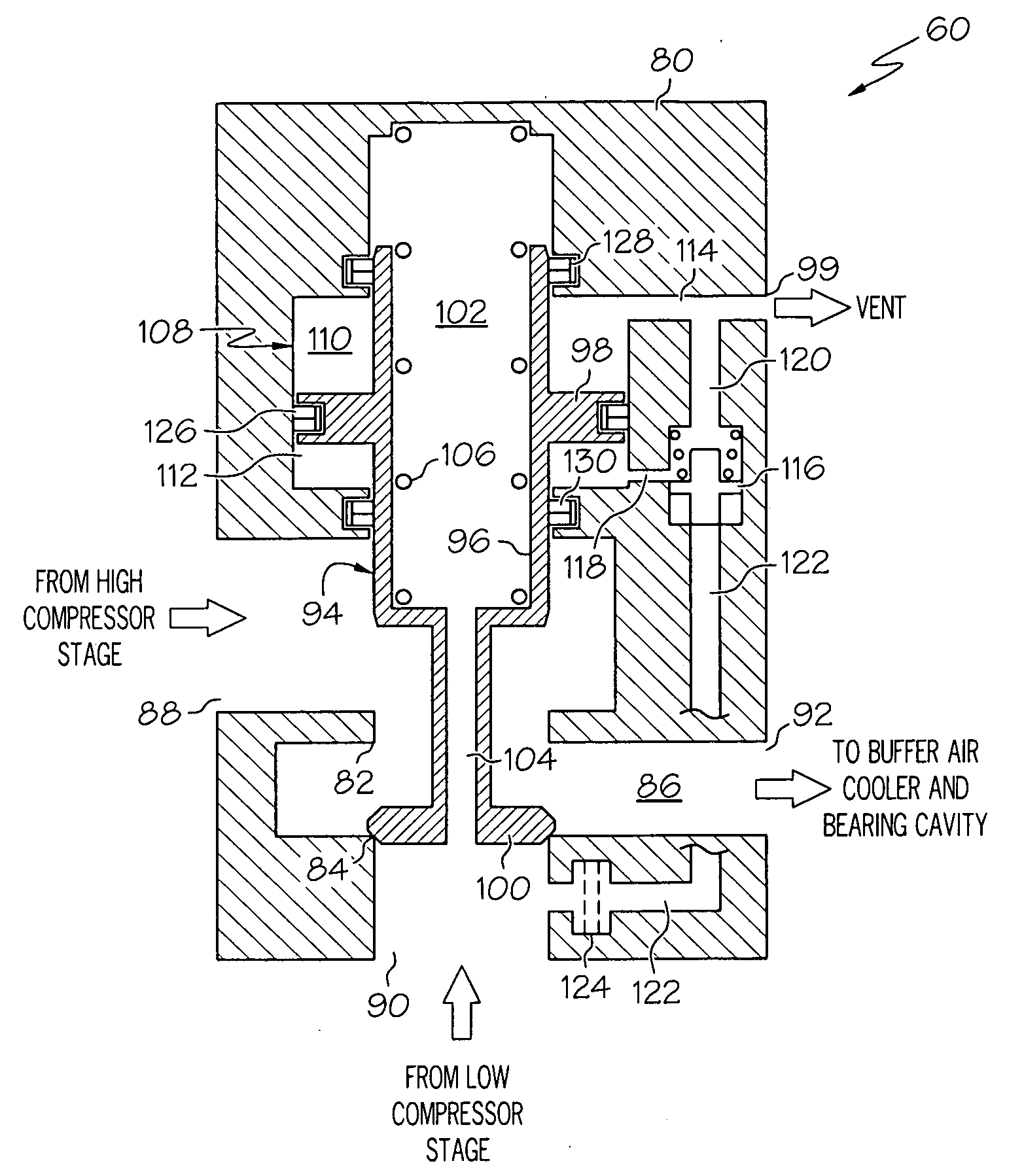

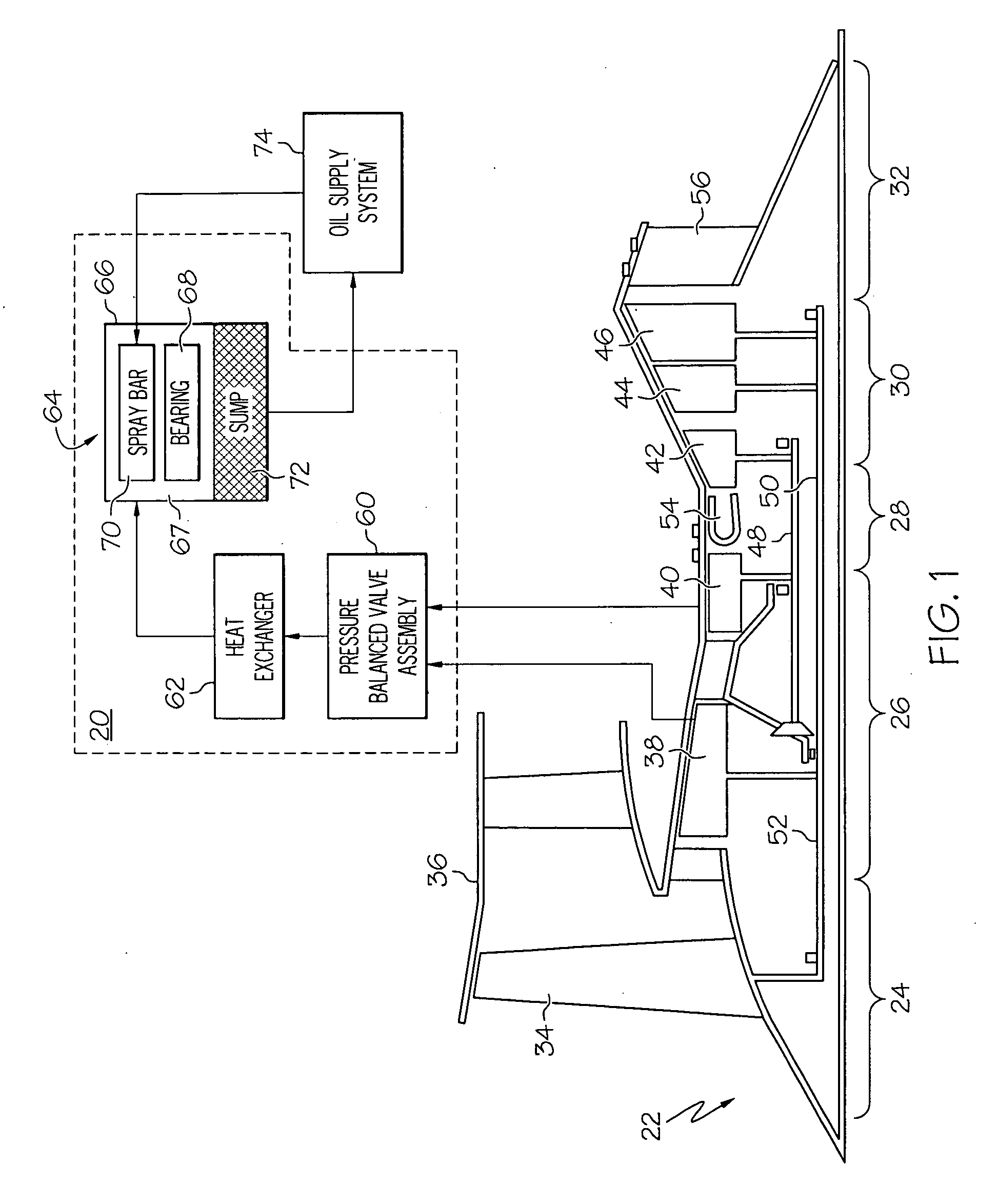

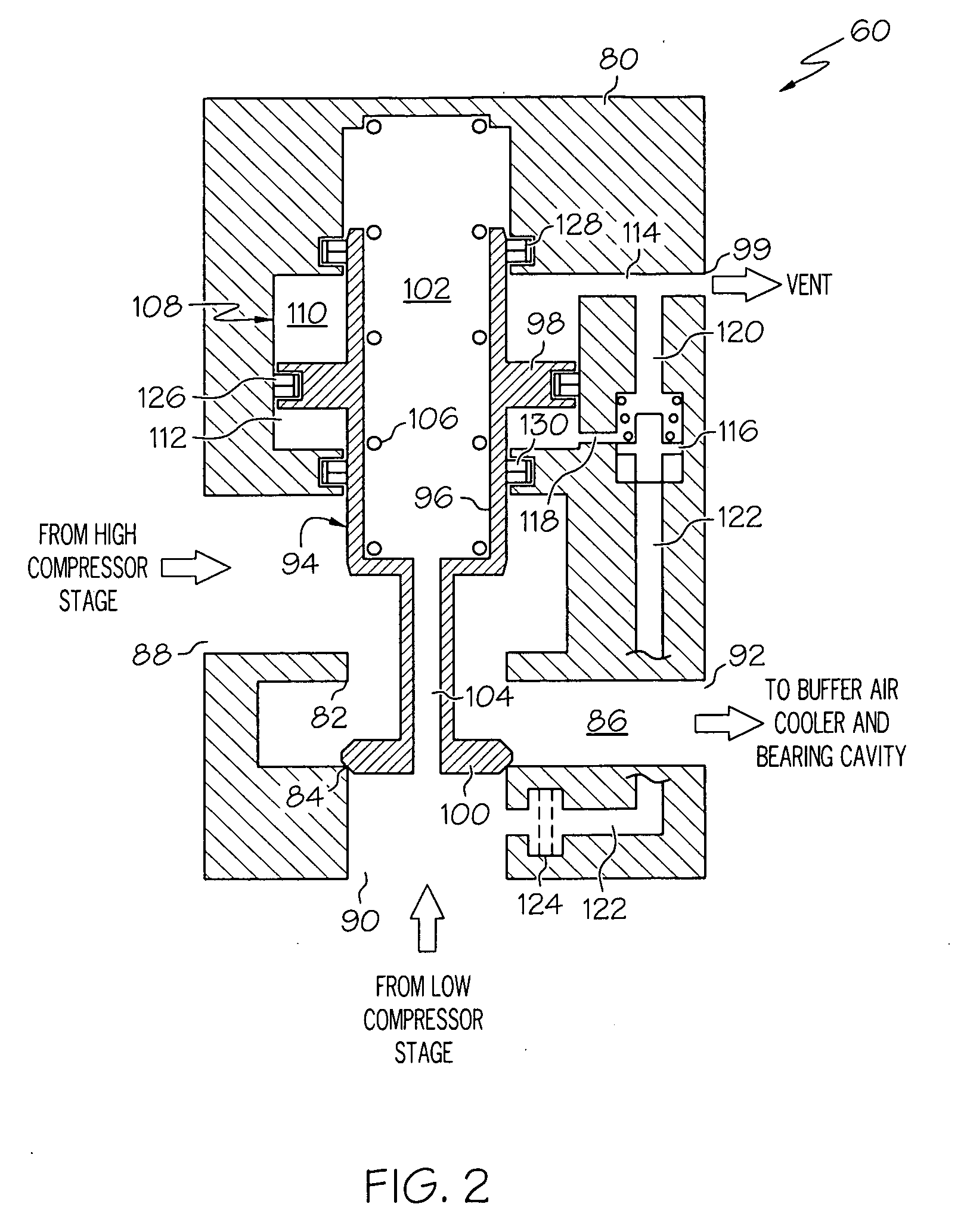

Pressure balanced valve assembly and aircraft buffer cooler system employing the same

A pressure balanced valve assembly is provided. In one embodiment, the pressure balanced valve assembly includes a housing assembly having first and second seats. A flow passage formed through the housing assembly includes a first inlet, a second inlet, and an outlet. A piston is slidably mounted in the housing assembly for movement between: (i) a first position wherein the piston contacts the second seat to restrict fluid flow from the second inlet to the outlet, and (ii) a second position wherein the piston contacts the first seat to restrict fluid flow from the first inlet to the outlet. First and second dynamic seals are mounted in the housing assembly. The first and second dynamic seals sealingly engage first and second portions of the piston over areas substantially equivalent to the sealing areas of the second and first seats, respectively.

Owner:HONEYWELL INT INC

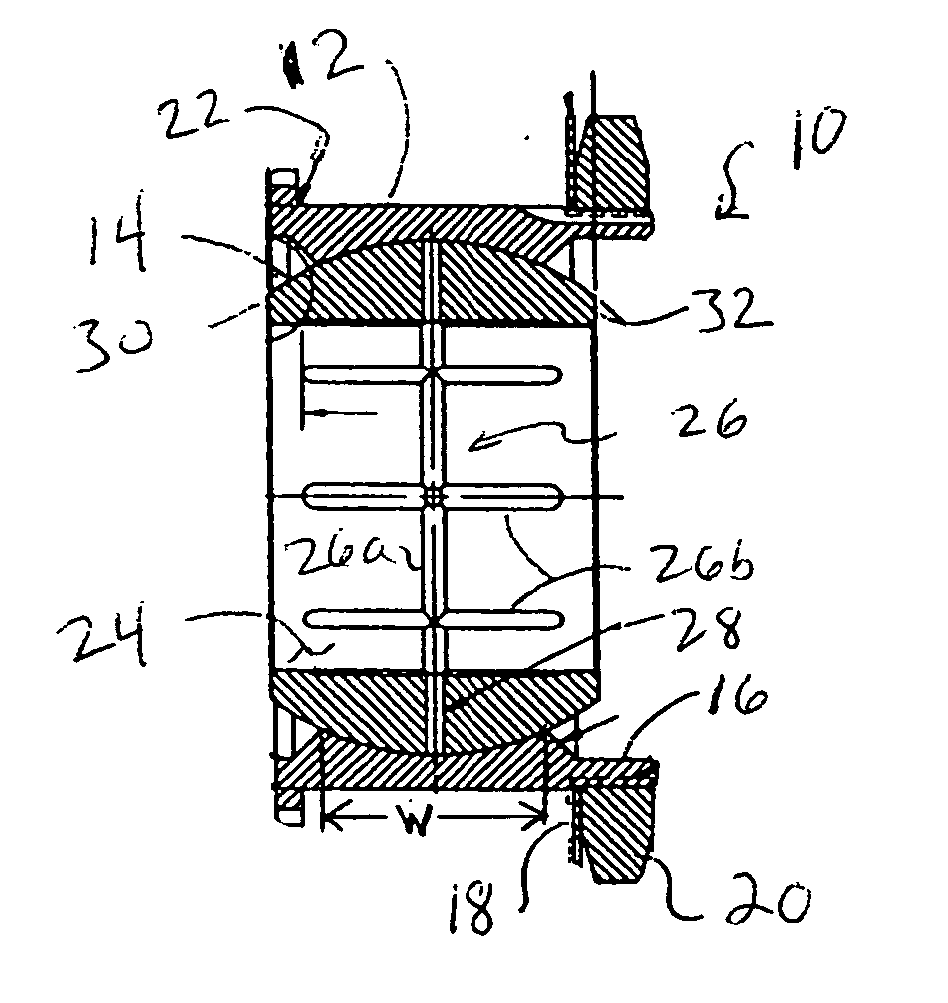

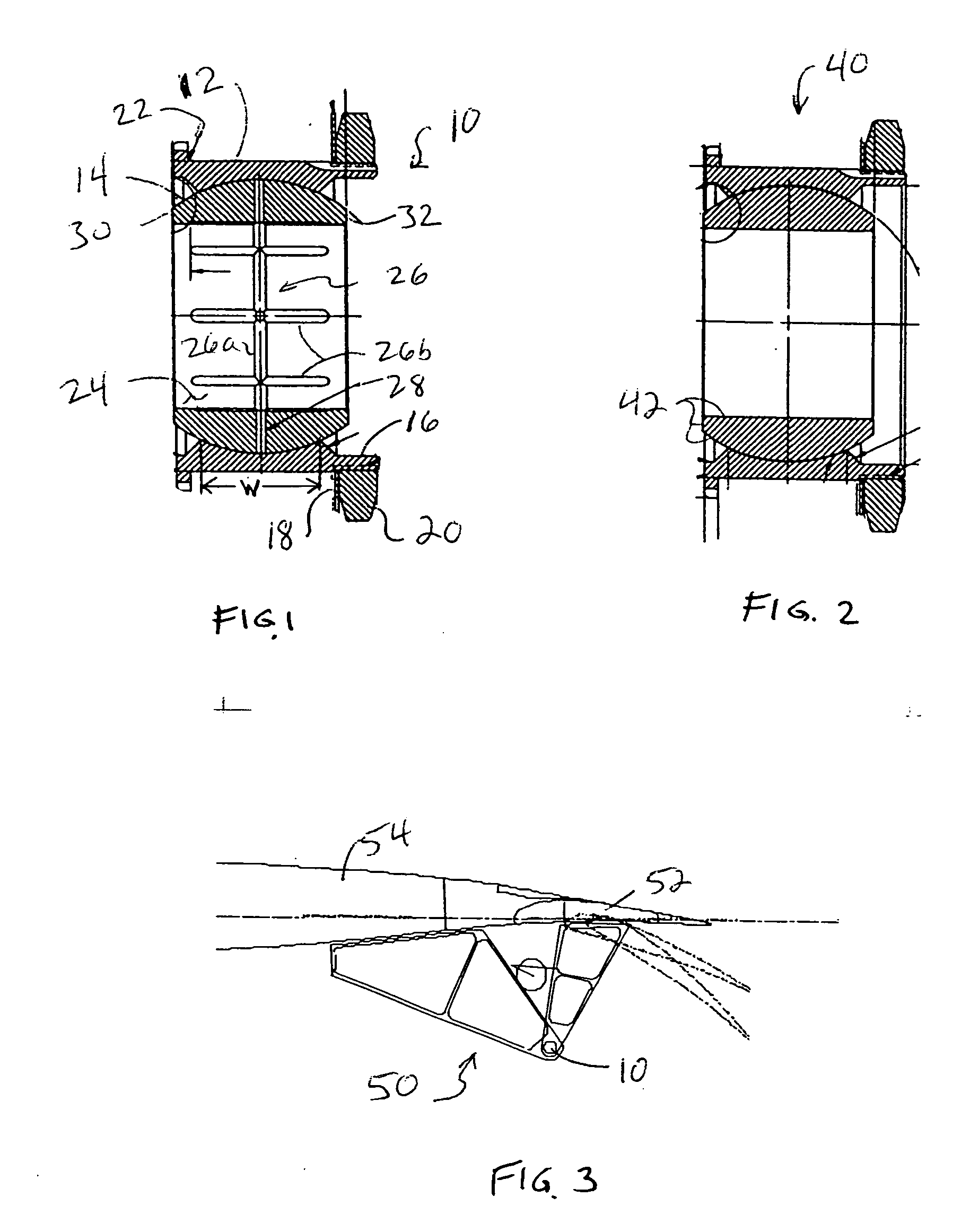

Bearing and hinge mechanism

A spherical plain bearing has an outer ring having a concave first bearing surface and an inner ring having a convex second bearing surface slidably disposed to the first bearing surface. The inner ring member also has a third bearing surface for engaging a pin to be mounted in the bearing. At least one bearing surface has a lubrication groove, and one of the outer ring and the inner ring is made from 440 stainless steel while the other is made from a precipitation-hardened martensitic stainless steel. Alternatively, the outer ring and the inner ring may be made from steel and a copper-beryllium alloy. In yet another alternative, the bearing need not have a lubrication groove, but may have a lubrication liner on the third bearing surface. A dropped hinge mechanism for a flap on a fixed wing aircraft has a hinge that includes such a bearing.

Owner:ROLLER BEARING OF AMERICA

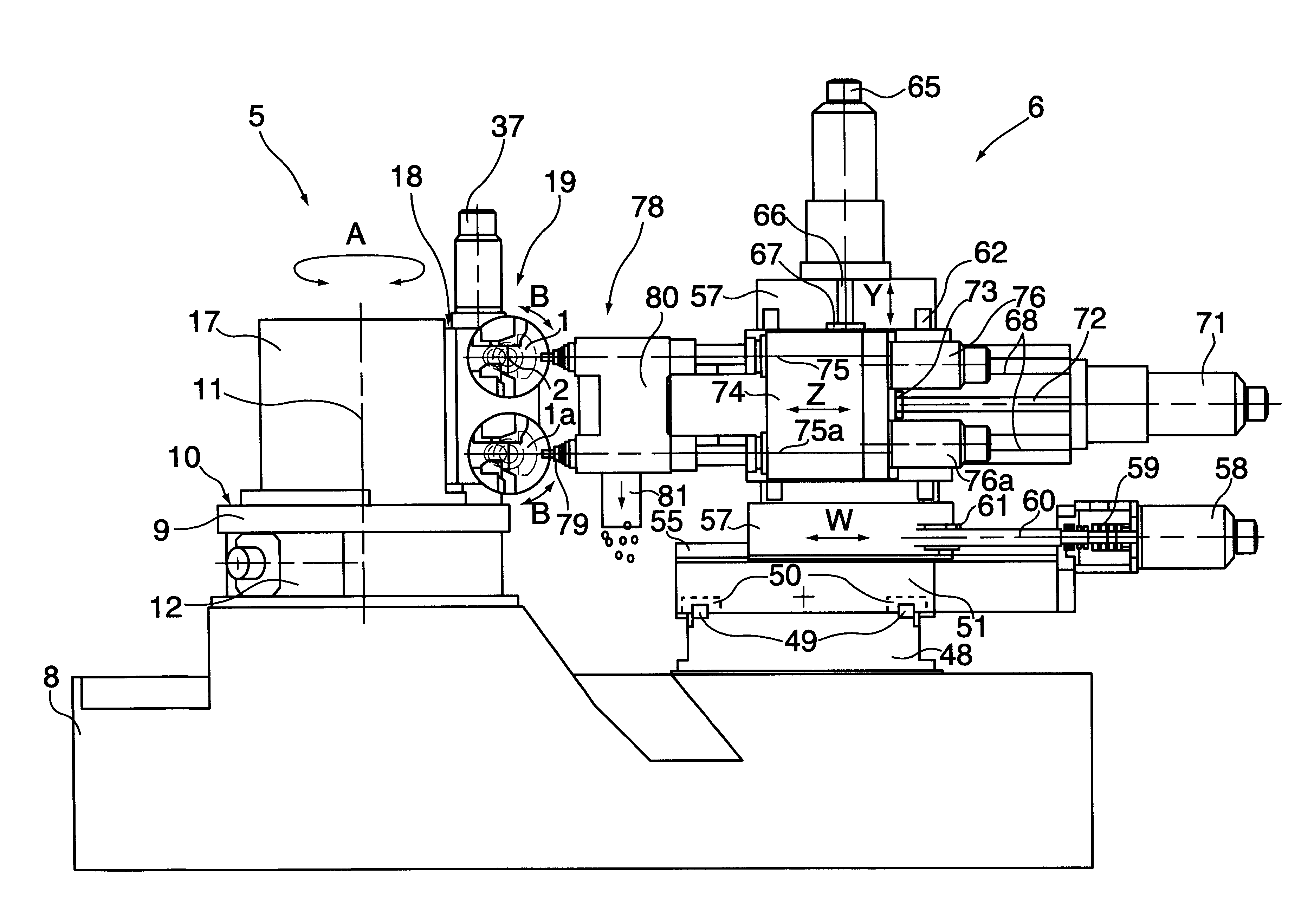

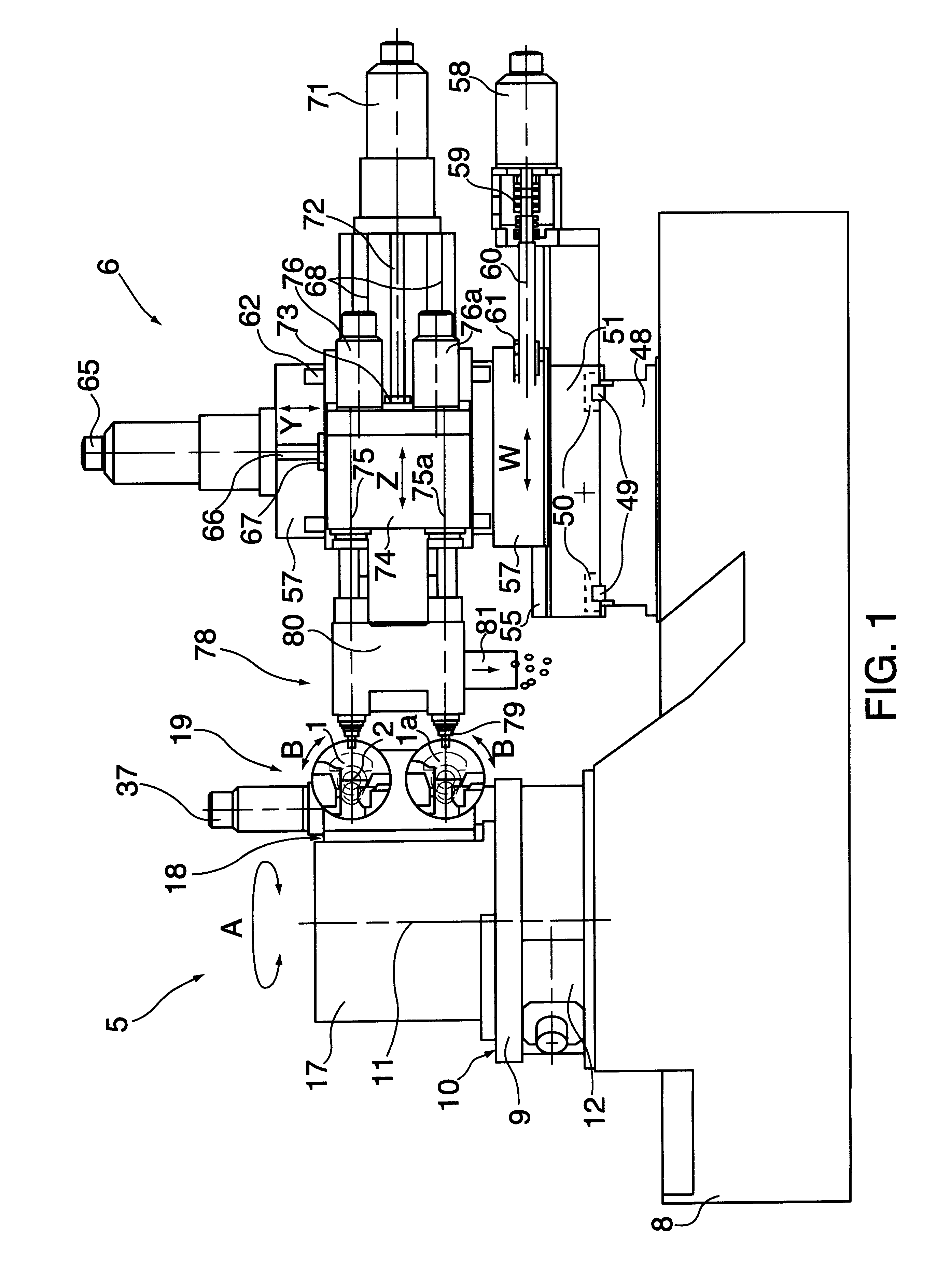

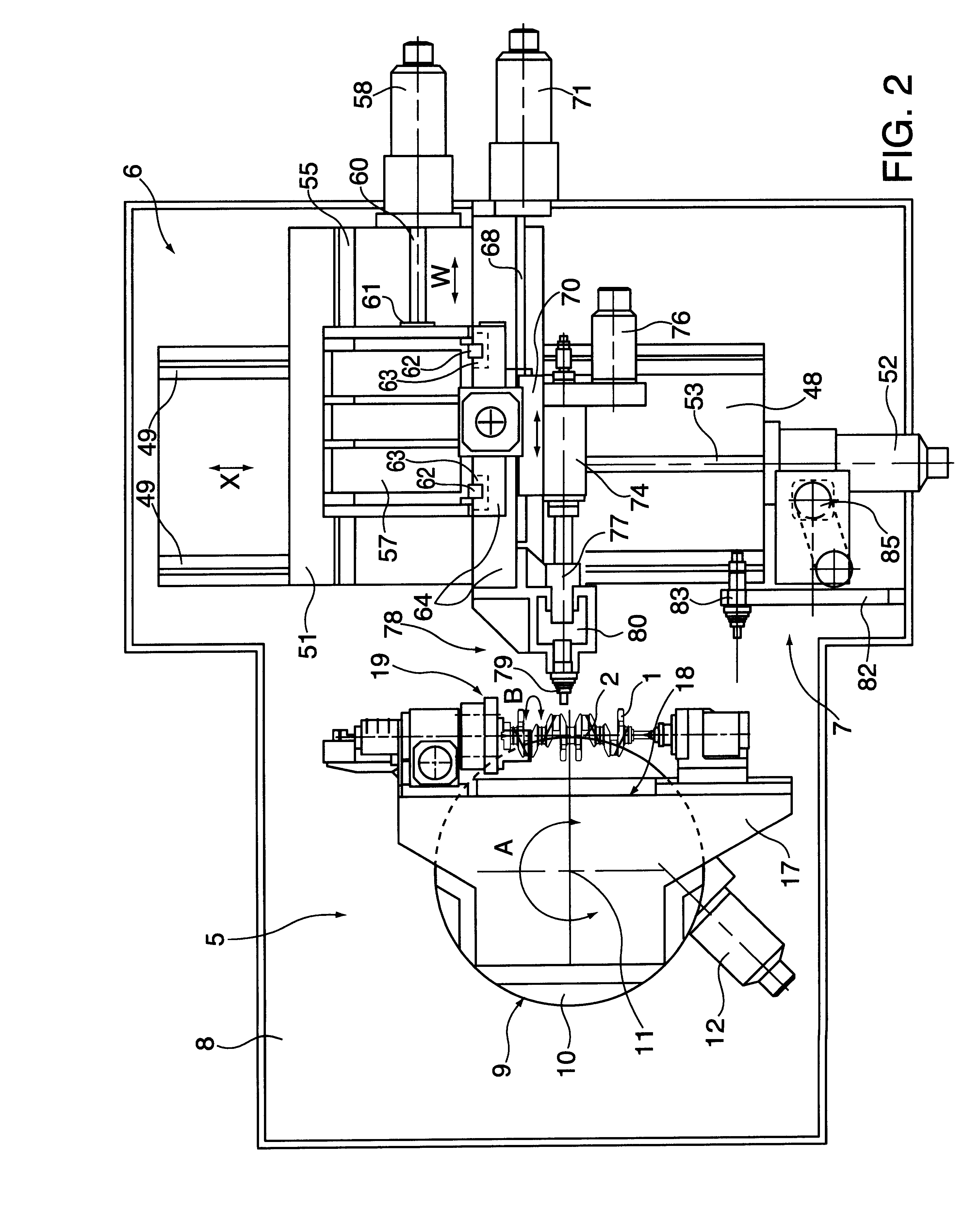

Machine for drilling oil holes in crankshafts

InactiveUS6203478B1Remove complicationsEliminate investmentCrankshaftsThread cutting machinesEngineeringCo ordinate

A machine for drilling oil-holes in crankshafts and the corresponding procedure. It can be used to drill one, two or more crankshafts per cycle. Each crankshaft can revolve on its own axis. The unit described is mounted on a horizontally-faced rotary table with vertical rotating axis, to place the crankshafts at different angles to the Z axis of the machining module, maintaining the horizontal position of the longitudinal axes of the crankshafts. Facing the unit is the machining module, provided with two horizontal spindles, drill tool-holders, with their corresponding guide bushings and parallel to each other, one on top of the other, at the same distance as the two crankshafts. The module has movement in three co-ordinates: axis X (horizontal-transverse), Y (vertical ) and Z (horizontal-presenting tools). A fourth axis W, (with additional module and independent action), moves parallel to Z and carries the guide bushings. It is provided with an automatic changeover, (tool+bushing or just the bushing), incorporating simultaneously the pair of spindles.

Owner:ETXE TAR SA

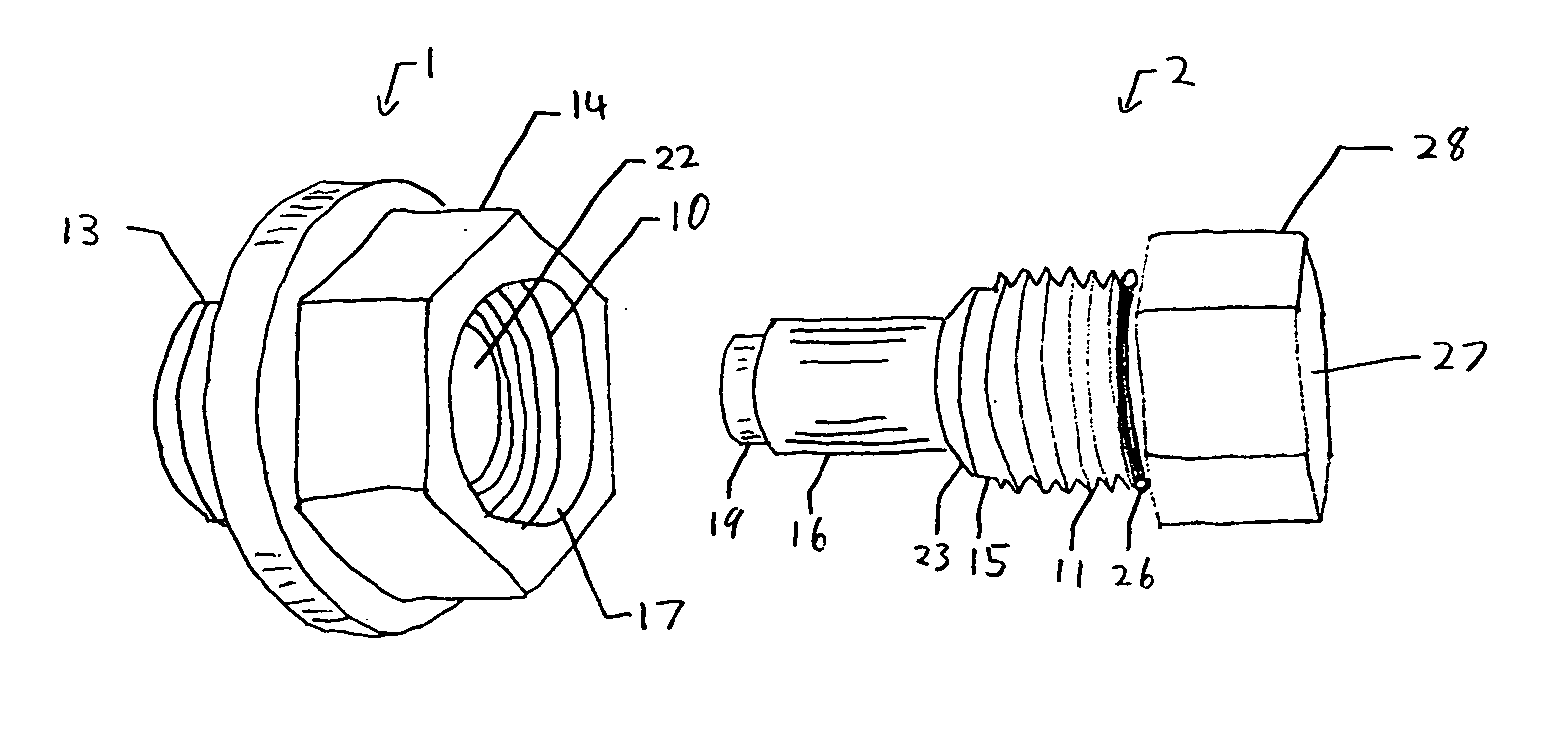

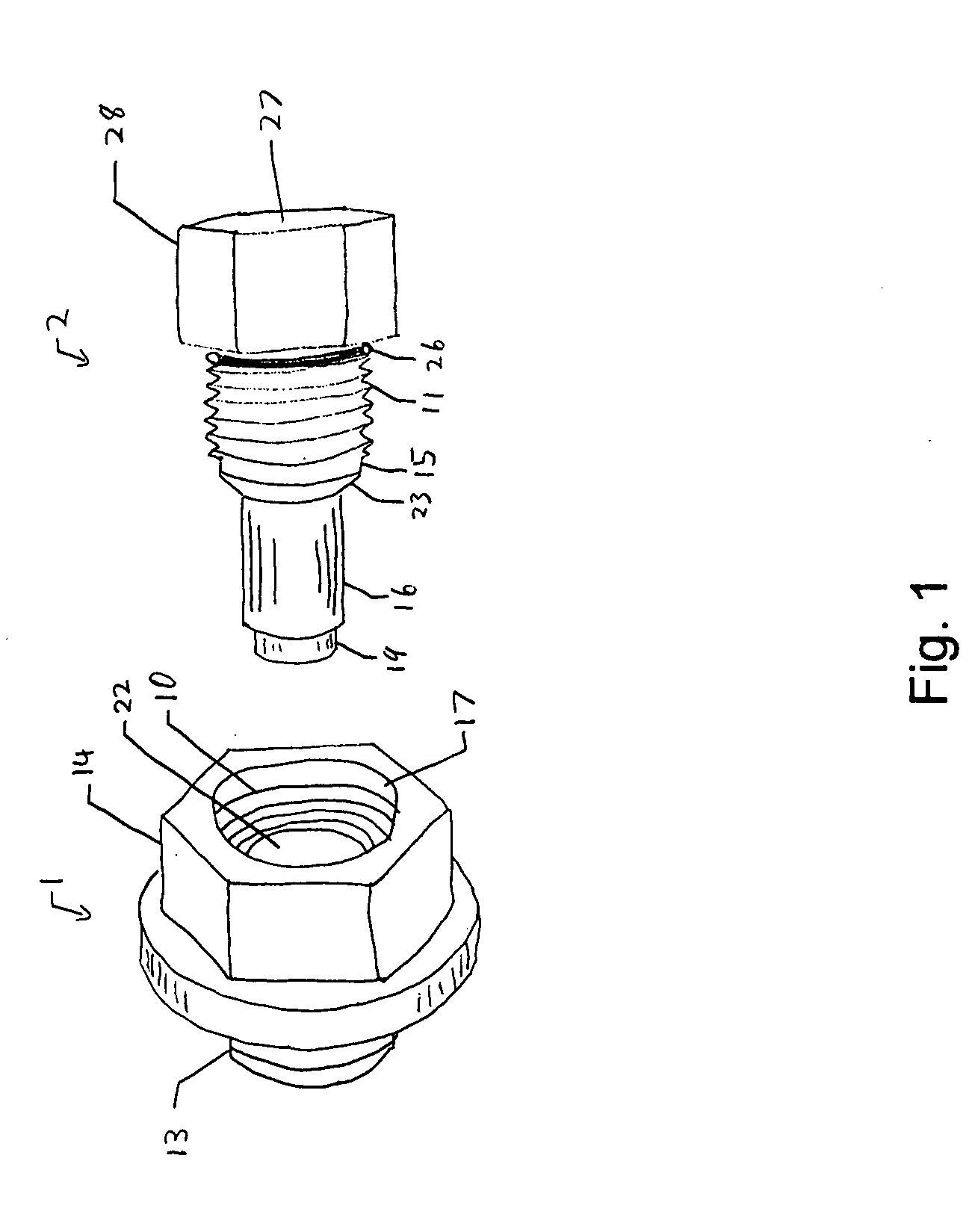

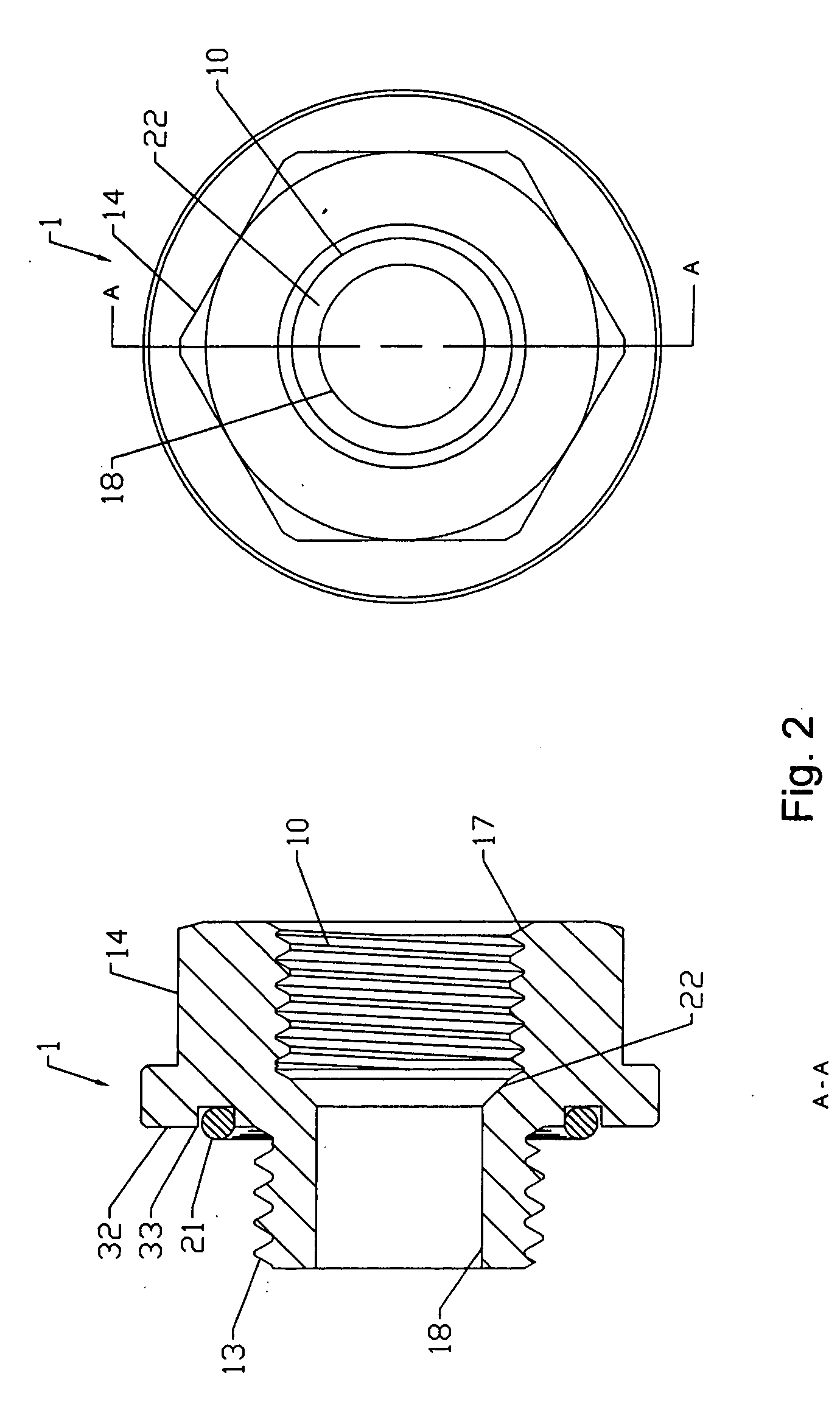

Two part oil or fluid drain plug with magnet

ActiveUS20060054402A1Precise positioningAvoid partialCrankshaftsElectrostatic separationEngineeringMagnet

This invention performs several functions. First; facilitating the draining of oil or fluid from a sump. Second; as a proactive and preventive method of preventing the threads of the sump (which receive the drain plug) from becoming striped or damaged. Third; adding in the determination of the physical condition (ware) of the engine, transmission, or the like, in which the sump is attached to.

Owner:DORIAN GEORGE P

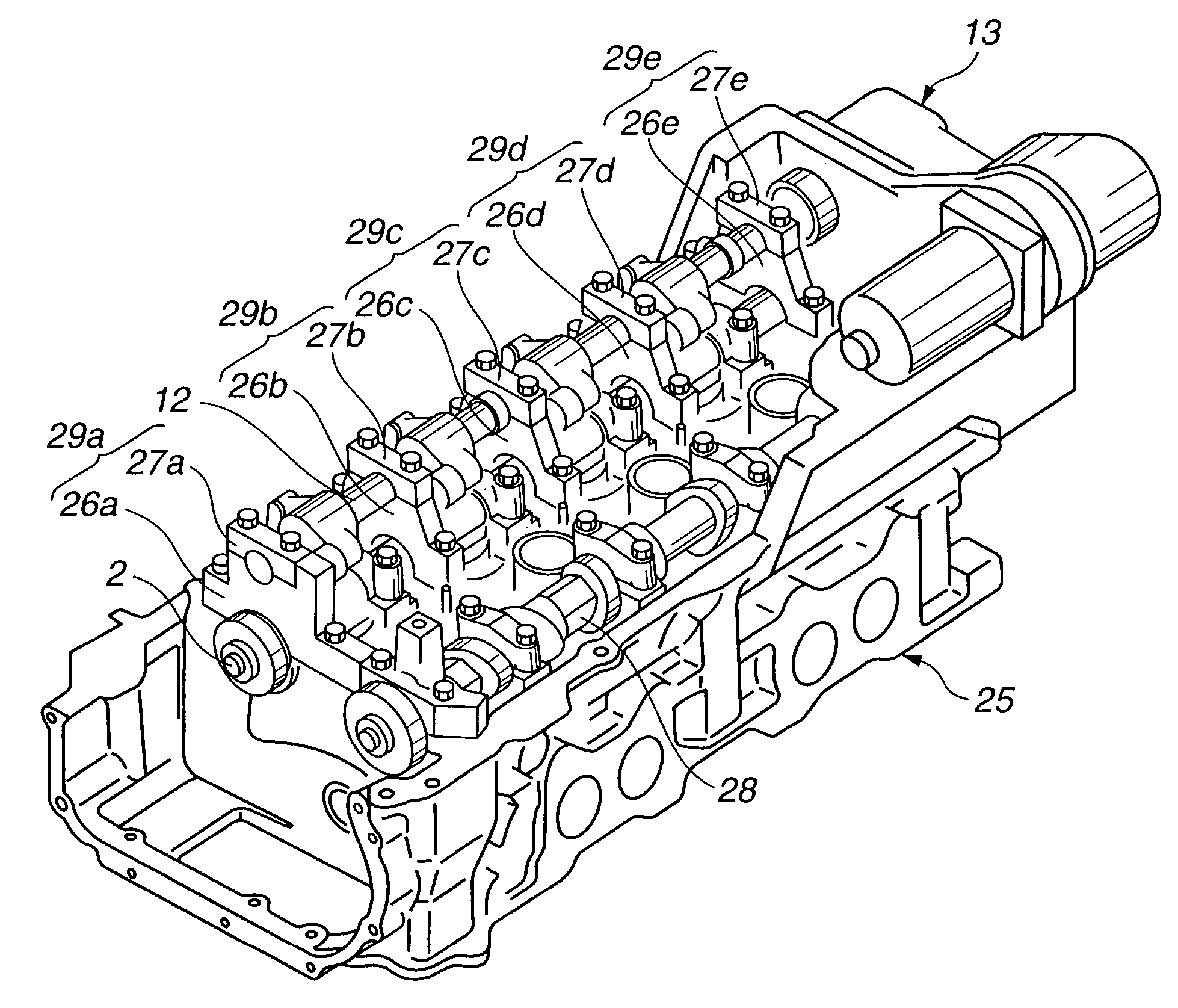

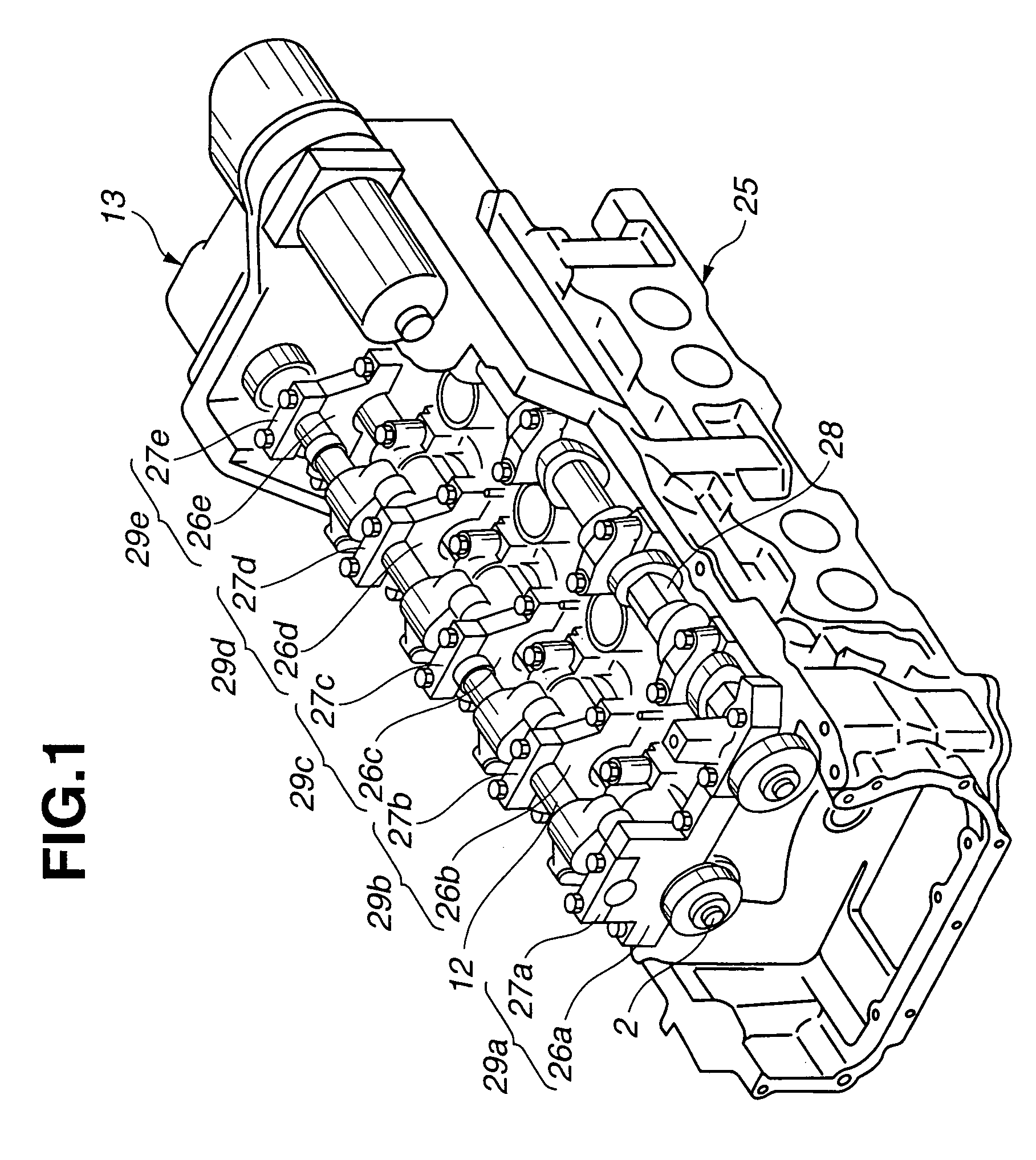

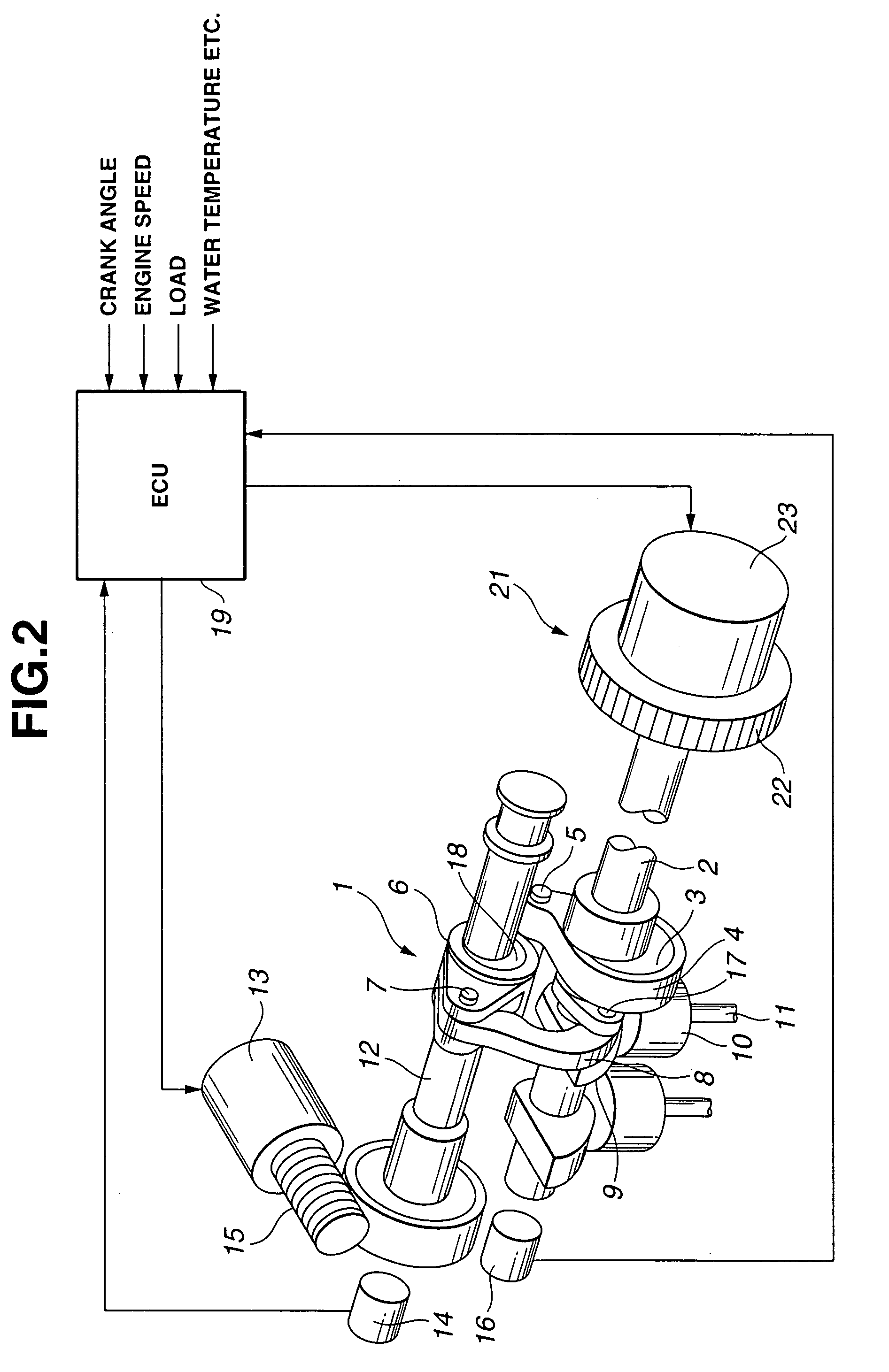

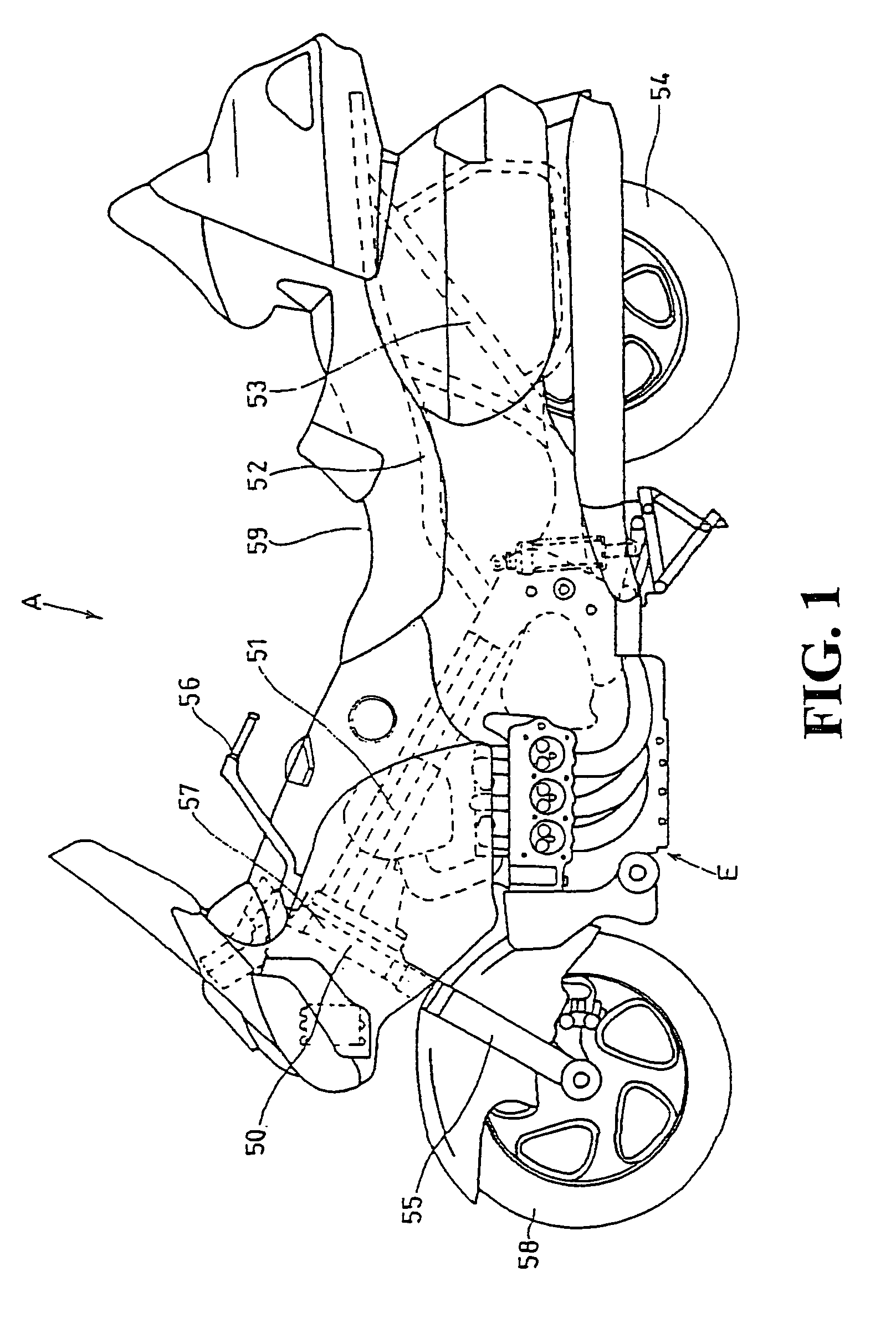

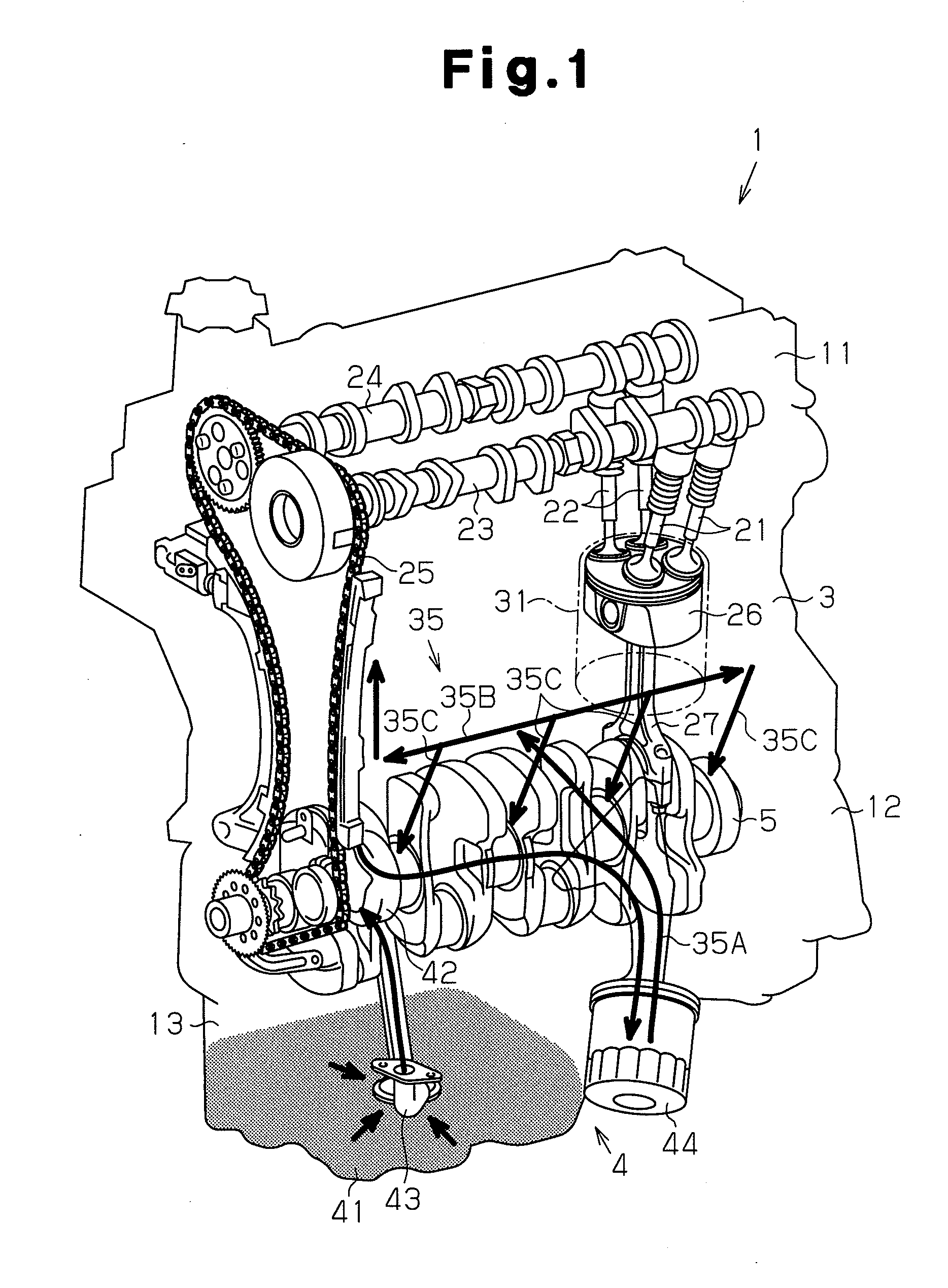

Variable valve actuating mechanism for internal combustion engine

ActiveUS7107950B2Reduce temperature non-uniformityReduce unevennessClutchesCrankshaftsExternal combustion engineInlet valve

A lift and operating angle varying mechanism is arranged to vary an intake valve operation angle and an intake valve lift of the engine continuously by rotating a control shaft with an actuator disposed at an end of the control shaft which is rotatably supported by a plurality of bearings. A lubricating oil is supplied to the bearings so as to reduce nonuniformity in temperature distribution of the control shaft in the longitudinal direction.

Owner:NISSAN MOTOR CO LTD

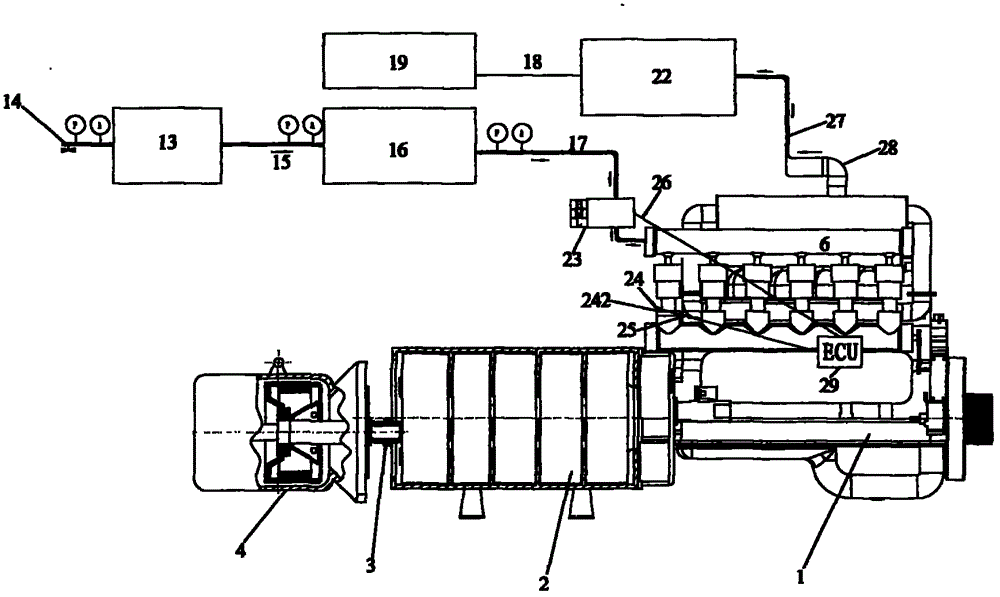

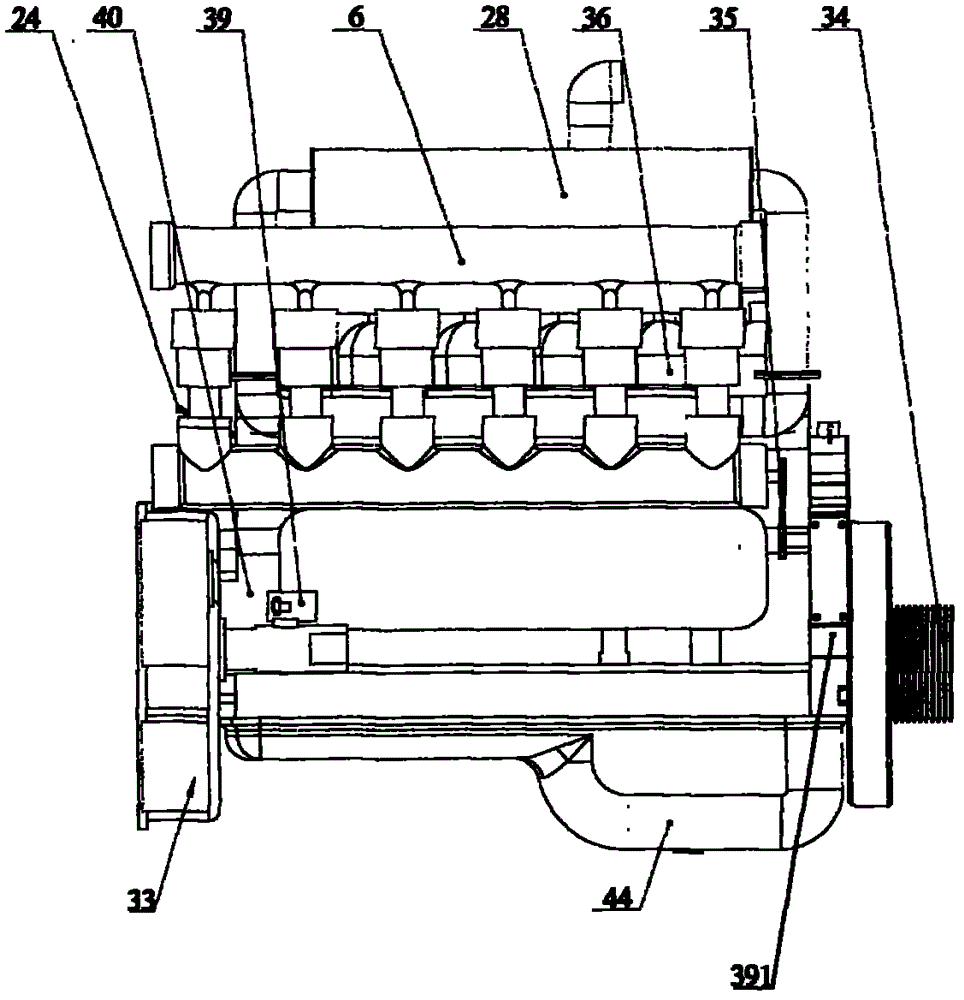

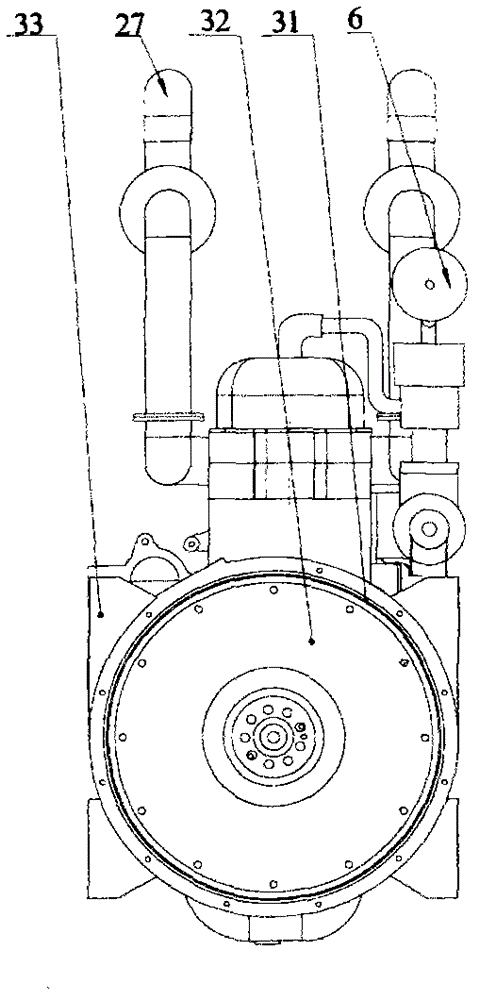

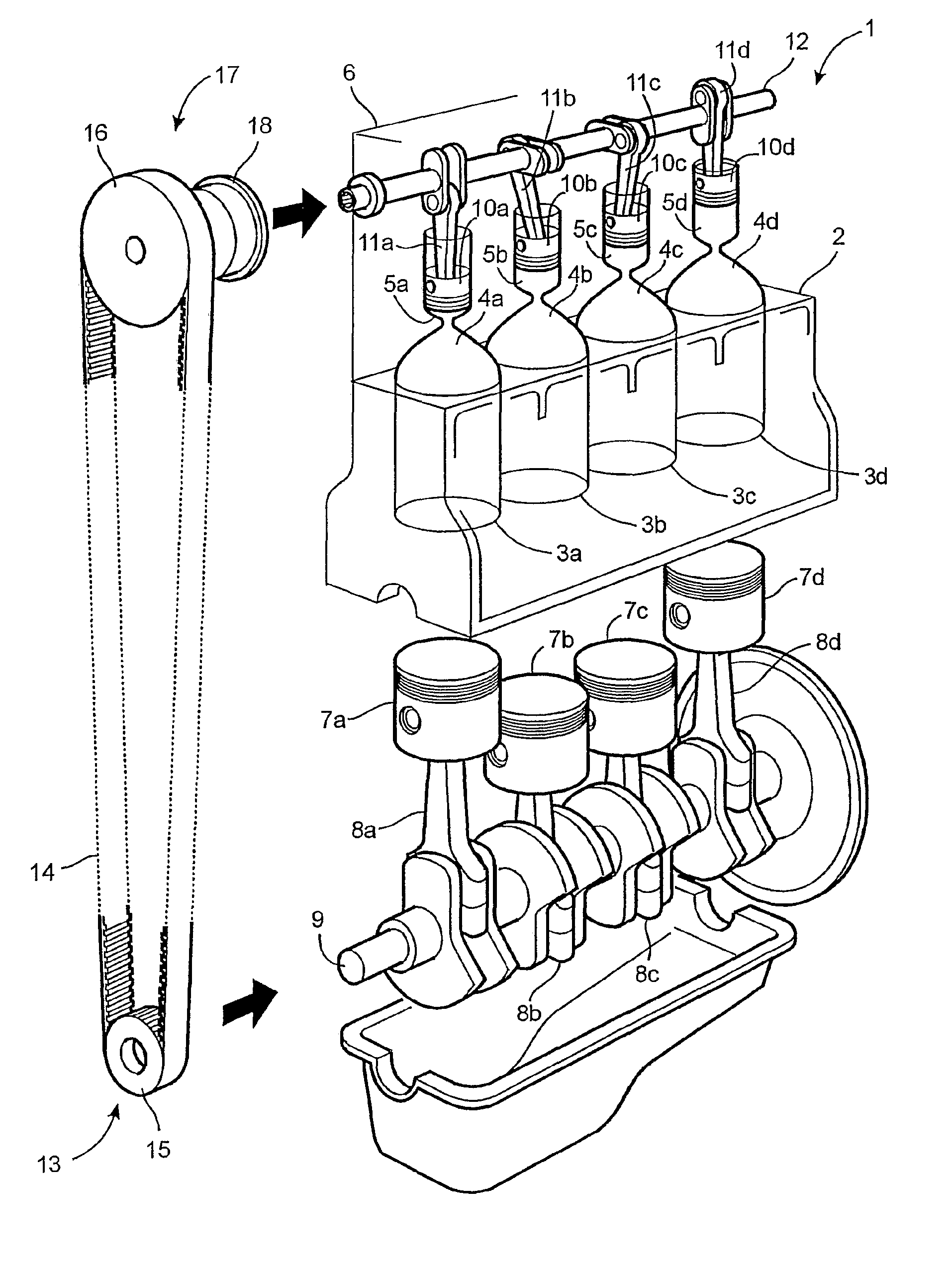

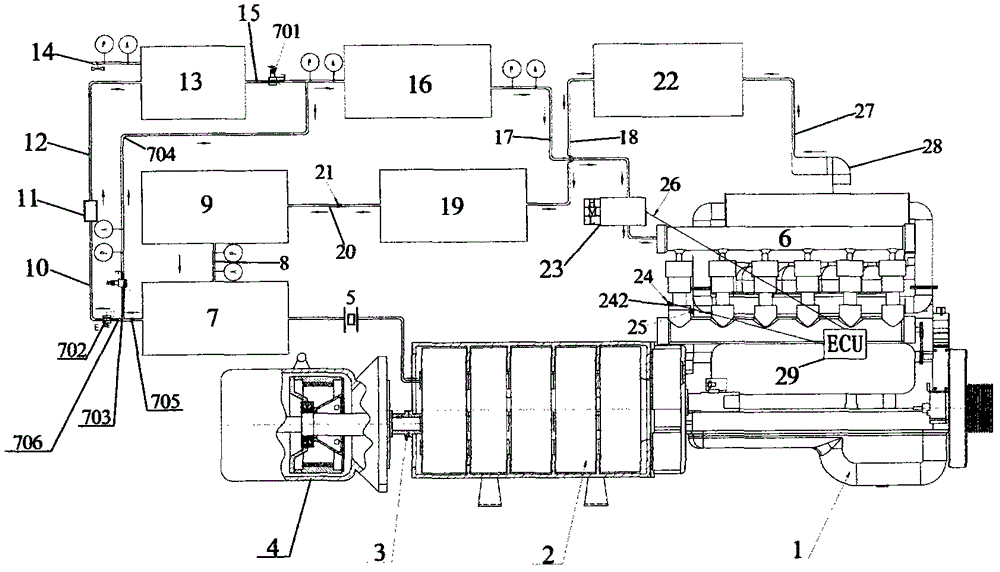

Two-stroke aerodynamic engine assembly

The invention relates to a two-stroke engine, in particular to a two-stroke aerodynamic engine assembly which takes compressed air as a power source. The two-stroke aerodynamic engine assembly comprises an engine body (1), a multicolumn power distributor (2), a power device (3), a controller system (6), an air inlet control compensated flow control valve (23), a high-pressure air tank set (13), a constant-pressure tank (16) and an electric control unit (ECU) (29).

Owner:周登荣 +1

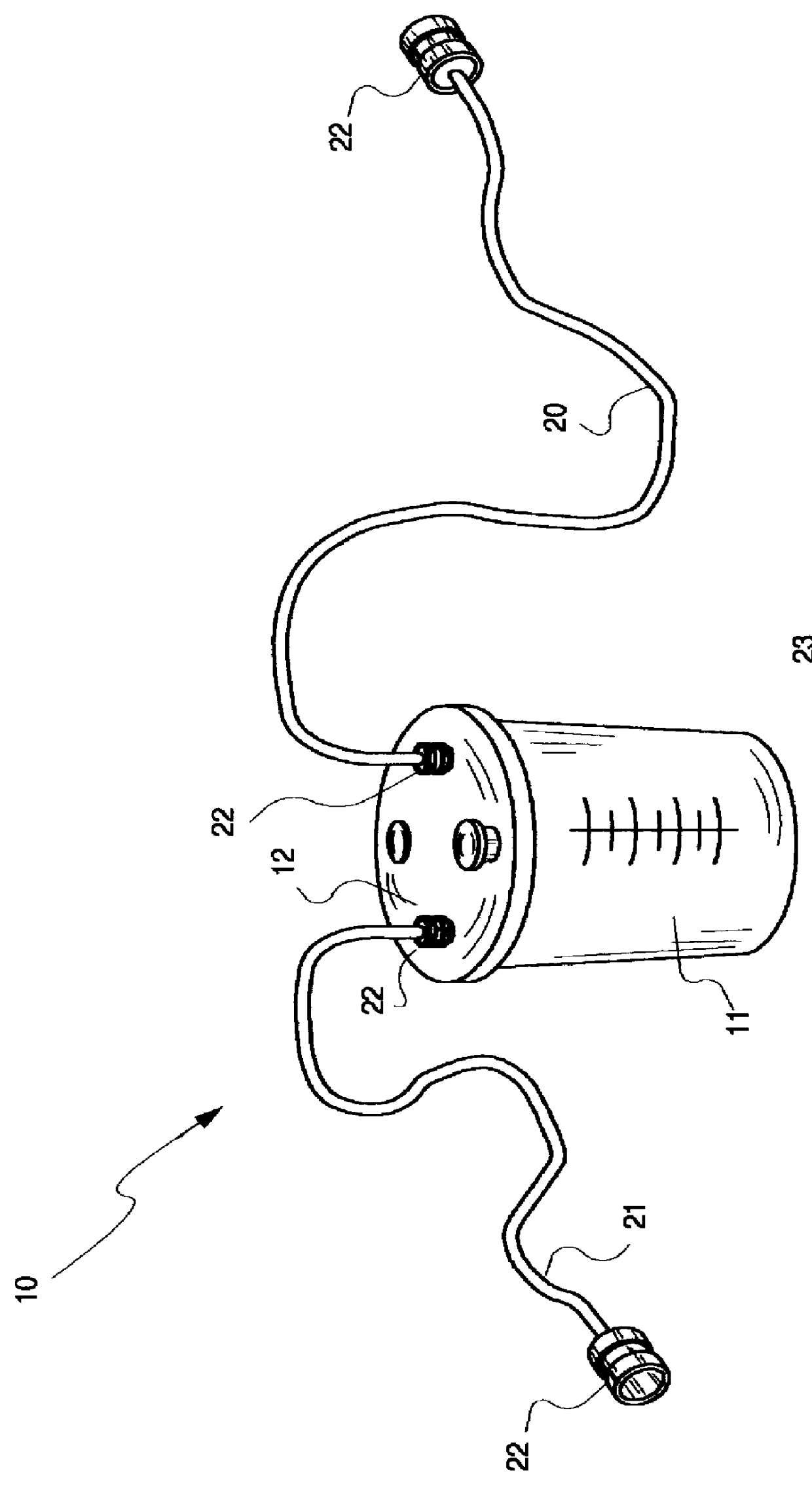

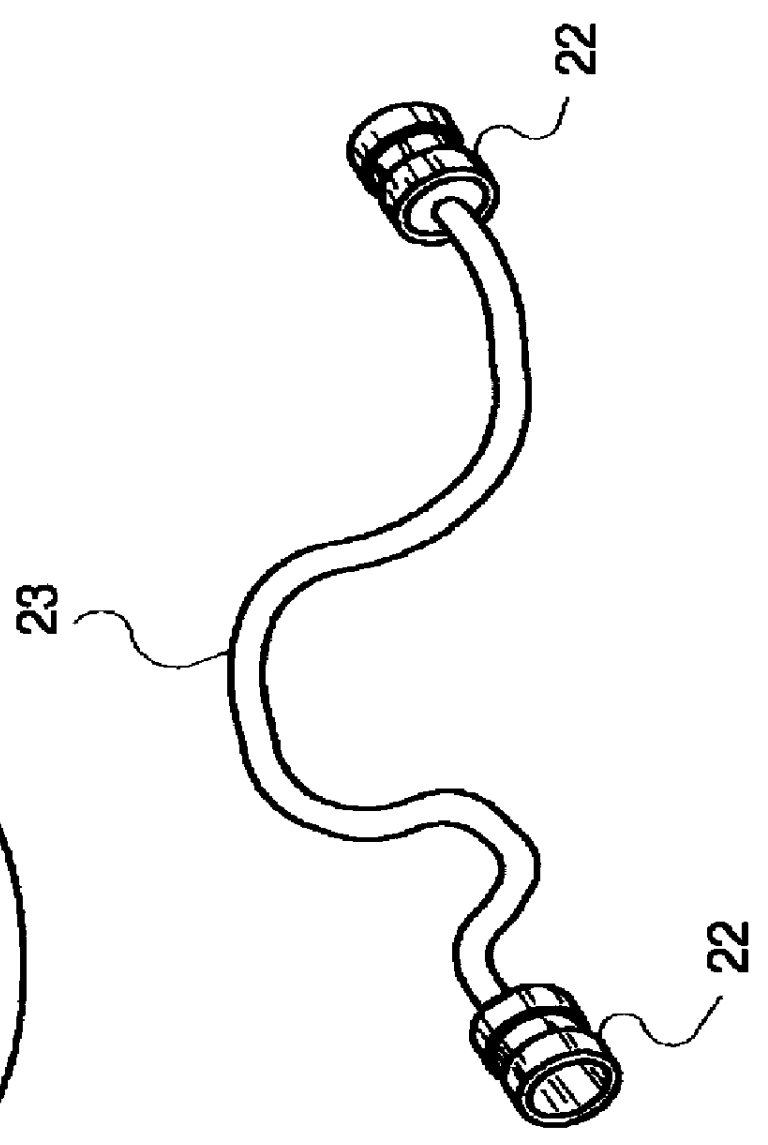

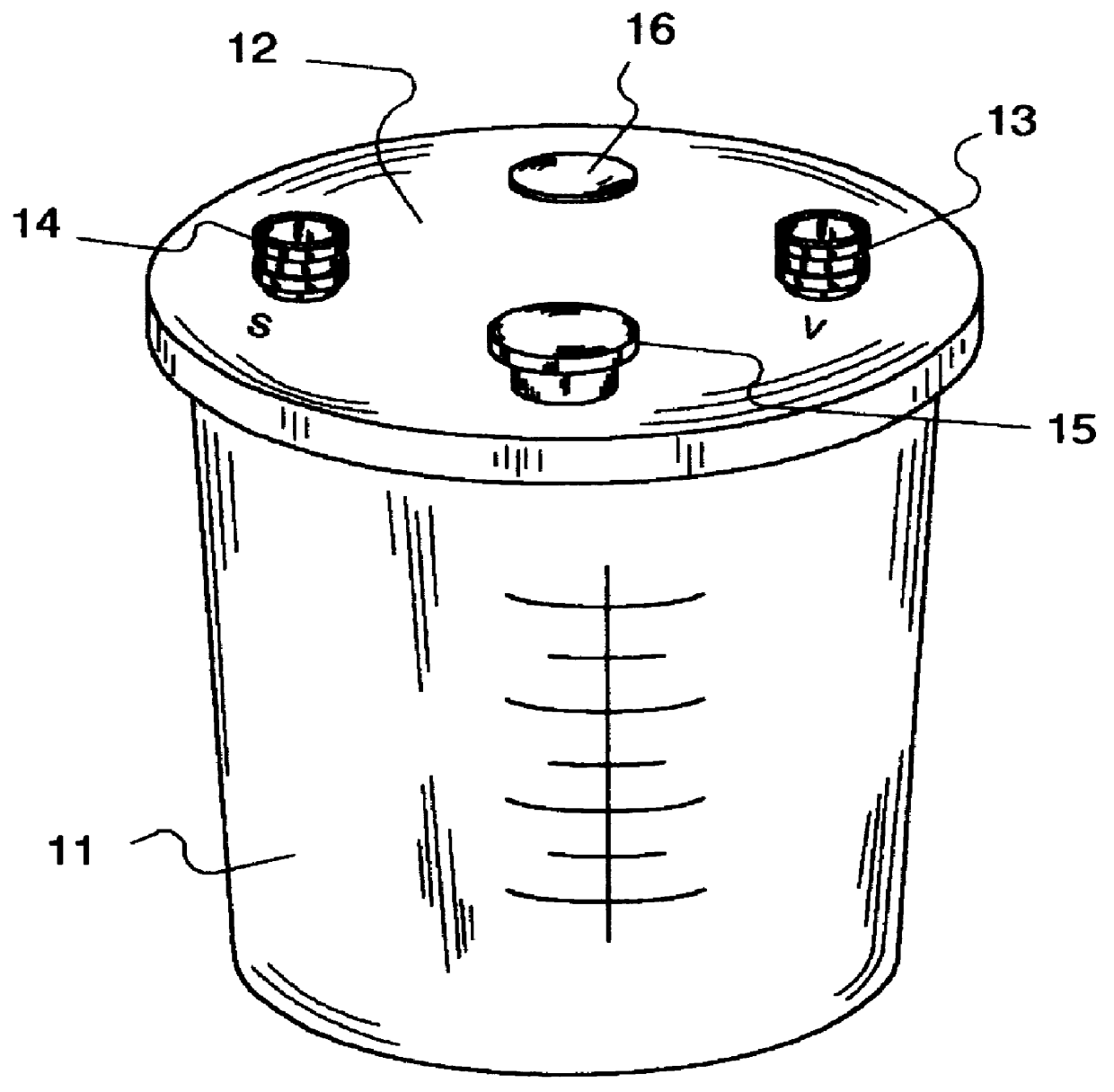

Portable, automatic, oil recovery system

InactiveUS6092390APrevent oil from overflowingPrevent overflowCrankshaftsMachines/enginesEngineeringAir conditioning

A compressor oil recovery device for use in removing oil from compressors typically found on condensing units used in air conditioning or refrigeration applications is disclosed. The device consists of a canister with a lid that contains a vacuum port, a suction port, a drain port, and a vacuum release port. A vacuum hose is connected at one end to the vacuum port and at the other end to an electric vacuum pump. A suction hose is connected at one end to the suction port and at the other end to the gauge manifold of a compressor. Upon activating the vacuum pump, a vacuum is created that draws the compressor oil into the canister where it is collected for disposal.

Owner:GRIFFITH JR DAVID R

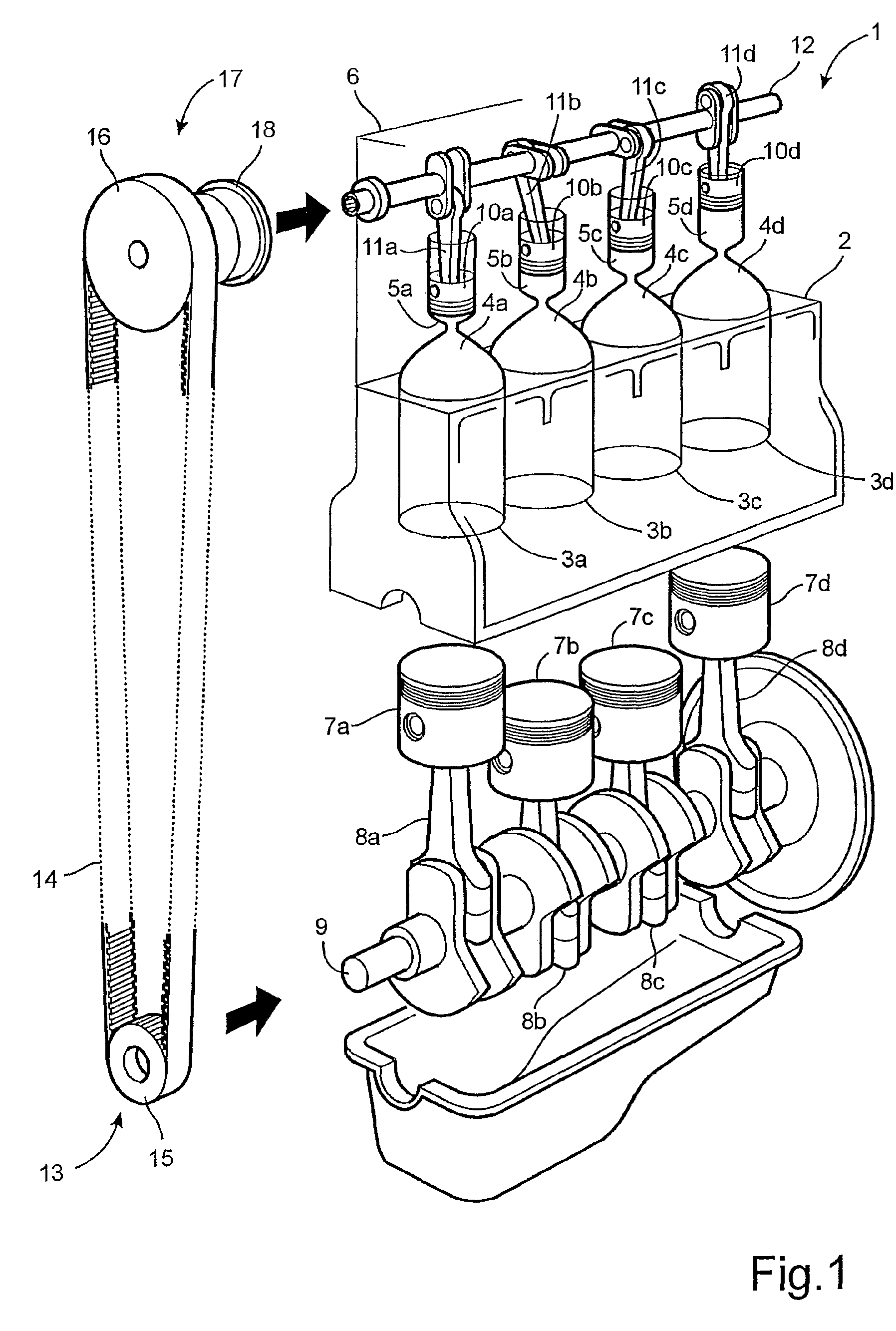

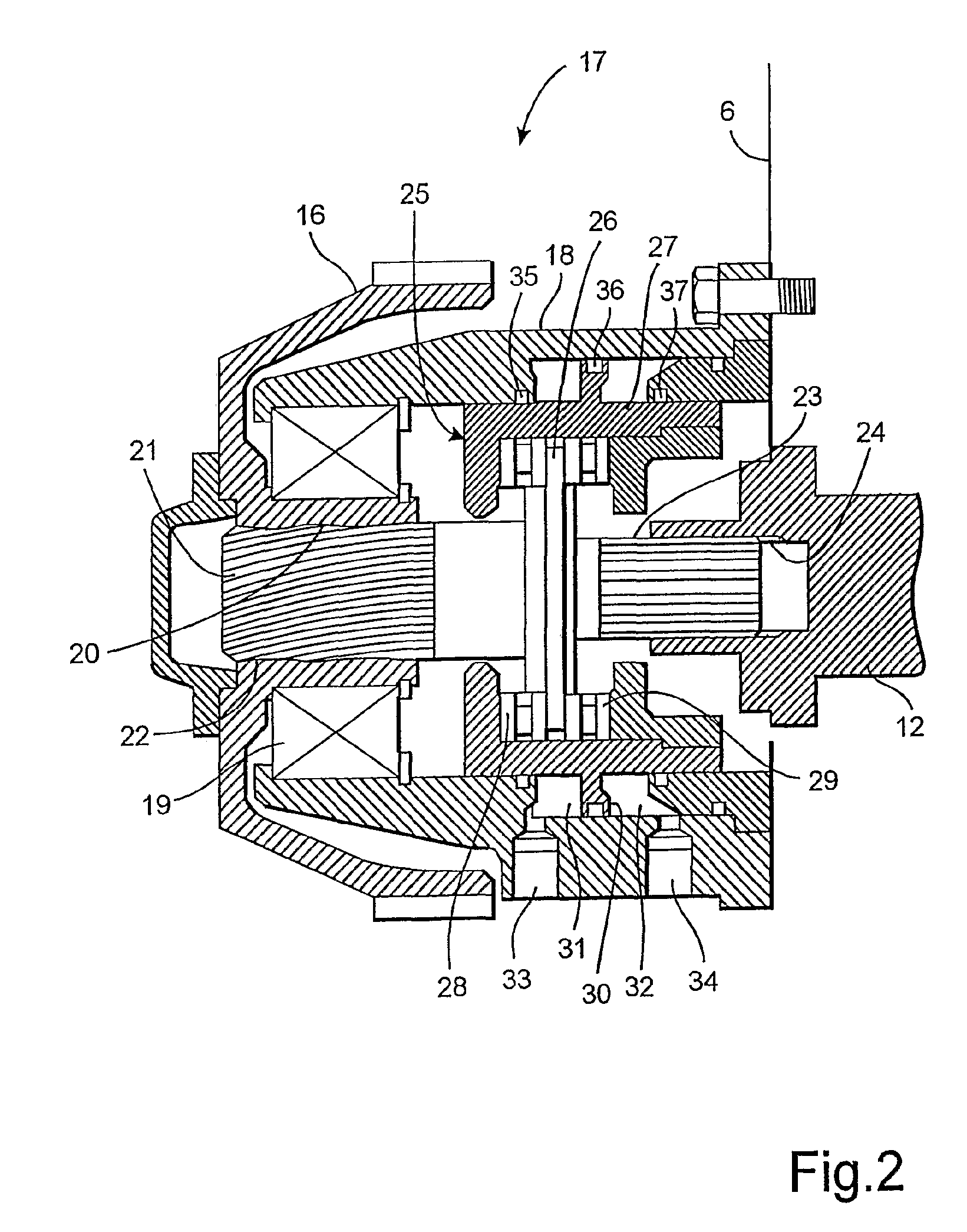

Device for controlling the phase angle between a first and a second crankshaft

InactiveUS20030111028A1Cost efficient to manufactureGood precisionCrankshaftsYielding couplingEngineeringInternal combustion engine

Abstract of Disclosure Method and device for regulating the phase angle between a first and a second crankshaft of an internal combustion engine. The engine includes primary cylinders that communicate with secondary cylinders and in every primary cylinder there is movably arranged a primary piston that is connected to the first crankshaft and in every secondary cylinder there is movably arranged a secondary piston that is connected to the second crankshaft. The first and second crankshafts are connected to each other by means of a transmission adapted with the device that includes a crankshaft extension for obtaining the control of the phase angle, the extension being fixed against rotation and displaceably connected to one of the crankshafts and via a grooved portion rotationally connected to the second of the crankshafts. When the crankshaft extension in displaced, rotation is obtained in the grooved portion that results in a corresponding phase angle shift.

Owner:ALVAR ENGINE

Apparatus and method for automatically performing fluid changes

InactiveUS6123174AEfficient and successful completionMinimize the possibilityCrankshaftsPackaging by pressurising/gasifyingSequence controlControl signal

An environmentally sound apparatus and method for automatically extracting fluids such as lubricating fluids from a target reservoir such as a crankcase for a vehicle engine, and injecting the proper type and quantity of fresh fluid into the reservoir is disclosed. The apparatus includes one or more sources of lubricating fluid, a waste fluid tank, a pump, and a flow meter. A programmed microprocessor produces selected sequences of control signals to govern the flow of fluid among the fluid sources, the waste fluid tank, and the target reservoir in response to input identification information and signals produced by a flow monitoring pulse meter. Input identification information is compared with data in a stored database to determine the correct type and quantity of fresh fluid to inject. Operator identification information is compared with a stored operator database to determine what operations each operator is permitted to perform. A display and selection switches allows the operator to select from different procedure options. Evacuation, injection and clearing operations are initiated by an operator and executed automatically through status monitored sequences controlled by the microprocessor. All fluid exchange sequences are performed without exposing the operator or the environment to either waste or fresh fluid.

Owner:HLDG CAPITAL GRP

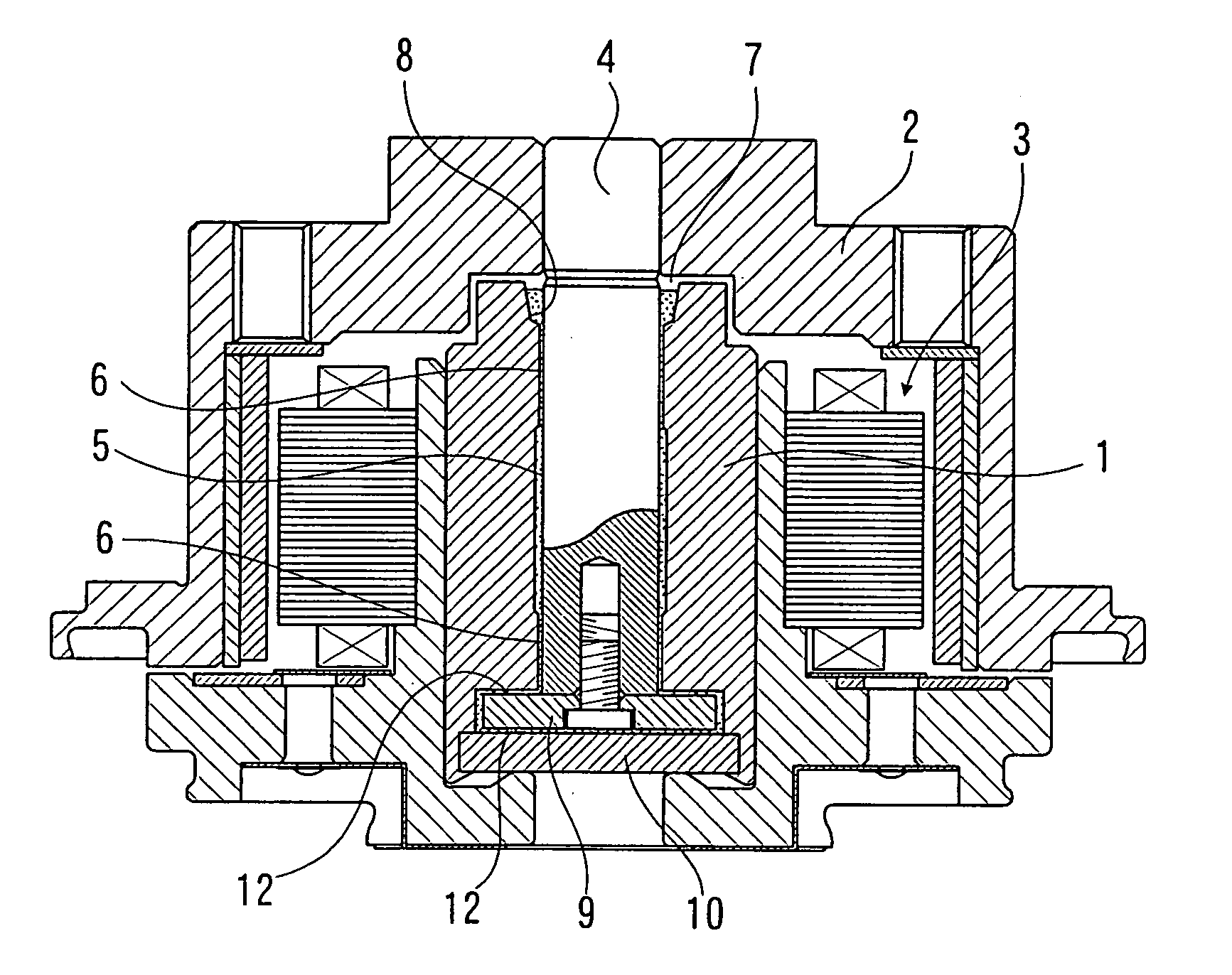

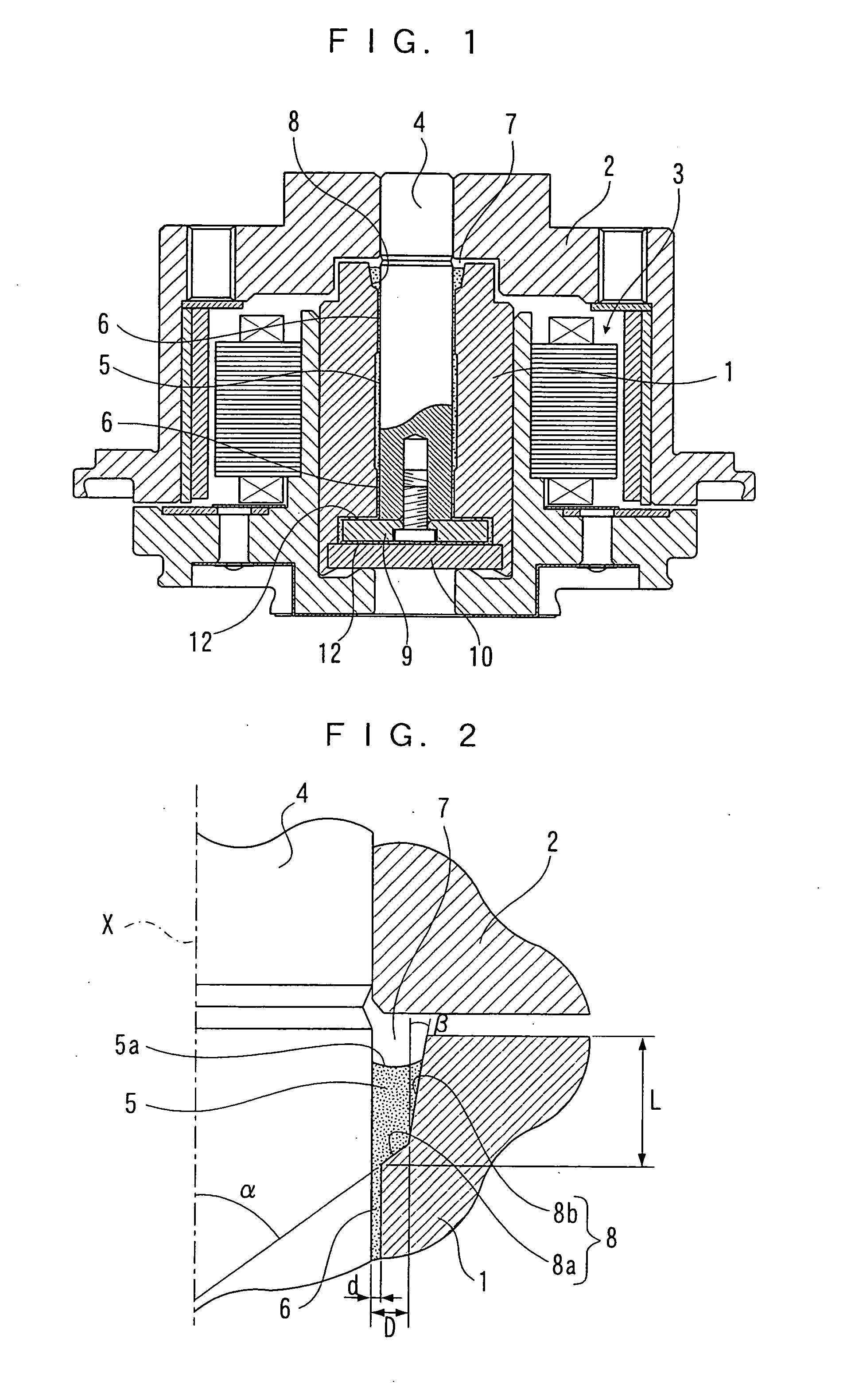

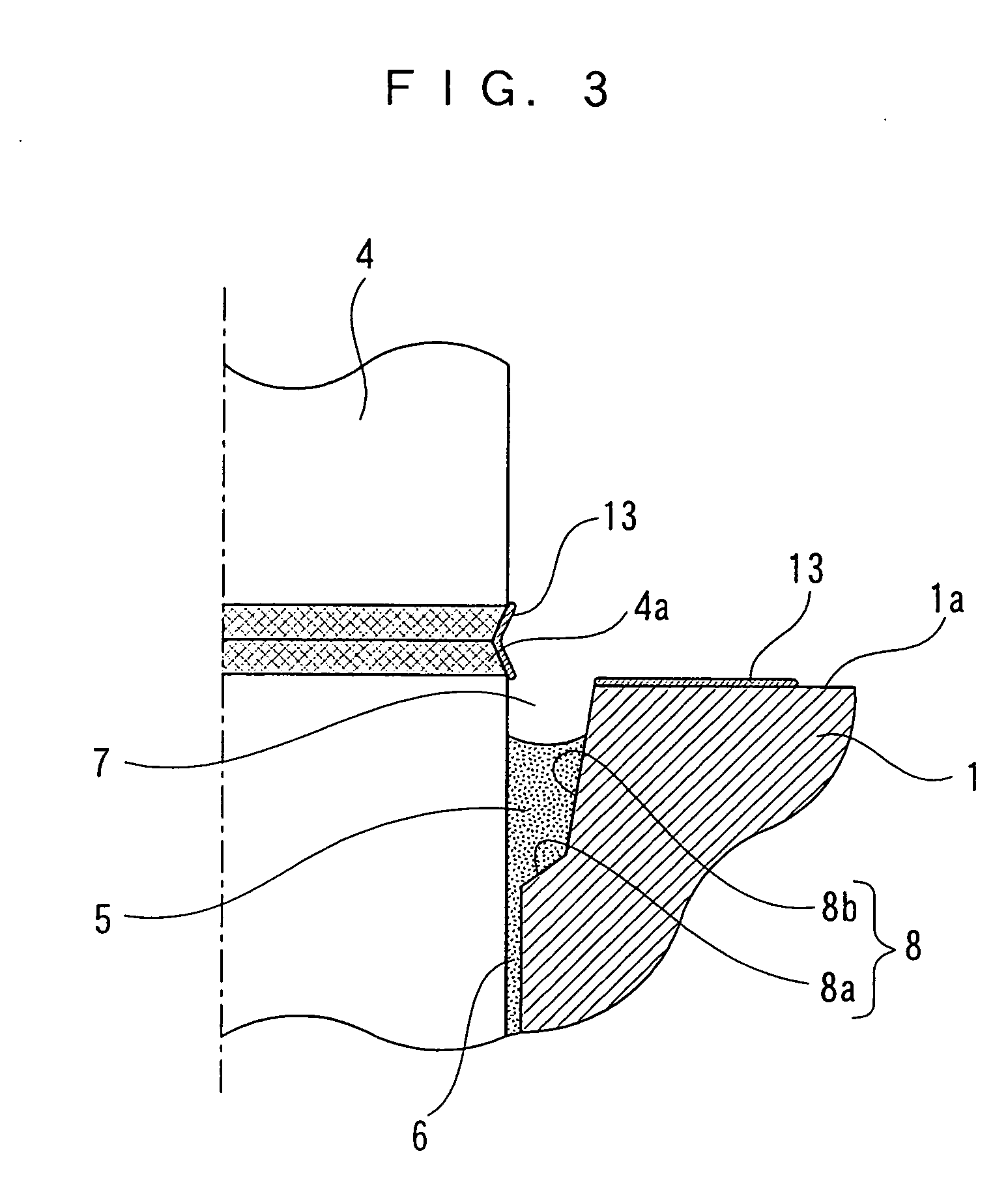

Fluid bearing device

ActiveUS20050111769A1Sufficient length dimensionSmall depthCrankshaftsRecord information storageEngineeringFluid bearing

A fluid bearing device capable of preventing a lubricant from scattering outward even during rotation thereof, while holding a relatively large amount of lubricant at a seal surface portion. A lubricant is filled between a sleeve and a shaft, a seal surface portion is formed on the sleeve in a location facing an open end thereof, the seal surface portion has a sectional shape defined by a plurality of inclined surfaces, and an inclination angle α of the inclined surface of the seal surface portion adjacent a radial bearing portion with respect to a shaft axis is formed to be larger than an inclination angle β of the inclined surface of the seal surface portion distant away from the radial bearing portion with respect to the shaft axis.

Owner:PHC HLDG CORP

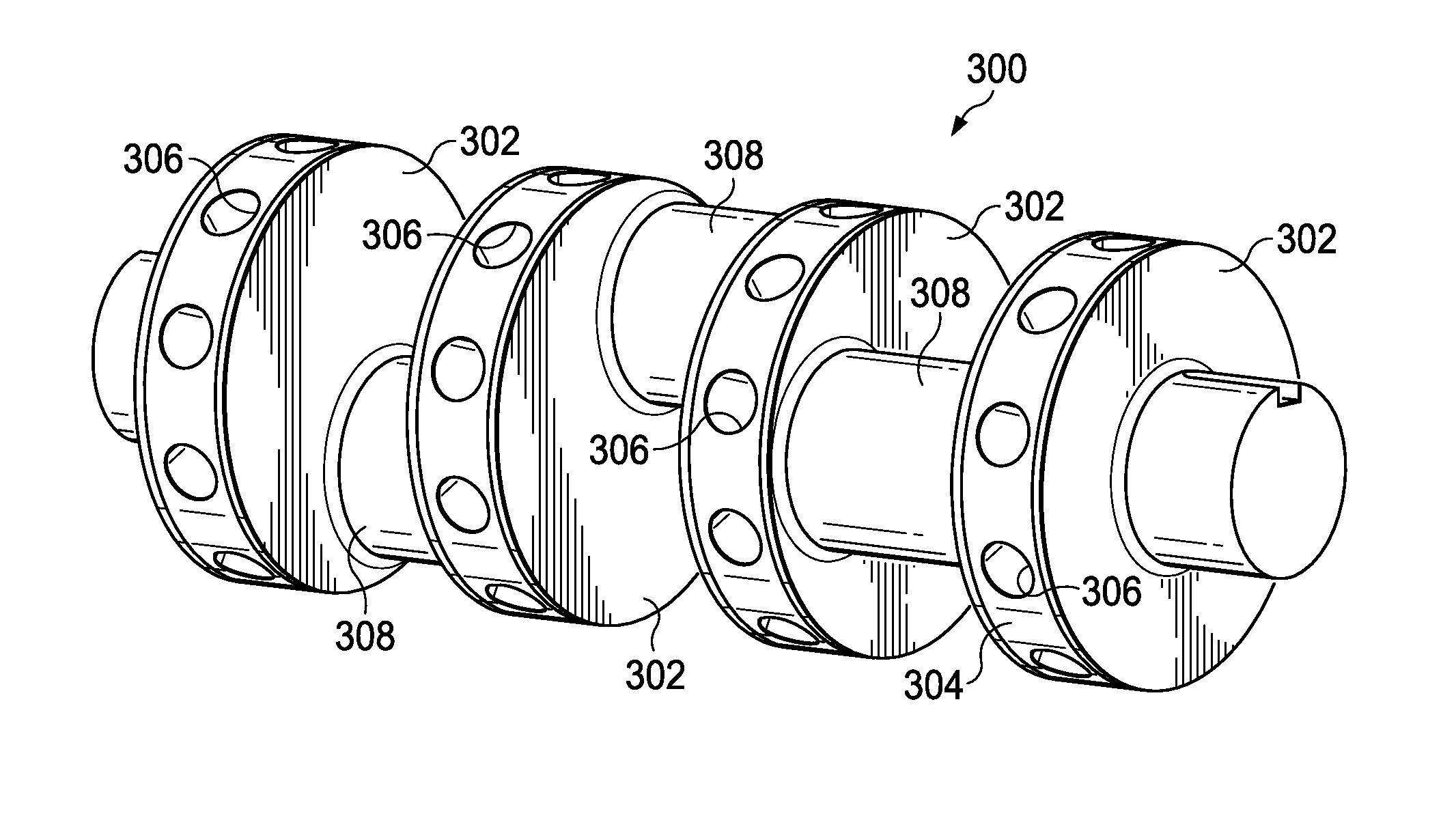

Lightened Rotating Member and Method of Producing Same

InactiveUS20140196570A1Reduce inertiaReducing balanceCrankshaftsRoller bearingsEngineeringMain bearing

A lightened rotating member for a machine. The lightened member includes a plurality of radially machined penetrations within at least one main bearing support journal of the rotating member. The plurality of penetrations is formed around the circumference of the main bearing journal face, with the penetration centerline directed radially toward the rotating member's axial centerline. An even number of penetrations may be utilized with minimal adverse effect on the balance of the rotating member. Odd numbers of penetrations may require subsequent rebalancing. The rotating member may be any rotating member that utilizes one or more main bearing support journals.

Owner:FTS INT SERVICES

Bearing assembly with fluid circuit for delivery of lubricating fluid between bearing surfaces

An integral thrust / journal bearing assembly, e.g., useable in a turbocharger is provided. The assembly includes a journal bearing configured to operate at a first mechanical load. The assembly further includes a thrust bearing including a thrust bearing face. The thrust bearing may be configured to operate at a second mechanical load different than the first mechanical load. A fluid circuit that includes parallel branches is provided within the integral bearing assembly for delivering parallel flows of lubricating fluid to the thrust bearing face and the journal bearing.

Owner:GENERAL ELECTRIC CO

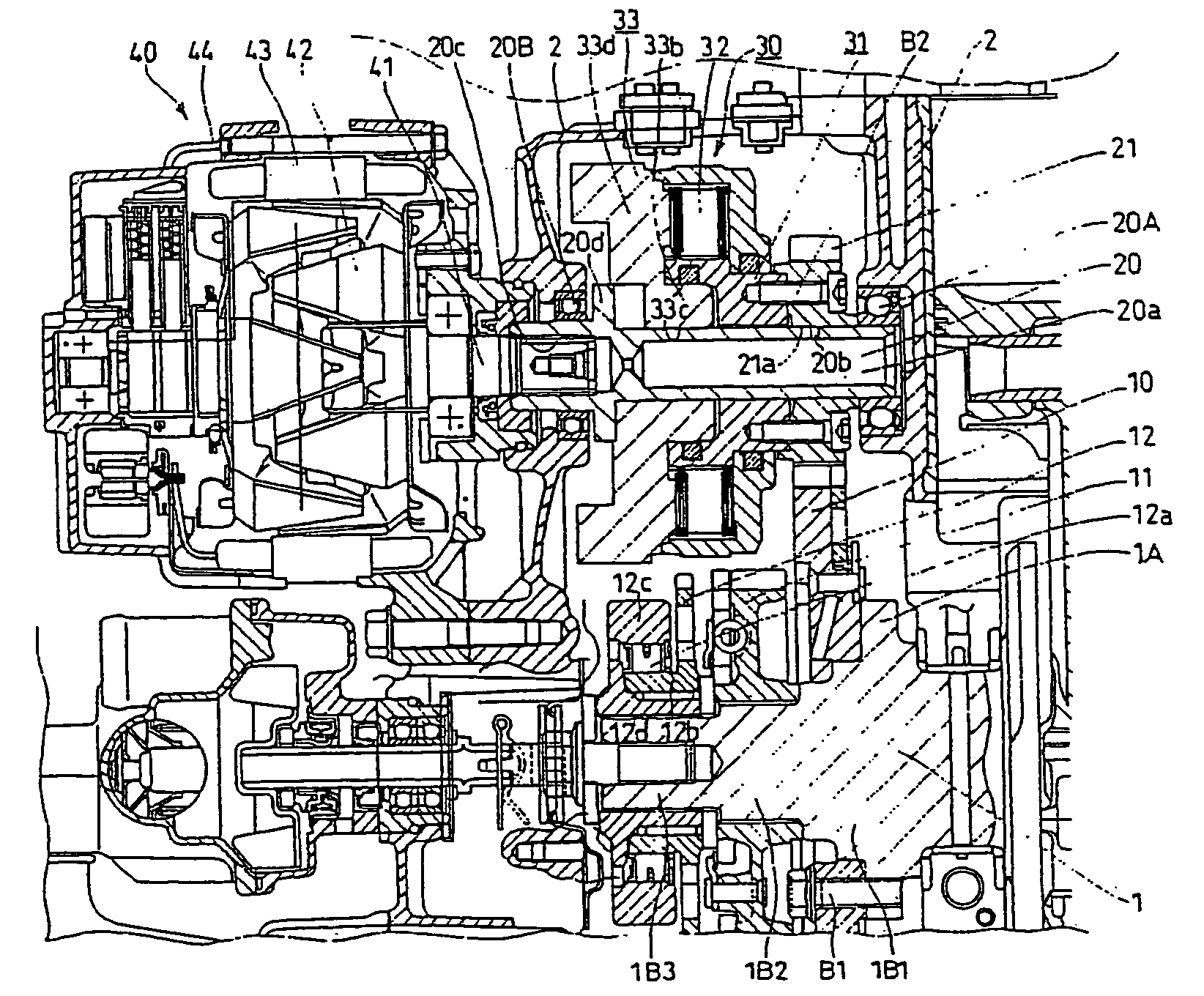

Viscous damper

ActiveUS7201263B2Designing of the power transmission device is facilitatedReduce the number of partsCrankshaftsRotating vibration suppressionAlternatorControl theory

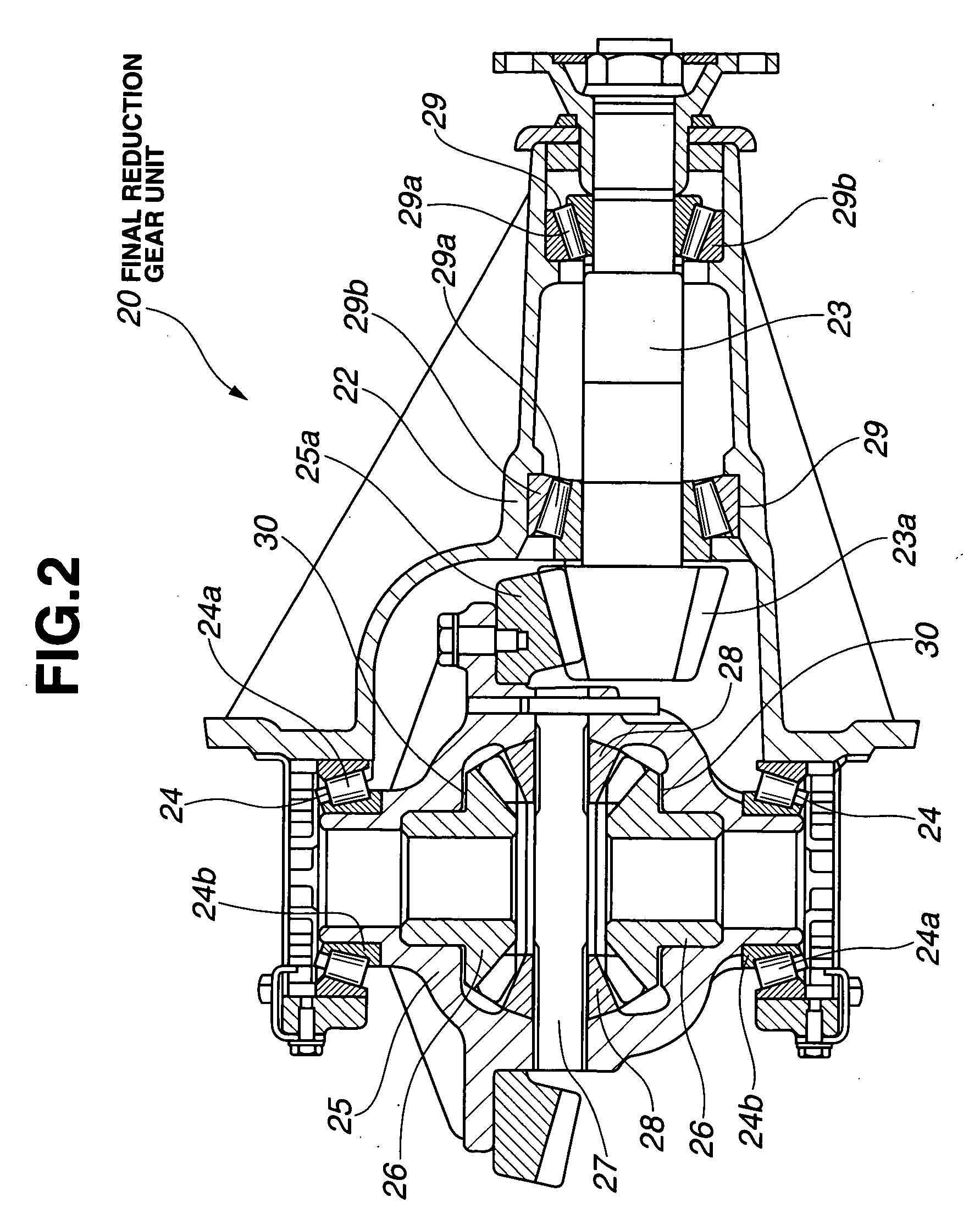

A viscous damper for driving accessories by a crankshaft though a viscous coupler of the viscous damper. The rotational driving force of the crankshaft is transmitted to the viscous damper hub through the meshing of a large diameter gear and a driven gear, the viscous damper forming a unit with the driven gear. The rotational driving force is further transmitted to a viscous damper housing through the hub and the viscous coupler, i.e., the viscous coupler including a number of plates which are movable relative to each other in a space filled with silicon oil. The rotational driving force, which is transmitted to the housing and is dampened in torque changes by the function of the coupler, is transmitted to a rotor shaft of an alternator to smoothly rotate the alternator rotor. A smooth performance in driving the accessories is ensured by the viscous damper having the viscous coupler.

Owner:HONDA MOTOR CO LTD

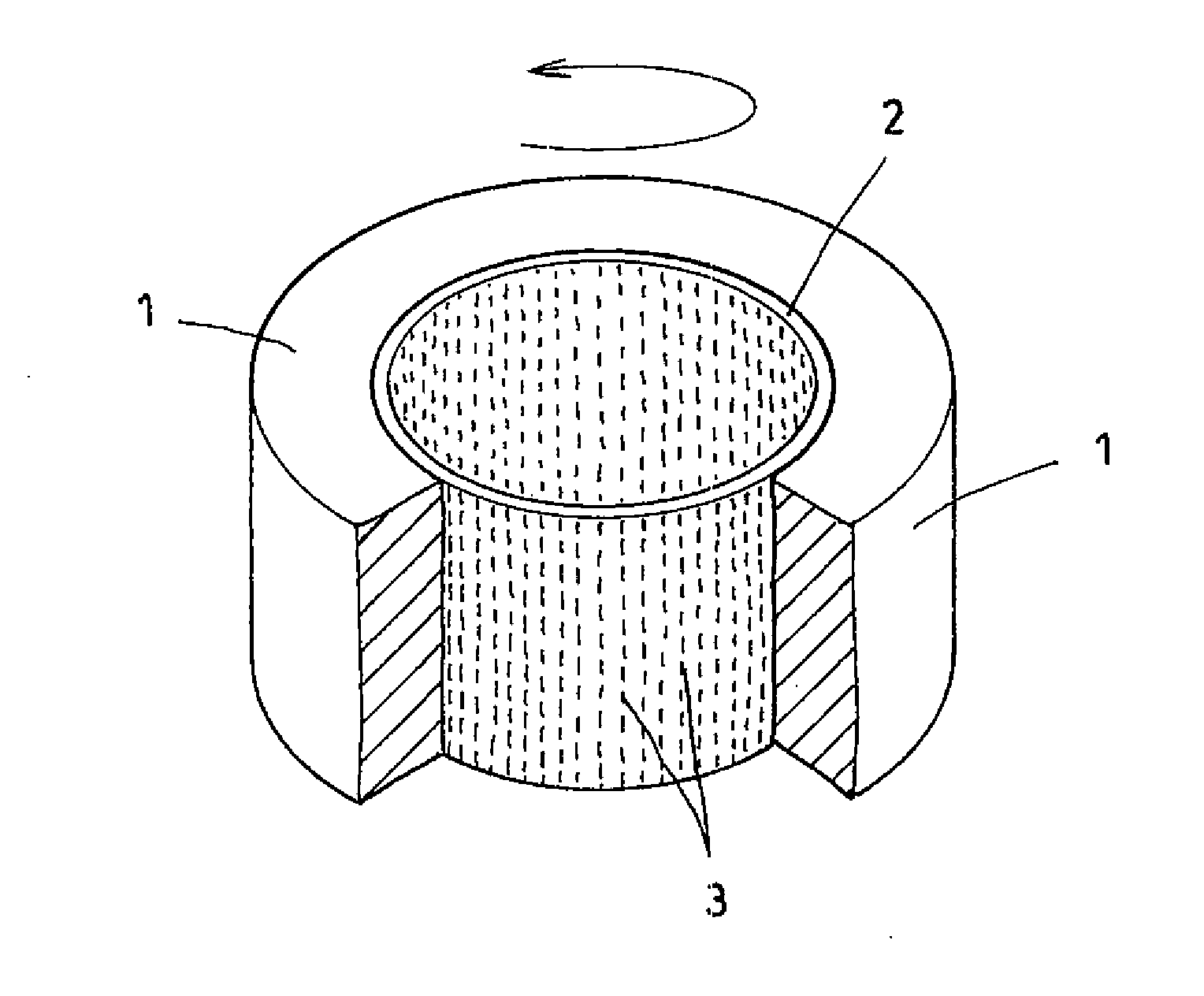

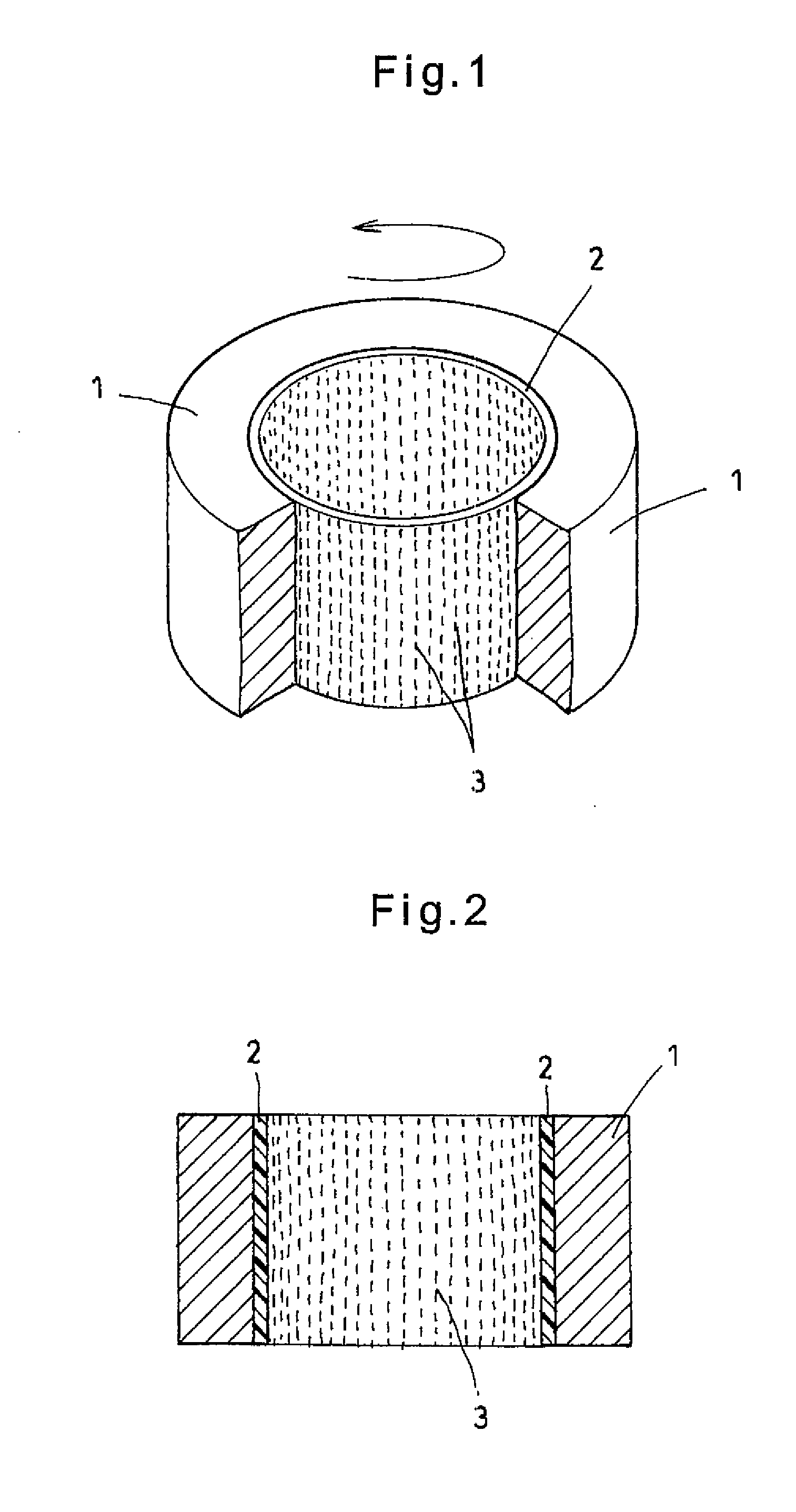

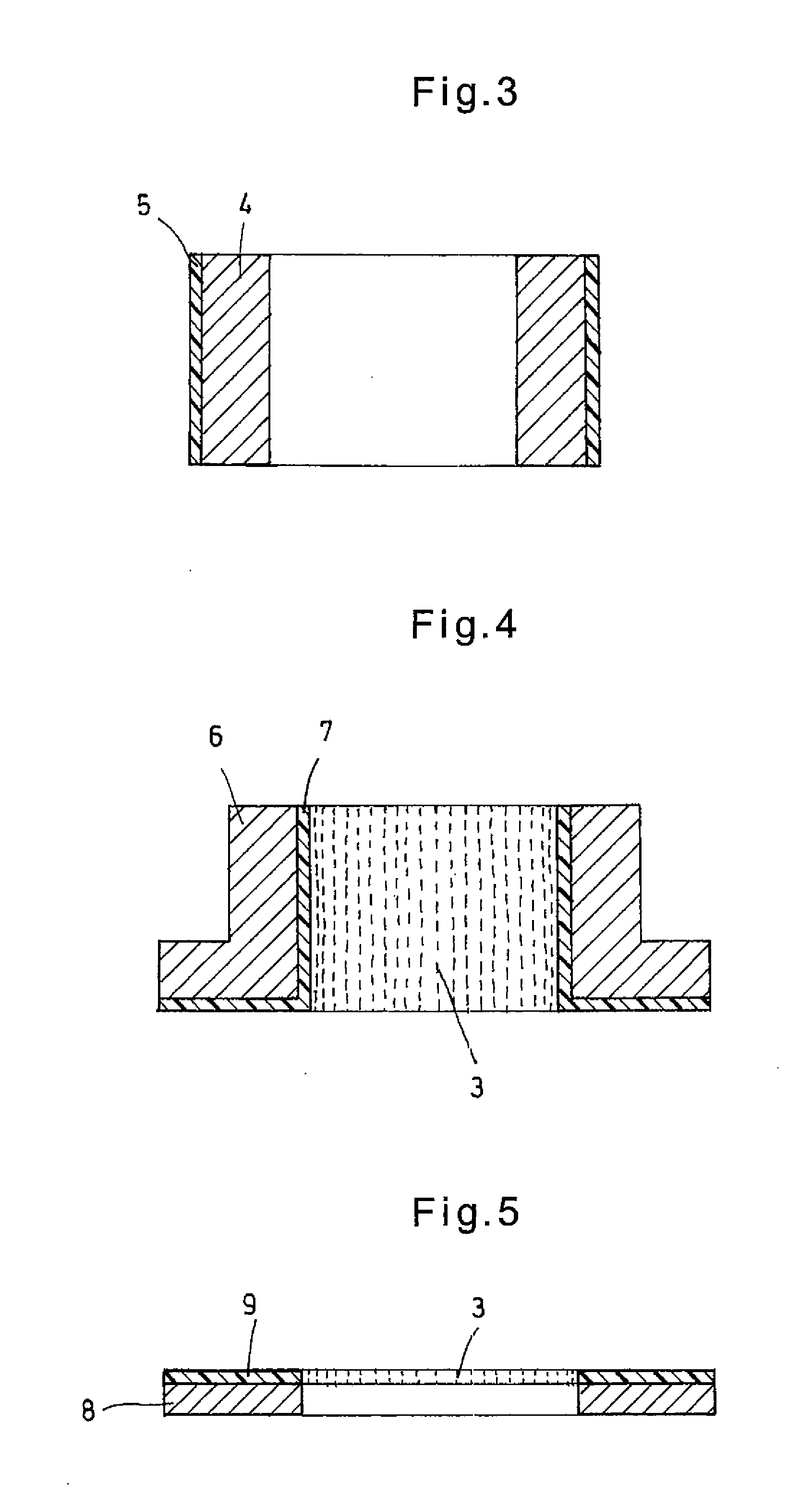

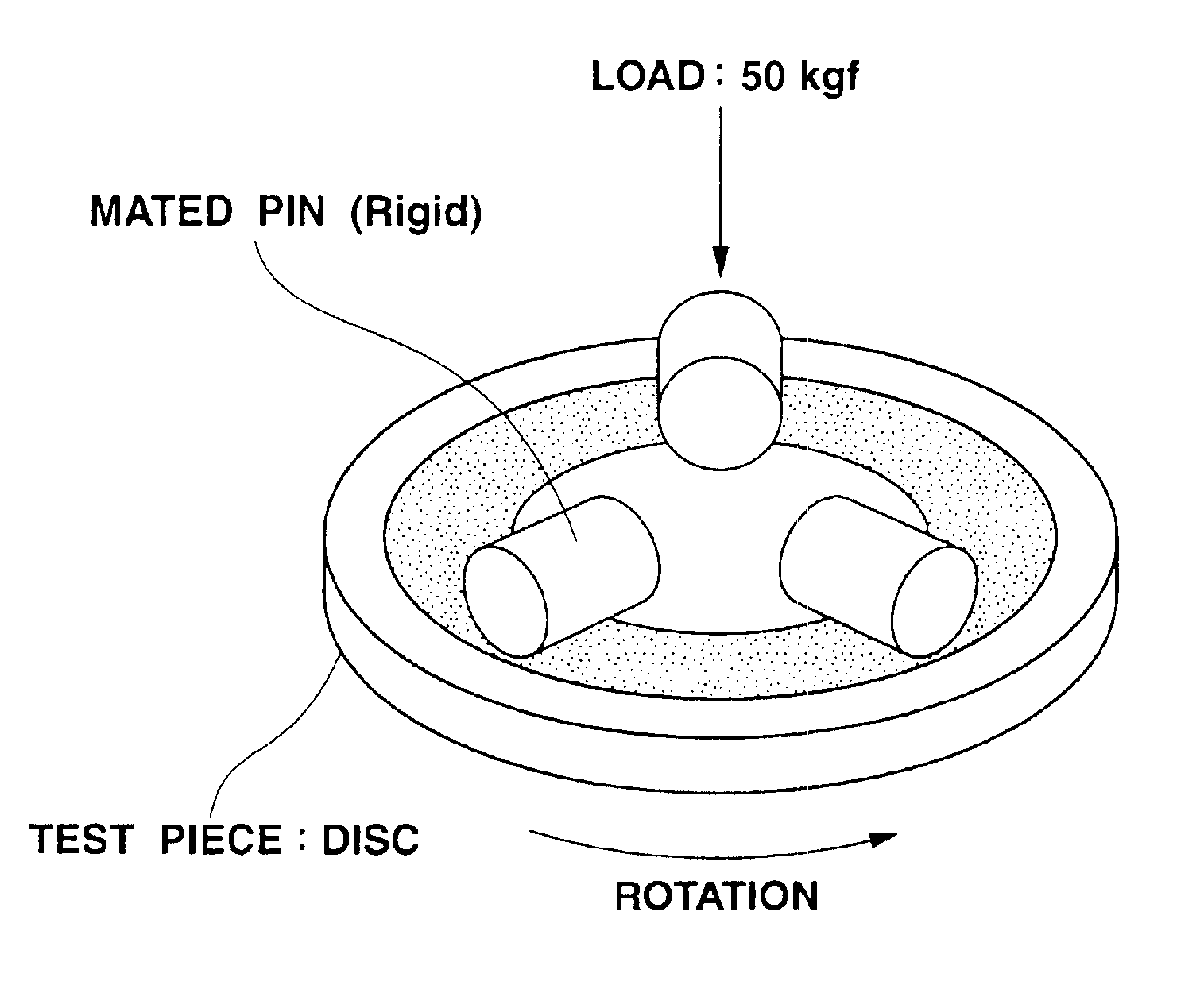

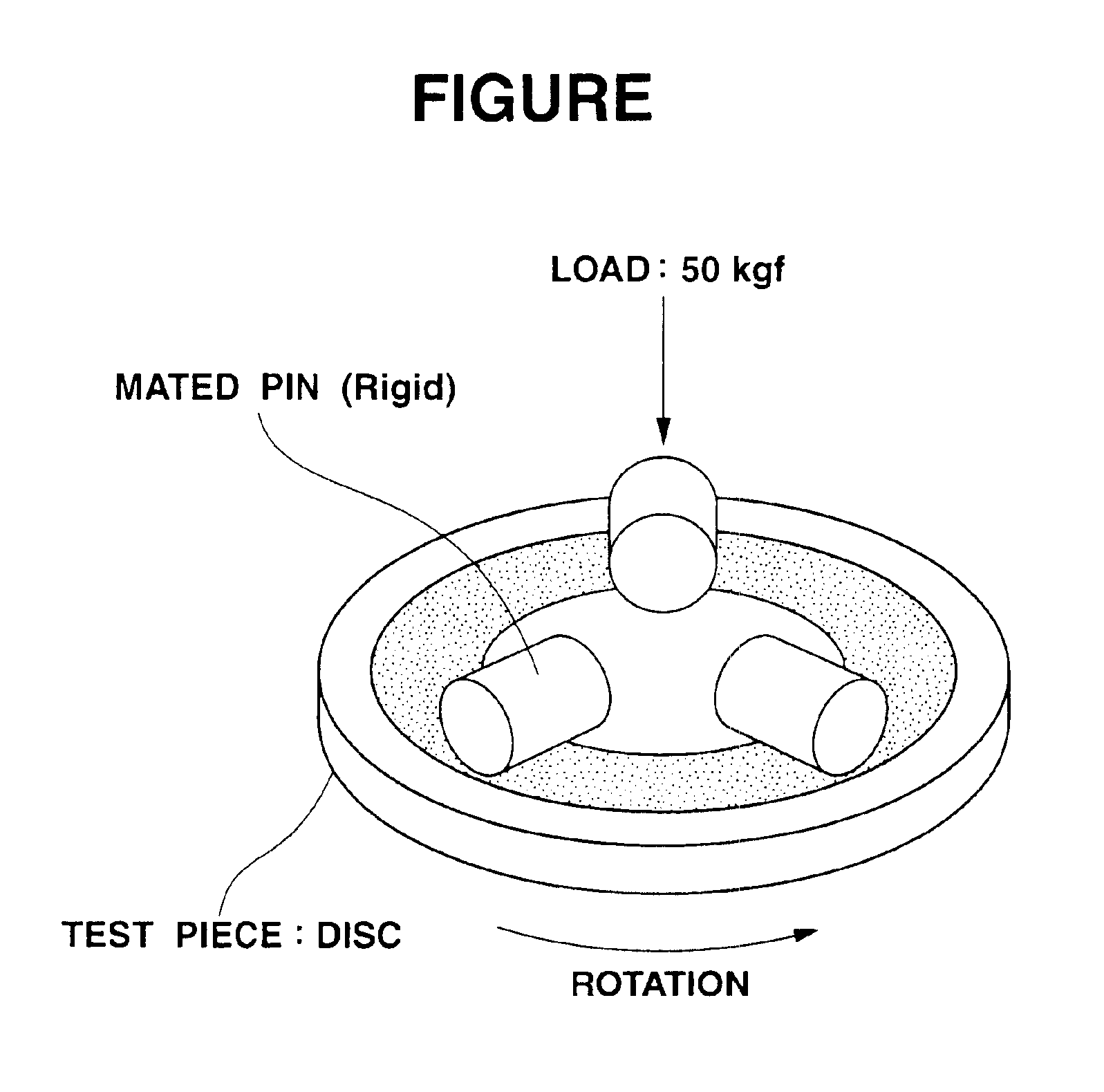

Composite slide bearing

A high-precision slide bearing is provided which includes a substrate of sintered metal and a synthetic resin layer. This bearing can be used e.g. for rotary shafts in compressors of room air-conditioners or in transmissions of motor vehicles and construction machines to support relatively large radial and axial loads. The resin layer is integrally superposed on the radially inner surface of the sintered metal substrate of the slide bearing, which is a cylindrical member. The resin layer is made of a resin composition of an aromatic polyetherketone resin containing a fibrous filler. The fibrous filler are made up of fibers dispersed in the resin layer and oriented such that their length directions intersect the rotational direction of the bearing at angles of 45 to 90 degrees. The resin layer has a thickness of 0.1 to 0.7 mm.

Owner:NTN CORP

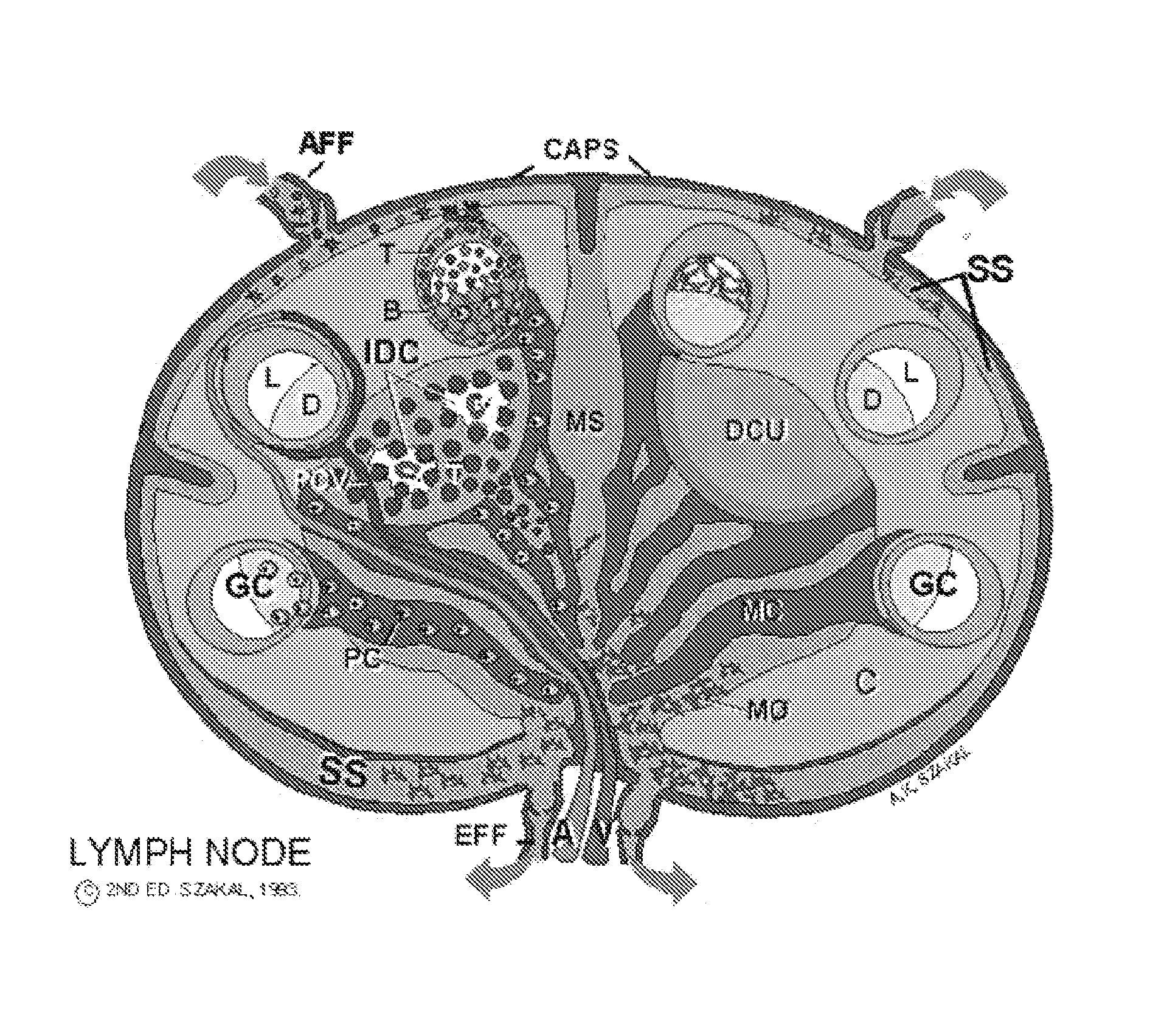

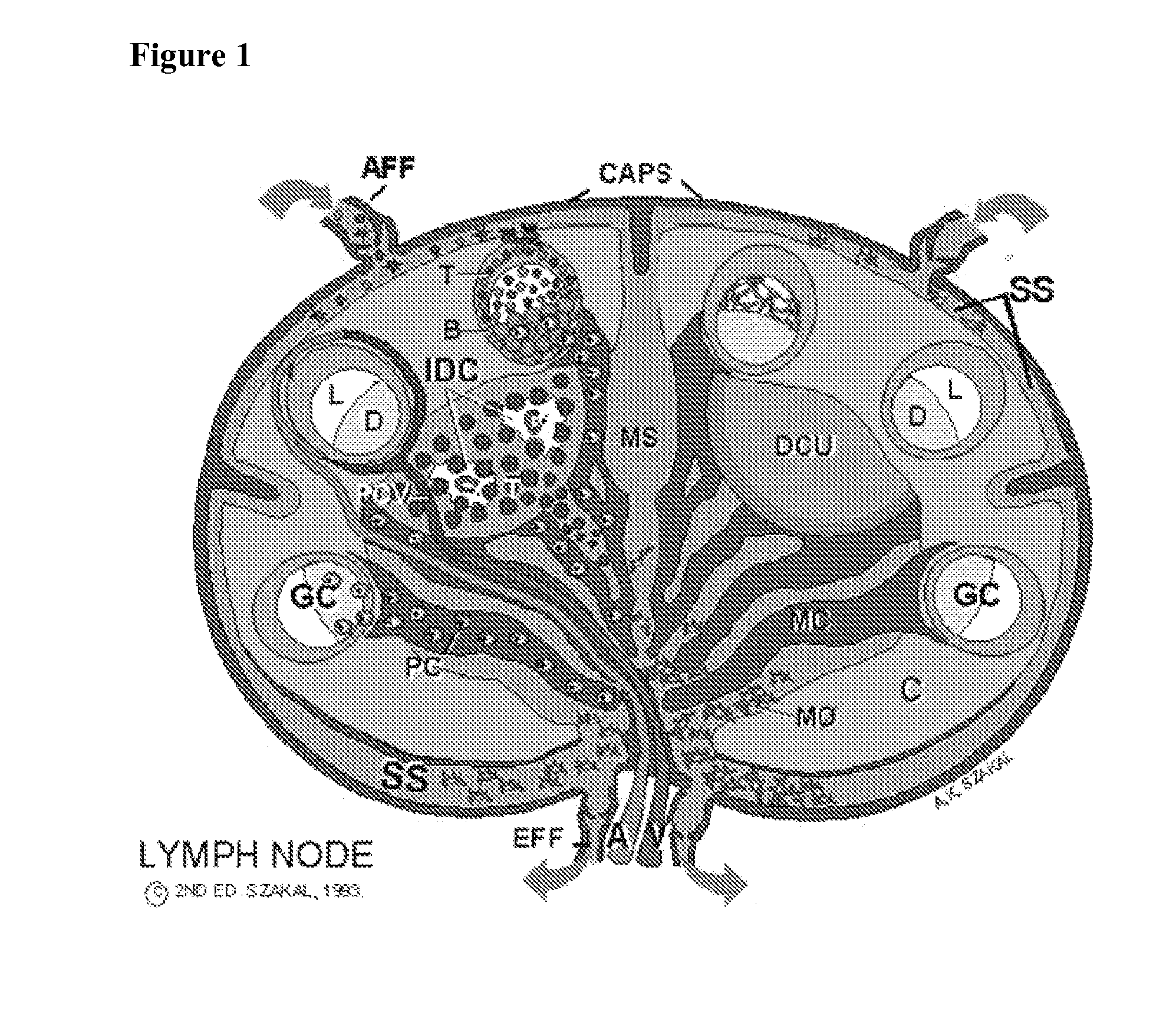

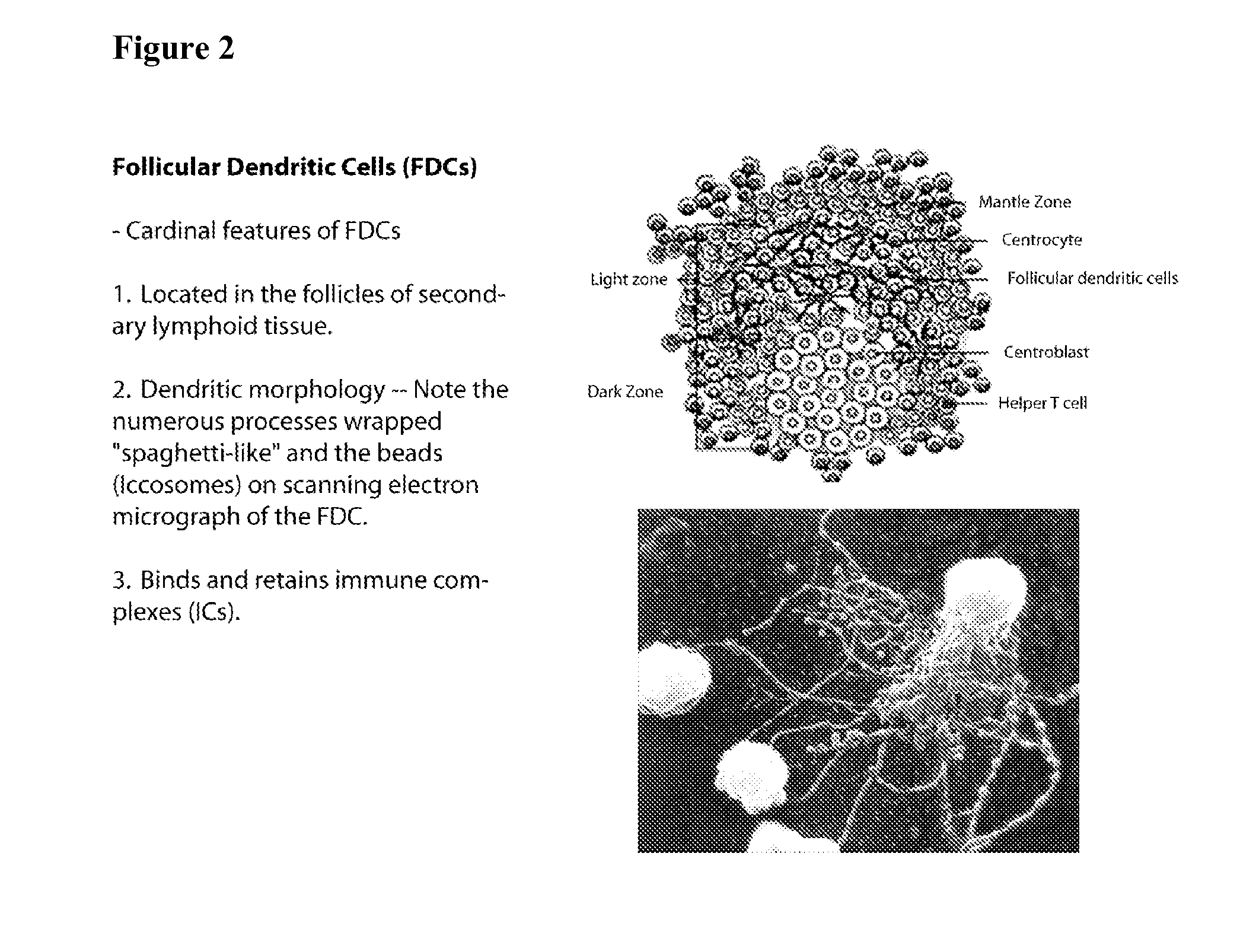

Models for vaccine assessment

ActiveUS20080008653A1Improve accuracyImprove predictabilityCompounds screening/testingCrankshaftsAdjuvantBiological Immunotherapy

The present invention is directed to methods for constructing and using in vivo and in vitro models of aspects of human immunity and, in particular, construction of a human immune system model for the testing of, for example, vaccines, adjuvants, immunotherapy candidates, cosmetics, drugs, biologics and other chemicals. The present invention comprises both in vivo and in vitro models of aspects of human immunity that are useful for assessing the interaction of substances with the immune system, and thus can be used to accelerate and improve the accuracy and predictability of, for example, vaccine, drug, biologic, immunotherapy, cosmetic and chemical development. The invention is also useful for the generation of human monoclonal and polyclonal antibodies.

Owner:VIRGINIA COMMONWEALTH UNIV +1

Sealing system between bearing and compressor housing

ActiveUS8348595B2Extend your lifeEfficient and cost-effective structureCrankshaftsPump componentsTurbochargerThrust bearing

A turbocharger oil discharge assembly (301, 501, 701, 901) can have a thrust collar (324, 524, 724, 924) with a first radially outwardly extending wall and a second radially outwardly extending wall to define a first annular channel. The first radially outwardly extending wall can have an annular flange that at least in part defines a second annular channel. The assembly can also have a thrust bearing (340, 540, 740, 940) having a radially inner end received in the first annular channel, and an insert (400, 600, 800, 1000). An oil collection chamber (440, 640, 840, 1040) can be defined at least in part by a drainage channel of the insert (400, 600, 800, 1000), the annular flange of the thrust collar (324, 524, 724, 924) and the thrust bearing (340, 540, 740, 940). Pressurized oil discharged from an oil release interface can be directed towards a radially outer region of the oil collection chamber (440, 640, 840, 1040) and can be collected in the oil collection chamber (440, 640, 840, 1040) for subsequent exhaust.

Owner:BORGWARNER INC

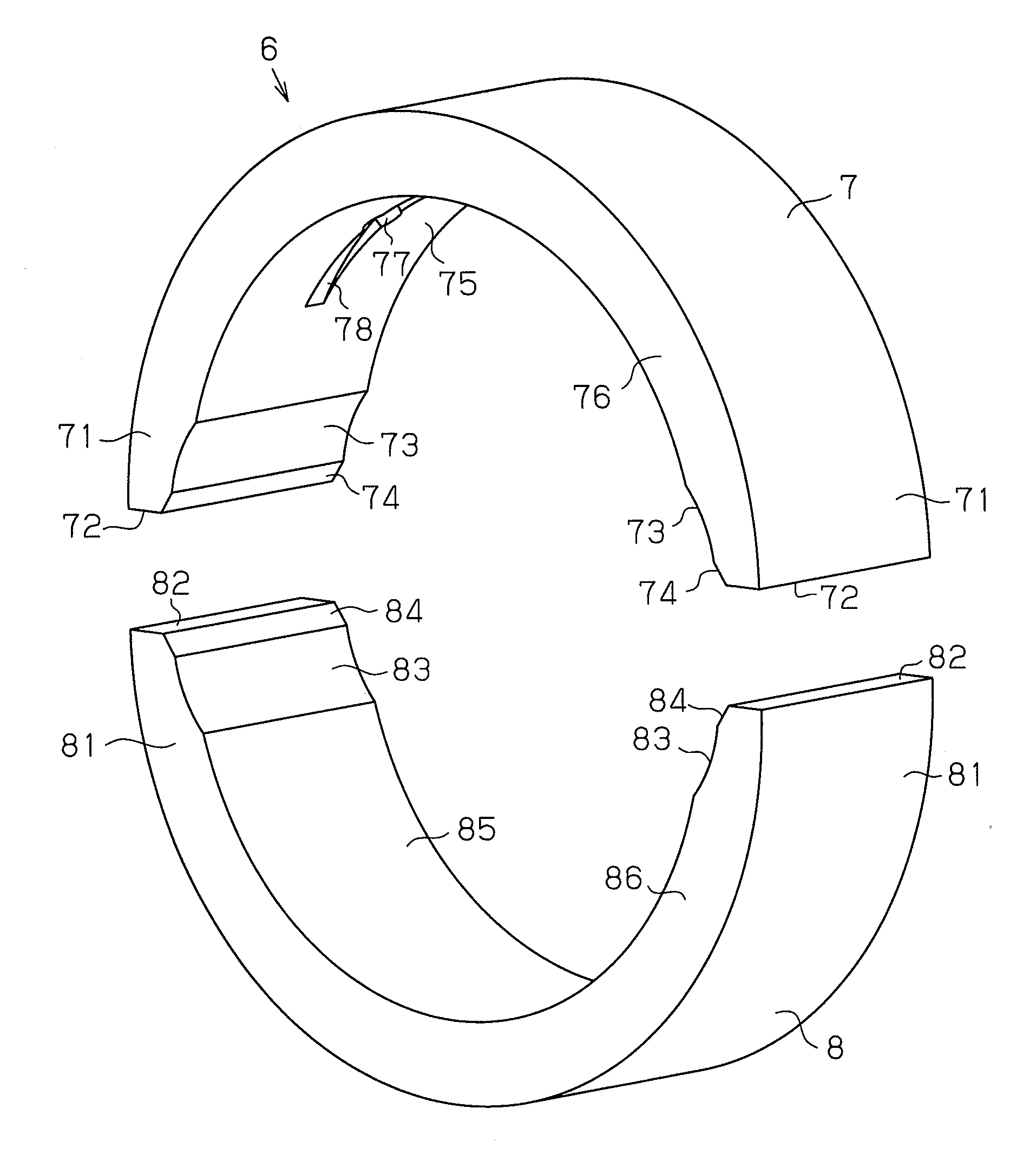

Slide bearing

ActiveUS20100046869A1Reduces amount of lubricantAvoid damageCrankshaftsConnecting rod bearingsEngineeringMechanical engineering

A crank bearing is disclosed that includes a semicircular upper bearing and a semicircular lower bearing, which can be split from each other. The upper bearing includes a first oil passage for introducing engine oil from the outside to a gap between the crank bearing and a crank journal, and a second oil passage for permitting the engine oil to flow in the circumferential direction of the crank bearing. The first oil passage includes an inner circumference opening, which is open to the inner circumference of the main bearing. The upper bearing includes a non-undercut portion in which no oil passage is formed on the trailing side of the inner circumference opening in the rotational direction of the crank journal. A chamfer oil passage for discharging the engine oil in the second oil passage to the outside from the axial direction of the crank bearing is provided in at least one of the lower bearing and a region on the proceeding side of the circumference opening in the rotational direction of the crank journal.

Owner:TOYOTA JIDOSHA KK

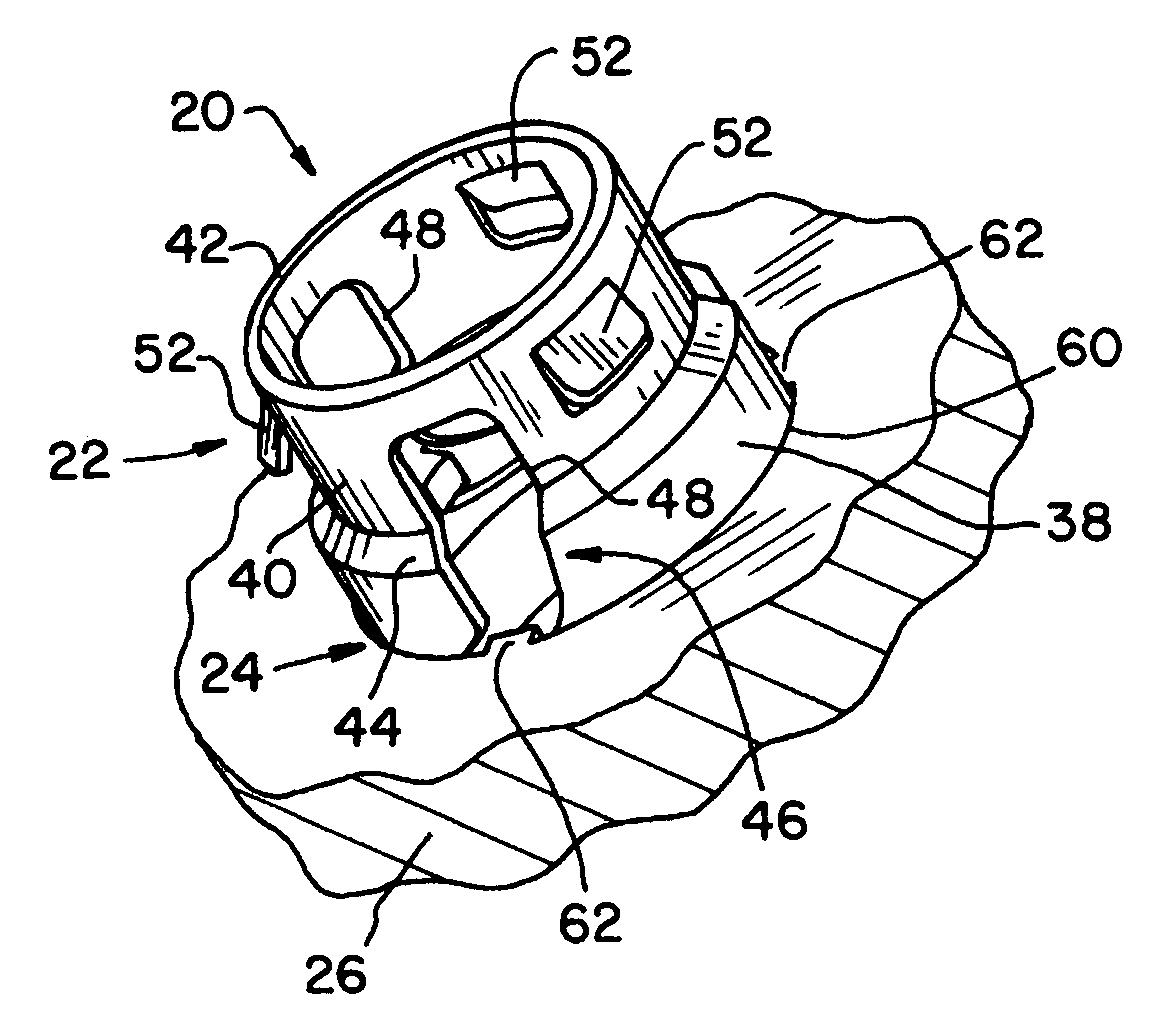

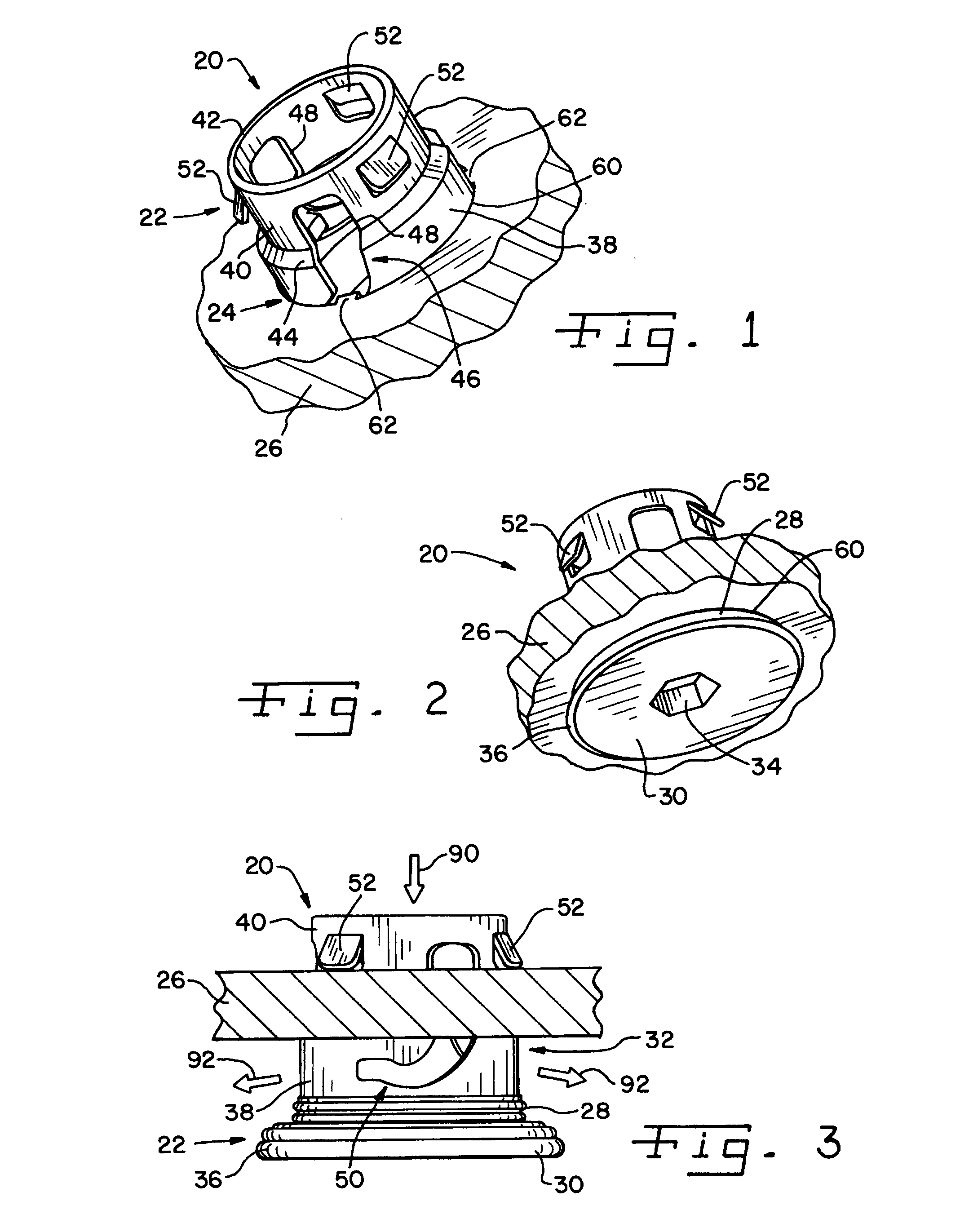

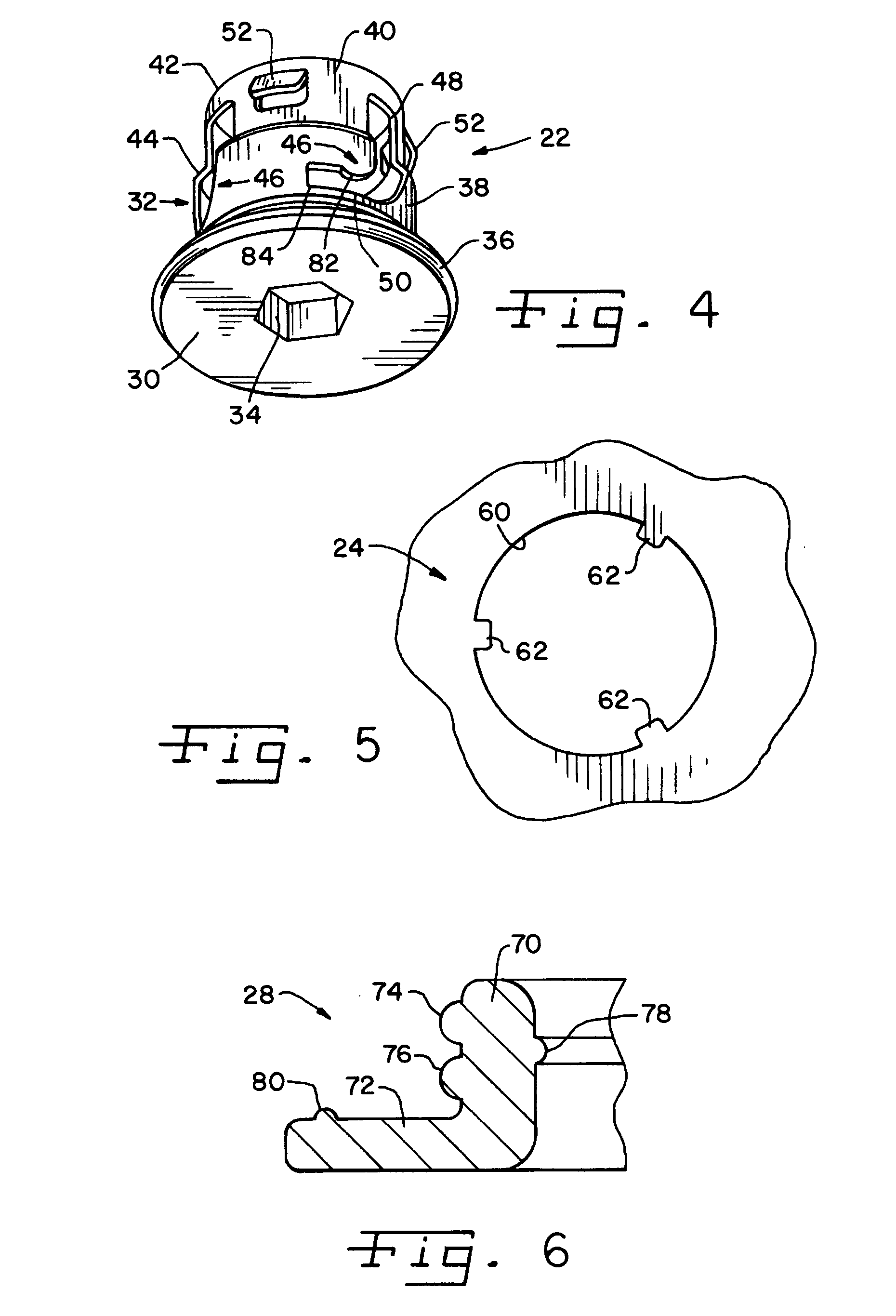

Drain Valve

A drain valve for an oil pan of a vehicle lubrication system includes an aperture and a drain plug. The drain plug is rotatable relative to the aperture between closed and opened positions with less than a full rotation of the plug. The plug remains secured to the aperture even when the valve is opened.

Owner:ILLINOIS TOOL WORKS INC

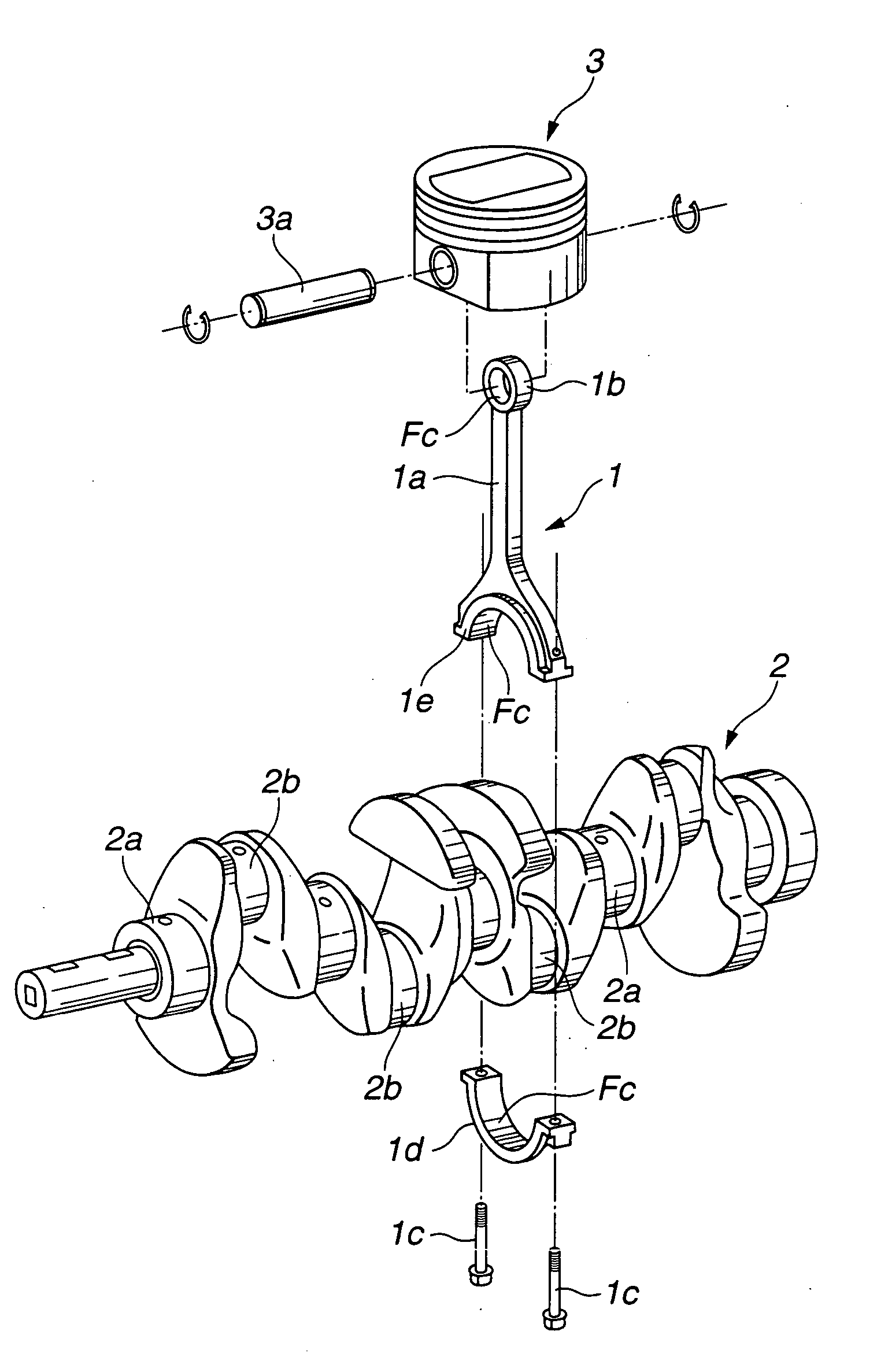

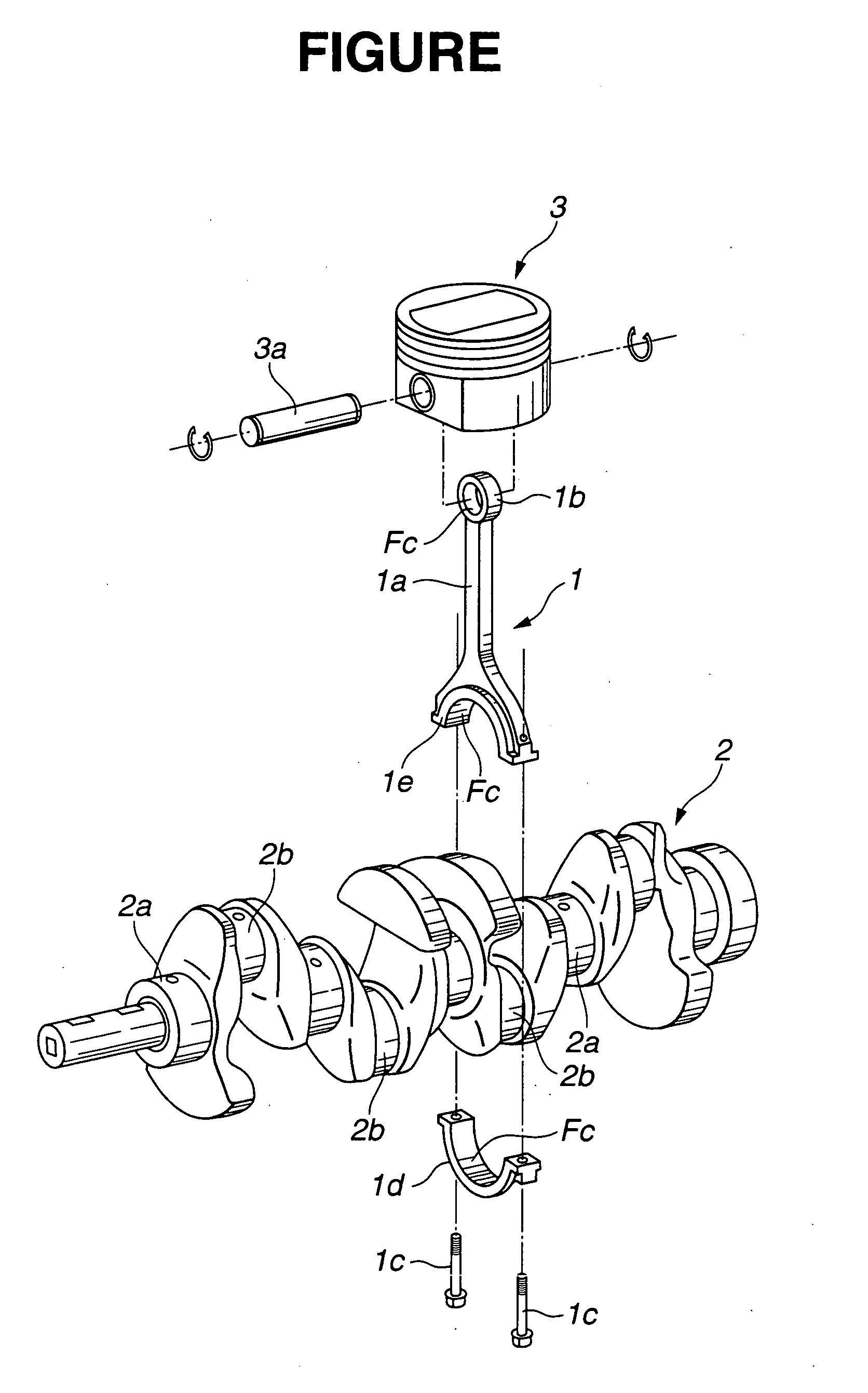

Structure for connecting piston to crankshaft

InactiveUS20050061291A1Reduce sliding frictionImprove engine performanceCrankshaftsConnecting rodsCarbon coatingHydrogen content

There is provided a structure for connecting a piston to a crankshaft in an internal combustion engine, including a piston pin fitted into the piston, a crankpin integral with the crankshaft and a connecting rod having a piston pin bearing portion slidably engaged with an outer cylindrical portion of the piston pin and a crankpin bearing portion slidably engaged with an outer cylindrical portion of the crankpin. At least one of the piston pin bearing portion of the connecting rod and the outer cylindrical portion of the piston pin and at least one of the crankpin bearing portion of the connecting rod and the outer cylindrical portion of the crankpin have hard carbon coatings formed thereon with a hydrogen content of 20 atomic % or less.

Owner:NISSAN MOTOR CO LTD

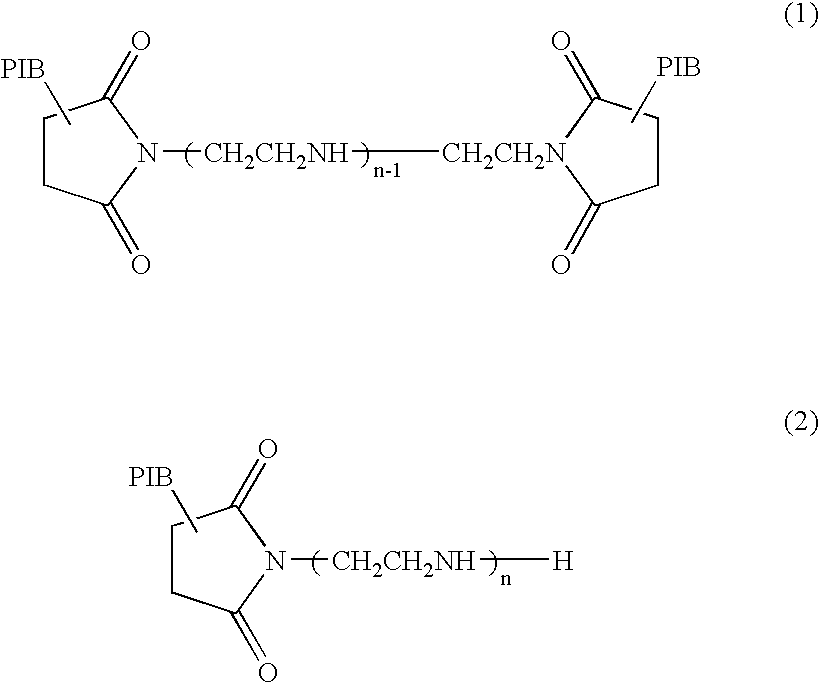

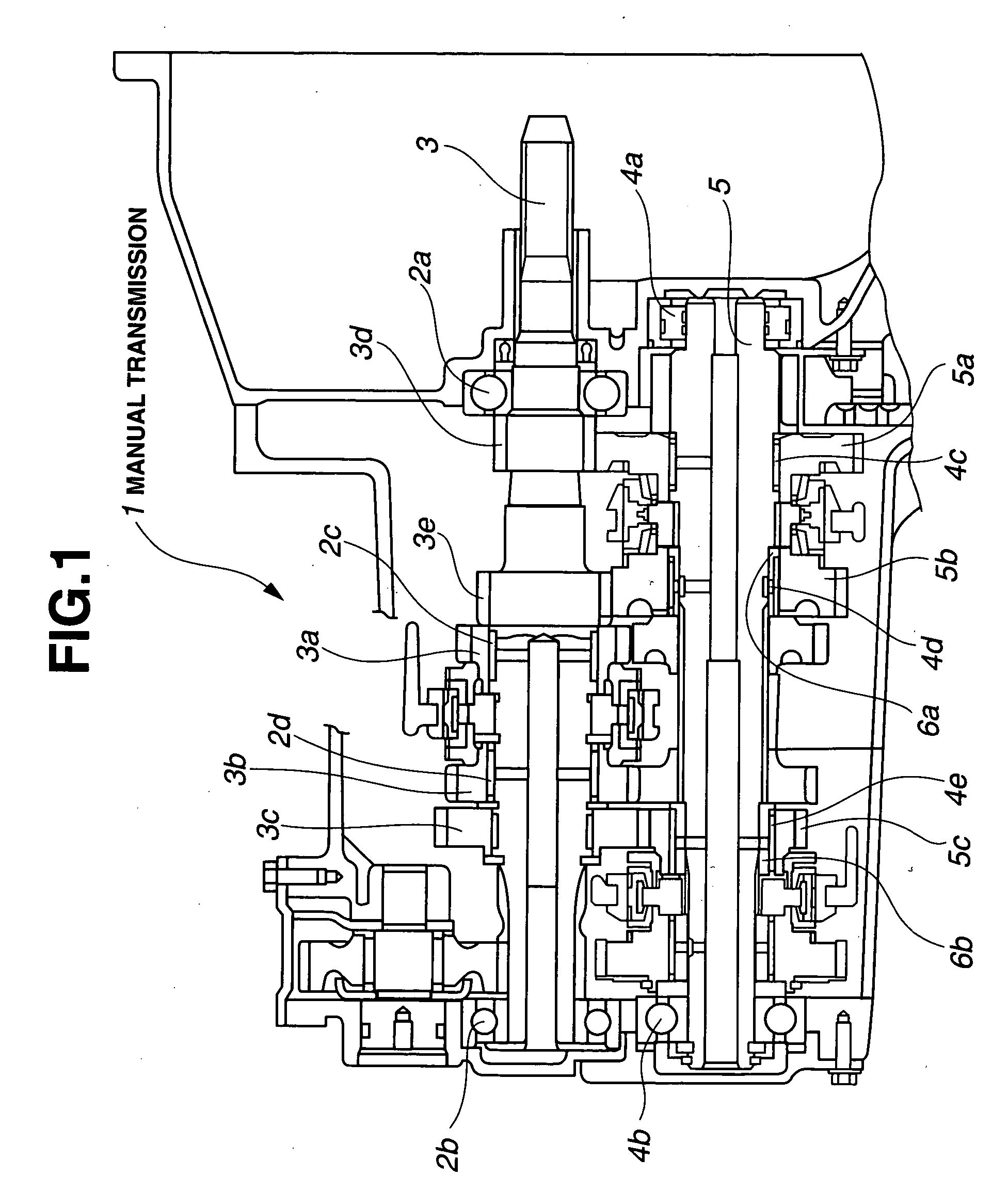

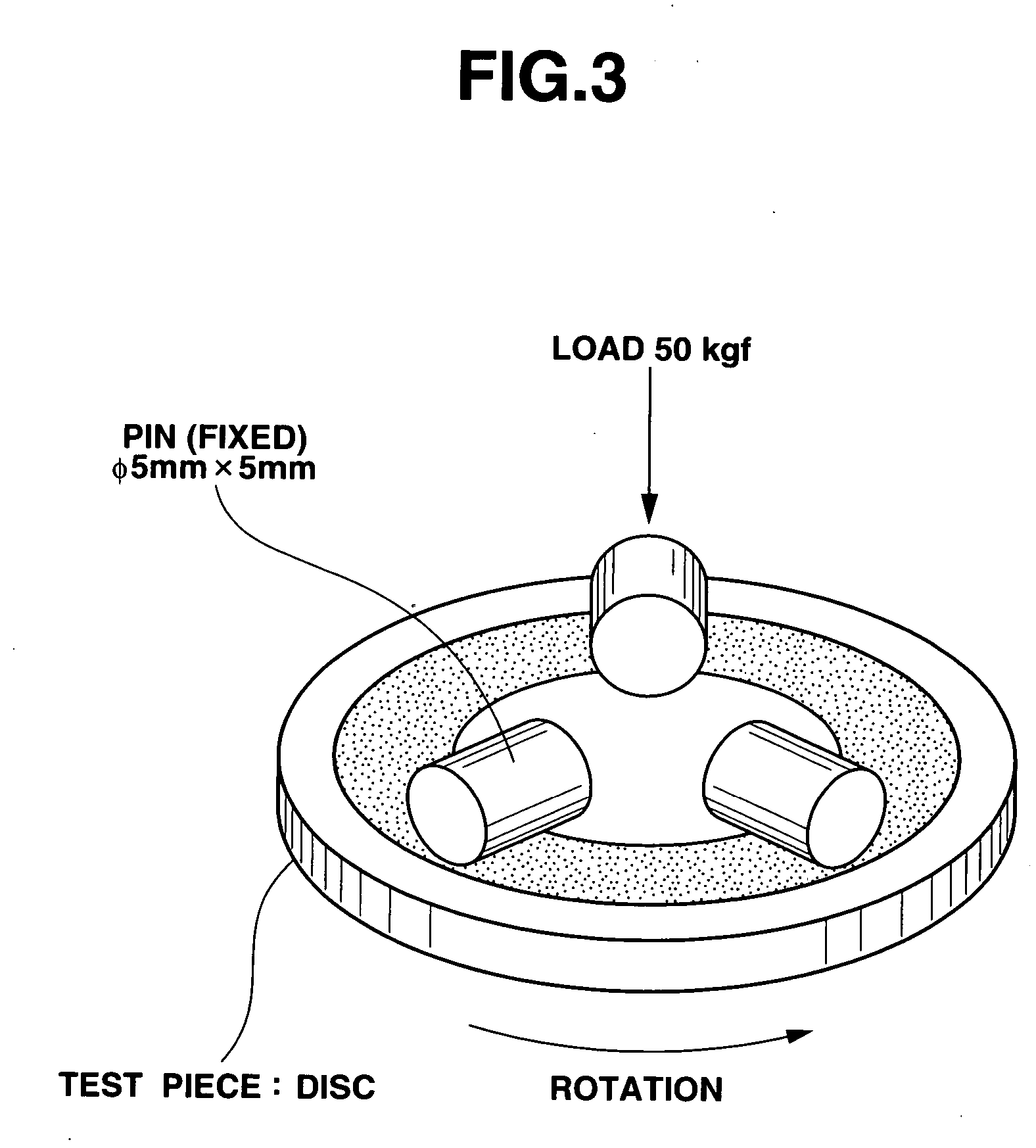

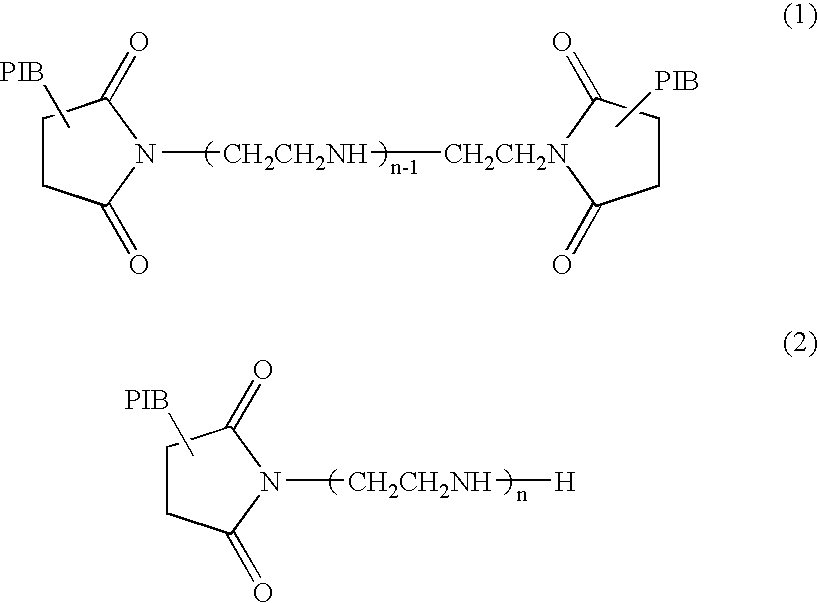

Low-friction sliding mechanism, low-friction agent composition and method of friction reduction

ActiveUS20060263604A1Reduce coefficient of frictionImprove fuel efficiencyCrankshaftsGear lubrication/coolingSimple Organic CompoundsFriction reduction

The invention provides a low-friction sliding mechanism, a low-friction agent composition, a friction reduction method, a manual transmission and a final reduction gear unit that can exert very excellent low friction characteristics to sliding surfaces present under various applications, and, in particular, that have more excellent low friction characteristics than that of a combination of an existing steel material and an organic Mo compound. The low-friction sliding mechanism has an oxygen-containing organic compound or an aliphatic amine compound interposed between sliding surfaces that a DLC coated sliding member and a sliding member form. The low-friction agent composition contains an oxygen-containing organic compound or an aliphatic amine compound. The friction reduction method includes supplying the low-friction agent composition between sliding surfaces that a DLC coated sliding member and a sliding member form. The manual transmission includes, as at least one of sliding members, a DLC coated sliding section. The final reduction gear unit includes, as at least one of sliding members, a DLC coated sliding section.

Owner:NISSAN MOTOR CO LTD +2

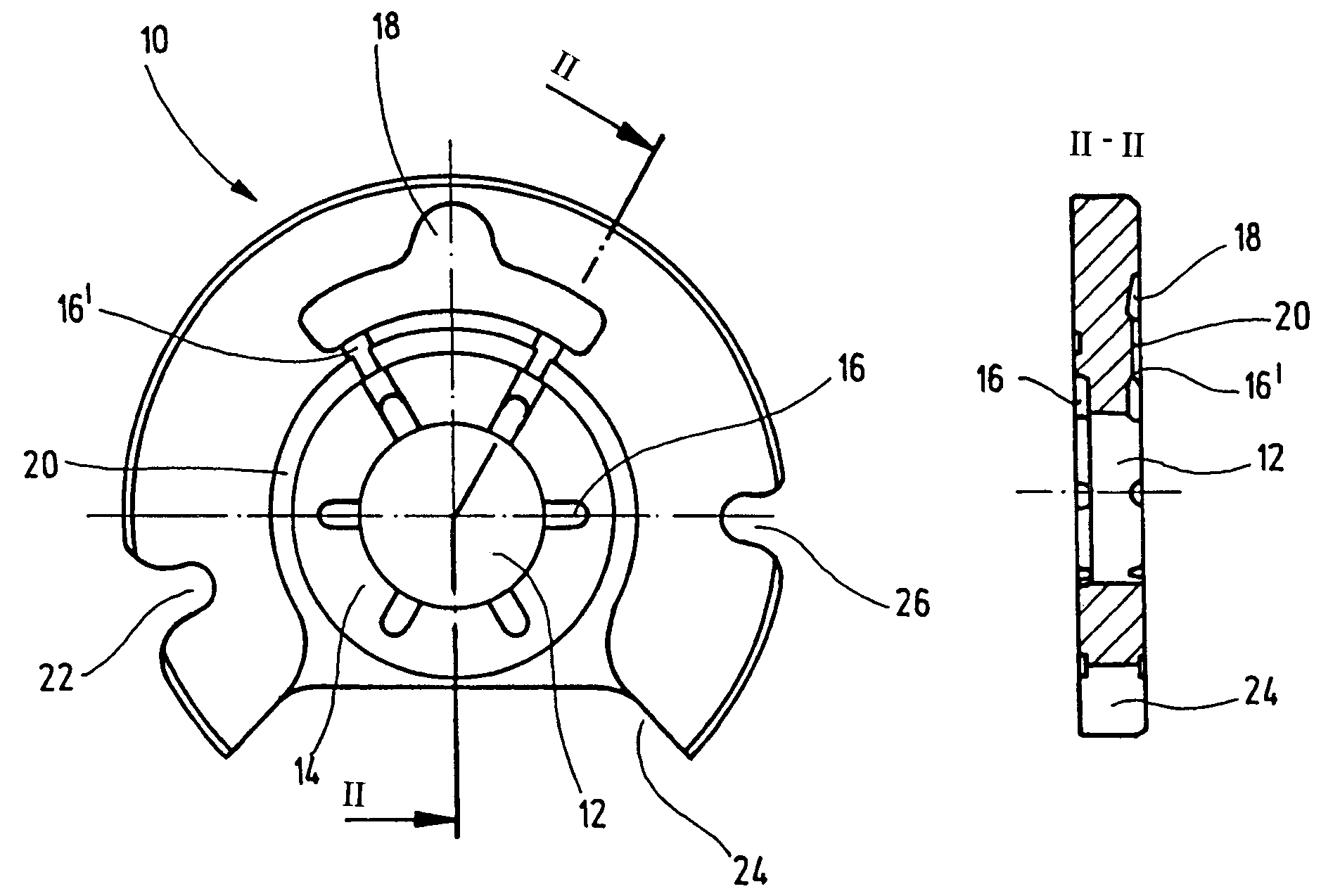

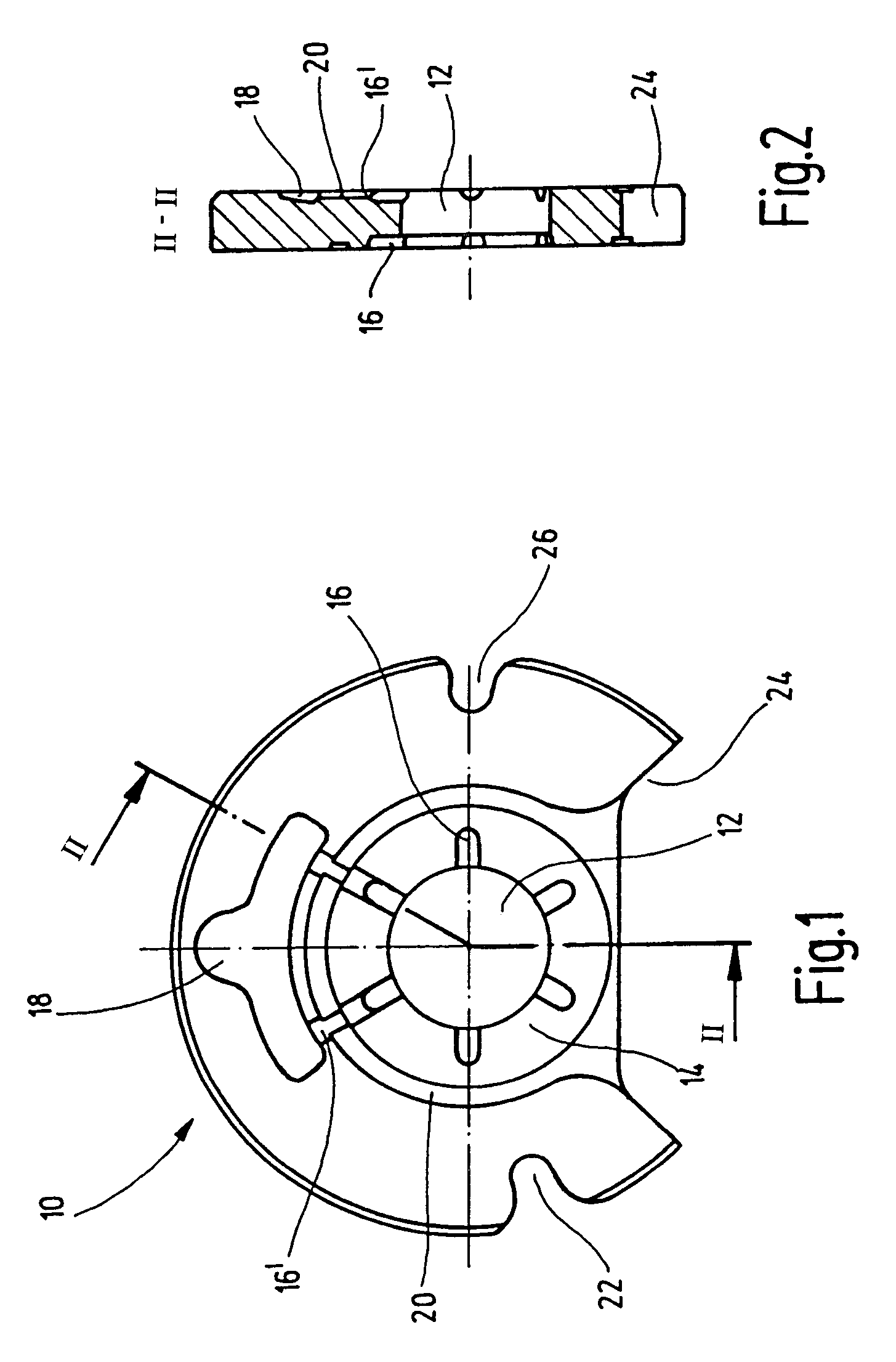

Axial bearing

ActiveUS7401980B2Safe and cost-effectiveReduce manufacturing costCrankshaftsCrossheadsTurbochargerThrust bearing

A thrust bearing, in particular for a turbo charger, has an essentially disc shaped bearing body (10) with a central through opening (12) for a shaft, at least one bearing surface (14) surrounding the through opening (12) for a collar which is placed on the shaft, and at least one oil supply channel which leads from a radially outer region of the bearing body to the through opening (12). In order to realize a cost effective manufacture of the thrust bearing it is proposed according to the invention that the at least one oil supply channel is designed to be a groove (16′).

Owner:BORGWARNER INC

Low-friction sliding mechanism

ActiveUS6969198B2Increase resistanceReduce coefficient of frictionCrankshaftsCrossheadsDiamond-like carbonAliphatic amine

A low-friction sliding mechanism includes first and second sliding members having respective sliding surfaces slidable relative to each other and a lubricant applied to the sliding surfaces of the first and second sliding members. At least the sliding surface of the first sliding member is made of a diamond-like carbon material, and at least the sliding surface of the second sliding member is made of either an aluminum-based alloy material, a magnesium-based alloy material or a diamond-like carbon material. The lubricant contains a base oil and at least one of an ashless fatty-ester friction modifier and an ashless aliphatic-amine friction modifier.

Owner:NISSAN MOTOR CO LTD +1

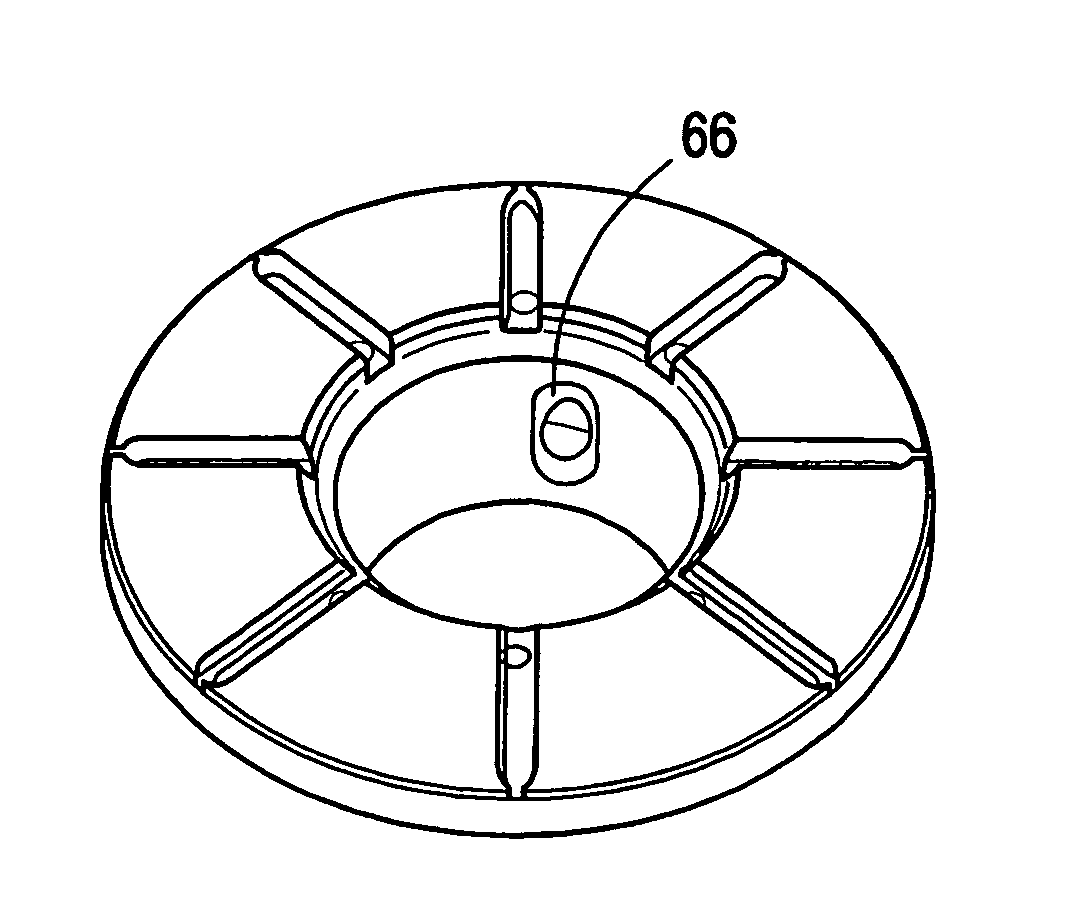

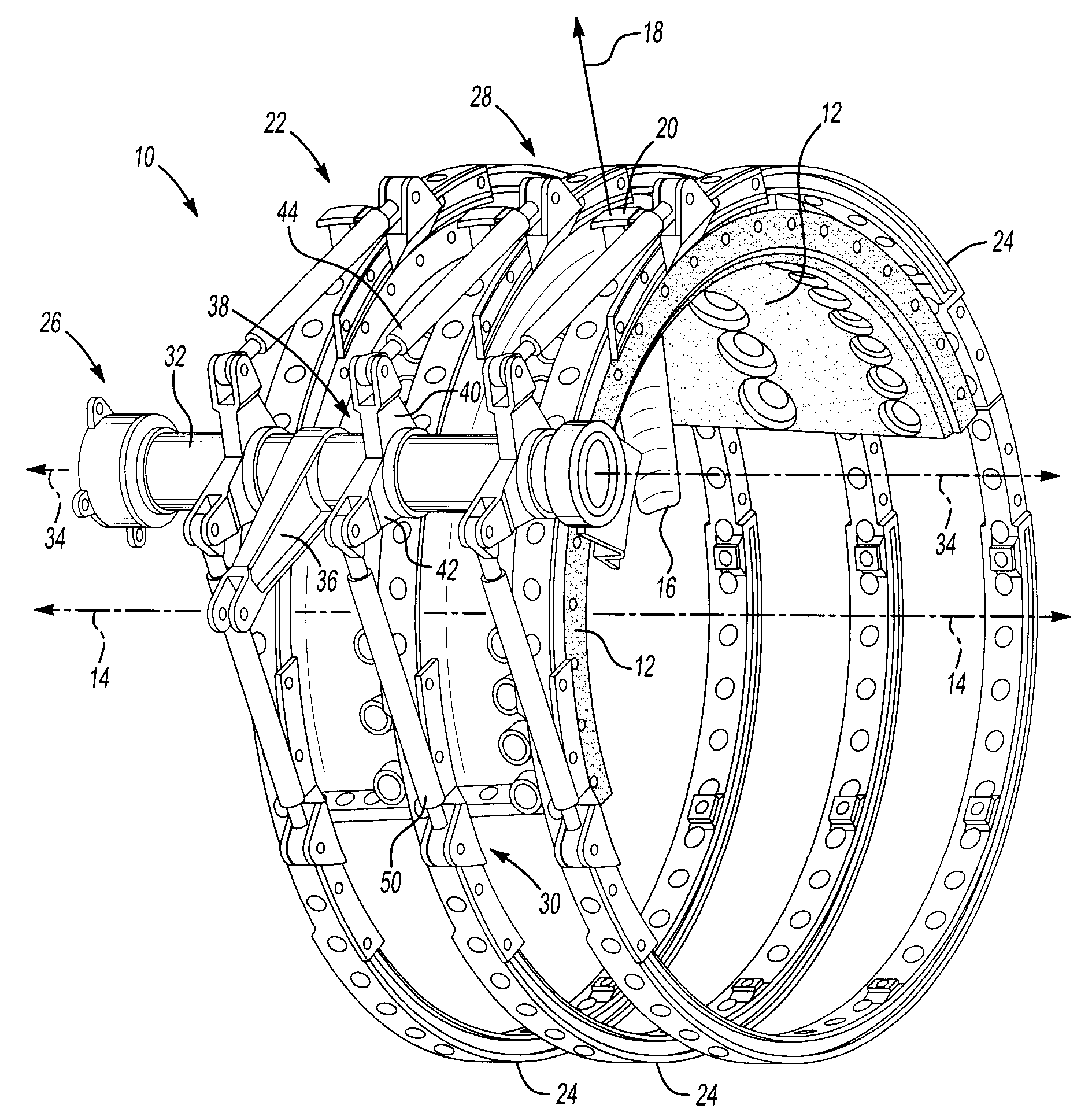

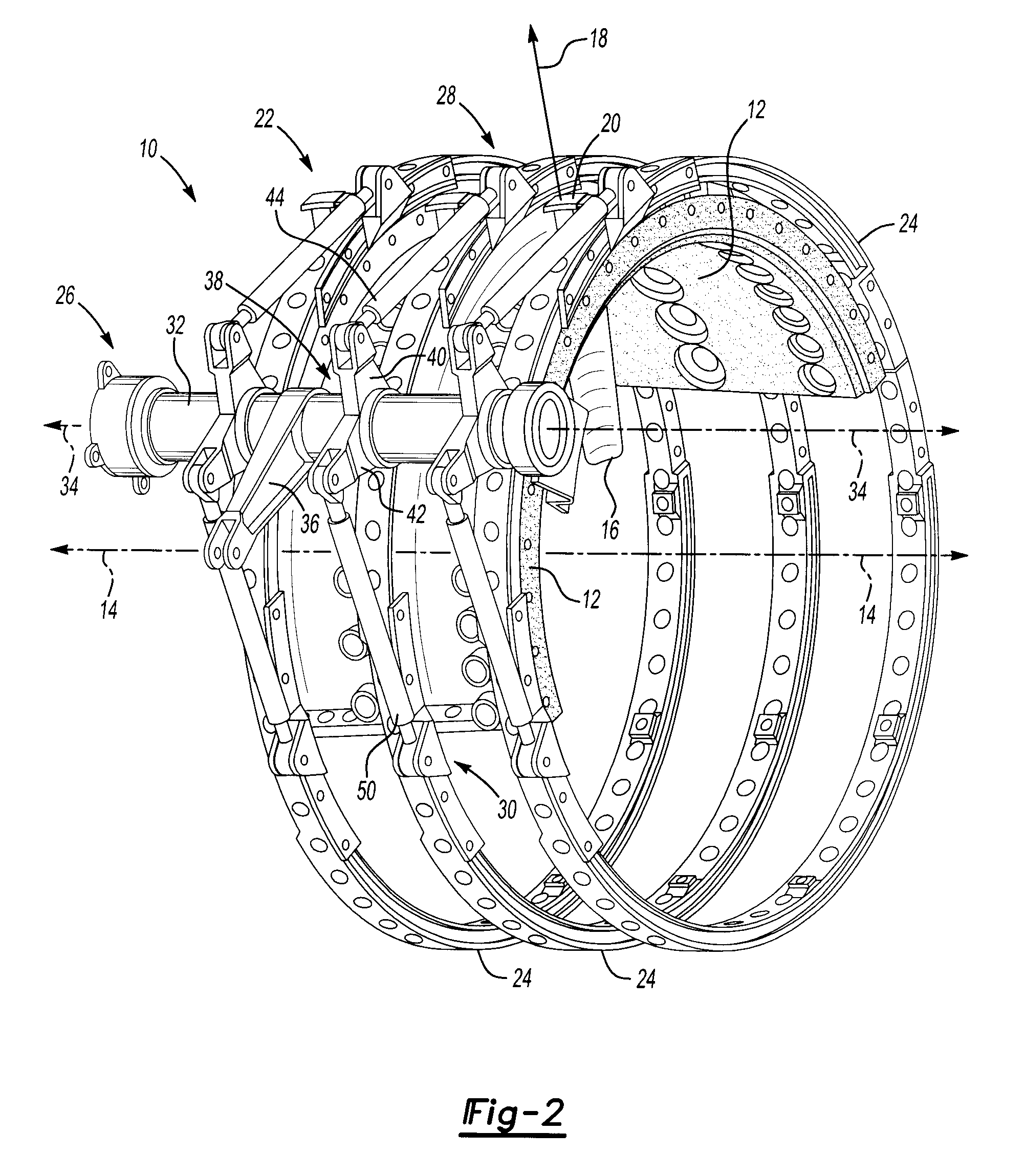

Variable vane actuation system

A variable vane actuation system is disclosed herein. The variable vane actuation system includes a ring member disposed for pivoting movement about a centerline axis. The ring member is engaged with a plurality of vanes in a turbine engine such that the plurality of vanes pivot in response to the pivoting movement of the ring member. The variable vane actuation system also includes a ring moving device engaged with the ring member at first and second positions spaced from one another about the centerline axis. The ring moving device is operable to apply first and second forces, respectively, at the first and second positions to pivot the ring member.

Owner:ROLLS ROYCE CORP

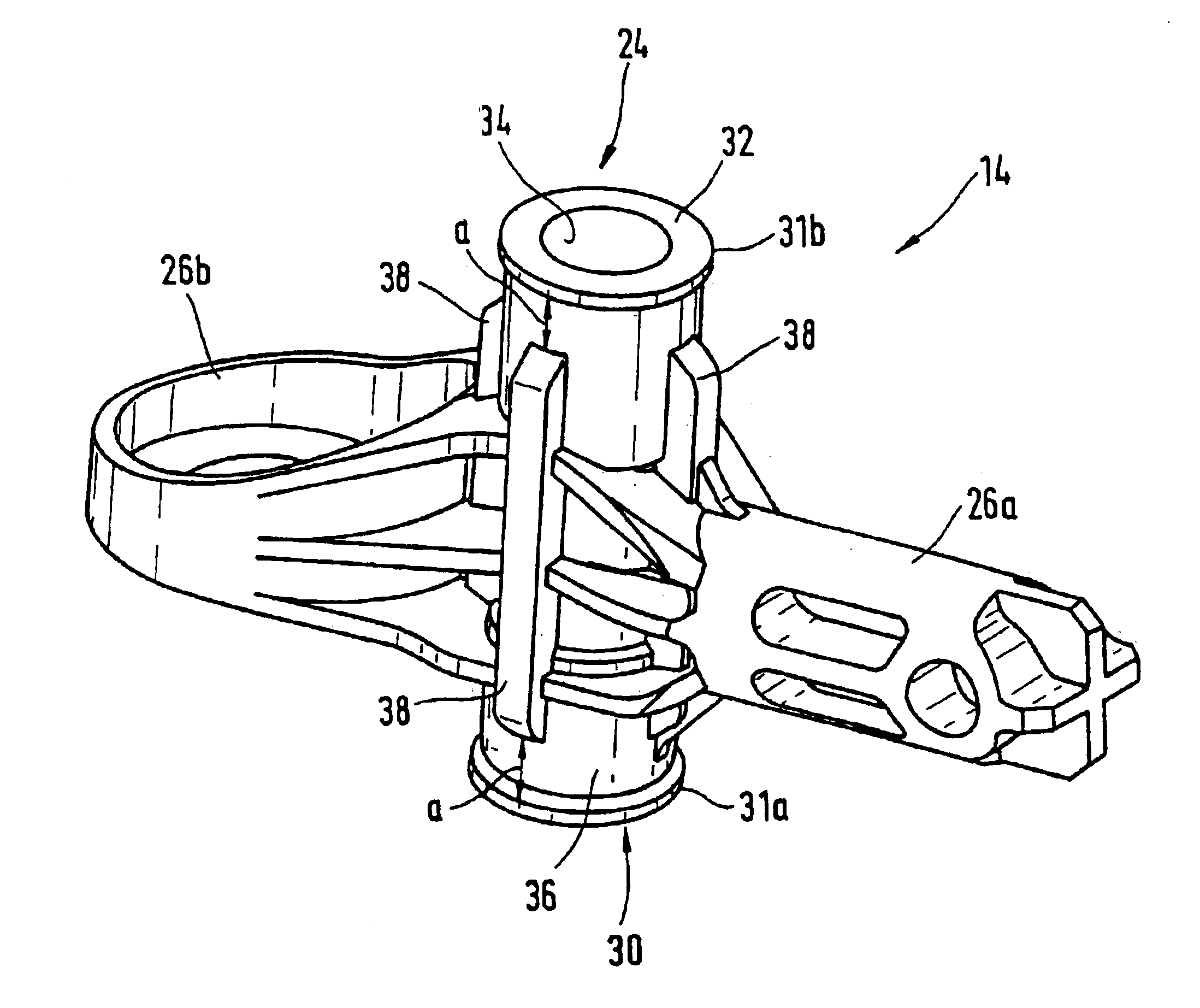

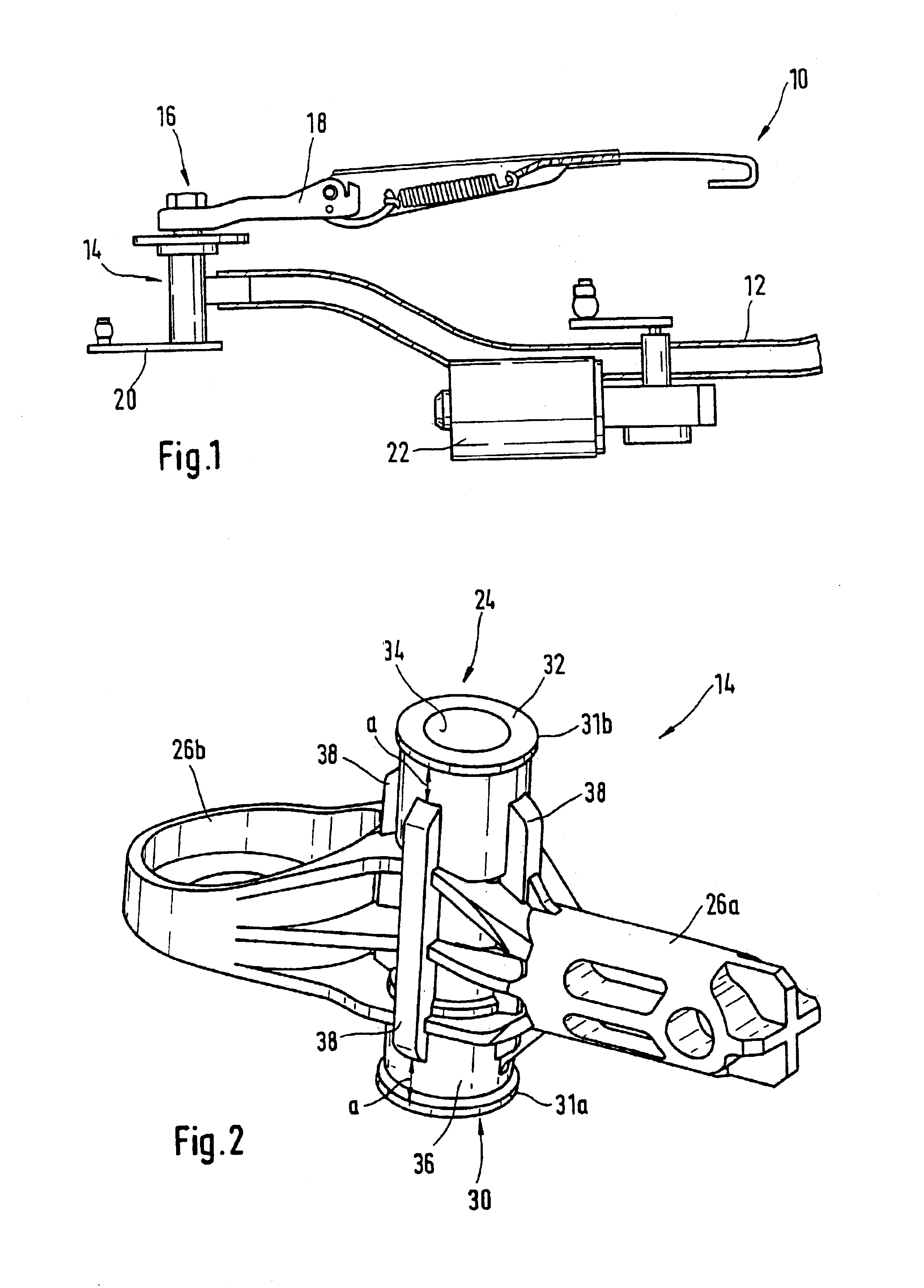

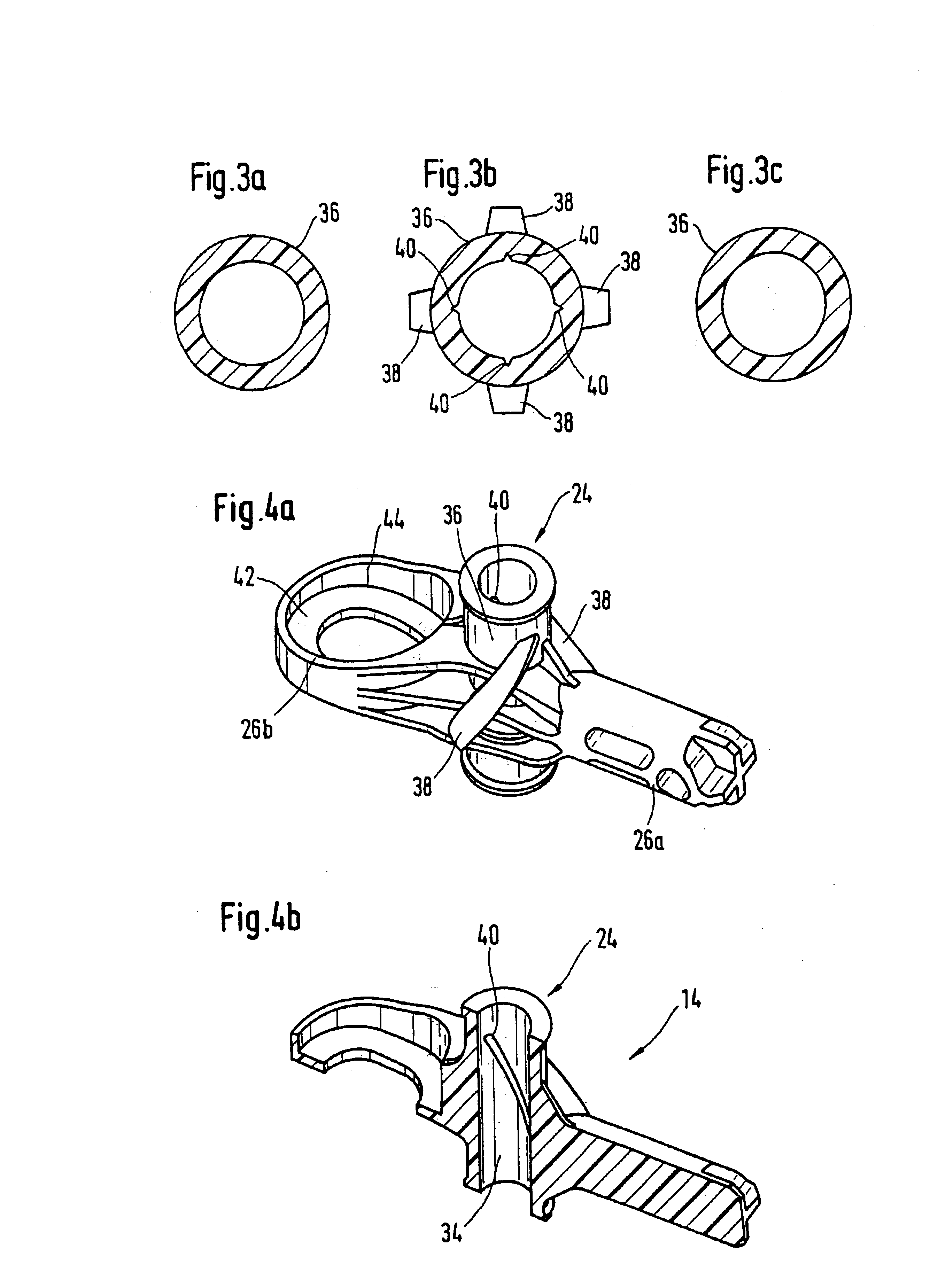

Windshield wiper, especially for motor vehicles and method for production of said windshield wiper

InactiveUS6883966B2Reduce tooling costsSmall diameterCrankshaftsCrossheadsMobile vehicleMotor vehicle part

A windshield wiper system, and a method for producing such a system, in particular for a motor vehicle, having at least one wiper bearing (14) substantially comprising an injection-moldable material, in particular plastic, in which a wiper shaft (16) is supported at least in such a way that it can swing back and forth, and in the region of the wiper shaft (16), the wiper bearing (14) has a substantially hollow-cylindrical segment (24) on whose inner surface (34) at least one groove (40) is provided; at least one, in particular riblike, accumulation of material (38) is provided on the outer surfaces of the hollow-cylindrical segment (24), which accumulation is disposed in the radially outward direction of the groove (40) relative to the axis of rotation of the wiper shaft (16).

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com