Five-cylinder plunger pump with integral power end structure

A power end, integrated technology, applied in the field of plunger pumps, can solve the problems of increased maintenance and overhaul costs, increased frequency of problems, low displacement of a single pump, etc., to facilitate well site layout, reduce vibration, The effect of reducing the vibration of the whole pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

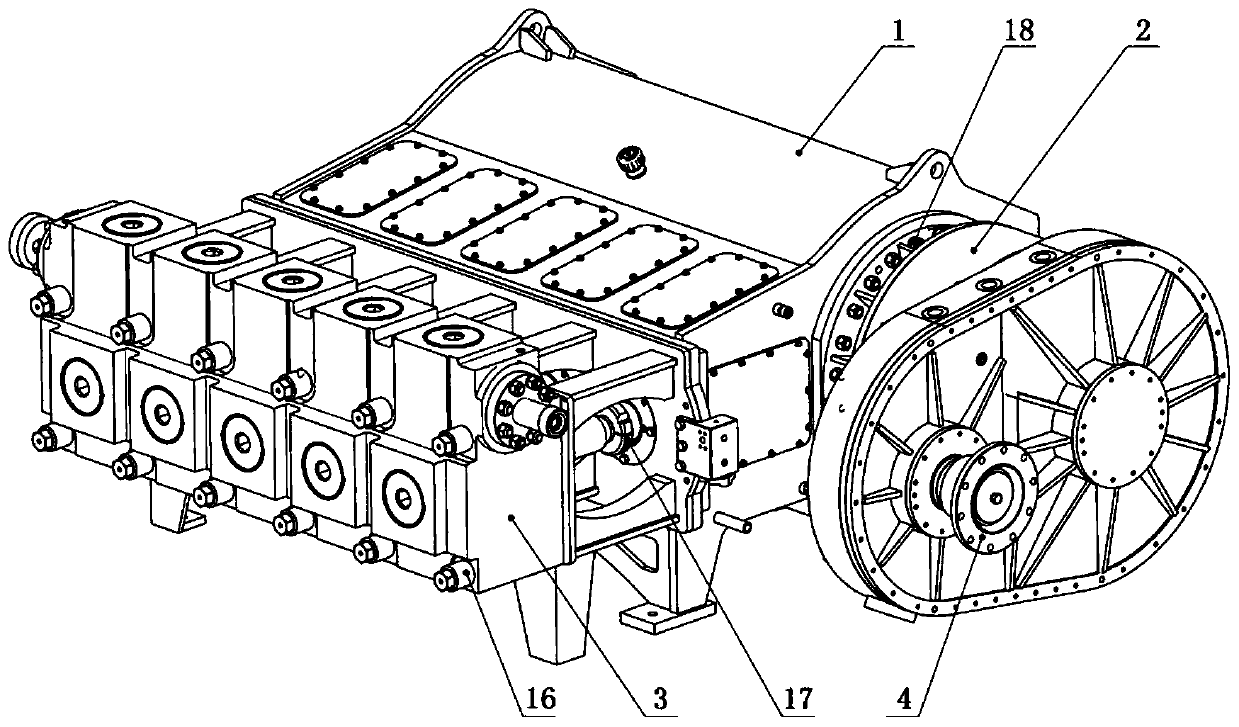

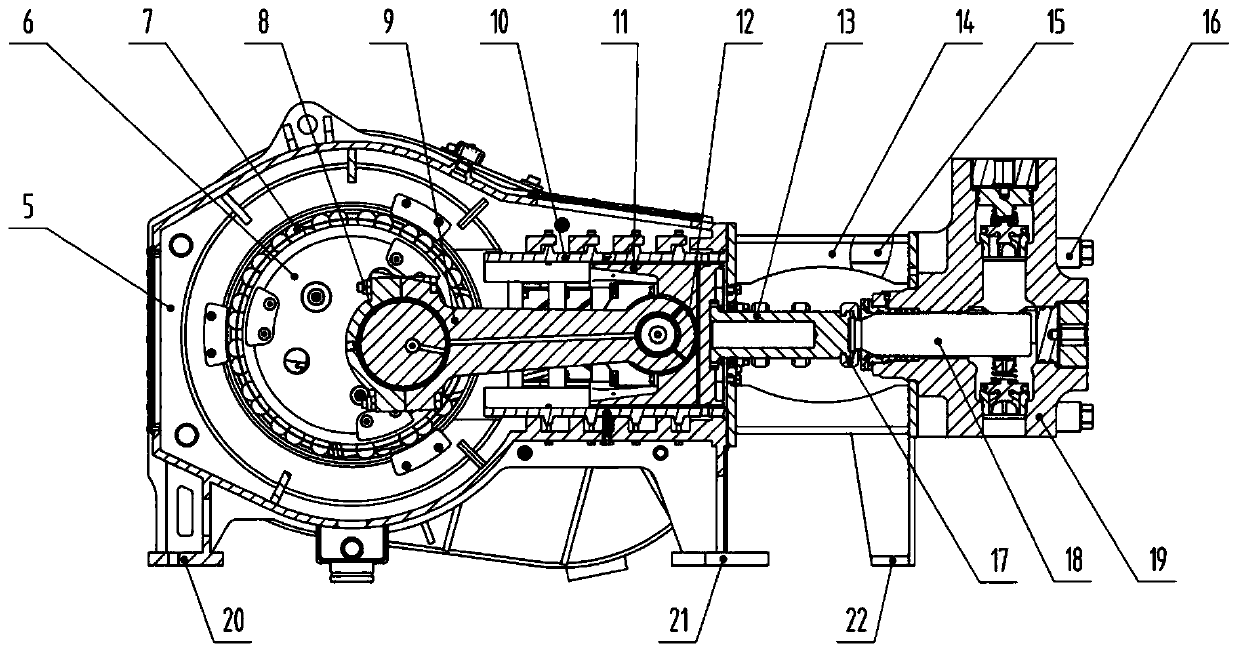

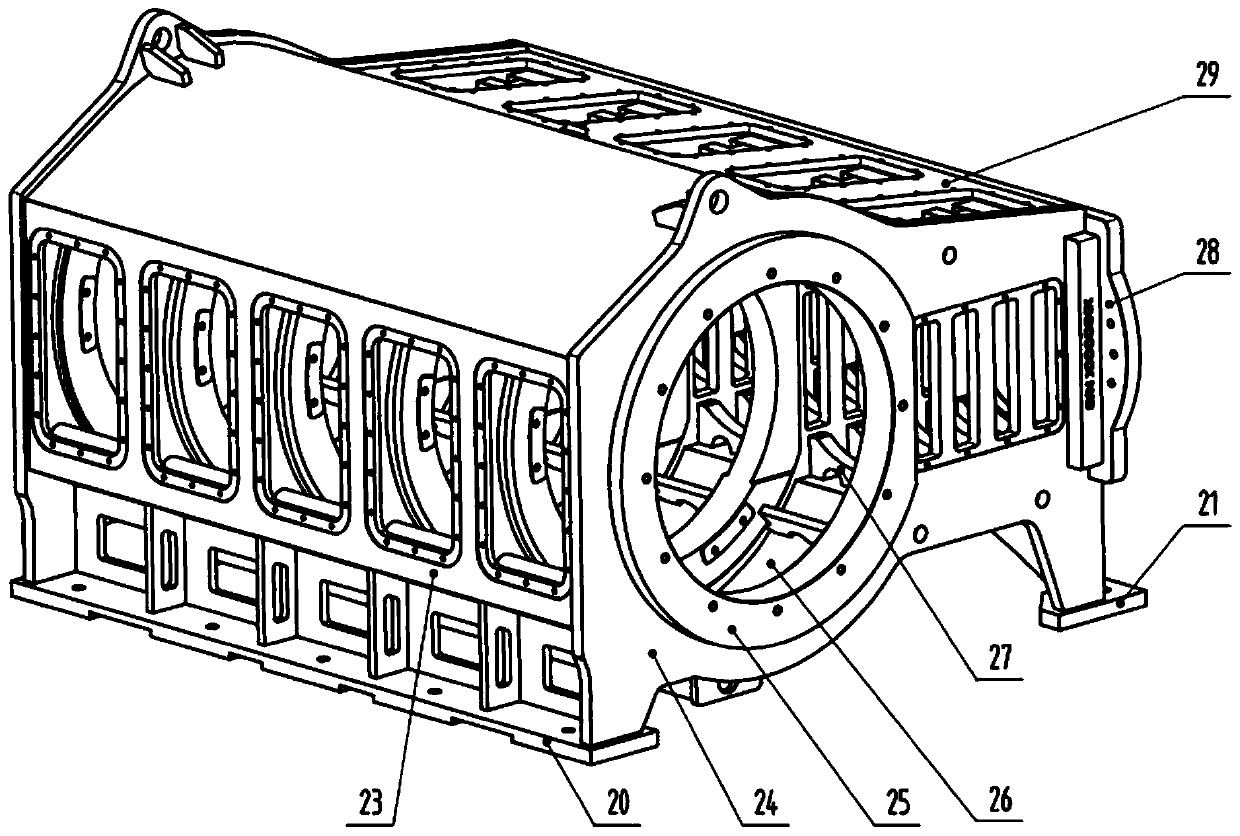

[0025] example, as Figures 1 to 8 As shown, a five-cylinder plunger pump with an integral power end structure includes a power end assembly 1, a hydraulic end assembly 3 and a reduction box assembly 2. One end of the power end assembly 1 is connected to the hydraulic end assembly. The assembly 3 is connected, and the other end of the power end assembly 1 is connected with the reduction box assembly 2. The power end assembly 1 includes a crankcase, a crosshead case and a spacer 14. The crankcase and the cross The head box is integrally welded to form the power end housing 5, which is connected to the spacer 14. The power end housing 5 includes a vertical plate 24, a bearing seat 25, a front end plate 28, a rear cover plate 23, and a bottom plate. 26, the support plate 27 and the upper cover plate 29, the number of the vertical plates 24 is 6, the number of bearing seats 25 is 6, one vertical plate 24 is connected to one bearing seat 25 correspondingly, and the 6 vertical plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com