Patents

Literature

4973 results about "Crankcase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

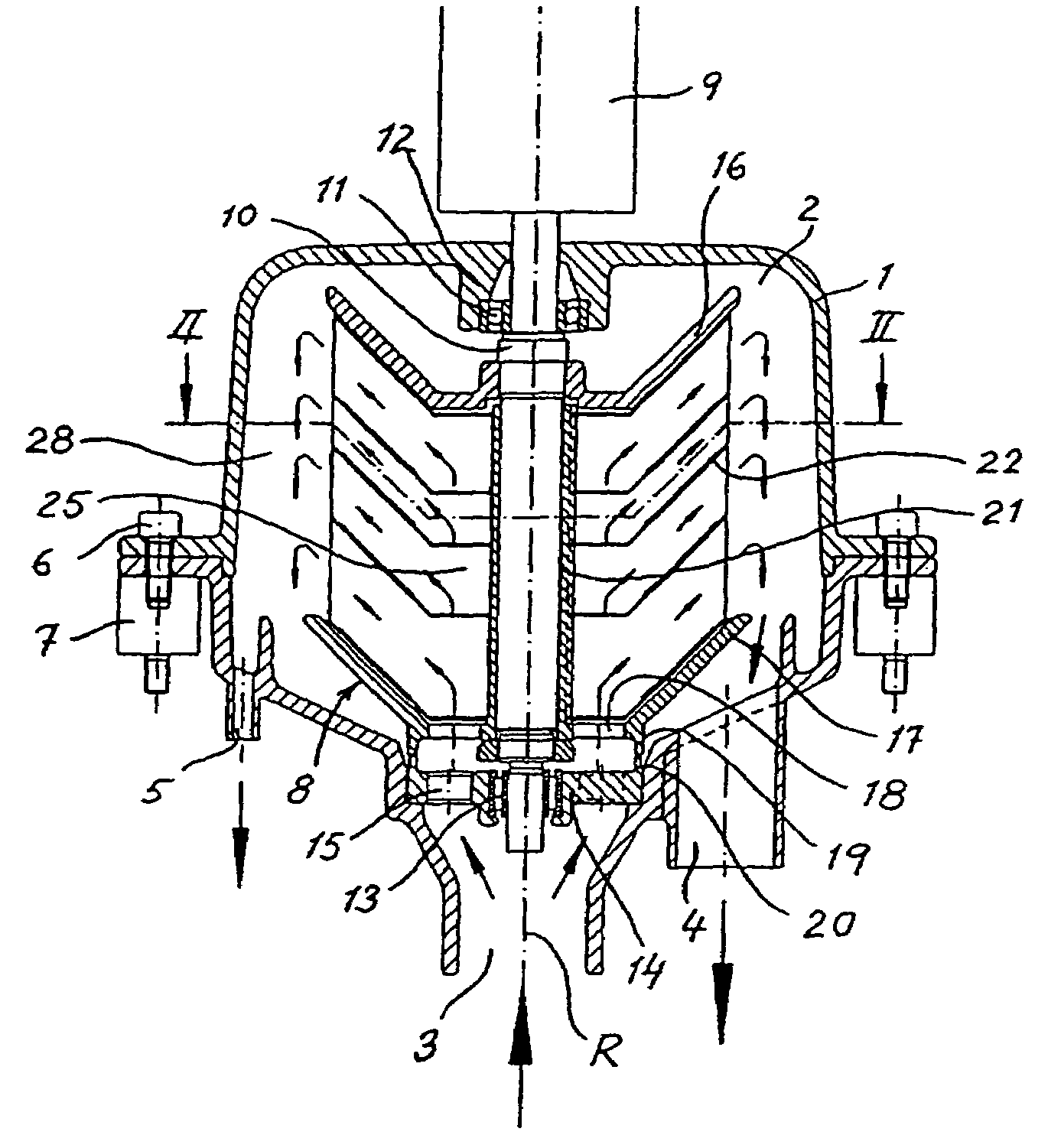

A crankcase is the housing for the crankshaft in a reciprocating internal combustion engine. In most modern engines, the crankcase is integrated into the engine block. Two-stroke engines typically use a crankcase-compression design, resulting in the fuel/air mixture passing through the crankcase before entering the cylinder(s). This design of engine does not include an oil sump in the crankcase.

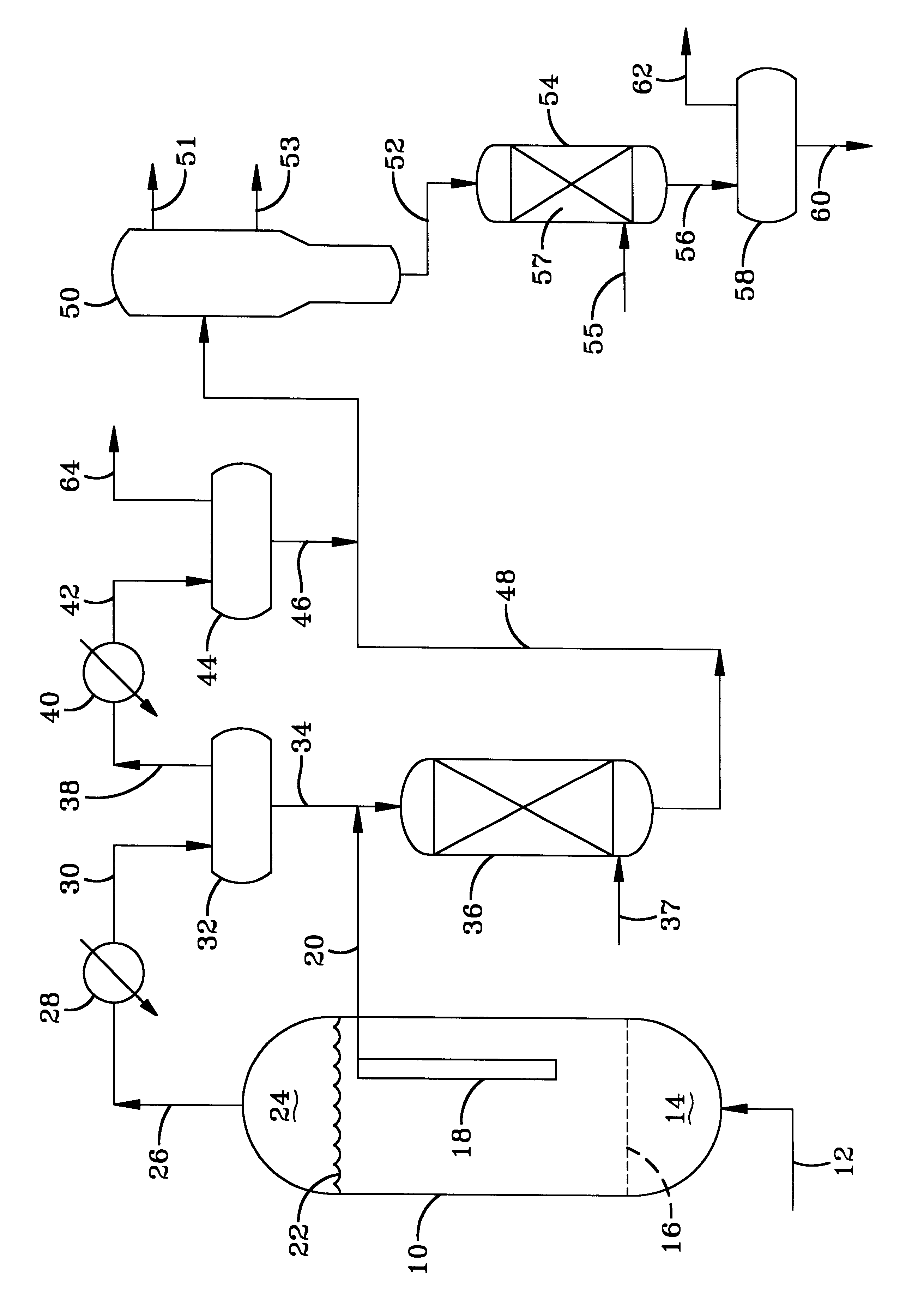

Production of synthetic lubricant and lubricant base stock without dewaxing

InactiveUS6103099AThermal non-catalytic crackingRefining to change hydrocarbon structural skeletonAutomatic transmissionBoiling point

A lubricating base stock useful for forming lubricants such as a multigrade automotive oils, automatic transmission oils, greases and the like is prepared by hydroisomerizing a waxy hydrocarbon feed fraction having an initial boiling point in the 650-750 DEG F. range and an end point of at least 1050 DEG F., synthesized by a slurry Fischer-Tropsch hydrocarbon synthesis process. The hydroisomerization forms a hydroisomerate containing the desired base stock which is recovered, without dewaxing the hydroisomerate. The hydroisomerization is conducted at conditions effective to convert at least 67 wt. % of the 650-750 DEG F.+ waxy feed hydrocarbons to lower boiling hydrocarbons. When combined with a standard lubricant additive package, these base stocks have been formed into multigrade automotive crankcase oils, transmission oils and hydraulic oils meeting the specifications for these oils.

Owner:EXXON RES & ENG CO

Premium synthetic lubricants

InactiveUS6475960B1Refining to change hydrocarbon structural skeletonHydrocarbon purification/separationAntioxidantBoiling point

Premium synthetic lubricants comprise a synthetic isoparaffinic hydrocarbon base stock and an effective amount of at least one, and typically a plurality of lubricant additives such as a detergent, dispersant, antioxidant, antiwear additive, pout point depresant, VI improver and the like. The base stock is derived from a waxy, paraffinic, Fischer-Tropsch synthesized hydrocarbon feed fraction having an initial boiling point in the range of about 650-750° F. and continuously boiling up to at least 1050° F., by a process which comprises hydroisomerizing the feed and dewaxing the isomerate. The waxy feed has a T90-T10 temperature difference of at least 350° F. and is preferably hydroisomerized without any pretreatment, other than optional fractionation. The lubricant may also contain hydrocarbonaceous and synthetic base stock material. Lubricants, such as fully formulated multigrade automotive crankcase and transmission oils formed by adding a suitable additive package to the isoparaffinic base stock have exhibited performance superior to similar fully formulated oils based on both PAO and conventional, petroleum derived base stocks.

Owner:EXXON RES & ENG CO

Wide-cut synthetic isoparaffinic lubricating oils

A wide-cut lubricant base stock is made by hydroisomerizing and then catalytically dewaxing a waxy Fischer-Tropsch synthesized hydrocarbon fraction feed and comprises the entire dewaxate having an initial boiling point in the 650-75O° F.+ range. Formulated lubricating oils made by admixing the base stock with a commercial automotive additive package meet all specifications, including low temperature properties, for multigrade internal combustion engine crankcase oils. The waxy feed has an initial boiling point in the 650-750° F. range and continuously boils to an end point of at least 1050° F.+. Lower boiling hydrocarbons produced by the process are separated from the base stock by simple flash distillation. The base stock comprises the entire dewaxate having an initial boiling point in the 650-750° F. range.

Owner:EXXON RES & ENG CO

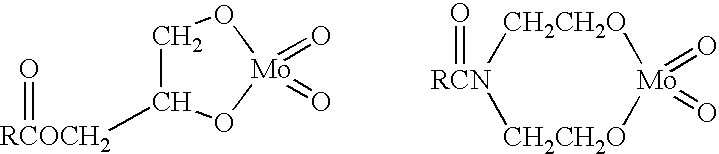

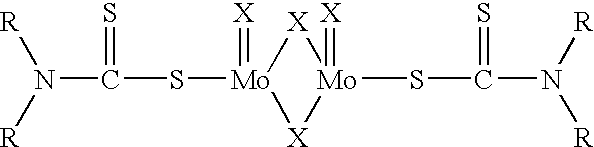

Lubricant containing molybdenum compound and secondary diarylamine

InactiveUSRE38929E1Low treat levelLow costLiquid carbonaceous fuelsAdditivesSulfurMolybdenum compounds

Owner:AFTON CHEM INTANGIBLES

Lubricant containing molybdenum compound and secondary diarylamine

There is disclosed a lubricating oil composition which contains from about 100 to 450 parts per million of molybdenum from a molybdenum compound which is substantially free of active sulfur and about 750 to 5,000 parts per million of a secondary diarylamine. This combination of ingredients provides improved oxidation control and friction modifier performance to the lubricating oil. The composition is particularly suited for use as a crankcase lubricant.

Owner:AFTON CHEM INTANGIBLES

Lubricant containing molybdenum compound and secondary diarylamine

InactiveUSRE40595E1Lower levelSupplemental oxidation protection and frictional propertiesOrganic chemistryLiquid carbonaceous fuelsSulfurMolybdenum compounds

There is disclosed a lubricating oil composition which contains from about 100 to 450 parts per million of molybdenum from a molybdenum compound which is substantially free of active sulfur and about 750 to 5,000 parts per million of a secondary diarylamine. This combination of ingredients provides improved oxidation control and friction modifier performance to the lubricating oil. The composition is particularly suited for use as a crankcase lubricant.

Owner:AFTON CHEM INTANGIBLES

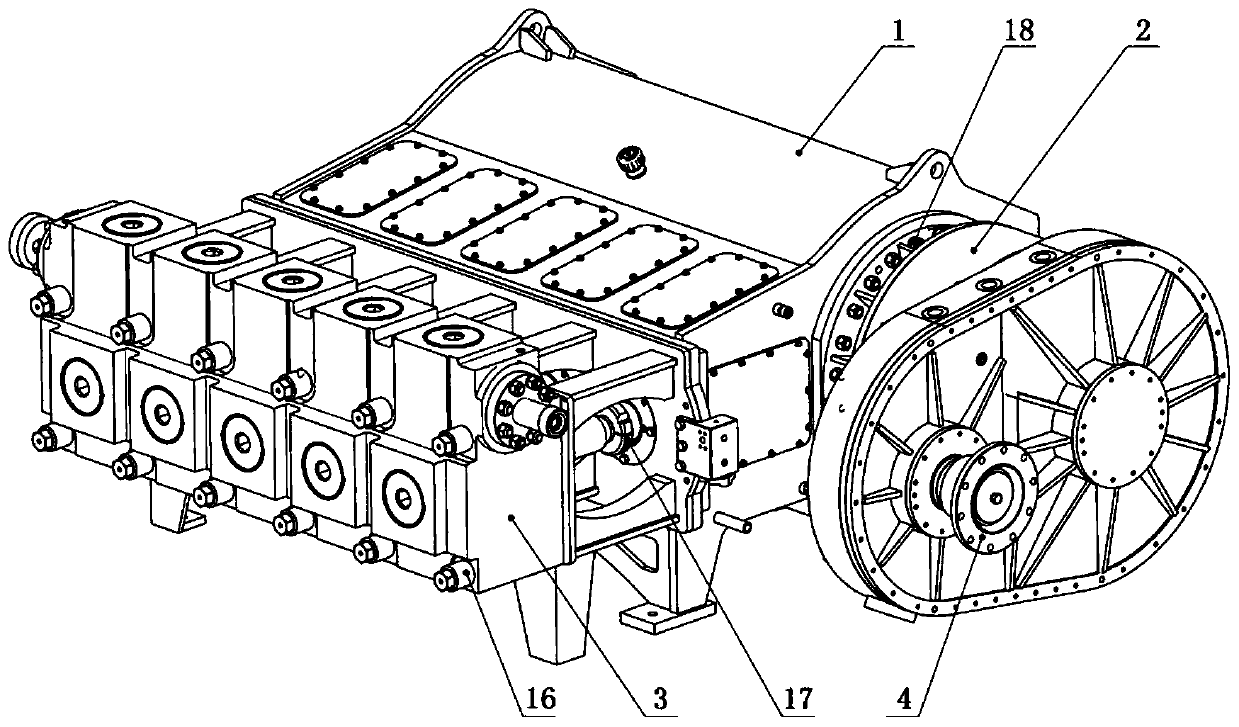

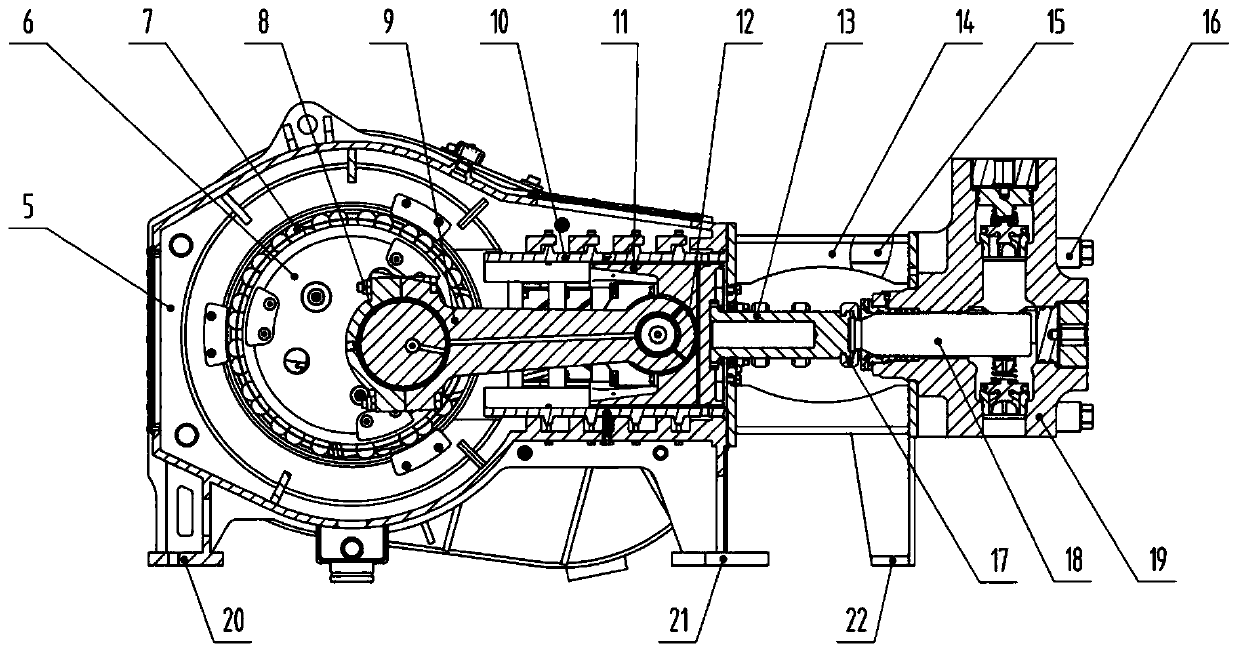

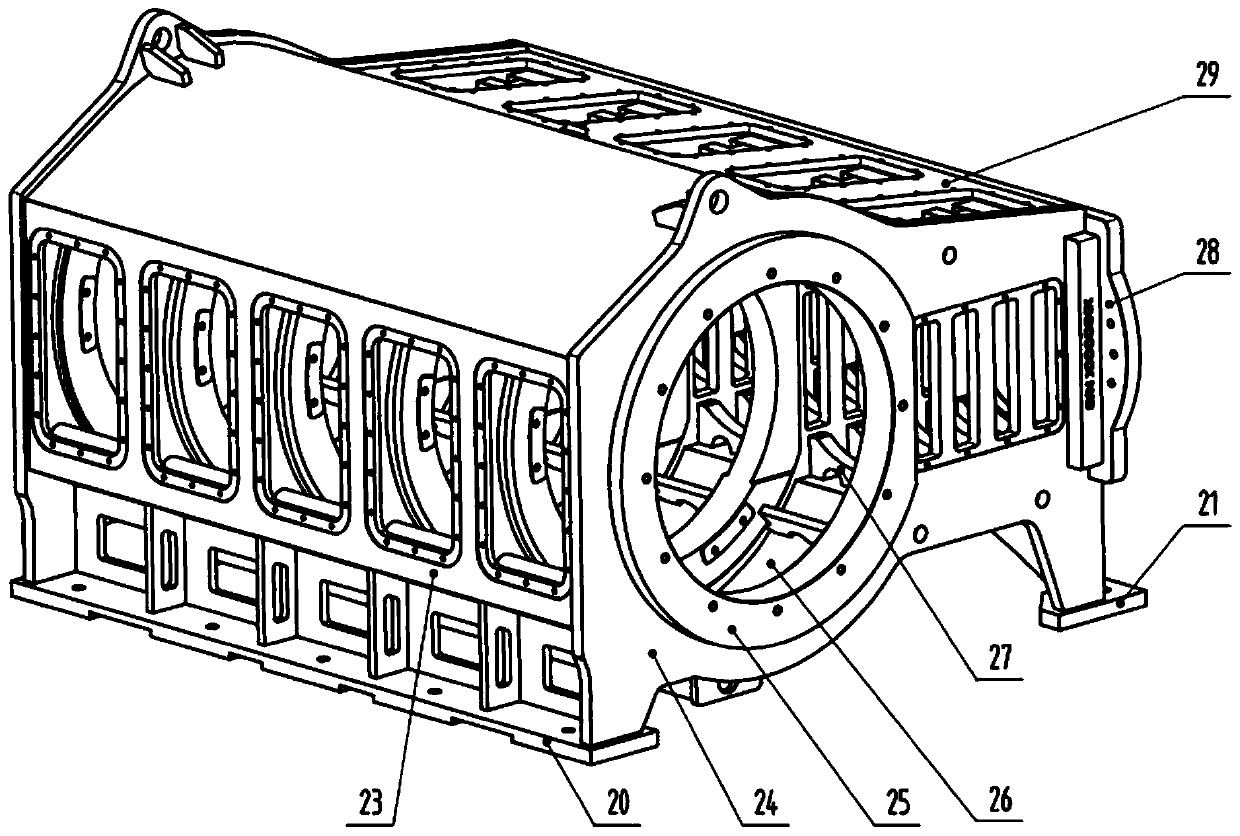

Five-cylinder plunger pump with integral power end structure

PendingCN110617318AExtended service lifeLow strokeCrankshaftsConnecting rod bearingsCrankcaseHigh load

The invention discloses a five-cylinder plunger pump with an integral power end structure. According to the five-cylinder plunger pump, an integral welding structure is adopted for a crankshaft box body and a crosshead box body in a five-cylinder plunger pump power end assembly, so that the structural strength of the power end assembly is higher, the supporting stability is better, and the whole pump vibration can be reduced; the cylinder spacing is 13-14 inches, the bearing area of connecting rods, crossheads and bearing bushes is increased, a guarantee is provided for the output of the high-power of the five-cylinder plunger pump, the high-power five-cylinder plunger pump can effectively solve the problem that the shale gas fracturing well site area is narrow and the required fracturingequipment is relatively large, the use of equipment can be reduced, and the wellsite arrangement is facilitated; the 11-inches long-stroke design can better realize large-displacement operation requirements and improve the operation efficiency; and according to the multi-point supporting design of crankcase bodies, crosshead box bodies and the hydraulic end assembly, the supporting strength of thefive-cylinder plunger pump can be improved, the vibration is reduced, the high-load operation is better guaranteed, and the operation is more stable.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Lubricant and additive formulation

InactiveUS20030119682A1Improve the lubrication effectImprove engine performanceBiocideLiquid carbonaceous fuelsPolyolesterChemical composition

Owner:ASHLAND OIL INC +1

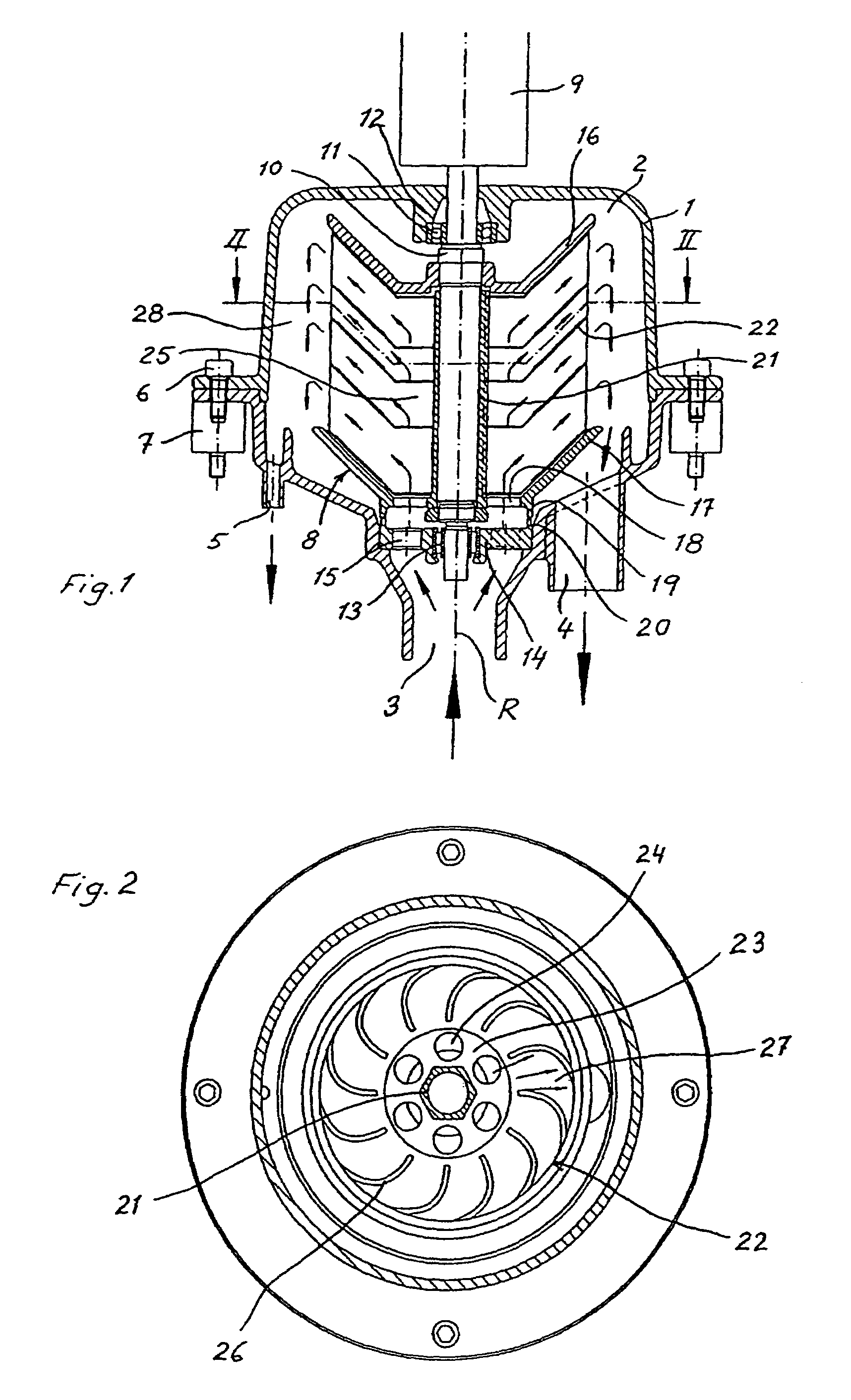

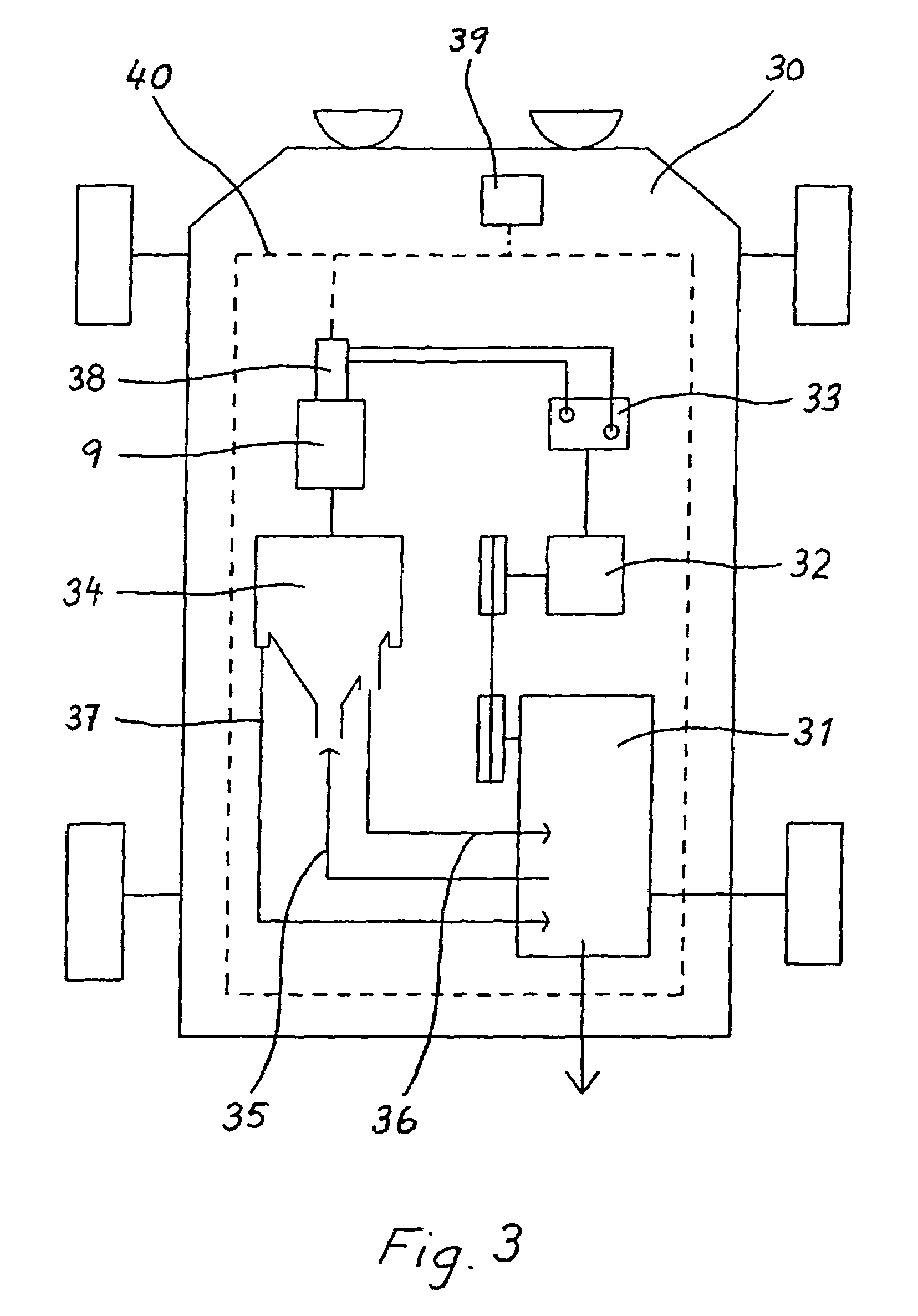

Method and a device for cleaning of crankcase gas

InactiveUS7152589B2Satisfy cleanlinessShorten speedDispersed particle separationCombustion enginesCombustionUnit of time

Owner:ALFA LAVAL CORP AB

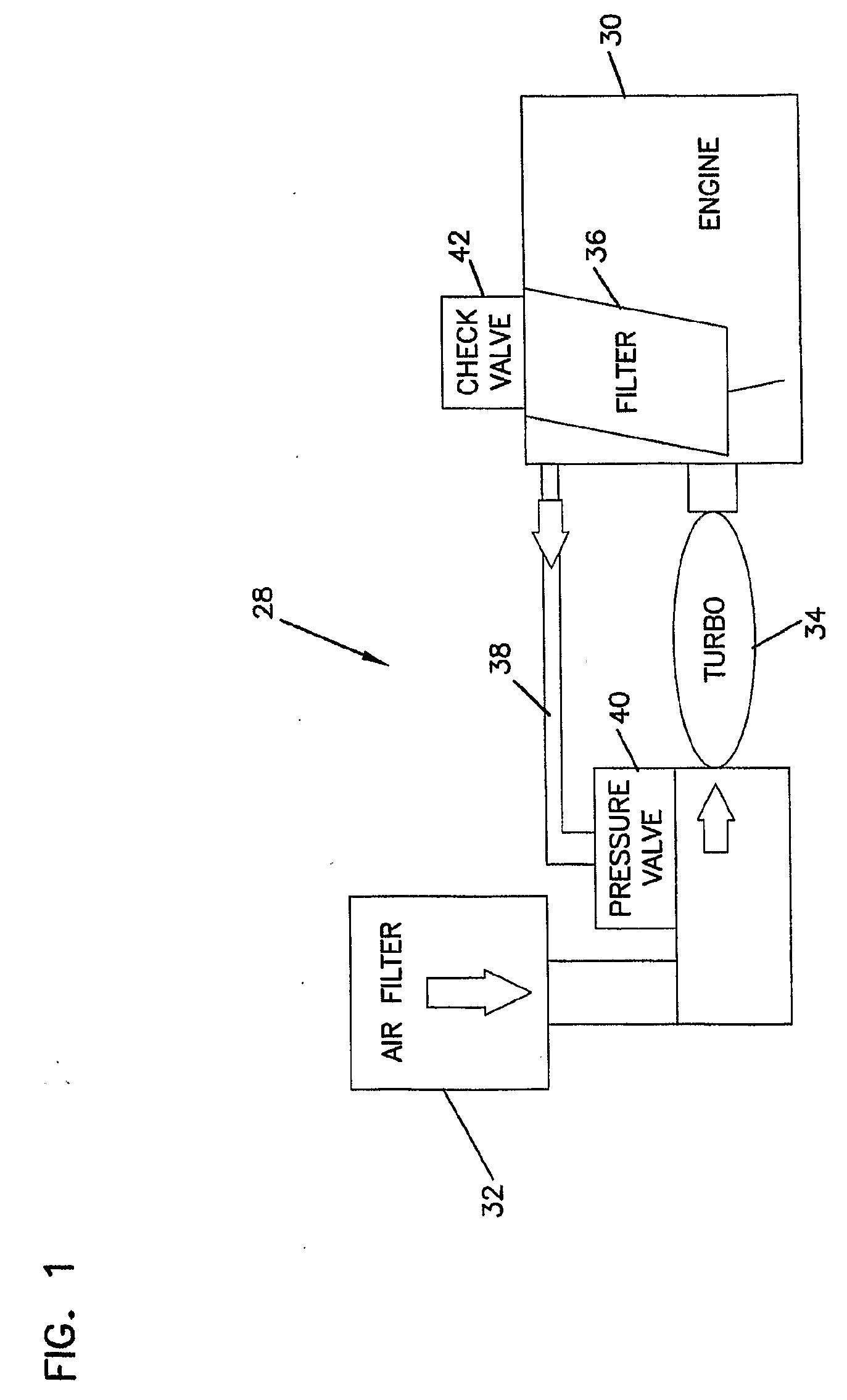

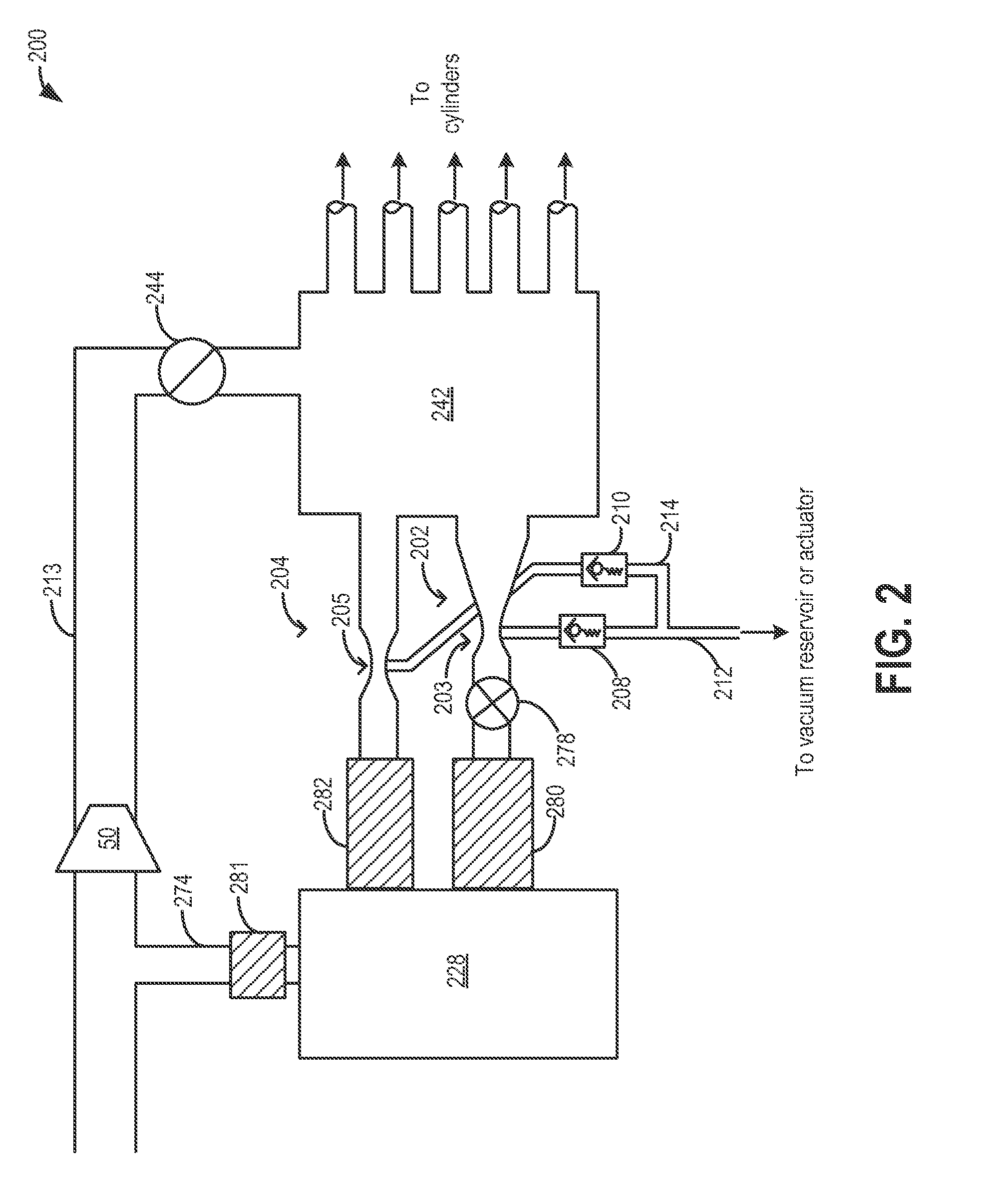

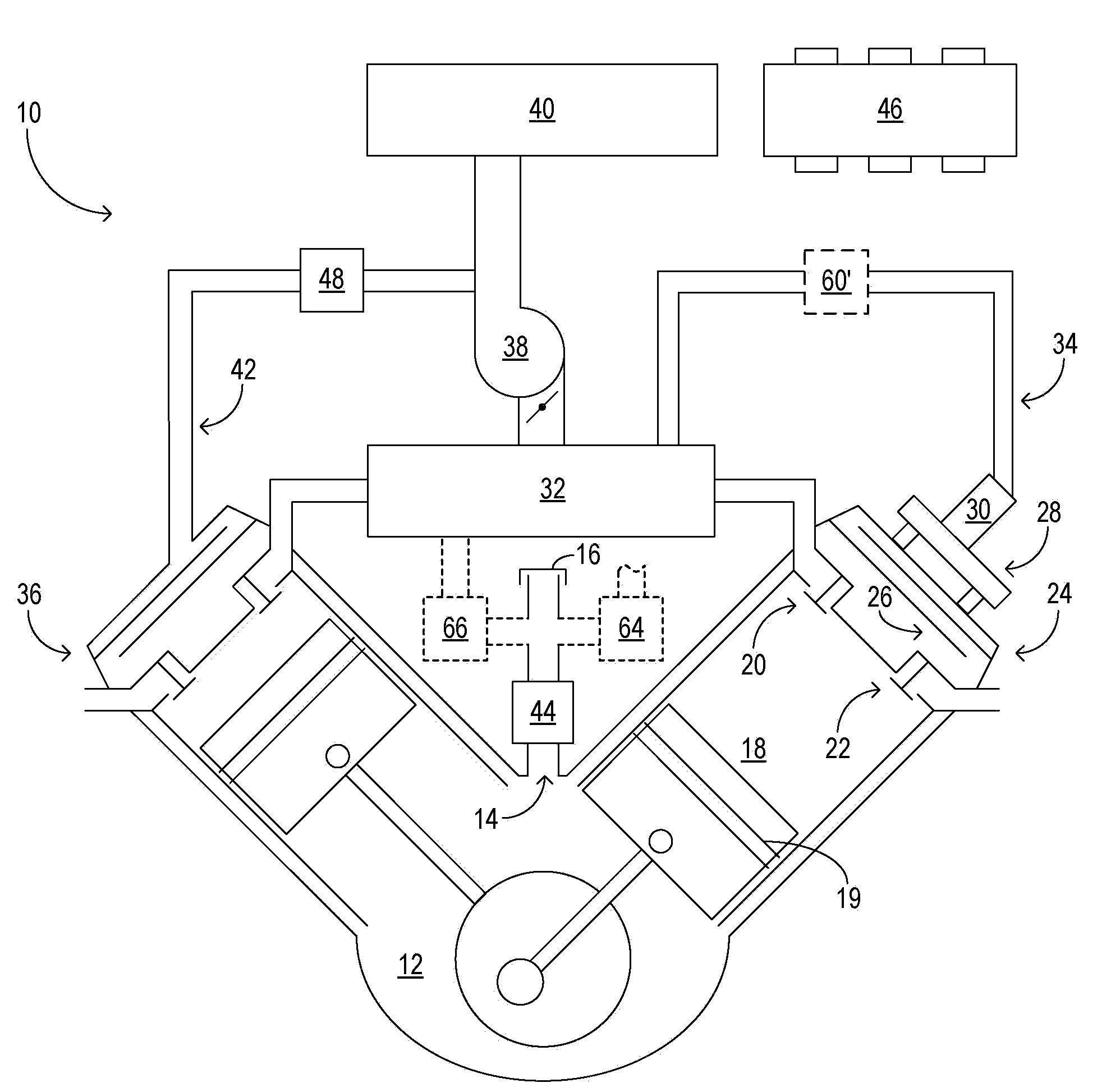

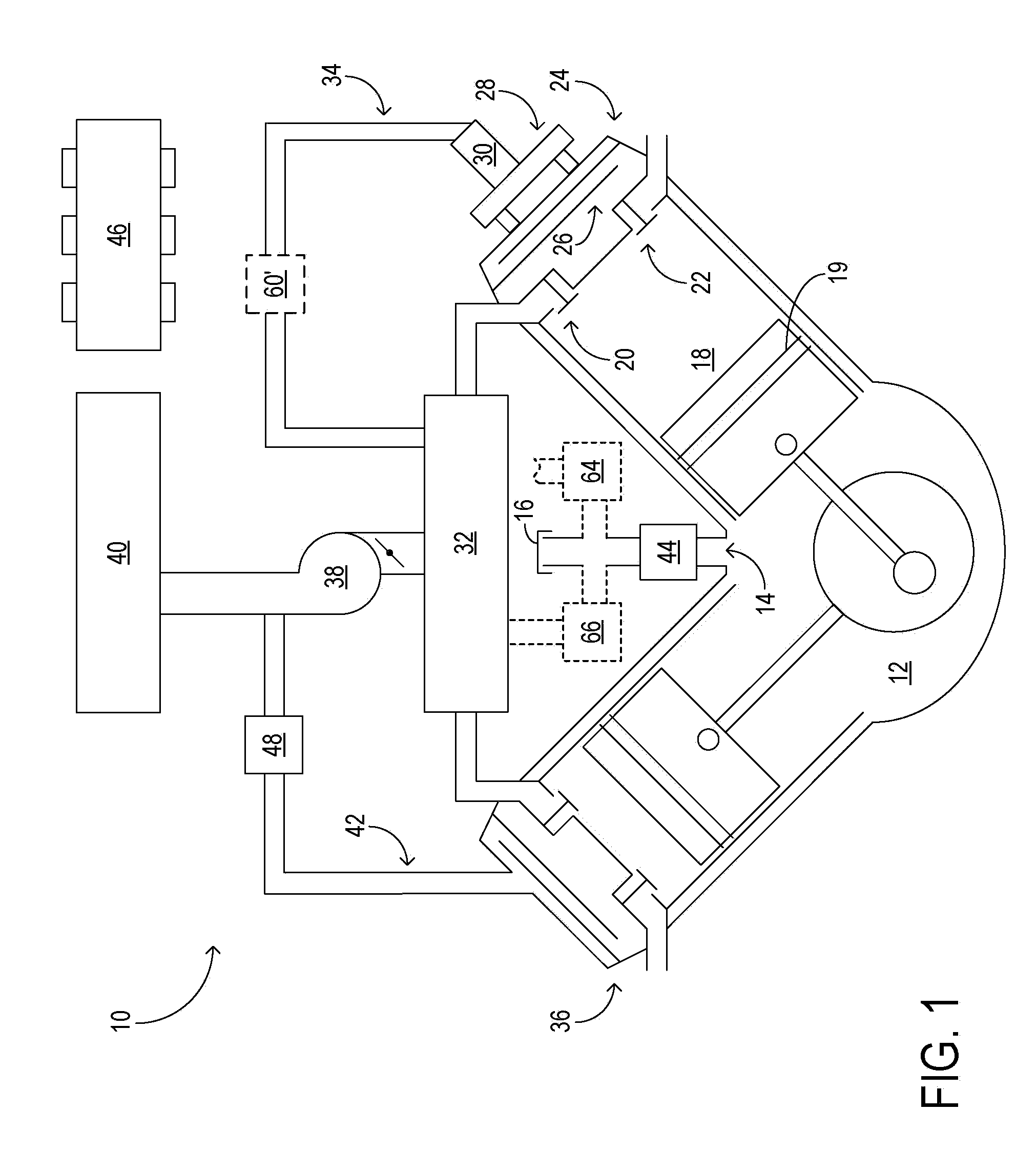

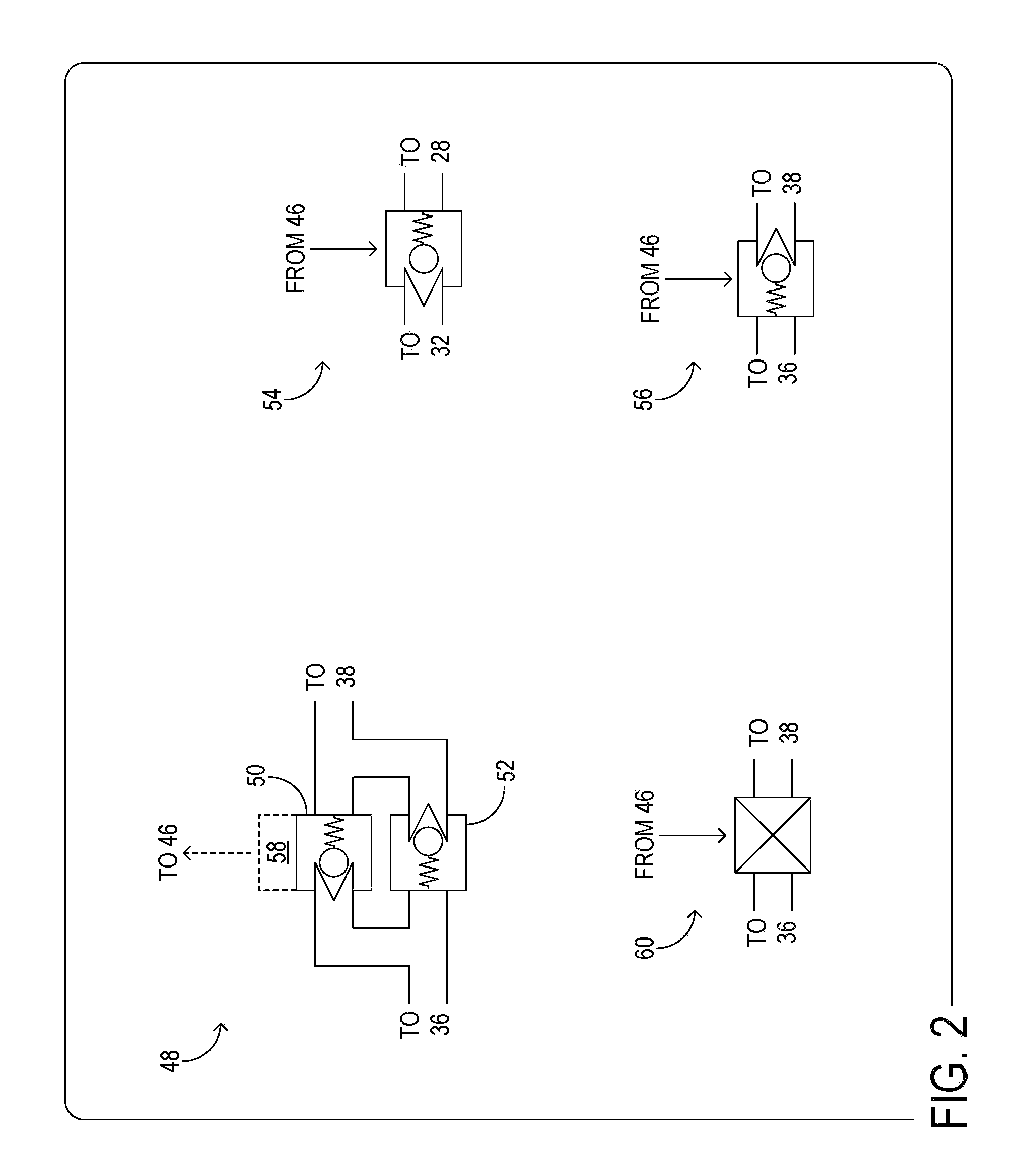

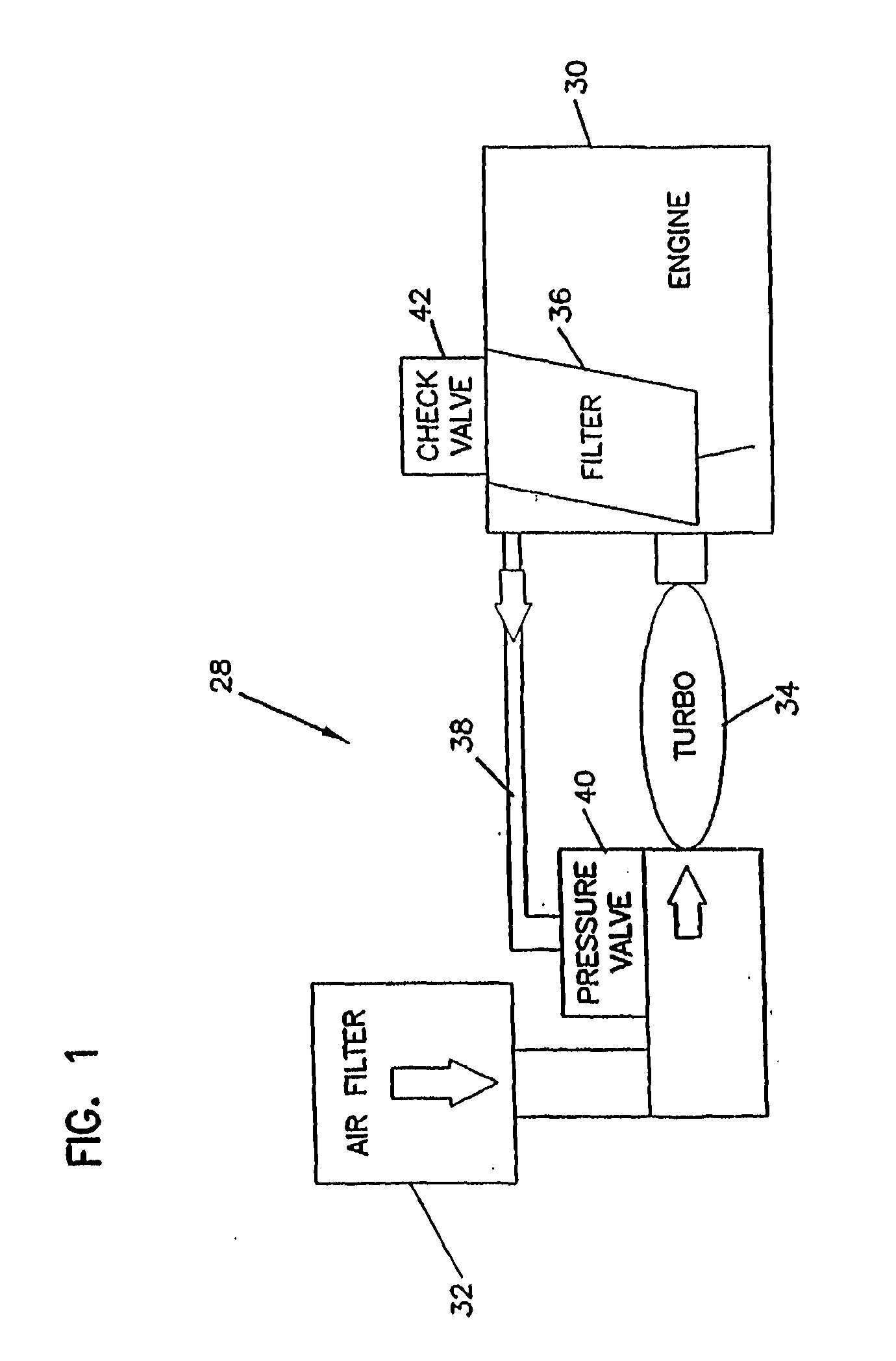

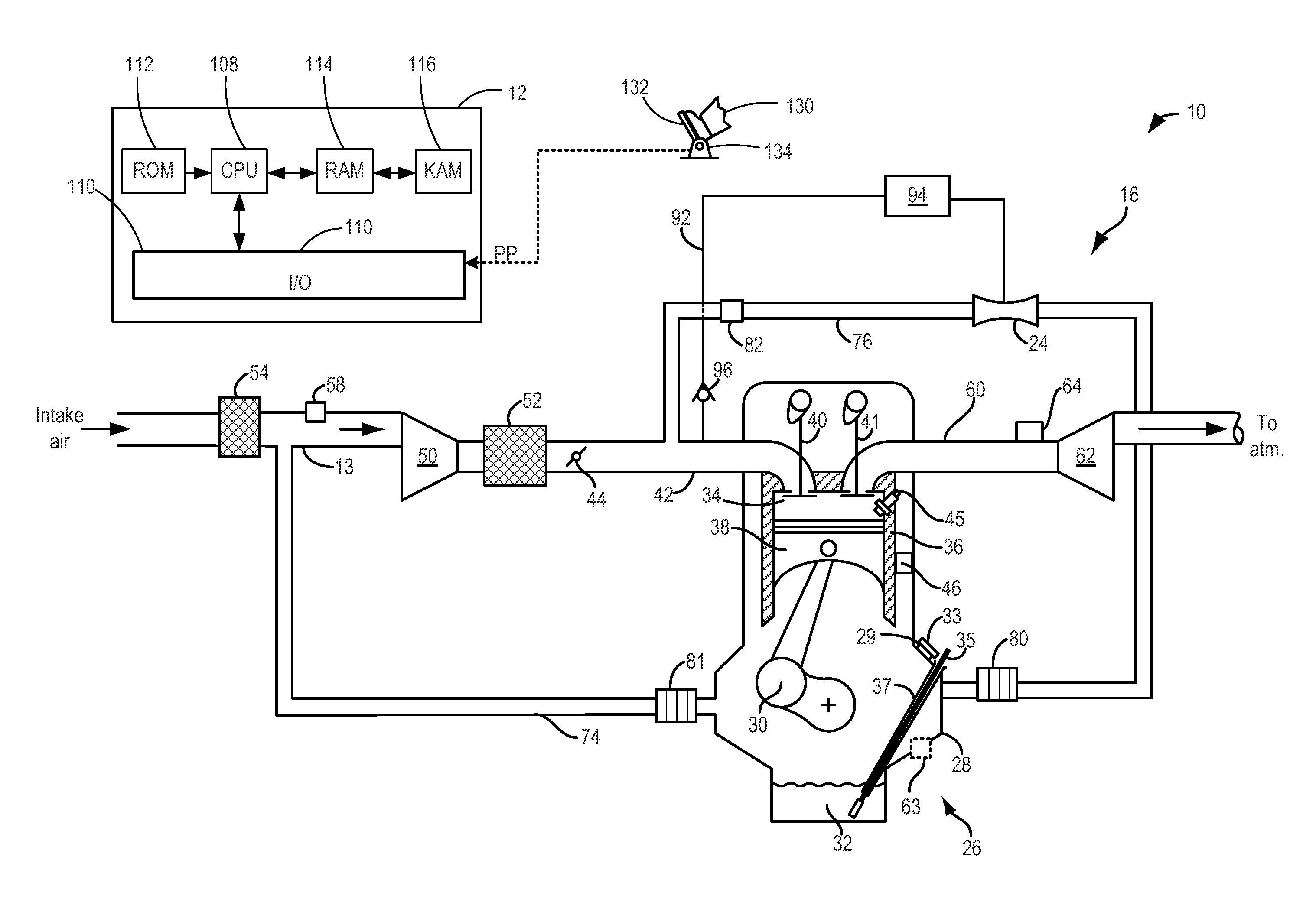

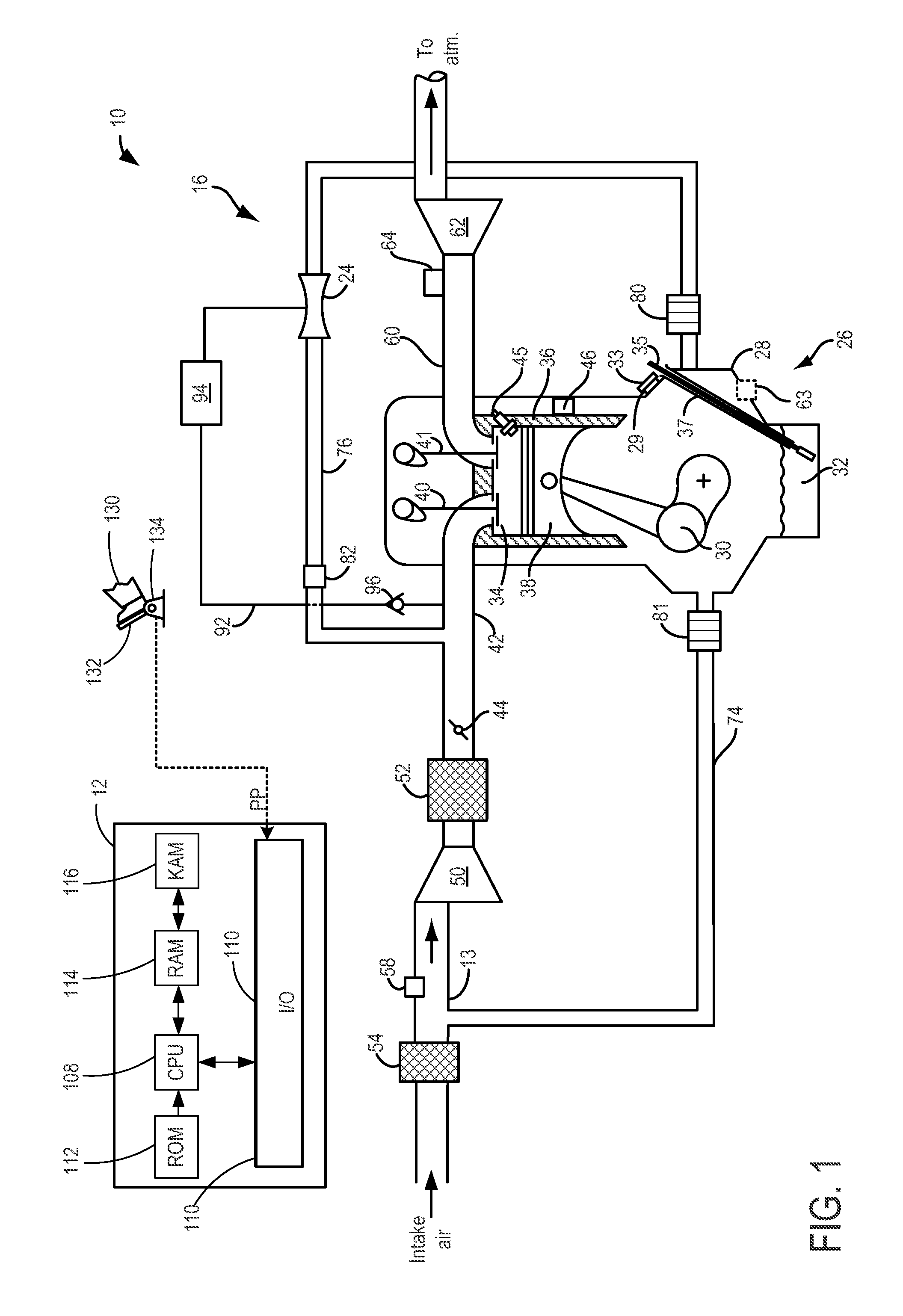

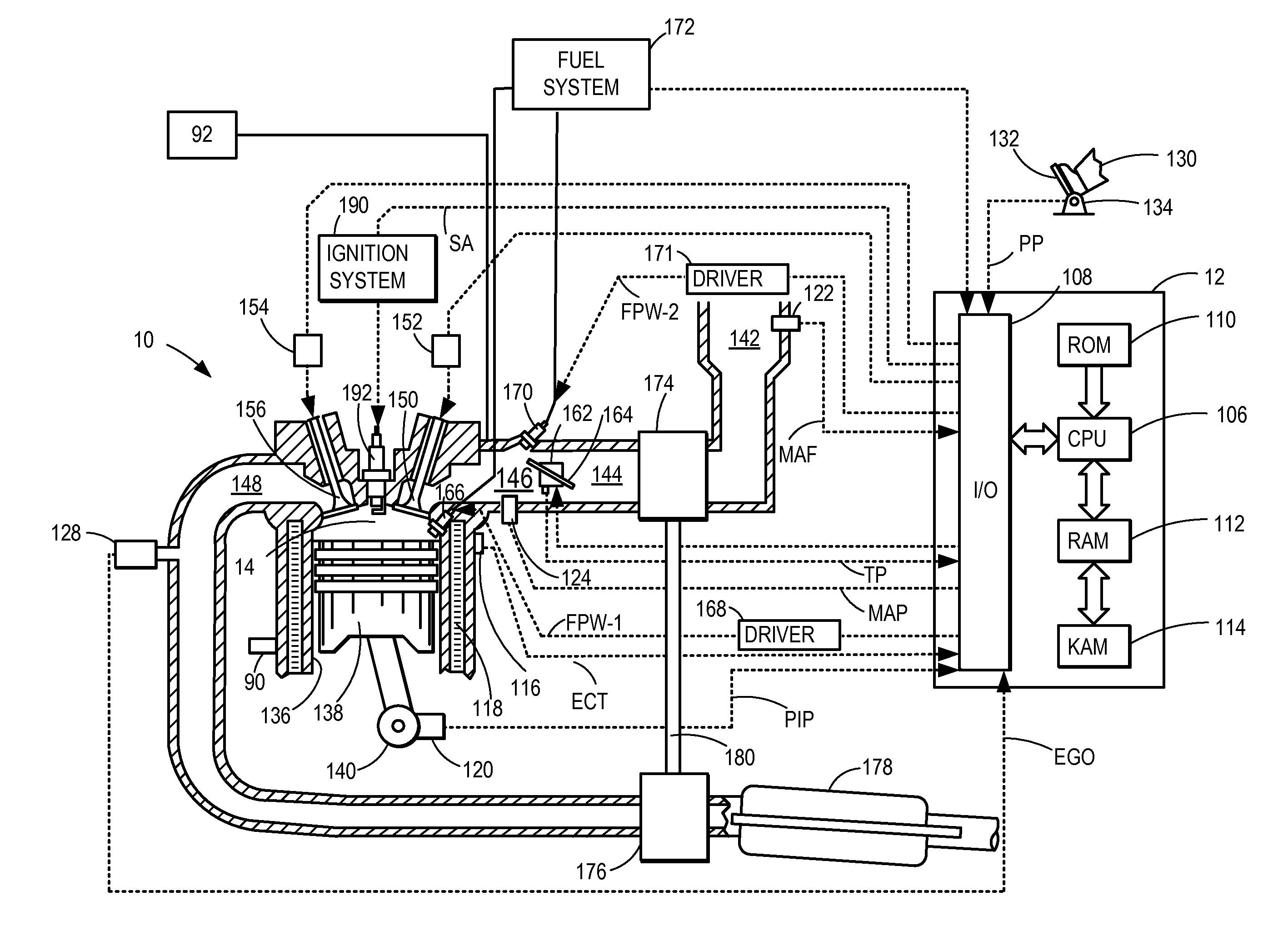

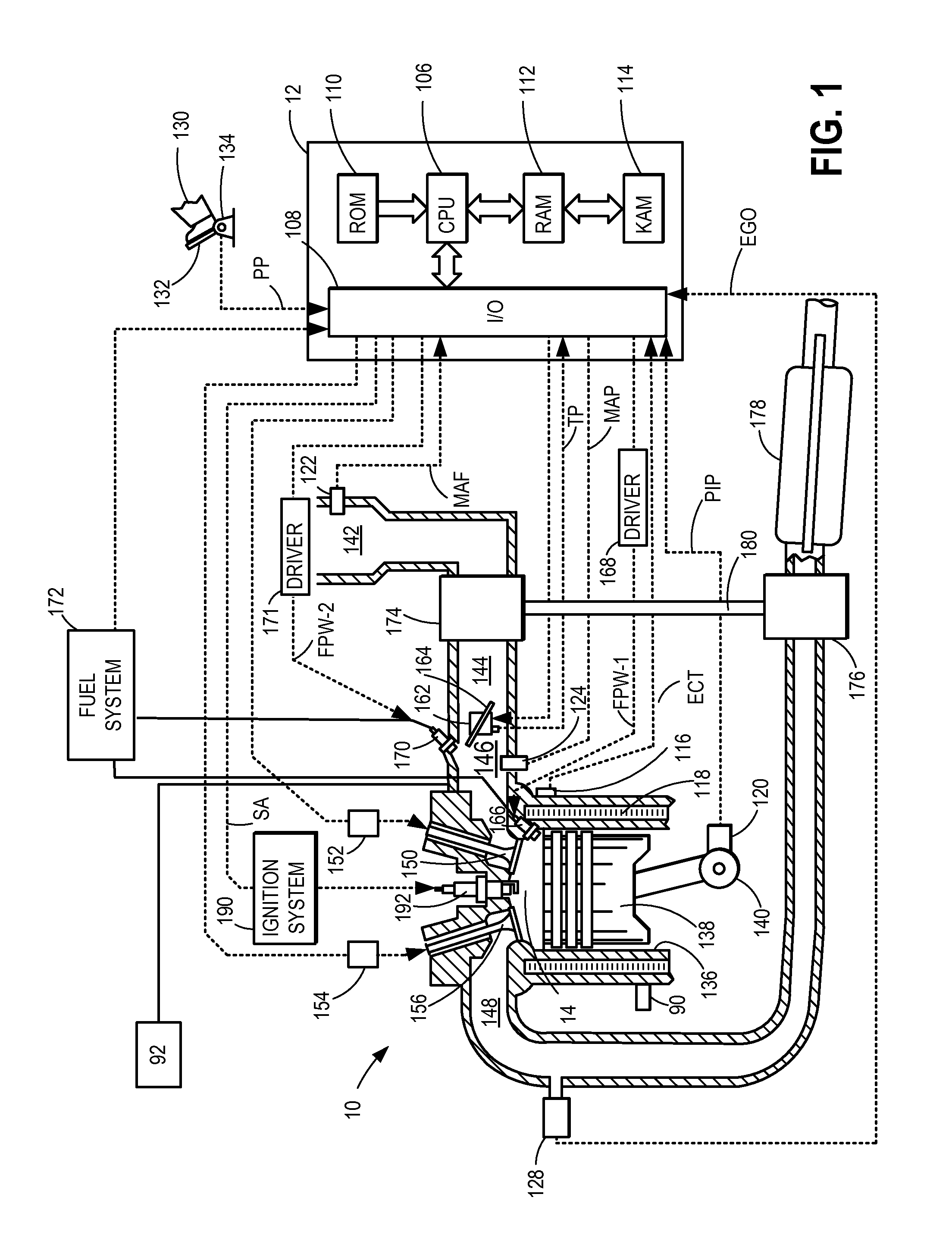

Crankcase ventilation and vacuum generation

InactiveUS20130340732A1Increase vacuum generationImprove power generation efficiencyInternal combustion piston enginesNon-fuel substance addition to fuelInspiratorProcess engineering

Methods and systems are provided for generating vacuum from crankcase ventilation flow. During both directions of gas flow between an engine intake manifold and a crankcase, gases are directed through one or more aspirators to produce vacuum. The drawn vacuum may then be used to operate various engine vacuum actuators.

Owner:FORD GLOBAL TECH LLC

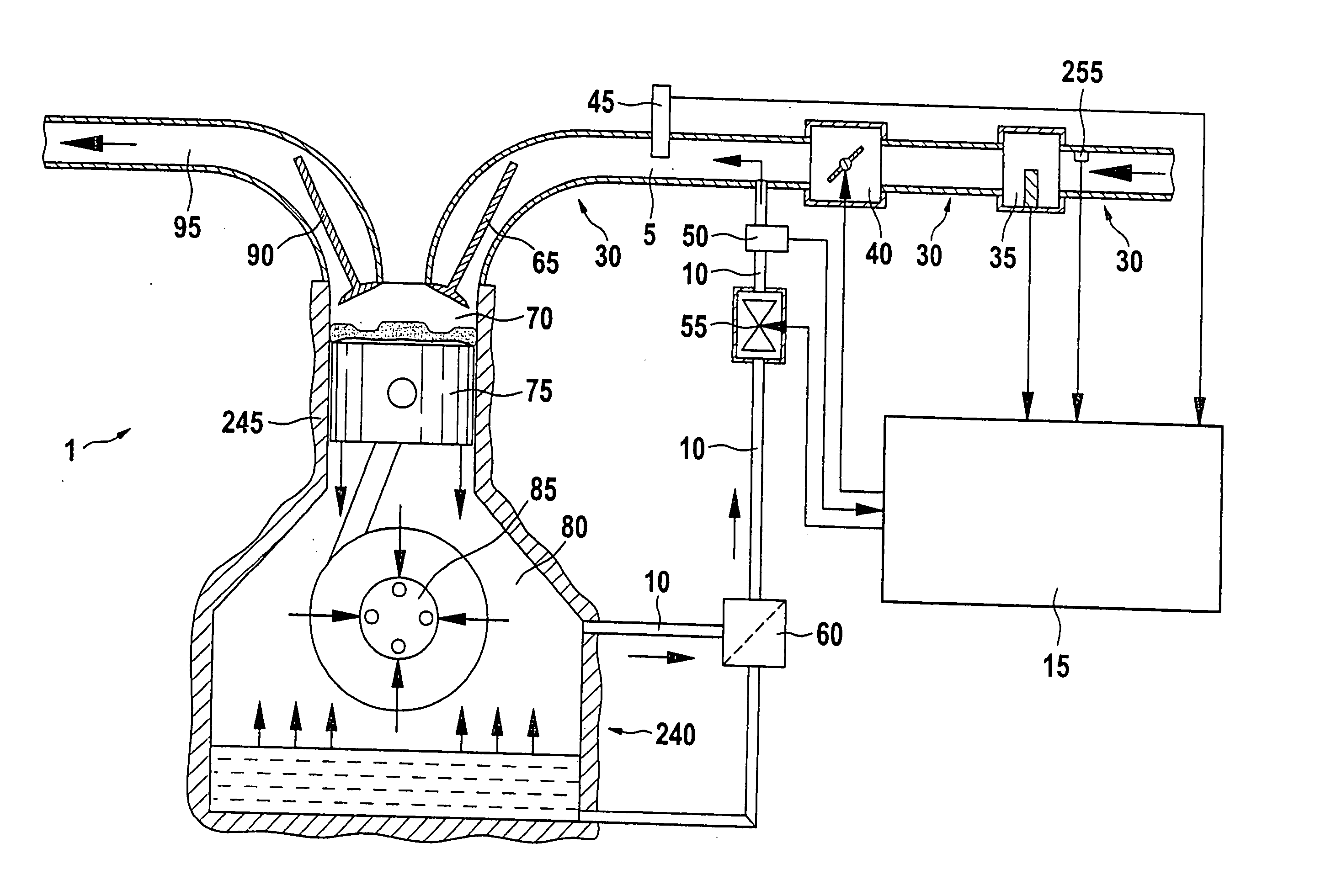

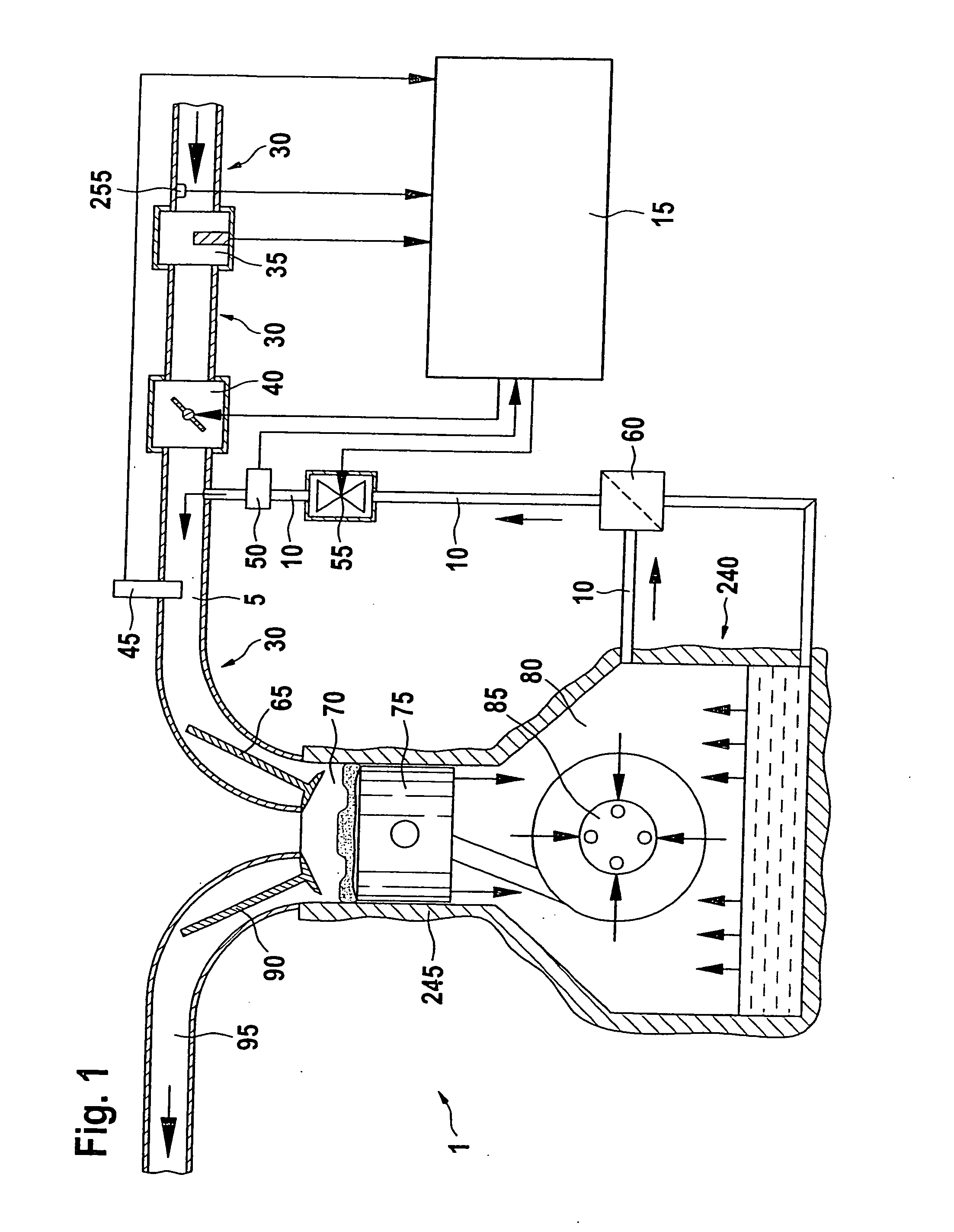

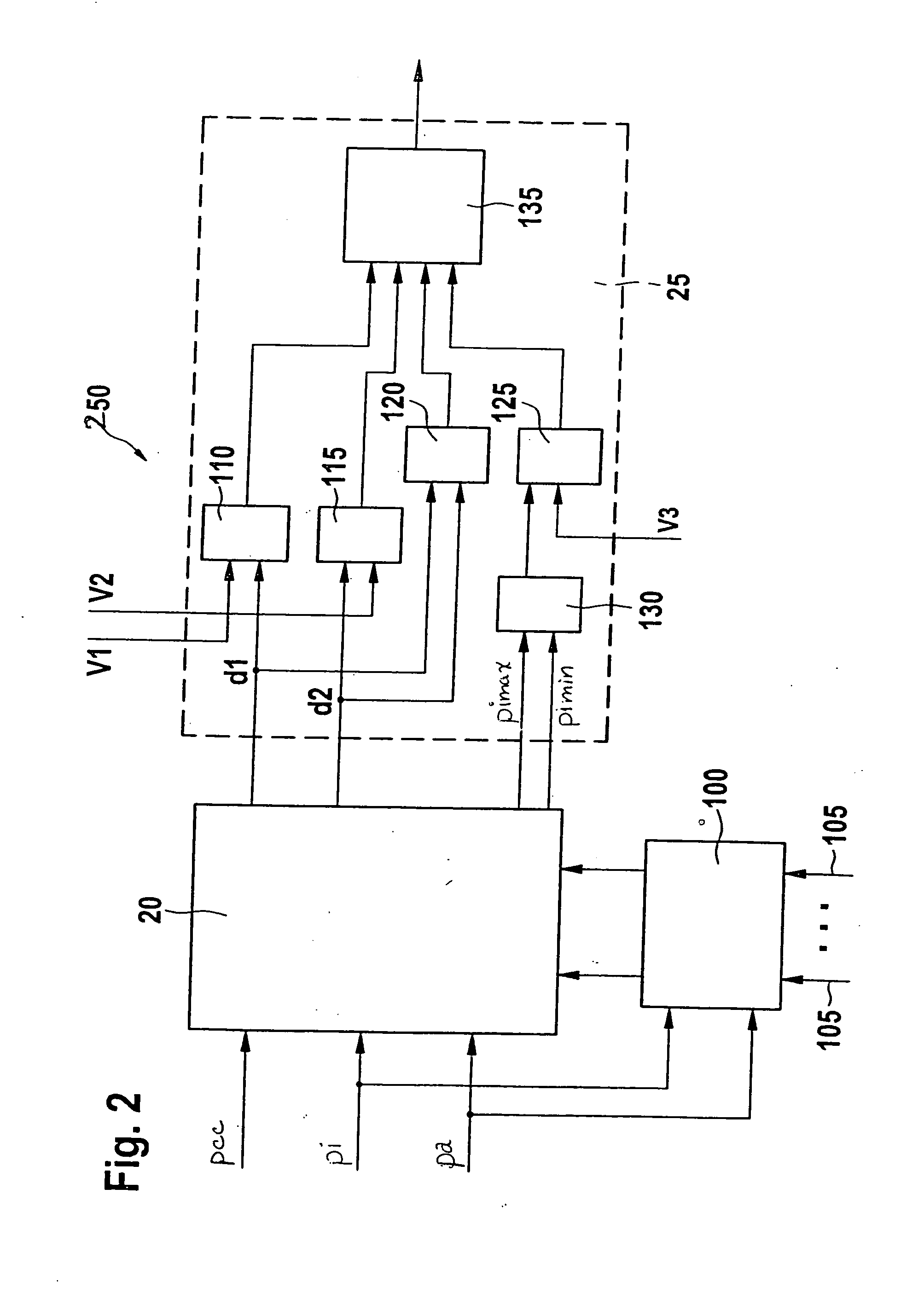

Method and device for operating an internal combustion engine

InactiveUS20050022795A1Reliable detectionReduce riskEngine pressureElectrical controlFuel tankAmbient pressure

A method and a device for operating an internal combustion engine having an intake manifold and a ventilation system may allow a reliable and fault-free diagnosis of a fault in the ventilation. The ventilation system may be a tank ventilation or a crankcase ventilation. The ventilation duct is conducted to the intake manifold of the internal combustion engine. At least one pressure differential may be determined between an intake-manifold pressure or an ambient pressure, on the one hand, and a pressure in the ventilation duct, on the other hand. A fault in the ventilation may be diagnosed as a function of the at least one pressure differential.

Owner:ROBERT BOSCH GMBH

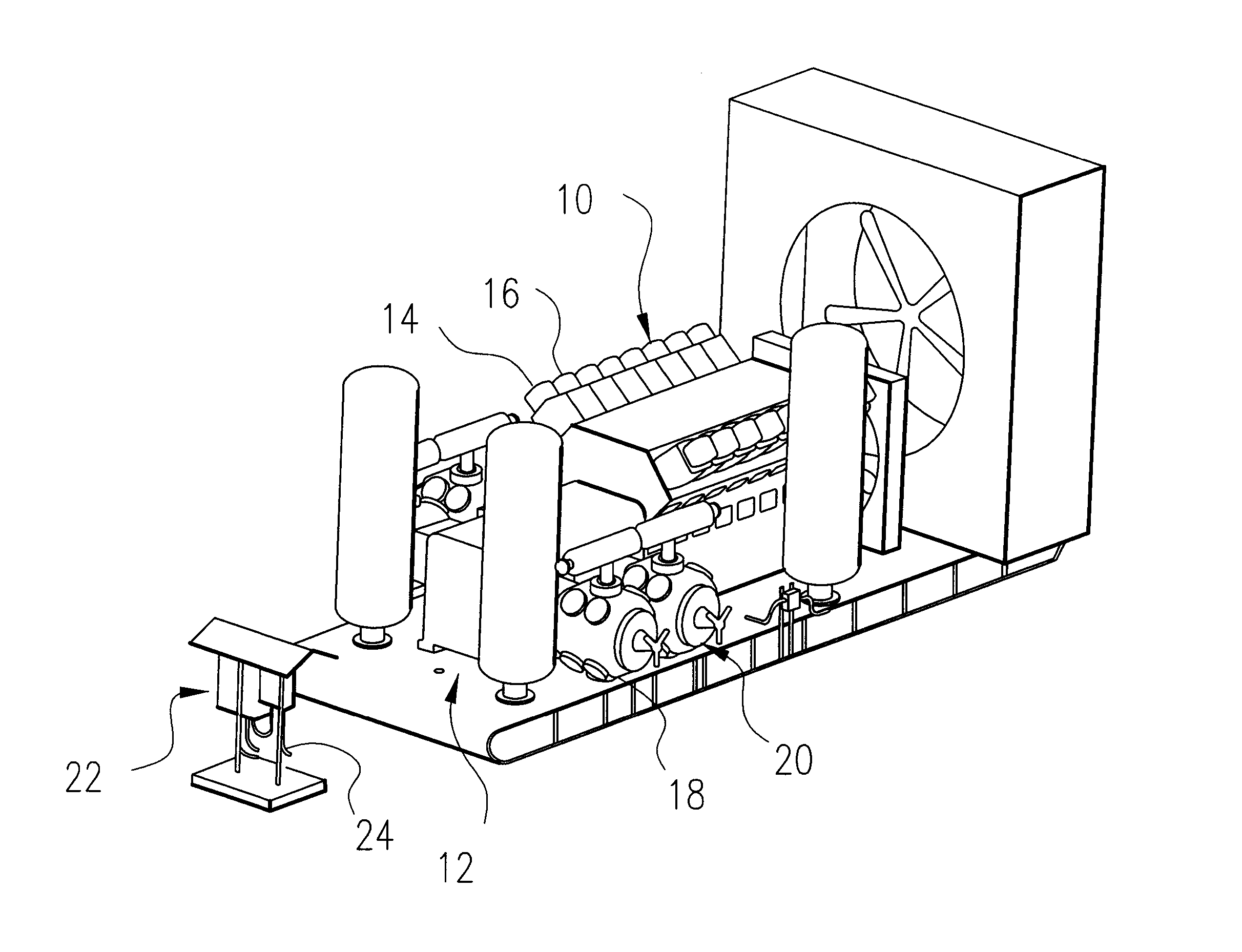

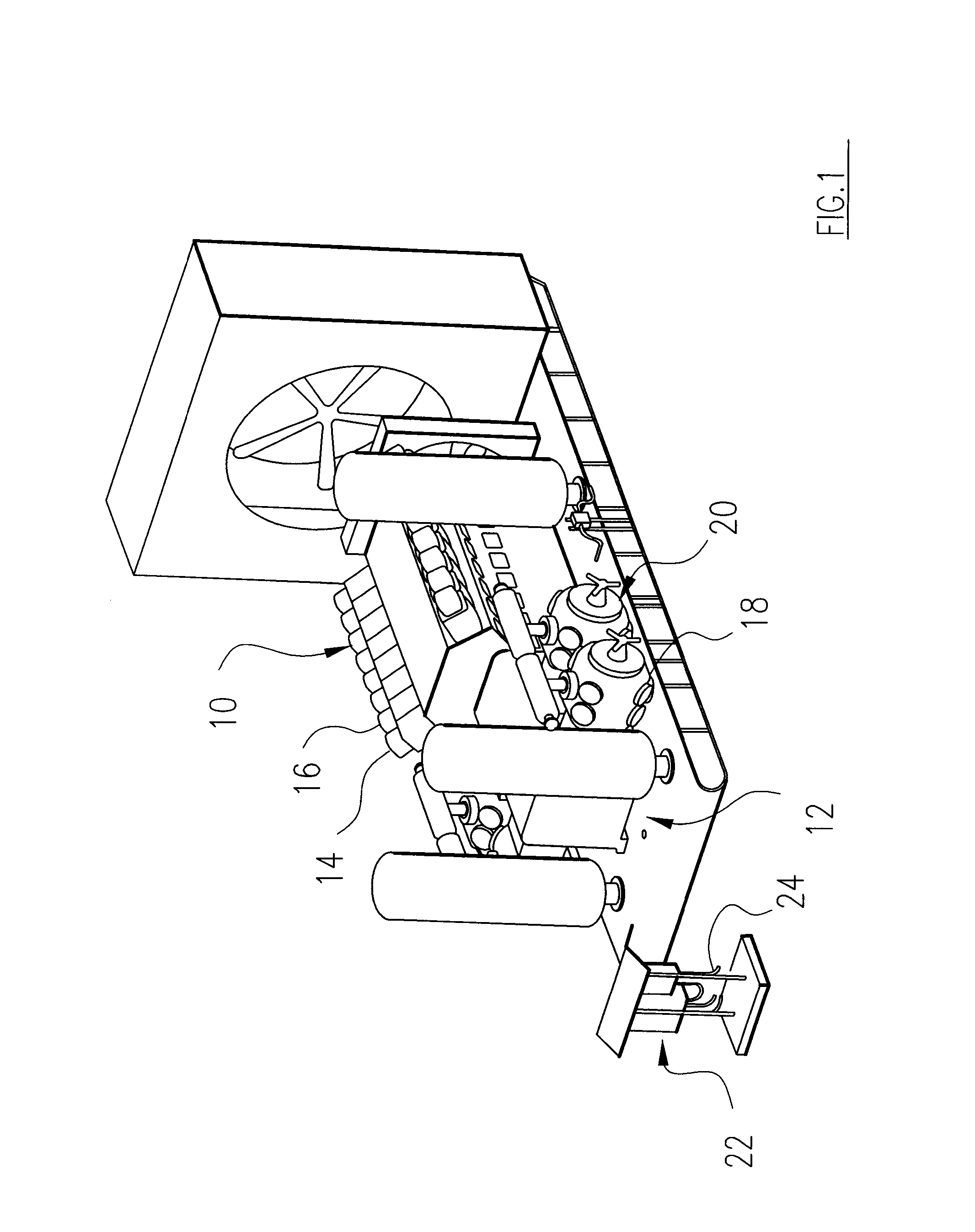

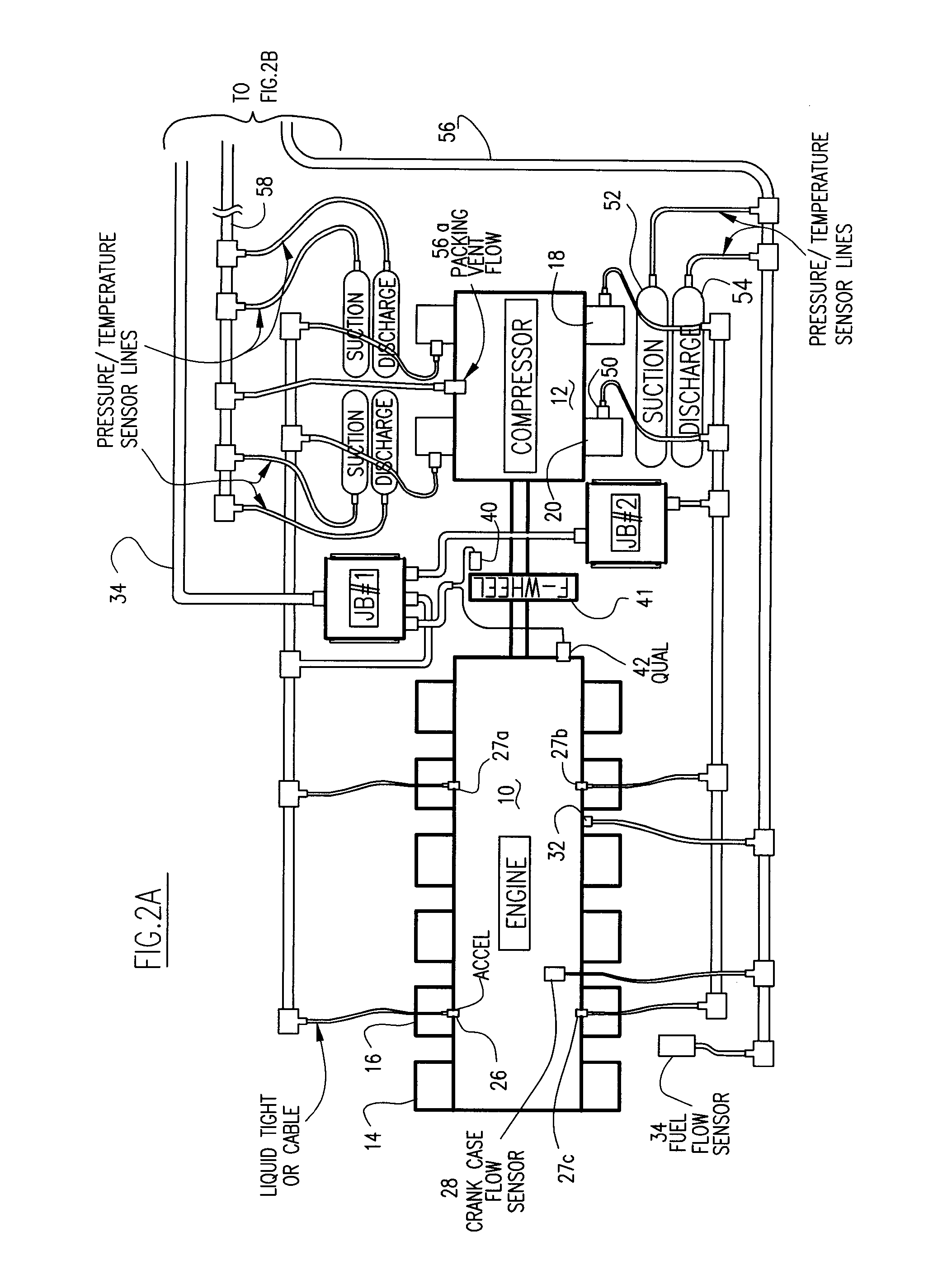

Automated fault diagnosis method and system for engine-compressor sets

InactiveUS7403850B1Improve economic performanceIncrease fuel consumptionInternal-combustion engine testingAutomatic initiationsBaseline dataData acquisition

The automated fault diagnostic system operates on engine-compressor sets with one vibration sensor per sub-group of engine cylinders and one sensor per compressor cylinder. Vibration signals linked to crankshaft phase angle windows (“VT”) mark various engine events and compressor events. In data-acquisition-learning mode, VT is stored for each engine and compressor event per operating load condition, statistical process control (SPC) theory identifies alarm threshold bands. Operator input-overrides are permitted. If no baseline data is stored, the system automatically enters the learn mode. To monitor, current VT are obtained and current load condition is matched to the earlier load set and alarms issue linking predetermined engine or compressor event to the over-under VT. Baseline data, SPC analysis, alarms and monitoring are set for crankcase flow, engine cylinder exhaust temperatures, ignition system diagnostic messages. Compressor performance alarms use suction and discharge temperatures and pressures.

Owner:WINDROCK

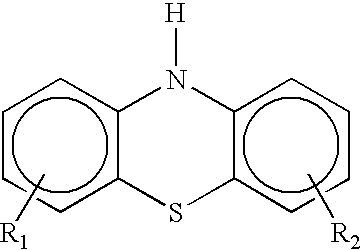

Antioxidant combination for oxidation and deposit control in lubricants containing molybdenum and alkylated phenothiazine

InactiveUS6797677B2Easy to controlPromote oxidationLiquid carbonaceous fuelsAdditivesAntioxidantOxidation resistant

The invention relates to a lubricating oil composition having improved antioxidant properties, and which contains a molybdenum compound and an alkylated phenothiazine. Further, it may also include a secondary diarylamine, preferably an alkylated diphenylamine. This combination of additives provides improved oxidation control and friction modifier performance to the lubricating oil. The composition is particularly suited for use as a crankcase lubricant, or a transmission lubricant, including low levels and zero levels of phosphorus.

Owner:AFTON CHEMICAL +1

Crankcase breech detection for boosted engines

InactiveUS20100147270A1Prolonged duty cycleIncreased blow-byCombustion enginesLubrication pressure controlMobile vehicleAtmospheric air

Methods for indicating whether a crankcase of an engine is breeched are provided. One example method comprises restricting a communication of the crankcase with atmosphere, acting to increase or decrease a crankcase pressure, and indicating whether the crankcase is breeched based on the crankcase pressure. Another example method comprises sensing a crankcase pressure component, and indicating whether the crankcase is breeched based on the crankcase pressure component, the crankcase communicating with atmosphere via a conduit, a restrictedness of the conduit responsive to one or more of a crankcase pressure and a signal from an electronic control unit of the motor vehicle. Still other examples provide more particular methods for indicating whether the crankcase is breeched, and example configurations that enable the various methods.

Owner:FORD GLOBAL TECH LLC

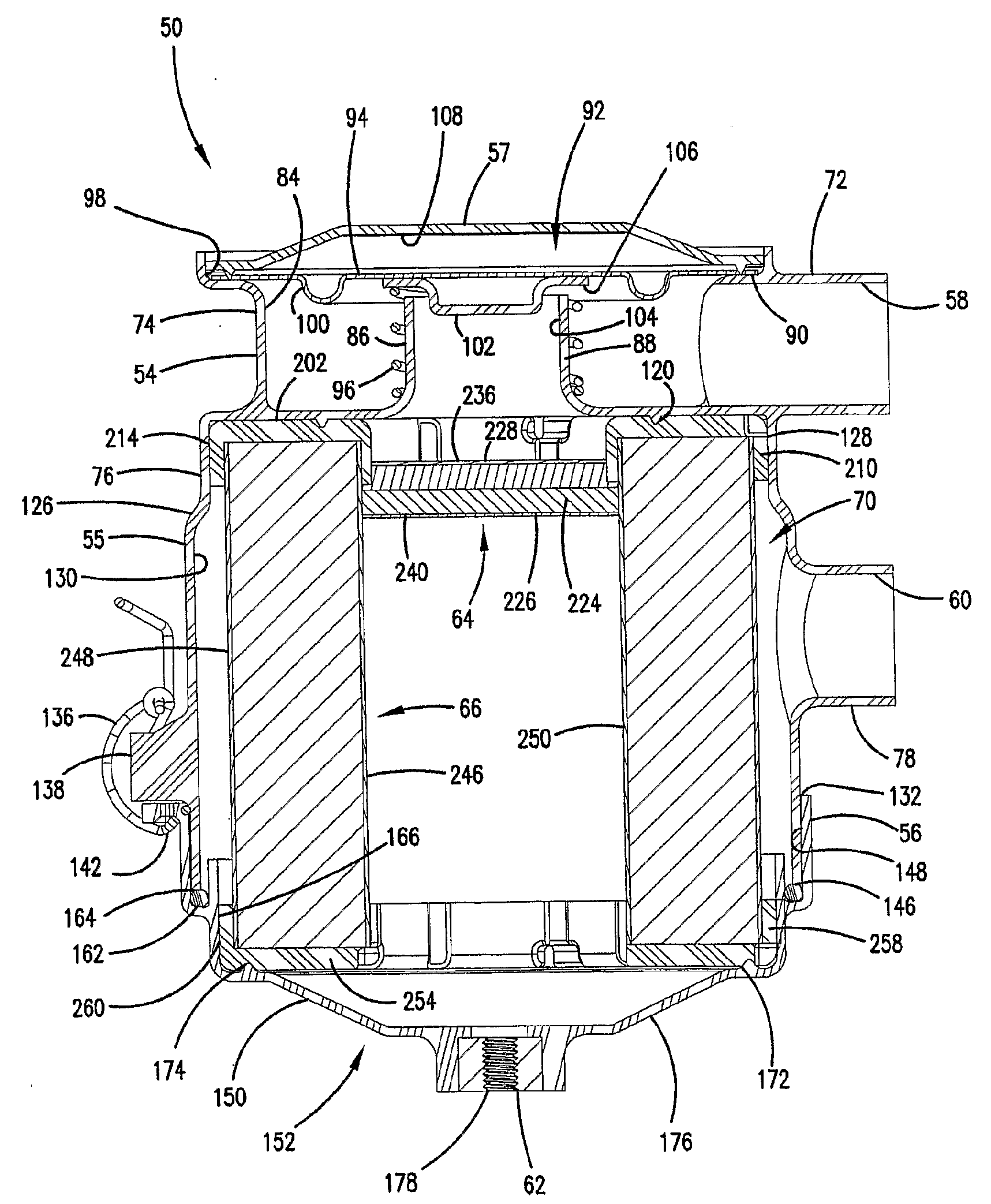

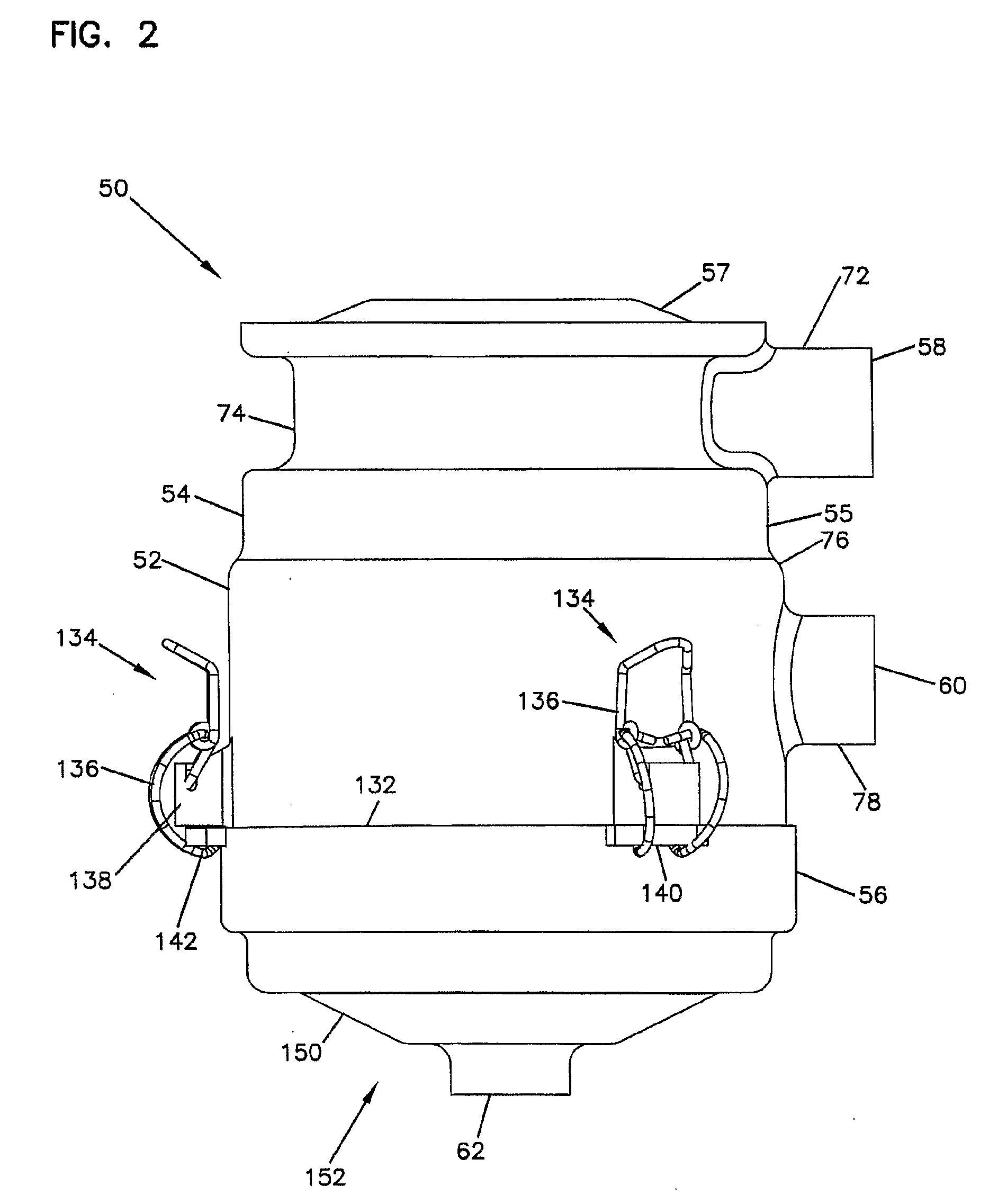

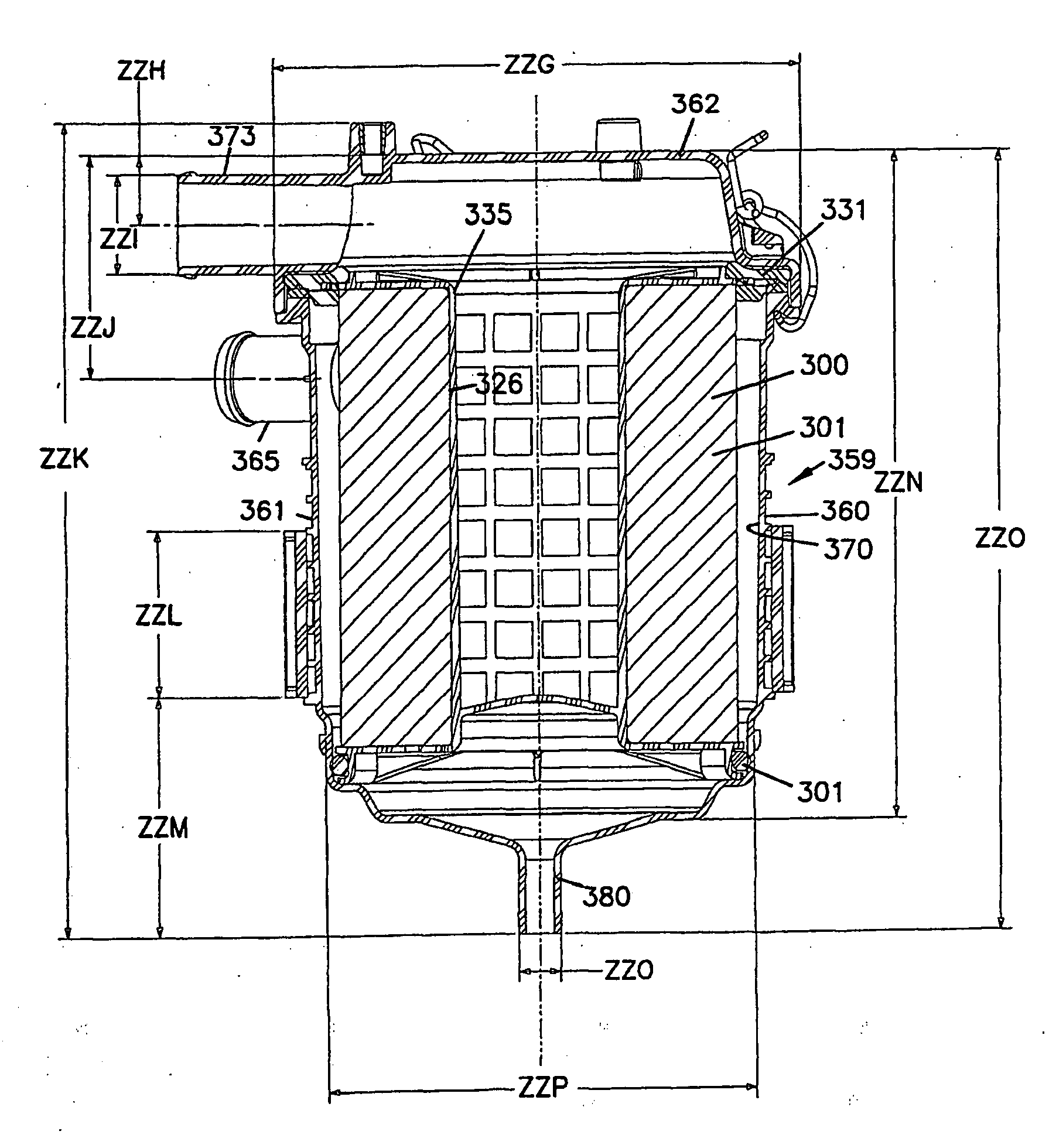

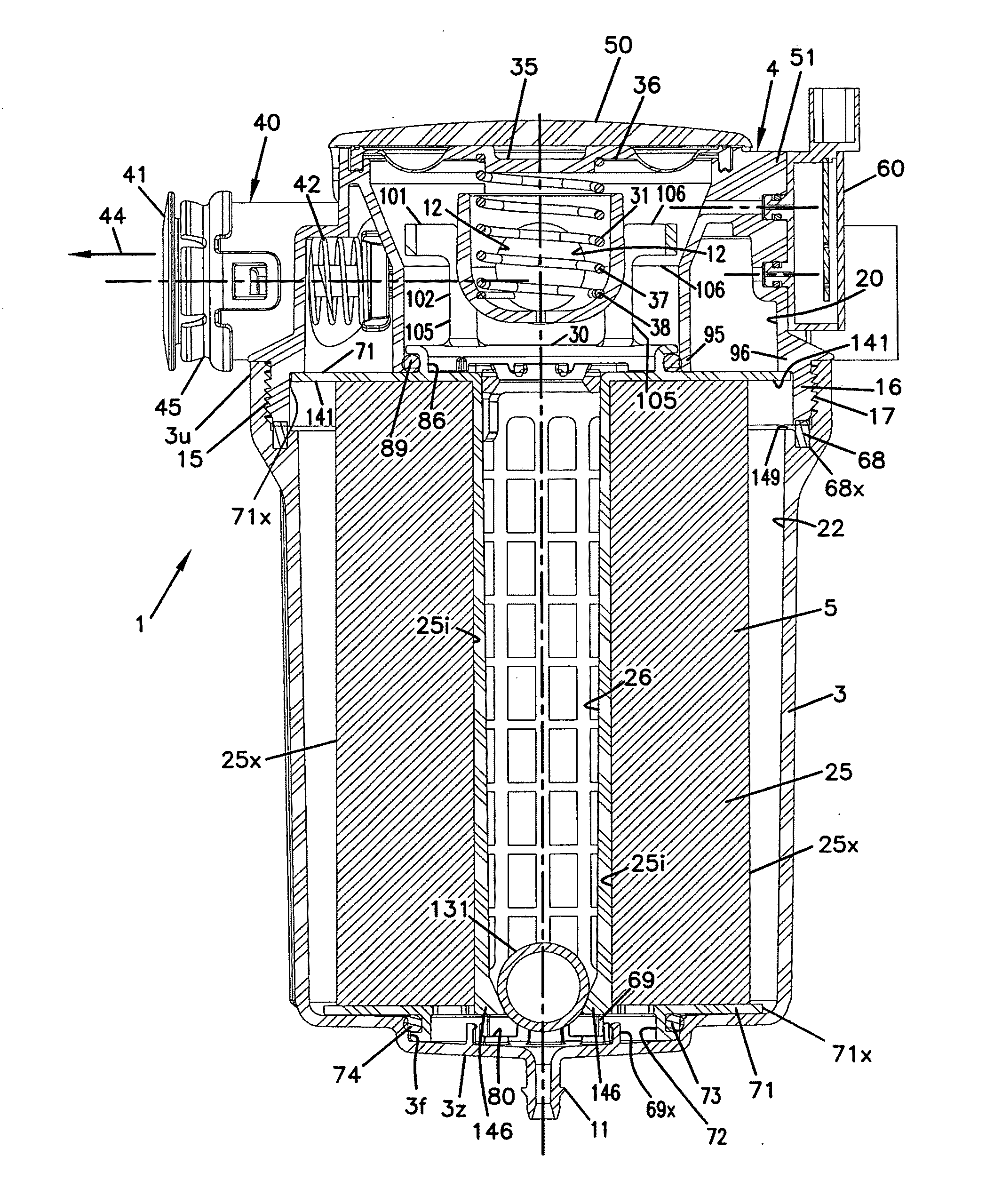

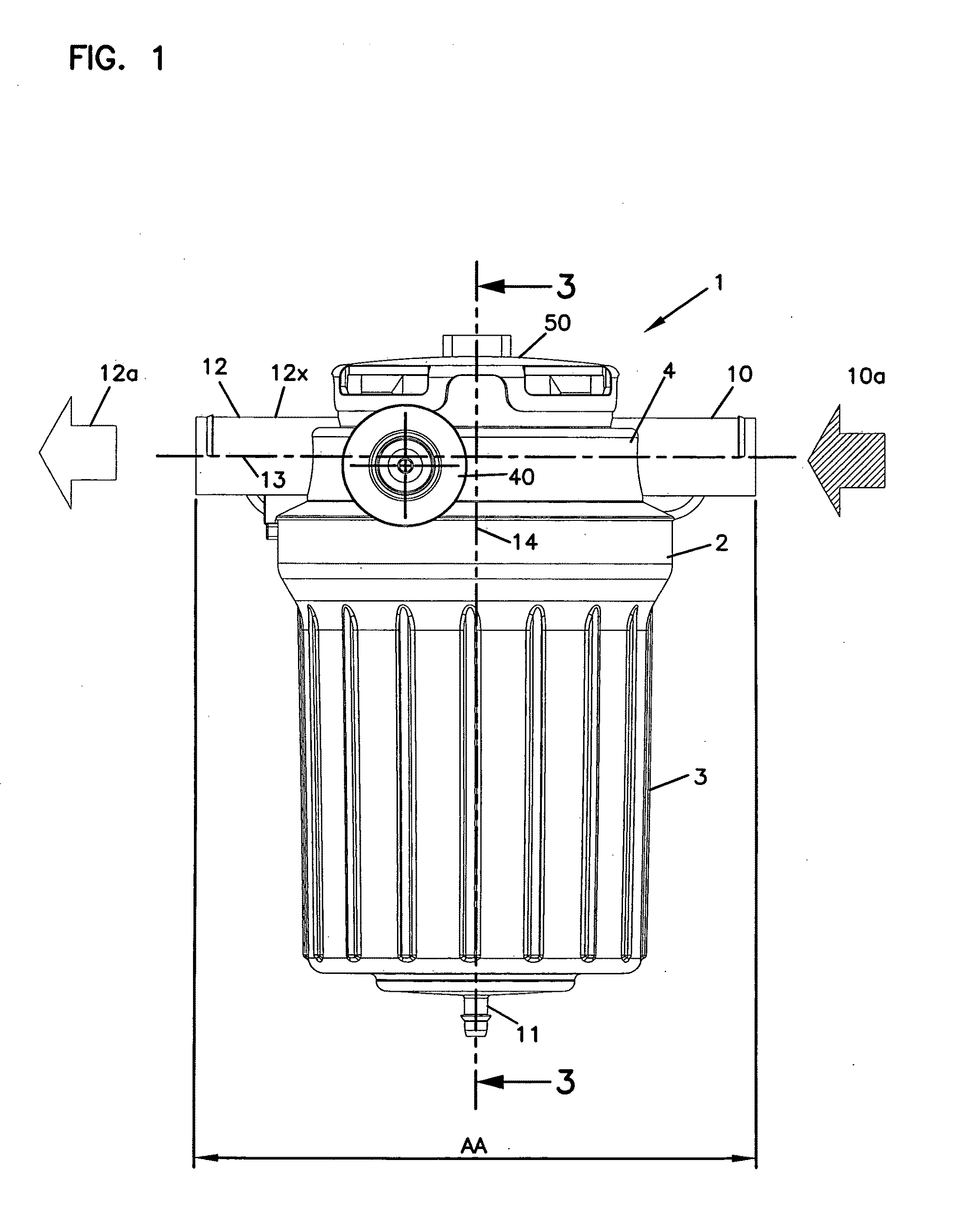

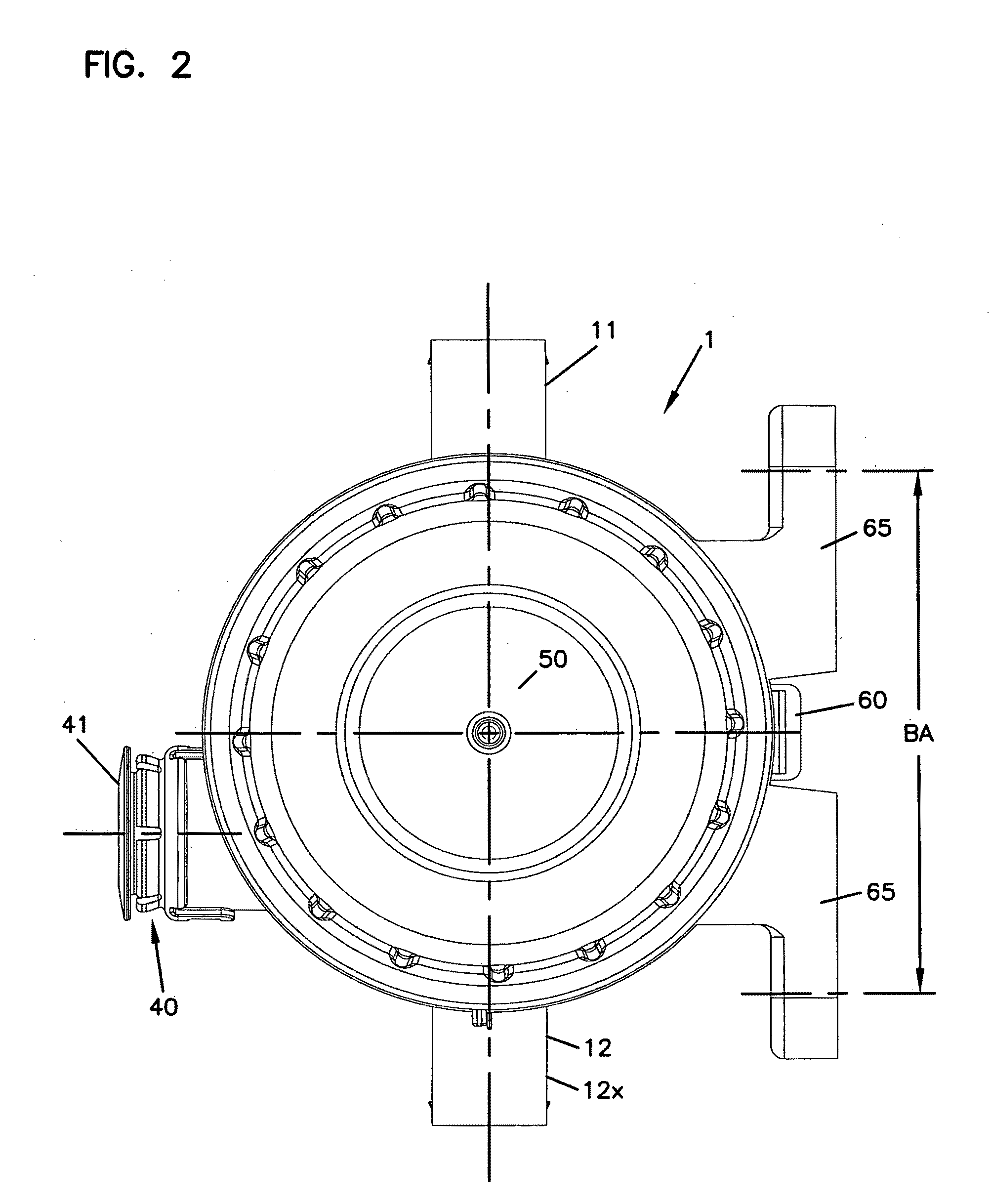

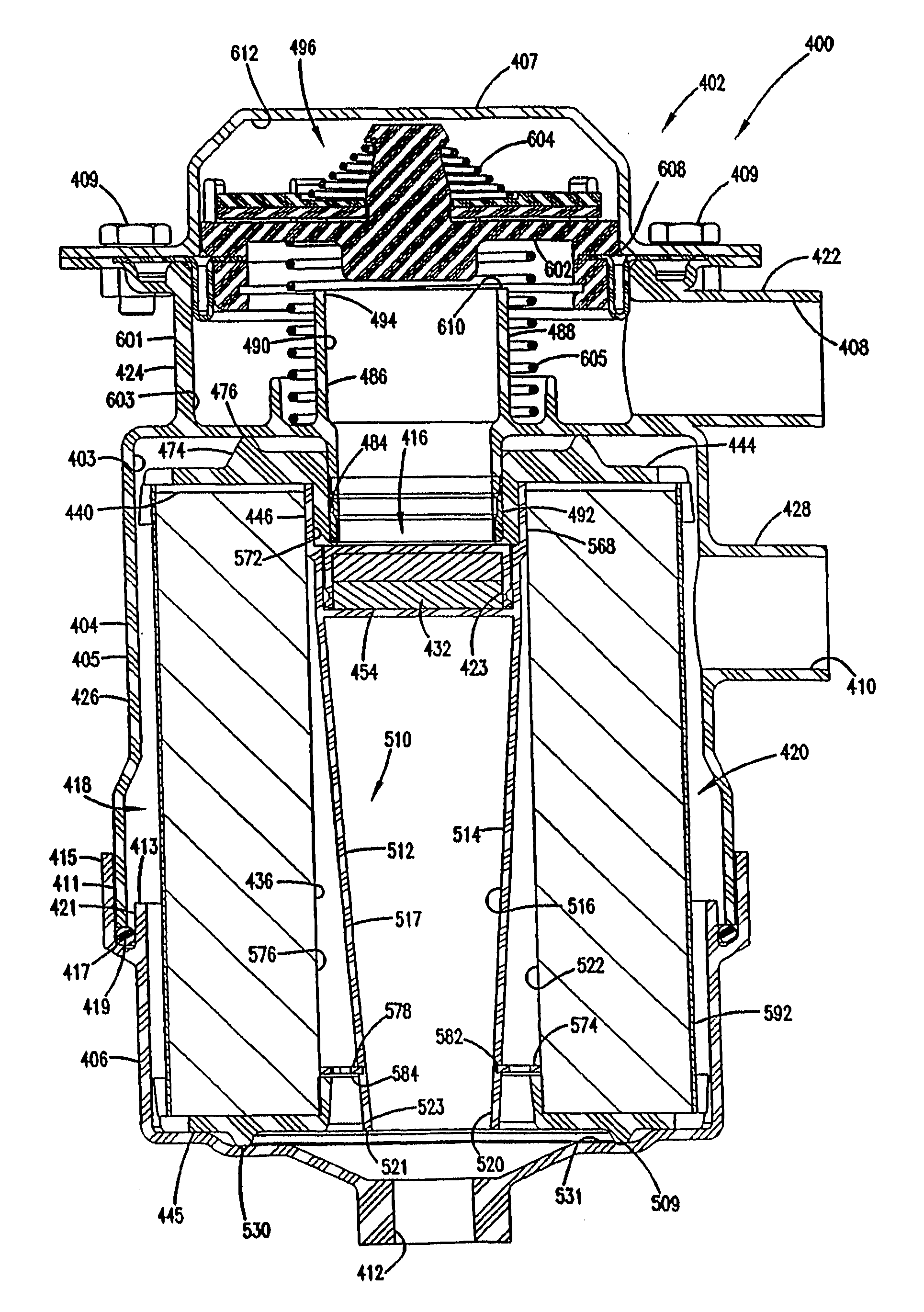

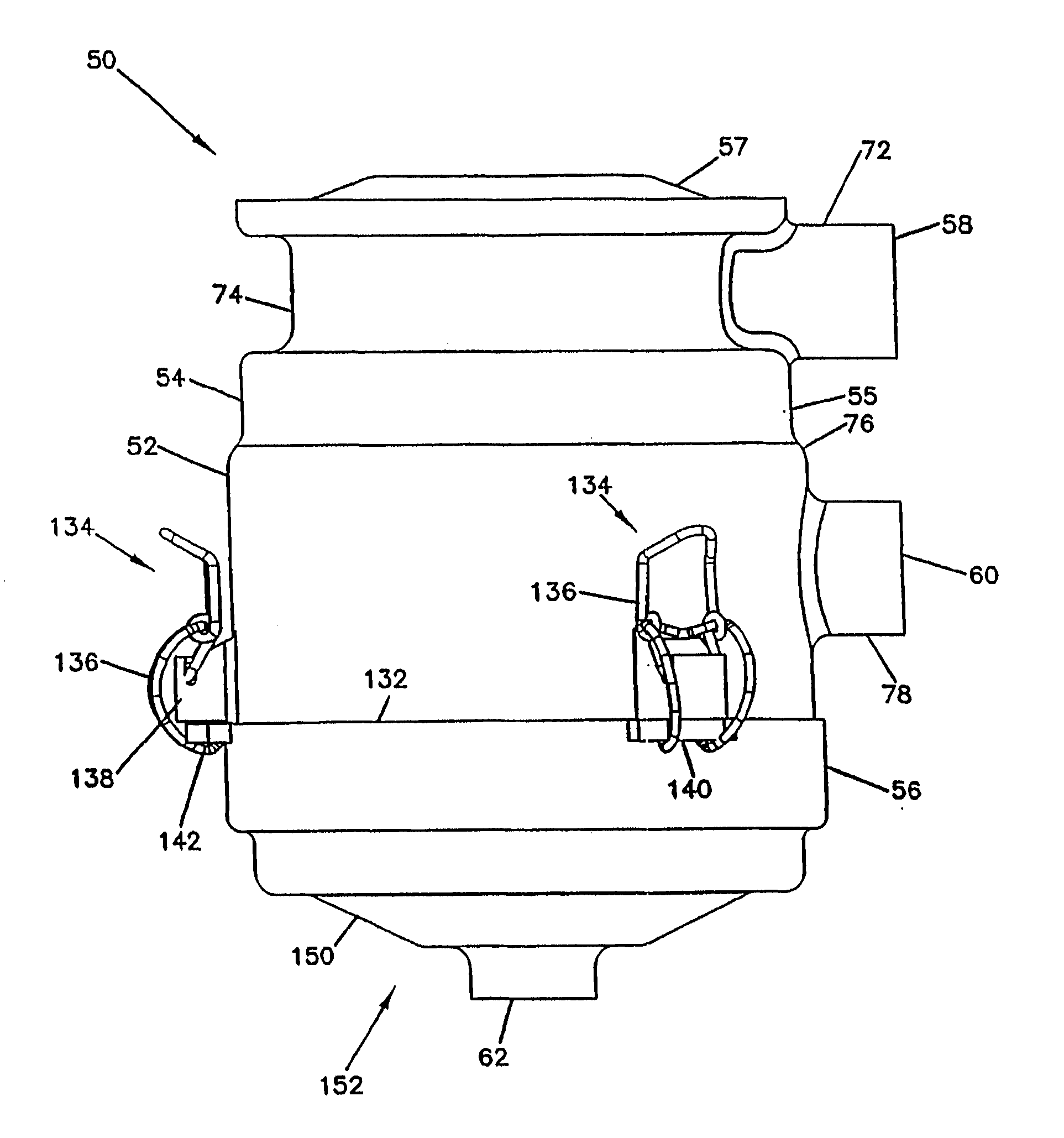

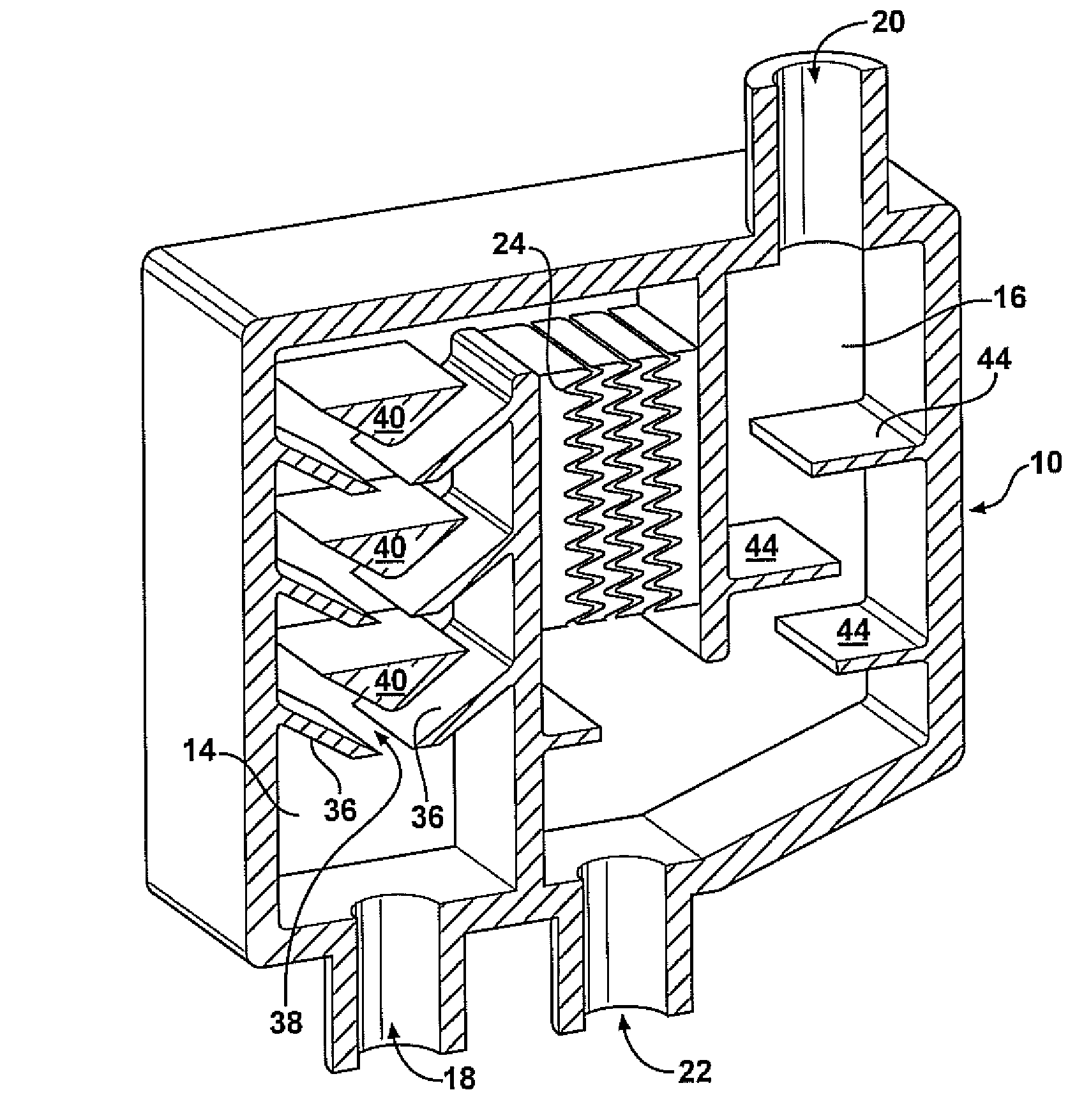

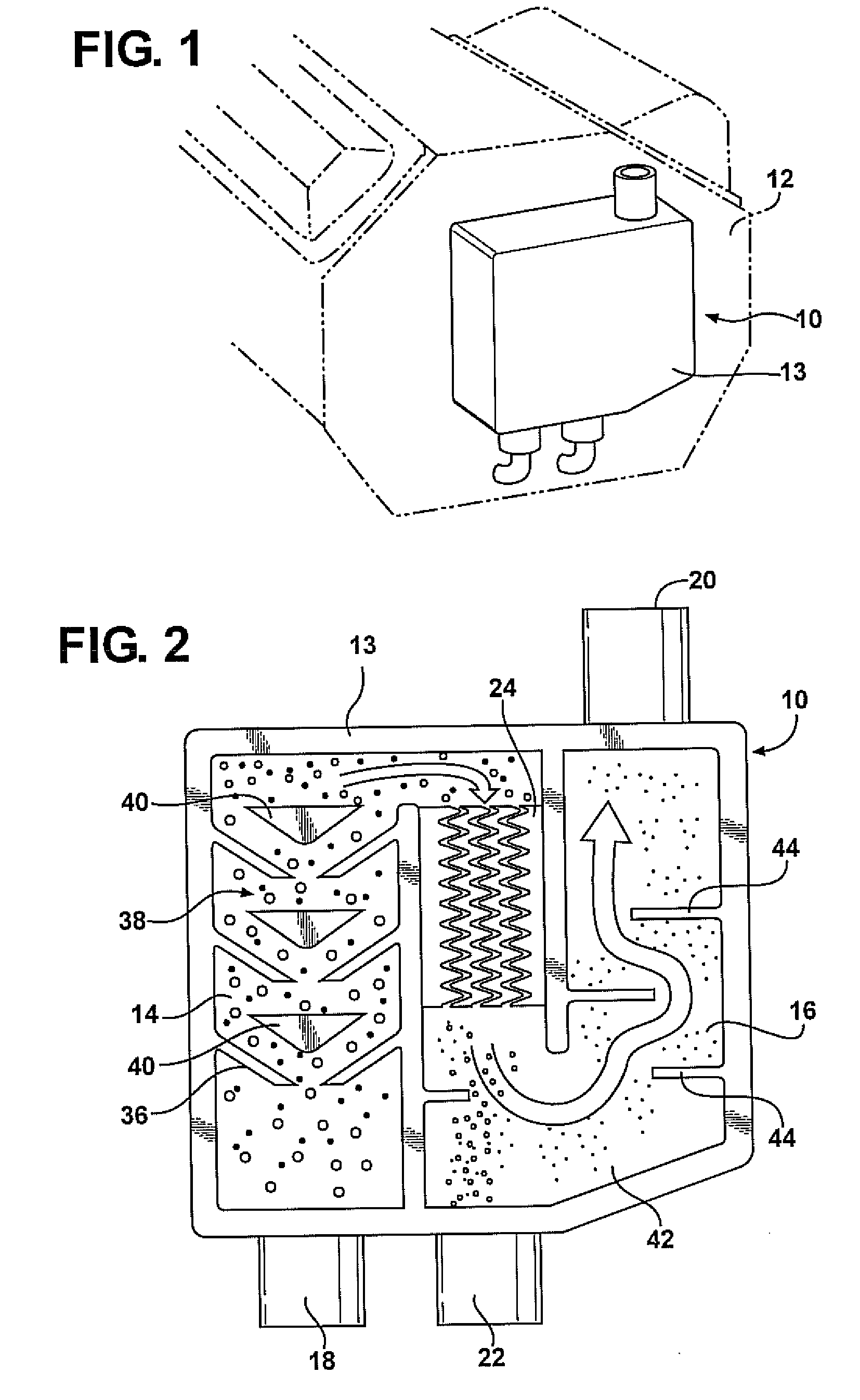

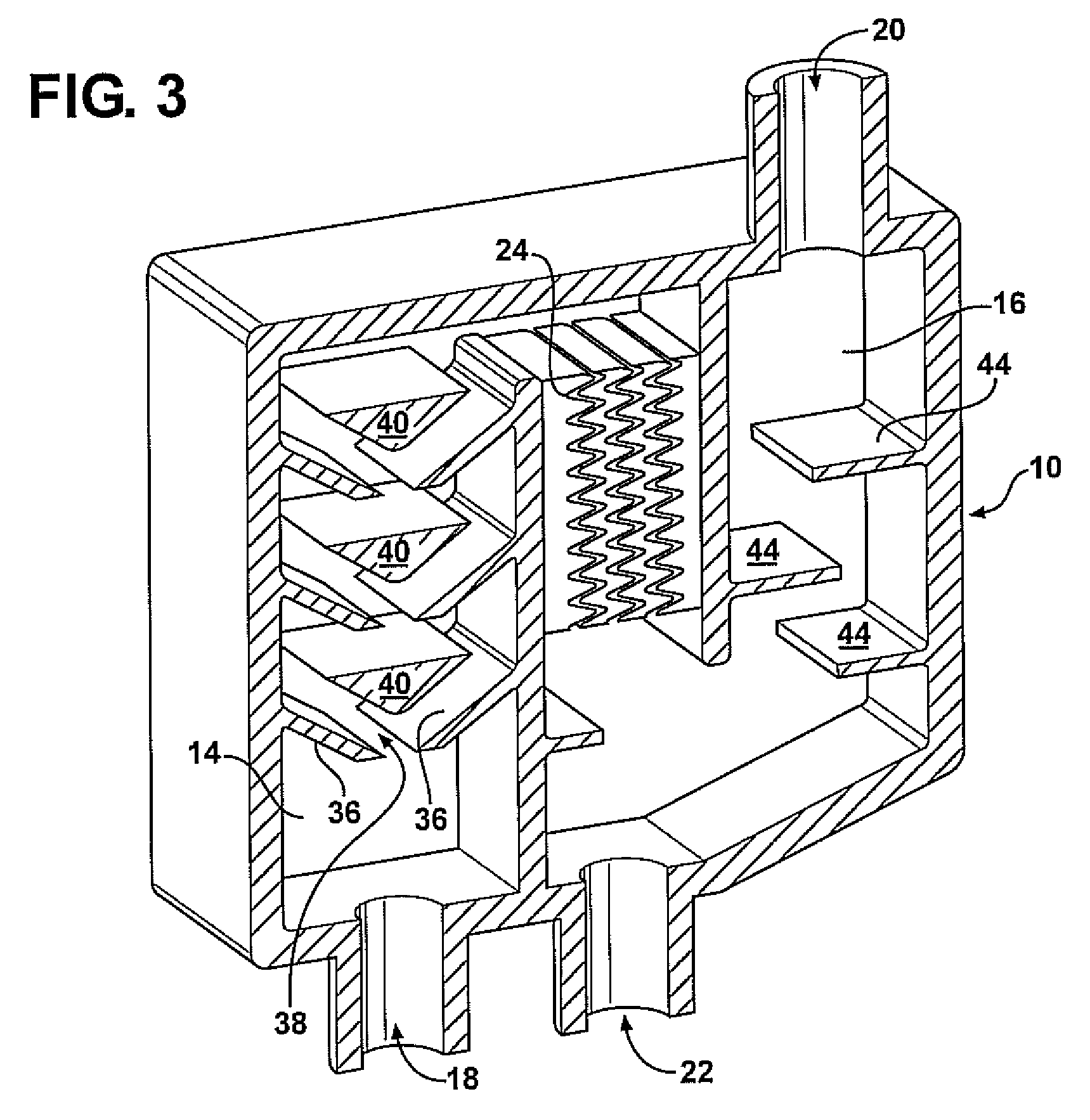

Aerosol Separator; Components; and, Methods

Arrangements for use in crankcase ventilation are described and shown. Included are serviceable crankcase ventilation filter cartridges which include a media pack axial drain arrangement, for preferred, efficient, operation. A crankcase ventilation filter arrangements including a housing and such a serviceable cartridge is shown. Also shown and described are methods of assembly, operation and use.

Owner:DONALDSON CO INC

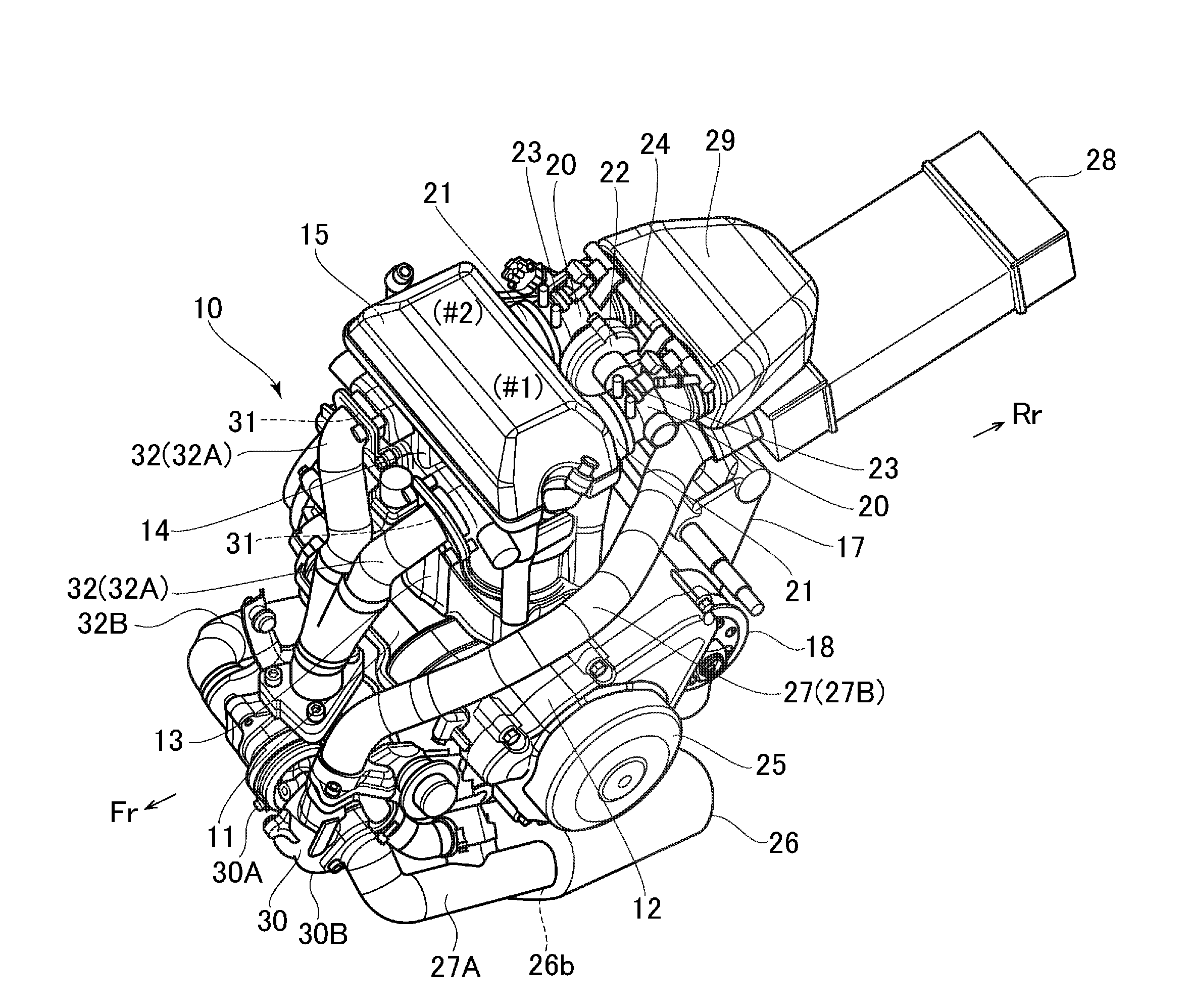

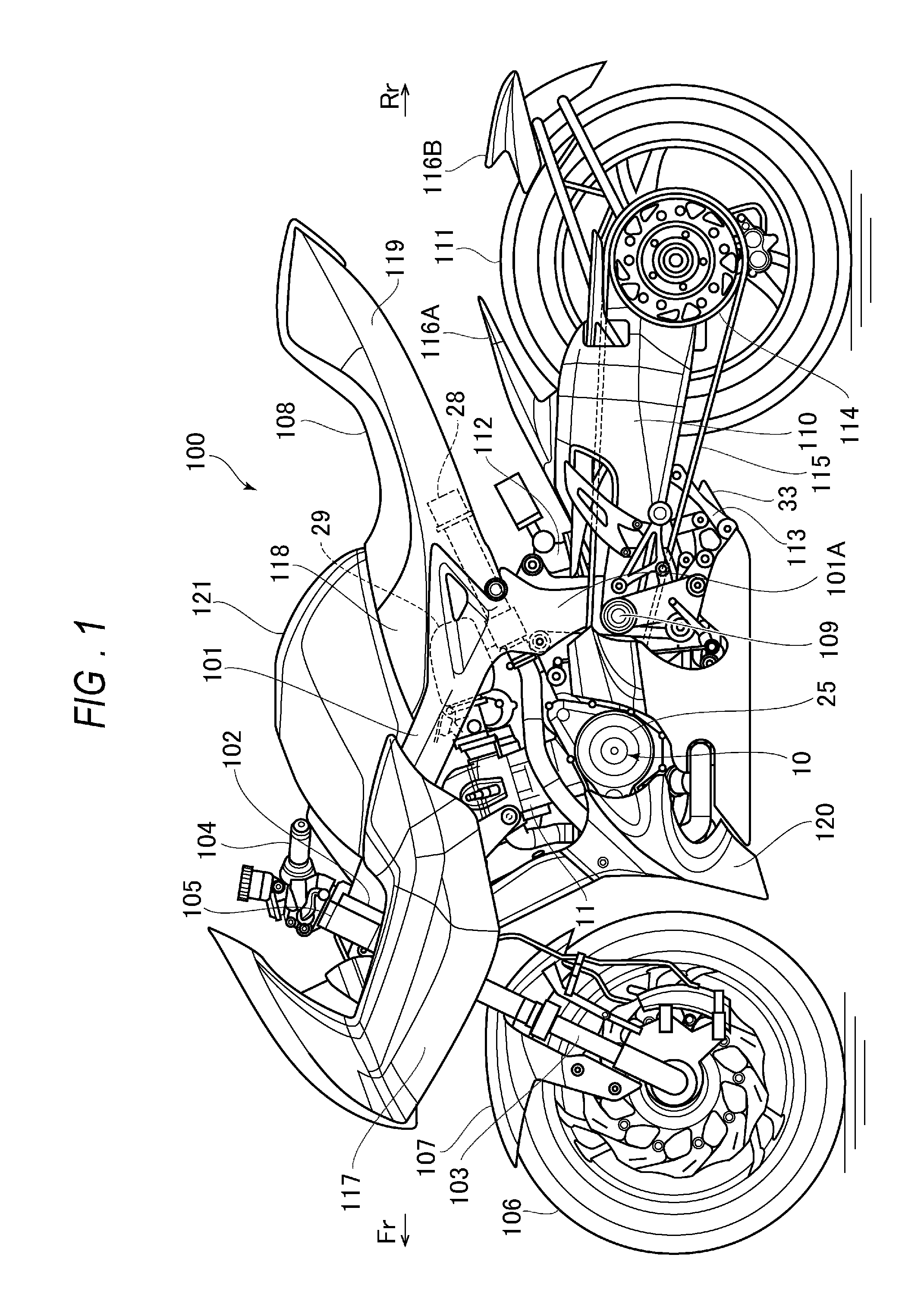

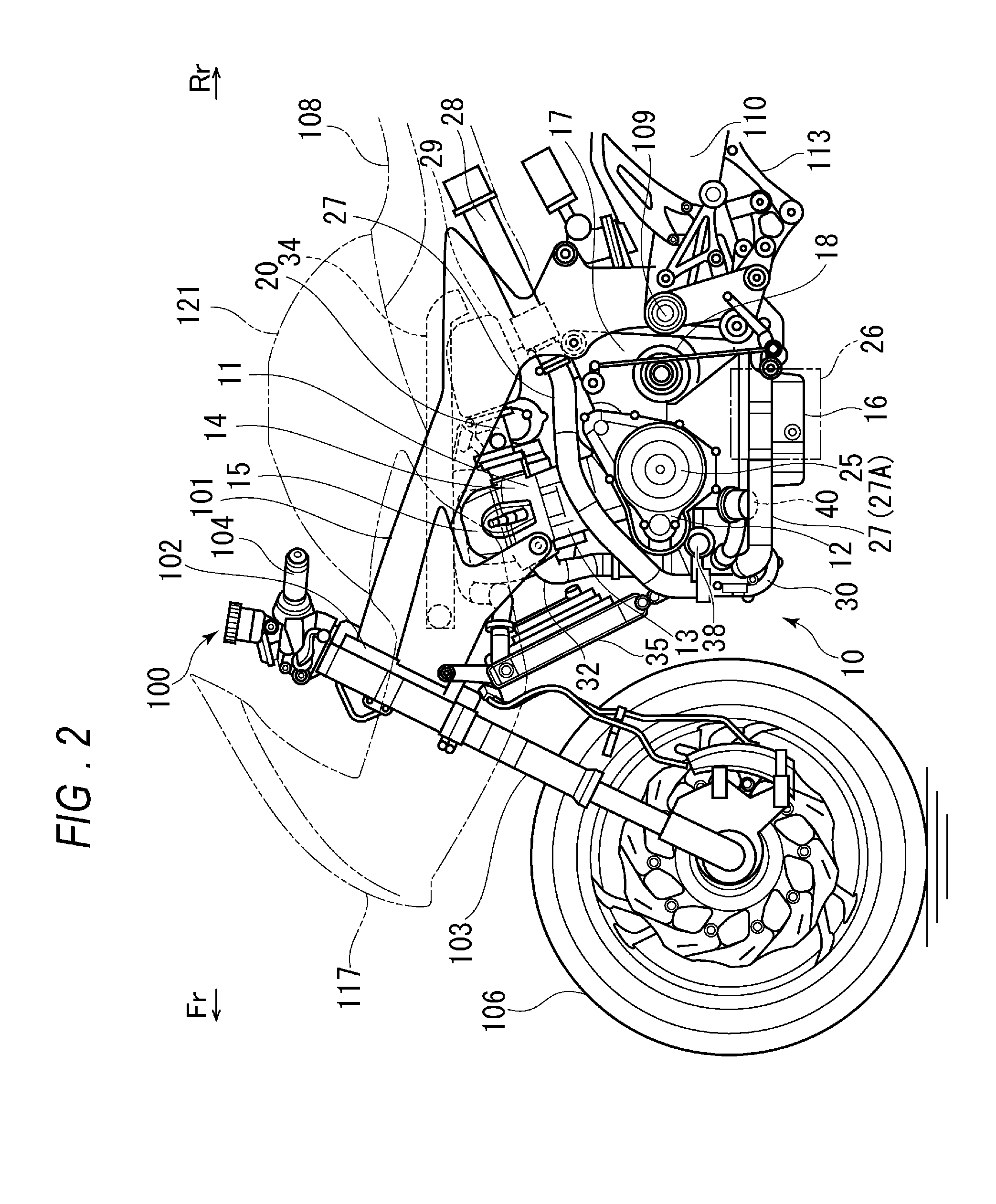

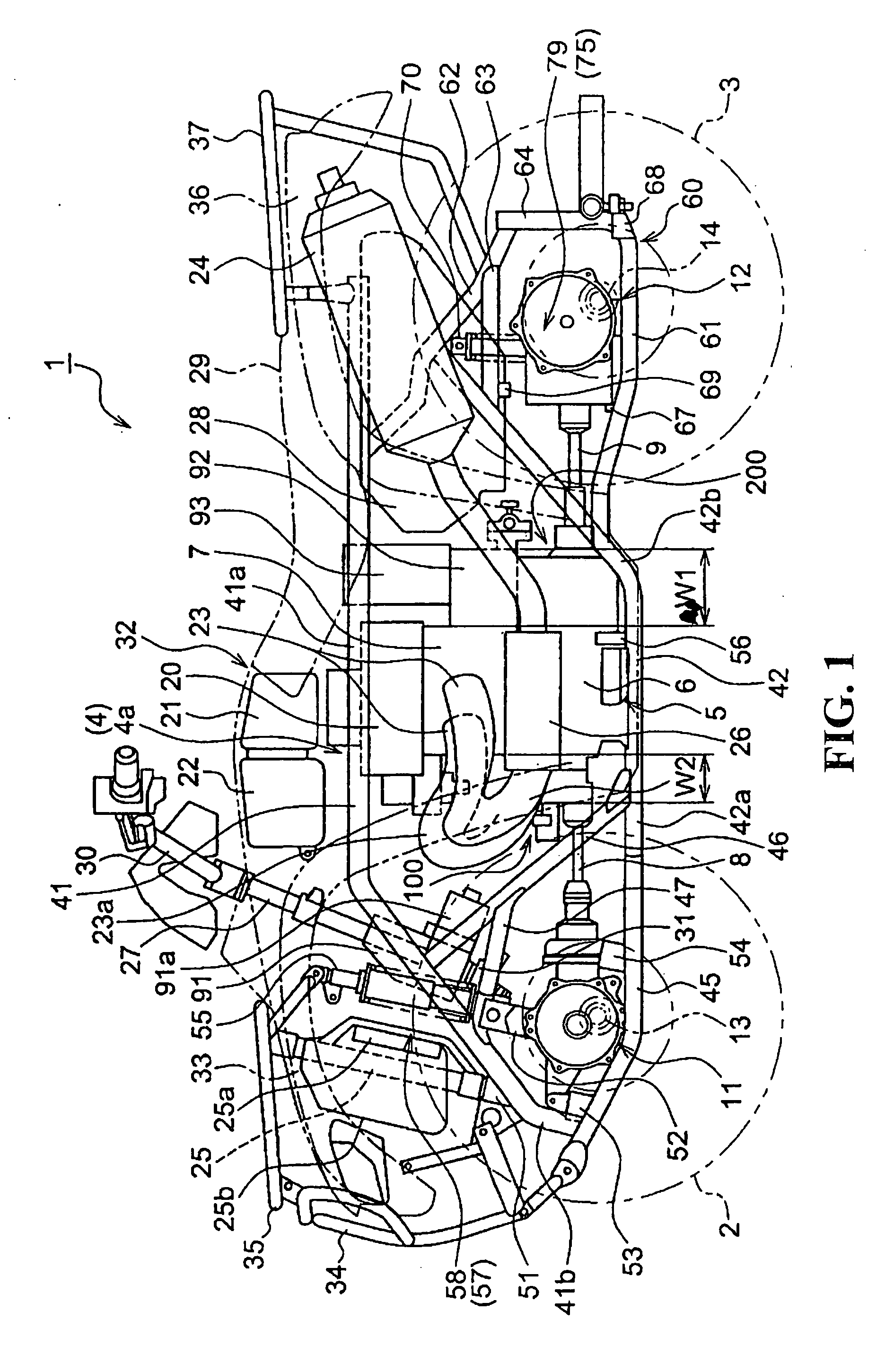

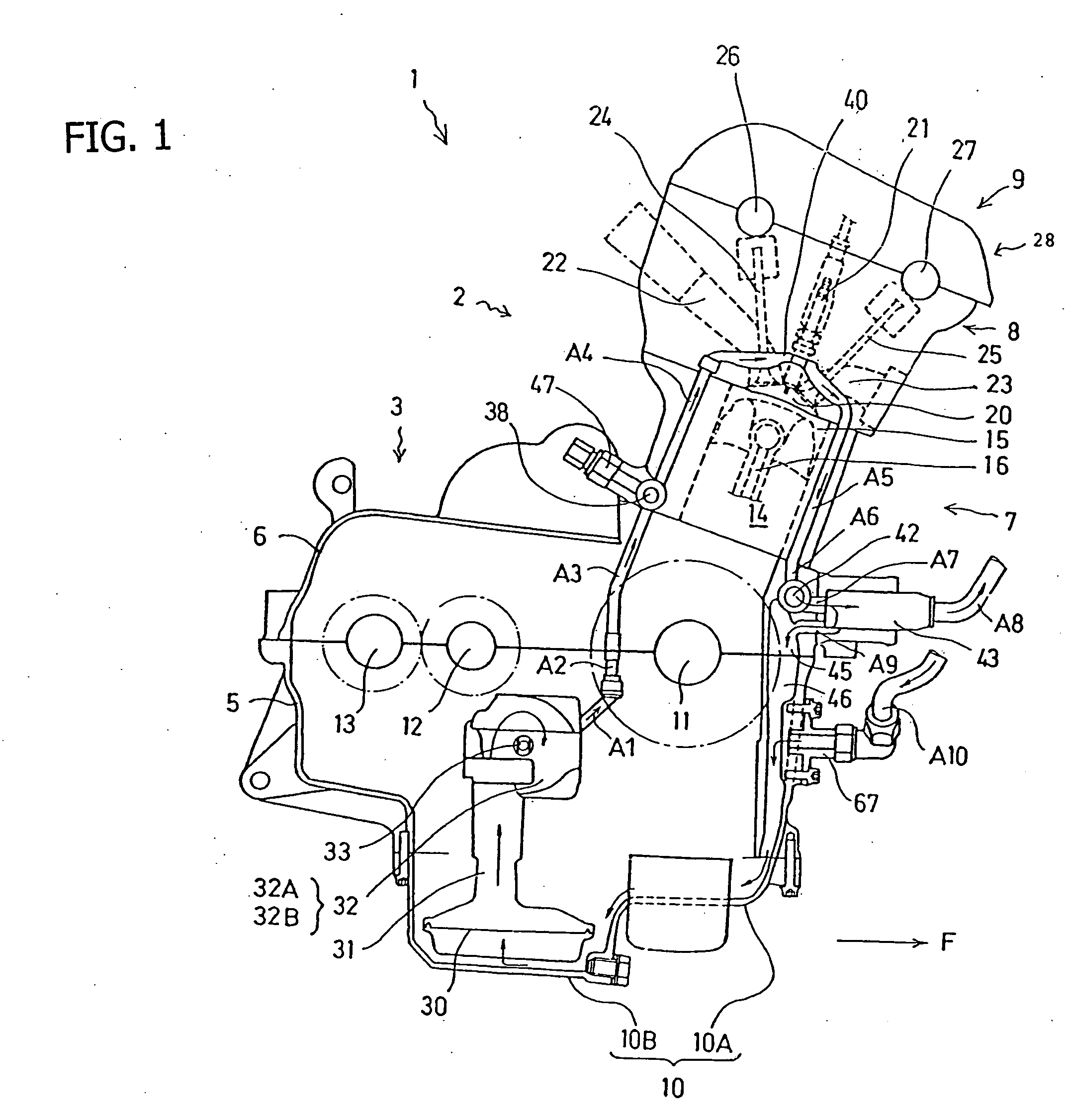

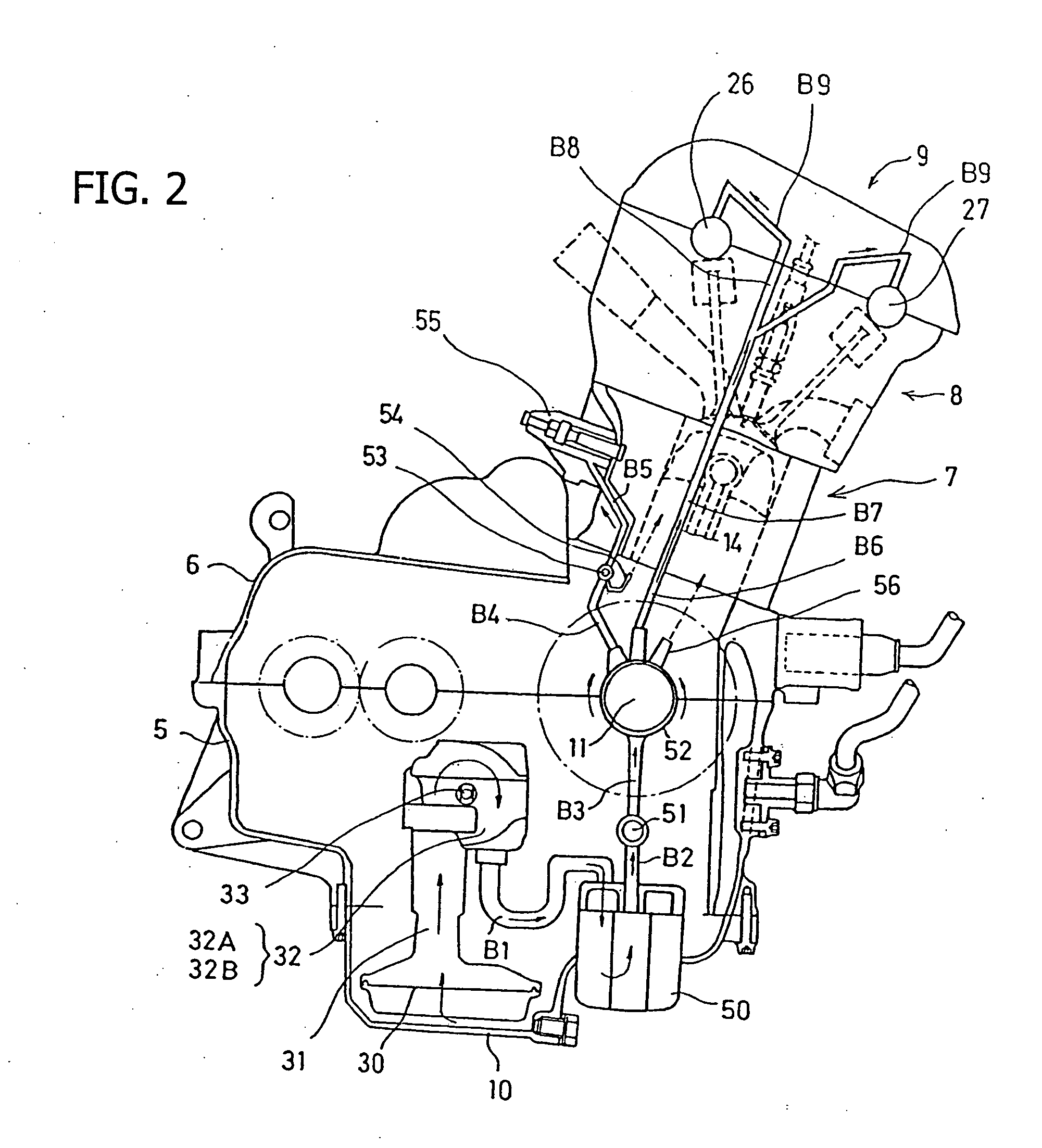

Motorcycle with turbocharger

ActiveUS20150101875A1Simple and optimum pipe dispositionLower center of gravityInternal combustion piston enginesEngine controllersTurbochargerEngineering

An engine; an air cleaner which filtrates fuel air; a turbocharger which compresses intake fuel air; an intake pipe which connects the air cleaner and the turbocharger; and an intake passage which induces the fuel air taken from an intake port at an end part to the air cleaner, are included. The turbocharger is located at a front side lower part of the engine, and the air cleaner is located under a crankcase. The intake passage extends rearward from a rear part of the air cleaner, and thereafter, bends upward.

Owner:SUZUKI MOTOR CORP

Crank case ventilation filter assembly; and methods

Crankcase ventilation filter arrangements and components therefore are described. Example arrangements are described. In one, a serviceable filter cartridge includes a check valve therein, for protection during vehicle rollover. Handle arrangements are also described. Methods of use are described.

Owner:DONALDSON CO INC +1

Crankcase Ventilation Filter

A crankcase ventilation filter includes a media stage comprising continuous, extruded fibres having a largest cross sectional size of at least 10 microns, a calculated pore size in the x-y direction of 10-60 microns, an added binder resin content if any of no greater than 7% by weight of the total fibre material; the continuous fibres being bonded at spaced locations. An assembly comprising the filter and a housing including a gas flow inlet, a gas flow outlet and a liquid drain.

Owner:DONALDSON CO INC

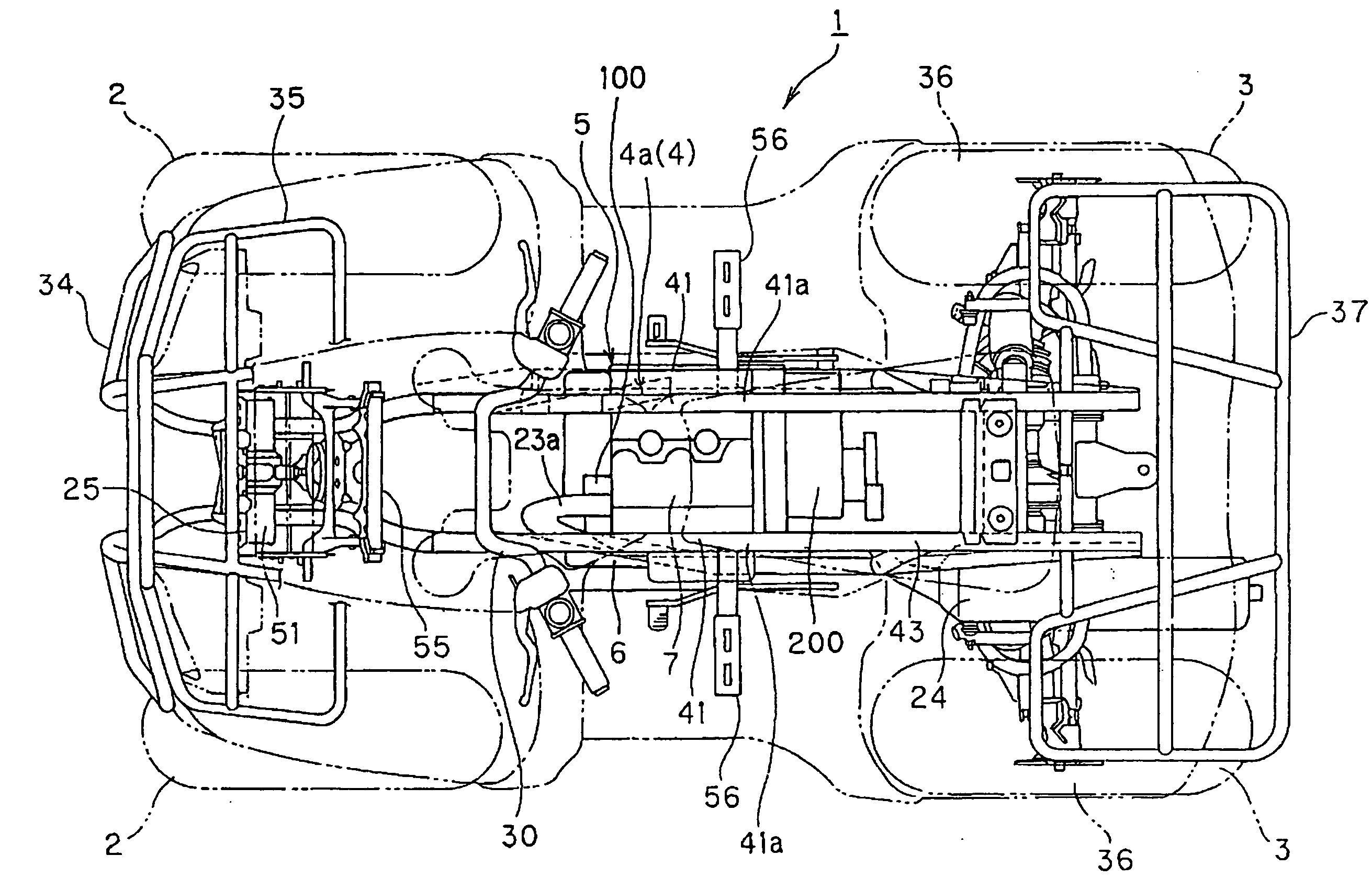

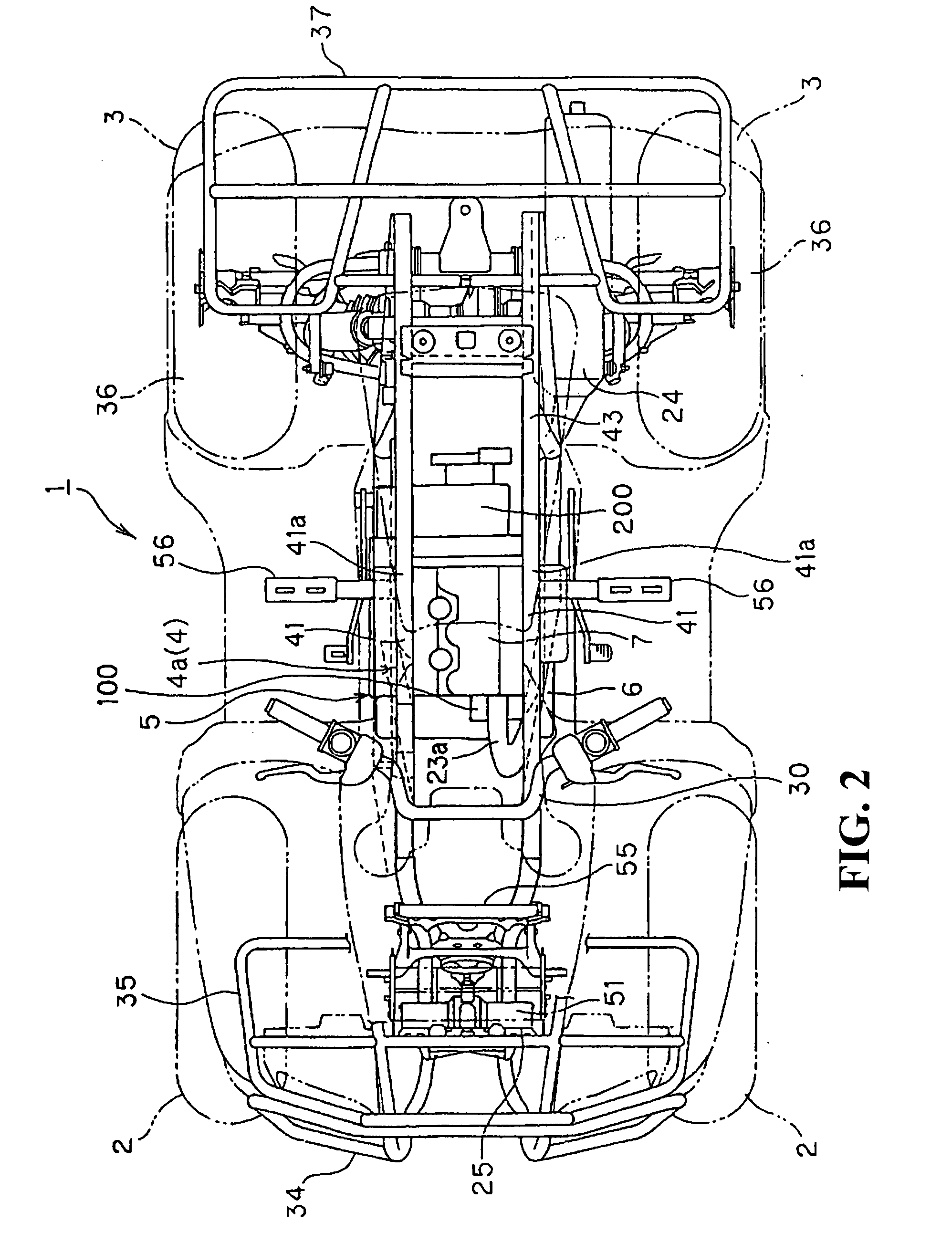

Engine arrangement structure of saddle-ride type vehicle

ActiveUS20080257630A1Convenient ArrangementElectric propulsion mountingGas pressure propulsion mountingCrankcaseAlternating current

An engine arrangement structure of a saddle-ride type vehicle includes an engine having a crankcase and a cylinder part overhung upwardly from the crankcase. An alternating current generator is provided at one end of the crankshaft with a power transmission system member being provided at the other end thereof. The alternating current generator and the power transmission system member are overhung ahead of and behind the engine relative to the engine cylinder part, respectively. A width by which the power transmission system member is overhung is larger than that by which the alternating current generator is overhung. The alternating current generator of the engine is arranged so as to be directed to the front side of the vehicle body and the power transmission system member is arranged so as to be directed to the rear side of the vehicle body.

Owner:HONDA MOTOR CO LTD

Five-axis plunge milling method of aeroengine crankcase

InactiveCN101767218AImprove processing efficiencyReduce processing costsMilling equipment detailsNumerical controlNumerical controlMilling cutter

The invention discloses a five-axis plunge milling method of an aeroengine crankcase, which is characterized by comprising the technical processes of part processing technology analysis, technology route formulation, cutter selection, cutting parameter selection, numerical control programming and processing. The invention overcomes the key technique of generating the paths of five-variable-axis plunge milling cutters of complex crankcase pieces, provides an effective means for crankcase processing, improves the crankcase processing efficiency and reduces the processing cost. The method can be used in the technical filed of numerical control processing of the parts of the aeroengine crankcases.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

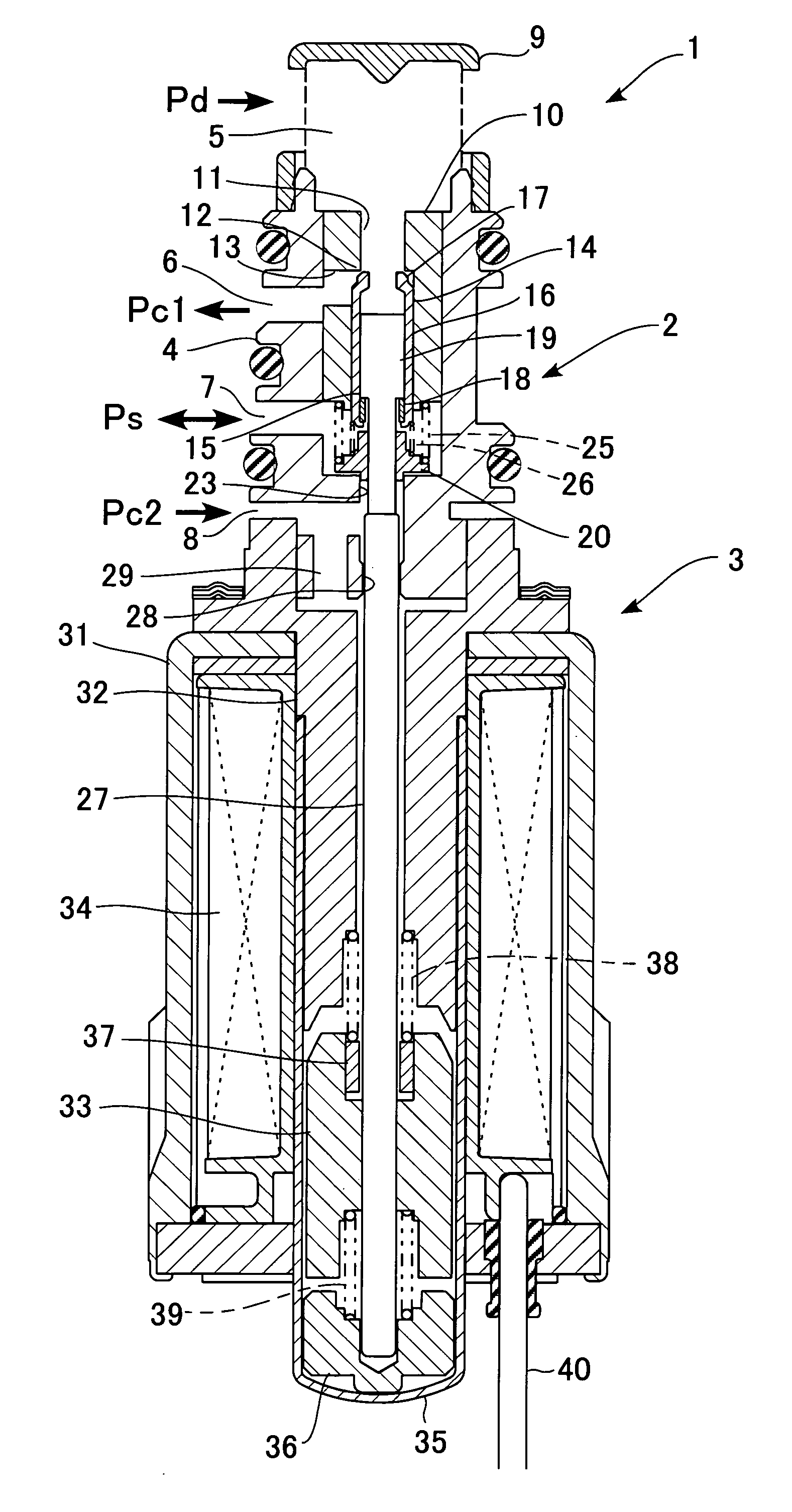

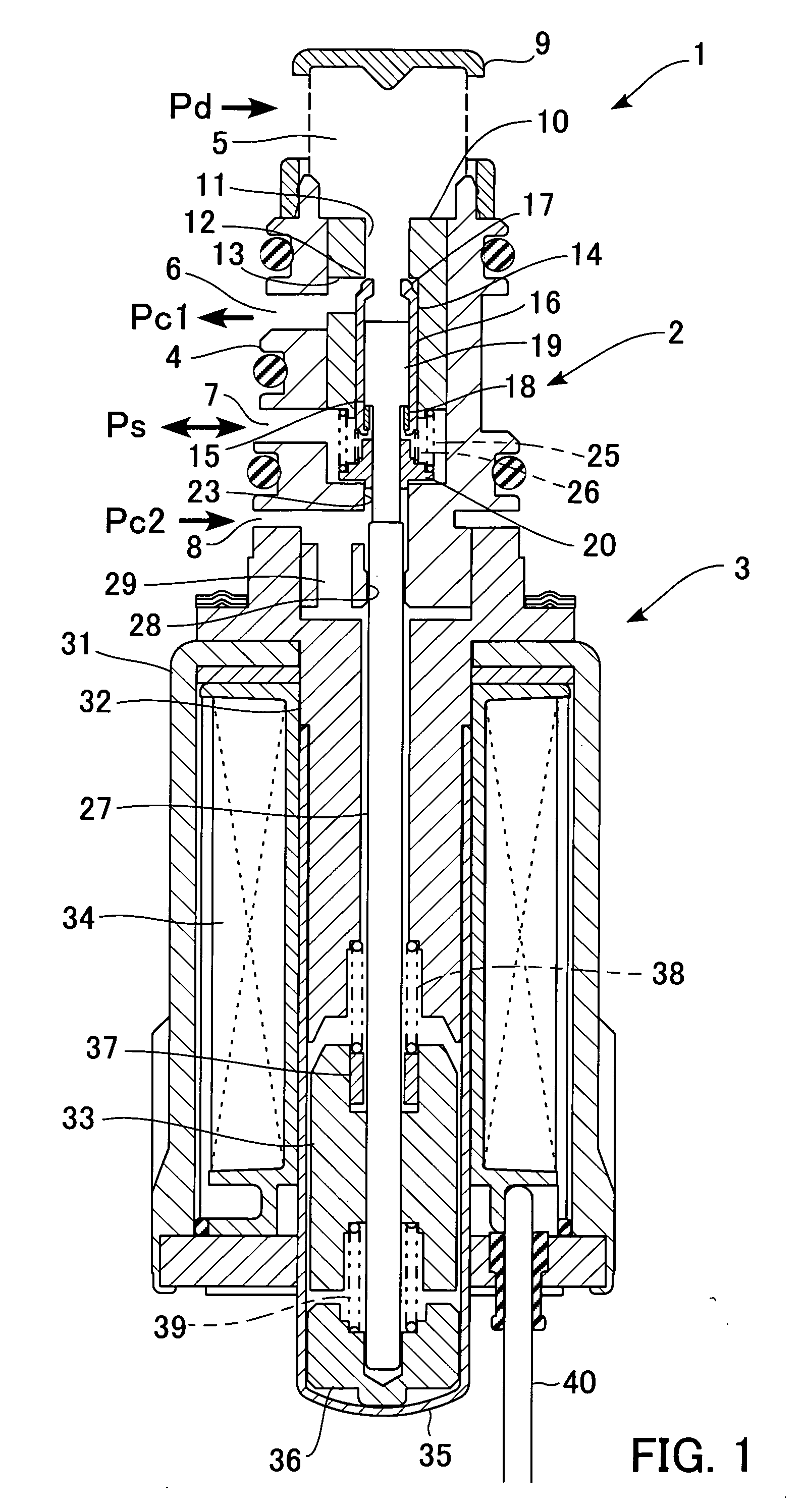

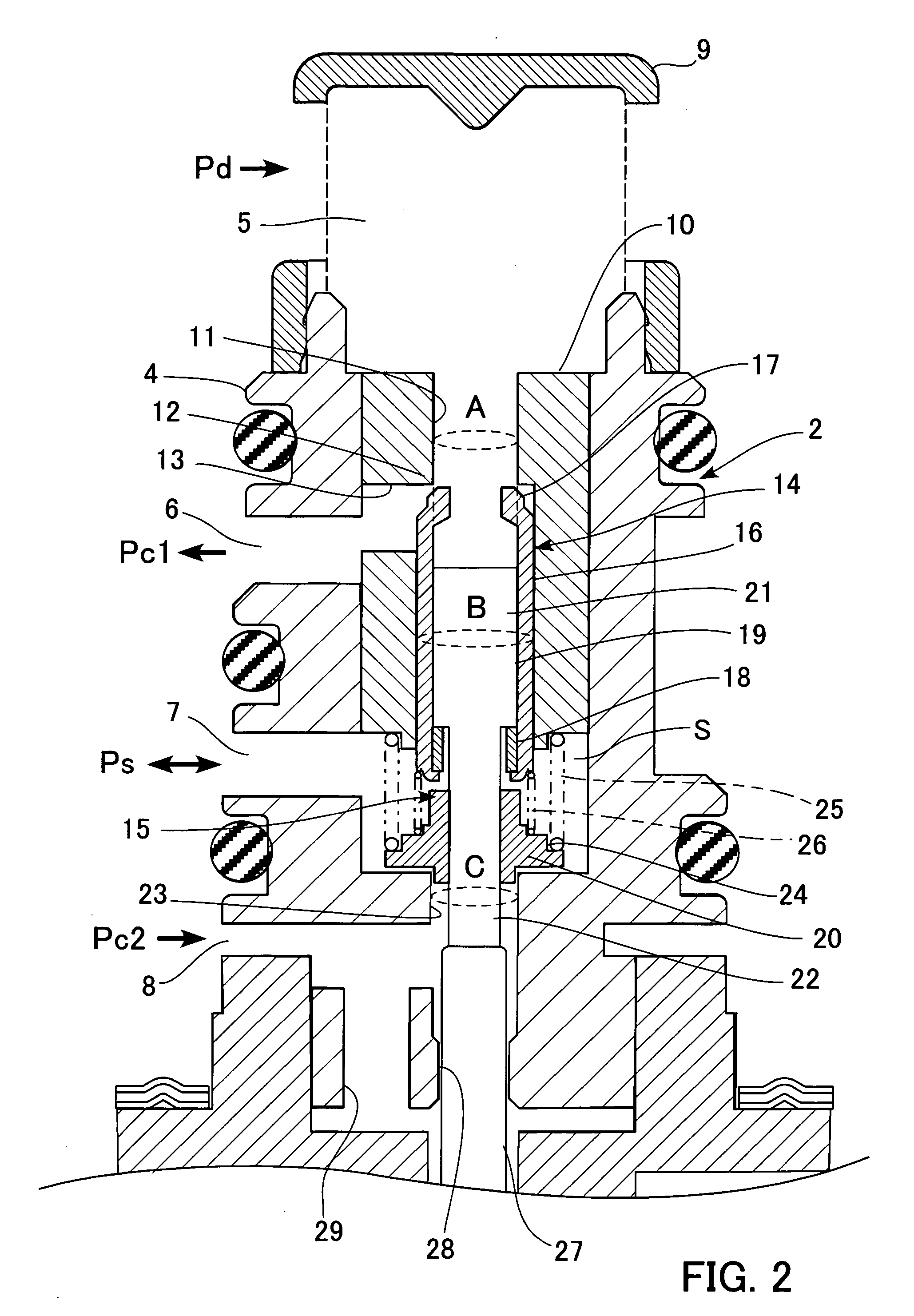

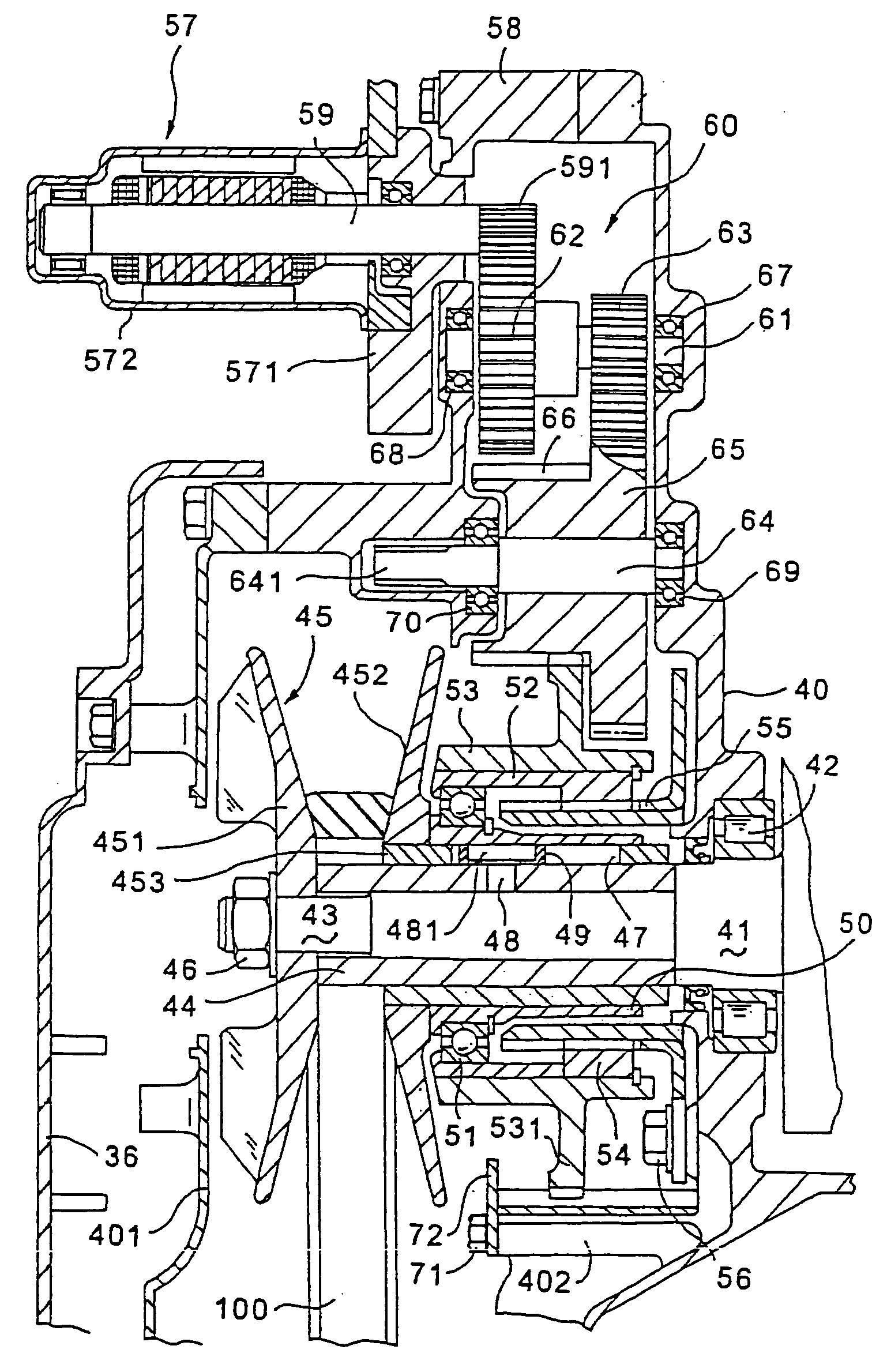

Control valve for variable displacement compressor

InactiveUS20060218953A1Improve compression efficiencyOperating means/releasing devices for valvesCompression machines with non-reversible cycleDifferential pressureEngineering

To enable a control valve for a variable displacement compressor, which operates by sensing a differential pressure between discharge pressure and suction pressure or between the discharge pressure and crankcase pressure, to enhance compression efficiency inside the compressor. In the control valve for a variable displacement compressor, according to the present invention, after a valve element on a high pressure side closes a valve hole, a valve element on a low pressure side opens a valve hole. Therefore, it is possible to eliminate a region in which both the valves on the high pressure side and the low pressure side are simultaneously open. This makes it possible to prevent refrigerant introduced into a crankcase from being immediately delivered, which makes it possible to obtain a sufficient compression efficient.

Owner:TGK

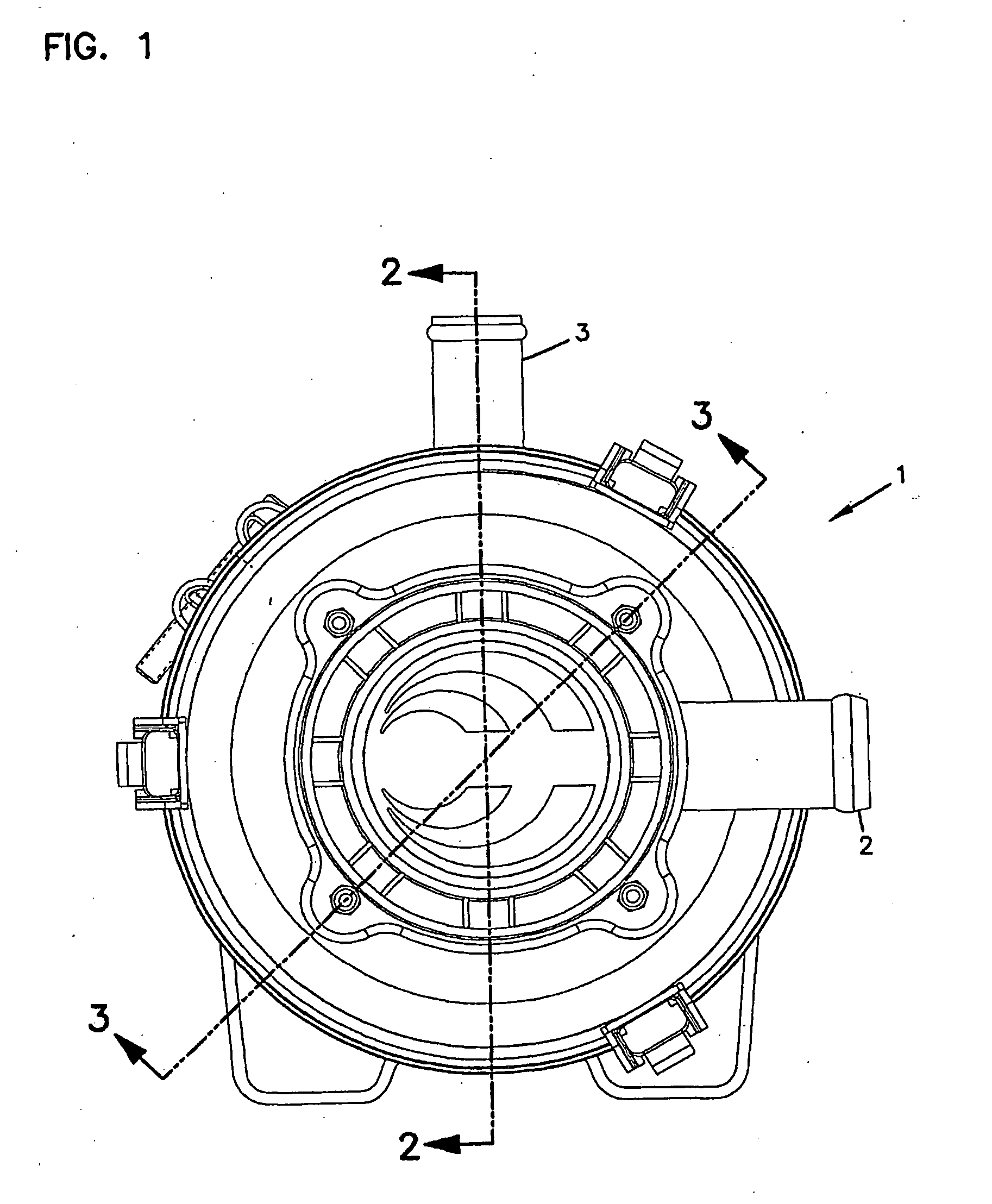

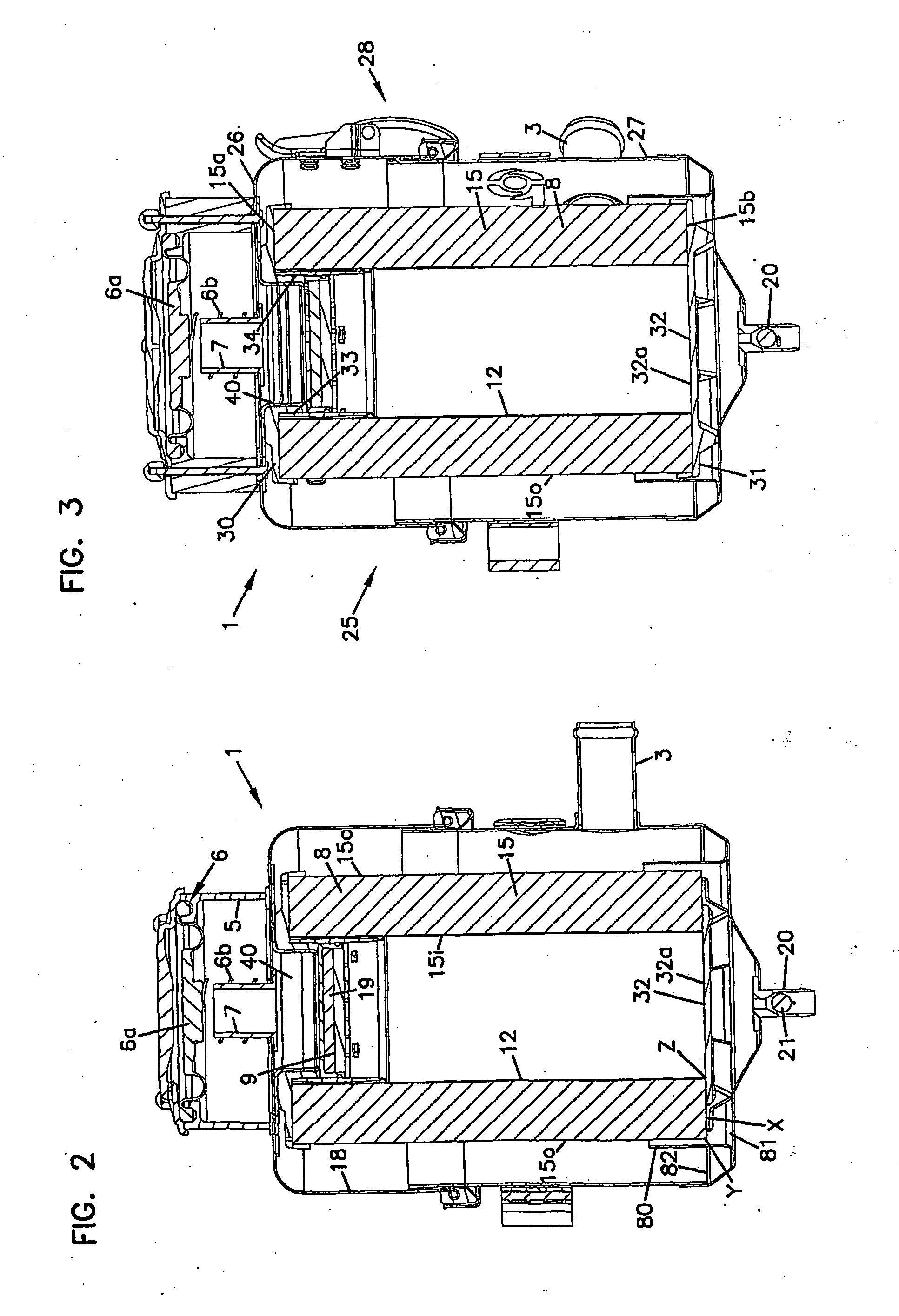

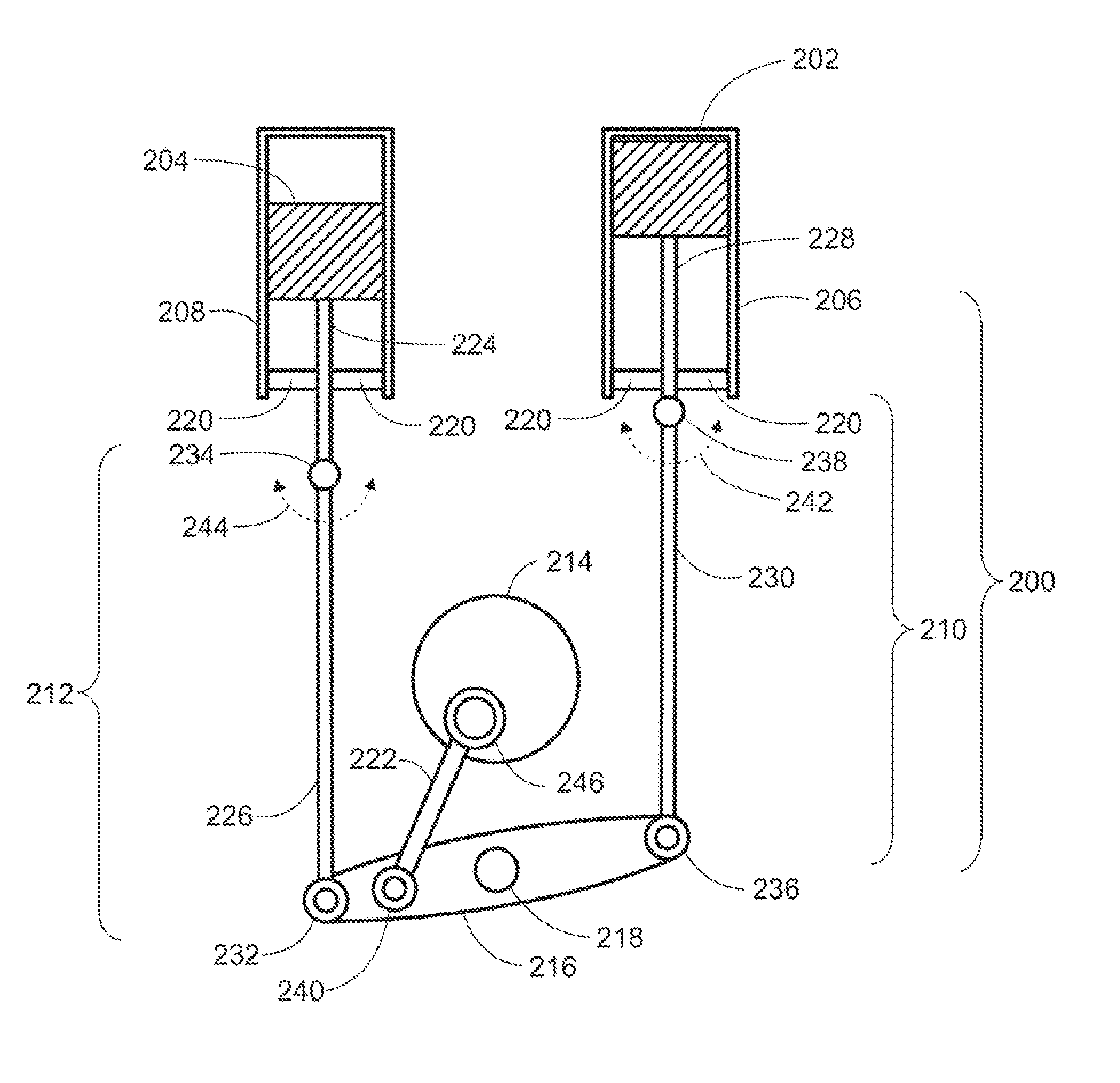

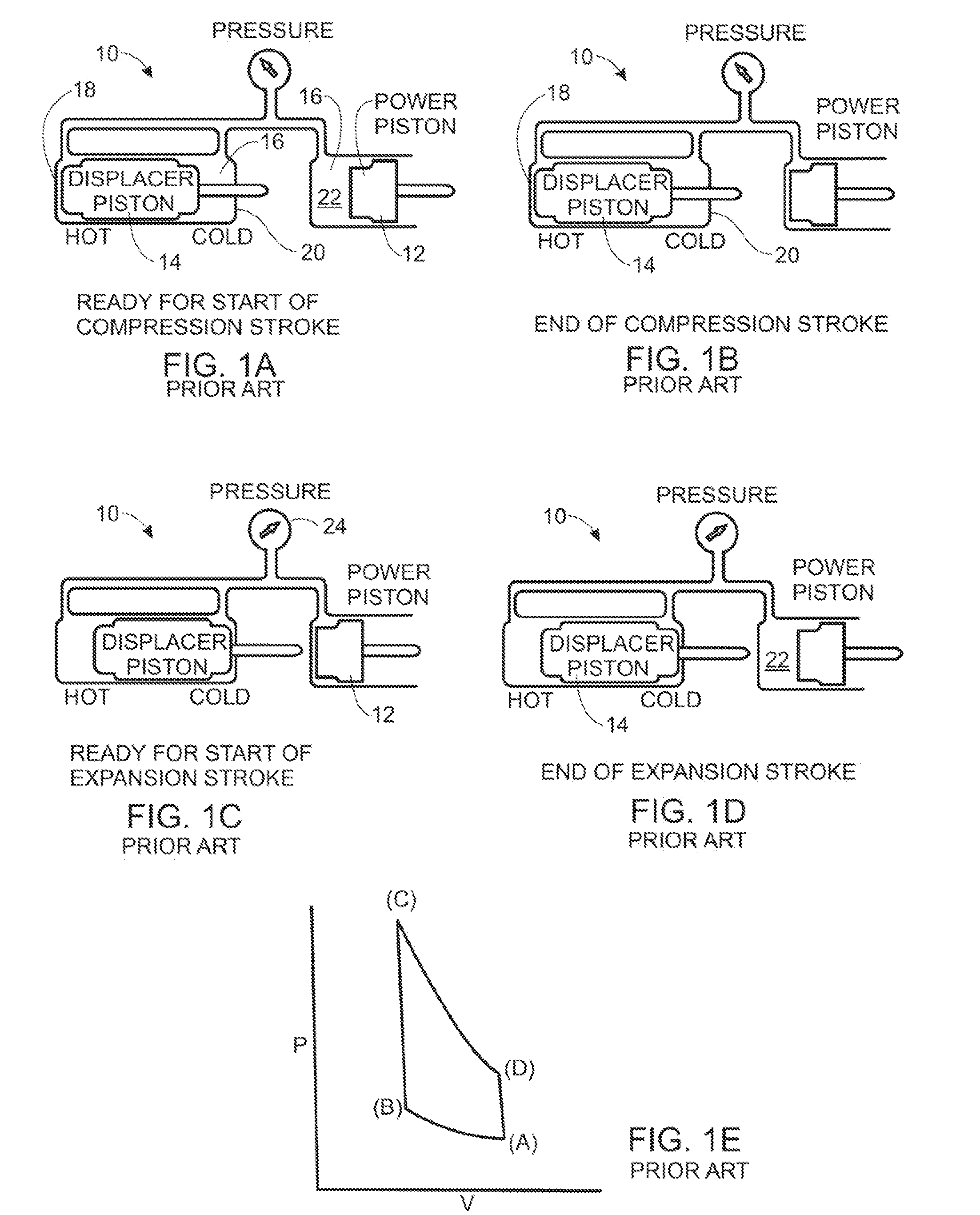

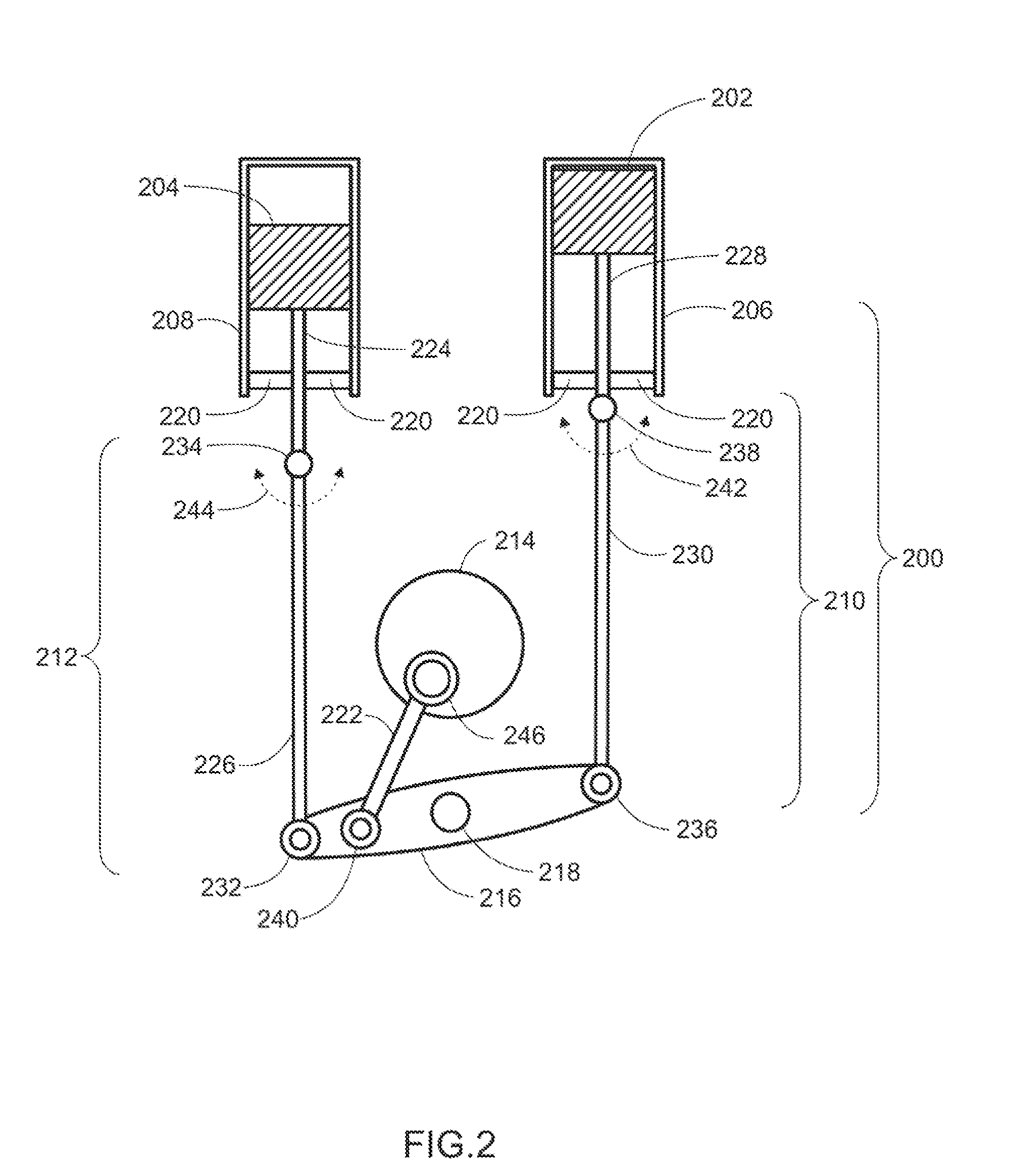

Stirling Cycle Machine

A Stirling cycle machine. The machine includes at least one rocking drive mechanism which includes: a rocking beam having a rocker pivot, at least one cylinder and at least one piston. The piston is housed within a respective cylinder and is capable of substantially linearly reciprocating within the respective cylinder. Also, the drive mechanism includes at least one coupling assembly having a proximal end and a distal end. The proximal end is connected to the piston and the distal end is connected to the rocking beam by an end pivot. The linear motion of the piston is converted to rotary motion of the rocking beam. Also, a crankcase housing the rocking beam and housing a first portion of the coupling assembly is included. A crankshaft coupled to the rocking beam by way of a connecting rod is also included. The rotary motion of the rocking beam is transferred to the crankshaft. The machine also includes a working space housing the at least one cylinder, the at least one piston and a second portion of the coupling assembly. A seal is included for sealing the workspace from the crankcase.

Owner:NEW POWER CONCEPTS

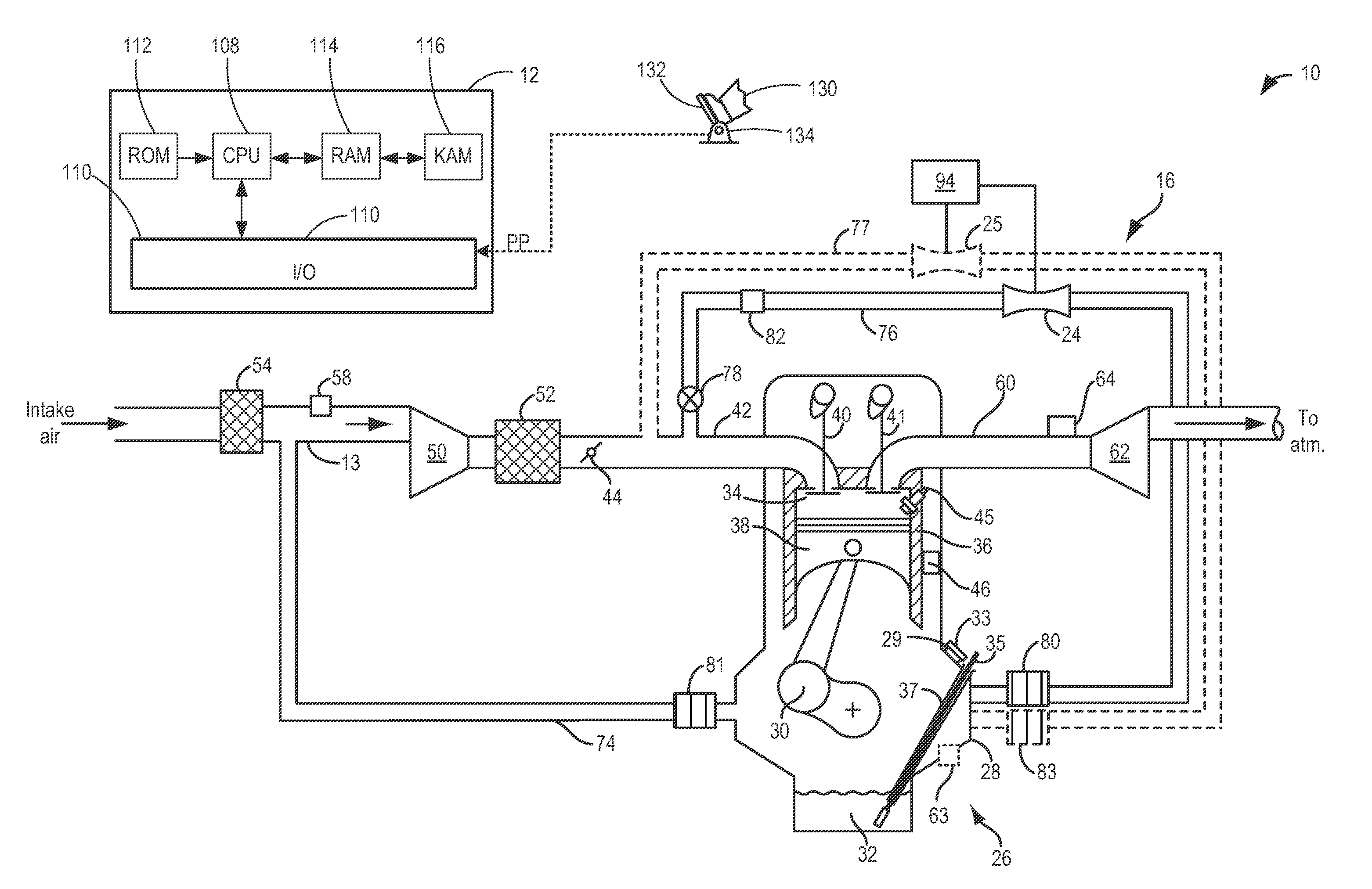

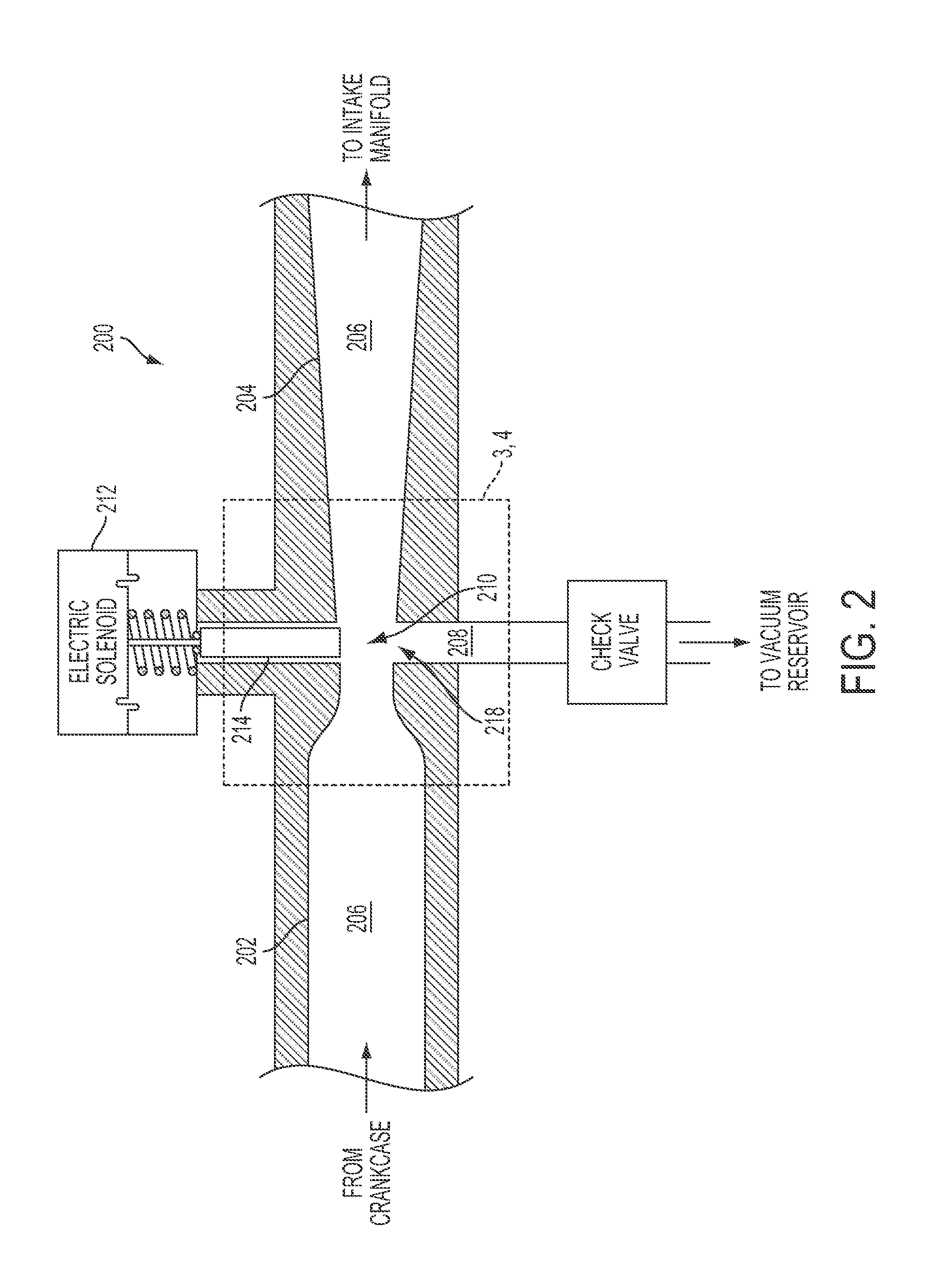

Aspirator for crankcase ventilation and vacuum generation

InactiveUS20140014080A1Avoid problemsCommunication is limitedInternal combustion piston enginesCrankcase ventillationCrankcaseEngineering

Methods and systems are provided for flowing crankcase gases through an aspirator arranged in a PCV line. The aspirator regulates PCV flow, and may also generate vacuum depending on a position of a pintle extendable across a horizontal passage of the aspirator. When regulating PCV flow and not generating vacuum, the aspirator is fully closed and crankcase gases in the horizontal passage are metered through an orifice in the pintle. When generating vacuum, the aspirator is at least partially opened and PCV flow through the horizontal passage generates vacuum at a vacuum port of the aspirator.

Owner:FORD GLOBAL TECH LLC

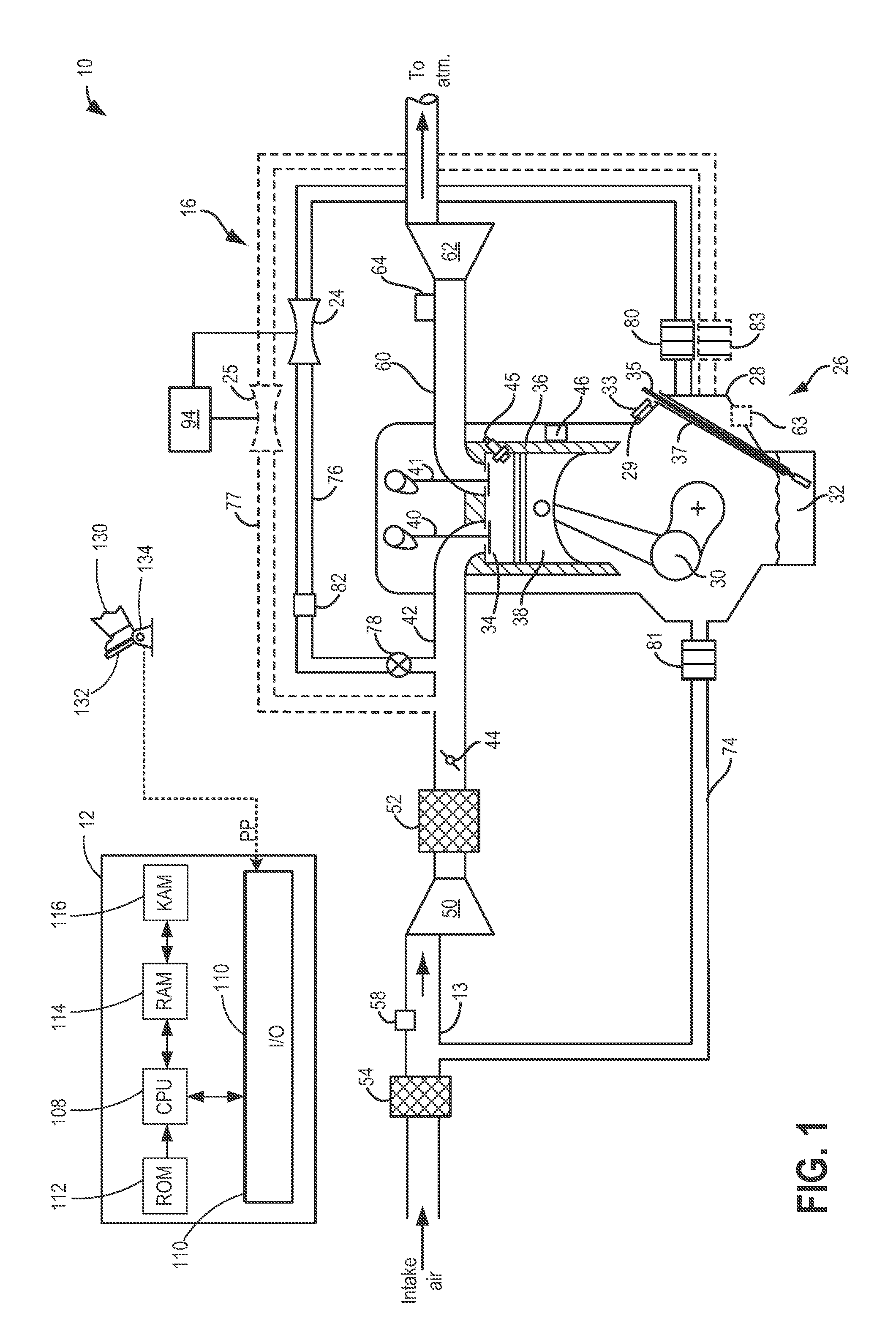

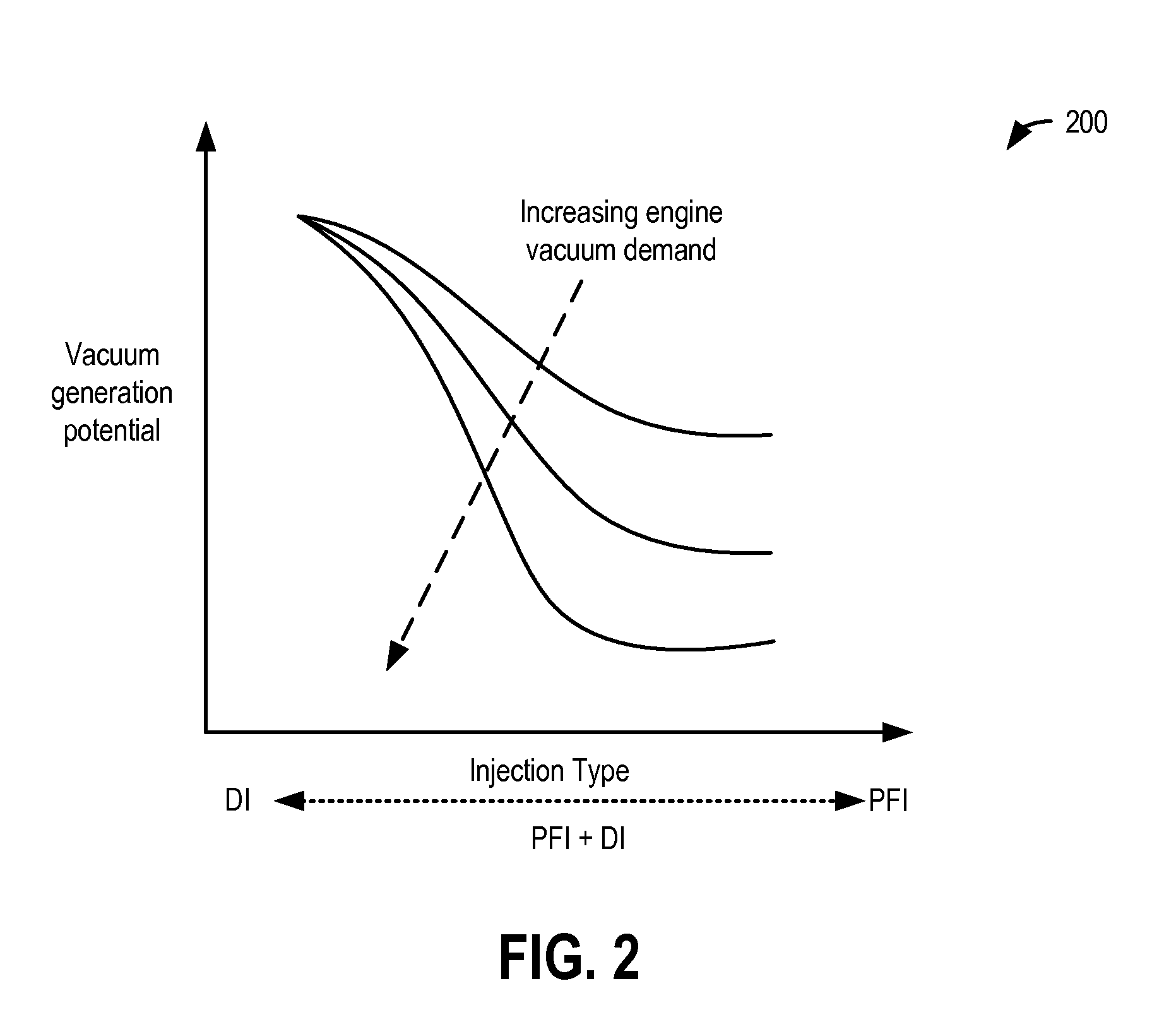

Method and system for vacuum control

ActiveUS20140261301A1Small droplet sizeImprove volumetric efficiencyElectrical controlInternal combustion piston enginesEngineeringCrankcase

Methods and systems are provided for adjusting a fuel injection split between a direct injection and a port injection based on engine vacuum demand. When more intake manifold vacuum is required, relatively more direct injection is used to take advantage of the associated throttling for generating vacuum. The vacuum may then be used for canister purging, crankcase ventilation, or actuating an engine vacuum consumption device.

Owner:FORD GLOBAL TECH LLC

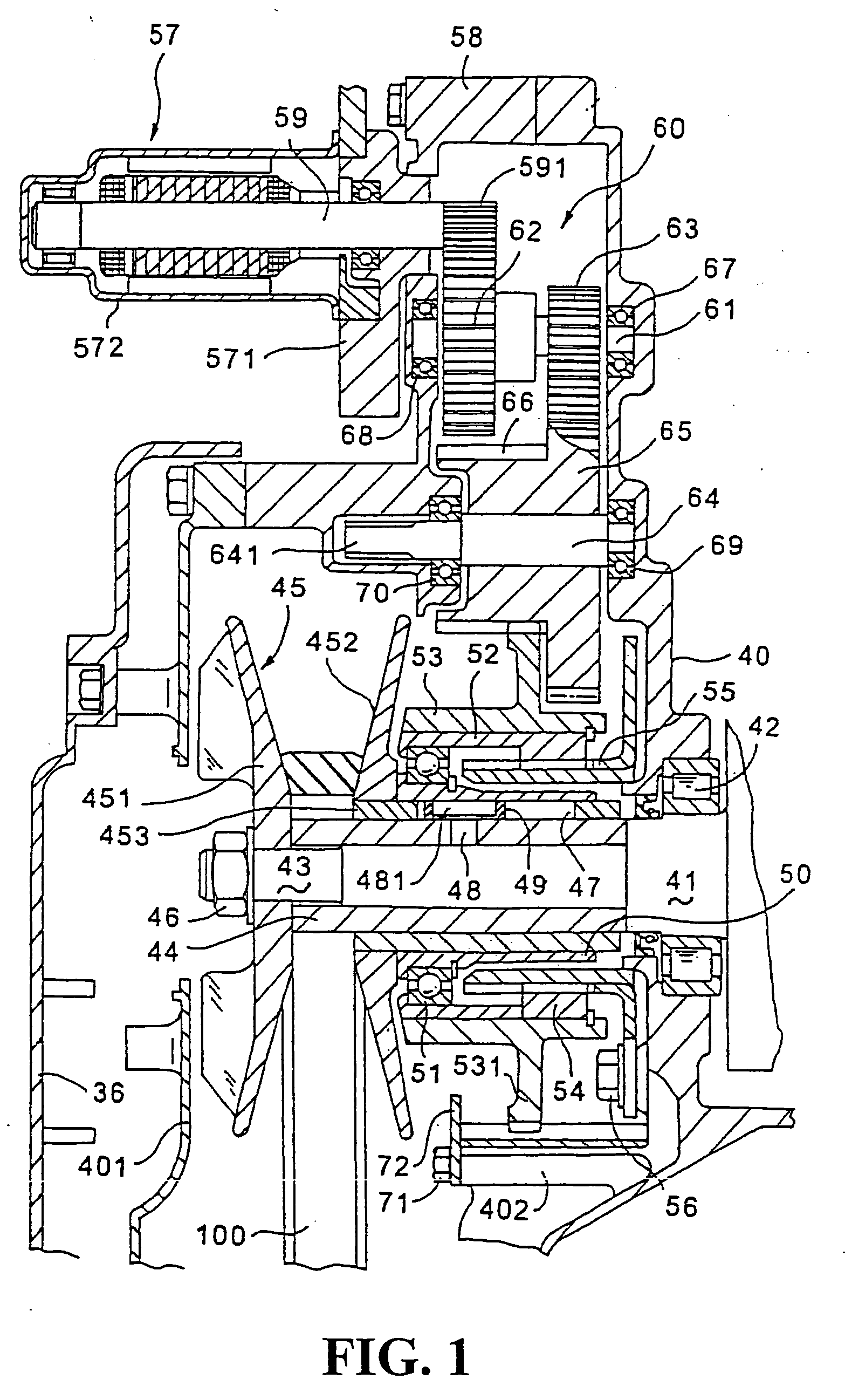

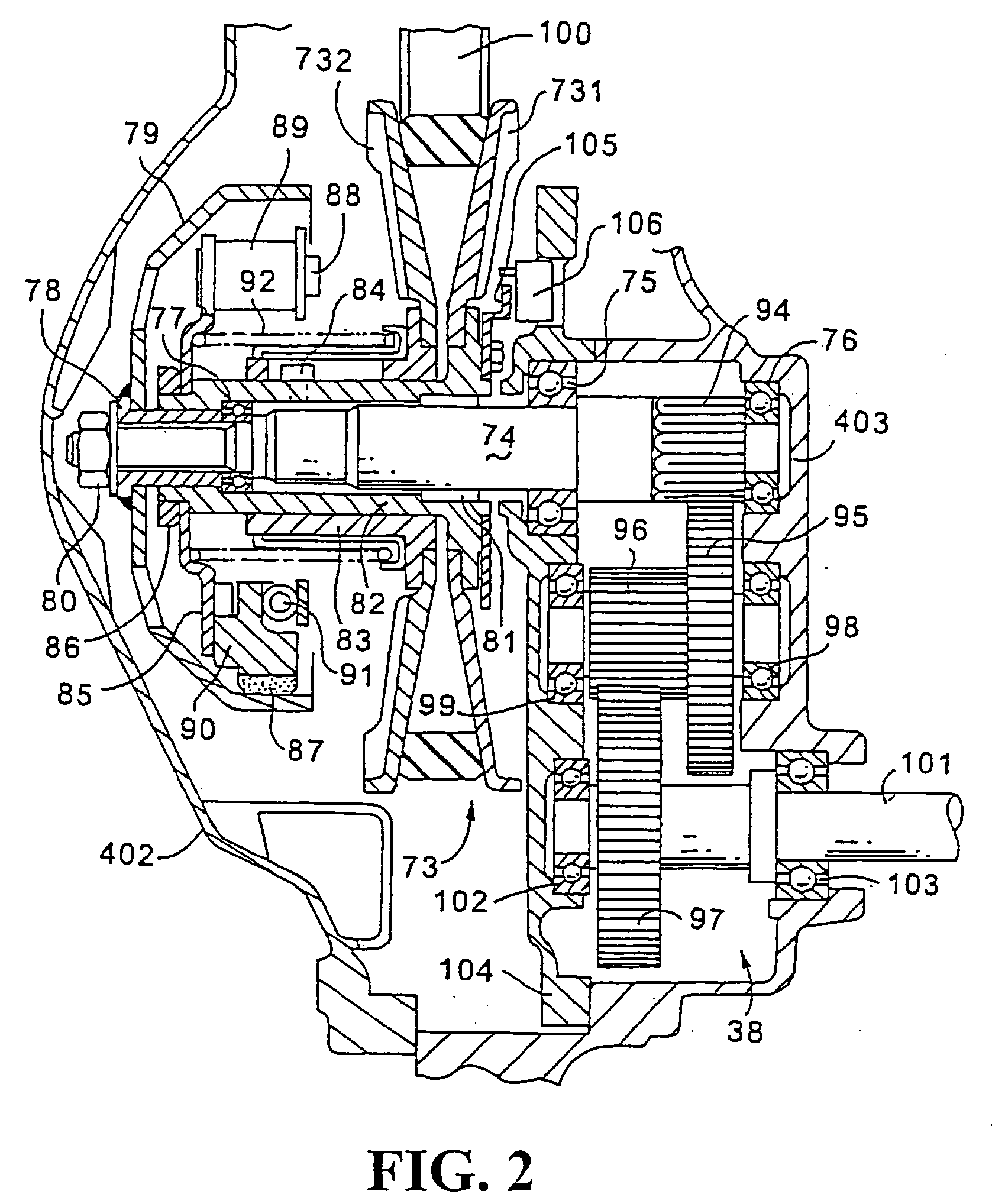

V-belt type continously variable transmission

ActiveUS20050109554A1Simplify the configuration processEasy to manufactureGearboxesGearingGear systemCrankcase

A belt continuously variable transmission apparatus having a case which includes a power transmission case (which is part of a crankcase of an engine), a power transmission case cover, and an actuator cover assembled forwardly of the power transmission case cover (displaced forwardly on a vehicle body). The actuator cover is formed as a separate member from the power transmission case cover, and supports a motor for driving a movable part of a driving pulley. In addition, the actuator cover covers a gear system. The actuator cover is integrated with a cover of the water pump. The resulting configuration improves the assembling of the actuator cover of the belt continuously variable transmission apparatus.

Owner:HONDA MOTOR CO LTD

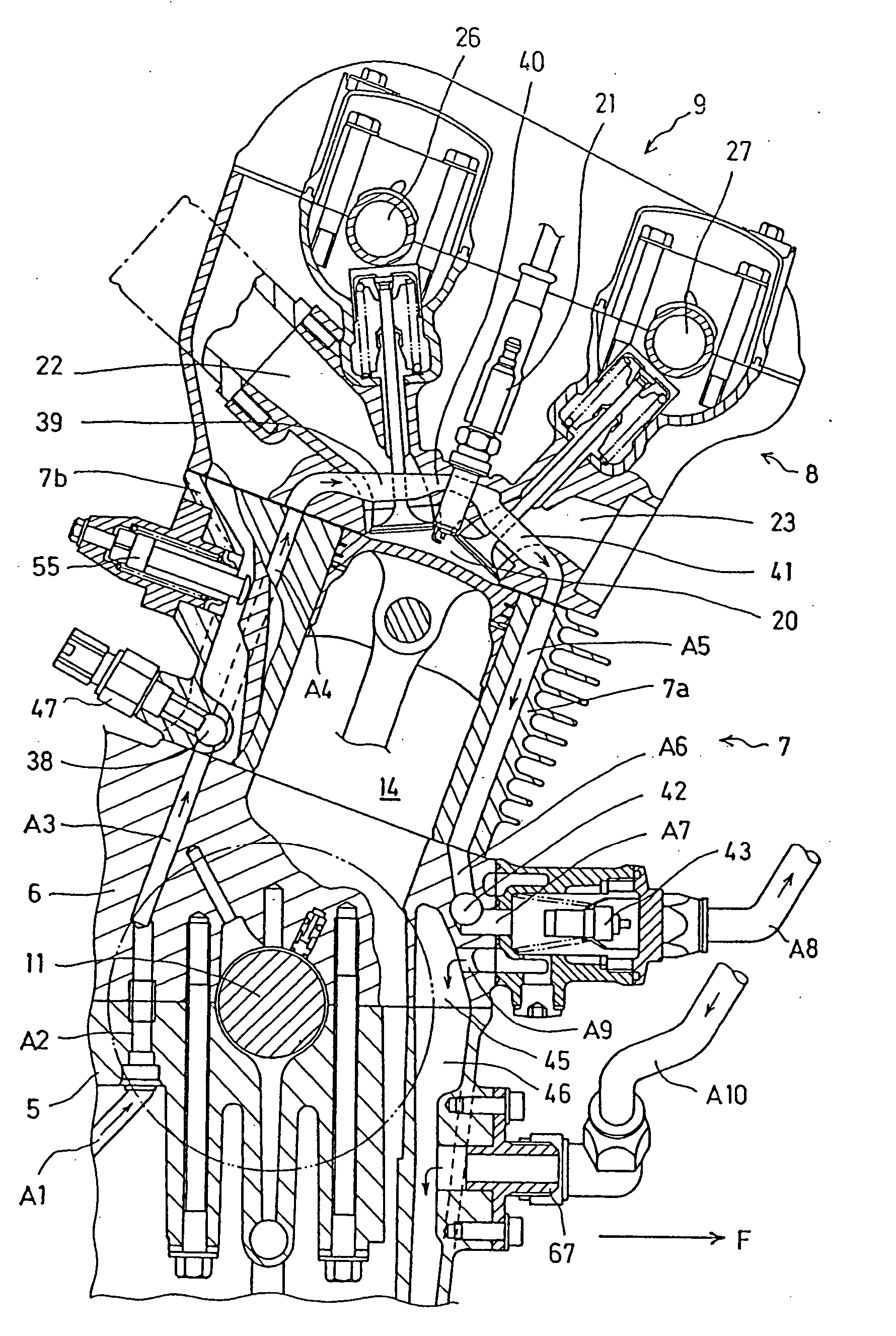

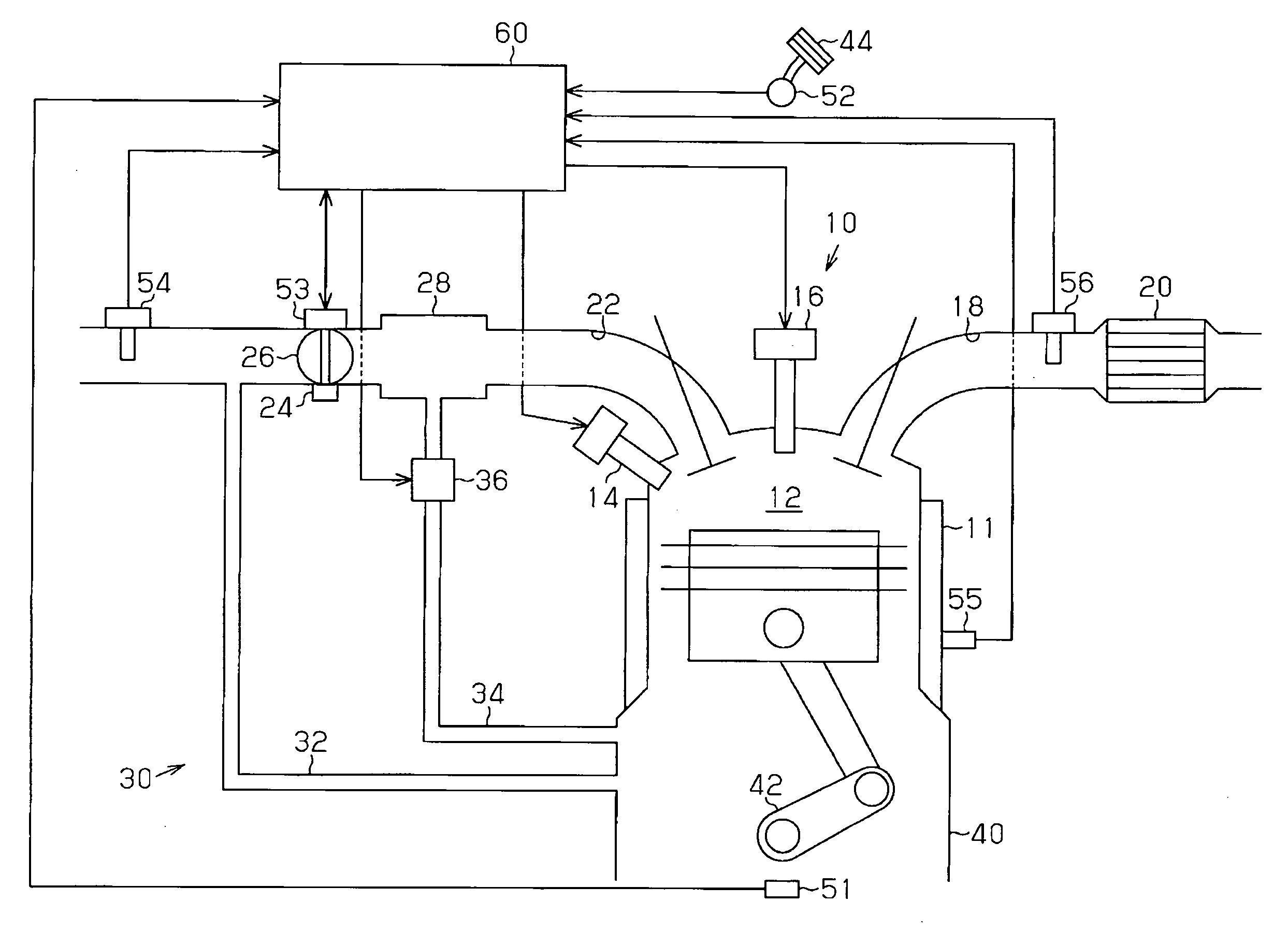

Cylinder head cooling structure for an internal combustion engine, including an oil temperature sensor and an oil temperature control system

ActiveUS20060065218A1Efficient use ofAvoid contactLiquid coolingCoolant flow controlTemperature controlCylinder head

A cylinder head cooling structure and an oil temperature control system are provided for an internal combustion engine having a plurality of cylinders, each having a plurality of intake ports and a plurality of exhaust ports. The engine includes cooling oil jackets surrounding the spark plugs in the cylinder head, a thermostat attached to the front surface of the crankcase independently of an oil filter, and an oil temperature sensor disposed on a rear face of the cylinder block above the crankcase in an oil supply path formed on the cylinder rear face for supplying oil to the oil jackets. Oil passages conducting oil into the oil jacket are provided between two separate parts of a bifucated intake port and between two separate parts of a bifurcated exhaust port, and only cooling system oil reaching high temperatures is allowed to flow through the thermostat, thereby improving temperature control response.

Owner:HONDA MOTOR CO LTD

Oil separator

An oil separating device for separating micron and sub-micron particles of oil from crankcase gases is provided. The oil separating device includes a housing having a first chamber in communication with a second chamber, and a narrow wave-shaped passage disposed between the first chamber and the second chamber. The narrow wave-shaped passage is defined by a first inner wall having a first undulating surface opposite and spaced apart from a second inner wall having a second undulating surface mirroring the first undulating surface. The narrow wave-shaped passage is disposed downstream of the first chamber and above the oil drain so as to allow oil particles in crankcase gases passing from the inlet to the outlet to accumulate on the first and second inner walls and assist gravity in forcing the accumulated oil through the narrow wave-shaped passage into the oil drain.

Owner:TOYOTA MOTOR CO LTD

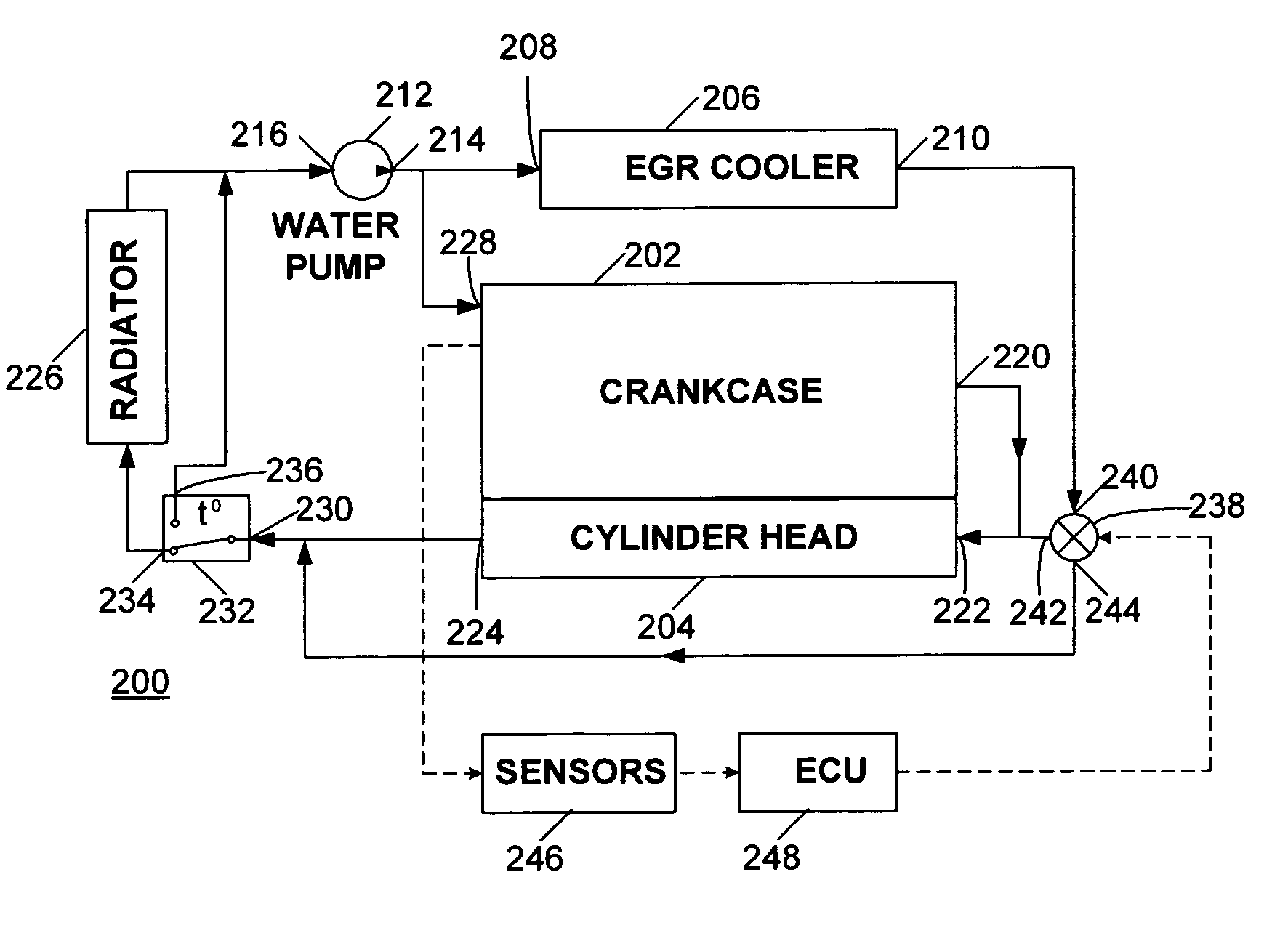

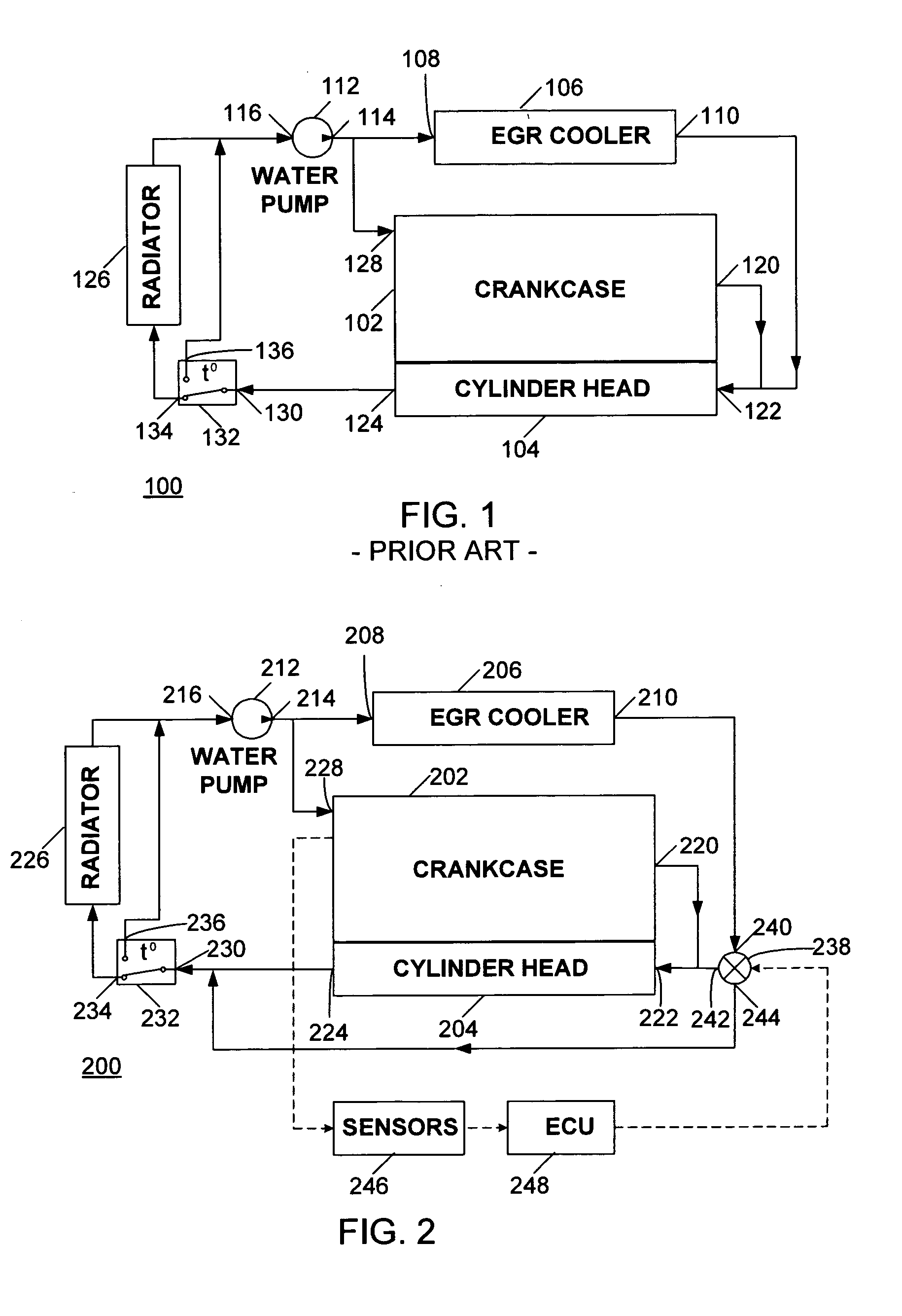

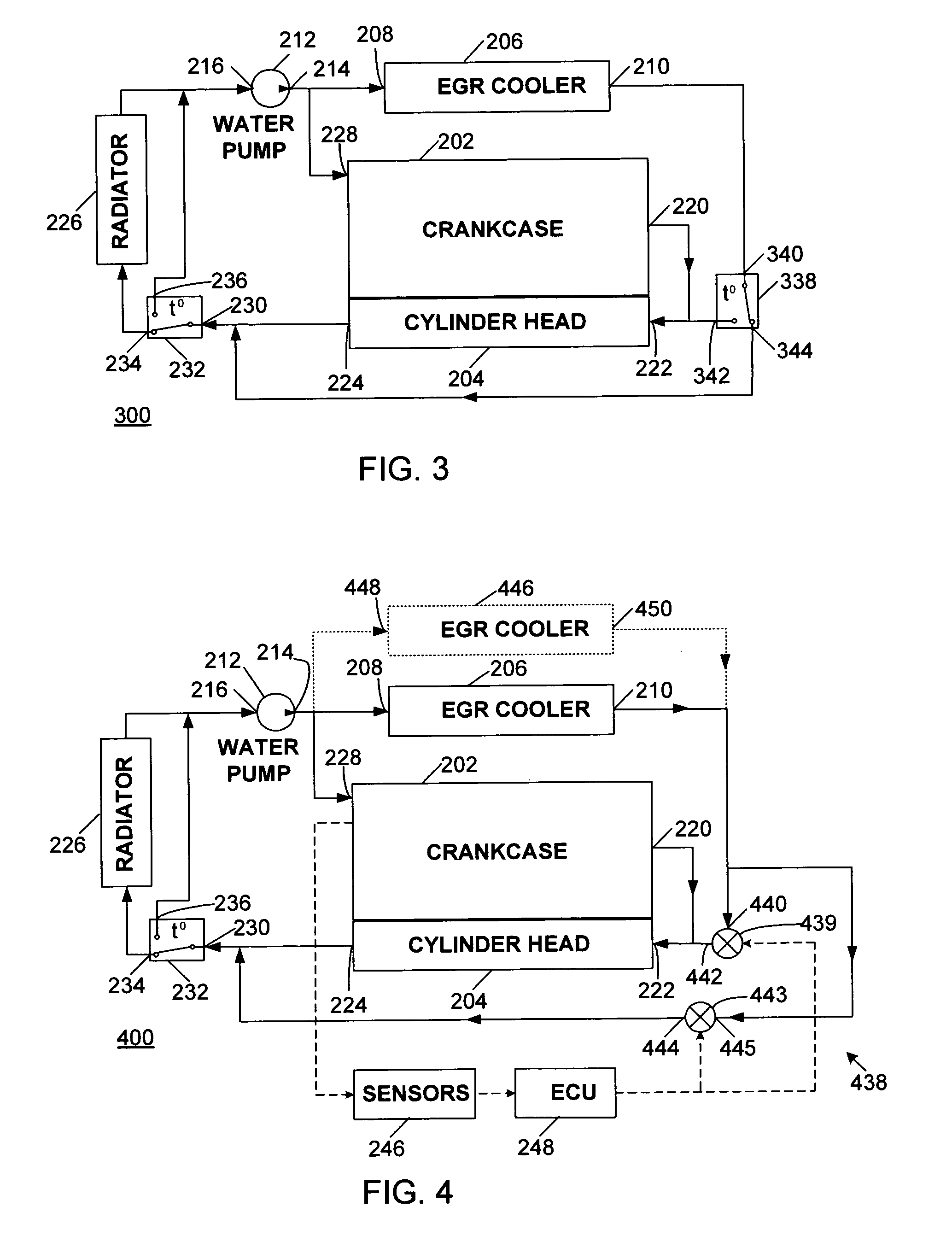

Coolant valve system for internal combustion engine and method

Owner:INT ENGINE INTPROP CO LLC

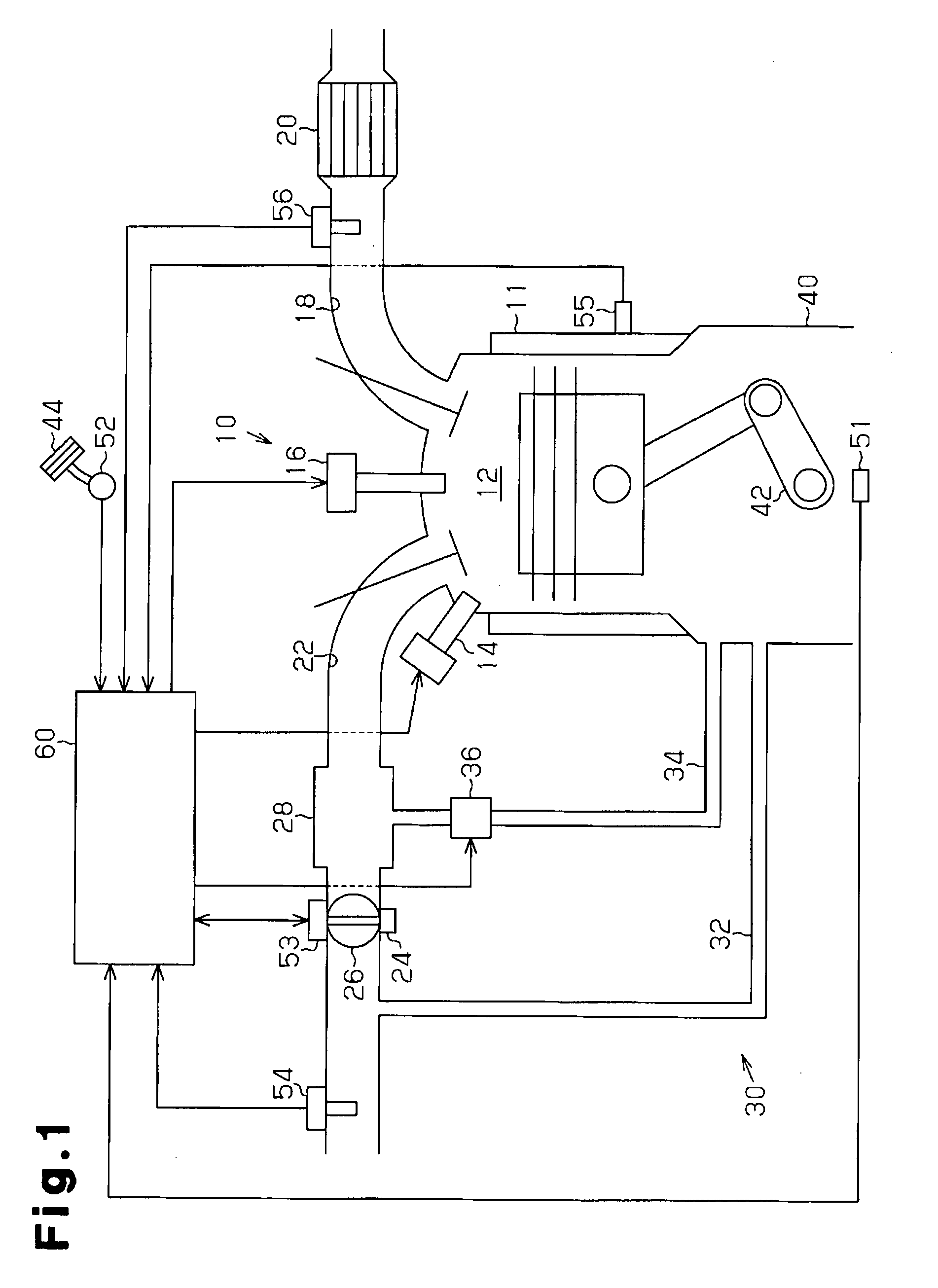

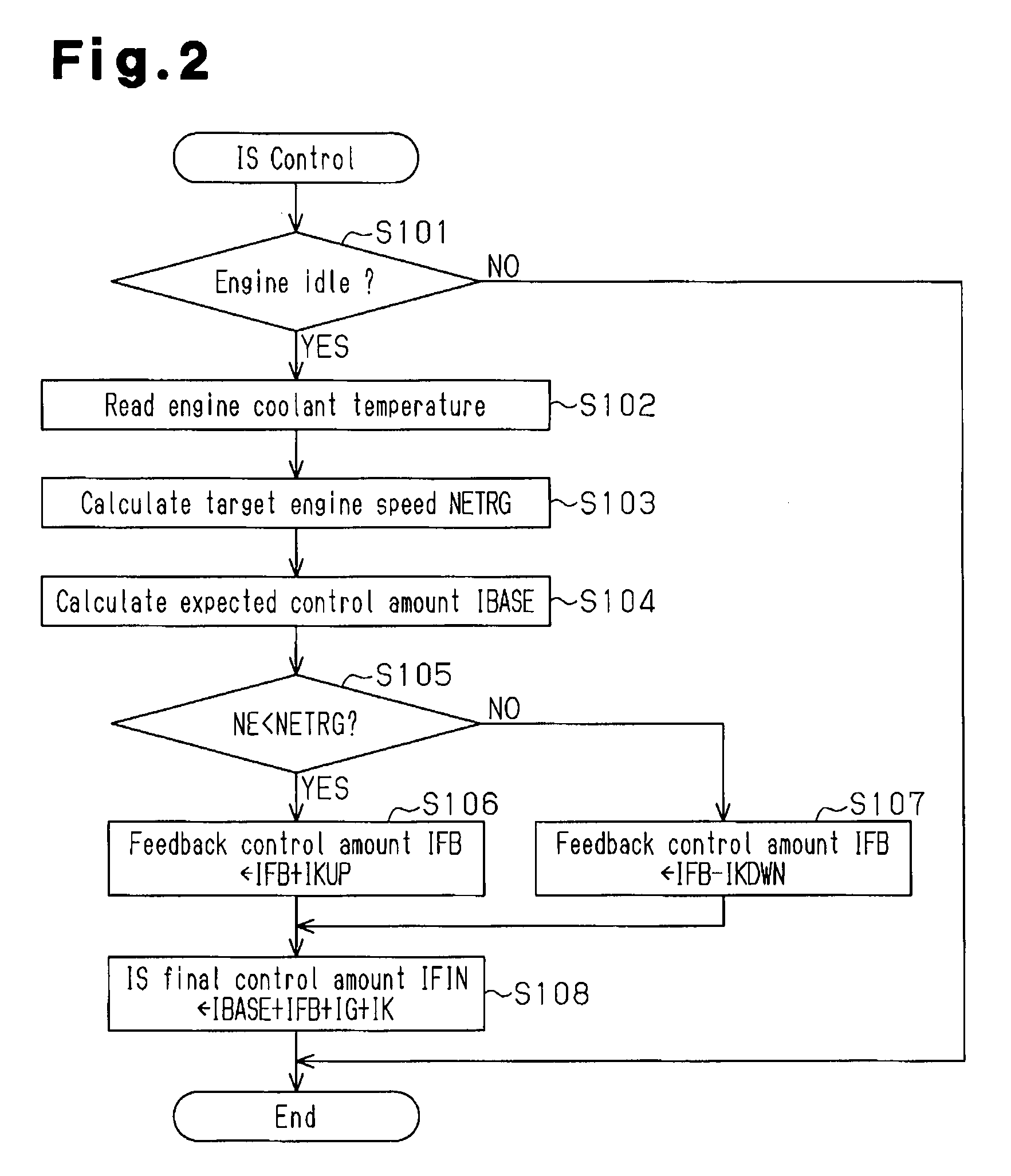

Abnormality diagnosis device for positive crankcase ventilation apparatus

InactiveUS20090211545A1Excessively enrichingPrecise processElectrical controlInternal combustion piston enginesEngineeringCrankcase

An abnormality diagnosis device for diagnosing abnormality in a positive crankcase ventilation apparatus including a PCV passage, which is for supplying blow-by gas to an intake passage of an engine, and a PCV valve, which is for regulating the flow rate of blow-by gas in the PCV passage. The diagnosis device varies a control amount of the PCV valve to determine the occurrence of an abnormality in the PCV passage and PCV valve and performs abnormality diagnosis in a first determination mode when the amount of fuel components in the blow-by gas is less than a reference amount and in a second determination mode when the amount is greater than the reference amount. A varying amount of the control amount of the PCV valve in the second determination mode is smaller than that of the control amount of the PCV valve in the first determination mode.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com