Patents

Literature

46946 results about "Pre treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The purpose of the pre-treatment is to remove most of the non-soluble solids physically in order to reduce the pollutant loads and to protect all the subsequent steps in the treatment plant. Providing a reliable, high-quality supply of treated water is critical to many processes.

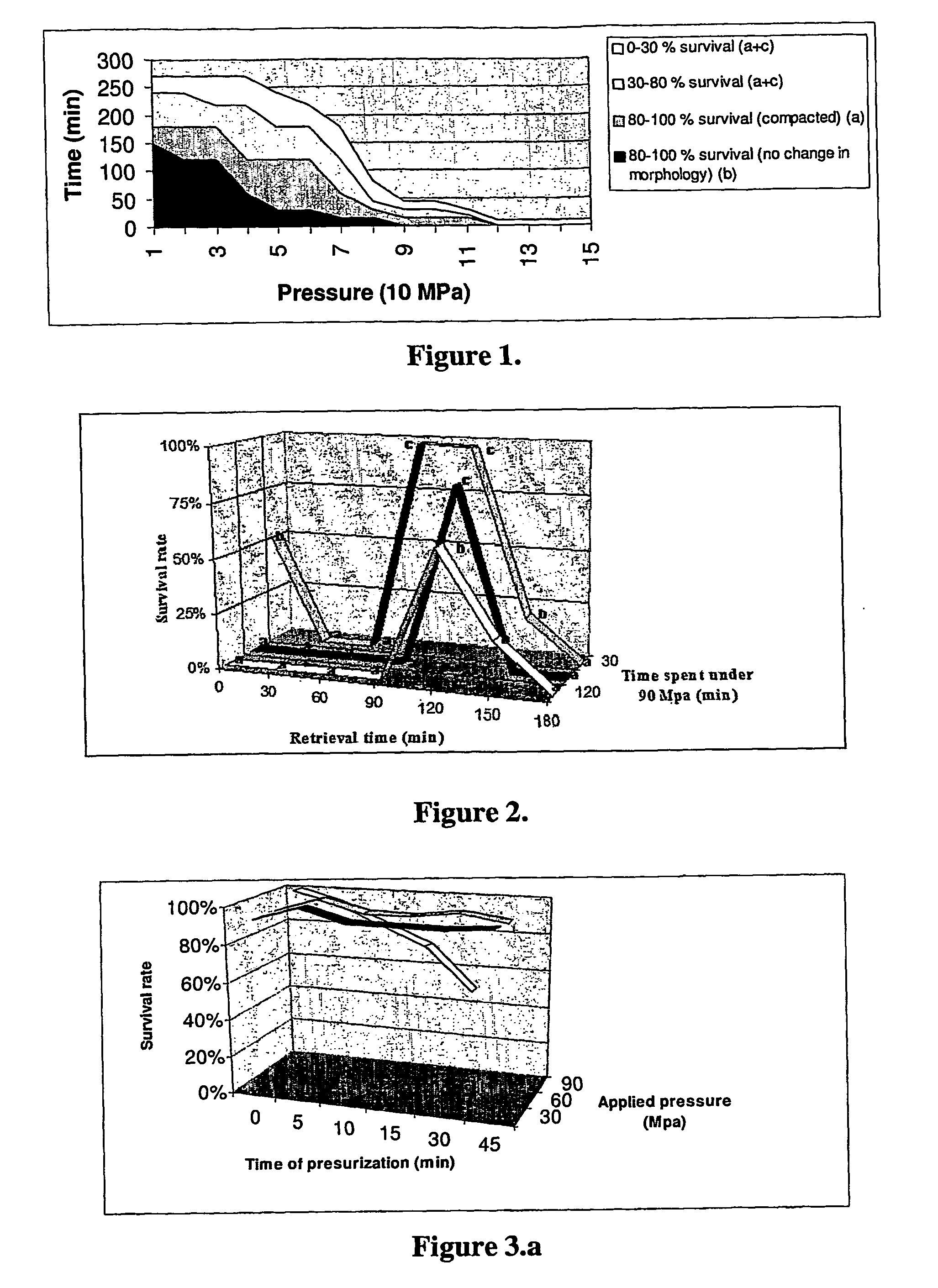

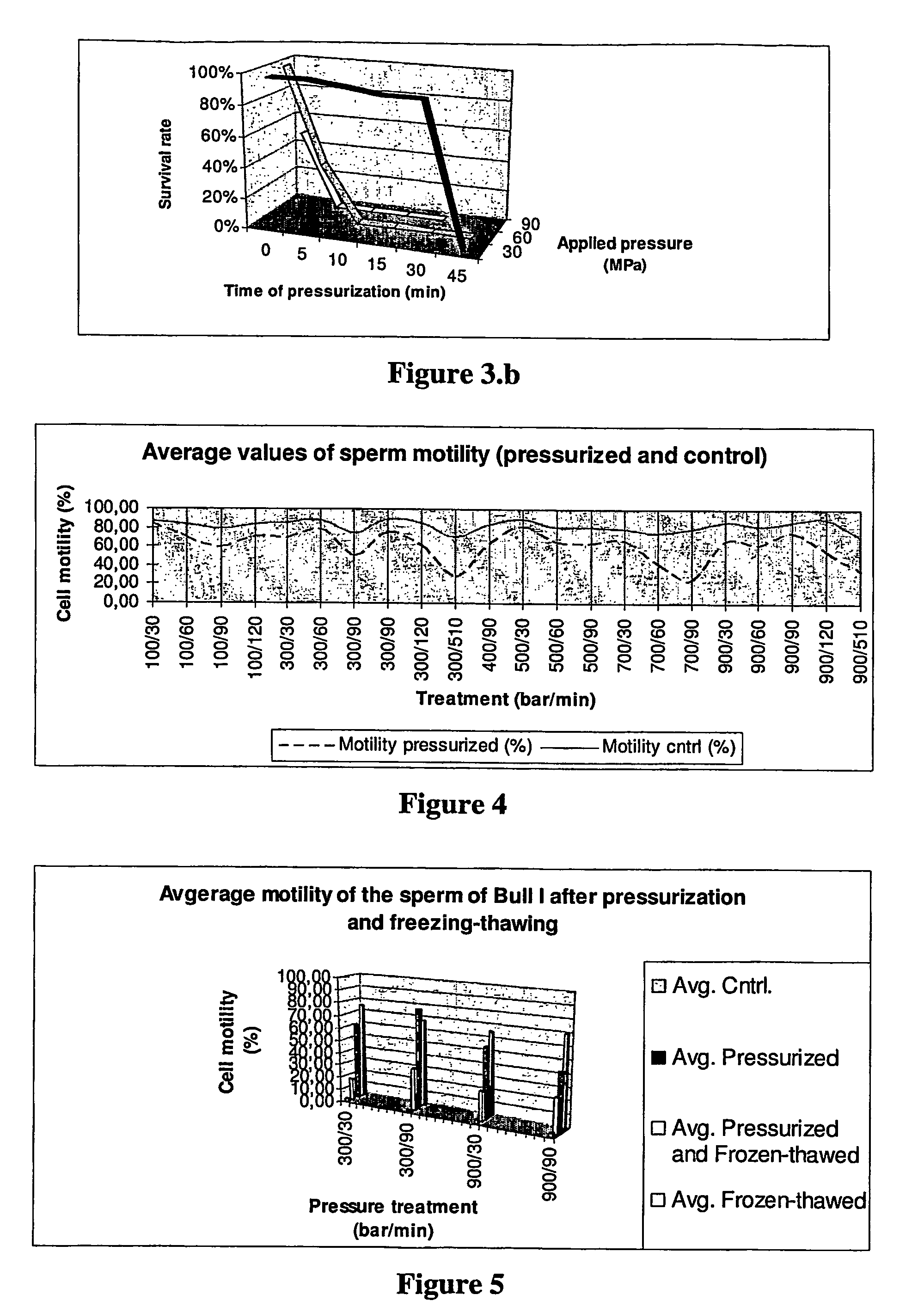

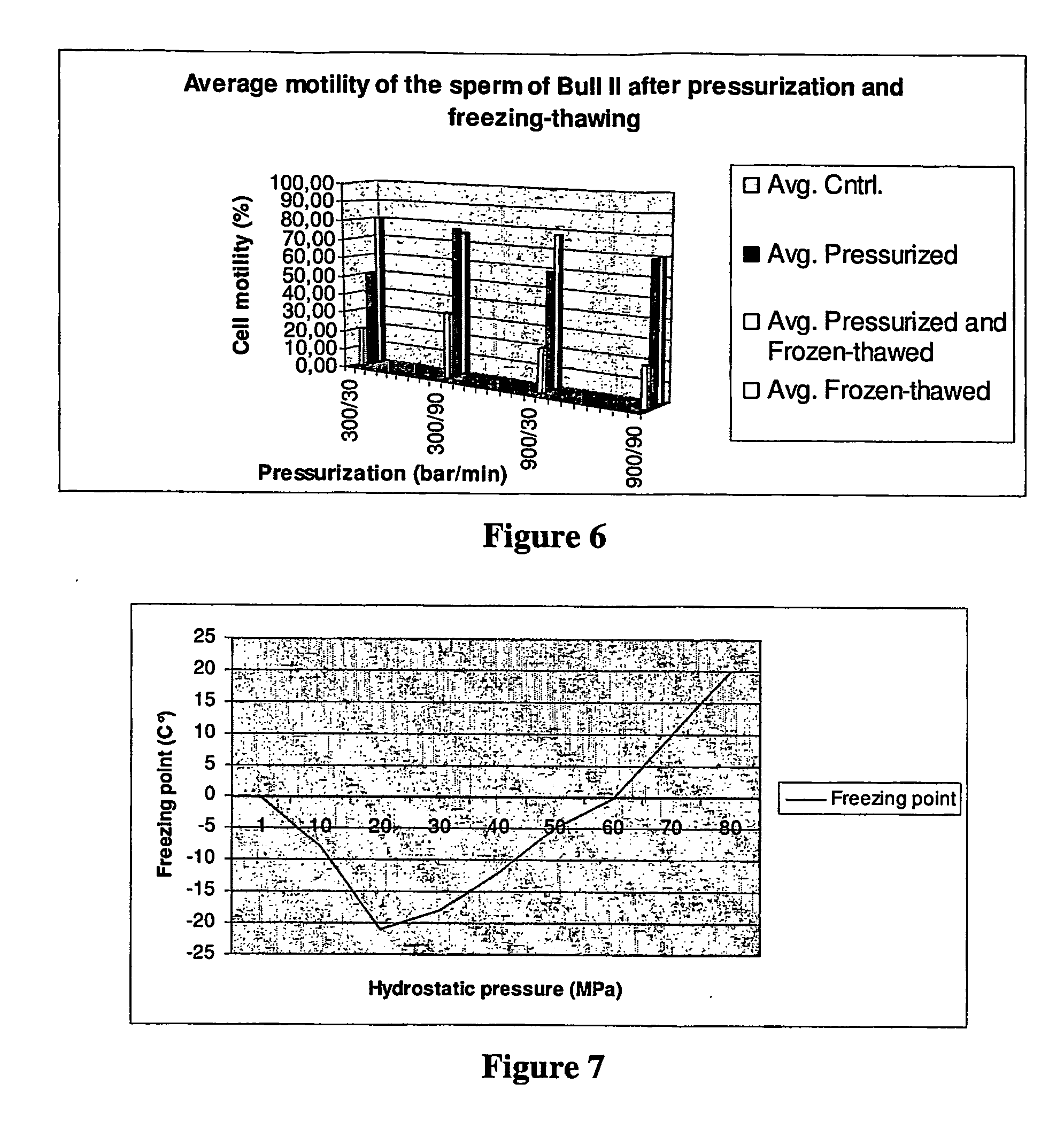

Post-thaw survival of chryopreserved biological material by hydrostatic pressure challenge

InactiveUS20070087321A1Improve survivalSimple methodDead animal preservationHydrostatic pressurePre treatment

The present invention relates to a method for improving post-thaw survival of cryopreserved biological material comprising applying hydrostatic pressure to said biological material; keeping the said biological material at the hydrostatic pressure for a predetermined time period; releasing the hydrostatic pressure; and freezing the said biological material using any protocol applicable thereto. The invention also relates to the use of a pressurizing device for the pretreatment of a biological material that is to be cryopreserved, as well as to a pressurizing device for the pretreatment of a biological material that is to be cryopreserved, said device comprising a pressure chamber for receiving biological material, means to produce said pressure, and means to maintain said pressure in said chamber.

Owner:APPL CELL TECH KORLATOLT FELELOSSEGU TARSASAG

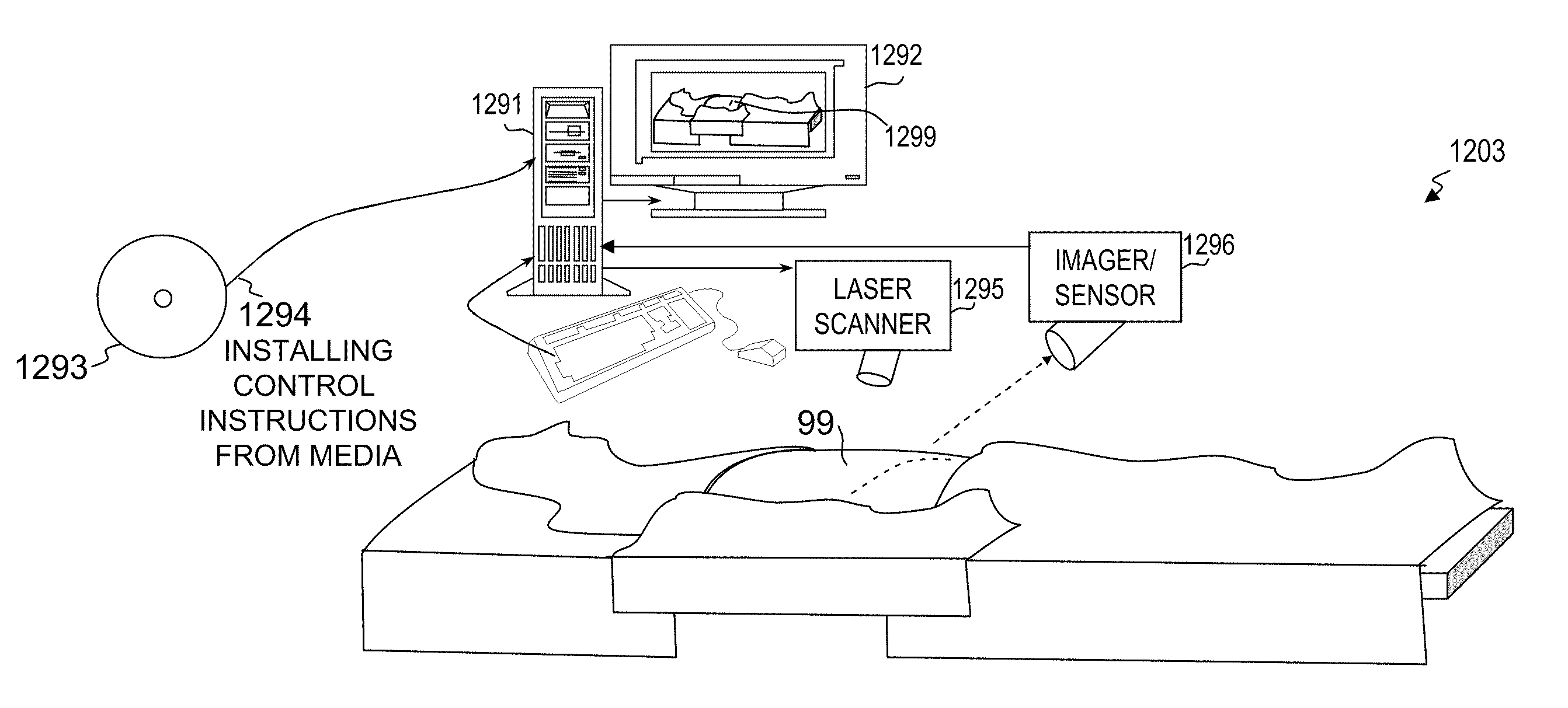

System and method for conditioning animal tissue using laser light

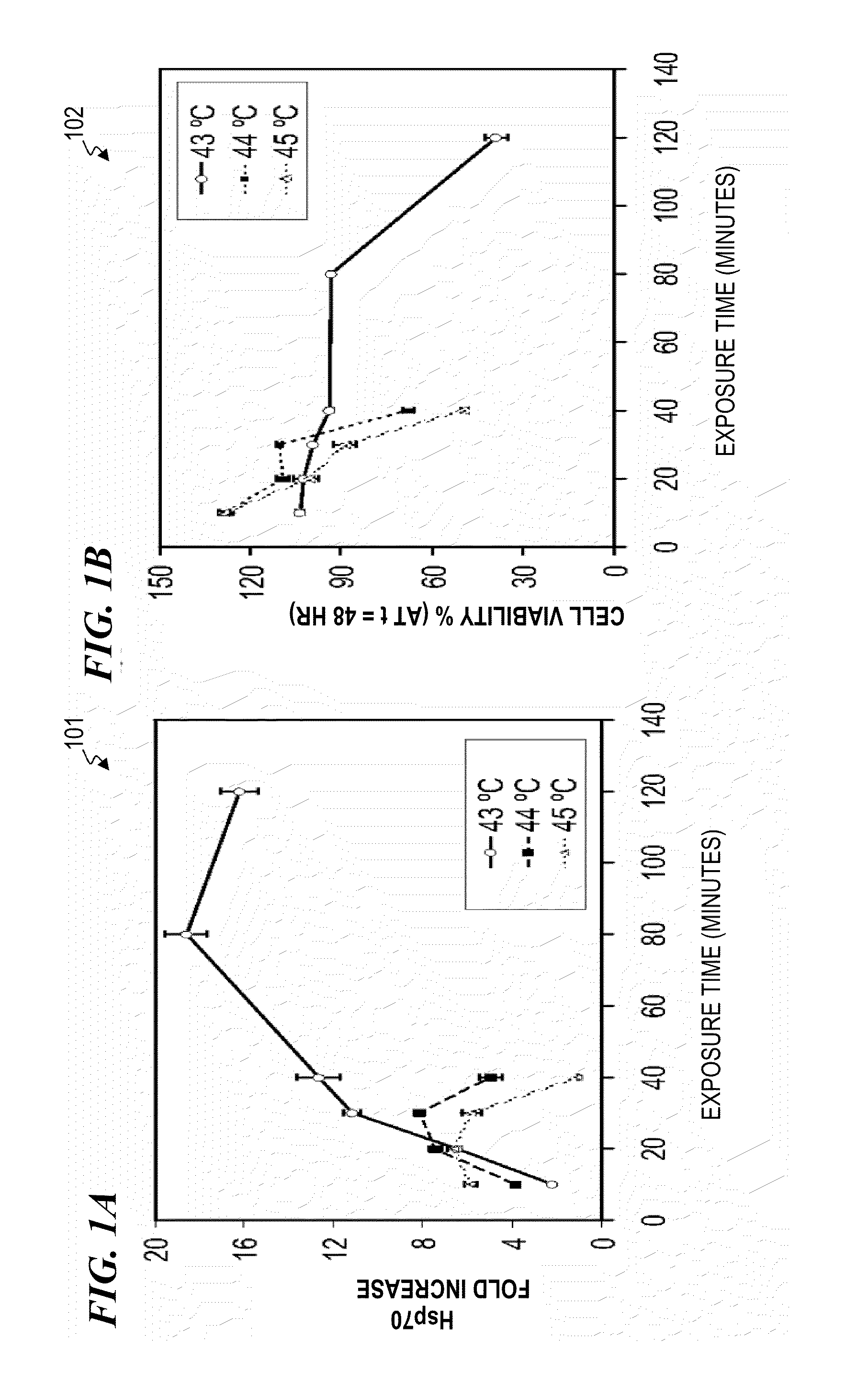

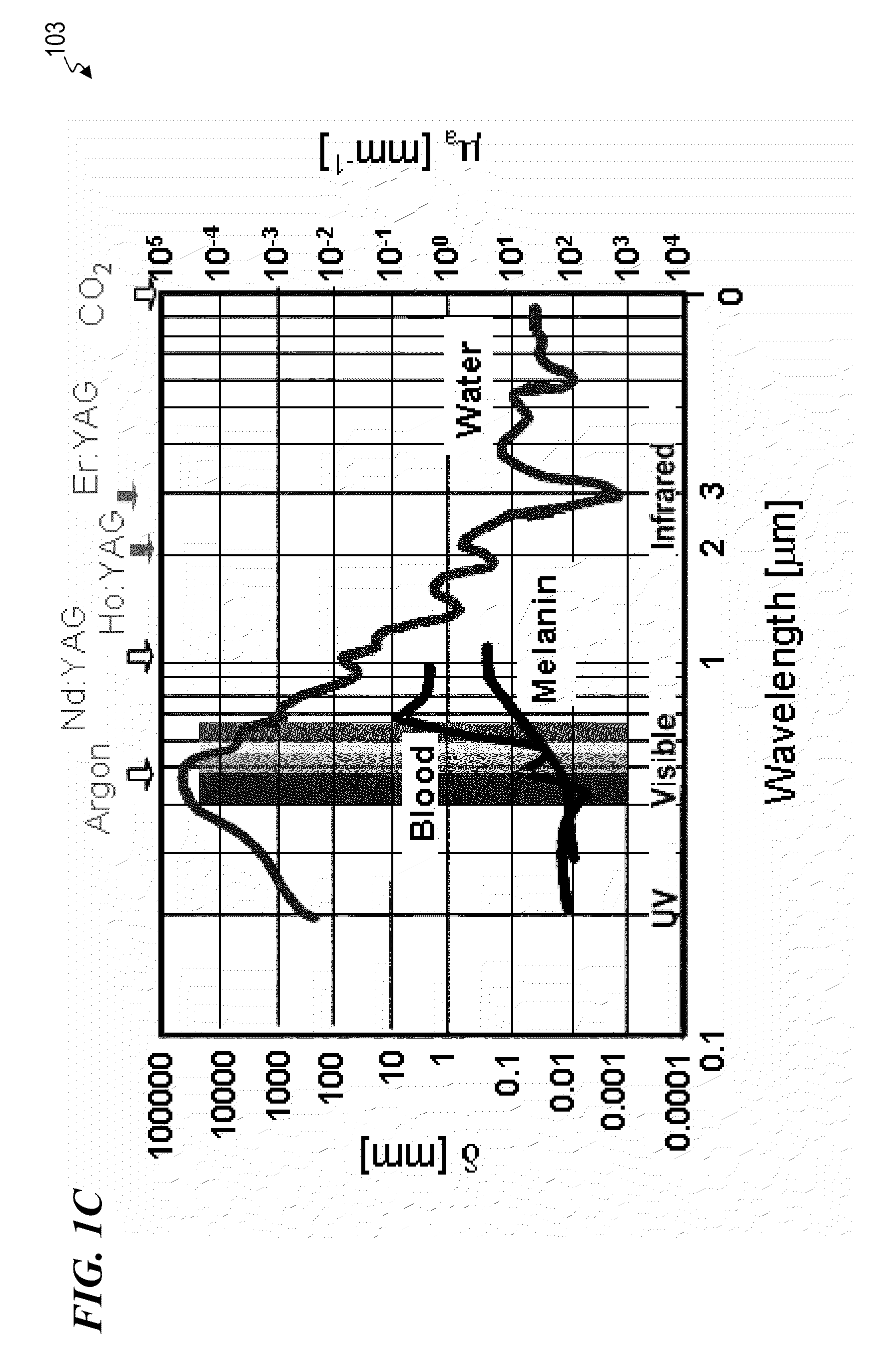

InactiveUS20100049180A1Promote wound repairEnhances surgical wound healingSurgical instrument detailsLight therapyLaser lightHsp70 expression

Systems and methods for prophylactic measures aimed at improving wound repair. In some embodiments, laser-mediated preconditioning would enhance surgical wound healing that was correlated with hsp70 expression. Using a pulsed laser (λ=1850 nm, Tp=2 ms, 50 Hz, H=7.64 mJ / cm2) the skin of transgenic mice that contain an hsp70 promoter-driven luciferase were preconditioned 12 hours before surgical incisions were made. Laser protocols were optimized using temperature, blood flow, and hsp70-mediated bioluminescence measurements as benchmarks. Bioluminescent imaging studies in vivo indicated that an optimized laser protocol increased hsp70 expression by 15-fold. Under these conditions, healed areas from incisions that were laser-preconditioned were two times stronger than those from control wounds. Our data suggest that these methods can provide effective and improved tissue-preconditioning protocols and that mild laser-induced heat shock that correlated with an expression of Hsp70 may be a useful therapeutic intervention prior to or after surgery.

Owner:LOCKHEED MARTIN CORP +2

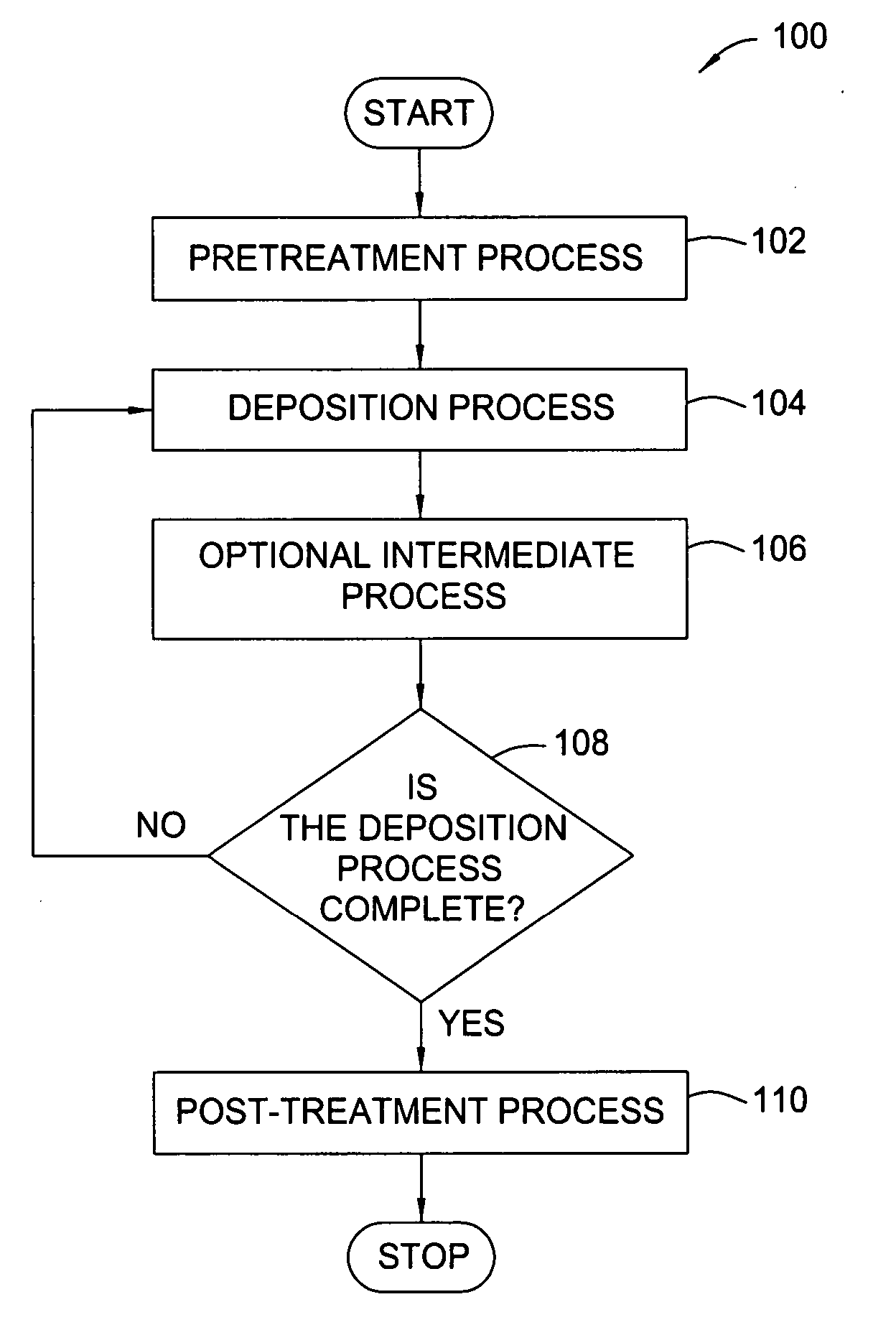

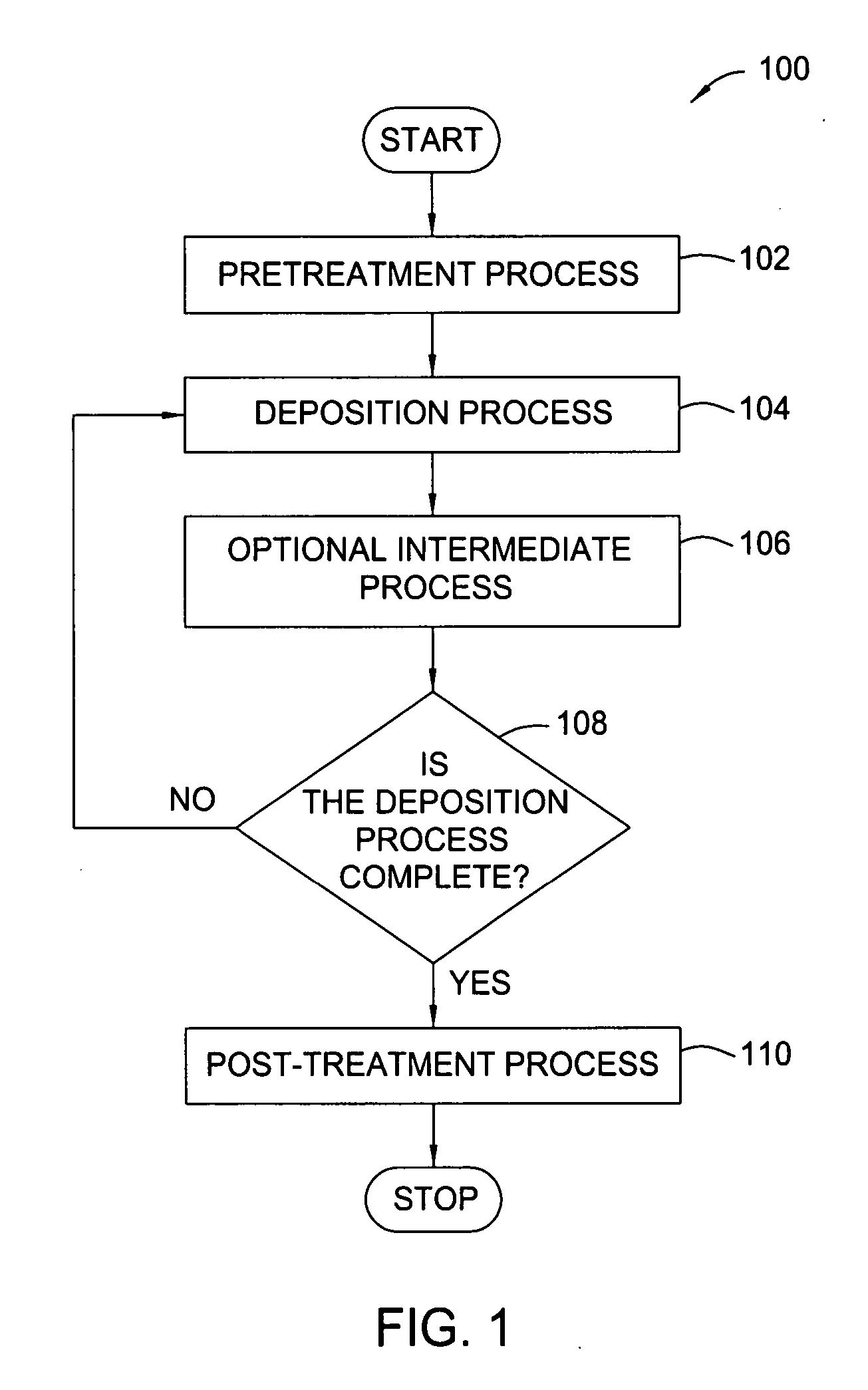

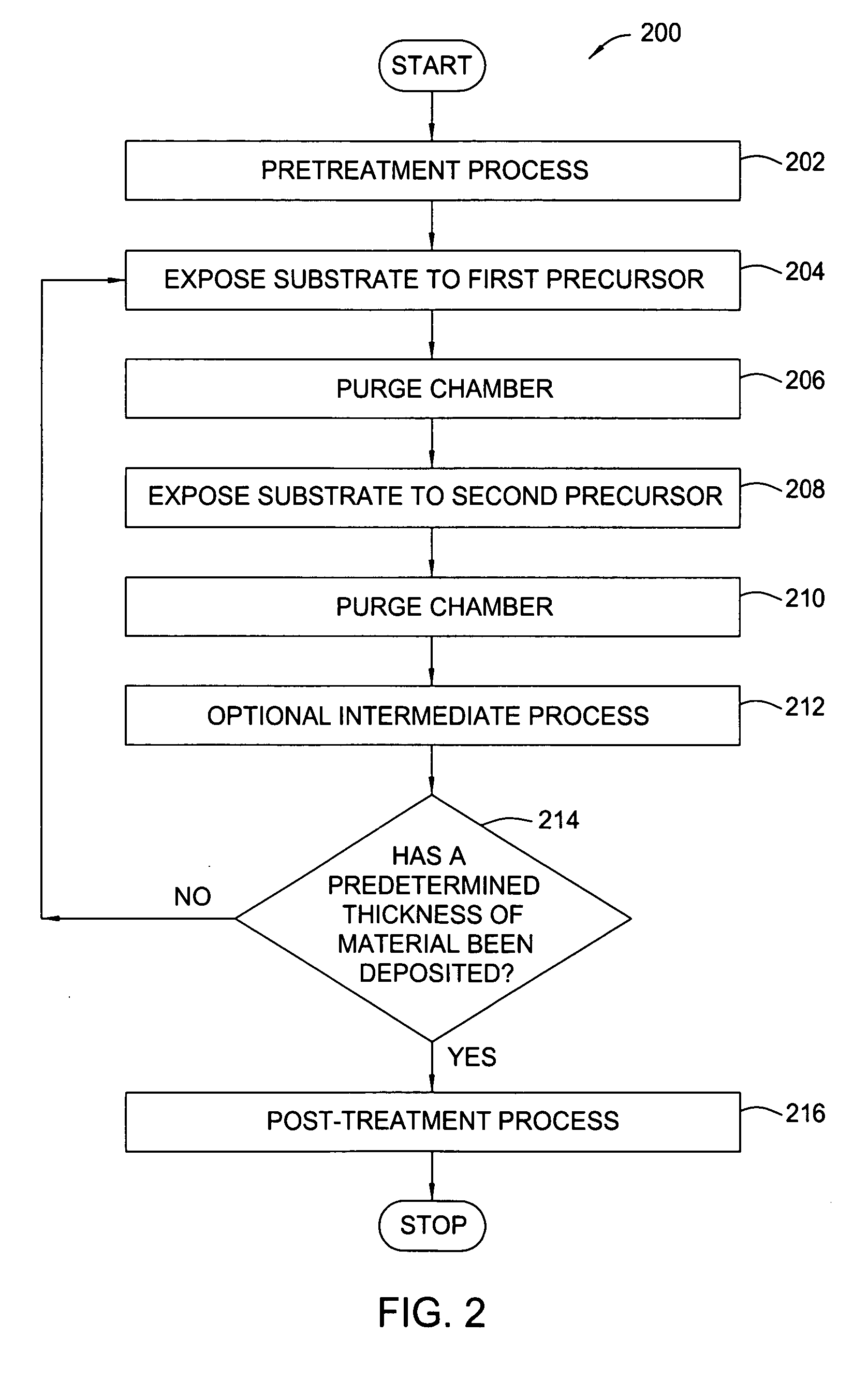

Treatment processes for a batch ALD reactor

Embodiments of the invention provide treatment processes to reduce substrate contamination during a fabrication process within a vapor deposition chamber. A treatment process may be conducted before, during or after a vapor deposition process, such as an atomic layer deposition (ALD) process. In one example of an ALD process, a process cycle, containing an intermediate treatment step and a predetermined number of ALD cycles, is repeated until the deposited material has a desired thickness. The chamber and substrates may be exposed to an inert gas, an oxidizing gas, a nitriding gas, a reducing gas or plasmas thereof during the treatment processes. In some examples, the treatment gas contains ozone, water, ammonia, nitrogen, argon or hydrogen. In one example, a process for depositing a hafnium oxide material within a batch process chamber includes a pretreatment step, an intermediate step during an ALD process and a post-treatment step.

Owner:APPLIED MATERIALS INC

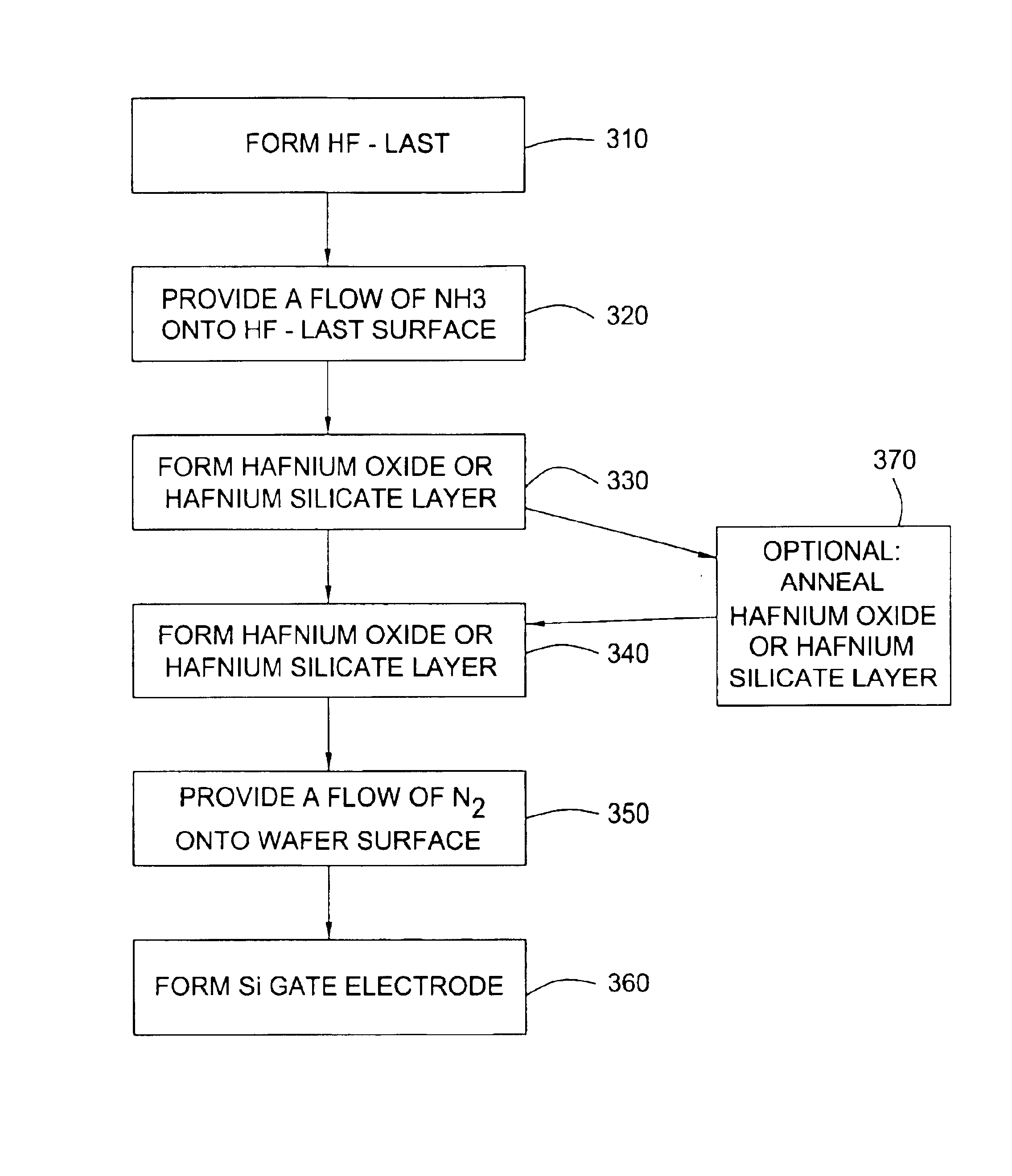

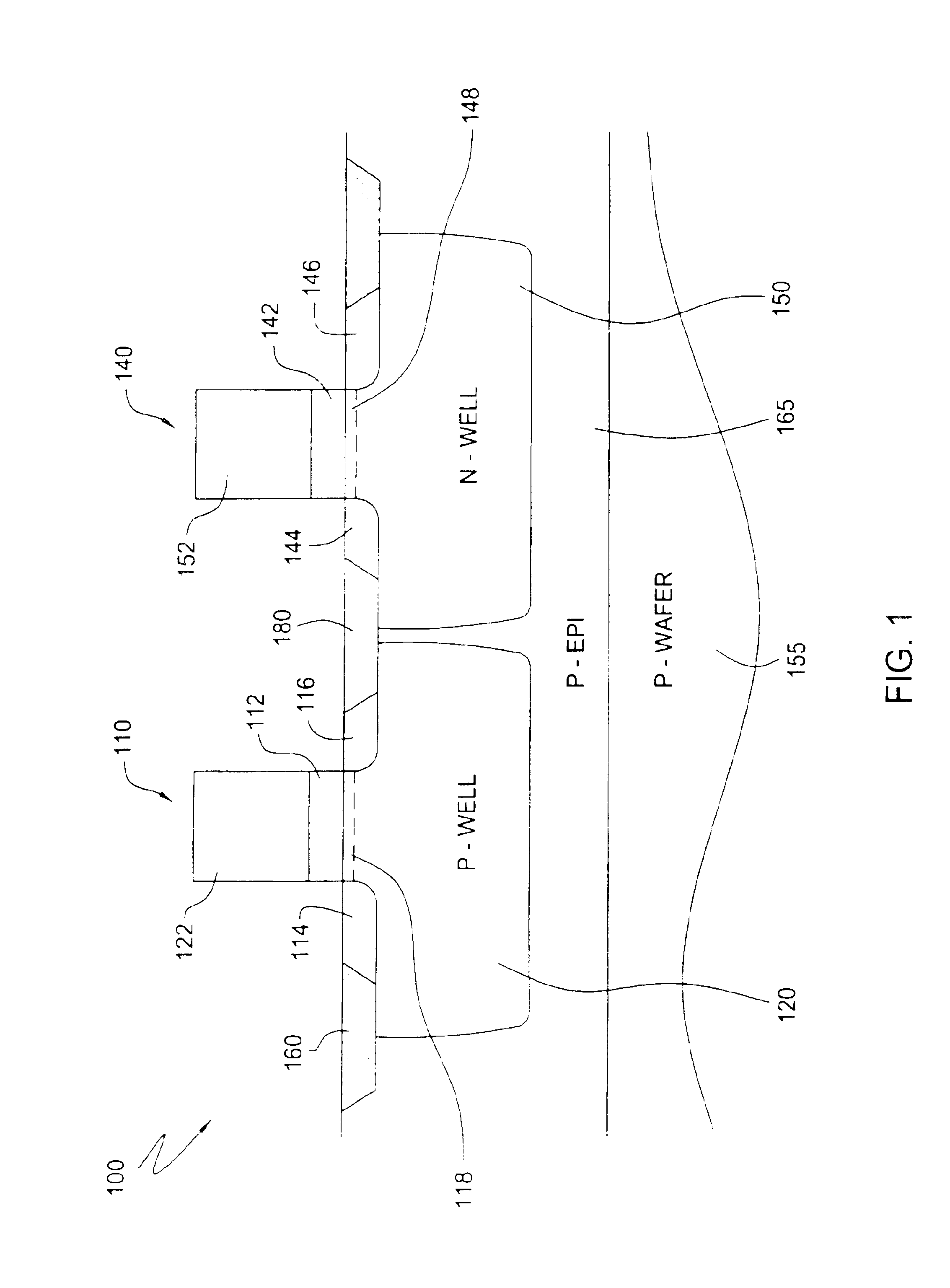

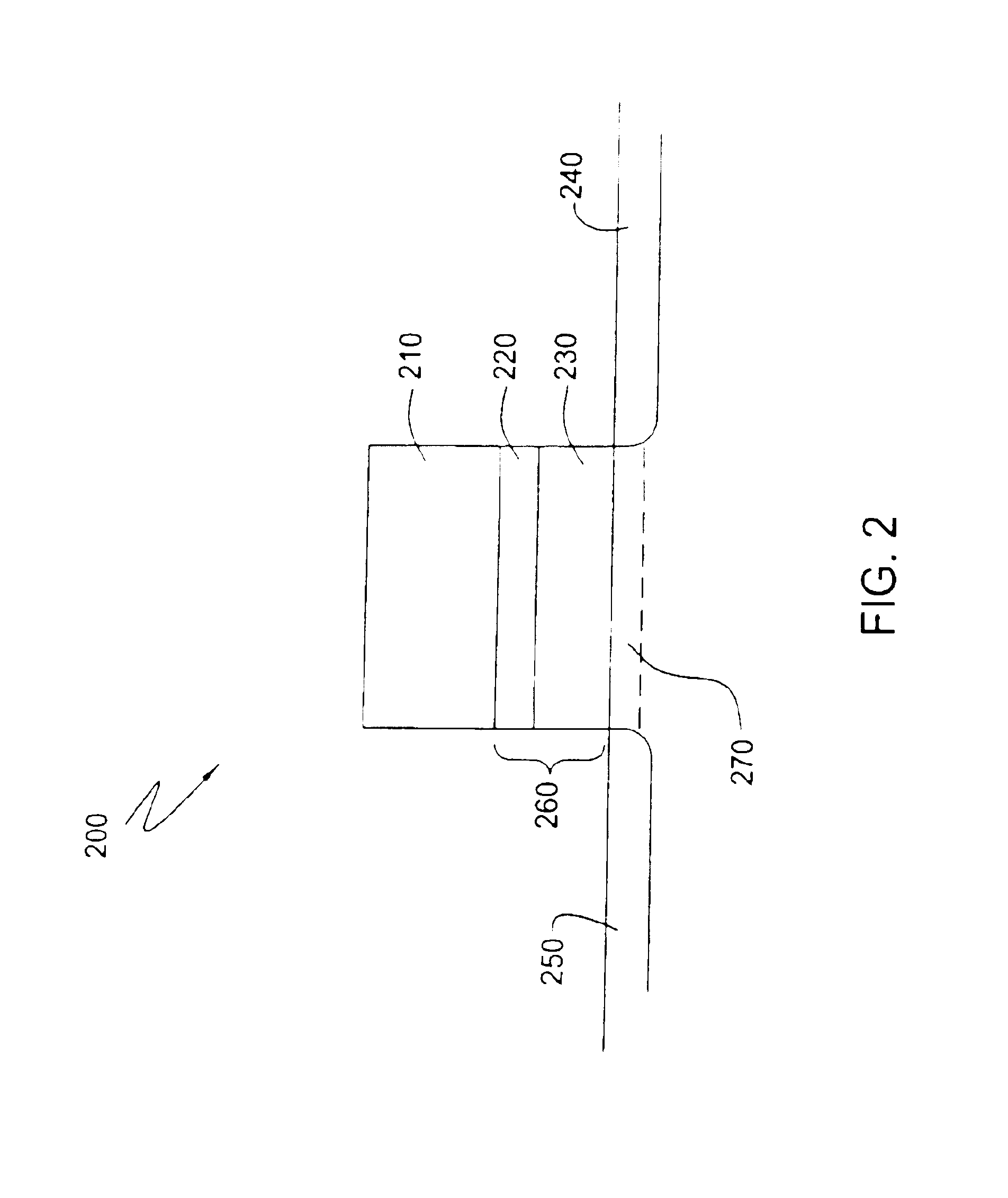

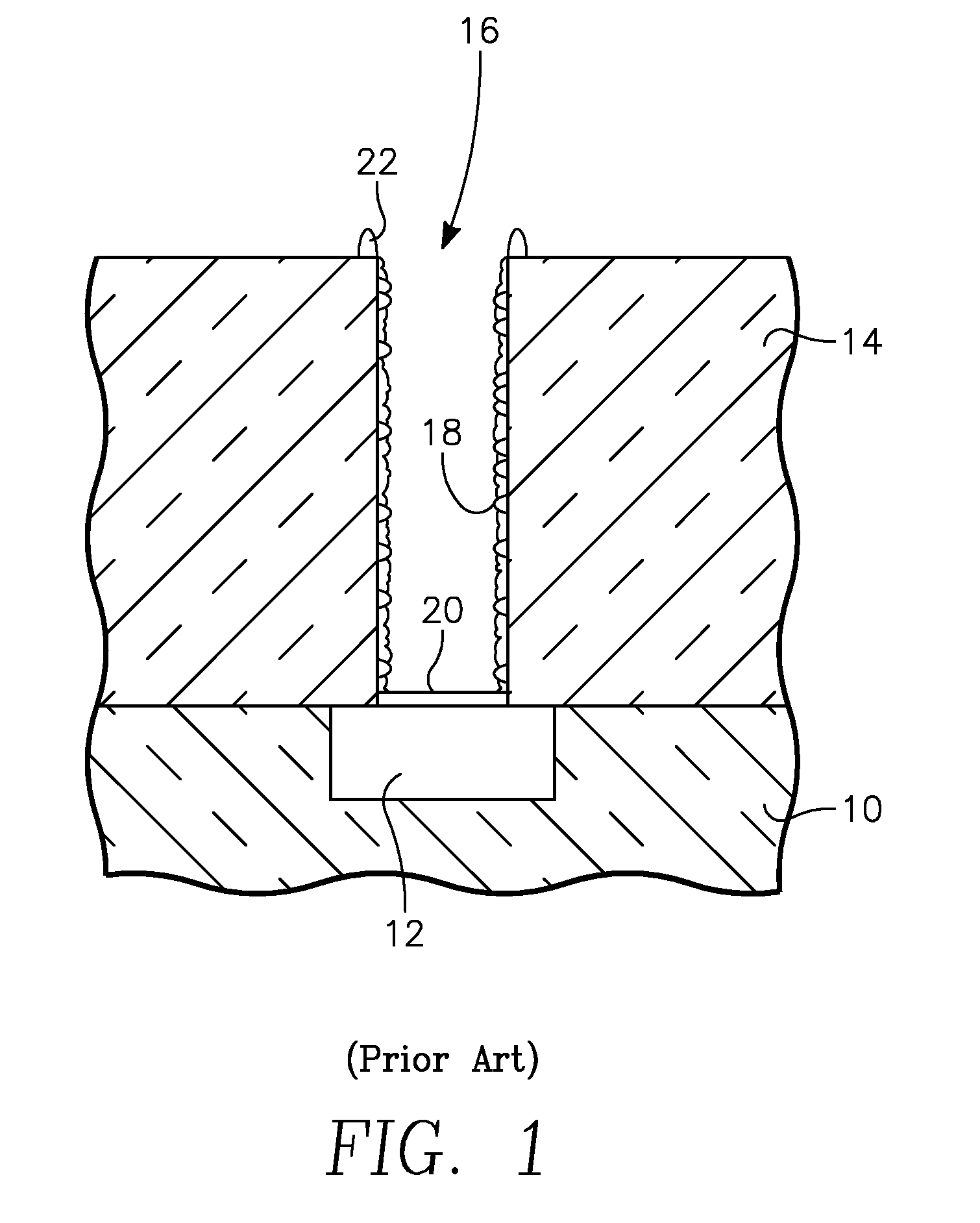

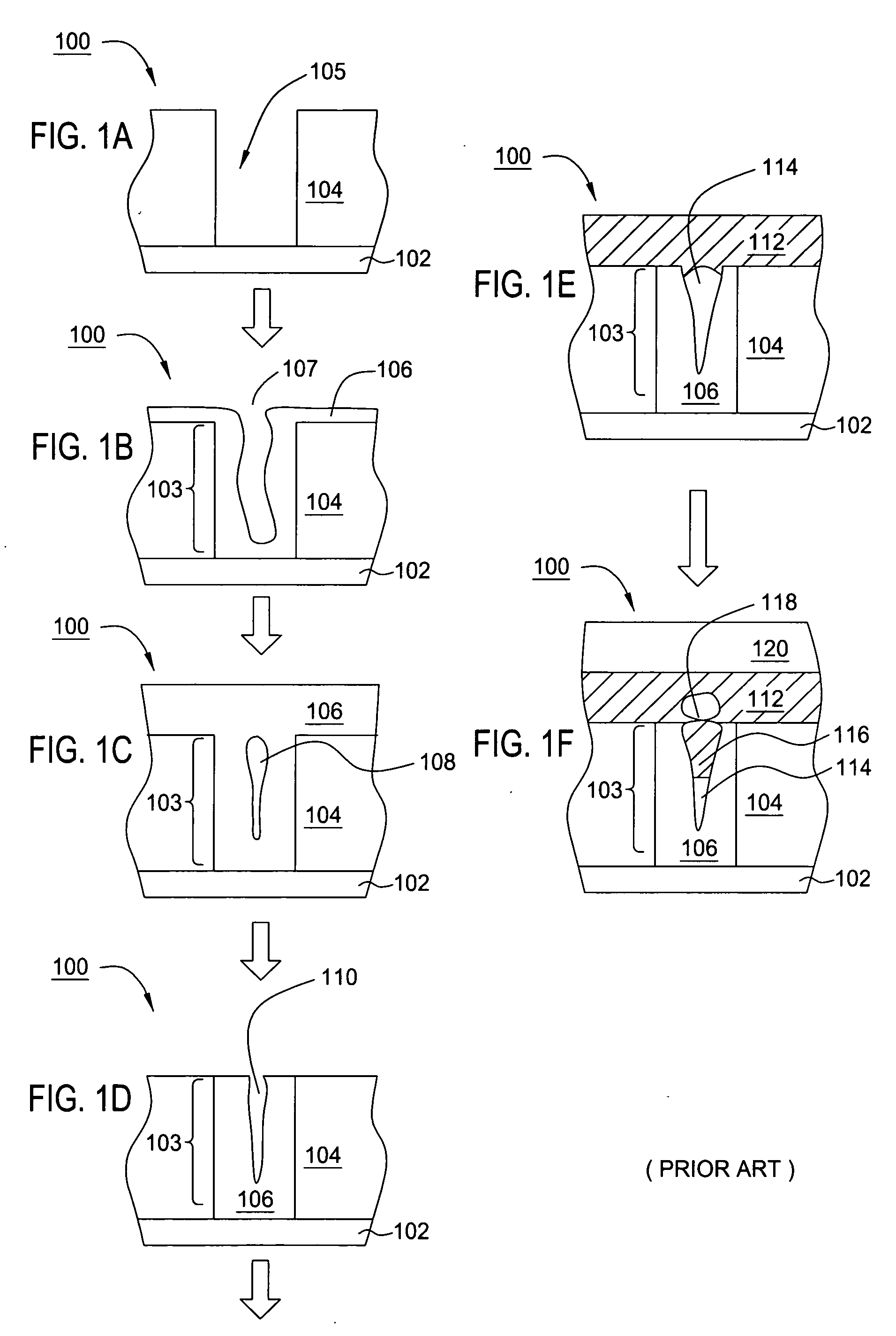

System and method for forming a gate dielectric

InactiveUS6858547B2Vacuum evaporation coatingSemiconductor/solid-state device manufacturingHydrofluoric acidGate dielectric

A method of forming a dielectric stack on a pre-treated surface. The method comprises pre-cleaning a semiconductor wafer to remove native oxide, such as by applying hydroflouric acid to form an HF-last surface, pre-treating the HF-last surface with ozonated deionized water, forming a dielectric stack on the pre-treated surface and providing a flow of NH3 in a process zone surrounding the wafer. Alternately, the method includes pre-treating the HF-last surface with NH3, forming the stack after the pre-treating, and providing a flow of N2 in a process zone surrounding the wafer after the forming. The method also includes pre-treating the HF-last surface using an in-situ steam generation process, forming the stack on the pre-treated surface, and annealing the wafer after the forming. The pre-treating includes providing an inert gas flow in a process zone surrounding the HF-last surface, reacting hydrogen with an oxidizer in the process zone for a very short duration, and providing an inert gas flew in the process zone after the reacting.

Owner:APPLIED MATERIALS INC

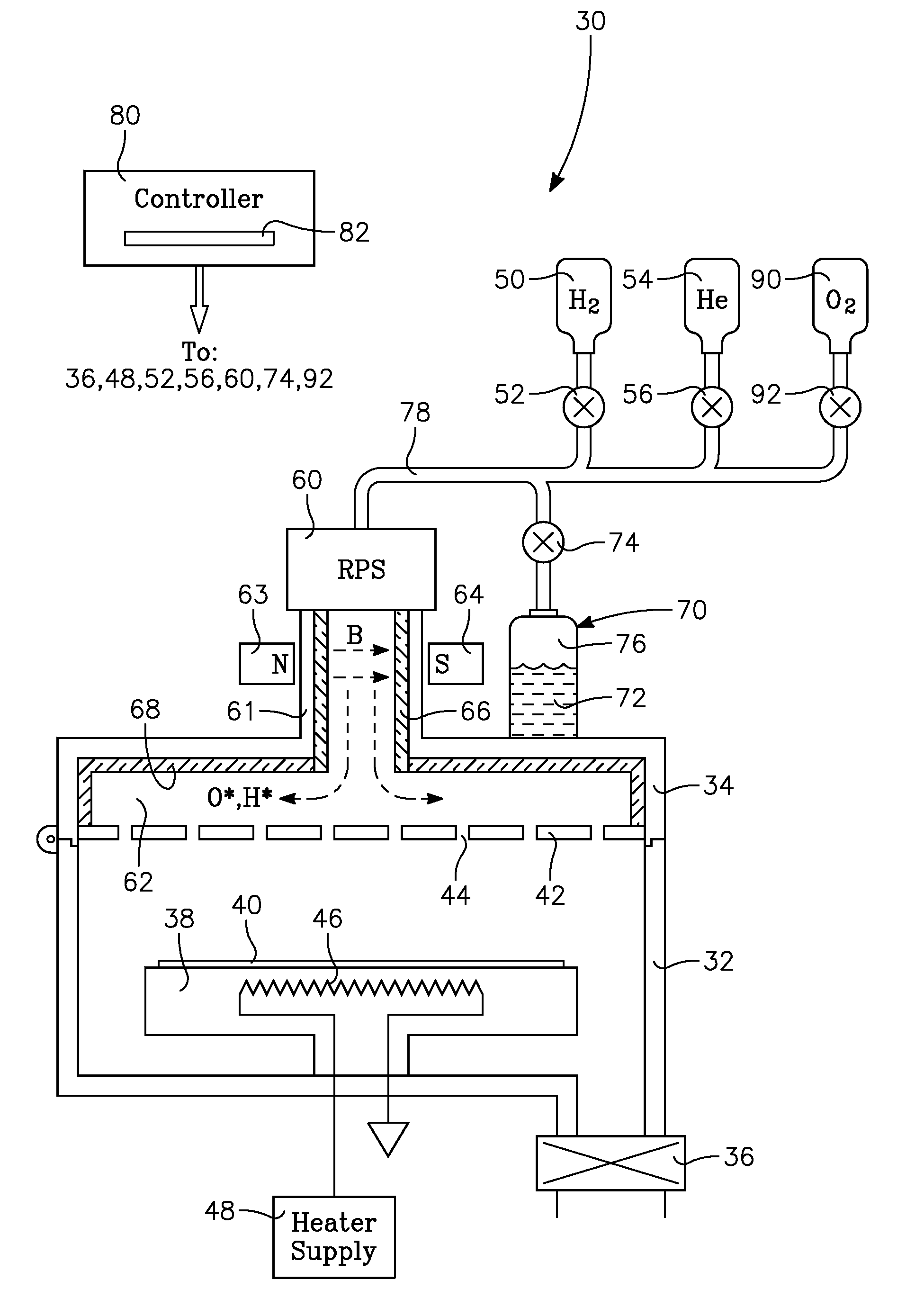

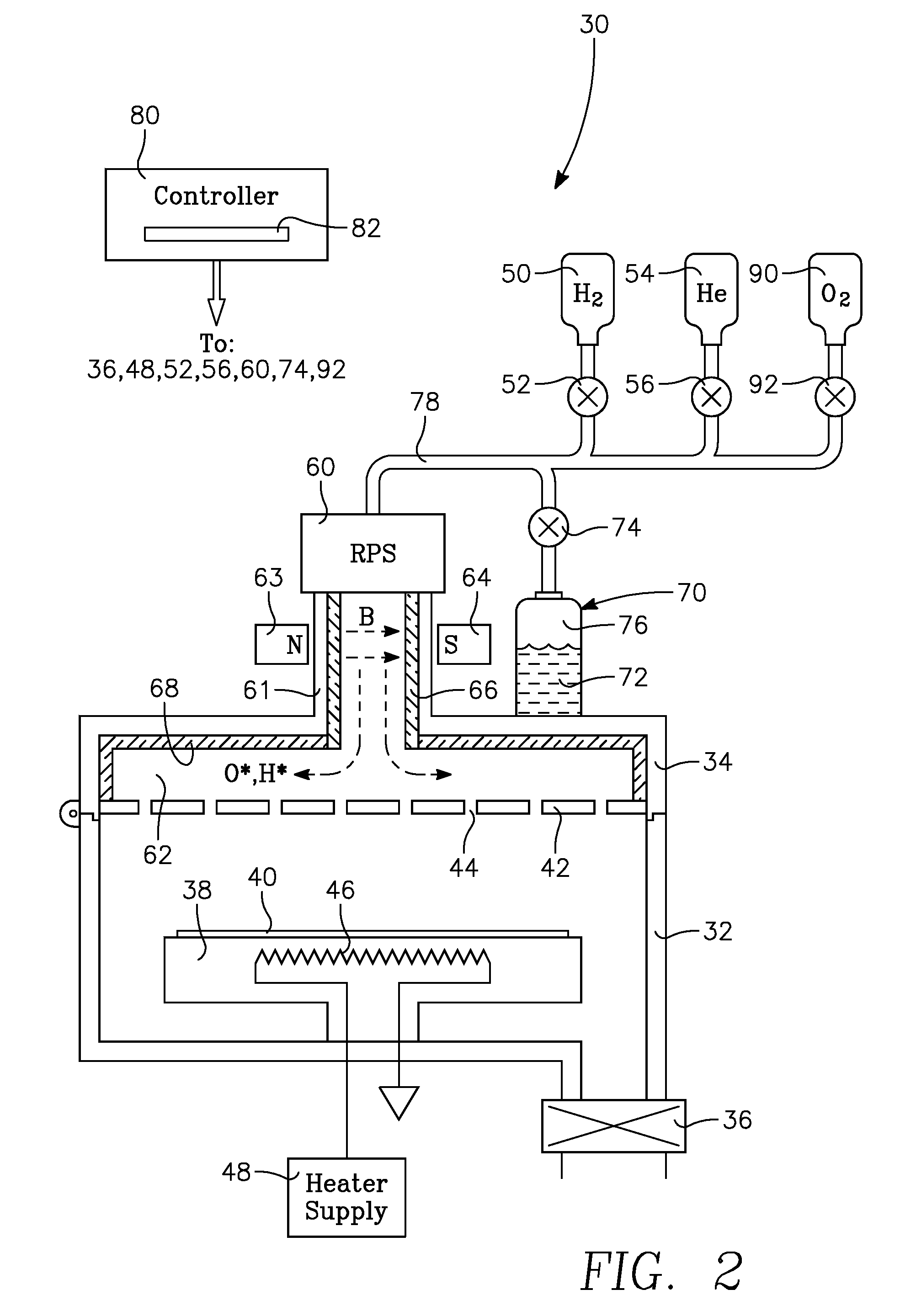

Remote Plasma Source for Pre-Treatment of Substrates Prior to Deposition

ActiveUS20090017227A1Electric discharge tubesSemiconductor/solid-state device manufacturingOxygenRefractory metals

A plasma processing chamber particularly useful for pre-treating low-k dielectric films and refractory metal films subject to oxidation prior to deposition of other layers. A remote plasma source (RPS) excites a processing gas into a plasma and delivers it through a supply tube to a manifold in back of a showerhead faceplate. The chamber is configured for oxidizing and reducing plasmas in the same or different processes when oxygen and hydrogen are selectively supplied to the RPS. The supply tube and showerhead may be formed of dielectric oxides which may be passivated by a water vapor plasma from the remote plasma source. In one novel process, a protective hydroxide coating is formed on refractory metals by alternating neutral plasmas of hydrogen and oxygen.

Owner:APPLIED MATERIALS INC

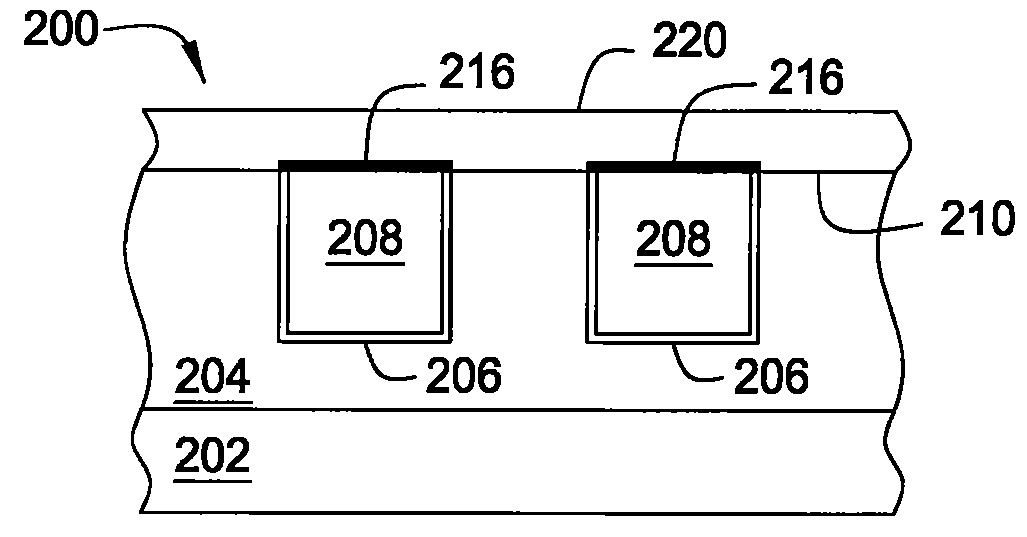

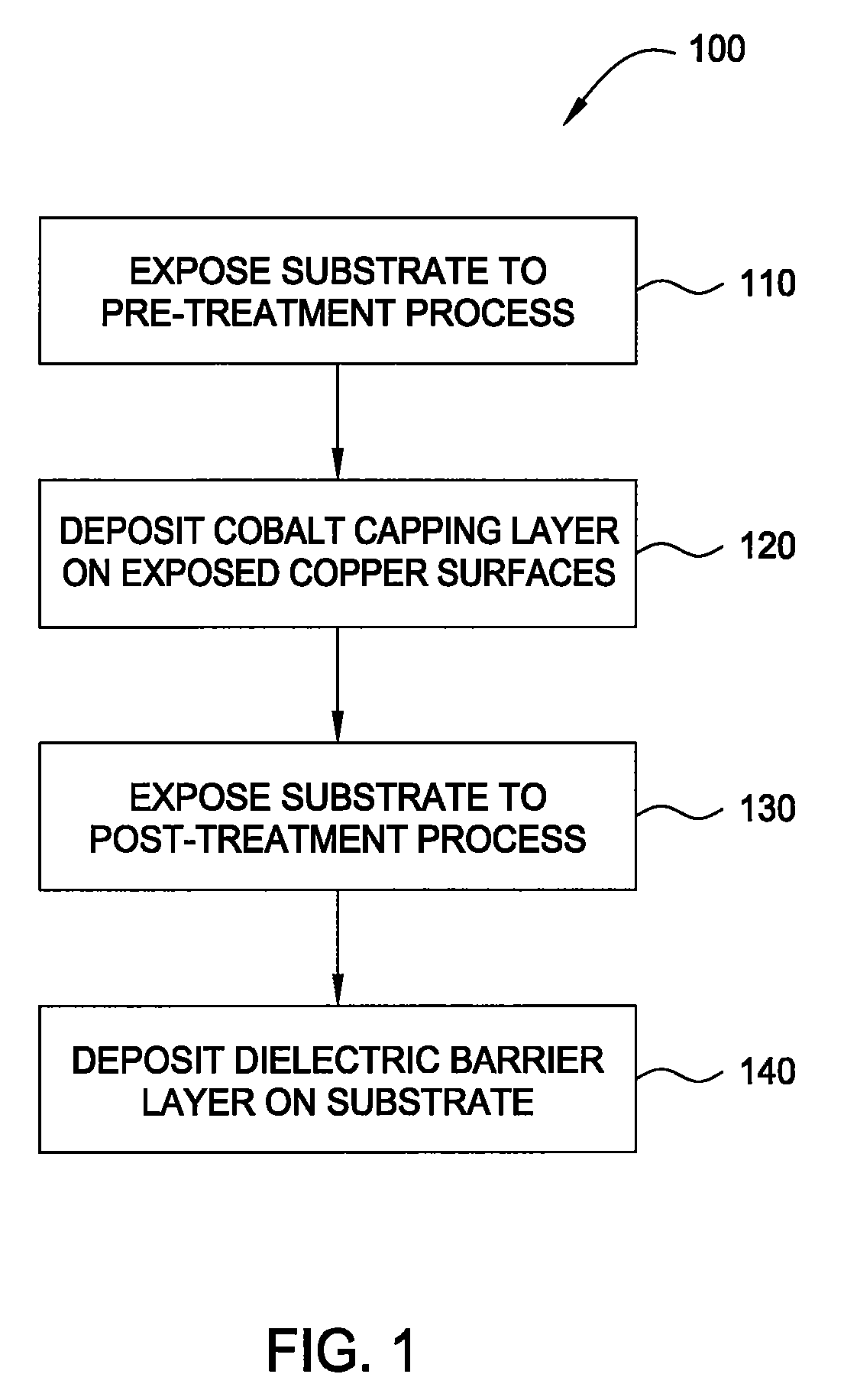

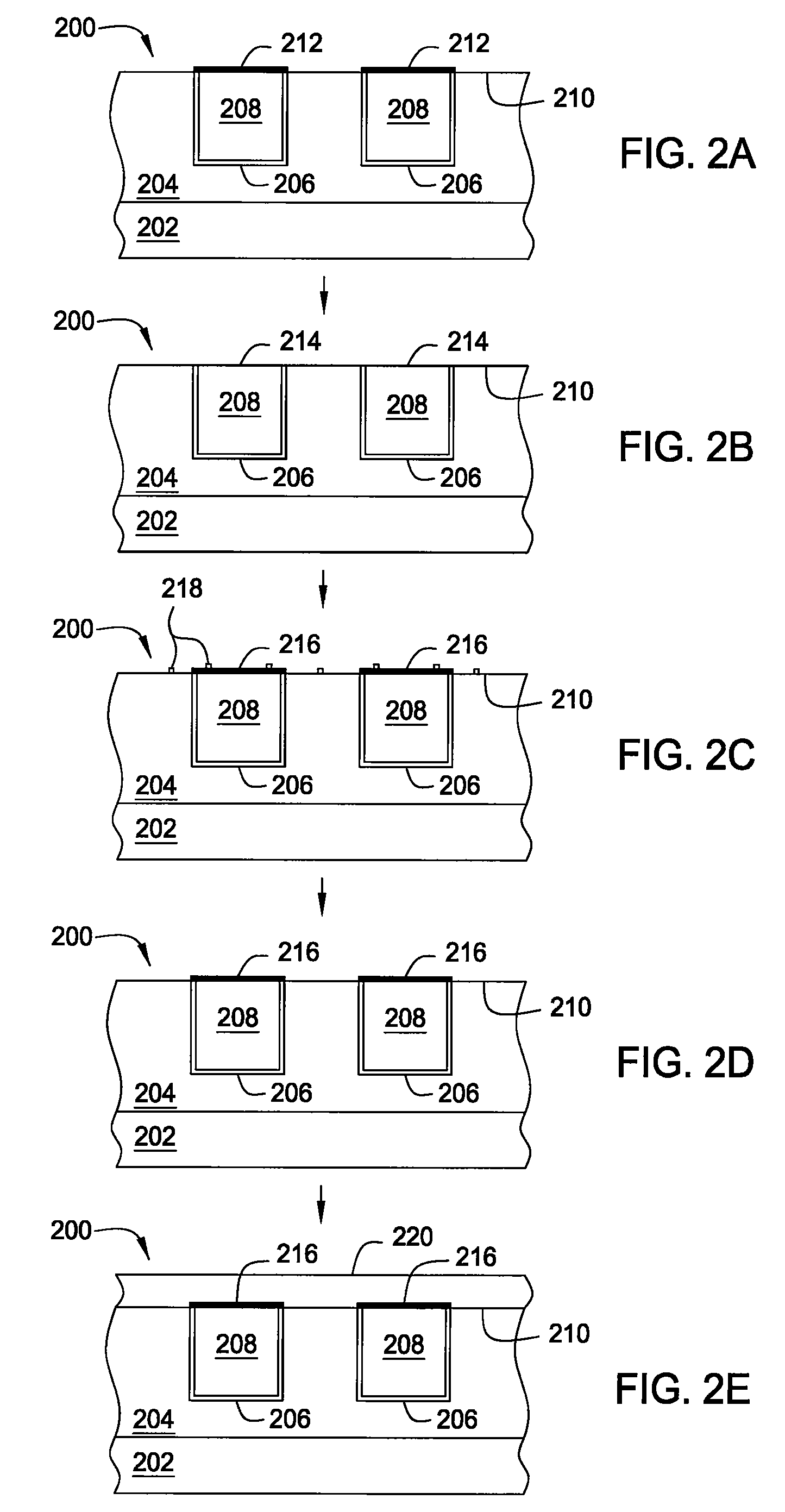

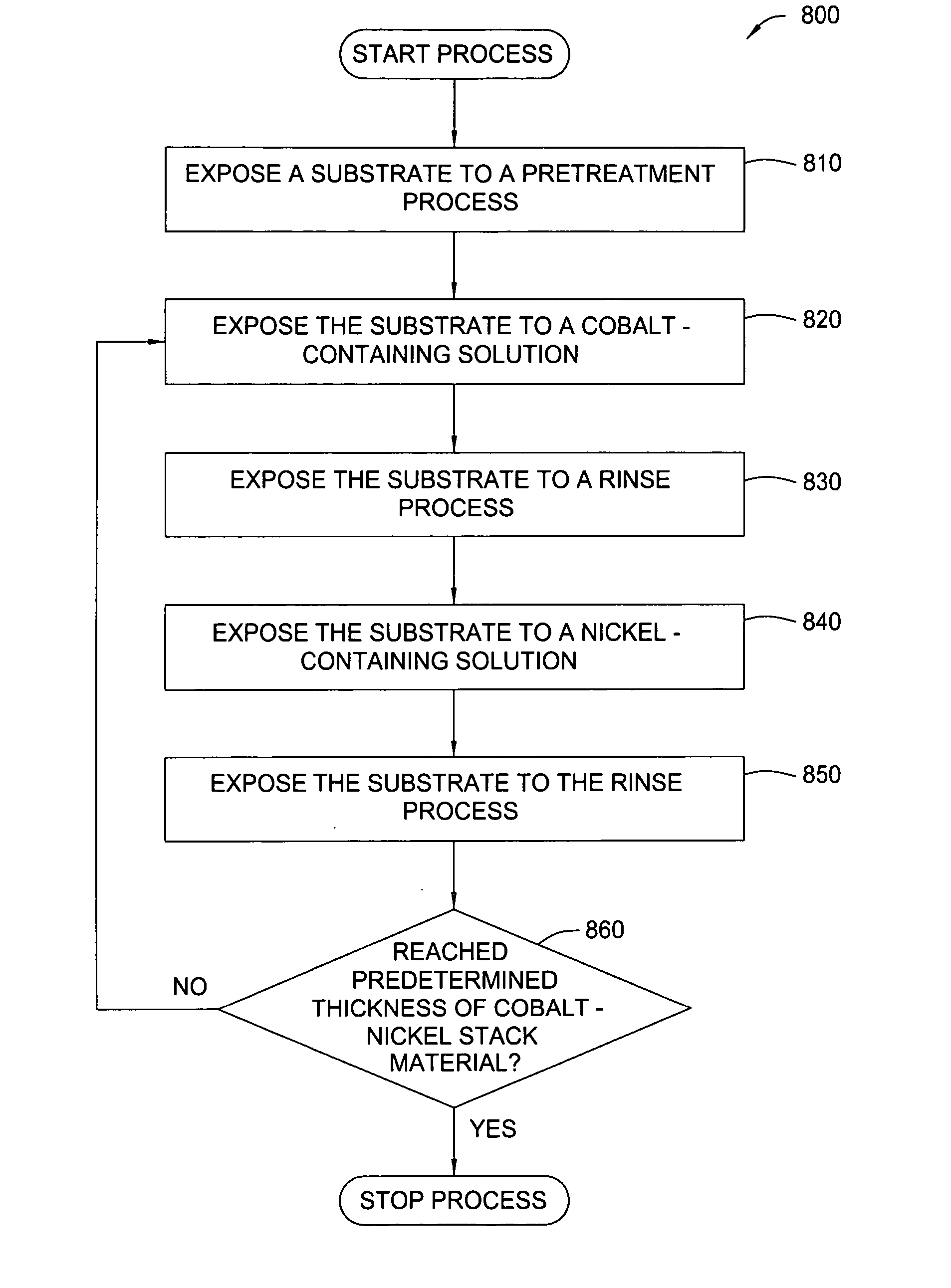

Selective cobalt deposition on copper surfaces

InactiveUS20090269507A1Pretreated surfacesSemiconductor/solid-state device manufacturingGas phaseDielectric surface

Embodiments of the invention provide processes to selectively form a cobalt layer on a copper surface over exposed dielectric surfaces. In one embodiment, a method for capping a copper surface on a substrate is provided which includes positioning a substrate within a processing chamber, wherein the substrate contains a contaminated copper surface and a dielectric surface, exposing the contaminated copper surface to a reducing agent while forming a copper surface during a pre-treatment process, exposing the substrate to a cobalt precursor gas to selectively form a cobalt capping layer over the copper surface while leaving exposed the dielectric surface during a vapor deposition process, and depositing a dielectric barrier layer over the cobalt capping layer and the dielectric surface. In another embodiment, a deposition-treatment cycle includes performing the vapor deposition process and subsequently a post-treatment process, which deposition-treatment cycle may be repeated to form multiple cobalt capping layers.

Owner:APPLIED MATERIALS INC

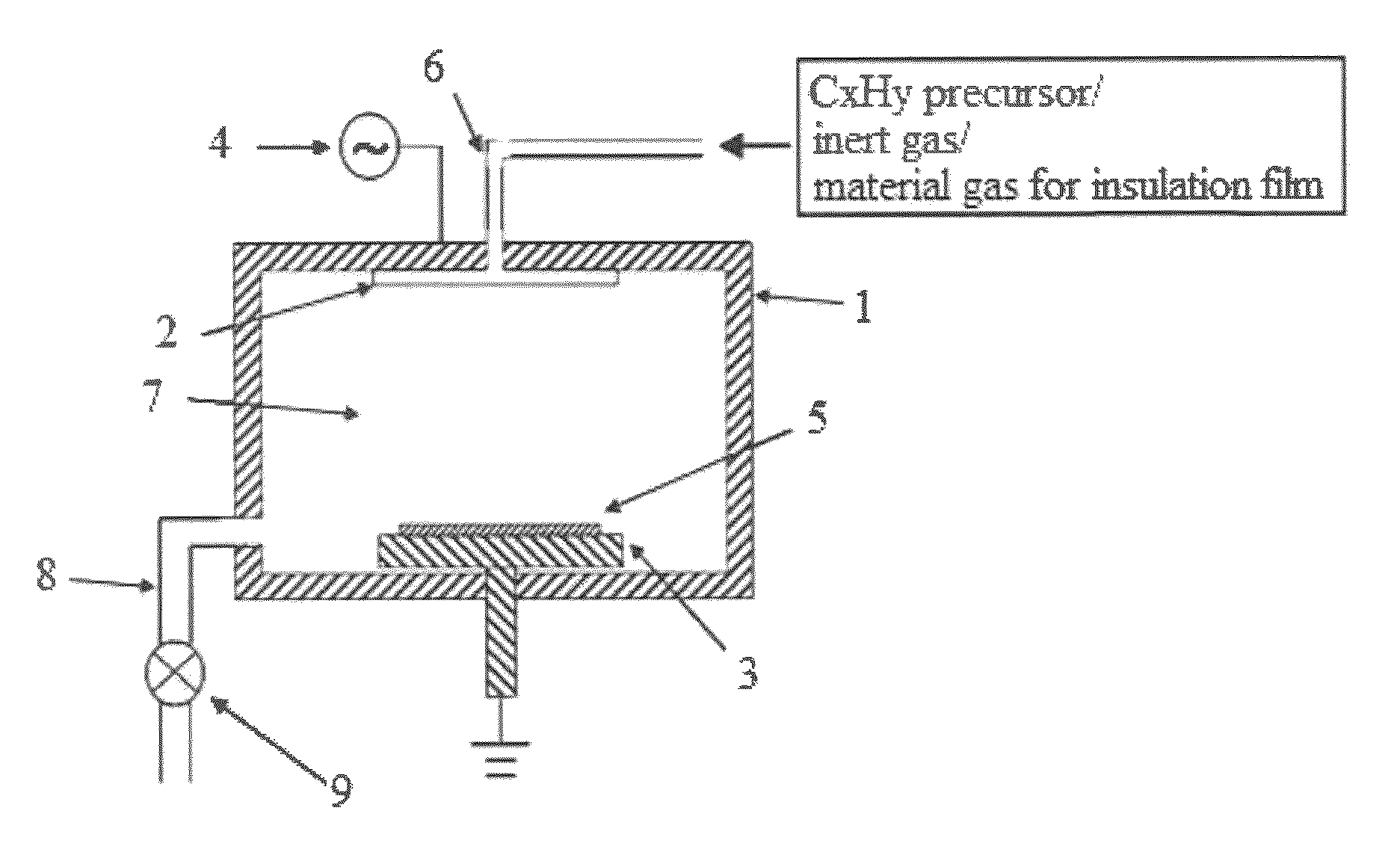

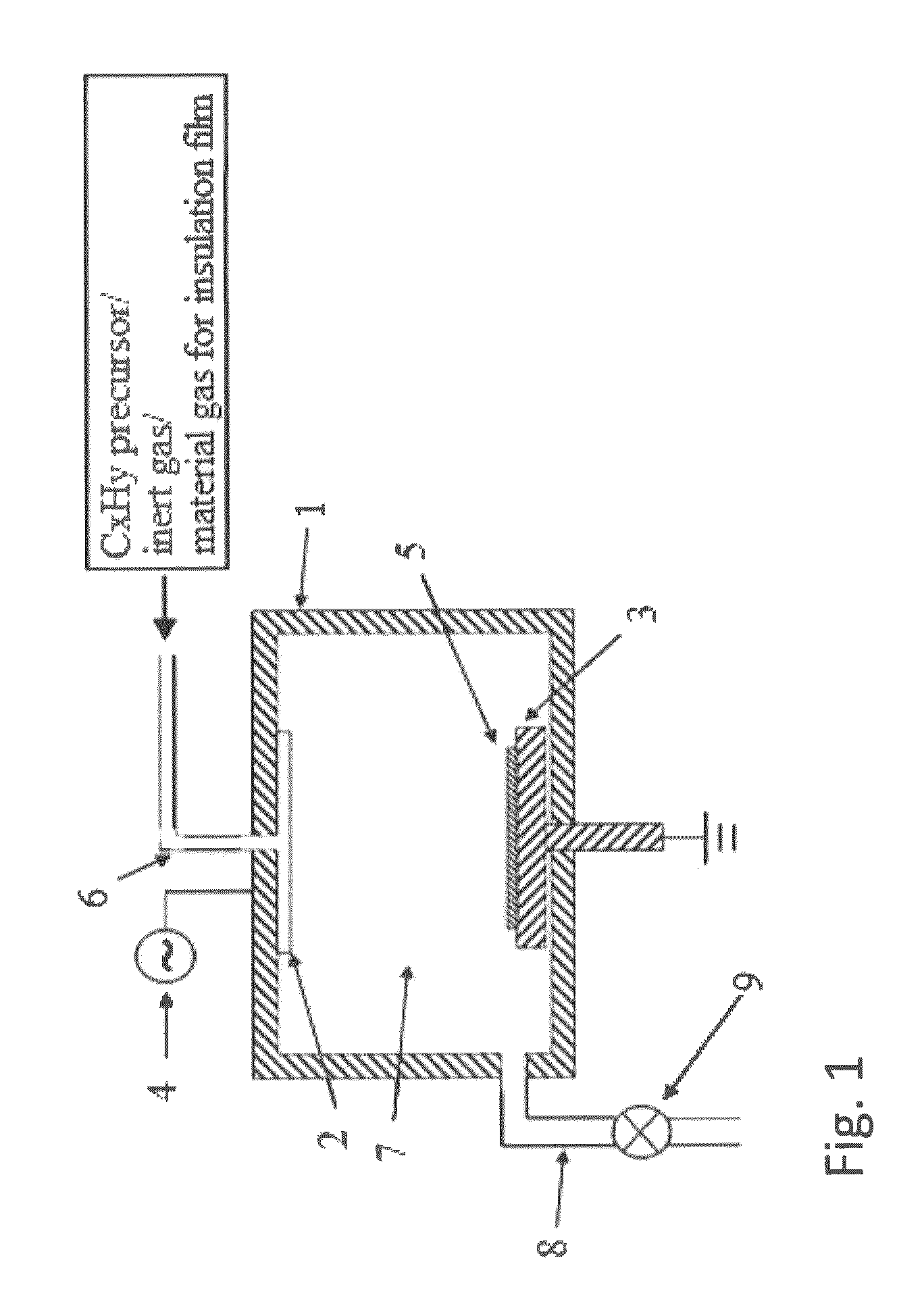

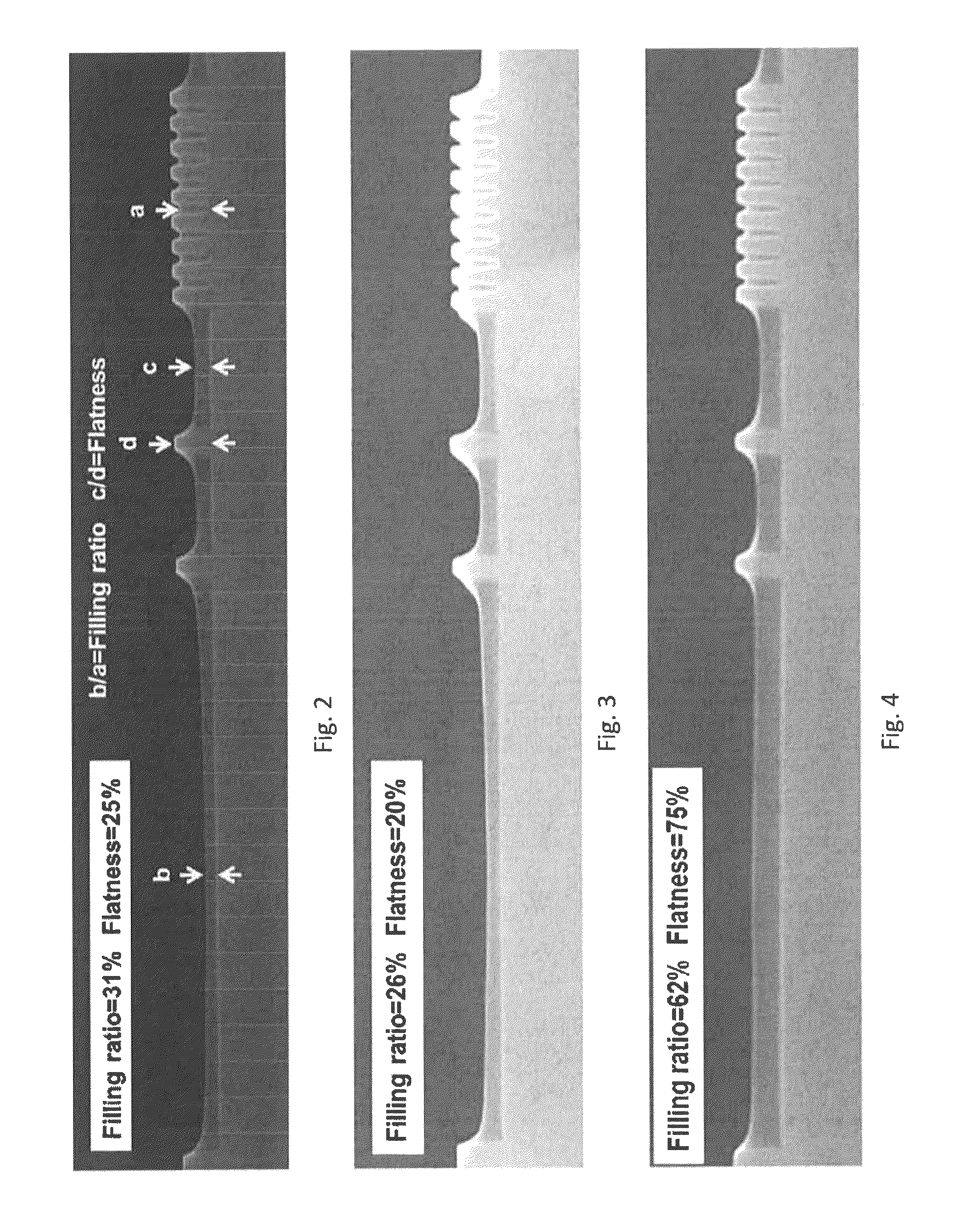

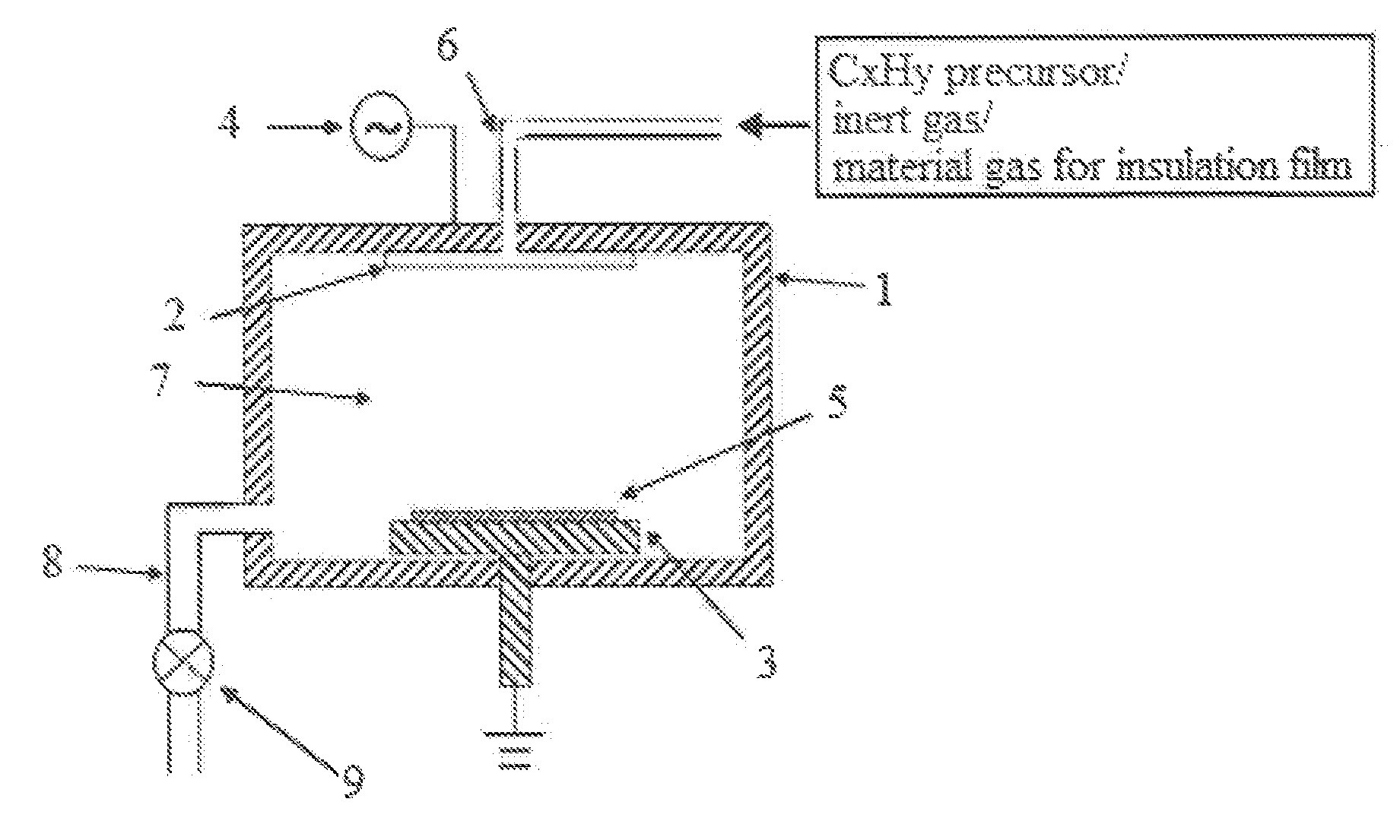

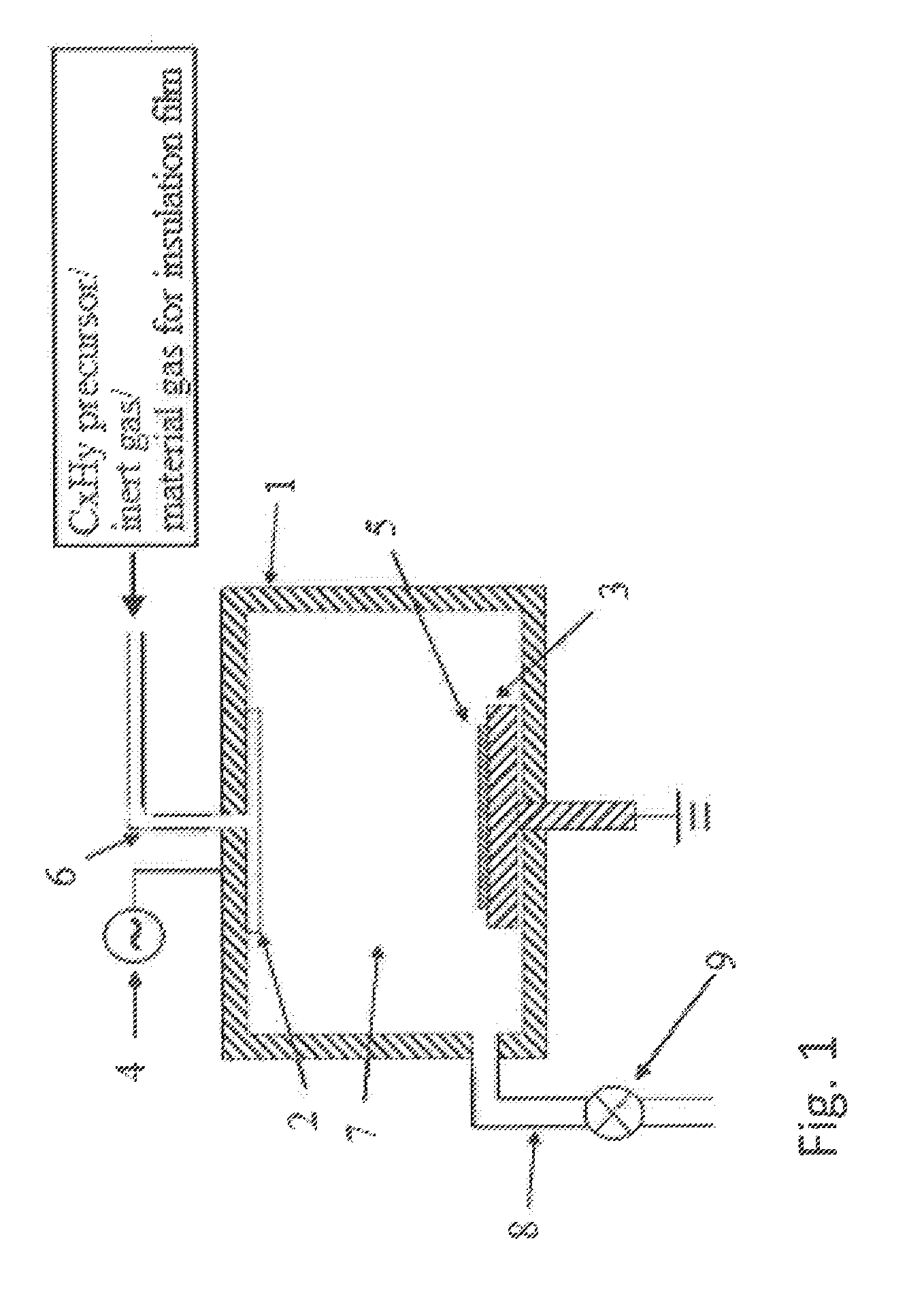

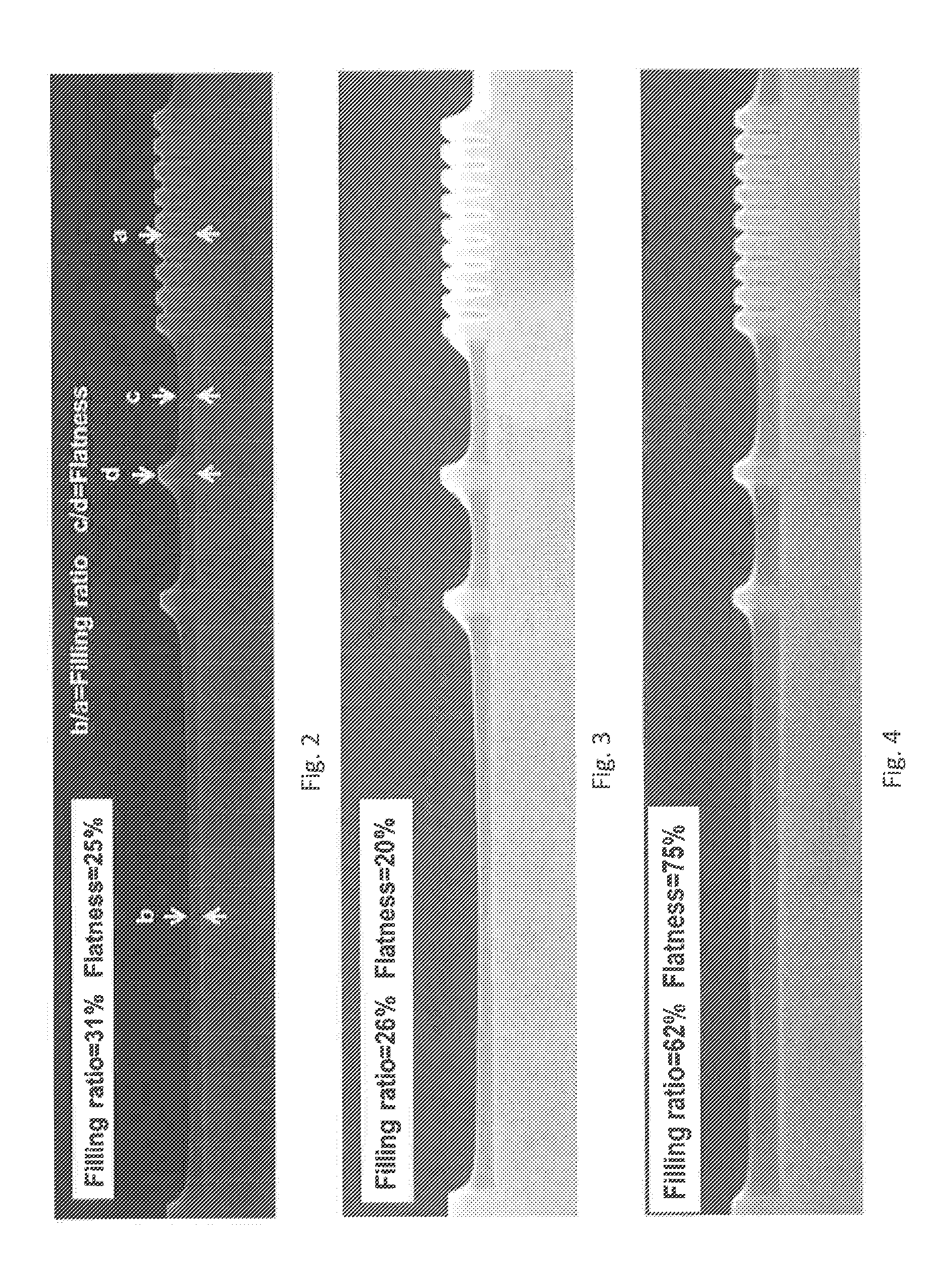

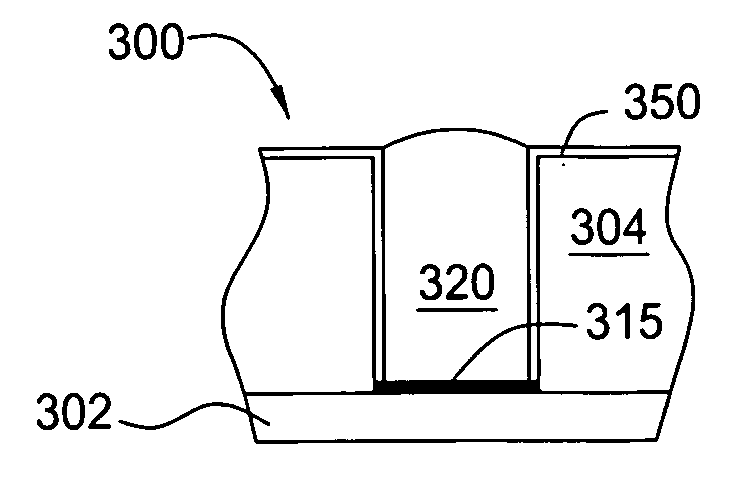

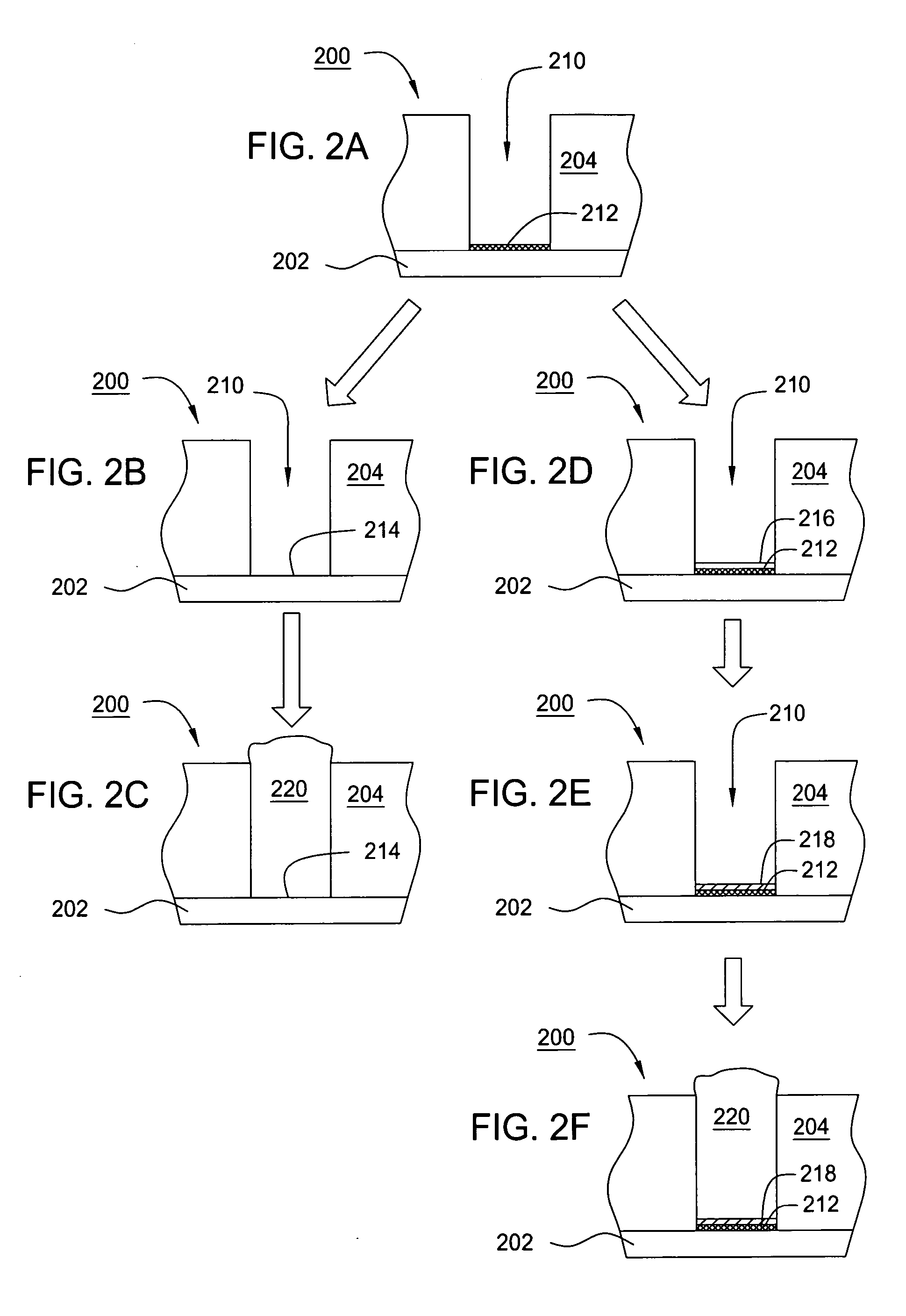

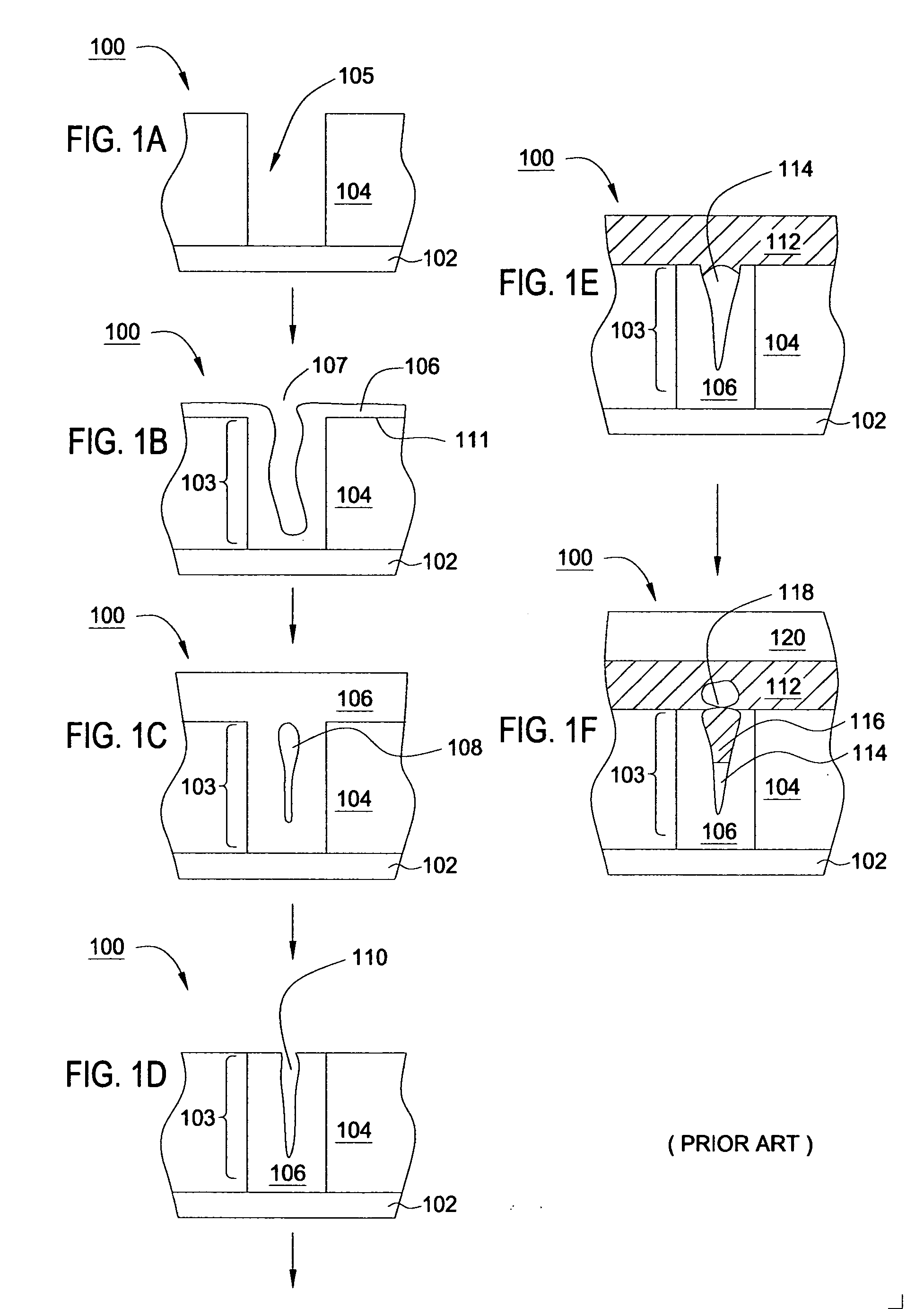

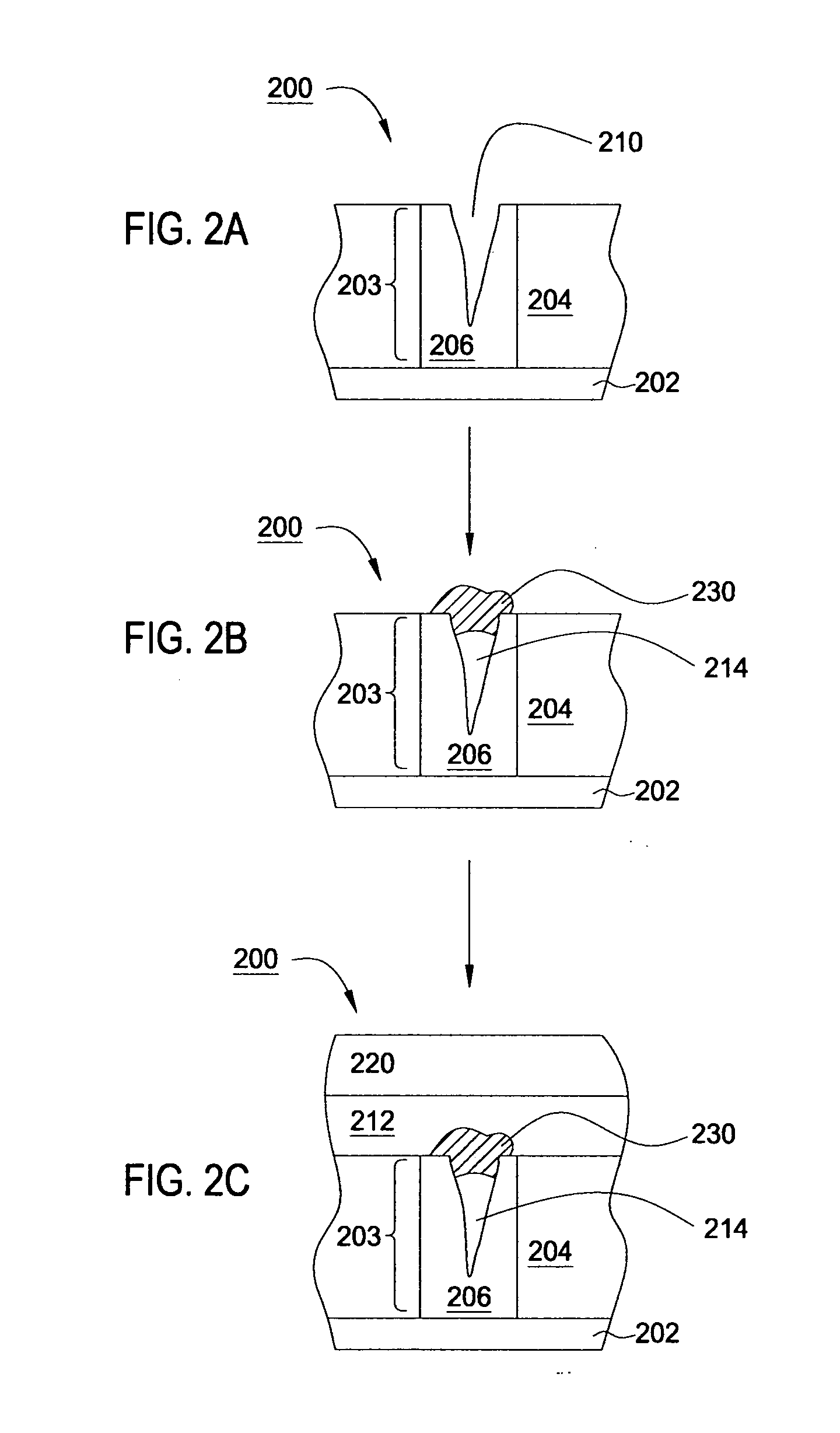

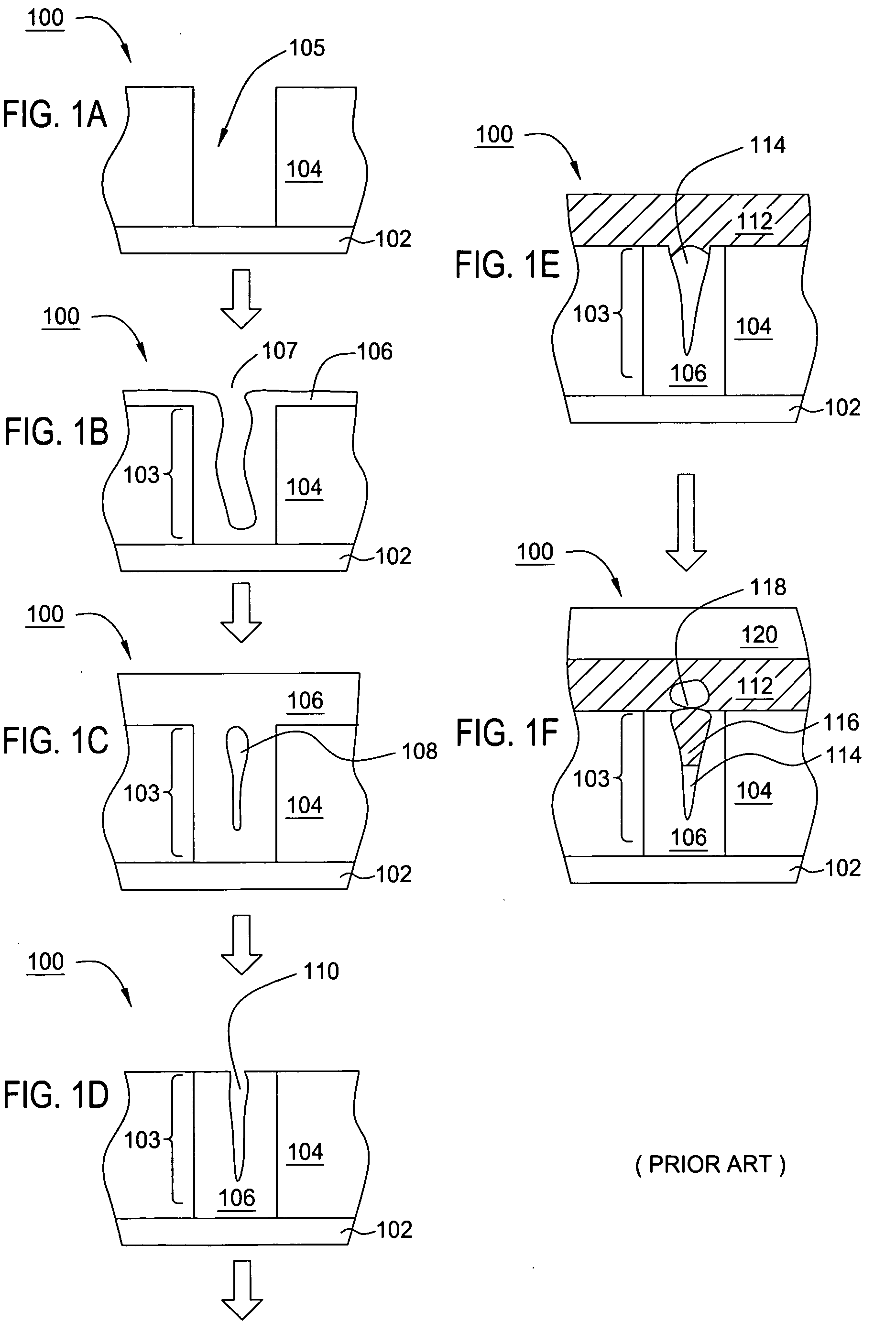

Method for filling recesses using pre-treatment with hydrocarbon-containing gas

ActiveUS9117657B2Improve flatnessHighly effectiveSemiconductor/solid-state device manufacturingChemical vapor deposition coatingPre treatmentPre deposition

A method for filling recesses of a substrate with an insulation film includes: (i) exposing surfaces of the recesses of the substrate to a pre-deposition gas in a reactive state in a reaction space to treat the surfaces with reactive hydrocarbons generated from the pre-deposition gas without filling the recesses; and (ii) depositing a flowable insulation film using a process gas other than the pre-deposition gas on a surface of the substrate to fill the recesses treated in step (i) therewith by plasma reaction. The pre-deposition gas has at least one hydrocarbon unit in its molecule.

Owner:ASM IP HLDG BV

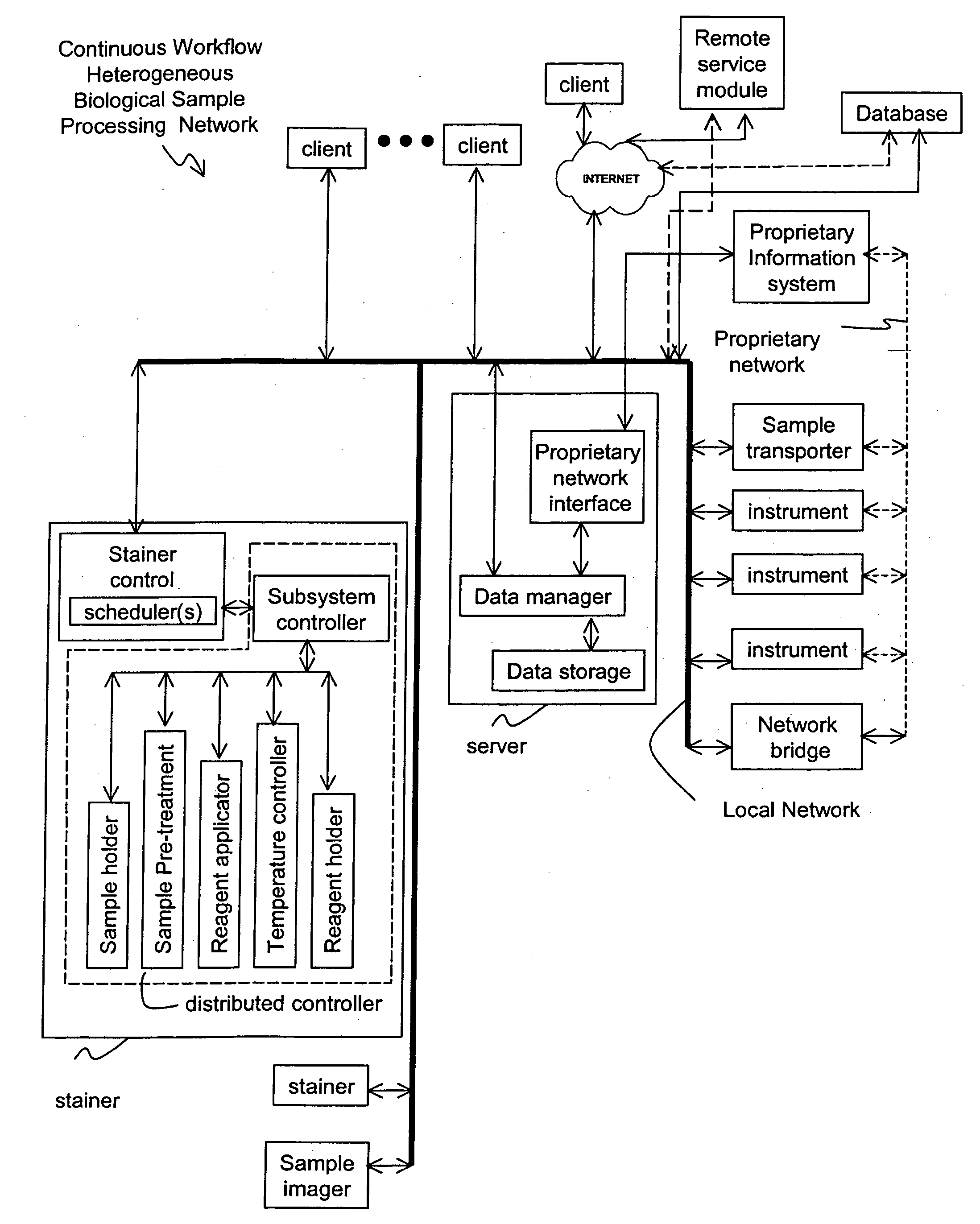

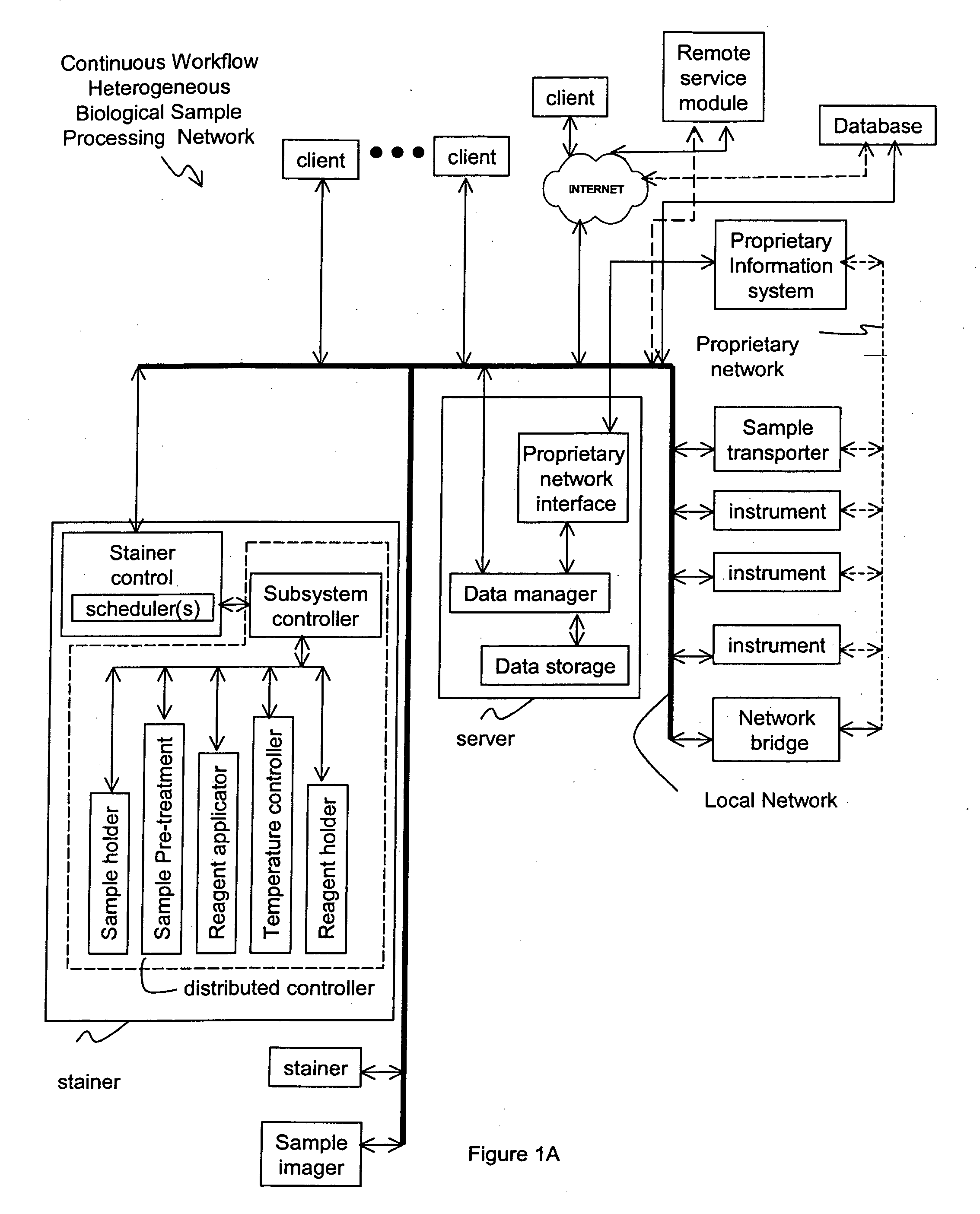

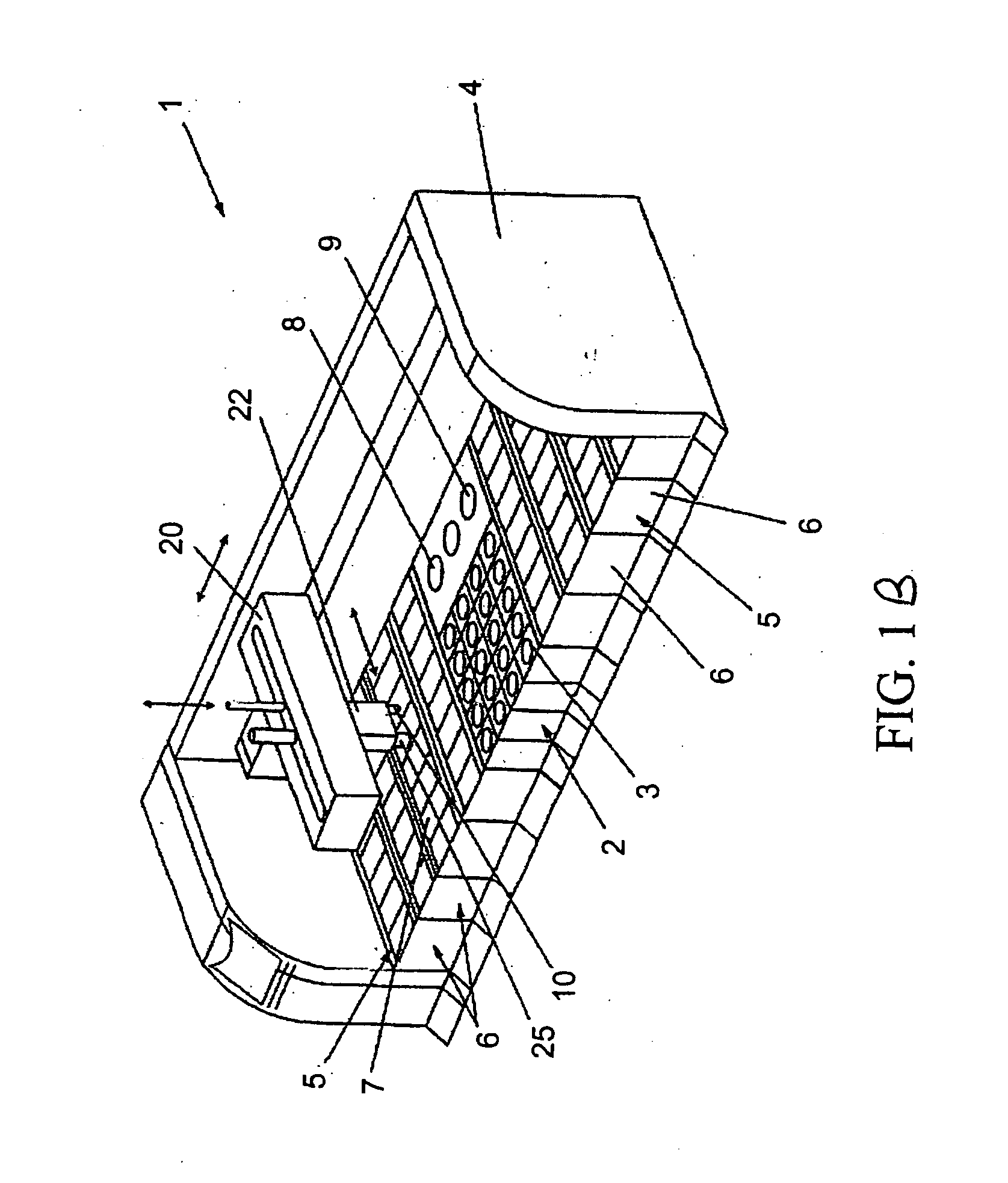

Method and apparatus for automated pre-treatment and processing of biological samples

ActiveUS20060148063A1Maximize throughputImprove efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsPre treatmentComputer science

A method and apparatus for continuous workflow processing of biological samples. In one embodiment, the appratus includes a probe for dispensing one or more reagents from one or more reagent containers onto one or more biological sample carriers. The method and apparatus includes processing each biological sample according to a respective sequence of protocol steps which may be ordered by a scheduler protocol. The method and apparatus also includes network capability for connectivity with additional equipment for receiving or transmitting pertinent data via the network.

Owner:AGILENT TECH INC

Method For Filling Recesses Using Pre-Treatment With Hydrocarbon-Containing Gas

ActiveUS20140363983A1Improve flatnessHighly effectiveSemiconductor/solid-state device manufacturingChemical vapor deposition coatingPre treatmentPlasma reaction

A method for filling recesses of a substrate with an insulation film includes: (i) exposing surfaces of the recesses of the substrate to a pre-deposition gas in a reactive state in a reaction space to treat the surfaces with reactive hydrocarbons generated from the pre-deposition gas without filling the recesses; and (ii) depositing a flowable insulation film using a process gas other than the pre-deposition gas on a surface of the substrate to fill the recesses treated in step (i) therewith by plasma reaction. The pre-deposition gas has at least one hydrocarbon unit in its molecule.

Owner:ASM IP HLDG BV

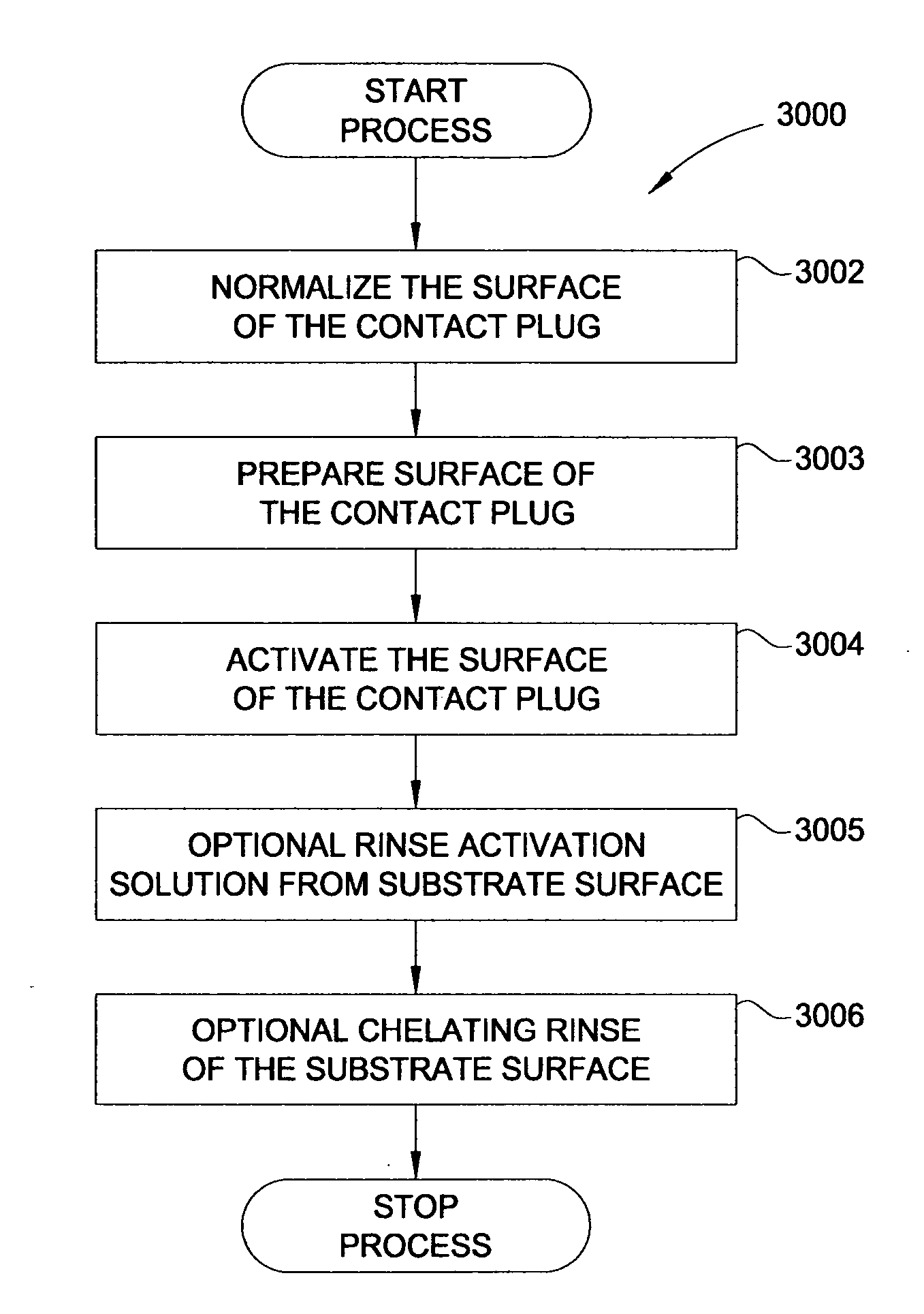

Electroless deposition process on a silicon contact

ActiveUS20060264043A1Material nanotechnologySemiconductor/solid-state device manufacturingSalicideAlloy

Embodiments as described herein provide methods for depositing a material on a substrate during electroless deposition processes, as well as compositions of the electroless deposition solutions. In one embodiment, the substrate contains a contact aperture having an exposed silicon contact surface. In another embodiment, the substrate contains a contact aperture having an exposed silicide contact surface. The apertures are filled with a metal contact material by exposing the substrate to an electroless deposition process. The metal contact material may contain a cobalt material, a nickel material, or alloys thereof. Prior to filling the apertures, the substrate may be exposed to a variety of pretreatment processes, such as preclean processes and activations processes. A preclean process may remove organic residues, native oxides, and other contaminants during a wet clean process or a plasma etch process. Embodiments of the process also provide the deposition of additional layers, such as a capping layer.

Owner:APPLIED MATERIALS INC

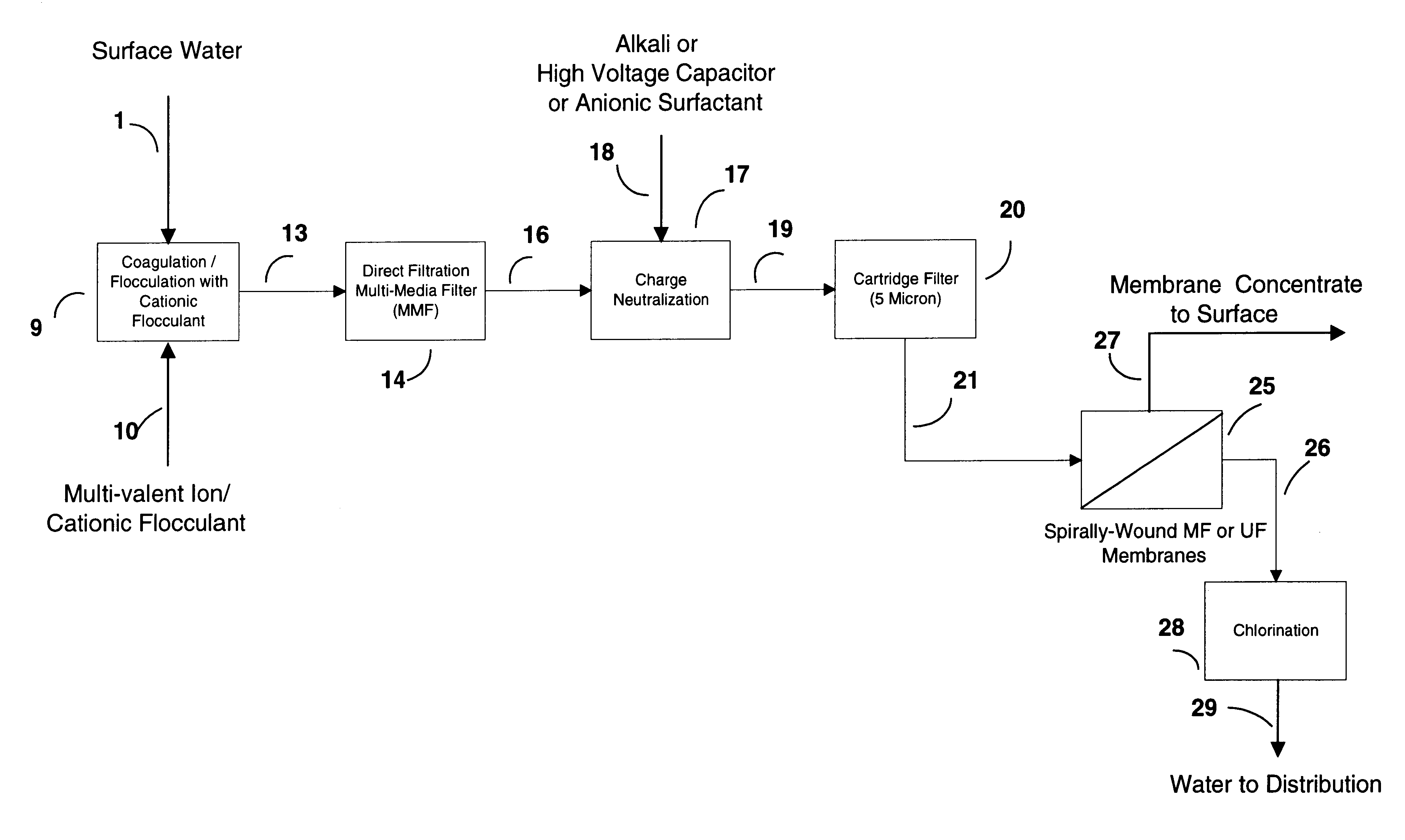

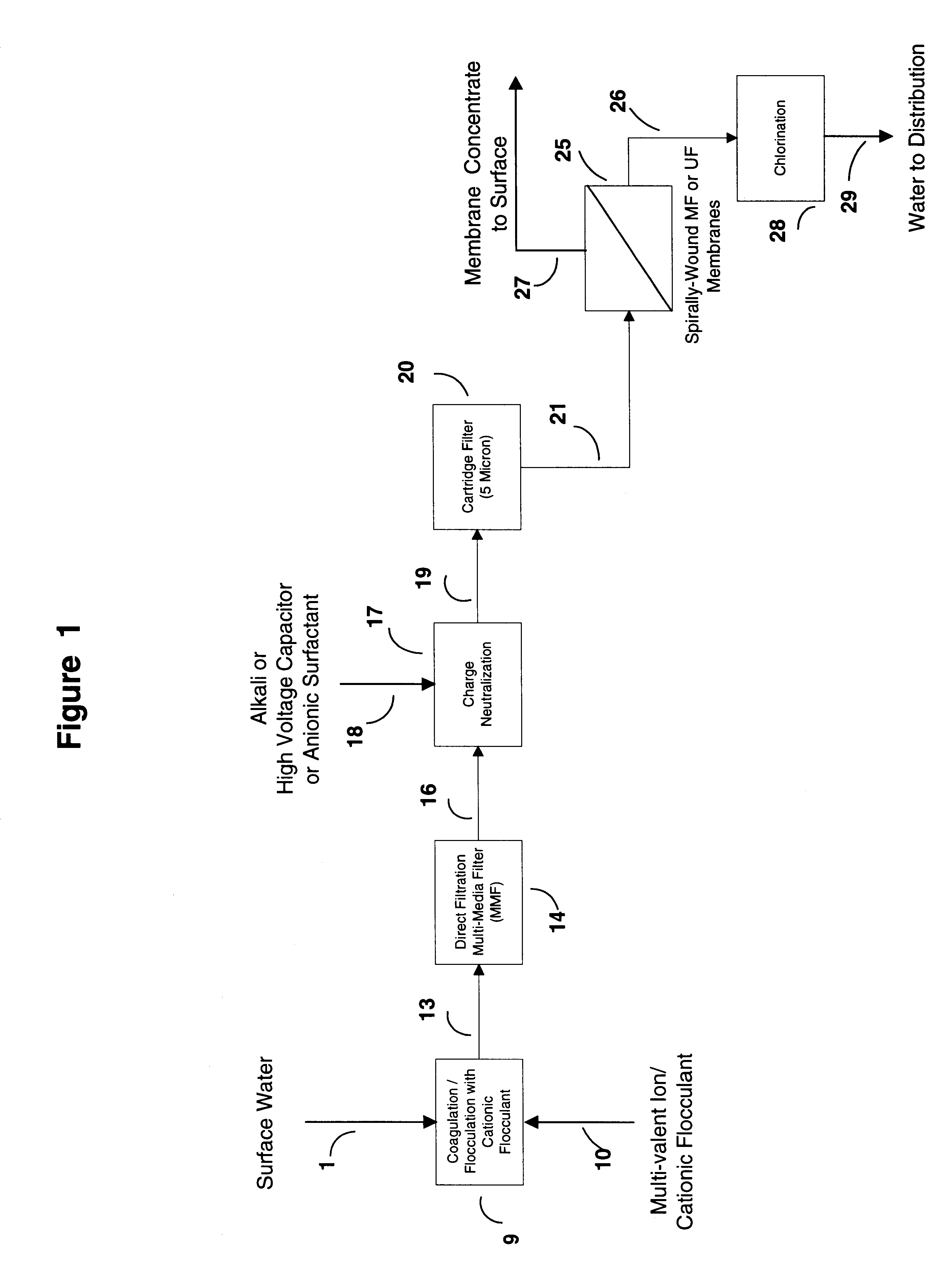

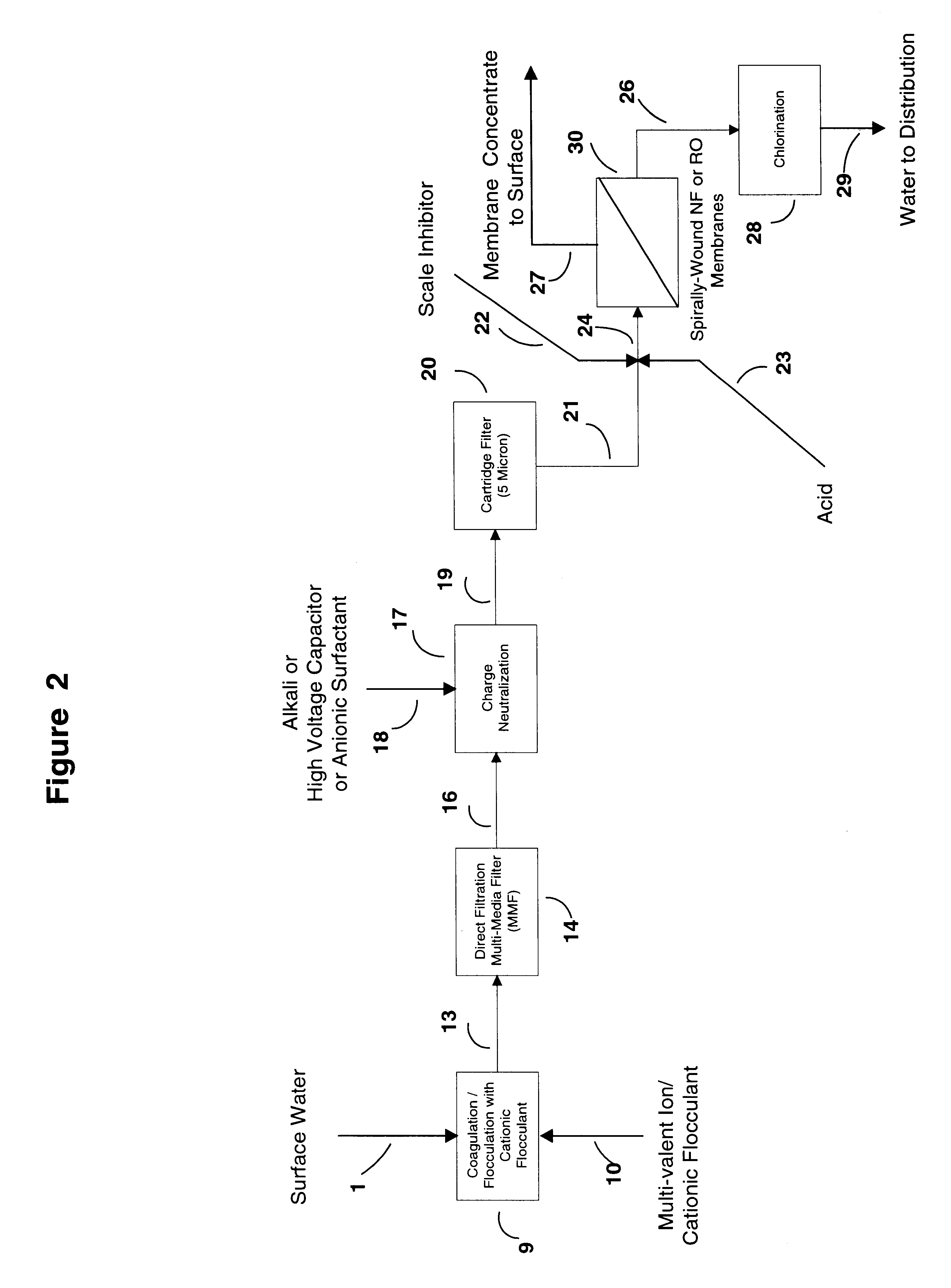

Water treatment process for membranes

InactiveUS6416668B1Effective and safe and reliable to produceCapital and operating costMembranesUltrafiltrationZeta potentialFiltration

This invention discloses a cost-effective process for separating contaminants and a wide-range of fouling material from surface water, ground water and from industrial effluents. Having undergone effective pre-treatment, the water can be purified further by using high-surface area spirally wound micro-filtration (MF), ultra-filtration (UF), nano-filtration (NF) or reverse osmosis (RO) membranes. High-quality potable water free from pathogen and other contaminants is thus produced at low-cost from the pre-treated surface water and ground-water. Conversely, pre-treated industrial effluents are further purified at a relatively low-cost using NF or RO membranes, thus producing water suitable for recycle or surface discharge. The process of this invention uses cationic inorganic and / or polymeric flocculants to coagulate and flocculate the water-borne colloidal matter (e.g. clays, iron hydroxides, naturally occurring matter (NOM's), etc.), followed by filtration using a multi-media filter, charge neutralization and reversal and final filtration using a 5-micron cartridge filter. These pre-treatment steps provides a good quality water having a low Silt Density Index and a significant negative zeta potential, thereby ensuring against irreversible chemical fouling of the spirally-wound membranes.

Owner:AL SAMADI RIAD A

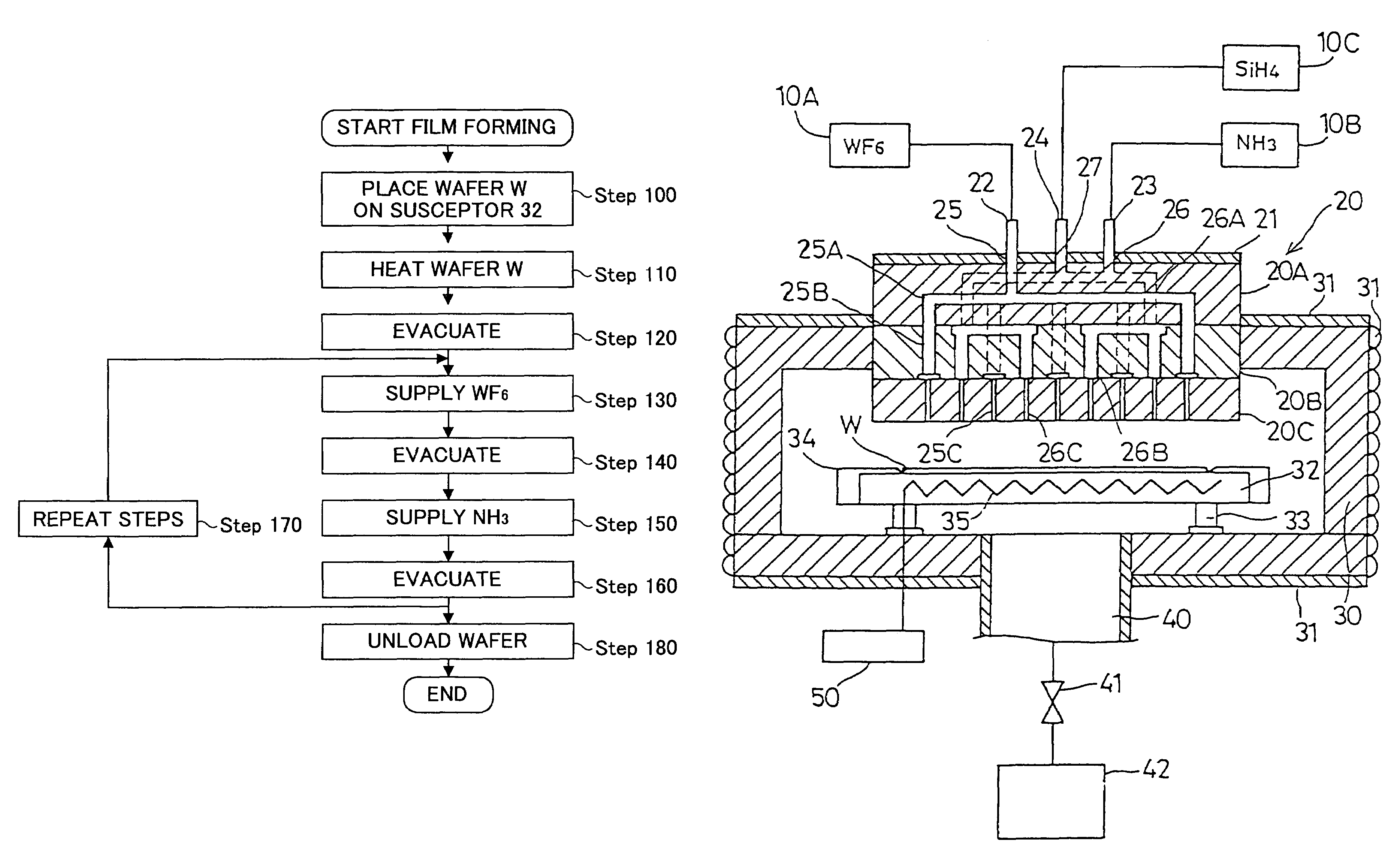

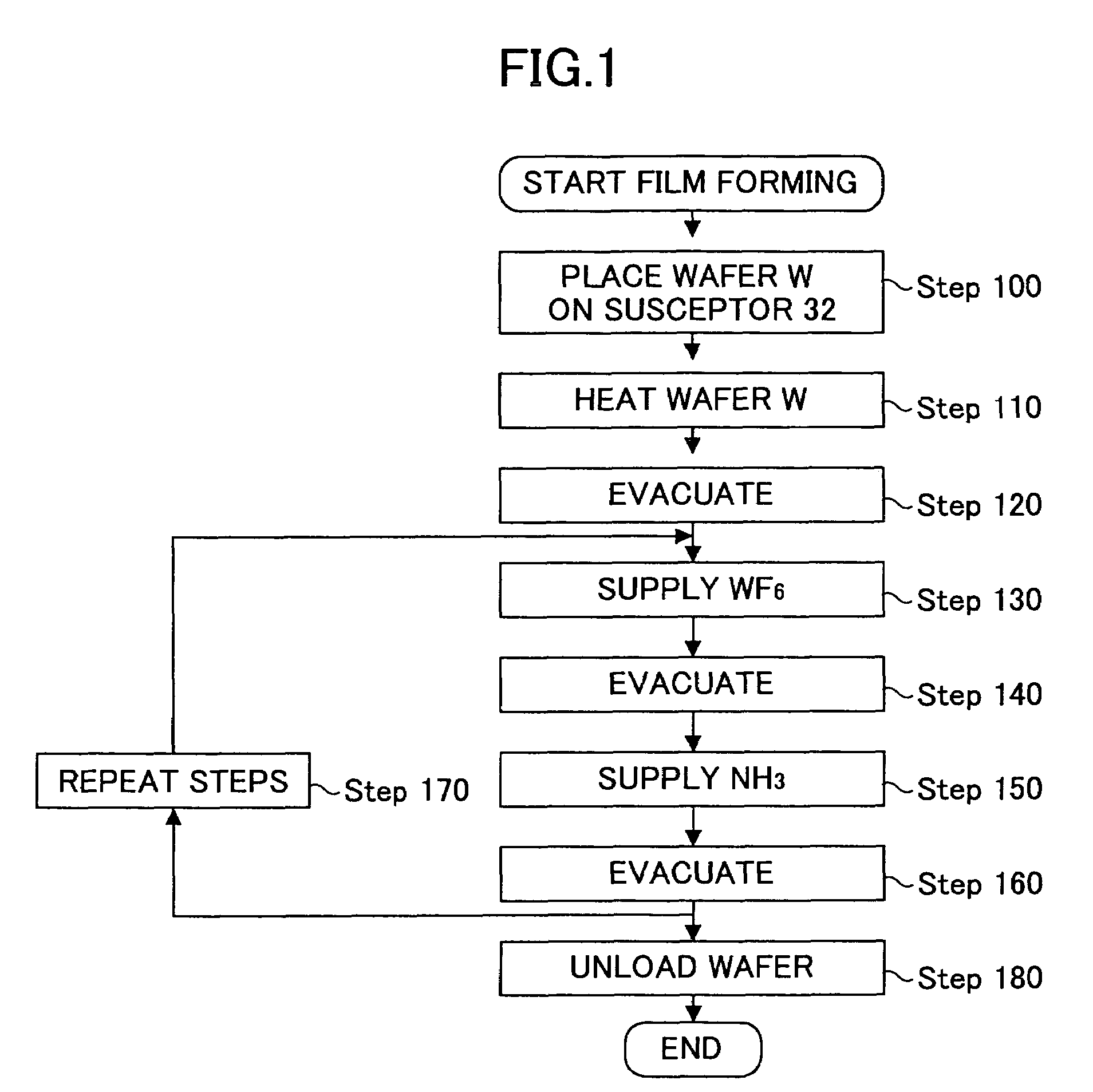

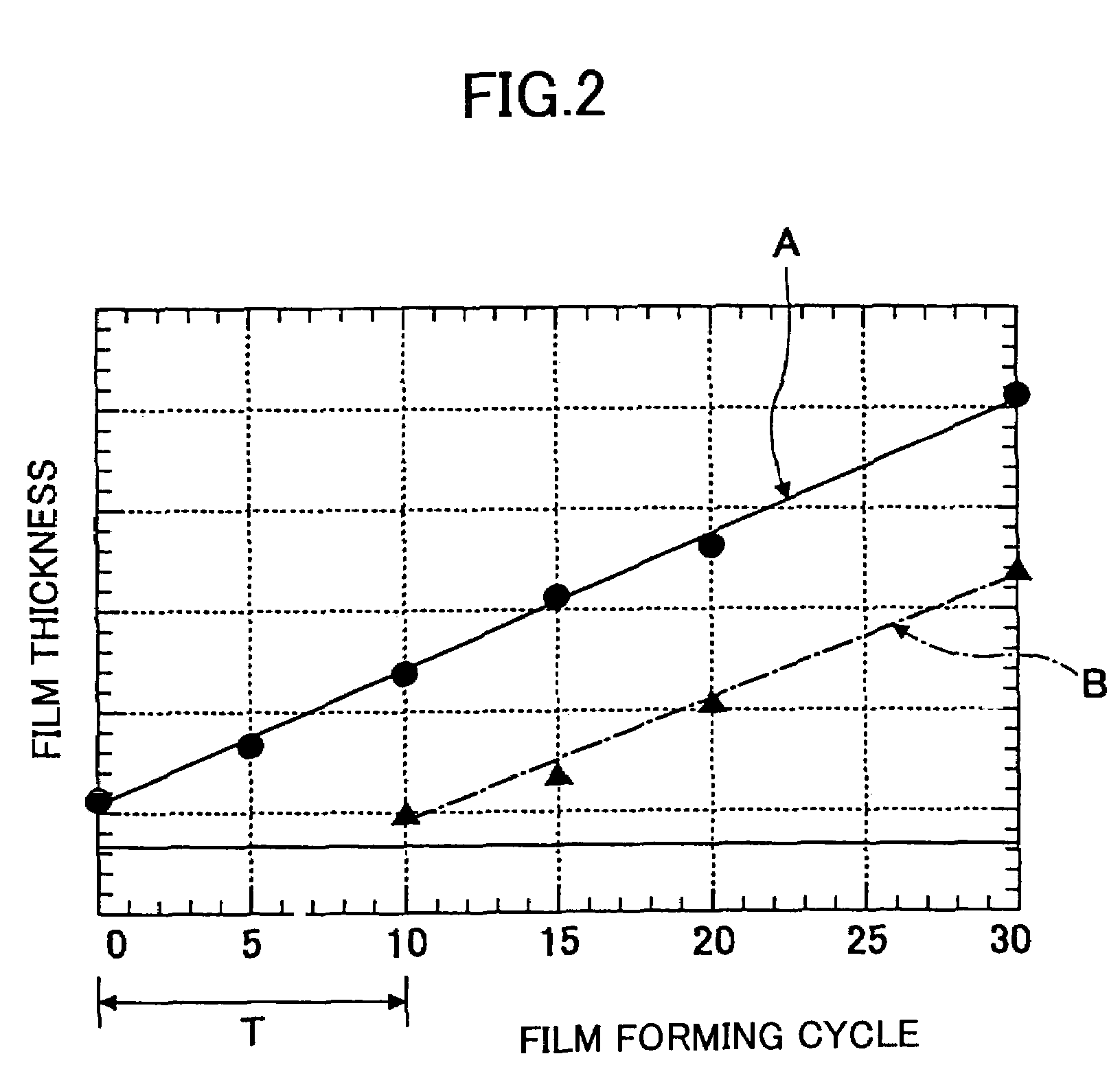

Thin film forming method and thin film forming device

InactiveUS7482283B2Shorten the overall cycleImprove throughputElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringProduct gas

The present invention relates to a method and apparatus for forming a thin film using the ALD process. Prior to the ALD process where each of a plurality of source gasses is supplied one by one, plural times, a pretreatment process is performed in which the source gasses are simultaneously supplied to shorten an incubation period and improve throughput.

Owner:TOKYO ELECTRON LTD

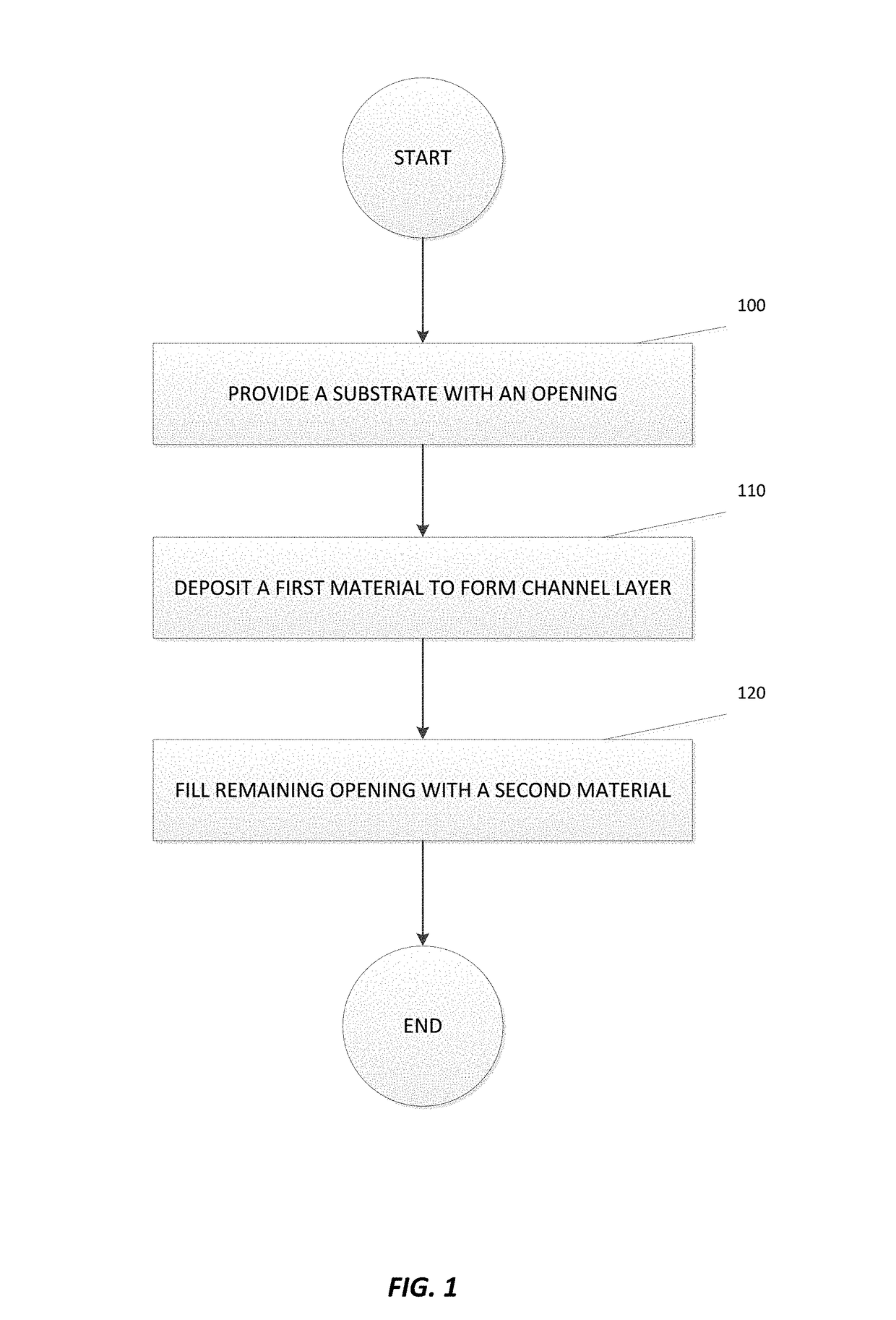

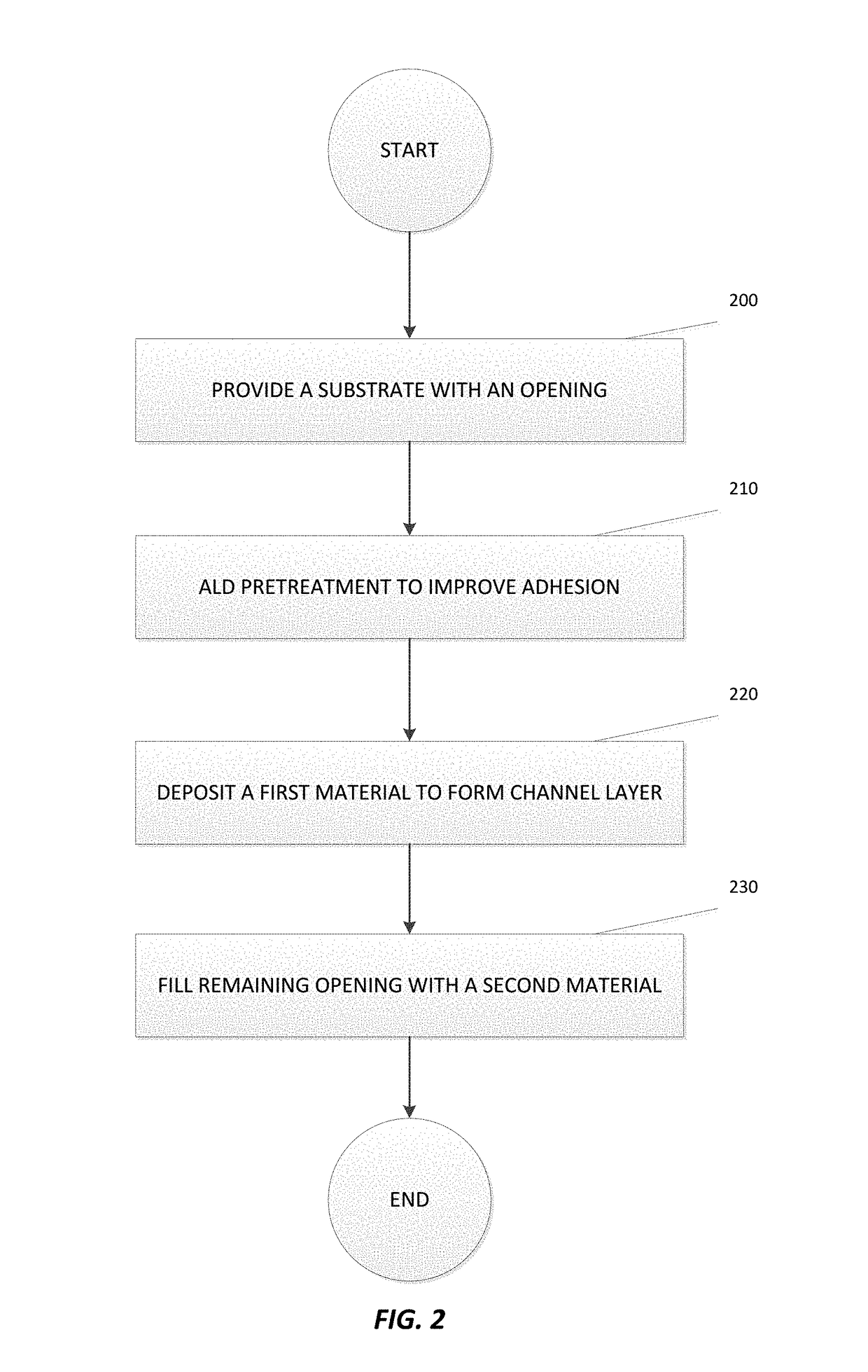

Atomic layer deposition of iii-v compounds to form v-nand devices

ActiveUS20170186754A1Solid-state devicesSemiconductor/solid-state device manufacturingElectricityConductive materials

A method for forming a V-NAND device is disclosed. Specifically, the method involves deposition of at least one of semiconductive material, conductive material, or dielectric material to form a channel for the V-NAND device. In addition, the method may involve a pretreatment step where ALD, CVD, or other cyclical deposition processes may be used to improve adhesion of the material in the channel.

Owner:ASM IP HLDG BV

Electroless deposition processes and compositions for forming interconnects

InactiveUS20060252252A1Material nanotechnologySemiconductor/solid-state device detailsHydrogen fluorideTungstate

In one embodiment, a method for depositing a material on a substrate is provided which includes positioning a substrate containing a contact within a process chamber, exposing the substrate to at least one pretreatment step and depositing a fill the contact vias by an electroless deposition process. The pretreatment step contains multiple processes for exposing the substrate to a wet-clean solution, a hydrogen fluoride solution, a tungstate solution, a palladium activation solution, an acidic rinse solution, a complexing agent solution or combinations thereof. Generally, the HARC via contains a tungsten oxide surface and the shallow contact via may contain a tungsten silicide surface. In some example, the substrate is pretreated such that both vias are filled at substantially the same time by a nickel-containing material through an electroless deposition process.

Owner:APPLIED MATERIALS INC

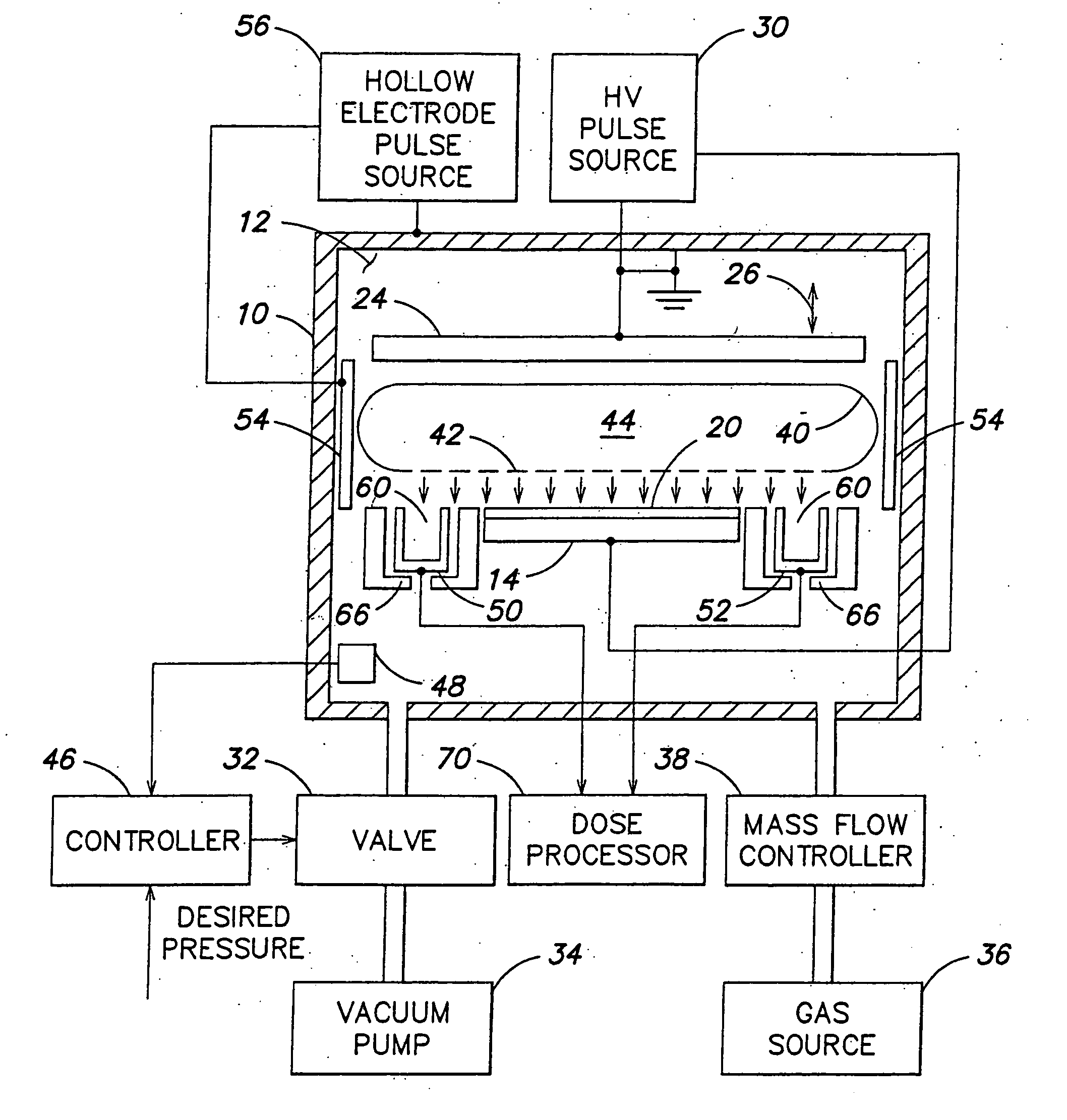

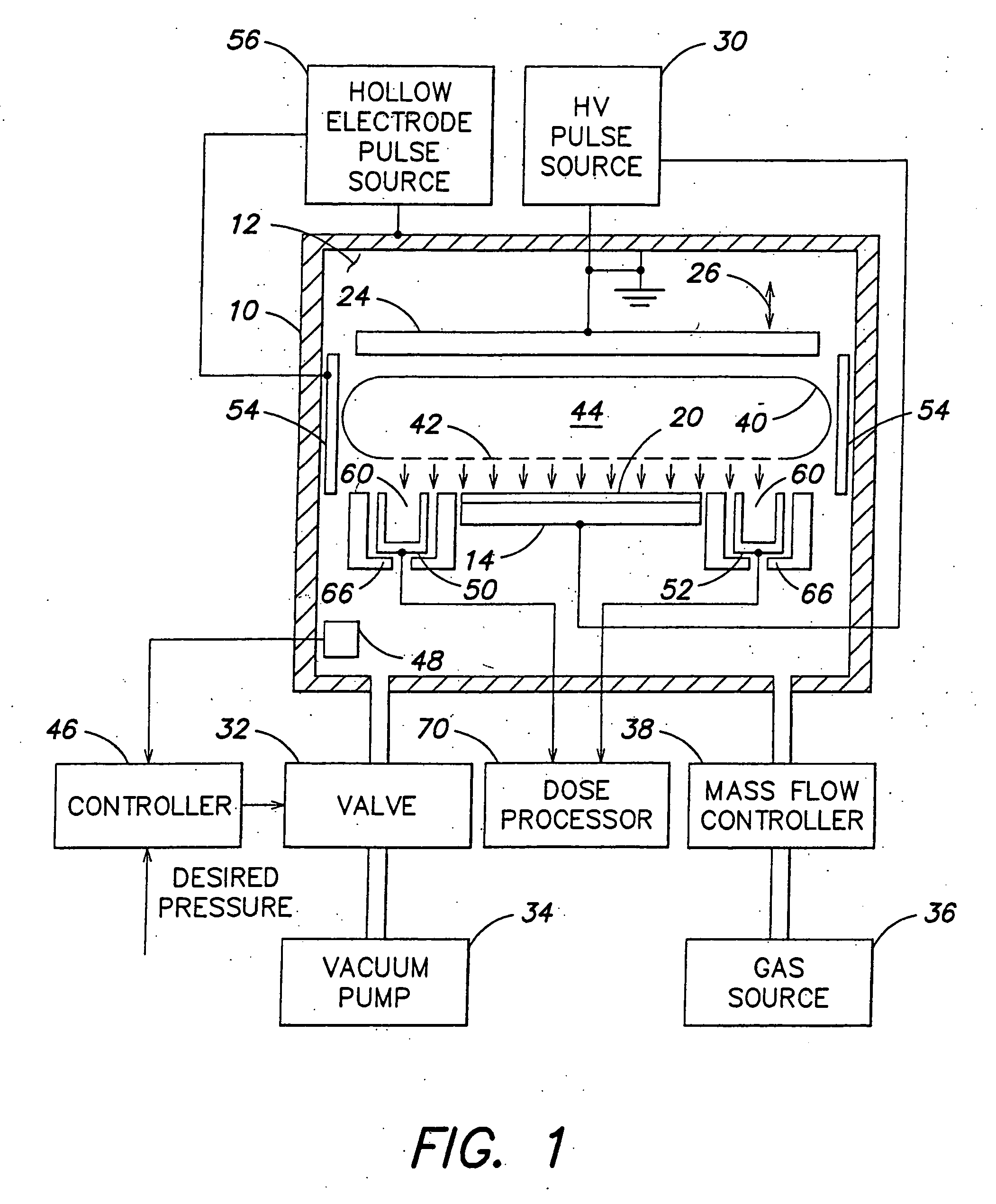

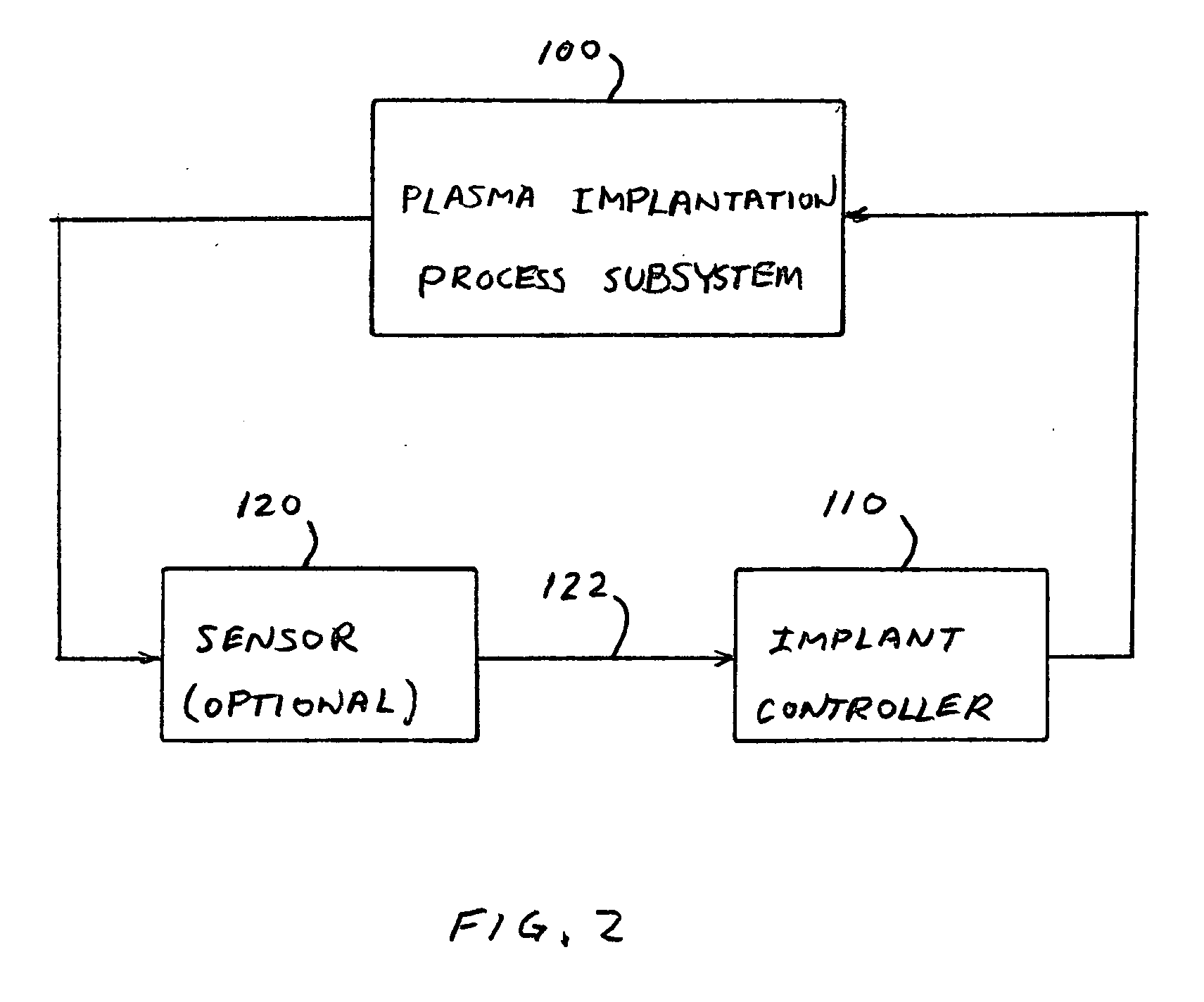

Methods for stable and repeatable ion implantation

A method for plasma ion implantation of a substrate includes providing a plasma ion implantation system having a process chamber, a source for producing a plasma in the process chamber, a platen for holding a substrate in the process chamber, an anode spaced from the platen, and a pulse source for generating implant pulses for accelerating ions from the plasma into the substrate. In one aspect, a parameter of an implant process is varied to at least partially compensate for undesired effects of interaction between ions being implanted and the substrate. For example, dose rate, ion energy, or both may be varied during the implant process. In another aspect, a pretreatment step includes accelerating ions from the plasma to the anode to cause emission of secondary electrons from the anode, and accelerating the secondary electrons from the anode to a substrate for pretreatment of the substrate.

Owner:VARIAN SEMICON EQUIP ASSOC INC

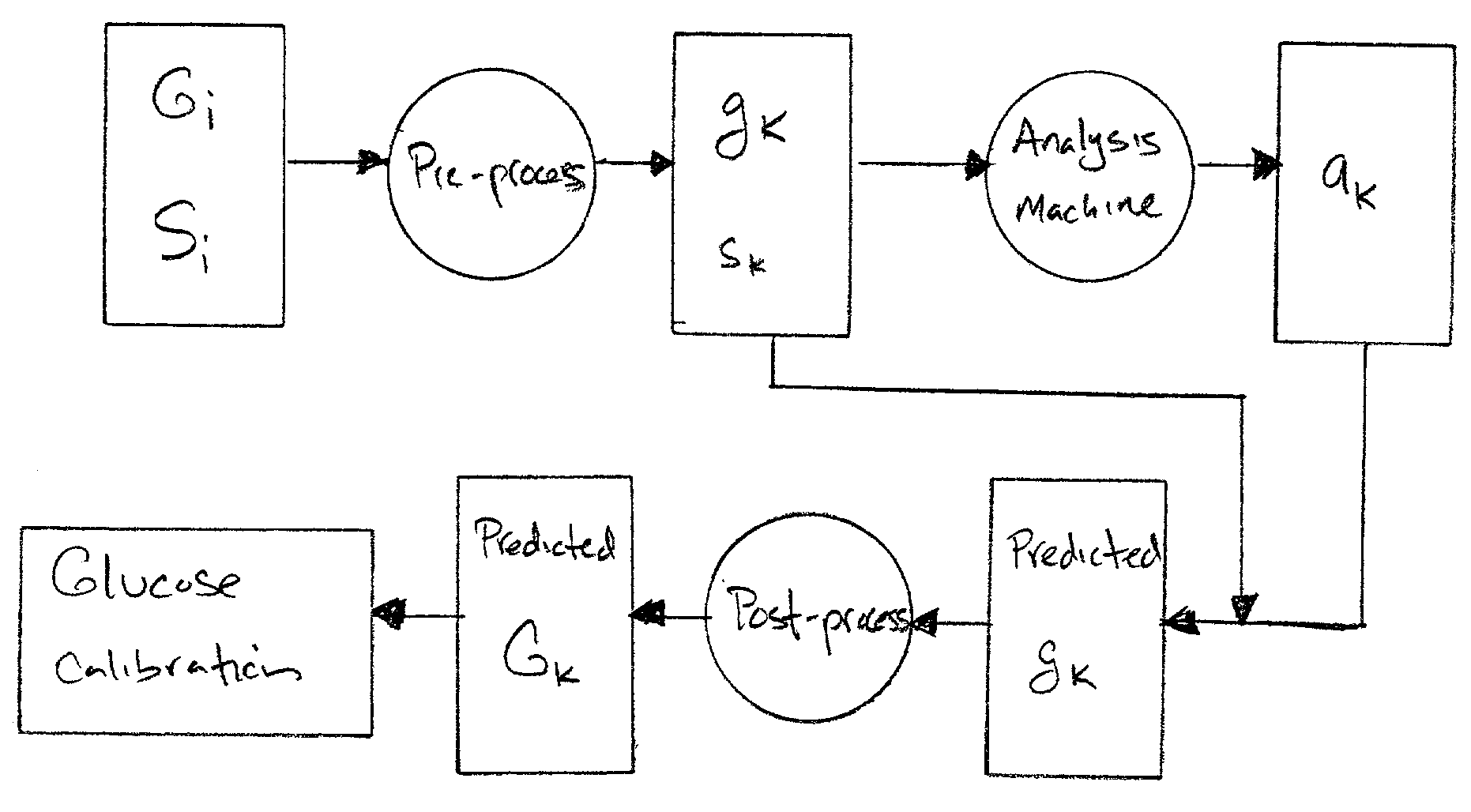

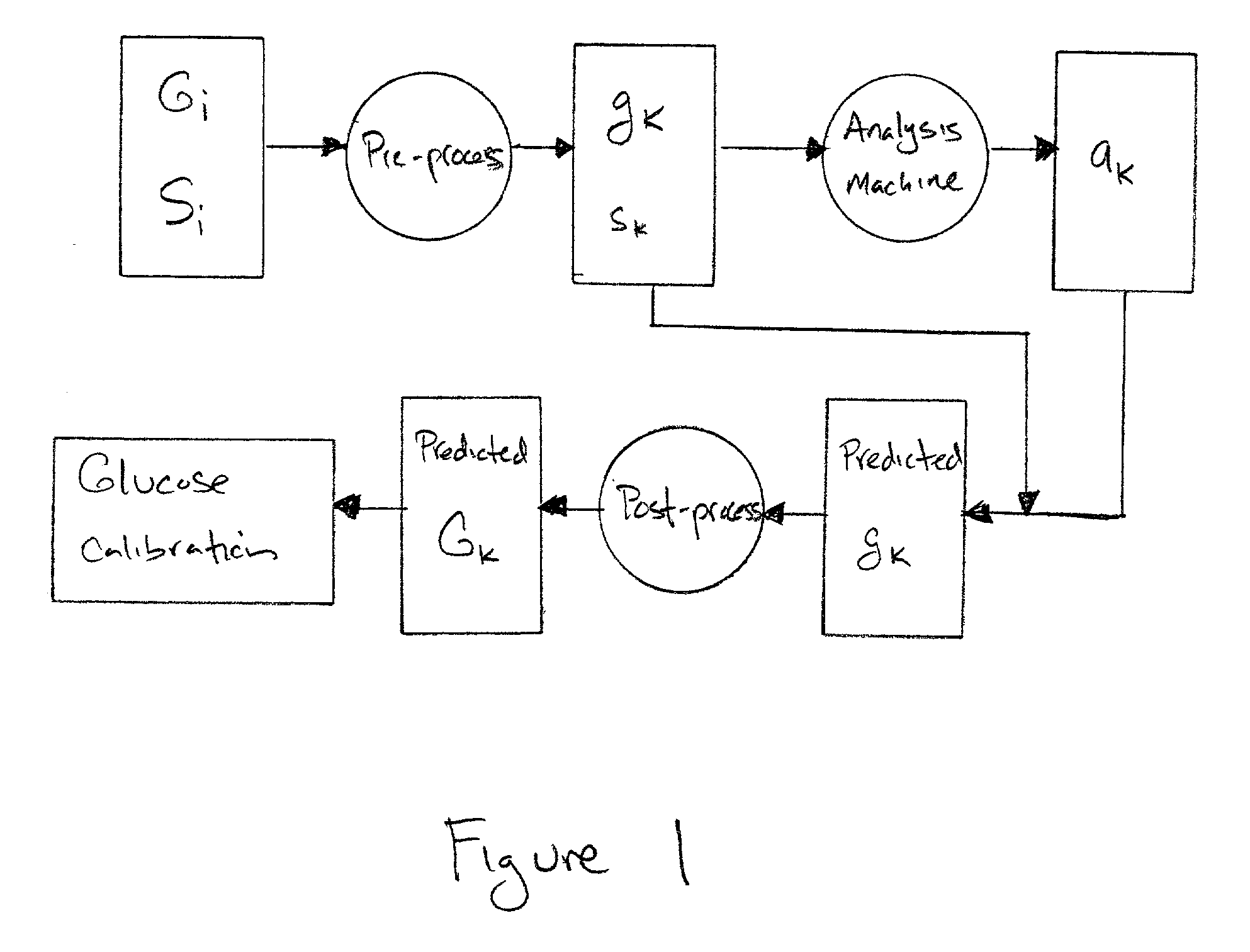

Pre- and post-processing of spectral data for calibration using mutivariate analysis techniques

Owner:ARGOSE

Electroless deposition process on a silicide contact

InactiveUS20060246217A1Material nanotechnologySemiconductor/solid-state device manufacturingSalicideElectroless deposition

Embodiments as described herein provide methods for depositing a material on a substrate during electroless deposition processes, as well as compositions of the electroless deposition solutions. In one embodiment, the substrate contains a contact aperture having an exposed silicon contact surface. In another embodiment, the substrate contains a contact aperture having an exposed silicide contact surface. The apertures are filled with a metal contact material by exposing the substrate to an electroless deposition process. The metal contact material may contain a cobalt material, a nickel material, or alloys thereof. Prior to filling the apertures, the substrate may be exposed to a variety of pretreatment processes, such as preclean processes and activations processes. A preclean process may remove organic residues, native oxides, and other contaminants during a wet clean process or a plasma etch process. Embodiments of the process also provide the deposition of additional layers, such as a capping layer.

Owner:APPLIED MATERIALS INC

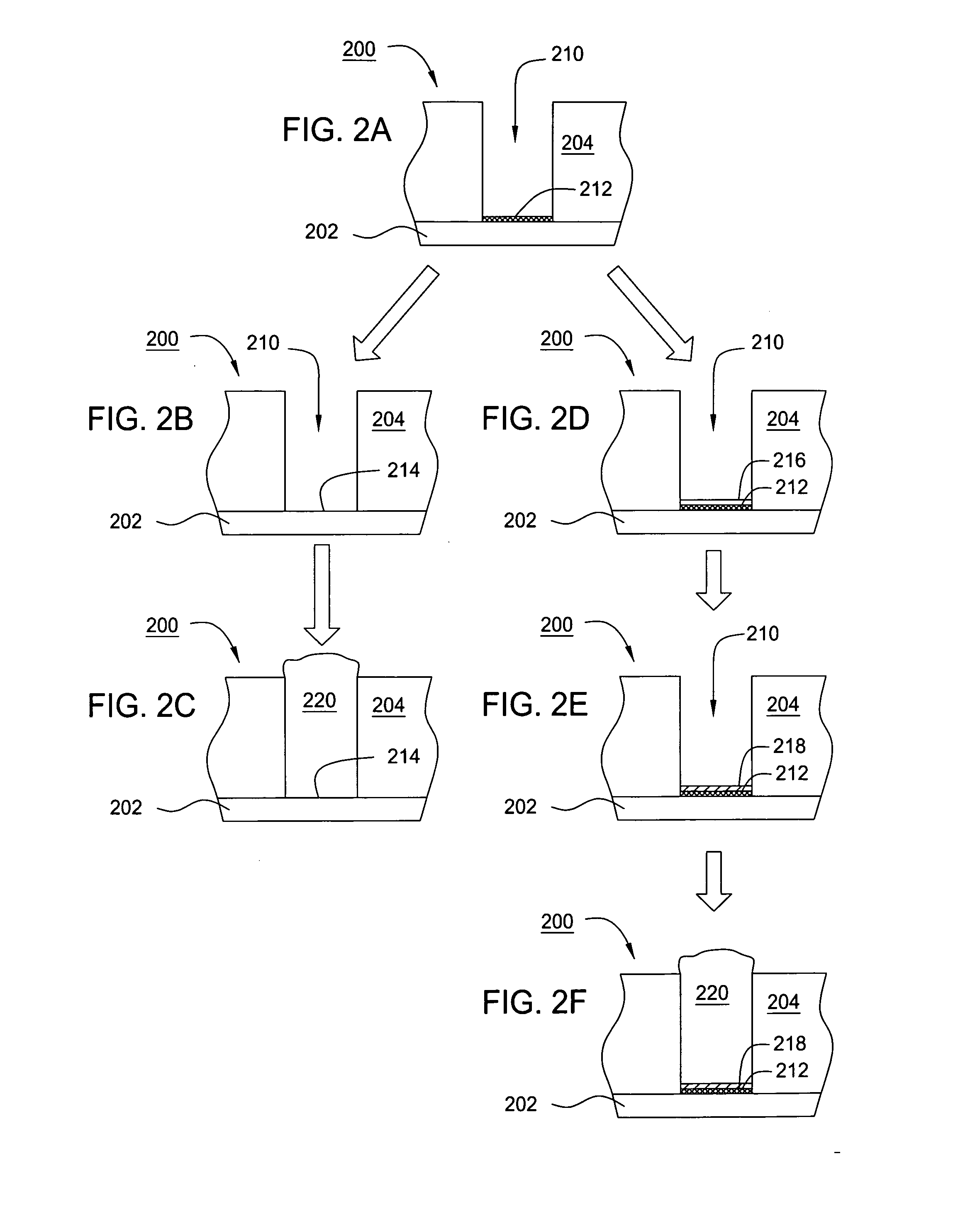

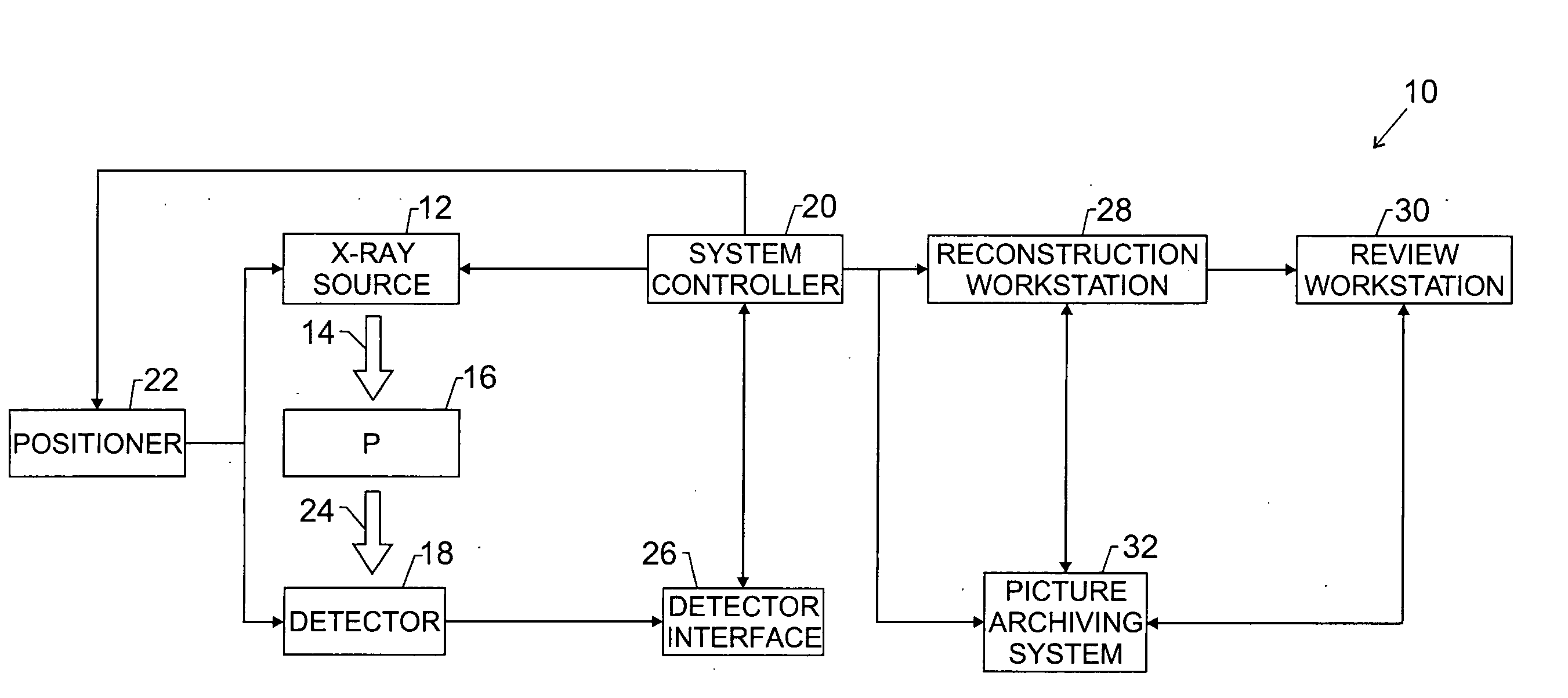

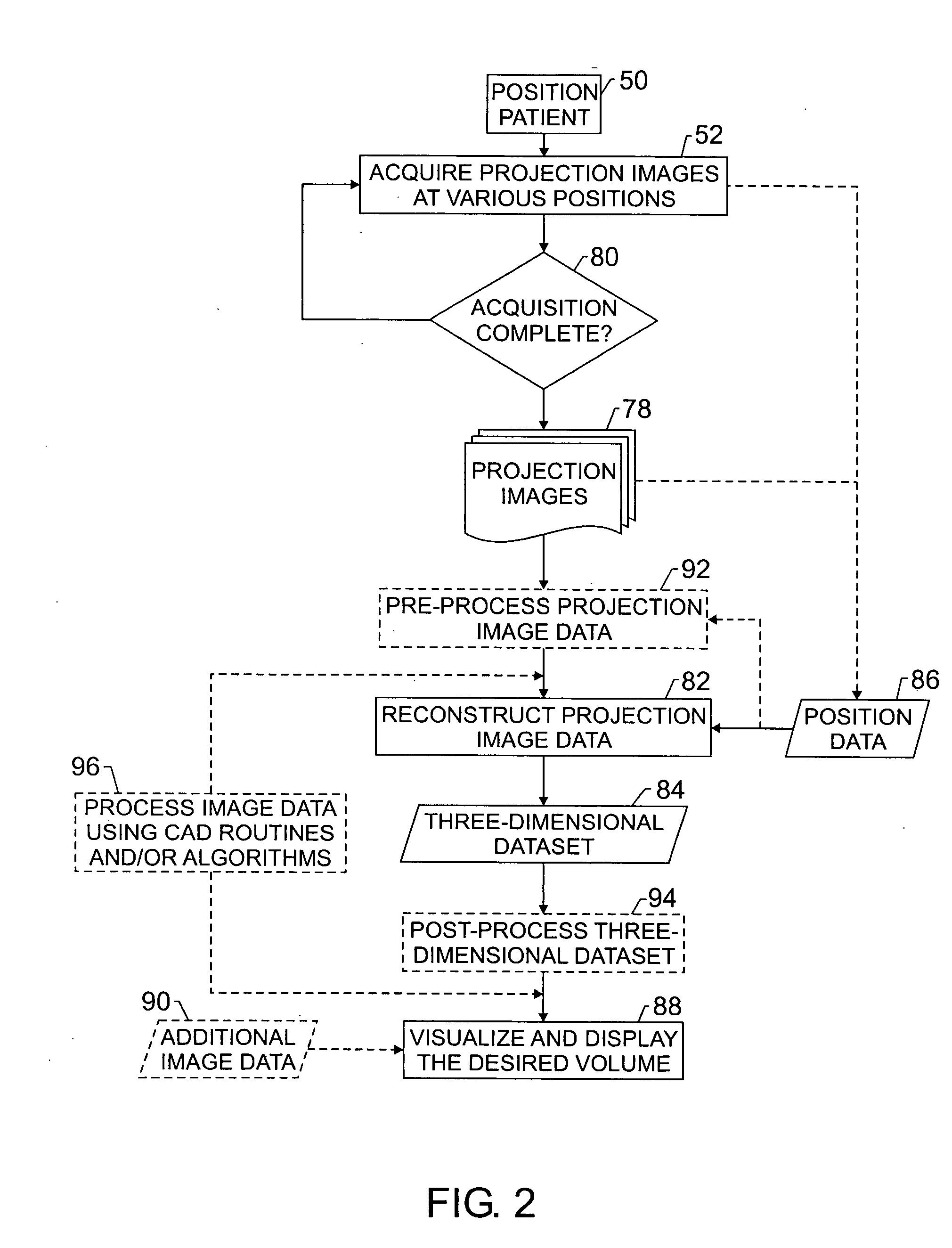

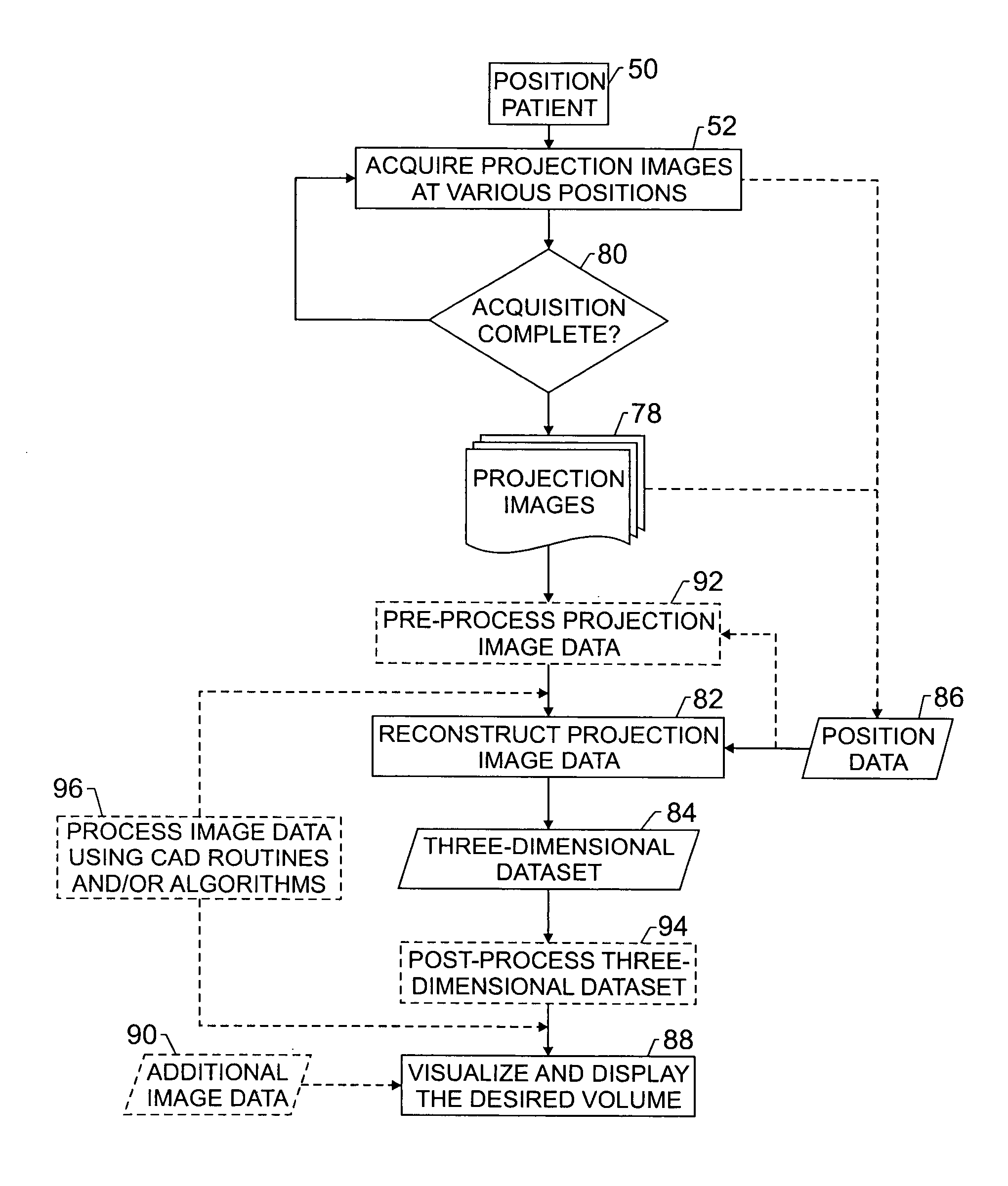

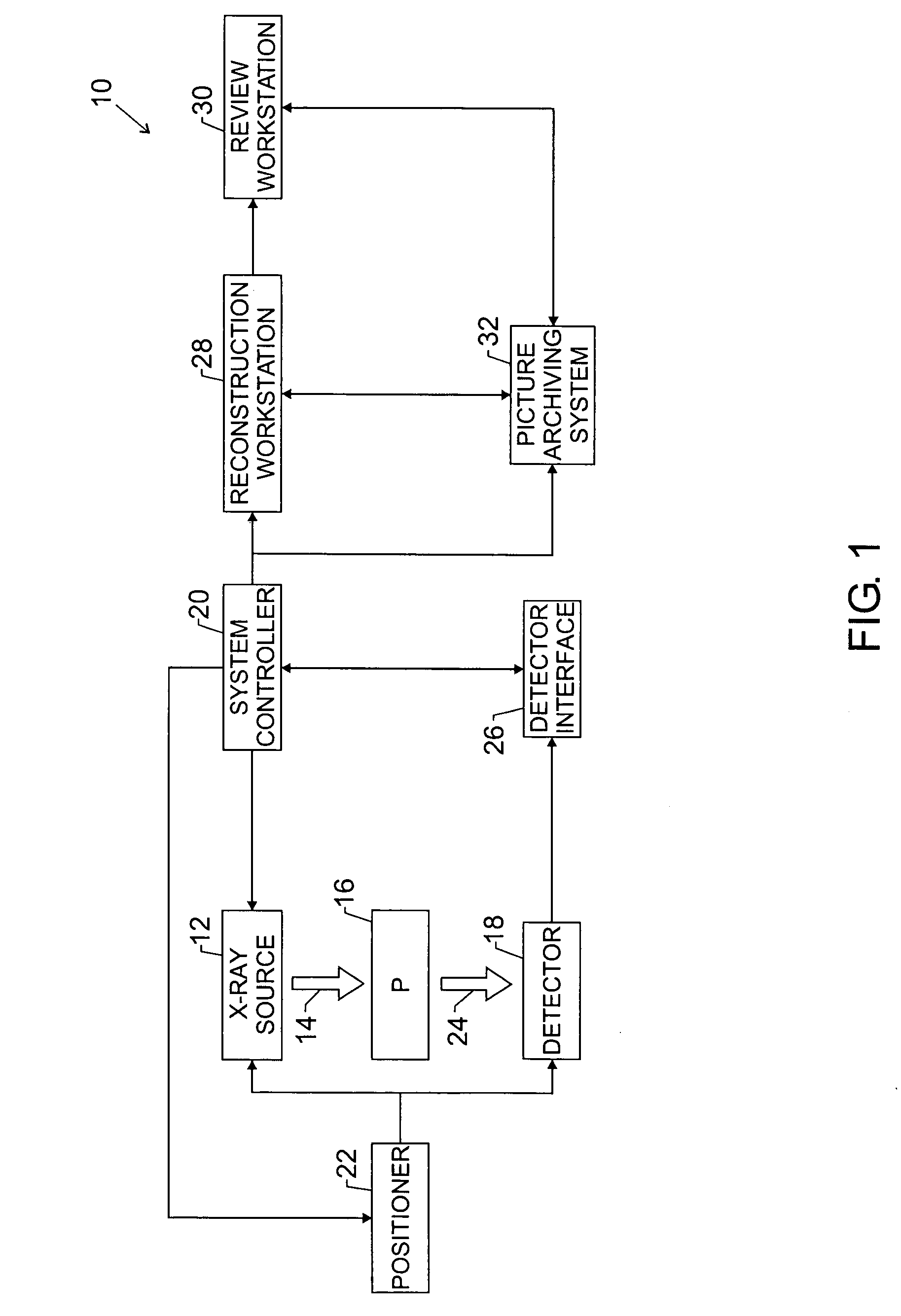

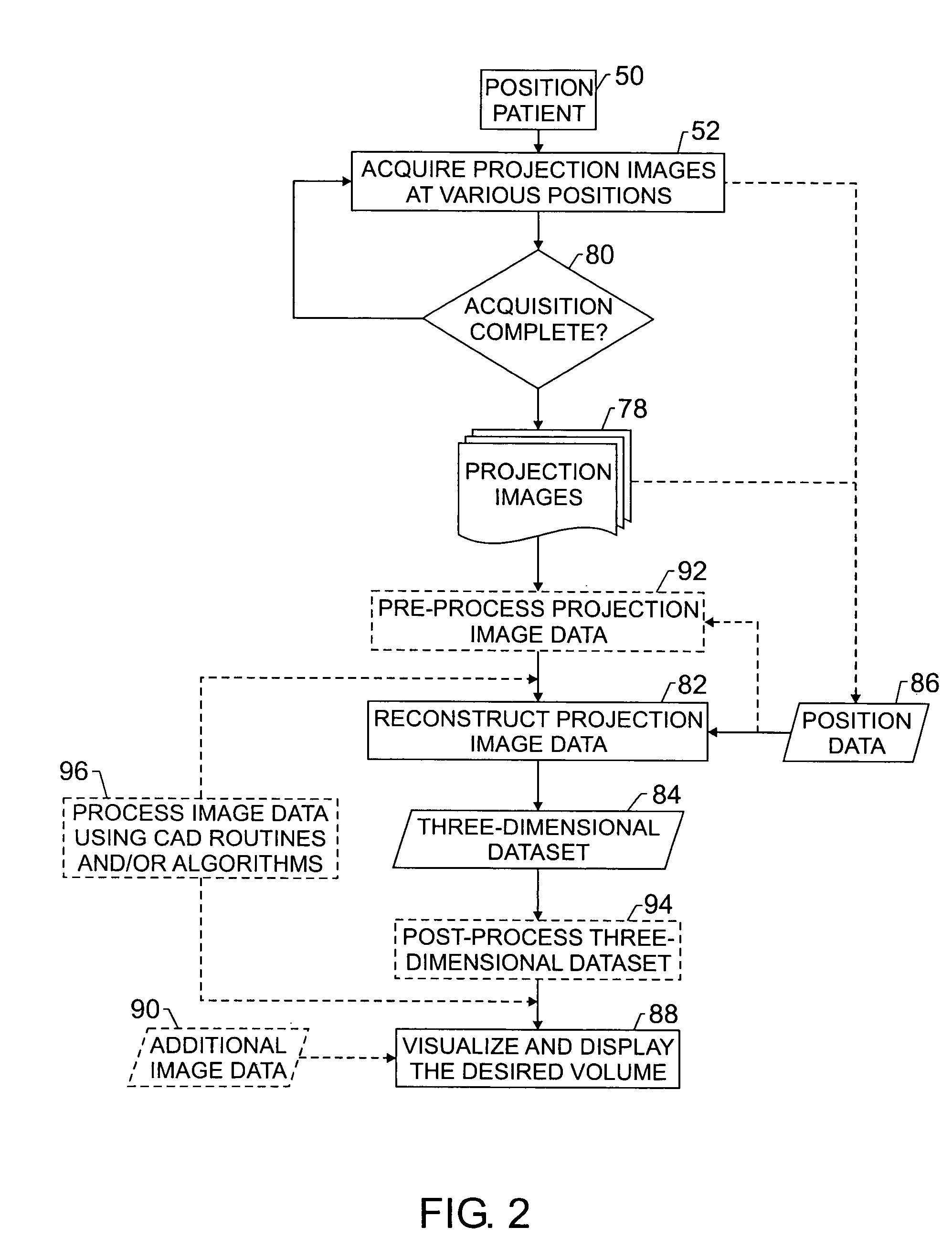

Enhanced X-ray imaging system and method

Techniques are provided for generating three-dimensional images, such as may be used in mammography. In accordance with these techniques, projection images of an object of interest are acquired from different locations, such as by moving an X-ray source along an arbitrary imaging trajectory between emissions or by individually activating different X-ray sources located at different locations relative to the object of interest. The projection images may be reconstructed to generate a three-dimensional dataset representative of the object from which one or more volumes may be selected for visualization and display. Additional processing steps may occur throughout the image chain, such as for pre-processing the projection images or post-processing the three-dimensional dataset.

Owner:GENERAL ELECTRIC CO

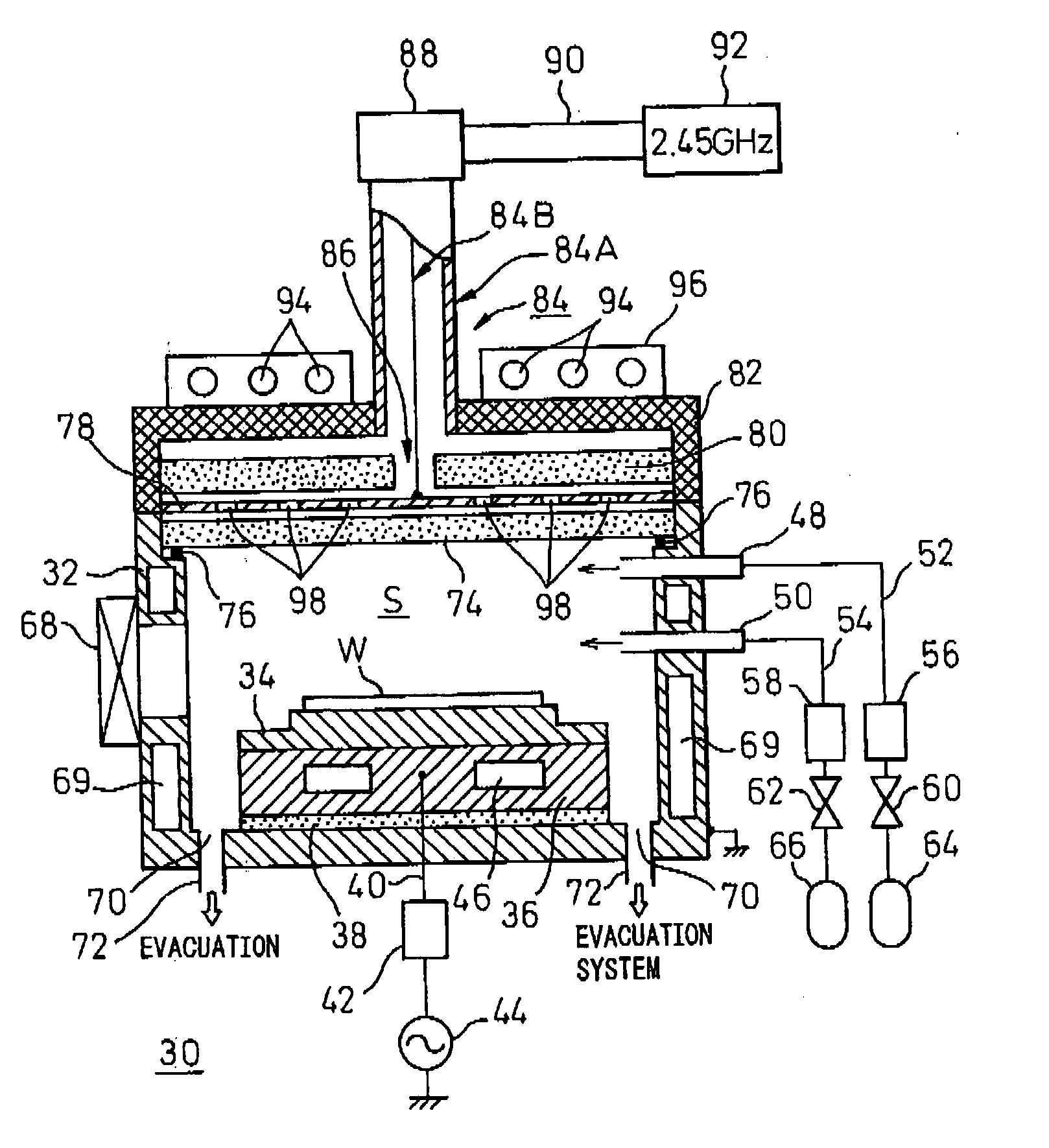

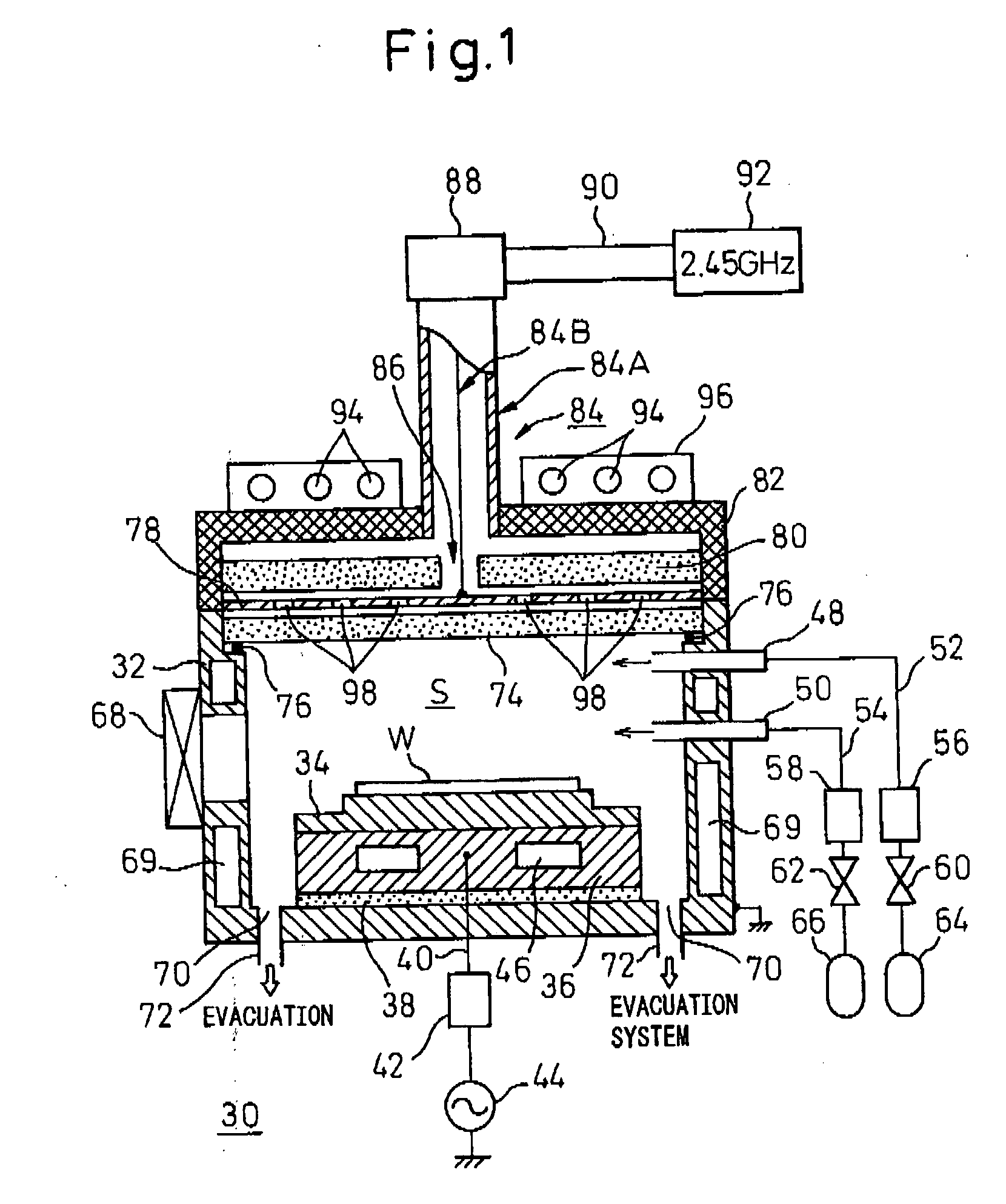

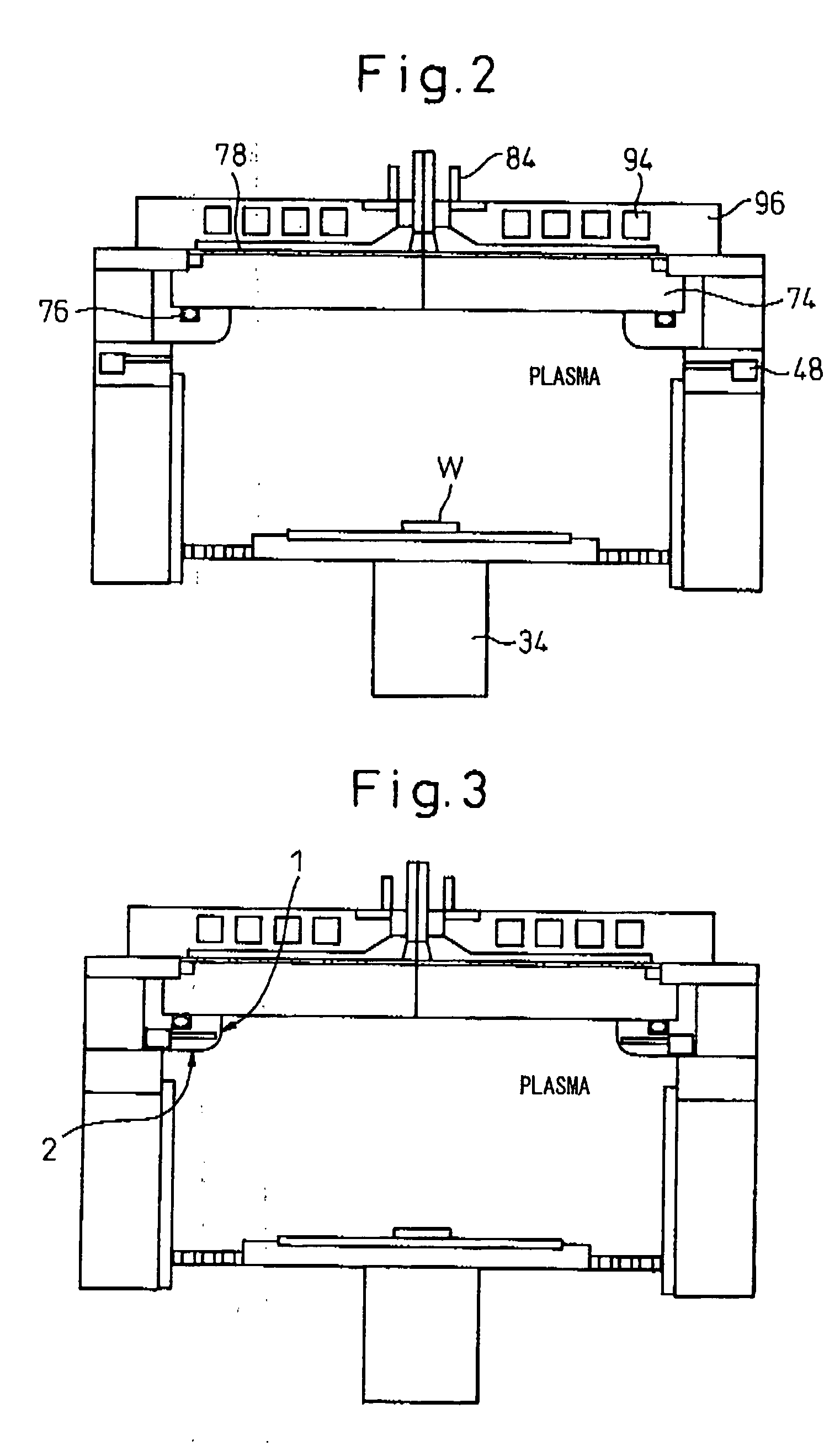

Plasma processing apparatus and plasma processing method

InactiveUS20060108331A1Reduce defectsPollution suppressionElectric discharge tubesSemiconductor/solid-state device manufacturingEtchingPre treatment

A plasma processing apparatus comprising at least a plasma processing chamber for plasma-processing an object; object-holding means for disposing the object in the plasma processing chamber; and plasma-generating means for generating a plasma in the plasma processing chamber. The inner wall of the plasma processing chamber is at least partially covered with an oxide film based on a pre-treating plasma. A plasma processing apparatus and a plasma processing method effectively prevent the spluttering and the etching of the inner wall of the plasma processing chamber while suppressing contamination to the object.

Owner:TOKYO ELECTRON LTD

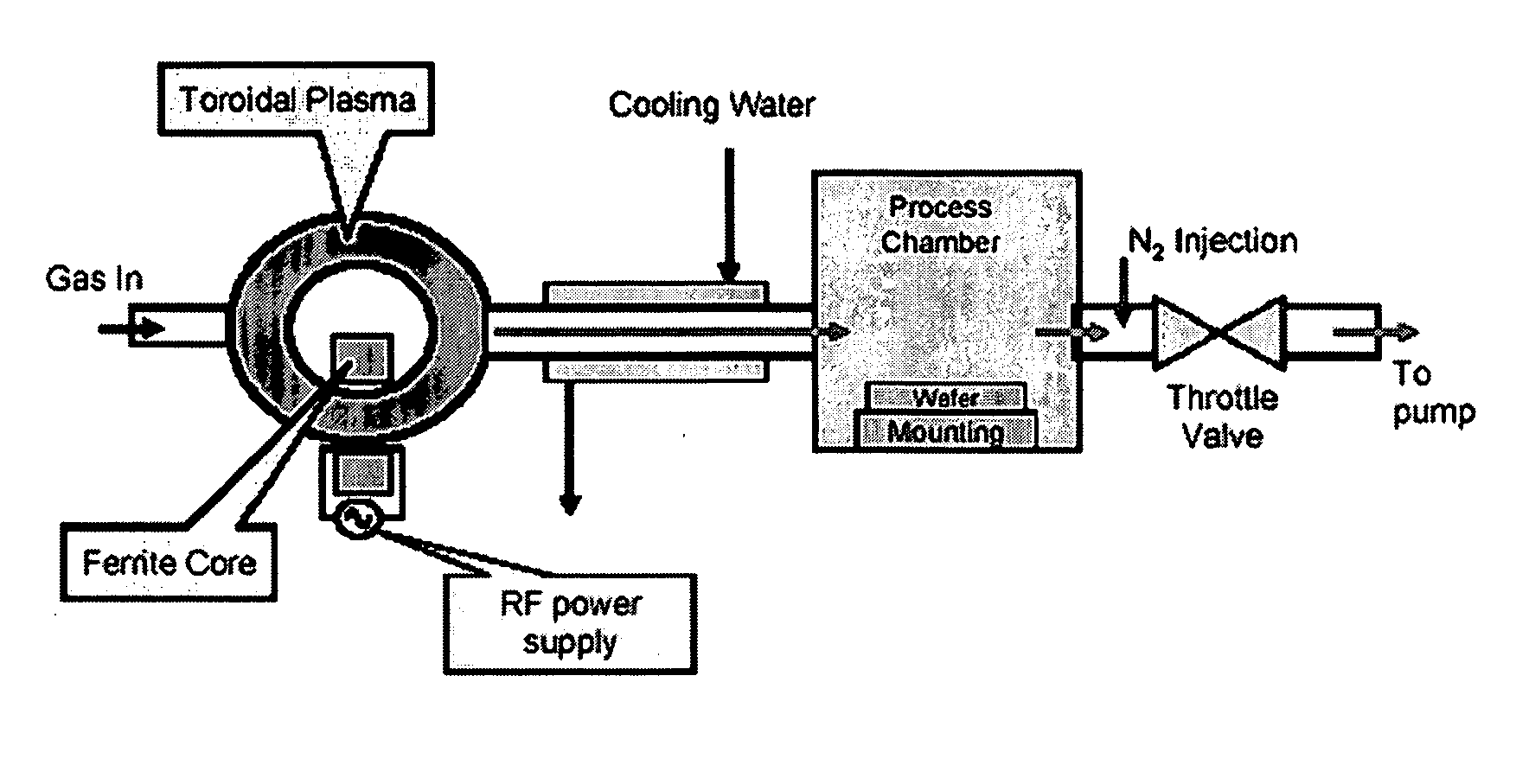

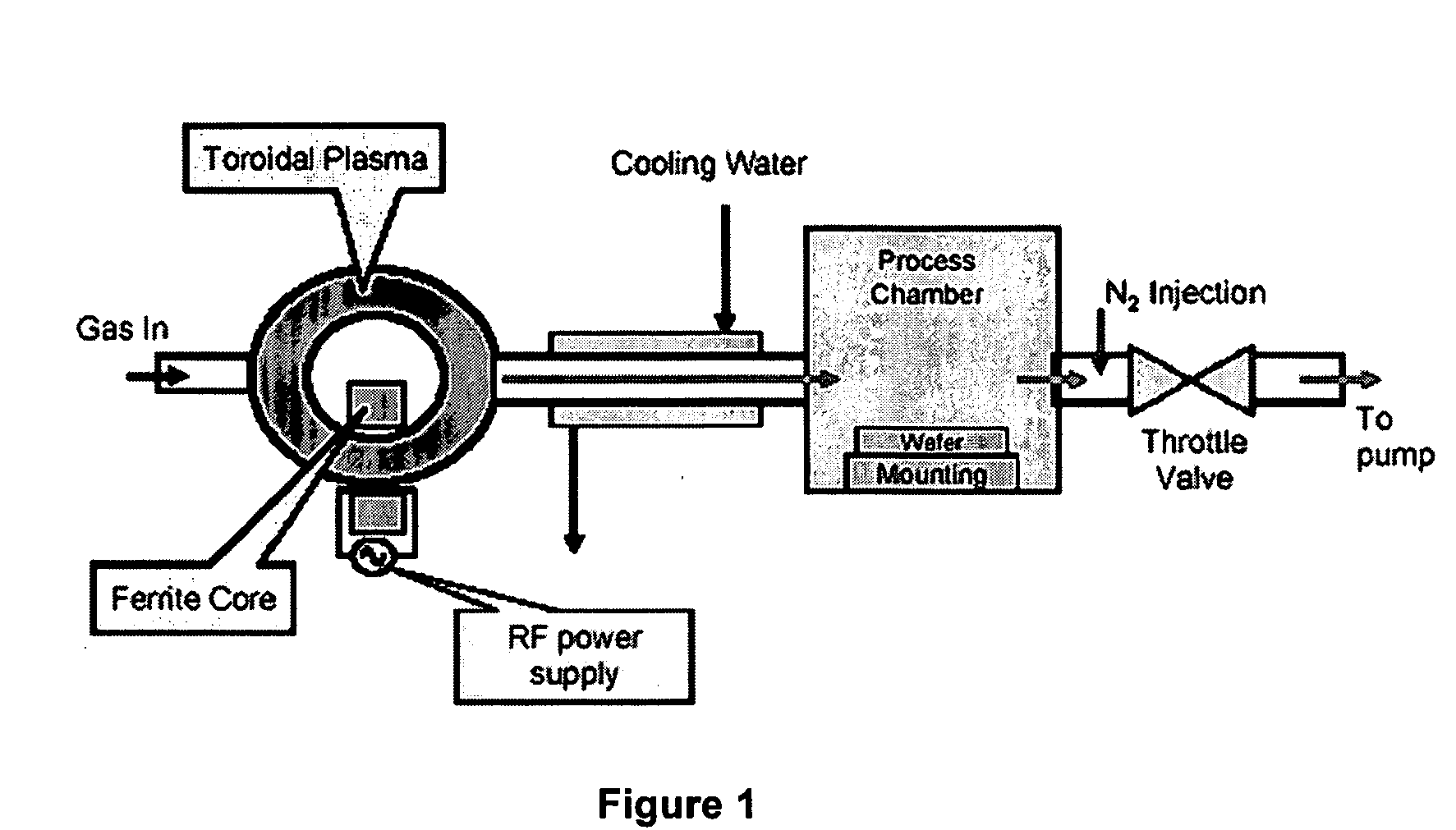

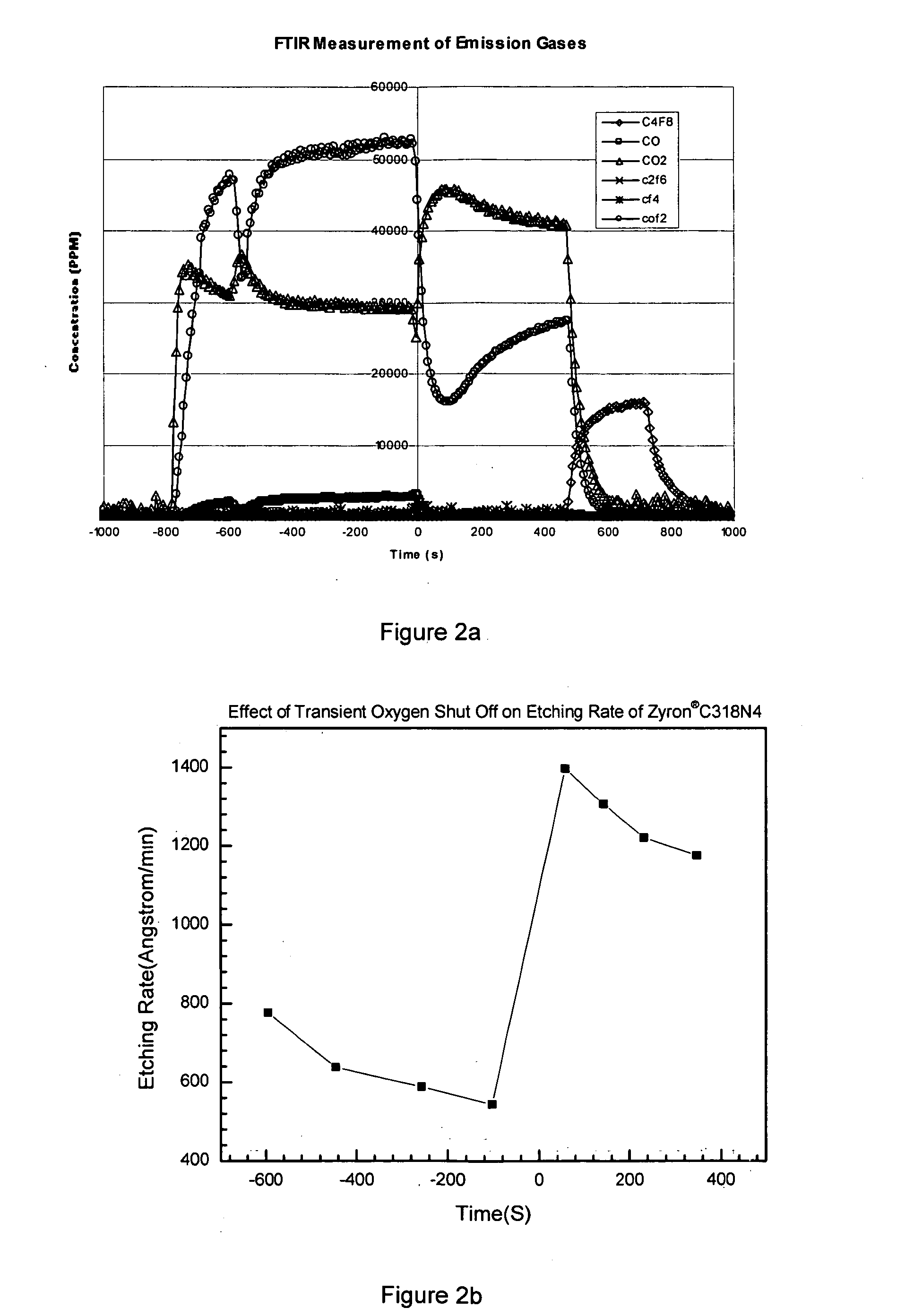

Remote chamber methods for removing surface deposits

The present invention relates to an improved remote plasma cleaning method for removing surface deposits from a surface, such as the interior of a deposition chamber that is used in fabricating electronic devices. The improvement involves a fluorocarbon rich plasma pretreatment of interior surface of the pathway from the remote chamber to the surface deposits.

Owner:MASSACHUSETTS INST OF TECH +1

Enhanced X-ray imaging system and method

Techniques are provided for generating three-dimensional images, such as may be used in mammography. In accordance with these techniques, projection images of an object of interest are acquired from different locations, such as by moving an X-ray source along an arbitrary imaging trajectory between emissions or by individually activating different X-ray sources located at different locations relative to the object of interest. The projection images may be reconstructed to generate a three-dimensional dataset representative of the object from which one or more volumes may be selected for visualization and display. Additional processing steps may occur throughout the image chain, such as for pre-processing the projection images or post-processing the three-dimensional dataset.

Owner:GENERAL ELECTRIC CO

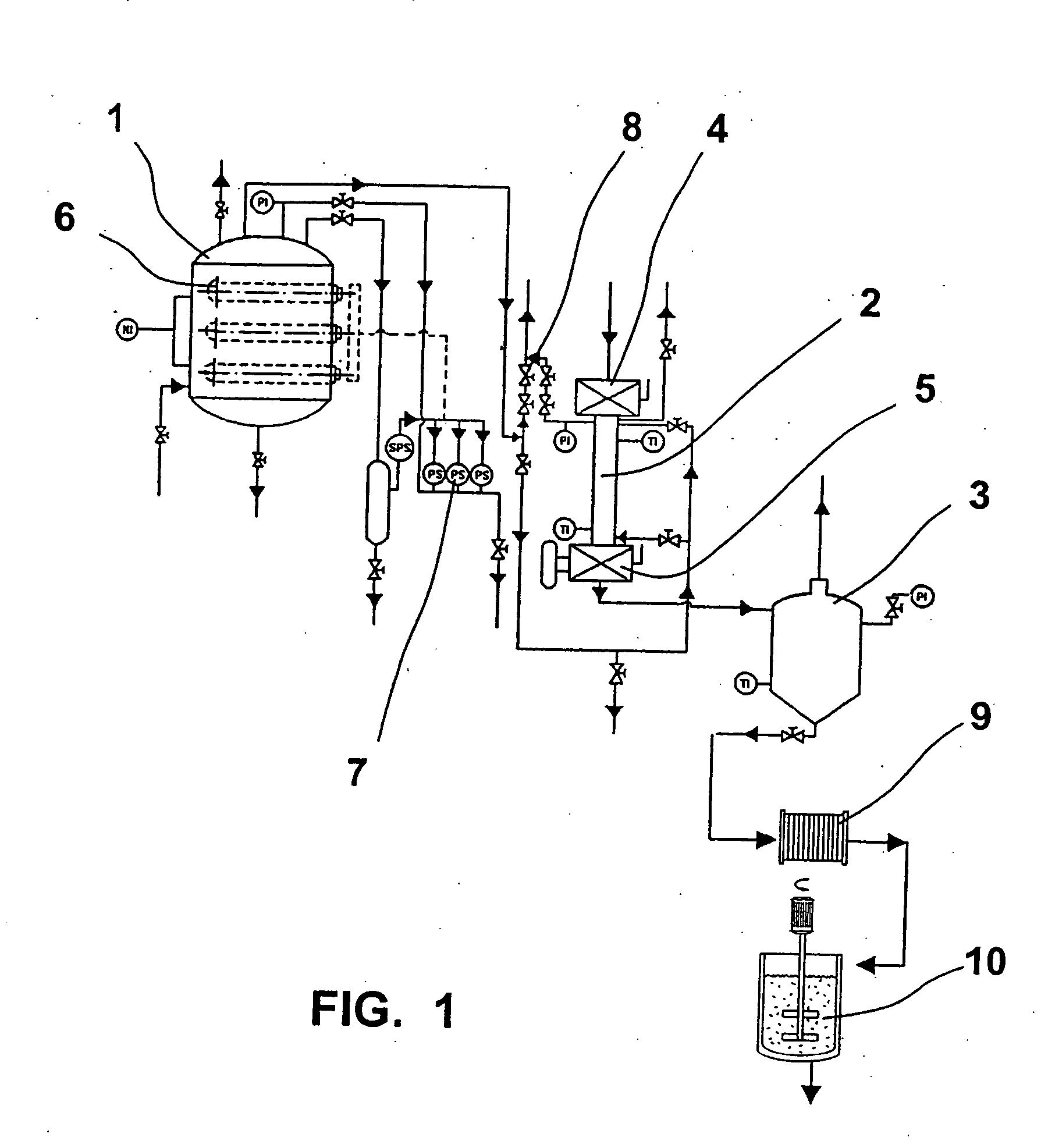

Procedure for the production of ethanol from lignocellulosic biomass using a new heat-tolerant yeast

InactiveUS20050069998A1Low conversion rateReduce yieldFungiBiological substance pretreatmentsFiltrationSolid fraction

It includes the stages of grinding the lignocellulosic biomass to a size of 15-30 mm, subjecting the product obtained to steam explosion pre-treatment at a temperature of 190-230° C. for between 1 and 10 minutes in a reactor (2), collecting the pre-treated material in a cyclone (3) and separating the liquid and solid fractions by filtration in a filter press (9), introducing the solid fraction in a fermentation deposit (10), adding a cellulase at a concentration of 15 UFP per gram of cellulose and 12.6 International Units of β-glucosidase enzyme dissolved in citrate buffer pH 4.8, inoculating the fermentation deposit (10) with a culture of the heat-tolerant bacteria Kluyveromyces marxianus CECT 10875, obtained by chemical mutagenesis from strain DER-26 of Kluyveromyces marxianus and shaking the mixture for 72 hours at 42° C.

Owner:CENT DE INVESTIGACIONES ENERGETICAS MEDIO AMBIENTALLES Y TECNOLOGICAS (C I E M A T)

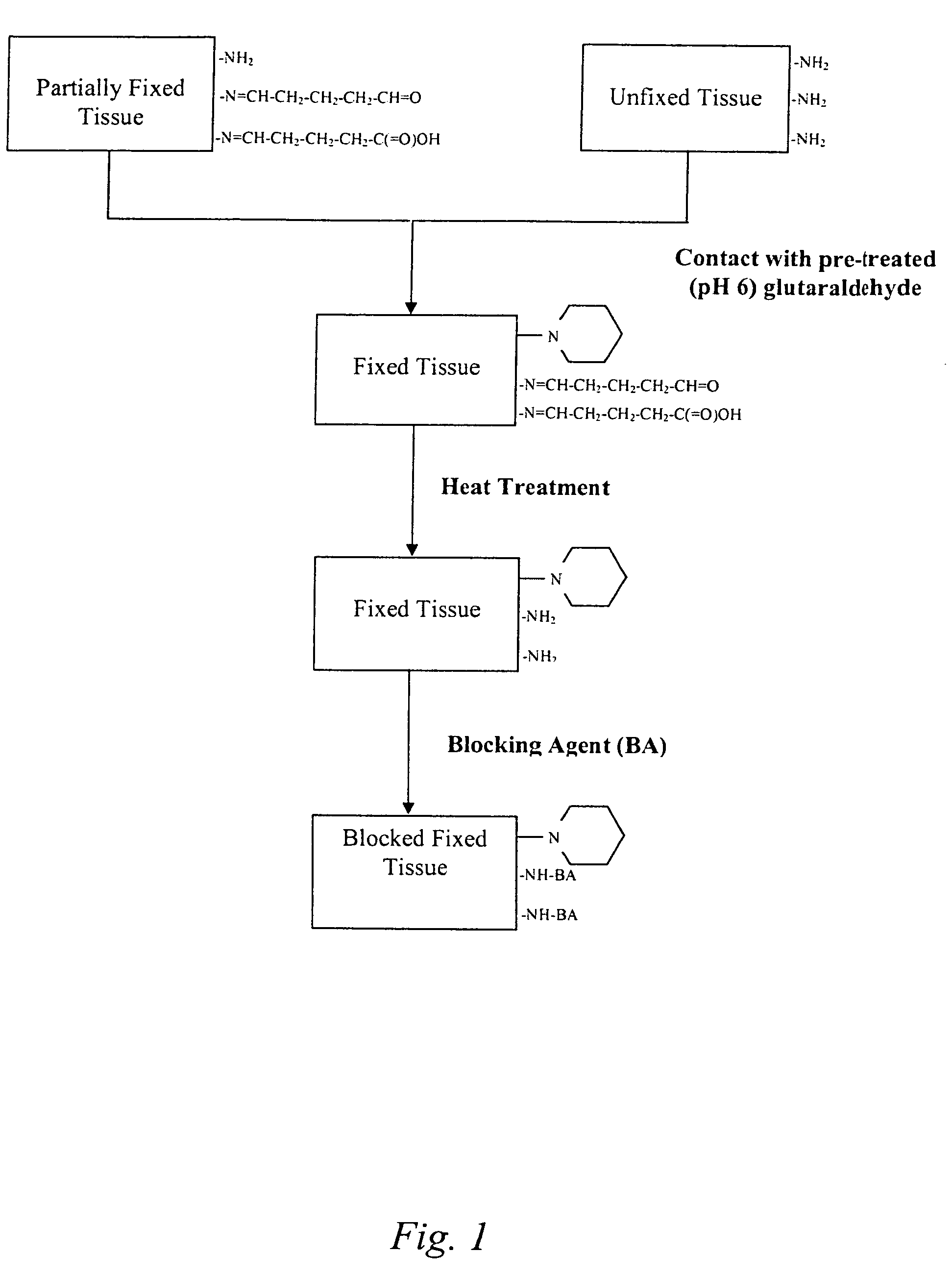

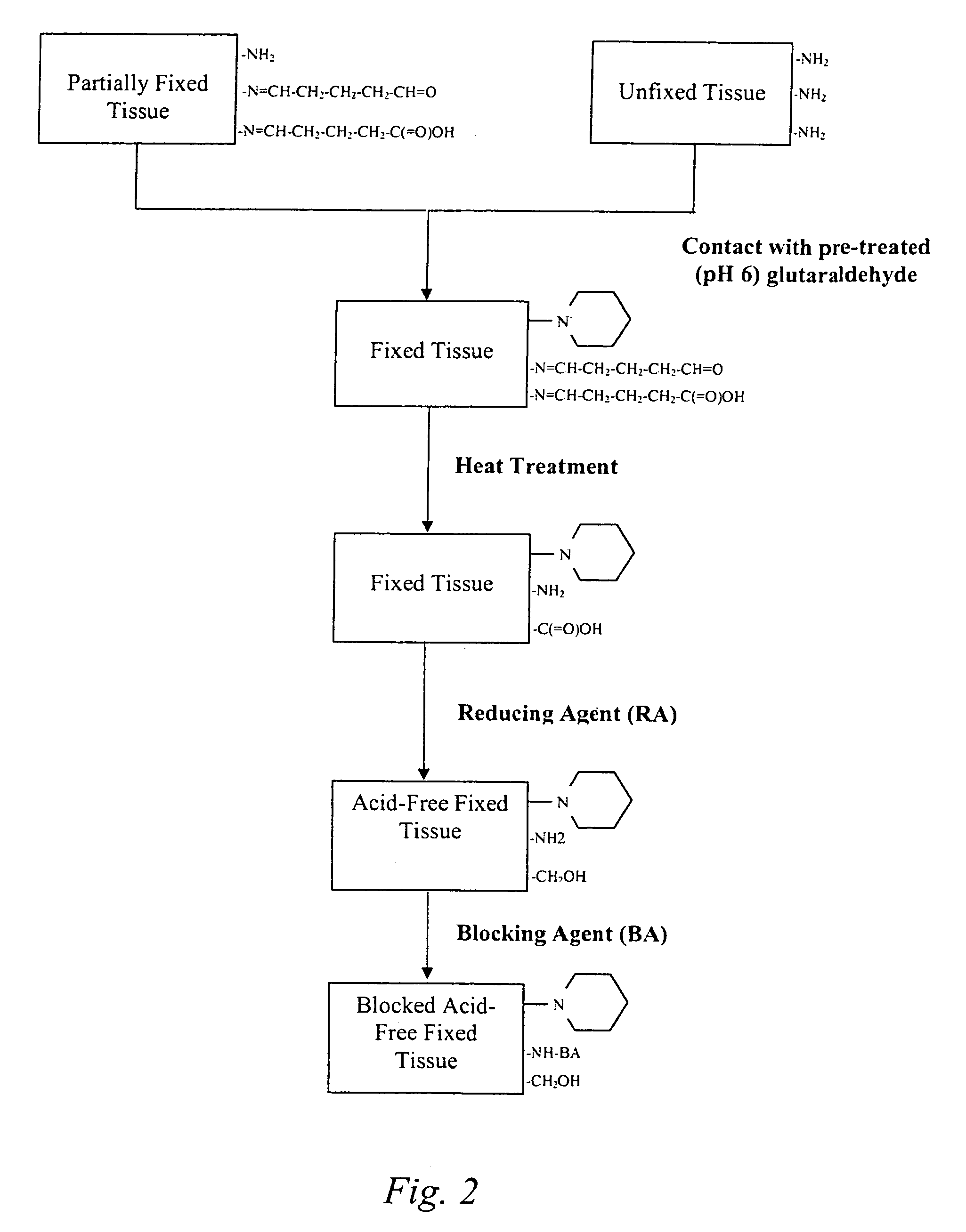

Treatment of bioprosthetic tissues to mitigate post implantation calcification

The present invention provides methods for treating tissue to inhibit post-implant calcification of a biological tissue. In one method of this invention, a tissue is immersed in or otherwise contacted with a pretreated glutaraldehyde solution, i.e., a heat-treated or pH-adjusted glutaraldehyde solution. The tissue may be partially fixed with glutaraldehyde prior to, after, or concurrently with the step of contacting the tissue with the pretreated gluteraldehyde. Contact with the pretreated gluteraldehyde produces free amine groups on the tissue, which are subsequently blocked by contacting the crosslinked tissue with a blocking agent. In another embodiment, a tissue is contacted with either a non-pretreated glutaraldehyde or a pH-adjusted glutaraldehyde solution for a period of time sufficient to crosslink the tissue. The crosslinked tissue is then treated with a reducing agent that reduces aldehyde and carboxylic acid groups on the fixed tissue.

Owner:EDWARDS LIFESCIENCES CORP

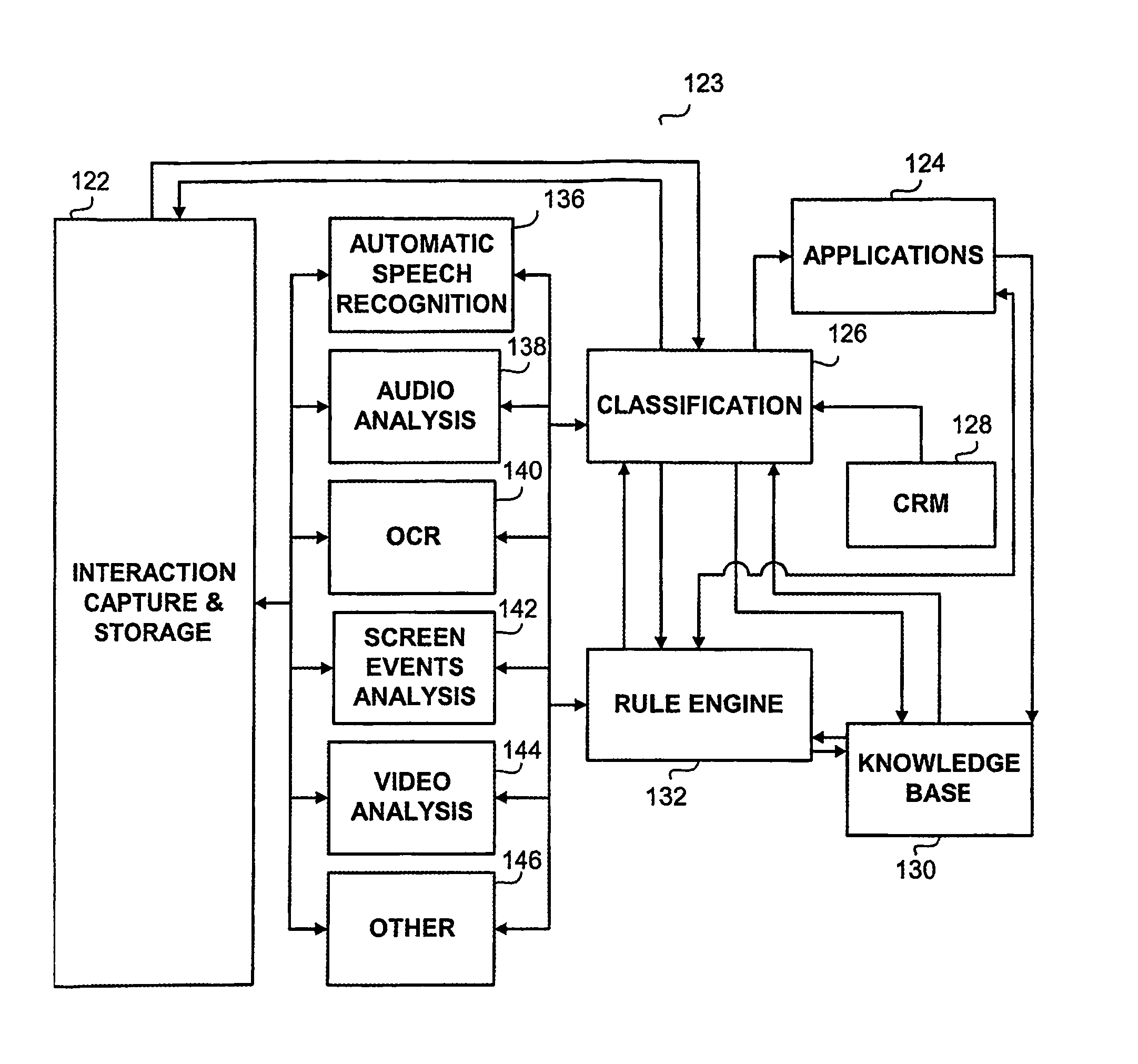

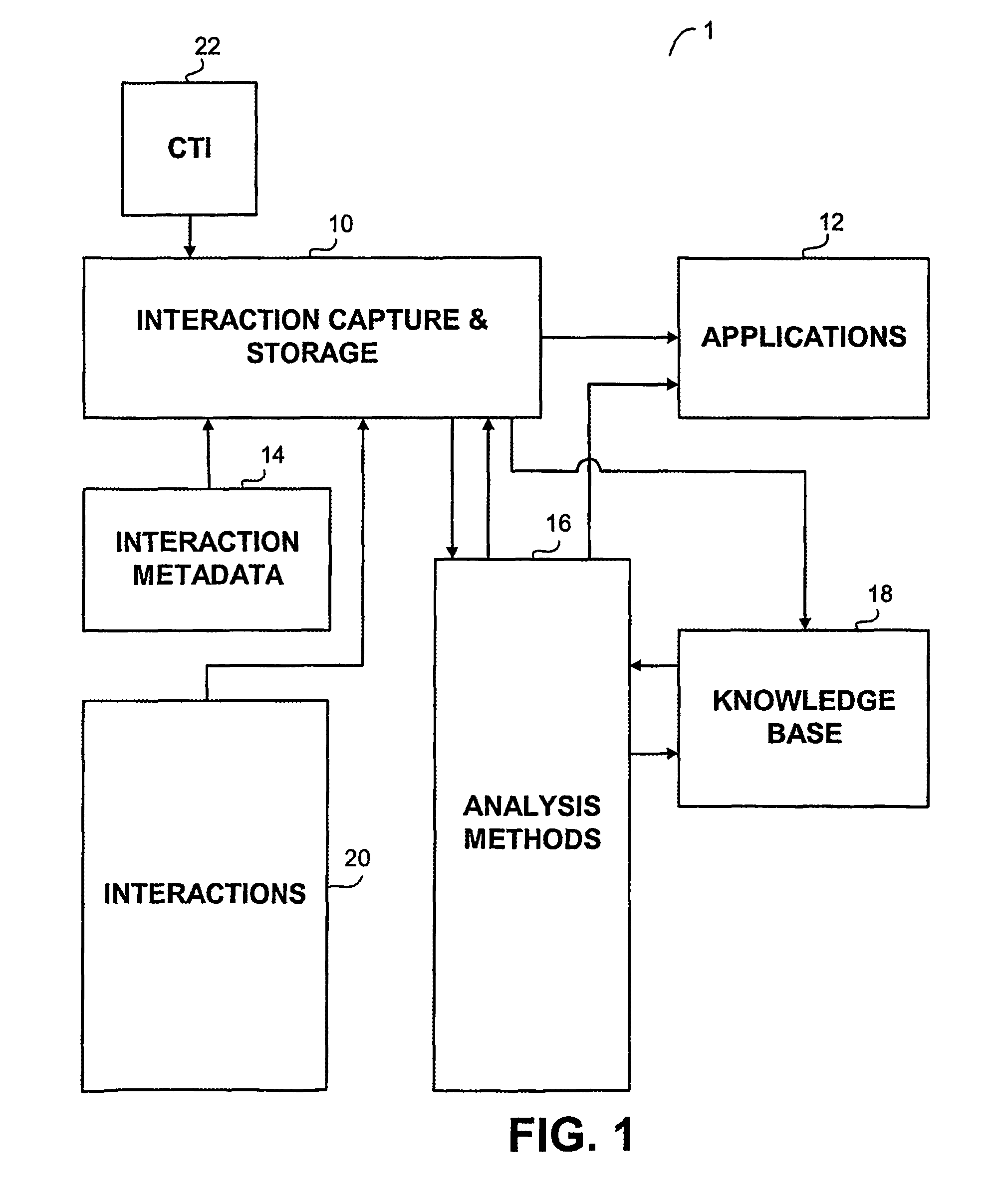

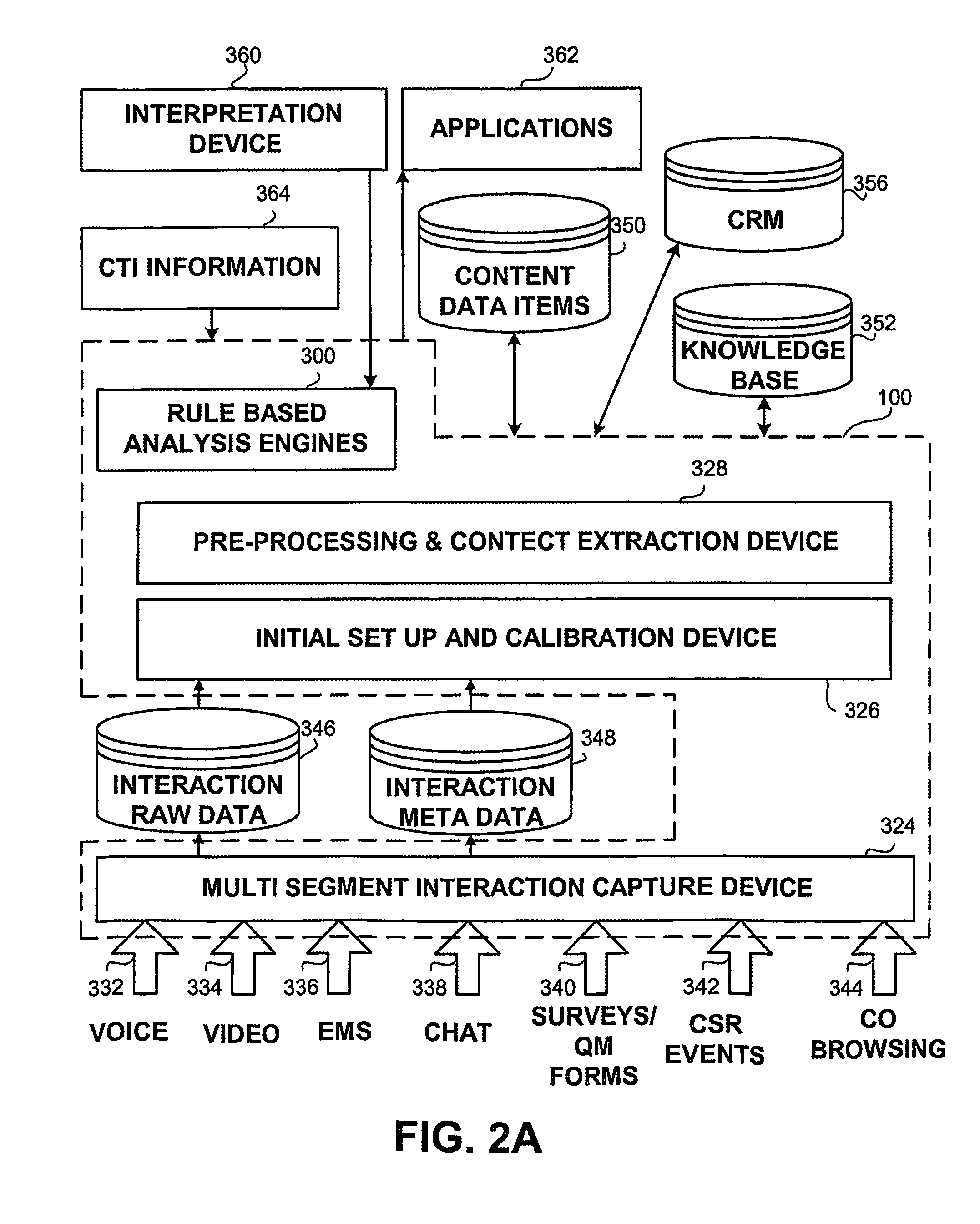

Method apparatus and system for capturing and analyzing interaction based content

The present invention provides a method and apparatus (100) for capturing and analyzing customer interactions, the apparatus comprising a multi-segment interaction capture device (324), an initial set up and calibration device (326), a pre-processing and context extraction device (328) and a rule-based analysis engine (300).

Owner:NICE LTD

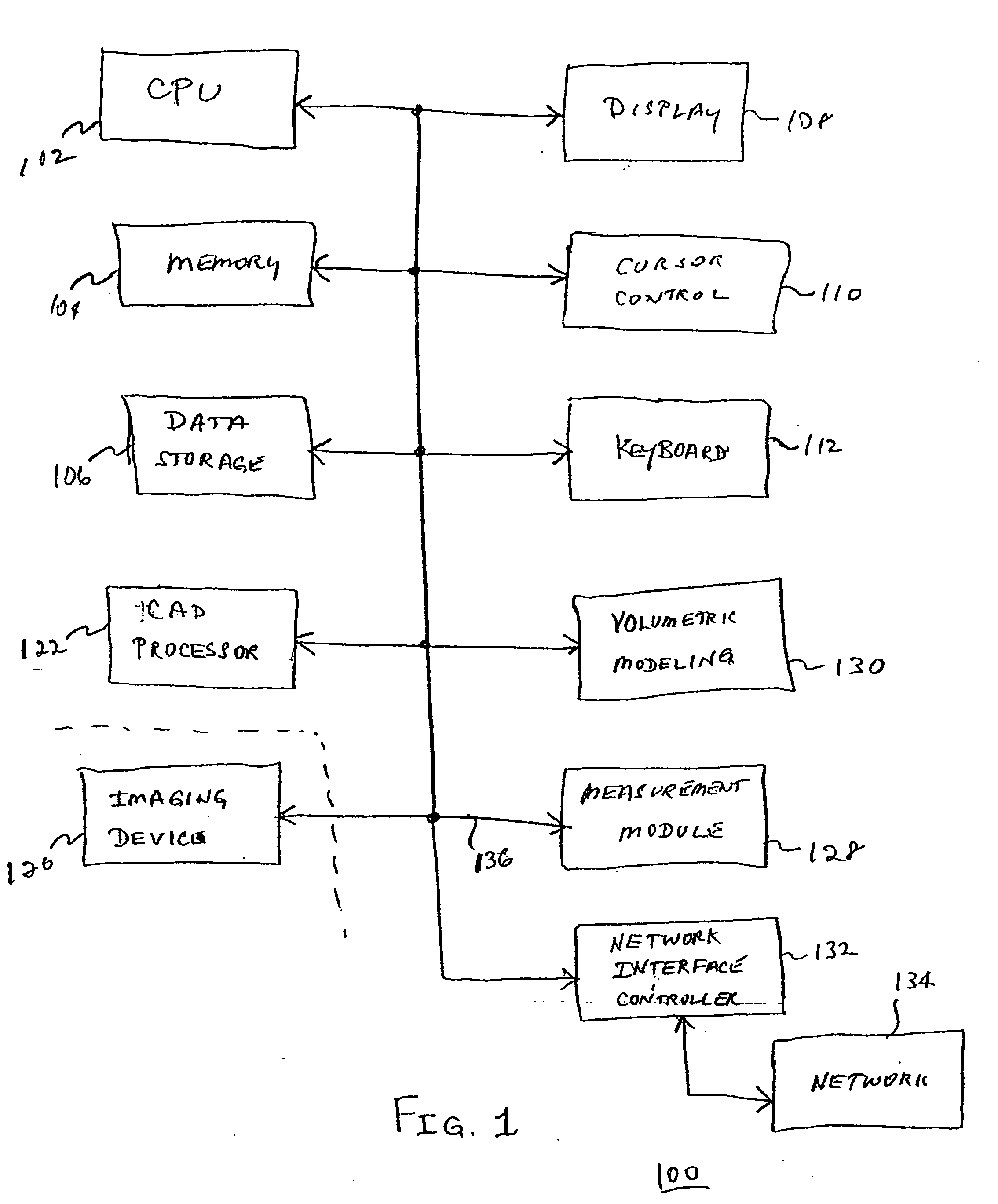

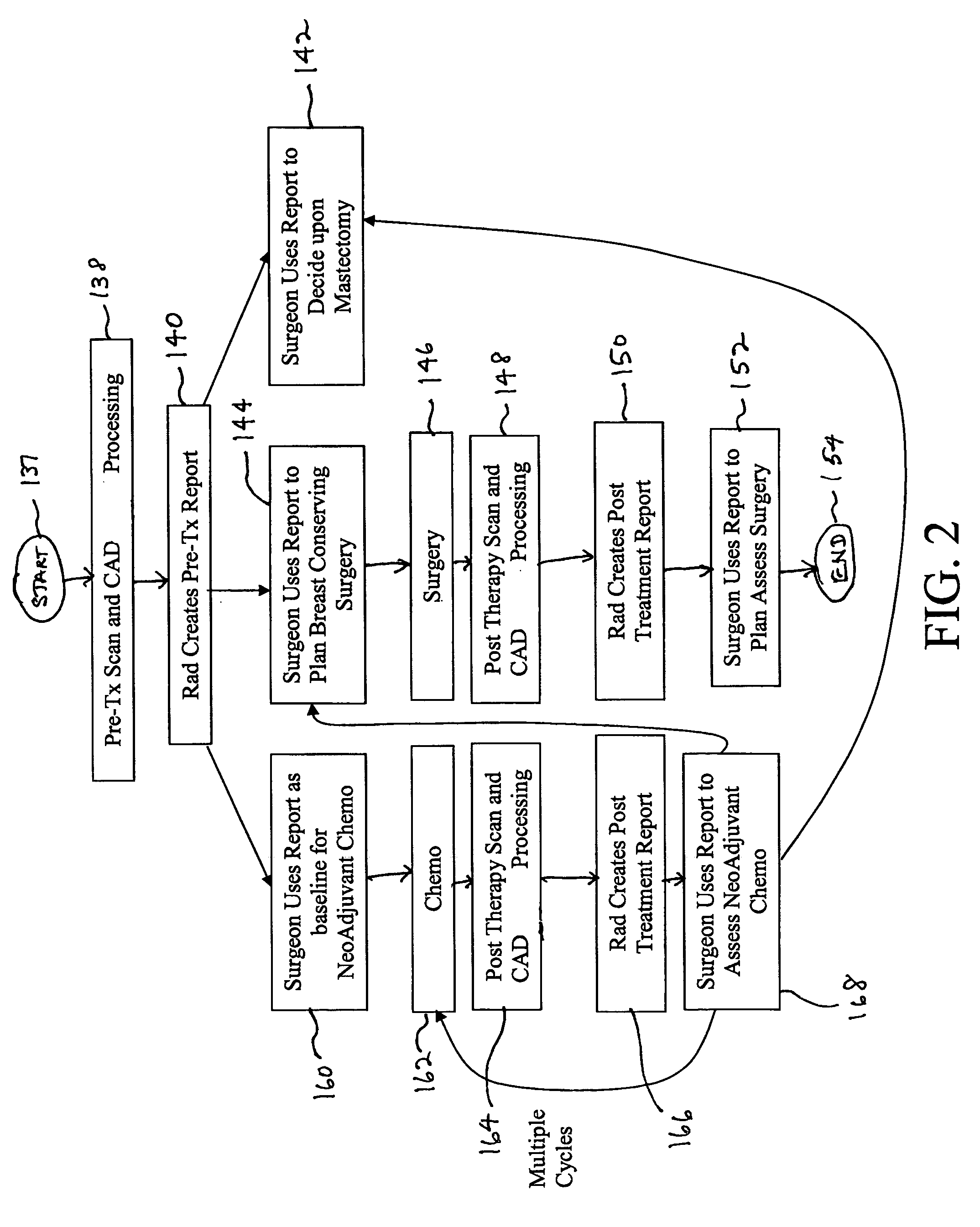

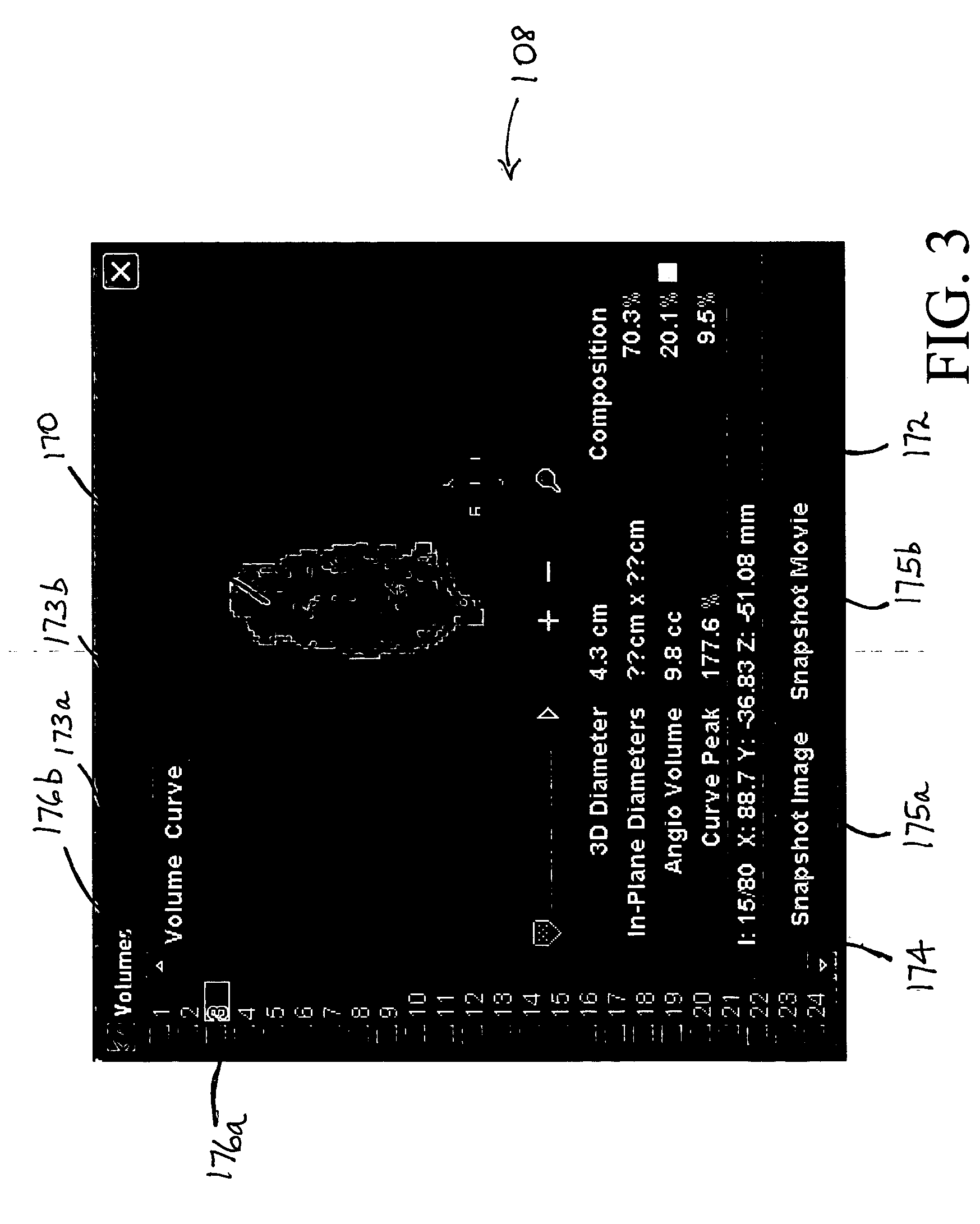

Apparatus and method for surgical planning and treatment monitoring

A system for surgical planning and therapeutic monitoring utilizes imaging data and computer-aided detection (CAD) technology to identify cancerous tumors. A pre-treatment report identifies all volumes of interest (VOIs) and provides data regarding the size and location of each VOI as well as volumetric data for use in surgical planning. The system can be used to monitor the progress of adjuvant chemotherapy or other non-surgical treatment and measures changes in tumor size and location. Post-treatment reports provide data regarding changes in tumor size and location as well as trend data to provide guidance to the physician.

Owner:FUJIFILM HEALTHCARE CORP +1

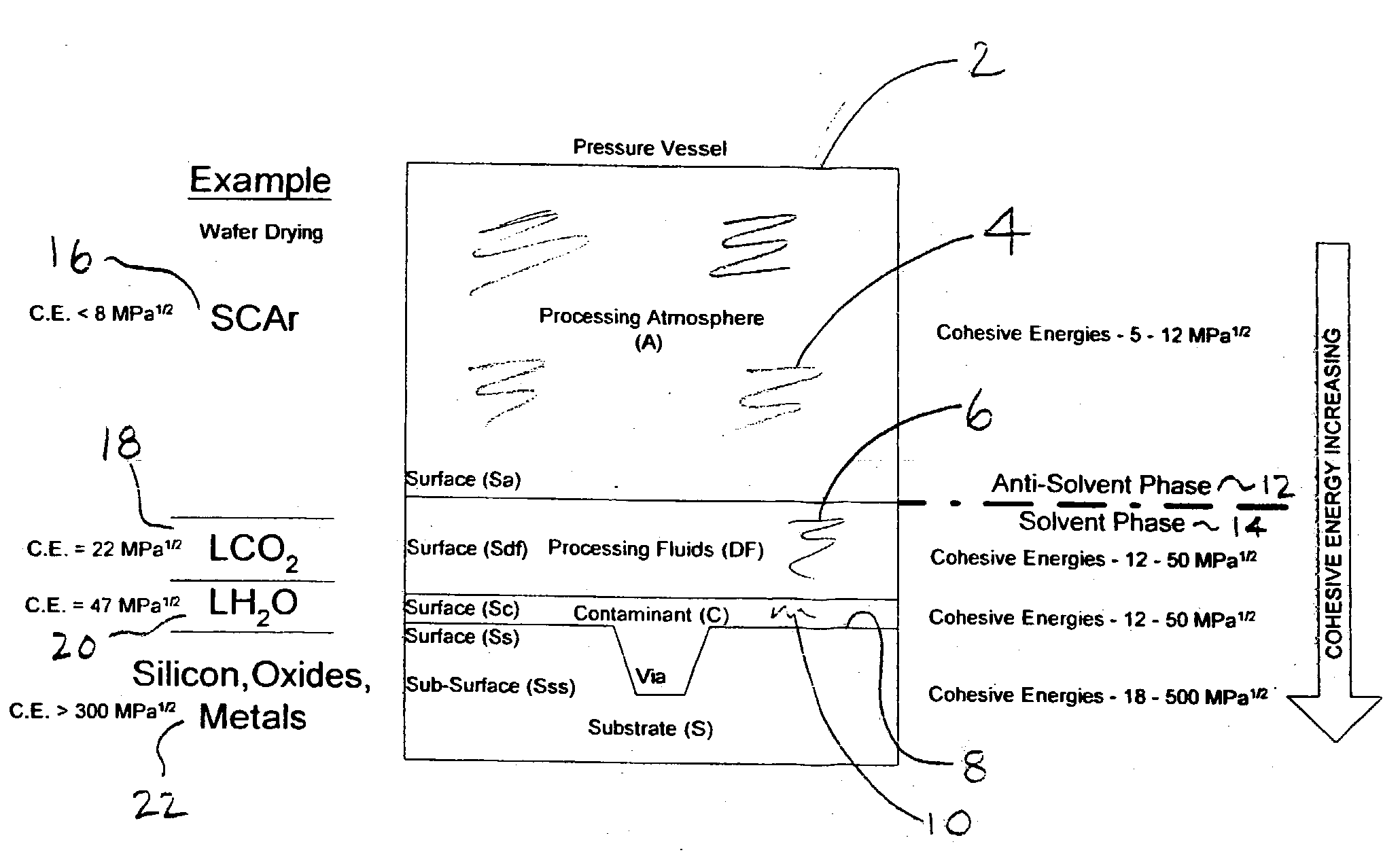

Precision surface treatments using dense fluids and a plasma

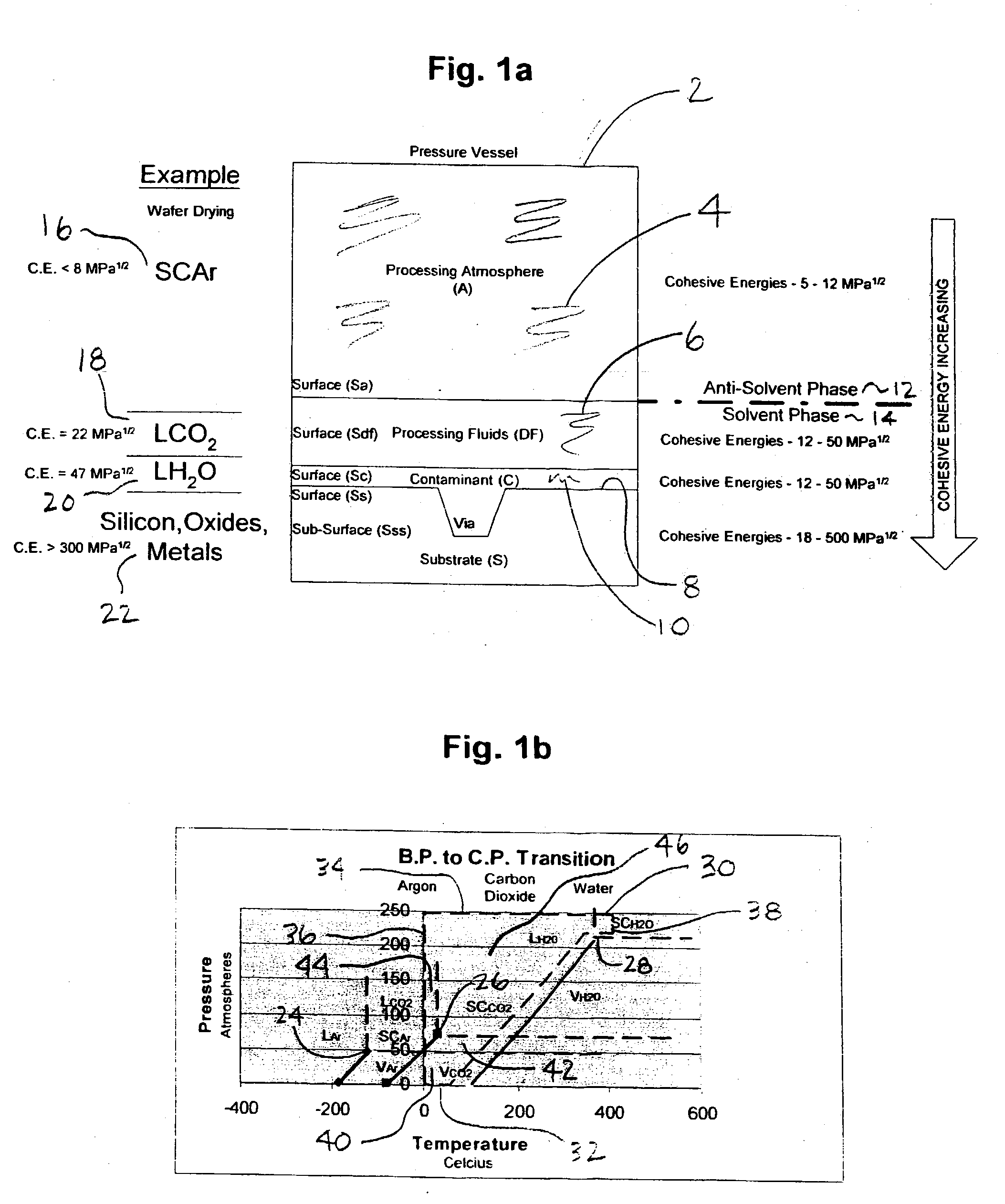

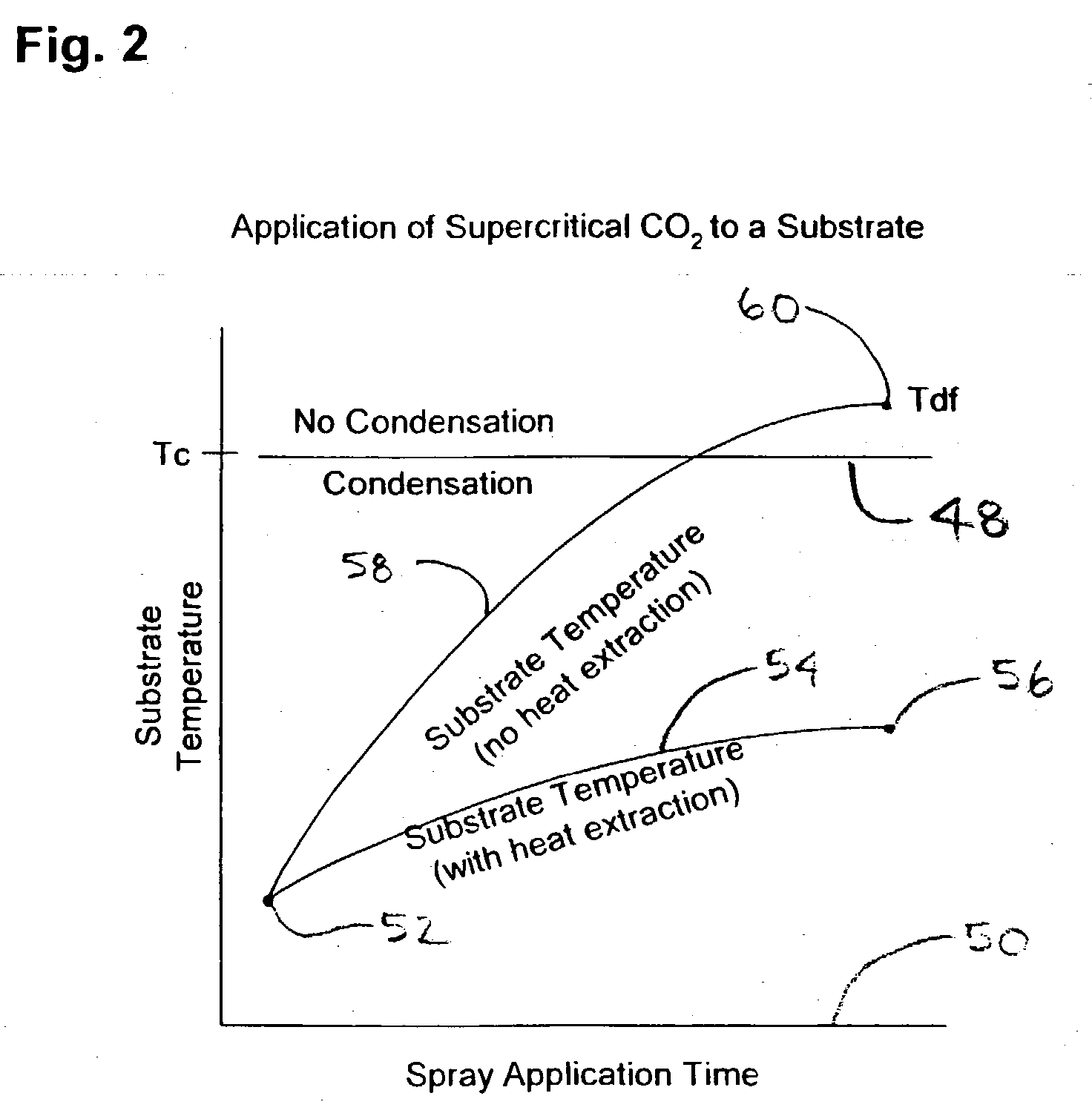

InactiveUS20040003828A1Reduce the temperatureEasy to separateElectric discharge tubesElectrostatic cleaningSolventSolid phases

The present invention is a method, process and apparatus for selective cleaning, drying, and modifying substrate surfaces and depositing thin films thereon using a dense phase gas solvent and admixtures within a first created supercritical fluid antisolvent. Dense fluids are used in combination with sub-atmospheric, atmospheric and super-atmospheric plasma adjuncts (cold and thermal plasmas) to enhance substrate surface cleaning, modification, precision drying and deposition processes herein. Moreover, conventional wet cleaning agents such as hydrofluoric acid and ammonium fluoride may be used with the present invention to perform substrate pre-treatments prior to precision drying and cleaning treatments described herein. Finally, dense fluid such as solid phase carbon dioxide and argon may be used as a follow-on treatment or in combination with plasmas to further treat a substrate surface.

Owner:JACKSON DAVID P

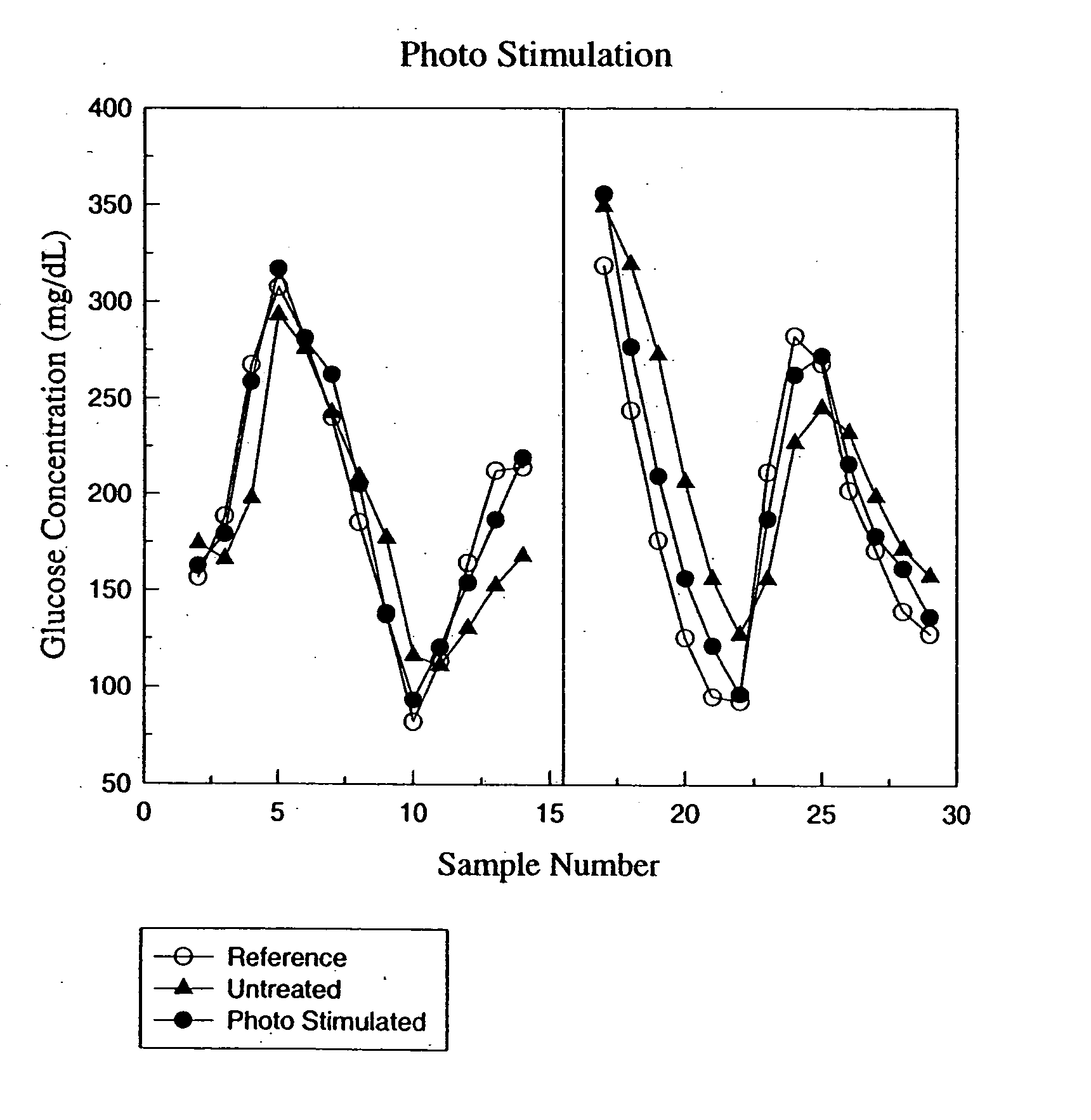

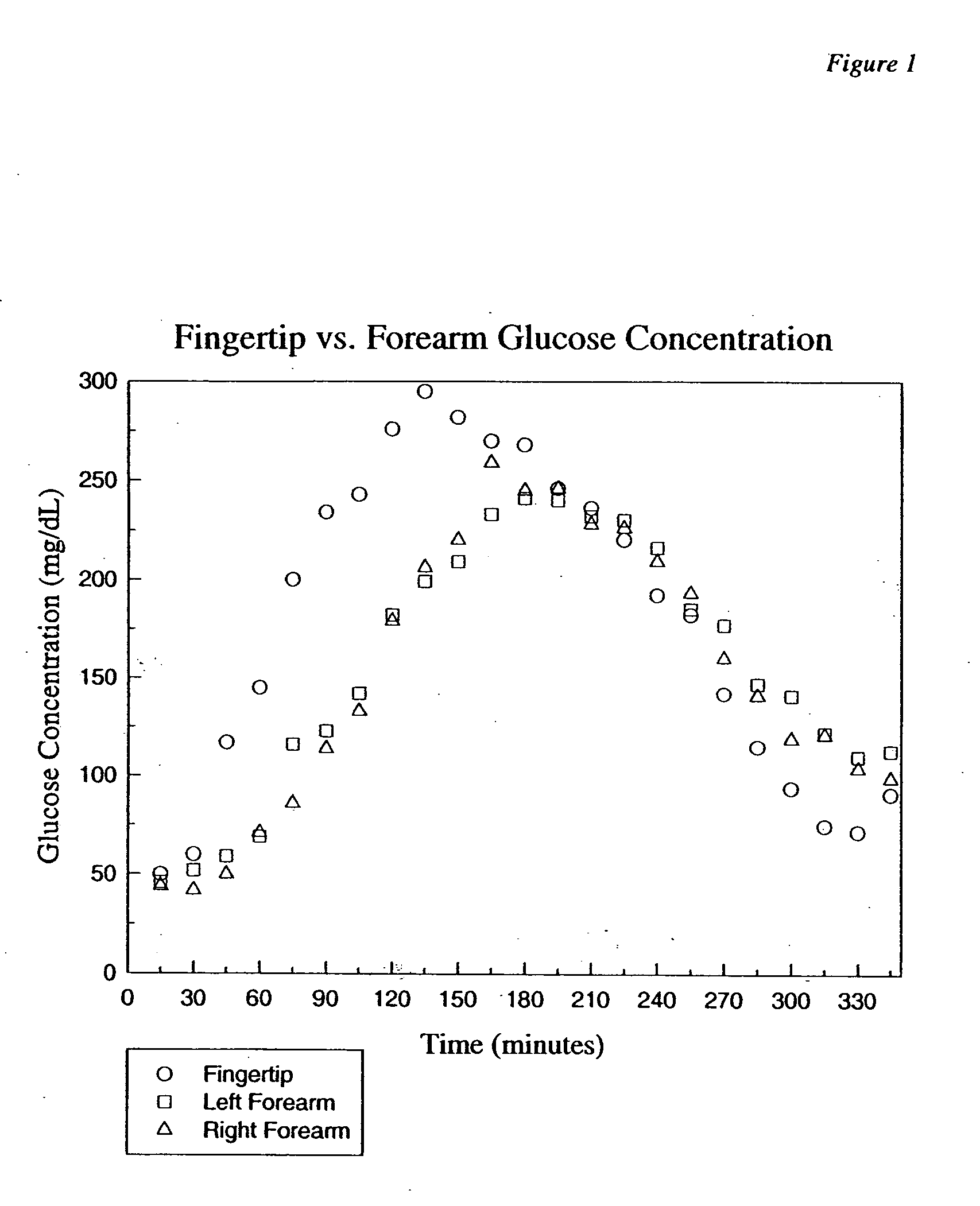

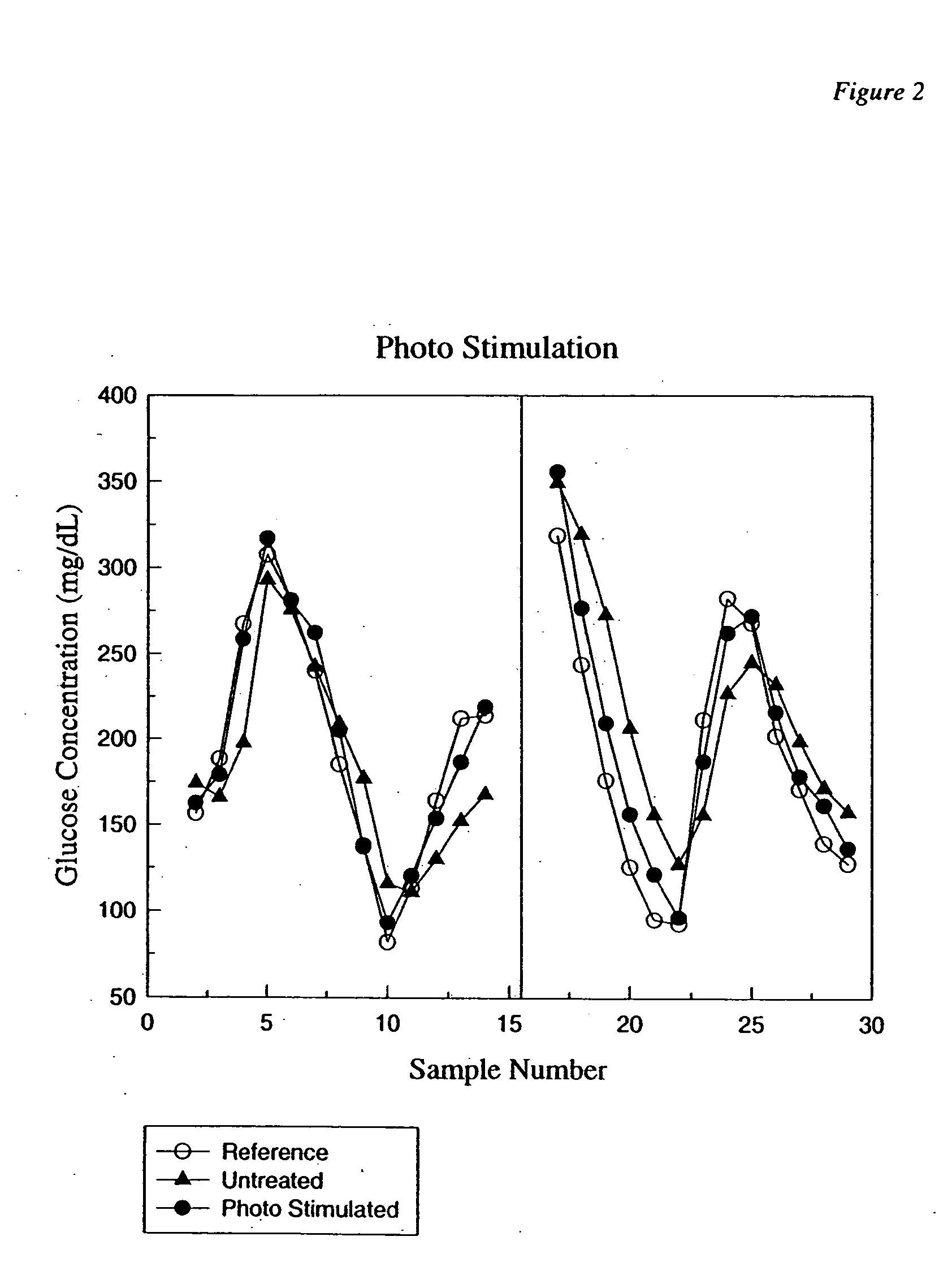

Photostimulation method and apparatus in combination with glucose determination

InactiveUS20050054908A1Increase perfusionReduce errorsDiagnostics using spectroscopyColor/spectral properties measurementsBody compartmentPerfusion

A method and apparatus using photo-stimulation to treat or pretreat a sample site prior to analyte concentration determination is presented. More particularly, photo-stimulation at or near at least one sample site is used to enhance perfusion of the sample site leading to reduced errors associated with sampling. Increased perfusion of the sample site leads to increased volume percentages of the target analyte and / or allows the blood or tissue constituent concentrations to more accurately and / or precisely track corresponding sample constituents in more well perfused body compartments or sites such as arteries, veins, or fingertips. In one embodiment, analysis of the photo-stimulated site is used in conjunction with glucose analyzers to determine the analyte concentration with greater ease, accuracy, or precision and may allow determination of the analyte concentration of another non-sampled body part or compartment.

Owner:GLENN PATENT GROUP

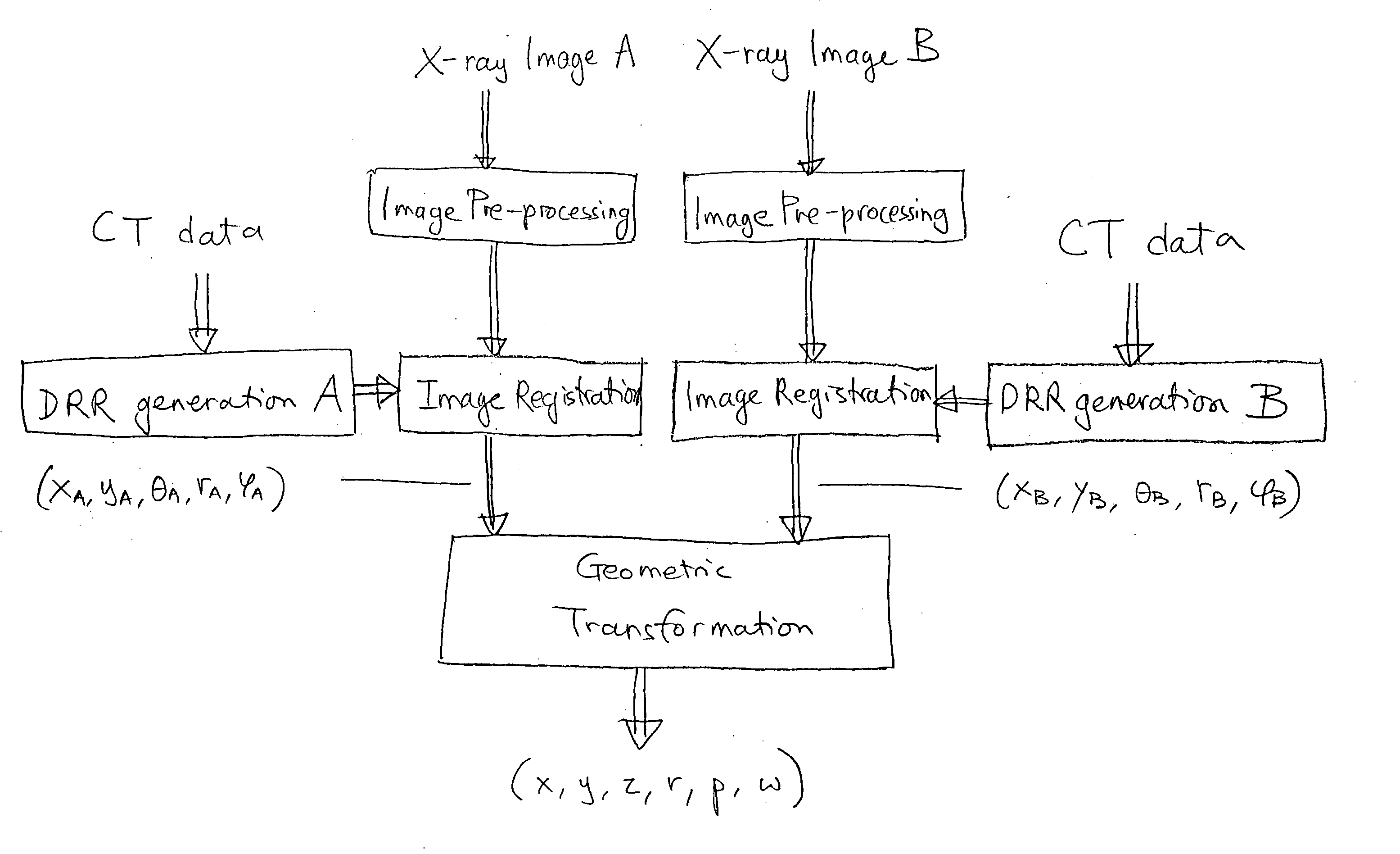

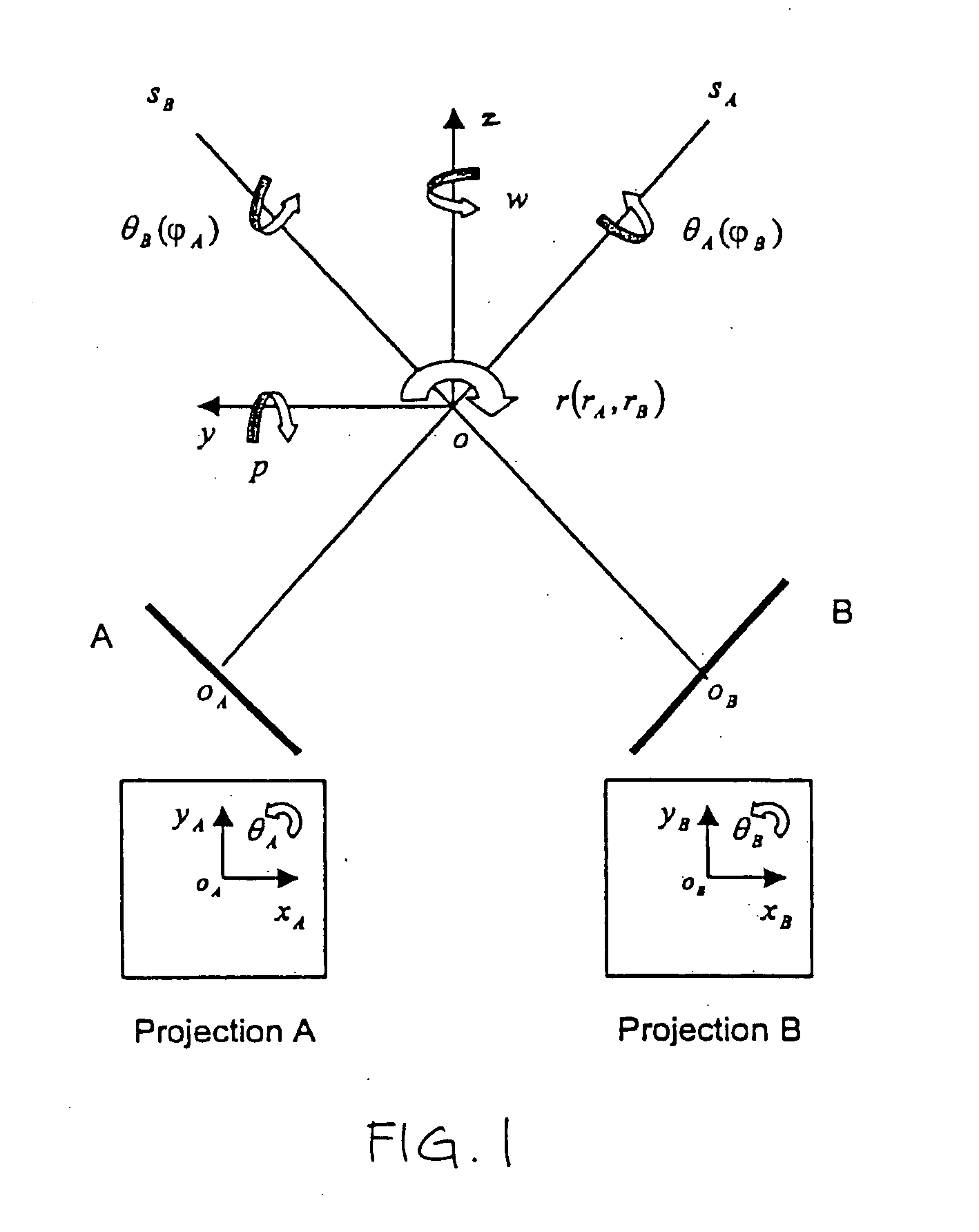

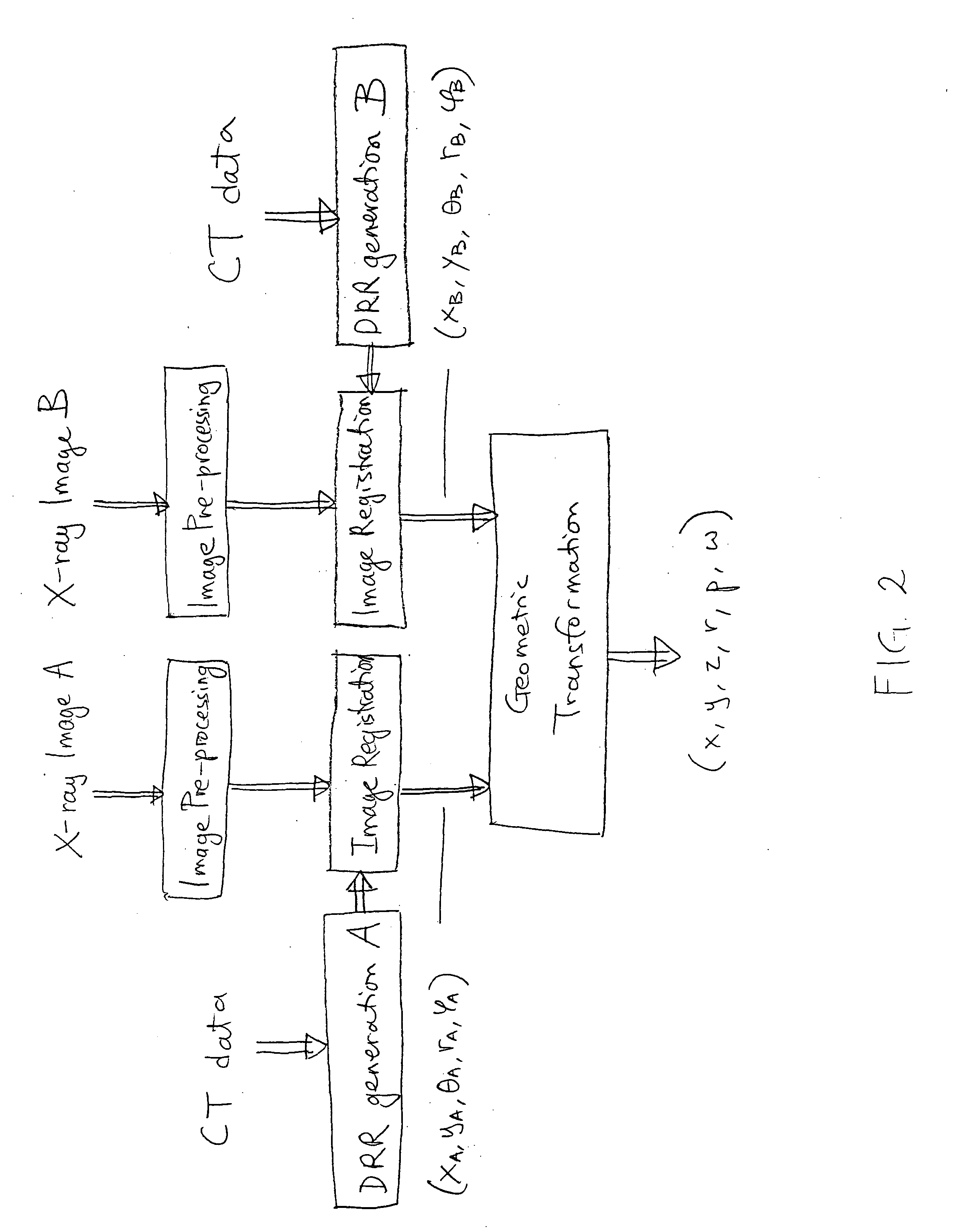

Image guided radiosurgery method and apparatus using registration of 2D radiographic images with digitally reconstructed radiographs of 3D scan data

ActiveUS20050049478A1Rapid and accurate methodThe process is fast and accurateImage enhancementImage analysisIn plane3d image

An image-guided radiosurgery method and system are presented that use 2D / 3D image registration to keep the radiosurgical beams properly focused onto a treatment target. A pre-treatment 3D scan of the target is generated at or near treatment planning time. A set of 2D DRRs are generated, based on the pre-treatment 3D scan. At least one 2D x-ray image of the target is generated in near real time during treatment. The DRRs are registered with the x-ray images, by computing a set of 3D transformation parameters that represent the change in target position between the 3D scan and the x-ray images. The relative position of the radiosurgical beams and the target is continuously adjusted in near real time in accordance with the 3D transformation parameters. A hierarchical and iterative 2D / 3D registration algorithm is used, in which the transformation parameters that are in-plane with respect to the image plane of the x-ray images are computed separately from the out-of-plane transformation parameters.

Owner:ACCURAY

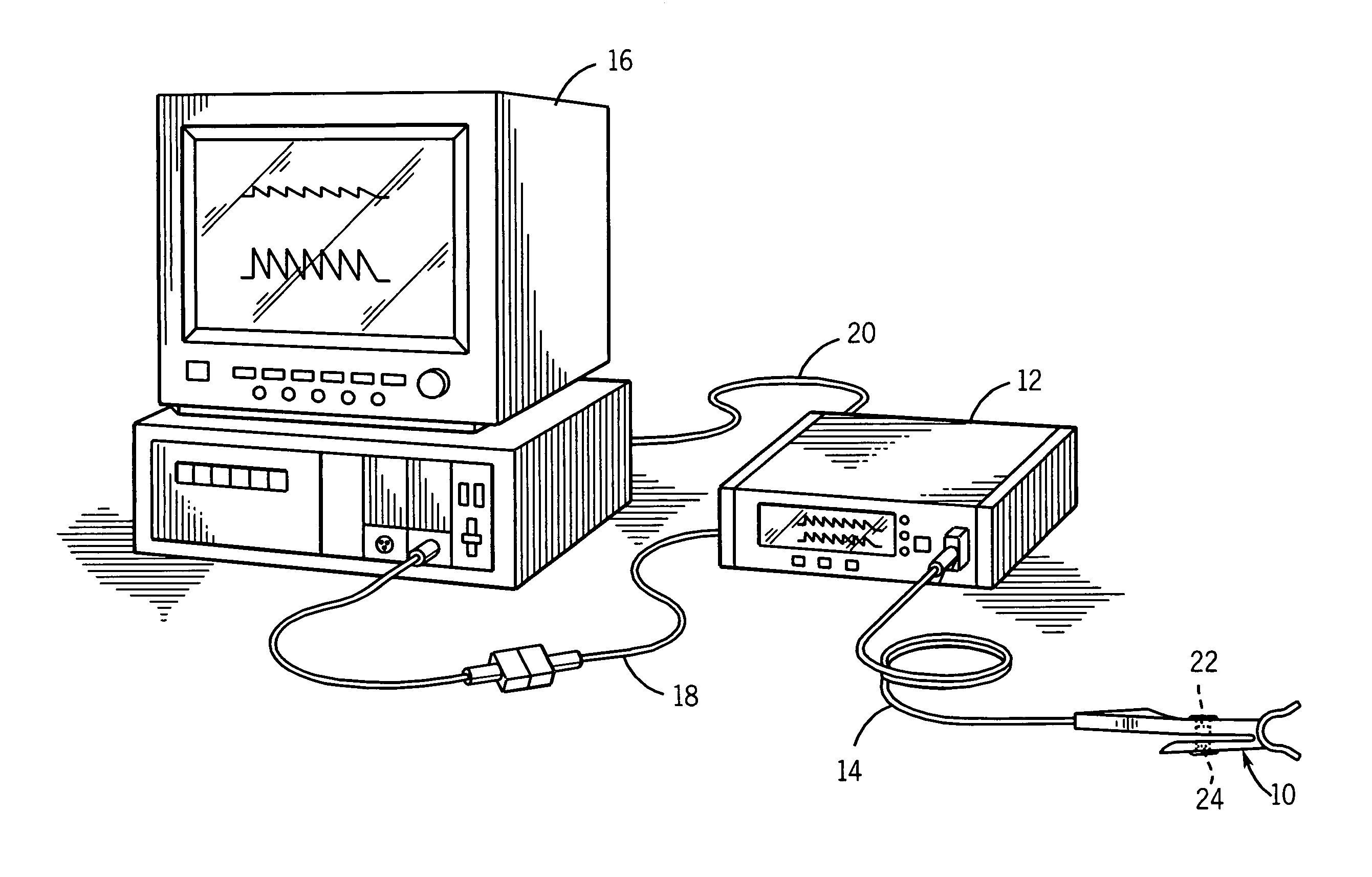

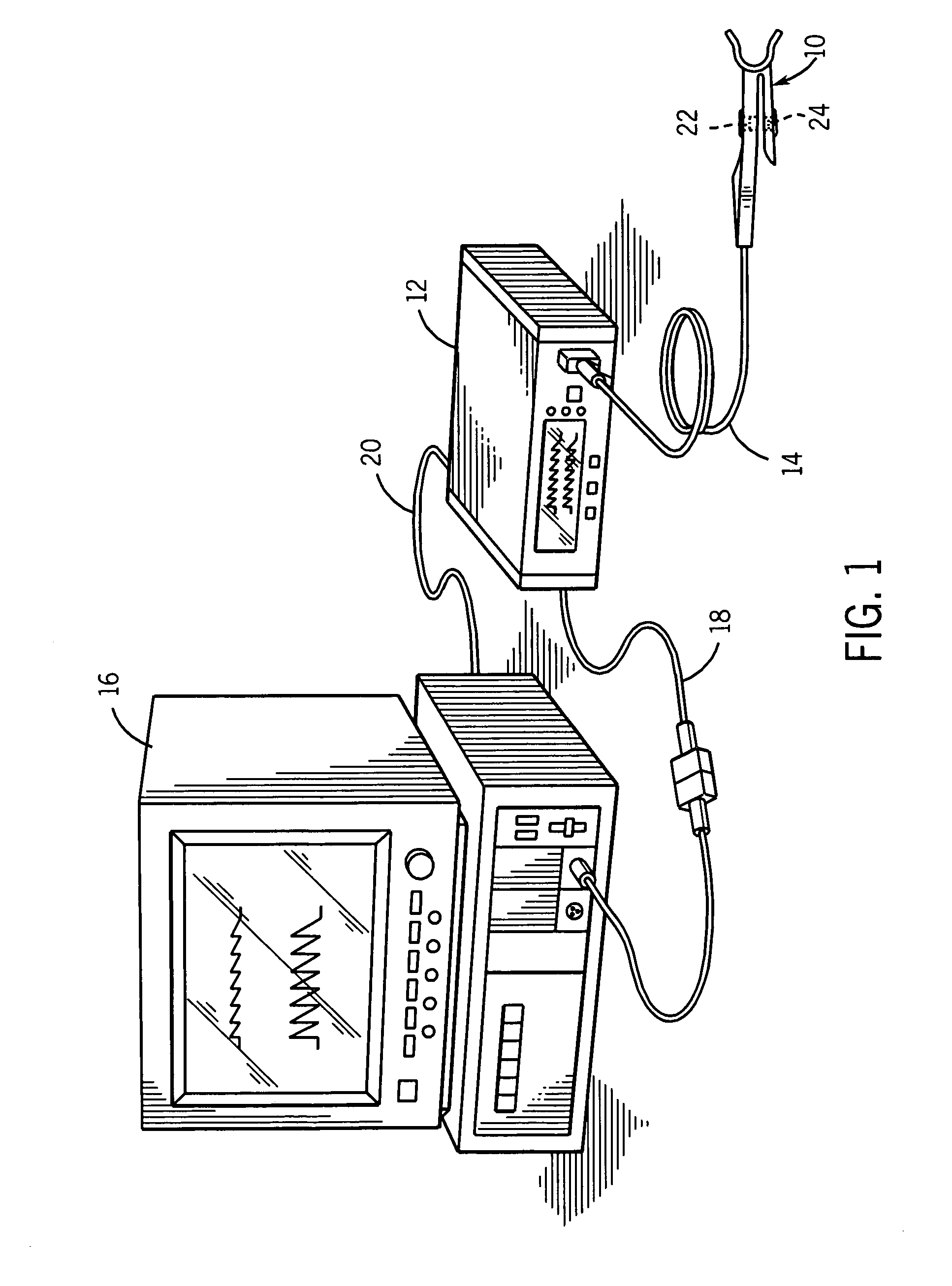

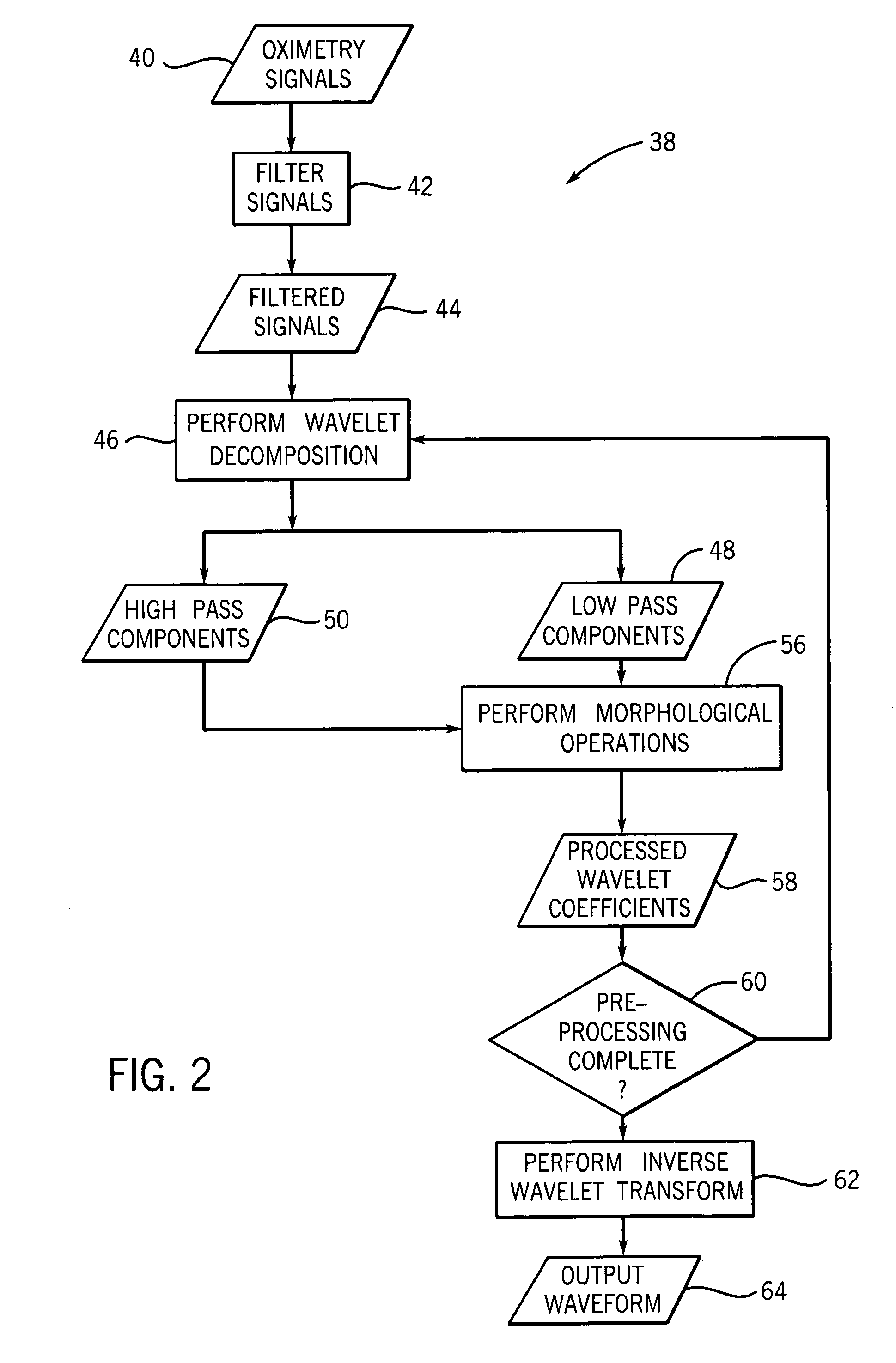

System and method for pre-processing waveforms

A technique is provided for processing a physiological signal. The technique includes performing one or more multi-resolution decompositions on a physiological signal and one or more morphological operations on some or all of the respective decomposition components. In one embodiment, the technique is implemented as iteratively wavelet transformations where morphological operations, such as erosions and dilations, are applied to modify some or all of the respective wavelet coefficients. The modified wavelet coefficients may then be reconstructed to generate a clean version of the physiological signal from which some or all of the noise and / or artifacts have been removed.

Owner:TYCO HEALTHCARE GRP LP

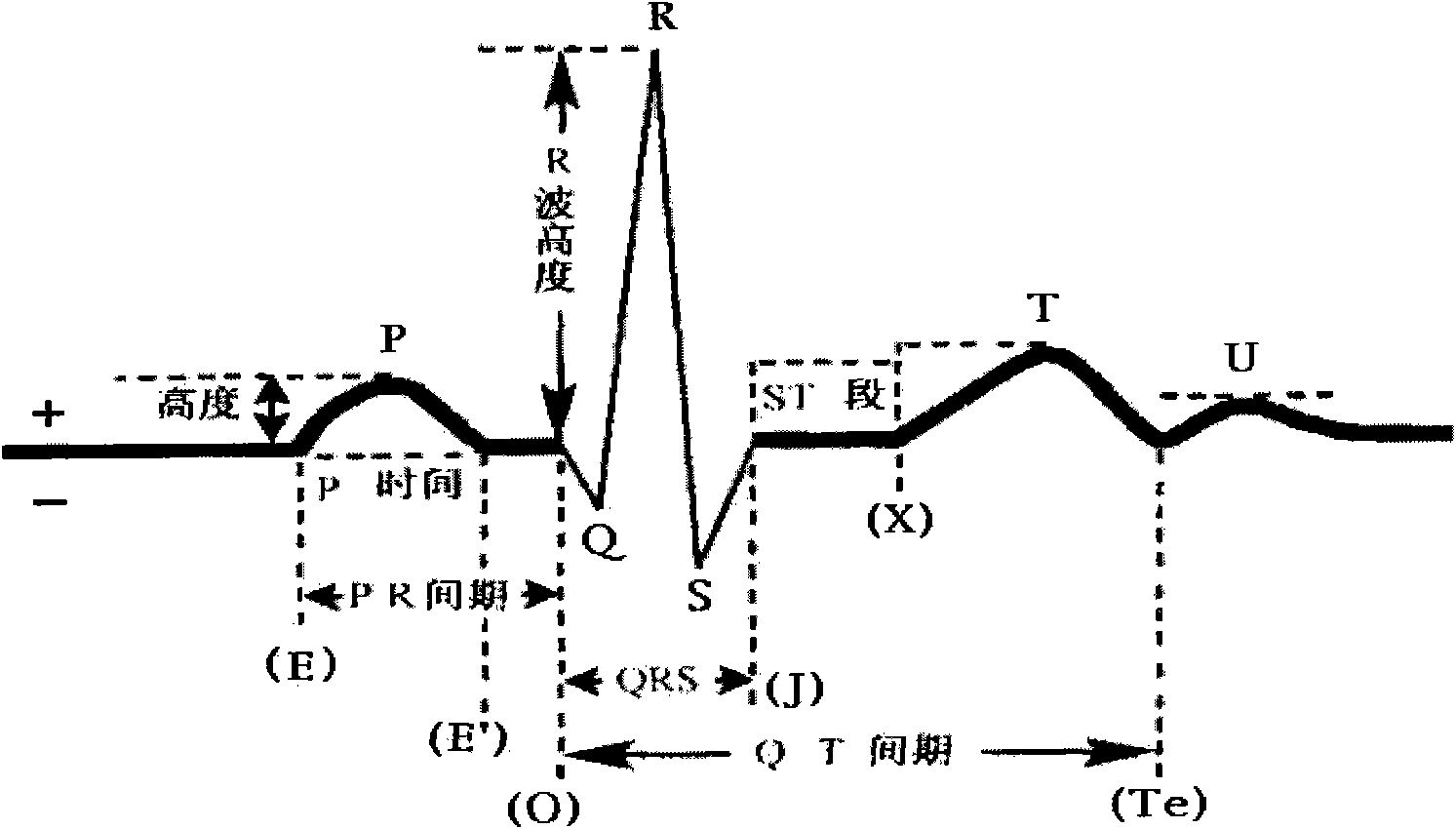

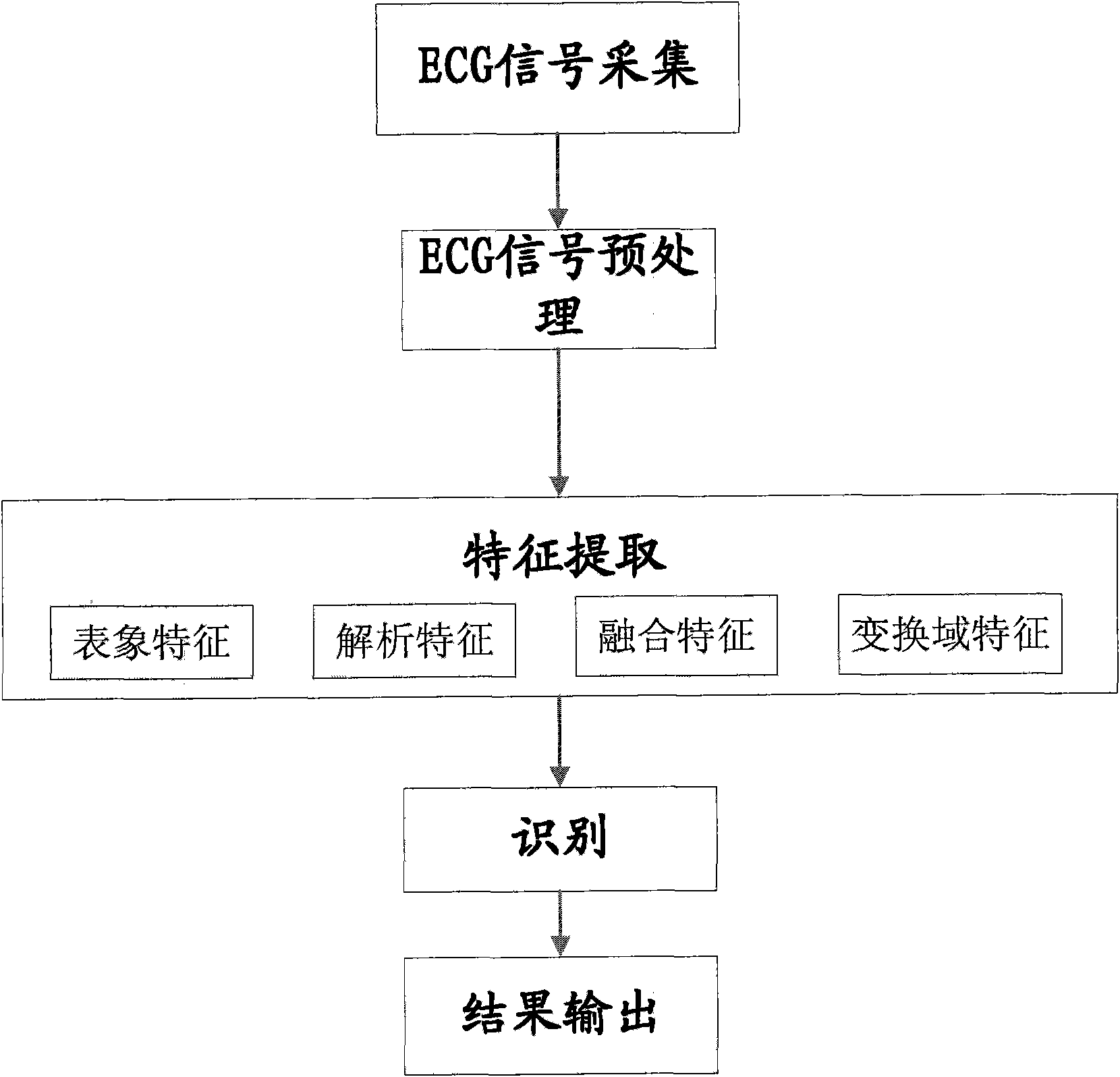

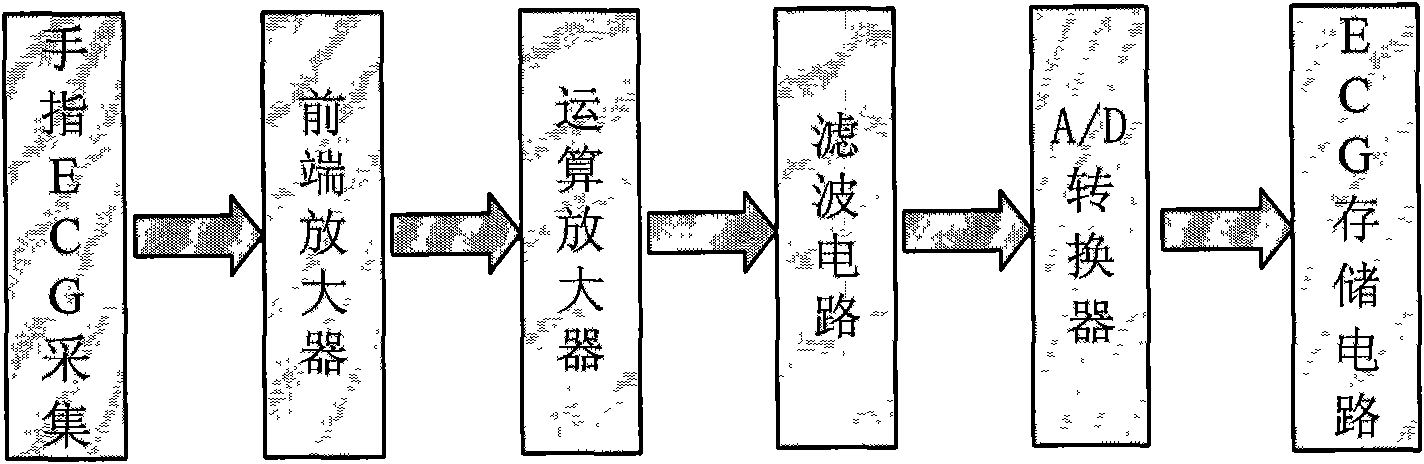

Identification method and identification system using identification method

The invention provides an identification method, which performs identification by using an electrocardio (ECG) signal. The method comprises the following steps of: (a) ECG signal collection; (b) ECG signal pre-treatment, wherein the collected ECG signal is filtered; (c) characteristic extraction, wherein the characteristics of the ECG signal are extracted to build an identification characteristic vectors and the built identification characteristic vectors comprise analysis characteristics, presentative characteristics, transformation-domain characteristics and fusion characteristics; (d) identification process, wherein the identification characteristic vectors of a person to be identified is compared with the identification characteristic vectors which are pre-stored in an ECG characteristic template base; and (e) result output. The invention also provides an identification system using the identification method.

Owner:SCI RES TRAINING CENT FOR CHINESE ASTRONAUTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com