Patents

Literature

11064 results about "Reverse osmosis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reverse osmosis (RO) is a water purification process that uses a partially permeable membrane to remove ions, unwanted molecules and larger particles from drinking water. In reverse osmosis, an applied pressure is used to overcome osmotic pressure, a colligative property, that is driven by chemical potential differences of the solvent, a thermodynamic parameter. Reverse osmosis can remove many types of dissolved and suspended chemical species as well as biological ones (principally bacteria) from water, and is used in both industrial processes and the production of potable water. The result is that the solute is retained on the pressurized side of the membrane and the pure solvent is allowed to pass to the other side. To be "selective", this membrane should not allow large molecules or ions through the pores (holes), but should allow smaller components of the solution (such as solvent molecules, i.e., water, H₂O) to pass freely.

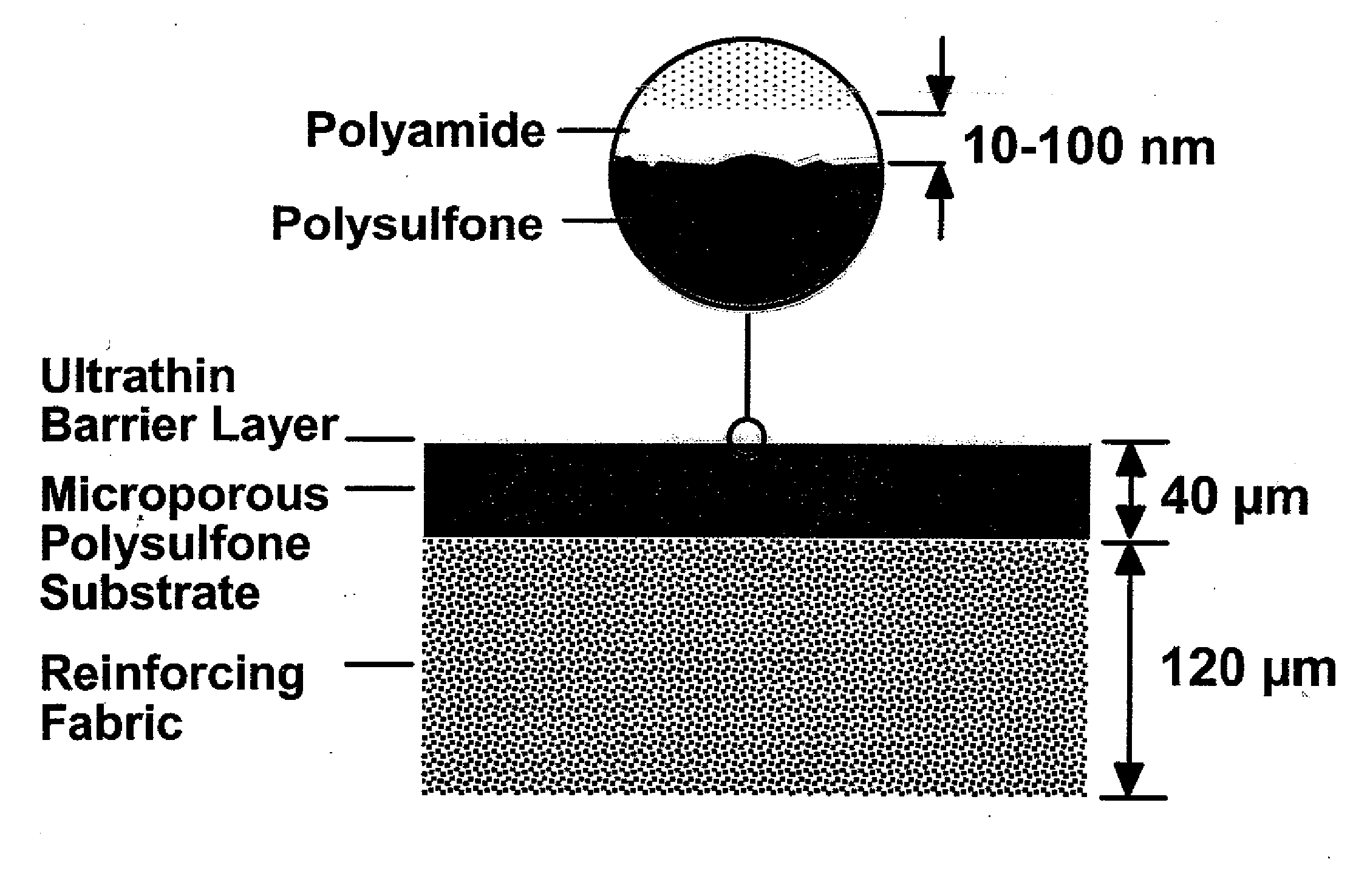

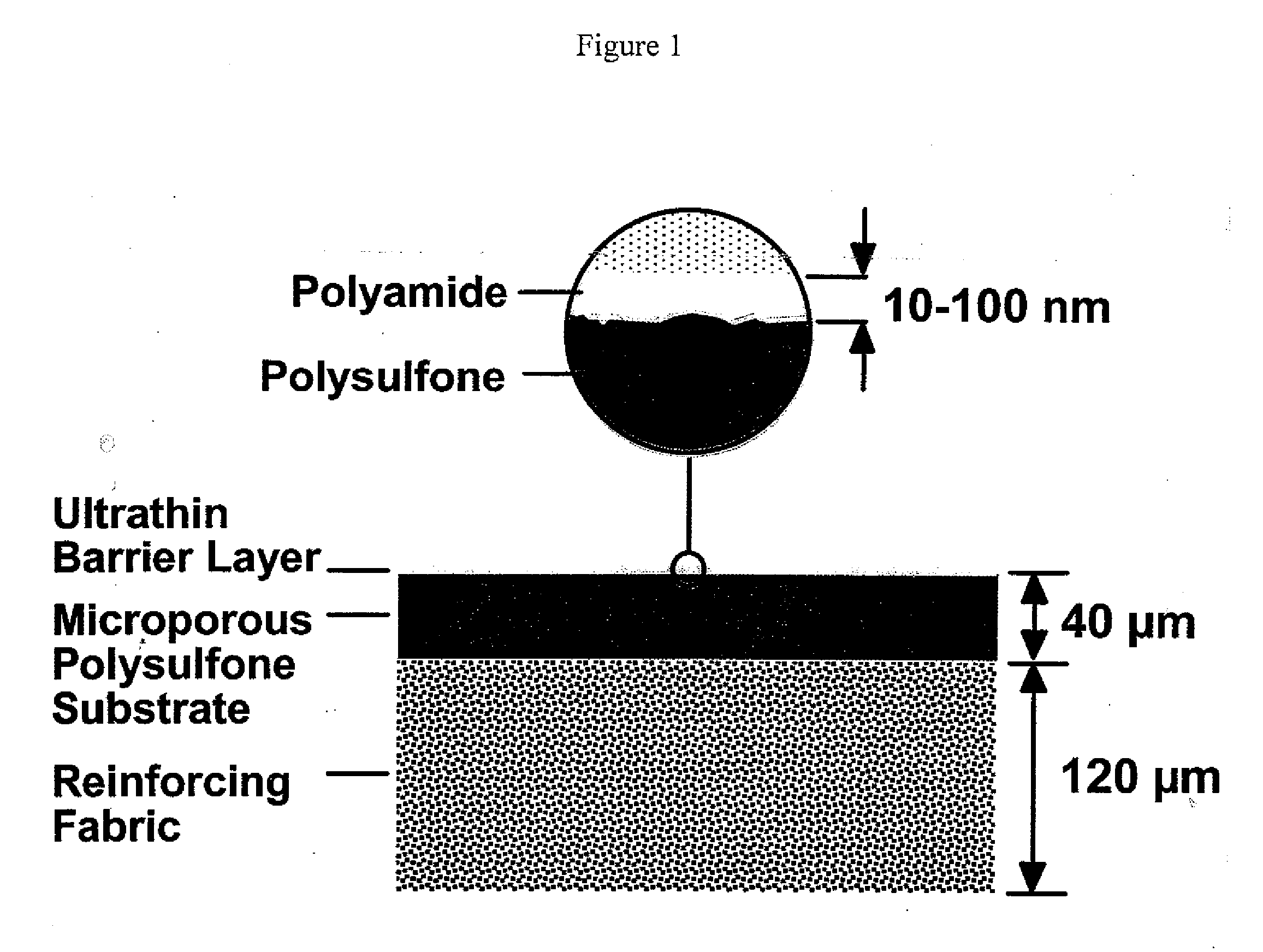

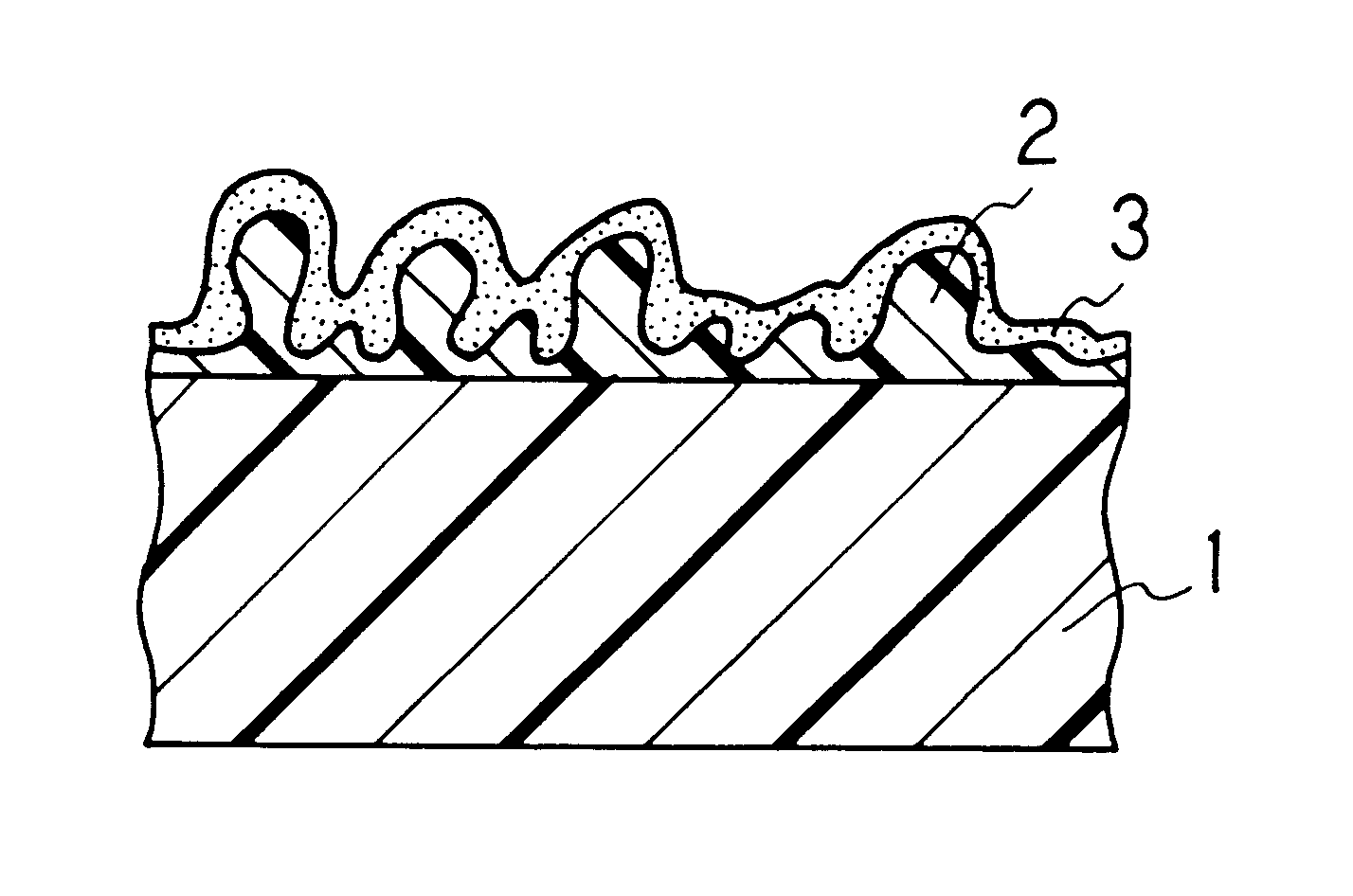

Composite membrane and method for making the same

InactiveUS6878278B2Improve throughputEasy to adaptSemi-permeable membranesLoose filtering material filtersPolyamideReverse osmosis

A composite membrane and method for making the same, comprising a porous support and a polyamide surface. The subject membrane provides improved flux and / or rejection rates. The subject membrane is further capable of operating at lower operating pressures. The subject method includes reacting a polyfunctional amine with a polyfunctional acyl halide to form a polyamide. The method includes the step of contacting a complexing agent with the polyfunctional acyl halide prior substantial reaction between the polyfunctional acyl halide and a polyfunctional amine. The subject process is easily adapted to commercial scale manufacturing processes and is particularly suited for making nanofiltration and reverse osmosis composite membranes.

Owner:DOW GLOBAL TECH LLC

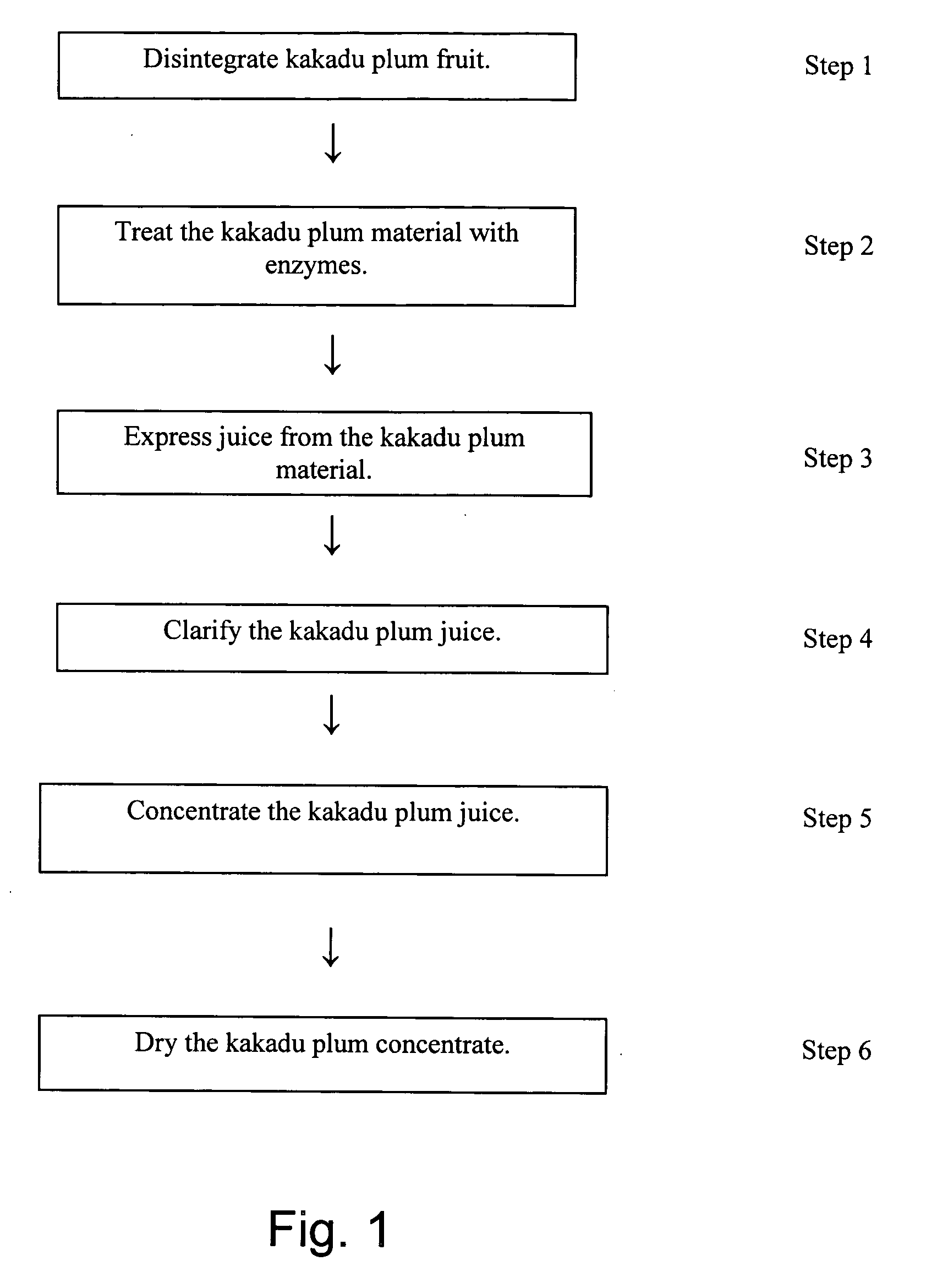

Method of preparing kakadu plum powder

ActiveUS20050163880A1High viscosityImpede efficient processingBiocideUnknown materialsAbsorption capacityUltrafiltration

A process for producing a kakadu plum powder having an increased amount of naturally occurring ascorbic acid and high ORAC value. The process of preparing the extract includes the following: disintegrating kakadu plum fruit; treating the disintegrated kakadu plum material with enzymes to at least partially digest the material; juicing the kakadu plum material and drying the juice to produce a powder. In a preferred embodiment, the kakadu plum juice is further clarified with ultrafiltration and concentrated by performing reverse osmosis on the kakadu plum juice. The resultant kakadu plum powder has a natural ascorbic acid content of at least about 15% and a naturally occurring Oxygen Reduction Absorption Capacity value of at least 1500.

Owner:ACCESS BUSINESS GRP INT LLC +1

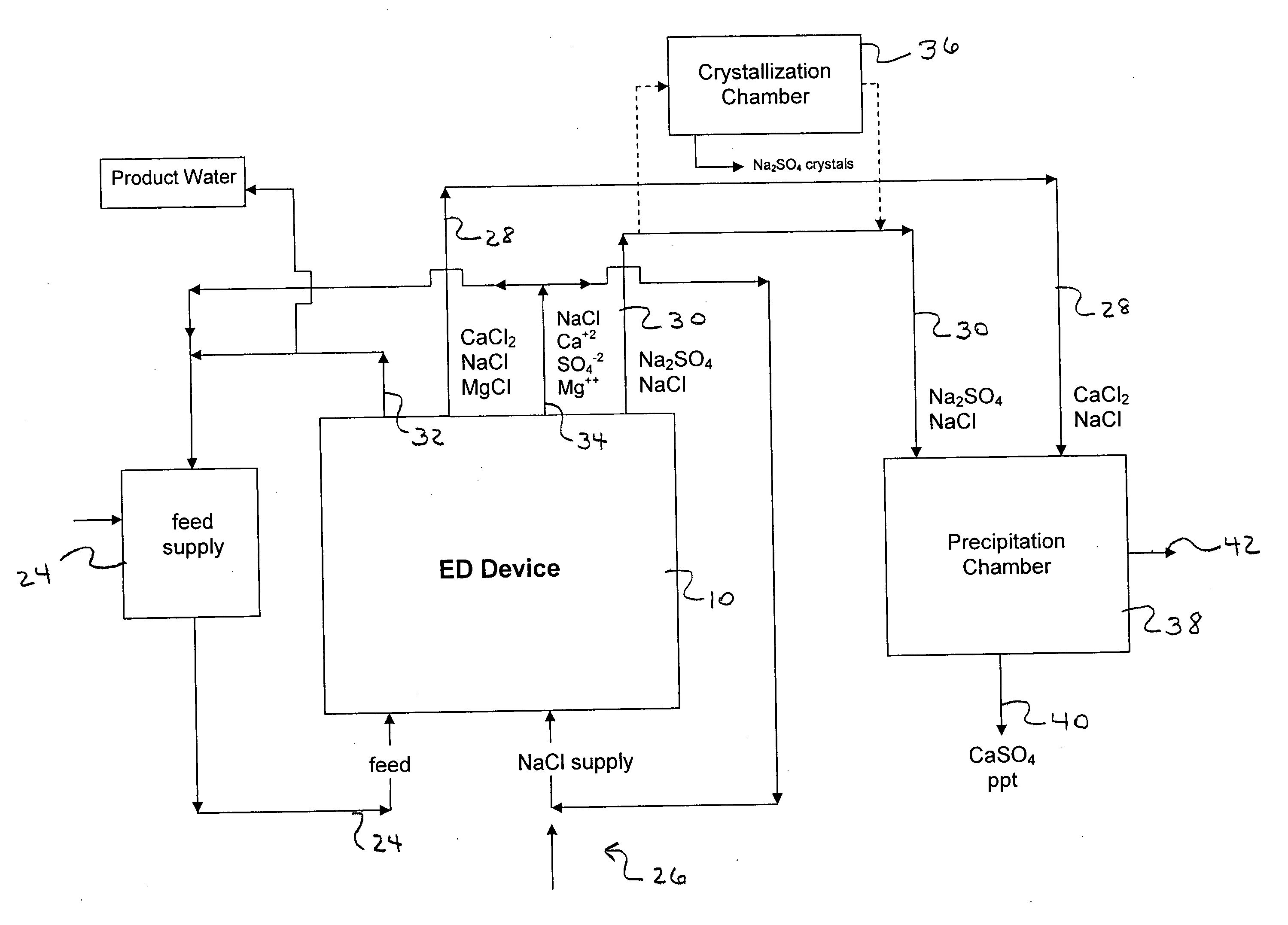

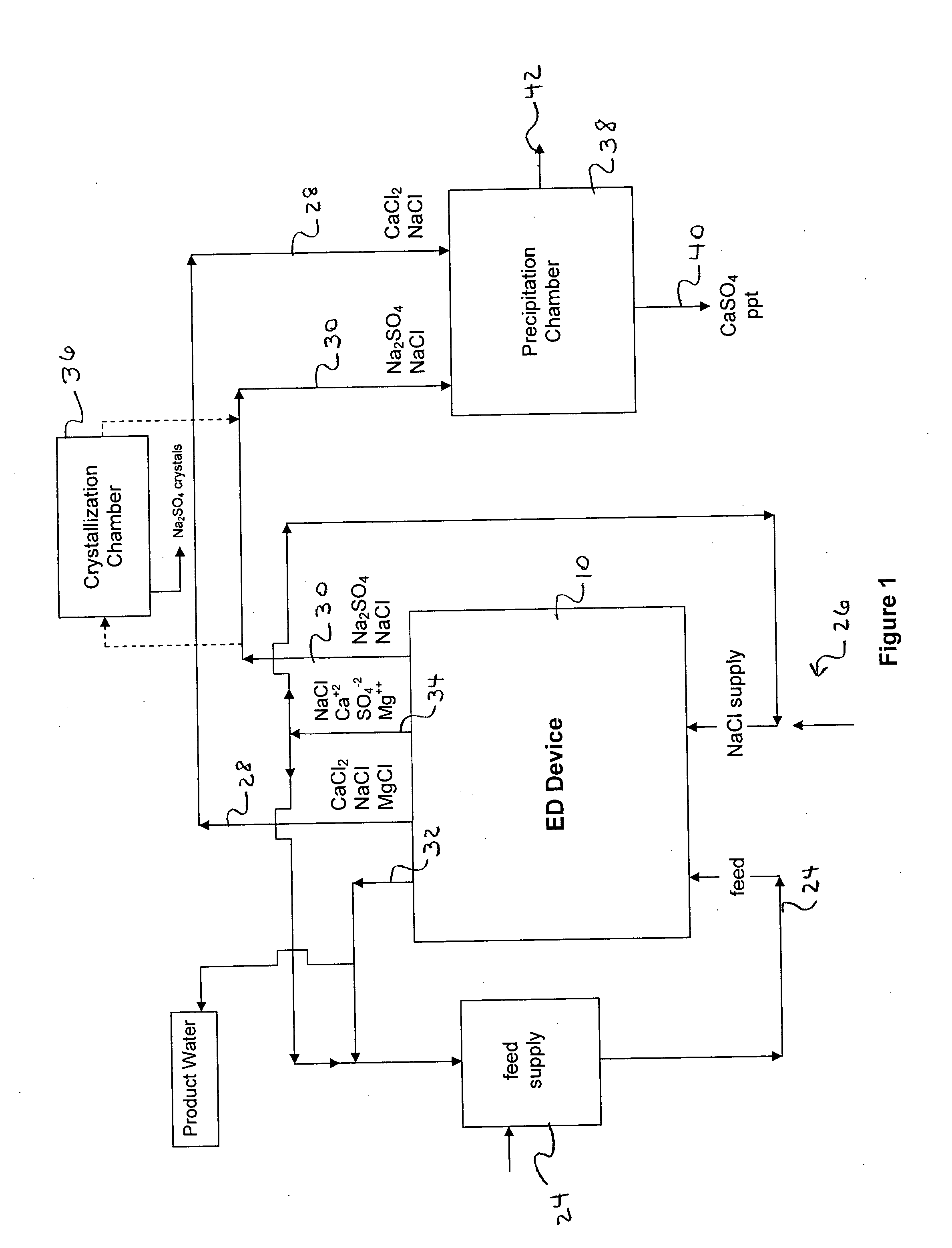

Water desalination process and apparatus

ActiveUS20060060532A1Electrolysis componentsGeneral water supply conservationSolubilityWater desalination

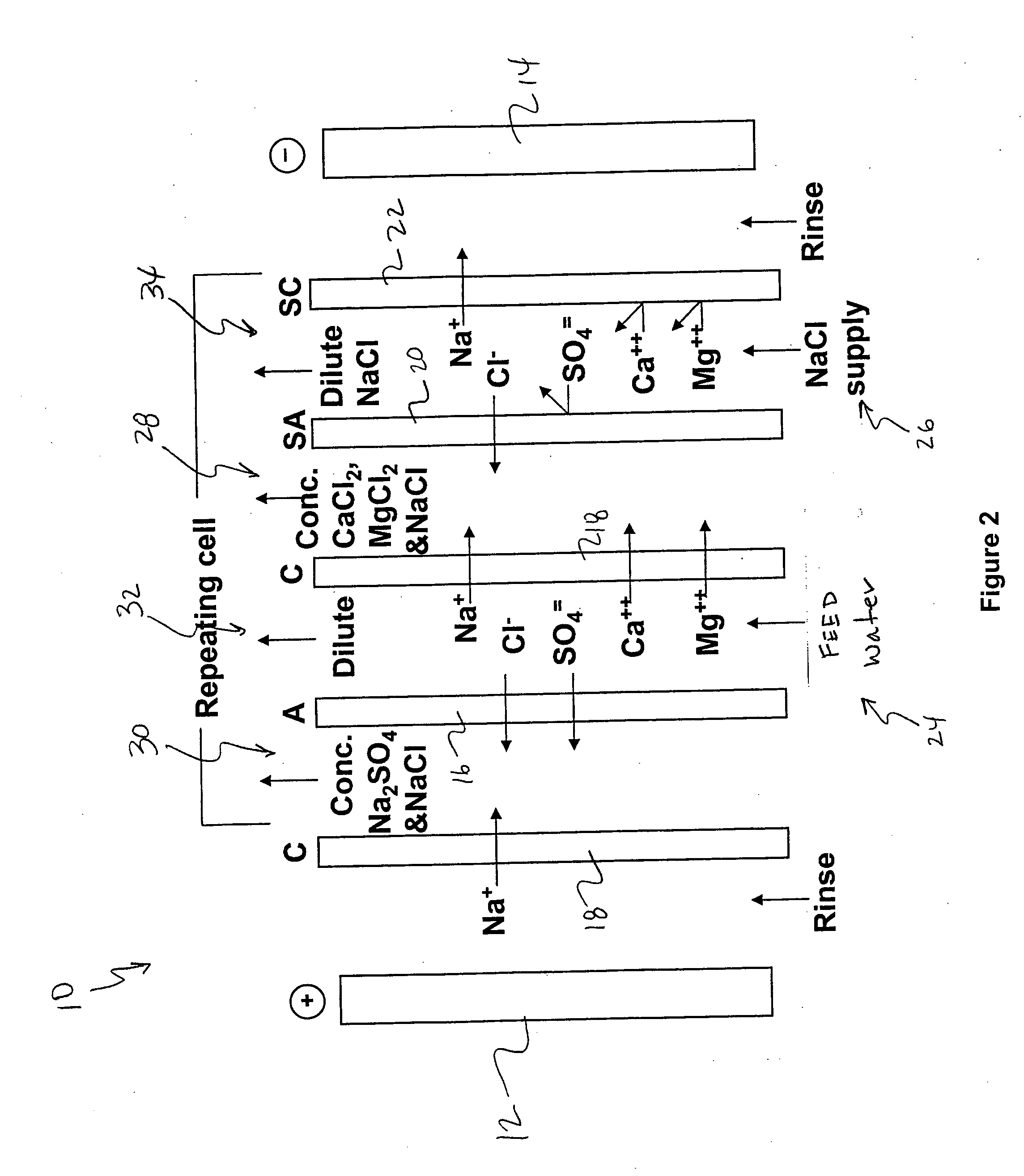

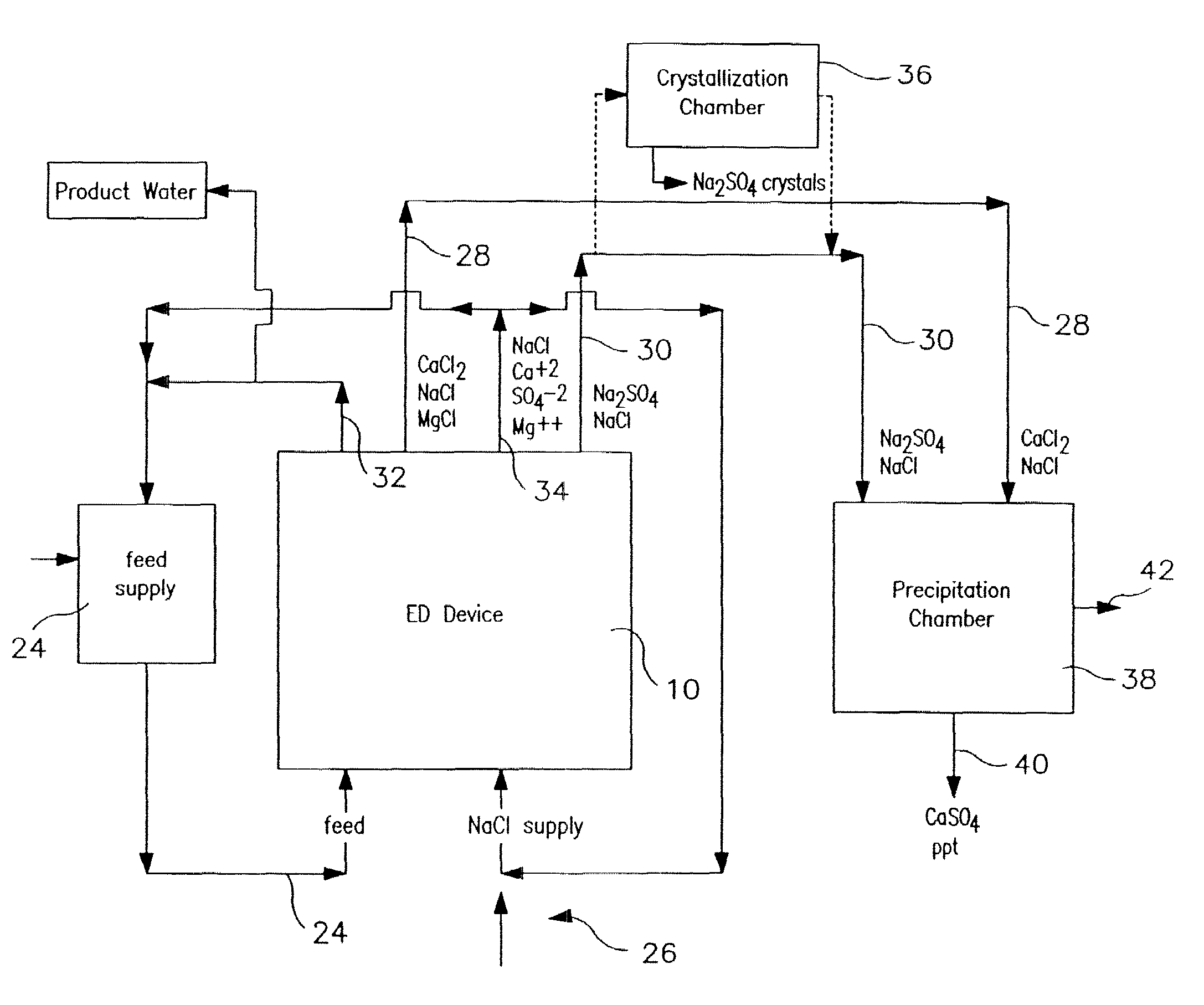

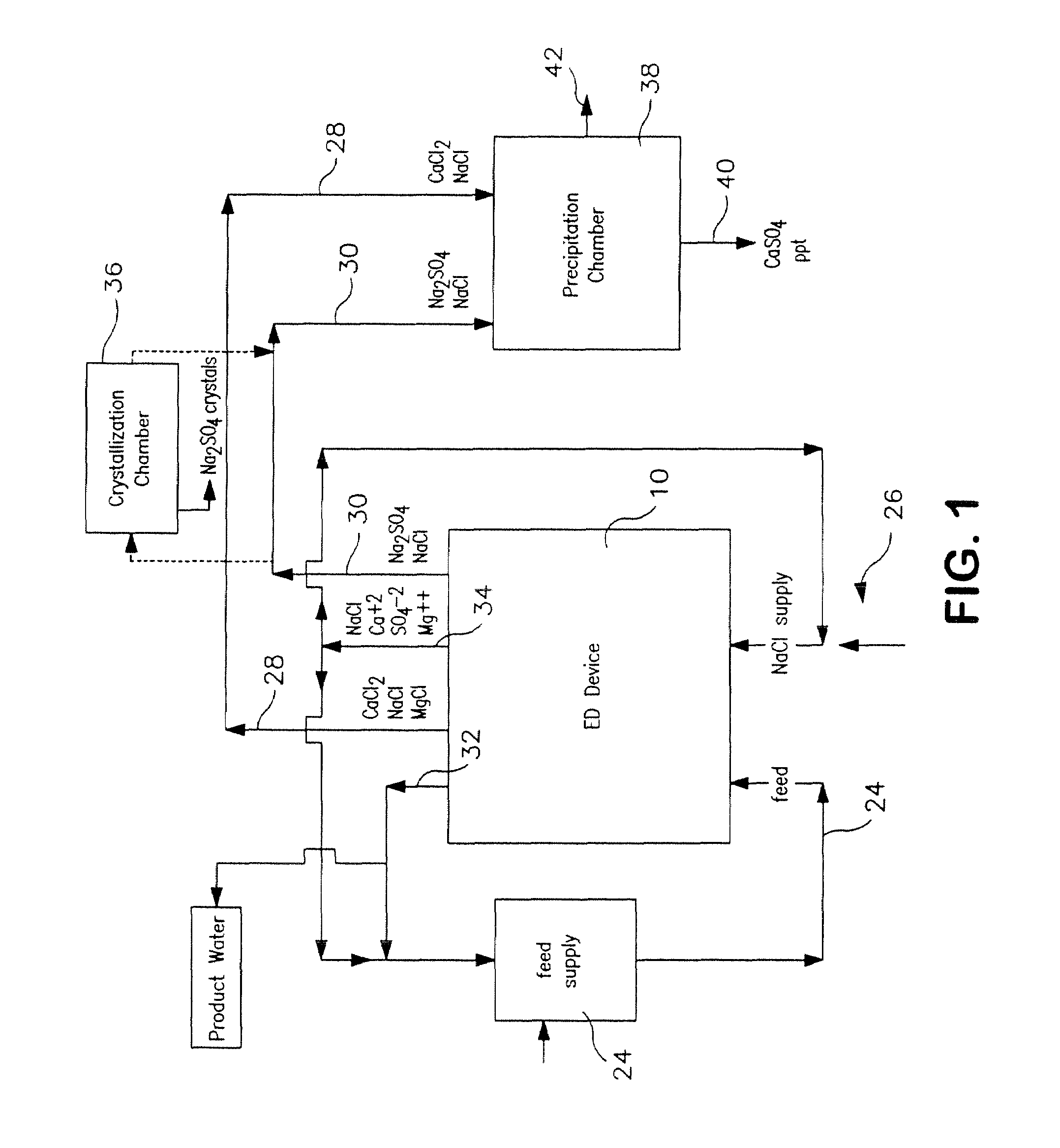

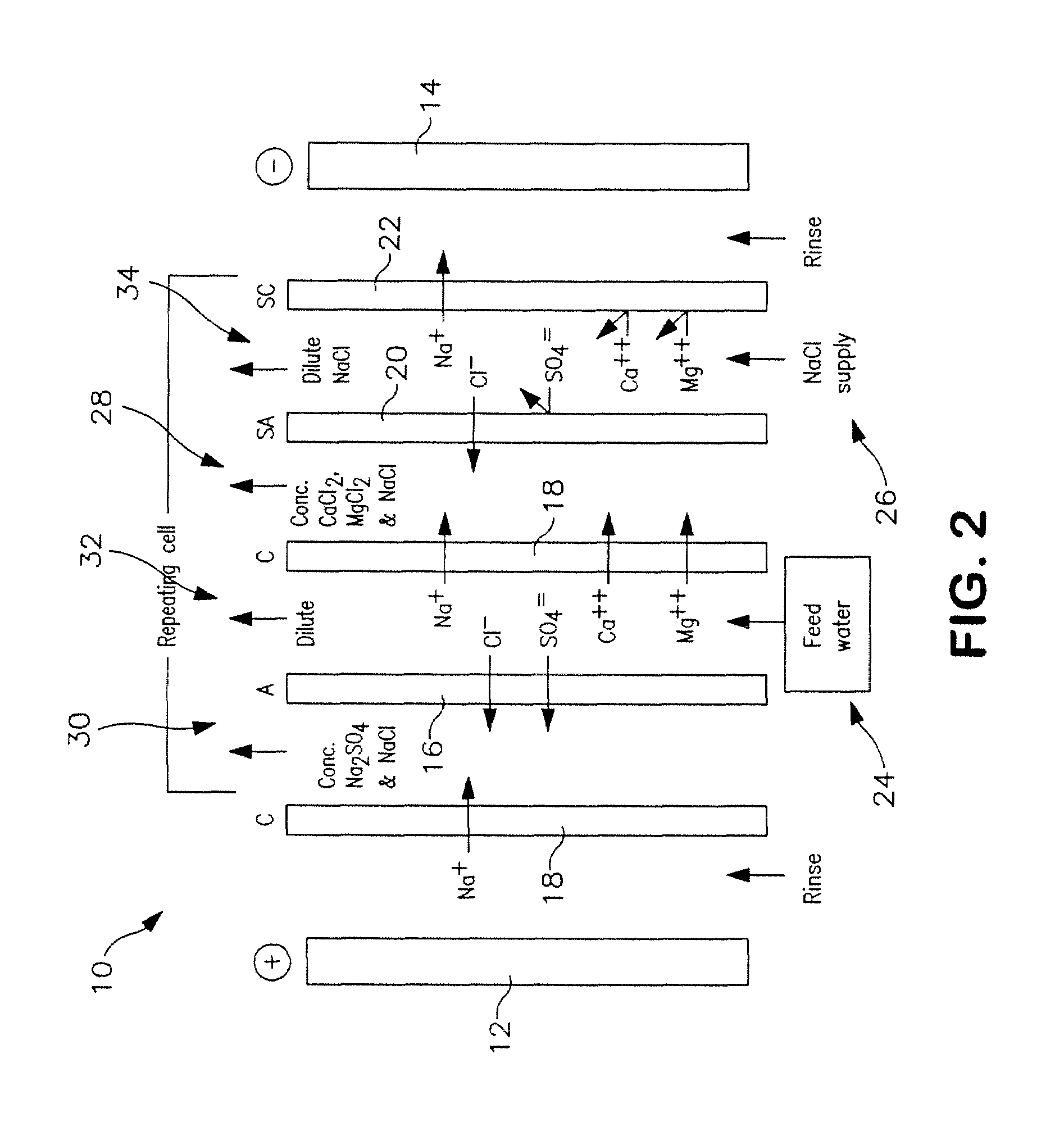

A process and system for purifying water is disclosed. For example, in one embodiment, the process may be used to remove a divalent salt, such as calcium sulfate, from a water source in order to prevent the divalent salt from precipitating during the process. The water source, for instance, may be fed to an ion separating device, such as an electrodialysis device. In the electrodialysis device, an ion exchange takes place between the divalent salt and another salt, such as a monovalent salt to produce two concentrated salt streams that contain salts having greater solubility in water than the divalent salt. In one embodiment, the two salt streams that are produced may then be combined to precipitate the divalent salt in a controlled manner. During the process, various other components contained within the water feed stream may also be removed from the stream and converted into useful products. In one particular embodiment, the process is configured to receive a byproduct stream from a reverse osmosis process.

Owner:SOUTH CAROLINA THE UNIV OF

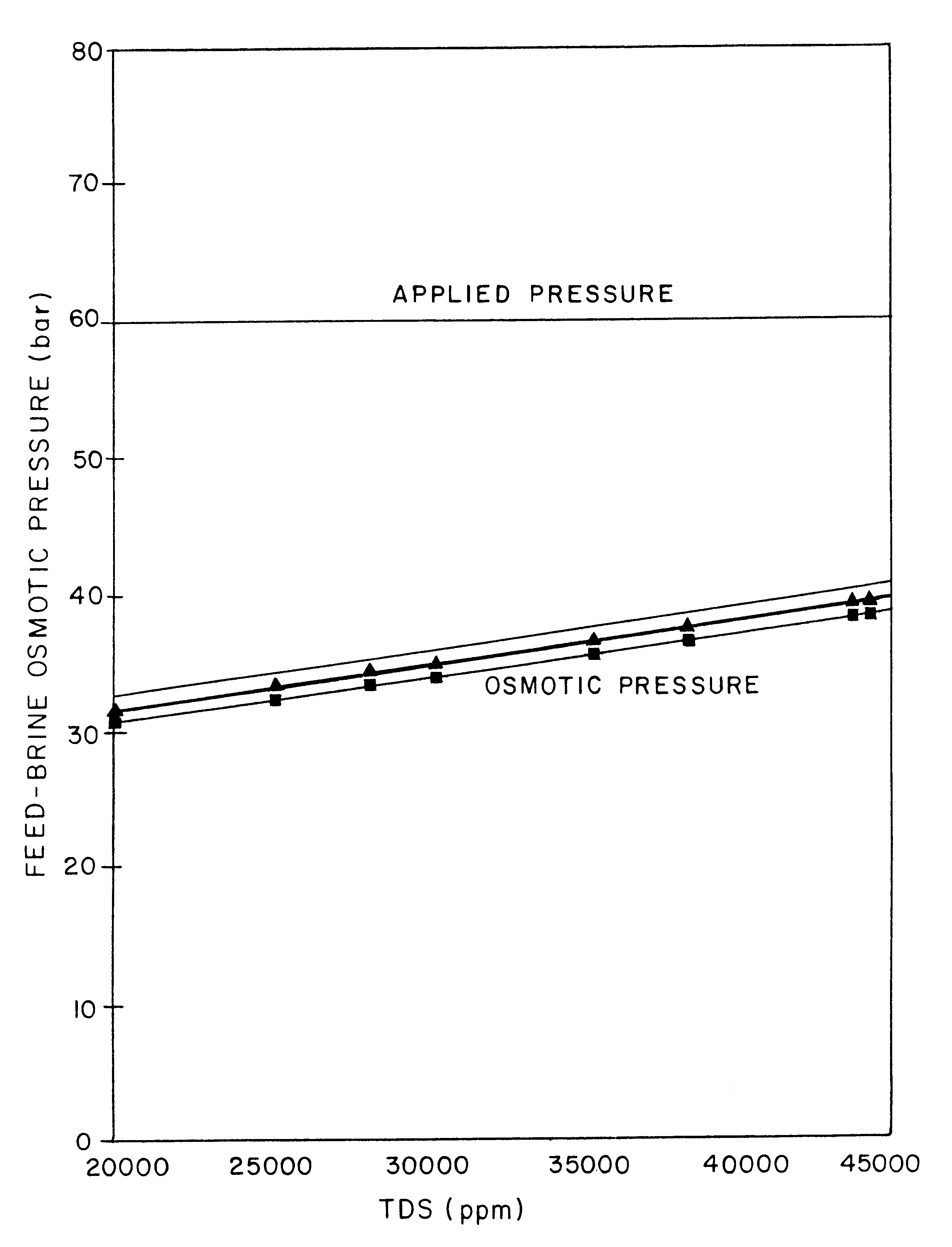

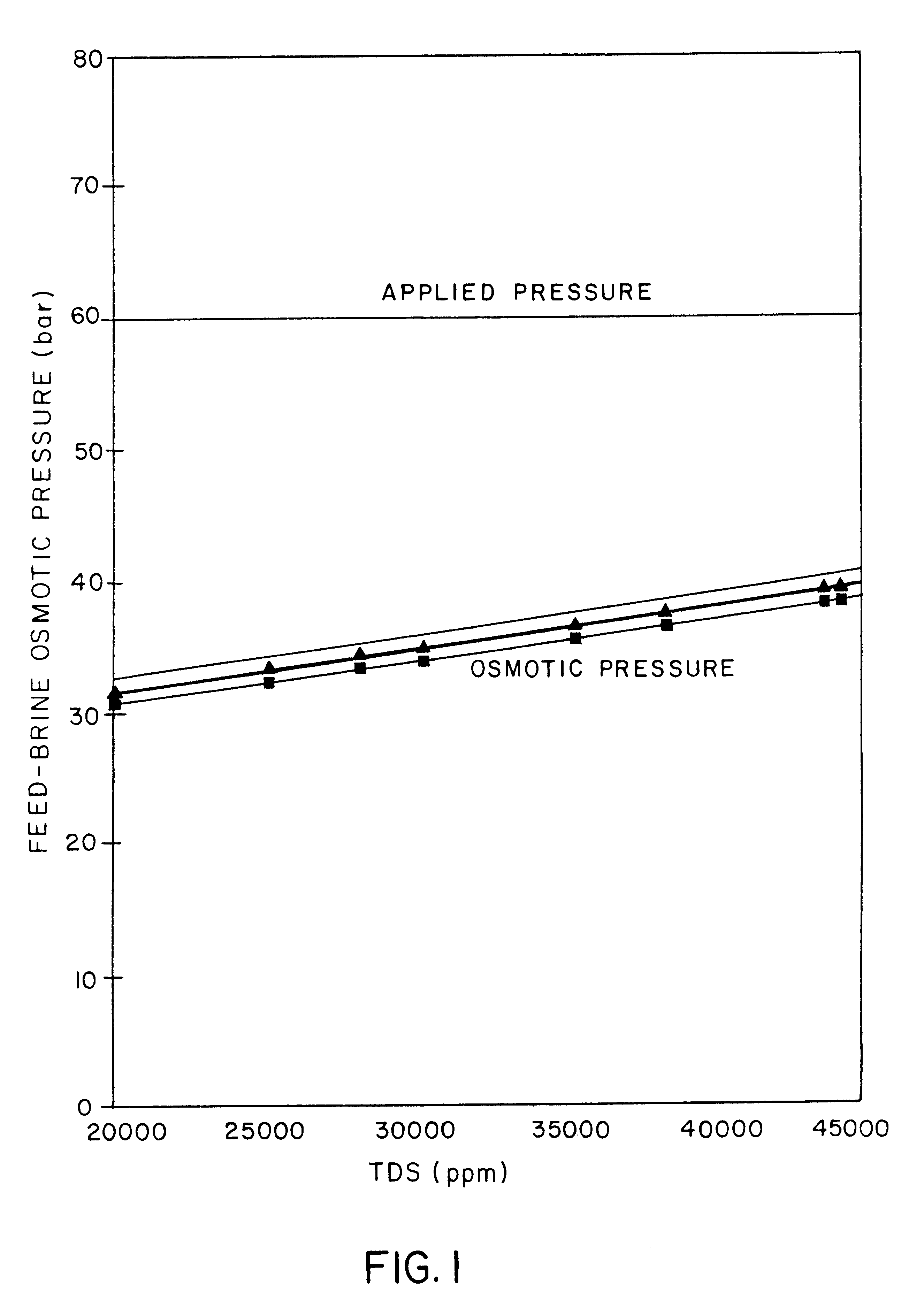

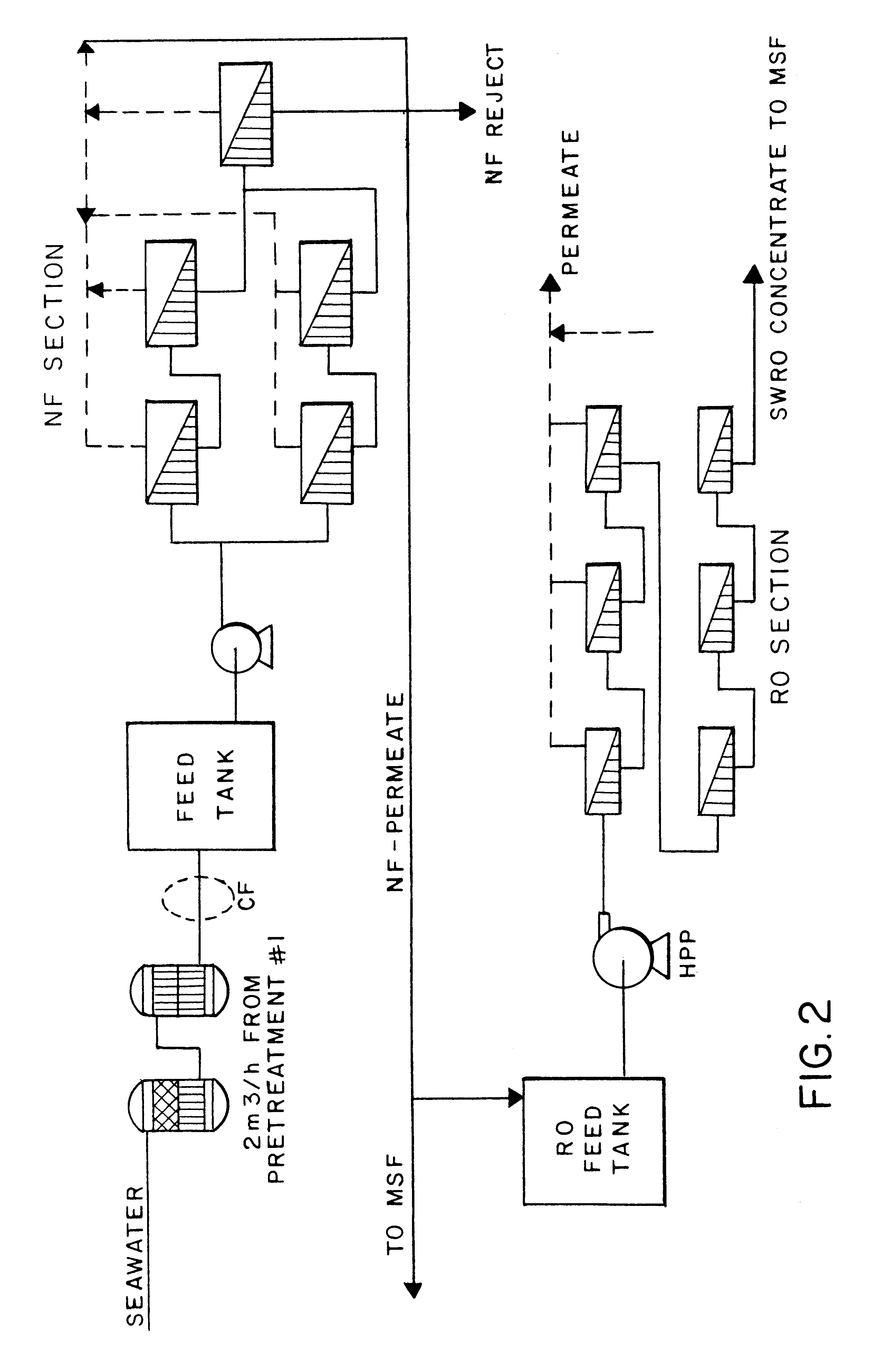

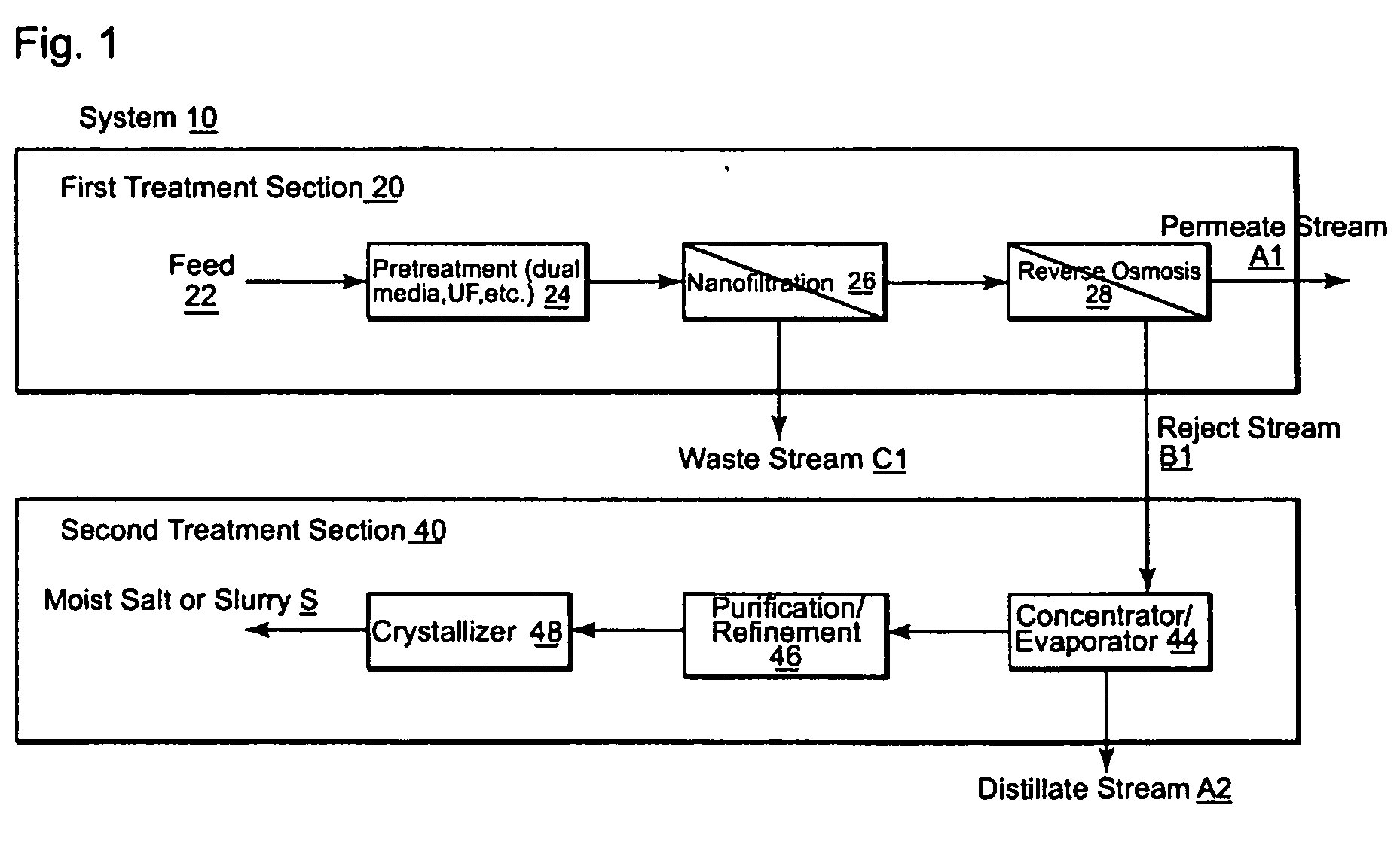

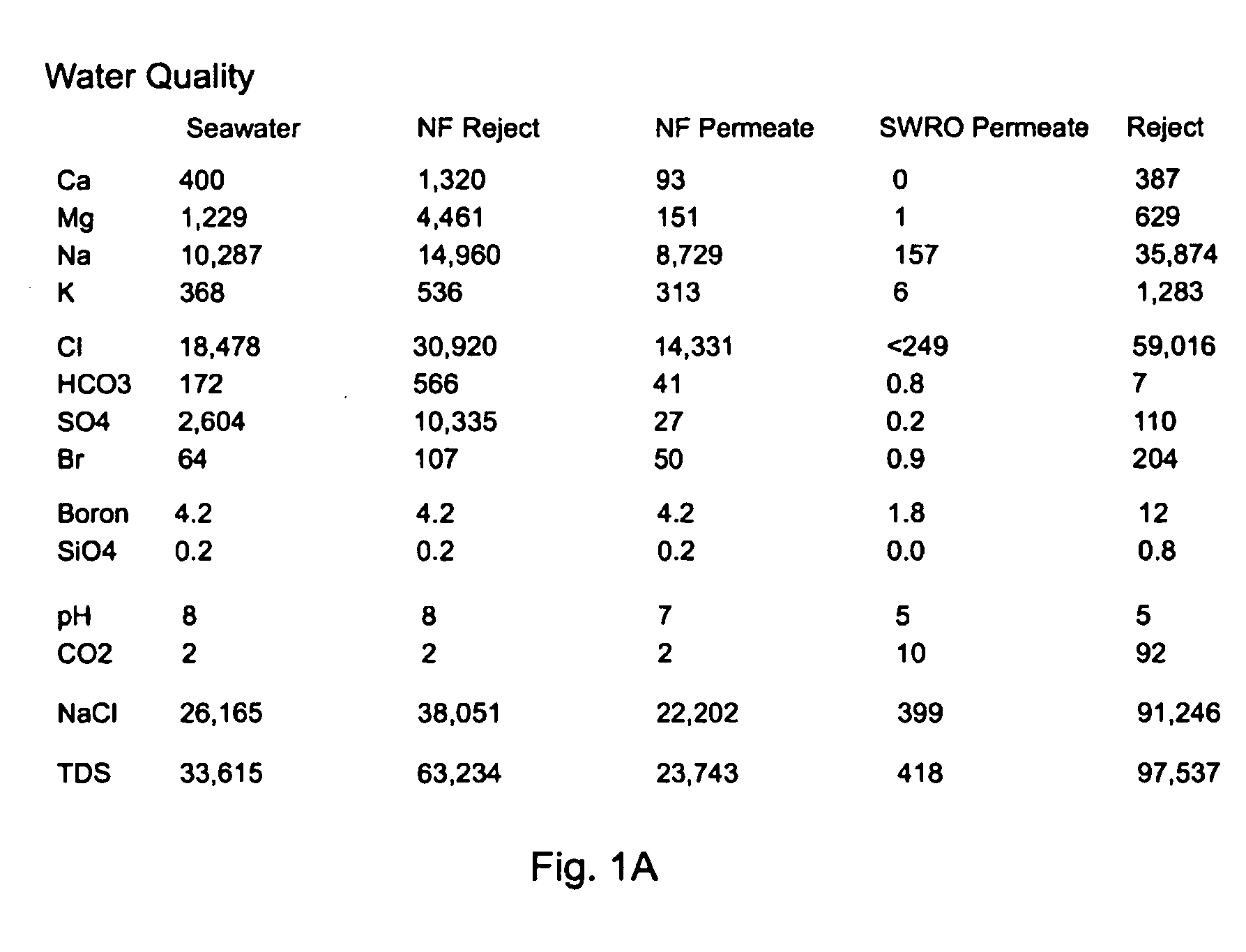

Process for desalination of saline water, especially water, having increased product yield and quality

InactiveUS6508936B1General water supply conservationSeawater treatmentTotal dissolved solidsDistillation

A desalination process is disclosed which combining two or more substantially different water treatment processes in a unique manner to desalinate saline water, especially sea water, to produce a high yield of high quality fresh water, including potable water, at an energy consumption equivalent to or less than much less efficient prior art desalination processes. In this process a nanofiltration step is synergistically combined with at least one of sea water reverse osmosis, multistage flash distillation. multieffect distillation of vapor compression distillation to provide an integrated desalination system by which sea water can be efficiently and economically converted to high quality potable water in yields which are at least 70%-80% greater than the yields available from the prior art processes. Typically a process of this invention using the nanofiltration initial step will produce, with respect to sea water feed properties, calcium, magnesium, sulfate and bicarbonate ion content reductions of 63%-94%, pH decreases of about 0.4-0.5 units and total dissolved solids content reductions of 35%-50%.

Owner:SALINE WATER CONVERSION CORP

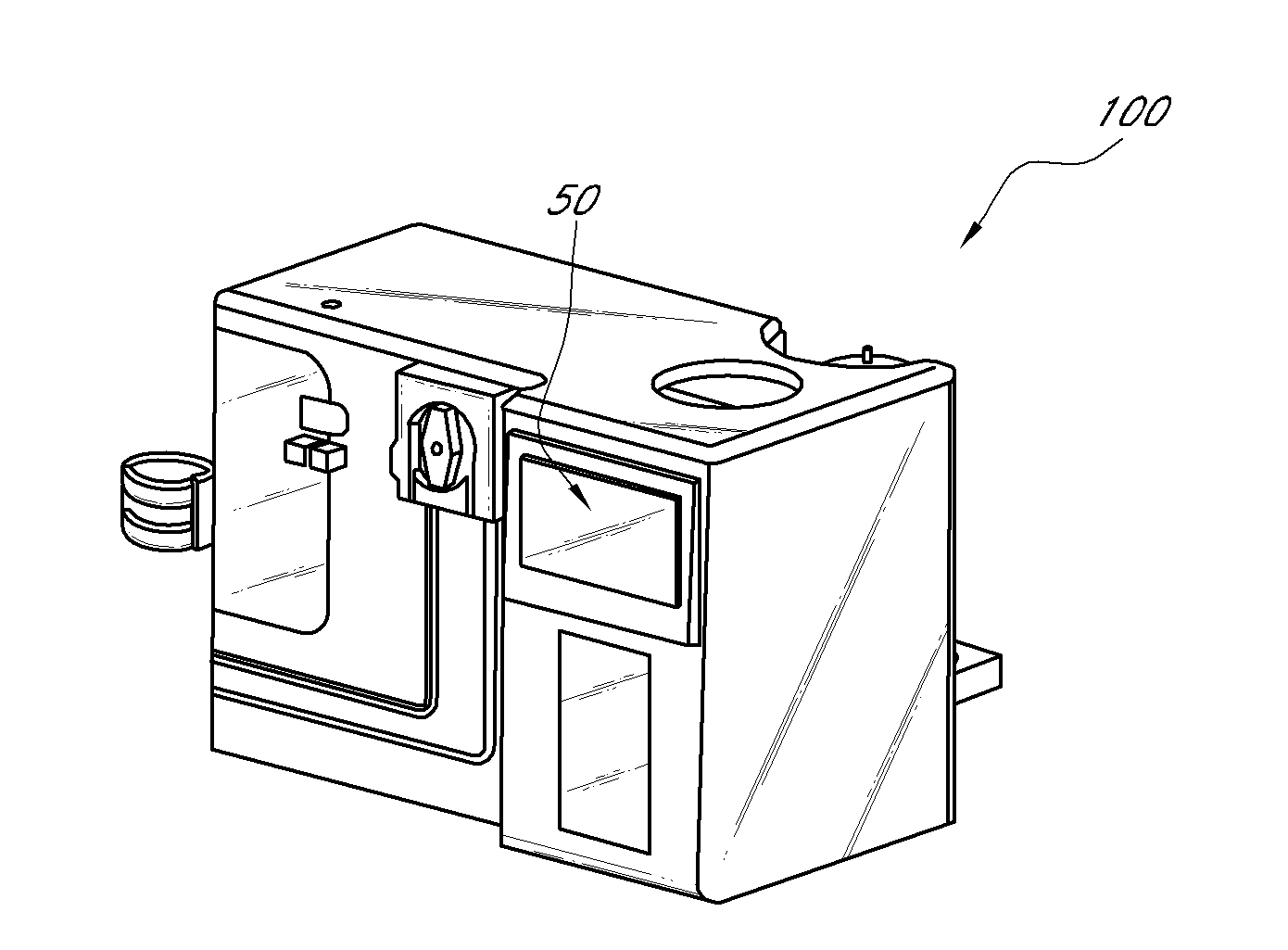

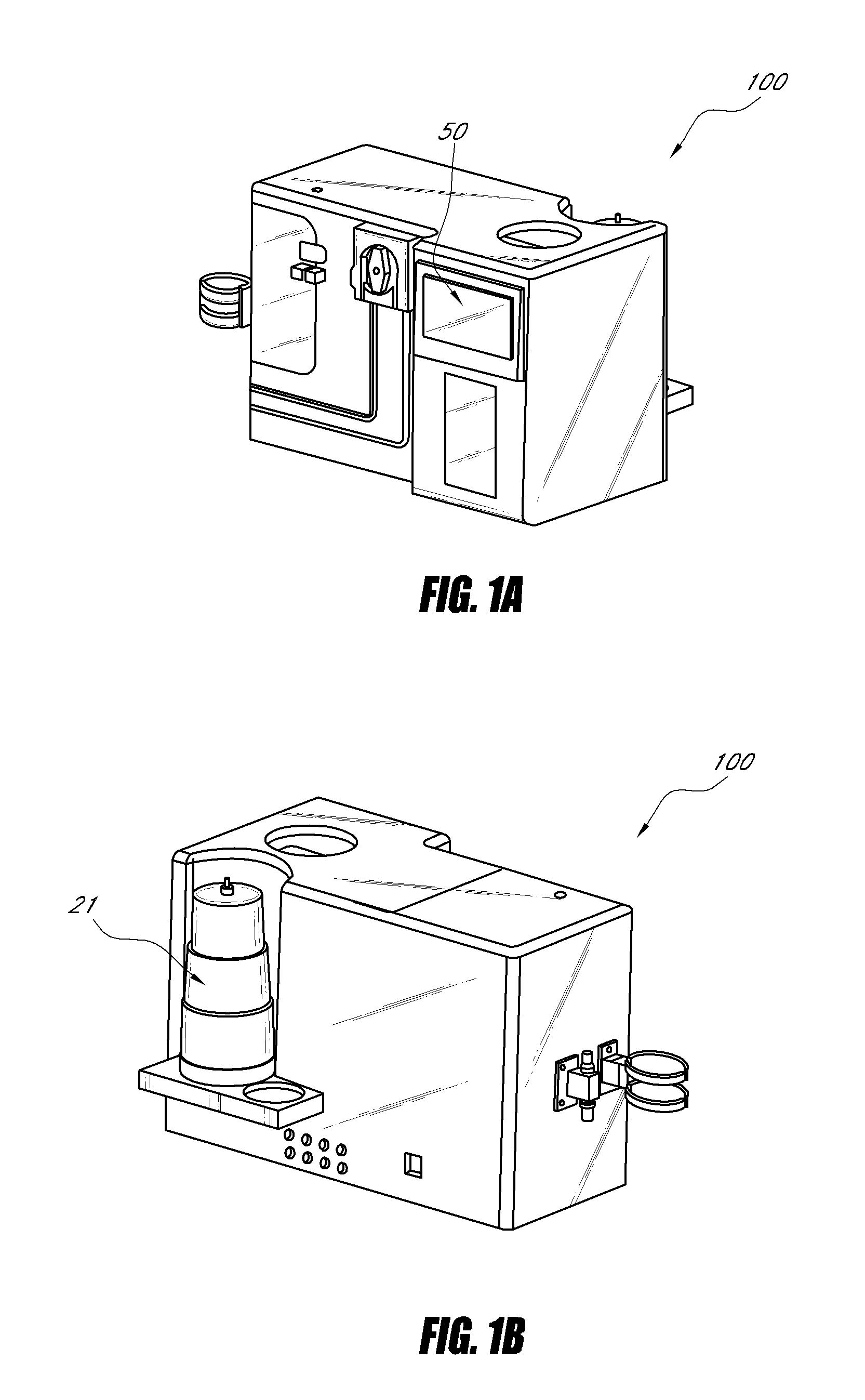

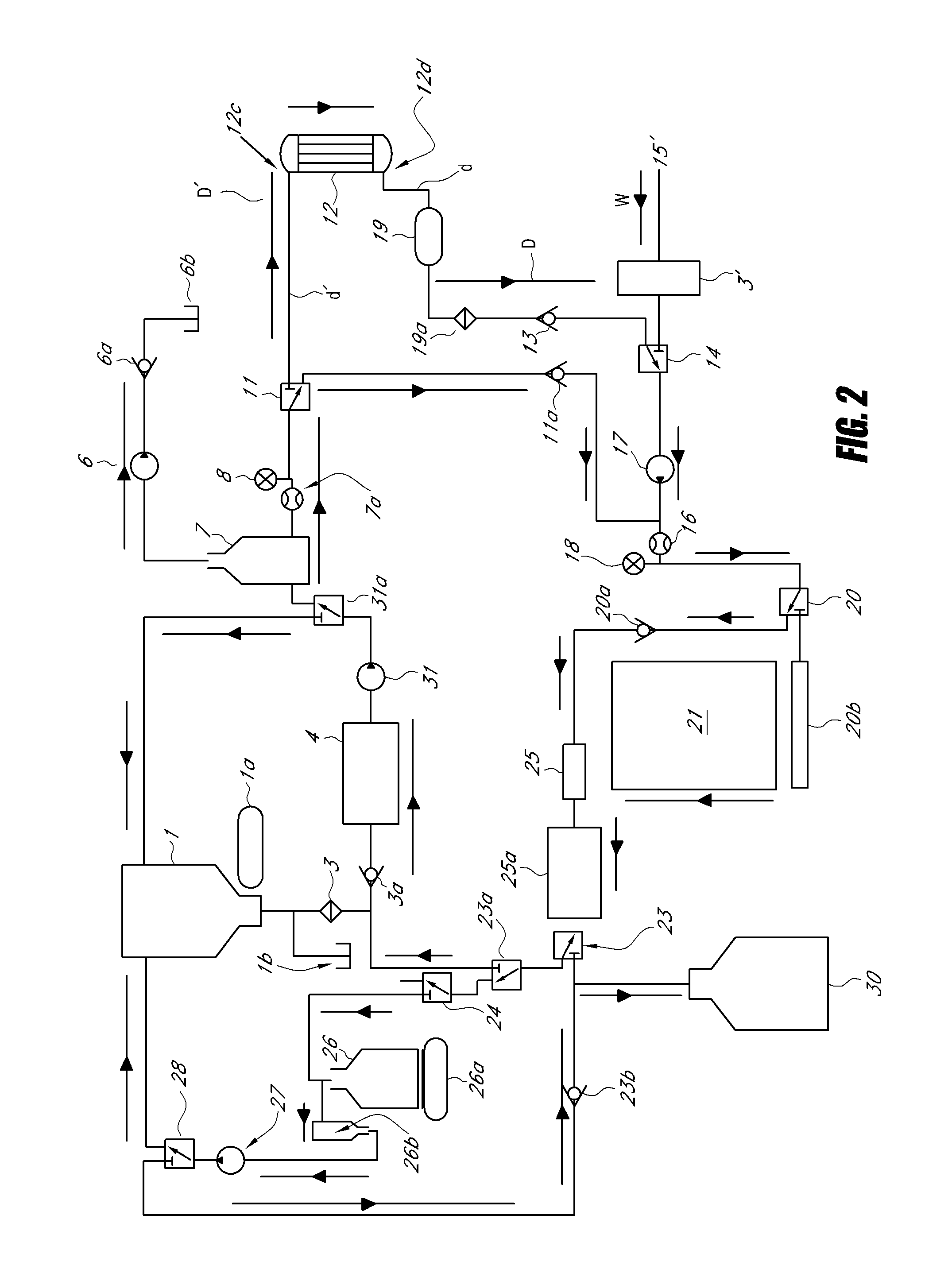

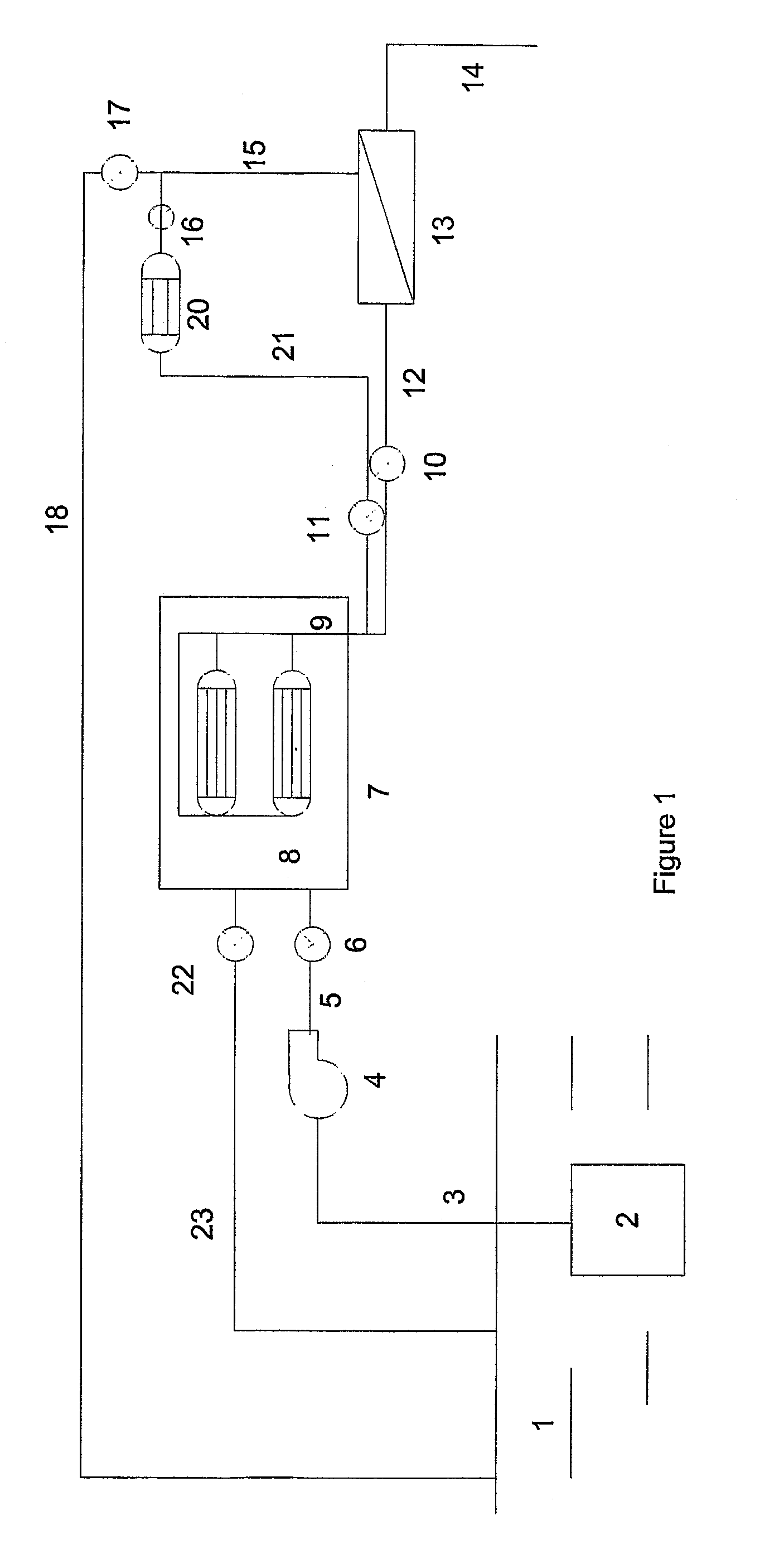

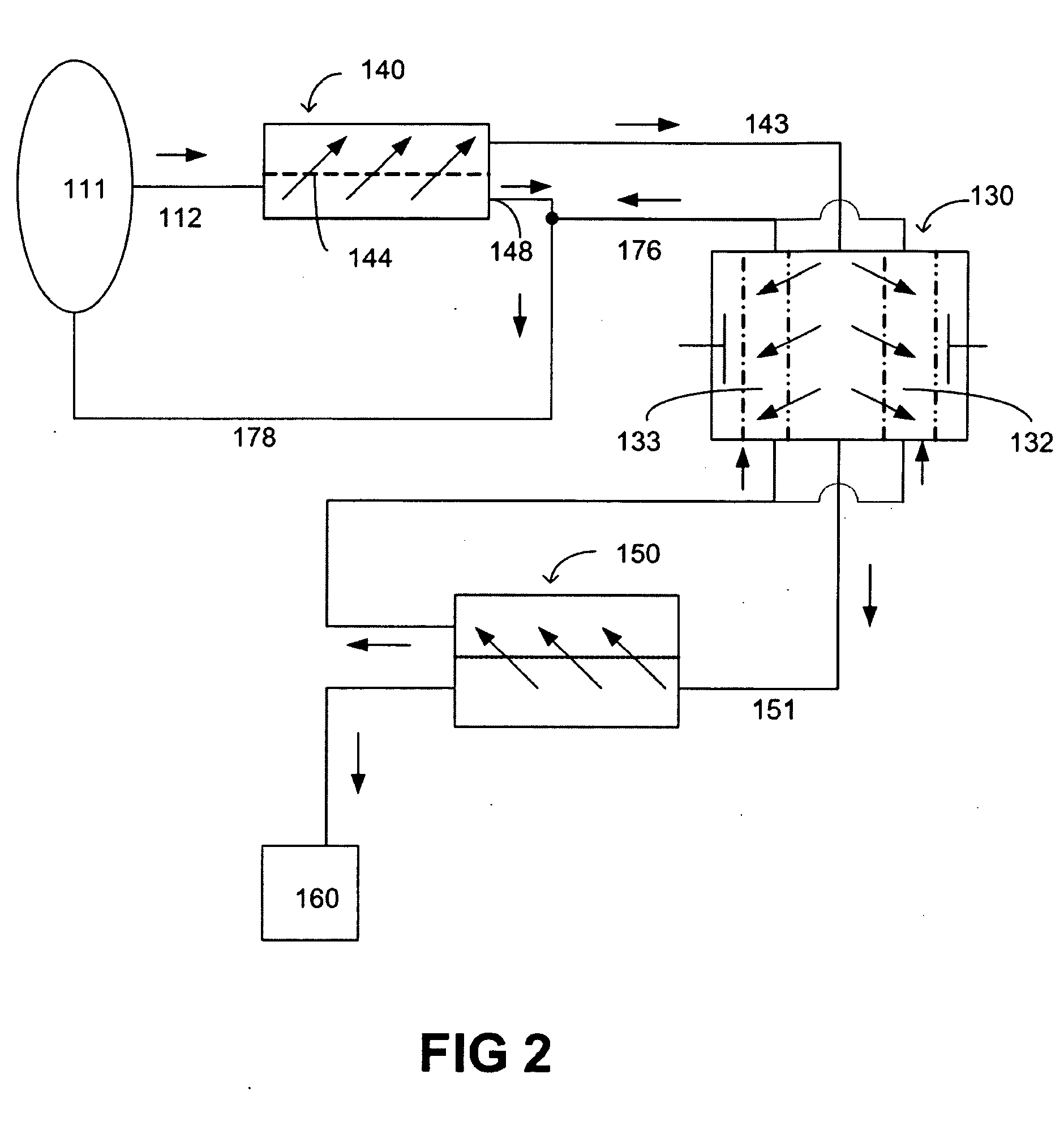

Dual mode hemodialysis machine

A compact portable dual mode hemodialysis machine system is provided. The system includes a sorbent dialysis module with a sorbent cartridge that purifies a dialysate fluid that flows therethrough, where the sorbent dialysis module returns the purified dialysate fluid from the sorbent cartridge to an inlet of a dialyzer. The system also includes a single-pass dialysis module with an acetate pump, a bicarbonate pump and a mixing chamber, where the acetate and bicarbonate pumps flow acetate and bicarbonate mixtures, respectively, into the mixing chamber. The single-pass dialysis module receives a desired amount of water from a reverse osmosis device, the single-pass dialysis module operated to direct used dialysate from the dialyzer to a drain. The machine system can be operated to replace the sorbent cartridge with the single-pass dialysis module to switch the operation of the dual mode hemodialysis machine system from a sorbent dialysis mode to a single-pass dialysis mode

Owner:C TECH BIOMEDICAL

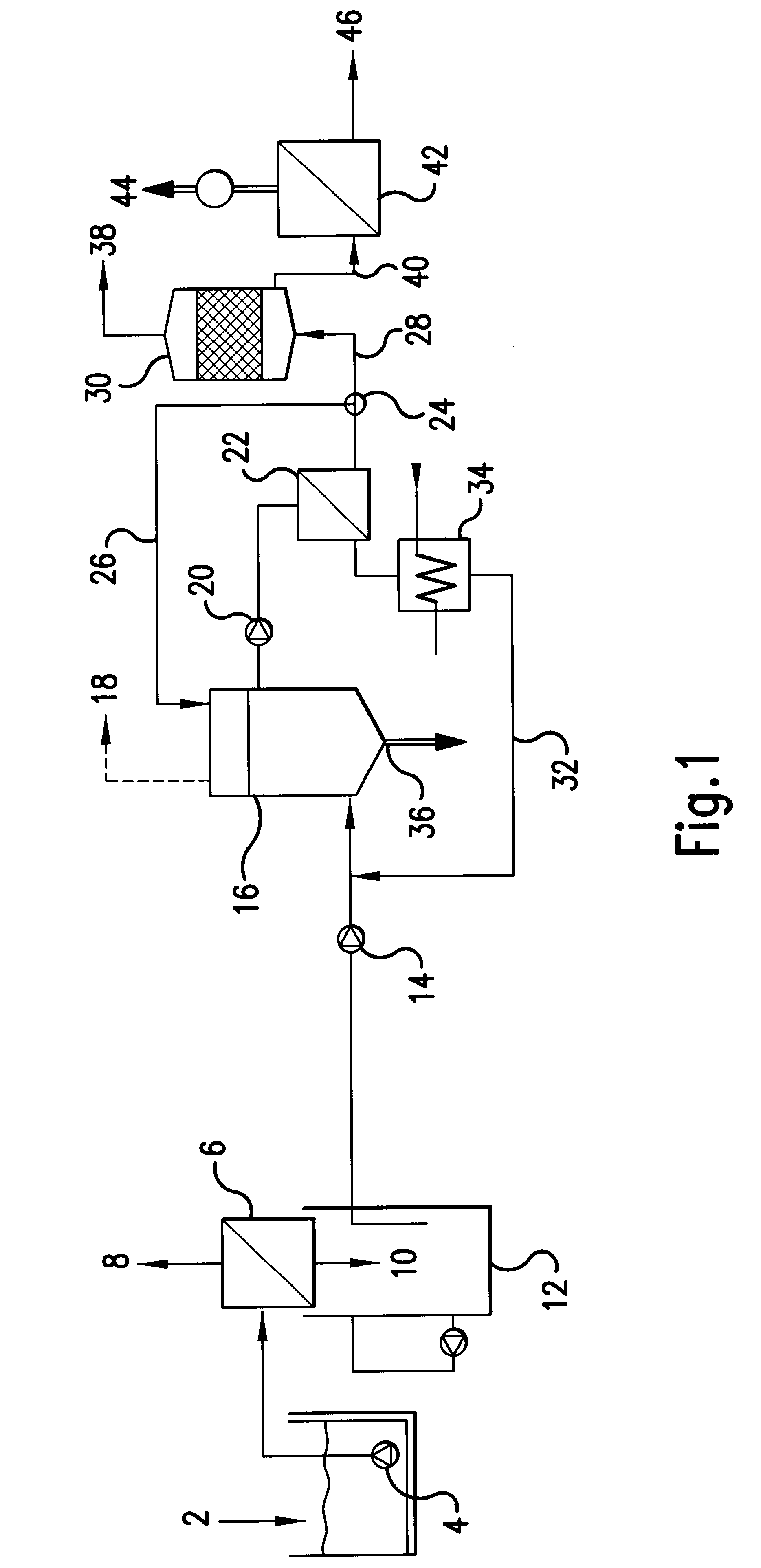

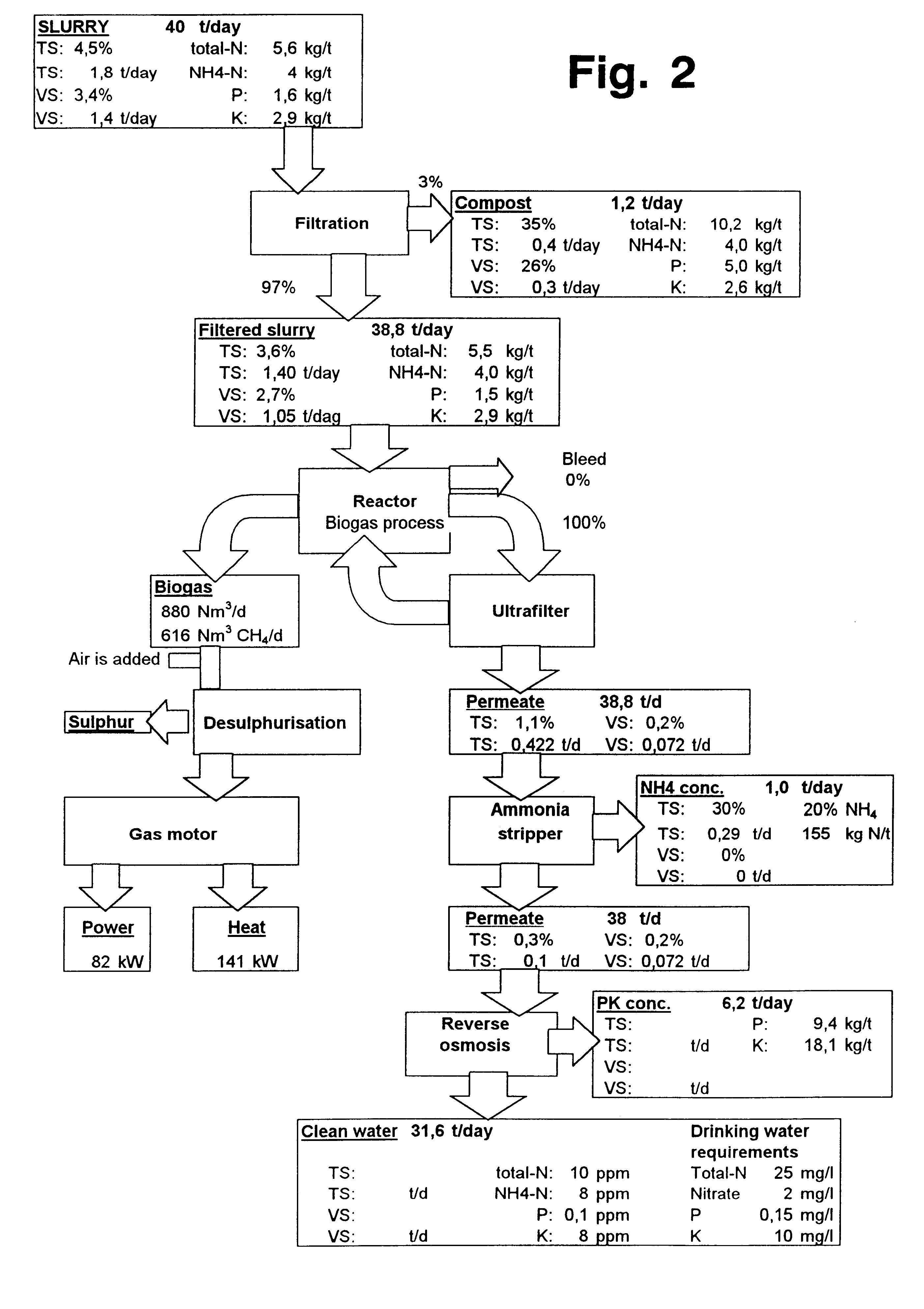

Method and plant for the treatment of liquid organic waste

InactiveUS6368849B1Increase profitReduce environmental impactBioreactor/fermenter combinationsBio-organic fraction processingFiberUltrafiltration

A method and plant for the treatment of an organic waste material in liquid form, e.g. liquid manure from livestock, the method comprising filtering fibres and particles from the liquid, subjecting the liquid to anaerobic fermentation in a biogas reactor, separating a substantially sterile and particle-free permeate stream from the biogas reactor, e.g. using ultrafiltration, subjecting the permeate stream to treatment with an ammonia stripper at an elevated temperature and preferably at reduced pressure to remove substantially all ammonia and carbon dioxide and to result in an ammonia fraction and a nutrient salt fraction, and separating the nutrient salt fraction into a fertiliser concentrate fraction and a water fraction, e.g. using reverse osmosis. The end products of the method are clean water, ammonia concentrate, fertiliser concentrate containing salts of P and K, compost and high-quality biogas with a high methane content.

Owner:GR BIOTECH

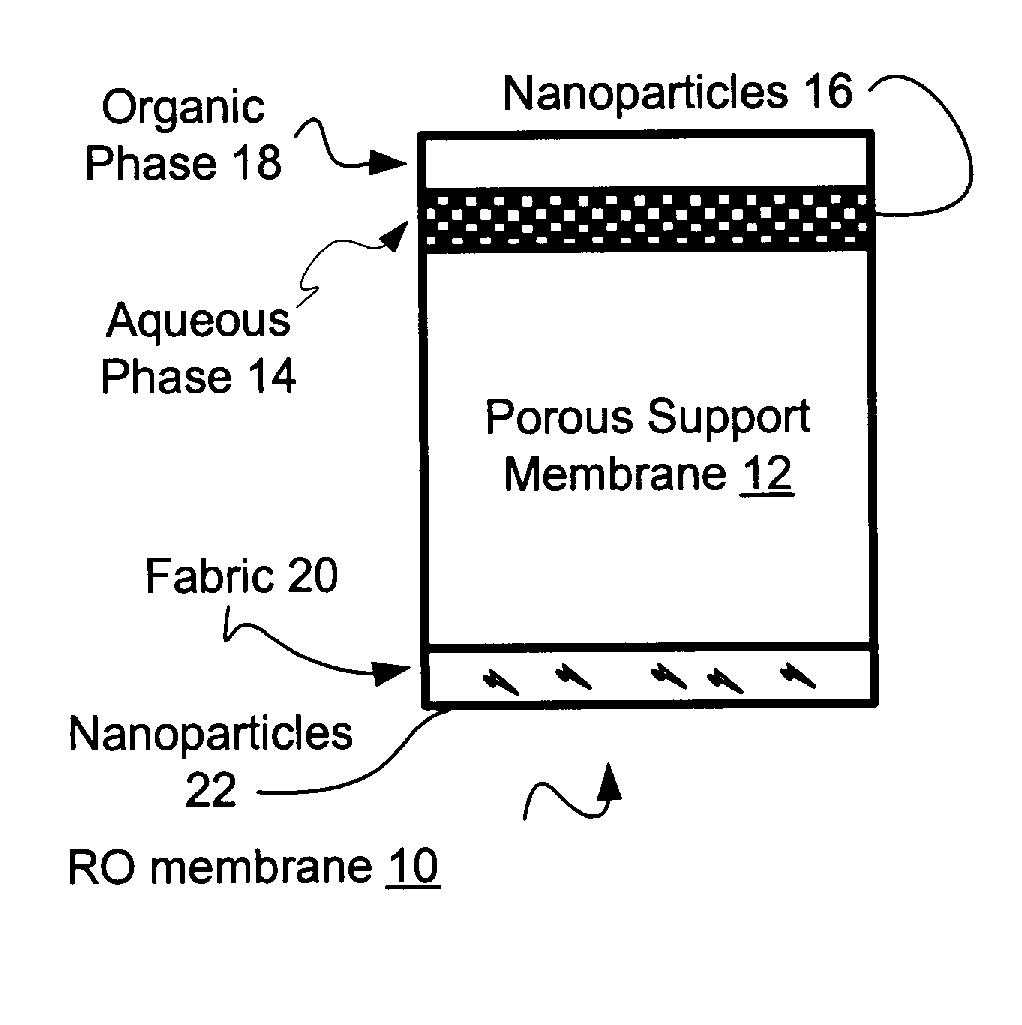

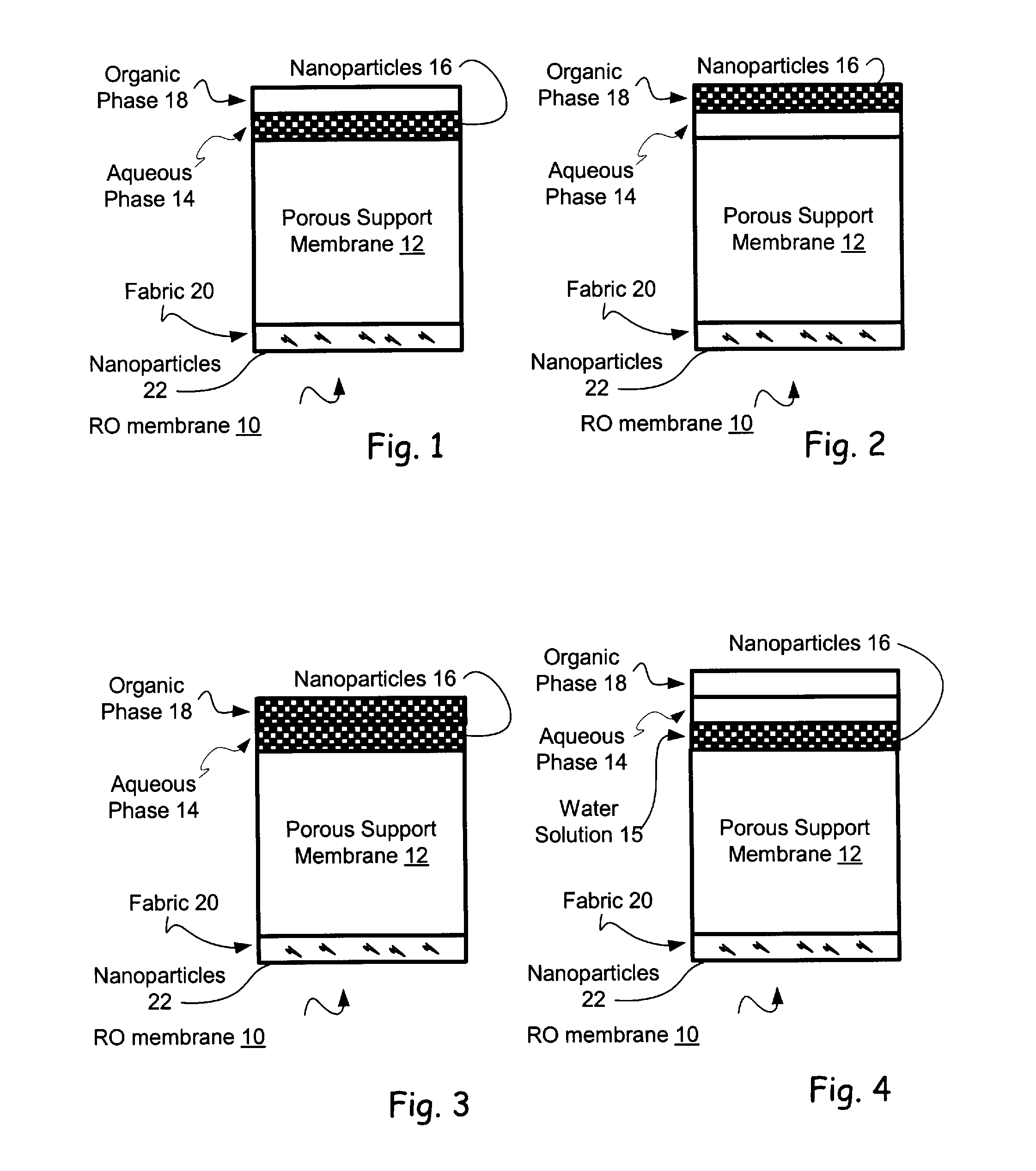

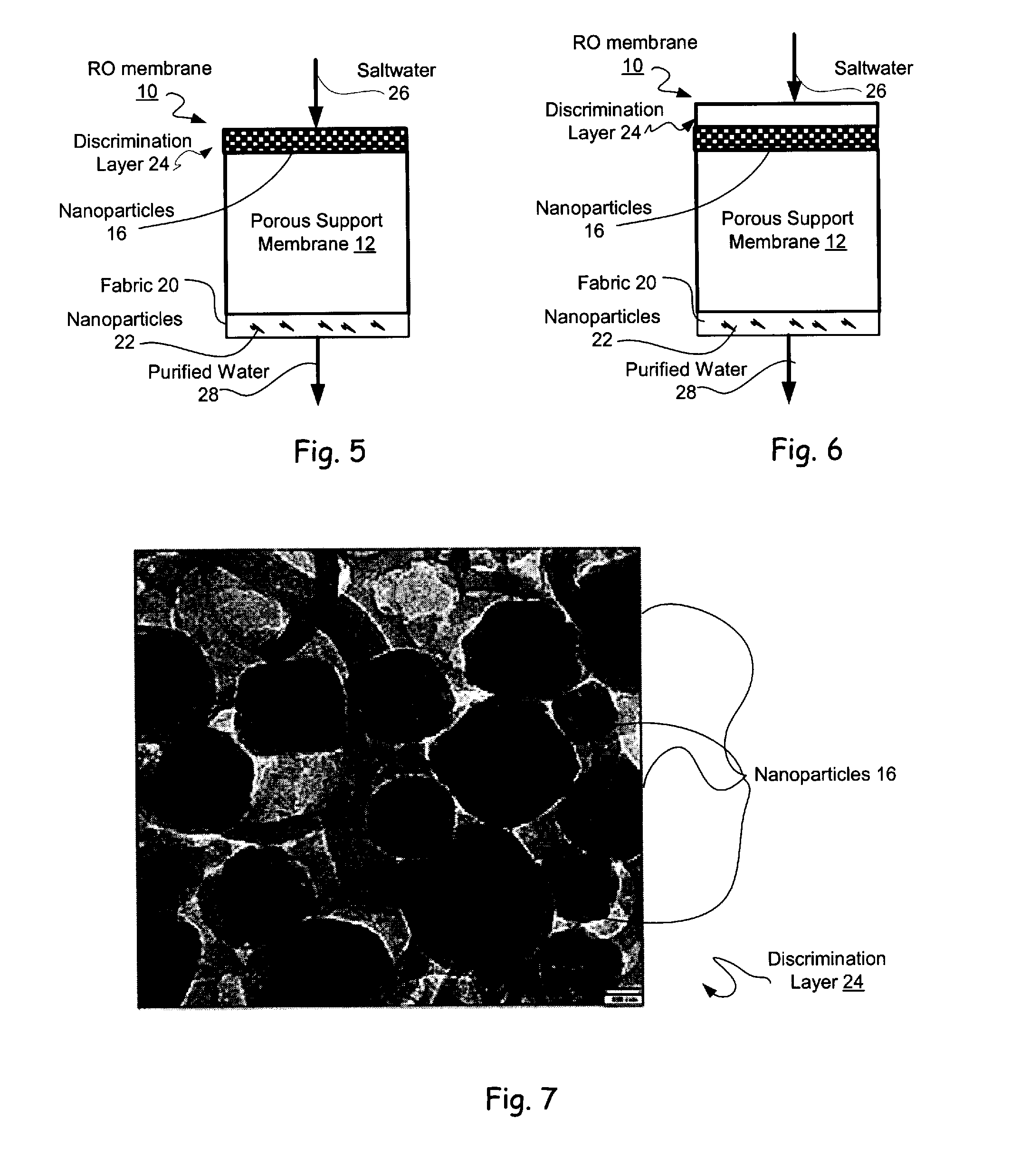

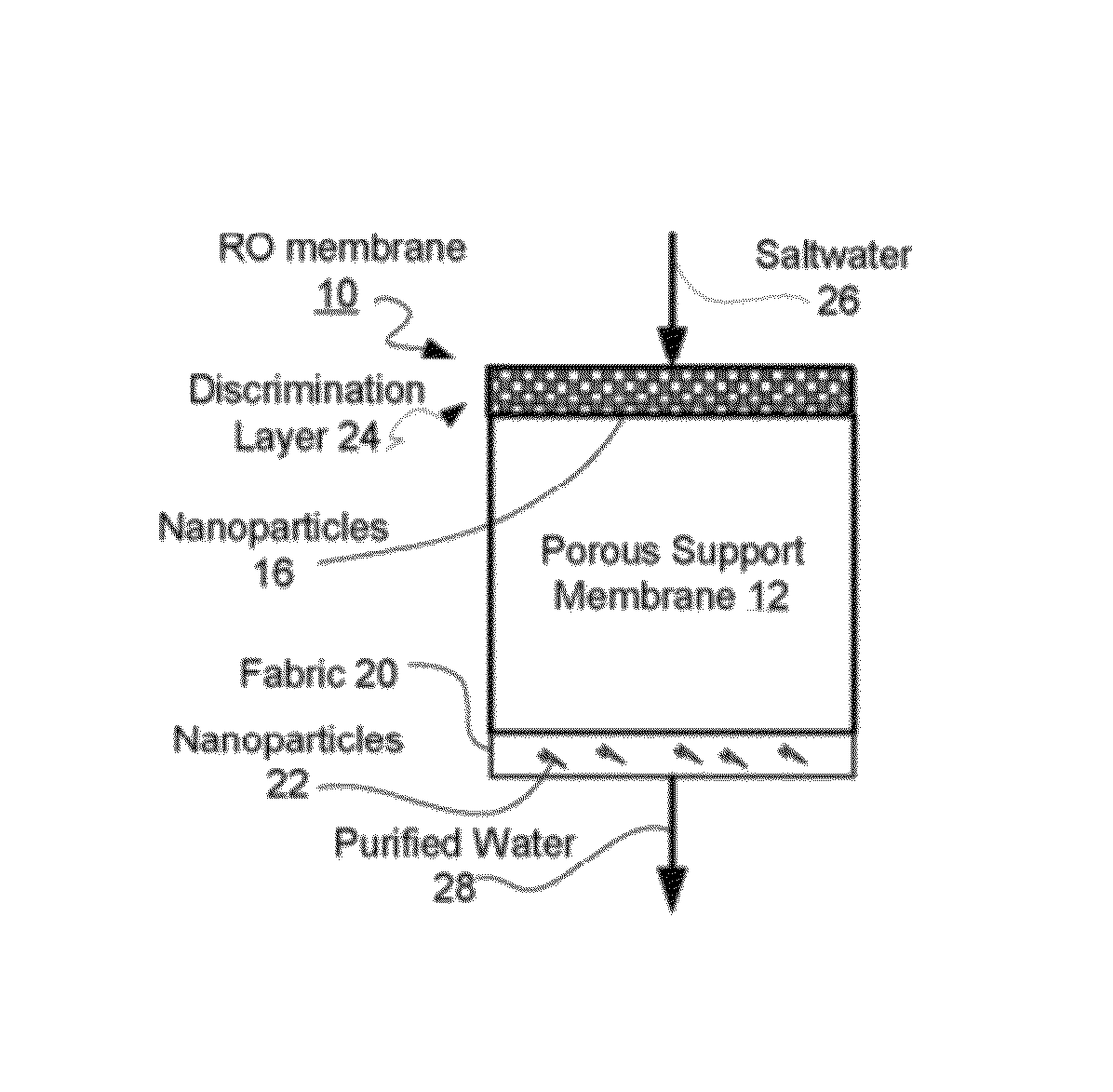

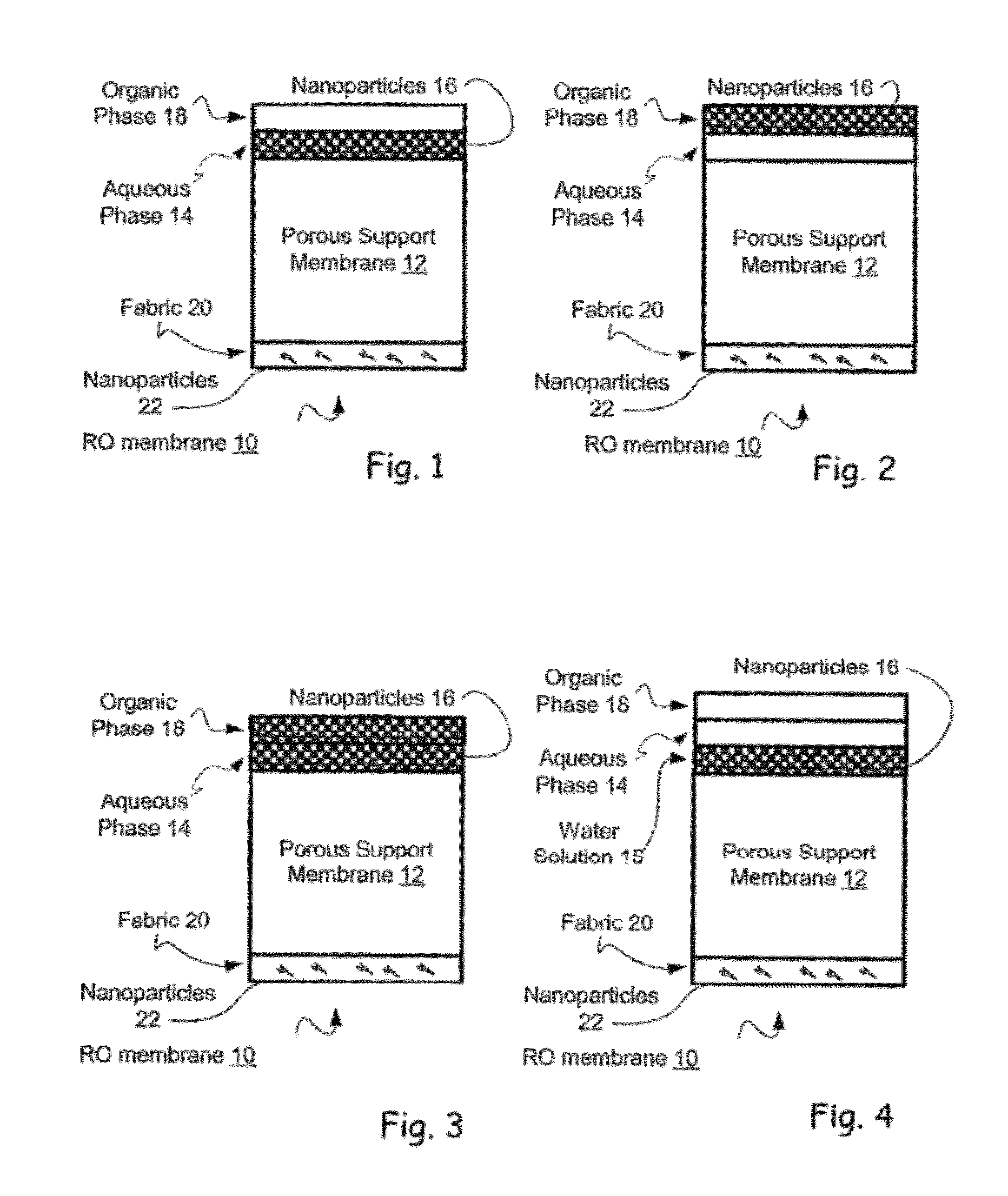

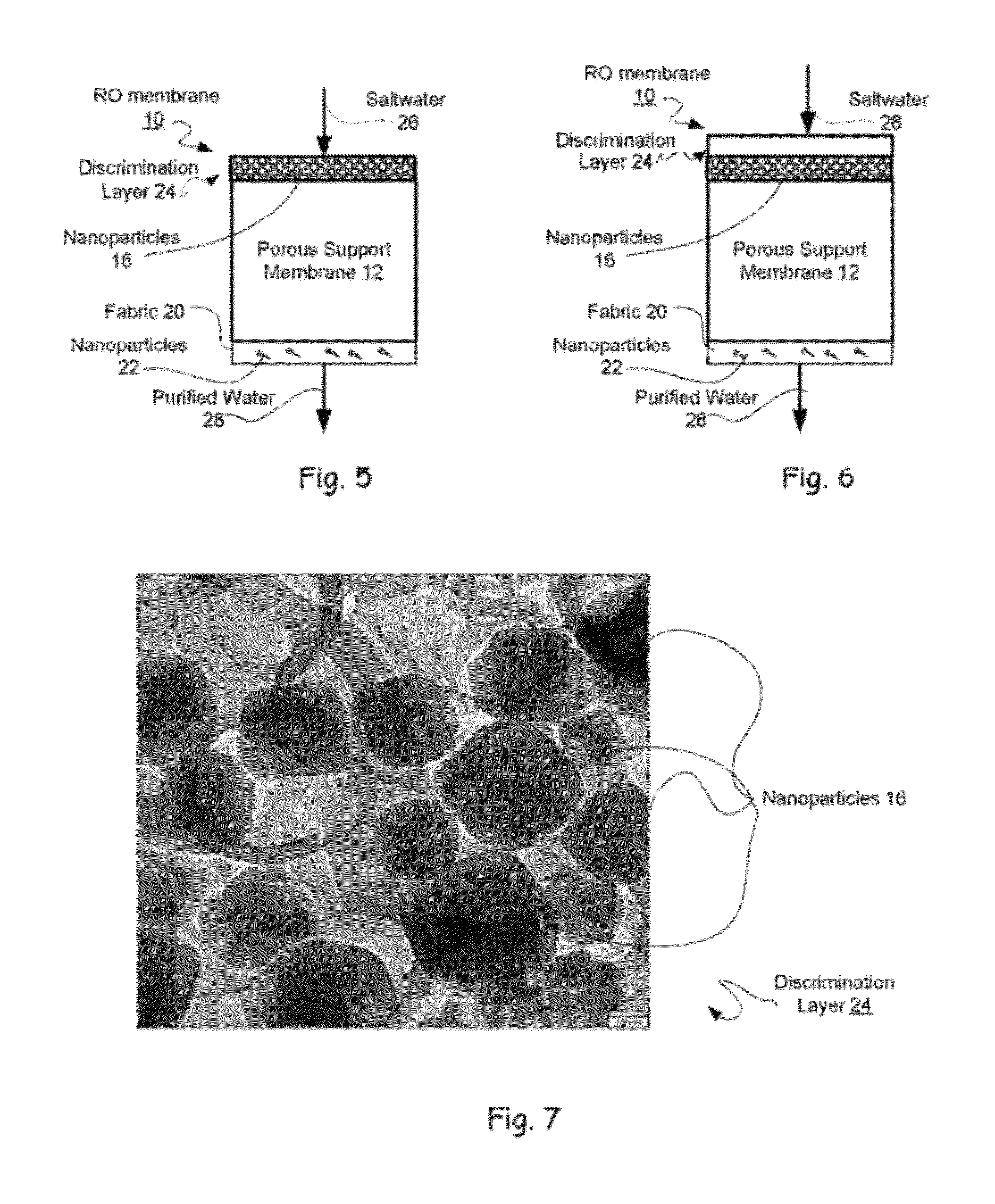

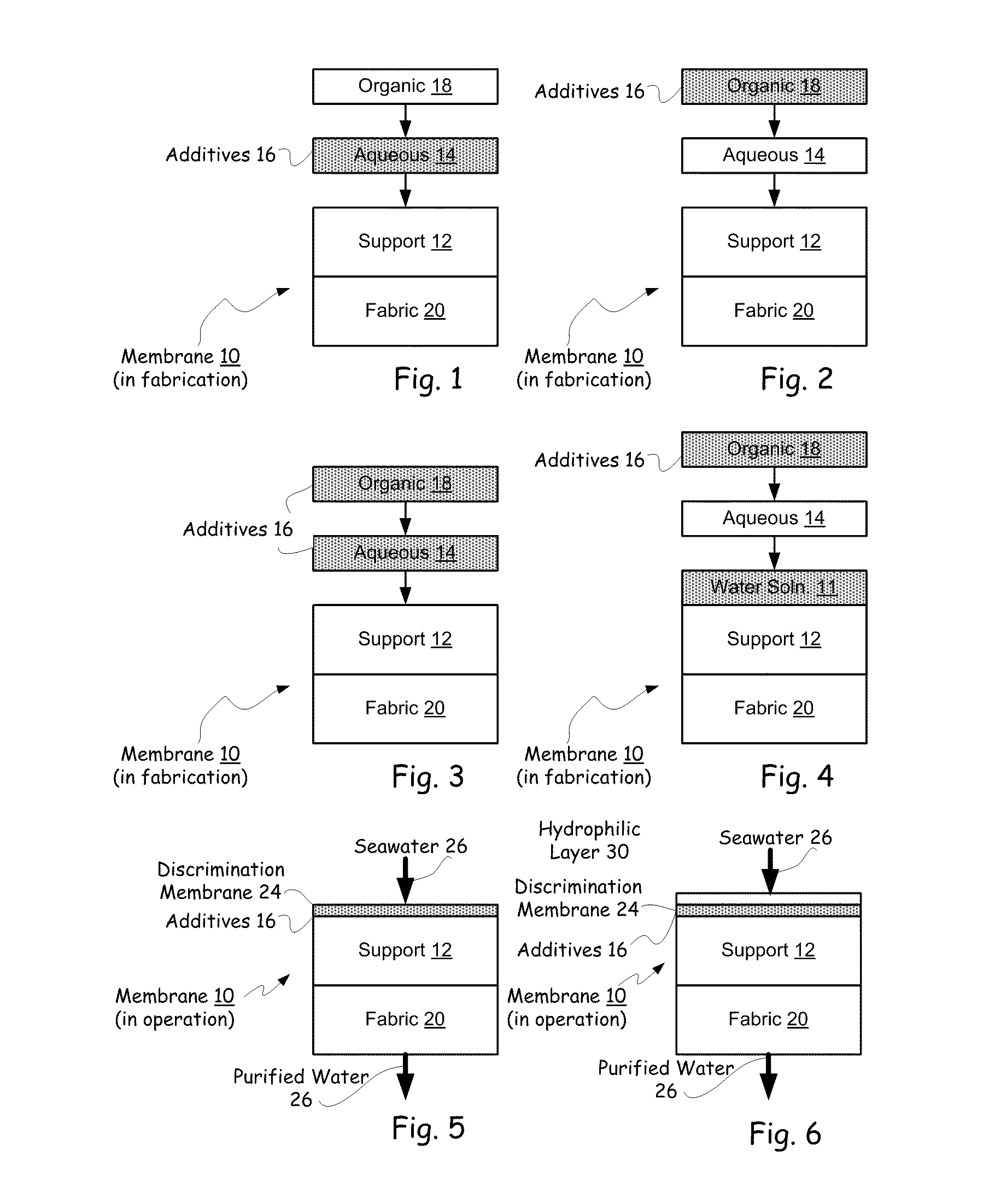

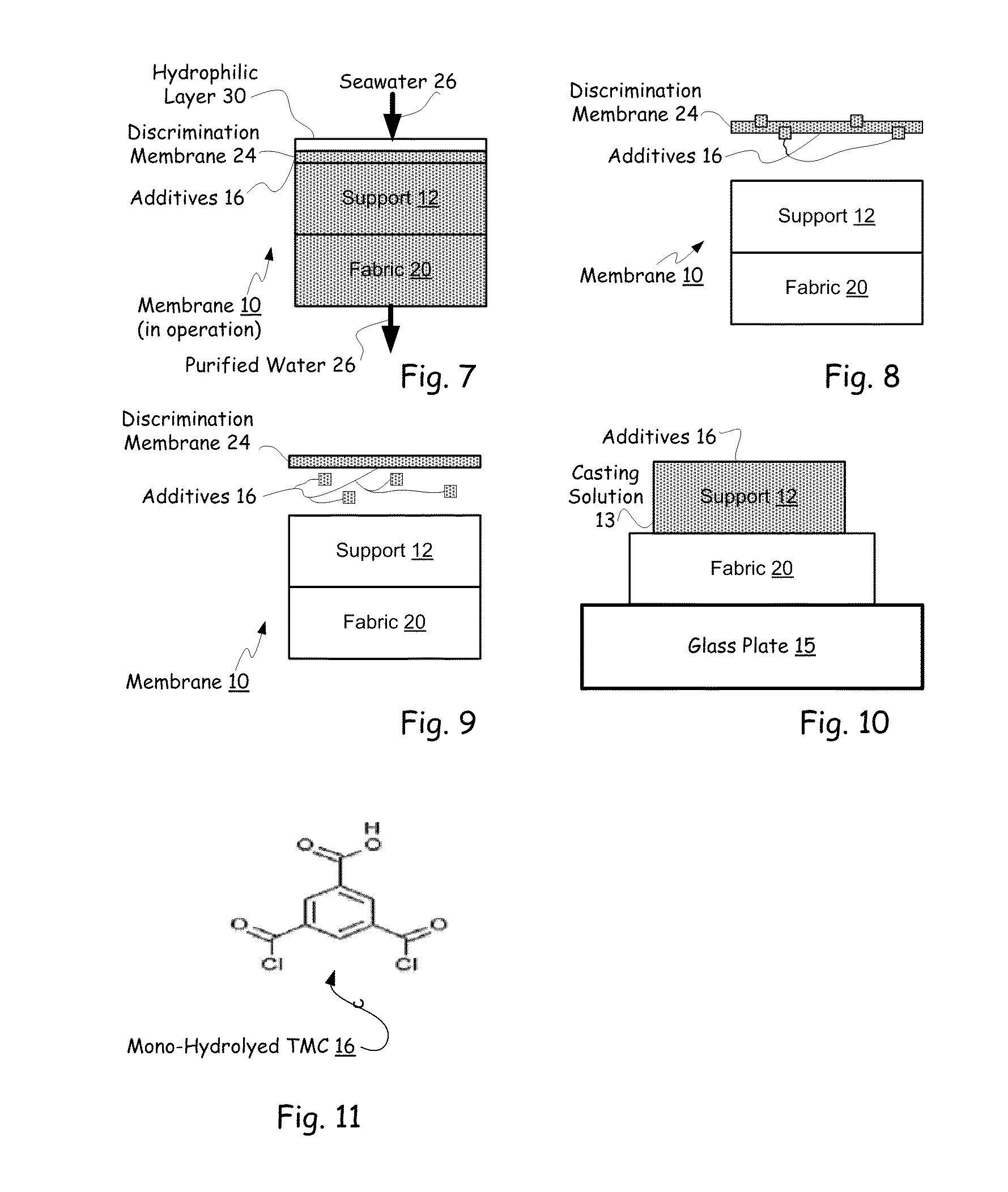

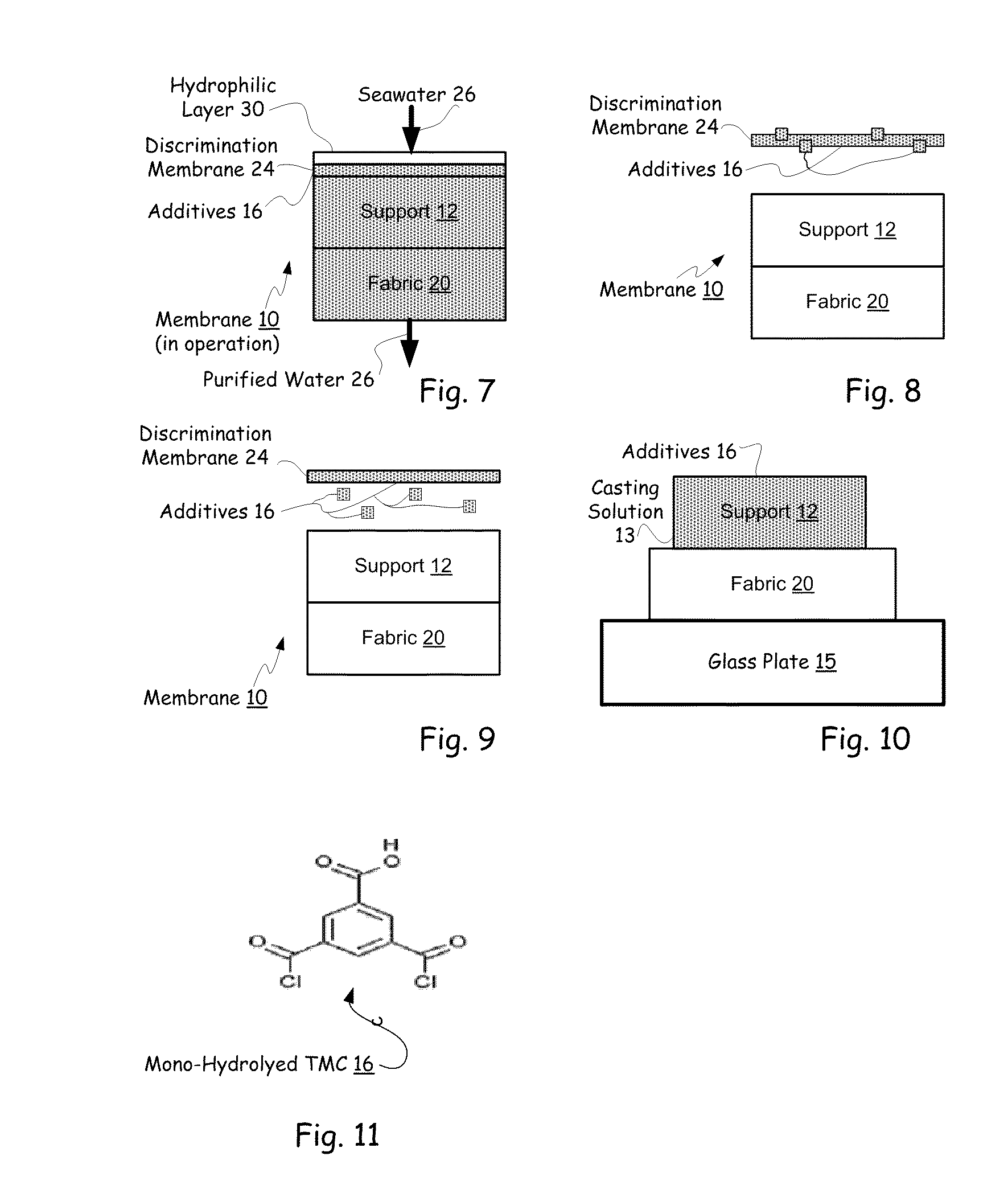

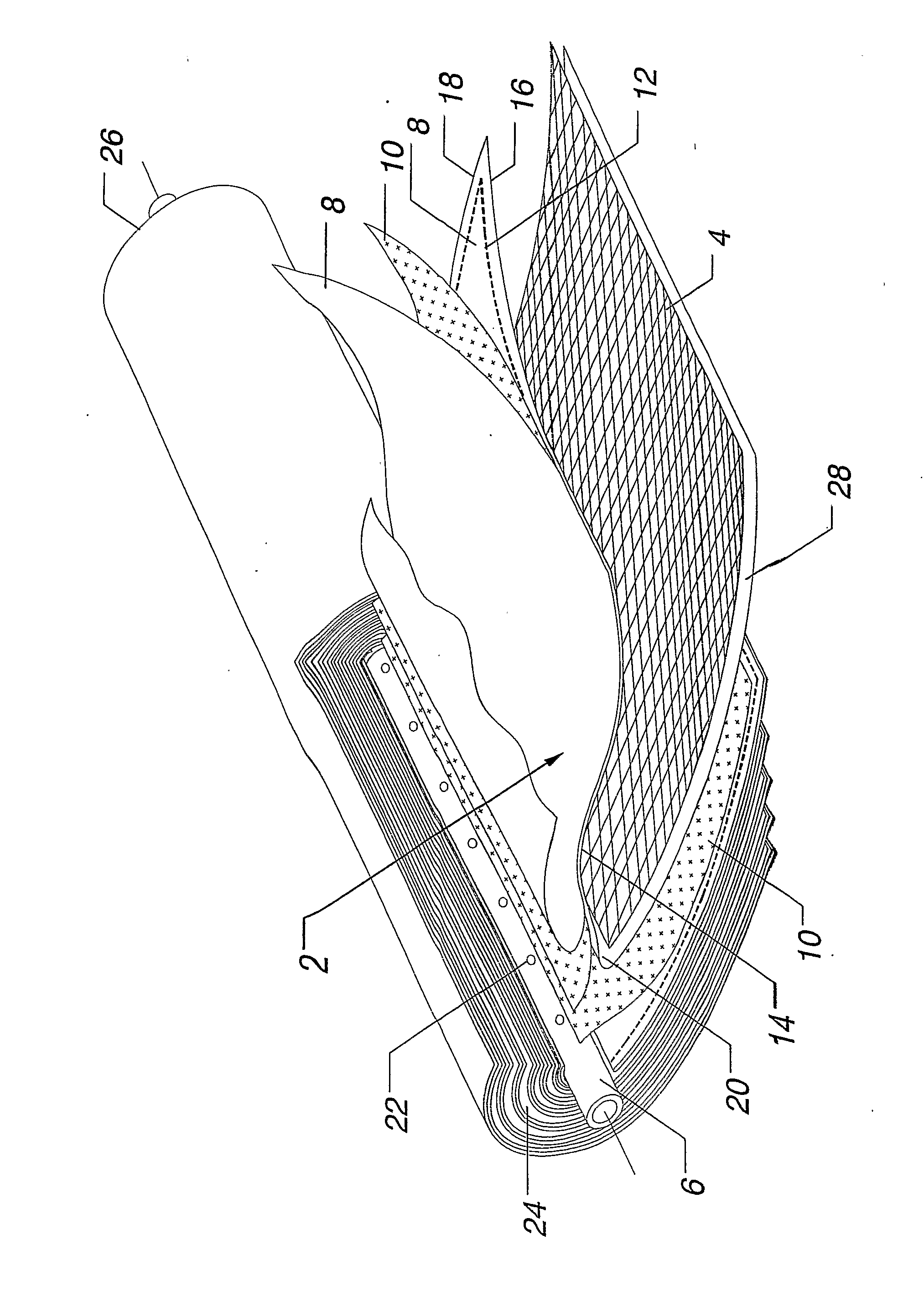

Reverse Osmosis Membranes

Reverse osmosis membranes made by interfacial polymerization of a monomer in a nonpolar (e.g. organic) phase together with a monomer in a polar (e.g. aqueous) phase on a porous support membrane. Interfacial polymerization process is disclosed for preparing a highly permeable RO membrane, comprising: contacting on a porous support membrane, a) a first solution containing 1,3-diaminobenzene, and b) a second solution containing trimesoyl chloride, wherein at least one of solutions a) and b) contains nanoparticles when said solutions are first contacted, and recovering a highly permeable RO membrane.

Owner:NANOH2O

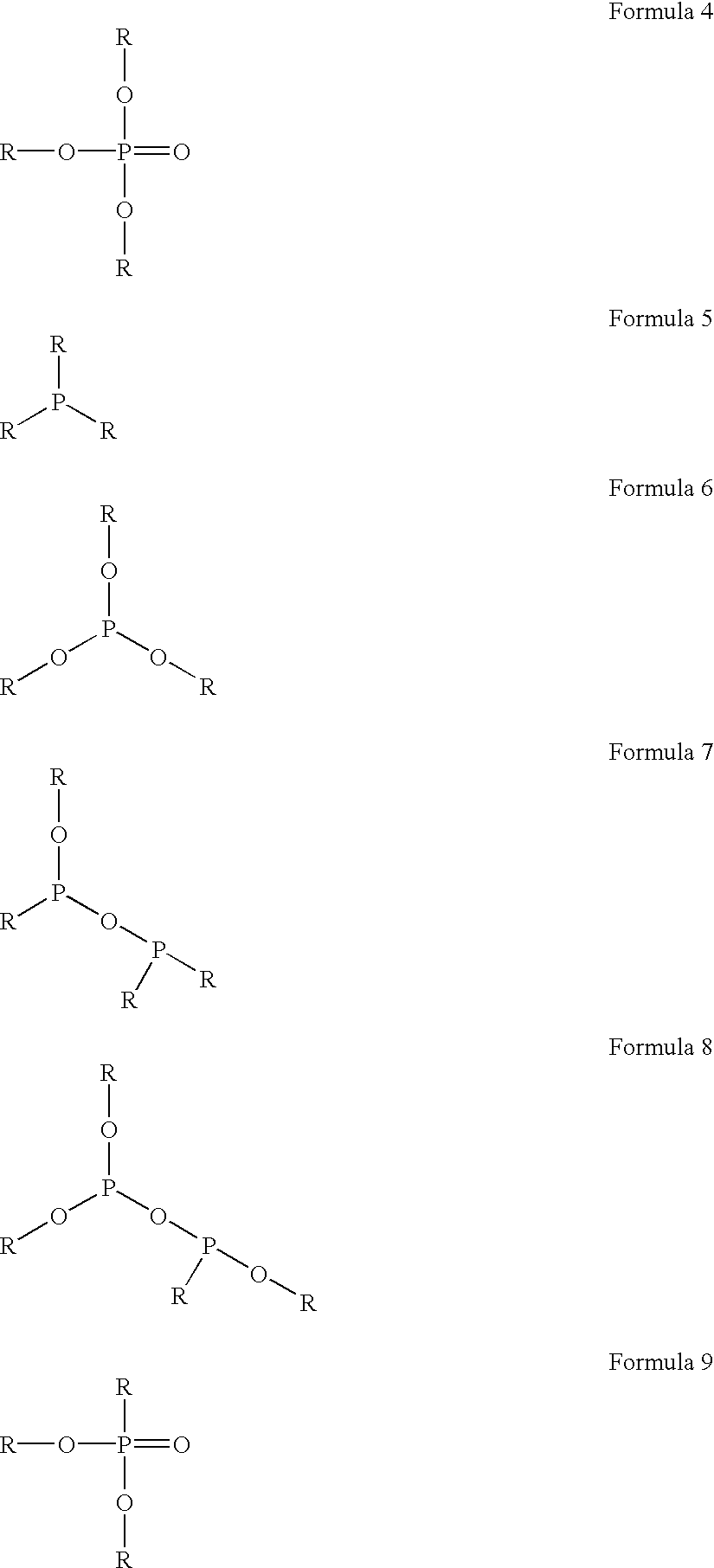

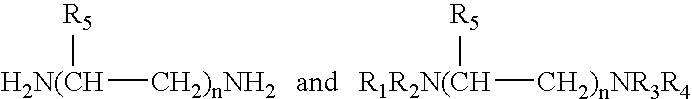

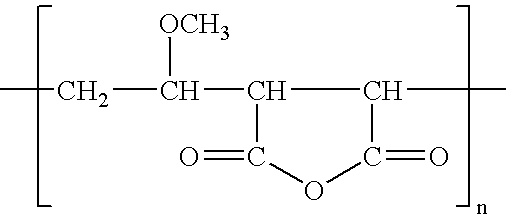

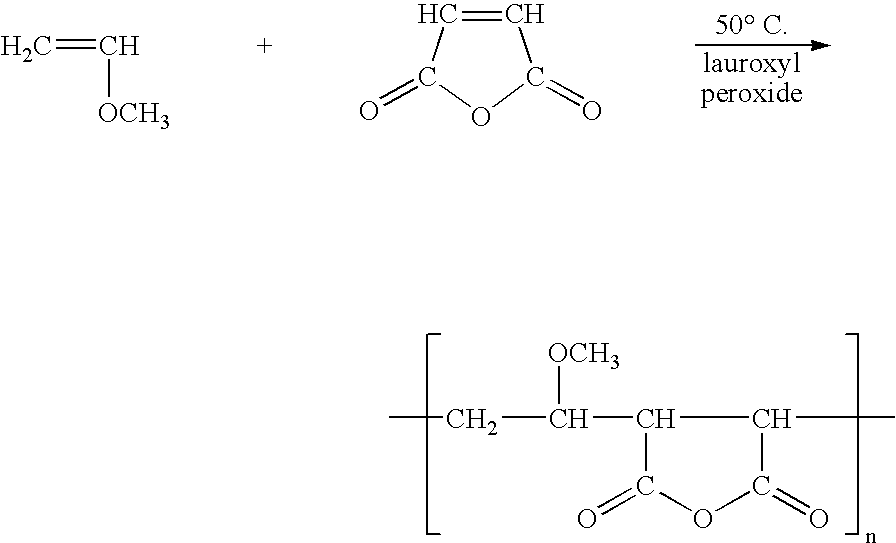

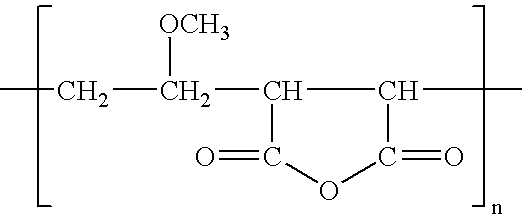

Reverse Osmosis Membrane with Branched Poly(Alkylene Oxide) Modified Antifouling Surface

InactiveUS20070251883A1Avoid problemsReduce dirtMembranesGeneral water supply conservationHydrogenEnd-group

Composite membranes that exhibit long-term resistance to biofouling comprise a porous support and a crosslinked polyamide discriminating layer having an external surface, the discriminating layer comprising a branched poly(alkylene oxide) (PAO) polymer attached to its external surface. The branched PAO polymer typically has the structure of a molecular comb or brush, and is made by polymerization of a PAO macromonomer of the following formula: RO—[(CHR′)n—O]m-V in which R is hydrogen or a C1-20 aliphatic or aromatic group, V is any group containing a polymerizable site, each R′ is independently hydrogen or a short chain alkyl group, n is an integer of 1-6, and m is an integer of 1 to about 200. The α end group can be either polymerized or copolymerized.

Owner:DOW GLOBAL TECH LLC

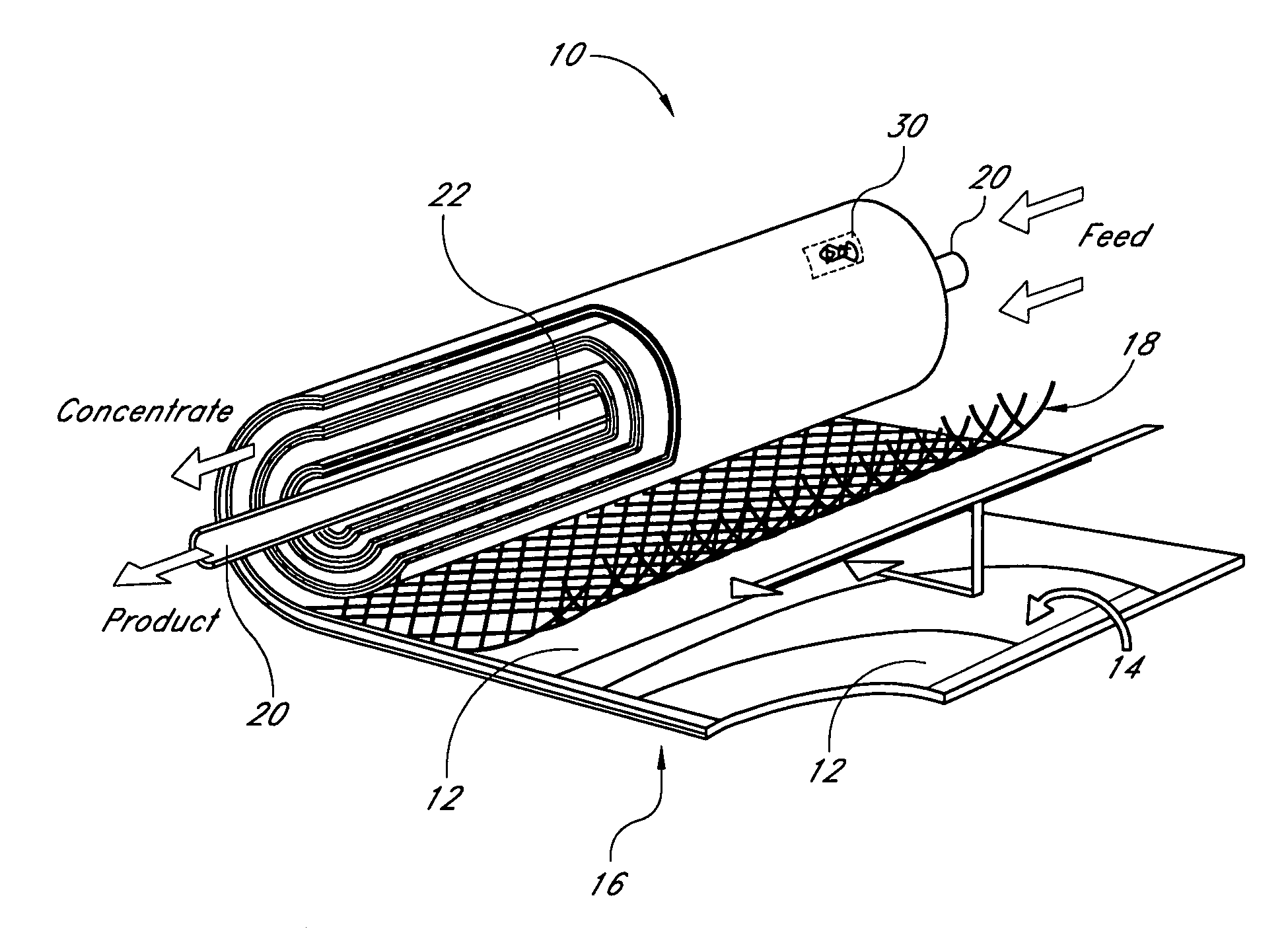

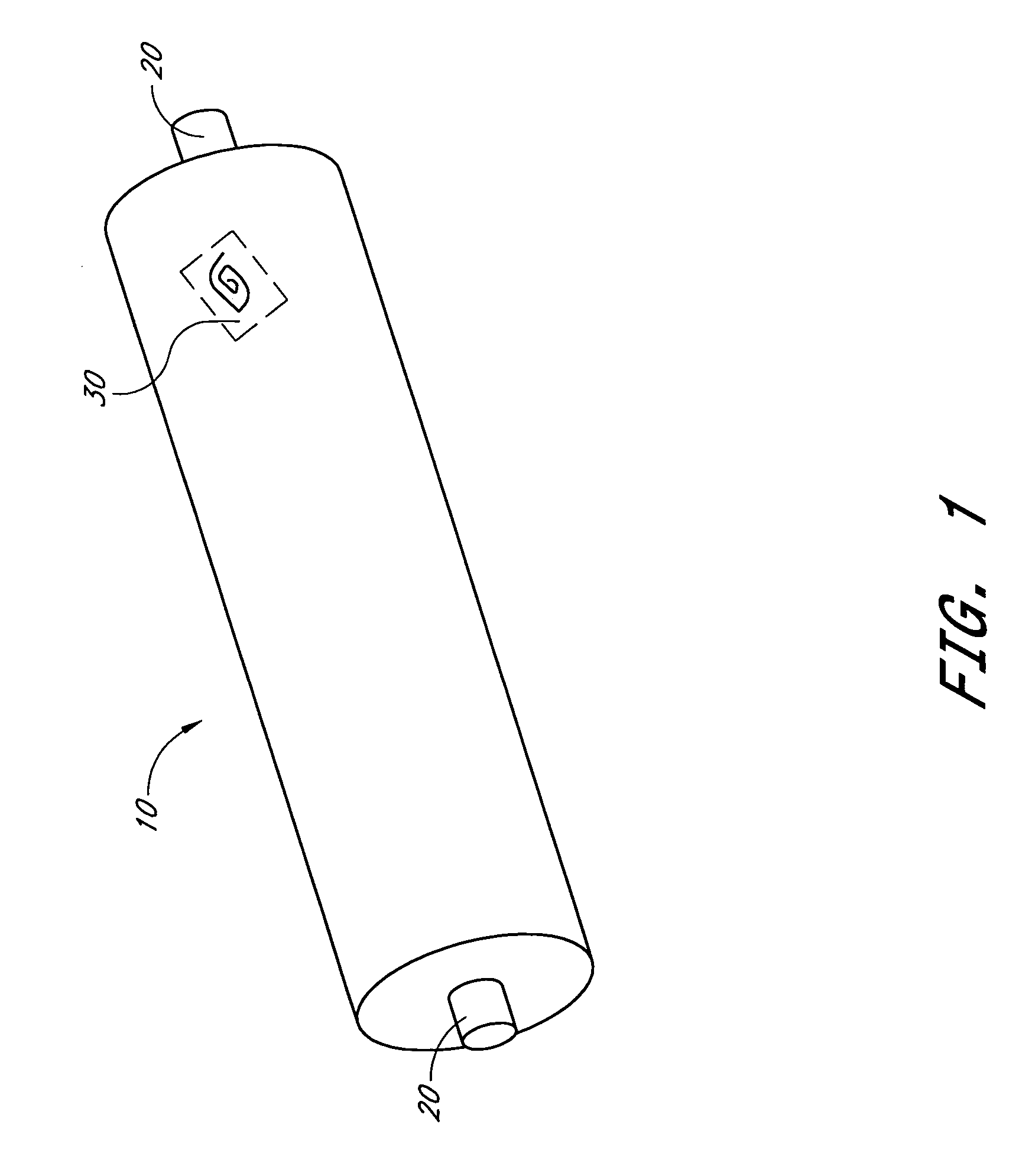

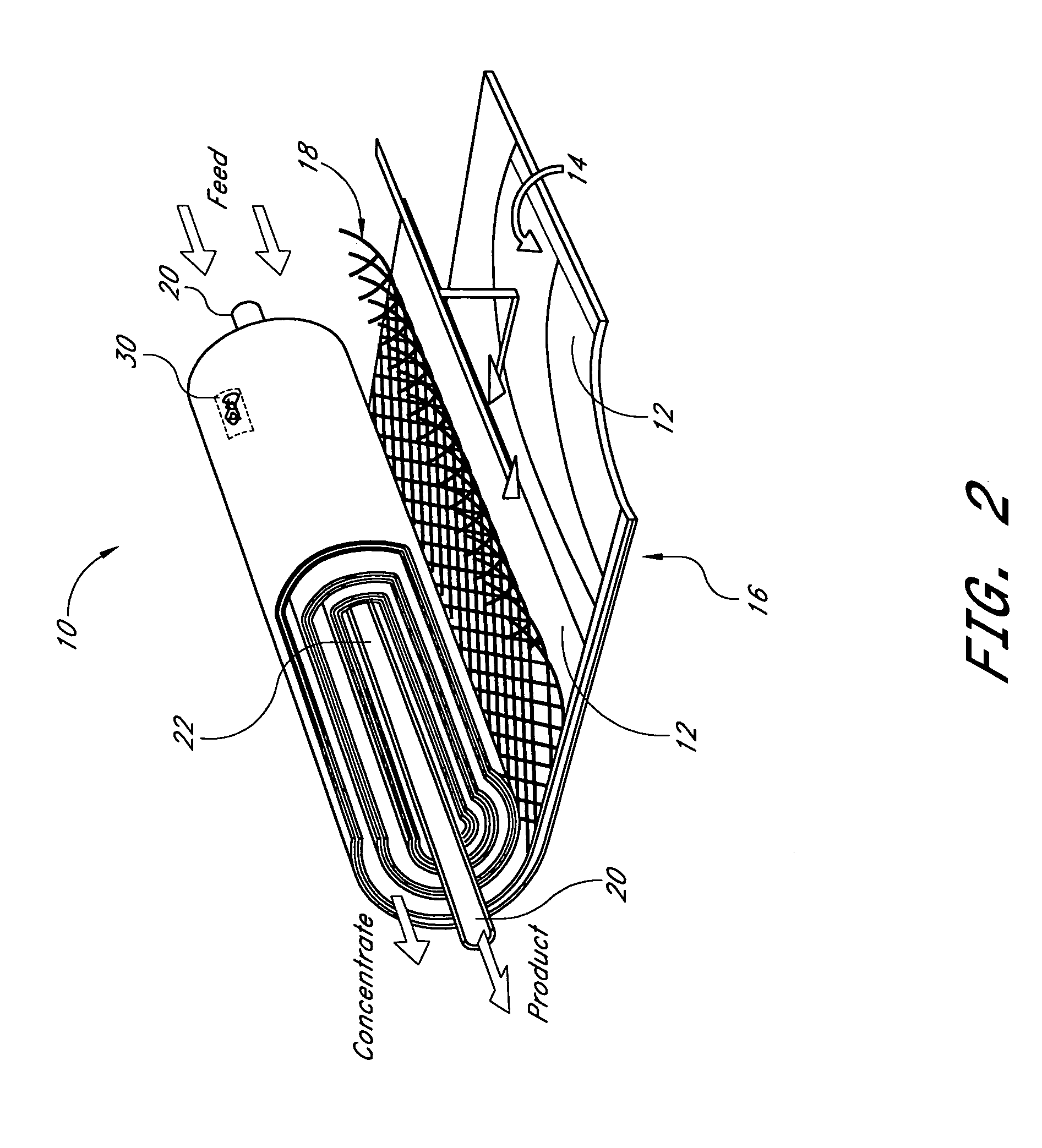

Filtration devices with embedded radio frequency identification (RFID) tags

ActiveUS20050194317A1Easily store and retrieve dataEasy loadingWater/sewage treatment bu osmosis/dialysisReverse osmosisReverse osmosisFluid filtration

Embodiments of the present invention comprise reverse osmosis filters and systems comprising embedded radio frequency identification (RFID) tags for storing and retrieving data. The RFID tags can be preferably embedded under a filtration device's protective outer shell. Information can be easily stored onto and retrieved from the embedded RFID tags. The ability to easily store and retrieve data from the embedded RFID devices facilitates the creation of loading maps, monitoring, addition, and replacement of fluid filtration devices.

Owner:NITTO DENKO CORP +1

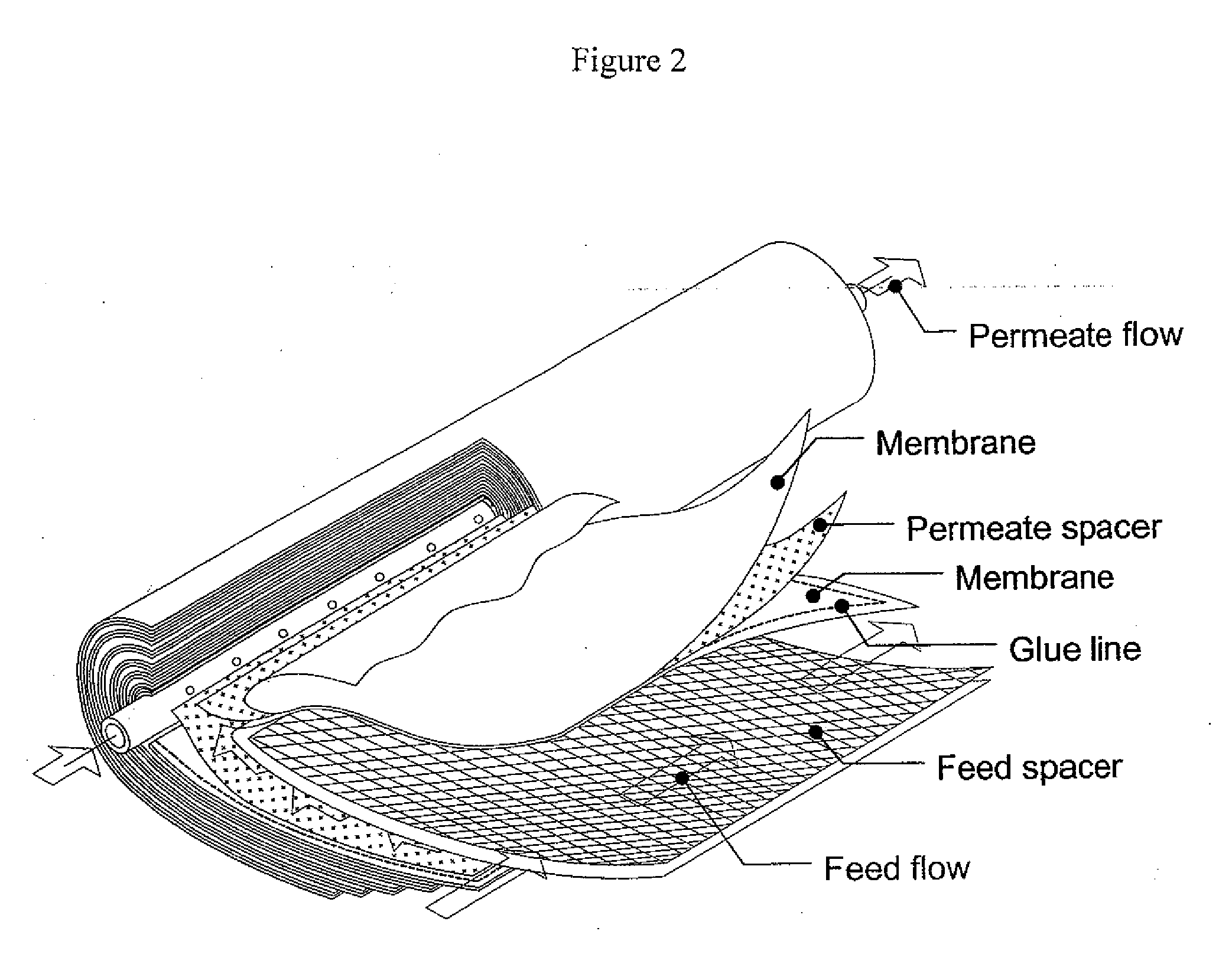

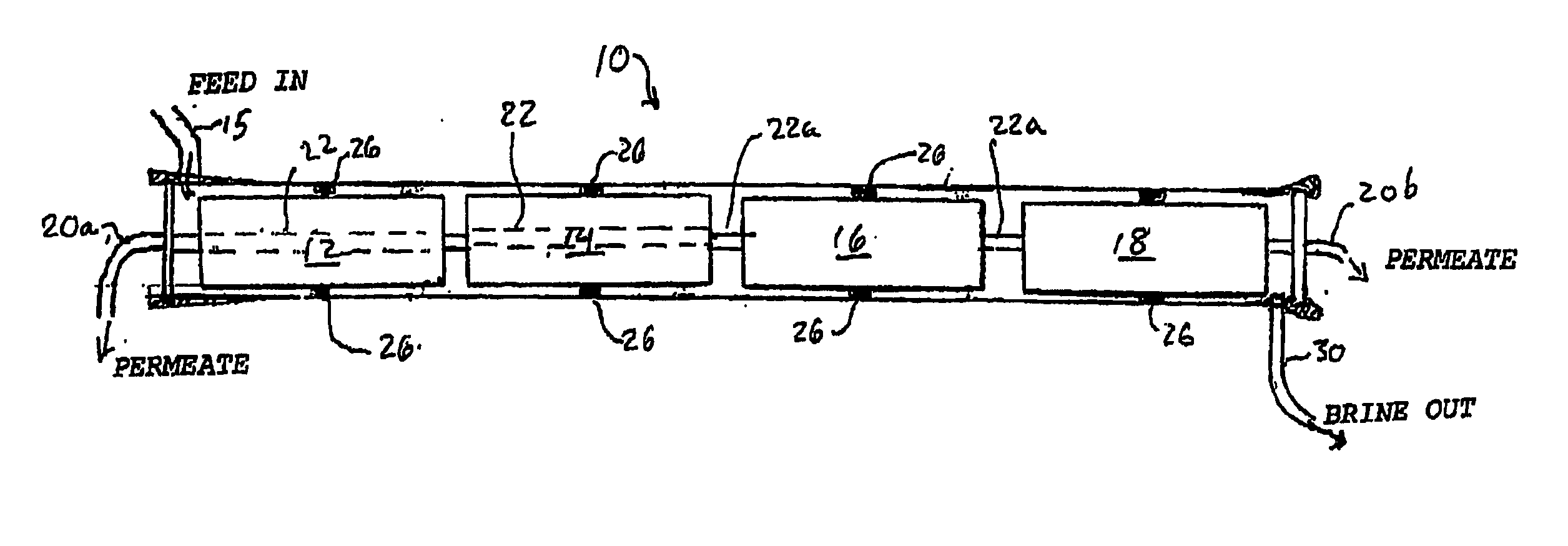

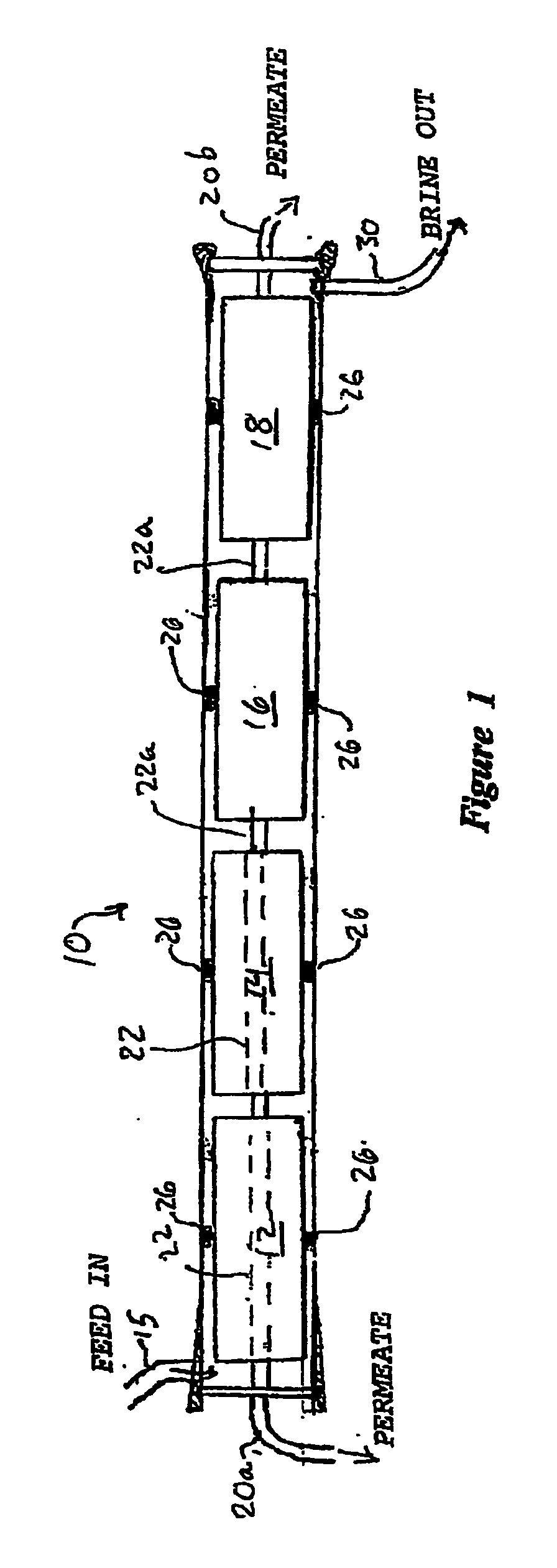

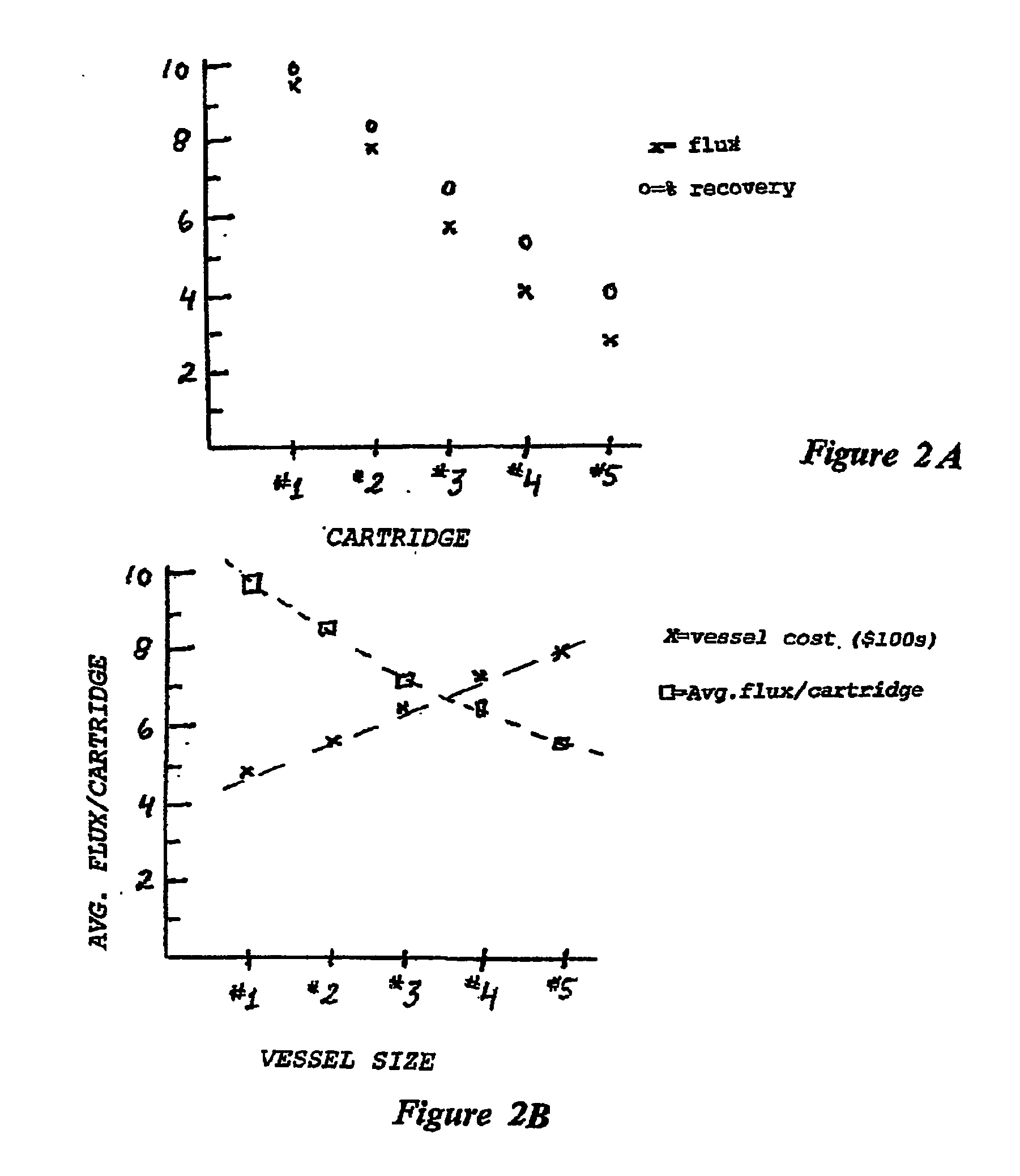

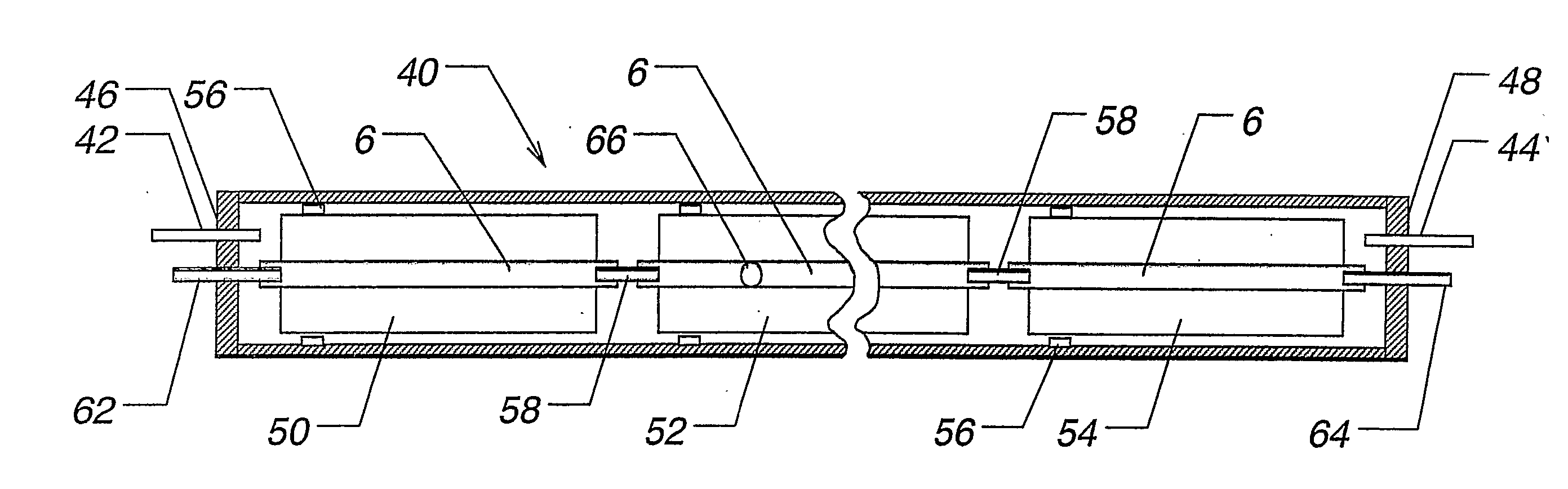

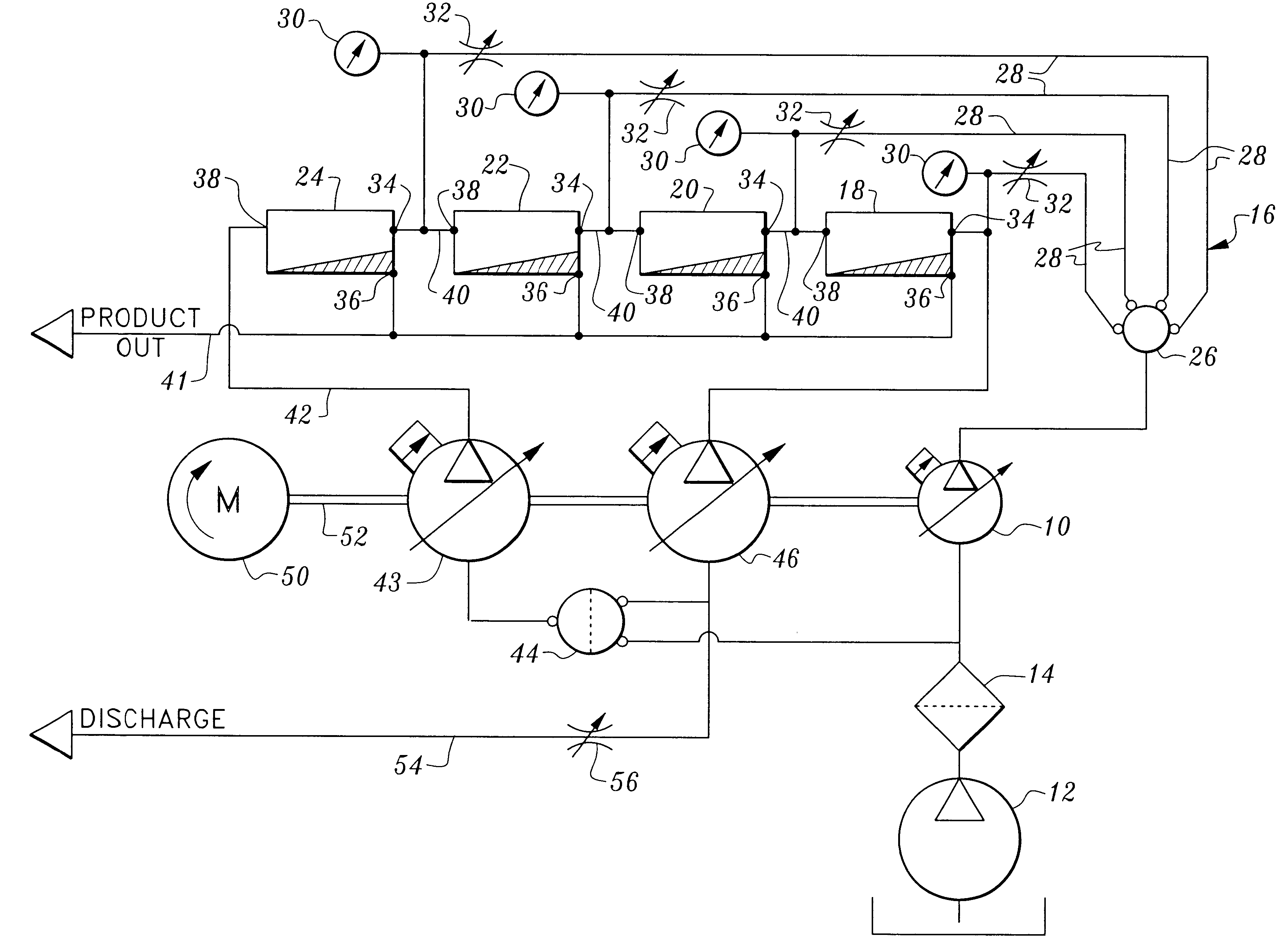

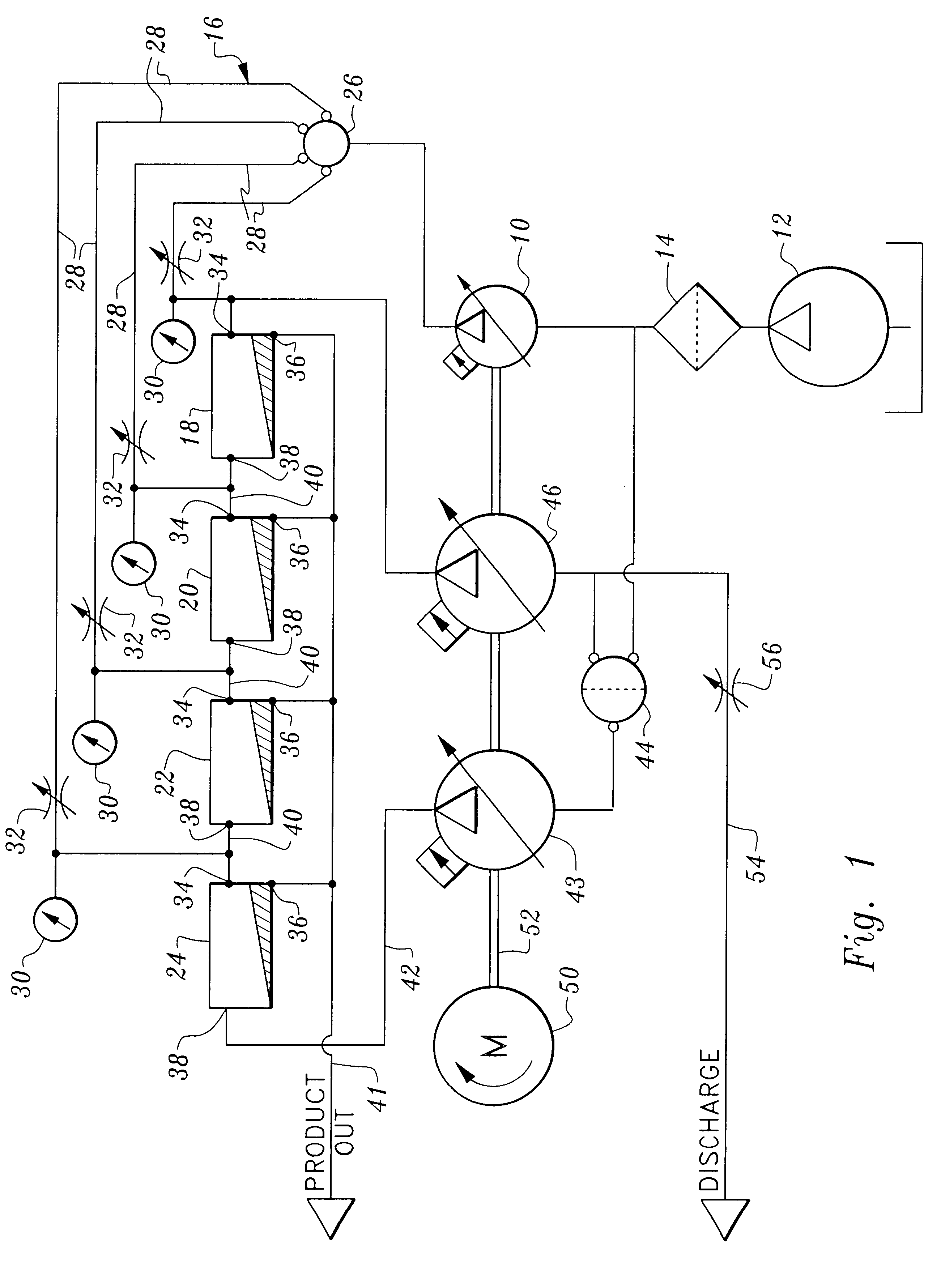

Branched flow filtraction and system

InactiveUS20050029192A1Improve operationImprove performanceMembranesWater/sewage treatment bu osmosis/dialysisReverse osmosisCross-flow filtration

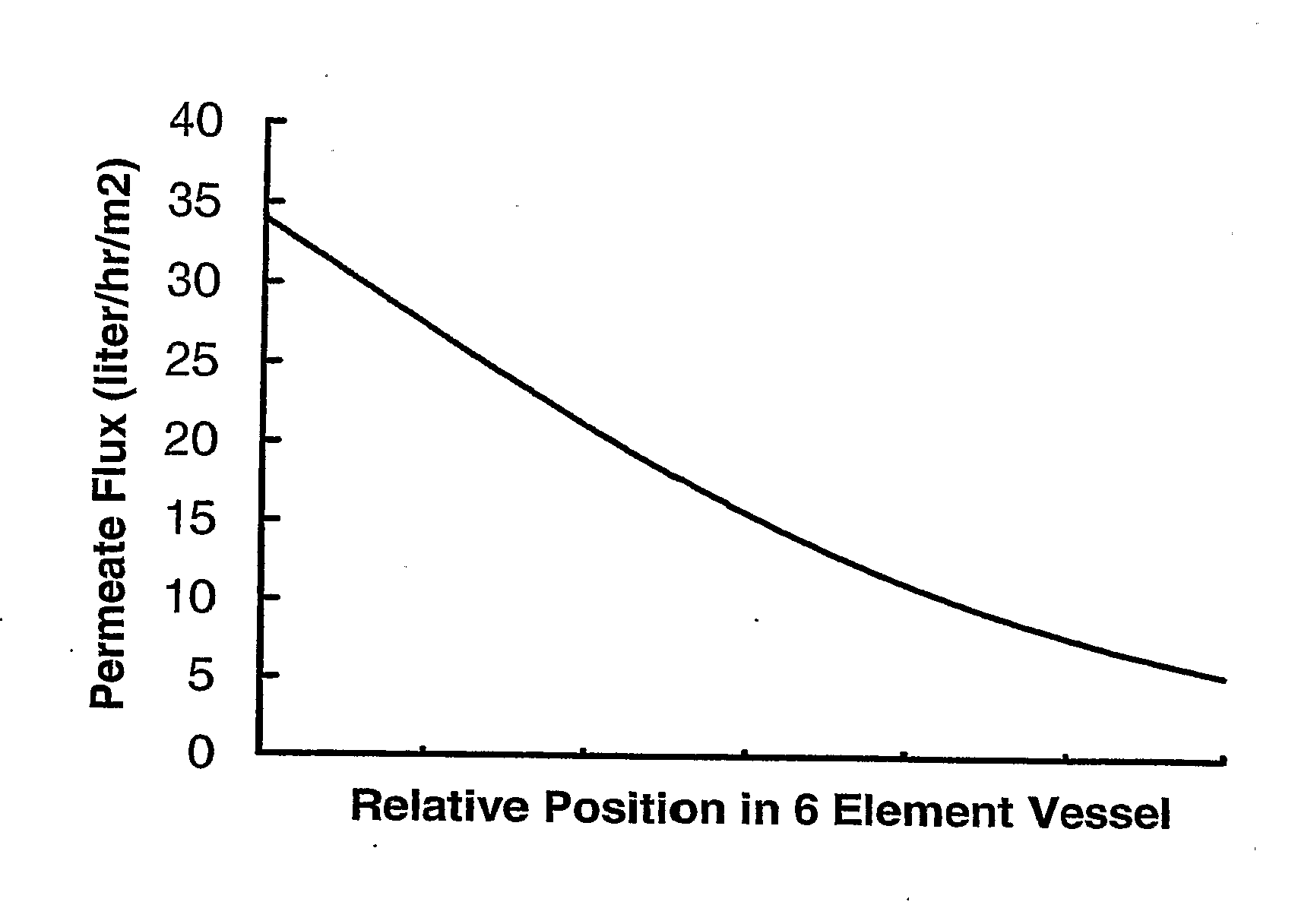

A cross flow filtration apparatus for nanofiltration or reverse osmosis has pressure vessels with a plurality of filter cartridges in each vessel. A feed port is provided at an intermediate position on the side of the vessel, and two permeate flows or branches exit opposite ends of the vessel, and the first branch has a characteristically high “upstream” flux and quality, while the second is of lesser flux and / or quality. The system provides a high degree of moduarity, enhancing flux or yield at a reduced driving pressure or overall pressure drop. Centered or off-center port, and a stop or valve in the permeate stream may apportion flows between the two outlets. Staged systems may employ a first stage bypass to achieve a target quality with increased yield. A flow divider or adaptor permits the cartridges to fit and seal in the vessel and an installation tool or sleeve may facilitate installation or replacement of cartridges having a directional perimeter seal. A tool permits modules to be bi-directional installed in the pressure vessel. Other embodiments involve adapting a conventional vessel designed for end-to-end feed flow utilizing a restrictor, obstruction or valve inside the filter cartridge to bifurcate or otherwise split or apportion the permeate. RO elements may be modified to movably position an obstruction or valve along a string of the elements and vary the take-off to two or more permeate outlets, or to provide pressure relief valves that present different pressure conditions for different elements of a string. A pressure vessel may have an intermediate inlet, with symmetric or asymmetric branching of permeate flow to opposed ends of the vessel, enhancing permeate flux, permeate quality and / or energy efficiency.

Owner:IONICS INC

Composite reverse osmosis membrane having a separation layer with polyvinyl alcohol coating and method of reverse osmotic treatment of water using the same

InactiveUS6177011B1High Salt RejectionPermit practical desalinationGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisZeta potentialWater use

A reverse osmosis composite membrane that has a high salt rejection, a high water permeability, and a high fouling tolerance, and permits practical desalination at a relatively low pressure is provided by coating the surface of a reverse osmosis membrane of aromatic polyamide with polyvinyl alcohol (PVA), for example, and controlling the surface zeta potential of the separation layer within±10 mV at pH 6. This reverse osmosis composite membrane is electrically neutral and controls the electrical adsorption of membrane-fouling substances having a charge group present in water. Therefore, a high separation property can be maintained without fouling the membrane even if water containing a surfactant or a transition metal component is supplied as raw water.

Owner:NITTO DENKO CORP

Reverse osmosis membranes

Owner:NANOH2O

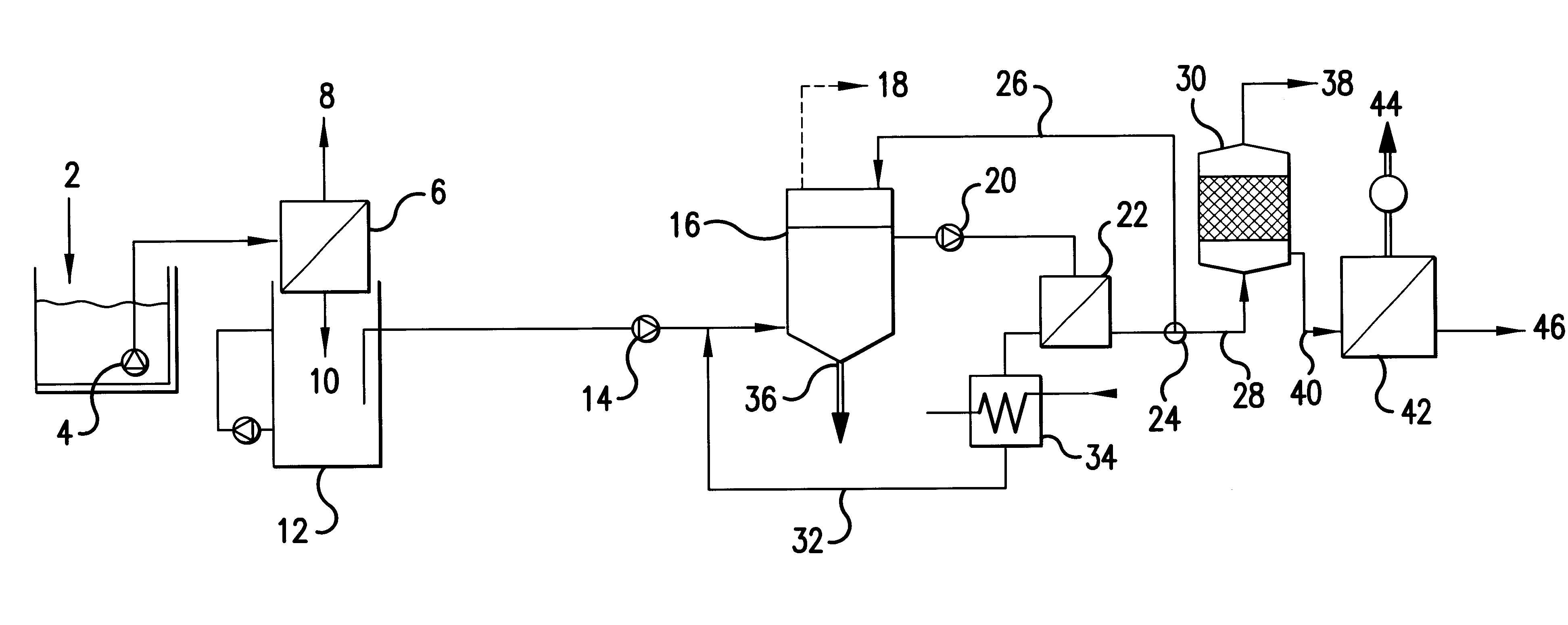

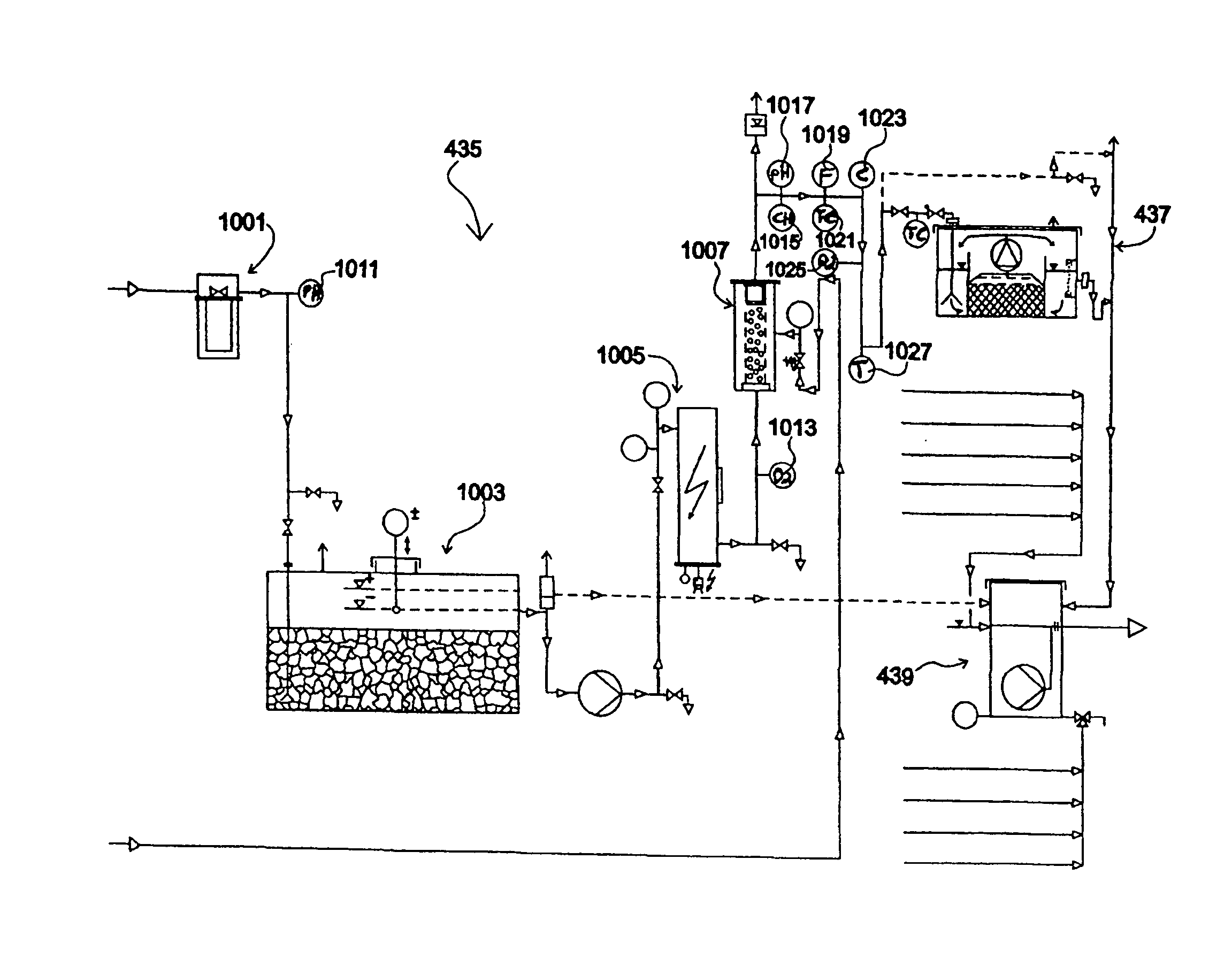

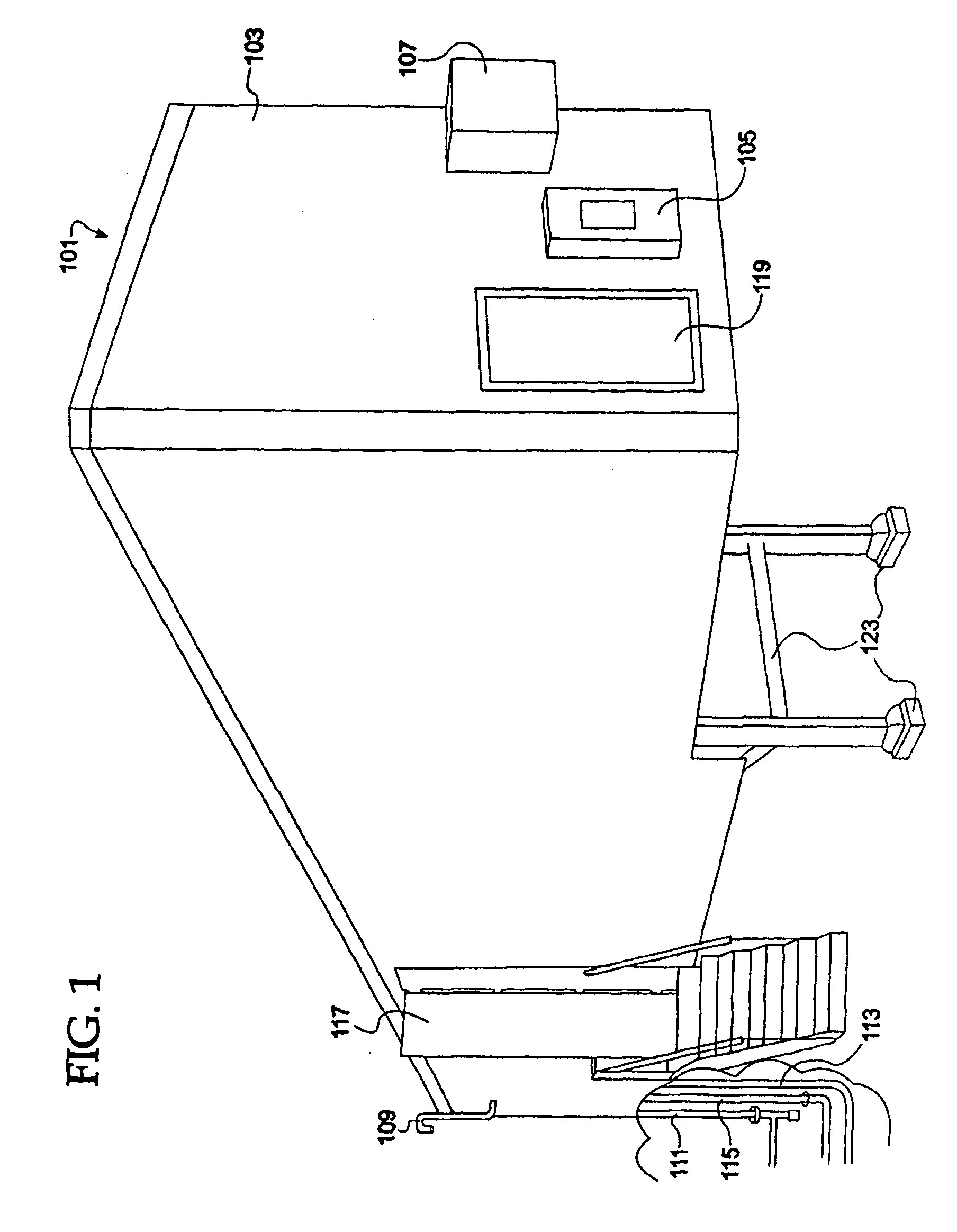

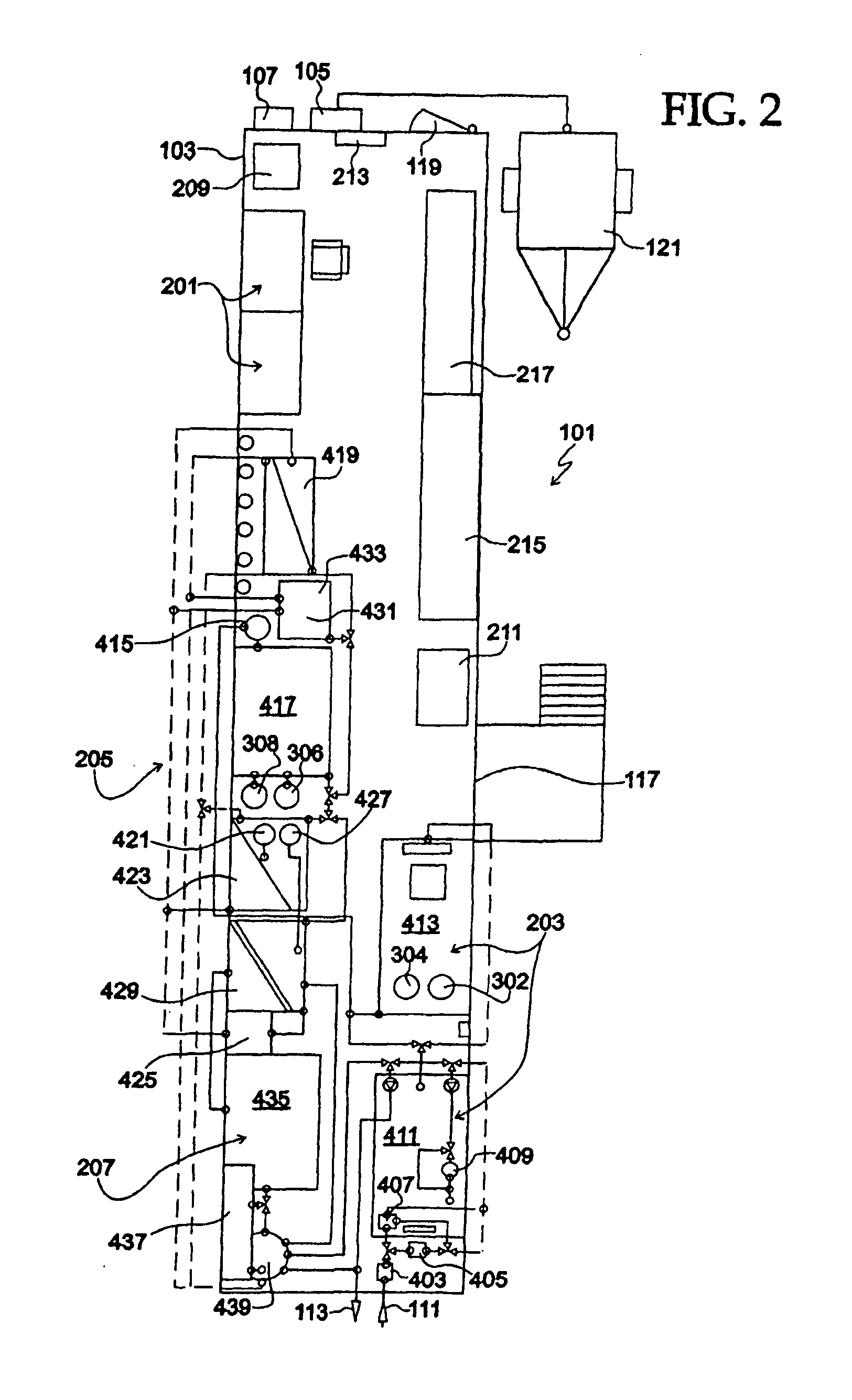

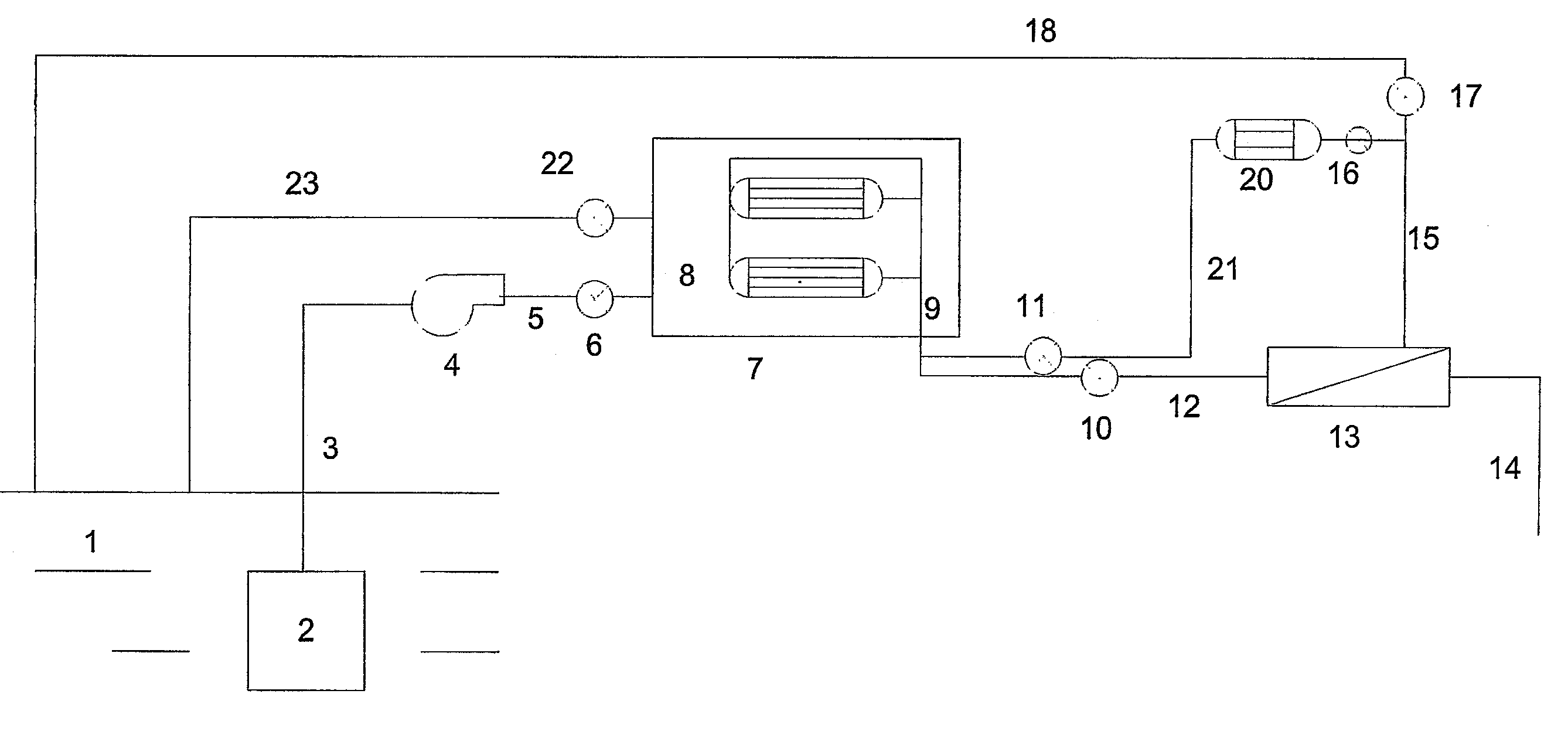

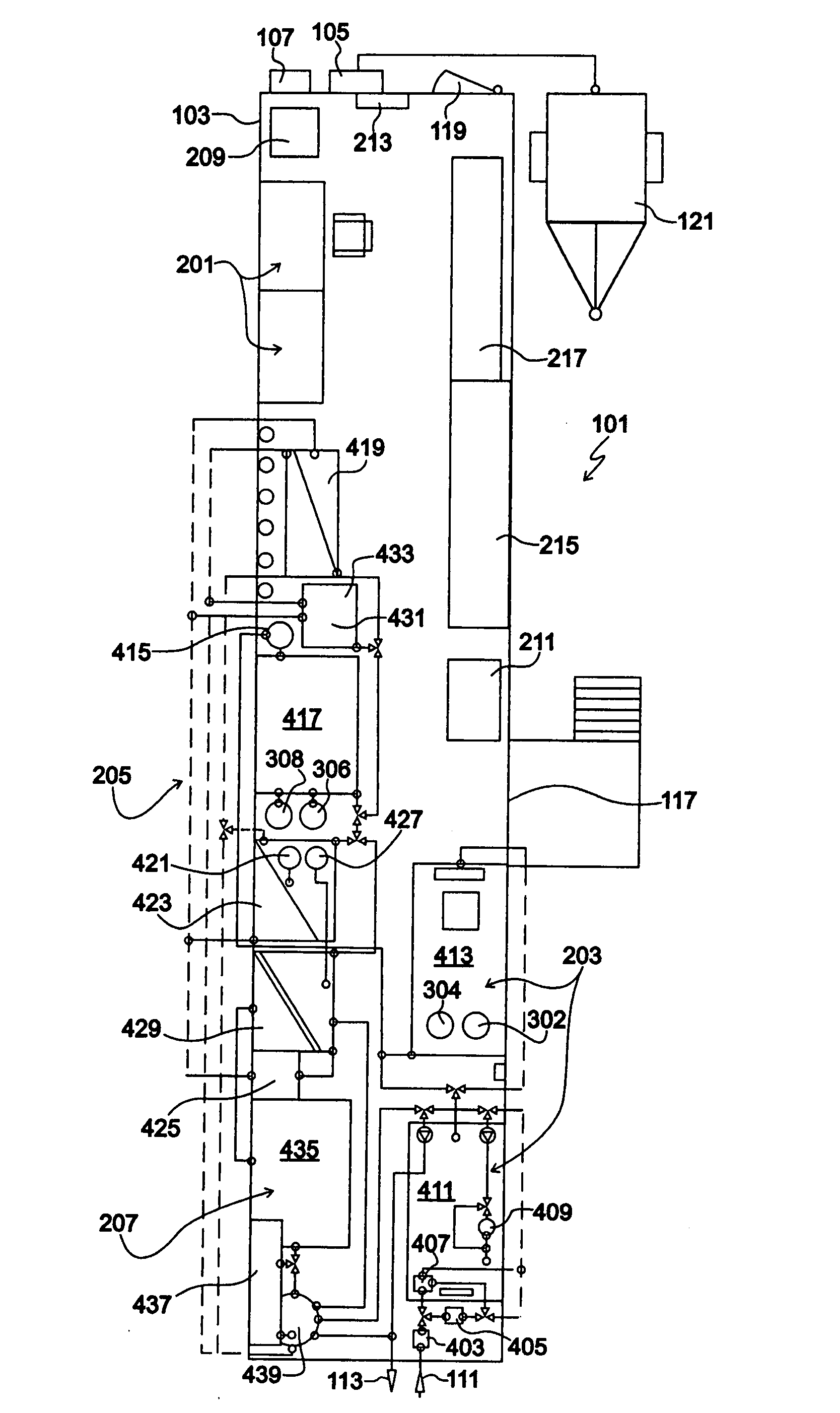

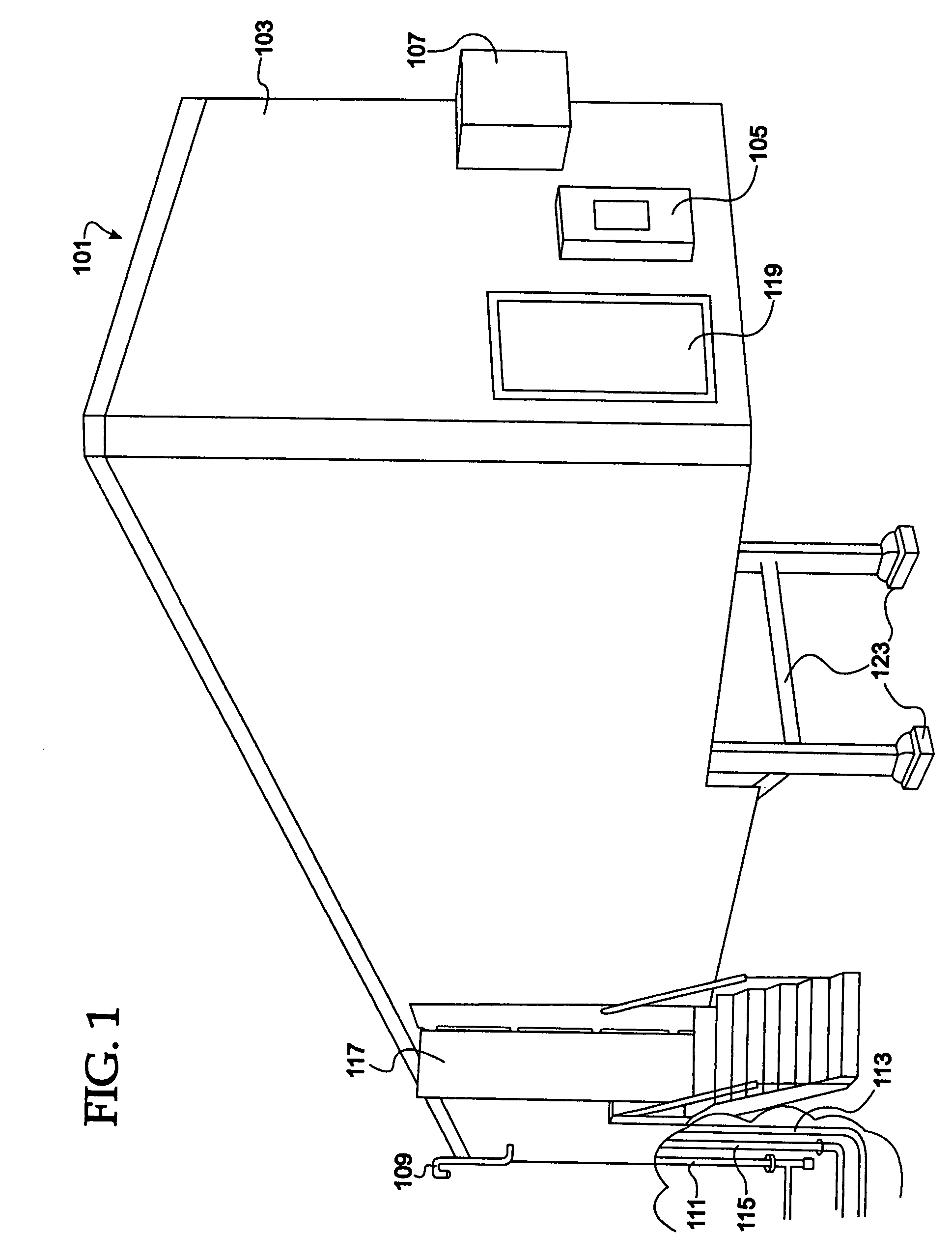

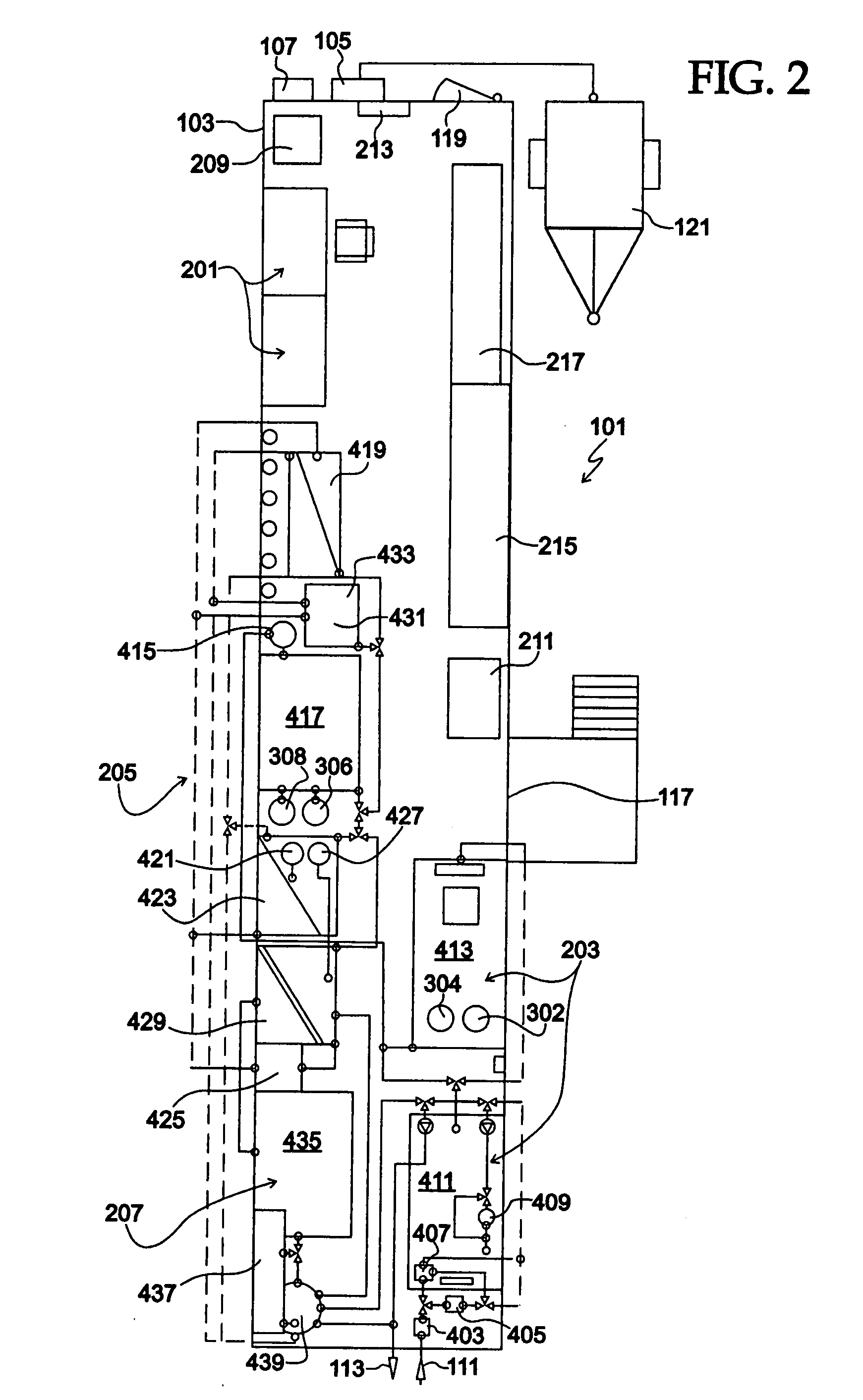

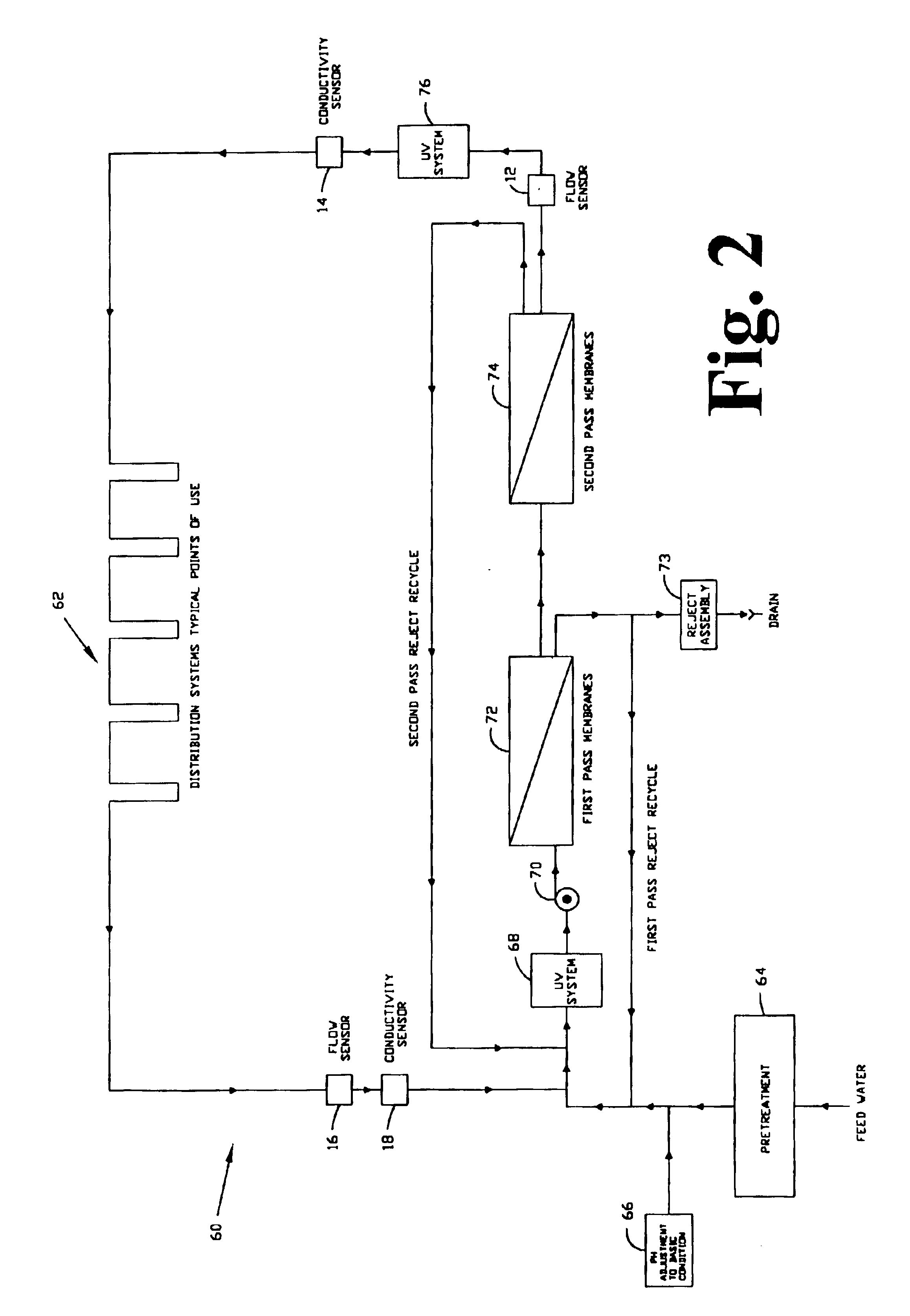

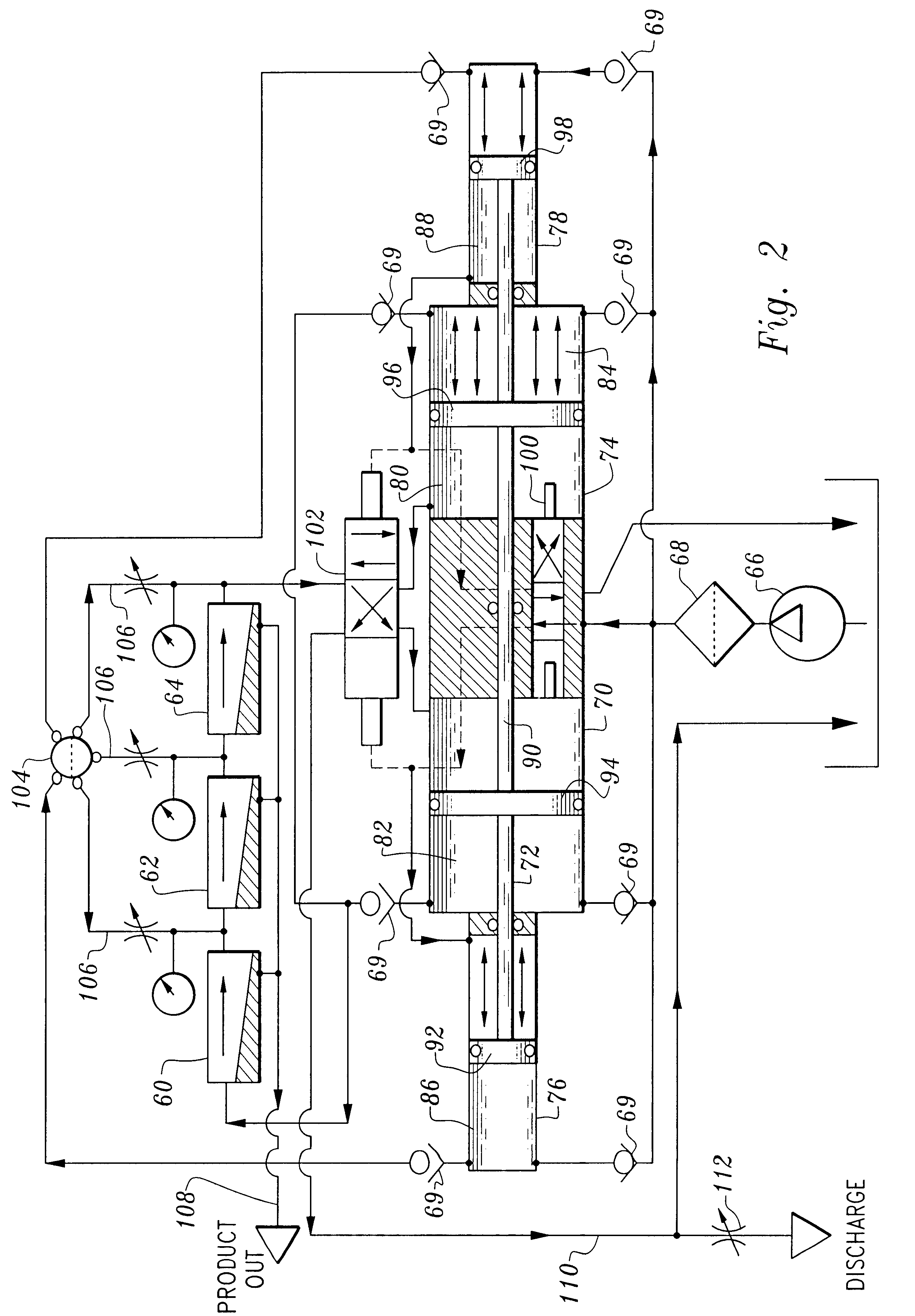

Mobile station and methods for diagnosing and modeling site specific full-scale effluent treatment facility requirements

InactiveUS20110257788A1Reduce financial riskHigh continuity of operationWater/sewage treatment by neutralisationSustainable biological treatmentInitial treatmentIon exchange

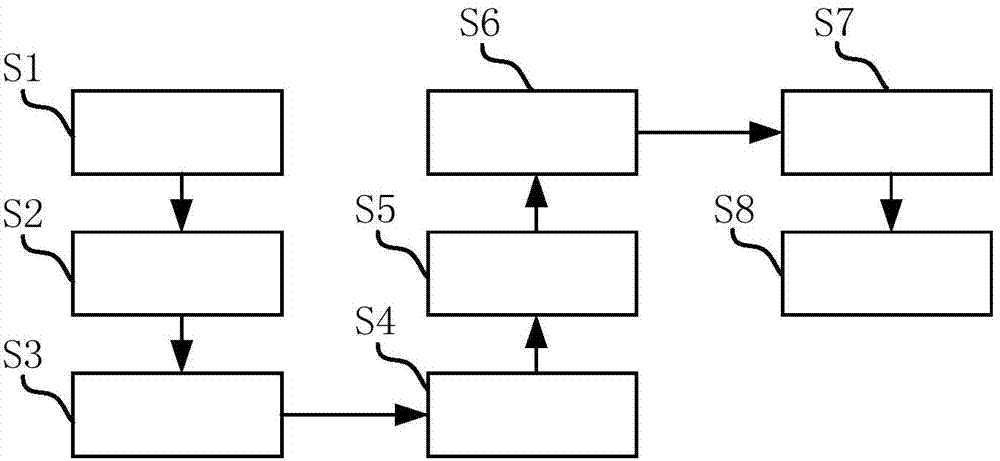

A mobile station and methods are disclosed for diagnosing and modeling site specific effluent treatment facility requirements to arrive at a treatment regimen and / or proposed commercial plant model idealized for the particular water / site requirements. The station includes a mobile platform having power intake, effluent intake and fluid outflow facilities and first and second suites of selectably actuatable effluent pre-treatment apparatus. An effluent polishing treatment array is housed at the station and includes at least one of nanofiltration, reverse osmosis and ion-exchange stages. A suite of selectively actuatable post-treatment apparatus is housed at the station. Controls are connected at the station for process control, monitoring and data accumulation. A plurality of improved water treatment technologies is also disclosed. The modeling methods include steps for analyzing raw effluent to be treated, providing a field of raw effluent condition entry values and a field of treated effluent condition goals entry values, and utilizing said fields to determine an initial treatment model including a selection of, and use parameters for, treatment technologies from the plurality of down-scaled treatment technologies at the facility, the model dynamically and continuously modifiable during treatment modeling.

Owner:ROCKWATER RESOURCE

Hybrid tfc ro membranes with nitrogen additives

ActiveUS20110005997A1Increase fluxIncreased rejectionMembranesPretreated surfacesChloramine BAlkaline earth metal

Owner:NANOH2O

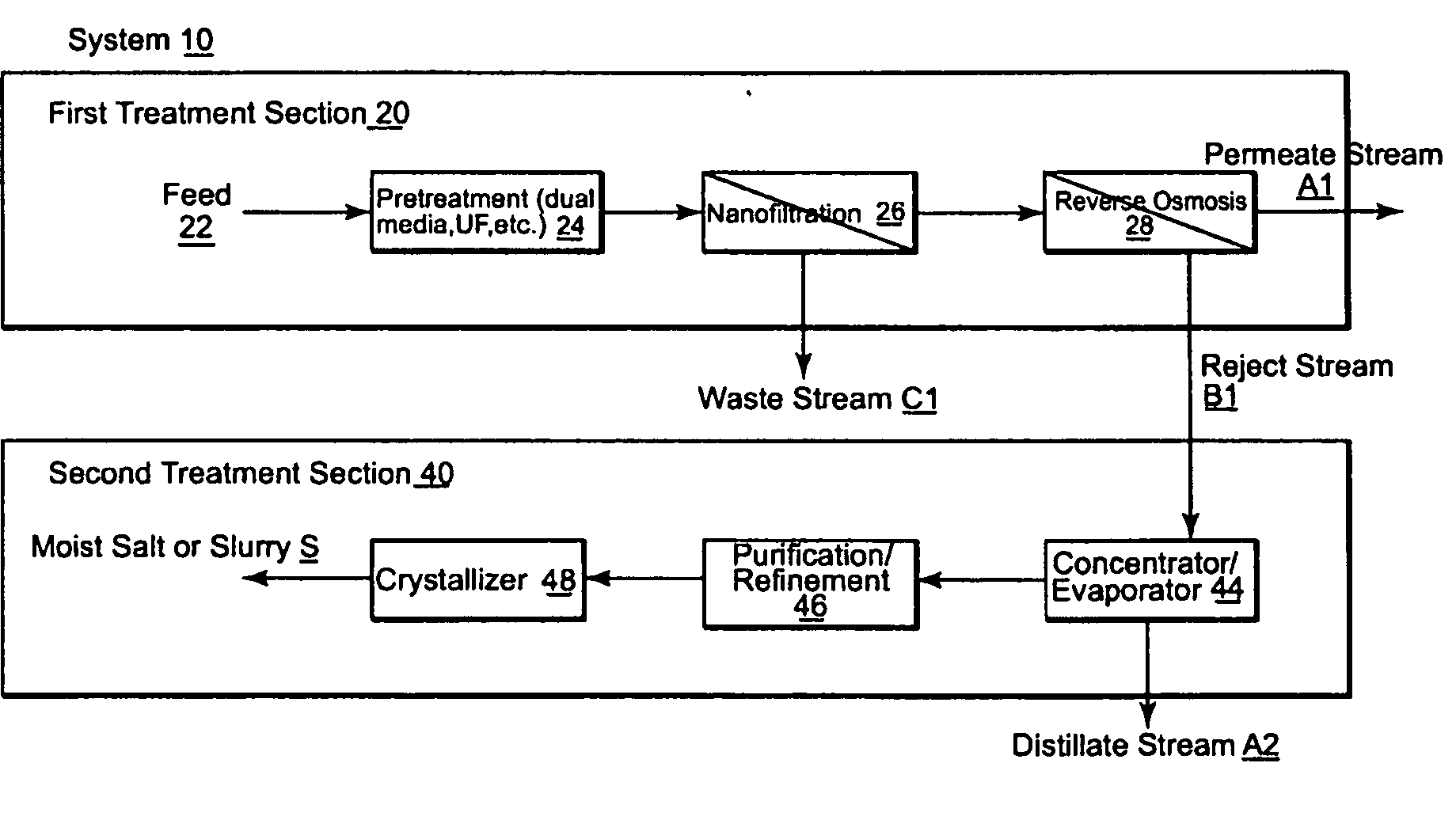

Water desalination plant and system for the production of pure water and salt

InactiveUS20100163471A1Large industrial capacitySimplified and cost-effective processSludge treatmentGeneral water supply conservationWater desalinationTotal dissolved solids

The present invention discloses a desalination plant that operates with a sea water or brackish water feed and produces a concentrated and selectively improved salt reject stream and a pure water permeate stream from a first treatment section that is arranged to produce primarily water at high recovery using membrane desalination processes. The reject stream from the first treatment line has a component distribution that is substantially reduced in native di- and polyvalent scaling ions, essentially depleted of sulfate, has substantially higher total dissolved solids than a traditional sea water reverse osmosis reject, yet is suitable for thermal treatment processes. The system may be enhanced by monovalent salt components. The unit may be integrated with a second treatment section, in which the first reject stream is further concentrated, purified, and processed to produce a high purity salt product.

Owner:GENERAL ELECTRIC CO

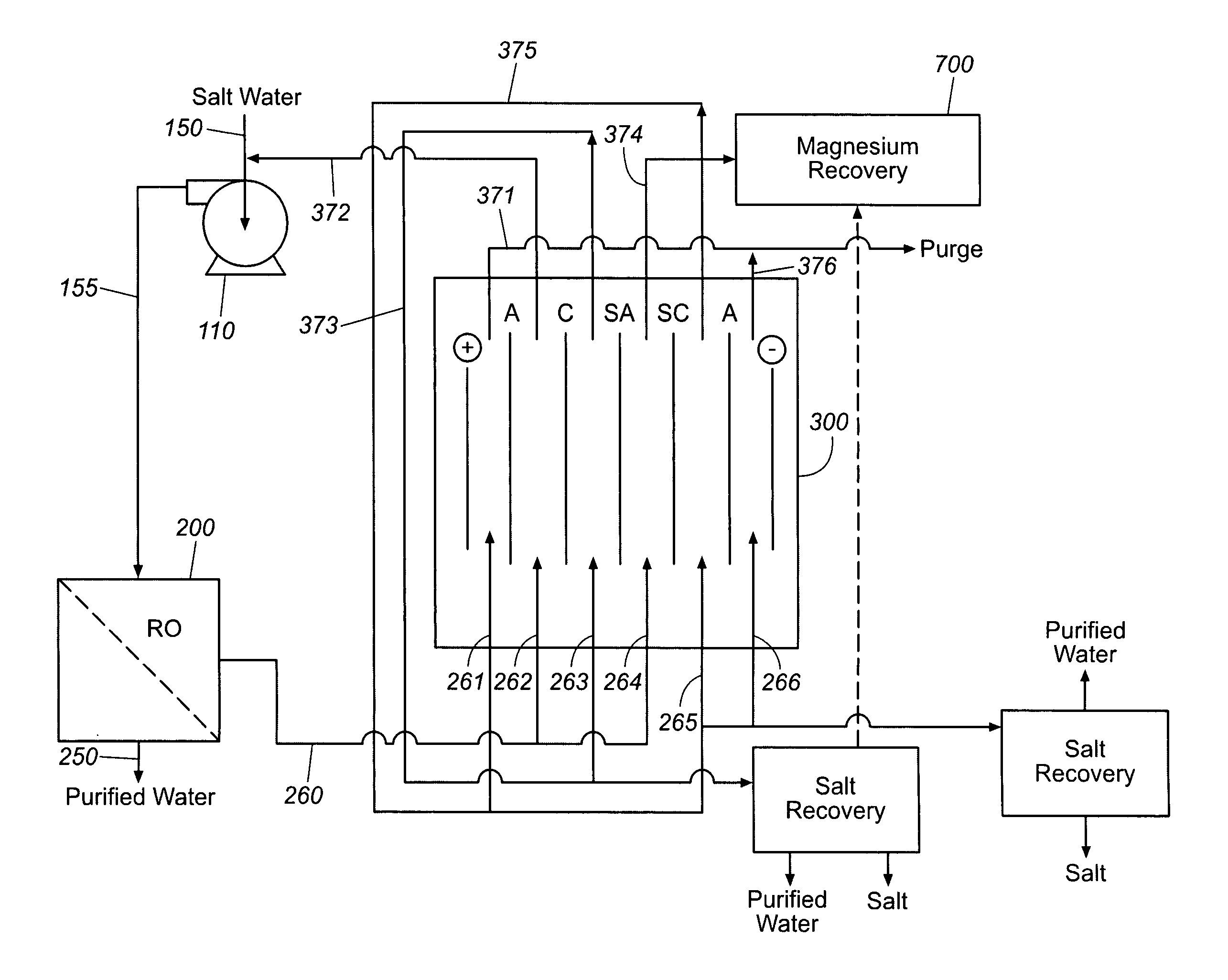

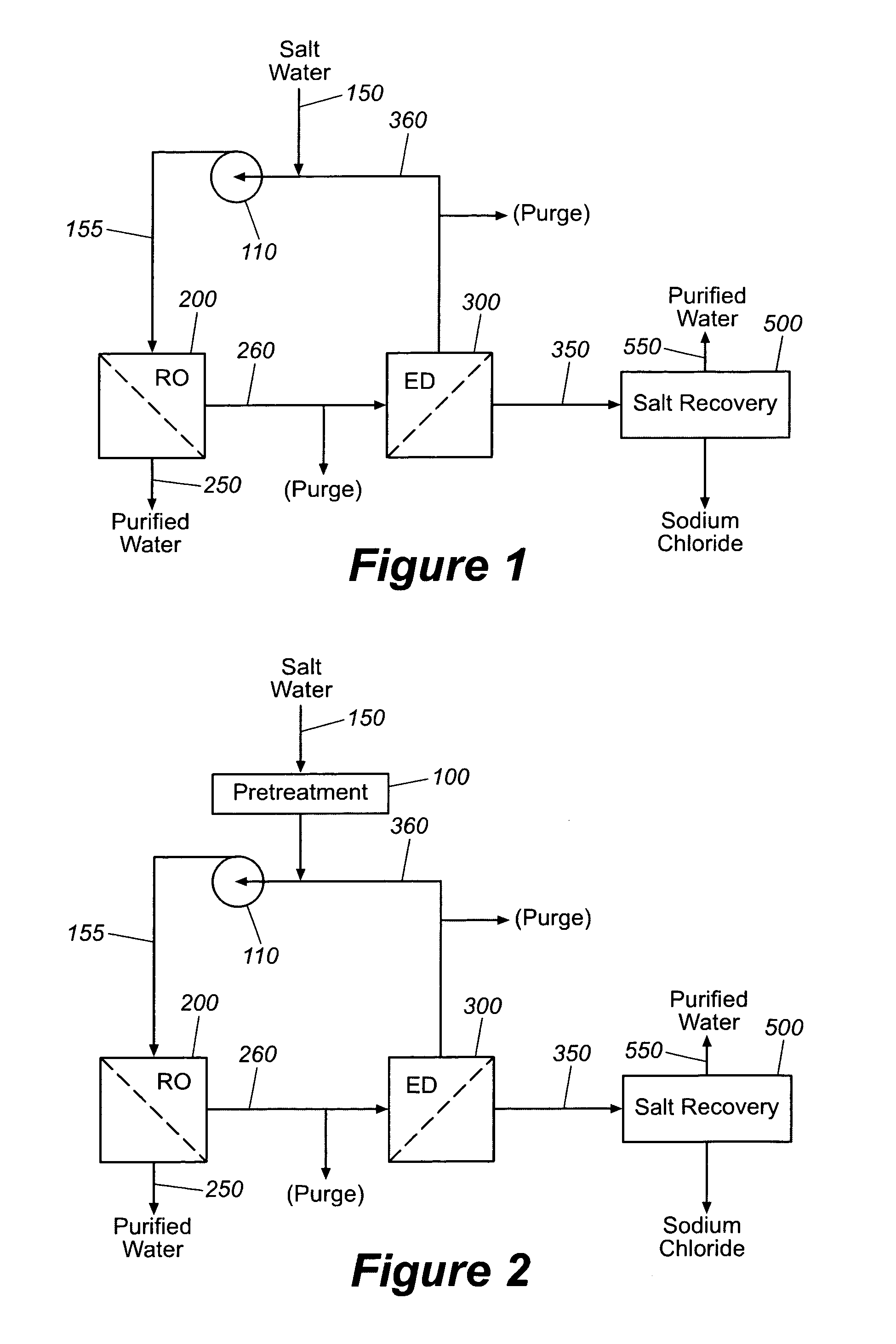

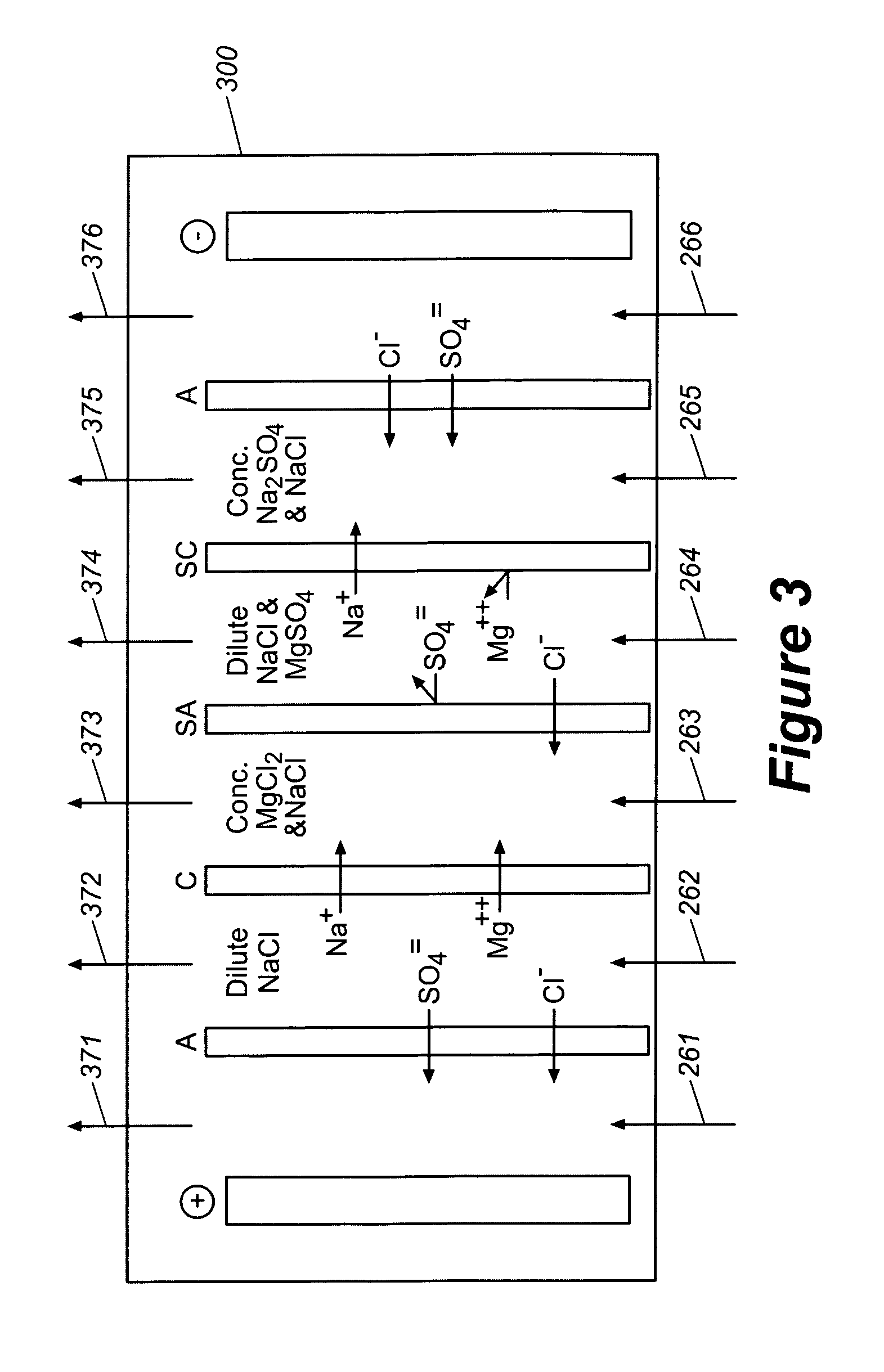

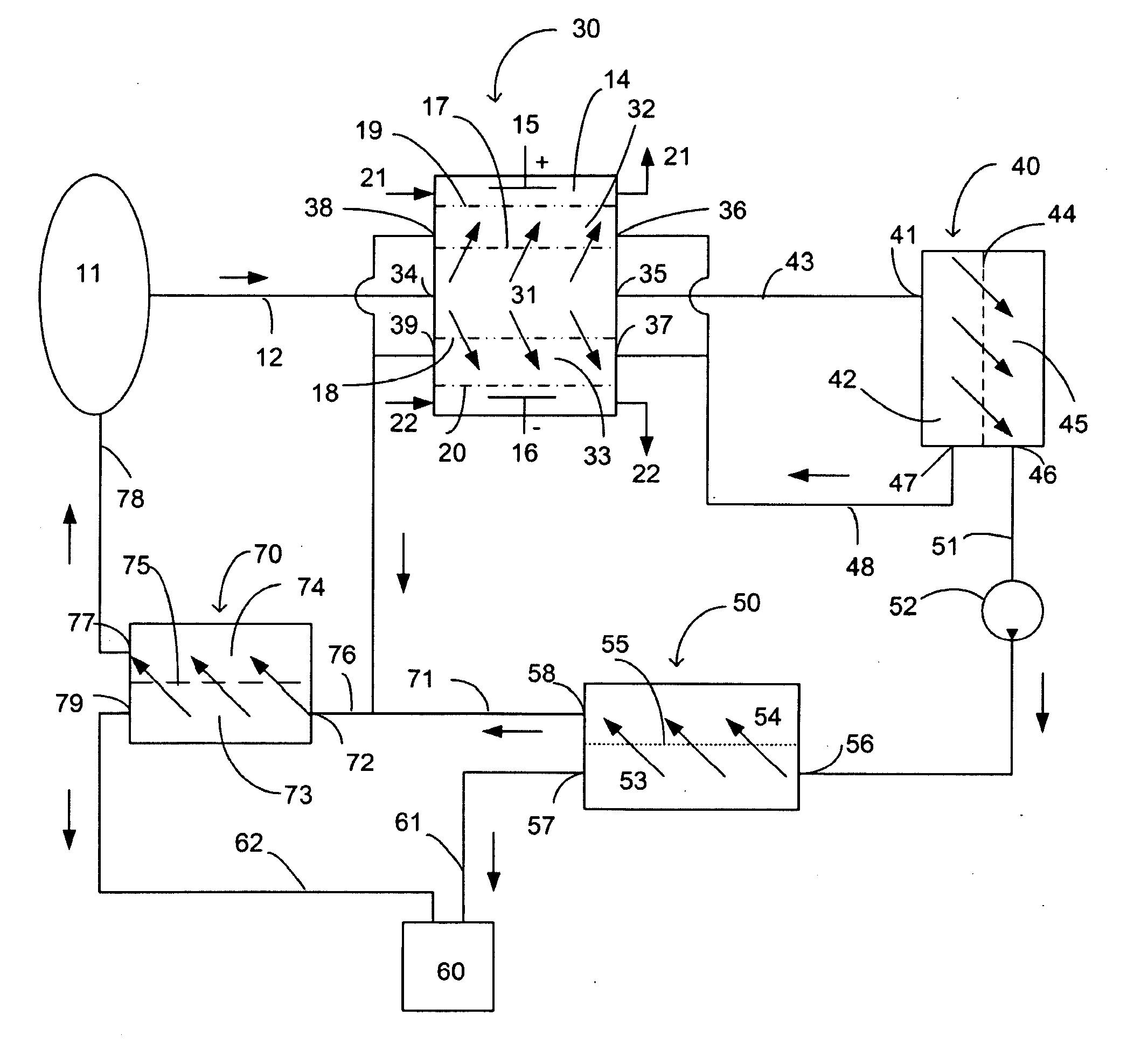

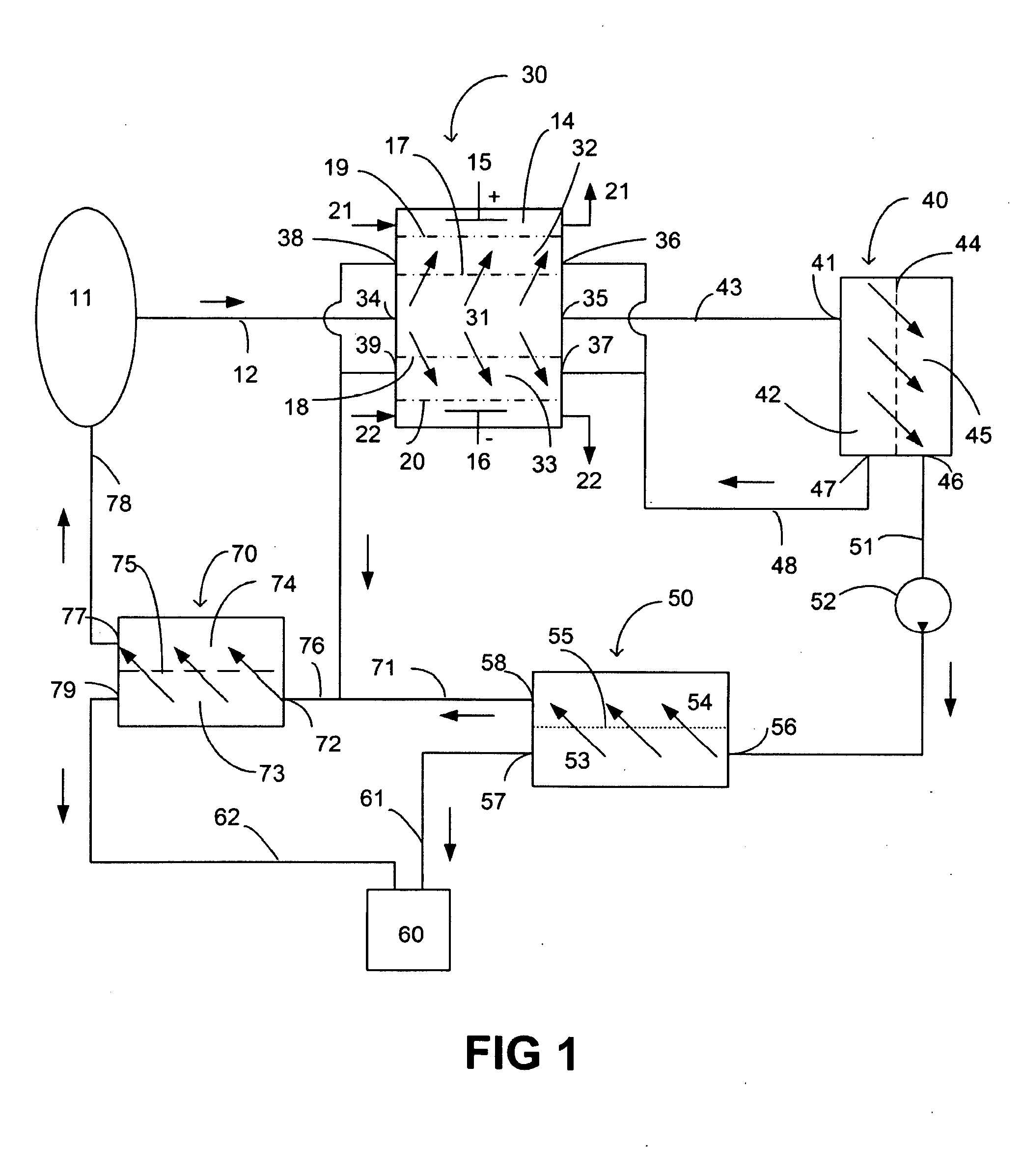

Production of purified water and high value chemicals from salt water

ActiveUS7083730B2Effective recoveryElectrolysis componentsSolvent extractionReverse osmosisHigh pressure

Sodium chloride and purified water are recovered by treating salt water that contains sodium chloride with an integrated reverse osmosis and electrodialysis system, which includes an efficiency-enhancing feature that is one or more of the following: the use of univalent anion and univalent cation selective membranes in the electrodialysis unit; the addition of a nanofiltration unit to process the diluate from the electrodialysis unit; or operation of the electrodialysis unit at an elevated pressure. Magnesium and bromine can optionally be produced when the salt water contains these materials.

Owner:SOUTH CAROLINA UNIV OF

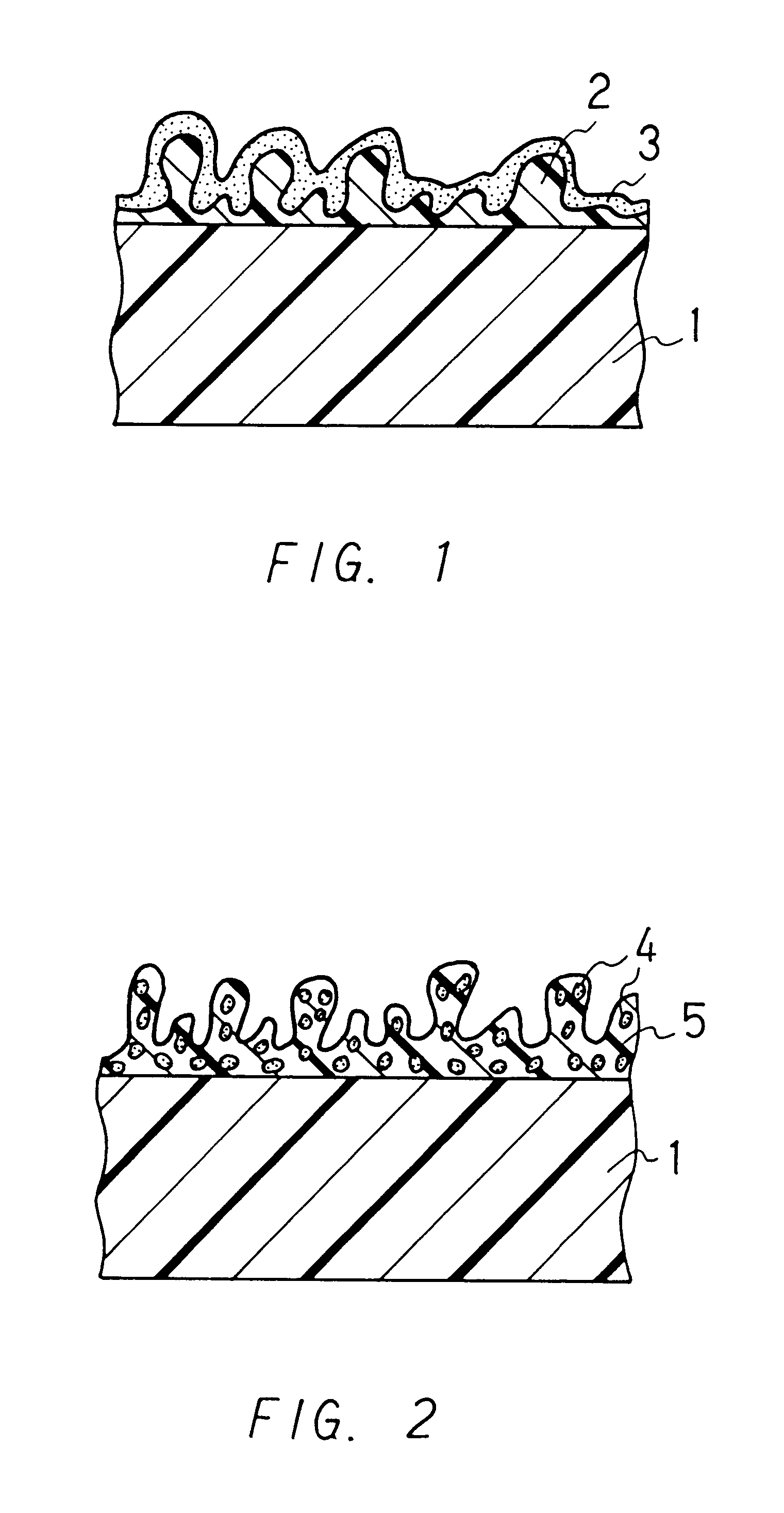

Selective membrane having a high fouling resistance

InactiveUS6913694B2Improve antifouling performanceImprove the immunitySemi-permeable membranesSynthetic resin layered productsEpoxyCross-link

Owner:SAEHAN INDS CO LTD

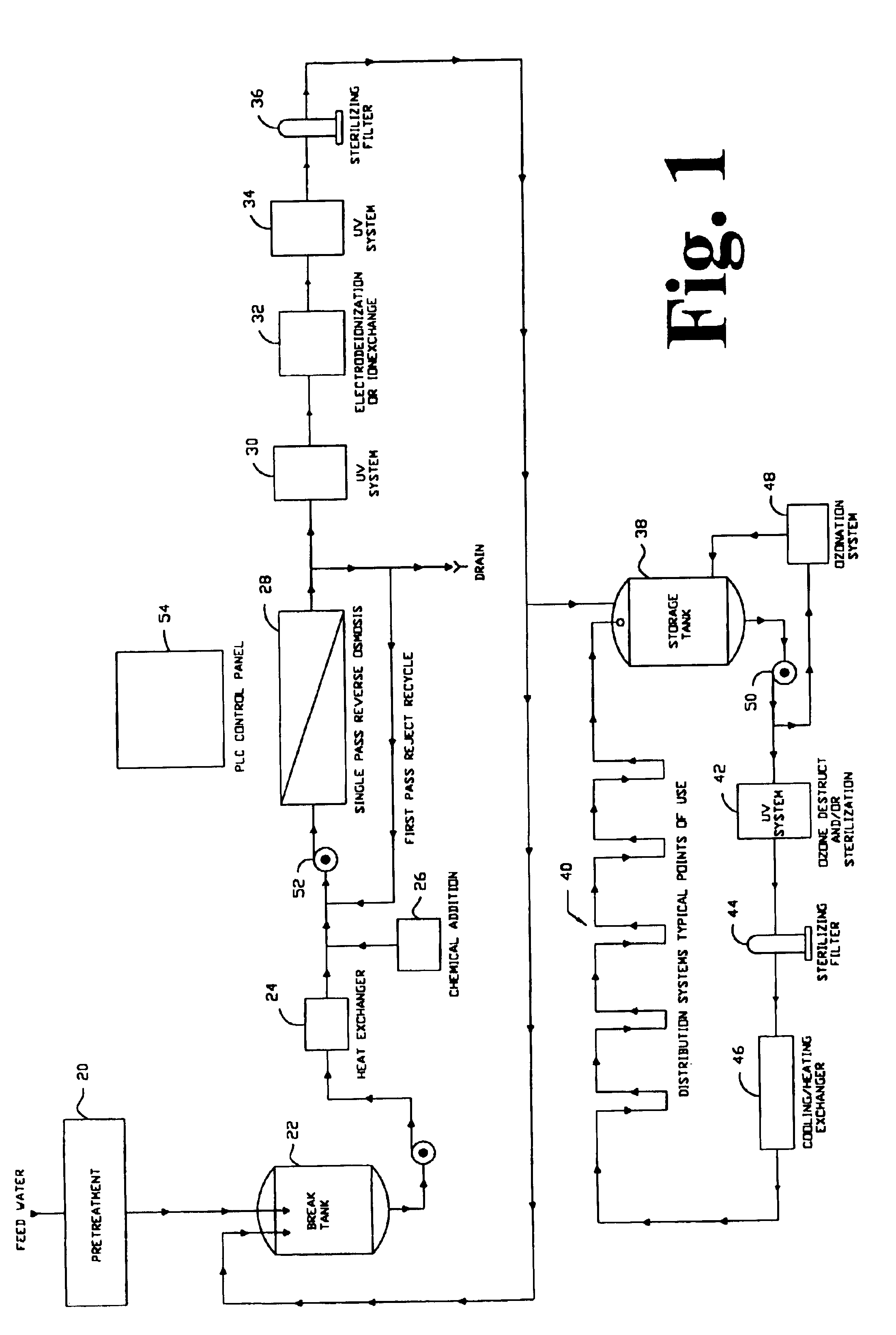

Apparatus and method for continuous depyrogenation and production of sterile water for injection

InactiveUS7122149B2Simple yet dependableReduce contact timeDialysis systemsTreatment involving filtrationDepyrogenationIon exchange

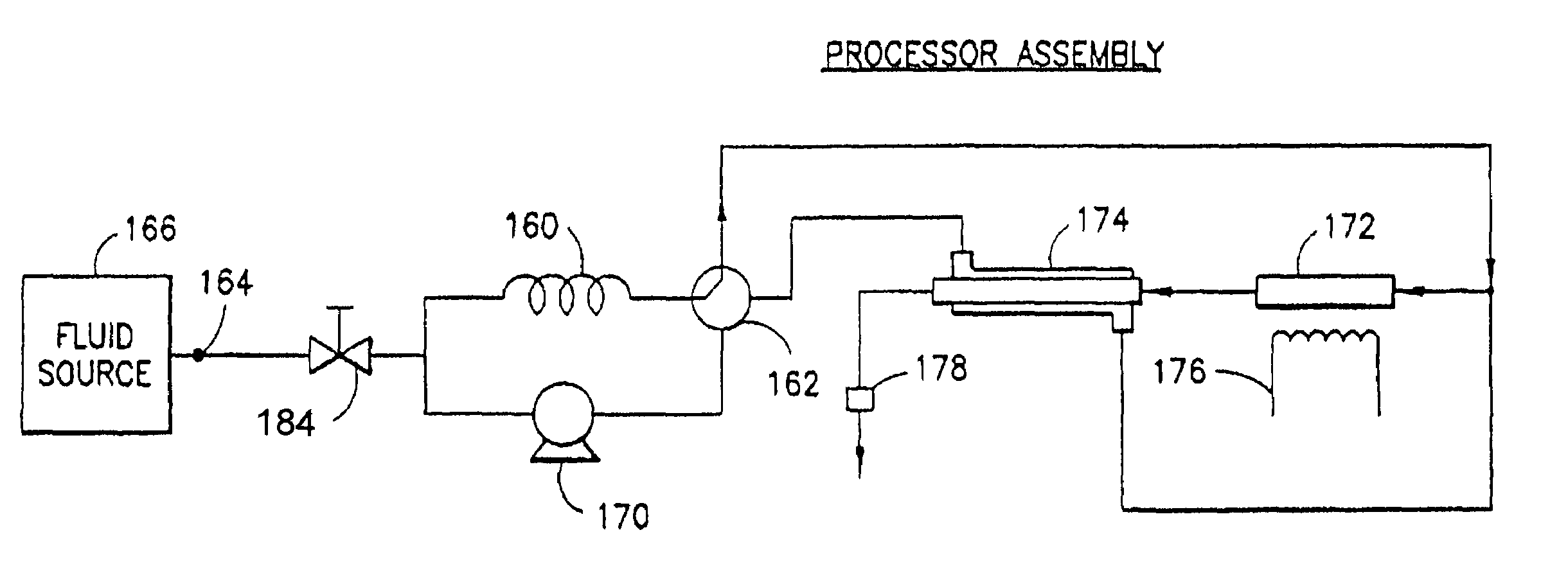

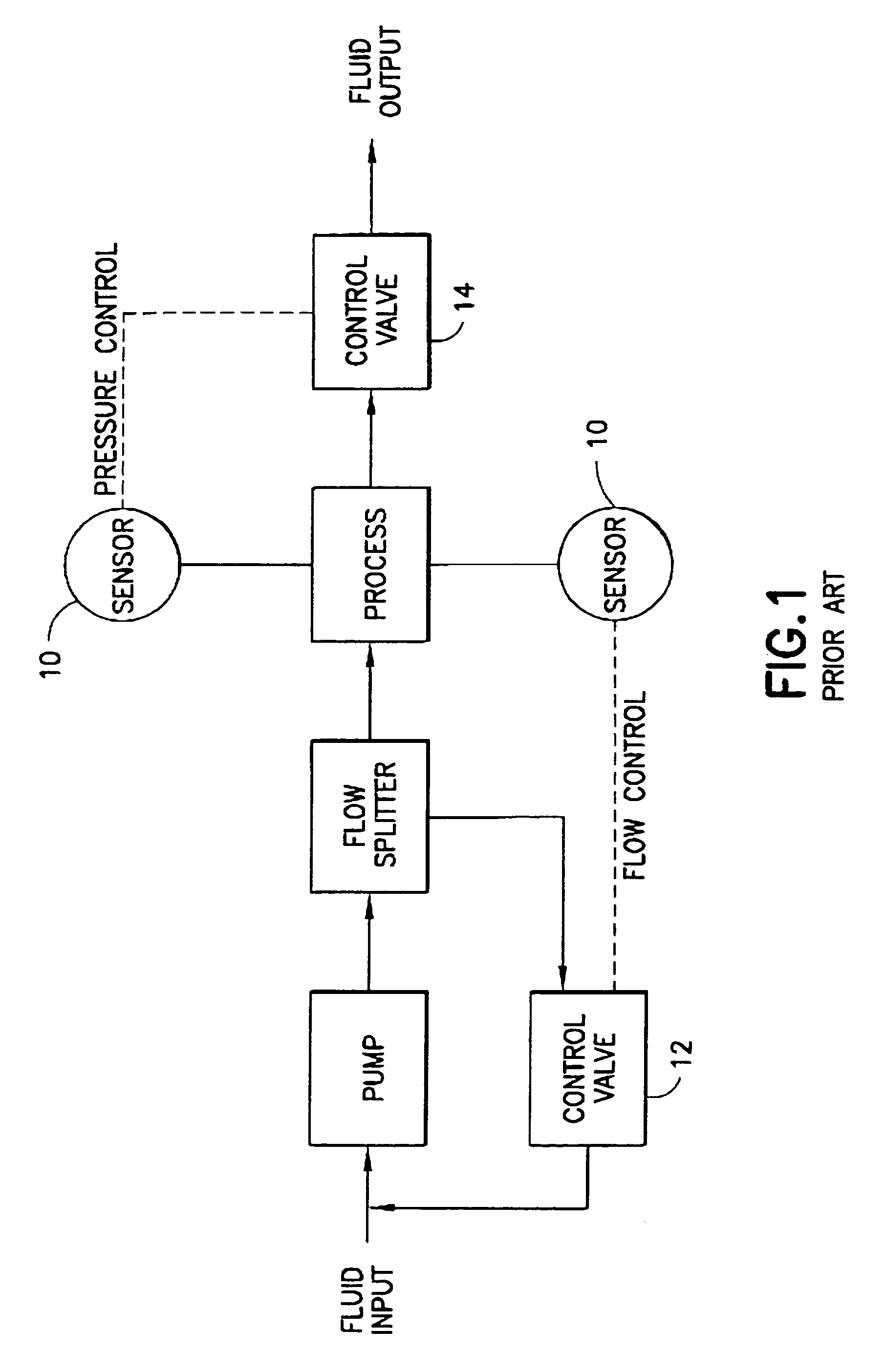

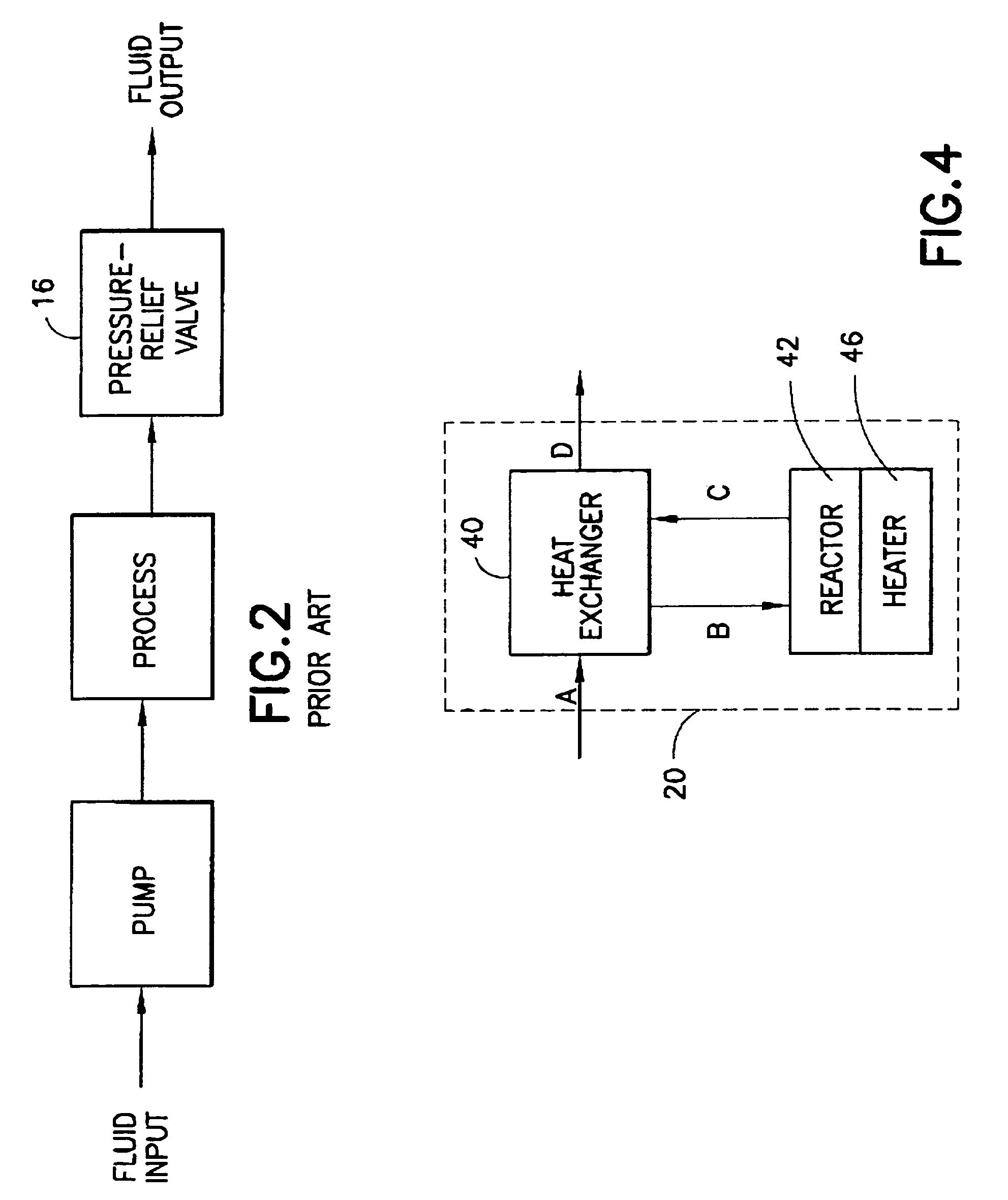

A fluid processor, suitable for the production of sterile water for injection, having a processor assembly and a process control system comprising a pump, a flow splitter, flow restrictors and a pressure relief valve. In a preferred embodiment, the processor assembly comprises a heat exchanger, a reactor and a heater arranged in a nested configuration. The preferred embodiment of the present invention also include a treatment assembly having a combination of filter, reverse osmosis and ion exchange devices and further incorporates an assembly and method allowing for the in situ sanitization of the fluid processor during cold start and shutdown to prevent bacteria growth during storage of the fluid processor. The fluid processor may include an electronic control system comprising a touch screen operator interface, a programmable logic controller and sensors for measuring temperature, pressure, flow rate, conductivity and endotoxin level.

Owner:APPLIED RES ASSOCS INC

Process and apparatus for purifying impure water using microfiltration or ultrafiltration in combination with reverse osmosis

InactiveUS20070181496A1Avoid Particulate ContaminationReduces and eliminates amountGeneral water supply conservationUltrafiltrationWater usePotable water

A method of purifying impure water contaminated with a filterable impurity and a dissolved impurity, such as sea-water, comprising the steps of: providing impure water to a primary microfiltration or ultrafiltration unit to remove the filterable impurity and produce impure filtered water contaminated with a dissolved impurity; providing the impure filtered water contaminated with a dissolved impurity to a reverse osmosis unit to produce a potable water stream and a residual reverse osmosis stream; and treating the residual reverse osmosis stream prior to reuse. The treatment may be in the form of passing through a secondary filter (such as another microfiltration or ultrafiltration membrane or a cartridge filter, and the subsequently treated reverse osmosis reject may be used to backwash the microfiltration or ultrafiltration unit.

Owner:EVOQUA WATER TECH LLC

Mobile station and methods for diagnosing and modeling site specific effluent treatment facility requirements

InactiveUS20090032446A1Reduce financial riskHigh continuity of operationReverse osmosisFlash degasificationIon exchangeReverse osmosis

A mobile station and methods are disclosed for diagnosing and modeling site specific effluent treatment facility requirements to arrive at a treatment regimen and / or proposed commercial plant model idealized for the particular water / site requirements. The station includes a mobile platform having power intake, effluent intake and fluid outflow facilities and first and second suites of selectably actuatable effluent pre-treatment apparatus. An effluent polishing treatment array is housed at the station and includes at least one of nanofiltration, reverse osmosis and ion-exchange stages. A suite of selectively actuatable post-treatment apparatus are housed at the station. Controls are connected at the station for process control, monitoring and data accumulation. A plurality of improved water treatment technologies are also disclosed.

Owner:ROCKWATER RESOURCE

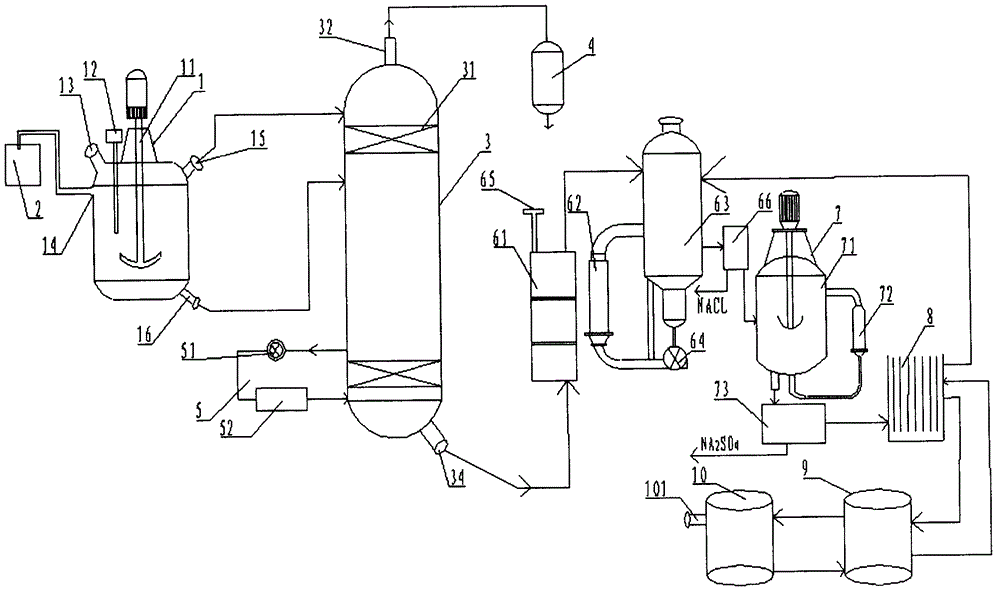

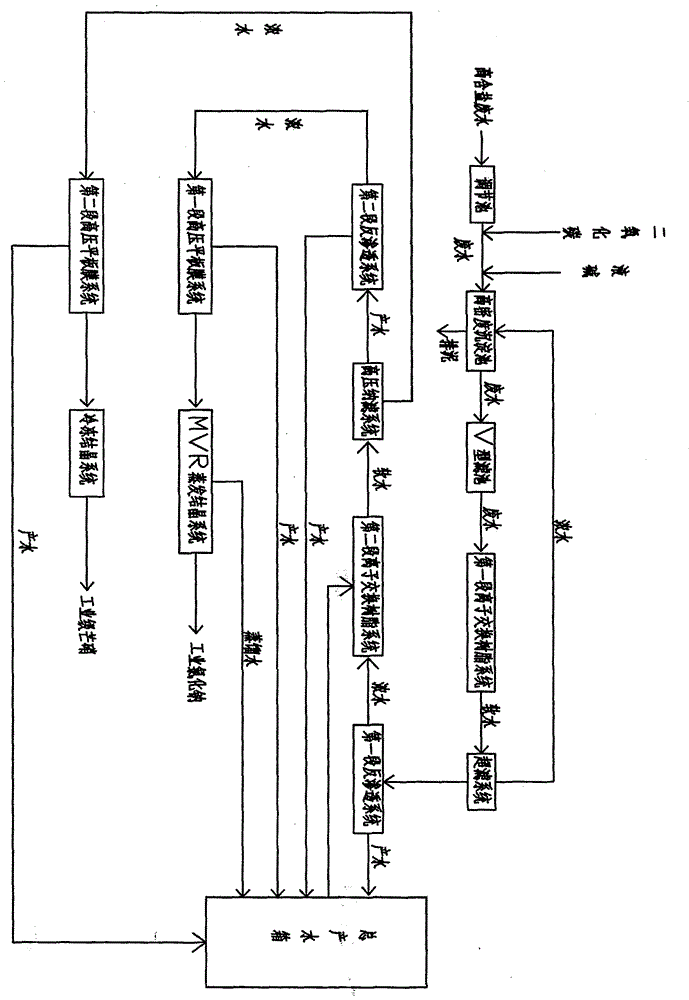

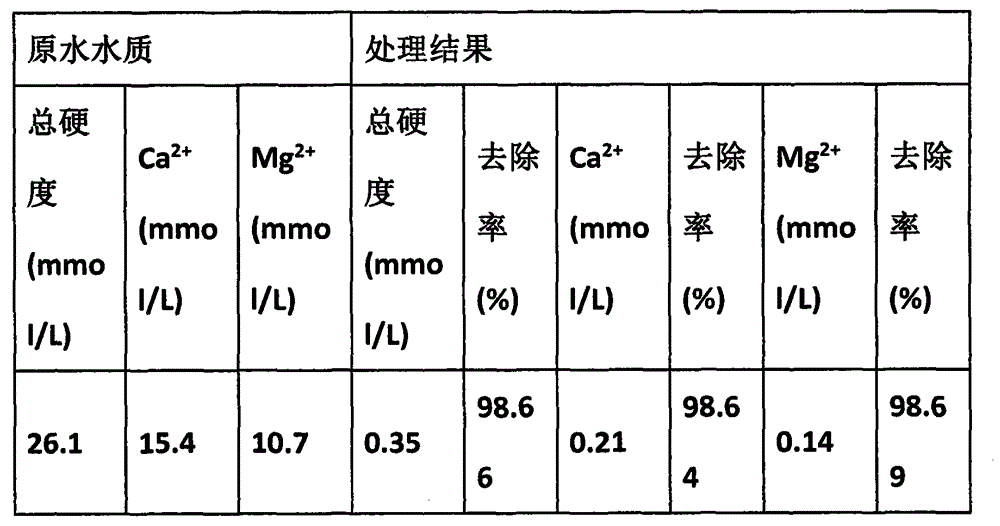

Desulfurization waste water zero discharging process and system

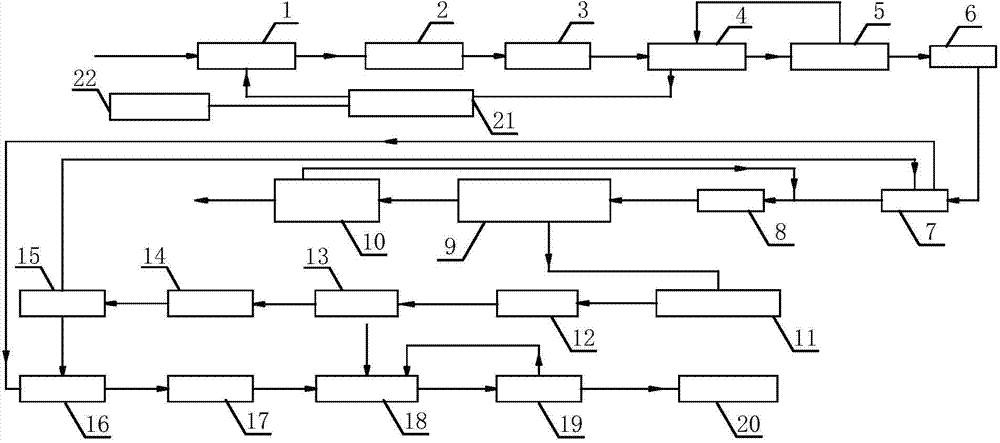

ActiveCN104843927ASolve pollutionWaste water treatment from gaseous effluentsMultistage water/sewage treatmentWater useHydration reaction

The invention discloses a desulfurization waste water zero discharging process. The process comprises a chemical dosing softening process and a microfiltration membrane treatment process; after incoming water is subjected to two-stage softening, nanofiltration and reverse osmosis separation are performed; sodium sulfate decahydrate with the purity of more than 99% is separated out by utilizing freezing crystallization; a reverse osmosis concentrated water regeneration sodium ion exchange device is utilized; sodium chloride with the purity of more than 98% is separated out by utilizing evaporative crystallization; solids are comprehensively utilized, and no liquid is discharged outside. The invention further provides a desulfurization waste water zero discharging system. According to the desulfurization waste water zero discharging process and the system, water in desulfurization waste water can be separated to be reutilized as domestic and industrial usable water, and other impurities in the desulfurization waste water are separated in solid form, so that pollutants harmful to the natural environment do not generate, and the problem that the desulfurization waste water pollutes the environment can be completely solved.

Owner:华电水务工程有限公司

Apparatus for Treating Solutions of High Osmotic Strength

InactiveUS20070272628A1Improves pressure vesselUniform flux distributionGeneral water supply conservationSeawater treatmentFiltrationReverse osmosis

The present invention pertains to an apparatus and method for treating a solution of high osmotic strength, especially seawater and solutions of greater than 20 bar osmotic pressure, by passing the solution through a vessel containing spiral wound reverse osmosis or nanofiltration elements. The vessel contains at least three elements in series and at least two of these elements have standard specific fluxed that differ by at least 50%. The invention allows a more even flux distribution within a filtration system to be obtained, and it may advantageously be combined with variations en element construction and feed spacers.

Owner:MICKOLS WILLIAM EDWARD +4

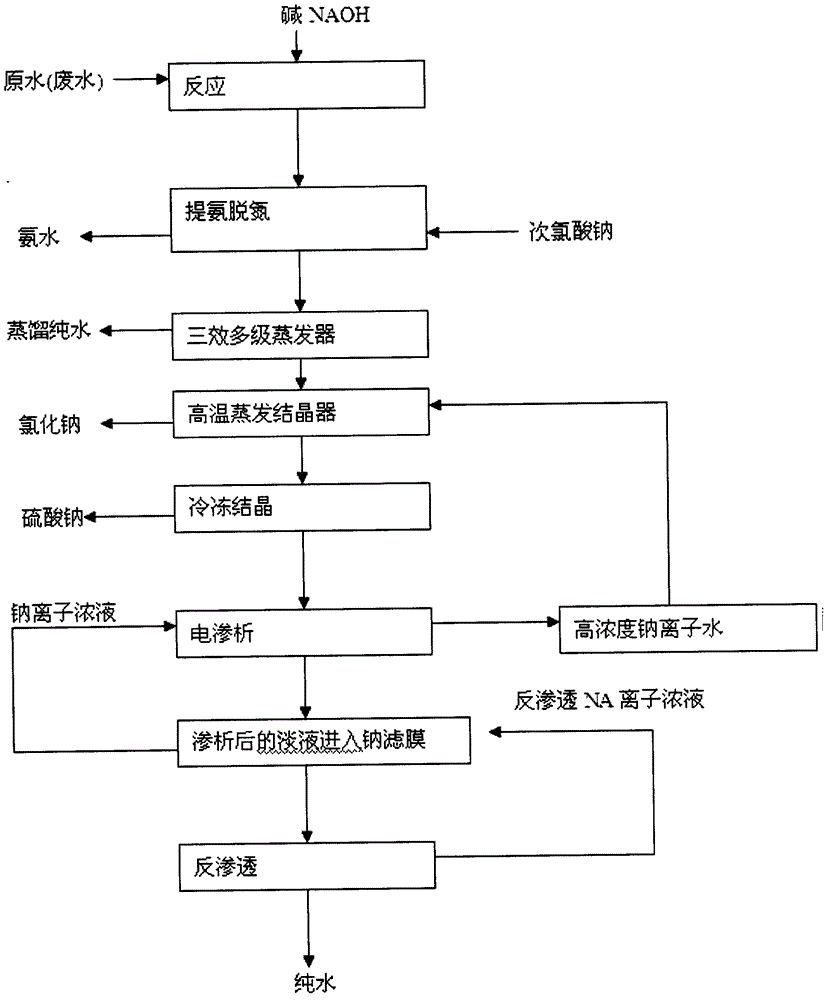

Method and device for utilizing sewage containing ammonia and sodium

ActiveCN104609633AReduce energy consumptionSave energyWater contaminantsMultistage water/sewage treatmentResource utilizationReverse osmosis

The invention discloses a method and device for utilizing sewage containing ammonia and sodium. The method comprises the steps of deamination reaction, denitrification reaction, gas-liquid separation, triple-effect multistage evaporation, evaprative crystallization and freezing crystallization, electrodialysis and sodium filteration membrane, and concentration of reverse osmosis membrane, so that distilled water and membrane deion pure water are recovered, and the resource utilization of sole sodium chloride and sodium sulfate is realized.

Owner:RUANSHI CHEM CHANGSHU

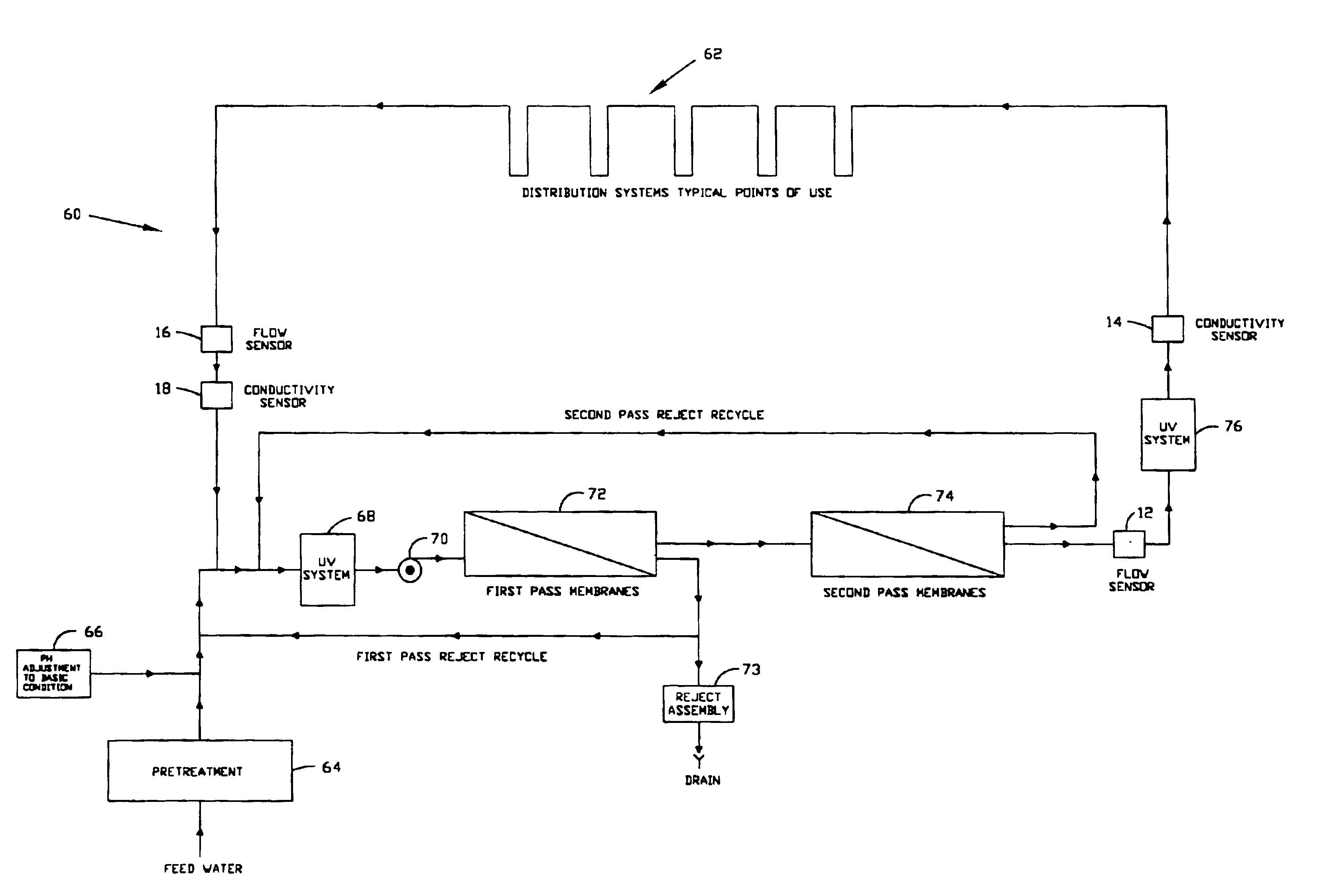

Apparatus and method for producing purified water having microbiological purity

InactiveUS6908546B2Reduce capital cost investmentReduce operating costsMembranesOther chemical processesNO storageReverse osmosis

A process is provided to produce water that will meet the specifications of the United States Pharmacopeia Inc. for Purified Water and Water for Injection, and water for dialysis as circumscribed by the American Association for Advancement of Medical Instrumentation (AAMI). The system has no storage tanks where stagnant water will be fouled by biofilm colonizing the tank surface. Water is circulated throughout the purification system and drawn as required, on demand. The water is purified and used immediately or recycled and repurified to ensure quality. Sanitation of the purification system, maintaining microbiological purity and cleaning is done by controlling the pH so that it is normally acidic by maintaining a high carbon dioxide concentration in solution, the carbon dioxide being allowed to pass into the permeate from a reverse osmosis membrane assembly used to purify the water.

Owner:BONOMICS LTD

Treatment method of high saline wastewater

ActiveCN104692574ATake advantage of the combinationAlkali metal sulfite/sulfate purificationMultistage water/sewage treatmentSocial benefitsFiltration

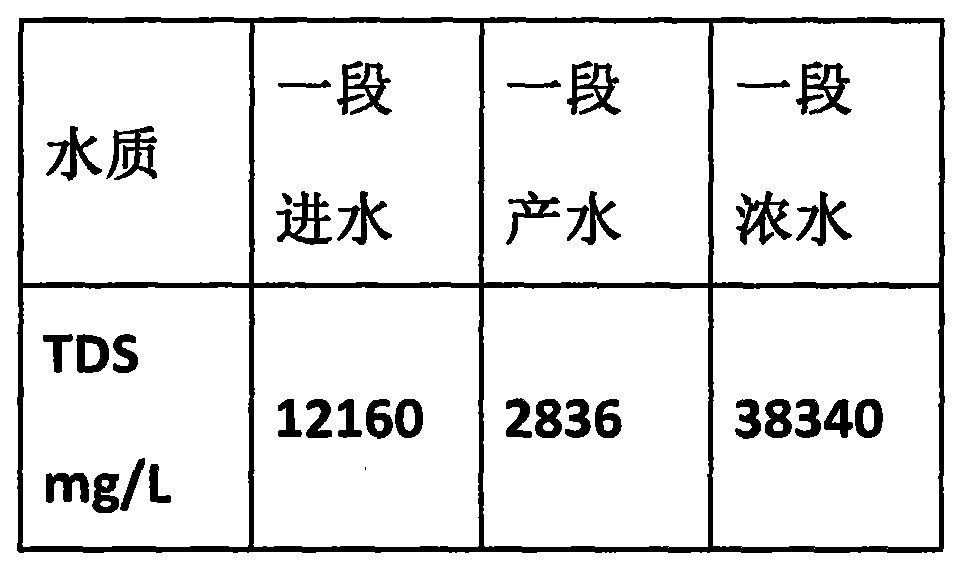

The invention discloses a treatment method of high saline wastewater, and relates to the treatment technology. The method comprises the following steps: preparing high saline wastewater, regulating in a regulating pond, chemically pre-treating in a settling pond, filtering in a V-shaped filter pond, the first section ion exchange softening, ultrafiltering in an ultrafiltration system, reverse osmosis treating through a first section reverse osmosis system, the second ion exchange softening, nano-filtering through a high-pressure nano-filtration system, nano-filtering to produce water, reverse osmosis treating through a second section reverse osmosis system, concentrating through a first section high-pressure flat film system, MVR evaporating and crystallizing to obtain the industrial level sodium chloride; nano-filtering to concentrate water, concentrating through a second section high pressure flat film system, freezing and crystallizing to obtain the industrial level mirabilite. The ultra-filtration, the nano-filtration, the reverse osmosis and high-pressure flat film methods are reasonably coupled to combine with the MVR crystallization and freezing crystallization to treat the high saline wastewater, the defect of single technology is overcome, the combination advantage is developed, the problems of efficiently and economically treating and recycling the high saline wastewater can be solved, and the treatment method has obvious economic benefit and social benefit.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

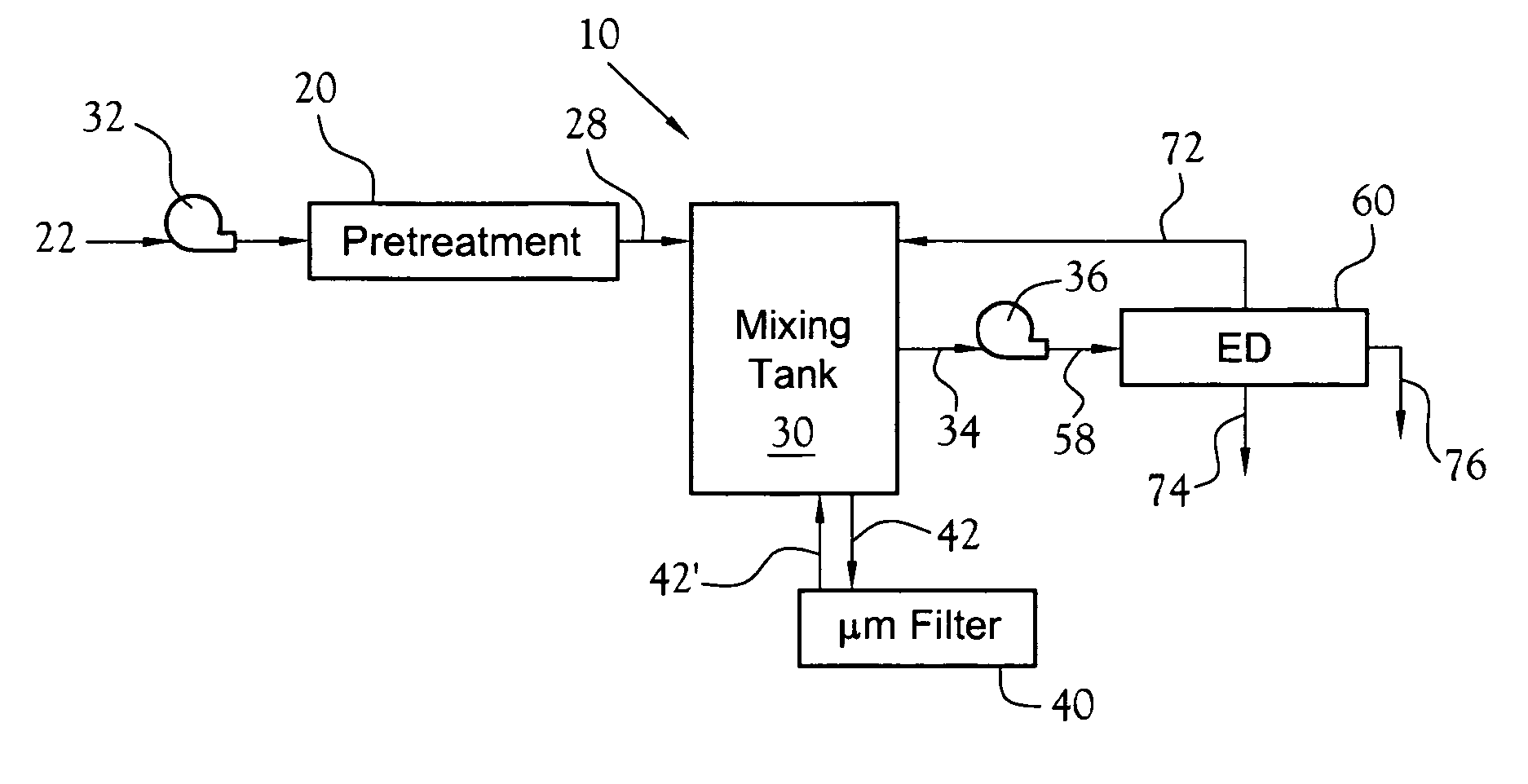

Water desalination process and apparatus

ActiveUS7459088B2Electrolysis componentsGeneral water supply conservationWater desalinationSolubility

A process and system for purifying water is disclosed. For example, in one embodiment, the process may be used to remove a divalent salt, such as calcium sulfate, from a water source in order to prevent the divalent salt from precipitating during the process. The water source, for instance, may be fed to an ion separating device, such as an electrodialysis device. In the electrodialysis device, an ion exchange takes place between the divalent salt and another salt, such as a monovalent salt to produce two concentrated salt streams that contain salts having greater solubility in water than the divalent salt. In one embodiment, the two salt streams that are produced may then be combined to precipitate the divalent salt in a controlled manner. During the process, various other components contained within the water feed stream may also be removed from the stream and converted into useful products. In one particular embodiment, the process is configured to receive a byproduct stream from a reverse osmosis process.

Owner:SOUTH CAROLINA THE UNIV OF

Modified membranes

InactiveUS20050029186A1Reduce dirtEssential mechanical properties of the membranesSemi-permeable membranesMembranesVinyl etherReverse osmosis

A porous polymeric membrane formed from a blend of a polymeric membrane forming material, such as polyvinylidene fluoride or polysulfone and a polymeric reactivity modifying agent adapted to modify the surface active properties of the porous polymeric membrane. The reactivity modifying agent is preferably a linear polymeric anhydride, such as poly(alkyl vinyl ether / maleic anhydride). The surface activity modifications include modification of the hydrophilicity / hydrophobicity balance of the membrane, or hydrolysis followed by reaction with a polyamine to form a crosslinked polyamide layer. Such modified membranes have use as reverse osmosis membranes.

Owner:EVOQUA WATER TECH LLC

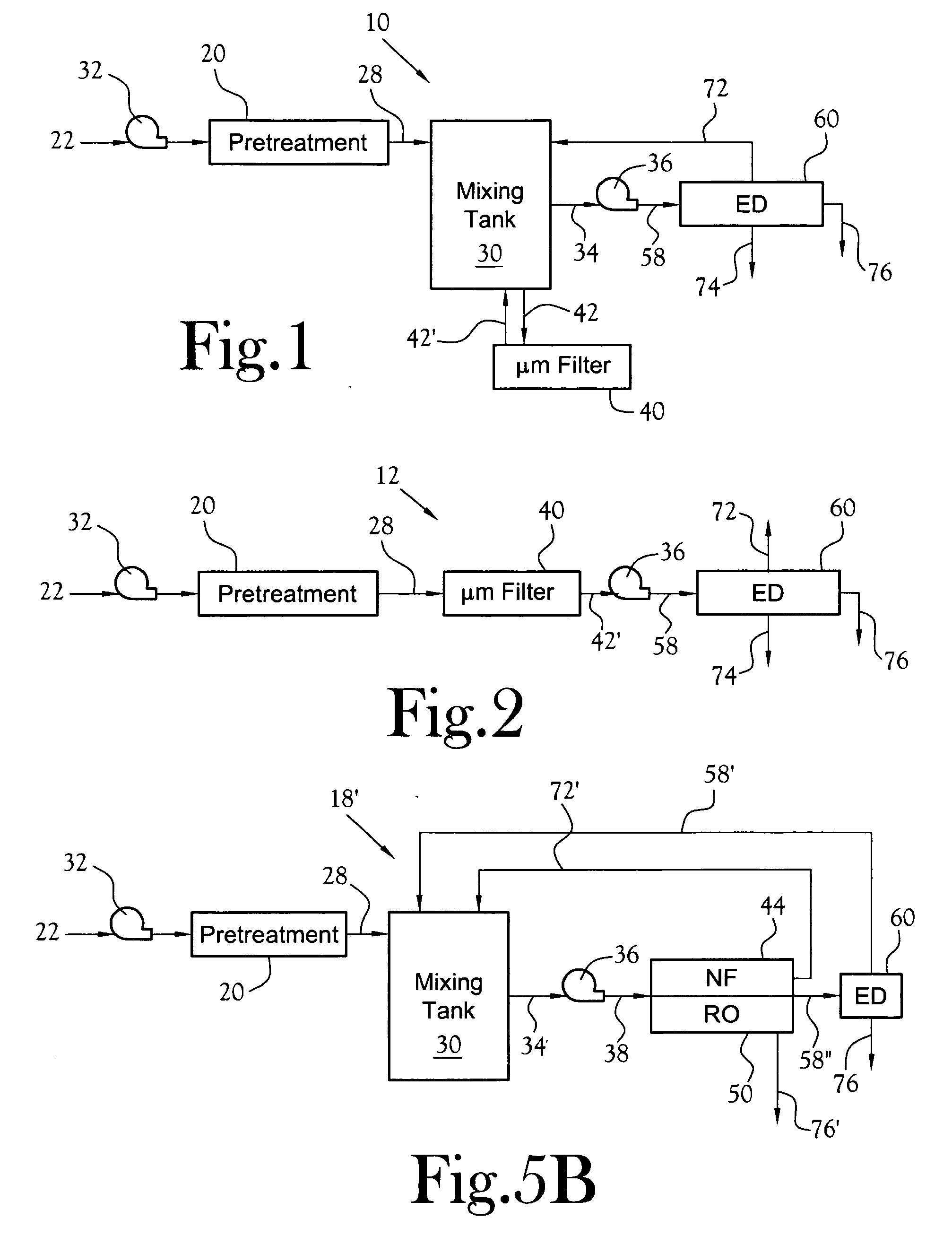

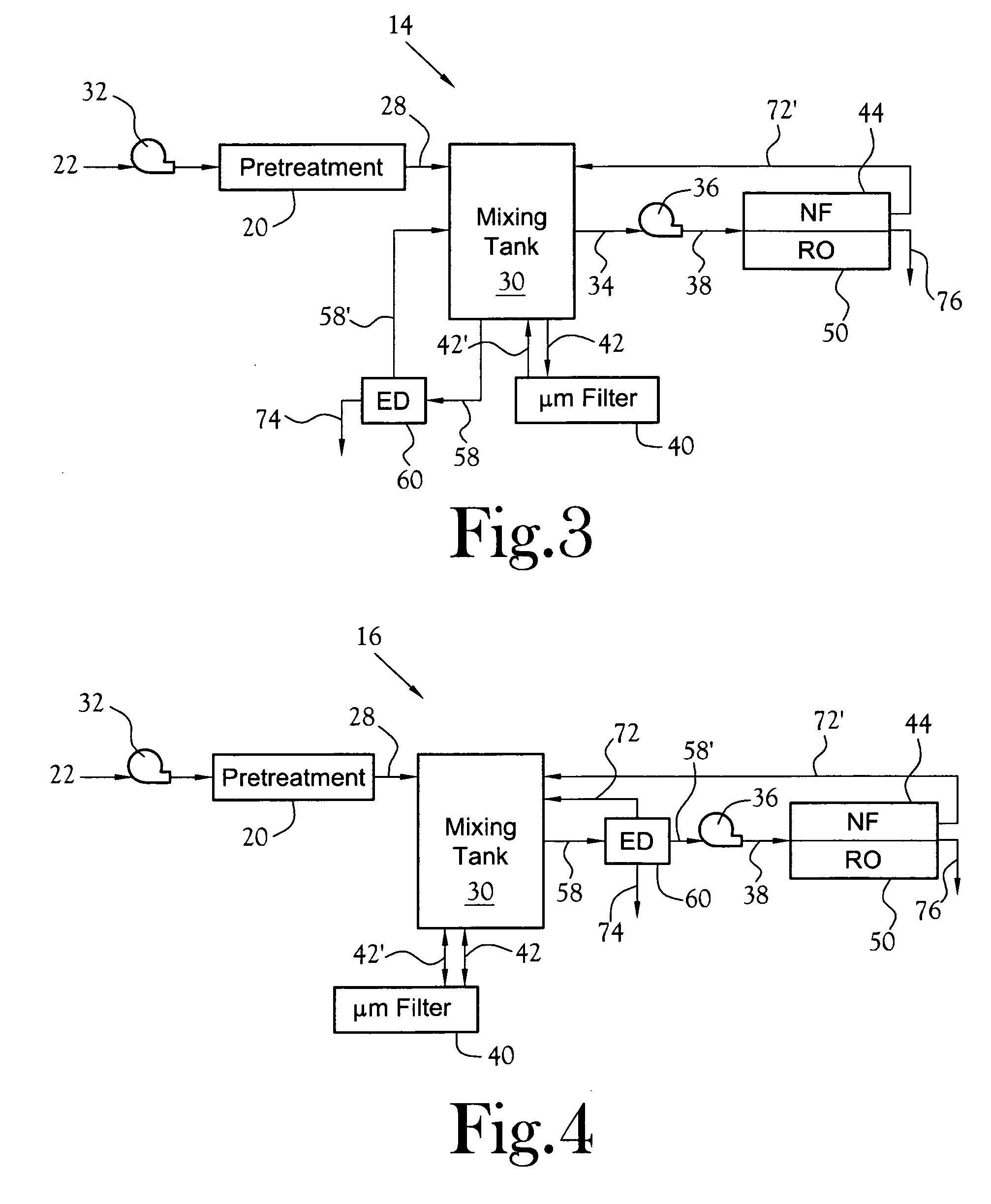

Integrated electro-pressure membrane deionization system

InactiveUS20060144787A1High capital costImprove utilization efficiencyLiquid separation auxillary apparatusVolume/mass flow measurementPressure.driveReverse osmosis

An integrated treatment system using electrodialysis and pressure-driven membranes for deionizing and decontaminating liquids to a near-pure quality for use or reuse in industrial or municipal operations. The integrated system includes steps of pre-filtering contaminated feed liquids blending the filtered liquids in preparation for treating the mixed liquids in parallel or sequential treatment steps utilizing nanofiltration or reverse osmosis, proceeded by or followed by an integrated electrodialysis treatment. A control means selectively directs mixed liquids to each of the treatment units for treatment in parallel or in series depending on the conductivity and residual contaminants in the mixed liquids. In comparison with nanofiltration or reverse osmosis only systems, or electrodialysis only systems, the integrated system provides improved efficiencies for treatment, requires less energy to operate, and reduces maintenance and capital costs.

Owner:EET TN

System and method for regeneration of a fluid

A method and a system for regenerating a body fluid, such as a peritoneal dialysis fluid. The body fluid is removed into an extracorporeal circuit comprising an electrofilter for removing charged ions from the body fluid, a nanofilter for removing large molecules, such as Dextran 40, and a reverse osmosis filter for concentrating the body fluid, for producing a synthetic urine to be discarded. The removed ions and large molecules are returned to the patient together with pure water from the reverse osmosis filter through an ultrafilter.

Owner:TRIOMED AB

Reverse osmosis filtering apparatus with concentrate dilution

InactiveUS6299766B1HEPA filterLess energyDialysis systemsSedimentation separationReverse osmosisSalt water

Liquid filtering apparatus includes a plurality of reverse osmosis filters for receiving seriatim under pressure a mixture of feed liquid and recirculated concentrate. Feed liquid such as salt water is introduced into the inlet of each reverse osmosis filter to dilute the recirculated concentrate.

Owner:PERMAR CLARK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com