Reverse Osmosis Membrane with Branched Poly(Alkylene Oxide) Modified Antifouling Surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific embodiments

Preparation of Membranes

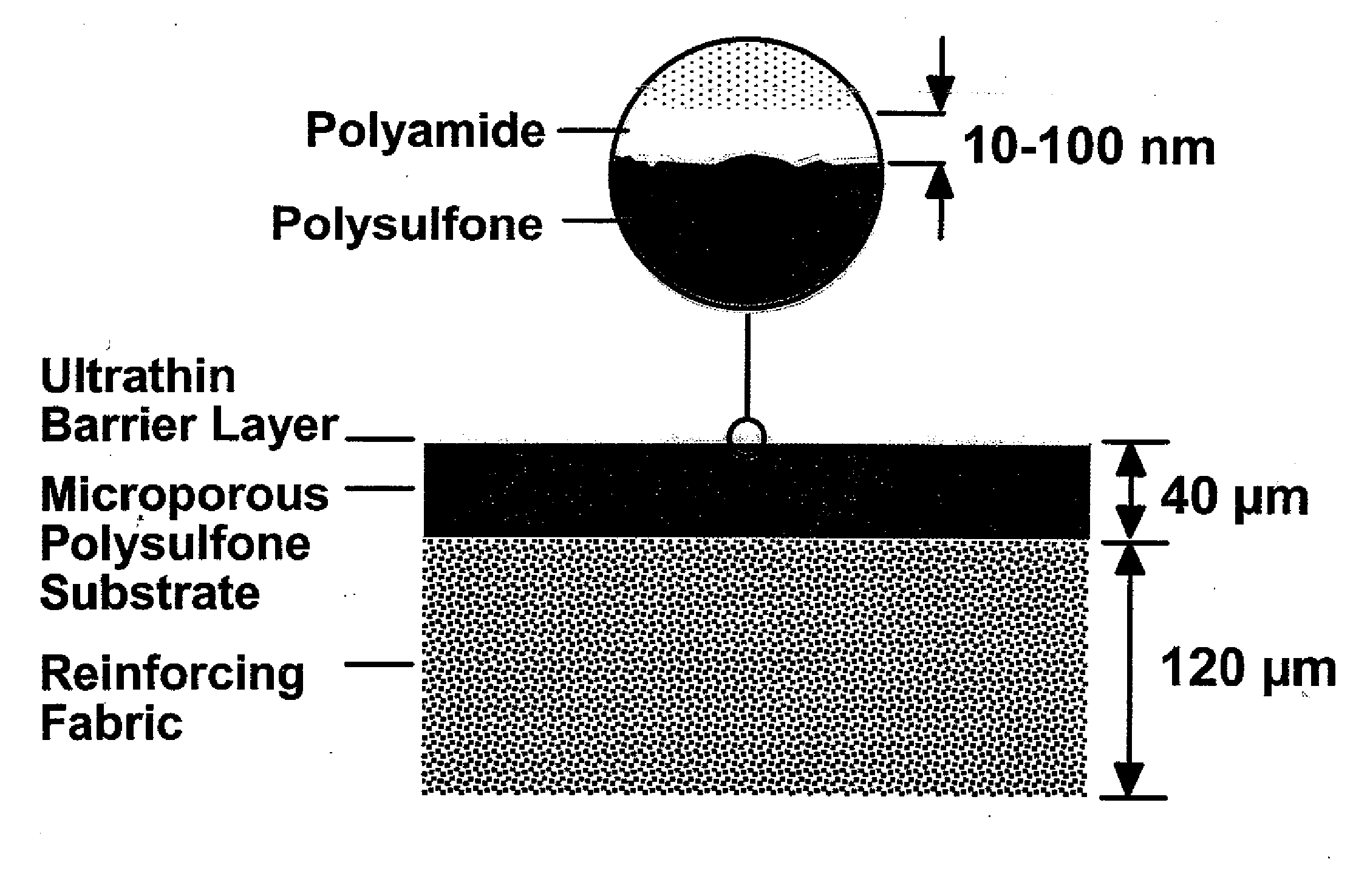

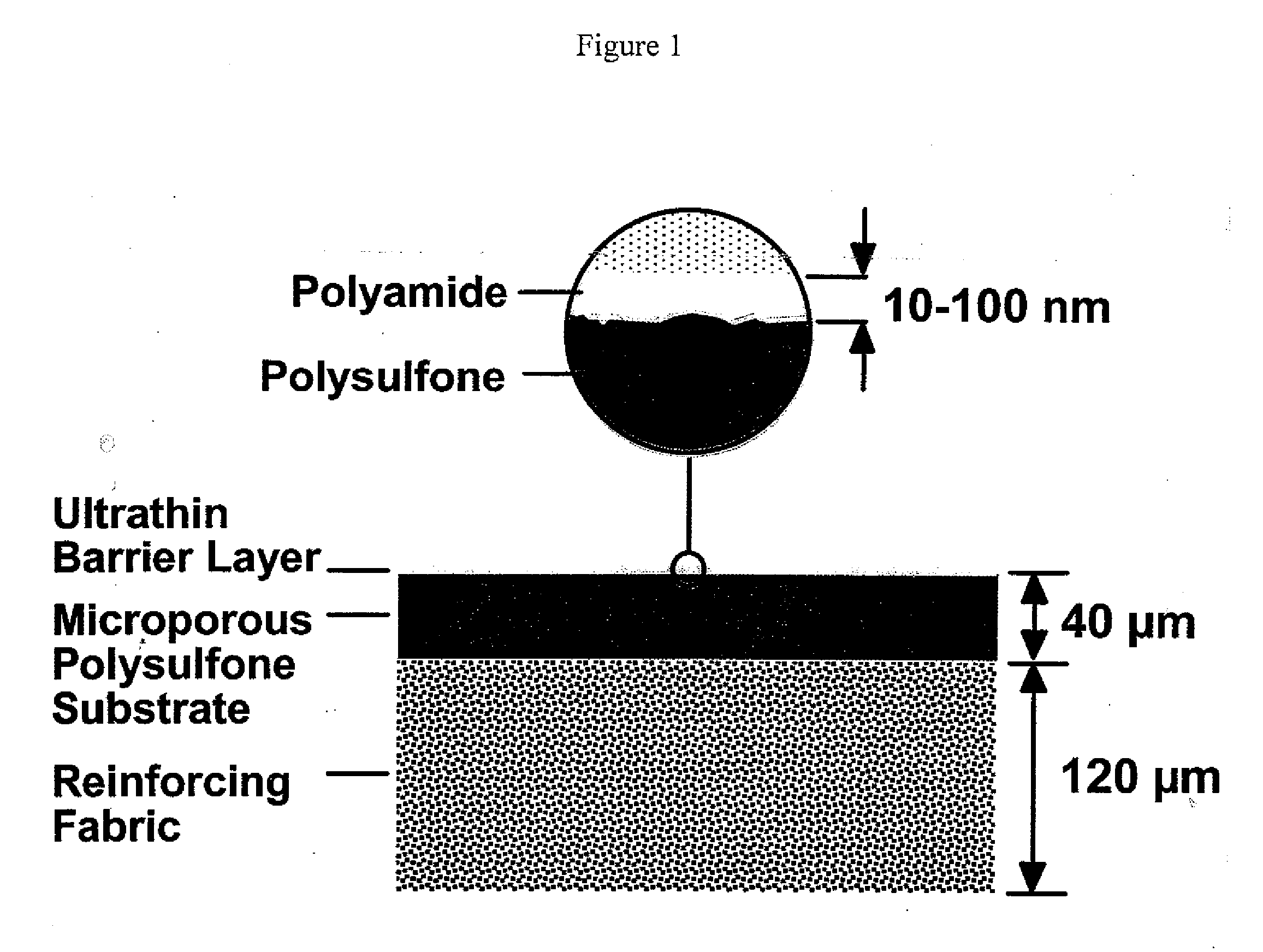

[0055] FT-30 reverse osmosis composite membranes were prepared on a FilmTec Corporation pilot coater in a continuous process. First the MPD was applied in water to the pre-made microporous polysulfone support including the backing non-woven fabric, and then the support was drained and nip rolled to remove the excess aqueous solution. The top surface of the support was sprayed with a solution of TMC in Isopar L (available from ExxonMobil Corp.).

[0056] At the oil water interface the polyamide was formed. The first coating was made with a MPD solution of 2.0 to 4.0%, and the second coating was made with a TMC concentration of 0.13% (5 mM). The TMC solution also included a molar stoichiometric ratio of TBP (tributyl phosphate) to TMC of 1:1. The membrane traveled first through a room temperature water bath after application of the second coating, then through a 98 C bath that contained 3.5% of glycerin. At this stage, a layer of PEO brush was coated onto the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com