Patents

Literature

1350 results about "Tributyl phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tributyl phosphate, known commonly as TBP, is an organophosphorus compound with the chemical formula (CH₃CH₂CH₂CH₂O)₃PO. This colourless, odorless liquid finds some applications as an extractant and a plasticizer. It is an ester of phosphoric acid with n-butanol.

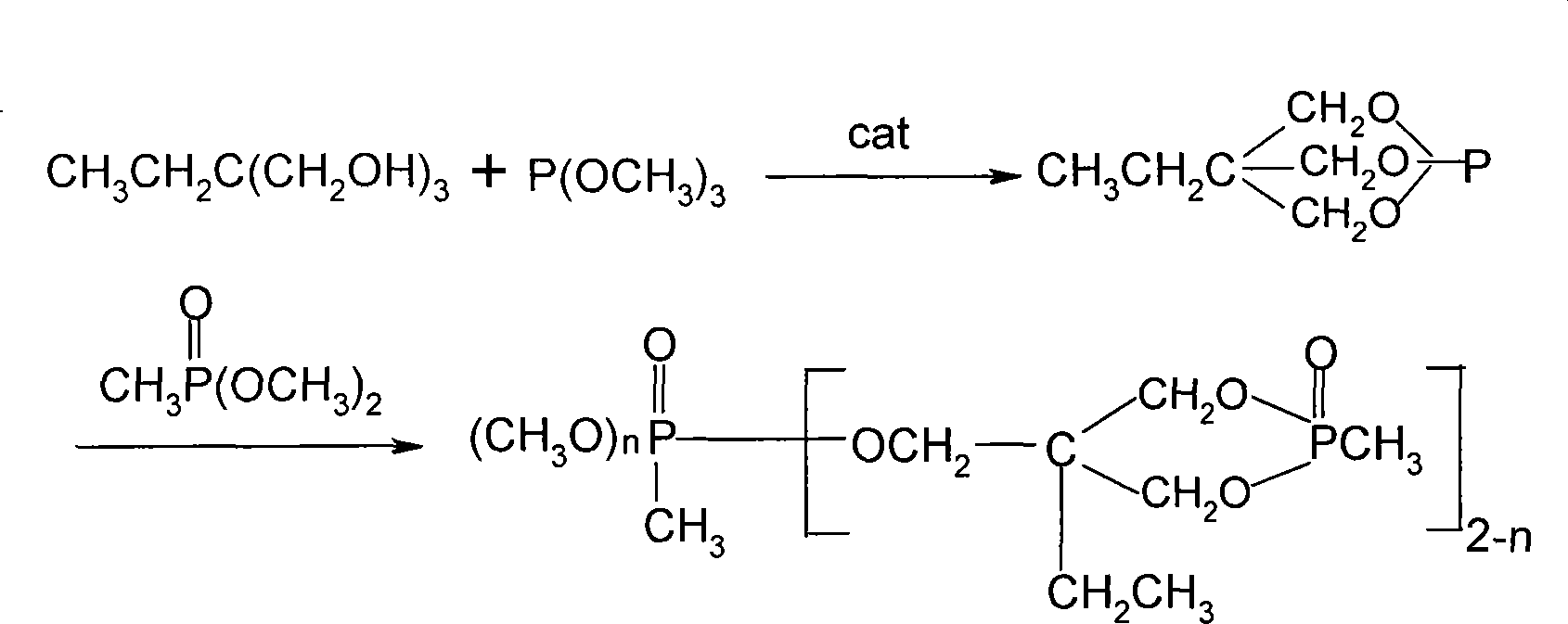

Method for preparing annular phosphonate or annular phosphate flame retardant

InactiveCN101230274AThe preparation method is simple and environmentally friendlyEasy to operateFlame-proof filament manufactureGroup 5/15 element organic compoundsDimethyl methylphosphonateTriethylphosphite

The invention provides a preparation method of annular phosphonate or annular organic phosphate flame retardant. The steps are that (1) trimethylolpropane and trimethyl phosphate or triethyl phosphate are taken as the material, and react to synthesize into midbody under the condition of catalyzer; (2) phosphonate or organic phosphate is added into the midbody and is heated, and then the product of annular phosphonate or annular organic phosphate flame retardant can be obtained. The phosphite ester is selected from trimethyl phosphate and triethyl phosphate. The phosphonate is selected from dimethyl-phosphine and diethyl ethyl phosphine. The organic phosphate is selected from trimethyl phosphate, triethyl phosphate, phosphate propyl, tributyl phosphate and tricresyl aromatic ester. The invention overcomes the shortcomings of the prior art, the new preparation method of annular phosphonate or annular organic phosphate flame retardant is environment-friendly, solution is not needed, and the operation is simple. The termination product has excellent color and luster, low acid value and excellent viscosity; and does not need additional decoloration.

Owner:NANJING NORMAL UNIVERSITY +1

Modified urea-formaldehyde resin adhesive and production method thereof

ActiveCN103450832AHigh viscosityViscosity increases relatively gentlyNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesPolymer sciencePhosphoric acid

The invention provides a modified urea-formaldehyde resin adhesive low in formaldehyde residue and a production method thereof. The modified urea-formaldehyde resin adhesive is characterized by being prepared from the following raw materials in parts by weight: 100 parts of modified urea-formaldehyde resin, 20-25 parts of reinforcing agent and 0.1-0.2 part of defoamer, wherein the reinforcing agent is any one or a composition of several of white carbon black, titanium dioxide, calcium carbonate and kaolin having the particle size greater than 300 meshes; the defoamer is polydimethylsiloxane or tributyl phosphate. The formaldehyde residue of the modified urea-formaldehyde resin adhesive provided by the invention is less than 0.1 mg / L; the modified urea-formaldehyde resin adhesive is used as an adhesive for an artificial board; as the modified urea-formaldehyde resin adhesive is low in release amount of formaldehyde, the health of customers is protected.

Owner:广西横州丽冠环保材料有限公司

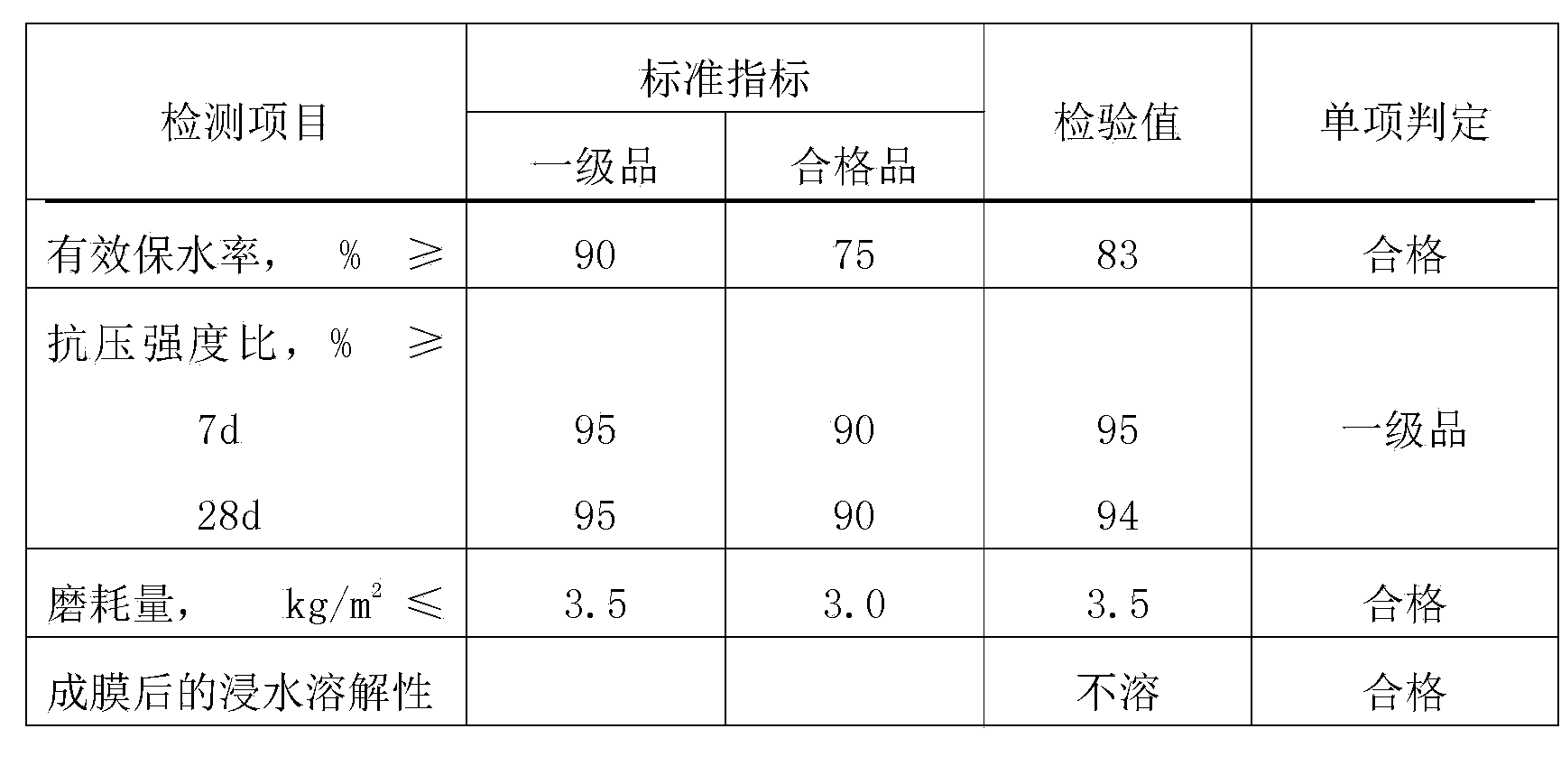

Lightening gypsum suspended ceiling

The invention discloses a light-quality plaster ceiling in the architectural decorative material domain, which comprises the following parts: 50-70% architectural plaster, 8-15% light filler, 0.5-1.5% modifier, 1-2% waterproofing agent and 5-10% polyvinyl alcohol solution, wherein the lightweight fill is one or two or three of light calcium carbonate or lightweight magnesium carbonate or white carbon black according to random rate; the modifier is composed of 100g water, 15-20g silicasol, 5-7g sodium fluoride, 4-6g aluminum potassium sulfate, 7-9g potassium bichromate and 0.5-1g tributyl phosphate; the waterproofing agent is organic silicon waterproofing agent of sodium silanol methyl or potassium silanol methyl; the glass fiber is low-alkaline or non-alkaline glass fiber.

Owner:云南天之豪装饰材料有限公司

Aqueous rust-conversion rust-inhibiting primer

The invention relates to a water-based rust conversion antirust primer which is characterized in that: the primer comprises the following components with the corresponding percentage by weight : main conversion agent 5-35, auxiliary conversion agents 2-15, film forming material 40-55, penetrant 0.2-1.0, humectant 1-10, anti-forming agent 0.1-0.5, corrosion inhibitor 0.2-0.5 and solvent 0.5-8; the process is as follows: adding deionized water to a charging basket and heating the water to 60-80 DEG C with aliphatic alcohol polyethenoxy ether added, adding propylene glycol and starting a high-speed dispersion machine for agitation, later on adding tributyl phosphate, potassium sorbate, tannic acid and one of the auxiliary conversion agents and cooling down to 20-33 DEG C after agitating for 30-55 minutes, and adding vinyl chloride-modified acrylic resin latex and discharging material after agitating for 10-20 minutes. The invention has the advantages of direct application to steel surfaces with rust, thorough conversion of rust, excellent adhesive force of a conversion film, good flexibility, adaptation to various forms, and good compatibility with various top coatings.

Owner:安泰能(上海)高分子材料有限公司

Stainless steel degreasing agent

InactiveCN101979711AImprove solubilityImproves the properties of uniform corrosionActive agentBrominated hydrocarbon

The invention provides a stainless steel degreasing agent, which comprises the following components in percentage by weight: 5 to 25 percent of organic solvent, 2 to 5 percent of corrosion inhibitor, 10 to 25 percent of surfactant, 5 to 10 percent of inorganic salt, 1 to 3 percent of defoaming agent and the balance of deionized water, wherein the organic solvent is bromohydrocarbon; the corrosion inhibitor is sodium benzoate, ammonium benzoate, triethanolamine, ethanolamine or benzotriazole; the surfactant is one or more of alkylphenol polyoxyethylene ether and fatty alcohol-polyoxyethylene ether; the inorganic salt is alkaline salt; and the defoaming agent is tributyl phosphate, organic silicon, oleic acid or sodium oleate. The stainless steel degreasing agent can replace the currently used ODS cleaning agents, can achieve the cleaning effect of the ODS cleaning agents, does not damage the surface of the stainless steel, has obvious cleaning effect, can clean a large number of products, and does not harm a human body; and the preparation method is simple, safe, and environment-friendly.

Owner:JIANGSU TIANHENG NANO SCI & TECH

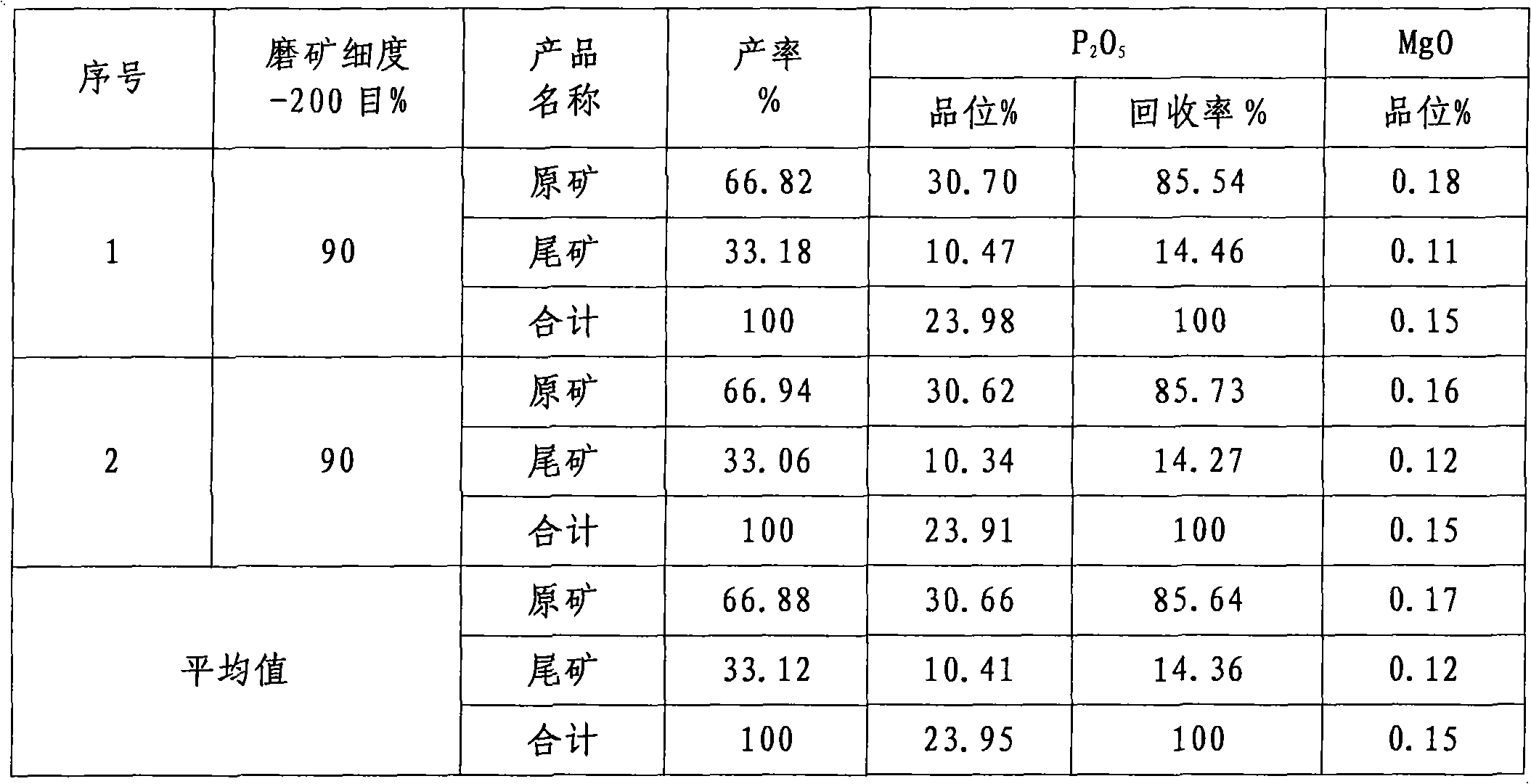

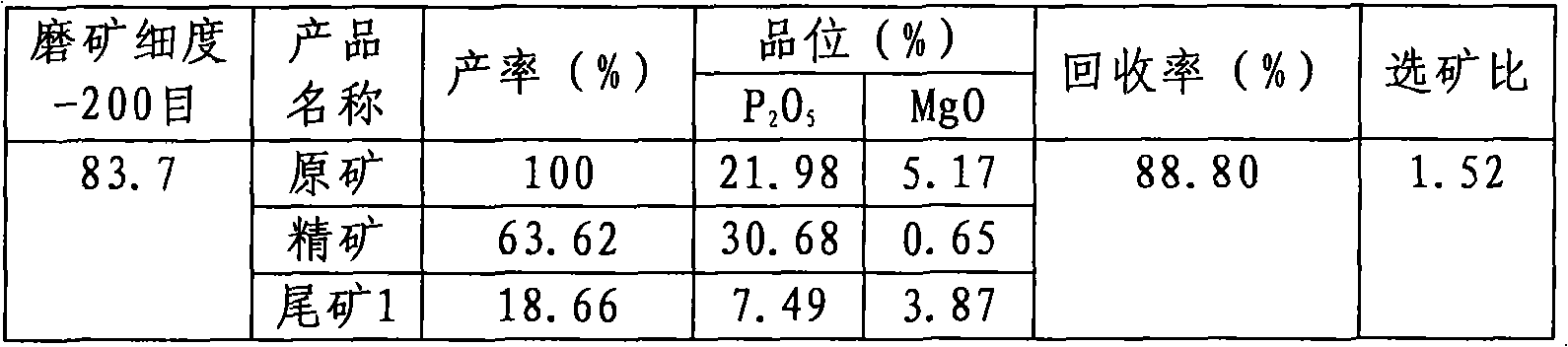

Collophanite flotation collector and method for preparing same

ActiveCN101797536AStable chemical propertiesGood water solubilityFatty acids production/refiningFlotationSolubilityFatty acid

The invention relates to a collophanite normal-temperature flotation collector, in particular to collophanite flotation collector prepared from natural rubber seed oil fatty acid, belonging to the collector. The invention also relates to a method for preparing the collophanite flotation collector. The collophanite flotation collector comprises natural rubber seed oil fatty acid, tall oil, tributyl phosphate, tween 80, dodecyl benzene sulfonic acid, inorganic base and water. The collophanite flotation collector has stable chemical performance, good water solubility, high flotation speed, suitable viscosity and strong selectivity and collection performance, is easy to diffuse in collophanite pulp, can be used for obverse floatation and reverse flotation and can generate uniform bubbles, obviously shorten the floatation time, improve the concentrate grade and reduce the content of impurities in the concentrate product.

Owner:YUNNAN CHEM RES INST

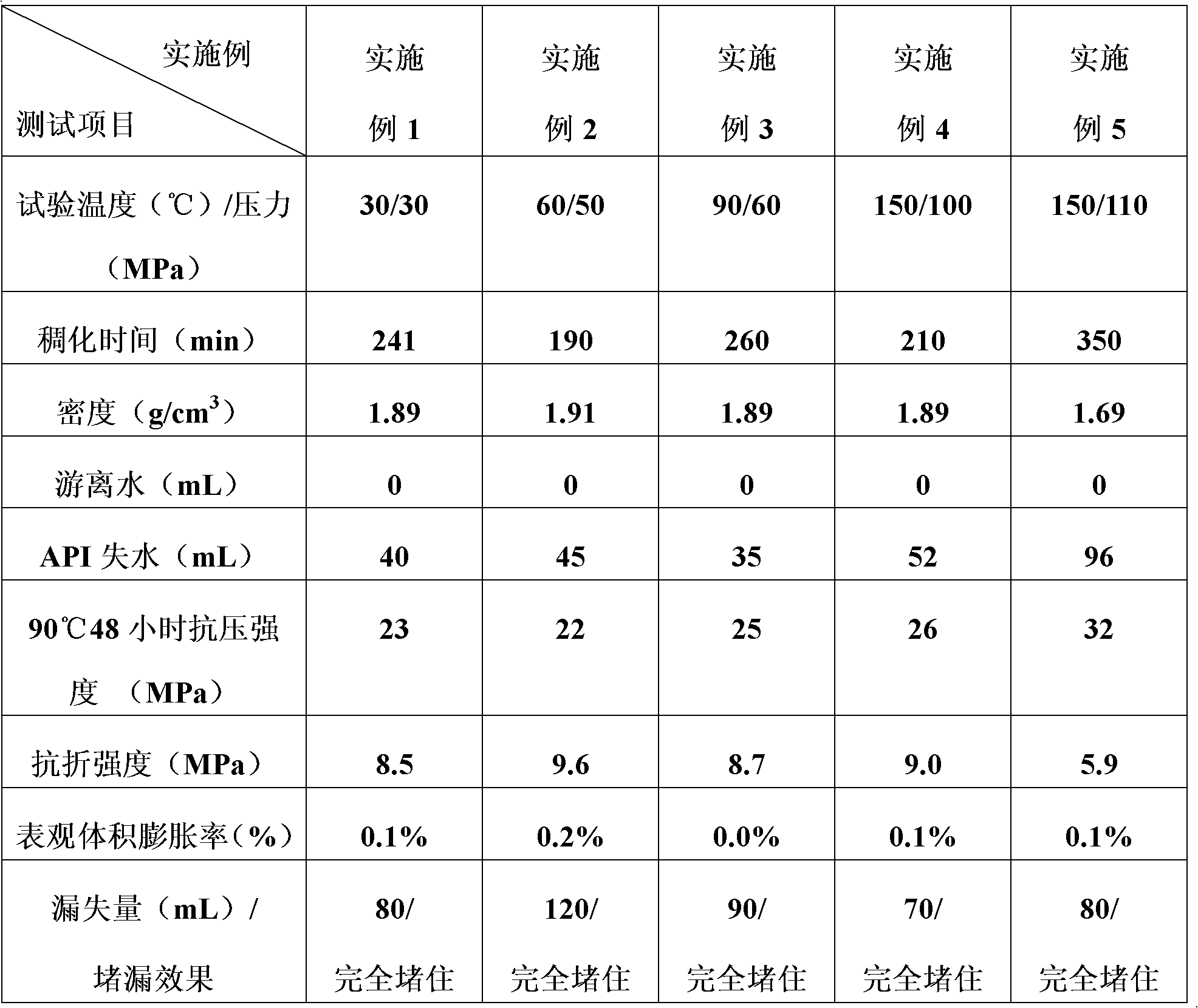

Leaking stoppage cement slurry for well cementation and preparation method thereof

InactiveCN101857800AGood high temperature application performanceEvenly dispersedDrilling compositionCementation processSodium sulfate

The invention relates to leaking stoppage cement slurry for well cementation and a preparation method thereof. The leaking stoppage cement slurry consists of the following components in parts by weight: 100 parts of oil-well cement, 50-150 parts of water, 0.01-8 parts of fibrilia, 1-20 parts of dispersing agent, 1-20 parts of filtrate reducer, 5-50 parts of alkali regulator, 1-10 parts of retarder and 0-1 part of defoaming agent, wherein the dispersing agent is lauryl sodium sulfate or sodium hexametaphosphate; the filtrate reducer is 2-acrylamide-2-methylpropanesulfonic acid or hydroxyethylcellulose; the alkali regulator is silicon powder; the retarder is sodium lignin sulfonate or citric acid; the defoaming agent is dimethyl silicon oil or tributyl phosphate; and the fibrilia is one or the mixture of two or more of jute, flax, hemp, ramie and sisal. The invention effectively solves the problem of leakage loss of cement slurry and inherent brittleness of set cement in the well cementation process on the premise of meeting various engineering performances required by the well cementation and provides the guarantee for subsequent operation of oil well gas.

Owner:SOUTHWEST PETROLEUM UNIV

Complex extracting and dephenolizing method for alkaline slag of smeltery

InactiveCN1683475AHigh removal rateHigh purityOrganic chemistryOrganic compound preparationSlagSludge

The comprehensive refinery caustic sludge complex extracting and dephenolizing process includes mixing tributyl phosphate, hybrid C4-C7 alcohol and toluene, ethyl benzene or xylene to obtain extractant I; mixing saturated C8-C12 hydrocarbon, hybrid C4-C7 alcohol and toluene, ethyl benzene or xylene to obtain extractant II; mixing extractant I with caustic sludge system for complex extraction; adding extractant II to obtain triphase extraction system for complex extraction including raffinate, extractant I phase rich in phenol and extractant II phase rich in sulfide; adding saturated NaOH solution into extractant I phase for re-extracting to eliminate phenol and obtain extractant I; and heating extractant II phase for re-extracting to eliminate sulfide and obtain extractant II. The present invention has raised extracting rate, and raised phenol purity and utilization.

Owner:CHINA PETROLEUM & CHEM CORP +1

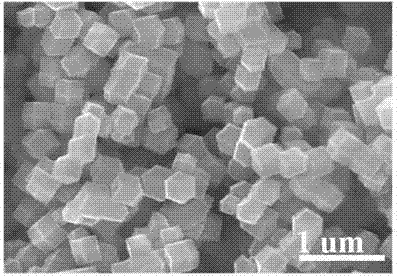

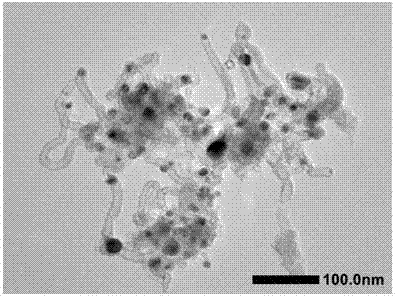

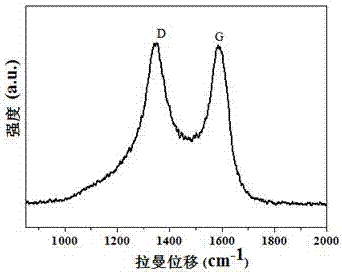

Nitrogen-containing graphitized carbon material adopting double-metal MOFs (metal organic frameworks)

InactiveCN107399729ALarge specific surface areaImprove performanceMaterial nanotechnologyPhysical/chemical process catalystsElectrolysisPorous carbon

The invention provides a nitrogen-containing graphitized carbon material adopting double-metal MOFs (metal organic frameworks). The material is prepared with a method as follows: S1, 2-methylimidazole is dissolved to form a solution A, cobalt salt and zinc salt are mixed to form a solution B, the solution A and the solution B are mixed, left to stand, centrifugalized, washed and dried, and double-metal MOF precursors are obtained; S2, the double-metal MOF precursors formed in S1 are calcined in an inert gas atmosphere, and the calcined double-metal MOF precursors are obtained; S3, the calcined double-metal MOF precursors formed in S2 are mixed with triphenylphosphine or tributyl phosphate in a solution, the mixture is calcined in an inert gas atmosphere, washed and dried, and the nitrogen-containing graphitized carbon material adopting the double-metal MOFs is obtained. The invention provides a highly-graphitized porous carbon material which is high in specific surface area and hierarchically porous, realizes uniform nitrogen doping and contains rich metal-nitrogen structures, the activity of the product in oxygen evolution through water electrolysis is more excellent than that of commercial ruthenium oxide, and the material has great application prospects in energy storage materials.

Owner:SUN YAT SEN UNIV

Far infrared negative ion functional non-woven fabric and preparation method thereof

InactiveCN103757820AHeat resistantCorrosion resistanceSynthetic resin layered productsNon-woven fabricsPolyethylene glycolCis-Butenedioic Acid

The invention discloses a far infrared negative ion functional non-woven fabric. The far infrared negative ion functional non-woven fabric consists of a top surface layer, a back face layer and a fiber cotton layer clamped between the top surface layer and the back face layer, wherein the top surface layer and the back face layer are made of a non-woven fabric material. The non-woven fabric is prepared from the following raw materials in parts by weight through a melt blowing method: 100 parts of isotactic polypropylene, 3-4 parts of tourmaline, 2-3 parts of aluminum oxide, 1-2 parts of zinc oxide, 12-15 parts of tributyl phosphate, 1-2 parts of titanium dioxide, 6-8 parts of dibutyl maleate, 2-3 parts of 3-aminopropyltrimethoxysilane, 2-3 parts of polyethylene glycol, 3-4 parts of urea, 2-3 parts of grassleaf sweelflag rhizome, 1-2 parts of lily, 2-3 parts of kudzuvine root and 4-5 parts of aid. The non-woven fabric has far infrared, negative ions, antibacterial and deodorization functions. Due to the adoption of the isotactic polypropylene, the non-woven fabric has the characteristics of heat resistance, corrosion resistance, nontoxicity and no odor, is high in tensile strength and bonding property, does not produce dust or scrap, and has the functions of perfuming and health care.

Owner:芜湖跃飞新型吸音材料股份有限公司

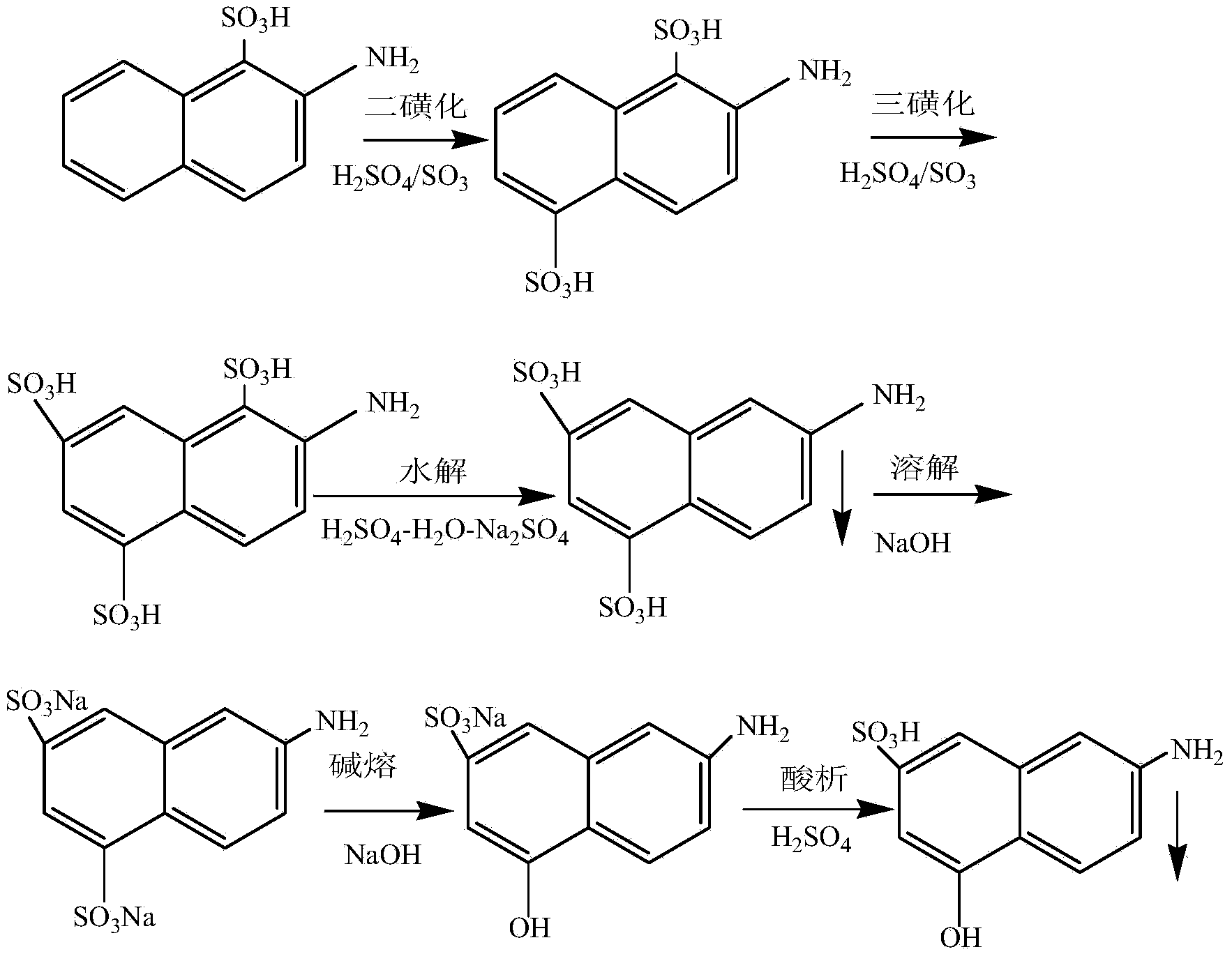

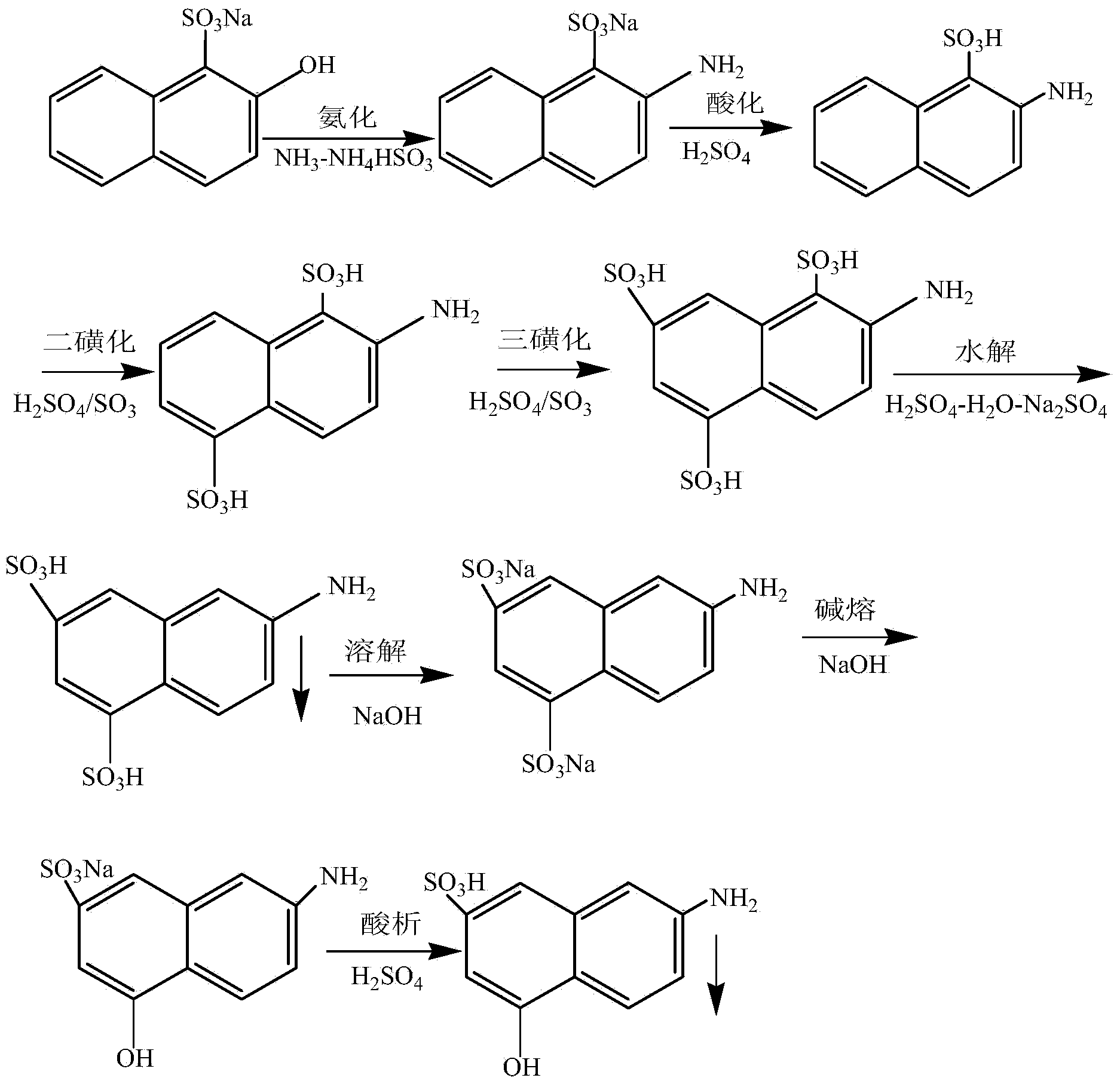

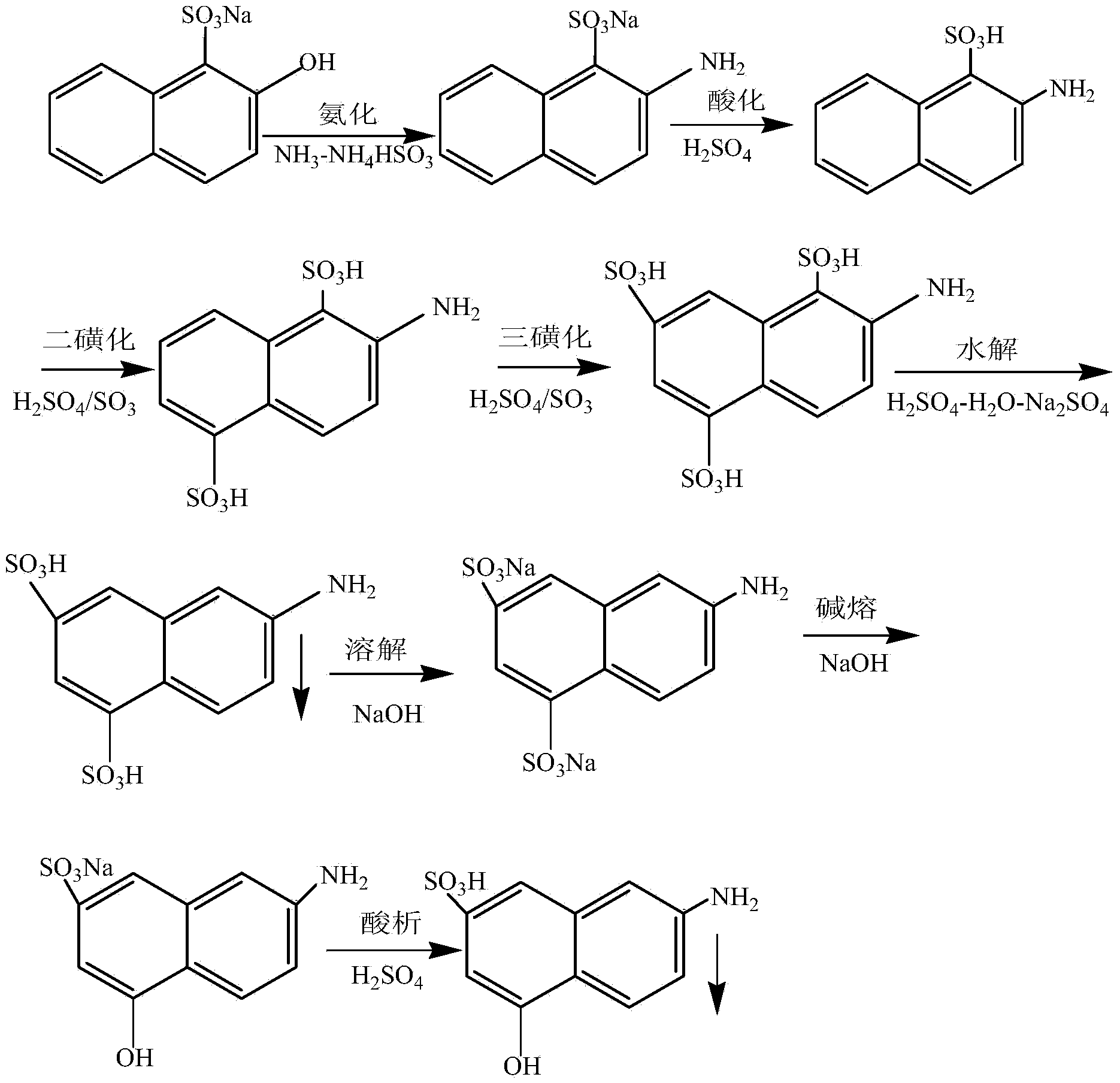

Preparation method of J acid and J acid waste water comprehensive treatment and recycling method

ActiveCN103896438ALow costDoes not affect productivityMultistage water/sewage treatmentSulfonic acid preparationWastewaterHydrolysis

The invention relates to a preparation method of J acid and a J acid waste water comprehensive treatment and recycling method. The J acid waste water comprehensive treatment and recycling method is as follows: the following treatment is carried out on hydrolysis waste water: (1) 30-40% of the total quantity of the hydrolysis waste water is used in an acidification reaction for preparing 2-naphthylamine-1-sulphonic acid by utilizing sodium 2-naphthylamine-1-sulphonate; (2) extraction and reextraction are carried out on the residual hydrolysis waste water, so that Na2SO4 and extraction waste liquor are obtained, the extraction waste liquor is used in a hydrolysis working procedure in a J acid production process, an extraction agent adopted during extraction is composed of 10-30wt% of complex agent, 30-70wt% of diluent and 5-20wt% of tributyl phosphate, and the complex agent is trioctylamine, or trialkyl tertiary amine or combination of trioctylamine and trialkyl tertiary amine. By adopting the preparation method of the J acid, the cost of water for the J acid and waste water treatment cost can be greatly reduced, and environmental pollution can be reduced.

Owner:XIANGSHUI HENRYDA TECH CHEM

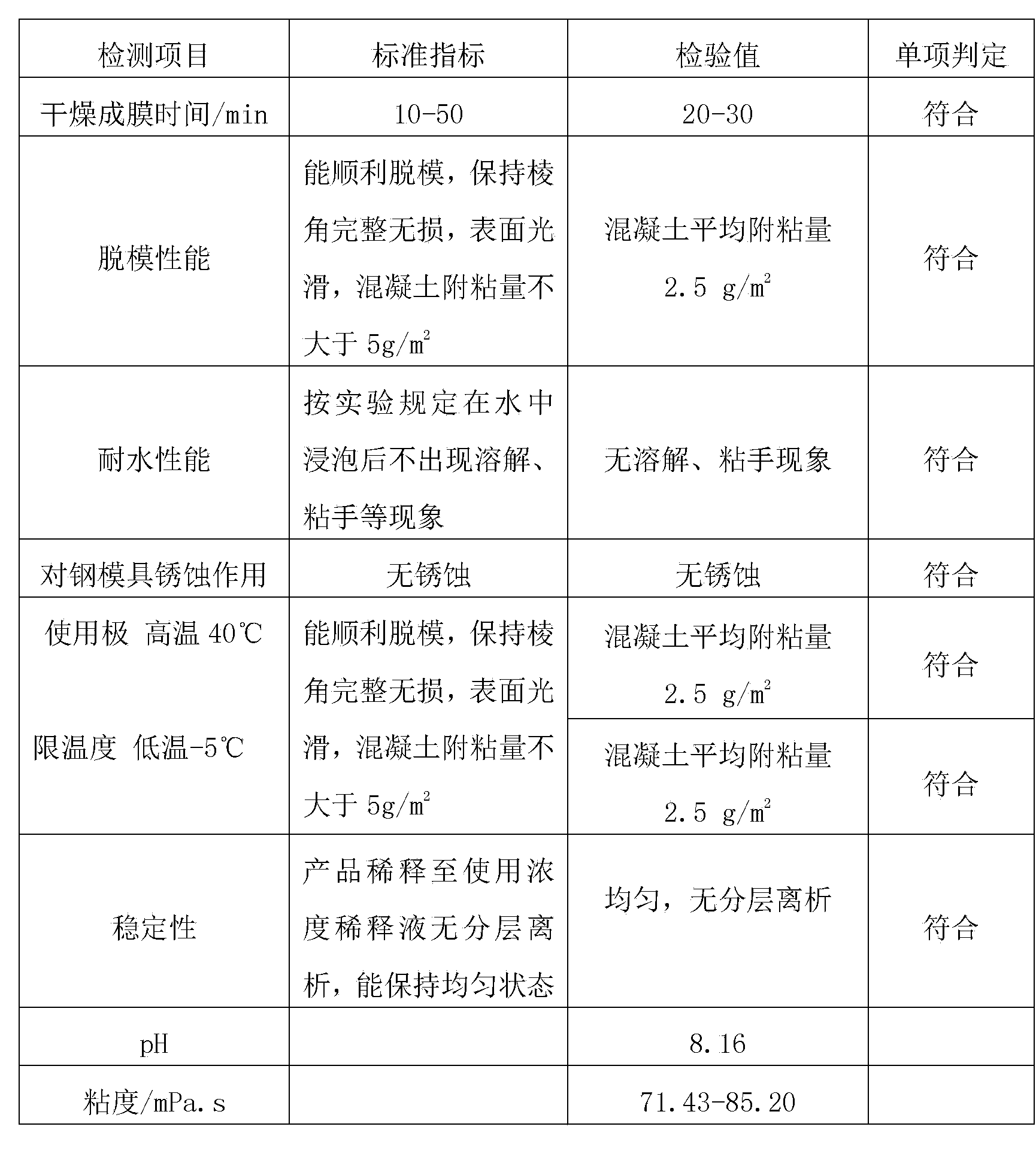

Concrete mold release agent and preparation method thereof

The present invention discloses a concrete mold release agent and a preparation method thereof. The raw material formula of the mold release agent is that: the amount of water is 80-95% of the total mass, a mass ratio of lard to rosin is 5:1, and other materials comprise, by the total amount of the lard and the rosin, 10-26% of sodium hydroxide, 10-30% of an emulsifying agent, 0.1-1% of tributyl phosphate, 0.2-1.5% of formaldehyde, 0.3-2.2% of dodecyl betaine, and an appropriate amount of organic montmorillonite. The preparation method comprises: carrying out a saponification reaction of lard, rosin and sodium hydroxide at a temperature of 95-105 DEG C under a mechanical stirring condition, and then adding other additives to obtain the finished product. Compared with other types of mold release agents, the mold release agent of the present invention has advantages of stable quality, longe product storage period, low use concentration, long service life, repeated use after one spraying, low pollution on the product after mold releasing, no influence on secondary product processing, maintenance performance providing and the like.

Owner:ANHUI ZHONGTIE ENGINEER MATERIAL SCI & TECH CO LTD +1

Attapulgite washable inner wall paint

InactiveCN101531494AGood water dispersibilityExcellent optical performanceCoatingsSodium silicateTitanium

The invention discloses attapulgite washable inner wall paint. The technical proposal comprises the following key points that: the attapulgite washable inner wall paint consists of creamy attapulgite clay, nano-alumina, polyvinyl alcohol superfine powder, instant sodium silicate, anatase type titanium pigments, tributyl phosphate, optical bleaching agent VBL and deionized water. A production method of the attapulgite washable inner wall paint comprises: compounding, crushing, stirring, dispersing, dissolving, homogenizing, emulsifying, defoaming, grinding, and canning into the finished product of the attapulgite washable inner wall paint. The attapulgite washable inner wall paint has the characteristics of no toxicity, odorlessness, hard paint film, fine and soft hand feel, water resistance, alkali resistance and good adhesion. The washable time can be more than 1,000 times, and stains cannot be left after washing for many times. The attapulgite washable inner wall paint is applicable to decorating inner walls of various civil and public buildings and the like.

Owner:LIWANG CHEM NANTONG

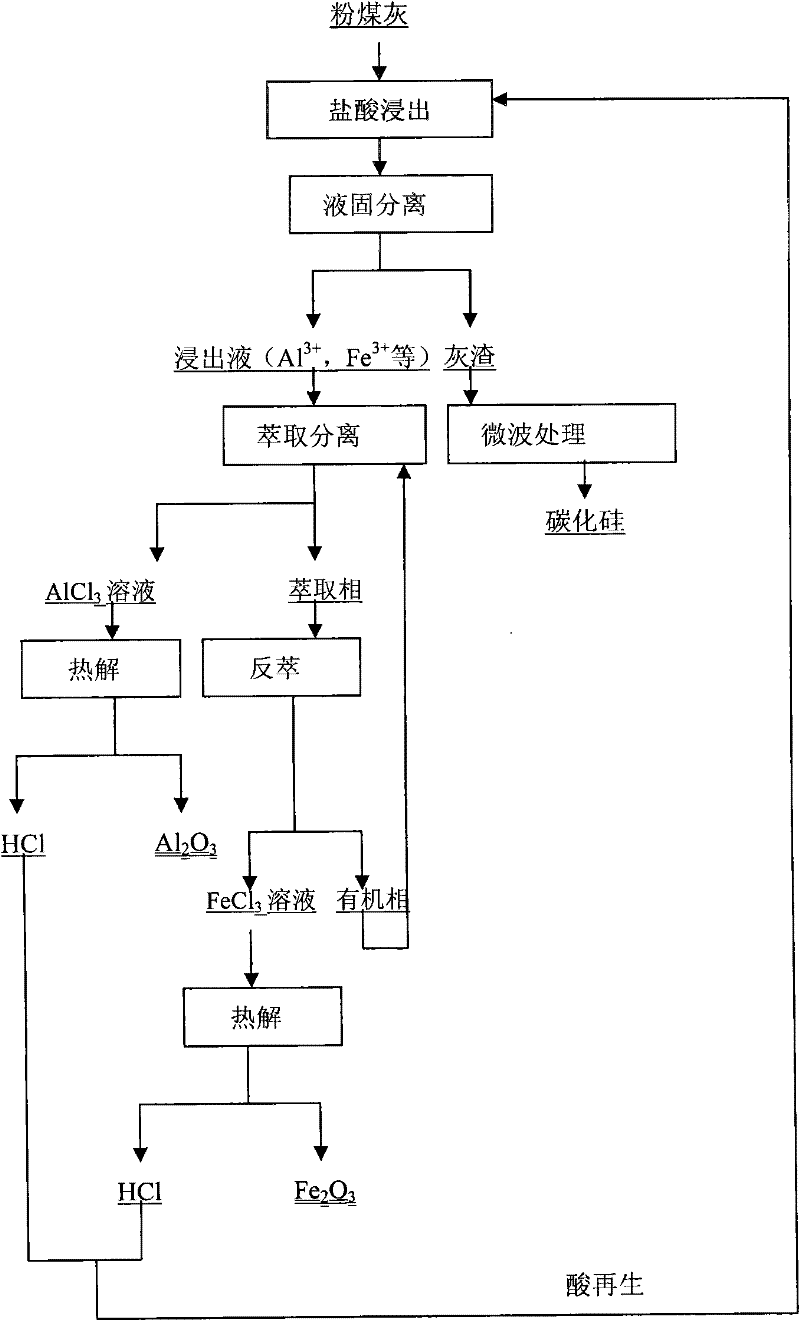

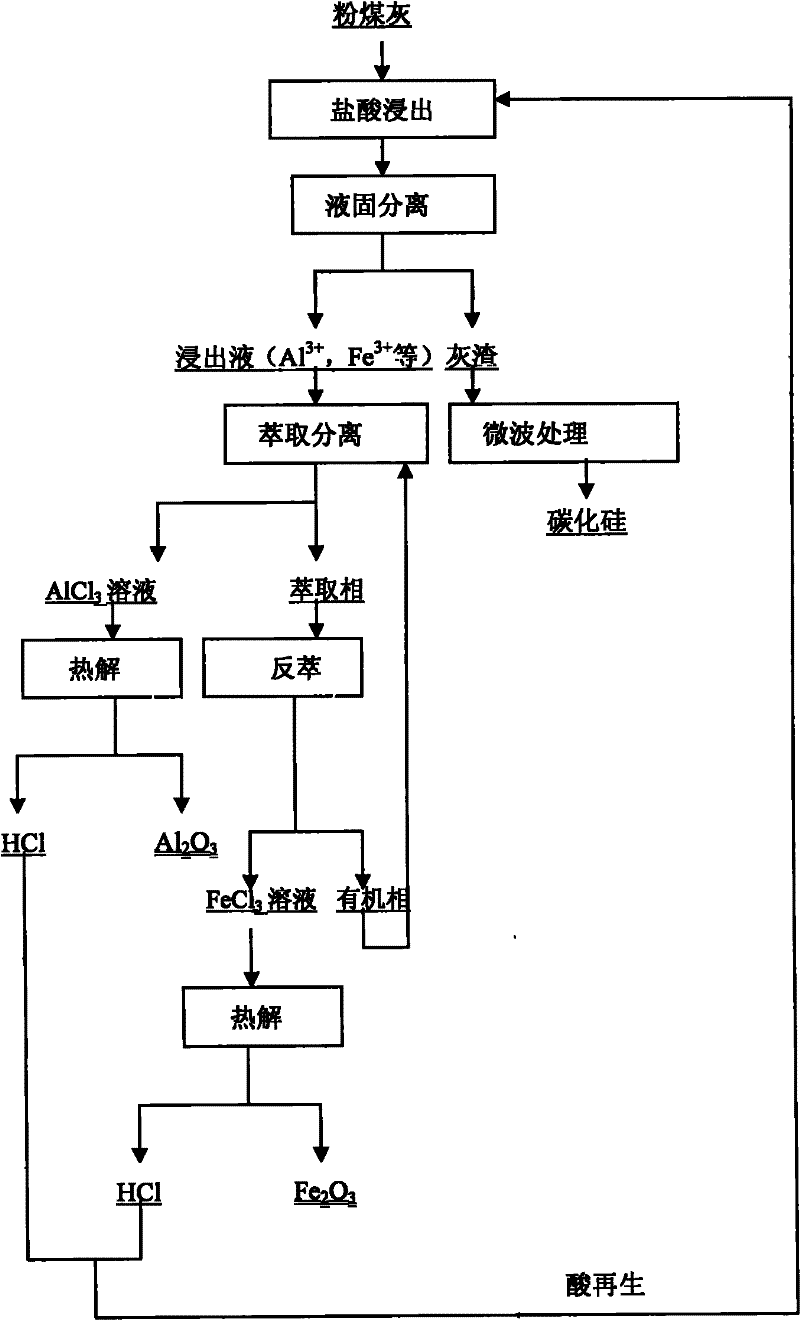

Ecological synthetic utilization method of fly ash

ActiveCN102241410ARealize comprehensive utilizationShort processChlorine/hydrogen-chlorideSolid waste disposalSilicon oxideMaterials science

The invention relates to an ecological synthetic utilization method of fly ash, and the method has the following steps: (1) selecting fly ash which contains aluminum oxide, iron oxide and silicon oxide as a raw material, wherein the mass content of aluminum oxide, iron oxide and silicon oxide are respectively 20-45%, 10-40% and 30-50%, performing a fine grinding and then leaching; (2) filtering and separating to obtain a leaching solution and leaching residue; adding tributyl phosphate and a diluent in the leaching solution to extract, wherein aluminum enters in raffinate phase to form an aluminum chloride solution as well as iron enters in raffinate phase; (3) performing a liquid atomizing pyrolysis to aluminum chloride to obtain aluminum oxide; (4) using water as a re-extraction preparation in raffinate phase for carrying out a re-extraction, wherein iron enters in the re-extraction preparation to form an iron chloride solution; performing a liquid atomizing pyrolysis to iron chloride to obtain iron red. According to the invention, the valuable elements of aluminum, iron, silicon and the like in fly ash are synthetically utilized, the process flow is short and the operation is simple, so that the ecological synthetic utilization method realizes the synthetic utilization of all the valuable elements of aluminum, iron, silicon and the like in fly ash.

Owner:DONGDA NONFERROUS SOLID WASTE TECH RES INST LIAOLING CO LTD

Alkali-resistant penetrant for short-process pretreatment of pure-cotton woven fabric

The invention discloses alkali-resistant penetrant for short-process pretreatment of pure-cotton woven fabric, wherein the penetrant comprises the following components by weight portion: 5 to 20 portions of heterogeneous fatty alcohol polyoxyethylene ether, 10 to 25 portions of heterogeneous fatty alcohol polyoxyethylene ether phosphate, 5 to 25 portions of heterogeneous fatty alcohol phosphate, 1 to 5 portions of tributyl phosphate, and 1 to 10 portions of maleic acrylic polymer. The invention aims to overcome the deficiencies of the prior art and provide the penetrant which is used for the short-process pretreatment of pure-cotton woven fabric and has good permeability, alkali resistance and strong decontamination and washing capability.

Owner:中山市巴斯基纺织助剂有限公司

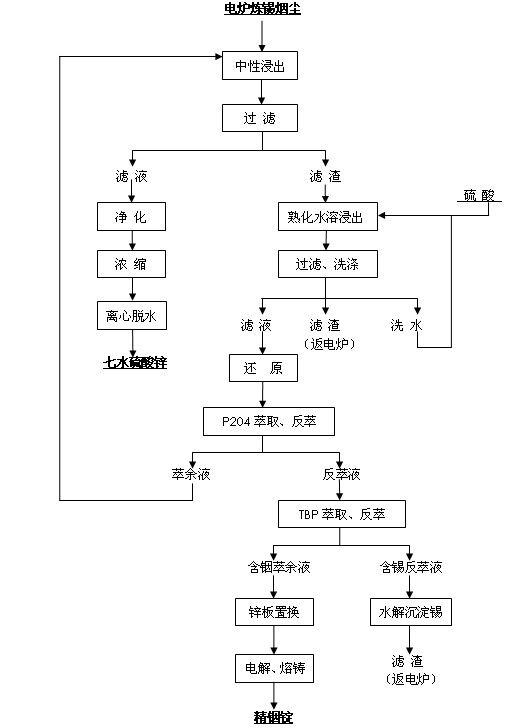

Multi-metal recycling method of electric furnace tin-smelting dust

InactiveCN102140580AImprove leaching rateEfficient extractionProcess efficiency improvementHigh concentrationIndium

The invention discloses a multi-metal recycling method of electric furnace tin-smelting dust. The method comprises the following steps: electric furnace tin-smelting dust is placed in a reaction kettle, sulfuric acid or / and raffinate are added to perform neutral leaching so that metals such as zinc are leached in the neutral solution and indium, tin and lead are left in residues; the neutral residues are placed in a reaction kettle, concentrated sulfuric acid is added for cure leaching, cleaning solution is added after the reaction to ensure that indium and a part of tin are leached in the solution and most of tin and lead are left in residues; extractant P204 is used to extract the indium and tin of the leachate and separate indium and tin from zinc, hydrochloric acid is used to perform backextraction to the extract so that tin and indium can be separated from the organic phase through backextraction and high concentration indium-tin mixed backextraction solution can be obtained; tributyl phosphate (TBP) extractant is used to extract tin to obtain material solution with indium and material solution with tin; and the material solution with indium is replaced by using a zinc plate and casted to obtain crude indium, the crude indium is electrolyzed and purified to obtain a refined indium product. The method combines the mature concentrated acid curing technology, extraction technology and other technologies into a whole, solves the separation problem of indium and tin and ensures that various high-value metals in the electric furnace dust can be recycled efficiently, continuously and largely; and the actual indium yield is more than 80% and the purity of the refined indium is more than 99.93%.

Owner:刘辉 +1

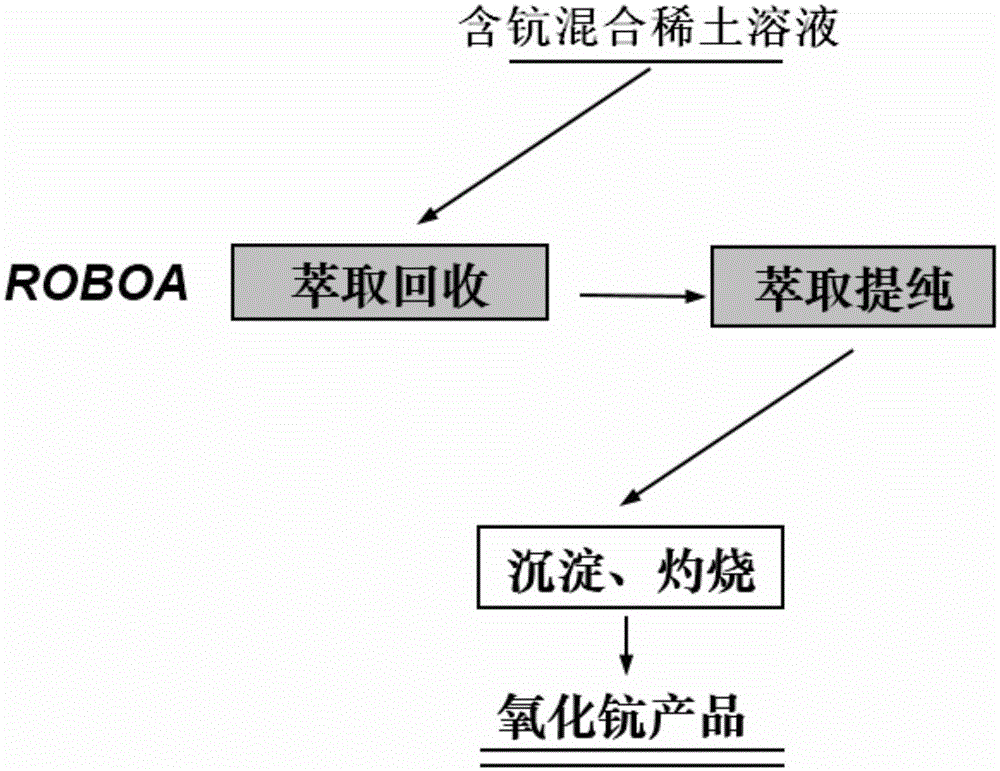

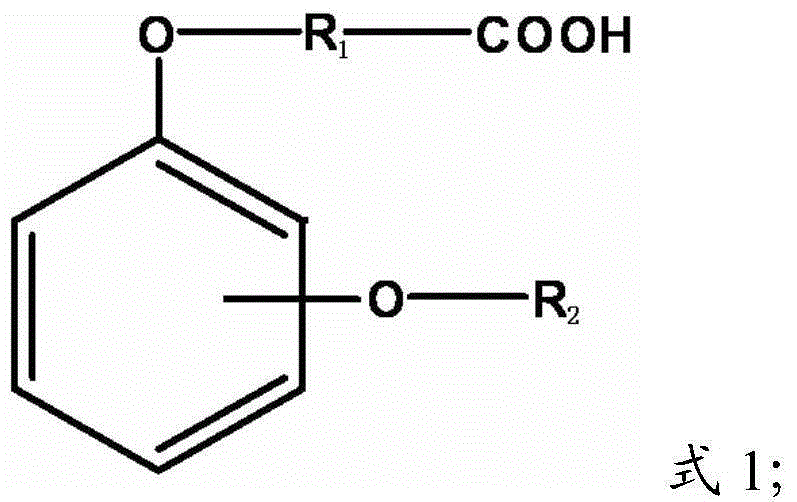

Scandium element extraction method

ActiveCN106702180AReduce concentrationHigh separation selectivityProcess efficiency improvementRare-earth elementEmulsion

Theinvention provides a scandium element extraction method. The scandium element extraction method comprises the following steps of: (A) mixing alkoxy phenoxy carboxylic acid, tributyl phosphate and a diluting agent to obtain an organic phase; and (B) extracting a scandium-containing mischmetal solution by using the organic phase to obtain a scandium ion-containing solution. The scandium element extraction method has the beneficial effects that the separation selectivity between the scandium element and other rare earth elements can be effectively improved by adopting the alkoxy phenoxy carboxylic acid as the extraction agent on the basis of ensuring the purity of a scandium product and relatively high yield; the concentration of the organic phase is effectively prevented from decreasing after extraction by adopting the tributyl phosphate as an additive, so that the organic phase can be recycled; meanwhile, an emulsion phenomenon in an extraction process can be avoided; and experimental results show that the separation coefficients of the scandium element and a lanthanide element are 526 due to adoption of the scandium element extraction method.

Owner:王艳良

Method for separating zirconium hafnium by tributyl phosphate extraction chromatography method

ActiveCN101209858AHigh separation factorReduce consumptionLiquid solutions solvent extractionZirconium oxidesHafniumChromatographic column

The invention relates to a separation method of zirconium and hafnium by adopting extraction chromatography, in particular to extraction chromatography of zirconium and hafnium by employing tributylphosphate. The method comprises the following steps that: extractant-containing resin TBP is adopted to load the extraction chromatographic column; mixed solution of chlorhydric acid and nitric acid with total free acid acidity being 3.5-7.5 mol / l is adopted for eluting the extraction chromatographic column; then the obtained material is added with material liquid which is the mixed solution of chlorhydric acid and nitric acid with total free acid acidity being 3.5-7.5 mol / l; the total concentration of zirconium and hafnium is 0.05-1.5 mol / l; next, the mixed solution of chlorhydric acid and nitric acid with total free acid acidity being 4-8 mol / l is used for eluting the obtained material, until the concentration of overflowed hafnium solution is less than 0.01 g / l; then the mixed solution containing 0-1.5mol / l chlorhydric acid and nitric acid or 0-1.5mol / l chlorhydric acid solution is used for eluting, so as to get the zirconium solution containing no hafnium.

Owner:有研资源环境技术研究院(北京)有限公司

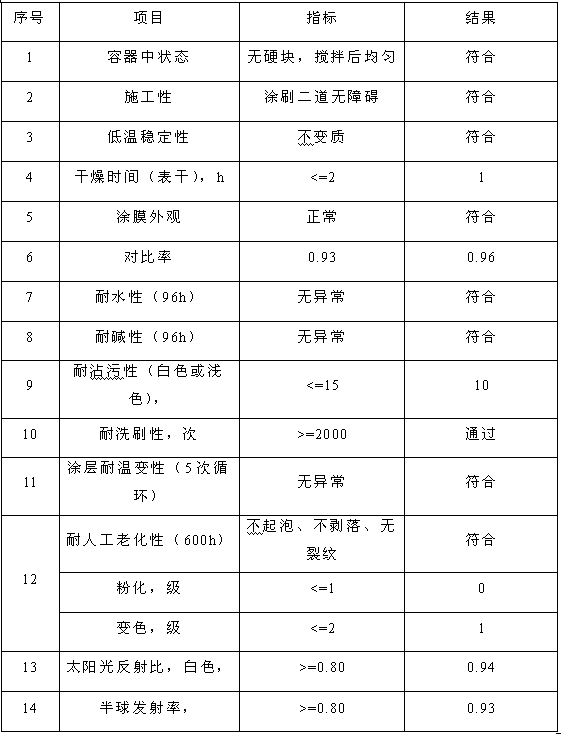

Reflection heat insulating coating for building

InactiveCN103013266ASmall particle sizeEvenly dispersed and more stableReflecting/signal paintsEmulsionAnti freezing

The invention discloses a reflection heat insulating coating for a building. The reflection heat insulating coating comprises the following components in parts by weight: 9.5 to 23 parts of water, 0.44 to 1.08 parts of thickener, 0.45 to 0.55 part of dispersing agent, 0.1 to 0.2 part of wetting agent, 0.4 to 0.8 part of defoaming agent, 0.05 to 0.25 part of multifunctional auxiliary agent, 0.05 to 0.15 part of preservative, 0.05 to 0.25 part of mildew preventive, 15 to 25 parts of titanium dioxide, 0 to 22.5 parts of nano heat insulating powder slurry, 2 to 6.5 parts of filling, 1 to 2 parts of anti-freezing agent, 1.25 to 2 parts of coalescing agent, 0.01 to 0.02 part of emulsifying agent, 25 to 40 parts of emulsion, 2.5 to 5 parts of hydrophobing agent, 0.05 to 0.15 part of pH value adjustment agent and 0.02 to 0.07 part of tributyl phosphate. After the coating is formed into a film, the surface of the coating is high in hydrophobicity; the coating has hydrophobic, water-proof and self-cleaning functions; and the heat insulating performance of the coating film can be improved.

Owner:SUZHOU RES INST OF ARCHITECTURE SCI

Polymer cement based composite waterproof coating material for construction and its preparation

InactiveCN1472259AMake up for lack of flexibilityCompensation for re-swelling of polymer emulsion filmAntifouling/underwater paintsPaints with biocidesPliabilityPropanediol

A composite water-proof cement-base polymer paint for building is composed of the organic liquid (component A) prepared from acrylate emulsion, siloxane emulsion, dibutyl phthalate, propanediol, sodium tripolyphosphate, and tributyl phosphate, and the inorganic powder (component B) prepared from silicate cement, talk powder and pigment. Said two components are proportionally mixing before it is used. Its advantages are better elasticity and flexibility, high adhesion, and no environmental pollution.

Owner:TONGJI UNIV

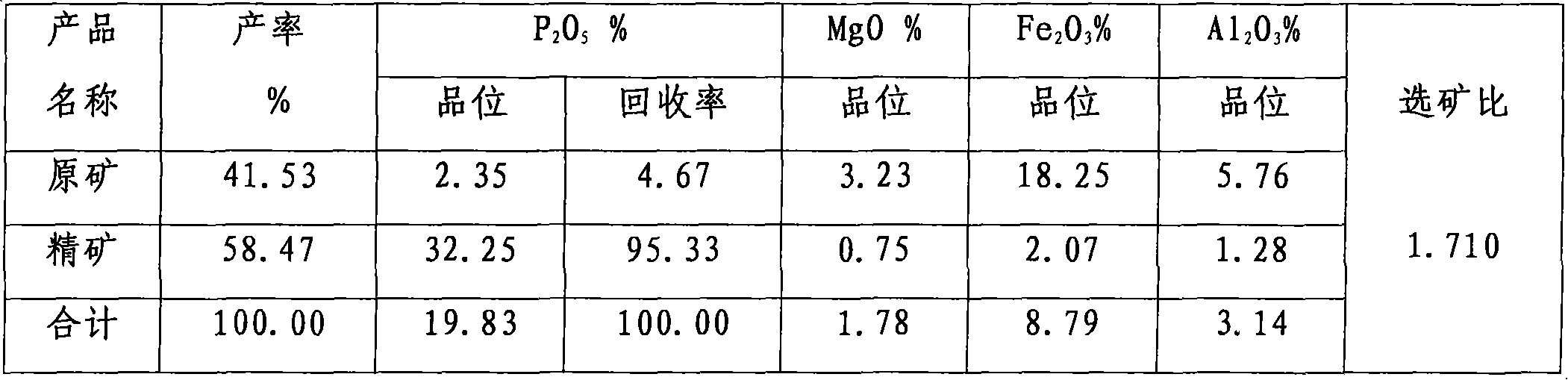

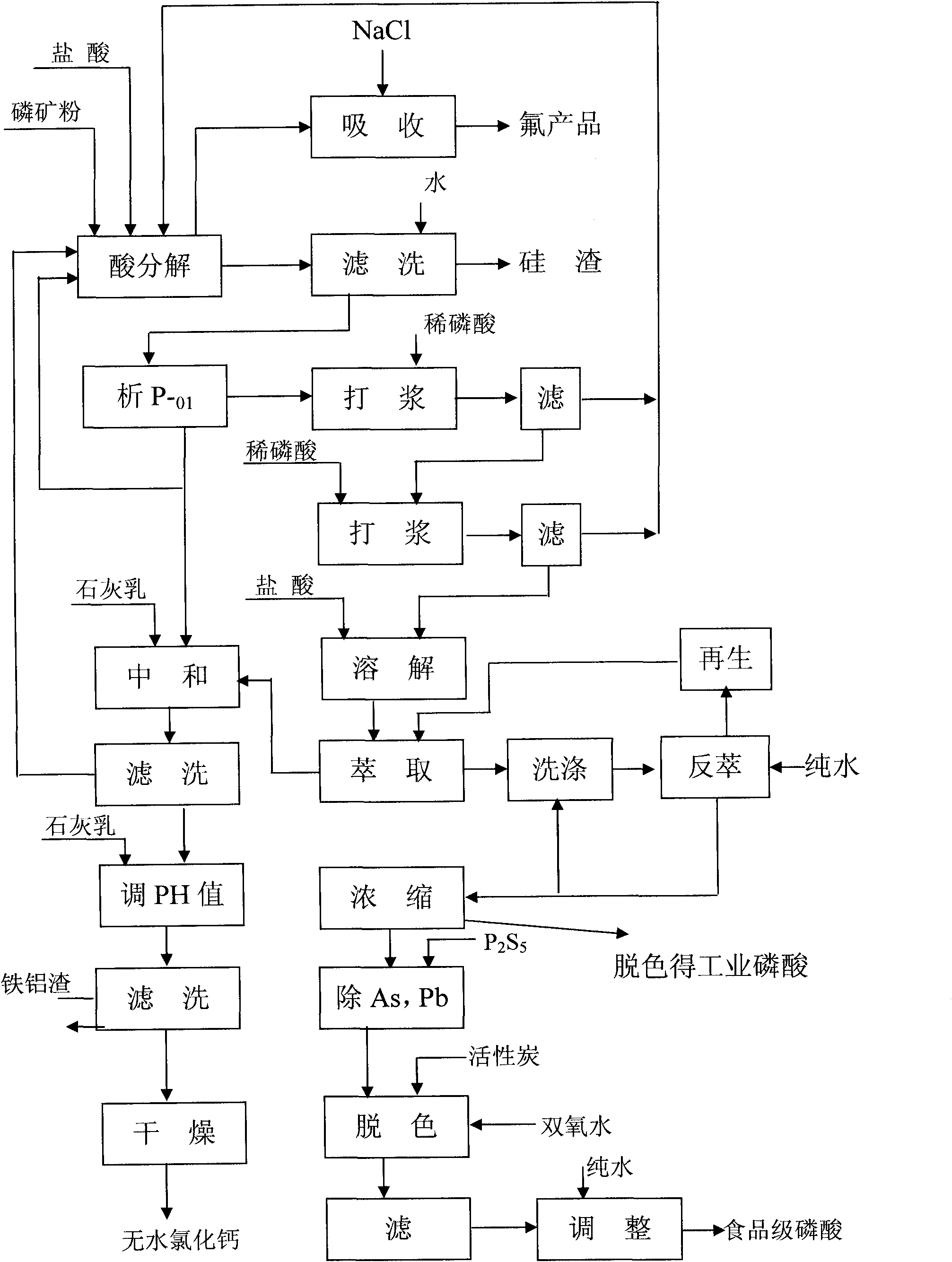

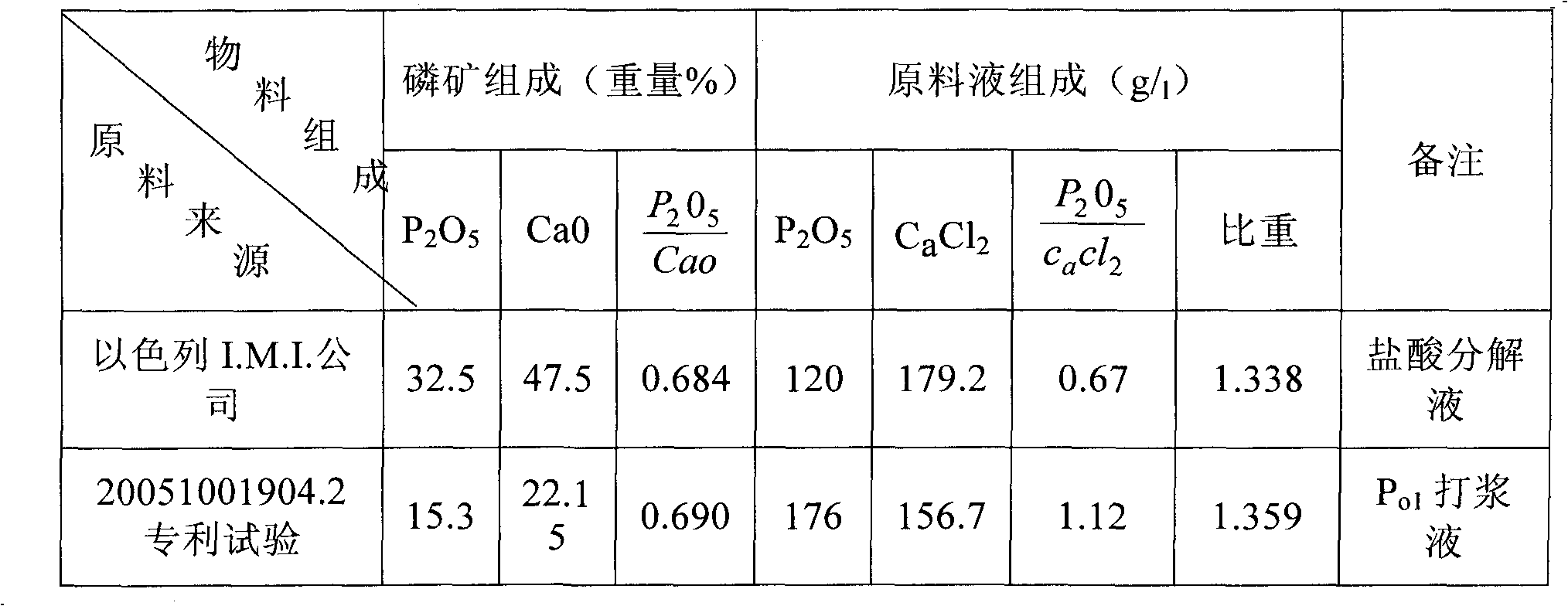

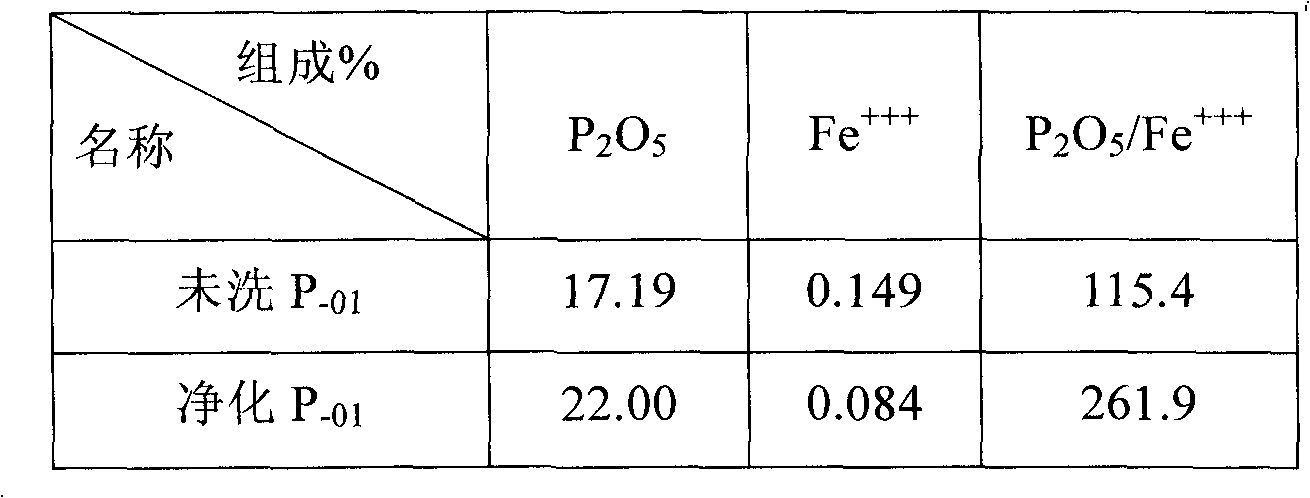

Method for manufacturing industrial phosphoric acid, industrial ammonium phosphate and food-grade phosphoric acid from medium and low-grade phosphorite by one-step extraction of hydrochloric acid method

InactiveCN102134063AHigh energy consumptionCalcareous fertilisersPhosphatesPhosphoric acidHydrogen peroxide

The invention discloses a method for manufacturing industrial phosphoric acid, industrial ammonium phosphate and food-grade phosphoric acid from medium and low-grade phosphorite by one-step extraction of a hydrochloric acid method. The method is characterized by comprising the following steps of: decomposing any phosphorite (the P2O5 of which is more than or equal to 6 weight percent) by using hydrochloric acid, preparing calcium chloride dihydrogen phosphate CaClH2PO4.H2O (P-01 for short), adding dilute phosphoric acid, pulping, filtering and purifying the P-01, pulping and dissolving the P-01 with hydrochloric acid, performing extraction by using tributyl phosphate, performing concentration and decolorization to obtain the industrial phosphoric acid, adding ammonia into the industrial phosphoric acid to obtain the industrial ammonium phosphate, or adding P2S5 into the concentrated industrial phosphoric acid to remove arsenic and heavy metal, performing decolorization by using active carbon and hydrogen peroxide and removing easily oxidized substances to reach the index requirement of the food-grade phosphoric acid.

Owner:上海协达精细化工研发有限公司

Hydrophobic silica aerogel modified acrylate emulsion coating

InactiveCN105199521AHigh strengthImprove toughnessAntifouling/underwater paintsPaints with biocidesStainEmulsion

The invention discloses a hydrophobic silica aerogel modified acrylate emulsion coating. The hydrophobic silica aerogel modified acrylate emulsion coating is prepared from, by weight, 100 parts of organic silicone modified acrylate emulsion, 10-25 parts of water-soluble alkyd resin, 10-25 parts of hydrophobic silica aerogel, 10-25 parts of pigment and filler, 3-10 parts of propylene glycol, 5-12 parts of n-caprylic alcohol, 3-8 parts of vinyl trimethoxy silane, 5-10 parts of cellulose nanocrystalline, 1-5 parts of sodium carboxymethylcellulose, 5-15 parts of film-forming agent, 2-5 parts of defoaming agent, 0.5-1.5 parts of sodium hexametaphosphate, 1-3 parts of benzotriazole, 1-2 parts of tributyl phosphate, 0.5-1.2 parts of triphenyl phosphate and 50-70 parts of deionized water. The hydrophobic silica aerogel modified acrylate emulsion coating is good in water resistance, weather resistance, thermal insulation and stain resistance and capable of meeting requirements of exterior wall coatings.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

Method of directly catalytic epoxidation

InactiveCN101045717AUniversal applicabilityOrganic chemistryPhysical/chemical process catalystsHeteropoly acidReaction temperature

This invention relates to a method of directly catalyze epoxide. In existing technology takes low concentration H2O2 water solution as oxidizer, phosphorus tungsten heteropoly acid quaternary ammonium salt as catalyzer to prepare epoxide. This invention mainly solve the problem in existing technology of separation energy high caused by water, as well as catalyst stability low caused by decompound of phosphorus tungsten heteropoly acid quaternary ammonium salt, and problem of H2O2 activity factor descending. This invention takes olefine, cyclenes or aromatic alkene contain 1 to 10 carbon atom and aqueous hydrogen peroxide solution as raw material, takes phosphorus tungsten heteropoly acid quaternary ammonium salt as catalyzer, takes at least one of toluene, benzene, ethylbenzene, cumene , chloroform or tributyl phosphate as solvent, takes phosphatic inorganic salt as additive, under 20 to 100deg reaction temperature and 0 to 3.0 Mpa reaction pressure, to carry out reaction for 0.5 to 24 hours. It best solve existing problem, can be used in industrial production of epoxide.

Owner:CHINA PETROLEUM & CHEM CORP +1

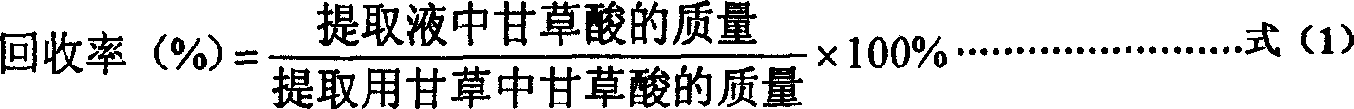

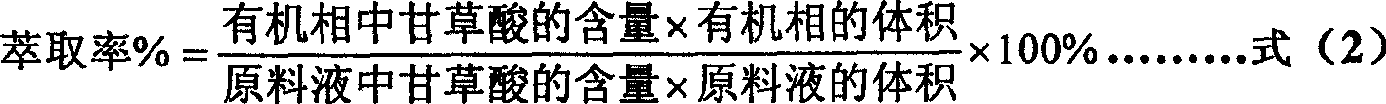

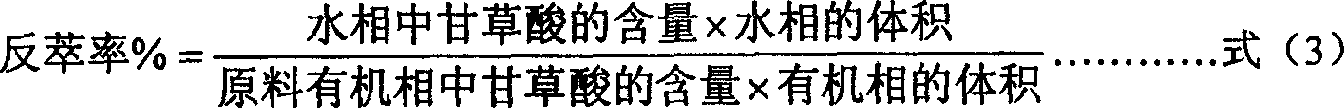

Method for extracting glycerrhizic acid from licorice

specifically a process for extracting glycyrrhizic acid from licorice roots, wherein the glycyrrhizic acid is extracted from the licorice root rapidly and effectively by using the method of microwave auxiliary extraction, and then organic extracting agent, e.g. tributyl phosphate, trialkyl phosphine oxide, isooctanol, n-hexyl alcohol, isopentyl alcohol are used for solvent extraction, after stewing or centrifugal phase-splitting, the glycyrrhizic acid will be enriched in organic phase, by using water as solution, and regulating the pH of the miscible liquids to 6.0-12.0, the inverse extraction for glycyrrhizic acid can be carried out, thus obtaining the aqueous solution of the enriched glycyrrhizic acid, and the refined glycyrrhizic acid is obtained through decoloration, acidification, stewing, centrifugal deposition and drying.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

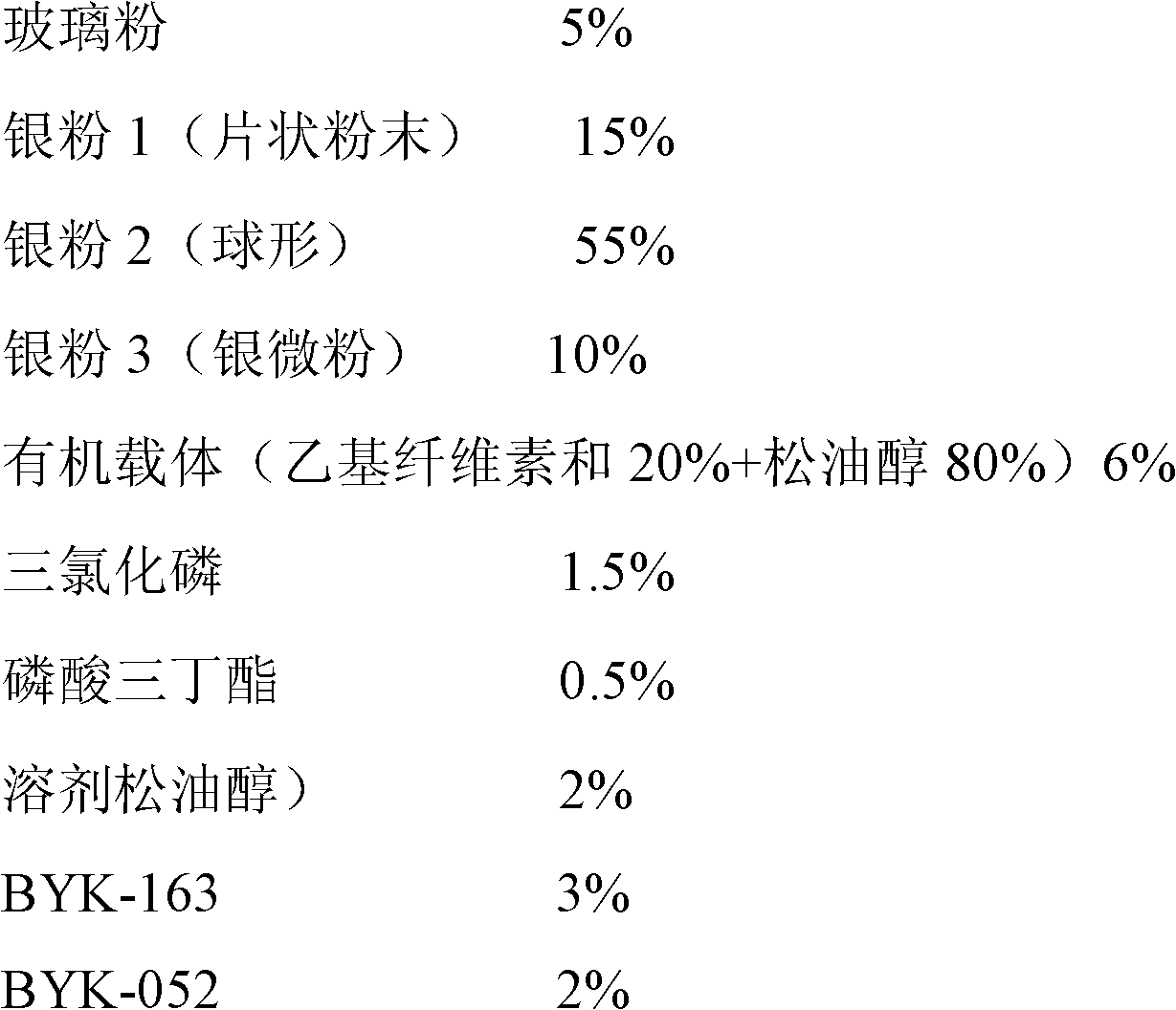

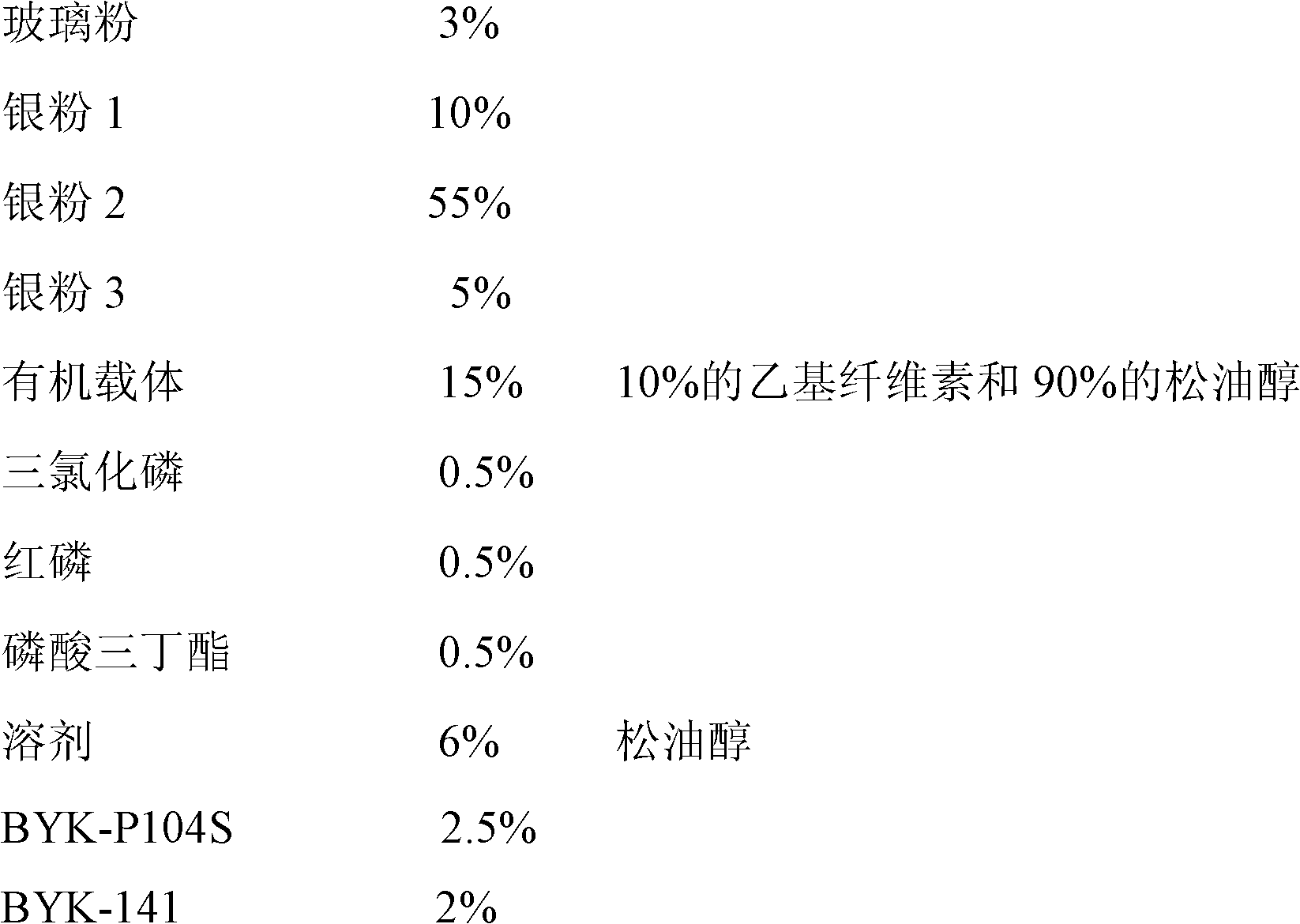

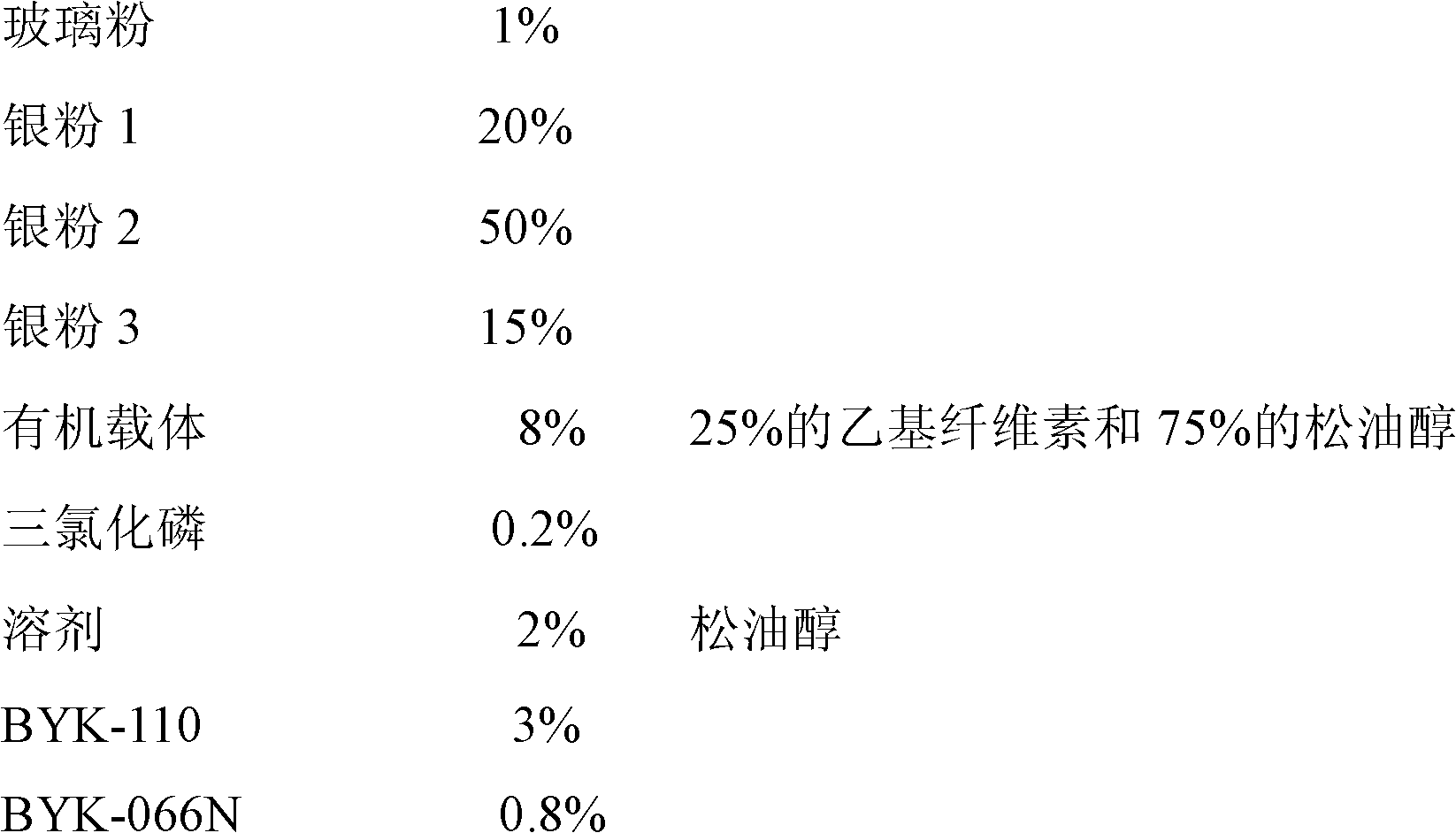

Front silver paste for silicon solar cells and preparation method thereof

InactiveCN102426874AImprove photoelectric conversion efficiencyImprove conductivityNon-conductive material with dispersed conductive materialCable/conductor manufactureConductive pasteSilver paste

The invention relates to front silver paste for silicon solar cells and a preparation method thereof. The silver paste is characterized by comprising the following components by weight percent: 6-15% of organic carrier, 1-5% of binders, 2-6% of solvents, 0.5-5% of auxiliaries, 0.1-2% of additives and the balance of conductive silver powder. The invention relates to conductive paste for front electrodes of silicon solar cells. The paste comprises conductive silver powder, an organic carrier, binders, solvents and auxiliaries. The paste also comprises additives selected from one or more of phosphorus trichloride, red phosphorus and tributyl phosphate. The additives in the conductive paste can conduce to improvement of the conductivity of the conductive paste, therefore the finally prepared solar cells have higher photoelectric conversion efficiency.

Owner:IRICO

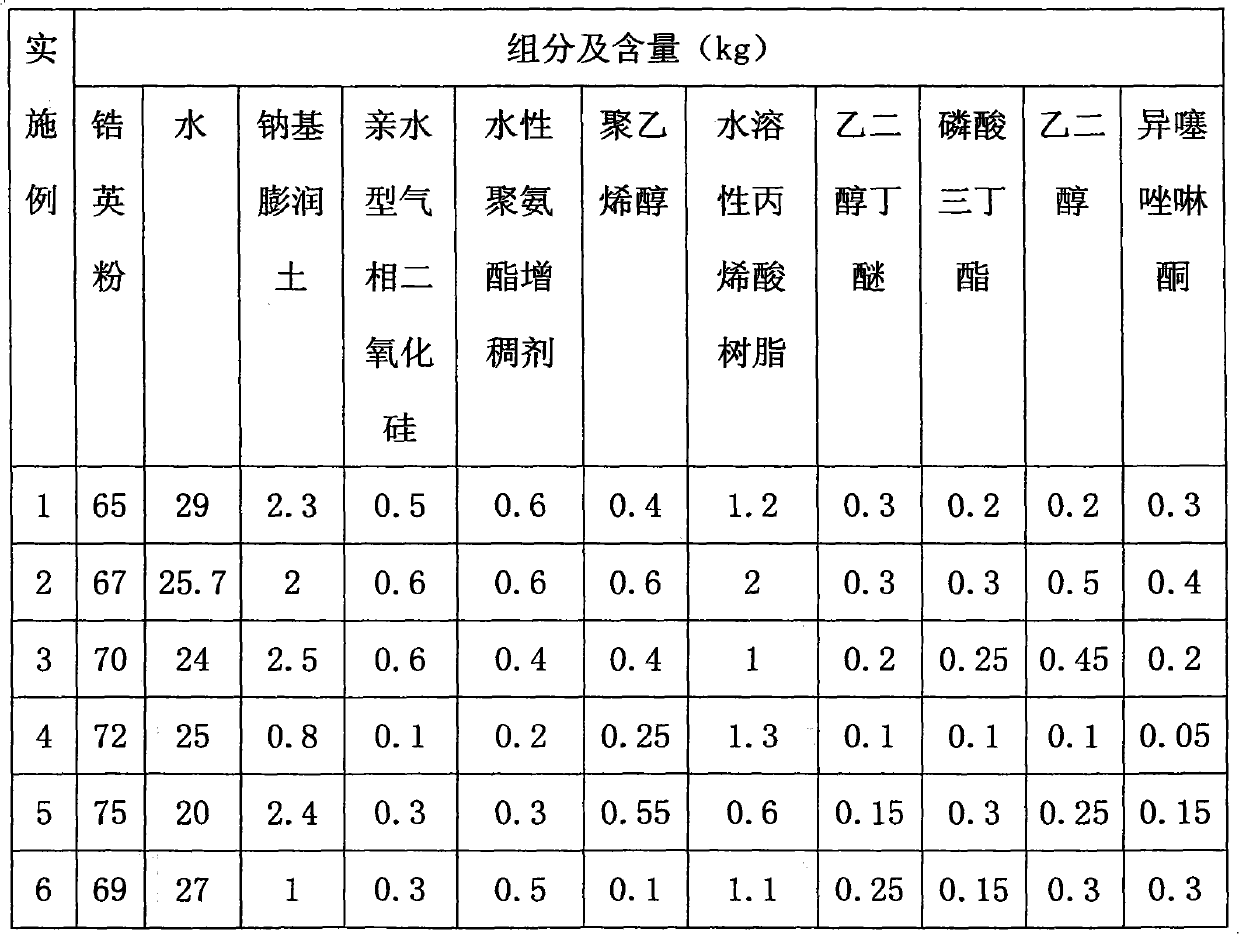

Water base casting coating for heavy casting and manufacturing method thereof

InactiveCN101767183AFast trickleImprove liquidityFoundry mouldsFoundry coresWater basedSodium Bentonite

The invention discloses a water base casting coating for a heavy casting and a manufacturing method thereof. The coating is composed of the following components according to proportion by weight: 65-75% of zircon powder, 20-30% of water, 0.8-2.5% of sodium bentonite, 0.1-0.6% of hydrophilic gaseous phase silica, 0.2-0.8% of waterborne polyurethane, 0.2-0.8% of polyvinyl alcohol, 0.6-2% of Water-based acrylic resin, 0.1-0.4% of butyl cellosolve, 0.1-0.3% of tributyl phosphate, 0.1-0.5% of ethylene glycol and 0.05-0.4% of isothiazolinone.The preparation method is advanced and feed compositions are effectively combined.The product features excellent technical indicators such as rheological behaviour, thixotropy, brushing property, suspension property, storage property, film-forming quality, brushing viscosity, thus being capable of meeting technical quality requirements in heavy casting production, in particular to the heavy casting which weighs more than 100 tons.

Owner:德阳立达化工有限公司

Transparent coating capable of absorbing visible light and infrared light, preparing method and use thereof

ActiveCN101033357AReduced full emissivity valueGood infrared transparencyInksRadiation-absorbing paintsNear infrared absorptionNanometre

The invention relates to a kind of absorption transparent coating for visible and infrared light as well as its preparation and application. The coatings is prepared as follow: Firstly, it mixes alpha-methyl acrylate, methyl methacrylate, azobisisobutyronitrile, tributyl phosphate according to the ratio of 1-2:10-12:1-1.5:2-4, then it prepolymerizes them in water to a viscosity of 100 ~ 500cP to achieve the bonding agent of the infrared absorption coating. Secondly, it takes out 40%~60% of the above bonding agent and adds the nano-particles of TiO2, Fe3O4, MnO2, CuO, CdTe, PbS and / or Cr2O3 to achieve an organic near infrared absorber, then it mixes the organic near infrared absorber and the remaining bonding agent to achieve the visible infrared absorption transparent coating.

Owner:HUBEI ZHONGXIN JINGHUA COLOR PRINTING

Organic silicon defoamer and preparation method thereof

ActiveCN103641195AFast defoaming speedLong foam suppression timeWater/sewage treatment by degassingPolypropylene glycolSilicone oil

The invention discloses an organic silicon defoamer and a preparation method thereof. The organic silicon defoamer is obtained by emulsifying an organic silicon defoaming composition. The organic silicon defoaming composition comprises a silicon paste composition, emulsifiers and auxiliaries, wherein the silicon paste composition comprises polysiloxane, hydrophobic fumed silica and MQ silicon resin particles; polysiloxane is methyl silicone oil or hydroxyl silicone oil with viscosity of 10000-500000mPa.s; the particle sizes of the MQ silicon resin particles are 5-20mu m; the specific surface area of hydrophobic fumed silica is 100-300m<2> / g; the auxiliaries include tributyl phosphate and / or polypropylene glycol. The invention further provides the preparation method of the organic silicon defoamer. The organic silicon defoamer with high defoaming speed, long foam inhibition time, excellent dispersing performance and prominent defoaming permanence is prepared by a special method, has good storage and dilution stability, is not easy to demulsify and is free from floating oil. The preparation method is simple and is low in cost.

Owner:SHENZHEN ANPIN SILICONE MATERIAL

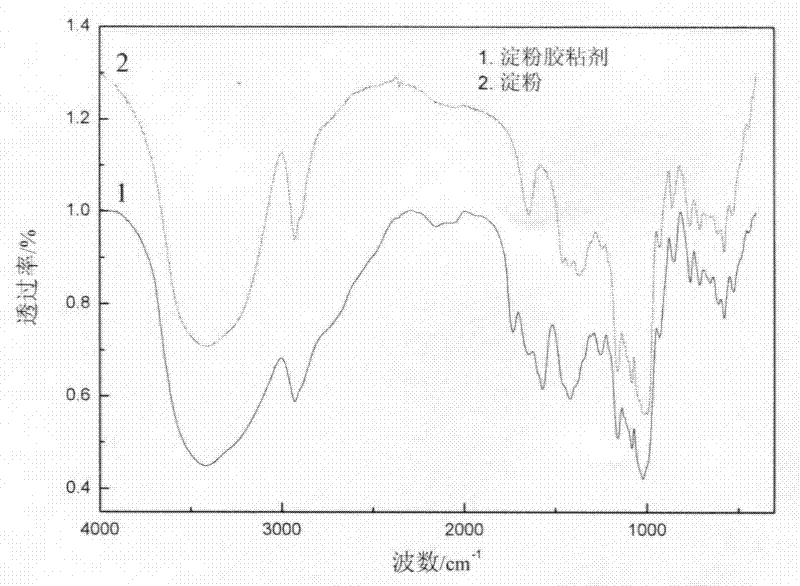

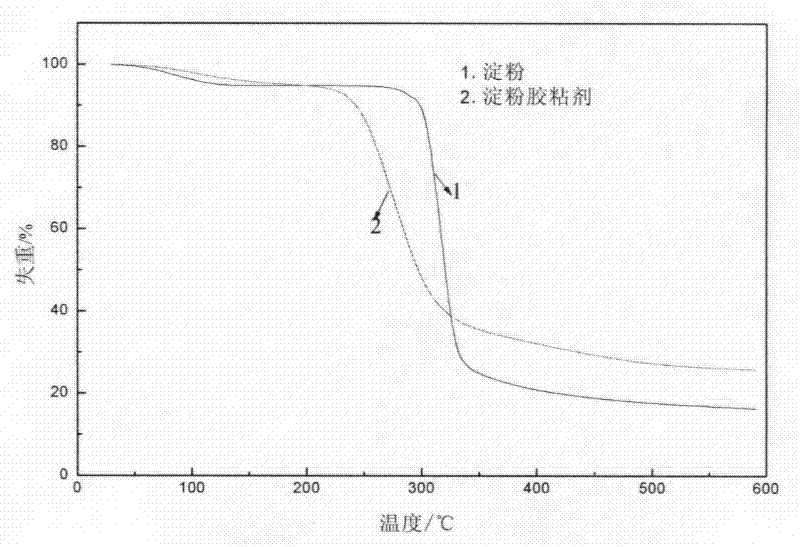

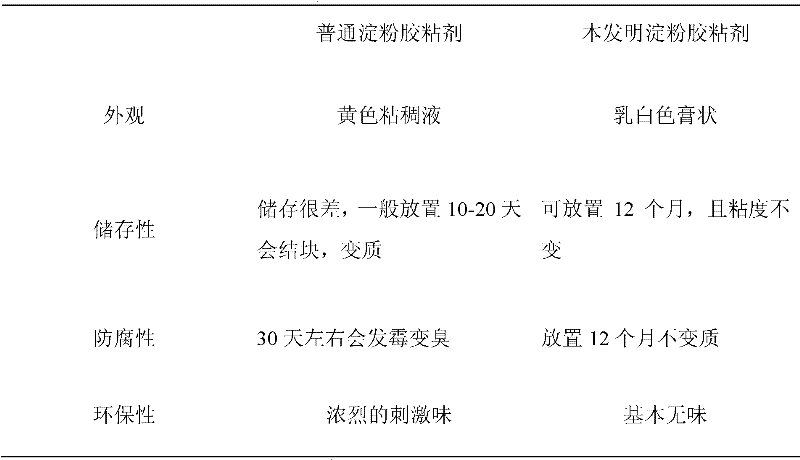

Corn starch adhesive for building and preparation method thereof

InactiveCN102391797AReduce consumptionReduce oxidationStarch derivtive adhesivesAcetic anhydrideAdhesive

The invention provides a corn starch adhesive for a building and a preparation method thereof. The adhesive is prepared from the following components in parts by mass: 10-30 parts of corn starch, 50-150 parts of tap water, 0.1-0.8 part of oxidant, 0.5-2 parts of esterifying agent, 0.4-0.8 part of alkali, 0.4-0.5 part of acid regulating agent, 0.1-0.2 part of preservative, 0.005-0.001 part of tributyl phosphate and 0.01-0.02 part of catalyst, wherein the oxidant is hydrogen peroxide; the esterifying agent is acetic anhydride, maleic anhydride or phthalic anhydride; and the catalyst is ferrous sulfate, copper sulfate or ferric chloride. The corn starch adhesive is a starch adhesive formed by directly gelatinizing oxidized and esterified starch, has good bonding effect and has the advantages of simple process, low cost, no environment pollution and the like.

Owner:SHANXI UNIV

Solar cell back electric field aluminium paste and preparation method thereof

ActiveCN102142467AAvoid cleaningNot blockedFinal product manufactureNon-conductive material with dispersed conductive materialWaxScreen printing

The invention provides a solar cell back electric field aluminium paste comprising the following components in percentage by weight based on the total mass of a conductive paste: 70-85% of aluminite powder, 0.2-10% of glass powder and 10-30% of organic carrier. The solar cell back electric field aluminium paste is characterized in that the organic carrier comprises a thickening agent, micro powder wax, tributyl phosphate and an organic solvent; and micro powder wax accounts for 0.5-3.0wt% and tributyl phosphate accounts for 0.2-5wt% by taking the total mass of the organic carrier as a reference. By utilizing the solar cell back electric field aluminium paste and the preparation method thereof, the technical problems of screen leakage and blockage in the screen printing process can be solved. In addition, the photoelectric conversion rate of a crystalline silicon solar cell can be improved.

Owner:BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com