Patents

Literature

106 results about "Trimethyl phosphite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

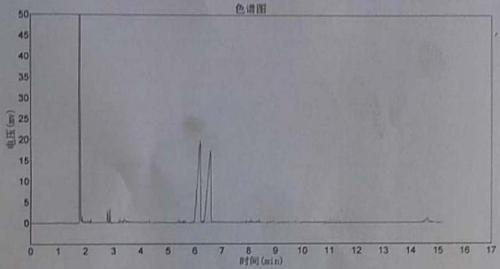

Trimethyl phosphite is an organophosphorus compound with the formula P(OCH₃)₃, often abbreviated P(OMe)₃. This colorless liquid is used as a ligand in organometallic chemistry and as a reagent in organic synthesis. The material also has a highly pungent smell. The molecule features a pyramidal phosphorus(III) center bound to three methoxy groups.

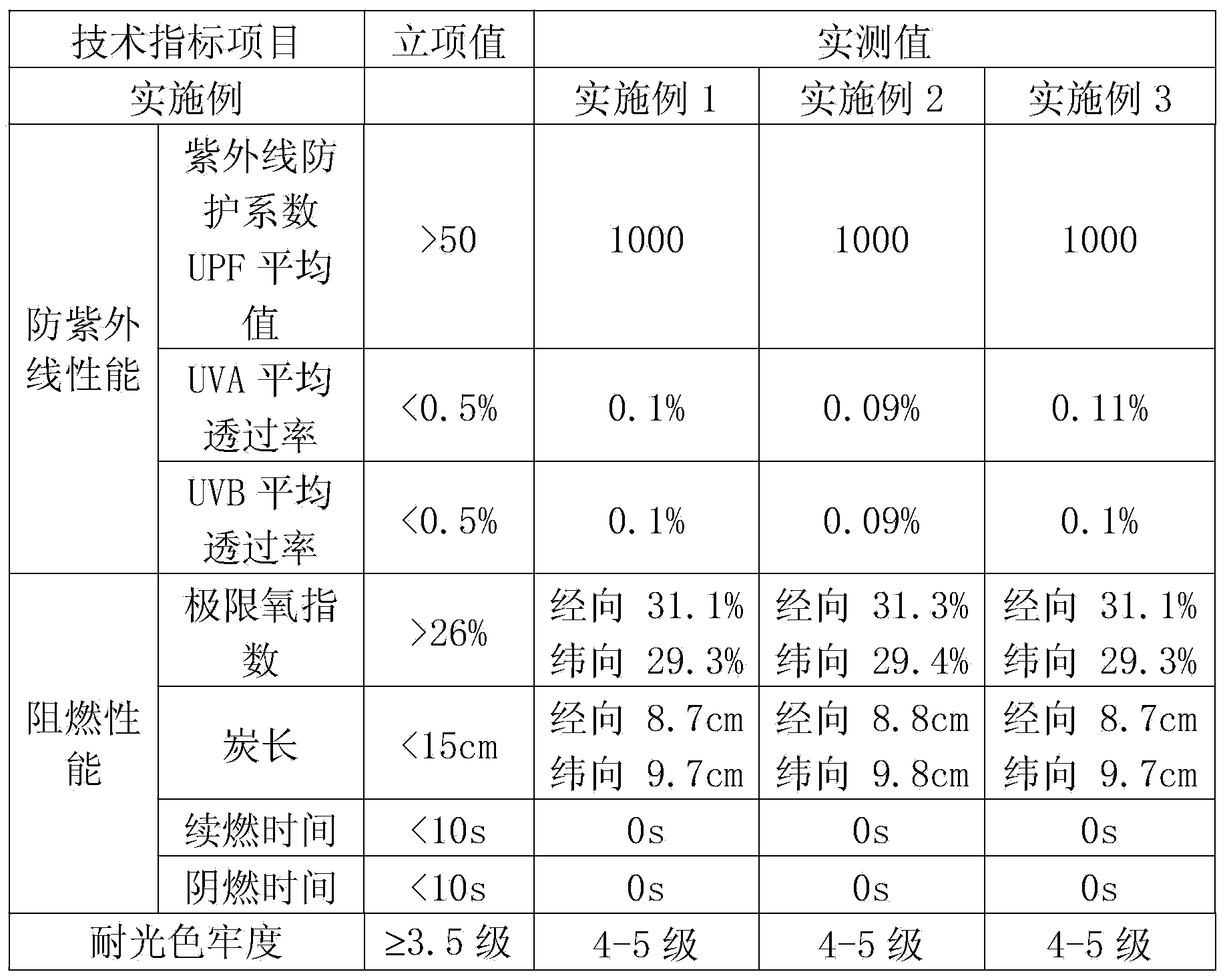

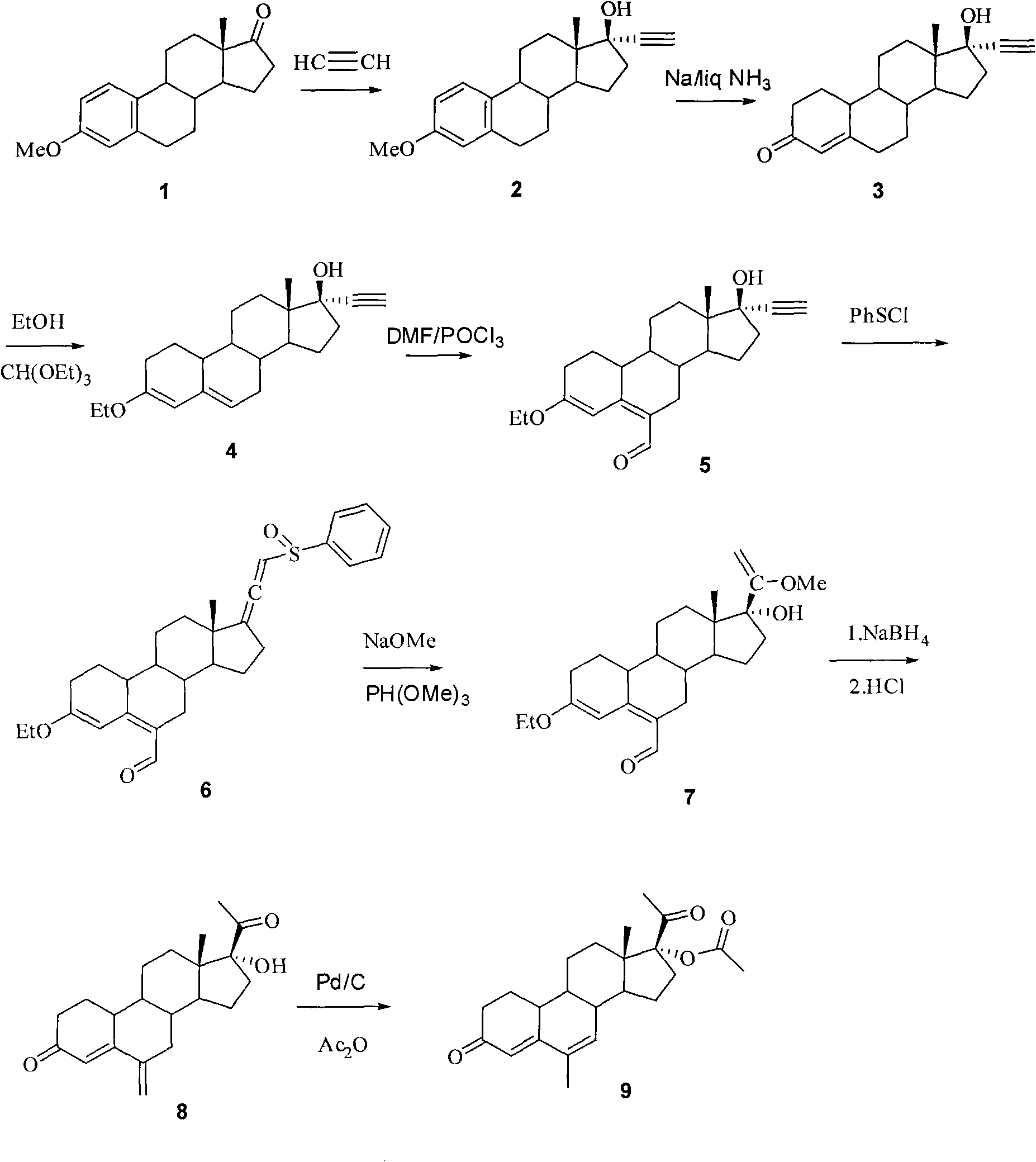

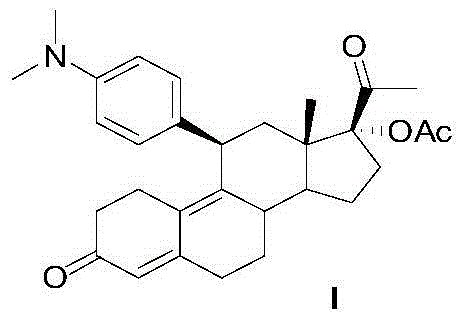

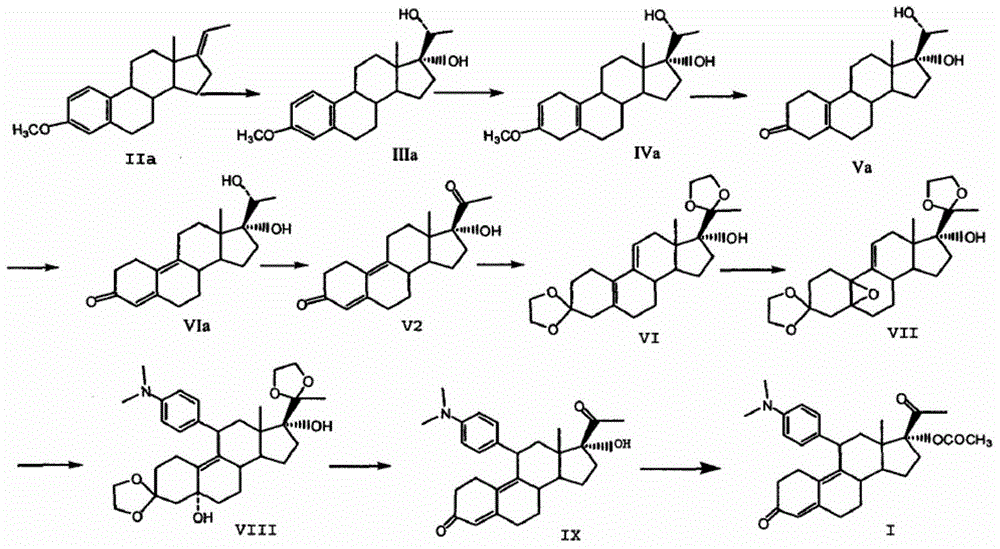

Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process

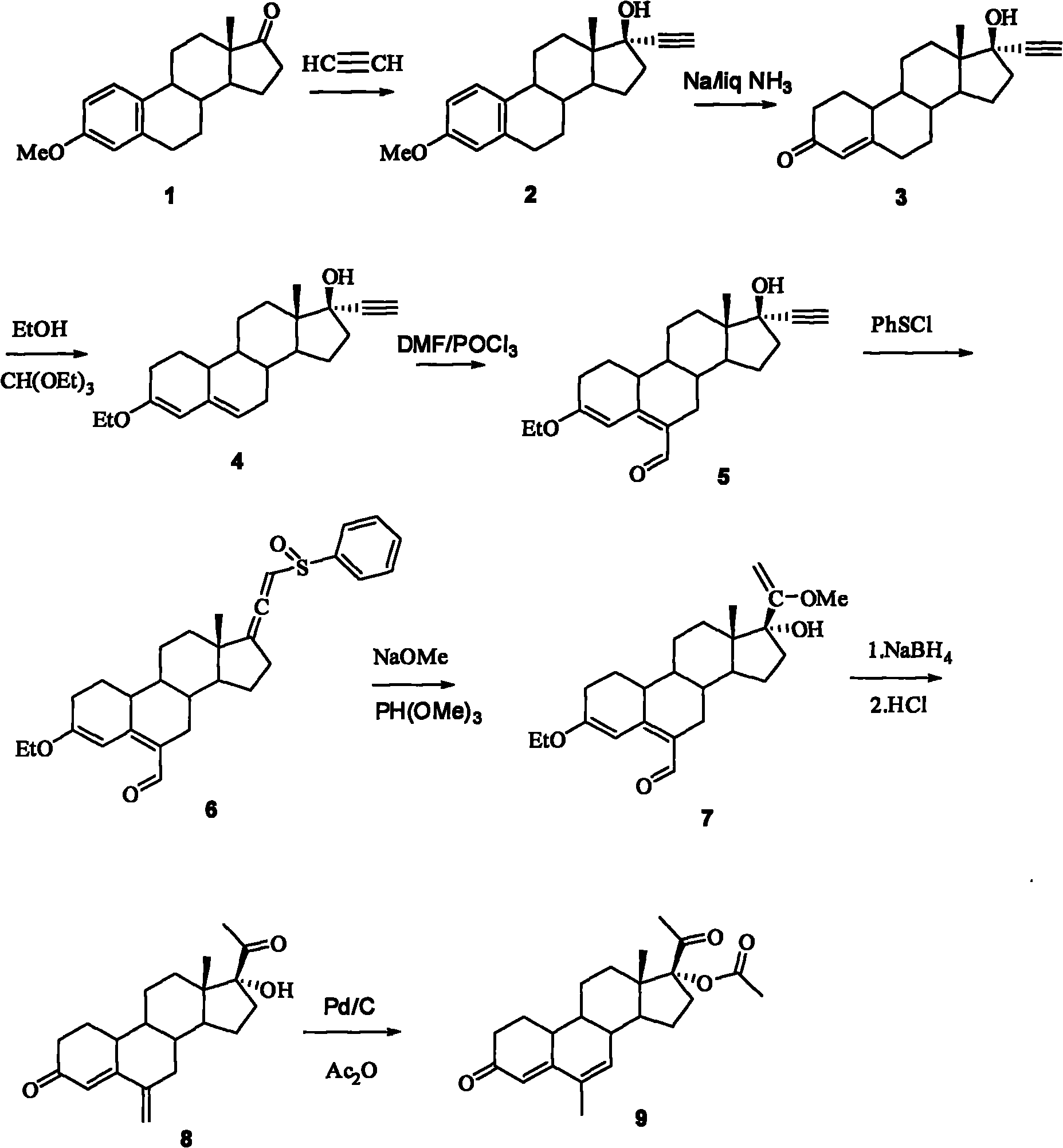

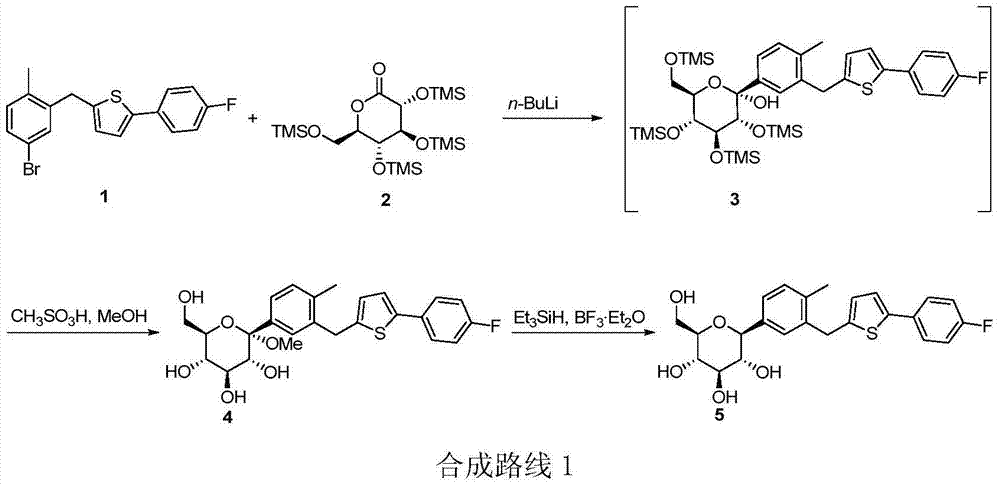

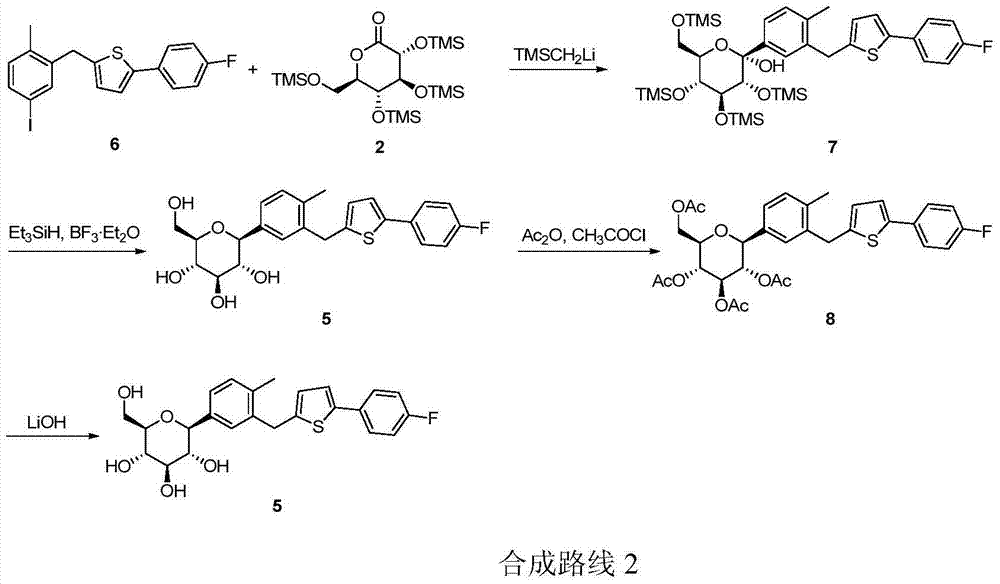

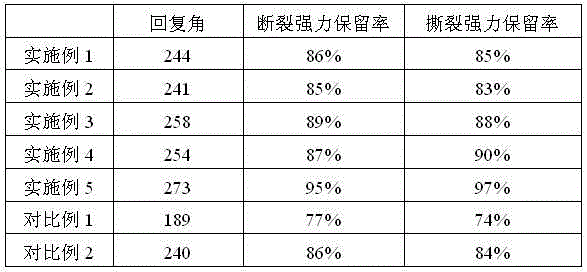

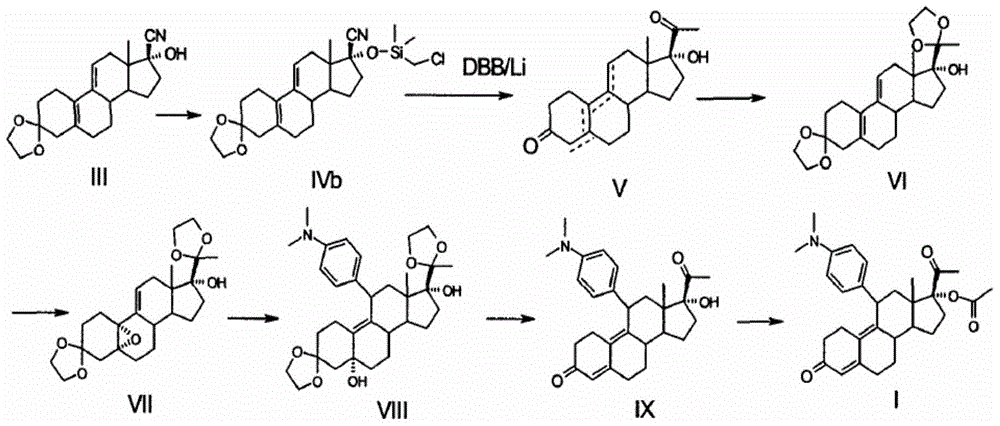

The present invention relates to a new industrial process for the synthesis of solvate- free 17a-acetoxy-11ss-[4-(N,N-dimethyl-amino)-phenyl]-19-norpregna-4,9-diene-3,20-dione [CDB -2914] of formula (I) which is a strong antiprogestogene and antiglucocorticoid agent. The invention also relates to compounds of formula (VII) and (VIII) used as intermediates in the process. The process according to the invention is the following: i) 3-(ethylene-dioxy)-estra-5(10),9(11)-diene-17-one of formula (X) is reacted with potassium acetilyde formed in situ in dry tetrahydrofuran by known method, ii) the obtained 3-(ethylene-dioxy)-17a-ethynyl-17ss-hydroxy-estra-5(10),9(11)-diene of formula (IX) is reacted with phenylsulfenyl chloride in dichloromethane in the presence of triethylamine and acetic acid, iii) the obtained isomeric mixture of 3-(ethylene-dioxy)-21-(phenyl-sulfinyl)-19-norpregna-5(10),9(11),17(20),20-tetraene of formula (VIII) is reacted first with sodium methoxide in methanol, then with trimethyl phosphite, iv) the obtained 3-(ethylene-dioxy)-17a-hydroxy-20-methoxy-19-norpregna-5(10),9(11),20-triene of formula (VII) is reacted with hydrogen chloride in methanol, then v) the obtained 3-(ethylene-dioxy)-17a-hydroxy-19-norpregna-5(10),9(11l); -diene-20- one of formula (VI) is reacted with ethylene glycol hi dichloromethane in the presence of trimethyl orthoformate and p-toluenesulfonic acid by known method, vi) the obtained 3,3,20,20-bis(ethylene-dioxy)-17a-hydroxy-19-norpregna- 5(10),9(11)-diene of formula (V) is reacted with hydrogen peroxide in a mixture of pyridine and dichloromethane in the presence of hexachloroacetone by known method, vii) the obtained 3,3,20,20-bis(ethylene-dioxy)-17a-hydroxy-5,10-epoxy-19-norpregn-9(11)-ene of formula (IV), containing approximately a 1:1 mixture of 5a,10a- and 5ss,10ss-epoxides, is isolated from the solution and reacted with a Grignard reagent obtained from 4-bromo-N,N-dimethyl-aniline in tetrahydrofuran.

Owner:RICHTER GEDEON NYRT

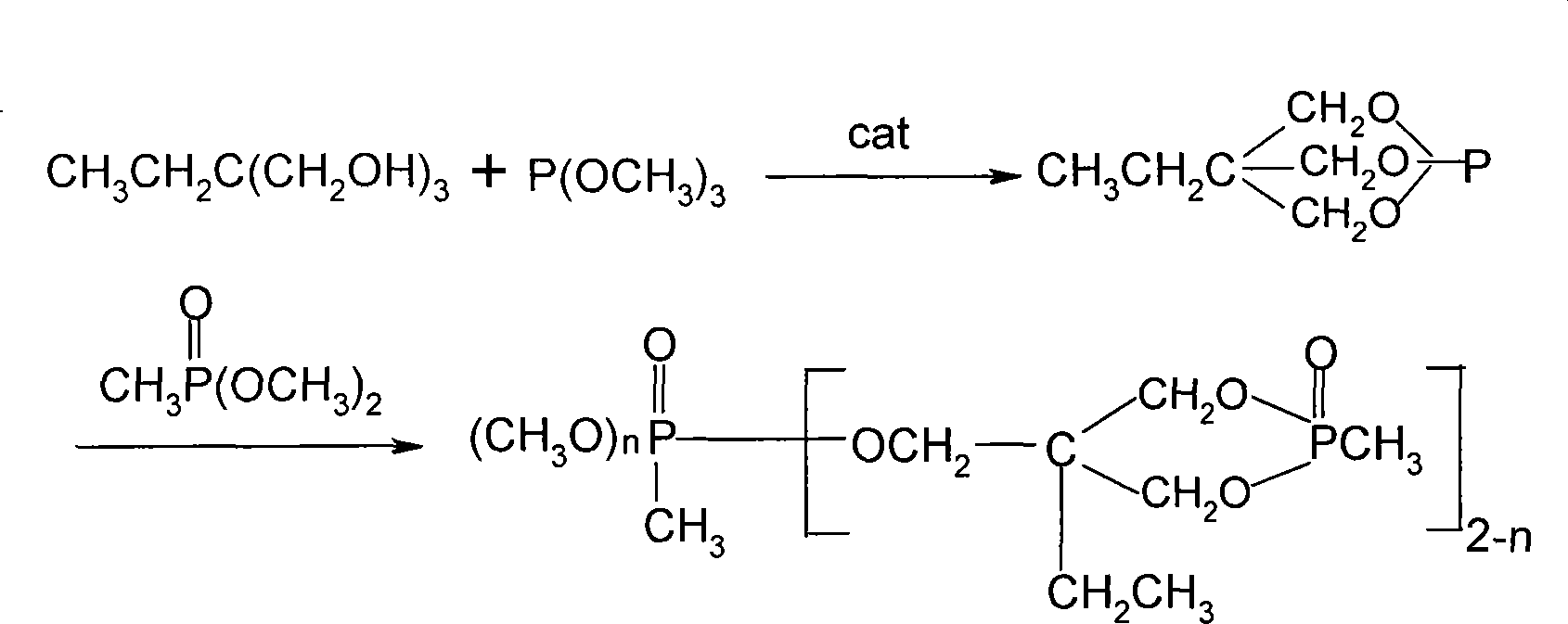

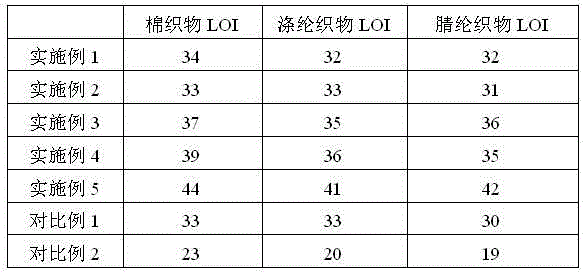

Method for preparing annular phosphonate or annular phosphate flame retardant

InactiveCN101230274AThe preparation method is simple and environmentally friendlyEasy to operateFlame-proof filament manufactureGroup 5/15 element organic compoundsDimethyl methylphosphonateTriethylphosphite

The invention provides a preparation method of annular phosphonate or annular organic phosphate flame retardant. The steps are that (1) trimethylolpropane and trimethyl phosphate or triethyl phosphate are taken as the material, and react to synthesize into midbody under the condition of catalyzer; (2) phosphonate or organic phosphate is added into the midbody and is heated, and then the product of annular phosphonate or annular organic phosphate flame retardant can be obtained. The phosphite ester is selected from trimethyl phosphate and triethyl phosphate. The phosphonate is selected from dimethyl-phosphine and diethyl ethyl phosphine. The organic phosphate is selected from trimethyl phosphate, triethyl phosphate, phosphate propyl, tributyl phosphate and tricresyl aromatic ester. The invention overcomes the shortcomings of the prior art, the new preparation method of annular phosphonate or annular organic phosphate flame retardant is environment-friendly, solution is not needed, and the operation is simple. The termination product has excellent color and luster, low acid value and excellent viscosity; and does not need additional decoloration.

Owner:NANJING NORMAL UNIVERSITY +1

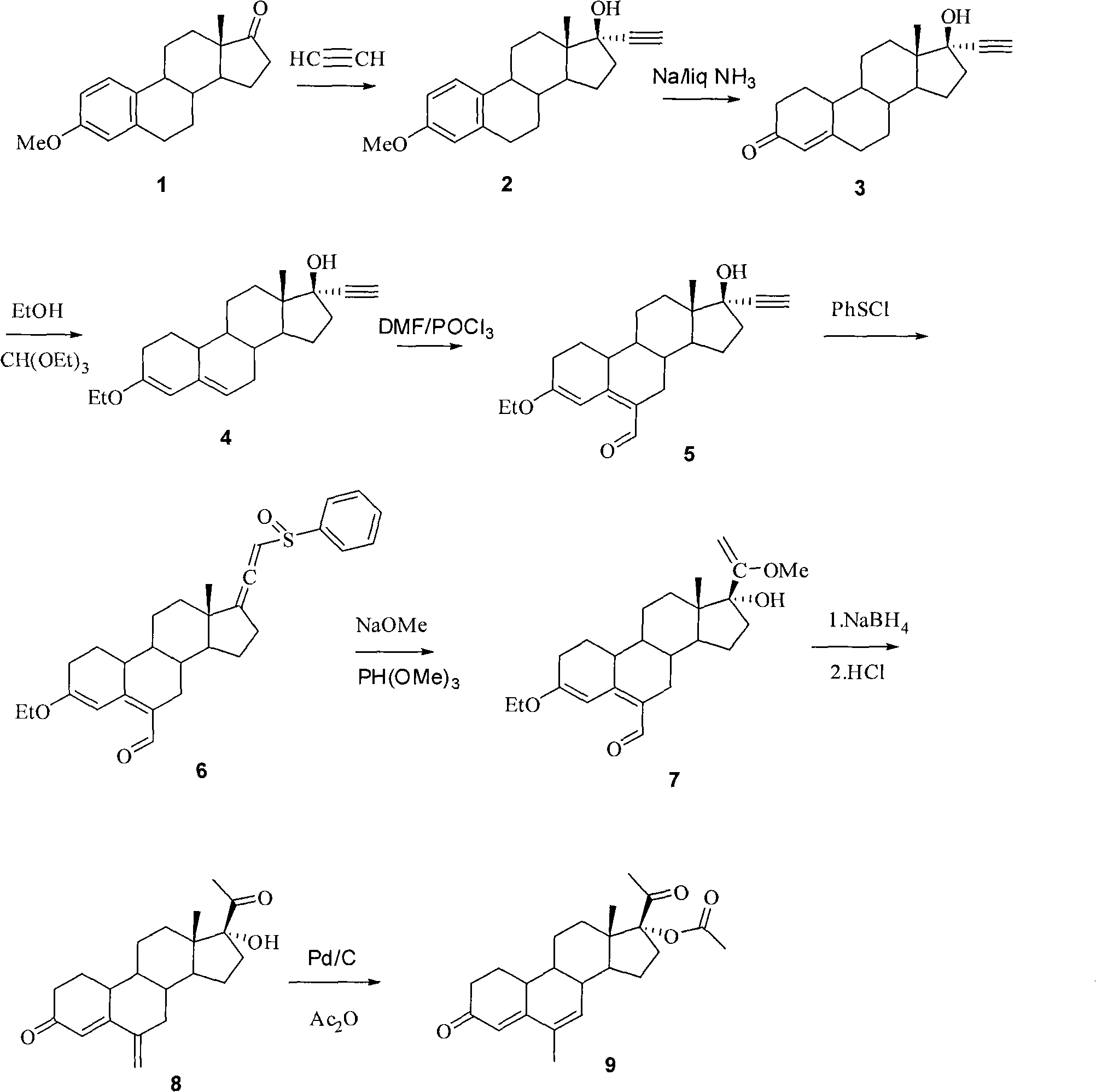

Production process for anti-ultraviolet flame-retardant light-resistant curtain shell fabric

The invention discloses a production process for an anti-ultraviolet flame-retardant light-resistant curtain shell fabric. The production process comprises the following steps: mixing and spinning flame-retardant polyester fiber, polyacrylonitrile fiber, refined sulfur cotton and flame-retardant nylon into yarns; spinning the yarns into a semi-finished shell fabric; padding the semi-finished shell fabric into a finishing solution for padding, and then drying and cooking the semi-finished shell fabric to obtain a finished curtain shell fabric, wherein the finishing solution comprises a coating, a Gemini cationic softener, a flame retardant, a micro-nano-oxide, polyoxyethylene alkyl ether sulfonates succinate and the like; the flame retardant is obtained by synthesizing trimethylolpropane, trimethyl phosphate and trimethyl phosphate in the molar ratio of 1:1:1; and the Gemini cationic softener is obtained by synthesizing stearyl amidopropyl dimethyl amine and bis(2-chloroethyl) ether in the molar ratio of 2:1. The curtain shell fabric prepared by the method has high ultraviolet resistance, high light resistance and high flame retardant performance.

Owner:ZHEJIANG HUIDE NEW MATERIAL

Method for synthesizing 6-methyl-17alpha-acetoxyl-19-norpregnane-4,6-diene-3,20-diketone

The invention relates to a method for synthesizing 6-methyl-17alpha-acetoxyl-19-norpregnane-4,6-diene-3,20-diketone. The method comprises the following steps: 1) reacting acetylene with estrone-3-methyl ether so as to obtain 17alpha-acetenyl estrone-3-methyl ether; 2) carrying out Birich reaction at a low temperature; 3) carrying out alkene etherification on the product obtained in the step 2); 4) carrying out a Vilsmeier reaction on the product obtained in the steps 3); 5) reacting the product obtained in the step 4) with benzene sulfenyl chloride; 6) reacting the product obtained in the step 5) with sodium methoxide and trimethyl phosphate; 7) reducing the formoxyl at the 6-position of the product obtained in the step 6); and 8) reacting the product obtained in the step 7) with Pd-C / cyclohexene, then reacting with acetic oxide so as to obtain the target product 6-methyl-17alpha-acetoxyl-19-norpregnane-4,6-diene-3,20-diketone. By using the method, the operation is simplified, and theproduction cost is reduced; and the reactions involved in the invention are simple to operate, and the yield is high.

Owner:黄云生 +1

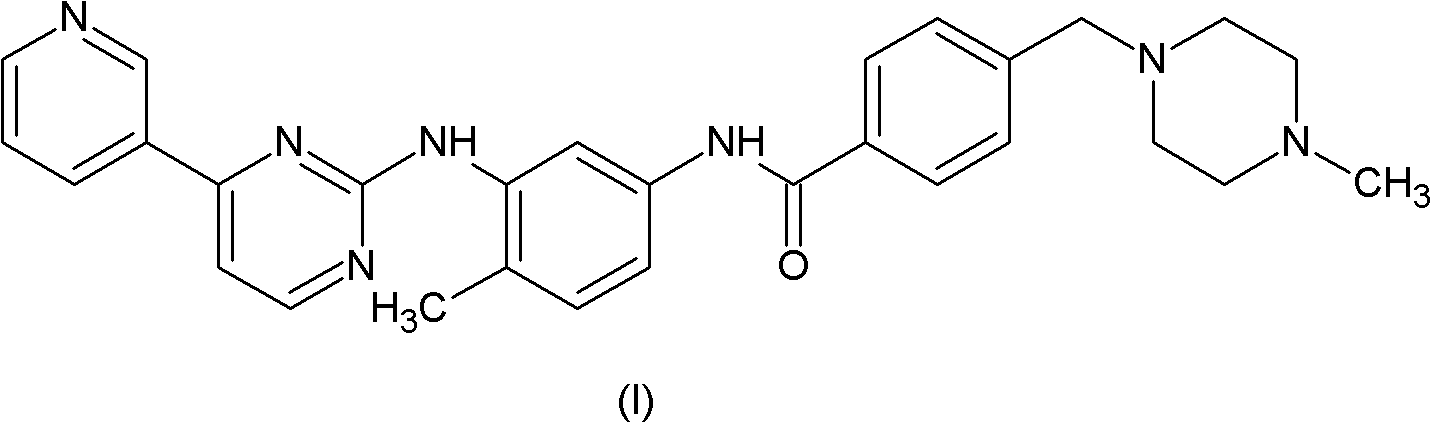

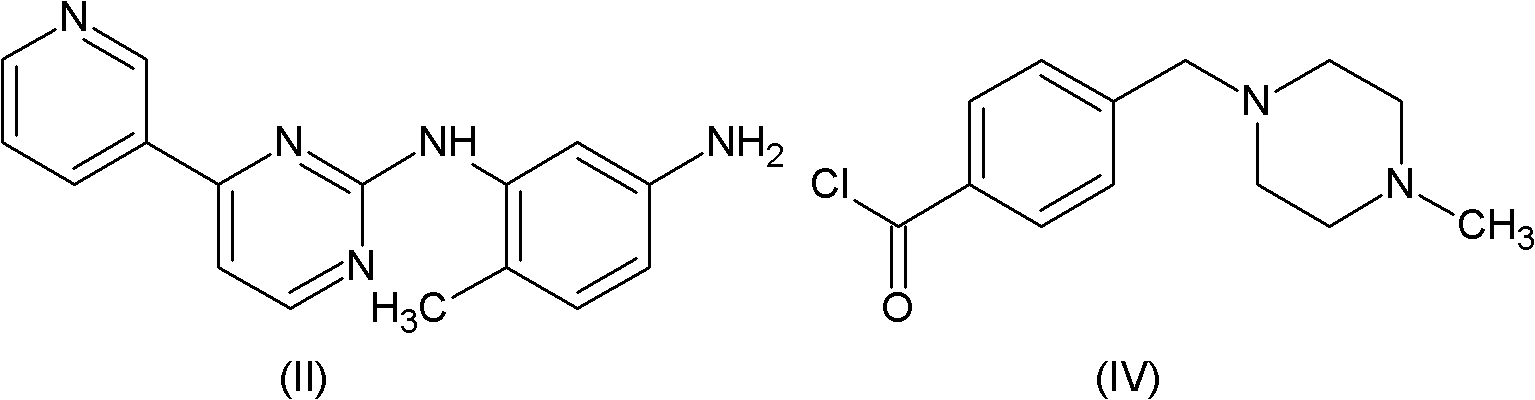

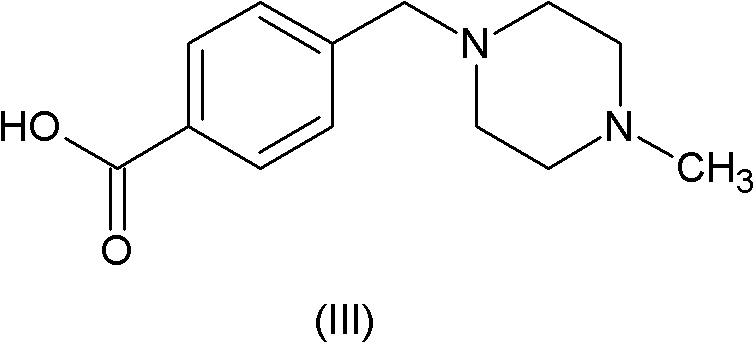

Method for preparing imatinib

ActiveCN101921260AThe reaction steps are simpleShorten the production cycleOrganic chemistryBenzoic acidN dimethylformamide

The invention relates to a method for preparing imatinib, which comprises the following steps of: with a compound N-(5-Amino-2-methylphenyl)-4-(3-pyridyl)-2-pyrimidineamine shown as the structural formula (II) and a compound 4-[(4-Methylpiperazin-l-yl)methyl]benzoic acid shown as the structural formula (III) as initial raw materials, dropwise adding phosphite ester at 50-90 DEG C for 1-2 hours inthe presence of a catalyst in an organic solvent; and continuously insulating and reacting at 50-90 DEG C to obtain the compound imatinib shown as the structural formula (I). The organic solvent is N,N-dimethylformamide, N,N-dimethylacetylamide or N-methylpyrrolidone. The catalyst is pyridine; and the phosphite ester is trimethyl phosphate, triethyl phosphate or triphenyl phosphate. The technical scheme of the invention has the advantages of simple reaction step, easy control of reaction, short production cycle, low toxicity of used raw materials, less pollution to the environment and higher product quality, and the yield can reach 95 percent, and the purity reaches 99.5 percent.

Owner:山东金城昆仑药业有限公司

Hydrotalcite-lanthanum cyanurate composite environmental protection stabilizer for PVC, and preparation method thereof

The present invention provides a hydrotalcite-lanthanum cyanurate composite environmental protection stabilizer for PVC, wherein the hydrotalcite-lanthanum cyanurate composite environmental protection stabilizer is prepared from the following raw materials by weight: 20-30 parts of modified magnesium aluminum hydrotalcite, 10-12 parts of dibutyl tin oxide, 6-8 parts of lanthanum cyanurate, 6-9 parts of cerium laurate, 1-3 parts of trimethyl phosphite, 13-15 parts of tri(2-ethylhexyl) acetylcitrate, 3-6 parts of barium stearate, 2-4 parts of diphenyl thiourea, 5-6 parts of zinc stearate, 1-2 parts of hexamethylphosphoric triamide, 1-2 parts of stearic acid, and 10-13 parts of vermiculite powder. According to the present invention, the PVC stabilizer has characteristics of good thermal stability, good processing performance, environmental protection, no toxicity, low cost, good plasticity and balance torque reducing during the PVC processing process, and low cost.

Owner:HWASU

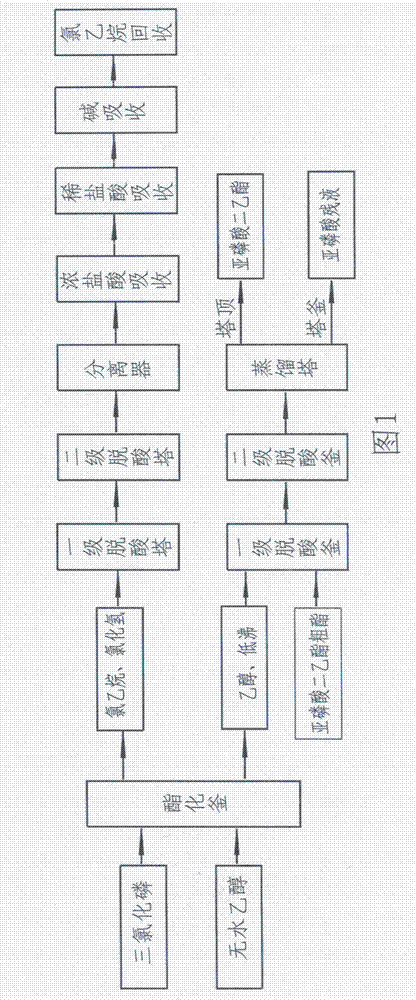

Trimethyl phosphite producing process

InactiveCN1900085AWill not polluteProcess conditions are clear and completeGroup 5/15 element organic compoundsDimethylaniline N-oxideAfter treatment

The trimethyl phosphite producing process with the materials including methanol, phosphorus trichloride, xylene and N, N-dimethyl aniline includes the steps of introducing ammonia to produce synthesis reaction, water washing, laminating, drying and distilling. The present invention has sealed operation, one-step distillation, circular use of the residual liquid and the tail gas after treatment, etc. Trimethyl phosphite is used as important material for medicine, pesticide intermediate, plastic and many other materials.

Owner:泰州市天成化工有限公司

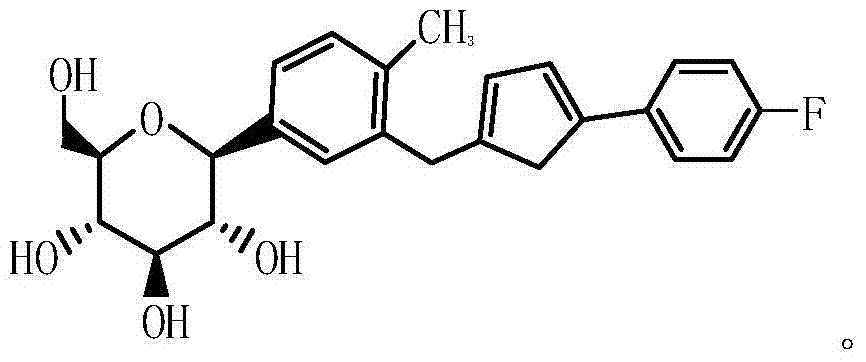

Preparation method of canagliflozin

ActiveCN104119324AReduce usageReduce security risksOrganic chemistrySodium methoxideAnhydrous ethanol

The invention discloses a preparation method of canagliflozin. The method comprises the following steps: (1) by using DMF (N,N-dimethylformamide) as a solvent, carrying out protective reaction on the main raw material SM1 by using benzoyl chloride to obtain an intermediate I; (2) by using acetonitrile as a solvent, removing methoxy group from the intermediate I under the action of trimethyl phosphite to obtain an intermediate II; and (3) by using tetrahydrofuran and anhydrous ethanol or methanol as solvents, removing benzoyl protection from the intermediate II under the action of sodium methoxide to obtain the canagliflozin. The purity of the product is at least 99.9%, and the yield is at least 81.6%. The method has the advantages of mild reaction conditions, high yield and high product quality, is economical and environment-friendly, and can easily implement industrial production.

Owner:QILU PHARMA HAINAN +1

Alcohol ether fuel additive

InactiveCN1876774ARaise MethanolIncrease ethanol contentLiquid carbonaceous fuelsAlcohol fuelDiethyl carbonate

The invention relates the alcohol ether fuel and addition agent. The addition agent comprises methyl formate, methyl methacrylate, trimethyl phosphate, dimethyl carbonate or 10-50wt% diethyl carbonate, dimethyl ether, isopropyl ether, propyl ether, 15-40wt% ethyl ether, isoamyl alcohol, isobutyl alcohol or 15-50wt% isoheptyl alcohol, aminoethyl alcohol, diethyl ethanolamine, triethylamine, hexadecylamine, octadecyl ammonium, 0.5-5wt% nitroaniline, and 0.1-1wt% nufenoxole. The invention has the advantages of non emulsification, non three wastes, low energy consumption and high productivity.

Owner:SHANGHAI FINE ALCOHOL PETROCHEM TECH DEV

Flame-retardant anti-wrinkle finishing agent for fabric and preparation method and application thereof

ActiveCN104695233AIncreased flame retardant strengthImprove wrinkle resistanceVegetal fibresPhosphorous acidPhosphoric Acid Esters

The invention discloses a flame-retardant anti-wrinkle finishing agent for fabrics and a preparation method and application thereof. The flame-retardant anti-wrinkle finishing agent for fabrics comprises the following components in parts by weight: 8-15 parts of trimethyl phosphite, 4-9 parts of tri-isopropyl phosphite, 4-7 parts of triisopropyl borate, 3-7 parts of amino propanol ascorbyl phosphate, 8-15 parts of polyglycerol polyricinoleate, 14-20 parts of dimethyl silicone, 5-13 parts of dimethiconol stearate, 4-8 parts of secondary alcohol ethoxylate, 12-20 parts of propylene glycol and 300-400 parts of water. The preparation method comprises the following steps: mixing, heating, performing magnetic stirring, and the like. The anti-wrinkle property and the flame retardancy of a fabric treated by using the finishing agent are remarkably improved.

Owner:SUZHOU INST OF TRADE & COMMERCE

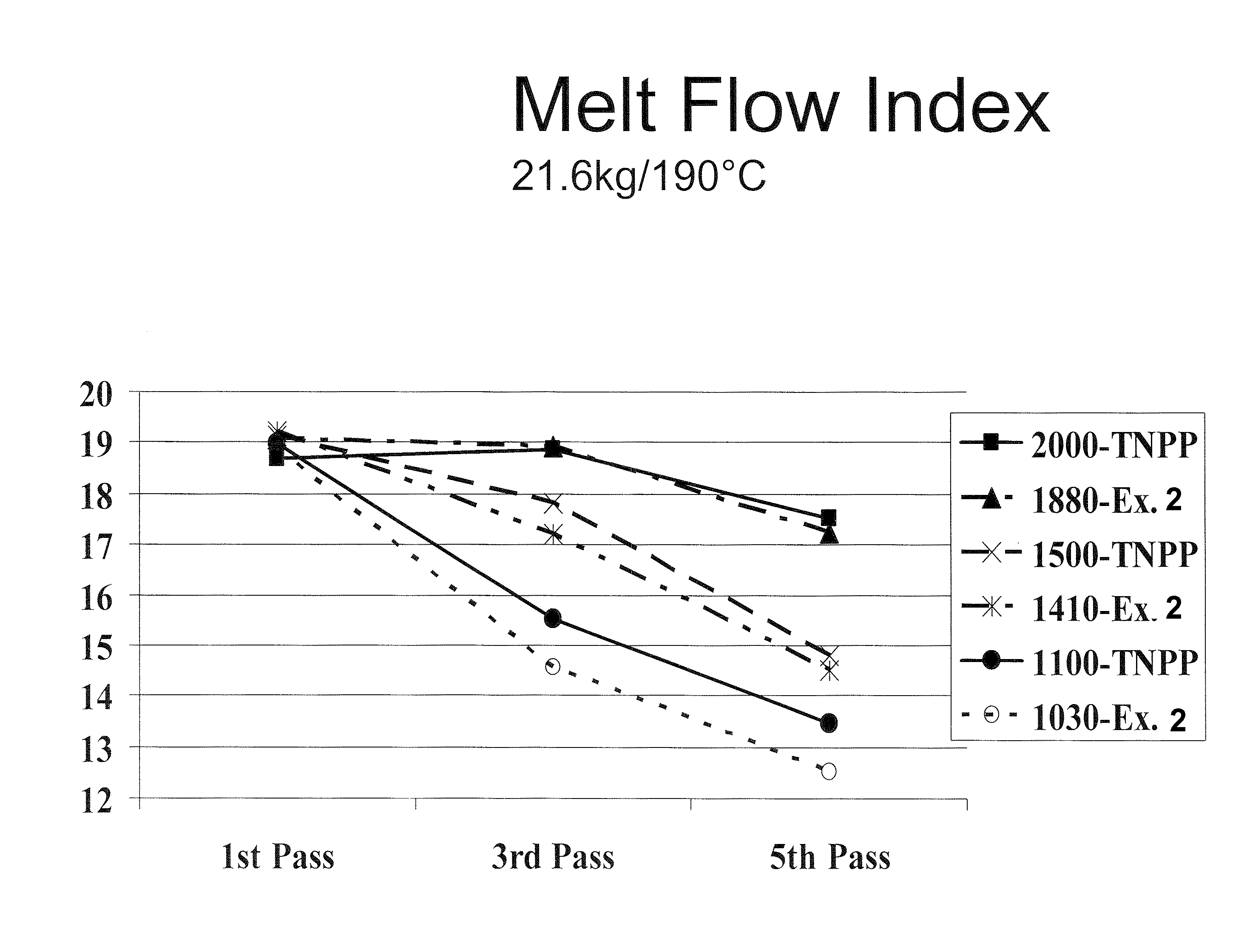

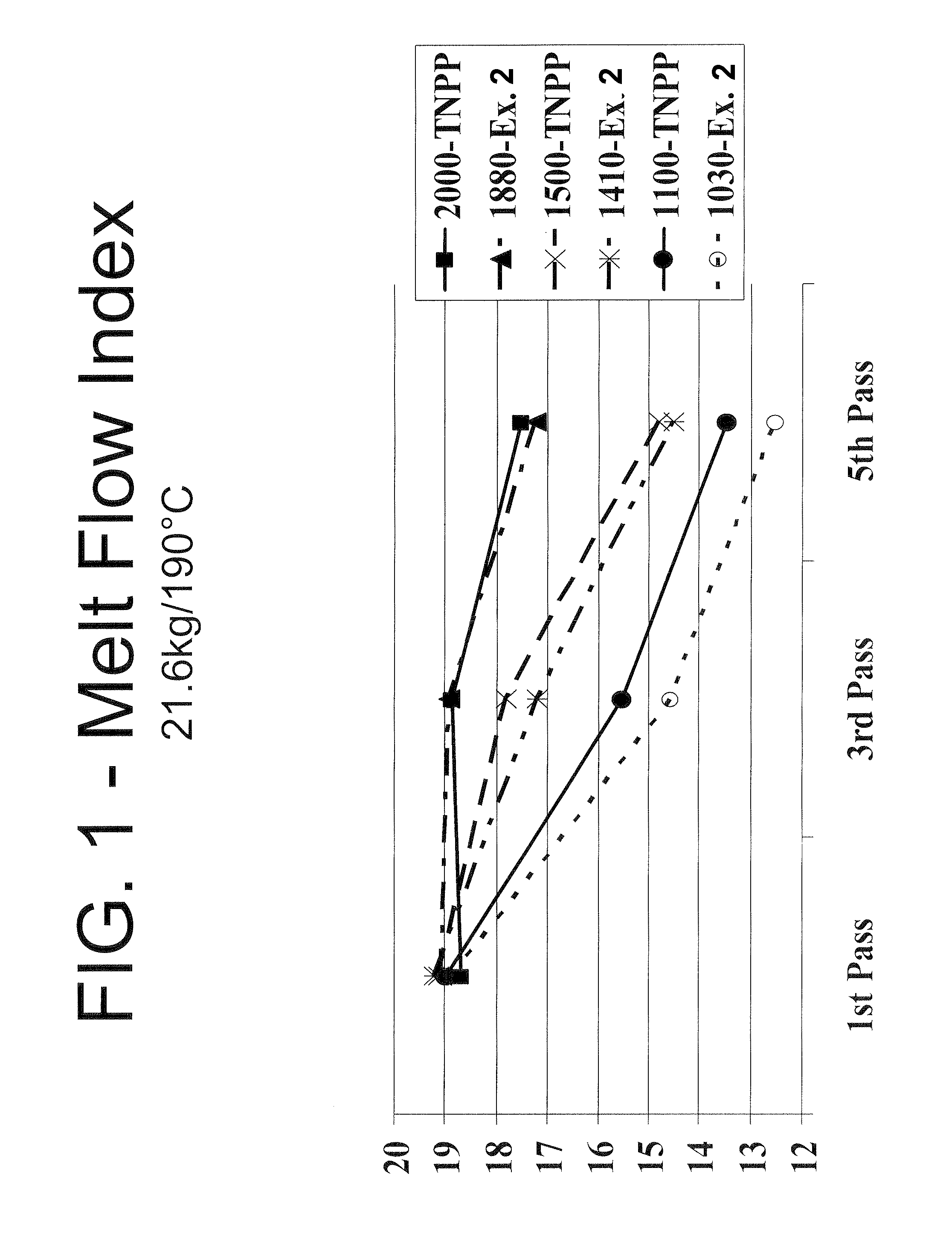

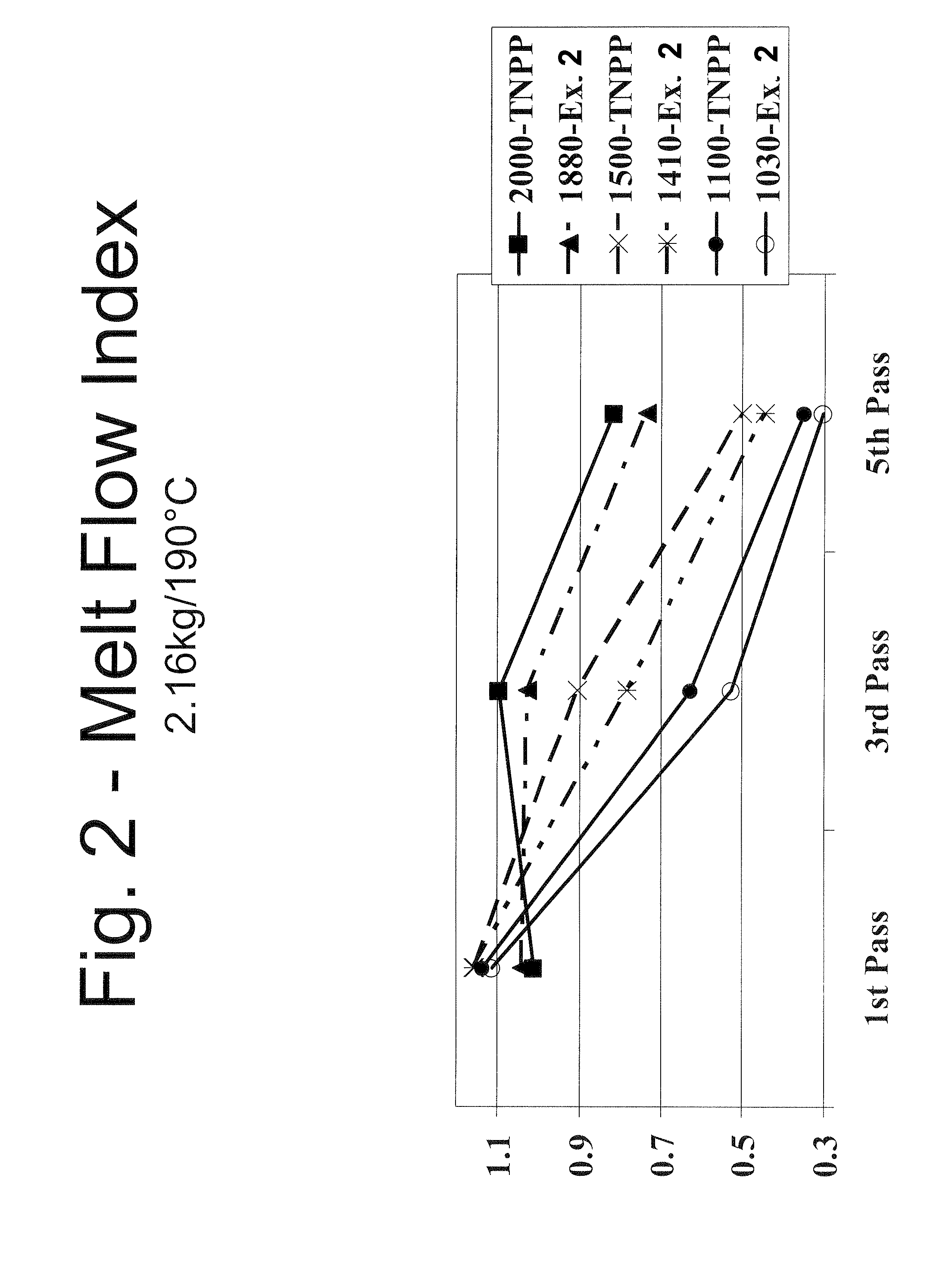

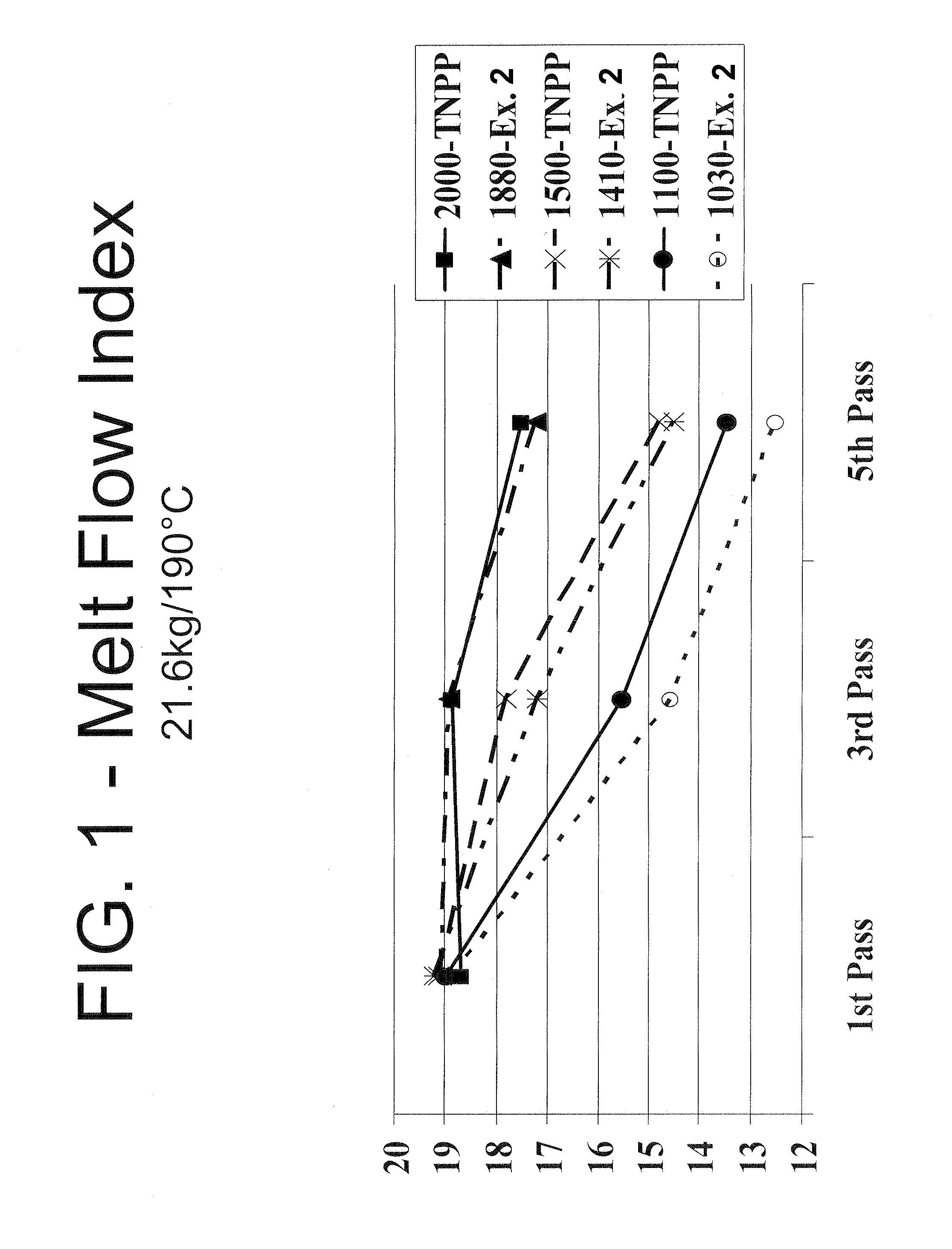

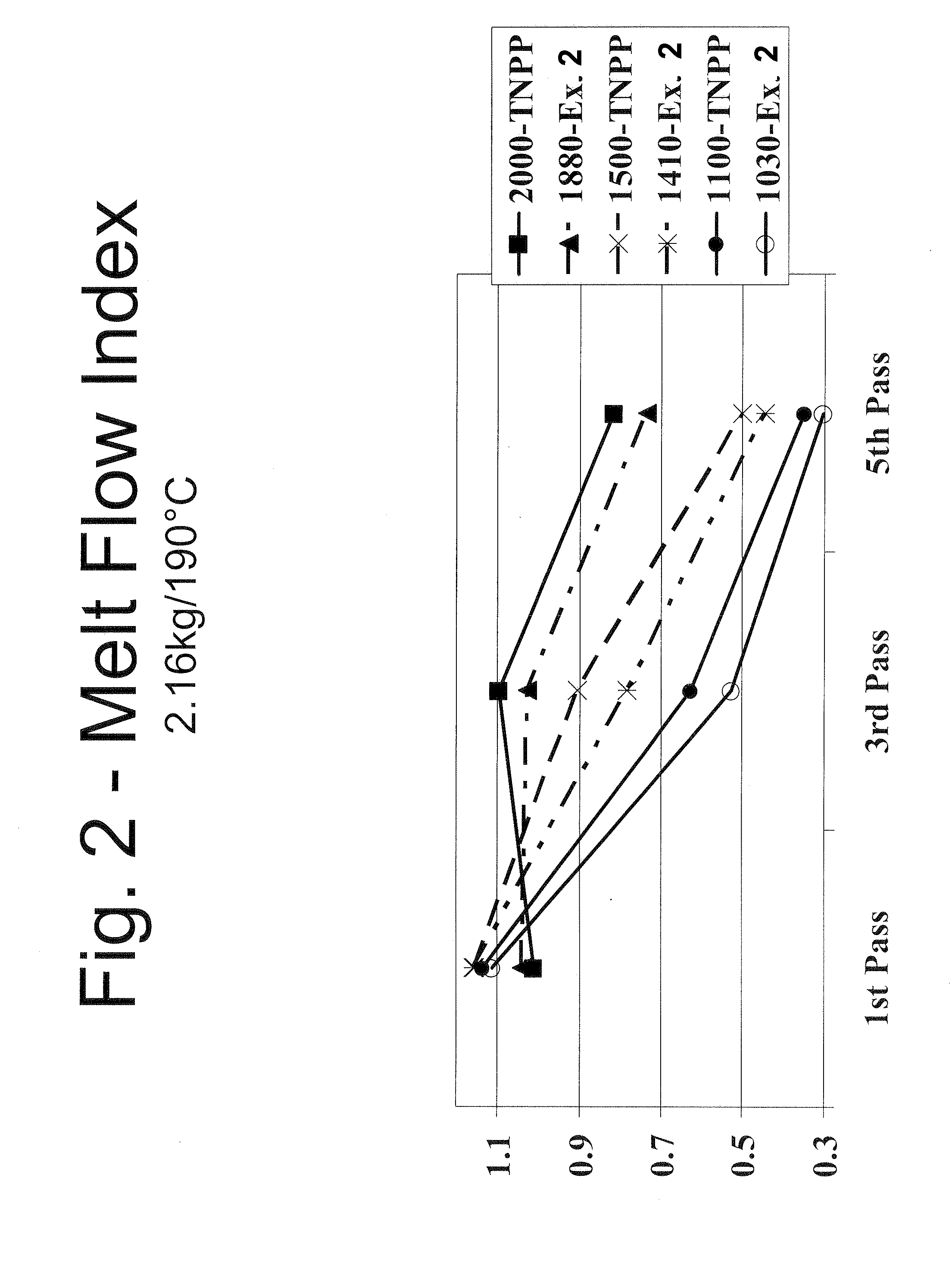

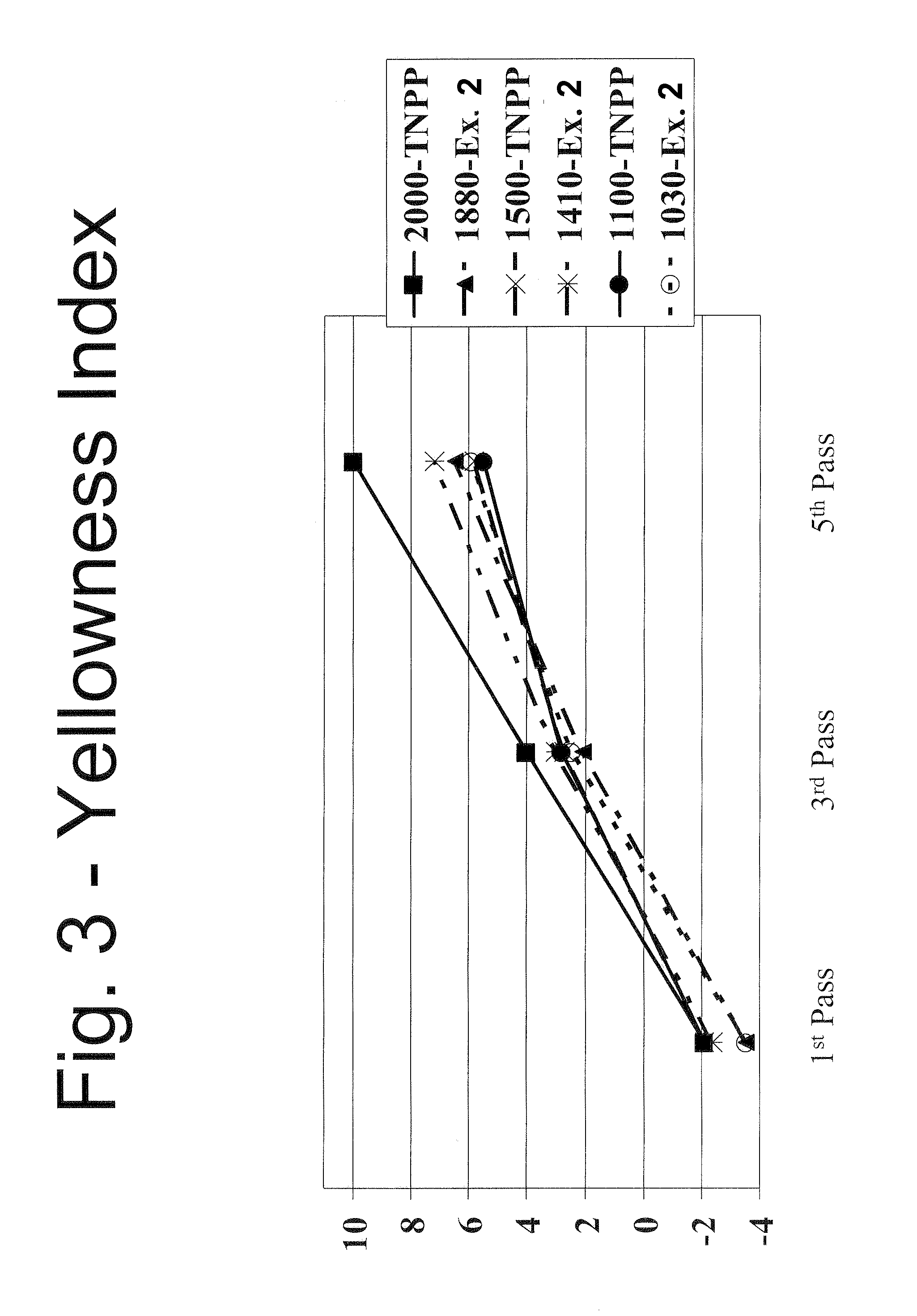

Mixed alkyl-alkylaryl-phenyl phosphite polymer additive

A process to stabilize a polymer is described utilizing the step of adding a phosphite reaction product of a triphenyl phosphite or lower molecular weight trialkyl phosphite (e.g., trimethyl phosphite) or triaryl phosphite, with from approximately 1 to 2 moles of preferably a paracumyl phenol, and with from approximately 1 to 2 moles of at least C12-20 carbon alkyl or C12-20 alkenyl alcohol. In one embodiment of the invention, the phosphite reaction product is formula (I)whereinR1 is independently selected from the group consisting of H and C1-2 alkyls;R2 is independently selected from the group defined previously for R1;x is an integral value ranging from 0 to 4 inclusive;y is an integral value ranging from 0 to 4 inclusive;n is an integral value ranging from 1 to 2;R3 is independently selected from the group consisting of C12-20 alkyl or C12-20 alkenyl;R4 is independently selected from the group consisting of C1-10, alkyl and C9-15 arylalkyl;R5 is independently selected from the group defined previously for R4.

Owner:DOVER CHEM CORP

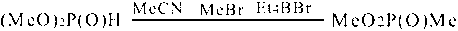

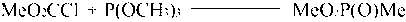

Preparation method of halogen-free retardant dimethyl methylphosphonate

InactiveCN102702256ALow costEasy to separateGroup 5/15 element organic compoundsPhosphorous acidDimethyl methylphosphonate

The invention relates to a preparation method of halogen-free retardant dimethyl methylphosphonate. The preparation method comprises the steps of 1) treating a three-mouth flask and trimethyl phosphate (TMP) at 0 DEG C; adding the trimethyl phosphate (TMP) and the catalyst p-toluenesulfonic acid methyl into the three-mouth flask under protection of nitrogen according to the mass ratio of 100:(8-12); putting the three-mouth flask to oil bath, installing a condenser pipe, starting to stir, performing the whole reaction under protection of nitrogen; 2) heating up to 18-200 DEG C with stirring; reacting for 9-13 hours, cooling to room temperature, using the oil bath to warm; and performing reduced pressure distillation, collecting fraction at 105-110 DEG C, namely, dimethyl methylphosphonate. The catalyst adopted by the method is environment-friendly catalyst p-toluenesulfonic acid methyl, which can be used repeatedly, so that the cost is low; the product dimethyl methylphosphonate is separated easily, so that the yield is high; according to the method, the synthetic process is simple, the material cost is low, and the industrial production is easy to realize.

Owner:WUHAN UNIV OF TECH

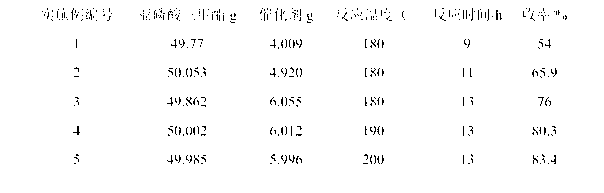

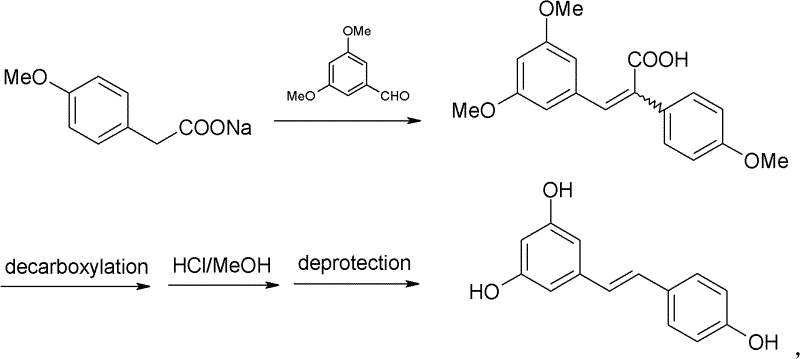

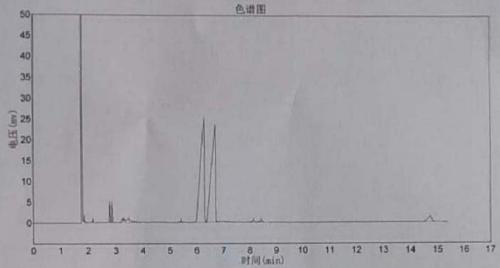

Process for synthesizing trimethoxyphenyl stilbene

ActiveCN102617302ALow priceEasy to recycleOrganic chemistryOrganic compound preparationSodium methoxideAlcohol

The invention discloses a process for synthesizing trimethoxyphenyl stilbene, which includes subjecting 3, 5-dimethoxybenzyl alcohol to chloro by triphosgene to obtain 3,5-dimethoxybenzyl chloride in a high selectivity mode, then subjecting the 3,5-dimethoxybenzyl chloride and trimethyl phosphate to reaction to obtain phosphonate, then subjecting the phosphonate and anisic aldehyde to condensation under the action of sodium methoxide to obtain 3, 4', 5- trimethoxyphenyl stilbene. The yield of crude products can reach around 95%, and the yield of synthetical pure products is above 90%. According to the process for synthesizing the trimethoxy phenyl stilbene, all materials can be fully used, and the discharging of three wastes is low; the process for synthesizing the trimethoxy phenyl stilbene is environment-friendly in producing process and has the advantages of high conversion ratio, high selectivity, easiness in obtaining raw materials and recycling auxiliary raw materials, little in three waste pollution and suitable for industrial production. The 3, 4', 5- trimethoxy phenyl stilbene can be used as a key intermediate for synthesizing trans-resveratrol.

Owner:浙江新赛科药业有限公司

Highly safe electrolyte of lithium battery

InactiveCN104393341ALow viscosityImprove flame retardant performanceSecondary cells servicing/maintenanceOrganic solventTrimethyl phosphite

The invention relates to a highly safe electrolyte of a lithium battery. The highly safe electrolyte comprises a lithium salt, a flame retardant and an organic solvent, the lithium salt is LiPF6, the flame retardant is trimethyl phosphite, the organic solvent is propylene carbonate, and a weight ratio of the flame retardant to the organic solvent is 1:1. The highly safe electrolyte of the lithium battery has very good compatibility with a positive material, has good electrochemical stability, inhibits the peeling of propylene carbonate to a negative graphite material, fully utilizes of the advantages of small viscosity and good flame retardation effect of trimethyl phosphate, and solves the safety problem of lithium ion batteries.

Owner:HEFEI CAIXIANG INFORMATION TECH

Mixed alkyl-alklaryl-phenyl phosphite polymer additive

A process to stabilize a polymer is described utilizing the step of adding a phosphite reaction product of a triphenyl phosphite or lower molecular weight trialkyl phosphite (e.g., trimethyl phosphite) or triaryl phosphite, with from approximately 1 to 2 moles of preferably a paracumyl phenol, and with from approximately 1 to 2 moles of at least C12-20 carbon alkyl or C12-20 alkenyl alcohol. In one embodiment of the invention, the phosphite reaction product is formula (I)whereinR1 is independently selected from the group consisting of H and C1-2 alkyls;R2 is independently selected from the group defined previously for R1;x is an integral value ranging from 0 to 4 inclusive;y is an integral value ranging from 0 to 4 inclusive;n is an integral value ranging from 1 to 2;R3 is independently selected from the group consisting of C12-20 alkyl or C12-20 alkenyl;R4 is independently selected from the group consisting of C1-10, alkyl and C9-15 arylalkyl;R5 is independently selected from the group defined previously for R4.

Owner:DOVER CHEM CORP

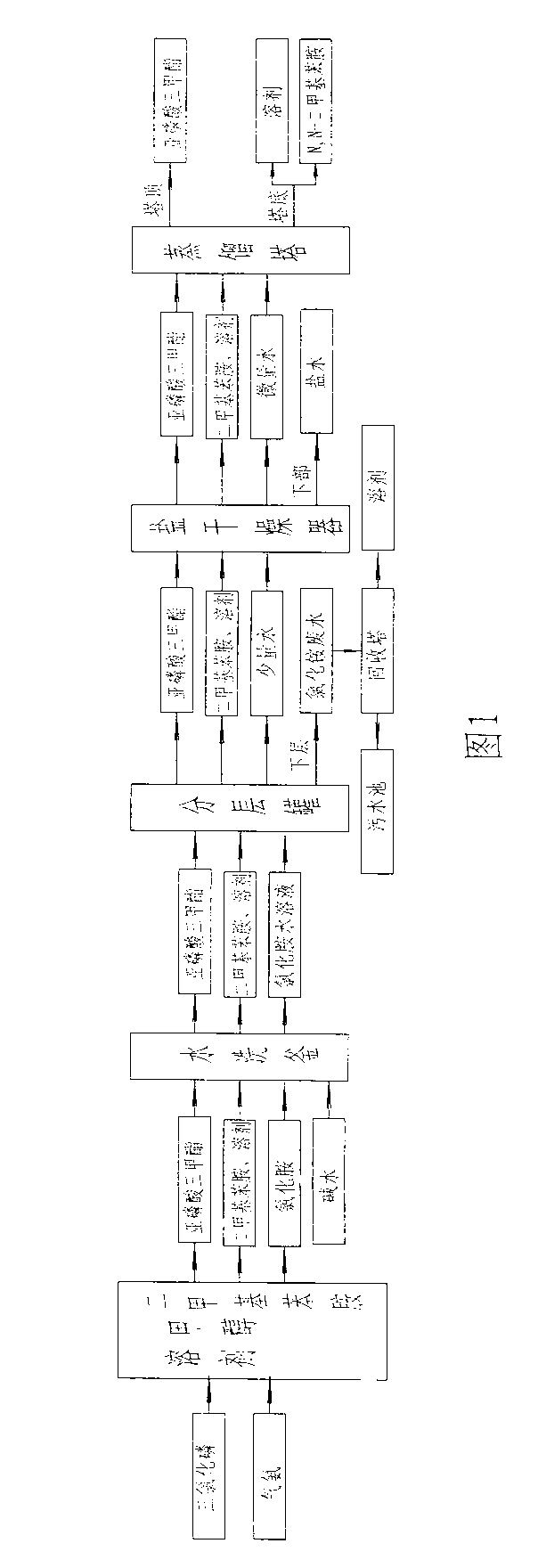

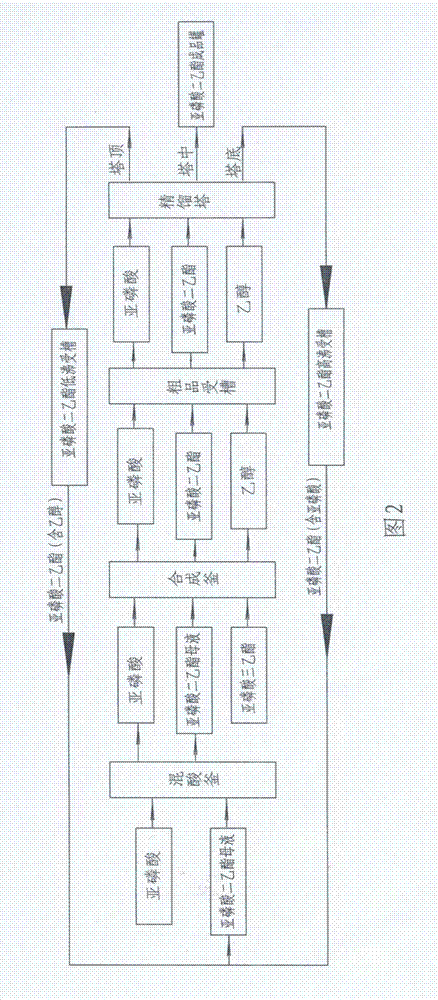

Process for treating waste water for production of trimethyl phosphite

InactiveCN101306900AAchieve recyclingSave waterFatty/oily/floating substances removal devicesGeneral water supply conservationDistillationWater vapor

The invention discloses a method for processing wastewater in the production of trimethyl phosphite, belonging to the wastewater treatment in the chemical process technical field. The processing method comprises the following: firstly, a step of standing and delamination, which is to delaminate oily solvent and water in the wastewater; secondly, a step of heating and concentration, which is to heat the wastewater to between 100 and 140 DEG C and to make the proportion of concentrated solution reach between 10.5 and 1.20; thirdly, a step of cooling crystallization, which is to obtain crystal ammonium chloride and mother liquor; fourthly, a step of separation and drying, which is to separate out, dry and dehydrate ammonium chloride products and to recycle the mother liquor. The method adopts the preferable proposal that: standing and the delamination are performed by a two-stage wastewater disposal basin in turn; the wastewater is preheated by distillation waste heat during the producing procedure before heating and concentration; and evaporated water vapor during the concentration process is condensed and then recycled. The method has simple and feasible technique, low cost and good effect, has the content of the reclaimed ammonium chloride reach between 90 and 99.8 percent, realizes resource recycle, avoids environmental pollution, and generates good environmental benefit, economic benefit and social benefit.

Owner:申厚宝

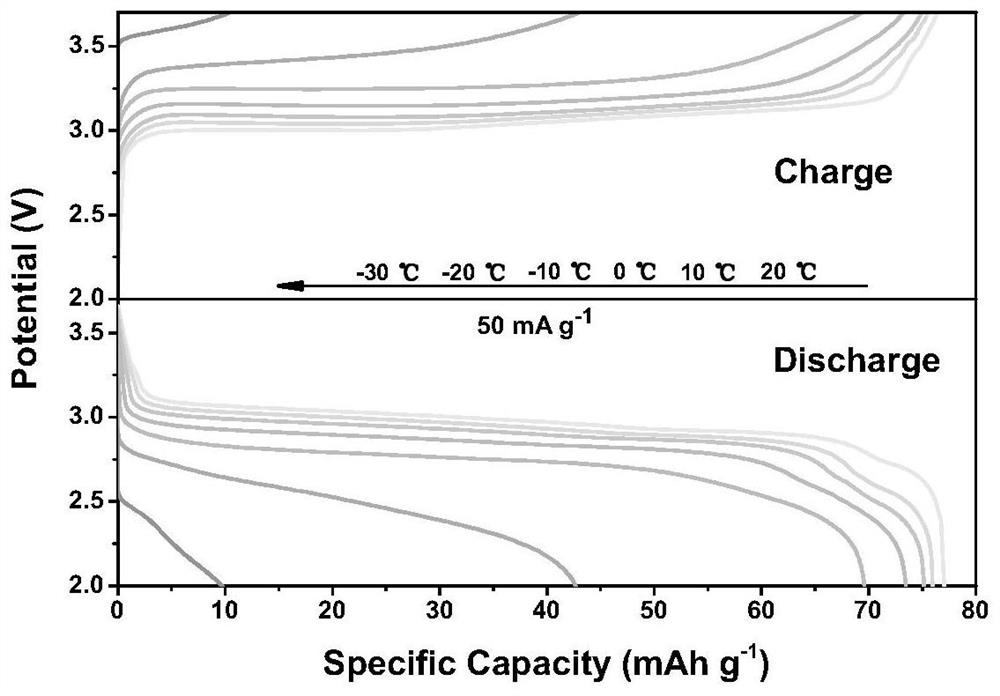

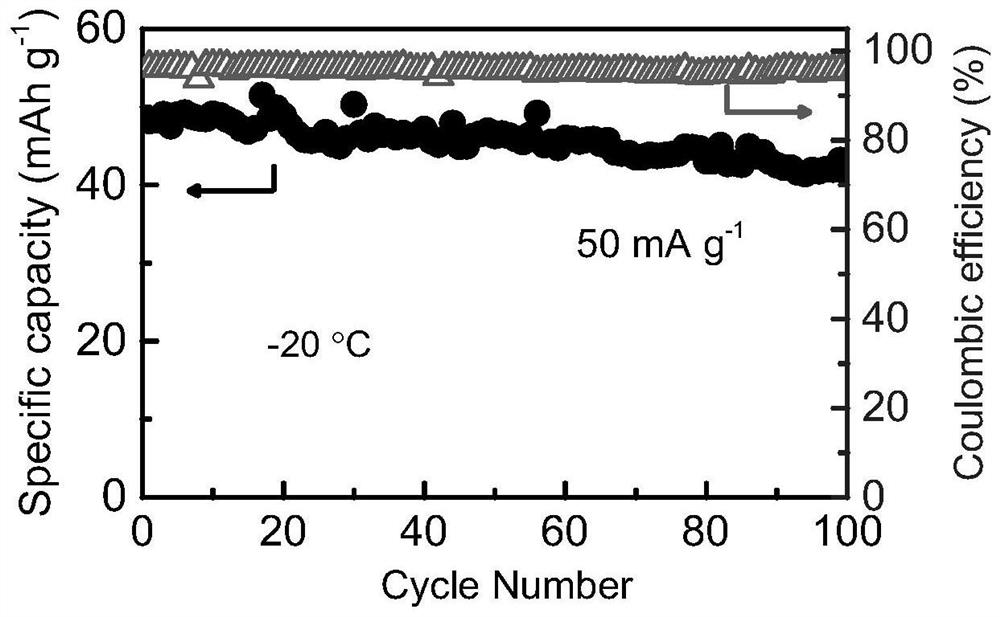

Low-temperature sodium-ion battery electrolyte with flame-retardant function

The invention provides a low-temperature sodium-ion battery electrolyte with a flame-retardant function, which comprises a solute, a solvent and an additive, and the solute is bis(fluorosulfonyl)imide sodium salt 0.9-2M; the solvent is a mixed solution of one or more of tributyl phosphate, triethyl phosphate, trimethyl phosphite, tris (2, 2, 2-trifluoroethyl) phosphate, ethyl nonafluorobutyl ether and 1, 1, 2, 2-tetrafluoroethyl-2, 2, 2-trifluoroethyl ether, and the additive is one or more of fluoroethylene carbonate, vinylene carbonate, 1, 3-propane sultone, succinic anhydride and ethylene sulfate. According to the invention, the sodium ion battery can stably work under a low-temperature environment condition, the electrolyte has the characteristic of non-combustion, and the problem of poor performance of the sodium ion battery at a low temperature can be solved while the battery is prevented from being on fire. The low-temperature-resistant flame-retardant lithium ion battery electrolyte can keep the battery at a relatively large capacity at a low temperature, adapts to a low-temperature environment, has a flame-retardant function and has relatively high viscosity at the low temperature.

Owner:徐州浩华能源科技有限公司

Process for continuously producing trimethyl phosphite by using N, N-dimethylaniline

ActiveCN102838632AReduce energy consumptionIncrease productionGroup 5/15 element organic compoundsAmmonium halidesDimethylaniline N-oxideDistillation

The invention relates to a process for continuously producing trimethyl phosphite by using N, N-dimethylaniline, belonging to the technical field of trimethyl phosphite preparation. Through steps such as synthesis, water washing, layering, drying, distillation and wastewater reclamation, wastewater treatment expenses are low, the quality and the production capacity of trimethyl phosphite products are guaranteed, and the wastewater can be produced into a widely used ammonium chloride fertilizer through concentration and crystallization. The defects that the energy consumption is higher, the alkali charge is great, the production cost is higher, the produced wastewater contains a large quantity of sodium chloride and the sodium chloride obtained after concentration cannot be used when triethylamine is used for continuously producing trimethyl phosphite are overcome; and the problems that a batch process is only suitable for small-scale enterprise production, the output is smaller, the yield is low and the environmental pollution is great are also solved. Besides, products and solvent in water washing liquid are separated through a centrifugal separator, ammonium chloride is effectively removed through second alkali washing, and the problem that the ammonium chloride blocks distillation equipment is well solved.

Owner:荆州三才堂化工科技有限公司

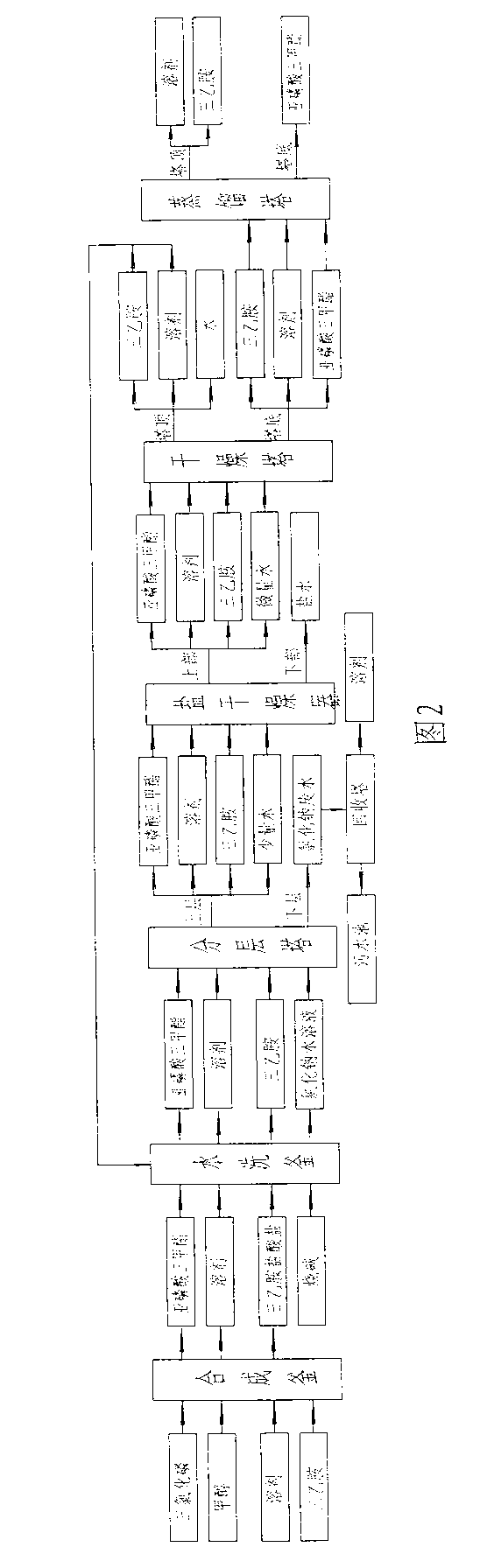

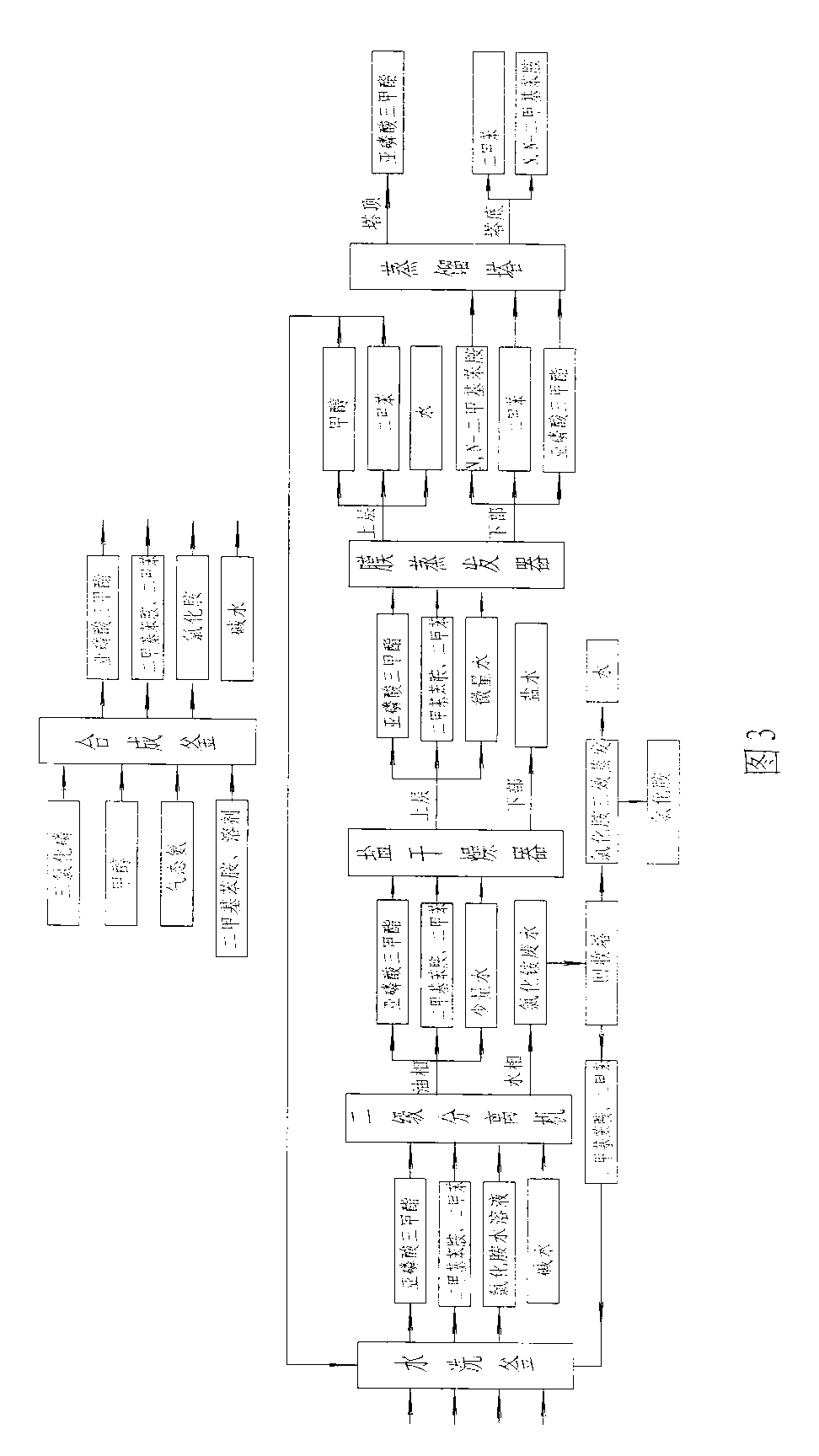

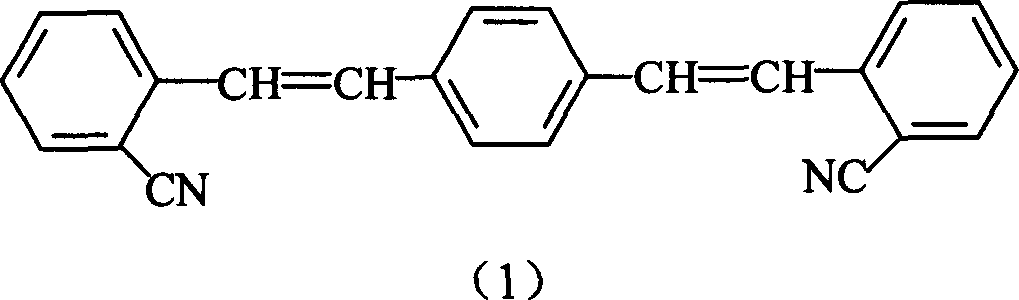

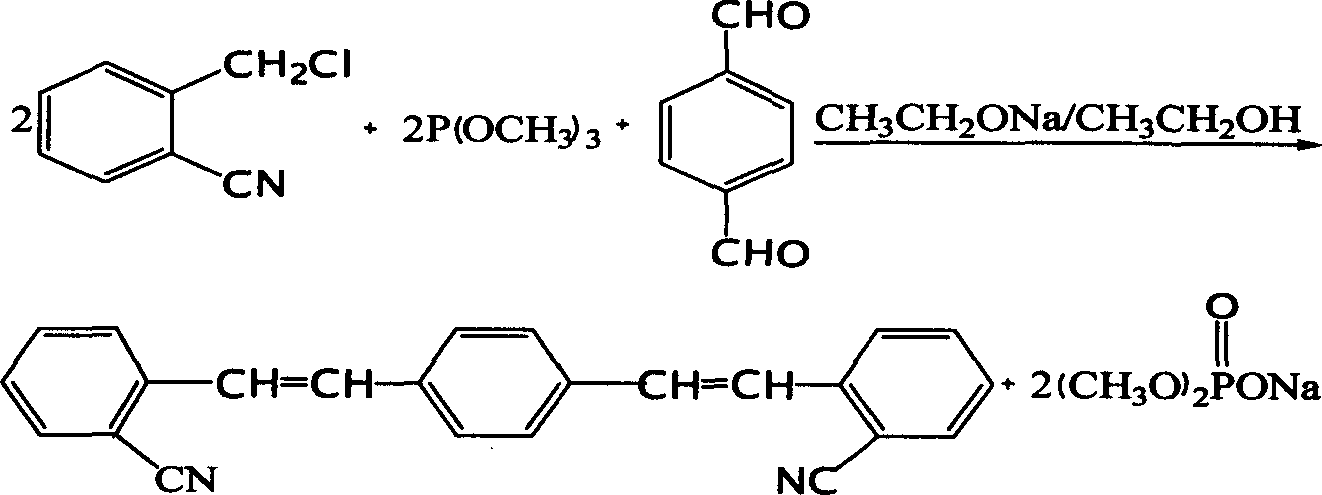

Production of 1,4-bis(O-styryl)

InactiveCN1817857AHigh yieldEasy to operateCarboxylic acid nitrile preparationOrganic compound preparationBenzeneAlcohol

Production of 1,4-diphe(ortho-cyano phenylethylene) is carried out by putting ortho-cyano benzyl chloride into closed reactor with condensing refluxing device at normal pressure, agitating at 100~110DEG C for 2~3hrs, adding into trimethyl phosphite in proportion of ortho-cyano benzyl chloride: trimethyl phosphite=1:1, heating to 120~130DEG C while reacting for 2~3hrs, cooling reactant to 20~30DEG C, adding into terephthalic aldehyde and solvent in proportion of terephthalic aldehyde: ortho-cyano benzyl chloride=1:2mol, dripping into sodium ethylate alcohol solution with concentration 10~16wt%, in 2~3hrs, reacting, filtering to obtain reactant after 2hrs, washing by alcohol and water separately and drying to obtain final product. It is simple and safe, has less consumption and more yields.

Owner:EAST CHINA UNIV OF SCI & TECH

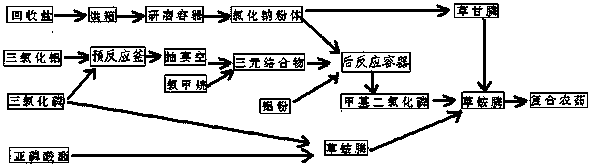

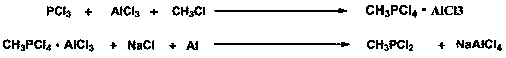

Method and apparatus to prepare glufosinate ammonium composite pesticide via recovered salts containing glufosinate ammonium and trimethyl phosphite

PendingCN107912446ARealize resource utilizationEmission reductionBiocideGroup 5/15 element organic compoundsPhosphorous acidAluminium chloride

The invention provides a method and apparatus to prepare glufosinate ammonium composite pesticide via recovered salts containing glufosinate ammonium and trimethyl phosphite. Chloromethane, aluminum trichloride and phosphorus trichloride are subjected as raw materials to reaction to generate a ternary complex; the ternary complex is distilled under the catalytic reduction of aluminum powder and double decomplexing action of sodium chloride to obtain methylphosphorus dichloride that is further used to synthesize the glufosinate ammonium composite pesticide. The method and apparatus according tothe scheme have the advantages that industrially-produced recovered salt wastes such as glufosinate ammonium and trimethyl phosphite are resourcefully utilized and the composite pesticide is more effective than common glufosinate ammonium.

Owner:NANTONG JIANGSHAN AGROCHEM & CHEM LIMITED LIABILITY

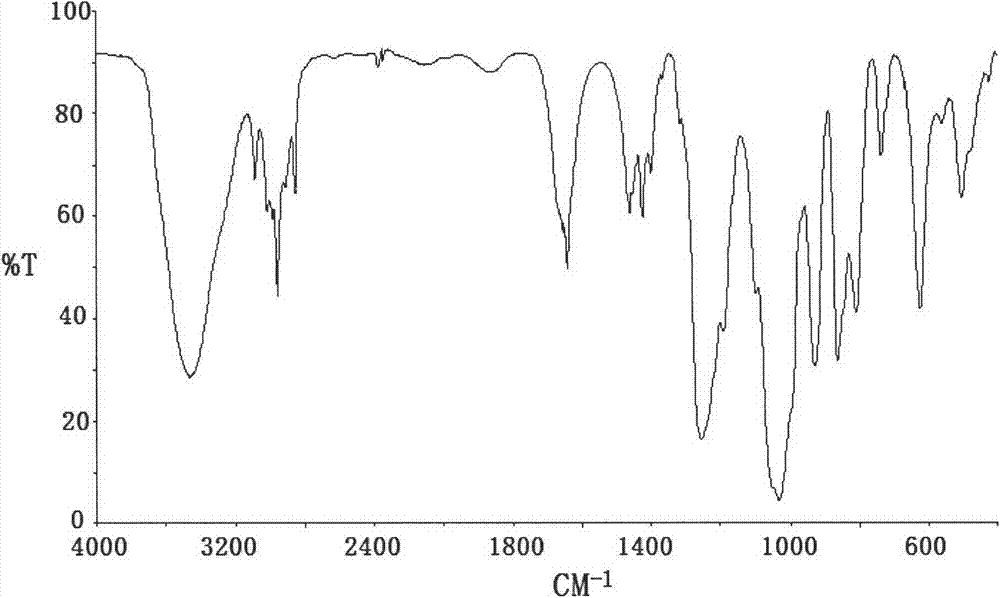

Preparation method of ulipristal acetate and intermediate thereof

The invention discloses a preparation method of ulipristal acetate and an intermediate thereof, and belongs to the field of pharmaceutical synthesis. The preparation method of the ulipristal acetate comprises the following steps: by taking 3,3-(ethylenedioxy)-19-methylestra-5(10),9(11)-diene-3,17-diketone as raw material, enabling the raw material to react with sodium acetylide or potassium acetylide to obtain a compound III, carrying out high-selectivity epoxidation by oxide to obtain a compound IV, subsequently enabling the compound IV to react with 4-(N,N-dimethyl amino) phenyl magnesium bromide Grignard reagent to obtain a compound V, then enabling the compound V to react with phenyl sulfonic acid chloride to obtain a compound VI, enabling the compound VI to respectively react with sodium methoxide and trimethyl phosphate to obtain a compound VII, hydrolyzing and removing a protection group to obtain a compound VIII, finally carrying out acetylation reaction to obtain the ulipristal acetate, wherein the reaction formulae are as shown in the description. The method is short in synthetic route, mild in reaction conditions, high in yield and purity of products, low in cost, stable and controllable in quality, and is suitable for industrial production.

Owner:CHENGDU ORGANOCHEM CO LTD

Technology for preparing diethyl phosphite by by-product of triethyl phosphite

ActiveCN102827202AIncrease production capacitySimple processGroup 5/15 element organic compoundsPhosphorous acidTriethylphosphite

The invention relates to a technology for preparing diethyl phosphite by by-product of triethyl phosphite, belonging to the field of a preparation technology of diethyl phosphite. The method utilizes the by-product generated in the production of the triethyl phosphite to react with phosphorous acid, and the diethyl phosphite in the by-product of the triethyl phosphite can be recycled; the product is high in yield and good in purity, the equipment investment is less and the production cost is low; and the technology has the characteristics of being less in emission load of waste gas and waste water, environment-friendly and the like. According to the technology, the whole production process can be completed by one set of acid mixing kettle, one set of synthesis kettle and one set of rectifying tower, so that a production device is simple, the production capacity is high, the equipment investment is less, the operation is simple, and the production efficiency is high. The technology is low in consumption and high in yield. The distillate on the top of the tower and the high boiling point material discharged from the bottom of the tower can be recycled in the acid mixing kettle, so that air pollution and waste water are not generated in the whole production process, and the sewage treatment cost is very low. The technology solves the problems that the existing triethyl phosphite production technology is complicated, low in product yield, higher in energy consumption and higher in production cost.

Owner:荆州三才堂化工科技有限公司

Flame-retardant electrolyte for lithium ion battery and preparation method thereof

InactiveCN108183259AImprove securityImprove flame retardant performanceSecondary cellsOrganic electrolytesSulfite saltHeat stability

The invention provides a flame-retardant electrolyte for a lithium ion battery and a preparation method thereof, and relates to the technical field of an electrolyte for the lithium ion battery. The flame-retardant electrolyte for the lithium ion battery is prepared from the following raw materials of adiponitrile, dimethylacetamide, diacetic acid lithium borate, sodium sulfite, propylene carbonate, trimethyl phosphite, lithium salt, a filming agent, and a flame-retardant agent. The flame-retardant electrolyte for the lithium ion battery has the advantages that the burning and firing are avoided, and the safety of the lithium ion battery is effectively improved; the heat stability is obviously improved, and the discoloring and precipitate separation-out of the electrolyte are avoided whenthe electrolyte is stored for five months or more at the temperature of 50 DEG C. The lithium ion battery prepared by the electrolyte has the advantages that the flame-retardant property is good, thecyclic property is good, and the electric conductivity is good.

Owner:广州鸿森材料有限公司

Method for synthesizing dimethyl methylphosphonate

ActiveCN102964382AAvoid oxidative hydrolysis reactionsIncrease distillation timeGroup 5/15 element organic compoundsChemical recyclingRecyclable catalystDimethyl methylphosphonate

A method for synthesizing dimethyl methylphosphonate. Under protection of inert gas, A raw material trimethyl phosphite and a proper amount of benzene sulfonic acid catalyst are mixed and stirred; and a the mixture is subjected to a rearrangement reaction through a pressurized heating way, so as to synthesize a target product dimethyl methylphosphonate with yield up to 93% and purity higher than 99%. The invention has advantages of easily available raw materials, short synthesis time, simple production control, cheap and recyclable catalyst and little pollutant emission.

Owner:HUBEI XINGFA CHEM GRP CO LTD +1

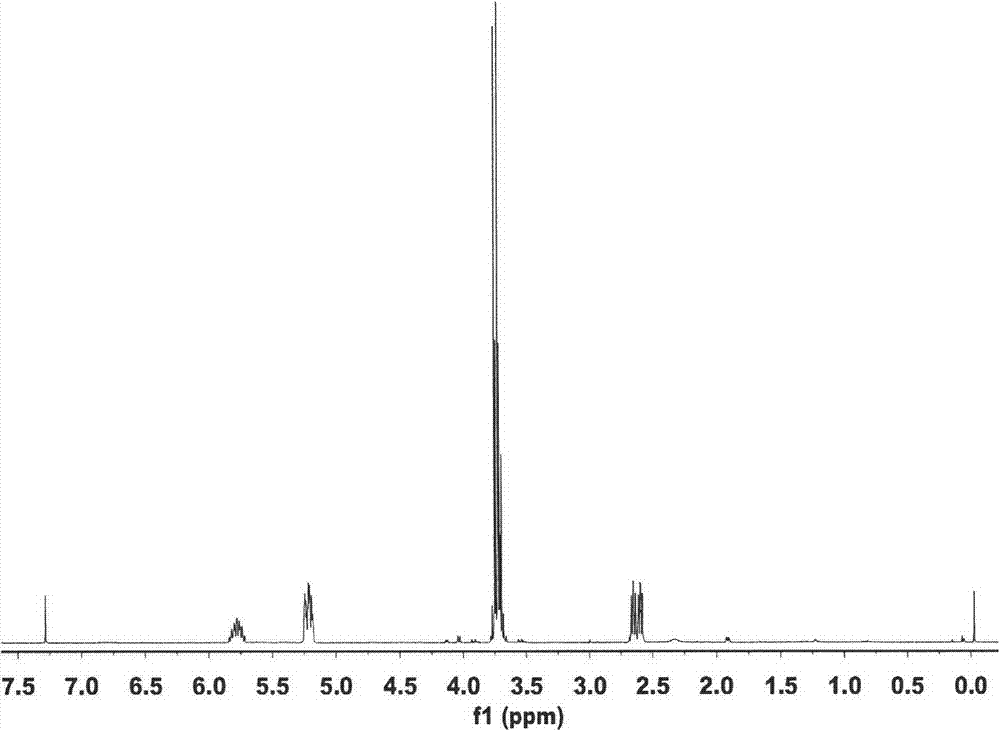

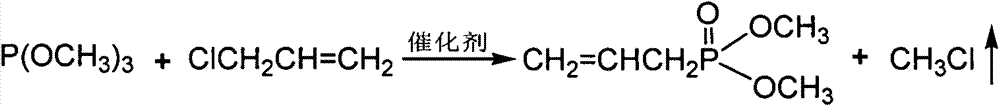

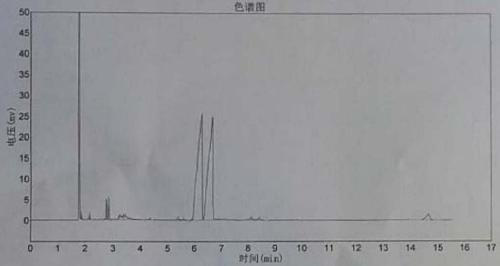

Method for preparing allyl phosphonic acid dimethyl ester

ActiveCN103880881AEscape in timeInhibit side effectsGroup 5/15 element organic compoundsOrganic solventPolymer science

The invention relates to a method for preparing allyl phosphonic acid dimethyl ester. The method comprises the following steps: adding an organic solvent, trimethyl phosphate, a proper amount of catalyst and a small amount of polymerization inhibitor hydroquinone into a reaction device, heating to be 110 DEG C, within 4-6 hours, injecting chloropropene of which the mole amount is 1-2 times that of the trimethyl phosphate below the liquid level, after injection, raising the temperature of the system to be 110-160 DEG C, keeping the temperature for reacting for 4-6 hours, distilling to recycle excessive chloropropene, further performing reduced pressure distillation to remove the solvent, and subsequently collecting fraction under the pressure of 3950Pa at 88-92 DEG C, thereby obtaining the product allyl phosphonic acid dimethyl ester. The preparation method of the allyl phosphonic acid dimethyl ester is high in product yield and simple to operate, the reaction is performed at normal pressure, the product is easy to separate and purify, the equipment investment is small, on-scale production is easy to achieve, and a good application and development prospect is achieved.

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

Preparation method of cyclic phosphonate flame retardant

InactiveCN111377967AConvenient sourceEasy to manageGroup 5/15 element organic compoundsHeat resistant fibresPhosphorous acidDimethyl methylphosphonate

The invention discloses a preparation method of a cyclic phosphonate flame retardant, which relates to the technical field of organic phosphorus flame retardant synthesis. The method comprises the following steps of taking trimethylolpropane and trimethyl phosphite as raw materials with the feed mole ratio of 1: 2-4, selecting methyl benzenesulfonate or methyl p-toluenesulfonate as a catalyst, controlling proper process parameters such as catalyst quantity, temperature, time and the like, and carrying out transesterification and rearrangement reaction to obtain the phosphonate flame retardantwith a cyclic structure and the byproduct dimethyl methylphosphonate flame retardant. The method provided by the invention has the advantages of few raw material varieties, easy source, low cost, rapid reaction, high efficiency, environment-friendly process, energy conservation and consumption reduction; the product prepared by the method is the same as the product prepared by the existing method,but the production period is shortened by 2 / 3-3 / 4, the production capacity is greatly improved, and the method is suitable for industrial production.

Owner:青岛长荣化工科技有限公司

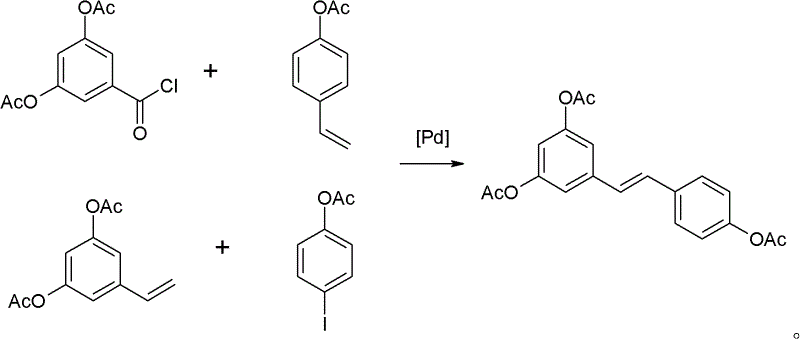

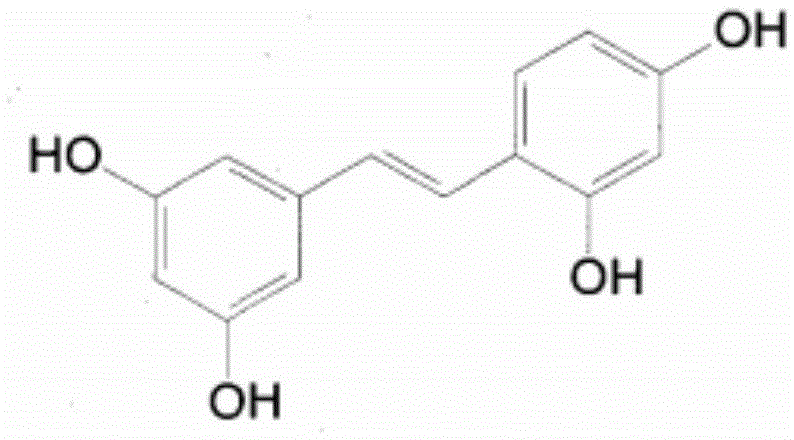

Oxyresveratrol synthesis method

InactiveCN105418381ARaw materials are easy to getHigh yieldOrganic chemistryOrganic compound preparationSynthesis methodsBenzaldehyde

The invention provides an oxyresveratrol synthesis method which comprises the following steps: firstly performing a reflux reaction between raw materials 3,5-dimethoxybenzyl alcohol and phosphorus oxychloride; after the reaction is complete, pressurizing and recycling the solvent; filtering, washing to neutrality and drying to obtain 3,5-dimethoxybenzyl chloride; performing a reflux reaction between the obtained 3,5-dimethoxybenzyl chloride and trimethyl phosphite in a solvent DMF (dimethyl formamide); after the reaction is complete, adding a catalyst sodium methylate solution, and adding a mixed solution of 2,4-dimethoxy benzaldehyde and DMF to obtain tetramethoxy diphenyl ethylene; and finally, performing a reflux reaction between the obtained tetramethoxy diphenyl ethylene and aluminum trichloride and xylene, wherein oxyresveratrol is obtained after the reaction is complete. According to the method provided by the invention, a Witting-Homer reaction is adopted, the raw materials are easily available, the yield is high, the cost is low, and the method is suitable for industrial production.

Owner:SHAANXI JIAHE PHYTOCHEM

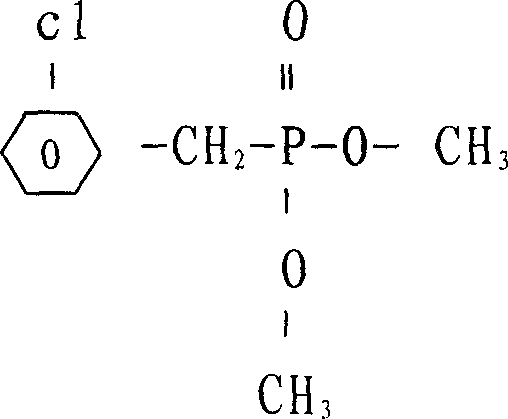

Production of o-chlorobenzyl dimethyl phosphonate

InactiveCN1680404ALow priceReduce stepsGroup 5/15 element organic compoundsPhosphateTrimethyl phosphite

Production of chlorobenzyl dimethyl ester phosphate is carried out by taking chlorochlor, trimethyl phosphite, benzyl chloride and soda as material, commissioning and synthesizing reacting, separating low boiler, coarse distilling, refining distilling, loading, and obtaining chlorobenzyl dimethyl ester phosphate with purity 70-99.9%. It controls temperature, pressure and time in production, it can be used for insecticide and bactericide. Its advantages include low cost, simple operation, high output, and industrial production.

Owner:泰州市天成化工有限公司

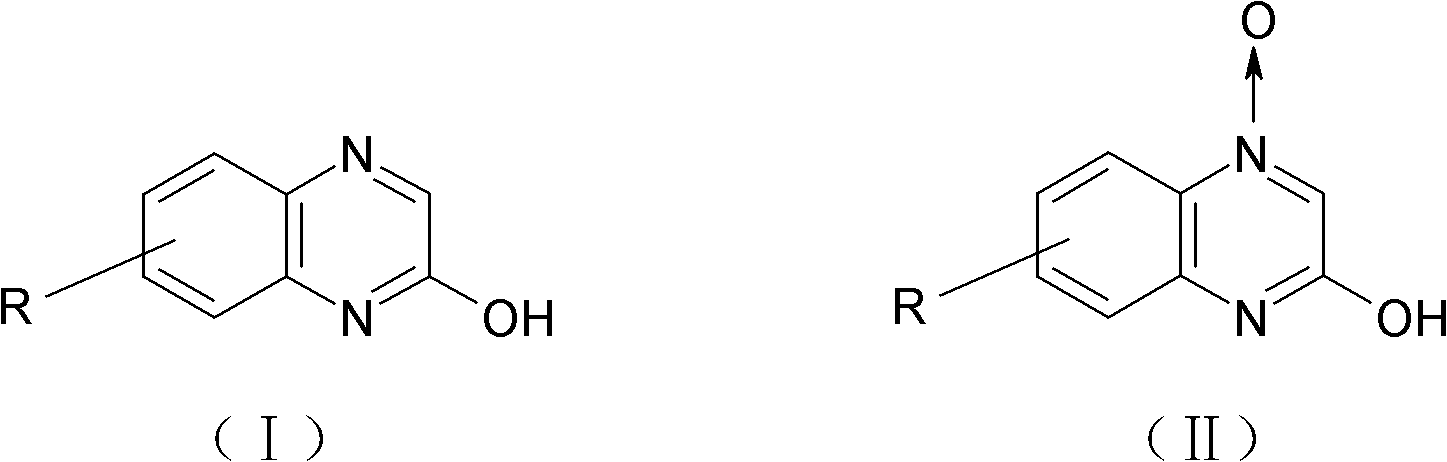

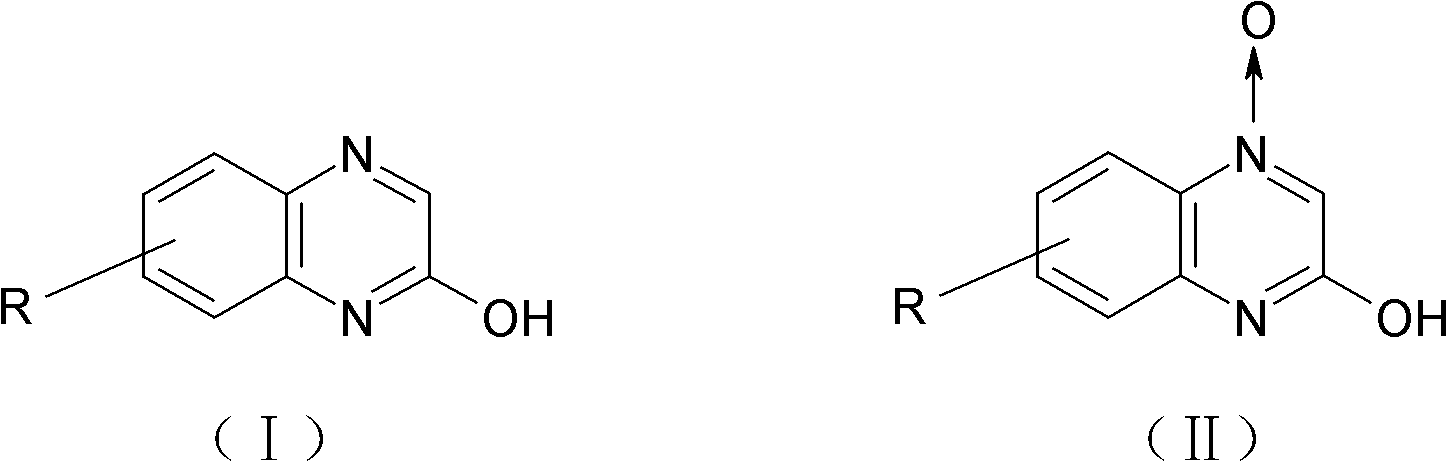

Method for preparing 2-quinoxalinol

The invention discloses a method for preparing 2-quinoxalinol, which comprises the following steps: preparing 2-quinoxalinol-4-oxide by the cyclization of chloro-m-nitroacetoacetanilide serving as a raw material in the presence of a hydroxide; and preparing 2-quinoxalinol by reducing the 2-quinoxalinol-4-oxide with phosphorous acid or trimethyl phosphate serving as a reducer. In the invention, the phosphorous acid or trimethyl phosphate is used as a reducer to reduce 2-quinoxalinol-4-oxide with high selectivity to prepare 2-quinoxalinol, so the byproducts are reduced, and product yield and purity are high; the conditions of the reduction reaction are mild, and the possibility of explosion generated by low-pressure catalytic hydrogenation with hydrogen serving as a reducer is lowered; because the phosphorous acid or trimethyl phosphate commodity serving as the reducer is cheap and readily available, the production cost of the 2-quinoxalinol is reduced; and as the reaction raw materials and the products produced in the reaction process are nontoxic, the method contributes to environmental protection.

Owner:ZHEJIANG HETIAN CHEM CO LTD +1

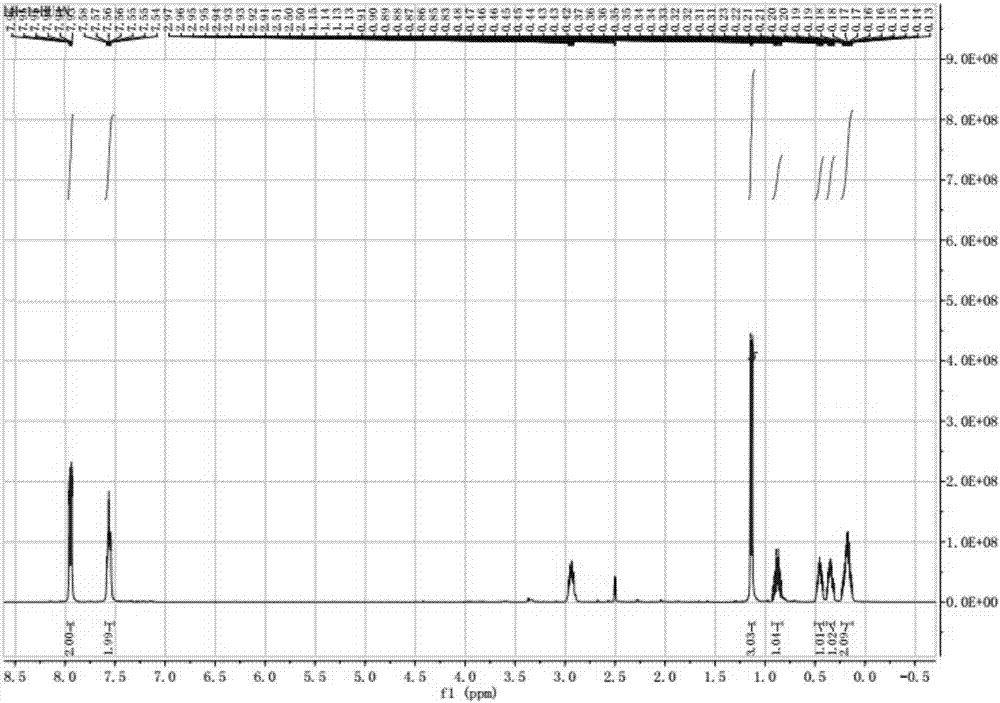

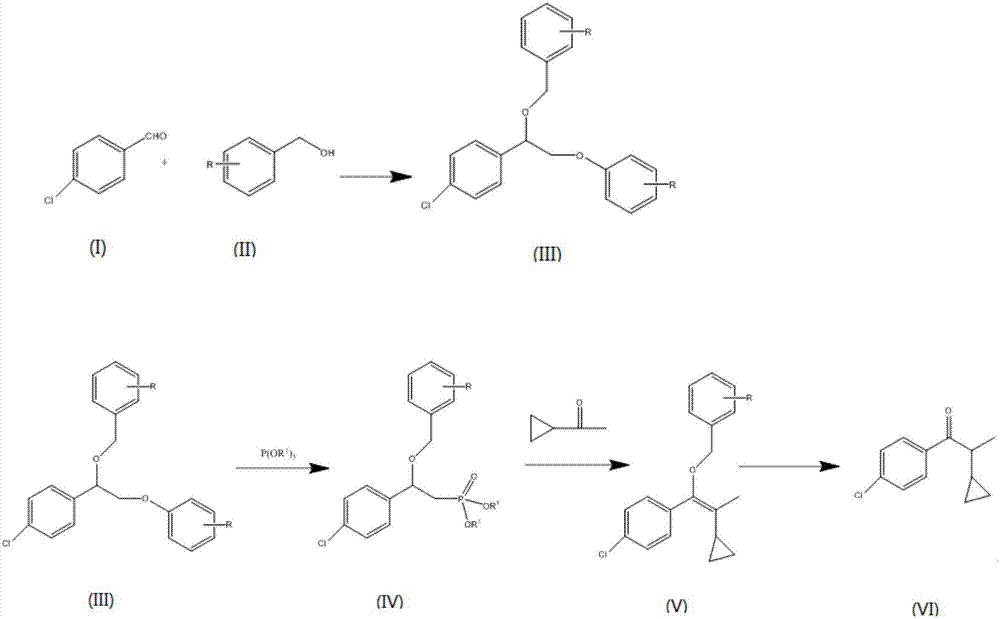

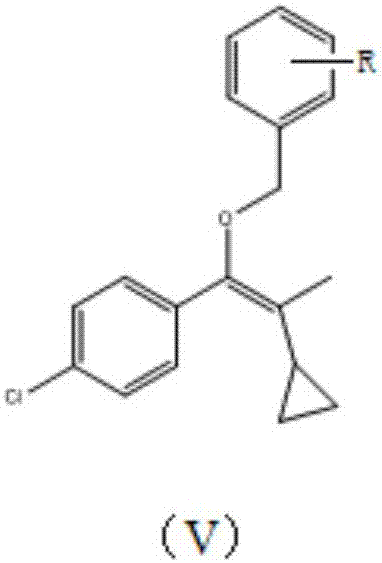

Preparation method of 1-(4-chlorphenyl)-2-cyclopropyl-1-acetone

ActiveCN107285998AOperational securityEasy to controlOrganic compound preparationGroup 5/15 element organic compoundsTriethylphosphiteP-chlorobenzaldehyde

The invention discloses a preparation method of 1-(4-chlorphenyl)-2-cyclopropyl-1-acetone. The method comprises the steps of preparing acetal by adopting p-chlorobenzaldehyde and phenylcarbinol or a derivative thereof as raw materials under the action of a catalyst, reacting an acetal product with trimethyl phosphite or triethyl phosphite in an environment of a polar solvent under the catalysis of lewis acid to generate alpha-benzyloxy p-chlorobenzyl dimethyl phosphate, further reacting the alpha-benzyloxy p-chlorobenzyl dimethyl phosphate with cyclopropyl methyl ketone under the combined action of a base catalyst, a phase transfer catalyst and a cocatalyst to prepare a benzyloxy-propylene derivative; and then carrying out acidifying hydrolysis on the benzyloxy-propylene derivative to obtain the1-(4-chlorphenyl)-2-cyclopropyl-1-acetone. Compared with the prior art, the method has the advantages of being safe in operation, controllable in process, low in toxicity in the process, mild in reaction condition, suitable for industrial production and high in product purity.

Owner:JIANGSU SWORD AGROCHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process](https://images-eureka.patsnap.com/patent_img/9a66d1cf-4b54-4dee-bae5-7e40fd7cdedf/A200780021915E00221.PNG)

![Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process](https://images-eureka.patsnap.com/patent_img/9a66d1cf-4b54-4dee-bae5-7e40fd7cdedf/A200780021915E00231.PNG)

![Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process](https://images-eureka.patsnap.com/patent_img/9a66d1cf-4b54-4dee-bae5-7e40fd7cdedf/A200780021915E00232.PNG)