Patents

Literature

520results about How to "Thermally stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

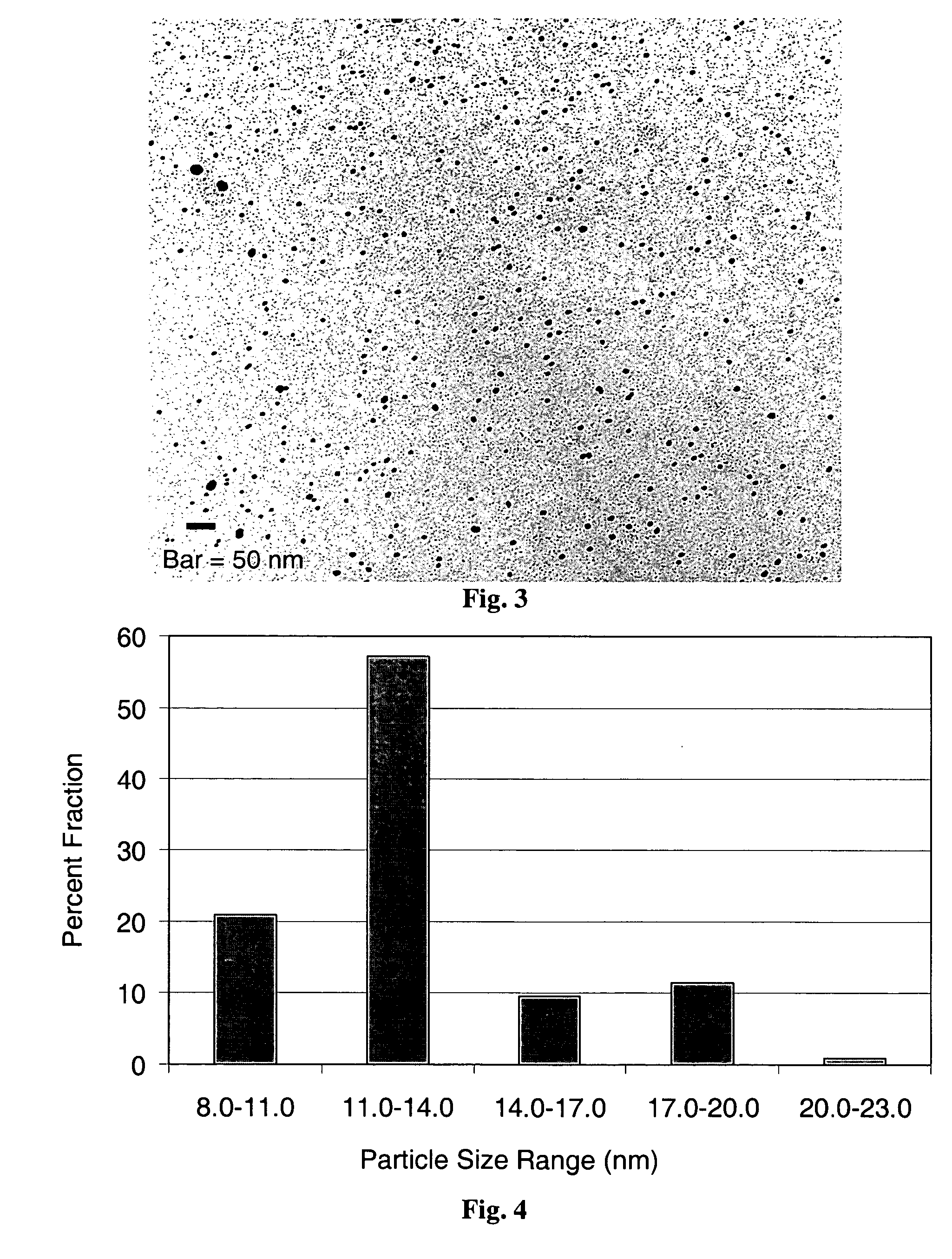

Antimicrobial silver compositions

The present invention comprises methods and compositions for antimicrobial silver compositions comprising silver nanoparticles. The present invention further comprises compositions for preparing silver nanoparticles comprising at least one stabilizing agent, one or more silver compounds, at least one reducing agent and a solvent. In one aspect, the stabilizing agent comprises a surfactant or a polymer. The polymer may comprise polymers such as polyacrylamides, polyurethanes, and polyamides. In one aspect, the silver compound comprises a salt comprising a silver cation and an anion. The anion may comprise saccharinate derivatives, long chain fatty acids, and alkyl dicarboxylates. The methods of the present invention comprise treating devices with the silver nanoparticle compositions, including, but not limited to, such devices as woven wound care materials, catheters, patient care devices, and collagen matrices. The present invention further comprises treatment of humans and animals wacr6ith the antimicrobial devices described herein.

Owner:AVENT INC

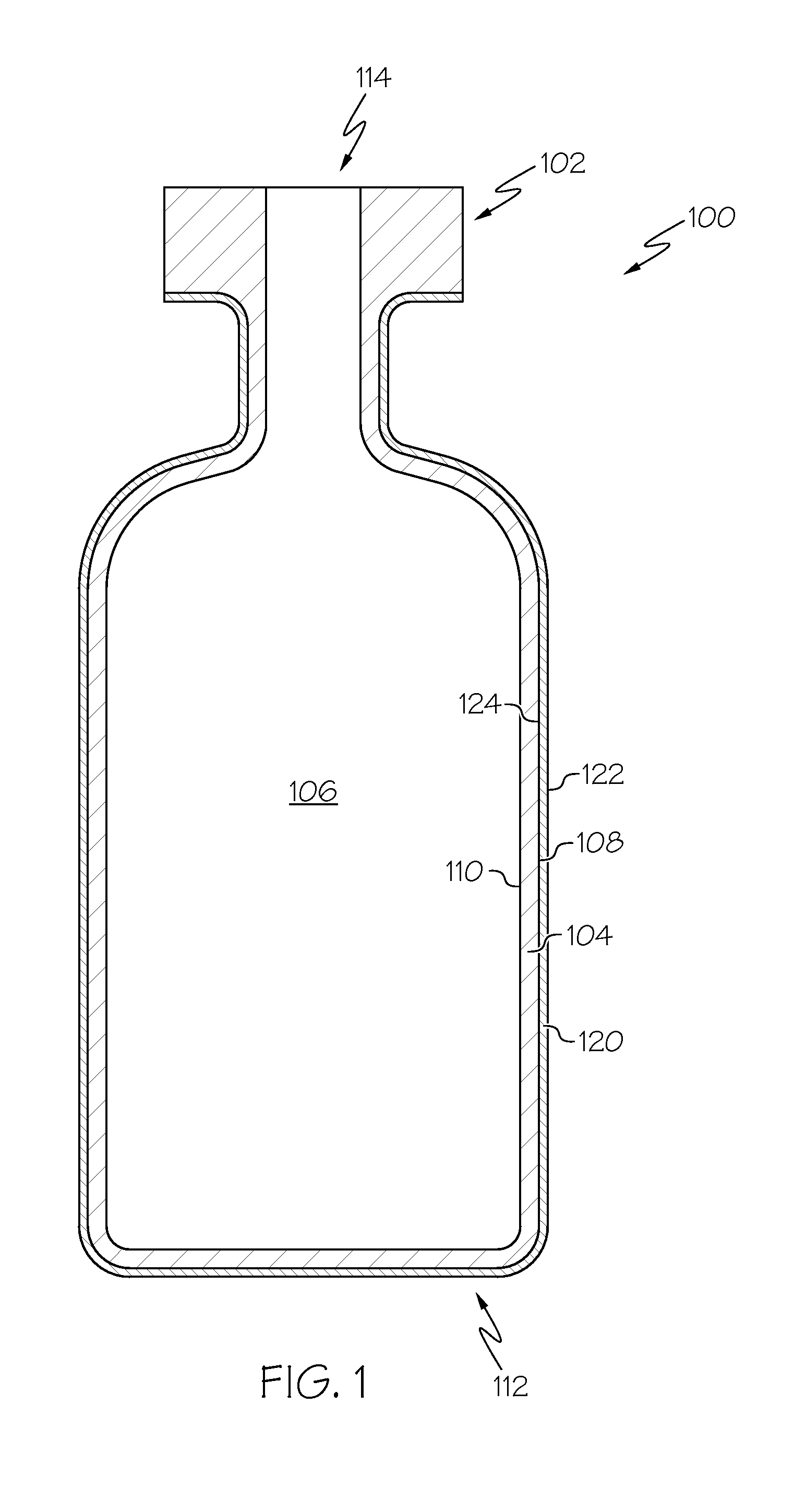

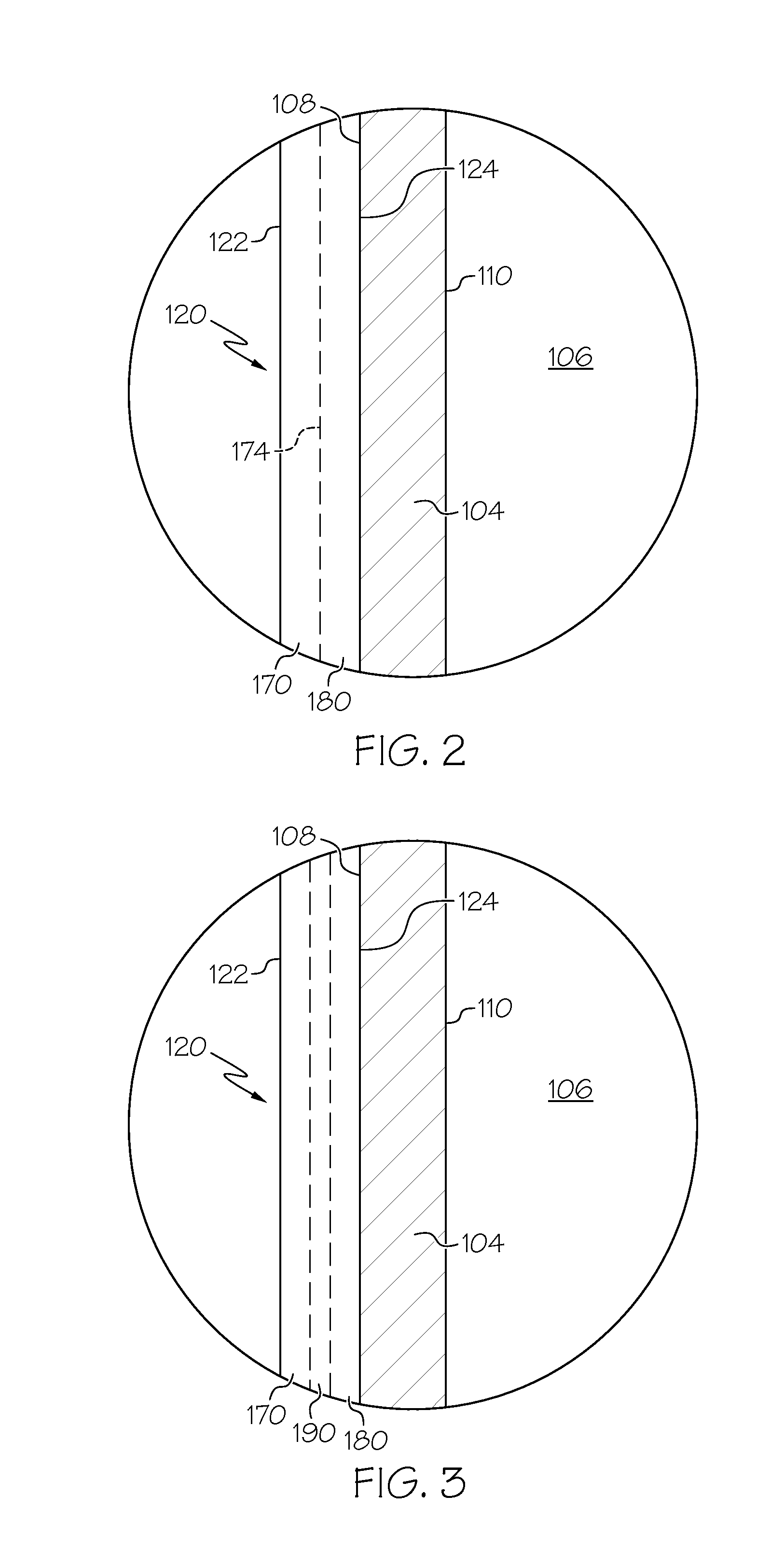

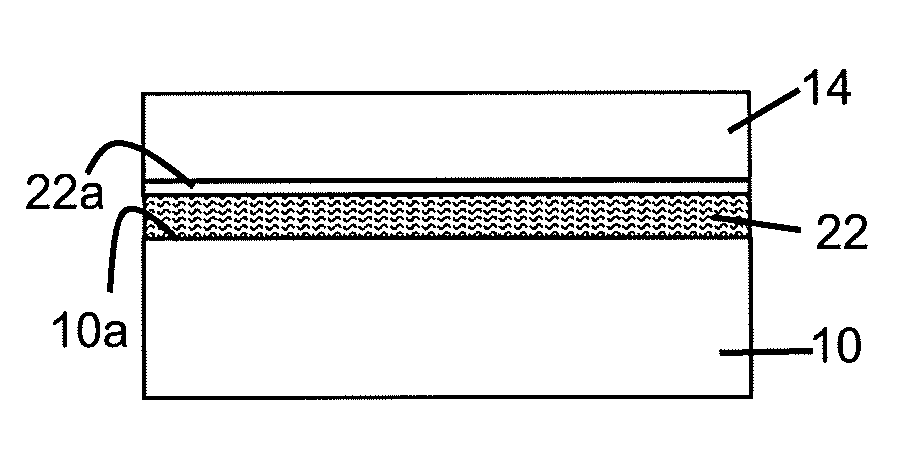

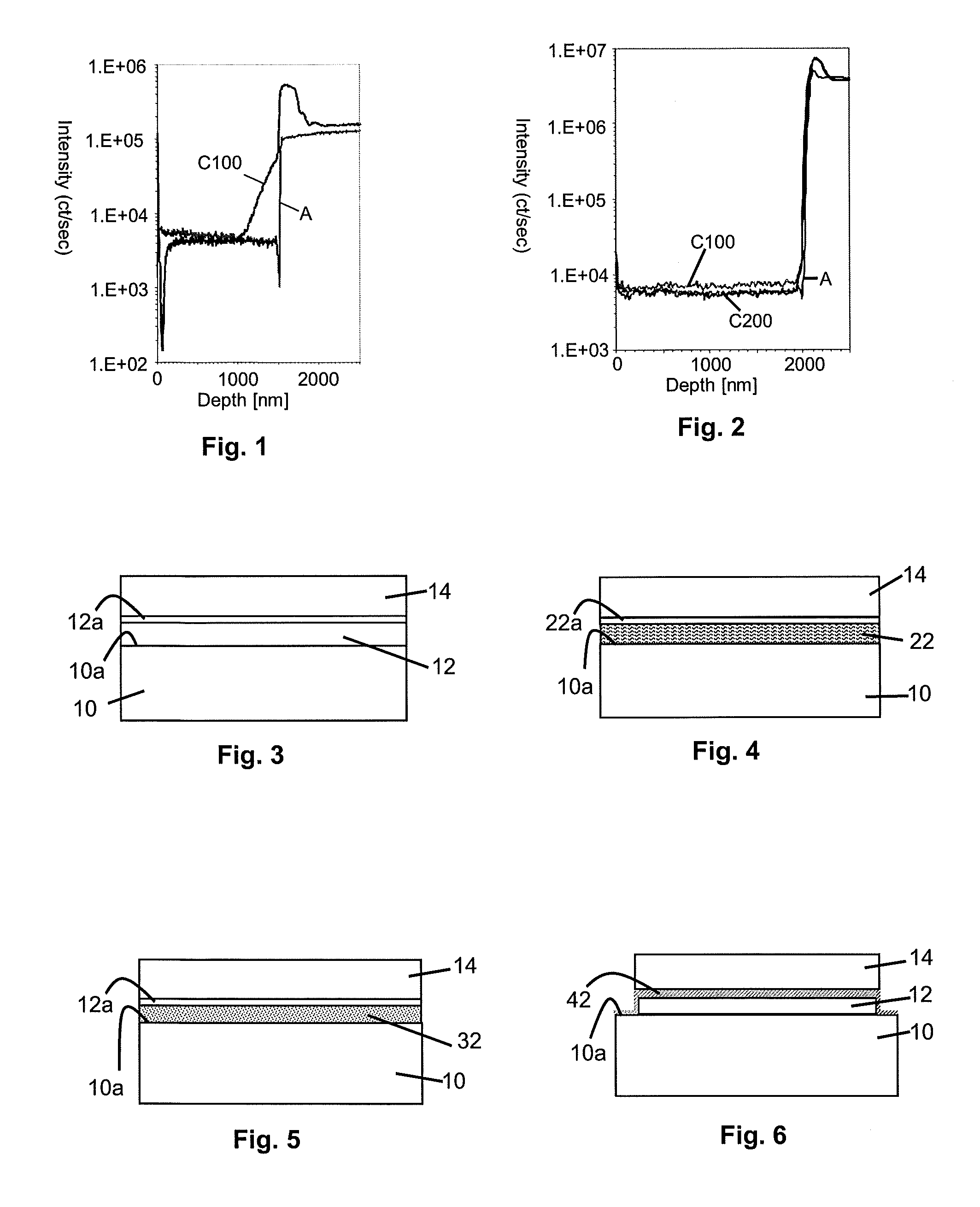

Glass Articles With Low-Friction Coatings

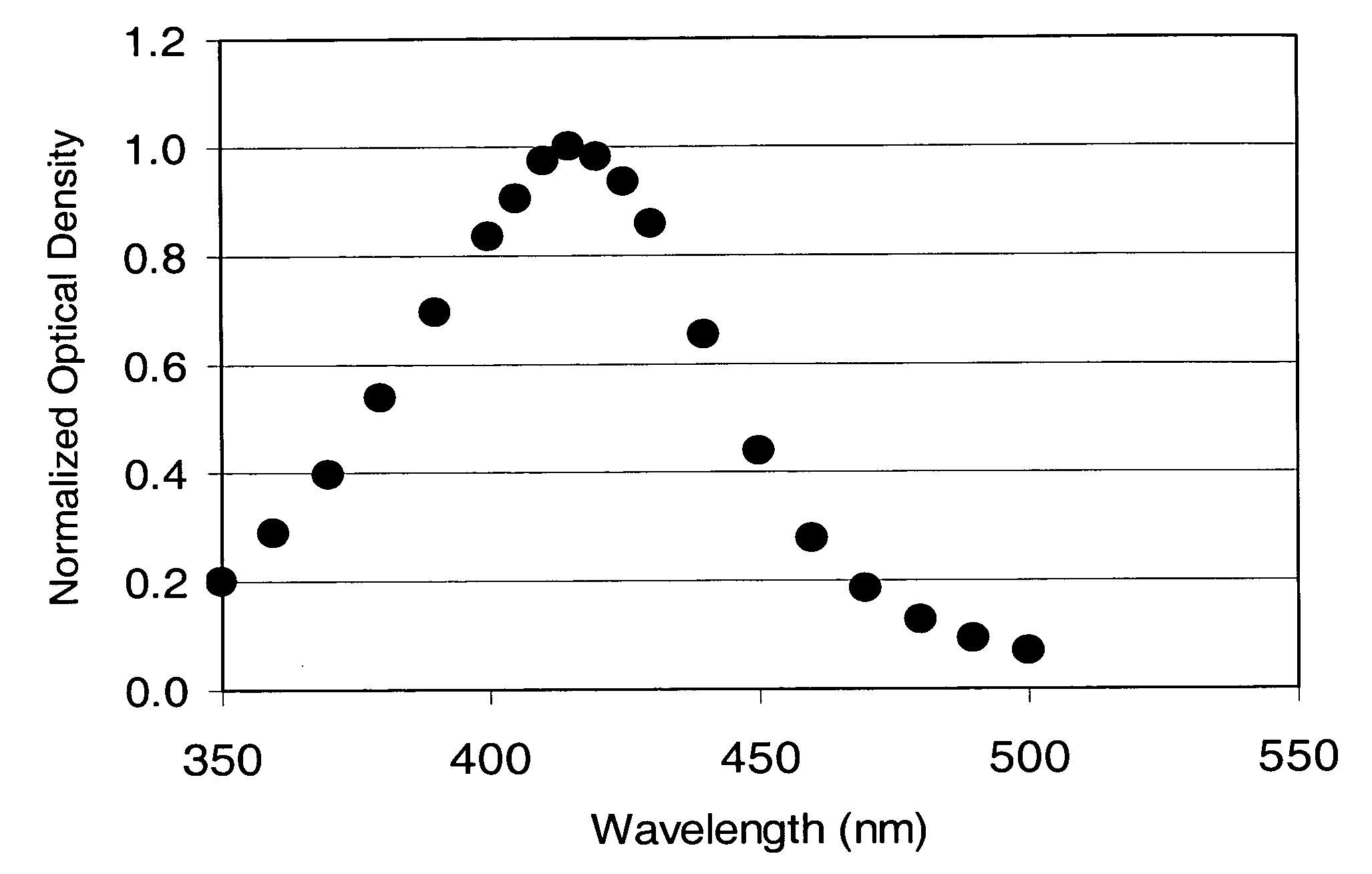

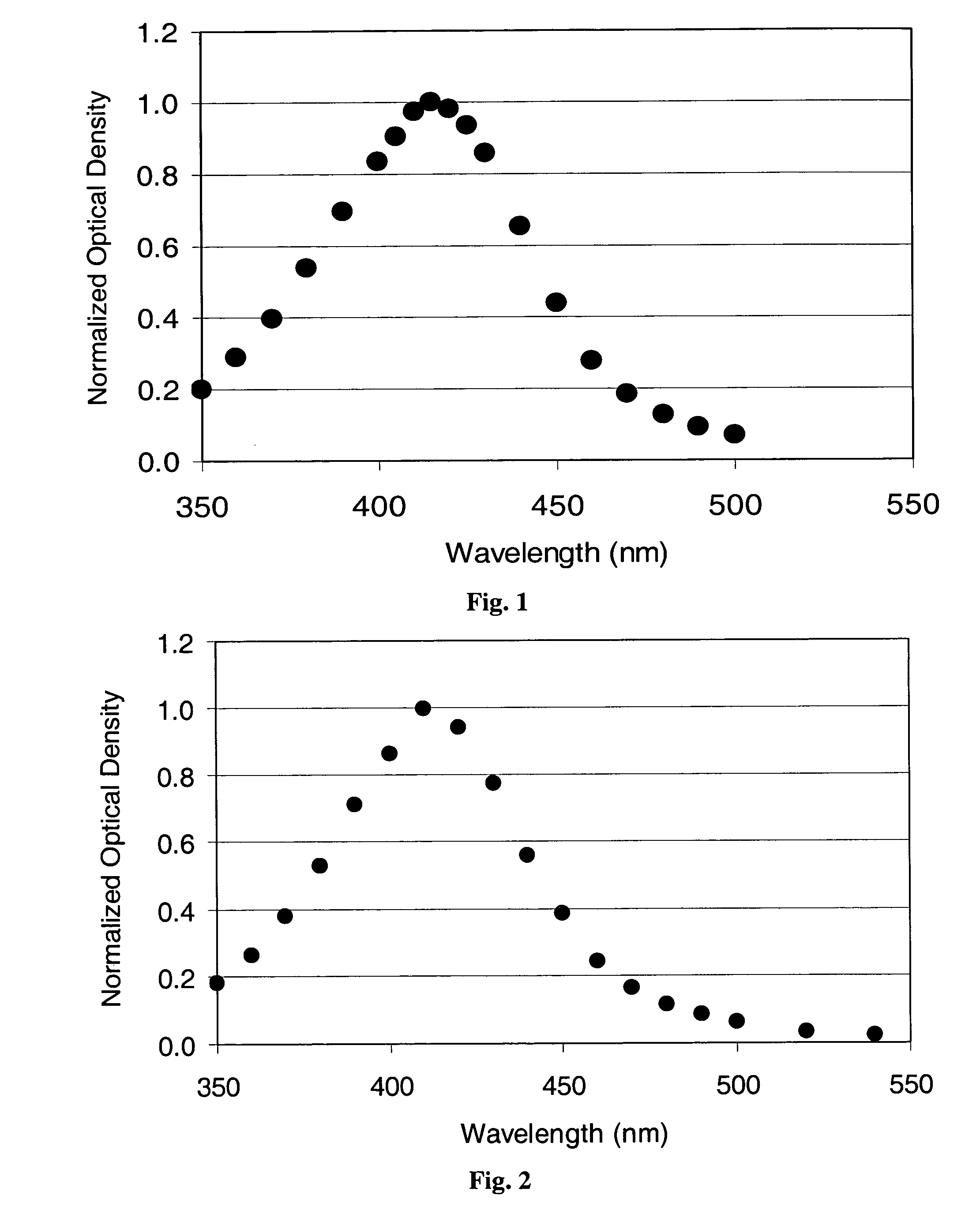

ActiveUS20130171456A1Thermally stablePharmaceutical containersMedical packagingChemical compositionLength wave

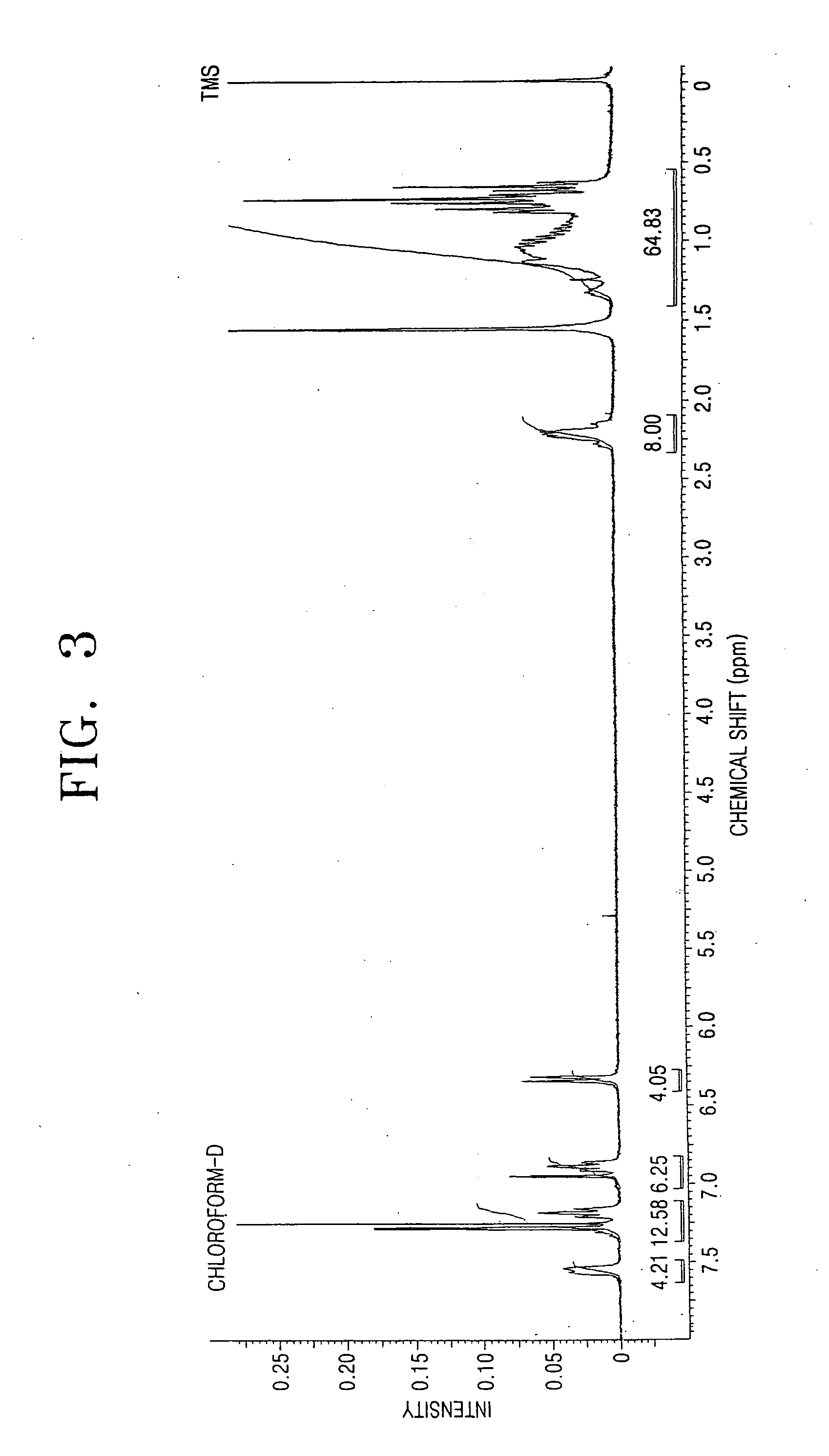

Low-friction coatings and glass articles with low-friction coatings are disclosed. According to one embodiment, a coated glass article may include a glass body comprising a first surface and a low-friction coating positioned on at least a portion of the first surface of the glass body. The low-friction coating may include a polymer chemical composition. The coated glass article may be thermally stable at a temperature of at least about 260° C. for 30 minutes. A light transmission through the coated glass article may be greater than or equal to about 55% of a light transmission through an uncoated glass article for wavelengths from about 400 nm to about 700 nm. The low-friction coating may have a mass loss of less than about 5% of its mass when heated from a temperature of 150° C. to 350° C. at a ramp rate of about 10° C. / minute.

Owner:CORNING INC

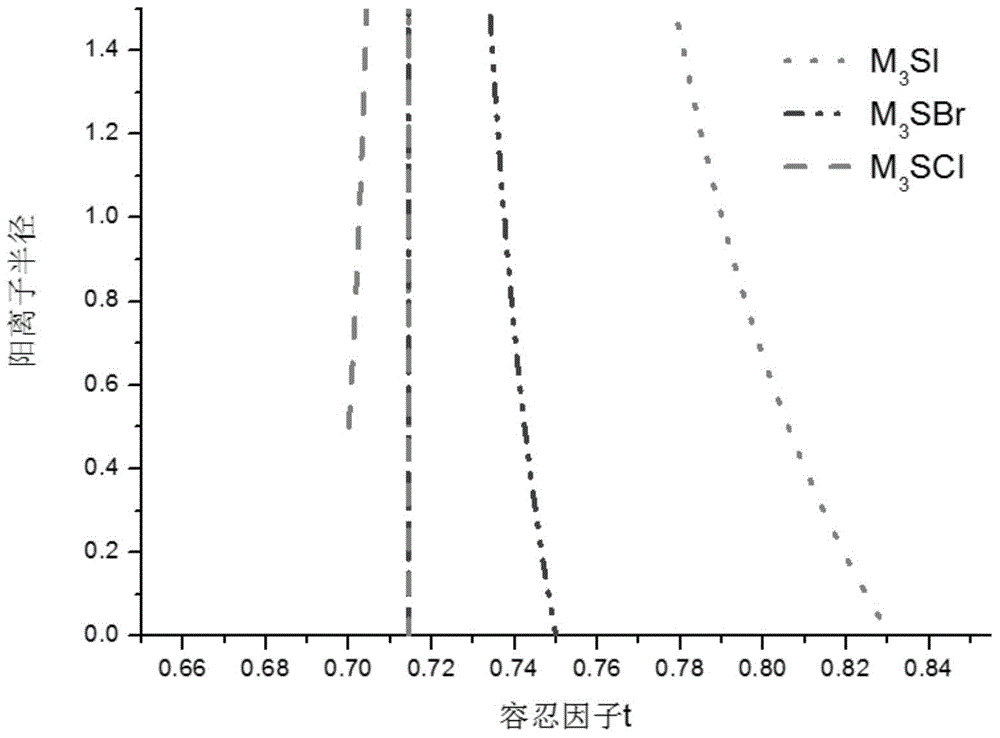

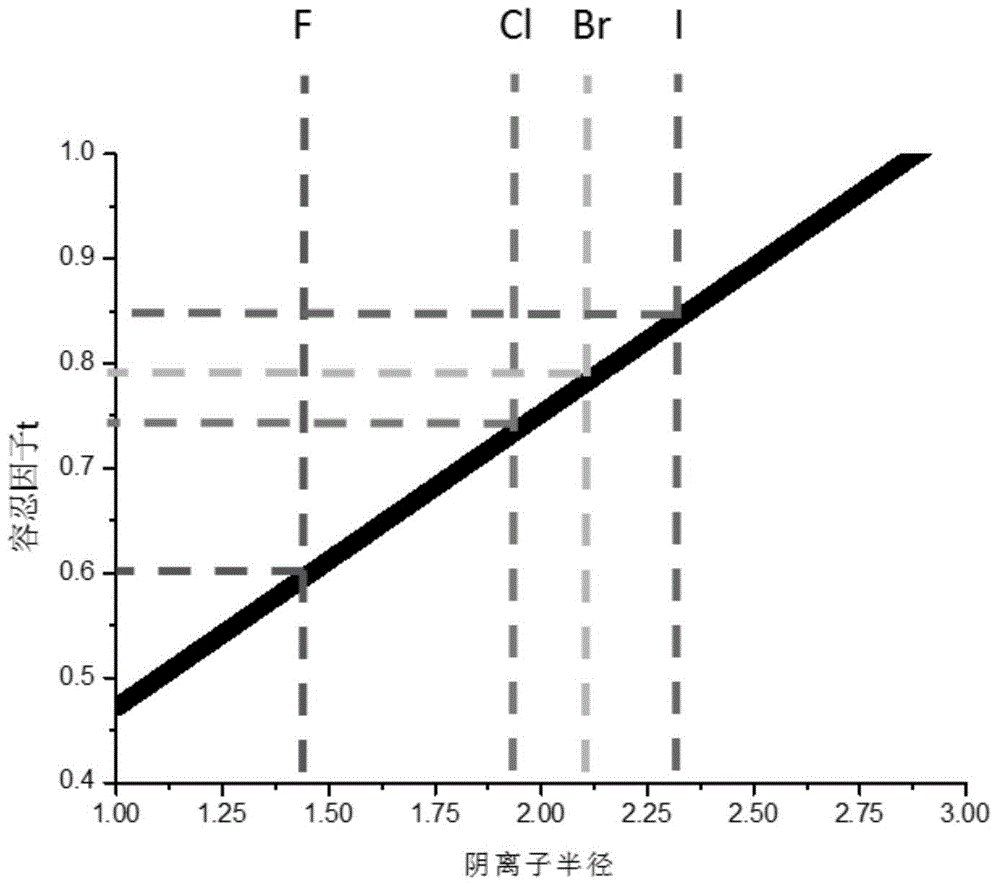

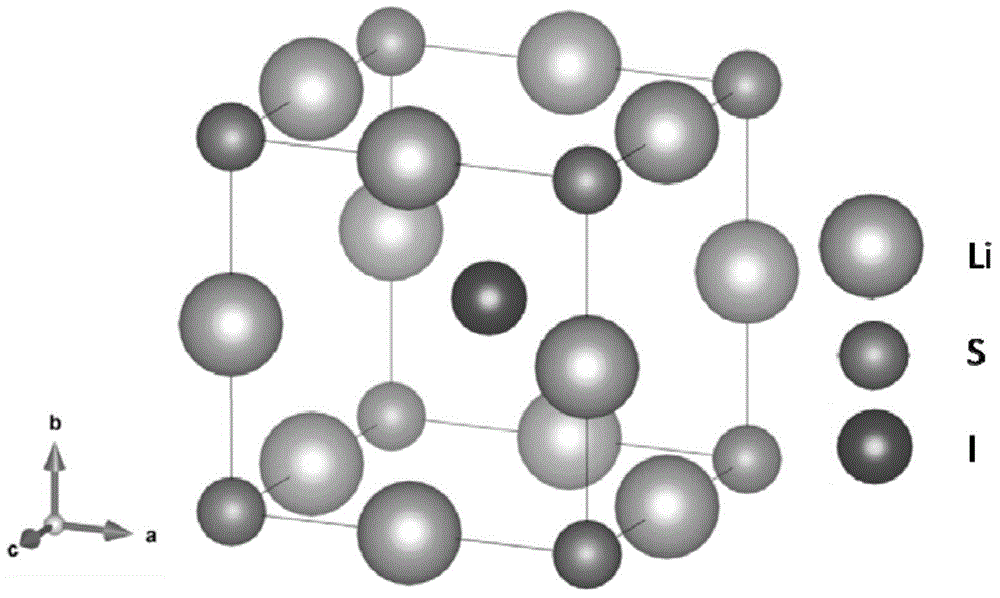

Lithium-enriched anti-perovskite sulfides, solid electrolyte material containing lithium-enriched anti-perovskite sulfides and application of solid electrolyte material

ActiveCN104466239AIncrease the carrier concentrationIncrease charge and discharge rateSecondary cellsElectrolytesWorking temperatureOperating temperature range

The invention discloses lithium-enriched anti-perovskite sulfides and a solid electrolyte material. The general formula of the lithium-enriched anti-perovskite sulfides is (LimMn)3-xS1-y(XaYb)1-z, wherein m is more than 0 and less than or equal to 1, n is more than or equal to 0 and less than to 0.5, (m+n) is less than or equal to 1, a is more than 0 and less than or equal to 1, b is more than or equal to 0 and less than 1, (a+b) is less than or equal to 1, x is more than or equal to 0 and less than or equal to 0.5, y is more than or equal to 0 and less than or equal to 0.5, z is more than or equal to 0 and less than or equal to 0.5 and x=2y+z; M is H, Na, K, Rb, Mg, Ca, Sr, Ba, Y, La, Ti, Zr, Zn, B, Al, Ga, In, C, Si, Ge, P, S or Se; and X is Fe, Cl, Br or I, and Y is a negative ion. The solid electrolyte material has high ion conductivity and thermal stability and a wide working temperature range, and can be applied to lithium ion batteries, rechargeable metal lithium batteries, lithium liquid flow batteries or lithium ion capacitors.

Owner:BEIJING WELION NEW ENERGY TECH CO LTD

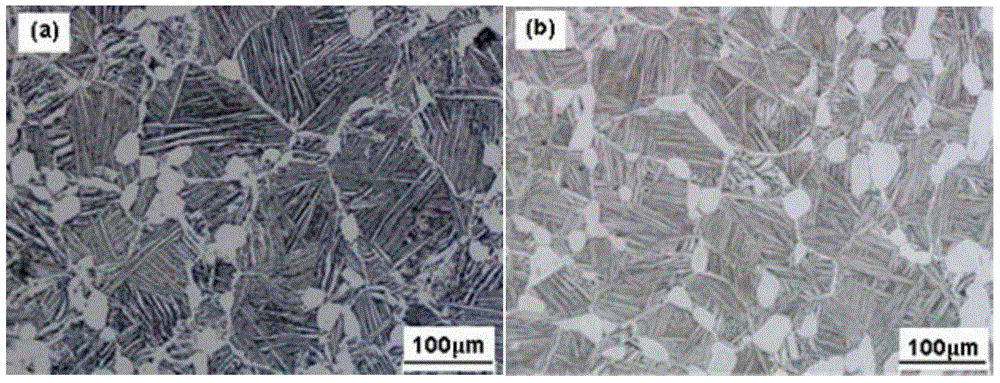

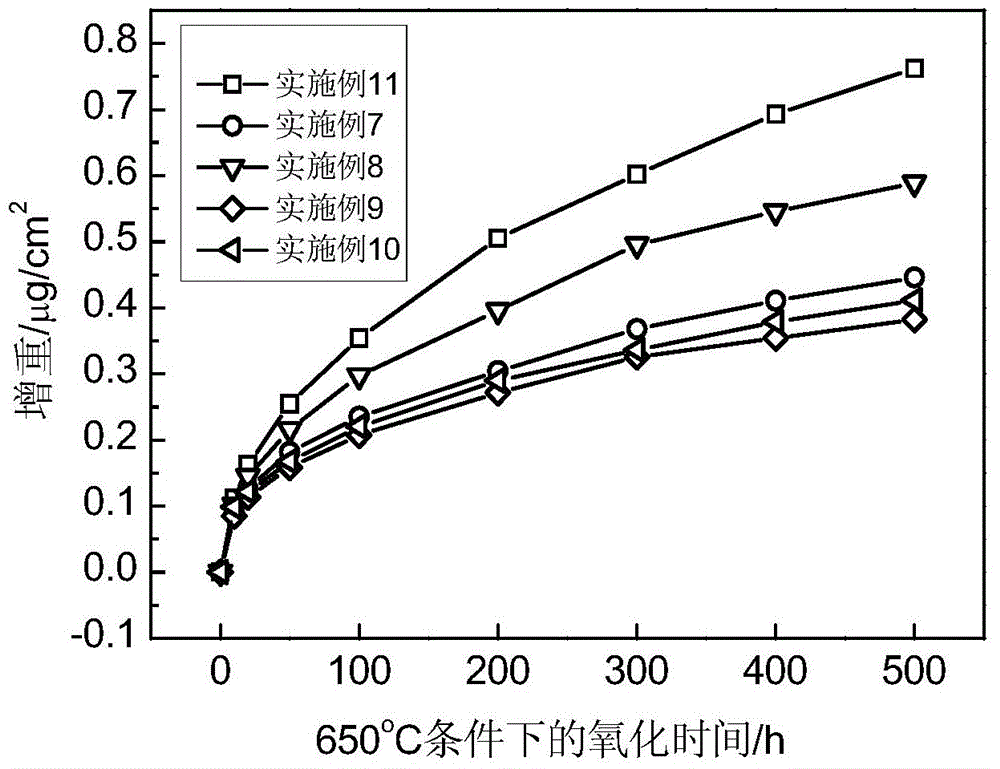

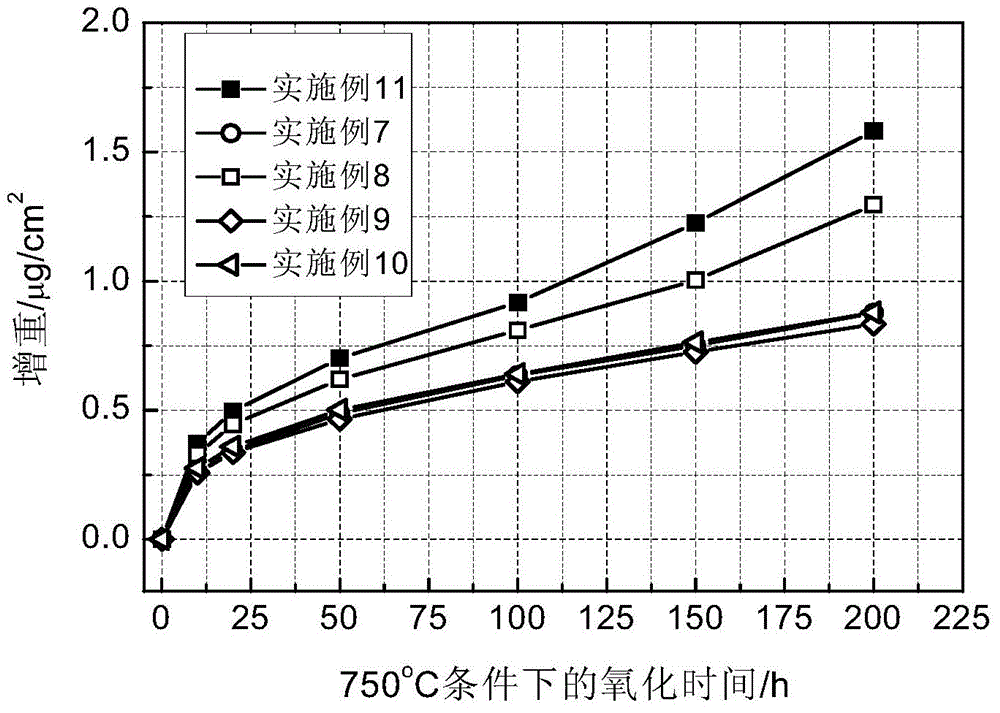

Novel heat-resisting titanium alloy and processing and manufacturing method and application thereof

The invention belongs to the field of titanium-based alloys, and particularly relates to a novel heat-resisting titanium alloy and a processing and manufacturing method and application thereof. The processing and manufacturing method comprises the composition elements of alloy components, smelting, heat processing, heat treatment and the like, wherein the alloy components are as follows (in percentage by weight): 5.4%-6.3% of Al, 3.0%-5.0% of Sn, 2.5%-6.4% of Zr, 0.0%-0.96% of Mo, 0.25%-0.5% of Si, 0.2%-0.5% of Nb, 0.3%-3.4% of Ta, 0.2%-1.6% of W, 0.0%-0.07% of C, less than or equal to 0.17% of O, less than or equal to 0.03% of Fe and the balance of Ti and inevitable impurity elements. The novel heat-resisting titanium alloy disclosed by the invention can obtain different matching of tensile strength, plasticity, permanence, creep strength and heat stability through the combination of different heat processing process and heat treatment processes, can be used for manufacturing parts, namely blades, coil assemblies and the like which are positioned on the high-temperature parts of an advanced aircraft engine, is used for a long time within a range of 600-650 DEG C, can also be used for manufacturing high temperature-resistant structural members, namely aerospace craft skin and the like, is used for a short time at about 700 DEG C and can be used as a material and the like used for high temperature-resistant corrosion-resistant valves of an automobile and a boiler.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

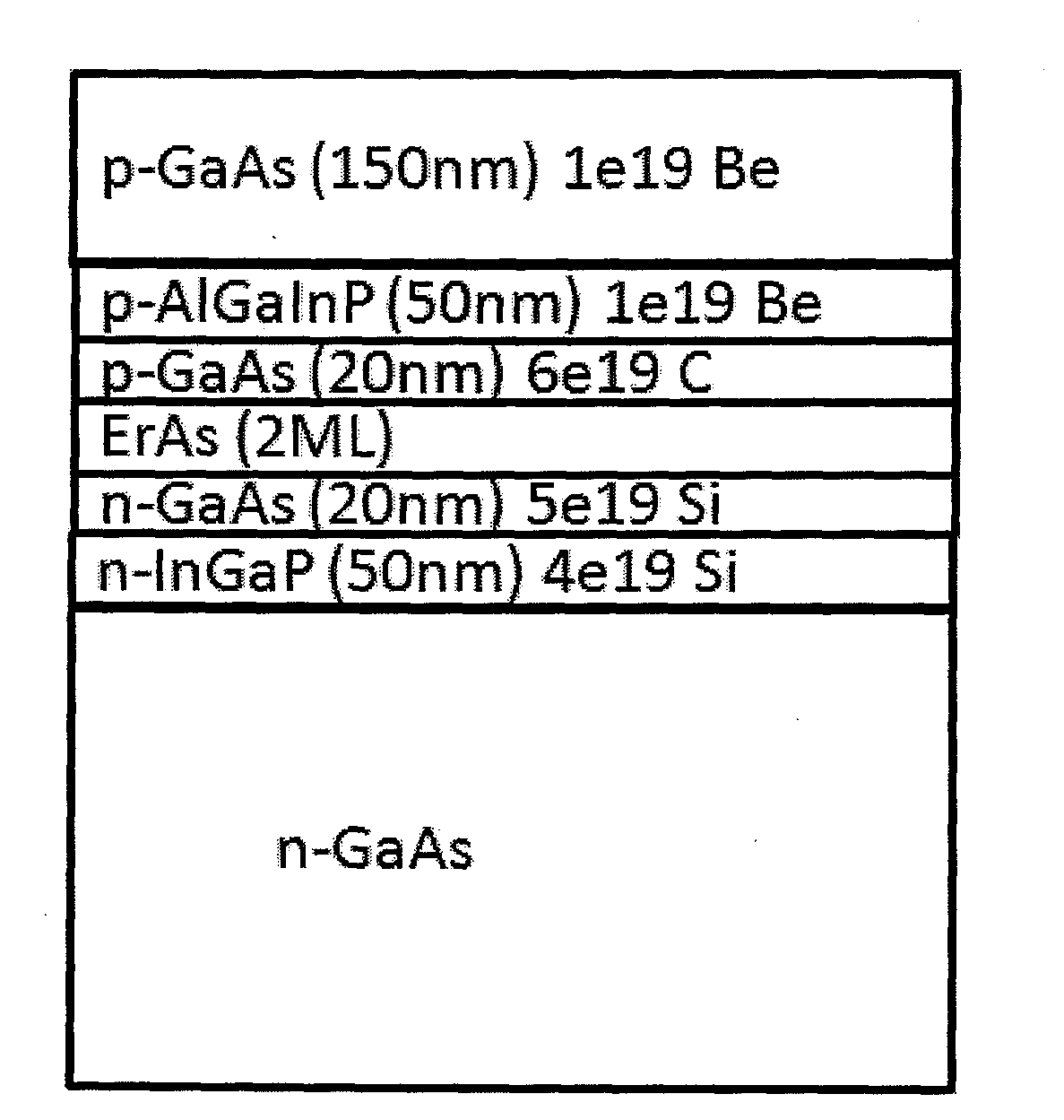

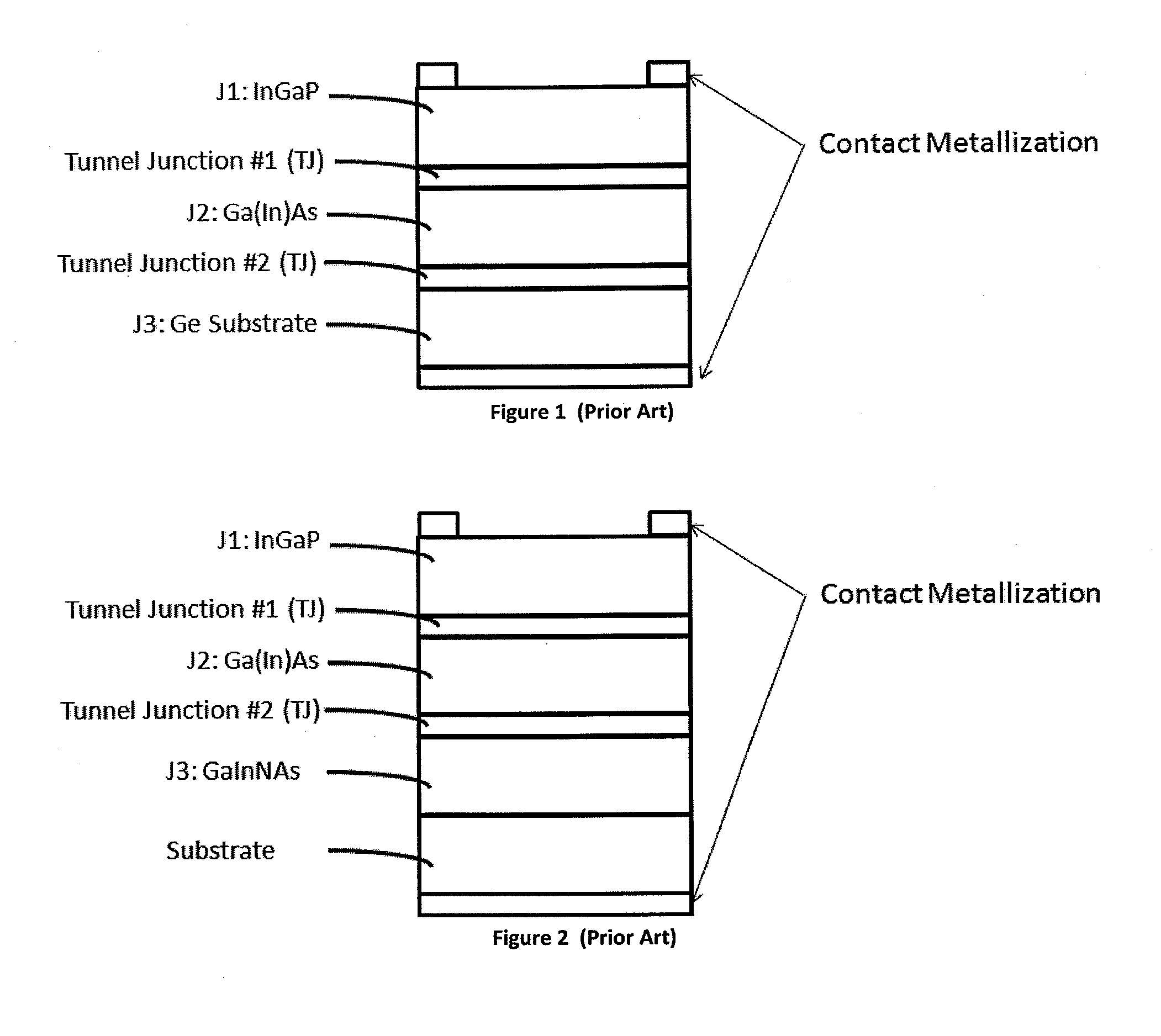

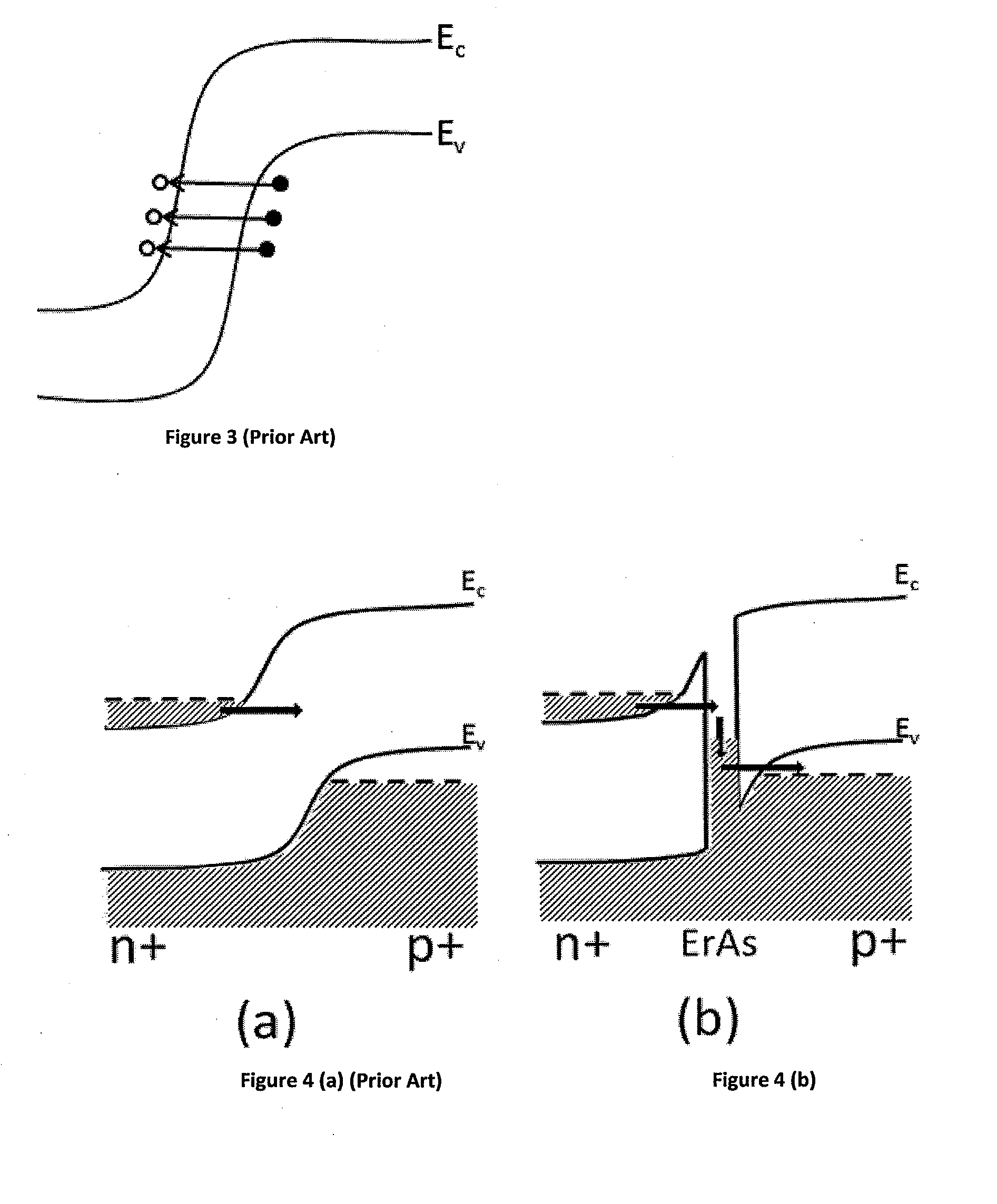

Functional Integration Of Dilute Nitrides Into High Efficiency III-V Solar Cells

InactiveUS20100319764A1Thermally stableGood performanceSemiconductor/solid-state device manufacturingPhotovoltaic energy generationTunnel diodeMultijunction photovoltaic cell

Tunnel junctions are improved by providing a rare earth-Group V interlayer such as erbium arsenide (ErAs) to yield a mid-gap state-assisted tunnel diode structure. Such tunnel junctions survive thermal energy conditions (time / temperature) in the range required for dilute nitride material integration into III-V multi-junction solar cells.

Owner:ARRAY PHOTONICS INC

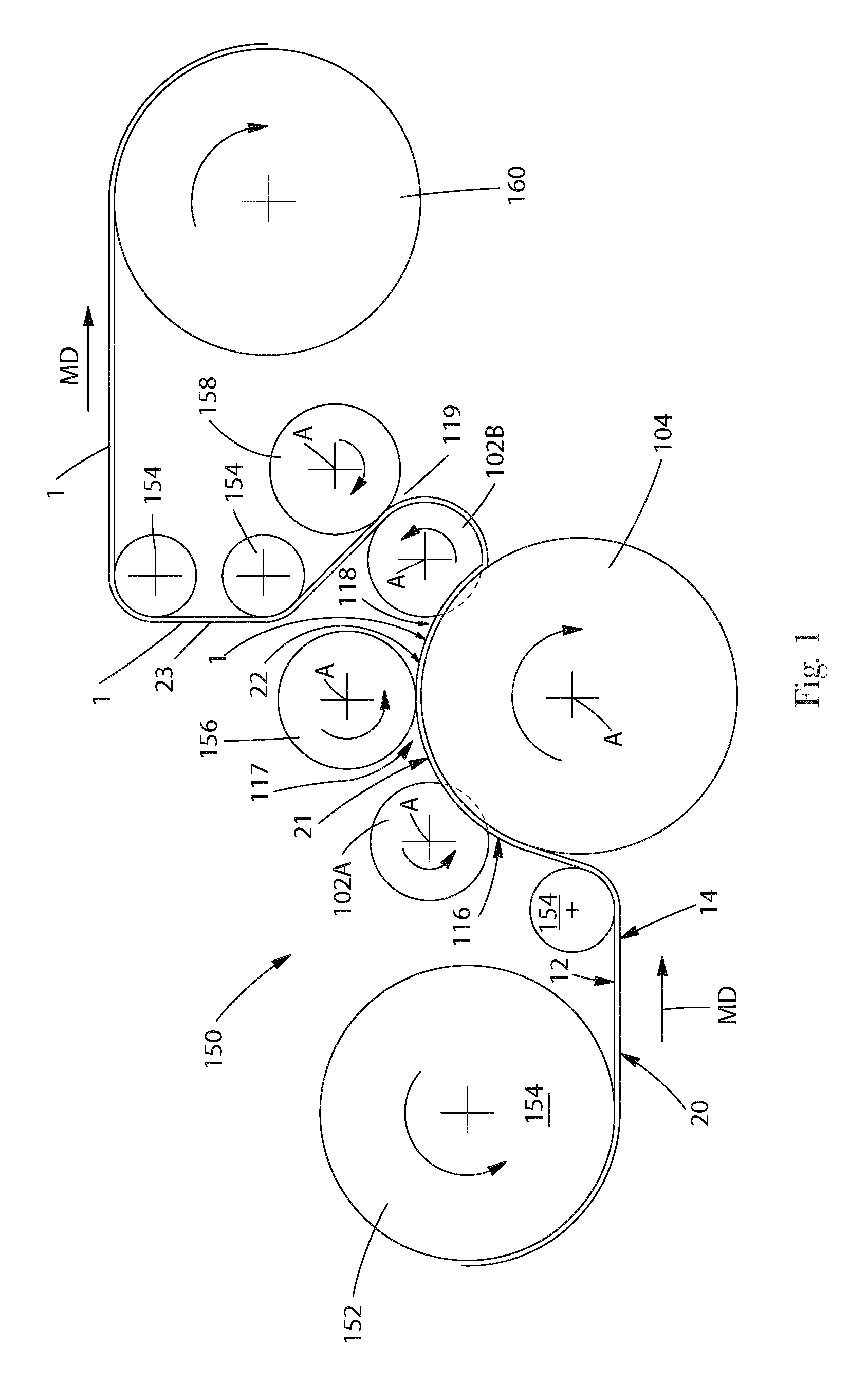

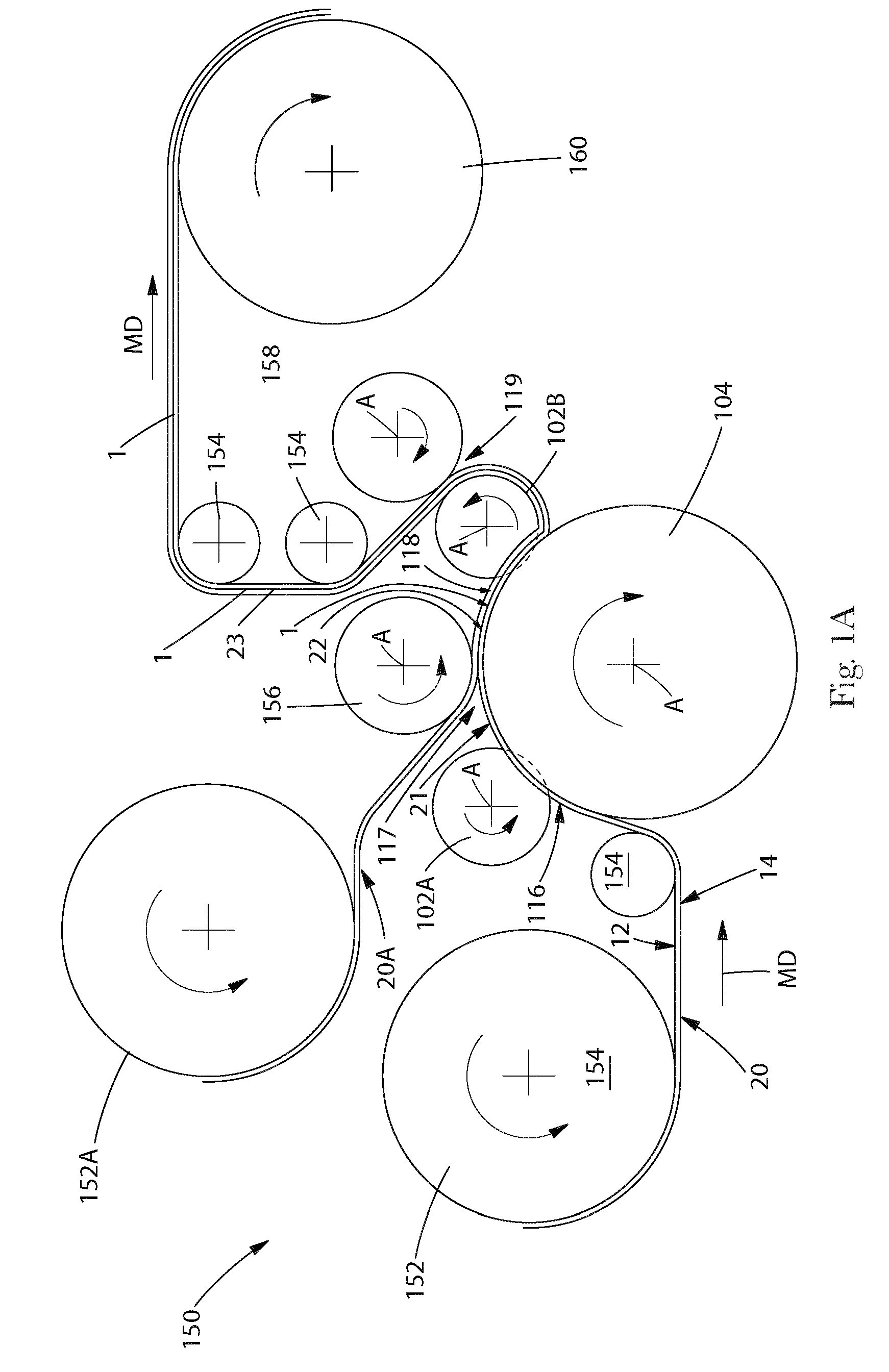

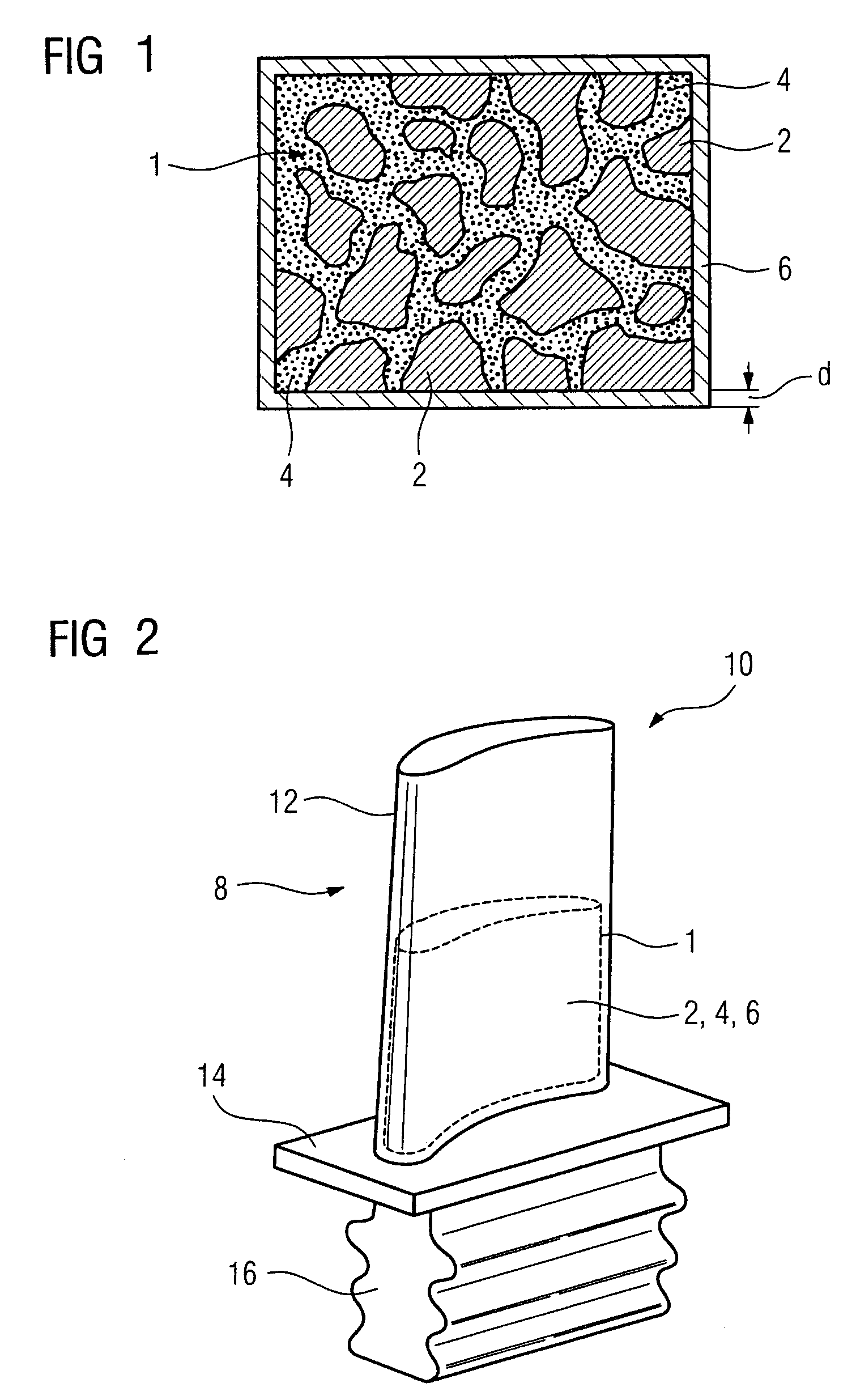

Structured Fibrous Web

InactiveUS20100310810A1Thermally stablePersonal careSynthetic resin layered productsFiberPolymer science

The present disclosure is directed to disposable absorbent articles comprising a structured fibrous web, the structured fibrous web comprising thermally stable, hydrophilic fibers that are thermally bonded together using heat producing a base substrate that is thermally stable. The base substrate is textured via mechanical treatment to increase its thickness and optionally modified via over bonding to improve its mechanical and fluid handling properties. The structured fibrous web provides optimal fluid wicking and fluid acquisition capabilities and is directed toward fluid management applications.

Owner:THE PROCTER & GAMBLE COMPANY

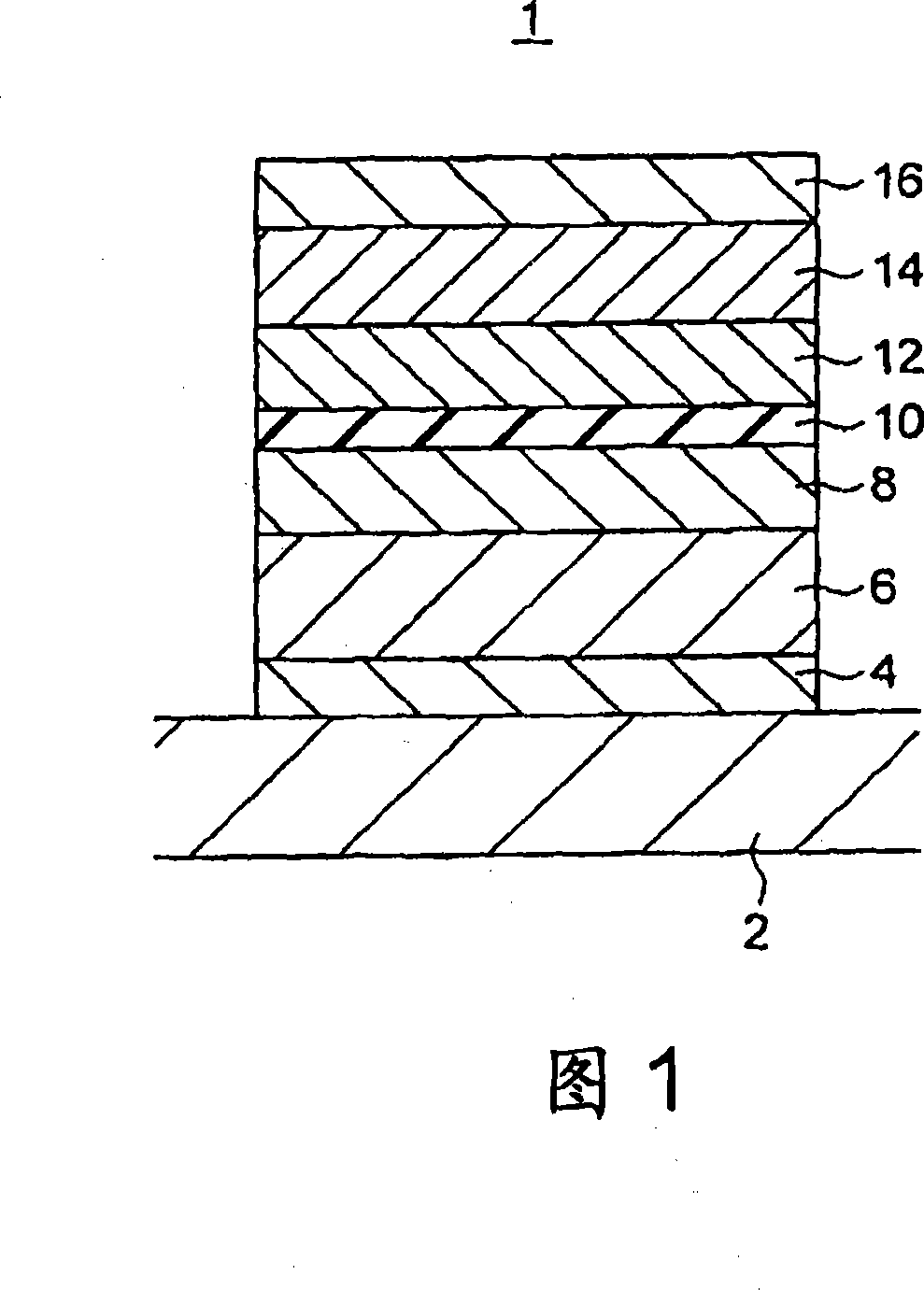

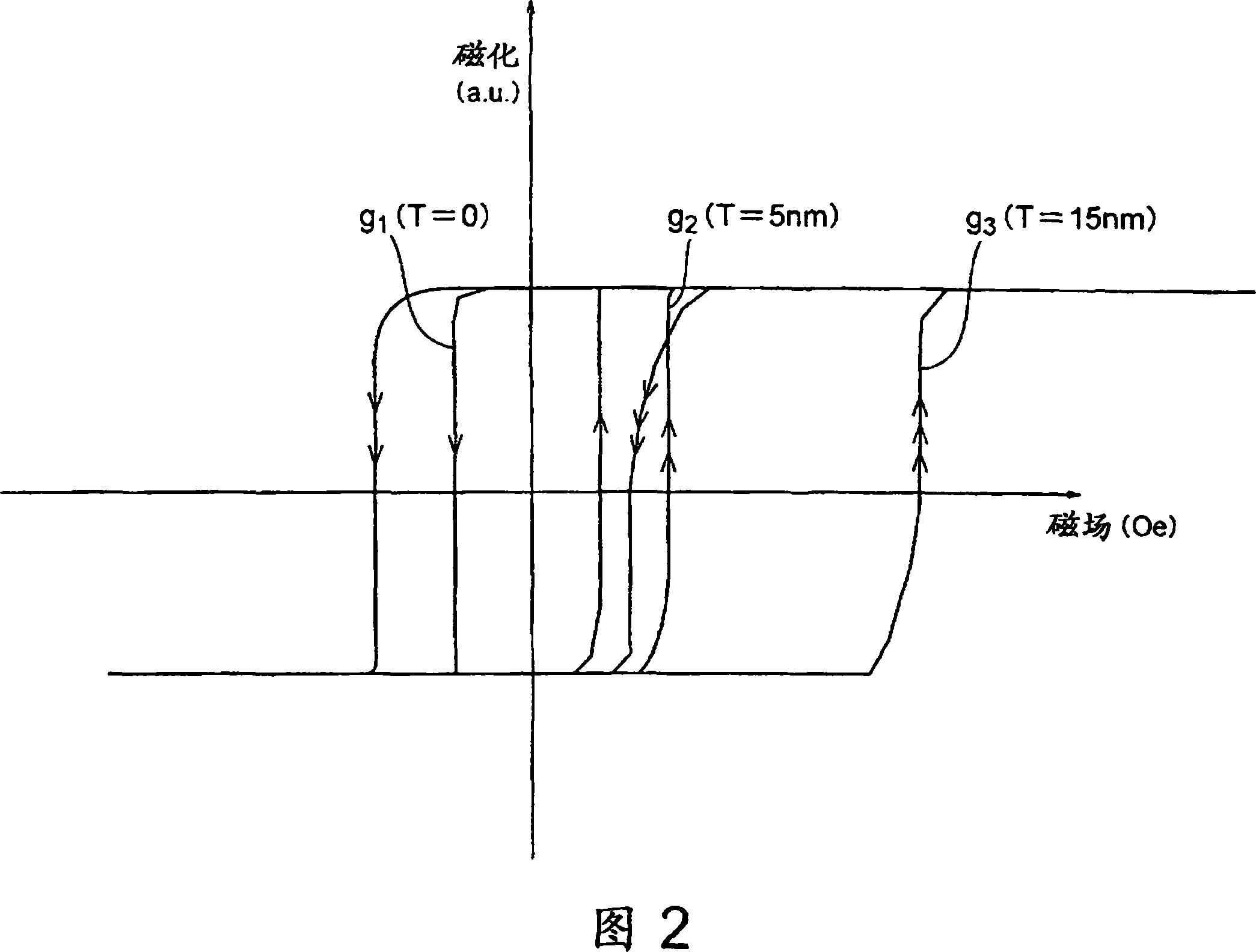

Magnetoresistive effect element and magnetic memory

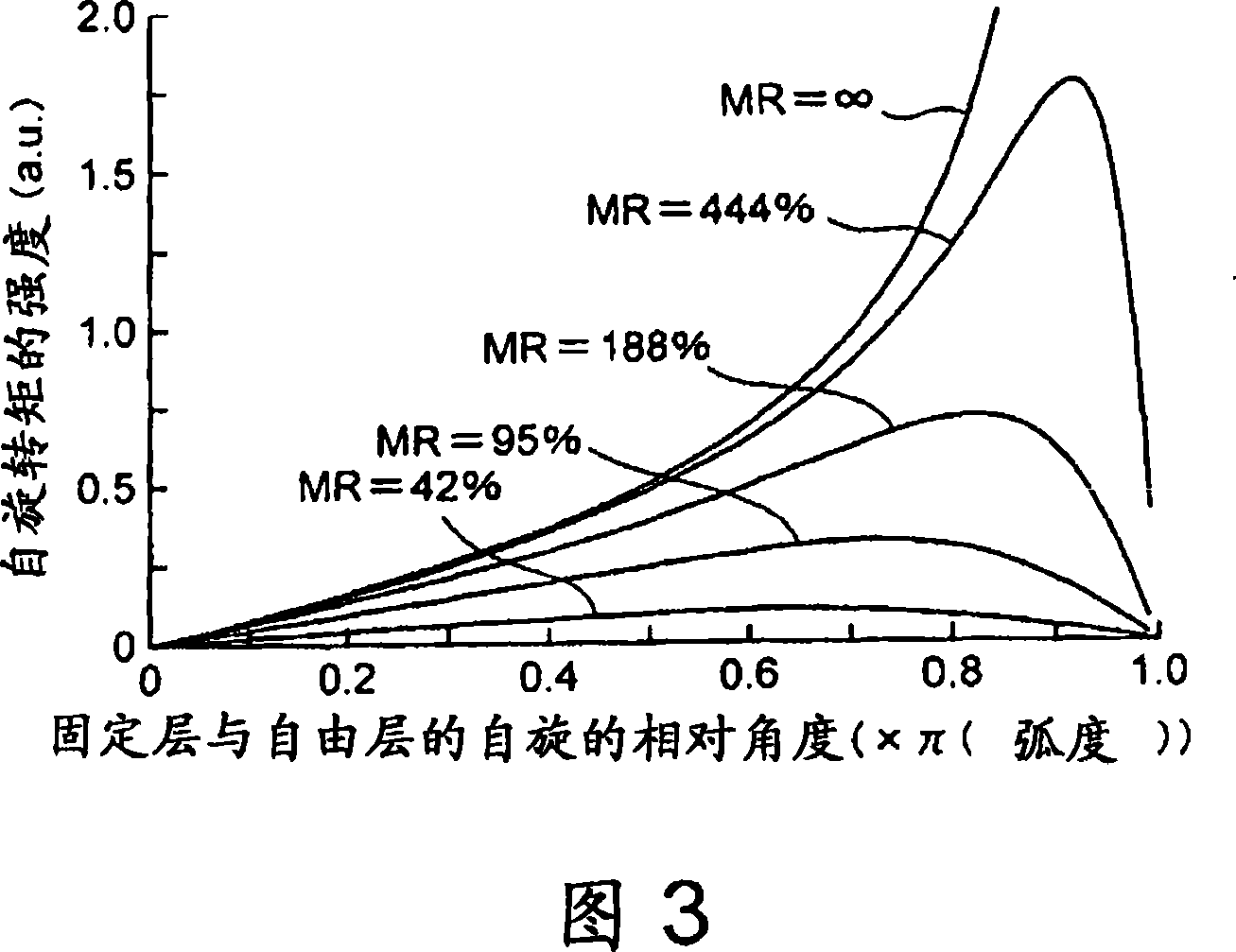

InactiveCN101064114AThermally stableGalvano-magnetic devicesSolid-state devicesMagnetic memoryRecording layer

It is possible to provide a magnetoresistive effect element and a magnetic storage which has thermal stability even if it is made fine and in which the magnetization in the magnetic recording layer can be inverted at a low current density. A magnetoresistive effect element includes: a magnetization pinned layer having a magnetization pinned in a direction; a magnetization free layer of which magnetization direction is changeable; a tunnel barrier layer provided between the magnetization pinned layer and the magnetization free layer; a first antiferromagnetic layer provided on the opposite side of the magnetization pinned layer from the tunnel barrier layer; and a second antiferromagnetic layer which is provided on the opposite side of the magnetization free layer from the tunnel barrier layer and which is thinner in thickness than the first antiferromagnetic layer, wherein the direction of the magnetization of the free magnetization layer can be converted by pouring an electron whose polarity is changed in spin polarization into the free magnetization layer.

Owner:KK TOSHIBA

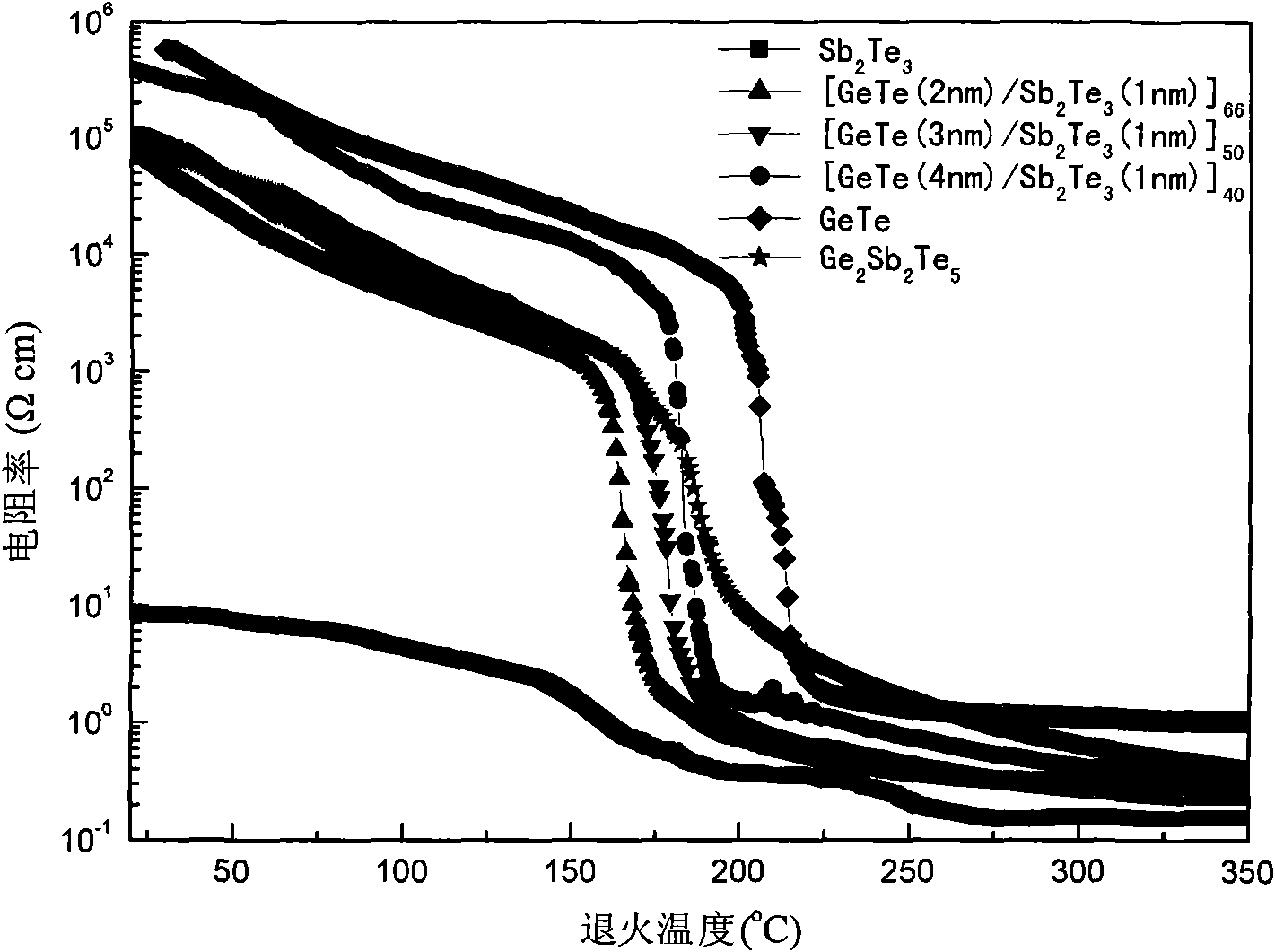

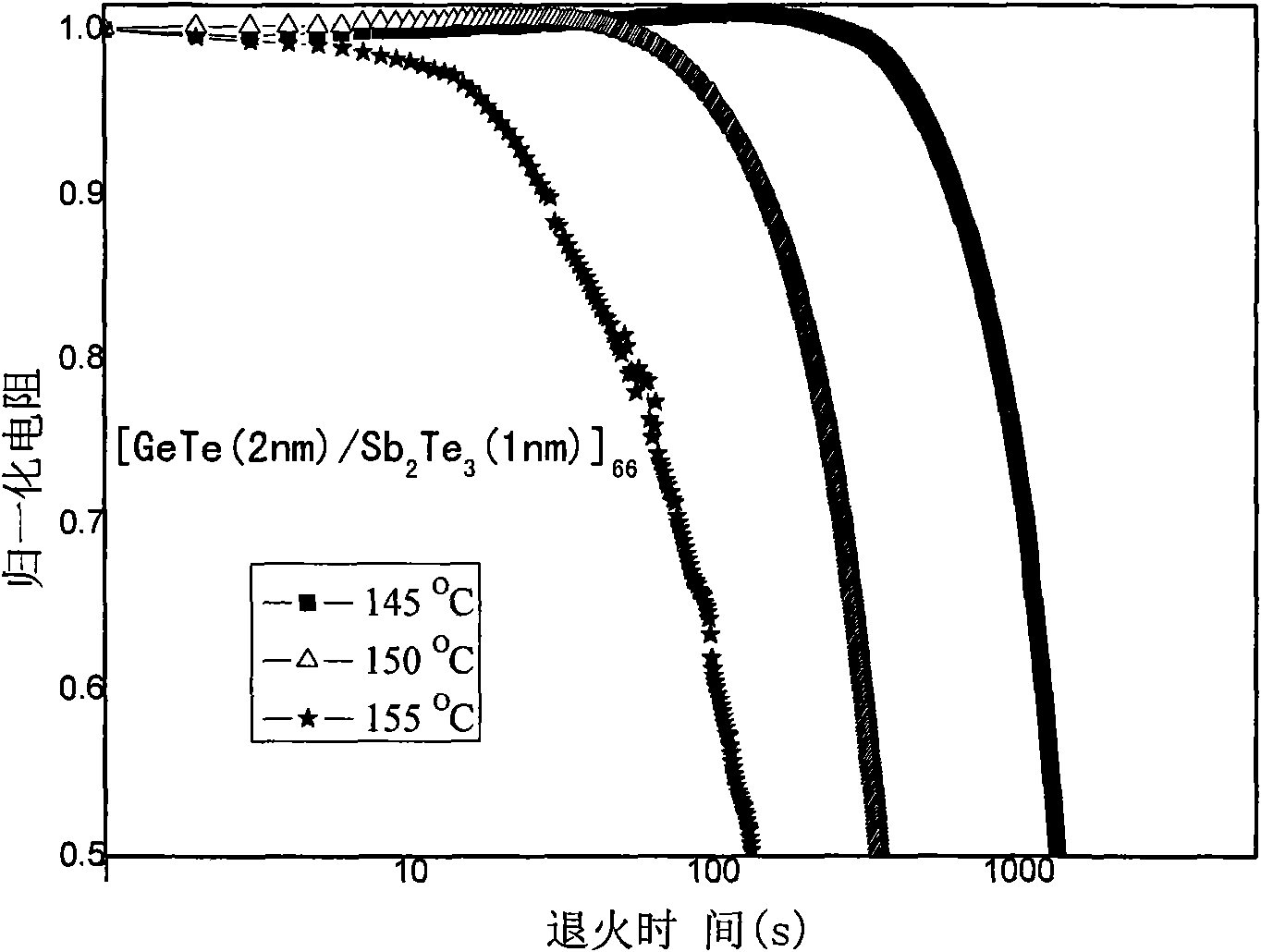

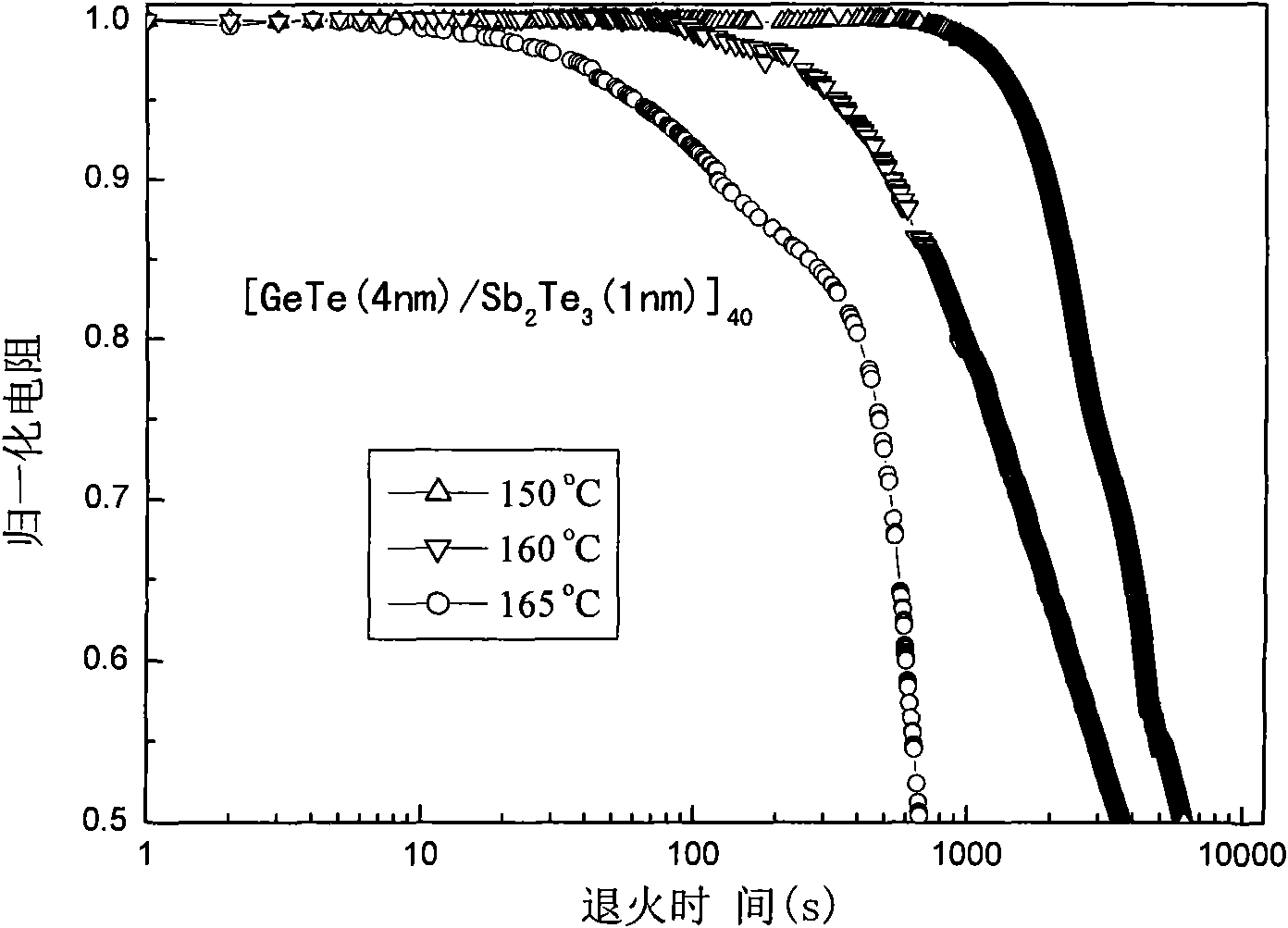

GeTe/Sb2Te3 multilayer nanocomposite phase transition film and preparation method

InactiveCN101540370AImprove on/off ratioThermally stableElectrical apparatusLayered productsPolymer sciencePhase-change memory

The invention relates to a GeTe / Sb2Te3 multilayer nanocomposite phase transition film, the GeTe film and the Sb2Te3 film of the GeTe / Sb2Te3 multilayer nanocomposite phase transition film are arranged alternately. The GeTe / Sb2Te3 multilayer nanocomposite phase transition film of the invention enjoys high phase change rate and high thermal stability; the invention can effectively enhance the on and off ratio of a phase change memory, thus ensuring the reliability of the data readout better.

Owner:TONGJI UNIV

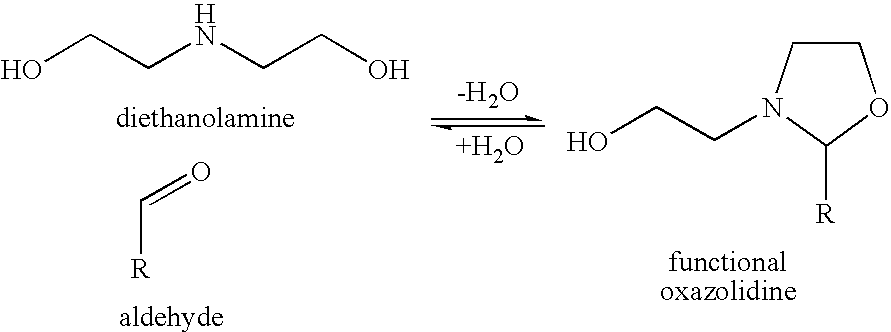

Reactive hot melt adhesive

ActiveUS20100152394A1Low volatile monomer contentImprove mechanical propertiesOrganic chemistryPolyureas/polyurethane adhesivesPolymer scienceOxazolidine E

Solvent free, moisture curable reactive hot melt adhesives are prepared using an oxazolidine functional prepolymer and a polyfunctional isocyanate.

Owner:HENKEL KGAA

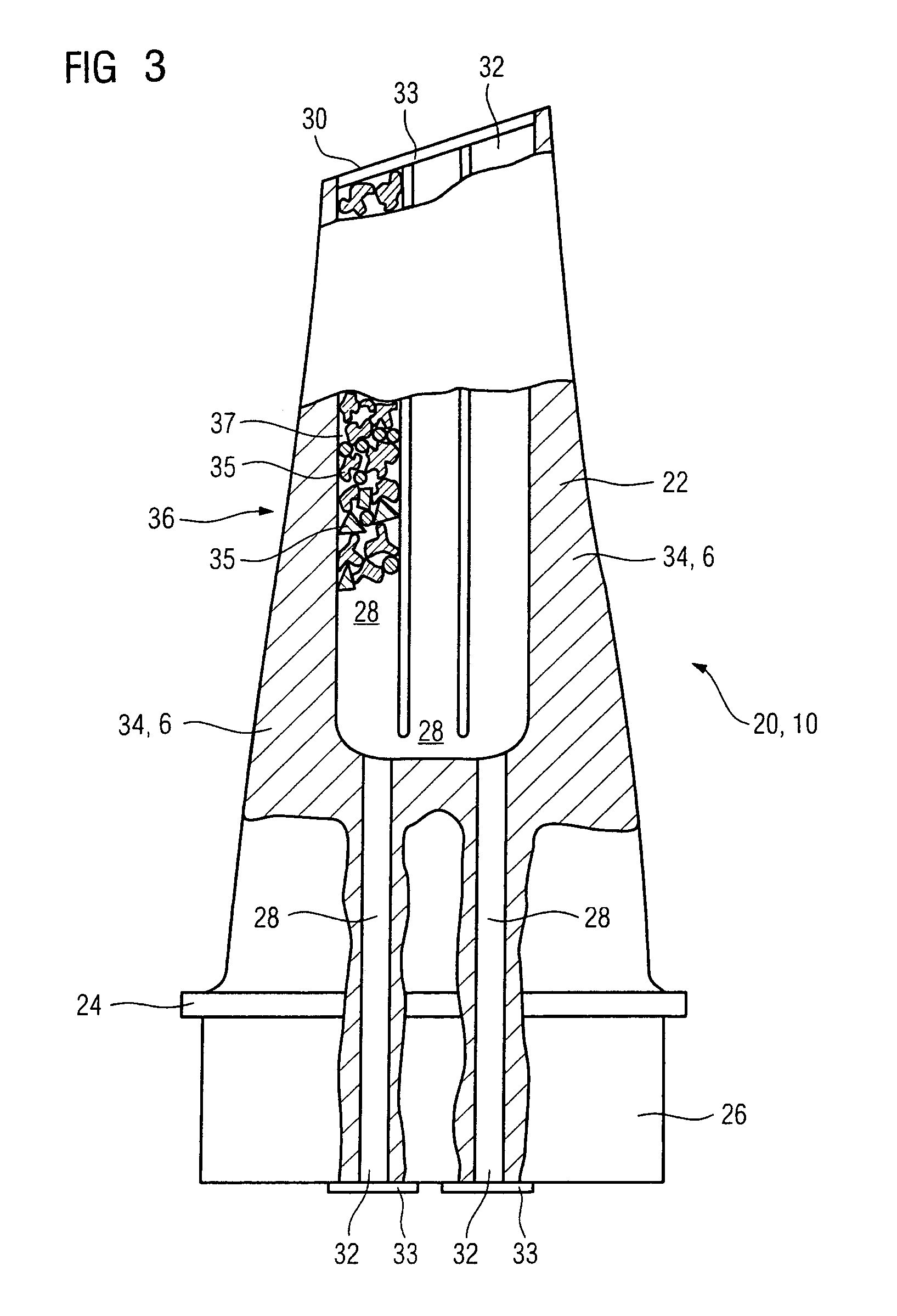

High-temperature component for a turbomachine, and a turbomachine

InactiveUS7347664B2Simple designProtect the loadPump componentsReaction enginesEngineeringMechanical engineering

Owner:SIEMENS AG

Nonaqueous coating composition for elastomeric articles and articles containing the same

InactiveUS20080020023A1Improved therapeutic propertyEasy transferCosmetic preparationsToilet preparationsSkin contactIrritation

The invention described herein relates to a therapeutic, moisturizing coating composition for elastomeric articles which is applied directly onto the skin-contacting surface of the article as part of the manufacturing process. The coating composition is thermally stable and subsequently transfers when in contact with a skin surface to convert into a liquid “lotion” form during wearing of the article. The coating composition provides therapeutic benefits to the wearer's skin as a result of wearing the article, such as improved skin moisturization, softness of feel, improved skin elasticity and firmness, and reduced redness and irritation. The invention is particularly useful in medical gloves, including examination and surgical gloves.

Owner:ALLEGIANCE CORP

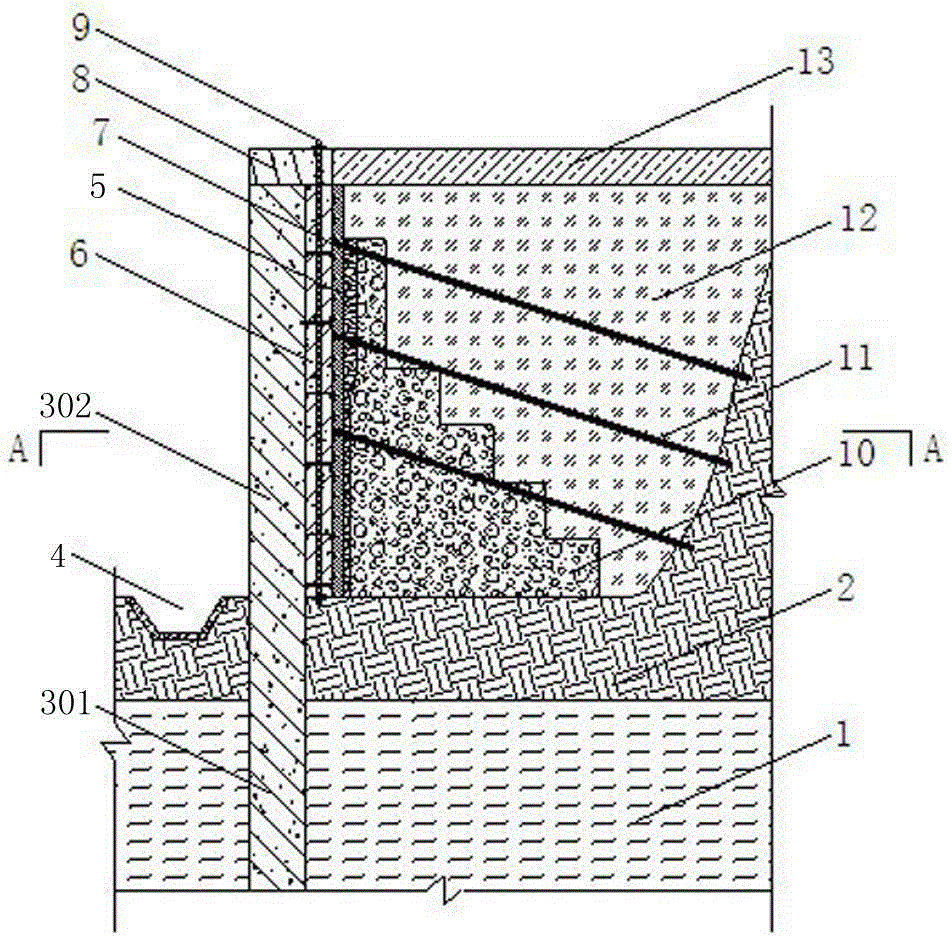

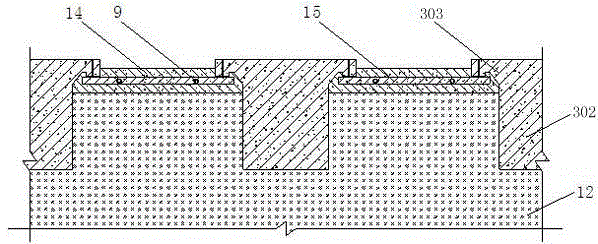

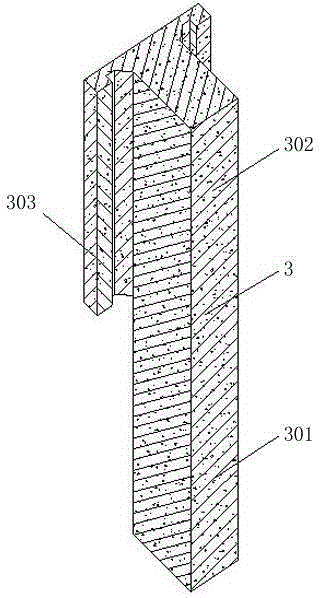

Construction method of high-fill prefabricated cast-in-situ combined pile slab wall protection structure

ActiveCN105421485AImprove securityFast constructionArtificial islandsUnderwater structuresPre stressStructural stability

The invention relates to a construction method of a high-fill prefabricated cast-in-situ combined pile slab wall protection structure. The construction method comprises the steps of construction preparation, construction of an anti-slide pile, construction of a prefabricated breast board, construction of a prefabricated cover beam, construction of a heat insulating board, installation of a drainage pipe, construction of an oblique breast board anchor cable, construction of a vertical gravel drainage body, construction of a bubble concrete backfill layer, construction of a drainage ditch and the like. According to the construction method of the high-fill prefabricated cast-in-situ combined pile slab wall protection structure, the high-fill prefabricated cast-in-situ combined pile slab wall protection structure is formed by combining the anti-slide pile provided with a connecting wing plate with the breast board, the prefabricated cover beam is installed at the top, the breast board, the anti-slide pile and the cover beam are connected into a whole through the prestressed anchor cable, and thus compared with a traditional high-fill retaining wall, the construction speed is high, the stability of the structure is good, and the safety performance is high. According to the construction method, the construction technique is simple, pile slabs and grouped piles can be constructed synchronously, the construction period is short, and the obtained protection structure has the advantages that the overall stability is good, the adaptability is high, the ant-slide performance is good, and breast boards can be prefabricated in a centralized mode.

Owner:杭州市交通规划设计研究院有限公司

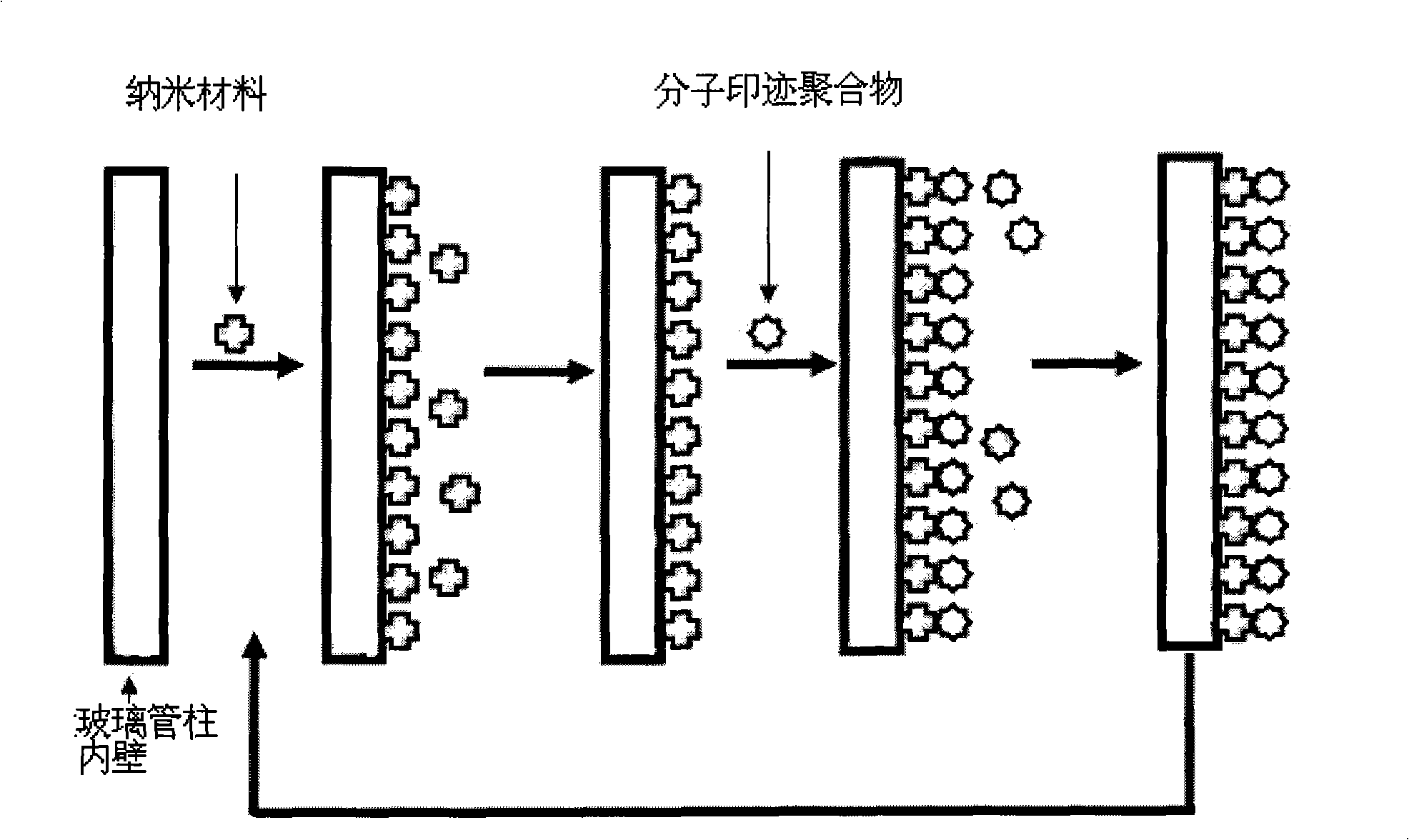

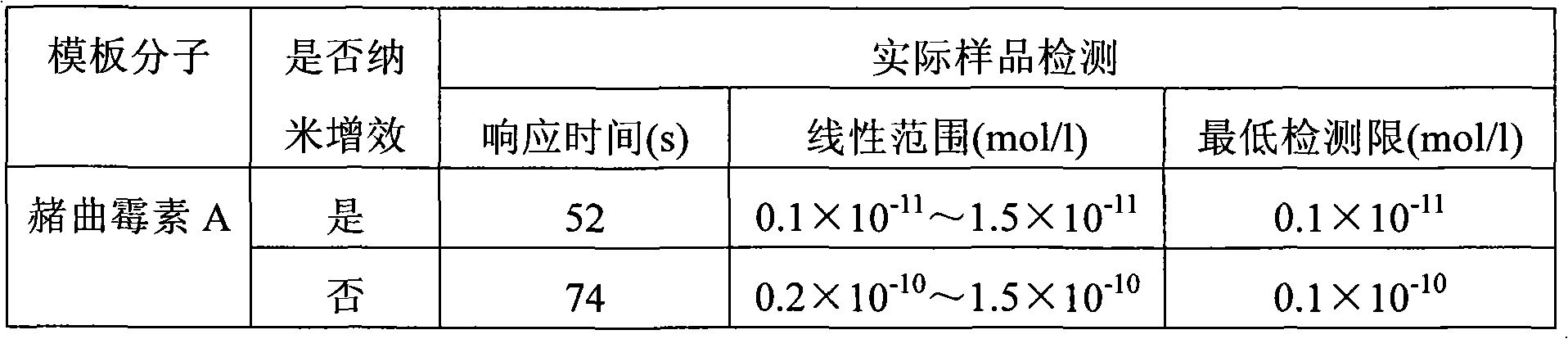

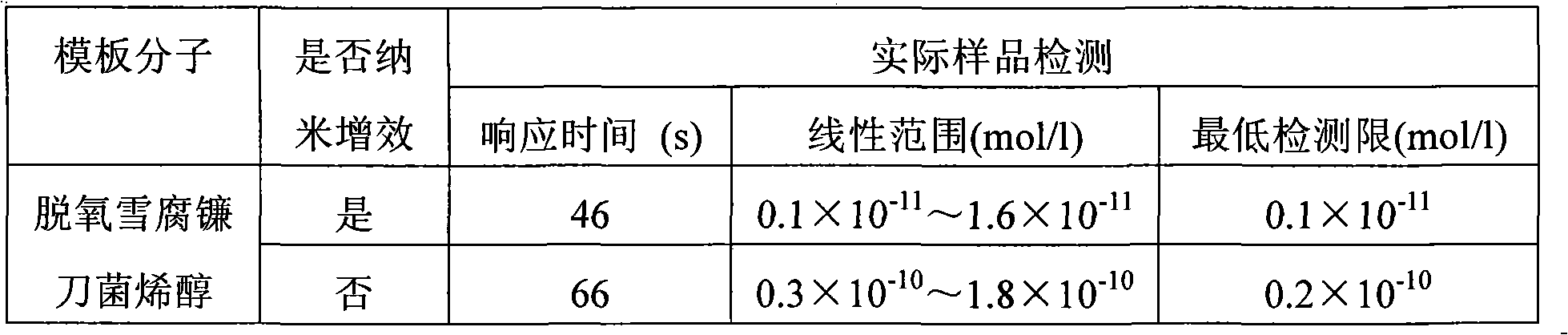

Trace amount mycotoxins molecular blotting column preparation method and application

InactiveCN101308066AIncreased sensitivityExpand the scope of detectionComponent separationChemiluminescene/bioluminescenceCross-linkFunctional monomer

The invention discloses a process for preparing a trace amount mycotoxin molecular imprinted column, which comprises the following steps of: selecting a functional monomer; evenly mixing a mycotoxin template molecule, the functional monomer, a cross-linking agent, a pore-forming agent, an initiator and an organic solvent by a certain molar ratio to prepare a molecular imprinting polymer solution; preparing a nano-solution; and dressing the nano-material and a molecular imprinting polymer on the internal surface of a glass pipe column. A method for detecting the trace amount mycotoxins includes: pumping a chemiluminescence system solution and a sample solution into a chemiluminescence analyzer respectively and detecting the mycotoxins in the sample. The molecular imprinted column of the invention has advantages of high sensitivity and accuracy. The nano-enhanced trace amount mycotoxin molecular imprinted column obtained in the invention is connected to the chemiluminescence analyzer for detecting mycotoxins, and purposes of high specificity, high sensitivity and fast detection to mycotoxins in the sample can be realized.

Owner:UNIV OF JINAN

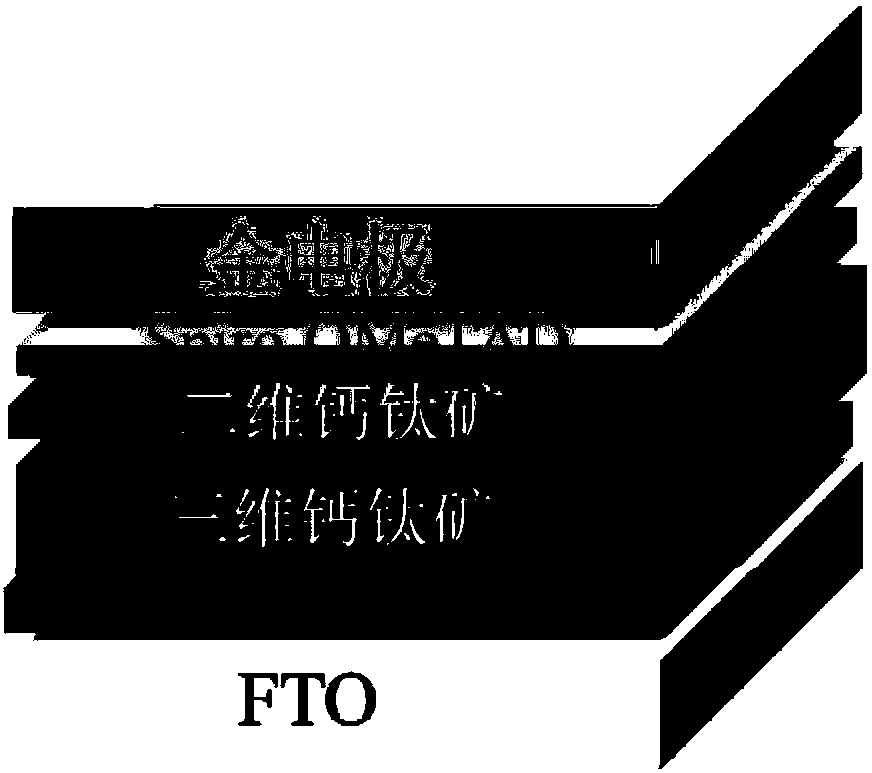

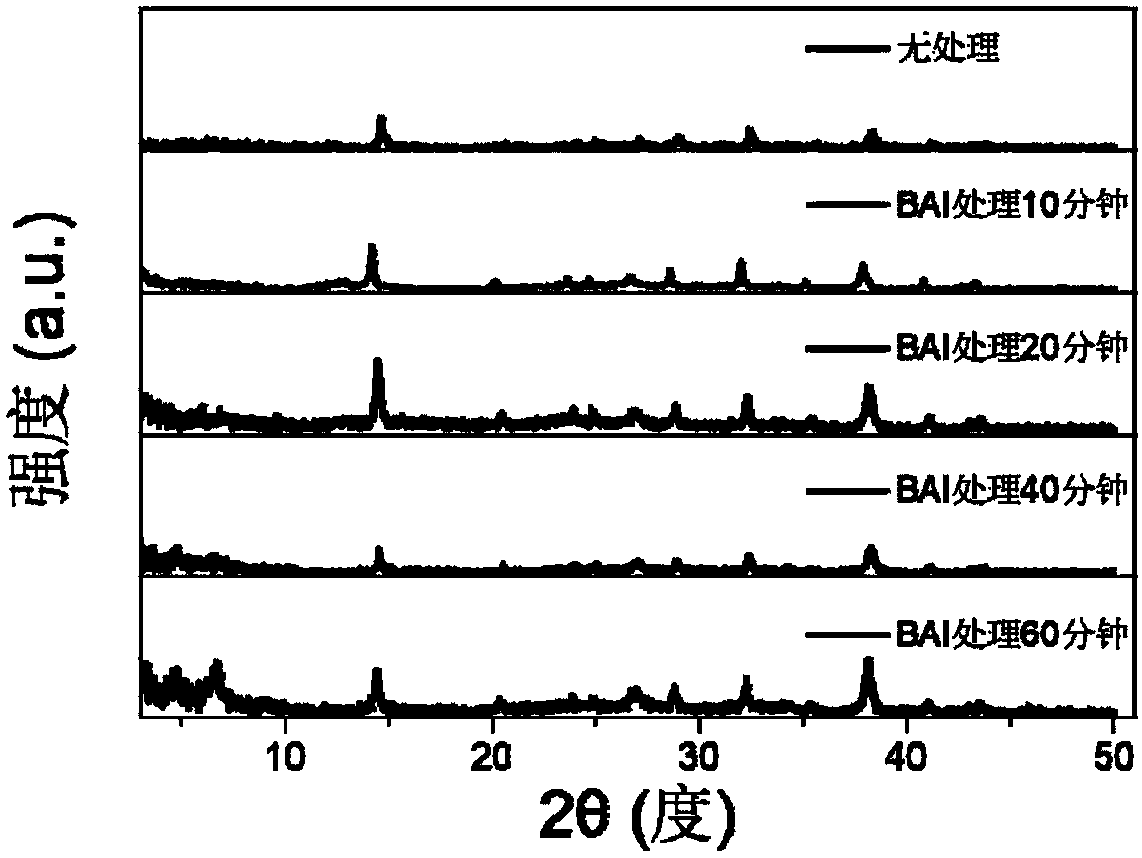

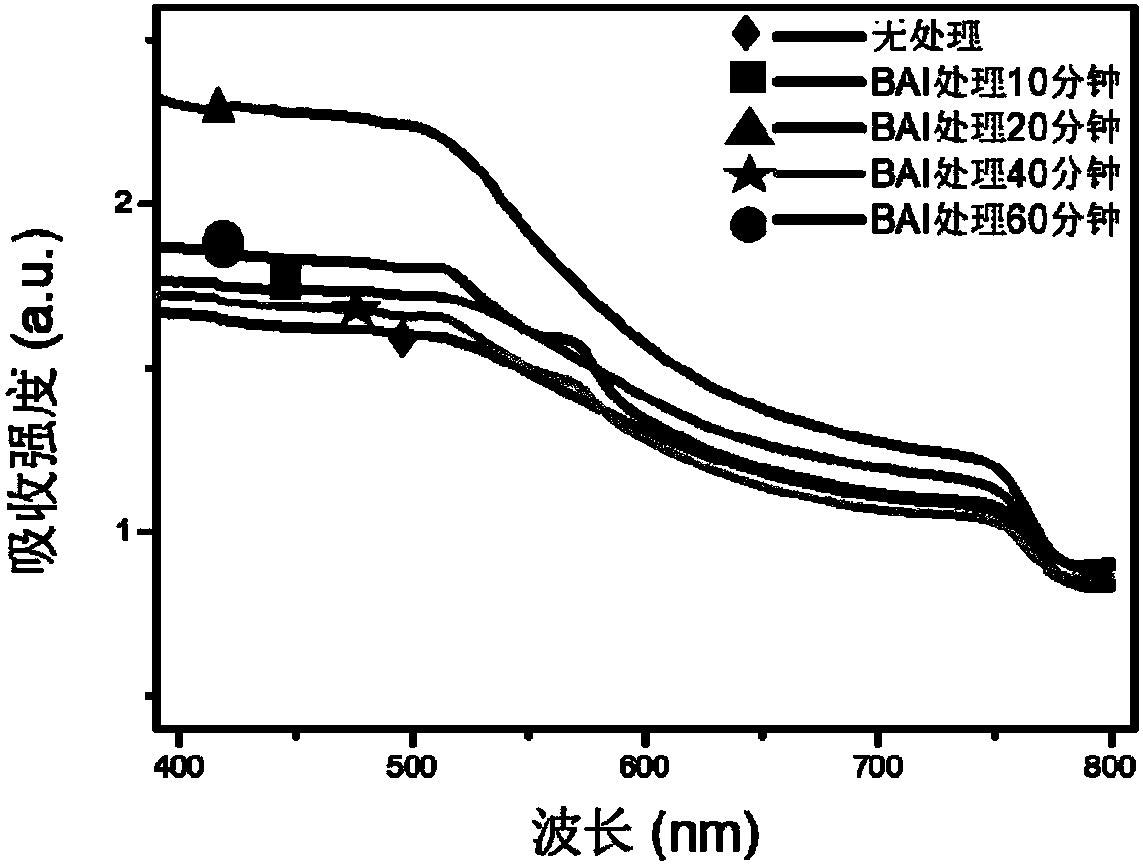

Perovskite plane heterojunction solar cell and preparation method therefor

ActiveCN108269921AAvoid introducingReduce consumption costFinal product manufactureSolid-state devicesHeterojunctionOrganic solvent

The invention relates to a perovskite plane heterojunction solar cell and a preparation method therefor. The solar cell comprises a conductive substrate FTO, an electron transmission layer, a three dimensional-two dimensional perovskite layer, a hole transmission layer, and electrodes. The three dimensional-two dimensional perovskite layer is prepared through a vapor phase method. The three dimensional-two dimensional perovskite layer serves as a light absorbing layer, thereby greatly improving the humidity and temperature stability of the solar cell, reducing the requirements for the packaging technology, and reducing the consumption of an organic solvent. Moreover, the three dimensional-two dimensional perovskite layer prepared through the vapor phase method is higher in industrial production value, and provides a new idea for the industrial production of the perovskite solar cell with the high stability.

Owner:JINAN UNIVERSITY

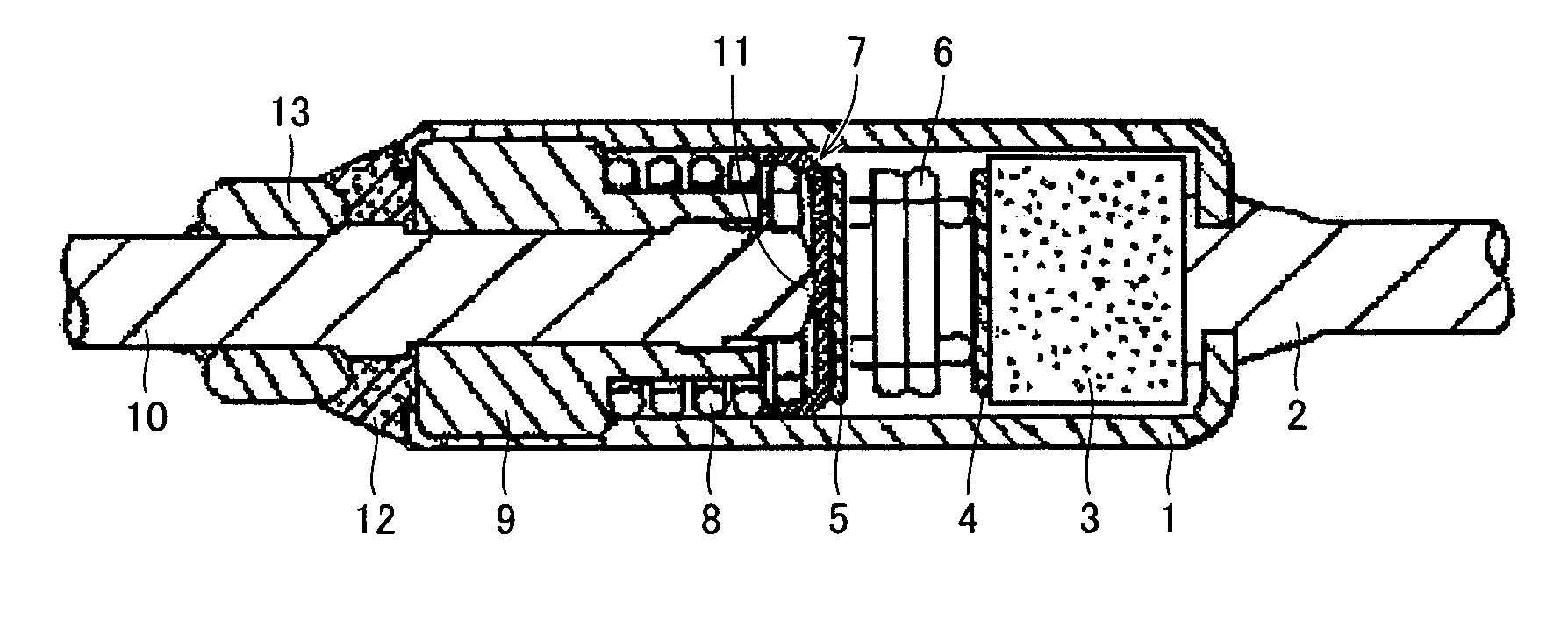

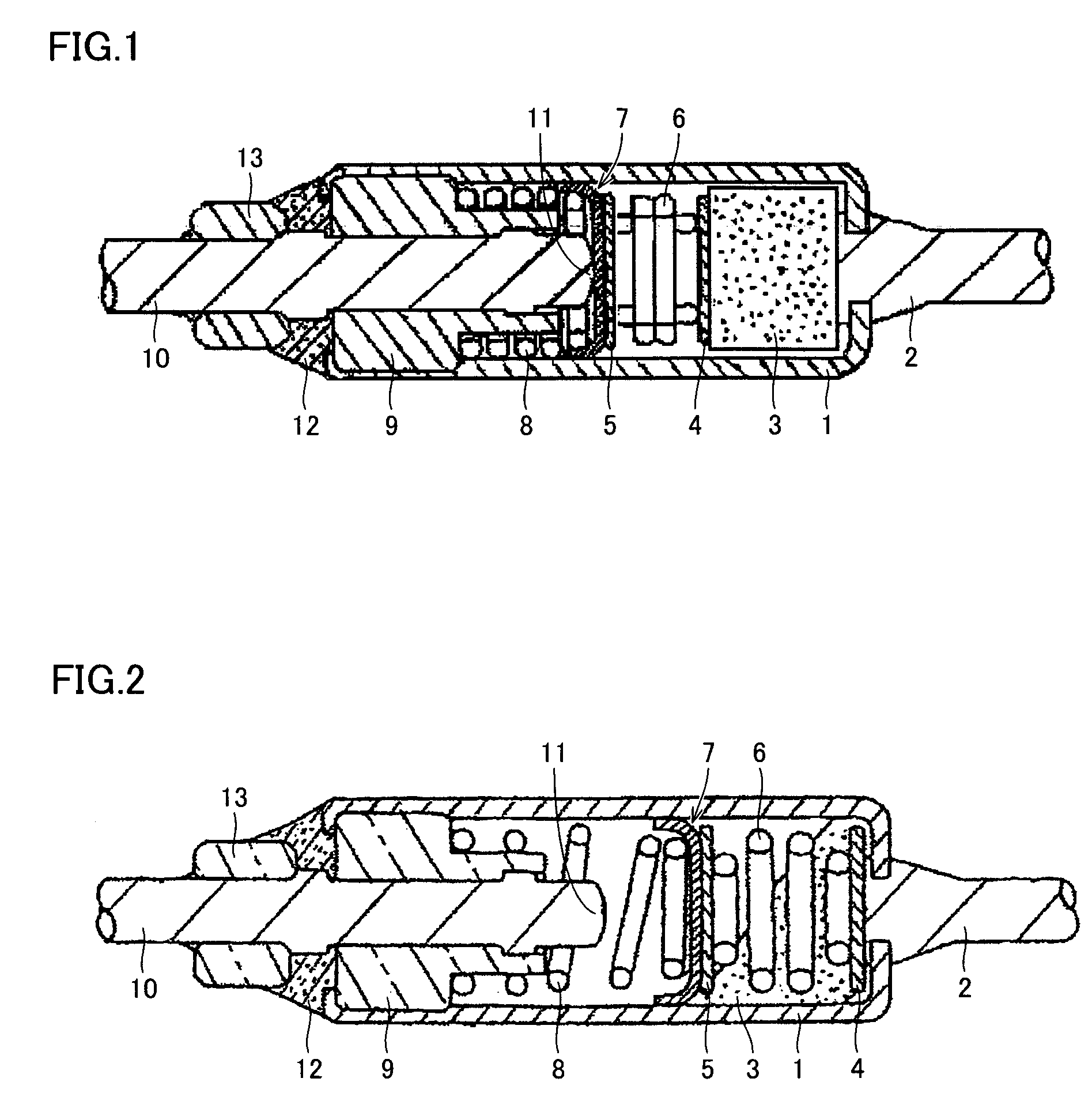

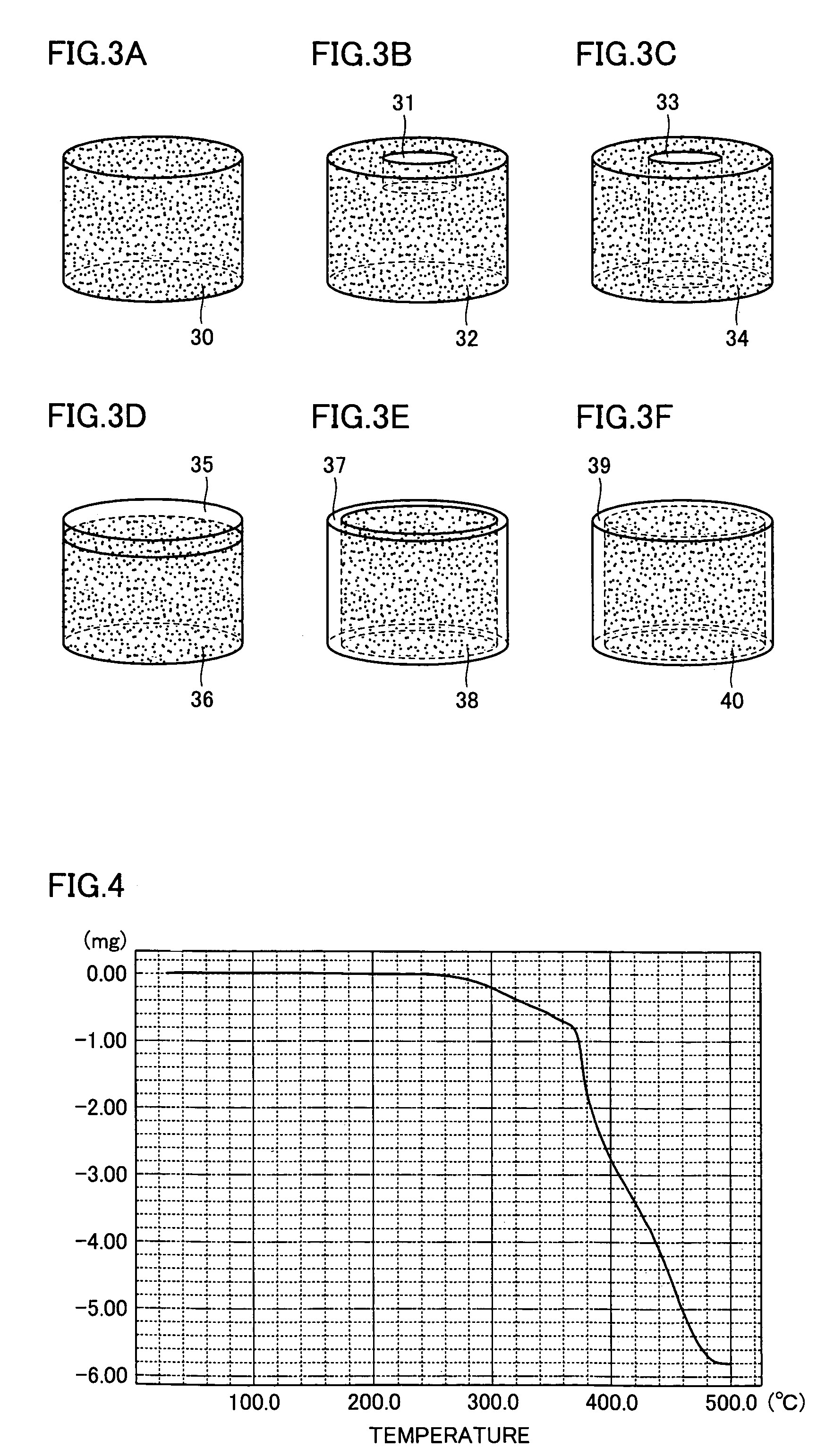

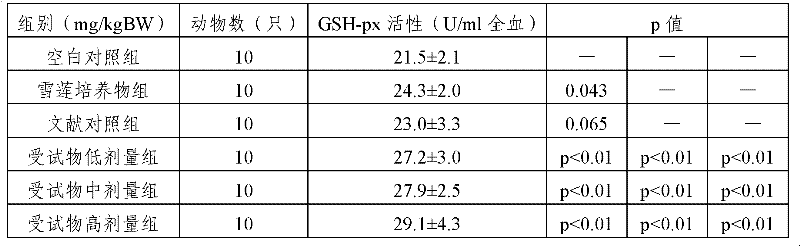

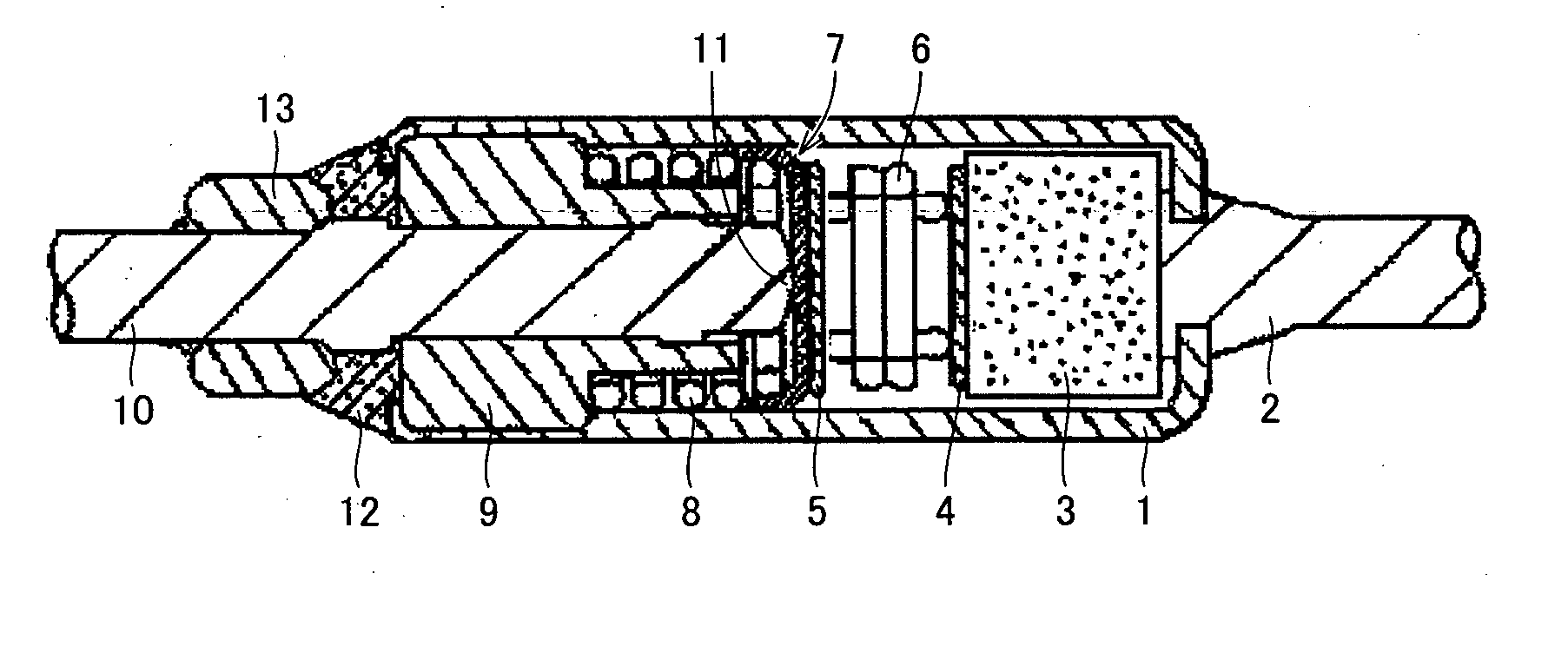

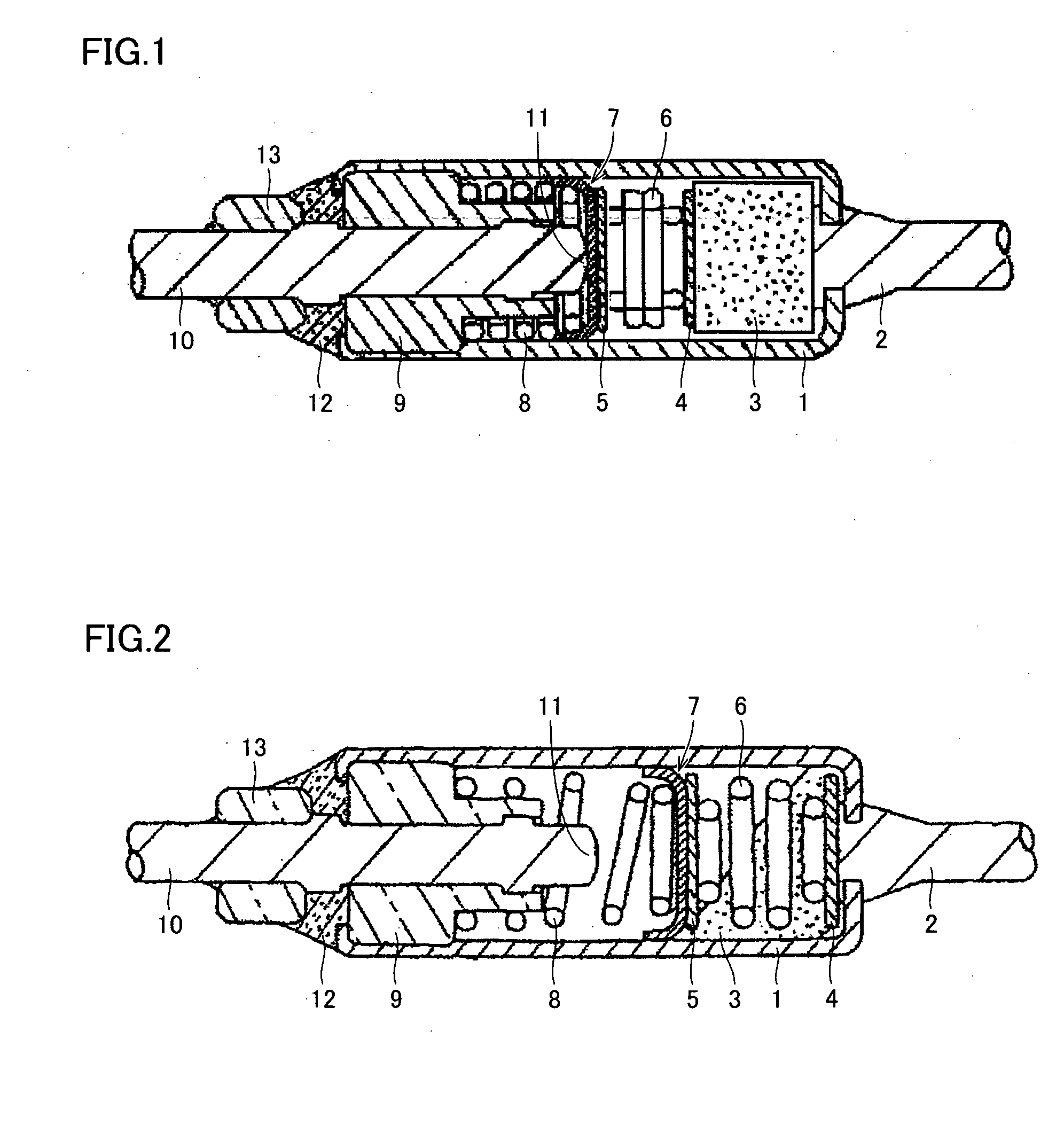

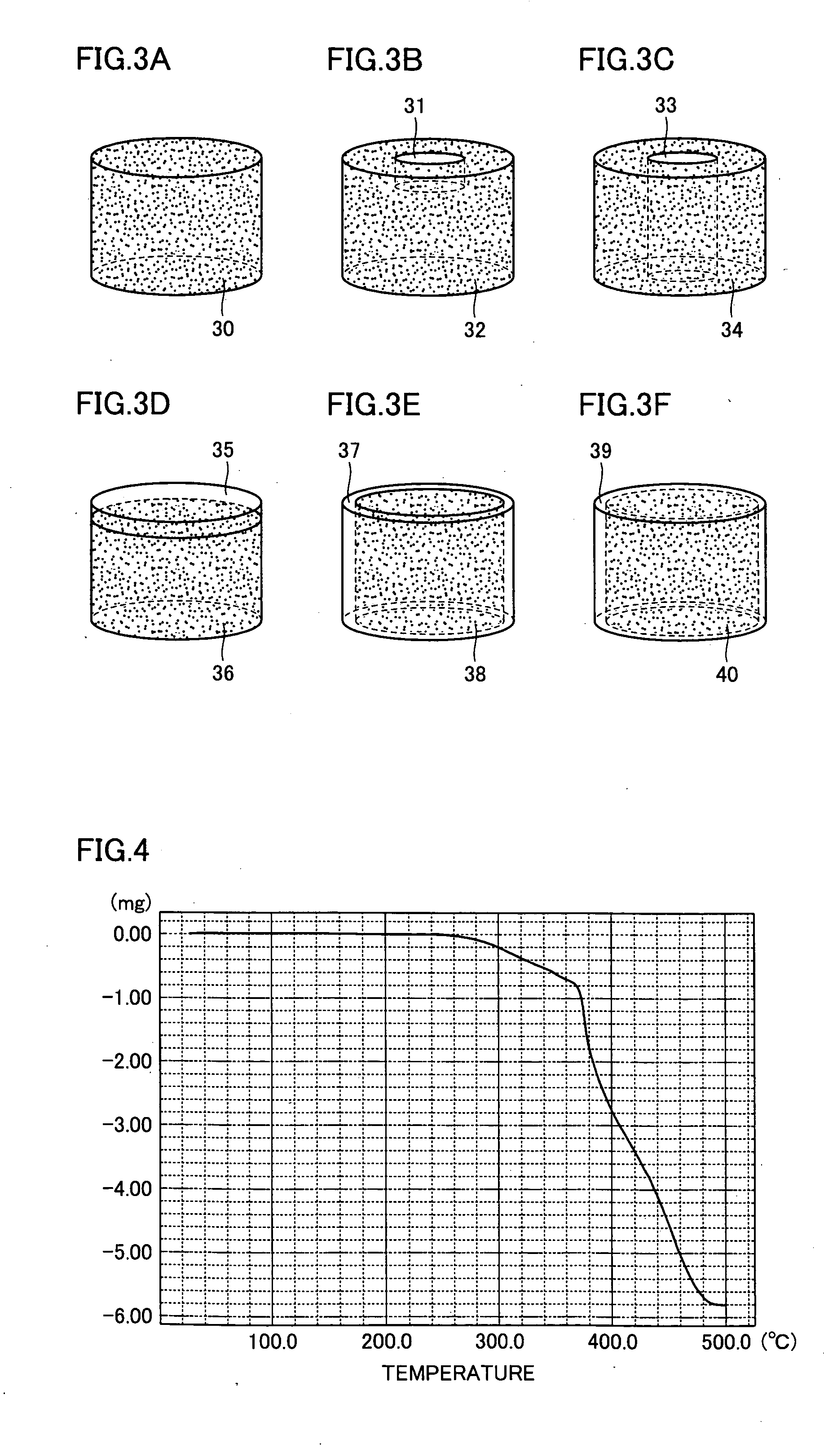

Thermal pellet incorporated thermal fuse and method of producing thermal pellet

ActiveUS7323966B2Improve featuresReduce deliquescenceFuse device manufactureHeating/cooling contact switchesHeat deflection temperatureHot melt

A thermal fuse incorporating a thermal pellet has its operating temperature, or heat distortion temperature, adjusted and the thermosensitive material of the pellet avoids deformation, modification or similar deficiency if it is exposed to a severe external environment. The inexpensive thermal fuse provides a wider range from which an operating temperature can be selected, improved insulation resistance after operation, faster response speed in operation, and enhanced strength of the thermal pellet. The thermosensitive material is formed of a thermoplastic resin corresponding to a high molecular weight substance. The thermal pellet's heat distortion temperature is adjusted by a temperature setting method. An enclosure of the fuse has a metal casing with a spring member's strong and weak compression springs both accommodated therein and hermetically sealed.

Owner:SCHOTT JAPAN CORP

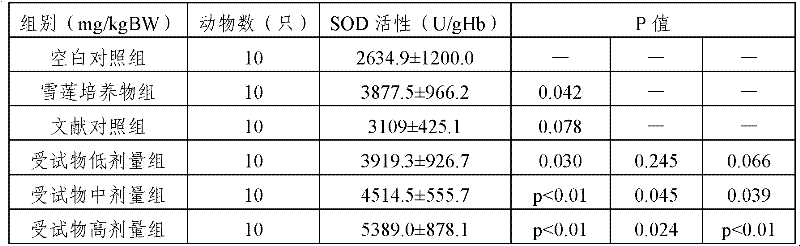

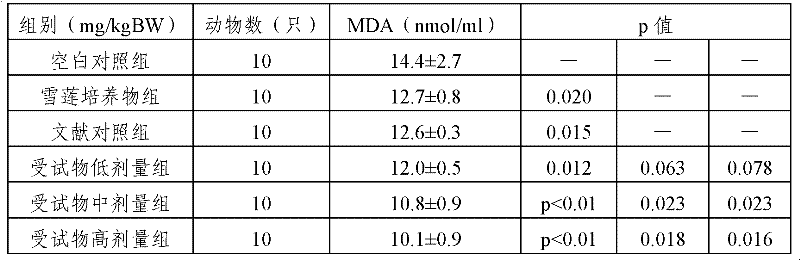

Female whitening skin-nourishing composition

ActiveCN102512669AUnique pharmacological effectsMiraculous medicinal valueOrganic active ingredientsPeptide/protein ingredientsBiotechnologyMalpighia emarginata

The invention relates to a female whitening skin-nourishing composition, which contains the following components of: by weight, 10-160 parts of saussurea involucrata culture, 100-700 parts of collagen, 20-120 parts of an acerola cherry extract product, 2-40 parts of sodium hyaluronate, and 0-20 parts of a natural sweetener. The composition provided by the invention has substantial efficacy in aspects of antiradiation and antioxidation, can has whitening and skin-nourishing effects for female, and is suitable for female of all ages.

Owner:BEIJING TONGRENTANG HEALTH PHARMA

Glass-forming tools and methods

InactiveUS20120047953A1Thermally stableVacuum evaporation coatingSputtering coatingGlass formingCover glass

Refractory glass-forming tools, including glass-forming molds incorporating protective metal nitride surface coatings, with optional alumina barrier layers disposed between the mold bodies and coating for high-temperature nitride coating stability, offering particular advantages for the manufacture by direct molding of optically finished glass products such as information display cover glasses from refractory alkali aluminosilicate glasses at molding temperatures up to and above 800° C.

Owner:CORNING INC

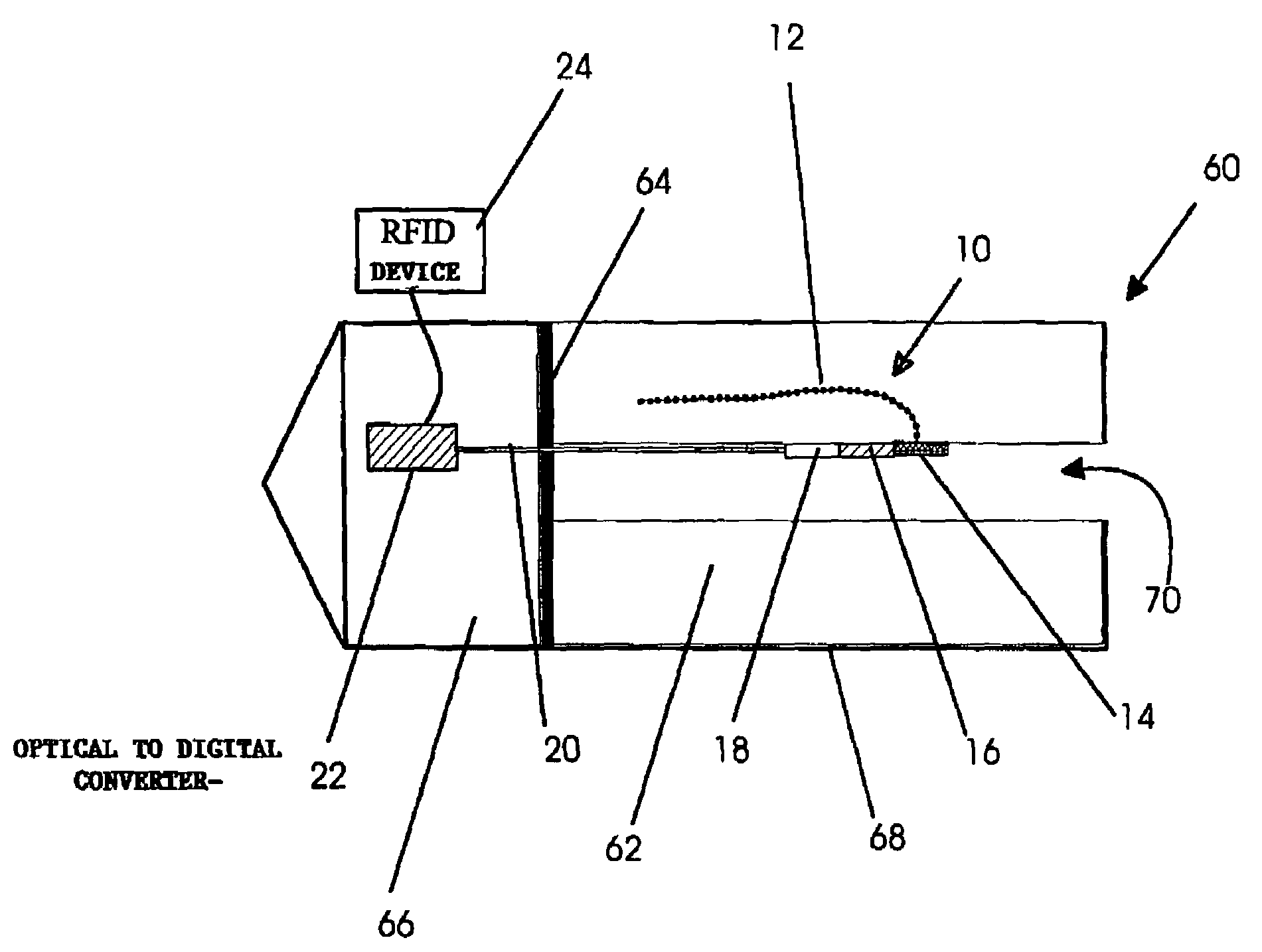

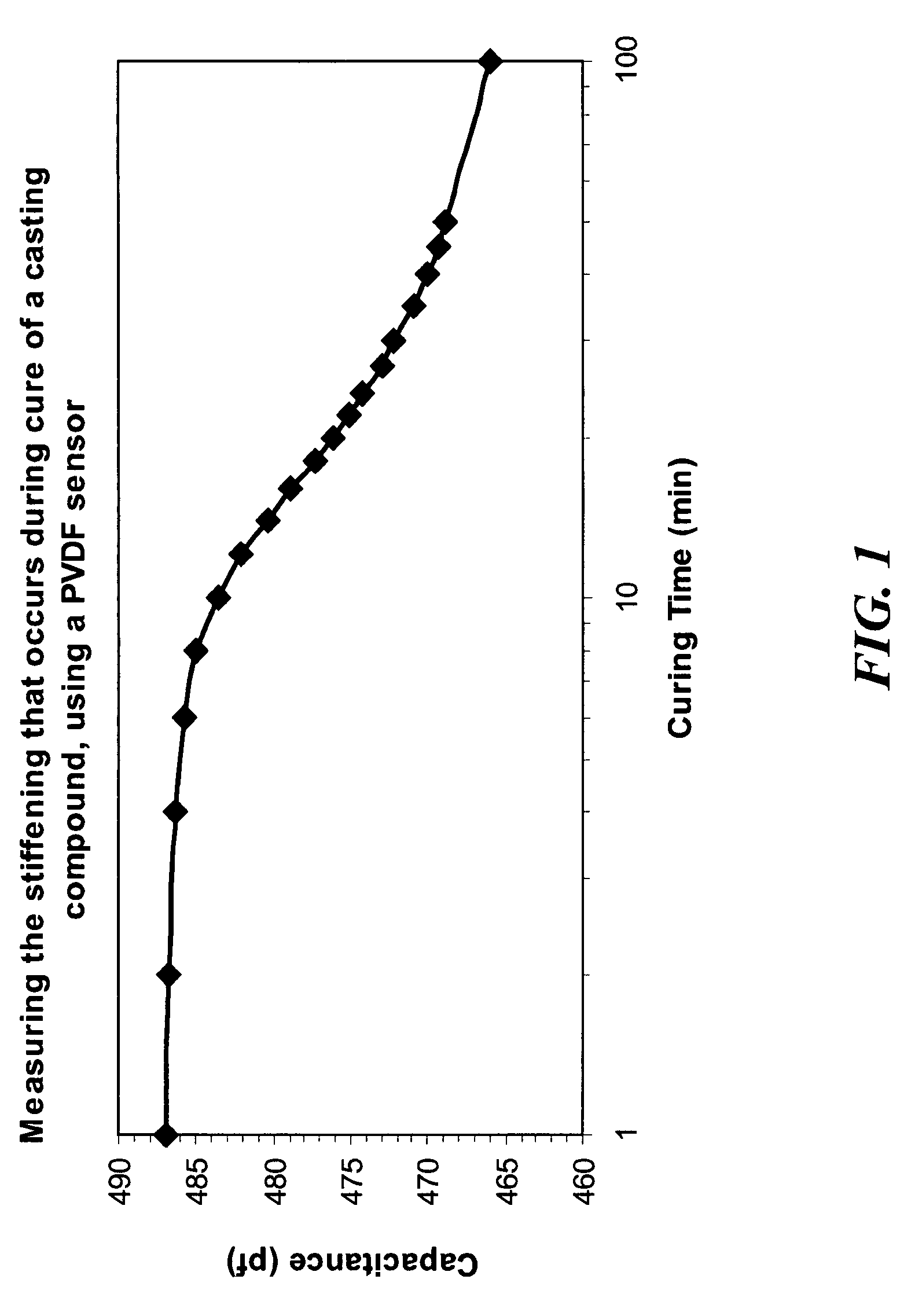

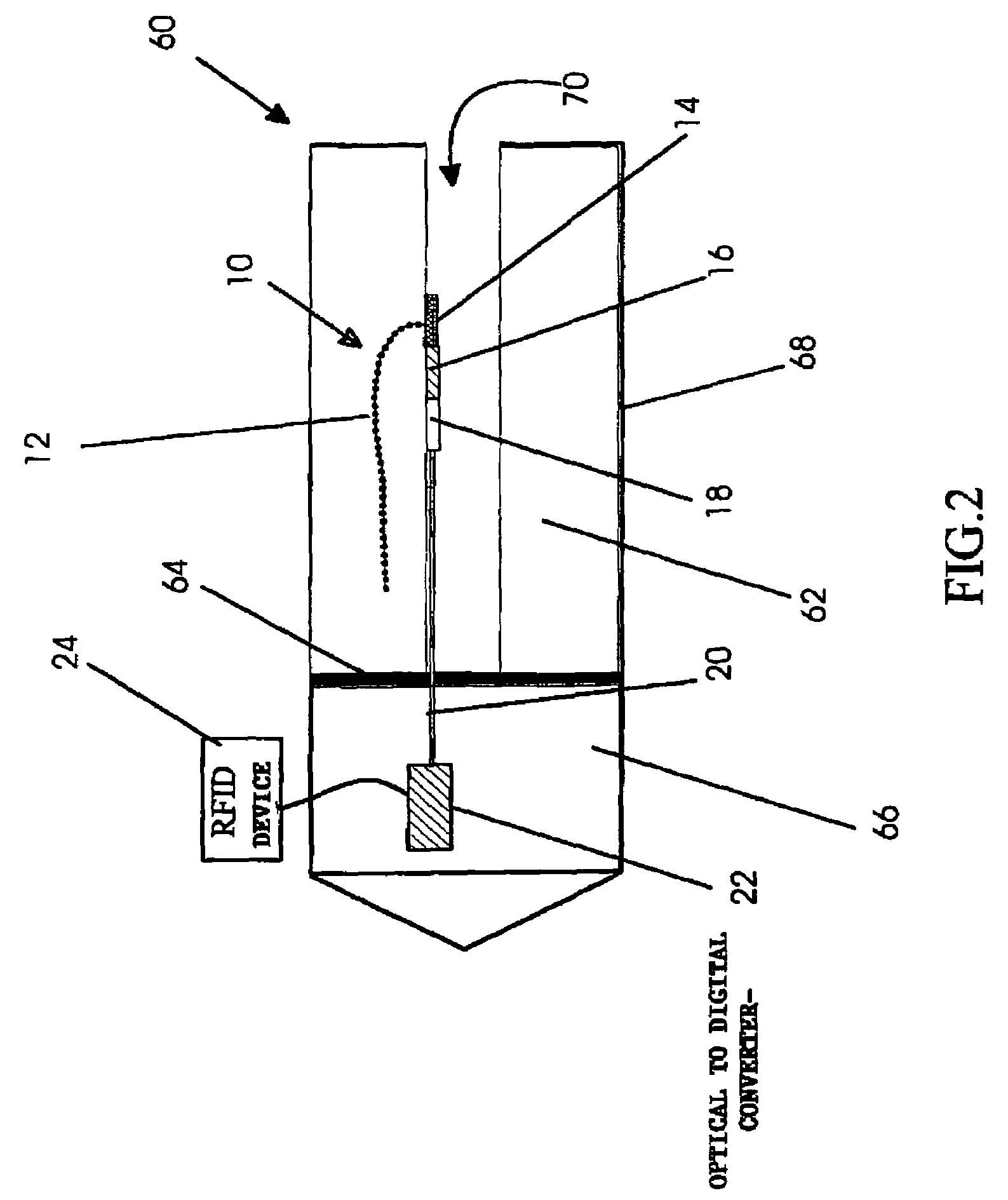

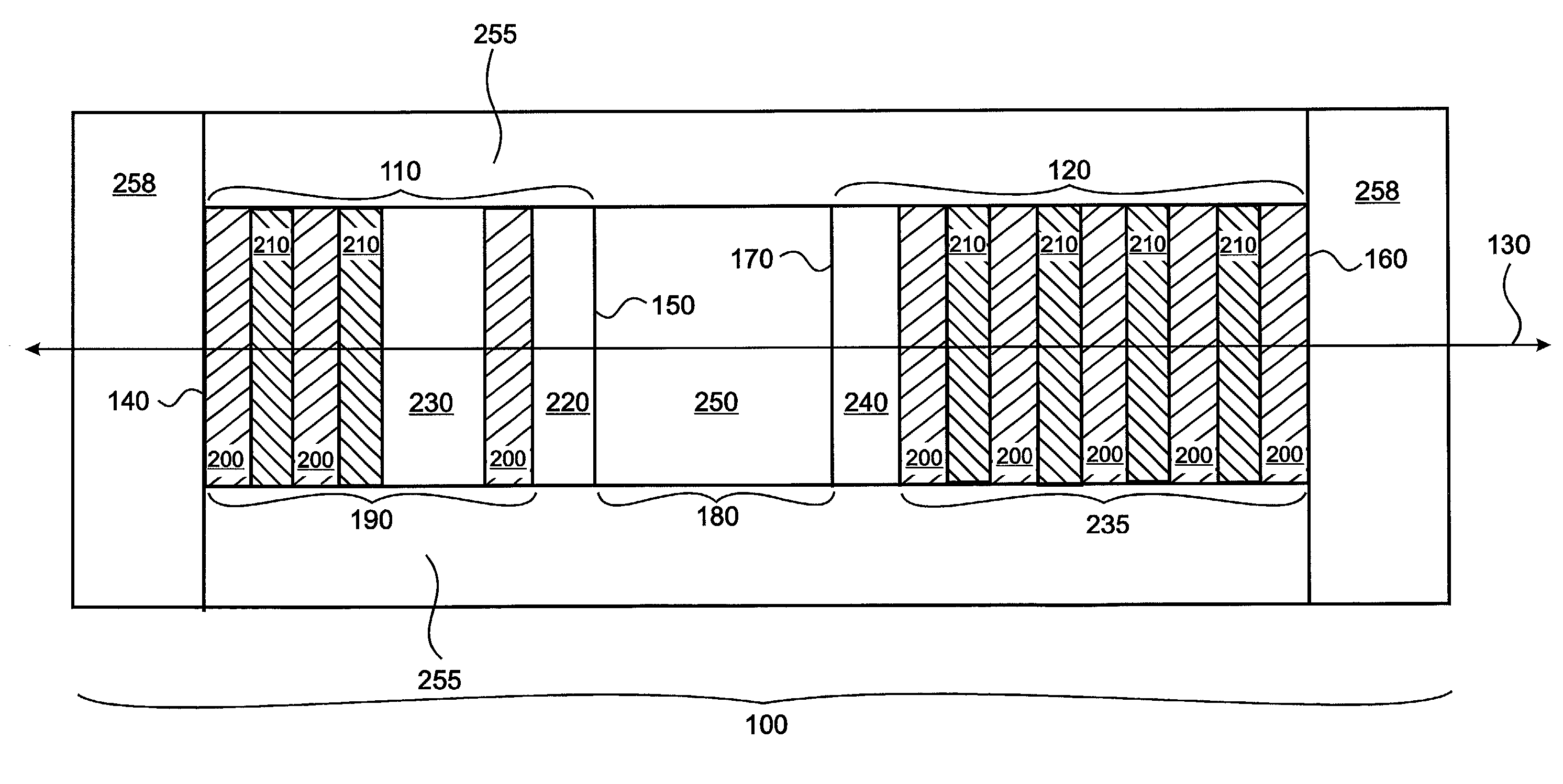

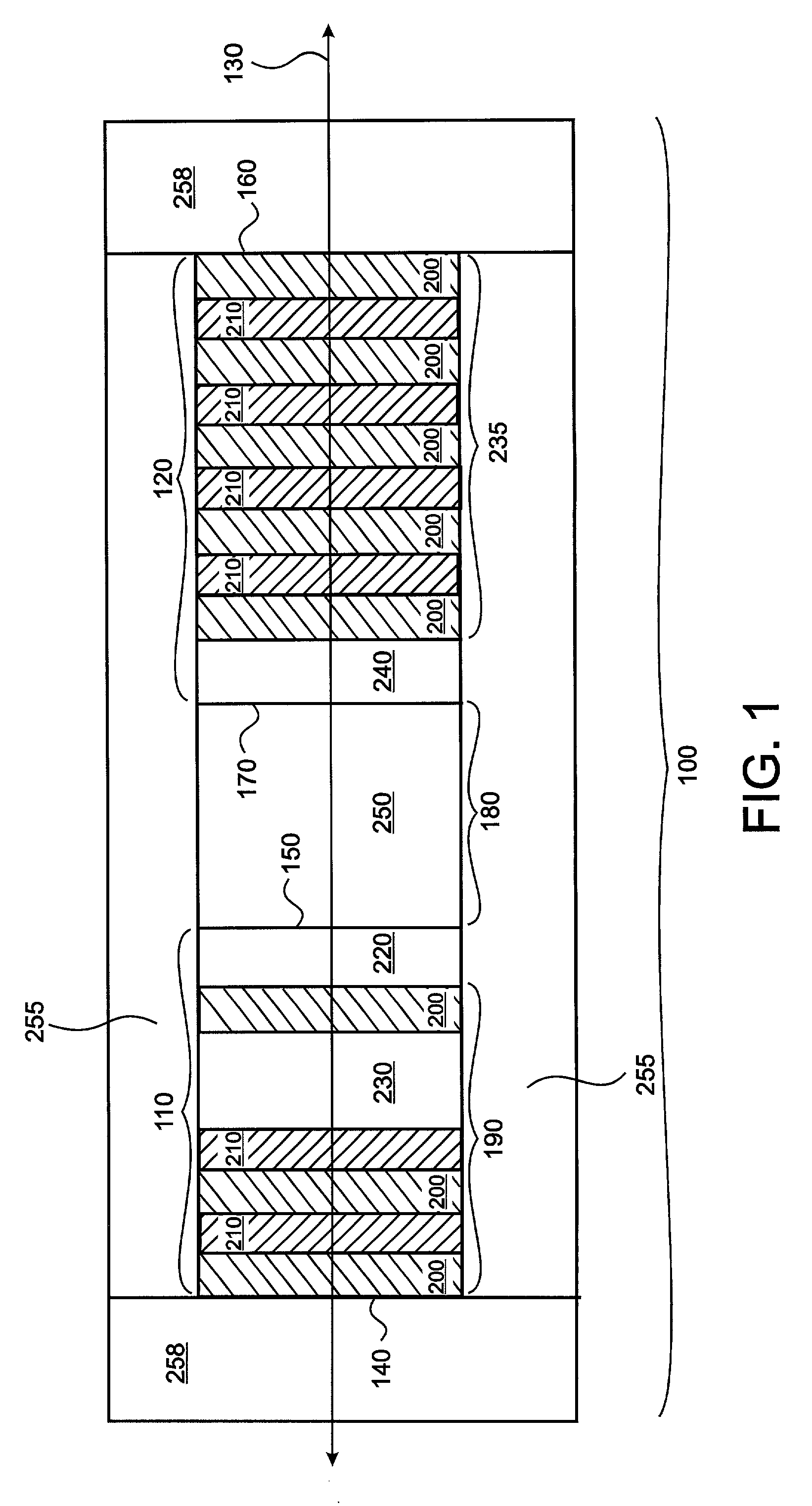

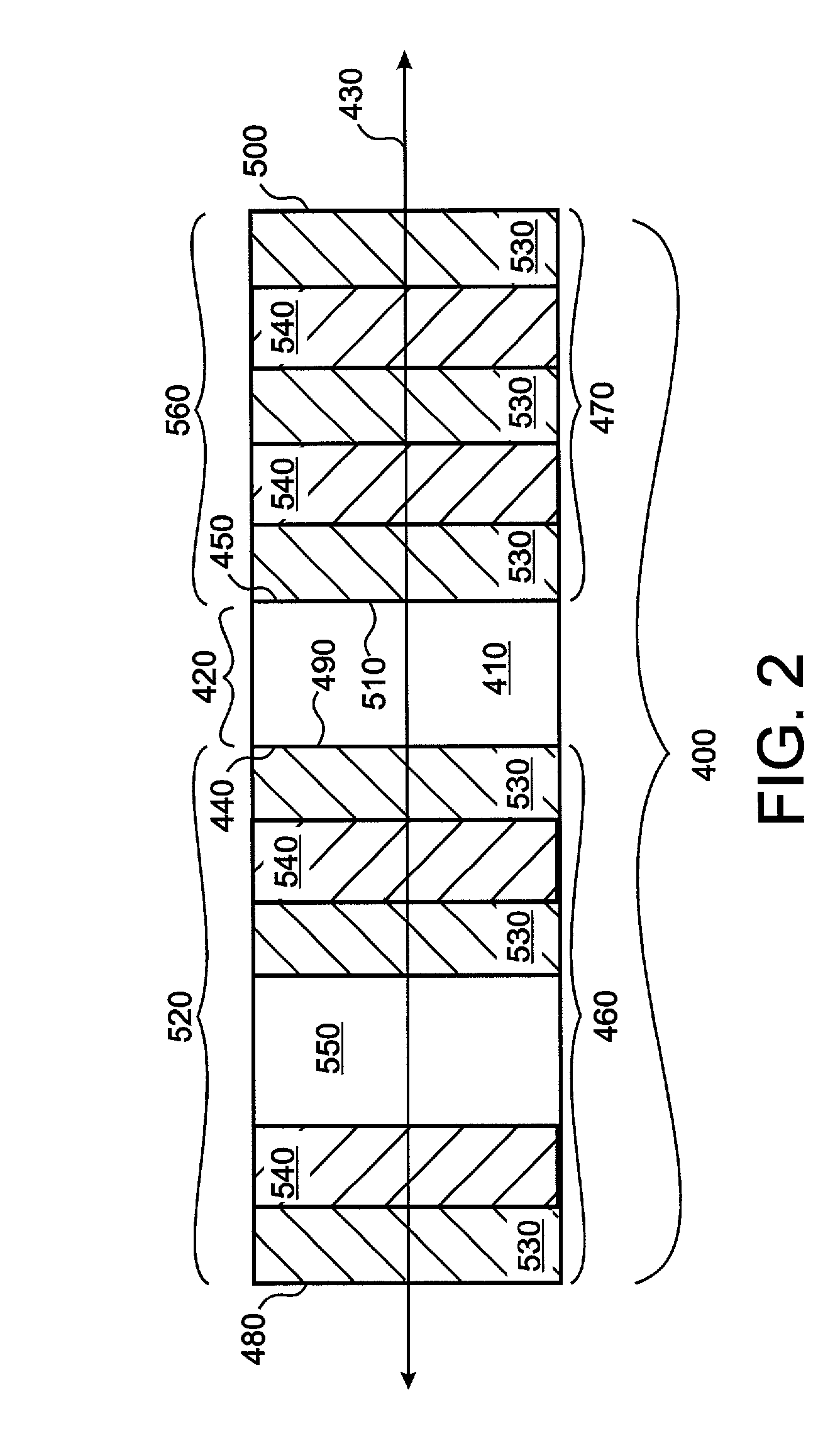

Method for measuring the health of solid rocket propellant using an embedded sensor

InactiveUS7652488B1Reduce capacitancePoor impedance matchingResistance/reactance/impedenceForce measurementElectricityShear modulus

The invented method for measuring the health of a solid rocket propellant includes embedding at least one piezoelectric capacitance sensor in the propellant, where the capacitance of the sensor is a function of a modulus of the propellant, and where the position is selected to measure manifestations of stress failure as a consequence of changes in the shear modulus. The capacitance of the sensor is measured at a predetermined frequency. The capacitance of the piezoelectric capacitance sensor is converted into a digital representation which is then converted into the digital representation of a modulus (or gradient modulus). In subsequent analysis, the modulus (or gradient of the modulus) is correlated to the health of the solid rocket propellant.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

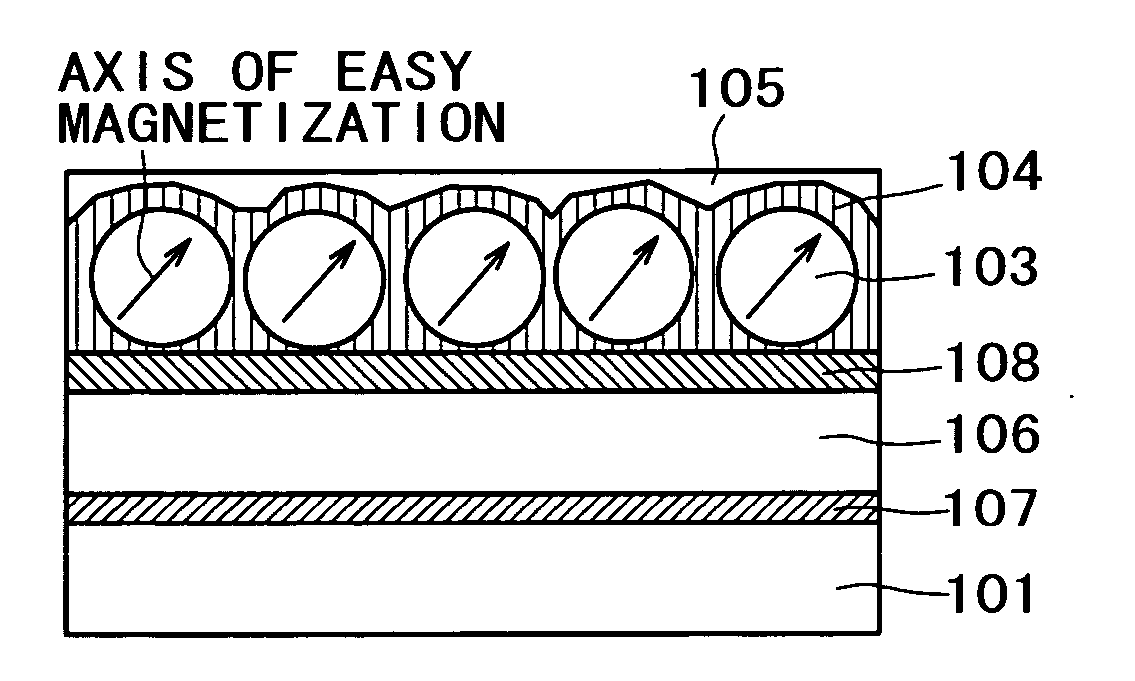

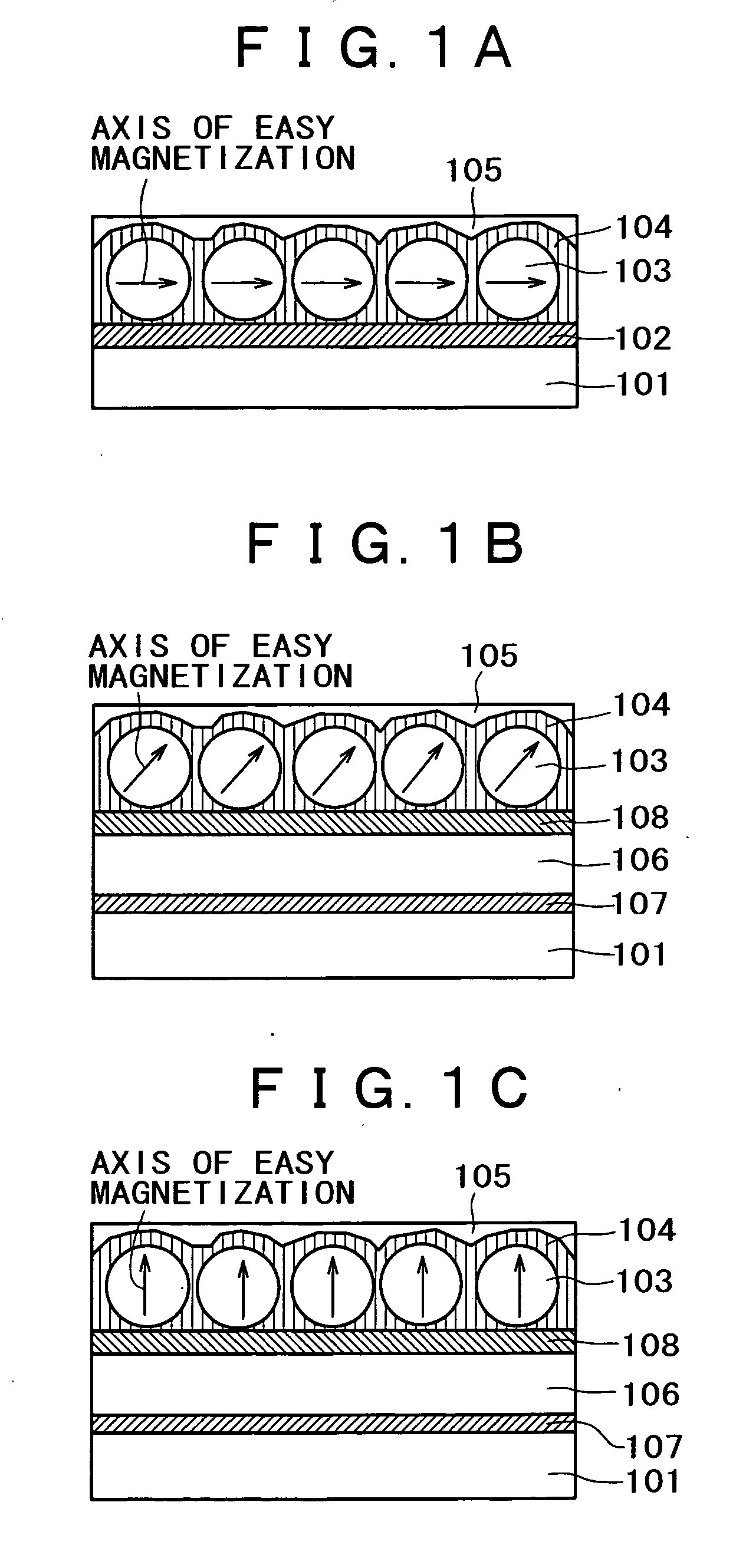

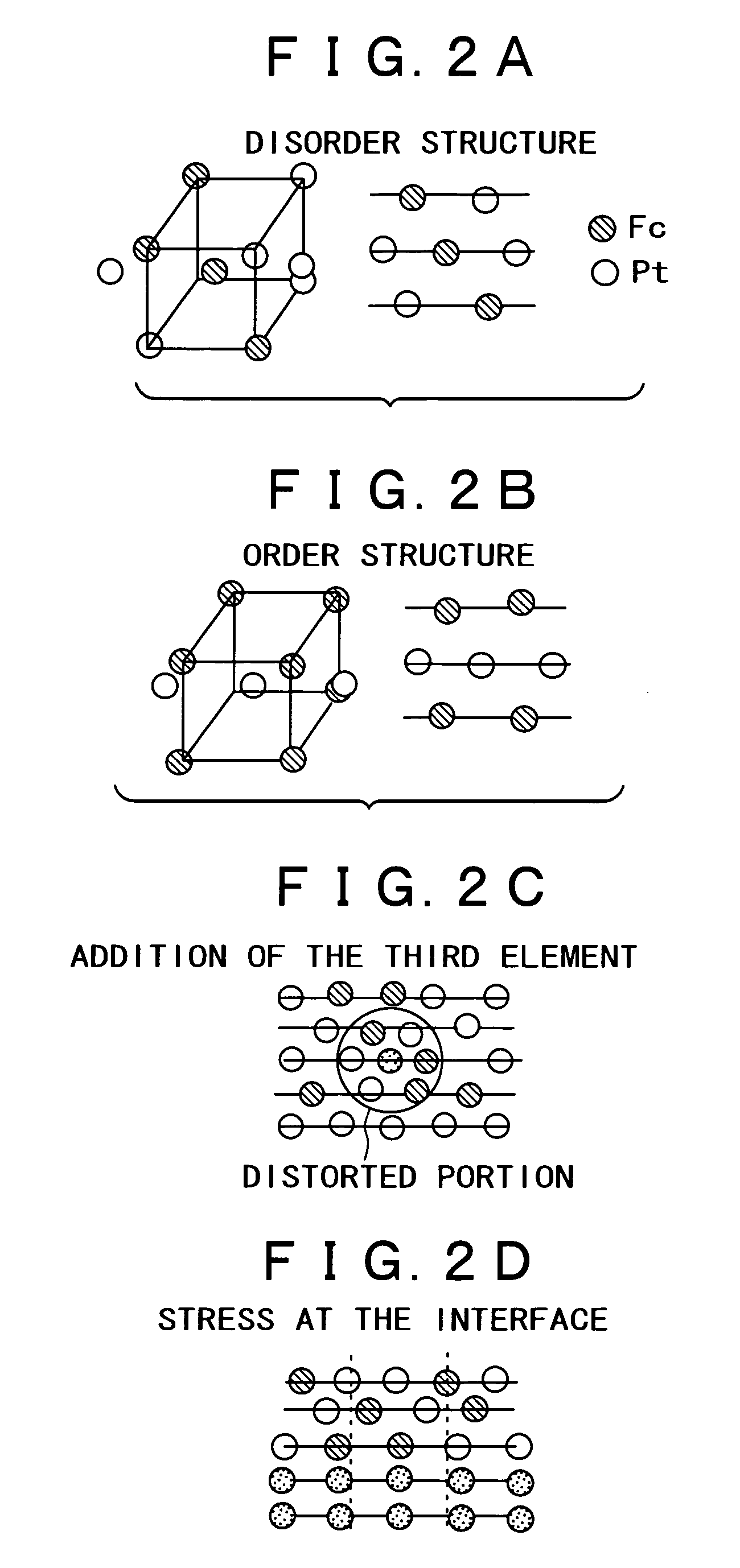

Magnetic recording medium and hard disk drive using the same, and manufacturing method thereof

InactiveUS20060153976A1Reduce the overall diameterReduce dispersionRecording by magnetic meansNanomagnetismNanometreHard disc drive

A magnetic recording medium, a hard disk using the same, and a manufacturing method thereof are provided. In one example, the magnetic nano-particle medium is formed by depositing a magnetic nano-particle colloid on a substrate, wherein the axes of easy magnetization of respective crystalline particles are aligned with high accuracy. A layer of L10 alloy nano-particles which will exhibit magnetic properties through an order-disorder transition, and arranged at a substantially uniform spacing on a substrate, and a carbon-containing covering film for surrounding these nano-particles and making the spacing substantially uniform are provided. To the L10 alloy of the nano-particles, at least one non-magnetic element is added, or a covered layer comprising at least one non-magnetic layer is formed therearound. This makes it possible to implement a magnetic recording medium wherein the average diameter of nano-particles is small, and the nano-particle diameter dispersion is small, and the axes of magnetic anisotropy are aligned.

Owner:HITACHI LTD

Thermal pellet incorporated thermal fuse and method of producing thermal pellet

ActiveUS20050088272A1Rapid responseLow costFuse device manufactureHeating/cooling contact switchesHeat deflection temperatureHot melt

There is provided a thermosensitive material allowing a thermal pellet incorporated thermal fuse's operating temperature, or heat distortion temperature, to be adjusted and preventing deformation, modification or similar deficiency if it is exposed to severe external environment, and there is provided an inexpensive thermal fuse that provides a wider range from which an operating temperature is selected, improved insulation resistance after operation, faster response speed in operation, and enhanced strength of the thermal pellet. To do so, the thermosensitive material is formed of thermoplastic resin corresponding to a high molecular substance, the thermal pellet's heat distortion temperature is adjusted by a temperature setting method, and an enclosure has a metal casing with a spring member's strong and weak compression springs and both accommodated therein and hermetically sealed.

Owner:SCHOTT JAPAN CORP

Amine-terminated hyperbranched polymer solid amine adsorption material as well as preparation method and application thereof

ActiveCN104923186AThermally and chemically stableHigh adsorption capacityOther chemical processesDispersed particle separationComposite materialAddition reaction

The invention discloses an amine-terminated hyperbranched polymer solid amine adsorption material as well as a preparation method and application thereof. The preparation method comprises the following steps: carrying out a Michael addition reaction between an amination reagent and an unsaturated monomer, so as to generate a hyperbranched polymer precursor; realizing polycondensation reactive synthesis in programmed temperature, so as to obtain an amine-terminated hyperbranched polymer; carrying out cross-linking and solidifying; reducing amide groups and imine groups so as to obtain the solid amine adsorption material. The solid amine adsorption material prepared according to the method has high alkyl amine density, has not only very high adsorption capacities for acid gases such as CO2, SO2 and H2S, but also excellent adsorptive regeneration performance, is high in heat stability and chemical stability, and high in adsorption capacity even after multiple regeneration, and can be used in the fields of acid gas adsorption trapping and environmental management, and the field of CO2 removing in a closed system.

Owner:SUN YAT SEN UNIV

Fabry-perot etalon with independently selectable resonance frequency and free spectral range

InactiveUS20040042083A1Substantial linearityConstant lengthUsing optical meansNon-linear opticsFrequency spectrumResonance

The invention relates generally to optical interference filters and interferometers. Methods, devices and device components for optical signal generation and processing using optical interference filters and interferometers are presented. The invention provides optical interference filters and interferometers having a selected cumulative reflectance phase dispersion capable of providing substantially independent selectable resonance frequency and free spectral range. An exemplary interference filter of the present invention provides a multi-peak transmission spectrum with substantially independent, selectable control over absolute transmission band frequencies and relative transmission band spacing. The methods and devices provided herein are particularly well suited for frequency matching optical signals to a selected frequency standard, such as the International Telecommunication Union frequency standard.

Owner:EXCELITAS TECH

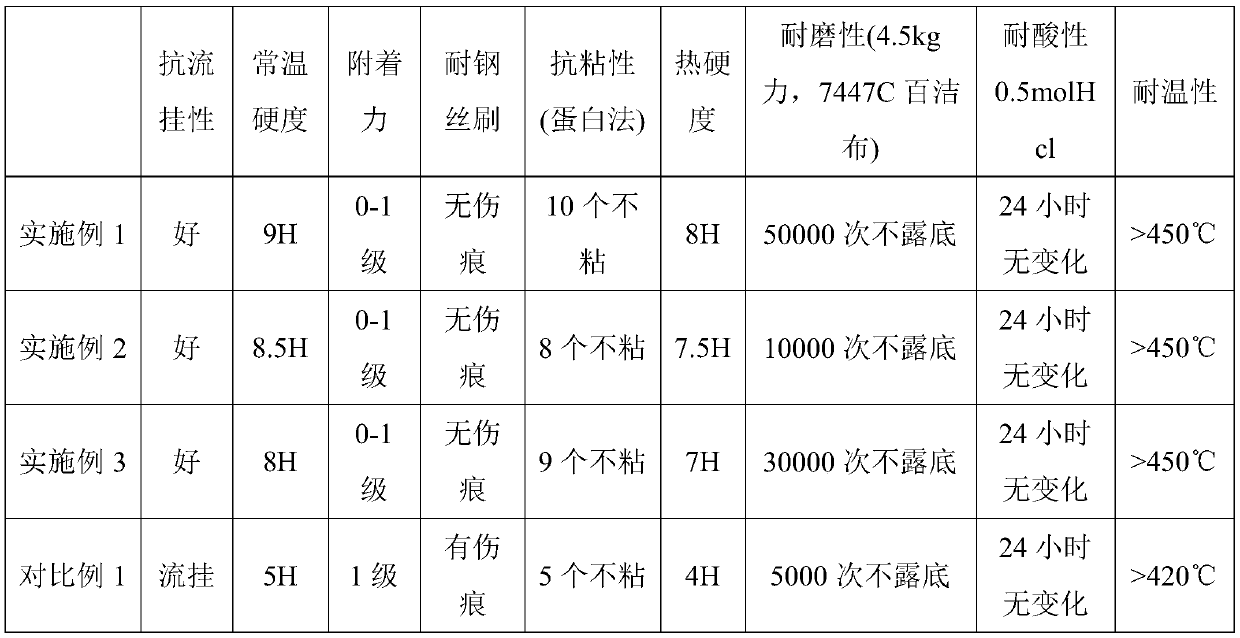

Ceramic coating and preparation method thereof

InactiveCN111073504AEasy constructionBroad applicationFireproof paintsAnti-corrosive paintsSilane couplingCeramic coating

The invention belongs to the field of coatings, the invention discloses a ceramic coating, which comprises a primer and a finishing paint. The primer is prepared from the following components in partsby weight: 30 to 60 parts of waterborne nano silica sol resin, 30 to 50 parts of water, 3 to 25 parts of a filler, 3 to 20 parts of pigment, 0.1 to 3 parts of a thickener, 30 to 60 parts of a silanecoupling agent, 0.1 to 3 parts of a leveling agent, 0.1 to 3 parts of non-stick additive and a pH regulator; and the finish paint comprises the following components in parts by weight: 30-60 parts ofwater-based nano silica sol resin, 30-50 parts of the water, 0.1-3 parts of the thickener, 30-60 parts of the silane coupling agent, 0.1-3 parts of the leveling agent, 0.1-3 parts of the non-stick additive, 0.1-3 parts of the pigment and the pH regulator. The ceramic coating provided by the invention overcomes the problems of unsatisfactory temperature resistance, flame resistance and hardness oftraditional organic coatings, can resist a high temperature of 450 DEG C or above for a long time, can resist a high temperature of 600 DEG C or above for a short time, and has excellent thermal stability, wear resistance, scratch resistance and incombustibility.

Owner:JIANGMEN SIFANG INTERBLE COATING CO LTD

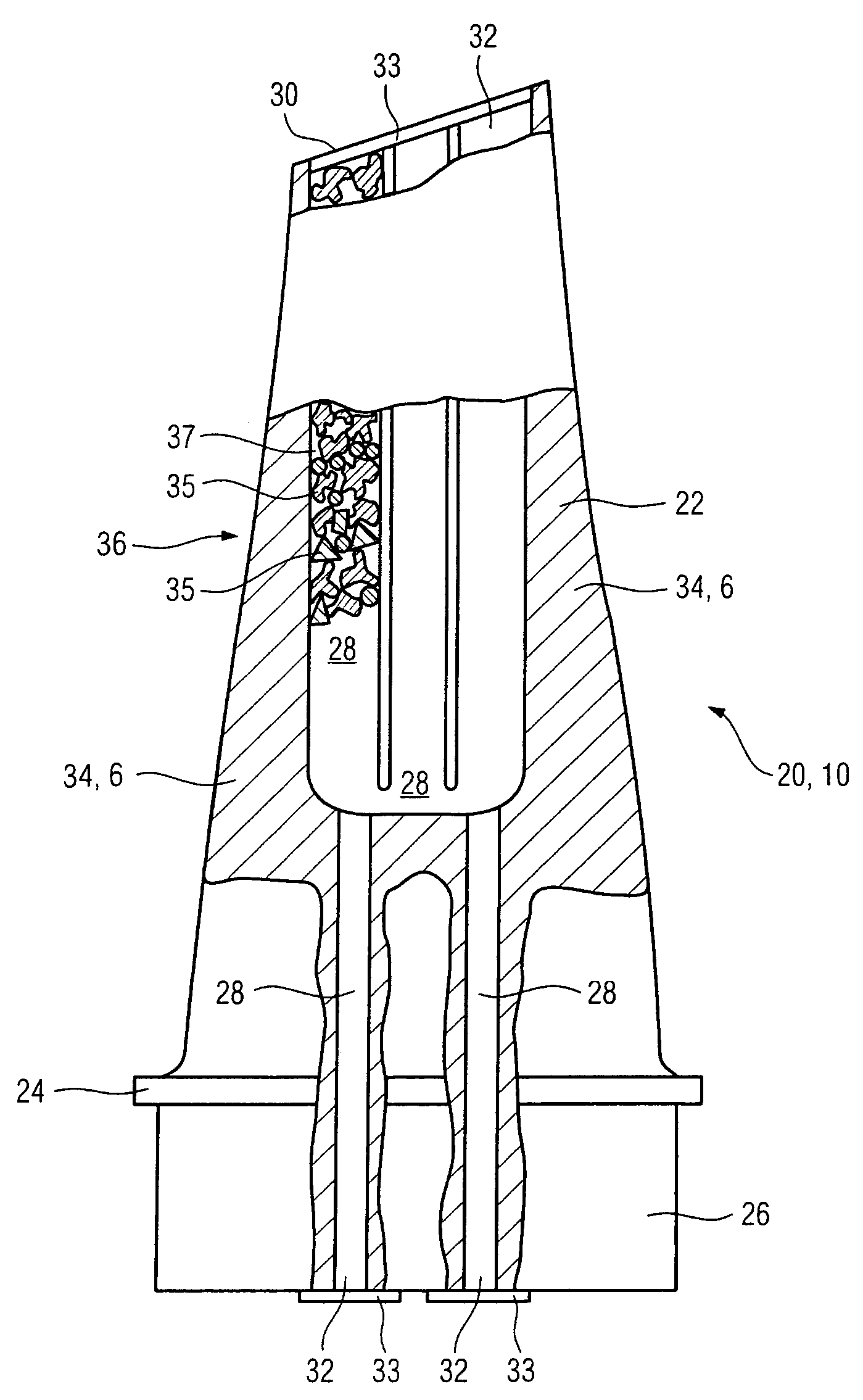

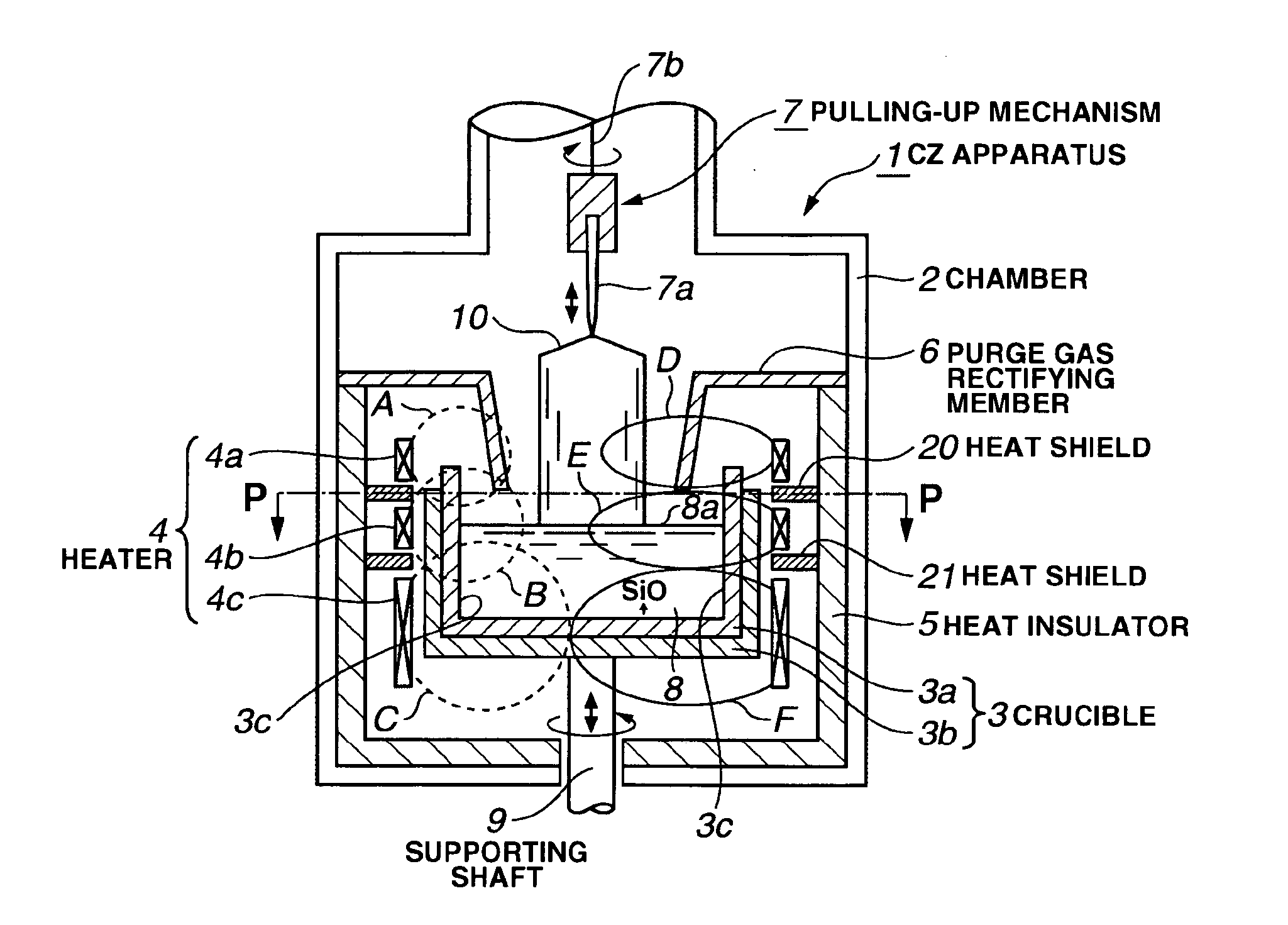

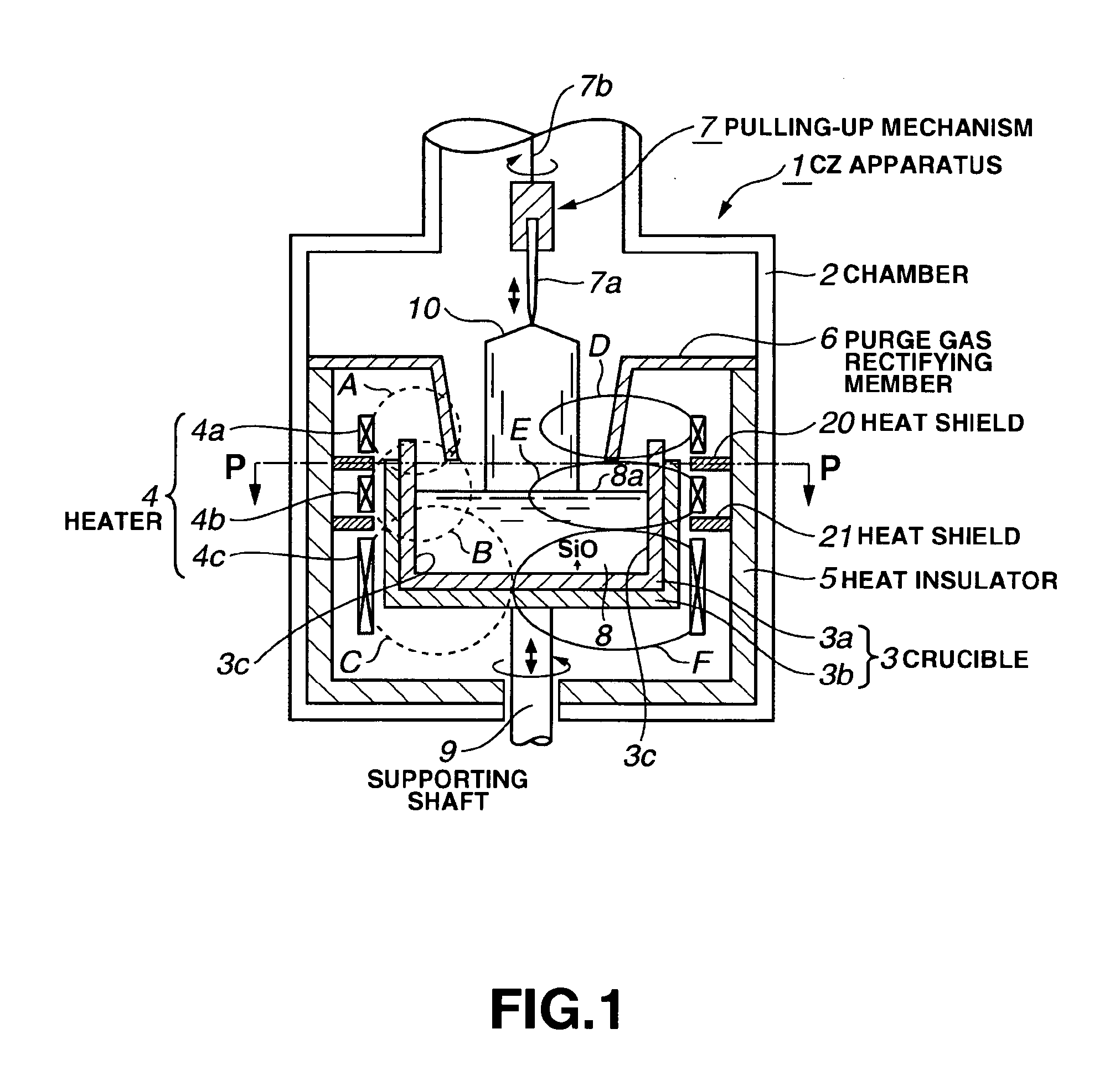

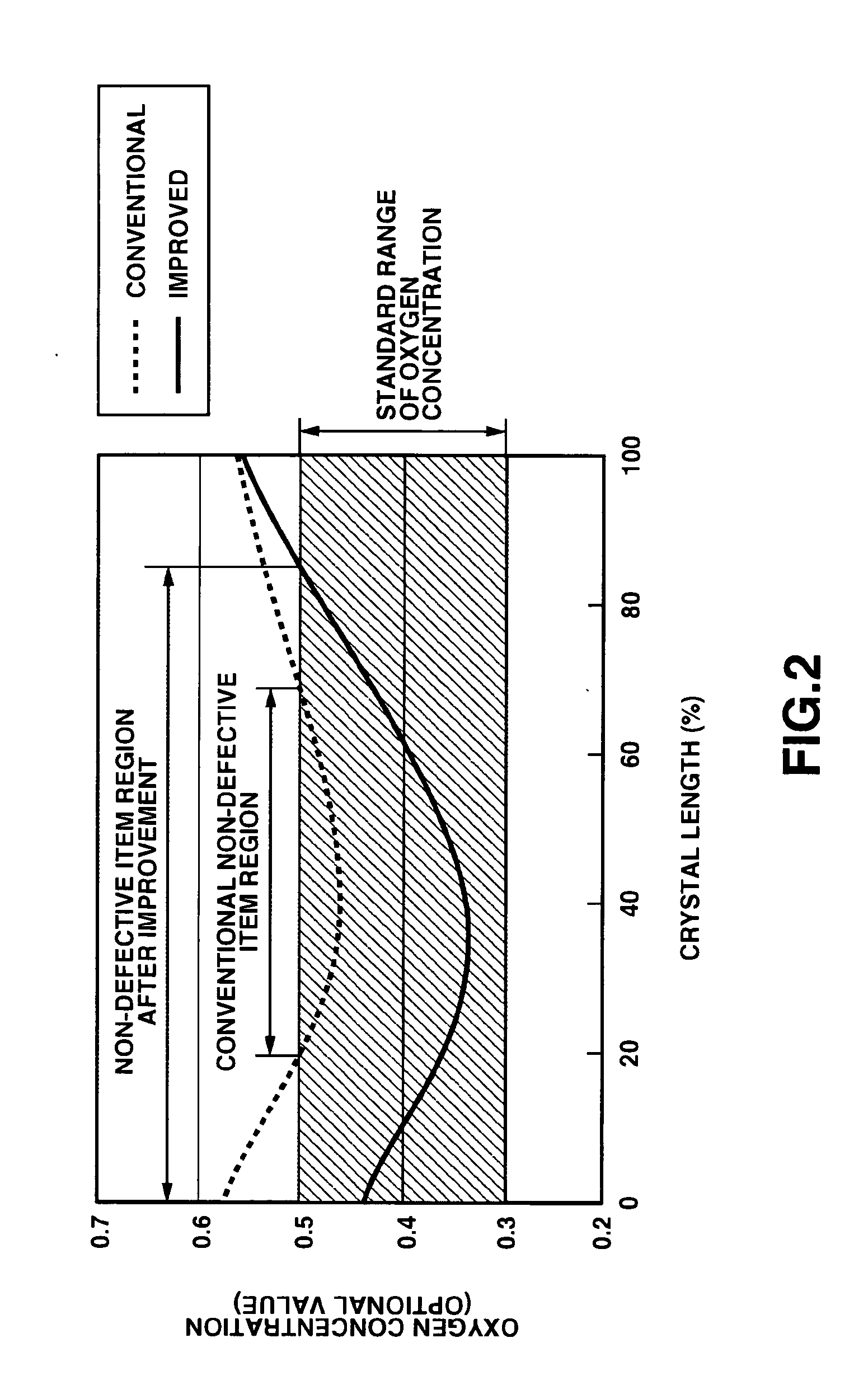

Semiconductor Single Crystal Manufacturing Apparatus and Graphite Crucible

ActiveUS20070215038A1Improve directionalityImprove directivityPolycrystalline material growthBy zone-melting liquidsSingle crystalEngineering

A semiconductor single crystal manufacturing apparatus which can manufacture a single crystal of high oxygen concentration to that of low oxygen concentration within a prescribed standard range of oxygen concentration, as a wafer material for semiconductor integrated circuits, with a high yield, is provided. Heat shields 20, 21 are provided in the entire annular area between respective adjacent heaters of the heaters 4a, 4b, 4c for heating the crucible 3 from the outside periphery side. By using the heat shields 20, 21 for localizing the respective heating regions for the heaters to actively control the temperature distribution for the crucible 3 and melt 8 in the crucible, a single crystal of high oxygen concentration to that of low oxygen concentration can be manufactured within a prescribed standard range of oxygen concentration with a high yield.

Owner:SUMCO TECHXIV

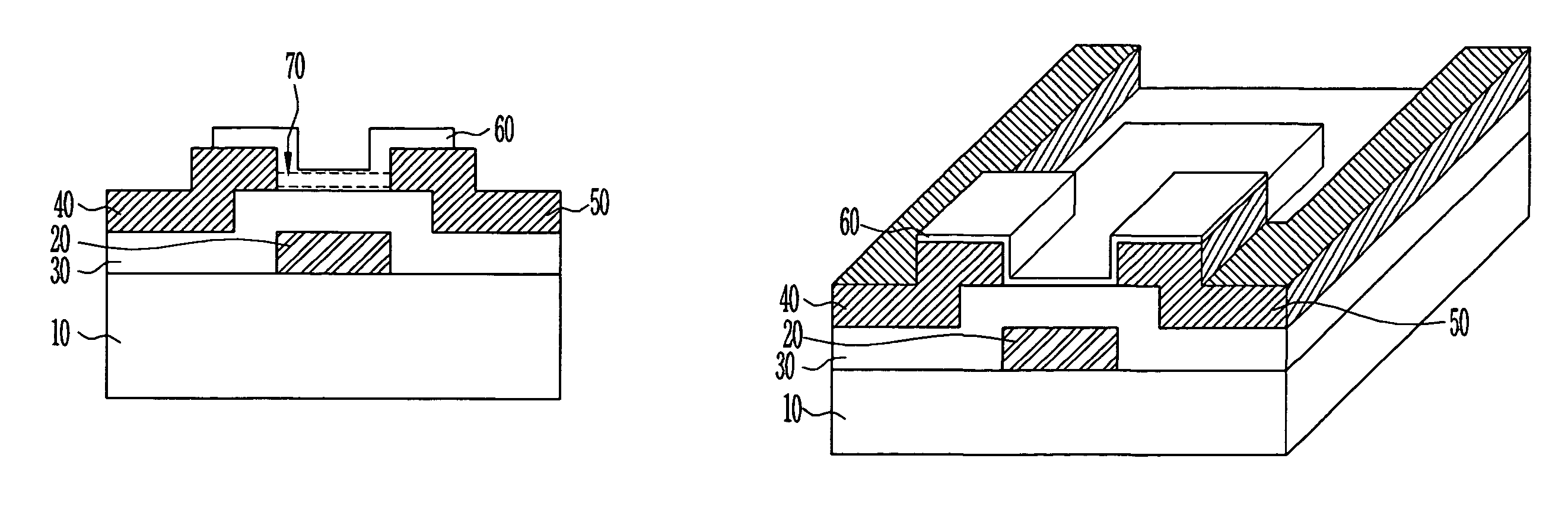

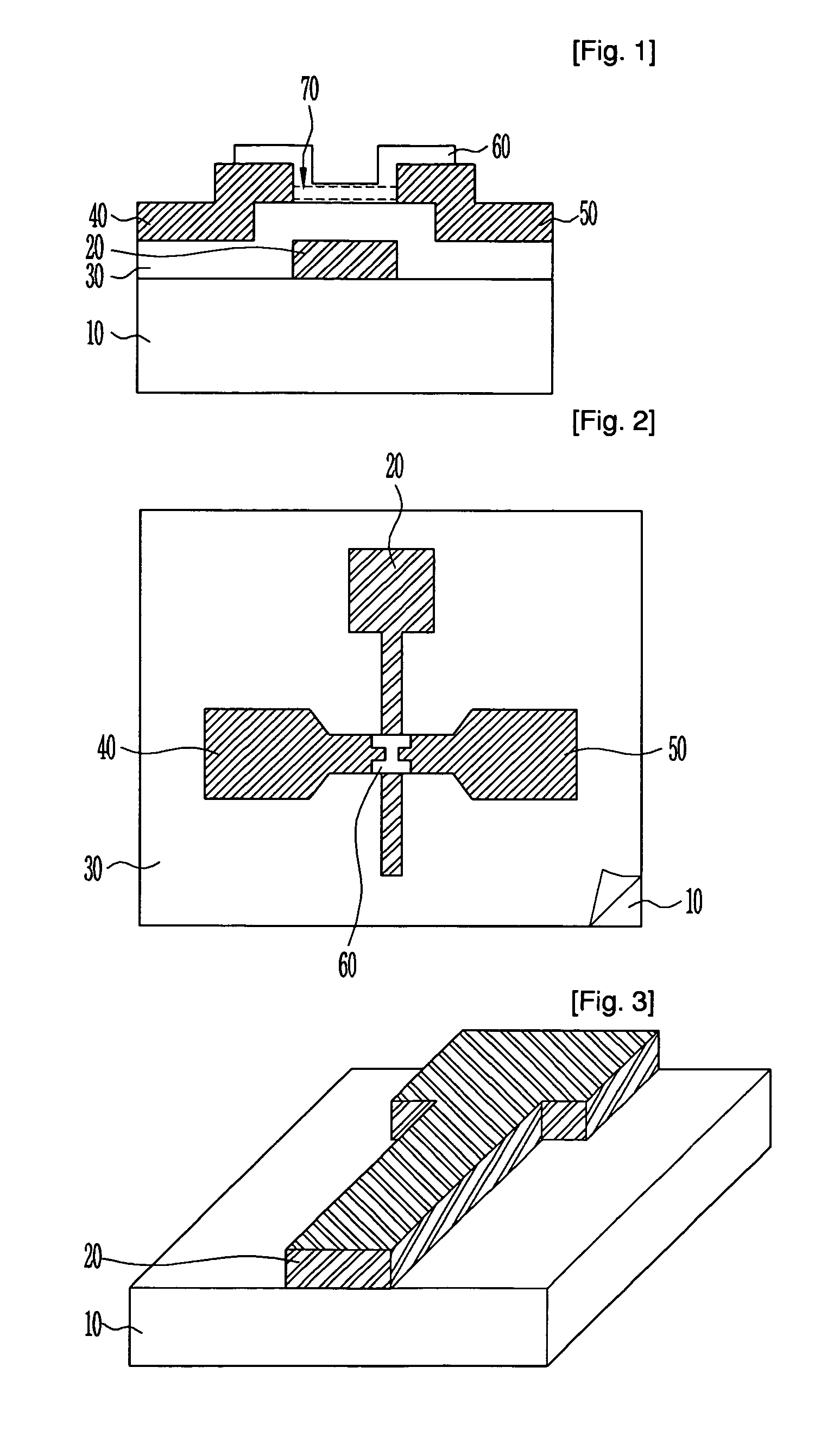

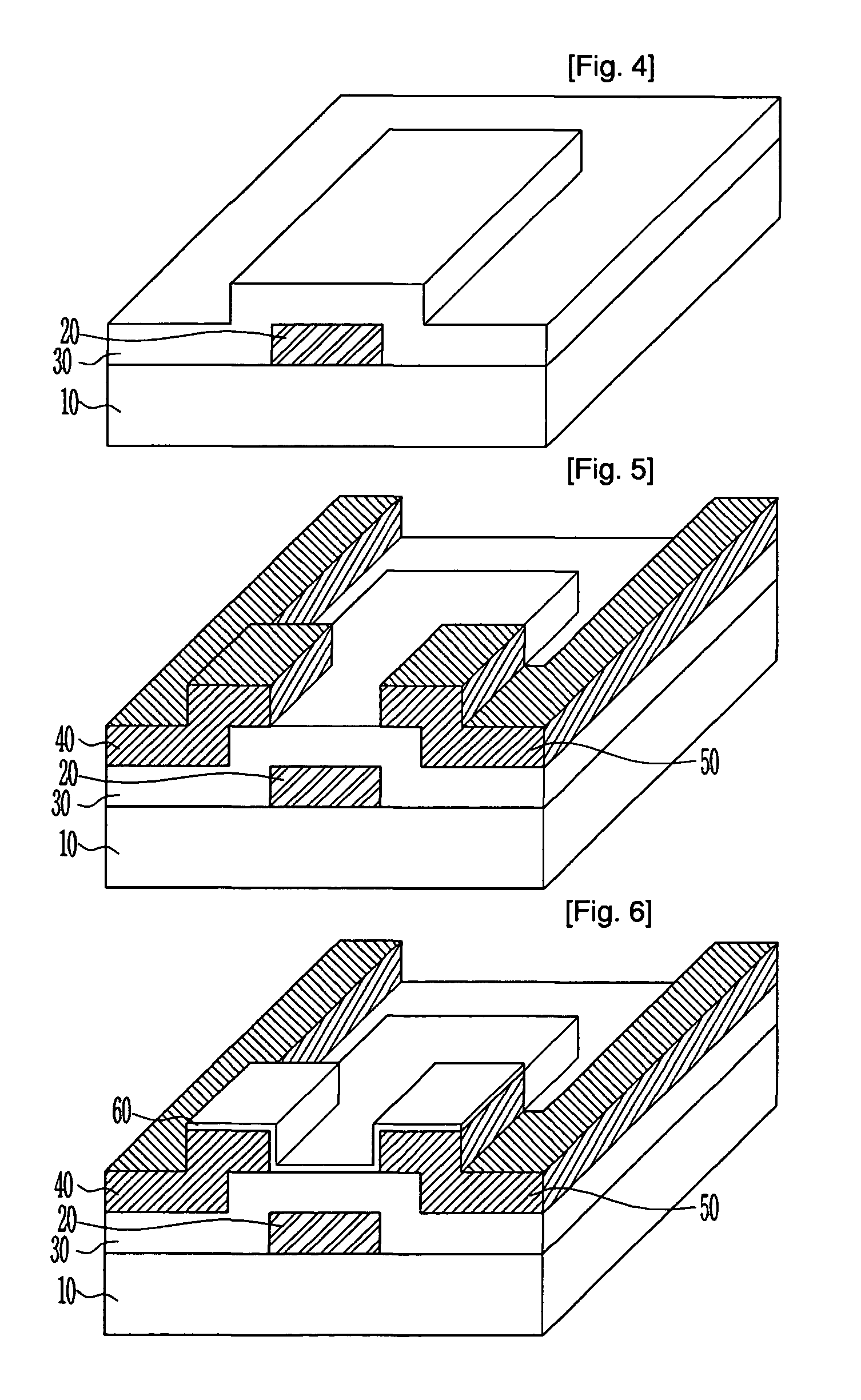

Metal-insulator transition switching transistor and method for manufacturing the same

InactiveUS7408217B2Small sizeHigh current gain characteristicTransistorSolid-state devicesMetal–insulator transitionSilicon

Provided is a metal-insulator-transition switching transistor with a gate electrode on a silicon substrate (back-gate structure) and a metal-insulator-transition channel layer of VO2 that changes from an insulator phase to a metal phase, or vice versa, depending on a variation of an electric field, and a method for manufacturing the same, whereby it is possible to fabricate a metal-insulator-transition switching transistor having high current gain characteristics and being stable thermally.

Owner:ELECTRONICS & TELECOMM RES INST

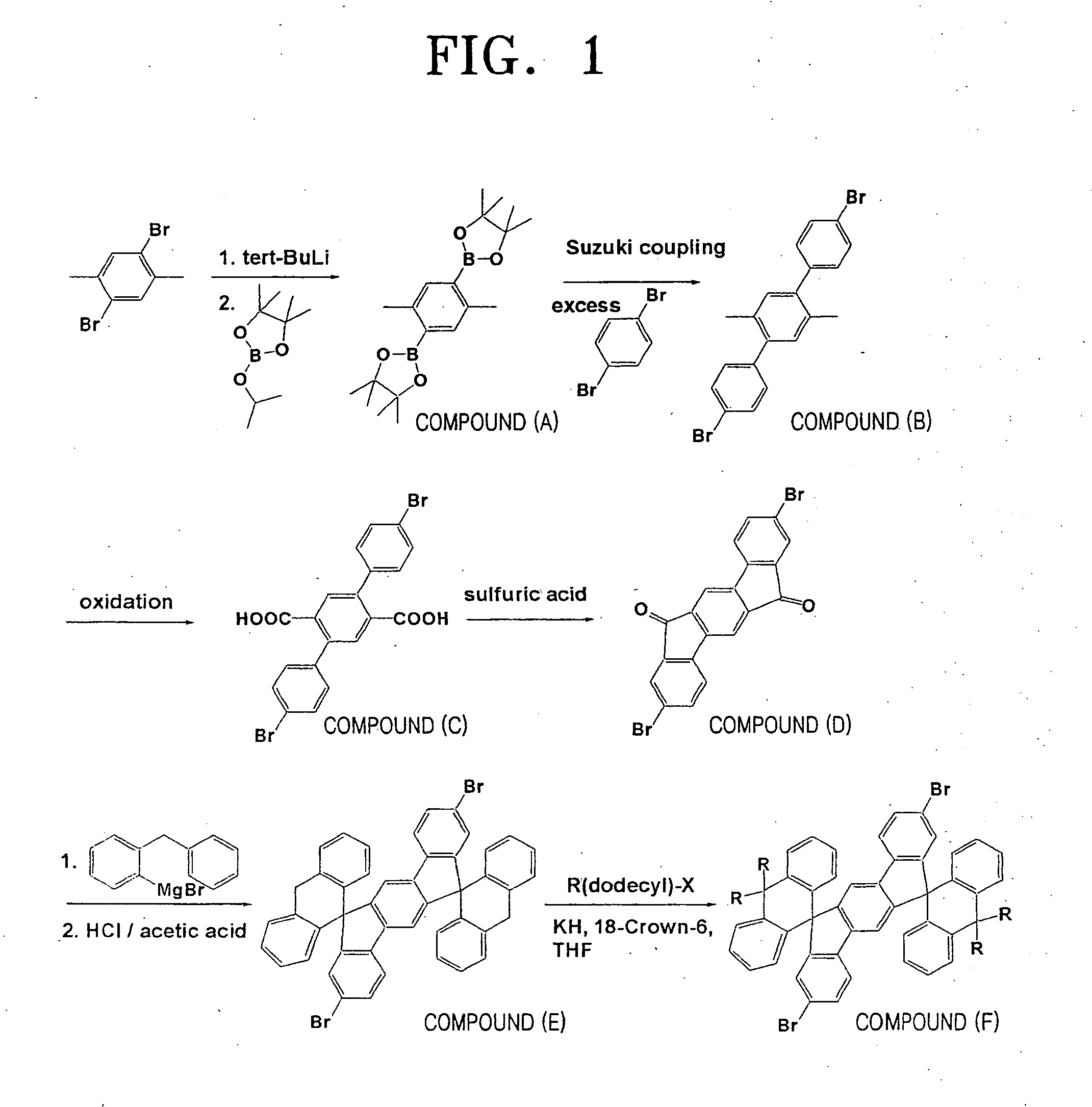

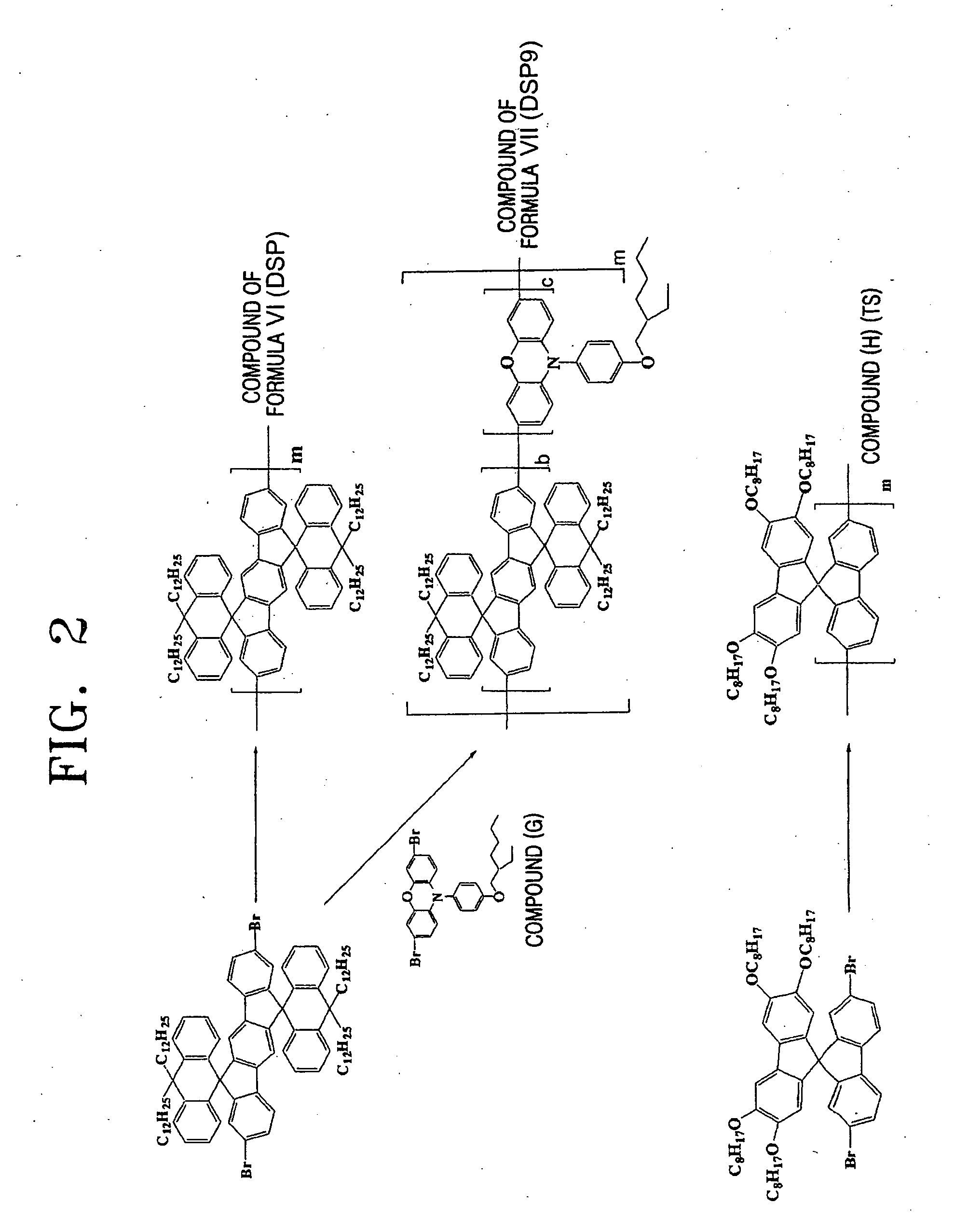

Light-emitting polymer and organoelectroluminescent display using the same

ActiveUS20050123802A1Improved light-emitting polymerImprove mobilityDischarge tube luminescnet screensElectroluminescent light sourcesLuminescent polymersOrganic electroluminescence

A spirofluorene-type of a blue light-emitting polymer including an indenofluorene repeating unit having a spiroanthracene structure, and an organic electroluminescent display using the polymer. The brightness and efficiency property of the organic electroluminescent display are improved.

Owner:SAMSUNG DISPLAY CO LTD

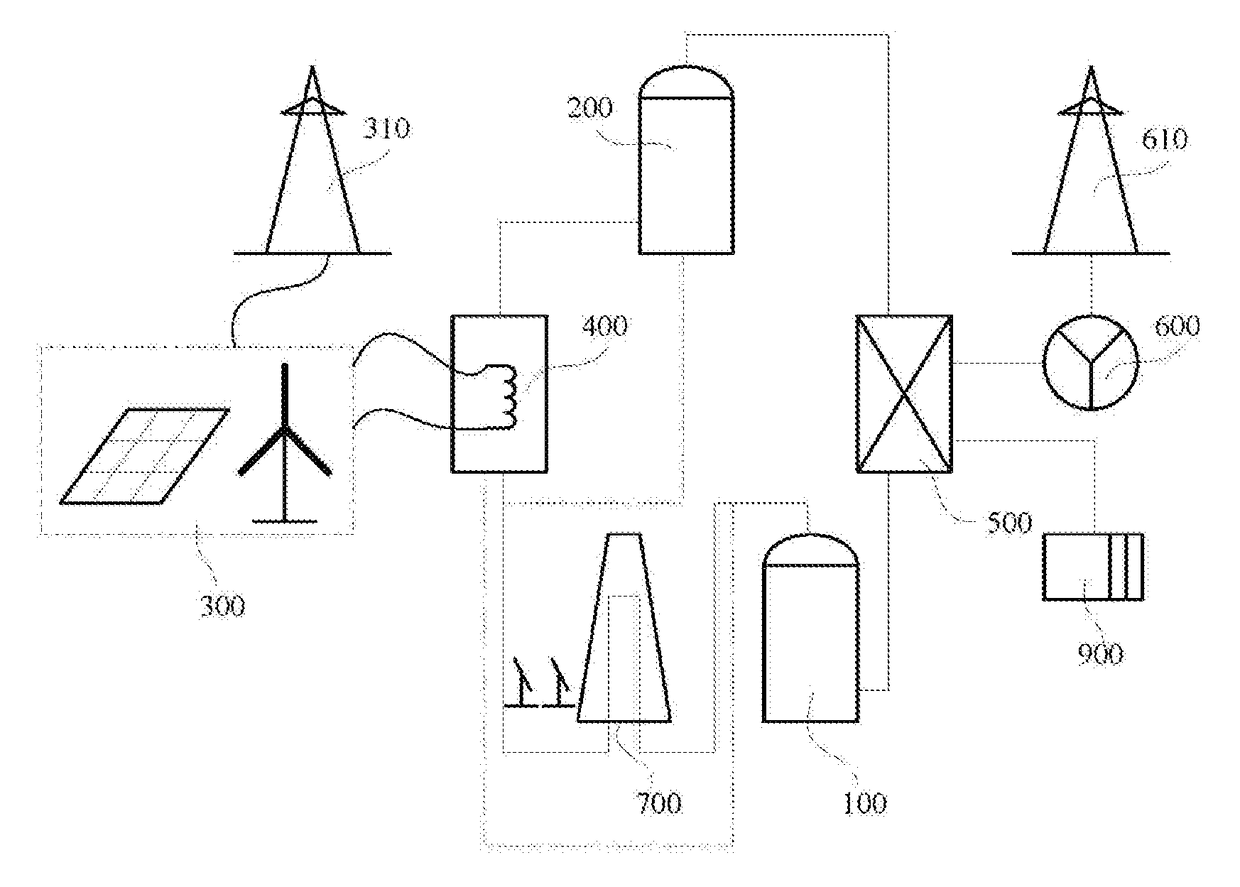

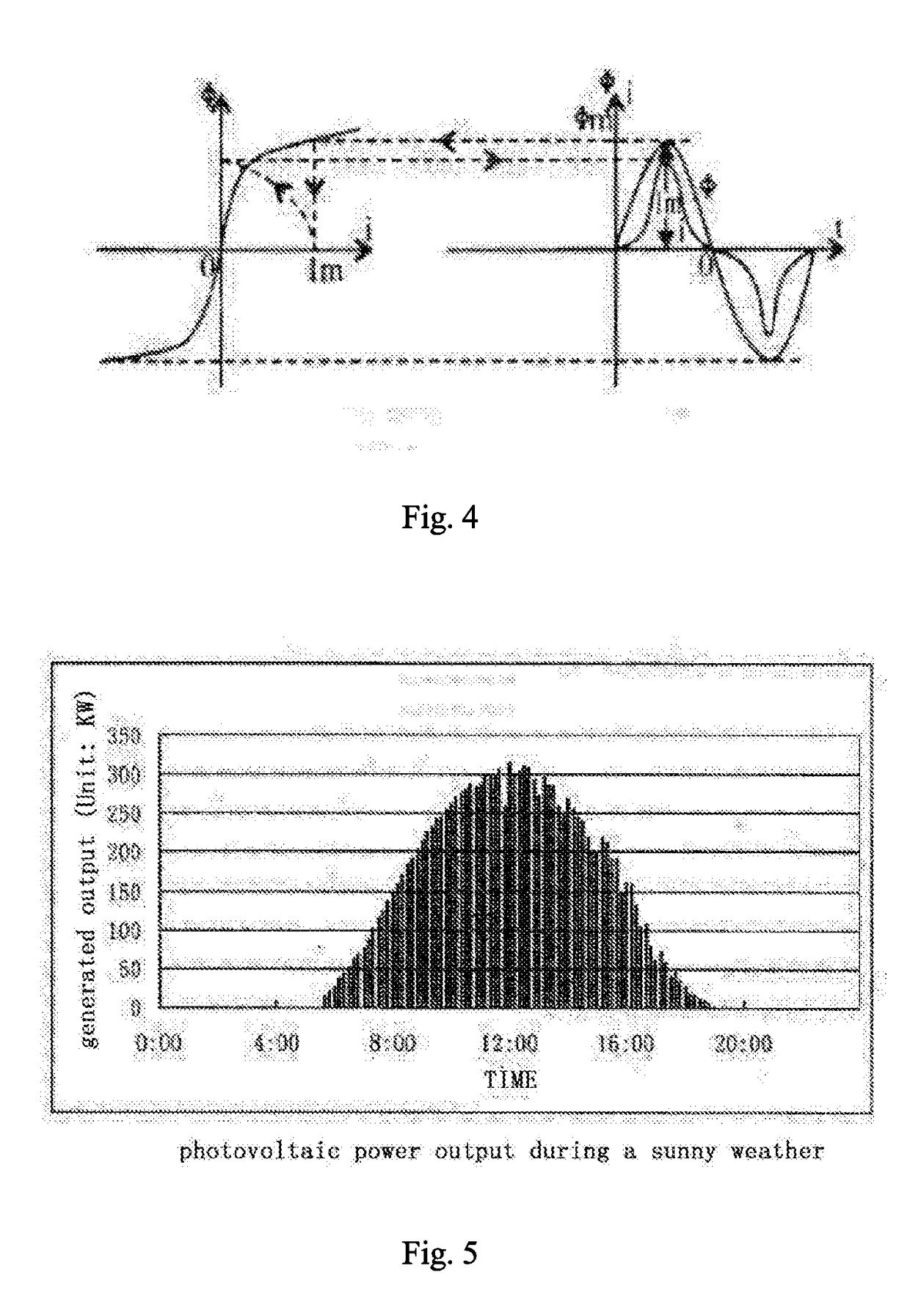

Combined energy supply system of wind, photovoltaic, solar thermal power and medium-based heat storage

ActiveUS20170370250A1Avoid energy wasteReduce the impactWind motor with solar radiationFrom solar energyPower gridEngineering

Disclosed is a combined energy supply system of wind, photovoltaic, solar thermal power and medium-based heat storage, capable of storing the energy which would have been “abandoned wind” and “abandoned light” temporarily in the form of heat by medium-based energy storage. Heat is released during peaks in the power grid to generate power, which serves the function of adjusting the peaks in the power grid. With the medium-based energy storage, unstable photovoltaic electric energy can be converted into stable heat energy output when a relatively large fluctuation occurs in wind and photovoltaic power generation, and therefore the stable supply of energy sources can be guaranteed efficiently. Furthermore, a second heater can also be used for heating the low-temperature media outputted by a first medium tank (100), or a third heater is used for heating water in a heat exchanger (500), and therefore the energy storage of the medium or the heating efficiency of the heat exchanger is improved.

Owner:SHENZHEN ENESOON SCI & TECH

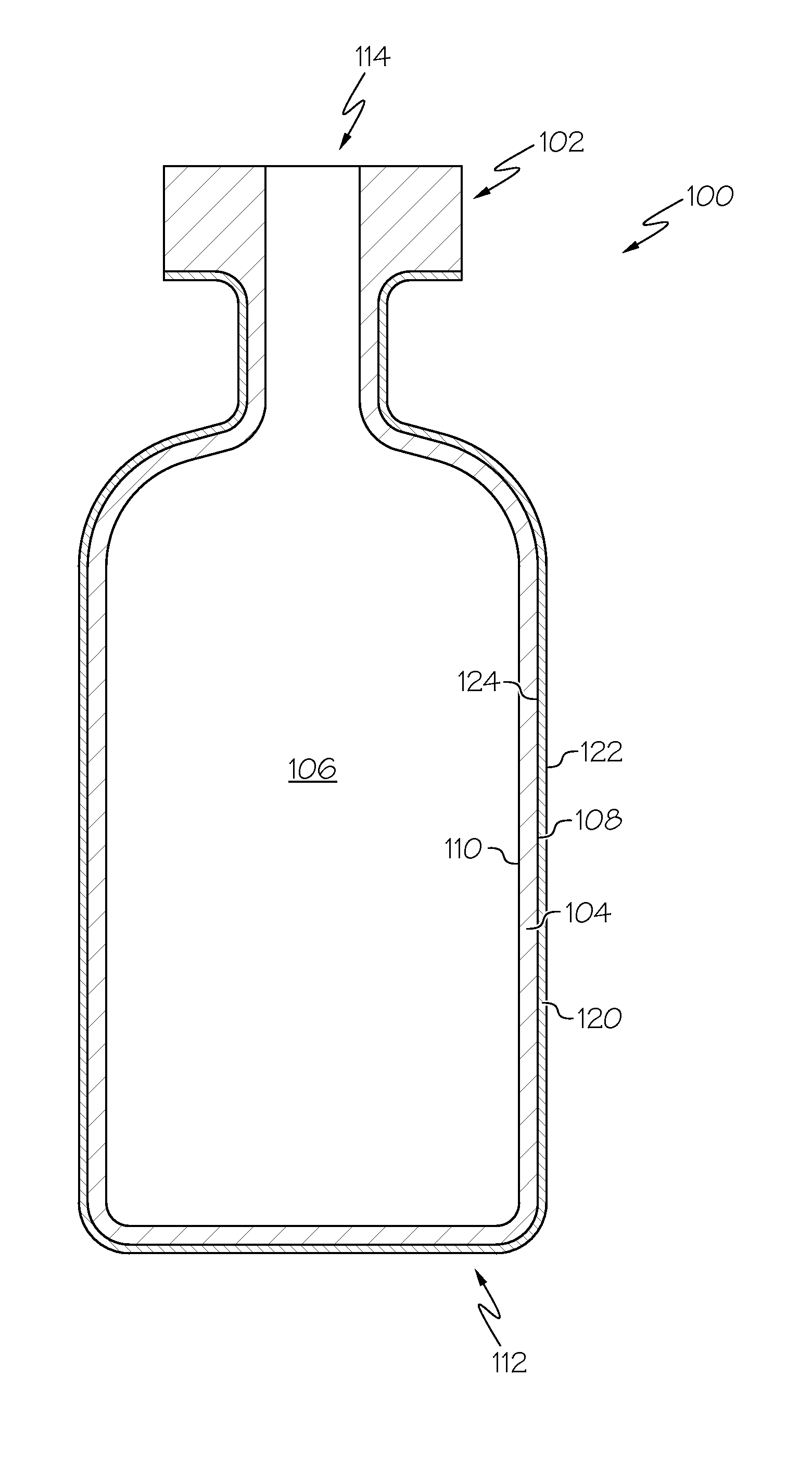

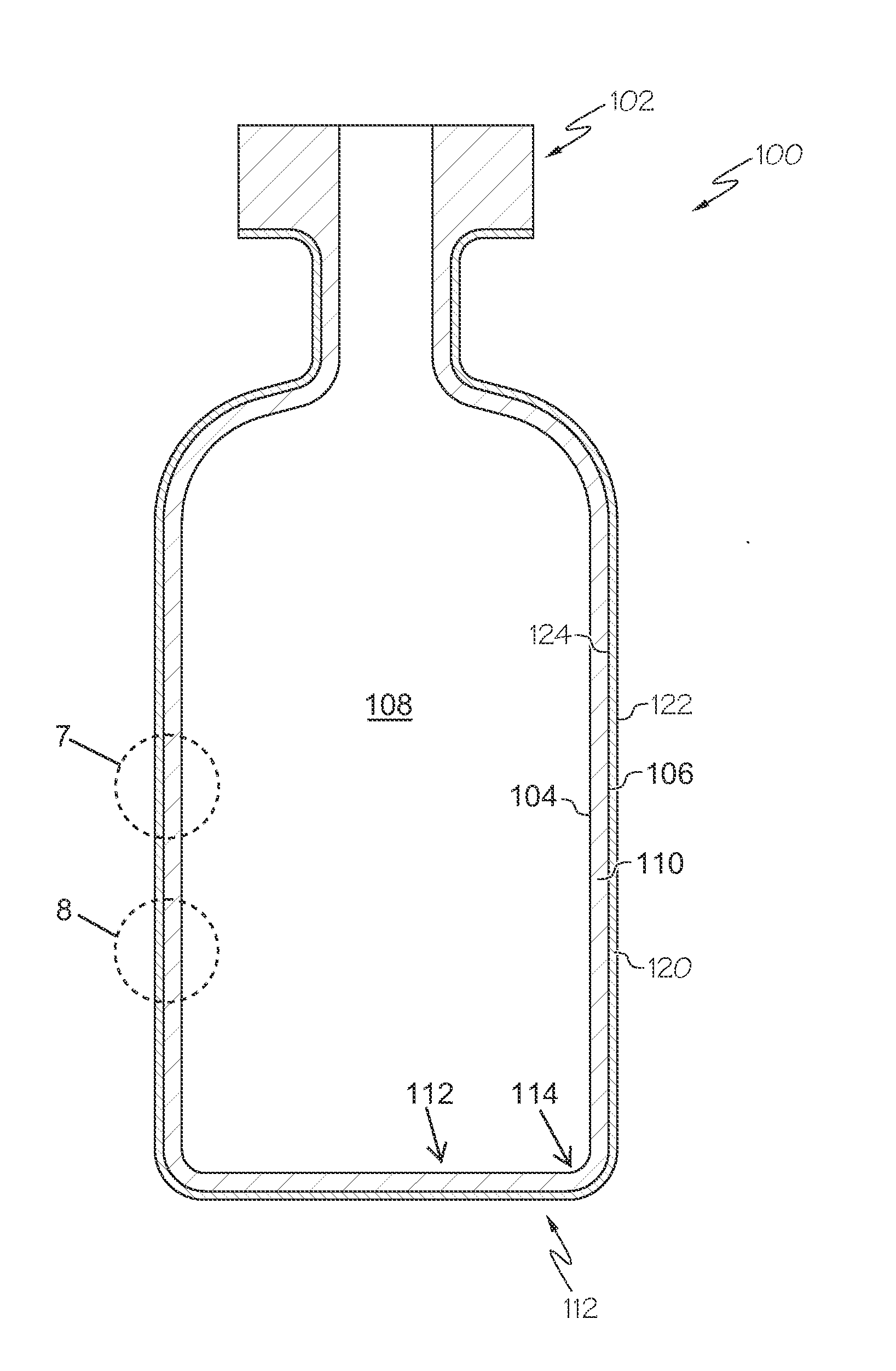

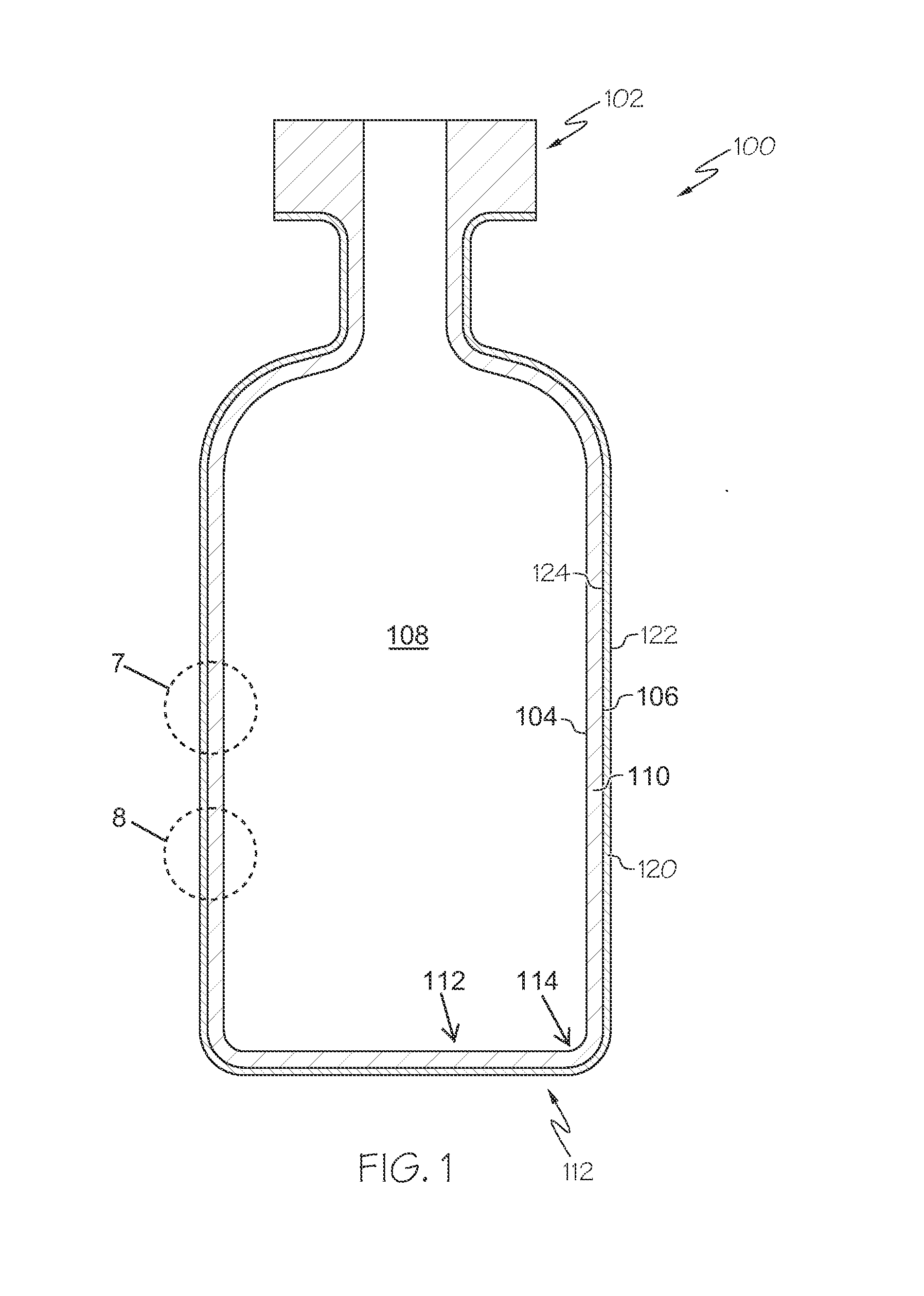

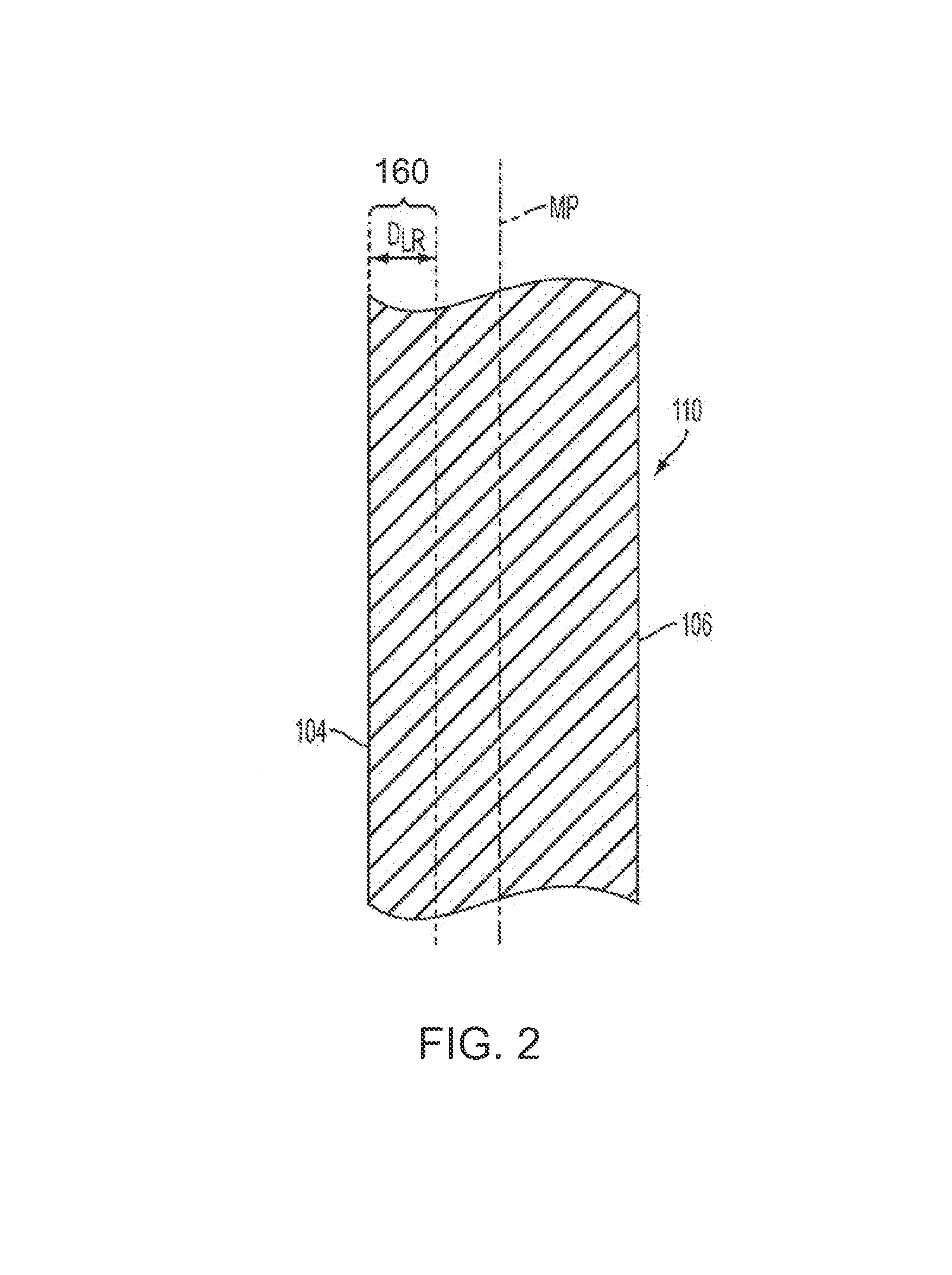

Delamination resistant glass containers with heat-tolerant coatings

ActiveUS20140001076A1Thermally stablePharmaceutical containersMedical packagingMaterials scienceCoating

Delamination resistant glass containers with heat-tolerant coatings are disclosed. In one embodiment, a glass container may include a glass body having an interior surface, an exterior surface and a wall thickness extending from the exterior surface to the interior surface. At least the interior surface of the glass body is delamination resistant. The glass container may further include a heat-tolerant coating positioned on at least a portion of the exterior surface of the glass body. The heat-tolerant coating may be thermally stable at temperatures greater than or equal to 260° C. for 30 minutes.

Owner:CORNING INC

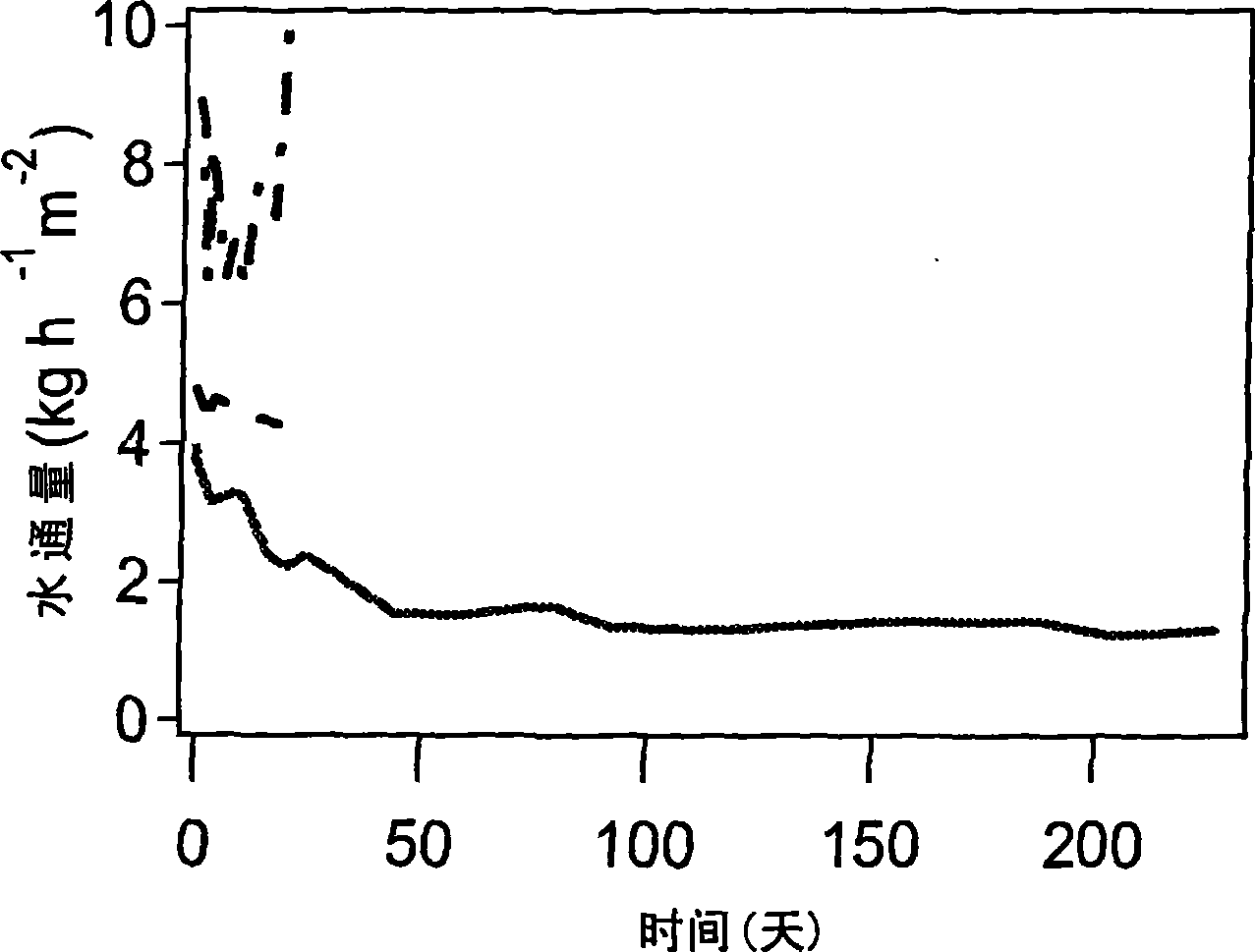

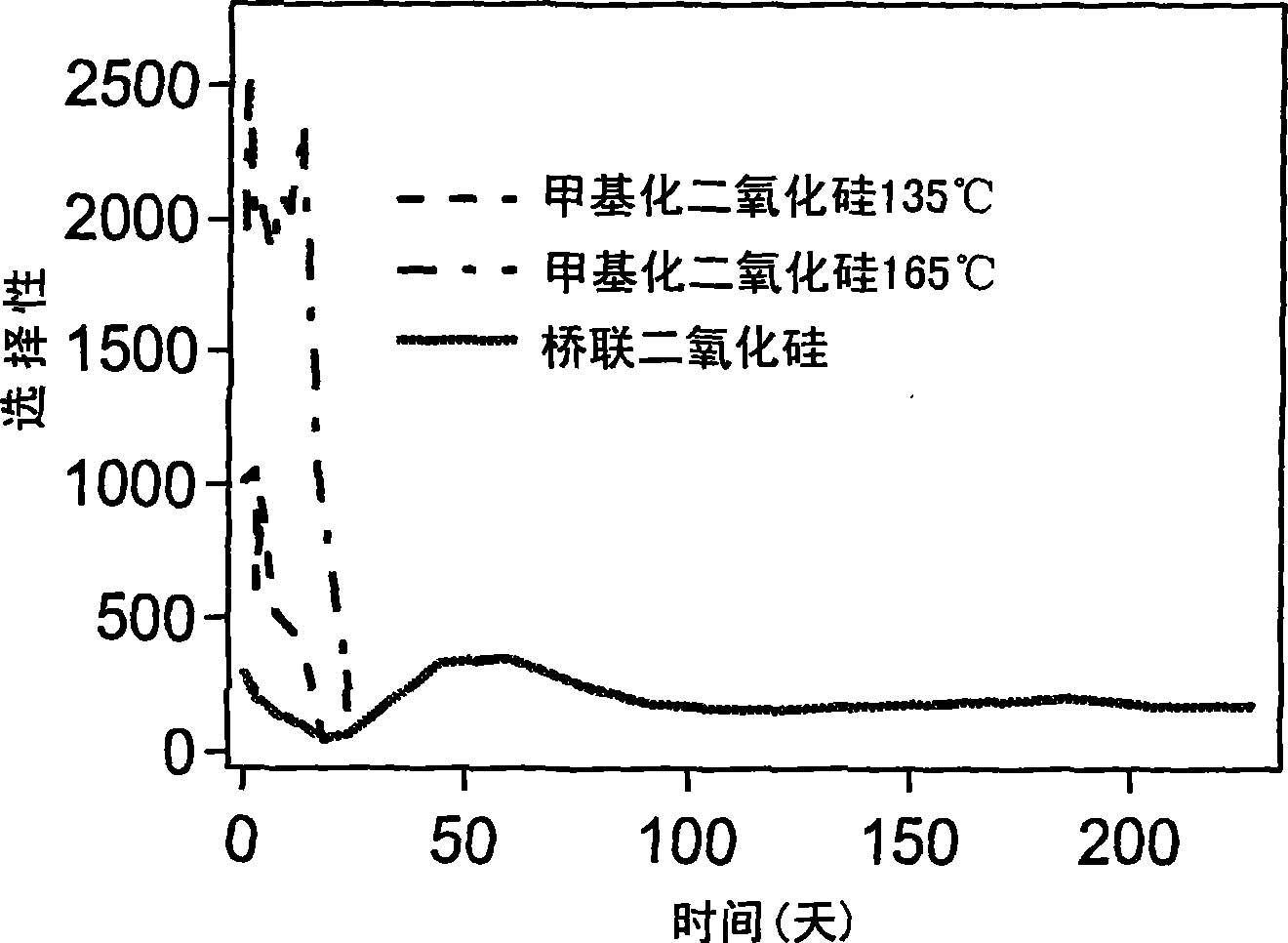

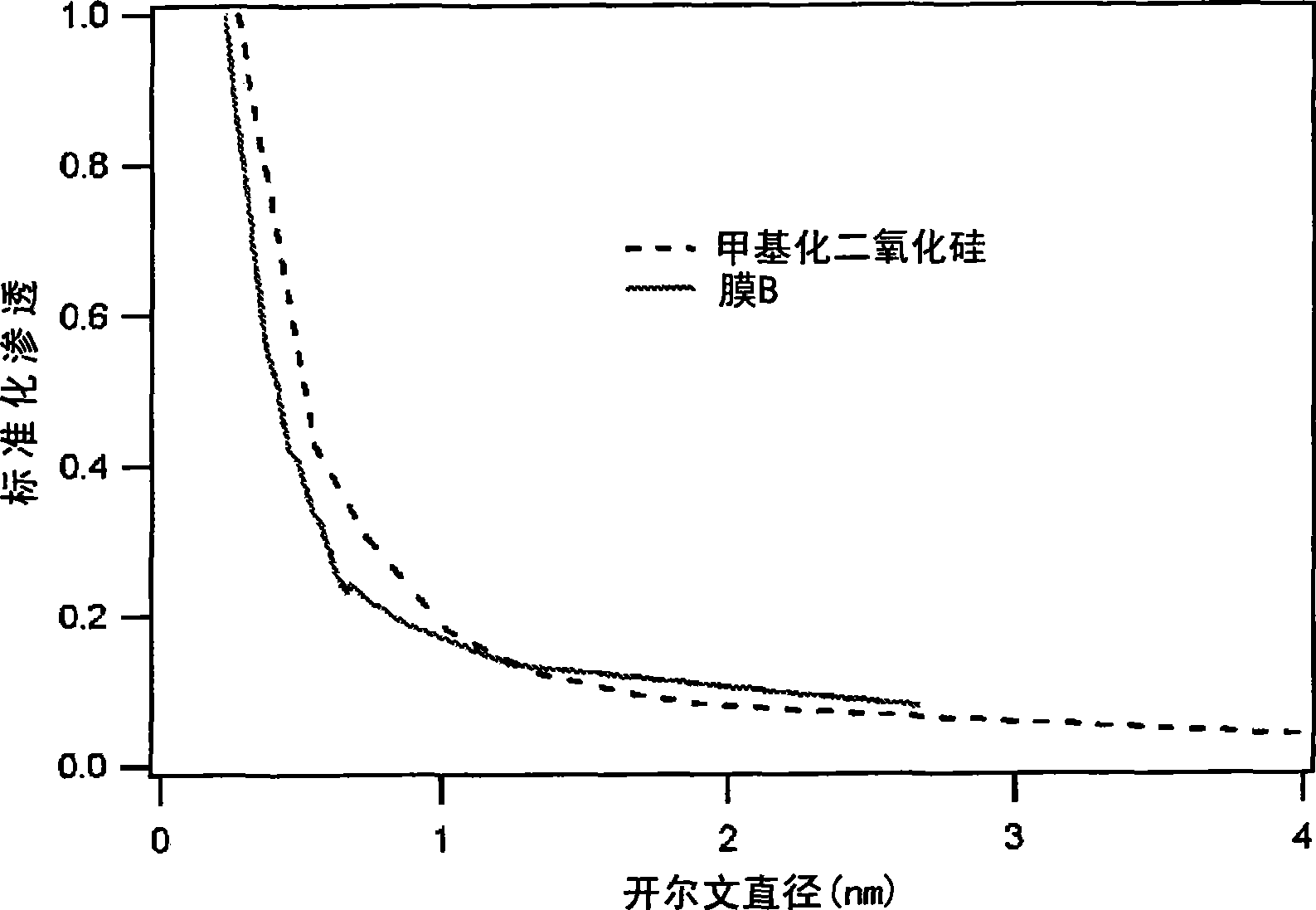

Microporous molecular separation membrane with high hydrothermal stability

ActiveCN101421022AEasy to separateThermally stableMembranesSemi-permeable membranesSilanesPore diameter

A hydrothermally stable, microporous organic-inorganic hybrid membrane based on silica, having an mean pore diameter of between 0.2 and 1.5 nm, is characterised in that between 5 and 40 mole% of the Si-O-Si bonds have been replaced by mo ieties having the one of the formulas: Si-{[CmH(n-1)X]-Si-}q, Si-[CmH(n-2)X2]-Si or Si-CmHn-Si{(CmHn)-Si-}y in which m = 1-8, n = 2m, 2m-2, 2m-4, 2m-6 or 2m-8; provided that n = 2, X = H or (CH2)pSi, p = 0 or 1, and q = 1, 2, 3 or 4. The membrane can be produced by acid-catalysed hydrolysis of suitable bis- silane precursors such as bis(trialkoxysily)alkanes, preferably in the presence of monoorganyl-silane precursors such as trialkoxy-alkylsilanes.

Owner:NEDERLANDSE ORG VOOR TOEGEPAST-NATUURWETENSCHAPPELIJK ONDERZOEK (TNO)

Preparation process of fuel cell electrode porous diffusion layer material carbon fiber paper

InactiveCN102936867AHave mechanical strengthChemically stableSpecial paperPaper/cardboardFiberCarbon fibers

The invention relates to the field of fuel cell electrode porous diffusion layer materials, in particular to a preparation process of basic material carbon fiber paper for manufacturing fuel cell electrode porous diffusion layers. The carbon fiber paper can be produced on common paper machine production lines in a batch mode and meets the requirement for manufacture of fuel cell electrode porous diffusion layer electrodes. The preparation process comprises the steps of (1) performing surface treatment to short carbon fiber; (2) performing surface treatment to conductive carbon black; (3) smashing raw wood pulp and placing the raw wood pulp into a pulping pond, wherein the ratio of the raw wood pulp to water is 5-15%; and the like. The carbon fiber paper produced by means of the preparation process can meet the requirement for manufacture of the fuel cell electrode porous diffusion materials, can evenly support catalyst layers in electrodes and stabilizing electrode structures, further has functions of providing gas channels, electronic channels and drainage channels for electrode reaction and the like, and has porous structures, excellent gas generating performance, high conductivity, certain mechanical strength, chemical stability and heat stability.

Owner:SHENYANG HUATIANXIN CARBON FIBER ELECTRIC HEATINGPROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com