Patents

Literature

35results about How to "Lower grain boundary resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene fiber and preparation method thereof

ActiveCN104099687AArranged in orderConvenient ArrangementElectroconductive/antistatic filament manufactureInorganic material artificial filamentsFiberDoped graphene

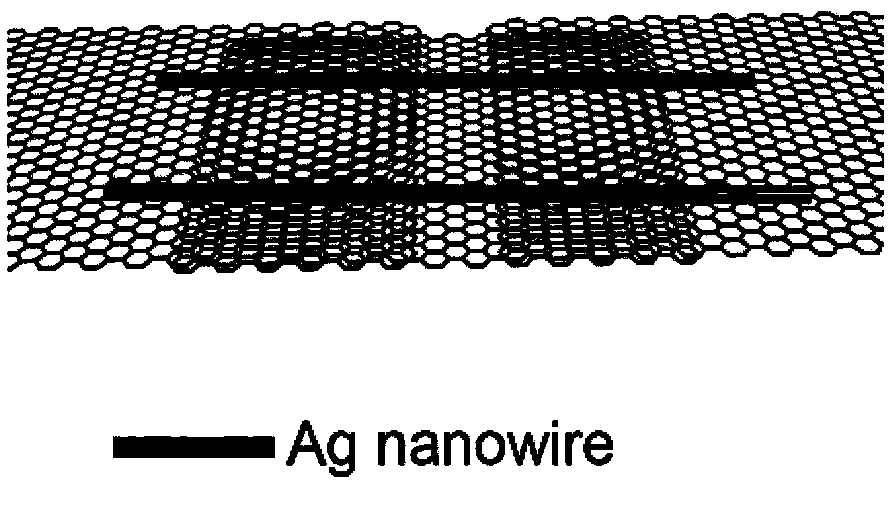

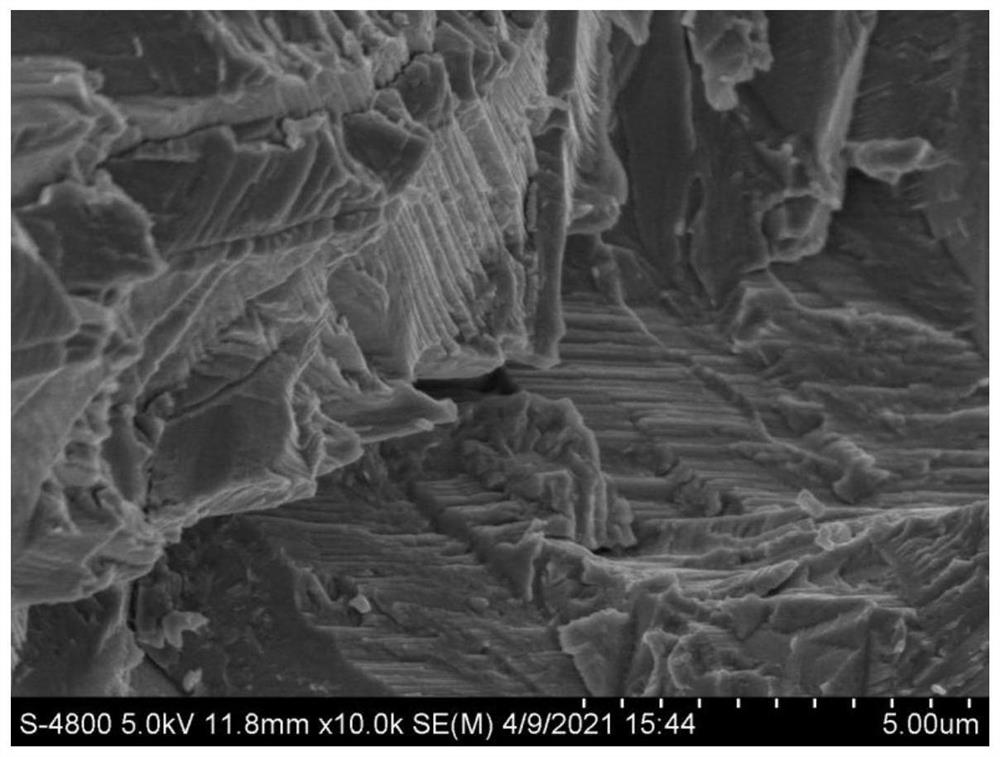

The invention discloses a graphene fiber and a preparation method thereof, wherein the graphene fiber is a composite fiber obtained by doping graphene fiber with metal nanowires, the composite fiber comprises the main components of graphene and the metal nanowires, wherein the mass ratio of the metal nanowires is 0.1% ~ 50%, the graphene is in lamellar morphology, and the metal nanowires and the graphene layers are parallelly and simultaneously arranged along the axial direction of the graphene fiber. The metal nanowire doped graphene fiber is a new high performance and multifunctional fiber material, by doping of the metal nanowires, fiber conductive rate is greatly improved, meanwhile the graphene fiber exhibits good tensile strength and excellent toughness, has the very strong potential application value in many fields such as use as lightweight flexible wires and the like.

Owner:HUAWEI TECH CO LTD +1

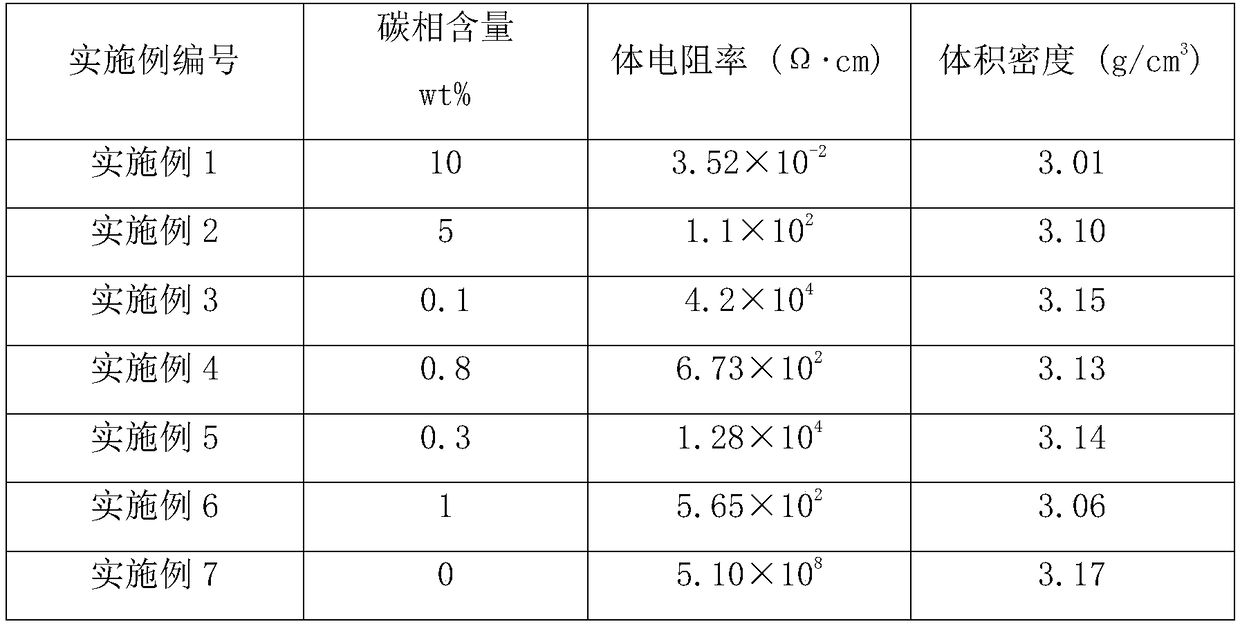

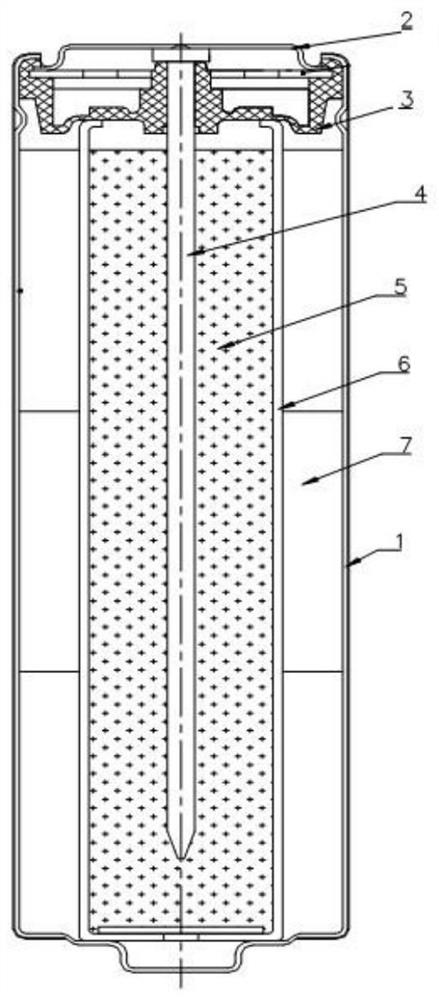

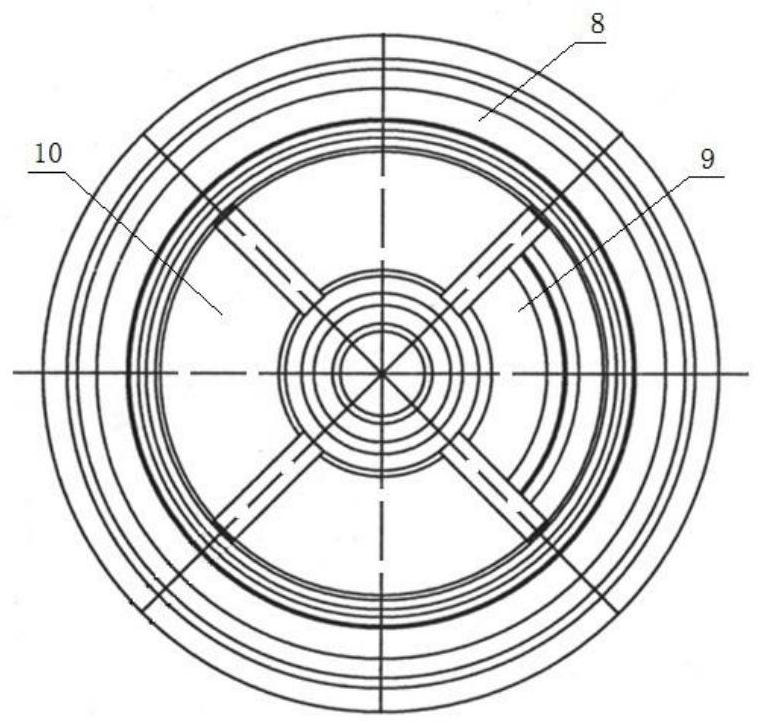

Silicon carbide ceramic with adjustable resistance and preparation method thereof

InactiveCN108911756ALower grain boundary resistanceLower bulk resistanceElectrical resistance and conductanceBoron carbide

The invention discloses silicon carbide ceramic with adjustable resistance and a preparation method thereof. The ceramic material mainly comprises a silicon carbide phase as a main phase, boron carbide as a sintering aid phase, and a carbon phase as a conductive phase, and the ceramic material can be prepared and has the bulk resistivity adjustable from 10<-2> to 10<8> Omega.cm. The silicon carbide ceramic has a density of 3.00 to 3.20 g / cm<3>. The core of the method is to coat the surface of silicon carbide raw material powder with a graphene-based material layer, and to adjust the content ofthe conductive phase in the silicon carbide ceramic to obtain the silicon carbide ceramic with adjustable bulk resistivity.

Owner:NINGBO VULCAN TECH CO LTD

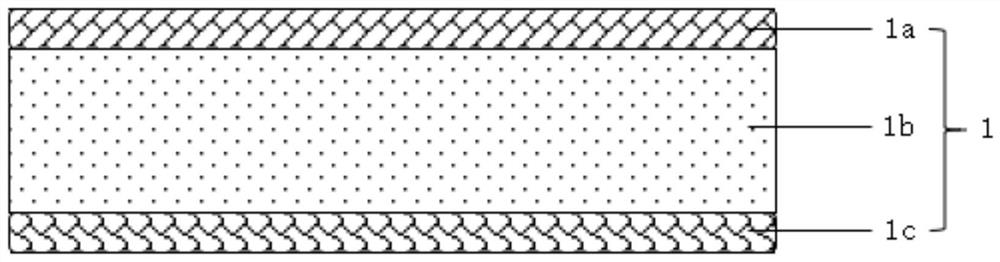

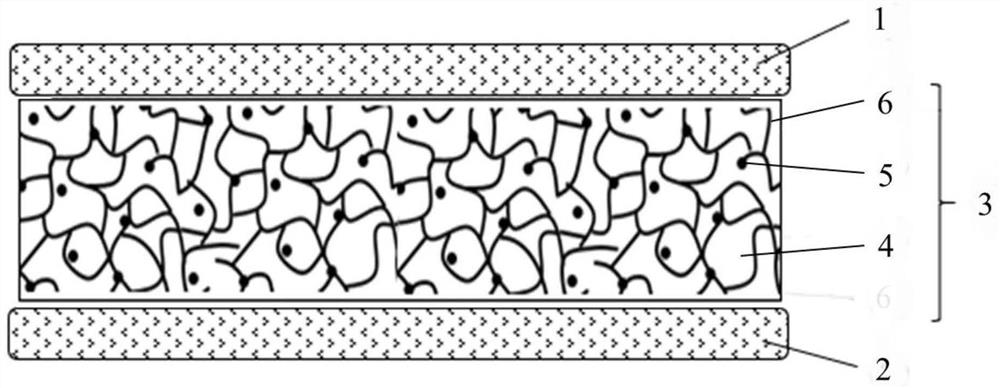

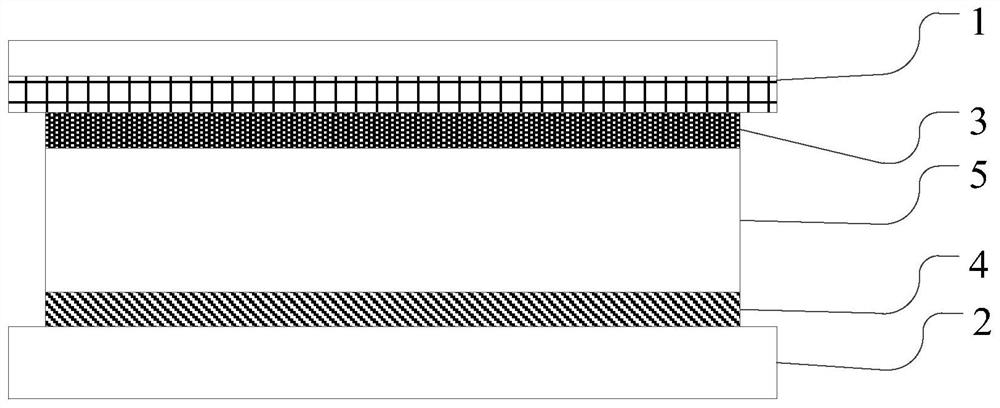

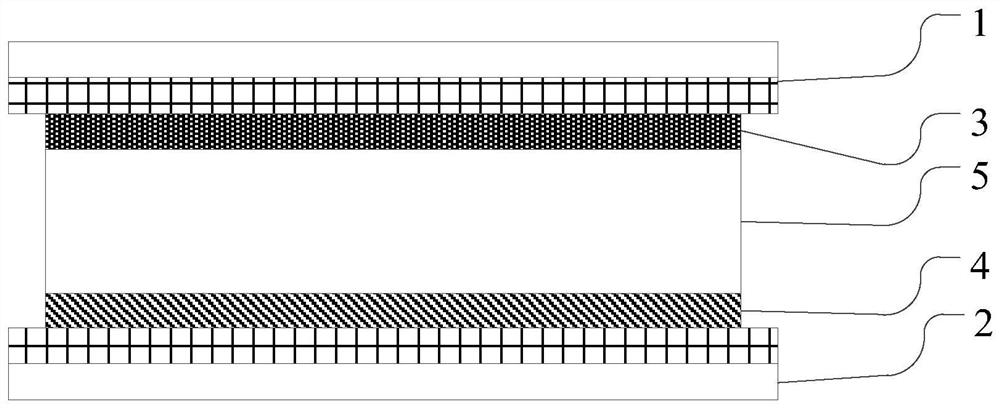

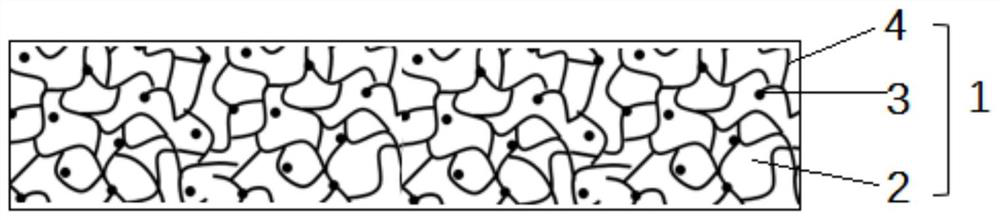

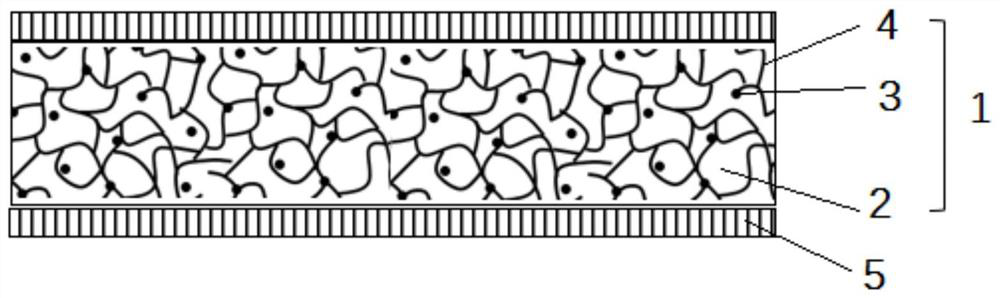

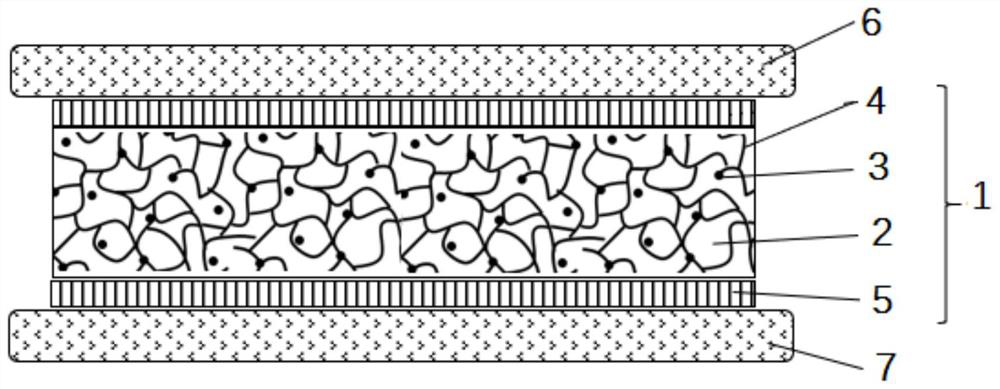

Solid electrolyte composite layer and lithium ion battery

InactiveCN112599850AImprove interfacial wettabilityHigh mechanical strengthSecondary cells servicing/maintenanceElectrolyte immobilisation/gelificationSolid state electrolyteMetallic lithium

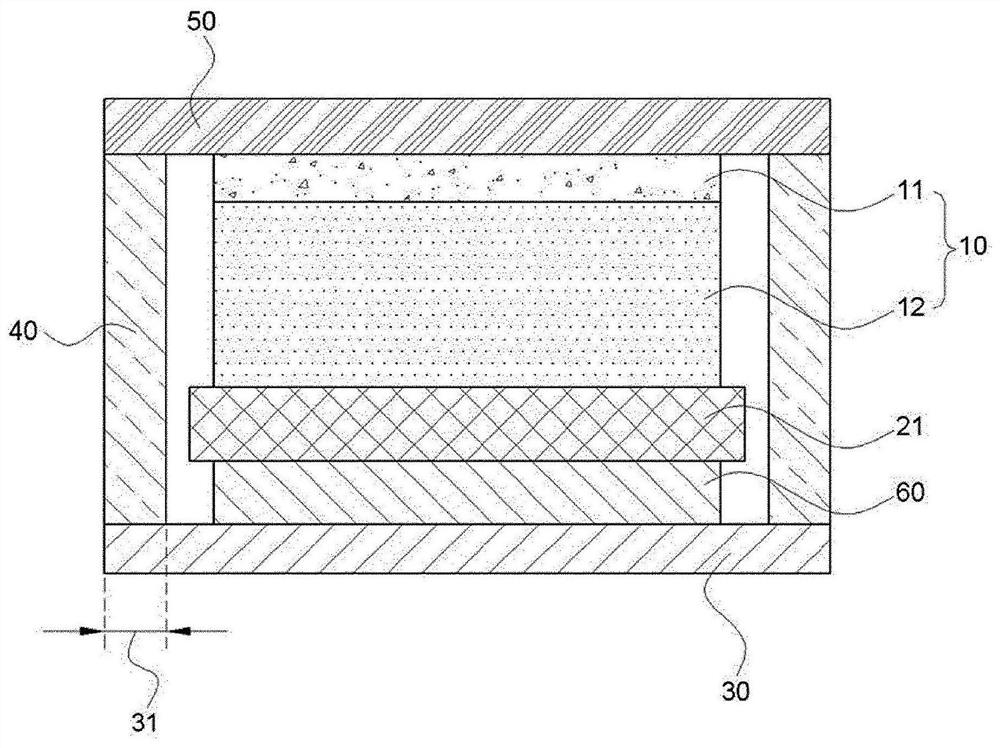

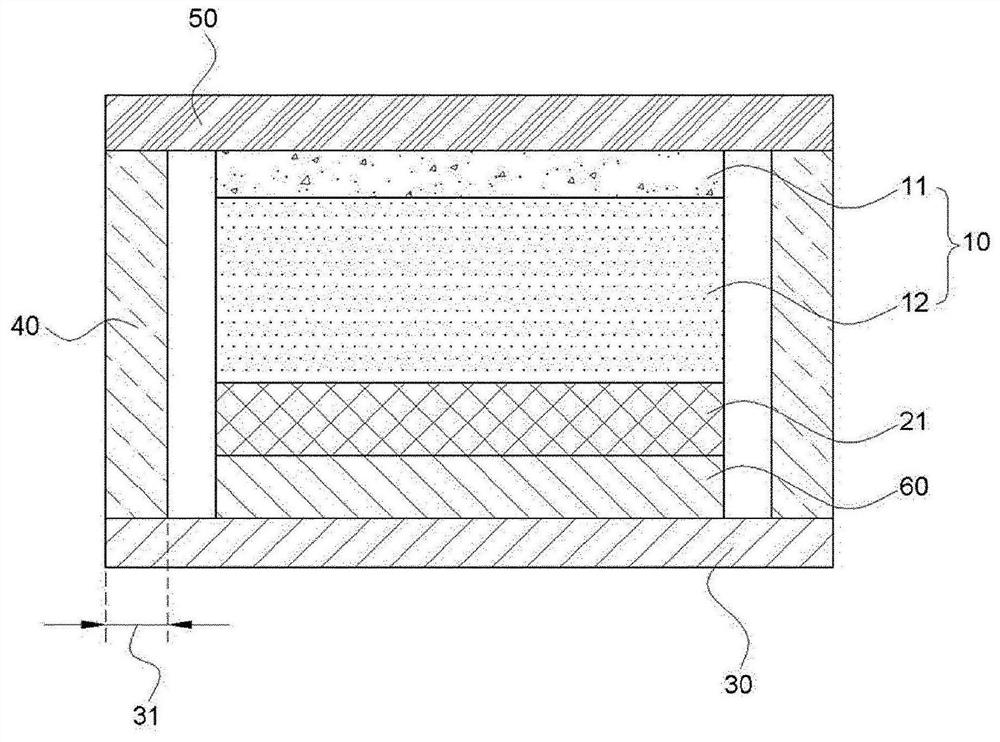

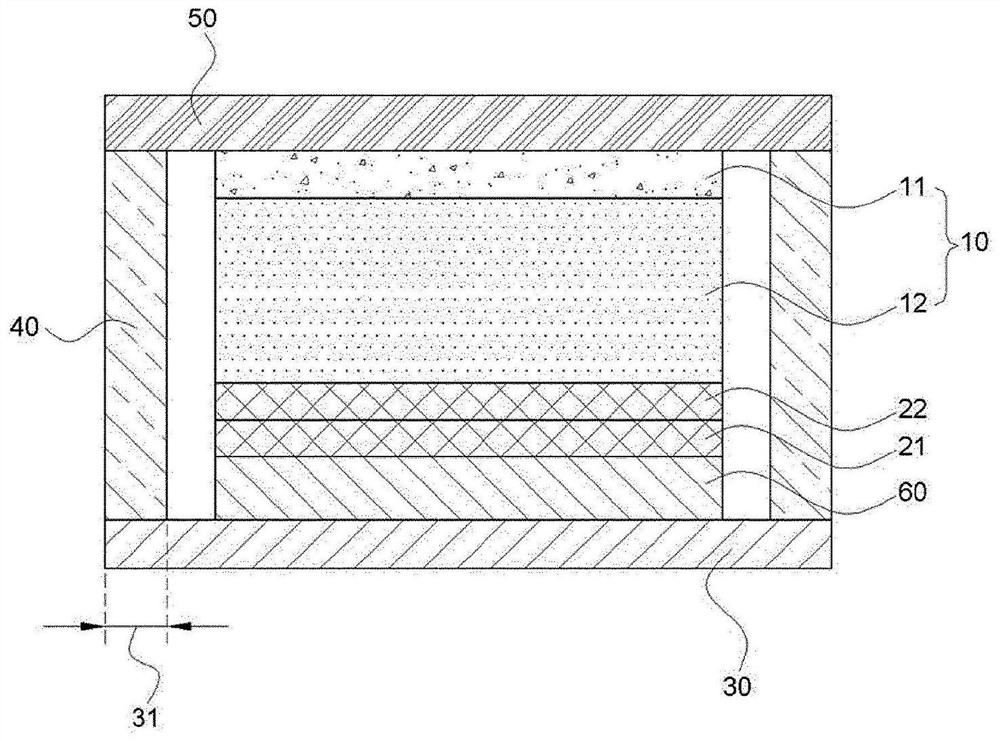

The invention provides a solid electrolyte composite layer and a lithium ion battery. The solid-state electrolyte composite layer comprises a near-positive-electrode-side solid-state electrolyte layer, a middle solid-state electrolyte layer and a near-negative-electrode-side solid-state electrolyte layer which are sequentially arranged in a stacked mode. The middle solid-state electrolyte layer comprises the inorganic ceramic electrolyte, the near-positive-electrode-side solid electrolyte layer comprises near-positive-electrode-side polymer with high oxidation resistance, and the near-negative-electrode-side solid electrolyte layer comprises a near-negative-electrode-side compound stable with metal lithium, so that the solid electrolyte composite layer is high in mechanical strength, and lithium dendrites are prevented from piercing the electrolyte; the requirements of high-voltage resistance of a positive electrode side and stability of a negative electrode side and metal lithium aremet, and meanwhile, the interface wettability of the solid electrolyte composite layer is good. The lithium ion battery comprises the solid electrolyte composite layer, and due to the fact that the solid electrolyte composite layer is high in mechanical strength, excellent in wettability and good in stability with positive and negative electrode interfaces, the lithium ion battery has the advantages of being small in battery internal resistance, good in cycle performance and high in safety.

Owner:ZHUHAI COSMX BATTERY CO LTD

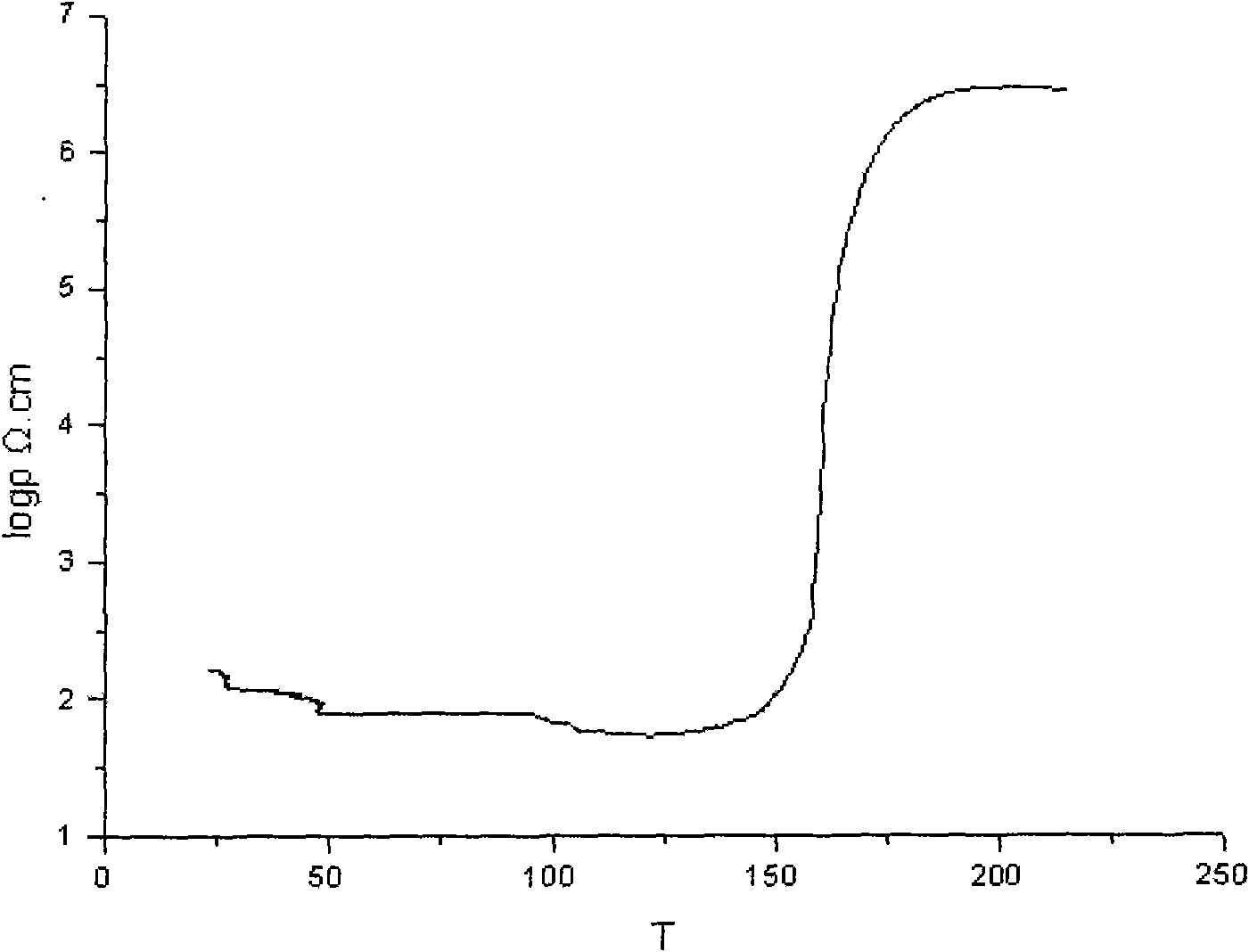

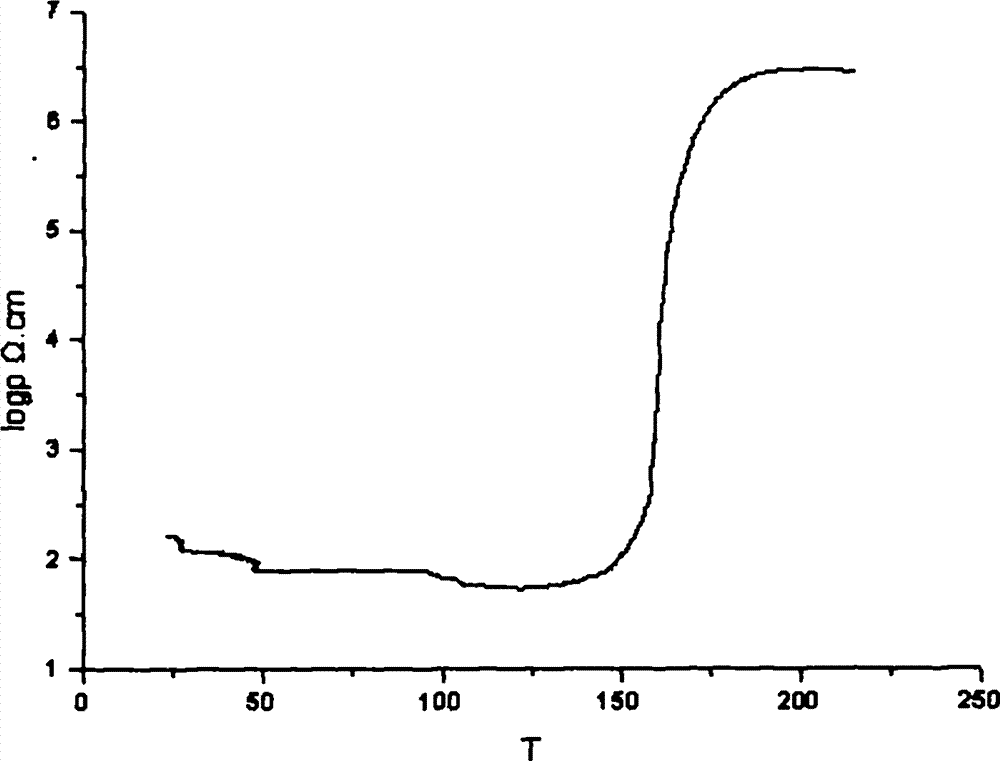

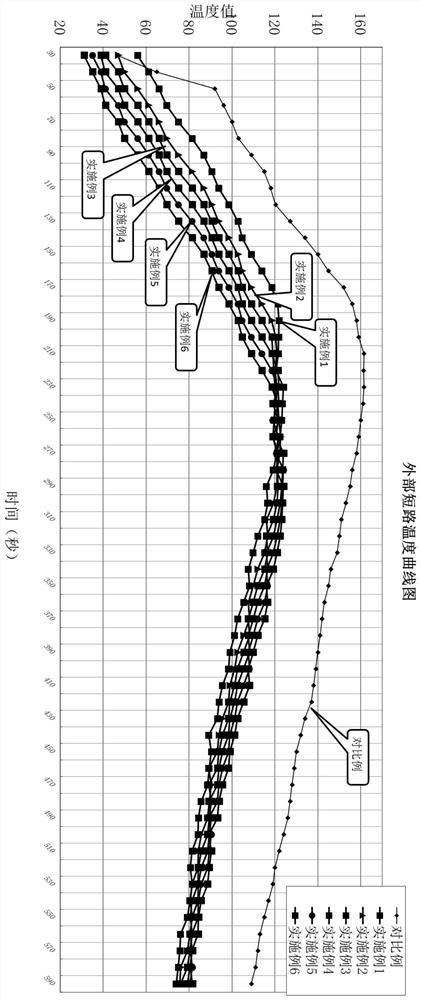

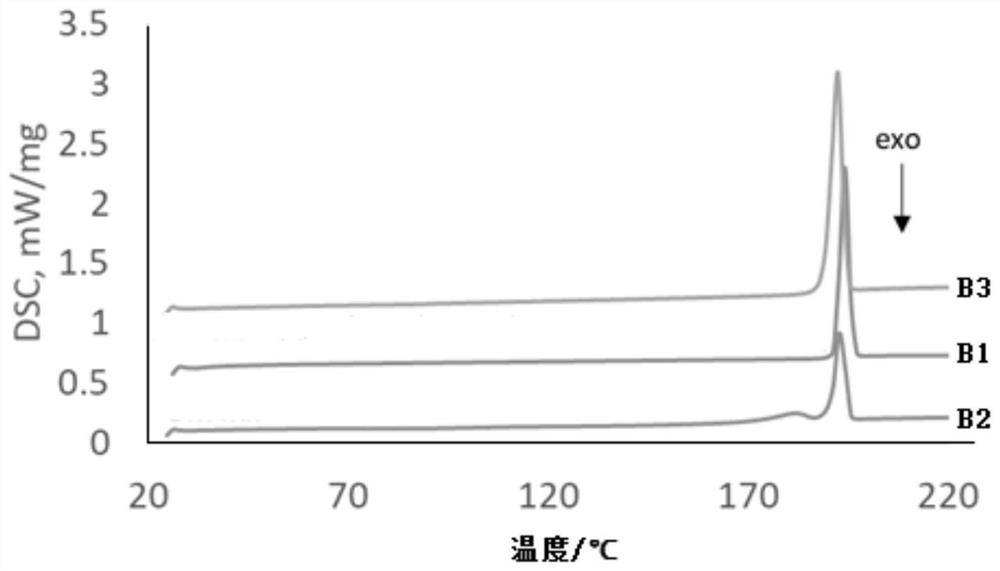

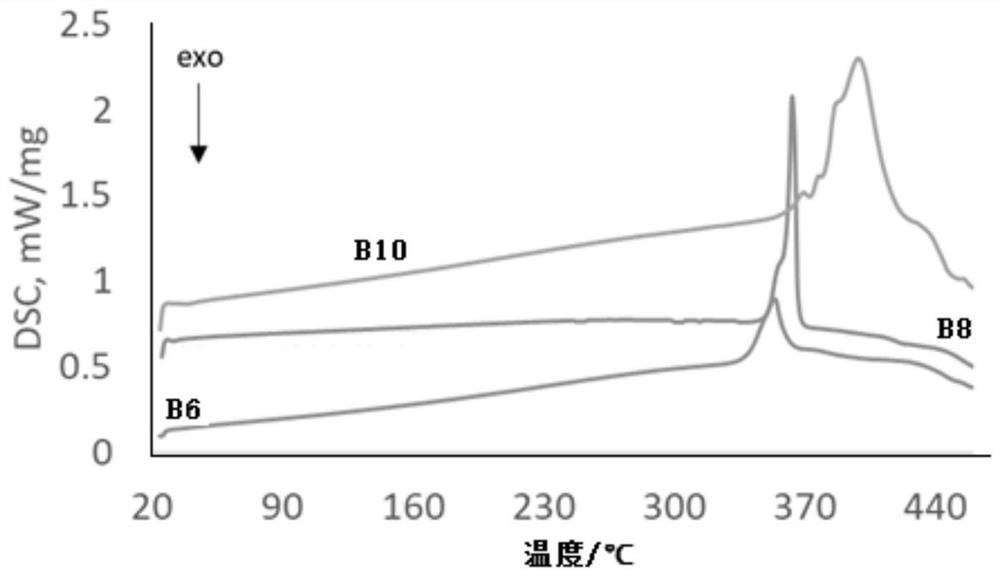

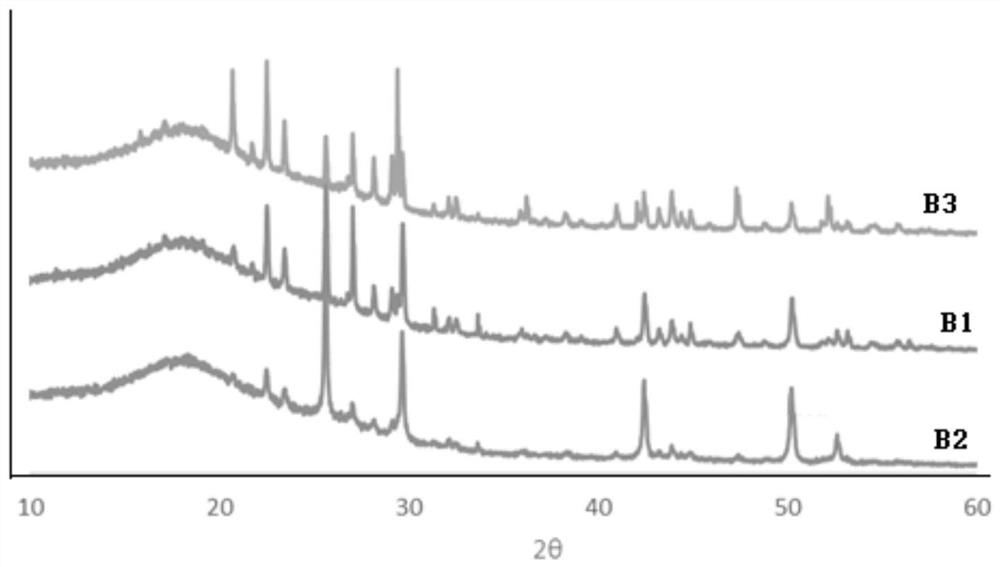

Doped BKT-BT series lead-free PTCR ceramic material and preparation method thereof

InactiveCN101624284AIncrease the slopeRaise resistance kickThermometers using electric/magnetic elementsUsing electrical meansTemperature coefficientPositive temperature

The invention relates to a doped BKT-BT series lead-free positive temperature coefficient resistance ceramic material and a prepration method thereof, the general formula of the composition of the material is (Bi0.5K0.5)*1(Ba1-*1-*2)AX2)Ti1-yMyO3+Zmol%D, wherein, x1 is more than 0 and not more than 0.7, x2 is more than 0 and not more than 0.6%, y is more than 0 and less than 0.2%, Z is not less than 0 and less than 1, A is one or more of Ce, Y, La and Bi, M is one or more of Nb, Sb, Ta and Mo, and D is one or more of MnO2, TiO2, SiO2 and B2O3. For a series of the lead-free ceramic materials, TC, alpha, betaRT and resistance sudden jump Rmax / Rmin are respectively changed between 140 and 250 DEG C, between 10 and 45% / DEG C, between 20 and 60 omega.Cm and between 10<2> and 10<5> along with the change of x1, x2, y and Z.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

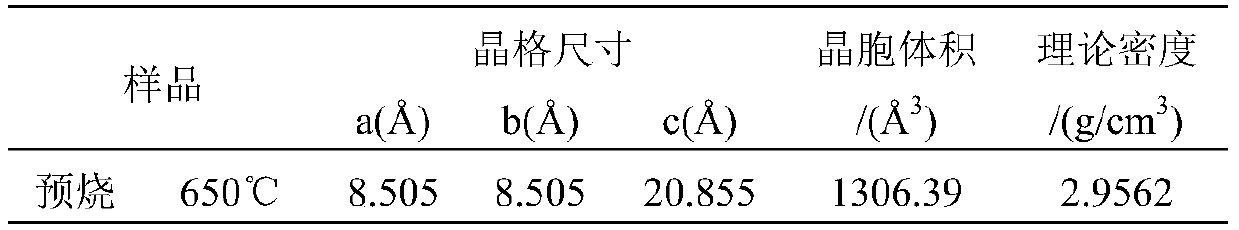

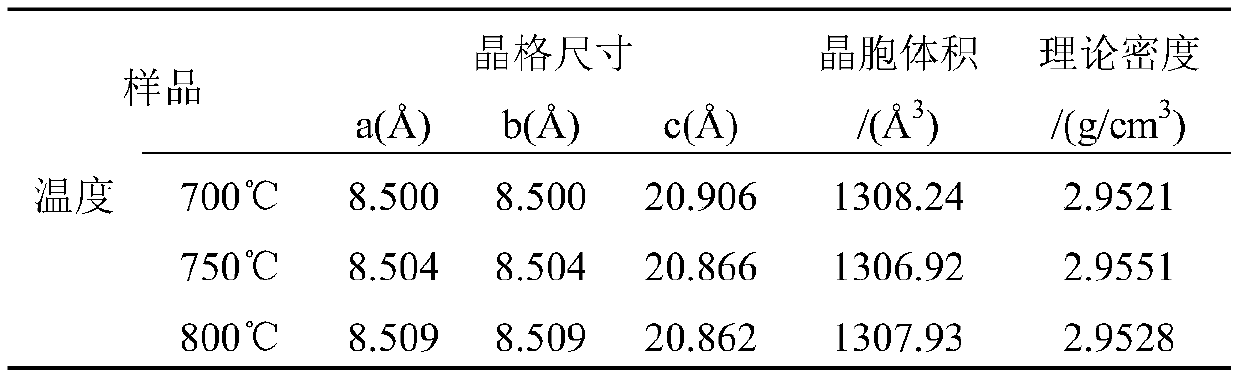

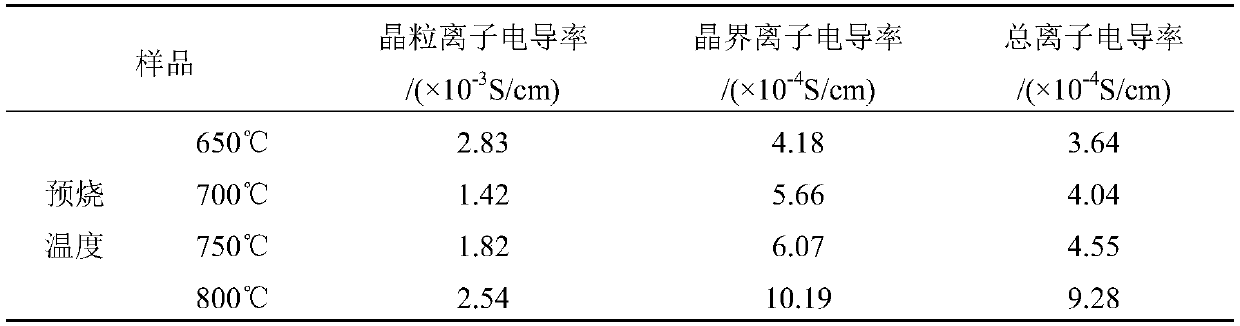

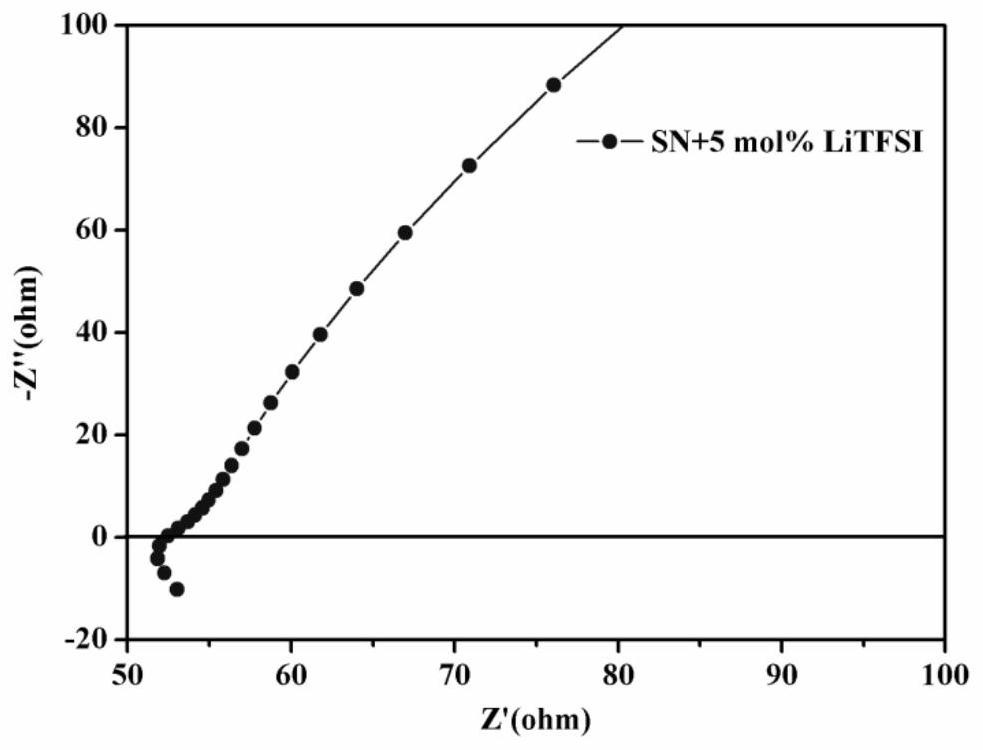

High-conductivity solid electrolyte prepared by sol-gel method

InactiveCN110885246ALower grain boundary resistanceImprove ionic conductivitySol-gelGlycol synthesis

The invention relates to the technical field of solid electrolyte, and in particular, relates to a high-conductivity solid electrolyte prepared by a sol-gel method. Any one or a composition of more oflithium nitrate, germanium oxide and tetraethoxysilane is used as a doping agent, lithium titanium aluminum phosphate is used as a main material, the doping agent is embedded into the lithium titanium aluminum phosphate framework by the sol-gel method, and an NASICON structure is formed; the solid electrolyte disclosed by the invention is small in grain boundary impedance, high in ionic conductivity, low in sensitivity to heat treatment temperature and suitable for industrial production, and integrates the characteristics of low synthesis temperature, low energy consumption, high product purity, small particle size and high density of traditional sol-gel; citric acid and ethylene glycol are adopted as auxiliary agents, environmental pollution is prevented, the temperature and the stirringrate are reasonably controlled, and the cost is reduced.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

Preparation method of lithium lanthanum niobium oxygen solid electrolyte diaphragm

InactiveCN106898821AIncrease success rateSimple methodFinal product manufactureElectrolyte accumulators manufactureNiobiumLithium hydroxide

The invention relates to a preparation method of a lithium lanthanum niobium oxygen solid electrolyte diaphragm, and belongs to the field of electrochemical engineering and ceramic industry. The method comprises the following steps that lithium carbonate, acetic acid and lithium hydroxide are taken as lithium sources, the mixed material powder is sintered in advance to form lithium lanthanum niobium oxygen solid electrolyte powder, then a powder body is placed in a crucible, is compacted by vibration, and is then directly sintered at high temperature to obtain a compact block body; and the block body is cut and grinded to obtain a lithium lanthanum niobium oxygen solid electrolyte diaphragm sheet. The method avoids the complicated mold tableting process in the traditional method, does no need a high-tension apparatus, and does not need the addition of a sintering assistant either; and the powder body is aggregated to form the compact block body by utilizing the surface tension of a liquid phase generated through melting of the lithium salt at high temperature. The preparation method has the advantages of simple process, smoothness and compactness of a product, easy large-scale production and the like, and is particularly suitable for the preparation of the lithium lanthanum niobium oxygen solid electrolyte diaphragm in a solid state battery.

Owner:NO 63971 TROOPS PLA

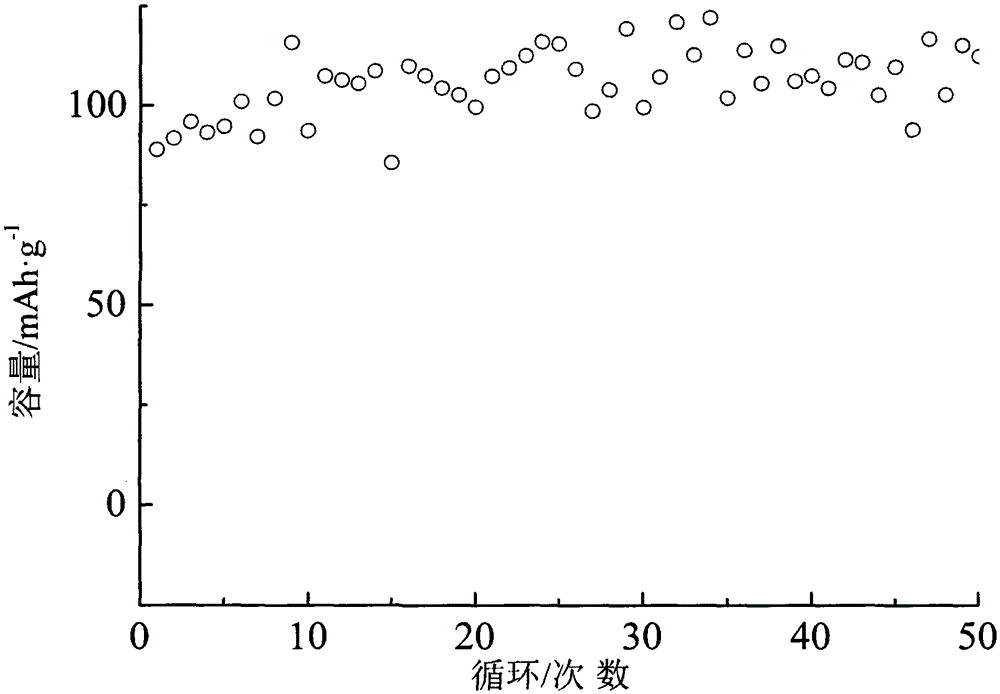

Metal oxide energy storage material with special microstructure and preparation method

PendingCN112110419AImprove stabilityImprove energy storage capacityOxide/hydroxide preparationHybrid capacitor electrodesHigh energySingle crystal

The invention relates to a metal oxide material with a special microstructure for electrochemical energy storage and a preparation method thereof, and the microstructure of the metal oxide material ischaracterized in that the metal oxide material is of a single crystal, quasi-single crystal or twin crystal structure, has a defect and porous structure and contains mixed valence metal elements. Thestructural general formula is MxOy-z. The method can be used for solving the problem of insufficient performance of an electrochemical energy storage negative electrode material under a high-rate working condition. On one hand, the existence of mixed valence metal elements greatly increases the electronic conductivity of the material; on the other hand, due to the existence of the defects and thepores, the ion transport property and the electrochemical activity of the material are improved, more lithium storage sites appear, and buffer can also be provided for the volume change of the electrode; and the special microstructure provides guarantee for high power, high energy and high stability of the material. The metal oxide provided by the invention can be used as an electrode material ofan energy storage device in the fields of electric vehicles and the like requiring high power density and high-stability energy storage.

Owner:PEKING UNIV

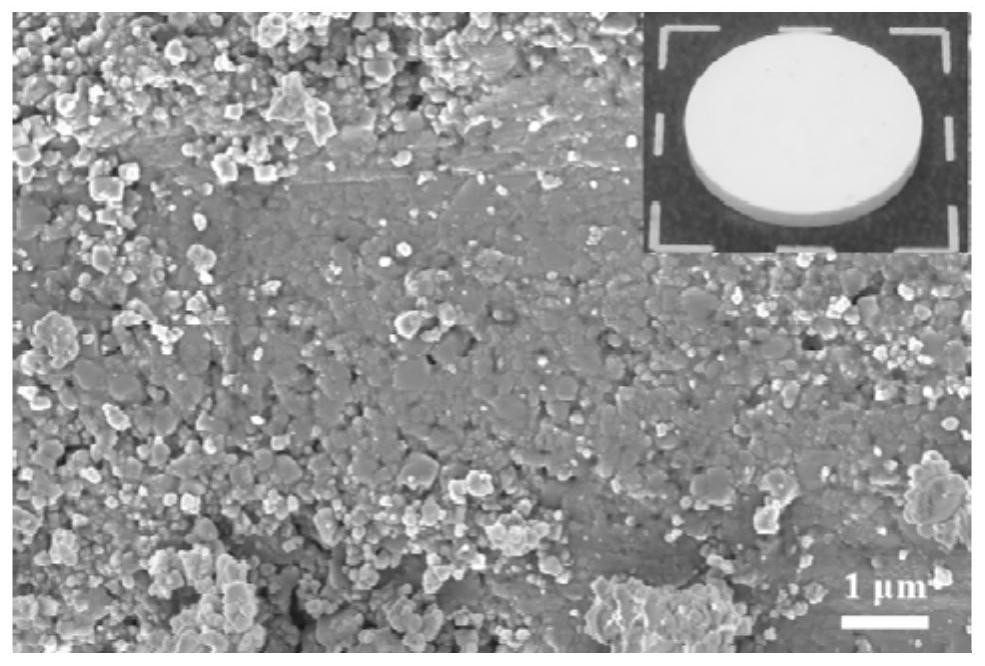

Plastic crystal-ceramic composite solid electrolyte and low-temperature hot-pressing preparation method thereof

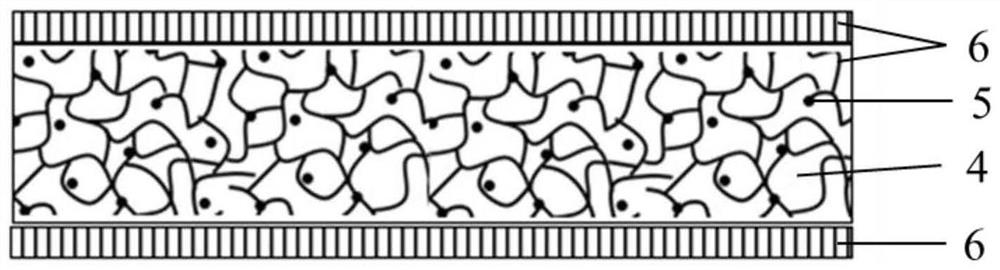

InactiveCN112531204APrevent decomposition reactionHigh mechanical strengthFinal product manufactureLi-accumulatorsOxide ceramicPlastic crystal

The invention discloses a plastic crystal ceramic composite solid electrolyte and a low-temperature hot-pressing preparation method thereof. The method comprises the following steps of step 1, weighing oxide ceramic powder and the plastic crystal solid electrolyte, and uniformly mixing to obtain mixed powder; the plastic crystal solid electrolyte comprising a plastic crystal and a lithium salt, step 2, putting the mixed powder into a mold, and flattening the mixed powder; 3, the mixed powder being subjected to compression molding, meanwhile, the mixed powder being subjected to heat treatment,the heating temperature being lower than 600 DEG C, and the plastic crystal solid electrolyte absorbing heat to be molten; and then reducing the temperature to solidify and mold the plastic crystal solid electrolyte to obtain the plastic crystal ceramic composite solid electrolyte. According to the method, densification of the solid electrolyte can be realized at a relatively low temperature, thesolid electrolyte has relatively high ionic conductivity, and the processing time, energy loss and volatilization of a lithium element at a high temperature are greatly reduced.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

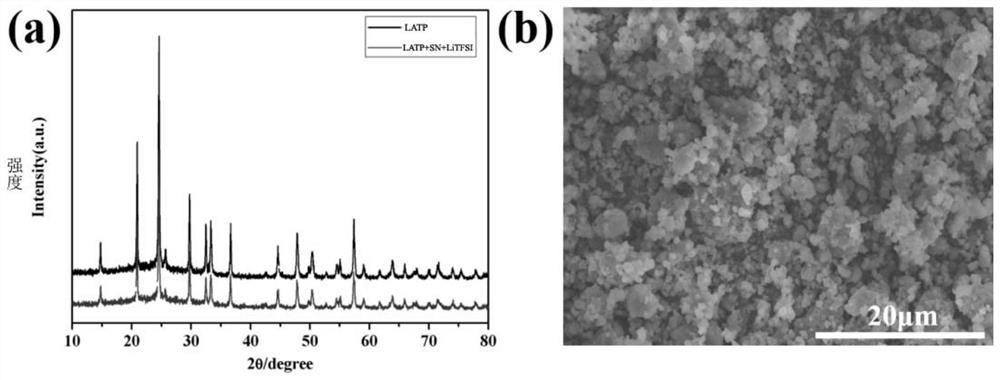

Composite solid electrolyte, preparation method thereof and all-solid-state lithium ion battery

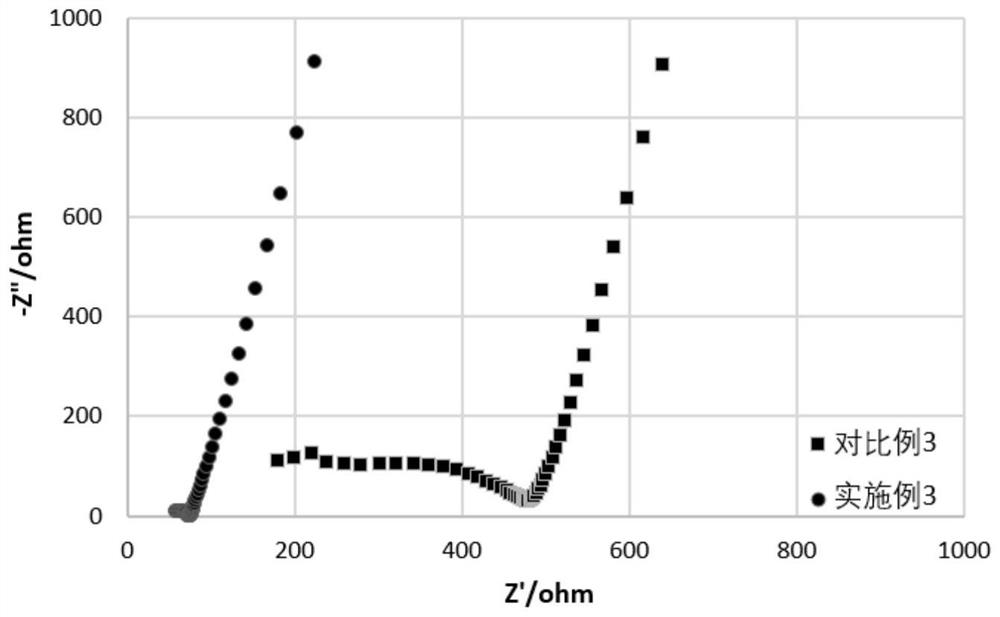

PendingCN112635818ALower grain boundary resistanceImprove interface performanceSecondary cells servicing/maintenanceSolid state electrolyteAll solid state

The invention provides a composite solid electrolyte, a preparation method thereof and an all-solid-state lithium ion battery. The composite solid electrolyte comprises an oxide electrolyte, and a sintering aid, a plasticizer, a polymer and a lithium salt which are filled in the oxide electrolyte, wherein the mass ratio of the oxide electrolyte to the sintering aid to the polymer to the lithium salt to the plasticizer is (50-95):(1-10):(0.1-40):(0.1-40):(0.1-40). The composite solid electrolyte provided by the invention can effectively reduce the interface impedance between electrolyte grains, and improve the cycle efficiency, the cycle stability and other qualities of the lithium ion battery.

Owner:ZHUHAI COSMX BATTERY CO LTD

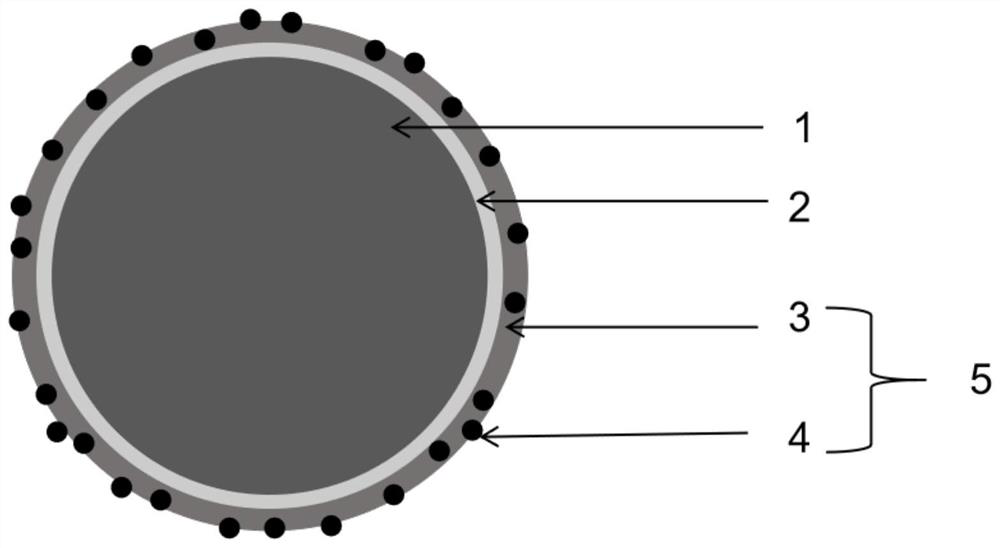

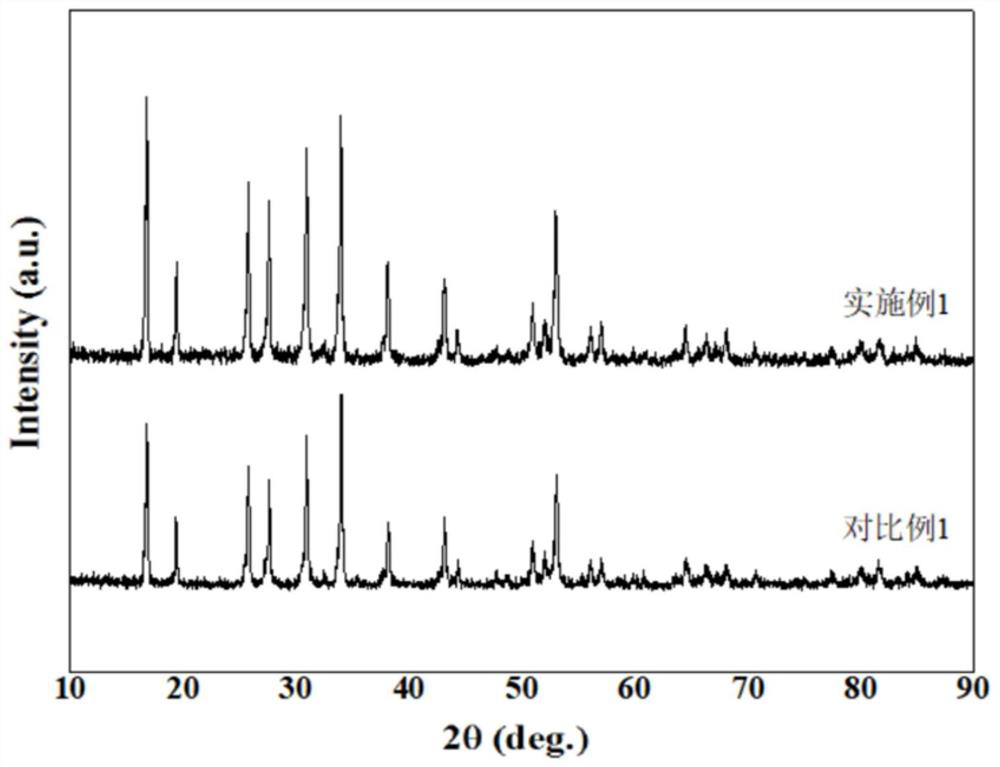

Composite coated nickel-rich positive electrode material as well as preparation method and application thereof

ActiveCN114678500AEasy to storeImprove efficiencySolid electrolytesCell electrodesSolid state electrolyteLithium-ion battery

The invention discloses a composite coated nickel-rich positive electrode material as well as a preparation method and application thereof, and belongs to the technical field of lithium ion battery positive electrode materials. The composite coated positive electrode material comprises a nickel-rich positive electrode base material, a transition layer and a composite coating layer coated on the surface of the base material. The composite coating layer is composed of the composite solid electrolyte and the lithium-boron compound, the positive electrode material can be effectively protected through the combined action of the composite solid electrolyte and the lithium-boron compound, the safety performance of the material is improved, and the rate capability of the material can be further improved.

Owner:BEIJING WELION NEW ENERGY TECH CO LTD

Lithium-rich antiperovskite sulfides, solid electrolyte materials including them, and applications thereof

ActiveCN104466239BIncrease the carrier concentrationIncrease charge and discharge rateSecondary cellsElectrolytesWorking temperatureOperating temperature range

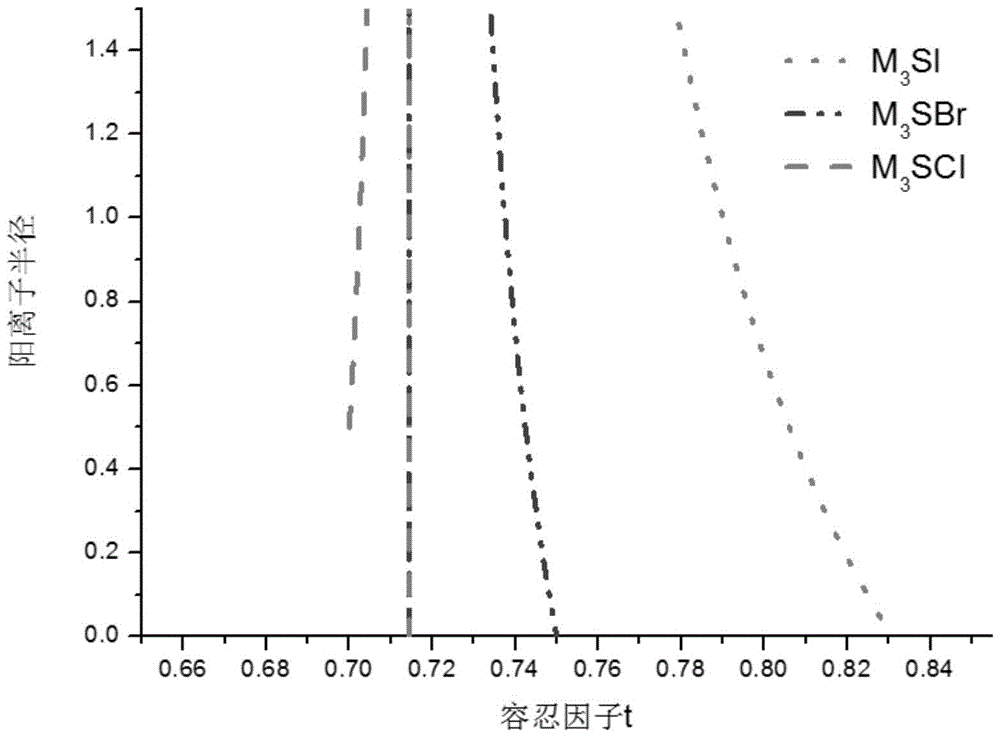

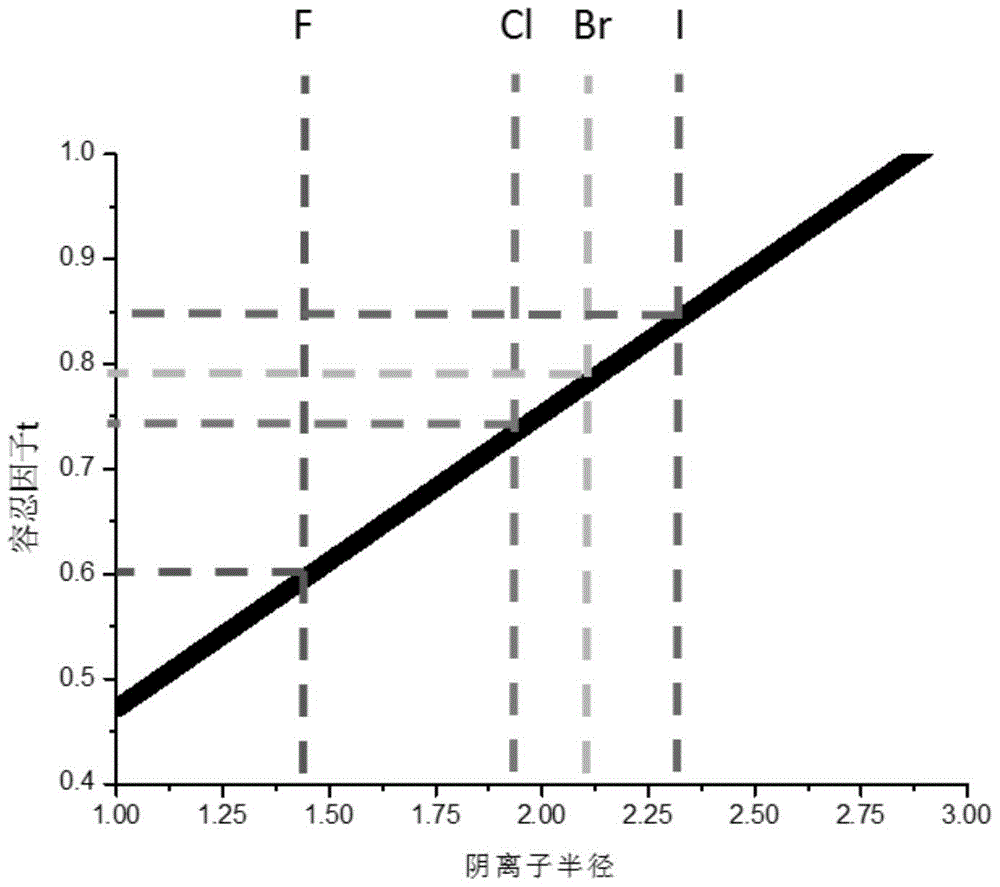

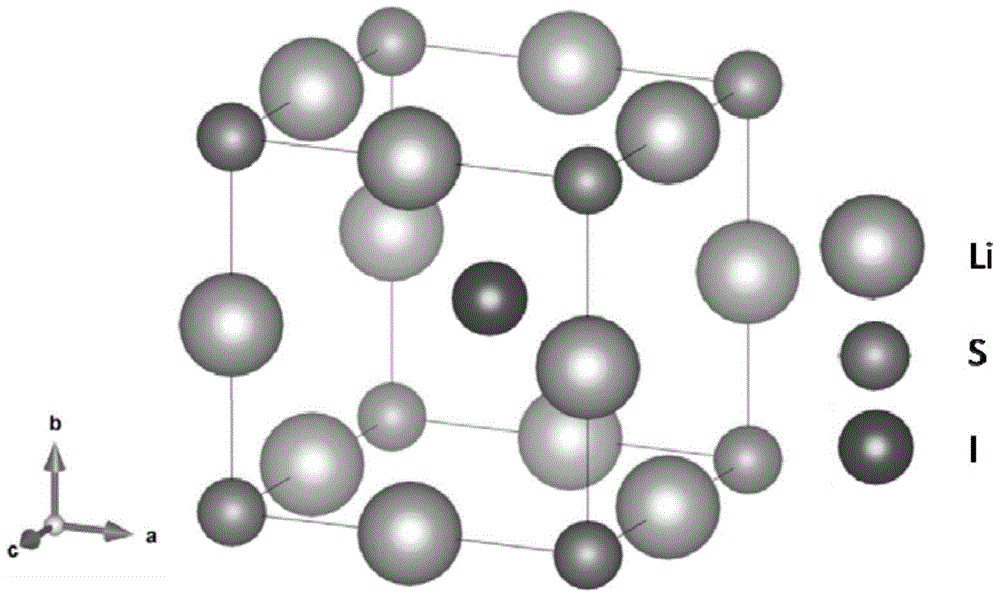

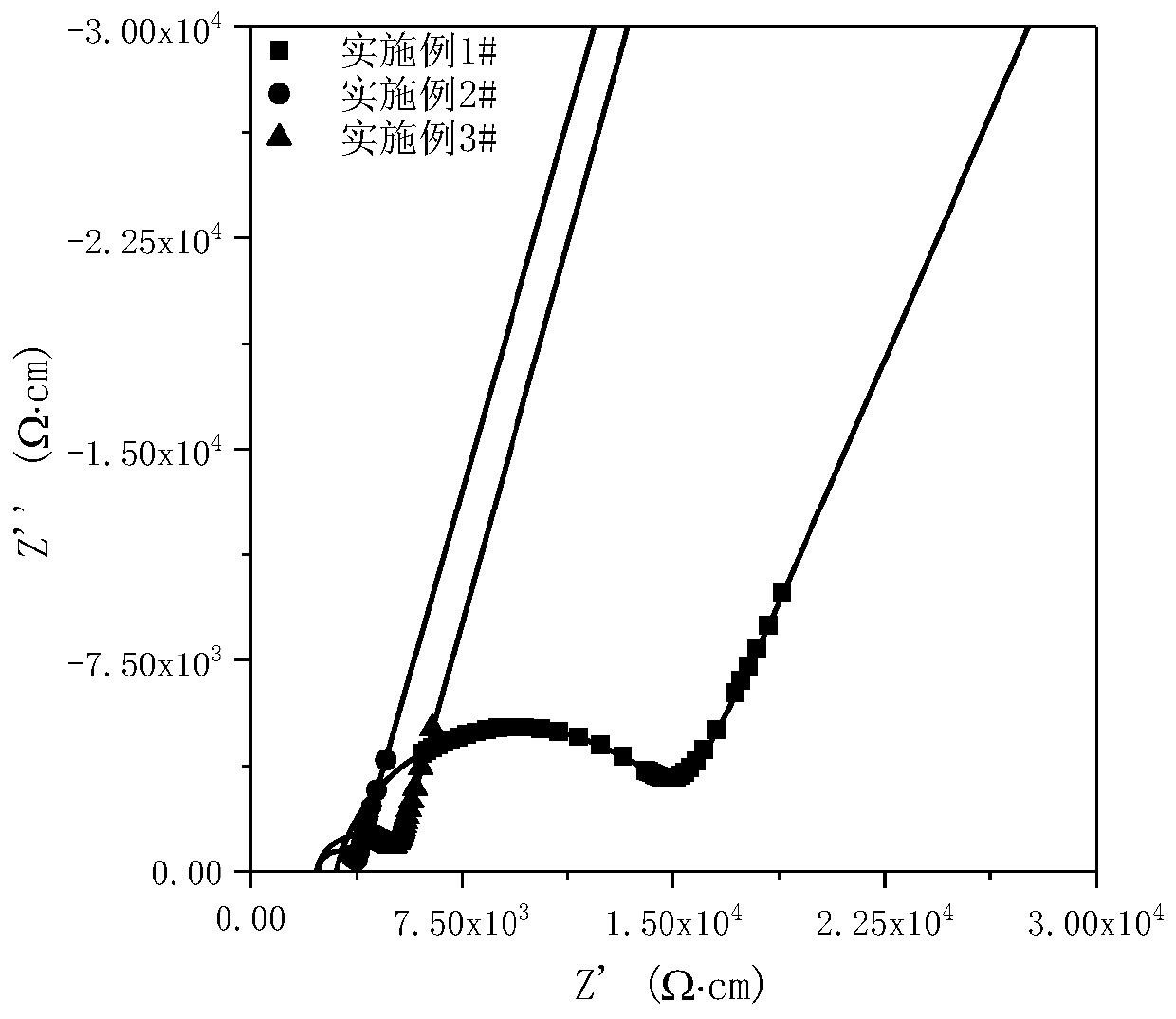

The invention discloses lithium-enriched anti-perovskite sulfides and a solid electrolyte material. The general formula of the lithium-enriched anti-perovskite sulfides is (LimMn)3-xS1-y(XaYb)1-z, wherein m is more than 0 and less than or equal to 1, n is more than or equal to 0 and less than to 0.5, (m+n) is less than or equal to 1, a is more than 0 and less than or equal to 1, b is more than or equal to 0 and less than 1, (a+b) is less than or equal to 1, x is more than or equal to 0 and less than or equal to 0.5, y is more than or equal to 0 and less than or equal to 0.5, z is more than or equal to 0 and less than or equal to 0.5 and x=2y+z; M is H, Na, K, Rb, Mg, Ca, Sr, Ba, Y, La, Ti, Zr, Zn, B, Al, Ga, In, C, Si, Ge, P, S or Se; and X is Fe, Cl, Br or I, and Y is a negative ion. The solid electrolyte material has high ion conductivity and thermal stability and a wide working temperature range, and can be applied to lithium ion batteries, rechargeable metal lithium batteries, lithium liquid flow batteries or lithium ion capacitors.

Owner:BEIJING WELION NEW ENERGY TECH CO LTD

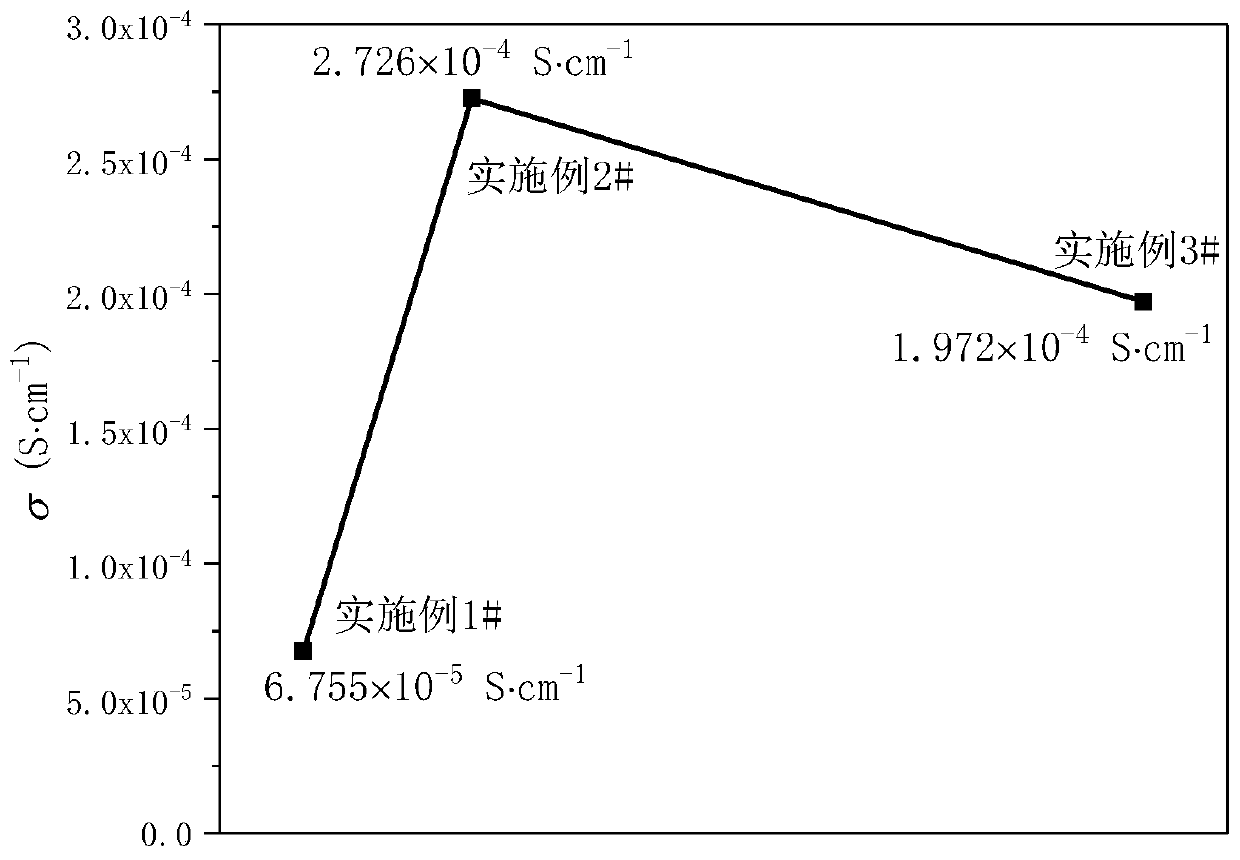

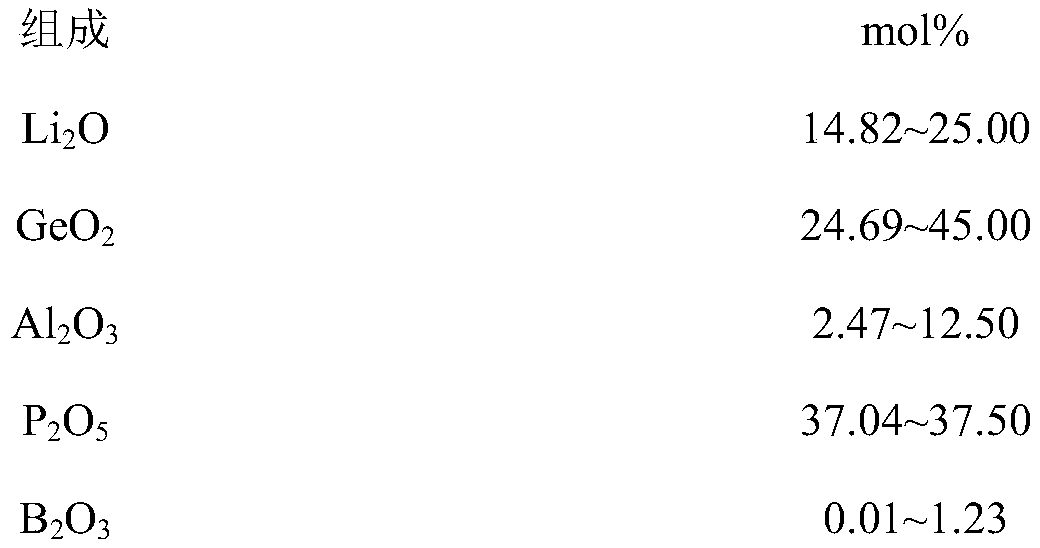

NASICON type solid electrolyte with high ionic conductivity and preparation method thereof

InactiveCN110323486AImprove compactnessLower grain boundary resistanceSecondary cellsElectrolytesMuffle furnaceAll solid state

The invention relates to a NASICON type solid electrolyte with high ionic conductivity and a preparation method thereof. The method comprises the following steps that B2O3 is introduced into Li1+xAlxGe2-xP3O12 (x is greater than or equal to 0 and less than or equal to 1, and the following x is within the range) microcrystalline glass to further lower the activation energy of Li+ ions, so that theionic conductivity of the microcrystalline glass is improved. The NASICON solid electrolyte main body is Li1+xAlxGe2-xP3O12 microcrystalline glass, which comprises the following molar components: 14.82-25.00mol% of Li2O, 24.69-45.00mol% of GeO2, 2.47-12.50mol% of Al2O3, 37.04-37.50mol% of P2O5 and 0.01-1.23mol% of B2O3. According to the preparation method disclosed by the invention, a platinum crucible is adopted to prepare a glass precursor, and then the glass precursor is subjected to heat treatment in a muffle furnace to obtain the microcrystalline glass solid electrolyte with the NASICON structure. By controlling the doping concentration of B2O3, the ionic conductivity of the NASICON type solid electrolyte at normal temperature is improved by about four times; and the solid electrolytehas the advantages of high ionic conductivity, no toxicity, safety, stability, easiness in processing and the like, and has a great application prospect in all-solid state lithium batteries.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Doped BKT-BT series lead-free PTCR ceramic material and preparation method thereof

InactiveCN101624284BIncrease the slopeRaise resistance kickThermometers using electric/magnetic elementsUsing electrical meansTemperature coefficientPositive temperature

The invention relates to a doped BKT-BT series lead-free positive temperature coefficient resistance ceramic material and a prepration method thereof, the general formula of the composition of the material is (Bi0.5K0.5)*1(Ba1-*1-*2)AX2)Ti1-yMyO3+Zmol%D, wherein, x1 is more than 0 and not more than 0.7, x2 is more than 0 and not more than 0.6%, y is more than 0 and less than 0.2%, Z is not less than 0 and less than 1, A is one or more of Ce, Y, La and Bi, M is one or more of Nb, Sb, Ta and Mo, and D is one or more of MnO2, TiO2, SiO2 and B2O3. For a series of the lead-free ceramic materials, TC, alpha, betaRT and resistance sudden jump Rmax / Rmin are respectively changed between 140 and 250 DEG C, between 10 and 45% / DEG C, between 20 and 60 omega.Cm and between 10<2> and 10<5> along with the change of x1, x2, y and Z.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

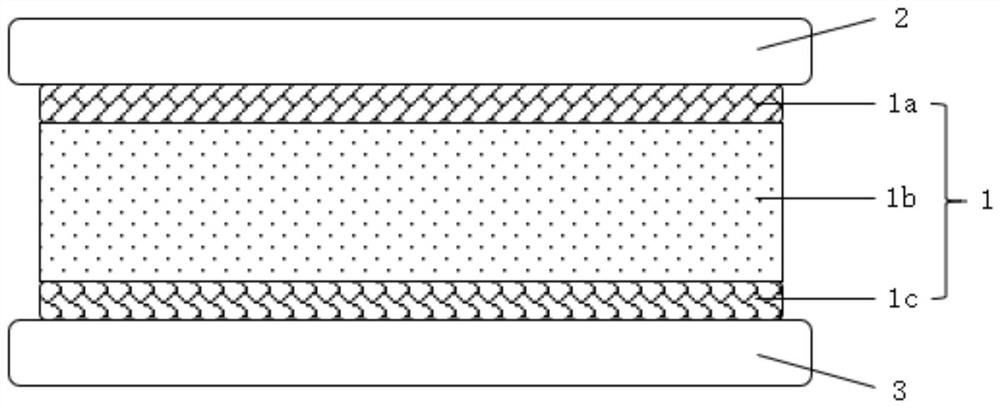

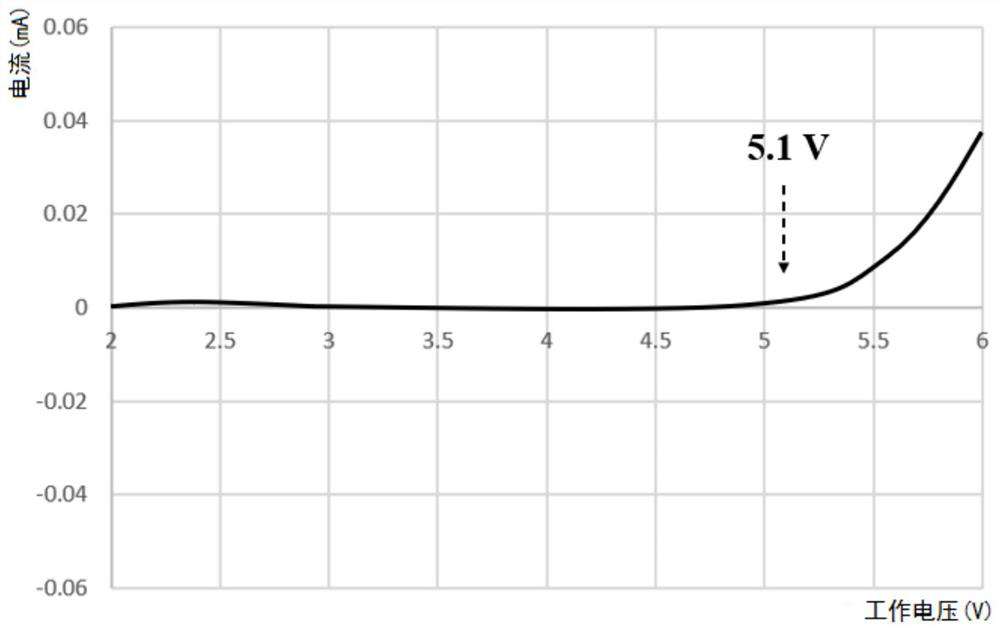

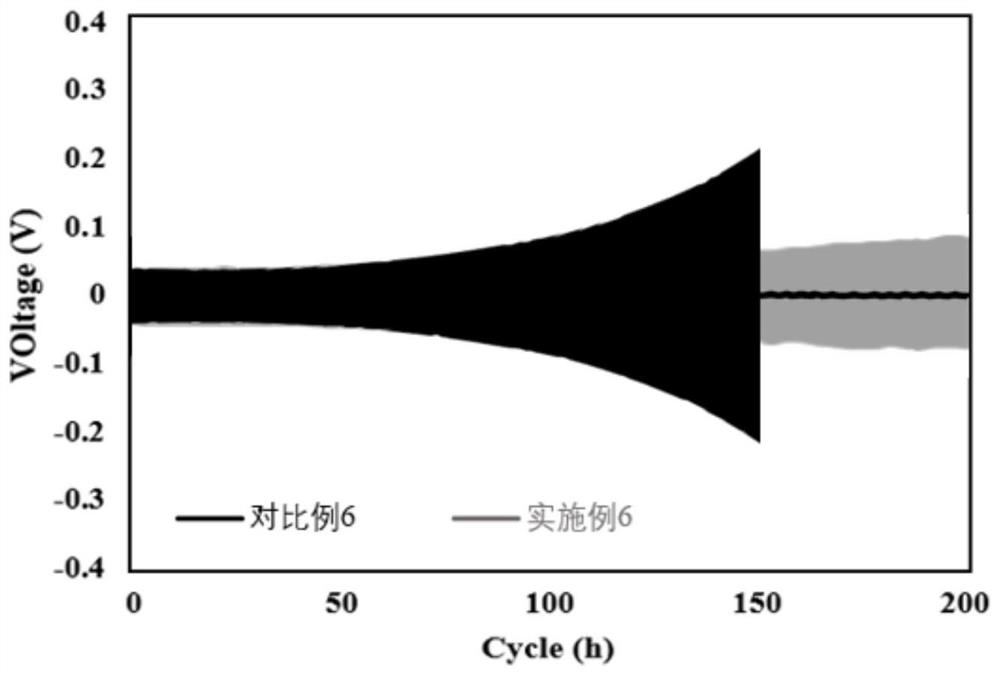

Electrochemical device and electronic equipment

ActiveCN112701347AImprove surface wettabilityLower grain boundary resistanceSecondary cellsElectrolyte immobilisation/gelificationPhysicsCyclic stability

The invention provides an electrochemical device and electronic equipment. The electrochemical device comprises an electrolyte layer, a positive electrode layer and a negative electrode layer, the electrolyte layer comprises a near-positive-electrode-side electrolyte layer, an intermediate electrolyte layer and a near-negative-electrode-side electrolyte layer which are sequentially stacked, the electrolyte layer is arranged between the positive electrode layer and the negative electrode layer, the near-positive-electrode-side electrolyte layer is close to the positive electrode layer, and the near-negative-electrode-side electrolyte layer is close to the negative electrode layer; the near-positive-electrode-side electrolyte layer and the near-negative-electrode-side electrolyte layer are polymer electrolyte layers; the positive electrode layer comprises a positive electrode electrolyte skeleton and a positive electrode active layer filling the positive electrode electrolyte skeleton, and the composition of the positive electrode electrolyte skeleton is the same as that of the near positive electrode side electrolyte layer; and the intermediate electrolyte layer is an inorganic solid electrolyte layer. The electrochemical device is high in mechanical property, the physical contact between the electrolyte layer and the electrode layer is good, the interface stability is good, and the lithium ion transmission capacity and the cycling stability are high.

Owner:ZHUHAI COSMX BATTERY CO LTD

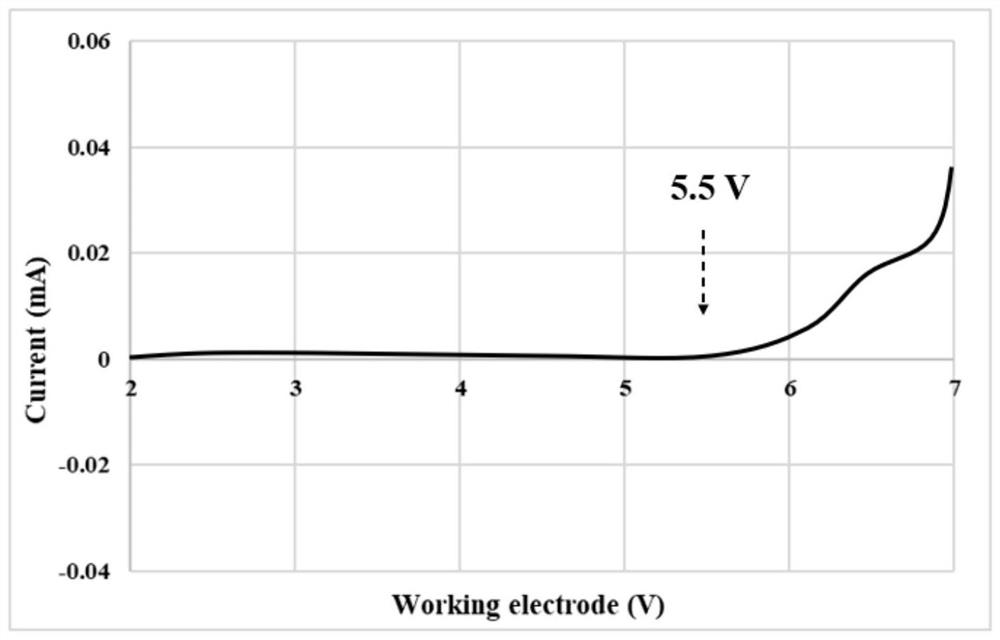

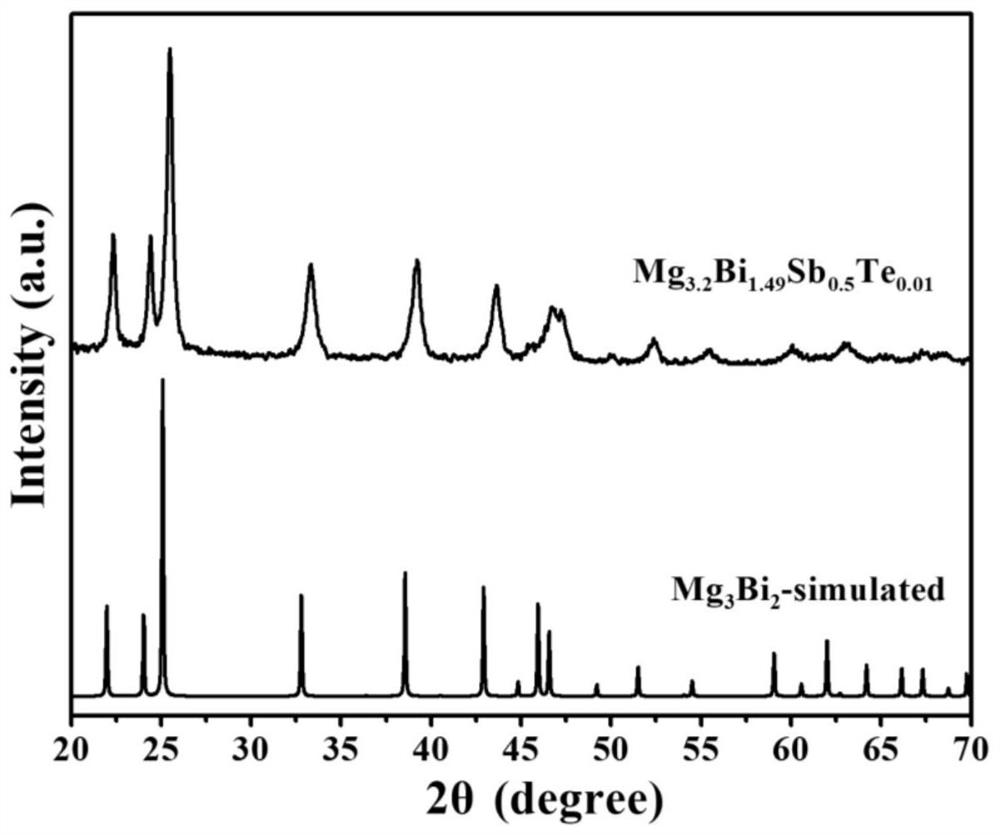

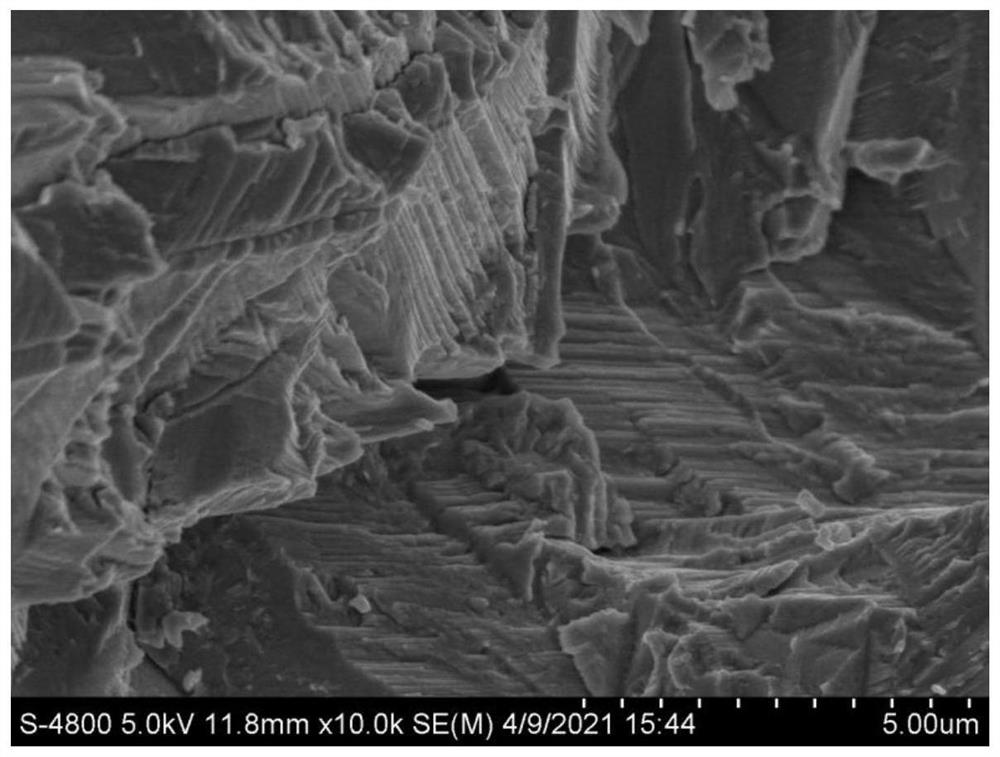

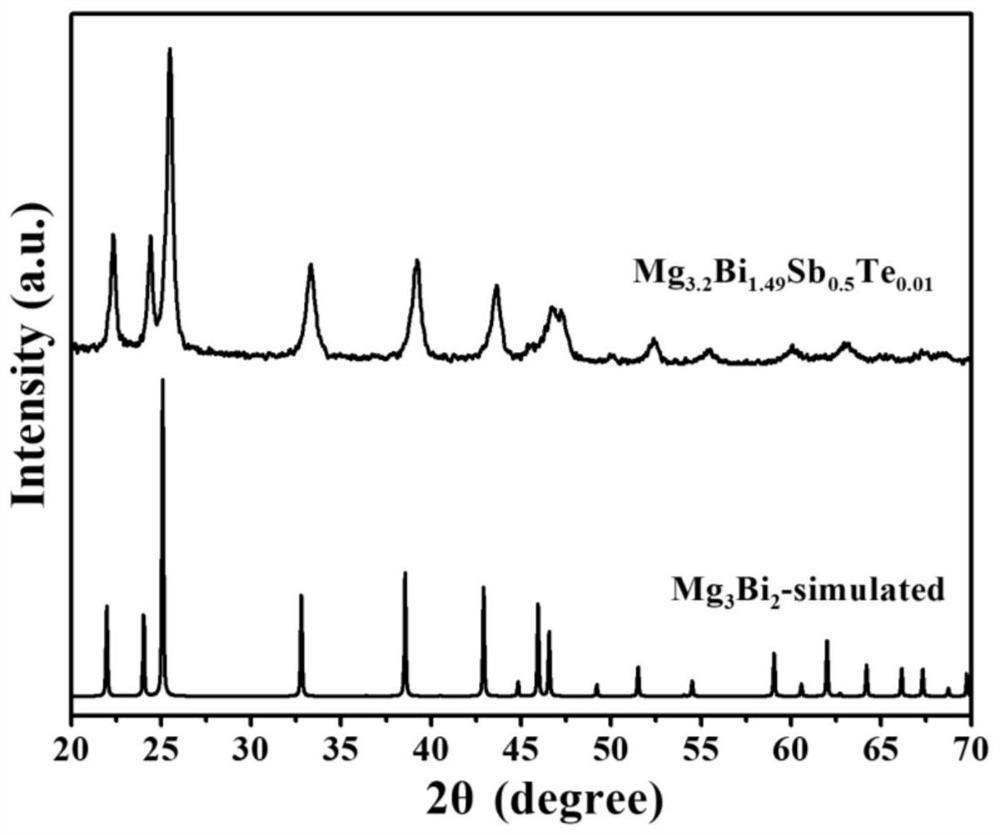

Mg-Bi-based lamellar block crystal material and growth method thereof

ActiveCN113235167AReuse high efficiencyLow cost preparationPolycrystalline material growthFrom frozen solutionsPhysicsSeed crystal

The invention provides an Mg-Bi-based lamellar block crystal material and a growth method thereof. The crystal structure of the crystal material is Mg3Bi2 configuration and presents a shale-shaped morphology. The growth method comprises the following steps: under the protection of vacuum or inert atmosphere, heating a vacant non-metal crucible for growing crystals to a preset temperature; and injecting a molten Mg-Bi-based crystal growth raw material solution into the non-metal crucible which is heated to the preset temperature, and carrying out crystal growth through a Bridgman-Stockbarger method or a seed crystal oriented growth method to obtain the Mg-Bi-based lamellar block crystal material. The growth method is simple in process and low in cost, crystals can be prepared in an amplified mode, and the Mg-Bi matrix block crystal material obtained through the growth method has a large-size, high-quality and regular layered structure, shows excellent thermoelectric performance near the room temperature and can be directly applied to preparation of thermoelectric devices.

Owner:SHANDONG UNIV

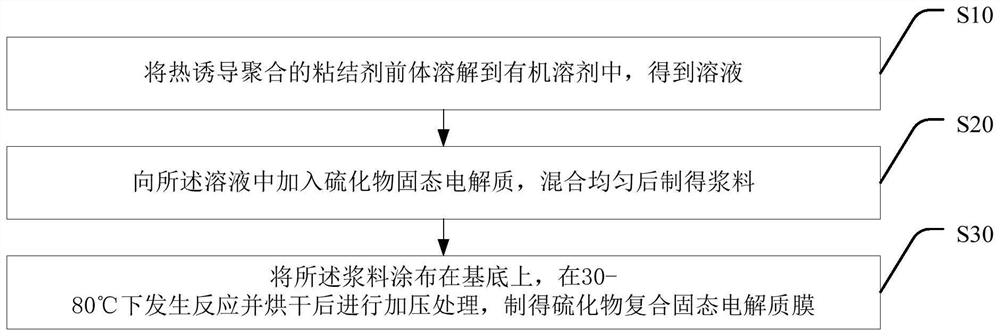

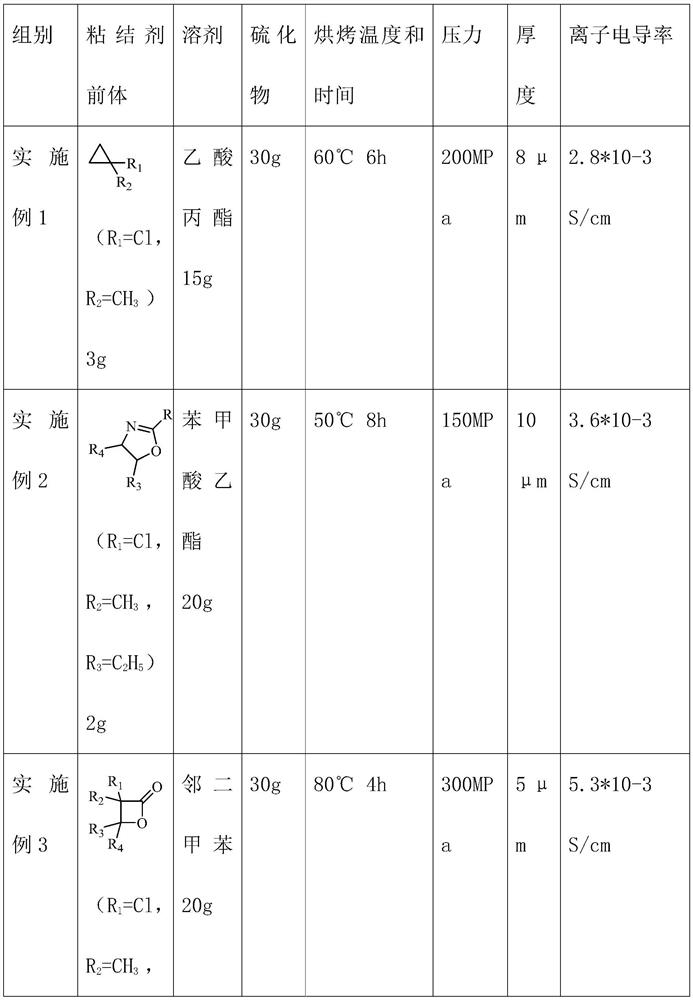

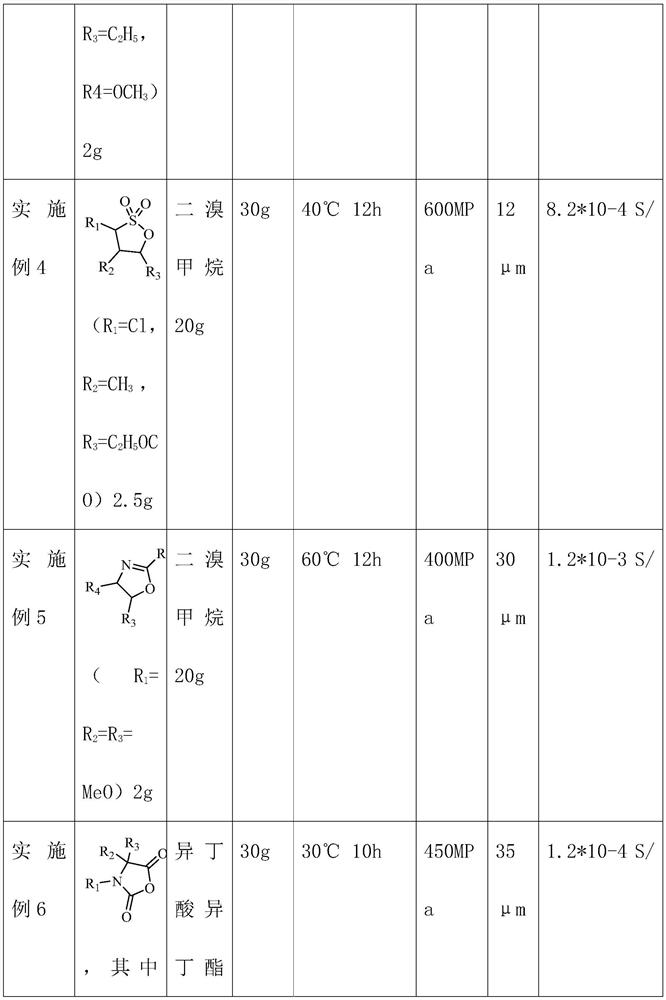

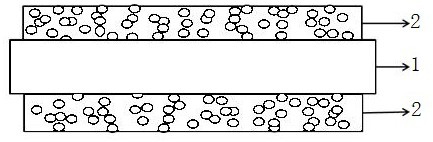

Sulfide composite solid-state electrolyte membrane, preparation method thereof and solid-state battery

ActiveCN114824273ALower grain boundary resistanceHigh mechanical strengthCell electrodesLi-accumulatorsSolid state electrolyteOrganic solvent

The invention discloses a sulfide composite solid-state electrolyte membrane, a preparation method thereof and a solid-state battery, and the preparation method comprises the following steps: dissolving a thermally-induced polymerized binder precursor in an organic solvent to obtain a solution; adding sulfide solid electrolyte into the solution, and uniformly mixing to obtain slurry; and coating the slurry on a substrate, reacting at 30-80 DEG C, drying, and pressurizing to prepare the sulfide composite solid electrolyte membrane. Due to the adoption of the thermally-induced polymerized binder precursor, the large-area preparation process of the composite solid electrolyte membrane is simple and convenient, and the composite solid electrolyte membrane has higher mechanical strength and flexibility and higher ionic conductivity (greater than or equal to 10 <-4 > S / cm).

Owner:广东马车动力科技有限公司

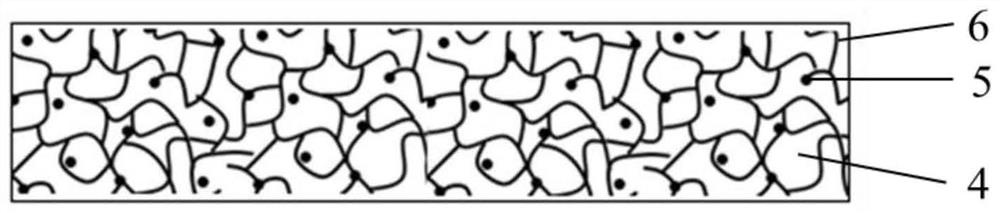

All-solid-state three-layer electrolyte and preparation method of all-solid-state battery

InactiveCN112467199AEasy to makeReduce manufacturing costSolid electrolytesFinal product manufactureSolid state electrolyteComposite electrolyte

The invention discloses an all-solid-state three-layer electrolyte and a preparation method of an all-solid-state battery. The composite electrolyte has a three-layer structure, and comprises a compact layer in the middle and porous layers located at two sides of the compact layer, the whole preparation process is simple, the preparation cost is low, and no pollution is caused to the environment.The solid electrolyte with the composite structure can effectively improve the interface compatibility of the electrolyte / electrode and reduce the interface impedance, and is beneficial to rapid transmission of metal ions (lithium, sodium, potassium ions and the like) on an interface; the electrolyte comprises the porous layer which is crosslinked with the anode and the cathode, so that the electrolyte has an ion conduction phase and an electron conduction phase at the same time, and the electrode activity and the structural stability can be improved; the effective contact area between the cathode and anode active materials and the electrolyte is increased, so that reaction activation sites are increased, the capacity and rate capability of the solid-state battery are improved, and the electrolyte can be used in all-solid-state lithium, sodium, potassium, Al and Zn plasma solid-state batteries.

Owner:JIANGSU UNIV OF SCI & TECH

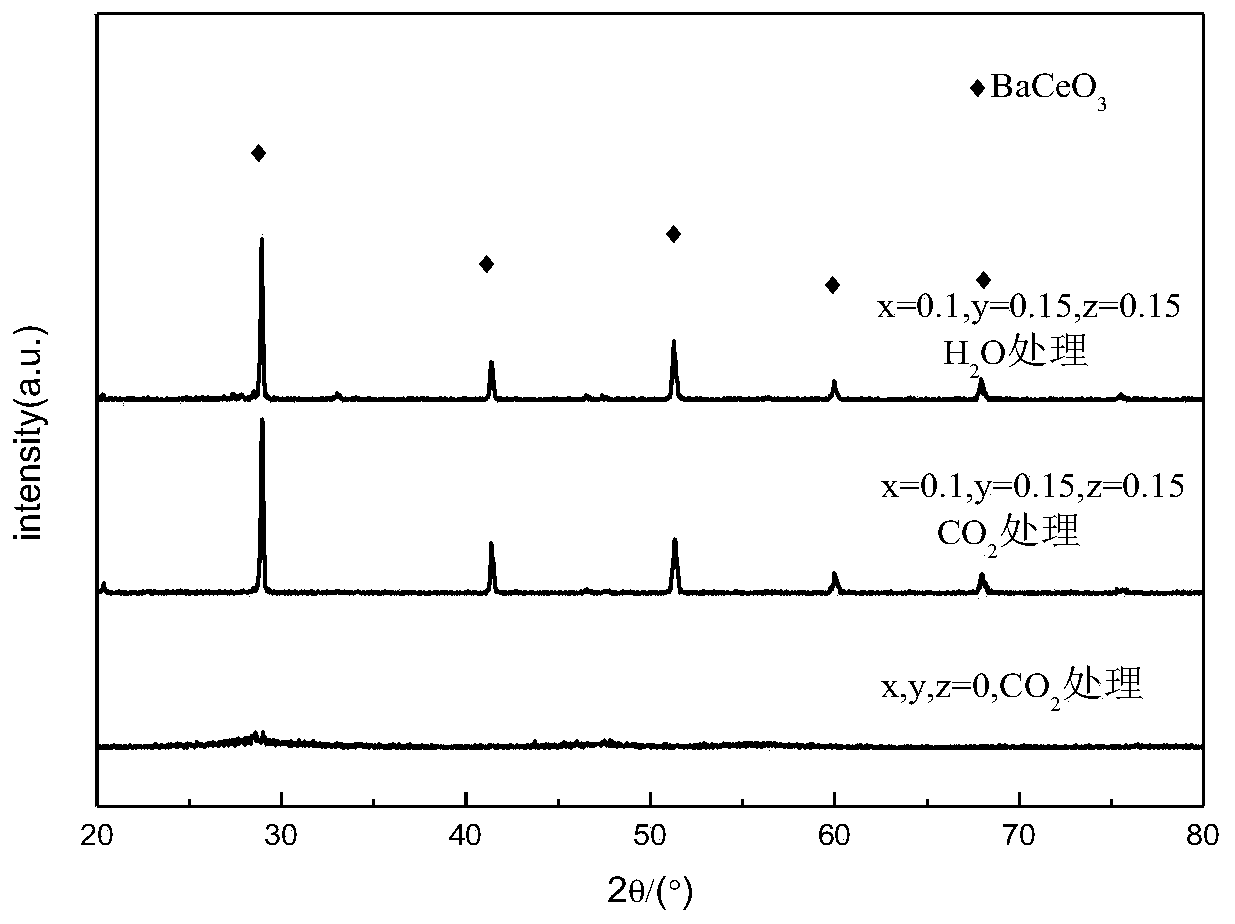

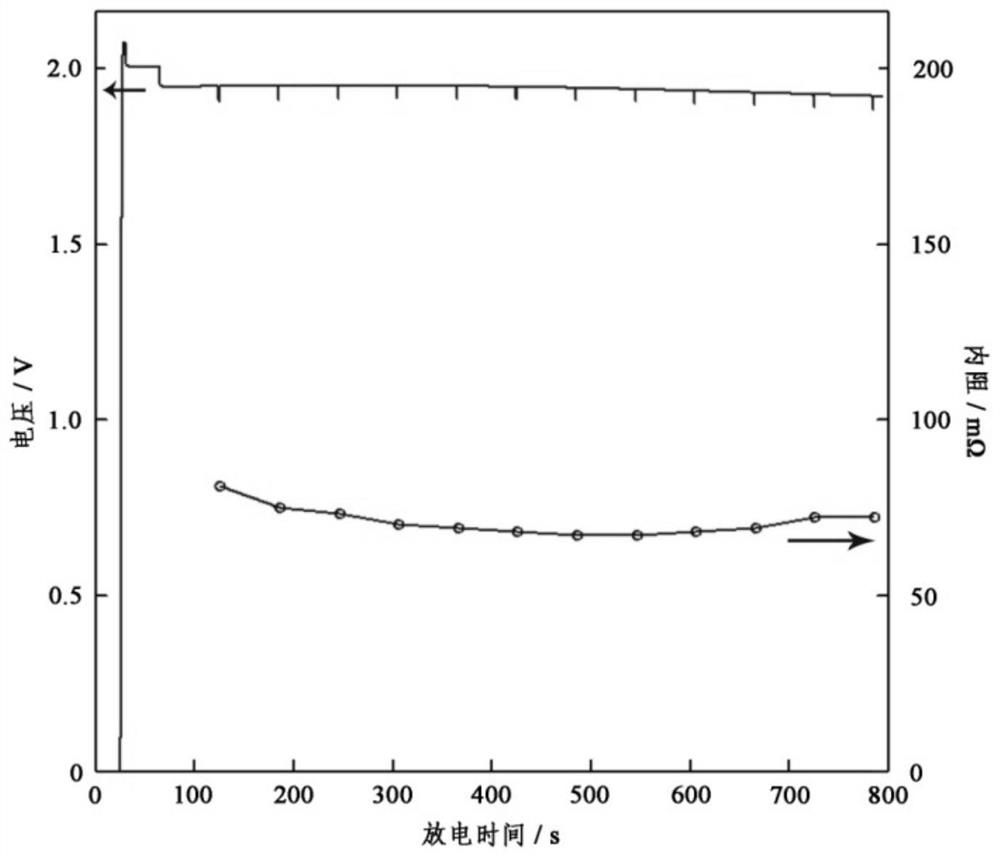

Double-doped BaCeO3-based proton conduction electrolyte material as well as preparation and application thereof

PendingCN110707346AAddressing Chemical Stability IssuesImprove sintering performanceElectrolytesFuel cellsFuel cellsPhysical chemistry

The invention relates to the technical field of fuel cell electrolytes, in particular to a double-doped BaCeO3-based proton conduction electrolyte material as well as preparation and application thereof. The double-doped BaCeO3-based proton conduction electrolyte material is prepared by doping different elements to Ba and Ce sites in a BaCeO3 material and taking the nano antimony tin oxide powderas an additive, wherein the Ba site in the BaCeO3 material is doped with K, the Ce site in the BaCeO3 material is doped with Zr and Sm at the same time, so that the chemical stability problem of the BaCeO3 electrolyte material in an acid gas and an H2O environments can be solved, and the sintering performance of the BaCeO3 electrolyte material is remarkably improved. In addition, the ATO is used as an additive, so that the sintering performance and the proton conduction performance can be further improved.

Owner:GUANGDONG UNIV OF TECH

Composite solid electrolyte and lithium ion battery comprising same

PendingCN113285117AImprove performanceReduce impuritySecondary cellsElectrolytesSolid state electrolytePhysical chemistry

The invention relates to the technical field of lithium ion batteries, in particular to a composite solid electrolyte and a lithium ion battery comprising the same. According to the composite solid electrolyte, impurities on the surface of the oxide solid electrolyte can be eliminated, the oxide solid electrolyte is converted into lithium halide in situ, continuous reaction between the oxide solid electrolyte and water and carbon dioxide in air can be blocked through formation of the lithium halide, and the oxide solid electrolyte is not corroded; the stability of the oxide solid electrolyte in the air is improved; meanwhile, the introduced sintering aid can be filled in gaps among crystal grains of the oxide solid electrolyte, so that the density of the oxide solid electrolyte is improved, the grain boundary resistance of the oxide solid electrolyte is reduced, and the performance of the composite solid electrolyte is further improved.

Owner:ZHUHAI COSMX BATTERY CO LTD

Solid electrolyte, preparation method thereof and lithium ion battery

PendingCN112635819AReduce porosityLower grain boundary resistanceSolid electrolytesSecondary cellsLithium dendriteLithium electrode

The invention relates to a solid electrolyte, a preparation method thereof and a lithium ion battery, the solid electrolyte comprises the following raw materials: an oxide electrolyte, and a sintering aid, a polymer and a lithium salt which are filled in the oxide electrolyte, the solid electrolyte provided by the invention has relatively small grain boundary resistance and good interface performance, when applied to a lithium ion battery, the solid electrolyte has high ionic conductivity, can effectively inhibit the growth of lithium dendrites, and improves the comprehensive properties such as safety, cyclicity and stability of the battery.

Owner:ZHUHAI COSMX BATTERY CO LTD

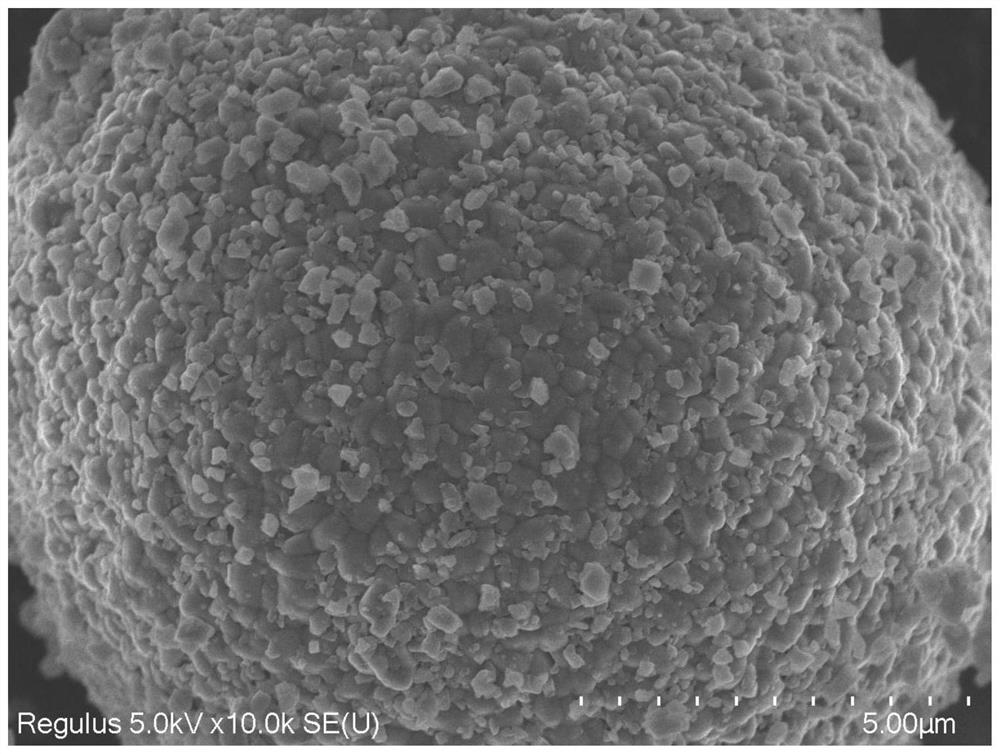

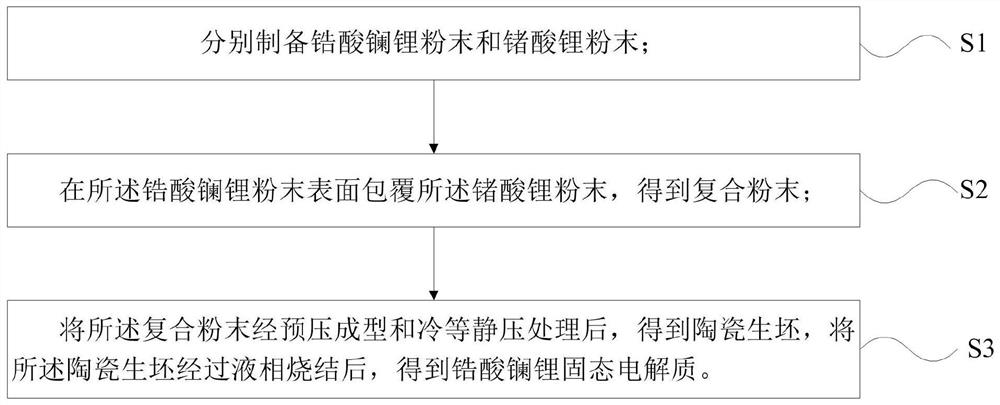

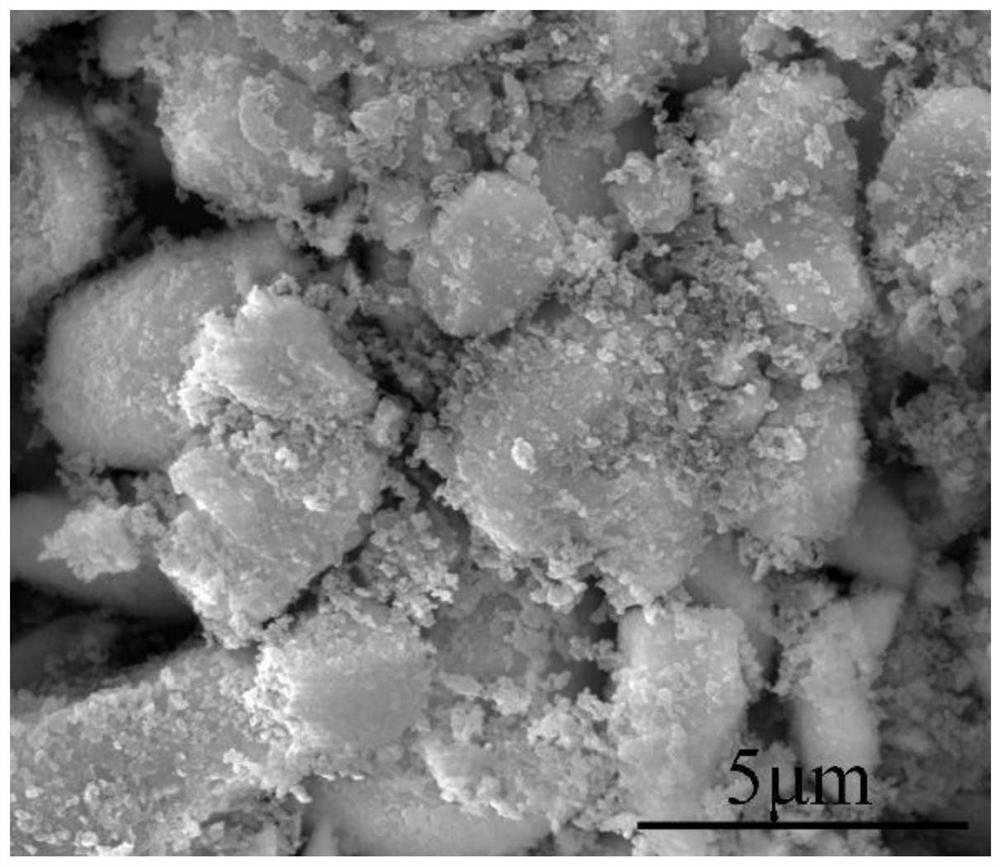

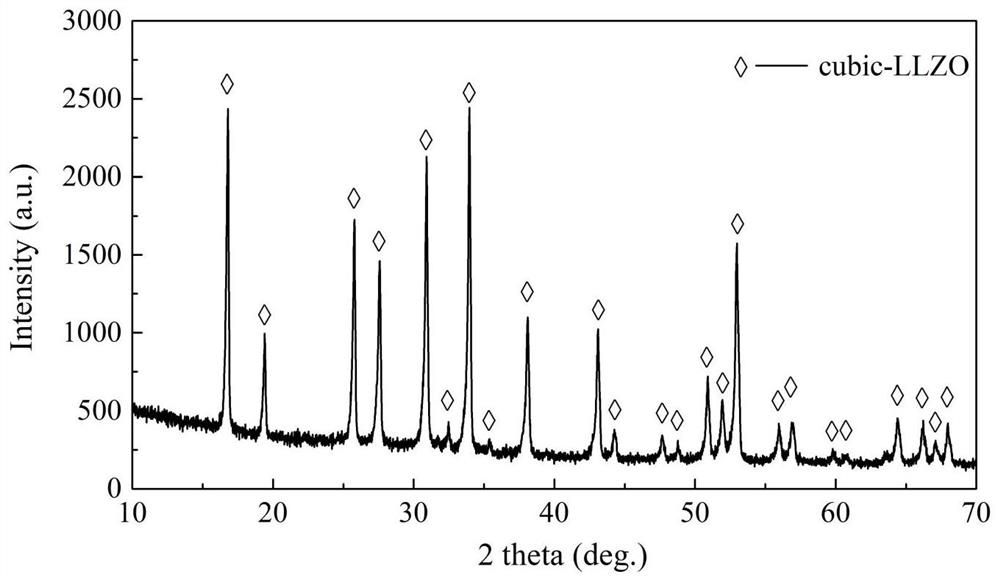

A kind of lanthanum lithium zirconate solid electrolyte and preparation method thereof

ActiveCN112537958BLower Intrinsic ResistanceMitigate volatilizationFinal product manufactureElectrolytesSolid state electrolyteCompression molding

The invention provides a lanthanum lithium zirconate solid electrolyte and a preparation method thereof, comprising the following steps: step S1, preparing lanthanum lithium zirconate powder and lithium germanate powder respectively; step S2, coating the surface of the lanthanum lithium zirconate powder Covering the lithium germanate powder to obtain a composite powder; step S3, subjecting the composite powder to pre-pressing and cold isostatic pressing to obtain a ceramic green body, and sintering the ceramic green body in liquid phase to obtain Lithium lanthanum zirconate solid electrolyte. The present invention reduces the volatilization of lithium ions during the sintering process and simultaneously reduces the grain boundary resistance and intrinsic resistance, thereby achieving the purpose of greatly improving the ion conductivity of the lithium lanthanum zirconate solid electrolyte.

Owner:HARBIN INST OF TECH

Anode material for alkaline zinc-manganese dry battery and alkaline zinc-manganese dry battery

ActiveCN107732231BImprove securityImprove stabilityElectrode manufacturing processesElectrode carriers/collectorsElectrolysisElectrical battery

The invention discloses a cathode material of alkaline zinc-manganese dioxide dry cells and alkaline zinc-manganese dioxide dry cells, and belongs to the field of chemical power supplies. The invention aims at solving a technical problem that is providing the cathode material of novel alkaline zinc-manganese dioxide dry cells and alkaline zinc-manganese dioxide dry cells containing the cathode material. The cathode material of alkaline zinc-manganese dioxide dry cells comprises the following components in parts by mass: 120-180 parts of electrolytic manganese dioxide, 8-14 parts of a cathode conductive material, 0.5-1.2 parts of a bonding agent, 3.5-6 parts of an aqueous solution of potassium hydroxide, and 0.02-9 parts of barium titanate. The alkaline zinc-manganese dioxide dry cells employ the cathode material of the alkaline zinc-manganese dioxide dry cells to prepare battery cathodes. Barium titanate is added into the cathode manufacture process of the alkaline zinc-manganese dioxide dry cells, continuous rise of cell short circuit temperature is blocked, and at the same time, addition of barium titanate does not induce reduction of discharge performance of cells; the alkalinezinc-manganese dioxide dry cells have the characteristics of high efficiency, high safety, and high stability.

Owner:SICHUAN CHANGHONG NEWENERGY TECH

Sulfur-based lithium-rich solid electrolyte and its preparation method and application

ActiveCN109830741BImprove ionic conductivityImprove stabilityLi-accumulatorsLithiumPhysical chemistry

The invention discloses a sulfur-based lithium-rich solid state electrolyte, a preparation method and application thereof. Wherein, the sulfur-based lithium-rich solid electrolyte includes wherein, 0≦x<3, 0≦a<1, M is at least one selected from Ba, Mg, Ca and Sr, and A is selected from Cl, I, Br and BF 4 at least one of the . The sulfur-based lithium-rich solid electrolyte has excellent ionic conductivity and stability.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

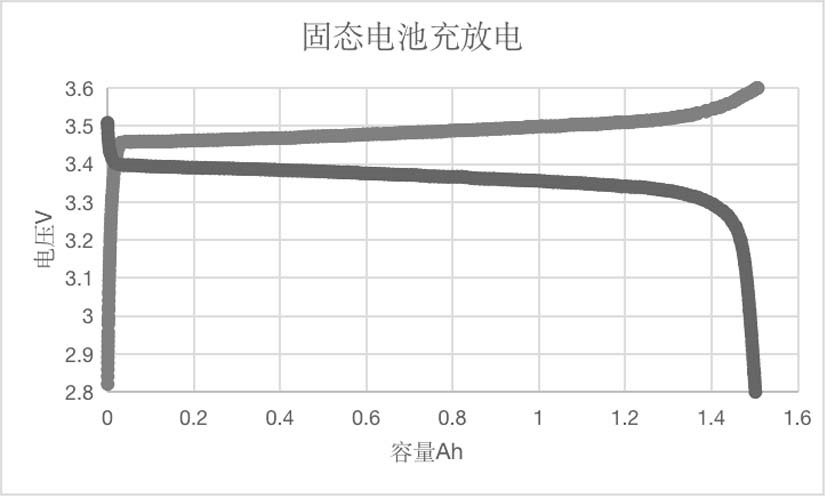

High-capacity all-solid-state battery and preparation method thereof

PendingCN113690486AImprove securityImprove electrochemical performanceLi-accumulatorsElectrolyte immobilisation/gelificationSolid state electrolyteElectrical battery

The invention discloses a high-capacity all-solid-state battery and a preparation method thereof. The preparation method comprises the steps: mixing an active component and a solvent to prepare slurry, coating a metal base foil with the slurry, removing the solvent, and obtaining a positive electrode; mixing PEO, LATP, LAGP, a lithium salt and a wetting agent to prepare a coating; coating the coating on the positive electrode, removing the wetting agent, and compounding with the negative electrode to obtain the high-capacity all-solid-state battery. LATP / LAGP cannot be prepared into a compact and uniform electrolyte membrane, and the contact wettability between the LATP / LAGP and an electrode material is relatively poor, so the transmission of lithium ions is hindered, and the performance of the battery is reduced. The PEO, the LATP and the LAGP are compounded to prepare the composite solid electrolyte, lithium ions can be conducted along the surface and can also penetrate through the solid electrolyte to be conducted, high ionic conductivity, thermal stability and a wide electrochemical window can be achieved, the grain boundary resistance of the solid electrolyte is reduced, and the conductivity of the electrolyte and the safety of a battery are improved.

Owner:星恒电源(滁州)有限公司

A two-component solid electrolyte layer-free interface all-solid-state thin-film battery and its preparation method

ActiveCN104183871BImprove close contactMove fastFinal product manufactureElectrolyte accumulators manufactureAll solid stateGrain boundary

A two-component solid electrolyte layerless interface all-solid-state thin-film battery and its preparation method, characterized in that it adopts supersonic flame spraying to deposit Al3+ doped Li7La3Zr2O12 and Li at the same time when using a liquid spray gun to electrostatically spray and pyrolyze the positive and negative active material precursors: The method of BPO4 two-component solid electrolyte eliminates the two contact interfaces of positive electrode material | solid electrolyte and negative electrode material | solid electrolyte, reduces the grain boundary between Al3+ doped Li7La3Zr2O12 particles, greatly reduces the interface and grain boundary impedance, and improves the overall performance. Solid-state thin-film lithium battery performance.

Owner:陕西宸立崇电子有限公司

Preparation method of llzo, quasi-solid electrolyte for thermal battery and preparation method thereof

ActiveCN109879316BImprove conductivityLoose structureElectrolye immobilisationSolid state electrolytePhysical chemistry

The invention relates to a preparation method of LLZO, a quasi-solid electrolyte for thermal batteries and a preparation method thereof. The preparation method of the quasi-solid electrolyte comprises: mixing Li 2 CO 3 , La 2 o 3 , ZrO 2 、H 2 C 2 o 4 and alkali metal halides and other raw materials for purification; weigh the required Li 2 CO 3 , La 2 o 3 、H 2 C 2 o 4 and ZrO 2 Put it into a sealed stainless steel tank after grinding evenly, bake it under the condition of 1200 °C, cool it naturally and grind it into a ball mill to get a lithium lanthanum zirconium oxygen solid electrolyte (Li 7 La 3 Zr 2 o 12 , LLZO); LLZO and alkali metal halide eutectic salt were mixed again, and the temperature was rapidly raised to 400‑500 °C under the protection of argon, and the eutectic salt was infiltrated into the porous LLZO by repeated vacuuming and slow pressure. In the process, the quasi-solid electrolyte for thermal batteries can be obtained after natural cooling and ball milling of the product. The quasi-solid electrolyte prepared by the invention has the advantages of small grain boundary resistance, high ion mobility, good thermal stability and the like.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

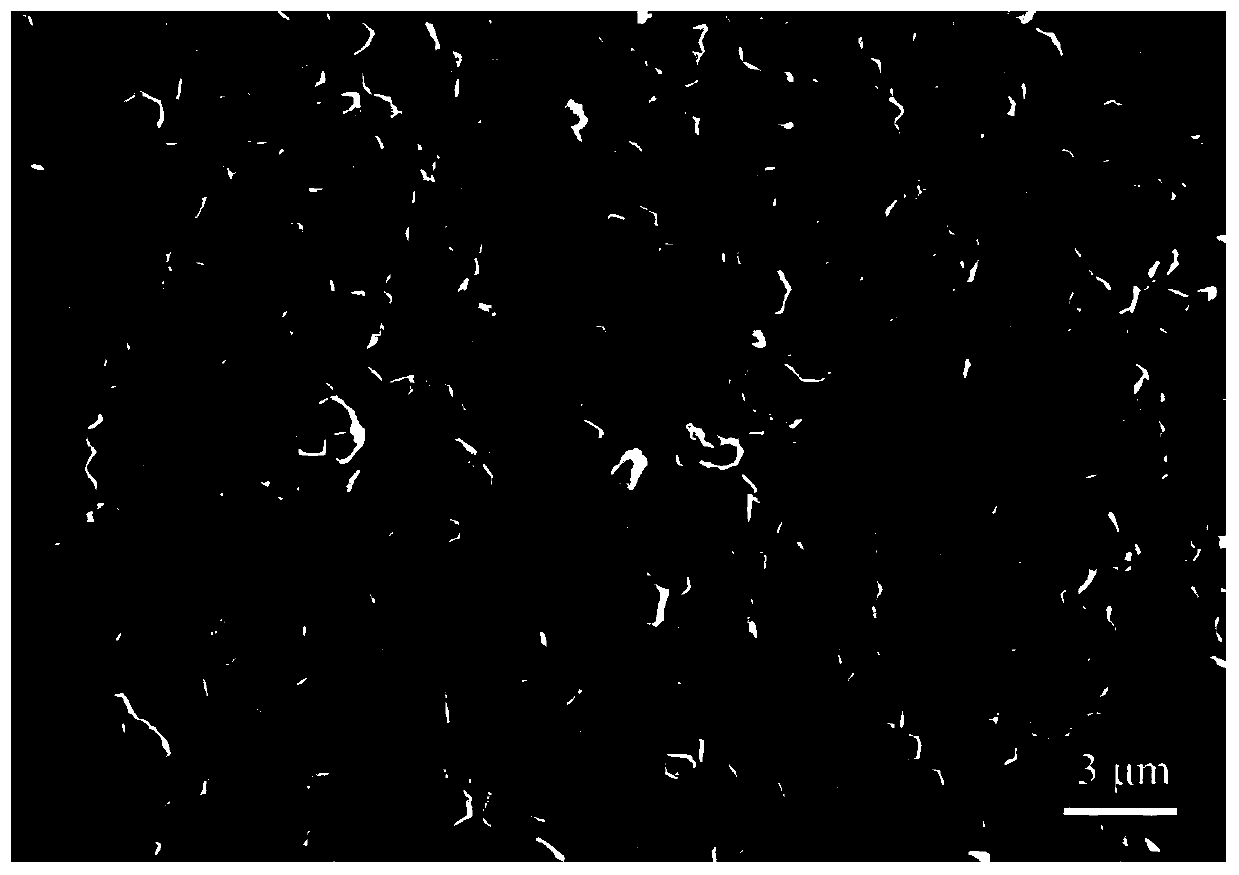

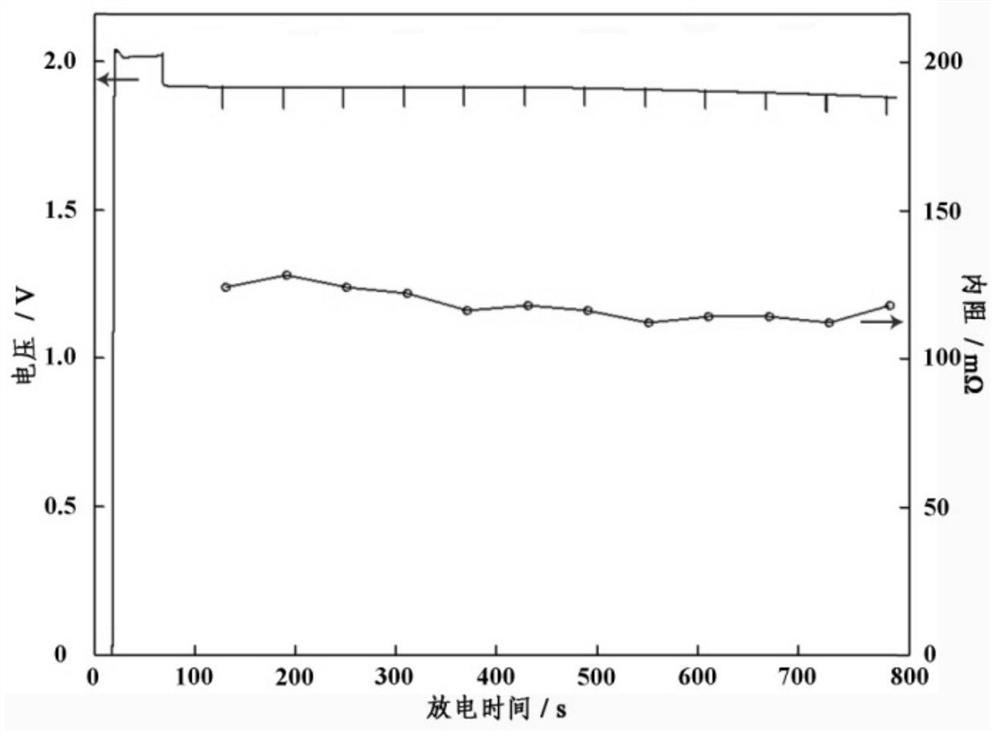

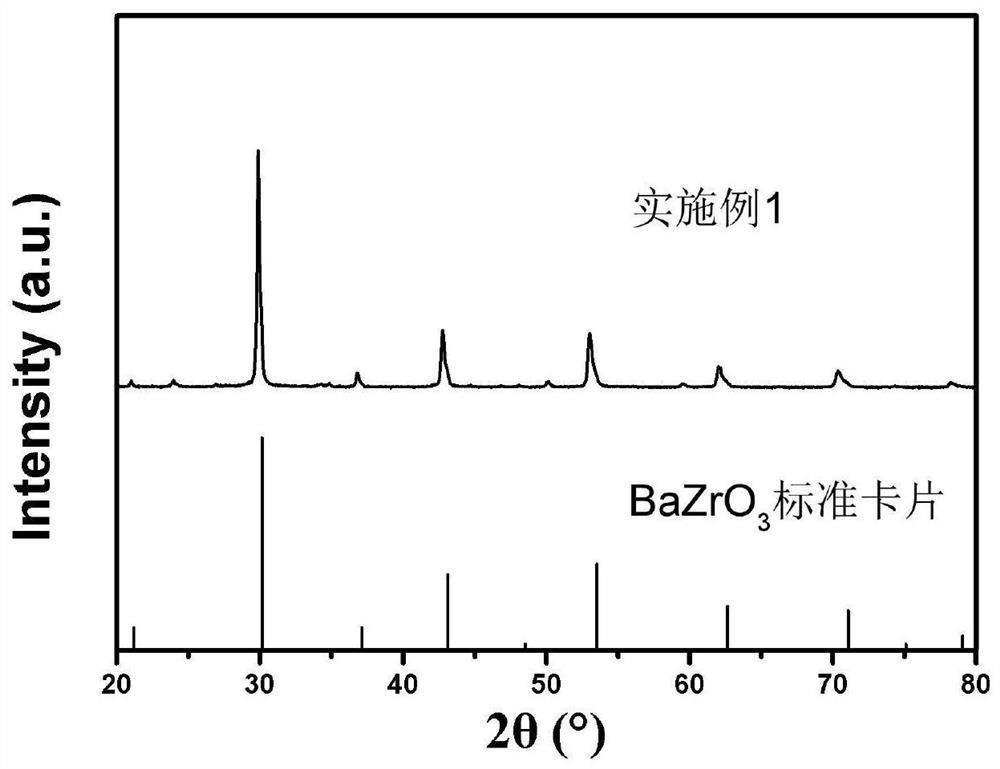

Preparation method of high-conductivity perovskite type BaZrO3-based proton conductor material with controllable grain size

ActiveCN113666415AEvenly dispersedControllable grain sizeZirconium compoundsFuel cellsChemical synthesisChemical composition

The invention discloses a preparation method of a high-conductivity perovskite type BaZrO3-based proton conductor material with a controllable grain size. According to the method, (ZrO2)1-x(Y2O3)x (x is larger than or equal to 0.05 and smaller than or equal to 0.08) powder is adopted as an initial raw material, and the BaZrO3-based proton conductor powder material with the controllable grain size is synthesized at the low temperature. According to the invention, the problems of wide grain size distribution and non-uniform chemical composition in the traditional solid-phase synthesis process, tedious steps and difficult grain growth in the wet-chemical synthesis process. and the like are solved; the perovskite type BaZrO3-based proton conductor material prepared by the method is regular in shape, high in crystallinity and uniform in dispersion; and after densification treatment, the proton conductivity is good, the grain boundary impedance is greatly reduced, and the conductivity at 600 DEG C can reach 4.92*10<-3> S cm<-1>.

Owner:NANJING UNIV OF TECH

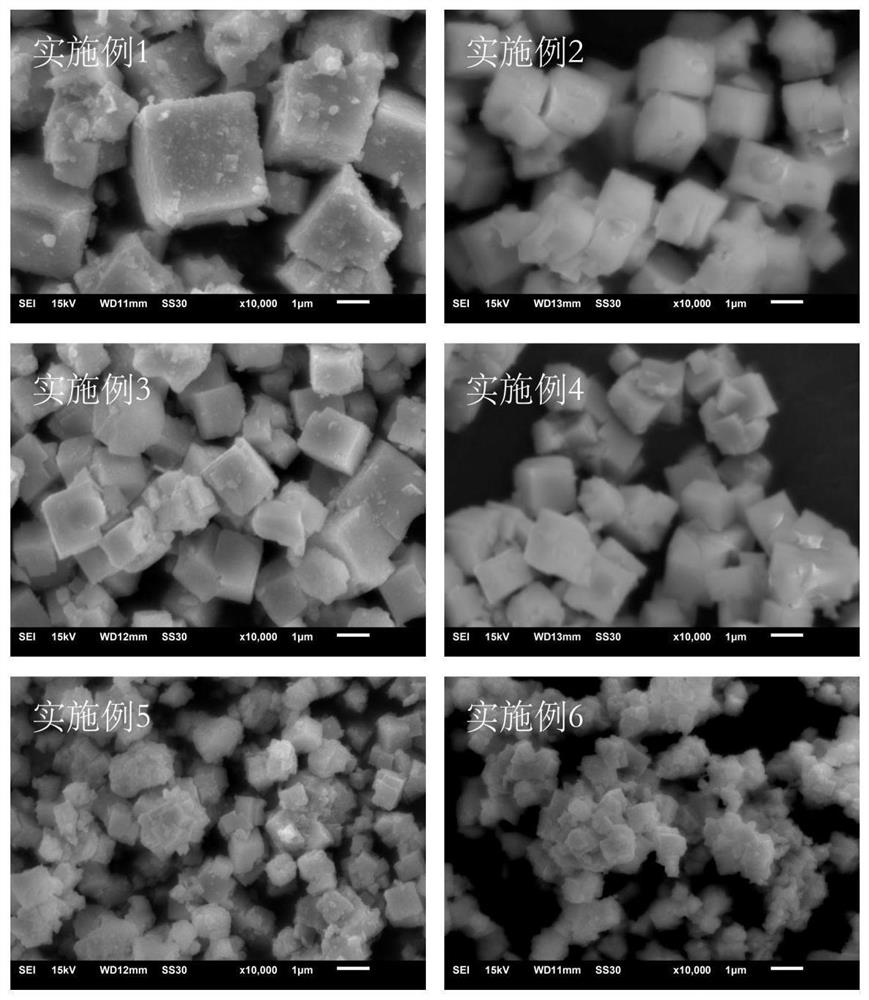

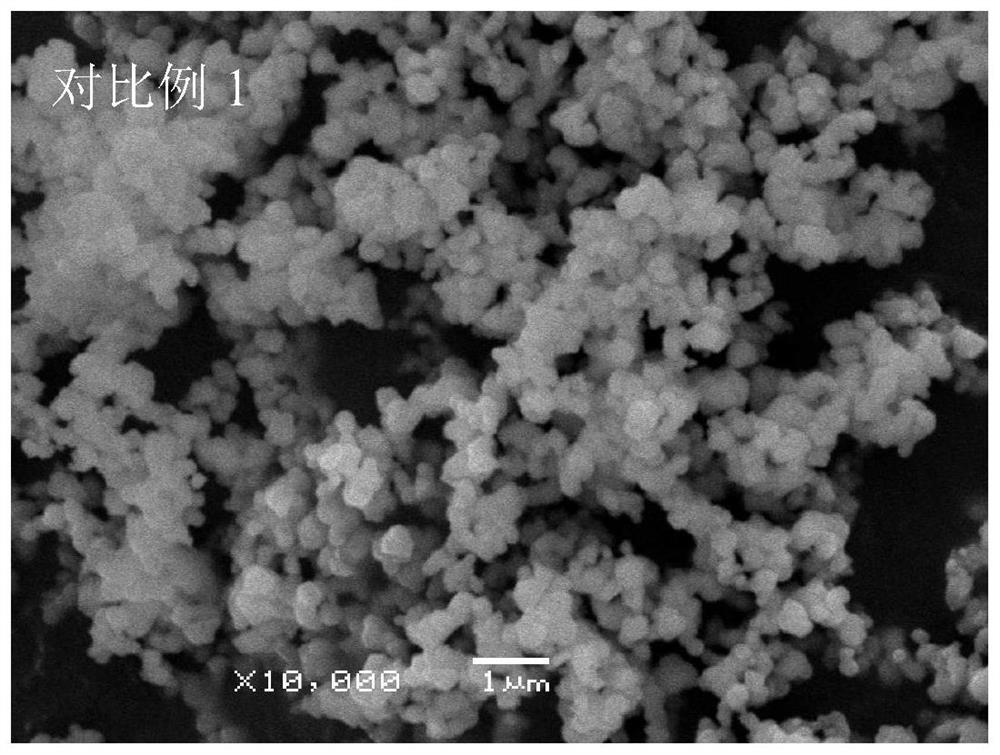

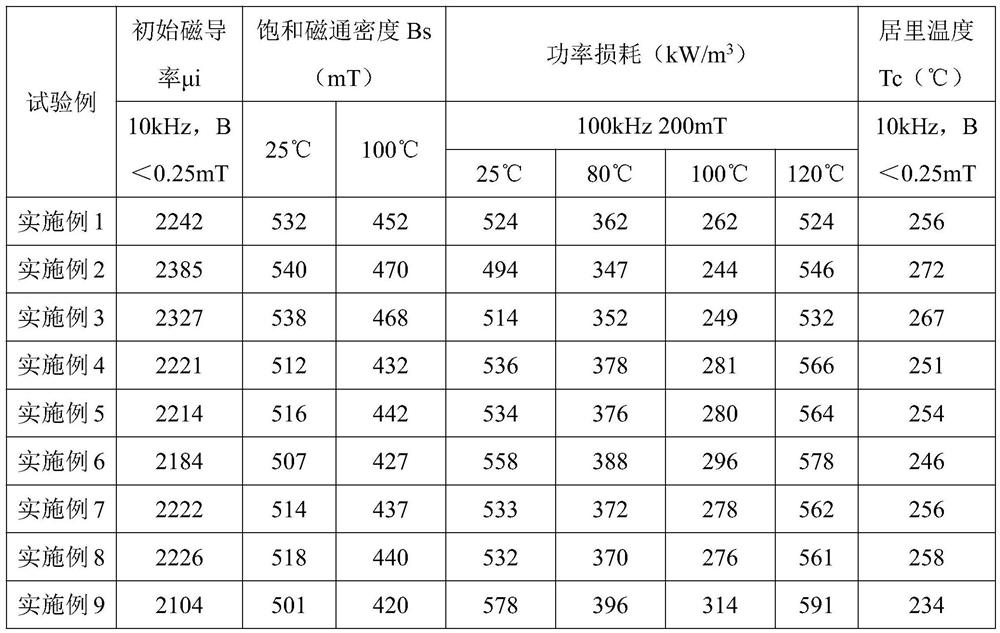

Preparation method of soft magnetic ferrite material

InactiveCN114656254AIncrease internal stressHigh densityInorganic material magnetismInductances/transformers/magnets manufactureMicron scaleSoft magnet

The invention provides a preparation method of a soft magnetic ferrite material, which comprises the following steps: S1, primary ball milling of a main material: grinding the main material in a ball mill to a micron level, drying, and cooling to room temperature; s2, pre-sintering: pre-sintering the cooled main material for a period of time, taking out, cooling, and blending with the auxiliary material; s3, secondary ball milling: putting the mixed main material and auxiliary material into a ball mill for secondary ball milling, and drying to obtain a pre-sintered mixture; and S4, mixing and grinding: grinding the pre-sintered mixture in a ball mill, drying after grinding, granulating, pressing, sintering and molding to obtain the target soft magnetic ferrite material. The invention provides the preparation method of the soft magnetic ferrite material with high saturation magnetic flux density and excellent magnetic performance.

Owner:湖北华磁电子科技有限公司

A kind of mg-bi based layered bulk crystal material and its growth method

ActiveCN113235167BSimplify processing stepsImprove quality and efficiencyPolycrystalline material growthFrom frozen solutionsBulk crystalCrucible

The invention provides a Mg-Bi-based layered bulk crystal material and a growth method thereof. The crystal structure of the crystal material is Mg 3 Bi 2 configuration, presenting a shale-like morphology; its growth method includes the steps of: under the protection of vacuum or inert atmosphere, heating an empty non-metallic crucible for growing crystals to a predetermined temperature; injecting molten Mg-Bi-based crystal growth raw material solution into In a non-metallic crucible heated to a predetermined temperature, the crystal is grown by a crucible descent method or a seed crystal directional growth method to obtain a Mg-Bi-based matrix bulk crystal material. The growth method of the present invention is simple in process, low in cost, and can be enlarged to prepare crystals. The Mg-Bi matrix bulk crystal material obtained by the growth method of the present invention has a large size, high quality and regular layered structure, and exhibits excellent crystallization near room temperature. Thermoelectric properties can be directly applied to the preparation of thermoelectric devices.

Owner:SHANDONG UNIV

Thin lithium battery and method for manufacturing same

PendingCN113785424AEasy to manufactureImprove productivitySolid electrolytesElectrochemical processing of electrodesPhysical chemistryLaser cutting

The present invention relates to a thin lithium battery and a method for manufacturing the same. Specifically, the present invention relates to a thin lithium battery having a tabless current collecting structure that does not require a separate tab or terminal unit because a current collector is exposed to the outside, and a method for manufacturing the same. In addition, the present invention relates to a thin lithium battery and a method for manufacturing the same, wherein the thin lithium battery has flexibility and can thus be applied to flexible devices, and does not require a separate terminal unit and can thus be manufactured into a wide variety of dimensions and designs by punching, such as by cutting, stamping, or laser cutting.

Owner:UBATT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com