Double-doped BaCeO3-based proton conduction electrolyte material as well as preparation and application thereof

A technology of electrolyte materials and matrix protons, applied in electrolytes, circuits, fuel cells, etc., can solve problems such as poor sintering performance and poor chemical stability, and achieve improved sintering performance, sintering performance and proton conductivity, and proton conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) According to double-doped BaCeO 3 The molecular formula of the proton-conducting electrolyte material is Ba 0.95 K 0.05 Ce 0.8 Zr 0.1 SM 0.1 o 3 The stoichiometric ratio weighs C 4 h 6 o 4 Ba(99.9%), KOH(99.9%), CeO 2 (99.9%), ZrO 2 (99.9%), Sm 2 o 3 (99.9%), and then using absolute ethanol as a dispersion medium, place the above-mentioned raw materials and grinding balls in a planetary ball mill for 12 hours at a speed of 300 rpm to obtain slurry 1;

[0045] (2) Place the slurry 1 prepared in step (1) in a vacuum drying oven to dry, and grind and sieve to obtain primary powder; then place the powder in a muffle furnace and heat up at a rate of 5°C / min Heating to 900°C, heat preservation and calcination for 8 hours to obtain white electrolyte powder, which is the primary powder;

[0046] (3) adding antimony tin oxide (ATO) as a sintering additive to the primary powder obtained in step (2) to obtain a mixed powder, wherein the consumption of antimony tin...

Embodiment 2

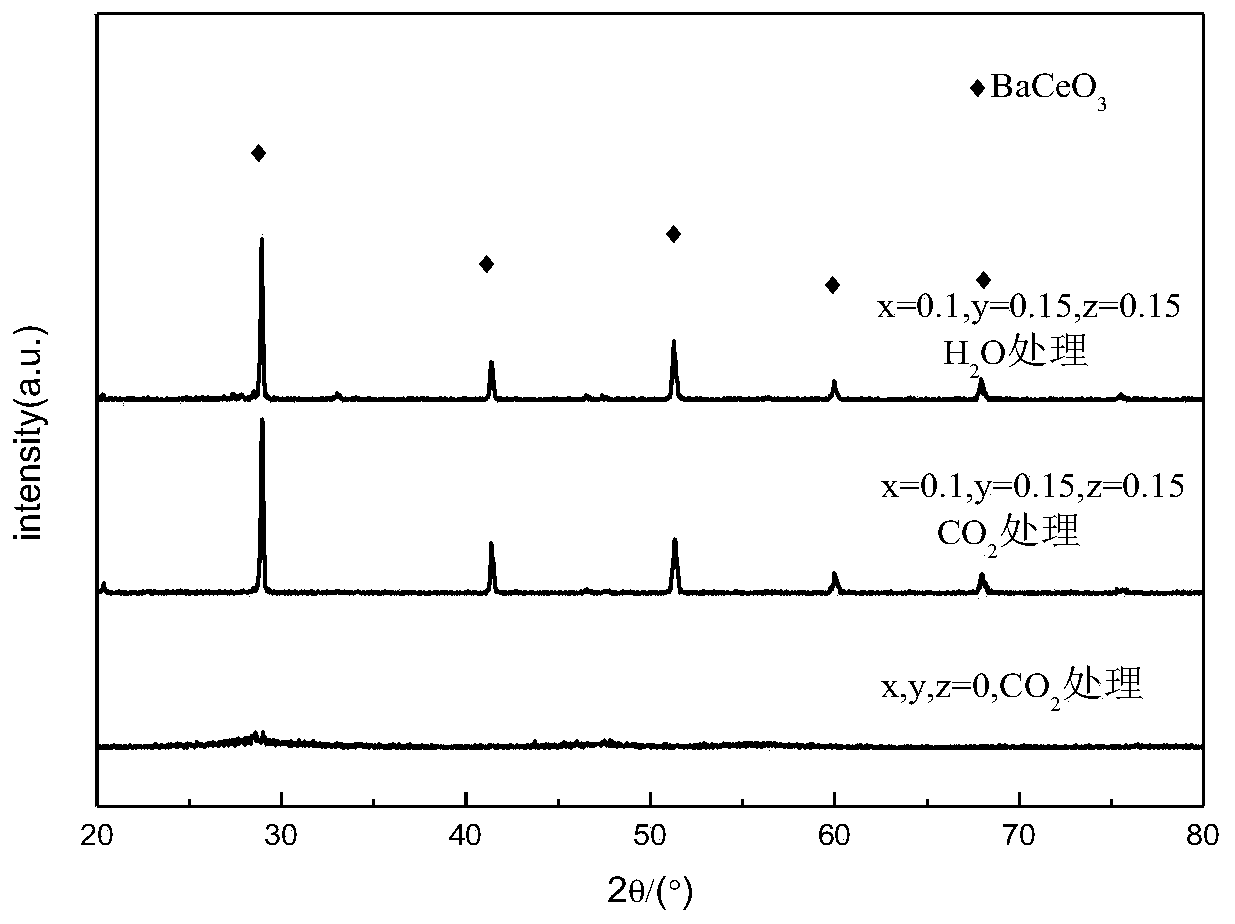

[0050] (1) According to double-doped BaCeO 3 The molecular formula of the proton-conducting electrolyte material is Ba 0.9 K 0.1 Ce 0.7 Zr 0.15 SM 0.15 o 3 The stoichiometric ratio weighs C 4 h 6 o 4 Ba(99.9%), KOH(99.9%), CeO 2 (99.9%), ZrO 2 (99.9%), Sm 2 o 3 (99.9%), and then using absolute ethanol as a dispersion medium, place the above-mentioned raw materials and grinding balls in a planetary ball mill for 12 hours at a speed of 300 rpm to obtain slurry 1;

[0051] (2) Place the slurry 1 prepared in step (1) in a vacuum drying oven to dry, and grind and sieve to obtain primary powder; then place the powder in a muffle furnace and heat up at a rate of 5°C / min Heating to 900°C, heat preservation and calcination for 8 hours to obtain white electrolyte powder, which is the primary powder;

[0052] (3) Add antimony tin oxide (ATO) as a sintering additive to the primary powder obtained in step (2) to obtain a mixed powder, wherein the consumption of antimony tin ox...

Embodiment 3

[0056] (1) According to double-doped BaCeO 3 The molecular formula of the proton-conducting electrolyte material is Ba 0.9 K 0.1 Ce 0.7 Zr 0.15 SM 0.15 o 3 The stoichiometric ratio weighs C 4 h 6 o 4 Ba(99.9%), KOH(99.9%), CeO 2 (99.9%), ZrO 2 (99.9%), Sm 2 o 3 (99.9%), and then using absolute ethanol as a dispersion medium, place the above-mentioned raw materials and grinding balls in a planetary ball mill for 12 hours at a speed of 300 rpm to obtain slurry 1;

[0057] (2) Place the slurry 1 prepared in step (1) in a vacuum drying oven to dry, and grind and sieve to obtain primary powder; then place the powder in a muffle furnace and heat up at a rate of 5°C / min Heating to 1200°C, heat preservation and calcination for 8 hours to obtain white electrolyte powder, which is the primary powder;

[0058] (3) Add antimony tin oxide (ATO) as a sintering additive to the primary powder obtained in step (2) to obtain a mixed powder, wherein the consumption of antimony tin o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com