Patents

Literature

2516 results about "Acid gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acid gas is a particular typology of natural gas or any other gas mixture containing significant quantities of hydrogen sulfide (H₂S), carbon dioxide (CO₂), or similar acidic gases. The term/s acid gas and sour gas are often incorrectly treated as synonyms. Strictly speaking, a sour gas is any gas that specifically contains hydrogen sulfide in significant amounts; an acid gas is any gas that contains significant amounts of acidic gases such as carbon dioxide (CO₂) or hydrogen sulfide. Thus, carbon dioxide by itself is an acid gas but not a sour gas.

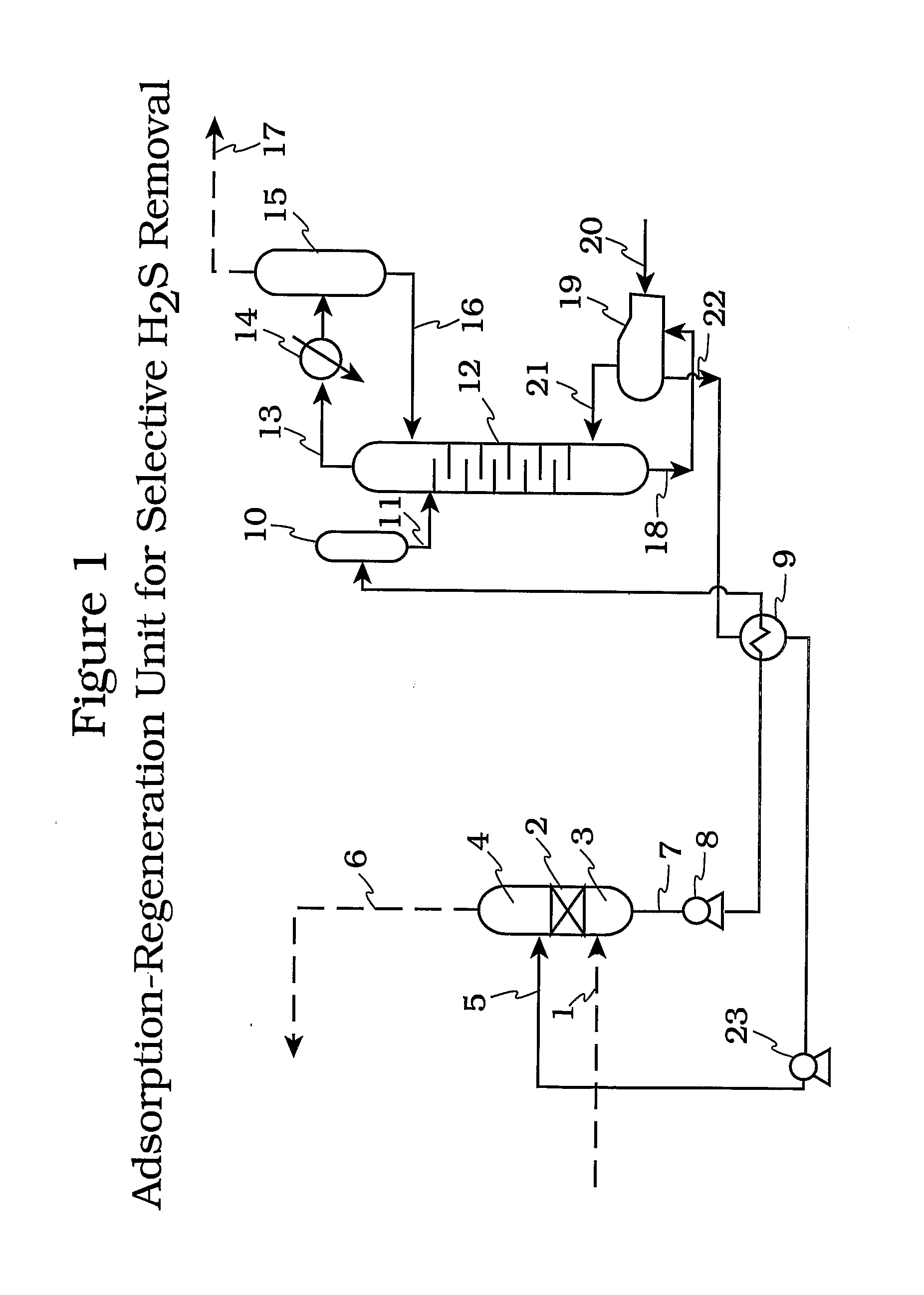

Selective Removal and Recovery of Acid Gases from Gasification Products

Processes and apparatuses are described for the selective removal and recovery of acid gases from a gas source comprising at least hydrogen sulfide and carbon dioxide. A step-wise approach is illustrated wherein hydrogen sulfide may be selectively removed from a gas source by treatment with methanol under conditions where substantially all the hydrogen sulfide may be removed. The partially purified gas source may then be provided with a second treatment with methanol under conditions which selectively remove carbon dioxide from the gas stream. Such methods are generally applicable to any gas source comprising at least hydrogen sulfide and carbon dioxide, for example, a gas source produced from the catalytic gasification of a carbonaceous material, the combustion of a carbonaceous material, or the oxy-blown gasification of a carbonaceous material.

Owner:SURE CHAMPION INVESTMENT LTD

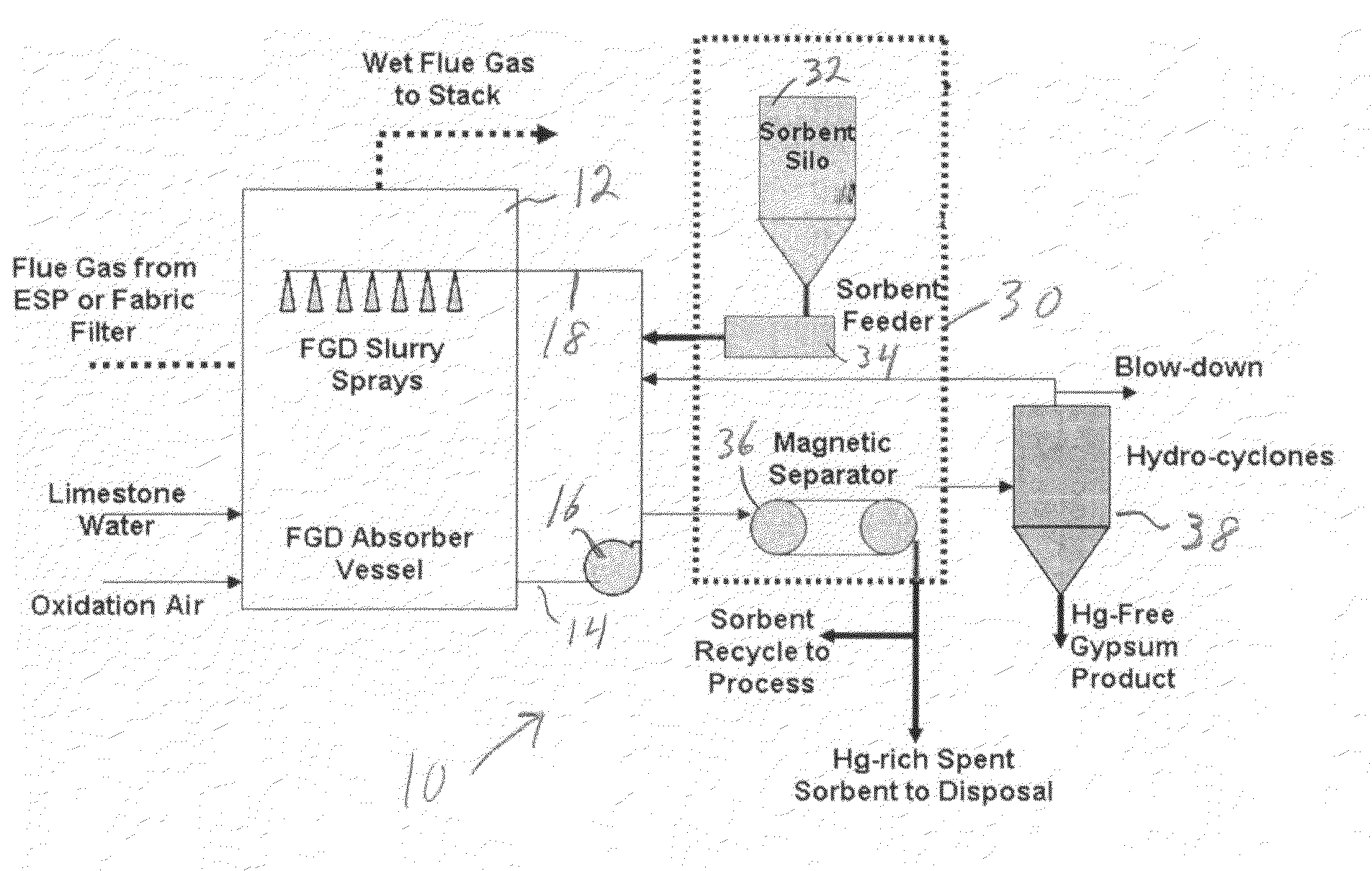

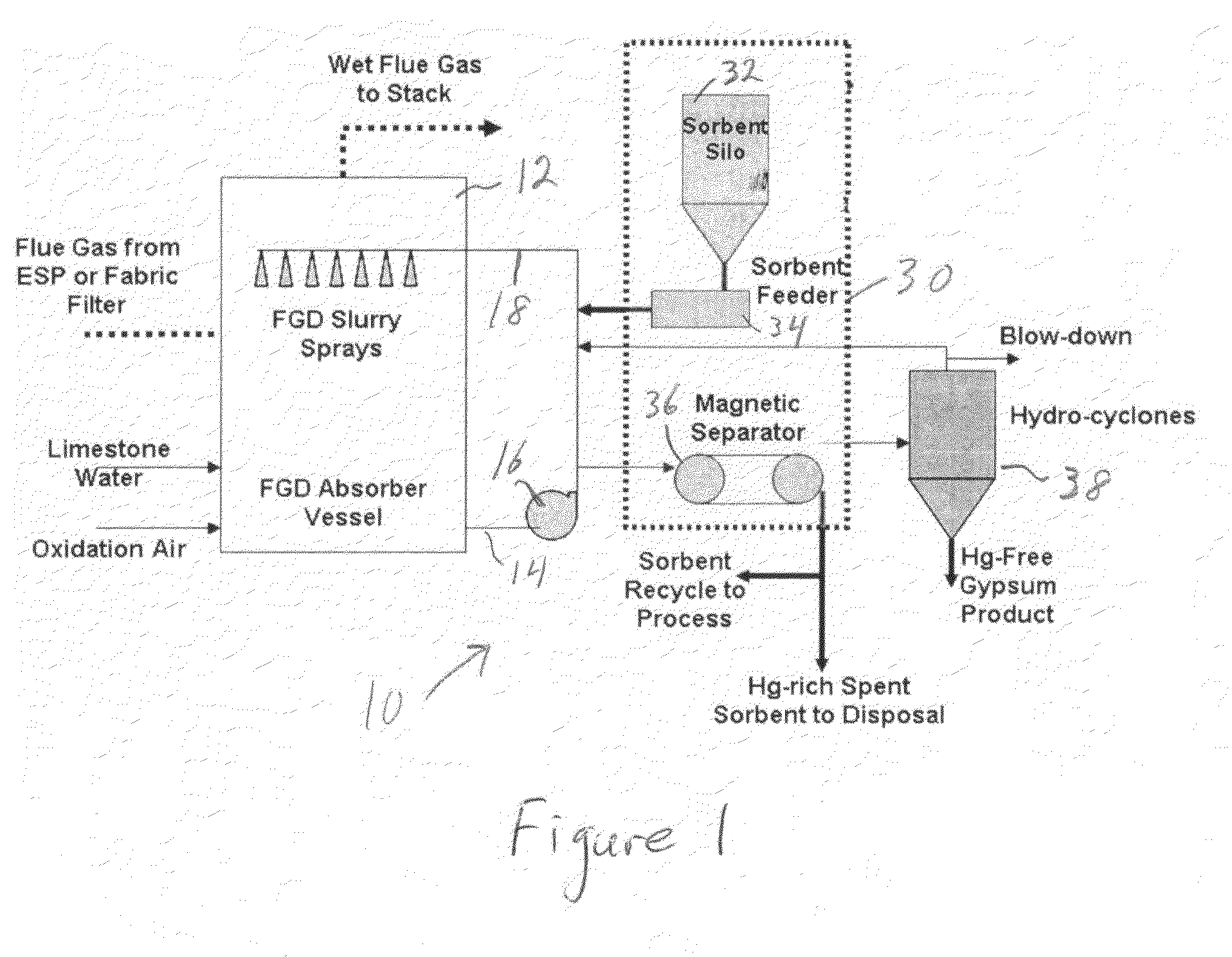

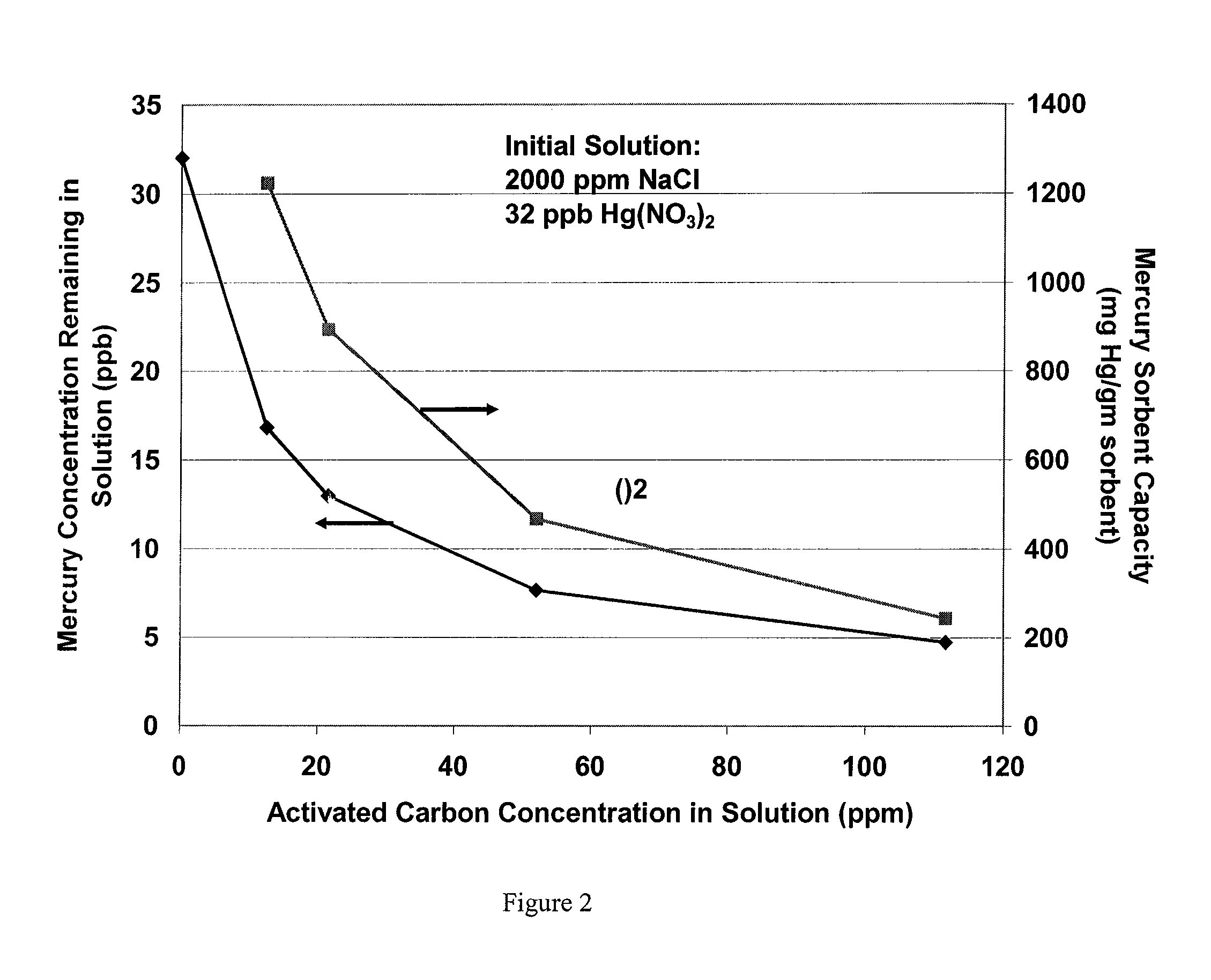

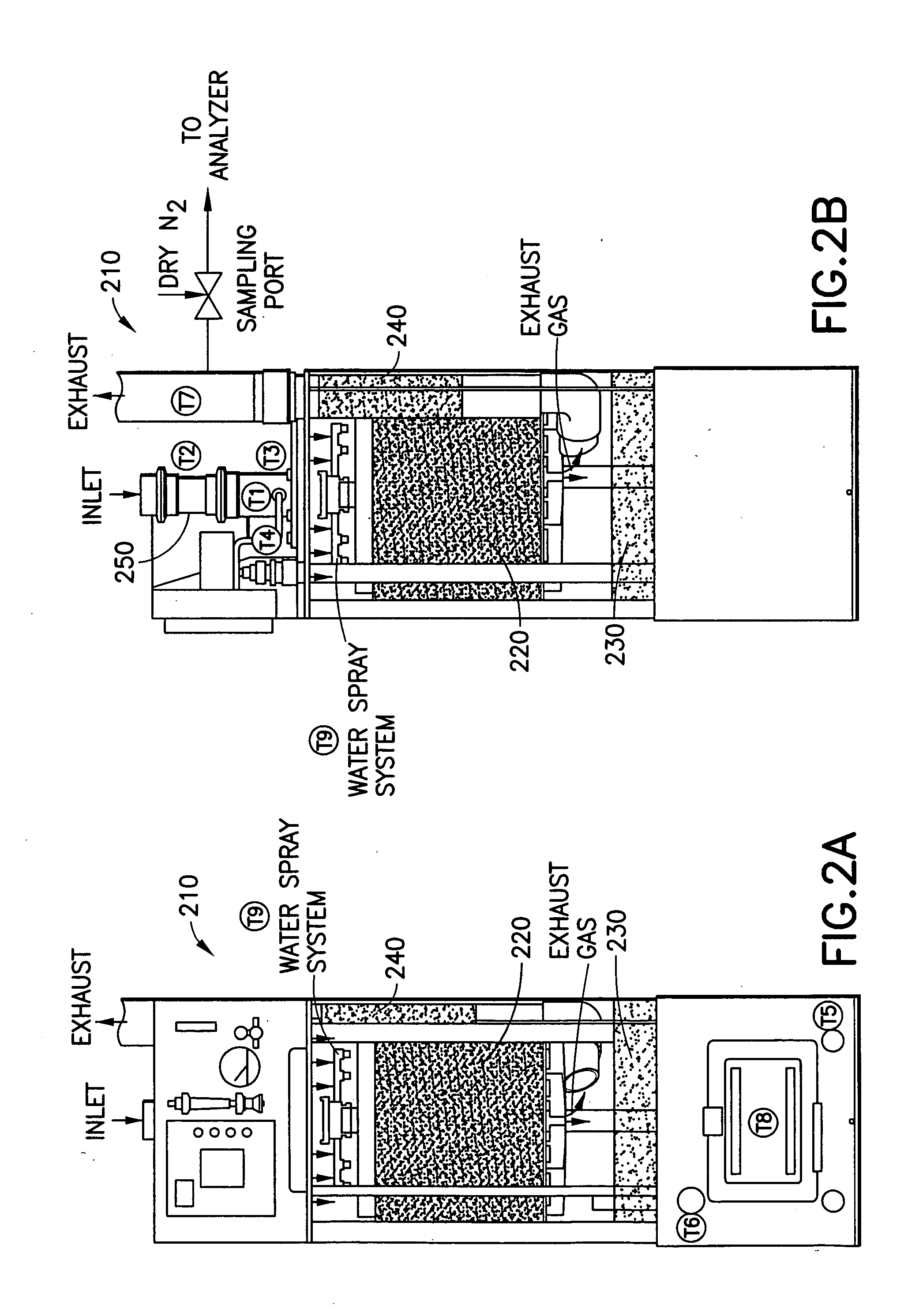

System and method for sequestration and separation of mercury in combustion exhaust gas aqueous scrubber systems

ActiveUS7722843B1Emission reductionMinimize re-emissionCombination devicesExhaust apparatusCombustionSorbent

A process, system and sorbent for removal of mercury from a combustion exhaust gas stream in a combustion exhaust gas purification scheme that includes a combustion exhaust scrubber system that uses an aqueous liquid to remove acid gases from the combustion exhaust gas. A powdered mercury sorbent is used. The sorbent is introduced into the aqueous scrubber liquid in the scrubber system. After introduction of the mercury sorbent into the scrubber liquid, at least some of the mercury sorbent is separated from the scrubber liquid.

Owner:SRINIVASACHAR SRIVATS

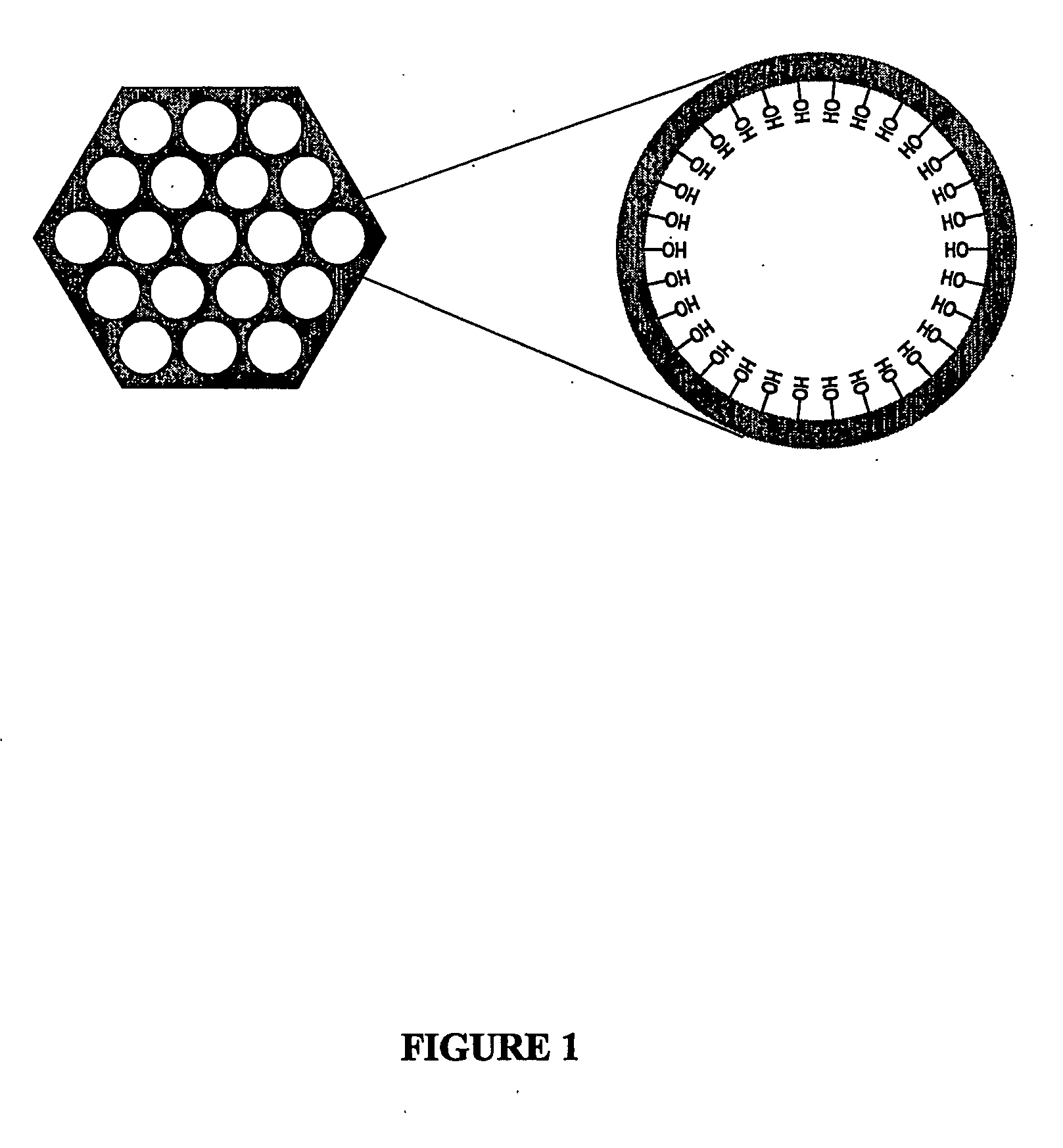

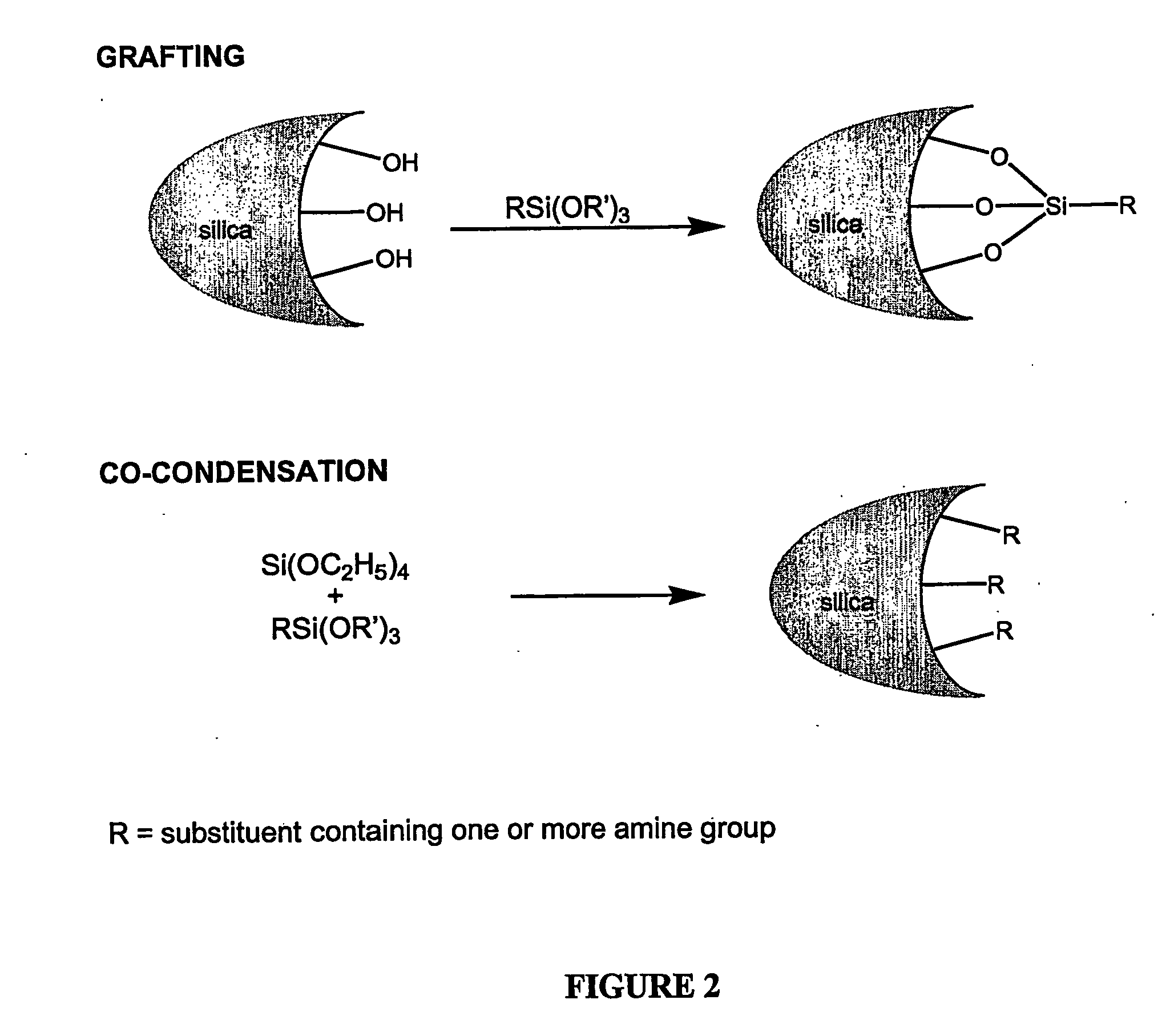

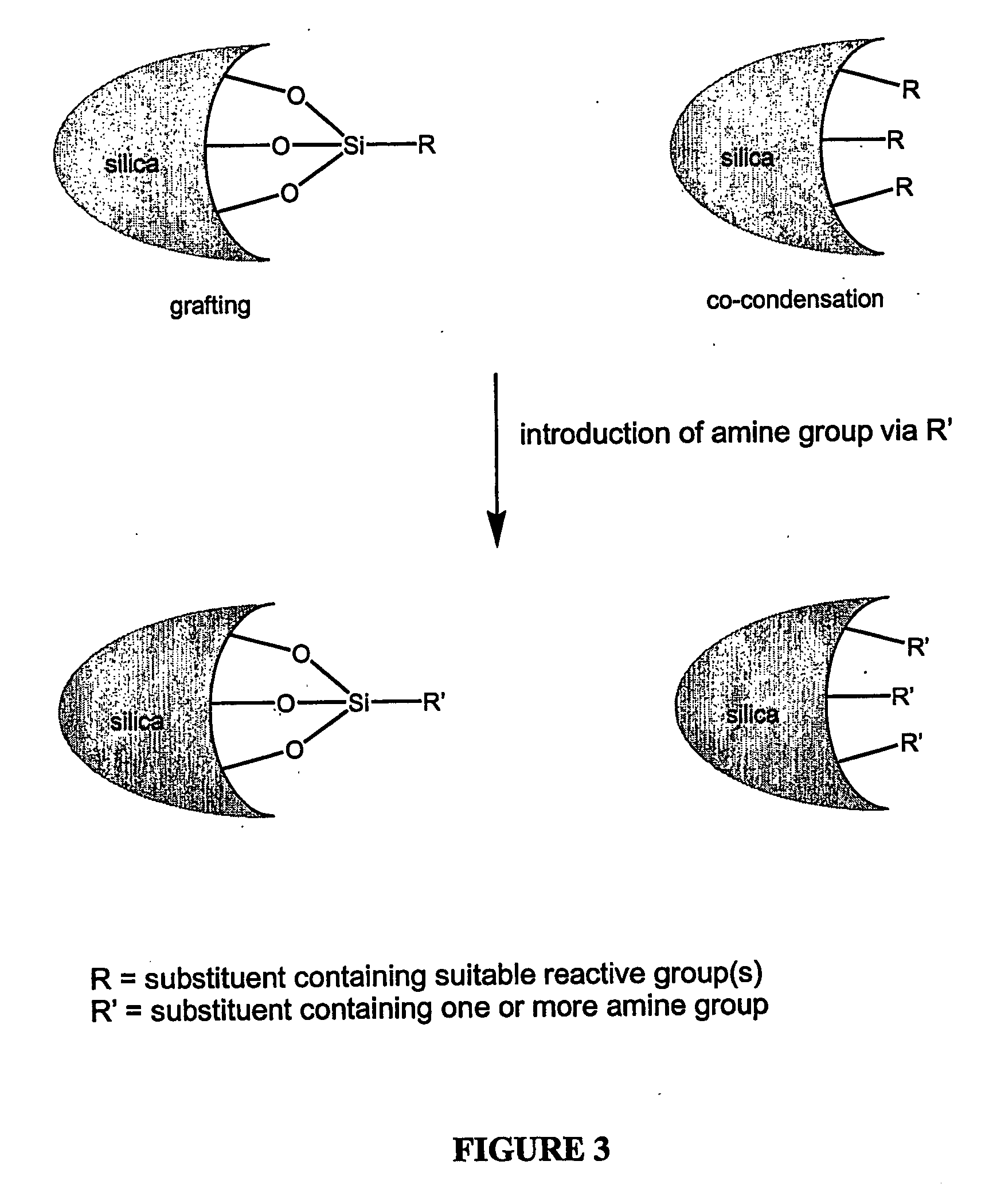

Modified adsorbent for dry scrubbing and use thereof

The present invention provides an amine functionalised adsorbent for use in dry scrubbing process. The adsorbent comprises amine functionalised mesoporous silica in which the amine groups are present at or near the surface of the silica, including within the pore walls and channels of the silica. The present invention further provides methods of preparing the adsorbent and of using the adsorbent for the adsorption of CO2 and / or other acid gases.

Owner:UNIVERSITY OF OTTAWA

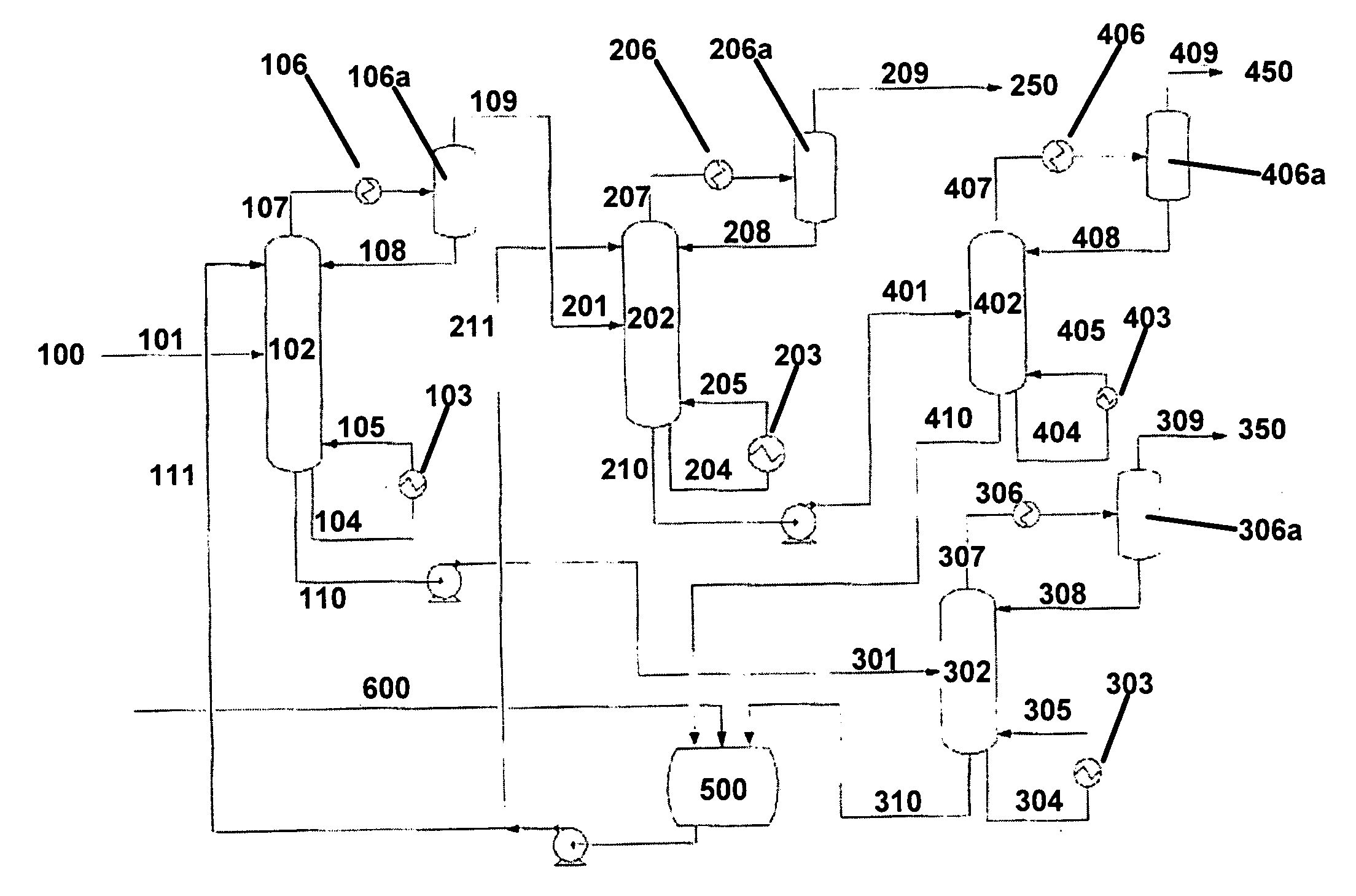

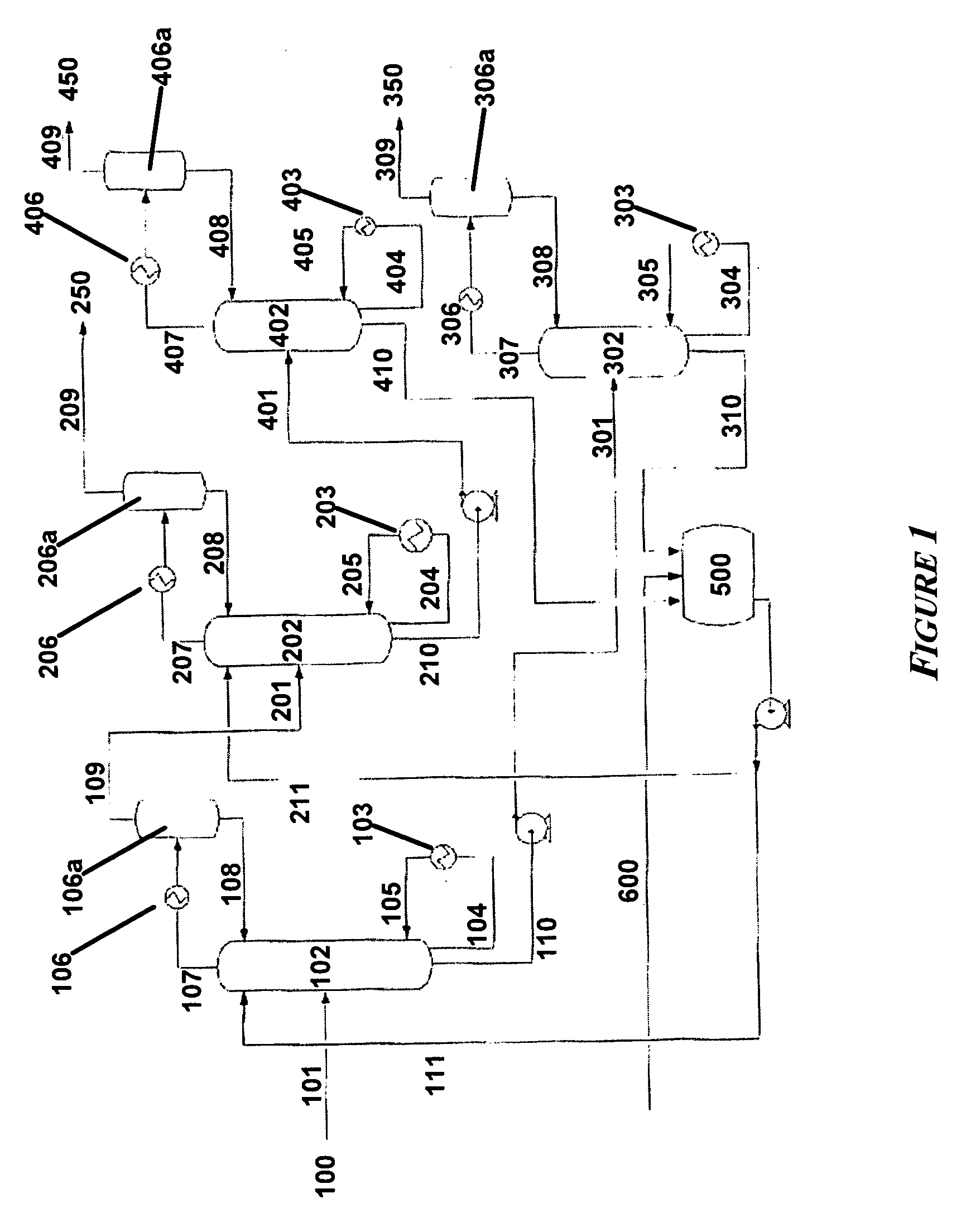

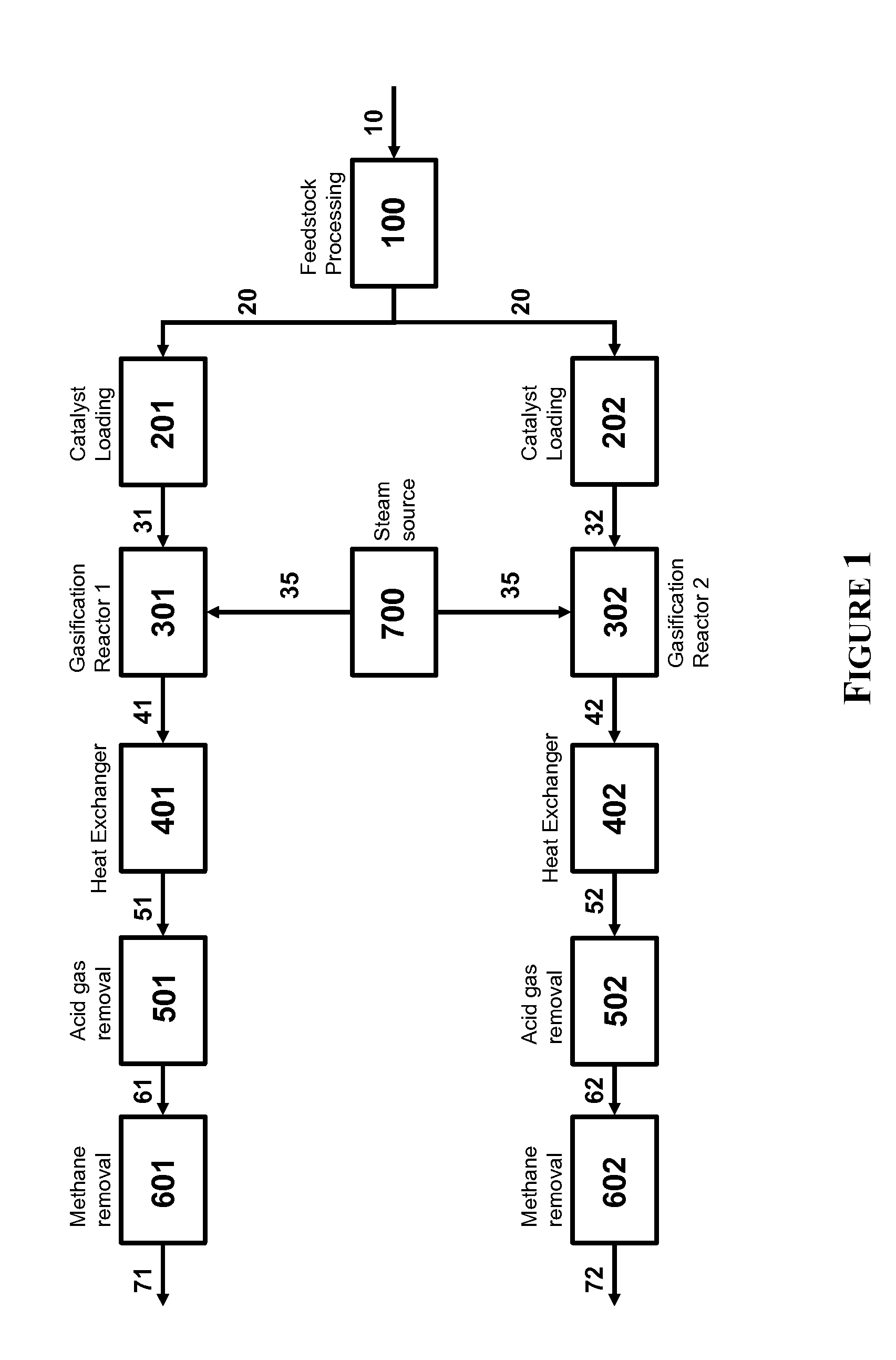

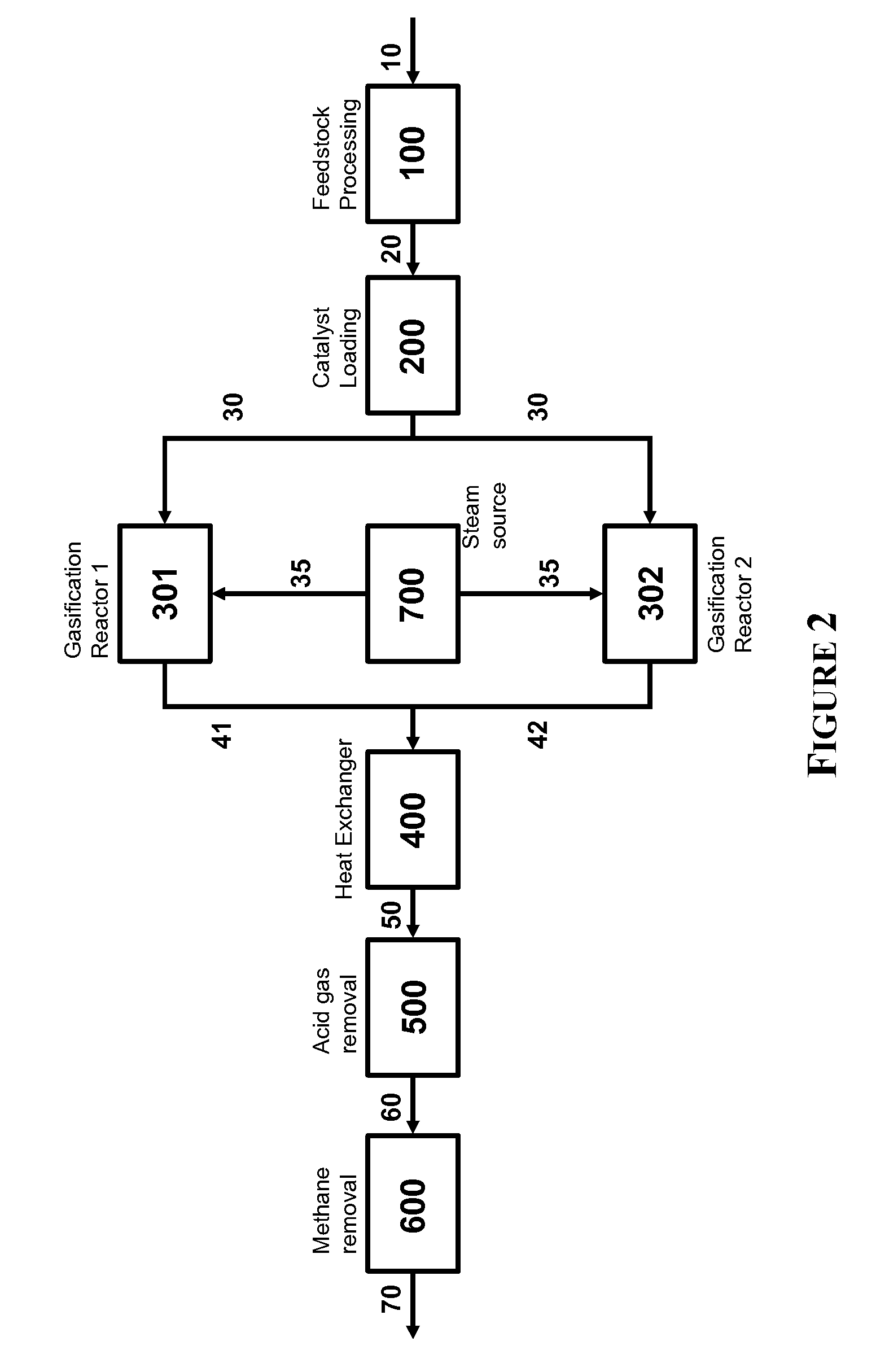

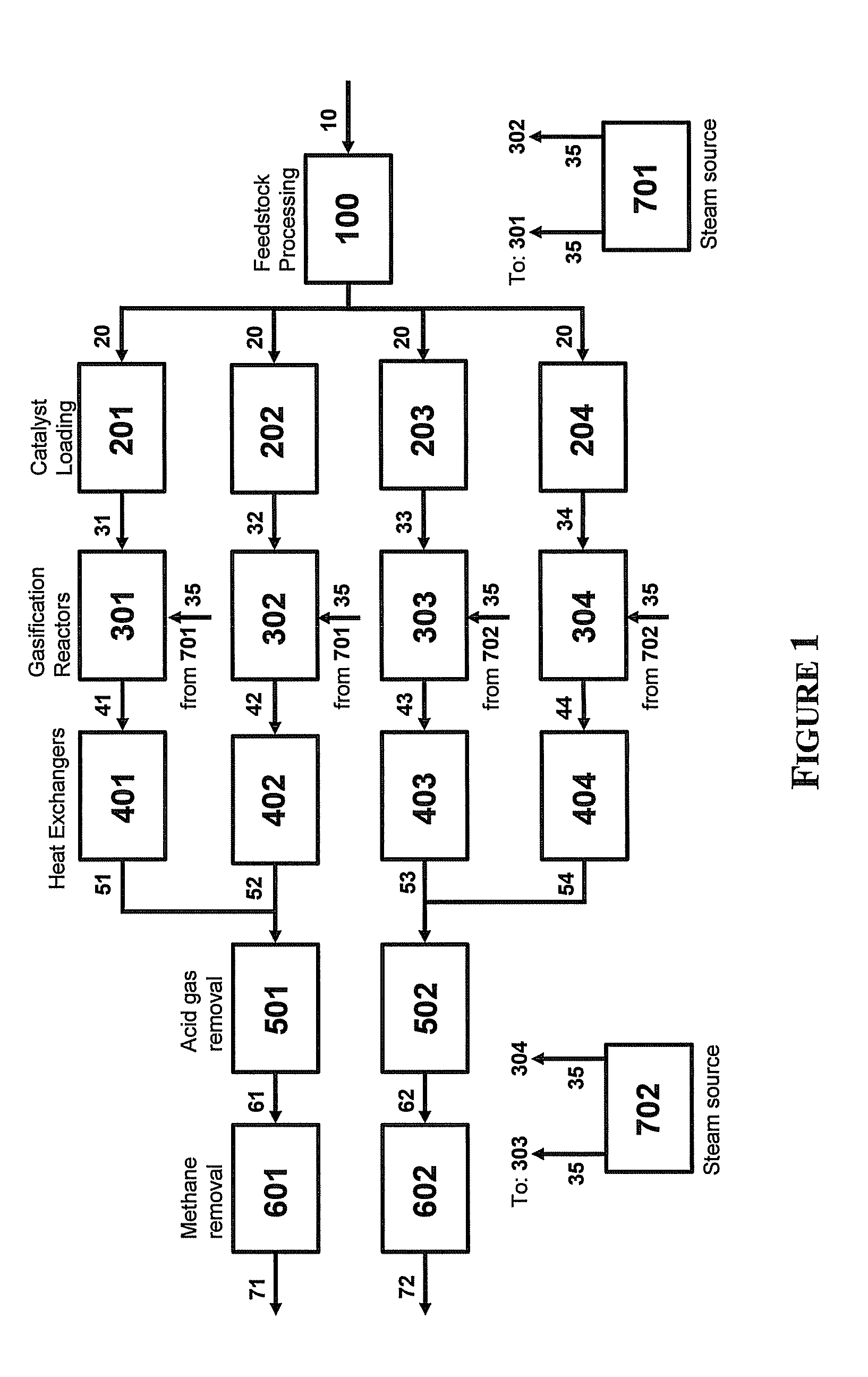

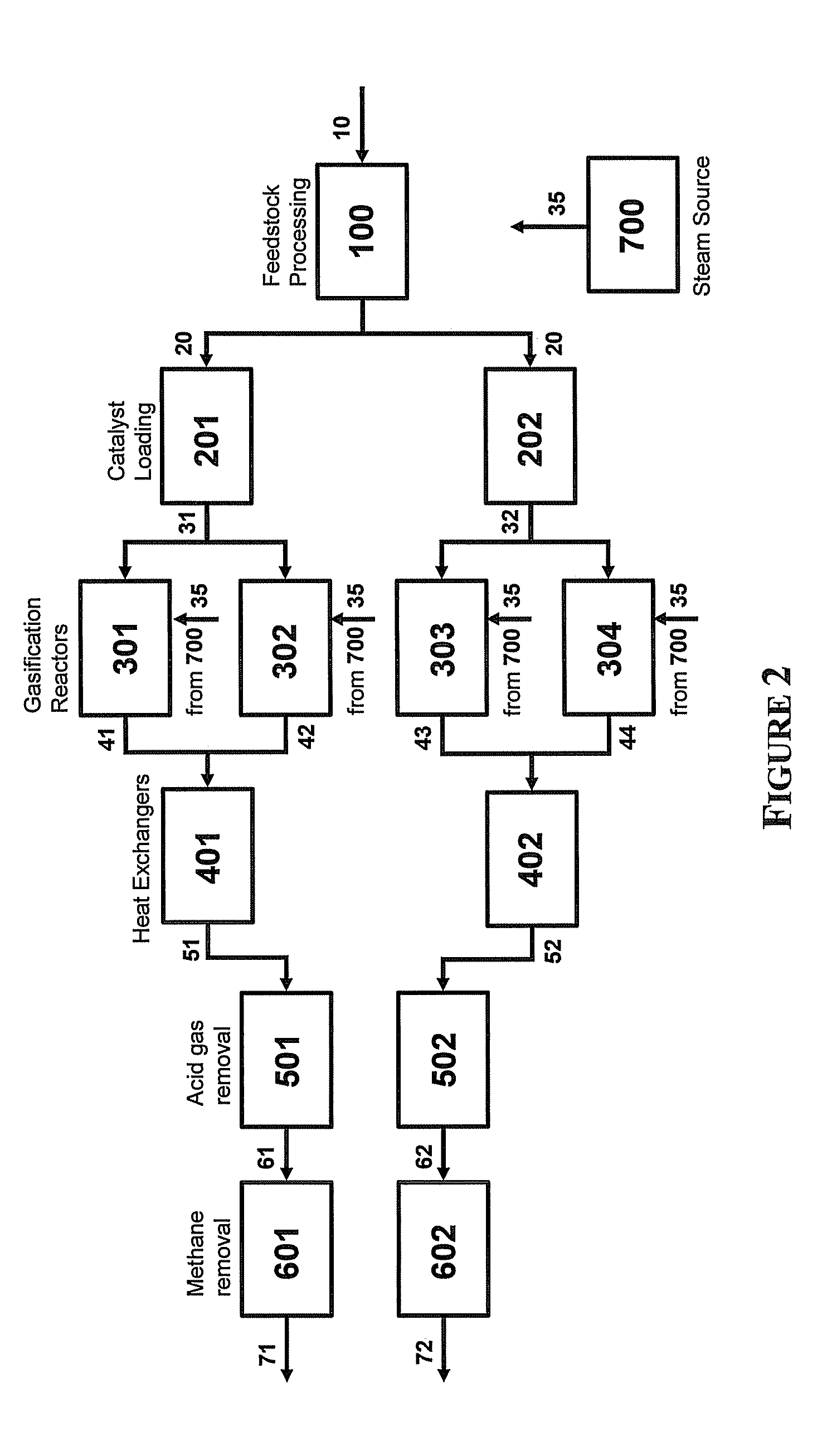

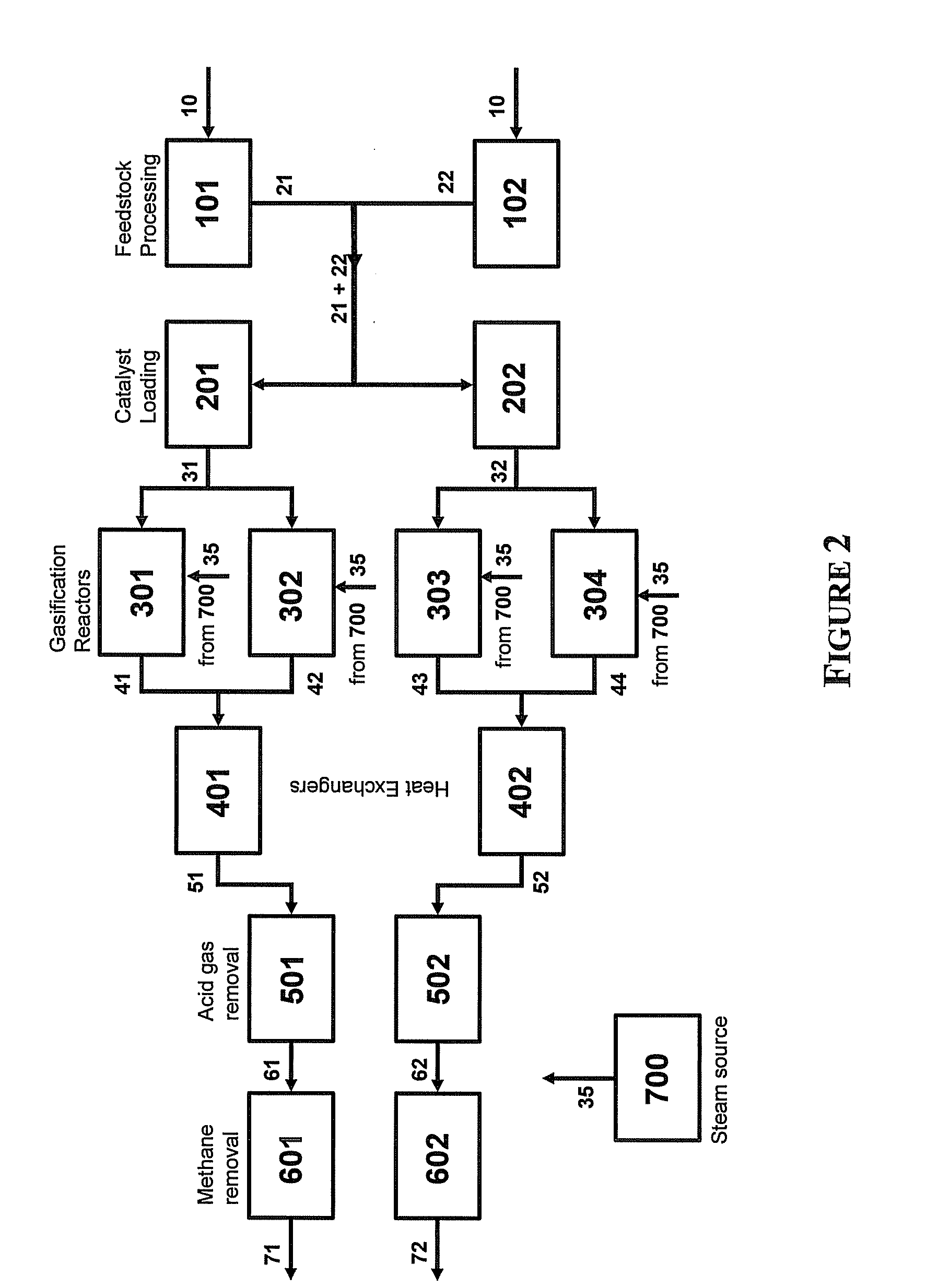

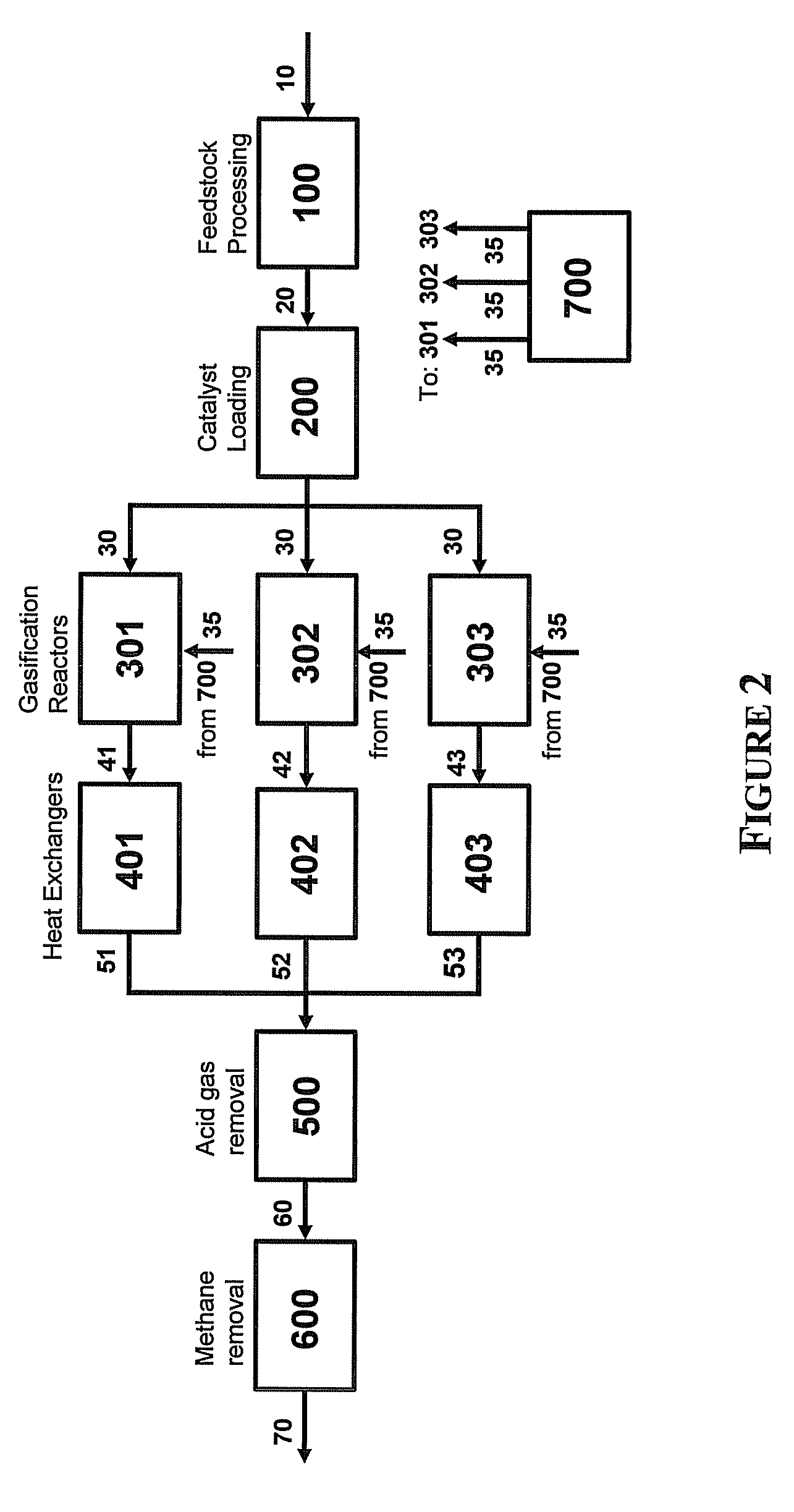

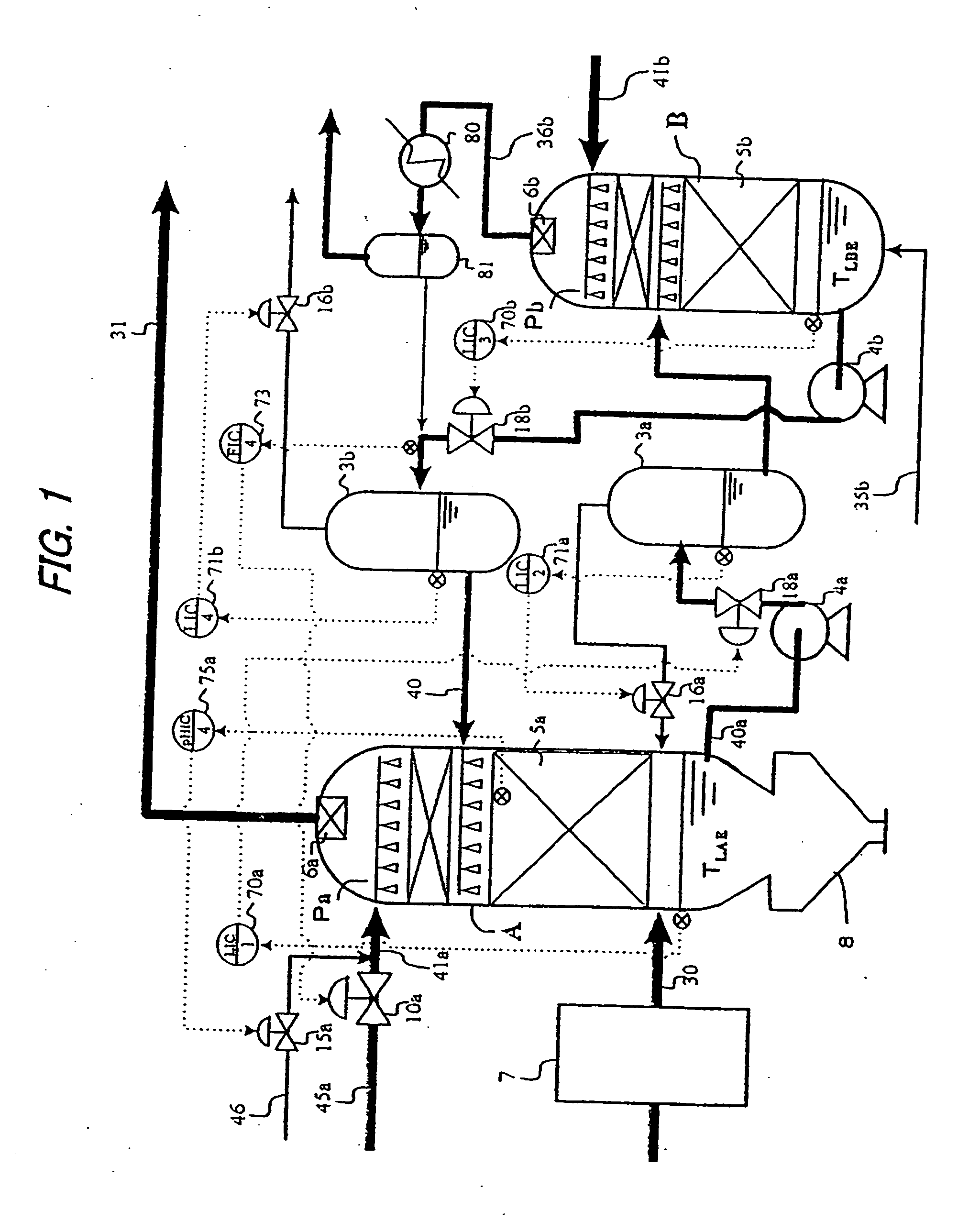

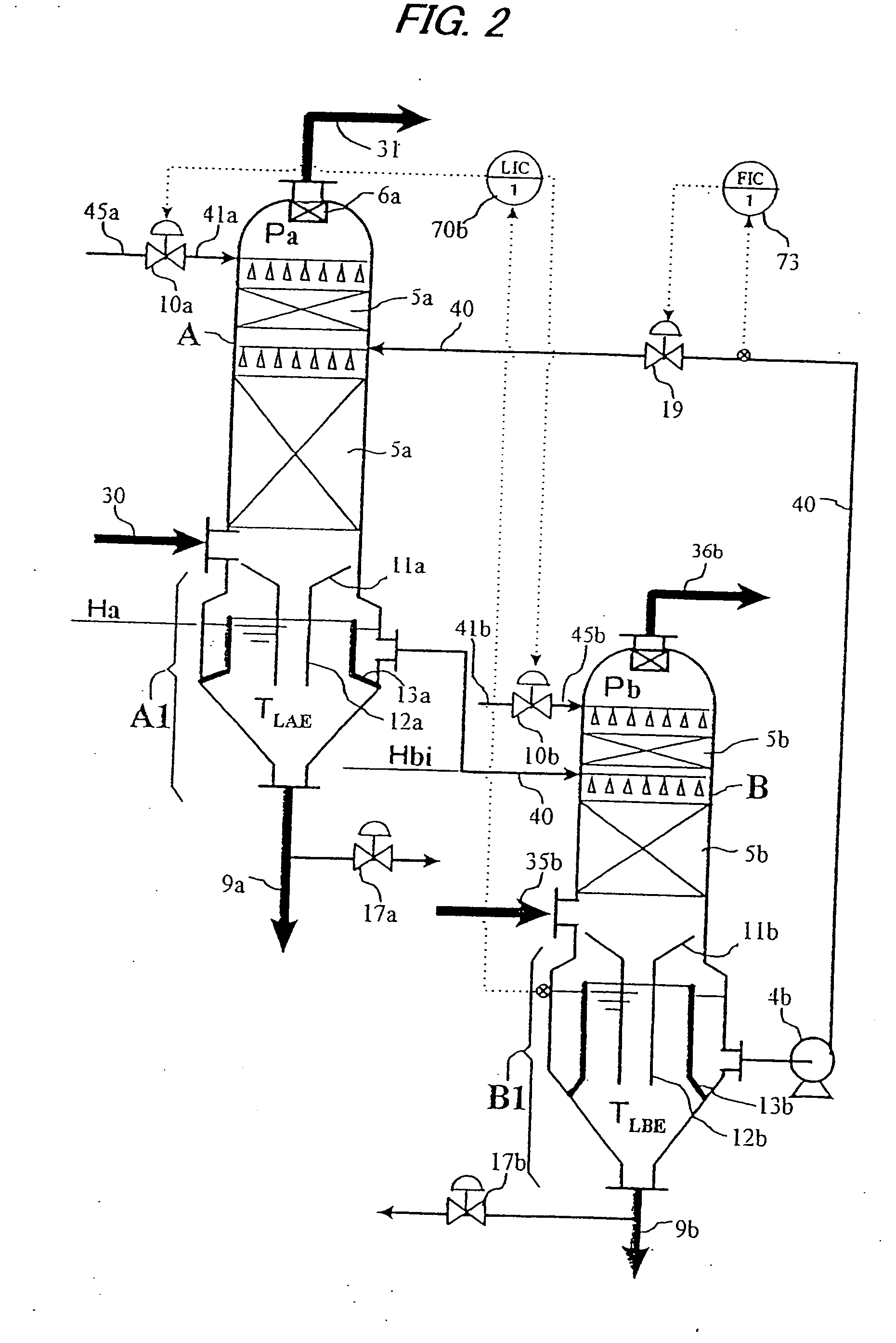

Two-Train Catalytic Gasification Systems

InactiveUS20090324458A1Reduce moisture contentGasifier mechanical detailsCombustible gas catalytic treatmentUnit operationAmmonia

Systems for converting a carbonaceous feedstock into a plurality of gaseous products are described. The systems include, among other units, two separate gasification reactors to convert a carbonaceous feedstock in the presence of an alkali metal catalyst into the plurality of gaseous products including at least methane. Each of the gasification reactors may be supplied with the feedstock from a single or separate catalyst loading and / or feedstock preparation unit operations. Similarly, the hot gas streams from each gasification reactor may be purified via their combination at a heat exchanger, acid gas removal, or methane removal unit operations. Product purification may comprise trace contaminant removal units, ammonia removal and recovery units, and sour shift units.

Owner:SURE CHAMPION INVESTMENT LTD

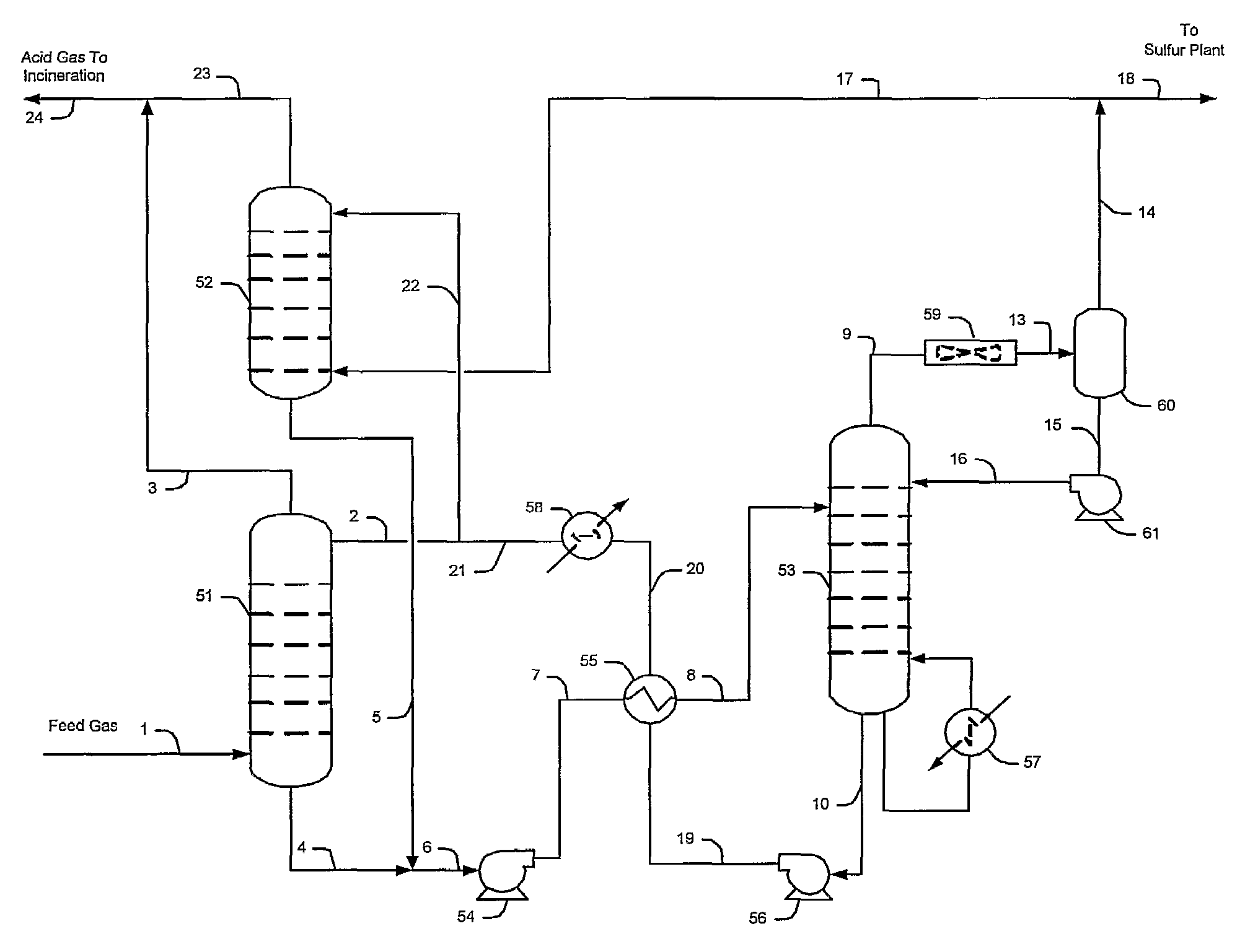

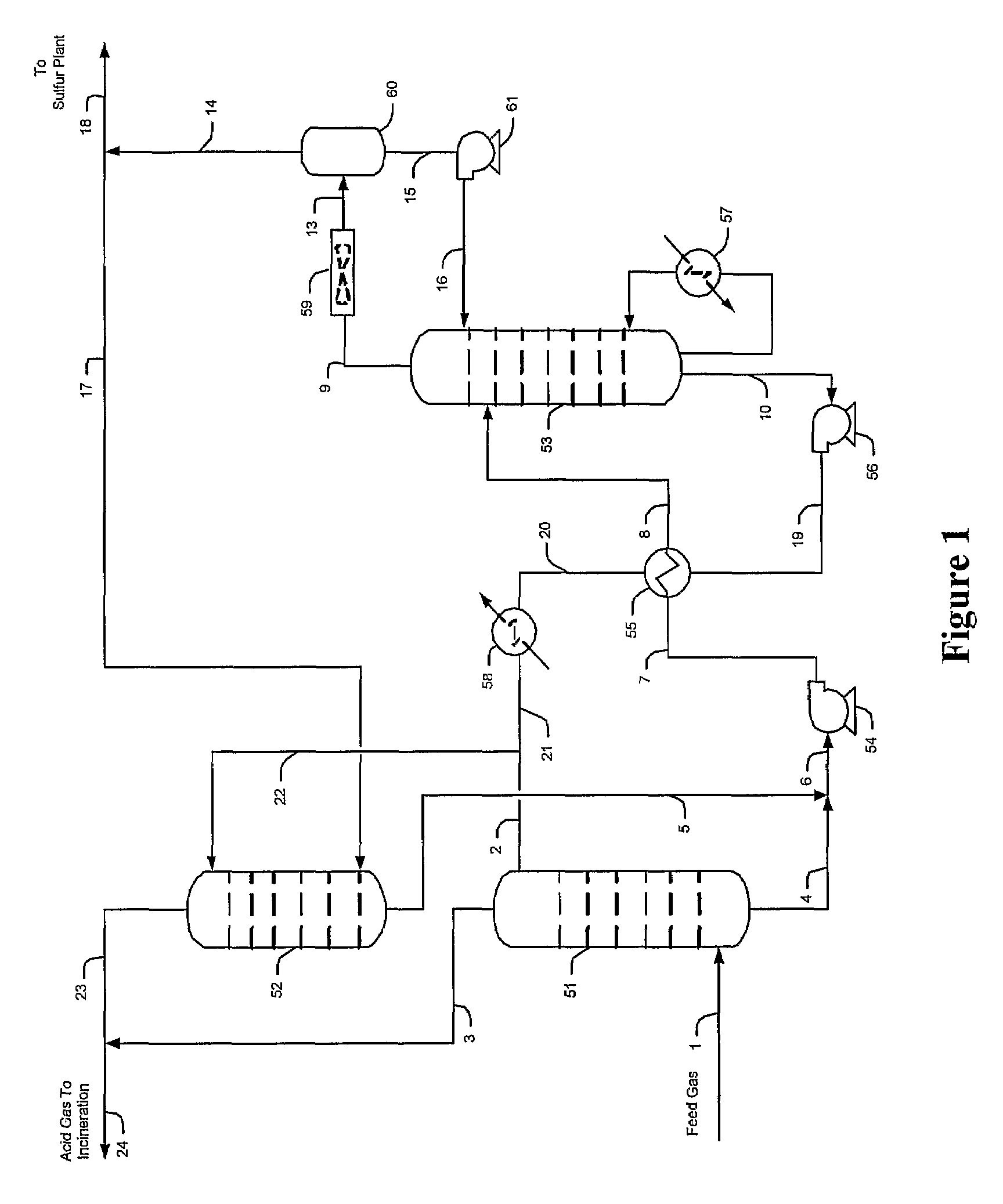

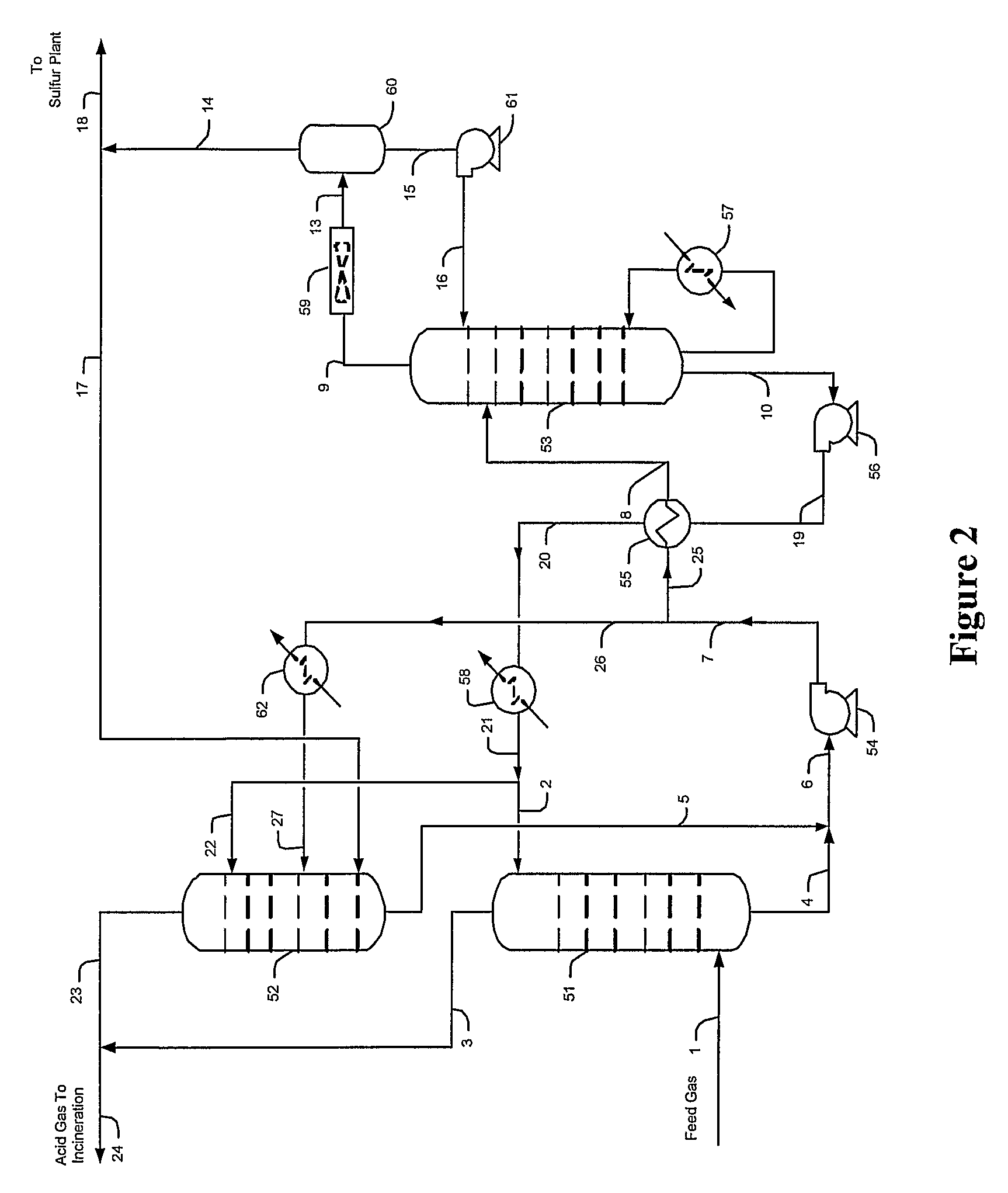

Methods and configurations for acid gas enrichment

ActiveUS7635408B2Increase the concentration of hydrogen sulfideSmall sizeGas treatmentCarbon compoundsSolventCarbon dioxide

Hydrogen sulfide is selectively enriched from an acid gas (1) that comprises relatively large quantities of carbon dioxide using a configuration in which a portion of an isolated hydrogen sulfide stream is introduced into an absorber (51) operating as a carbon dioxide rejecter. The resulting concentrated hydrogen sulfide enriched solvent (4) is then further used (directly or indirectly) to absorb hydrogen sulfide from an acid feed gas.

Owner:FLUOR ENTERPRISES

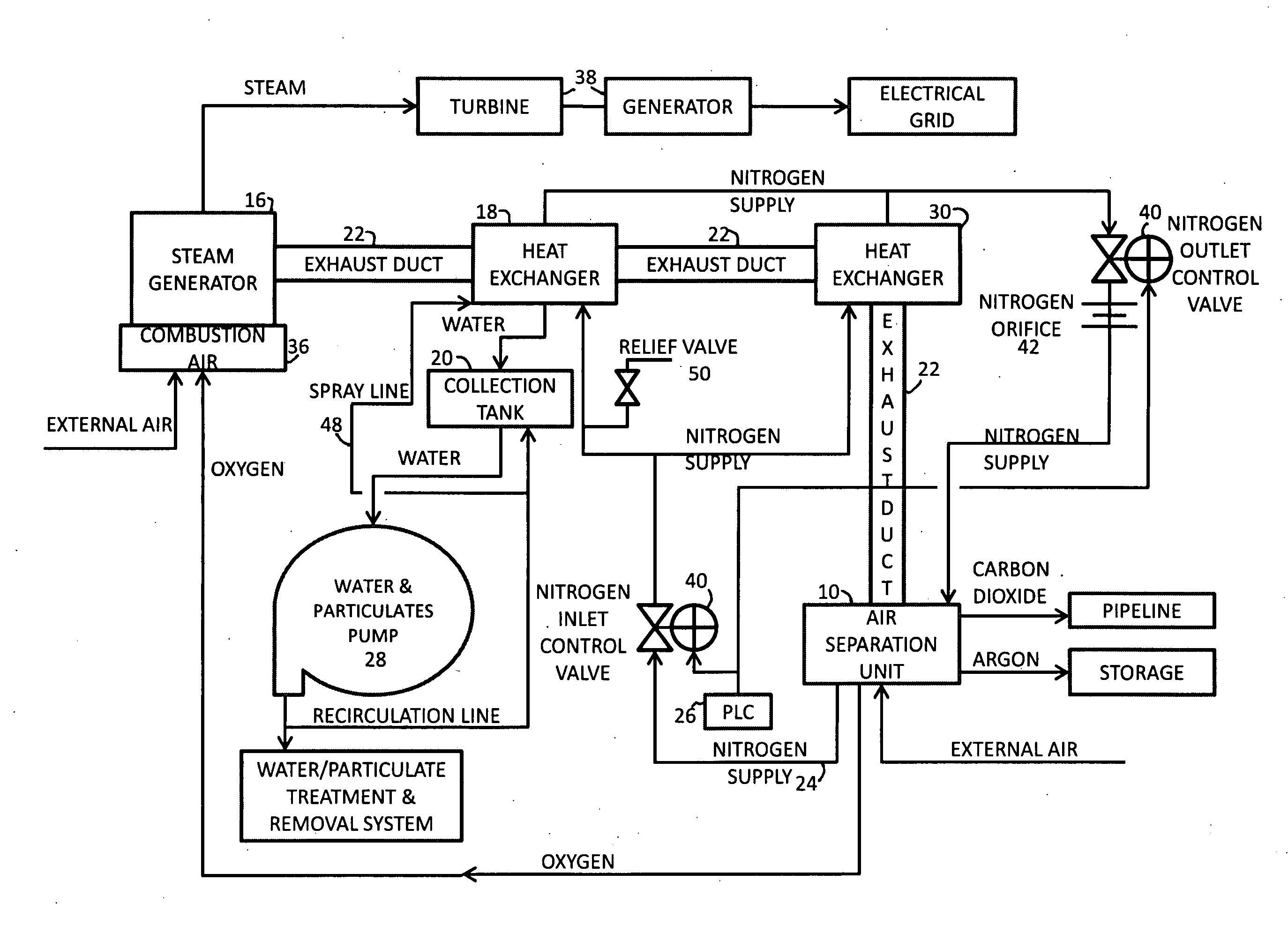

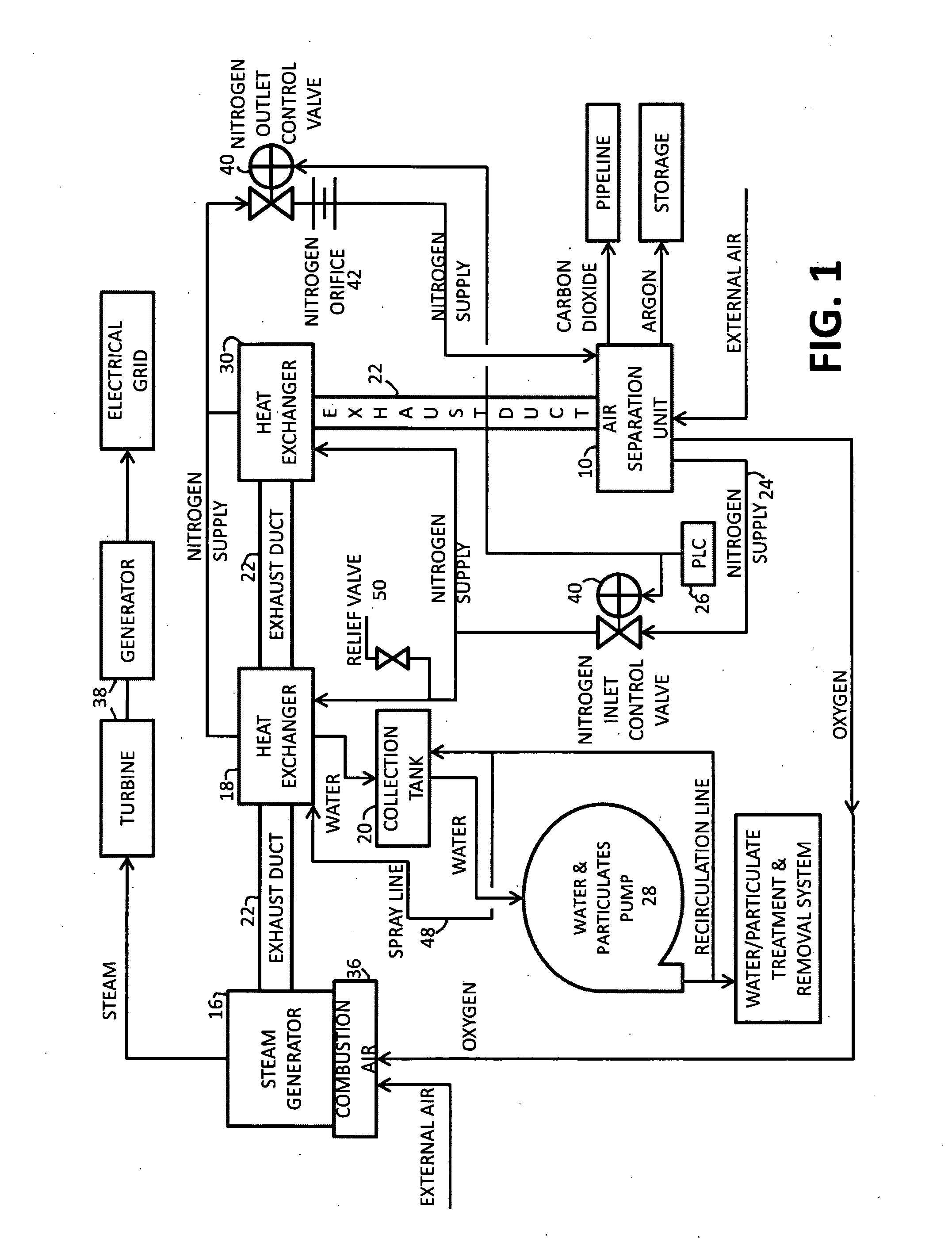

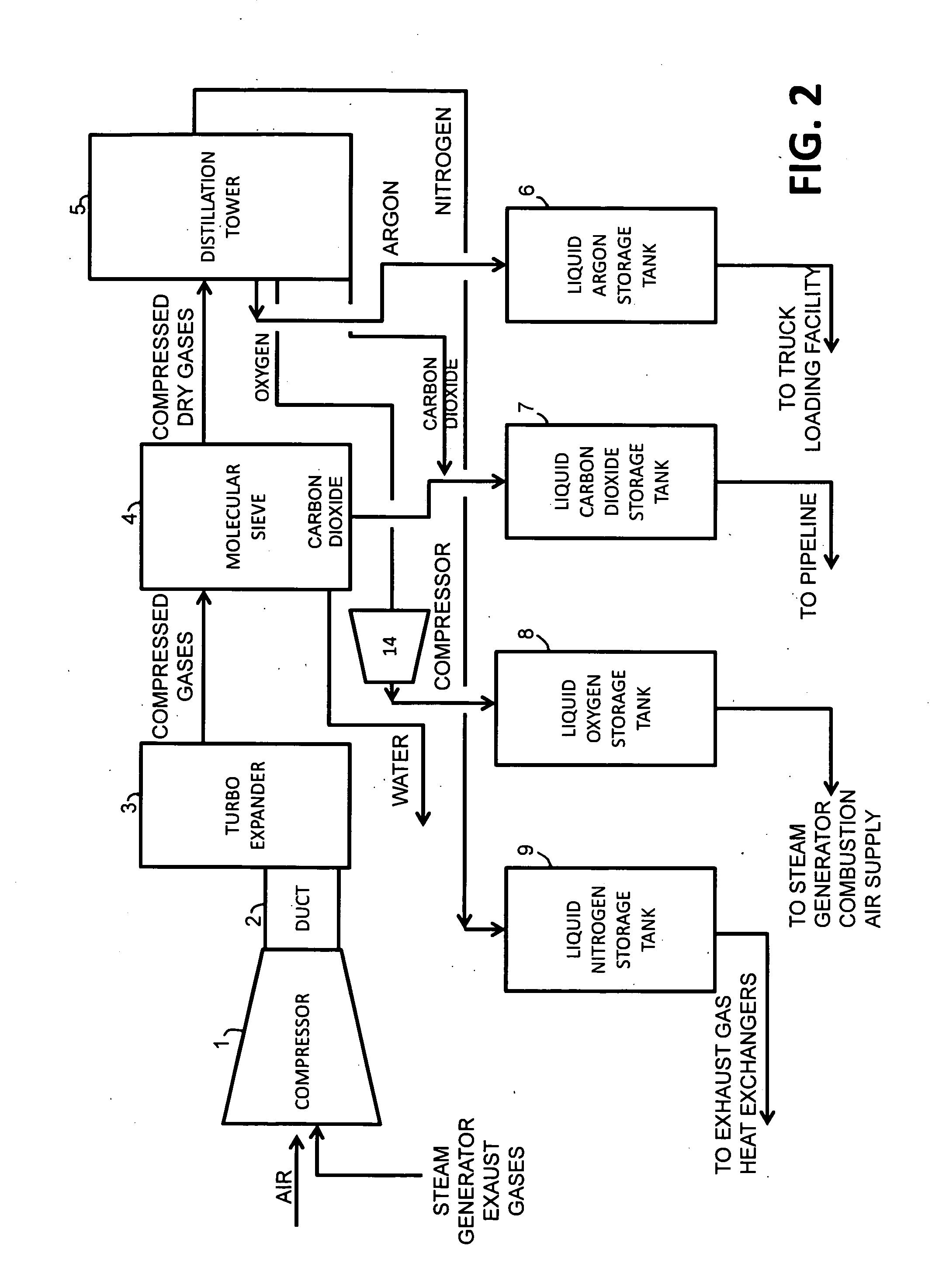

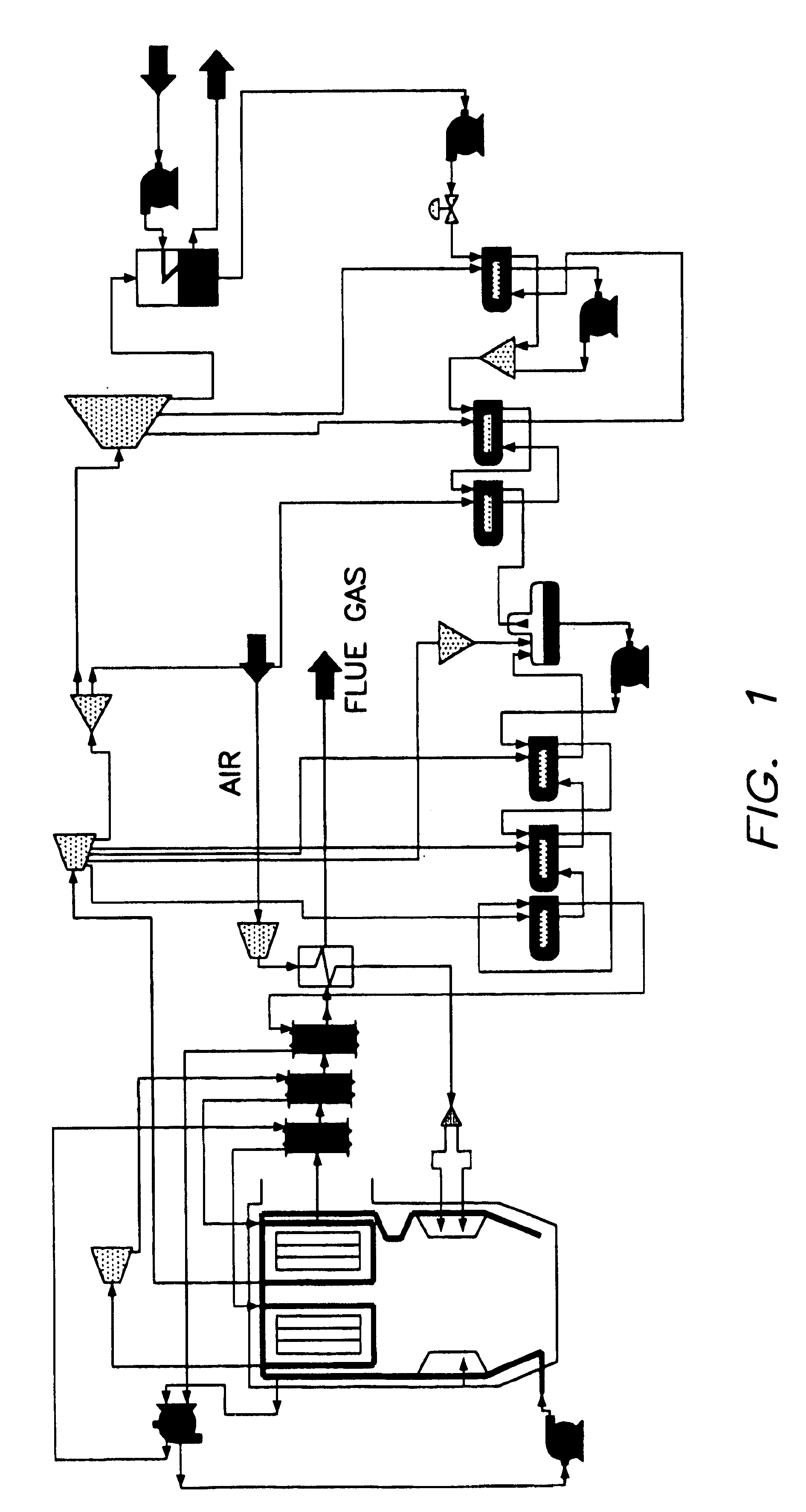

Power plant with emissions recovery

InactiveUS20100018218A1Reduce deliveryEnvironment safetySolidificationLiquefactionParticulatesNitrogen gas

A power plant including an air separation unit (ASU) arranged to separate nitrogen, oxygen, carbon dioxide and argon from air and produce a stream of substantially pure liquid oxygen, nitrogen, carbon dioxide and argon; a steam generator, fired or unfired, arranged to combust a fuel, e.g., natural gas, liquefied natural gas, synthesis gas, coal, petroleum coke, biomass, municipal solid waste or any other gaseous, liquid or solid fuel in the presence of air and a quantity of substantially pure oxygen gas to produce an exhaust gas comprising water, carbon dioxide, carbon monoxide, nitrogen oxides, nitrogen, sulfur oxides and other trace gases, and a steam-turbine-generator to produce electricity, a primary gas heat exchanger unit for particulate / acid gas / moisture removal and a secondary heat exchanger arranged to cool the remainder of the exhaust gases from the steam generator. Exhaust gases are liquefied in the ASU thereby recovering carbon dioxide, nitrogen oxides, nitrogen, sulfur oxides, oxygen, and all other trace gases from the steam generator exhaust gas stream. The cooled gases are liquefied in the ASU and separated for sale or re-use in the power plant. Carbon dioxide liquid is transported from the plant for use in enhanced oil recovery or for other commercial use. Carbon dioxide removal is accomplished in the ASU by cryogenic separation of the gases, after directing the stream of liquid nitrogen from the air separation unit to the exhaust gas heat exchanger units to cool all of the exhaust gases including carbon dioxide, carbon monoxide, nitrogen oxides, nitrogen, oxygen, sulfur oxides, and other trace gases.

Owner:TRIENCON SERVICES

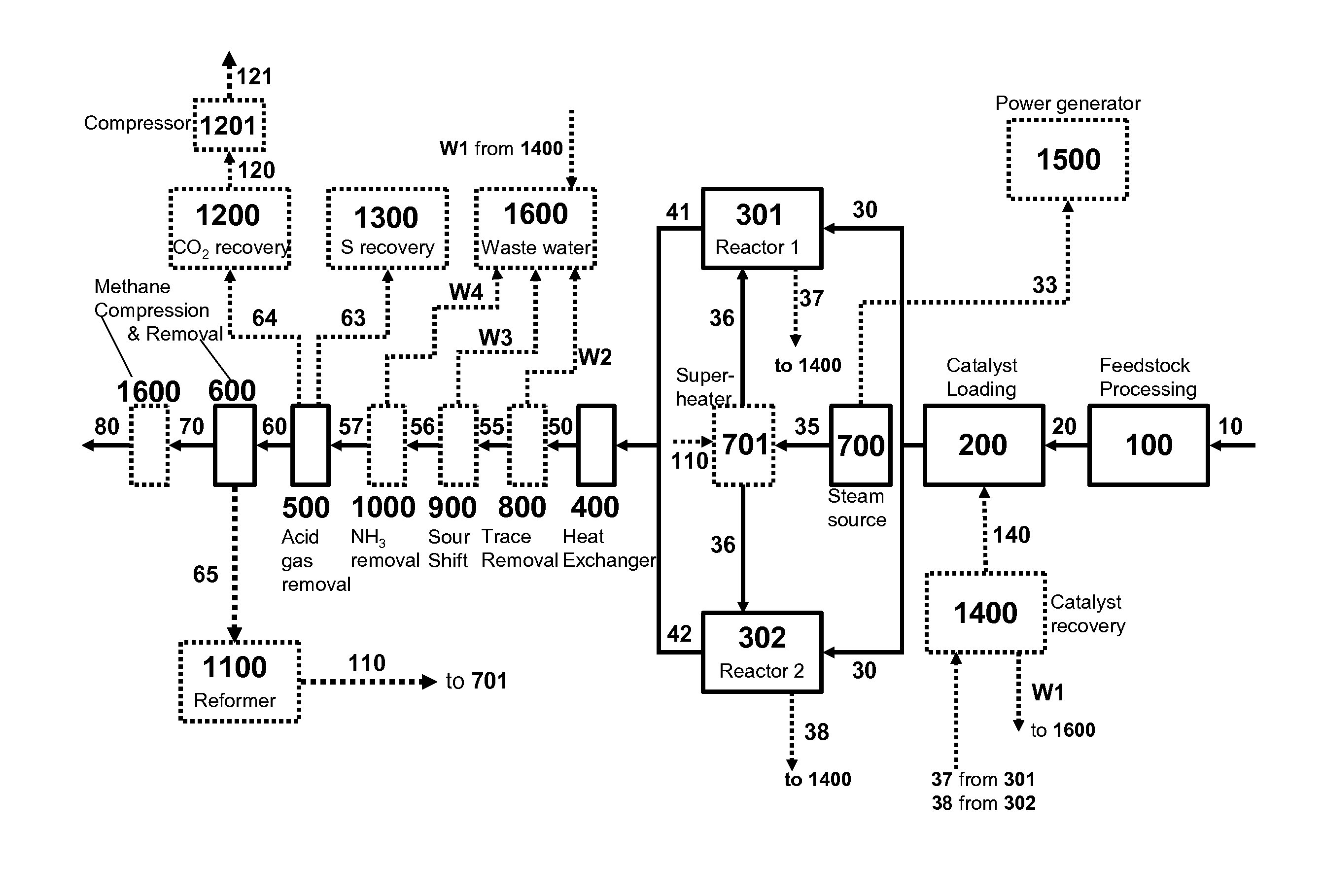

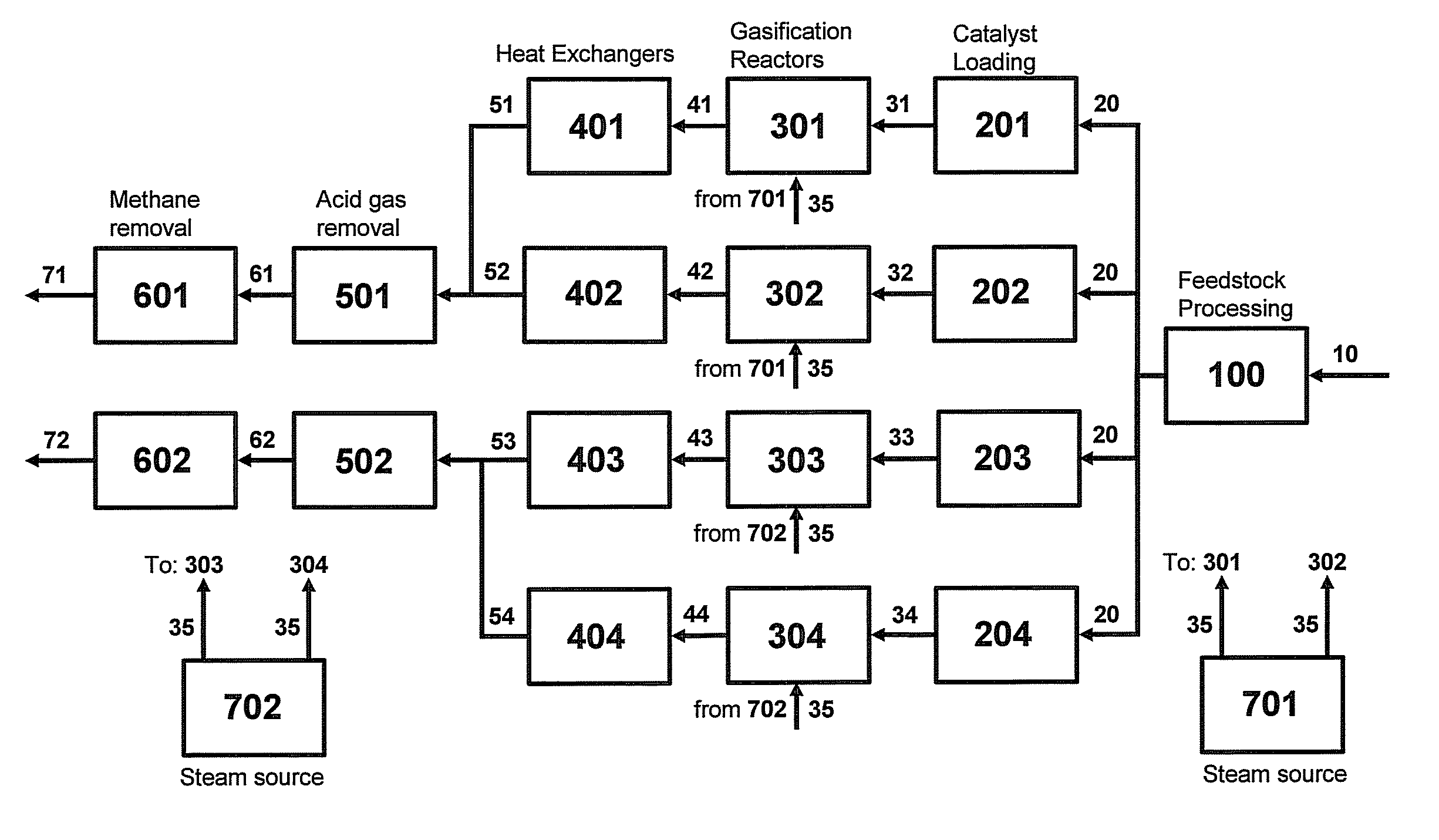

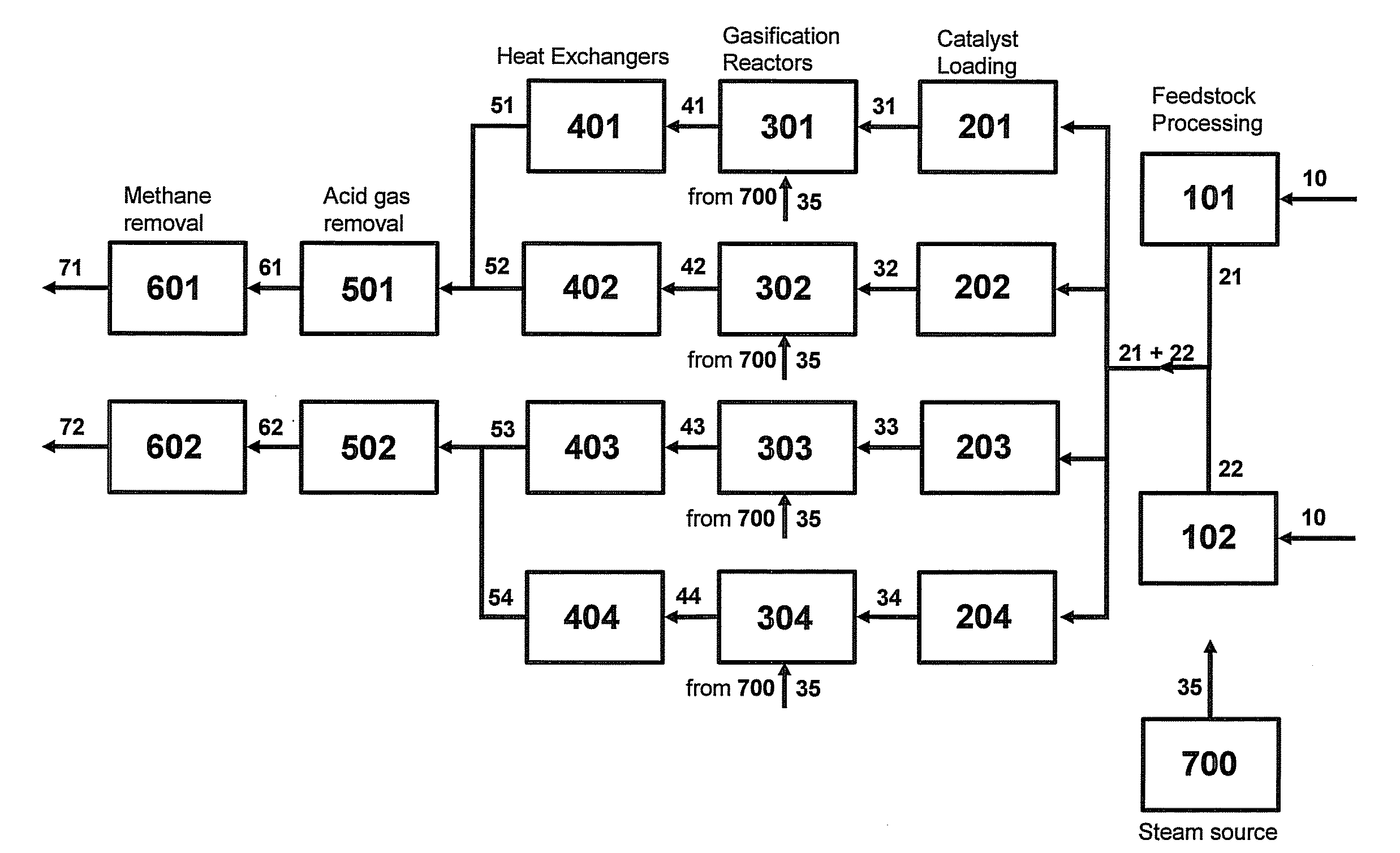

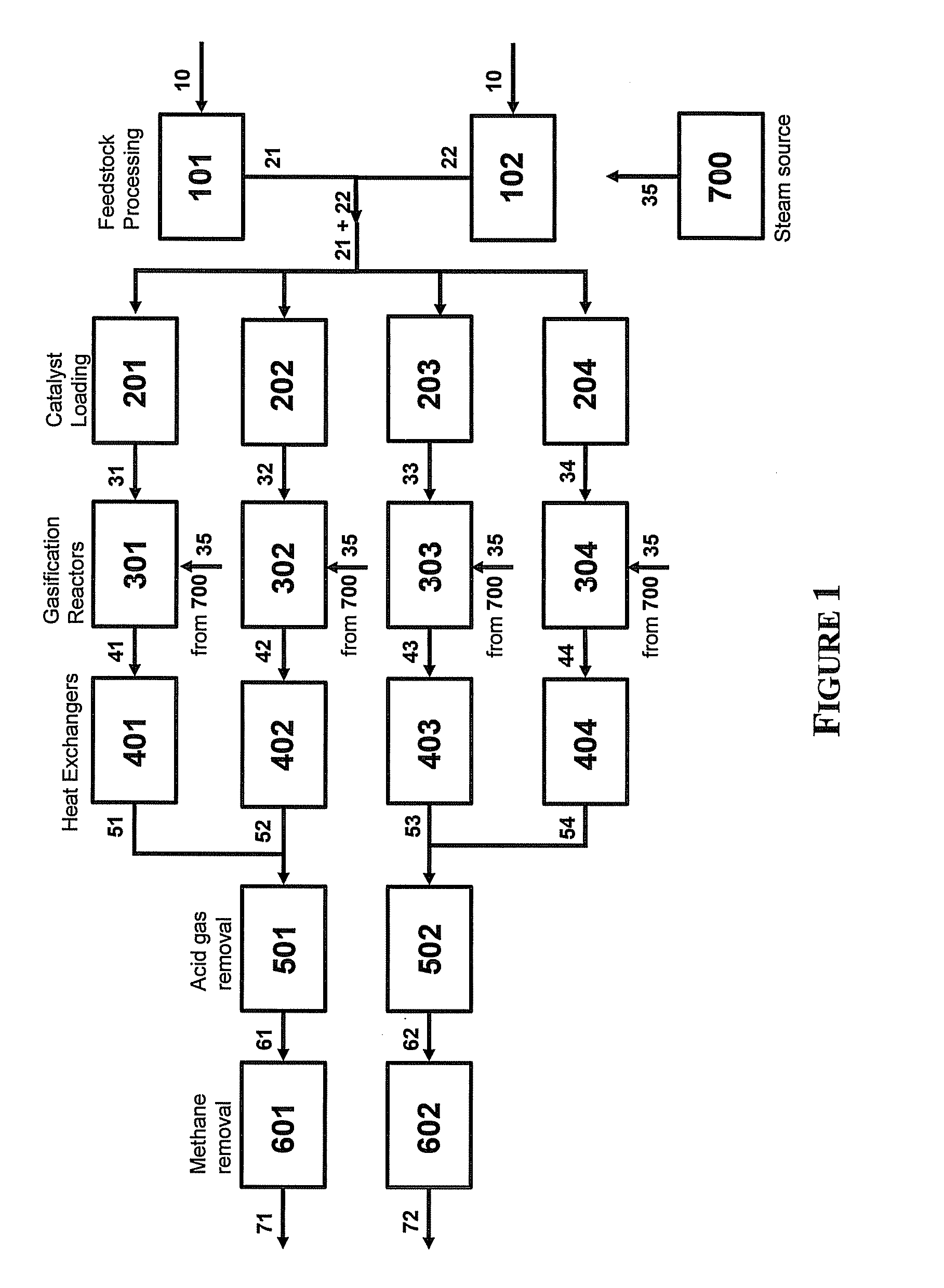

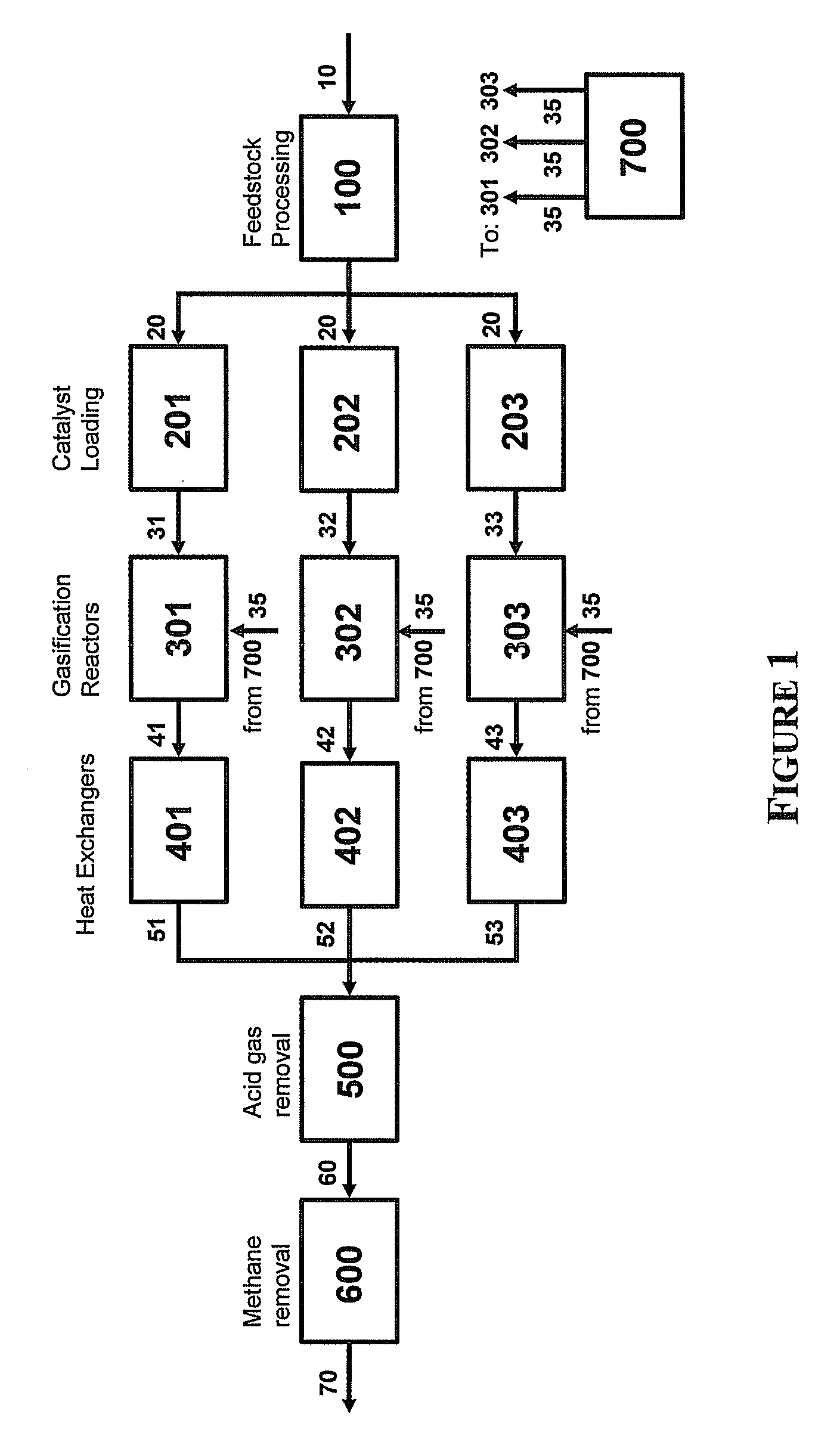

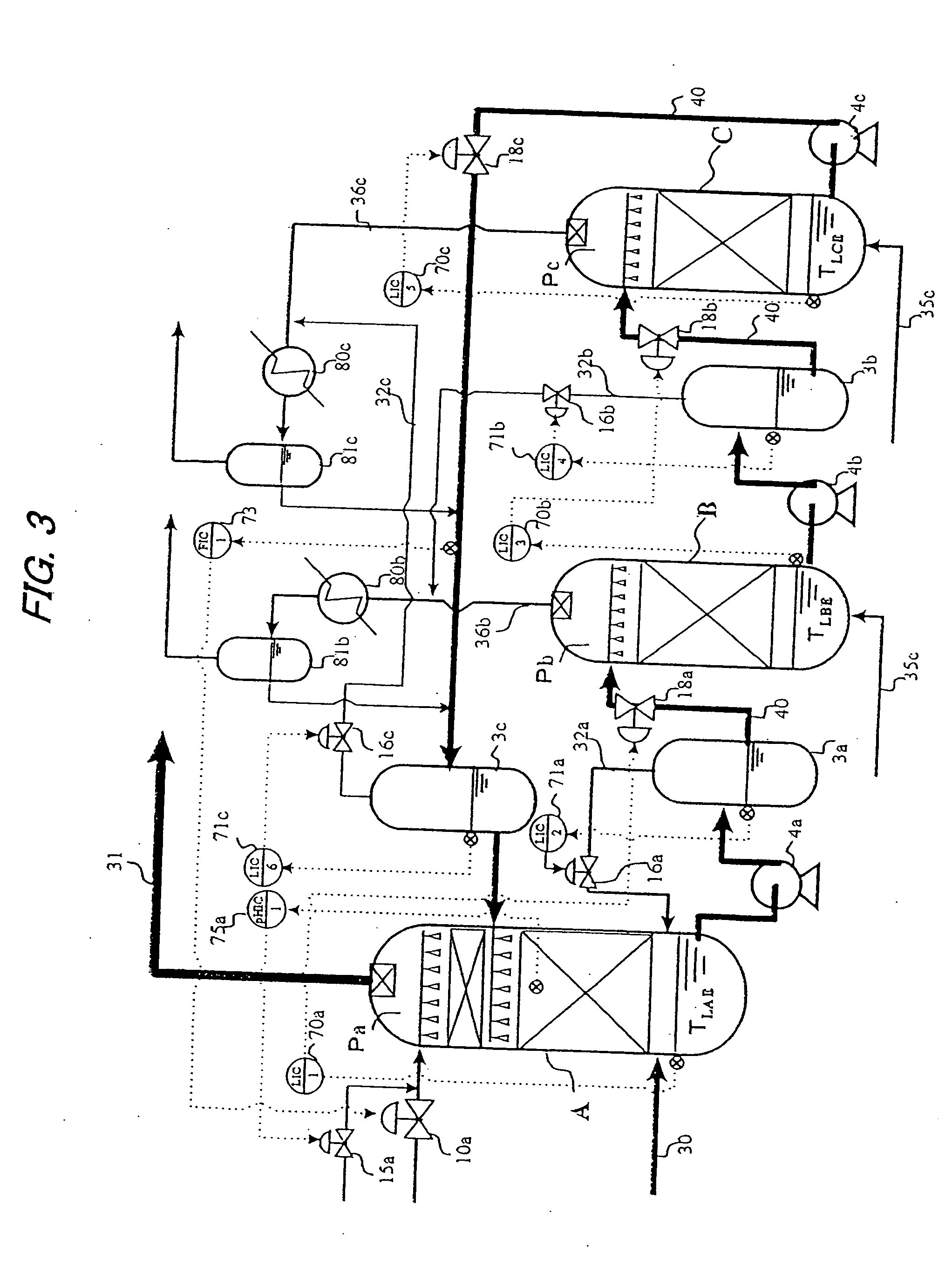

Four-Train Catalytic Gasification Systems

InactiveUS20090324460A1Reduce moisture contentHydrogen separation at low temperatureHydrogen separation using liquid contactUnit operationAmmonia

Systems to convert a carbonaceous feedstock into a plurality of gaseous products are described. The systems include, among other units, four separate gasification reactors for the gasification of a carbonaceous feedstock in the presence of an alkali metal catalyst into the plurality of gaseous products including at least methane. Each of the gasification reactors may be supplied with the feedstock from a single or separate catalyst loading and / or feedstock preparation unit operations. Similarly, the hot gas streams from each gasification reactor may be purified via their combination at a heat exchanger, acid gas removal, or methane removal unit operations. Product purification may comprise trace contaminant removal units, ammonia removal and recovery units, and sour shift units.

Owner:SURE CHAMPION INVESTMENT LTD

Four-Train Catalytic Gasification Systems

InactiveUS20090324461A1Reduce moisture contentGaseous fuelsGasification processes detailsUnit operationAmmonia

Systems to convert a carbonaceous feedstock into a plurality of gaseous products are described. The systems include, among other units, four separate gasification reactors for the gasification of a carbonaceous feedstock in the presence of an alkali metal catalyst into the plurality of gaseous products including at least methane. Each of the gasification reactors may be supplied with the feedstock from a single or separate catalyst loading and / or feedstock preparation unit operations. Similarly, the hot gas streams from each gasification reactor may be purified via their combination at a heat exchanger, acid gas removal, or methane removal unit operations. Product purification may comprise trace contaminant removal units, ammonia removal and recovery units, and sour shift units.

Owner:SURE CHAMPION INVESTMENT LTD

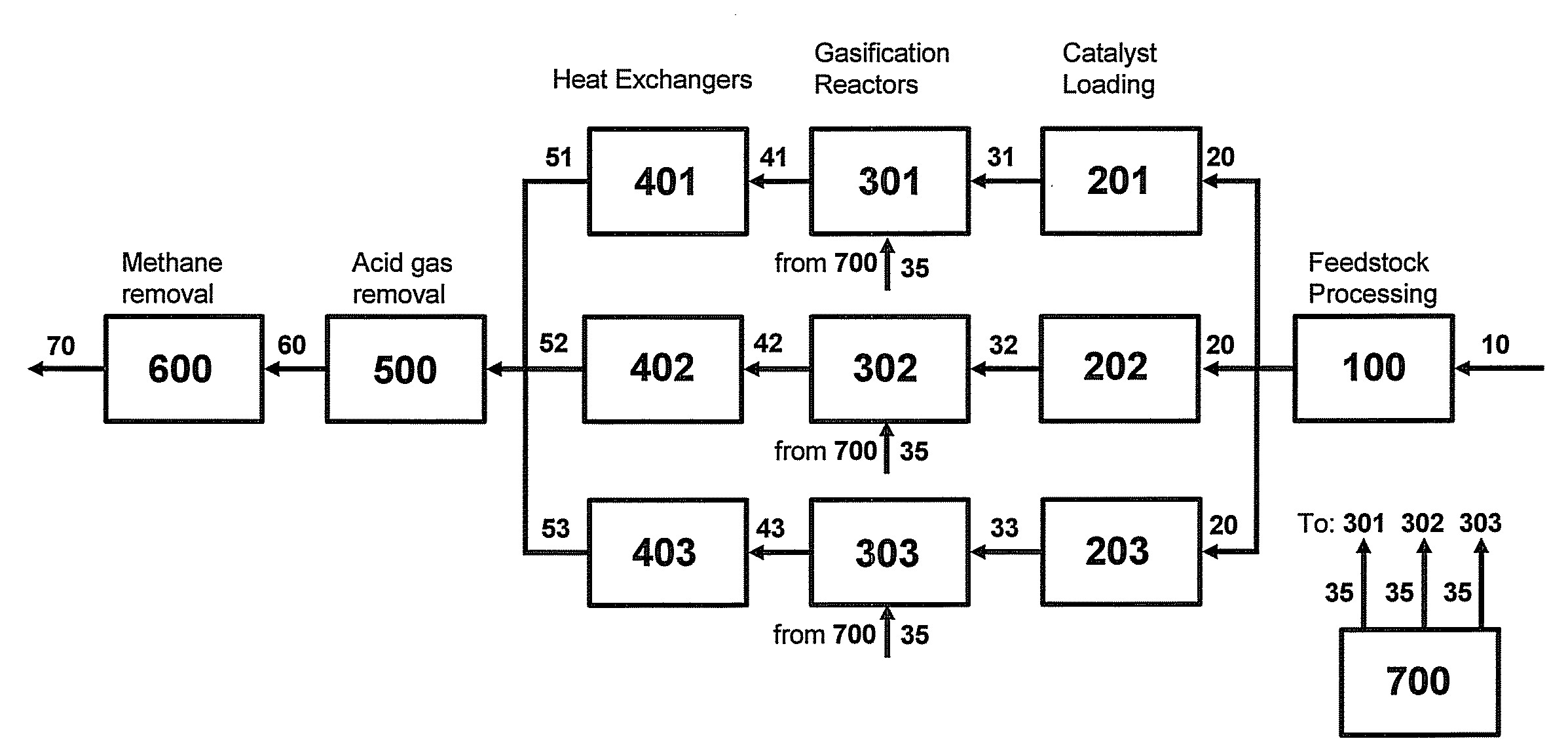

Three-Train Catalytic Gasification Systems

InactiveUS20090324459A1Reduce moisture contentCombustible gas catalytic treatmentGaseous fuelsUnit operationAmmonia

Systems to convert a carbonaceous feedstock into a plurality of gaseous products are described. The systems include, among other units, three separate gasification reactors for the gasification of a carbonaceous feedstock in the presence of an alkali metal catalyst into the plurality of gaseous products including at least methane. Each of the gasification reactors may be supplied with the feedstock from a single or separate catalyst loading and / or feedstock preparation unit operations. Similarly, the hot gas streams from each gasification reactor may be purified via their combination at a heat exchanger, acid gas removal or methane removal unit operations. Product purification may comprise trace contaminant removal units, ammonia removal and recovery units, and sour shift units.

Owner:SURE CHAMPION INVESTMENT LTD

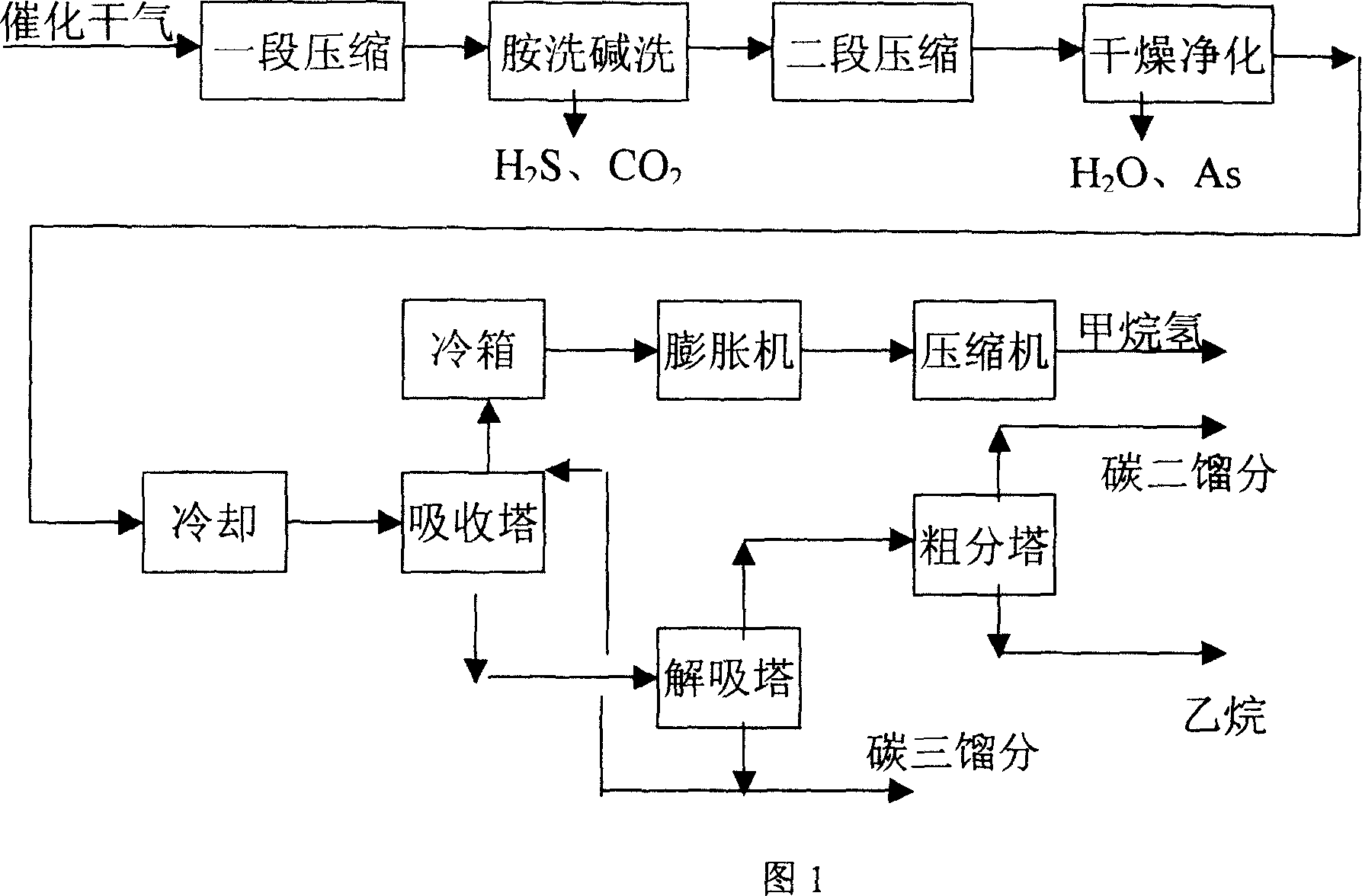

Method for separating plant catalytic dry gas by employing middle-cool-oil absorption process

InactiveCN101063048AEasy to getLow costOrganic chemistryEthylene productionProduct gasEnergy consumption

The invention discloses a separating refinery catalytic dry gas method with middle cold oil absorptive method in separating refinery catalytic dry gas technical domain, which comprises the following steps: compressing; stripping acid gas; drying; purifying; absorbing; desorbing; reclaiming cold energy; crude-separating. This invention possesses cheap cost, low lost, simple operation, little investment and low energy consumption, which can get C2 fraction and ethane.

Owner:CHINA PETROLEUM & CHEM CORP +1

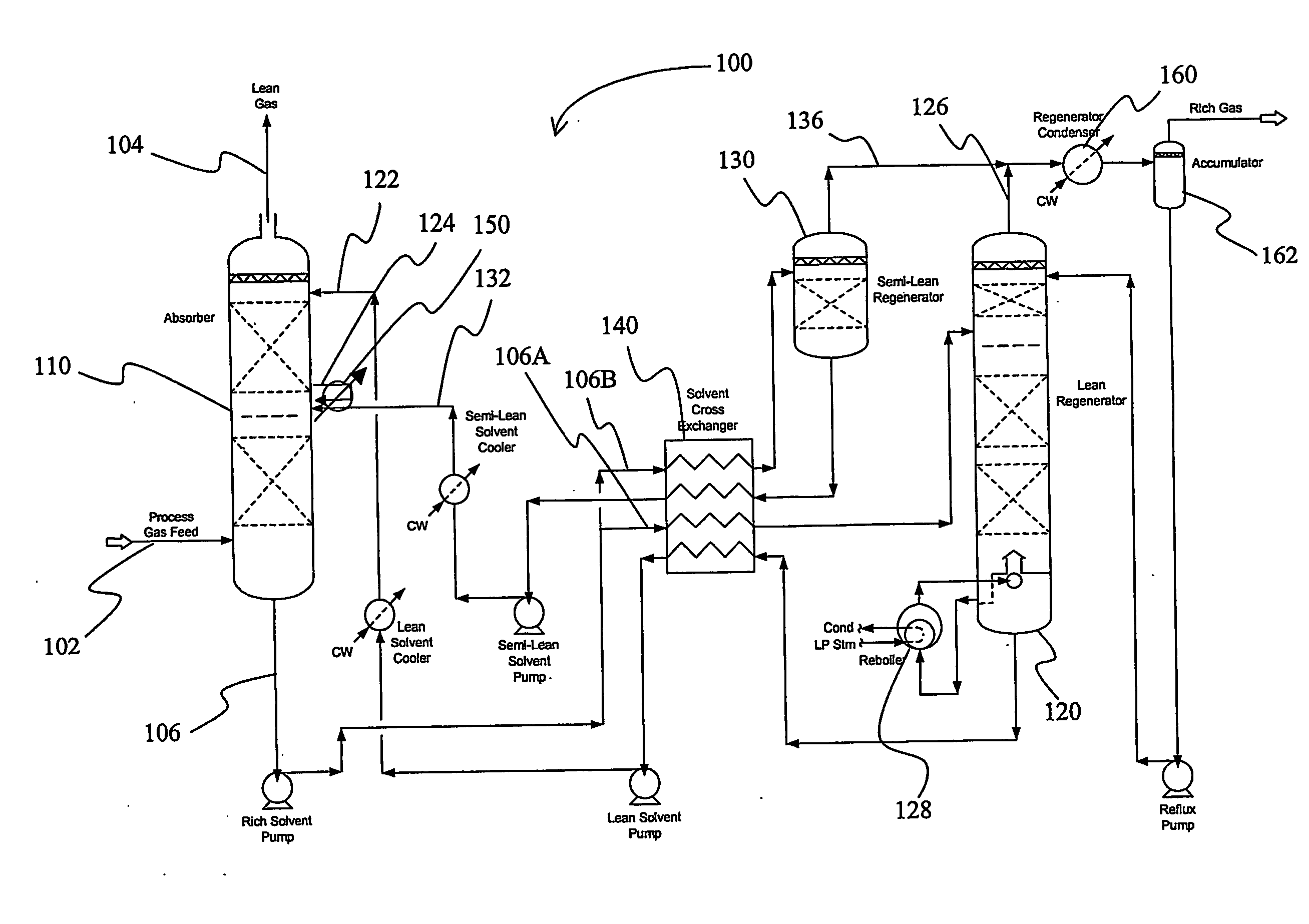

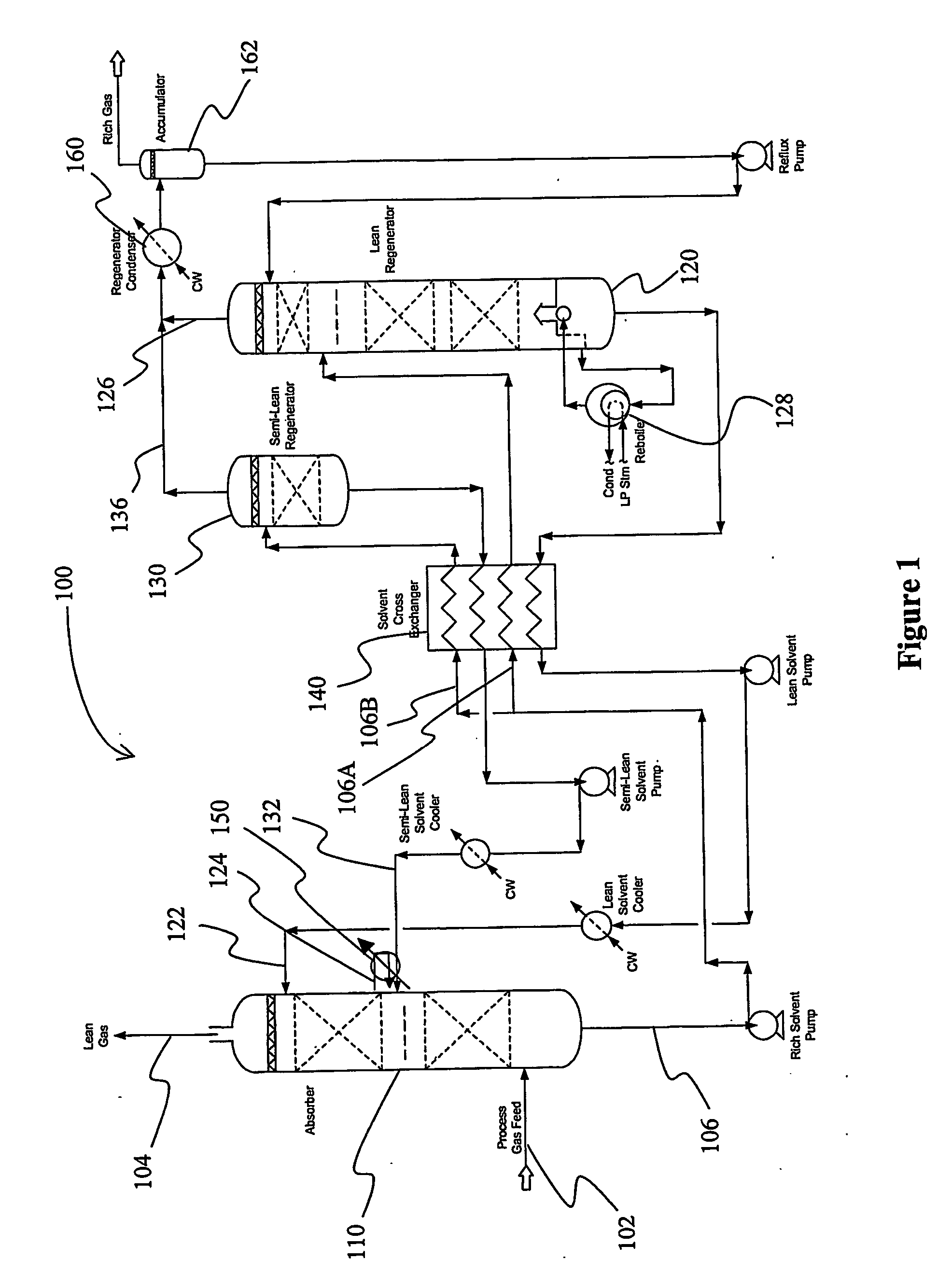

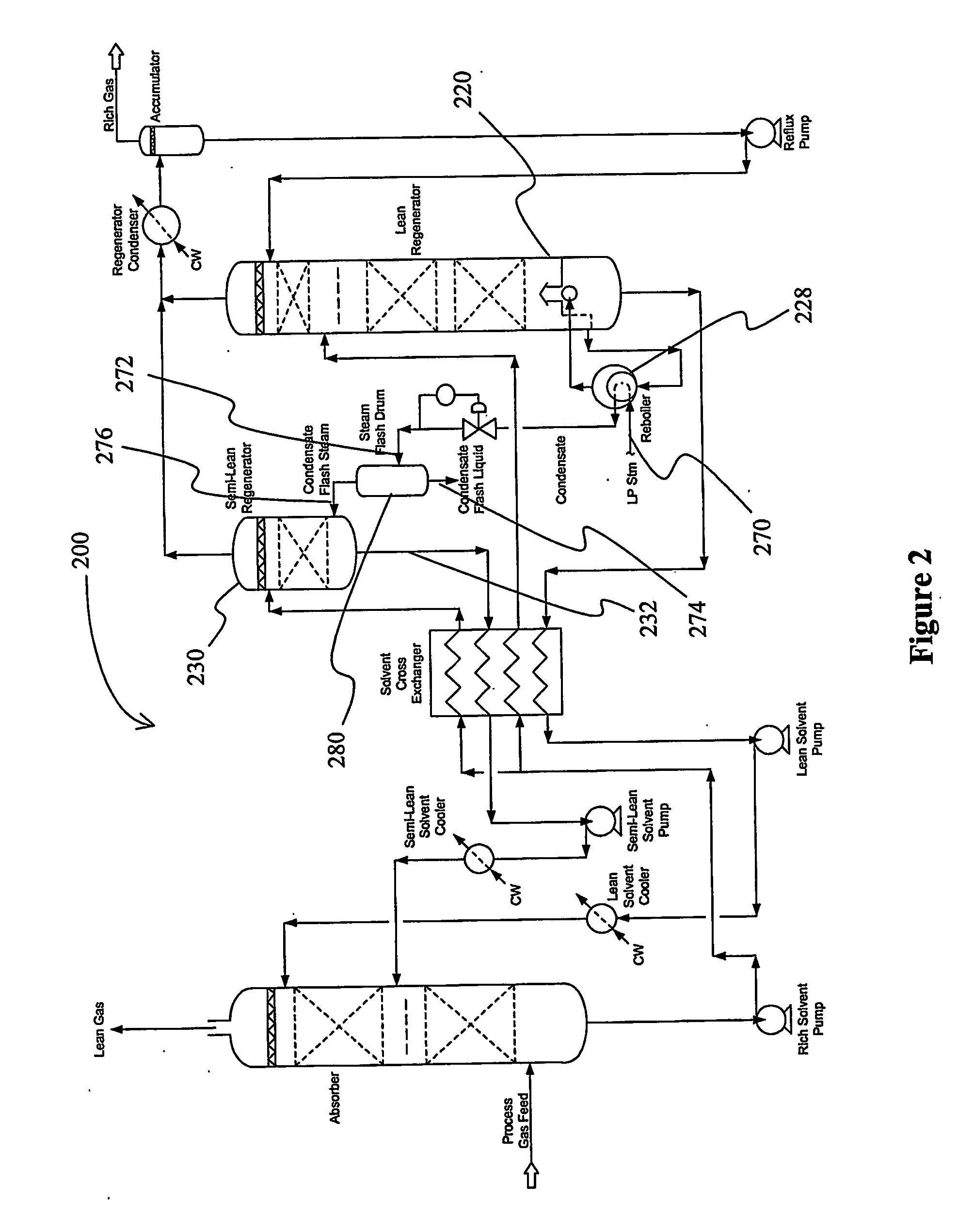

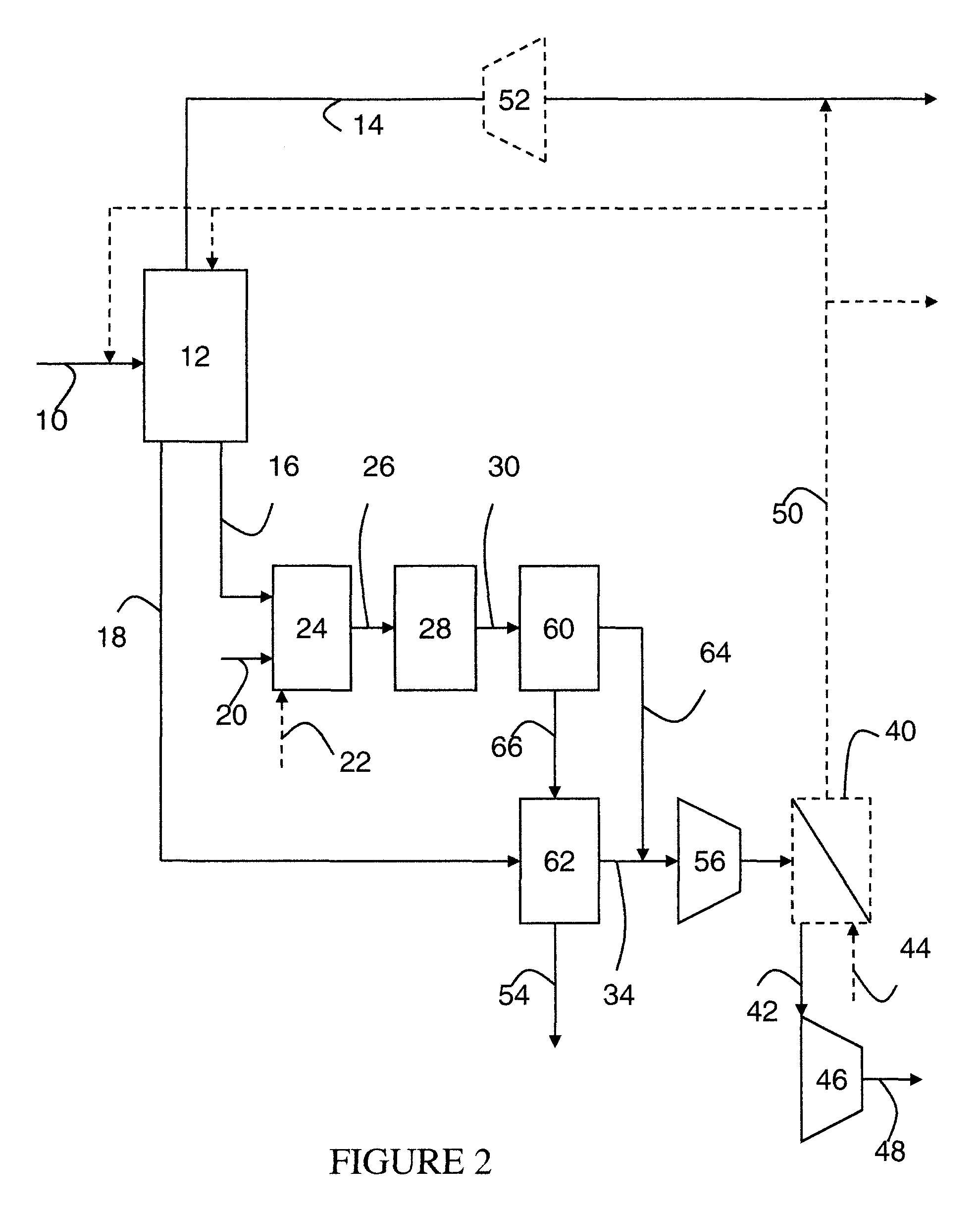

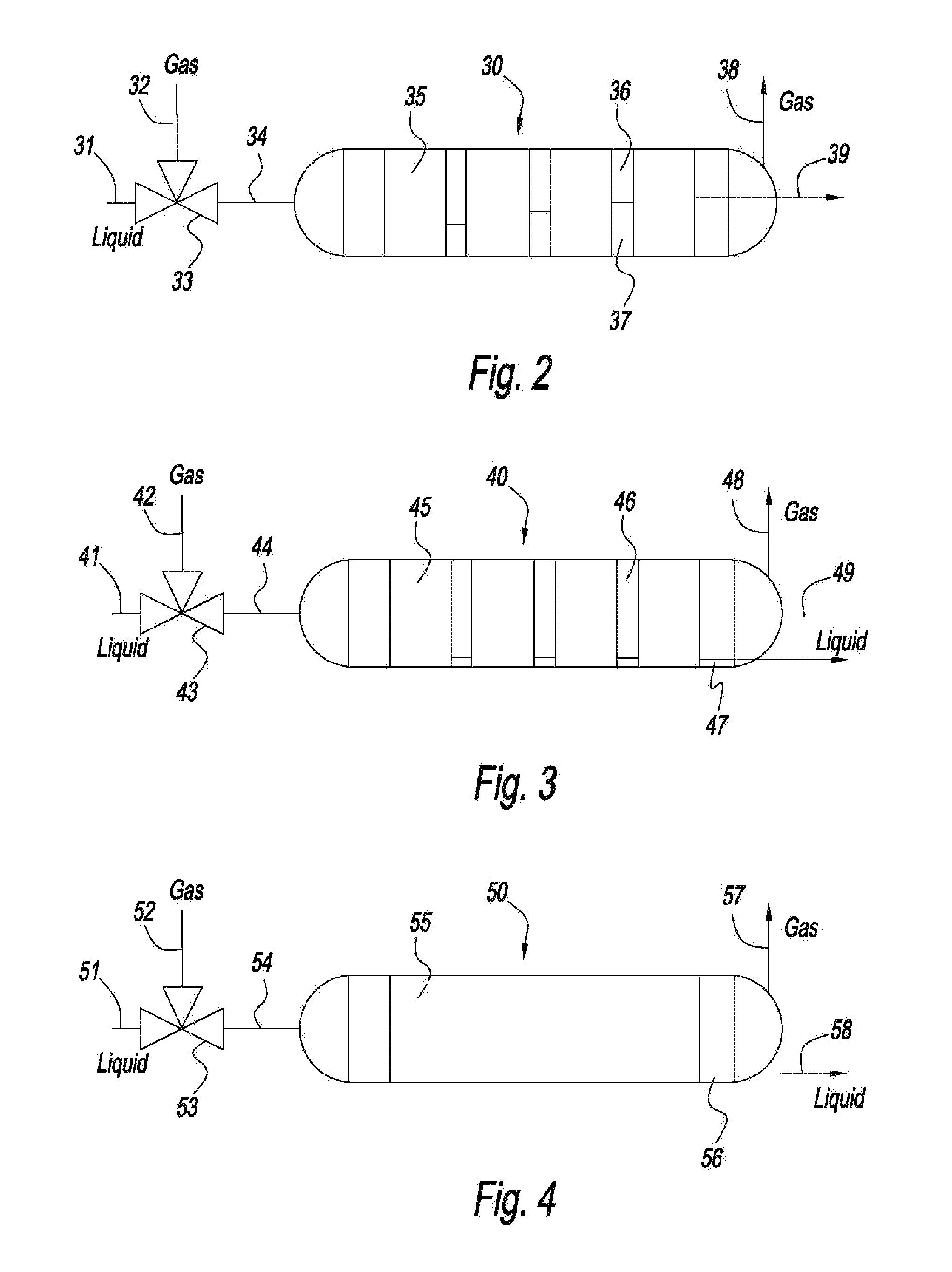

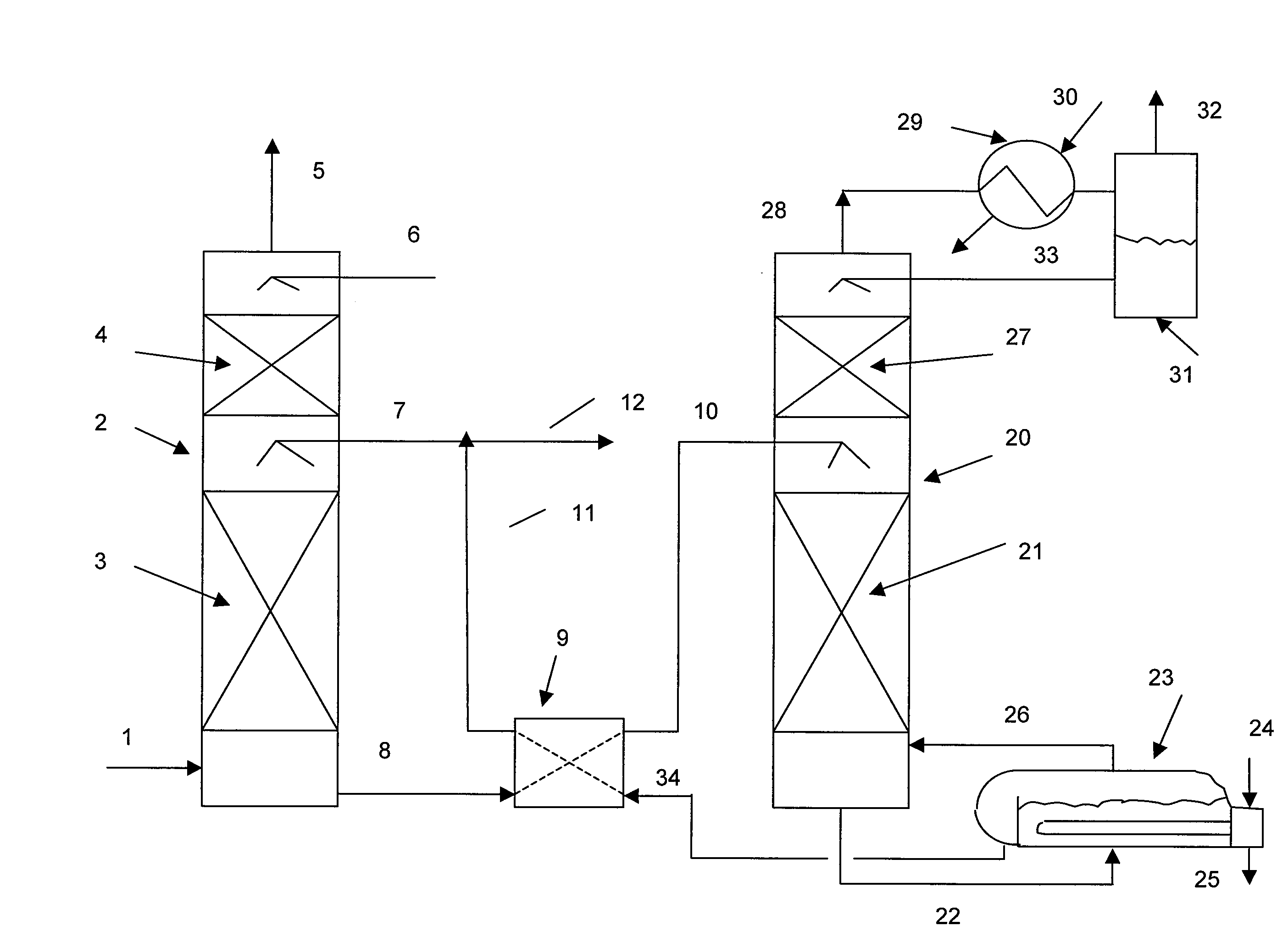

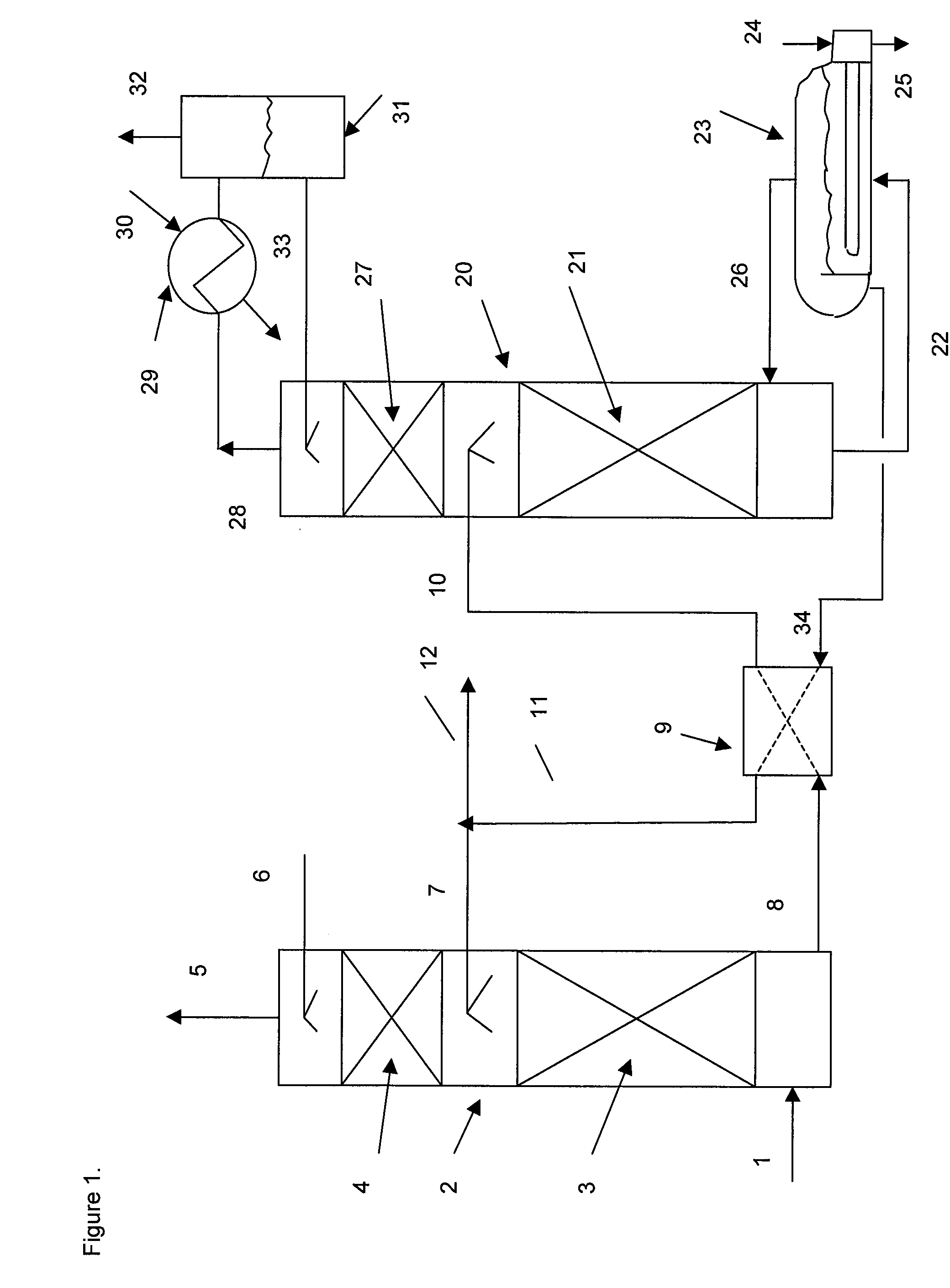

Split flow process and apparatus

An acid gas removal plant includes an absorber that provides a rich solvent to two regenerators that independently generate a lean and a semi-lean solvent, wherein the semi-lean solvent is produced in one of the regenerators using heat and / or steam derived from the other regenerator. Further heat integration is particularly contemplated with power plants in which the power plant provides high-level heat to the acid gas removal plant and wherein the power plant receives low-level heat from the acid gas removal plant.

Owner:FLUOR TECH CORP

Method and apparatus for treating a sour gas

Owner:AIR PROD & CHEM INC

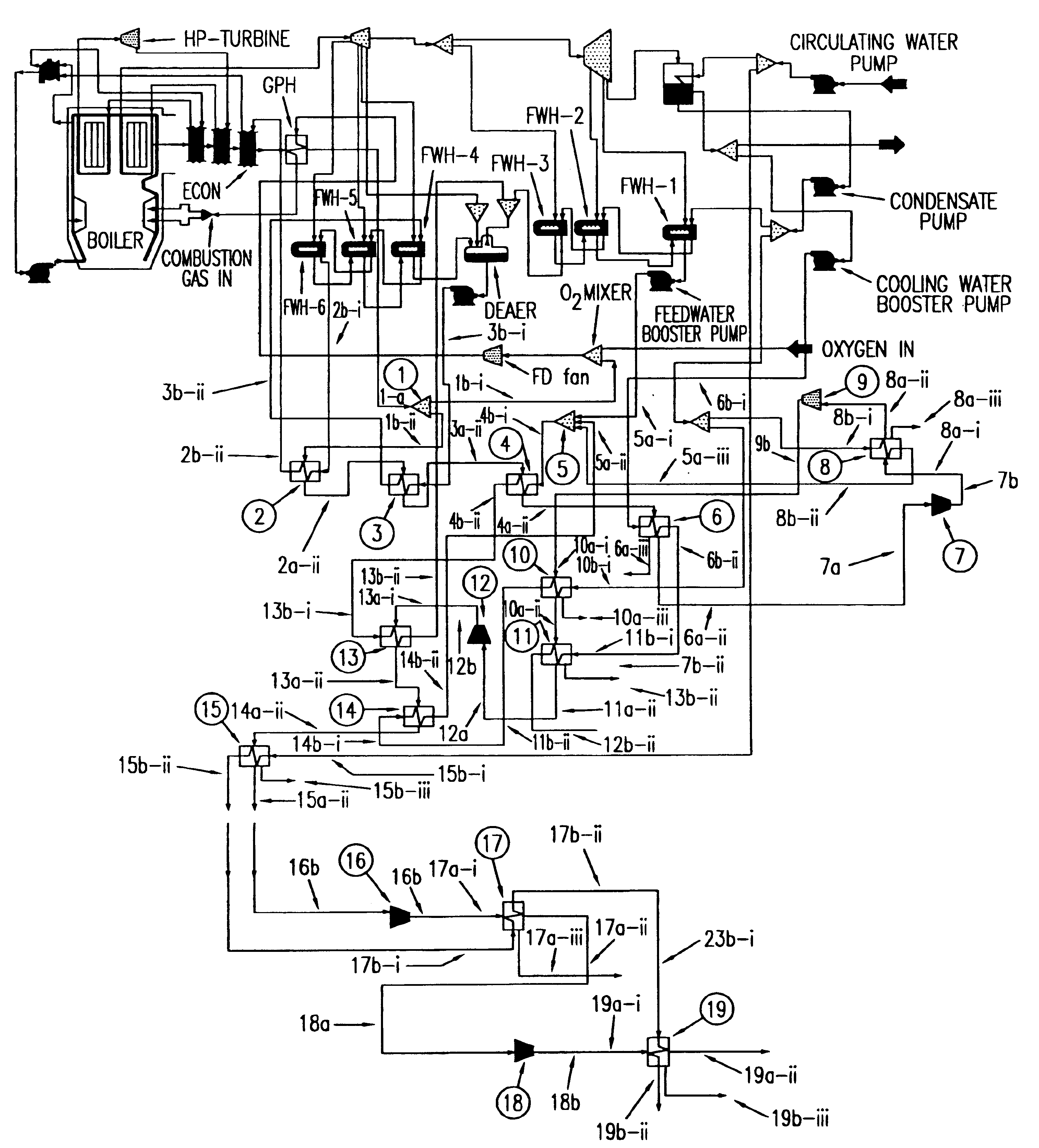

Compression stripping of flue gas with energy recovery

InactiveUS6898936B1Low costReduced Power RequirementsLiquid degasificationSteam regenerationWorking fluidWater vapor

A method of remediating and recovering energy from combustion products from a fossil fuel power plant having at least one fossil fuel combustion chamber, at least one compressor, at least one turbine, at least one heat exchanger and a source of oxygen. Combustion products including non-condensable gases such as oxygen and nitrogen and condensable vapors such as water vapor and acid gases such as SOX and NOX and CO2 and pollutants are produced and energy is recovered during the remediation which recycles combustion products and adds oxygen to support combustion. The temperature and / or pressure of the combustion products are changed by cooling through heat exchange with thermodynamic working fluids in the power generation cycle and / or compressing and / or heating and / or expanding the combustion products to a temperature / pressure combination below the dew point of at least some of the condensable vapors to condense liquid having some acid gases dissolved and / or entrained and / or directly condense acid gas vapors from the combustion products and to entrain and / or dissolve some of the pollutants while recovering sensible and / or latent heat from the combustion products through heat exchange between the combustion products and thermodynamic working fluids and / or cooling fluids used in the power generating cycle. Then the CO2, SO2, and H2O poor and oxygen enriched remediation stream is sent to an exhaust and / or an air separation unit and / or a turbine.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

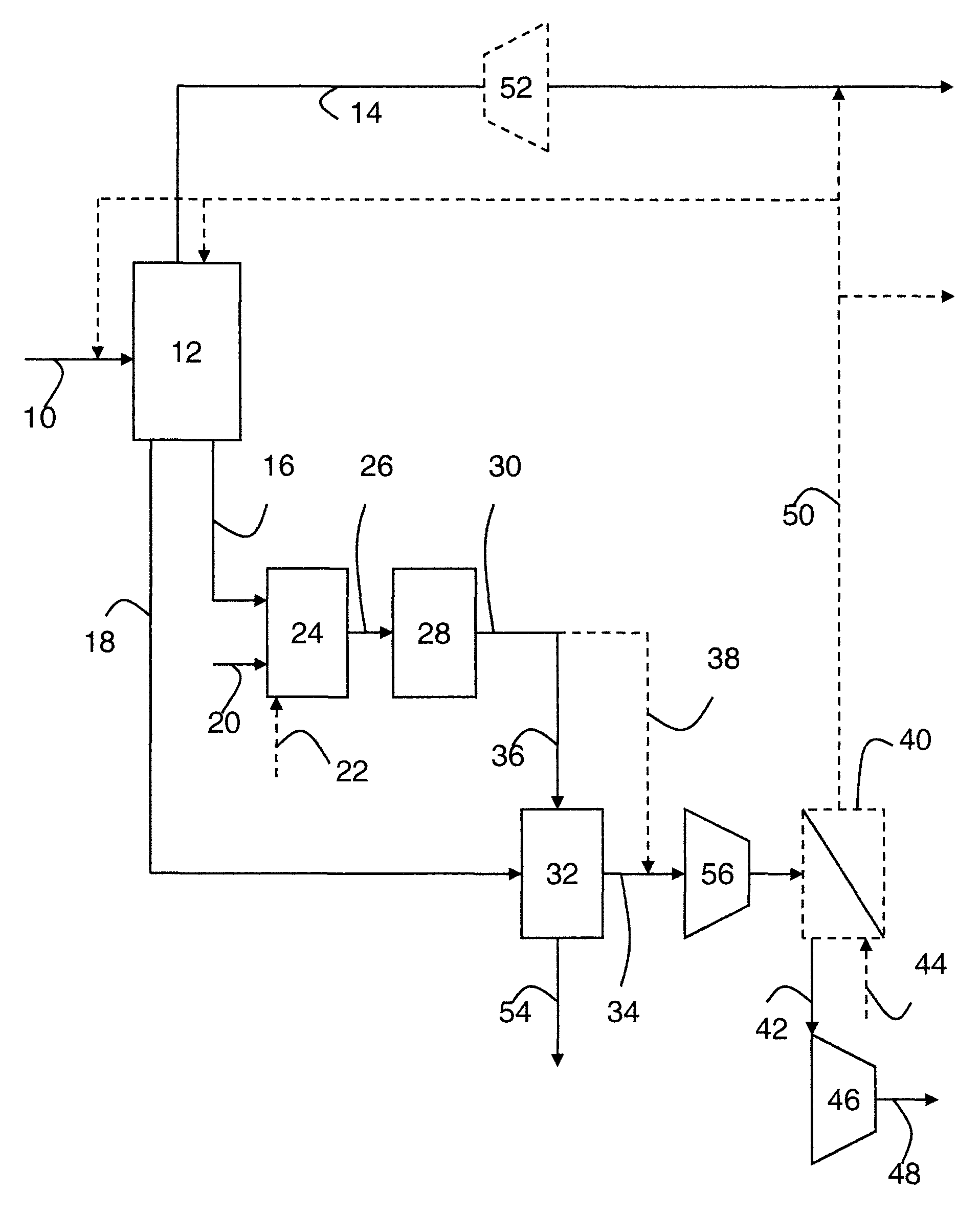

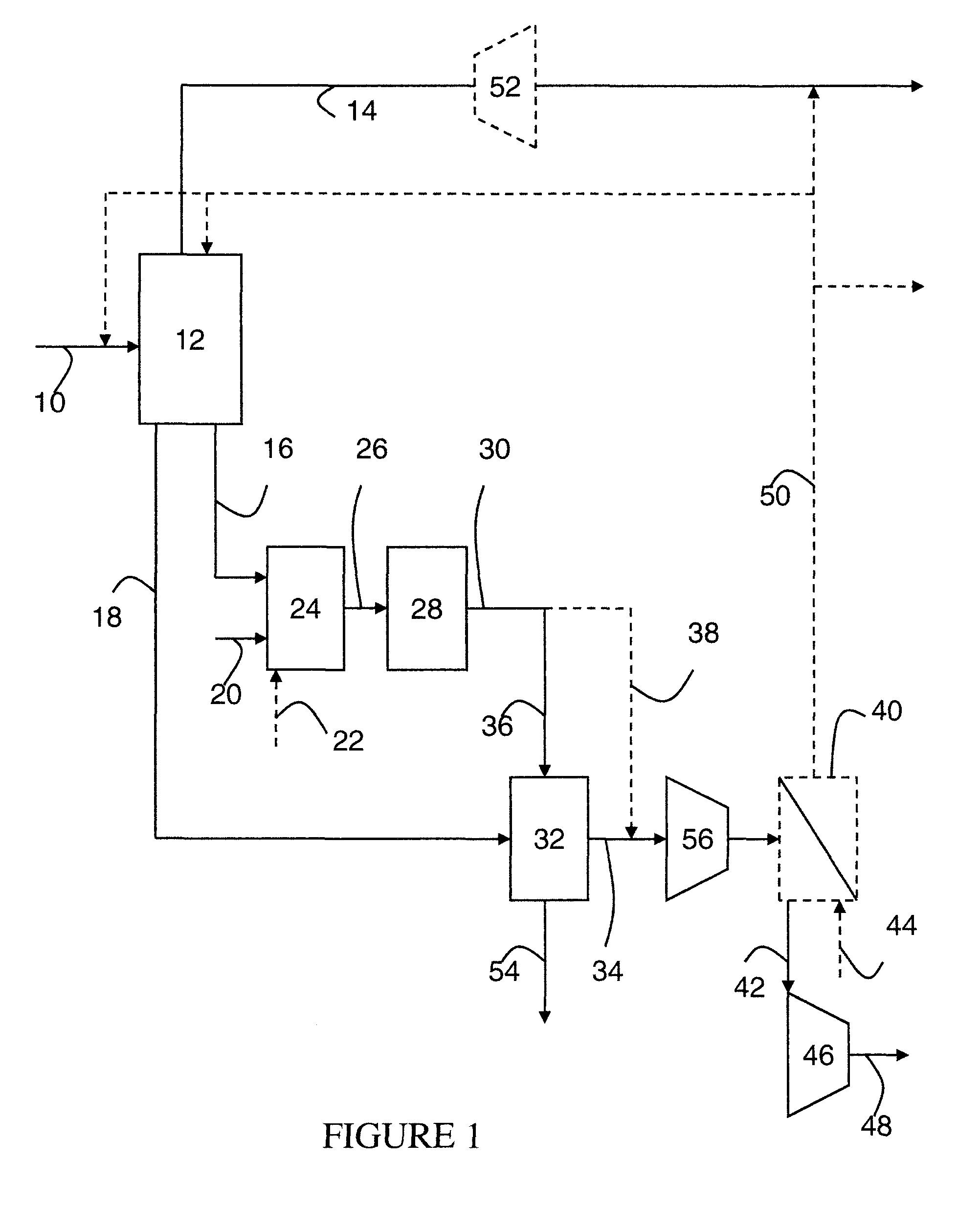

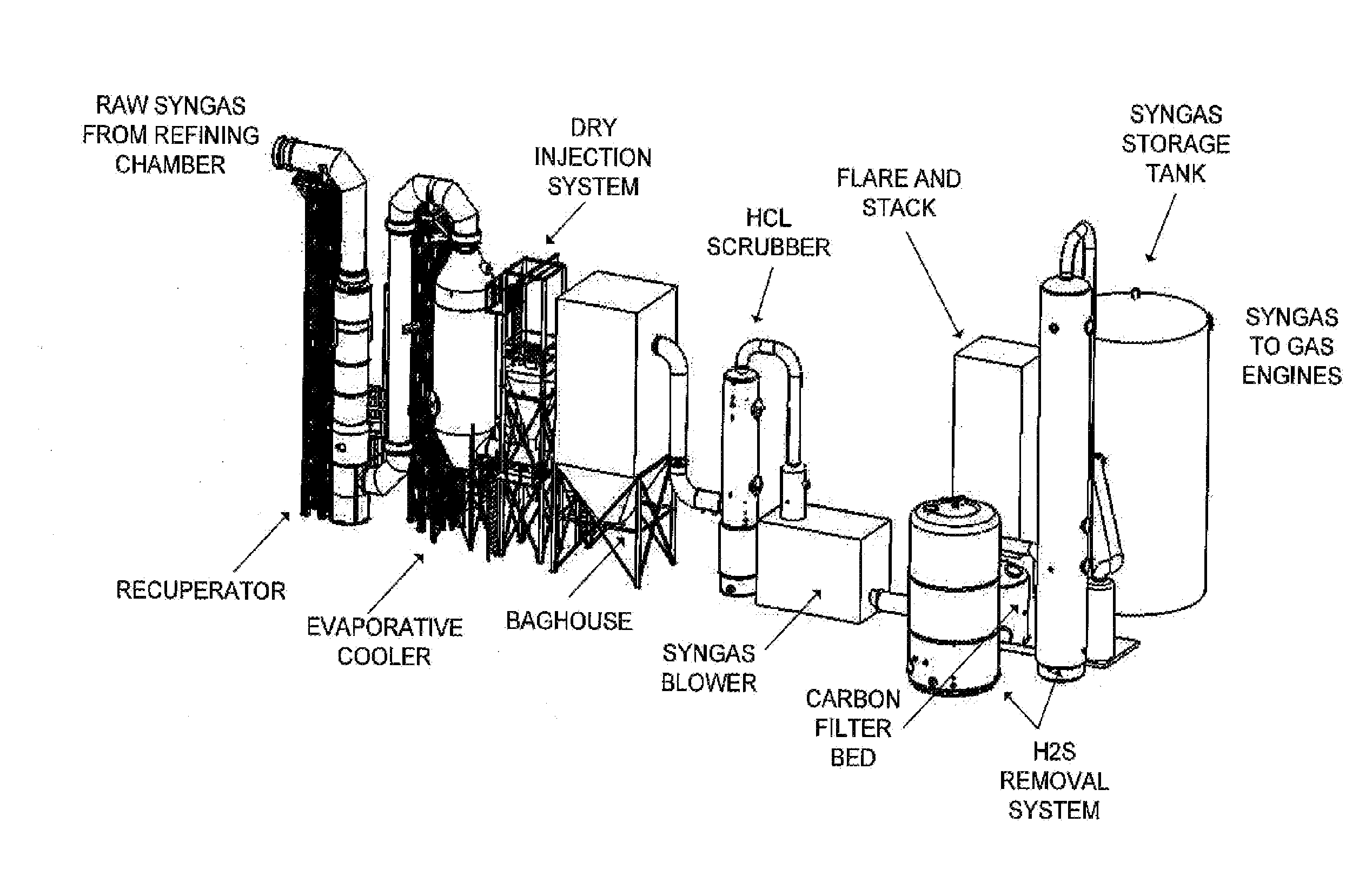

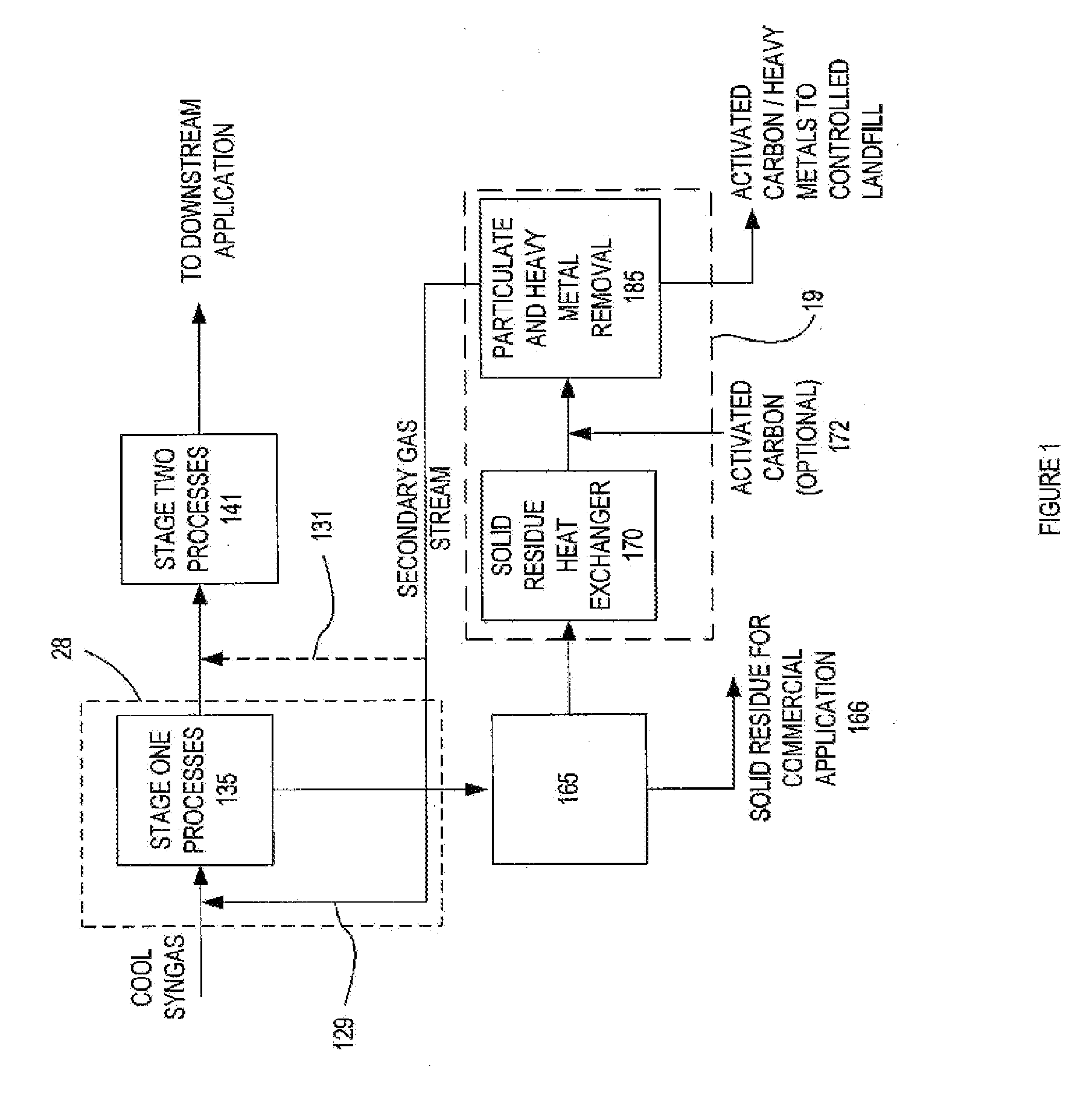

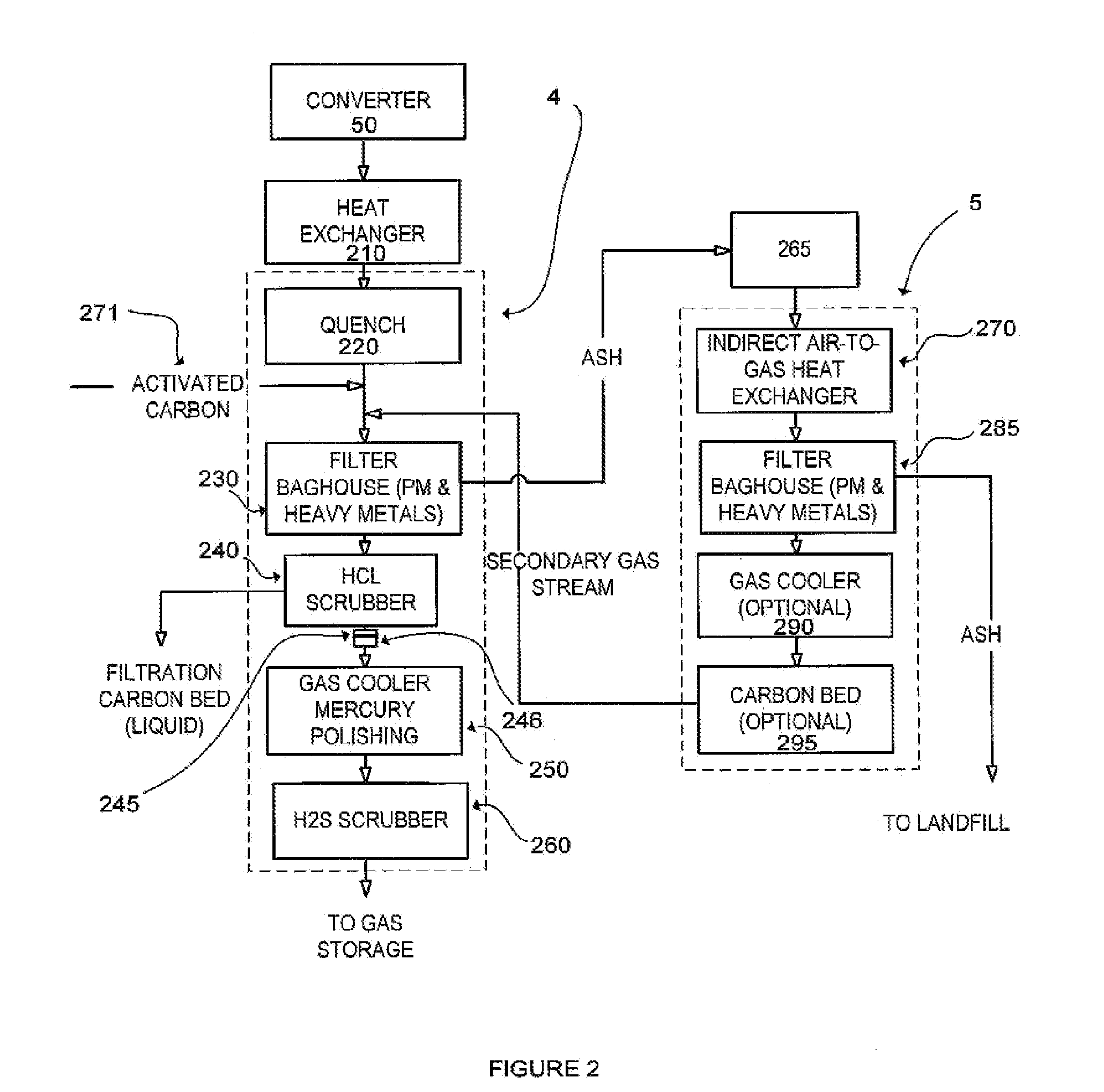

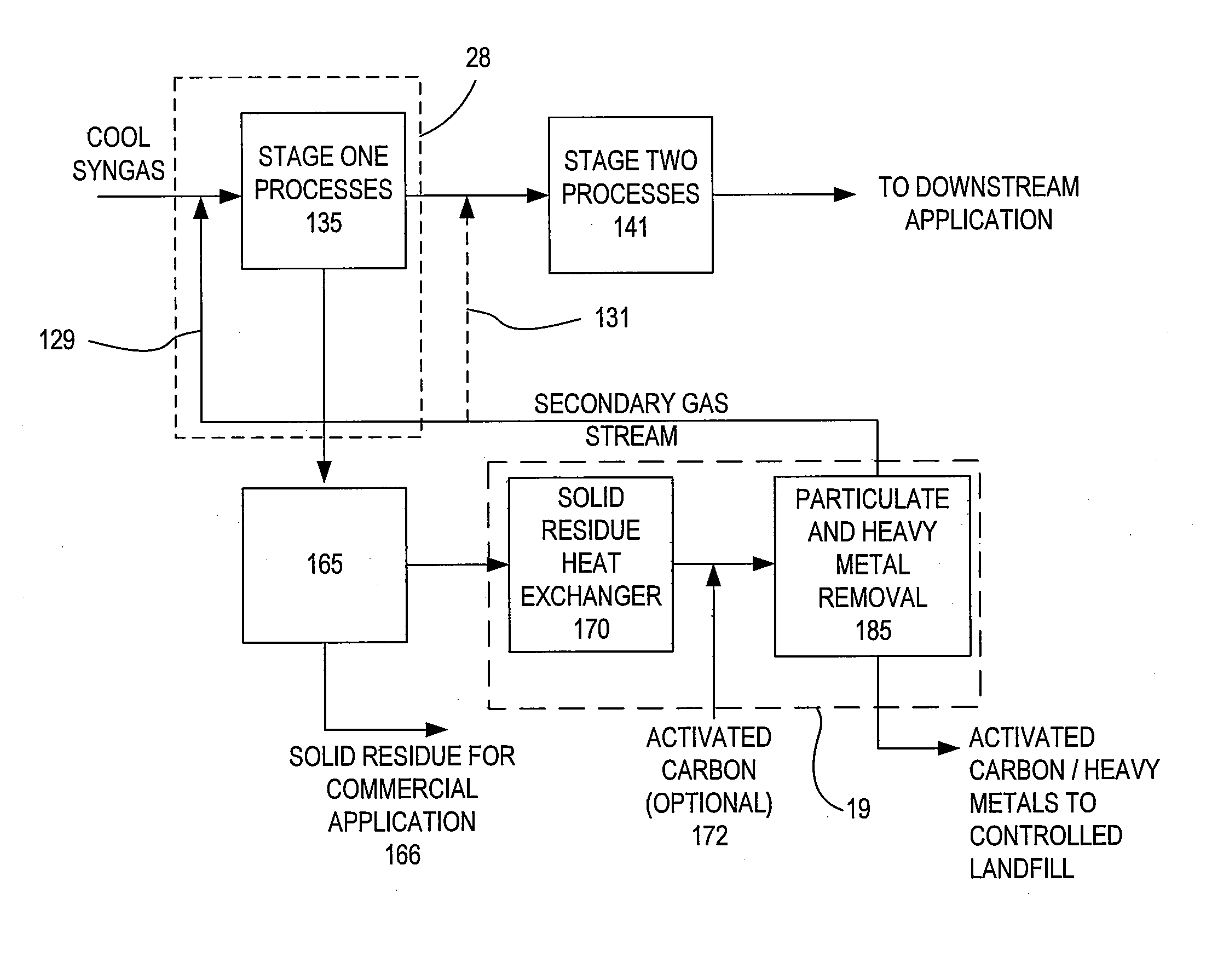

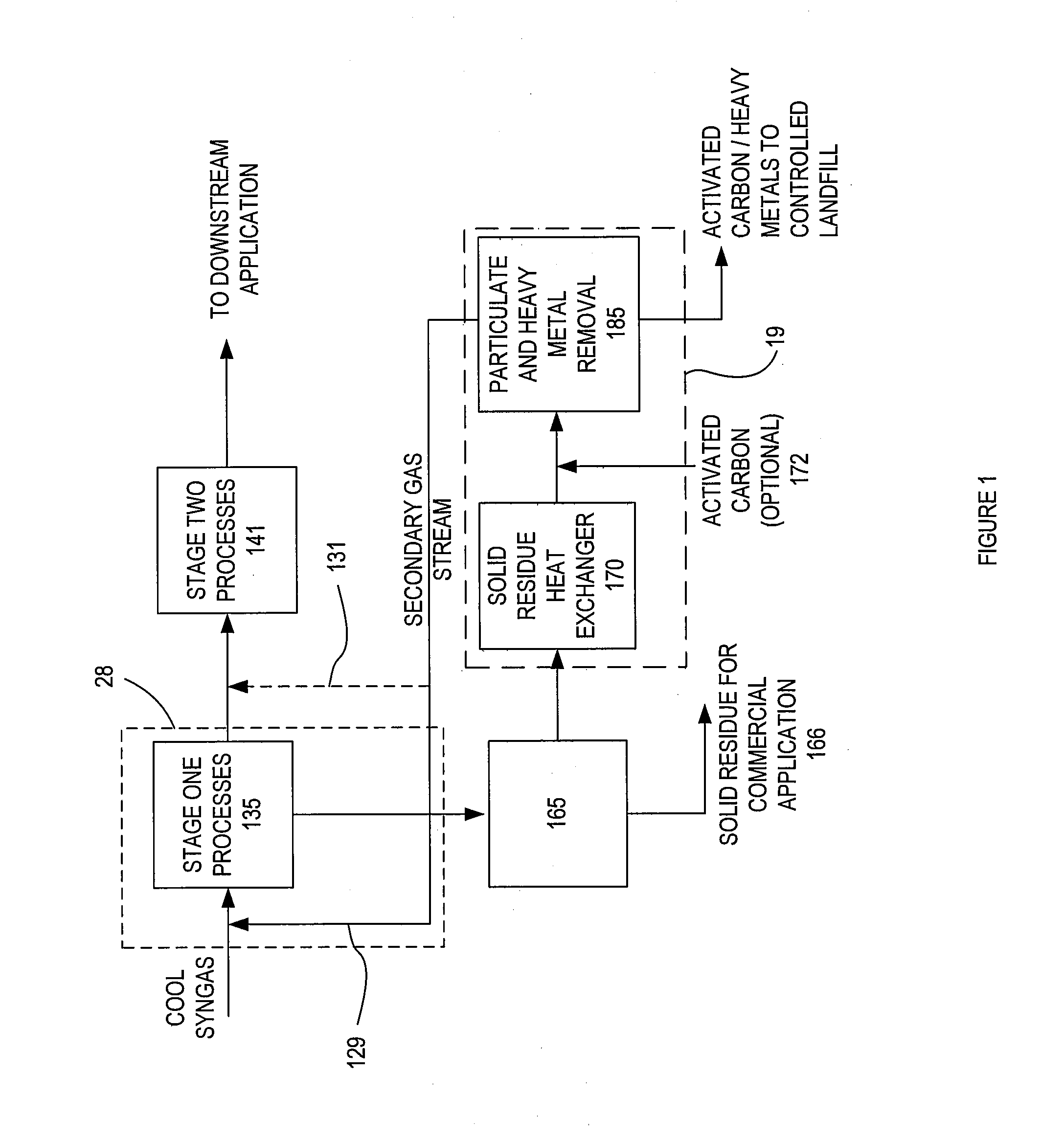

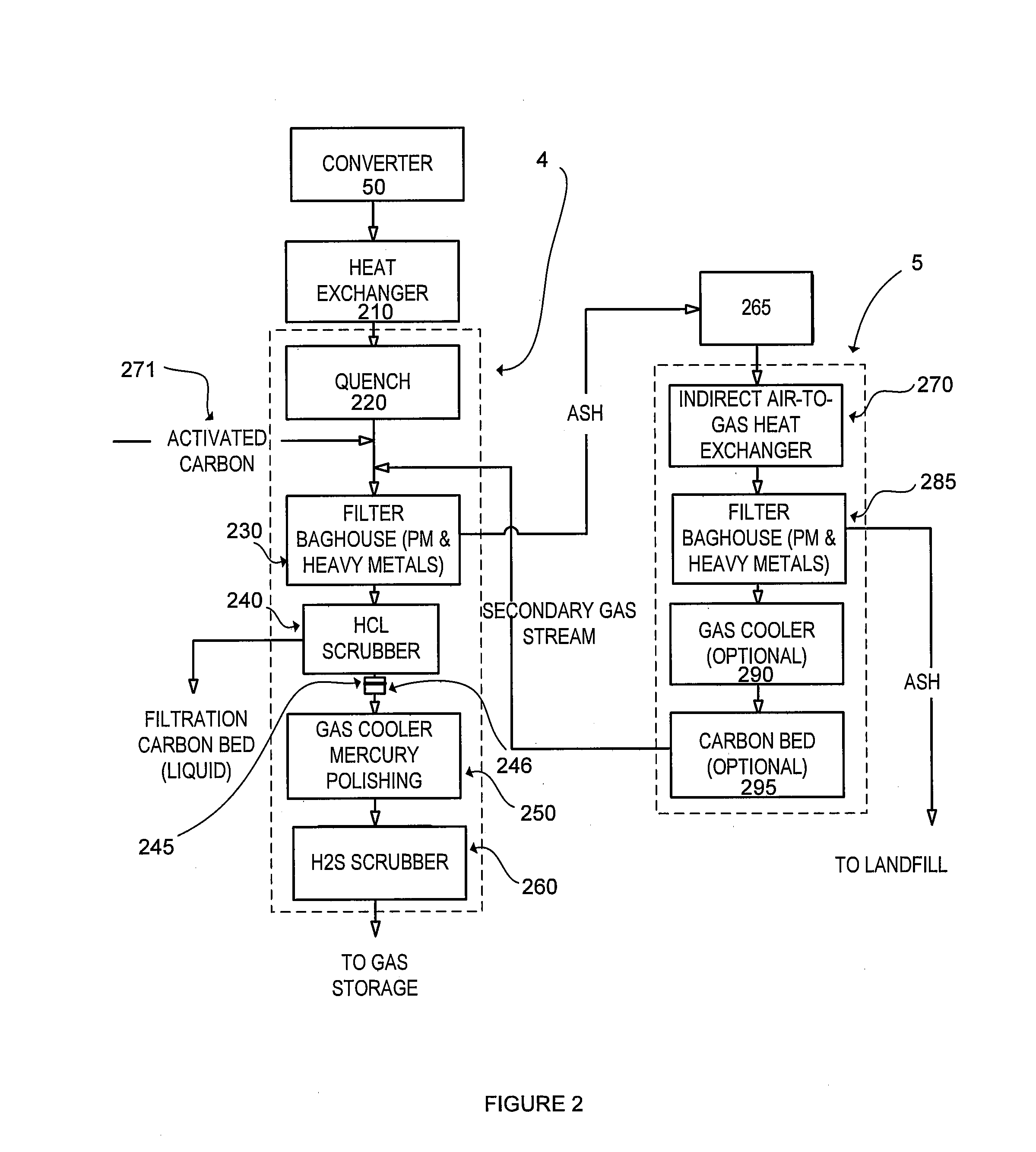

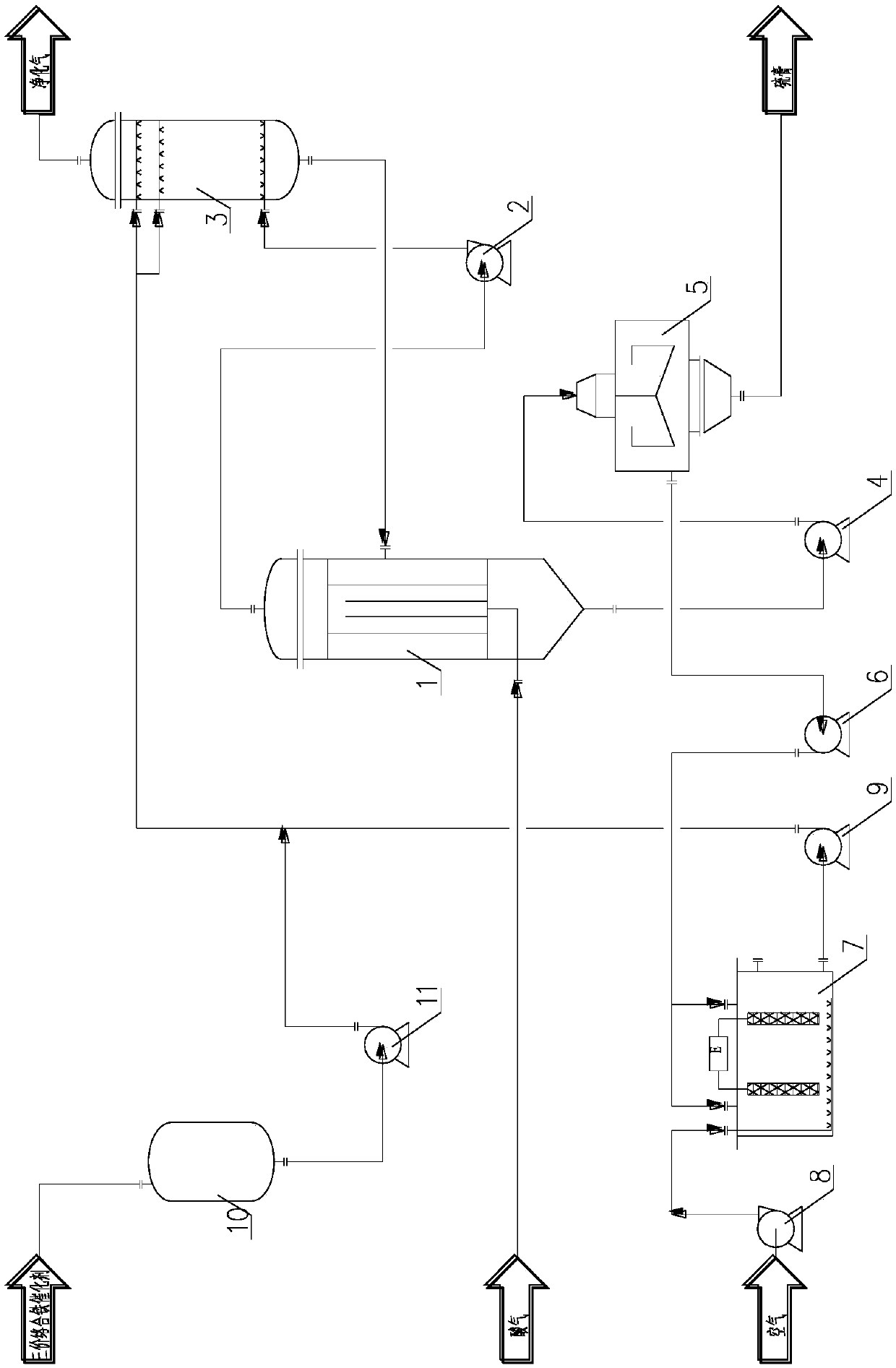

Gas conditioning system

The present invention provides a gas conditioning system for processing an input gas from a low temperature gasification system to an output gas of desired characteristics. The system comprises a two-stage process, the first stage separating heavy metals and particulate matter in a dry phase, and the second stage including further processing steps of removing acid gases, and / or other contaminants. Optional processes include adjusting the humidity and temperature of the input gas as it passes through the gas conditioning system. The presence and sequence of processing steps is determined by the composition of the input gas, the desired composition of output gas for downstream applications, and by efficiency and waste minimization.

Owner:PLASCO ENERGY GROUP INC

Gas Conditioning System

The present invention provides a gas conditioning system for processing an input gas from a low temperature gasification system to an output gas of desired characteristics. The system comprises a two-stage process, the first stage separating heavy metals and particulate matter in a dry phase, and the second stage including further processing steps of removing acid gases, and / or other contaminants. Optional processes include adjusting the humidity and temperature of the input gas as it passes through the gas conditioning system. The presence and sequence of processing steps is determined by the composition of the input gas, the desired composition of output gas for downstream applications, and by efficiency and waste minimization.

Owner:PLASCO ENERGY GROUP INC

Acid gas scrubbing apparatus and method

InactiveUS20050132883A1Improve energy efficiencyImprove acid gas removal capabilityUsing liquid separation agentCombustible gas catalytic treatmentScrubberCarbon dioxide

An acid gas scrubbing apparatus and method brings a gas, to be scrubbed, containing carbon dioxide into contact with a gas scrubbing liquid containing alkaline agent and cooled, and acid gases in the gas are removed. A gas scrubber removes acid gases in a gas, to be scrubbed, containing carbon dioxide by bringing the gas to be scrubbed into contact with a gas scrubbing liquid containing alkaline agent. A scrubbing liquid regenerator regenerates and cools the gas scrubbing liquid by bringing the gas scrubbing liquid into contact with a regenerating gas having components different from the gas scrubbing liquid and the gas to be scrubbed. A circulating device is provided between the gas scrubber and the scrubbing liquid regenerator for circulating the scrubbing liquid.

Owner:SU QINGQUAN +4

Natural gas desulfurization process suitable for offshore floating platform

InactiveCN108034466AFast regenerationImprove oxidation regeneration efficiencyGaseous fuelsChemical industryChemical reaction

The invention relates to the field of natural gas chemical industry, in particular to a natural gas desulfurization process suitable for an offshore floating platform. The natural gas desulfurizationprocess comprises a reactor, a re-reactor and a centrifugal machine; acid gas coming from a boundary region is directly introduced into the reactor, a trivalent complex iron catalyst enters the re-reactor, the trivalent complex iron catalyst at the bottom of the re-reactor enters the reactor under the control of a valve and a pipeline, a chemical reaction is then carried out, divalent complex ironobtained by means of the reaction is centrifuged, the divalent complex iron is conveyed to an electrochemical regeneration device by means of a regenerative feed pump so as to complete the regeneration, and the regenerated trivalent complex iron catalyst is returned to the re-reactor by means of a circulation pump. The natural gas desulfurization process is simple in technological process, smallin equipment size and compact in structure, and adapts to the condition limit of limited production space of offshore floating liquefied natural gas (FLNG).

Owner:SICHUAN HENGRI GAS ENG CO LTD

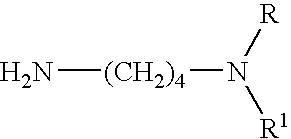

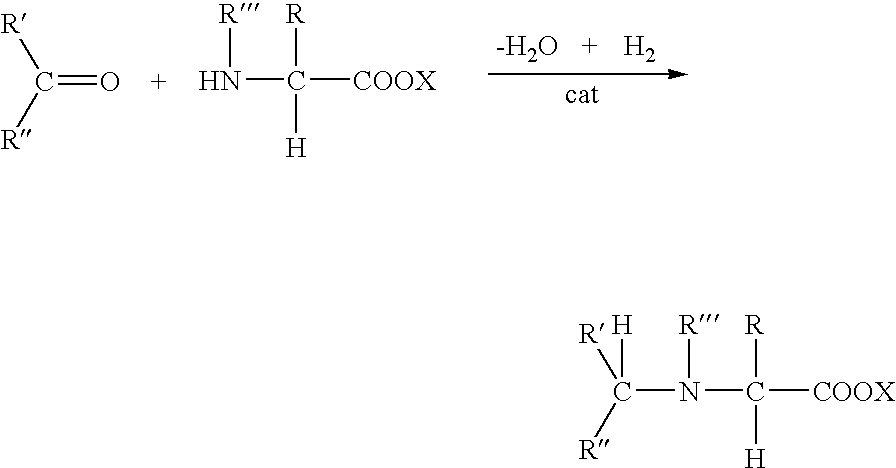

Amino acid ion liquid for acidic gas absorption

The present invention relates to amino acid ion liquid for absorbing acidic gas. The anion of ion liquid is amino acid, amino acid ramification, similar to amino acid ion, imidazole cation, phosphoric cation, amine cation, ammoniumate cation and etc. After dipping craft, all ions can adhere to poriferous solid to absorb acidic gas such as carbon dioxide, sulfur dioxide emitted by flue and motor vehicles.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

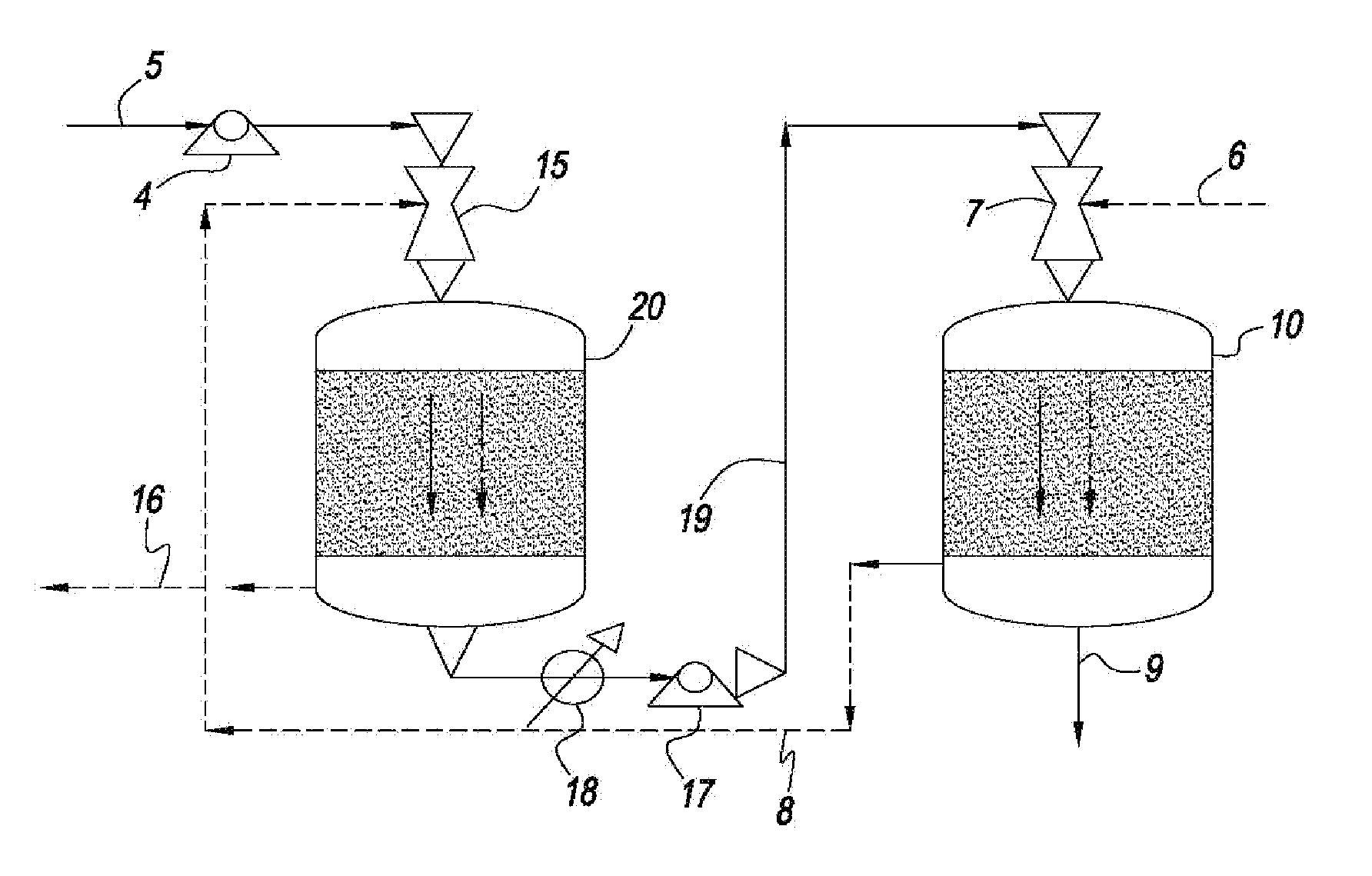

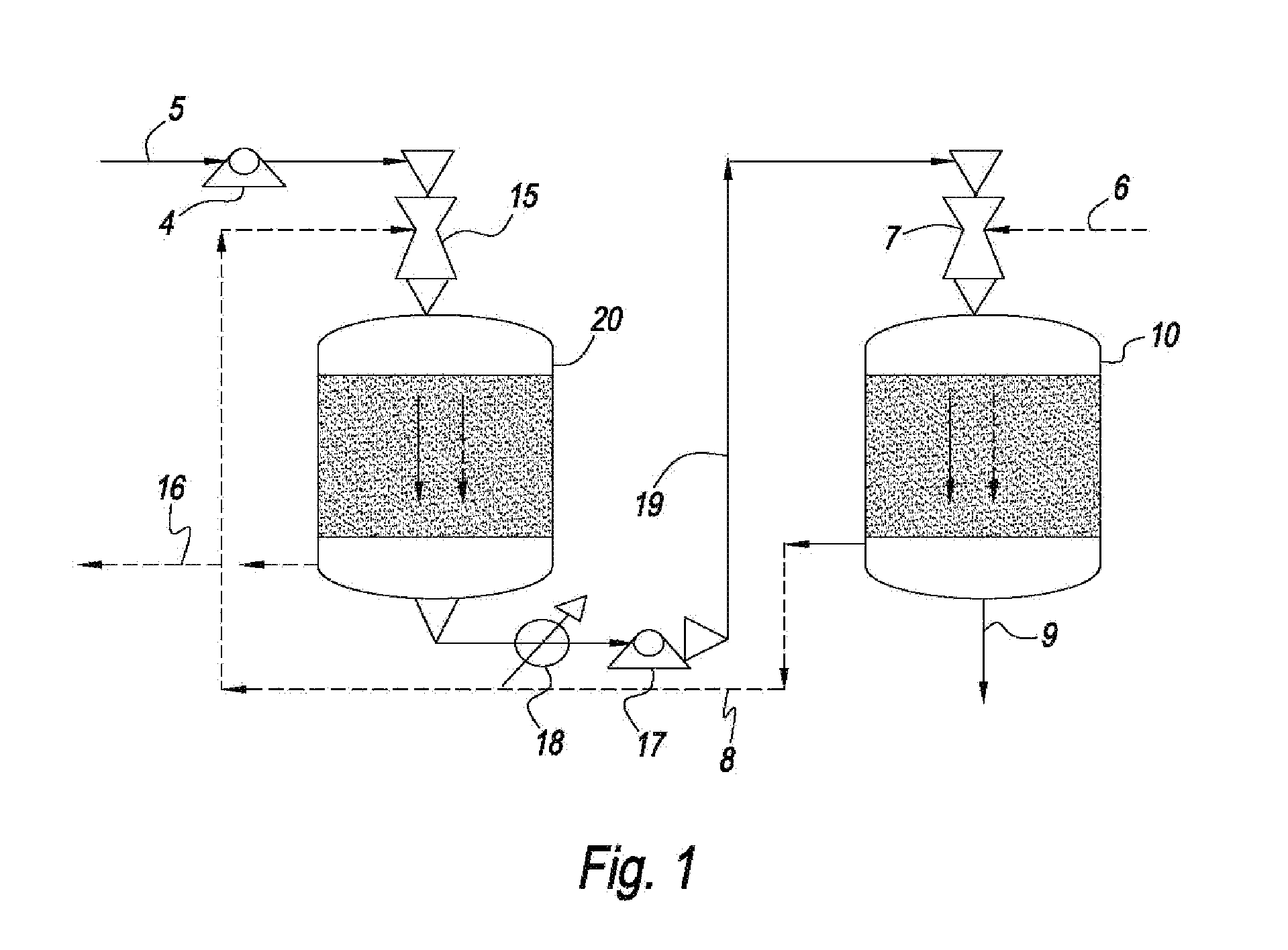

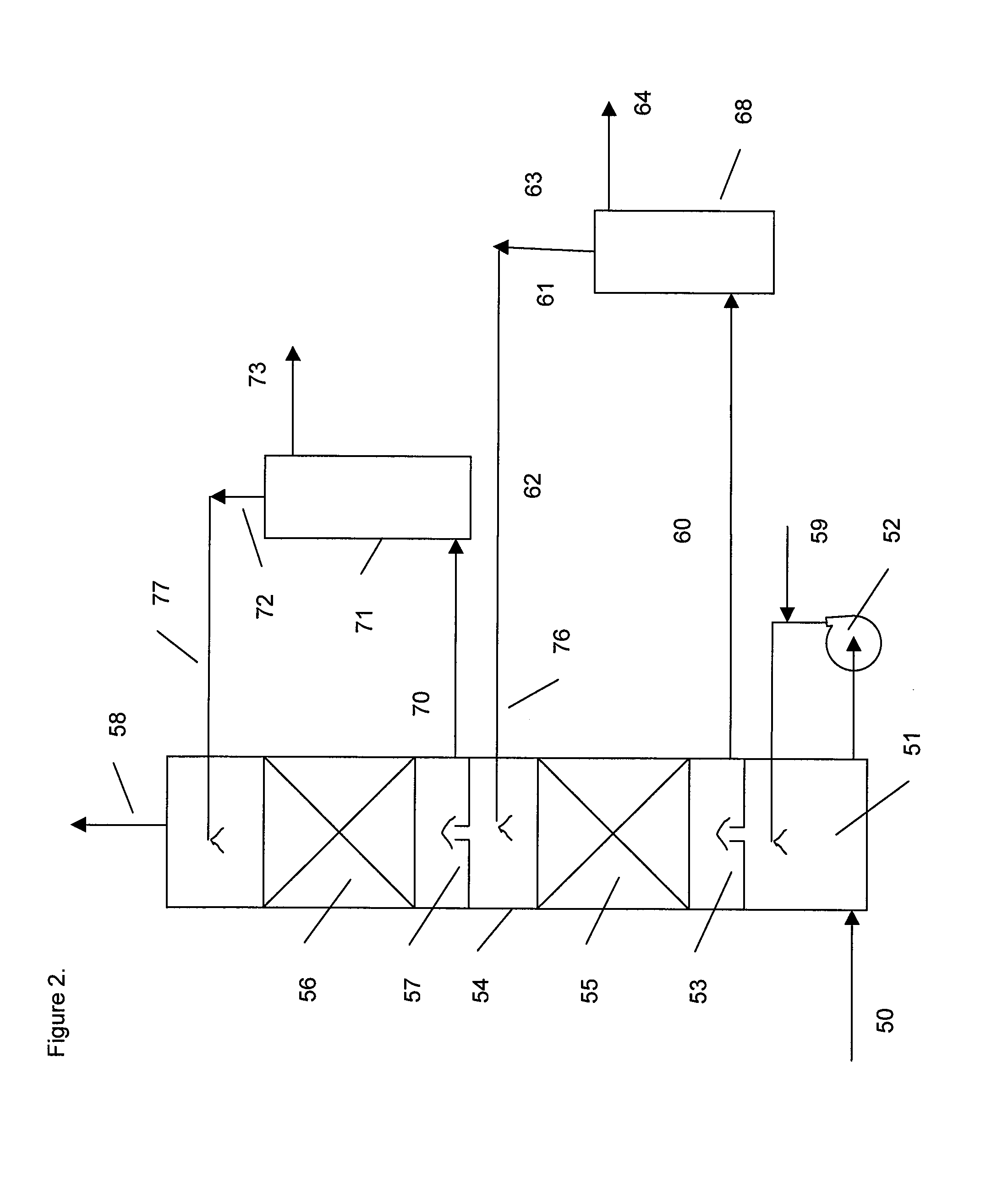

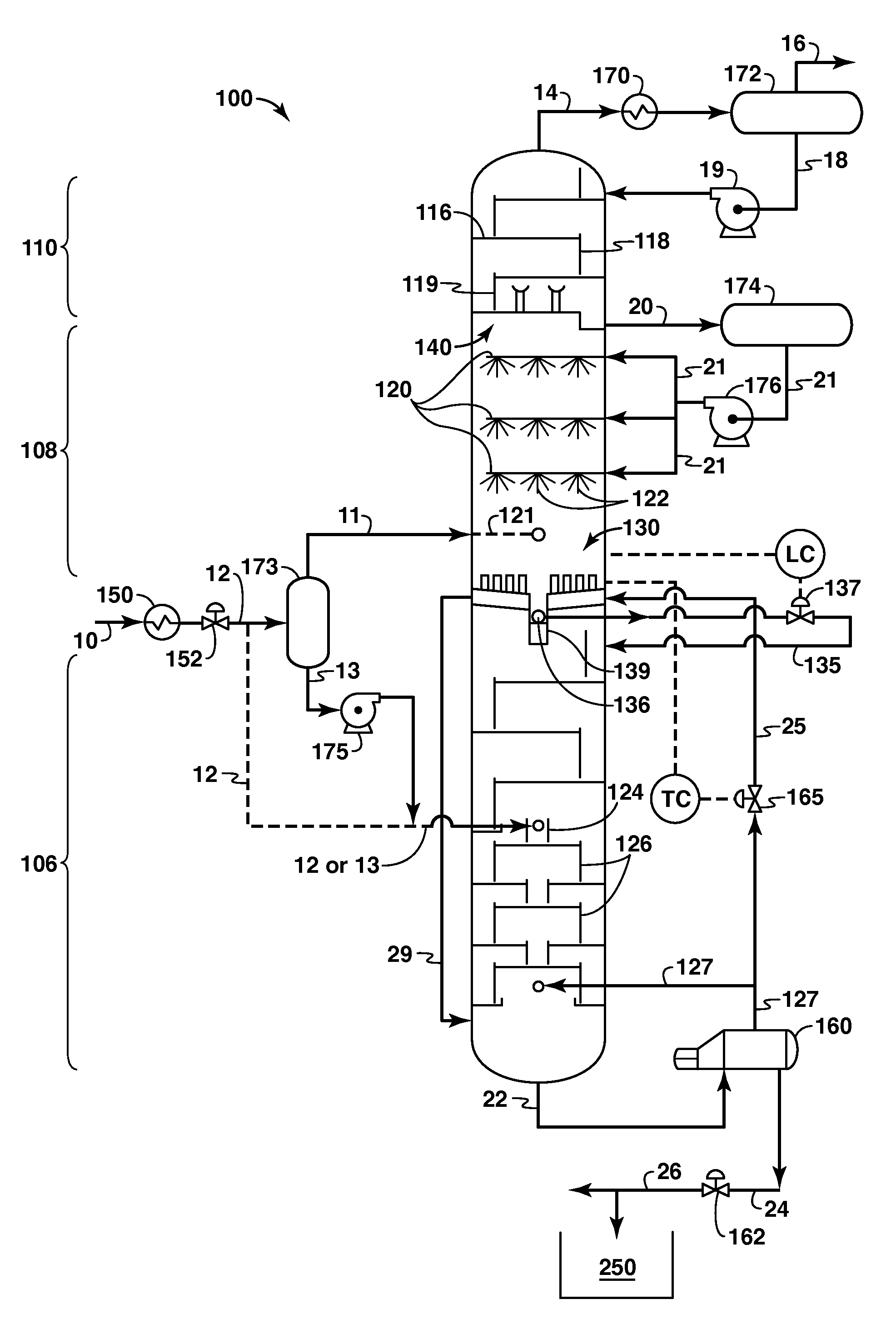

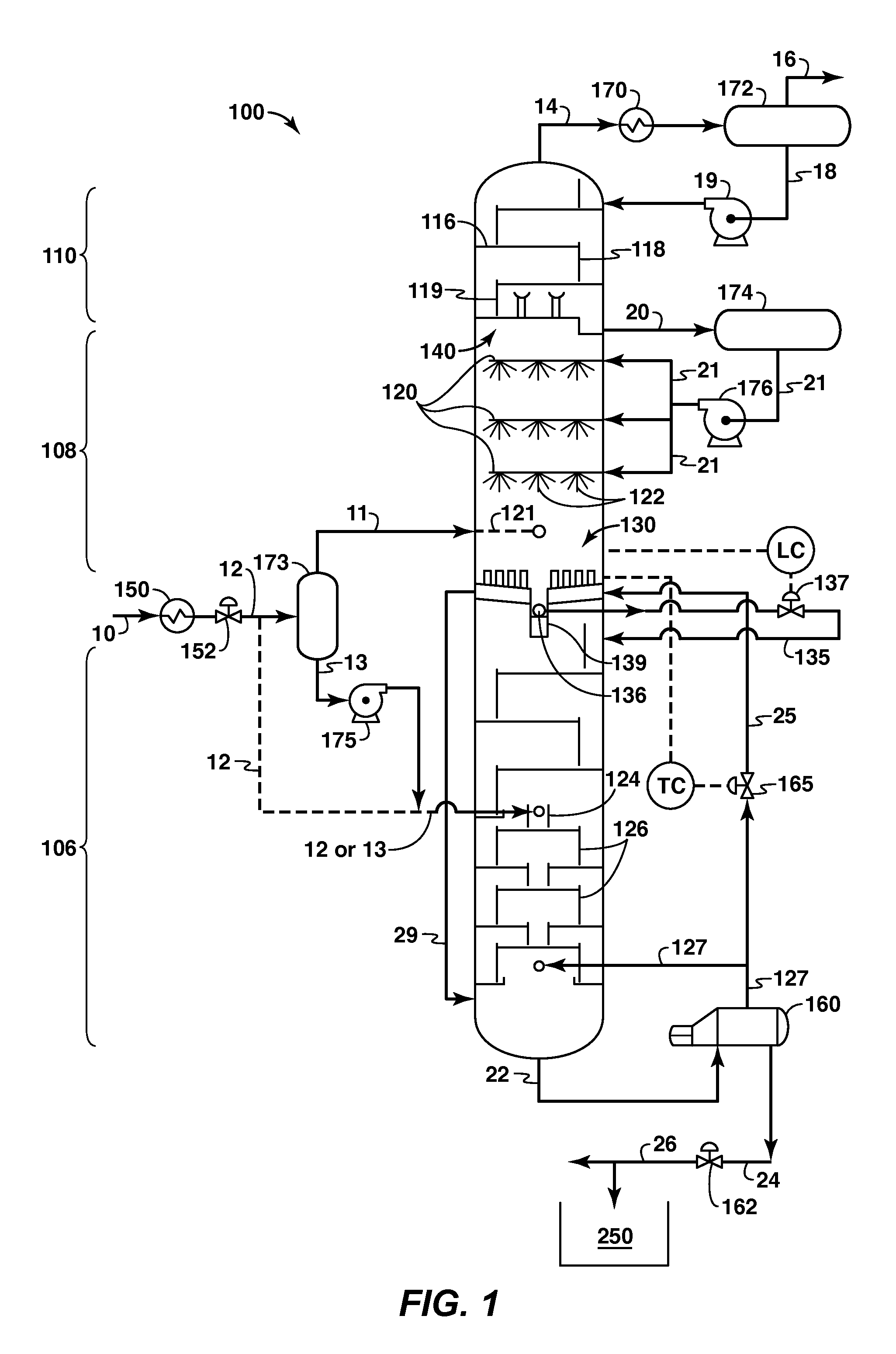

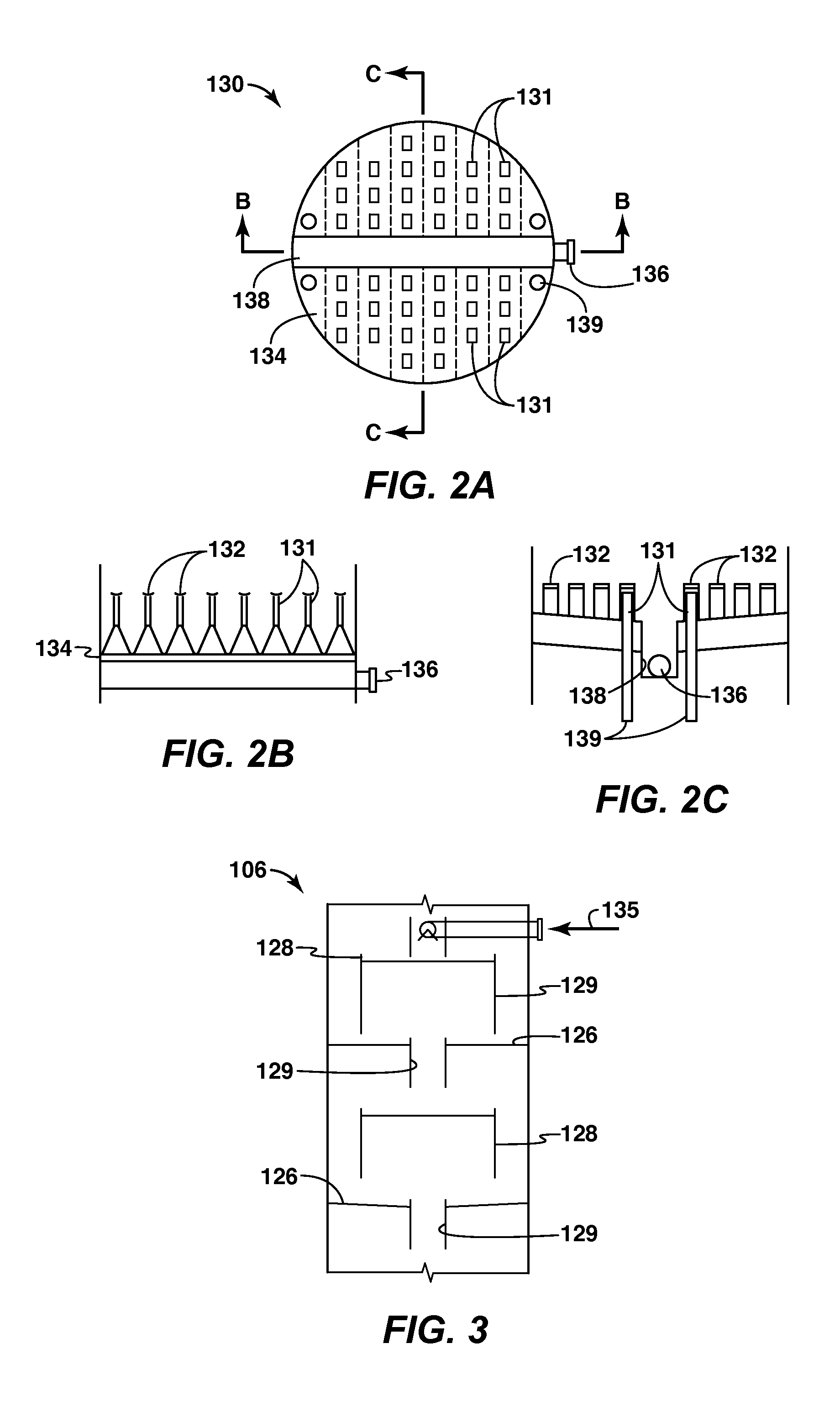

Systems and Methods for Acid Gas Removal

InactiveUS20110217218A1Reduce and eliminate needReduce investmentGas treatmentDispersed particle separationDesorptionProduct gas

A method and system for the selective removal of CO2 and / or H2S from a gaseous stream containing one or more acid gases. In particular, a system and method for separating CO2 and / or H2S from a gas mixture containing an acid gas using an absorbent solution and one or more ejector venturi nozzles in flow communication with one or more absorbent contactors. The method involves contacting a gas mixture containing at least one acid gas with the absorbent solution under conditions sufficient to cause absorption of at least a portion of said acid gas. The absorbent contactors operate in co-current flow and are arranged in a counter-current configuration to increase the driving force for mass transfer. Monoliths can be used that operate in a Taylor flow or slug flow regime. The absorbent solution is treated under conditions sufficient to cause desorption of at least a portion of the acid gas.

Owner:EXXON RES & ENG CO

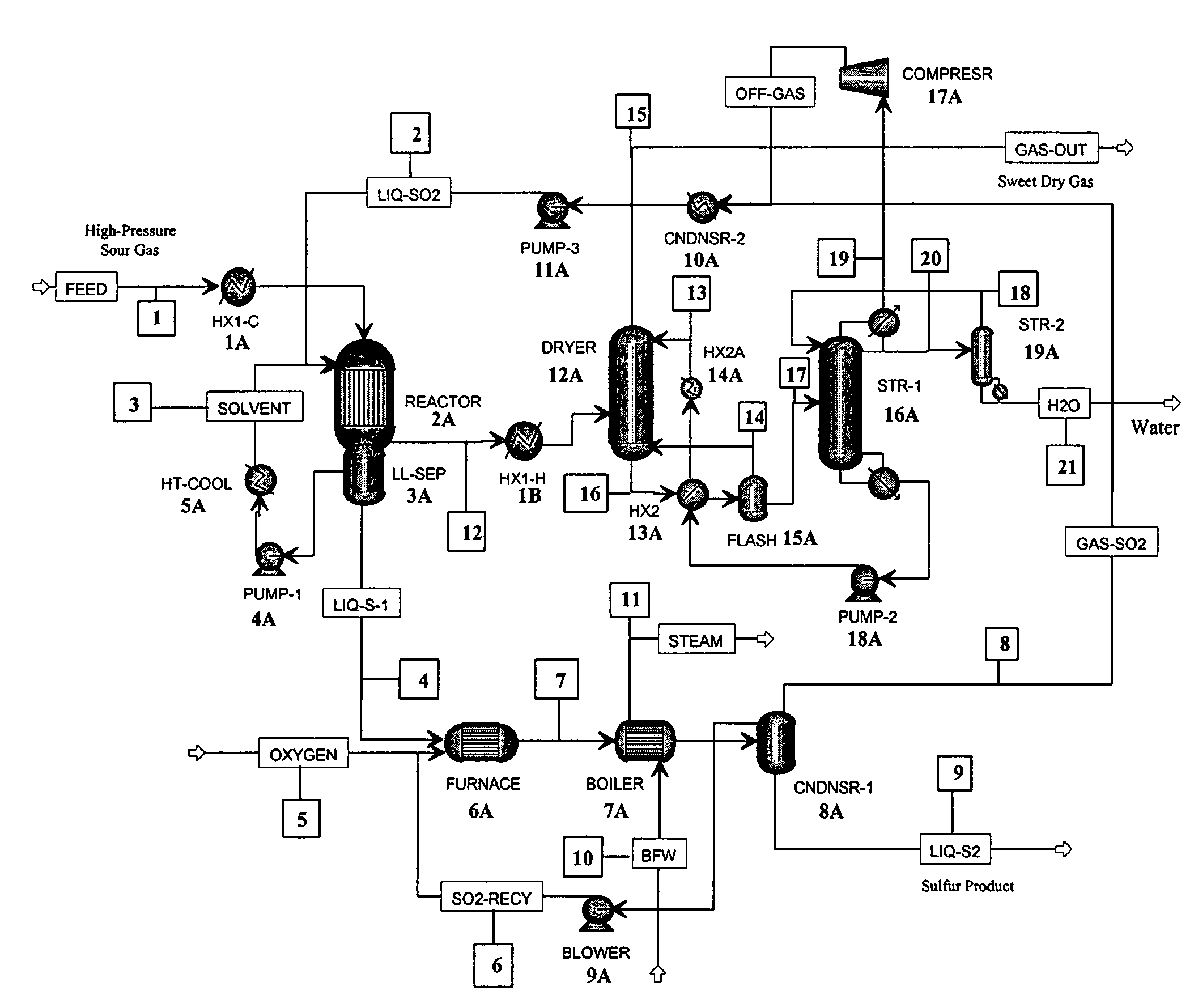

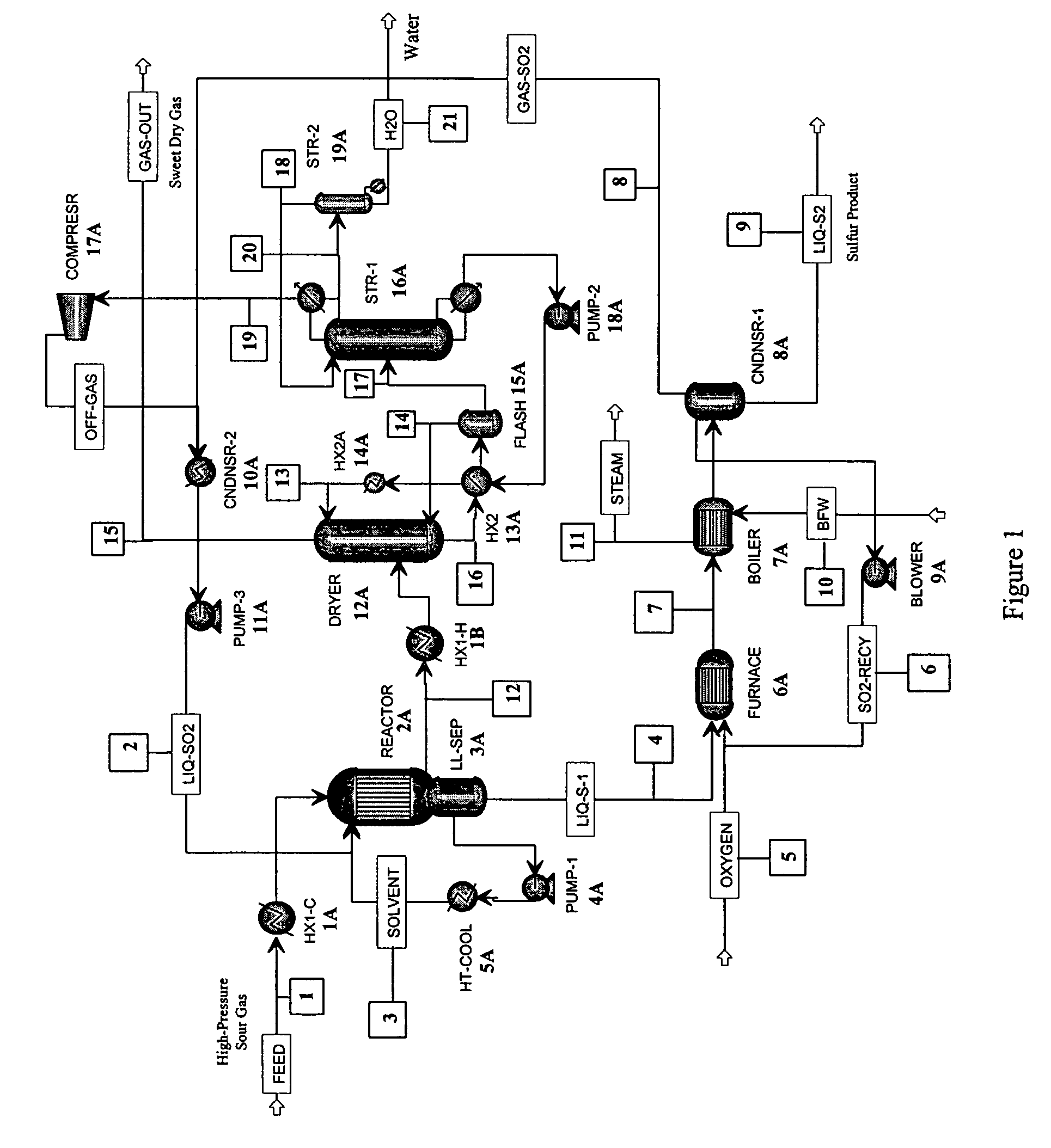

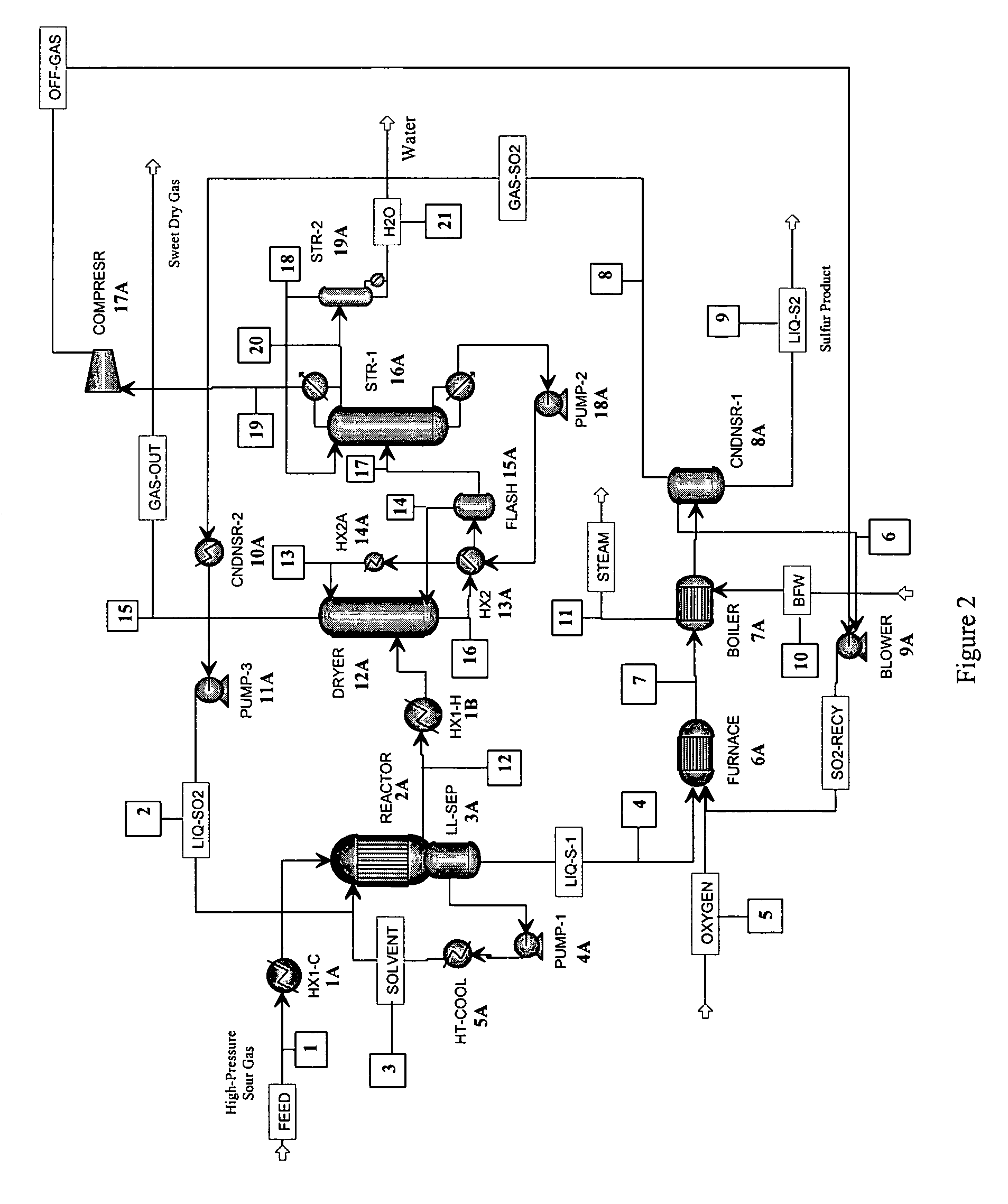

Process for sulfur removal suitable for treating high-pressure gas streams

InactiveUS7381393B2Dispersed particle separationSulfur preparation/purificationCombustionLiquid medium

H2S-containing gases, particularly such gases at elevated pressure, are treated to remove H2S by reaction in a liquid medium with SO2, the SO2 being present in stoichiometric excess with respect to the H2S. The SO2 is produced by combustion of sulfur, preferably sulfur produced in the reaction between H2S and SO2, preferably with oxygen. The process produces a treated gas that is substantially free of both H2S and SO2. An acid-gas absorber / stripper system or other system typically found in such processes to raise or concentrate the H2S level in the gas to be treated, is not needed in operations according to the invention.

Owner:RGT UNIV OF CALIFORNIA

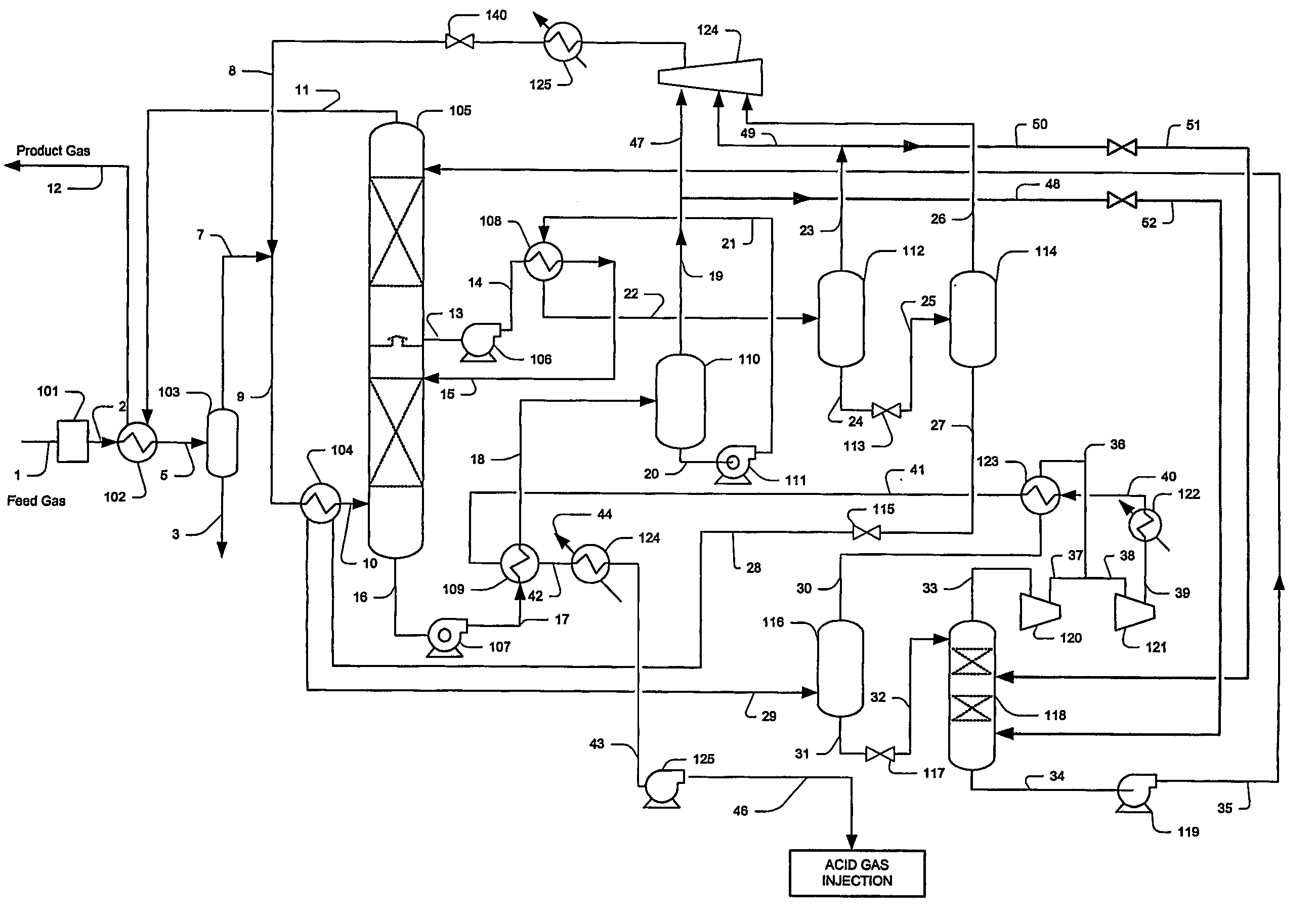

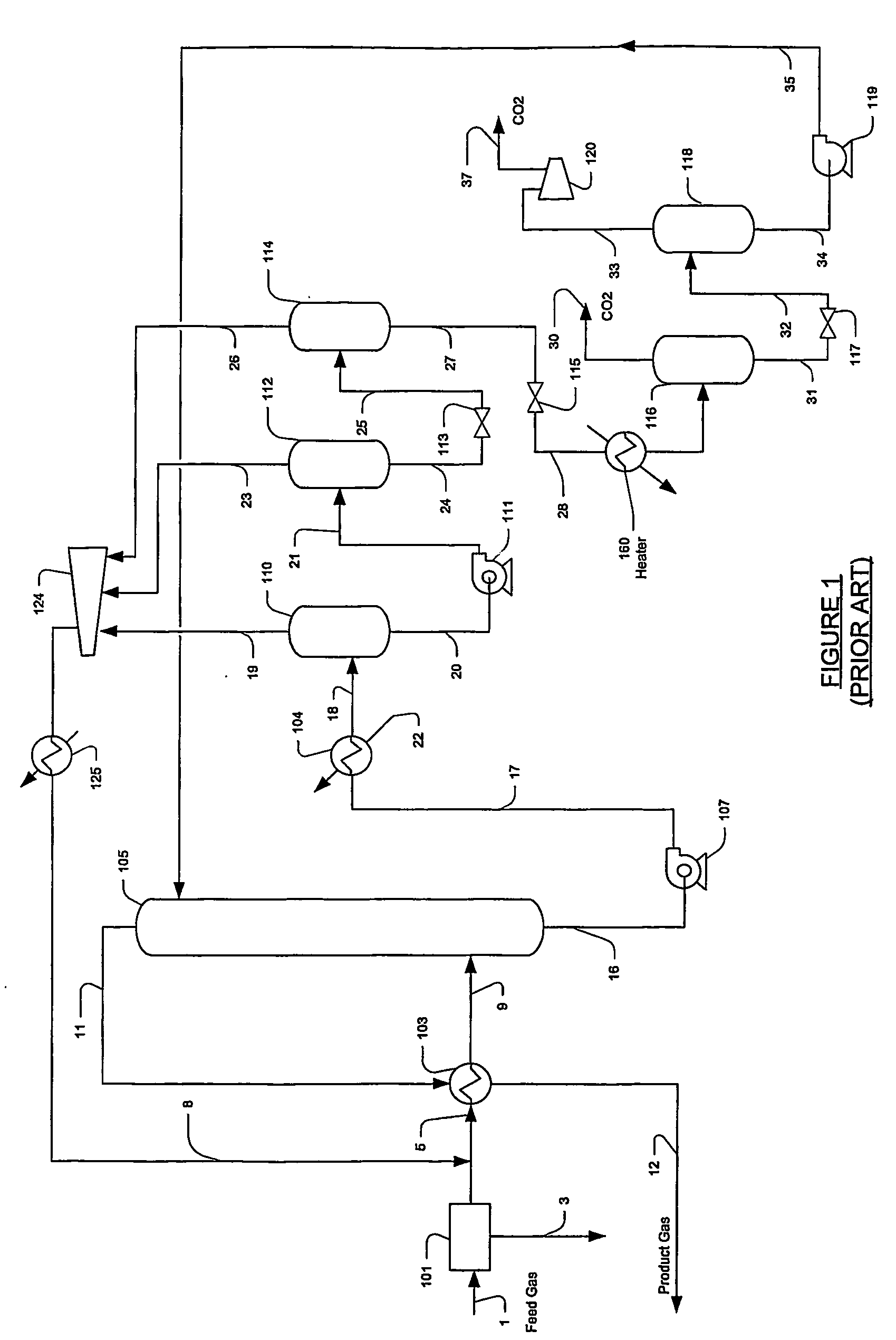

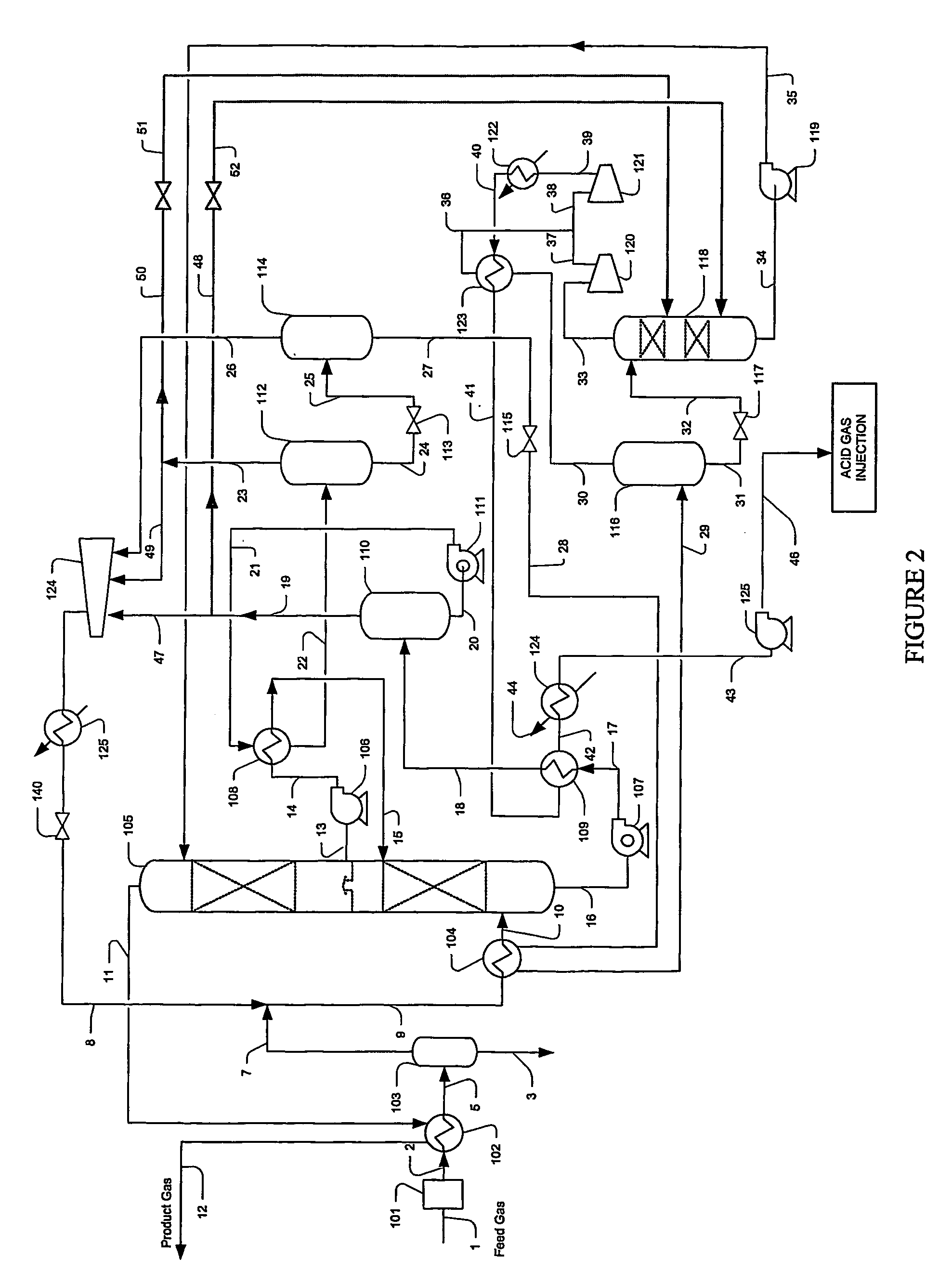

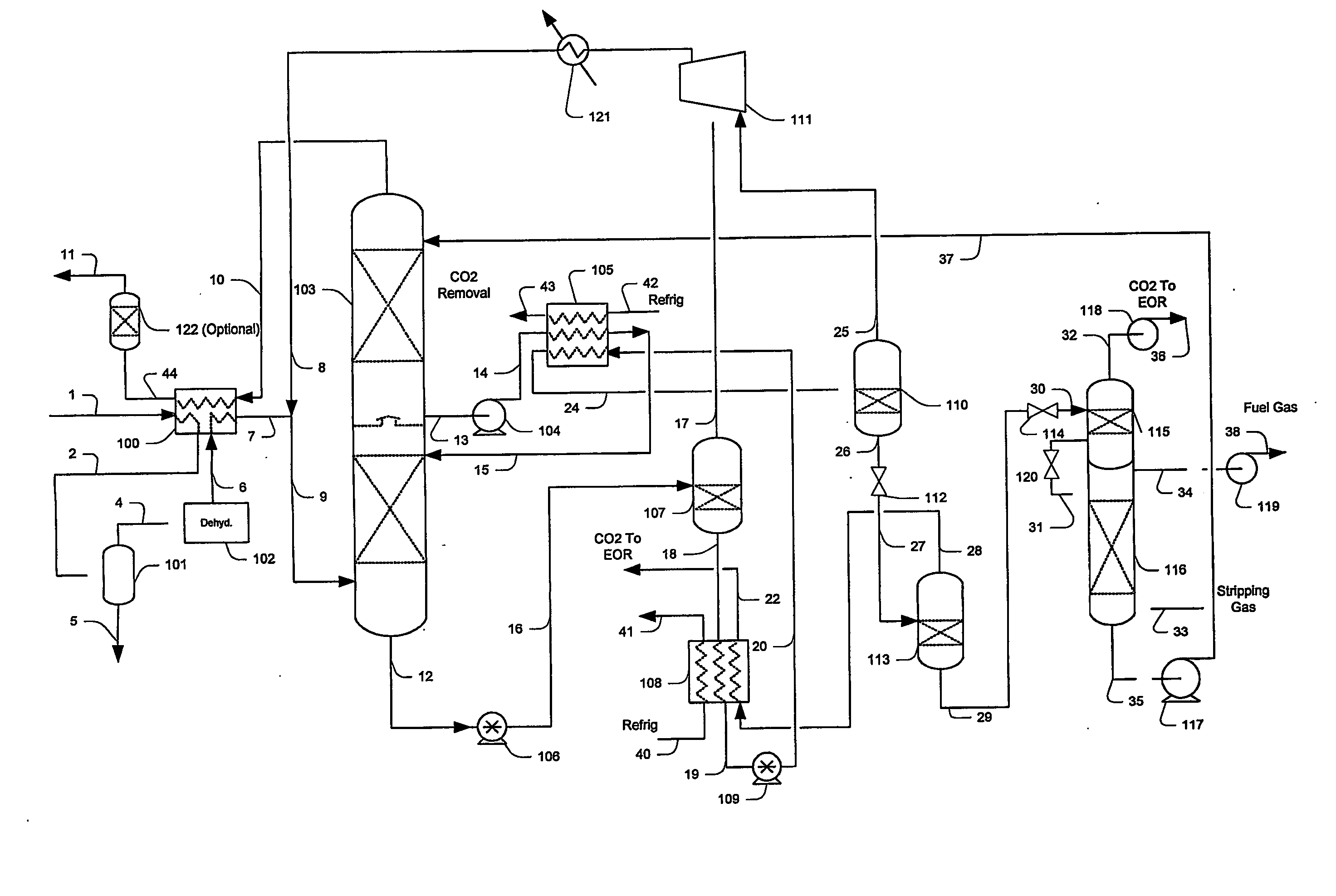

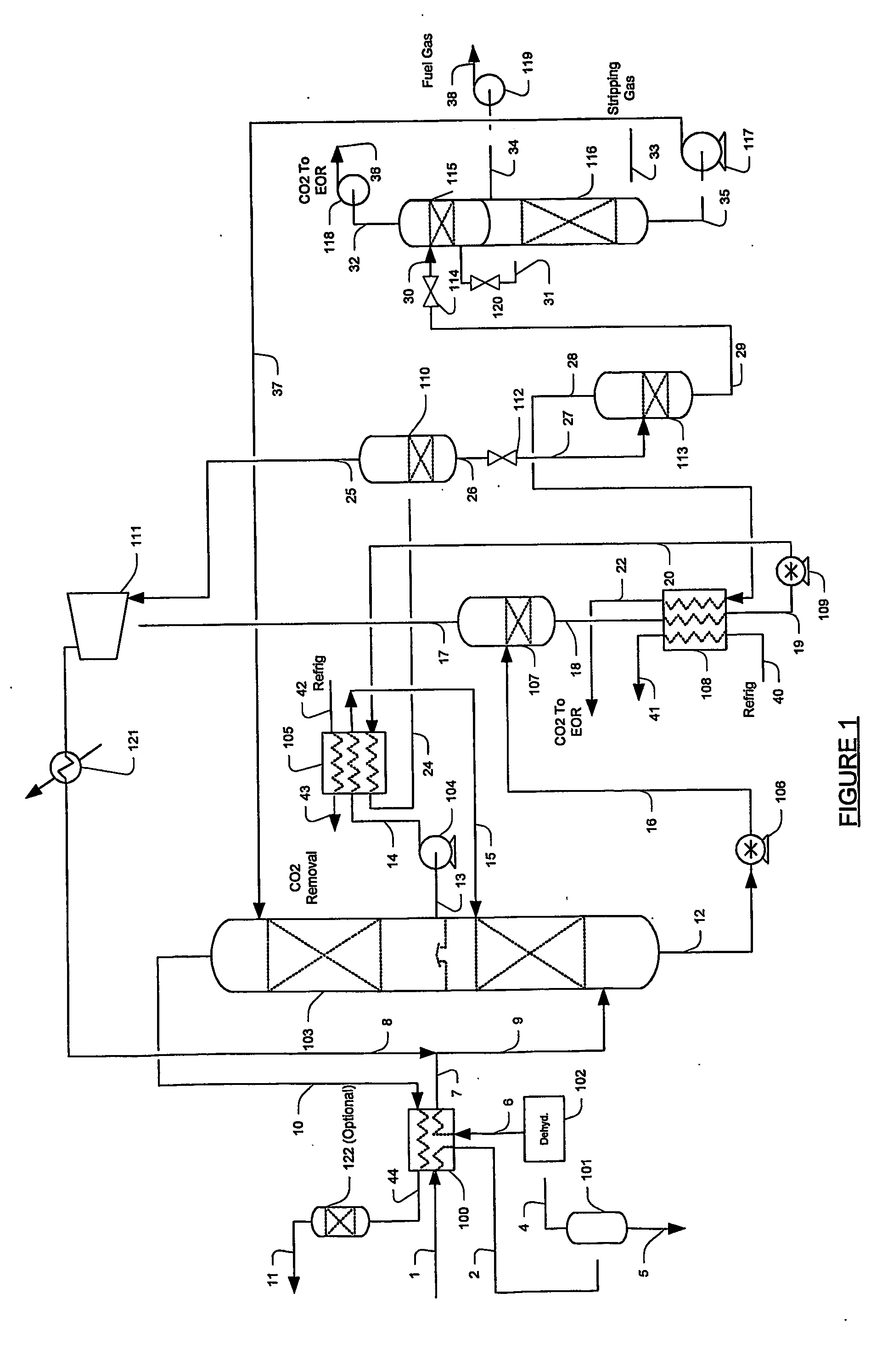

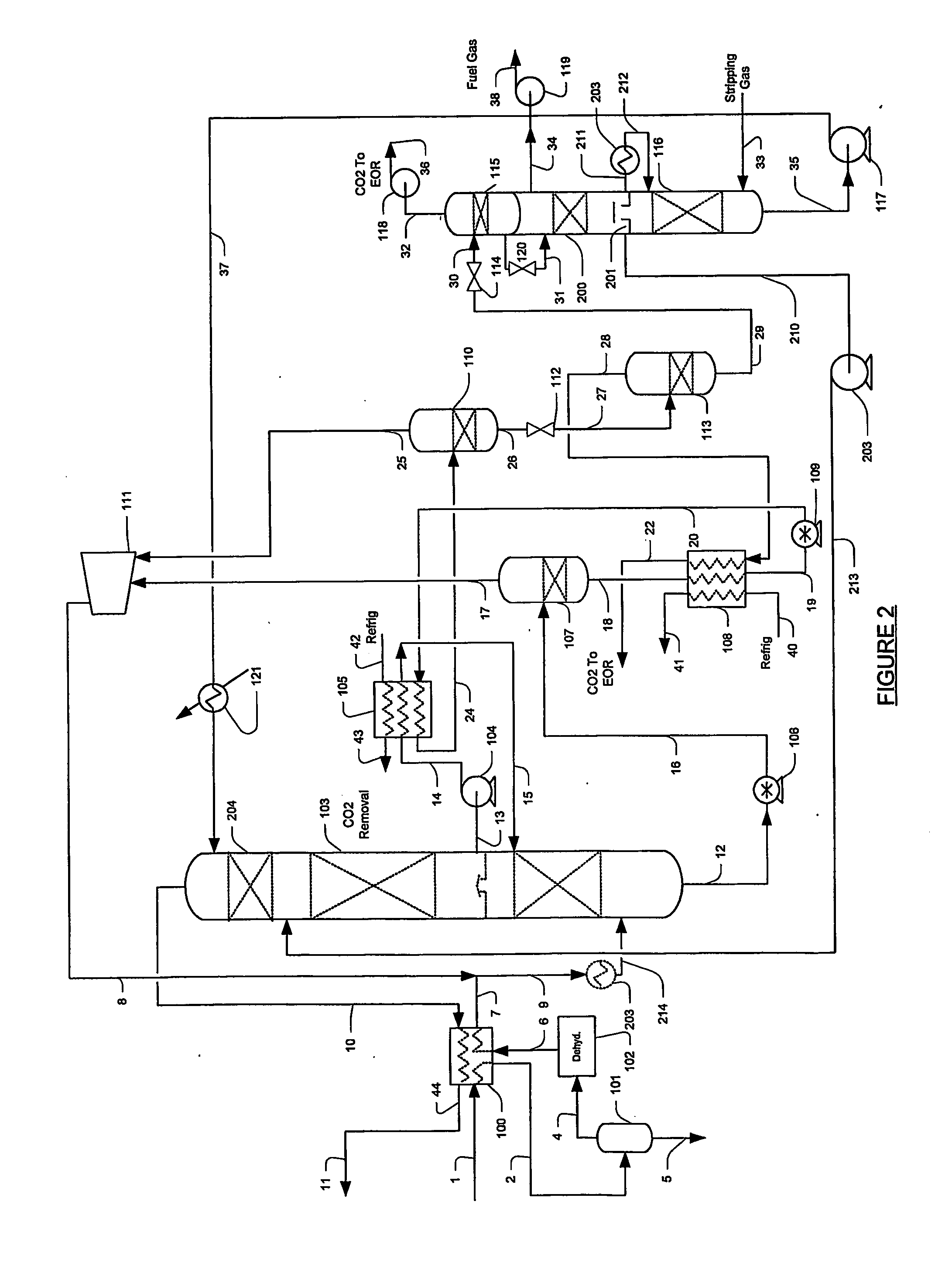

Configurations and methods of acid gas removal

A plant includes a vacuum stripper (118) that receives a lean hydrogen sulfide-containing physical solvent (32) and in which substantially hydrogen sulfide-free stripping gas (51,52) is provided by at least one of a high-pressure flash vessel (110) and a medium pressure flash vessel (112). Contemplated configurations advantageously extend the range of use for physical solvents to treat sour gas comprising carbon dioxide and hydrogen sulfide, and can be used to meet most pipeline specification of 4 ppm hydrogen sulfide.

Owner:FLUOR TECH CORP

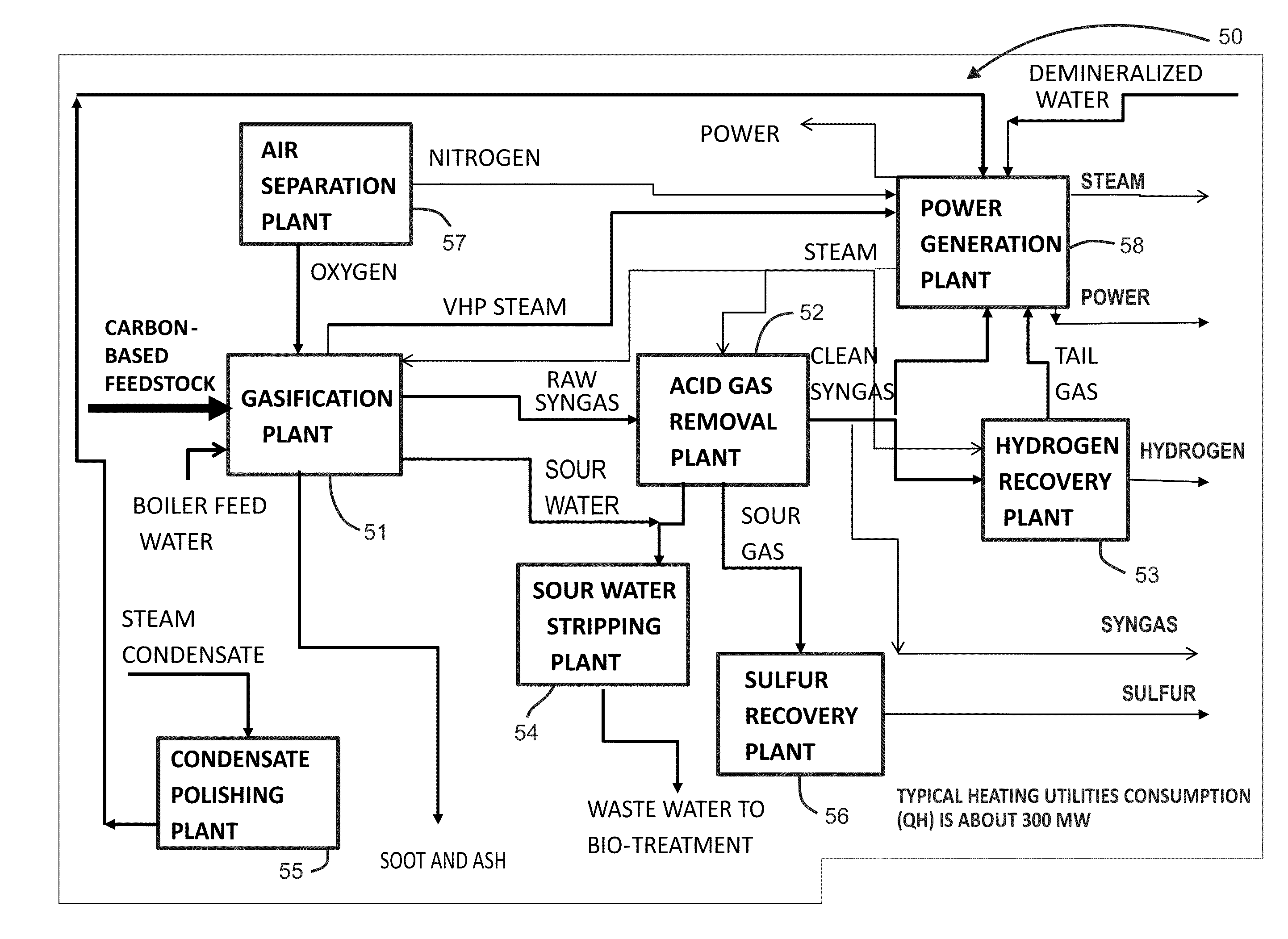

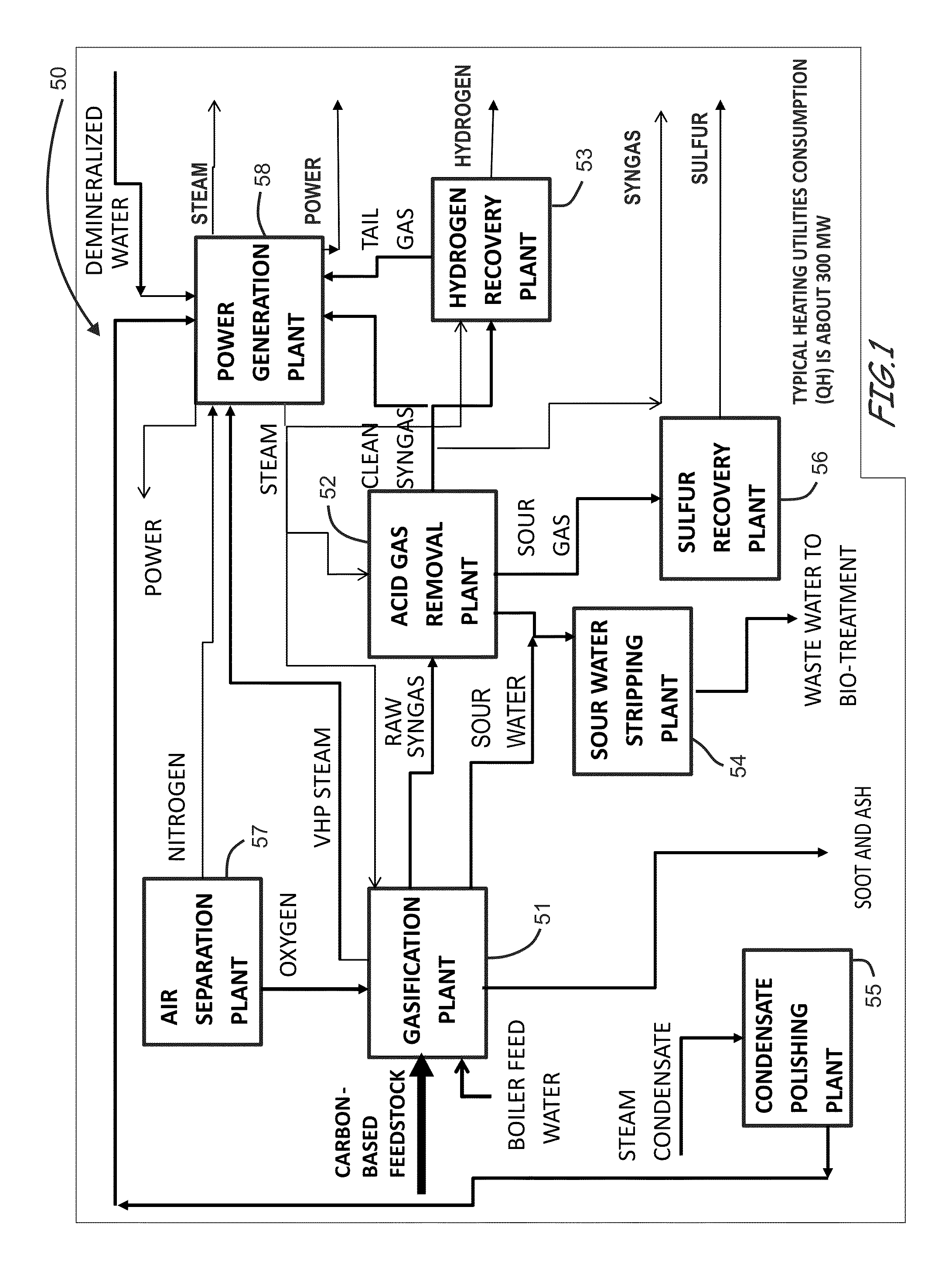

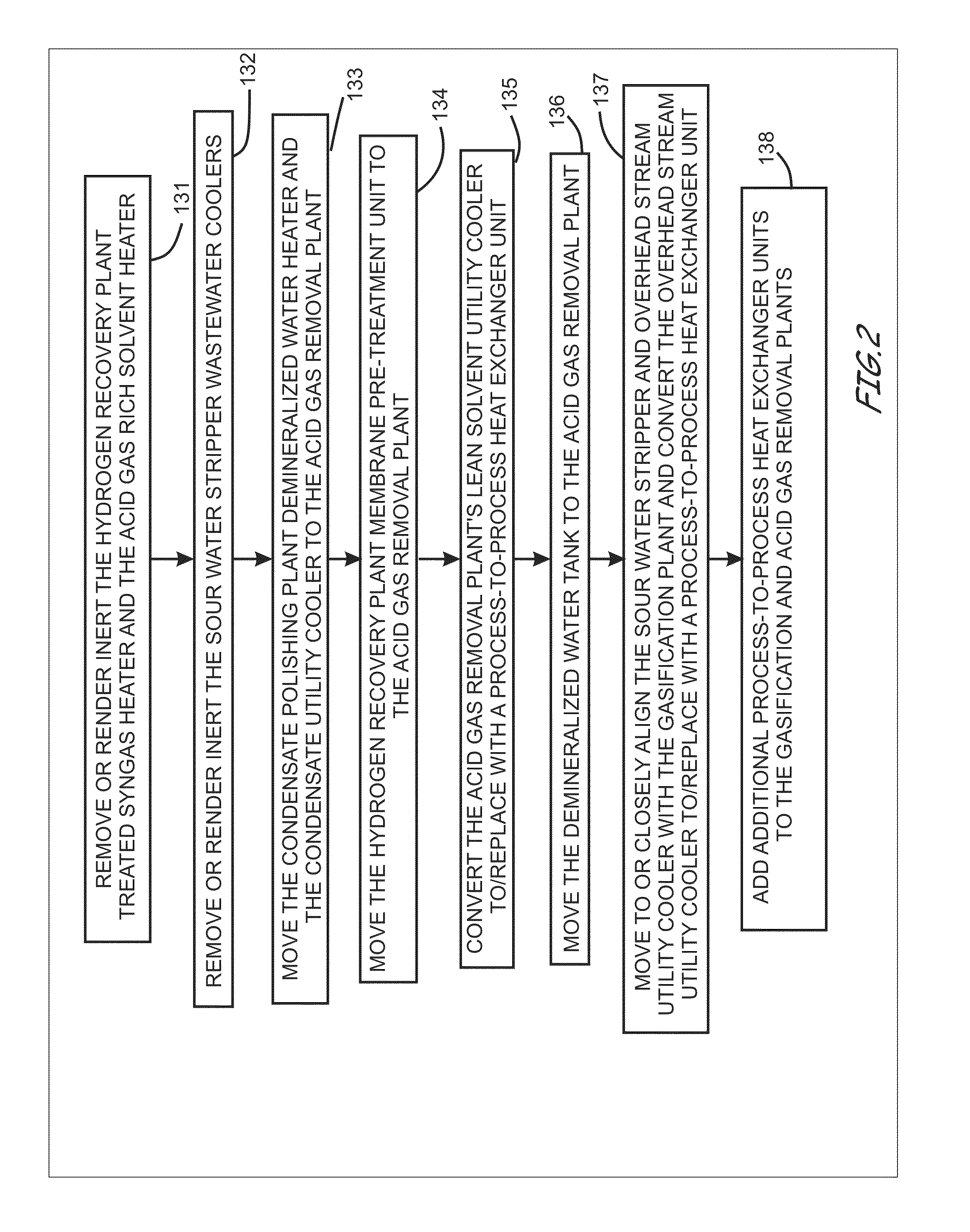

Energy efficient apparatus employing energy efficient process schemes providing enhanced integration of gasification-based multi-generation and hydrocarbon refining facilities and related methods

ActiveUS20150377079A1Less pollutionEasy to modifyProcess control/regulationGasifier mechanical detailsSolventMulti generation

Energy-efficient gasification-based multi-generation apparatus, facilities, or systems, and methods of modifying existing gasification-based multi-generation apparatus and the various conventional thermal coupling arrangements, are provided. Apparatus for managing waste heat recovery through integration of a gasification-based multi-generation facility or other multi-generation system with a hydrocarbon refining facility or other hydrocarbon refining system and methods of providing the respective integration are also provided. An exemplary apparatus includes an integrated site energy management system configured according to one or more process-based thermal coupling schemes comprising one or more thermal coupling arrangements between a gasification-based multi-generation system or facility and a hydrocarbon refining system or facility. The gasification-based multi-generation system or facility can include an acid gas removal system or plant configured to remove acidic contaminants from a raw syngas feed to thereby provide a treated syngas feed, the acid gas removal system or plant containing a separation section including a solvent regenerator, and a gasification system configured to generate the raw syngas feed from a carbon-based feedstock. The hydrocarbon refining system or facility can include an aromatics system or plant containing a xylene products separation section including one or more of the following: an Extract column and a Raffinate column. The integrated site energy management system can include a hot-water system extending between the separation section of the acid gas removal system or plant and the xylene products separation section of the aromatics system or plant, and a plurality of added heat exchanger units providing various advanced thermal coupling arrangements.

Owner:SAUDI ARABIAN OIL CO

Absorbent composition containing molecules with a hindered amine and a metal sulfonate, phosphonate or carboxylate structure for acid gas scrubbing process

An acid gas absorbent comprising a metal sulfonate, phosphonate or carboxylate of a hindered amine and a process for the selective removal Of H2S as well as other acidic components such as carbon disulfide, carbonyl sulfide and oxygen and sulfur derivatives of C1 to C4 hydrocarbons from mixtures containing such acidic components and CO2 using said absorbent.

Owner:EXXON RES & ENG CO

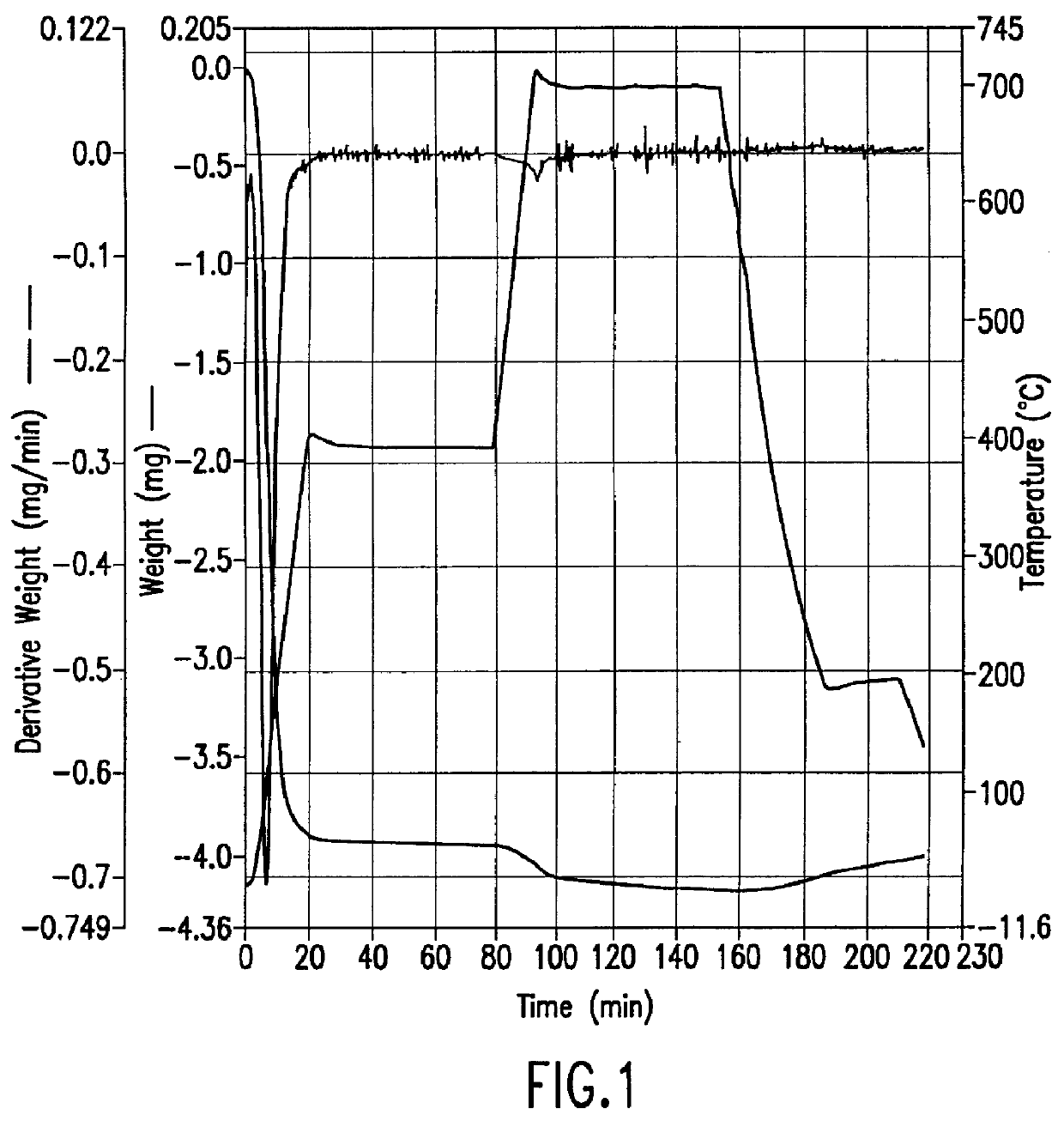

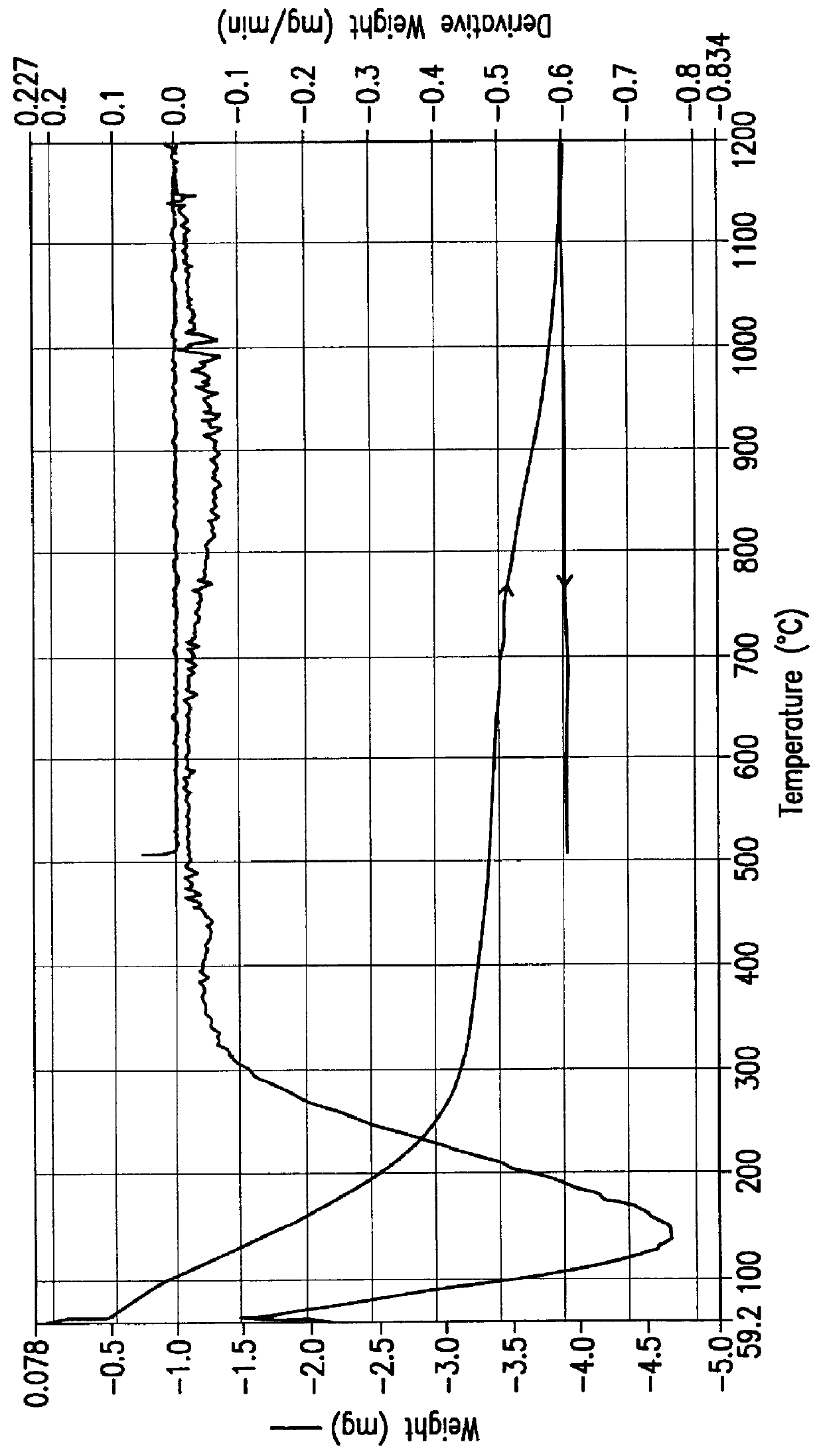

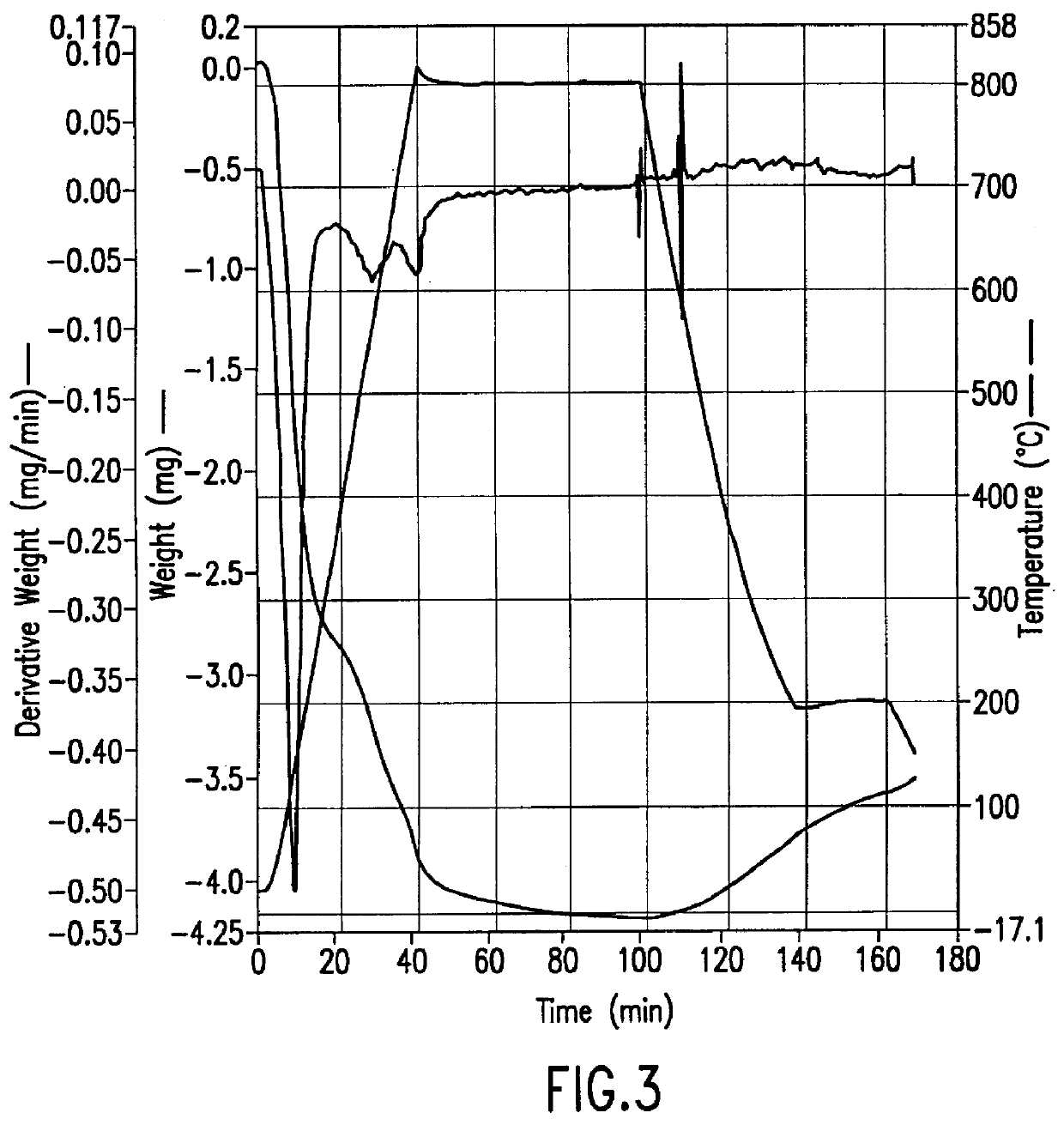

Methods for removal of water from gases using superheated zeolites

InactiveUS6110258AHigh silica-to-alumina ratioReduce metal contentGas treatmentMolecular sieve catalystsBoiling pointSilicon dioxide

A method for removing trace moisture from a gas is disclosed. The method involves heating a zeolite having a high silica-to-alumina ratio to about 400 DEG C. to remove physically absorbed water from the zeolite, followed by heating the zeolite to a temperature in excess of 650 DEG C., to form a superheated zeolite. Heating to temperatures of 650 DEG C. or above is believed to cause dehydroxylation of the zeolite. A method for the preparation of a dehydroxylated zeolite is also disclosed. The superheated zeolite is contacted with the gas, thereby adsorbing water from the gas. A dehydroxylated zeolite for removing trace moisture from a gas wherein the zeolite has a high silica-to-alumina ratio and a low level of metallic impurities is also disclosed. The zeolite and methods of the invention are particularly useful for removing trace water from acid gases such as hydrogen chloride and hydrogen bromide.

Owner:MATHESON TRI GAS INC

Configurations and method for improved gas removal

InactiveUS20050000360A1Reduce pressureLiquid degasificationUsing liquid separation agentGas phaseCarbon dioxide

A plant includes an absorber (103) that operates in a gas phase supercritical region and removes an acid gas from a feed stream (9) at high recovery of the feed stream (10) while producing a high purity acid gas stream (36). Particularly preferred plants include gas purification plants that receive a feed gas with at least 5 mol % carbon dioxide at a pressure of at least 3000 psi.

Owner:FLUOR TECH CORP

Process for the recovery of carbon dioxide from a gas stream

ActiveUS20080159937A1Reduction in overall mass transfer coefficientHigh viscosityGas treatmentCarbon compoundsViscosityCarbon dioxide

Owner:SHELL OIL CO

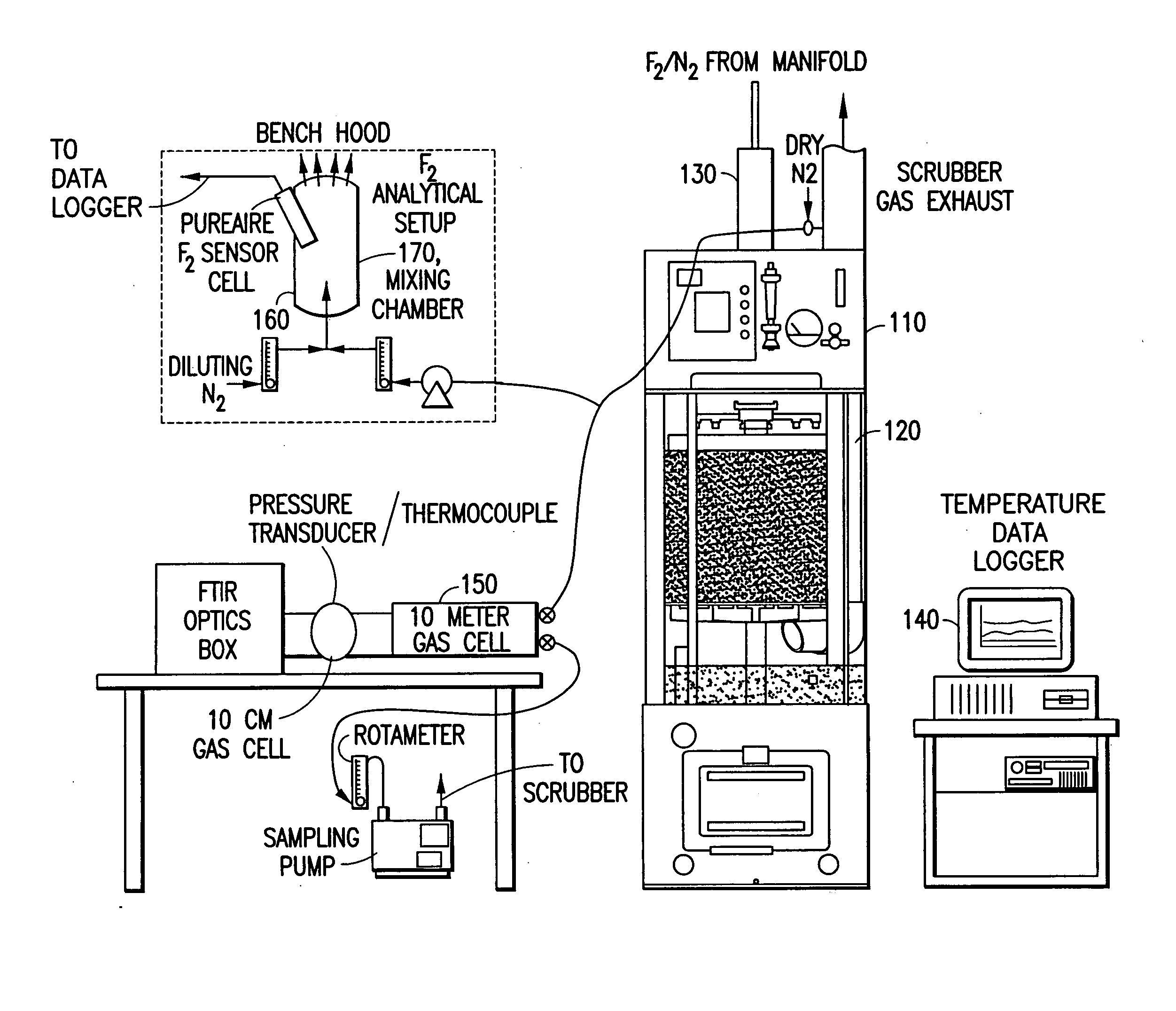

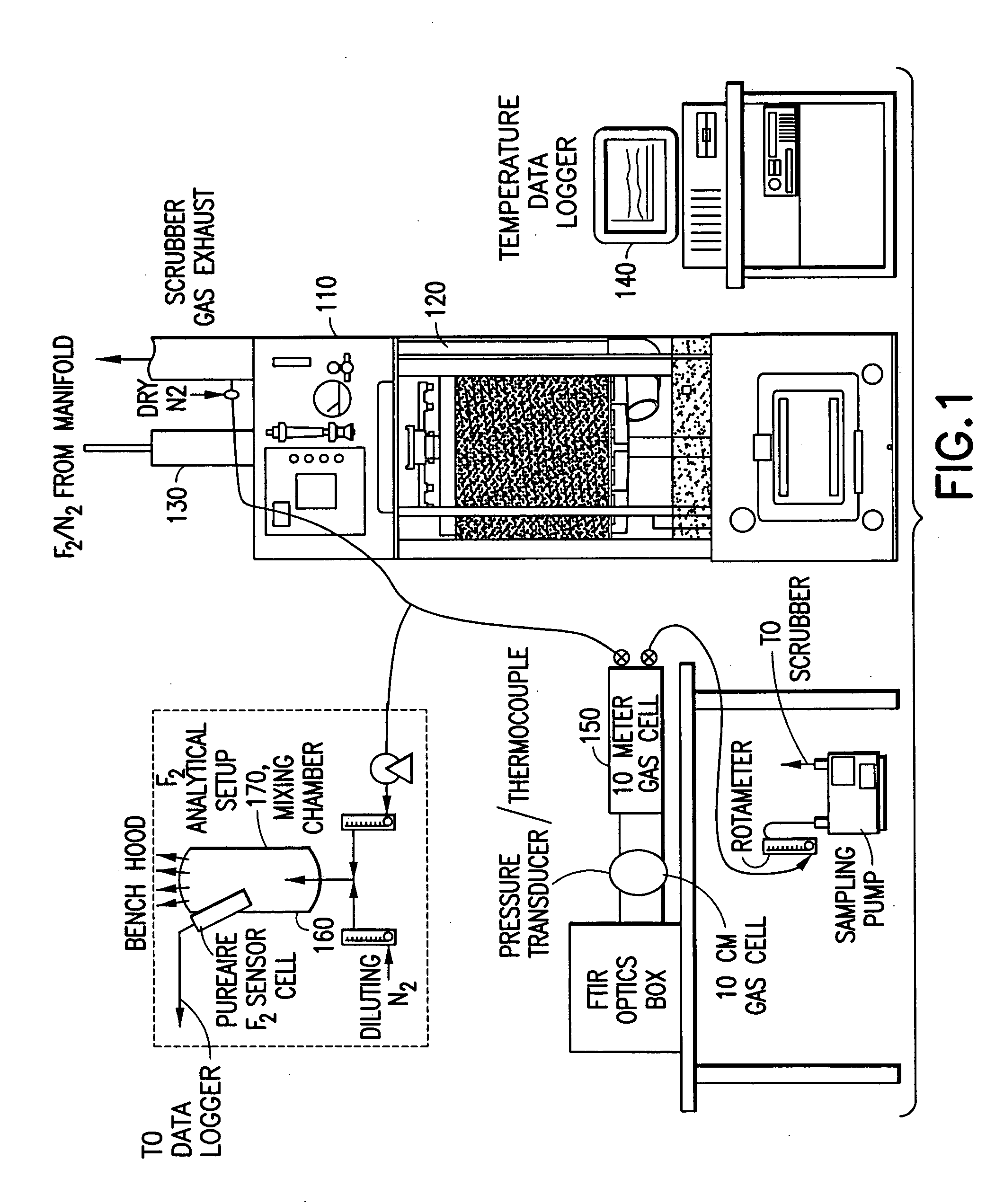

Apparatus and method for point-of-use treatment of effluent gas streams

InactiveUS20040213721A1Highly efficient mannerReduce foaming in the scrubbing systemProcess control/regulationHydrogenSilanesChlorofluorocarbon

A system for abating undesired component(s) from a gas stream containing same, such as halocompounds, acid gases, silanes, ammonia, etc., by scrubbing of the effluent gas stream with an aqueous scrubbing medium. Halocompounds, such as fluorine, fluorides, perfluorocarbons, and chlorofluorocarbons, may be scrubbed in the presence of a reducing agent, e.g., sodium thiosulfate, ammonium hydroxide, or potassium iodide. In one embodiment, the scrubbing system includes a first acid gas scrubbing unit operated in cocurrent gas / liquid flow, and a second "polishing" unit operated in countercurrent gas / liquid flow, to achieve high removal efficiency with low consumption of water. The scrubbing system may utilize removable insert beds of packing material, packaged in a foraminous containment structure. The abatement system of the invention has particular utility in the treatment of semiconductor manufacturing process effluents.

Owner:APPLIED MATERIALS INC

Systems and Methods for Removing Heavy Hydrocarbons and Acid Gases From a Hydrocarbon Gas Stream

A system for removing acid gases from a sour gas stream is provided. The system includes an acid gas removal system and a heavy hydrocarbon removal system. The acid gas removal system receives the sour gas stream and separates the sour gas stream into an overhead gas stream comprised primarily of methane, and a bottom acid gas stream comprised primarily of acid gases such as carbon dioxide. The heavy hydrocarbon removal system may be placed upstream or downstream of the acid gas removal system or both. The heavy hydrocarbon removal system receives a gas stream and separates the gas stream into a first fluid stream comprising heavy hydrocarbons and a second fluid stream comprising other components. The components of the second fluid stream will depend on the composition of the gas stream. Various types of heavy hydrocarbon removal systems may be utilized.

Owner:NORTHROP PAUL SCOTT +4

Temperature Swing Adsorption Process for the Separation of Target Species from a Gas Mixture

Owner:EXXON RES & ENG CO

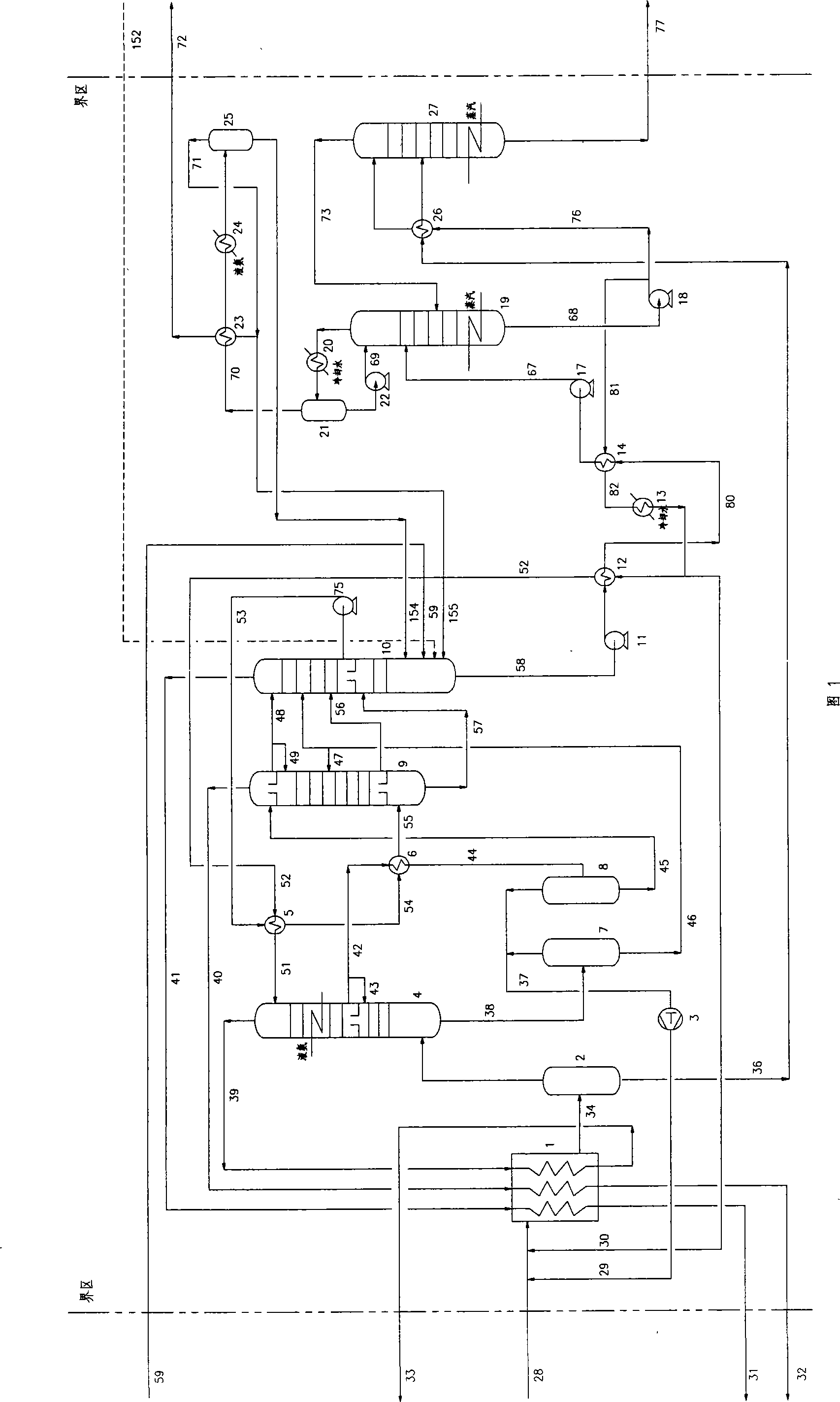

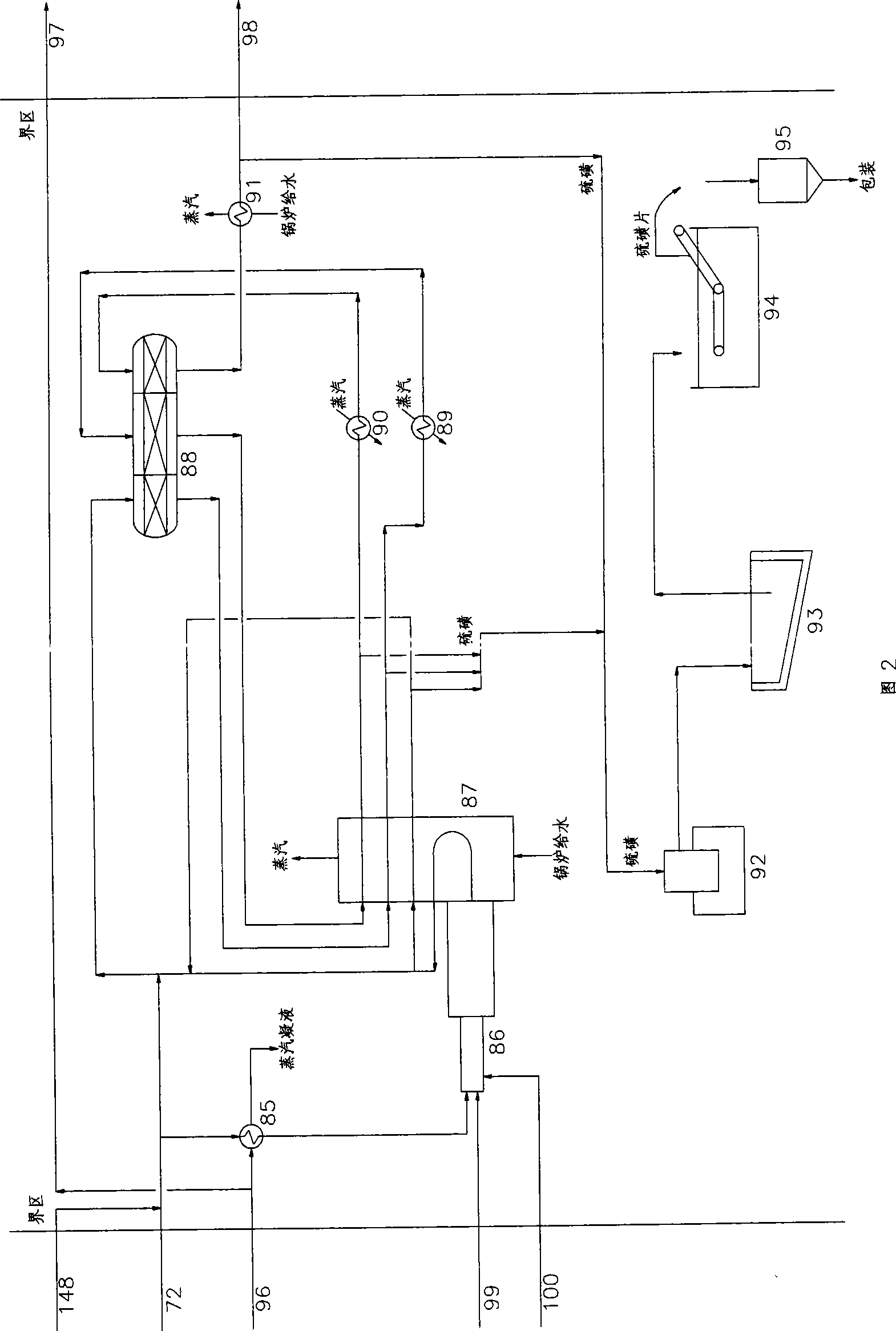

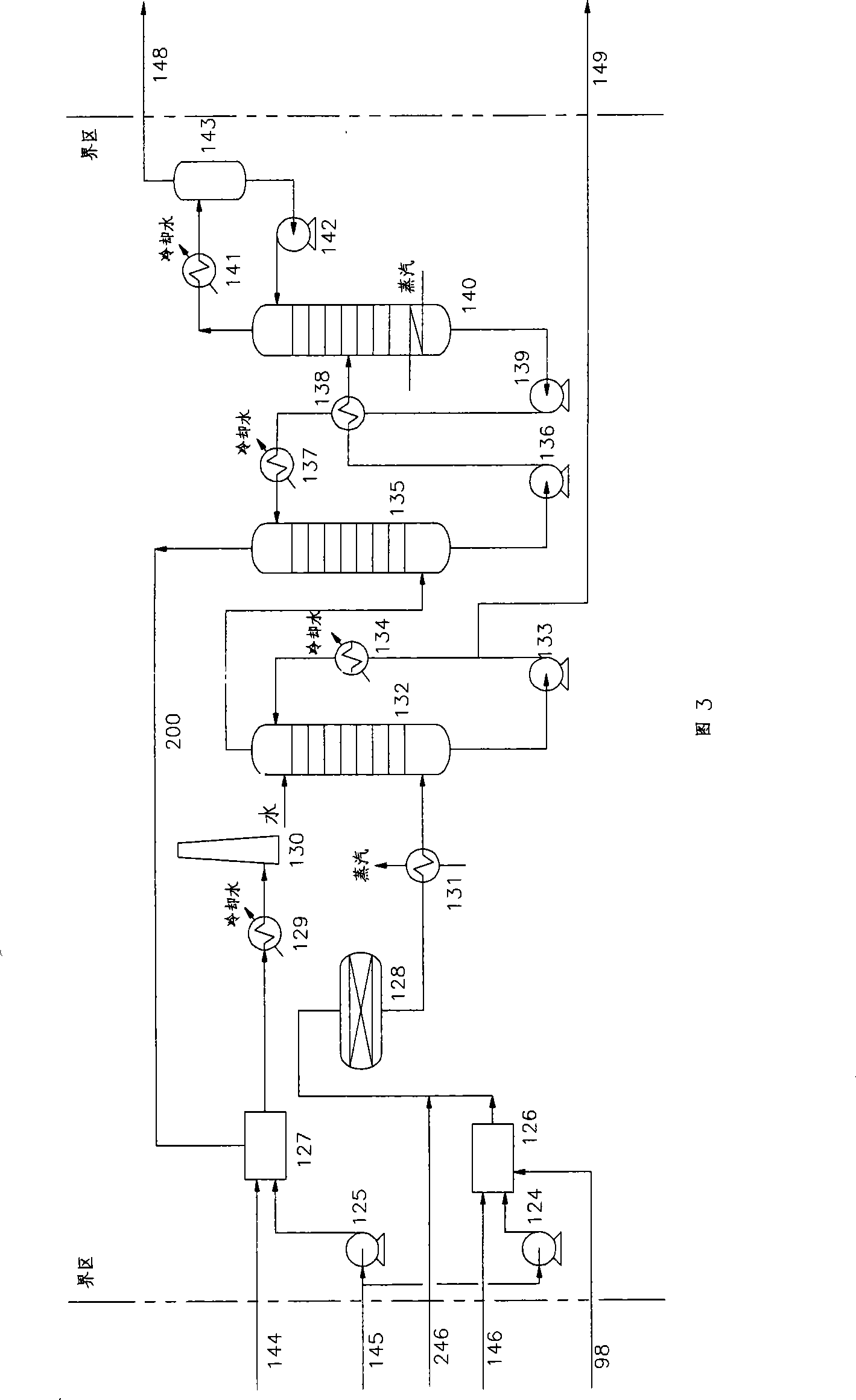

Low temperature methanol washing integrated Claus sulfur recovery system and process

ActiveCN101418246AFlexible processing capacityLow investment costProductsReagentsSulfurHydrogenation reaction

The invention relates to a reclaiming system and a process for low-temperature methanol washing integrated Claus sulfur of coal gas and natural gas. The system is additionally provided with a Claus tail gas washing tower and uses sulfur-free methanol saturated by CO2 from a CO2 product tower as a washing agent, and the washed liquid returns to an H2S concentrating tower; through combination of heating, gas stripping and pressure adjustment, concentration of H2S in acid gas washed by methanol is adjusted flexibly; at the same time, the system is additionally provided with a tail gas pre-heater before hydrogenation reaction to compensate heat loss of a hydrogenation reaction system. The process mainly comprises the following steps: removing H2S-CO2 gas, condensing H2S, reclaiming Claus sulfur, hydrogenising and reducing the gas, selectively absorbing and desulfurizing saturated cold methanol. The process has the advantages that the process can efficiently, flexibly, safely and energy-conservatively treat carbonyl gas with different pressures, temperatures, water content and sulfur concentration; and total sulfur reclamation ratio can reach more than 99.9 percent. The concentration of the H2S in emptied tail gas is below 25 mg / Nm3, so the H2S gas can meet the requirement of environmental protection, and can be exhausted directly without being burnt.

Owner:HUALU ENG & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com