Gas Conditioning System

a technology of gas conditioning system and gas filter, which is applied in the direction of gasification process details, gas dust removal, gas contamination removal, etc., can solve the problems of insufficient prior system and process treatment, less desirable waste material disposal by incineration, and almost impossible to know the exact concentration of heavy metals in the gasification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

A GCS for Production of Conditioned Gas Suitable for Use in Gas Engines

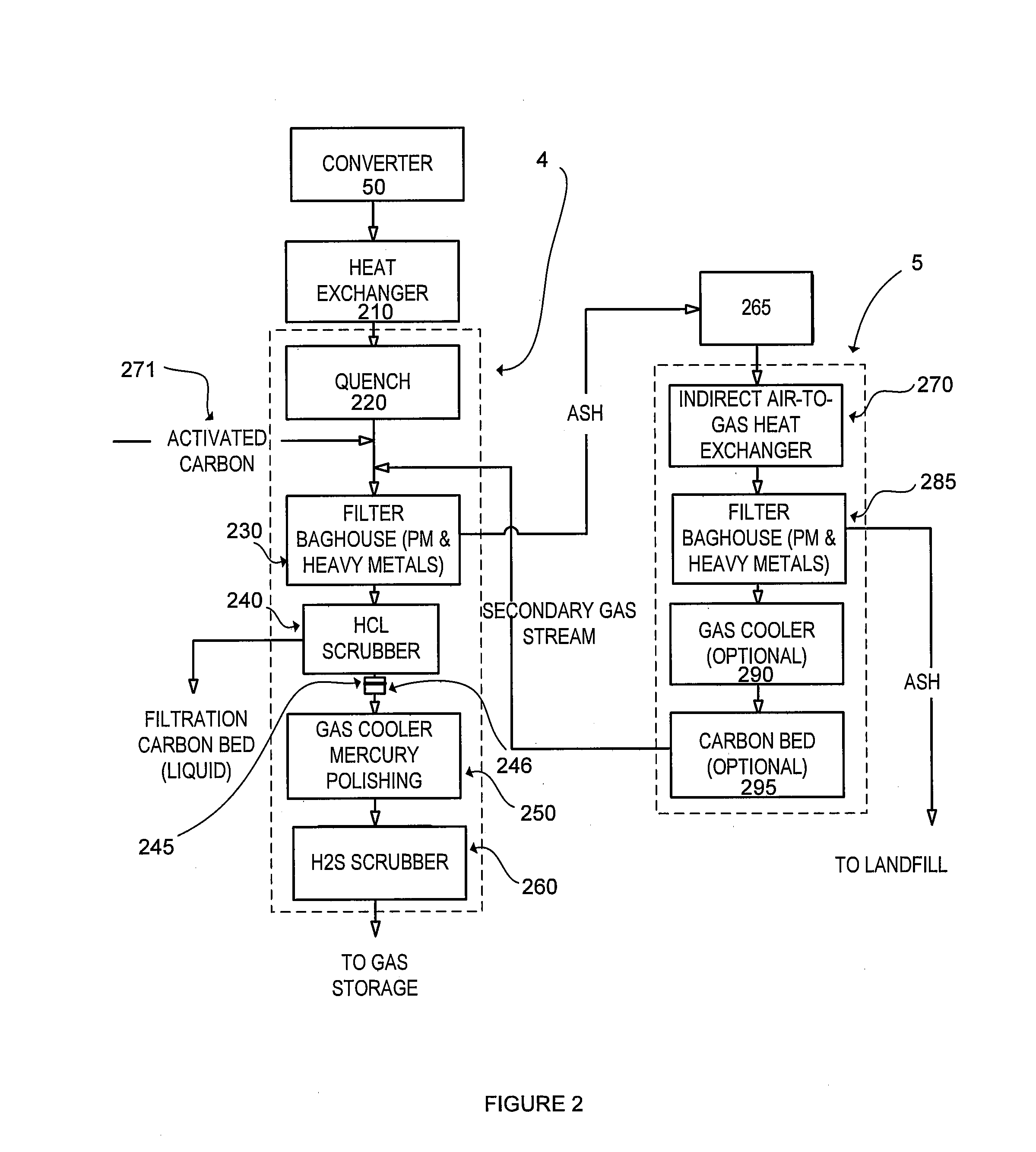

[0256]The following example describes a GCS that is configured to produce conditioned gas suitable for use in gas engines. The GCS comprises the following process operations:

Stage One Processes:

[0257]1. Evaporative Cooling (Quench)[0258]2. Dry injection system[0259]3. Particulate matter / heavy metal removal[0260]4. Processing of the solid residue in a solid residue gas conditioner and associated solid residue GC

Stage Two Processes:

[0261]5. HCl Scrubber[0262]6. Process Gas Blower[0263]7. Gas Cooler[0264]8. Mercury polisher[0265]9. Sulphur Removal

[0266]The conditioned gas produced by the above process operations is stored and subsequently heated prior to use.

[0267]The above process operations are shown in FIG. 2 and described below. As can be seen from FIG. 2 the GCS employs converging process steps and comprises a converter gas conditioner 4 integrated with a solid residue gas conditioner 5, as well as a solid resi...

example 2

Overview of a GCS Comprising Converging Process Steps

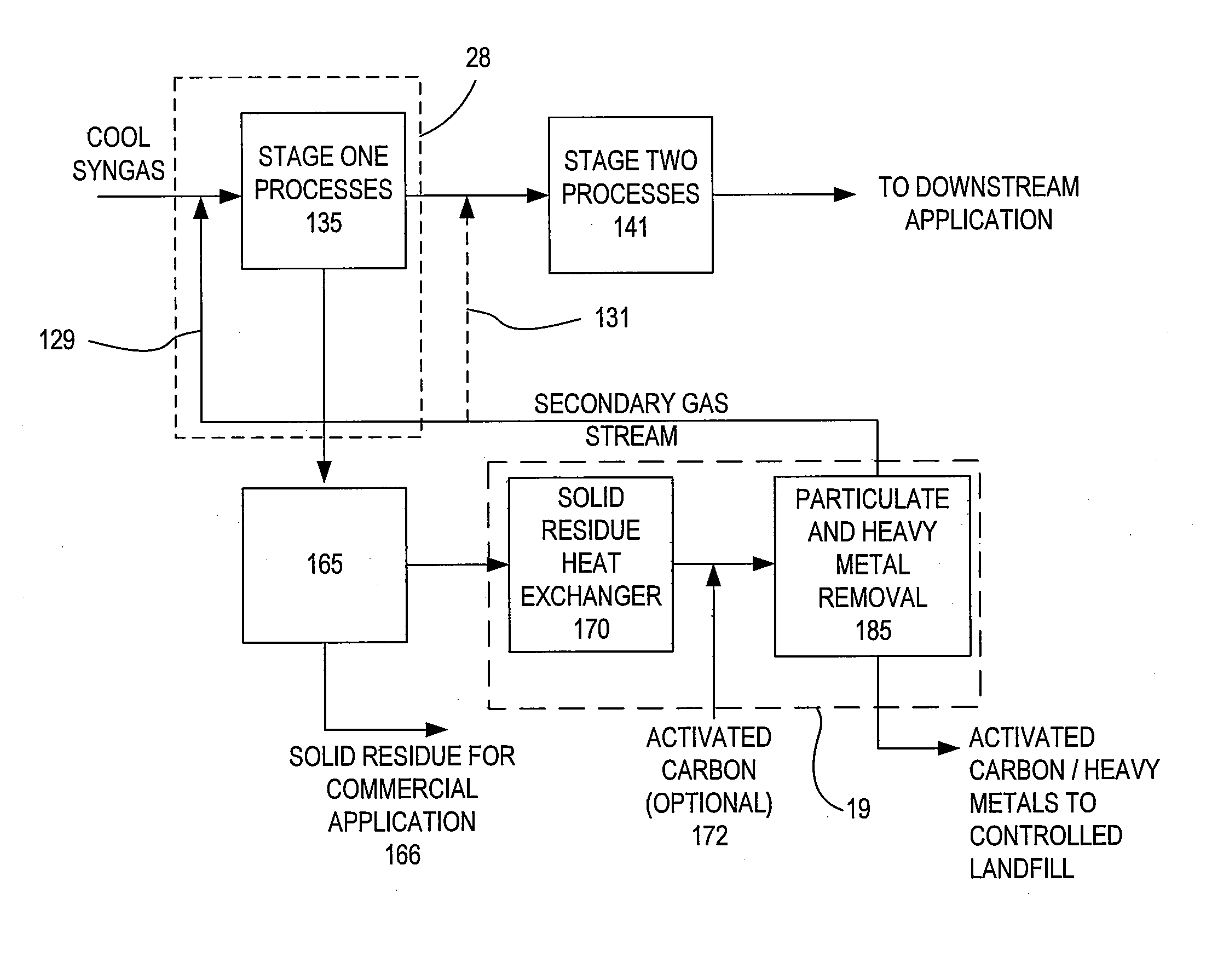

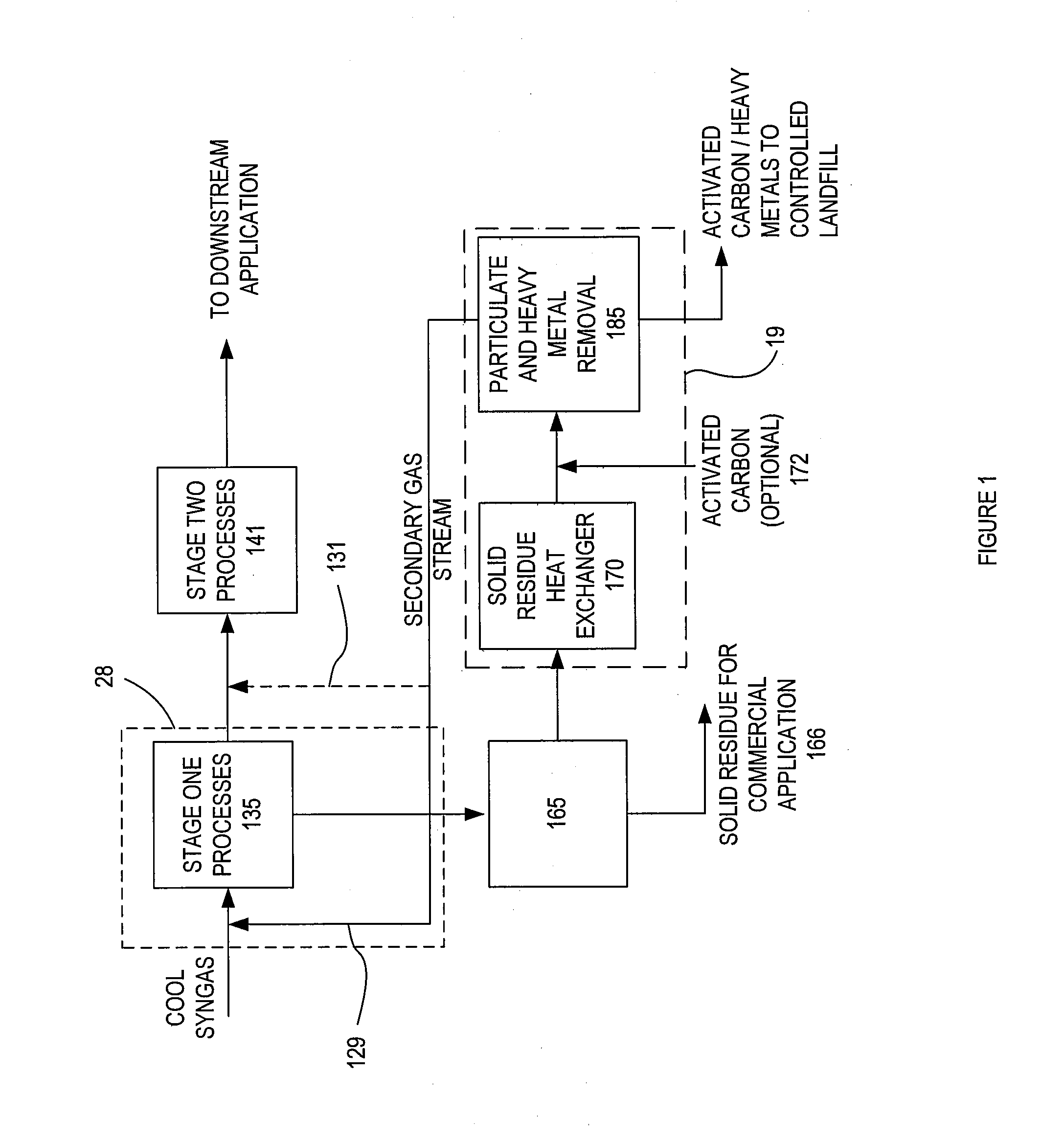

[0299]The following example provides an overview of a GCS which comprises converging process steps as shown in FIG. 9. In this example, the GCS comprises a converter gas conditioner 2 and a solid residue gas conditioner 3. in which a secondary gas stream generated in a solid residue conditioner 165 is processed in a solid residue gas conditioner 3 and then fed into the converter gas conditioner 2. In this example, the input gas has already been cooled prior to entering the GCS, for example, in a recuperator.

Stage One Processes

[0300]Activated carbon 171 is injected into the input syngas stream, and particulate matter and heavy metals are removed from the input gas using particle removal unit 130. The particulate matter and heavy metal removed from the input gas is collected and transferred to the solid residue conditioner 165 where it is converted to a solid residue and a secondary gas stream.

[0301]The secondary gas stream then ent...

example 3

Overview of a GCS for High Temperature Gas Conditioning

[0305]This example describes a GCS for high temperature gas conditioning and provides an example of a linear process sequence. An overview of the processing steps carried out by this GCS is shown in FIG. 3. At large capacity applications, in order to improve the overall thermal efficiency, the syngas can be cleaned at temperatures as high as 760° C. The syngas exiting the converter 51 is cooled to approximately 760° C. in a heat exchanger 310. This cooled syngas (input syngas) then enters the GCS 6. Particulate matter and heavy metals are then removed from the input syngas in a cyclone separator or filter 330 (Stage One Process). The following Stage Two Processes are then carried out. A chloride guard bed 340 (Nahcolite) is used to remove HCl, followed by H2S removal 360 by sorbents. Finally, a ceramic filter 362 is used to remove any particles in the hot input syngas, prior to storage of the conditioned syngas.

[0306]The GCS acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pressures | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com