Patents

Literature

2332 results about "Recuperator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A recuperator is a special purpose counter-flow energy recovery heat exchanger positioned within the supply and exhaust air streams of an air handling system, or in the exhaust gases of an industrial process, in order to recover the waste heat. Generally, they are used to extract heat from the exhaust and use it to preheat air entering the combustion system. In this way they use waste energy to heat the air, offsetting some of the fuel, and thereby improves the energy efficiency of the system as a whole.

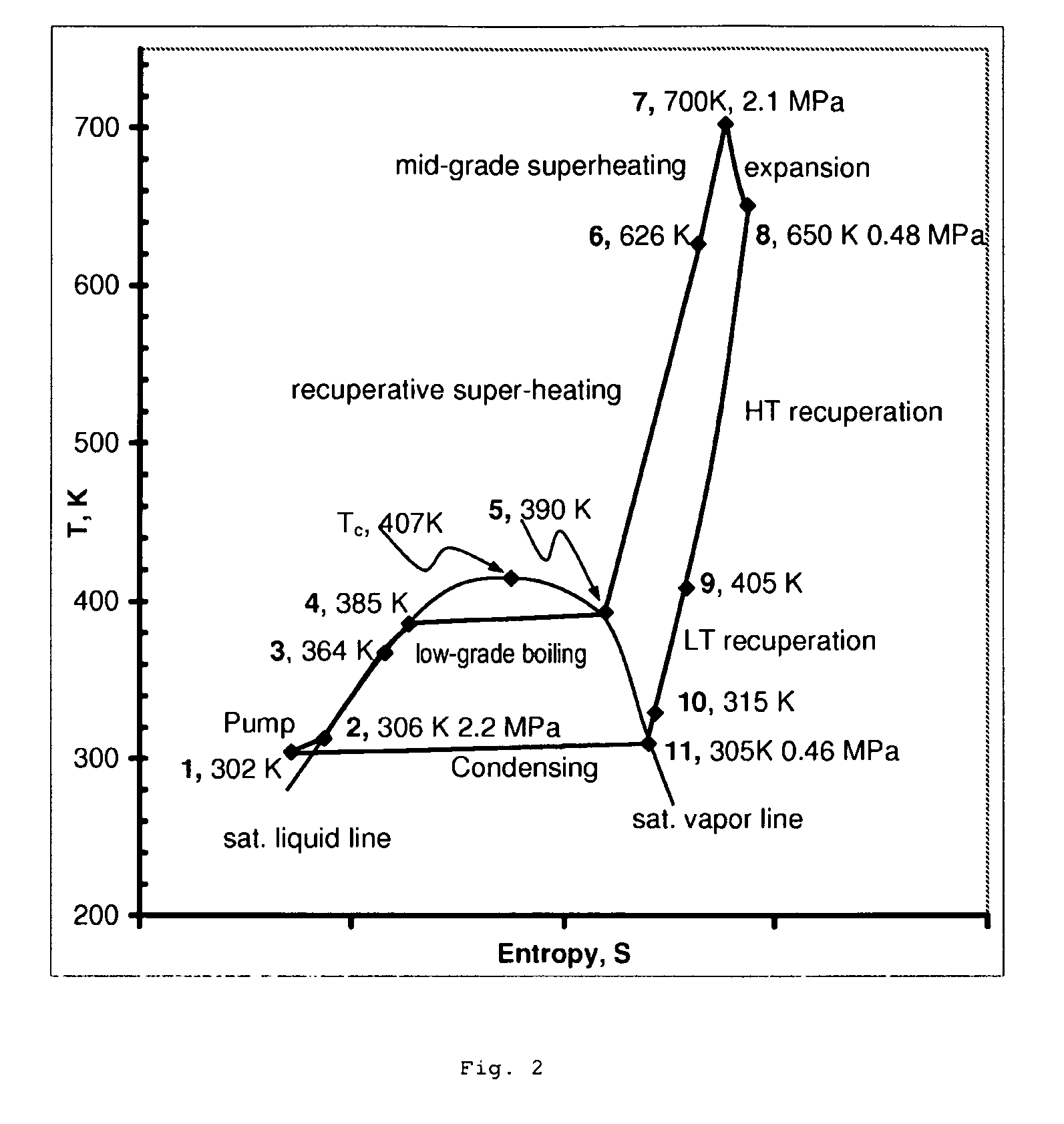

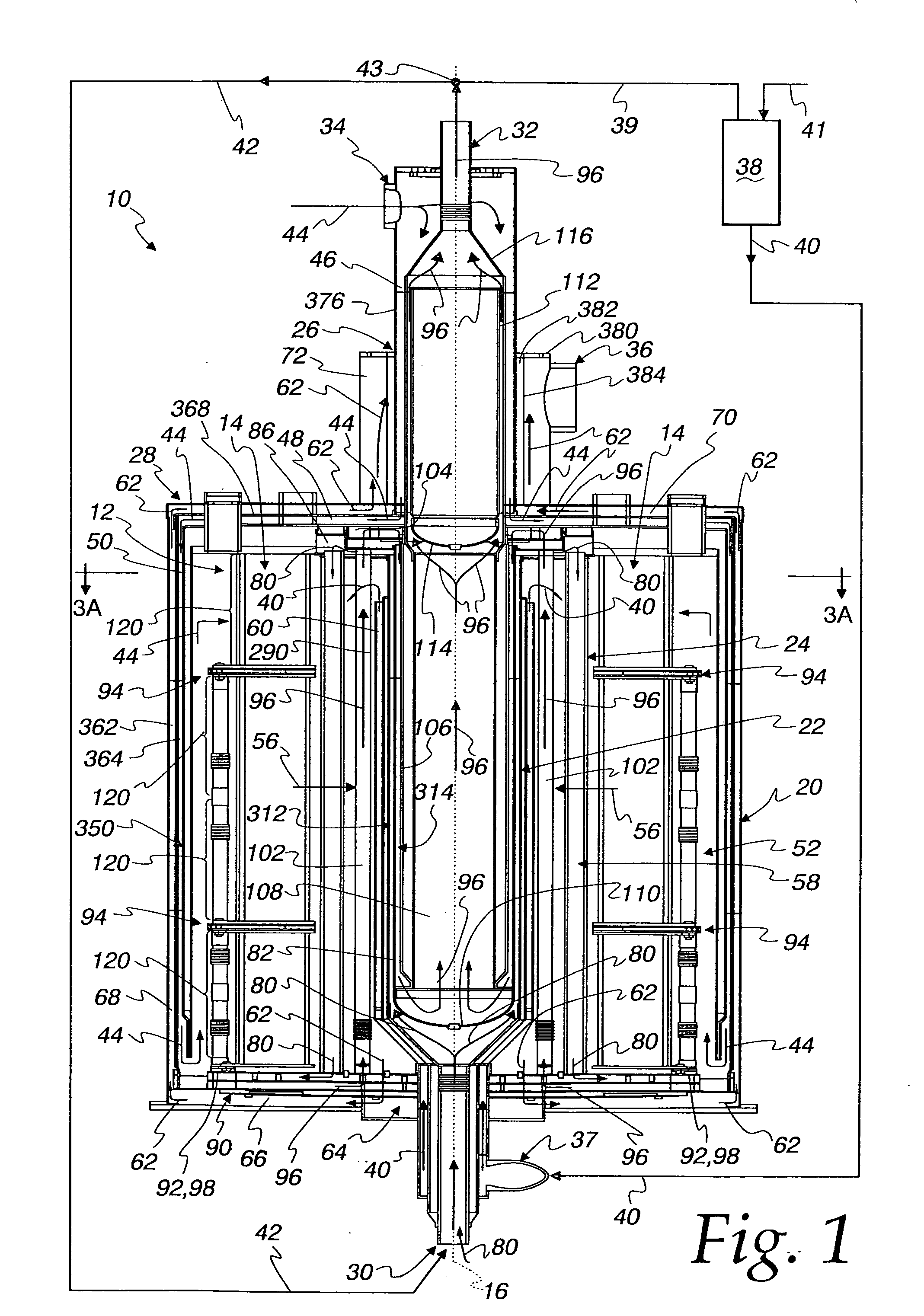

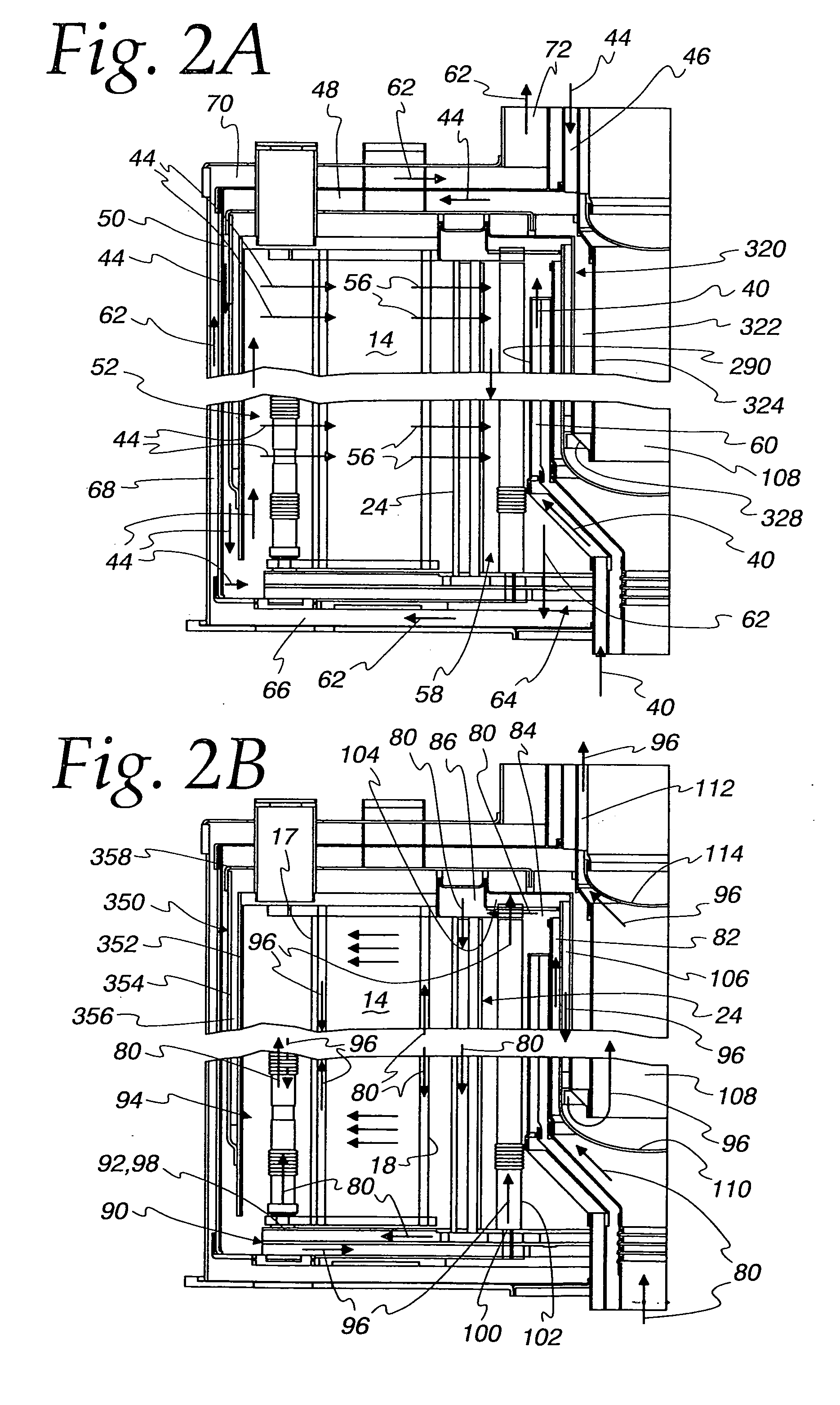

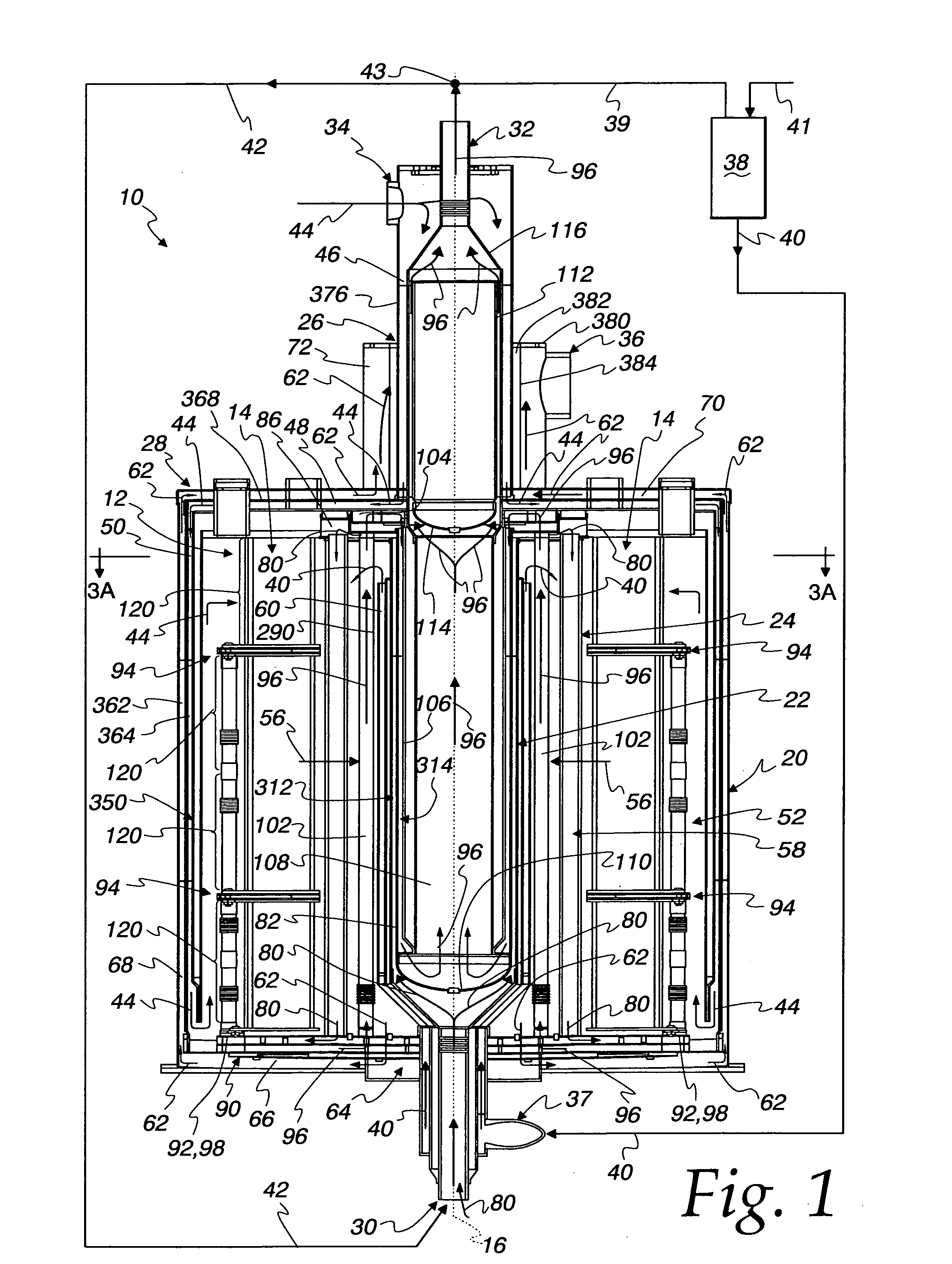

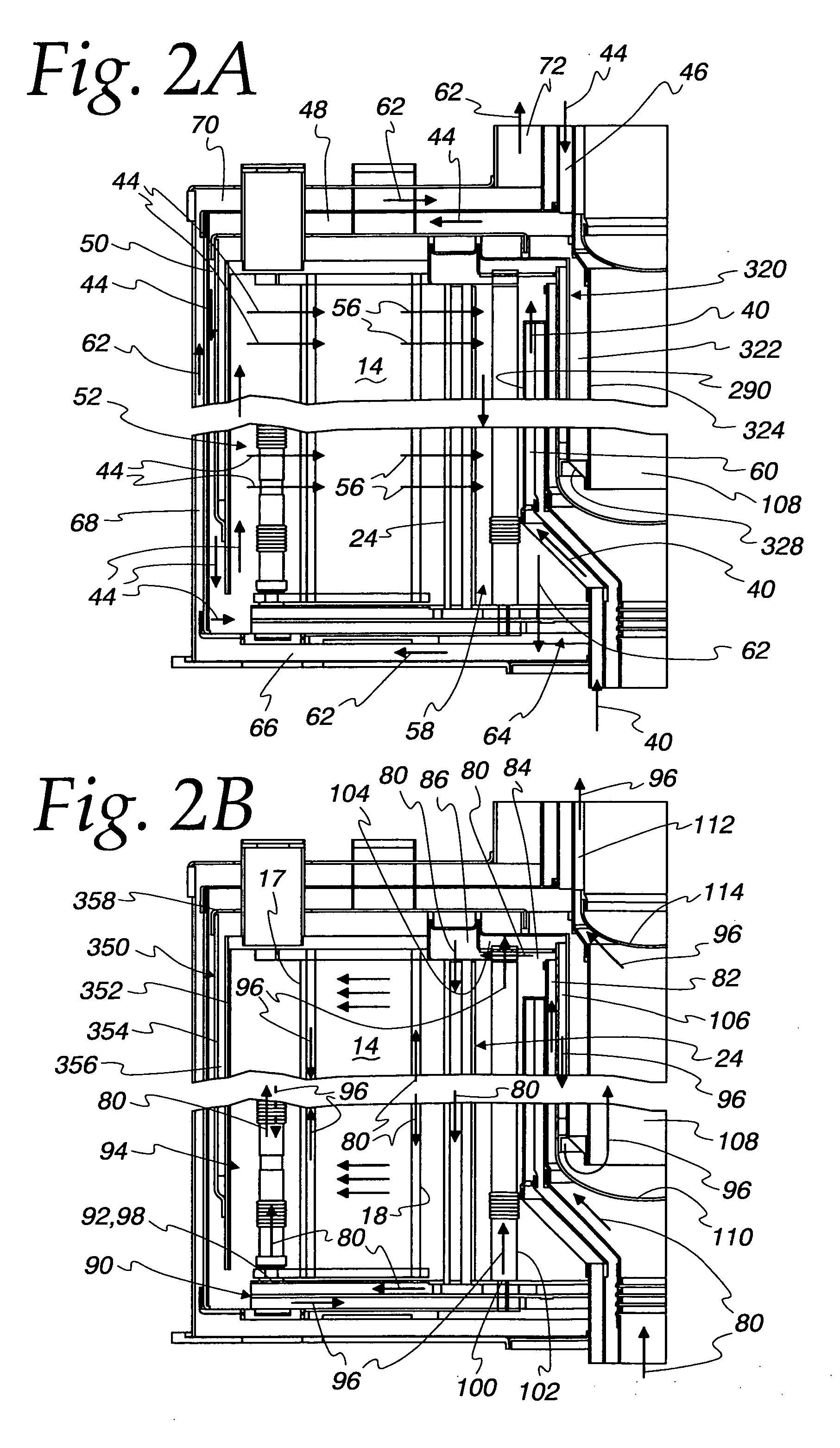

Intergrated solid oxide fuel cell and fuel processor

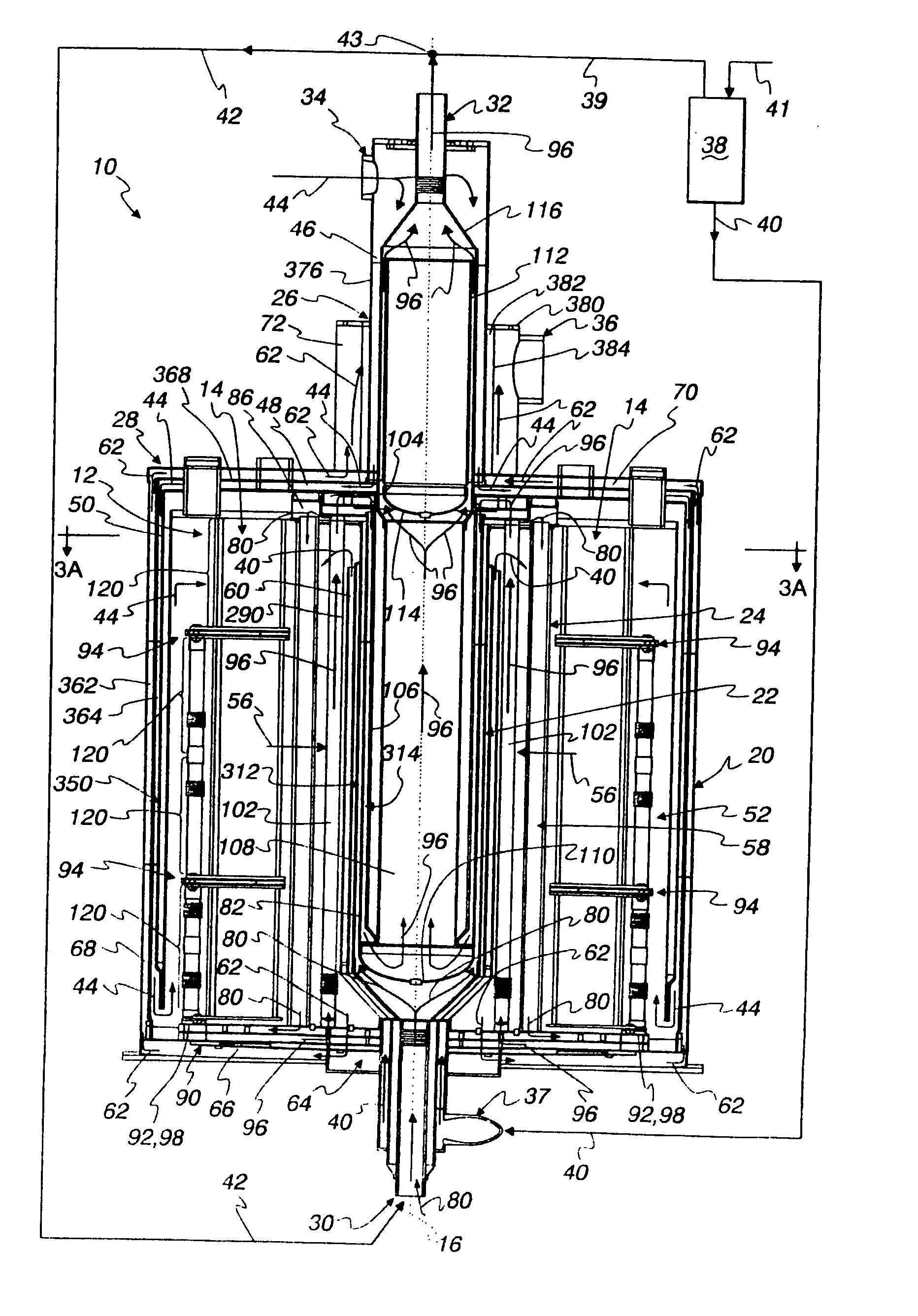

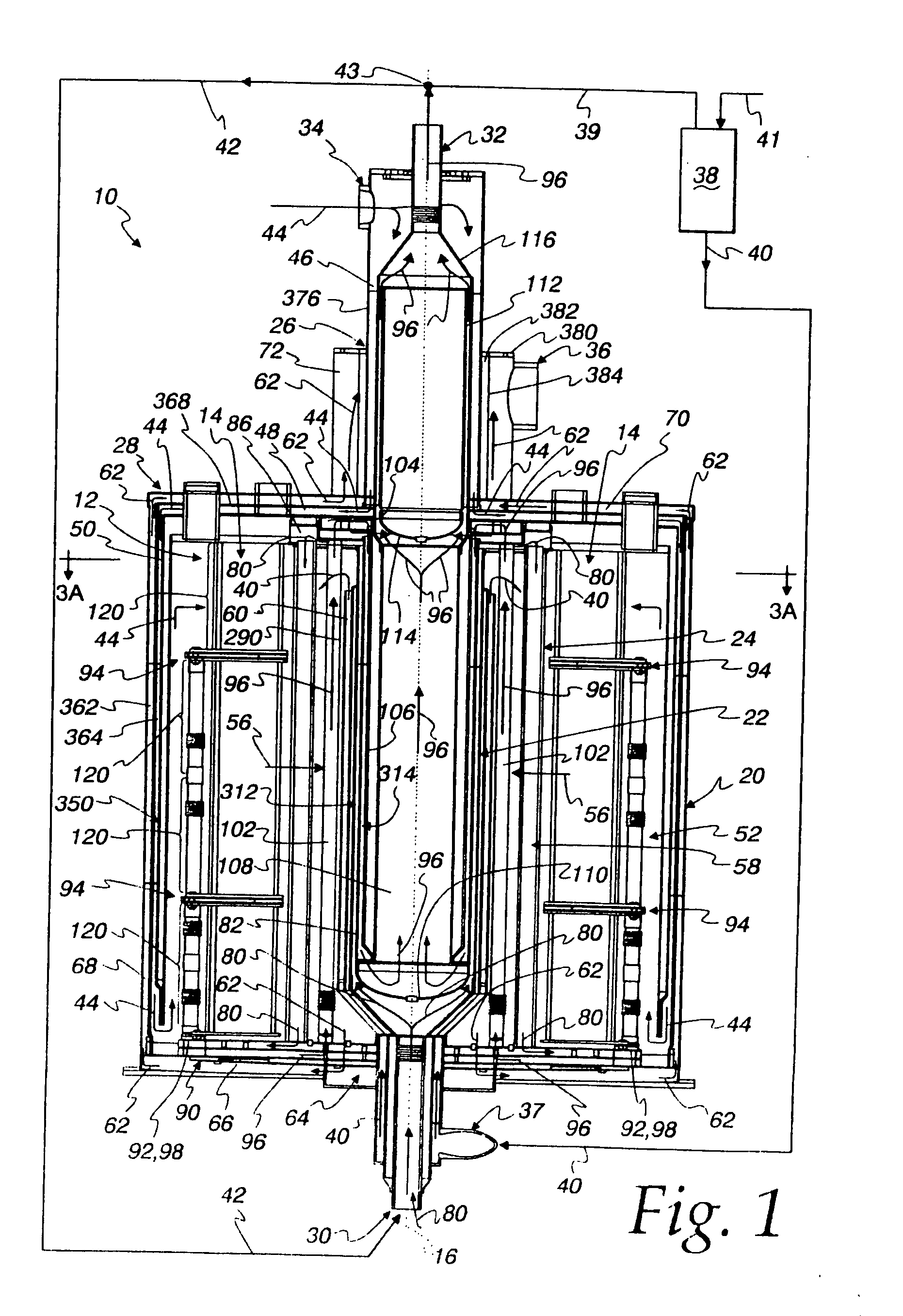

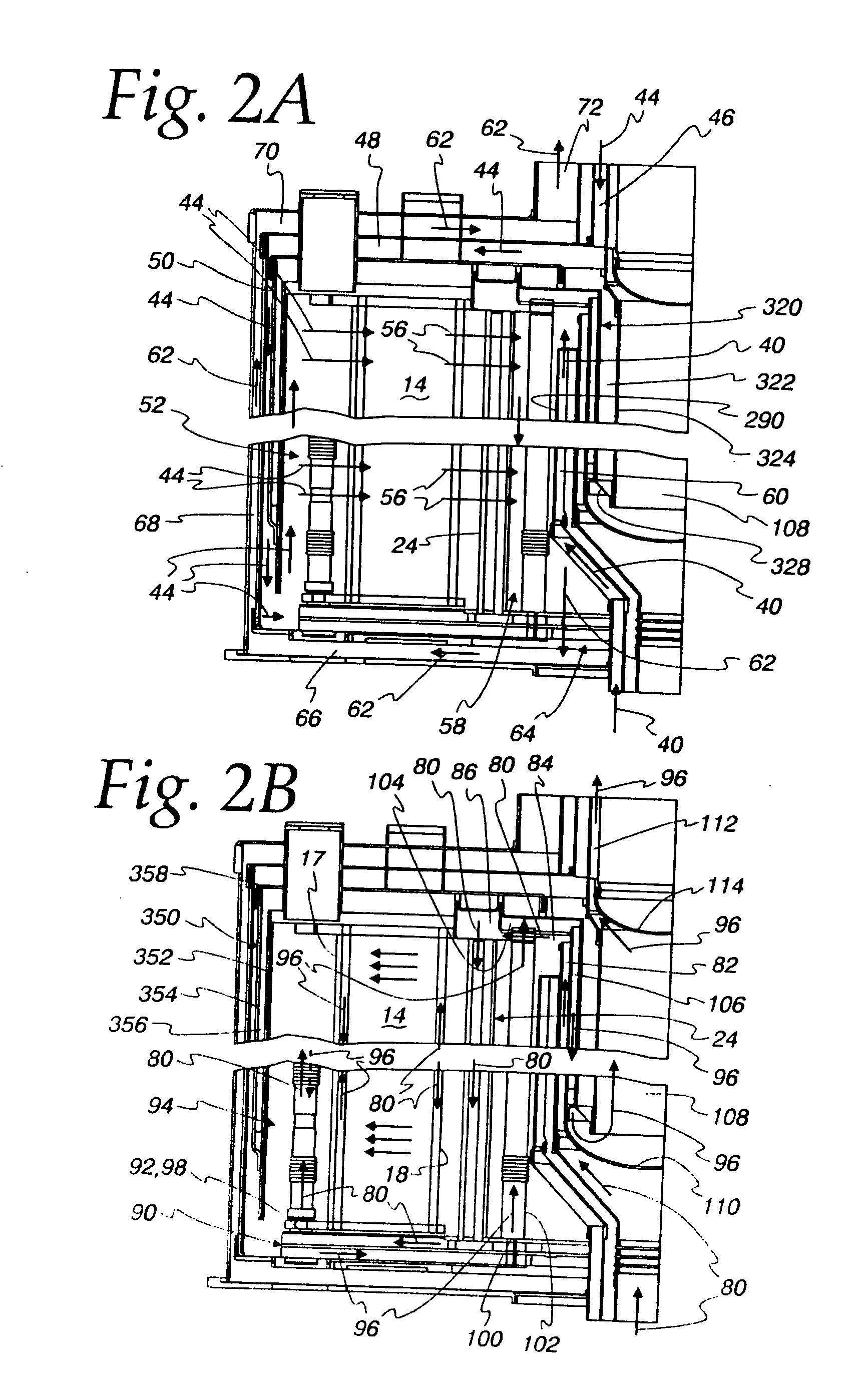

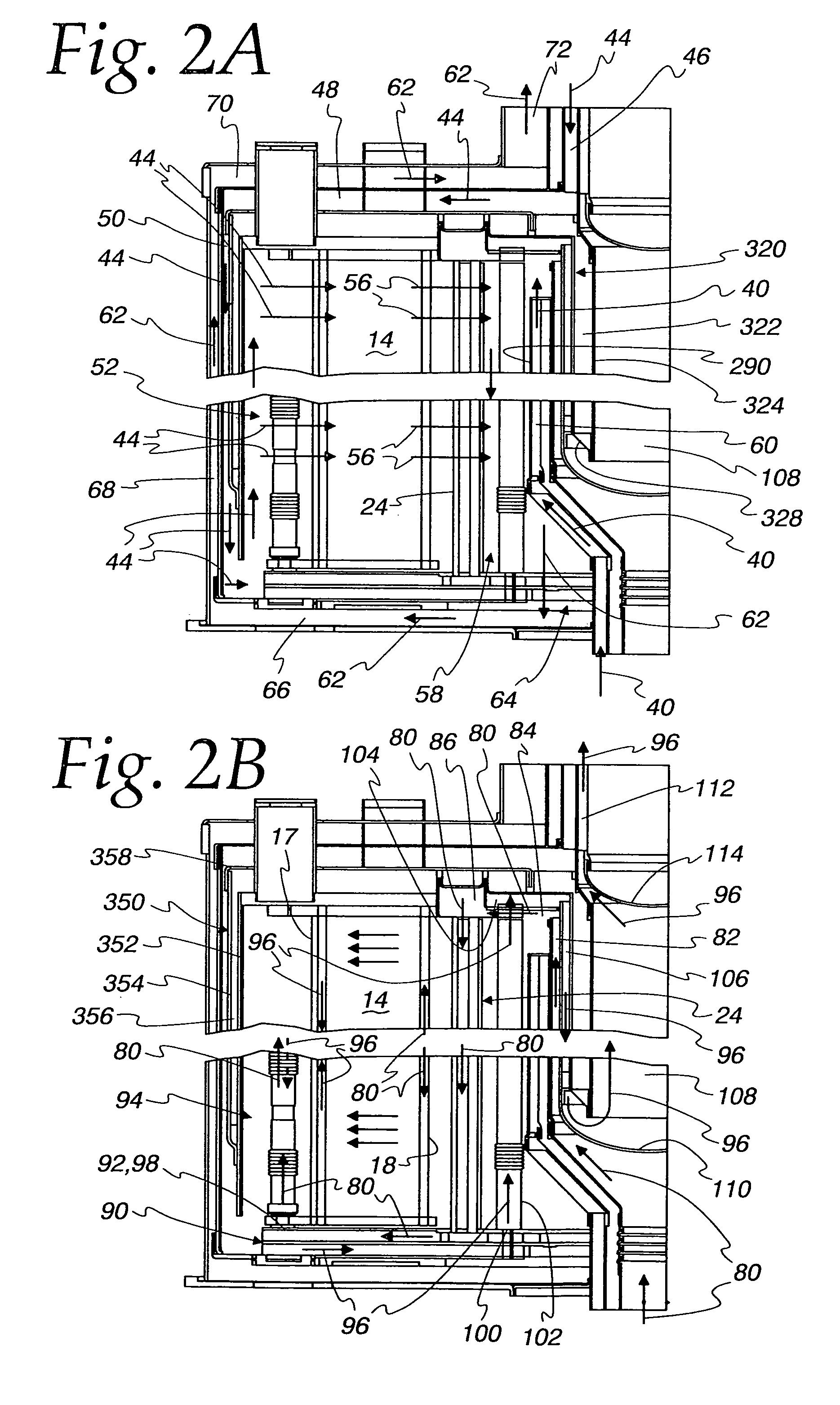

An integrated fuel cell unit (10) includes an annular array (12) of fuel cell stacks (14), an annular cathode recuperator (20), an annular anode recuperator (22), a reformer (24), and an anode exhaust cooler (26), all integrated within a common housing structure (28).

Owner:BLOOM ENERGY CORP

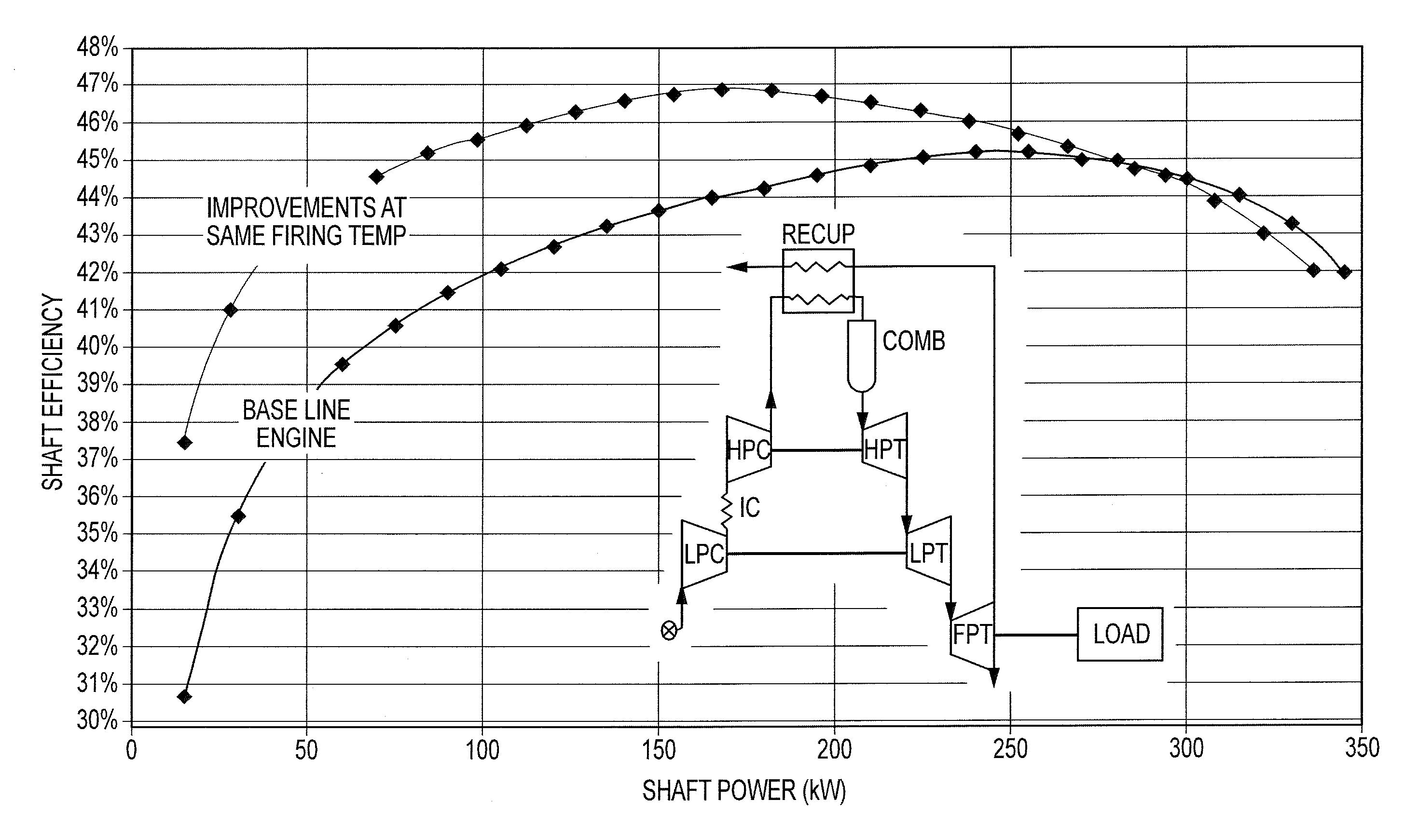

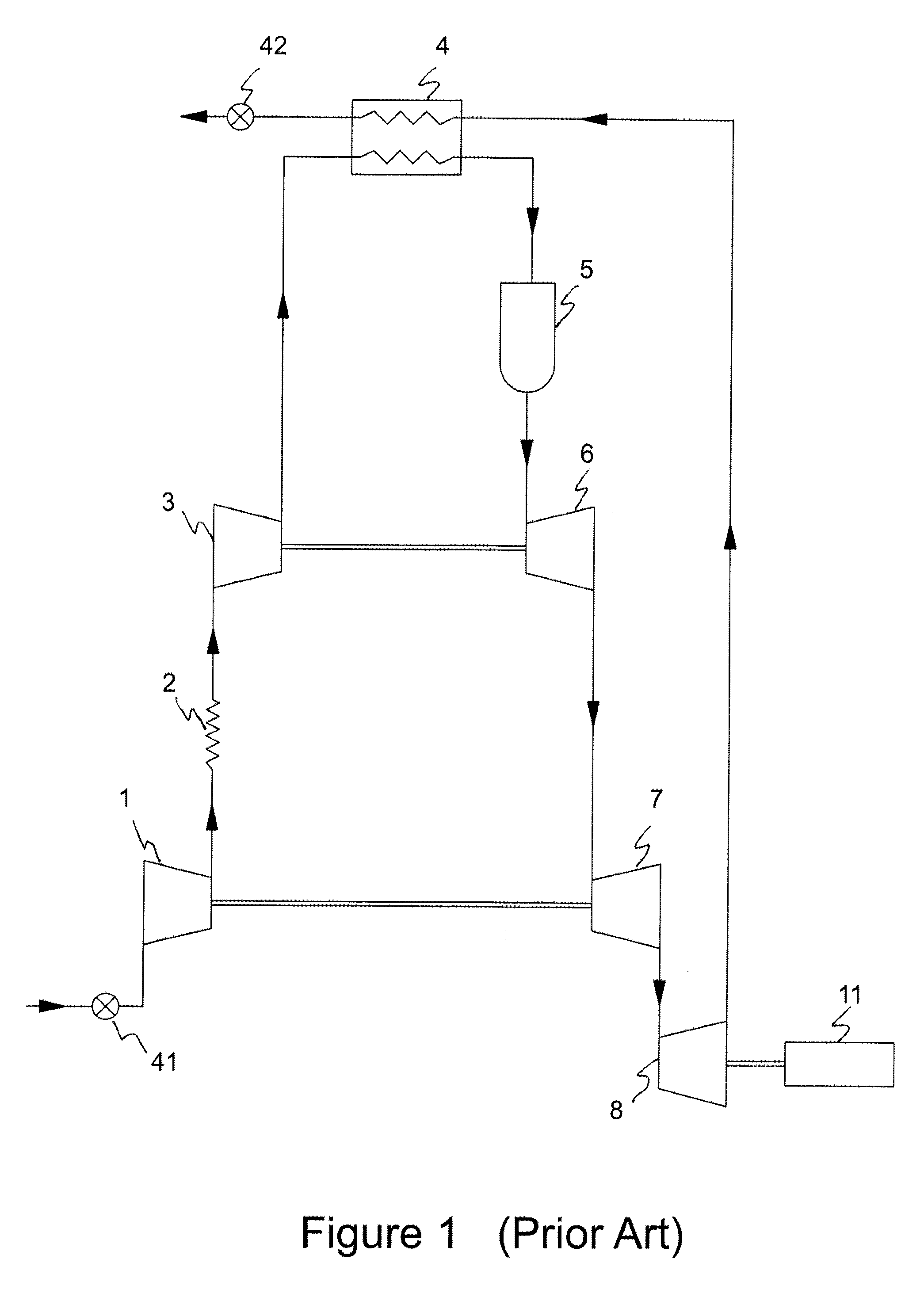

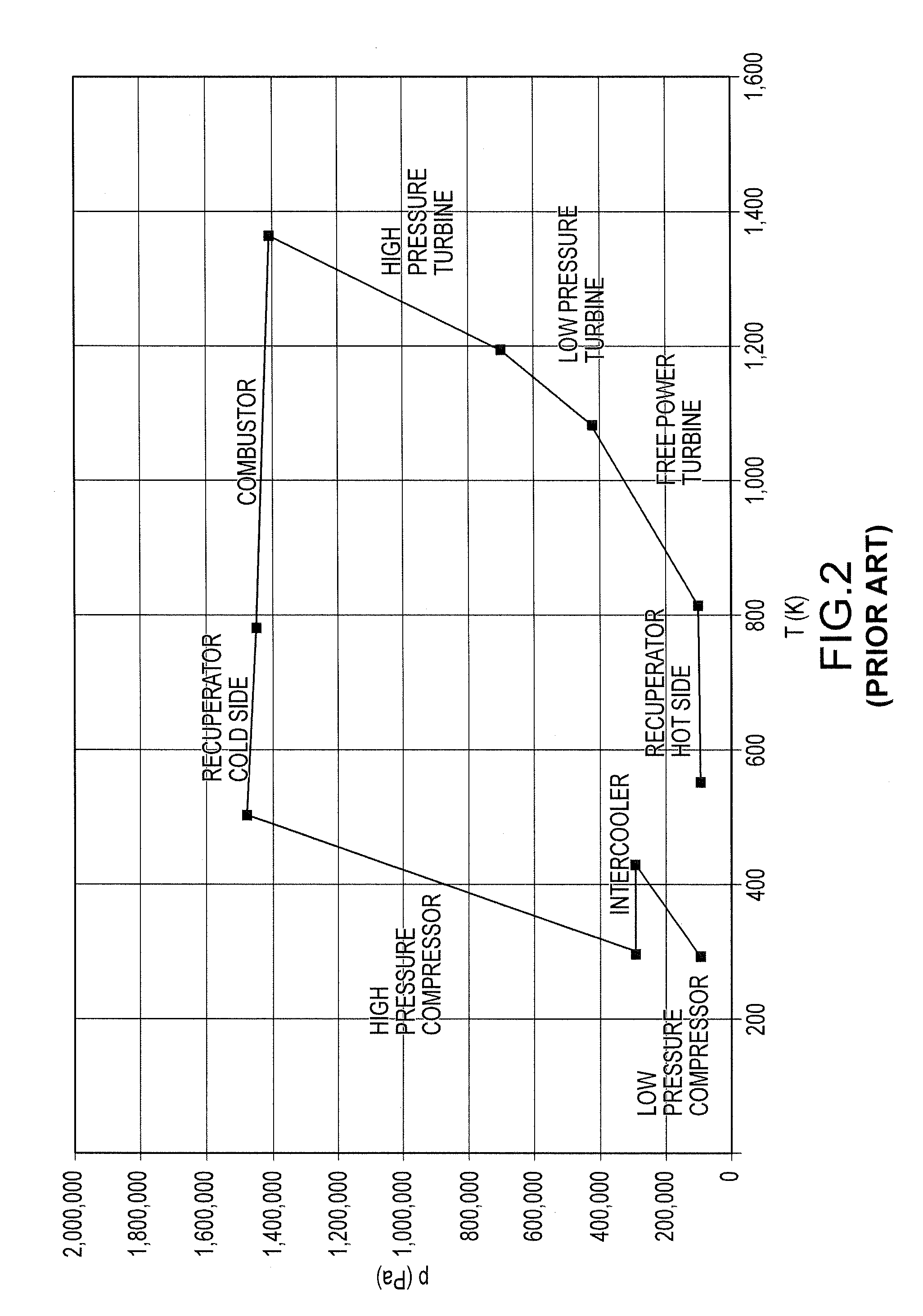

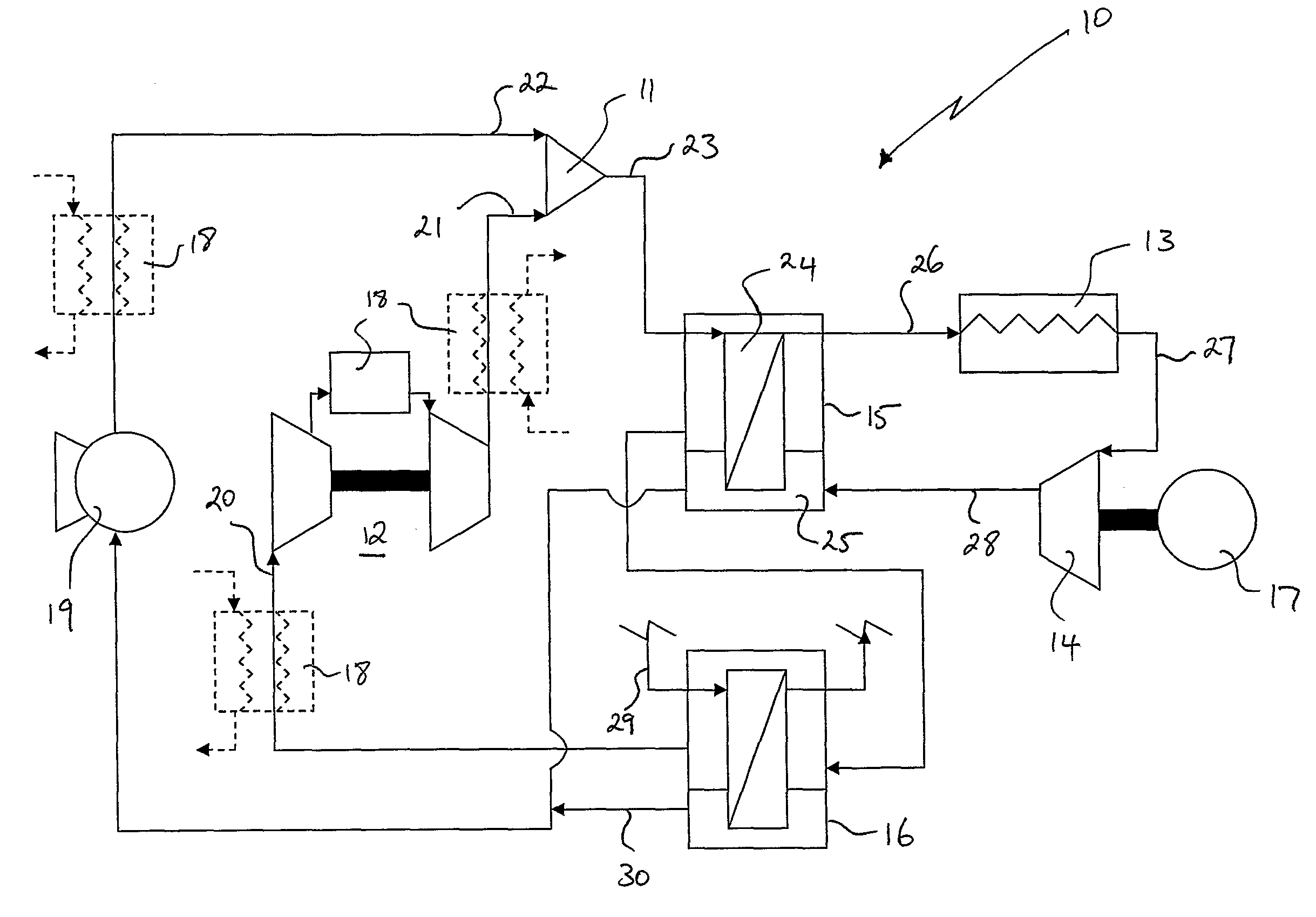

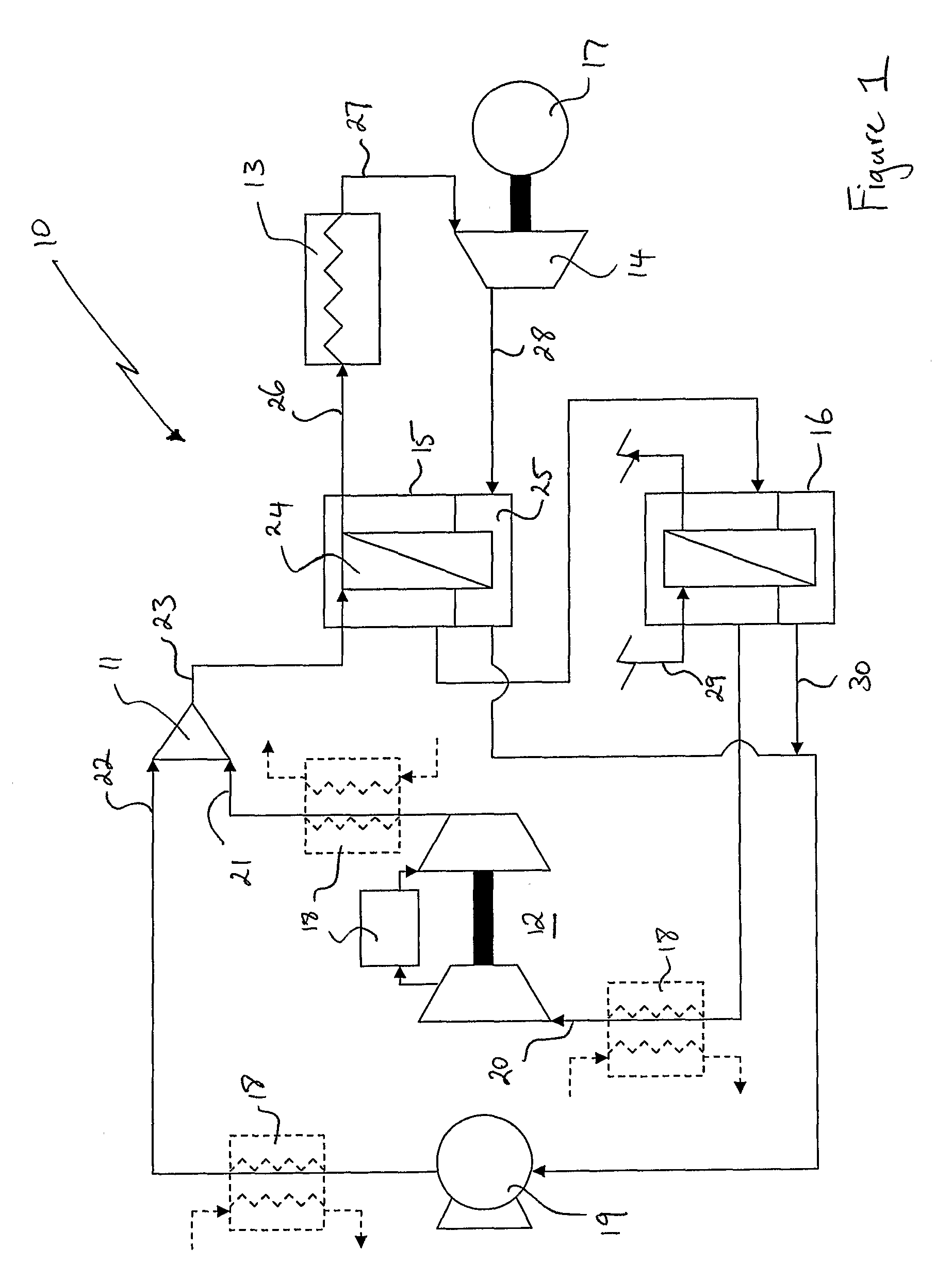

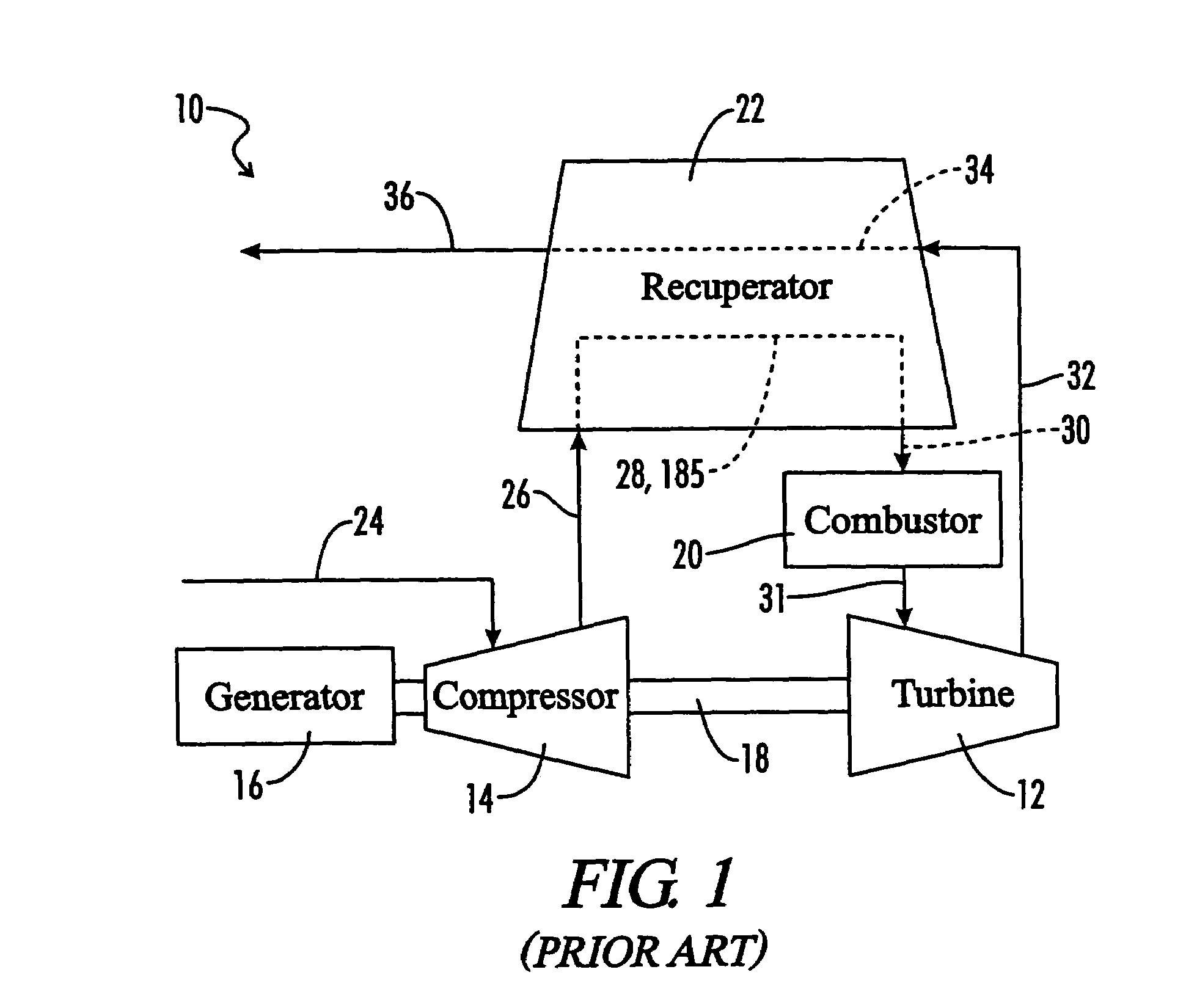

High efficiency compact gas turbine engine

InactiveUS20120324903A1Improve engine efficiencyThe process is compact and efficientGas turbine plantsEfficient propulsion technologiesWorking fluidCombustor

This disclosure relates to a highly efficient gas turbine engine architecture utilizing multiple stages of intercooling and reheat, ceramic technology, turbocharger technology and high pressure combustion. The approach includes utilizing a conventional dry low NOx combustor for the main combustor and thermal reactors for the reheat apparatuses. In a first configuration, there are three separate turbo-compressor spools and a free power turbine spool. In a second configuration, there are three separate turbo-compressor spools but no free power spool. In a third configuration, all the compressors and turbines are on a single shaft. Each of these configurations can include two stages of intercooling, two stages of reheat and a recuperator to preheat the working fluid before it enters the main combustor.

Owner:ICR TURBINE ENGINE CORP

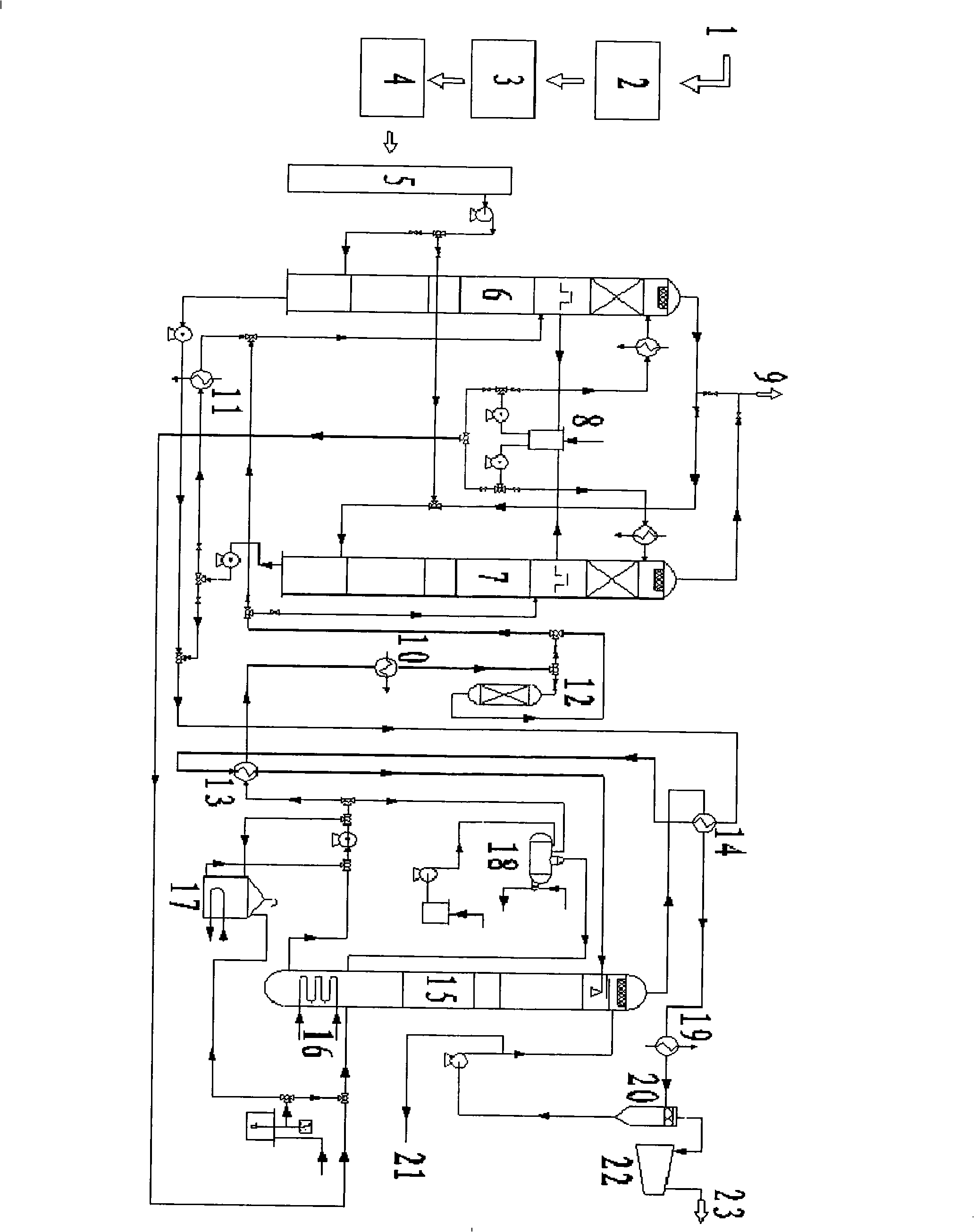

Method and apparatus for collecting carbonic anhydride in coal-fired plant flue gas

The invention provides a method and a device for collecting carbon dioxide in smoke gas of a coal-fired power plant. The device consists of a smoke gas pretreatment system, absorption towers, a regeneration tower, an exhaust scrubbing system, a solution heating recoverer, a product gas processing system (comprising a condenser, a gas-liquid separator and a compressor). The device is integrated with the prior smoke gas purification device of the coal-fired power plant, and is provided with a high-efficiency whirlcone and a chemical absorption system, so that mass carbon dioxide gas exhausted from a coal-fired boiler can be collected, and the emission of greenhouse gas can be reduced; the special arrangement of double absorption towers ensures more flexible operation of a collecting system, and improves the operational reliability; an absorption solution reclaiming process reduces the consumption of the solution; the arrangement of a lean-rich solution heat exchanger and a product gas rich solution heat exchanger reduces the energy consumption of the collecting system; and the steam consumption can be effectively reduced by adopting a built-in solution boiling unit.

Owner:XIAN THERMAL POWER RES INST CO LTD

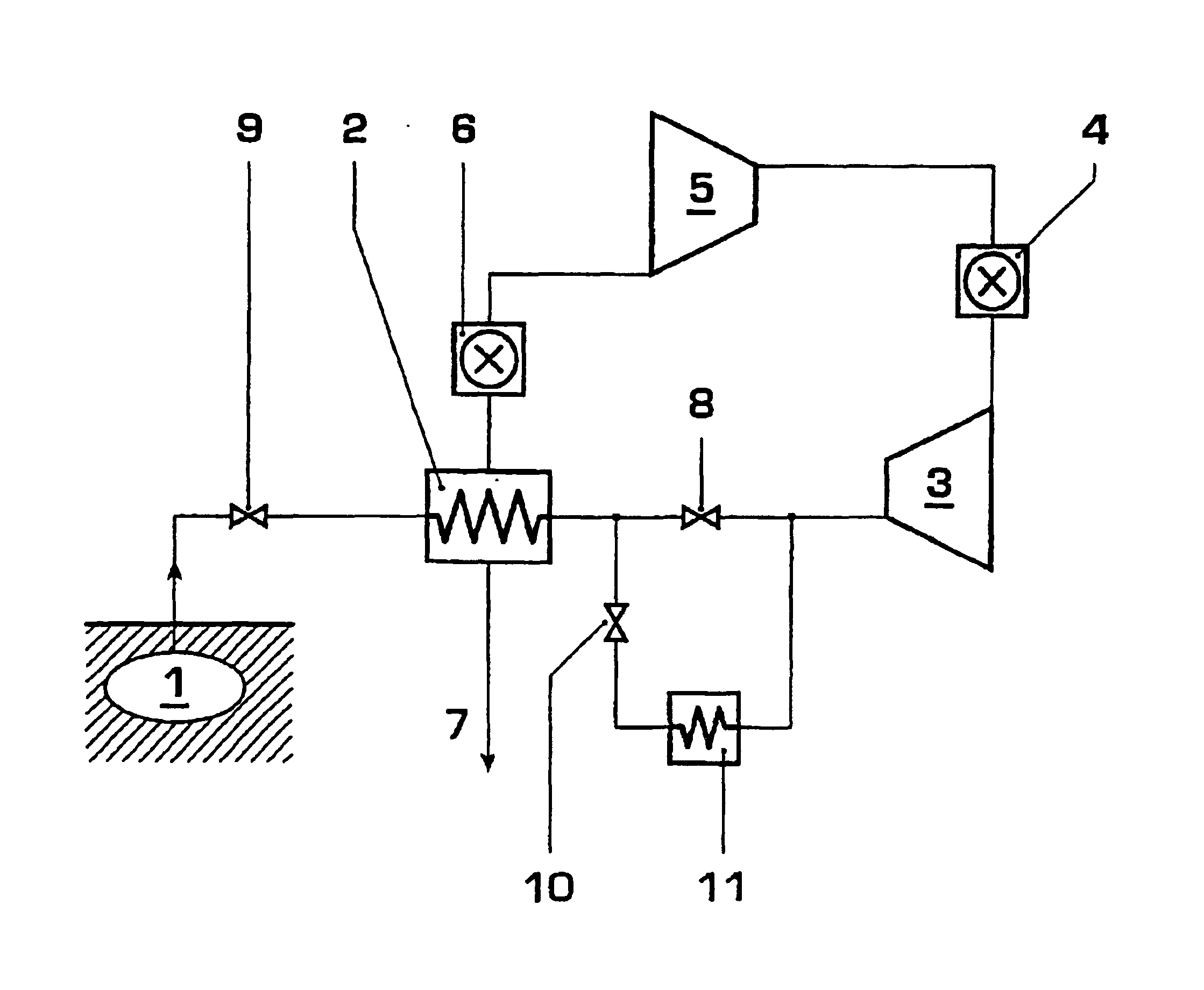

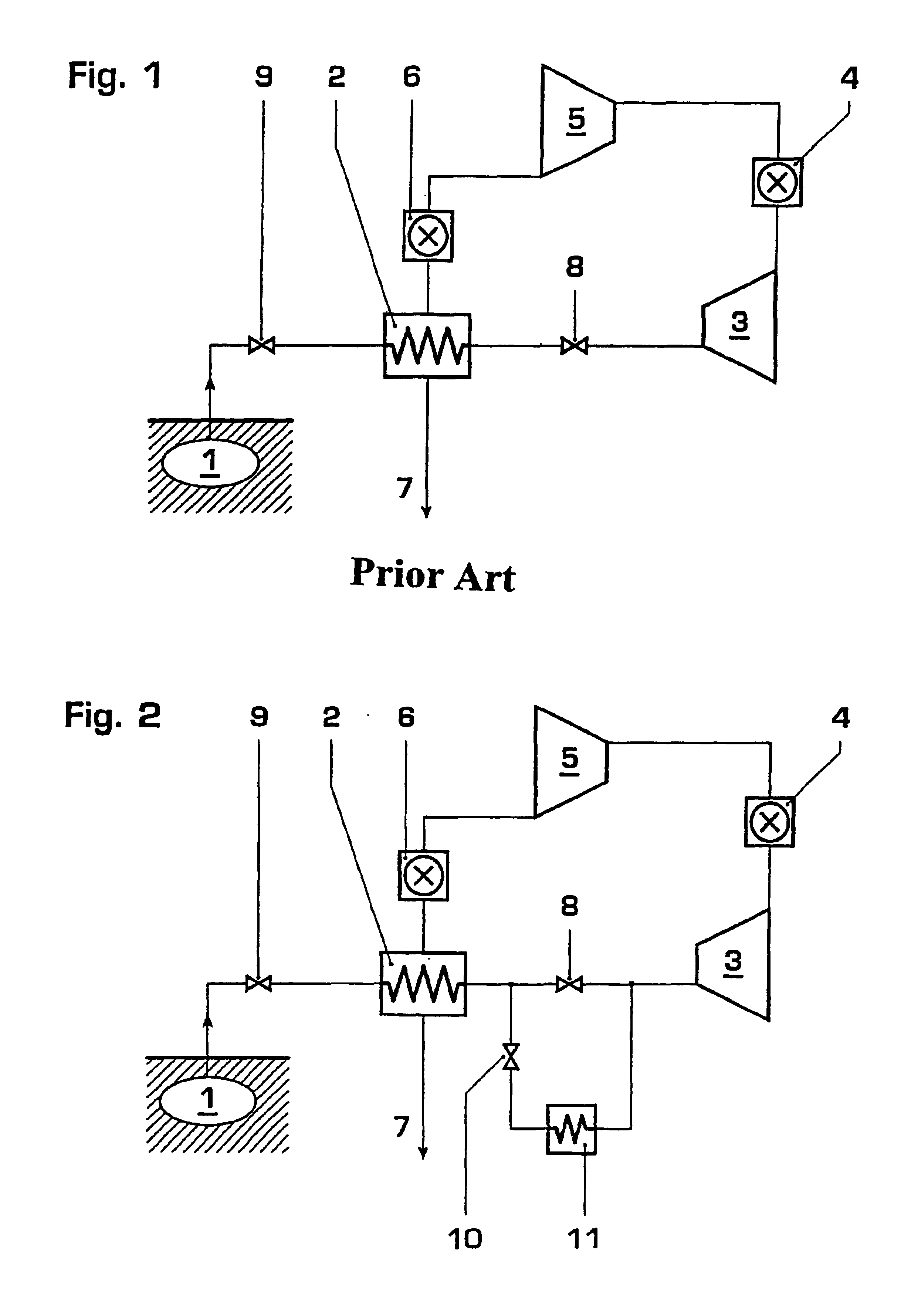

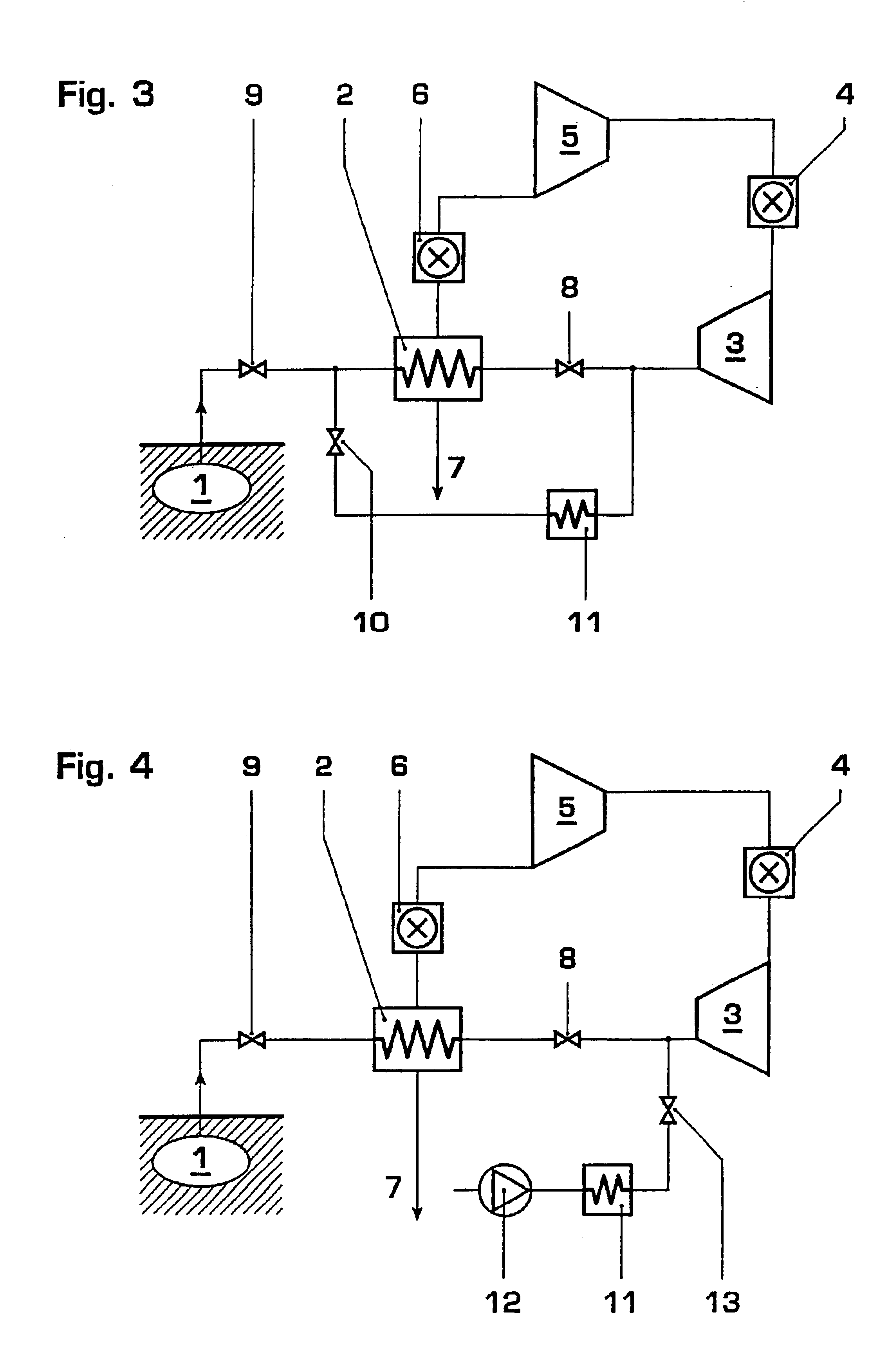

Compressed air energy storage system having a standby warm keeping system including an electric air heater

InactiveUS6848259B2Reduce thermal stressEasy temperature controlGas turbine plantsJet propulsion plantsTemperature controlCombustor

A compressed air energy storage system comprises a cavern (1) for stored compressed air and a system for providing the compressed air to a power train (3, 5), this system including a recuperator (7) and a first valve arrangement (8) that controls the flow of the compressed air from the recuperator and to the power train (3, 5). A system for warm-keeping of the power train (3, 5) during stand-by operation of the compressed air energy storage system comprises the recuperator (2) and / or an auxiliary electrical air heater (11) and a second valve arrangement (10, 13) for controlling the airflow for warm-keeping. The system for warm-keeping of the power train allows improved temperature control and avoids disadvantages associated with a warm-keeping system having a combustor.

Owner:GENERAL ELECTRIC TECH GMBH

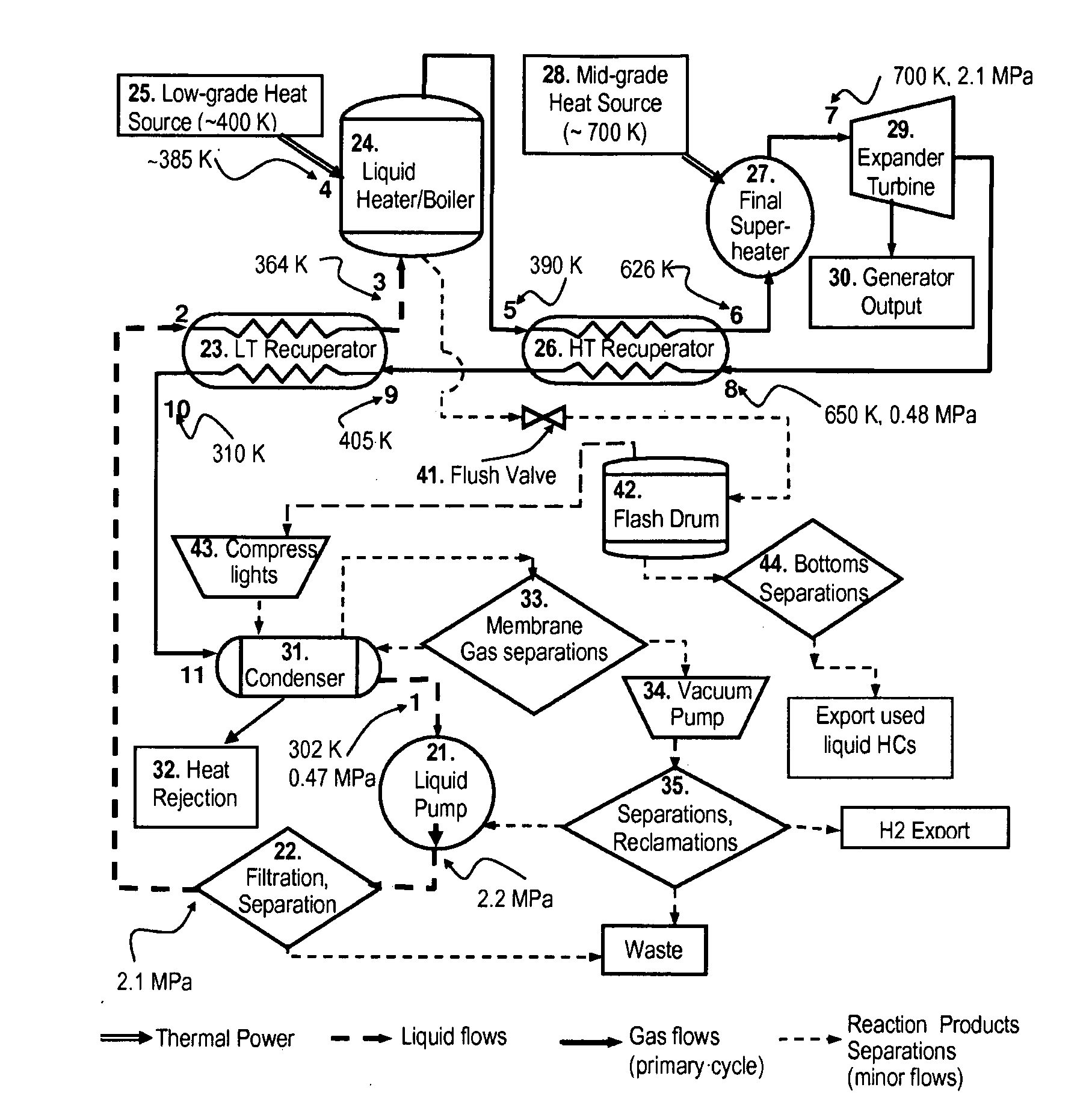

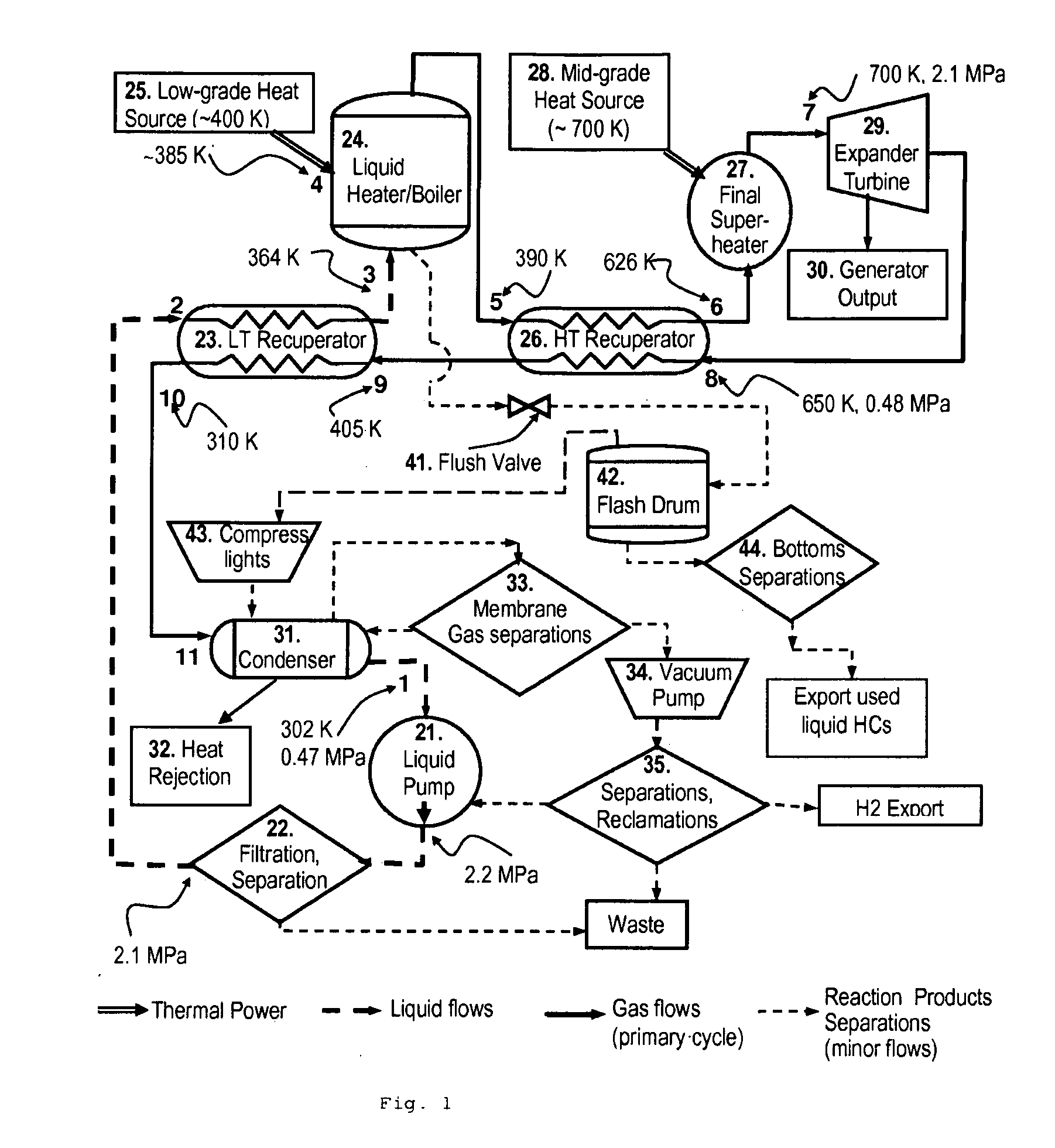

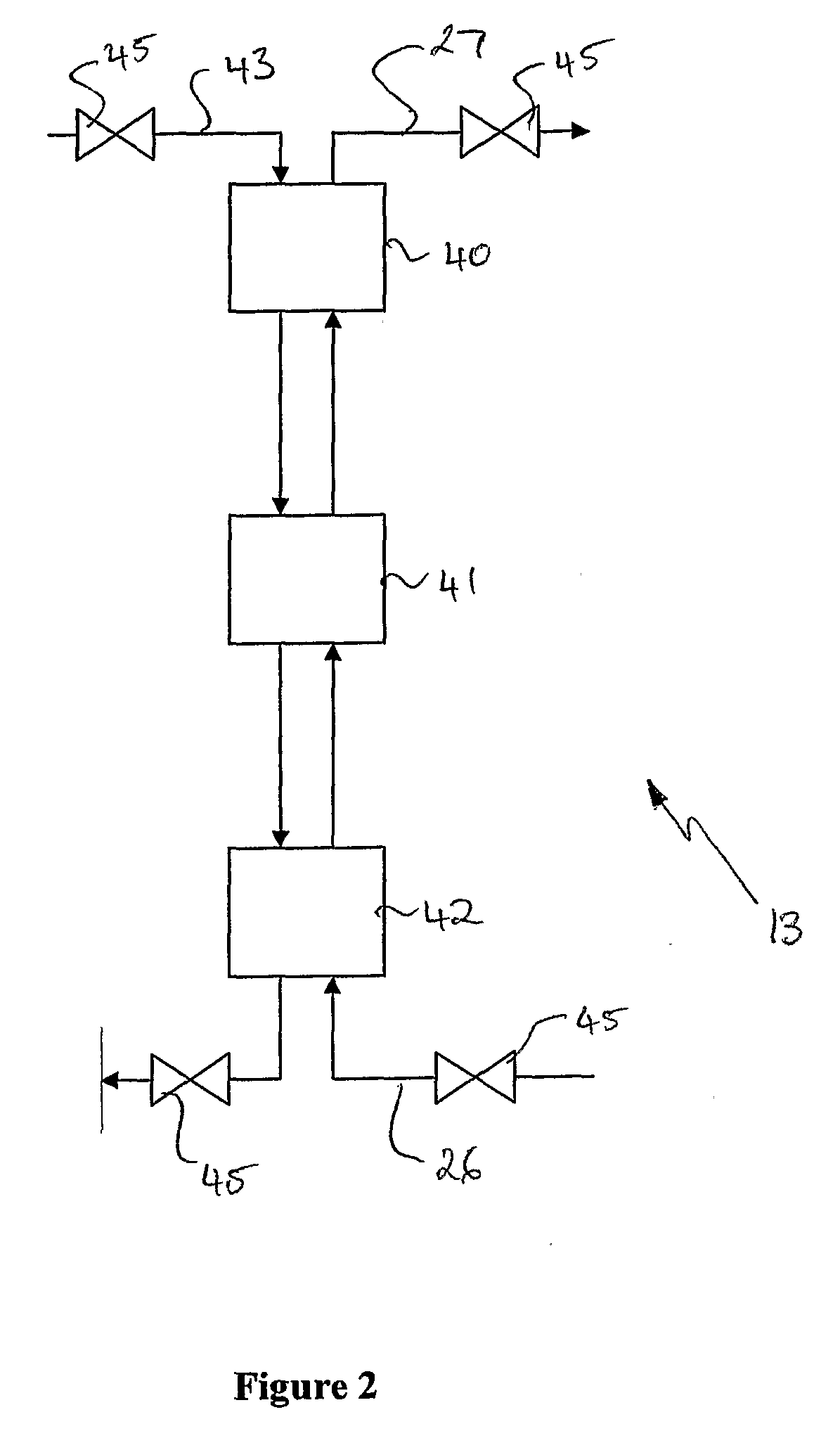

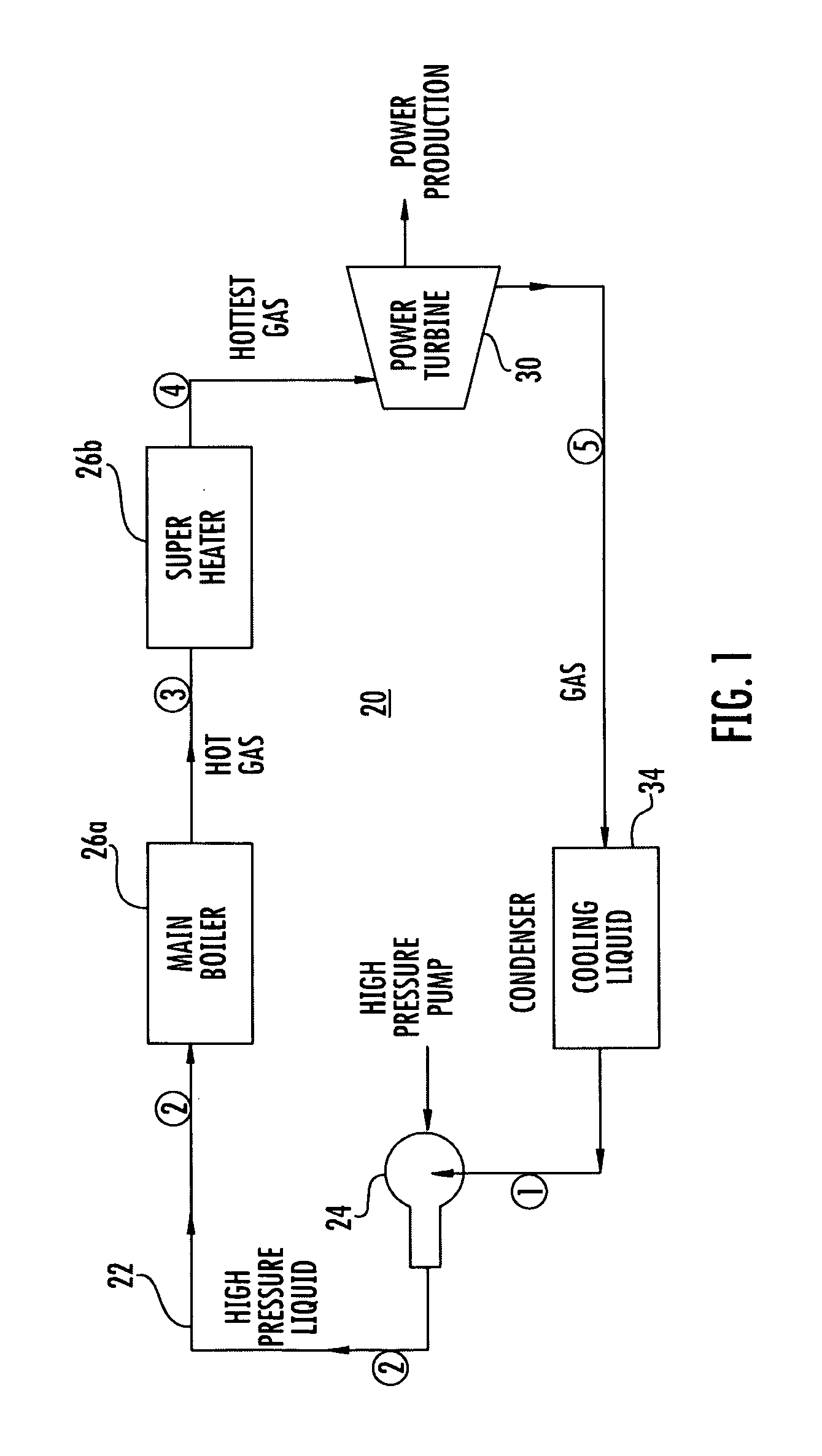

High-temperature dual-source organic Rankine cycle with gas separations

InactiveUS20100300093A1Increase temperatureMinimize timeAuxillary drivesInternal combustion piston enginesWorking fluidOrganic Rankine cycle

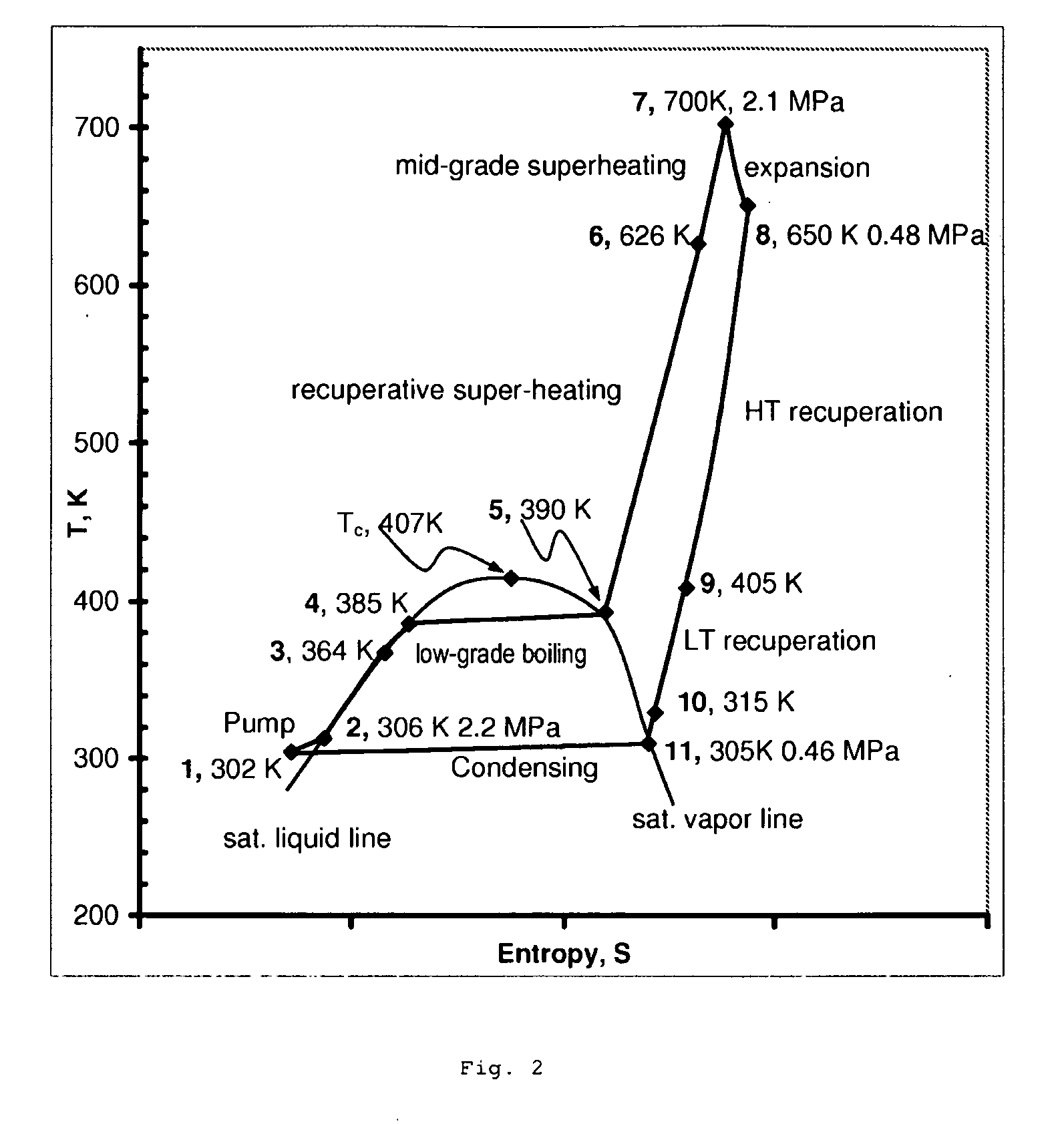

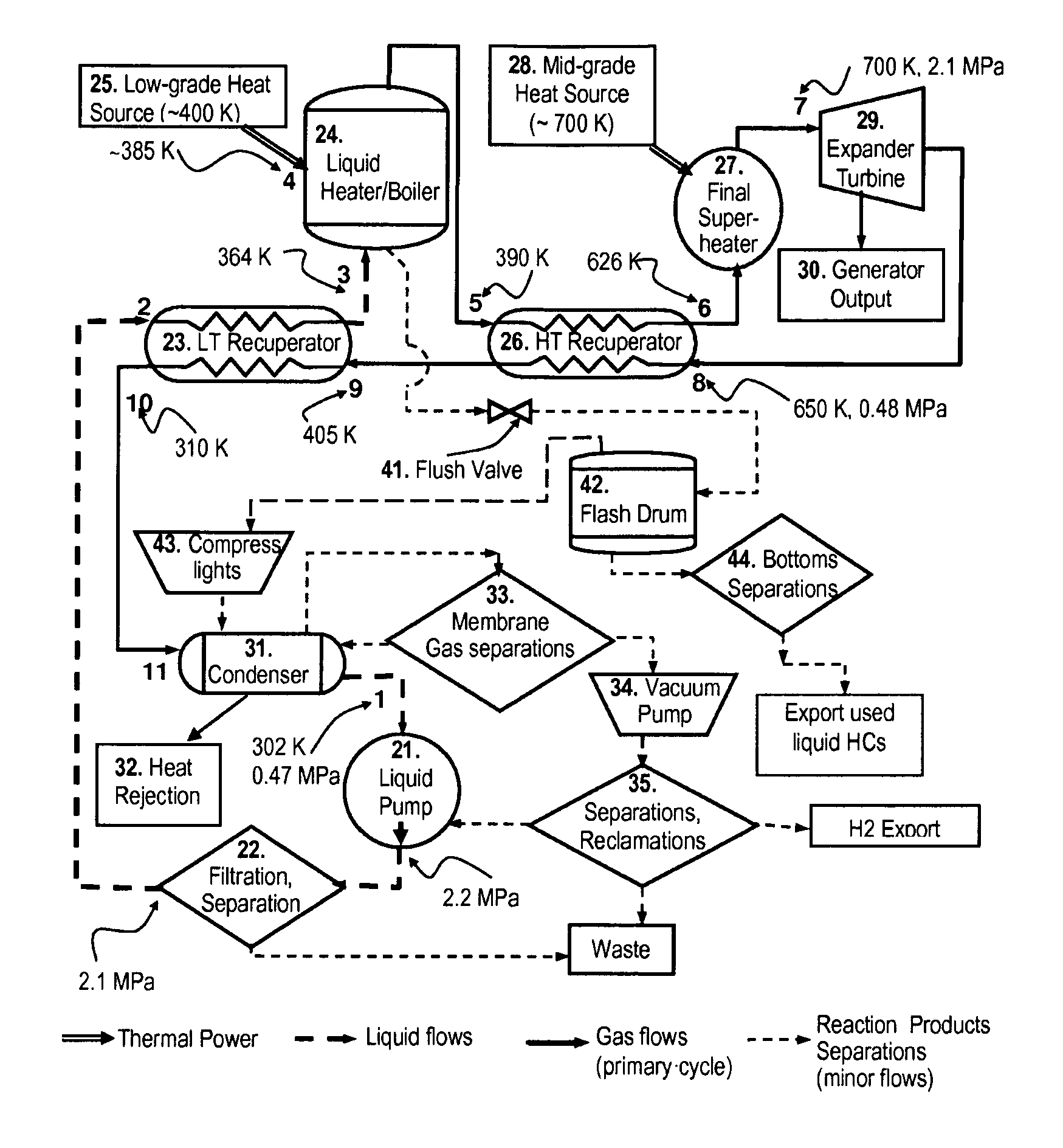

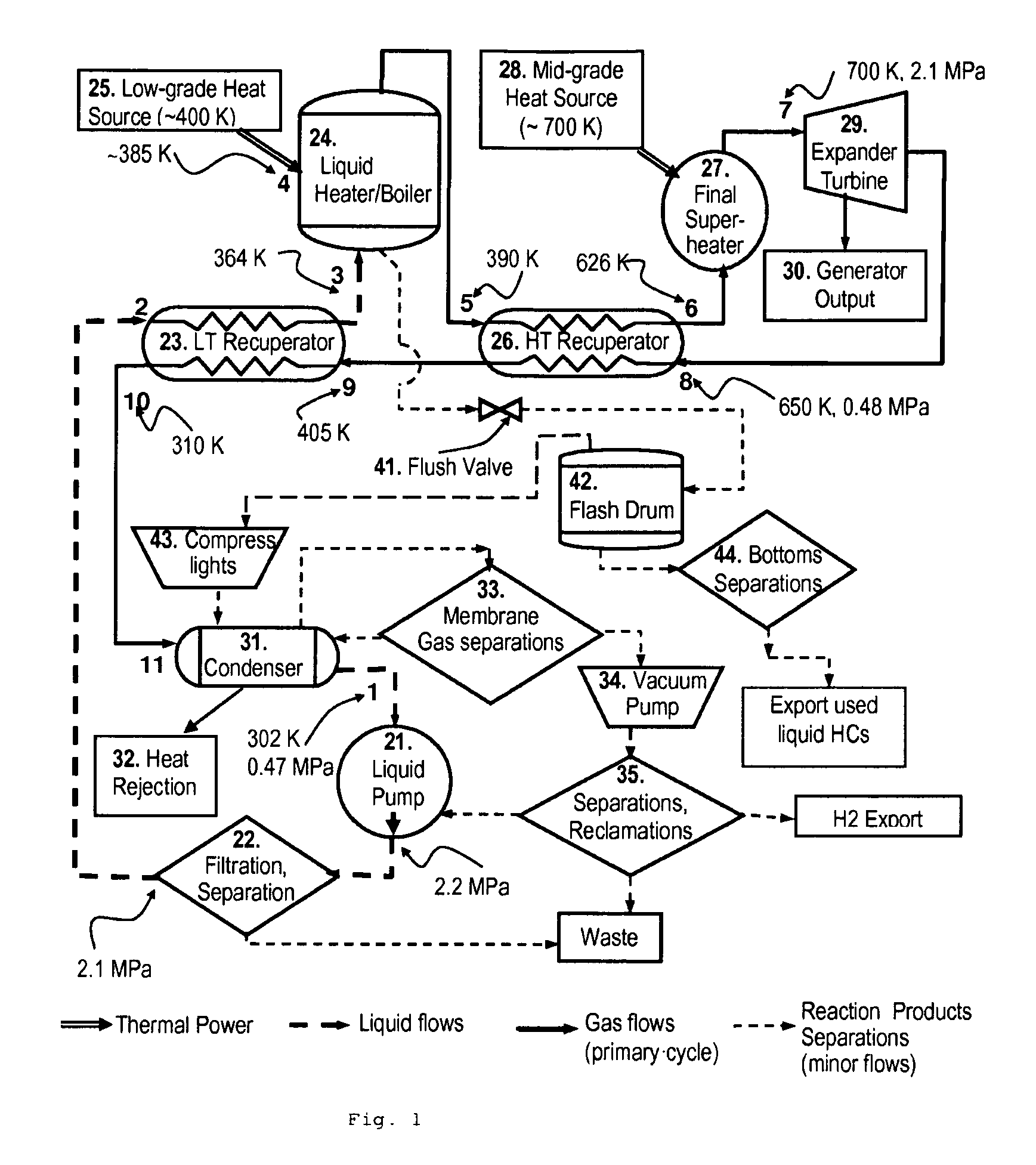

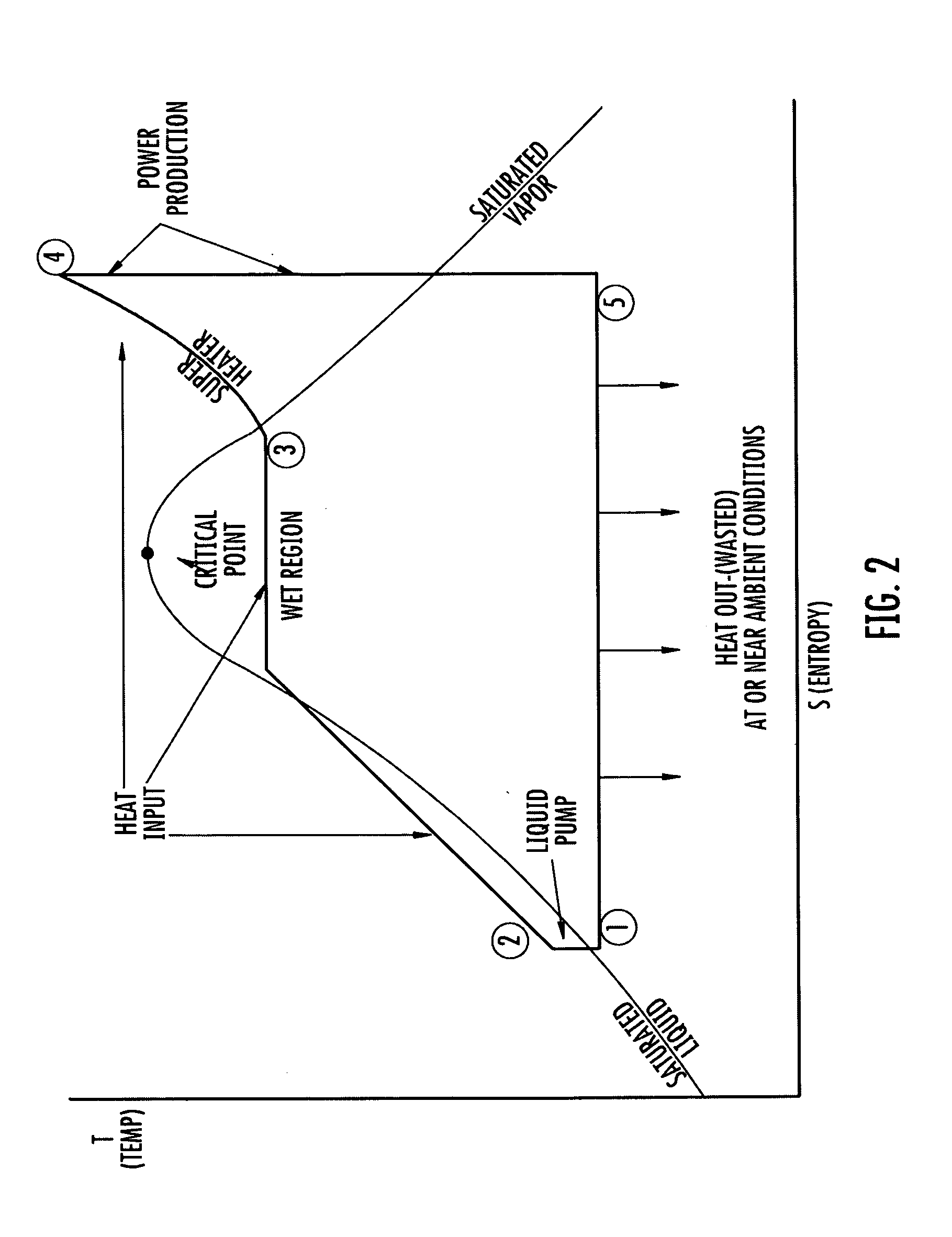

In a dual-source organic Rankine cycle (DORC), the condensed and slightly sub-cooled working fluid at near ambient temperature (˜300 K) and at low-side pressure (0.1 to 0.7 MPa) is (1) pumped to high-side pressure (0.5-5 MPa), (2) pre-heated in a low-temperature (LT) recuperator, (3) boiled using a low-grade heat source, (4) super-heated in a high-temperature (HT) recuperator to a temperature close to the expander turbine exhaust temperature using this exhaust vapor enthalpy, (5) further super-heated to the turbine inlet temperature (TIT) using a mid-grade heat source, (6) expanded through a turbine expander to the low-side pressure, (7) cooled through the HT recuperator, (8) cooled through the LT recuperator, (9) mostly liquefied and slightly subcooled in a condenser, and (10) the condensed portion is returned to the pump to repeat this cycle.

Owner:DOTY SCI

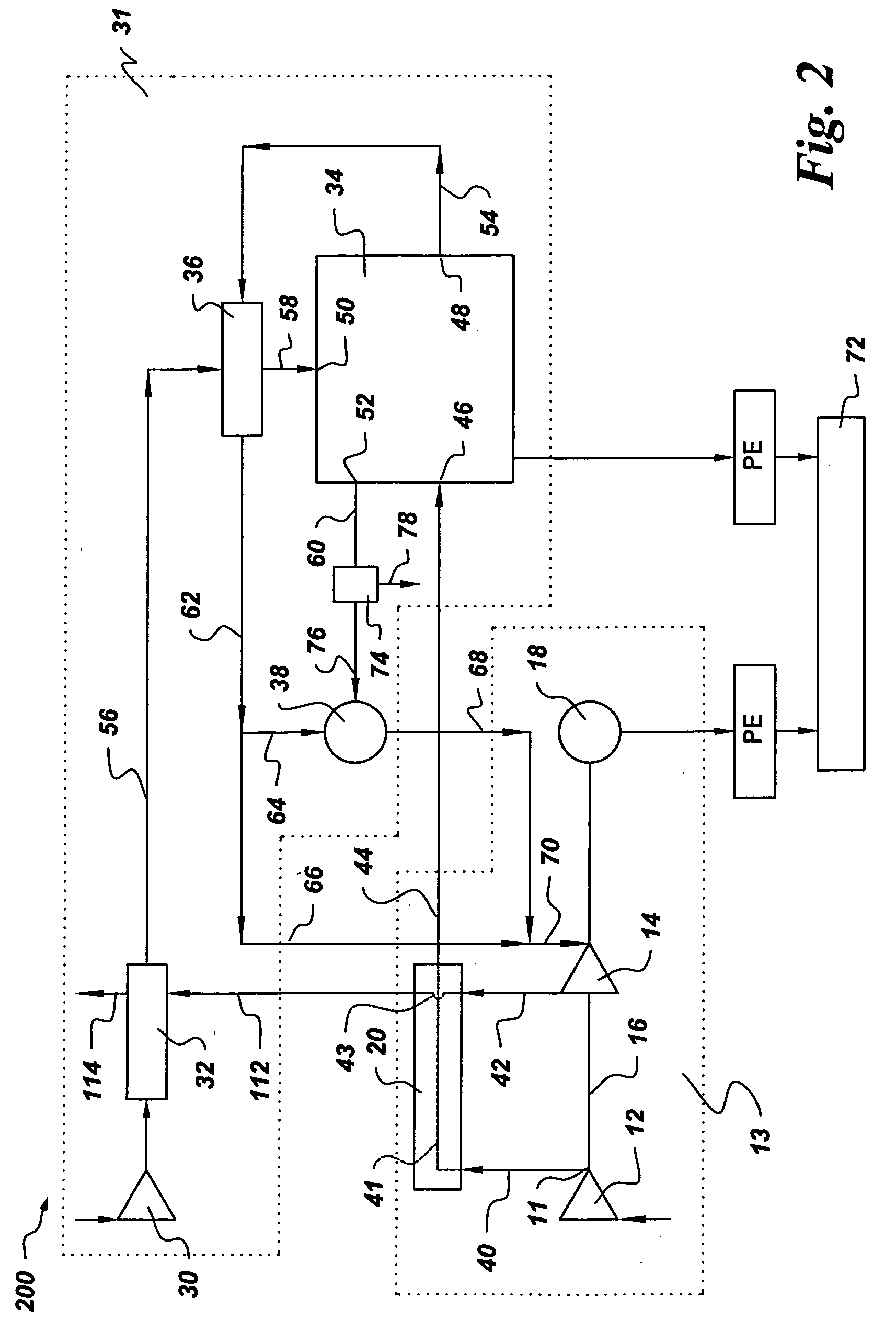

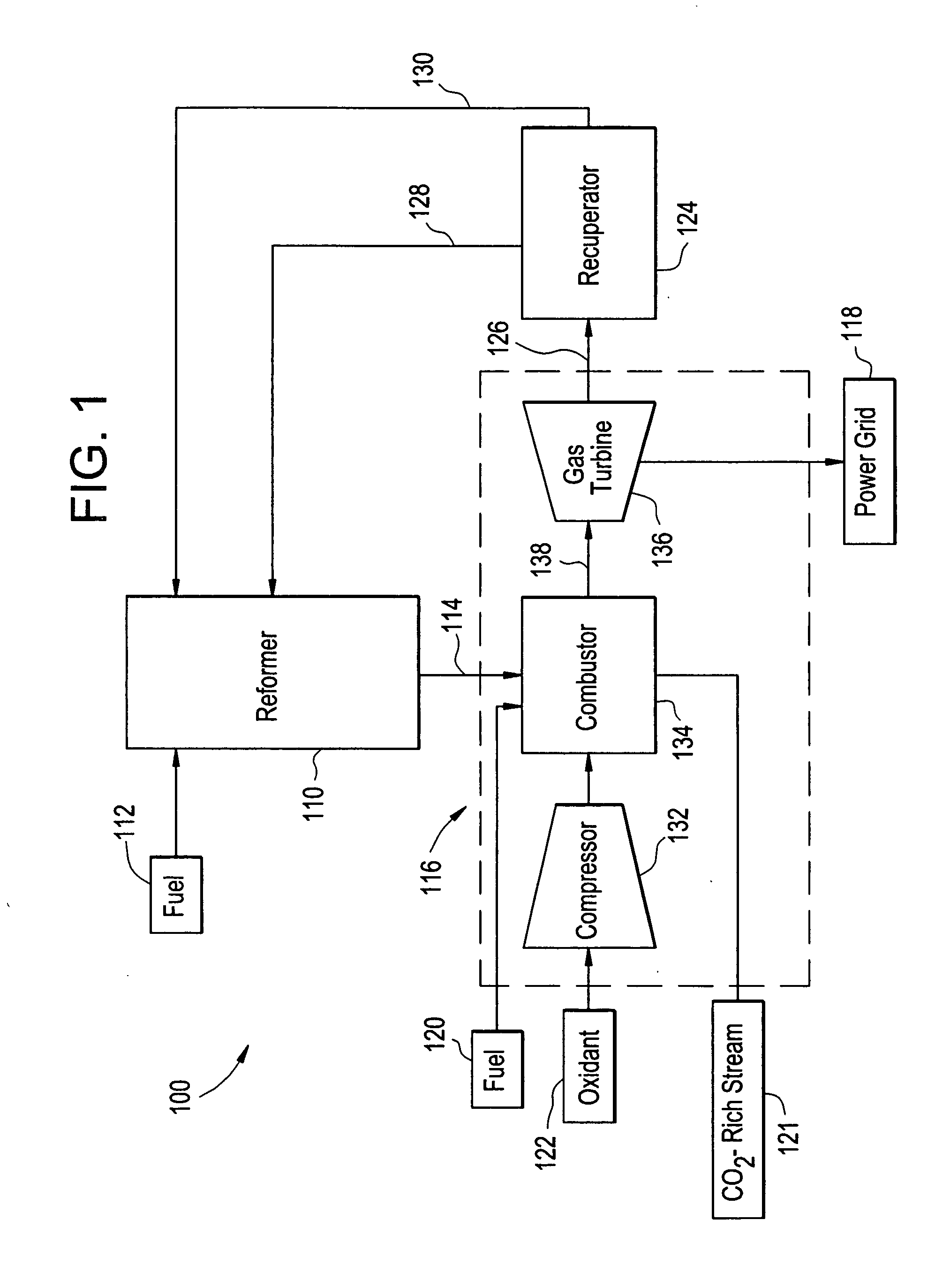

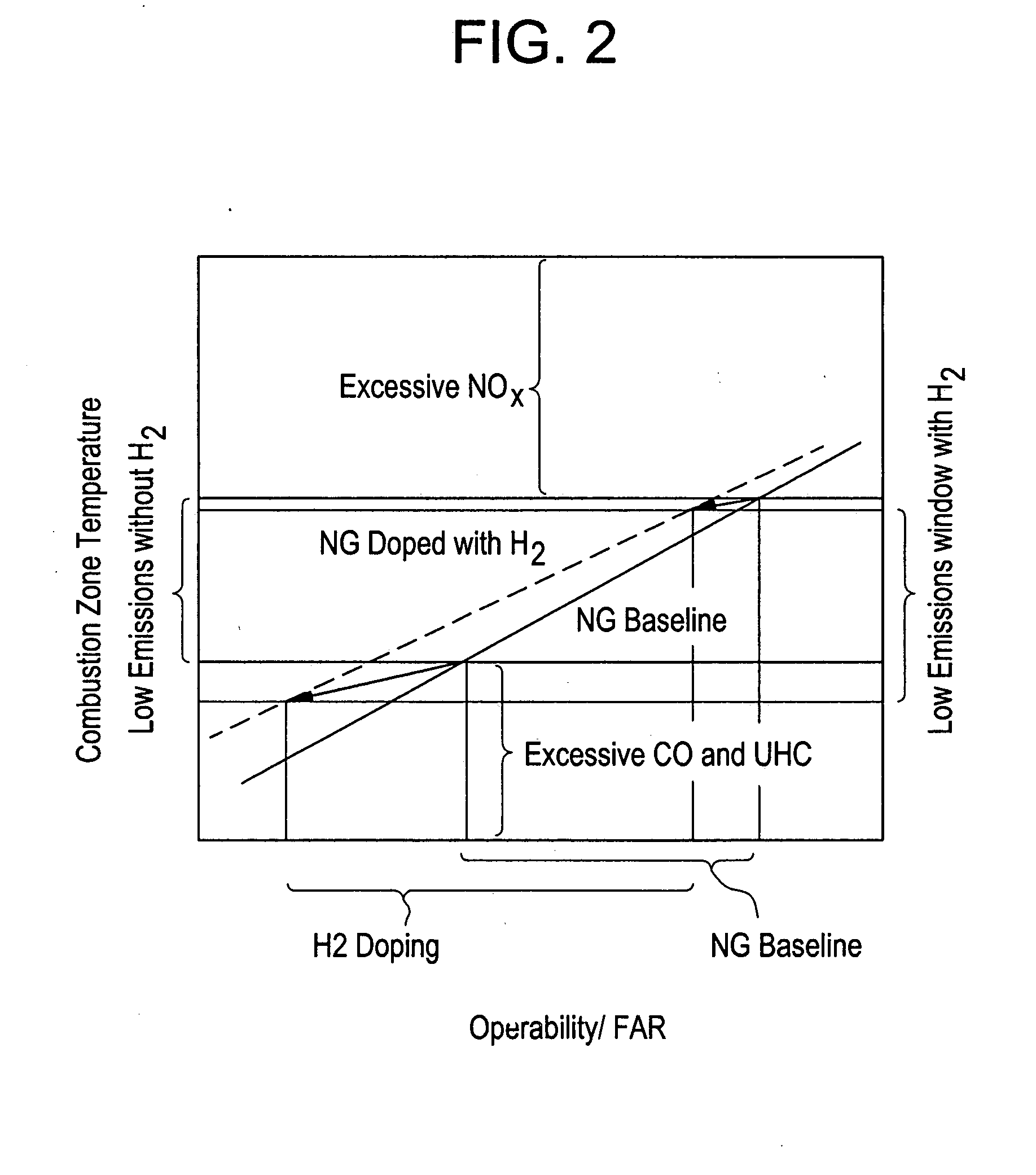

Systems and processes for reducing NOx emissions

A system for reducing NOx emissions, includes a reformer configured to receive a fuel and produce a hydrogen-enriched stream, a combustion system configured to burn the hydrogen enriched-stream and produce electricity and an exhaust stream, and a recuperator configured to recover heat from the exhaust stream, wherein the recovered heat is recycled back to the reformer.

Owner:GENERAL ELECTRIC CO

High-temperature dual-source organic Rankine cycle with gas separations

InactiveUS8046999B2Increase temperatureMinimize timeAuxillary drivesFrom solar energyWorking fluidOrganic Rankine cycle

In a dual-source organic Rankine cycle (DORC), the condensed and slightly sub-cooled working fluid at near ambient temperature (˜300 K) and at low-side pressure (0.1 to 0.7 MPa) is (1) pumped to high-side pressure (0.5-5 MPa), (2) pre-heated in a low-temperature (LT) recuperator, (3) boiled using a low-grade heat source, (4) super-heated in a high-temperature (HT) recuperator to a temperature close to the expander turbine exhaust temperature using this exhaust vapor enthalpy, (5) further super-heated to the turbine inlet temperature (TIT) using a mid-grade heat source, (6) expanded through a turbine expander to the low-side pressure, (7) cooled through the HT recuperator, (8) cooled through the LT recuperator, (9) mostly liquefied and slightly subcooled in a condenser, and (10) the condensed portion is returned to the pump to repeat this cycle.

Owner:DOTY SCI

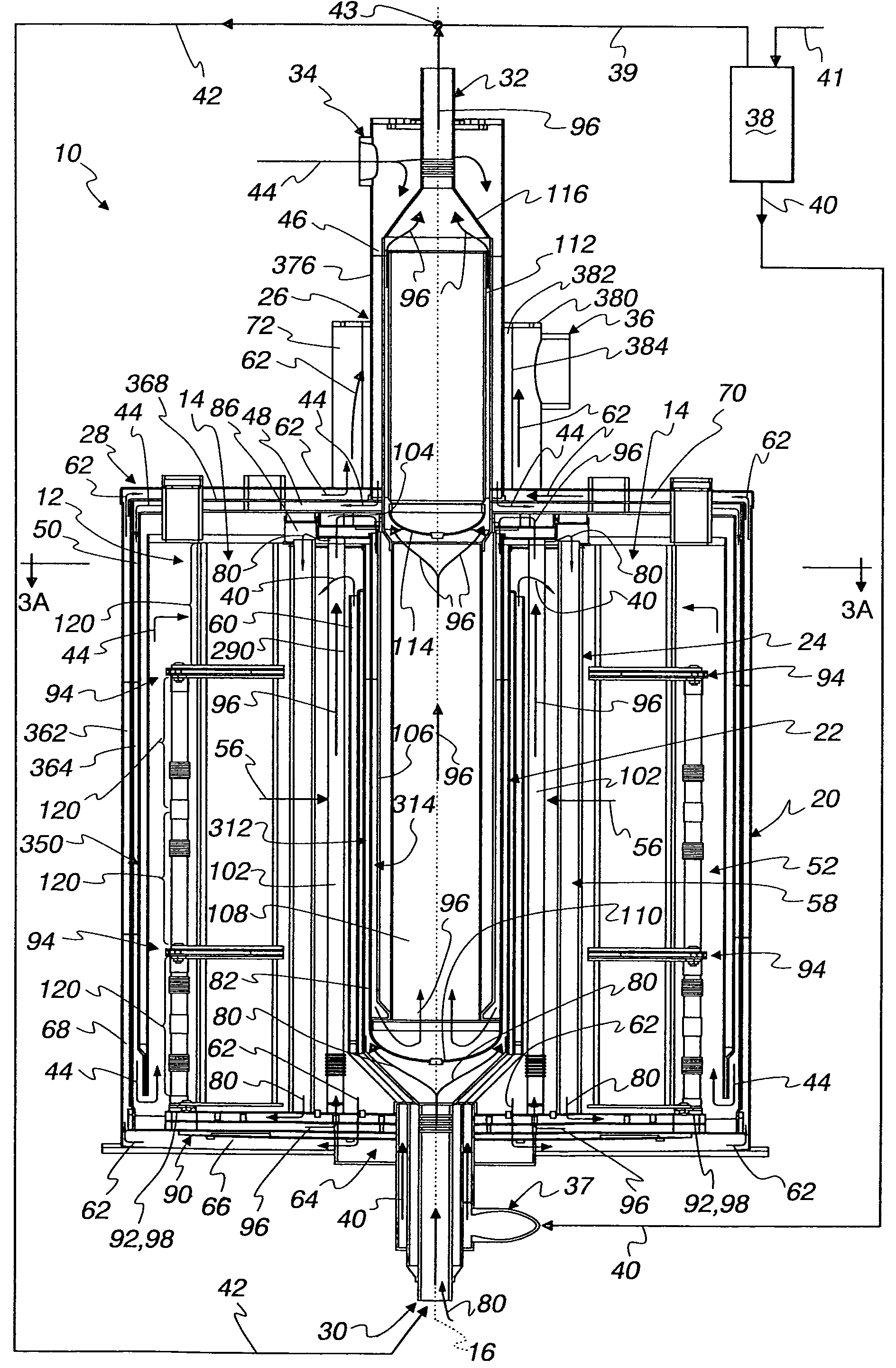

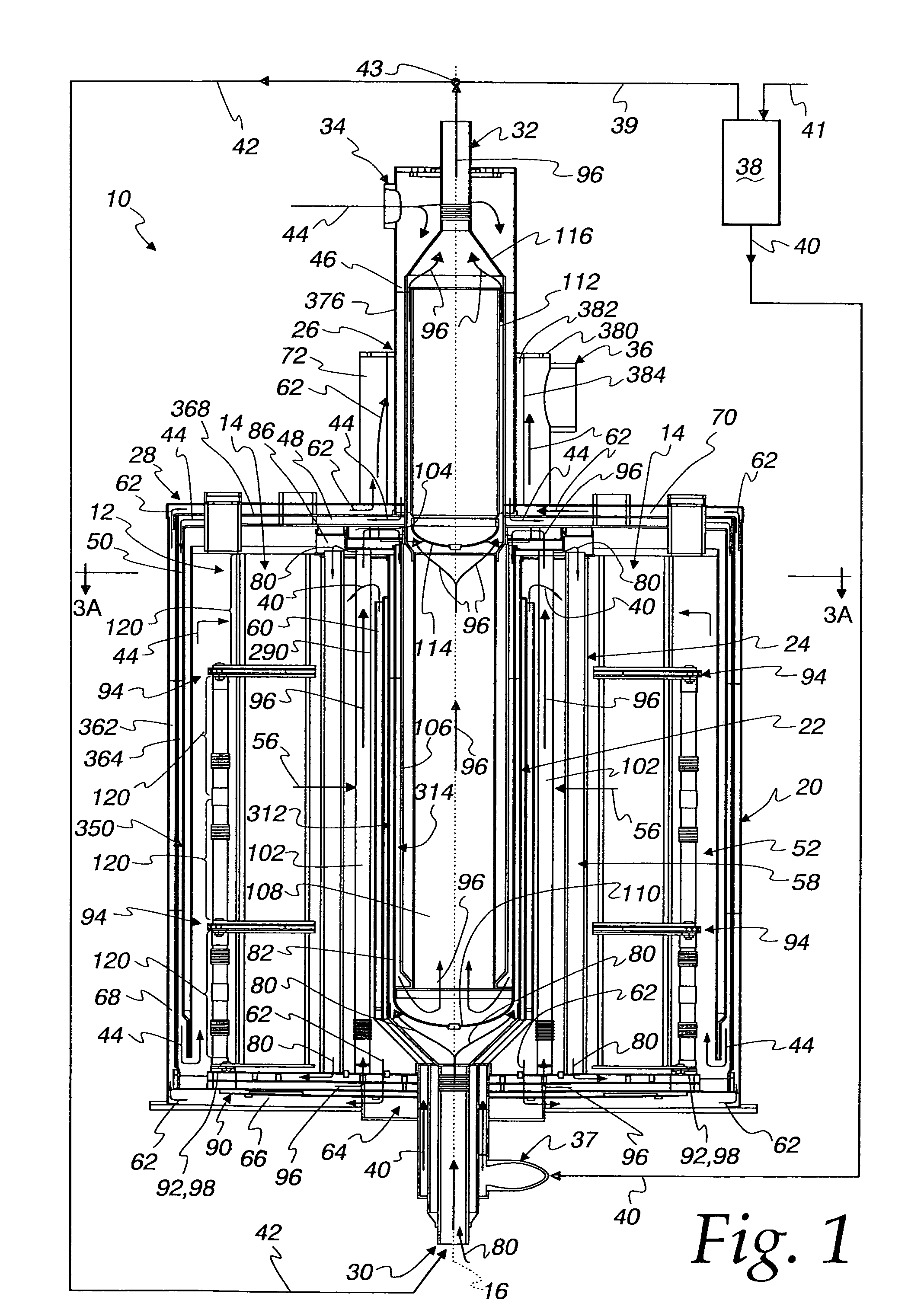

Integrated solid oxide fuel cell and fuel processor

An integrated fuel cell unit (10) includes an annular array (12) of fuel cell stacks (14), an annular cathode recuperator (20), an annular anode recuperator (22), a reformer (24), and an anode exhaust cooler (26), all integrated within a common housing structure (28).

Owner:MODINE MFG CO

Heat Engine System

InactiveUS20100287934A1Increase temperatureImprove heat transfer performanceHeat storage plantsSteam useEnergy transferWorking fluid

A heat engine system for producing work by expanding a working fluid comprising first and second components, the system comprising, an apparatus for combining the second component of the working fluid as a liquid with the first component, the first component being a gas throughout the system, a compressor for compressing the first component, a pump for compressing at least most of the second component, a heater for heating the first and second components, an expander for expanding the first and second components to produce the work, and a recuperator for transferring at least some of the energy of the working fluid from the outlet of the expander, to the working fluid from the outlet of the apparatus, wherein a substantial portion of the energy transferred in the recuperator is at least a portion of the latent heat of the second component from the outlet of the expander.

Owner:COMMONWEALTH SCI & IND RES ORG +1

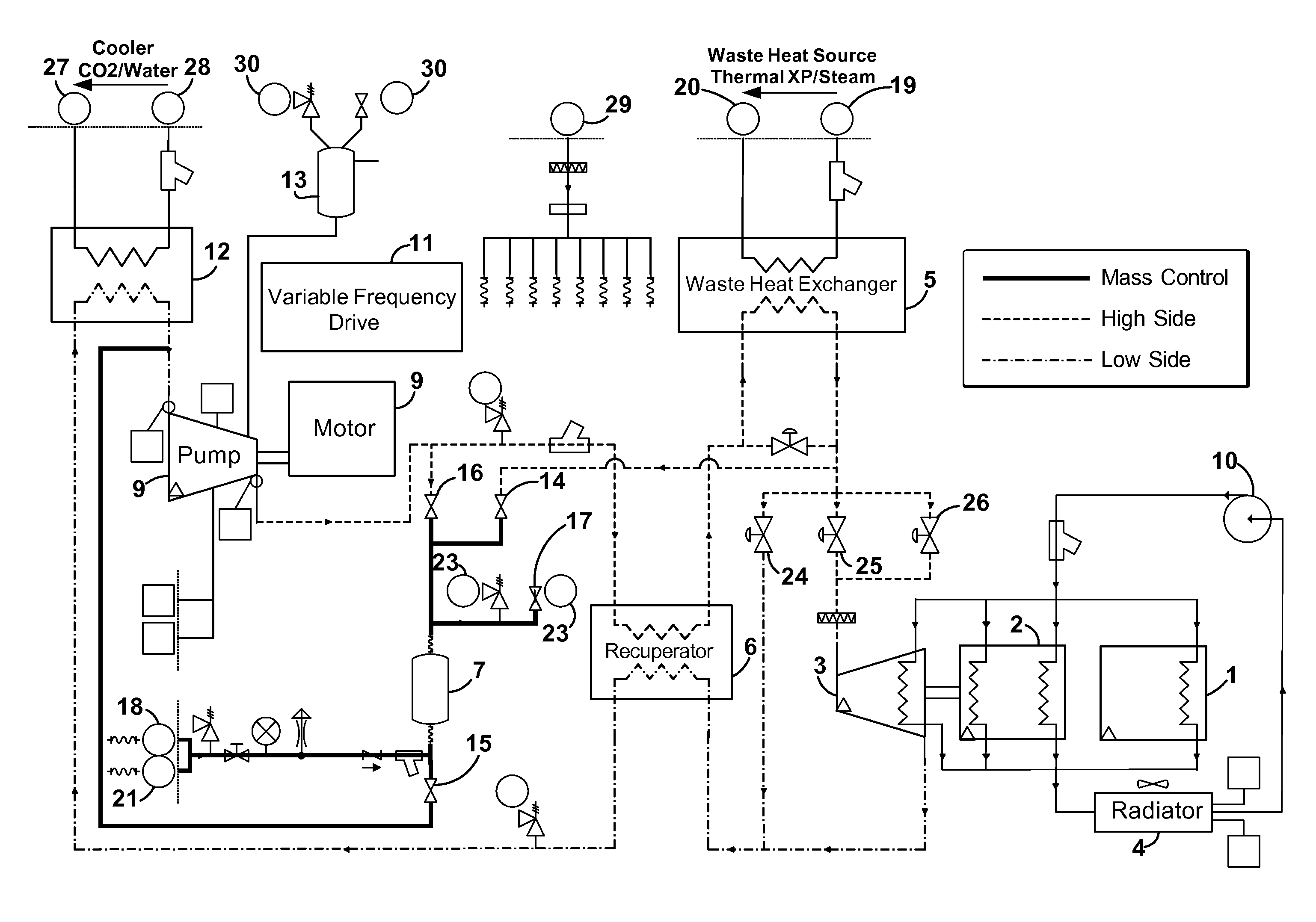

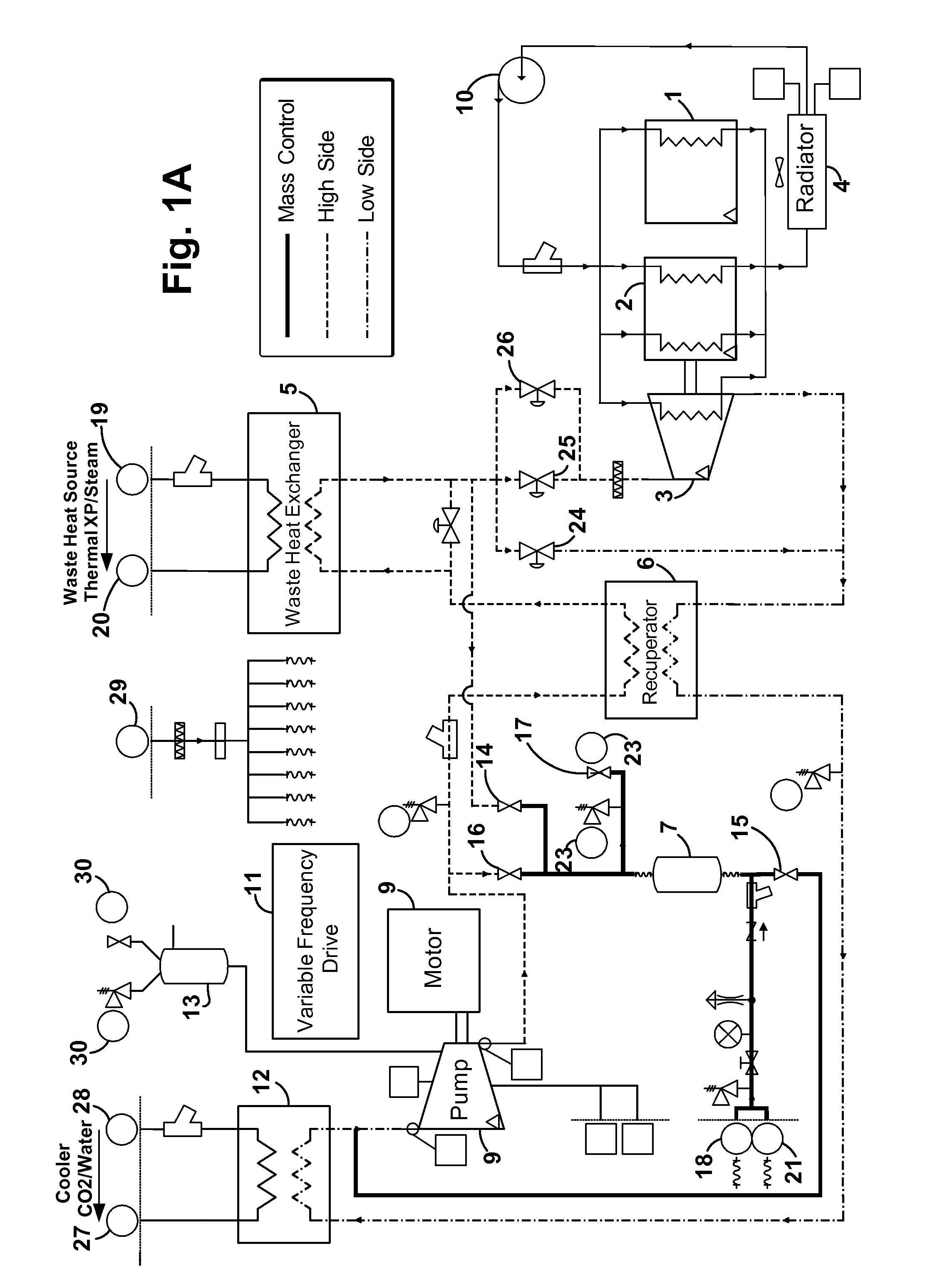

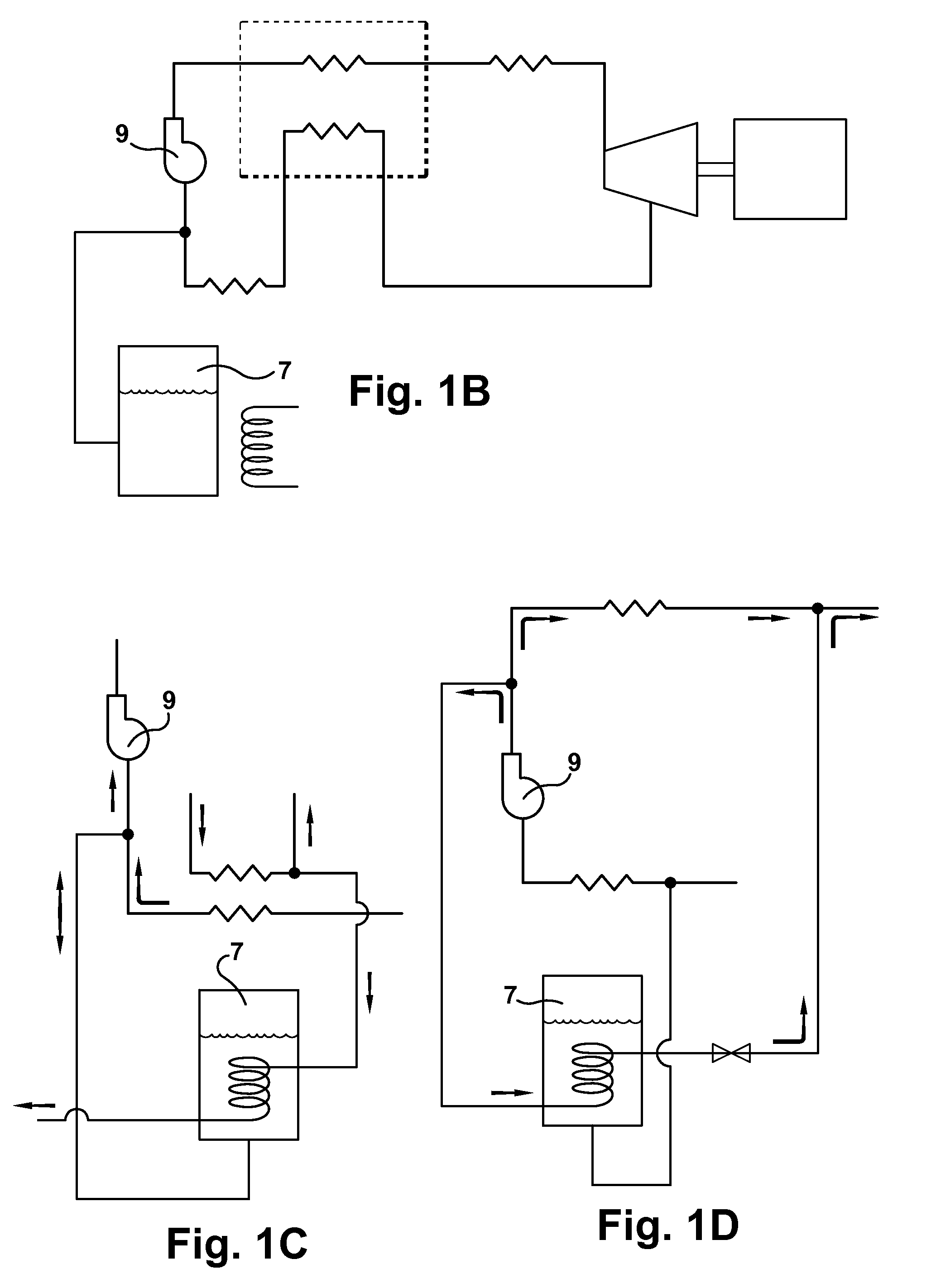

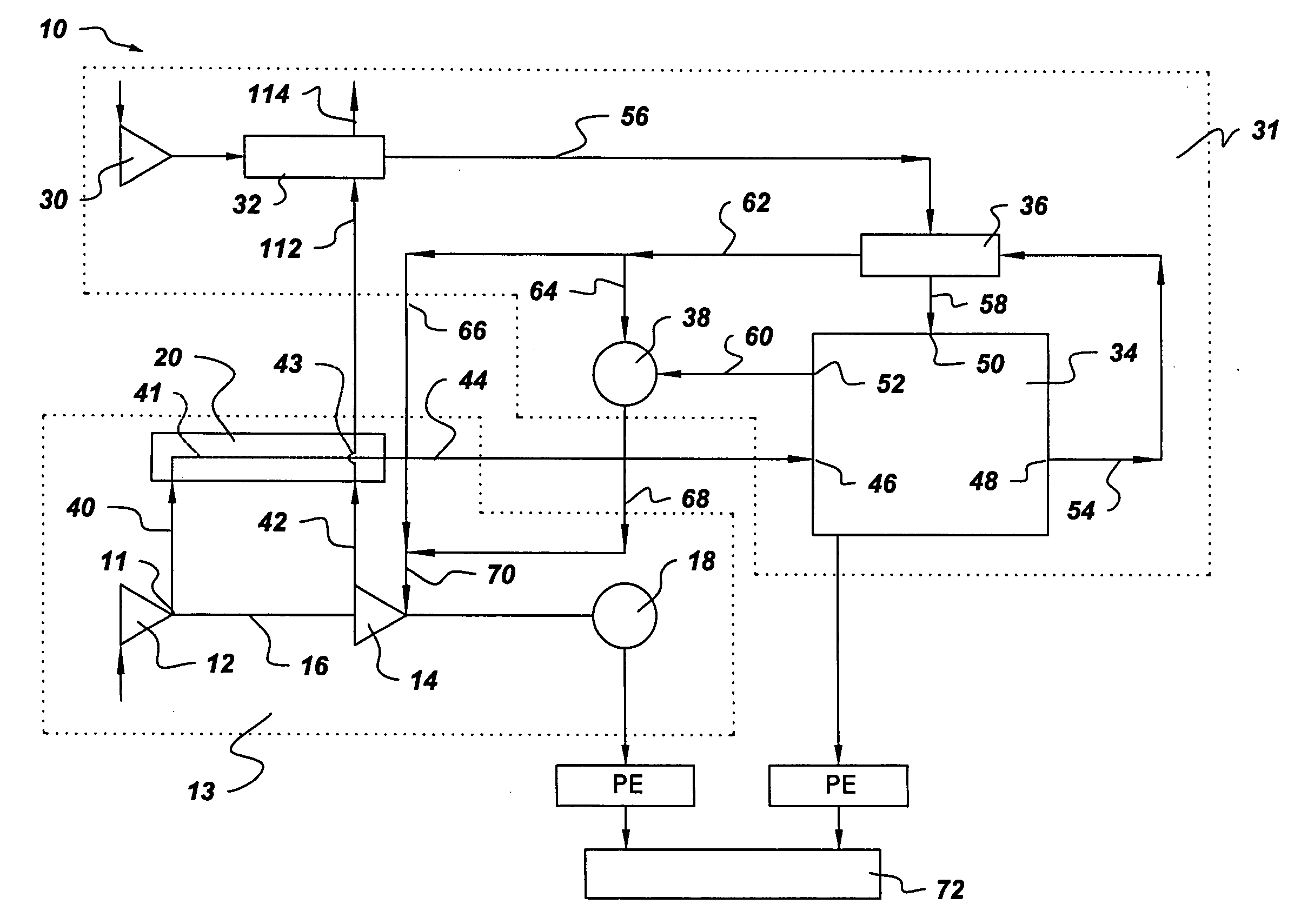

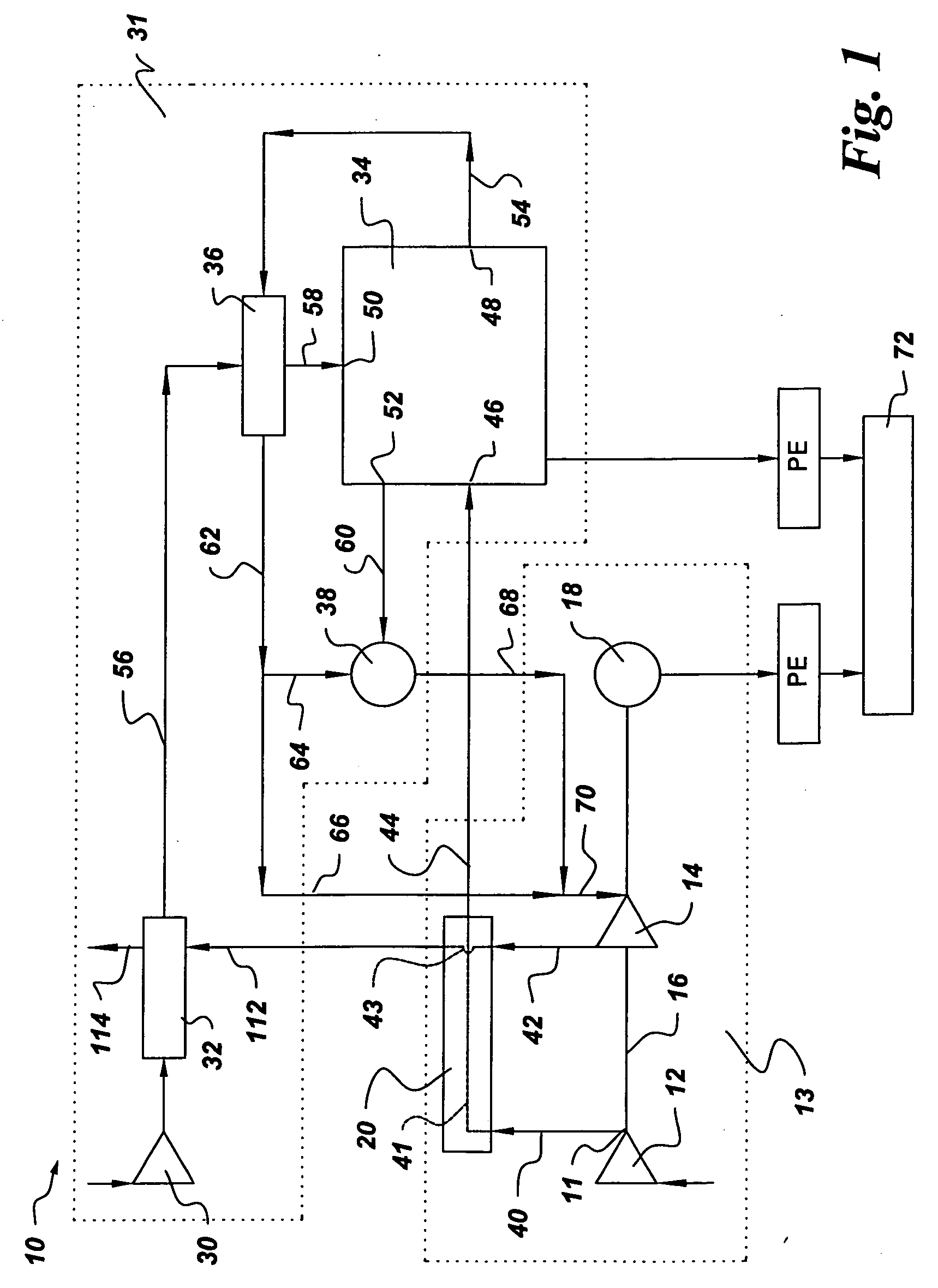

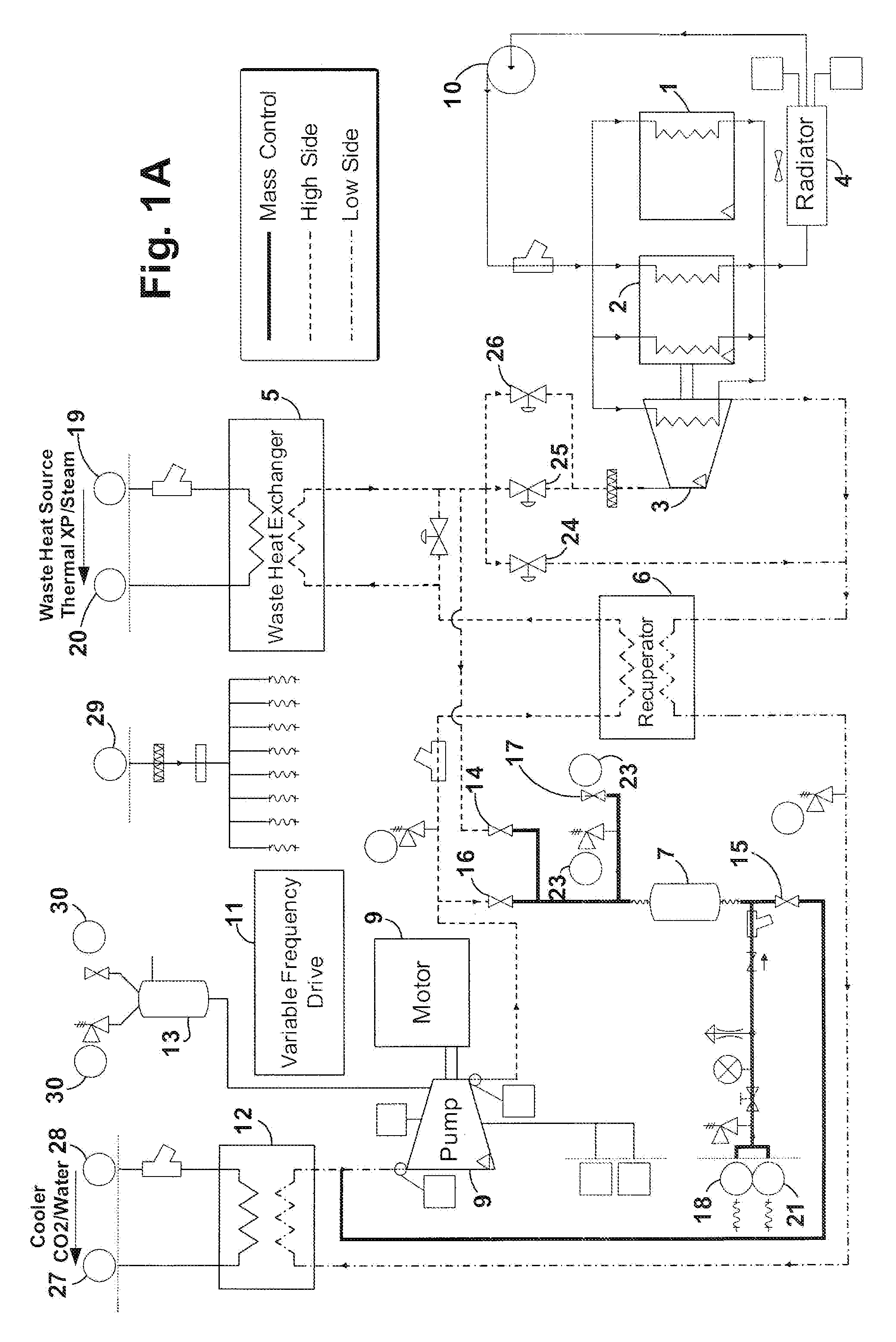

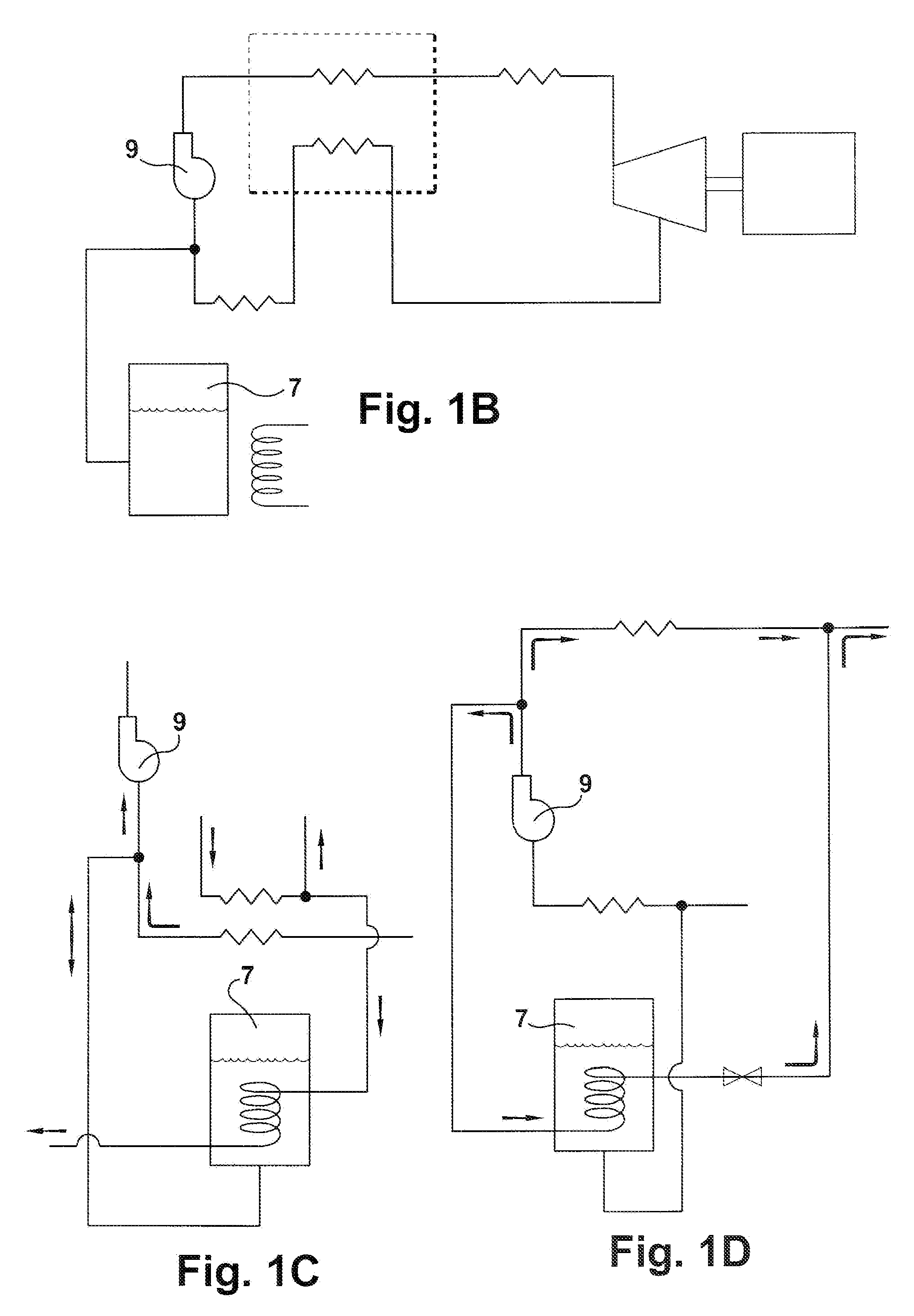

Heat engine and heat to electricity systems and methods

ActiveUS20100156112A1Efficiently and effectively produce powerFluid heatersInternal combustion piston enginesThermal energyWorking fluid

A waste heat recovery system, method and device executes a thermodynamic cycle using a working fluid in a working fluid circuit which has a high pressure side and a low pressure side. Components of the system in the working fluid circuit include a waste heat exchanger in thermal communication with a waste heat source also connected to the working fluid circuit, whereby thermal energy is transferred from the waste heat source to the working fluid in the working fluid circuit, an expander located between the high pressure side and the low pressure side of the working fluid circuit, the expander operative to convert a pressure / enthalpy drop in the working fluid to mechanical energy, a recuperator in the working fluid circuit operative to transfer thermal energy between the high pressure side and the low pressure side of the working fluid circuit, a cooler in thermal communication with the low pressure side of the working fluid circuit operative to control temperature of the working fluid in the low side of the working fluid circuit, a pump in the working fluid circuit and connected to the low pressure side and to the high pressure side of the working fluid circuit and operative to move the working fluid through the working fluid circuit, and a mass management system connected to the working fluid circuit, the mass management system, method and device having a working fluid vessel connected to the low pressure side of the working fluid circuit and configured to passively control an amount of working fluid mass in the working fluid circuit.

Owner:REXORCE THERMIONICS INC +1

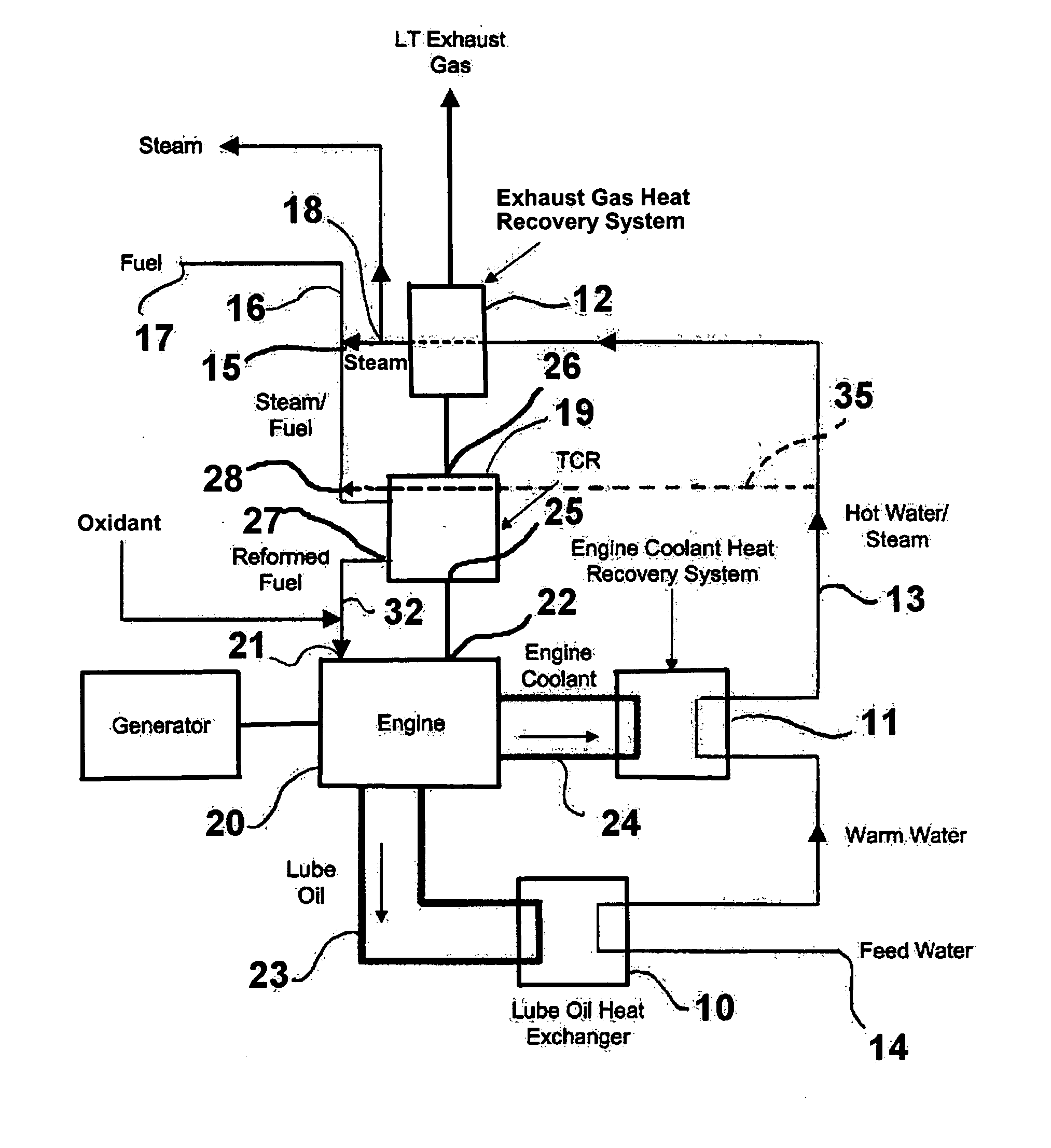

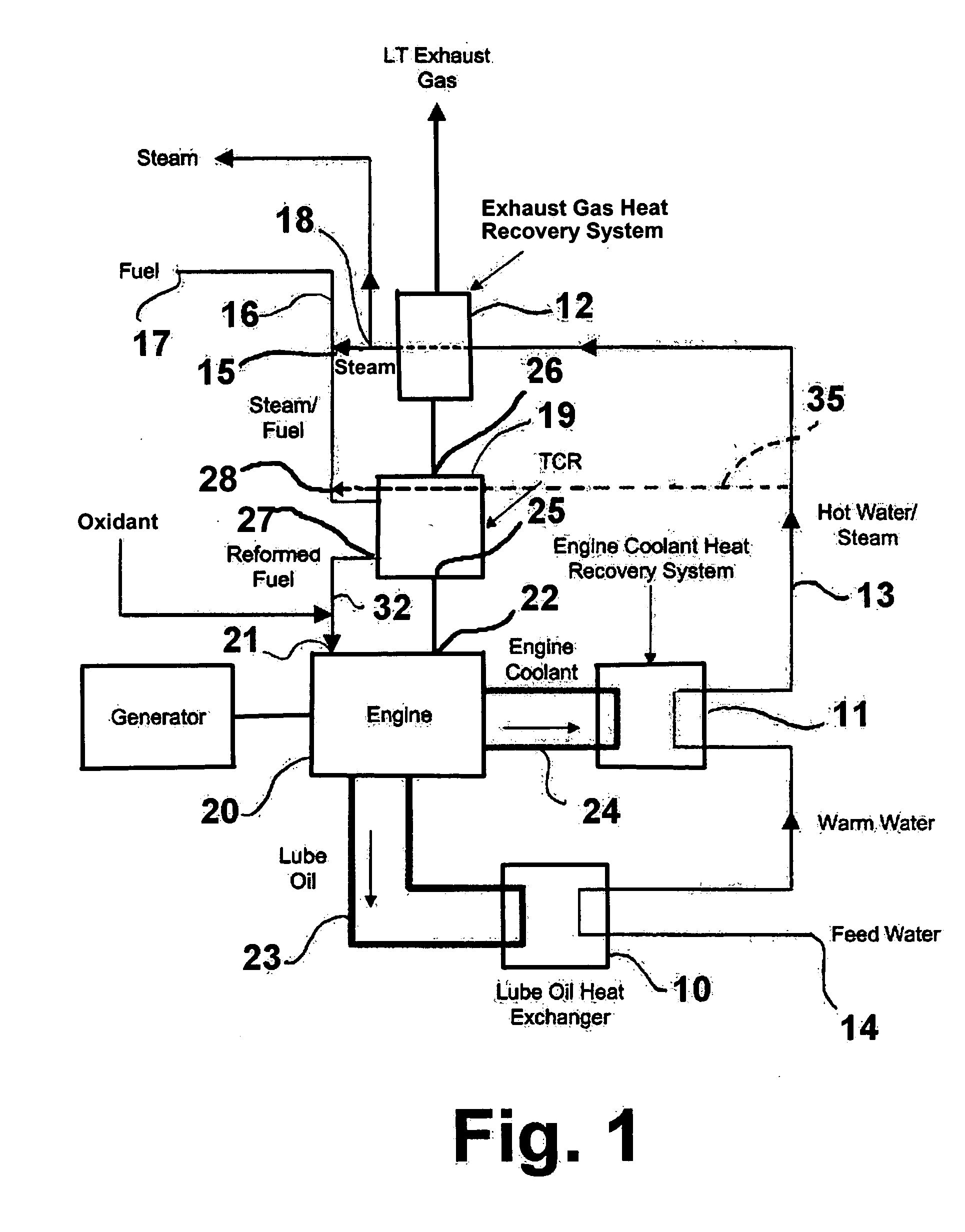

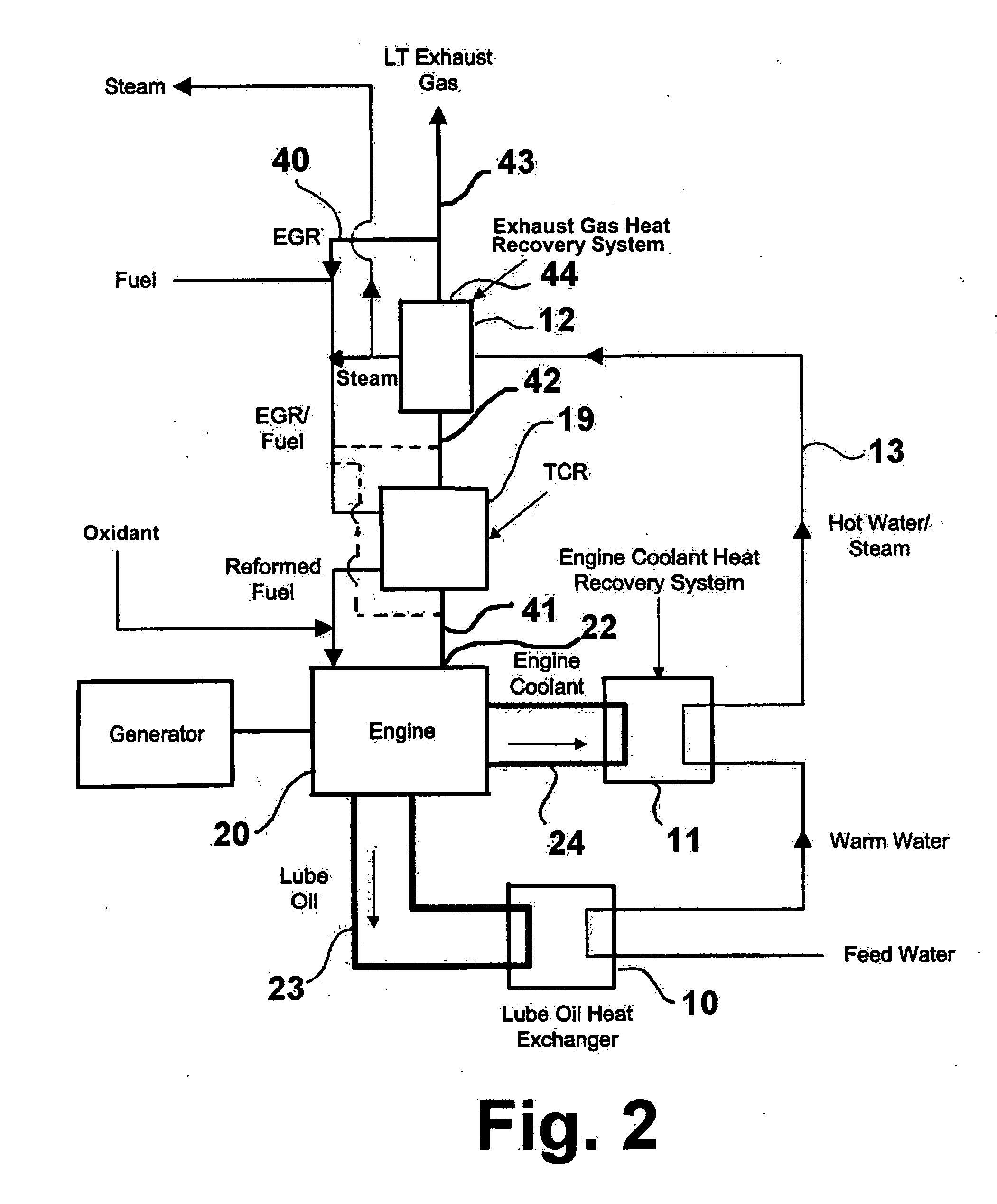

Advanced high efficiency, ultra-low emission, thermochemically recuperated reciprocating internal combustion engine

ActiveUS20050279333A1Improve engine efficiencyIncreases engine combustion efficiencyInternal combustion piston enginesExhaust apparatusEngineeringRecuperator

An apparatus including a reciprocating internal combustion engine and a thermochemical recuperator in which a fuel is reformed. The thermochemical recuperator is heated by exhaust gases from the reciprocating internal combustion engine and steam for the reforming process is produced by passing feed water through an engine lubricating oil heat exchanger, an engine cooling system heat recovery system and an exhaust gas heat recovery system arranged in series.

Owner:GAS TECH INST

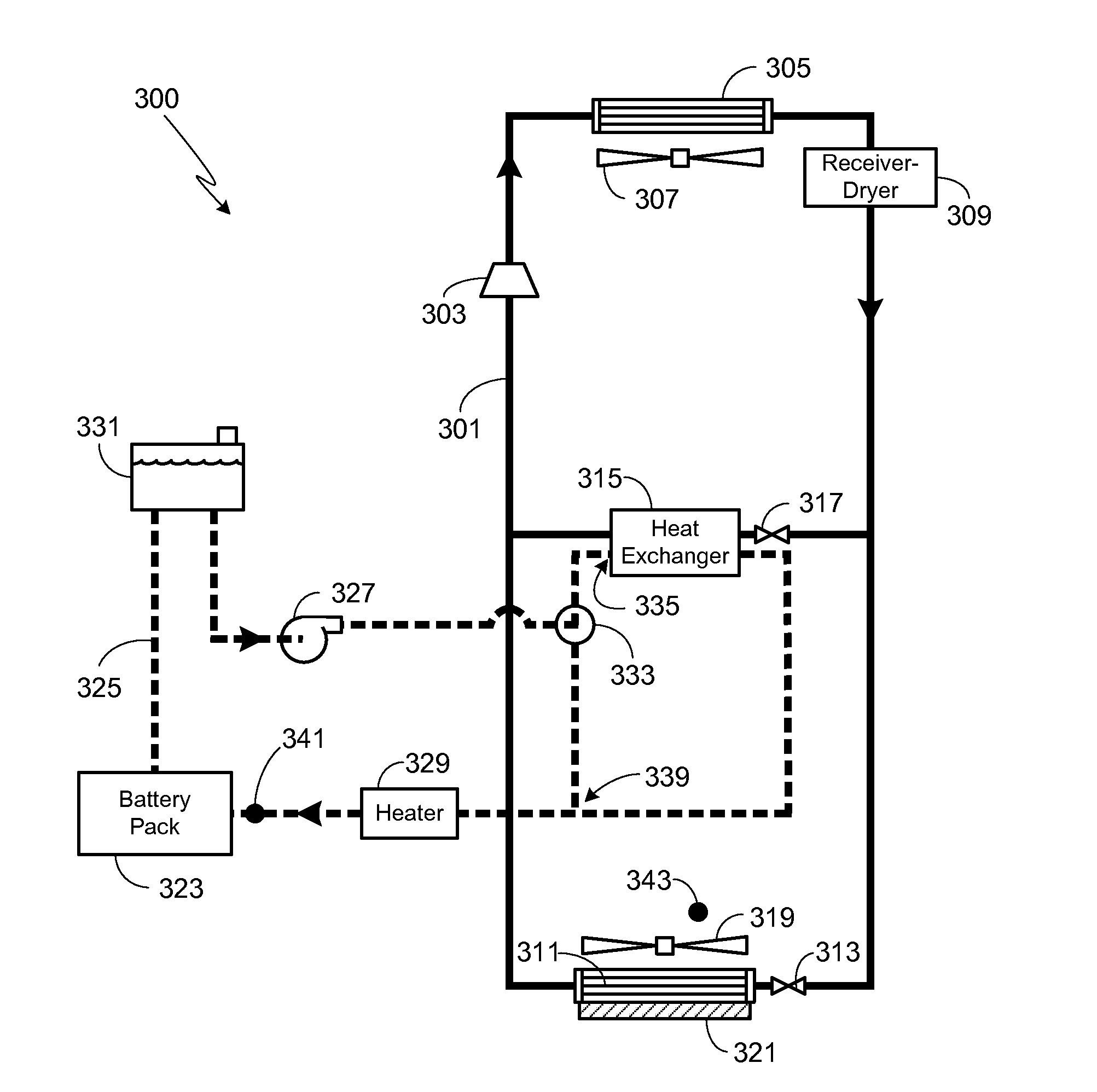

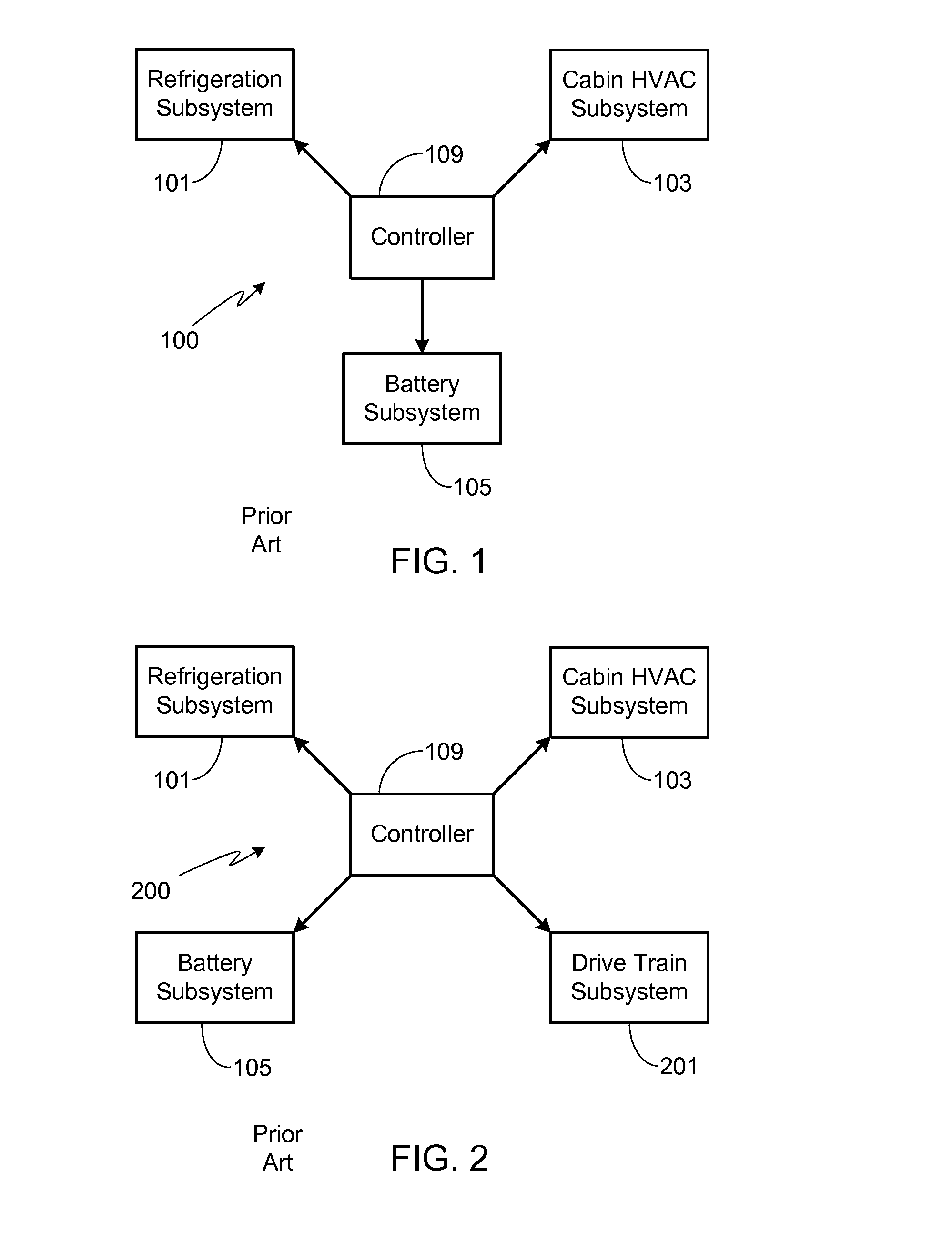

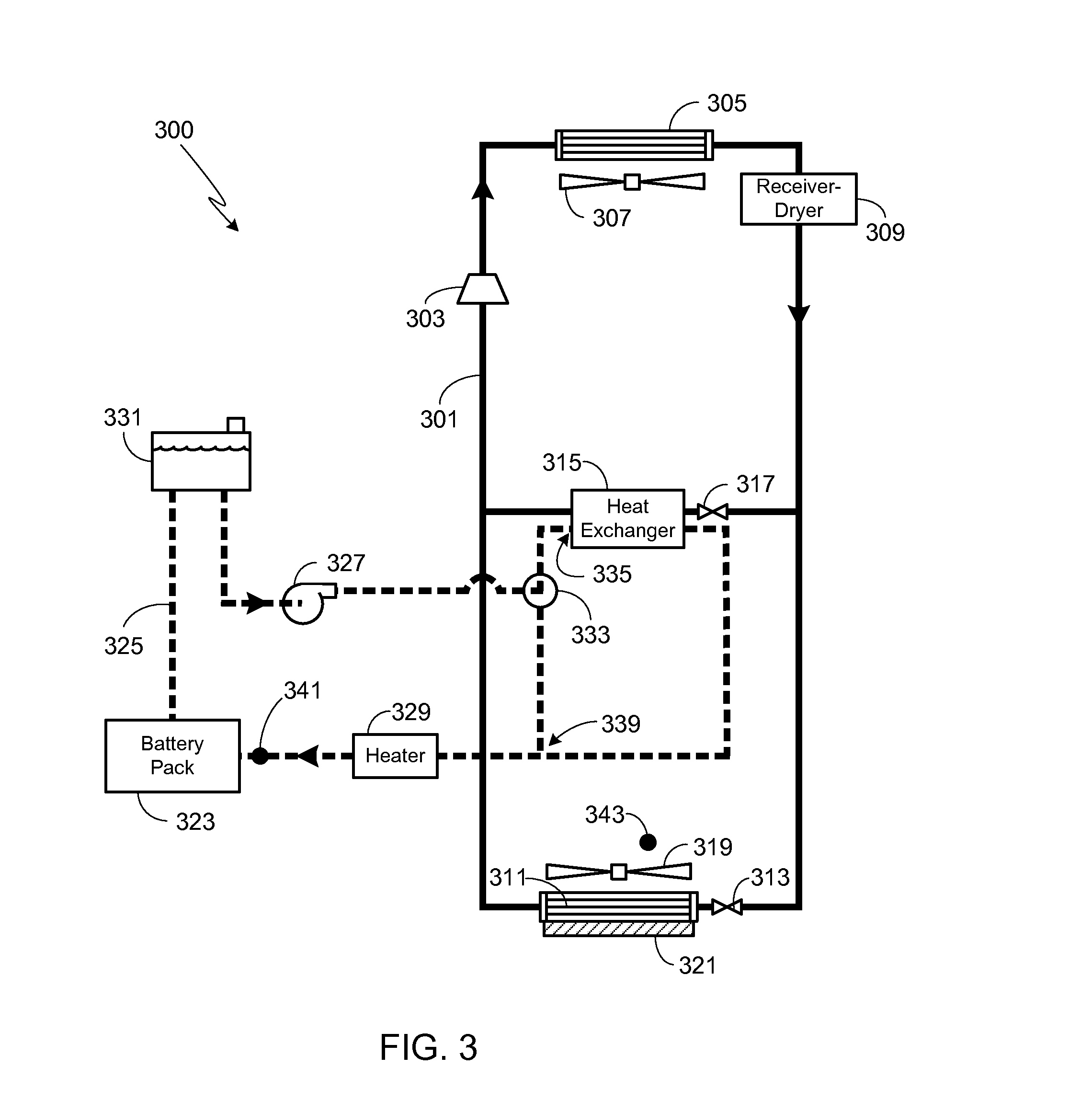

Thermal Management System with Heat Exchanger Blending Valve

ActiveUS20130074525A1Domestic cooling apparatusVehicle heating/cooling devicesNuclear engineeringThermal management system

A thermal management system and method of use are provided, the system including a heat exchanger, a refrigeration system, a coolant loop thermally coupled to the heat exchanger, and a by-pass valve that regulates the amount of coolant within the coolant loop that either passes through the heat exchanger or is diverted away from the heat exchanger. The coolant loop is thermally coupled to the battery pack of an electric vehicle.

Owner:TESLA INC

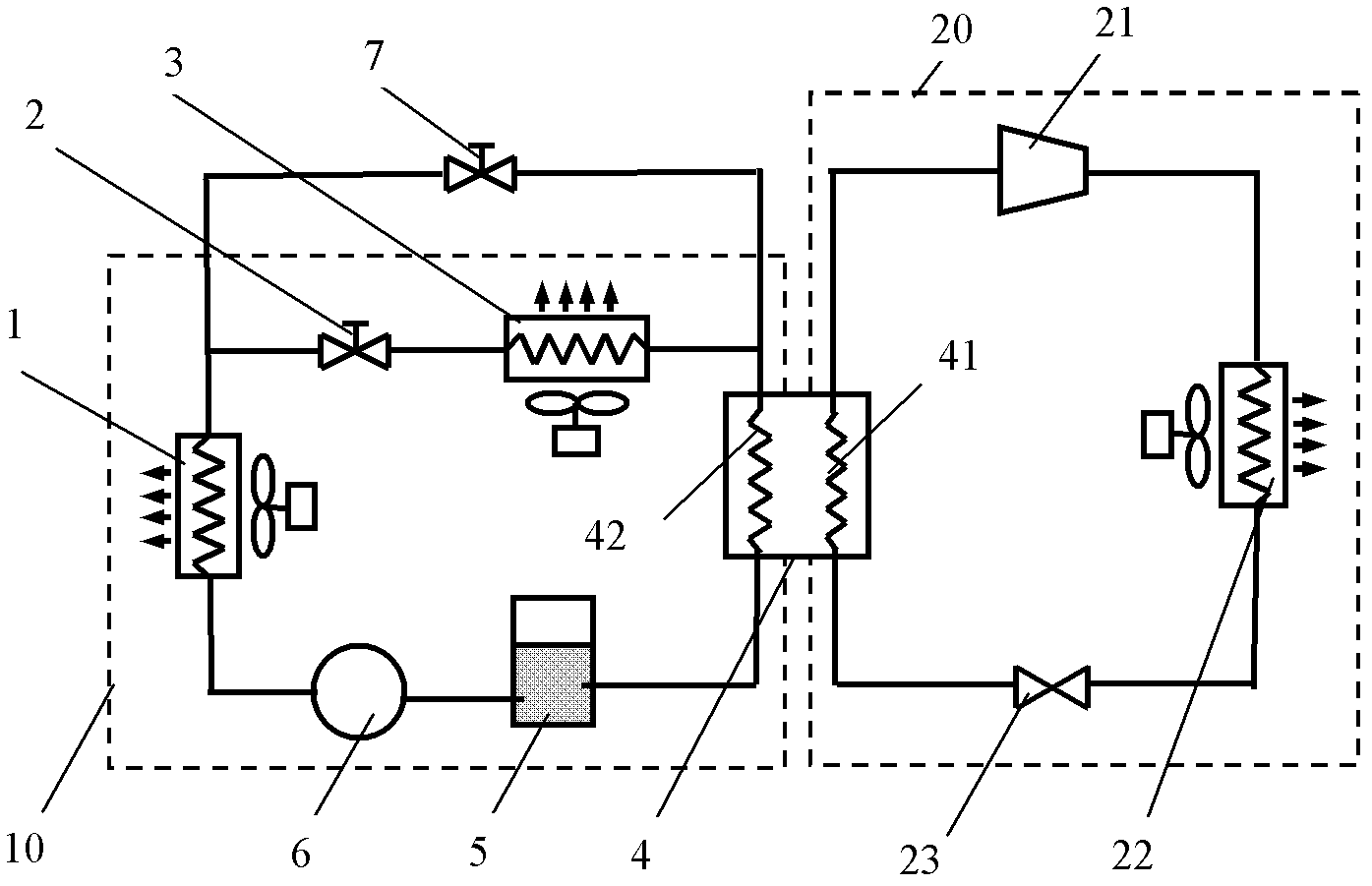

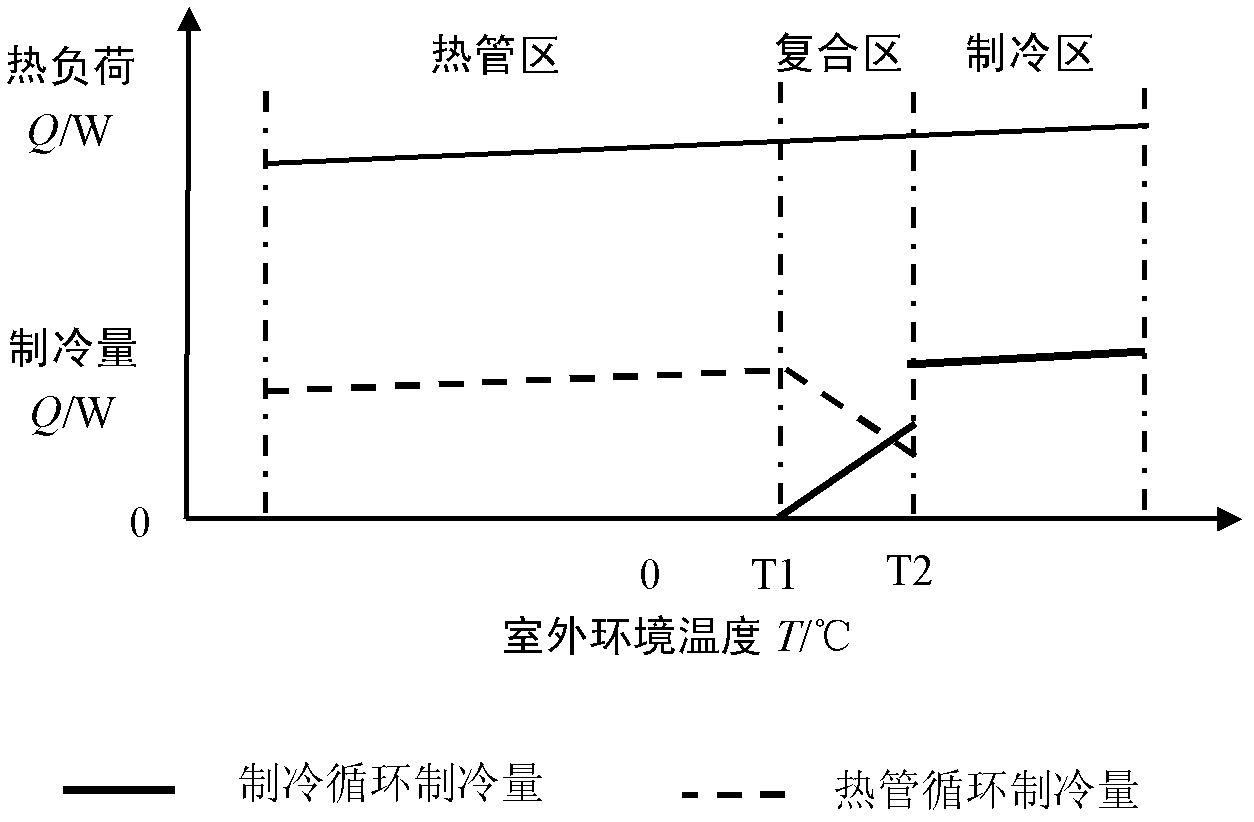

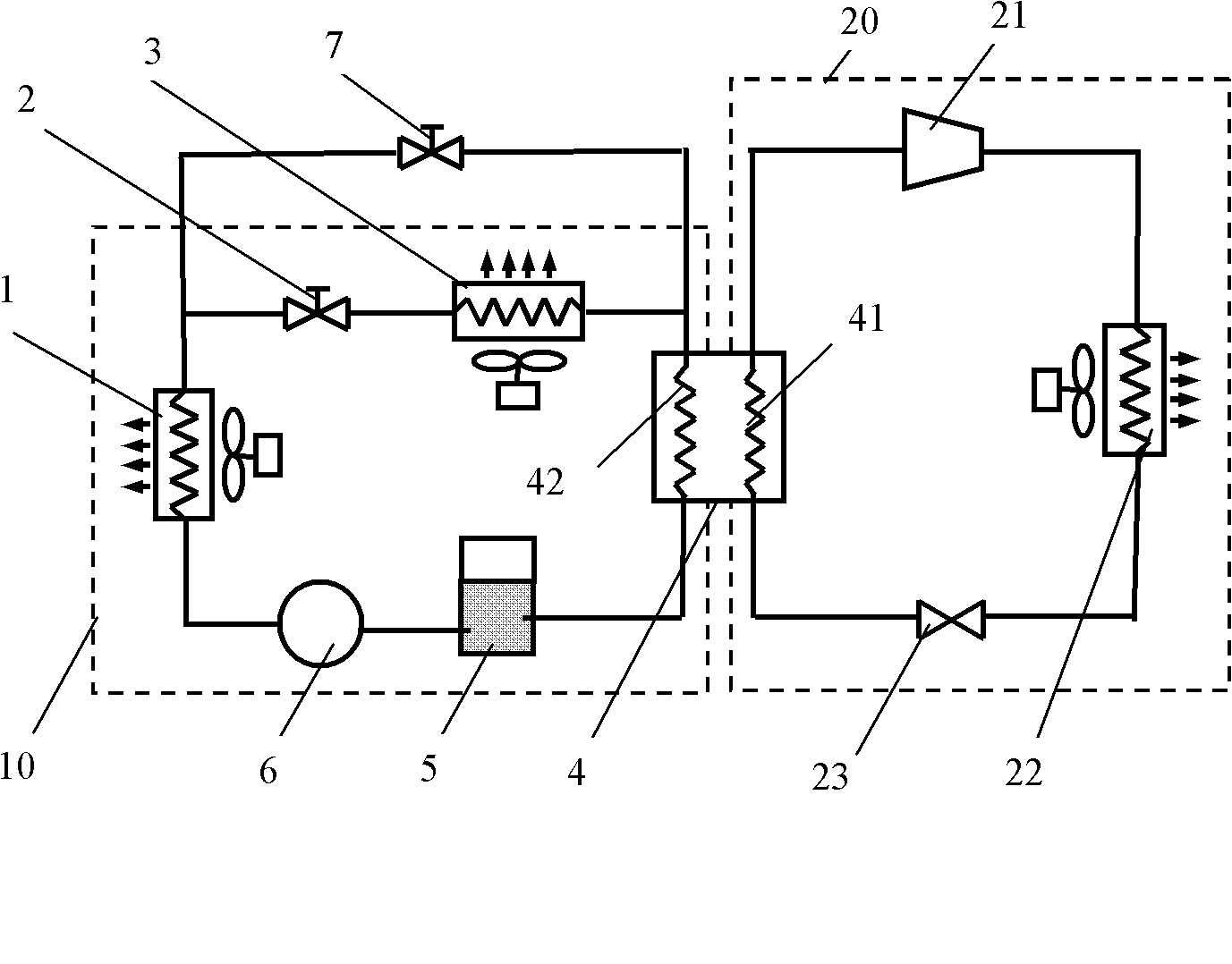

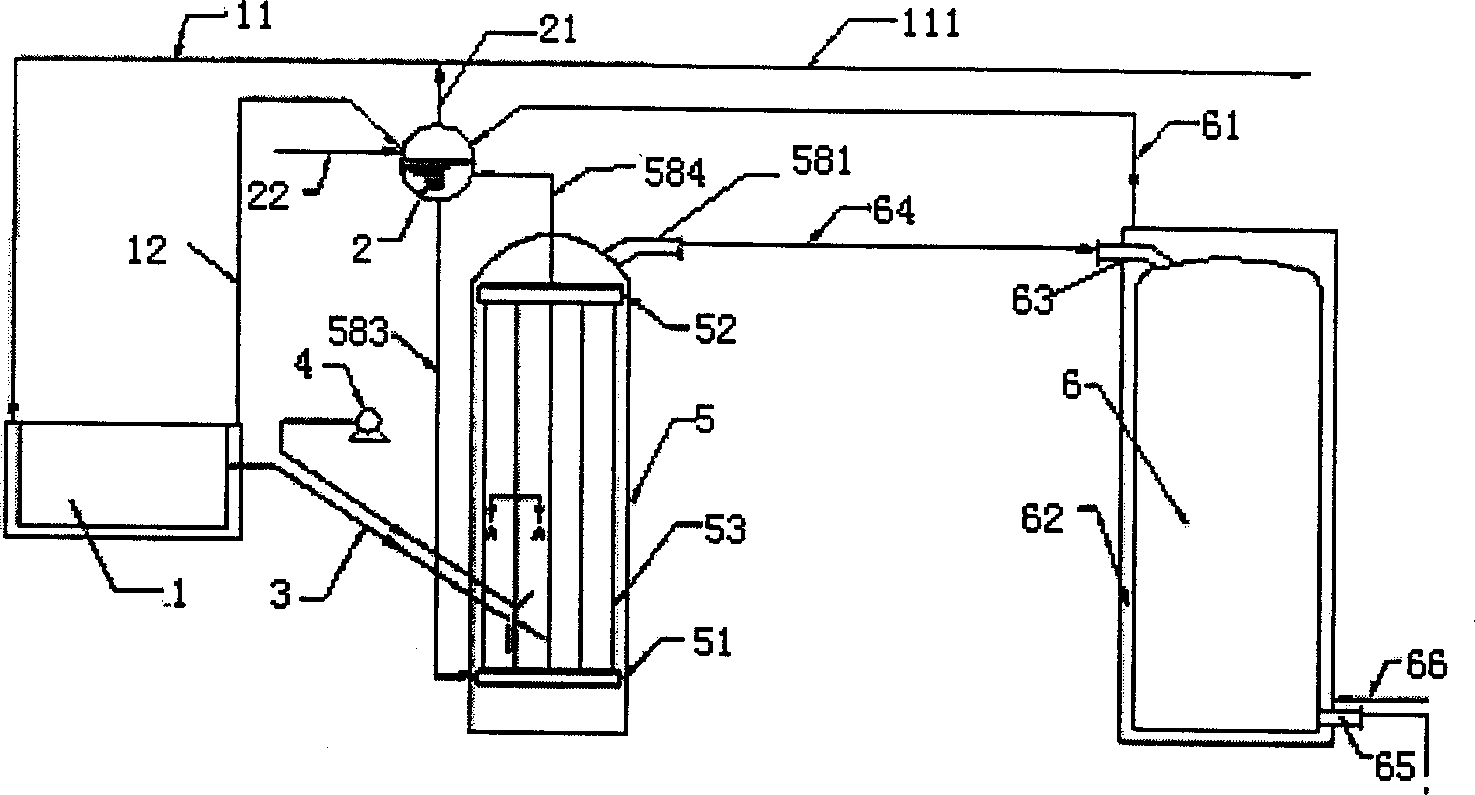

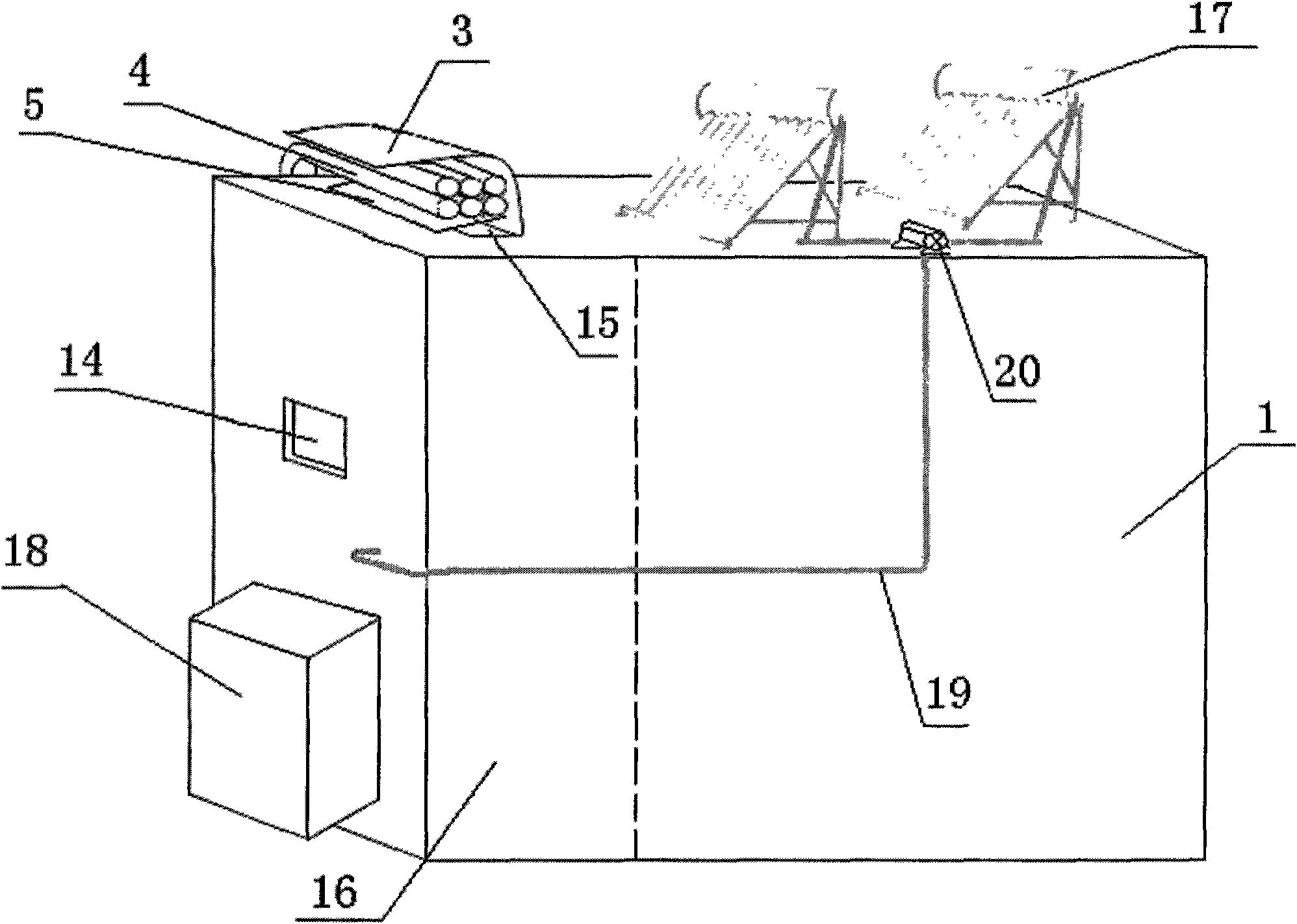

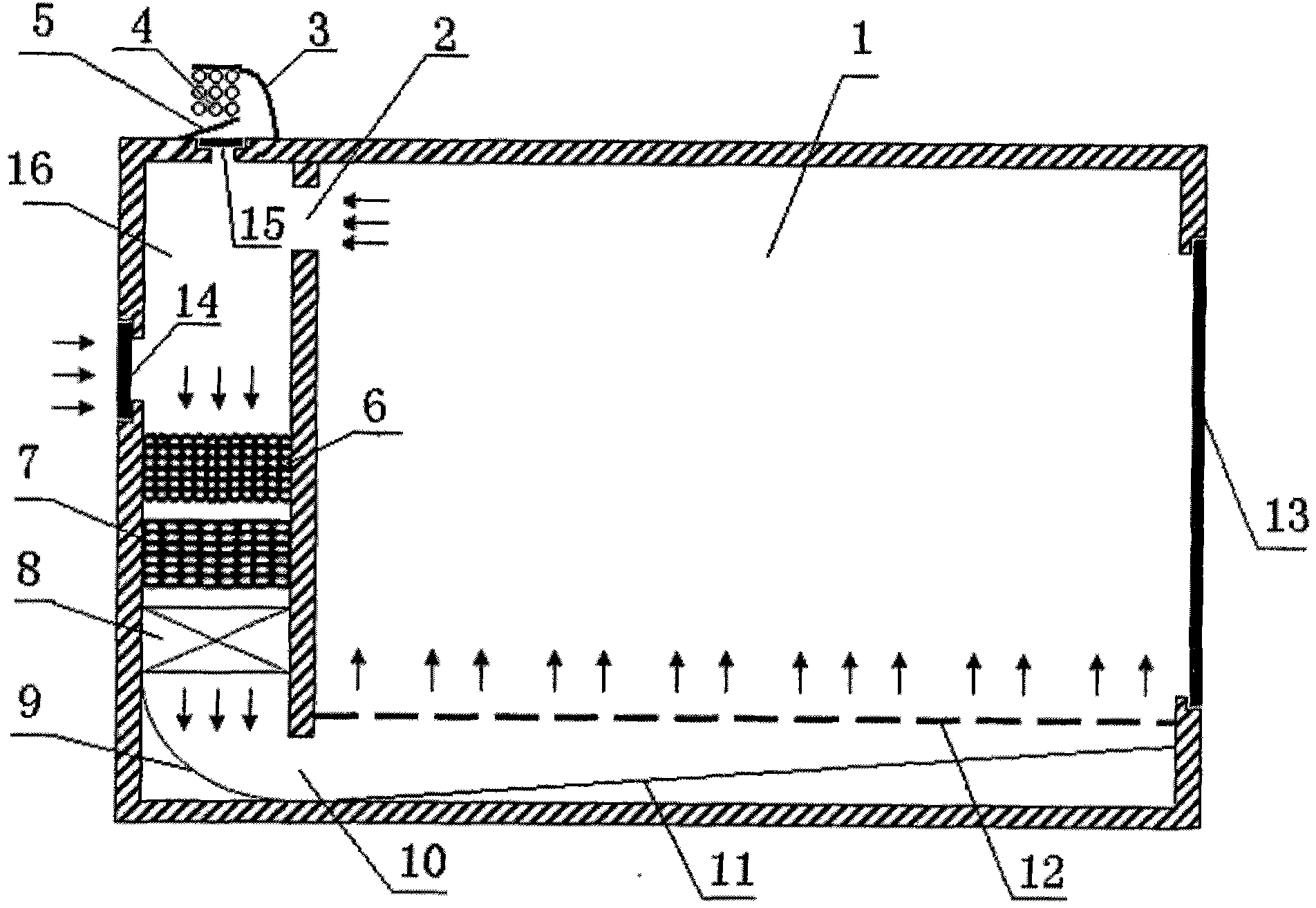

Heat pipe composite air conditioning unit for machine room and control method of heat pipe composite air conditioning unit

InactiveCN102538100ACompact structurePrevent intrusionSpace heating and ventilation safety systemsLighting and heating apparatusEvaporationEngineering

The invention discloses a heat pipe composite air conditioning unit for a machine room and a control method of the heat pipe composite air conditioning unit. The heat pipe composite air conditioning unit is characterized in that a heat pipe module and a refrigerating module are combined to form a cold source system in the air conditioning unit, the refrigerating module consists of a compression unit, a condenser, a throttling mechanism, an evaporation channel of an evaporation condenser and the like which form a first working medium circulating loop, the heat pipe module consists of an indoor heat exchanger, a main electromagnetic valve, an air-cooling heat exchanger, a condensation channel of the evaporation condenser, a liquid storage device, a liquid pump and the like which form a second working medium main loop, a bypass branch is arranged between an outlet of the indoor heat exchanger and an inlet of the condensation channel of the evaporation condenser, and a bypass electromagnetic valve is disposed in the bypass branch. A wide annular temperature zone is divided into three functional zones including a refrigerating zone, a composite zone and a heat pipe zone, and working modes of running refrigerating circulation, composite circulation and heat pipe circulation are correspondingly switched and run by the cold source system according to the different functional zones. By the aid of the heat pipe composite air conditioning unit and the control method thereof, utilization of outdoor natural cold sources can be maximized, and low-cost running and energy conservation can be realized.

Owner:HEFEI UNIV OF TECH

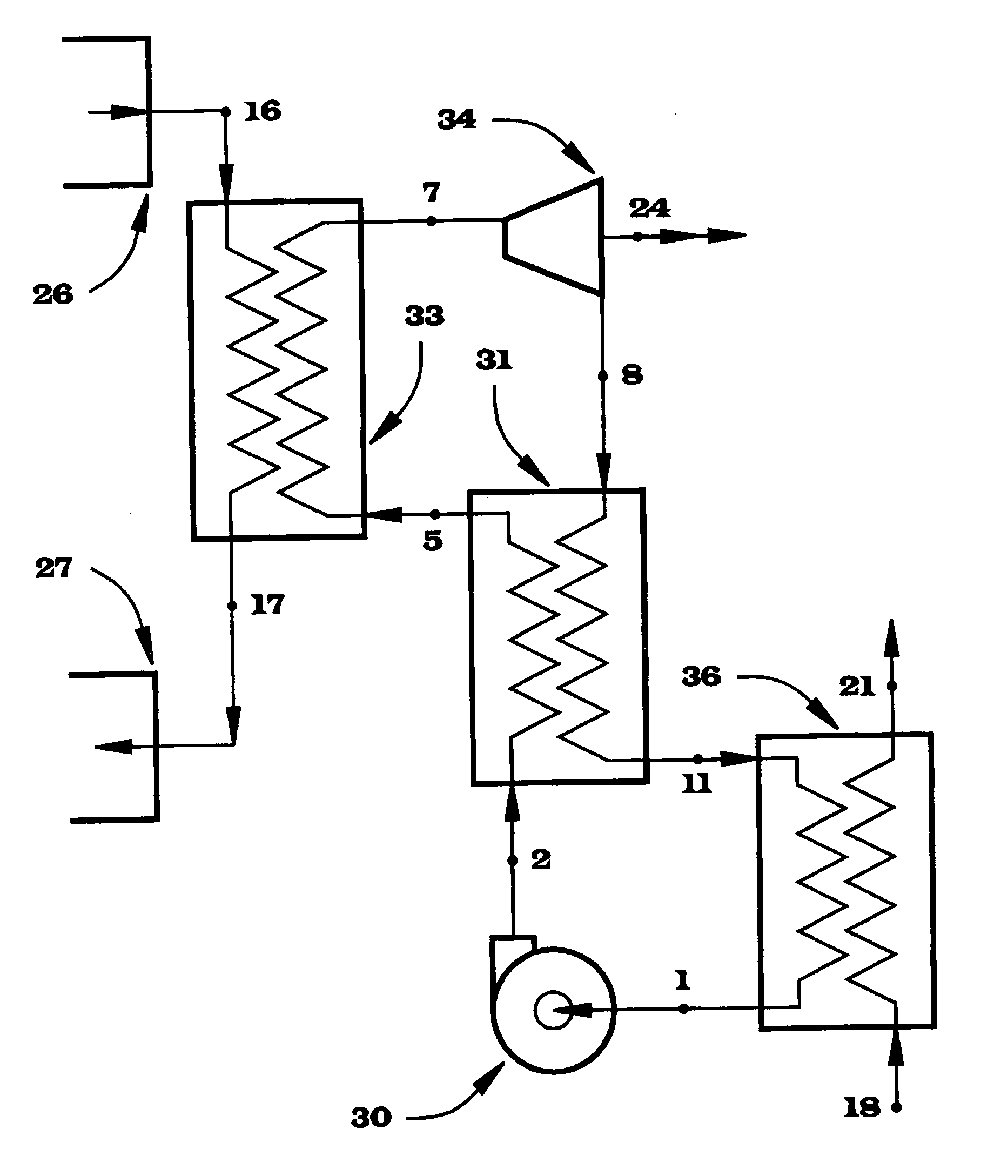

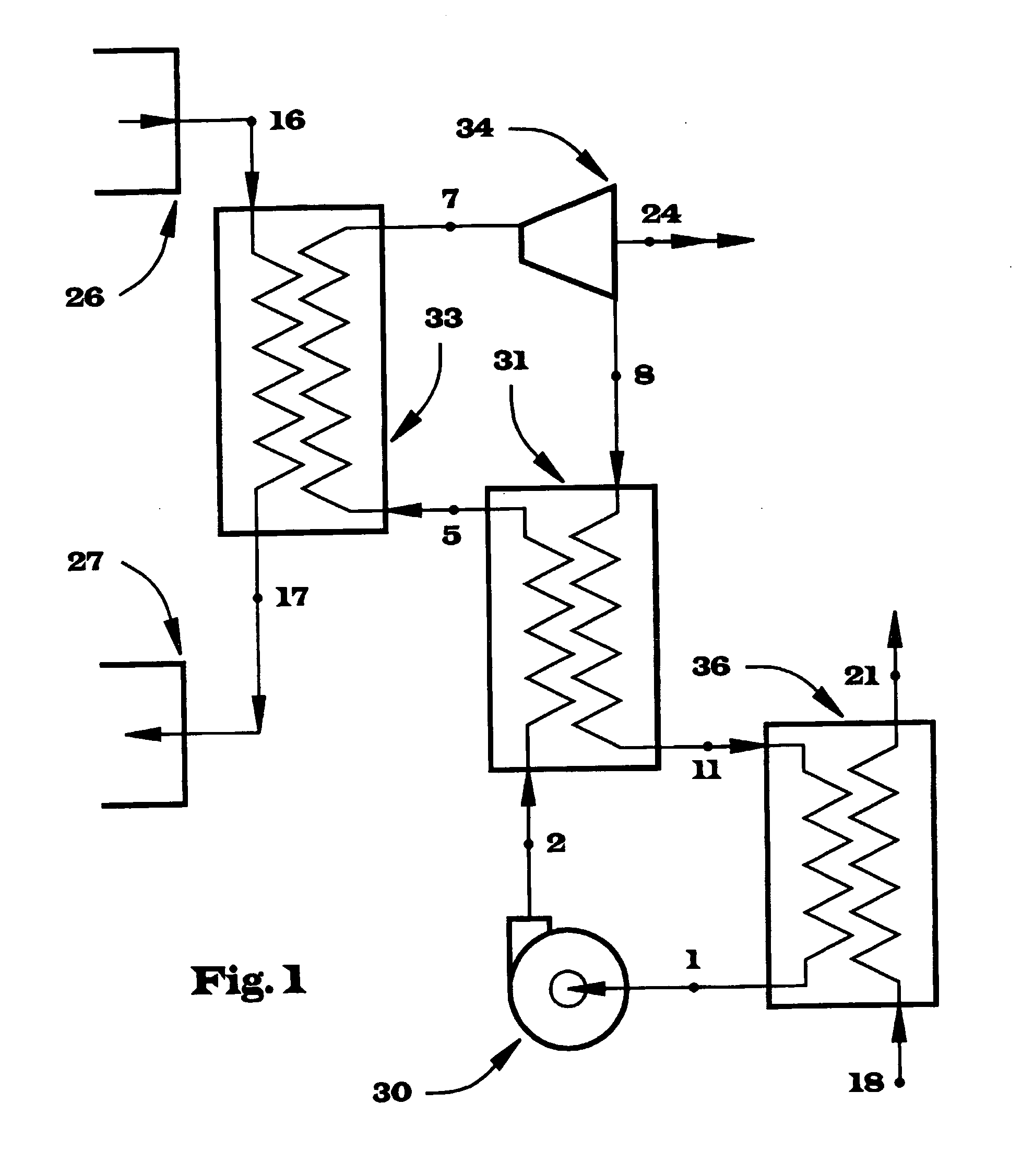

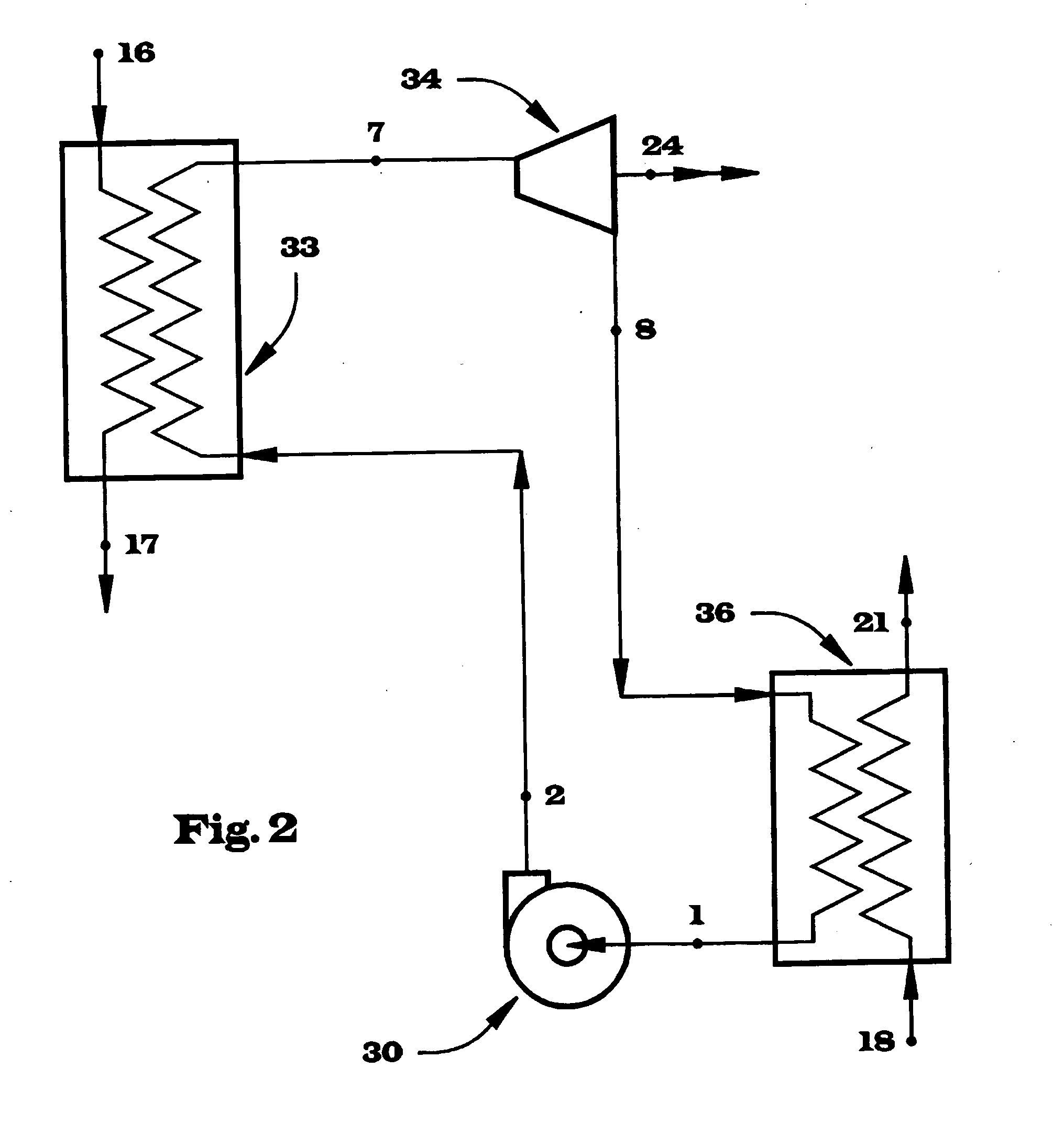

Method of converting energy

The invention provides a method of converting heat energy to a more usable form using a multi-component working fluid mixture that contains ammonia and water. The working fluid is operated in a thermodynamic cycle that includes liquid compression (30), vaporization (33), expansion through a turbine (34) and condensing (36). The multi-component fluid varies in temperature during phase change allowing for the use of counter-flow heat exchangers for the heater (33), cooler (36), recuperator and pre-heater (32). Significant recuperation is possible due to the temperature change during phase change. A pre-heater (32) can be applied to ensure only single-phase vapour exists within the heater. The invention can be used in conjunction with a biomass combustor or with waste flue gas from an existing industrial process. The coolant exits at a temperature sufficient to allow use in external heating applications or to minimize the size of external heat rejection equipment

Owner:SMITH & WESSON

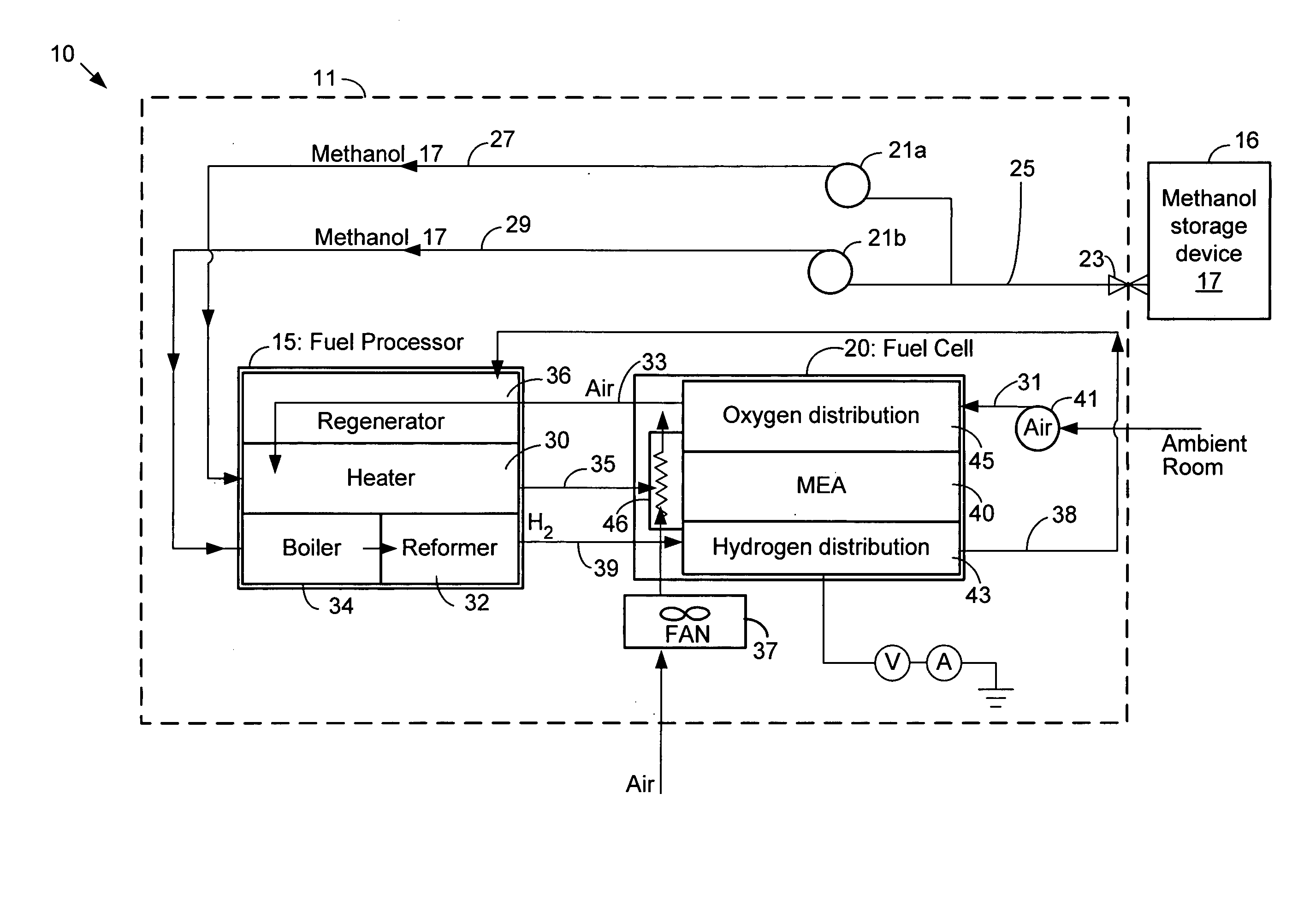

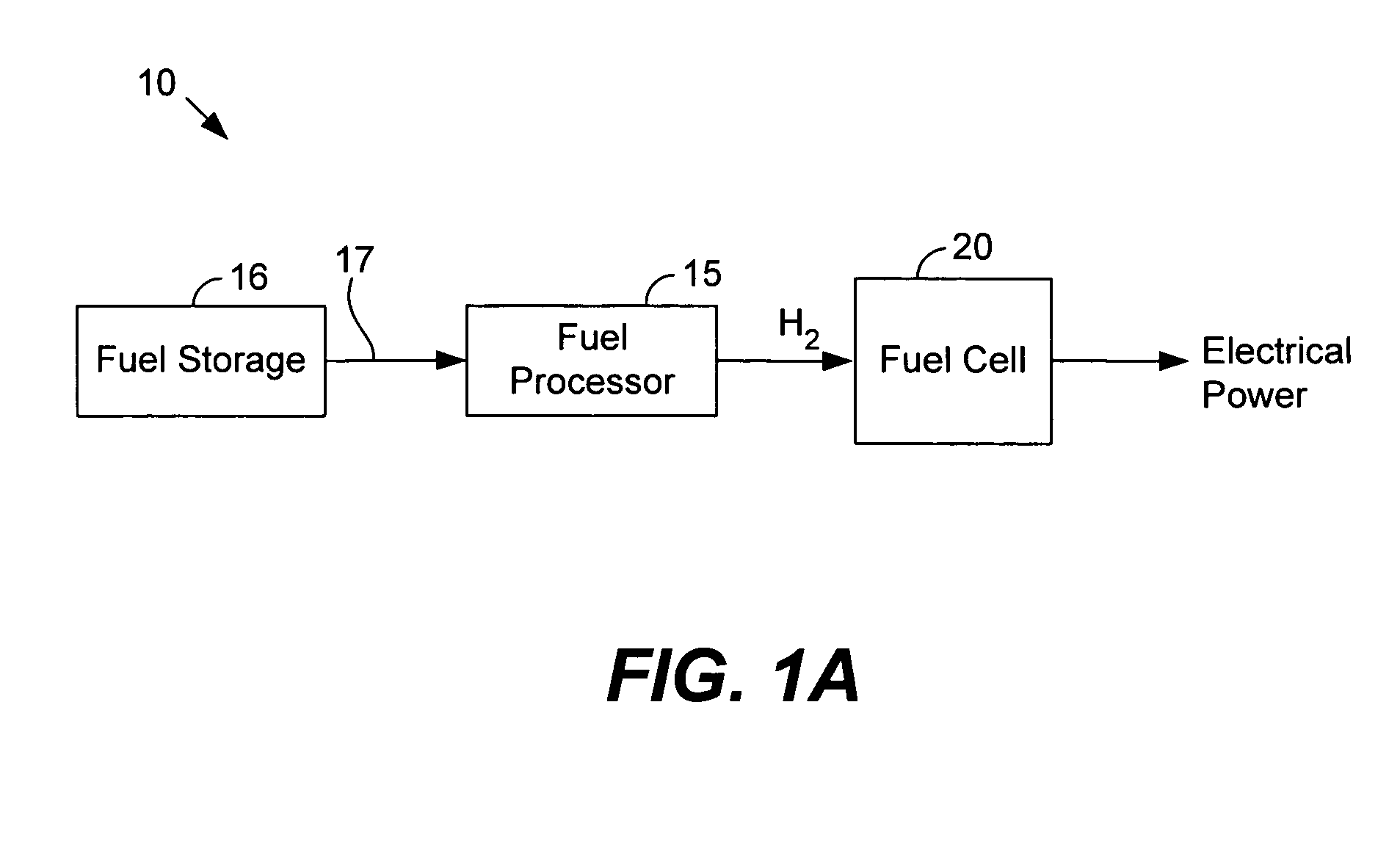

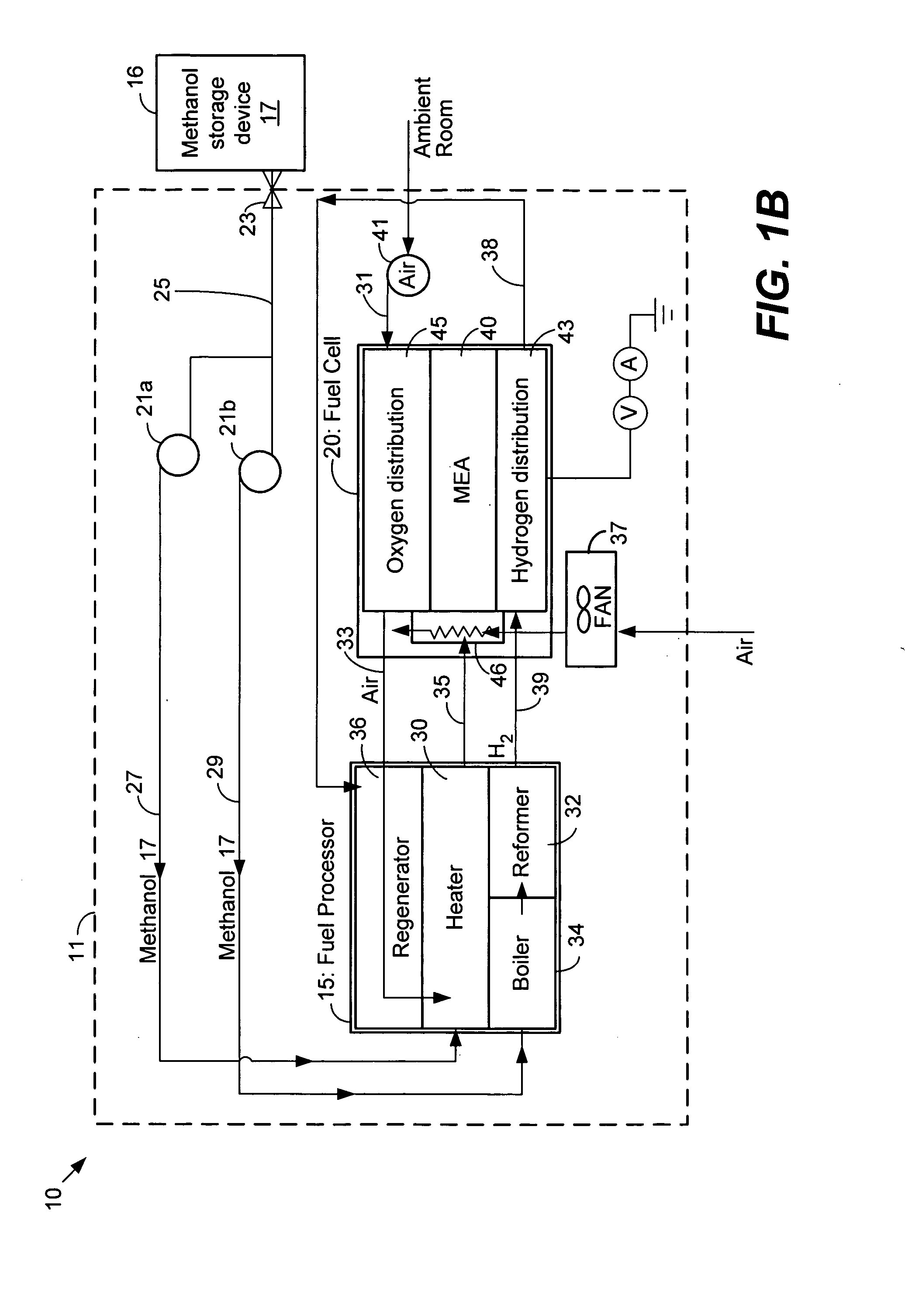

Heat efficient portable fuel cell systems

ActiveUS20060127719A1Reduce heat lossImprove thermal efficiencyHydrogenFuel cells groupingFuel cellsHydrogen

The invention relates to fuel cell systems with improved thermal efficiency. The systems include a fuel cell that generates electrical energy using hydrogen and a fuel processor that produces hydrogen from a fuel. Some heat efficient systems described herein include a thermal catalyst that generates heat when the catalyst interacts with a heating medium. The heat is used to heat the fuel cell. The thermal catalyst may be disposed in, proximity to the fuel cell, or remote from the fuel cell and a heat transfer pipe conducts heat from the catalyst to the fuel cell. Another thermally efficient embodiment uses a recuperator to transfer heat generated in the fuel cell system to incoming fuel. A fuel cell package may also include a multi-layer insulation arrangement to decrease heat loss from the fuel cell and fuel processor, which both typically operate at elevated temperatures.

Owner:ADVENT TECH LLC

Equipment for recovering and utilizing heat energy generated by phosphor combustion and system for preparing phosphoric acid by hot method

An equipment for recovering and utilizing the heat energy generated by burning yellow phosphorus and a system for preparing phosphoric acid by the hot method are disclosed. It is composed of steam manifold and burning tower with heat energy recovering function. The burning tower consists of ring-shaped membrane heat exchanger with fins, heat-insulaitng enclosed casing, P2O5 gas outlet tube, connecting tube of phosphorus sprayer, etc.. Its advantages include low consumption of coal, water and energy, low cost and reduced environmental pollution.

Owner:TSINGHUA UNIV +1

Integrated fuel cell hybrid power plant with controlled oxidant flow for combustion of spent fuel

InactiveUS20050079395A1Reduction of fuelReduction of carbon monoxide emissionFuel cells groupingFuel cell auxillariesElectric forceRecuperator

A hybrid power generation system for generating electrical power comprises a compressor for producing a compressed oxidant and a recuperator in flow communication with the compressor. The hybrid power generation system further comprises a fuel cell assembly comprising a plurality of fuel cells in flow communication with the recuperator to provide the compressed oxidant for the fuel cell assembly. The fuel cell assembly further comprises a cathode inlet for receiving the compressed oxidant, an anode inlet for receiving a fuel stream, an anode outlet in flow communication with an anode exhaust stream and a cathode outlet in flow communication with a cathode exhaust stream, wherein at least a portion of the fuel reacts with the oxidant to produce electrical power. The hybrid power generation system further comprises a tail gas burner in flow communication with the anode outlet and the cathode outlet. The tail gas burner is configured for combusting a mixture of at least a portion of the anode exhaust stream and at least a portion of the cathode exhaust stream and producing a hot compressed gas. A control system is used for controlling the amount of the cathode exhaust stream introduced in the tail gas burner for stable combustion and reduction of fuel and carbon monoxide emission. The hot compressed gas from the tail gas burner is introduced to a turbine, where the hot compressed gas is expanded, thereby producing electrical power and an expanded gas.

Owner:GENERAL ELECTRIC CO

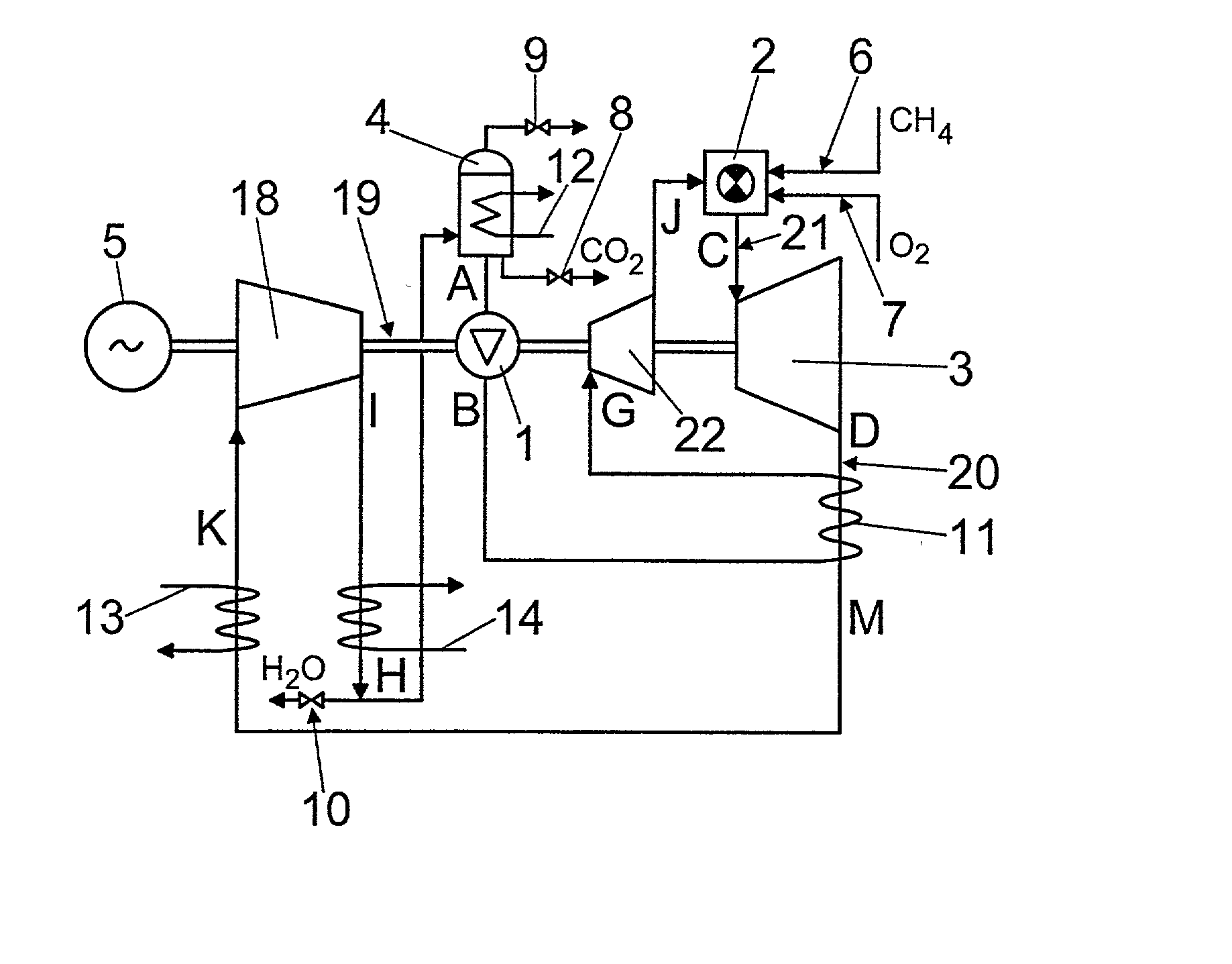

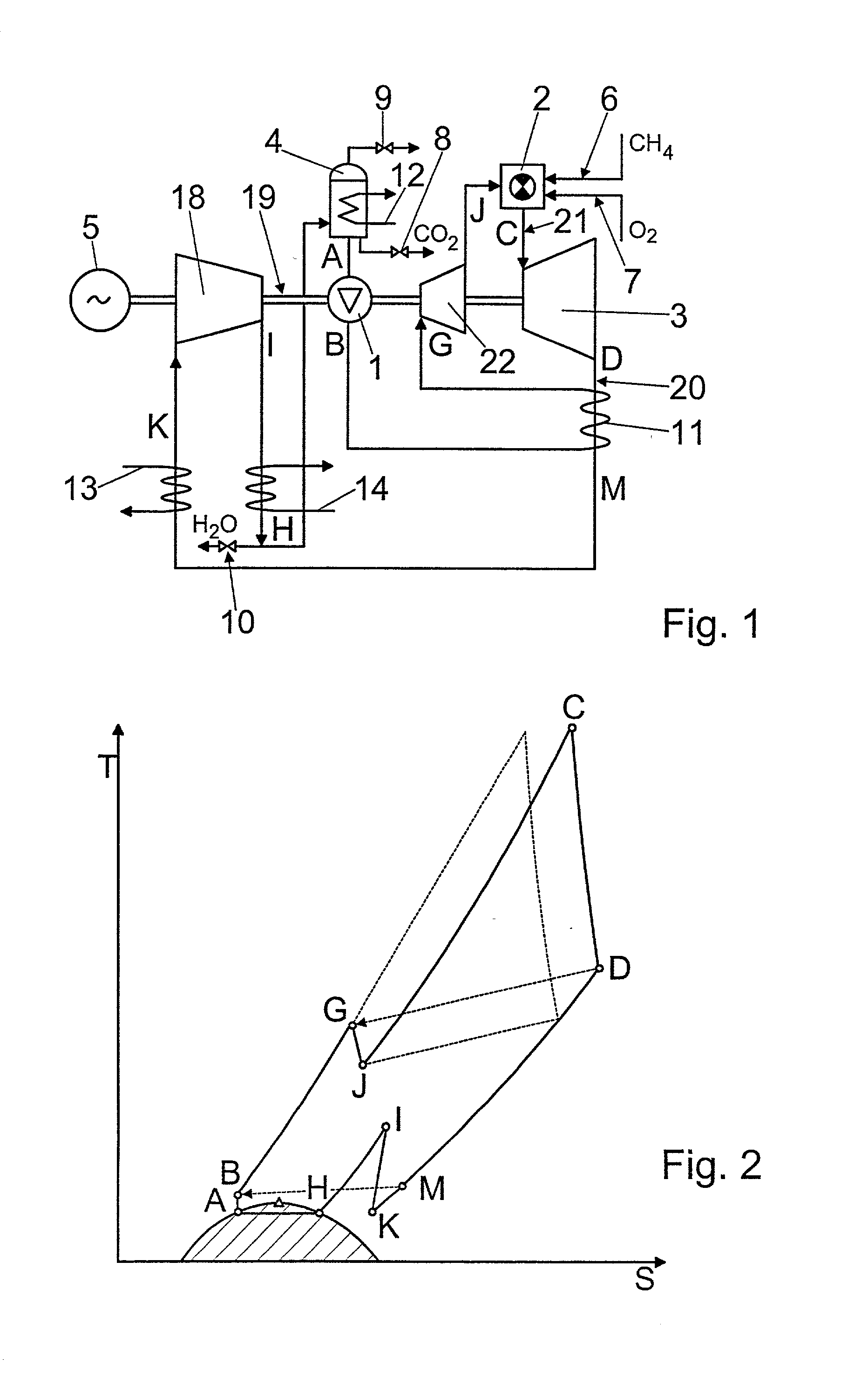

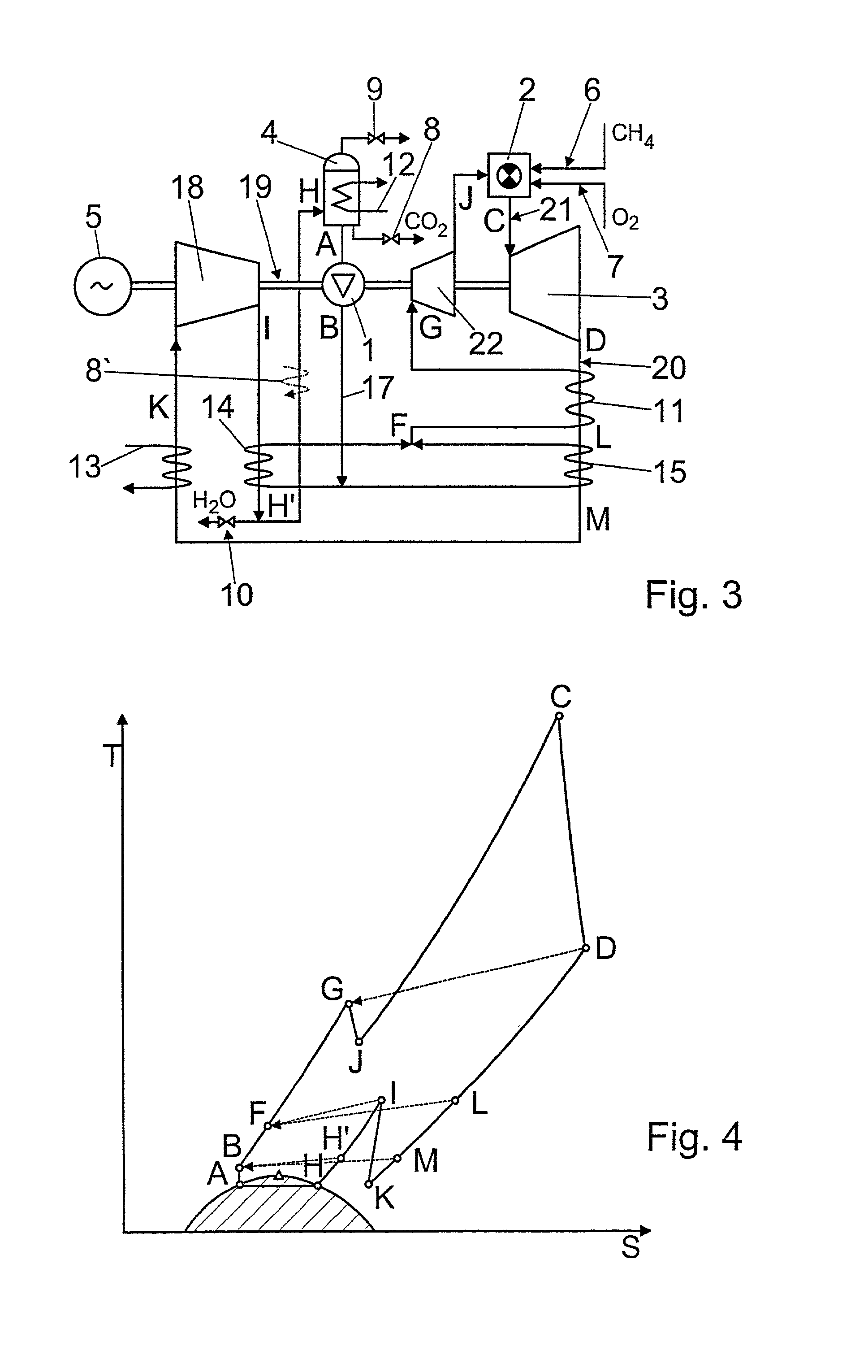

Process for the operation of a gas turbine plant and related gas turbine plant

A process is described for the operation of a gas turbine plant with CO2 as working medium, in which in at least one combustion chamber hydrocarbons are combusted in a CO2 atmosphere enriched with oxygen to flue gases, which largely consist of CO2 and H2O and which are expanded within a turbine stage following the at least one combustion chamber, and are then compressed in a compressor stage and also at least partially condensed in a following condenser, so that at least portions of the CO2 and H2O are liquefied and partially drawn off together with uncondensed flue gas constituents, and so that a main portion, not drawn off, of liquid CO2 is compressed by means of a pump unit, preheated in at least one recuperator stage, and is again supplied to the combustion chamber. The invention is distinguished in that the compressed and preheated main portion CO2 is pre-expanded to a combustion pressure and is supplied to the combustion chamber for combustion with the main portion CO2.

Owner:ANSALDO ENERGIA IP UK LTD

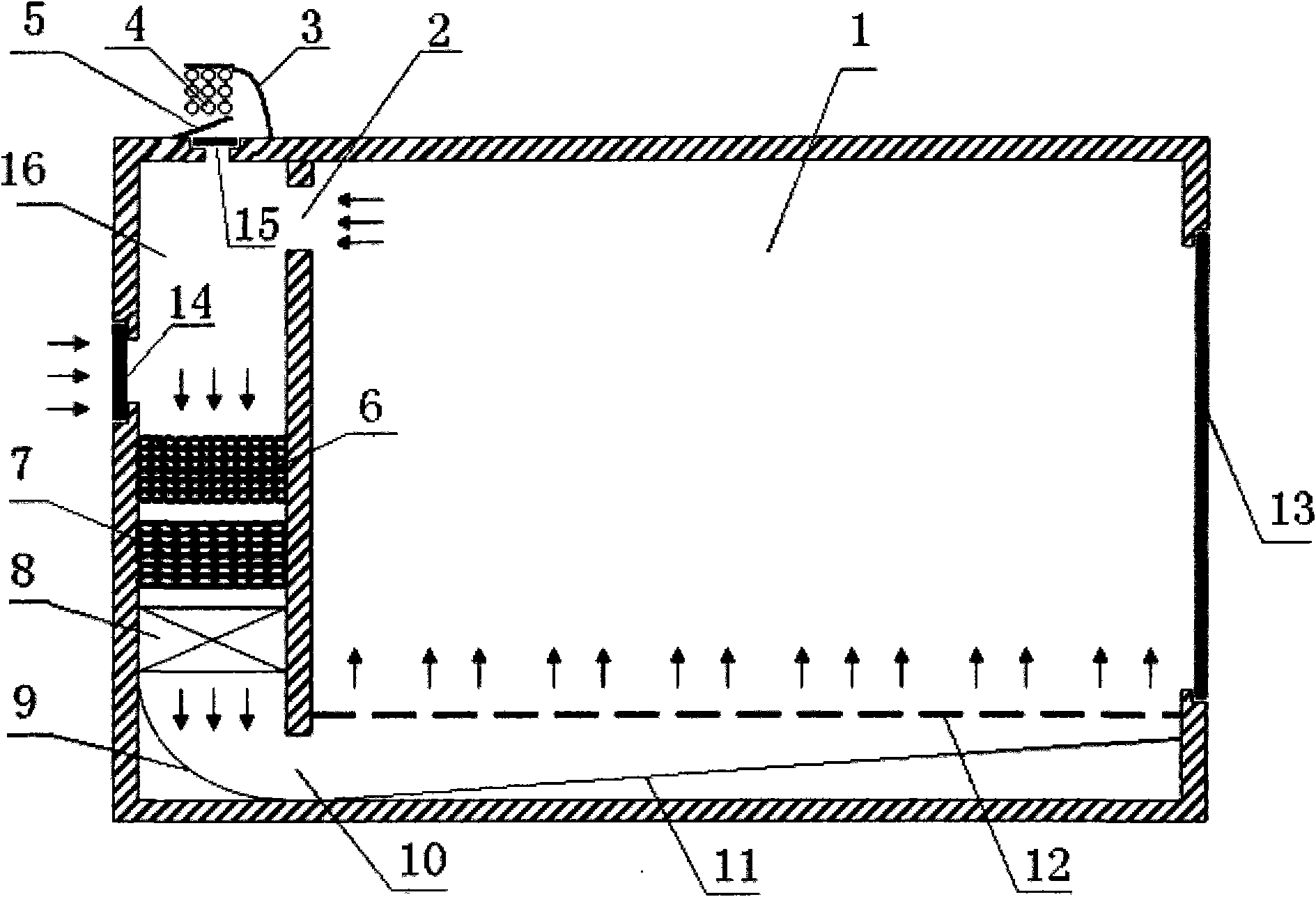

Hot air drying system heated by double energy sources

InactiveCN101936644AIncrease the heat exchange areaReduce deliveryTobacco preparationDrying solid materials with heatPlate heat exchangerBusiness efficiency

The invention discloses a hot air drying system heated by double energy sources, which comprises a heating chamber with a fresh air opening, a drying chamber, a solar heating device, an air source heat pump and a condenser fan of the air source heat pump, wherein the upper part of the heating chamber or the drying chamber is provided with a dehumidifying opening; a condenser and the condenser fan of the air source heat pump are arranged in the heating chamber; a hot water heat exchanger of the solar heating device is arranged at the front end of an air inlet of the condenser in the heating chamber; the condenser fan supplies air in an induced draft way; the ratio of the heat exchange area of the condenser to the input power of a compressor is 5.3 to 11 m<2> / kw; the ratio of the heat exchange area of the hot water heat exchanger to the input power of the compressor is not less than 1.5 m<2> / kw; and the total pressure of the condenser fan is 100 to 400 Pa. The hot air drying system heated by the double energy sources makes full use of solar energy as a hot air heat source for drying, solves the problems of the independent use of the solar energy, achieves high energy efficiency ratio by adopting the air heat pump as the hot air heat source, is energy-saving, environmentally-friendly and low in running cost, and manifests the advantages of the combined use of the air source and the solar energy in oven-drying.

Owner:湖南省浏阳市择明热工器材有限公司

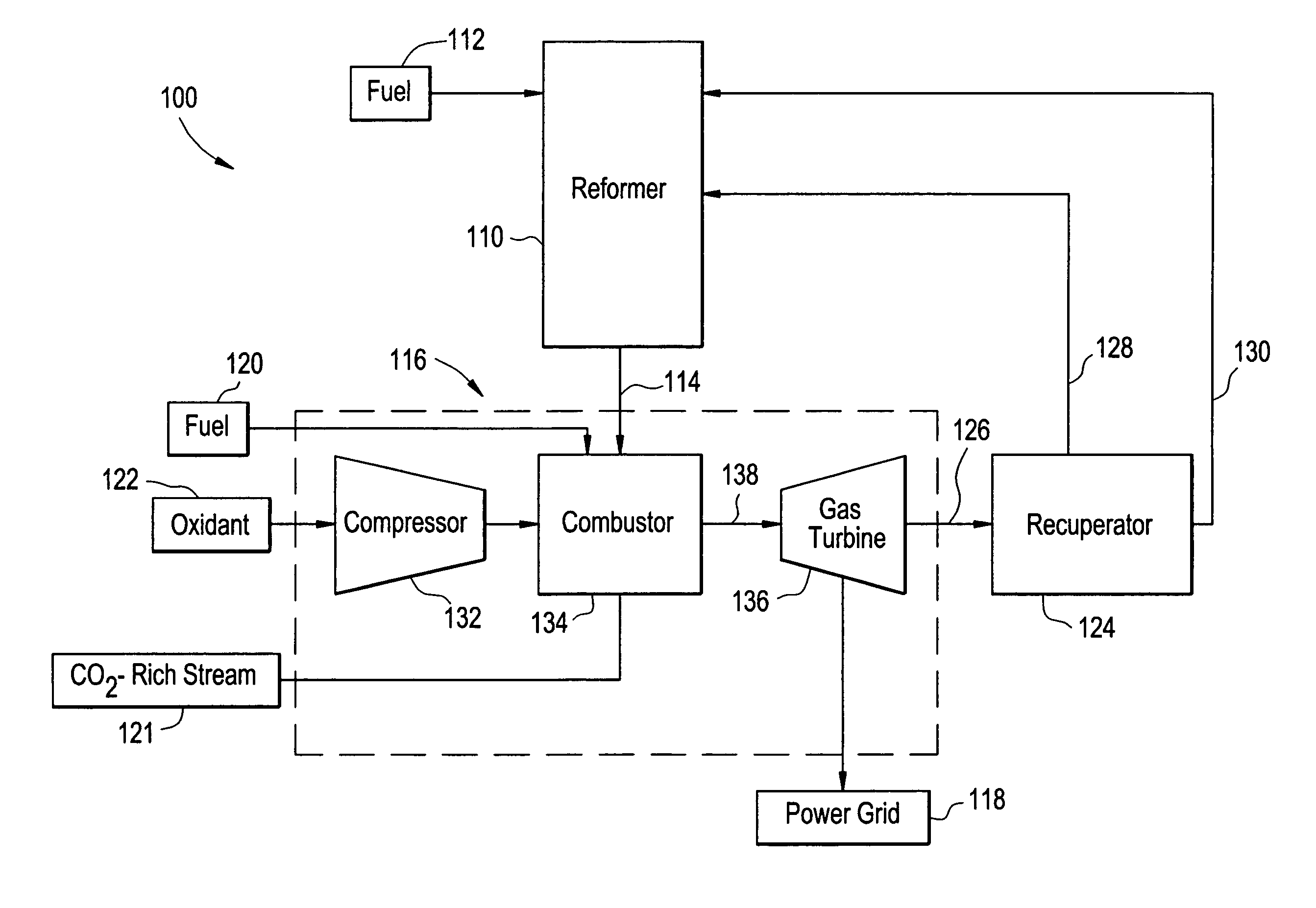

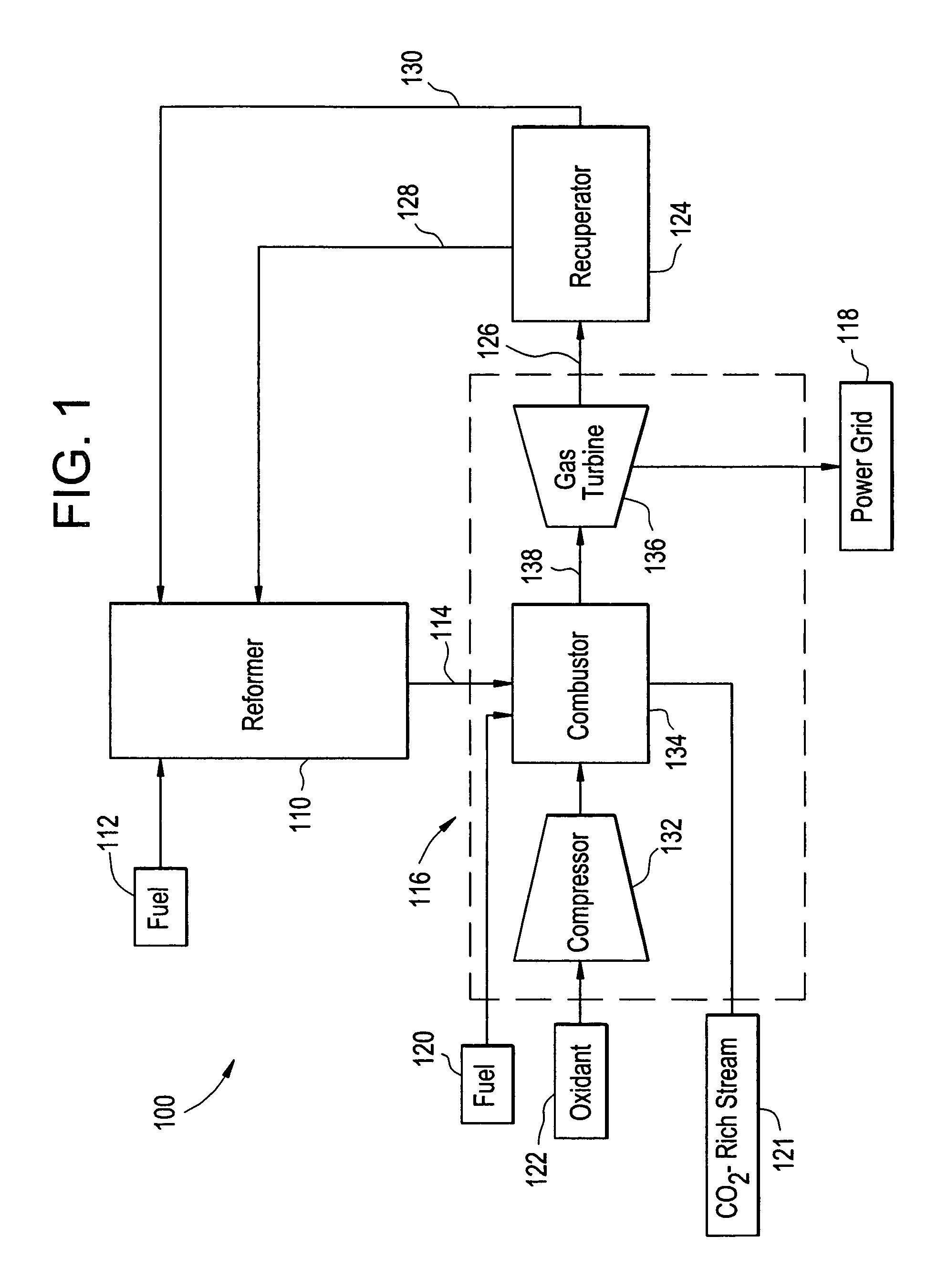

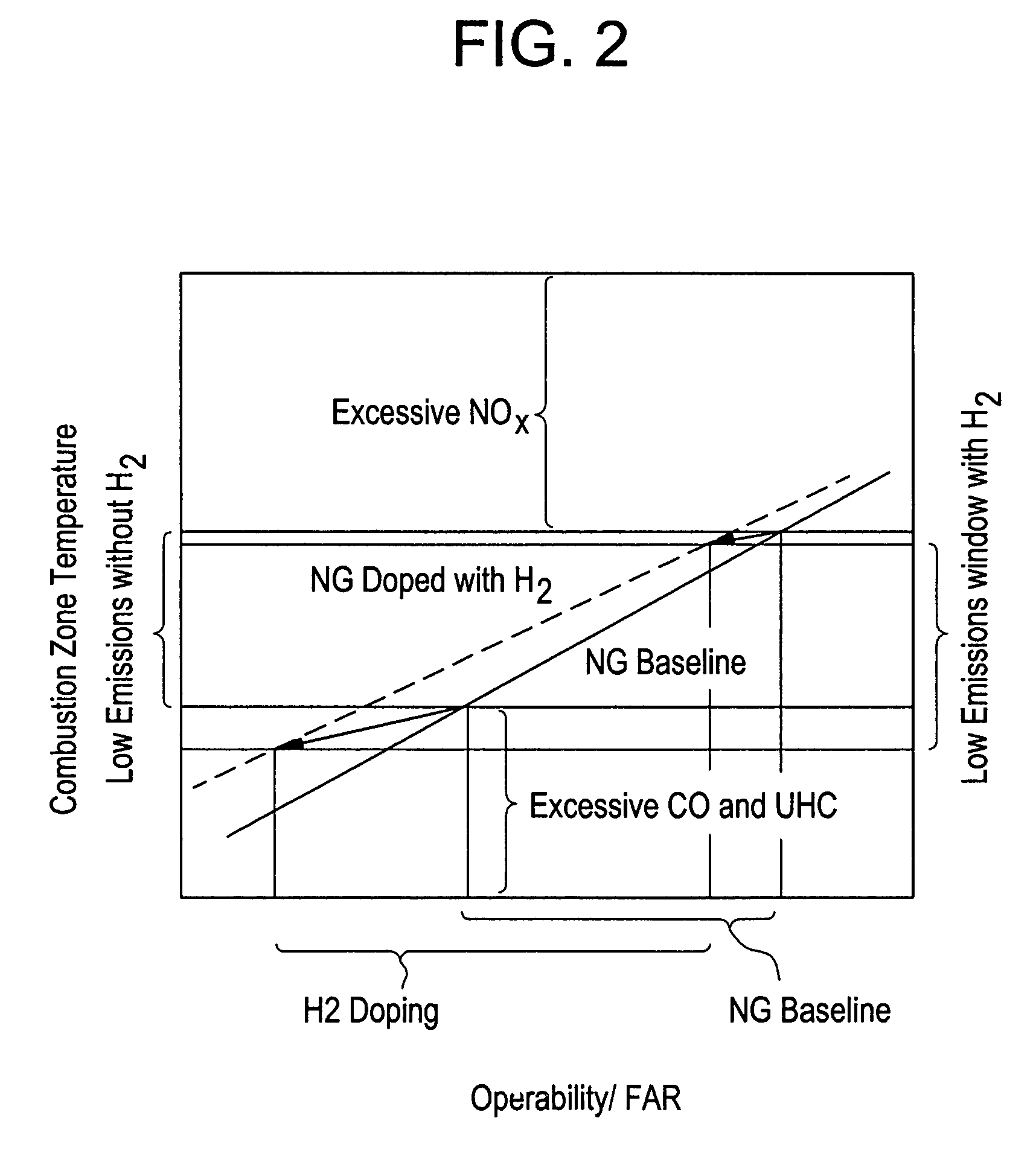

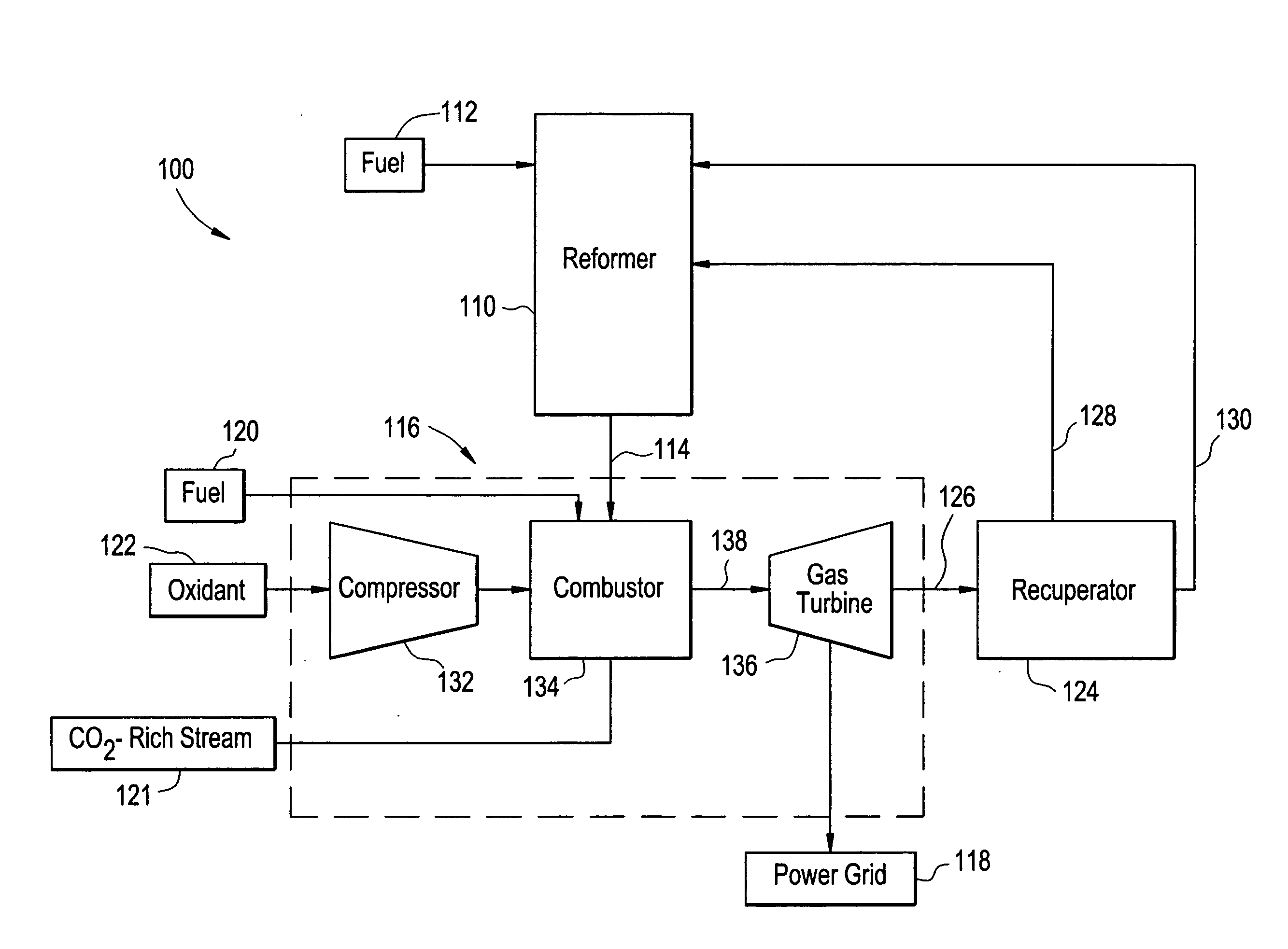

Systems and processes for reducing NOx emissions

ActiveUS20080141643A1Reduce harmful emissionsReduce nitrogen oxide emissionsGas treatmentDispersed particle separationElectricityCombustion system

A system for reducing NOx emissions, includes a reformer configured to receive a fuel and produce a hydrogen-enriched stream, a combustion system configured to burn the hydrogen enriched-stream and produce electricity and an exhaust stream, and a recuperator configured to recover heat from the exhaust stream, wherein the recovered heat is recycled back to the reformer.

Owner:GENERAL ELECTRIC CO

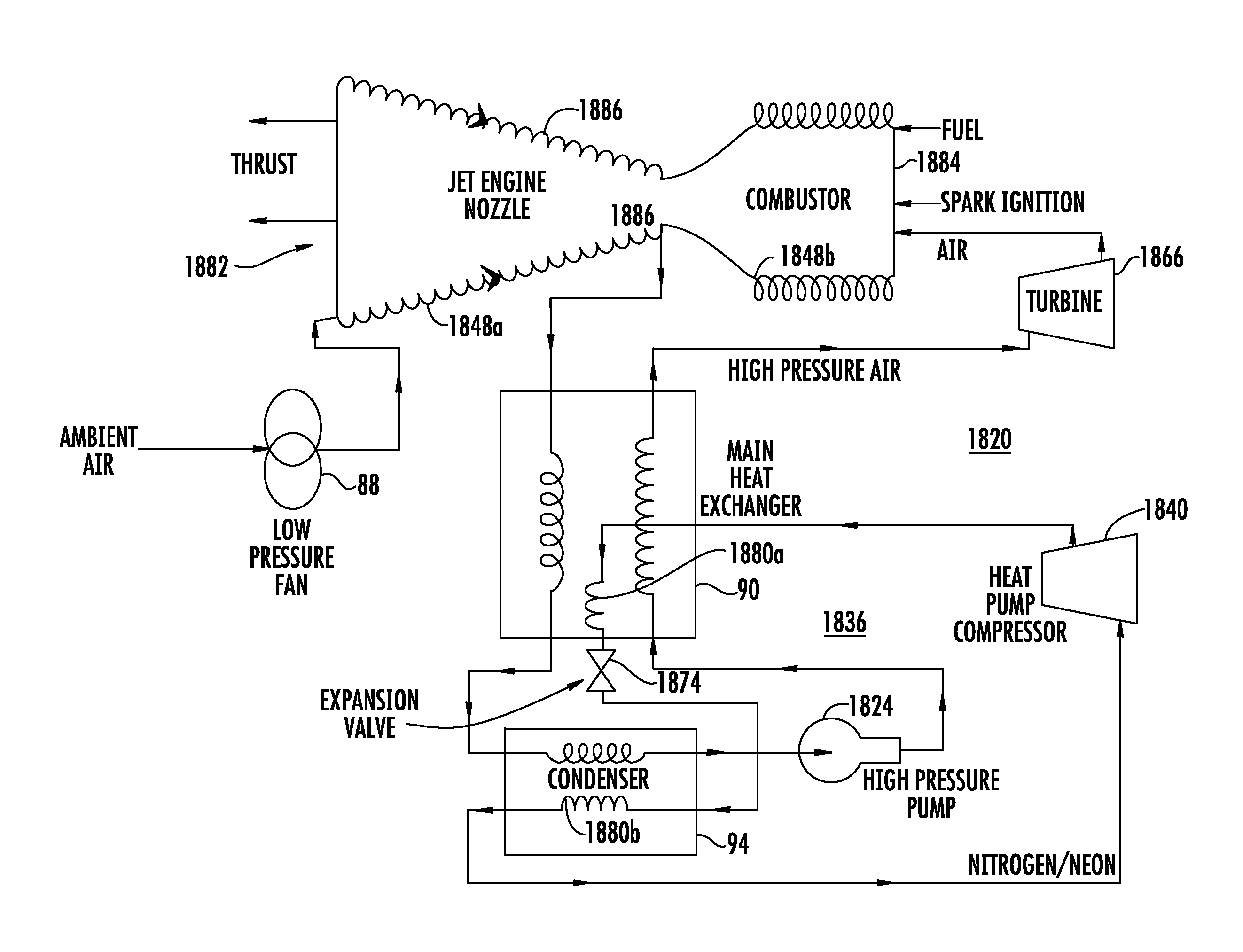

Ultra-high-efficiency engines and corresponding thermodynamic system

ActiveUS20110252796A1Improving the thermodynamic efficiency of a number of enginesImprove engine efficiencyGas turbine plantsEfficient propulsion technologiesWorking fluidEngineering

A thermodynamic system and method of producing useful work includes providing a working fluid and a fluid pump, or compressor, for pumping the working fluid in a cycle. A thermal input is provided for supplying heat to the working fluid. An expansion device downstream of the thermal input converts motion of the working fluid to useful work. A heat pump is provided. A number of different means of implementing the heat pump are presented, including direct transfer of working fluid mass flow. The heat pump pumps heat from one portion of the working fluid to another portion of the working fluid. For some applications, a regenerator, or recuperator, may be used to transfer heat from a high temperature portion of the working fluid to a lower temperature portion.

Owner:BURKHART TECH

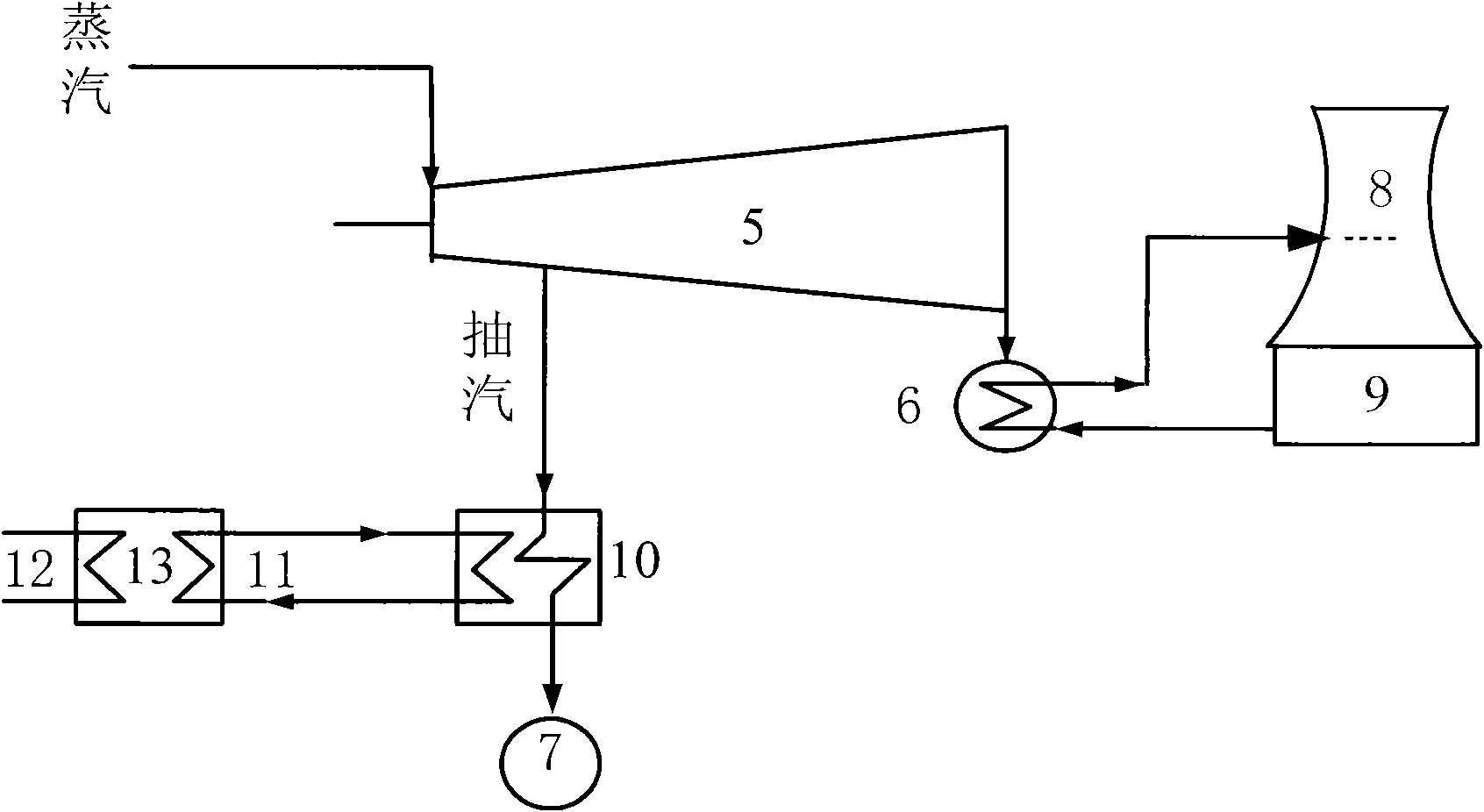

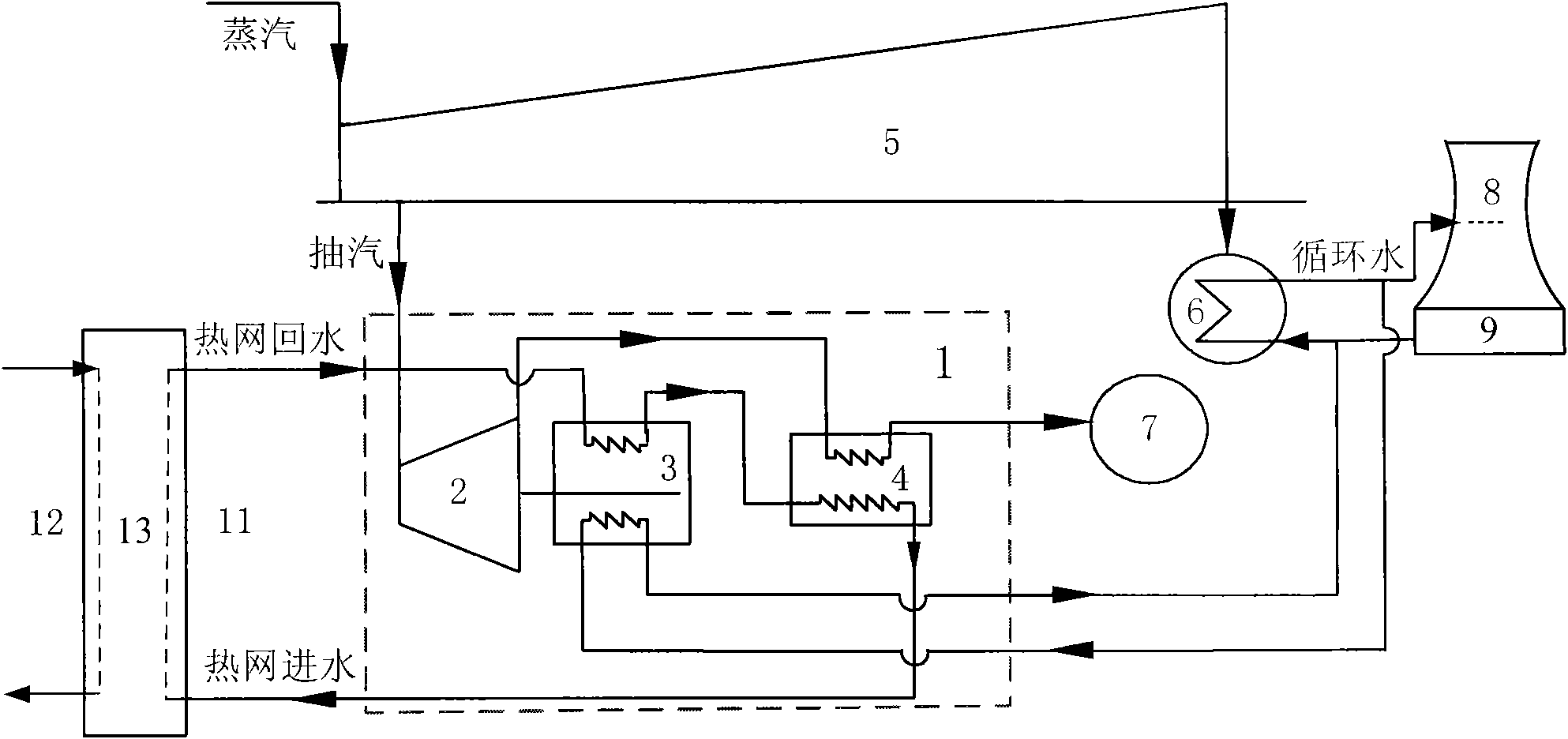

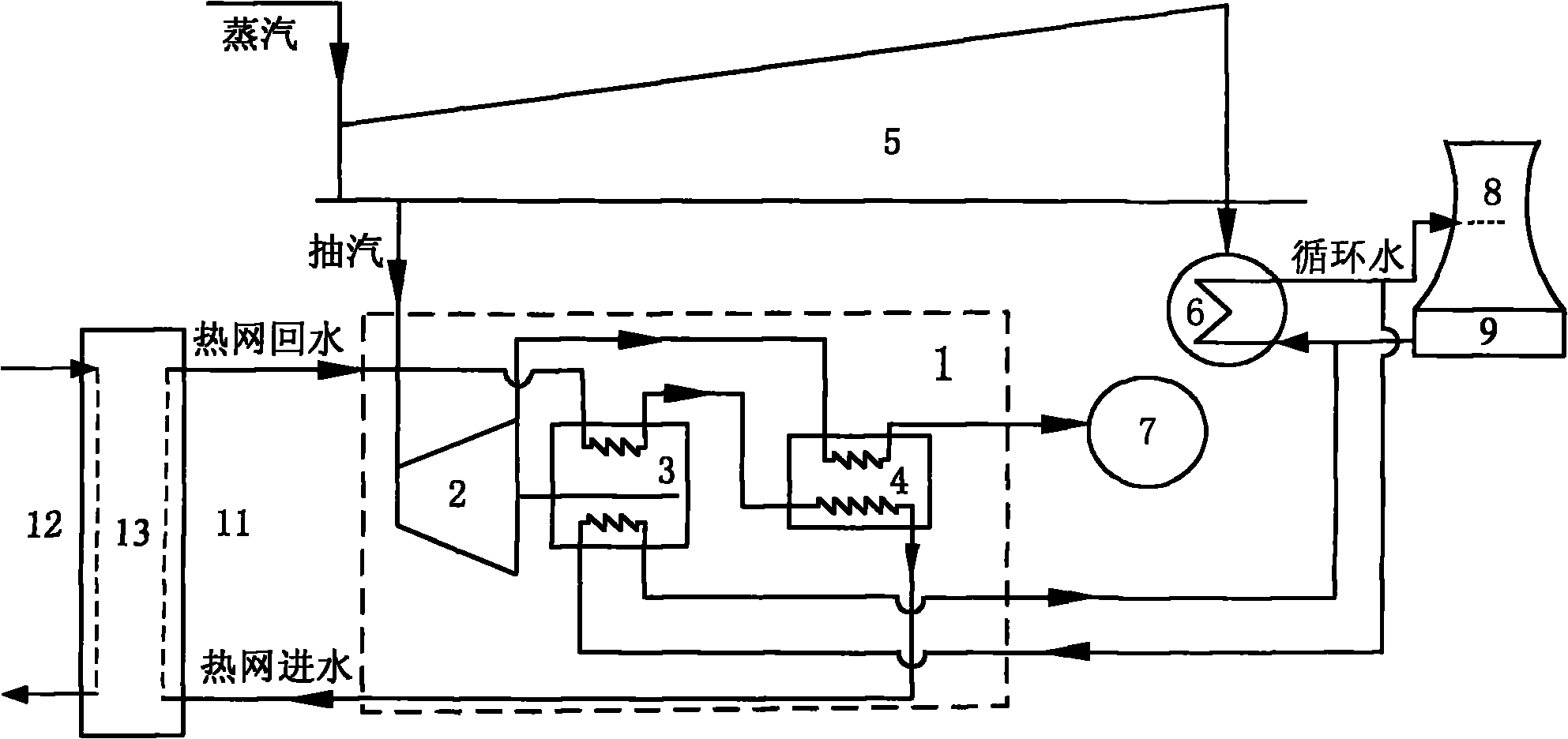

Combined heat and power generation energy saving device using afterheat to supply heat and energy saving method

InactiveCN101967999AIncrease small loopReduce heat transfer irreversible lossLighting and heating apparatusEnergy efficient heating/coolingCooling towerCogeneration

The invention relates to a combined heat and power generation energy saving device using afterheat to supply heat and an energy saving method. The combined heat and power generation energy saving device comprises a steam boiler, a steam extraction condensed type steam turbine, an electric generator, a condenser, a deaerator and a cooling tower, wherein the steam extraction condensed type steam turbine is connected with the condenser by an exhaust steam cylinder, and the condenser is connected with the cooling tower to form large waterway circulation; the combined heat and power generation energy saving device also comprises a backpressure turbine, a compression heat pump and a heat exchanger, wherein a steam inlet of the backpressure turbine is connected with a steam extraction hole of the steam extraction condensed type steam turbine, an exhaust steam hole is connected with a steam inlet of the heat exchanger, the compression heat pump is drawn by the backpressure turbine and is connected with the backwater end of a hot-water pipe network, the condenser and the compression heat pump are connected with the cooling tower to form small waterway circulation, the water inlet end of the heat exchanger is connected with the water outlet end of the compression heat pump, the water outlet end is connected with the water inlet end of the hot-water pipe network, and the drainage end is connected with the deaerator. The invention is capable of reducing cold source loss, increasing comprehensive heat efficiency and electrothermal proportion and reducing unit electric-generation coal consumption.

Owner:联合优发生物质能源徐州有限公司

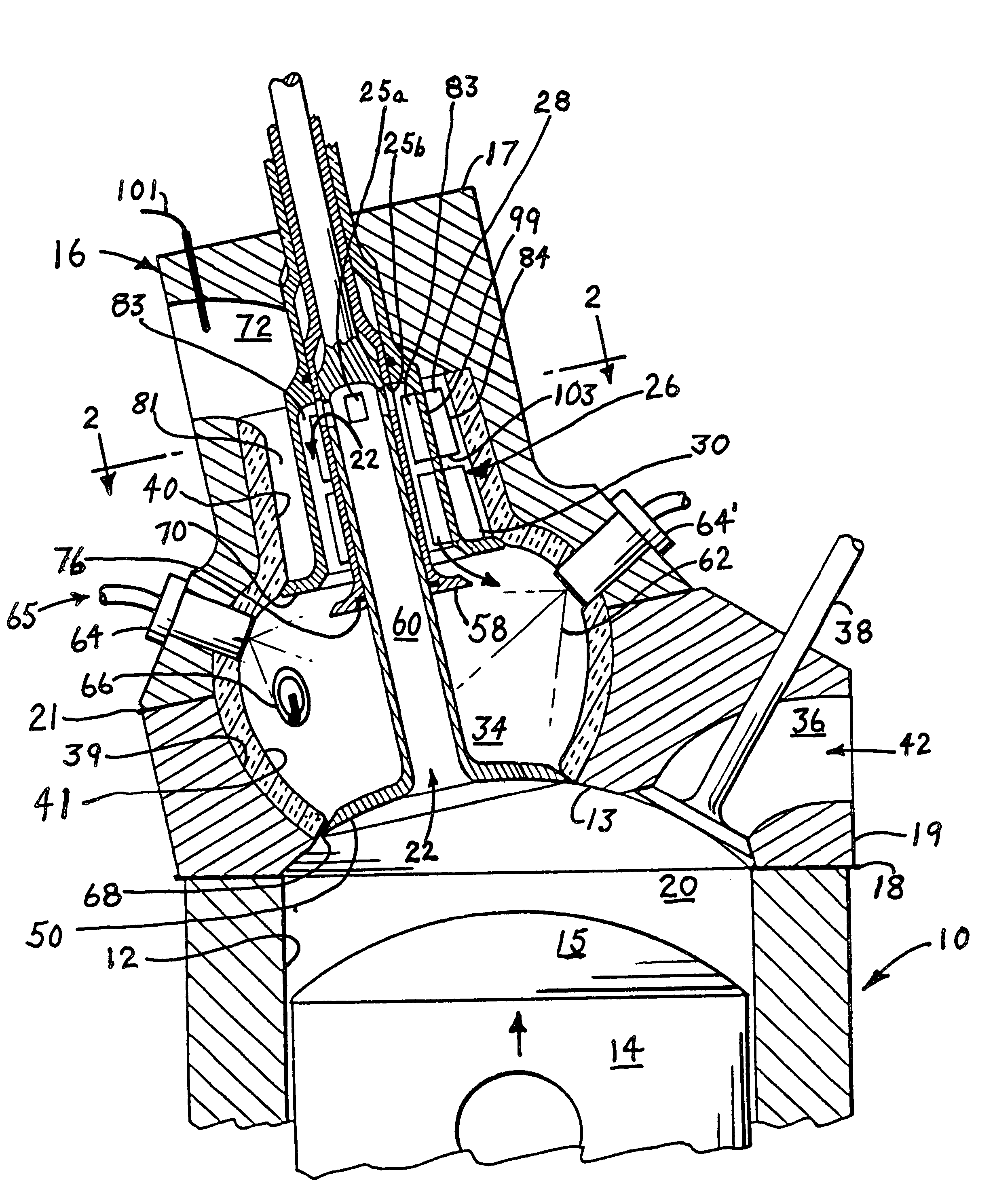

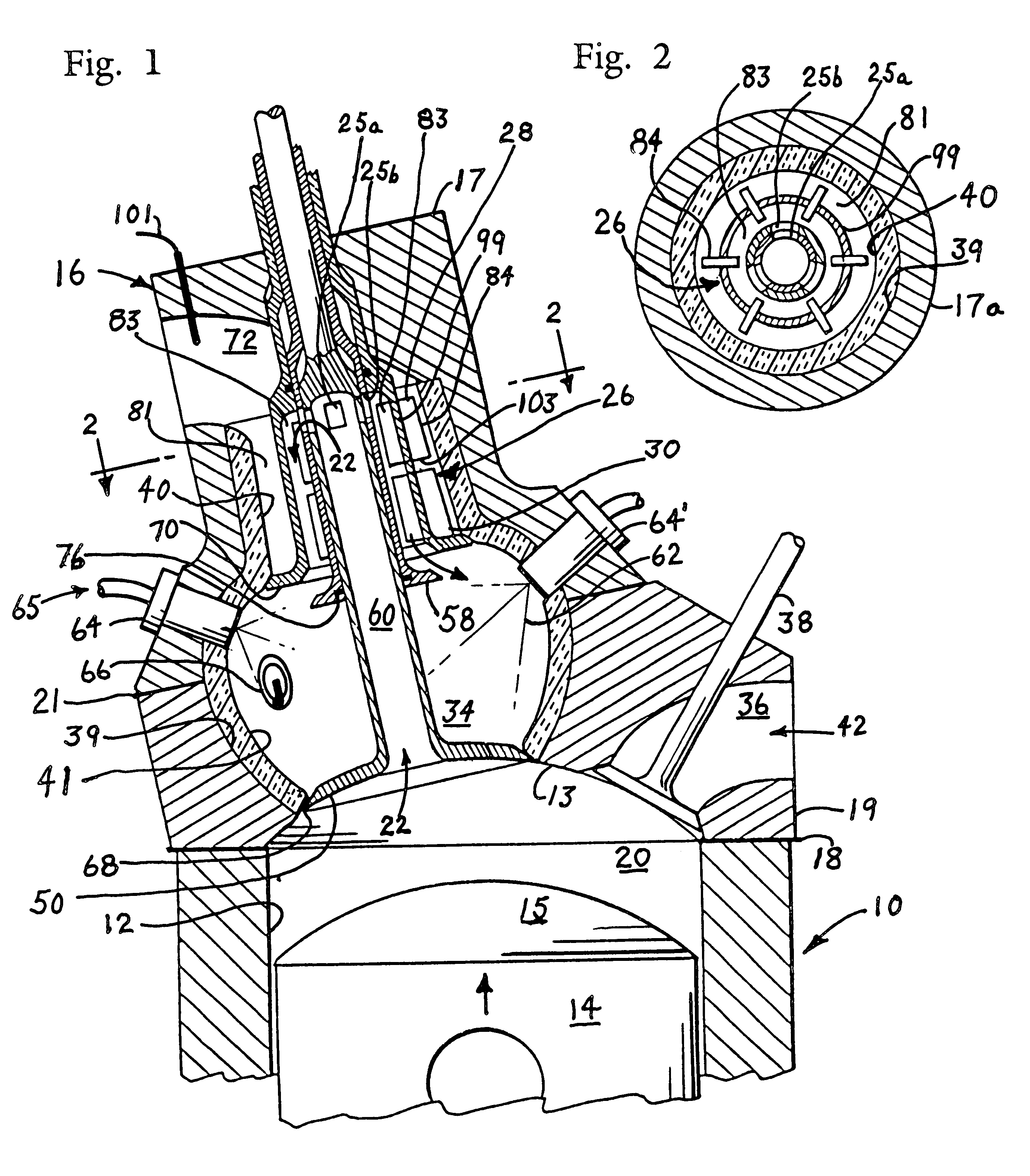

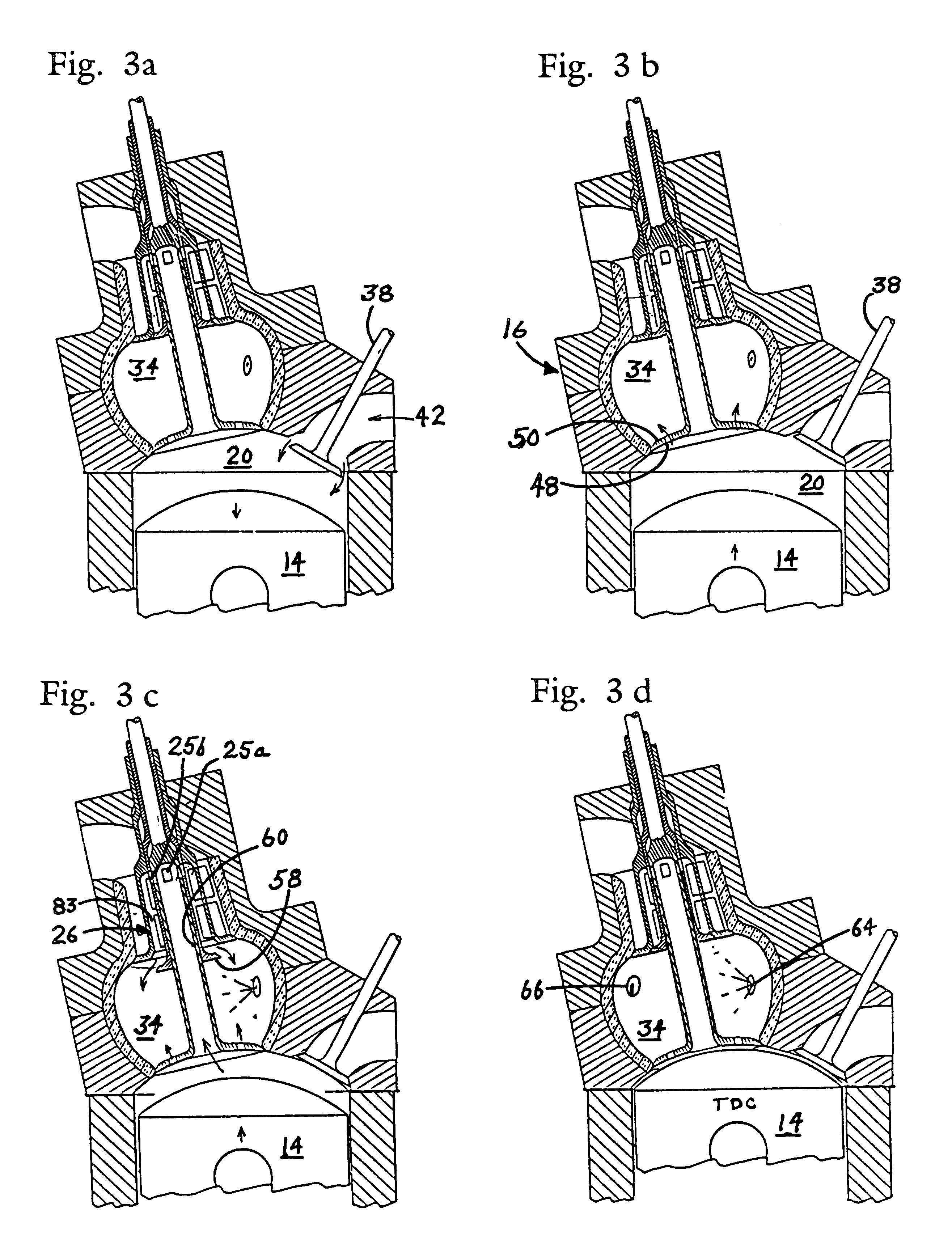

Four-stroke internal combustion engine with recuperator in cylinder head

InactiveUS6340013B1Prevent leakageQuick mixInternal combustion piston enginesCylinder headsThermal energyCommon Duct

A recuperating four-stroke internal combustion engine obtains improves Carnot efficiency by use of a new and novel cylinder head which captures thermal energy normally thrown away in the exhaust and re-introduces it to the working cycle. This result, long sought by others, has been achieved by incorporating within the head a compact internal recuperative heat exchanger in series with a combustion chamber or pre-chamber. A recuperator-protecting valve segregates the recuperator from hot combustion gases until the gases reach maximum expansion in the cylinder. Recuperators of both common-duct and seperated-duct design are described, the separated duct recuperator permitting higher recuperator temperature and increased efficiency and a reduction in the number of valves necessary to control gas flow. A preferred embodiment employs four valves per cylinder unit, a separated duct recuperator, and an insulating liner that surrounds both the combustion chamber and the recuperator. A similar prototype recuperative engine has demonstrated that recuperation can reduce exhaust temperature as much as 600° Rankine below that attainable in an equivalent Otto Cycle engine.

Owner:BRITTON RICHARD BERKELEY

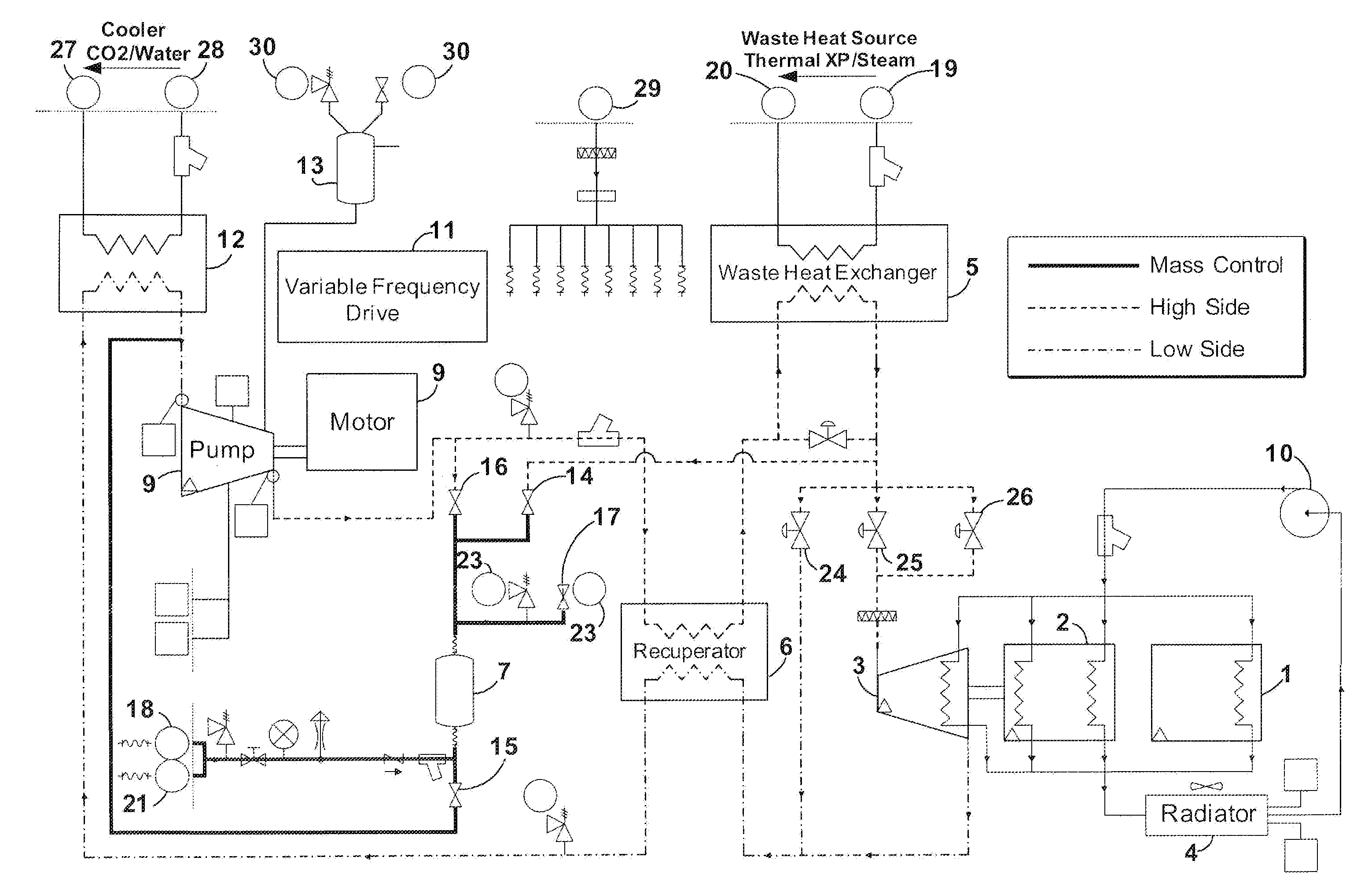

Heat engine and heat to electricity systems and methods with working fluid fill system

ActiveUS20110061384A1Easy to storeFluid heatersInternal combustion piston enginesThermal energyWorking fluid

A waste heat recovery system, method and device executes a thermodynamic cycle using a working fluid in a working fluid circuit which has a high pressure side and a low pressure side. Components of the system in the working fluid circuit include a waste heat exchanger in thermal communication with a waste heat source also connected to the working fluid circuit, whereby thermal energy is transferred from the waste heat source to the working fluid in the working fluid circuit, an expander located between the high pressure side and the low pressure side of the working fluid circuit, the expander operative to convert a pressure / enthalpy drop in the working fluid to mechanical energy, a recuperator in the working fluid circuit operative to transfer thermal energy between the high pressure side and the low pressure side of the working fluid circuit, a cooler in thermal communication with the low pressure side of the working fluid circuit operative to control temperature of the working fluid in the low side of the working fluid circuit, a pump in the working fluid circuit and connected to the low pressure side and to the high pressure side of the working fluid circuit and operative to move the working fluid through the working fluid circuit, and a mass management system connected to the working fluid circuit, the mass management system, method and device having a working fluid vessel connected to the low pressure side of the working fluid circuit and configured to passively control an amount of working fluid mass in the working fluid circuit. Systems and methods for supplying a working fluid to the working fluid circuit are disclosed.

Owner:ECHOGEN POWER SYST

Integrated solid oxide fuel cell and fuel processor

An integrated fuel cell unit (10) includes an annular array (12) of fuel cell stacks (14), an annular cathode recuperator (20), an annular anode recuperator (22), a reformer (24), and an anode exhaust cooler (26), all integrated within a common housing structure (28).

Owner:MODINE MFG CO

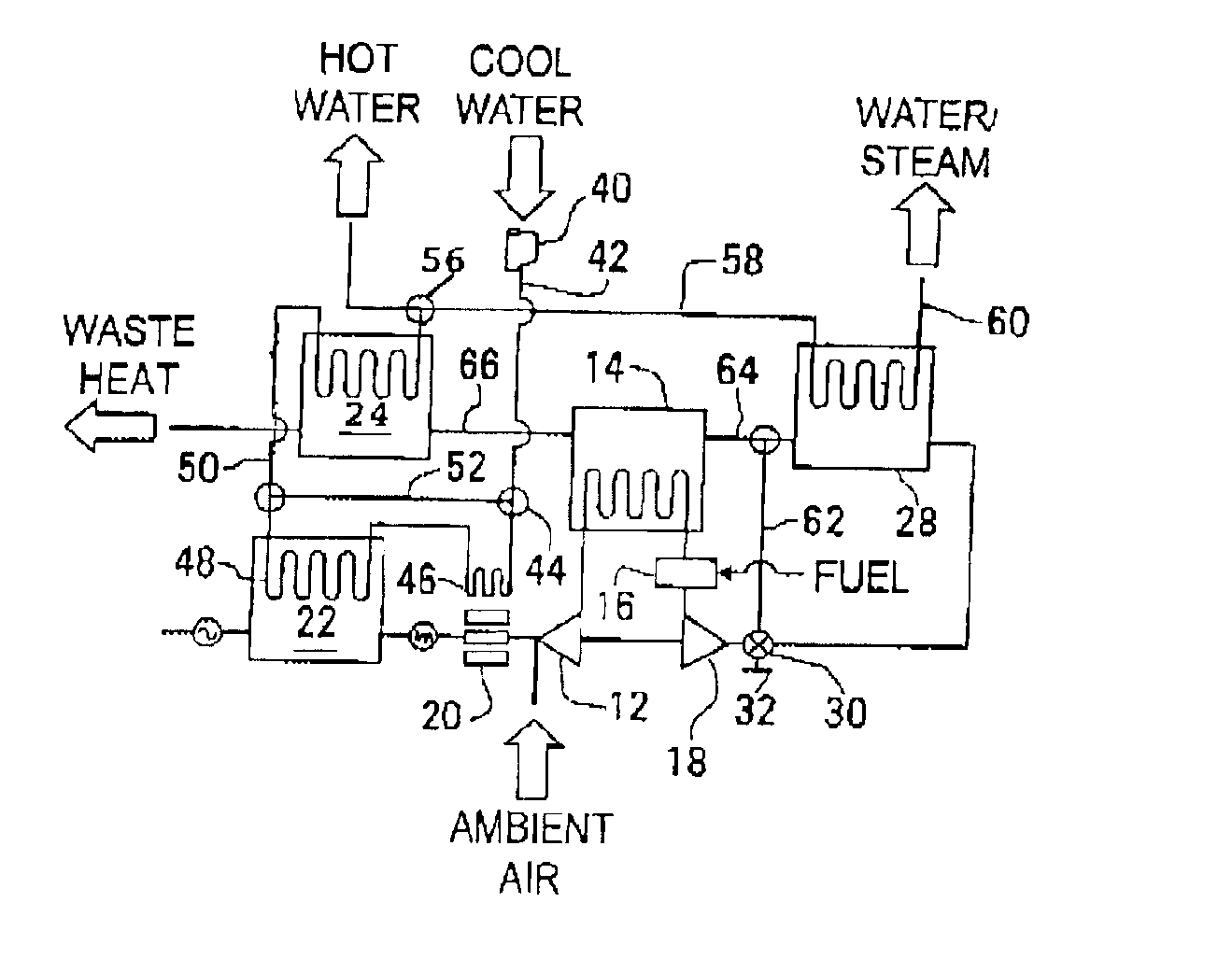

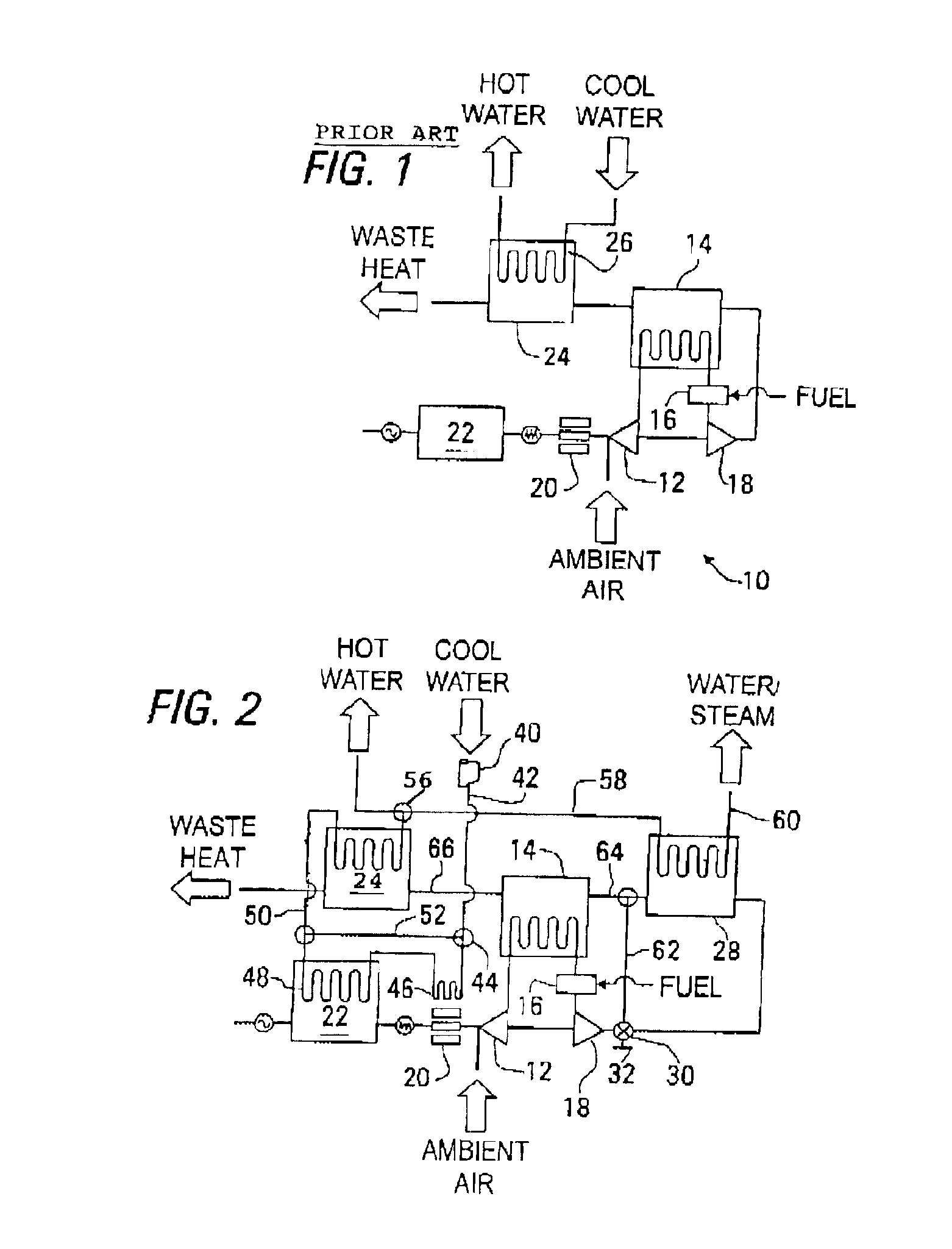

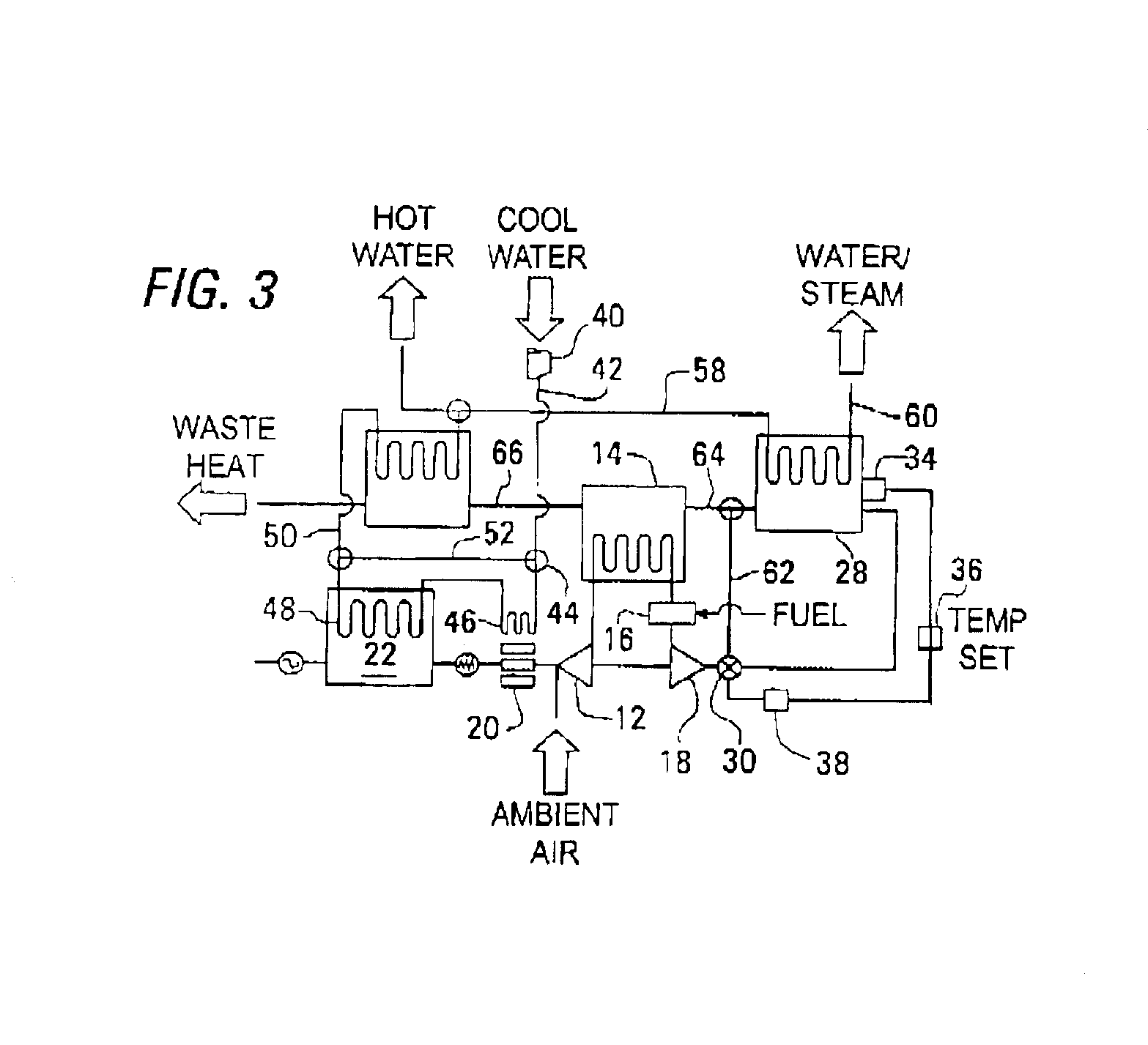

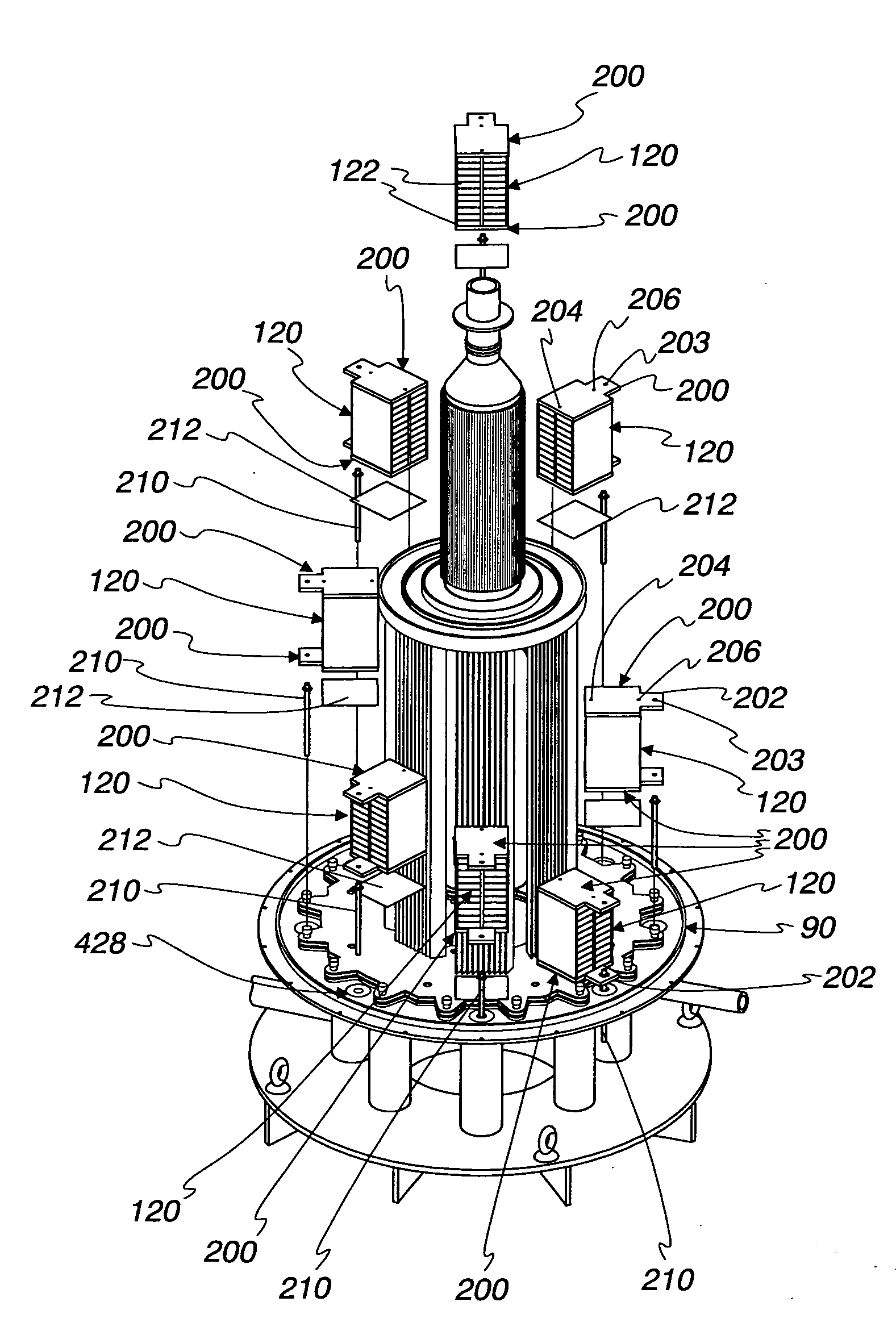

Microturbine exhaust heat augmentation system

InactiveUS6877323B2Efficiently transfer heatIncrease temperatureFluid heatersGas turbine plantsMicro gas turbineTransport medium

The microturbine engine that is typically utilized to power an electrical generating system and / or boiler, chiller and the like includes a second boiler and a by-pass system for providing heated water at two different levels or where one of the boilers provides steam. The turbine exhaust is utilized as the heat transport medium and is directly connected to one of the boilers while the other is connected to the recuperator. The system can optionally provide cooling to the electrical and electronic components of the system by providing a water circuit for leading water into the electric and electronic components prior to feeding the boilers. The system is designed to assure that the delta heat difference between the medium being heated and the waste heat of the turbine is sufficient so that the heat exchange will be done efficiently.

Owner:WELLS FARGO BANK NAT ASSOC

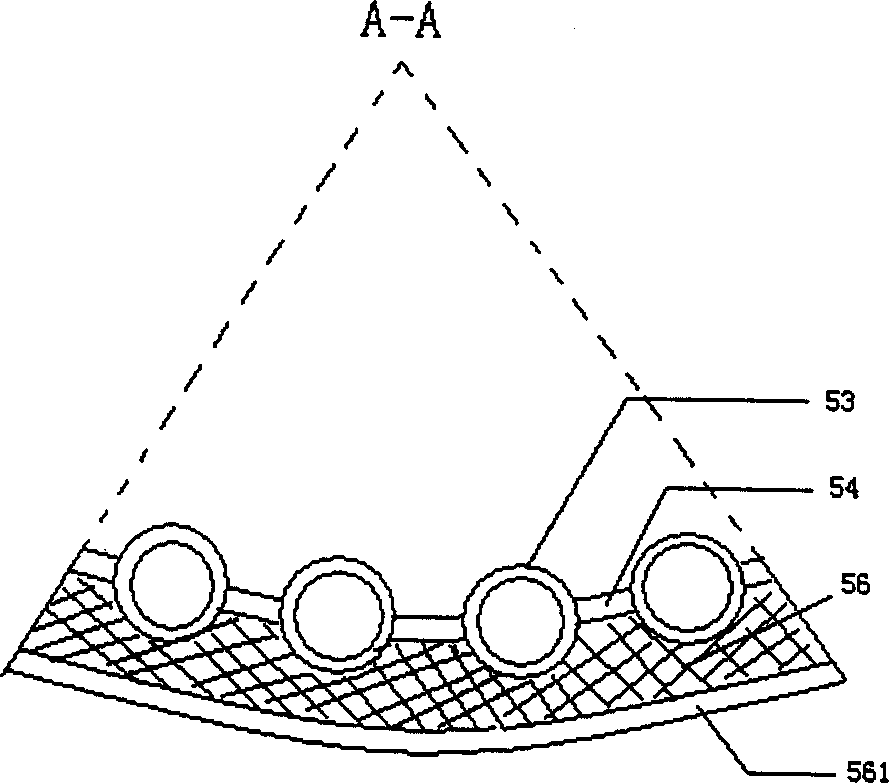

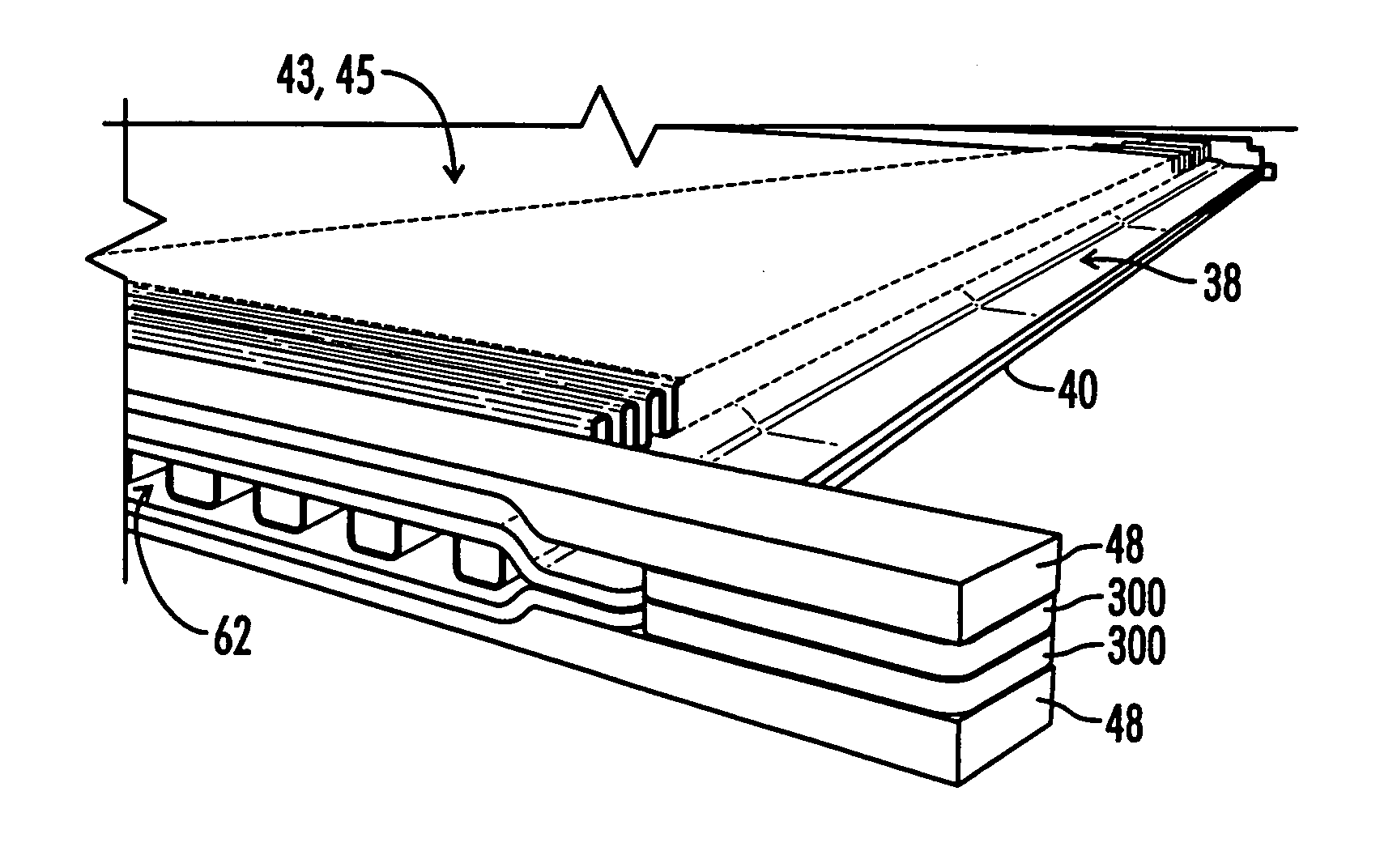

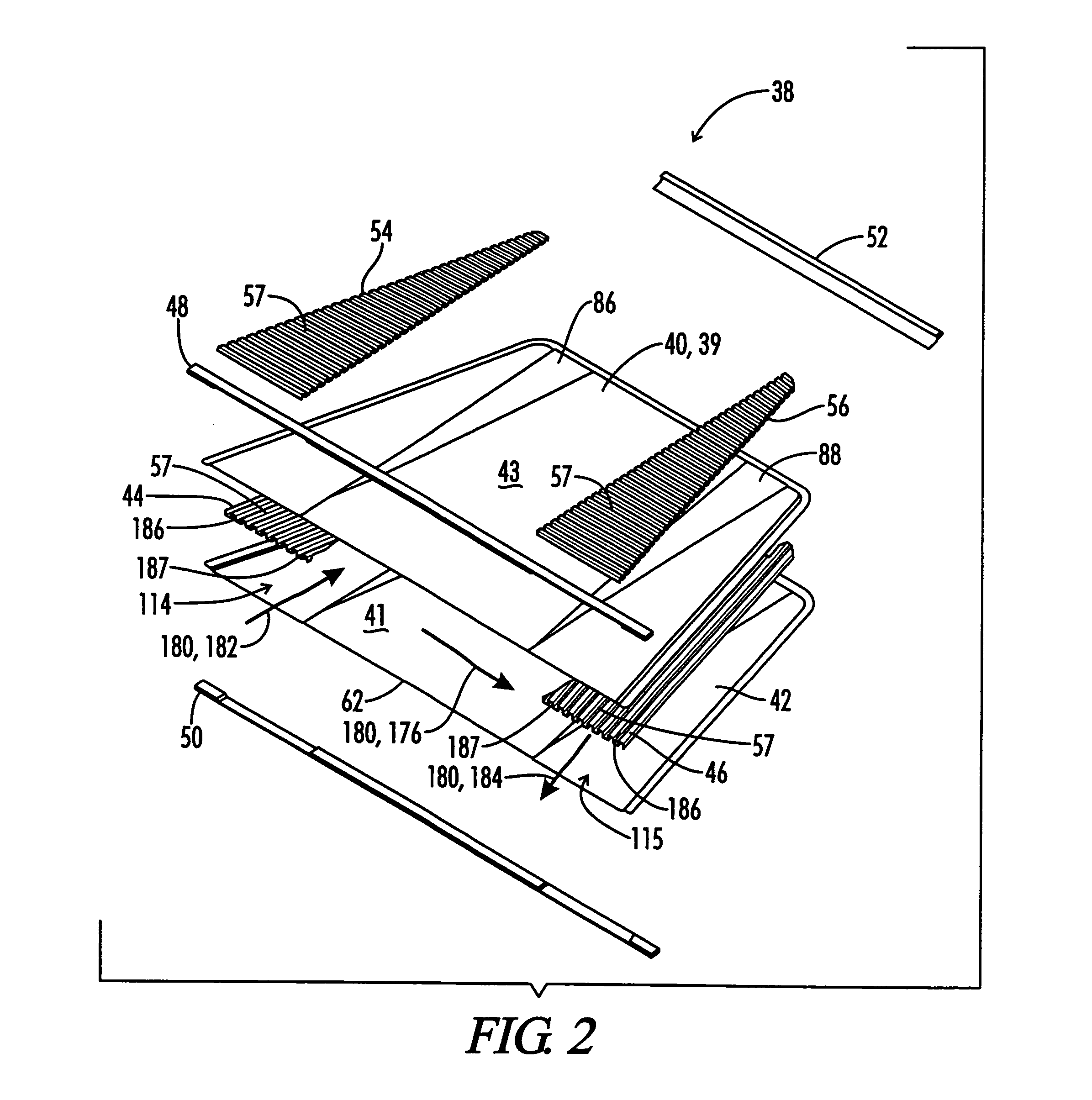

Recuperator assembly and procedures

ActiveUS7065873B2Increase in sizeImprove heat transfer performanceMetal-working apparatusMachines/enginesEngineeringRecuperator

A construction of recuperator core segments is provided which insures proper assembly of the components of the recuperator core segment, and of a plurality of recuperator core segments. Each recuperator core segment must be constructed so as to prevent nesting of fin folds of the adjacent heat exchanger foils of the recuperator core segment. A plurality of recuperator core segments must be assembled together so as to prevent nesting of adjacent fin folds of adjacent recuperator core segments.

Owner:CAPSTONE GREEN ENERGY CORP

Integrated solid oxide fuel cell and fuel processor

An integrated fuel cell unit (10) includes an annular array (12) of fuel cell stacks (14), an annular cathode recuperator (20), an annular anode recuperator (22), a reformer (24), and an anode exhaust cooler (26), all integrated within a common housing structure (28).

Owner:MODINE MFG CO

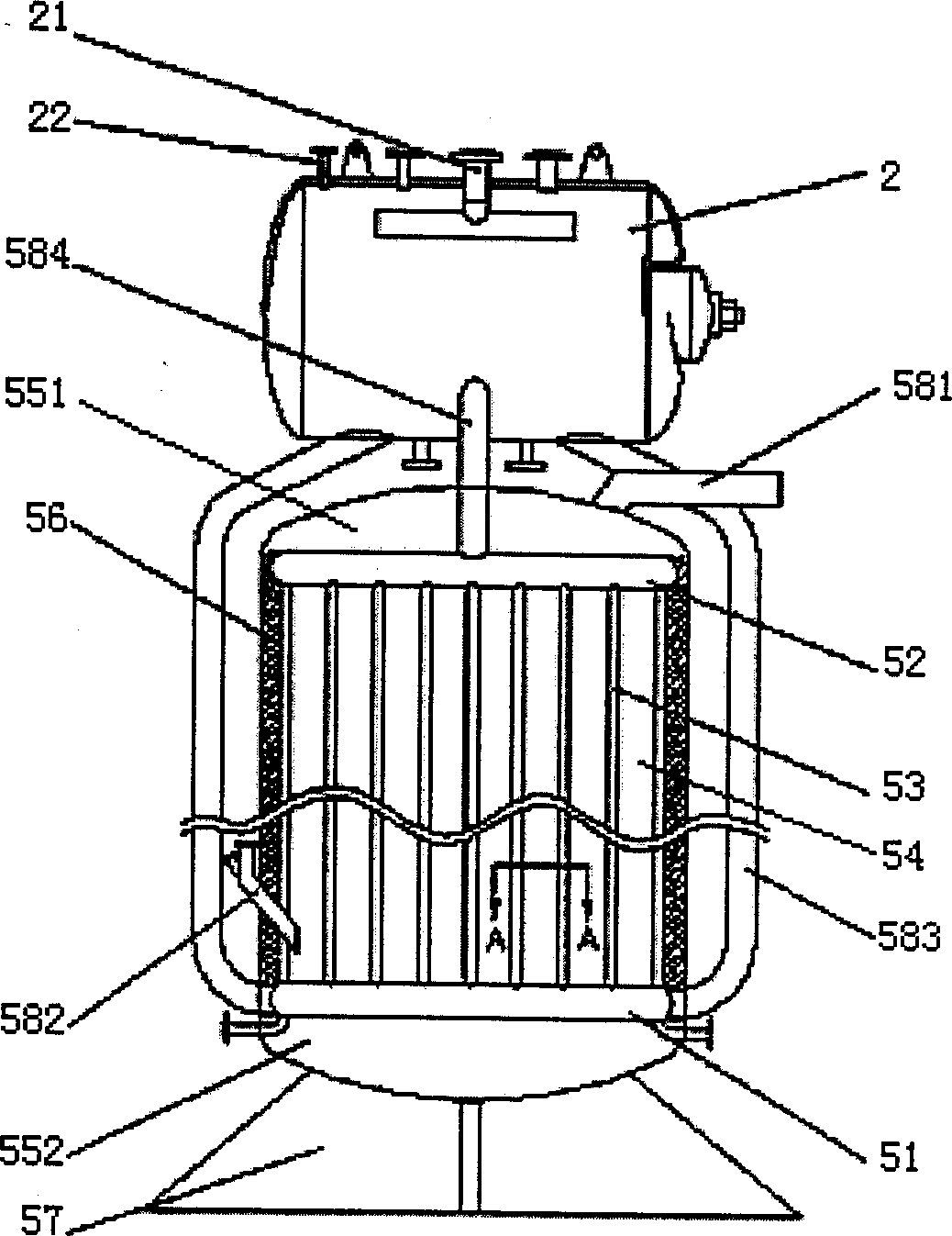

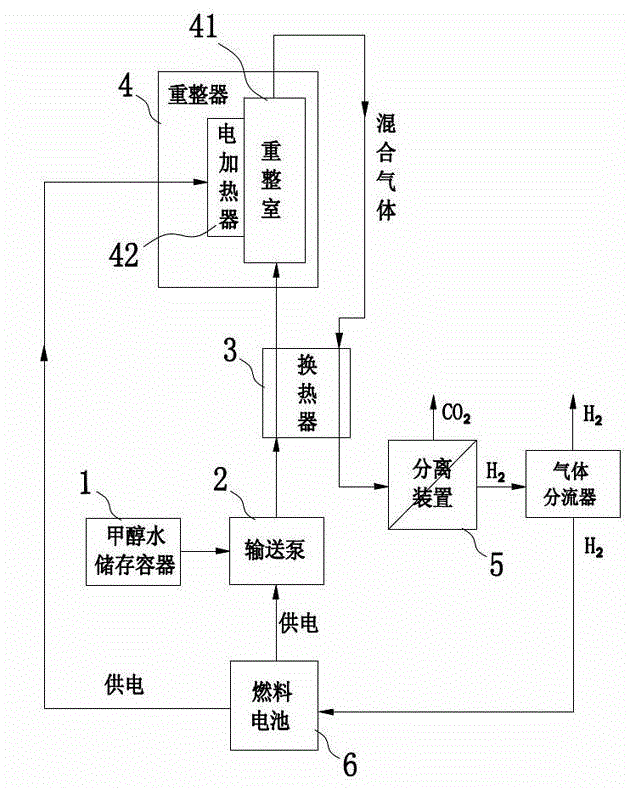

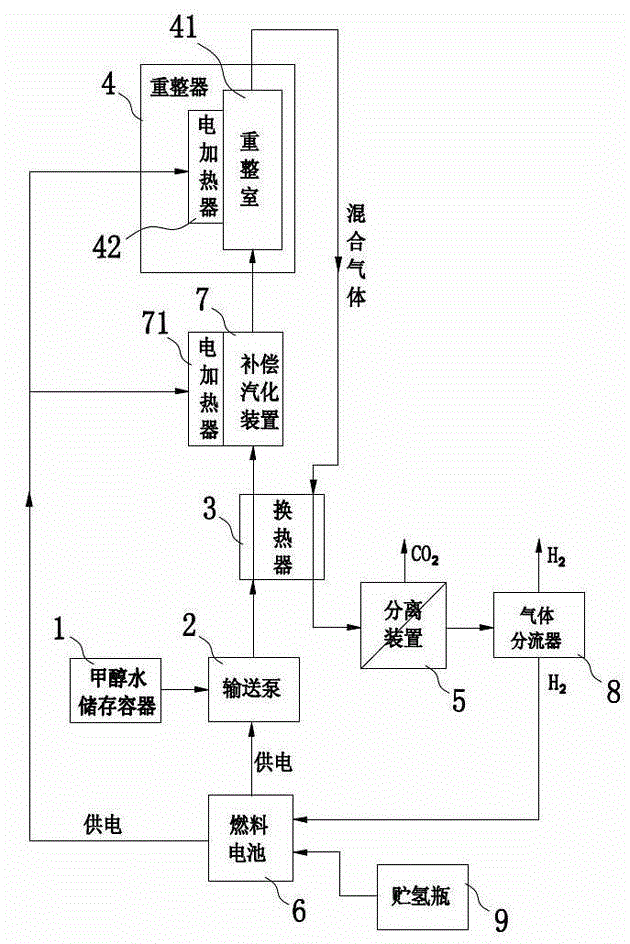

Methanol water hydrogen-making machine and hydrogen-making method thereof

InactiveCN104362355ASolve the damageReduce structural complexityHydrogenCell electrodesElectrochemical responseCombustion chamber

The invention discloses a methanol water hydrogen-making machine and a hydrogen-making method thereof. The methanol water hydrogen-making machine comprises a methanol water storage container, a delivery pump, a heat exchanger, a reformer, a separation device and a fuel cell, wherein the delivery pump is used for delivering methanol and water inside the methanol water storage container to a reforming chamber of the reformer; the heat exchanger is used for carrying out heat exchange on the low-temperature methanol and water and a high-temperature mixed gas output from the reforming chamber; the reformer is provided with the reforming chamber and an electric heater, and the electric heater provides heat energy for the reforming chamber; and the high-temperature mixed gas which takes carbon dioxide and hydrogen as main parts is prepared in the reforming chamber, passes through the heat exchanger and then enters the separation device to be separated to obtain the hydrogen, and a part of the hydrogen enters the fuel cell and generates electrochemical reaction in the fuel cell to generate electric energy to provide electricity for the delivery pump and the electric heater. According to the methanol water hydrogen-making machine, the reformer has no need of being provided with a combustion chamber, an air inlet fan, an air inlet channel and a smoke window, the heating temperature inside the reformer is easily controlled and stable, and the reformer is simple in structure, stable in work and low in overhaul difficulty.

Owner:GUANGDONG HYDROGEN ENERGY SCI & TECH

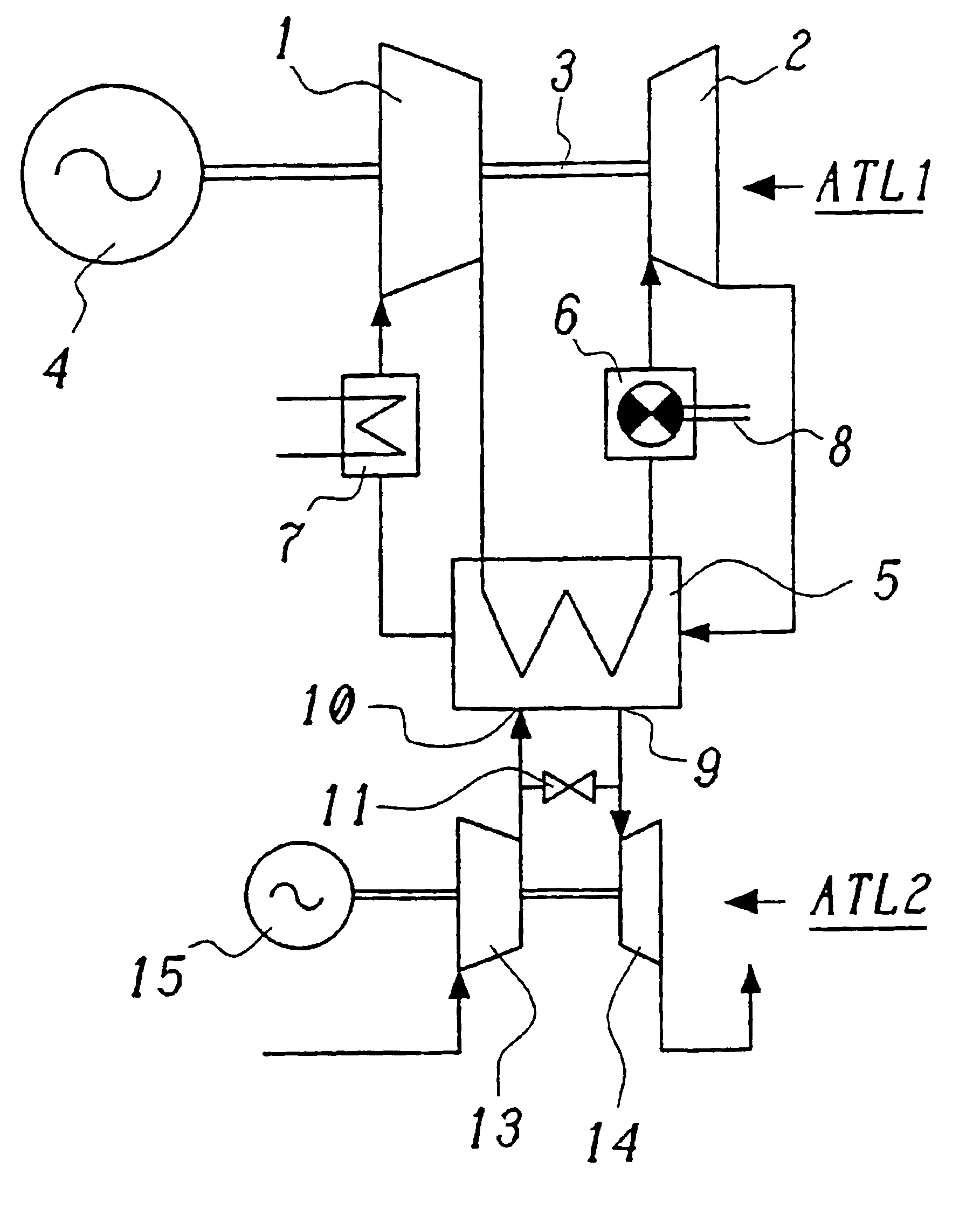

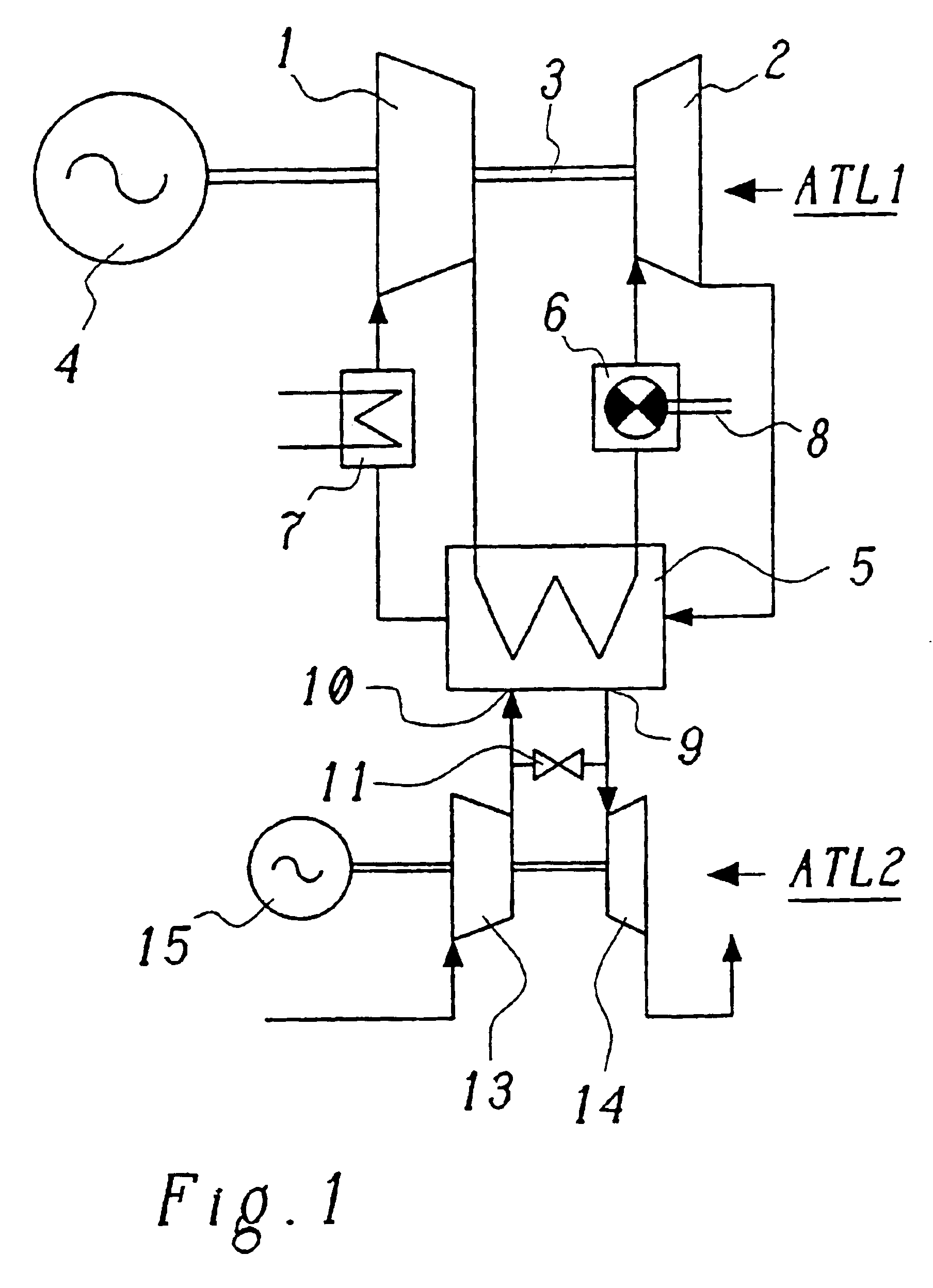

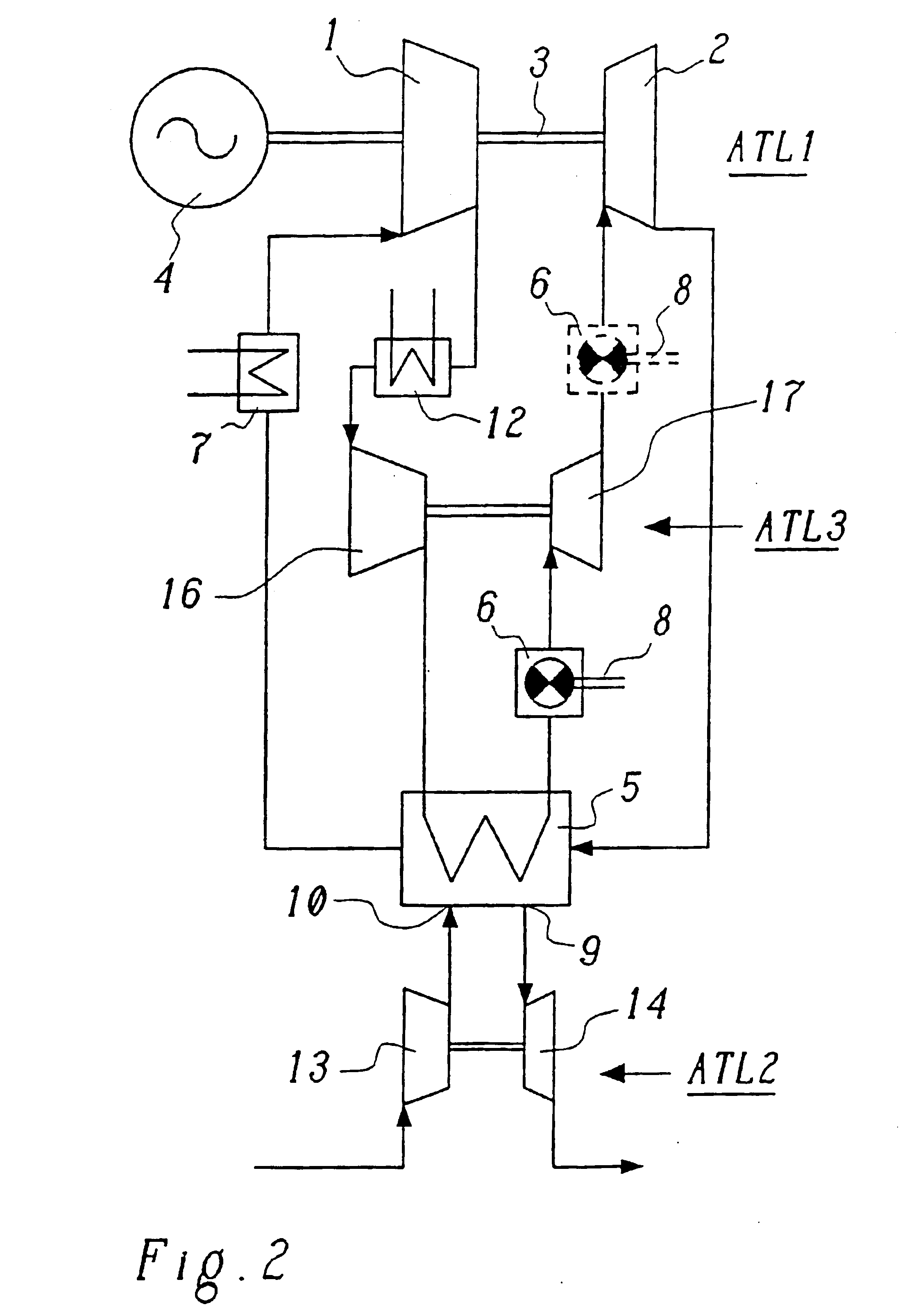

Method for operating a partially closed, turbocharged gas turbine cycle, and gas turbine system for carrying out the method

A gas turbine system includes a gas turbine (1, 2, 3) having a compressor (1) and a turbine (2), which via a common shaft (3) drive a generator (4), and a combustion chamber (6), the exit of which is connected to the entry to the turbine (2) of the gas turbine (1, 2, 3), has a fuel feed (8) and receives combustion air from the exit of the compressor (1) of the gas turbine (1, 2, 3) via the high-pressure side of a recuperator (5), the exit of the turbine (2) and the entry to the compressor (1) of the gas turbine (1, 2, 3) being connected via the low-pressure side of the recuperator (5), and a first exhaust-gas turbocharger (ATL2) which sucks in air being connected to different locations (9, 10) of the low-pressure side of the recuperator (4) via the exit of its compressor (13) and the entry to its turbine (14).

Owner:ALSTOM TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com