Patents

Literature

1129 results about "Yellow phosphorus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

White phosphorus is a translucent waxy solid that quickly becomes yellow when exposed to light. For this reason it is also called yellow phosphorus. It glows greenish in the dark (when exposed to oxygen) and is highly flammable and pyrophoric (self-igniting) upon contact with air.

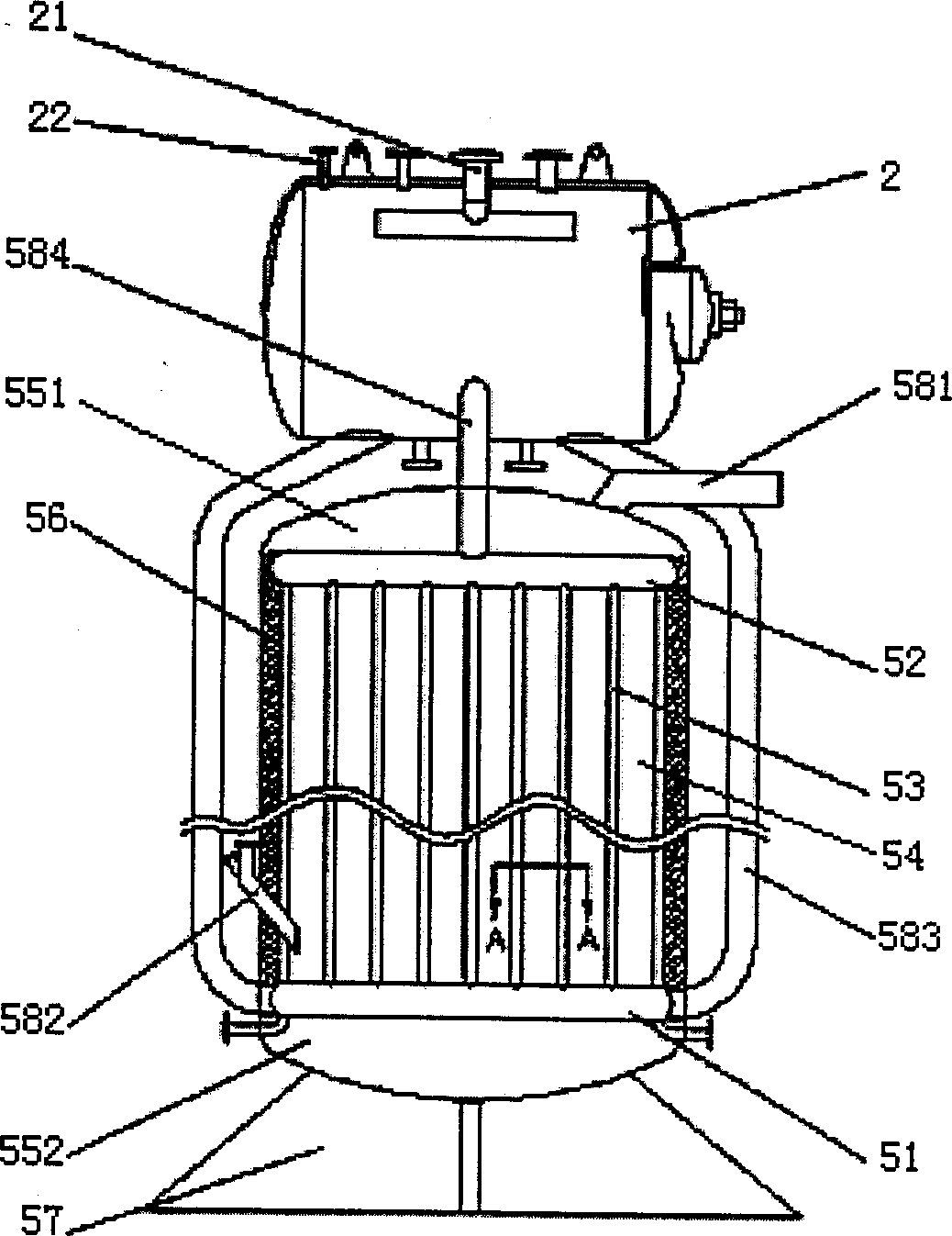

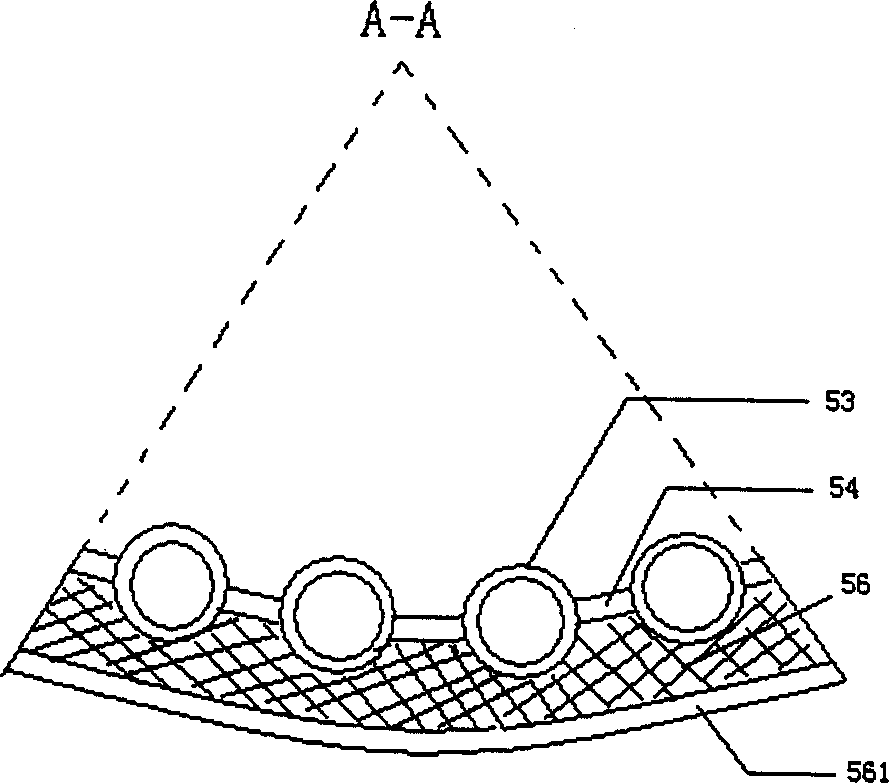

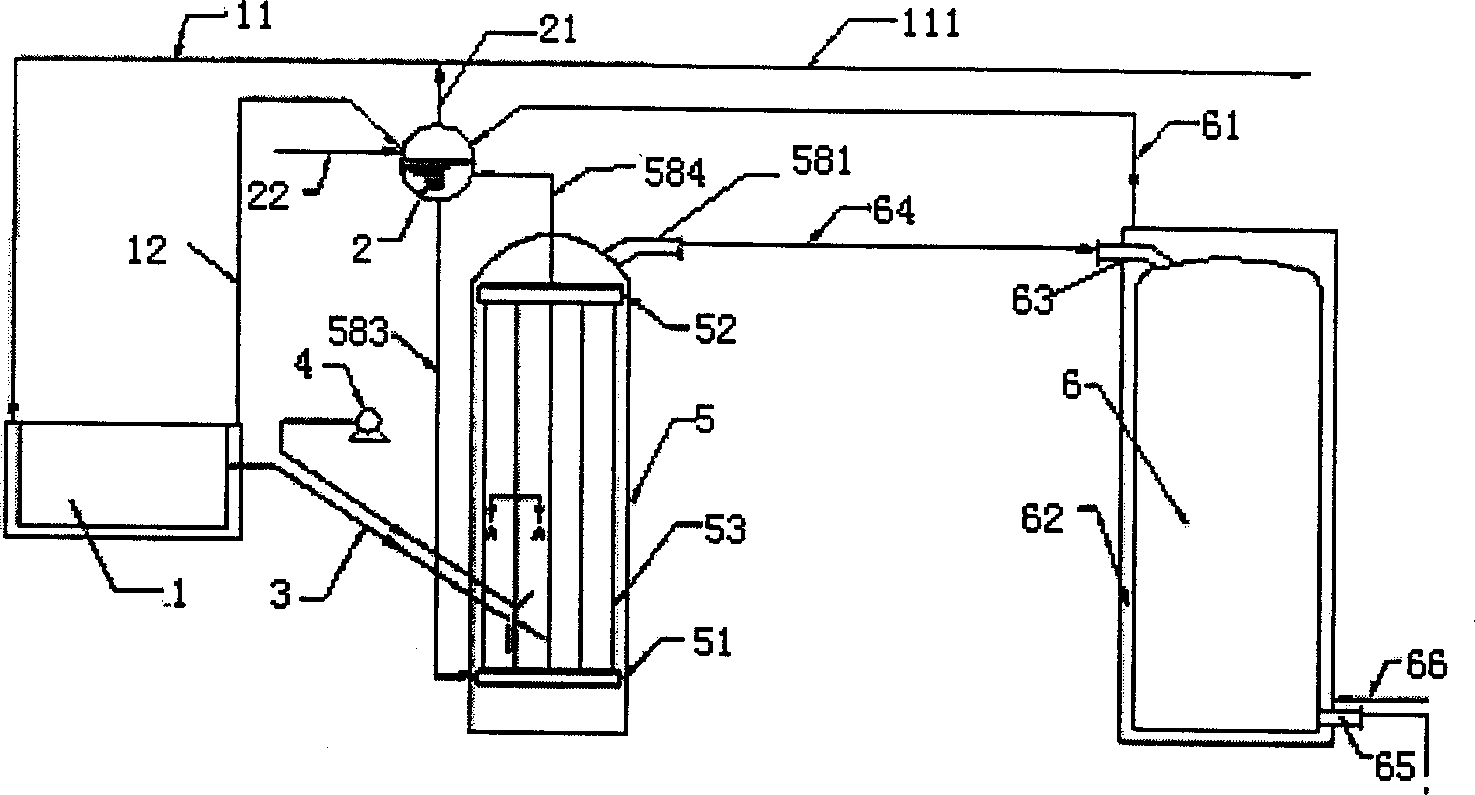

Equipment for recovering and utilizing heat energy generated by phosphor combustion and system for preparing phosphoric acid by hot method

An equipment for recovering and utilizing the heat energy generated by burning yellow phosphorus and a system for preparing phosphoric acid by the hot method are disclosed. It is composed of steam manifold and burning tower with heat energy recovering function. The burning tower consists of ring-shaped membrane heat exchanger with fins, heat-insulaitng enclosed casing, P2O5 gas outlet tube, connecting tube of phosphorus sprayer, etc.. Its advantages include low consumption of coal, water and energy, low cost and reduced environmental pollution.

Owner:TSINGHUA UNIV +1

Method for producing baking-free bricks by using phosphorous gypsum based cementitious material to solidify yellow phosphorous slags

InactiveCN101637936ASolve pollutionLow costSolid waste managementMixing operation control apparatusBrickSlag

Owner:KUNMING UNIV OF SCI & TECH

Method for producing air entrapping building block by utilizing ardealite

InactiveCN101648403AReduce secondary pollutionLow costSolid waste managementMixing operation control apparatusMass ratioSlag

The invention provides a method for producing an air entrapping building block by utilizing ardealite, comprising the following processing steps: mixing materials according to the following mass ratio: 50-70 percent of ardealite, 10-15 percent of cement, 15-25 percent of yellow phosphorus slag and 5-10 percent of lime, then adding water according to 85-100 percent of the mass of the mixture, adding aluminium powder according to 0.04-0.06 percent of the mass of the mixture and adding an auxiliary agent according to 0.5-0.8 percent of the mass of the mixture, and then mixing to prepare a sizingagent; and finally obtaining the air entrapping building block through foaming, standing and steam curing. The air entrapping building block has the advantages of stable physical properties, light weight, good heat-insulation property, high waste use ratio, simple process, low cost, environmental protection, natural resource saving and the like, and can be used as non-load bearing partitions of urban high-rise buildings and as heat-insulation building blocks of low-temperature warehouses, heat-insulation warehouses and cold storage warehouses of industrial equipment.

Owner:KUNMING UNIV OF SCI & TECH

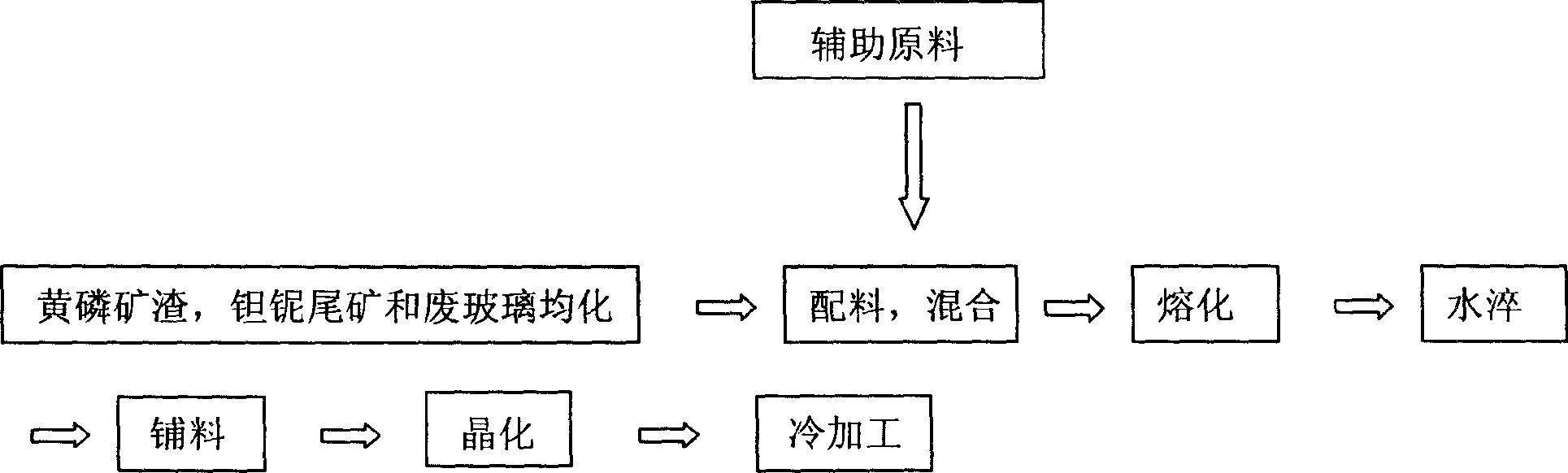

Waste residue microcrystal glass and its preparation method

A microcrystalline glass with low cost and low smelting temp is proportionally prepared from the industrial slag (yellow phosphorus slag), Ta-Nb ore tailings, rejected glass and auxiliary. It contains SiO2 (55-71 Wt%), Al2O3 (3-10), CaO (16-30), ZnO (2-4), BaO (1-4), Na2O+K2O+Li2O (1-10), P2O5 (0-3) and B2O3 (0-3). Its preparing process is also disclosed.

Owner:WUHAN UNIV OF TECH

Thermal preservation energy saving composite phase change energy storage gypsum board prepared by using phosphorous gypsum and preparation method thereof

InactiveCN102659377AImprove hydrophilicitySimple preparation processHeat-exchange elementsParaffin waxSlag

The invention provides a thermal preservation energy saving composite phase change energy storage gypsum board prepared by using phosphorous gypsum and a preparation method thereof. The thermal preservation energy saving composite phase change energy storage gypsum board comprises the following components: 45-60 parts of phosphorous gypsum, 3-35 parts of yellow phosphorus slag, 10-20 parts of cement, 2-5 parts of calcined lime, 0.8-1.4 part of polycarboxylic acid type water-reducer and 0.9-1.8 part of polypropylene fiber; and the composite phase change energy storage gypsum board is obtained after the components and a shape-stabilized phase change energy storage material are mixed. The paraffin wax-high density polyethylene polymer shape-stabilized phase change material prepared by the invention has good hydrophilicity and can be applied to a phosphorous gypsum gelatinization component; the thermal preservation energy saving composite phase change energy storage gypsum board has the advantages that the technology is simple, the operation is convenient, the continuous production can be carried out, and the application range of the phase change energy storage material can be widened, and the application of the phase change energy storage material in production and life is simplified; and the prepared composite phase change energy storage gypsum board has excellent thermal stability and better water repellency.

Owner:KUNMING UNIV OF SCI & TECH

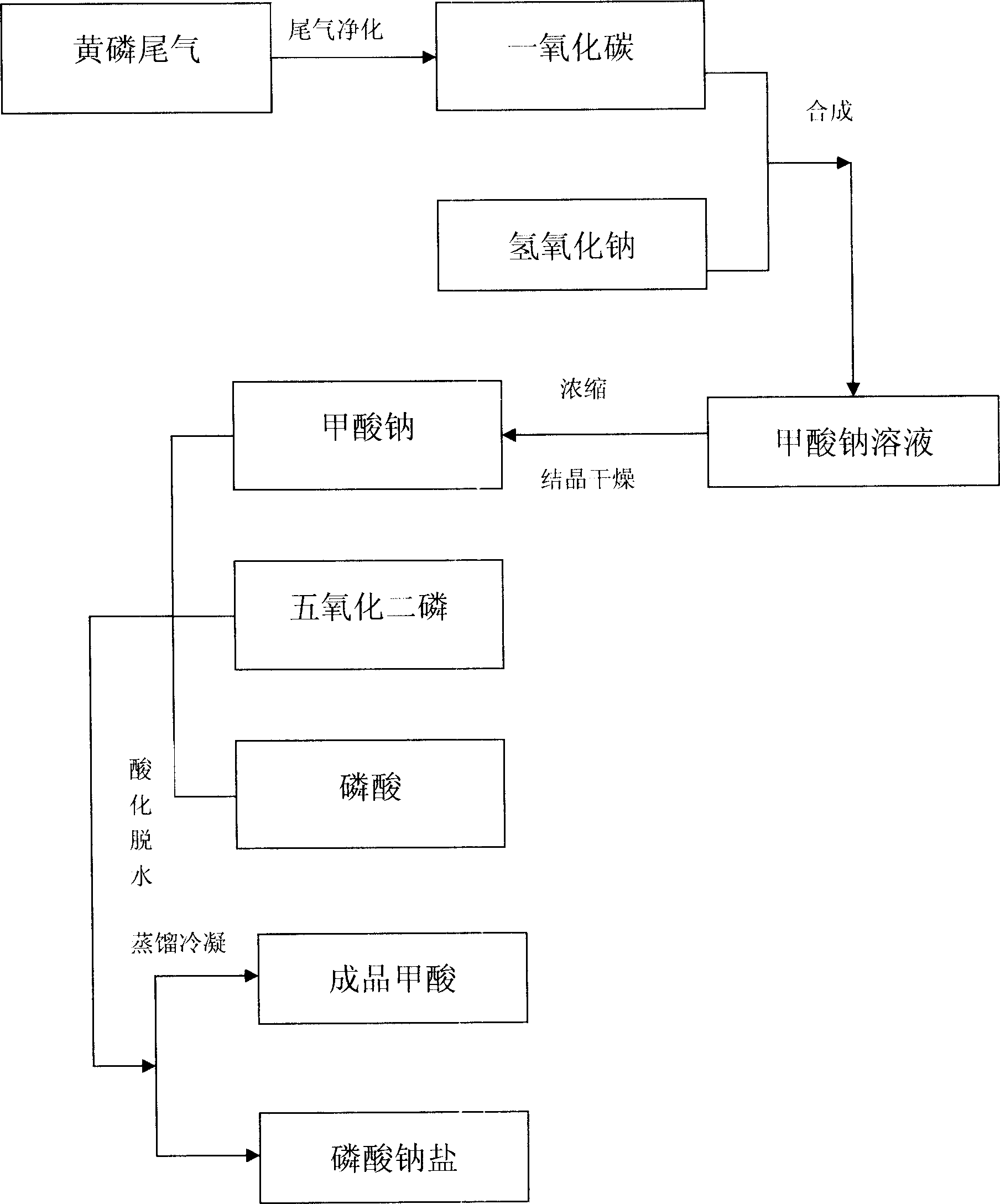

Method for producing formic acid through phosphoric acid and sodium formate

InactiveCN1915954AImprove utilizationEmission reductionPreparation from carboxylic acid saltsPhosphoric acidFormic acid

This invention discloses a method for preparing formic acid from phosphoric acid and sodium formate. The method comprises: reacting CO produced from yellow phosphorus manufacture with caustic soda to obtain sodium formate, then reacting with phosphoric acid, dehydrating with P2O5, and distilling to obtain formic acid. The method can reduce CO2 emission, thus is environmentally friendly. Besides, the method can lower the cost of yellow phosphorus and formic acid manufacture.

Owner:HUBEI XINGFA CHEM GRP CO LTD

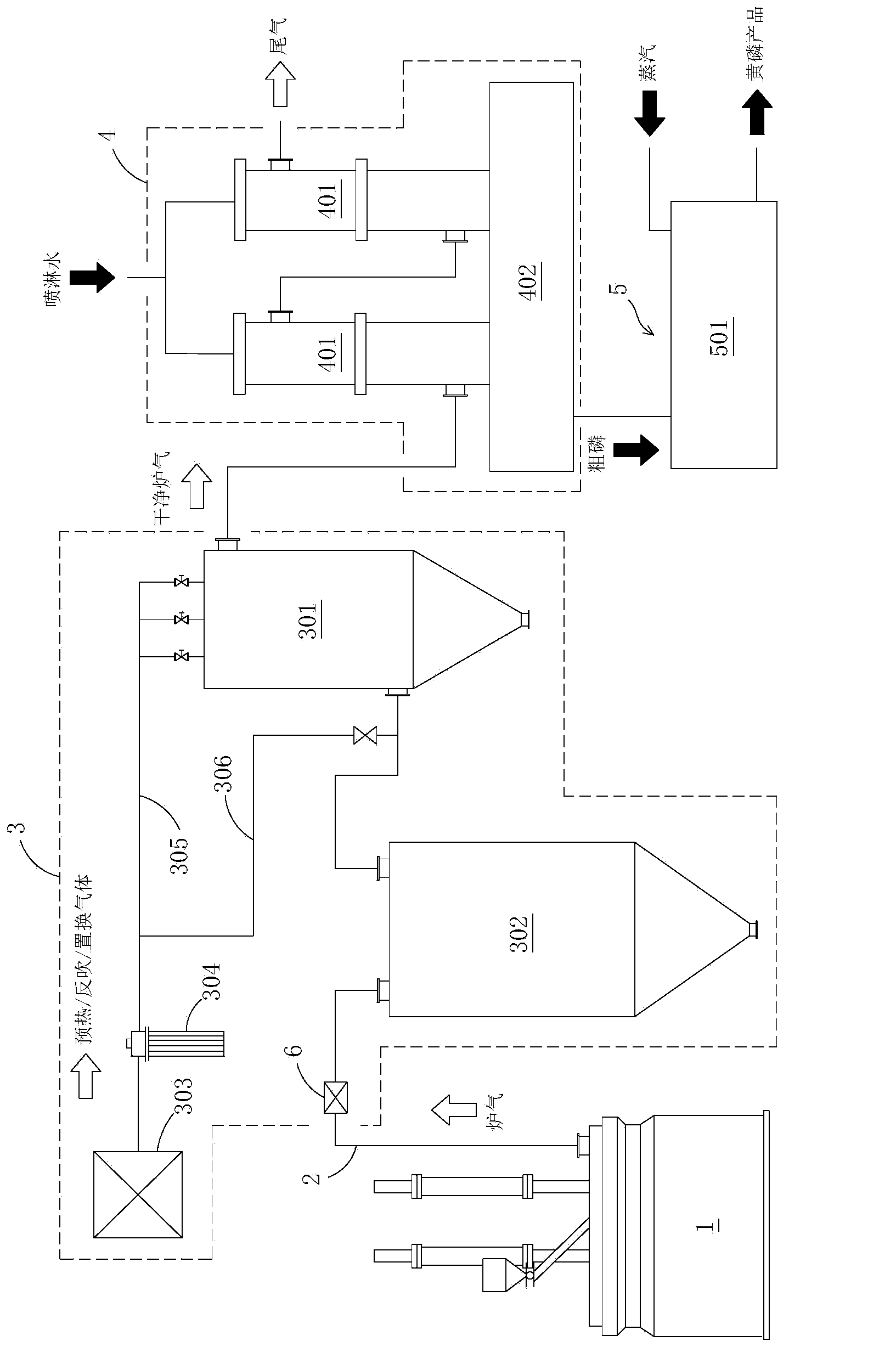

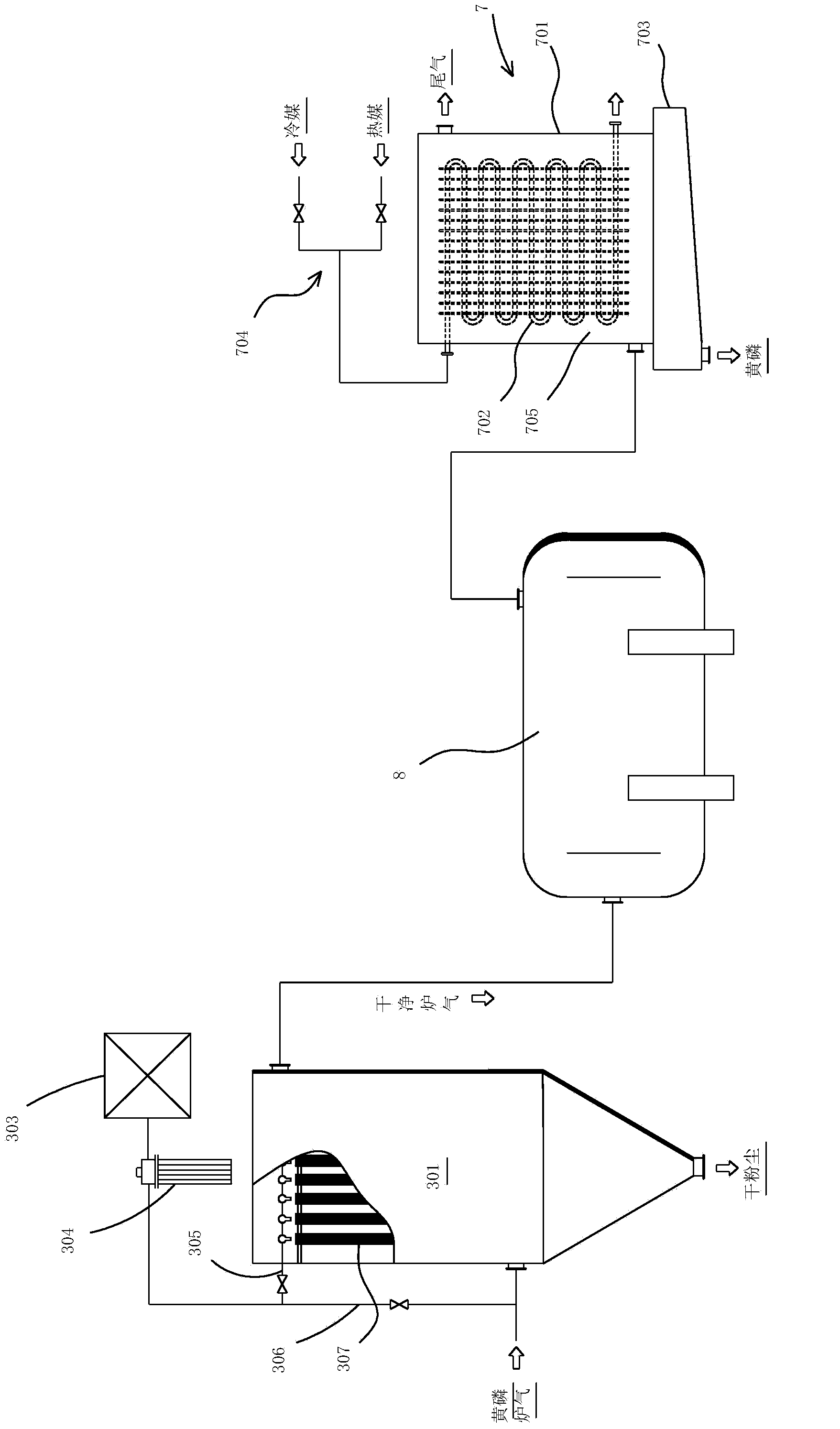

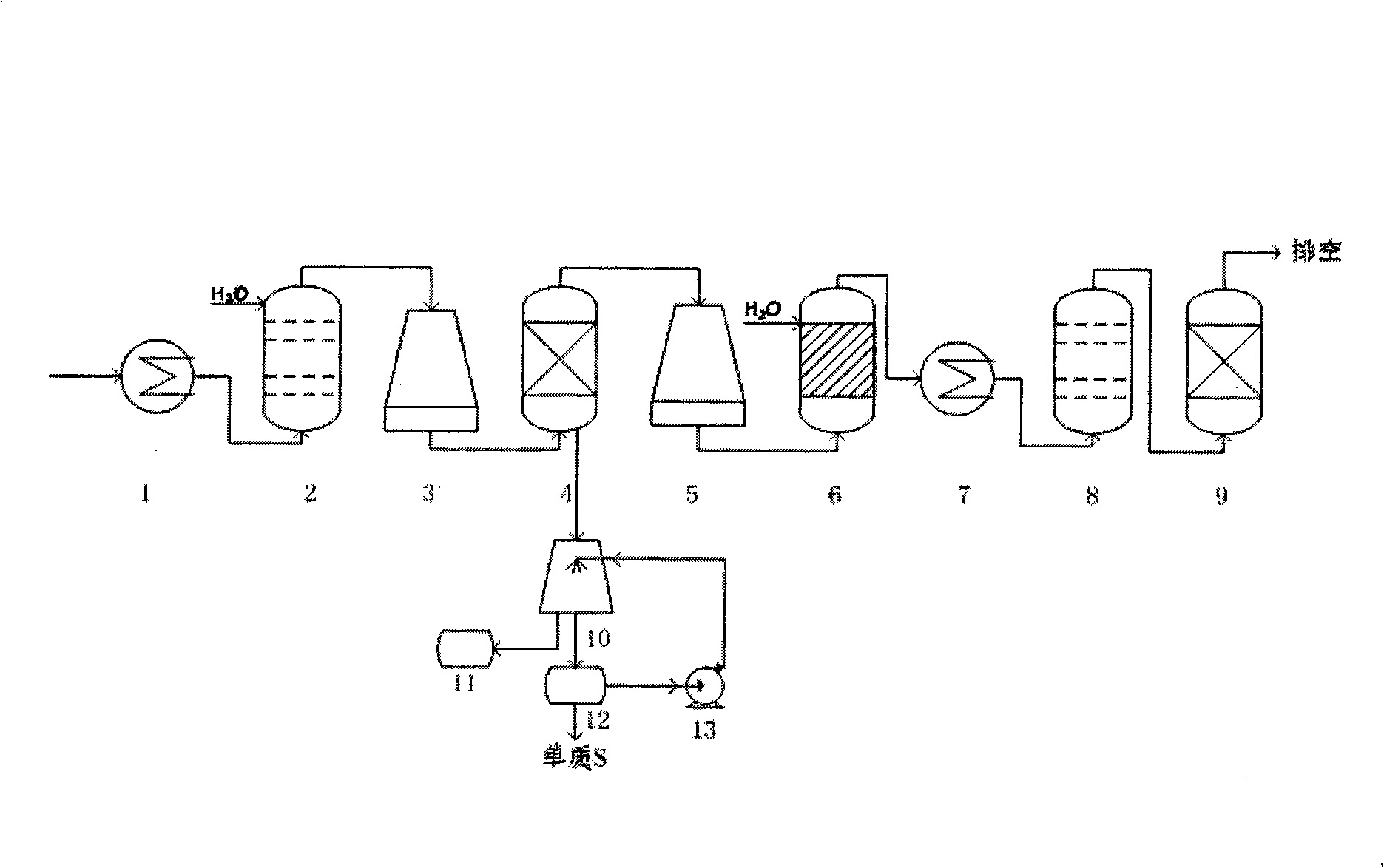

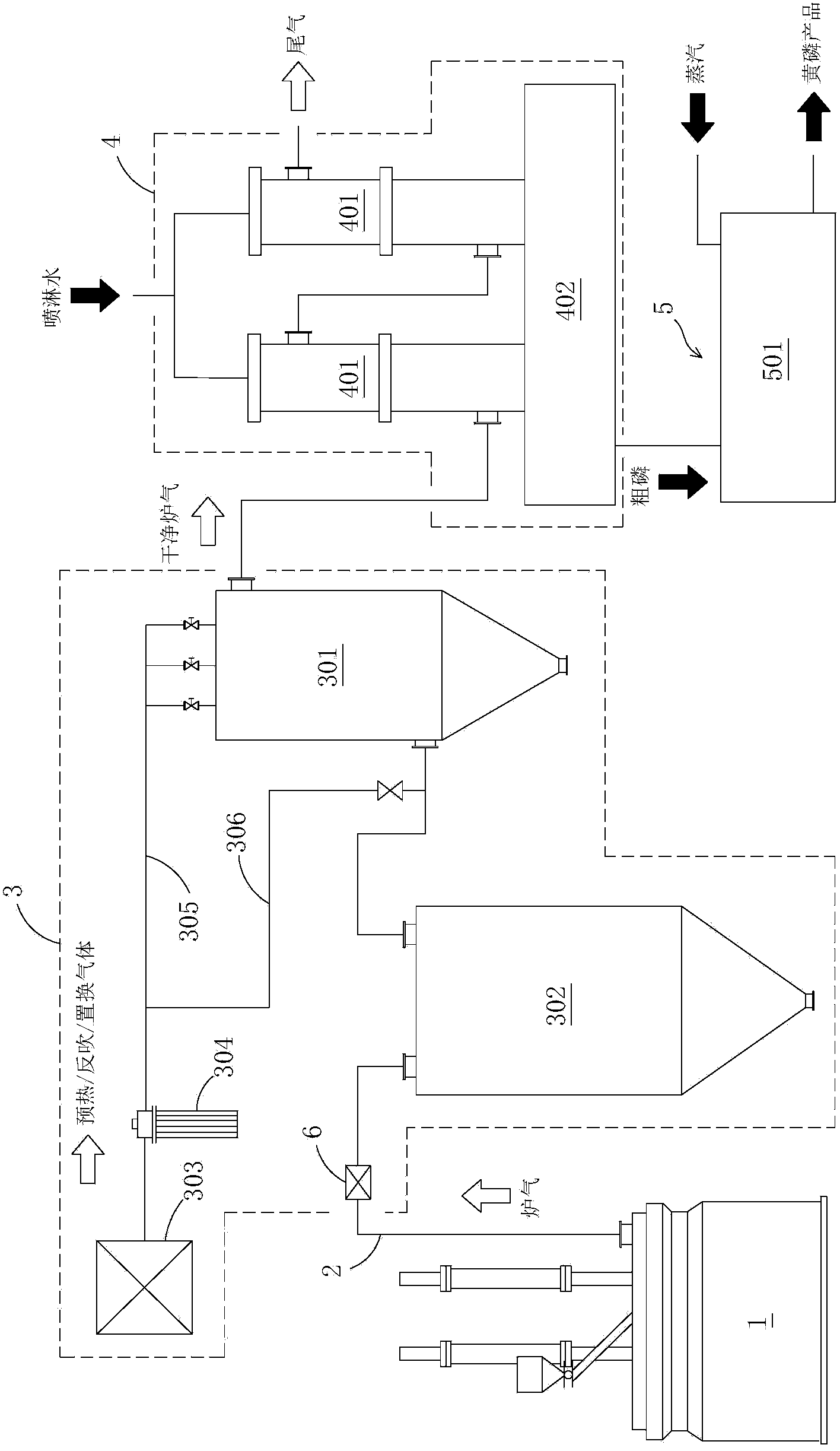

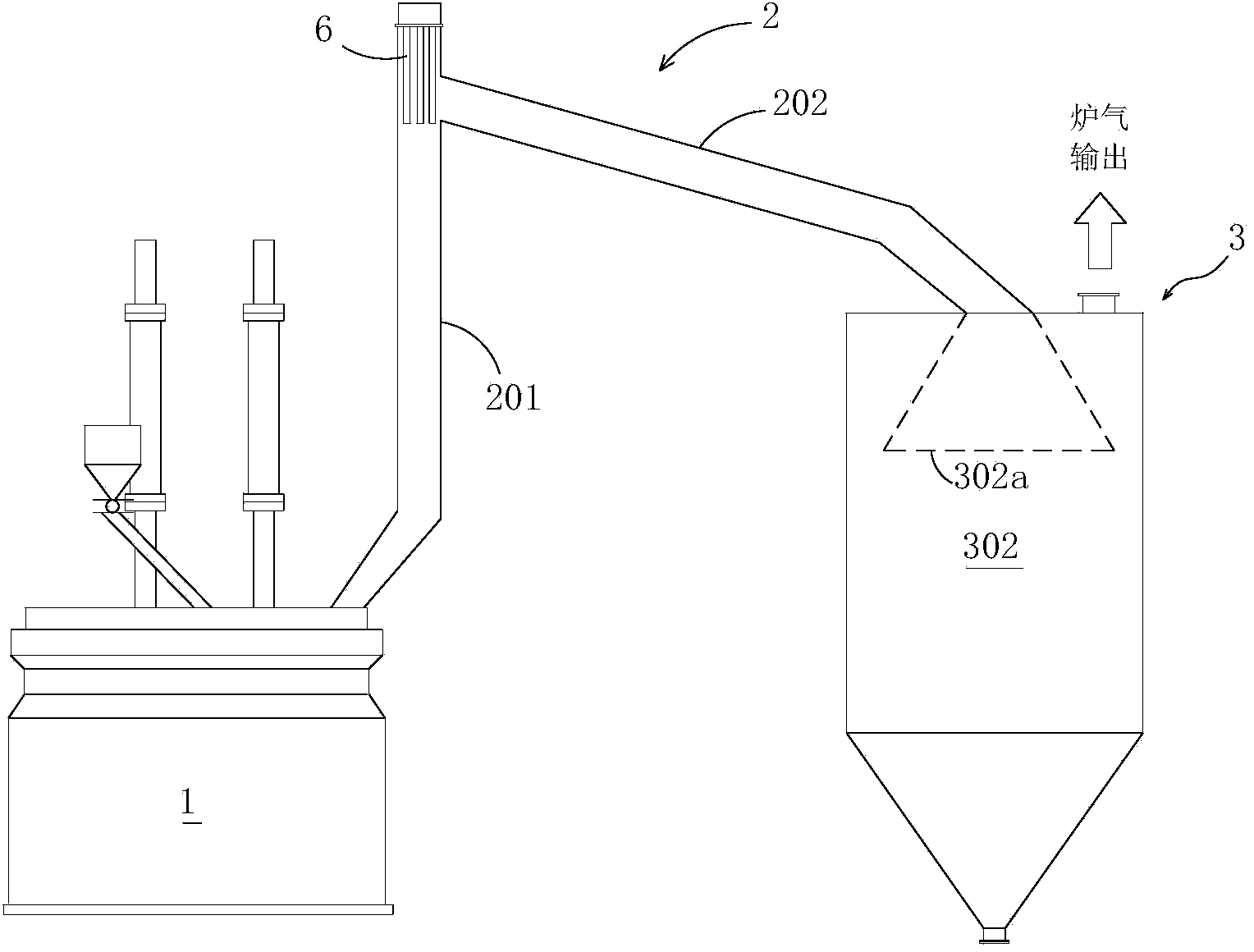

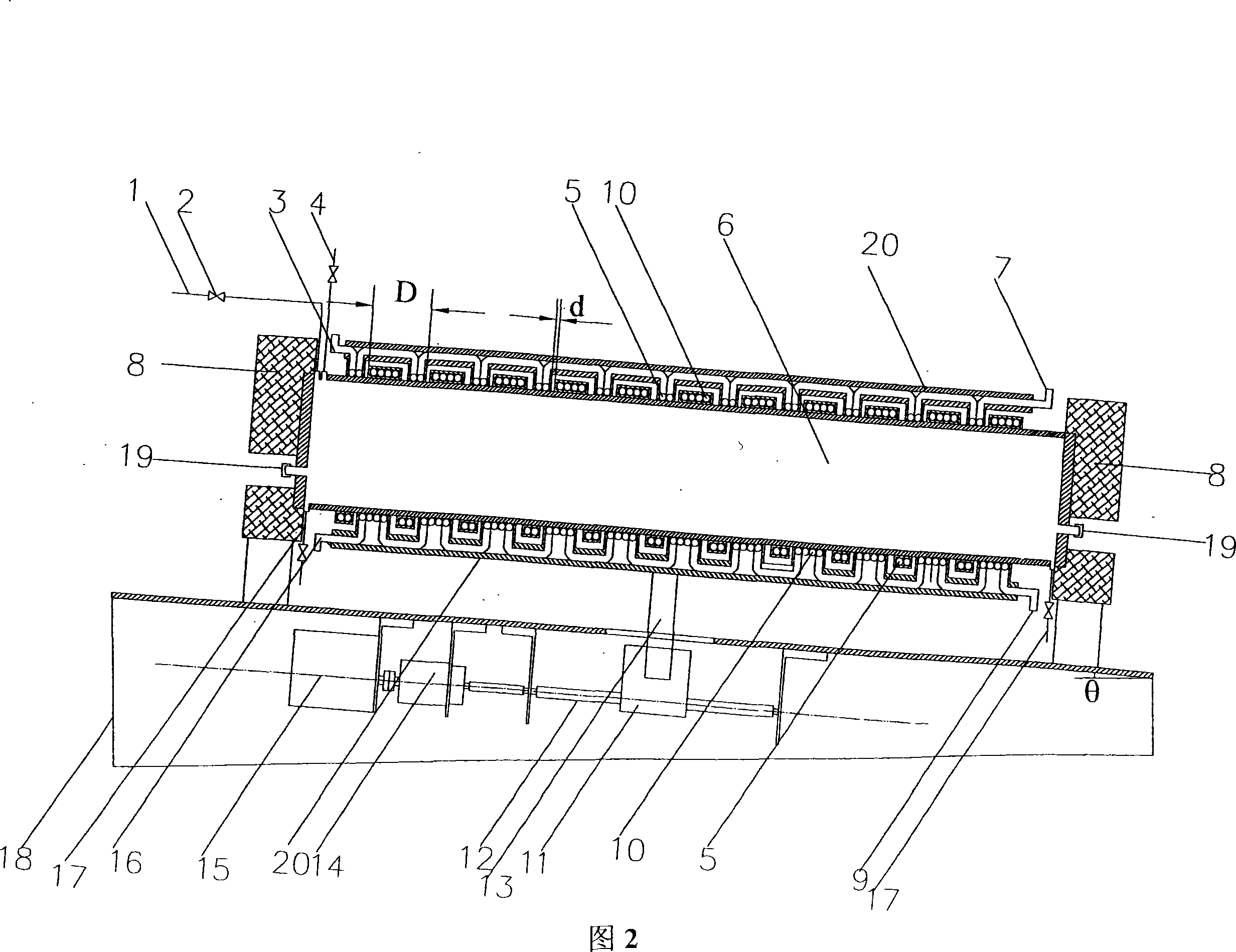

Method and equipment for recovering yellow phosphorus from electric furnace phosphorus-producing furnace gas and special phosphorus collecting device

ActiveCN103708432ADispersed particle separationChemical/physical/physico-chemical processesRecuperatorSolid content

The invention discloses a method and equipment for recovering yellow phosphorus from an electric furnace phosphorus-producing furnace gas without adopting a spray cooling mode in condensation of the electric furnace phosphorus-producing furnace gas, and a special phosphorus collecting device, so as to solve the common problem caused by the spray cooling mode at present. The method comprises the following steps: 1) dedusting and purifying the electric furnace phosphorus-producing furnace gas by using a dry-type dedusting system, so that the solid content of the electric furnace phosphorus-producing furnace gas achieves below 10-50mg / m<3>; 2) conveying the purified furnace gas to a phosphorus collecting device, wherein the phosphorus collecting device comprises a heat exchange chamber and a recuperator; the heat exchange chamber is formed by a shell; and the recuperator is arranged inside the heat exchange chamber; 3) leading in a low-temperature medium to an internal flow path of the recuperator, wherein the low-temperature medium and the furnace gas carry out non-mixing heat transfer under isolation of the recuperator, so that the yellow phosphorus is condensed and separated out and greatly attached on the surface of the recuperator, and the heat-exchange exhaust is discharged out of the phosphorus collecting device; 4) leading in a high-temperature medium for replacing the low-temperature medium to the internal flow path of the recuperator.

Owner:CHENGDU INTERMENT TECH

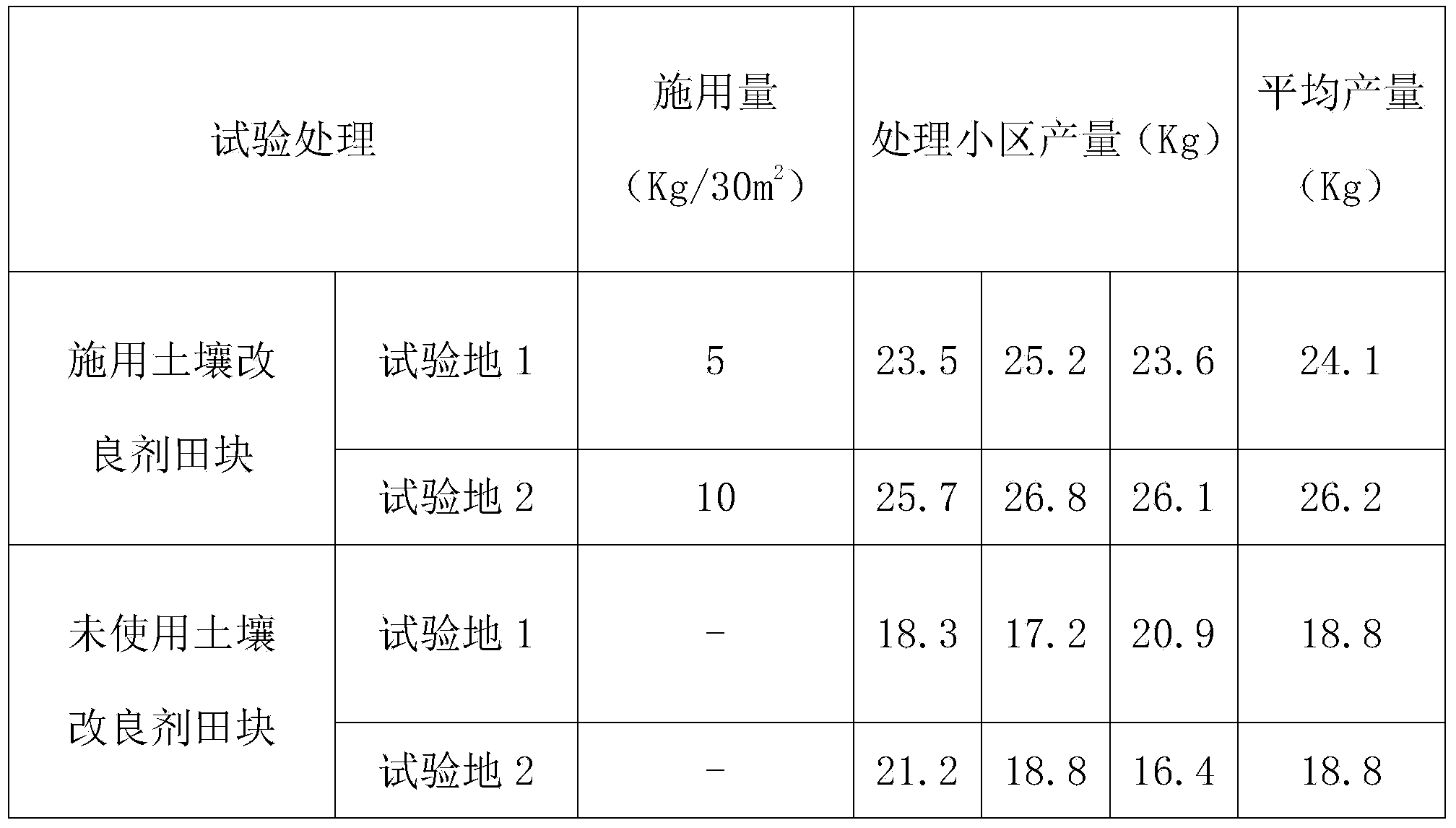

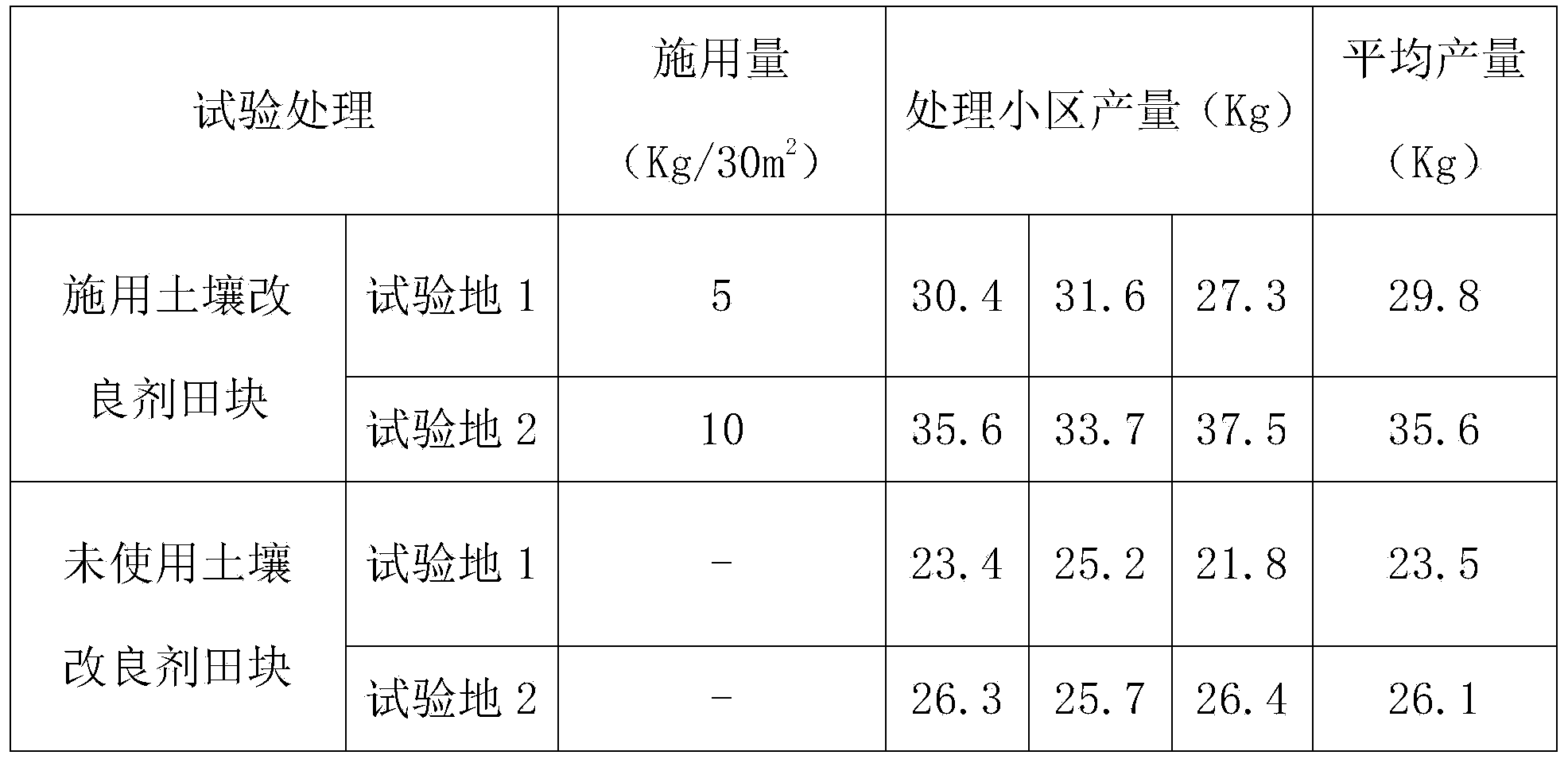

Modifier for acidic soil

InactiveCN104232099AEasy to operateLow costOrganic fertilisersSoil conditioning compositionsSodium BentoniteSlag

The invention relates to a modifier for acidic soil. The modifier comprises the following components in percentage by weight: 10-30% of yellow phosphorus slag, 5-20% of acidic soil modifier, 5-10% of artificially synthesized high-molecular compound, and the balance of mineral substances, wherein the yellow phosphorus slag mainly comprises CaSiO3; the acidic soil modifier refers to lime substances such as calcium carbonate, calcium oxide, lime nitrogen and the like; the artificially synthesized high-molecular compound refers to one or a mixture of more of polyacrylic acid, vinyl acetate maleic acid and polyvinyl alcohol type high-molecular compounds; mineral substances refer to peat, lignite, decomposed coal, vermiculite, bentonite, zeolite, perlite, sepiolite and the like. The modifier can effectively improve the yield reduction phenomenon of crops caused by an acidic hardened land, and has the advantages of being low in cost, fast, and simple to operate and the like.

Owner:YUNNAN RUNJIE AGRI SCI & TECHCO

Organic/inorganic slow-release fertilizer for flowers and preparation method of slow-release fertilizer

InactiveCN104355802AHigh nutrient contentExtended nutrient release periodAlkali orthophosphate fertiliserExcrement fertilisersSodium metasilicateSlag

The invention discloses an organic / inorganic slow-release fertilizer for flowers and a preparation method of the slow-release fertilizer. The organic / inorganic slow-release fertilizer is prepared from the following raw materials in parts by weight: 45 to 55 parts of horse manure, 20 to 30 parts of wheat bran, 15 to 25 parts of brewer's grains, 12 to 18 parts of flour beetle frass sand, 10 to 15 parts of residual tea, 5 to 10 parts of edible fungi waste, 18 to 26 parts of sorgo straw, 10 to 15 parts of mung bean shells, 5 to 10 parts of sugar beet meal, 1 to 3 parts of spawn powder, 16 to 22 parts of yellow phosphorus furnace slag, 20 to 30 parts of obsidian, 17 to 24 parts of hectorite, 10 to 15 of parts zeolite 4A, 32 to 44 parts of ammonium nitrate, 22 to 28 parts of ammonium hydrogen phosphate ammonium dihydrogen phosphate, 8 to 14 parts of potassium carbonate, 2 to 3 parts of diaminoferric xanthohumate, 3 to 6 parts of sugar calcium, 4 to 8 parts of sodium metasilicate, 15 to 20 parts of polyvinyl alcohol, 5 to 10 parts of carboxymethyl cellulose, 9 to 16 parts of hydroxypropyl xanthan gum, 2 to 4 parts of algal polysaccharides, and 3 to 5 parts of polyglutamic acid. The fertilizer provided by the invention is high in nutrient amount and high and long in fertilizer efficiency, can improve soil, enables soil to form granular structures, and harmonizes water and gas in soil to enable flowers to grow up well and quickly, thereby improving the quality and the yield of flowers and lowering the fertilization cost; important economic benefits are brought.

Owner:CHONGQING UNIV OF ARTS & SCI

Processing method for preparing phosphate rock powder into pellet yellow phosphorus charge

ActiveCN102701164AIncrease the content of phosphorus pentoxideHigh strengthPhosphorus compoundsPhosphateBall mill

The invention provides a processing method for preparing phosphate rock powder into pellet yellow phosphorus charge. For producing 1000kg of yellow phosphorus pellet charge, 1000kg of the phosphate rock powder, 100kg of humic acid and 20kg of sodium hydroxide are adopted. The preparation method comprises the following steps of: adding the phosphate rock powder (100 meshes) into a binding agent combined by the humic acid and the sodium hydroxide, uniformly stirring, pressing into pellets by a ball press, rolling by a disc pelletizer for ejection, entering an air heating furnace for preliminary drying, entering a vertical kiln for through drying, and then further entering a rotary kiln for performing high-temperature calcination treatment at the temperature of 1100 DEG C-1200 DEG C so as to obtain a yellow phosphorus charge finished product. According to the processing method provided by the invention, the phosphate rock powder is utilized, the 100-mesh phosphate rock powder is finely ground by a ball mill and pressed into the pellet-like yellow phosphorus charge finished product via the binding agent; and compared with lump ore charge, the removal rate of harmful carbonate impurities can be up to 95%, the power consumption per ton of yellow phosphorus is reduced by 35%, the discharge of pollutants is reduced, and the production cost is lowered. The processing method is the excellent processing method for producing yellow phosphorus by utilizing the phosphate rock powder in China at present.

Owner:瓮安烨烨磷化工实业有限公司

Method capable of utilizing mine tailings to produce aerated hollow brick

The invention discloses a method capable of utilizing mine tailings to produce an aerated hollow brick. The method comprises the following steps: (1), mixing such materials in dry basis mass part as main tailings, lime, coal ash or yellow phosphorus slag, and the like; (2), according to the step (1), adding water in 85-95 percent of the mixed material dry basis, adding waste aluminum power in 0.04-0.06 percent of the mixed material dry basis, adding gypsum in 9-11 percent of lime, and adding triethanolamine in 0.1-0.3 percent of waste aluminum power. According to the invention, a larger amount of mine tailings can be used to achieve the purposes of energy conservation and environment protection and relieve the environment pollution caused by processing the mine tailings pile, and a novel material source is provided for the hollow bricks.

Owner:安徽中龙建材科技有限公司

Filling slurry for filling mining method and preparation method for filling slurry

ActiveCN102531482ASolve a series of problems in mining fillingMeet environmental protection requirementsSolid waste managementHigh concentrationSocial benefits

The invention discloses filling slurry for a filling mining method and a preparation method for the filling slurry. The filling slurry is prepared from the following materials: tailings, ultrafine powder, cement and debris, wherein the tailings are mill tailings at the concentration of about 20 percent, and are thickened into high-concentration tailings at the concentration of over 65 percent; the ultrafine powder is obtained by finely grinding phosphorous slag which is discharged as waste residue after yellow phosphorus is prepared by a hot method or phosphate ores are calcined by other methods until the fineness is equivalent to that of the cement, and the cement and the ultrafine powder are jointly taken as a cementitous material; and the debris is crushed into particles with the particle size of less than 2cm, and the tailings at the concentration of over 65 percent are conveyed to a filling slurry preparation station through a pipeline and are prepared into filling slurry at the concentration of equal to or more than 70 percent by using stirring equipment. The invention is characterized in that: the filling slurry has a remarkable social benefit; a series of problems about mining filling are solved; and more importantly, the national environmental protection requirements are met, and the secondary harm is avoided. The filling slurry is applicable to the filling mining method and is particularly applicable to middle and low grade phosphorus mines.

Owner:WENGFU (GRP) CO LTD

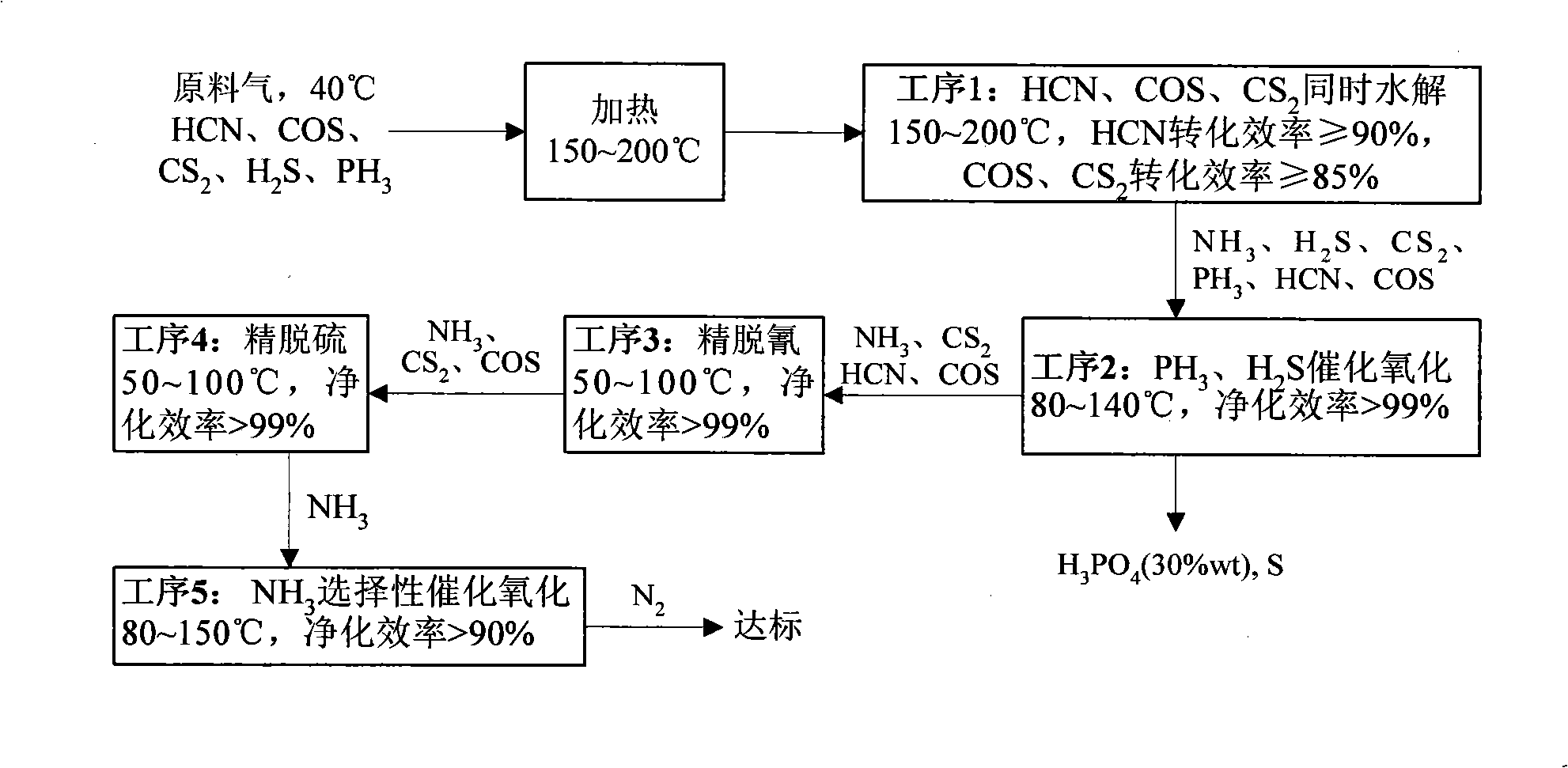

Low-temperature micro-oxygen purification method for removing harmful gas in yellow phosphorus tail gas

InactiveCN101352653AEliminate pollutionLow running costDispersed particle separationPurification methodsResource utilization

The invention provides a micro-oxygen purifying method used for removing harmful gas in yellow phosphorus tail gas, which is characterized in that mixed gas containing HCN, PH, H2S, COS and CS2, with the speed of 1000-5000 / h is heated to 150-200 DEG C by a heat exchanger and sent to a catalytic hydrolysis reactor; more than 90% of HCN and 85% of COS and CS2 can be respectively hydrolysed as NH3, CO, H2S and CO2; subsequently, the mixed gas enters a selective catalytic oxidation reaction; PH3 and H2S are catalysed and oxidated as P2O5 and S; harmful gas in the mixed gas which is disposed twice is removed further in a fine decyanation reactor and the sulfide thereof is removed by a fine desulfurization reactor; NH3 is selectively catalysed and oxidated as N2, thus purifying the mixed gas. The method of the invention leads the violent toxic matter to be converted into non-toxic matter, generates no secondary pollution, recovers the outgrowth sulphur, improves the utilization ratio of the resource, eliminates the environmental pollution due to waste gas exhausting, and has the advantages of simple process, few investment and low running expense.

Owner:KUNMING UNIV OF SCI & TECH

Balling method using medium- and low-grade phosphate rocks or ground phosphate rocks

ActiveCN103663396AHigh strengthHigh phosphorus contentPhosphorus compoundsPhosphoric acidCalciums magnesium

The invention relates to a balling method using medium- and low-grade phosphate rocks or ground phosphate rocks. The method comprises the following steps: S1, preparing materials, namely A, 85-100 parts of 60-120-mesh medium-grade and low-grade phosphate rocks or ground phosphate rocks, B, 1-10 parts of water or aqueous liquor of phosphoric acid, C, 2-8 parts of coke powder with the granularity of 60-120 meshes and D, 1-8 parts of one or more of phosphate fire clay, kaolin, sodium silicate, sodium carbonate, calcium carbonate and serpentine; S2, stirring, namely after uniformly mixing the raw materials, pressing the mixture into balls by use of a dry powder ball press machine, after pre-drying, delivering the mixture to a vertical calcining kiln, using purified yellow phosphorus tail gas, heating to 850-950 DEG C; starting roasting to obtain a finished product. The method is free from binders and low in cost, and the medium-grade and low-grade phosphate rocks are not hardened. The value of the medium-grade and low-grade phosphate rocks can be improved, and the ground phosphate rock of a mine can be fully utilized. The phosphate rock balls prepared are suitable for production of yellow phosphorus or calcium magnesium phosphate fertilizers.

Owner:刘静忠 +1

Multi-element and slow-released fertilizer

InactiveCN101284748AImprove physiological activityImprove physical functionSuperphosphatesAlkali orthophosphate fertiliserSodium BentoniteField experiment

The invention relates to a long-acting multi-element fertilizer which is prepared by raw materials of urea, overbearing calcium phosphate or diammonium phosphate, ammonium diacid phosphate, agricultural potassium sulphate, potassium oxide or potassium chloride and fertilizer additives. The fertilizer is based on nitrogen, phosphorus and potassium, and has humate and yellow phosphorus furnace slag silicon fertilizer or iron slag silicon fertilizer as well as blended raw ore powder containing porphyraceous feldspar granite, medical stone, bentonite clay and lanthanide rare earth added thereto, wherein, the humate and the yellow phosphorus furnace slag silicon fertilizer or iron slag silicon fertilizer contain many active materials, the blended raw ore powder contains long-acting elements such as phosphorus, potassium, middle elements, trace elements, as well as beneficial elements including silicon, sodium, cobalt, selenium, nickel, titanium and iodine, etc. According to the field experiments, the long-acting multi-element fertilizer can supply all nutrient elements required by crops, thereby promoting the crop growth.

Owner:谢浩

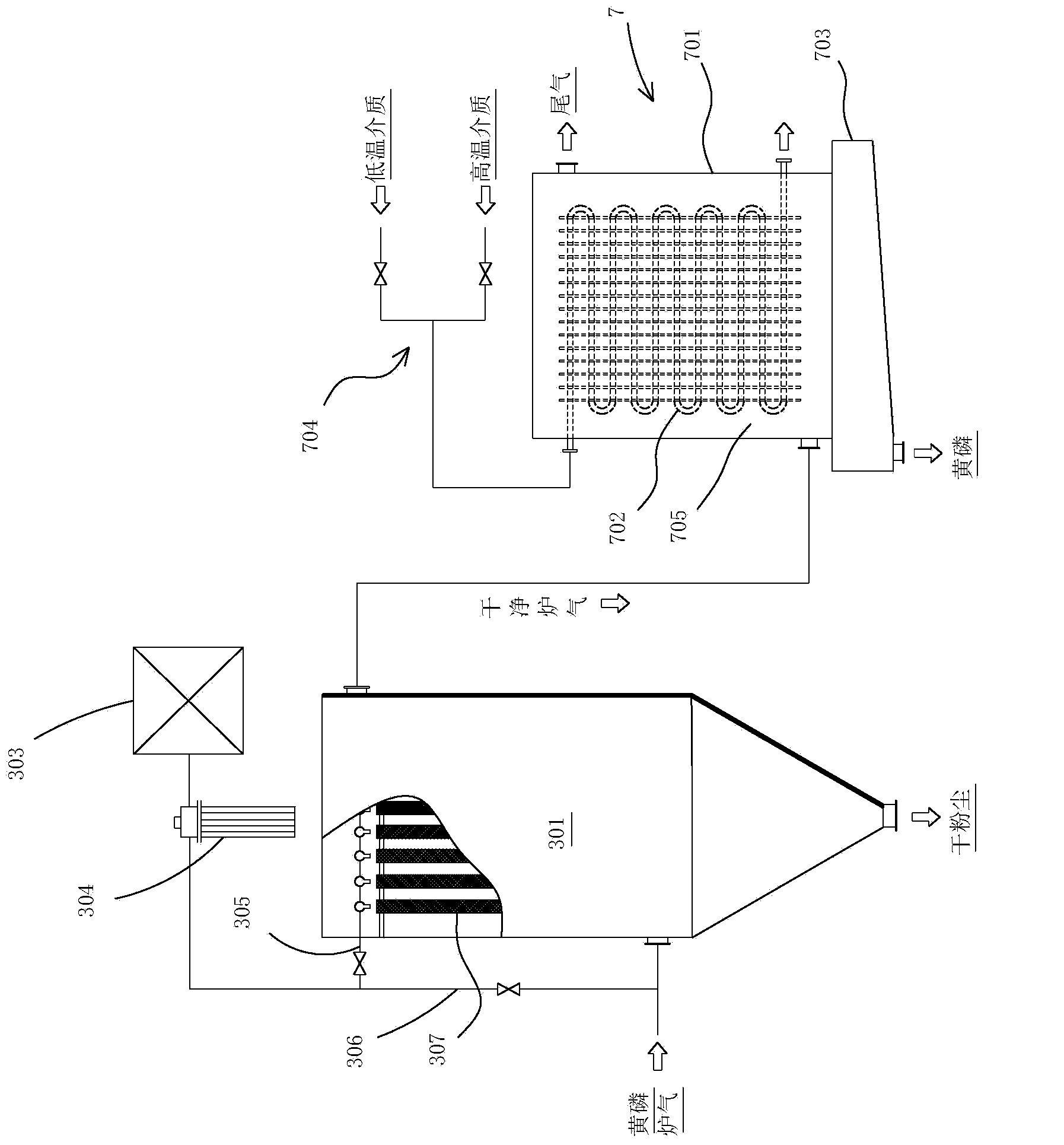

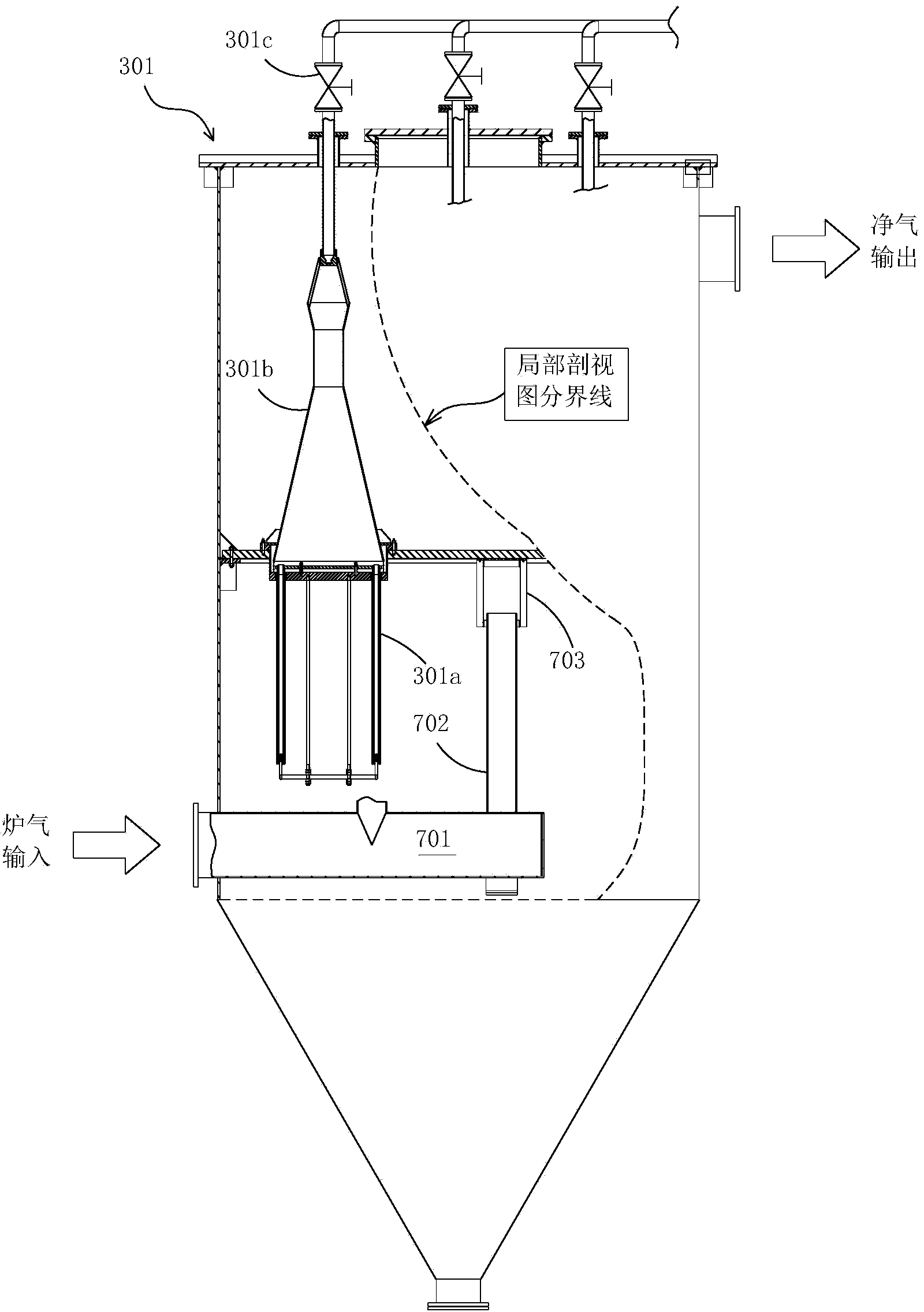

Yellow phosphorus preparation method and yellow phosphorus preparation equipment

ActiveCN103508429AHigh filtration precisionGood thermal shock resistancePhosphorus compoundsProcess engineeringSlurry

The invention discloses a yellow phosphorus preparation method and yellow phosphorus preparation equipment, which produce no phosphorous slurry and reduce the dust content of tail gas. The yellow phosphorus preparation method comprises the technological processes of electric furnace smelting, furnace gas purifying and phosphorus collecting and refining. In the process of furnace gas purifying, the furnace gas discharged out from an electric furnace is guided into a furnace gas dust-collection system through a smoke discharge pipeline, the furnace gas dust-collection system at least comprises a filter for filtering the furnace gas, the filter is provided with a sintering inorganic porous material filter element meeting the following working conditions, and the operations executed on the filter comprise the operation executed during starting a machine, the operation executed during normal operation, the operation executed during back flowing and the operation executed during stopping the machine; in the operation executed during starting the machine, pre-heated inertia gas is injected into the filter so as to preheat the sintering inorganic porous material filter element in the filter to the temperature of more than 187.5 DEG C, and in the operation executed during the normal operation, the to-be-filtered furnace gas of which the temperature is kept at 420-590 DEG C is input into the filter and the dust content of the filtered clean furnace gas is lower than 10-20 mg / m<3>.

Owner:CHENGDU INTERMENT TECH

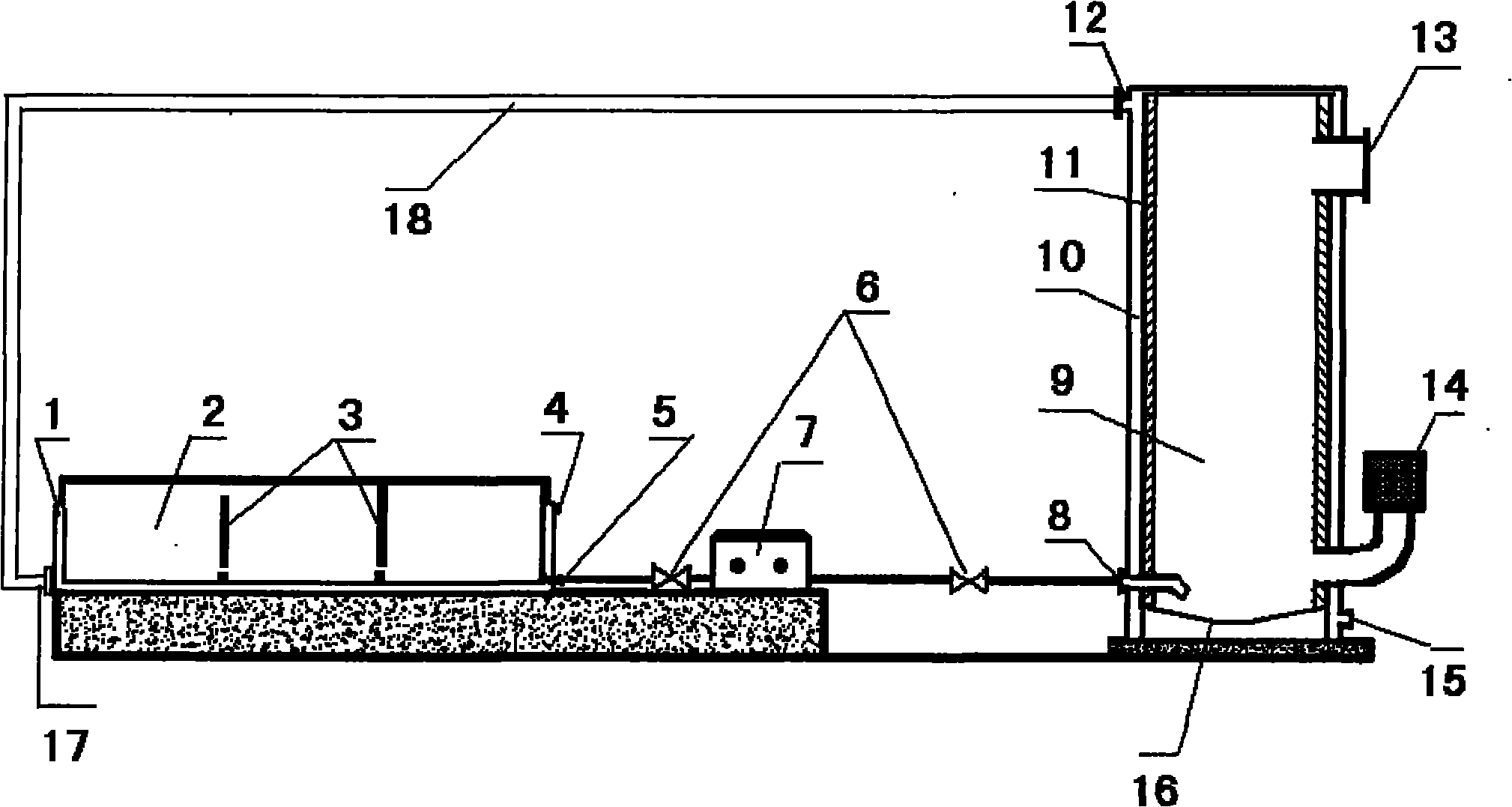

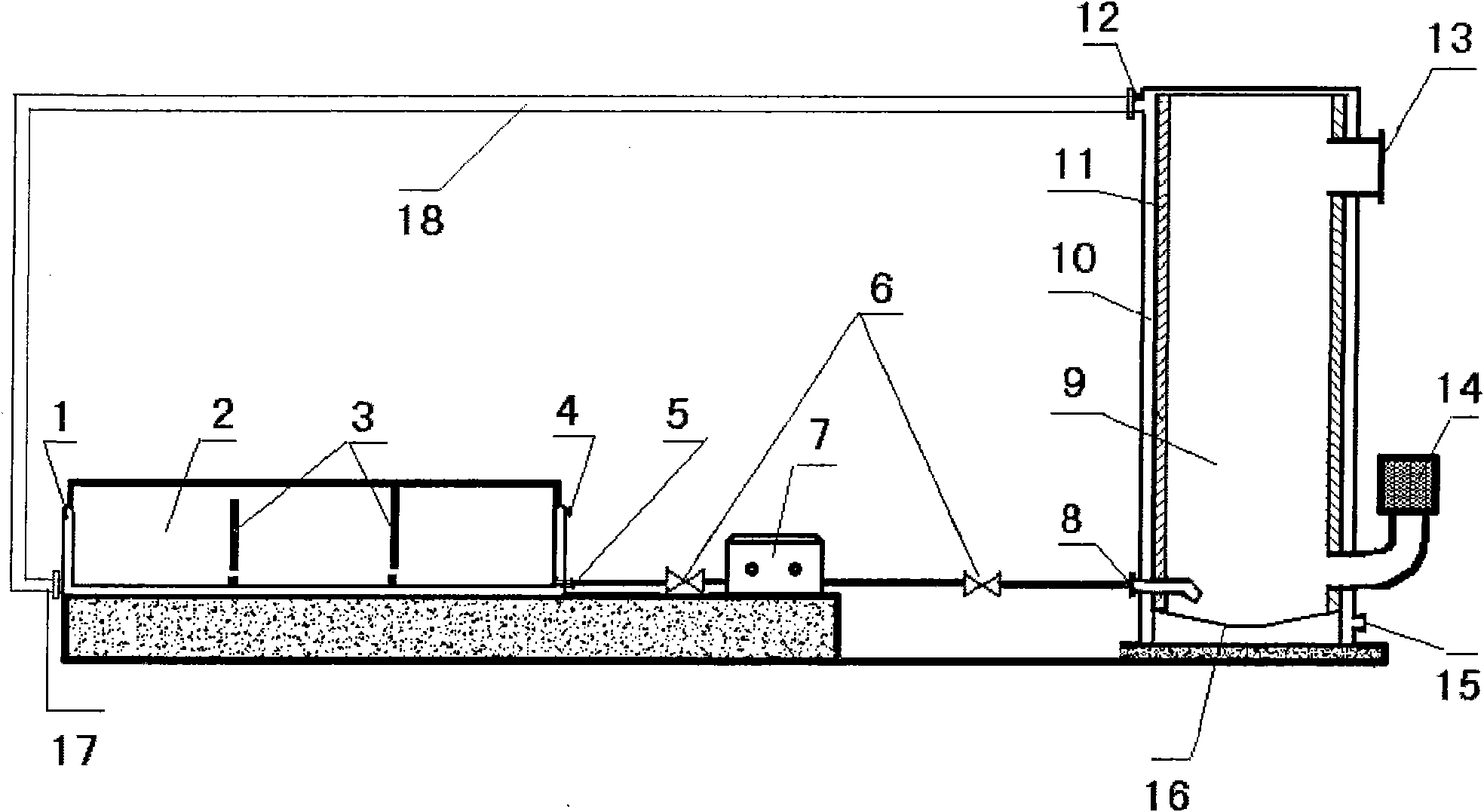

Water-tolerant gypsum hollow building block and production method thereof

InactiveCN101614051ASolve the problem of land occupation for emissionsRealize recycling of resourcesMixing operation control apparatusCeramic shaping apparatusSlagGypsum block

The invention discloses a water-tolerant gypsum hollow building block which is produced by taking chemical gypsum, hydraulic cementing material, exciting agent and LY gelling agent as raw materials and adopting the processes of mixing, shaping and maintenance. The chemical gypsum is an industrial gypsum of ardealite, desulfurization gypsum or fluorine gypsum. The hydraulic cementing material is an industrial slag of yellow phosphorus slag, blast furnace slag or fly ash. The exciting agent is lime, propylene macromoleclar polymer or inorganic mineral concavo-convex stick earth binder. A production method of the water-tolerant gypsum hollow building block can effectively solve the problem that the discharge of the industrial slag occupies land, relieve the environment-protection pressure brought to enterprises and the society and realize the cyclic use of resources inside the enterprises. The water-tolerant gypsum building block provides an approach for comprehensively utilizing the industrial slag, is an energy-saving and environment-friendly building material product and conforms to state policies for recycling economy and sustainable development. The production method requires simple apparatuses and low cost, and the finished product rate of the production method is over 95 percent. The production method is suitable for the enterprises producing byproduct industrial gypsum.

Owner:GUIZHOU KAILIN GRP CO LTD

Catalyst for preparing yellow phosphorus through catalytic decomposition of phosphine gas and preparation method thereof

InactiveCN102935371ALow costReduced activityPhosphorus compoundsMetal/metal-oxides/metal-hydroxide catalystsHalloysiteNickel salt

The invention discloses a catalyst for preparing yellow phosphorus through catalytic decomposition of phosphine gas and a preparation method thereof, and belongs to the technical fields of the discharge control technique for industrial tail gas pollutants and phosphine tail gas resource comprehensive utilization. The catalyst is characterized in that the catalyst takes fe-ni alloy containing M element or free of the M element (the M is boron or phosphorus) as an active component, takes a natural halloysite nanotube as a carrier, and has the advantages of being low in cost, high in activity, good in selectivity and the like. The preparation method includes taking soluble ferric salt and nickel salt, the natural halloysite nanotube, the compound containing the M element or free of the M element as the raw materials; and generating active components which are evenly loaded on the carrier in a nano particle form after processes of impregnation, evaporation, drying, calcinations, hydrogen reduction and the like. The preparation method is simple in process, low in cost, mild in conditions and free of pollution. According to the catalyst and the method, phosphine gas can be subjected to catalytic decomposition with a high efficiency and a low cost, and remarkable environmental and economical benefits are provided.

Owner:NANKAI UNIV

Method for producing micro crystal glass by combined using of yellow phosphorus slag and exhaust

The invention discloses a method for a multipurpose utilization of yellow phosphorus clinker and offgas to produce glass-ceramic which belongs to the manufacture field of building materials. The invention is with a simple technics and a low cost, stable, and can do an industry production including following steps: melting the yellow phosphorus into slag in the melting furnace in a temperature of 1450-1500 DEG C, meanwhile, doing a speedy bath analysis; making the material composition accord with SiO2 50-60, Al2O3 6-7, CaO 22-30, K2O+Na2O 3-9, than adding the material containing Si, Al, Na into the melting furnace; burning the clean and dried yellow phosphorus offgas by the arranged ejecting mouths on the top melting furnace after mixing with the oxygen and maintaining the temperature of 1450 DEG C in the furnace; controlling the temperature of 1450 DEG C in the furnace and keeping warm for 2 hours to make all of the material mold after melting, equalization and fining, then coring and crystallizing, getting finished products after anneal and cutting-abrading.

Owner:WENGFU (GRP) CO LTD

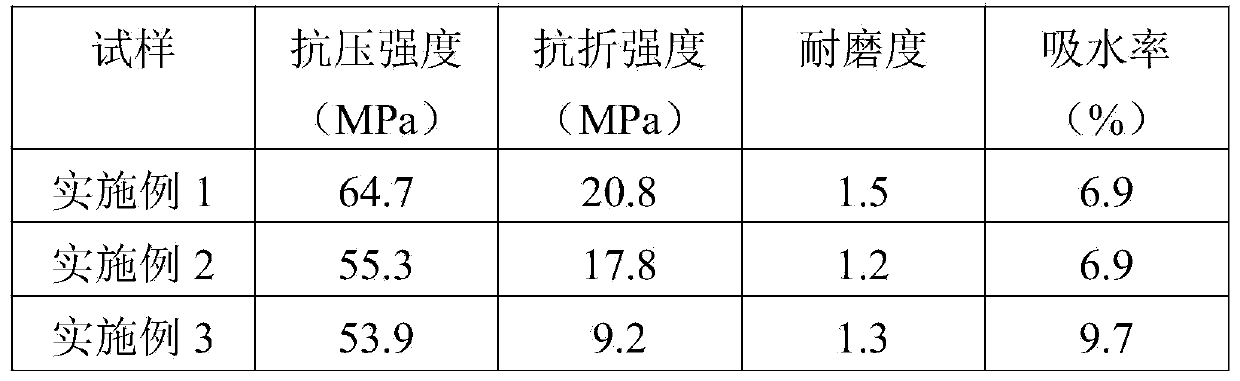

Autoclaved yellow phosphorus slag pavement brick and making method thereof

The invention discloses an autoclaved yellow phosphorus slag pavement brick and a making method thereof. The autoclaved yellow phosphorus slag pavement brick is made of yellow phosphorus slag powder, granular yellow phosphorus slag, quicklime powder and phosphogypsum. The making method comprises the steps of: grinding the dried yellow phosphorus slag into powder; then mixing the granular yellow phosphorus slag with the quicklime powder and the phosphogypsum, adding water, stirring and uniformly mixing; making a brick blank body; autoclaving to make the autoclaved yellow phosphorus slag pavement brick. The autoclaved yellow phosphorus slag pavement brick disclosed by the invention is superior to a common pavement brick product, and is simple in ingredients so that the input of types of raw materials is reduced; yellow phosphorus slag with different finenesses is matched to be used as a compound exciting agent, thus an unexpected effect is achieved; in a making process, a better exciting condition is provided, the production process is easy to control, and the product quality is more stable; in a case where no cement is used, the strength is enabled to reach the use requirement of the pavement brick, the production cost is lowered, and the yellow phosphorus slag resources are effectively utilized; although the consumption of the phosphogypsum is reduced, the problem that an autoclaved phosphorus slag brick is not suitable for pavement building is solved.

Owner:GUIZHOU KAILIN GRP CO LTD

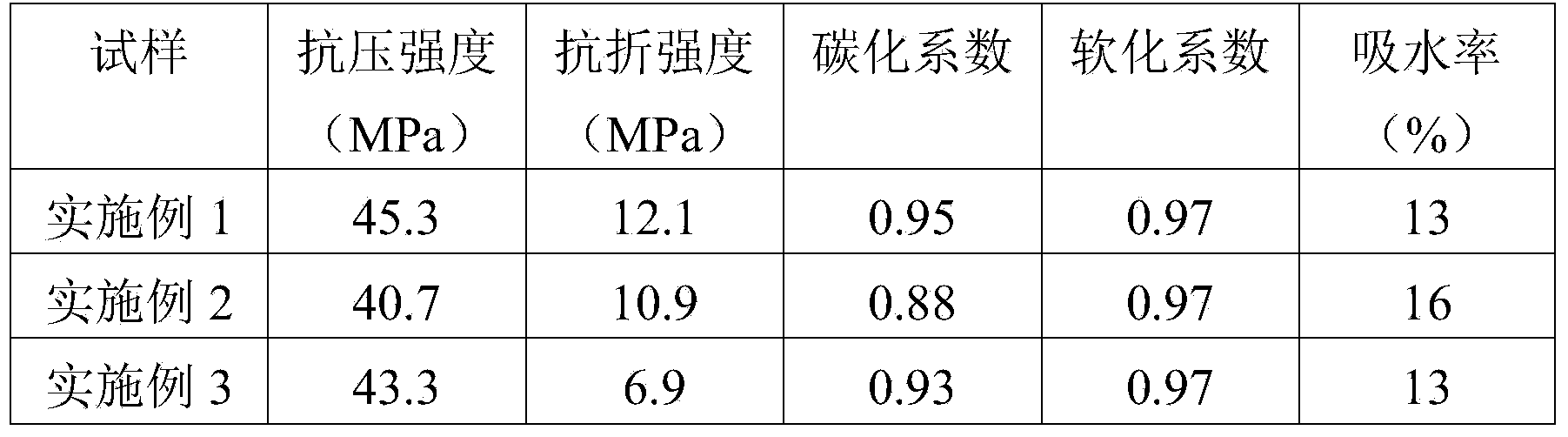

High strength phosphogypsum brick and manufacturing method thereof

The invention discloses a high strength phosphogypsum brick and manufacturing method thereof, and the product is made of phosphogypsum, yellow phosphorus slag, quicklime and fine aggregate; the manufacturing method comprises the following steps: mixing and grinding dry yellow phosphorus slag and quicklime; uniformly metering and mixing the mixedly grinded materials and phosphogypsum and fine aggregate; adding water into the mixed materials and stirring uniformly, controlling the water content content at 10%; manufacturing brick blanks by a hydraulic vibration forming machine; obtaining the finished product with saturated vapor at 1.35MPa. Compared with the prior art, the product is better than common high strength phosphogypsum brick, and the high strength phosphogypsum brick manufactured by the invention has the advantages of high intensity, good water resistance and good endurance; the compressive strength is between 30 and 45 MPa, and the flexural intensity is between 6.5 and 12.0 MPa, and the softening coefficient is between 0.85-0.95, and the carbonization coefficient is larger than 0.90, and the water absorption is less than 20%.

Owner:GUIZHOU KAILIN GRP CO LTD

Method for producing calendaring type glass-ceramic decorative board by phosphorous slag

The invention discloses a method for producing calendared glass-ceramic decorative board by phosphorous slag, comprising the following steps of: step 1: preparing, namely, taking phosphorous slag, arenaceous quartz, calcined soda, alumina, zinc oxide, magnesia, barium carbonate and colorant according to a formulation; step 2: compounding, namely, mixing the materials uniformly to be used later; step 3: sintering glass melting liquid; step 4: pressing the glass melting liquid as a rough plate body of the glass-ceramic decorative board; step 5: annealing and cooling to prepare the rough plate of glass-ceramic decorative board; and step 6: grinding, polishing and cutting the rough plate, thus preparing the finished product. The glass-ceramic decorative board produced by the method has the advantages of excellent physical and mechanical property, uniform and fine quality, durable luster of the plate, pollution resistance, color-adjusting, no-pore, no radioelement pollution and the like. The method has mature process, simple operation and easy control, can effectively reduce the pollution of the phosphorous slag and yellow phosphorus tail gas to the environment, and takes the yellow phosphorus slag as raw material and the tail gas as the heat energy raw material to produce the calendared glass-ceramic decorative board. The method complies with the requirements of emission reduction, energy-saving, environment-protection, health and safety requested by National Environment Protection Commission and National Development and Reform Commission, is beneficial for improving the environment, provides high-class and safe decorative material for the building and has excellent social environment.

Owner:岑春华

Safe phosphorus supply device for thermal phosphoric acid production

The invention discloses a safe phosphorus supply device for thermal phosphoric acid production. A melting material, namely yellow phosphorus is safely conveyed through water level difference in a low melting slot, and then enters a furnace from the bottom of the combustion furnace, so that a dangerous operation step that the melting yellow phosphorus in the high risk state is conveyed to a high slot through a high pressure pump or compressed air, and then is bunt by high pressure spraying in the traditional production line is avoided; and the effects of energy consumption reduction, equipment investment reduction and stable quality are achieved. The safe phosphorus supply device for the thermal phosphoric acid production has the advantages of strong practicability and better economic benefit.

Owner:GUANGXI MINGLI CHEM

Manufacturing method of ultra high power graphite electrode with diameter no less than 550mm

The invention relates to a manufacturing method of ultra high power graphite electrode with diameter not less than 550mm, which comprises the following steps: blending raw materials, wherein the raw materials in weight percentage are as follows: 60 to 69 percent of needle coke, 20 to 30 percent of conditioning asphalt, and the balance being ultra high power electrode cut, and the granulometric composition of the blended materials in weight percentage are as follows: 11 to 15 percent of 8 to 20mm, 15 to 21 percent of 4 to 7mm, and the balance being 0.15 to 0.075mm; heating and mixing prepared dry materials, causing the dry materials heated to 125 DEG C within 20 minutes, adding the conditioning asphalt bond to knead, causing temperature of paste to be 150 to 160 DEG C within 40 minutes, taking the paste out of a furnace to cool; cooling the paste to be 120 to 130 DEG C, prepressing the paste in a press of 2,500 tons in vacuum, and extruding the paste after the prepressing; and roasting, dipping, twice roasting, graphitizing and machining the extruded blank to final finished products. The method improves technical formula, and adopts the oil press of 2,500 tons to produce the ultra high power graphite electrode according with quality requirements of steel making and yellow phosphorus production.

Owner:SICHUAN GUANGHAN SHIDA CARBON

Catalytic oxidation purification method for hydrogen cyanide in industrial waste gas

InactiveCN101269297AHigh catalytic activityImprove stabilityDispersed particle separationPurification methodsPhosphoric acid

The invention relates to a method of the catalytic oxidation and purification of tail gas containing hydrocyanic acid, in particular to a method for purifying the tail gas containing hydrocyanic acid by using a chemical method. The tail gas containing hydrocyanic acid is enabled to react with a prepared mixed catalyst solution containing palladium and copper under the temperature of 4 to 100 DEG C in a absorption tower, and the tail gas containing hydrocyanic acid is blown into the absorption tower in a gas-liquid negative-direction contact way, part of the hydrocyanic acid contacts and reacts with the palladium ions to form insoluble palladium simple substance, and part of the hydrocyanic acid reacts with the copper ions to form insoluble phosphor copper, part of the hydrocyanic acid is oxidized into phosphoric acid; all the generated substances enter into the liquid phase, and the mixed catalyst solution which absorbs the hydrocyanic acid and the purified and qualified tail gas not containing the hydrocyanic acid are acquired, the mixed hydrocyanic acid catalyst solution is oxidized into a by-product of the phosphoric acid to be used as resources again, the problems of hydrocyanic acid pollution is effectively eliminated, and the method provided by the invention provides a practical purifying method for the calcium carbide furnace gas and yellow phosphorus exhaust gas used as monocarbide chemical raw materials.

Owner:KUNMING UNIV OF SCI & TECH

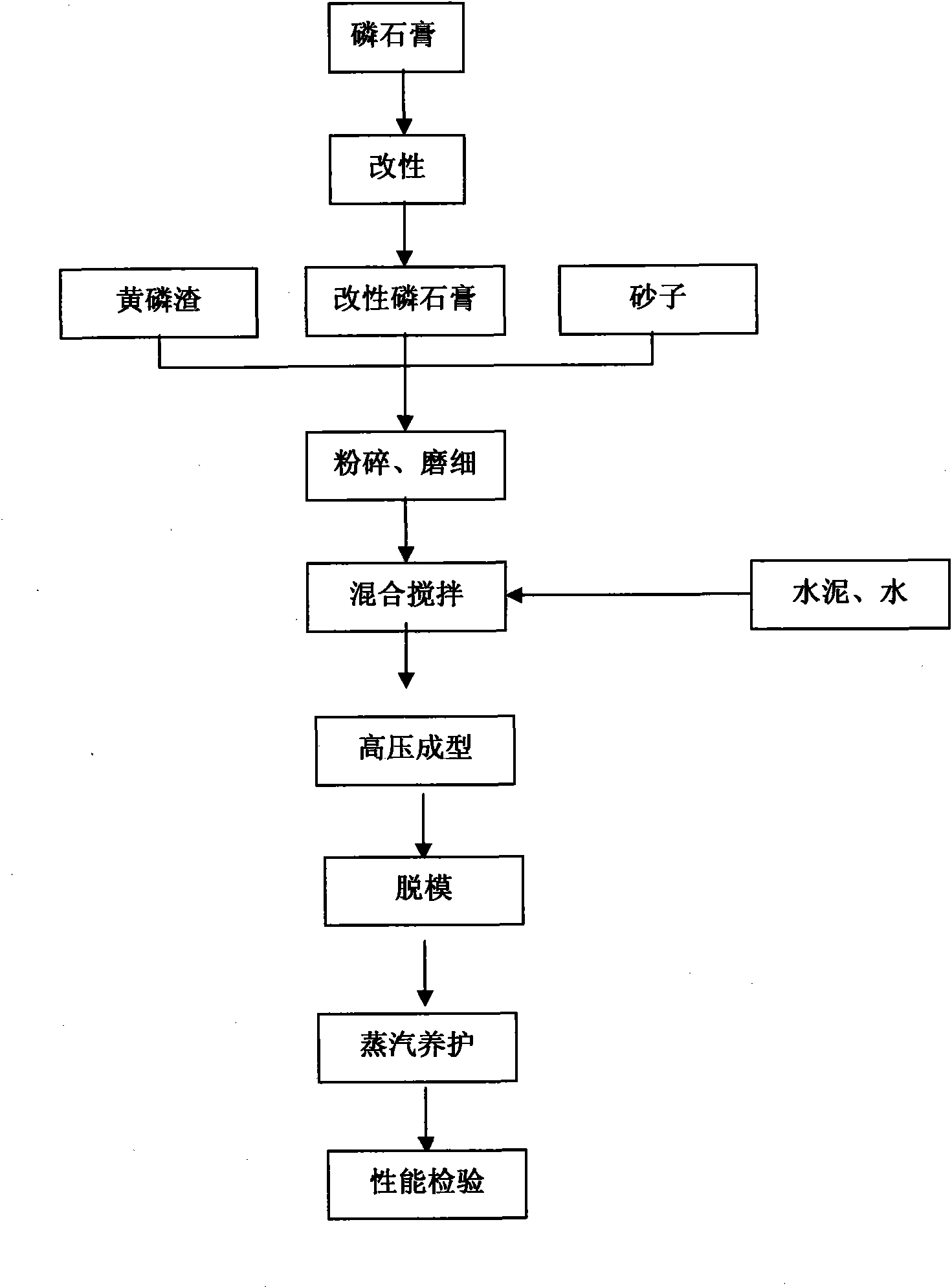

Method for preparing baking-free brick from yellow phosphorus slag and modified phosphogypsum

The invention provides a baking-free brick prepared by using yellow phosphorus slag and modified phosphogypsum as raw materials and a preparation method thereof. The industrial waste yellow phosphorus slag and the modified phosphogypsum are used as basic raw materials, sand and cement are added into the raw materials, and the mixture in a weight ratio is prepared into a finished product by processes of crushing, proportioning, mixing, stirring, high-pressure shaping, stripping, steam curing and the like. A large amount of yellow phosphorus slag discharged by the yellow phosphorus industry and a large amount of phosphogypsum discharged by the phosphoric acid industry are comprehensively utilized, and meanwhile, various environmental pollutions caused by long-term stacking of the yellow phosphorus slag and the phosphogypsum are reduced. The baking-free brick prepared from the yellow phosphorus slag and the phosphogypsum has the advantages of high utilization rate of industrial waste slag, high consumption, simple production process, short production period, low cost, environmental protection and energy conservation; and the brick meets the national standard requirements for baking-free common bricks, and is a novel environment-friendly building material. The steam curing is performed on the formed brick blank so as to shorten the curing time, improve the compressive flexural performance of the brick and facilitate large-batch production.

Owner:KUNMING UNIV OF SCI & TECH

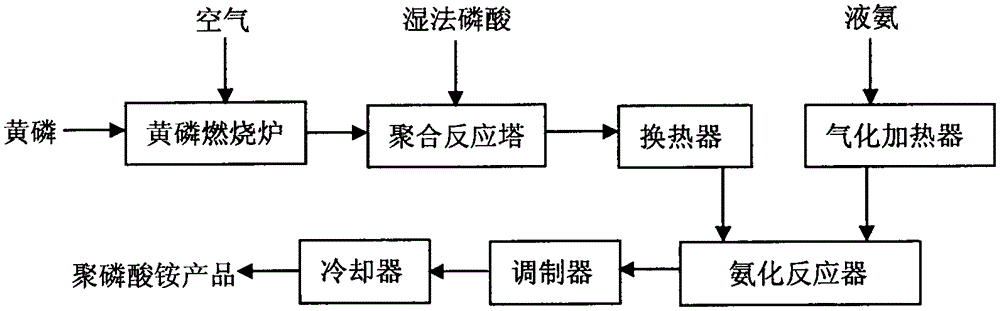

Method of preparing ammonium polyphosphate by using phosphoric acid by wet process and yellow phosphorus as raw materials

InactiveCN105347323AReduce manufacturing costBeneficial comprehensive fertilizer effectPhosphorus compoundsSolubilityPhosphoric acid

The invention belongs to the technical field of polyphosphate production in the inorganic chemistry industry, and is a novel production technology for preparing ammonium polyphosphate by using phosphoric acid by wet process and yellow phosphorus as raw materials. According to a method innovation, a low-polymerization-degree ammonium polyphosphate product with good water solubility is prepared by adopting the phosphoric acid by wet process with converted P2O5 content of 30-50 percent, the yellow phosphorus and liquid ammonia as main raw materials. The method can be used for directly producing the product in two forms of solid and liquid, the production is easy to control, the energy consumption is low, the operation is easier, the product is easy to pack, the use is facilitated, the production cost is greatly lowered, the produced low-polymerization-degree ammonium polyphosphate product has the insoluble matter content of less than 1 percent, the polymerization degree of 2-10 and the polymerization ratio of 40-80 percent, and is suitable for making high-quality fluid fertilizers, and the fast development of modern agriculture in China can be greatly promoted.

Owner:BLACK P2 USA INC

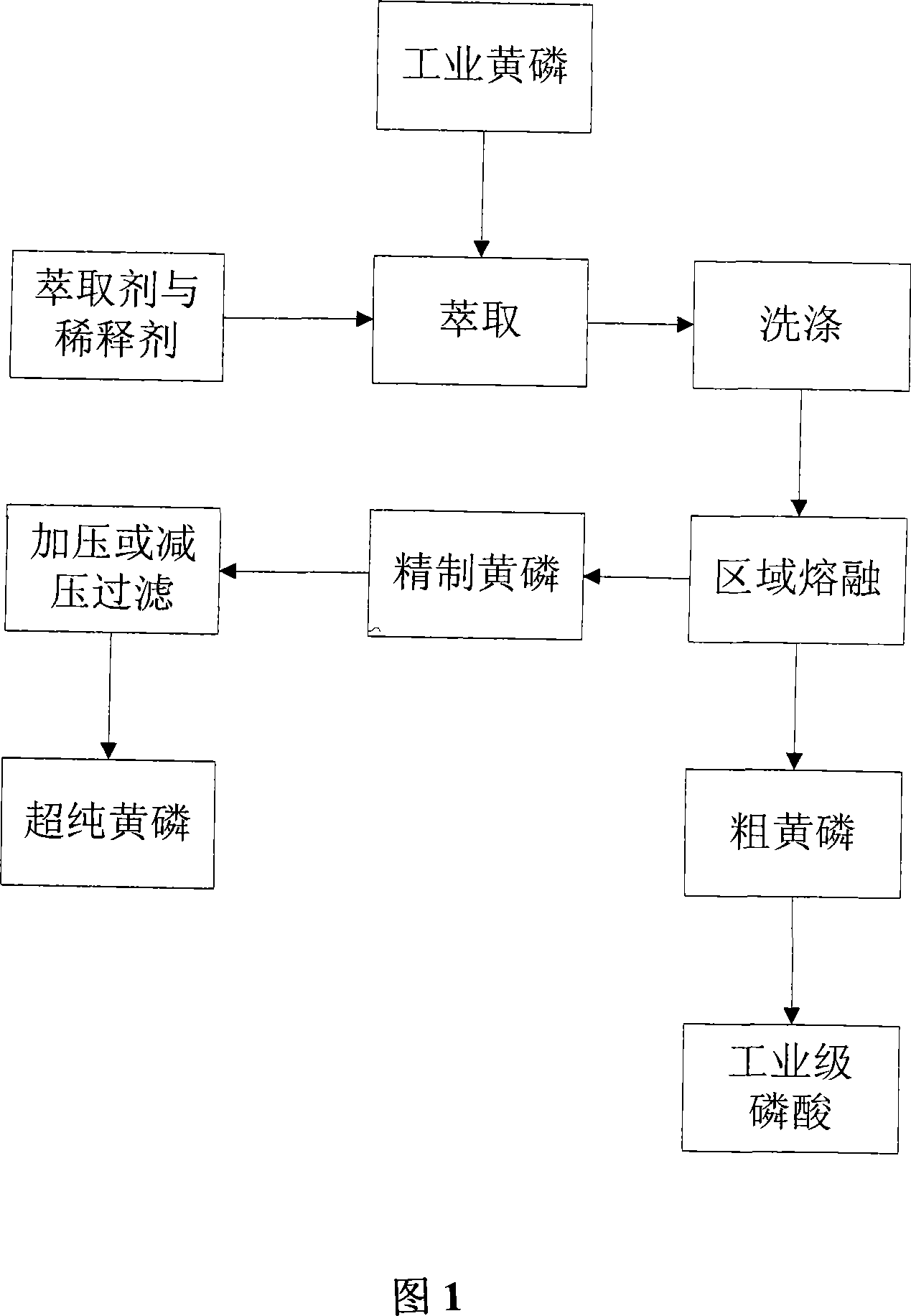

Method for producing ultra-pure yellow phosphorus

ActiveCN101214938AOperational securityNo pollution in the processPhosphorus compoundsFiltrationKerosene

Disclosed is a production method of ultra-pure yellow phosphorus, which uses the material of industrial yellow phosphorus, and the industrial yellow phosphorus is prepared to be the ultra-pure yellow phosphorus via extracting, zone melting, pressurizing or depressurizing micro-filtration sequentially. Extracting agent is at least one of di-(2-ethylhexyl) phosphoric acid, tributyl phosphate or calixarene, diluting agent is kerosene or paraffin oil or chloroform or carbon tetrachloride, and extraction technological parameter is that the volume ratio of organic phase and the industrial yellow phosphorus is 1:2-1:3. Apparatus for zone melting comprises a zone molten pool, a ring heater, an annular chiller and a driving device, wherein the ring heater and the annular chiller are assembled around the zone molten pool, and are arranged at intervals along the axial direction of the zone molten pool, the pressurizing or depressurizing micro-filtration utilizes a pressurizing or depressurizing filter with grade of 0.1 um-0.5 um. Utilizing the invention of the method to purify the industrial yellow phosphorus, the purity of yellow phosphorus products can reach 99.99%-99.9999%, and the yield coefficient can reach 73.2%-88.4%.

Owner:SICHUAN UNIV +1

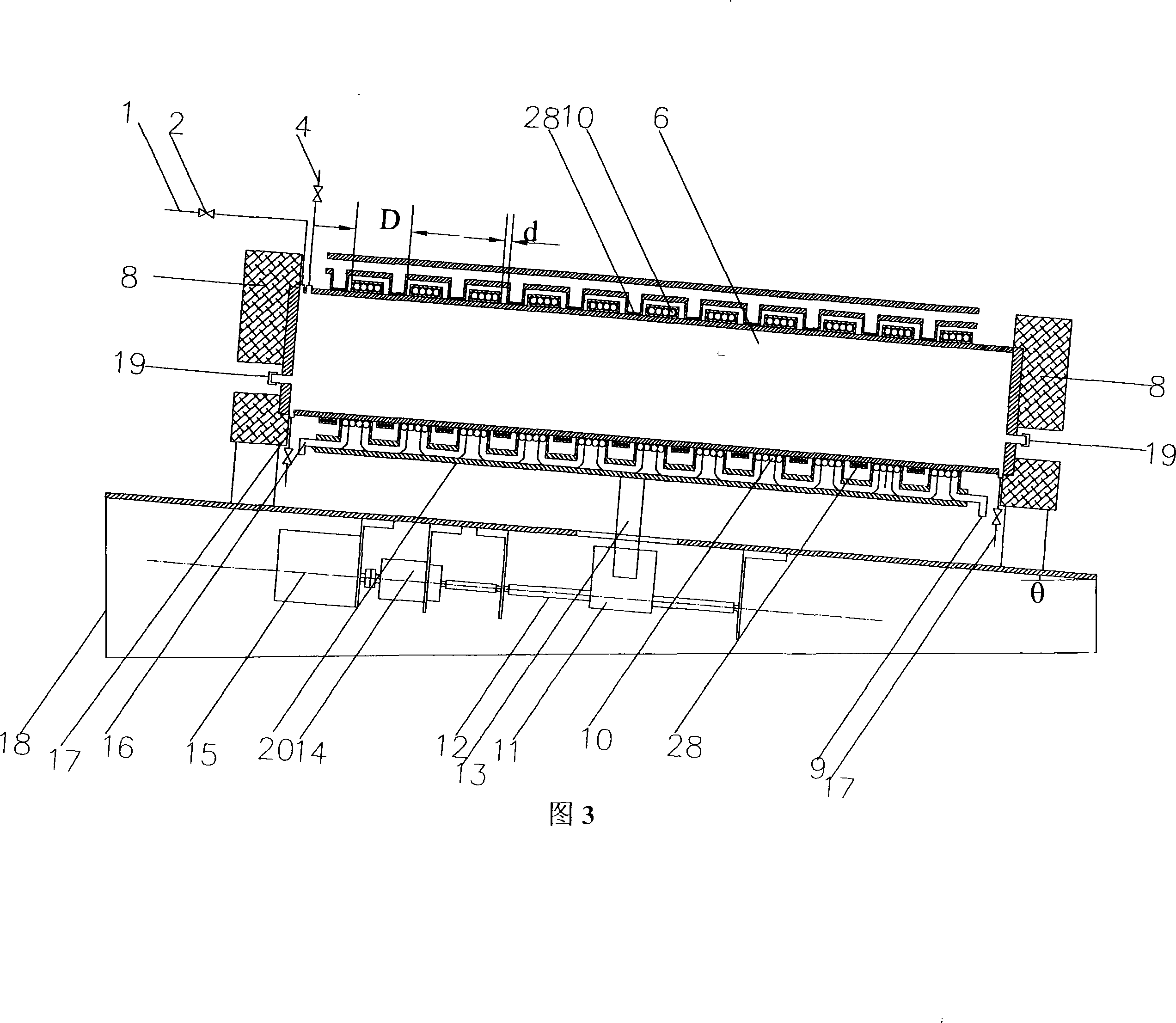

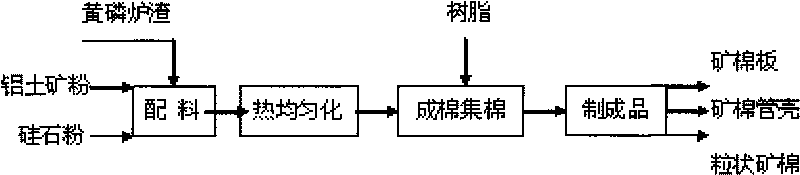

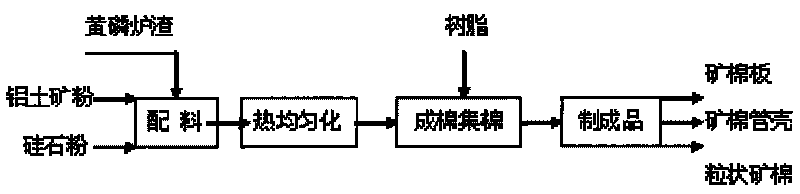

Method for directly manufacturing mineral wool by smelting yellow phosphorus slags

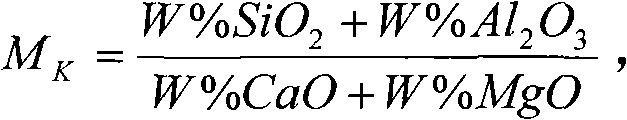

The invention provides a method for directly manufacturing mineral wool by smelting yellow phosphorus slags. In the method, a material charger for charging mineral powder rich in Al2O3 and SiO2 and an electro-thermal homogenizing furnace are additionally arranged near a slag discharging opening of the yellow phosphorus slags; the mineral powder rich in Al2O3 and SiO2 is added to adjust the composition of a melting material to be within the range of the acidity coefficient of the mineral wool, namely Mk=1.2-2.6; the yellow phosphorus slags and the powder are homogenized by the electro-thermal homogenizing furnace, are processed into wool through spray blowing or by a four-roller centrifugal machine, and are then processed into products such as a wool slab, a wool pipe shell, granular wool and the like.

Owner:武汉凌派化工科技有限公司

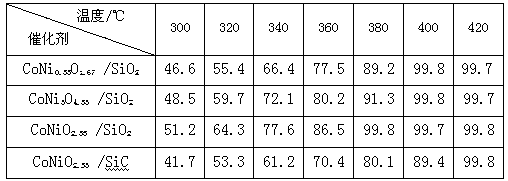

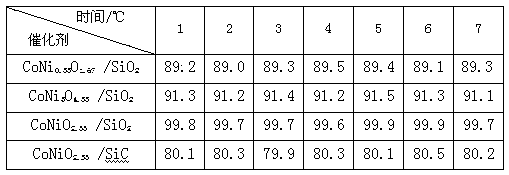

Catalyst for decomposing hydrogen phosphide gas as well as preparation method and application thereof

InactiveCN103506146AReduce the temperatureLow costPhosphorus compoundsMetal/metal-oxides/metal-hydroxide catalystsOxygenCobalt

The invention relates to a catalyst for decomposing hydrogen phosphide gas as well as a preparation method and application thereof. The catalyst uses SiO2 and SiC as carriers, and uses cobalt and nickel bimetal oxides as active components. The mol ratio of the nickel element to the cobalt element in the catalyst is (1-10) : (1-10); the mol ratio of the total amount of two metals to the oxygen element is 1: (1-1.3); the mass percent of two active components is 10-50% of the catalyst. The catalyst is directly applied in the control of industrial hydrogen phosphide tail gas pollute emission and the technical process of using hydrogen phosphide to prepare high-purity yellow phosphorus and hydrogen, has high low-temperature activity, good stability, and is simple in preparation and low in cost. The yellow phosphorus can be obtained by introducing hydrogen phosphide gas to perform the normal pressure reaction at 300-400 DEG C.

Owner:ZHOUKOU NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com