Autoclaved yellow phosphorus slag pavement brick and making method thereof

A technology of yellow phosphorus slag and pavement bricks, which is applied in the field of autoclaved yellow phosphorus slag pavement bricks and its production, can solve the problems of low effective utilization rate of yellow phosphorus slag, low strength of ordinary phosphorus slag bricks, and unsuitable pavement masonry, etc. Achieve the effects of avoiding adverse effects, easy control of the production process, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

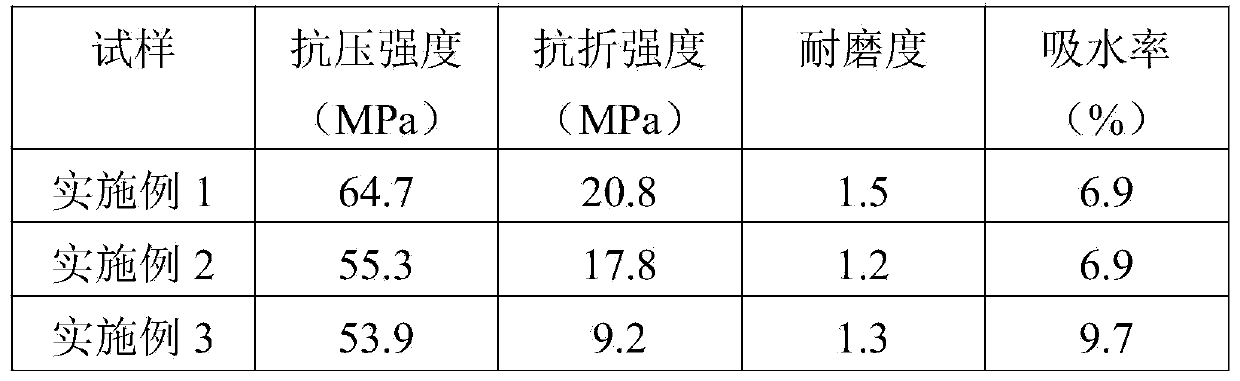

Embodiment 1

[0040] Prepare raw materials according to the batch test volume of 2000 pieces, yellow phosphorus slag powder 3600kg, granular yellow phosphorus slag 1200kg, quicklime powder 180kg, phosphogypsum 1020kg.

[0041] First grind the dried yellow phosphorus slag into powder; then uniformly measure and mix the yellow phosphorus slag powder, granular yellow phosphorus slag, quicklime powder and phosphogypsum in proportion; add water and stir to mix evenly, and control its moisture content at 7% ;Using a brick making machine to make the brick adobe body; and curing with 1.55MPa saturated steam to obtain the finished product.

[0042] Finished product inspection results:

[0043] Compressive strength: 64.7MPa;

[0044] Flexural strength: 20.8MPa;

[0045] Wear resistance: 1.5;

[0046] Water Absorption: 6.9%.

Embodiment 2

[0048] Prepare raw materials according to the batch test volume of 2000 pieces, yellow phosphorus slag powder 1800kg, granular yellow phosphorus slag 3300kg, quicklime powder 130kg, phosphogypsum 770kg.

[0049] First grind the dried yellow phosphorus slag into powder; then uniformly measure and mix the yellow phosphorus slag powder, granular yellow phosphorus slag, quicklime powder and phosphogypsum in proportion; add water and stir to mix evenly, and control its moisture content at 8% ;Using a brick making machine to make the brick adobe; curing with 1.60MPa saturated steam to obtain the finished product.

[0050] Finished product inspection results:

[0051] Compressive strength: 55.3MPa;

[0052] Flexural strength: 17.8MPa;

[0053] Wear resistance: 1.2;

[0054] Water Absorption: 6.9%.

Embodiment 3

[0056] Prepare raw materials according to the batch test volume of 2000 pieces, yellow phosphorus slag powder 2400kg, granular yellow phosphorus slag 3000kg, quicklime powder 100kg, phosphogypsum 500kg.

[0057] First grind the dried yellow phosphorus slag into powder; then uniformly measure and mix the yellow phosphorus slag powder, granular yellow phosphorus slag, quicklime powder and phosphogypsum in proportion; add water and stir to mix evenly, and control its moisture content at 10% ;Using a brick making machine to make the brick adobe body; and curing with 1.55MPa saturated steam to obtain the finished product.

[0058] Finished product inspection results:

[0059] Compressive strength: 53.9MPa;

[0060] Flexural strength: 9.2MPa;

[0061] Wear resistance: 1.3;

[0062] Water absorption: 9.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com