Ultrasonic metal surface processing device

A metal surface and processing device technology, applied in the direction of fluid using vibration, etc., can solve problems such as laborious, lower surface roughness Ra value, and large investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

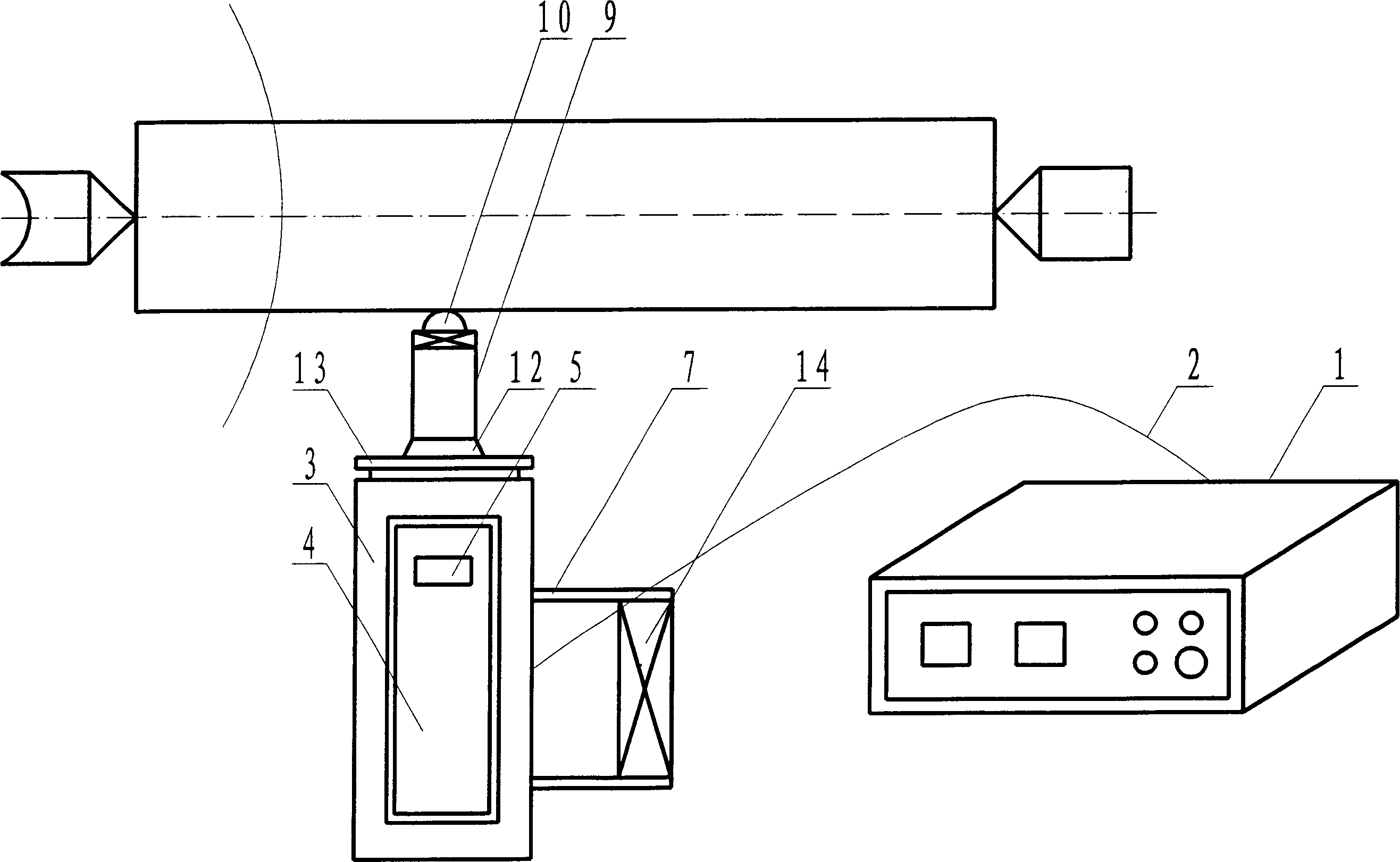

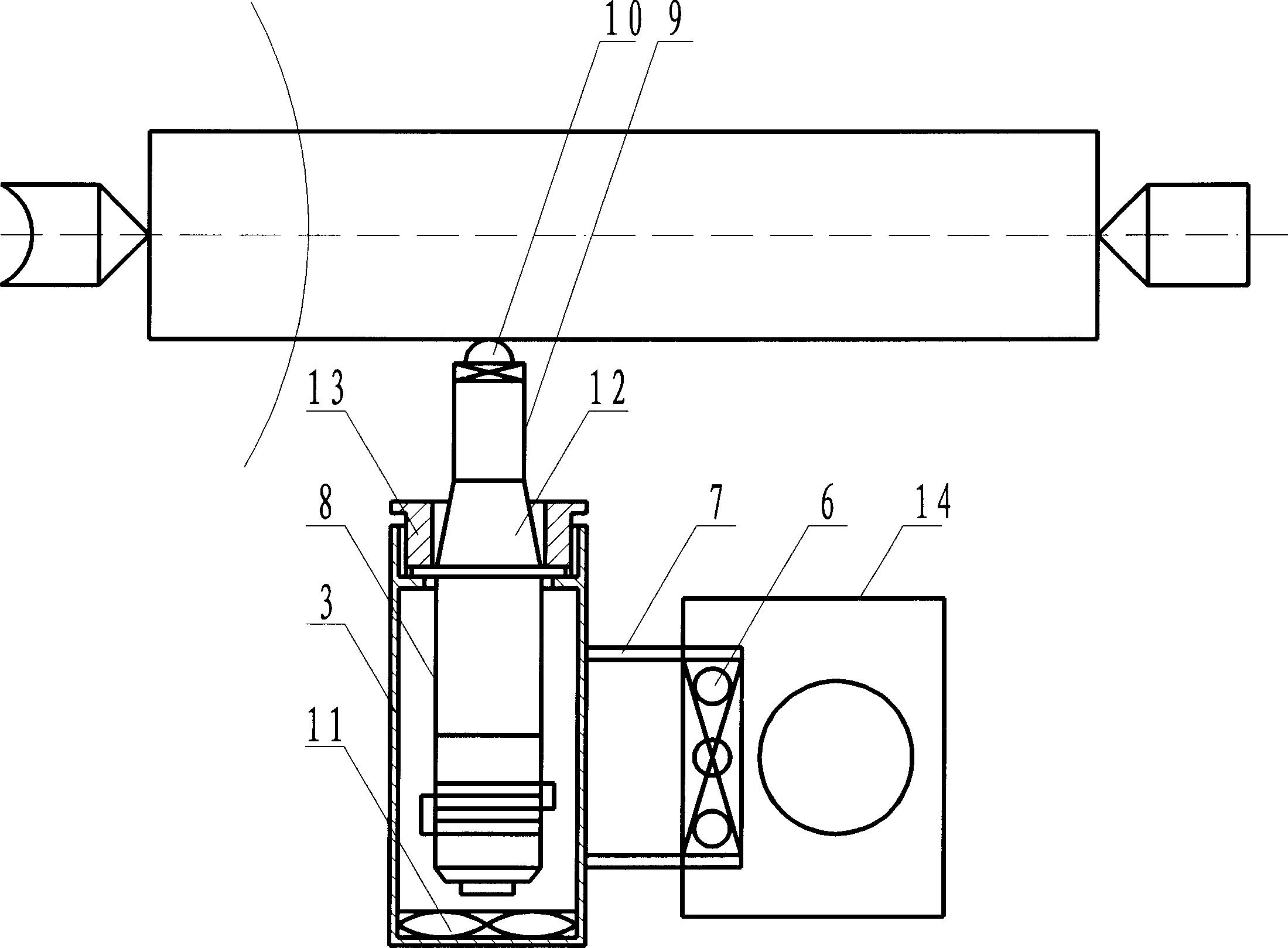

[0010] Attached below Figure 1-2 The ultrasonic metal surface processing device of the present invention will be described in detail below.

[0011] as attached Figure 1-2 Shown, the ultrasonic metal surface processing device of the present invention, its structure is made of ultrasonic generator 1 and ultrasonic processing device two parts, connects by cable 2 between ultrasonic generator 1 and ultrasonic processing device, ultrasonic generator 1 is In the prior art, the ultrasonic processing device is composed of a shell 3, a pressure detection device 4, a pressure display 5, a briquetting block 6, a spring 7, a piezoelectric ceramic transducer 8, a half-wavelength compound horn 9, a tool head 10 and The fan 11 is composed of a pressure detection device 4 and a pressure display 5 of the pressure detection device 4 on the casing 3, and a spring 7 connected to the pressure detection device 4 at one end and connected to the pressure block 6 at the other end is provided on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com