Patents

Literature

2387 results about "Briquette" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A briquette (French: [bʁikɛt]; also spelled briquet) is a compressed block of coal dust or other combustible biomass material (e.g. charcoal, sawdust, wood chips, peat, or paper) used for fuel and kindling to start a fire. The term derives from the French word brique, meaning brick.

Municipal waste briquetting system and method of filling land

InactiveUS6692544B1Conveniently and economically transportedReduce the impactBiofuelsSolid fuelsRefuse-derived fuelMunicipal sewage

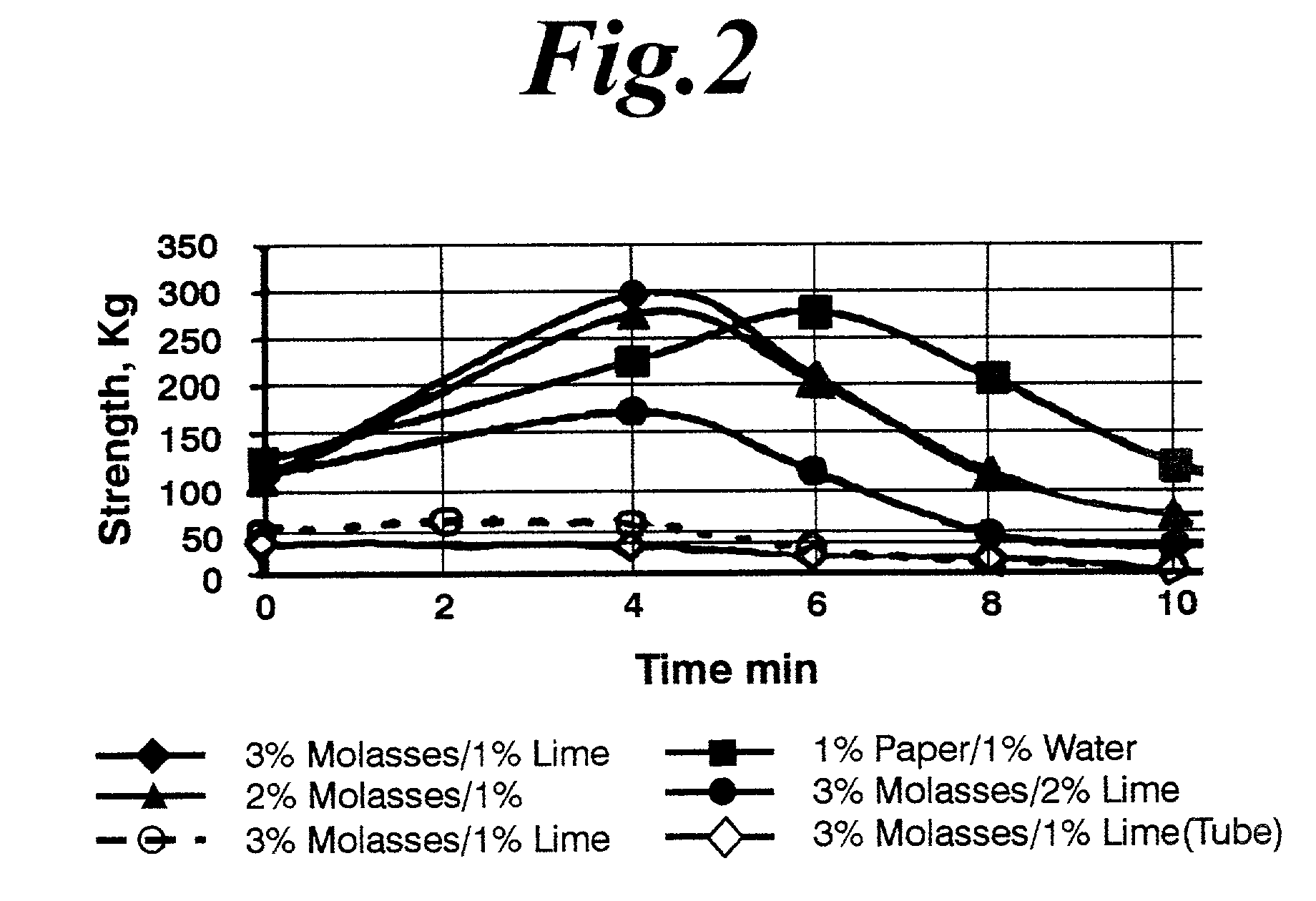

Mechanically and biologically stable briquettes and pellets are obtained from either municipal solid waste (MSW), Refuse Derived Fuel (RDF) or municipal sewage sludge and their combination for purposes of disposing said briquettes and pellets as fuel in waste-to-energy processes such as the one described herein or to form geometric aggregates with such briquettes for their disposal at landfill sites. The use of binding material is not required whereas fuel additives such as crushed coal and petroleum residues may be added to enhance fuel performance but are not needed to improve waste processing or product stability and mechanical properties.

Owner:ECOSYST PROJECTS

Fuel pellet briquettes from biomass and recovered coal slurries

The invention makes burnable renewal fuel (RF) briquettes from recovered coal from coal slurry ponds, biomass, and a binder. The briquettes may be augmented with one or more of recovered environmental burnable fraction from municipal solid waste (MSW), agricultural livestock waste, lumber processing residue, solid wood waste material, agricultural by-products and crops, and like burnable waste material. Accordingly, the method for making burnable renewal fuel (RF) briquettes includes the steps of recovering coal from coal slurry ponds; recovering biomass; adding a binder to said recovered coal and said biomass; and forming solid burnable RF fuel briquettes therefrom.

Owner:NEW ENERGY USA

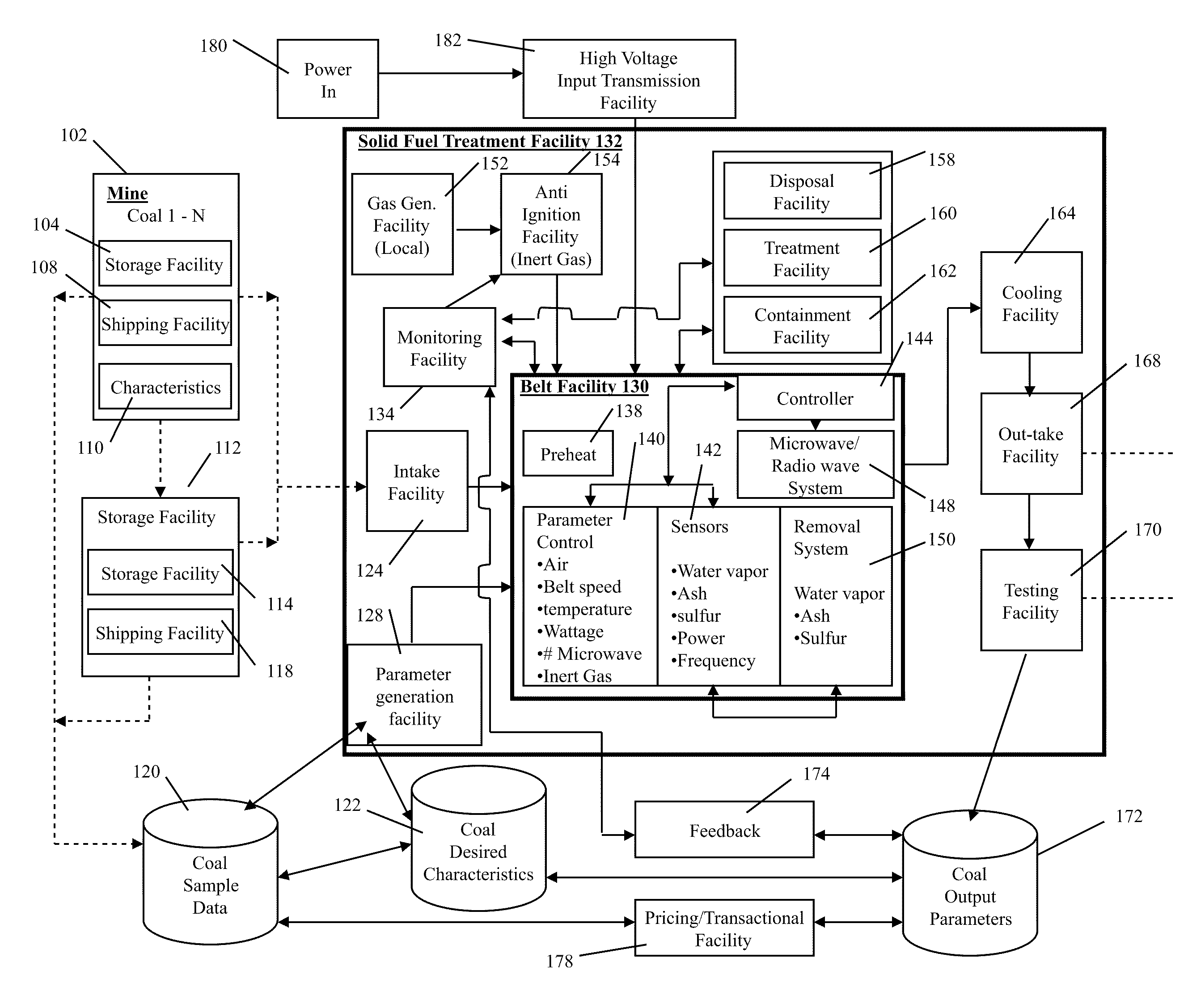

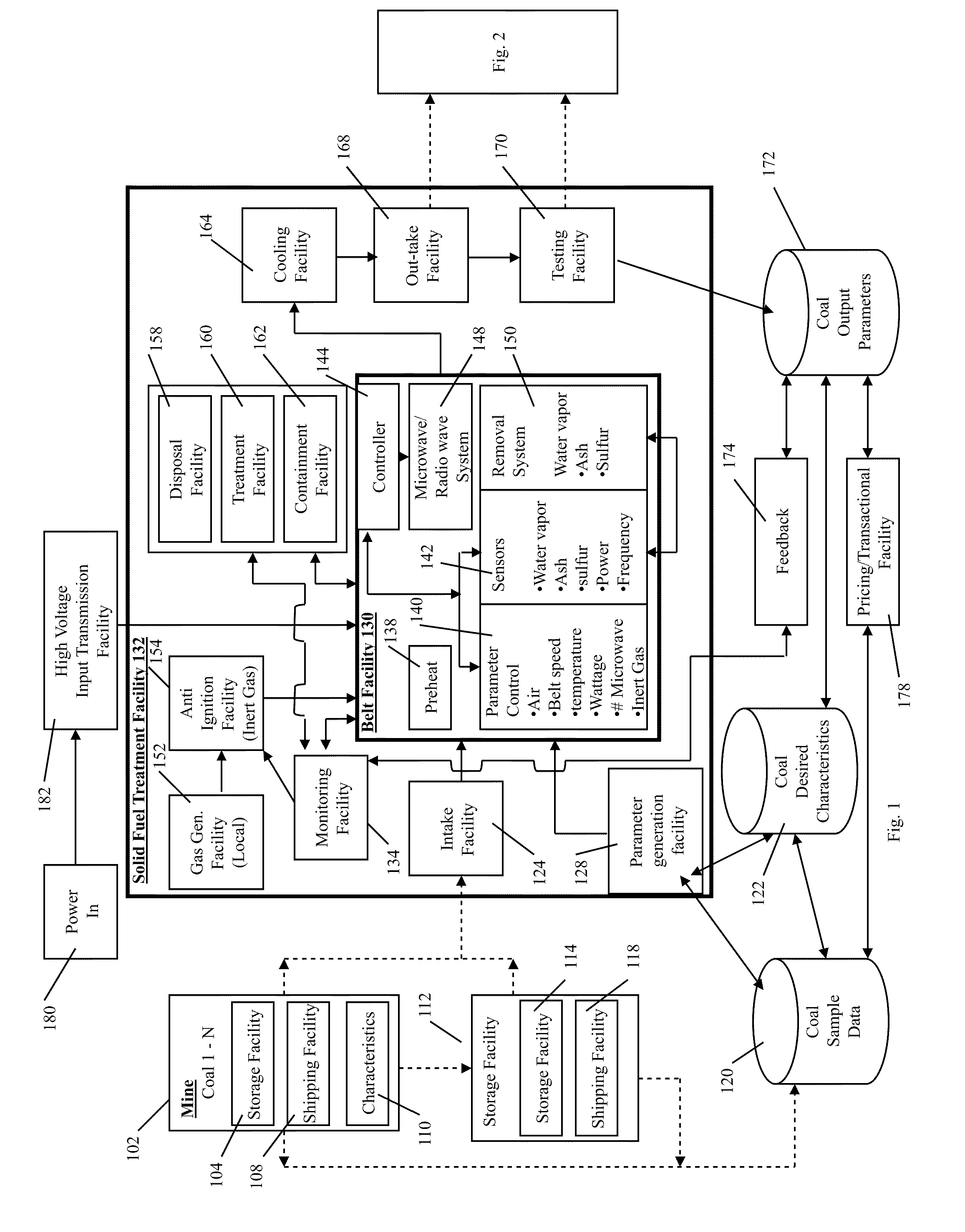

Methods and systems for processing solid fuel

InactiveUS20090272028A1Minimize return lossLow microwave lossBiofuelsSolid fuelsFuel treatmentSolid fuel

In embodiments of the present invention, a method of heat treating a solid fuel briquette may include heating the solid fuel briquette using energy from at least one of a heat furnace or an electromagnetic energy system of a solid fuel treatment facility as the solid fuel briquette is moved through the treatment facility to a specified internal temperature, and sealing the heat-treated solid fuel briquette in a vessel for a duration of time.

Owner:COALTEK INC

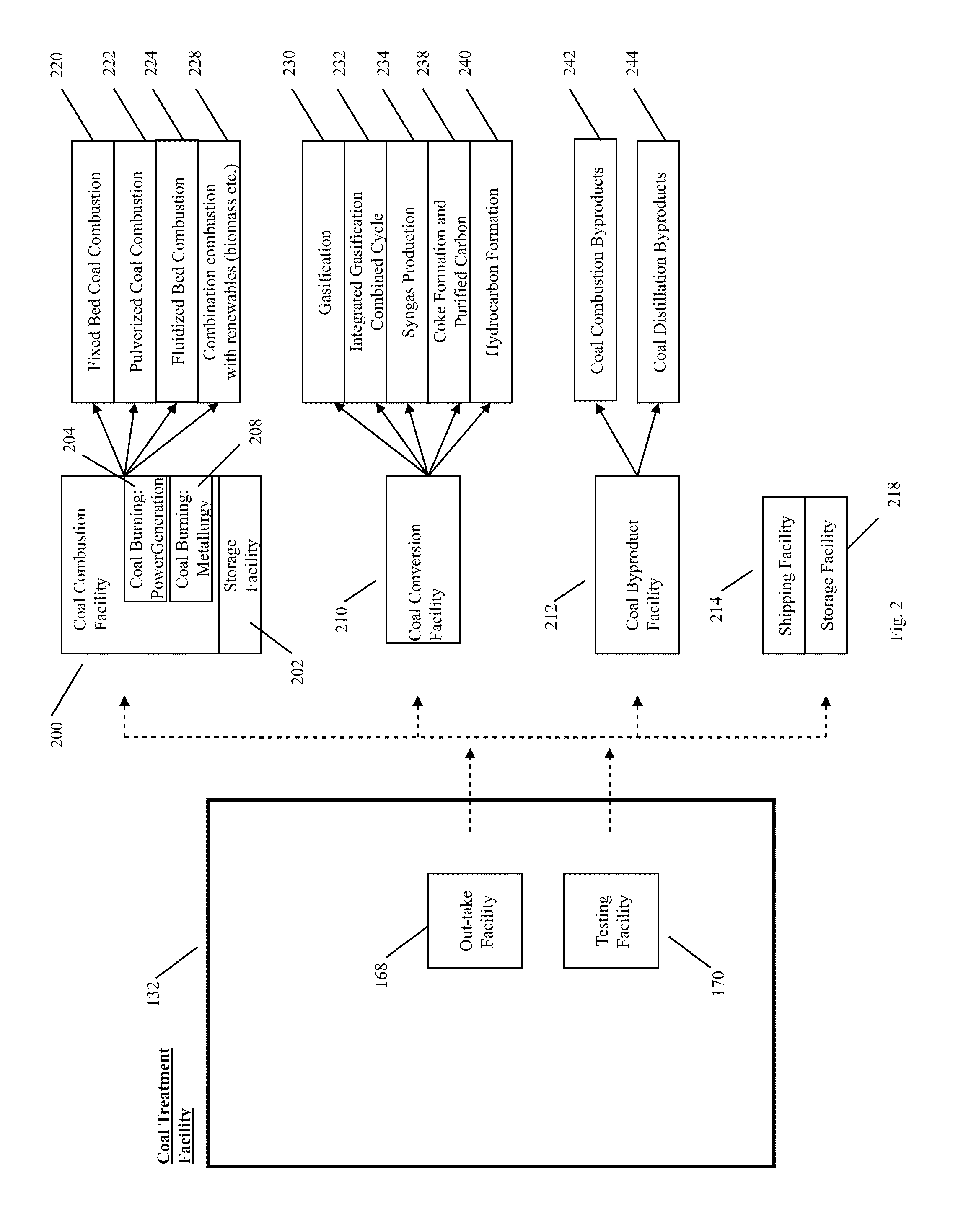

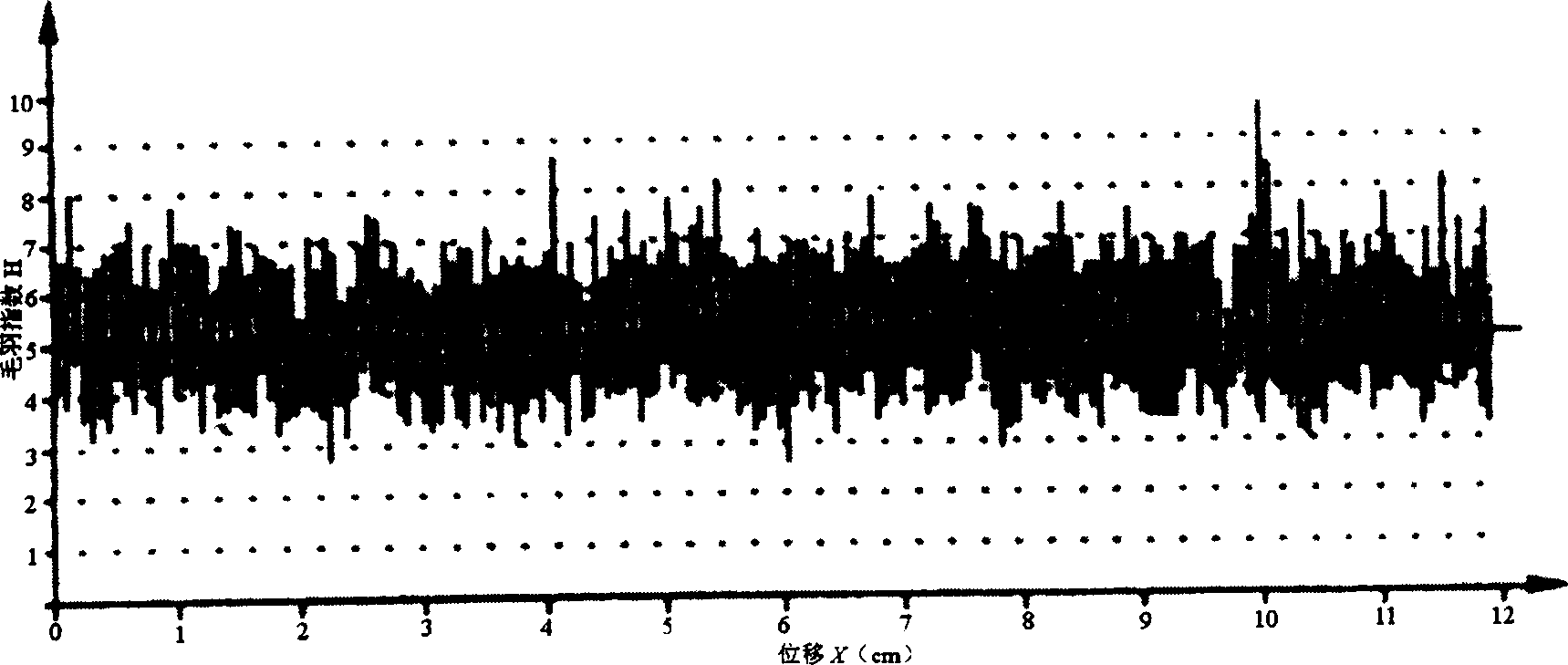

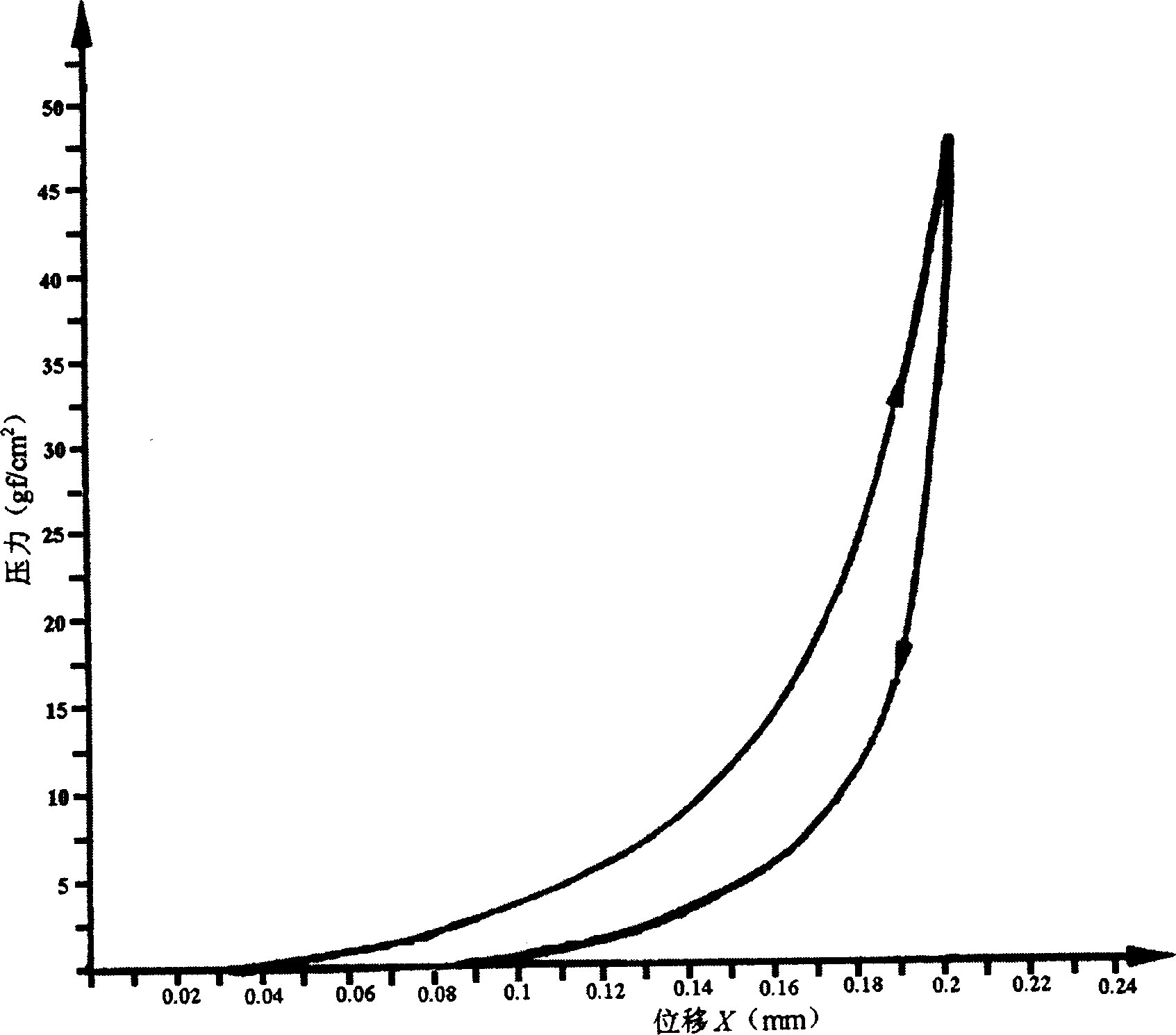

Yarn or fabric surface characteristics optical and mechanical combination measurement method and apparatus

InactiveCN1699999AImplement image captureRealize measurementMaterial analysis by optical meansTextile testingYarnEngineering

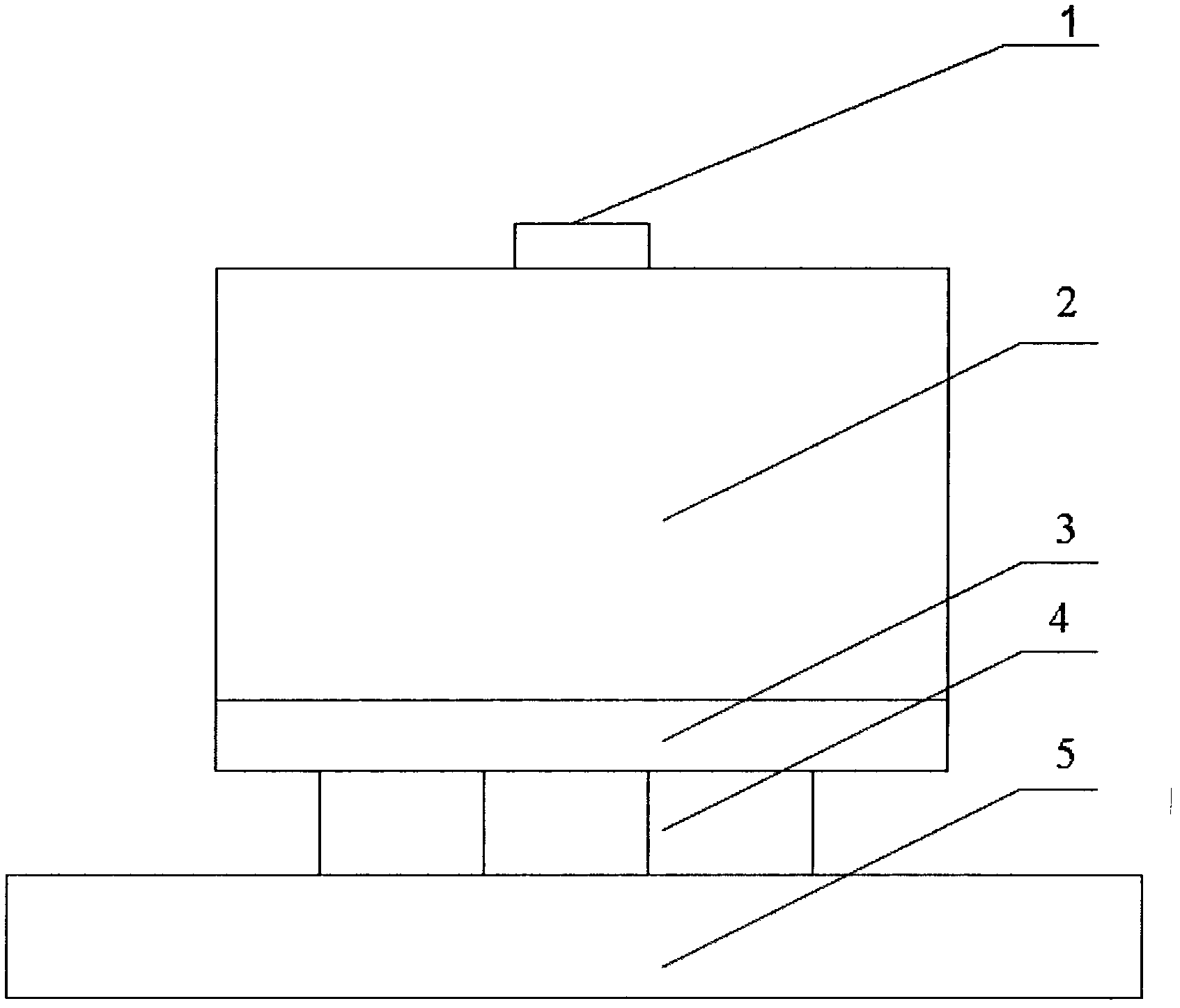

The invention relates to an optics mechanic composted measuring method and device of colored thread or clothe surface feather, apparent denseness, compression ability and frictional ability. The method comprises: picking up and roller drawing the sample by cord roller, taking sample's surface feather sharp dynamically by high-resolution figure CCD camera and obtaining feather quantity, compressing the picking up sample by driven compressing block, measuring sample's apparent denseness, doing up-and-down movement to compress the sample on the supporting block by driven compressing rod to measure sample's compression ability and compression resilience. The device comprises: cartage, stalling, operating rod, cord roller, compression block, a pair of fore-roller, briquette, back-up block, a pair of rear-roller, sample ladle, high-resolution figure CCD camera, sensor connected separately with compression block, briquette and back-up block, roller draw-off mechanism, alter steering mechanism, system for collecting, controlling and processing the force and shape signal and computers.

Owner:DONGHUA UNIV

Coking coal dust shaping technique

A process method of coking coal dust forming chiefly aims at settling the problem about a second dust emission in the course of transportation. First, the large quantity of small smut produced by a fluidized bed can be collected by a dust precipitator, be conveyed to a smut collecting storehouse, and constantly transmitted into a high pressure molding machine by an incessant closed conveyer. The feeding mouth of the high pressure molding machine is provided with a repressing screw to ensure the smut entering a high pressure rolling pair to be with certain pressure. Then the smut can be extruded into effigurate briquette, which at last is conveyed into a production coal conveying system after the molding. The process can prevent the production coal from producing the second dust emission during the transportation, thus reducing the engineering investment and environmental pollution with the advantages of less floor space and increasing the coke yield produced by coke oven.

Owner:SHANDONG IRON & STEEL CO LTD

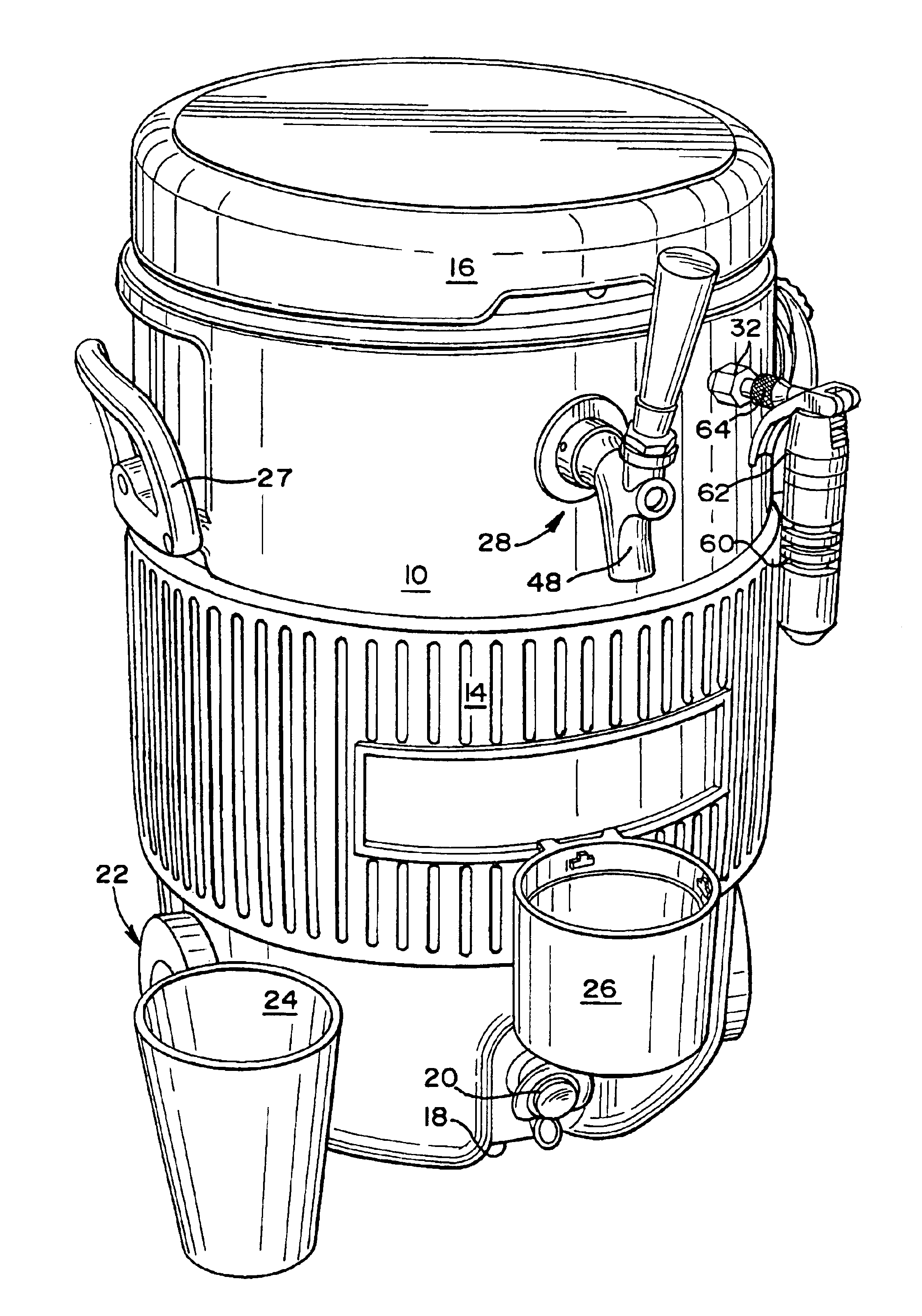

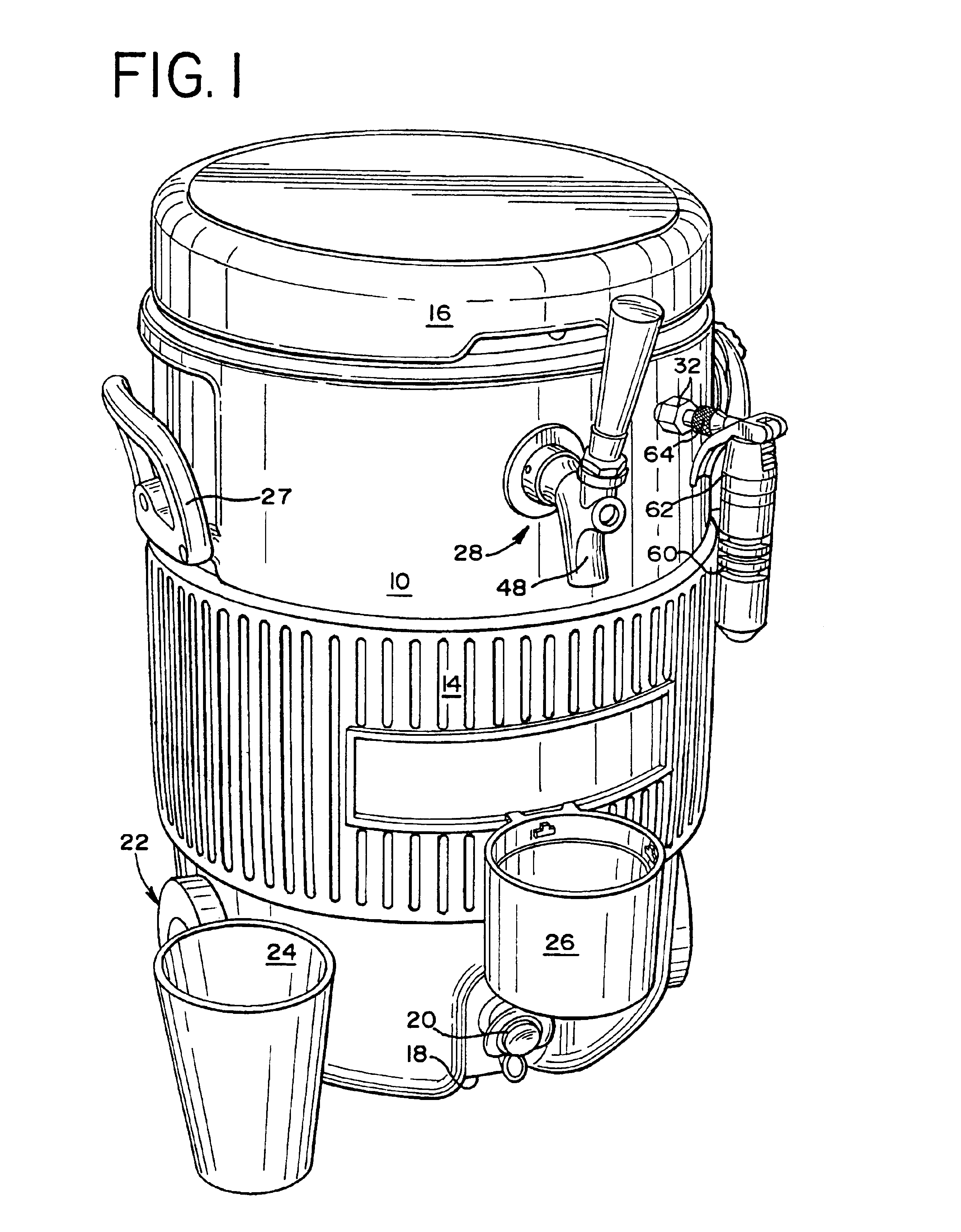

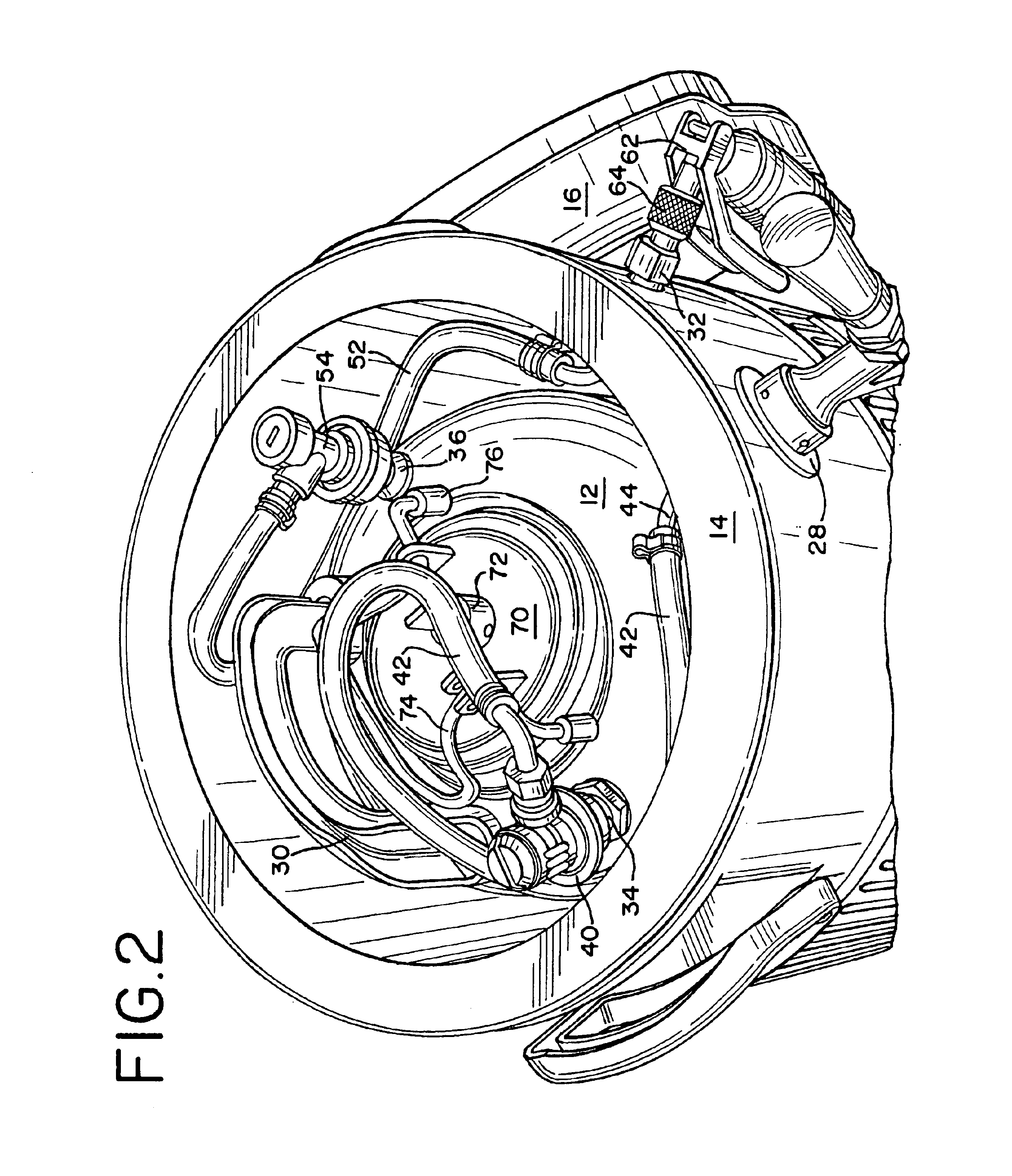

Liquid carrier article

A carrier of liquid is manually portable, thermally insulated, and pressurizable for dispensing the liquid, particularly cold or hot potable beverages such as beer, water, lemonade, sports drinks, tea, and the like. A container for holding the liquid can be pressurized by hand or other pump or by a gas cartridge, and the liquid flows when desired from the container through a tube and a dispensing valve mounted in the carrier wall. The carrier is thermally insulated to retain cold or heat in the liquid, and ice or hot briquettes can be placed about the container within the carrier walls to retain the desired temperature for a longer period. Handles and wheels can be mounted to the carrier to make the article more easily portable.

Owner:BRENT TIMOTHY

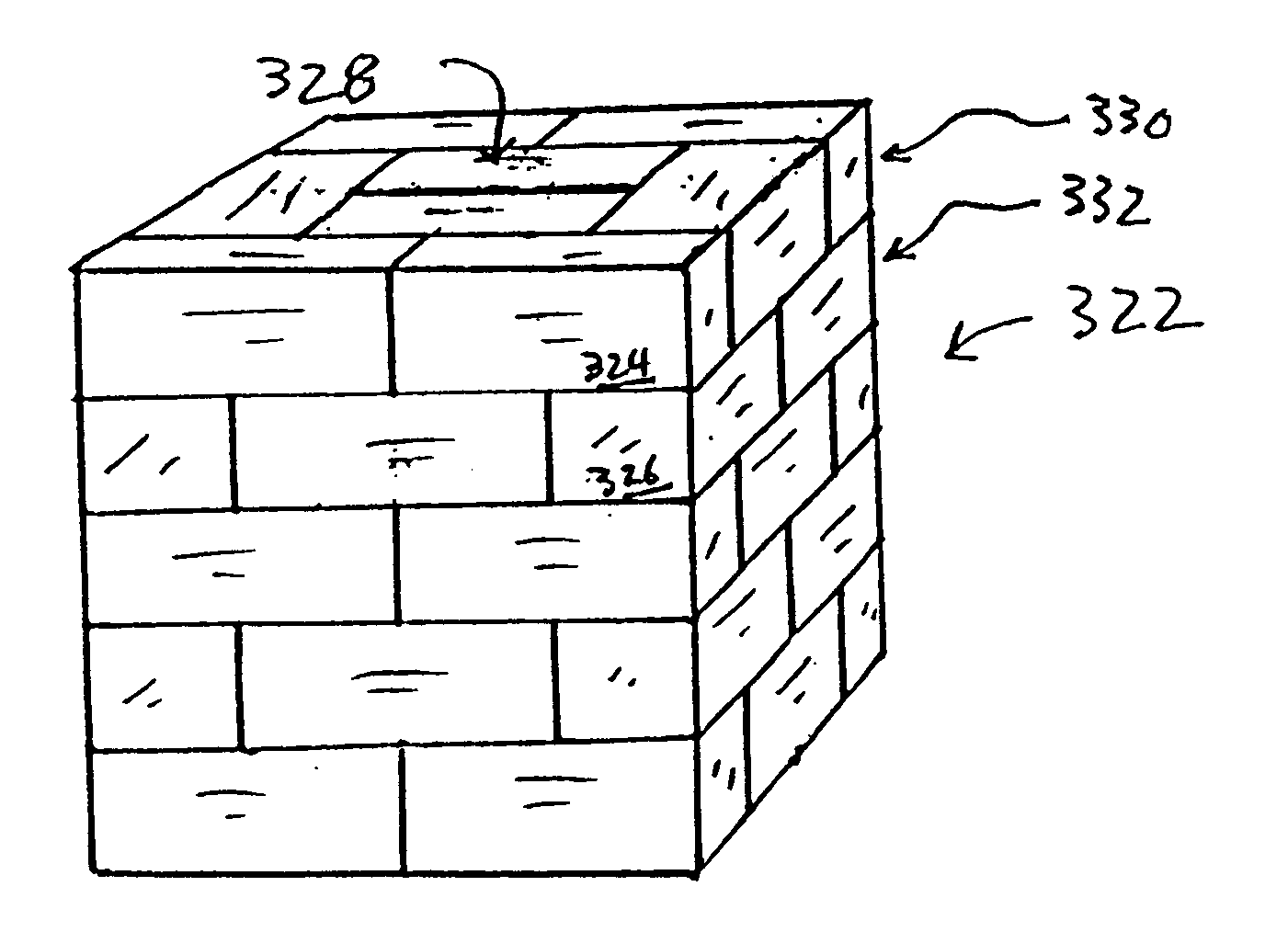

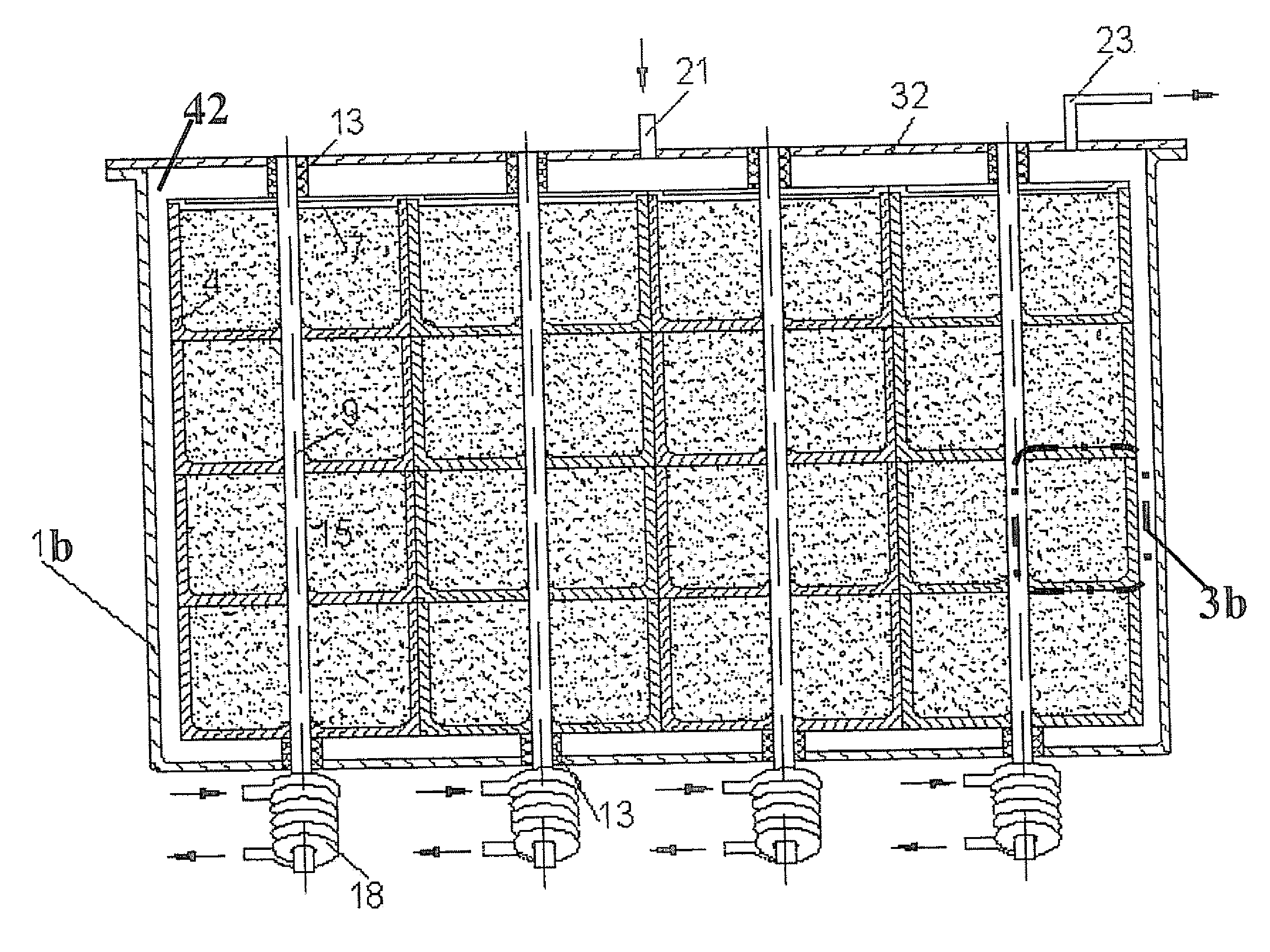

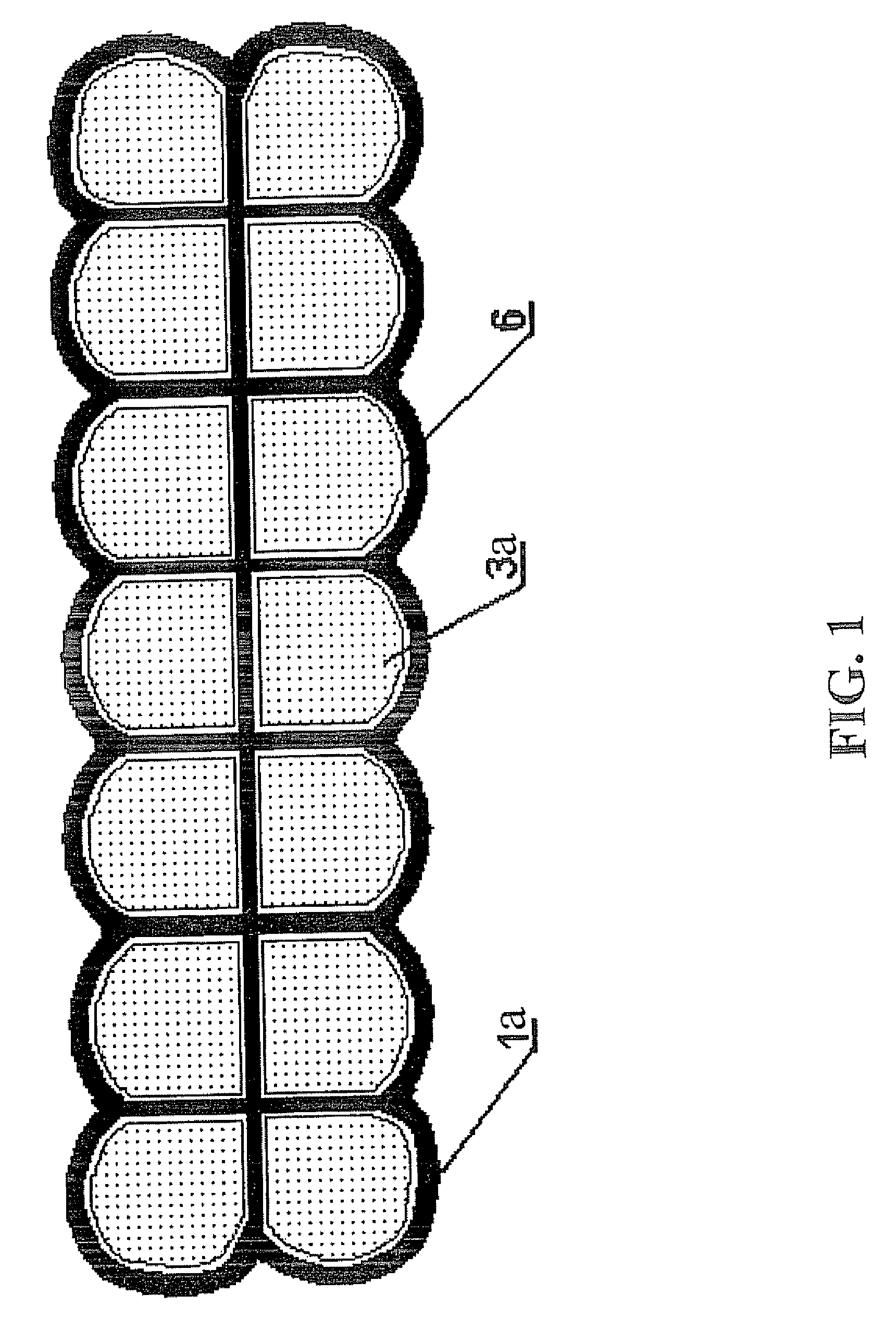

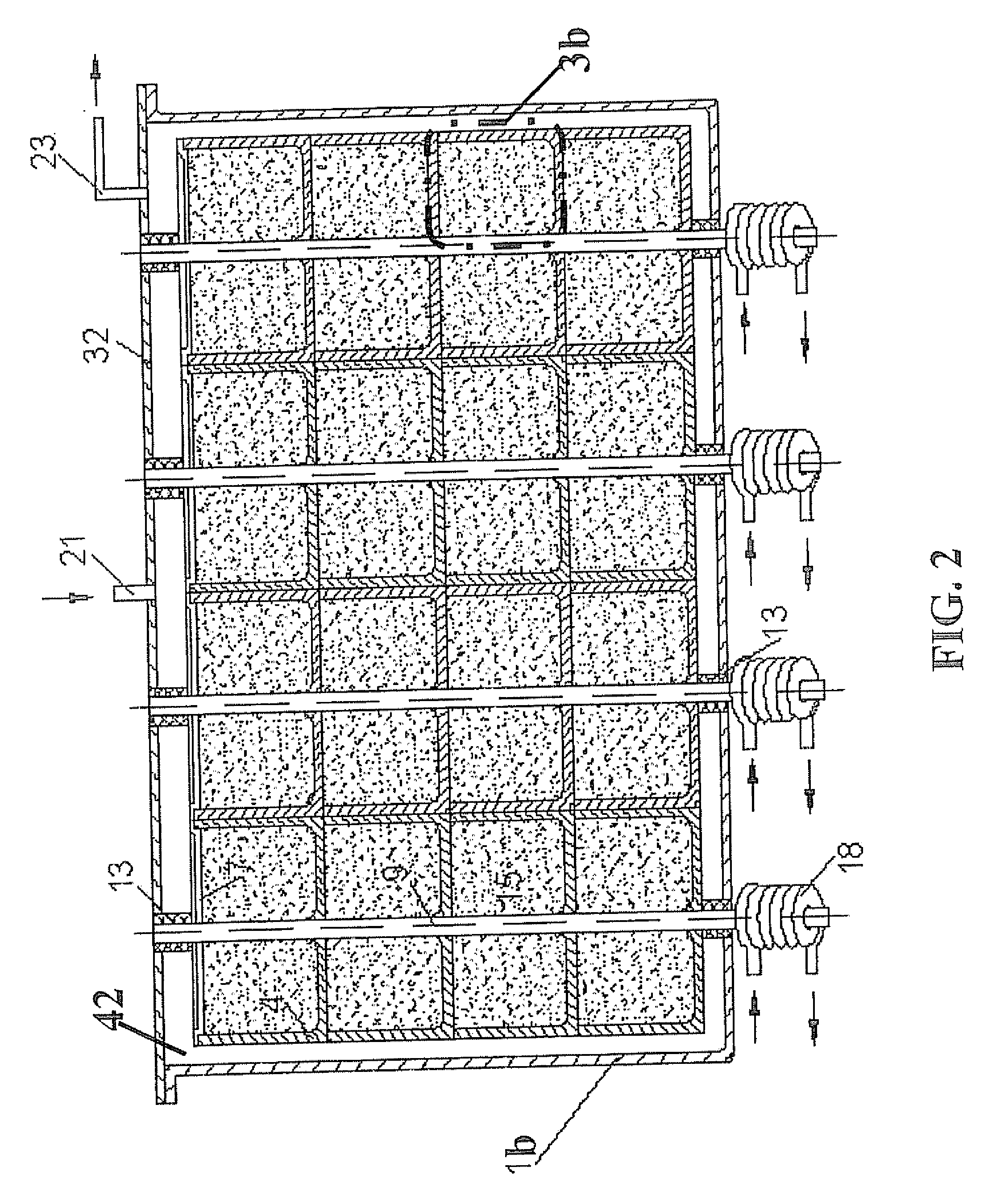

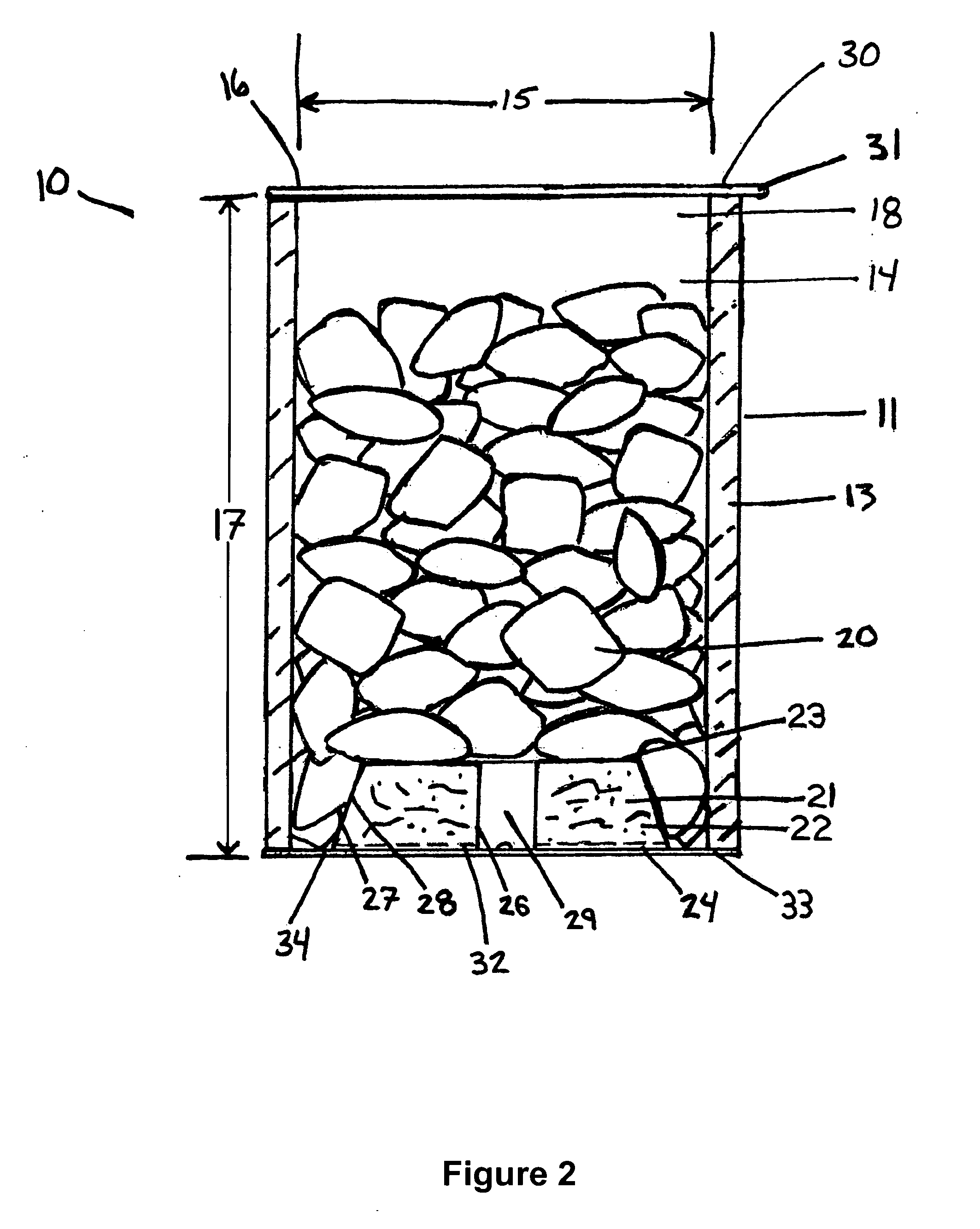

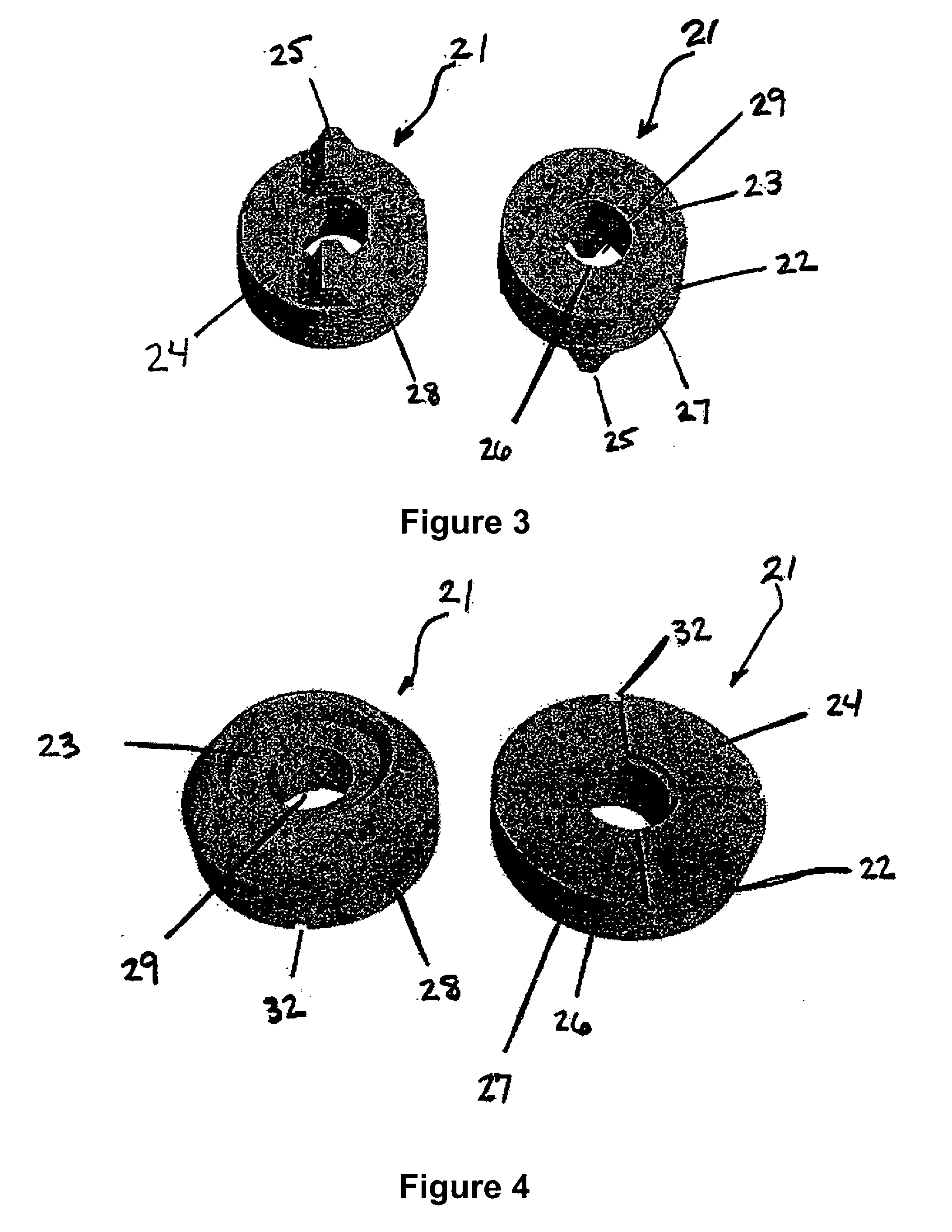

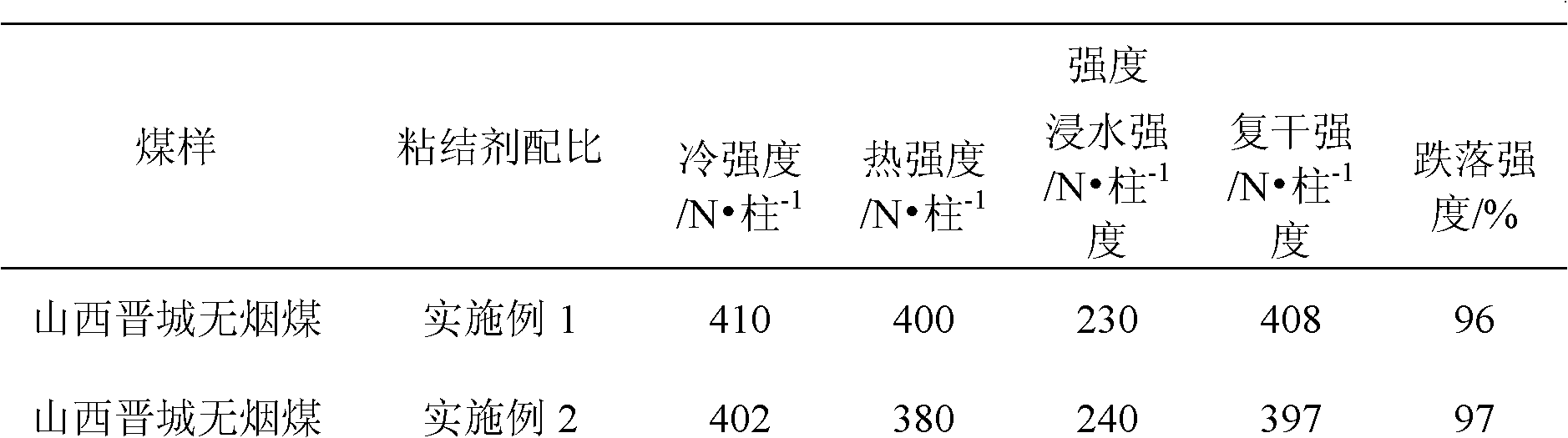

Storage Systems For Adsorbable Gaseous Fuel And Methods Of Producing The Same

InactiveUS20090229555A1Raise transfer toImprove efficiencyGas handling applicationsIsotope separationParticulatesLocal pressure

A storage system for an absorbing gas including a plurality briquette units situated within the storage tank is disclosed. In some embodiments each briquette unit includes a liner or open vessel, and compressed gas-absorbing particulate matter associated with the liner for external support In some embodiments, the liner or vessel maintains the form of the briquette unit. The liner or vessel do not form a pressure tight vessel, and in some embodiments, the local pressure rating of the liner or vessel is less than the gas pressure within the storage tank. Exemplary gas-absorbing materials include but are not limited to methane and hydrogen adsorbing materials such as activated carbon, zeolite, and other appropriate hydrocarbon gas and / or hydrogen adsorbing materials. Optionally, each briquette unit includes a wrapper for preventing circulation of said particulate matter within the storage tank. Optionally, the storage system includes a mechanism for supplying or removing heat to at least one briquette unit. Furthermore, a method for manufacturing any of the aforementioned gas storage systems is disclosed. Some embodiments of the present invention provide methane-powered motor vehicles including but not limited to automobiles, buses, trucks and ships including a storage system with compressed methane-adsorbing particulate matter

Owner:ANGSTORE TECH

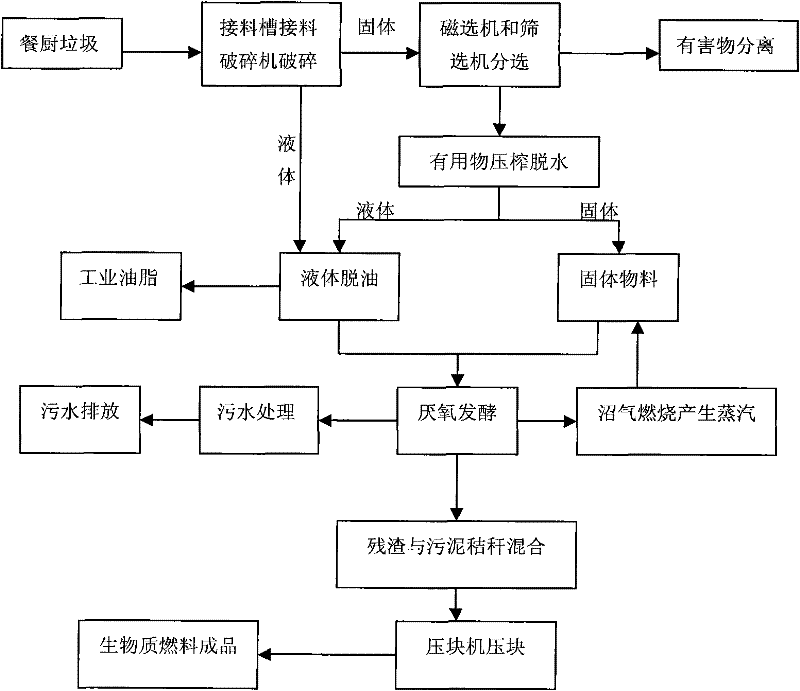

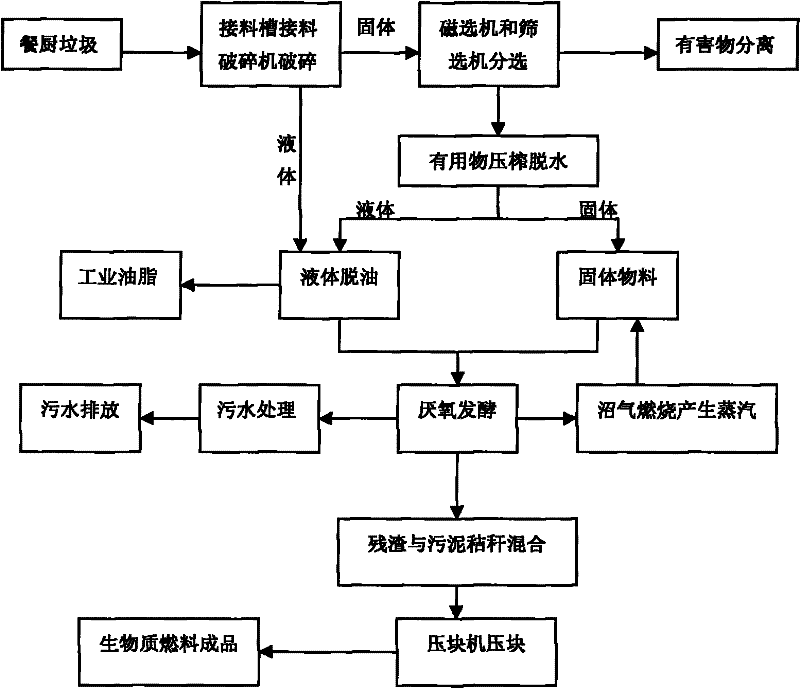

A method for preparing biomass fuel from kitchen waste

InactiveCN102268310AHarmlessAchieving processing powerFatty/oily/floating substances removal devicesSolid waste disposalSludgeSlurry

The invention relates to a method for recycling resources, in particular to a method for preparing biomass fuel from kitchen waste resources. The method for preparing biomass fuel from kitchen waste according to the present invention comprises sorting and crushing the kitchen waste, then dehydrating and deoiling, and anaerobically fermenting the solid materials in the kitchen waste after extracting the oil, and degrading the produced biogas Recycling, solid-liquid separation of the biogas slurry, the separated biogas residue is mixed with sludge, straw and other biomass materials, and dried and briquetted to make biomass fuel. The invention recycles kitchen waste and turns waste into treasure. It not only realizes the harmless and reduction treatment of kitchen waste, but also treats biomass waste such as sludge and straw, and the obtained products are completely burned without any waste. Secondary pollution, realize the comprehensive treatment of various wastes.

Owner:董雅清

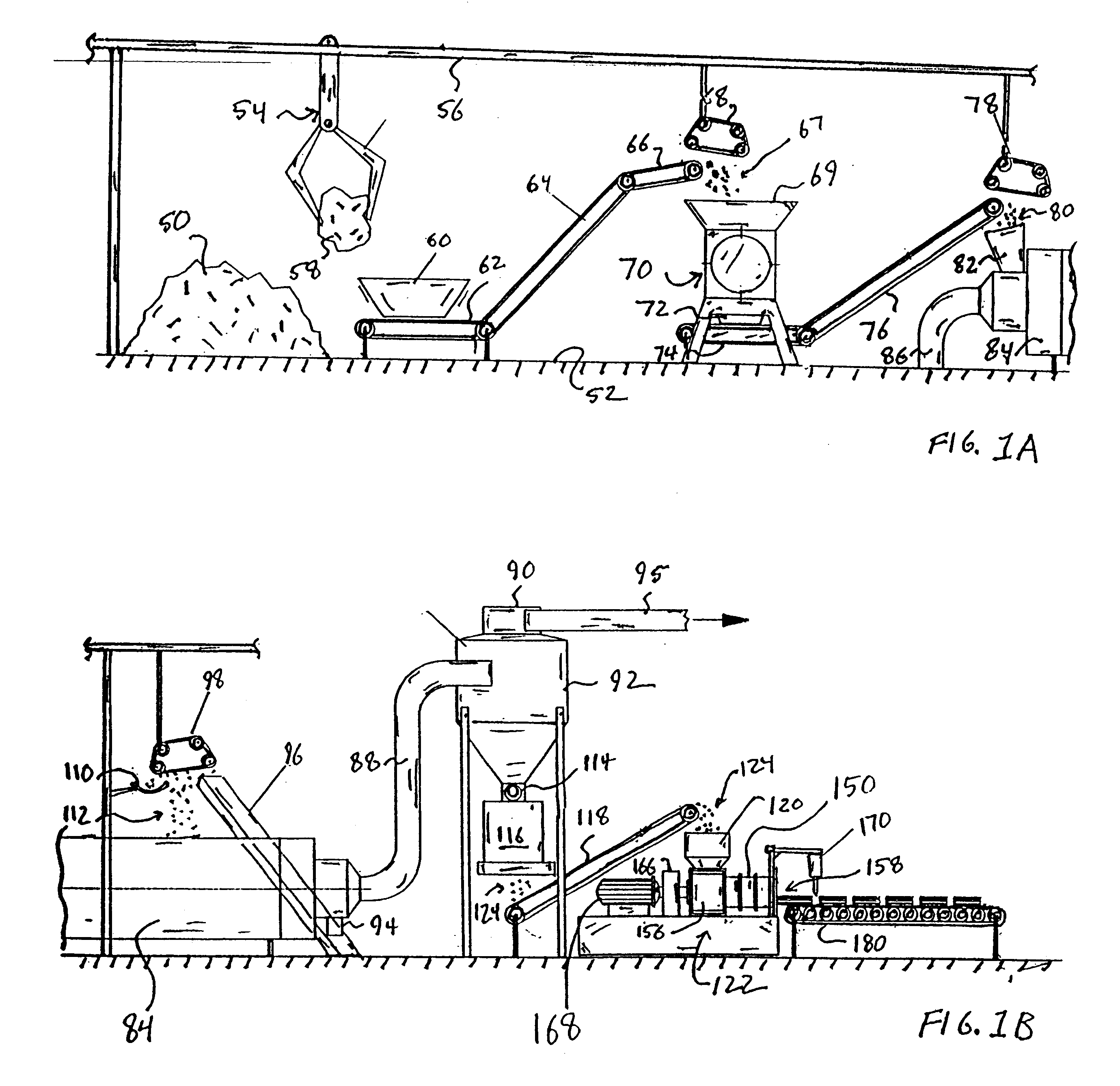

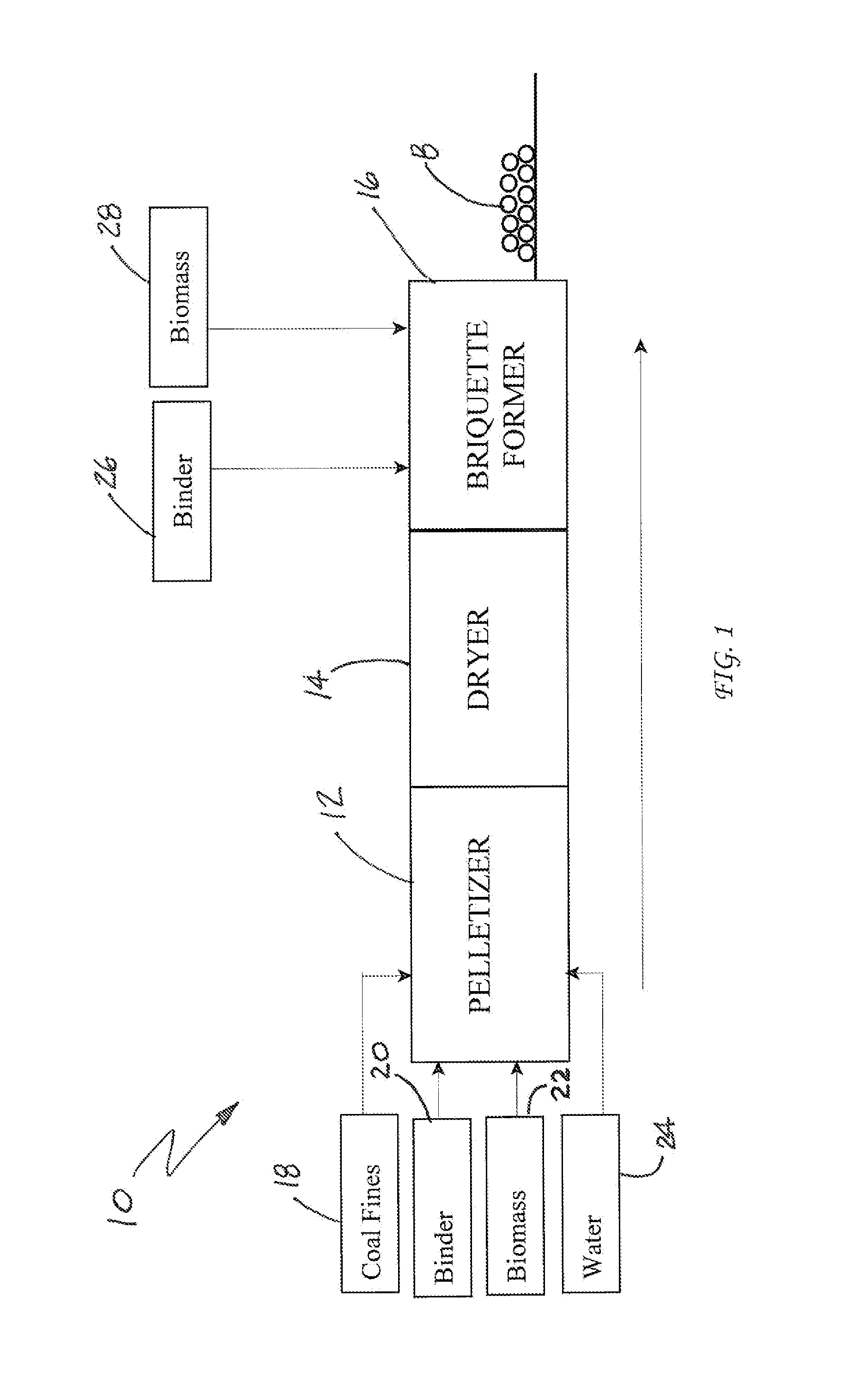

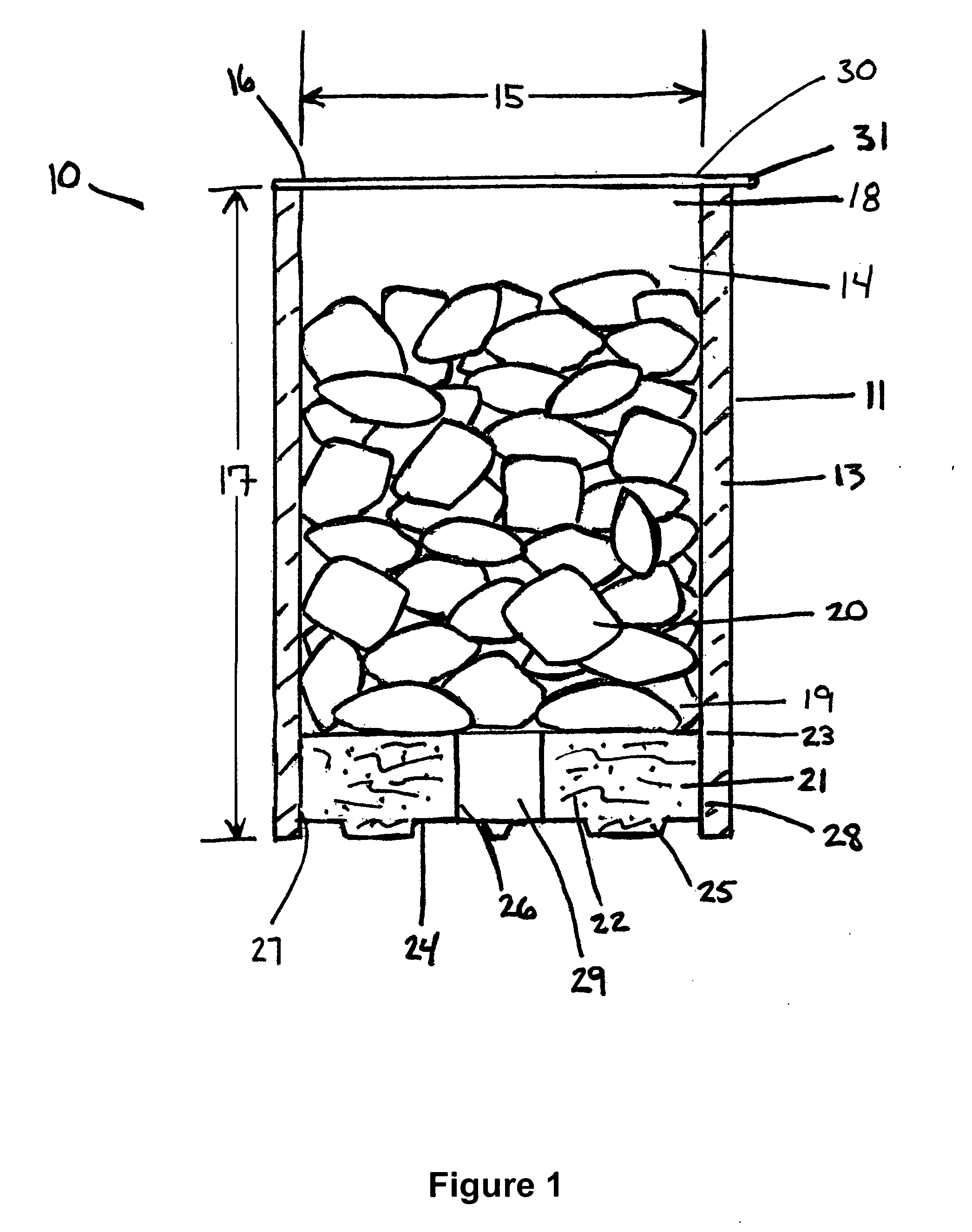

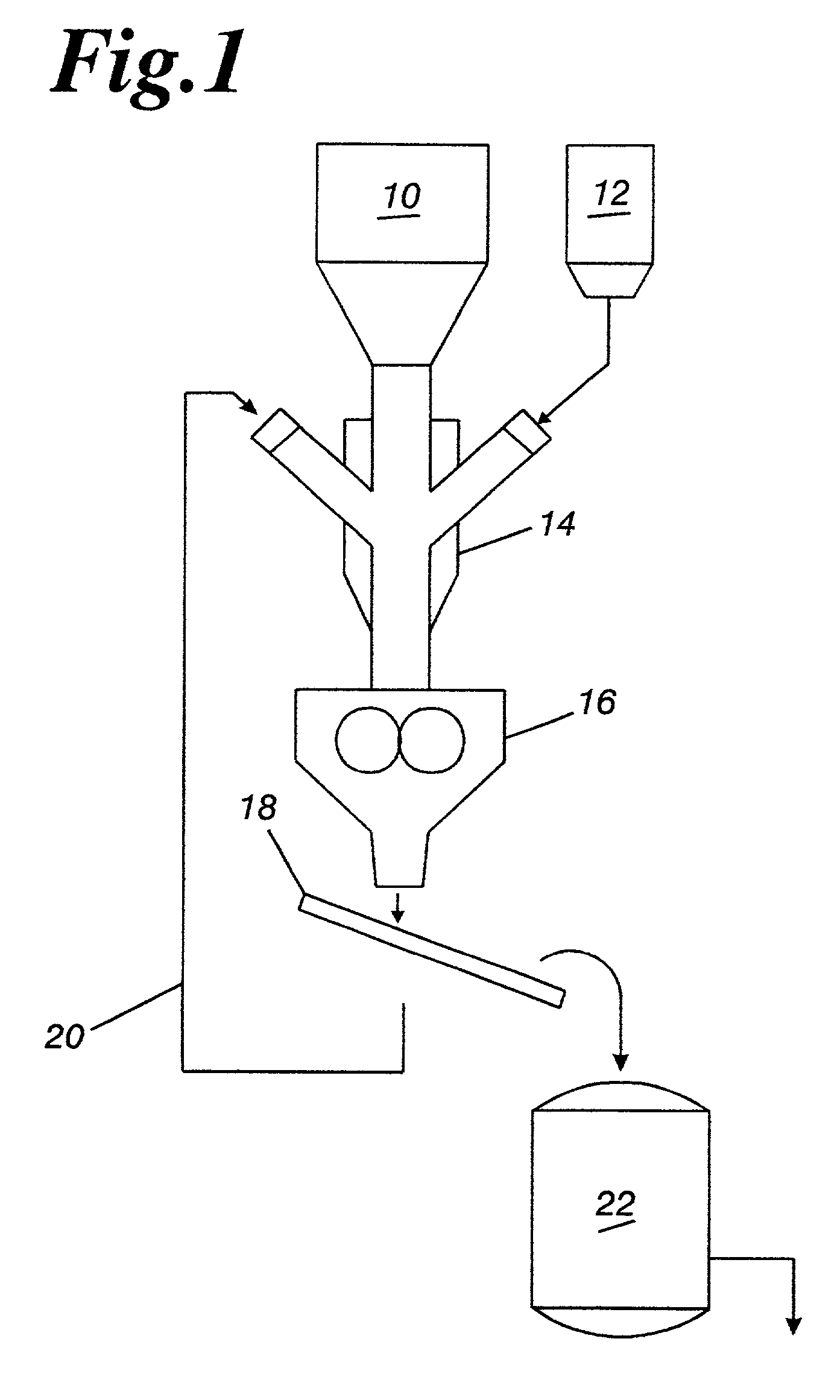

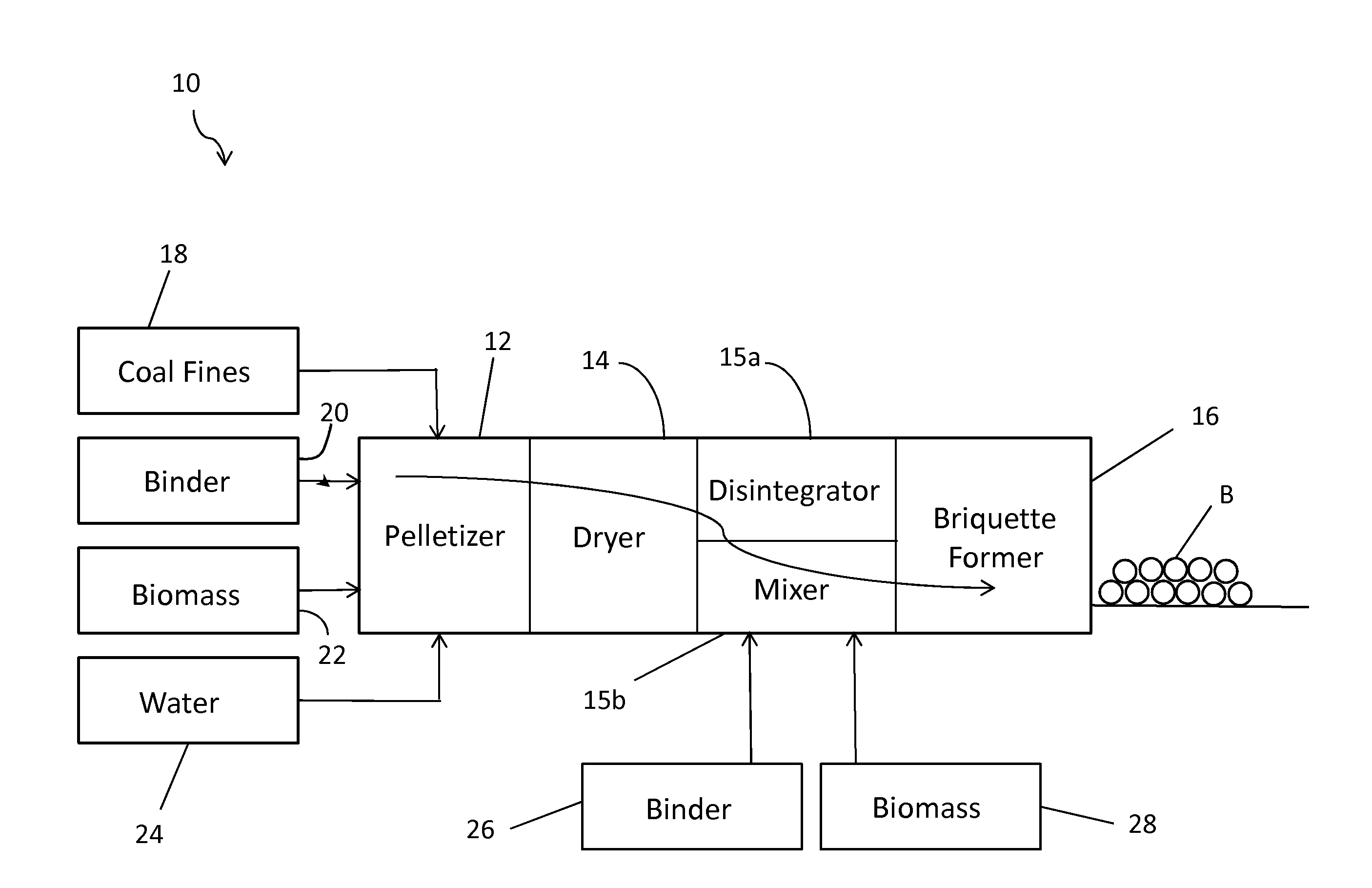

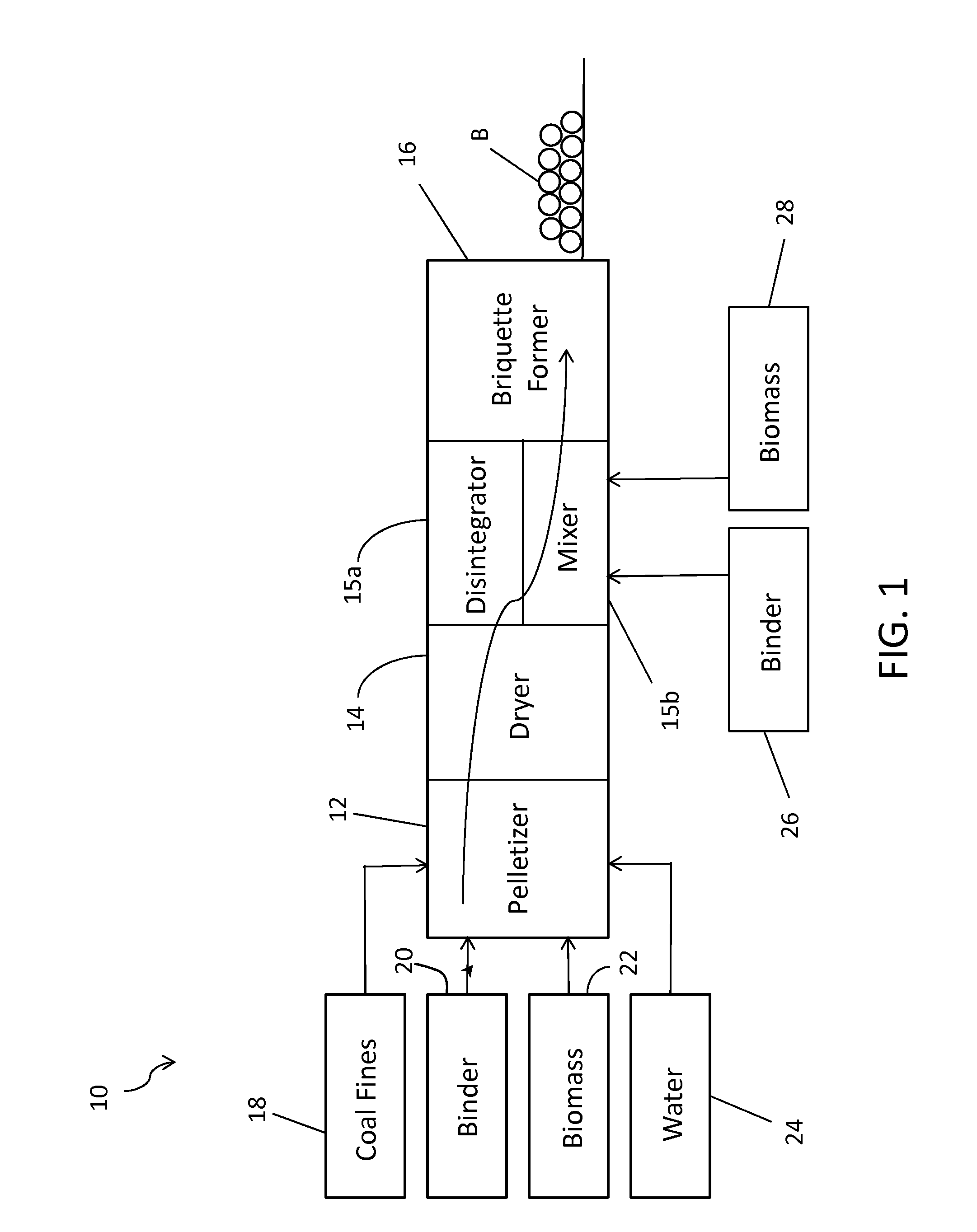

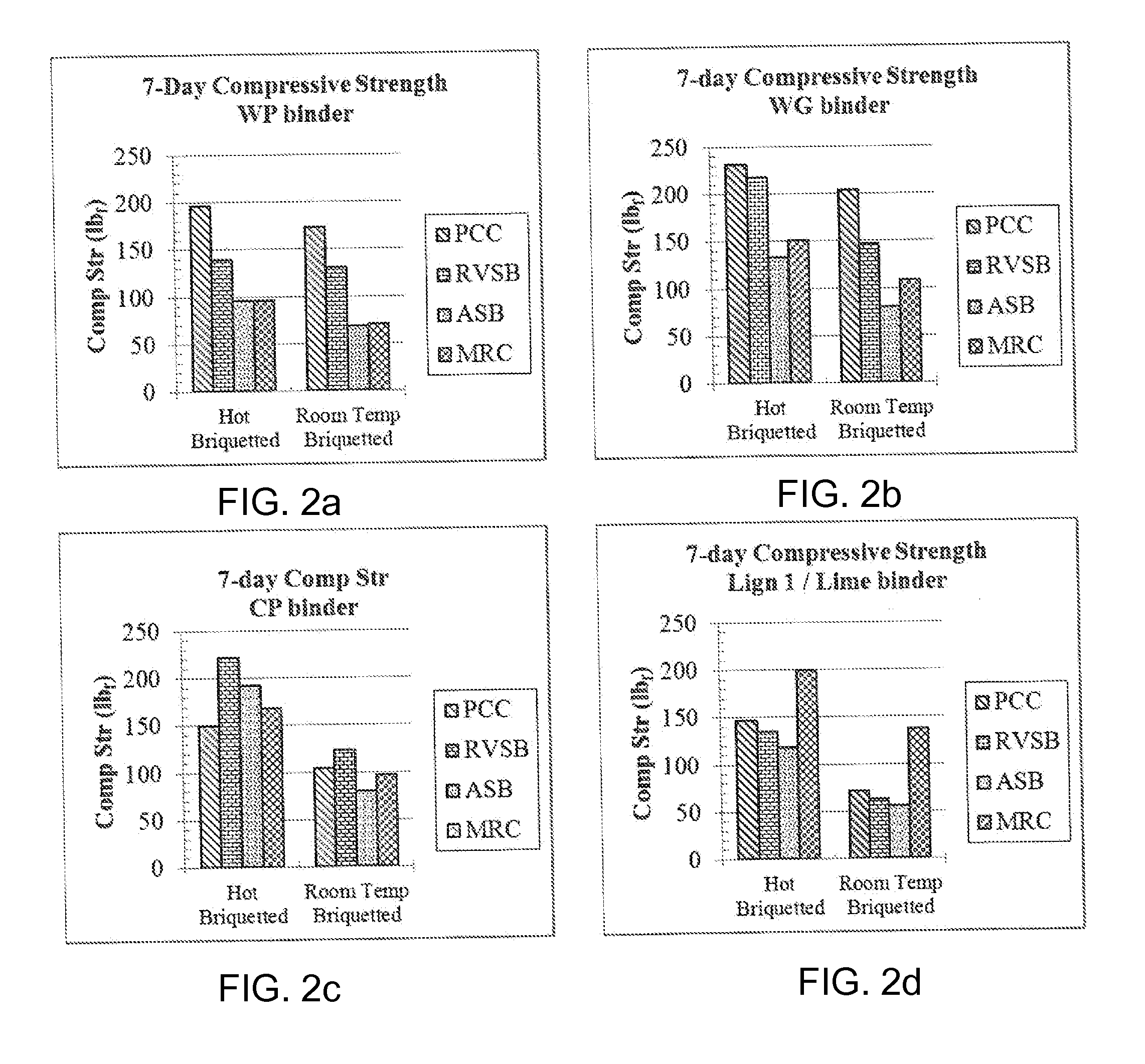

Method for producing fuel briquettes from high moisture fine coal or blends of high moisture fine coal and biomass

An apparatus and method are provided for producing fuel briquettes from high moisture fine coal. The apparatus includes a coal fine pelletizer, a pellet dryer and a fuel briquette former all provided in-line for the efficient production of fuel briquettes. The method comprises forming pellets from coal fines, drying those pellets to a desired moisture content of about 1 to about 10% and forming fuel briquettes from the dried pellets.

Owner:UNIV OF KENTUCKY RES FOUND

Titanium slag smelting method

The invention provides a titanium slag smelting method which comprises the following steps: preparing a mixture of titanium concentrates, a bonding agent and a carbonaceous reducing agent into pellets or briquettes; drying the pellets or briquettes; prereducing the pellets or briquettes by utilizing an annular furnace or a rotary hearth furnace, thereby preparing metallized pellets or metallized briquettes; and loading the metallized pellets or metallized briquettes into an electric furnace so as to melt and separate the metallized pellets or metallized briquettes, thus obtaining semisteel and titanium slag, wherein the smoke generated by prereducing the pellets or briquettes is used for providing heat for drying the pellets or briquettes, and the smoke generated in the melting and separating process is used for providing heat for prereducing the pellets or briquettes.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +1

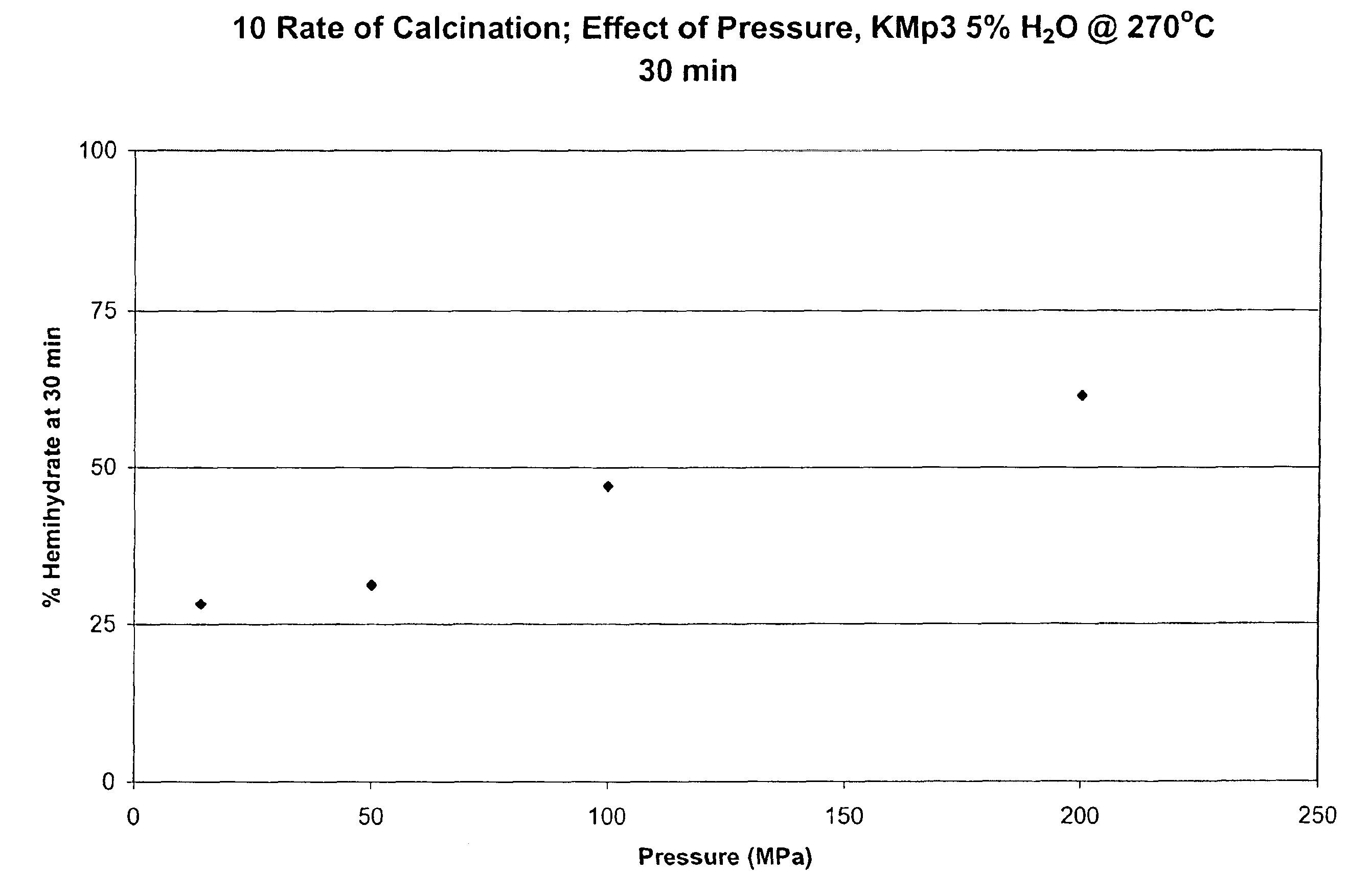

Calcium sulphate-based composition and methods of making same

InactiveUS6964704B2Good crystal shapeSolid waste managementCalcium/strontium/barium sulfatesHigh pressureBriquette

Owner:G B TECH LLC

Colorful ceramic and preparation method thereof

The invention provides colored ceramics and a preparation method thereof. Ceramic mud for the colored ceramics at least comprises the following compositions in weight percentage: 20 to 35 percent of kaoline, 60 to 70 percent of at least two of pottery stones, lithium pottery stones, feldspar and quartz, 0.2 to 6 percent of coloring matter, and 1 to 5 percent of nanometer quartz. The method for preparing the colored ceramics comprises the following: a step of pulp injection molding, in which part of colored mud cake or colored mud strip is mixed with liquefacient with 0.3 to 0.8 percent of total amount for pulping, and the mud which is screened from a screen of between 80 and 120 meshes is injected into a mold to produce a hollow or solid briquette; and a step of glazing and maturing, in which the briquette which is manufactured by pulp injection molding or plastic molding is cemented and dried according to creativities, and are directly applied with clear glaze, and the glazed briquette body is placed in an oxydizing flame roller kiln or an electrical kiln for 1 to 4 hours at a temperature of between 1,150 and 1,200 DEG C for maturing. The method can not only reduce clinkering cost, but also improve the moisture retention, bonding performance and corrosion resistance of strong ceramic mud, and further show energy conservation and environmental protection.

Owner:JINGDEZHEN HAHANI CERAMIC CULTURE DEV

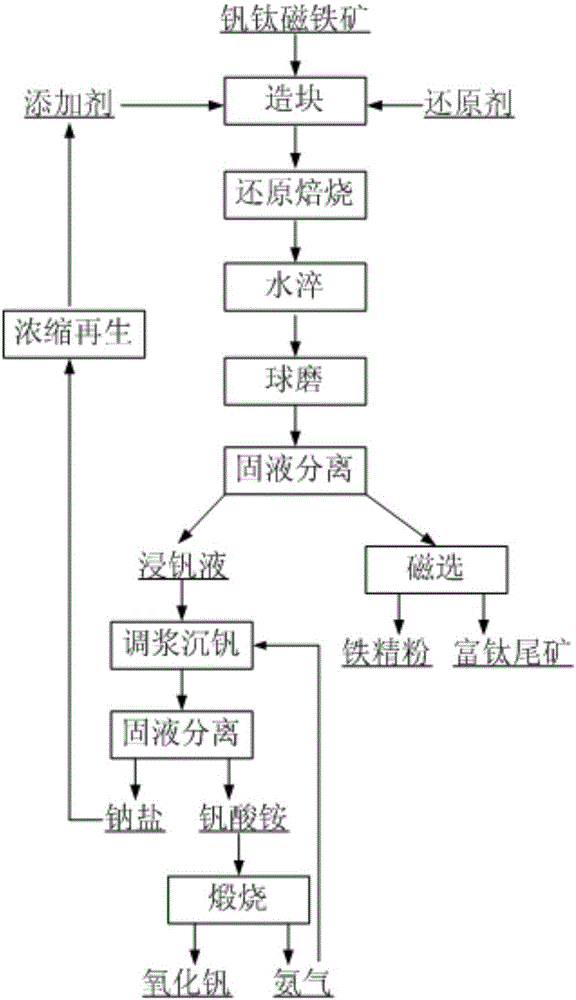

Method for separating iron, vanadium and titanium from vanadium-titanium magnetite

The invention discloses a method for separating iron, vanadium and titanium from vanadium-titanium magnetite. The method includes the steps that firstly, after the vanadium-titanium magnetite is smashed, an additive and / or reductant and an adhesive are added, and a pellet or a briquette is prepared; secondly, reduction roasting, water quenching, ball grinding and leaching are conducted on the pellet or the briquette; thirdly, after solid-liquid separation is conducted, vanadium soaking liquid and soaking slag are obtained, magnetic separating continues to be conducted on the soaking slag, and fine powdered iron and titanium-rich tailings are obtained; and fifthly, size mixing, vanadium precipitation and solid-liquid separation can continue to be conducted on the vanadium soaking liquid, and therefore sodium salt and ammonium vanadate are obtained. The method is simple in technology, low in energy consumption and high in metal recovery rate; and in addition, resources are reasonably used in the separation process, sodium salt and ammonia gas which are obtained through separation are effectively utilized, and the resource utilization rate of the whole separation process is high.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Organically clean biomass fuel

An organically clean biomass fuel formed of mixture of a powder, which may be either dried, cellulosic product, wood charcoal powder, and / or a combination of the two, and a fluid, which may be vegetable oil, vegetable alcohol or a combination of the two. A centrifugal machine dries moist, cellulosic product and extracts black liquor. A grinder transforms the dried, cellulosic product into powder. Gum may be extracted from the vegetable oil or vegetable alcohol. A batch mixer or vibrating vessel mixes the powder and the fluid together; the fluid moisturizes the powder. Depending upon the relative amount of the fluid as compared to powder, the mixture will either be in a liquid cream state or a doughy state. If the latter, the mixture may be pressed into briquettes or ingots.

Owner:ECOEM

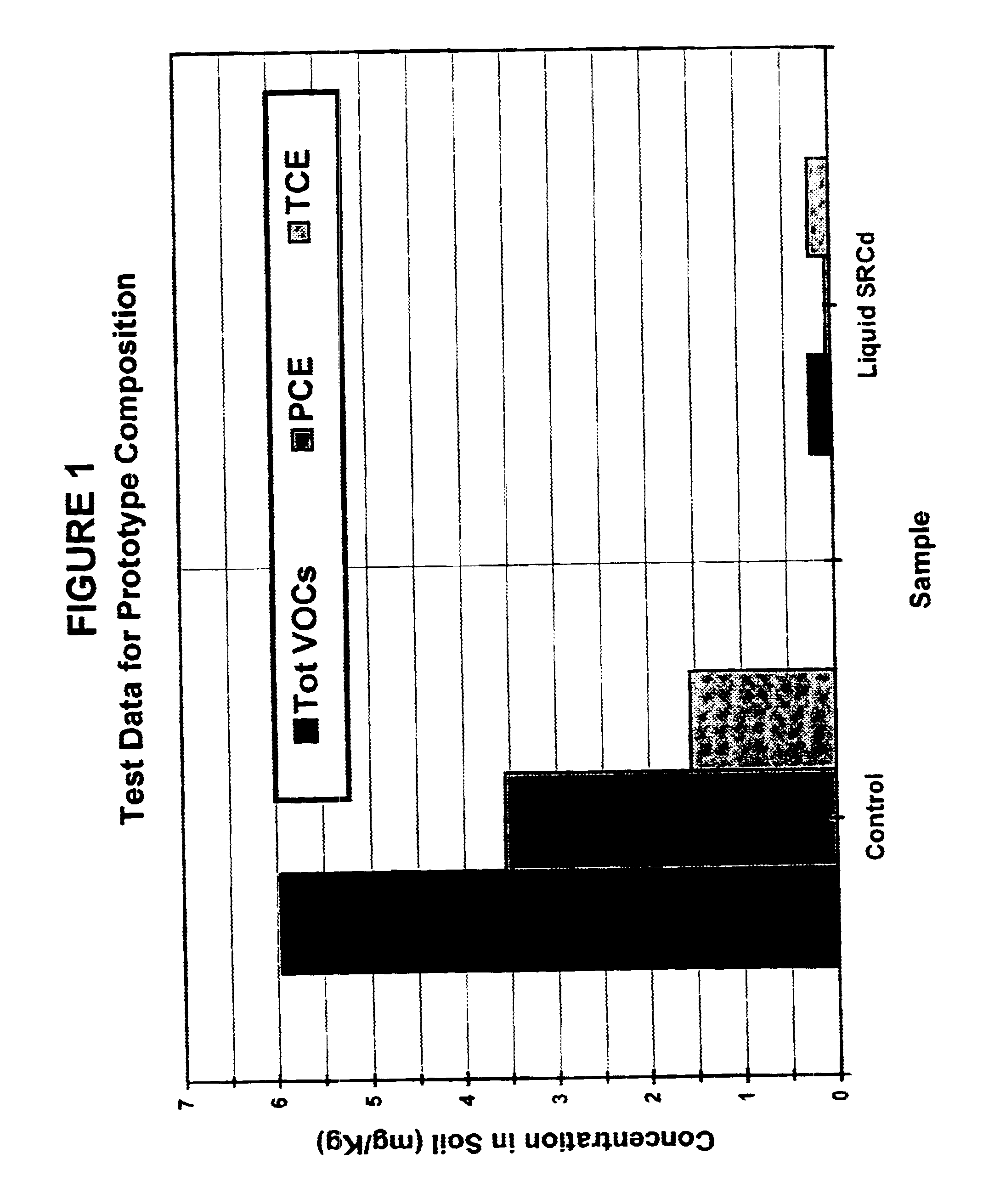

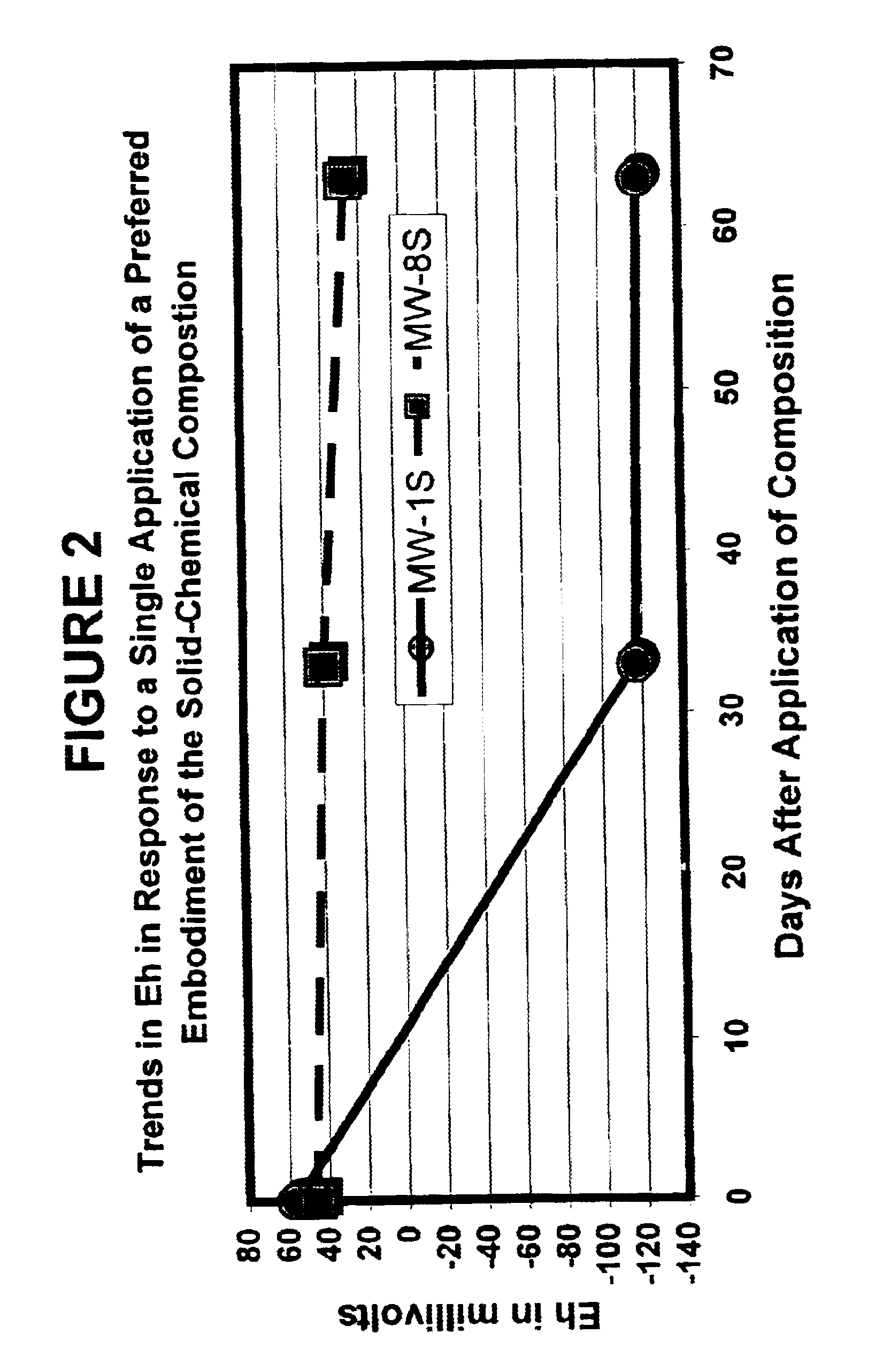

Solid-chemical composition for sustained release of organic substrates and complex inorganic phosphates for bioremediation

InactiveUS6620611B2Improve solubilityIncreasing speed and effectivenessBacteriaWater treatment compoundsPseudomonasTrichoderma spp

A slow-release solid chemical composition for environmental bioremediation is provided. The composition comprises a source of soluble organic substrates which include sugars, soluble organic polymers and mixtures of them in an amount of 7% to 90%, insoluble organic substrates an amount of 10% to 70%, complex inorganic phosphates in an amount of 0.5% to 7% and soluble organic salts in an amount of 2% to 70%. The insoluble organic substrates include fibrous plant materials, starches, cellulosic materials and mixtures of these substrates. The complex inorganic phosphates include ringed metaphosphates, linear polyphosphates and mixtures. The organic salts include lactates, formates, acetates, citrates, etc. Also the composition further comprises microorganisms which include Bacillus spp., Rhizobium spp., Bradyrhibzobium spp., Fibrobacter spp., Clostridium spp., Pseudomonas. spp., Geobacter spp., Arthrobacter spp., Nocardia, spp., aspergillus spp., Trichoderma spp., Candida spp., Yarrowia spp. and combinations of these microorganisms. The composition can be prepared in various forms, including granules, briquettes, pellets, tablets or capsules.

Owner:HINCE ERIC CHRISTIAN MR

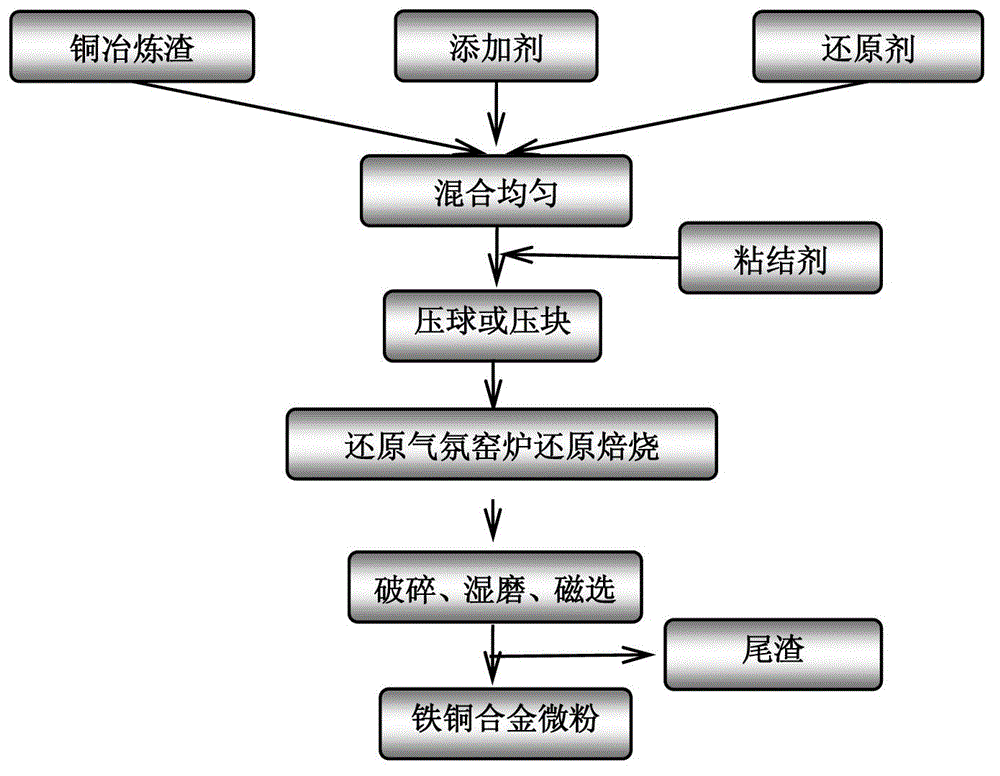

Method for rapidly reducing copper slags to produce iron-copper alloys in kiln in reducing atmosphere

ActiveCN102719676AIncrease added valueAchieve restorationProcess efficiency improvementSilicic acidReducing atmosphere

A method for rapidly reducing copper slags to produce iron-copper alloys in a kiln in a reducing atmosphere is characterized by including the steps: proportionally mixing the copper slags, reducing agents and additives, crushing or levigating the mixture to 200 meshes to obtain 20%-40% of residues on sieve; doping agglomerants and water occupying 5-20% of all materials on a dry mass basis, uniformly mixing, producing the uniformly mixed mixture to pellets with the diameters ranging from 15mm to 30mm and small cylindrical briquettes with all the heights ranging from 15mm to 30mm by a pellet press or a briquetting machine, and drying the pellets or small cylindrical briquettes; flatly laying the dried pellets or small cylindrical briquettes at the bottom of the kiln, wherein the material layer thickness ranges from 20mm to 45mm, the material layer reducing temperature ranges from 1250 DEG C to 1450 DEG C, and the reducing time is 10-40min; and subjecting the reduced pellets or the briquettes to cooling, crushing, wet grinding and wet separation so that iron-copper alloy powder with the iron recovery rate of 85%-99% is obtained. According to the method, iron in a great quantity of silicate iron in the copper slags, which cannot be separated out by the traditional technology, is extracted and turns into the iron-copper alloy micro powder with high added value so that iron and copper in the copper slags are extracted and used simultaneously, and physical and chemical heat energy in strong reducing waste gas can be completely recovered during rapid depth reduction.

Owner:TONGLING NON FERROUS METAL GROUP CORP +1

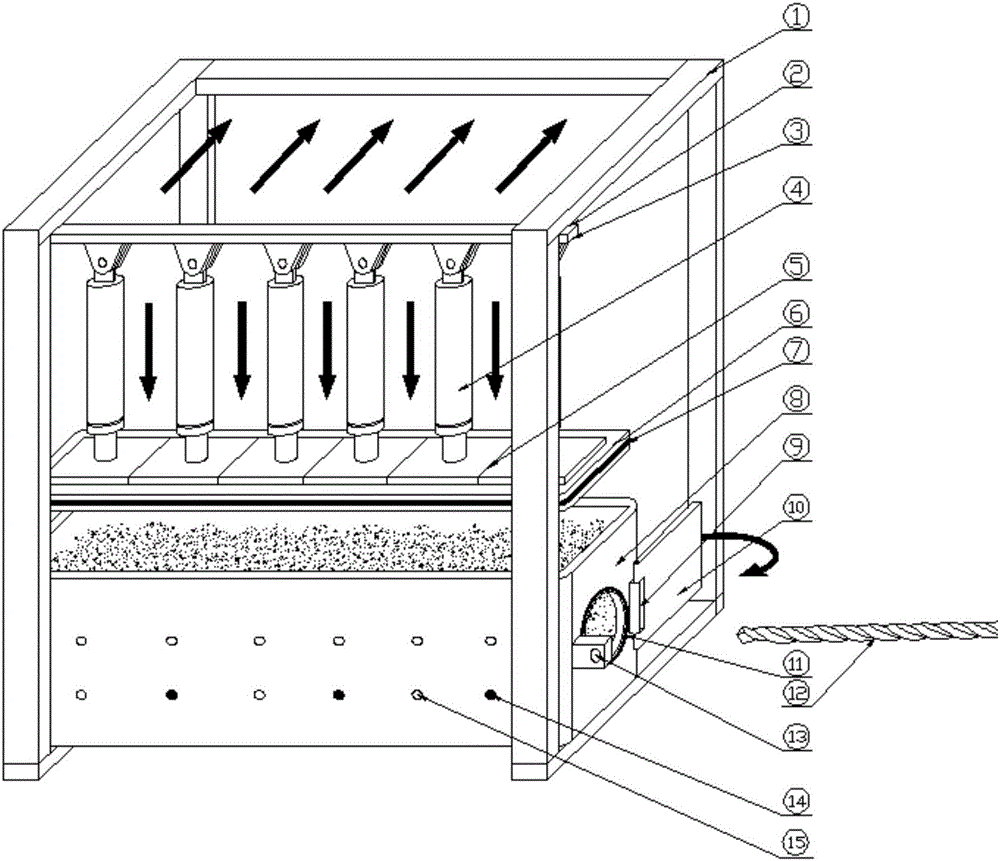

Verisimilitude briquette coal and gas outburst simulation test device and method

ActiveCN106483267ASimulate the realRealize the whole spaceFuel testingEnergy transferGeneration process

Owner:CHINA UNIV OF MINING & TECH +1

Coal gangue biomass solid forming fuel and preparation method thereof

InactiveCN101805651ACalorific value of combustion is stableGood benefitBiofuelsSolid fuelsSocial benefitsAdhesive

The invention discloses a coal gangue biomass solid briquettes fuel, which comprises the following components in percentage by weight: 40 to 85 percent of coal gangue with the combustion heat value higher than 2,000 kilocalories, 10 to 50 percent of agricultural organic waste, 1 to 5 percent of combustion improver, and 1 to 5 percent of adhesive. The method for preparing the coal gangue biomass solid fuel comprises the following steps: crushing the coal gangue with the combustion heat value higher than 2,000 kilocalories; and adding the agricultural organic waste, the combustion improver, and the adhesive in a certain proportion to directly produce the coal gangue biomass solid forming fuel with a stable combustion value by adopting forming machinery. The solid forming fuel is prepared by reasonably using a large quantity of agricultural organic waste and the coal gangue in a certain proportion; and the combustion heat value is stable. The biomass solid forming fuel can be used as the fuel of boilers, stoves and other combustion devices, and has good social benefits, environmental protection benefits, and economic benefits.

Owner:童风

Combustible package for charcoal briquettes and a fire starter

InactiveUS20060156621A1Low production costSimple processSolid fuelsFirelightersInterior spaceEngineering

A package made from all combustible materials for containing a fuel source, such as charcoal briquettes, and a fire starter. The package includes a wound paper tube with an interior space where the charcoal briquettes are stored along with the fire starter. The top of the interior space is closed off by a top lid made from combustible material. The fire starter is located underneath the charcoal briquettes at the lower end of the interior space. The fire starter may also function as bottom lid or a separate bottom lid may be employed.

Owner:SONOCO DEV INC

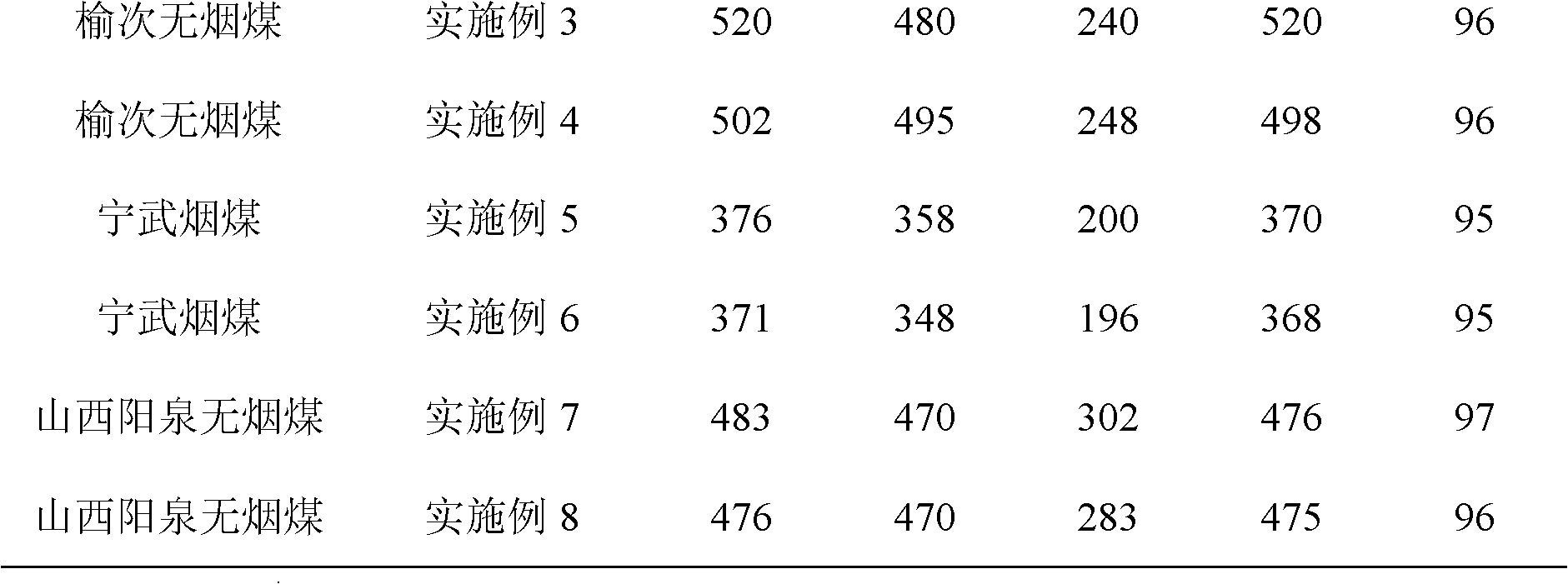

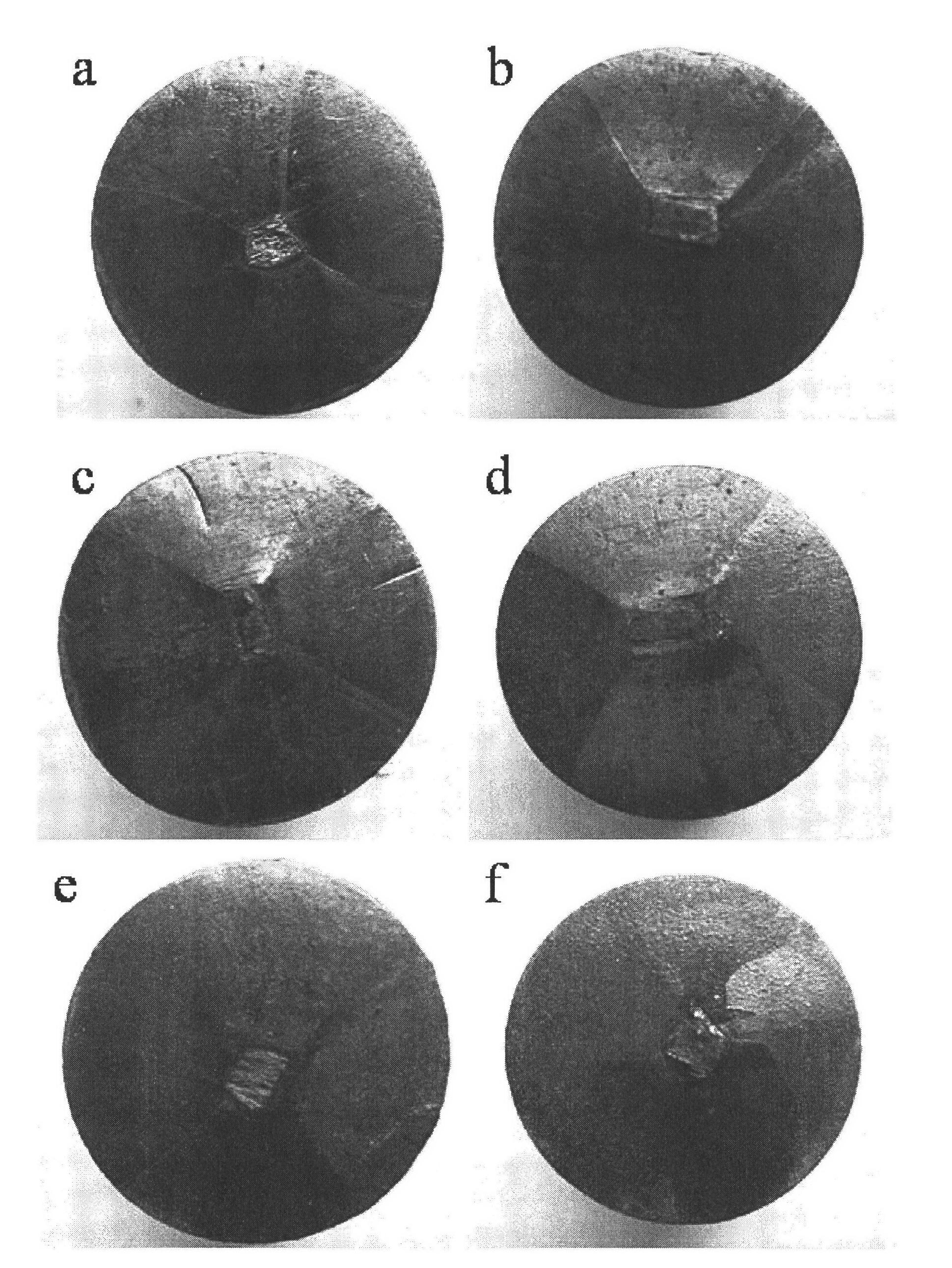

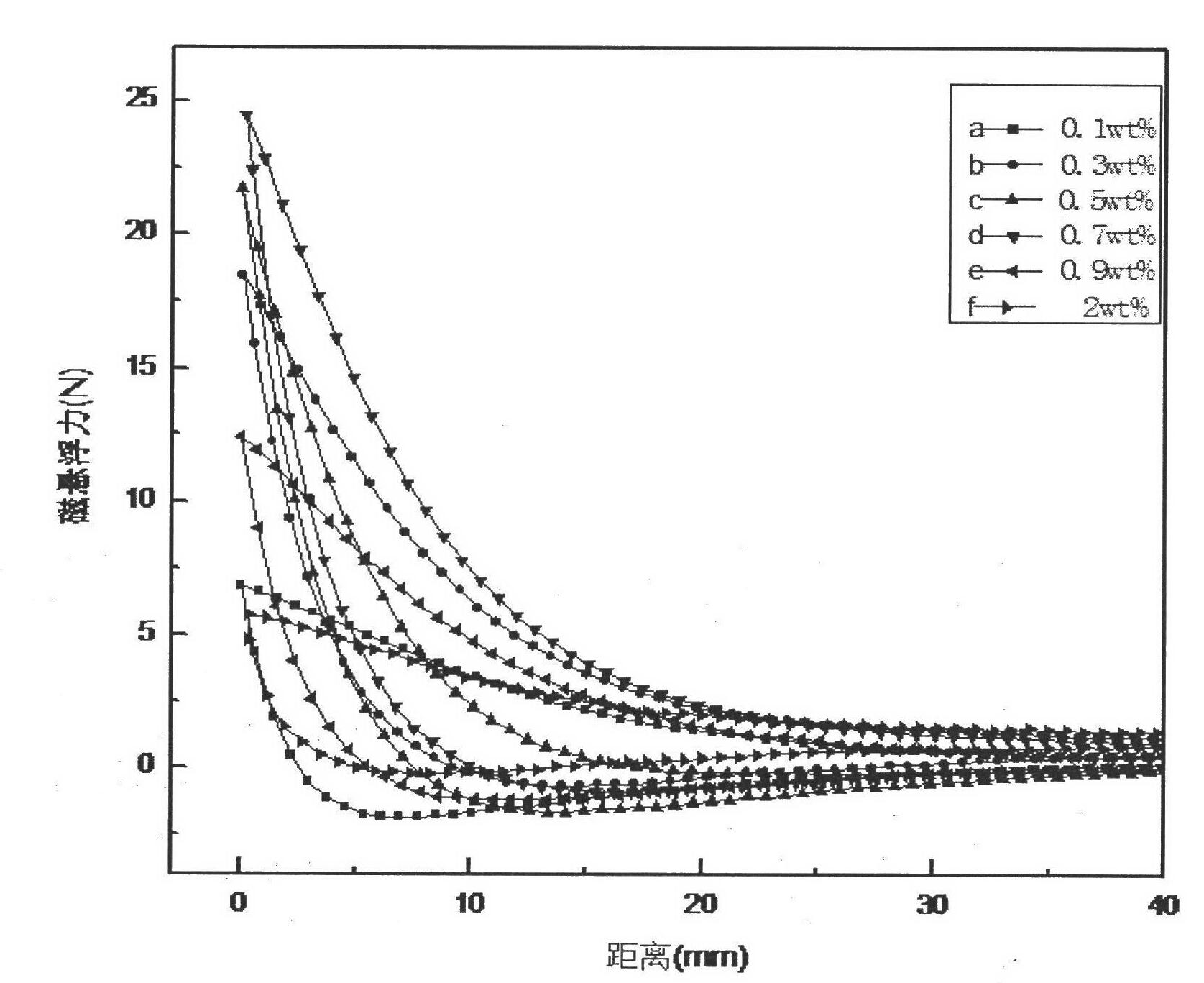

Briquette binder and briquette preparation method based on binder

The invention provides a briquette binder and a briquette preparation method based on the binder. The binder comprises 45 to 75 mass percent of humic acid, 8 to 20 mass percent of bentonite, 5 to 18 mass percent of kaolin, 1 to 5 mass percent of quartz sand, 2 to 8 mass percent of quicklime, 0.1 to 2 mass percent of sodium chloride, 0.1 to 2 mass percent of potassium permanganate and 0.05 to 0.1 mass percent of polyacrylamide. The binder has a simple preparation process, low cost, convenient use and no any secondary pollution and is applicable to various types of coal. The process for preparing the briquette by using the binder comprises the following steps of: only making little pretreatment on raw material coal and the binder, mixing the raw material coal and the binder in proportion, adding water into the mixture, uniformly stirring, pressing the mixture into a cylindrical briquette by using a press machine, and air-drying or drying the cylindrical briquette. The briquette prepared by using the binder of the invention has the characteristics of high cold strength, high water resistance, low cost, low ash increment, high thermal strength, high sulfur retention rate and wide source of raw materials.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of single domain yttrium barium copper oxide superconductor

ActiveCN102534787ASimple processImproved Flux Pinning PerformancePolycrystalline material growthFrom frozen solutionsFlux pinningYttrium barium copper oxide

The invention relates to a preparation method of a single domain yttrium barium copper oxide superconductor; and the preparation method comprises the following steps: preparing Y2BaCuO5 precursor powder and liquid phase source powder, pressing a Y2BaCuO5 precursor block, a liquid phase block and a supporting bock, preparing a green body, growing a single domain yttrium barium copper oxide block in an infiltration manner, and carrying out oxygen permeation processing. A second phase nanoparticle Y2Ba4CuBiOx / Y2Ba4CuMOx (M is Bi or W) is successfully introduced for forming a flux pinning center by adopting a top seed crystal infiltration growing method and adding a metallic oxide (Bi2O3 powder and WO3 powder) for doping, thereby the powder preparation technology is simplified, the experimental period is shortened, the experiment cost is reduced, and the flux pinning capacity of the superconductor is increased. Y2O3 is used for preparing the supporting block which stably supports two briquettes above the supporting block in the slow cold growing process of an yttrium barium copper oxide block so as to prevent liquid phase from running off. The preparation method can be used for preparing the yttrium barium copper oxide superconductor and can also be used for preparing high-temperature superconductors of other series such as Gd, Sm, Nd, Eu and the like.

Owner:SHAANXI NORMAL UNIV

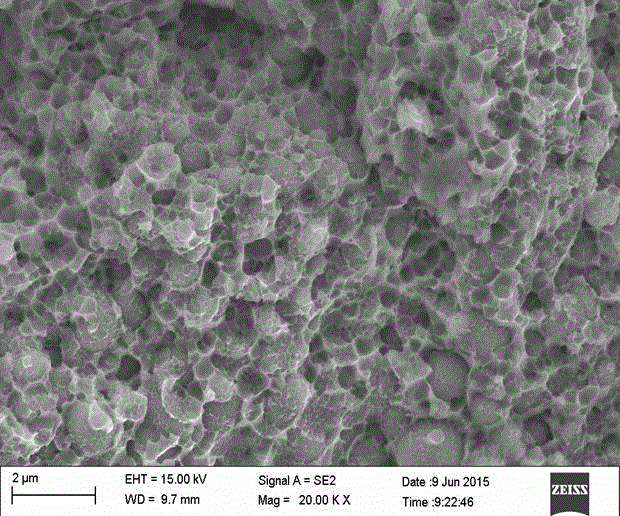

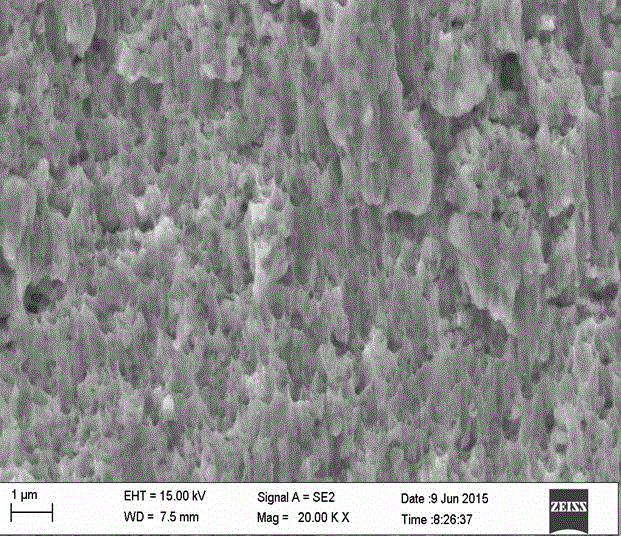

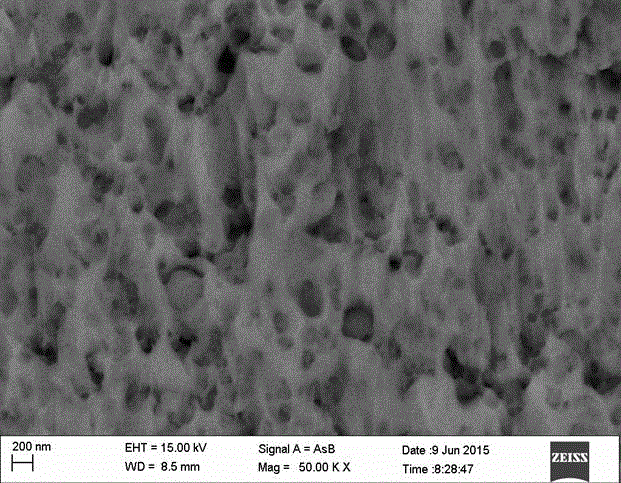

Preparation method of fine-grained CuCr alloy

The invention provides a preparation method of a fine-grained CuCr alloy, which comprises the processing steps that (1) an oxygen-free copper block and a chromium block are subjected to induction heating to be molten and dissolved mutually, molten liquid is ejected by argon gas pressure and subjected to centrifugal atomization by a copper roller rotation quenching melt spinning or a water-cooling rotating disk; (2) a fine-grained CuCr alloy material is subjected to ball milling by a high-energy ball mill under argon shield; (3) fine-grained composite CuCr alloy powder is loaded into a mould briquette to be made into a green blank; and (4) the green blank is loaded into a graphite drying pot, and placed in a vacuum sintering furnace to be sintered to form the fine-grained CuCr alloy. In the fine-grained CuCr alloy prepared by the method, the particle sizes of chromium particles are 0.5-10 micrometers, the surface hardness is 65-162HV, and the conductivity is 26.0-80.8% IACS (International Annealed Copper Standard); compared with the existing CuCr alloy with the equivalent chromium content, the particle sizes are reduced obviously, and the alloy performance is improved significantly; and the fine-grained CuCr alloy has more excellent effect in an application of an electrical contact material.

Owner:NORTHEASTERN UNIV

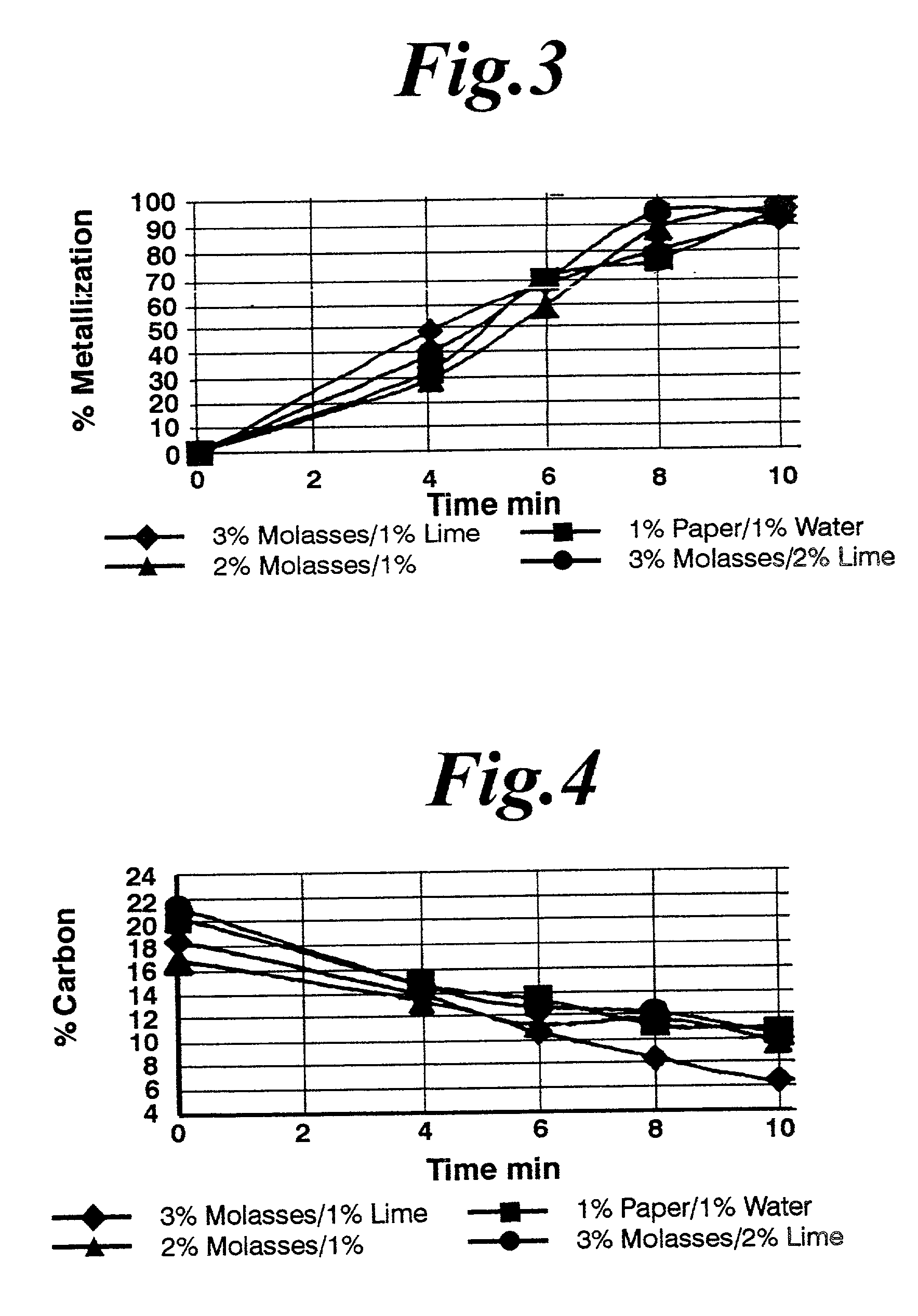

Method of producing a metallized briquette

InactiveUS20010047699A1High strengthCost-effectiveProcess efficiency improvementCellulose fiberBriquette

The invention is a method of making metallized iron agglomerates by combining iron / steel particles and a reductant material with a cellulose fiber binder material, compacting the combination to form a solid agglomerate, and reducing the iron portions of the agglomerate in a direct reduction furnace. The cellulose fiber binder material provides an agglomerate having improved strength and lower overall cost than comparable agglomerates using binders known in the art.

Owner:MIDREX TECH INC

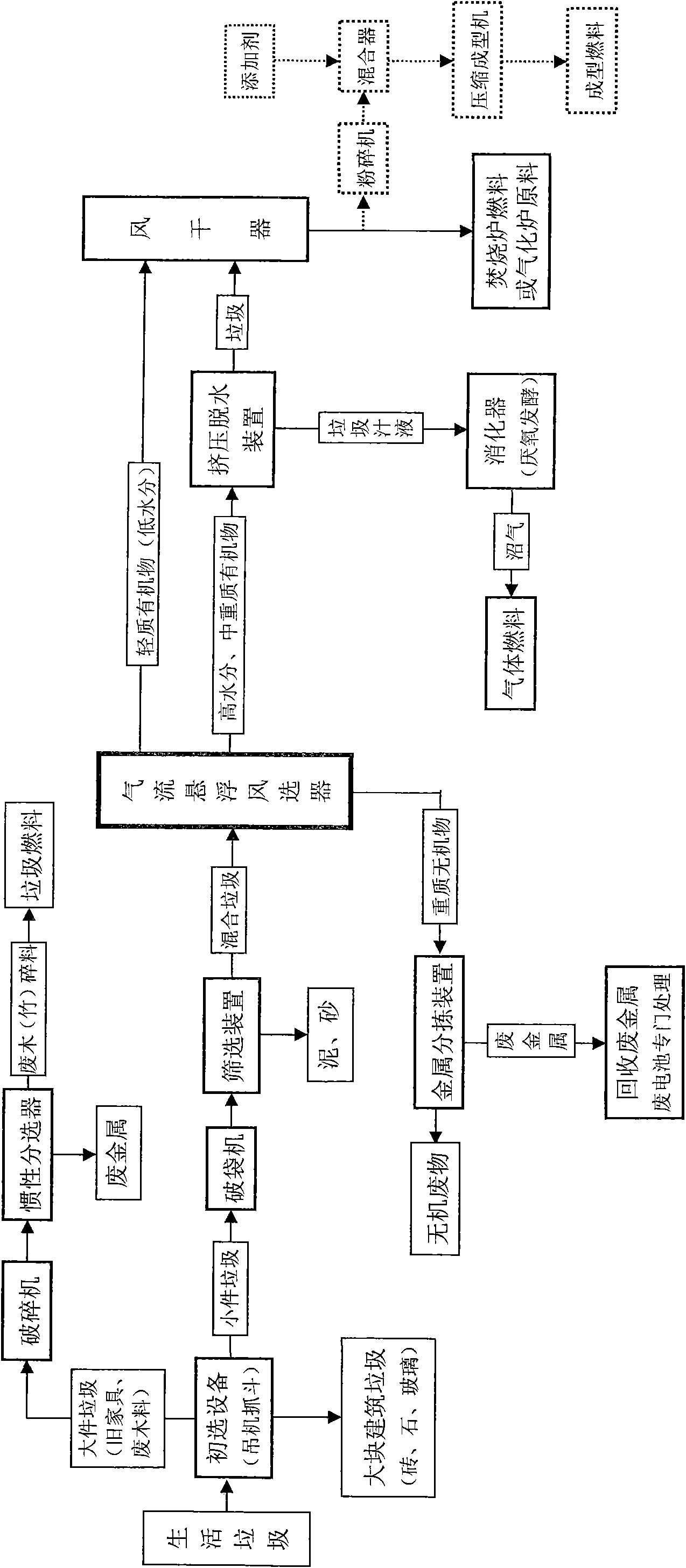

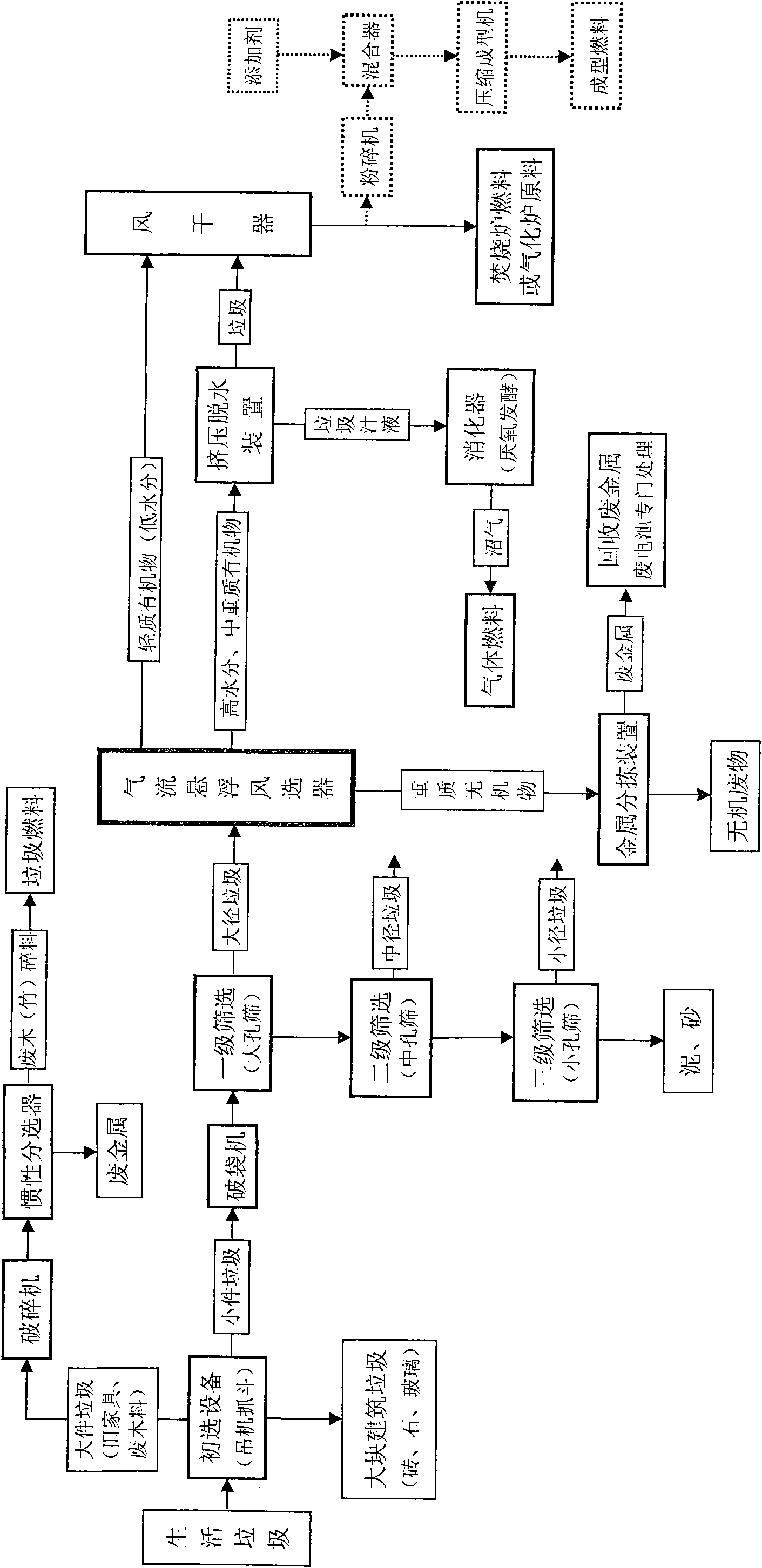

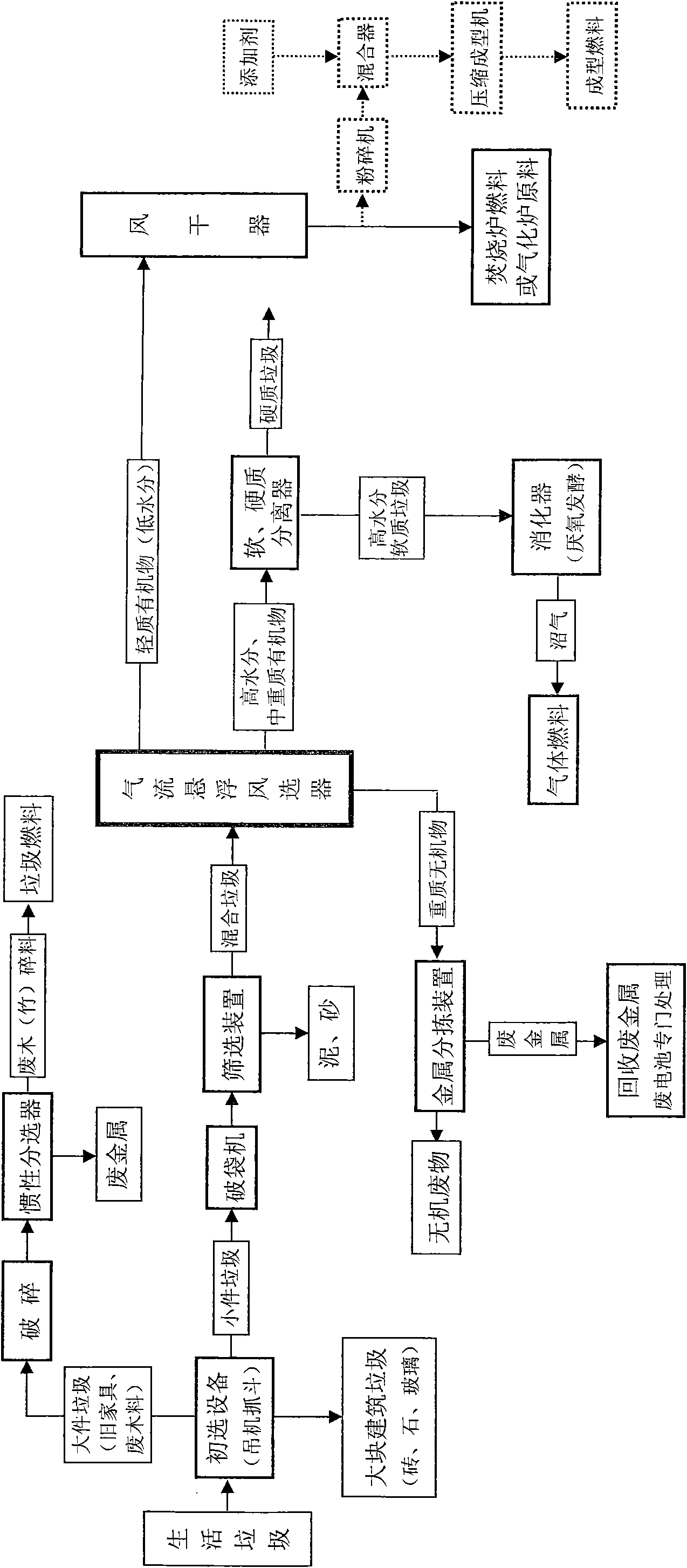

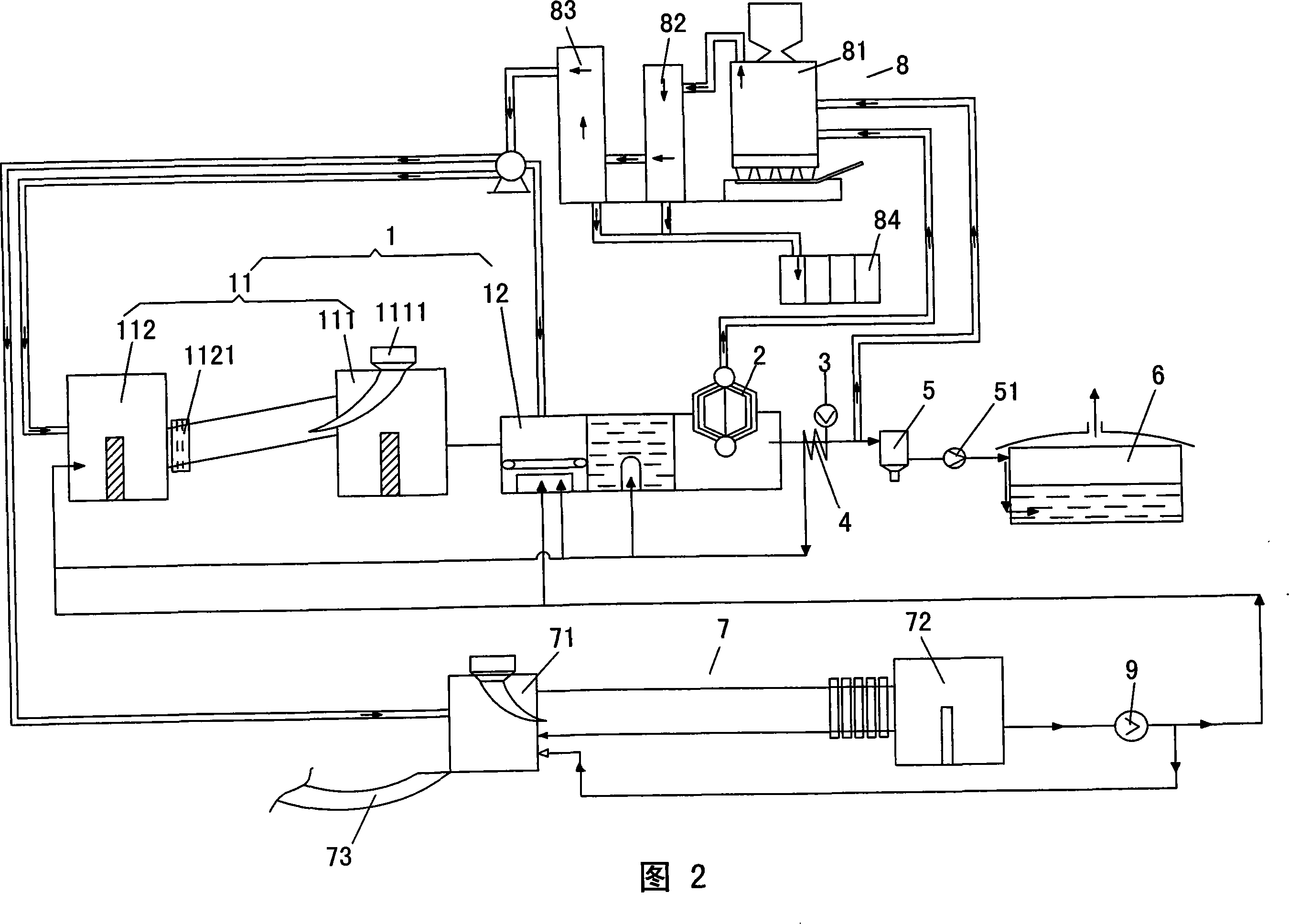

Pretreatment method and device for utilizing domestic garbage as fuel

InactiveCN101565647AHarmlessReduce moisture contentGas current separationBiofuelsWater contentBriquette

The invention discloses a pretreatment method and a pretreatment device for utilizing domestic garbage as fuel, and relates to prophase treatment technology for garbage fuel. The method is characterized in that: the domestic garbage is subjected to primary sorting, crushing or bag breaking, screening, airflow suspension air separation and air drying treatment, wherein in an air separation functional chamber of an airflow suspension air separator, working airflow makes mixed garbage suspend and roll to reach a loose state; and garbage materials are layered according to the density, low-moisture light organic matters, high-moisture heavy organic matters and heavy inorganic matters are discharged from corresponding outlets and then subjected to post treatment, and the garbage fuel has the moisture content less than 15 percent, the inorganic content less than 5 percent and the low caloric power over 9,700 kj / kg, so that the domestic garbage can be utilized as a gasification raw material of a gasification furnace, or can realize stable combustion in an incinerator or an industrial boiler without adding conventional fuel, or be prepared into briquette fuel with high density so as to realize processing the domestic garbage with environmental protection, decontamination, minimization and resource in real sense.

Owner:周开根

Method for producing fuel briquettes from high moisture fine coal or blends of high moisture fine coal and biomass

An apparatus and method are provided for producing fuel briquettes from high moisture fine coal. The apparatus includes a coal fine pelletizer, a pellet dryer and a fuel briquette former all provided in-line for the efficient production of fuel briquettes. The method comprises forming pellets from coal fines, drying those pellets to a desired moisture content of about 1 to about 10% and forming fuel briquettes from the dried pellets.

Owner:UNIV OF KENTUCKY RES FOUND

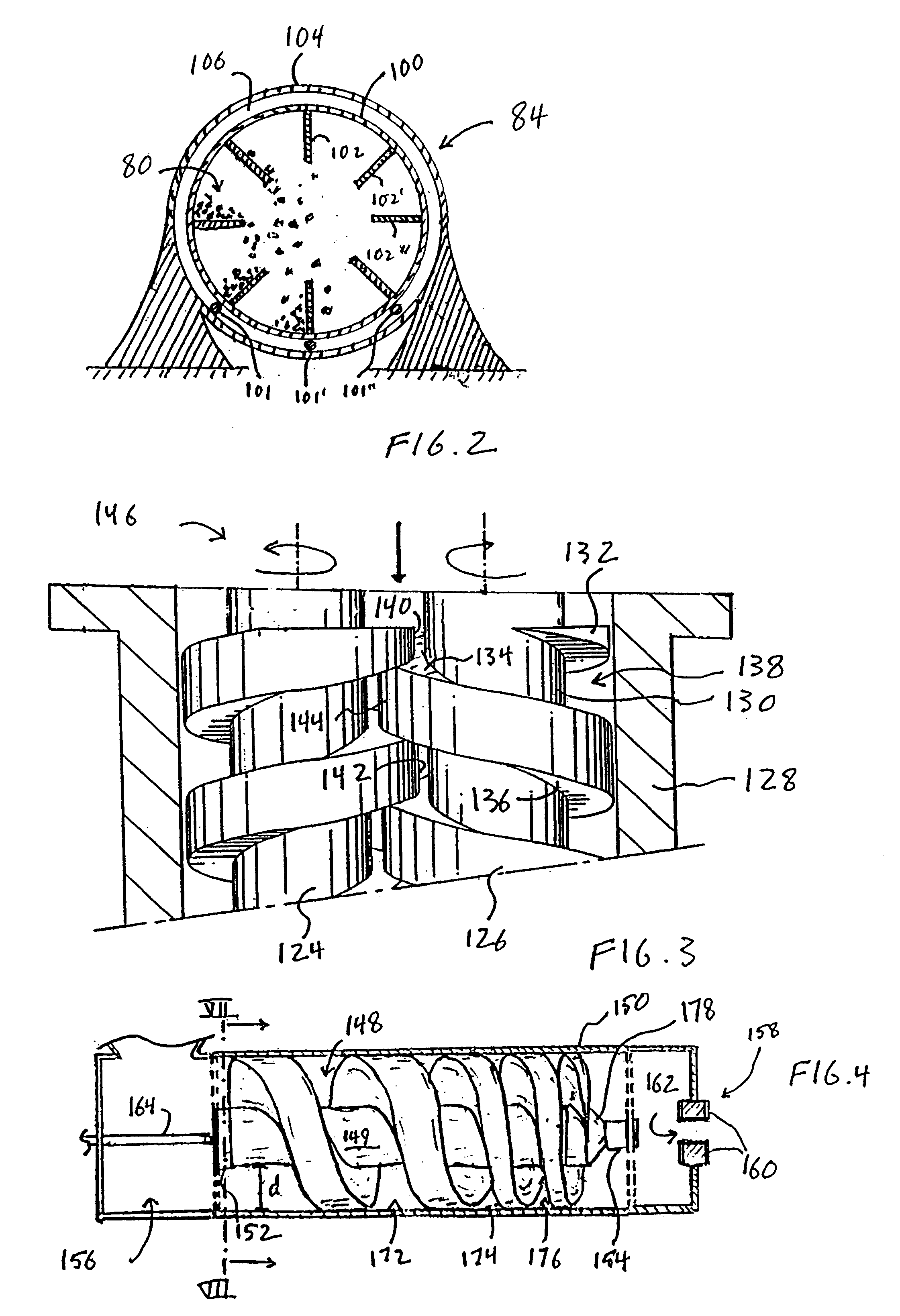

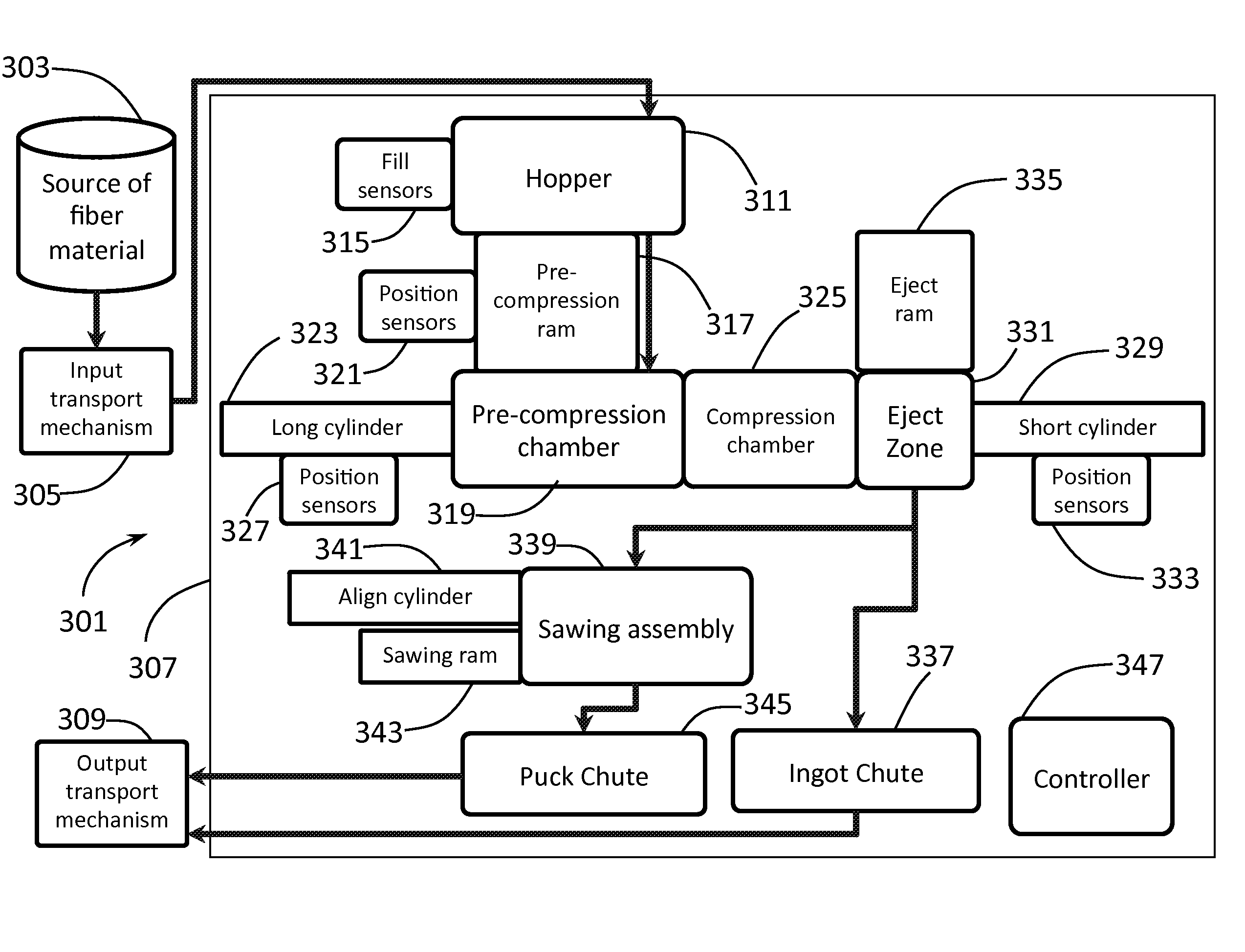

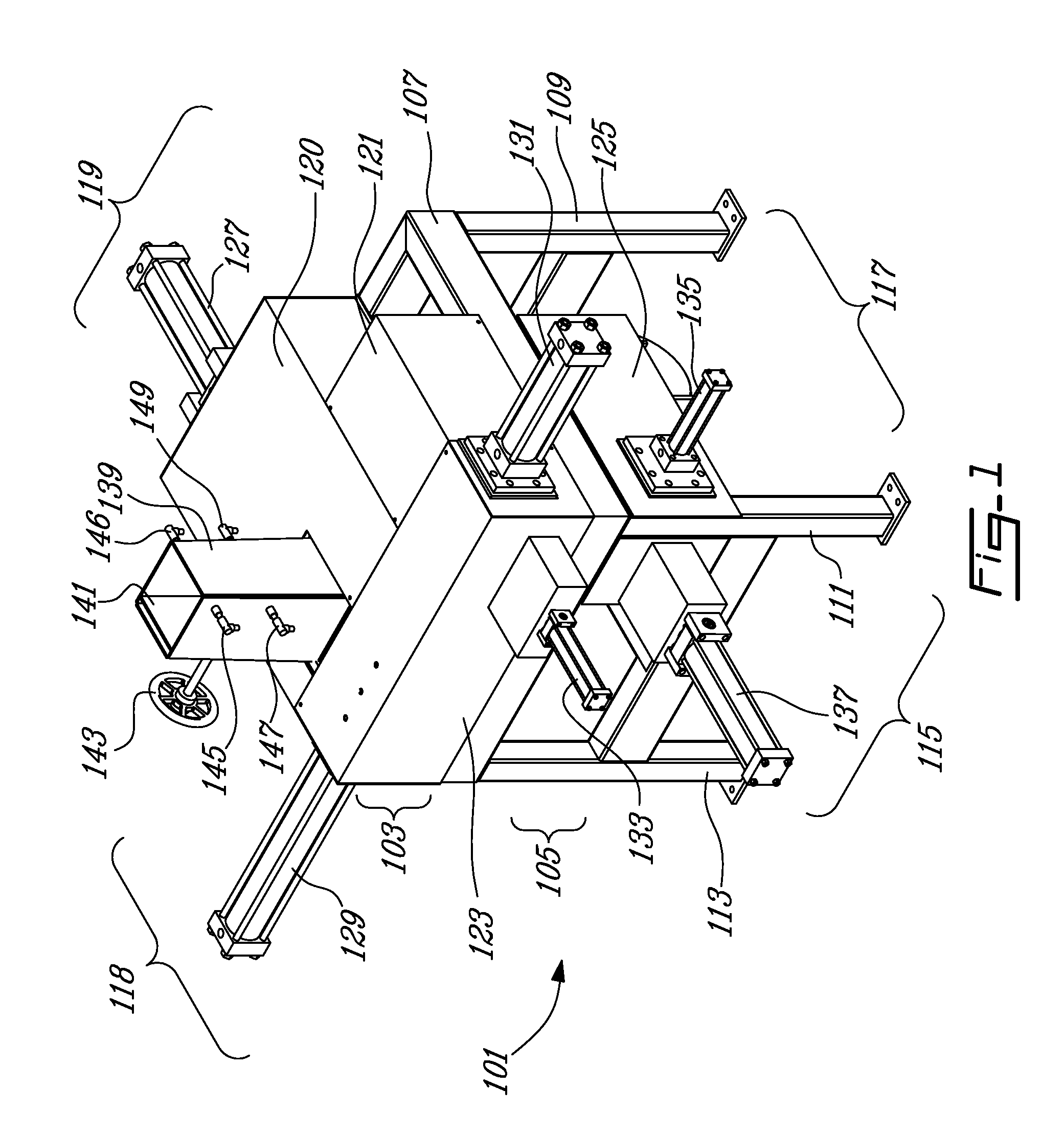

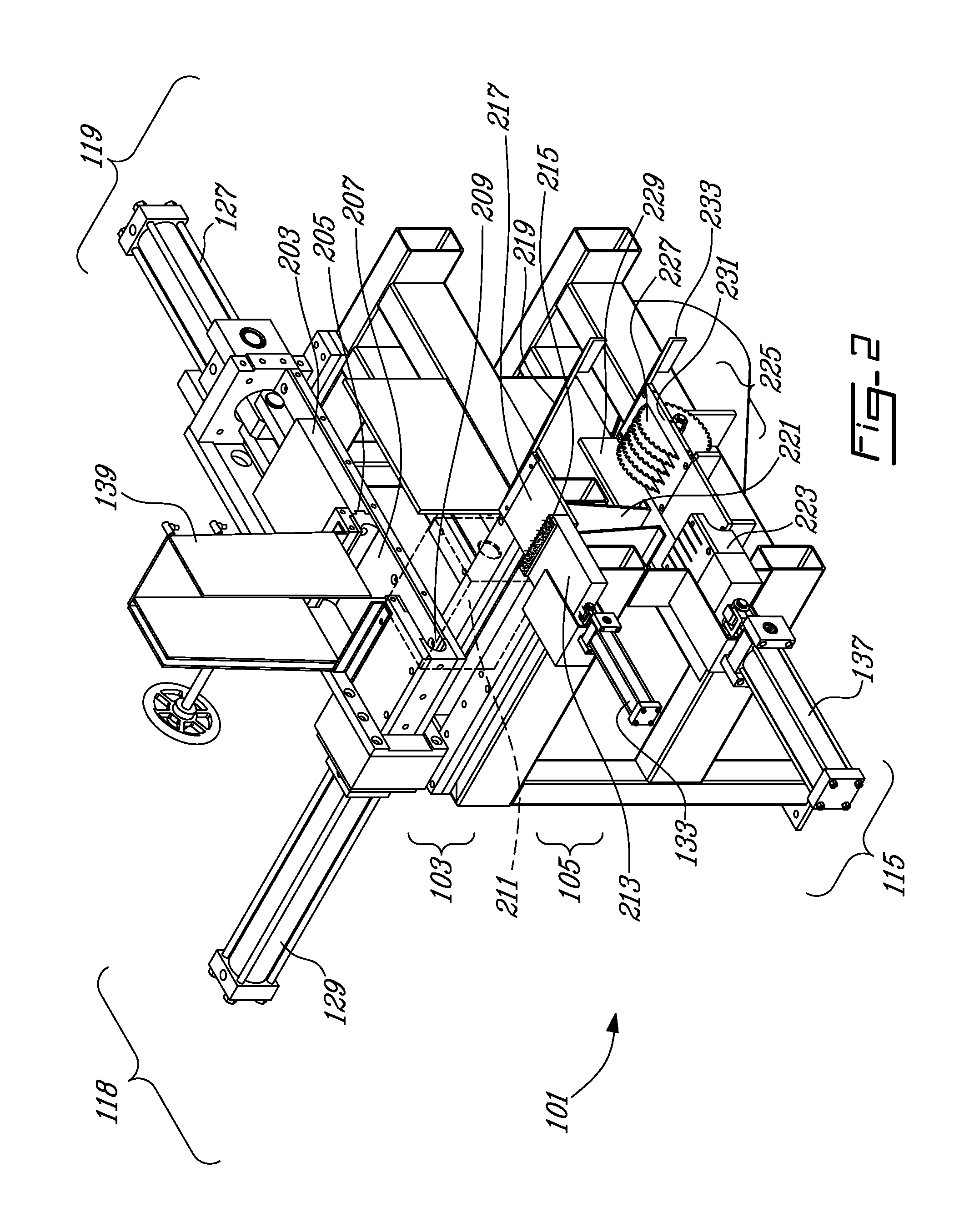

Method and mechanical press system for the generation of densified cylindrical briquettes

InactiveUS8726800B2Promote conversionMinimizes front-end processingBiofuelsSolid fuelsAbutmentBriquette

A method for preparing a pressed article comprises providing a first and a second pressing ram in a compression chamber; supplying biomass particles in the chamber closing the chamber; extending the first pressing ram; displacing the biomass particles with the first pressing ram towards the second pressing ram; detecting abutment of the biomass particles on the second pressing ram; applying pressure to the biomass particles with the first pressing ram and with the second pressing ram detecting a pressure applied to match a predetermined pressure and continuing to extend the first and the second pressing ram until a predetermined time at the matched compression pressure has elapsed; stopping the extension of the second pressing ram when a predetermined extension length is reached; continuing to extend the first pressing ram until a predetermined additional time has elapsed after the stopping; ejecting a pressed article.

Owner:MURRAY DONALD LOUIS +1

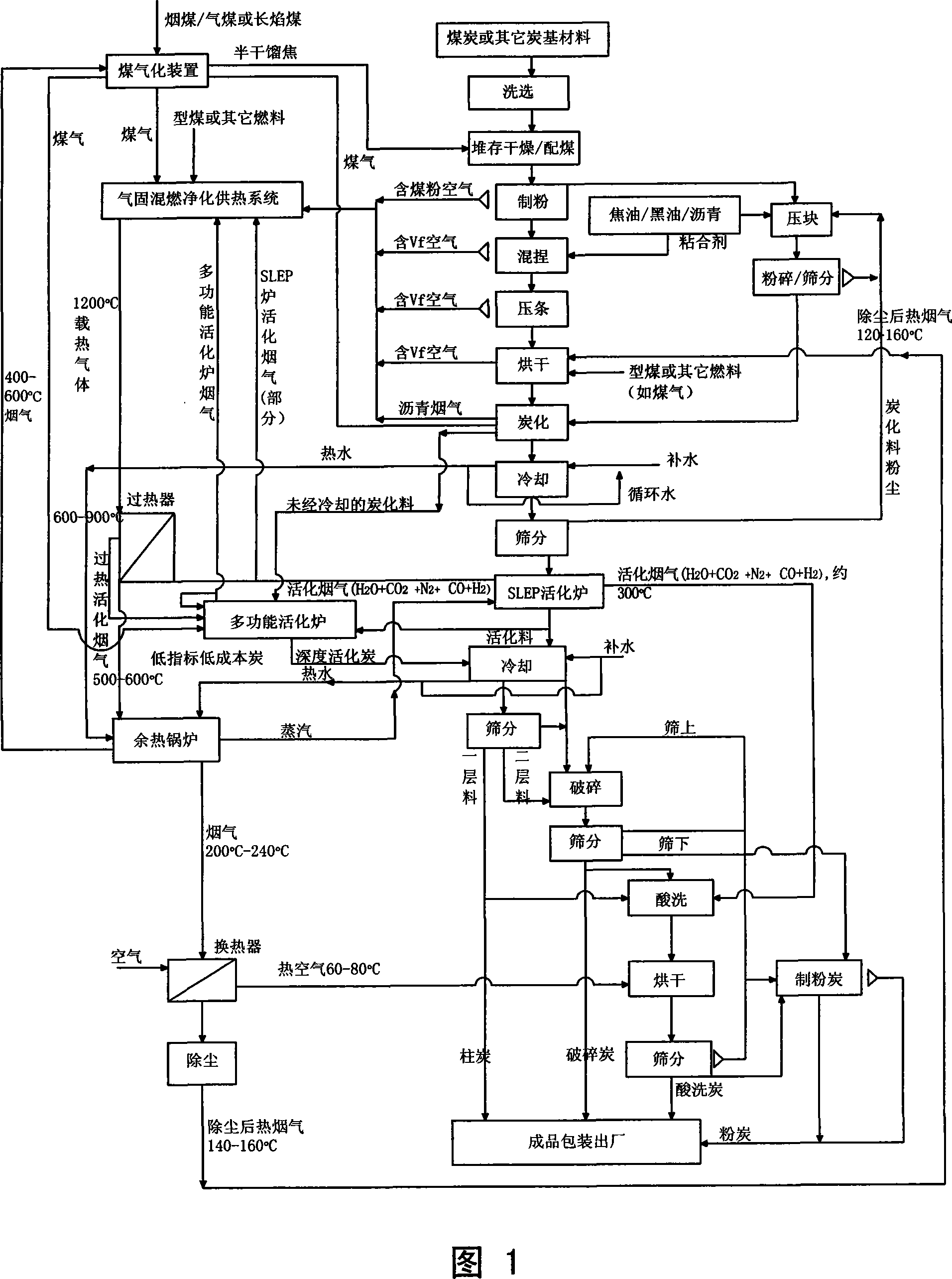

Physical method energy-saving cleaning technique for manufacturing active carbon

The invention relates to a technology for manufacturing activated carbon by a physical method of energy saving and cleaning, which includes the processes of mixing kneading and plating or coal blending and briquetting, airing strip, carbonization, screening, activating, screening and packaging as well as packaging after screening material and making into powder activated carbon to traditional milling, coal powder and tar. The technology adjusts and adds the processes: air with coal powder in the milling workshop, air with Vf (organic volatile) generated in the process of mixing kneading, plating and drying, pitch smoke generated in the process of charring, parts of smoke in a SLEP activated-stove, smoke in a multifunction activated-stove, coal gas out of a coal gasification device or other fuel are sent into a heating system of gas fixing, mixed burning and purifying for burning; through a waste heat boiler, generated heat loading gas generates steam for activating technology to use; tail gas is used for generating coal gas and drying material; after been heated, parts of smoke of the SLEP activated-stove is supplied for the multifunction activated-stove. The technology of the invention increases material yield, power source application which does not pollute the environment.

Owner:山西佳净环保工程有限公司

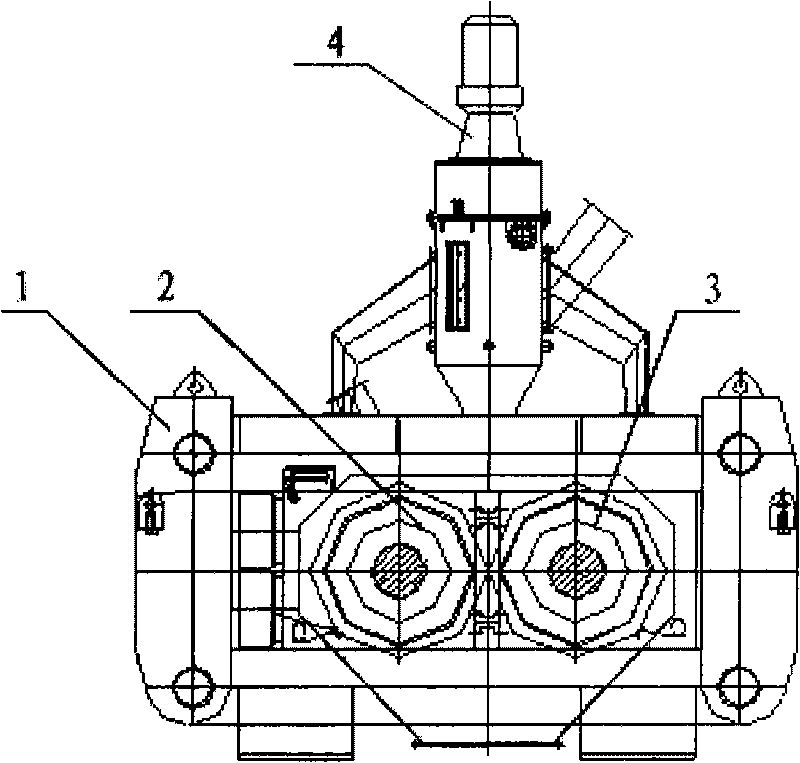

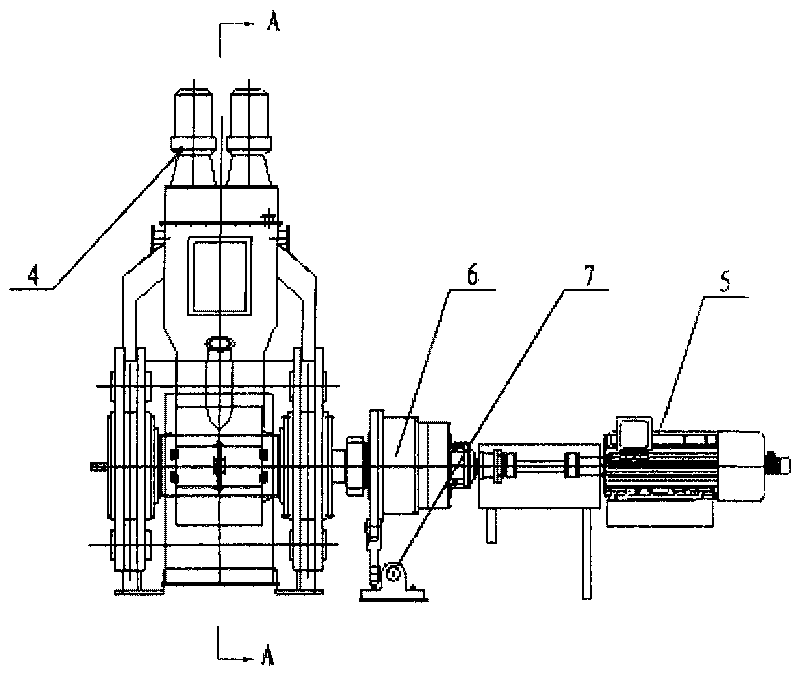

Pulverized coal molding method without binding agent and double-roller molding machine suitable for method

InactiveCN101722669AMeet shipping requirementsMeet industrial application requirementsShaping pressWater contentCircular surface

The invention provides a pulverized coal molding method without binding agent, which comprises the following steps of: 1. screening pulverized coal with the granularity of not more than 6mm by a screening device, carrying out drying dehydration processing on the pulverized coal and controlling the water content to be 2-15 percent; 2. forcibly compressing and feeding the pulverized coal obtained in the step 1 into a seam between double rollers of a double-roller molding machine by a feeding machine; and 3. running the double-roller molding machine, continuously rotating the double rollers of which at least one roller circular surface is distributed with pits and compacting and molding molded coal by the pits. The invention also provides the double-roller molding machine which is suitable for the method. The invention solves the problem of pulverized coal molding without binding agent of weak caking coal and non-caking coal, such as low-order bituminous coal, middle and old aged lignite, and the like.

Owner:CHNA ENERGY INVESTMENT CORP LTD +4

Agglomeration method for iron containing dust slime of iron and steel plants

The invention discloses an agglomeration method for iron containing dust slime of iron and steel plants; according to the method, the iron containing dust slime is shunted independently, is briquetted, is mixed with other iron ore powder, flux and coke powder, and then is sintered on the basis of the traditional technology. The agglomeration method comprises the following detailed steps of: 1), firstly, mixing the iron containing dust slime with composite binder, mixing uniformly, briquetting, so as to obtain dust slime briquette; 2), mixing the dust slime briquette with other iron ore powder, flux and coke powder, pelletizing, so as to obtain sintered mixture material; and 3), distributing the sintered mixture material by adopting the existing sintering method, igniting, sintering, cooling, granulating, finally the finished product of sintered ore is obtained. Compared with the traditional method of directly returning, sintering and mixing the dust slime, by adopting the agglomeration method, the ratio of the iron containing dust slime in the mixture material is greatly improved, and in addition, the sintered product quality index is improved. By adopting the agglomeration method, the problem on large-scale use of the iron containing dust slime of iron and steel plants is effectively solved, and the agglomeration method is beneficial for industrial production.

Owner:CENT SOUTH UNIV

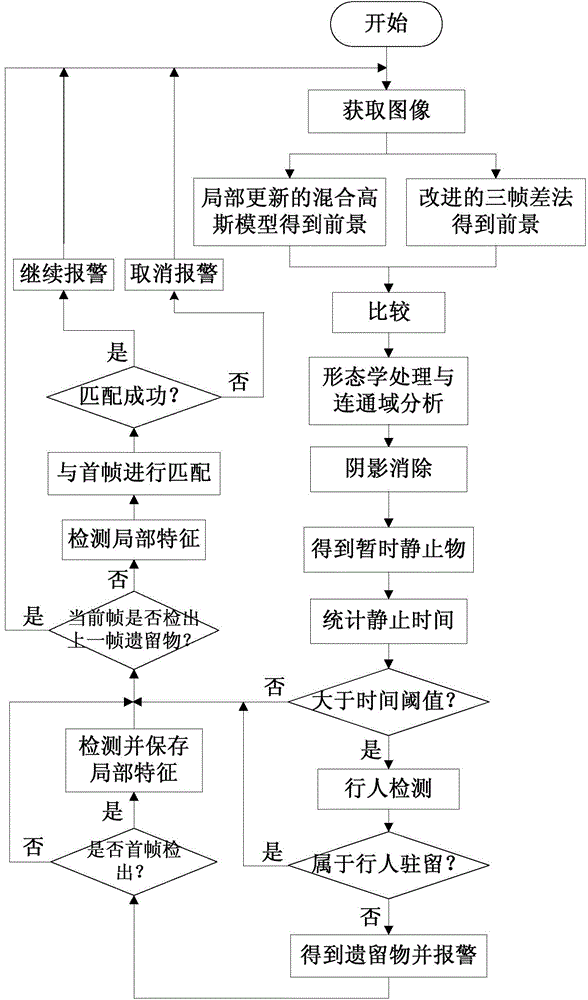

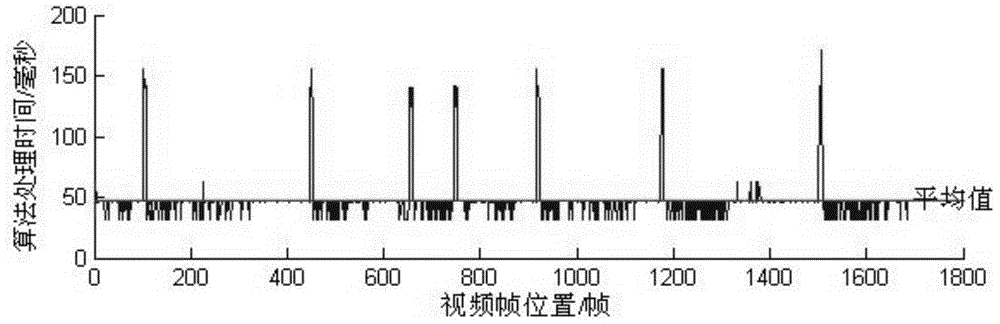

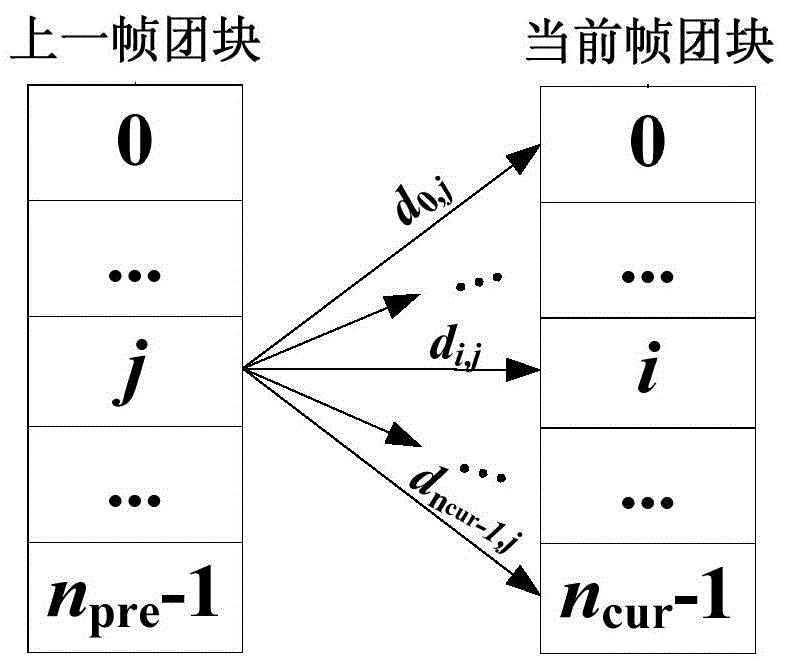

Detection method for remnants in complex environment

ActiveCN104156942AAvoid blending into the backgroundPrecise positioningImage analysisFrame differenceResting time

The invention discloses a detection method for remnants in the complex environment. The detection method comprises the following steps: comparing prospect targets obtained on the basis of both a partial updated Gaussian mixture background modeling method and a modified three-frame difference method; in combination with the YCbCr color space based shadow elimination method and the connected domain analysis, dividing to obtain temporary static briquettes within a scene; carrying out the centroid distance judging method on each frame of an image, and counting the rest time of each briquette; marking the static briquettes reaching to the temporal threshold as the remnants after eliminating the possibility of pedestrian residence through the HOG (Histograms of Oriented Gradients) pedestrian detection algorithm, and eliminating the possibility of pedestrian residence through the FAST (Features from Accelerated Segment Test) feature point detection algorithm. The detection method can improve detection accuracy of the remnants, lowers calculation complexity, can be better suitable for the complex environment crowded and frequent in shielding, and enhances the anti-interference capability.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com