Patents

Literature

206 results about "Yttrium barium copper oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

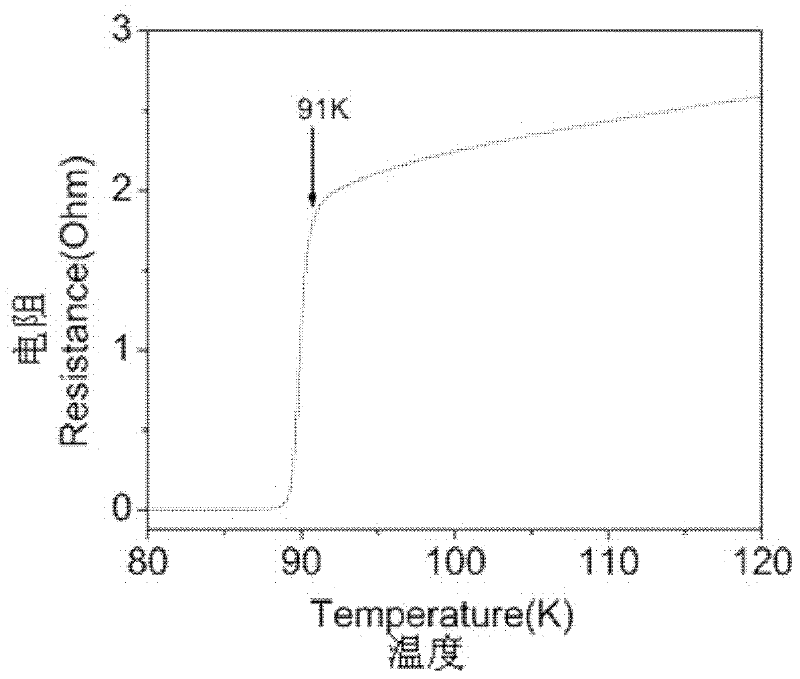

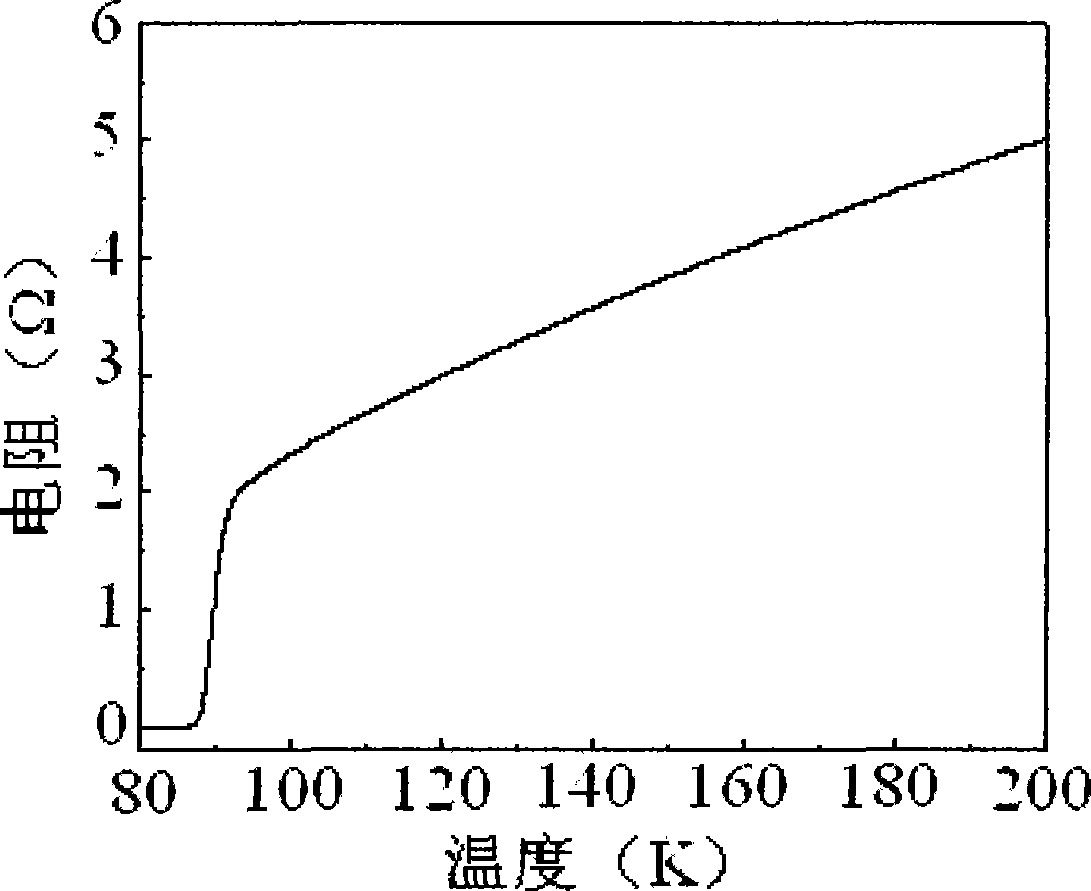

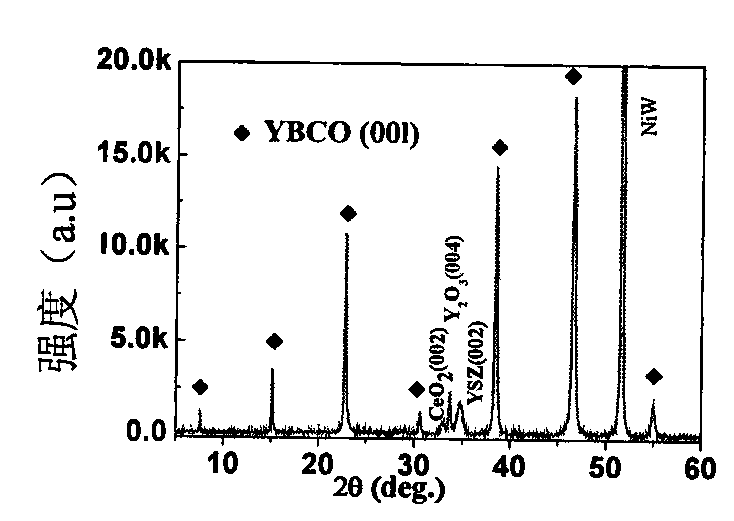

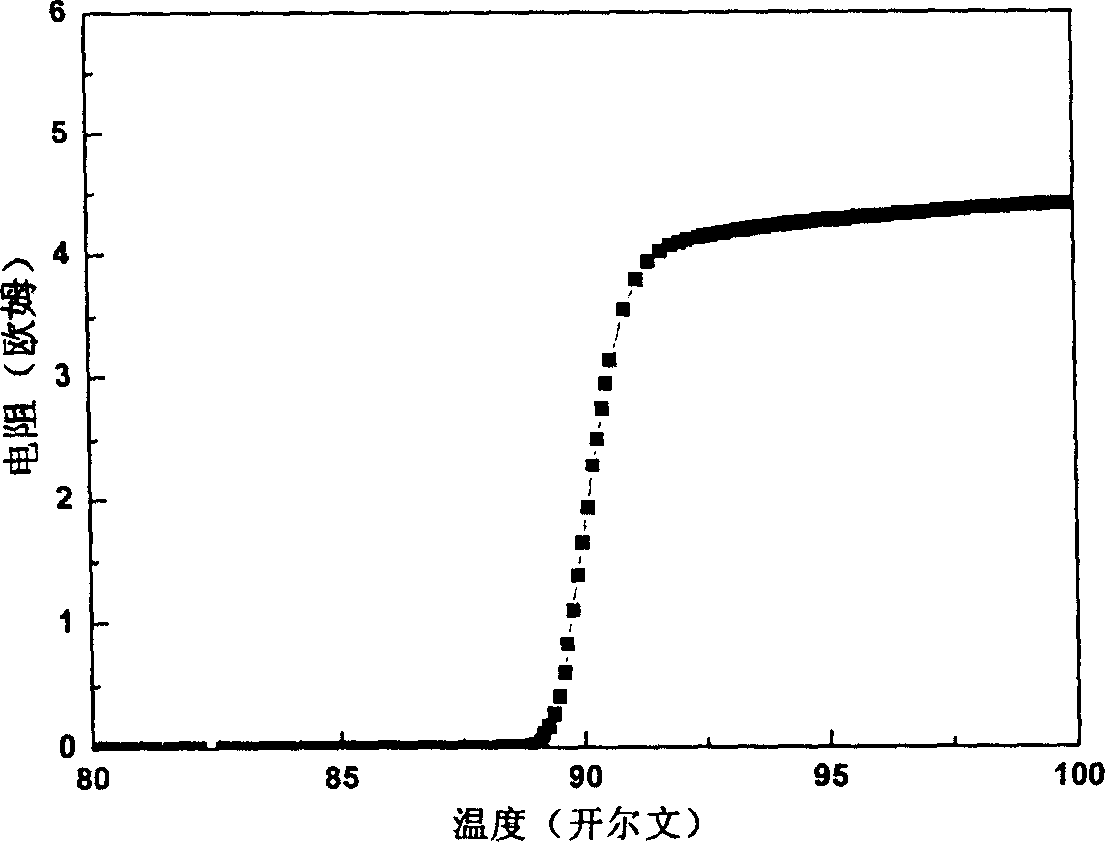

Yttrium barium copper oxide (YBCO) is a family of crystalline chemical compounds, famous for displaying high-temperature superconductivity. It includes the first material ever discovered to become superconducting above the boiling point of liquid nitrogen (77 K) at about 92 K. Many YBCO compounds have the general formula YBa₂Cu₃O₇₋ₓ (also known as Y123), although materials with other Y:Ba:Cu ratios exist, such as YBa₂Cu₄Oy (Y124) or Y₂Ba₄Cu₇Oy (Y247). They are GL-superconductors (their superconduction is explainable with the Ginzburg–Landau theory).

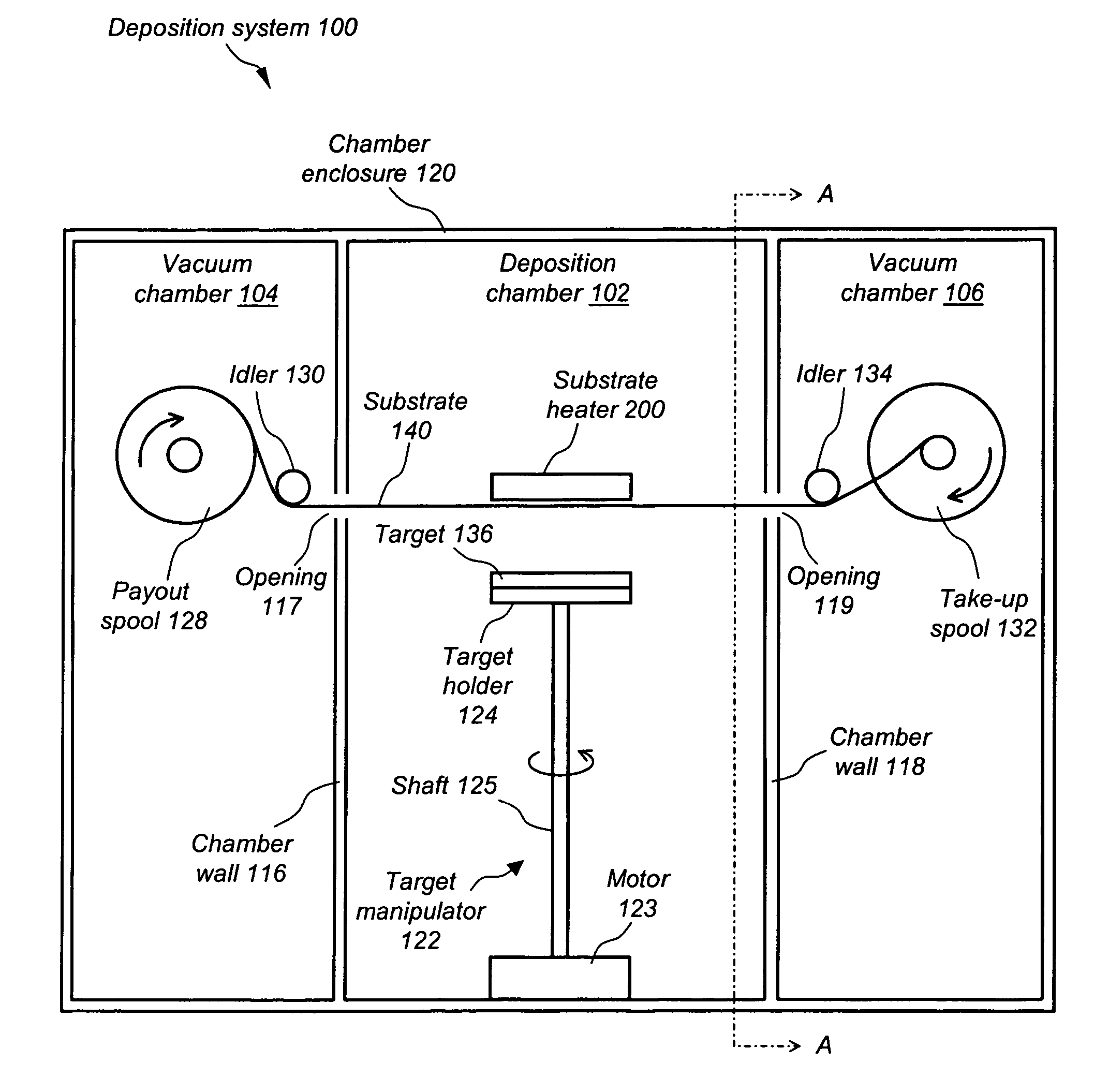

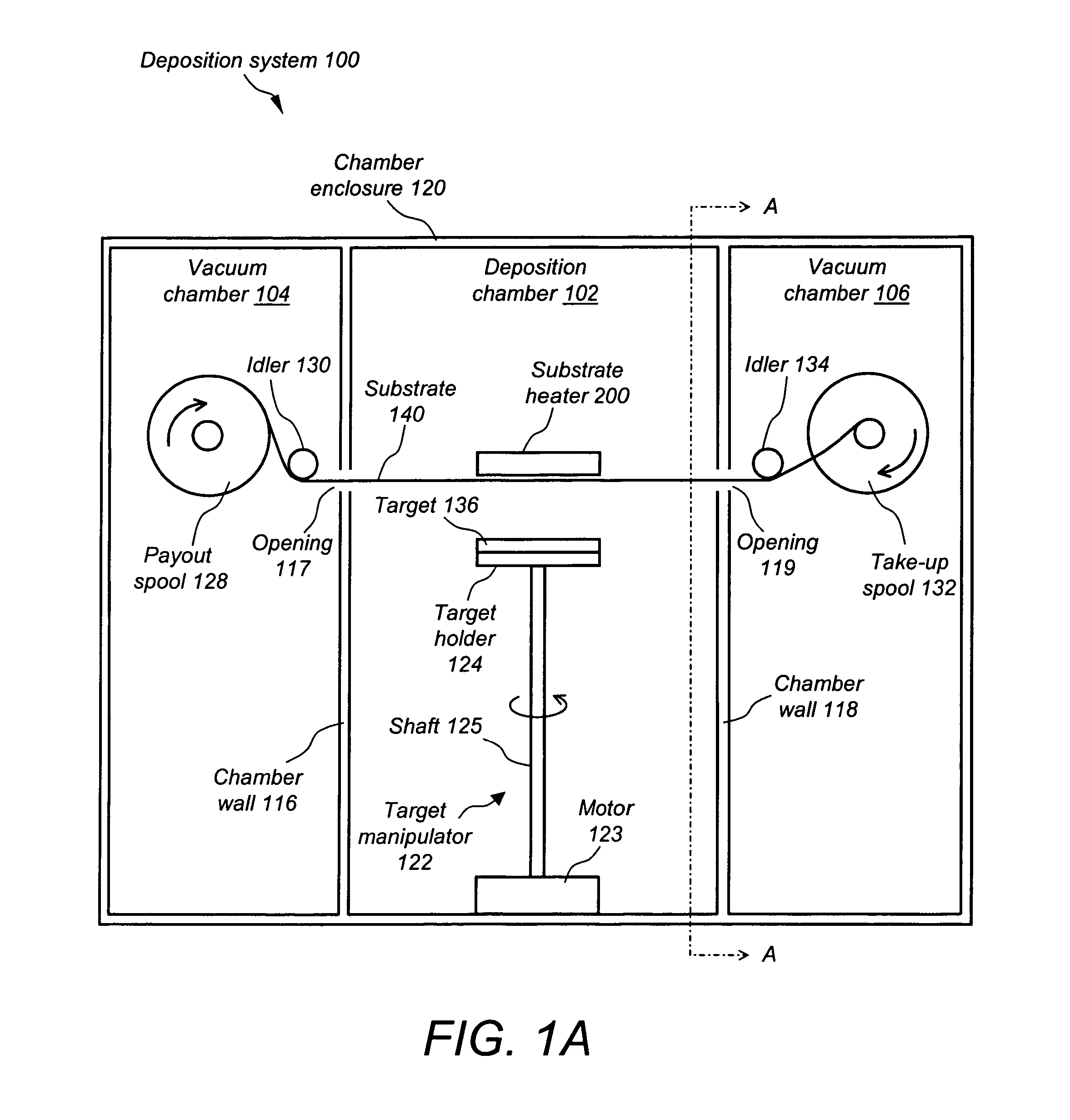

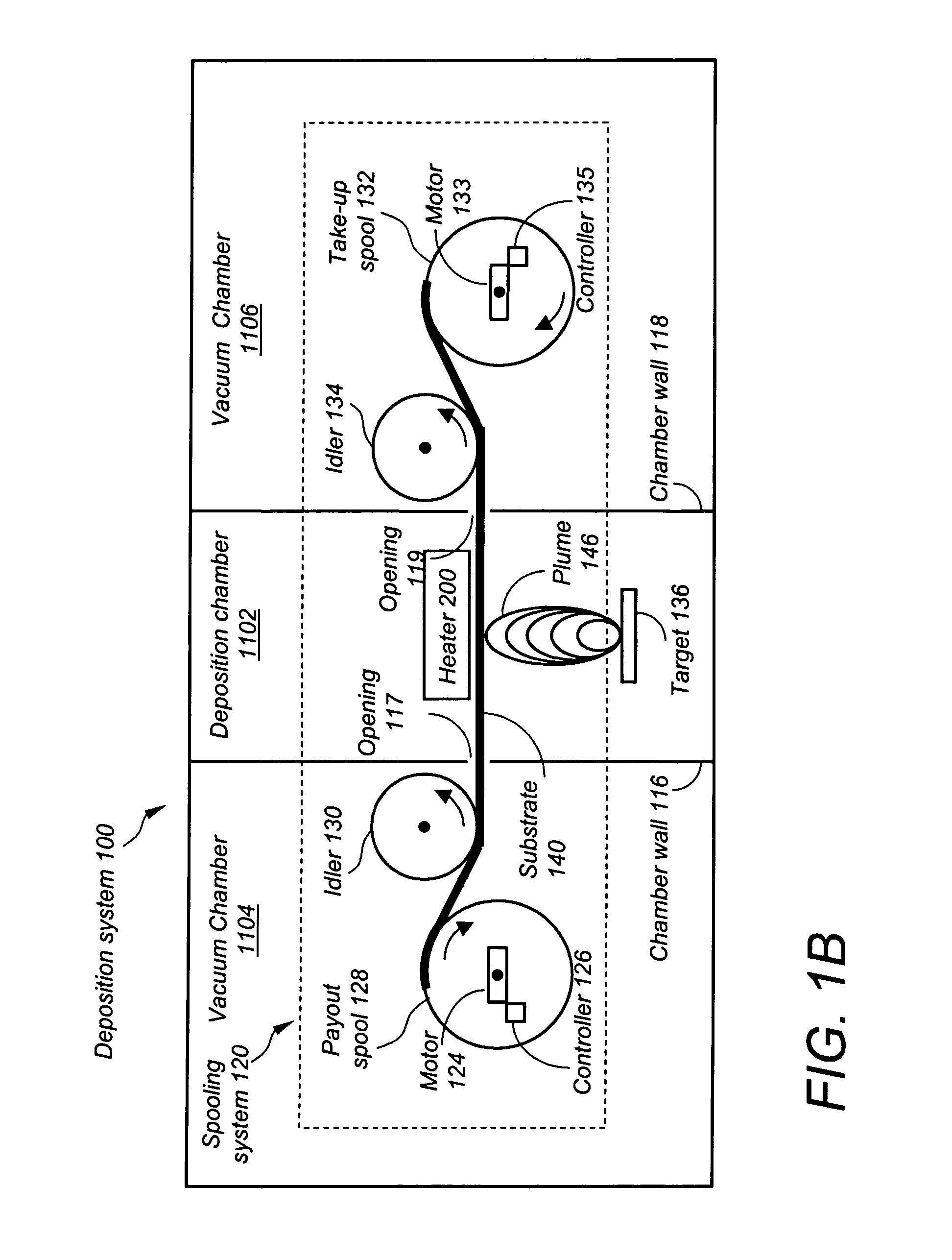

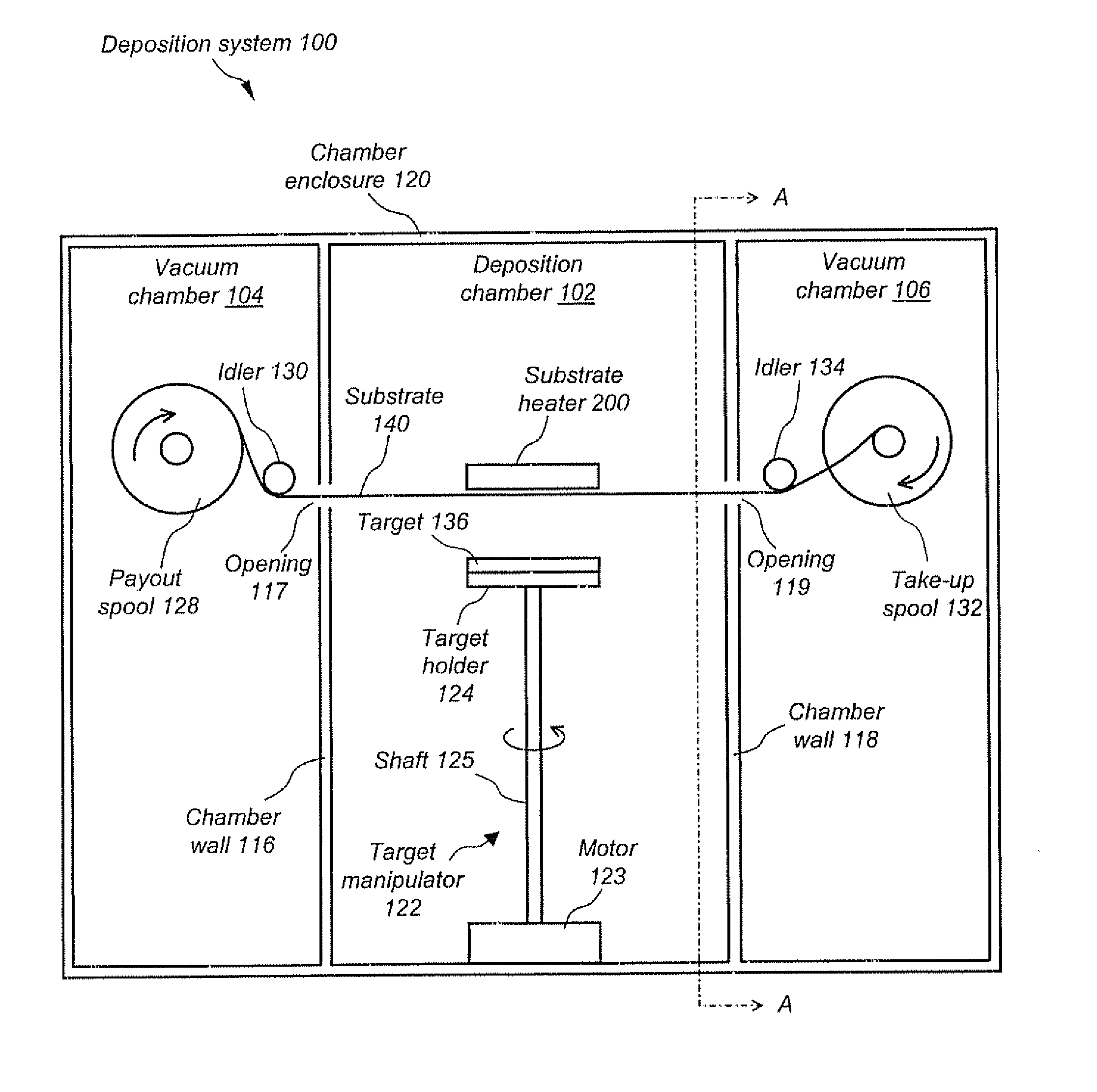

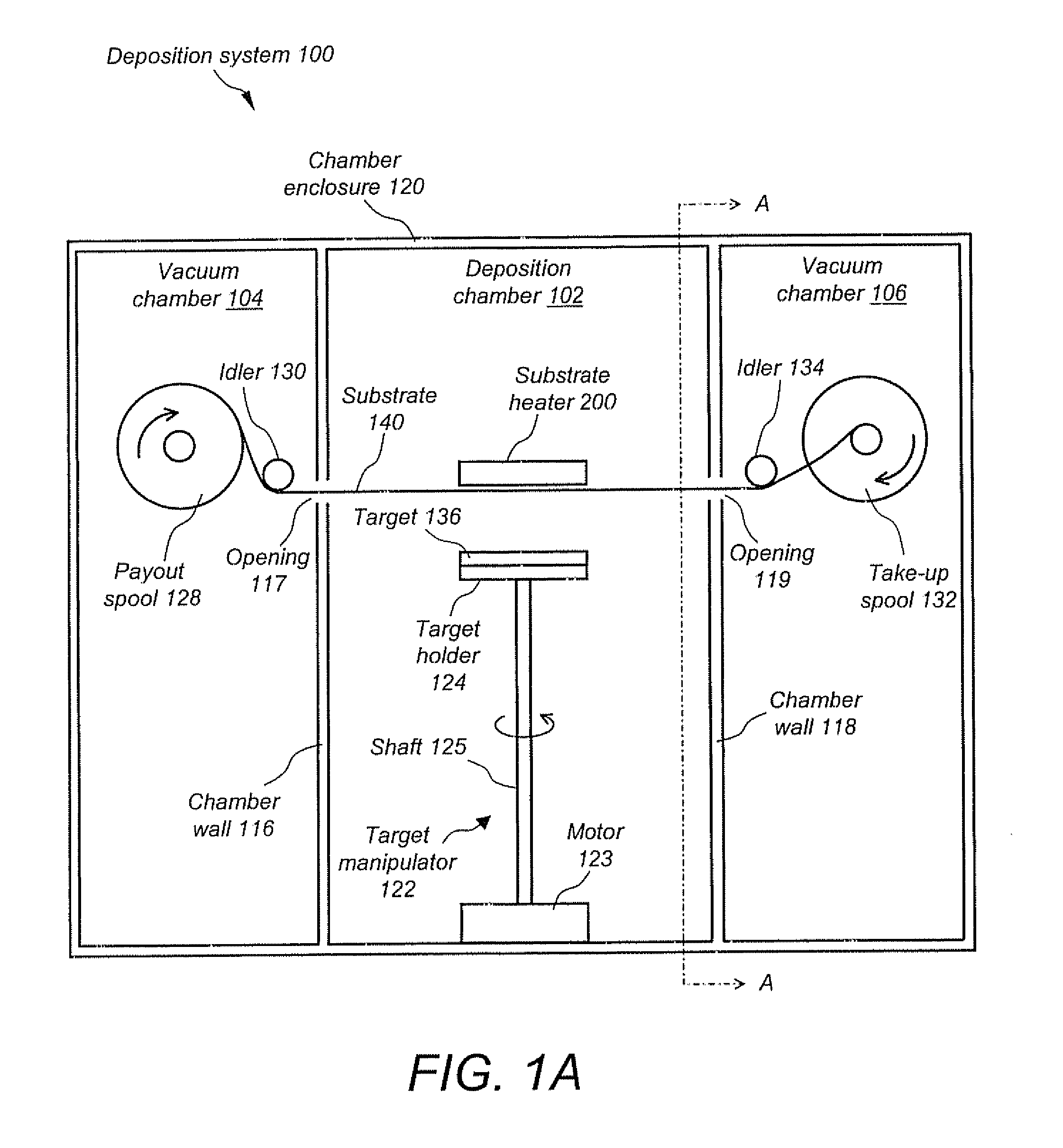

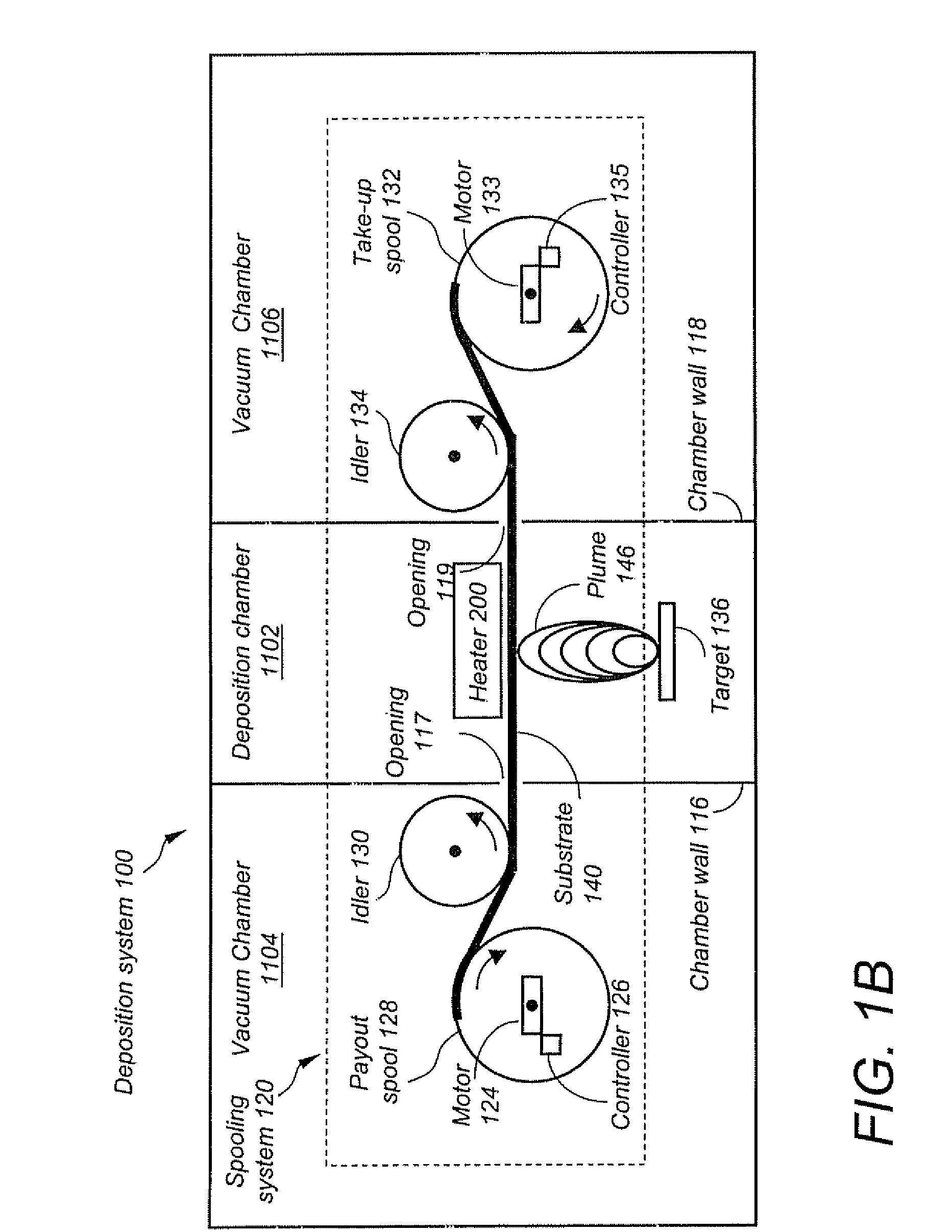

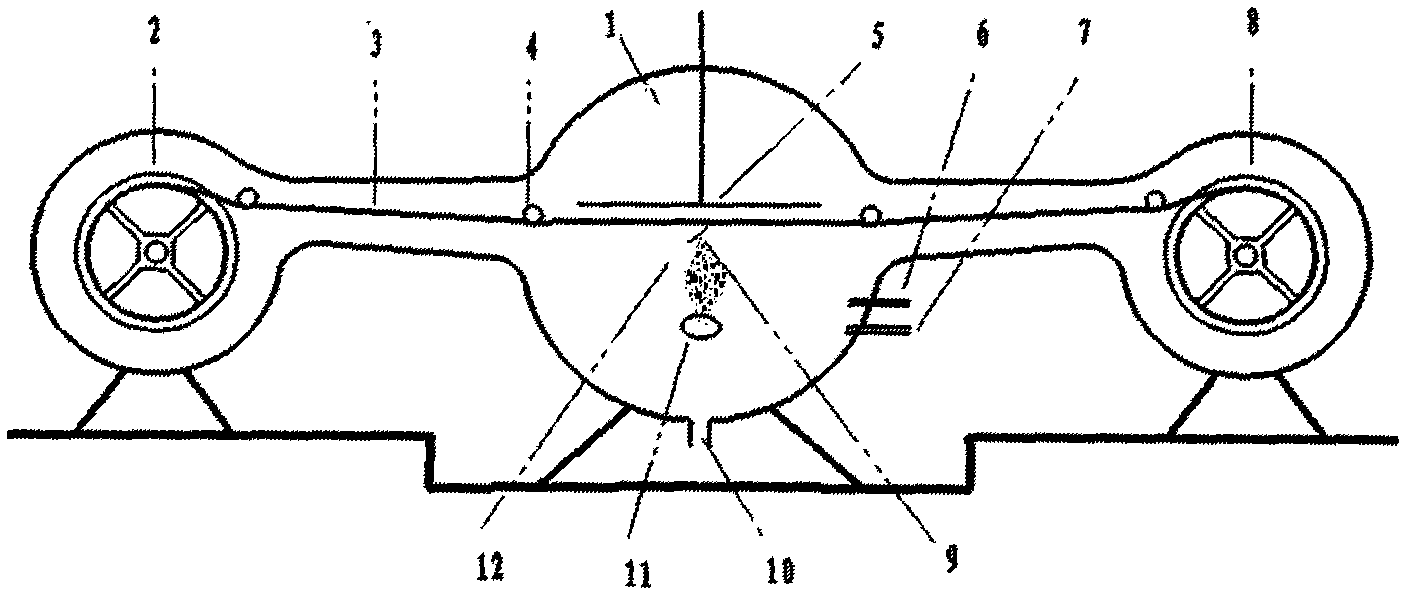

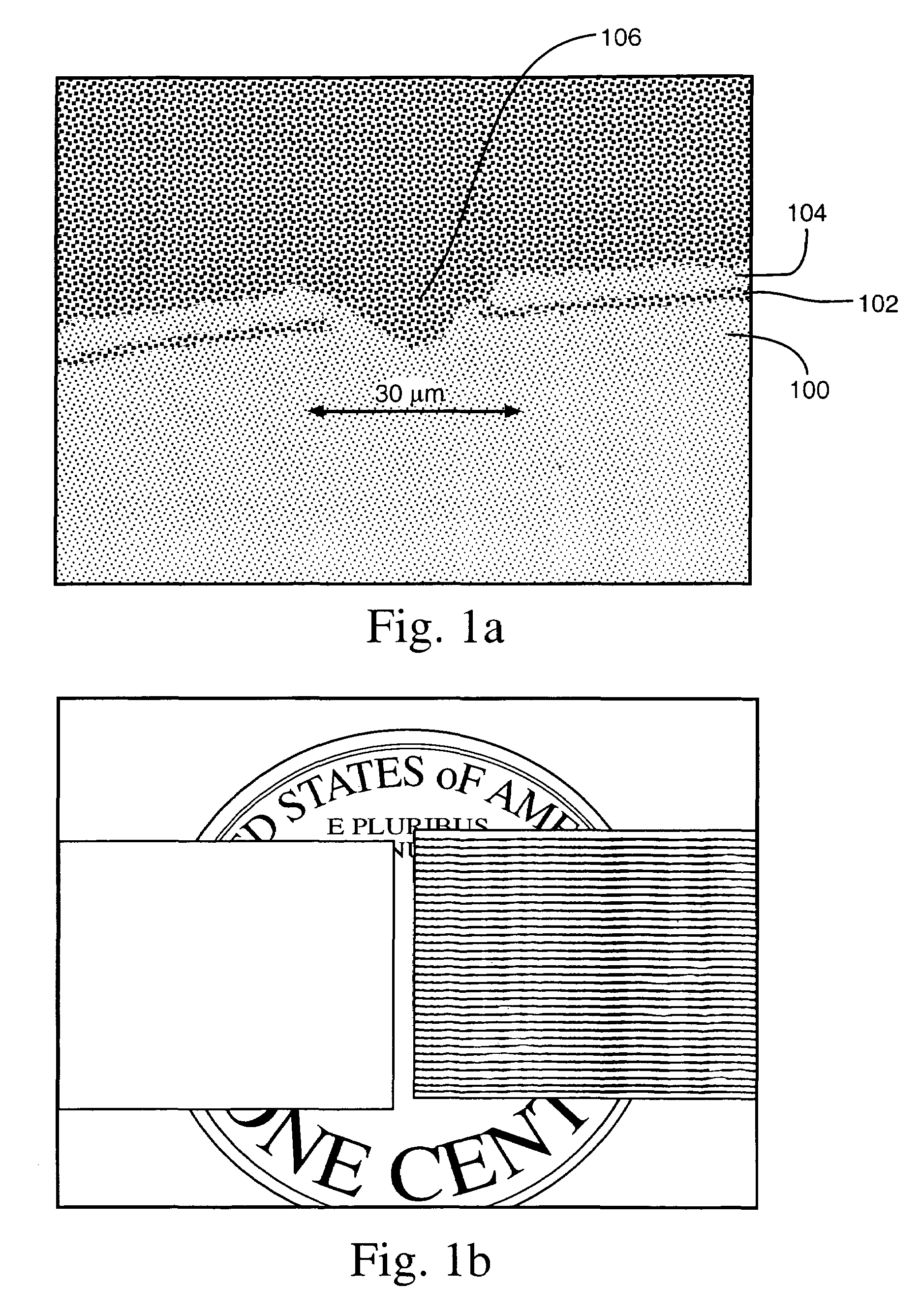

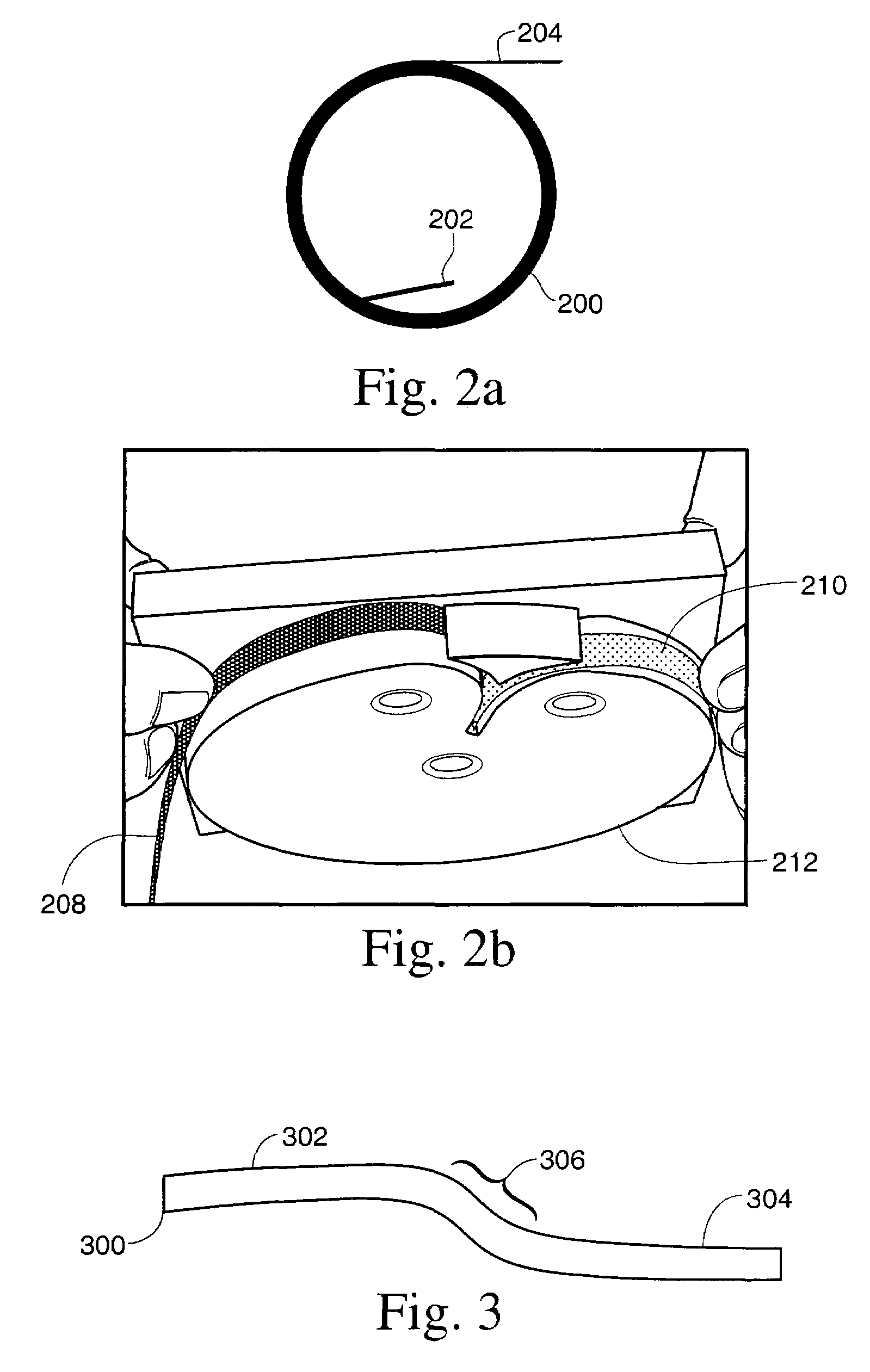

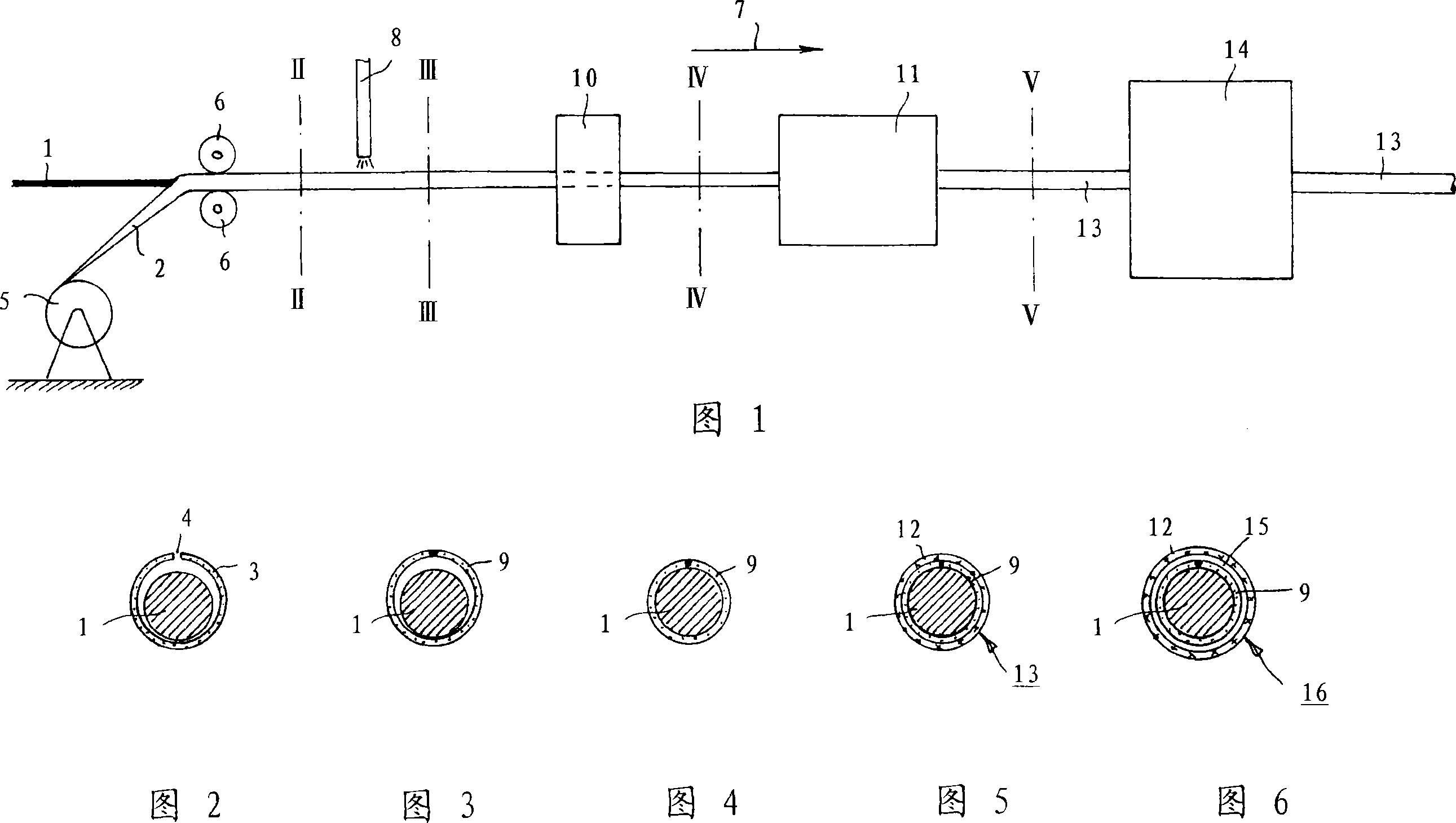

High throughput continuous pulsed laser deposition process and apparatus

InactiveUS20050005846A1Ensure uniformityAvoid scratchesVacuum evaporation coatingSputtering coatingYttrium barium copper oxideHigh flux

The present invention relates to an apparatus and method for forming a high-temperature superconducting film on a long tape substrate at speeds suitable for large-scale production. The method includes a spooling system for use in a high-throughput, continuous pulsed laser deposition (PLD) process in which a superconducting layer, such as yttrium-barium-copper-oxide (YBCO), is deposited atop a buffered metal substrate tape that is translated through one or more deposition chambers via the action of a reel-to-reel spooling system and a conductive-radiant multi-zone substrate heater. It also optionally includes a multi-target manipulator apparatus and multiple laser beams in which multiple targets are impinged upon simultaneously.

Owner:SUPERPOWER INC

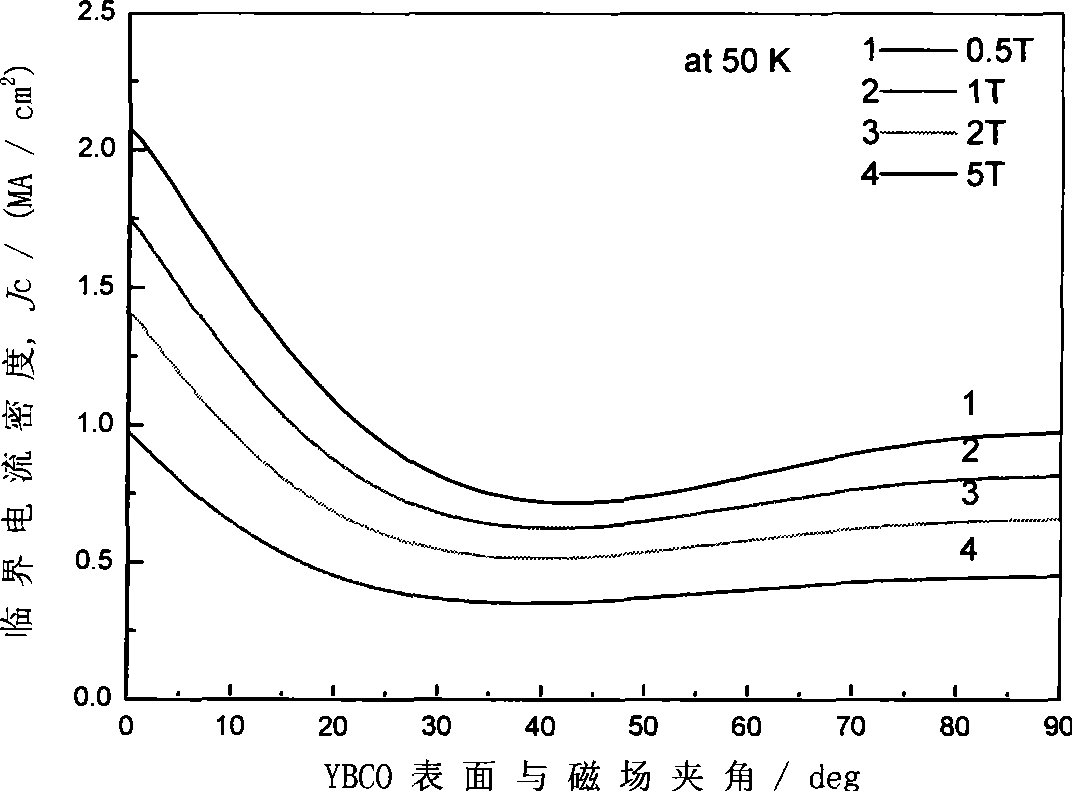

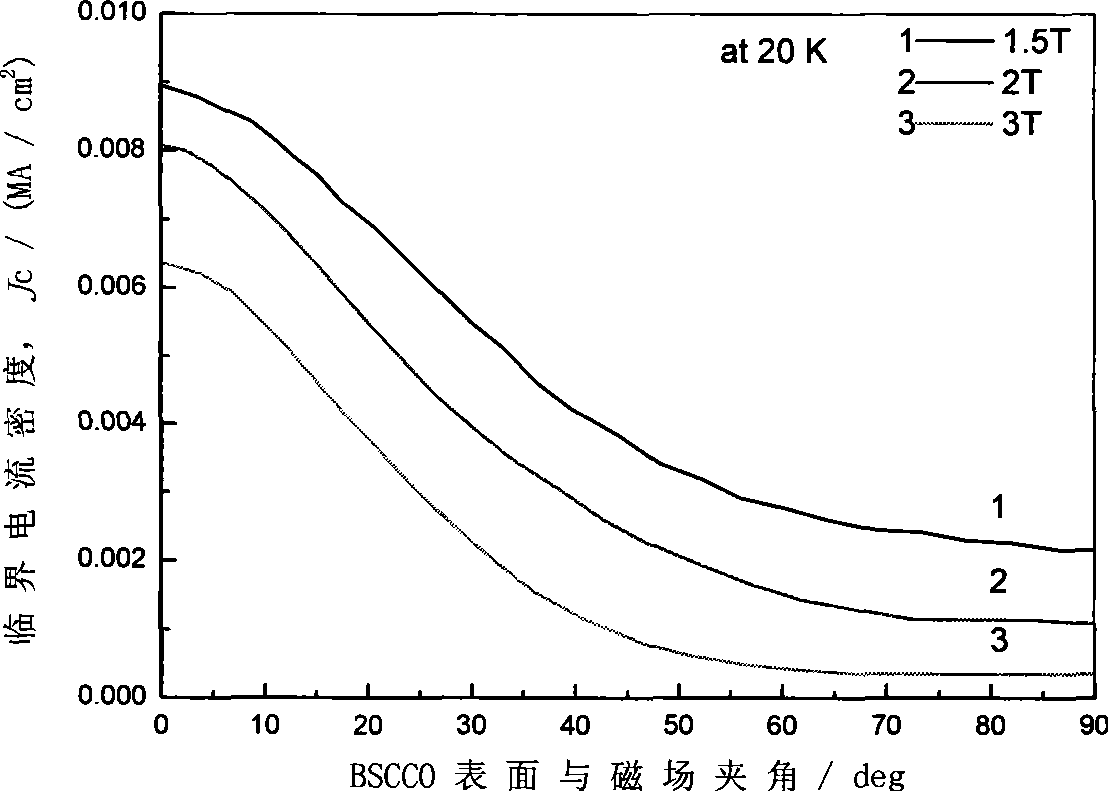

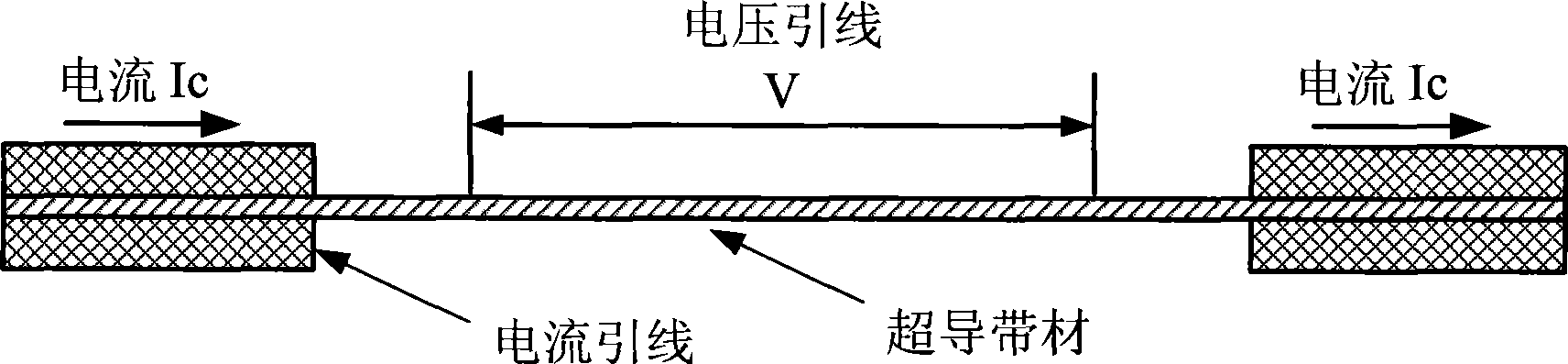

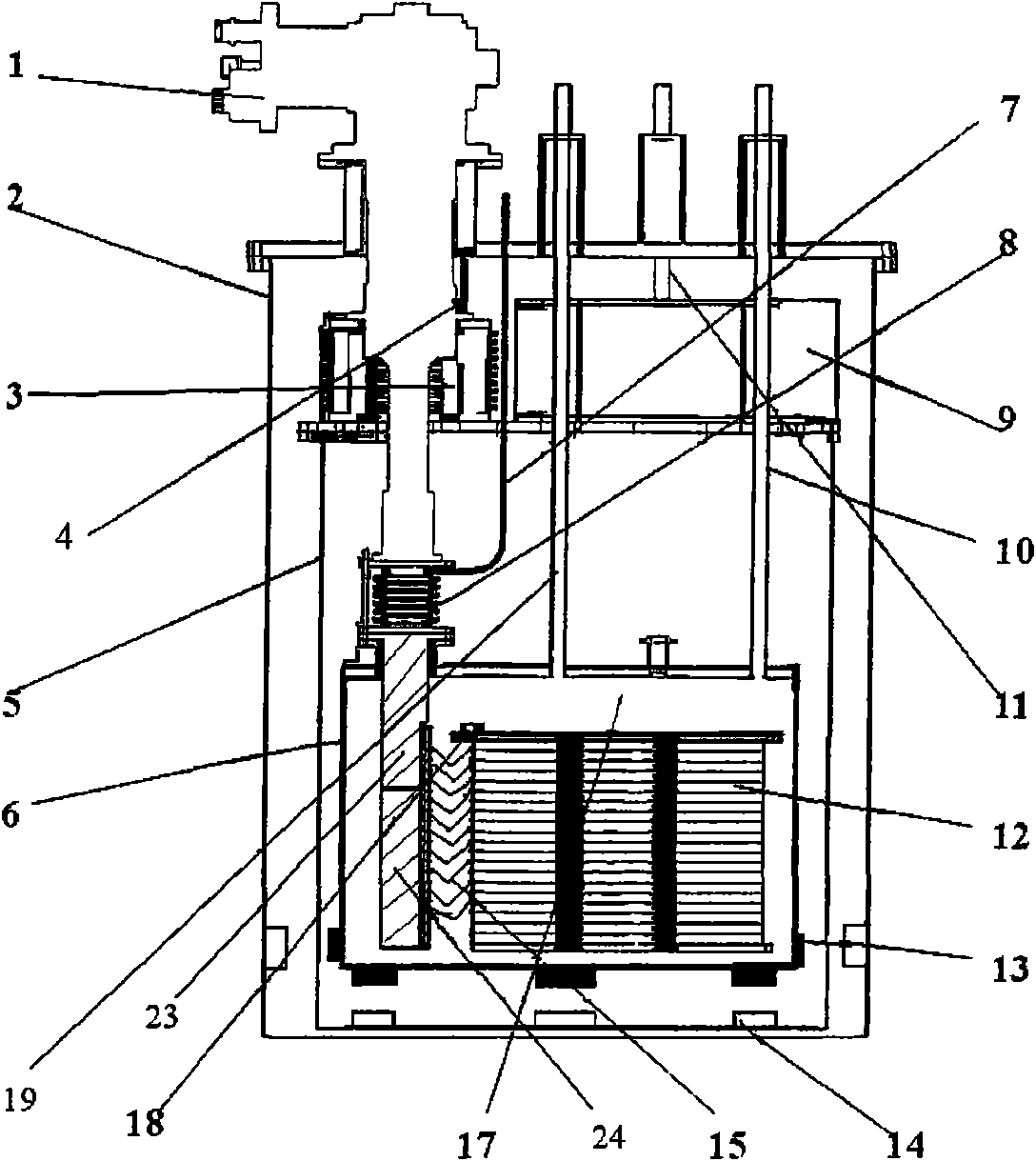

Measurement device of critical current properties of high-temperature superconducting tape

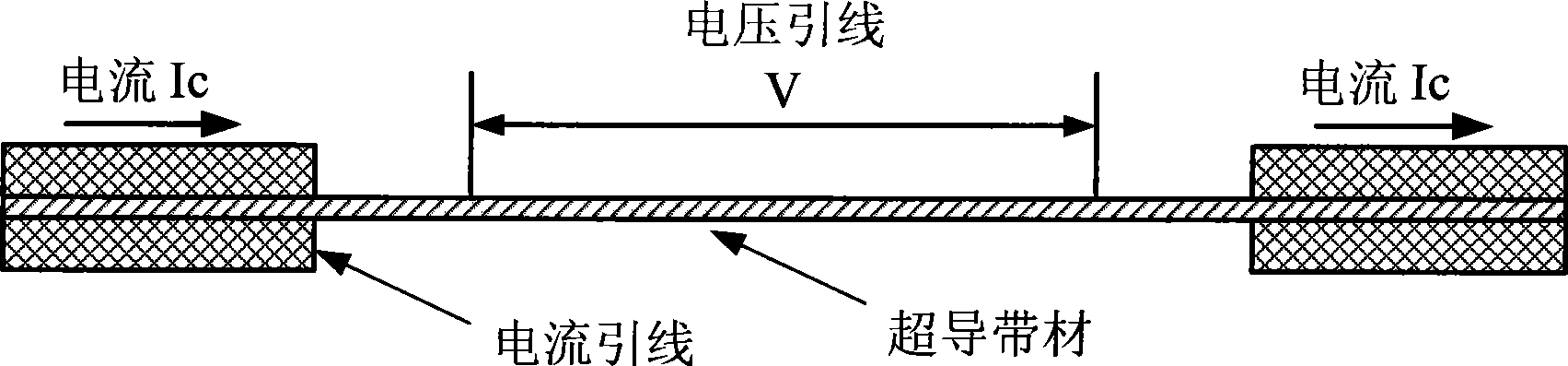

ActiveCN101446609AMeasuring critical current characteristicsRealize critical current characteristic measurementElectrical testingMagnitude/direction of magnetic fieldsYttrium barium copper oxideMeasurement device

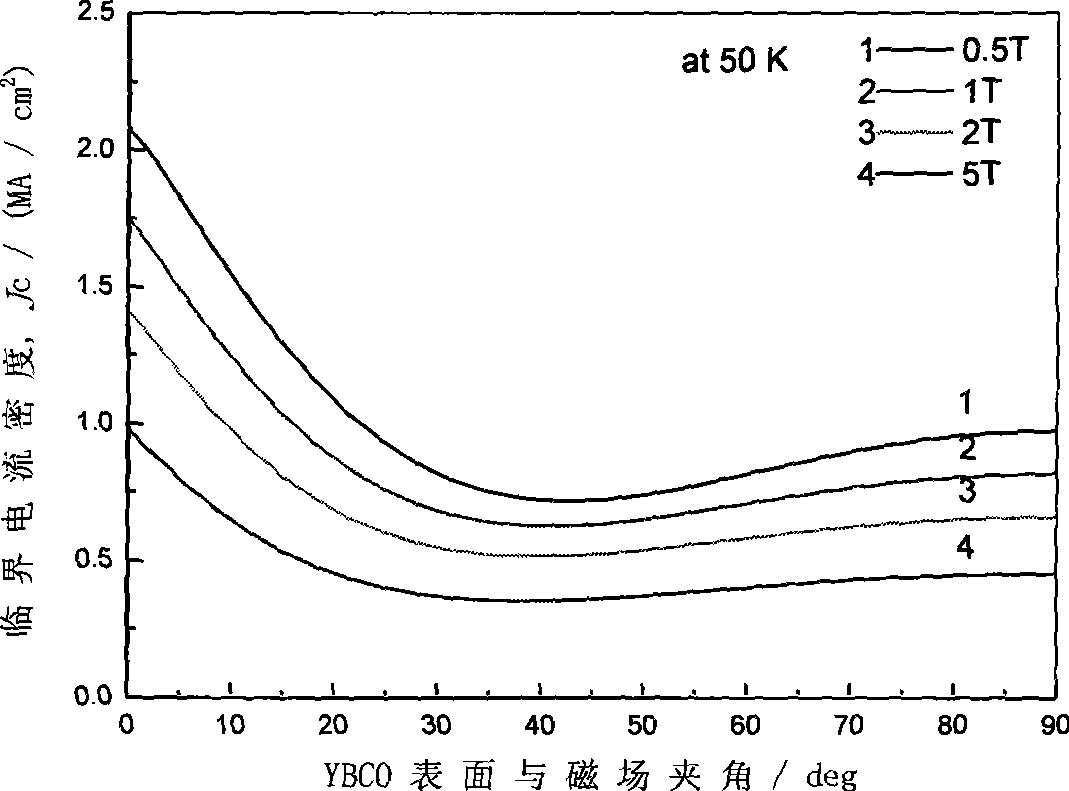

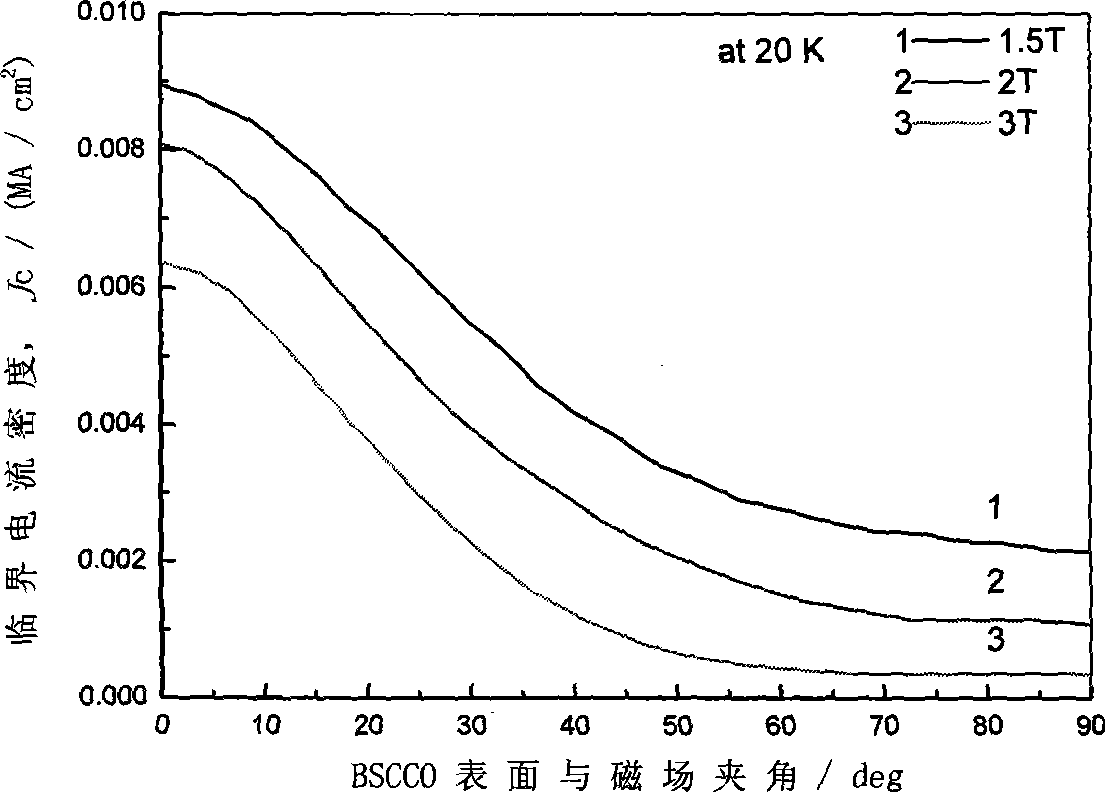

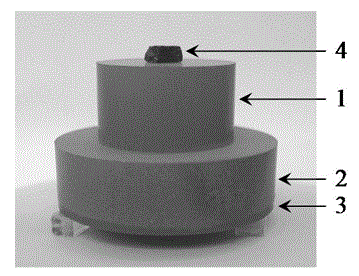

The invention provides a measurement device of critical current properties of a high-temperature superconducting tape, and the device comprises a superconducting tape sample rack 1, a Hall magnetic field probe 2, a temperature probe 3, a background magnetic field magnet 4, a rotary rod 5, a rotary handle 6, a superconducting tape current lead wire 7, a background magnetic field magnet current lead wire 8, a low-temperature dewar 9, a cooling medium storage container 10, a low-temperature cooling medium 11, an extraction valve 12, a carburetor 13, a vacuum unit 14, a GM refrigerator 15, a background magnetic field magnet DC power supply 16, a superconducting DC power supply 17 and a system control, data acquisition and processing system 18. The device can simply and rapidly calculate the temperature, the background magnetic field and the impact factors on the change of the direction of the magnetic field thereof, thereby being applicable to the measurement of the critical current properties of yttrium barium copper oxide YBCO high-temperature superconducting tape.

Owner:CHINA ELECTRIC POWER RES INST +1

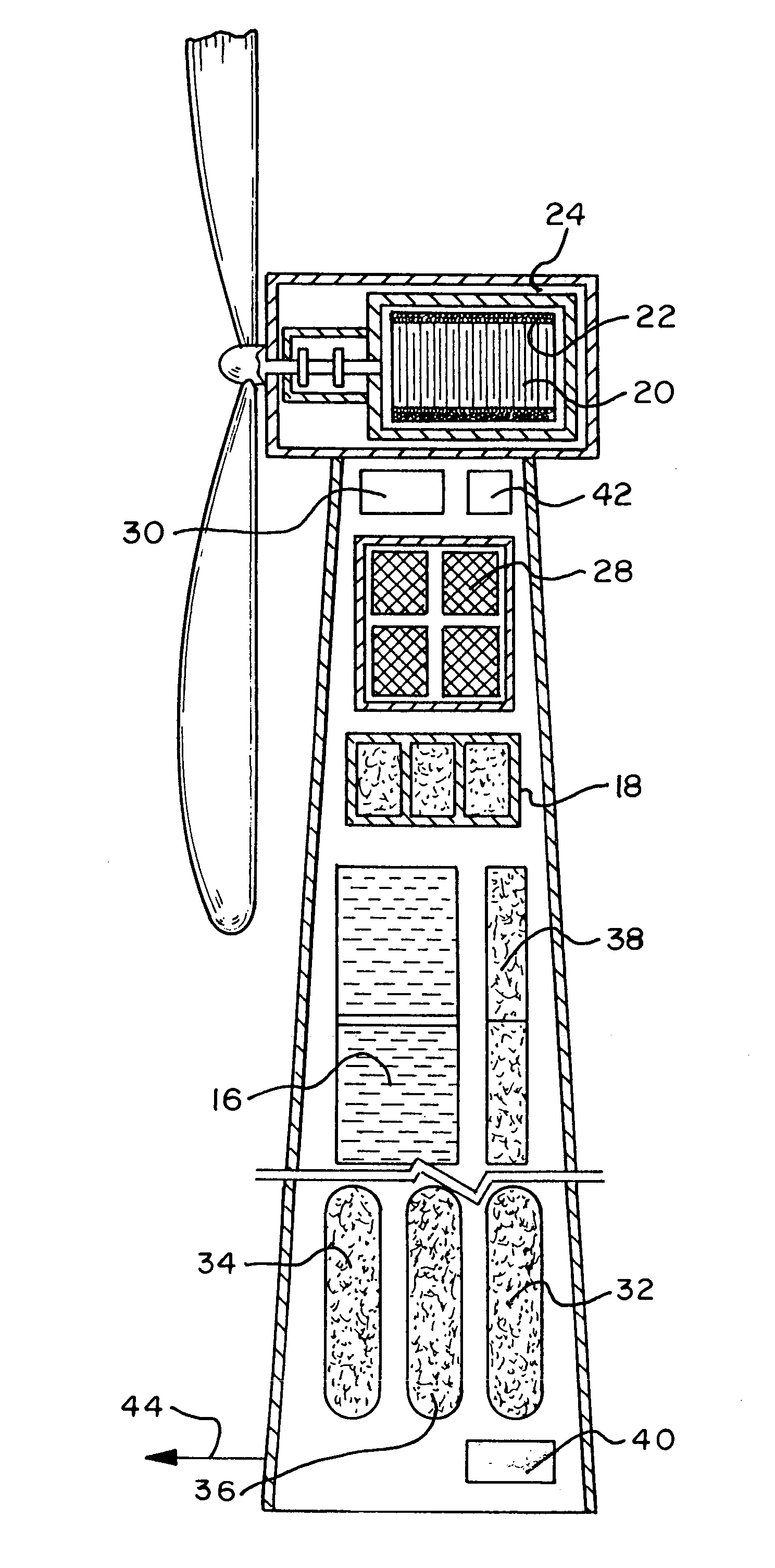

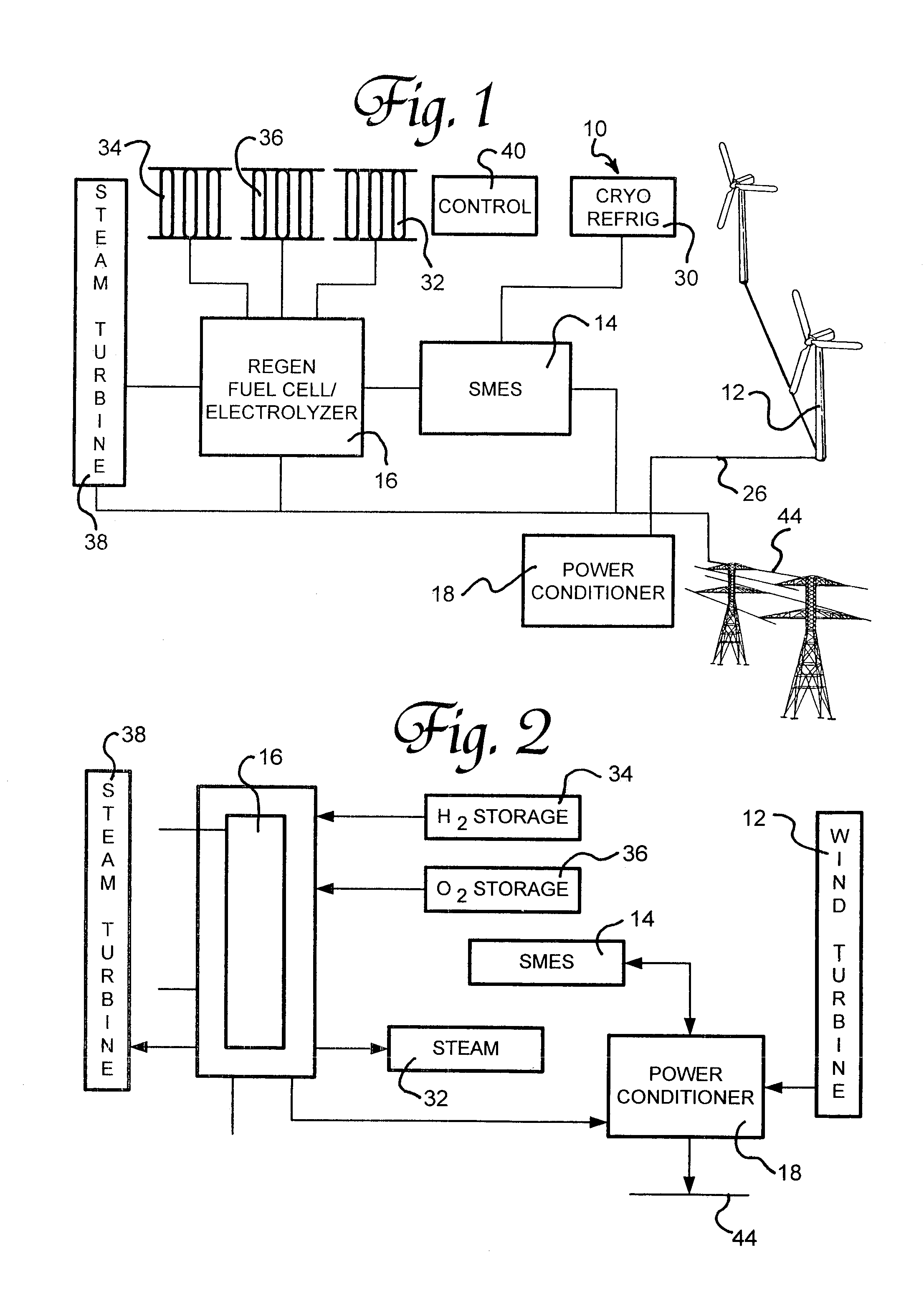

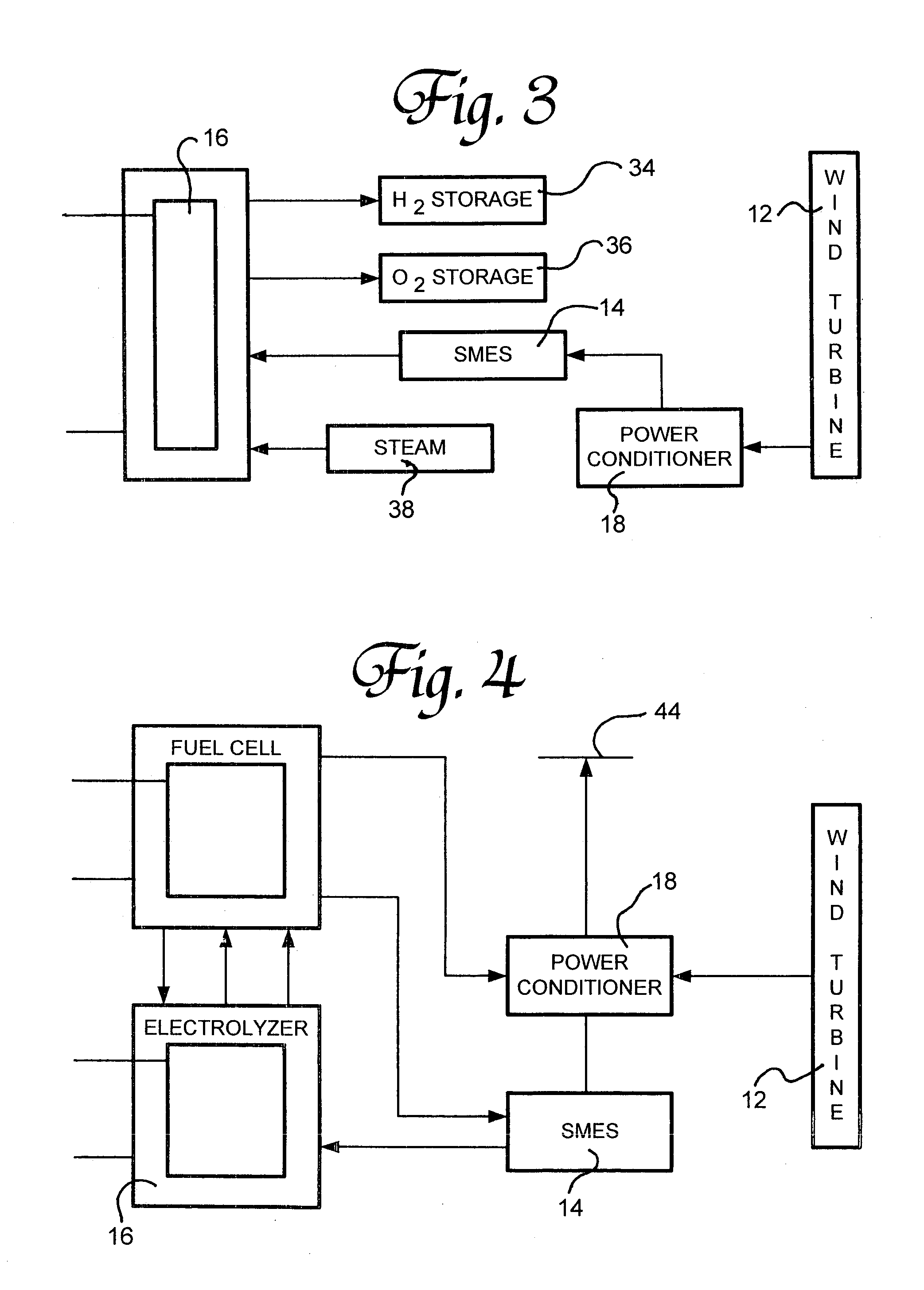

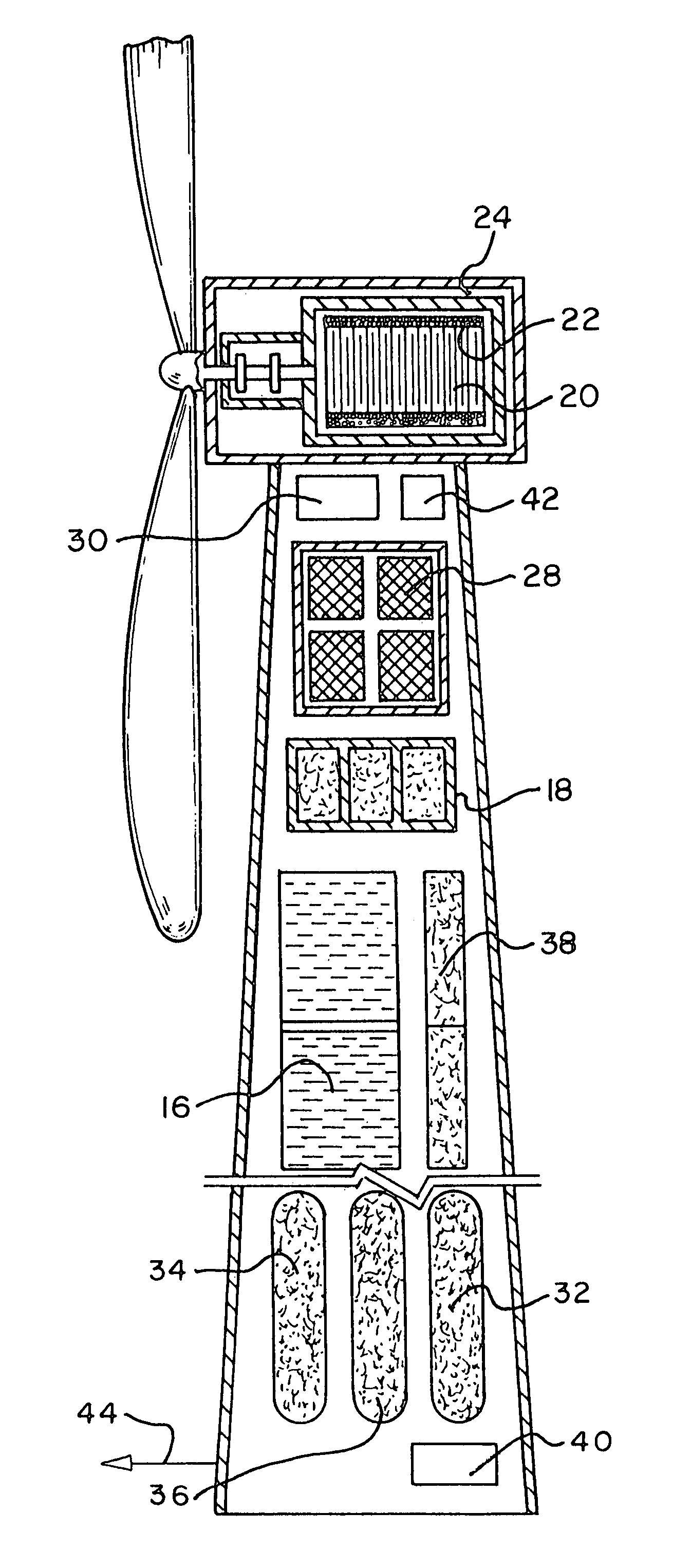

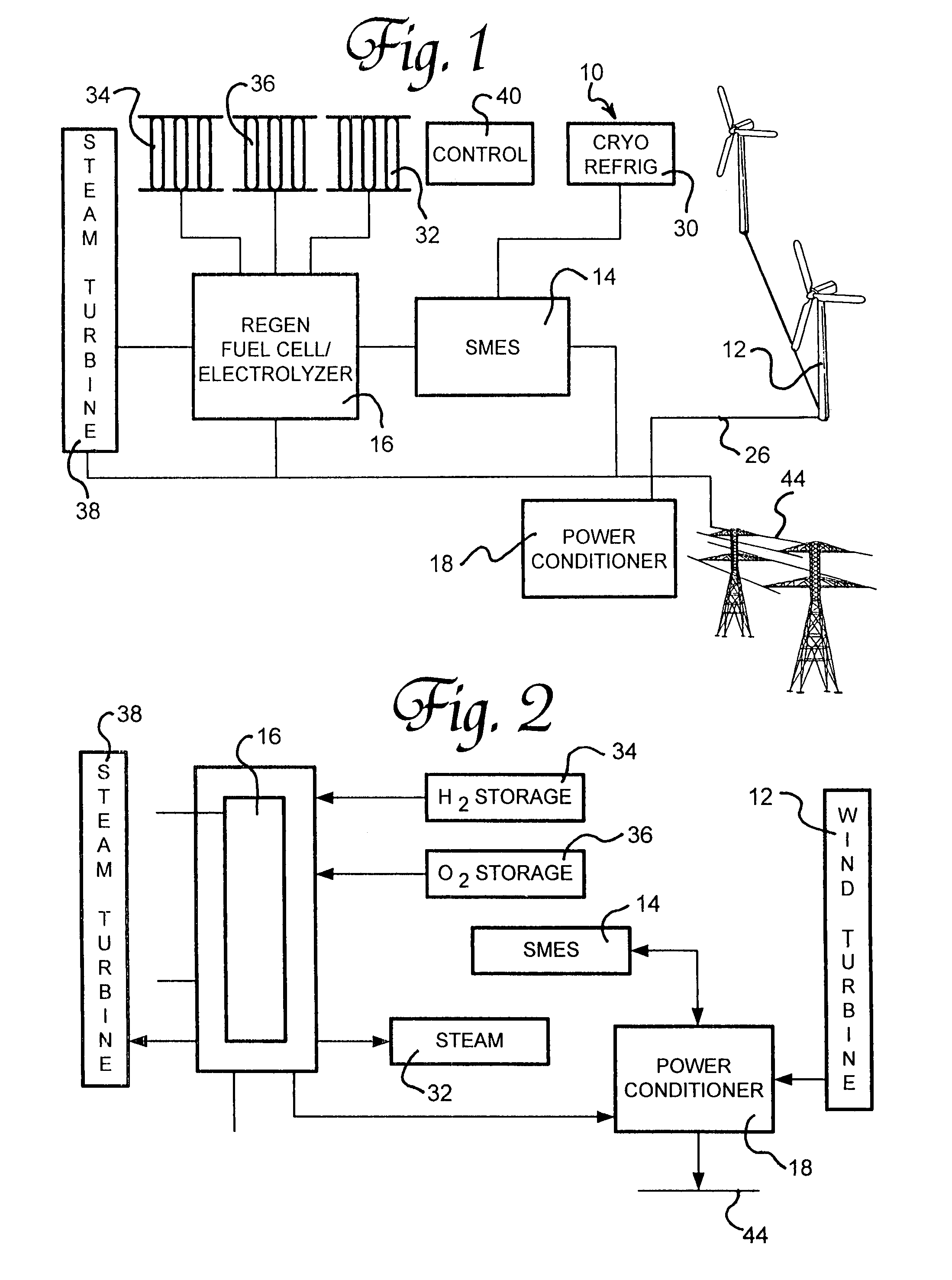

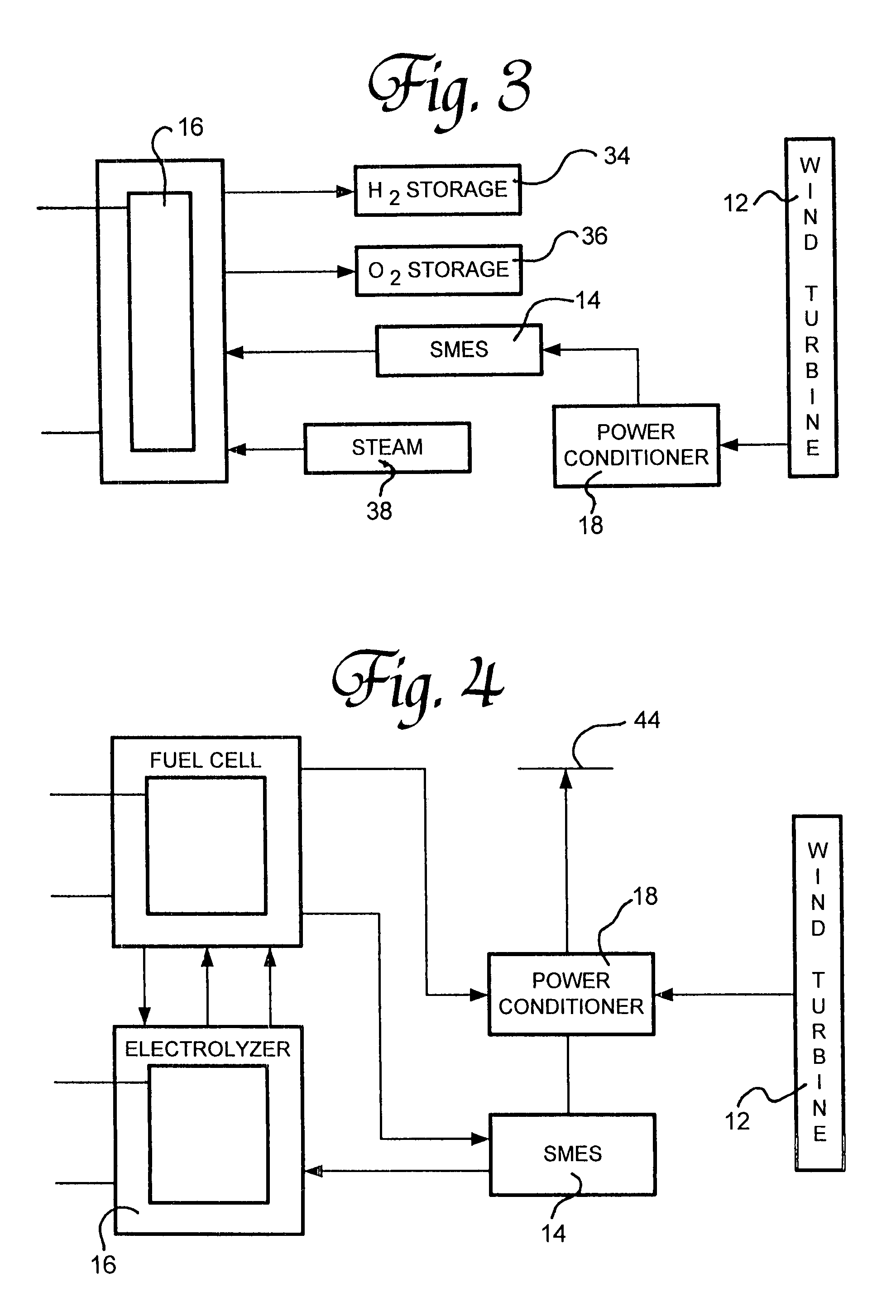

Renewable energy electric power generating system

InactiveUS7233079B1Large capacityEasy to useMachines/enginesWind energy generationElectrolysisMagnetic storage

A renewable electric power system includes a high temperature superconducting wind turbine using high temperature superconducting yttrium-barium-copper oxide for the rotor and stator windings as well as a superconducting bearing. Power from the turbine is stored in a high temperature superconducting magnetic storage system that also uses HTS YBCO. Also included is a regenerative solid oxide fuel cell / electrolyzer with steam turbine cogeneration. The system operates on a managed day / night cycle. During daytime, the energy produced by the wind turbines and fuel cells is transmitted to the grid. During nocturnal hours, the wind turbine is used to provide low cost electricity to the reversible fuel cells operating in the electrolysis mode producing hydrogen and oxygen that is stored for later use. Alternatively, the fuel cells can remain in electrolysis mode producing hydrogen and oxygen for the market. A modified interactive system generates power on a continuous twenty-four hour cycle.

Owner:COOPER WILLARD

Renewable energy electric power generating system

A renewable electric power system includes a high temperature superconducting wind turbine using high temperature superconducting yttrium-barium-copper oxide for the rotor and stator windings as well as a superconducting bearing. Power from the turbine is stored in a high temperature superconducting magnetic storage system that also uses HTS YBCO. Also included is a regenerative solid oxide fuel cell / electrolyzer with steam turbine cogeneration. The system operates on a managed day / night cycle. During daytime, the energy produced by the wind turbines and fuel cells is transmitted to the grid. During nocturnal hours, the wind turbine is used to provide low cost electricity to the reversible fuel cells operating in the electrolysis mode producing hydrogen and oxygen that is stored for later use. Alternatively, the fuel cells can remain in electrolysis mode producing hydrogen and oxygen for the market. A modified interactive system generates power on a continuous twenty-four hour cycle.

Owner:COOPER WILLARD

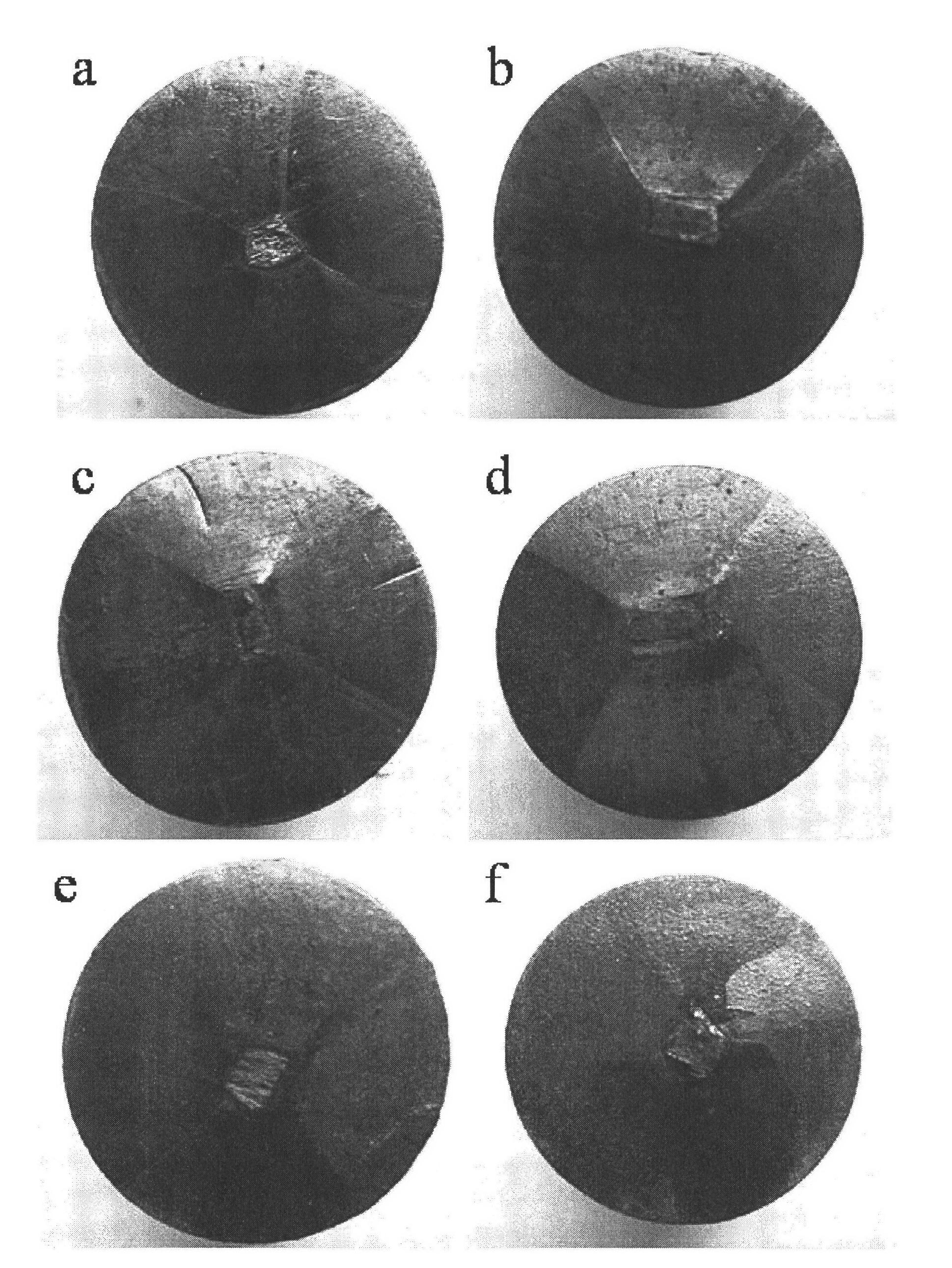

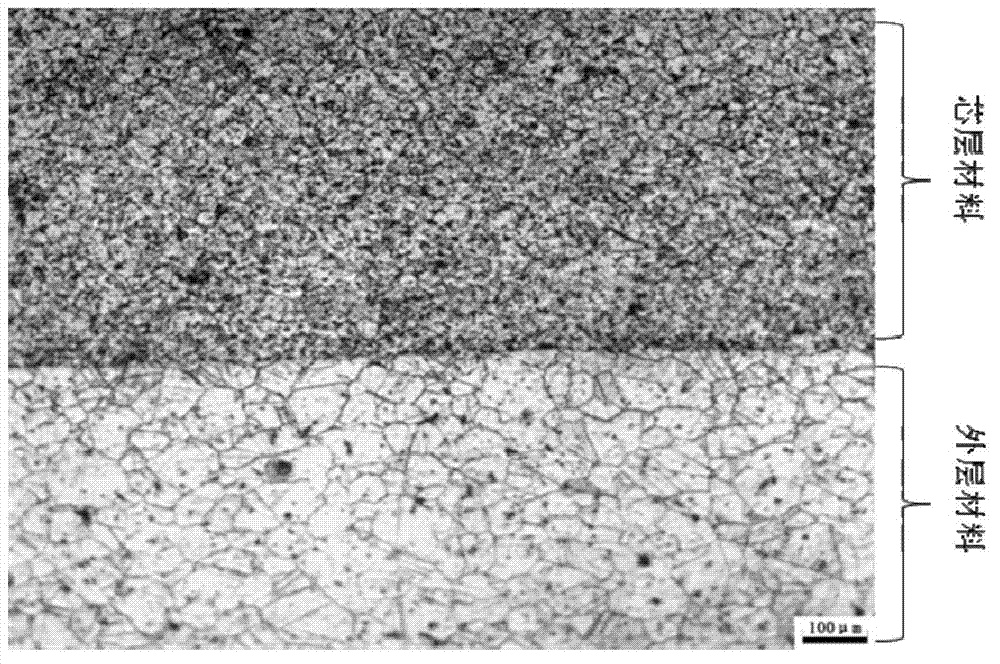

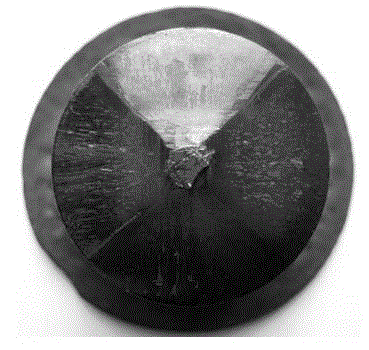

Preparation method of single domain yttrium barium copper oxide superconductor

ActiveCN102534787ASimple processImproved Flux Pinning PerformancePolycrystalline material growthFrom frozen solutionsFlux pinningYttrium barium copper oxide

The invention relates to a preparation method of a single domain yttrium barium copper oxide superconductor; and the preparation method comprises the following steps: preparing Y2BaCuO5 precursor powder and liquid phase source powder, pressing a Y2BaCuO5 precursor block, a liquid phase block and a supporting bock, preparing a green body, growing a single domain yttrium barium copper oxide block in an infiltration manner, and carrying out oxygen permeation processing. A second phase nanoparticle Y2Ba4CuBiOx / Y2Ba4CuMOx (M is Bi or W) is successfully introduced for forming a flux pinning center by adopting a top seed crystal infiltration growing method and adding a metallic oxide (Bi2O3 powder and WO3 powder) for doping, thereby the powder preparation technology is simplified, the experimental period is shortened, the experiment cost is reduced, and the flux pinning capacity of the superconductor is increased. Y2O3 is used for preparing the supporting block which stably supports two briquettes above the supporting block in the slow cold growing process of an yttrium barium copper oxide block so as to prevent liquid phase from running off. The preparation method can be used for preparing the yttrium barium copper oxide superconductor and can also be used for preparing high-temperature superconductors of other series such as Gd, Sm, Nd, Eu and the like.

Owner:SHAANXI NORMAL UNIV

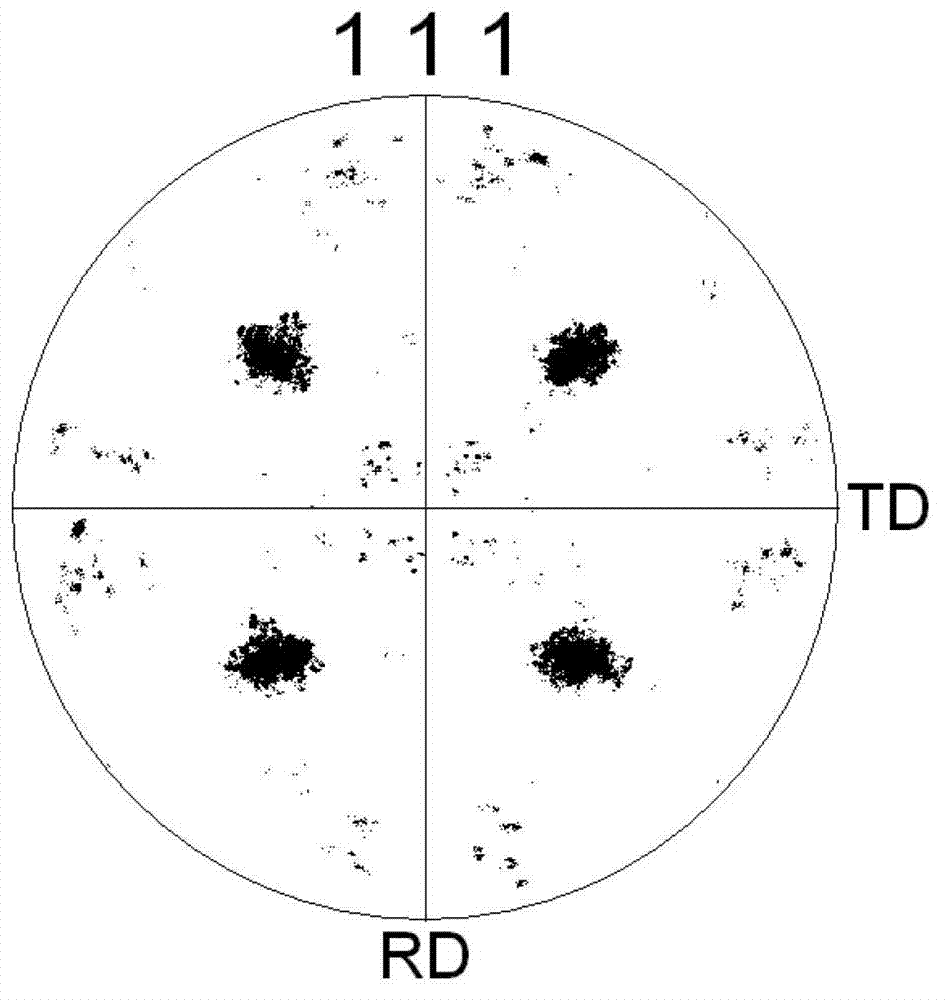

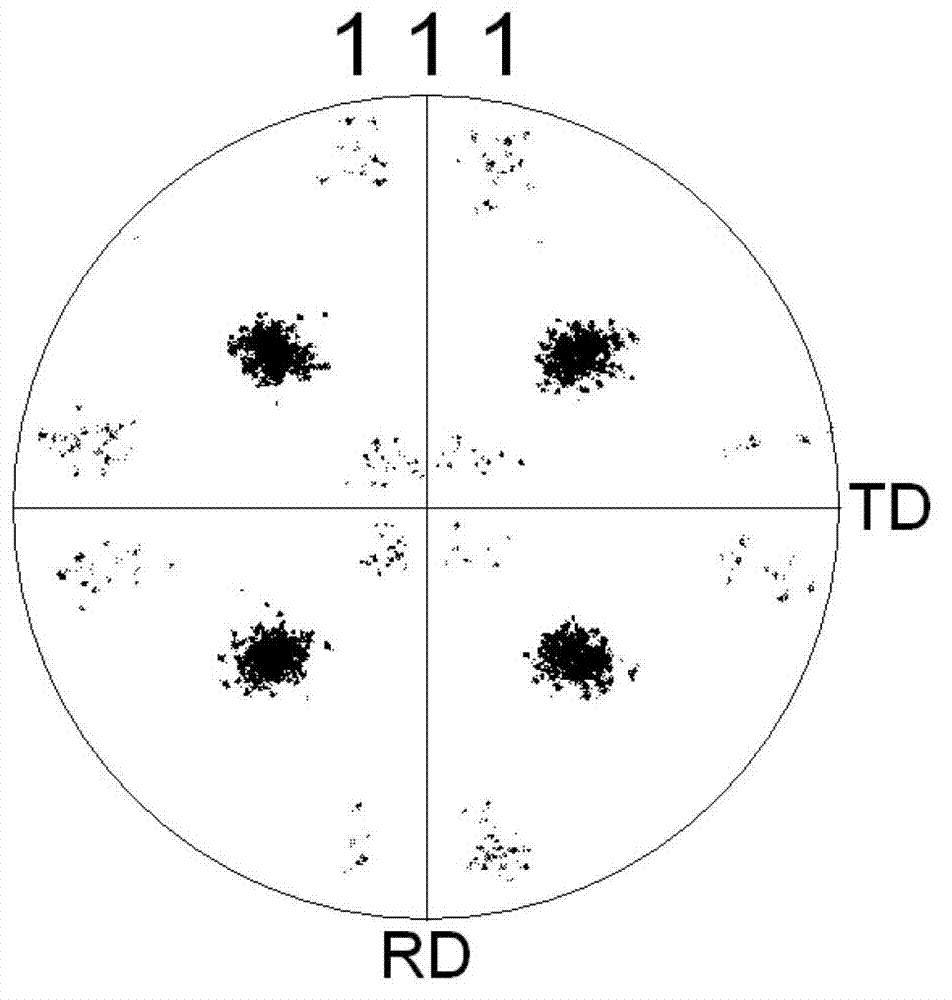

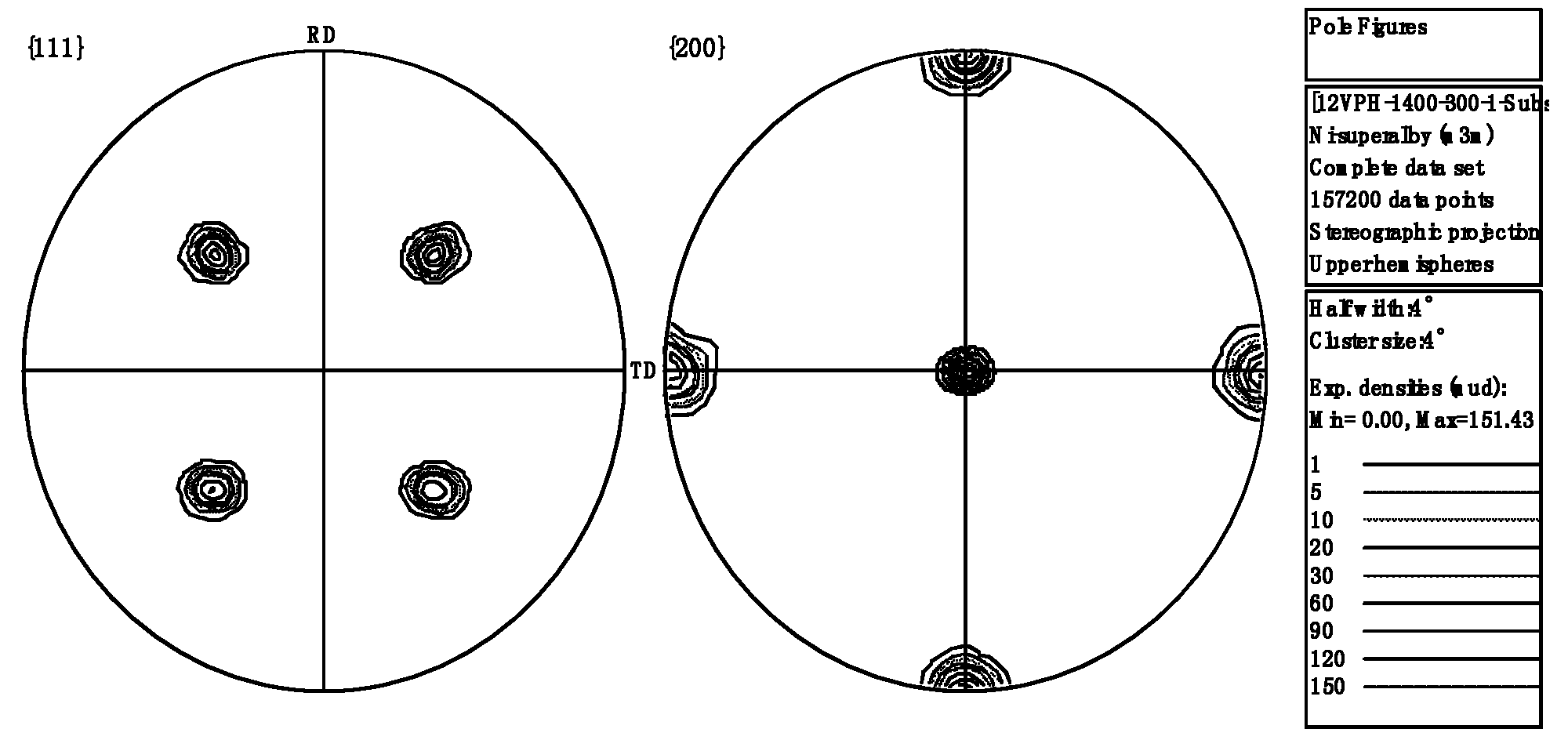

Low-magnetism or magnetism-free and high-strength Ni-W alloy composite base band and preparation method thereof

ActiveCN102756512AAchieve associativityImprove bindingMetal layered productsTungsten atomAlloy composite

The invention provides a low-magnetism or magnetism-free and high-strength Ni-W alloy composite base band and a preparation method thereof, belonging to the technical field of a high-temperature super-conductive coating conductor texture metal base band. According to the Ni-W alloy composite base band disclosed by the invention, a surface layer is a Ni-W alloy with high W content and the atom percentage content of the W is 7.5-9.3%; and a core layer is a nickel-tungsten alloy with the tungsten atom percentage content of 9.3-12%. The preparation method comprises the following steps of sequentially placing a high-W-content Ni-W alloy blank ingot (A) which is prepared by a smelting method and has the atom percentage content of the W of 7.5-9.3%, and Ni-W mixed powder (B) with the atom percentage content of the W of 9.3-12% into a mould according to the sequence of A-B-A; utilizing a discharge plasma sintering technology to sinter to obtain a composite blank ingot; then, carrying out hot rolling and carrying out cold rolling treatment on a hot rolling blank ingot; and then, crystallizing and annealing, carrying out cold rolling to obtain the composite base band, and re-crystallizing and annealing the base band under the protection of Ar / H2 mixed gas to obtain the Ni-W alloy composite base band. The composite base band has the advantages of high strength, low magnetism or no magnetism and strong cubic structure, and can further meet the requirement of further improving the performance of an YBCO (Yttrium Barium Copper Oxide) coating conductor.

Owner:深创超导(深圳)科技有限公司

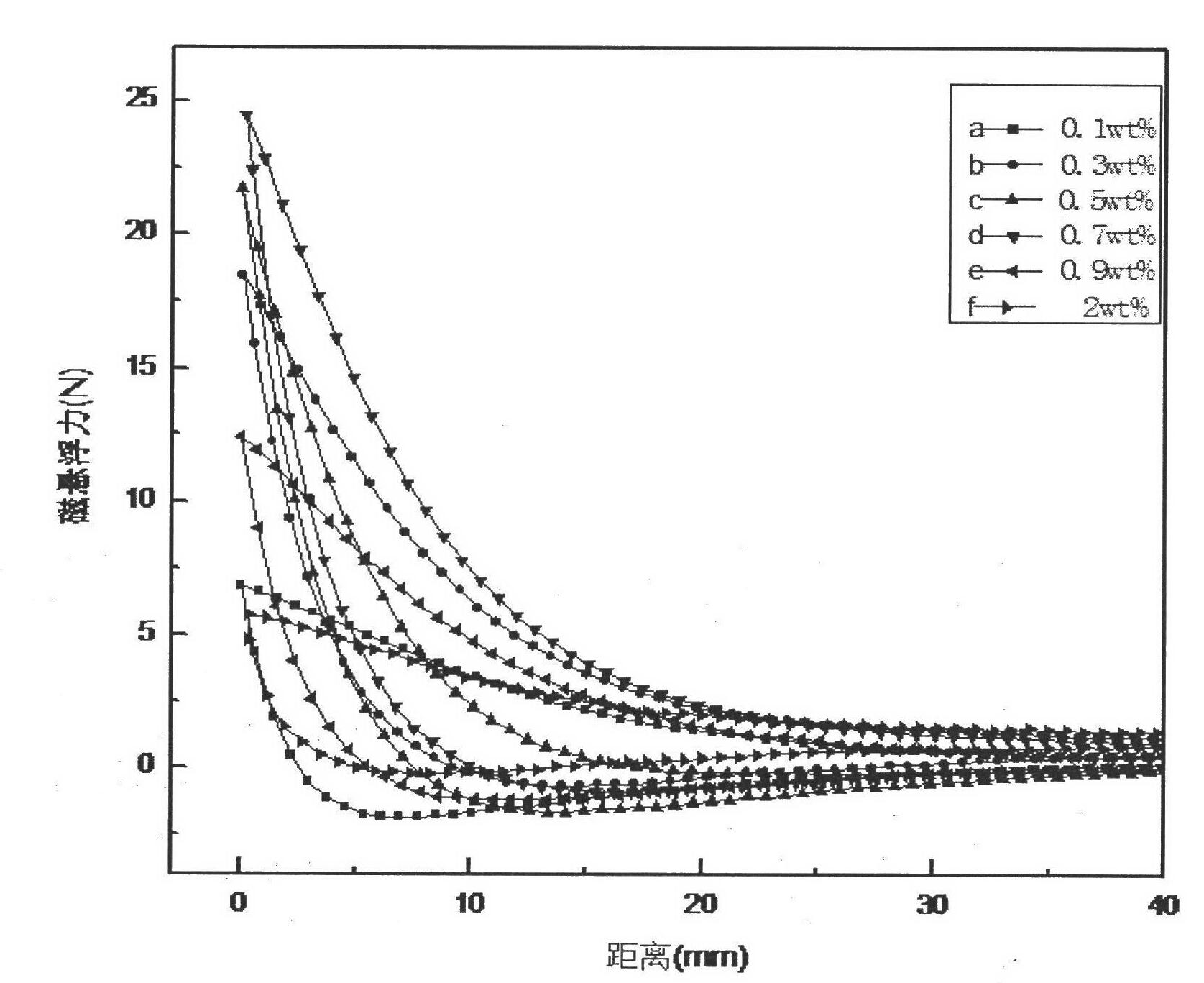

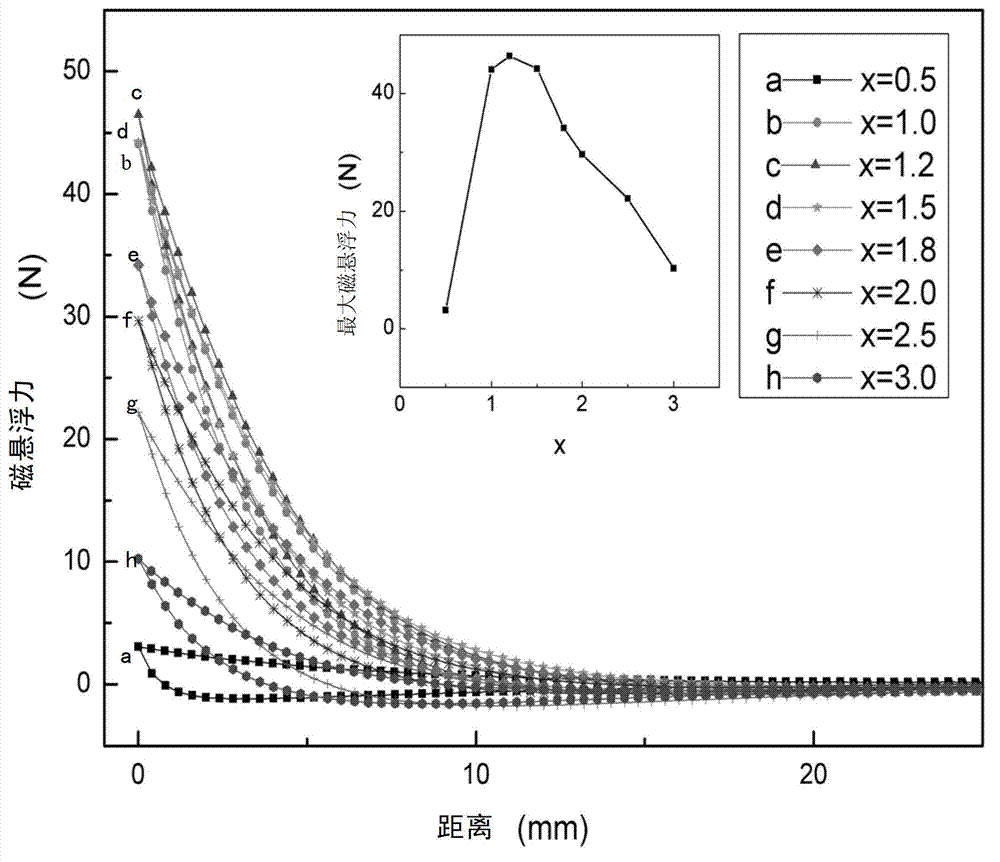

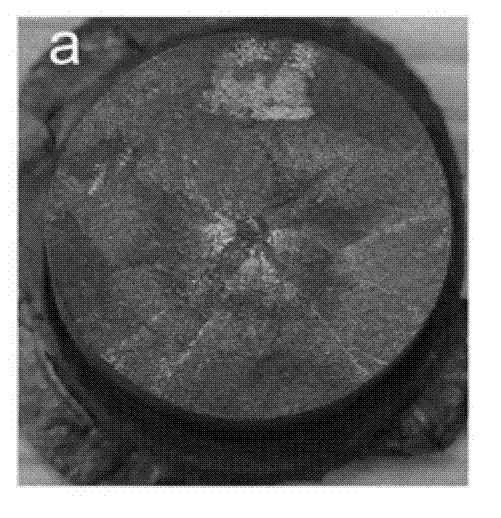

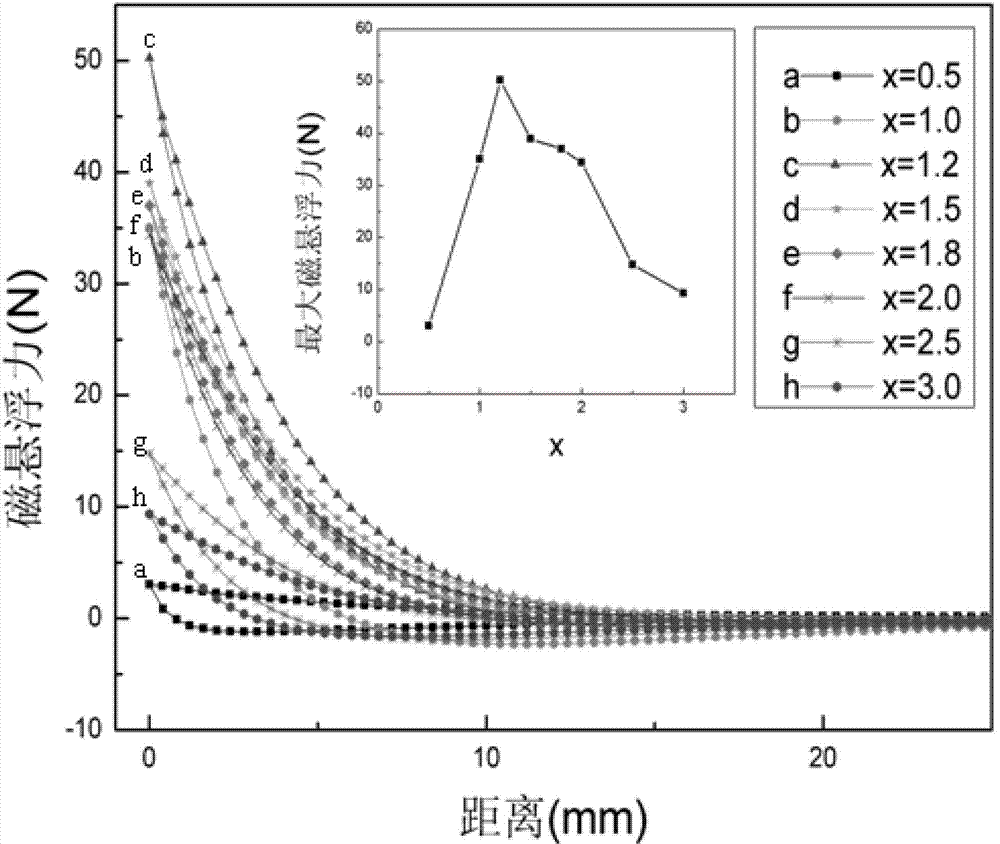

Method for preparing single domain yttrium barium copper oxide superconduction block

ActiveCN102925954AAvoid churnPromote growthPolycrystalline material growthFrom solid stateYttrium barium copper oxideMaterials science

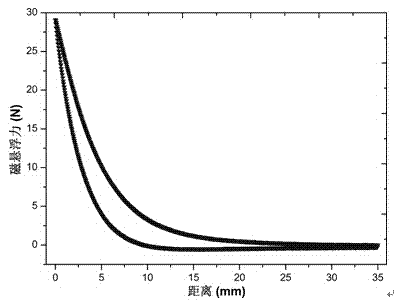

The invention relates to a method for preparing a single domain yttrium barium copper oxide superconduction block. Through changing components of solid phase source powder and liquid phase source powder which are used in a solid phase block, the whole infiltration growth process only needs precursor powder of BaCuO2, thus the experiment links are simplified, the experiment period is shortened, the experiment cost is lowered, and the efficiency is increased; and the single domain yttrium barium copper oxide superconduction block prepared by adopting the method provided by the invention has large magnetic levitation force and is beneficial to prevention of loss of a liquid phase and collapse of a sample, the full contact of the liquid phase with the solid phase and the orientated growth of crystals by adopting an assembly method that a liquid phase block is slightly larger than or equal to a solid phase precursor block in size.

Owner:SHAANXI NORMAL UNIV

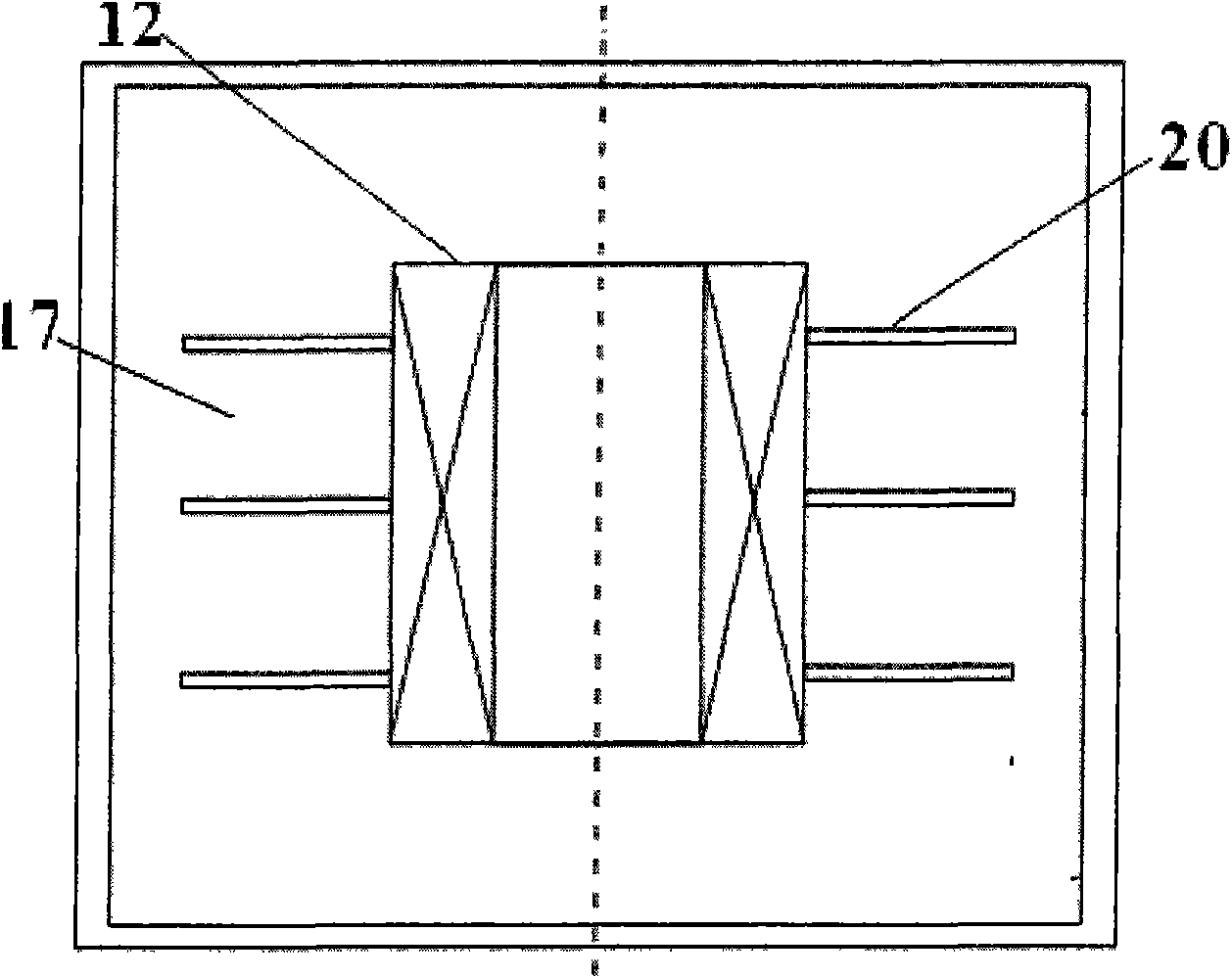

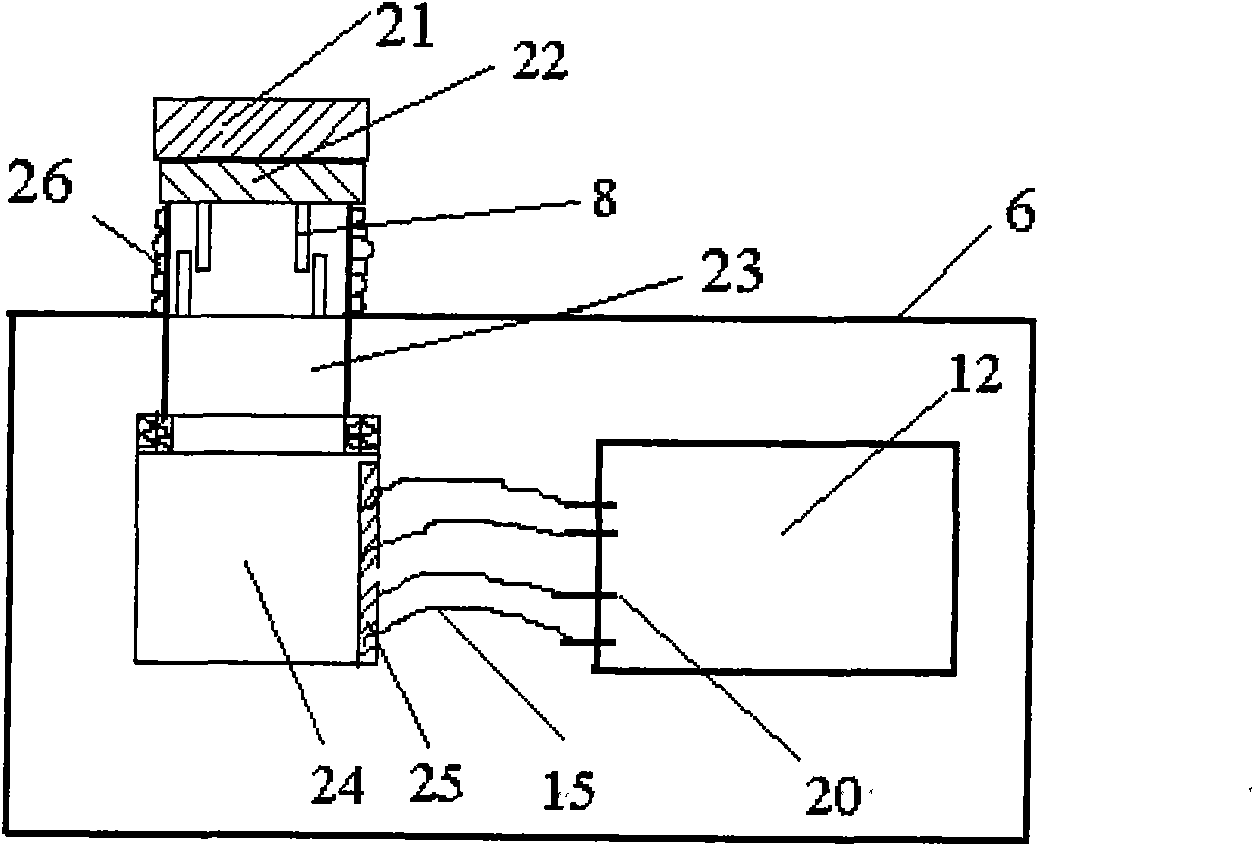

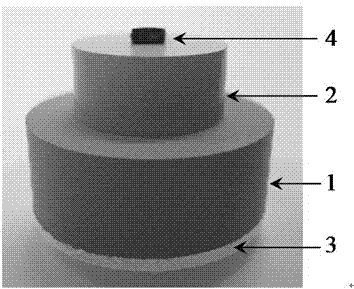

High temperature superconducting magnetic system protected by high heat capacity materials

InactiveCN101615469AMeet the requirements for offline operationExtended offline runtimeSuperconducting magnets/coilsYttrium barium copper oxideCold shield

The invention provides a high temperature superconducting magnetic system protected by high heat capacity materials, wherein, a high temperature superconducting magnet (12) is arranged in a low temperature container (6); the periphery of the high temperature superconducting magnet (12) is coated with high heat capacity cold accumulation materials (17); a refrigerator (1) is installed in a vacuum container (2), and a primary cold head of the refrigerator (1) is connected with a cold shield (5) of the vacuum container (2) through a first heat pipe (3); a secondary cold head of the refrigerator (1) is connected with a low temperature container (6) through a second heat pipe (8); a first and a second cold conduction copper rods (23, 24) which are at the lower end of the second heat pipe (8) are connected with the high temperature superconducting magnet (12) through a cold conduction plate (15); a Y-Ba-Cu-O high temperature superconducting block (13) which is installed in external symmetry on the low temperature container (6) interacts with a permanent magnetic block (14) which is on the inner wall of the vacuum container (2), thus suspending the low temperature container (6); and the temperature signal of the high temperature superconducting magnet (12) detected by a temperature probe (18) is used for controlling the startup and shutdown of the refrigerator (1).

Owner:金山研究(大连)核磁共振科技有限公司

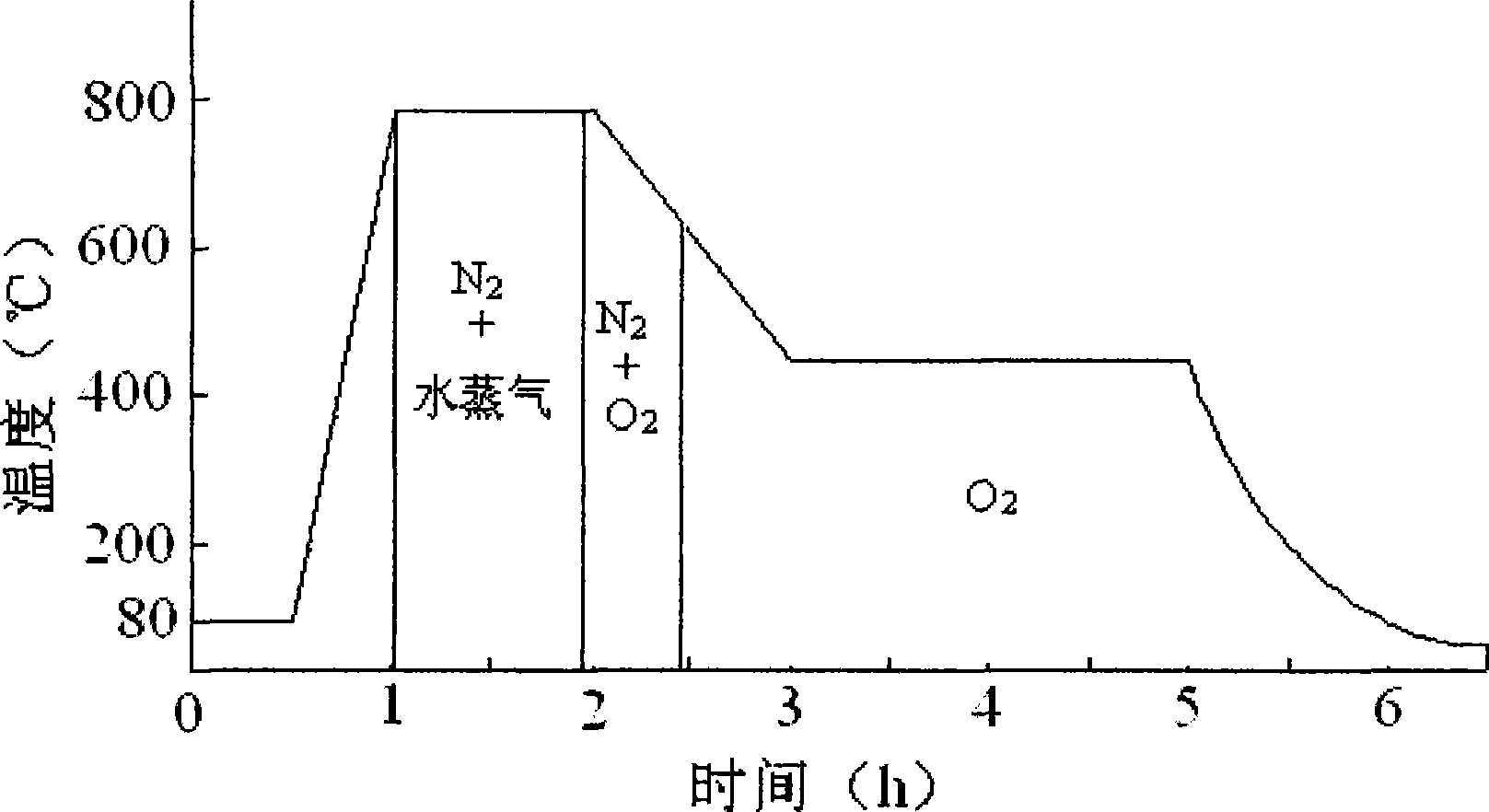

Collosol of yttrium barium cupper oxygen superconducting film and process for preparing high temp. superconducting film thereof

InactiveCN1792806AShorten heat treatment timeEasy to makeSuperconductors/hyperconductorsSuperconductor devicesPolymer scienceOxygen

A sol of the Y-Ba-Cu-O (YBCO) superconductor film is proportionally prepared from yttrium acetate, barium acetate, copper acetate, trifluoroacetic acid, water, alpha-methylacrylic acid, divinyltriamine and methanol. A process for preparing the high-temp superconductor film from said sol is also disclosed.

Owner:XIAN UNIV OF TECH

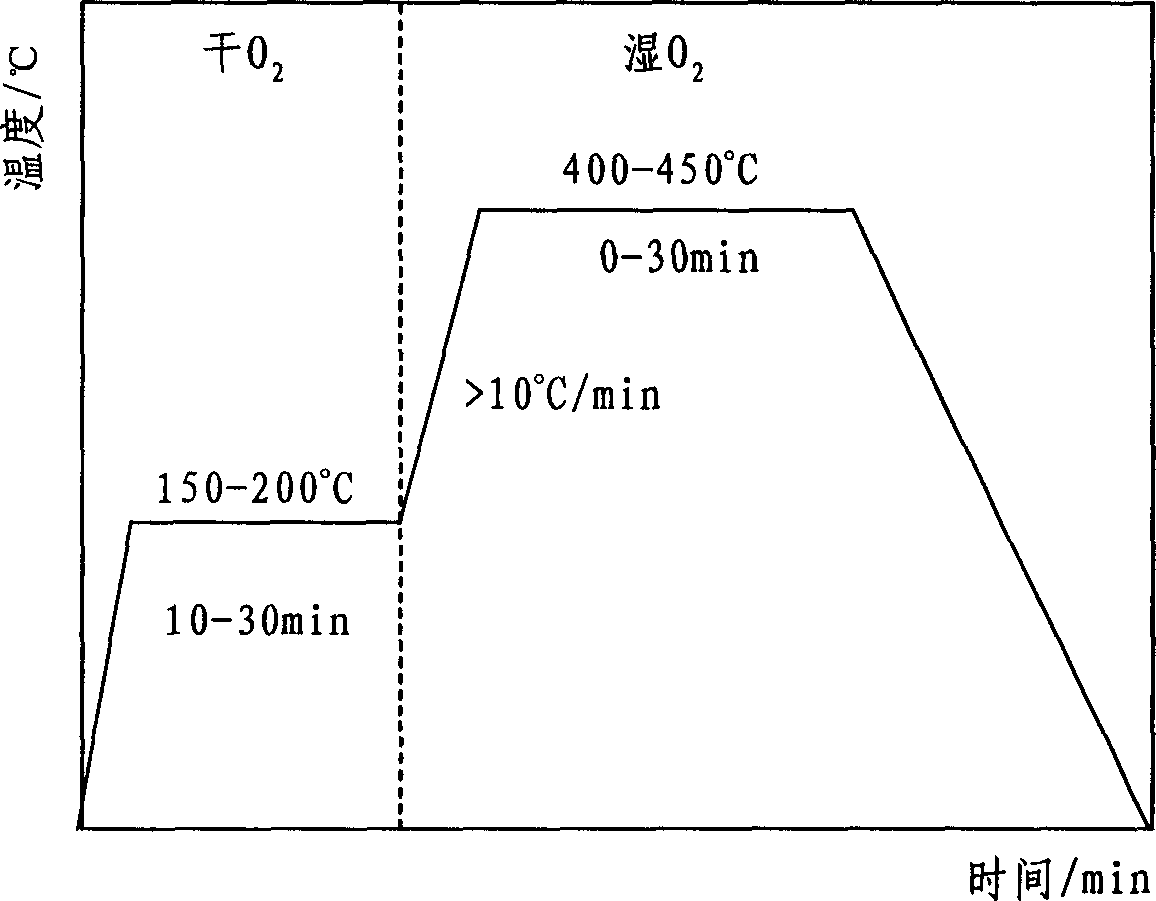

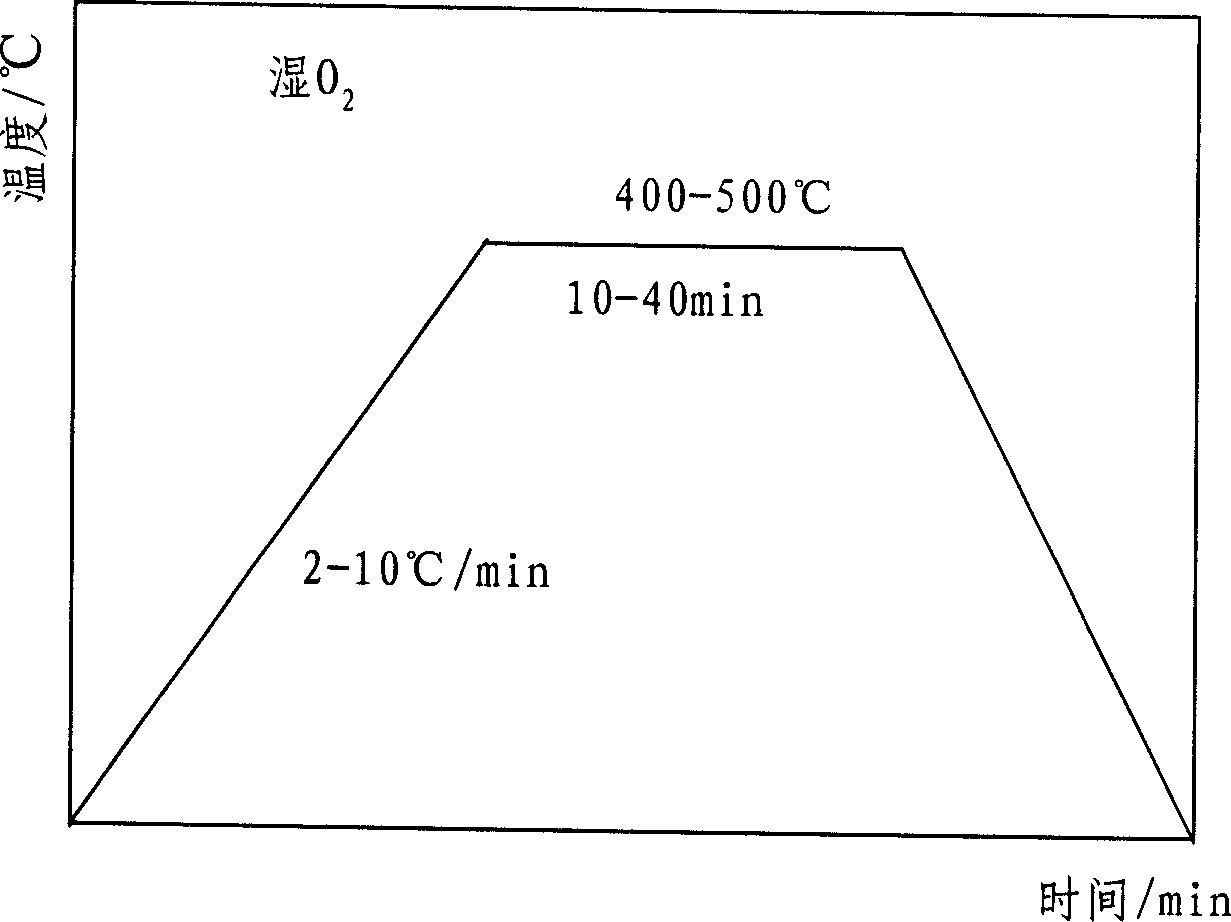

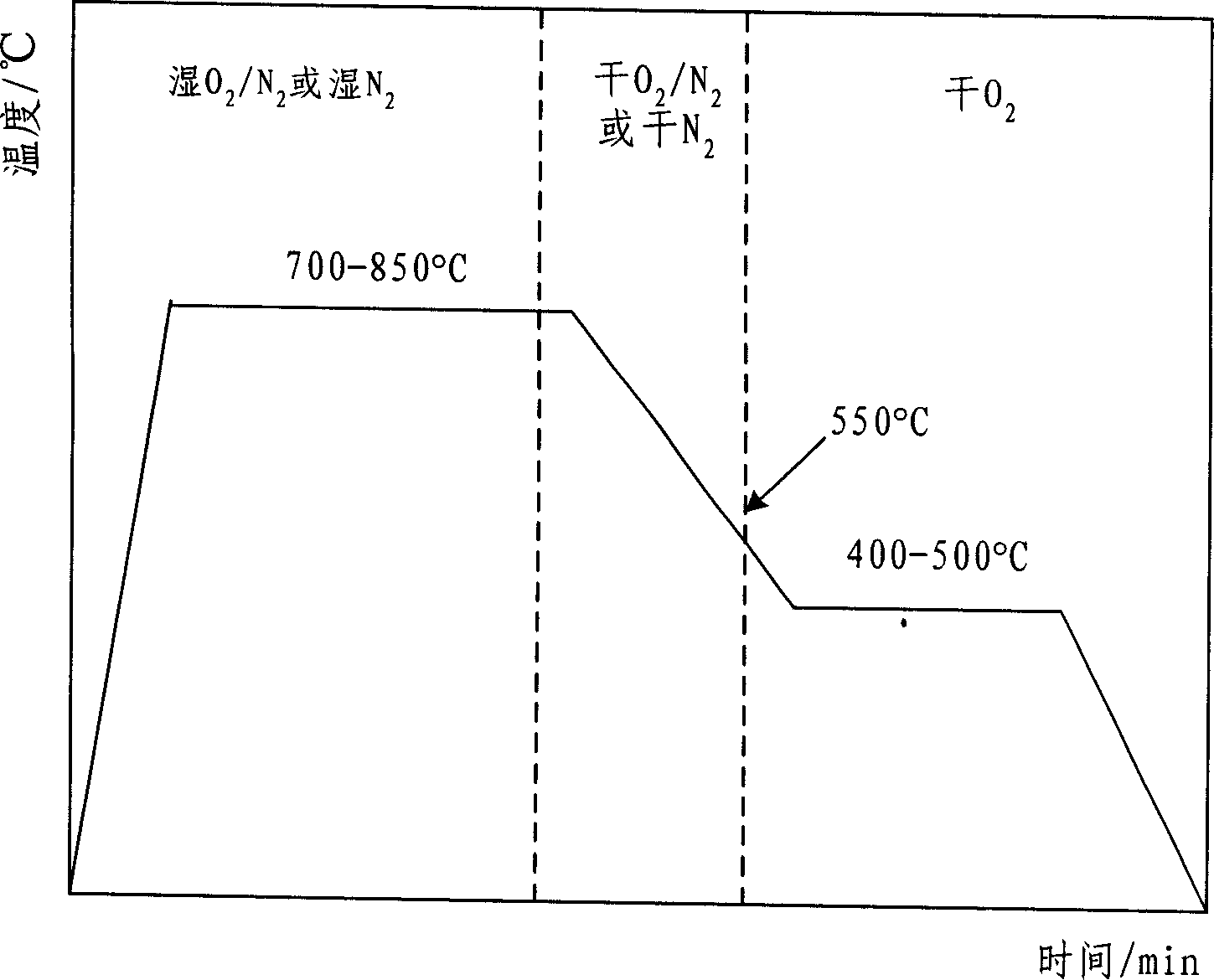

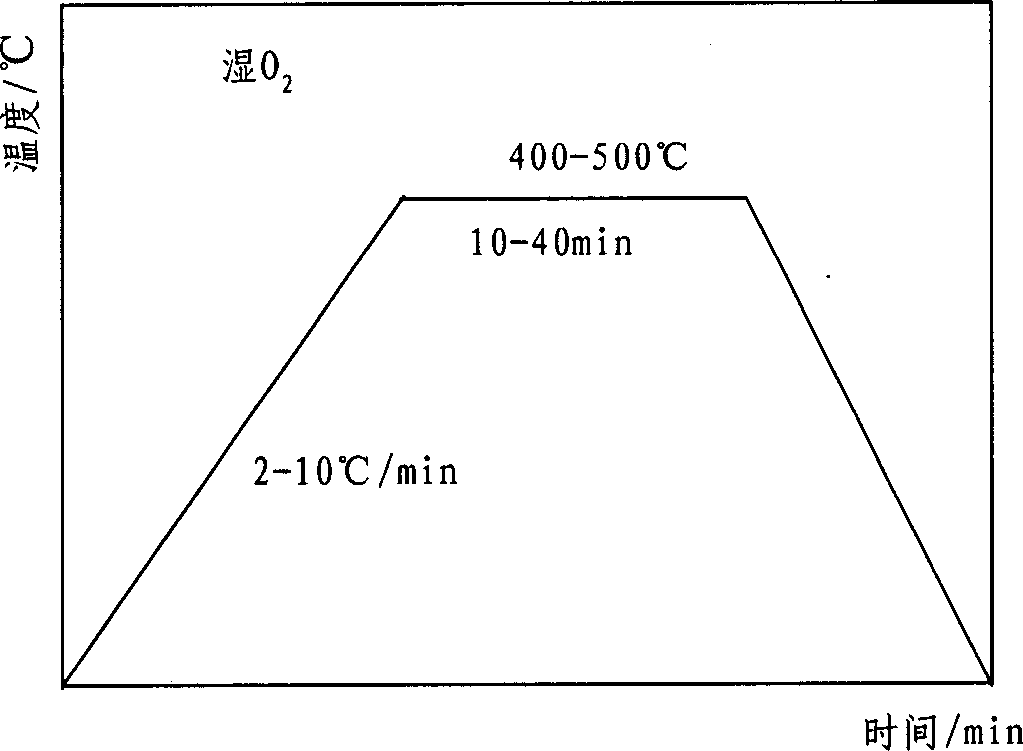

Preparation method of high temperature superconductive film adopting modified low fluoride solution method

InactiveCN102531567AGood superconducting propertiesReduce manufacturing costElectrical conductorOxygen

The invention discloses a preparation method of a high temperature superconductive film adopting a modified low fluoride solution method, which comprises the following steps: dissolving yttrium oxide, barium acetate and copper acetate as raw materials in a solvent using a complexing agent to obtain a low fluoride yttrium barium copper oxygen solution, preparing a gel film and drying, and performing pretreatment and end treatment of the film. The sol has easily adjustable composition, stable performance and good film forming property, the yttrium barium copper oxygen superconductive film can be easily prepared using the sol, and the heat treatment cycle is short and the process repeatability is high. In addition, the solution avoids the introduction of amine group, so as not only to avoid the loss of copper in the heat treatment, but also to avoid the problem that the film is easy to craze. The method of the invention is also used for preparing large-area or long-distance yttrium barium copper oxygen films and coated conductors, the obtained yttrium barium copper oxygen film has good surface smoothness and has good superconductivity.

Owner:XIAN UNIV OF TECH

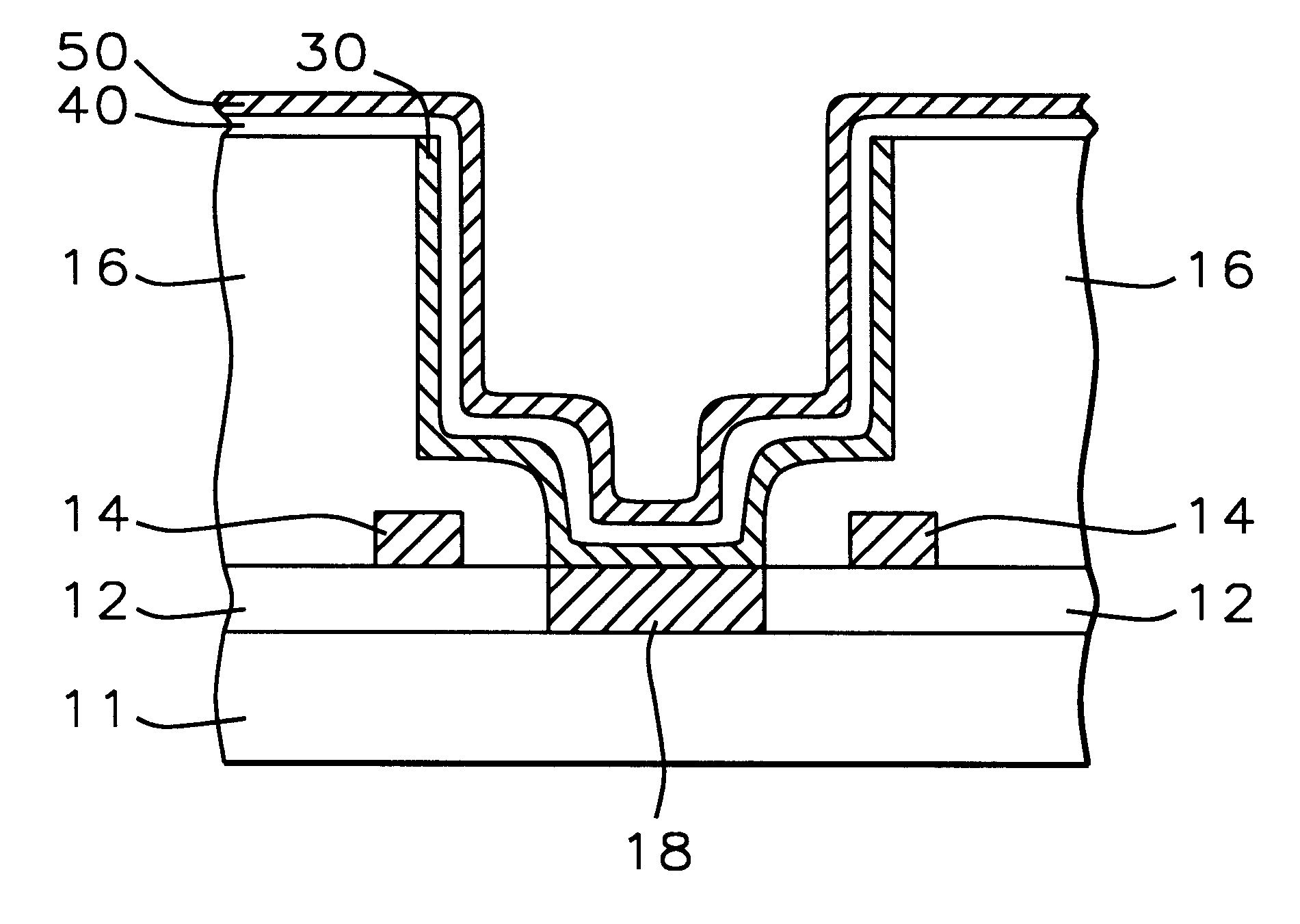

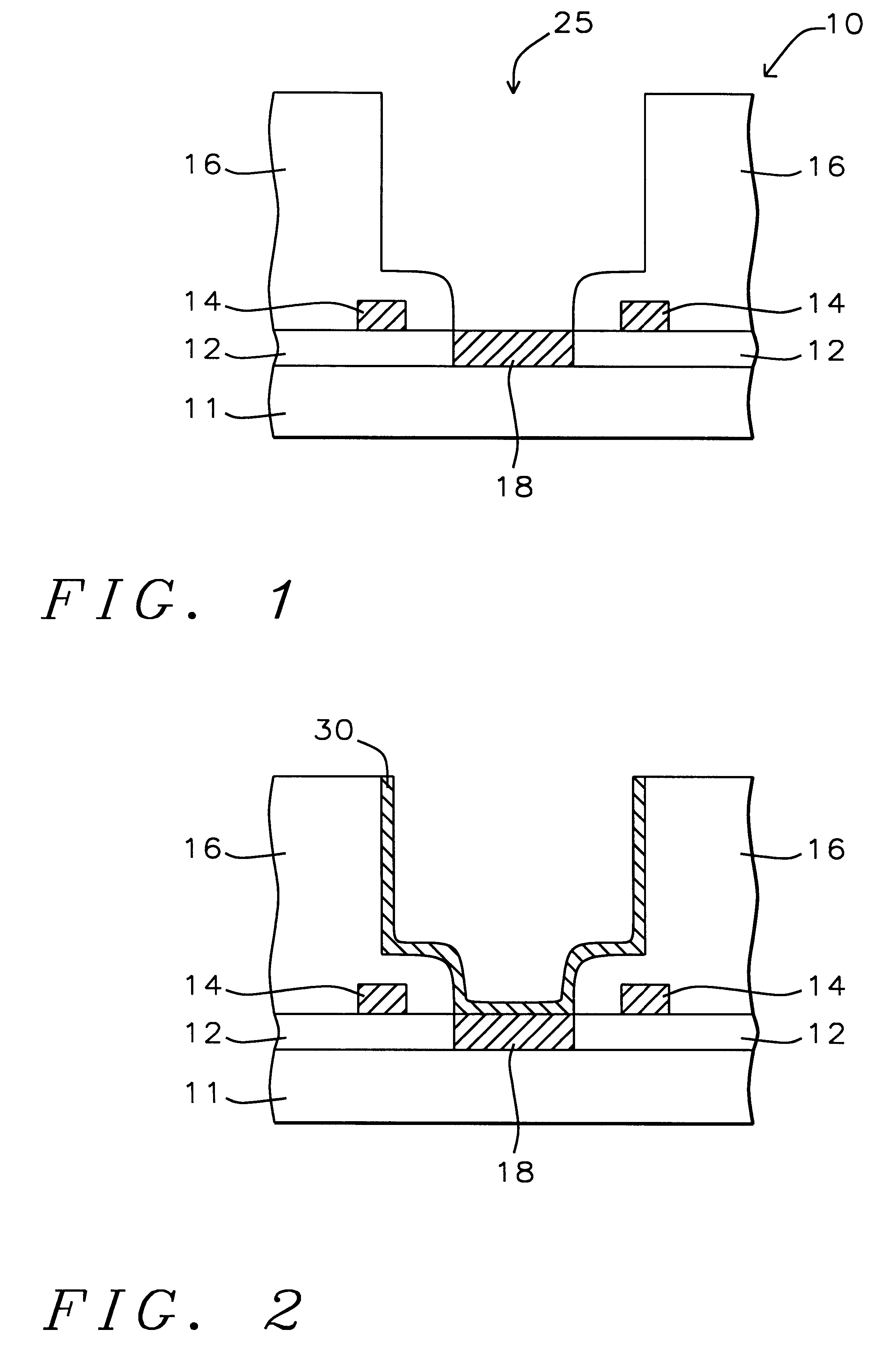

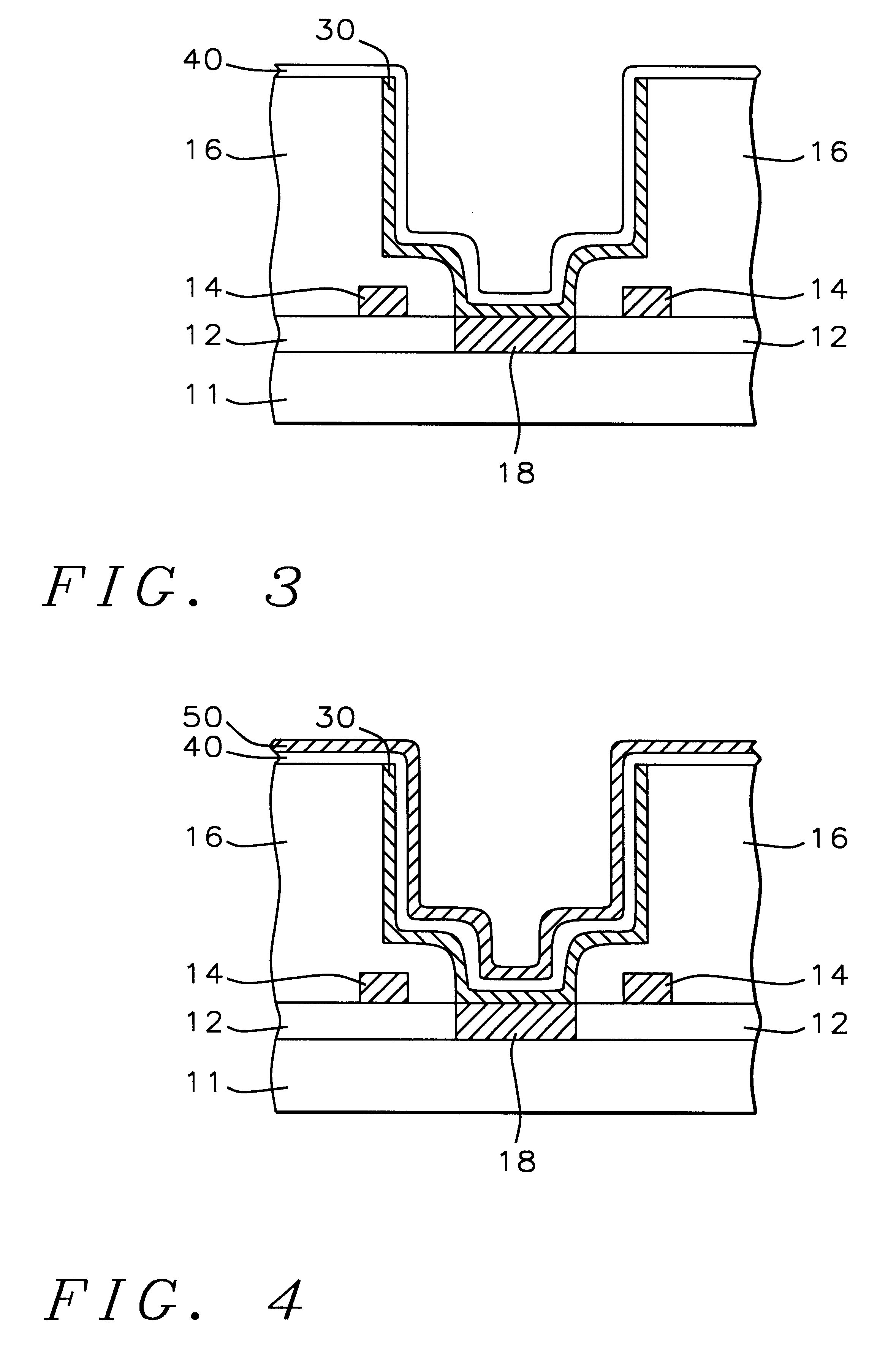

Structure and method for forming a capacitor dielectric using yttrium barium copper oxide

InactiveUS6300216B1Easy to patternEasy to detectSemiconductor/solid-state device manufacturingCapacitorsYttrium barium copper oxideSemiconductor structure

A method and structure for forming a capacitor in a semiconductor device using a high dielectric constant, yttrium barium copper oxide layer as the capacitor dielectric layer. The process begins by providing a semiconductor structure having a conductive plug therein and having an opening, with sidewalls, over the conductive plug. The opening is shaped to accomodate a capacitor structure as is known in the art. A first conductive layer is formed on the conductive plug and on the sidewalls of the opening. A yttrium barium copper oxide layer is deposited on the first conductive layer using a sputtering process with a YBa2Cu3O7 target. The yttrium barium copper oxide layer can be annealed to control the oxygen content. For example, YBa2Cu3O6+X can be controlled at between X=0.2 and X=0.5. A second conductive layer is formed on the yttrium barium copper oxide layer, thereby forming a capacitor comprising the first conductive layer, the yttrium barium copper oxide layer, and the second conductive layer.

Owner:TAIWAN SEMICON MFG CO LTD

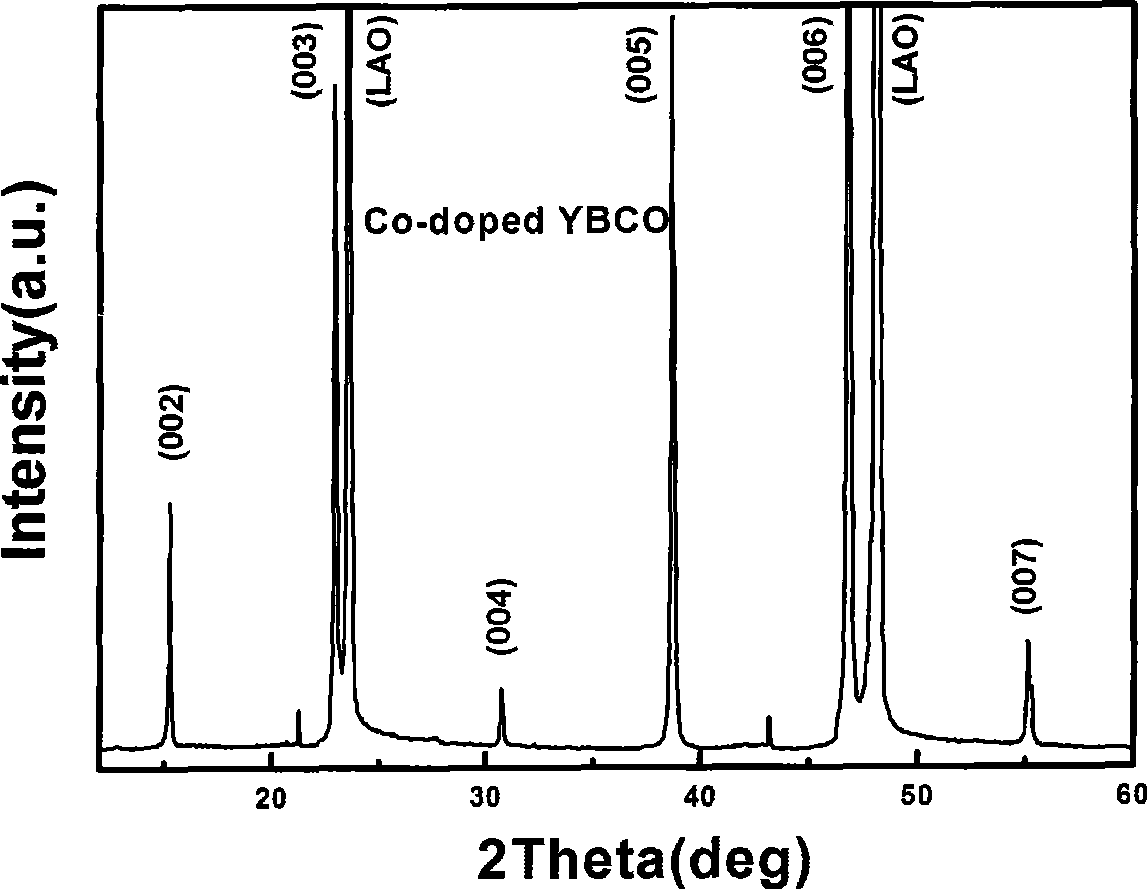

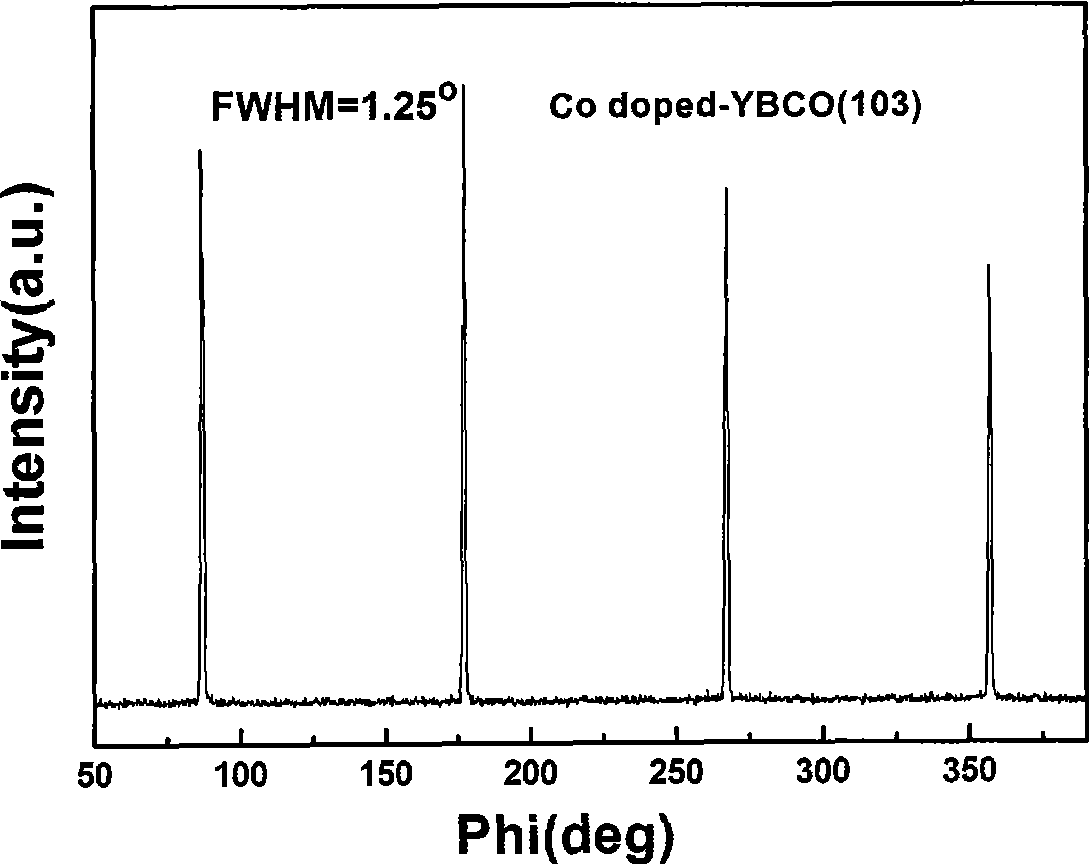

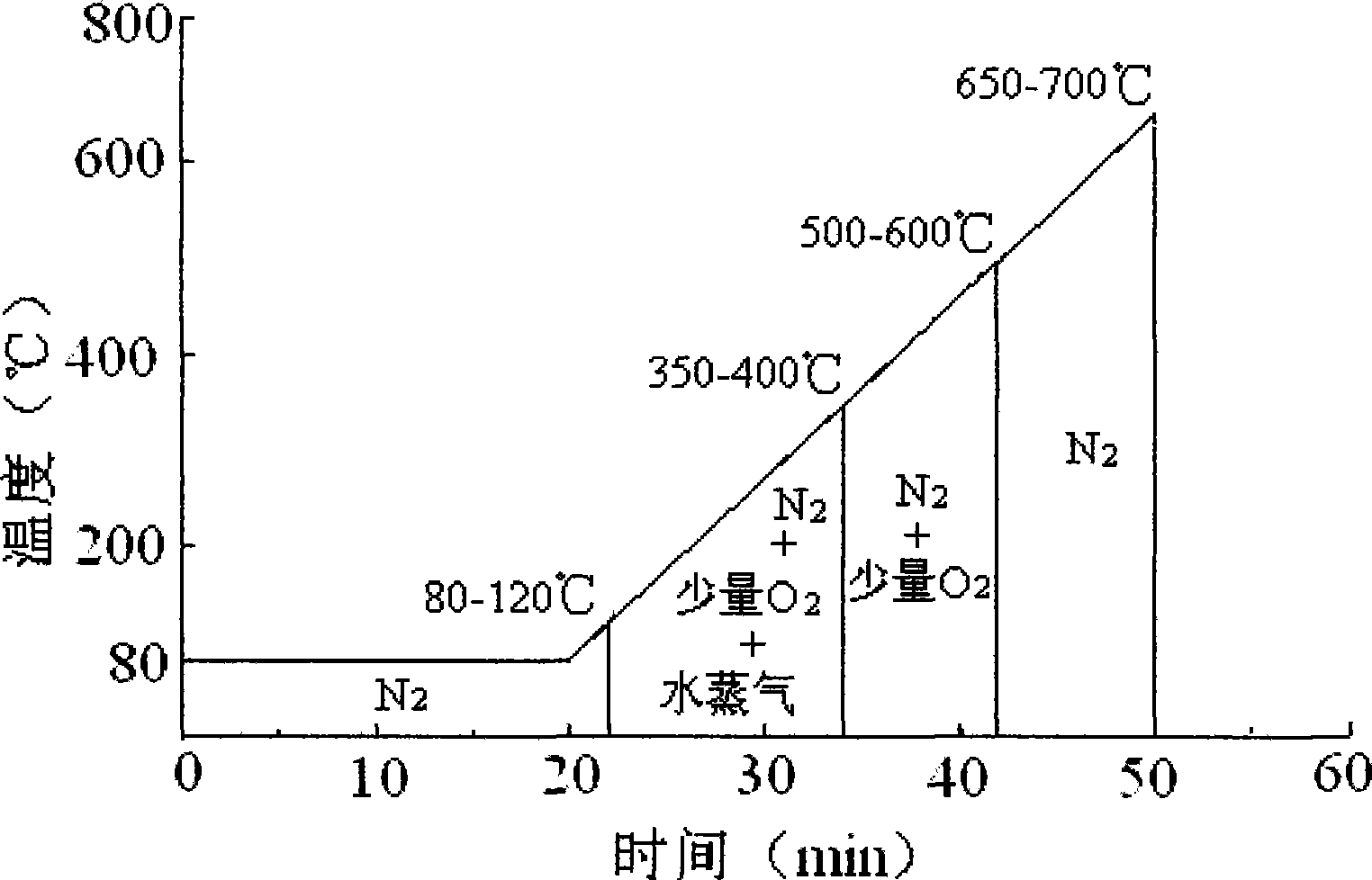

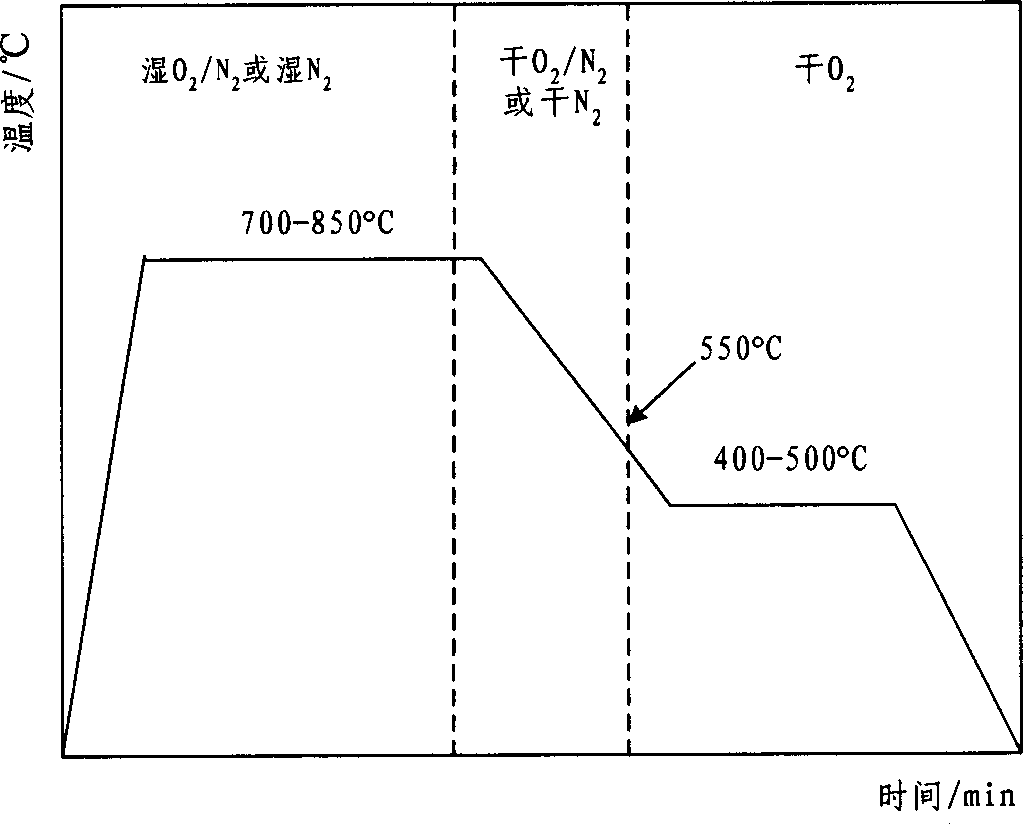

Method for preparing high critical current density yttrium barium copper oxide superconducting film

InactiveCN101456726ASimple processShorten the timeSuperconductors/hyperconductorsSuperconductor devicesPolyvinyl butyralPropanoic acid

The invention discloses a method for preparing a yttrium barium copper oxide superconducting film with high critical current density, which comprises the following concrete steps: a, preparing a precursor solution, which is to dissolve yttrium acetate, barium acetate, copper acetate and acetate of an impurity element into propionic acid according to the proportion that the stoichiometric ratio of yttrium: barium: copper: impurity element is 1: 2: 3-X: X (the X is more than or equal to 0.0002 and less than or equal to 0.008) to obtain the precursor solution, and the impurity element is one of Co, Fe, Zn, Ni, and Li; b, adding a polymer material polyvinyl butyral (PVB) into the precursor solution obtained in a step to obtain a coating colloid; c, coating and drying the coating colloid on a substrate to form a film; and d, performing thermal decomposition treatment on the substrate with the film prepared in c step and then imaging thermal treatment to obtain the YBCO superconducting film. The yttrium barium copper oxide superconducting film prepared by the method has high biaxial texture, smooth and compact surface, high critical current density under a magnetic field, low cost, and simple process, and is suitable for mass industrial production.

Owner:SOUTHWEST JIAOTONG UNIV

Method for producing single domain yttrium barium copper oxide superconduction block

The invention relates to a method for producing a single domain yttrium barium copper oxide superconduction block. A top-seeded infiltration growing method is adopted to change the ingredients of the solid source powder which is used by the solid block, so that the whole infiltration growing process only needs two precursor powders of YBa2Cu3O7-delta and BaCuO2, the time for preparing the precursor powders is greatly shortened, experimental links are simplified, the experimental period is shortened, the experimental cost is lowered, and the efficiency is increased; and moreover, the single domain yttrium barium copper oxide superconduction block which is prepared by the method has large magnetic suspension buoyancy force, an assembly method that the size of a liquid block is slightly larger than or equals to the size of a solid block is adopted, and the liquid loss, sample collapse, full contact of the solid phase and the liquid phase, crystal growth and oriented growth are benefited.

Owner:SHAANXI NORMAL UNIV

Measurement method of critical current properties of high-temperature superconducting tape

ActiveCN101446612ARealize critical current characteristic measurementMonitor temperatureElectrical testingMagnitude/direction of magnetic fieldsYttrium barium copper oxideVacuum pumping

The invention provides a measurement method of critical current properties of a high-temperature superconducting tape. The measurement method comprises the following steps: a vacuum unit is firstly utilized to carry out vacuum pumping of a low-temperature dewar through a decompression and cooling system, the test temperature range of the superconducting tape with 64K-77K is obtained, a certain DC current is introduced to a coil of a background magnetic field magnet through a current lead wire after reaching the expected temperature, the magnetic induction intensity of air gap can be obtained according to a calibration value, then a rotary handle above the outside of a dewar cover is rotated degree-by-degree at a certain temperature and a certain background magnetic field to drive a sample rack to rotate within the range of 0-90 degrees, the four-probe method is adopted under the different rotation angles, a system control, data acquisition and processing system is utilized to measure the critical current properties of the high-temperature superconducting tape, and a data file is further formed for output. The measurement method can simply and rapidly calculate the temperature, the background magnetic field and the impact factors on the change of the direction of the magnetic field thereof, thereby being applicable to the measurement of the critical current properties of the yttrium barium copper oxide YBCO high-temperature superconducting tape.

Owner:CHINA ELECTRIC POWER RES INST +1

Method for preparing yttrium-barium-copper-oxygen super conductive-film sol-gel

InactiveCN1850723AShorten heat treatment timeEasy to makeSuperconductors/hyperconductorsSuperconductor devicesPorosityOxygen

This invention discloses sol-gel preparation method of yttrium barium copper oxygen superconducting film. The materials are acetic yttrium, acetic barium, acetic copper, their mol ratio is that acetic yttrium 1 part, acetic barium 2 parts, acetic copper 3-4 parts, trifluoroacetic acid 4-10 parts, water 20-160 parts, acrylic acid 6-40, diethylene triamine 1-5, methanol 60-240, benzoyl acetone 1-10. Fluorine content of the sol is low, components are easy to adjust, chemical stability is good, and preparation process is simple. High temperature superconductive film made by this sol is easy to get superconductive thickness film, its technique repeatability is high, this method can be used to make large area yttrium barium copper oxygen film, the film porosity is low, surface purify is good, and good superconducting characteristic.

Owner:XIAN UNIV OF TECH

High throughput continuous pulsed laser deposition process and apparatus

InactiveUS20070116860A1Avoid scratchesAccurate monitoringVacuum evaporation coatingSputtering coatingYttrium barium copper oxideHigh flux

The present invention relates to an apparatus and method for forming a high-temperature superconducting film on a long tape substrate at speeds suitable for large-scale production. The method includes a spooling system for use in a high-throughput, continuous pulsed laser deposition (PLD) process in which a superconducting layer, such as yttrium-barium-copper-oxide (YBCO), is deposited atop a buffered metal substrate tape that is translated through one or more deposition chambers via the action of a reel-to-reel spooling system and a conductive-radiant multi-zone substrate heater. It also optionally includes a multi-target manipulator apparatus and multiple laser beams in which multiple targets are impinged upon simultaneously.

Owner:SUPERPOWER INC

Yttrium barium copper oxide fluorine-free sol and preparation of high temperature superconducting film

InactiveCN101475370AReduce porosityLow porositySuperconductors/hyperconductorsSuperconductor devicesDiethylenetriamineOxygen

The invention discloses a method for preparing yttrium barium copper oxide fluorine-free sol and a high-temperature superconductive membrane. The mol ratio of the following compositions of the fluorine-free sol, namely yttrium acetate to barium acetate or barium hydroxide to copper acetate to diethylenetriamine or ethanolamine or diethanolamine or trolamine to lactic acid to acrylic acid or alpha-methacrylic acid or metacetonic acid to methanol or ethylene glycol monomethyl ether or ethanol, is 1:2:3-4:1.5-5:6-10:6-40:60-360. The method for preparing the superconductive membrane is to adopt different complexing agents to dissolve acetate in a solvent to prepare the yttrium barium copper oxide fluorine-free sol, adopt a crystal pulling method to prepare the fluorine-free sol into a yttrium barium copper oxide gel membrane, perform heat treatment on the gel membrane, and prepare the yttrium barium copper oxide high-temperature superconductive membrane. During preparation of the membrane from the sol, the pyrolysis process is not required; the whole heat treatment time is shortened by approximately 10 hours compared with the prior fluorine-containing technology; and no corrosive HF gas is generated during preparation of the membrane, so that environmental pollution is low.

Owner:XIAN UNIV OF TECH

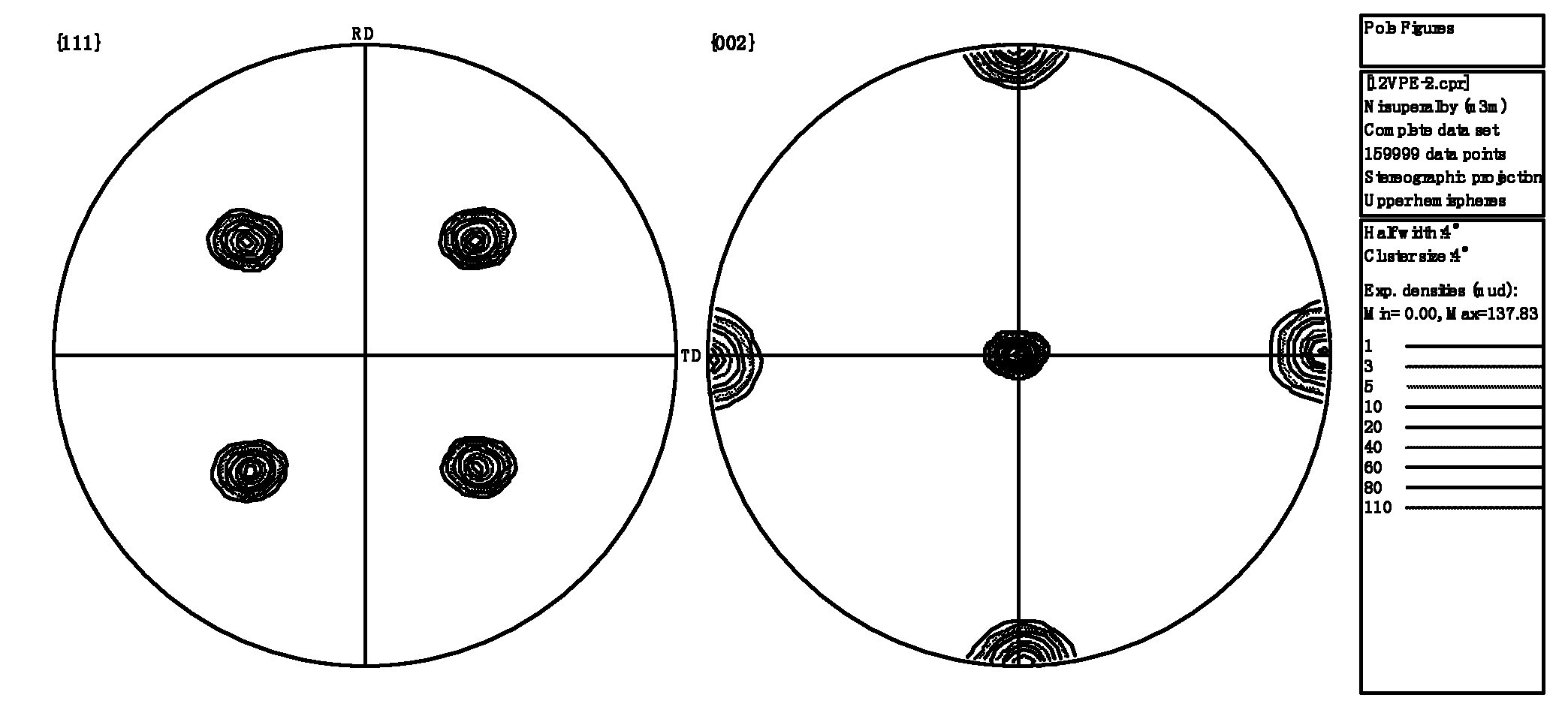

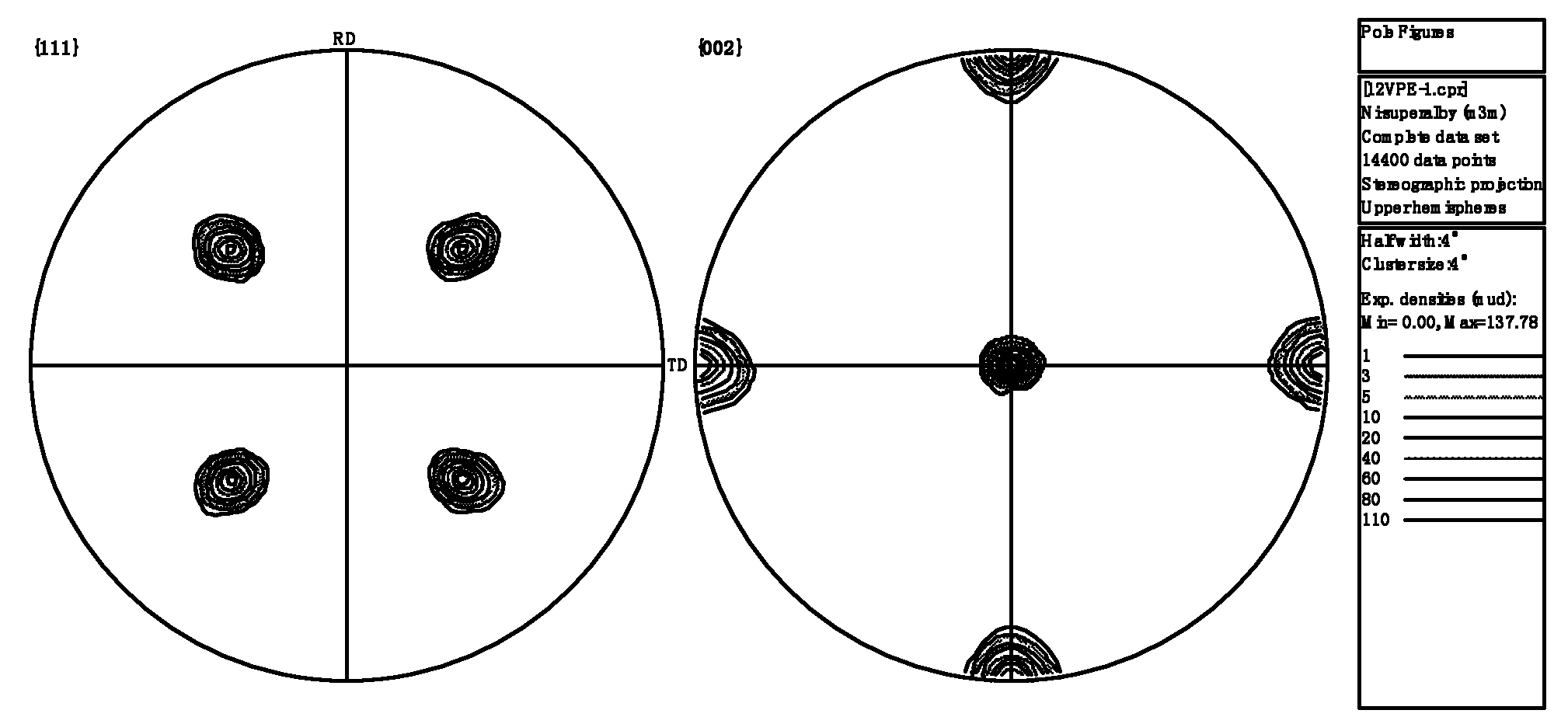

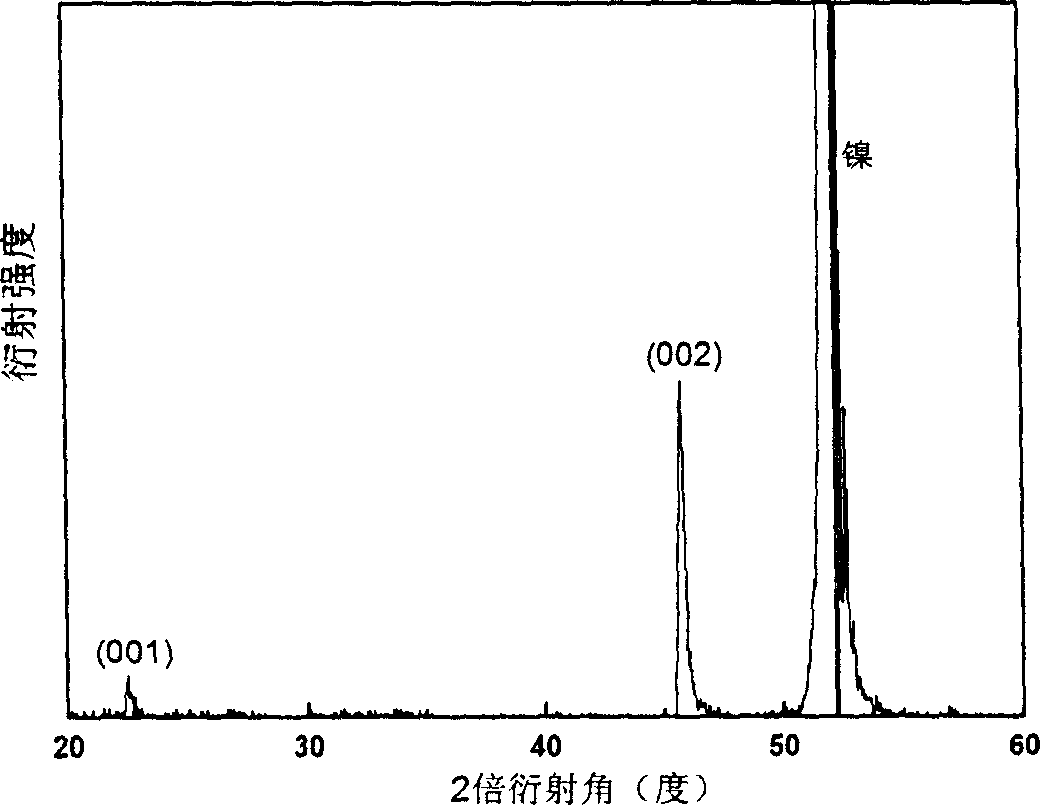

Preparation method of non-magnetic texture NiV alloy baseband

ActiveCN102154577AHigh atomic percentGood cubic textureSuperconductors/hyperconductorsSuperconductor devicesYttrium barium copper oxideElectrical conductor

The invention discloses a preparation method of a non-magnetic texture NiV alloy baseband, belonging to the technical field of high-temperature super-conduction coating conductor metal basebands and aiming to solve the problem that the magnetic performance and the cubic texture of the conventional Ni-W alloy baseband cannot meet the requirement of a YBCO (Yttrium Barium Copper Oxide) coating conductor on further wide application at the same time. The alloy baseband comprises the following components in percentage by atoms: 88-91at.% of Ni and 9-12at.% of V. In the preparation method, a powdermetallurgical method is adopted. The preparation method comprises the following steps of: (1) mixing initial powder and filling a mold; (2) preparing initial alloy billets; (3) deforming and rolling the initial billets; and (4) recrystallizing and thermally treating the cold-rolled baseband. The alloy baseband has the characteristics of non-magnetism, high cubic texture and the like.

Owner:深创超导(深圳)科技有限公司

Method for preparing single-domain yttrium barium copper oxide bulk superconductor by taking Y2BaCuO5 as base material

InactiveCN103979951AStable supportChange the initial ratioYttrium barium copper oxideMaterials science

The invention discloses a method for preparing a single-domain yttrium barium copper oxide bulk superconductor by taking Y2BaCuO5 as a base material. The method comprises the steps of preparing Y2BaCuO5 precursor powder; preparing liquid-phase source powder; pressing a precursor block; assembling the precursor block; infiltrating and growing a single-domain yttrium barium copper oxide bulk; carrying out oxygen infiltration treatment. BaCuO2 precursor powder is replaced with initial powder of BaO and CuO, so that only the Y2BaCuO5 precursor powder is needed in the whole infiltrating and growing processes, experimental links are simplified, experimental periods are shortened, and the preparation efficiency is increased. A supporting block pressed by using the Y2BaCuO5 precursor powder can be used for stably supporting two blanks on the supporting block in the slowly-cooled growing process of the yttrium barium copper oxide bulk, avoiding liquid-phase loss and avoiding the condition that the initial ratio of liquid-phase source bulks is changed because part of liquid is absorbed by the supporting block, so that the integral growth and superconductivity of the bulk are ensured. The method can be used for preparing the yttrium barium copper oxide bulk superconductor and other series of bulk high temperature superconductors such as Gd, Sm, Nd and the like.

Owner:TIANJIN NORMAL UNIVERSITY

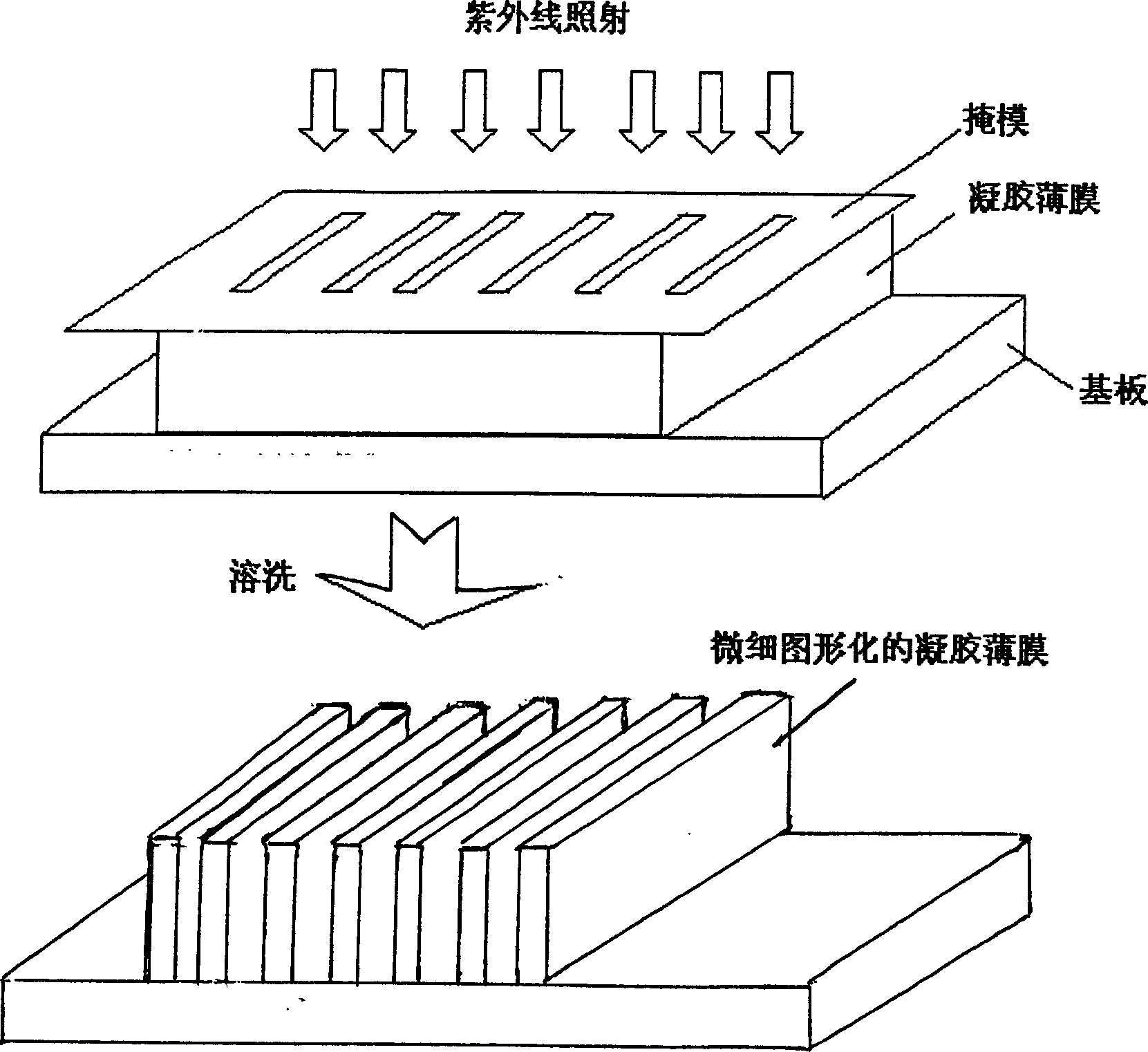

Method for preparing Yt-Ba-Cu-O high-temperature superconductive film fine-pattern

InactiveCN1851951APerformance is not affectedRegular graphicsSuperconductors/hyperconductorsSuperconductor device manufacture/treatmentYttrium barium copper oxideChemical modification

This invention discloses a preparation method for micrograph of YBCO high temperature and superconductive films, which utilizes YBCO gel with sensitive property and applies a micro-process method combining a chemical modification method and a Sol-Gel method to prepare the graph period reaching to the mum level.

Owner:XIAN UNIV OF TECH

Method for improving critical current for continuously preparing YBCO (Yttrium Barium Copper Oxide) strip

ActiveCN102560378BSolve the problem of increasing cubic texture variationImprove uniformityVacuum evaporation coatingSputtering coatingYttrium barium copper oxideOptoelectronics

The invention relates to a method for improving a critical current for continuously preparing a YBCO (Yttrium Barium Copper Oxide) strip, which comprises the following steps of: (1) in a vacuum chamber of equipment for continuously preparing a YBCO superconducting layer, fixing a metal substrate on a guide belt; (2) using YBCO as a target material, wherein the target-substrate distance is in the range of 40 to 60mm; (3) regulating a laser optical path before vacuumizing; (4) when the vacuum degree in the vacuum chamber is superior to 3*10<-4>Pa, heating the metal substrate to the temperature of 750 to 770 DEG C and controlling the pure oxygen atmosphere into 20 to 30Pa; (5) depositing a first layer of YBCO thin film under the laser frequency of 10 to 20Hz and at the traveling speed of 0.1 to 0.4mm / s, then depositing a plurality of layers of YBCO thin films, and when depositing the next layer of YBCO thin film every time, respectively rising the temperature of the metal substrate in the process of depositing the previous layer of YBCO thin film by 10 to 20 DEG C and depositing the next layer of YBCO thin film under the laser frequency of 10 to 40 Hz and at the traveling speed of 0.1 to 0.2mm / s; and (6) carrying out in-situ annealing to prepare the YBCO superconducting layer. According to the invention, the layered deposition is adopted, the temperature is properly risen between the layers, the problem of variation of a cube texture of the YBCO layer along with the increase of the thickness is solved, and the superconducting performance is effectively improved.

Owner:GRIMAT ENG INST CO LTD

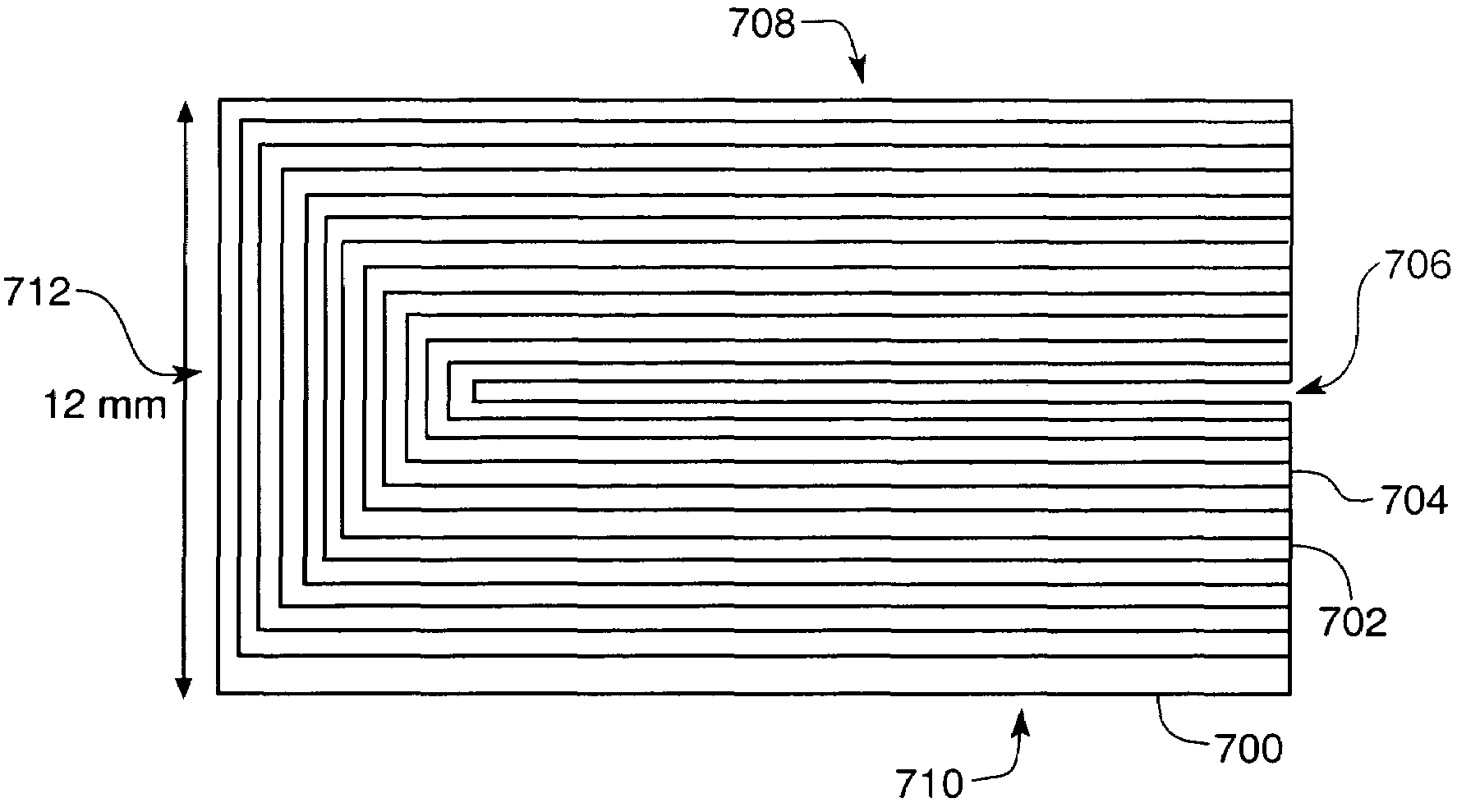

Machinery windings of yttrium barium copper oxide and related coated conductor

InactiveUS7566684B1Improve performanceSuperconductors/hyperconductorsDeferred-action cellsYttrium barium copper oxideElectrical conductor

A superconductor coating inclusive, tape-like electrical conductor and windings using such conductor for magnets and electrical machines, etc. The described windings are suited for inclusion of successor superconductor materials such as yttrium barium copper oxide wherein magnetic flux related losses can potentially be excessive and preclude successful machine operation. Winding orientation and configuration of the conductor in an alternating current machine for lower losses are disclosed along with methods and apparatus for achieving the desired windings. Windings intended for differing locations within a machine of this type are made possible by the invention. Equations relating to magnetic losses incurred in such windings are also disclosed.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

Yttrium barium copper oxide superconducting thin film mixed with samarium and manufacture method thereof

InactiveCN102491740AGood c-axis textureGood in-plane and out-of-plane textureYttrium barium copper oxideChemical composition

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Method for preparing specific mixed-orientation YBCO (Yttrium Barium Copper Oxide) high-temperature superconducting thick film

InactiveCN103276447ASimple processEasy to operatePolycrystalline material growthSingle crystal growth detailsYttrium barium copper oxideHigh temperature superconducting

The invention discloses a method for preparing a specific mixed-orientation YBCO (Yttrium Barium Copper Oxide) high-temperature superconducting thick film. The method comprises the following steps: 1) preparing Ba-Cu-O-phase precursor powder; 2) adding the Ba-Cu-O precursor powder in a Y2O3 crucible in a crystal growing furnace; heating to the first temperature for heat preservation, and obtaining a Y-Ba-Cu-O solution; 3) adding the Ba-Cu-O-phase precursor powder in the high-temperature solution, and preserving heat; 4) cooling the solution to the second temperature at a first cooling speed; and 5) inserting a seed crystal material fixed at a connecting rod into the solution obtained in the step 4) for liquid phase epitaxial growth to obtain the specific mixed-orientation YBCO high-temperature superconducting thick film. As the Ba-Cu-O powder is added again at the high-temperature period, the Y-Ba-Cu-O solution achieves a state of lower degree of supersaturation in a metastable region to grow the YBCO liquid-phase epitaxial film with consistent orientation and a mixed grain boundary structure. The process is simple, and the operation is convenient.

Owner:SHANGHAI JIAO TONG UNIV

Y-Ba-Cu-O coating conductor with conducting buffer layer and preparing process

InactiveCN1905081ASmall lattice mismatchQuality improvementNon-insulated conductorsSuperconductors/hyperconductorsStrontium titanateElectrical conductor

The invention relates to yttrium barium copper oxygen coating conductor with conduct buffer layer. It includes adulterated strontium titanate conduct buffer layer and YBCO superconducting layer. The former includes niobium strontium titanate SrTi1-xNbxO3, indium strontium titanate SrTi1-xInxO3, or lanthanum strontium titanate Sr1-xLaxTiO3 which x is between 5mol% and 30mol%. Its manufacturing method includes the following steps: using pulsed laser deposition technique to adjust pressure at 1-5Pa in reaction chamber, substrate temperature at 700-800 degree centigrade, conductive film deposition thickness at 30-50nm; pumping out the mixed gas from the reaction chamber; filling 10-2Pa oxygen with 99.99% purity; keeping the temperature not change; making the deposition thickness of the adulterated strontium titanate conductive film at 100-500nm.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

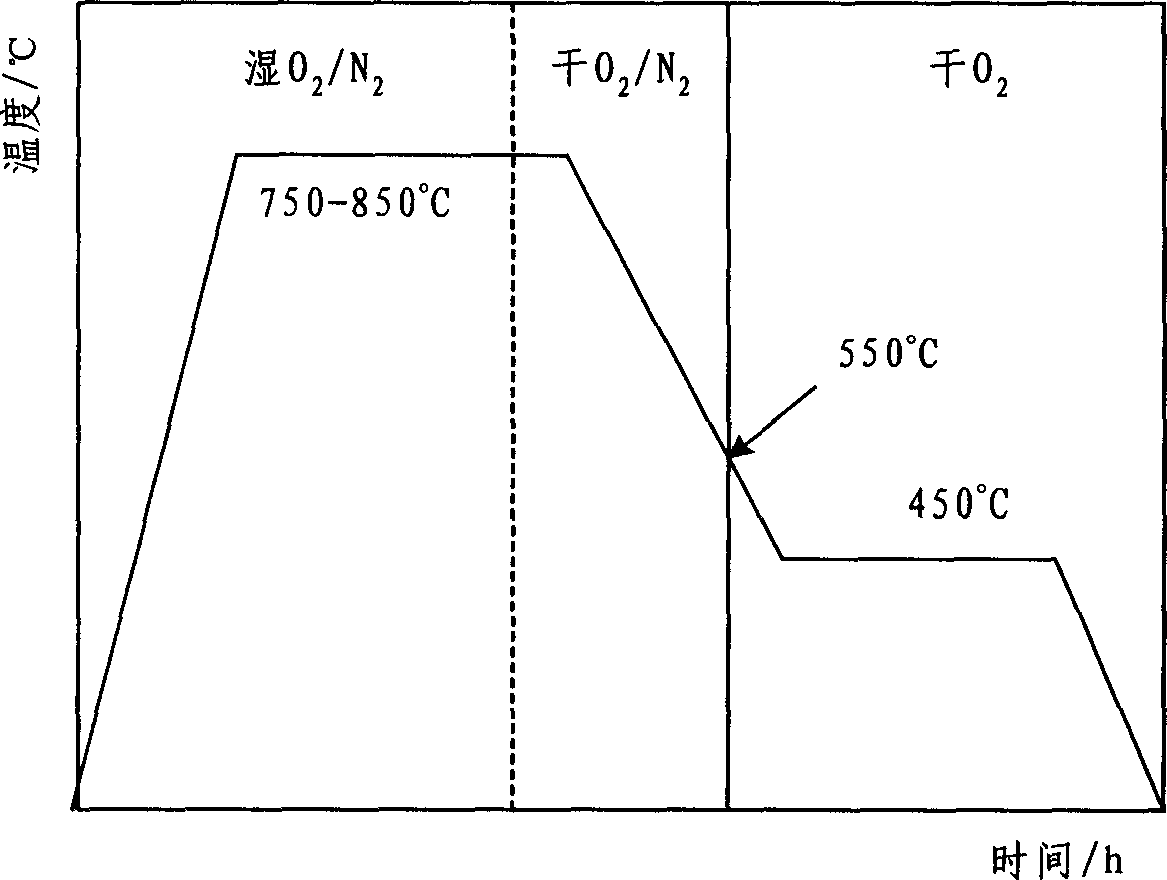

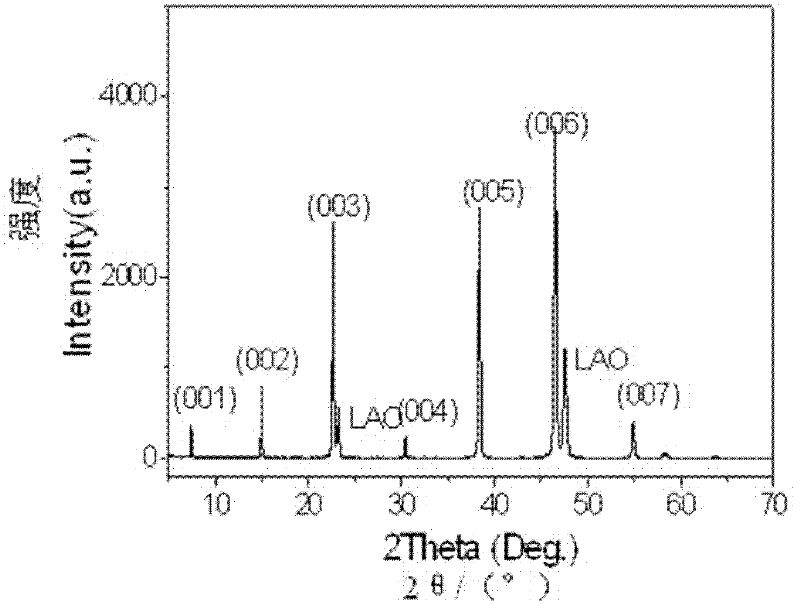

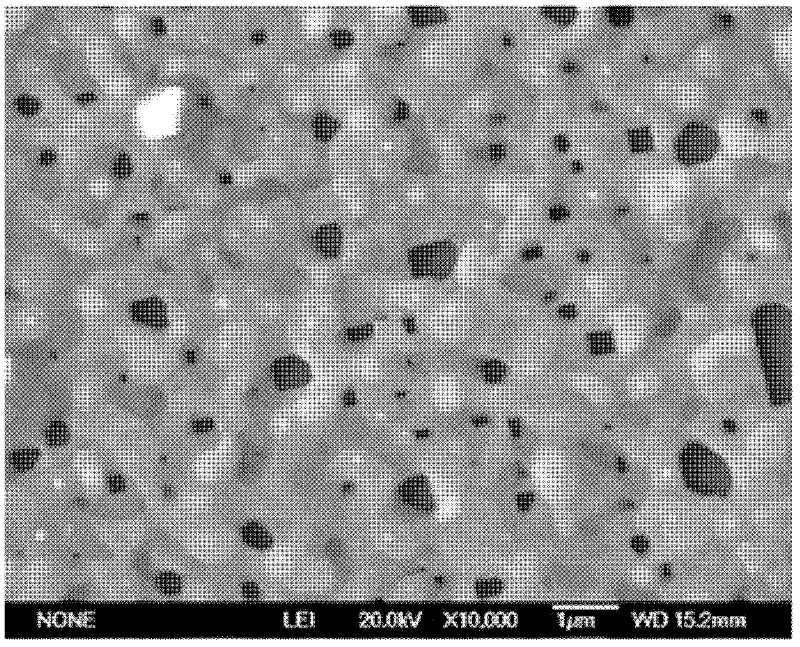

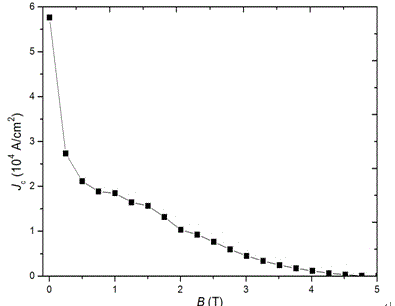

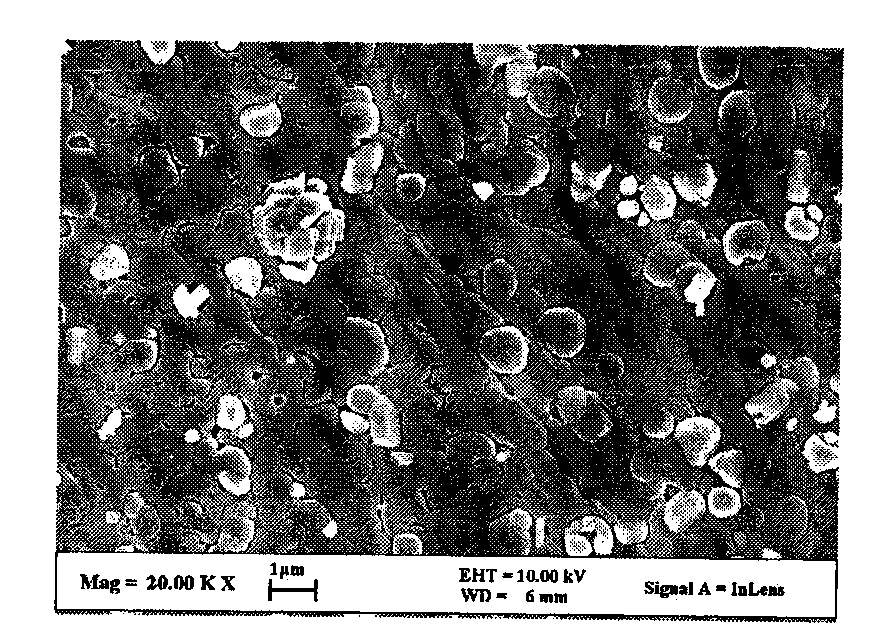

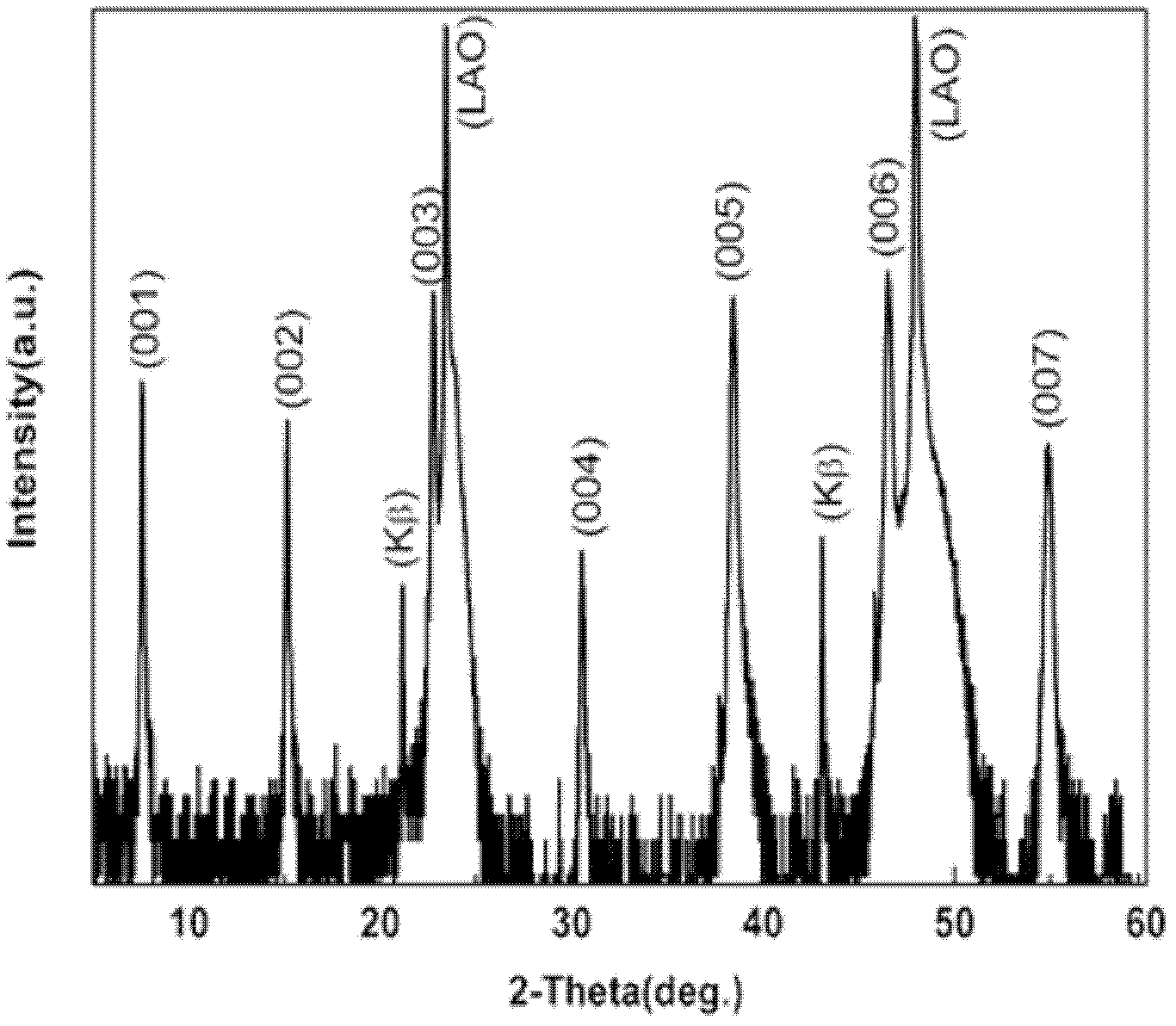

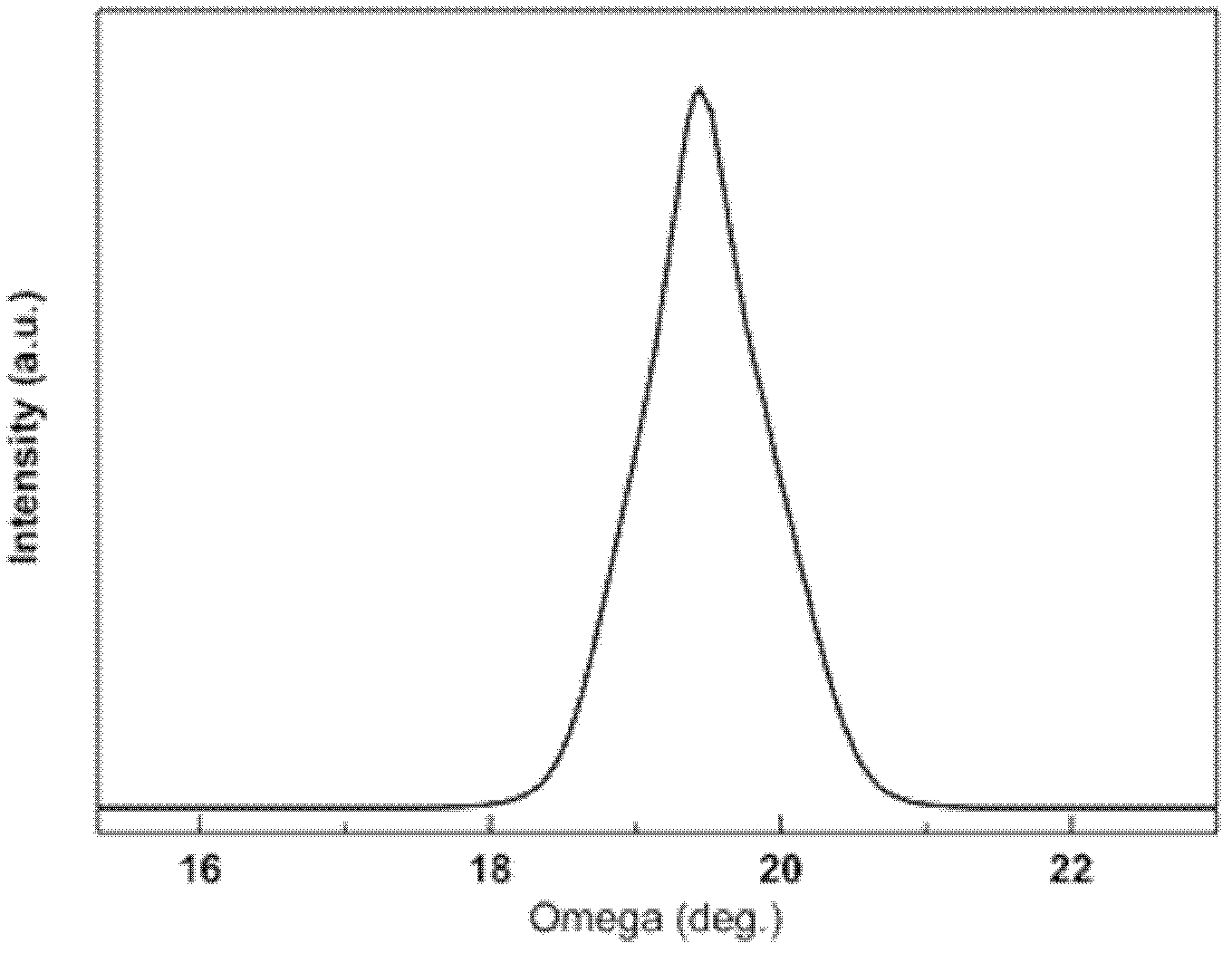

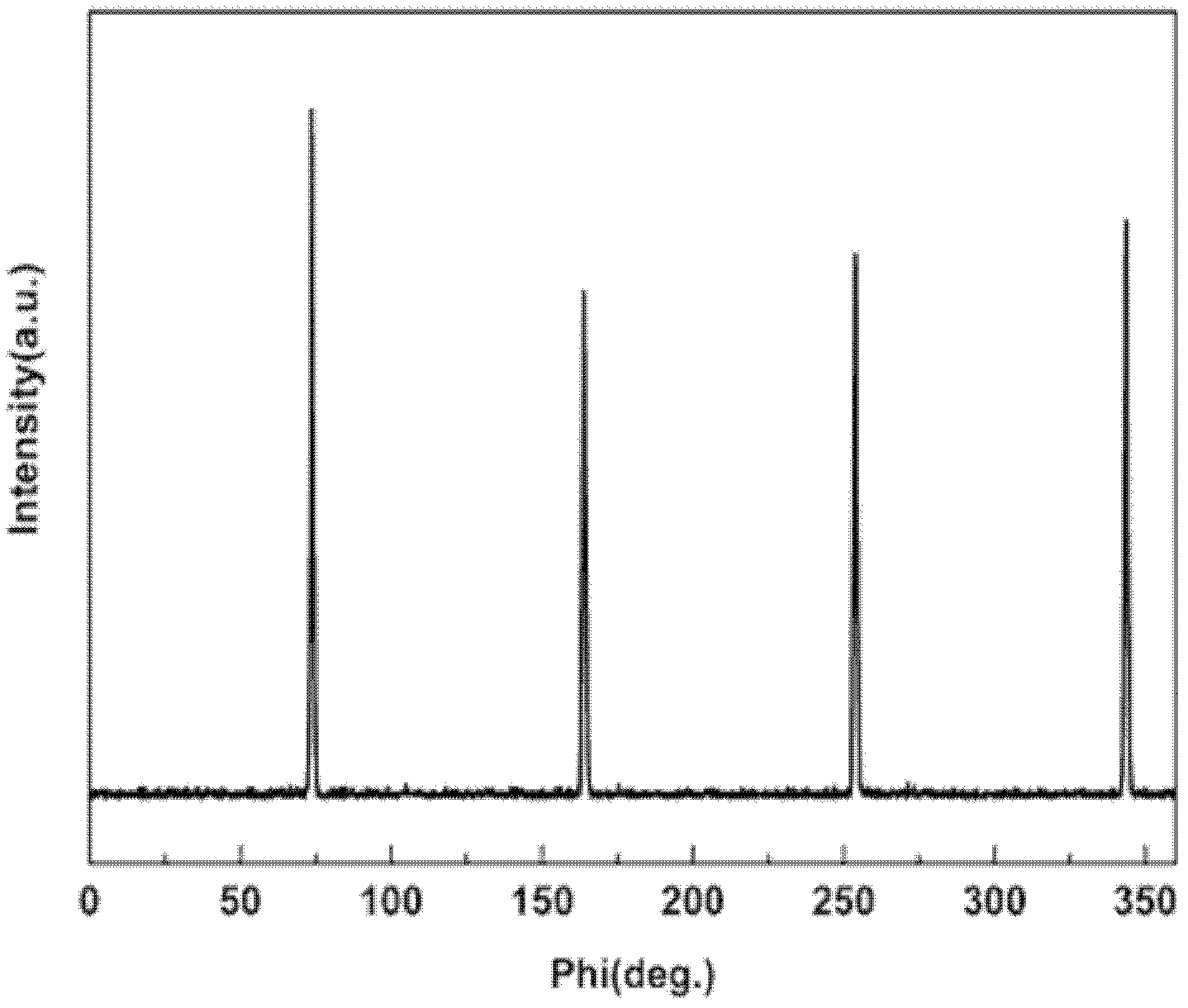

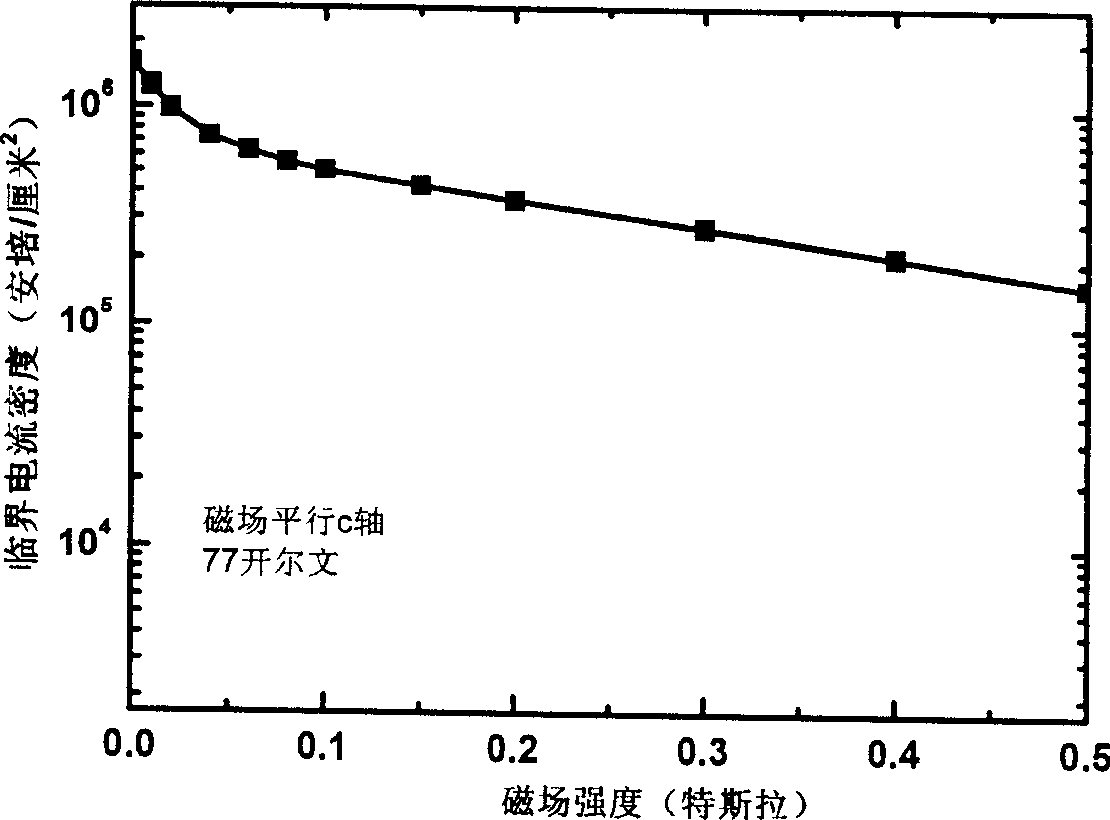

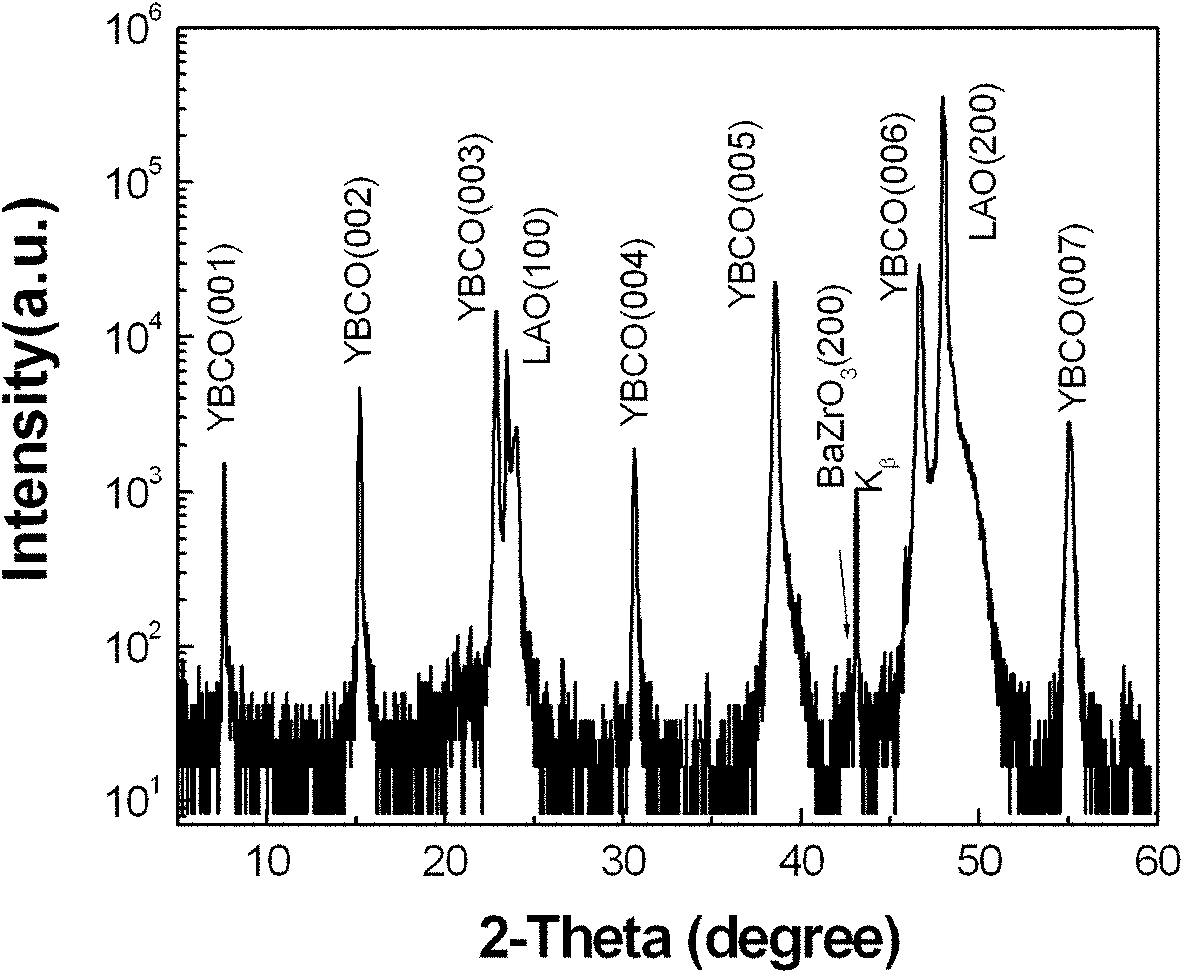

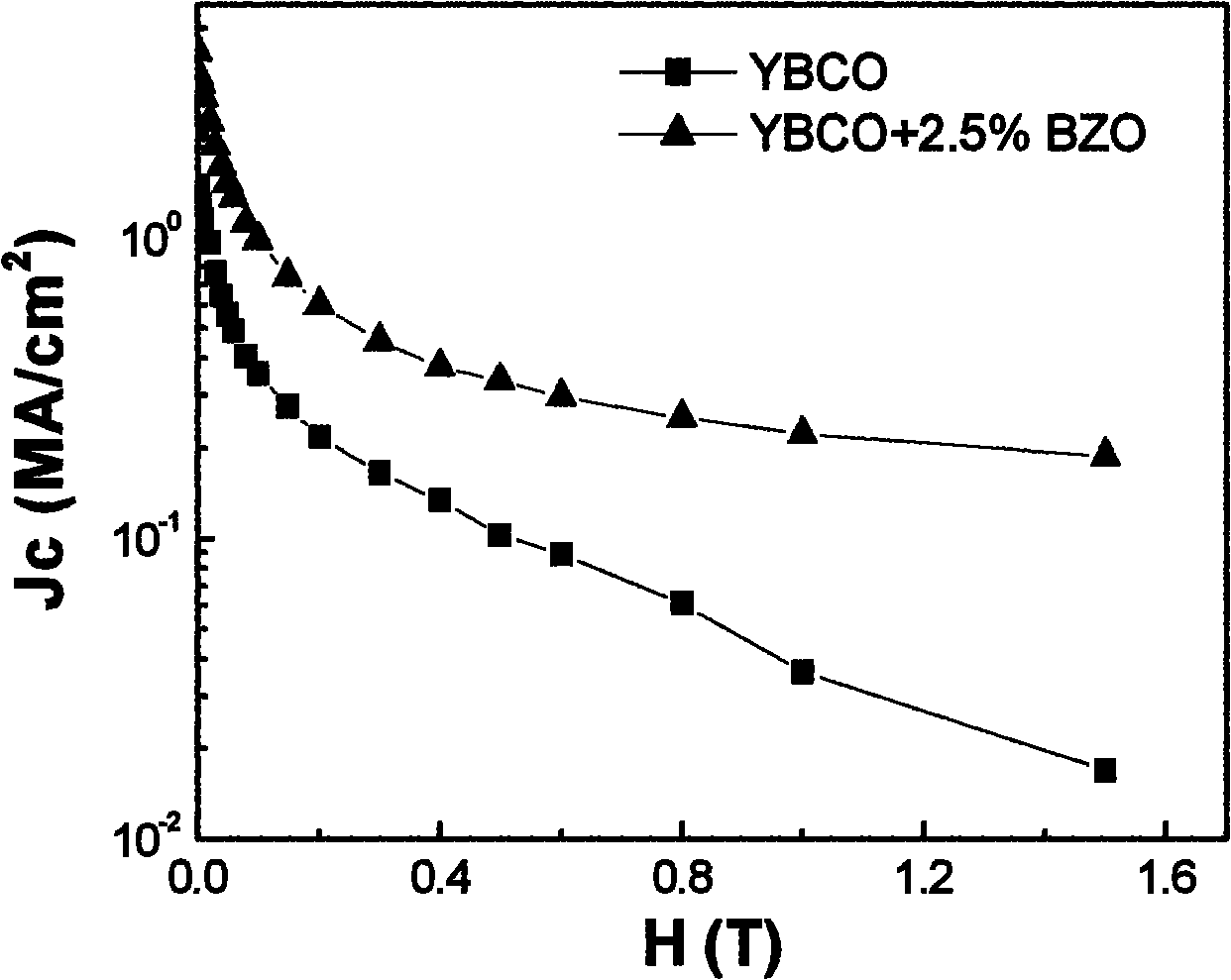

Second-phase nanoparticle doped YBCO (yttrium barium copper oxide) film and preparation method thereof

ActiveCN102142300AEvenly dispersedJc performance improvementSuperconductors/hyperconductorsSuperconductor devicesYttrium barium copper oxideSingle crystal substrate

The invention discloses a second-phase nanoparticle doped YBCO (yttrium barium copper oxide) film and a preparation method thereof. The film is composed of the following compositions in percentage by mass: 0.1-5% of second-phase nanoparticles and the balance of YBCO, wherein the second-phase nanoparticle is BaZrO3, BaHfO3 or Y2BaCuO5. The method for preparing the film comprises the following steps: 1, preparing a second-phase nanoparticle doped YBCO precursor solution; 2, uniformly coating the second-phase nanoparticle doped YBCO precursor solution on a lanthanum aluminate single crystal substrate; 3, carrying out low temperature pyrolysis on the obtained product; 4, carrying out high temperature crystallization and oxygen diffusion processing on the object obtained in the step 3 so as to obtain the second-phase nanoparticle doped YBCO film. The preparation method disclosed by the invention is easy to operate, simple in experimental facility, low in cost, and capability of satisfying the requirements of industrial production. Compared with a pure YBCO film, the Jc performance of the prepared second-phase nanoparticle doped YBCO film is obviously improved under a magnetic field.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

YBCO thick film resistor slurry

InactiveCN101727997AAdjustable resistanceStable resistanceConductive materialNon-conductive material with dispersed conductive materialAir atmosphereYttrium barium copper oxide

The invention relates to low-cost base metal oxide thick film resistor slurry which is formed by uniformly mixing a conductive phase (a YBCO series material), an inorganic cementing phase (glass powder or Bi oxide powder or Pb oxide powder) and an organic binder. The glass powder in the inorganic cementing phase is SiO2-Bi2O3-Na2O-CaO-Al2O3 series glass, and the glass powder comprises the following raw materials in percentage by weight: 20-80 percent of SiO2, 10-90 percent of Bi2O3, 5-20 percent of Na2O, 5-30 percent of CaO and 1-15 percent of Al2O3; the organic binder comprises the following components in percentage by weight: 20-98 percent of tributyl citrate, 1-30 percent of terpineol, 1-10 percent of pyroxylin, 0.1-6 percent of lecithin and 0.1-6 percent of bentonite. The proportion by weight of the conductive phase YBCO and the inorganic cementing phase (glass powder or Bi2O3 or PbO powder) can be adjusted according to required resistors and resistance temperature coefficients, and the range of the proportion by weight is 40-85: 60-15. The thick film resistor slurry can be burnt into a thick film resistor in the air atmosphere at the temperature of 500-1000 DEG C, the resistance can be adjusted within the range of 25-1000K(omega / port), the resistance value is stable, and the thick film resistor has lower cost than a traditional noble metal thick film resistor.

Owner:银锐明

Method for the production of superconducting electrical conductor

InactiveCN101192643AEasy to processSuperconductors/hyperconductorsSuperconductor device manufacture/treatmentYttrium barium copper oxideElectrical conductor

The invention provides a method for the production of a superconducting electrical conductor. The method involves applying an yttrium-barium-copper oxide (YBCO) layer on a textured metallic substrate as superconductive material, and performing thermal treatment. To produce a wire conductor, a slot tube (3) is formed from the textured metallic substrate longitudinally around an elongated metallic carrier (1) with a circular transverse cross-section where the textured metallic substrate is provided as a band (2). The slot tube has edges extending longitudinally and adjacent with each other at the slot part (4).The slot tube (3) is closed by welding the slot (4), and a closed tube (9) is dragged up to adhere to the carrier (1). An yttrium-barium-copper oxide layer is applied around the tube and finally a heat treatment is accomplished.

Owner:NEXANS

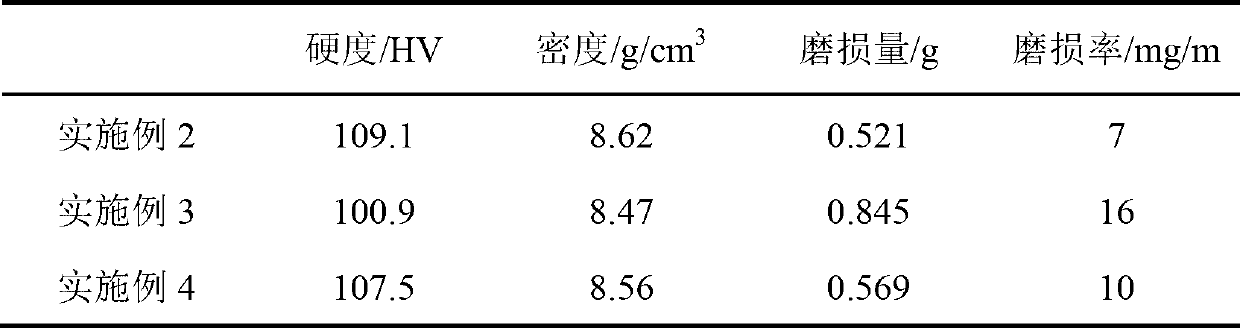

Copper-based self-lubricating composite material and preparation method thereof

ActiveCN102994799AHas superconducting propertiesThermally stableMaterials processingSuperconductivity

The invention discloses a copper-based self-lubricating composite material and a preparation method of the copper-based self-lubricating composite material, and belongs to the technical field of material processing and powder metallurgy. The composite material comprises the following components in percentage by weight: 2 to 4% of yttrium barium copper oxide (YBa2Cu3O7-x), and the balance of copper and inevitable impurities, wherein the yttrium barium copper oxide (YBa2Cu3O7-x) is a good solid lubricant and has the characteristics of superconductivity, thermal stability, friction reducing performance and wear resistance. According to the copper-based self-lubricating composite material and the preparation method, the YBa2Cu3O7-x powder with granularity of 20 to 500 nanometers and the copper powder screened by a sieve of 500 meshes are preferred; the raw materials are mixed and initially pressed, and then processed by the technical means combining processes of sectional heating, sectional pressurizing, sectional cooling and pressurizing, and therefore, the density of the structure of the composite material is improved, the defects such as air holes and cracks are prevented in the composite material; and the prepared composite material is excellent in physical properties, mechanical properties and frictional wear performance.

Owner:HENAN UNIV OF SCI & TECH

Preparation method of nano composite ytrium barium copper oxide superconducting bulks

InactiveCN104725035AImprove superconductivityImprove efficiencySuperconductors/hyperconductorsSuperconductor devicesYttrium barium copper oxideCopper oxide

The invention discloses a preparation method of nano composite ytrium barium copper oxide superconducting bulks, which comprises the steps of preparing solid phase powder, preparing liquid phase source powder, pressing precursor bulks, assembling the precursor bulks, carrying out infiltrated growth on nano composite ytrium barium copper oxide single-domain bulks, and carrying out oxygen permeation treatment. By taking a mixture of Y2O3 nano powder, BaCuO2 precursor powder and CeO2 initial powder as solid phase powder, after high-temperature infiltration and slowly-cooled growth are performed, nanoscale Y2BaCuO5 particles are successfully introduced into ytrium barium copper oxide superconducting bulks, so that higher superconducing properties are obtained. By taking a mixture of Yb2O3, and BaO, CuO initial powder as liquid phase source powder, the whole infiltrated growth process is implemented by only using BaCuO2 precursor powder, so that the method is simple in process and high in efficiency. The invention also can be used for preparing nano composite superconducting materials of Nd, Sm and Gd series and the like.

Owner:TIANJIN NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com