Copper-based self-lubricating composite material and preparation method thereof

A composite material and self-lubricating technology, which is applied in the field of material processing and powder metallurgy, can solve the problems of complex preparation process, high porosity and low density of composite materials, so as to improve the compactness of the structure, good wear resistance and avoid pores Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The present embodiment copper base self-lubricating composite material is made up of the following components by weight percentage:

[0030] 2.5% Yttrium Barium Copper Oxide (YBa 2 Cu 3 o 7-x ),

[0031] The balance is copper, and unavoidable impurities.

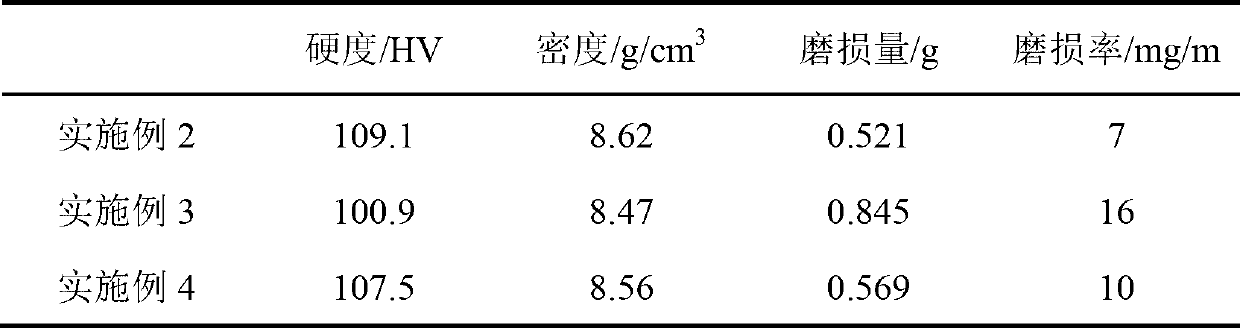

Embodiment 2

[0033] The present embodiment copper base self-lubricating composite material is made up of the following components by weight percentage:

[0034] 2% Yttrium Barium Copper Oxide (YBa 2 Cu 3 o 7-x ) powder with a particle size of 20nm and an x value of 0

[0035] The balance is copper powder (commercially available), and the copper powder is passed through a 500-mesh sieve.

[0036] and unavoidable impurities.

[0037] In this embodiment, yttrium barium copper oxide (YBa 2 Cu 3 o 7-x ) The preparation method of powder comprises the steps:

[0038] (1) Weigh Y(NO 3 ) 3 , Ba(NO 3 ) 2 , Cu(NO 3 ) 2 , add water and dissolve to obtain an aqueous solution, add polyethylene glycol accounting for 3% of the total mass of the three raw materials to obtain solution A, and then prepare an aqueous solution with a concentration of 0.06g / ml as solution B with oxalic acid;

[0039] (2) Add solution B to solution A drop by drop and mix evenly. Add too much solution B so that Y ...

Embodiment 3

[0047] The present embodiment copper base self-lubricating composite material is made up of the following components by weight percentage:

[0048] 2.5% Yttrium Barium Copper Oxide (YBa 2 Cu 3 o 7-x ) powder with a particle size of 300nm and an x value of 0.3,

[0049] The balance is copper powder, and the copper powder passes through a 500-mesh sieve.

[0050] and unavoidable impurities.

[0051] In this embodiment, yttrium barium copper oxide (YBa 2 Cu 3 o 7-x ) The preparation method of powder comprises the steps:

[0052] (1) Weigh Y(NO 3 ) 3 , Ba(NO 3 ) 2 , Cu(NO 3 ) 2 , add water and dissolve to obtain an aqueous solution, add polyethylene glycol accounting for 4% of the total mass of the three raw materials to obtain solution A, and then prepare an aqueous solution with a concentration of 0.08g / ml as solution B with oxalic acid;

[0053] (2) Add solution B to solution A drop by drop and mix evenly. Add too much solution B so that Y 3+ 、Ba 2+ 、Cu 2+ Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com