Patents

Literature

2515results about How to "Good suspension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cast form water borne coating and technique for preparing the same

InactiveCN101497105AGood water dispersibilityGood suspensionFoundry mouldsFoundry coresDefoaming AgentsCorrosion

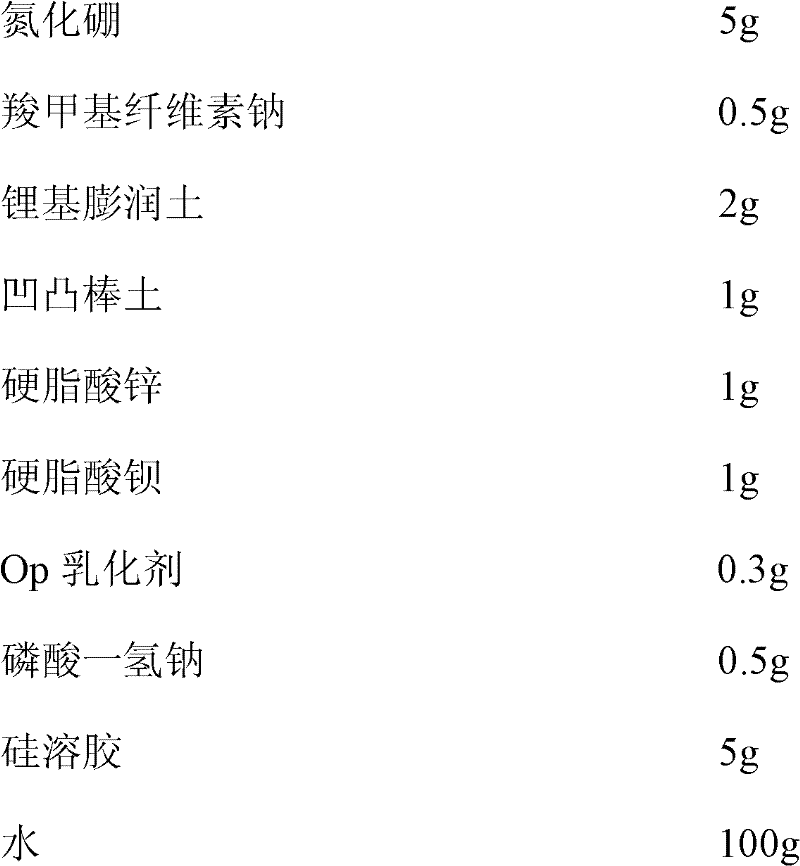

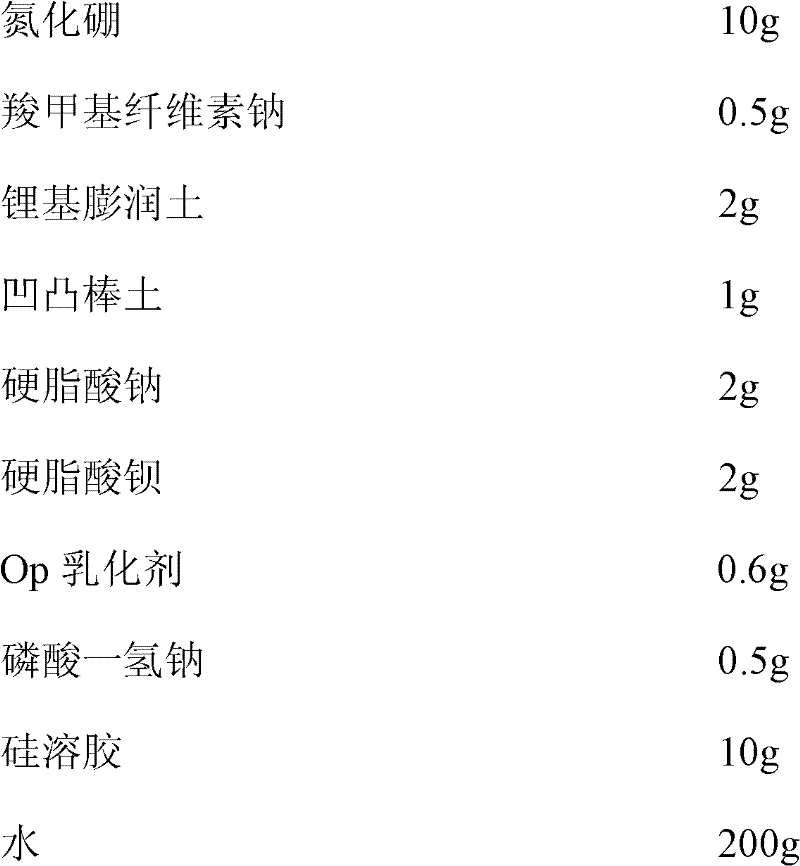

The invention relates to an auxiliary material for casting a mould, in particular to a casting mould water-based coating formulation for a sand mould or an expendable pattern casting (EPC), and a process for preparing the same. The casting mould water-based coating formulation consists of refractory powder, a suspending agent, a bonding agent, a surfactant, a defoaming agent, a corrosion remover and water. The process comprises the following steps: adding the suspending agent to the water directly, and mixing and dispersing the mixture in a high speed dispersion machine; adding auxiliary agents including the defoaming agent, the surfactant, the corrosion remover, and the like to the water, and mixing the auxiliary agents; adding the refractory powder to the mixture to be mixed; and adding the bonding agent to the mixture to be mixed, and then adding water to adjust the coating until the coating has the thickness in a using state to obtain the finished product. The coating prepared by the process has the effects that the coating ensures that a high-density low-viscosity coating has excellent suspension property and storage stability, a coating layer is not easy to crack after drying, the coating is advantageous to improve the capacity of the coating to resist high temperature metal corrosion, and the like.

Owner:深圳市景鼎现代科技有限公司

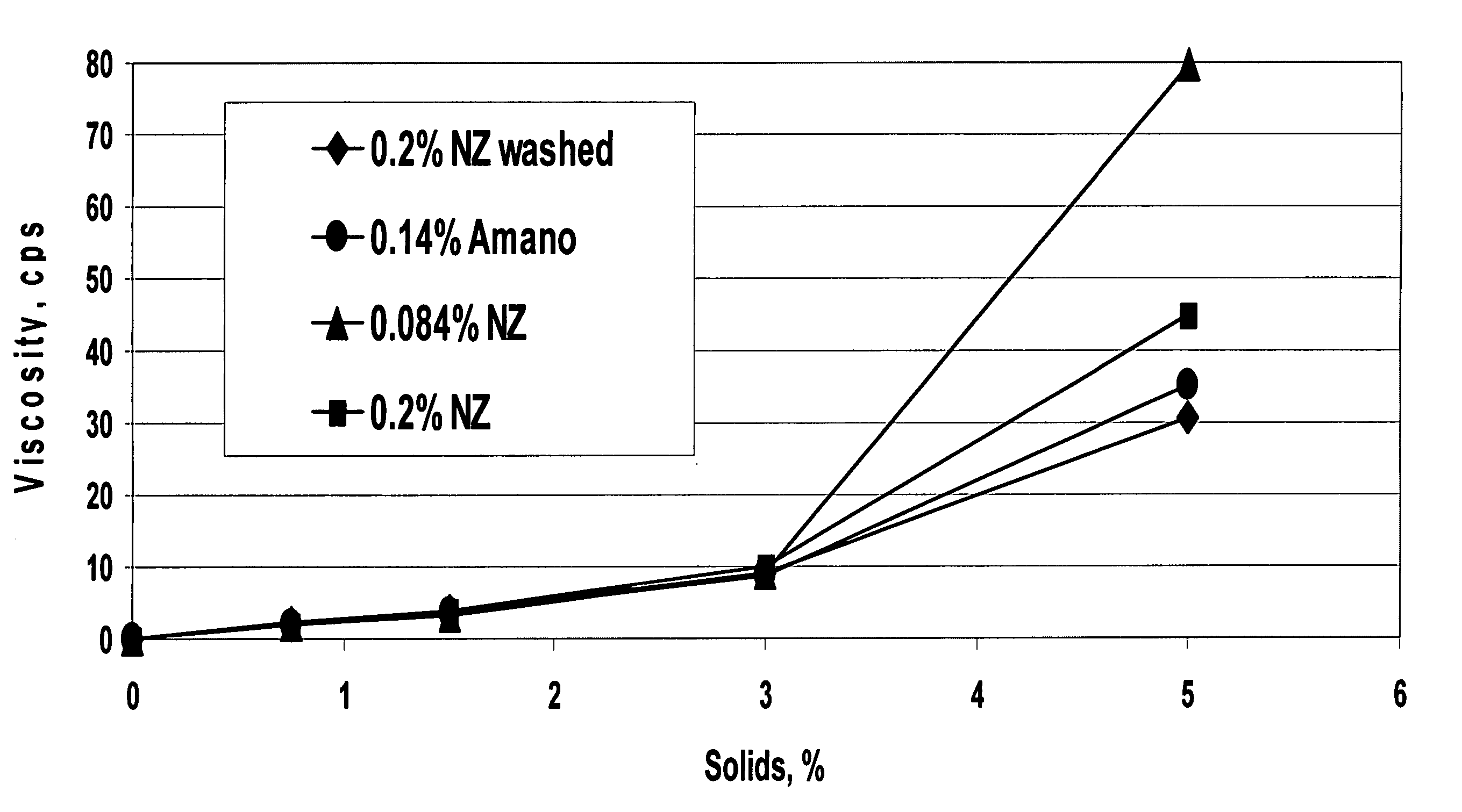

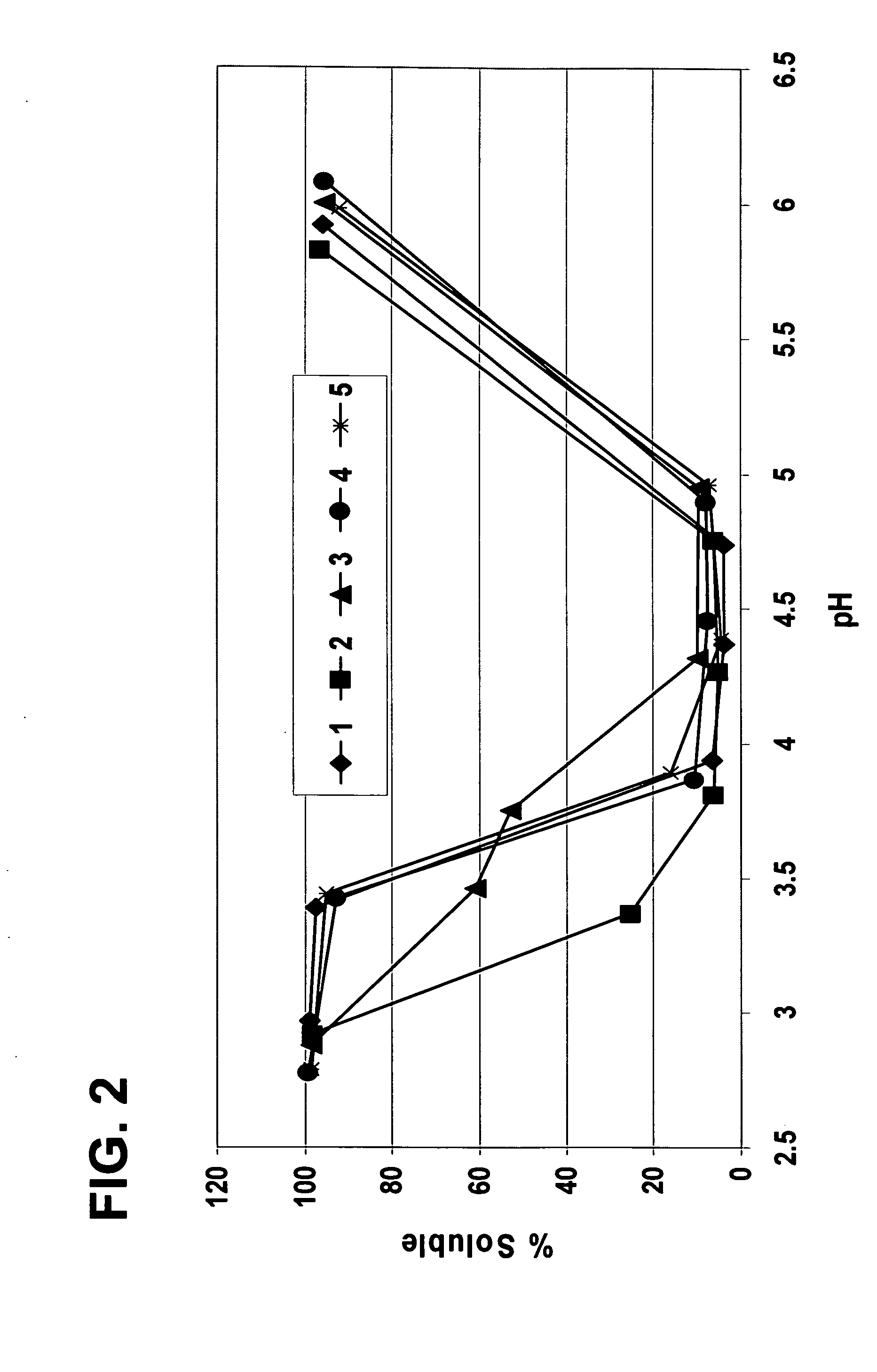

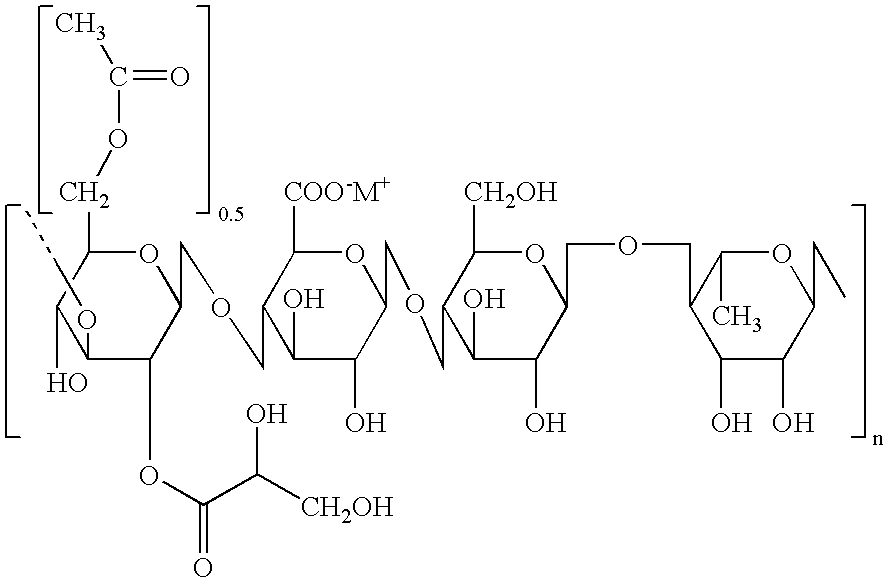

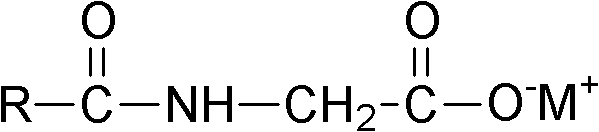

Formulations of 3-(6-(1-(2,2-difluorobenzo[d][1,3]dioxol-5-yl) cyclopropanecarboxamido)-3-methylpyridin-2-yl)benzoic acid

InactiveUS20090176839A1Improve propertyIncrease viscosityBiocideSenses disorder3-MethylpyridineBenzoic acid

The present invention relates to formulations of 3-(6-(1-(2,2-difluorobenzo[d][1,3]dioxol-5-yl)cyclopropanecarboxamido)-3-methylpyridin-2-yl)benzoic acid, pharmaceutical packs or kits thereof, and methods of treatment therewith.

Owner:VERTEX PHARMA INC

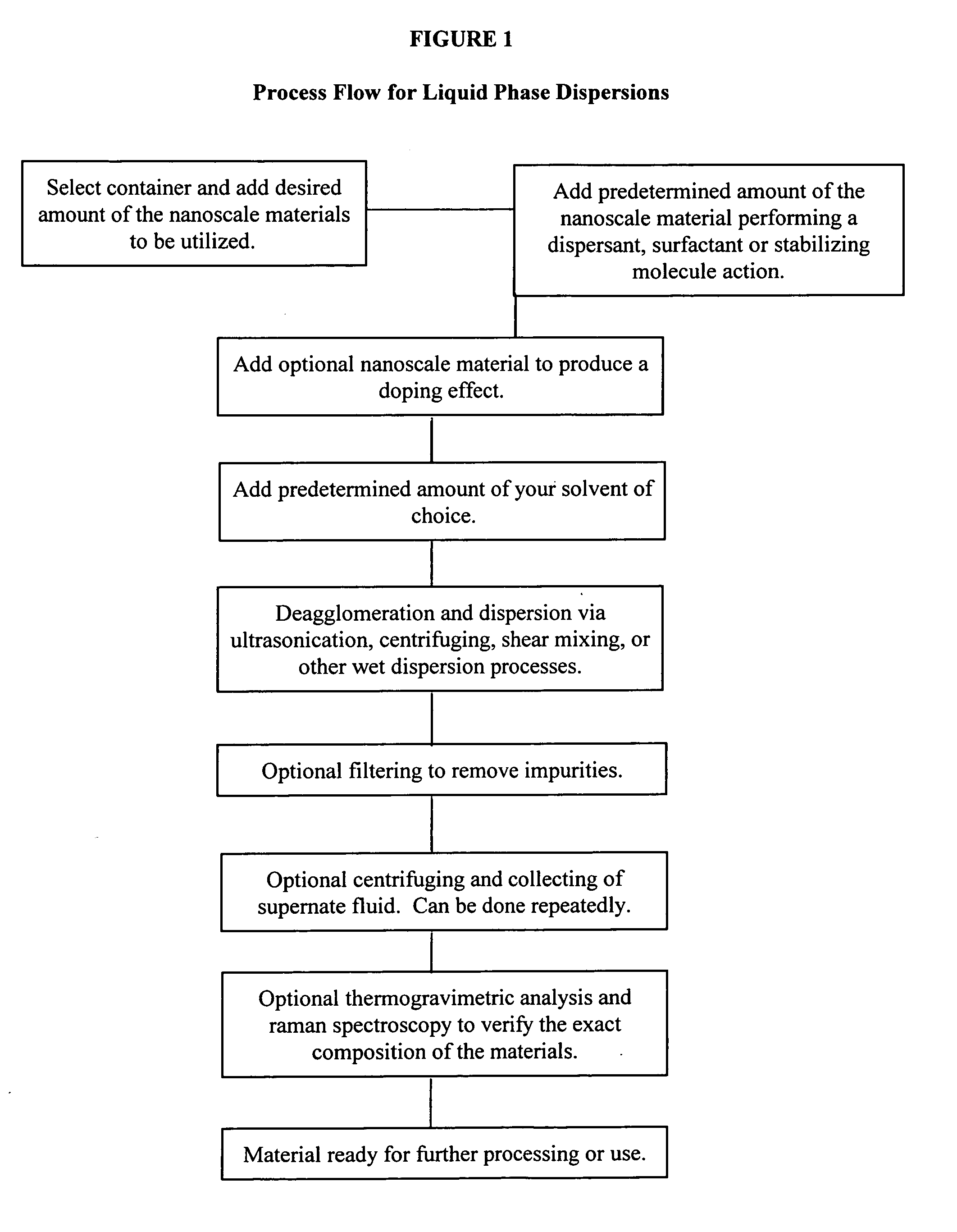

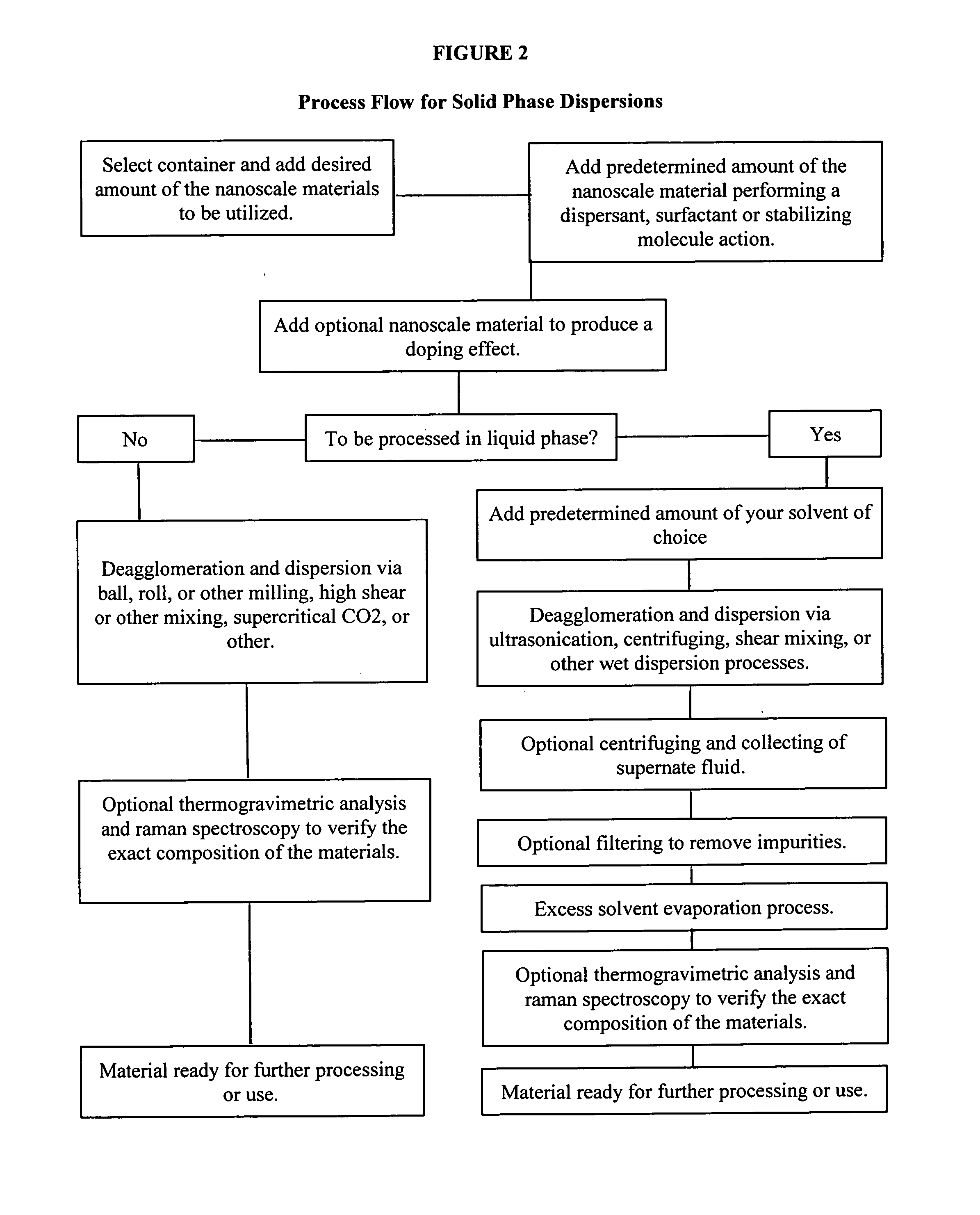

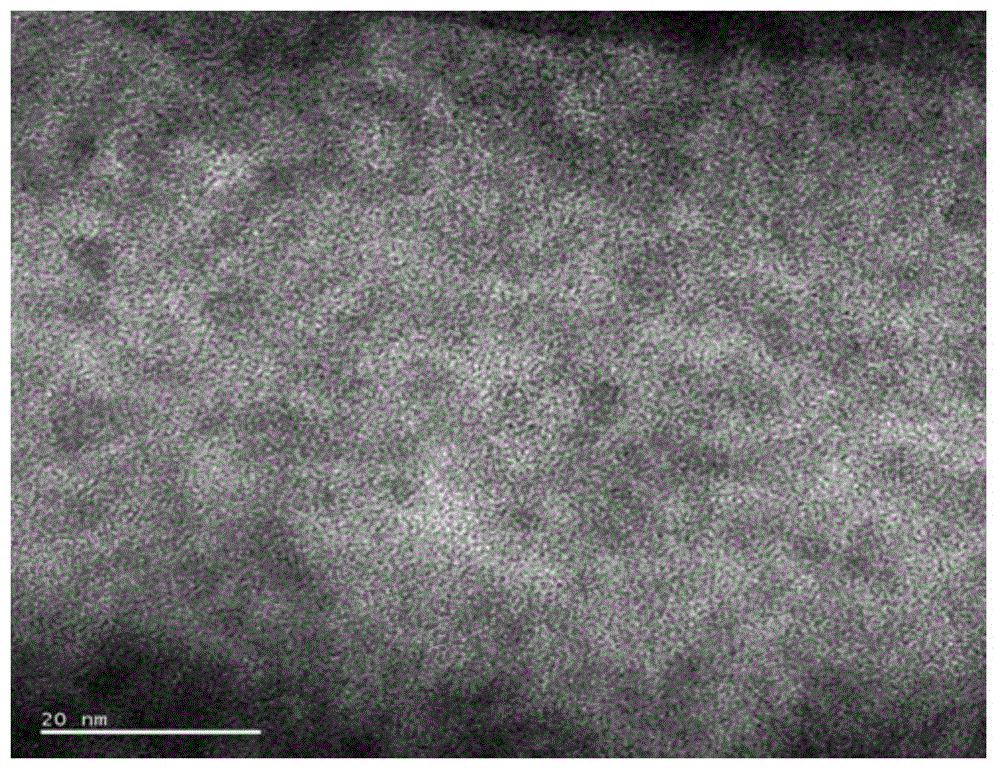

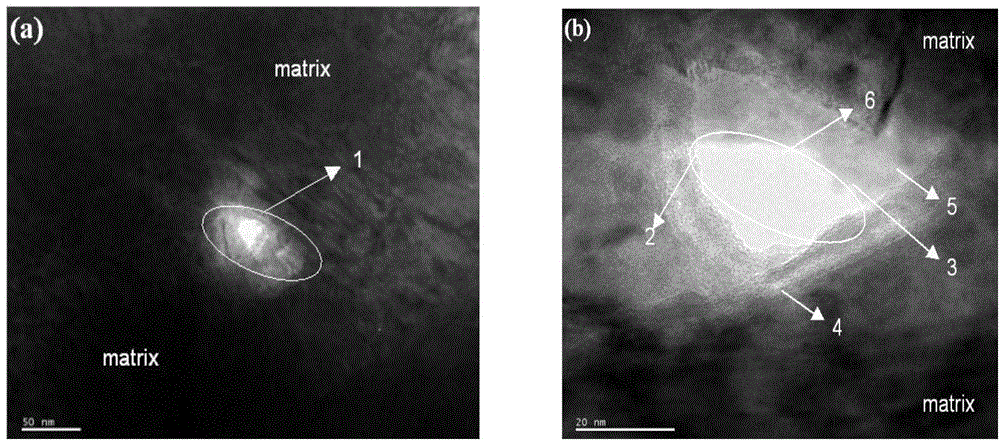

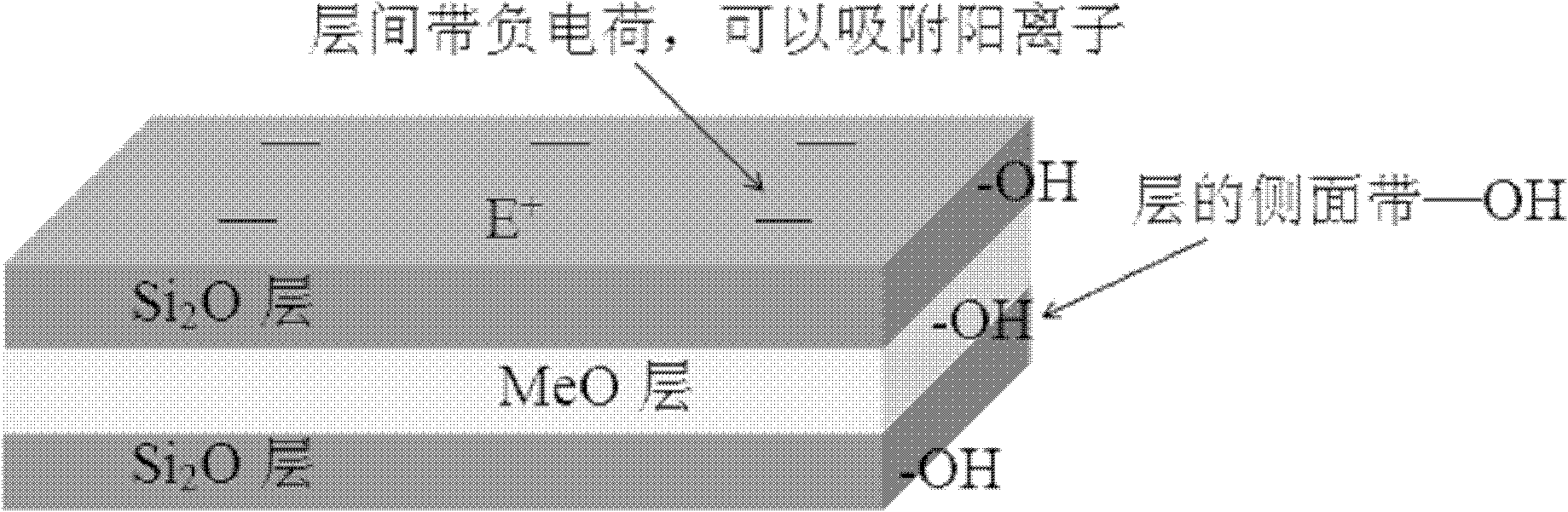

Utilizing nanoscale materials as dispersants, surfactants or stabilizing molecules, methods of making the same, and products produced therefrom

ActiveUS20110210282A1Good effectEasy to processMaterial nanotechnologyNanomagnetismDielectricCapacitance

Novel dispersions of nanoparticles such as carbon nanotubes, carbon nanofibers, boron nanotubes, clay nanotubes, other nanotube species, buckminster fullerenes, graphene, graphene nanoplatelets, elements, oxides, nanoparticles, nanoclusters, nanopowders, nanocrystals, nanoscale molecules, other nanoscale materials, as well as products produced therefrom are described. These dispersions can then be further processed into a wide variety of products including but not limited to composite materials, polymers, resins, epoxies, emulsions, cements, coatings, clays, films, membranes, paper, fibers, inks, paints, pastes, electronics, spintronics, optics, biotechnology materials, electrodes, field emission or other displays, plating, capacitance, ceramics, catalysts, clays, ballistic materials, drug delivery, doping, magnetics, dielectrics, barrier layers, selective ion flow membranes, batteries, fuel cells, solar and other applications. The invention can also be used to protect electronics from electromagnetic interference, radio frequency interference or radio frequency identification. Most applications that utilize nanoparticles can benefit from this invention.

Owner:CTI NANOTECH

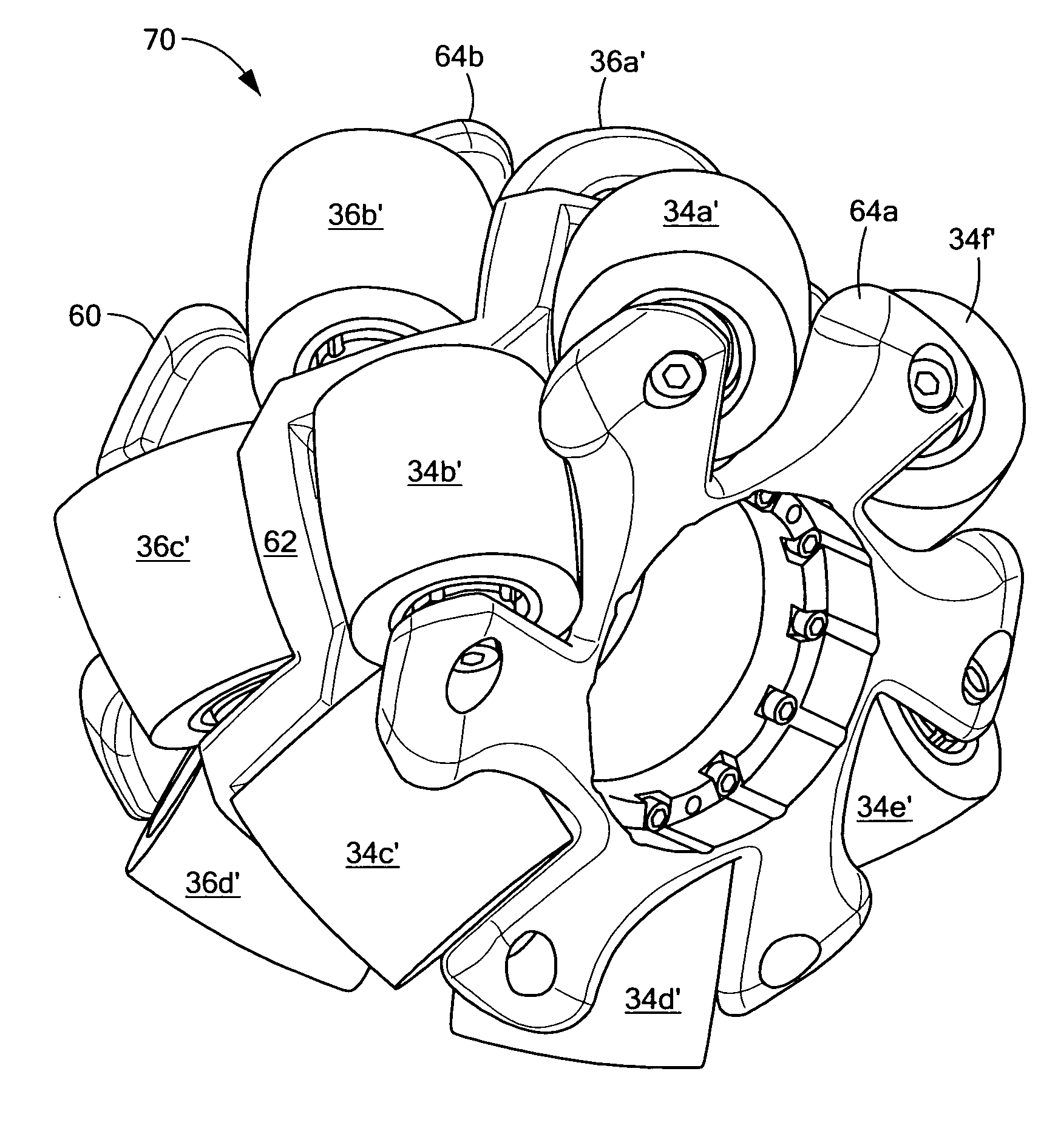

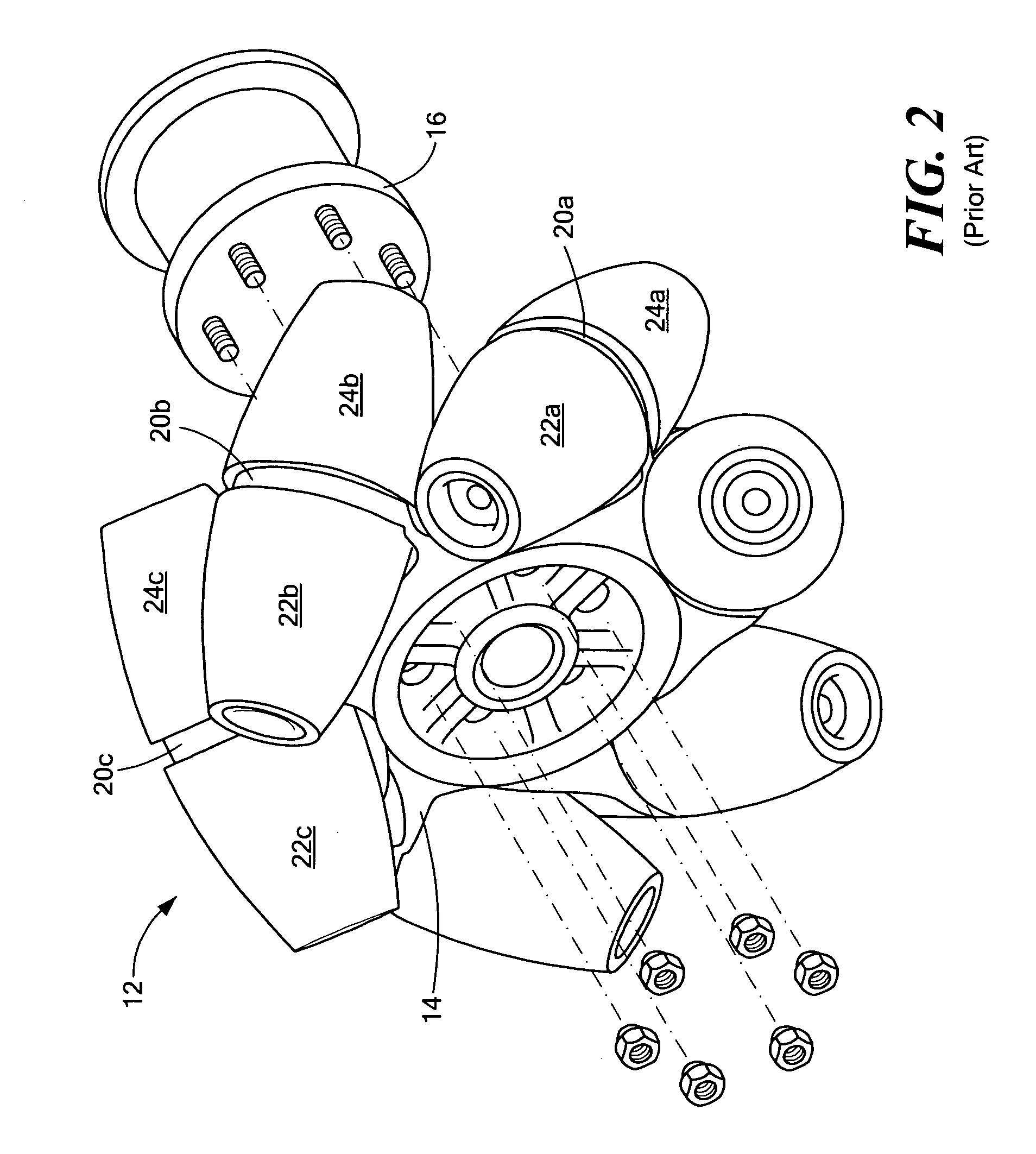

Omni-directional wheel

ActiveUS20100187779A1Vibration minimizationAvoid swingingVehicle body stabilisationHubsEngineeringOmni directional

Owner:FOSTER-MILLER

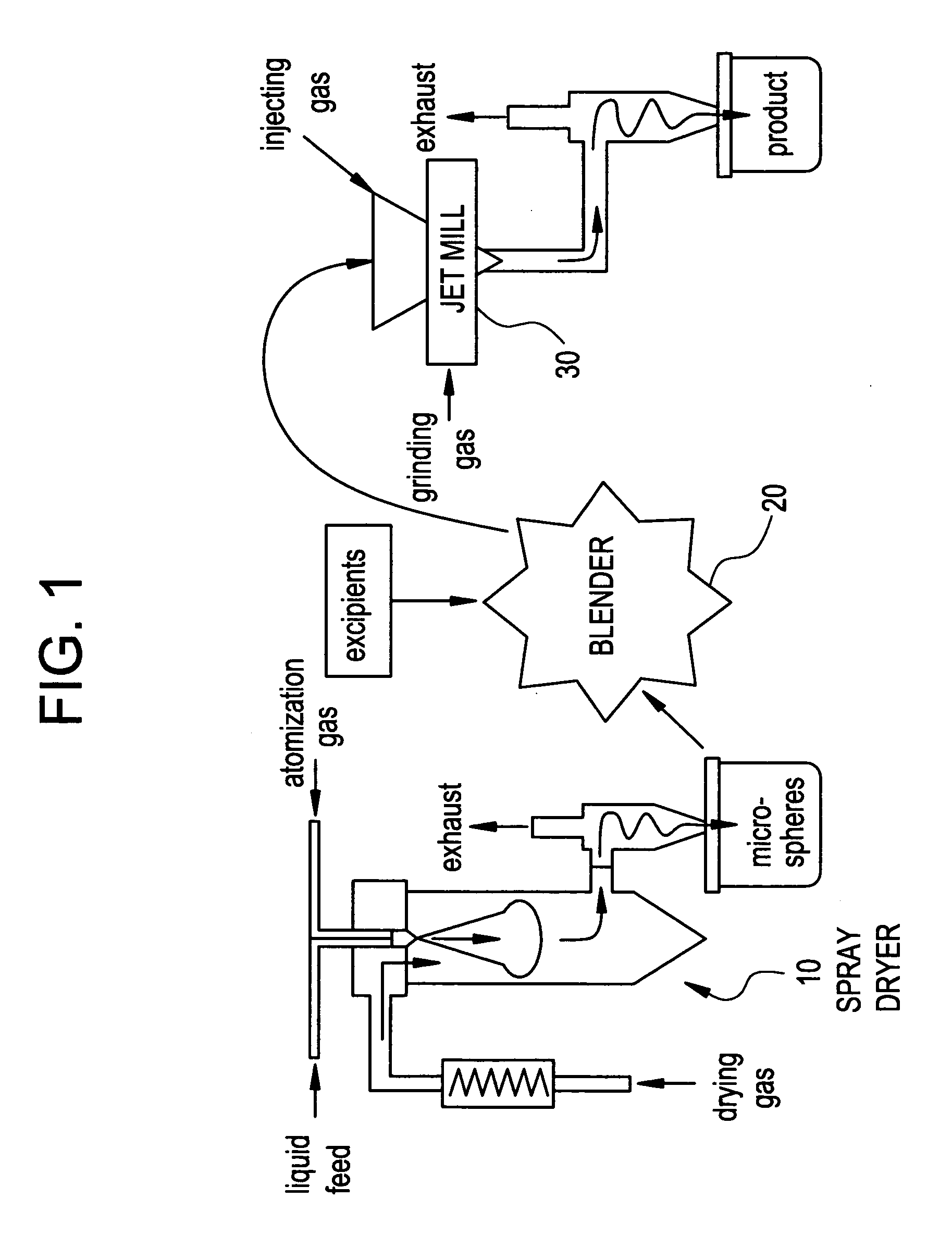

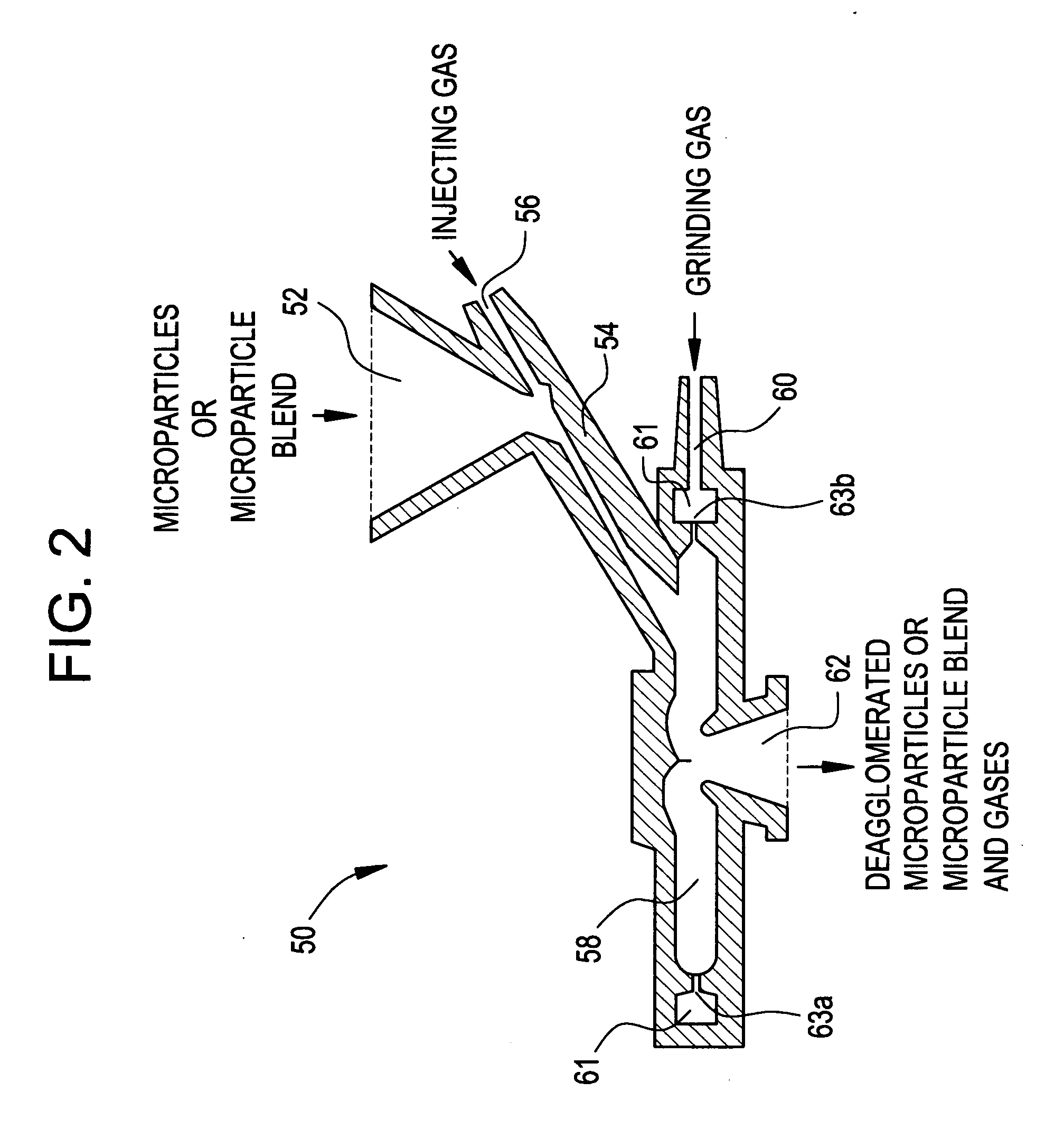

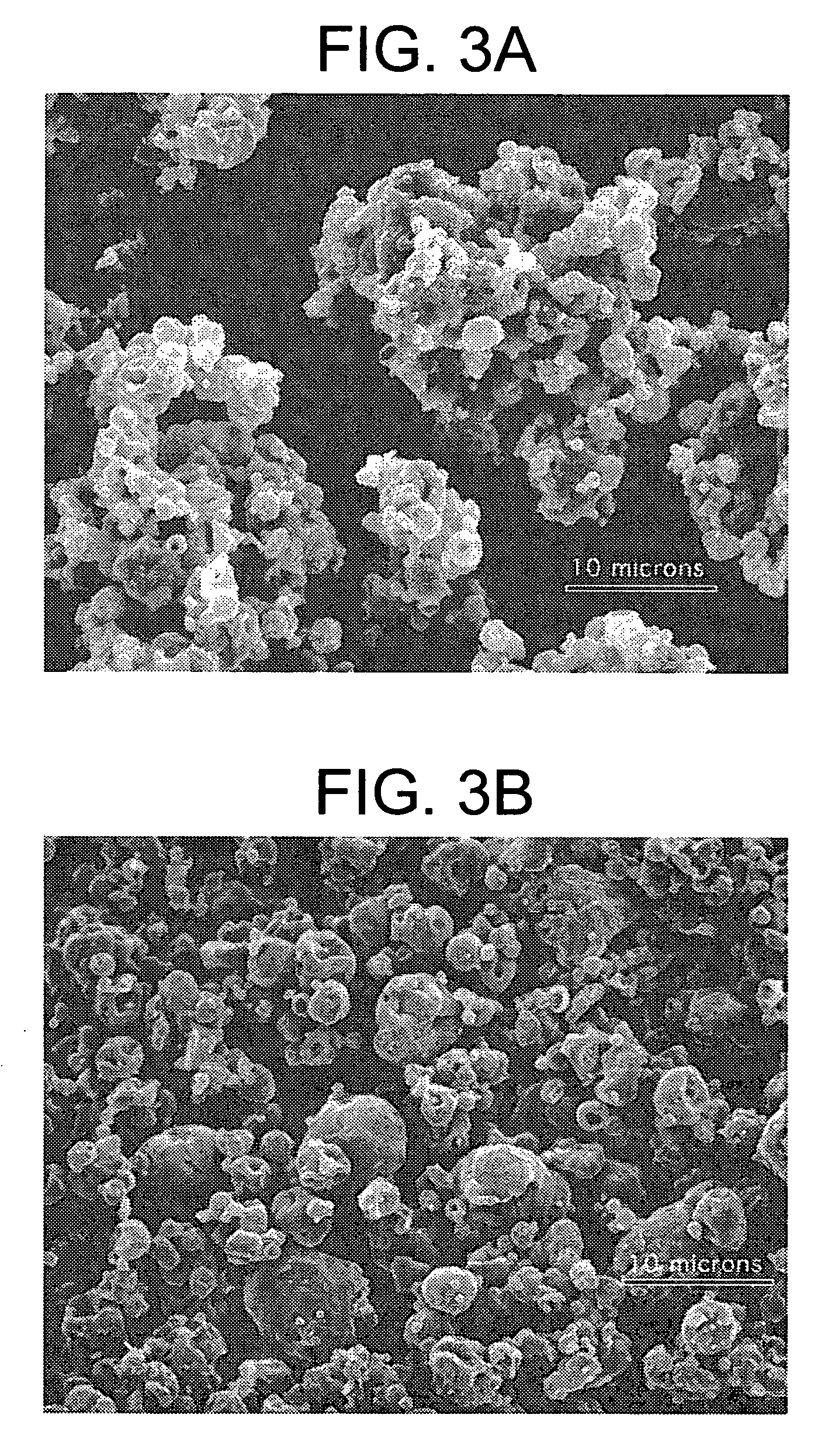

Methods for making pharmaceutical formulations comprising deagglomerated microparticles

InactiveUS20060093678A1High crystallinityReduce contentPowder deliveryGranulation by liquid drop formationMicroparticleVolume average

Methods are provided for making a dry powder blend pharmaceutical formulation comprising (i) forming microparticles which comprise a pharmaceutical agent; (ii) providing at least one excipient in the form of particles having a volume average diameter that is greater than the volume average diameter of the microparticles; (iii) blending the microparticles with the excipient to form a powder blend; and (iv) jet milling the powder blend to deagglomerate at least a portion of any of the microparticles which have agglomerated, while substantially maintaining the size and morphology of the individual microparticles. Jet milling advantageously can eliminate the need for more complicated wet deagglomeration processes, can lower residual moisture and solvent levels in the microparticles (which leads to better stability and handling properties for dry powder formulations), and can improve wettability, suspendability, and content uniformity of dry powder blend formulations.

Owner:CHICKERING DONALD E III +6

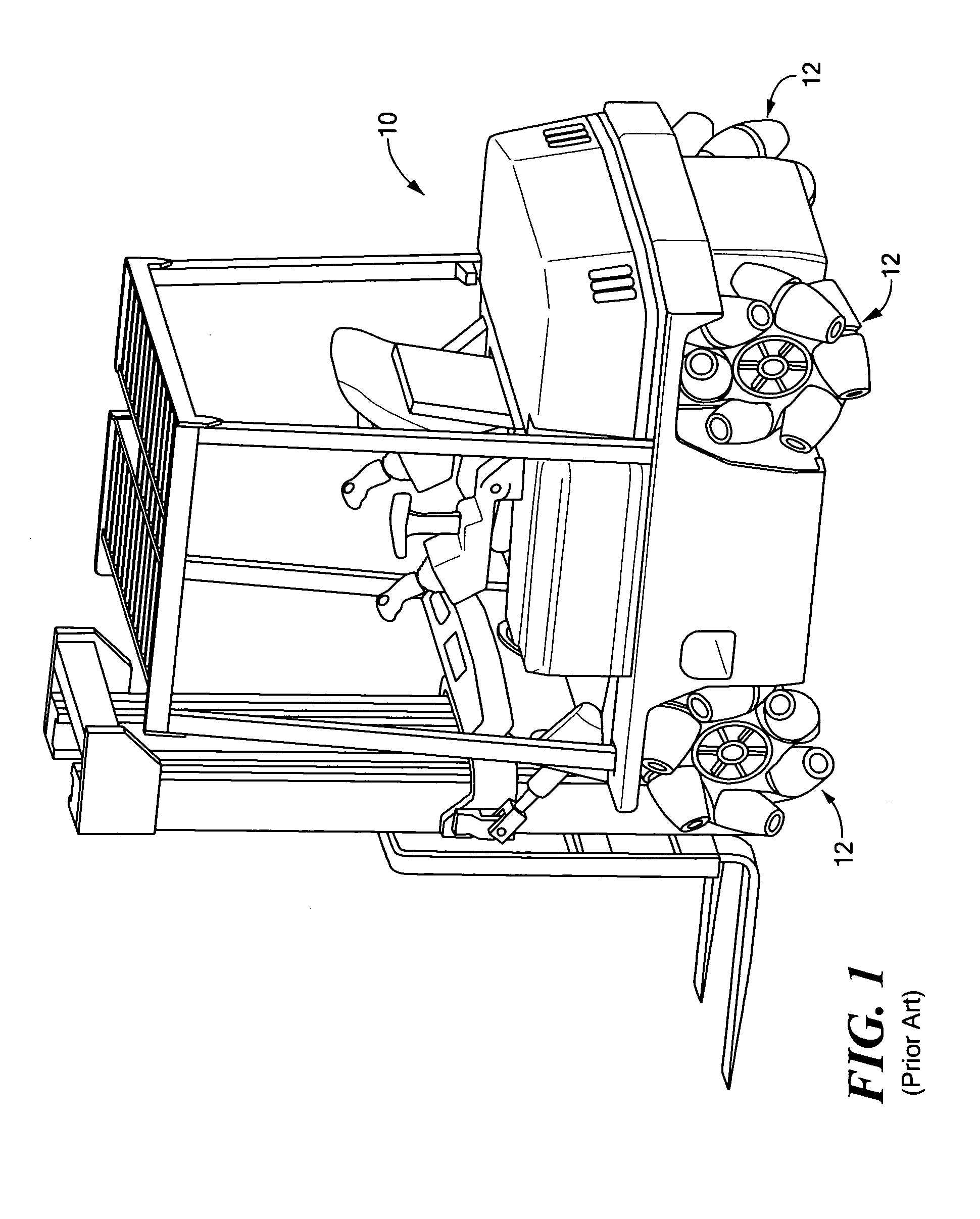

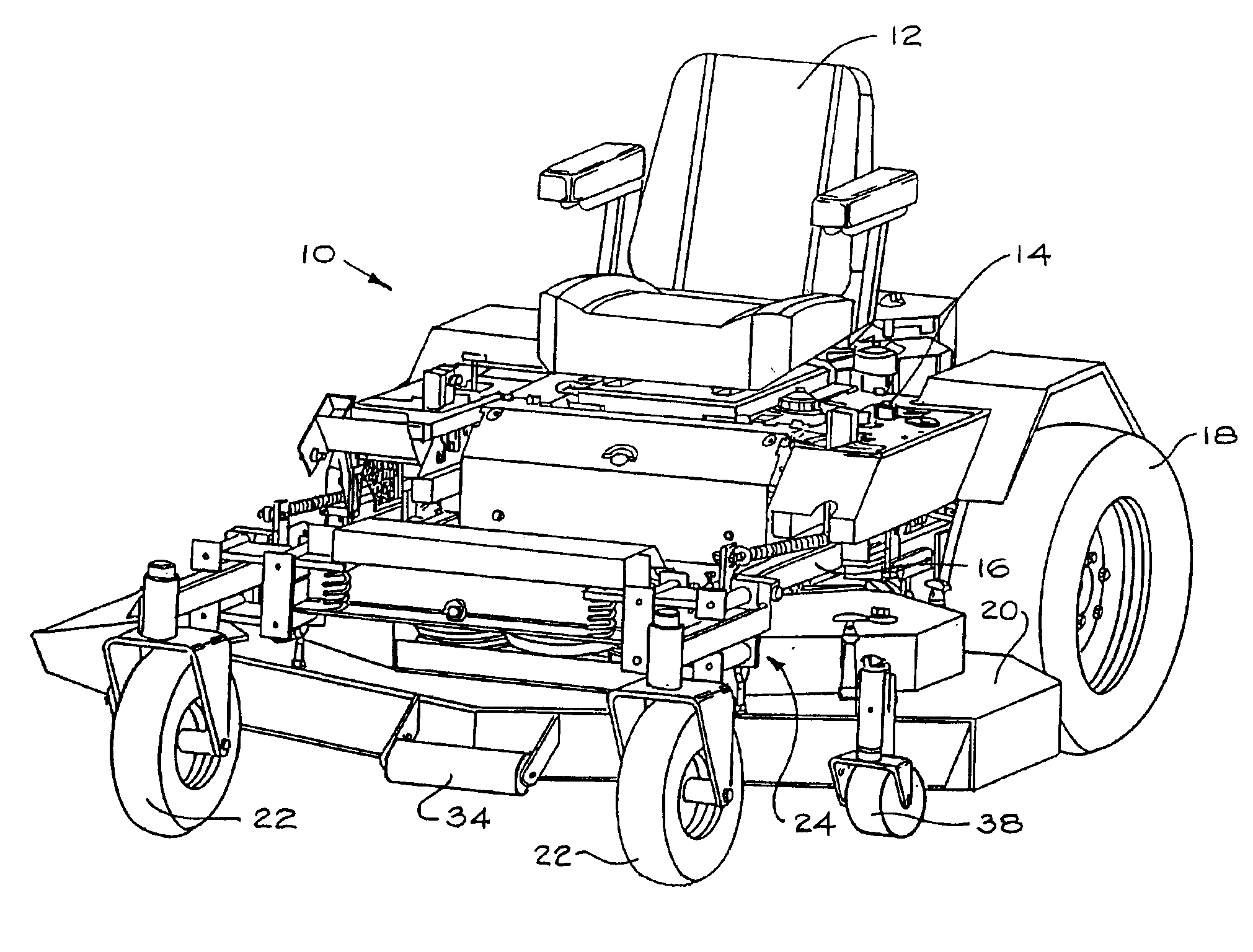

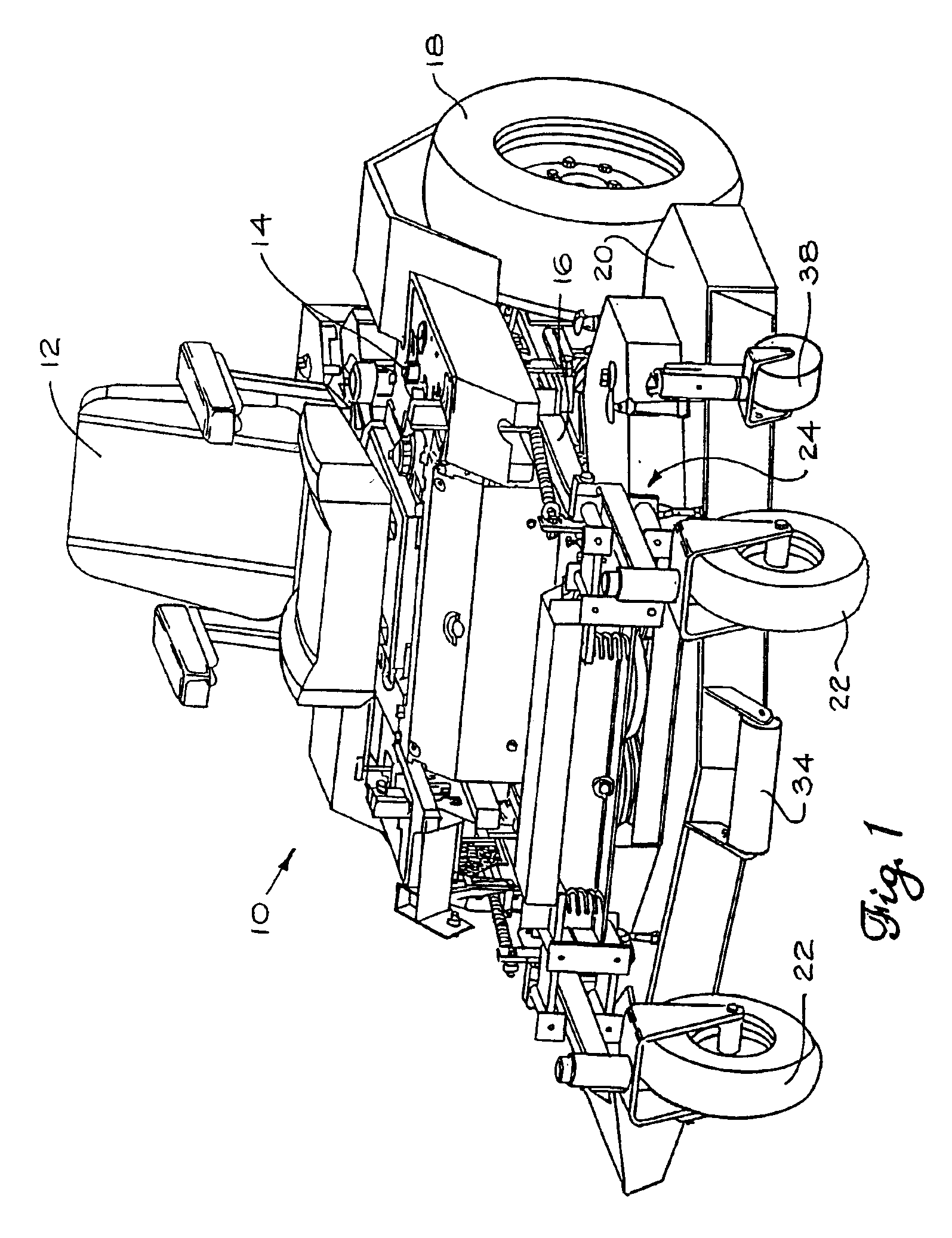

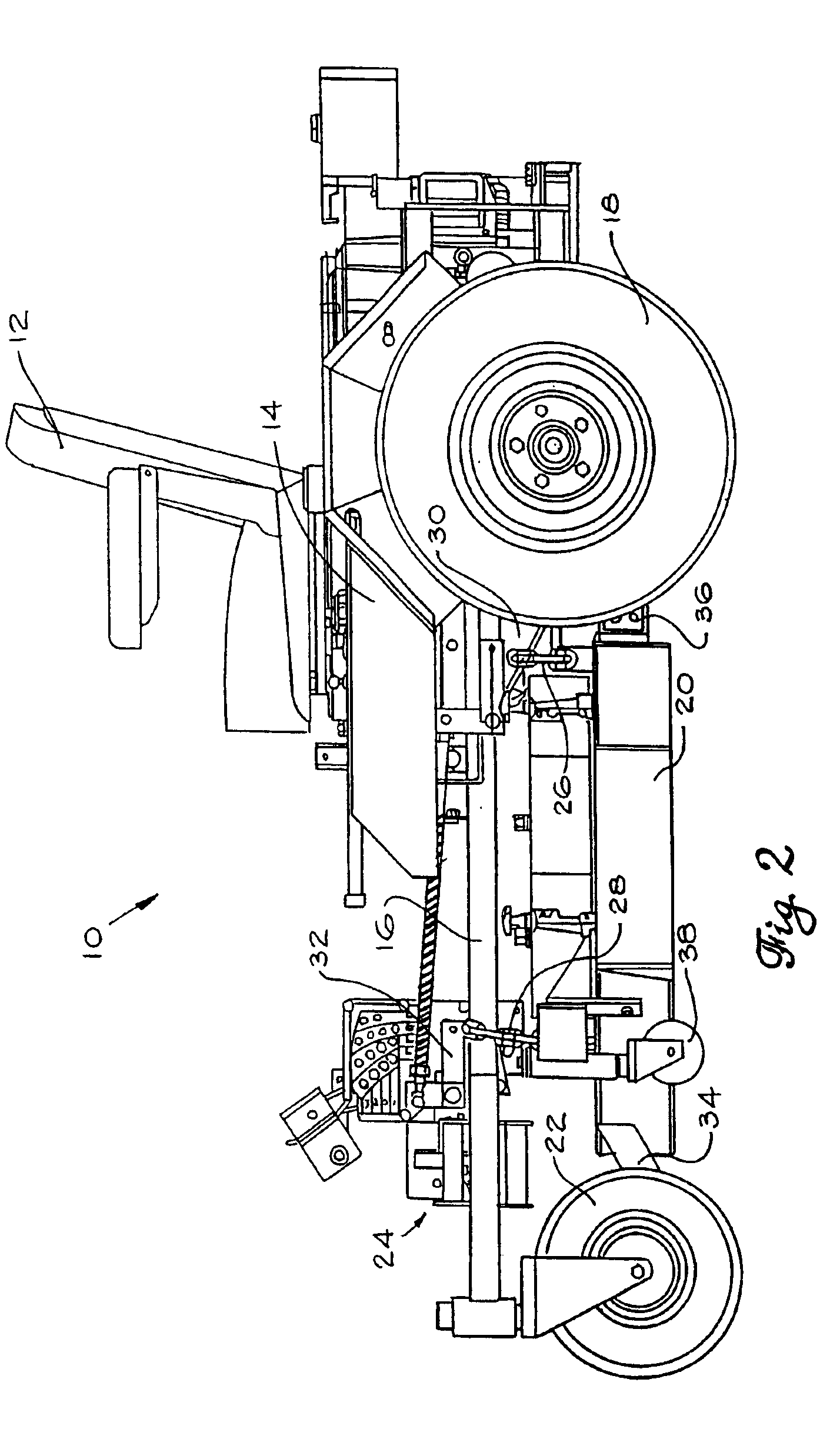

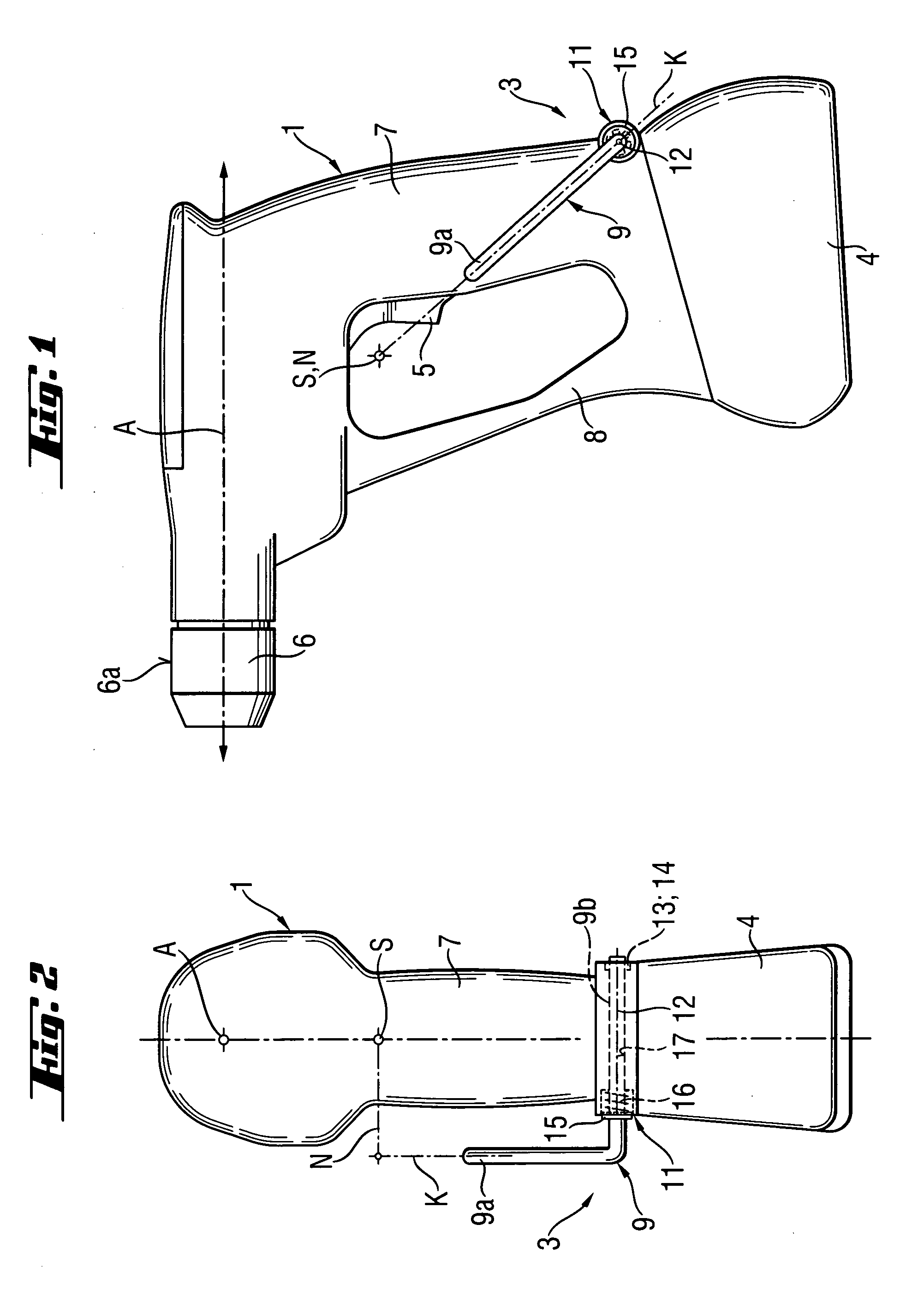

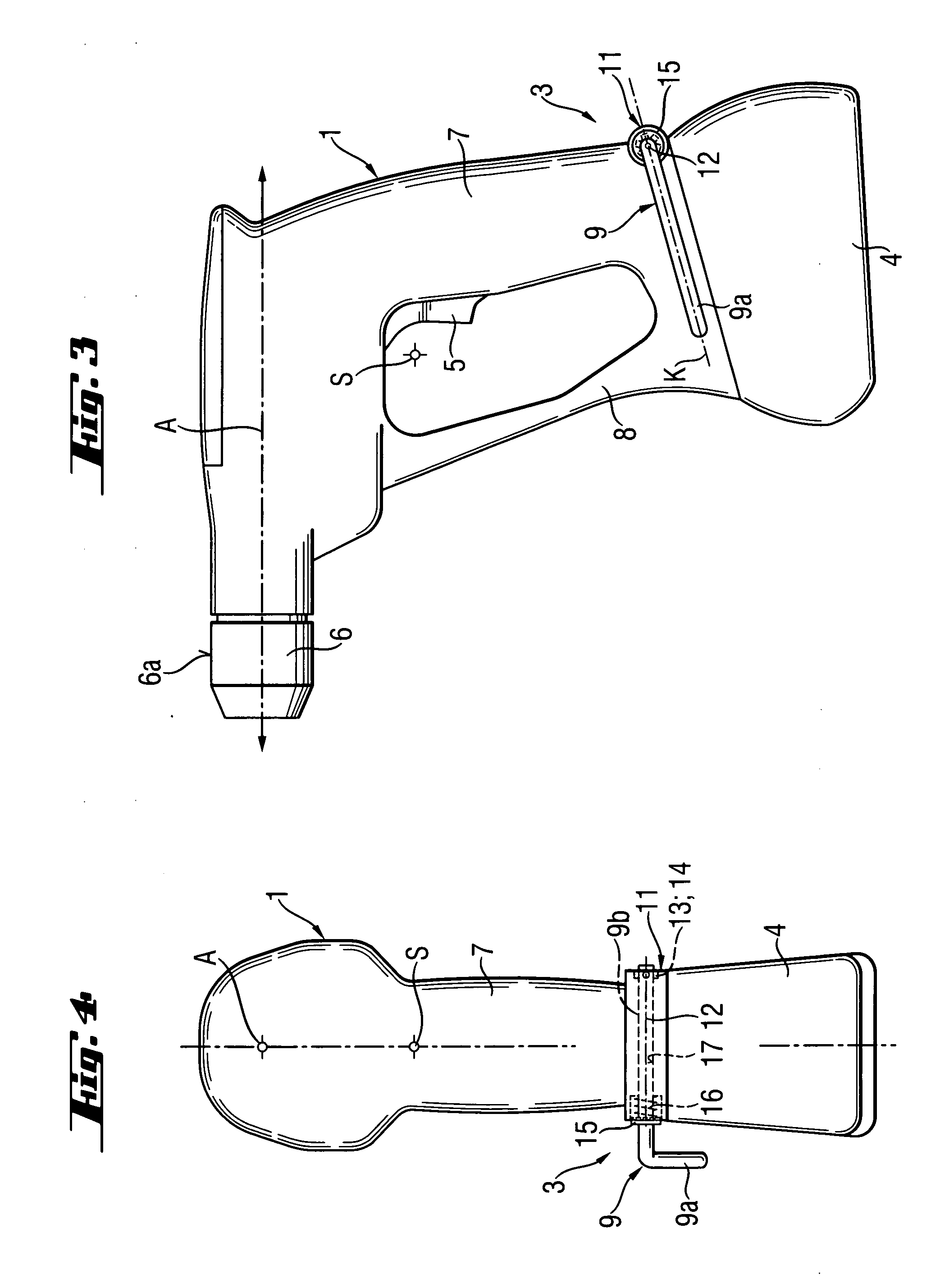

Mower suspension system and method

InactiveUS6857254B2Good suspensionImproved cutter deck movementHigh internal friction springsCastorsEngineeringCantilever

The mower front independent suspension assembly in some embodiments of the present invention includes a first suspension arm connected to the front of the lawn mower frame and a second suspension arm connected to the side of the lawn mower frame. In some embodiments, the first suspension arm is connected to the front of the frame at or near the longitudinal center of the frame, while the second suspension arm is connected to the side of the frame a distance from the front of the frame. Also, in some embodiments the cutter deck of the lawn mower is connected to the front independent suspension assemblies for movement therewith.

Owner:FERRIS IND

Aqueous grinding fluid applied to super precision grinding of hard and brittle materials and application method thereof

ActiveCN102311718AGood suspensionImprove dispersion stabilityOther chemical processesLapping machinesDispersion stabilitySuspending Agents

The invention discloses an aqueous grinding fluid applied to super precision grinding of hard and brittle materials and an application method thereof. The grinding liquid contains chelant 0.1-5, a pH value regulator 5-15, a suspending agent 0.2-5, a dispersion stabilizer 0.5-10, a lubricant 5-20, an antirusting agent 0.5-5, fungicide 0-2, a defoamer 0-2 and deionized water compensating the balance of total amount of 100 parts. Under an alkali condition, the aqueous grinding fluid applied to super precision grinding of hard and brittle materials is beneficial for grinding materials with various sizes, has good suspension property and dispersion stability; when the aqueous grinding fluid is used for super precision grinding of various different hard and brittle materials, especially high-hardness materials, scratches, etching pits and other defects are not produced easily; and the grinding speed is high, the subsequent cleaning is convenient; and the aqueous grinding fluid has excellent lubricating property and antirusting property when in matched use with the grinding materials, and the mixing liquid is uniform in color and has no sediment in 48 h. When the aqueous grinding fluid is used for grinding a wafer on a grinding machine, the ground wafer is subjected to water-added ultrasonic washing, and the wafer has good surface smooth finish, no scales, etching pits and other defects, and the surface roughness can be within 2 microns.

Owner:AMER TECH CO LTD

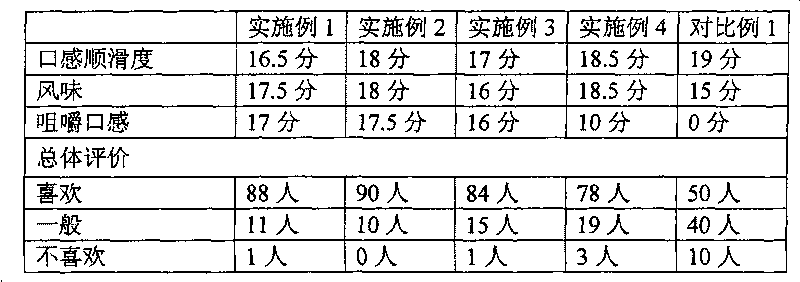

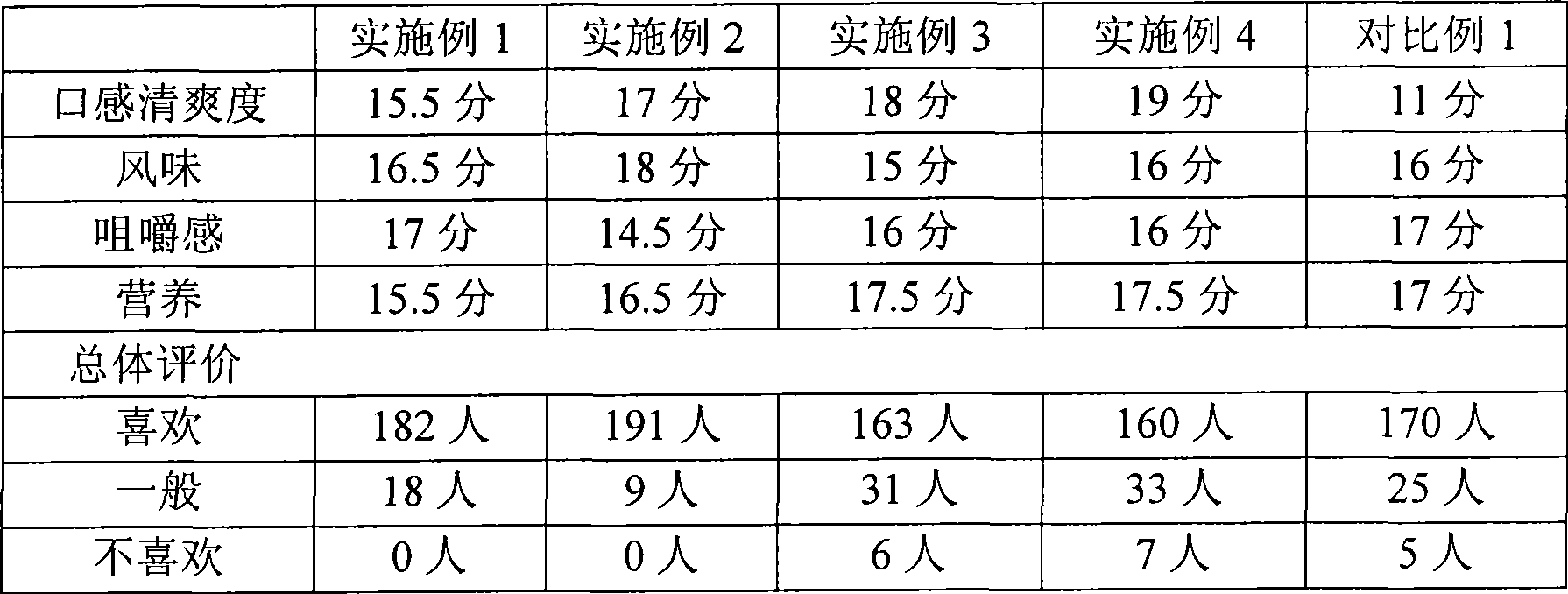

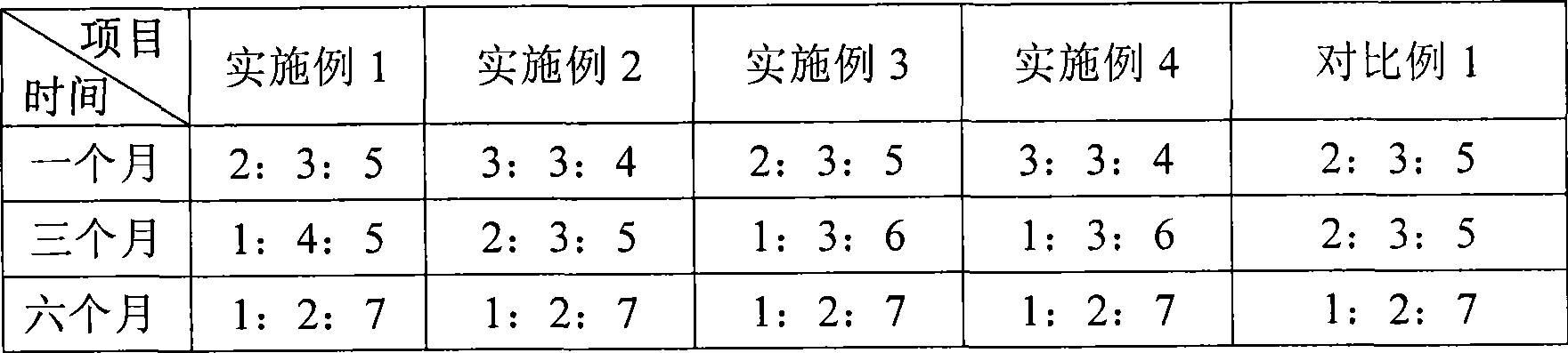

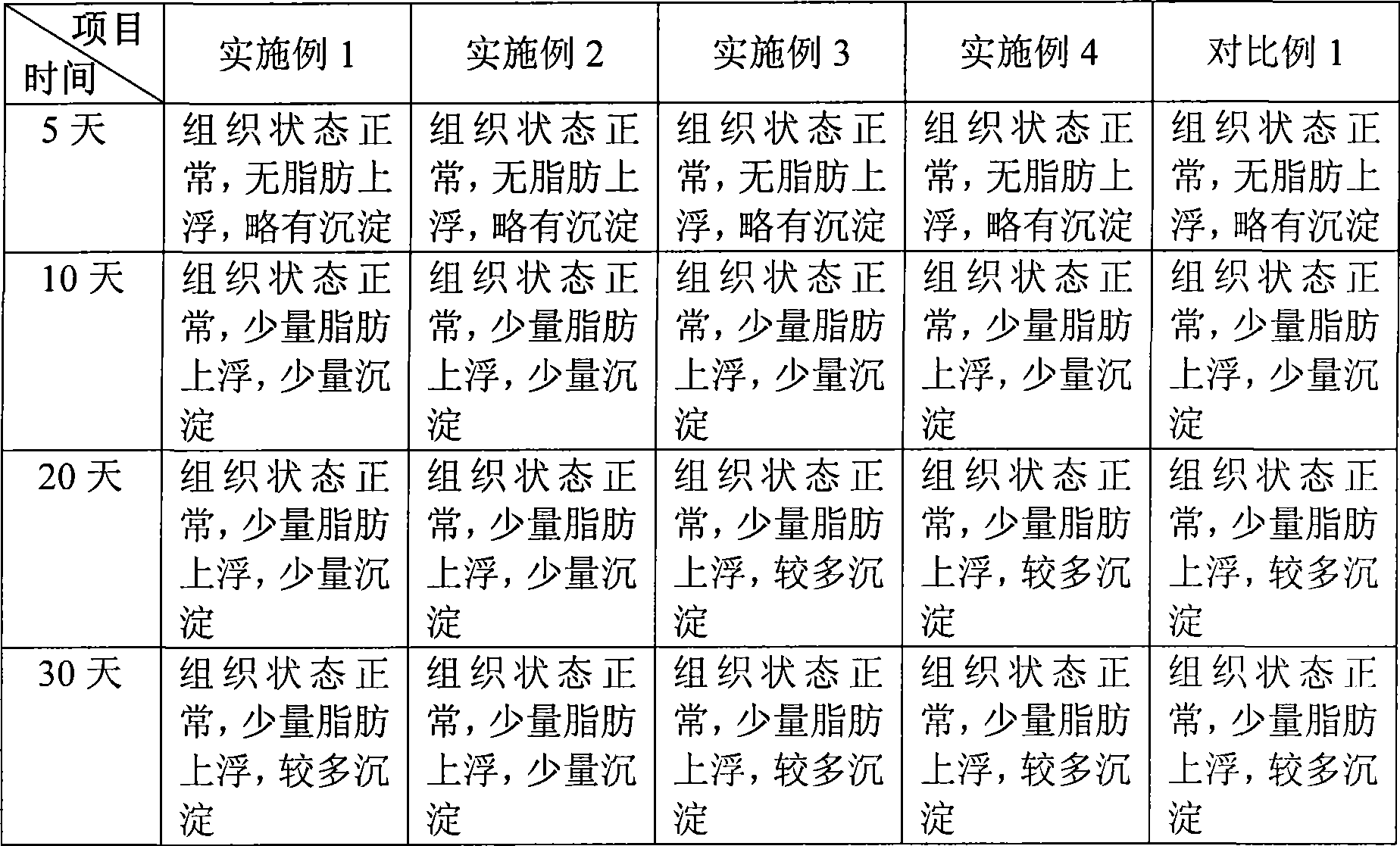

Milk tea beverage containing fruit and vegetable grains and production method thereof

ActiveCN101744051AImprove taste and flavorRich in nutritional valueMilk preparationPre-extraction tea treatmentLiquid systemChemistry

The invention provides a milk tea beverage containing fruit and vegetable grains and a production method thereof. Based on the total weight of the milk tea beverage, 1%-20% of the fruit and vegetable grains are contained in the raw materials, and the milk tea beverage is prepared by uniformly mixing various raw materials in the formula, sterilizing and filling. The milk tea beverage can realize excellent stability within shelf life and suspension stability of the fruit and vegetable grains of a product liquid system through reasonable formula and proper process.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

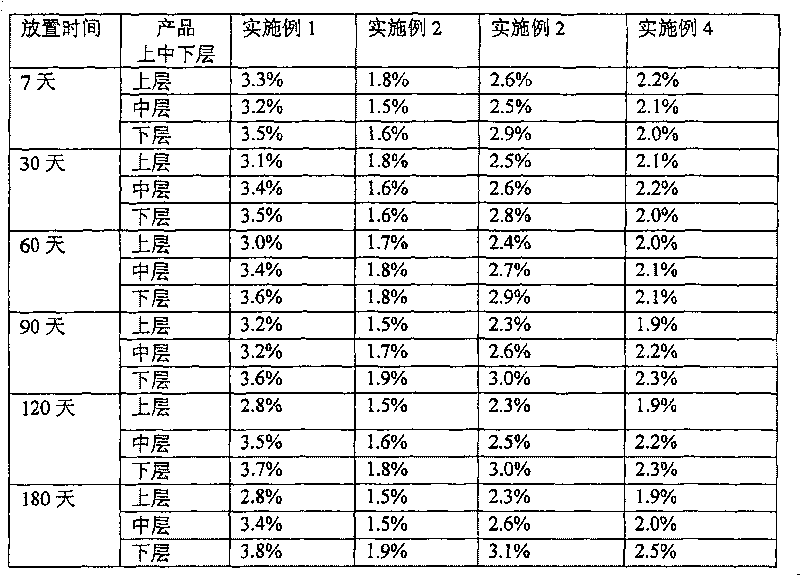

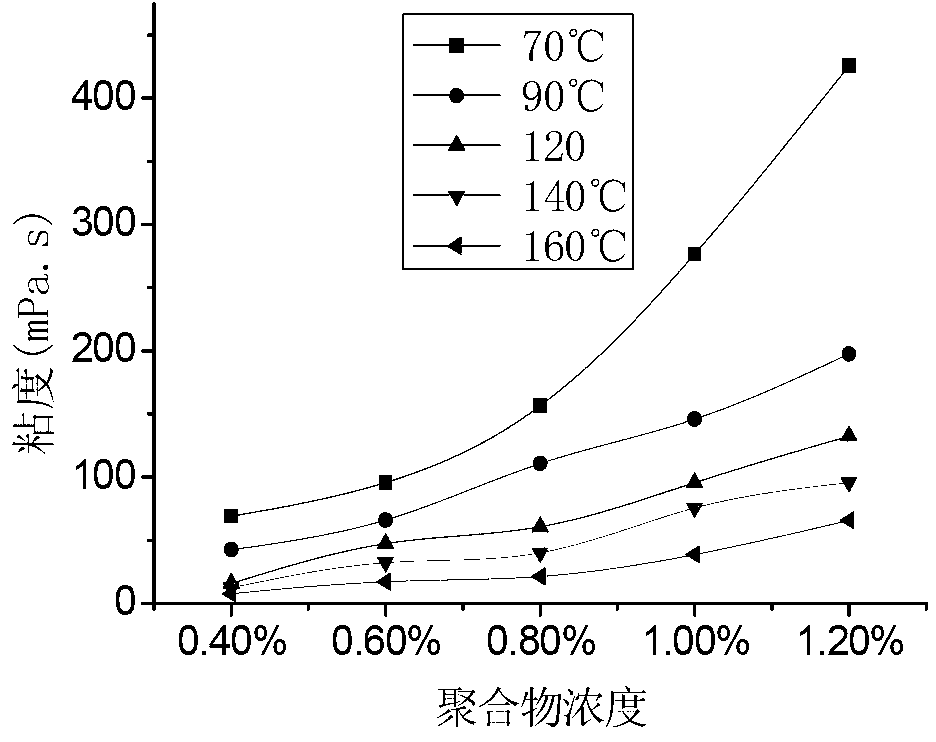

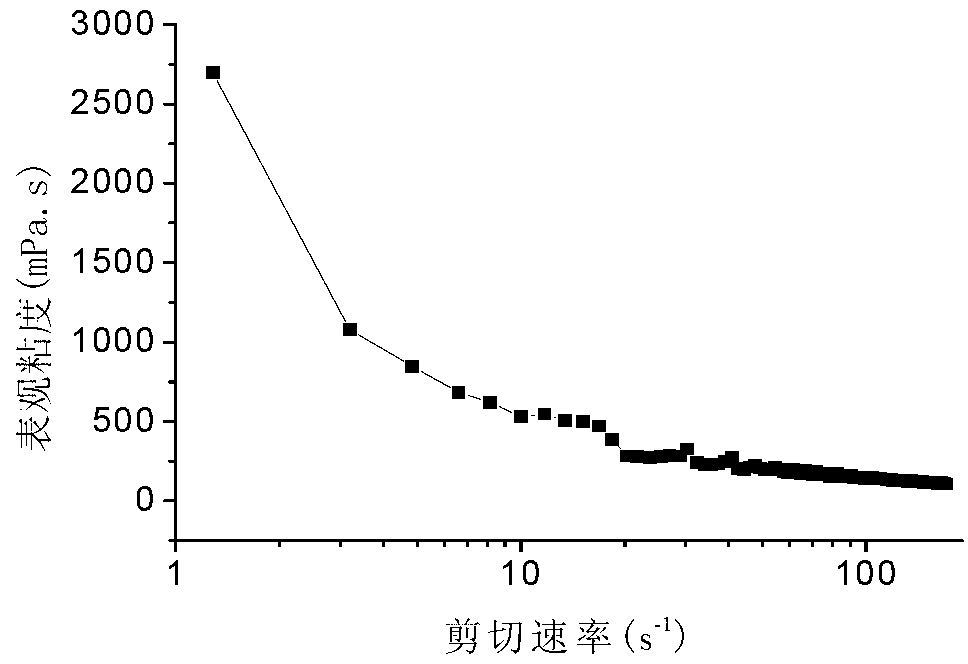

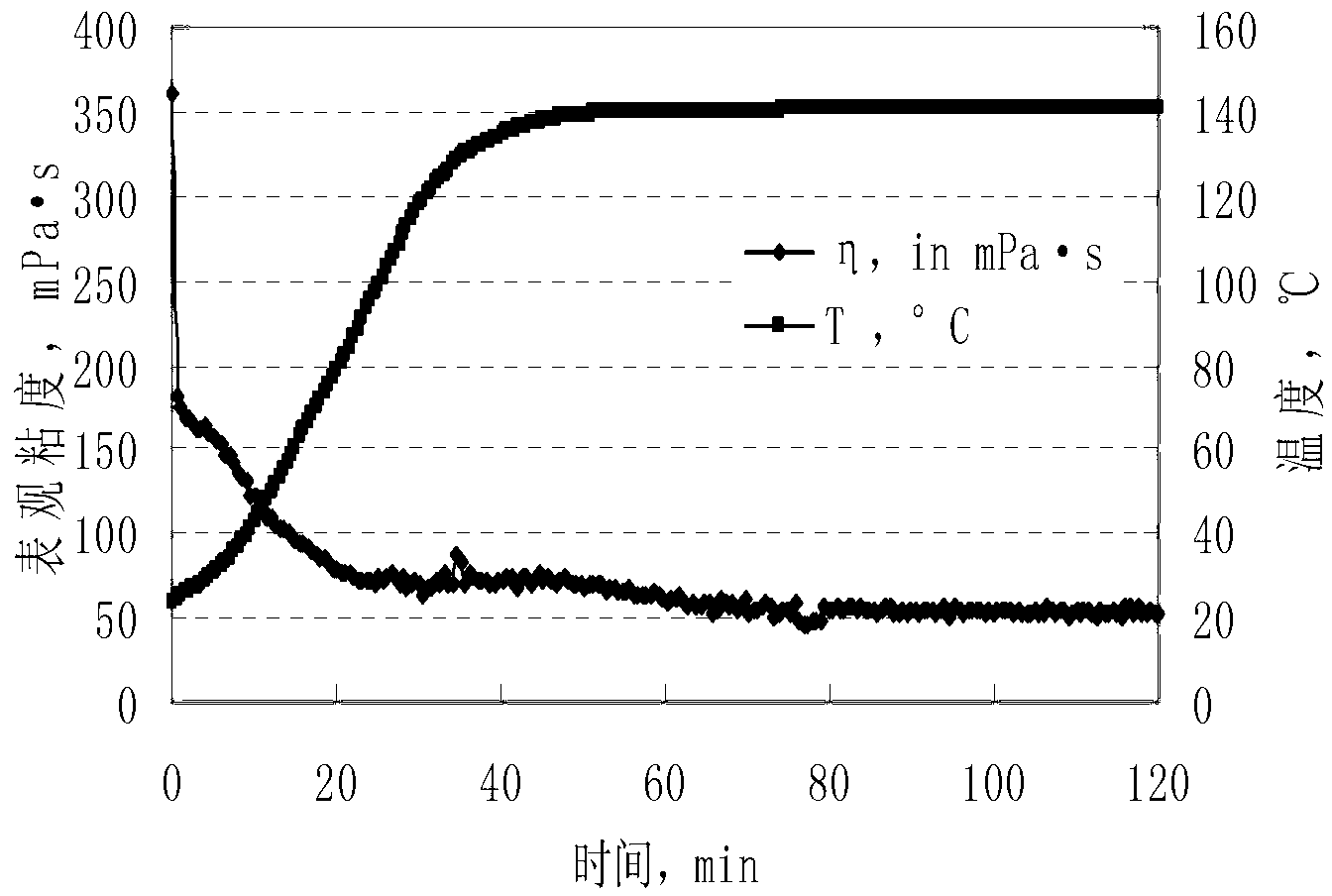

Association-type non-crosslinking fracturing fluid and preparation method thereof

Owner:SOUTHWEST PETROLEUM UNIV

Composite material with anti-bacterial and purifying functions and preparation method of composite material

ActiveCN104607039AImprove adsorption capacityImprove decomposition rateWater/sewage treatment by irradiationDispersed particle separationDecompositionRare earth

The invention relates to a composite material with anti-bacterial and purifying functions and a preparation method of the composite material, and belongs to the technical field of environmental-friendly materials. The composite material with the anti-bacterial and purifying functions comprises raw materials in parts by weight as follows: 70-95 parts of a mineral composite adsorption material, 3-25 parts of a photocatalytic degradation material, 2-15 parts of a rare earth inorganic anti-bacterial material and 1-10 parts of an additive, wherein the mineral composite adsorption material is prepared from sepiolite, diatomite, medical stone and attapulgite; the photocatalytic degradation material is prepared from titanium oxide, tourmaline and far infrared ceramic powder; the rare earth inorganic anti-bacterial material is prepared from zinc oxide, cerium oxide and silver oxide; the additive is a mixture of activated carbon, carboxymethylcellulose and pumice powder. The composite material with anti-bacterial and purifying functions has high adsorption and decomposition rate, can be resistant to water and damp and has excellent anti-bacterial effect. Meanwhile, the invention provides the preparation method. According to the preparation method, the cost is low, the amount of produced wastewater is low, and powder is simple and convenient to apply.

Owner:淄博木齐新材料科技有限公司

Acidic, protein-containing drinks with improved sensory and functional characteristics

InactiveUS20070014909A1Enhance sensoryImproved functional characteristicHydrolasesFood preparationOrganolepticPlant protein

Processes for producing acidic, protein-containing drinks are disclosed. Specifically, the processes comprise producing acidic, protein-containing drinks comprising plant protein material. The acidic, protein-containing drinks have improved sensory and functional characteristics such as reduced viscosity, improved sedimentation rate, and improved mouthfeel.

Owner:MAI JIMBIN +8

Blending type vegetable and fruit juice beverage and production method thereof

The invention provides a prepared type fruit and vegetable juice beverage and producing method thereof. The fruit and vegetable juice beverage of the present invention contains fruit and vegetable juice 10%-30%, lactoprotein 0.05%-1%, fruit and vegetable particles 1%-10% and stabilizing agent 0.1-0.05%; the pH value of the fruit and vegetable juice beverage is 3.2-4.2, and the sugariness can be converted to 3-15wt% of sucrose. The fruit and vegetable juice of the present invention contains milk protein, fruit and vegetable particles, achieves rich nutrition, refreshing mouth feel and good stability.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Powdery paint for lost foam casting of cast iron

The invention discloses a special coating for pulverous expendable pattern casting and casting iron, and the special coating comprises 60-70 percent of 180-200 mesh refractory materials, 2.0-3.0 percent of suspending agent, 1.5-2.5 percent of adhesive, 0.3-0.6 percent of organosilicon defoamer, 0.01-0.03 percent of preservative agent and 180-200 mesh residual mica powder in balancing amount. When the special coating is prepared, various pulverous materials are weighed according to the required proportion, interposed into the powder stirrer in sequence to stir for 20 to 40 minutes at a low speed and then discharged and packed. When the coating is used, appropriate water is interposed into the stirred vessel by the powder-to-water ratio of 1 to (1.1-1.4). After the stirred vessel is turned on, the powder coating weighed is interposed in batches. The coating is utilized after preparing into slurry; therefore, the special coating has the advantages of good suspension property, high intensity, uniform coating, good thixotropy, good leveling property, glabrous surface, no bubbles, no cracks and the like. Moreover, the user can adopts the dip-coating method, the hang-coating method and the brush-coating method, the viscosity change of coating materials can be decided upon the demands of the user, and different viscosities can realize different coating thicknesses.

Owner:HUAZHONG UNIV OF SCI & TECH

Acidic, protein-containing drinks with improved sensory and functional characteristics

InactiveUS20070014910A1Improve suspendabilityWell flavorHydrolasesVegetable proteins working-upPlant proteinReduced viscosity

Processes for producing acidic, protein-containing drinks are disclosed. Specifically, the processes comprise producing acidic, protein-containing drinks comprising plant protein material. The acidic, protein-containing drinks have improved sensory and functional characteristics such as reduced viscosity, improved sedimentation rate, and improved mouthfeel.

Owner:ALTEMUELLER ANDREAS G +1

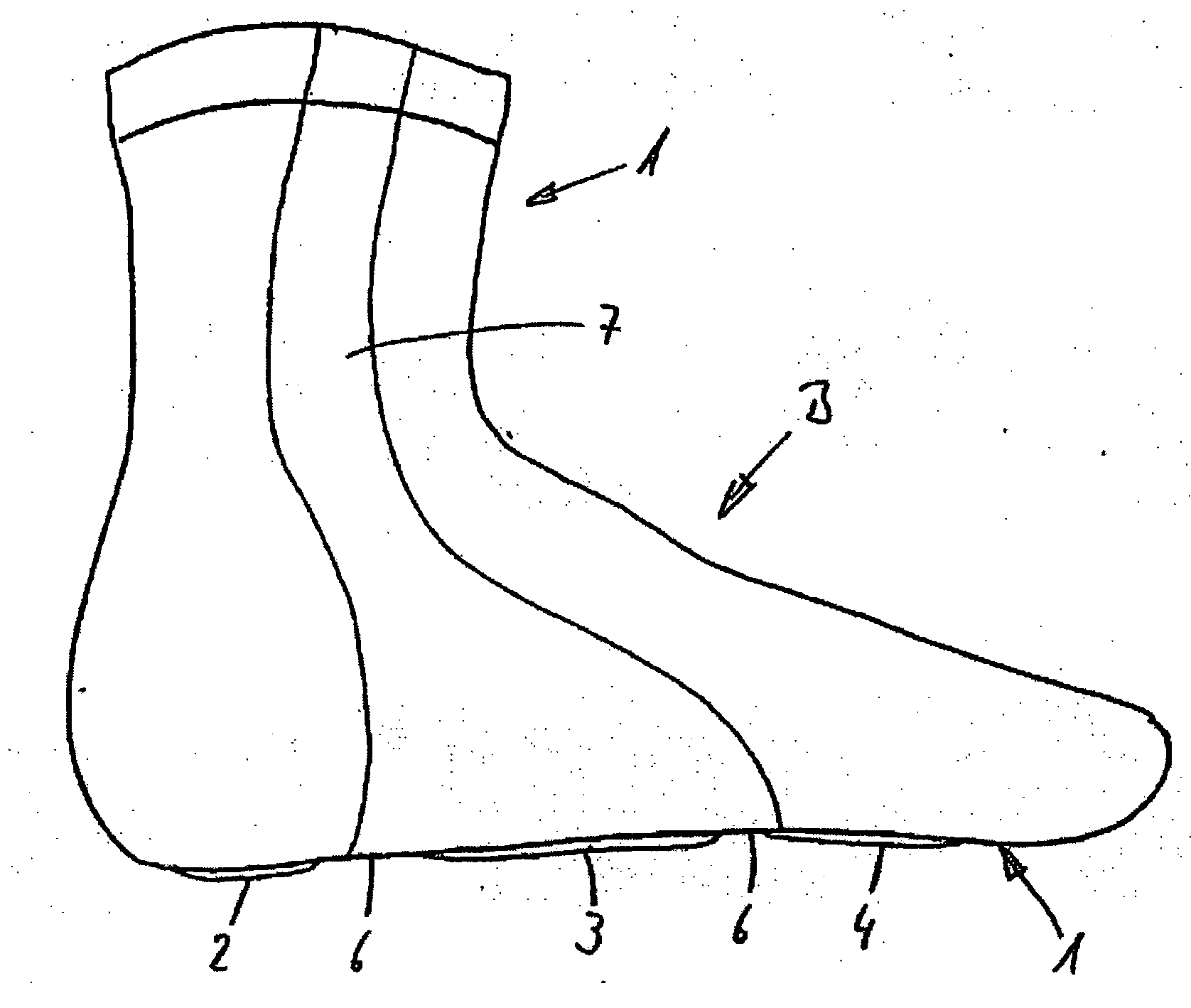

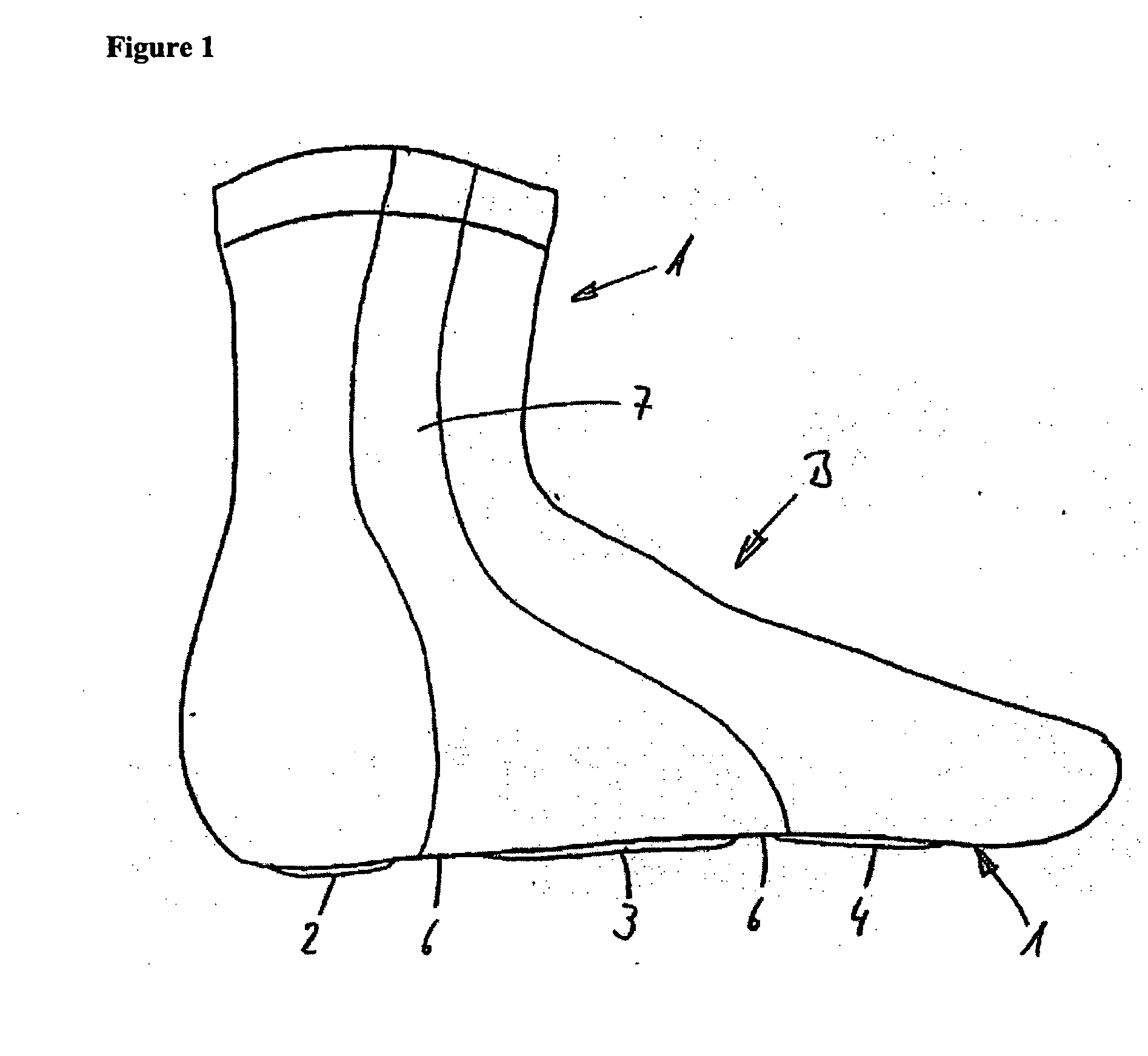

Sock

InactiveUS20060195971A1Continuous removalRemove any further loadInsolesHandkerchiefsSports activityEngineering

Owner:X TECH SWISS

Compound liquid fertilizer with high suspension degree, and preparation method and application thereof

The invention discloses a compound liquid fertilizer with high suspension degree, and a preparation method and an application thereof, and belongs to the liquid fertilizer industry field. The preparation method comprises the steps: adding macromolecule organic sugar into a clay material to be used as a basal suspending agent I, and carrying out first suspension chelation of a major element and a trace element at the temperature of 40-60 DEG C; followed by controlling the temperature at 20-30 DEG C, slowly adding a plant growth regulator and a surface active material, fully mixing uniformly, finally adding macromolecule cellulose and an analog thereof as a suspending agent II, carrying out second suspension chelation, and fully stirring to obtain the compound liquid fertilizer with high suspension degree. The prepared compound liquid fertilizer with high suspension degree has comprehensive nutrients, high content, low cost, good liquidity, good stability and good dissolvability, and is beneficial for crops to efficiently absorb and utilize. The preparation method is simple in process and easy to implement. The compound liquid fertilizer is an ideal fertilizer source for water and fertilizer integration for drip irrigation, sprinkler irrigation, water flushing and the like.

Owner:SOUTH CHINA AGRI UNIV +1

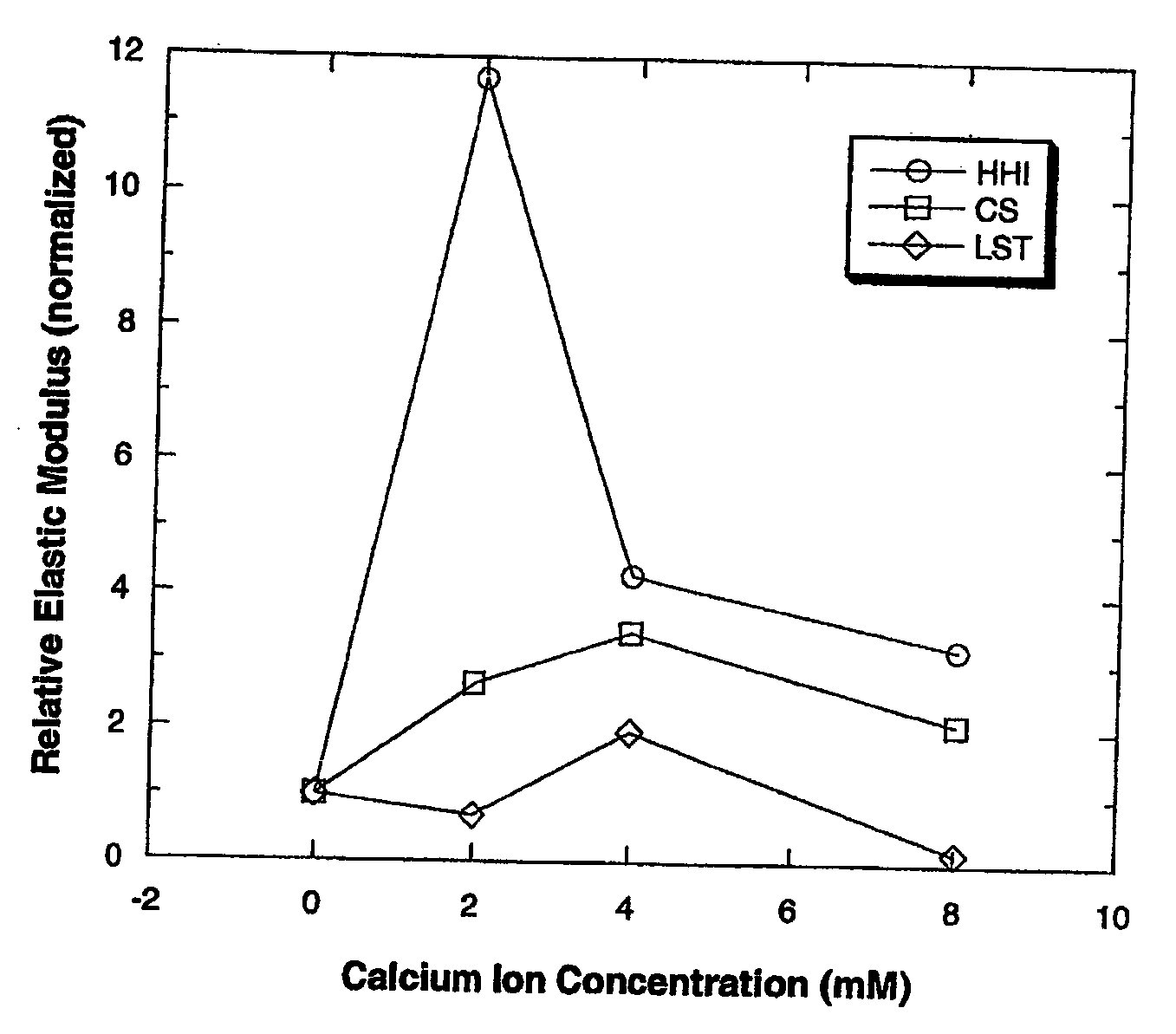

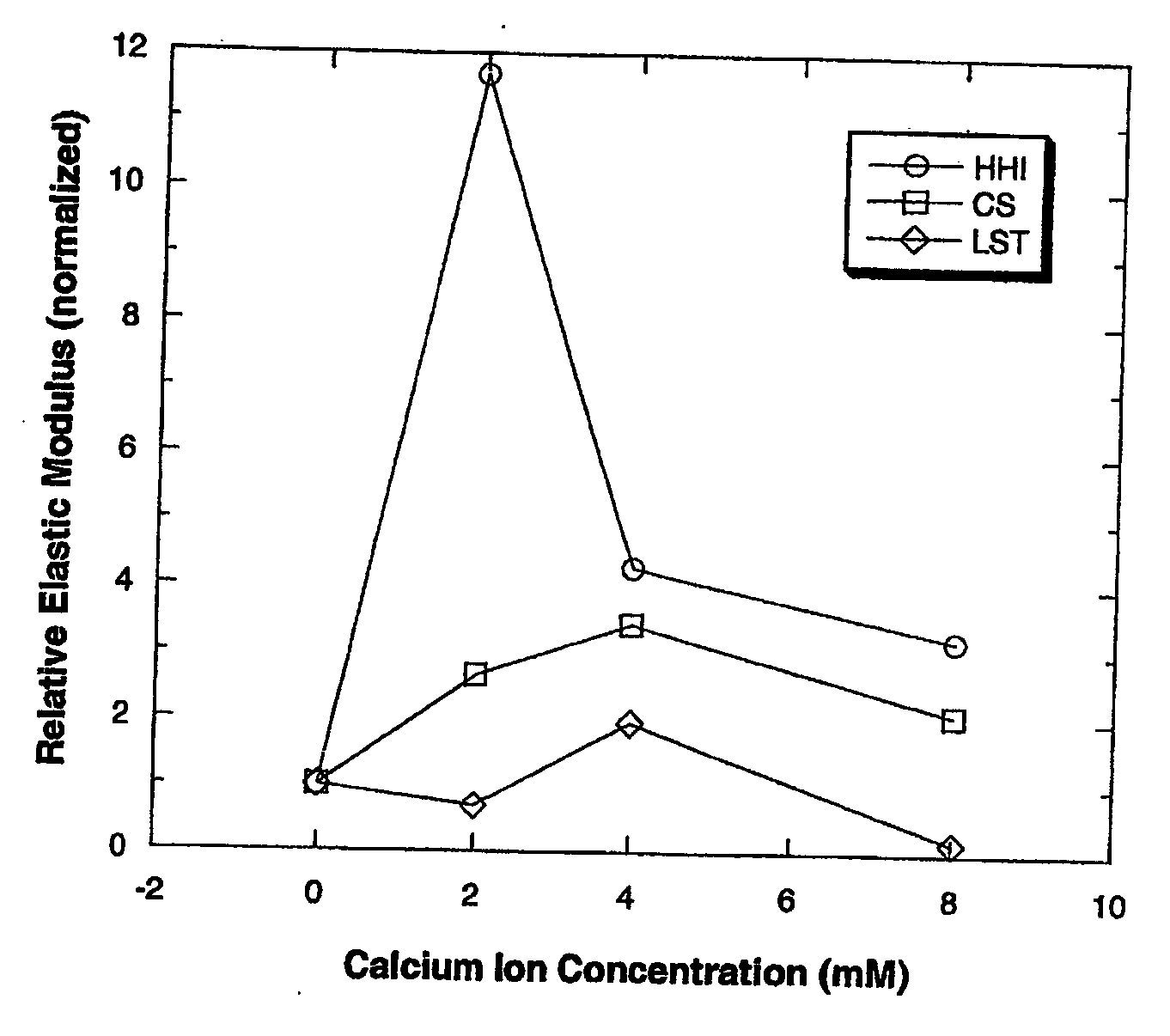

Calcium stable high acyl gellan gum for enhanced colloidal stability in beverages

ActiveUS20050266138A1Improve colloidal stabilityGood particle suspensionSugar derivativesOther chemical processesGellan gumSphingomonas elodea

A low calcium sensitive (calcium stable) high acyl gellan gum is prepared for enhanced colloidal stability in beverages. The low calcium sensitive high acyl gellan gum has superior suspension performance for colloidal stability compared to other high acyl gellan gums. The low calcium sensitive high acyl gellan gum is prepared by adjusting the pH of a gellan fermentation broth (polymer solution) prior to pasteurization and reducing the pasteurization hold time compared to conventional pH levels and hold times.

Owner:CP KELCO U S INC

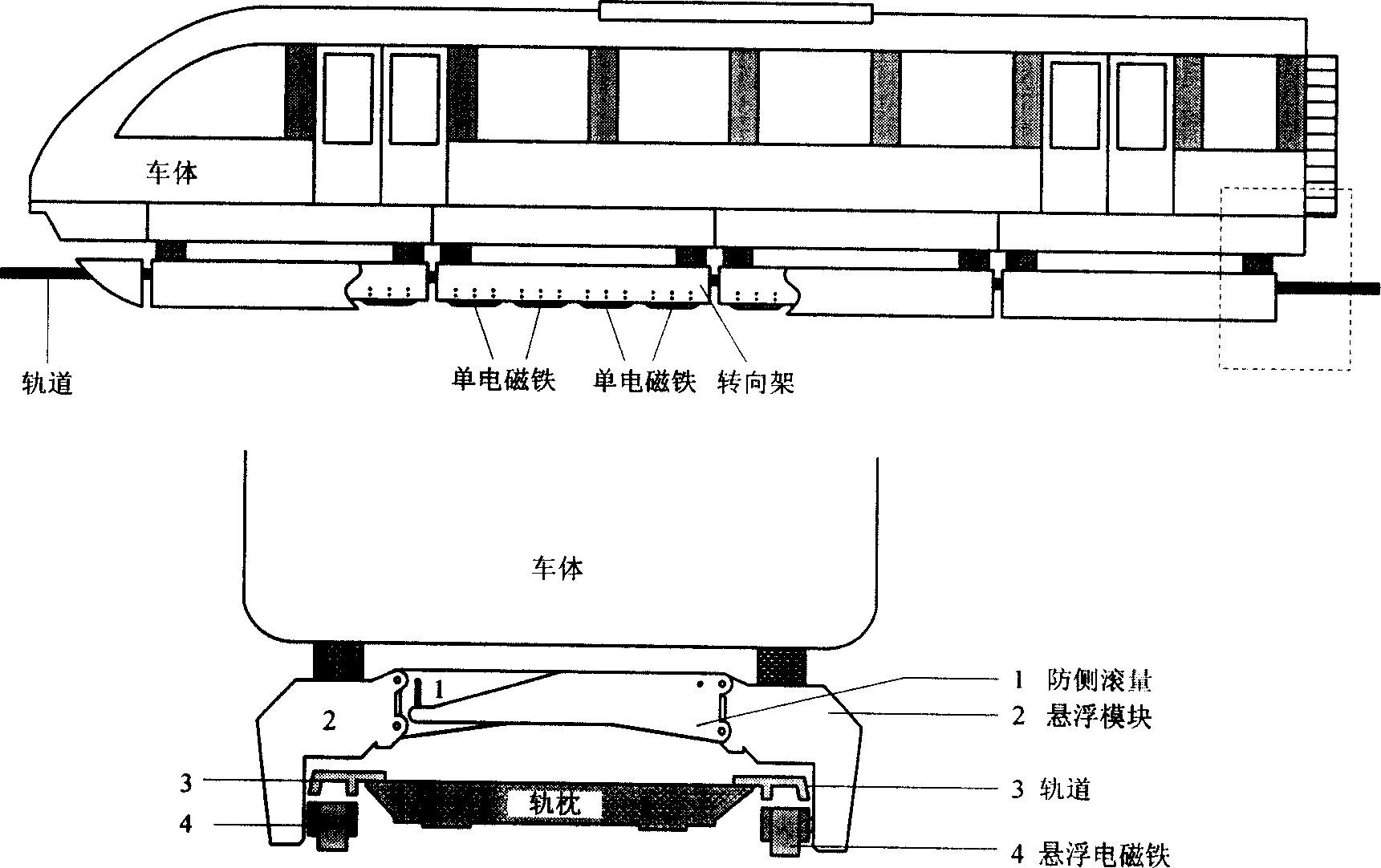

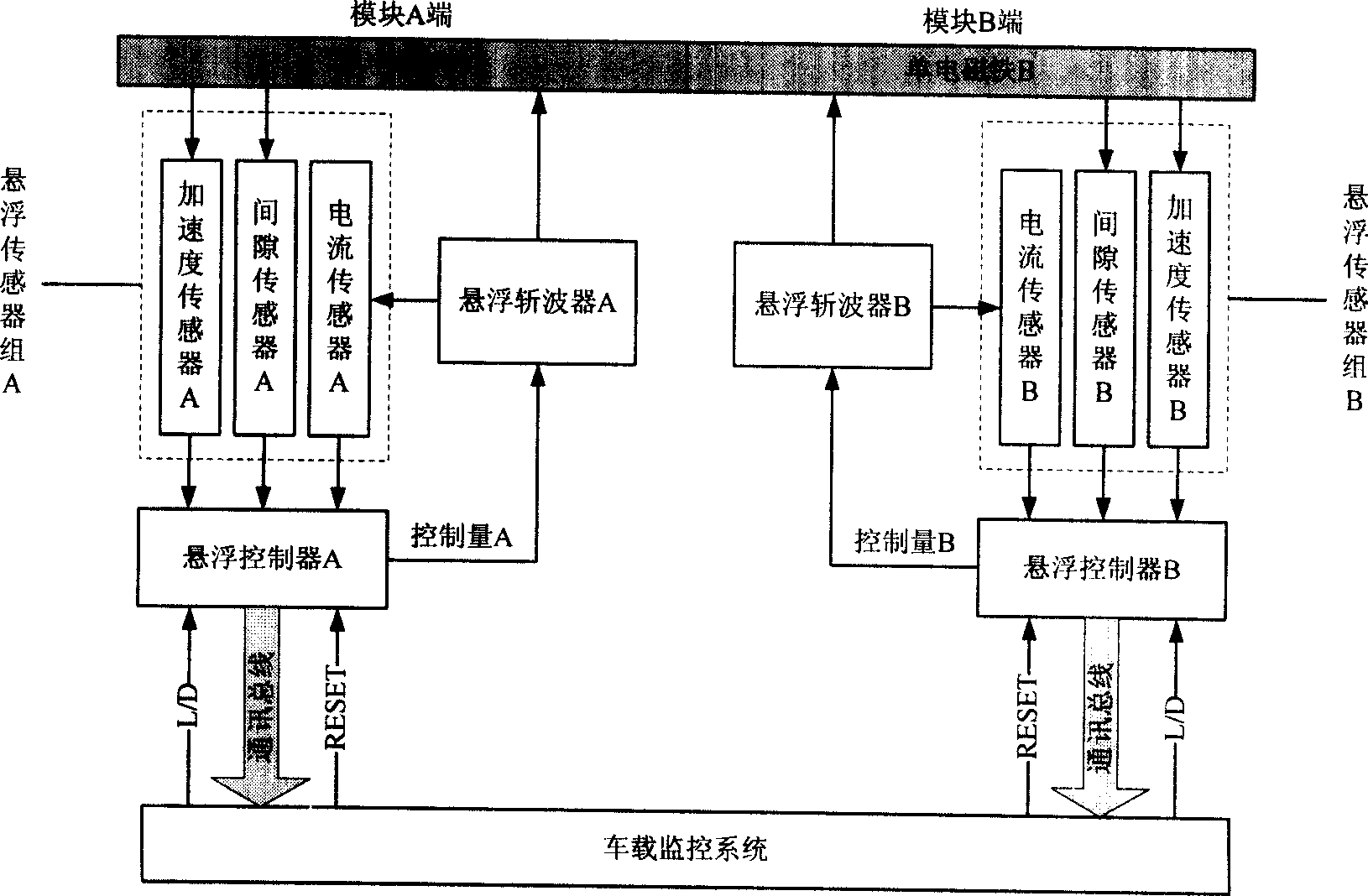

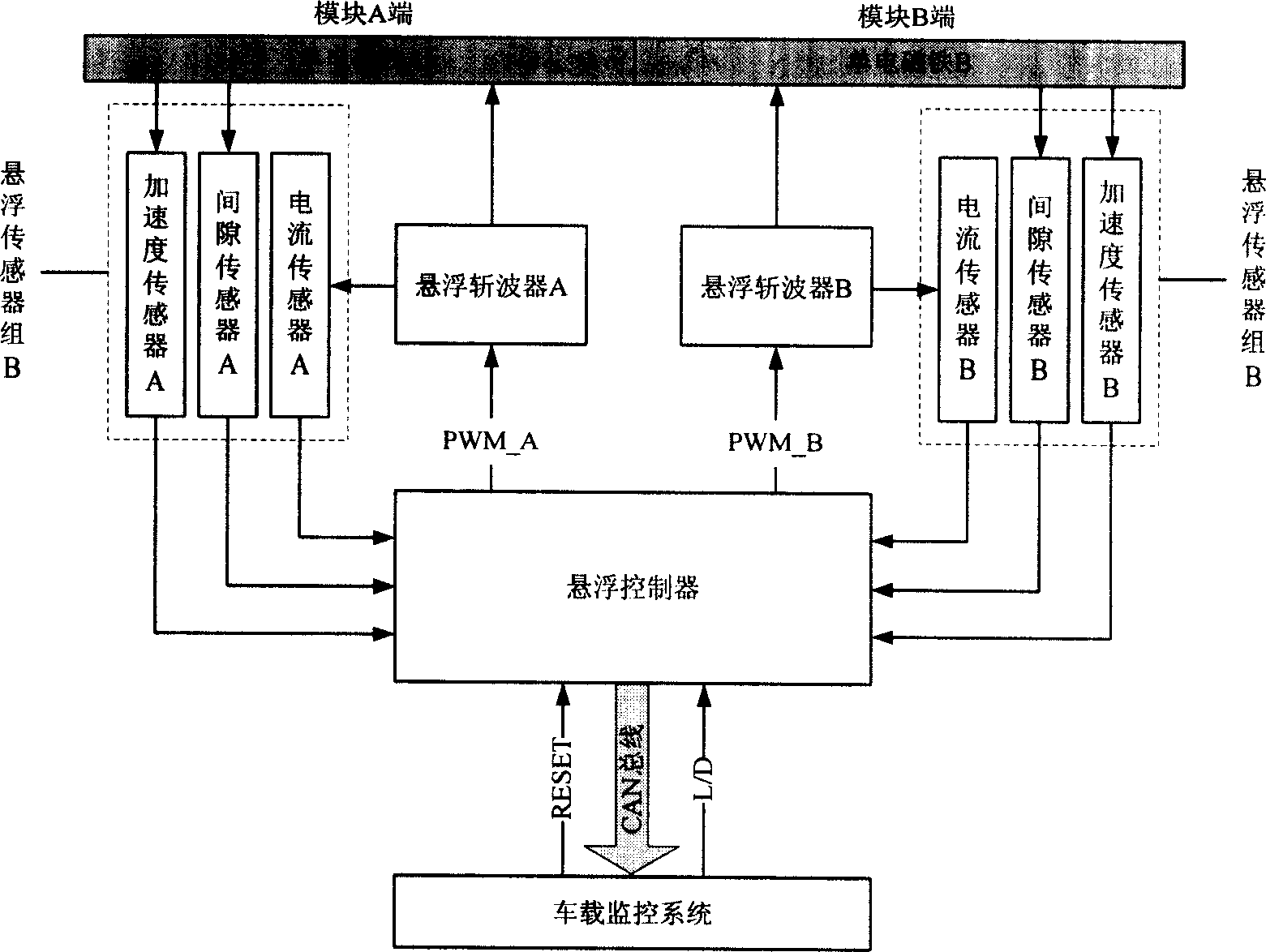

Suspension method for controling module of electromagnetism type magnetic suspension train in normal conduction and low temperature

InactiveCN1915704AAvoid interactionOvercome inherent flaws that existElectric propulsionMagnetic tension forceElectricity

A module levitation control method for the frequently conducting electromagnetic-type low-speed magnetic levitation train features that a levitation control system has only one levitation controller consisting of signal processing unit, A / D converter, clock signal generator, master DSP unit, PWM wave generator and auxiliary DSP unit. Said method includes such steps as measuring the levitation states of ends A and B of a module by two levitation sensors, calculating their control values, and controlling the current values of electromagnets A and B and in turn their electromagnetic forces, so ensuring the gap between module and track to be constant.

Owner:NAT UNIV OF DEFENSE TECH

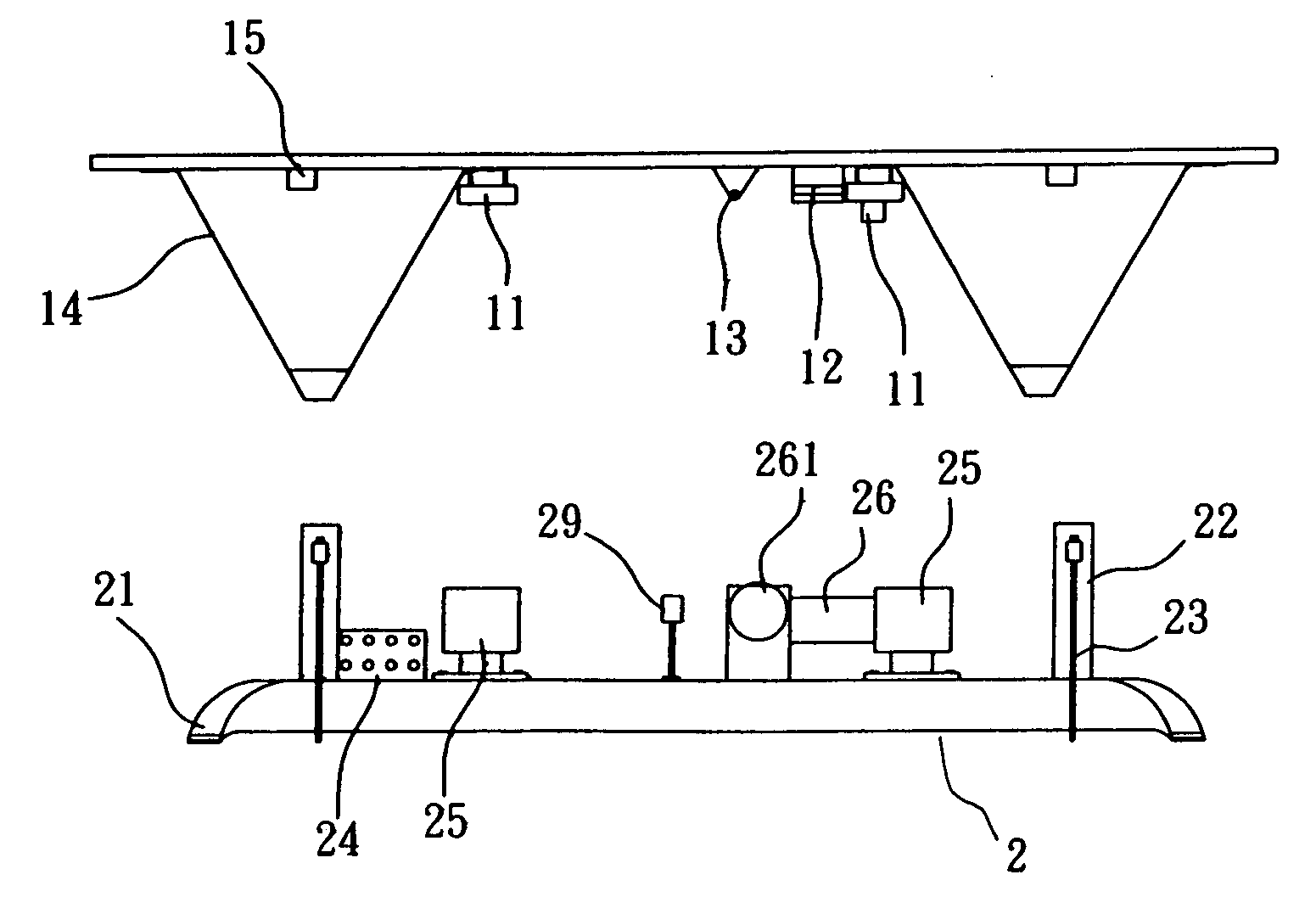

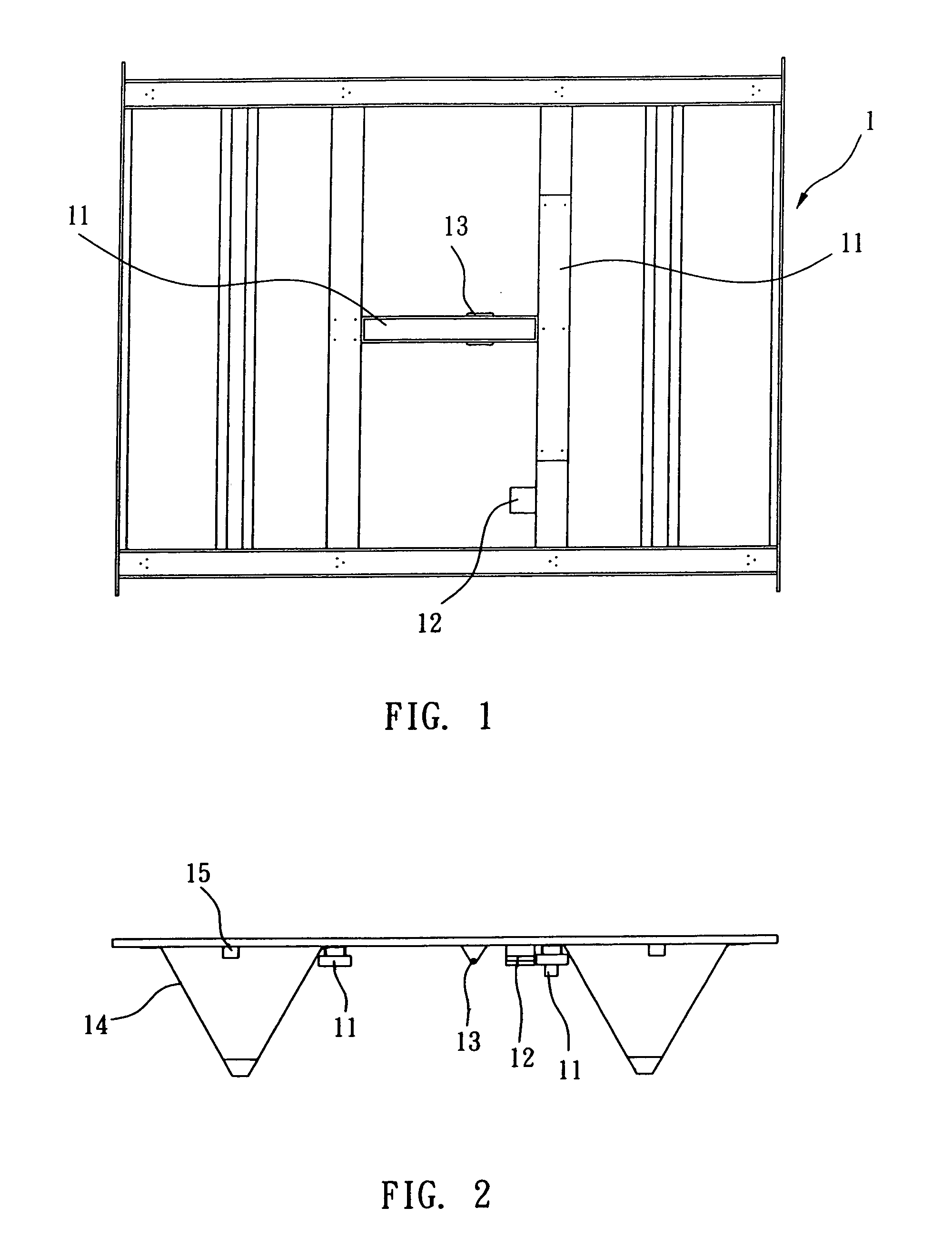

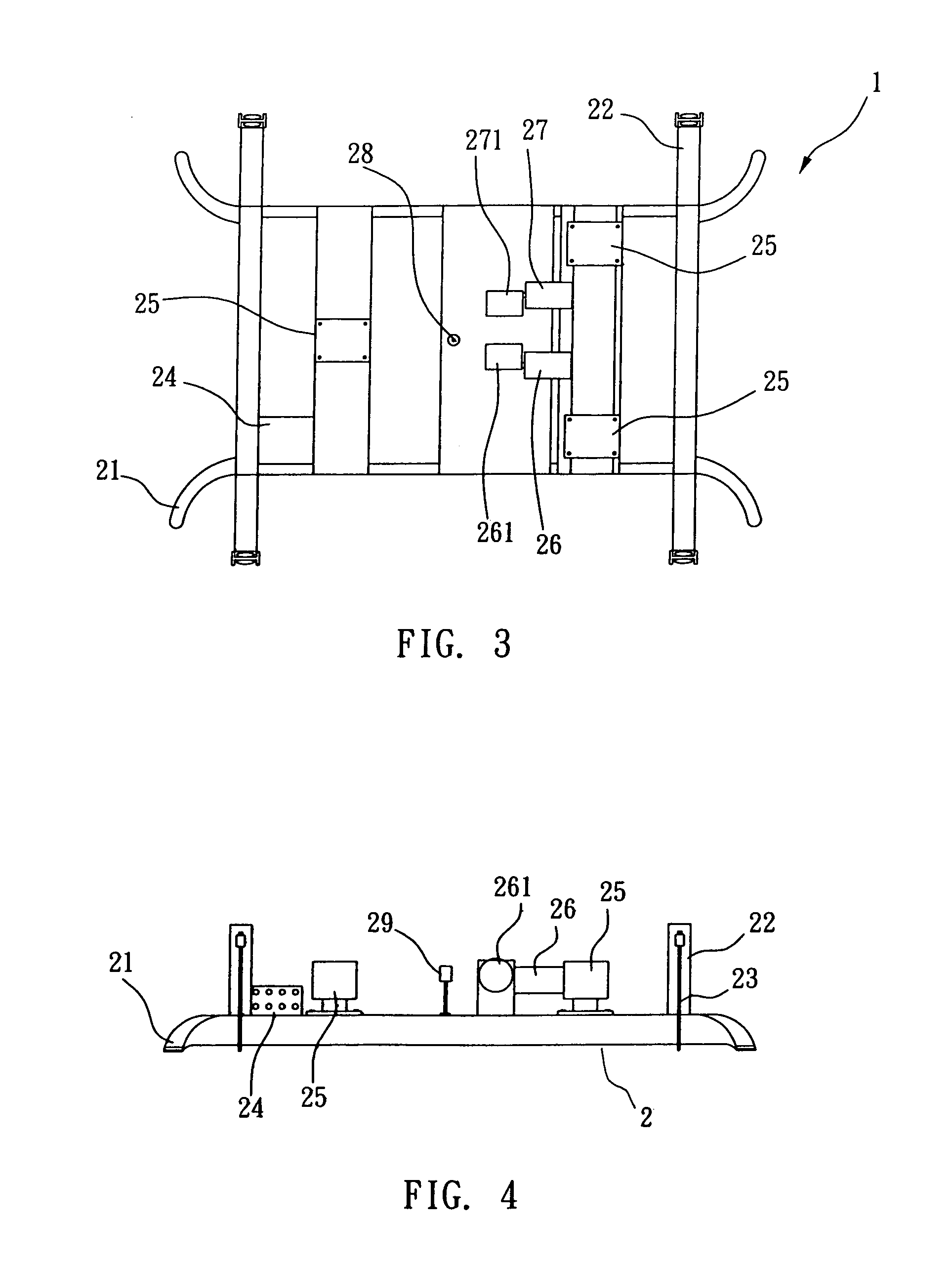

Magnetic levitation bed

InactiveUS6966083B1Good suspensionReduce energy consumptionCradleChiropractic devicesData controlLow speed

A magnetic levitation bed is disclosed to include a bed frame, which is equipped with a plurality of permanent magnet arrays, a first cam-fitting mechanism, and a second cam-fitting mechanism, and a base, which is equipped with a power control box controllable by a remote controller, a plurality of electromagnet arrays arranged corresponding to the permanent magnet arrays and controllable by the control box to attract and repulse the permanent magnet arrays, a first low-speed motor controllable by the power control box to turn a first cam relative to the first cam-fitting mechanism and to further cause the bed frame to oscillate in transverse direction, a second low-speed motor controllable by the power control box to turn a second cam relative to the second cam-fitting mechanism and to further cause the bed frame to oscillate in longitudinal direction, and sensors for detecting oscillation of the bed frame and providing a signal indicative of the position change of the bed frame to a microprocessor for enabling the power control box to control the operation of the first low-speed motor or second low-speed motor subject to the data received from the sensors.

Owner:CHENG SHAO SZU

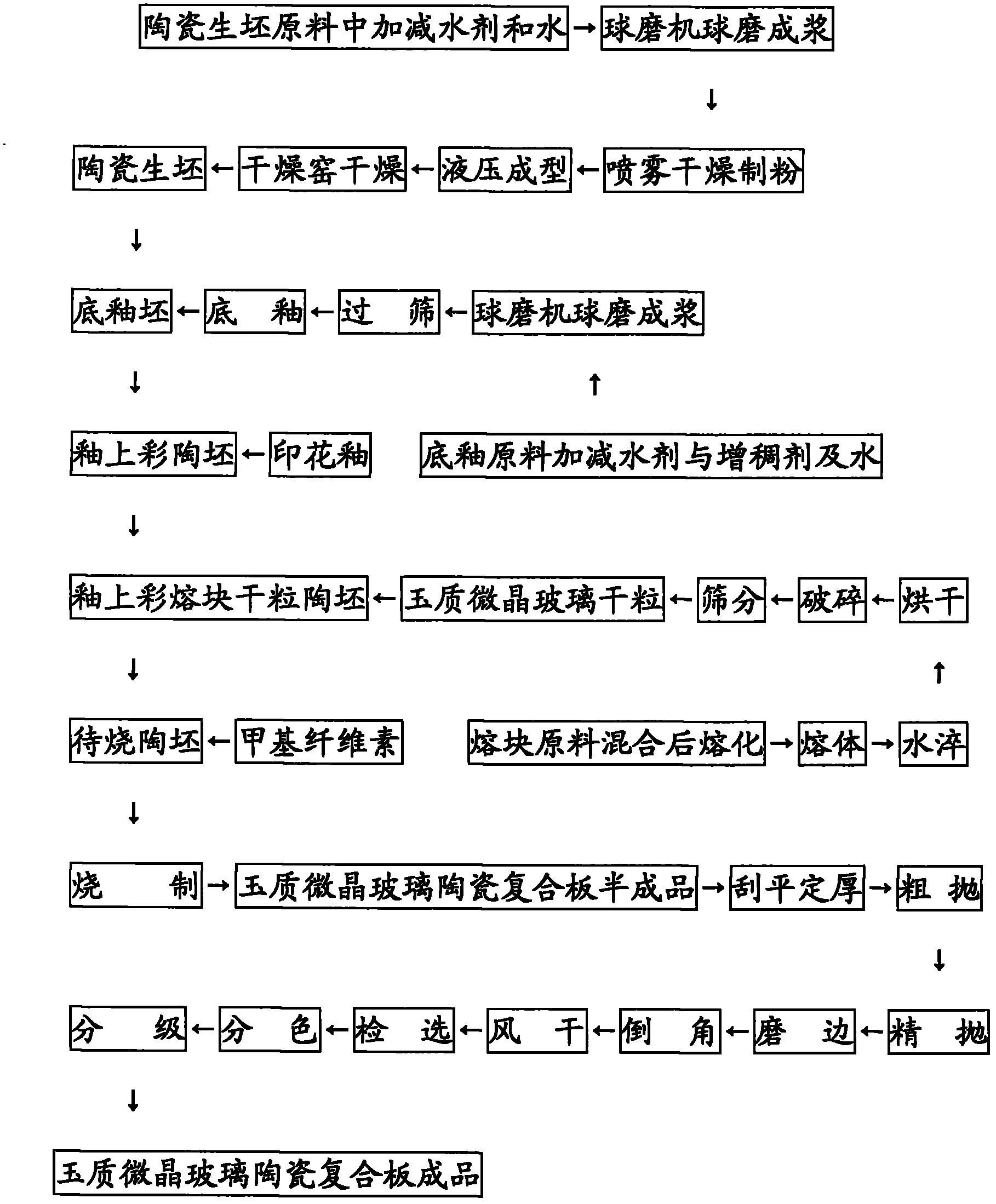

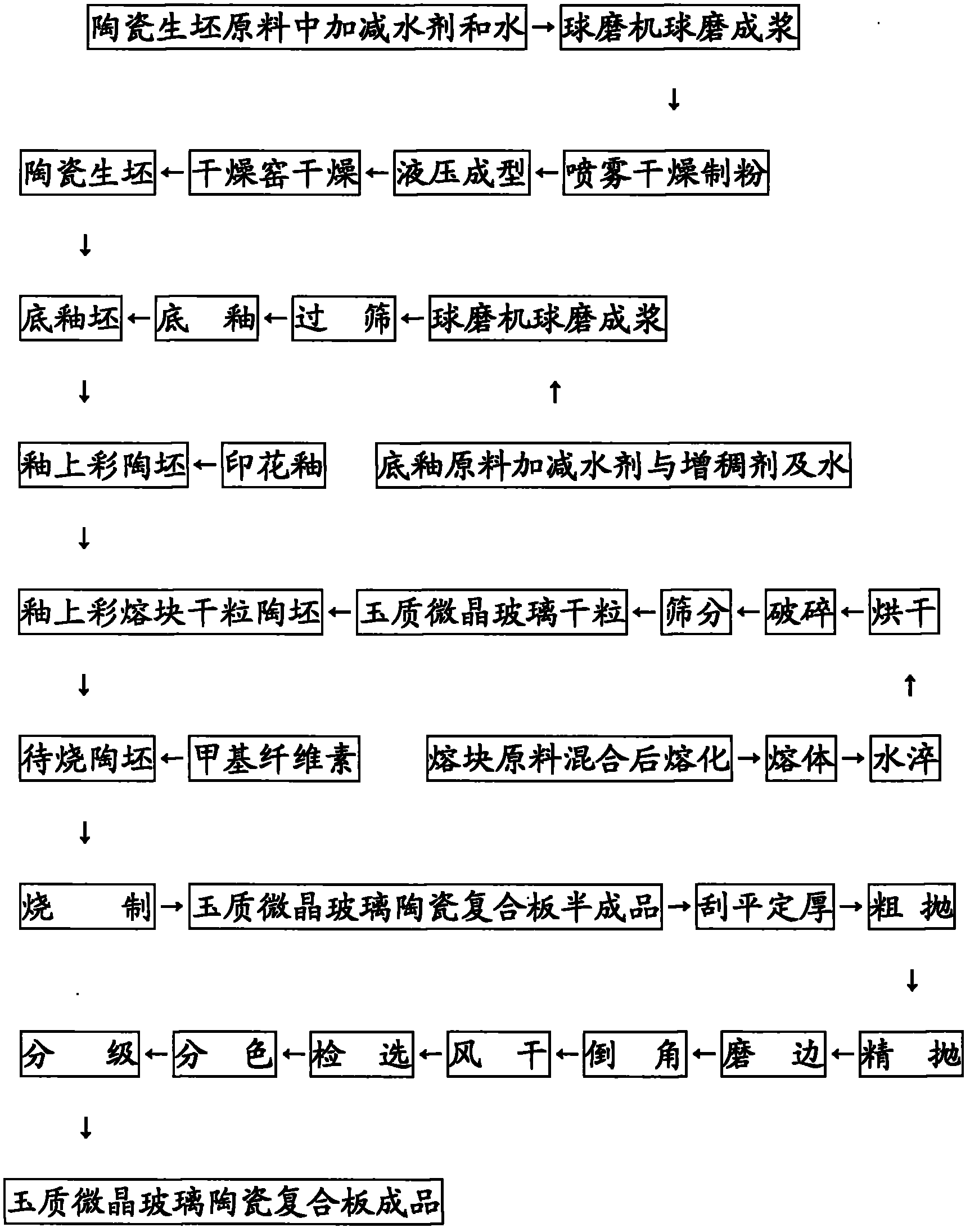

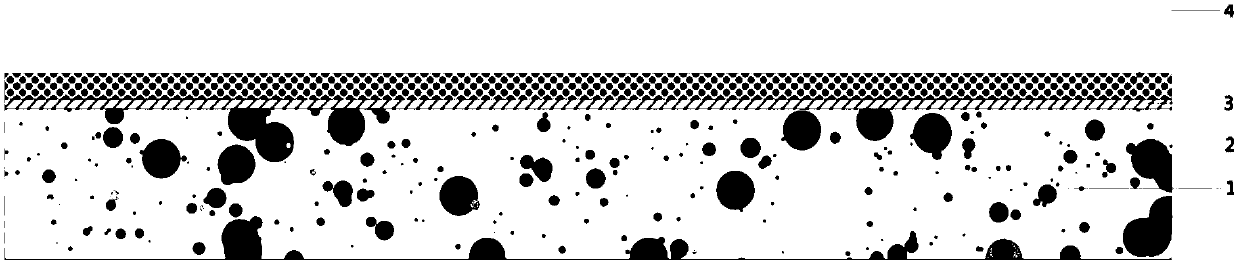

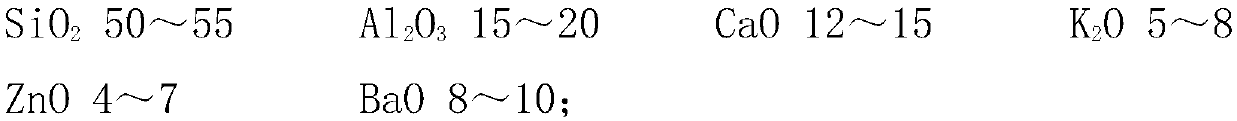

Method for preparing jadeite microcrystal glass ceramic composite board

The invention relates to a method for preparing a jadeite microcrystal glass ceramic composite board, and relates to the technical field of building materials. The method comprises the following steps of: on the basis of a key technology of 'jadeite microcrystal glass clinker dry granules obtained by selecting materials within a preset range of product ingredients', applying a ground coat on a ceramic blank to obtain a ground coat blank, and printing textile printing glaze on the ground coat blank to obtain an over-glaze colored ceramic blank; applying the jadeite microcrystal glass clinker dry granules on the over-glaze colored ceramic blank to obtain over-glaze colored clinker dry granular greenware, spraying methylcellulose for fixing to obtain greenware to be fired; and firing the greenware to be fired to obtain a semi-finished product, strickling, calibrating thickness, polishing coarsely, polishing finely, edging, chamfering, airing, sorting, performing color separation, and grading to prepare a finished product of the jadeite microcrystal glass ceramic composite board. The method is used for producing jadeite microcrystal glass ceramic composite boards, and adapts to a primary or secondary sintering process; and the product is high in quality, high in surface strength and wear resistance and wide in application range, and has a unique jadeite texture and a high comprehensive benefit.

Owner:GUANGDONG BODE FINE IND CONSTR MATERIAL

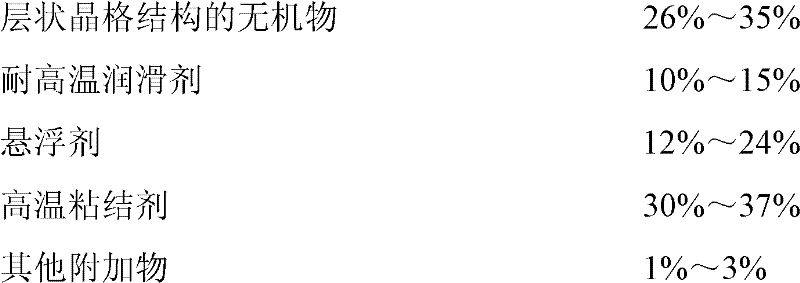

Non-graphite type lubricant for hot die forging of metal and preparation method of non-graphite type lubricant

The invention discloses a water-based non-graphite type lubricant, which is characterized by comprising the following ingredients in percentage by weight: 26%-35% of inorganic substance with layered lattice structures, 10%-15% of high-temperature-resistant lubricant, 12%-24% of suspending agent, 30%-47% of high-temperature adhesive and 1%-3% of adjuvant. The water-based non-graphite type lubricant is an environment-friendly lubricant for hot die forging, can replace a graphite type lubricant, and is especially suitable for the hot die forging of metal, in particular, for the hot die forging of large-sized aluminum pieces. The invention further discloses a preparation method of the water-based non-graphite type lubricant. The preparation method has the advantages of simple preparation process and excellent film-forming performance.

Owner:HUAZHONG UNIV OF SCI & TECH

Full-body anti-slip ceramic brick and production method thereof

The invention relates to a full-body anti-slip ceramic brick and a production method thereof. According to the full-body anti-slip ceramic brick, a compound layer brick body is composed of a colored spot green body layer, large-particle colored spots mixed into the colored spot green body layer, a pattern decoration layer on the surface of the green body layer and a dry-particle glaze layer attached to the pattern decoration layer; the production method comprises the following steps: (1) pressing a green body, wherein green body powder is composed of conventional powder and large-particle powder; (2) drying under the conditions that the drying temperature is 80 to 100 DEG C and the drying time is 60 to 80 min; (3) decorating a pattern: before decorating the pattern, not applying any glazelayer or other protection layers on the surface of the blank body, so as to directly realize inkjet printing decoration on the surface of the blank body; (4) applying dry-particle glaze: spraying theglaze through a bell jar; (5) firing under the conditions that the temperature is 1150 to 1160 DEG C and the time is 50 to 60 min.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +1

Lost foam casting cast iron coating for preventing carbon defects and preparation method thereof

InactiveCN101767184AGood suspensionImprove thixotropyFoundry mouldsFoundry coresPolyvinyl alcoholOctanol

The invention discloses a lost foam casting cast iron coating for preventing carbon defects, which comprises the following components by weight percent: 60.5%-64.5% of bauxite, 13.5-17.5% of kaolin, 3.5%-6.0% of talc powder, 1.7%-3.5% of attapulgite, 0.4%-0.8% of sodium lignosulphonate, 2.5%-6.0% of aluminum sulfate, 1.7%-3.5% of polyvinyl alcohol, 3.5%-5.0% of silica sol, 0.1%-0.2% of iron oxide powder and 0.01%-0.02% of n-octanol, and the sum of the components is 100%. The lost foam casting cast iron coating is prepared by respectively preparing water solution of the attapulgite, the polyvinyl alcohol and the aluminum sulfate, evenly mixing the bauxite, the kaolin, the talc powder and the iron oxide powder for preparing mixed powder material, mixing the water solution of the attapulgite, the polyvinyl alcohol and the aluminum sulfate, the silica sol and the refractory mixed powder material with the n-octanol, stirring and grinding. The coating has the advantages of good thixotropy, good coating property, high coating strength and good gas permeability; and the surface of a cast is smooth and has no wrinkles and other carbon defects.

Owner:NANTONG XINZHENGDA SPECIAL STEEL

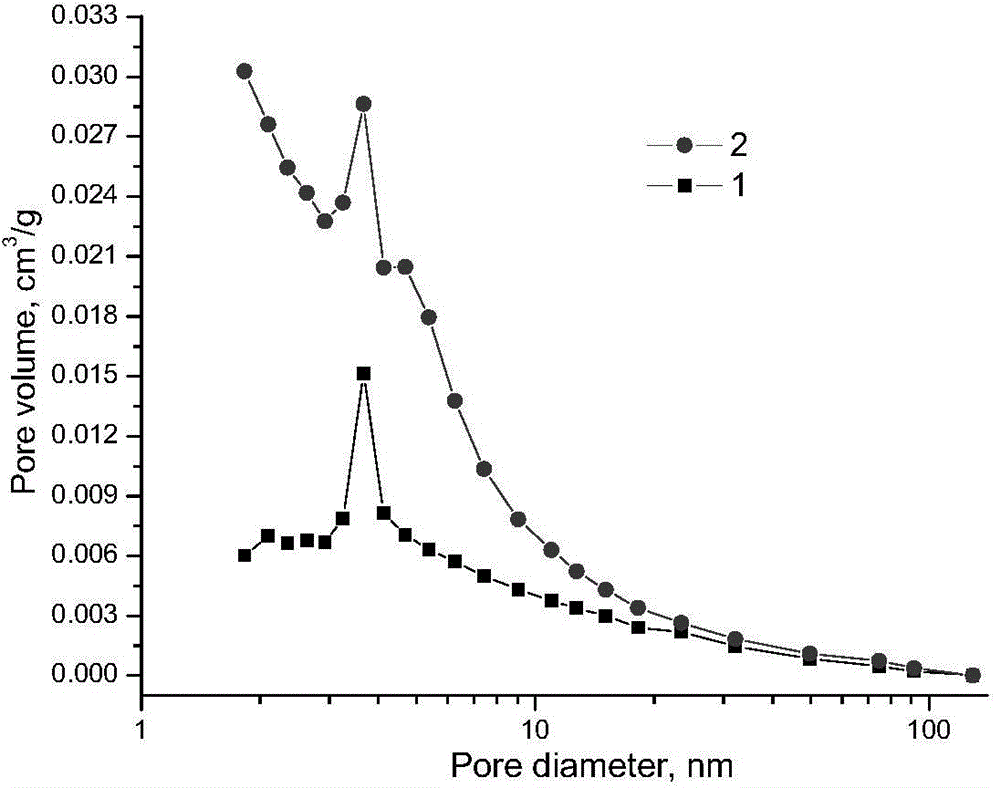

Polyaminoester /molecular sieve composite material and its preparation method

The invention relates to a polyurethane and inorganic porous granule composite material and method for preparation comprising the steps of, carrying out surface organic modifying treatment to the molecular screen whose grain diameter is 0.05-40 um and bore diameter is 0.3-3nm, mixing homogeneously with polyesters or polyethers polyhydric alcohol by the stirring with mechanical force, performing fabrication with polyisocyanates, chain expanded cross linking agent and auxiliary agent through the conventional polyurethane synthesizing process by one-step method or pre-aggressiveness, the mechanic property and solvent resistance of the obtained composite material are improved substantially.

Owner:TAIYUAN UNIV OF TECH +1

Centrifugal casting roller coatings and preparation method thereof

ActiveCN101491823AImprove heat resistanceGood chemical stabilityFoundry mouldsFoundry coresFatty alcoholN-Butyl Alcohol

The invention relates to a centrifugal casting roller coating and a preparation method thereof. The centrifugal casting roller coating is characterized by comprising the following compositions in percentage by mass: 12 to 15 percent of zircon powder, 8 to 10 percent of quartz powder, 8 to 10 percent of bauxite, 0.3 to 0.6 percent of silica sol, 0.1 to 0.4 percent of sodium carboxymethyl cellulose, 0.15 to 0.35 percent of alkyl benzene sodium sulfonate, 0.15 to 0.35 percent of sodium sulfate, 0 to 0.02 percent of n-butyl alcohol, 0 to 0.02 percent of n-octyl alcohol, 0.10 to 0.18 percent of fatty alcohol polyethenoxy ether, and the balance being water, wherein the mass percentage of the zircon powder + the quartz powder + the bauxite is more than or equal to 30 percent and less than or equal to 35 percent, the mass percentage of the alkyl benzene sodium sulfonate + the sodium sulfate is more than or equal to 0.35 percent and less than or equal to 0.55 percent, and the mass percentage of the n-butyl alcohol + the n-octyl alcohol is more than or equal to 0.02 percent and less than or equal to 0.03 percent. The coating is used for centrifugal casting roller production after stirring, grinding and sieving, and has good use effect.

Owner:靖江市黎明铸造材料厂

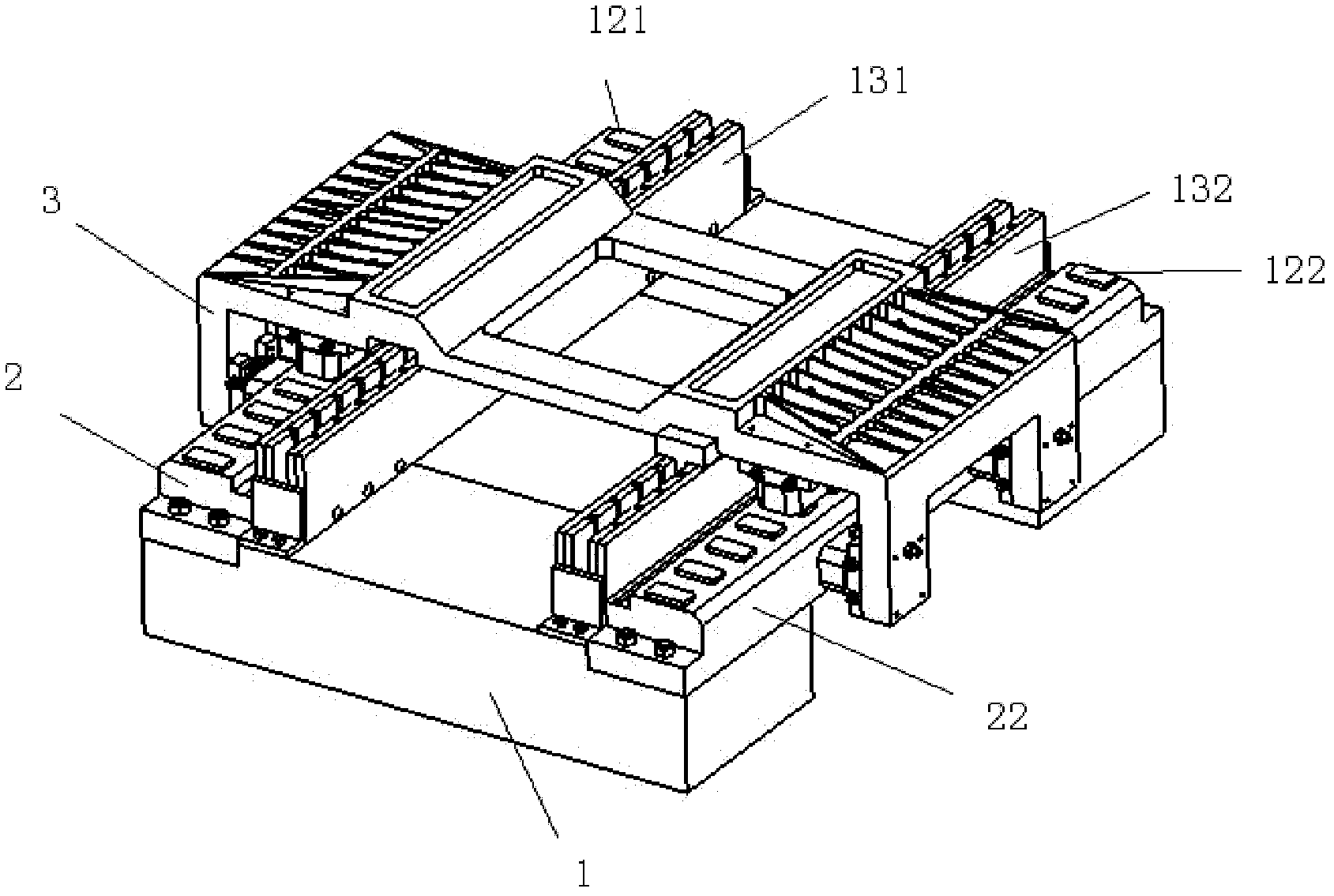

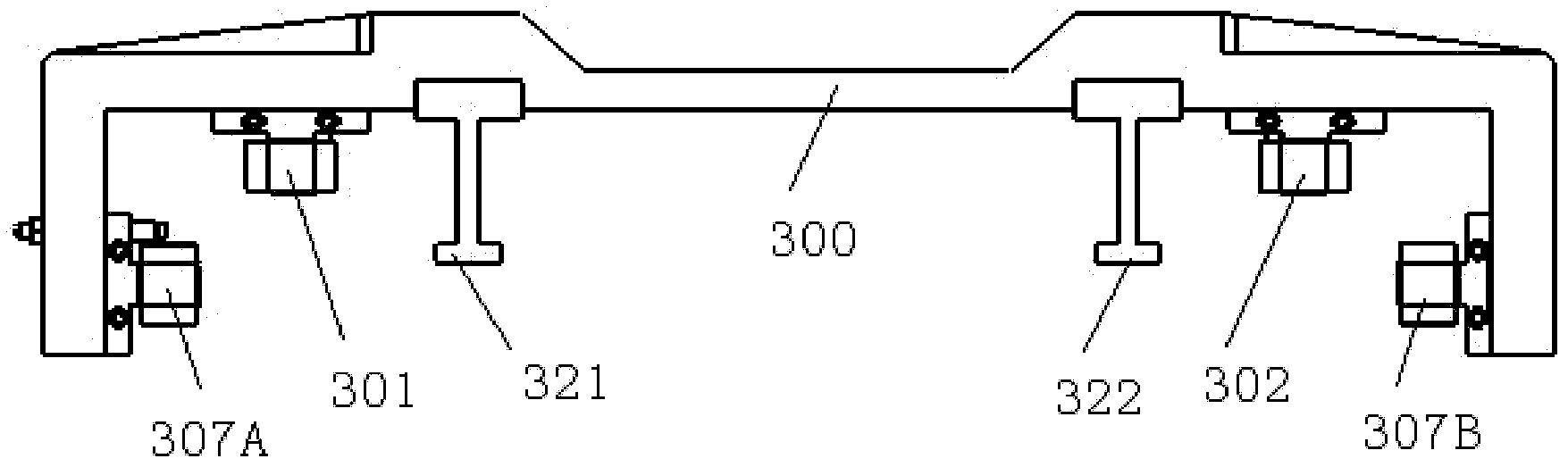

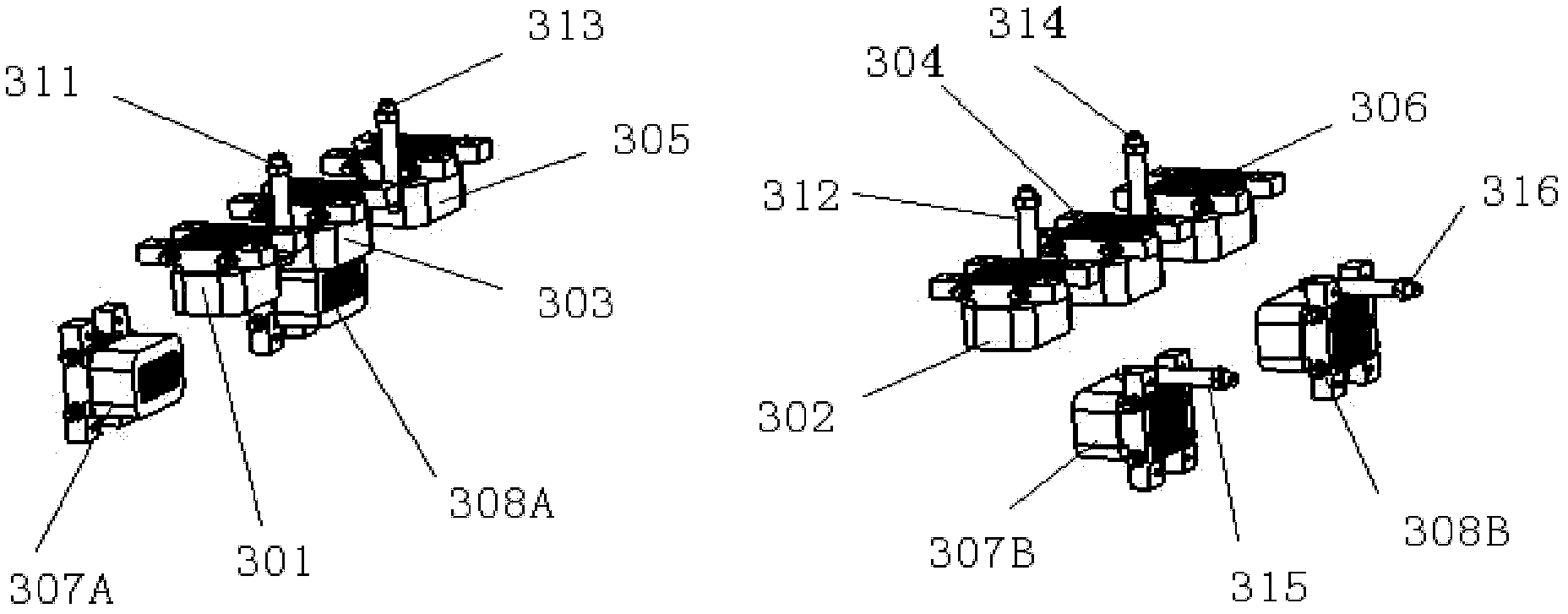

Magnetic suspension linear motion platform based on combination of permanent magnets and electromagnets

The invention discloses a magnetic suspension linear motion platform based on the combination of permanent magnets and electromagnets. The electromagnets are vertically installed in a suspensoid, array permanent magnets are arranged on the surface of a guide rail, the suspension of the suspensoid can be realized by utilizing the principle of holopolarity repulsion between the electromagnets and the permanent magnets; and meanwhile, an eddy current displacement sensor is combined to realize the stable suspension of the suspensoid above the guide rail; two pairs of electromagnets are horizontally installed in the suspensoid, which can provide guidance for the linear motion of the platform by combining with the eddy current displacement sensor; a linear motor stator is fixed on a base, a linear motor rotor is fixed on the suspensoid, a grating ruler is arranged on the surface of the guide rail, and the reading head of the grating ruler is installed on the suspensoid, thus the precise linear positioning motion of the suspensoid can be realized. The platform provided by the invention can realize the functions such as super cleaning, high speed, long stroke, precise positioning motion and the like, which can not be realized by the traditional scheme that a rotary servo motor is utilized to drive, a precise ball screw is utilized to transmit and a slide guide is utilized to support, and has the advantages of good load bearing characteristic and stable suspension performance.

Owner:CENT SOUTH UNIV

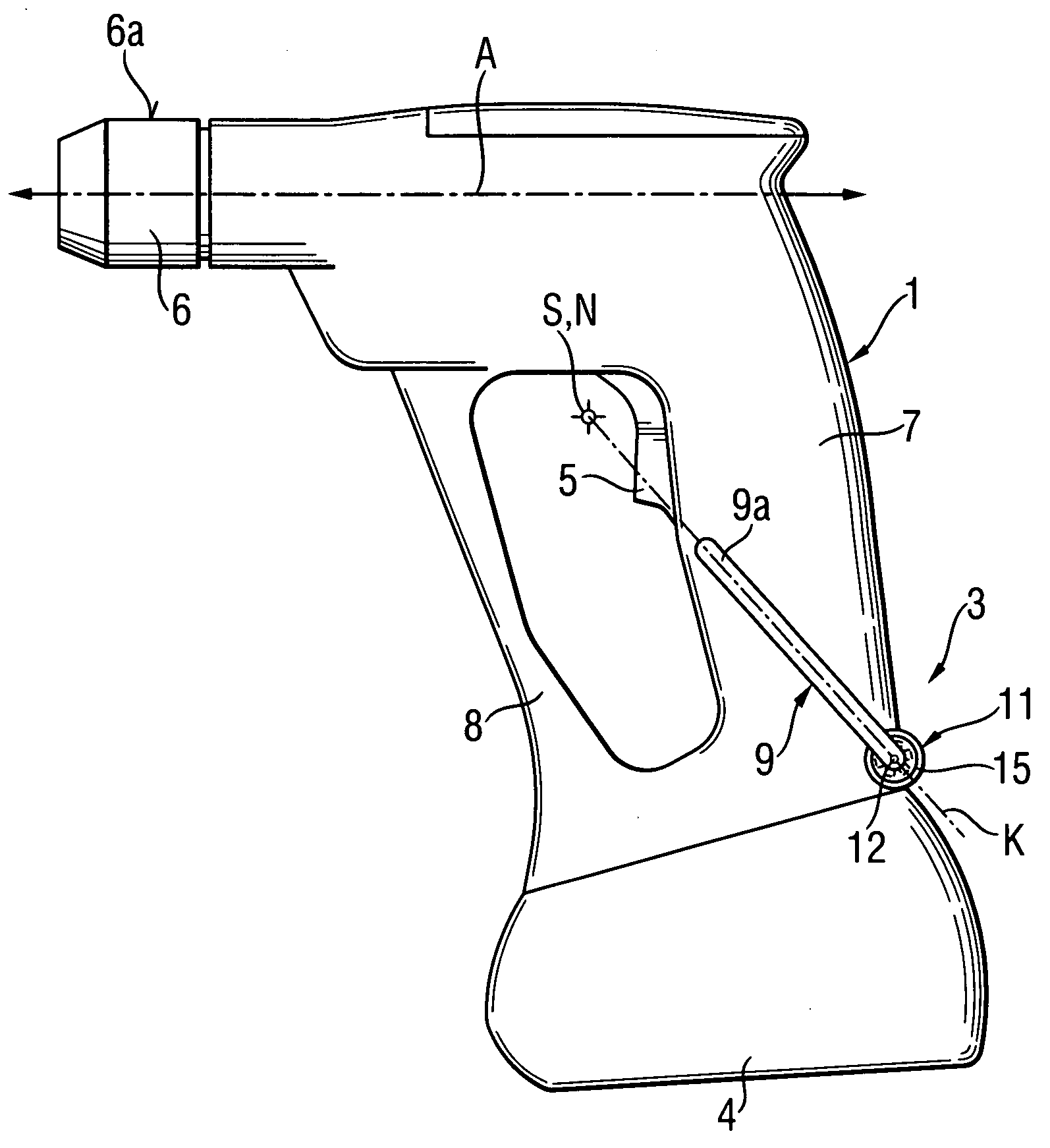

Hand-held power tool with a holding device

InactiveUS20050015935A1Reduce manufacturing costEasy to operateTravelling carriersHoldersClassical mechanicsHand held

A hand-held power tool including a housing (1) having a handle (7), and a holding device (3) having a catch element (9) with a free end (9a) for suspending the power tool, with the free end (9a) having a main axis (K) intersecting a normal live (N) that extends transverse to the tool plane which is defined by the plane of the handle and the operational direction of the tool, and passes through the center of gravity (S) of the tool.

Owner:HILTI AG

Well completion foamed spacer fluids and methods

InactiveUS6852676B1Drilling fluidEfficient removalOther chemical processesFlushingWellboreEnvironmental geology

Owner:HALLIBURTON ENERGY SERVICES INC

Semi-dry method gun mix for coal oven reparing

Owner:BAOSHAN IRON & STEEL CO LTD

Cream body bath composition and application thereof

ActiveCN103202781AIncrease dosageImprove foam propertiesCosmetic preparationsToilet preparationsSURFACTANT BLENDChemistry

The invention belongs to the field of daily-use chemicals, and relates to a cream body bath composition and an application thereof. The cream body bath composition is characterized by comprising 2.0-3.0% of an anionic surfactant based on the weight of the composition, 0.1%-20.0% of grease based on the weight of the composition, 0.5%-20.0% of a rheology modifier based on the weight of the composition, 0.1%-10.0% of an emulsifying agent based on the weight of the composition, and the balance being water. The composition can well solve the coexisting problems of the surfactant, the grease and water, has good foams, relatively good cleaning force and moistening skin feelings, and can be applied in preparation of daily chemical body washing articles.

Owner:浙江萃芙化妆品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Formulations of 3-(6-(1-(2,2-difluorobenzo[d][1,3]dioxol-5-yl) cyclopropanecarboxamido)-3-methylpyridin-2-yl)benzoic acid Formulations of 3-(6-(1-(2,2-difluorobenzo[d][1,3]dioxol-5-yl) cyclopropanecarboxamido)-3-methylpyridin-2-yl)benzoic acid](https://images-eureka.patsnap.com/patent_img/696463ed-33f8-4fec-aa4c-24a8efa3050e/US20090176839A1-20090709-D00000.png)

![Formulations of 3-(6-(1-(2,2-difluorobenzo[d][1,3]dioxol-5-yl) cyclopropanecarboxamido)-3-methylpyridin-2-yl)benzoic acid Formulations of 3-(6-(1-(2,2-difluorobenzo[d][1,3]dioxol-5-yl) cyclopropanecarboxamido)-3-methylpyridin-2-yl)benzoic acid](https://images-eureka.patsnap.com/patent_img/696463ed-33f8-4fec-aa4c-24a8efa3050e/US20090176839A1-20090709-D00001.png)

![Formulations of 3-(6-(1-(2,2-difluorobenzo[d][1,3]dioxol-5-yl) cyclopropanecarboxamido)-3-methylpyridin-2-yl)benzoic acid Formulations of 3-(6-(1-(2,2-difluorobenzo[d][1,3]dioxol-5-yl) cyclopropanecarboxamido)-3-methylpyridin-2-yl)benzoic acid](https://images-eureka.patsnap.com/patent_img/696463ed-33f8-4fec-aa4c-24a8efa3050e/US20090176839A1-20090709-D00002.png)