Magnetic suspension linear motion platform based on combination of permanent magnets and electromagnets

A linear motion, combined technology, applied in the direction of holding devices, electrical components, etc. using magnetic attraction or thrust, can solve problems such as unfavorable performance and quality of integrated circuit chips, metal dust generated by friction and wear, and low air bearing capacity. , to achieve the effect of low impact resistance and anti-interference ability, reducing mechanical loss, simple and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail in conjunction with the accompanying drawings and specific implementation process.

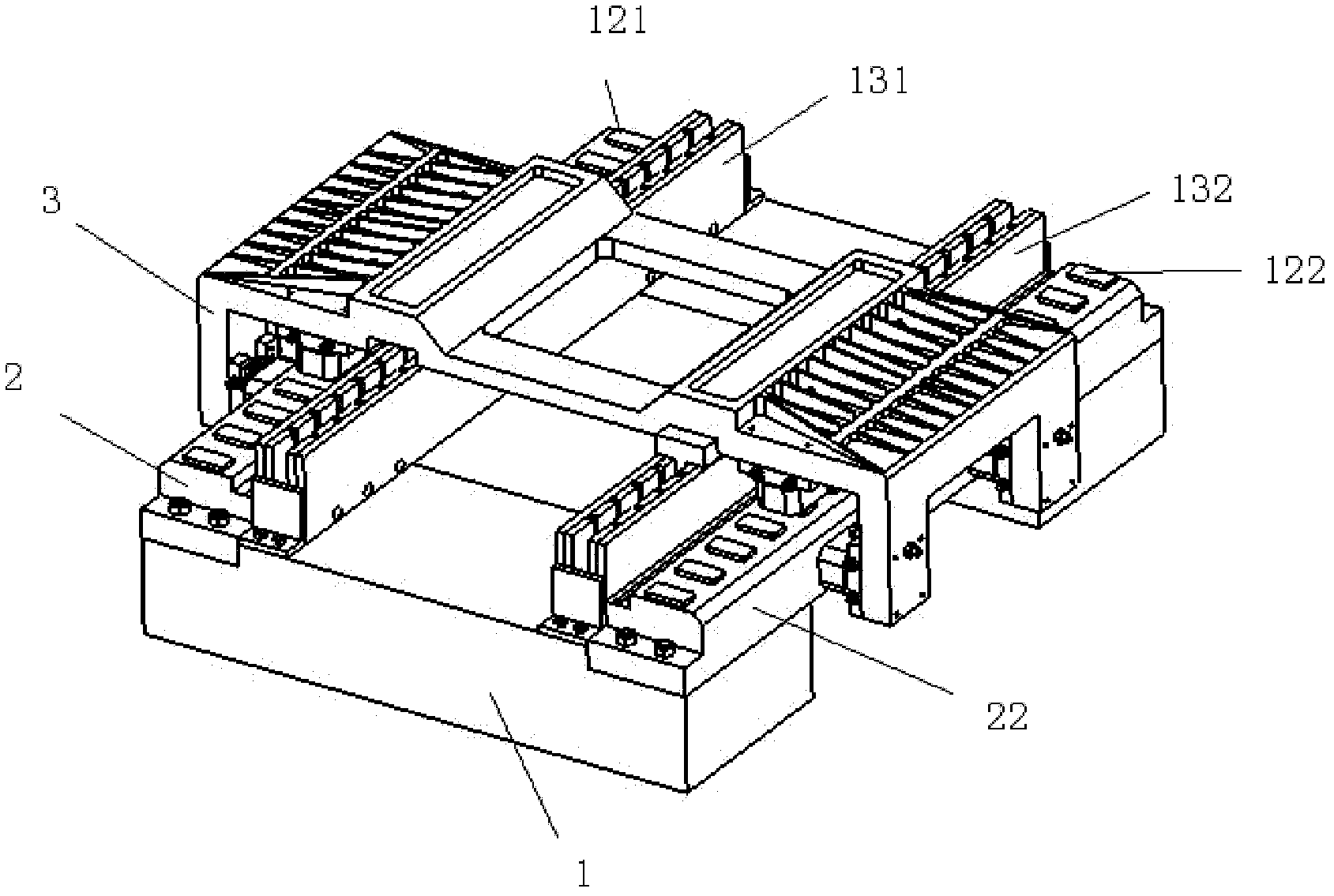

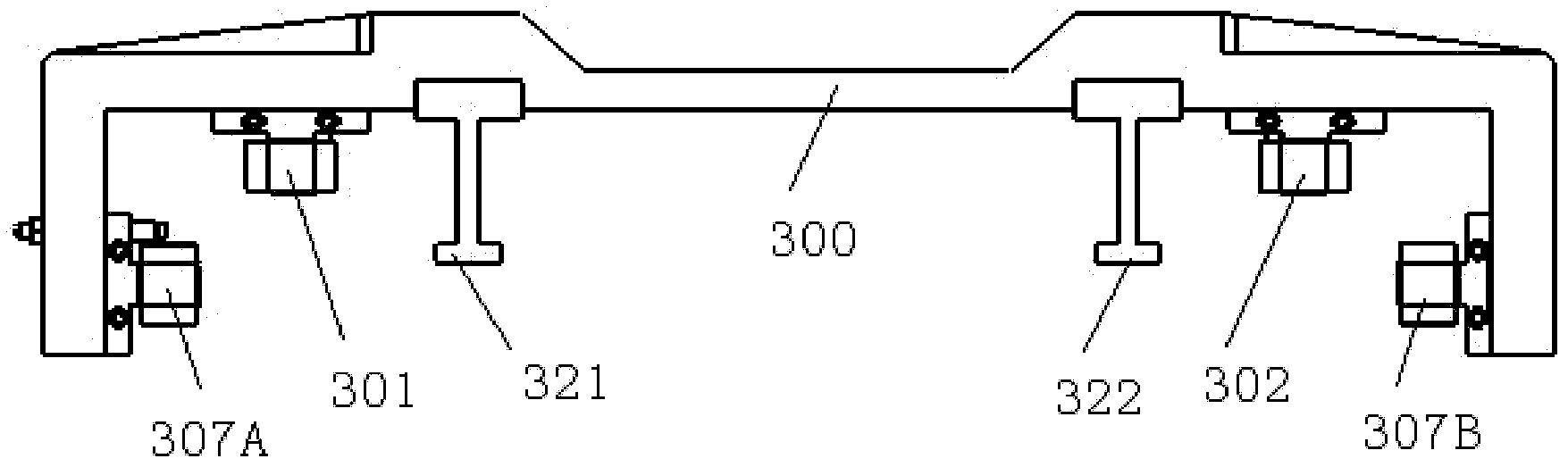

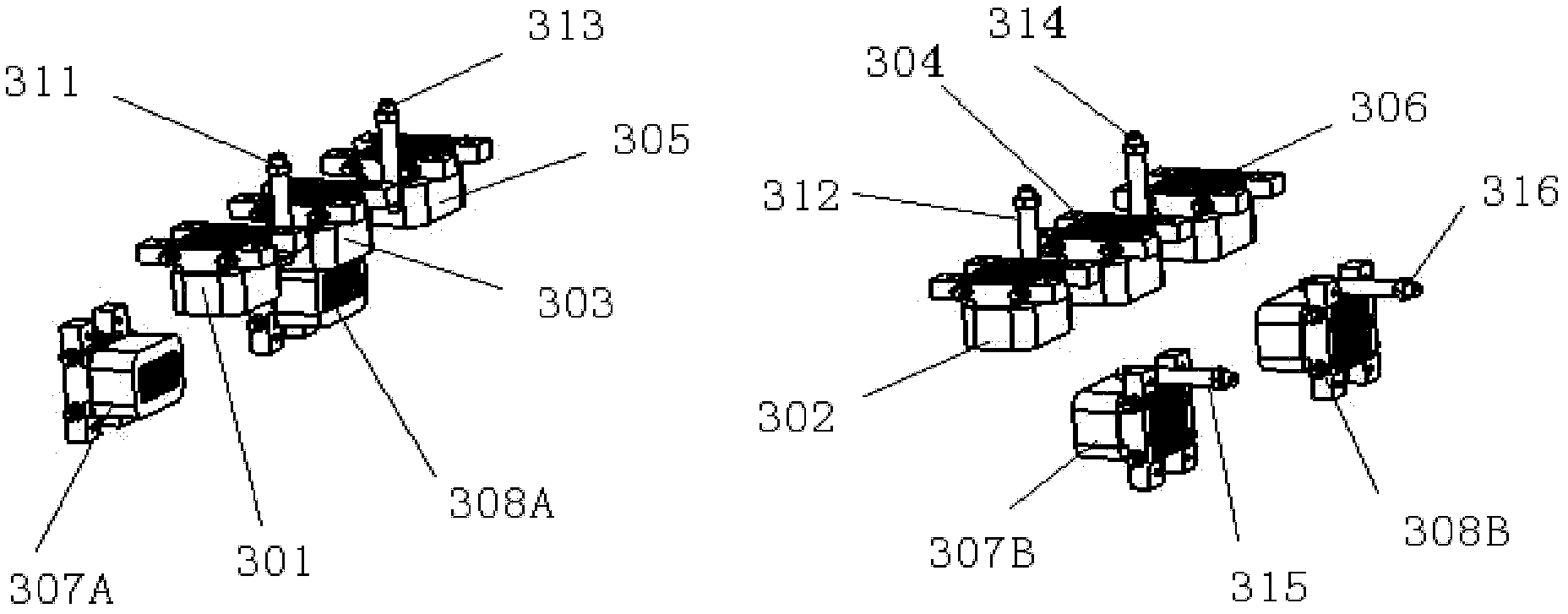

[0030] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 , from bottom to top by the granite foundation 1, the first linear guide 2, the second linear guide 22, suspension body 3 three parts. The guide rail surfaces of the first linear guide rail 2 and the second linear guide rail 22 corresponding to the electromagnet are all polished and homogenized, so that the flatness and verticality of the processed guide rail surface can reach micron-level precision. The guide rail surface of the first linear guide 2 is provided with the first permanent magnet 121 of array, the guide rail surface of the second linear guide 22 is provided with the second permanent magnet 122 of array, and the part structure of suspension body 3 is as follows figure 2As shown, there are mainly aluminum alloy U-shaped components 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com