Patents

Literature

1270 results about "Eddy-current sensor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

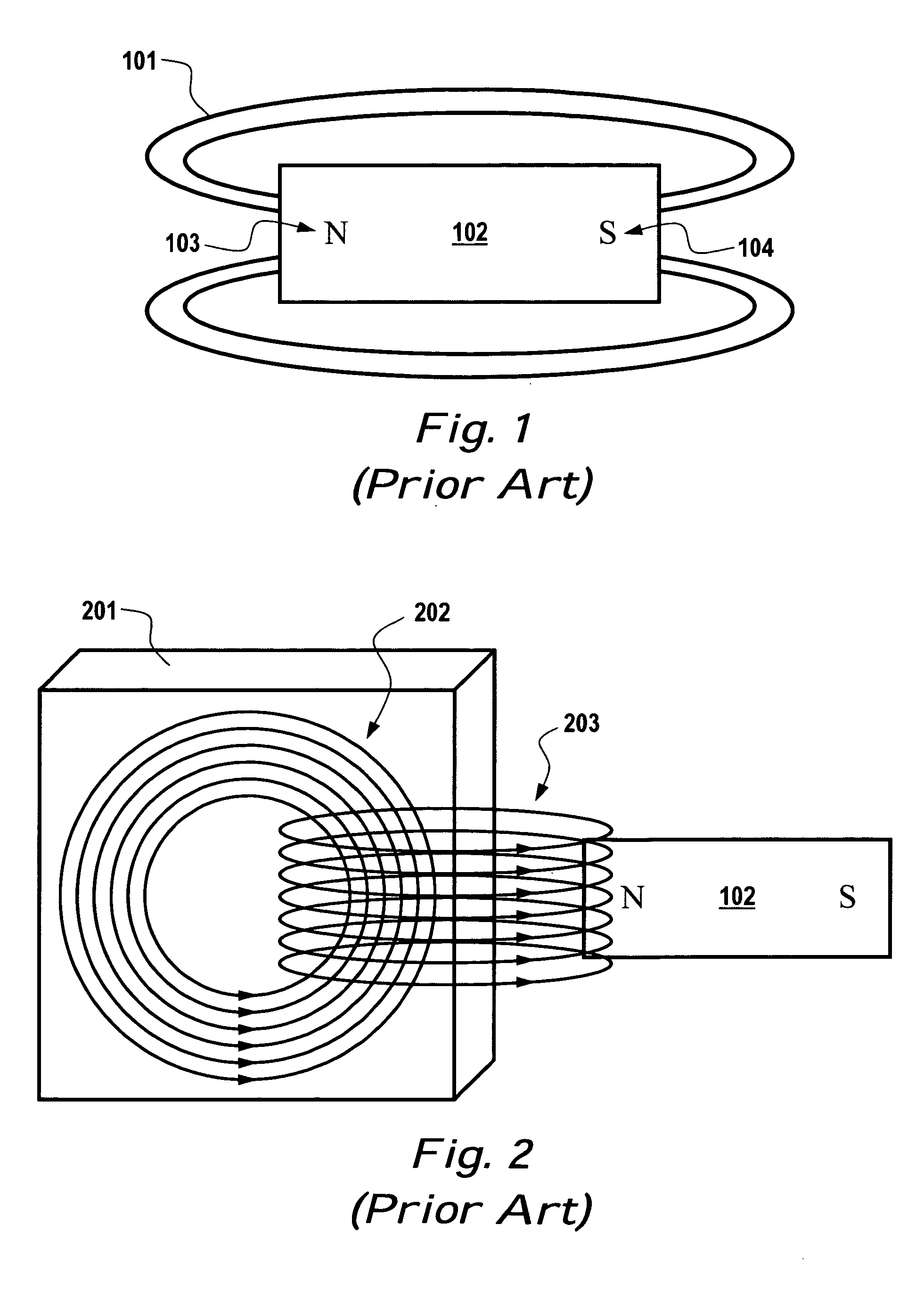

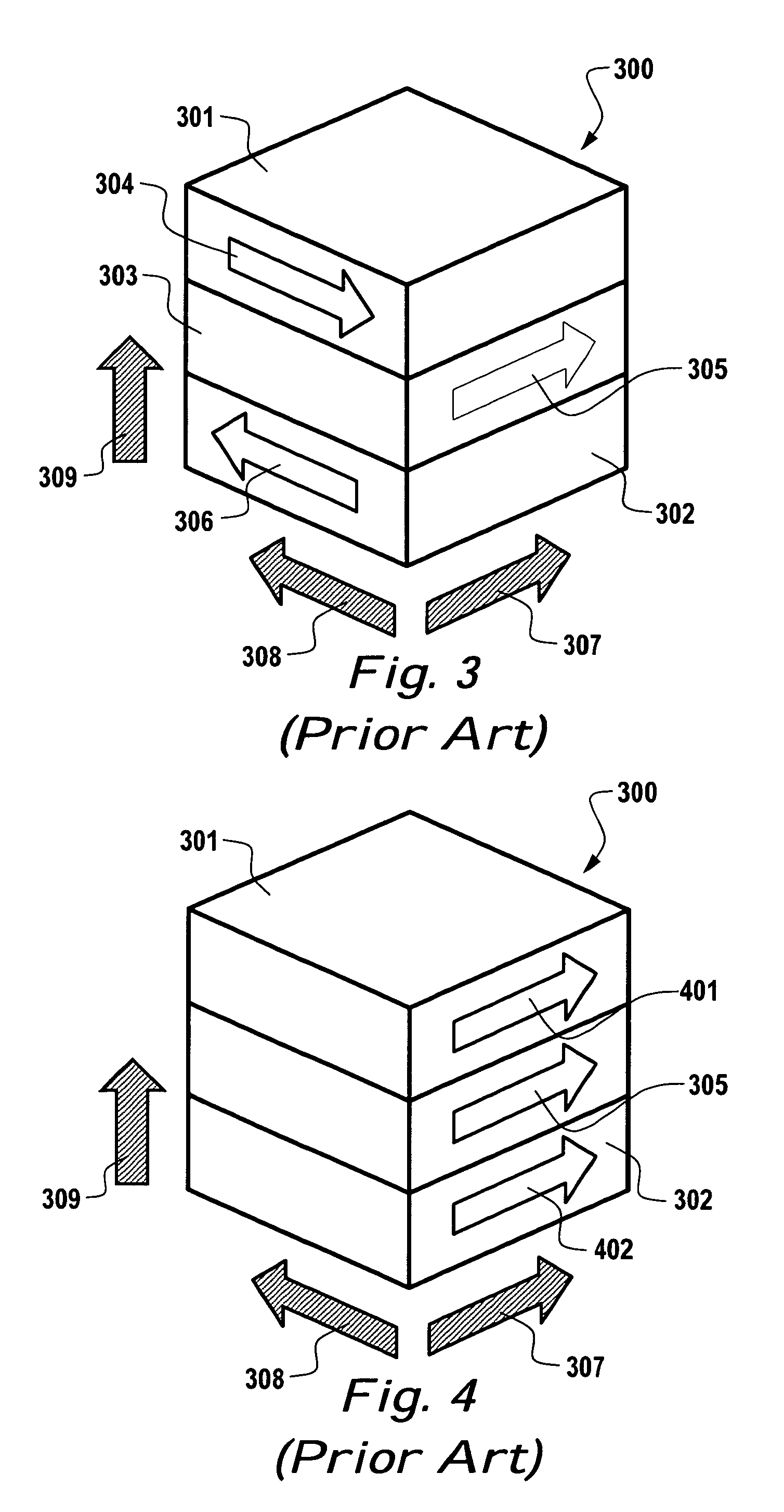

Eddy current sensors uses the principle of eddy current formation to sense displacement. Eddy currents are formed when a moving or changing magnetic field intersects a conductor or vice versa. The relative motion causes a circulating flow of electrons, or currents, within the conductor. These circulating eddies of current create electromagnets with magnet fields that oppose the effect of applied magnetic field. The stronger the applied magnetic field, or greater the electrical conductivity of the conductor, or greater the relative velocity of motion, the greater the currents developed and greater the opposing field. Eddy current probes senses this formation of secondary fields to find out the distance between the probe and target material.

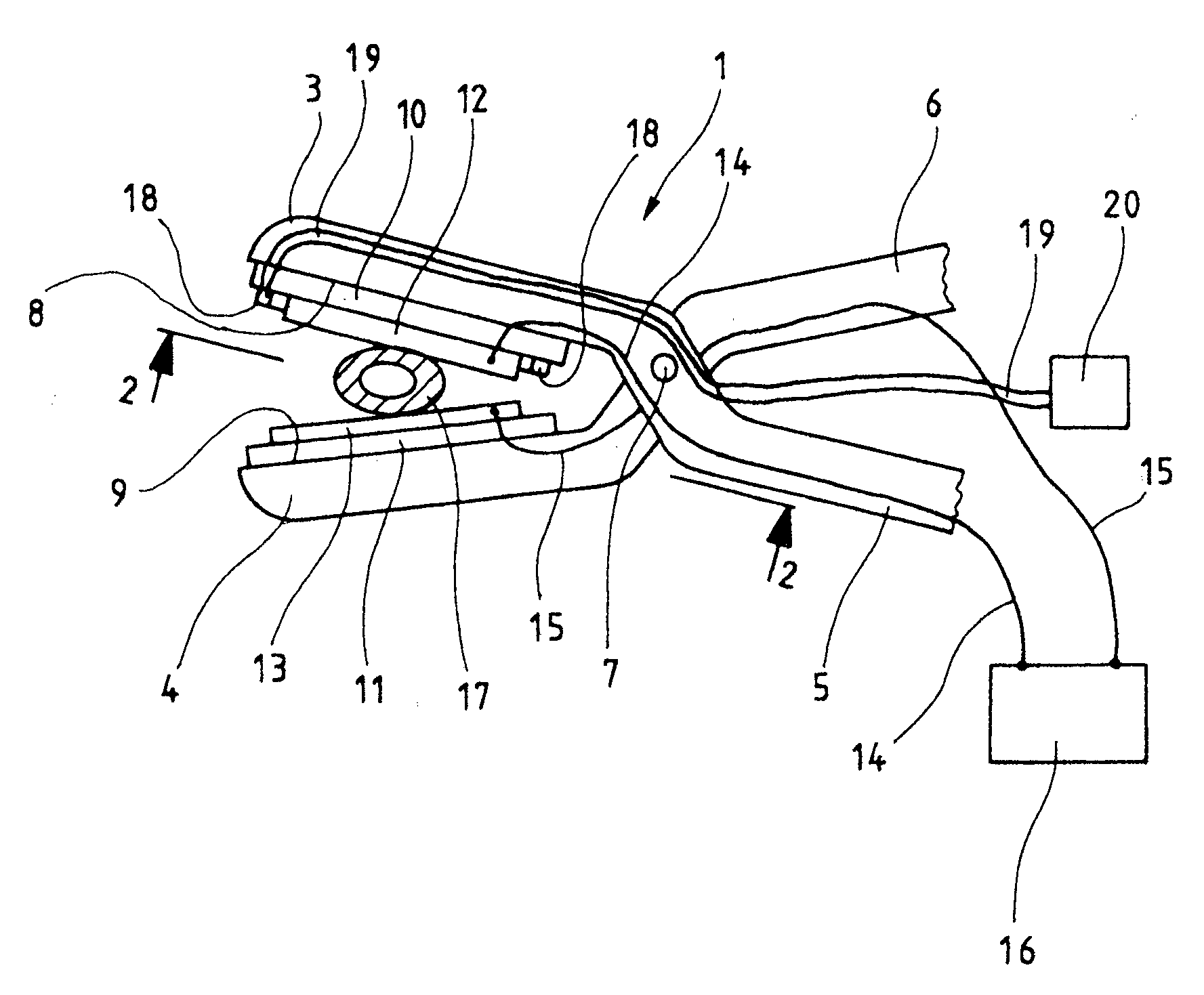

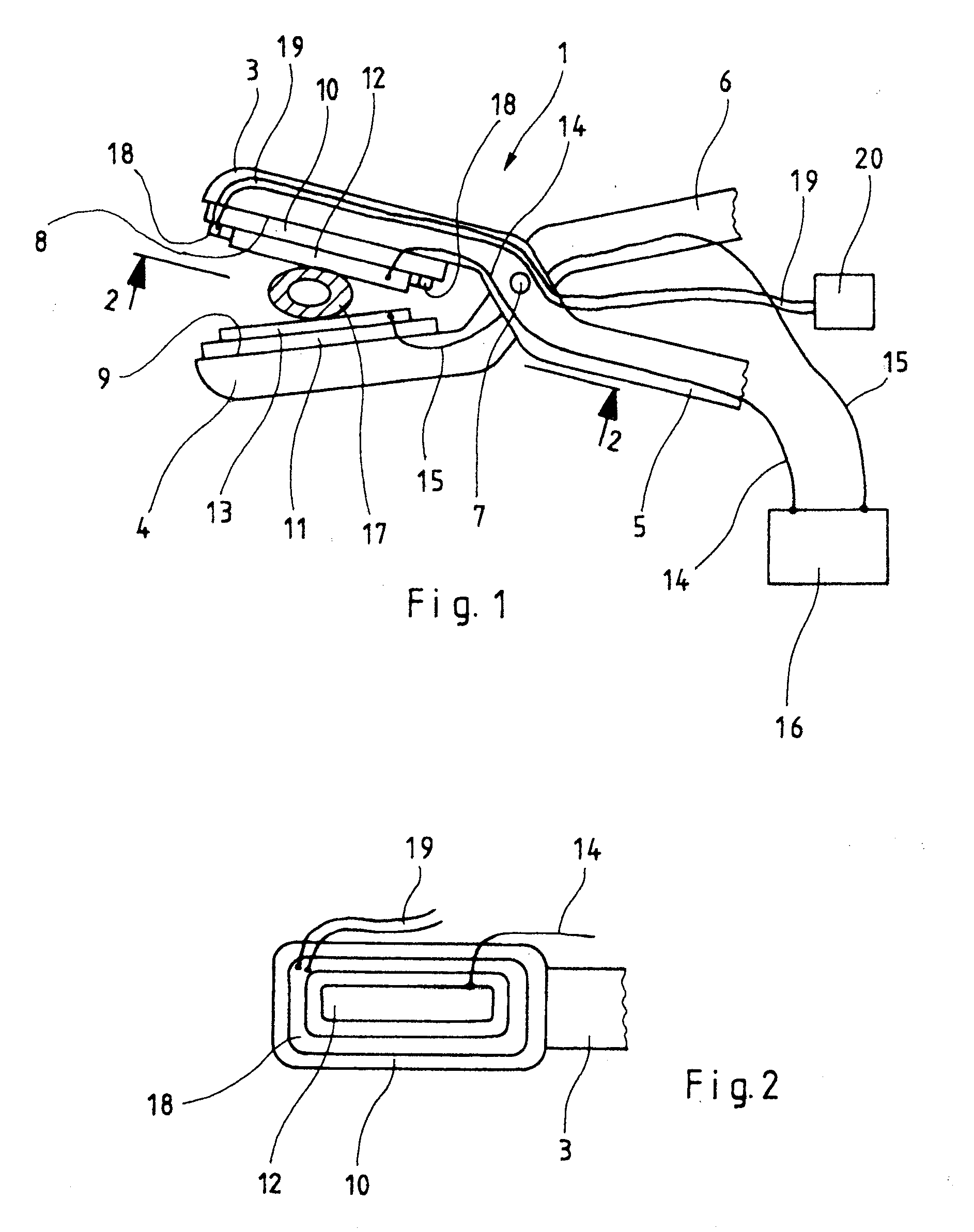

Vascular coagulation forceps

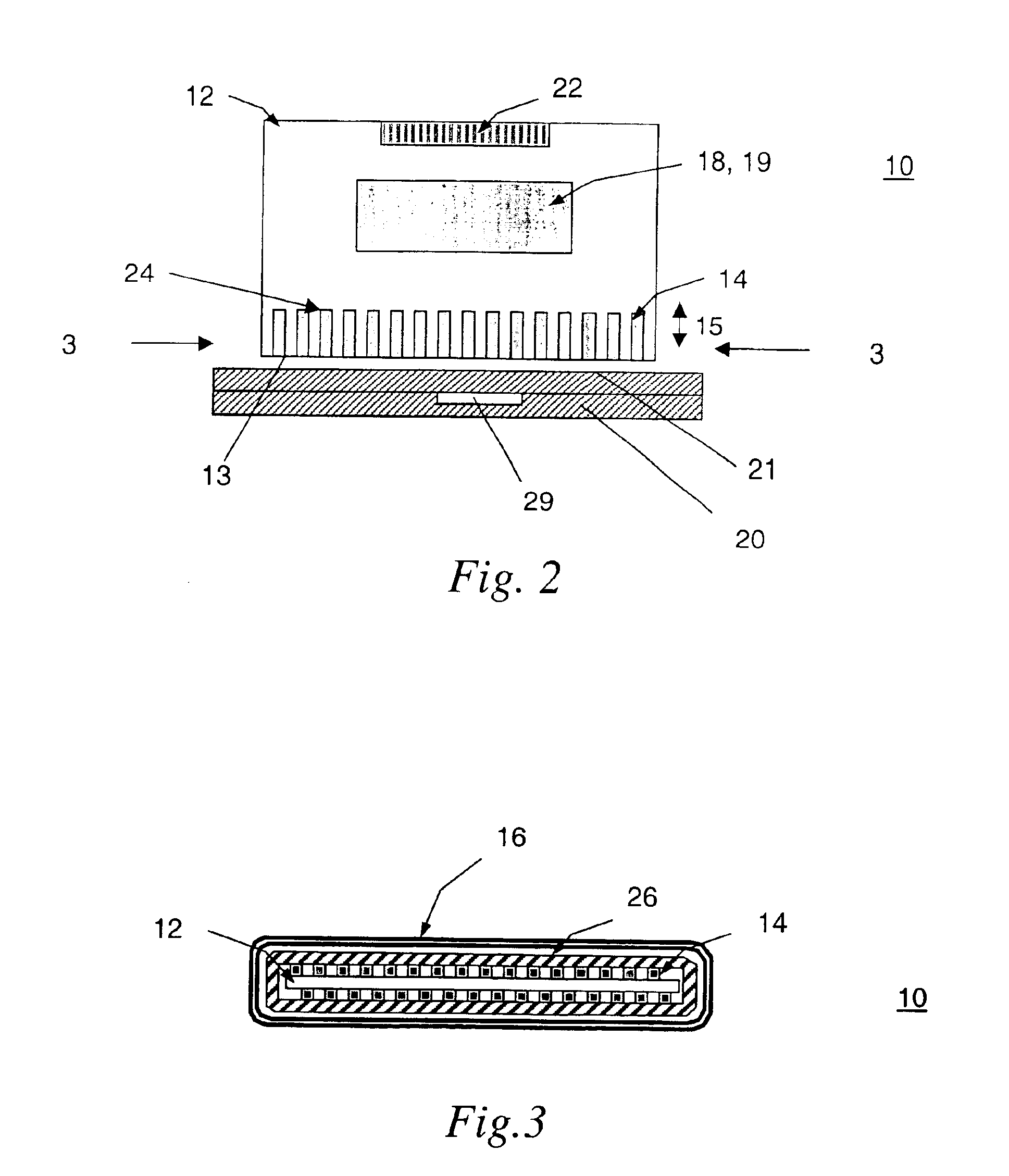

InactiveUS20070265620A1Improve accuracyMonitor progressSurgical instruments for heatingSurgical forcepsForcepsEngineering

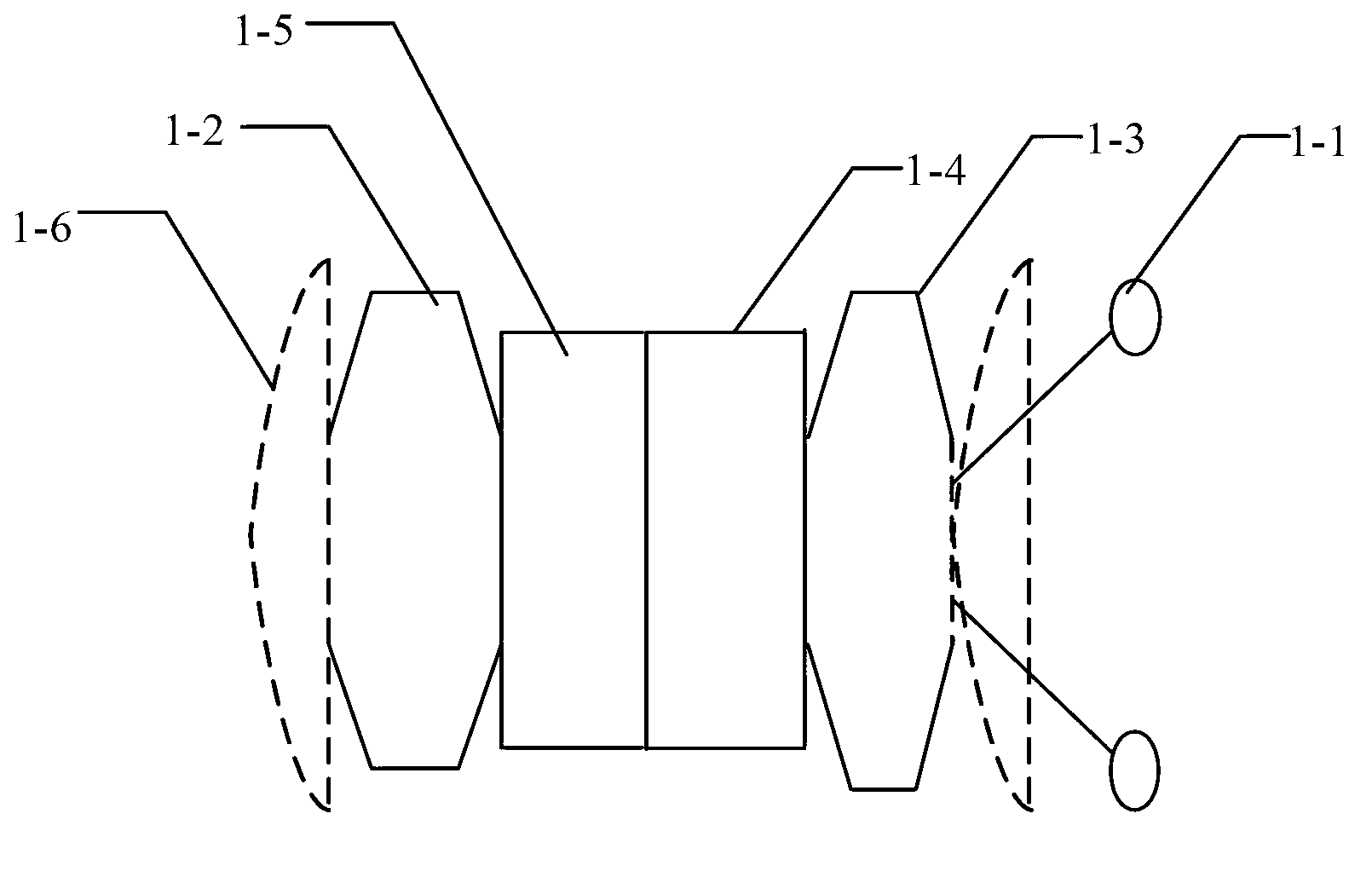

A surgical, vascular coagulation forceps (1) comprising two mutually displaceable jaws (3, 4) bearing flat electrodes (12, 13) connected to different terminals of an hf source (16), or one of said jaws being fitted with an ultrasonic oscillator, characterized in that a coil unit (18) connected to an eddy current sensor (20) is mounted on at least one of the jaws (3, 4).

Owner:OLYMPUS WINTER & IBE

Vortex transducer

InactiveUS7273459B2Reliably aimCheap and cost-effective manufacturing processPiezoelectric/electrostriction/magnetostriction machinesChiropractic devicesElectricityTransducer

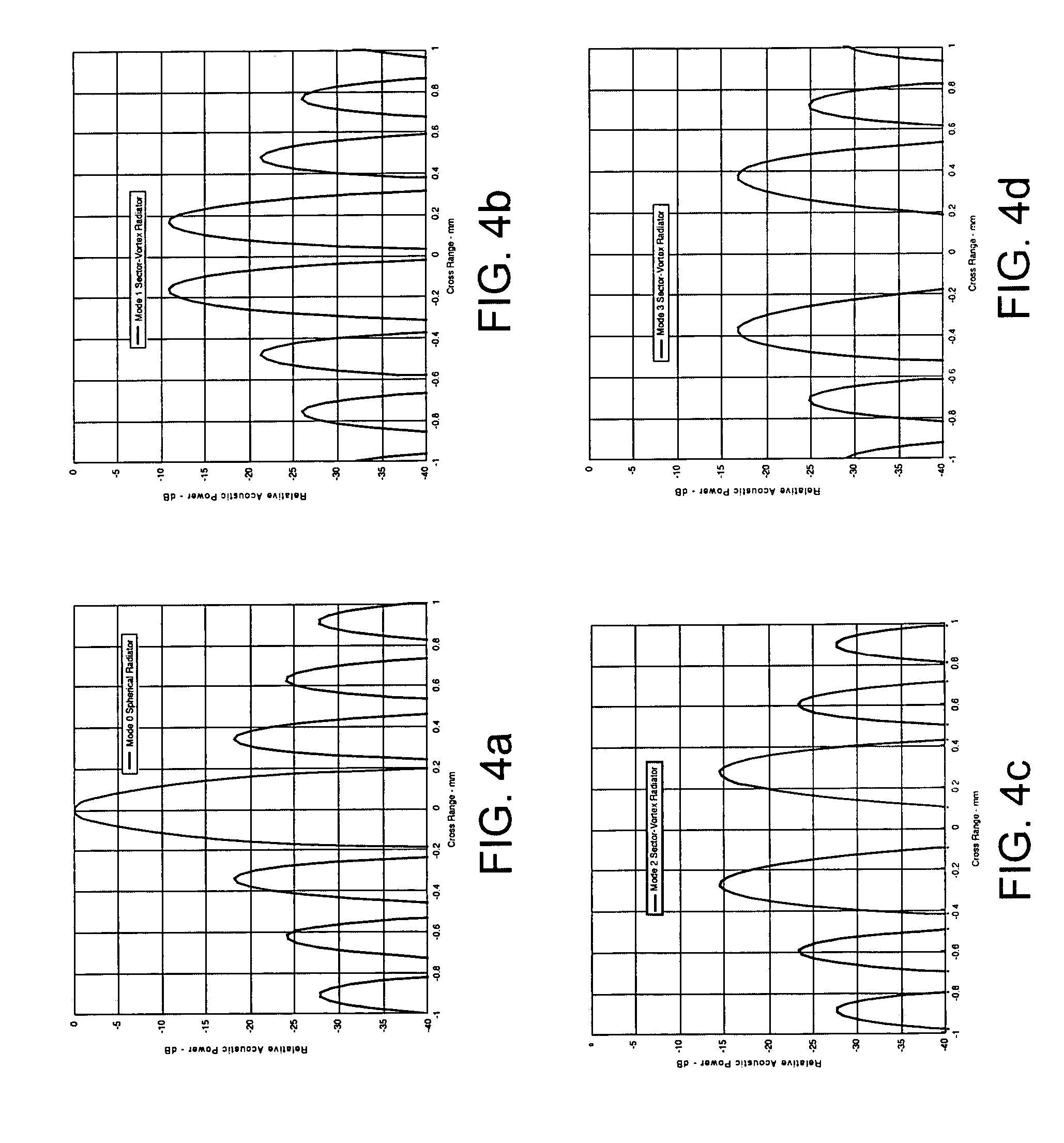

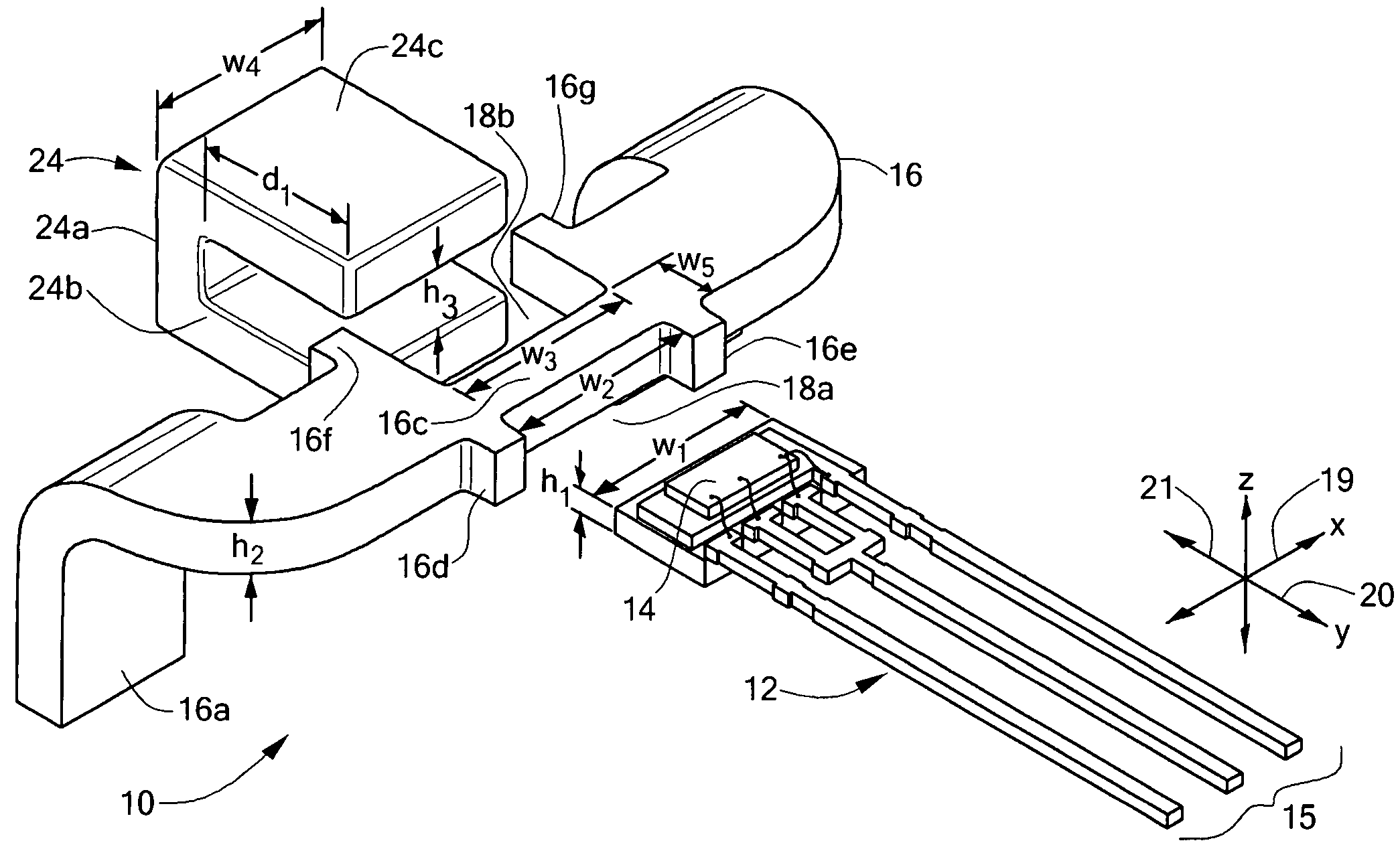

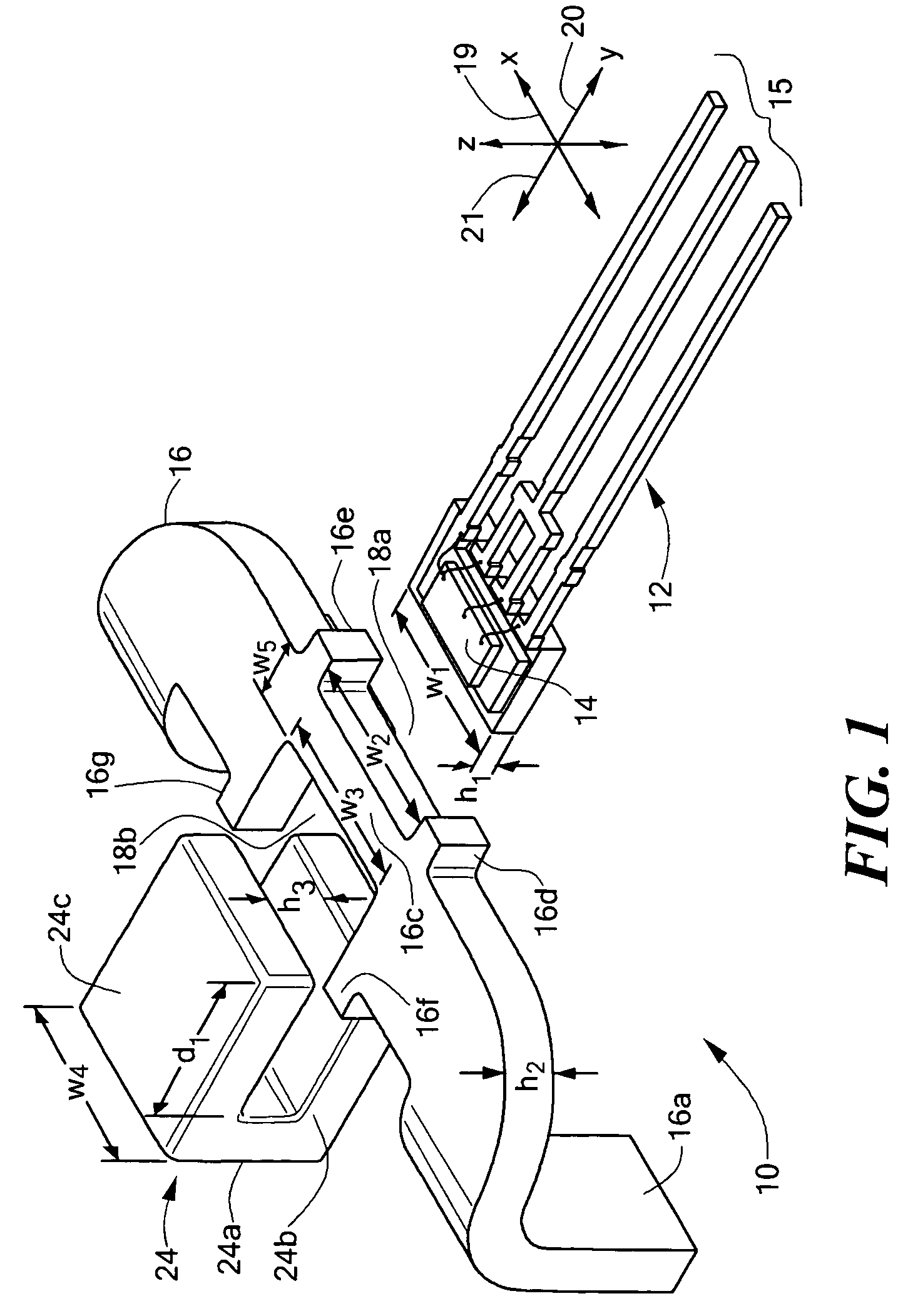

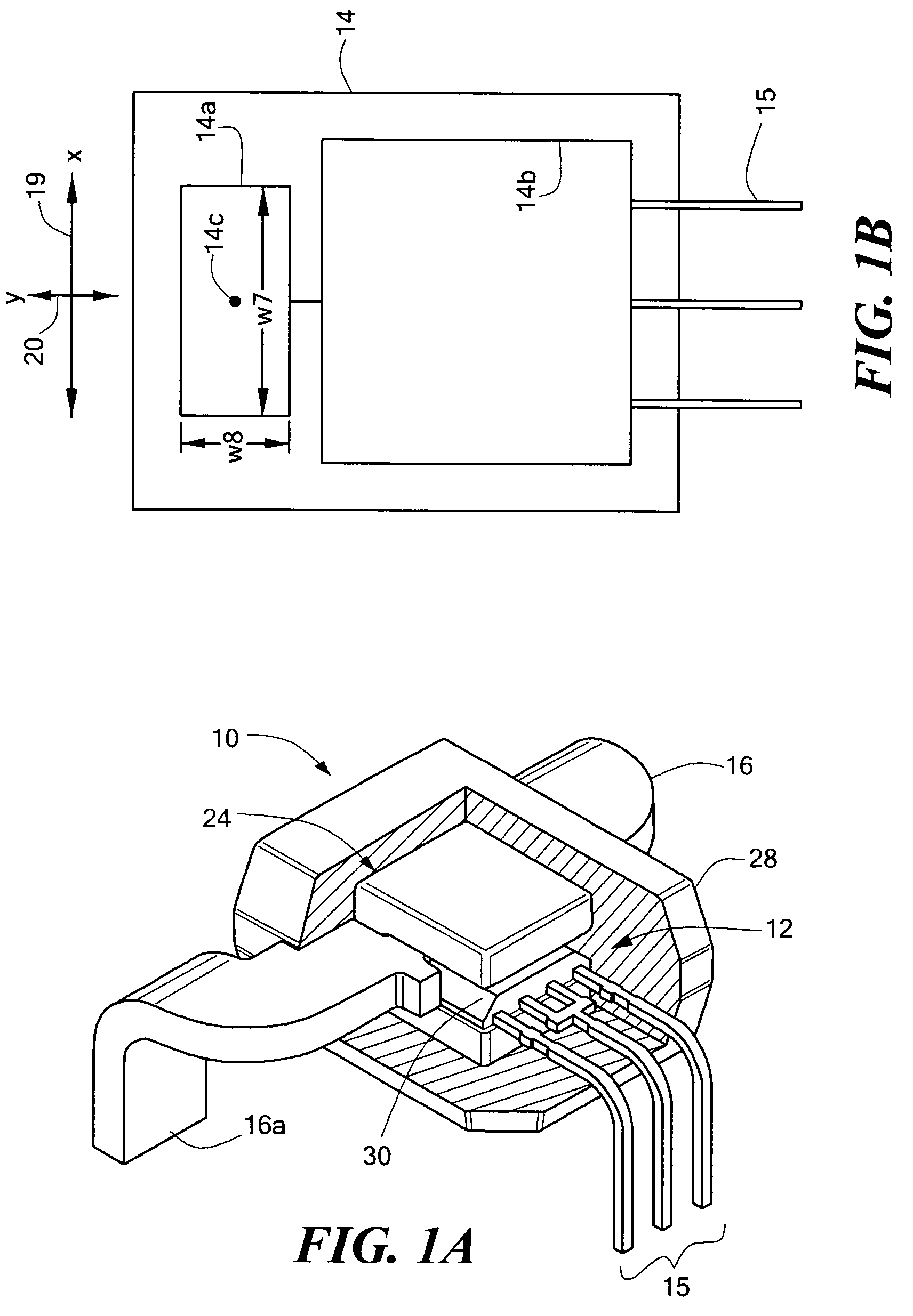

A mechanically formed vortex transducer is described. The transducer has a plurality of piezoelectric elements suspended in an epoxy and heat molded into a desired shape. An irregularity in the transducer shape provides for a mechanically induced vortex focal field without the need for electronic steering or lens focusing. A system and methods of making the same are also described.

Owner:LIPOSONIX

Integrated current sensor

InactiveUS7265531B2High sensitivityStrict controlMagnetic measurementsBase element modificationsElectrical conductorTransducer

An integrated current sensor includes a magnetic field transducer such as a Hall effect sensor, a magnetic core, and an electrical conductor. The conductor includes features for receiving portions of the Hall effect sensor and the core and the elements are dimensioned such that little or no relative movement among the elements is possible.

Owner:ALLEGRO MICROSYSTEMS INC

High sensitivity magnetic built-in current sensor

InactiveUS7619431B2Improve sensor sensitivityHigh sensitivityMagnetic measurementsDigital storageElectrical conductorEngineering

A sensor for contactlessly detecting currents, has a sensor element having a magnetic tunnel junction (MTJ), and detection circuitry, the sensor element having a resistance which varies with the magnetic field, and the detection circuitry is arranged to detect a tunnel current flowing through the tunnel junction. The sensor element may share an MTJ stack with memory elements. Also it can provide easy integration with next generation CMOS processes, including MRAM technology, be more compact, and use less power. Solutions for increasing sensitivity of the sensor, such as providing a flux concentrator, and for generating higher magnetic fields with a same current, such as forming L-shaped conductor elements, are given. The greater sensitivity enables less post processing to be used, to save power for applications such as mobile devices. Applications include current sensors, built-in current sensors, and IDDQ and IDDT testing, even for next generation CMOS processes.

Owner:ELIPOSKI REMOTE

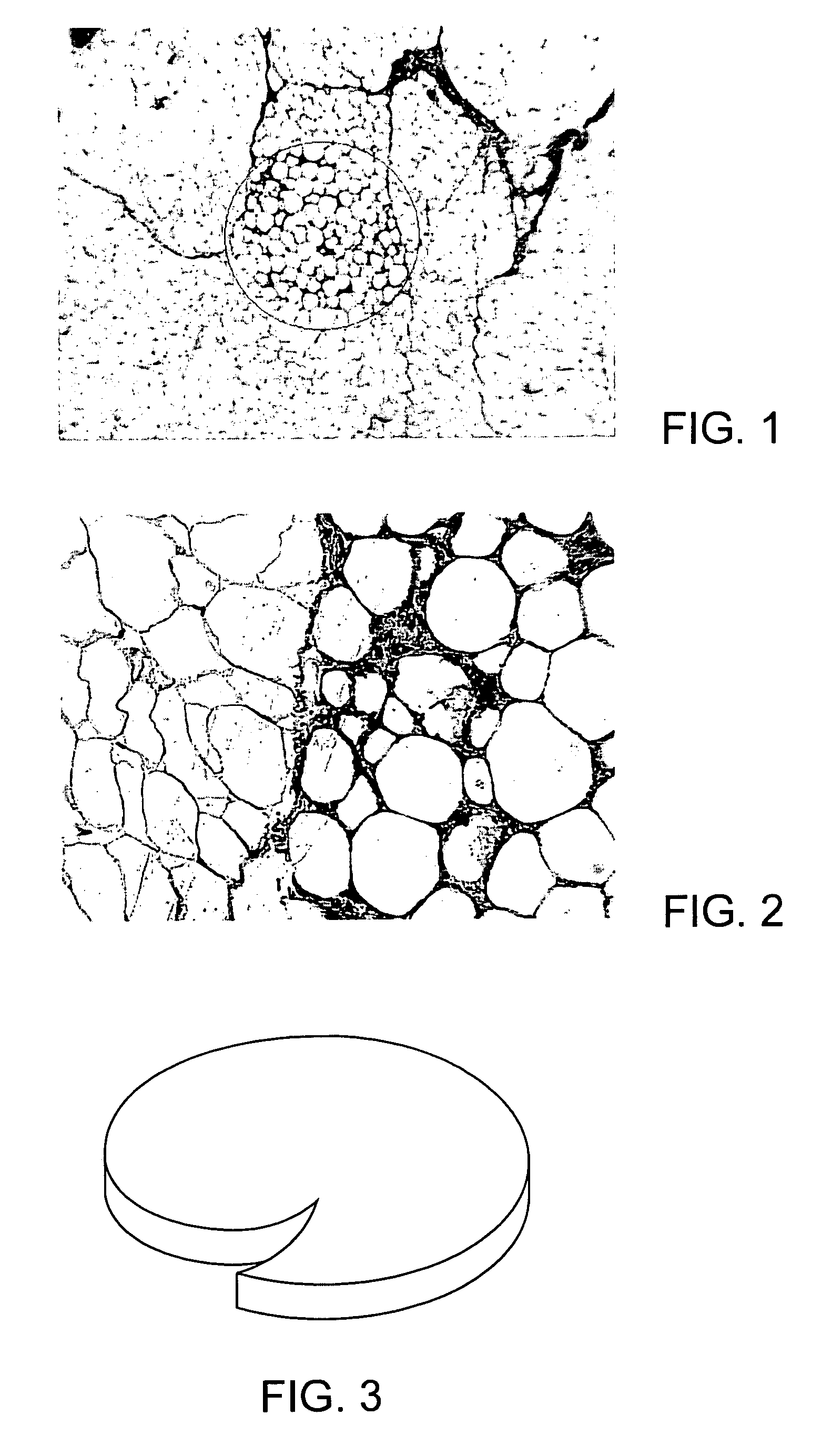

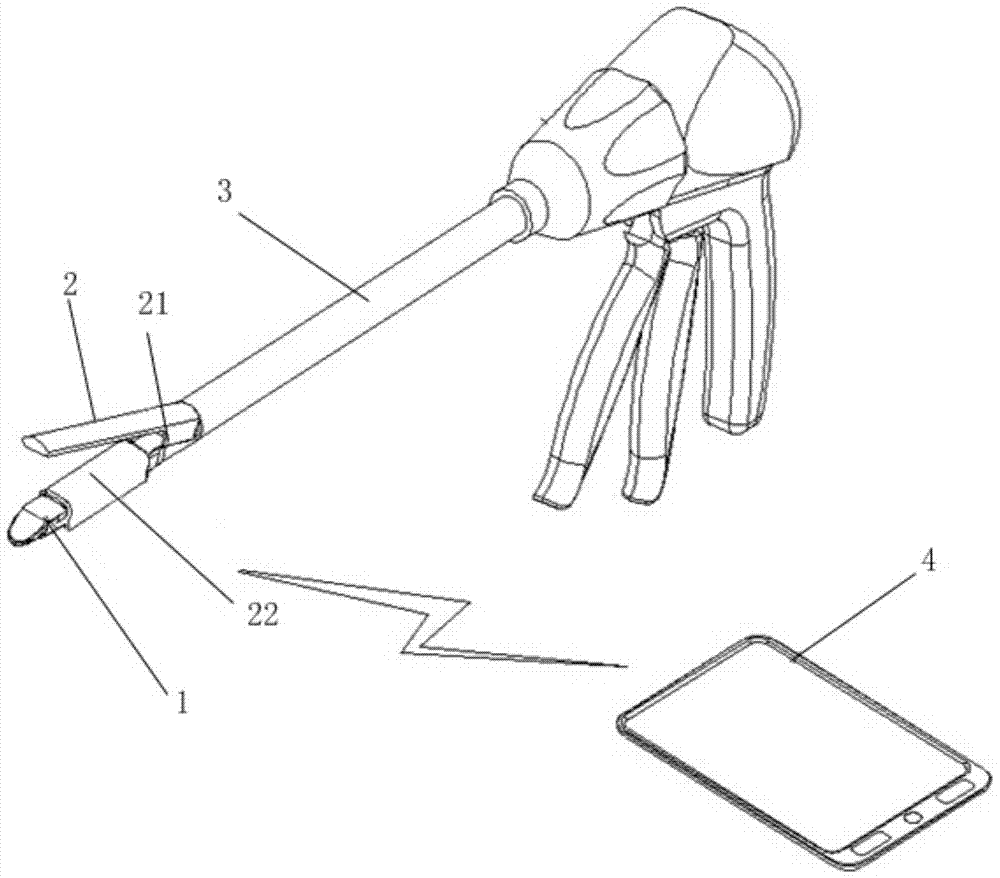

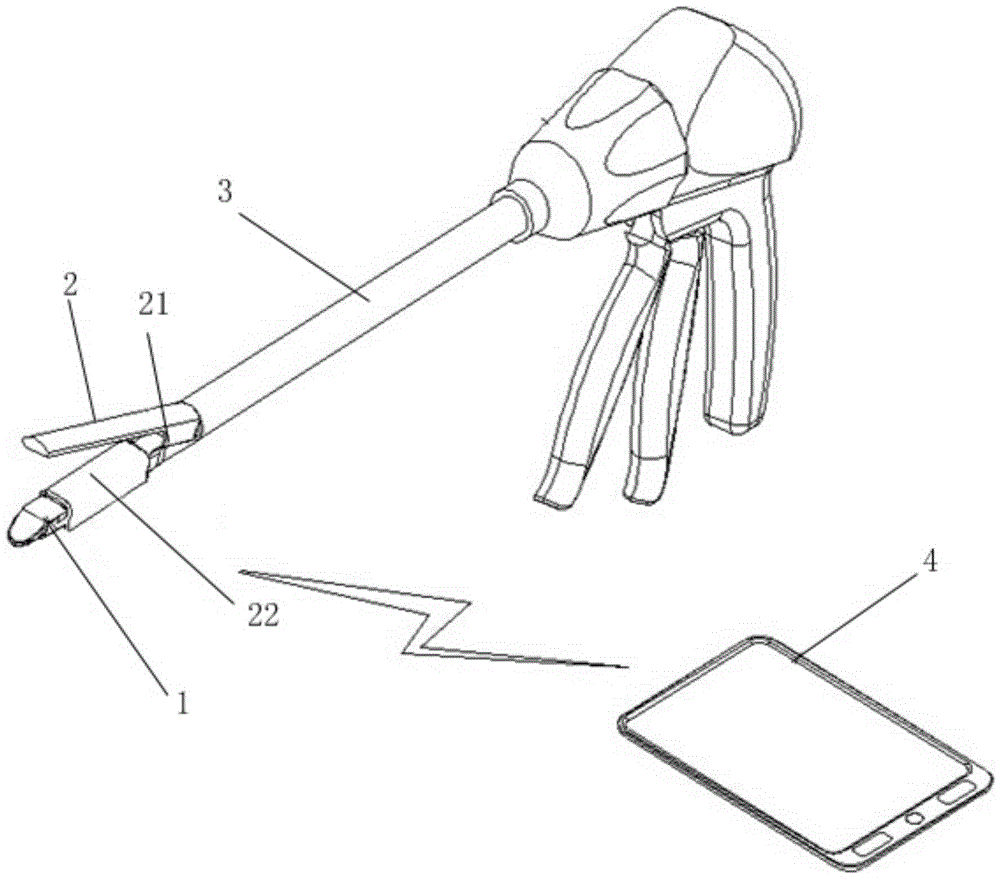

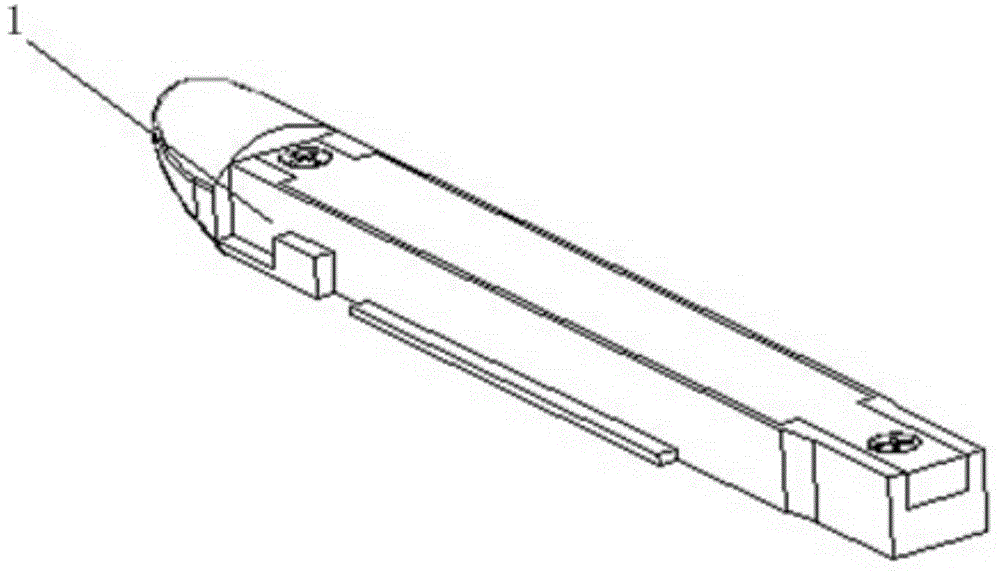

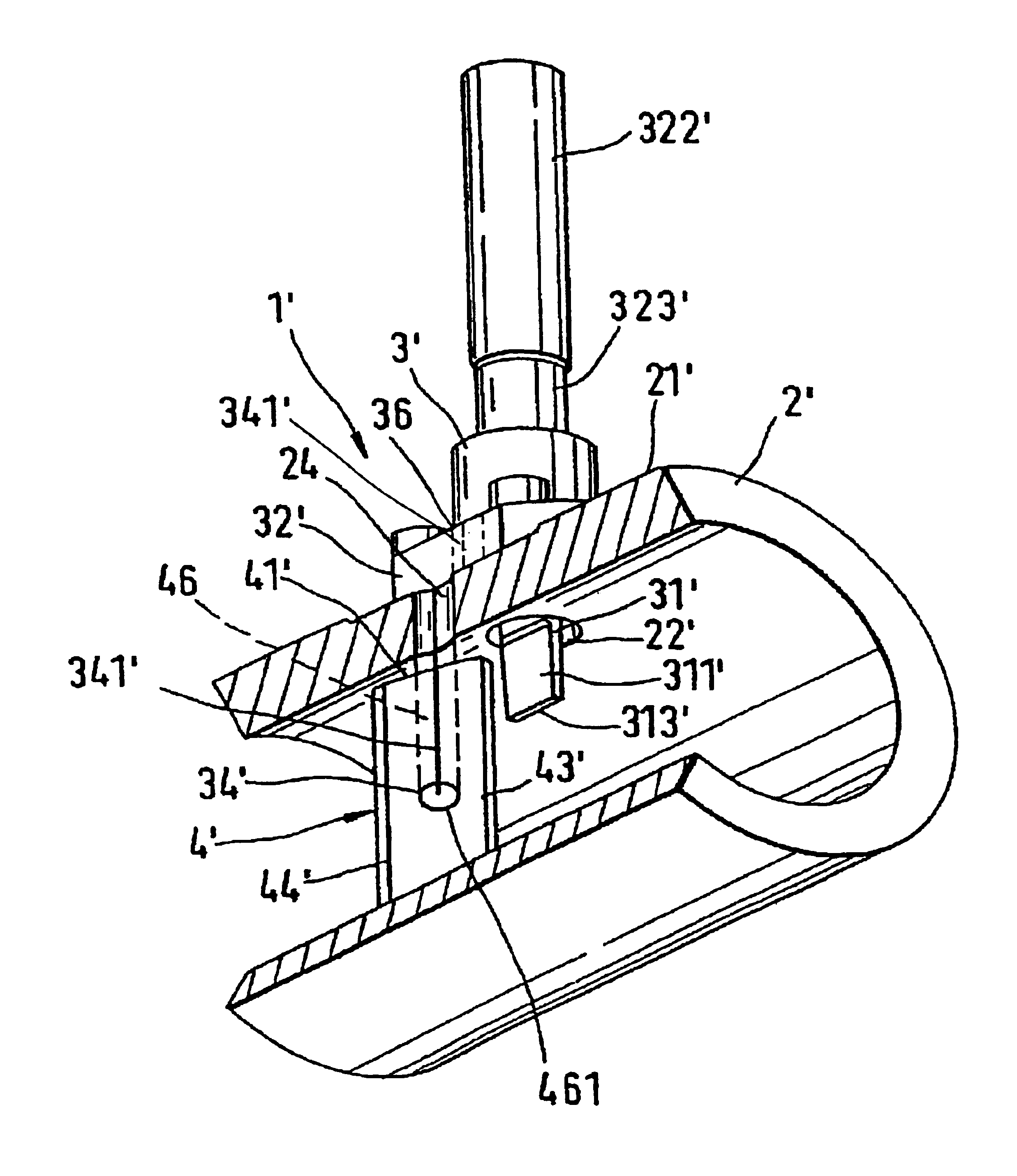

Smart device to measure tissue thickness

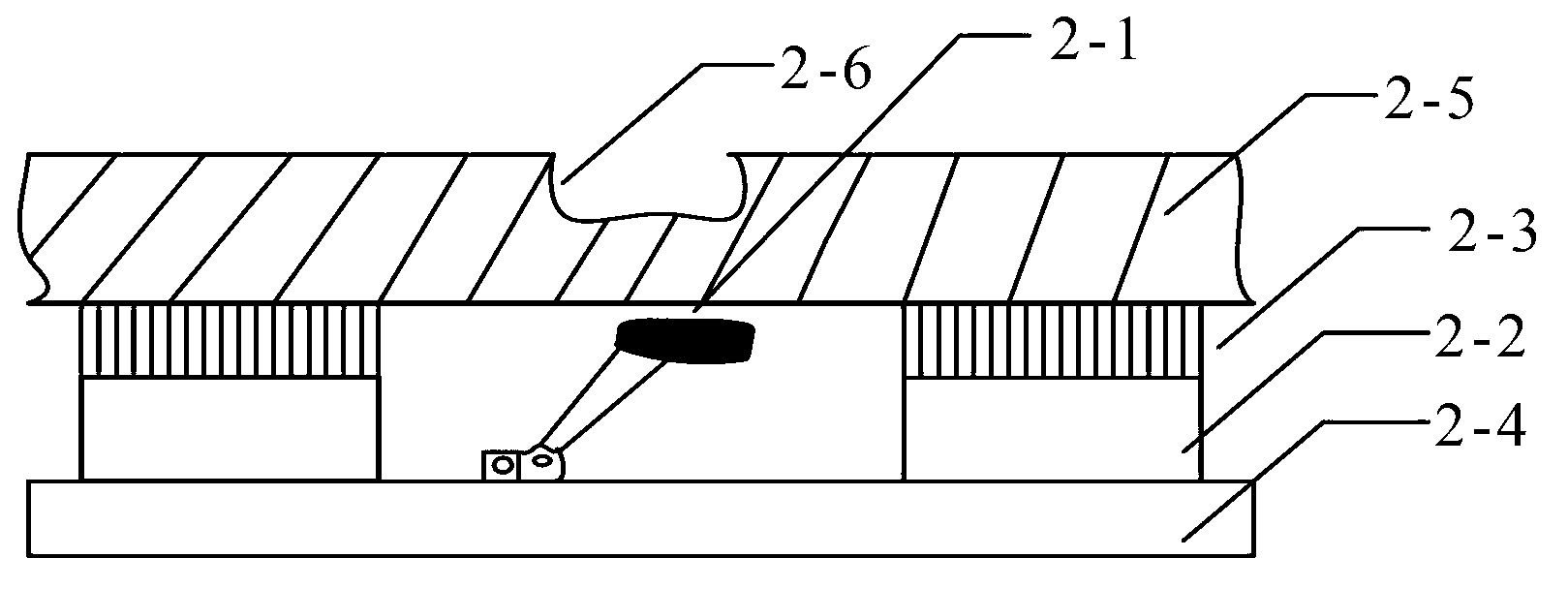

InactiveCN104921730BWon't hurtNo tissue damageDiagnostic recording/measuringSensorsButton batteryMeasuring instrument

The invention relates to an intelligent instrument for measuring the tissue thickness. The intelligent instrument comprises a button cell type intelligent thickness measuring clip or an external power supply type intelligent thickness measuring clip, a linear incision anastomat or a manual thickness measuring instrument or an automatic thickness measuring instrument, and a staple anvil. The button cell type intelligent thickness measuring clip comprises an outer shell, a pressing key, waterproof soft glass, an integrated circuit board and a bottom cover. The waterproof soft glass is arranged between the pressing key and the integrated circuit board and covers the surface of the pressing key. A button cell, a power module, a display module, a tissue pressure intensity measuring module, a tissue thickness measuring module, a control module and a wireless transmission module are mounted on the back face of the integrated circuit board. An eddy-current transducer and a pressure sensor are mounted on the front face of the integrated circuit board. The button cell type intelligent thickness measuring clip is matched with a wireless transmission device. The intelligent instrument for measuring the tissue thickness has the advantages that the tissue thickness can be measured in a quantitative mode, tissue thickness measurement is accurate, corresponding anastomotic staple cartridges can be selected conveniently, and the success rate of anastomotic surgery is increased.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Pulsed eddy current sensor probes and inspection methods

A pulsed eddy current sensor probe includes a sensor array board. A number of sensors are arranged on the sensor array board and are operable to sense and generate output signals from the transient electromagnetic flux in a part being inspected. Each of the sensors has a differential output with a positive and a negative output. At least one drive coil is disposed adjacent to the sensors and is operable to transmit transient electromagnetic flux into the part. A first and a second multiplexer are arranged on the sensor array board and are operable to switch between the sensors. The first and second multiplexers are connected to the positive and negative outputs of the sensors, respectively.

Owner:GENERAL ELECTRIC CO

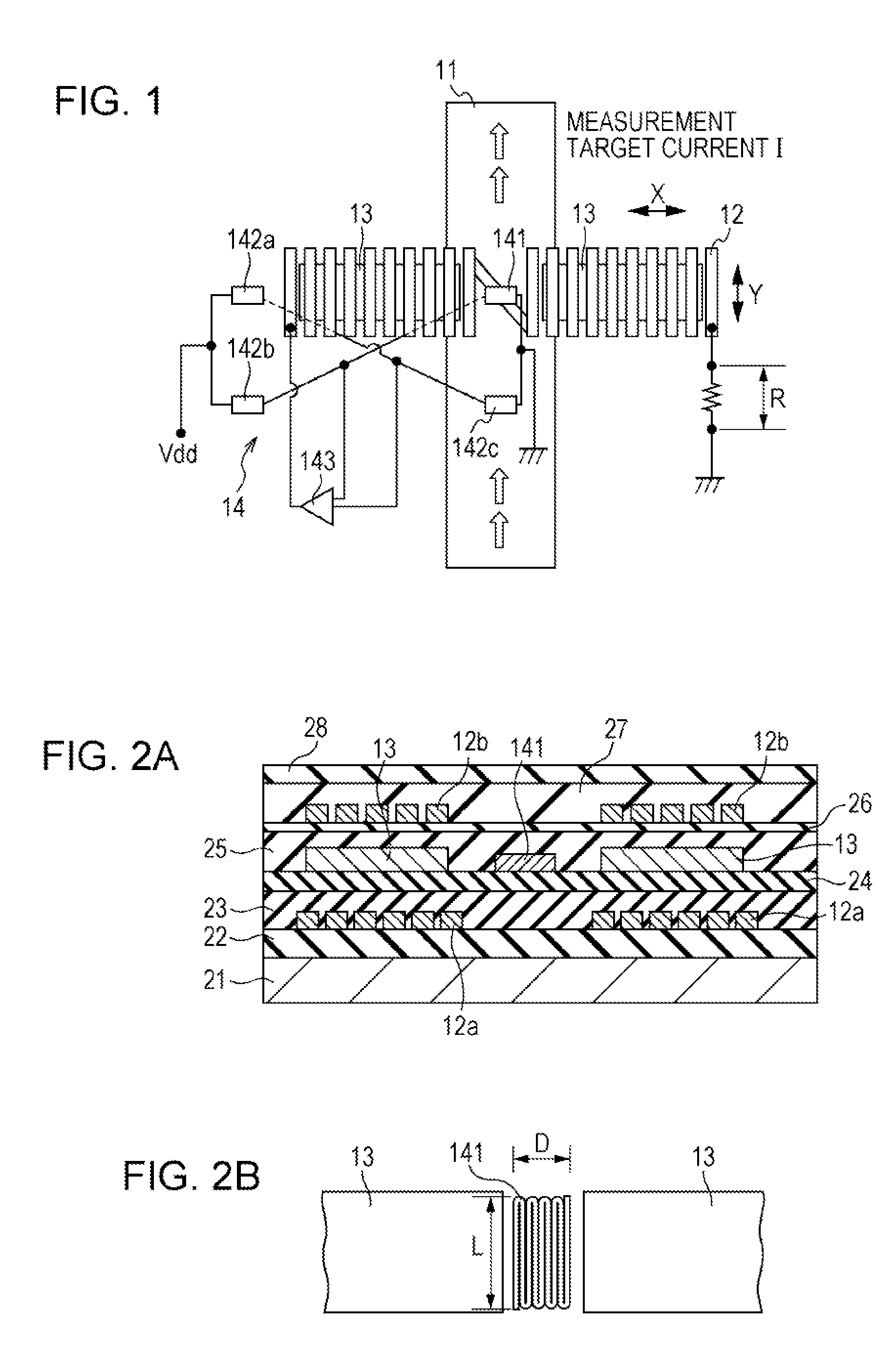

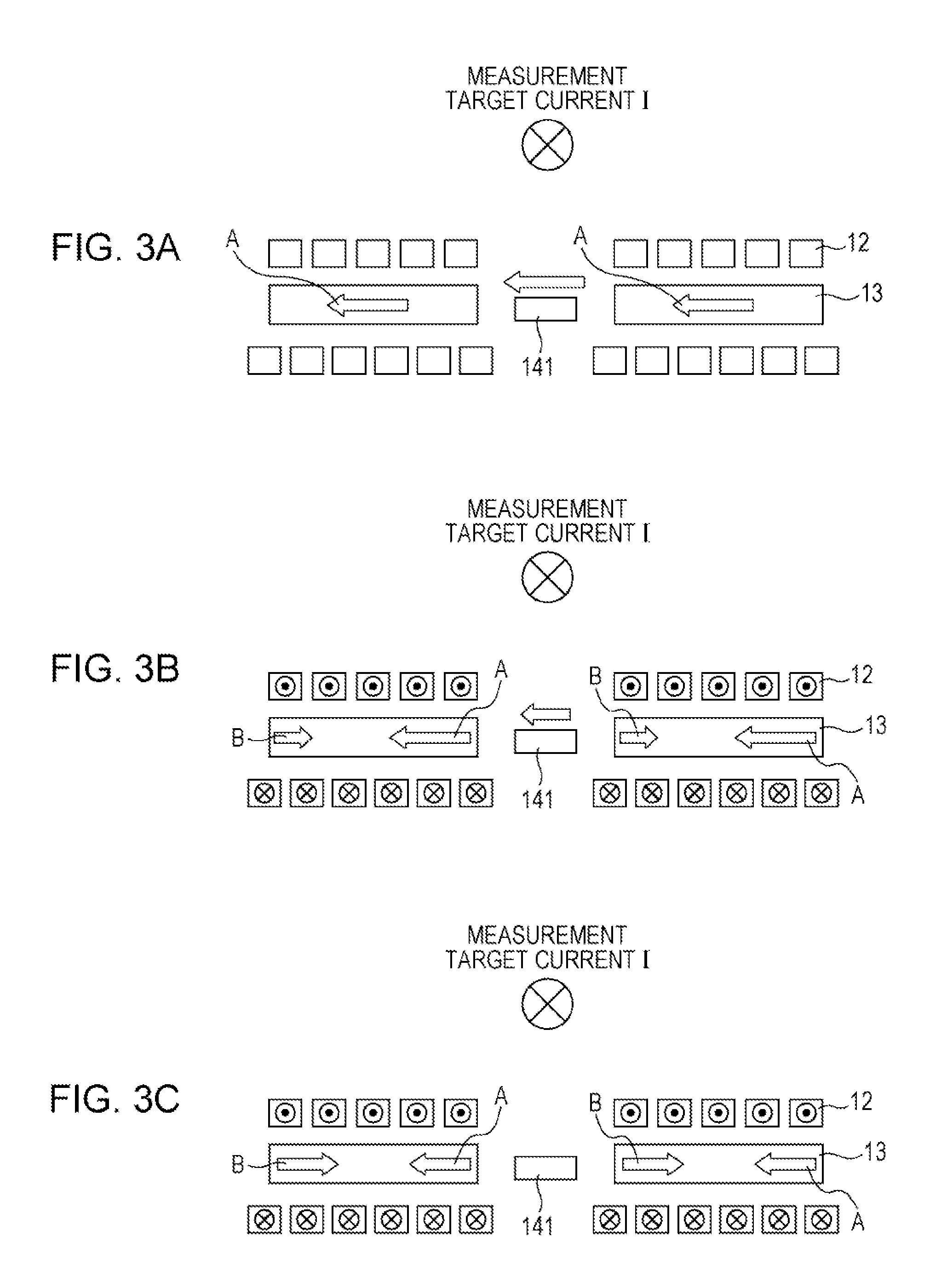

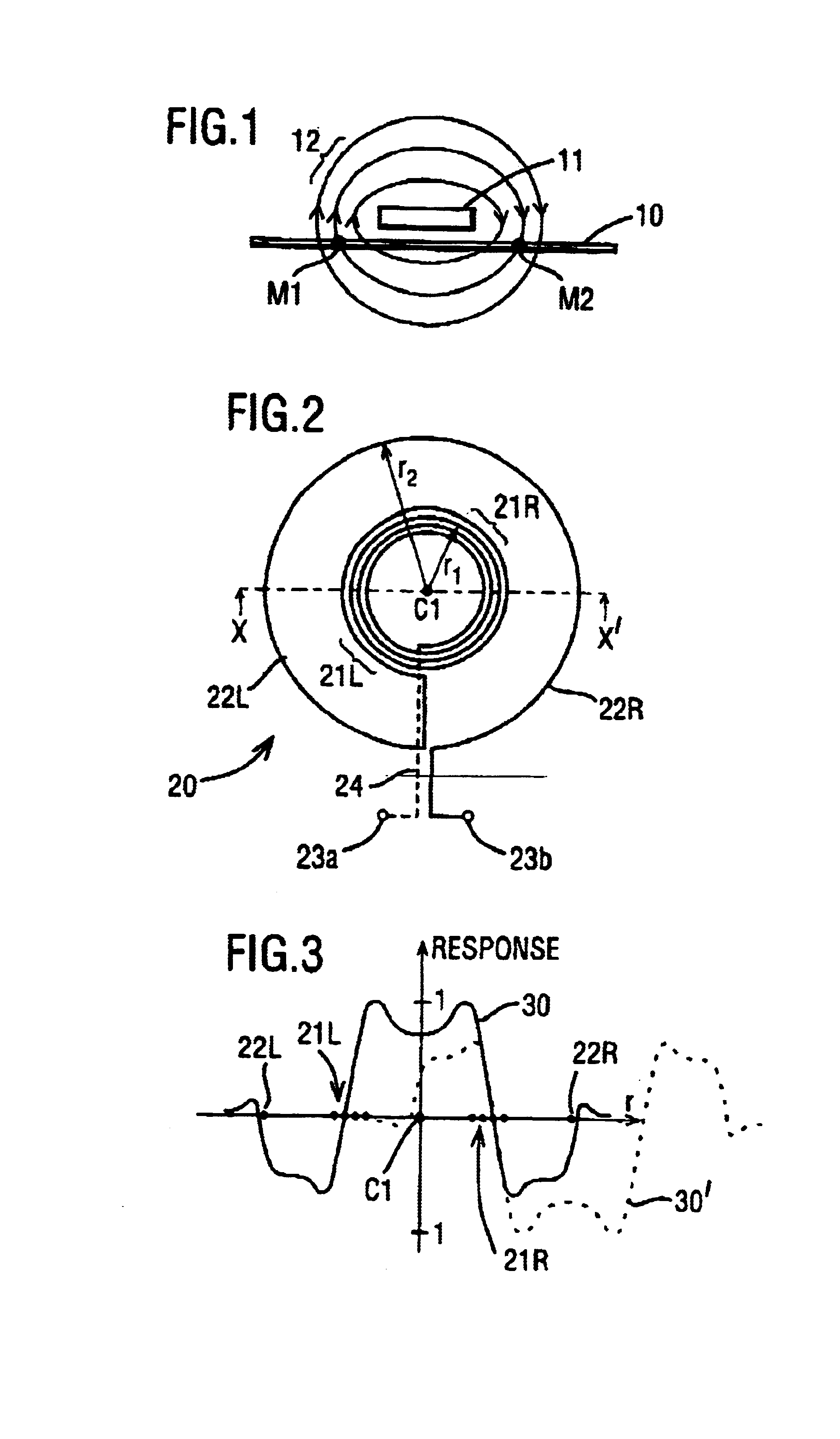

Magnetic sensor and current sensor

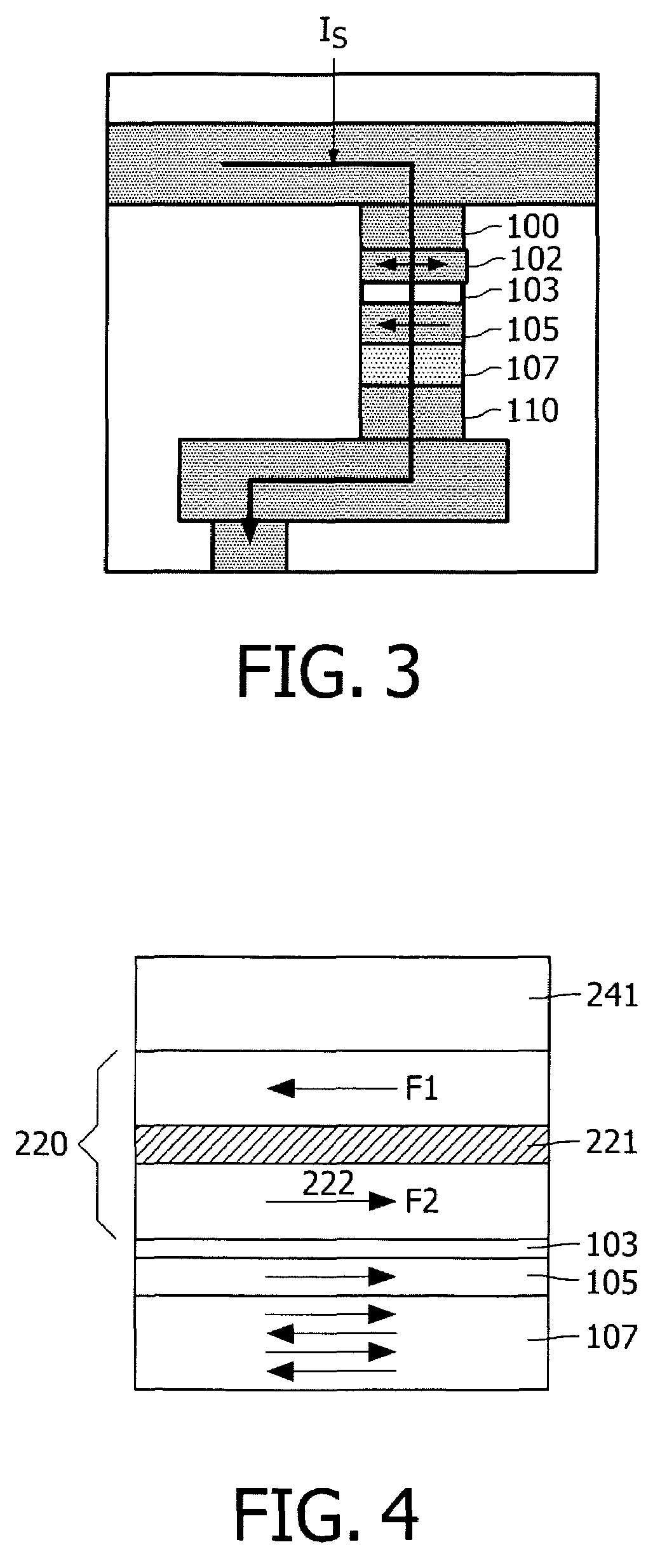

ActiveUS20070188946A1Many layersHigh precisionNanomagnetismMagnetic measurementsInter layerMagnetic reluctance

A current sensor capable of detecting current magnetic fields generated by a current to be detected with high precision and stability while realizing a compact configuration is provided. The current sensor includes: a conductor generating a current magnetic field in accordance with supplied current to be detected; a magnetoresistive element including a free layer having a magnetization direction that varies in accordance with the current magnetic field, a pinned layer having the magnetization direction that is pinned to a direction orthogonal to the magnetization direction of the free layer under no current magnetic field, and an intermediate layer provided between the free layer and the pinned layer; and a bias applying means for applying, to the magnetoresistive element, a bias magnetic field along a direction same with the magnetization direction of the free layer under no current magnetic field.

Owner:TDK CORPARATION

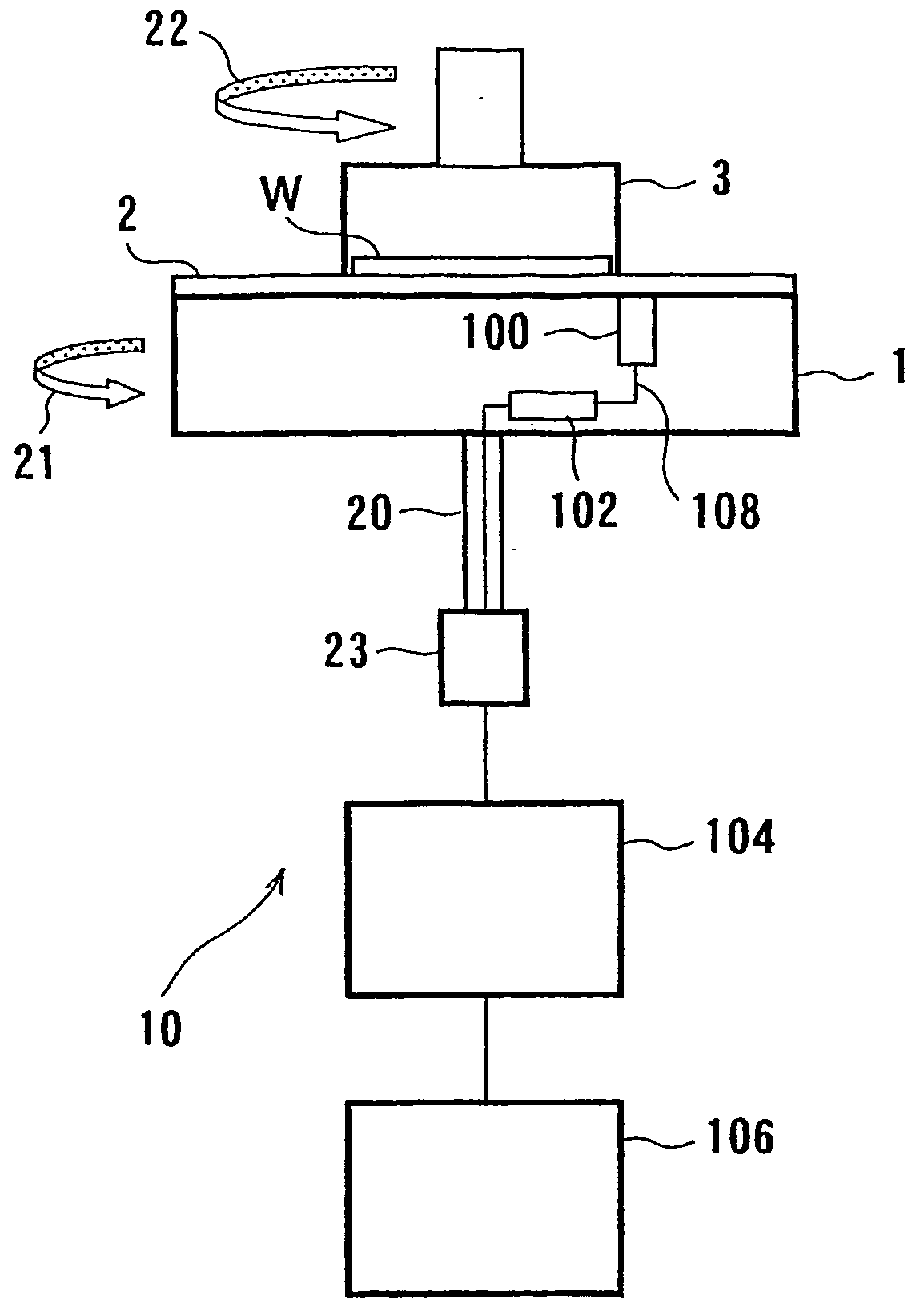

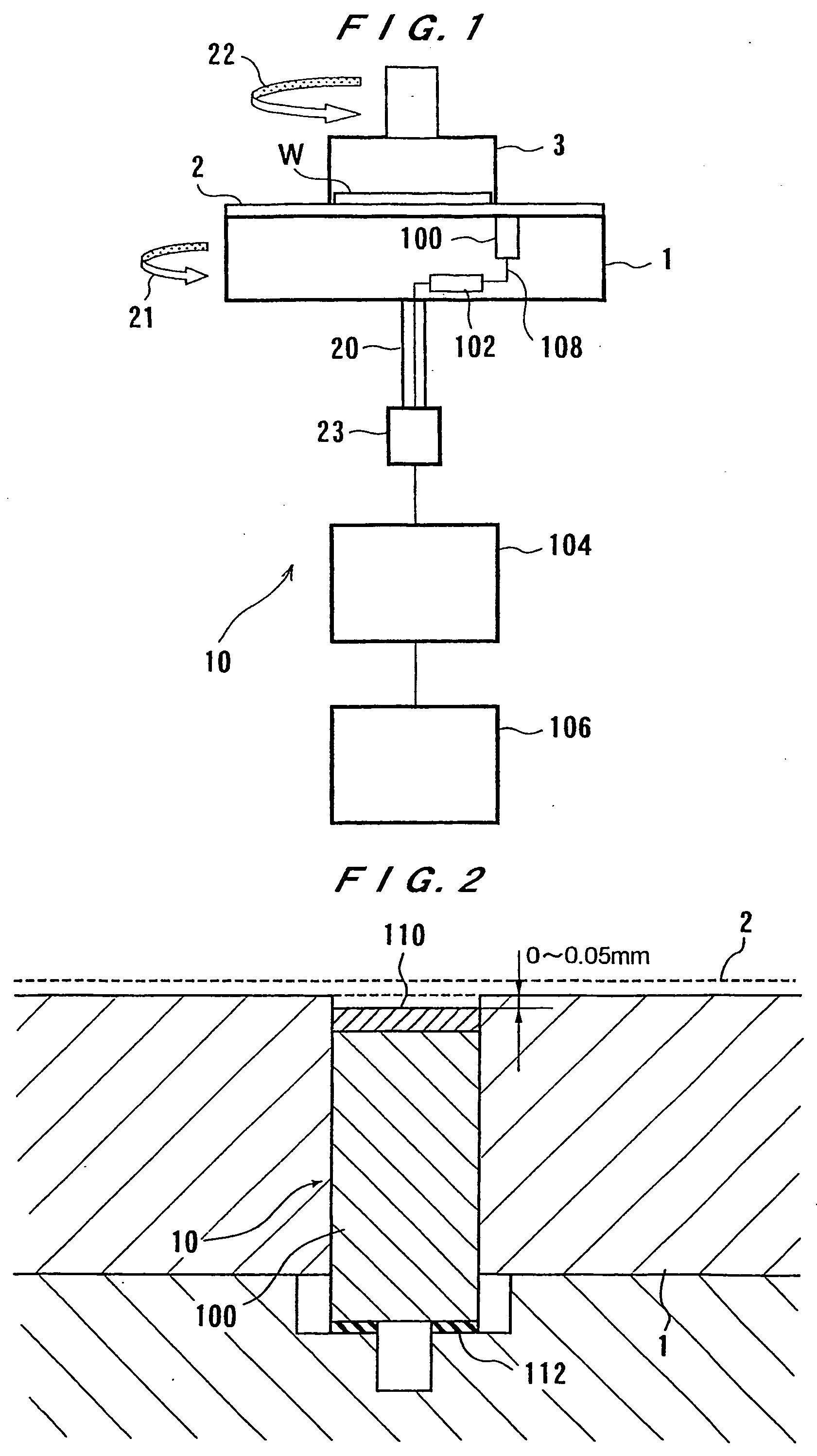

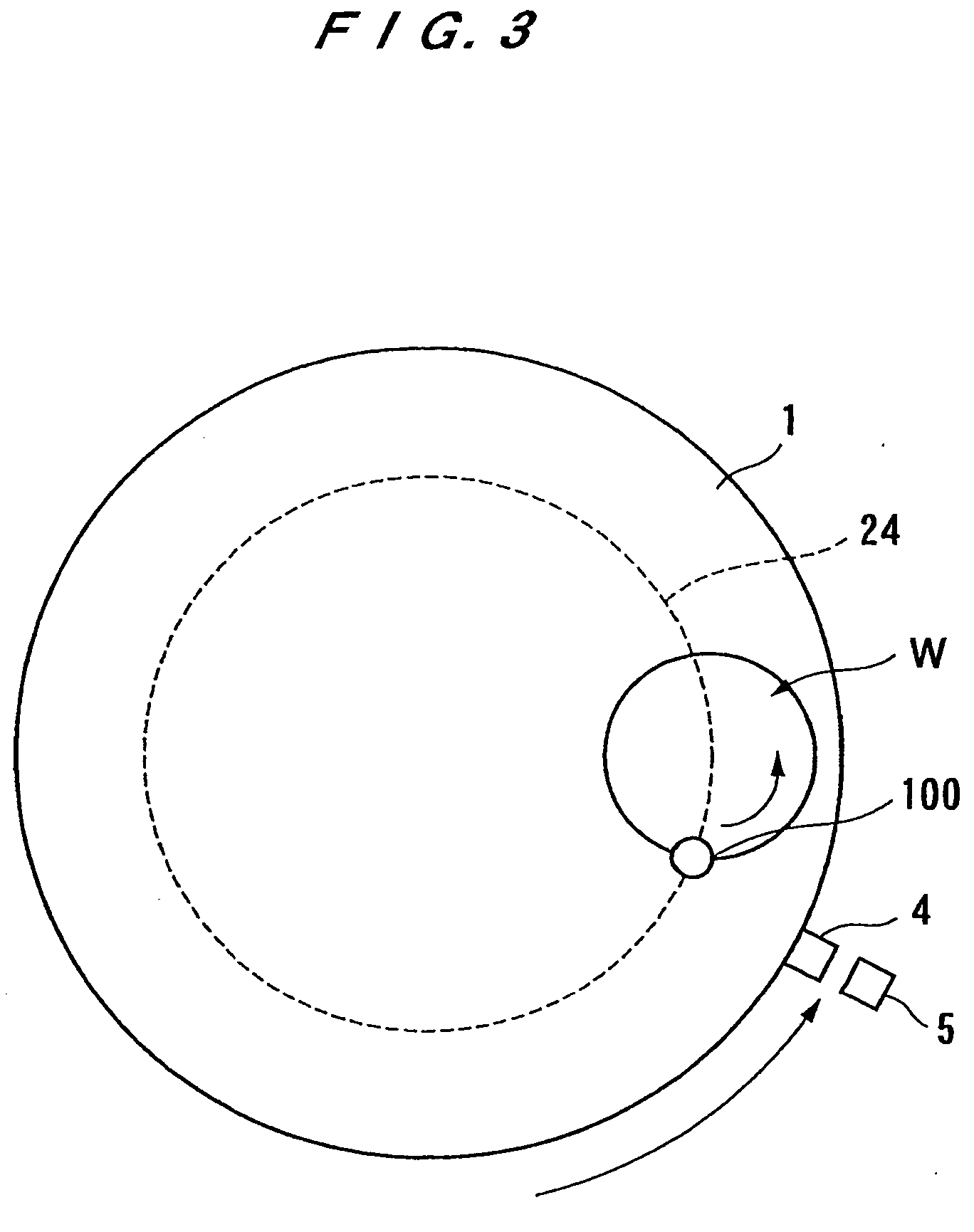

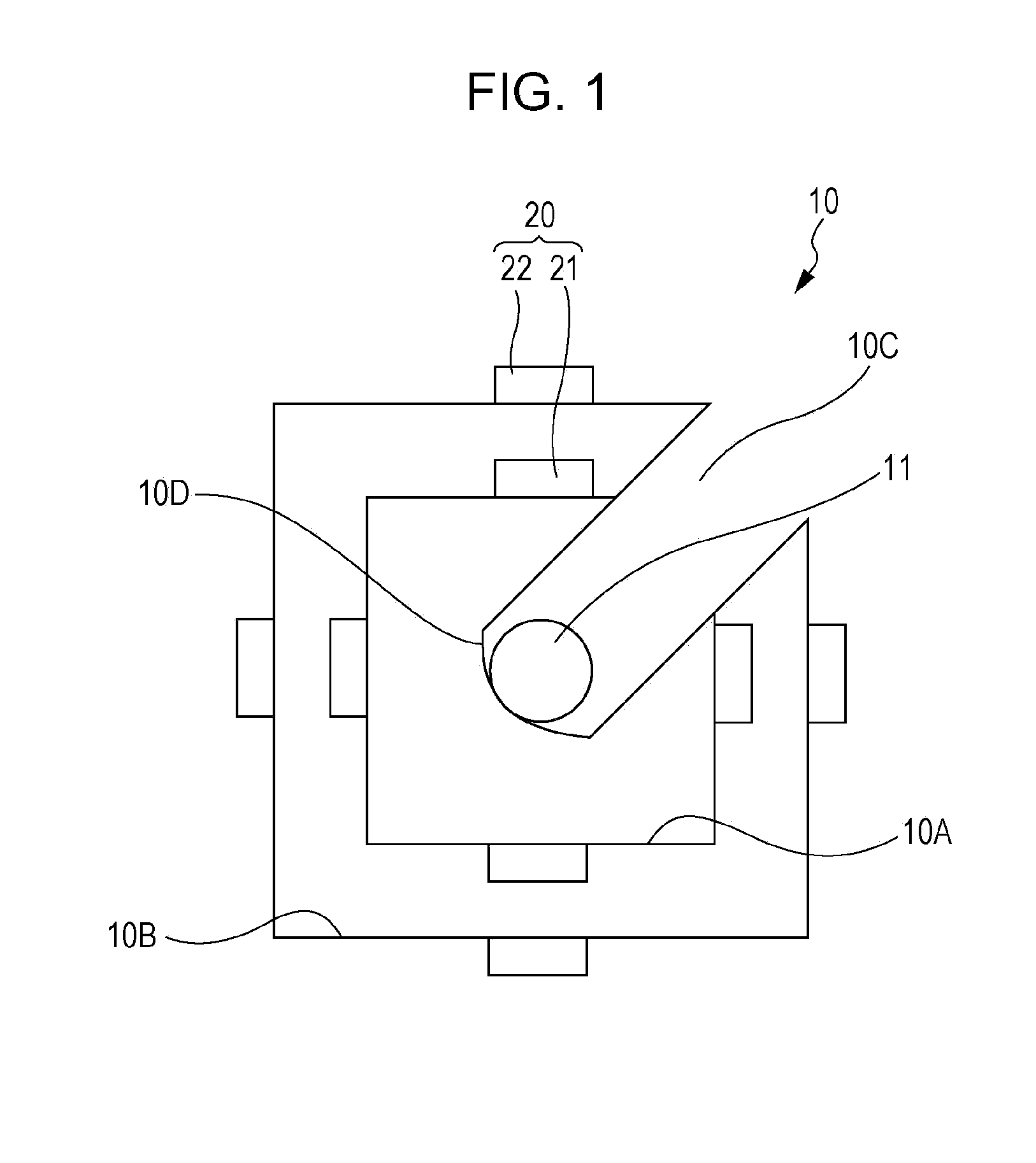

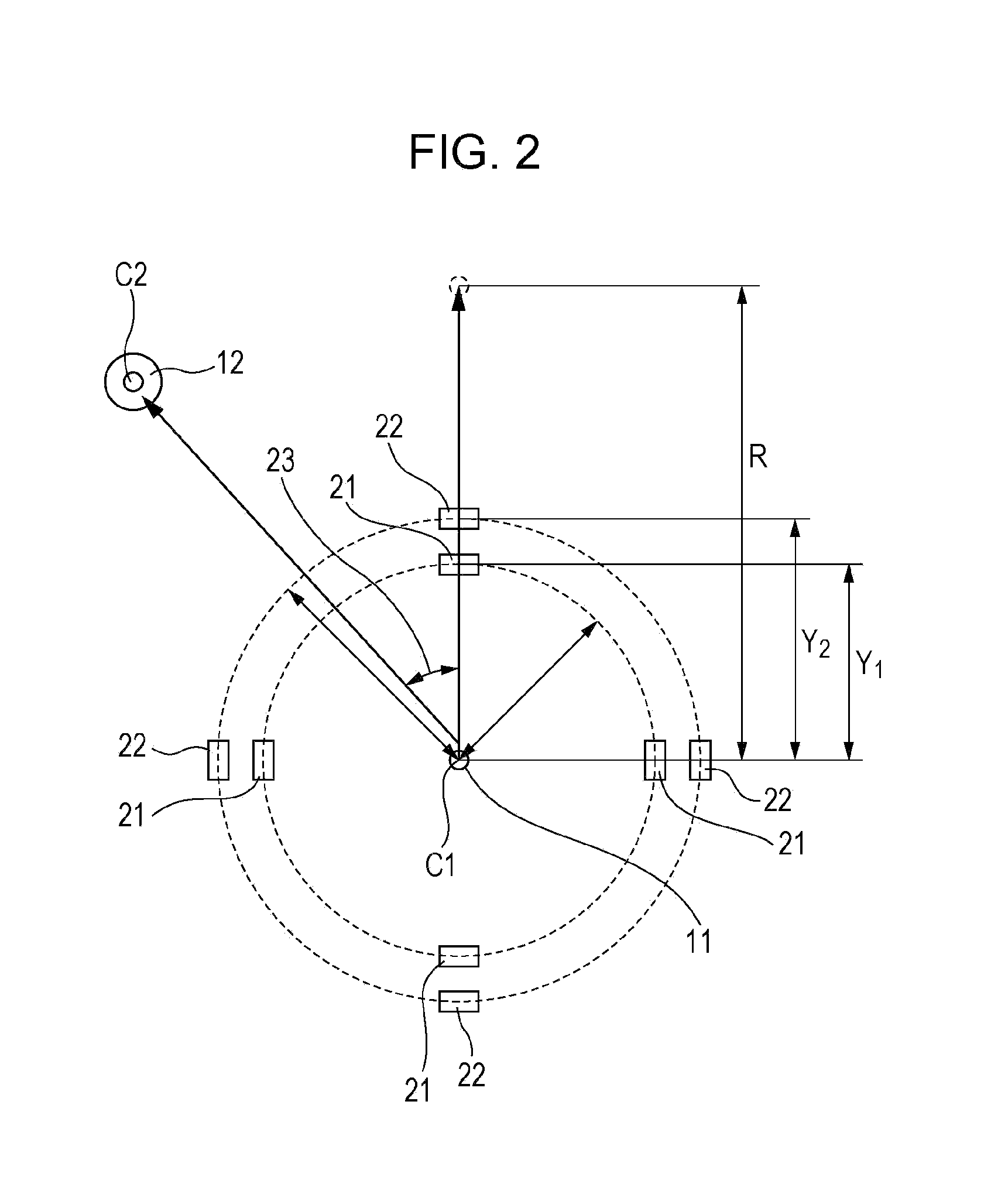

Eddy current sensor

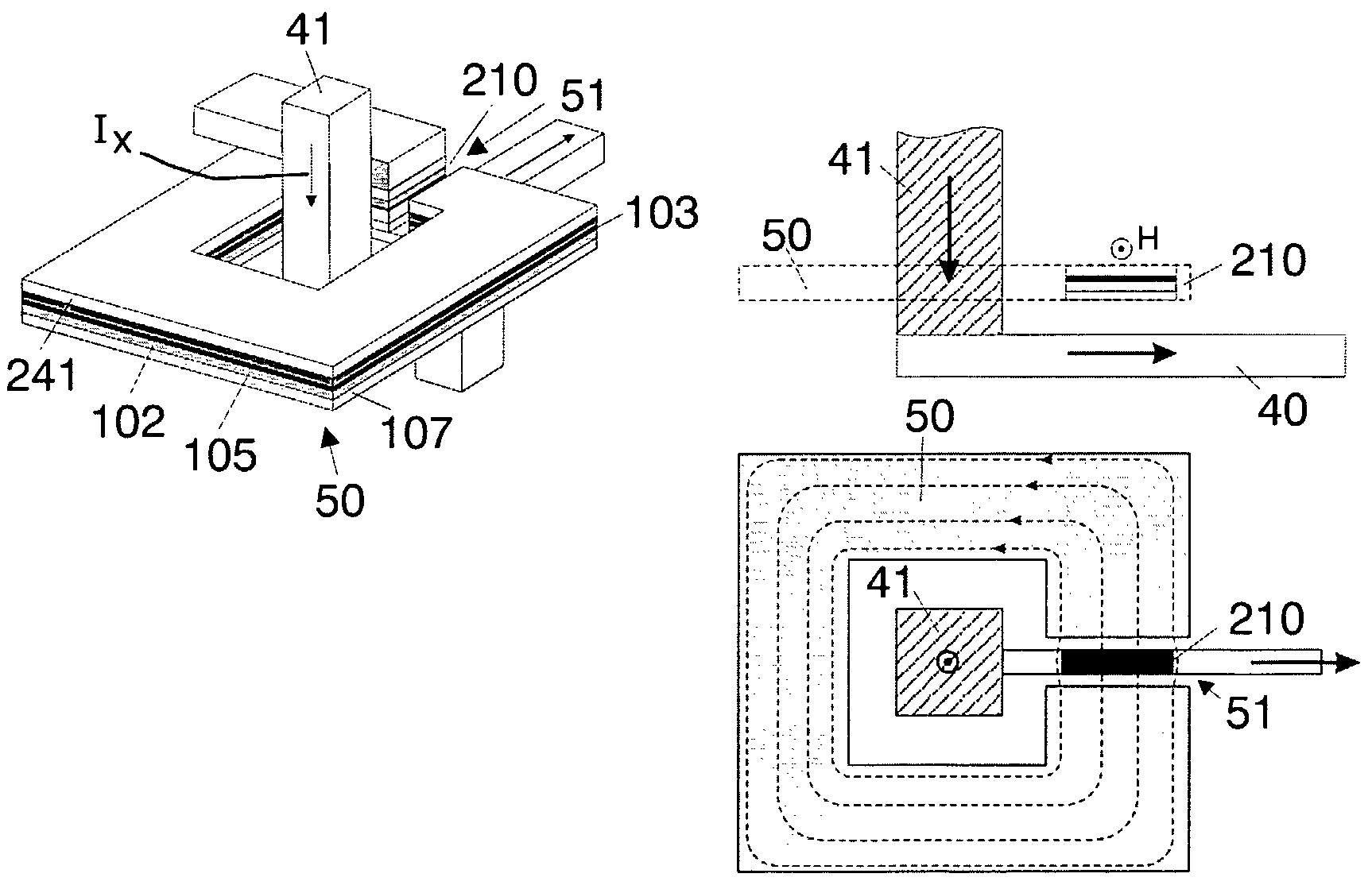

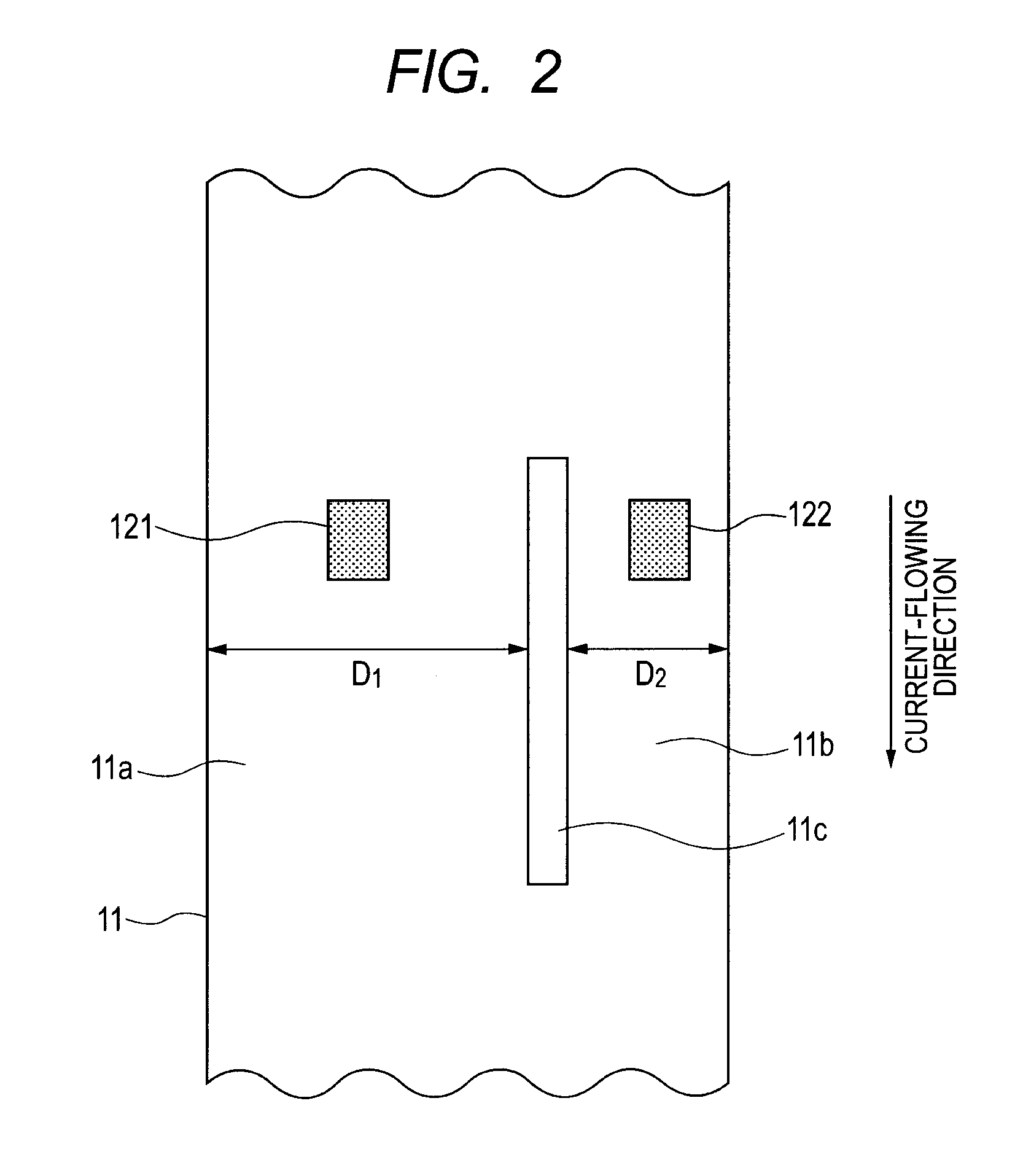

ActiveUS20070103150A1Easy to measureImprove accuracySemiconductor/solid-state device manufacturingMagnetic property measurementsEngineeringMagnetic flux

An eddy current sensor (10) has a sensor coil (100) disposed near a conductive film (6) formed on a semiconductor wafer (W) and a signal source (124) configured to supply an AC signal to the sensor coil (100) to produce an eddy current in the conductive film (6). The eddy current sensor (10) includes a detection circuit operable to detect the eddy current produced in the conductive film (6). The detection circuit is connected to the sensor coil (100). The eddy current sensor (10) also includes a housing (200) made of a material having a high magnetic permeability. The housing (200) accommodates the sensor coil (100) therein. The housing (200) is configured so that the sensor coil (100) forms a path of a magnetic flux (MF) so as to effectively produce an eddy current in the conductive film (6).

Owner:EBARA CORP

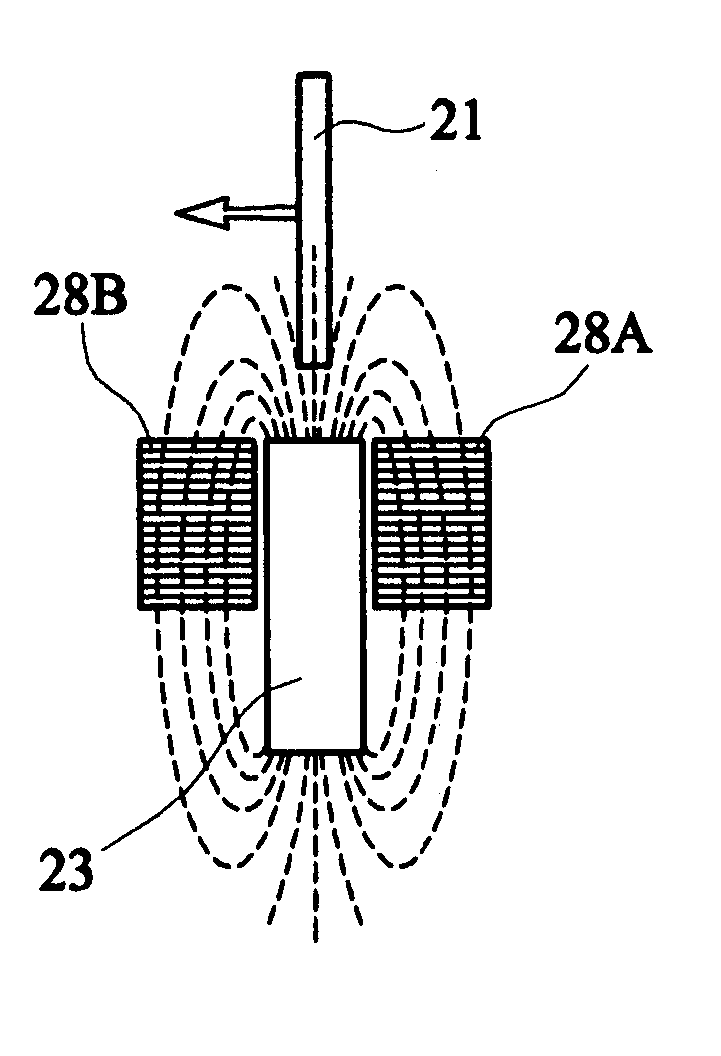

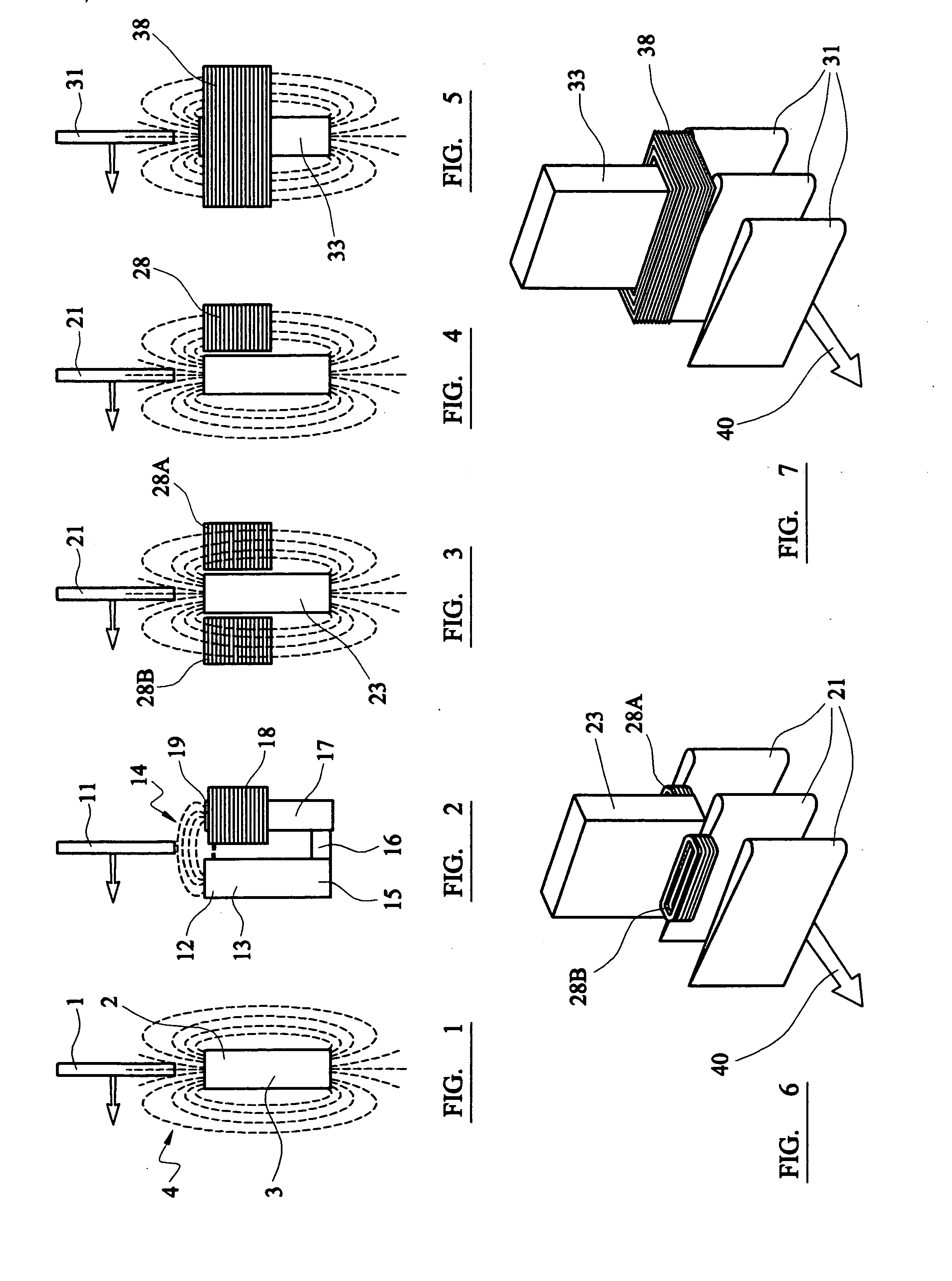

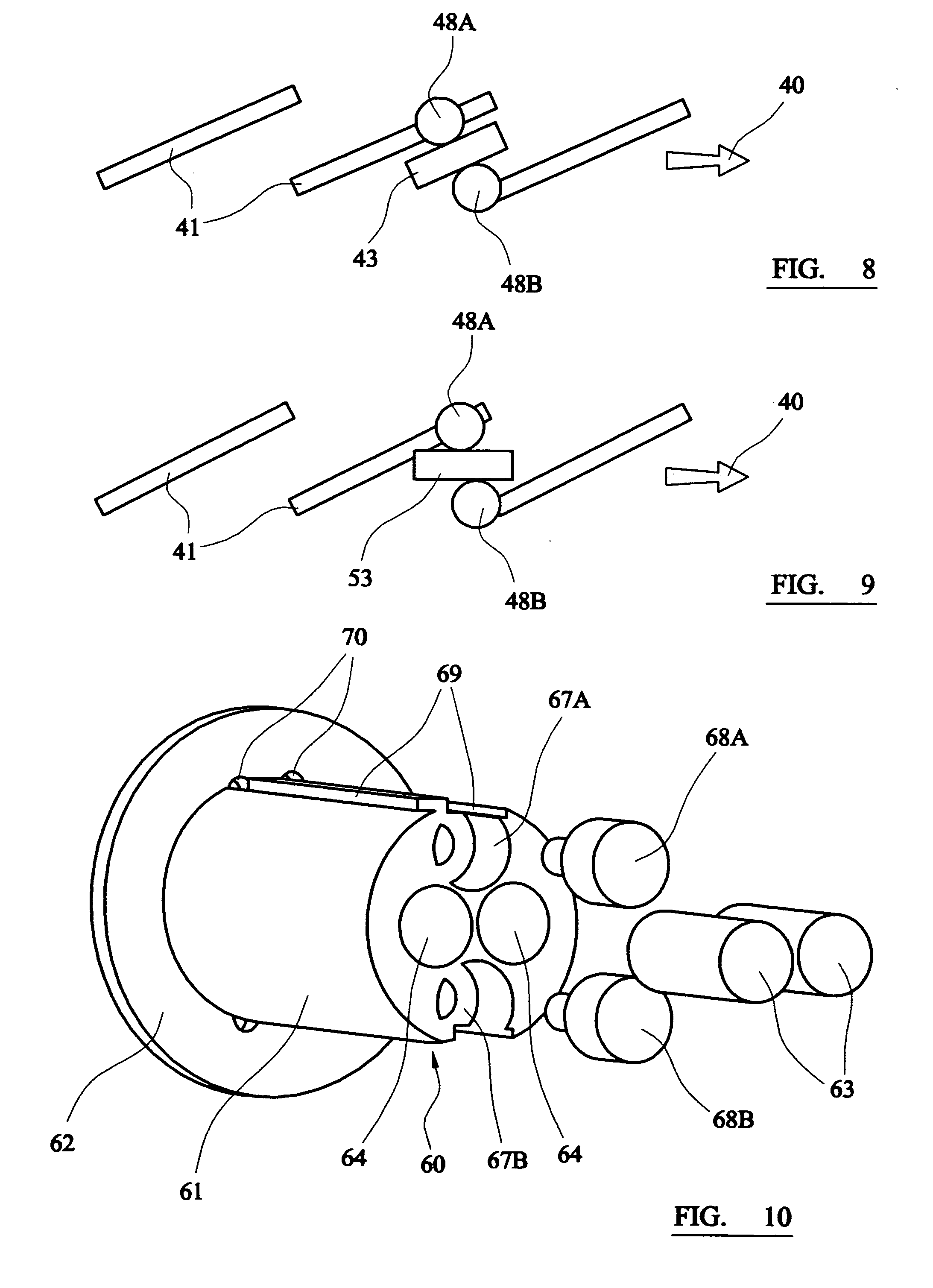

Eddy current sensors

InactiveUS20050127905A1Space minimizationReduce field strengthEngine fuctionsUsing electrical meansTurbine bladeEddy-current sensor

An inductive eddy current sensor, for use for example for measuring the speed of a turbine by detecting the passage of turbine blades (21) past a probe incorporating the sensor, includes a magnet (23) positioned so that the blades (21) pass through the flux pattern generated by the magnet (23). At least one pick-up coil (28) devoid of a core of soft magnetic is positioned alongside the magnet to pick up signals generated by eddy currents generated in the turbine blades as they cut through the flux pattern, without thereby altering the flux pattern. In a modified arrangement, the pick-up coil surrounds the magnet, again without affecting the flux pattern.

Owner:WESTON AEROSPACE

Intelligent instrument for measuring tissue thickness

InactiveCN104921730AWon't hurtNo tissue damageDiagnostic recording/measuringSensorsWireless transmissionButton battery

The invention relates to an intelligent instrument for measuring the tissue thickness. The intelligent instrument comprises a button cell type intelligent thickness measuring clip or an external power supply type intelligent thickness measuring clip, a linear incision anastomat or a manual thickness measuring instrument or an automatic thickness measuring instrument, and a staple anvil. The button cell type intelligent thickness measuring clip comprises an outer shell, a pressing key, waterproof soft glass, an integrated circuit board and a bottom cover. The waterproof soft glass is arranged between the pressing key and the integrated circuit board and covers the surface of the pressing key. A button cell, a power module, a display module, a tissue pressure intensity measuring module, a tissue thickness measuring module, a control module and a wireless transmission module are mounted on the back face of the integrated circuit board. An eddy-current transducer and a pressure sensor are mounted on the front face of the integrated circuit board. The button cell type intelligent thickness measuring clip is matched with a wireless transmission device. The intelligent instrument for measuring the tissue thickness has the advantages that the tissue thickness can be measured in a quantitative mode, tissue thickness measurement is accurate, corresponding anastomotic staple cartridges can be selected conveniently, and the success rate of anastomotic surgery is increased.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

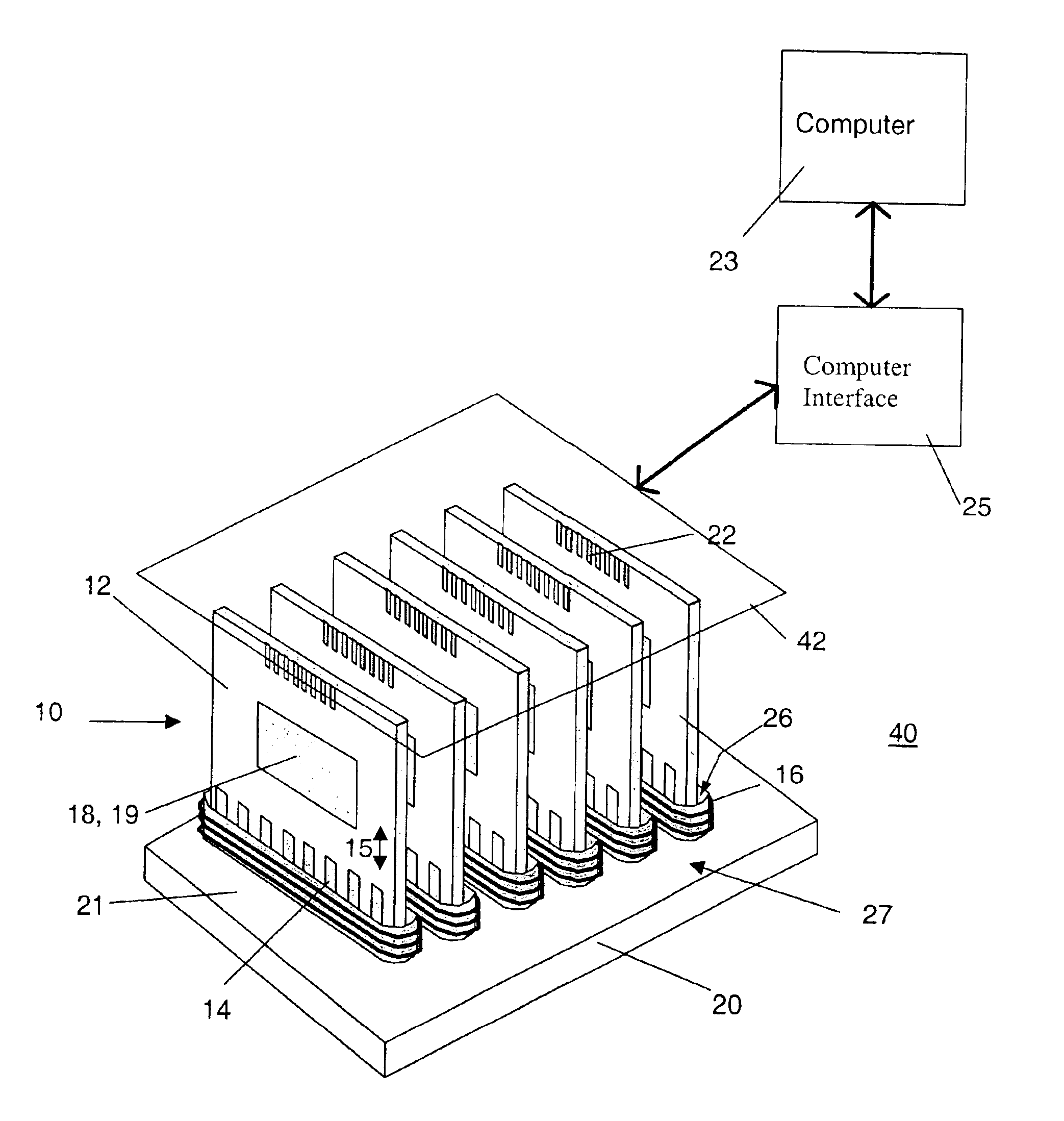

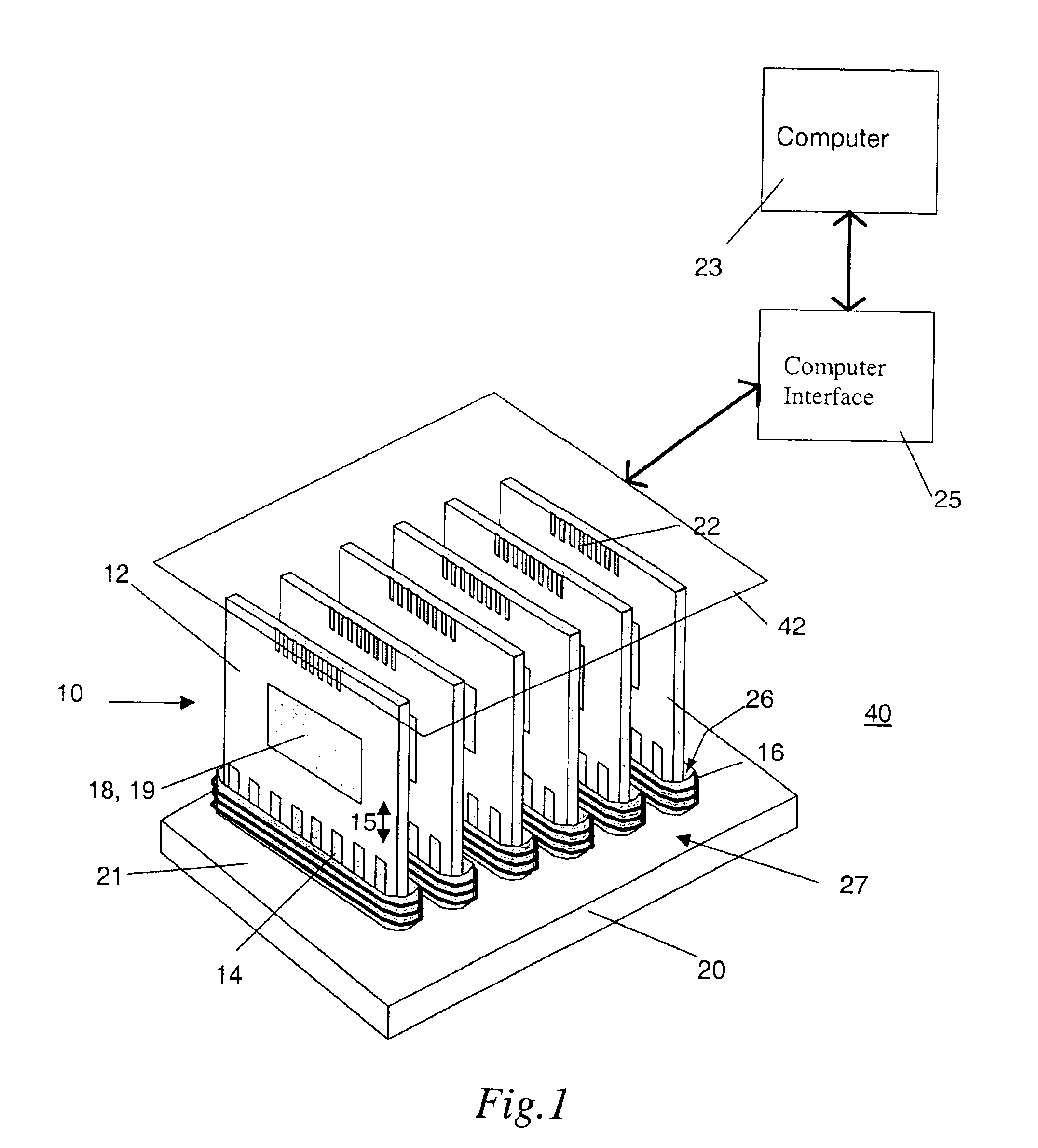

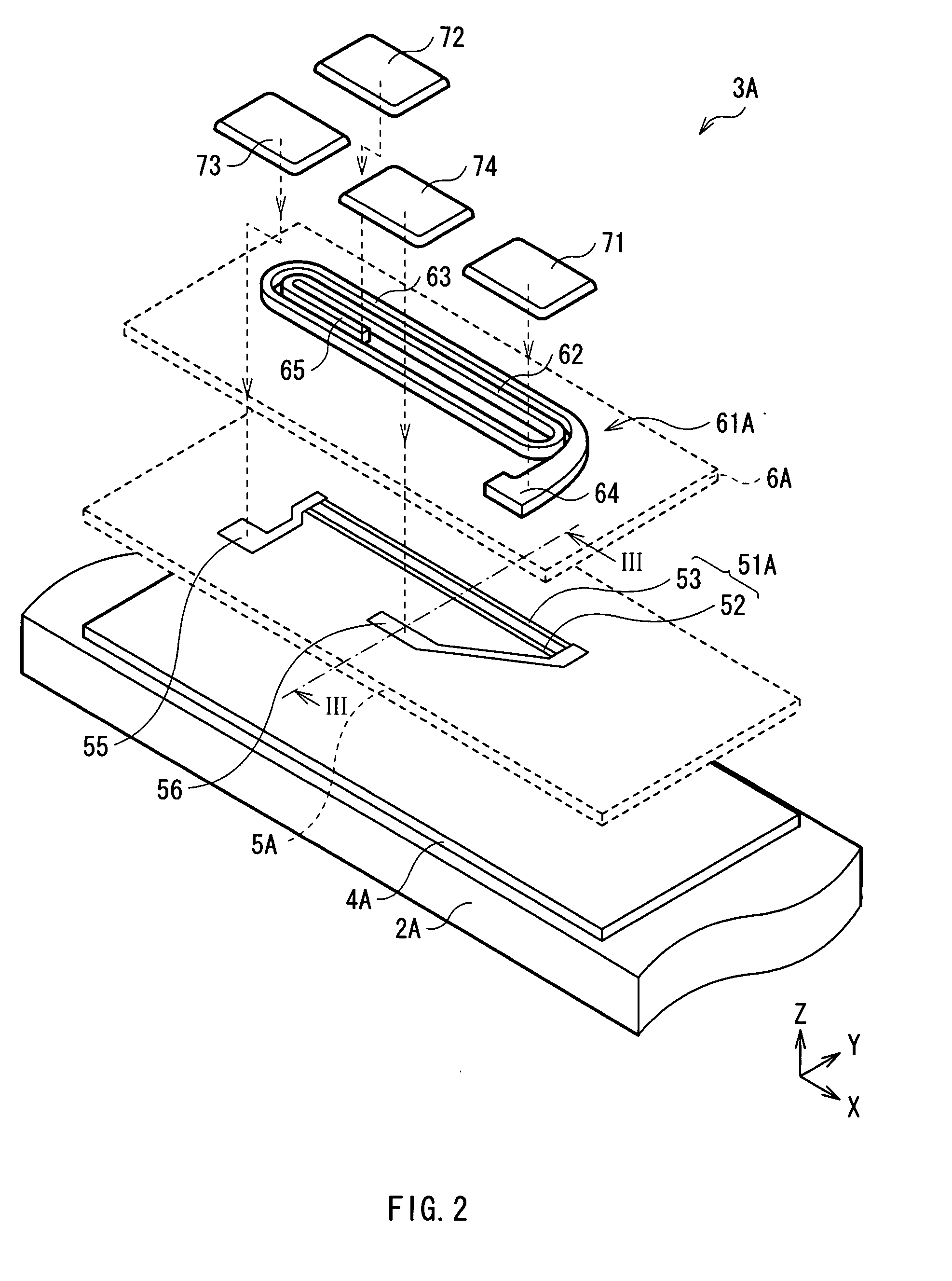

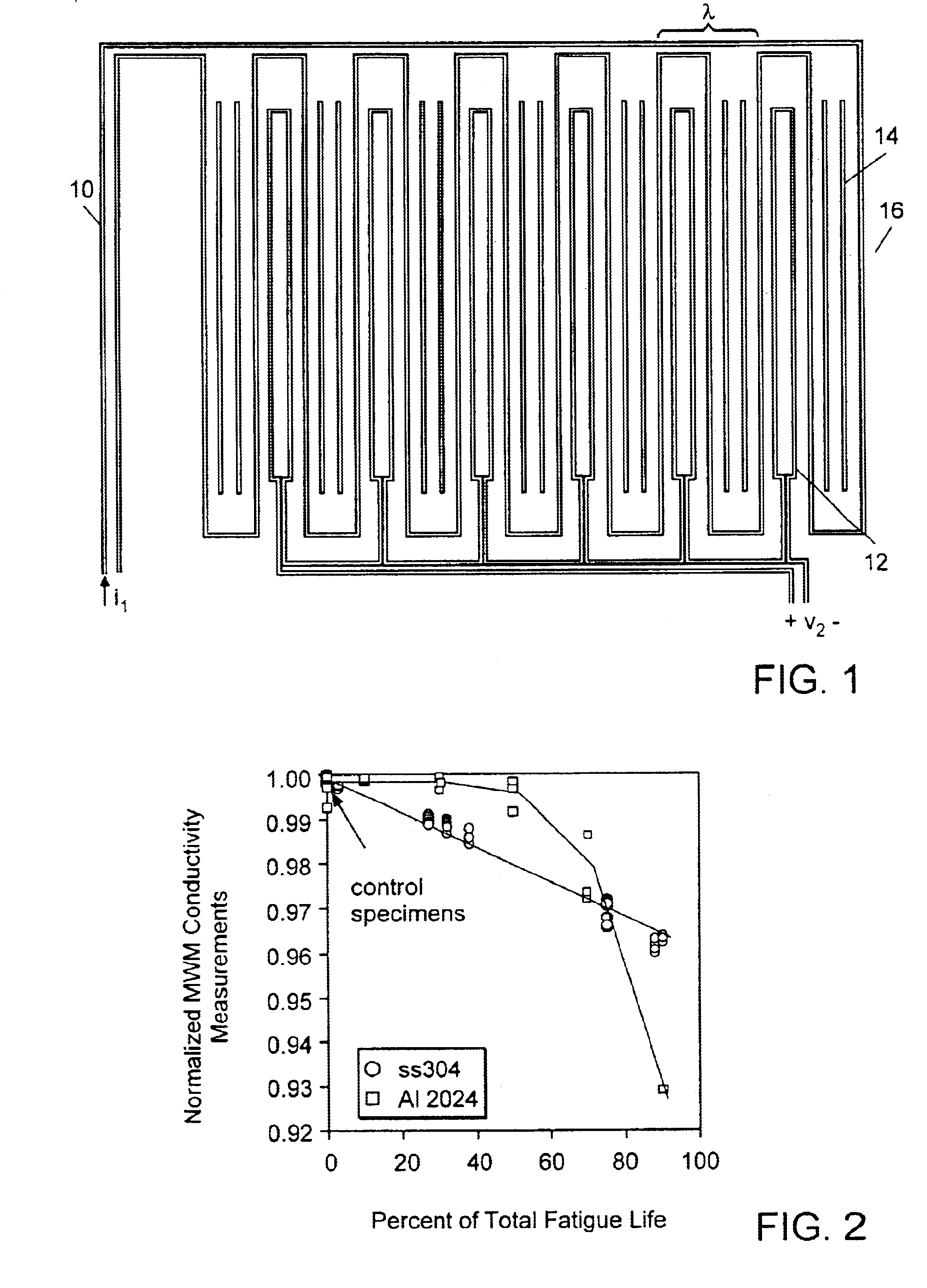

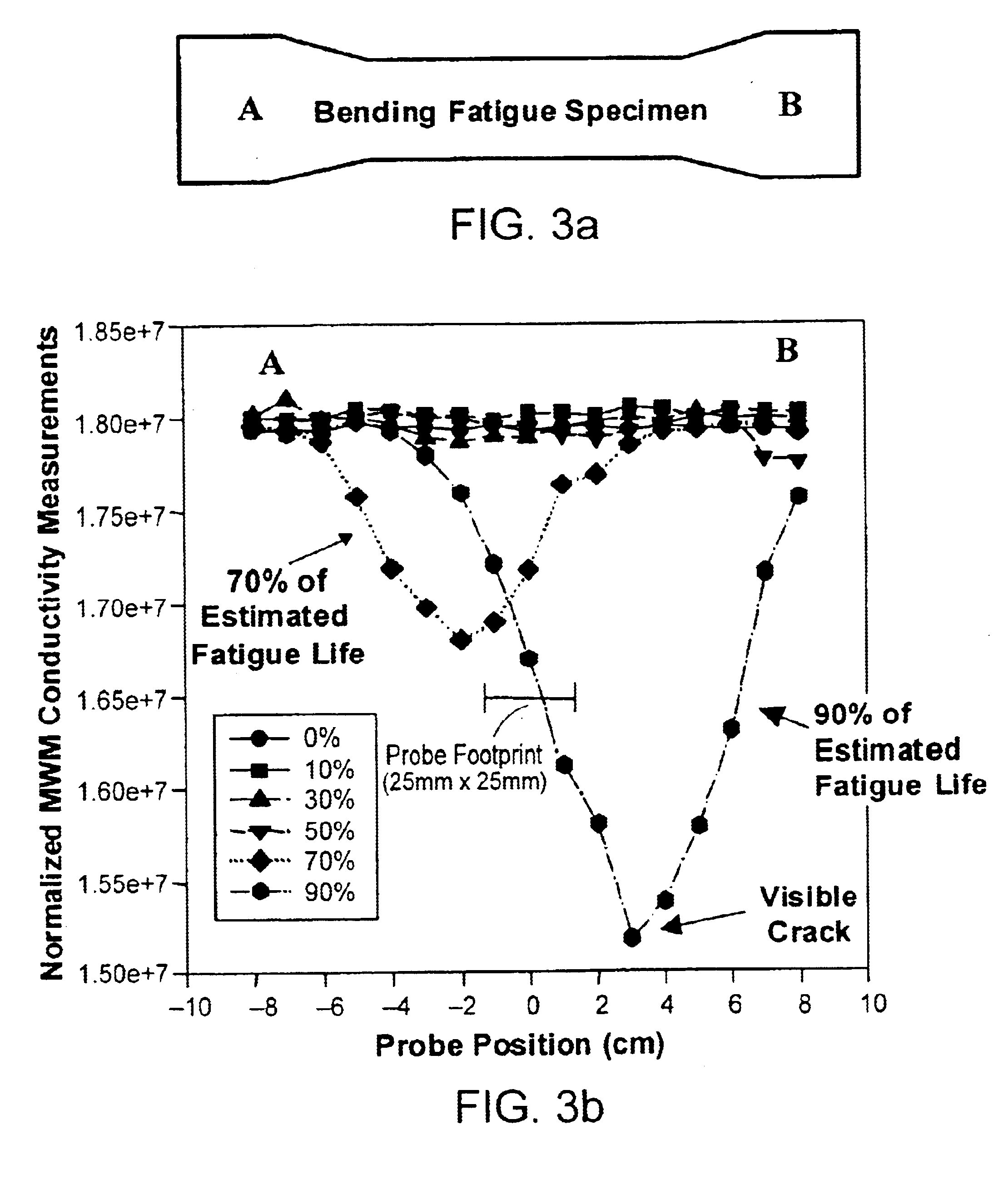

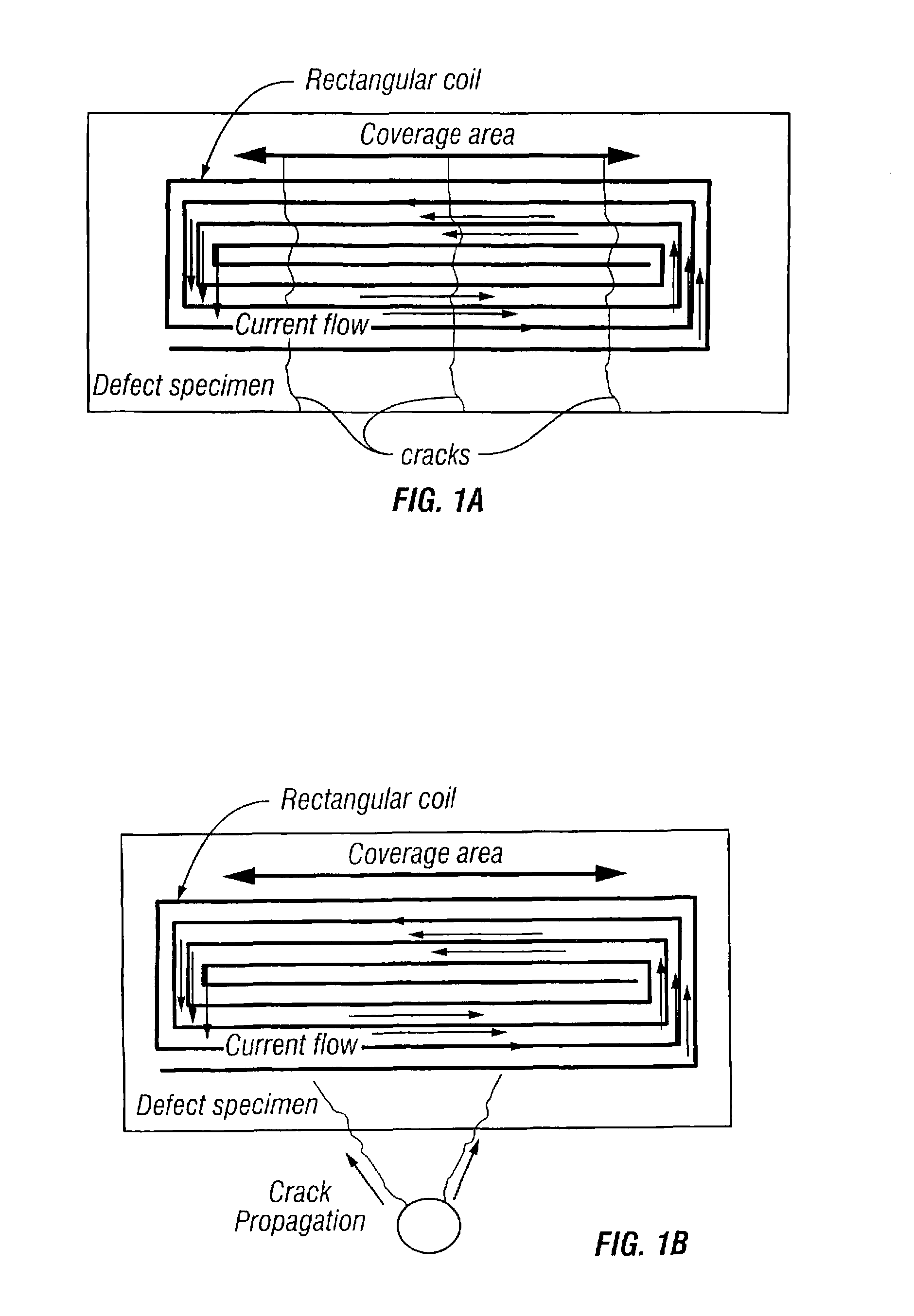

Surface mounted and scanning spatially periodic eddy-current sensor arrays

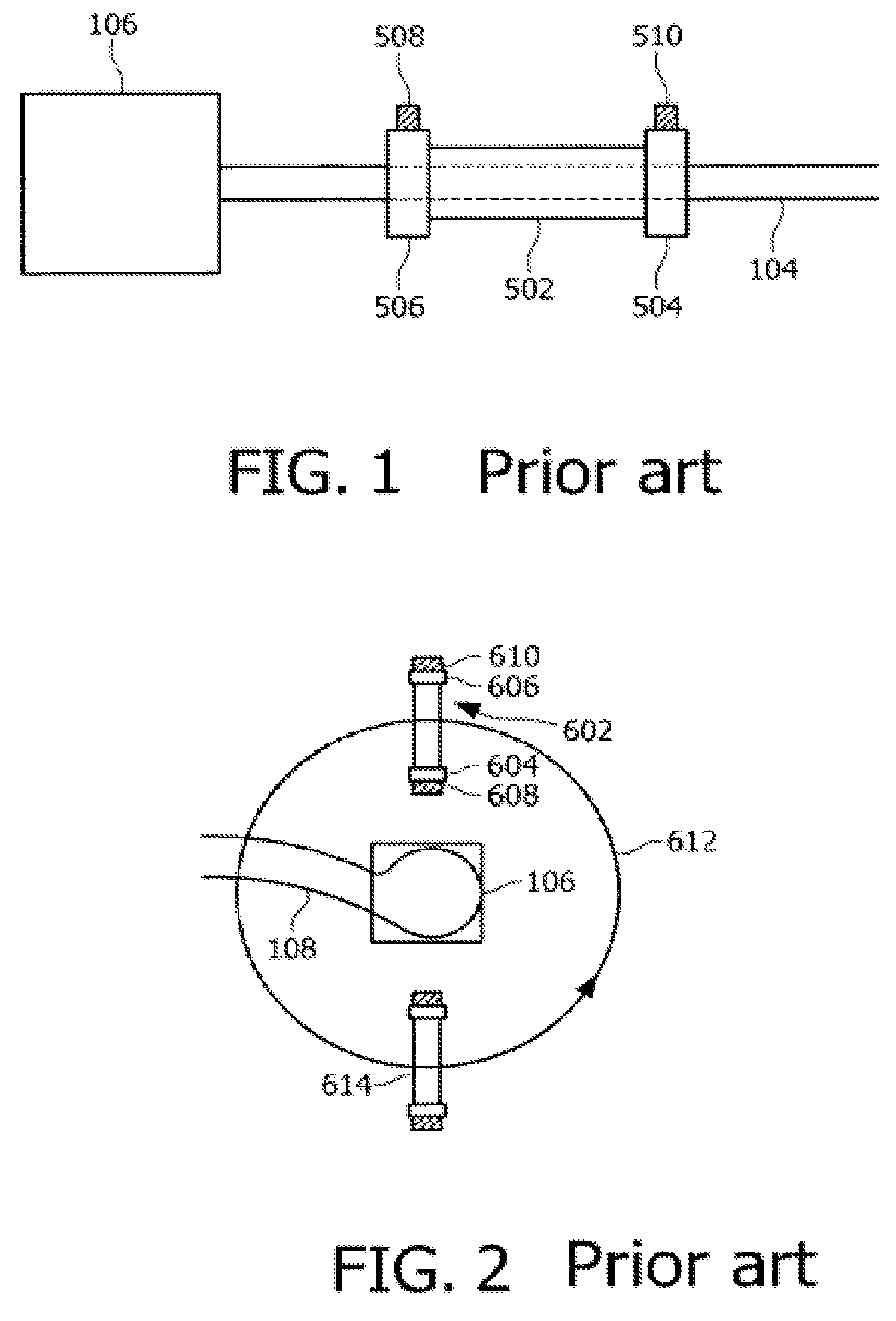

InactiveUS6952095B1Promote accurate modelingIncreased depth of sensitivityMagnetic property measurementsElectric/magnetic roughness/irregularity measurementsSurface mountingCurrent sensor

Inductive sensors measure the near surface properties of conducting and magnetic material. A sensor may have primary windings with parallel extended winding segments to impose a spatially periodic magnetic field in a test material. Those extended portions may be formed by adjacent portions of individual drive coils. Sensing elements provided every other half wavelength may be connected together in series while the sensing elements in adjacent half wavelengths are spatially offset. Certain sensors include circular segments which create a circularly symmetric magnetic field that is periodic in the radial direction. Such sensors are particularly adapted to surround fasteners to detect cracks and can be mounted beneath a fastener head. In another sensor, sensing windings are offset along the length of parallel winding segments to provide material measurements over different locations when the circuit is scanned over the test material. The distance from the sensing elements to the ends of the primary winding may be kept constant as the offset space in between sensing elements is varied. An image of the material properties can be provided as the sensor is scanned across the material.

Owner:JENTEK SENSORS

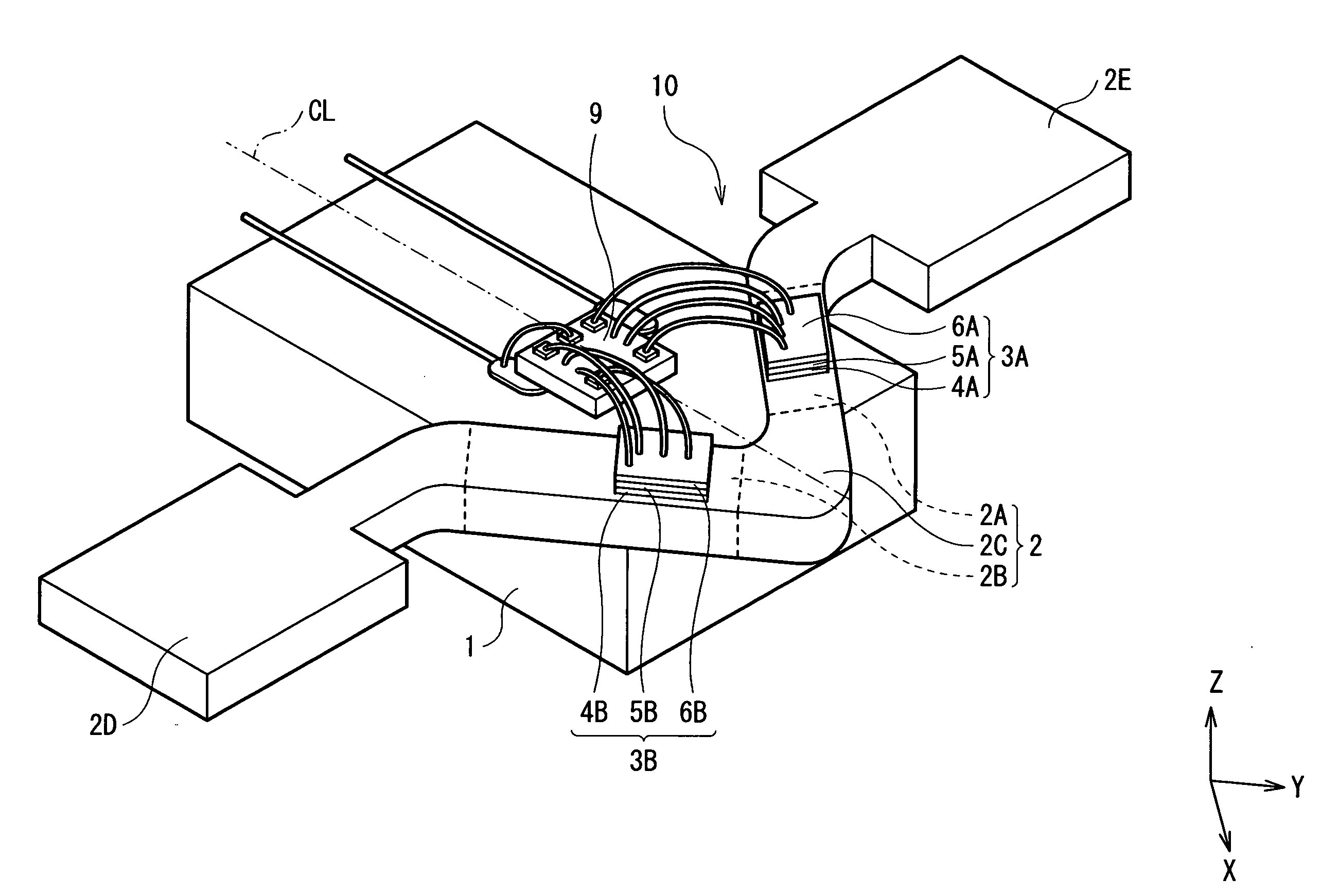

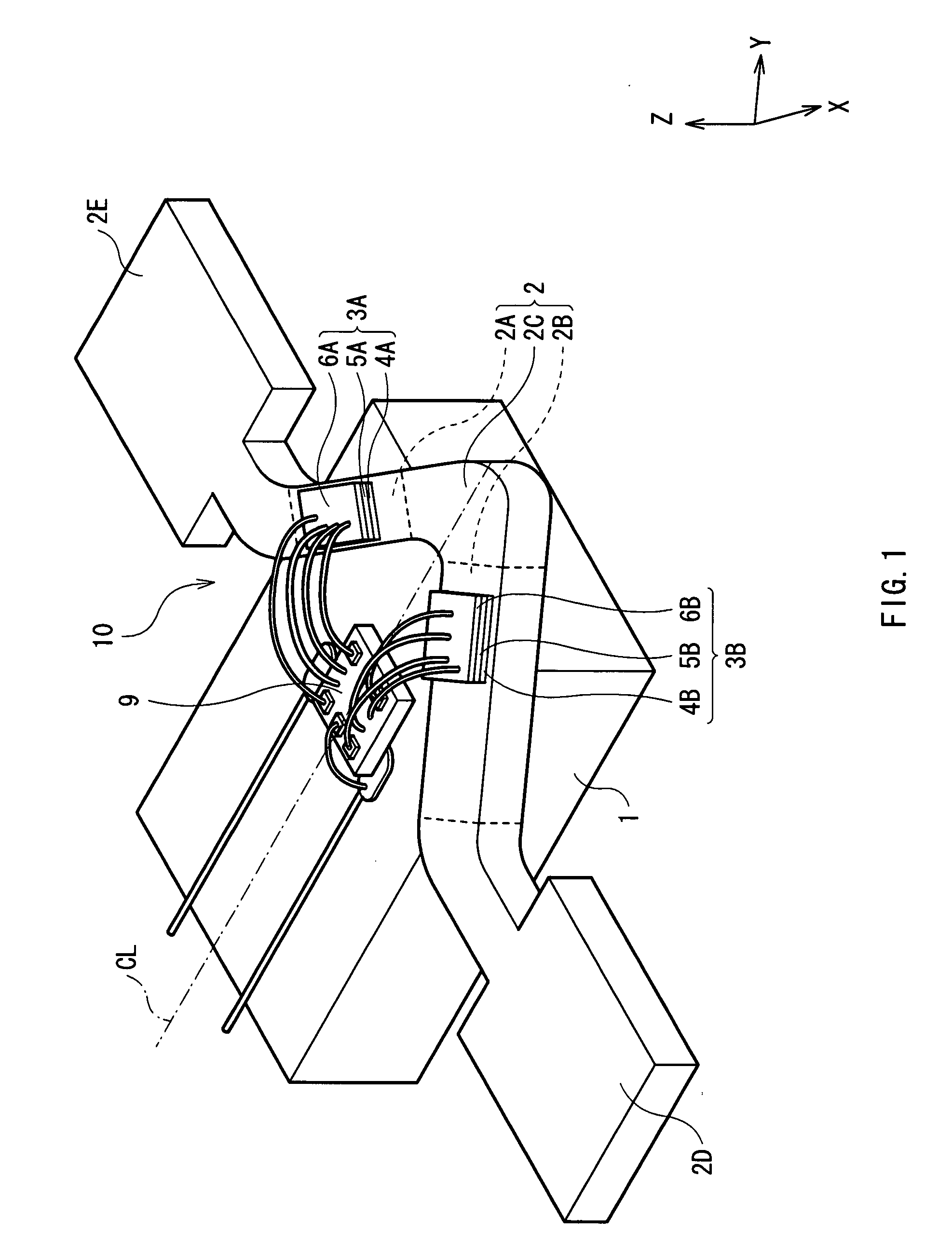

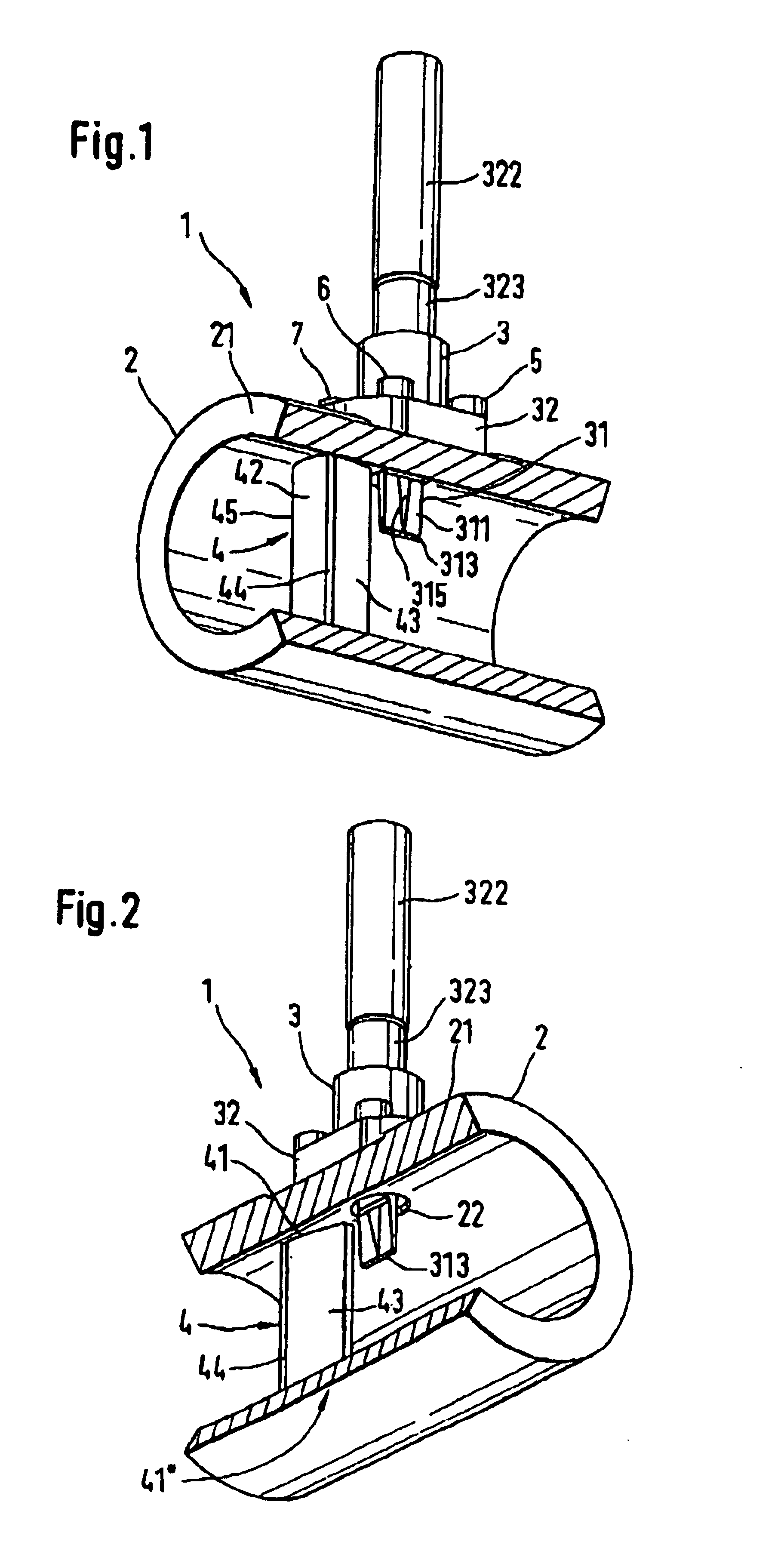

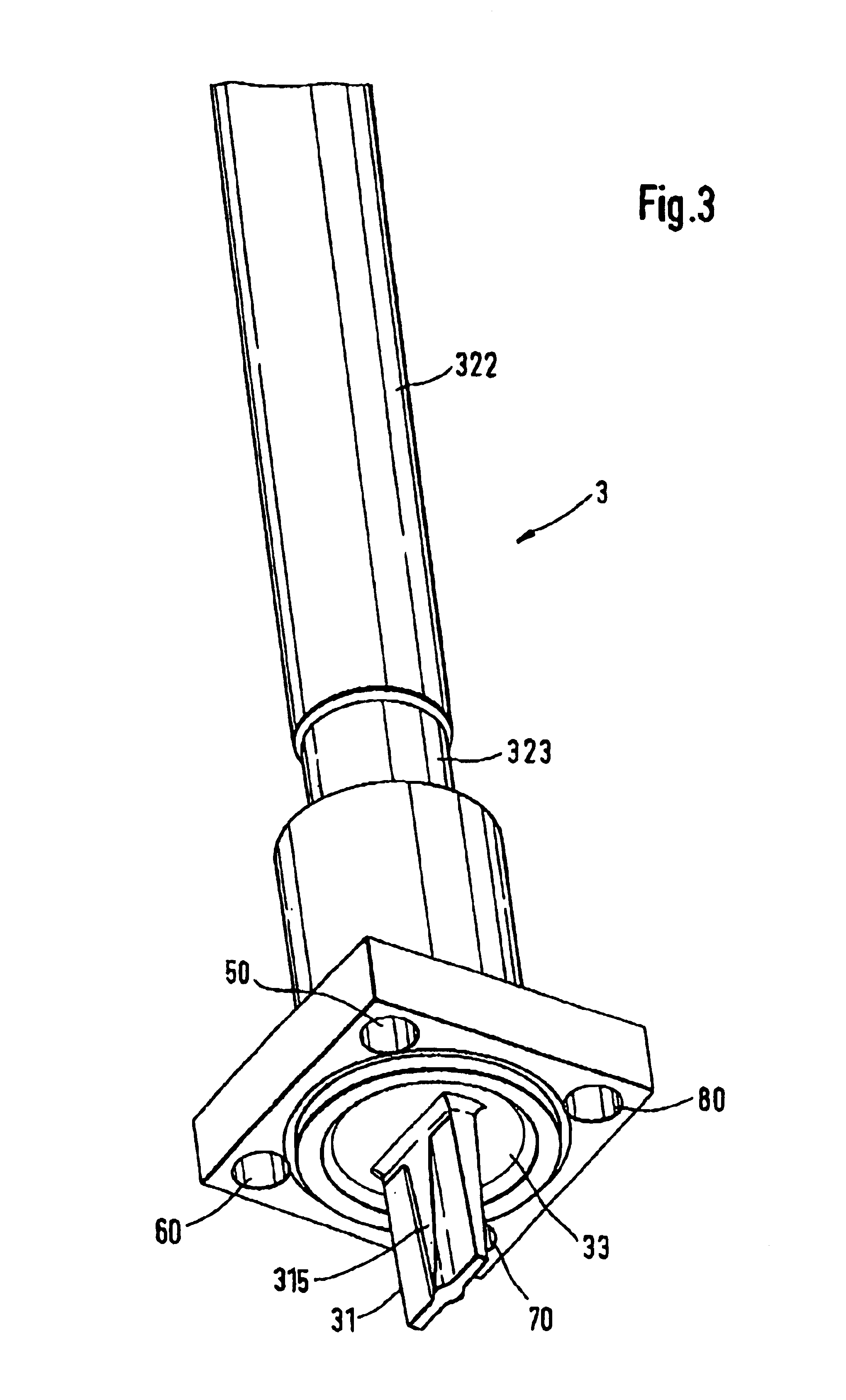

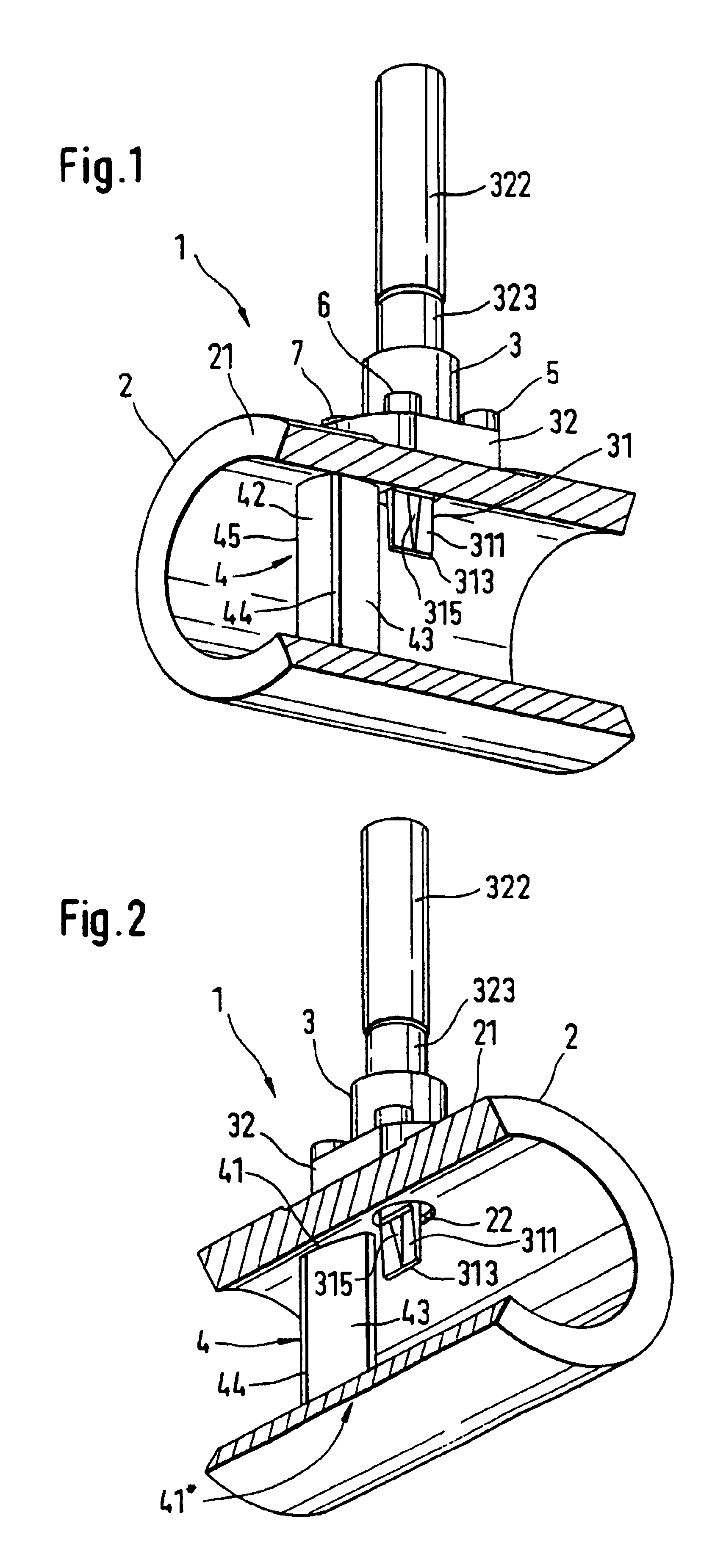

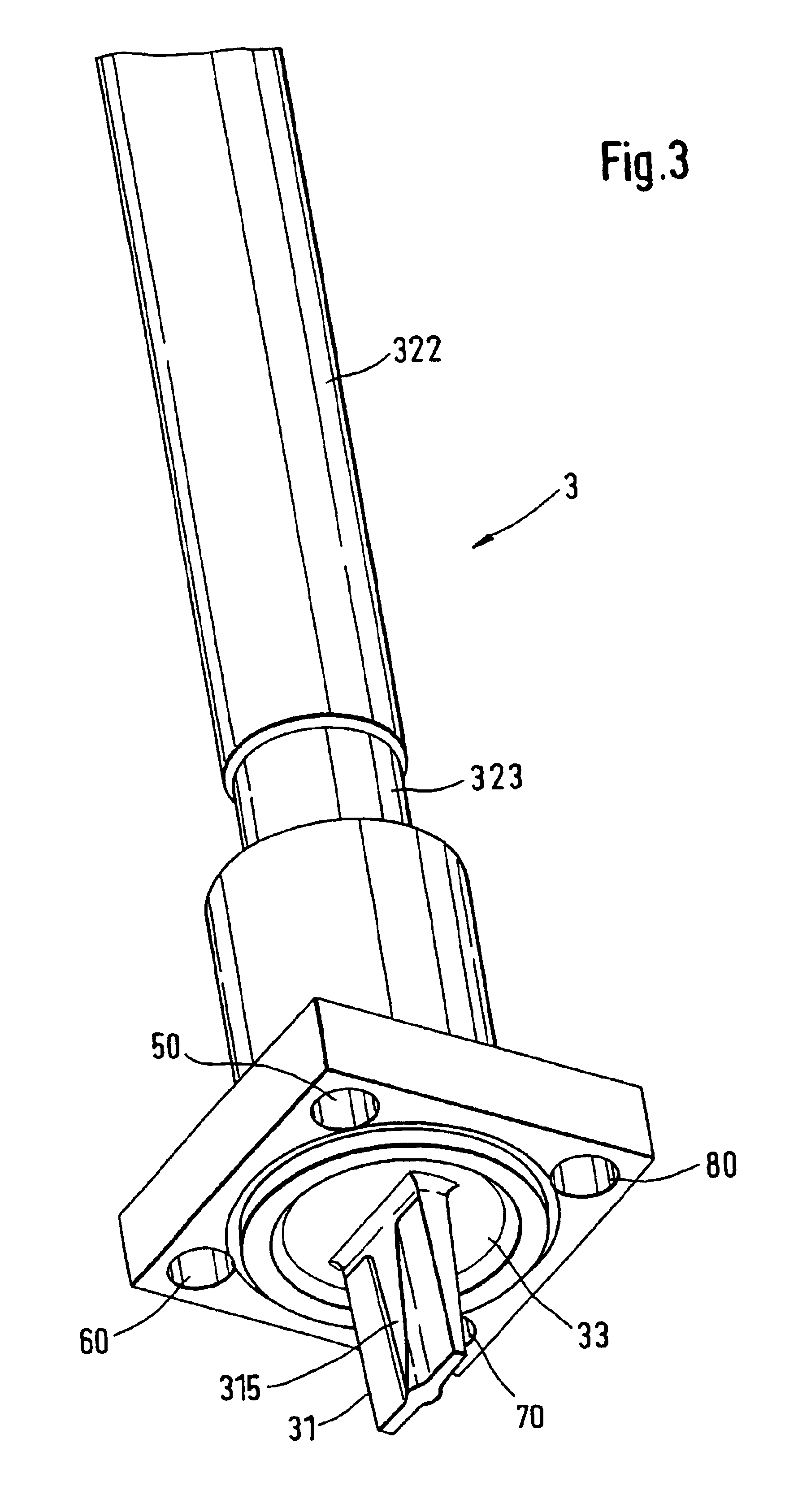

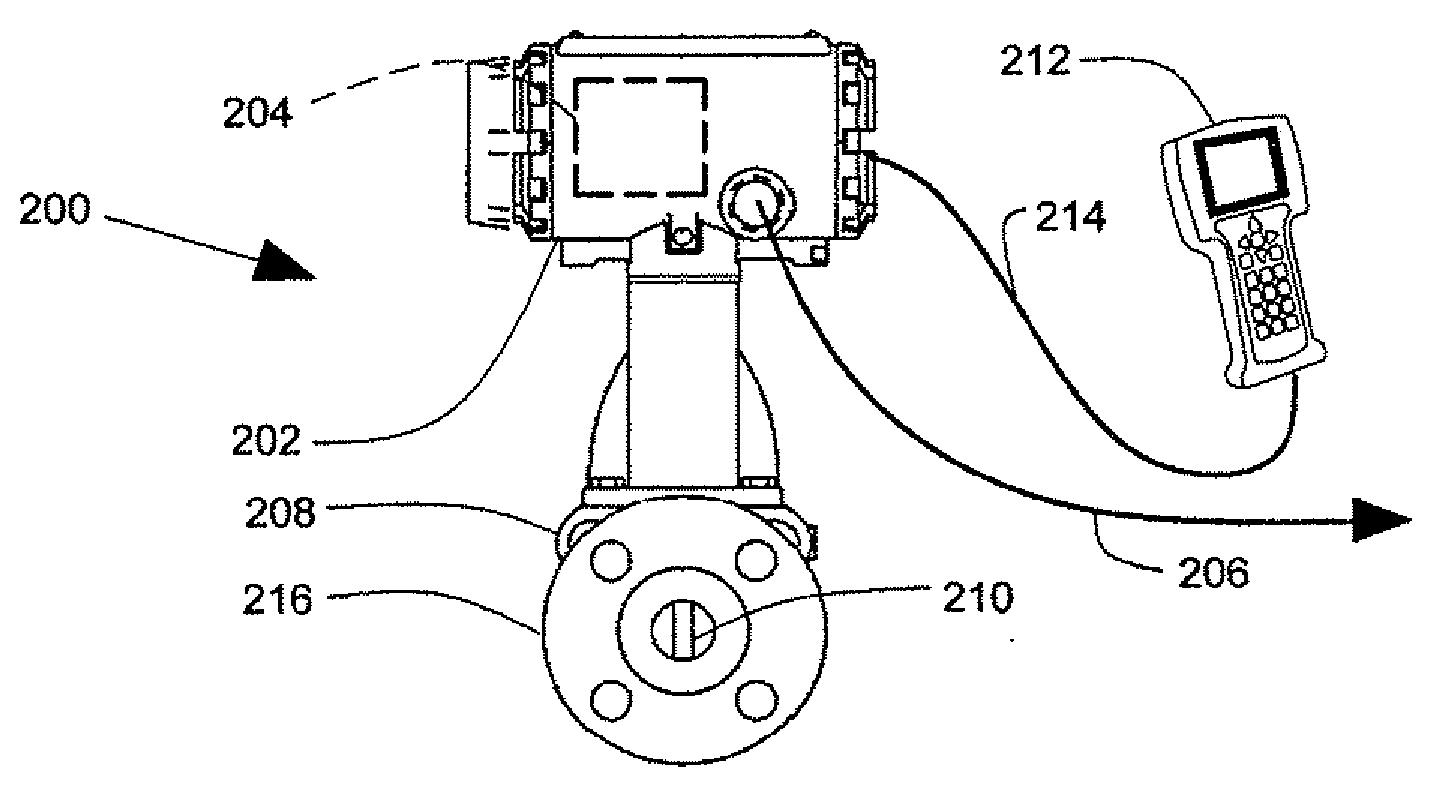

Vortex flow sensor for measuring fluid flow through a flow tube

InactiveUS6910387B2Improve thermal conductivityEasy to measureVolume/mass flow by dynamic fluid flow effectIndirect mass flowmetersTwo temperatureEngineering

The vortex flow sensor is designed to measure the mass flow rate, the volumetric flow rate, or the flow velocity of a fluid flowing in a flow tube having a tube wall, and has two temperature sensors arranged in such a way that the vortex flow sensor may also be used with fluids which would corrode the temperature sensors. A bluff body in the flow tube sheds vortices and thus causes pressure fluctuations. A vortex sensor device responsive thereto is fitted downstream of the bluff body in a hole provided in the wall of the flow tube. The vortex sensor device comprises a sensor vane extending into the fluid. The temperature sensors are disposed in a blind hole of the sensor vane. Alternatively, the temperature sensor may be disposed in blind hole of the bluff body.

Owner:ENDRESS HAUSER FLOWTEC AG

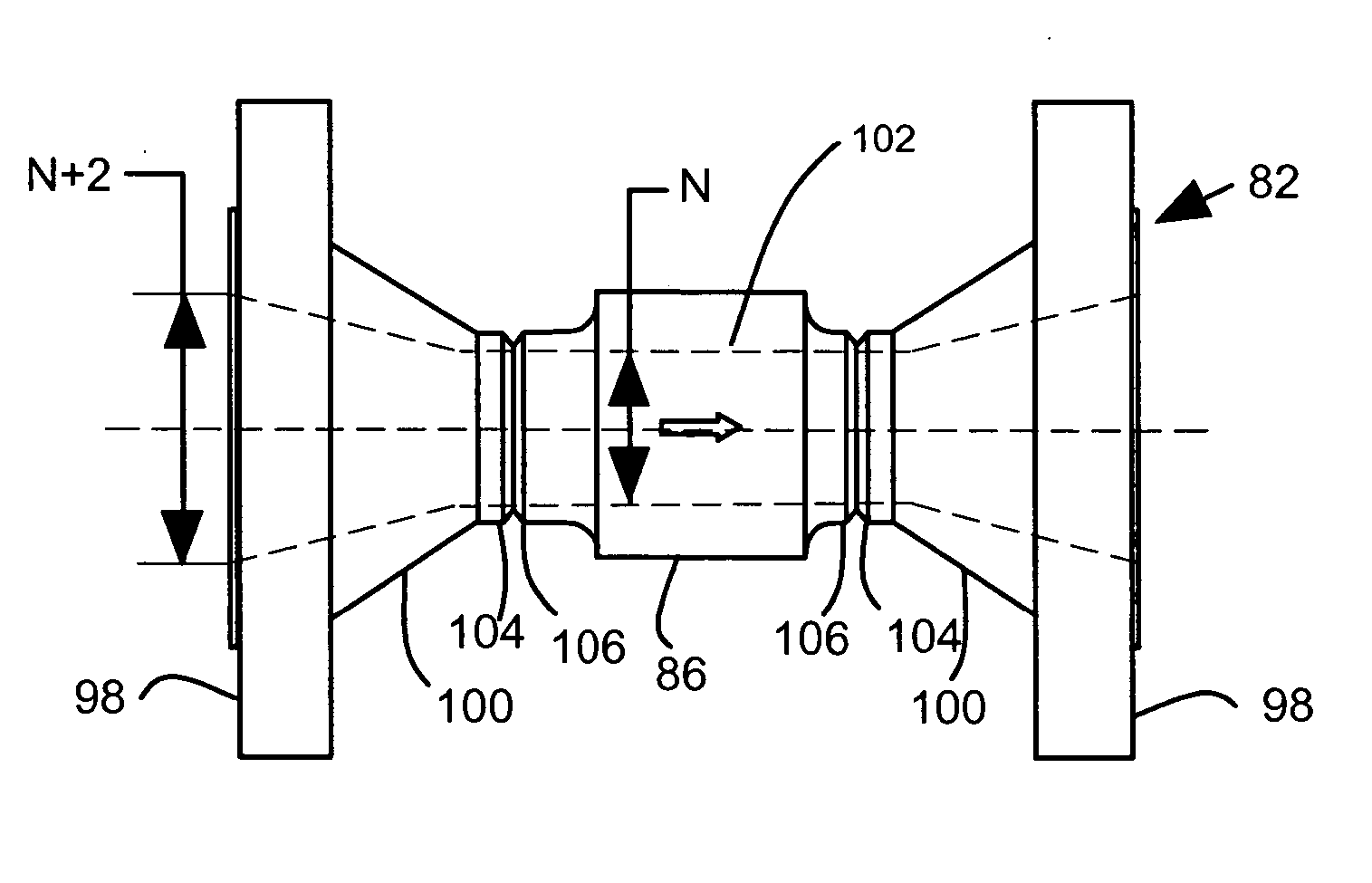

Flanged vortex flowmeter with unitary tapered expanders

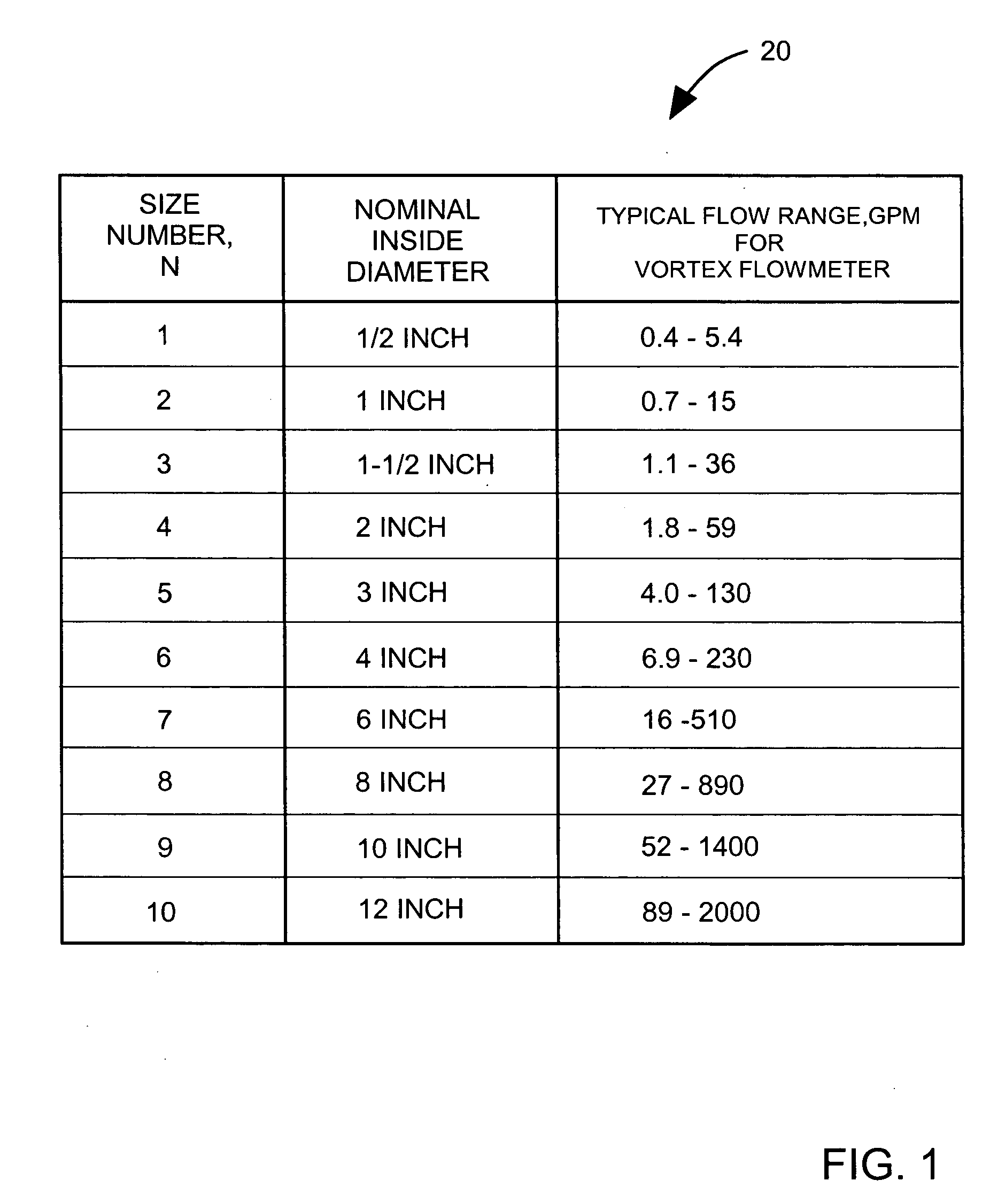

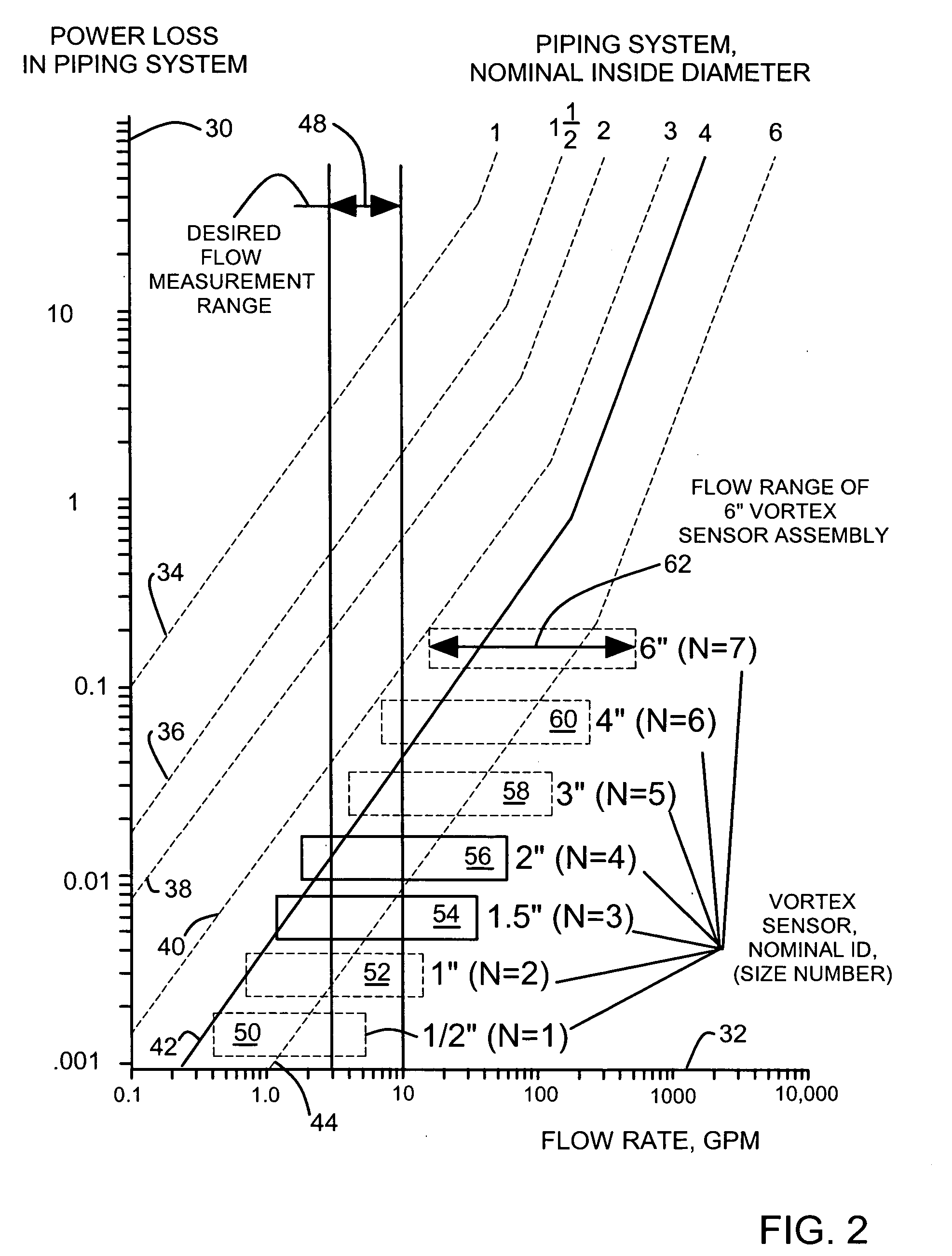

ActiveUS20050092101A1Smooth flow transitionSmooth transitionVolume/mass flow by dynamic fluid flow effectEngineeringReducer

A manufacturing procedure of a vortex flowmeter is disclosed that allows for assembly of a vortex sensor assembly with one of two or more unitary flowtubes that have bores that are smaller than the flowtube flanges in two or more size number steps. The unitary flowtubes include flanges, flowtube bores and expanders (also called reducers) that provide a smooth flow transition from the larger flanges to the smaller bores.

Owner:MICRO MOTION INC

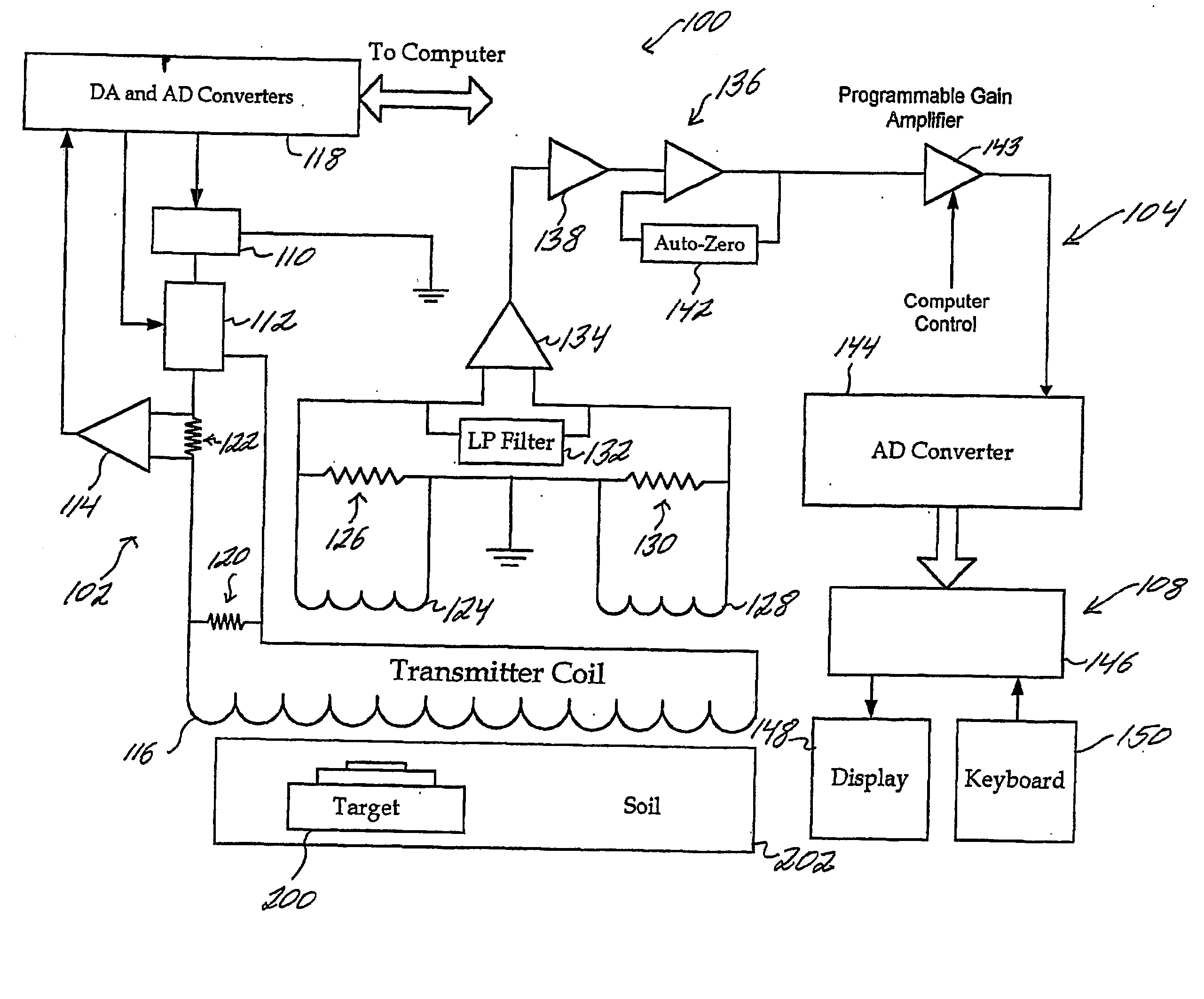

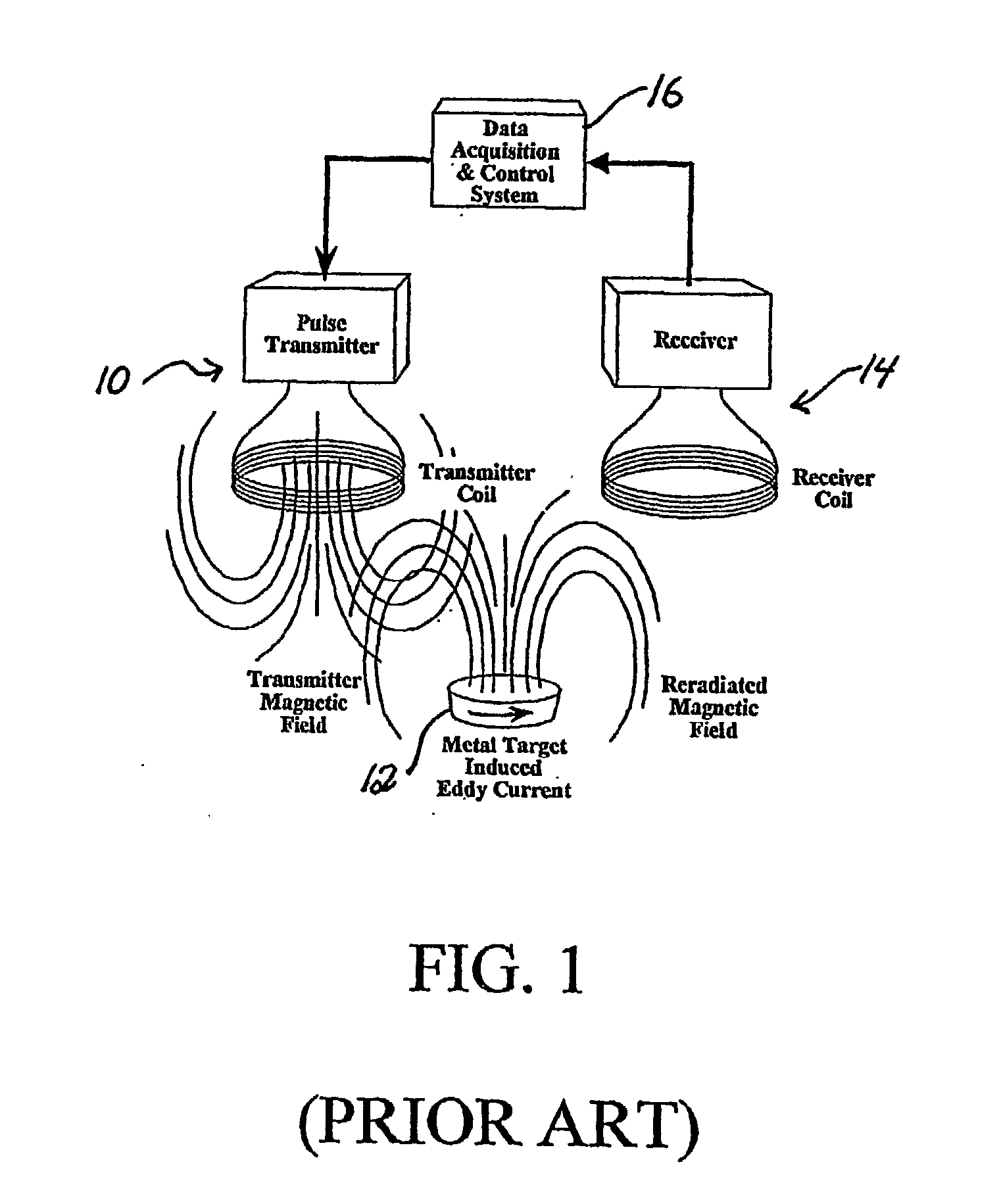

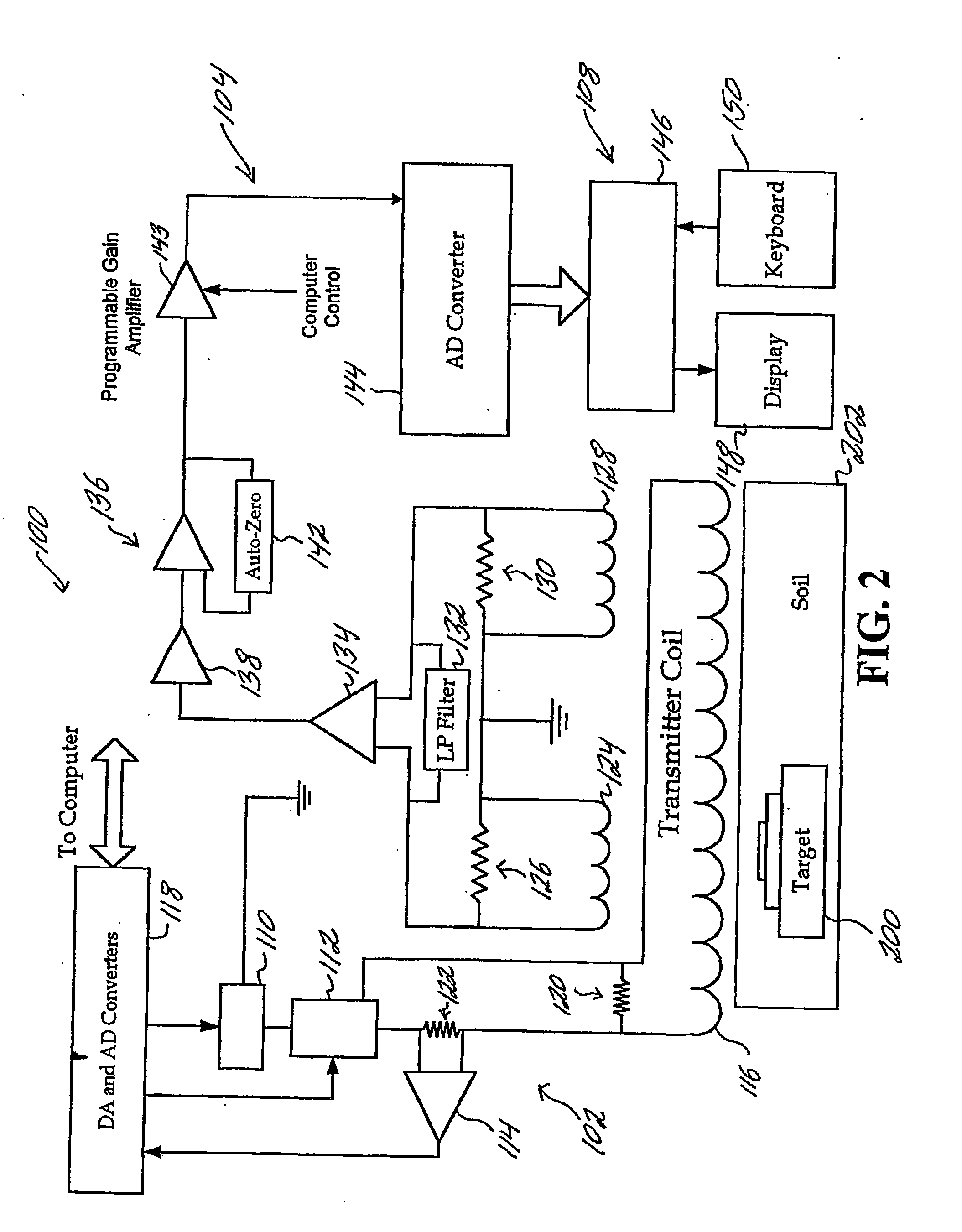

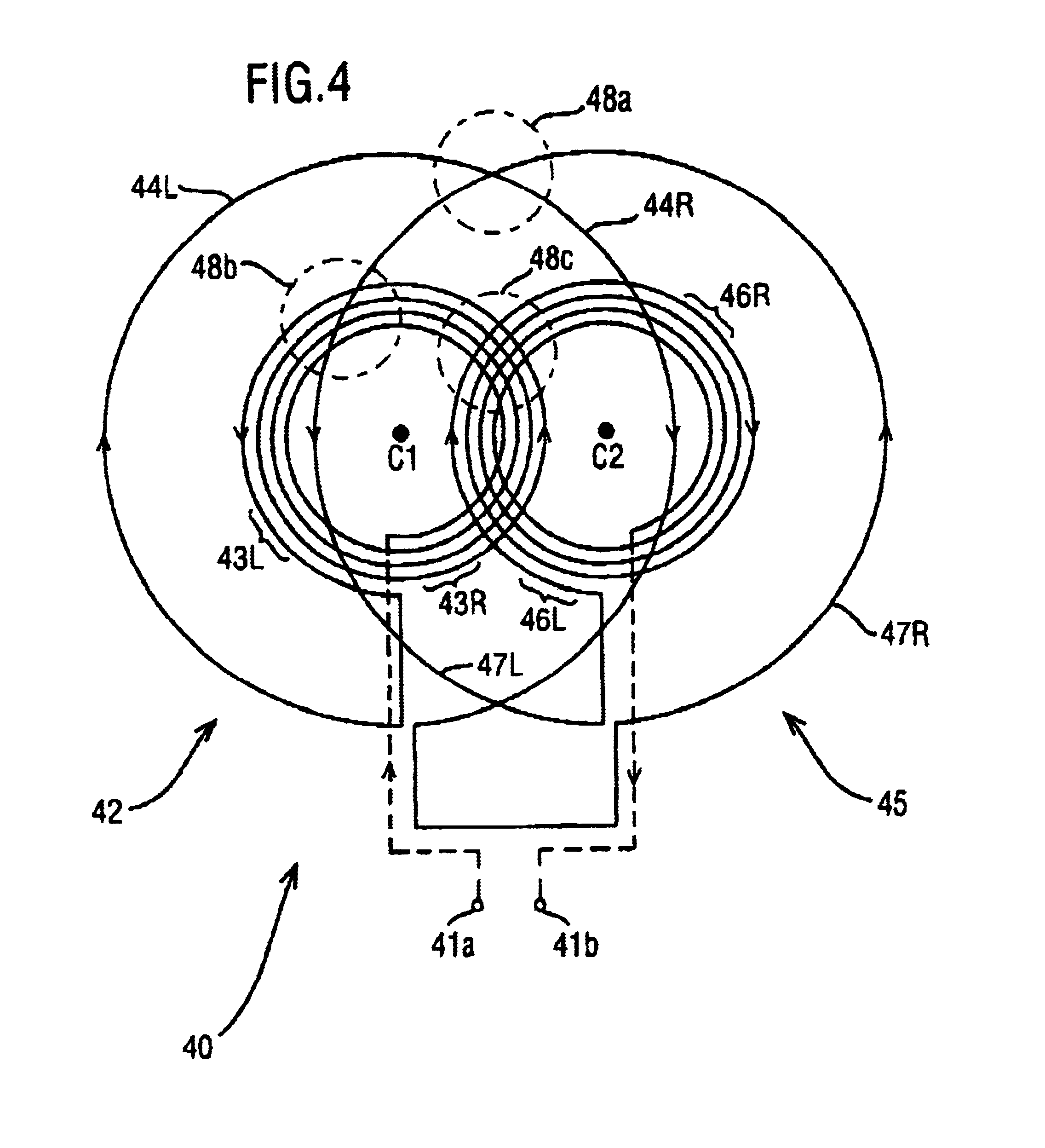

Electromagnetic target discriminator sensor system and method for detecting and identifying metal targets

InactiveUS20030052684A1Character and pattern recognitionElectric/magnetic detection for transportDiscriminatorControl system

A time-domain electromagnetic target discriminator (ETD) sensor system and method are provided capable of measuring a metal target's time decay response based on the physical parameters of the metal target and its environment and for identifying the metal target. The ETD sensor system includes a pulse transmitter connected to a receiver via a data acquisition and control system. The transmitter and receiver include coil configurations for placement in proximity to a visually obscured, e.g., buried, metal target (or underground void) for inducing eddy currents within the metal target. The ETD sensor system measures the eddy current time decay response of the metal target in order to perform target recognition and classification. The identification process entails comparing the metal target's (or, underground void or other object's) time decay response with a library of normalized object signatures, e.g., time decay responses and other characteristics.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

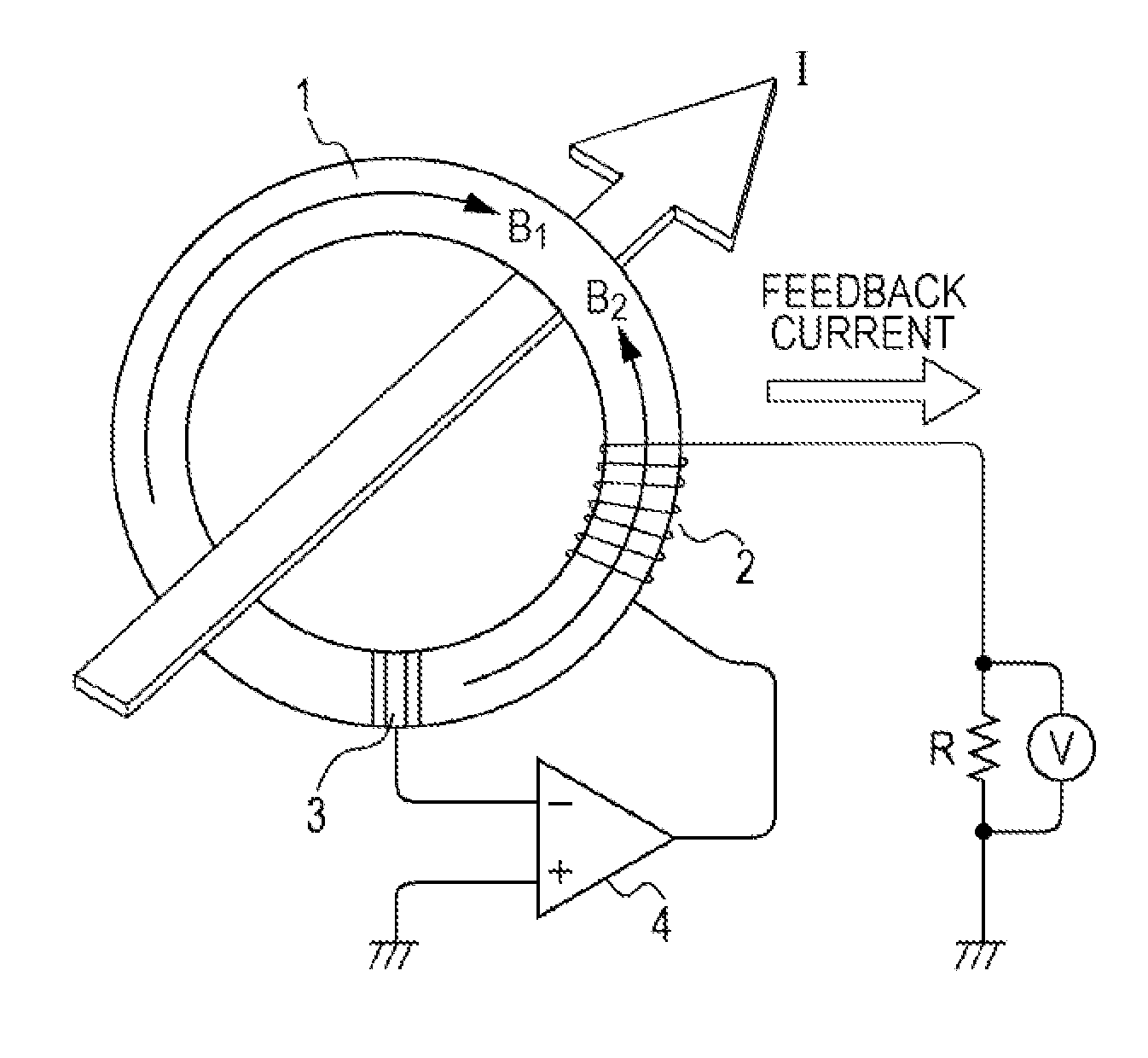

Magnetic-balance-system current sensor

ActiveUS20120062215A1High sensitivityIncreases magnitudeNanomagnetismMagnetic field measurement using flux-gate principlePower flowCurrent sensor

A magnetic-balance-system current sensor includes: a magnetoresistive element, a resistance value of the magnetoresistive element being changed by applying an induction magnetic field generated by a measurement target current; magnetic cores disposed near the magnetoresistive element; a feedback coil disposed near the magnetoresistive element and configured to generate a cancelling magnetic field that cancels out the induction magnetic field; and a magnetic-field detecting bridge circuit having two outputs. The measurement target current is measured on the basis of a current flowing through the feedback coil when the induction magnetic field and the induction magnetic field and the cancelling magnetic field cancel each other out. The feedback coil, the magnetic cores, and the magnetic-field detecting bridge circuit are formed on a same substrate. The feedback coil is of a spiral type, and the magnetic cores are provided above and below the feedback coil.

Owner:ALPS ALPINE CO LTD

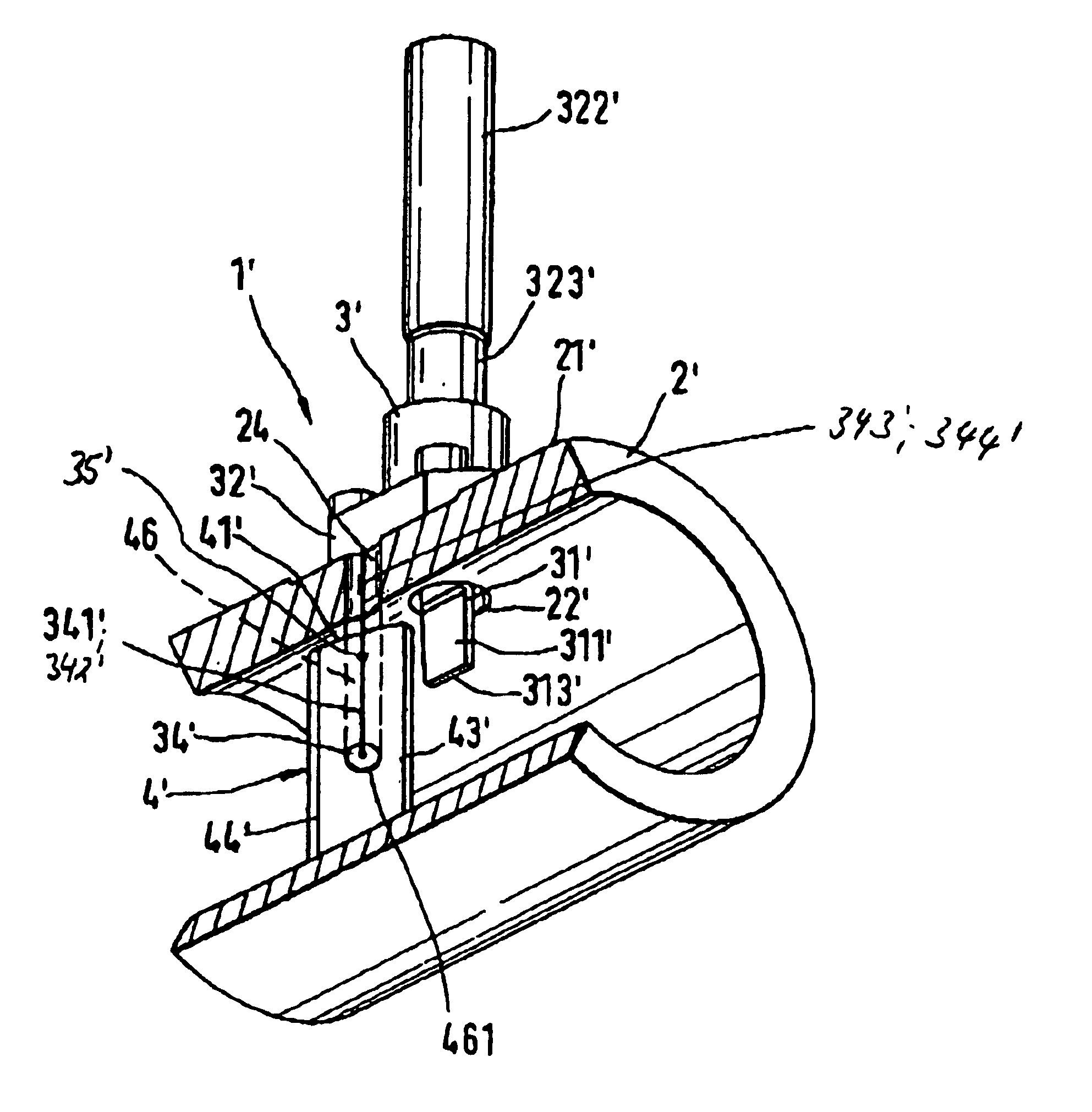

Vortex flow pickup

InactiveUS6938496B2Better heat conductorAccurate temperature measurementVolume/mass flow by dynamic fluid flow effectIndirect mass flowmetersEngineeringEddy-current sensor

A vortex flow pickup serves for measuring mass flow, volume flow or flow velocity of a fluid which is flowing in a measuring tube having a tube wall, and has a temperature sensor arranged in such a way that the vortex flow pickup may also be used together with those fluids which corrode the temperature sensor. A bluff body which produces vortices, and consequently pressure fluctuations, is arranged in the measuring tube. A vortex sensor responding to these pressure fluctuations is fitted downstream of the bluff body in a bore of the tube wall of the measuring tube. The vortex sensor comprises a diaphragm which covers the bore and on which a sensor vane protruding into the fluid is fastened. The temperature sensor is fixed on the bottom of a blind hole of the sensor vane. On the side of the diaphragm lying opposite the sensor vane, a sensor element is fastened. The temperature sensor may alternatively be arranged in a longitudinal bore of the bluff body.

Owner:ENDRESS HAUSER FLOWTEC AG

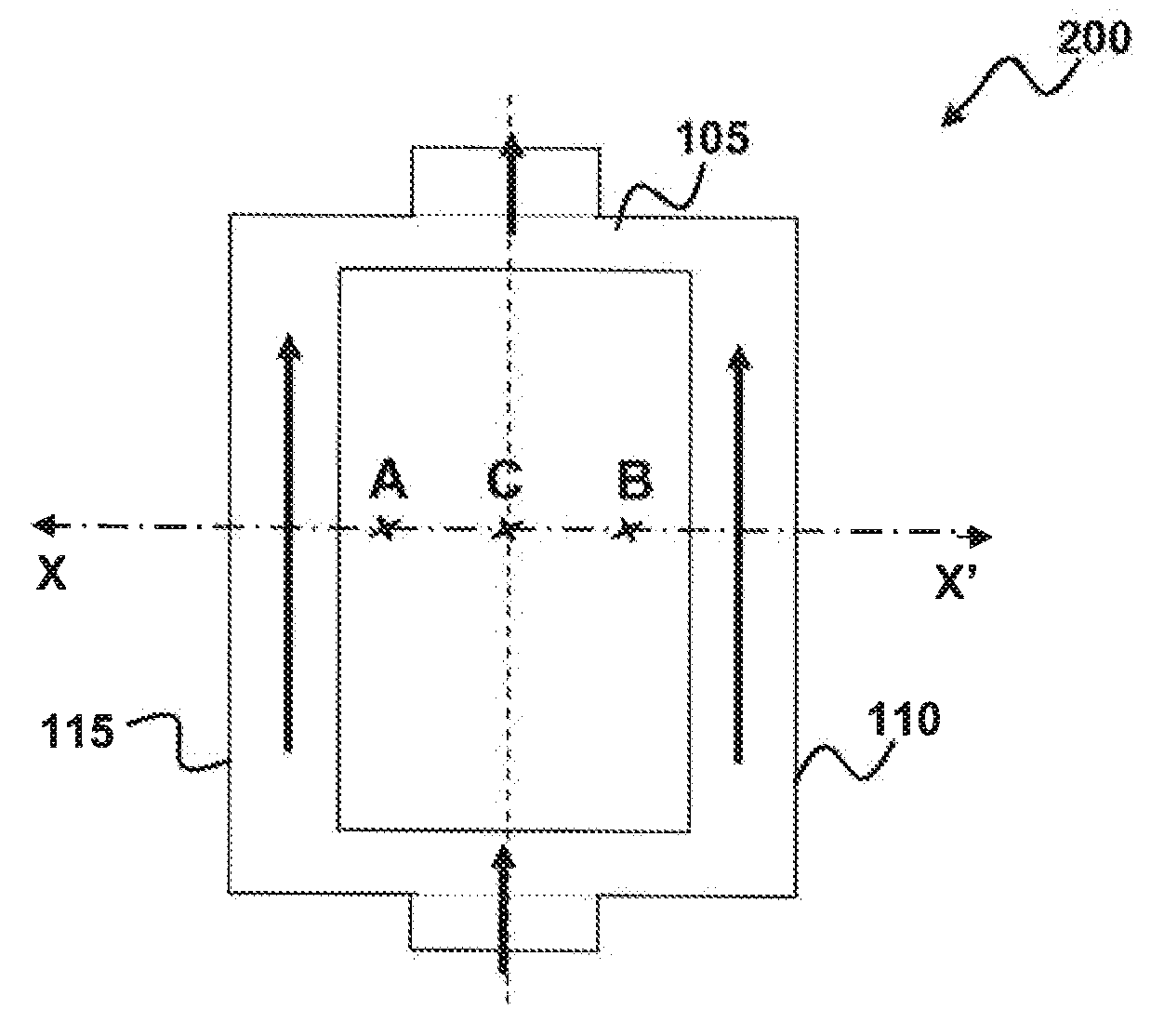

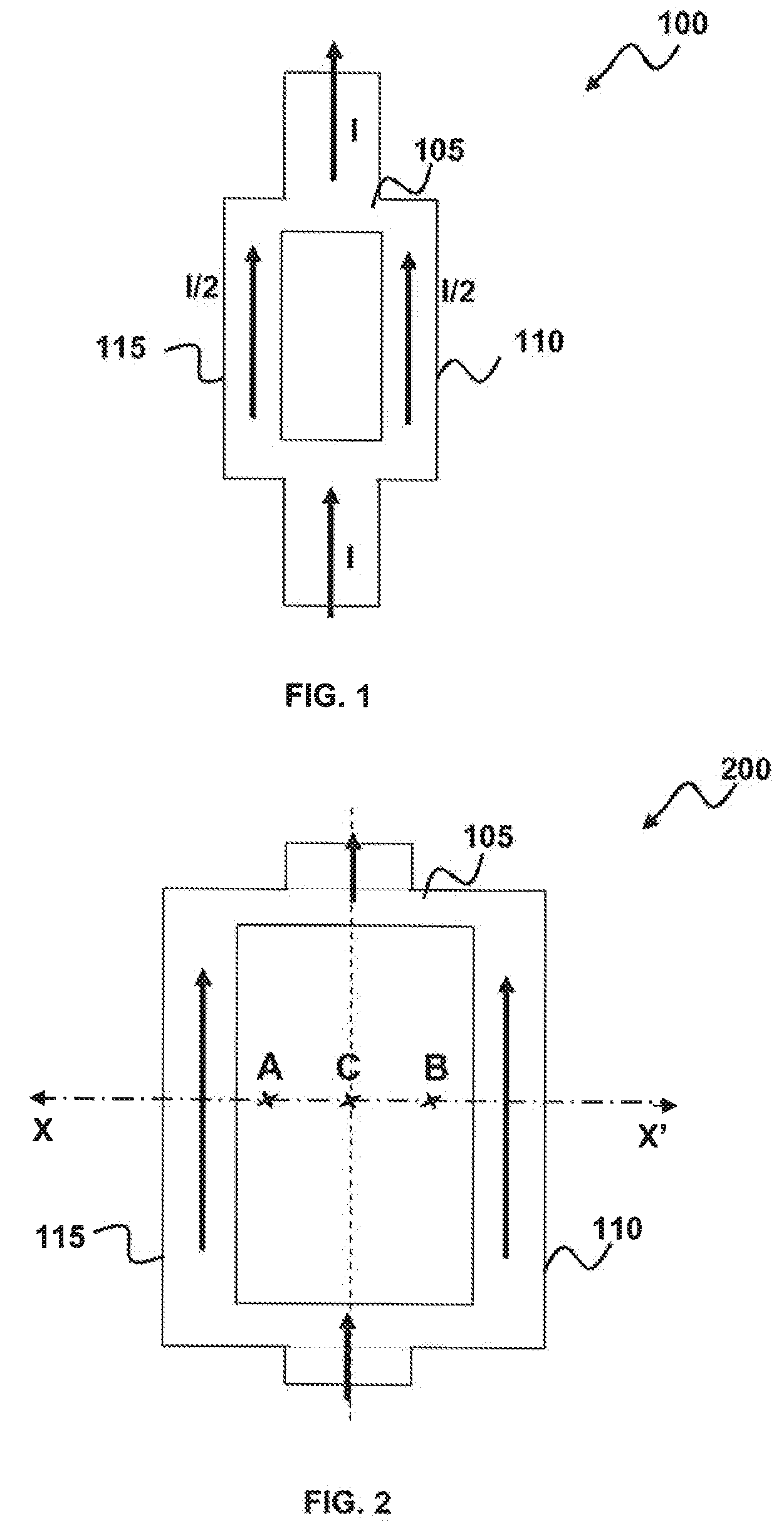

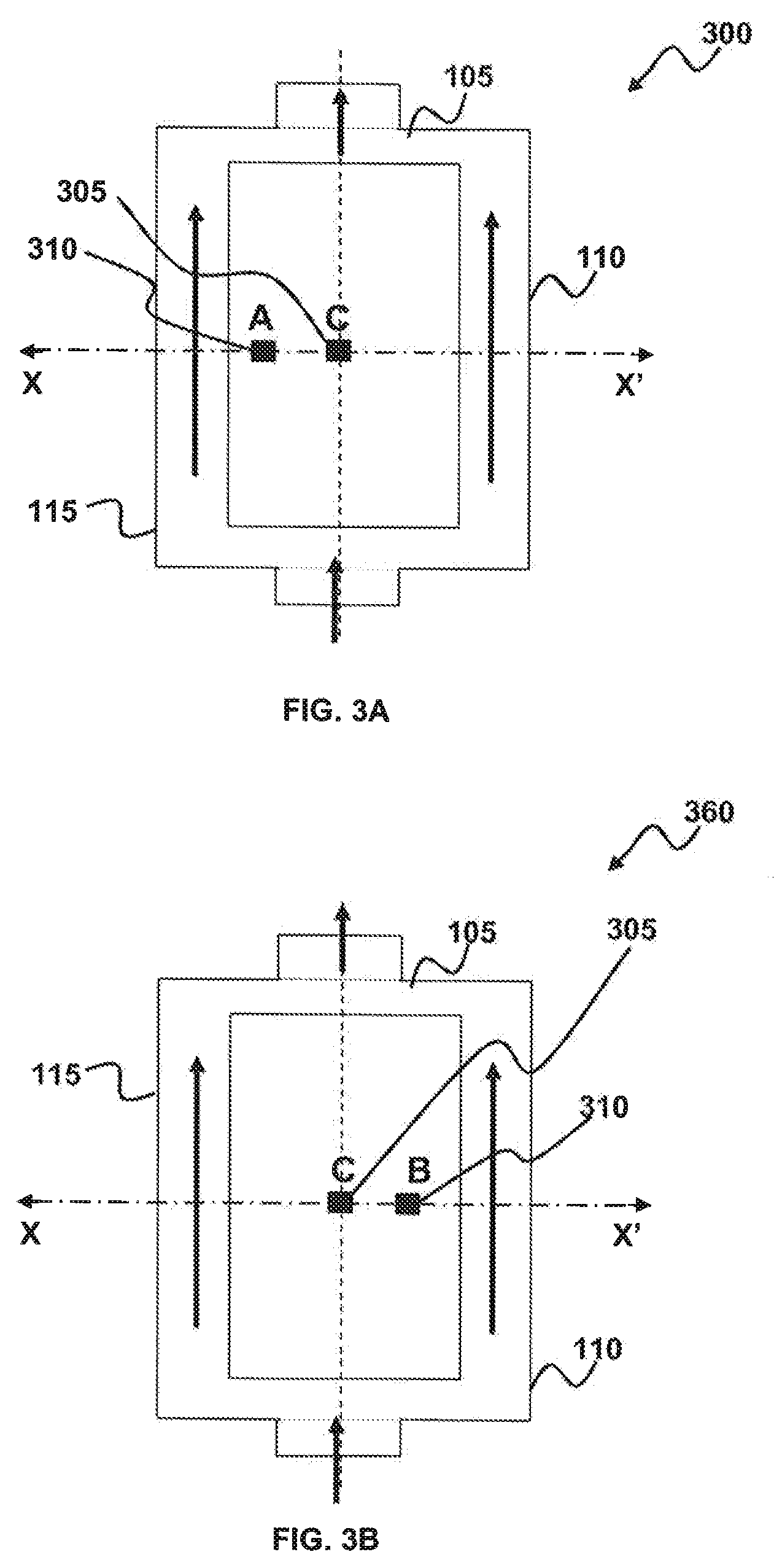

Core-less current sensor

InactiveUS20090021249A1Magnetic measurementsElectrical measurementsElectrical conductorCurrent sensor

Core-less current sensor comprises two parallel conductors carrying equal currents in the same direction. The magnetic field in mid location of the two parallel conductors carrying equal currents in the same direction for all current magnitudes is zero in absence of an external magnetic interference. Sum of magnetic fields in two points equidistant from the mid location on both the sides is zero as magnetic fields at these points are equal in magnitude and opposite in polarity for all current magnitudes and for equal amount of currents flowing through both conductors in same direction in absence of an external magnetic interference. Two sensing elements can be arranged between the two parallel conductors for sensing the magnetic field due to currents flowing through them for the purpose of current measurement. Sensor output is the difference between two outputs measured by the sensing elements. Outputs of sensing elements can vary due to external interference. As variation in the outputs of sensing elements due to external interference gets cancelled in sensor output, automatic external field compensation can be achieved.

Owner:HONEYWELL INT INC

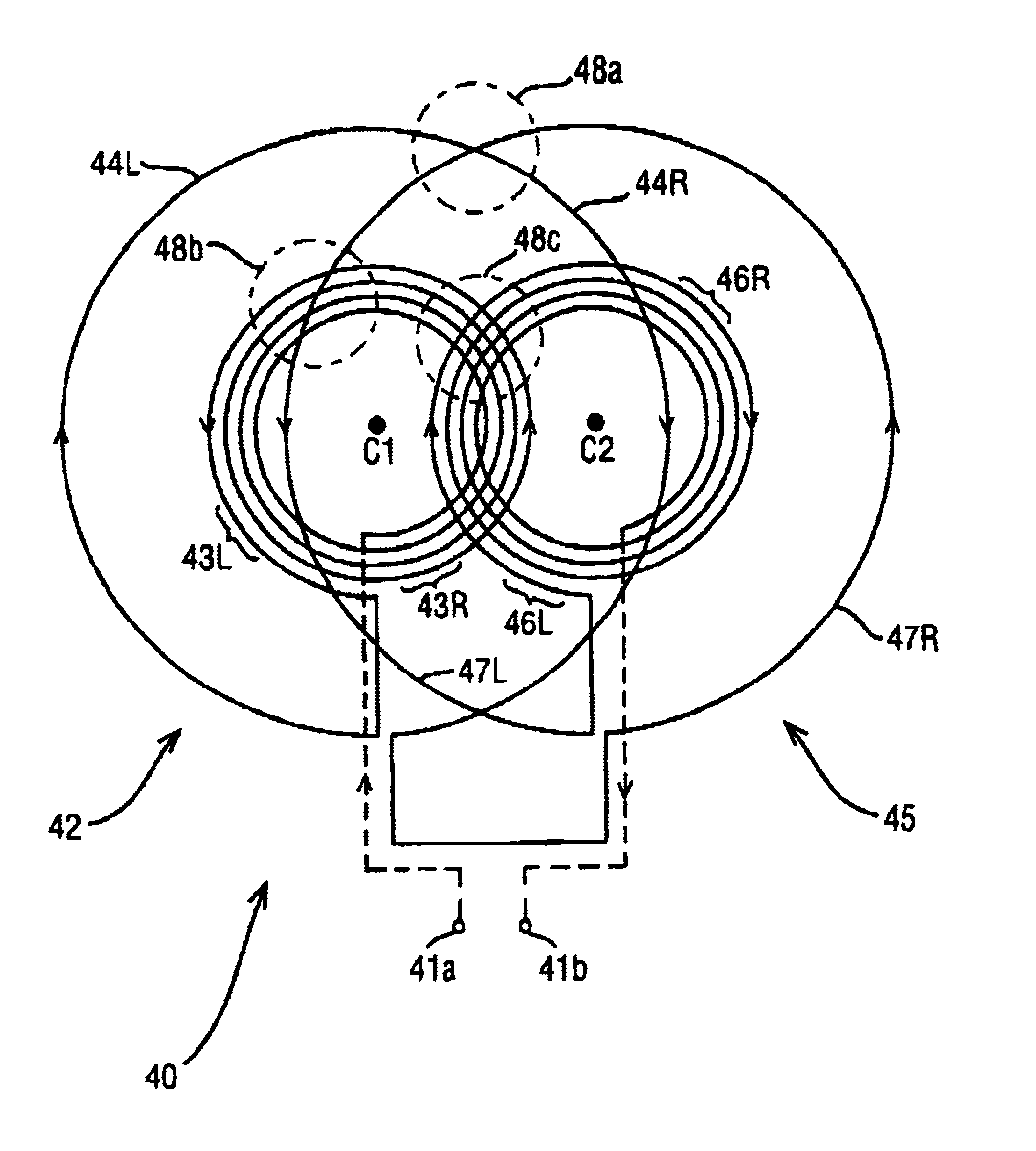

Current Sensor

InactiveUS6734661B2Reduce in quantityLess-expensive to manufactureMeasurement using dc-ac conversionDynamo-electric motor metersCurrent sensorWattmeter

A current sensor for measuring the load in a fiscal power meter has conductive paths connected between an inlet and an outlet for guiding the load currents through the sensor, and operates by sensing local magnetic fields generated around the conductive paths by the current flowing there through, thereby providing a current measure indicative of the magnitude of a given load. The sensor is distinguished by plural current coil elements arranged in a substantially common plane so as to be substantially insensitive to remotely generated magnetic fields but responsive to local magnetic fields for generating the current measure. The coil elements are disposed in zones having more than two effective centres and exhibiting mutually opposing responses to the remote field.

Owner:COLBY EDWARD GRELLIER

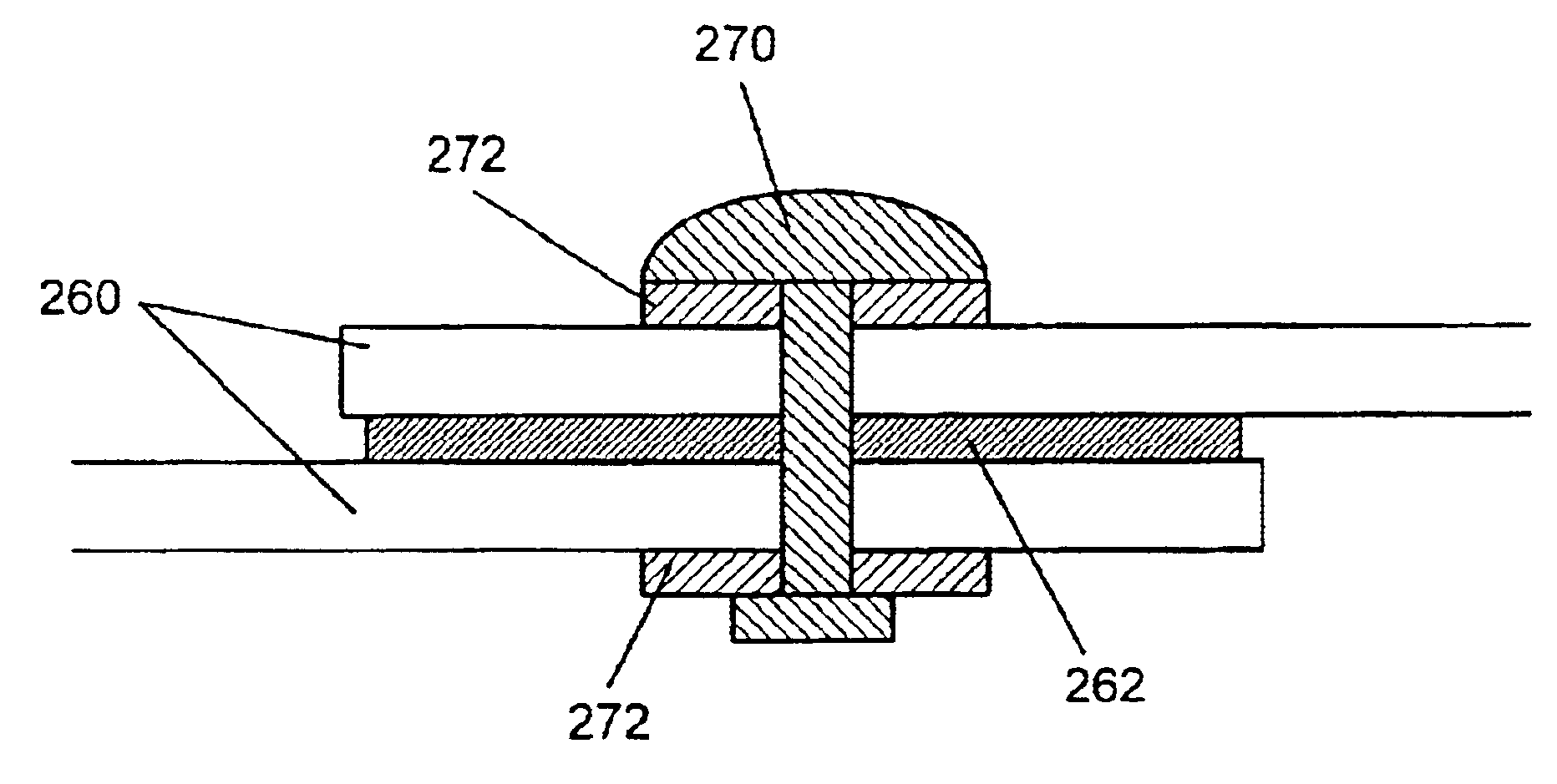

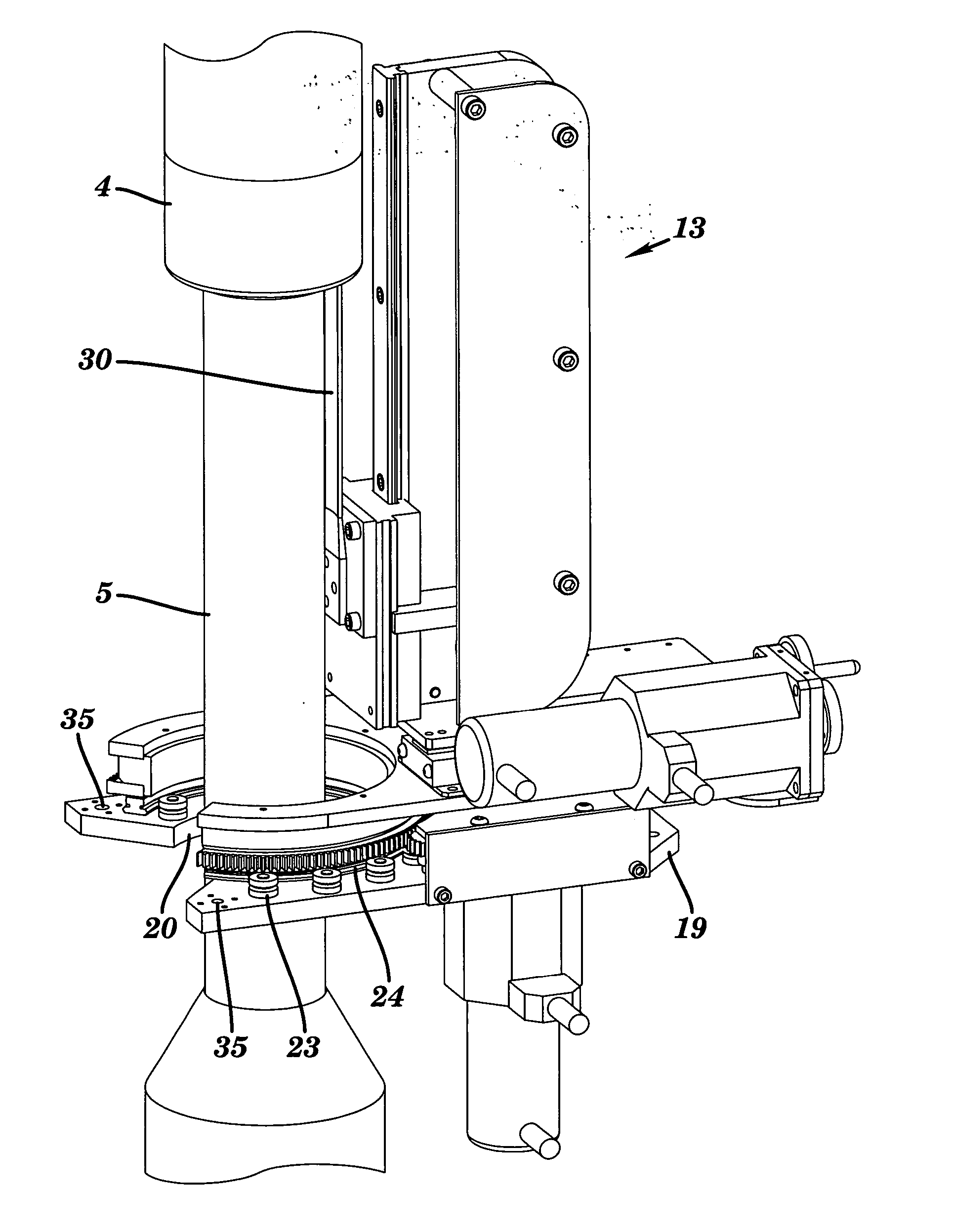

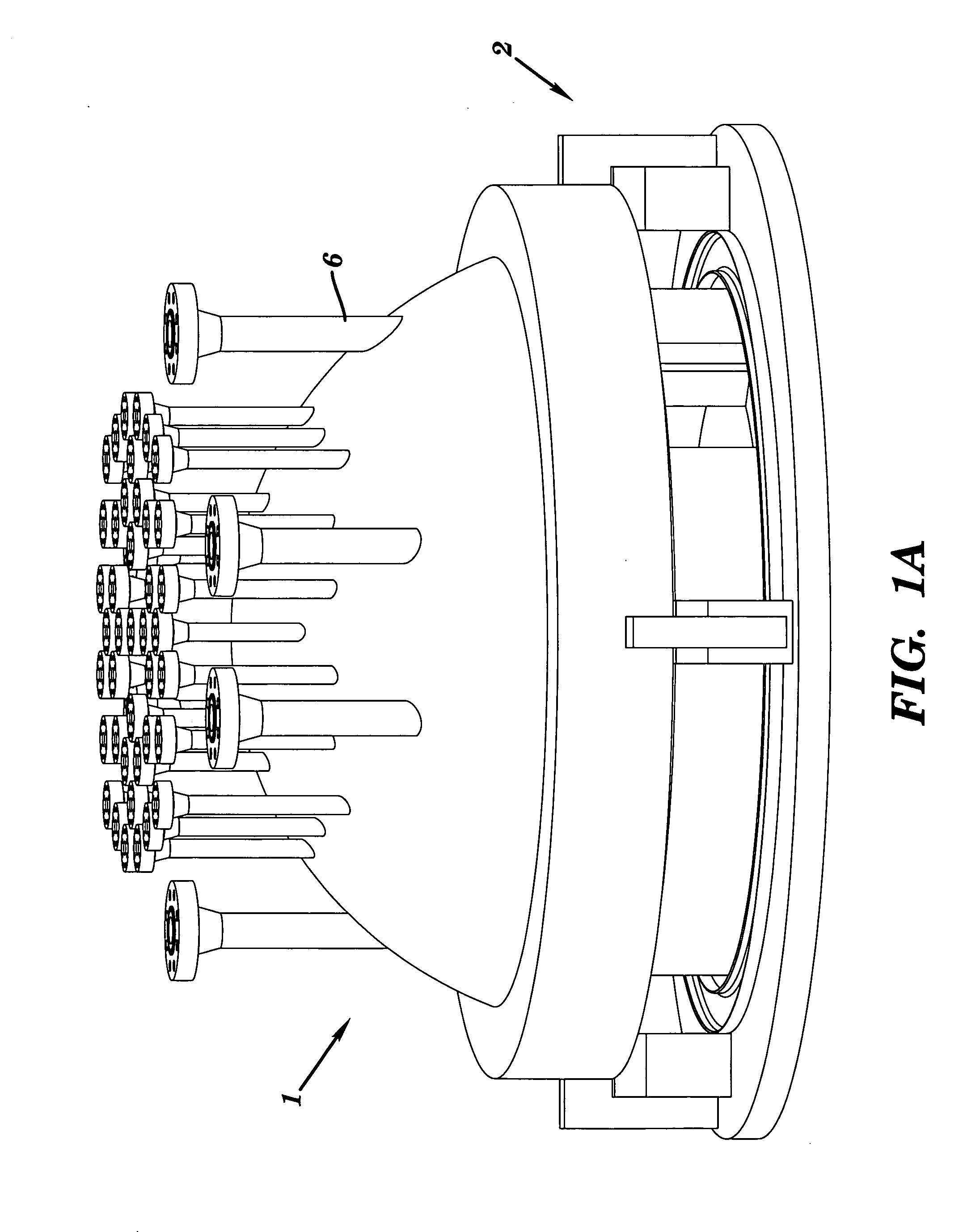

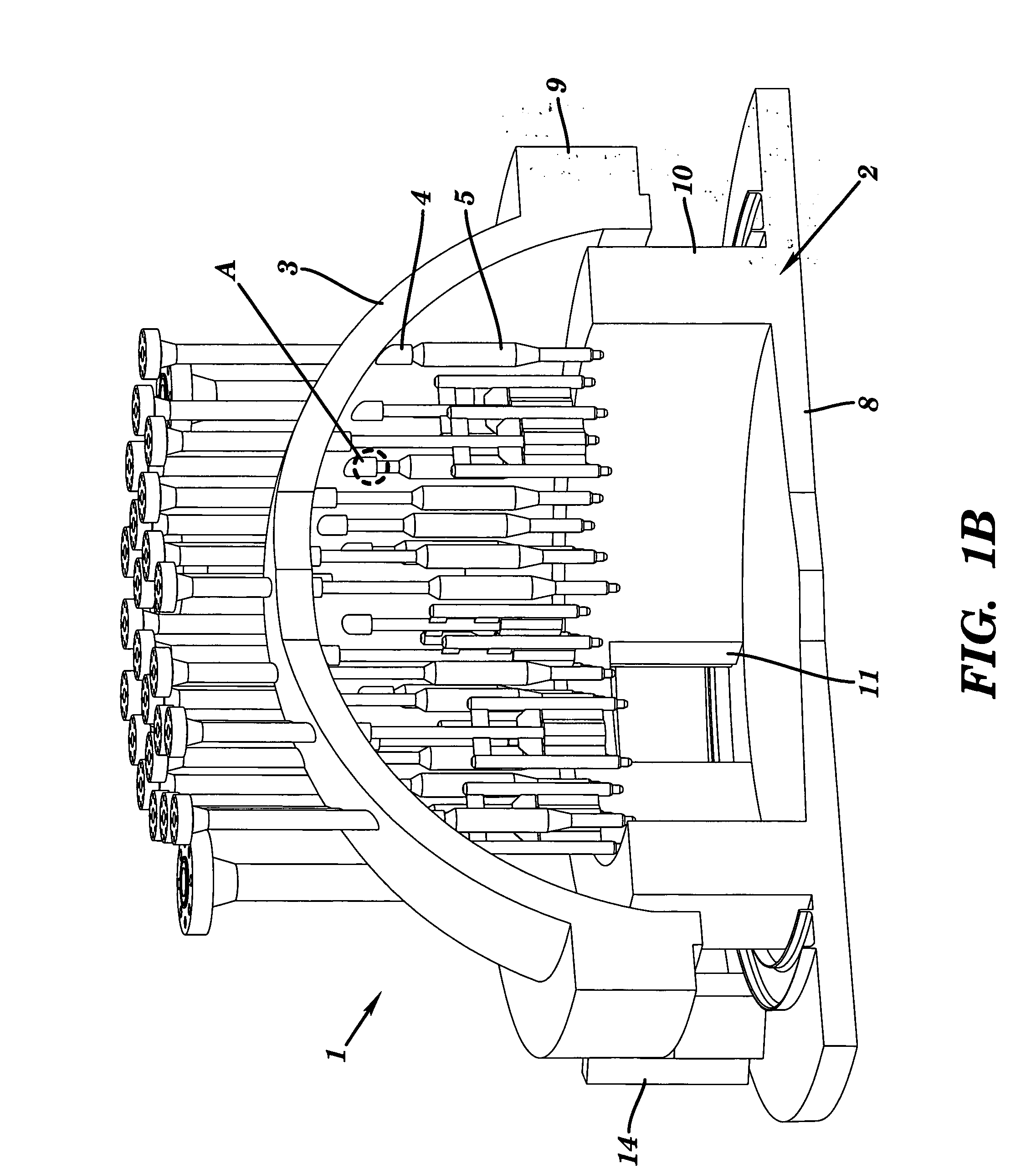

Method and apparatus for inspection of reactor head components

InactiveUS20050056105A1Loss of toleranceEasy to assembleMaterial analysis using sonic/ultrasonic/infrasonic wavesNuclear energy generationNon destructiveEngineering

A reactor head inspection system for use in performing a non-destructive inspection of tubular components mounted on an interior surface of a reactor head is disclosed. The inspection system includes a movable carriage assembly including a elevation arm and an inspection device mounted at a distal end of the elevation arm. The inspection device includes a C- or U-shaped collar having an interior surface of sufficient interior dimension to enable positioning of the interior surface of the collar in close proximity of an exterior surface of a tubular component and also includes a magnetic and / or eddy current sensor. A plurality of video cameras and light sources are also provided on a distal surface of the collar such that, when mounted on the elevation arm, the collar can be controllably positioned in close proximity adjacent a tubular component of the reactor head to achieve a 360° view and inspection of a surface of the tubular component.

Owner:R BROOKS ASSOC

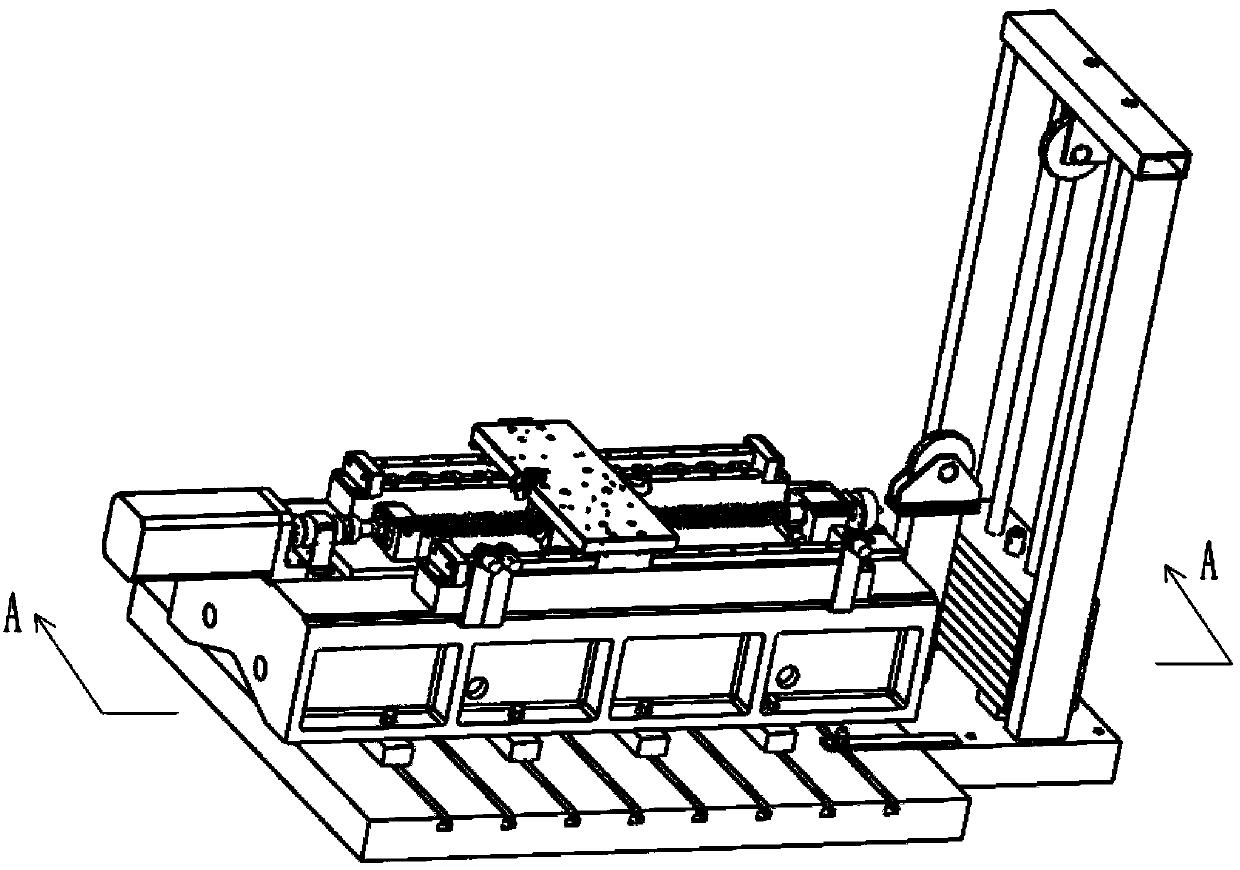

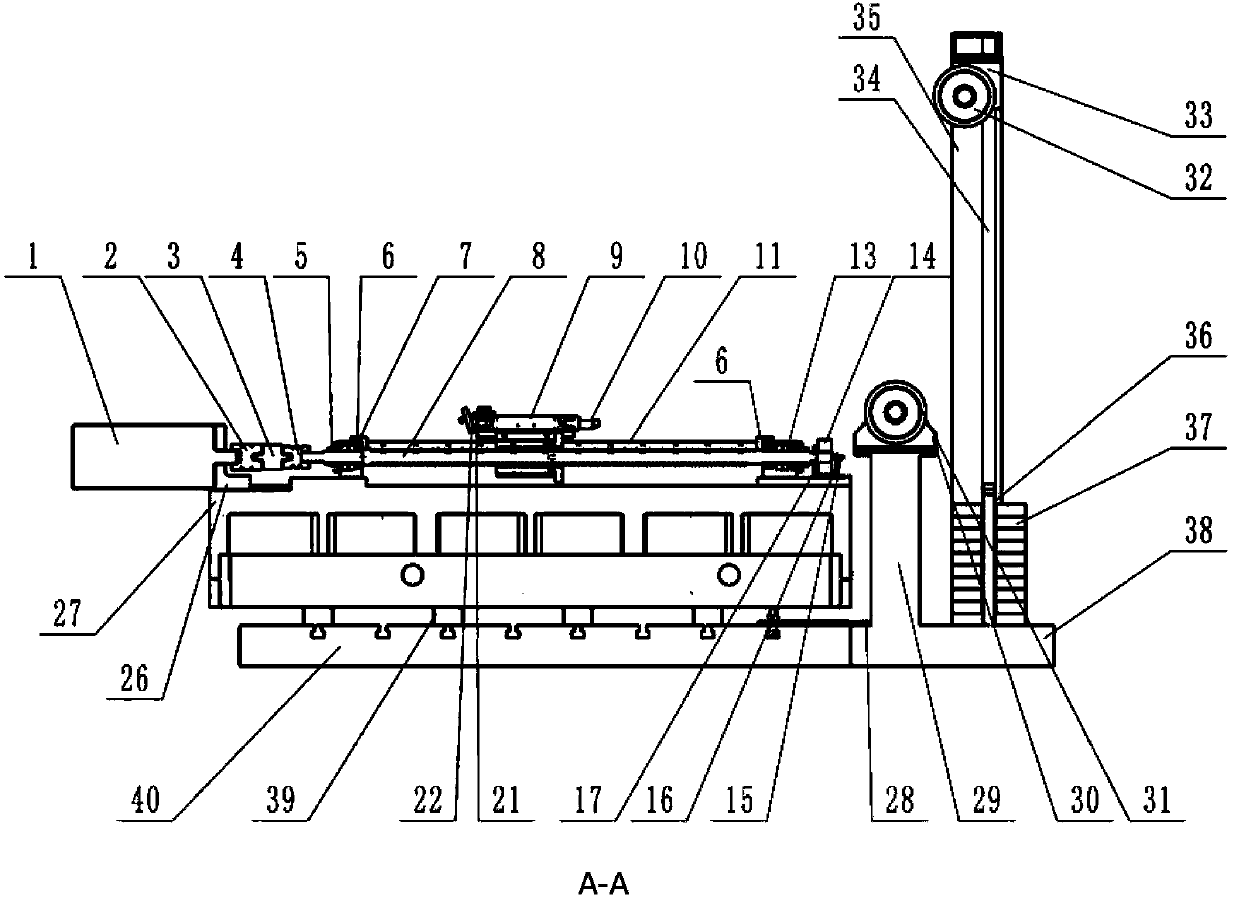

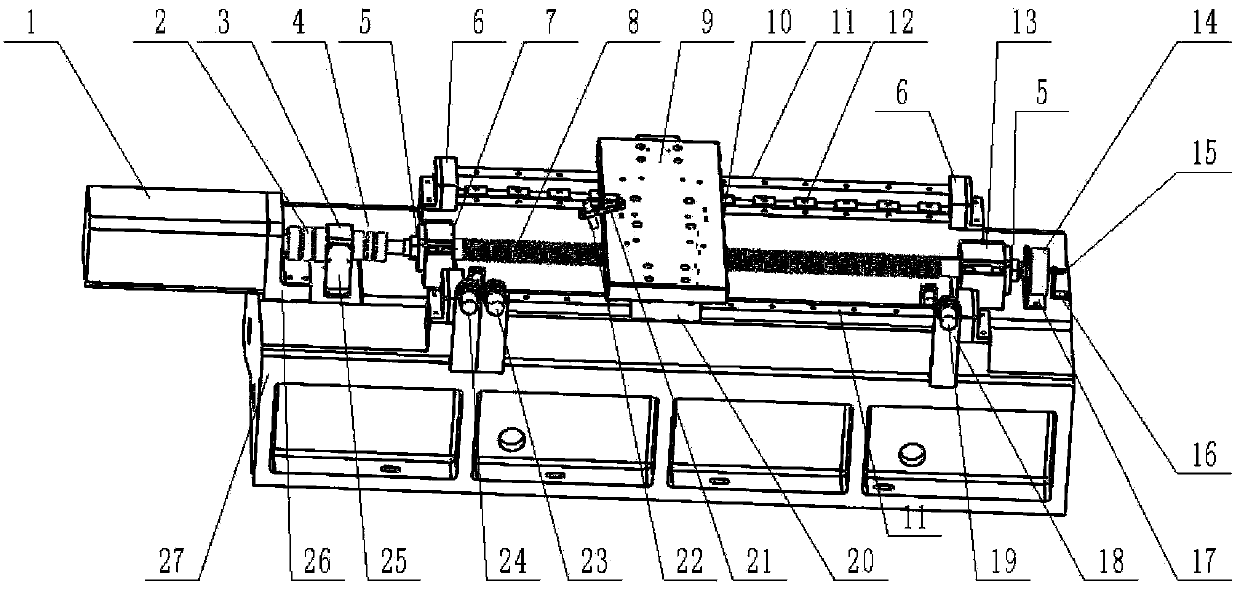

Device for detecting comprehensive performance of ball screw assembly in loaded state

InactiveCN103389205ARealize detectionReal-time detection of the number of rotationsMachine gearing/transmission testingCouplingBall screw

A device for detecting comprehensive performance of a ball screw assembly in a loaded state comprises a testboard machine body fixed on a cast iron platform, wherein a servomotor is arranged at one end of the testboard machine body; the output shaft of the servomotor is connected to one end of the ball screw assembly through a first coupler, a dynamic torque sensor and a second coupler; an eddy current sensor and a rotary encoder are arranged at the other end of the testboard machine body; a grating scale and an infrared temperature sensor are arranged on the testboard machine body; a rolling guide rail is arranged on the testboard machine body, and is provided with an analog working table; the analog working table is connected to the rolling guide rail through a rolling guide rail slide block, and is connected to a loading device; a ball screw assembly nut is arranged on the analog working table through a nut support base. The device is stable in properties, quick in movement and testing response speed, comprehensive and accurate in testing performance parameters, and simple in structure, and can realize the comprehensive performance detection of ball screw assemblies with different models in no-loaded states or loaded states.

Owner:XI AN JIAOTONG UNIV

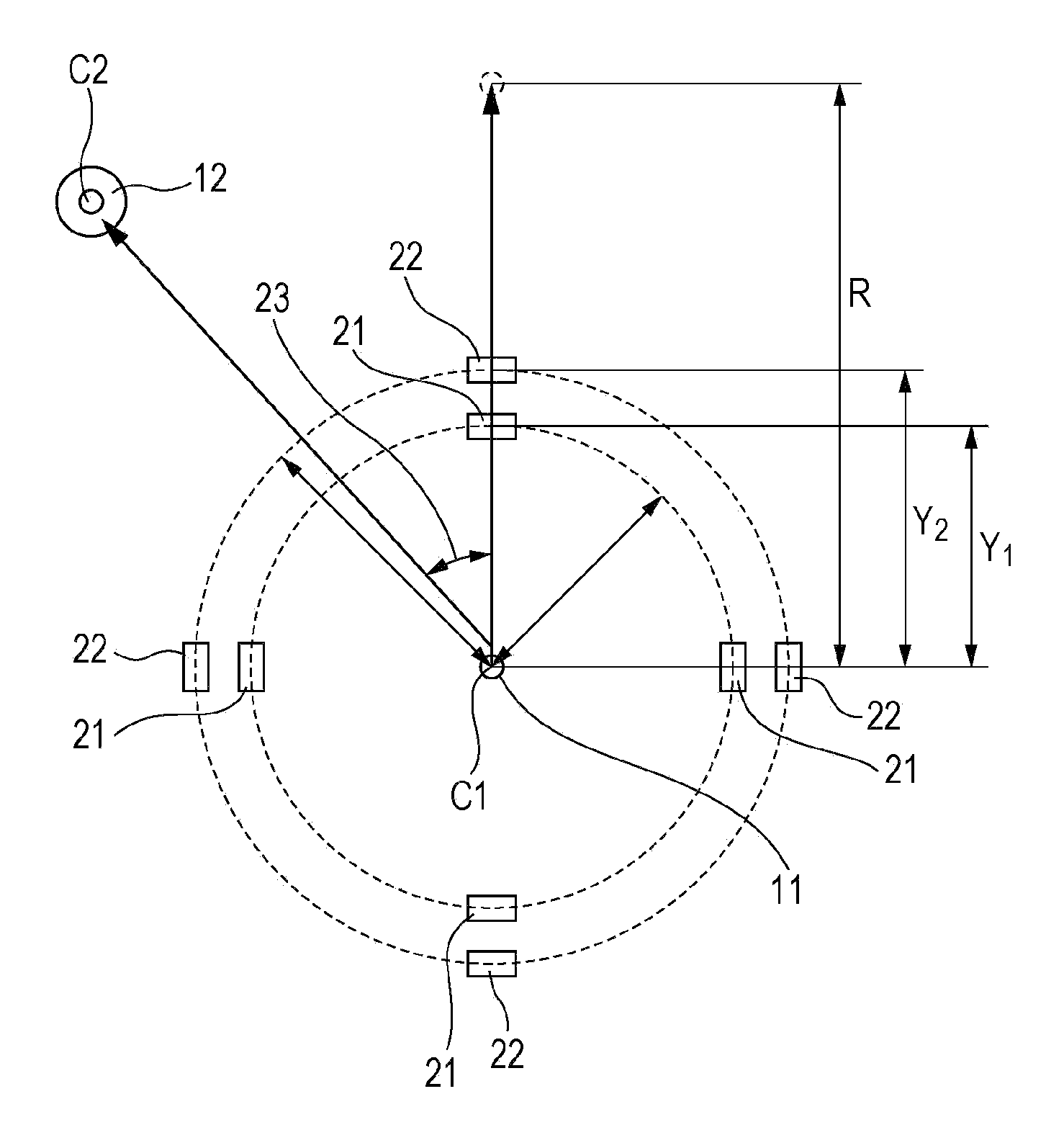

Current sensor for electric wire

InactiveUS20120290240A1Reduce external influenceReduce the impactResistance/reactance/impedenceVoltage-current phase angleCurrent sensorEngineering

A current sensor includes an electric wire to be measured, a guide portion for guiding the electric wire to be measured, a holding portion for holding the electric wire to be measured, and four pairs of magnetic sensor elements arranged at intervals of 90 degrees along a circumference around a center axis which is a virtual arrangement axis of the electric wire to be measured. The outputs of the magnetic sensor elements of each pair are appropriately linearly combined and the linearly combined outputs of all the pairs are added. Hence, a space for guiding the electric wire to be measured can be easily allocated, and the effects of variation sources such as the displacement of the electric wire to be measured, a constant external magnetic field, and an external magnetic field generated by a neighboring electric wire are compensated for, whereby a small high-accuracy current sensor is provided.

Owner:ALPS GREEN DEVICES

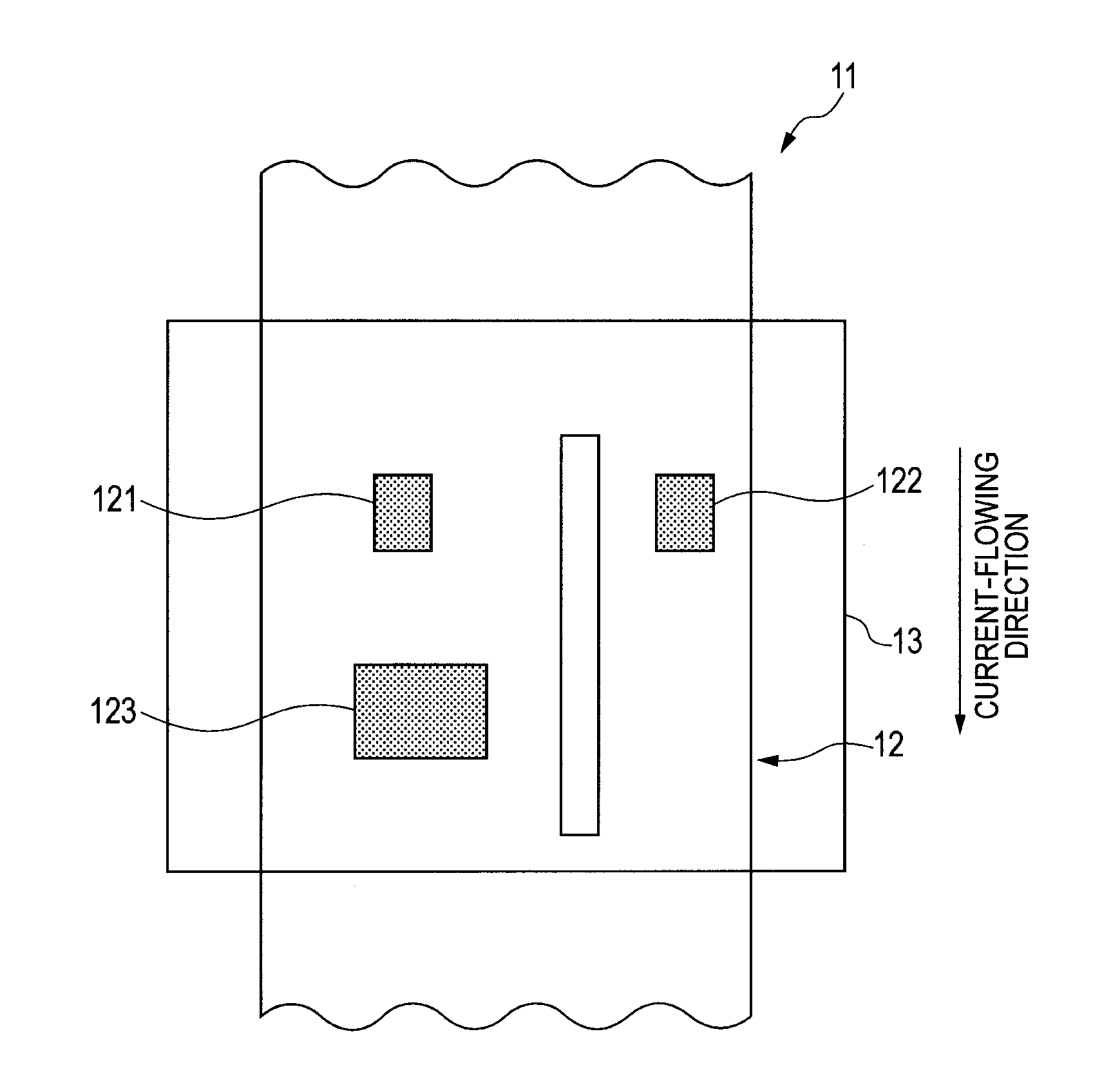

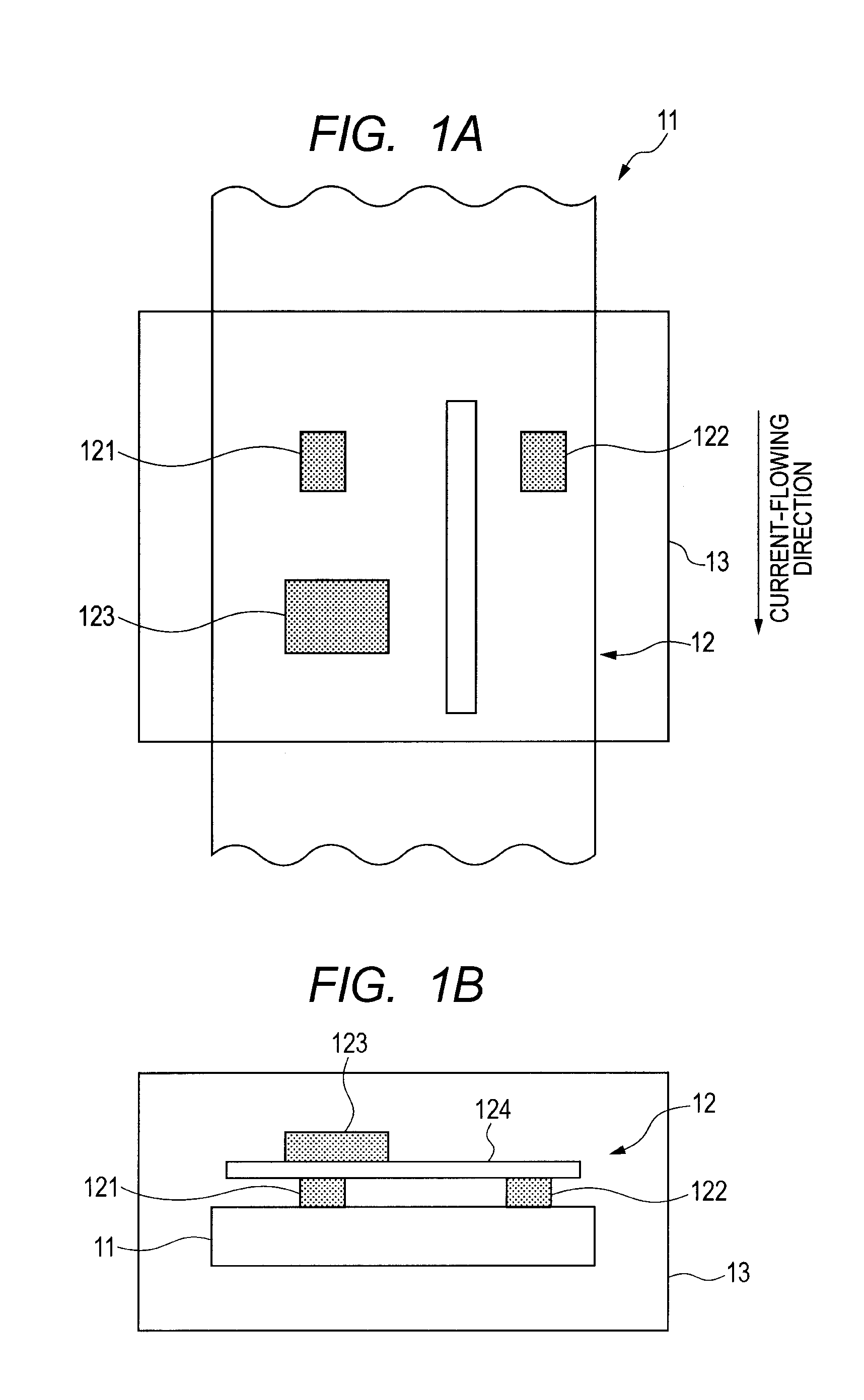

Current sensor

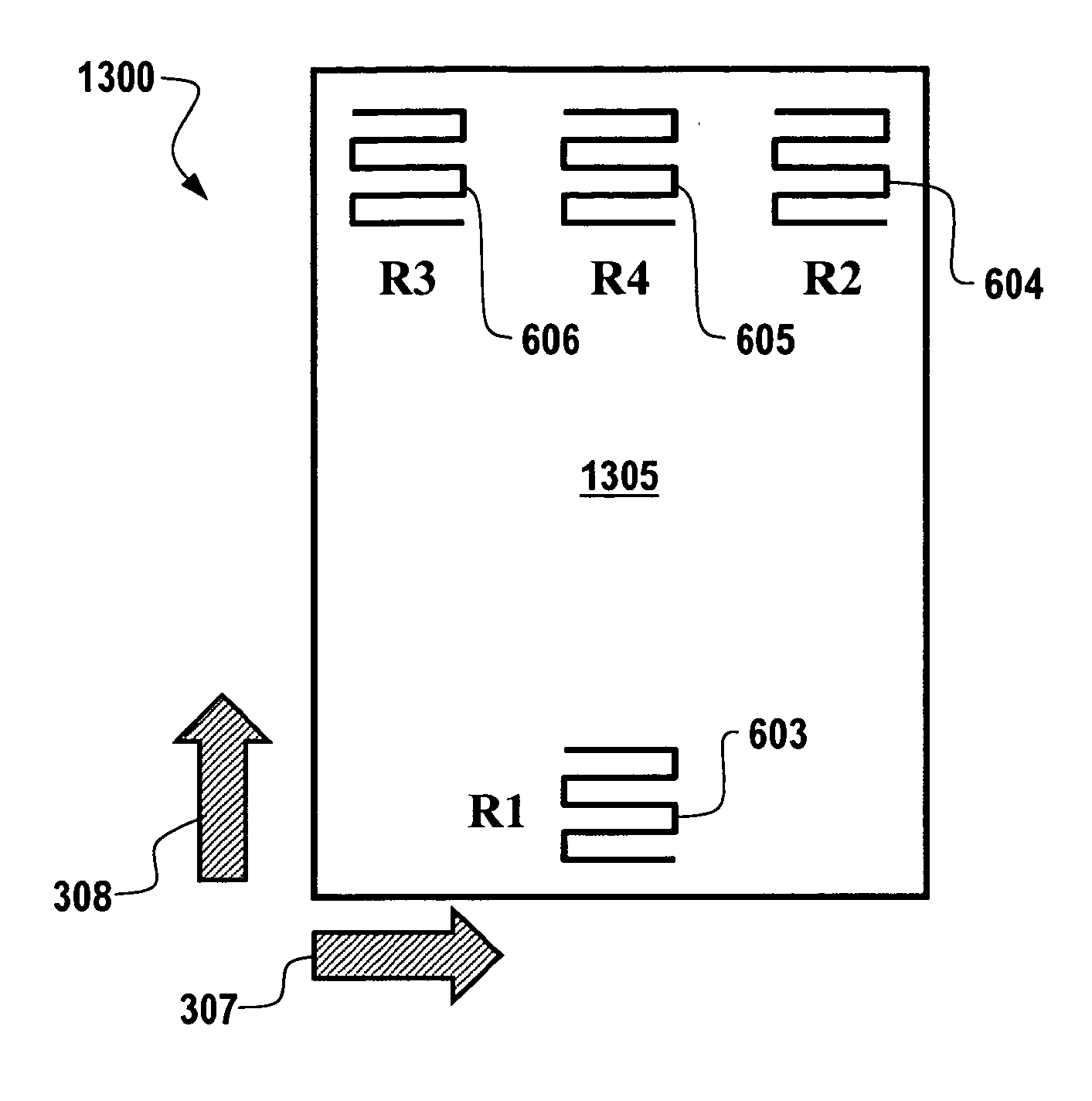

ActiveUS20110221429A1Widen current measuring rangeReduce noiseBatteries circuit arrangementsElectrical measurementsEddy-current sensorElectrical conductor

Disclosed is a current sensor including magnetic sensors disposed on a conductor having at least two separated current-carrying areas with different current magnitudes and detecting a magnetic field generated according to currents flowing through the conductor and a controller controlling outputs of the magnetic sensors, wherein the magnetic sensors are disposed in at least two respective areas having different current magnitudes and the controller switches outputs of the magnetic sensors.

Owner:ALPS ALPINE CO LTD

Magnetically biased eddy current sensor

InactiveUS20060038559A1Accurate inductionNanomagnetismMagnetic property measurementsMagnetic reluctanceConductive materials

Eddy currents arise when a conductive material moves through a magnetic field. Eddy currents, like all electric currents, generate a magnetic field. The generated magnetic field can be detected and measured through use of one or more magnetically biased GMR elements. In general, an eddy current sensor can be configured, which includes a magnet, and a first giant magnetoresistive element placed such that the magnetic field from the magnet biases the giant magnetoresistive element along its primary axis.

Owner:HONEYWELL INT INC

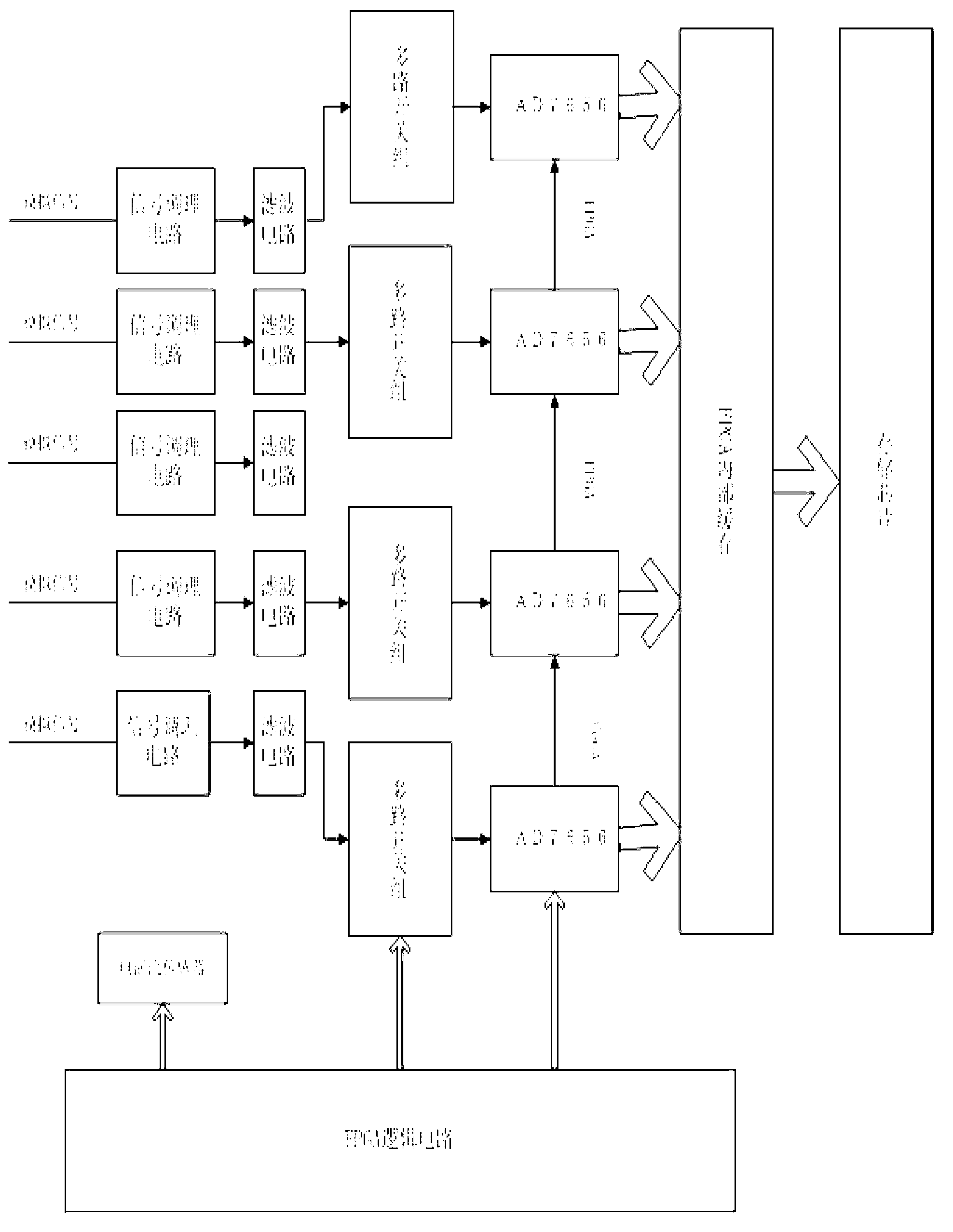

Device and method for detecting defects of inner and outer walls of pipeline based on three-axis magnetic flux leakage and eddy current

ActiveCN102798660ASave electricityImprove detection qualityMaterial magnetic variablesNon destructiveElectricity

The invention relates to a device and a method for detecting defects of inner and outer walls of a pipeline based on three-axis magnetic flux leakage and eddy current, and belongs to the technical field of non-destructive testing. The device comprises a magnetic flux leakage detector, a data processing and storing device, a power supply, at least three odometer wheels and an eddy current detector, wherein the eddy current detector consists of an eddy current sensor and is a device used for detecting the defects on inner and outer surfaces of the pipeline. According to the device provided by the invention, a magnetic flux leakage detection method and an eddy current detection method are combined by using different characteristics of the magnetic flux leakage detection method and the eddy current detection method, so that the function of distinguishing the defect of the inner wall from the defects of the outer wall is realized; and in addition, the method provided by the invention is favorable in detection quality and simple in operation and can be widely applied to non-destructive detection of oil transmission pipelines in the industrial fields of petroleum, petrifaction and the like.

Owner:NORTHEASTERN UNIV

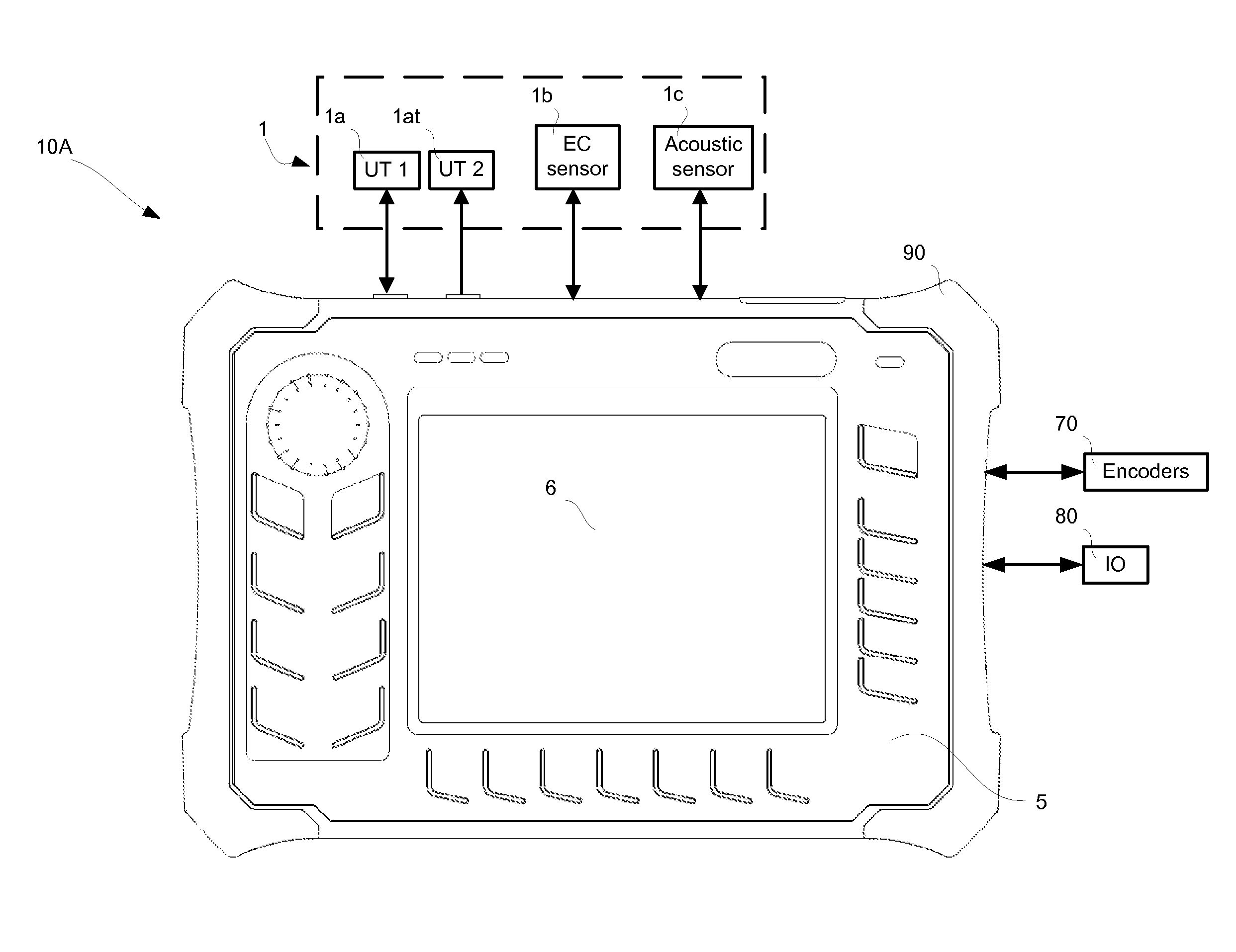

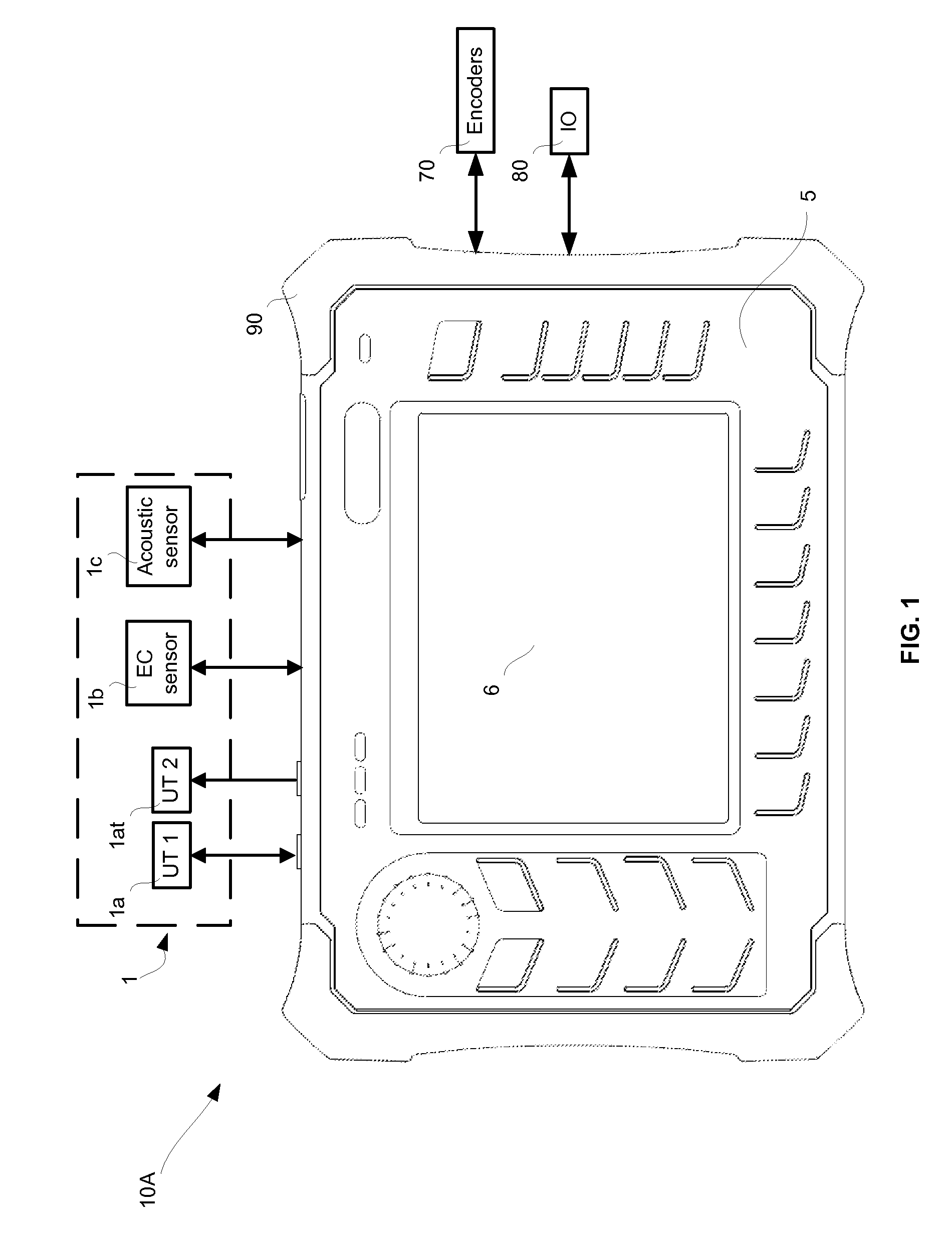

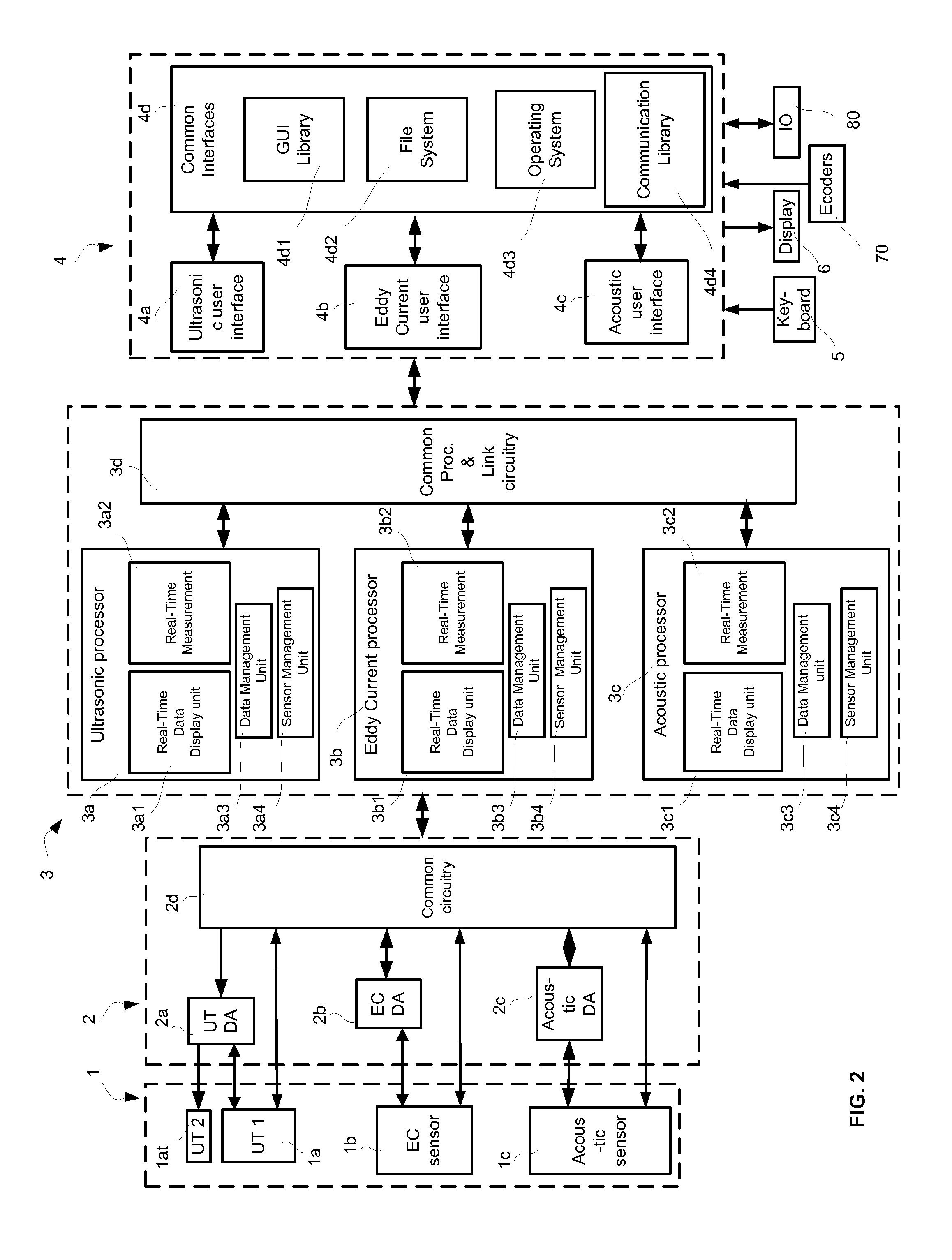

Non-destructive inspection instrument employing multiple sensor technologies in an integral enclosure

ActiveUS20120265491A1Low costSpace minimizationMaterial analysis using sonic/ultrasonic/infrasonic wavesAmplifier modifications to reduce noise influenceDigital dataNon destructive

A non-destructive inspection (NDI) instrument includes a sensor connection system configured to receive test signals from at least two different types of NDI sensors which are configured to obtain test signals from an object being tested. The sensor connection system has sensor-specific connection circuits and at least one common sensor connection circuit. A data acquisition circuitry is coupled to the sensor connection and has sensor-specific data acquisition circuits and at least one common data acquisition circuit. It is further coupled to a common digital data processor which executes sensor-specific processing modules and at least one common processing module. A common display screen and user interface is coupled to the data processor and enables programs including sensor-specific user interface modules and at least one common user interface module. The sensor types preferably include all of or any combination of an ultrasound sensor, an eddy current sensor and acoustic sensor.

Owner:OLYMPUS AMERICA

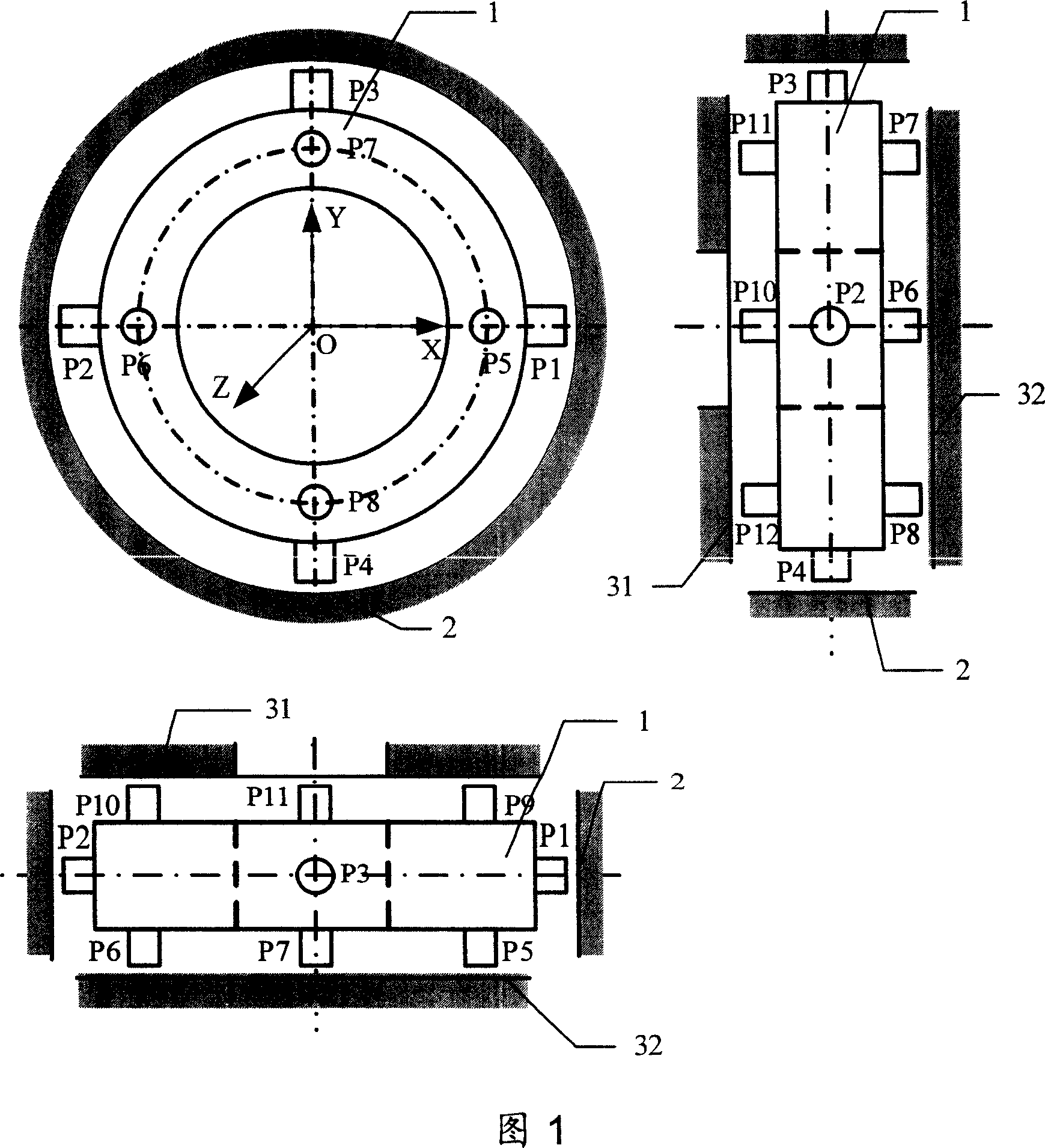

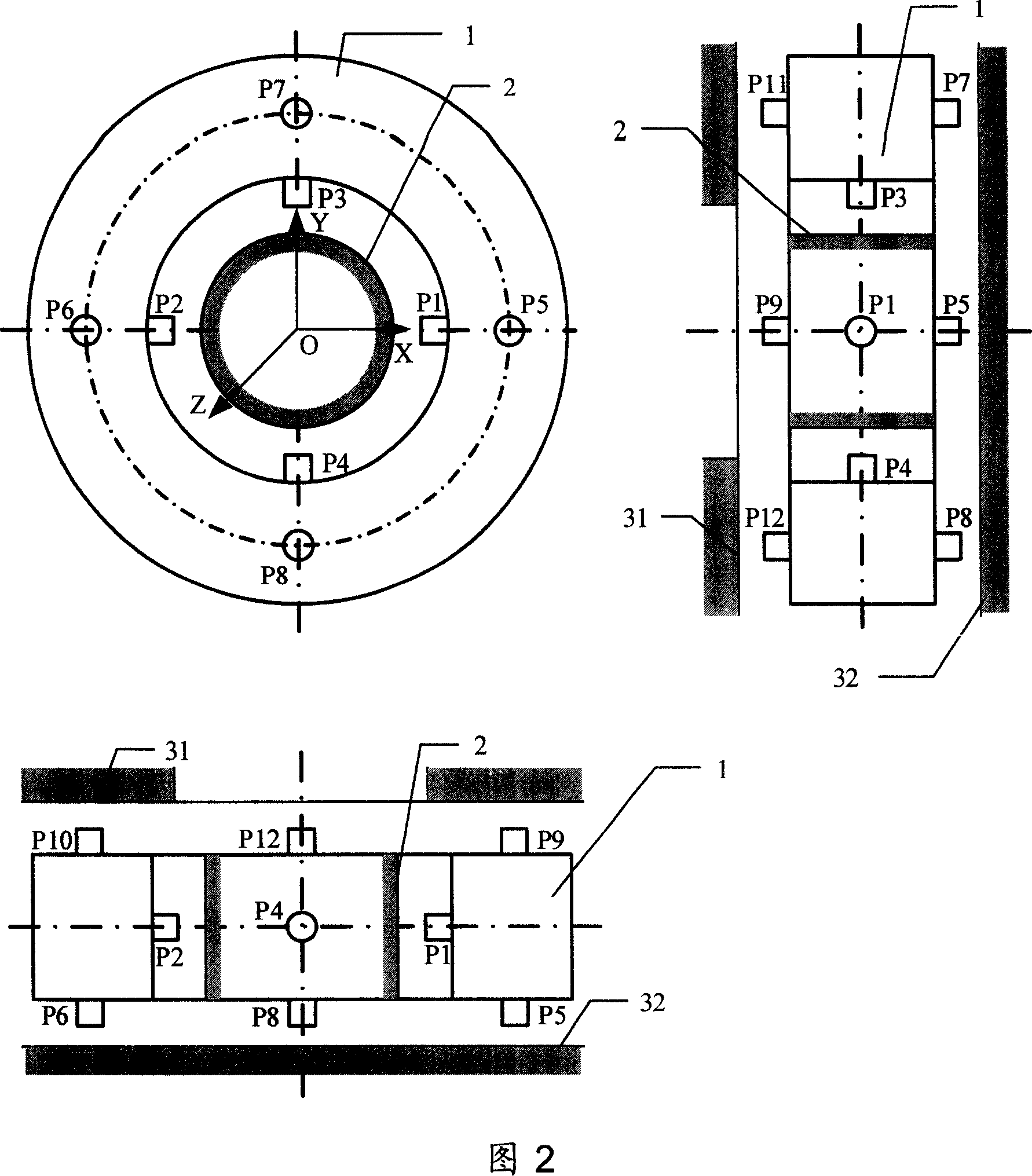

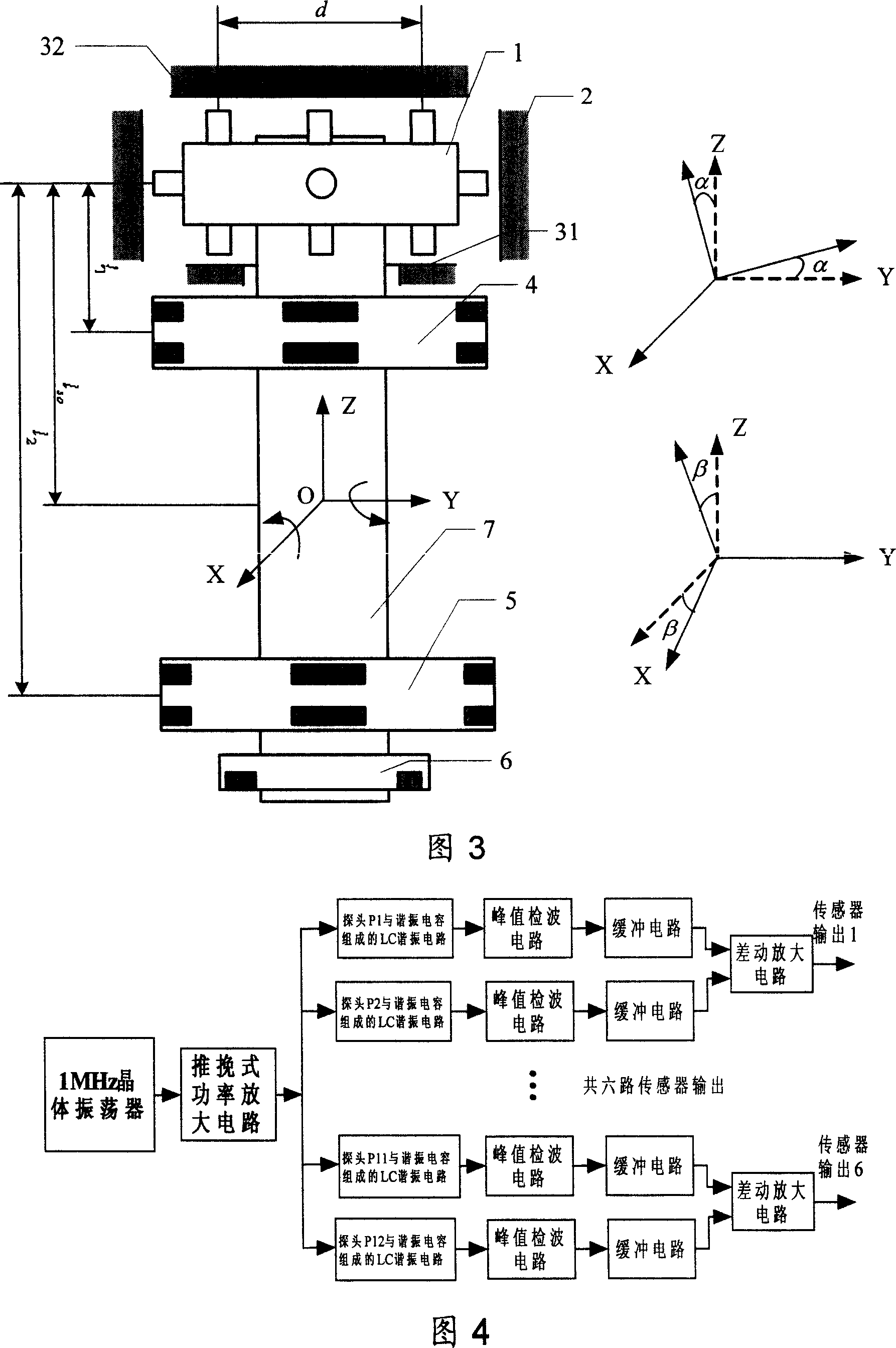

Integrated five freedom electric eddy sensor

InactiveCN1987367AEliminate errorsHigh measurement accuracyUsing electrical meansConverting sensor output electrically/magneticallyElectricityMagnetic bearing

The current vortex sensor can measure offset deviation signal between actual position and given position of magnetic bearing rotor so as to realize stable control. The sensor is composed of sensor probe, measuring circuit (MC), and shell. Integrated design is adopted for 12 pieces of sensor probe and MC so as to avoid interference brought by extended cables between sensor probes and MC. 4 pieces of radial sensor probe constitute differential type structure (DTS) to detect radial transnational motion of rotor in two orthogonal directions. 8 pieces of axial sensor probe constitute DTS to detect axial transnational motion of rotor, and rotational movement of rotor in two orthogonal directions. Simplifying two sensors configured at two ends in traditional magnetic bearing into one sensor, the invention provides displacement signals in 5 degrees of freedom needed for controlling rotor. The invention is applicable to pose actuator of spacecraft. Features are: reduced size and weight.

Owner:BEIHANG UNIV

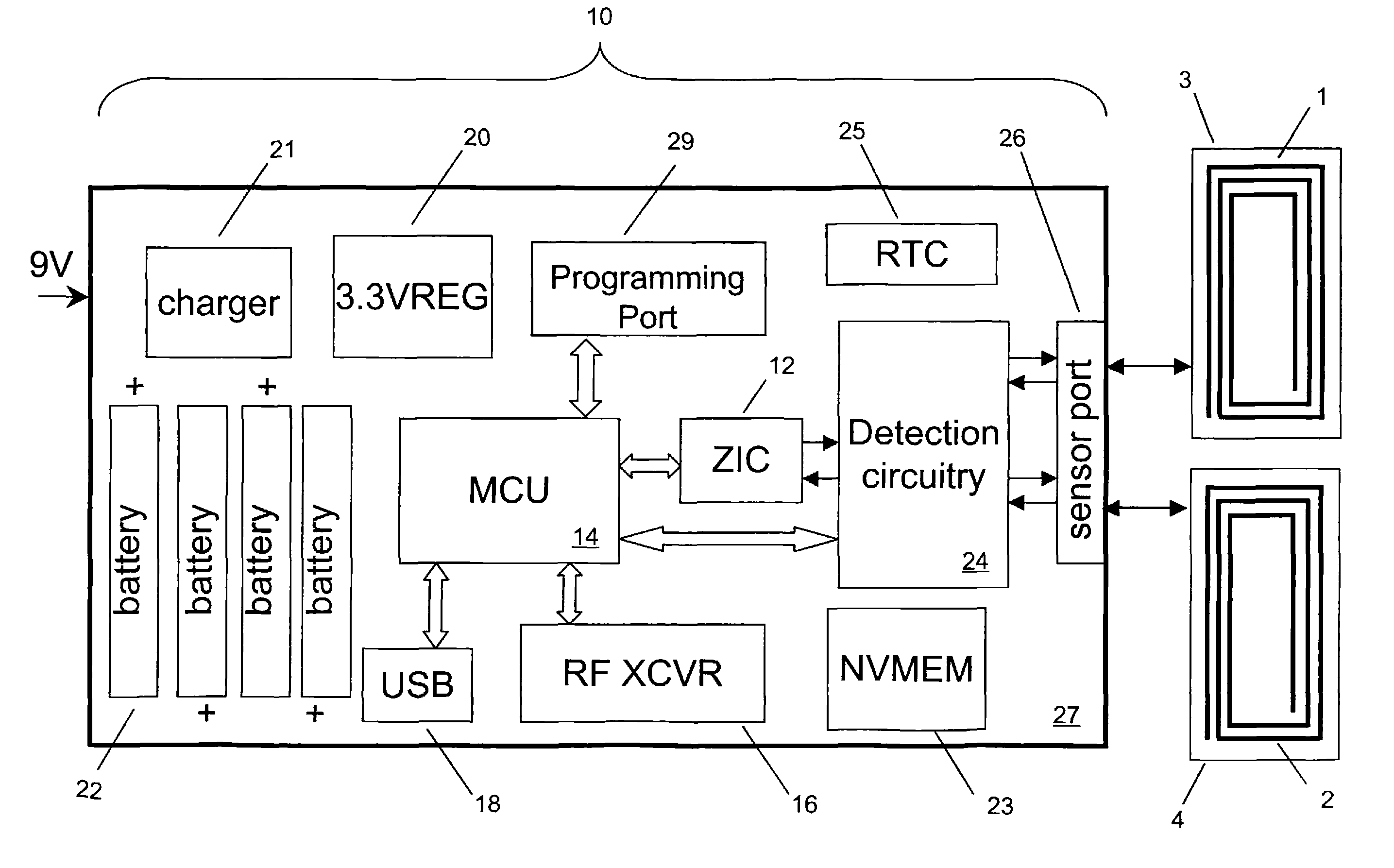

Mountable eddy current sensor for in-situ remote detection of surface and sub-surface fatigue cracks

A wireless, integrated, mountable, portable, battery-operated, non-contact eddy current sensor that provides similar accuracy to 1970's laboratory scale equipment (e.g., a Hewlett-Packard GP4194A Impedance Analyzer) at a fraction of the size and cost.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

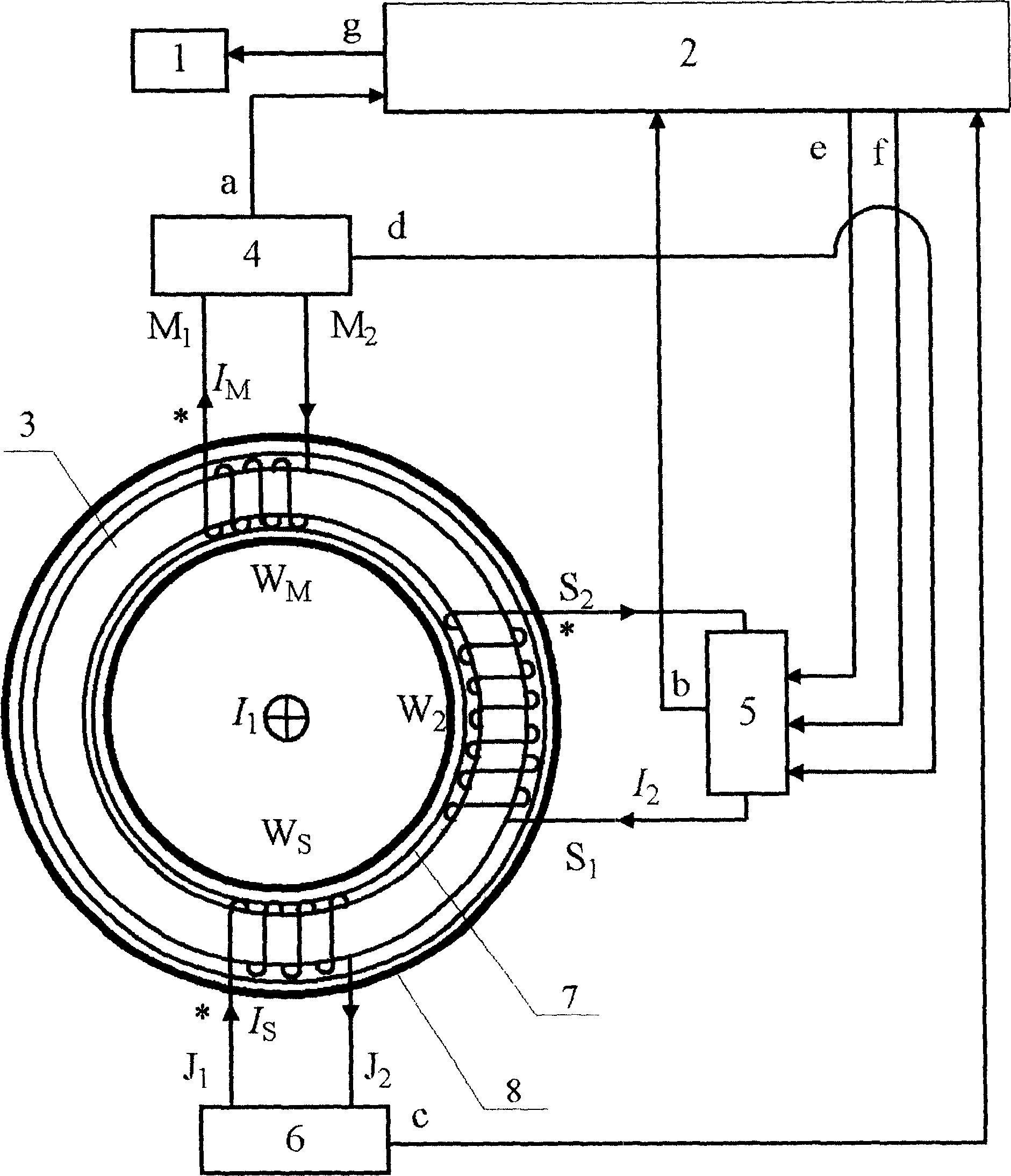

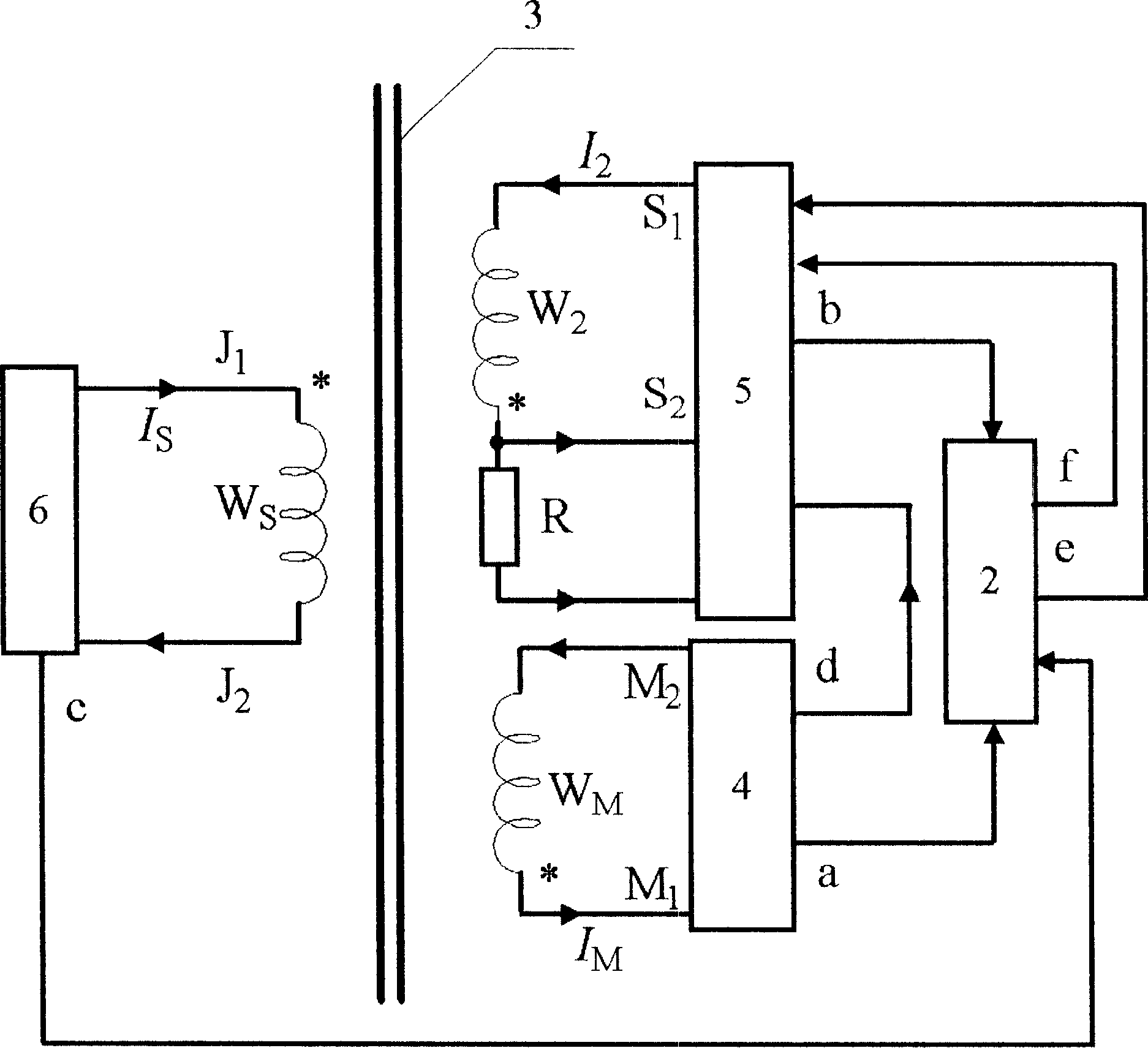

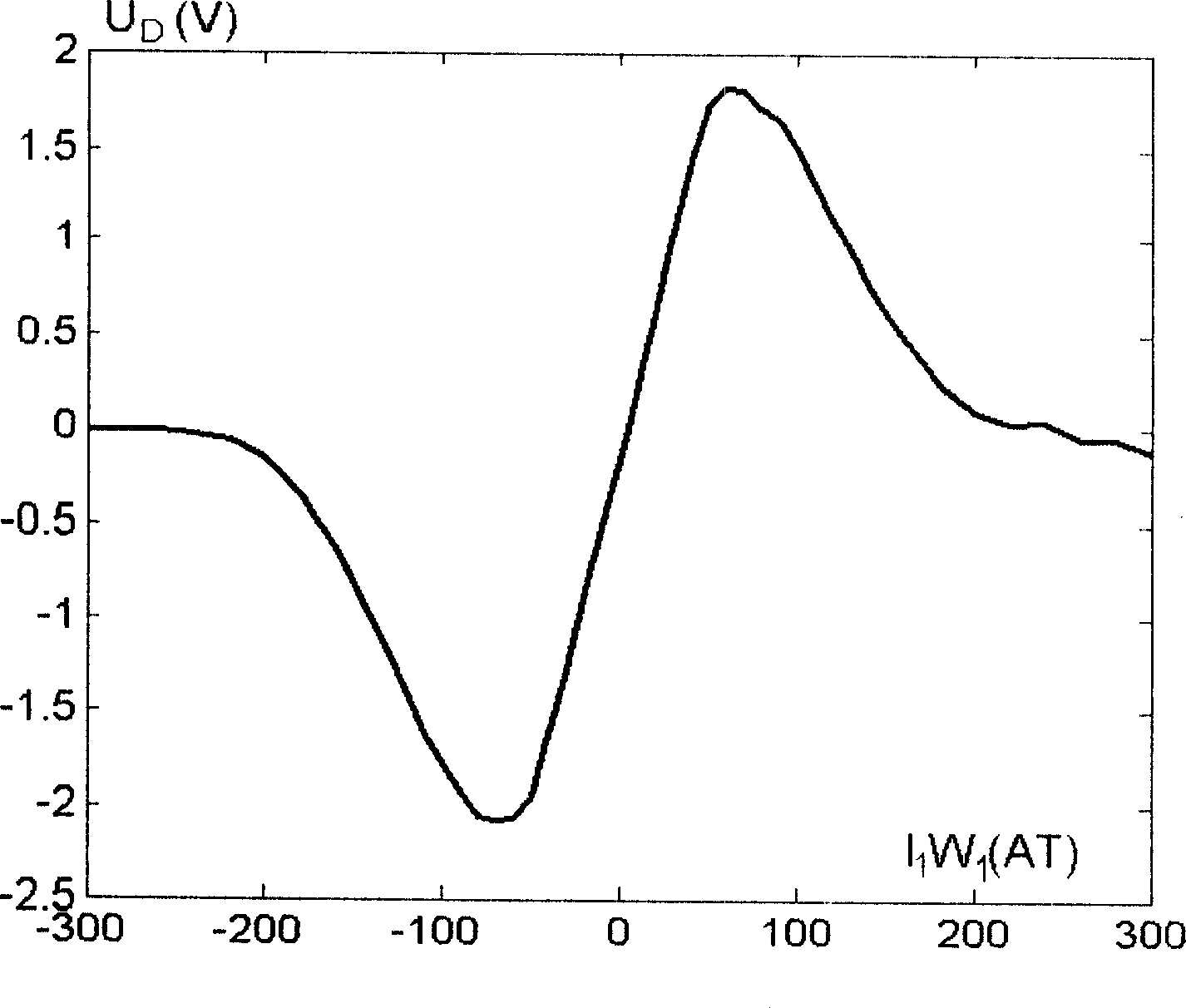

Direct current sensor

The present invention discloses a DC curren sensor. In said sensor a detection coil is added, said sensor adopts single-core three-winding structure, when a DC bias magnet is existed in the magnetic core, the induced potential obtained by detection coil can produce positive-negative half-wave unsmmetrical waveforms, said waveforms can be converted into the voltage signal of difference of positive-negative half-wave effective values, after voltage / current conversio, said signal can be fed into feedback winding, said feedback winding cap produce the DC magnetic potential whose direction is opposite to that of magnetic patential produced by detected direct current to balance the bias magnetic potential produced by detected direct current to form 'null-flux' state, so that it can obtain the detected direct current intensity so as to implement the detection of direct current.

Owner:HUAZHONG UNIV OF SCI & TECH

Vortex flowmeter with temperature compensation

ActiveUS20080141769A1Thermometer detailsVolume/mass flow by thermal effectsEddy-current sensorThermowell

A vortex flowmeter has a vortex sensor and terminals that receive a thermal junction output from a thermowell assembly that is remote from the vortex flowmeter. The vortex flowmeter has a data input that receives data representing a thermal property of the thermowell assembly. The vortex flowmeter has a circuit that receives the first thermal junction output and the vortex sensor output, and that provides a flowmeter output that is compensated for temperature and for the thermal property.

Owner:MICRO MOTION INC

Current sensor

InactiveCN101900754ALow costMagnetic measurementsCurrent/voltage measurementCurrent sensorEddy-current sensor

The invention provides a current sensor including, a current-measured wiring including parallel wiring sections in which portions of the same wiring are arranged in parallel such that electric current to be measured flows therein in opposite directions each other; a magnetism detection unit which is arranged between parallel wirings located in the parallel wiring sections and detects a magnetic field in a direction perpendicular to a plane formed by the parallel wirings; a current detection unit which detects electric current flowing in the current-measured wiring, based on the magnetic field detected by the magnetism detection unit; and a magnetic core surrounding the parallel wiring sections so as to intensify the magnetic field generated around the parallel wirings located in the parallel wiring sections when electric current flows in the wirings. The magnetic core has a pair of plates facing each other over a plane formed by the parallel wirings, the pair of plates having flat and parallel inner faces, and the magnetism detection unit is arranged between the pair of plates of the magnetic core.

Owner:SAE MAGNETICS (HK) LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com