Patents

Literature

145 results about "Laboratory scale" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

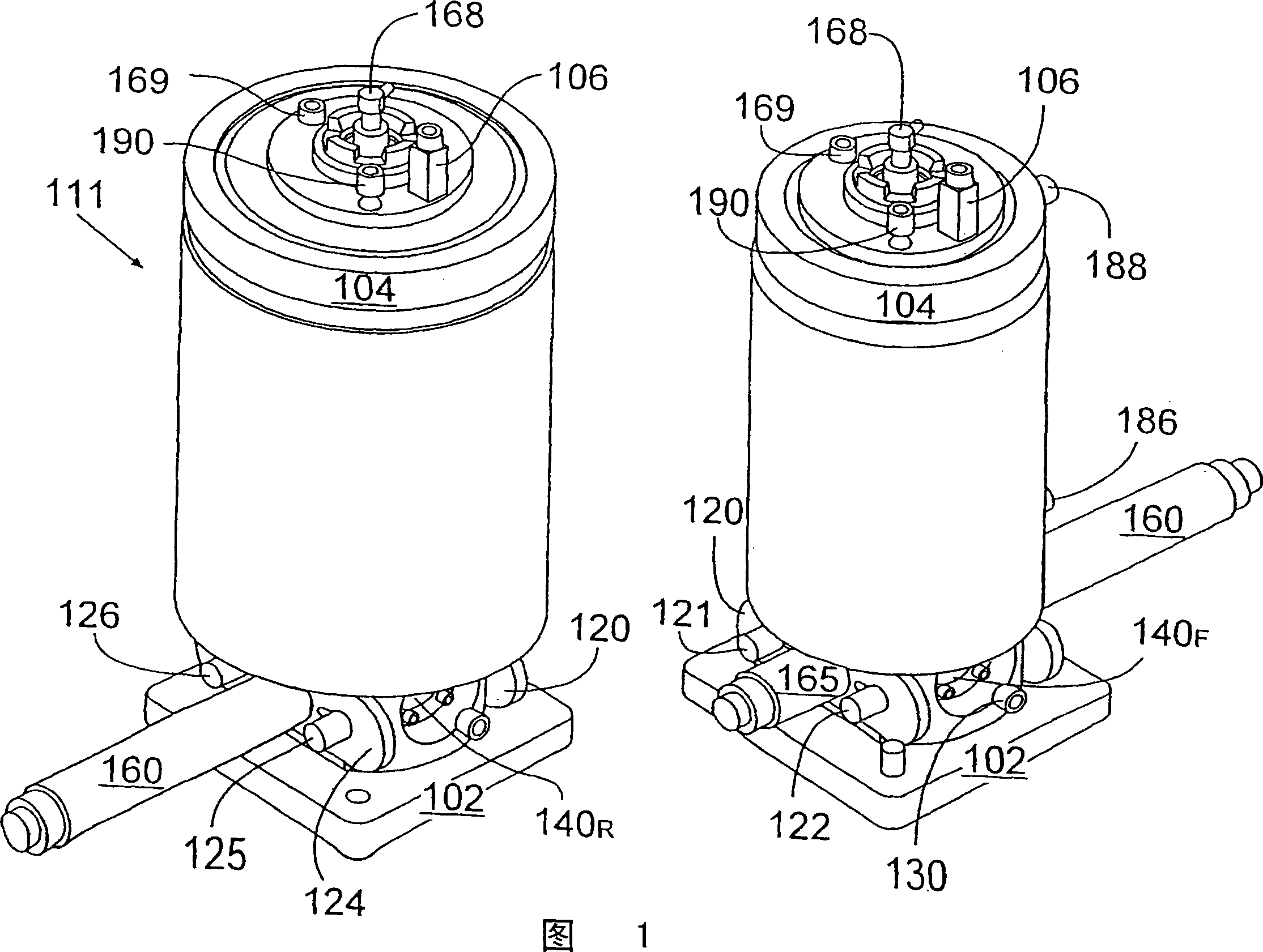

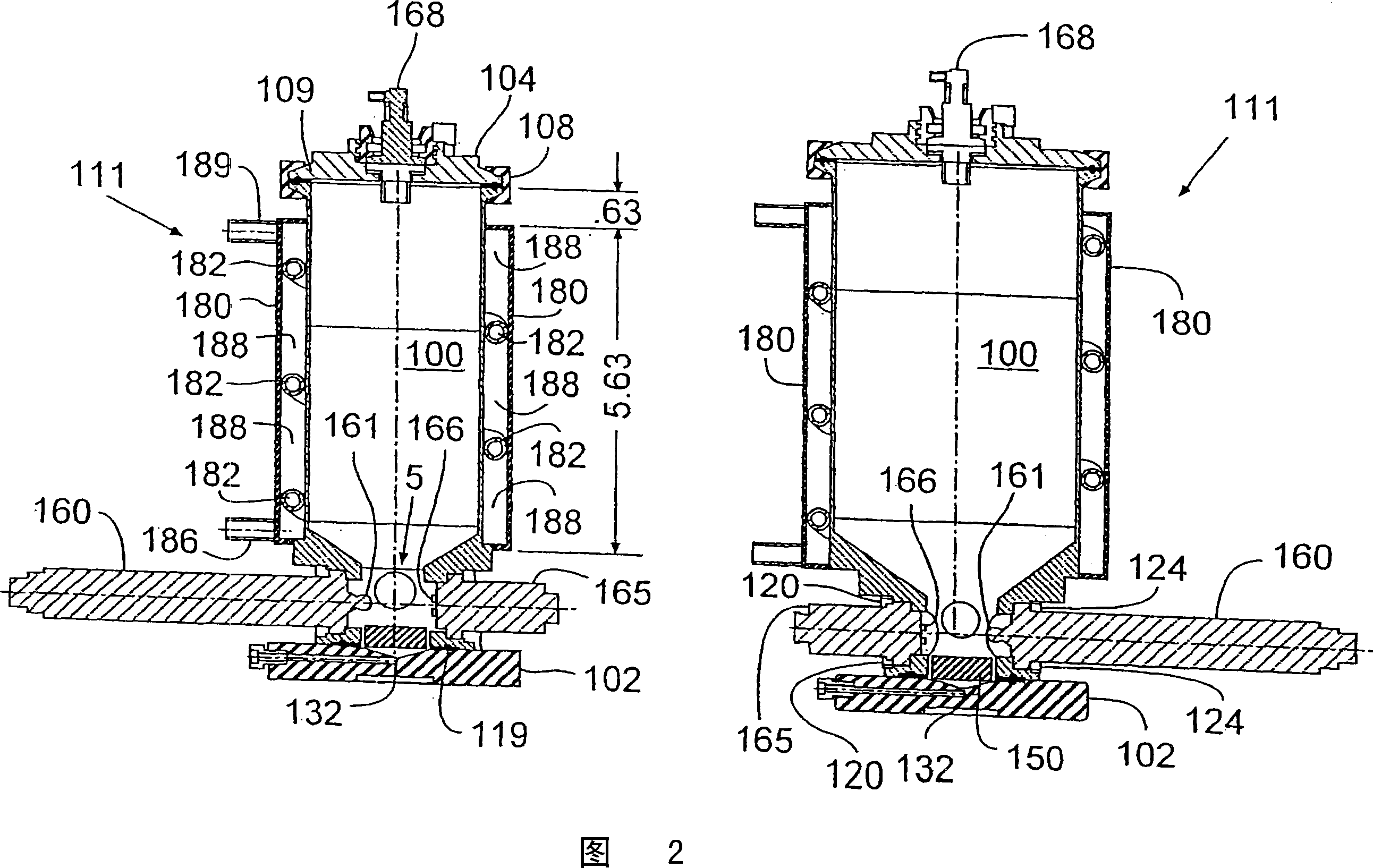

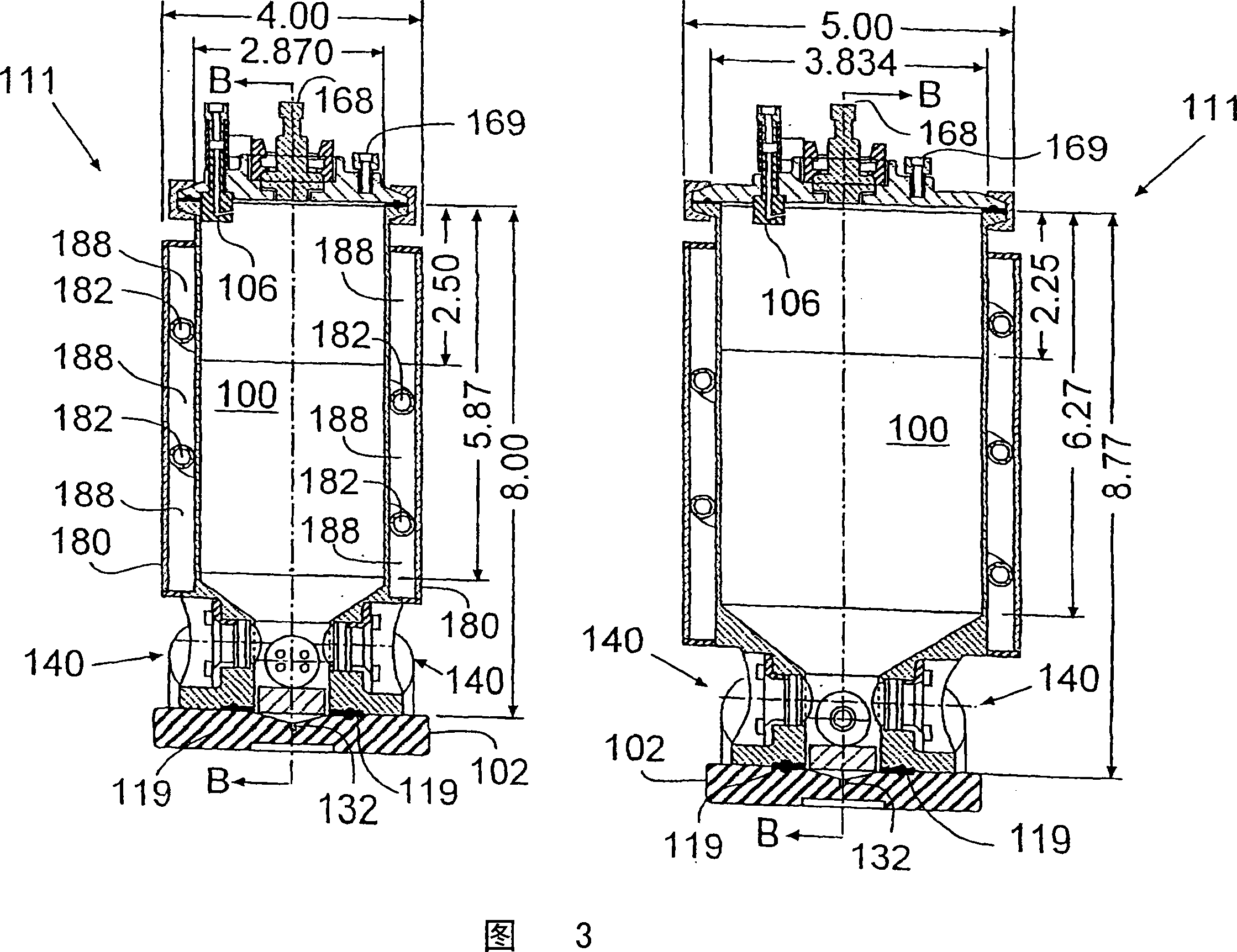

Automated fluid filtration system for conducting separation processes, and for acquiring and recording data thereabout

InactiveUS20030116487A1Economical and fastPreparing sample for investigationUltrafiltrationLaboratory scaleUser input

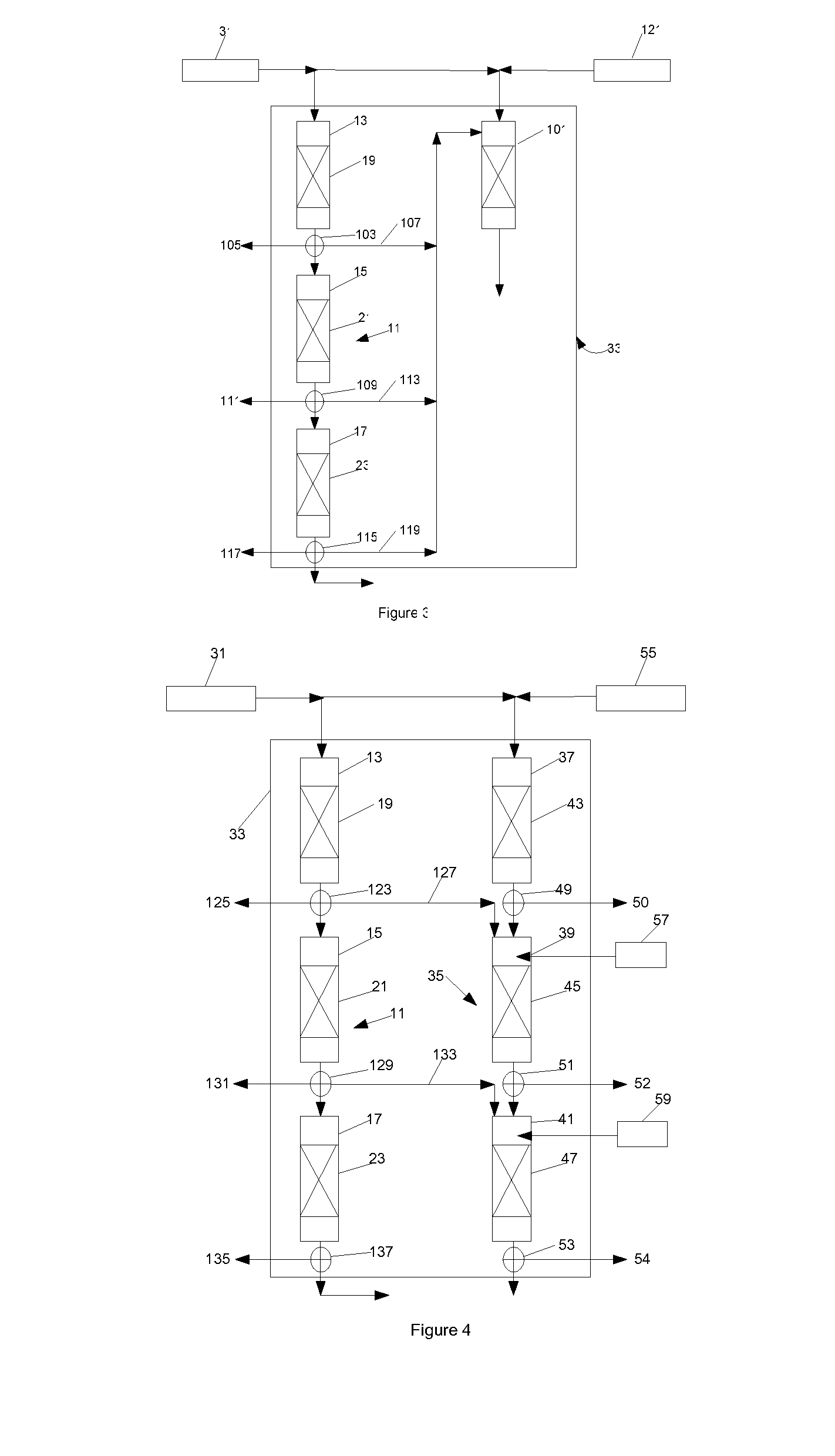

An automated fluid filtration system is disclosed, the system providing flexibility and accuracy for the investigative development of liquid separation processes. The system can be used for optimizing the protocol parameters of laboratory scale separation processes towards larger, commercial scale processes. The system-operable to an unprecedented minimum reliable recirculation volume of approximately 20 milliliters-comprises: (a) a reservoir; (b) a fluid filtration module; (c) a plurality of conduits defining, together with said reservoir and said fluid filtration module, a fluid process stream through which a liquid sample is conducted; (d) a plurality of pumps positioned along said fluid process stream for driving the flow of said liquid sample therethrough; (e) a plurality of valves positioned along the fluid process stream for regulating the flow of said liquid sample therethrough; (f) a plurality of sensors positioned along said fluid process stream for acquiring data about the liquid sample as it flows therethrough; and (g) an electronic data processing network capable of (i) receiving, processing, and recording data from said pumps, valves, and sensors and from an external source (e.g., user input), and (ii) transmitting signals to the pumps, valves, and sensors to effect the operation thereof.

Owner:MILLIPORE CORP

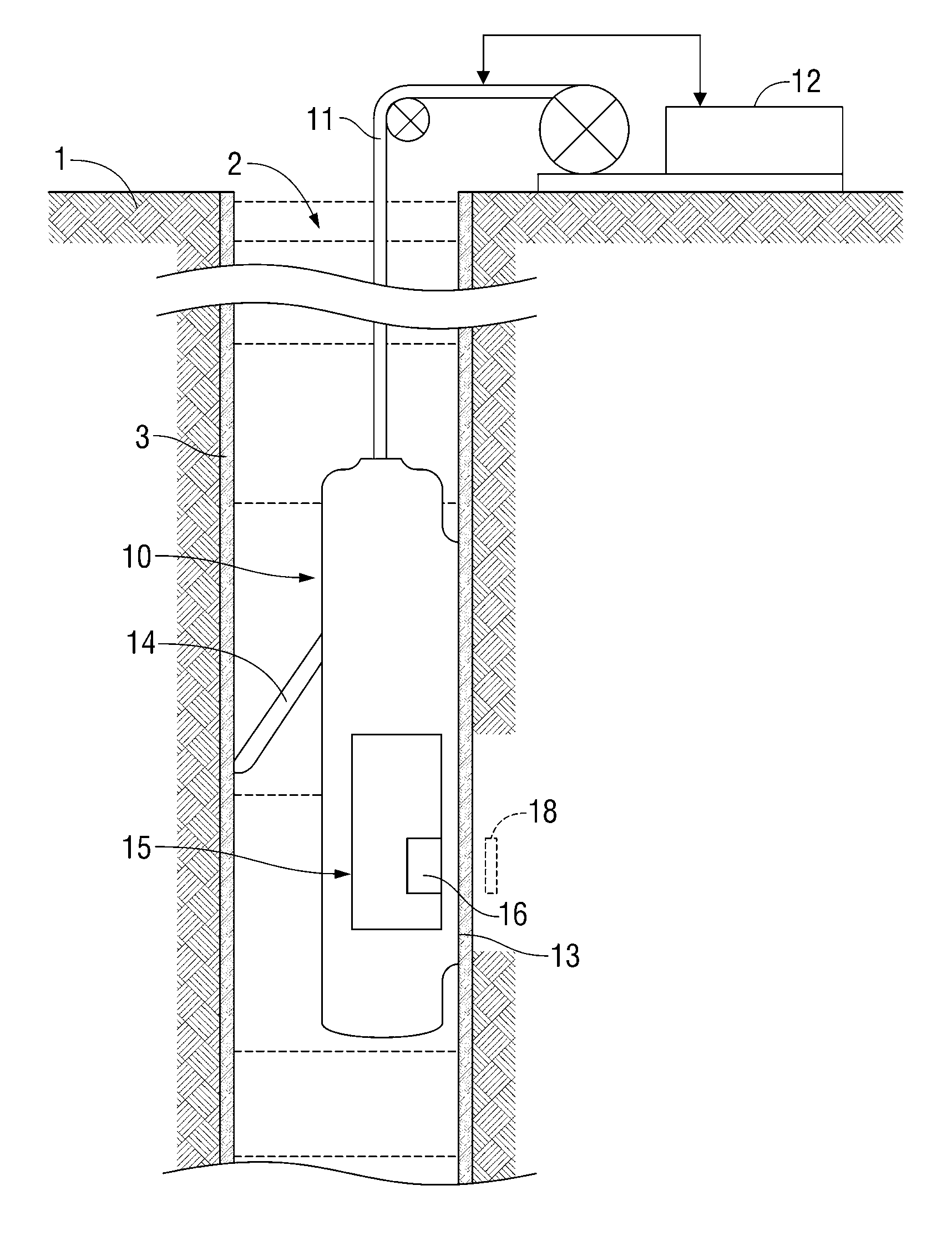

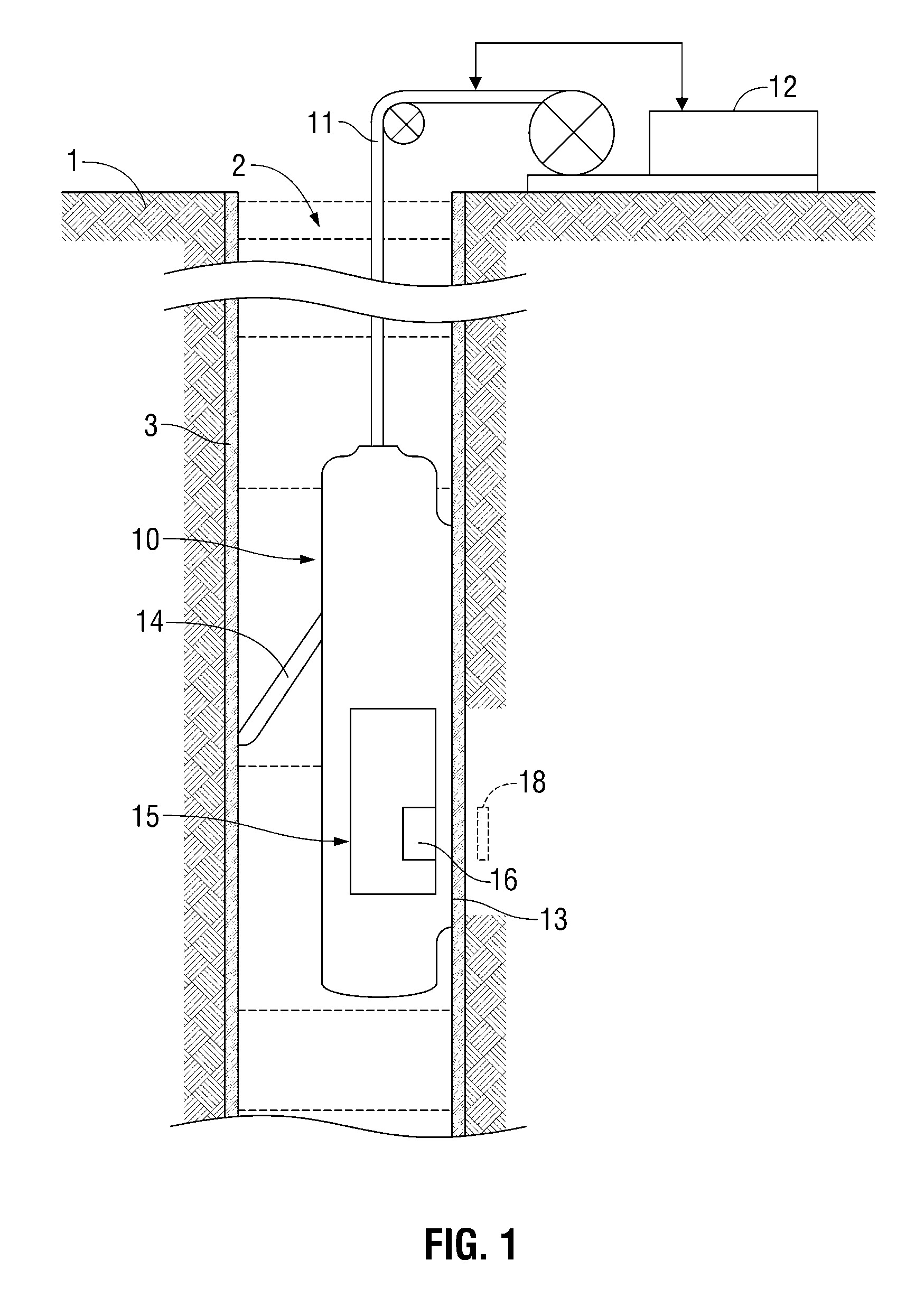

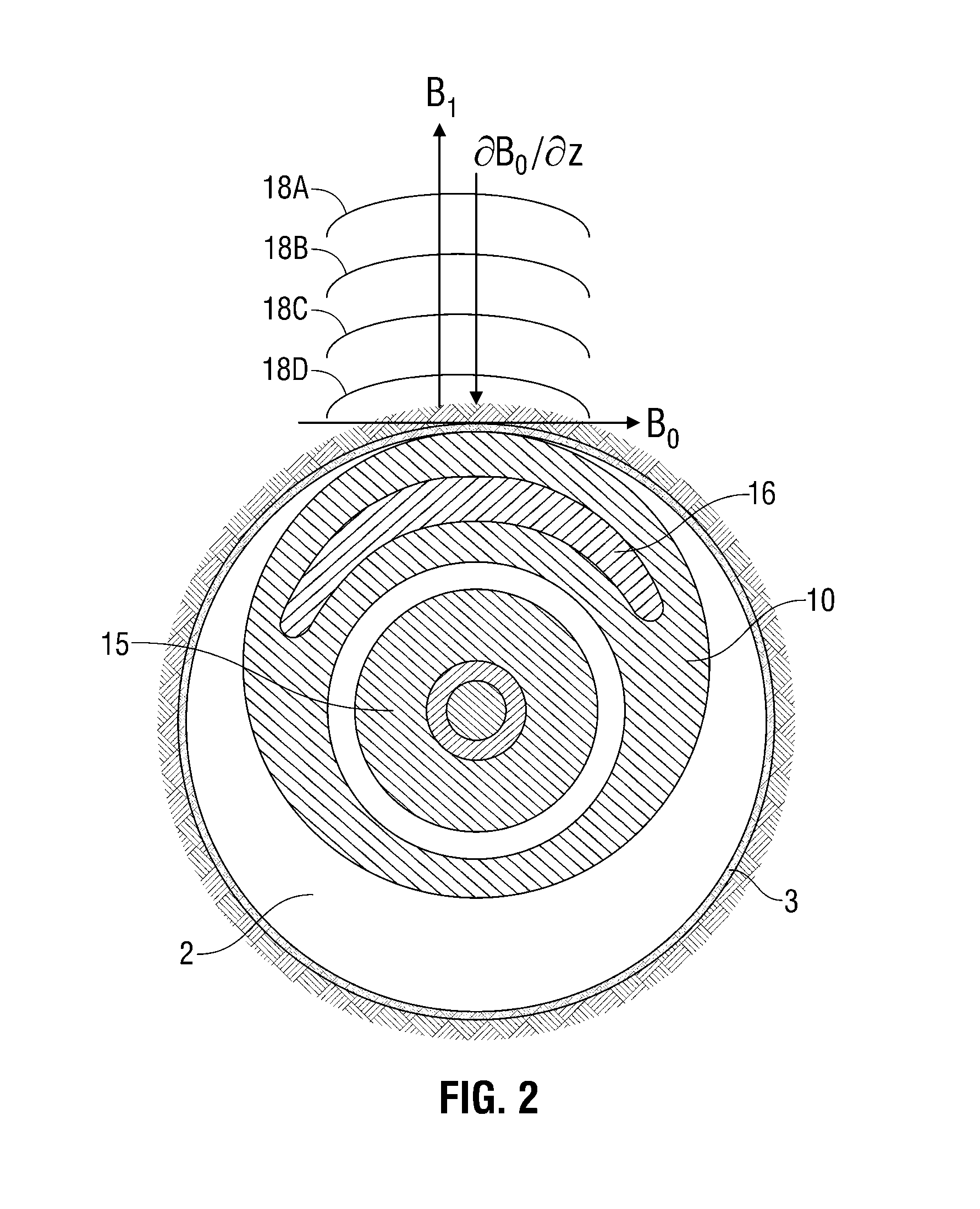

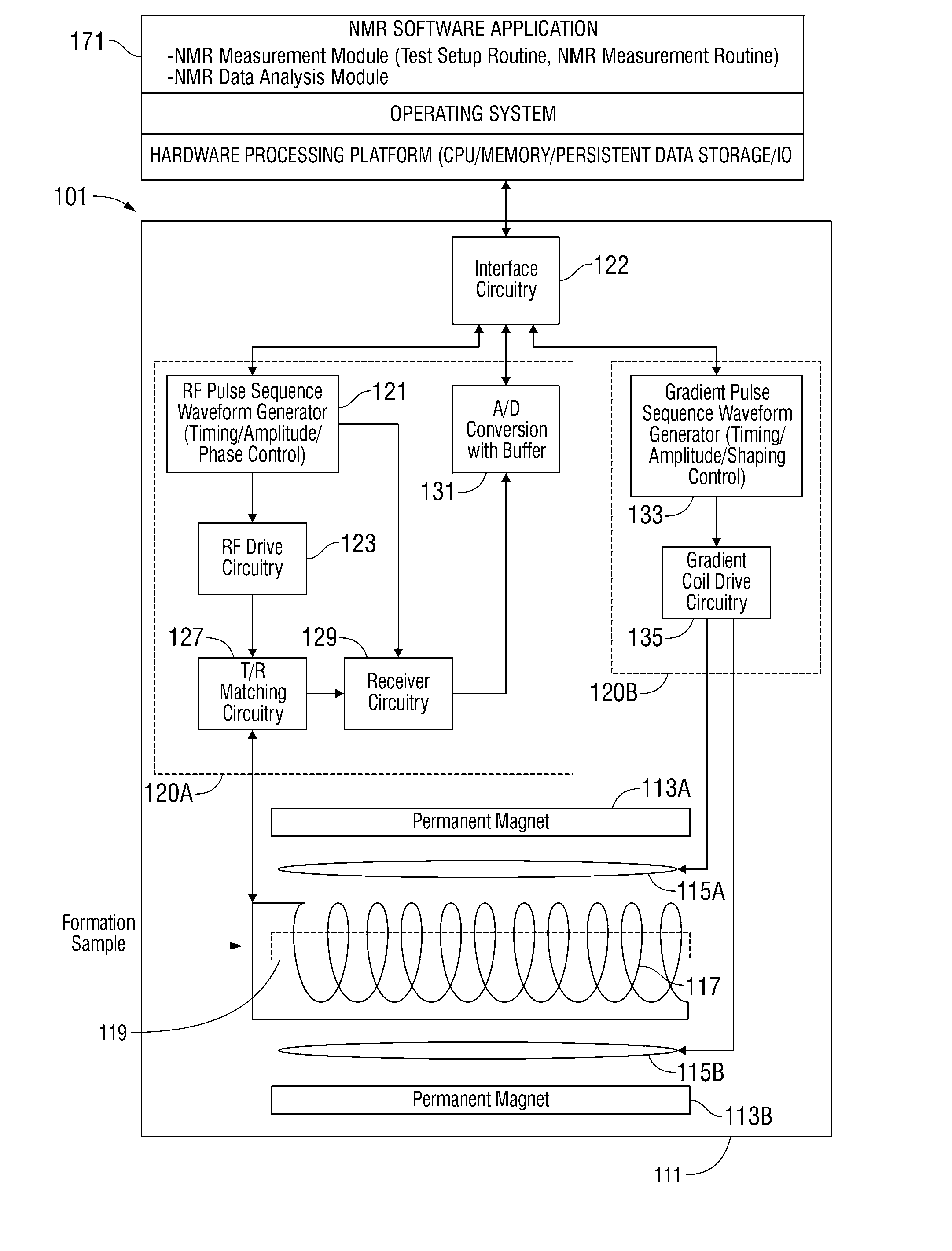

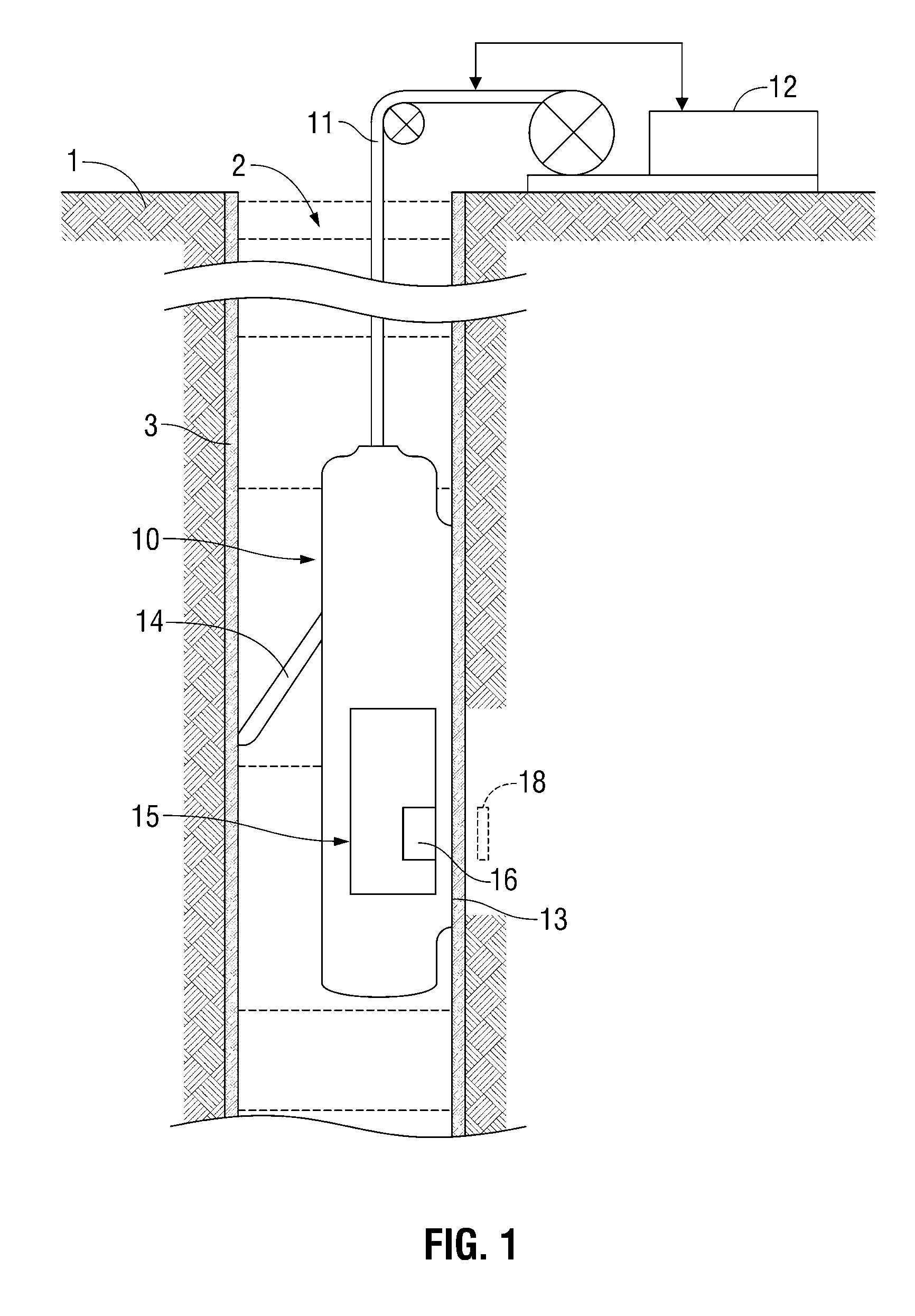

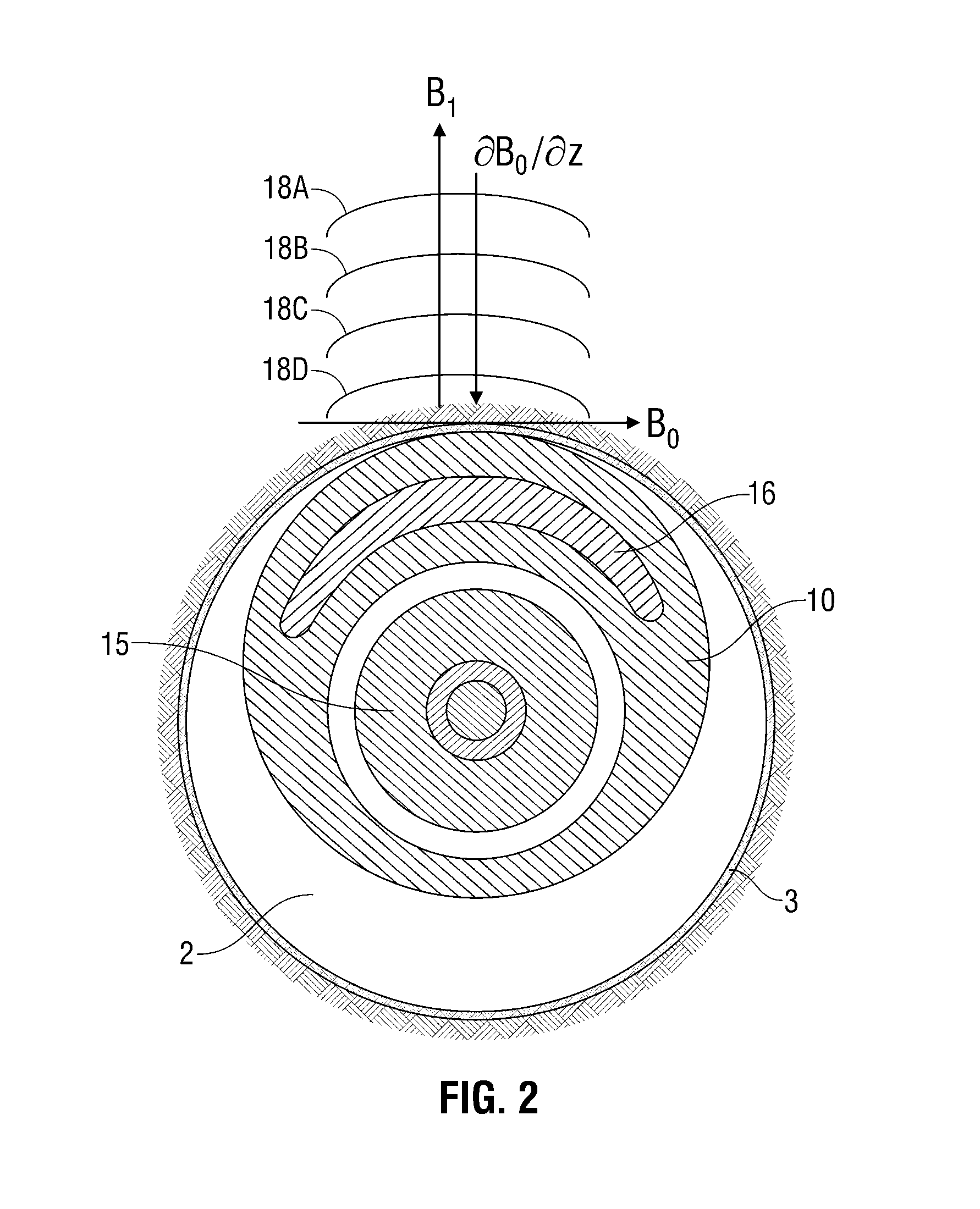

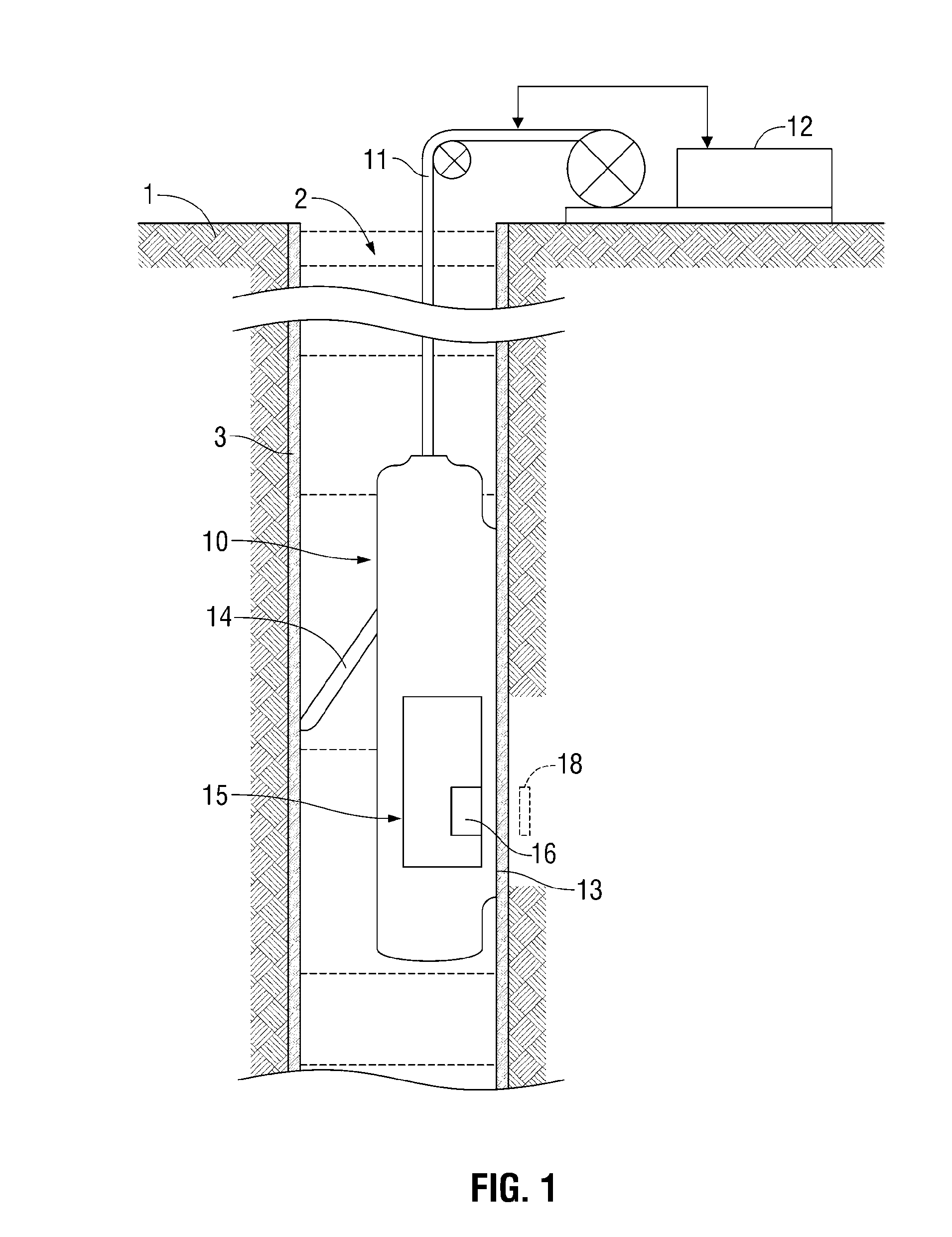

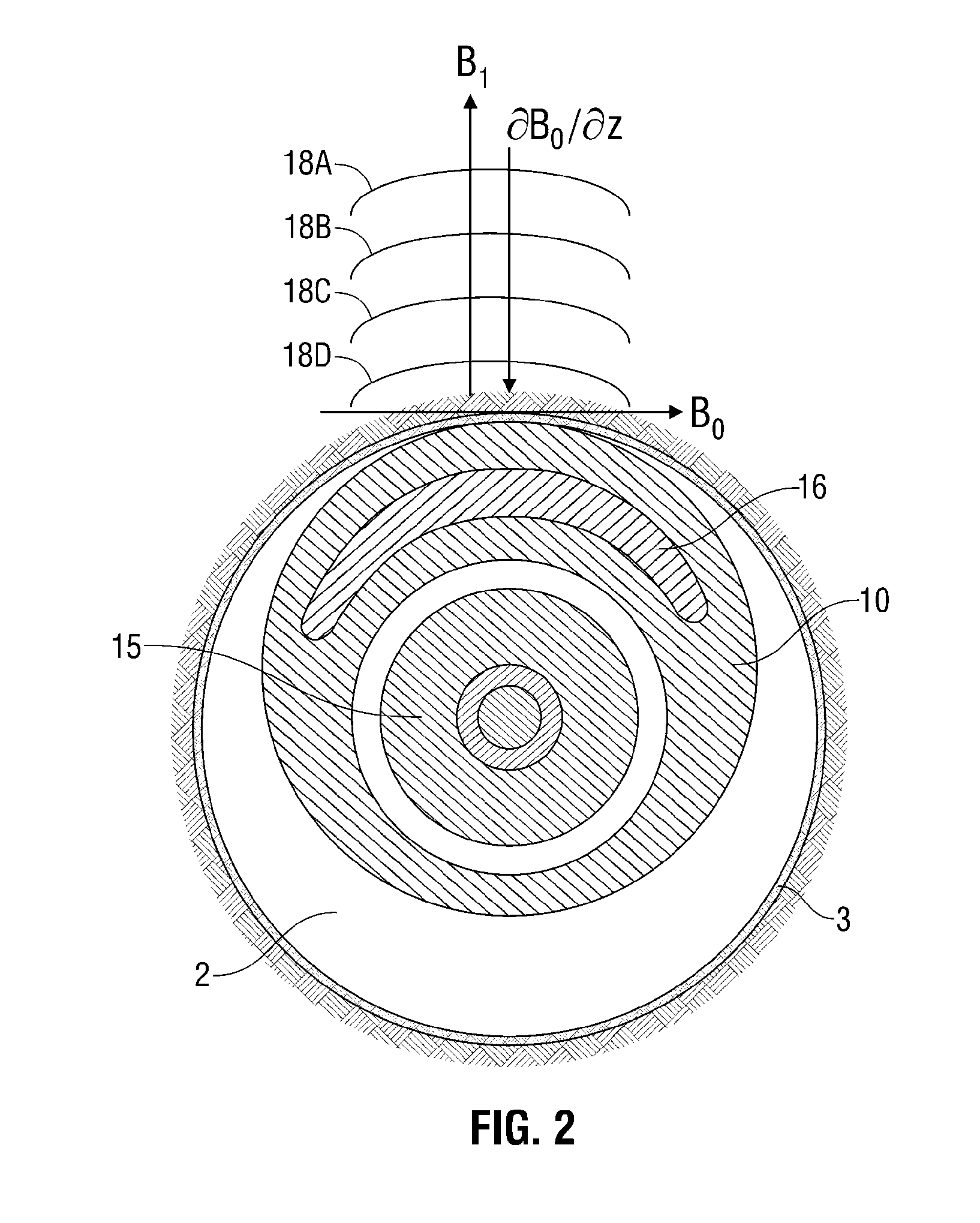

System and method for emulating nuclear magnetic resonance well logging tool diffusion editing measurements on a bench-top nuclear magnetic resonance spectrometer for laboratory-scale rock core analysis

InactiveUS20110234220A1Increase displacementPromote recoveryElectric/magnetic detection for well-loggingMeasurements using NMR imaging systemsWell loggingLaboratory scale

A laboratory NMR methodology (and corresponding laboratory apparatus) defines a sample volume. The method stores downhole tool data corresponding to a hydrocarbon-bearing sample collected from a given subsurface formation. The downhole tool data includes parameters pertaining to magnetic fields used by a downhole tool during a suite of NMR measurements of the given subsurface formation. The sample is positioned in the sample volume of the laboratory apparatus, which applies a static magnetic field in the sample volume. Furthermore, the laboratory apparatus applies a suite of NMR measurements to the sample volume to thereby determine a property of the sample. The NMR measurements of the suite each include a pulse sequence of oscillating magnetic field in conjunction with a pulsed-mode gradient field. The pulsed-mode gradient field is based on the stored downhole tool data corresponding to the sample. A laboratory NMR methodology for optimizing downhole NMR measurements is also described.

Owner:SCHLUMBERGER TECH CORP

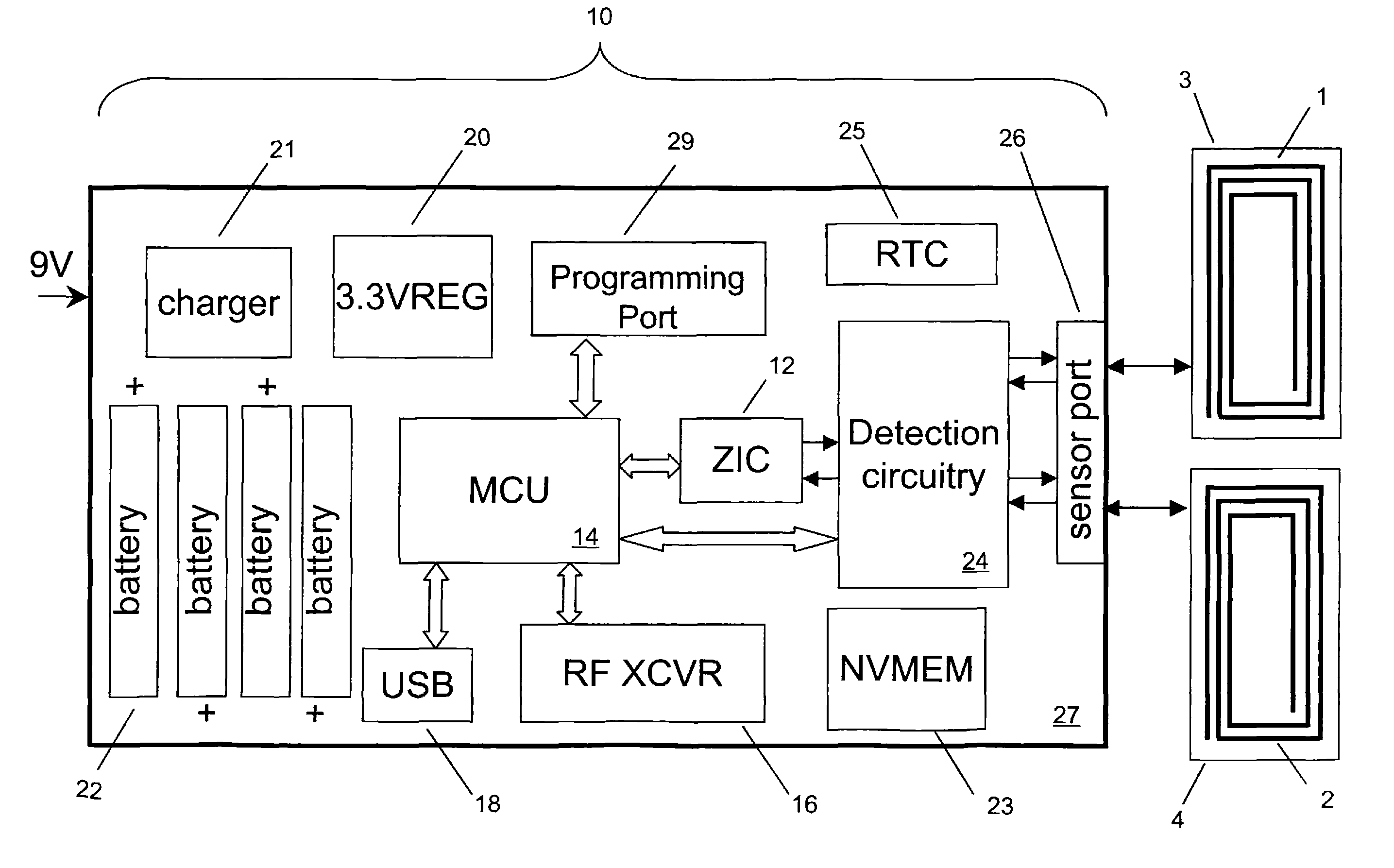

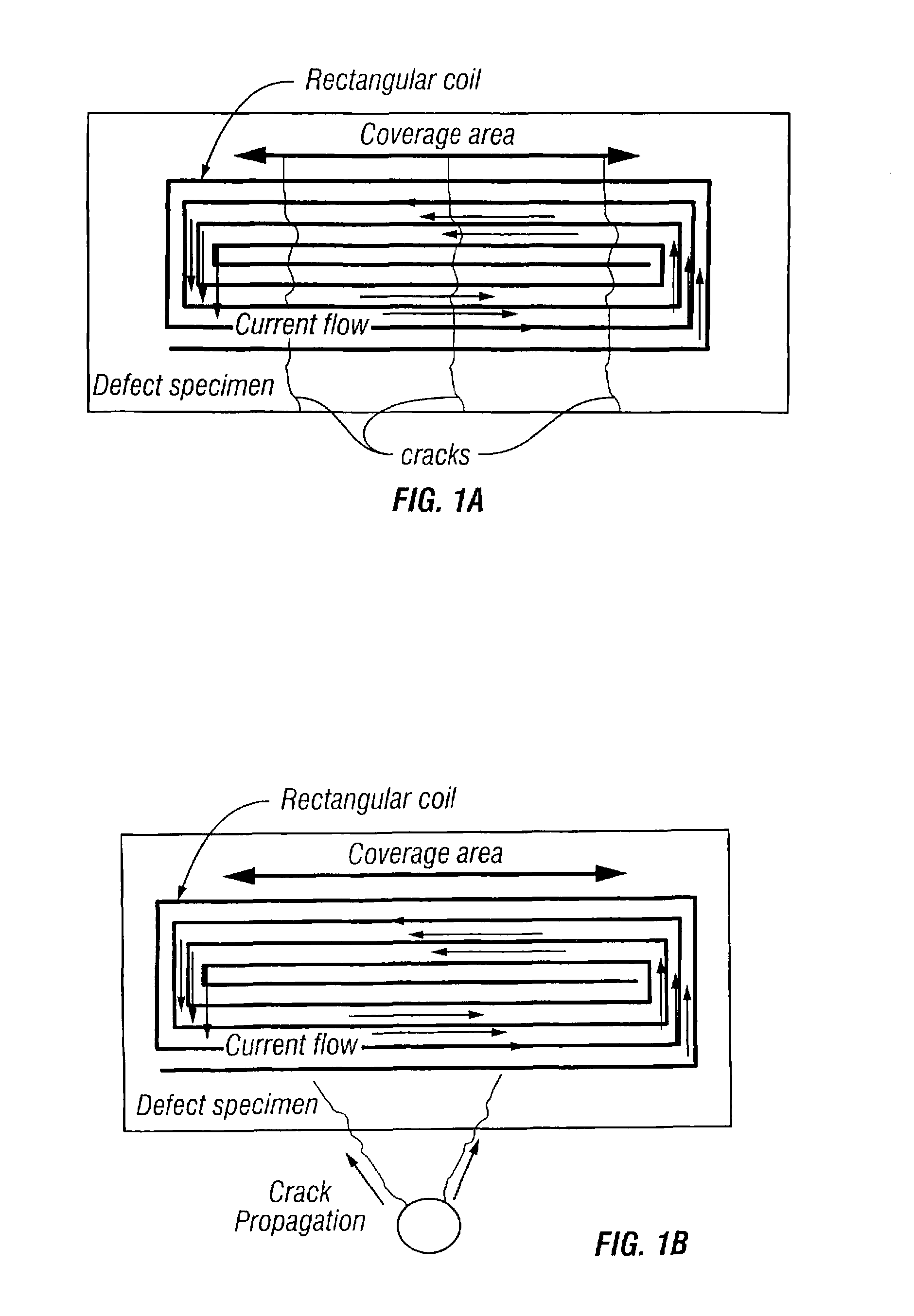

Mountable eddy current sensor for in-situ remote detection of surface and sub-surface fatigue cracks

A wireless, integrated, mountable, portable, battery-operated, non-contact eddy current sensor that provides similar accuracy to 1970's laboratory scale equipment (e.g., a Hewlett-Packard GP4194A Impedance Analyzer) at a fraction of the size and cost.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

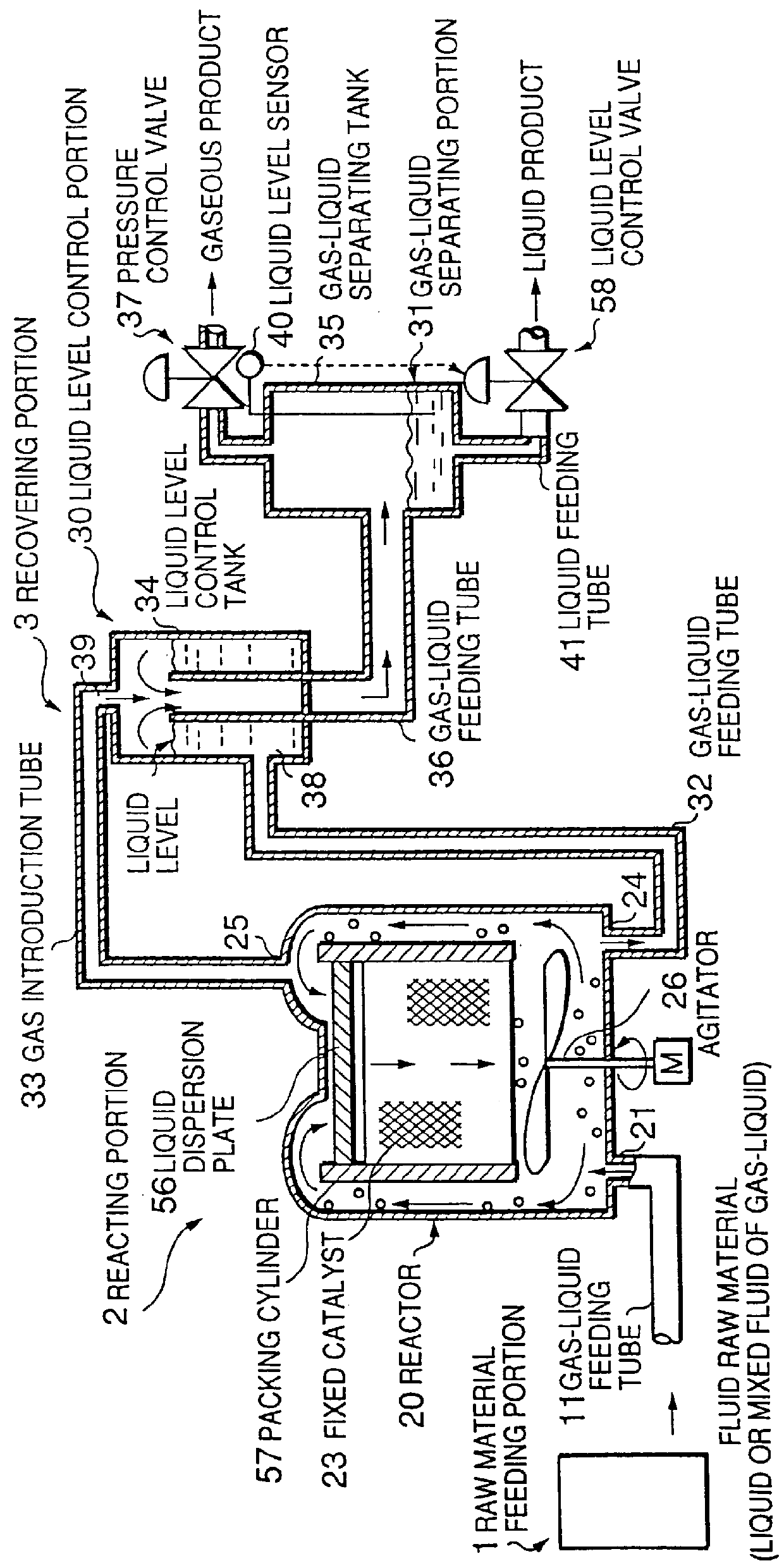

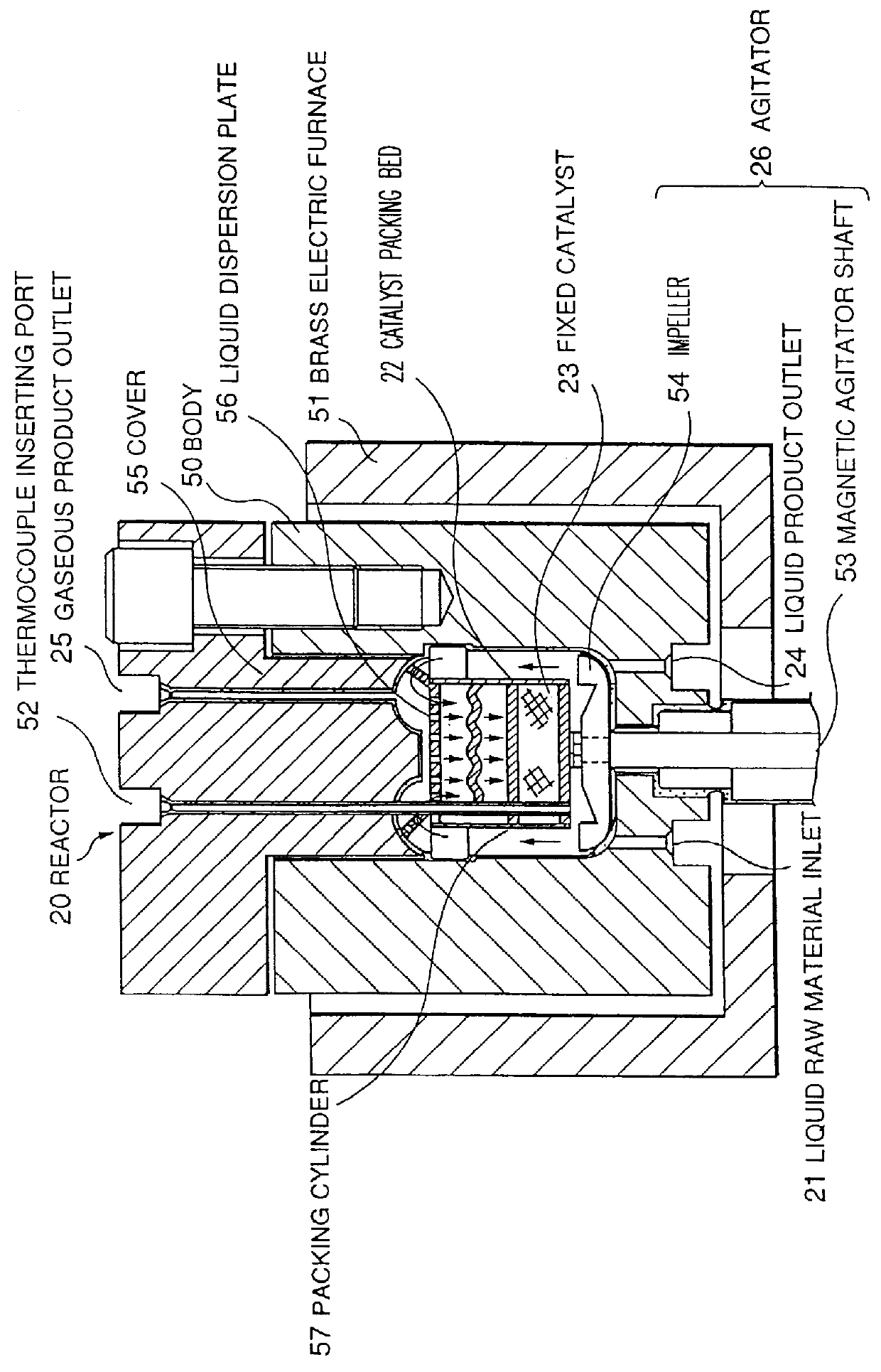

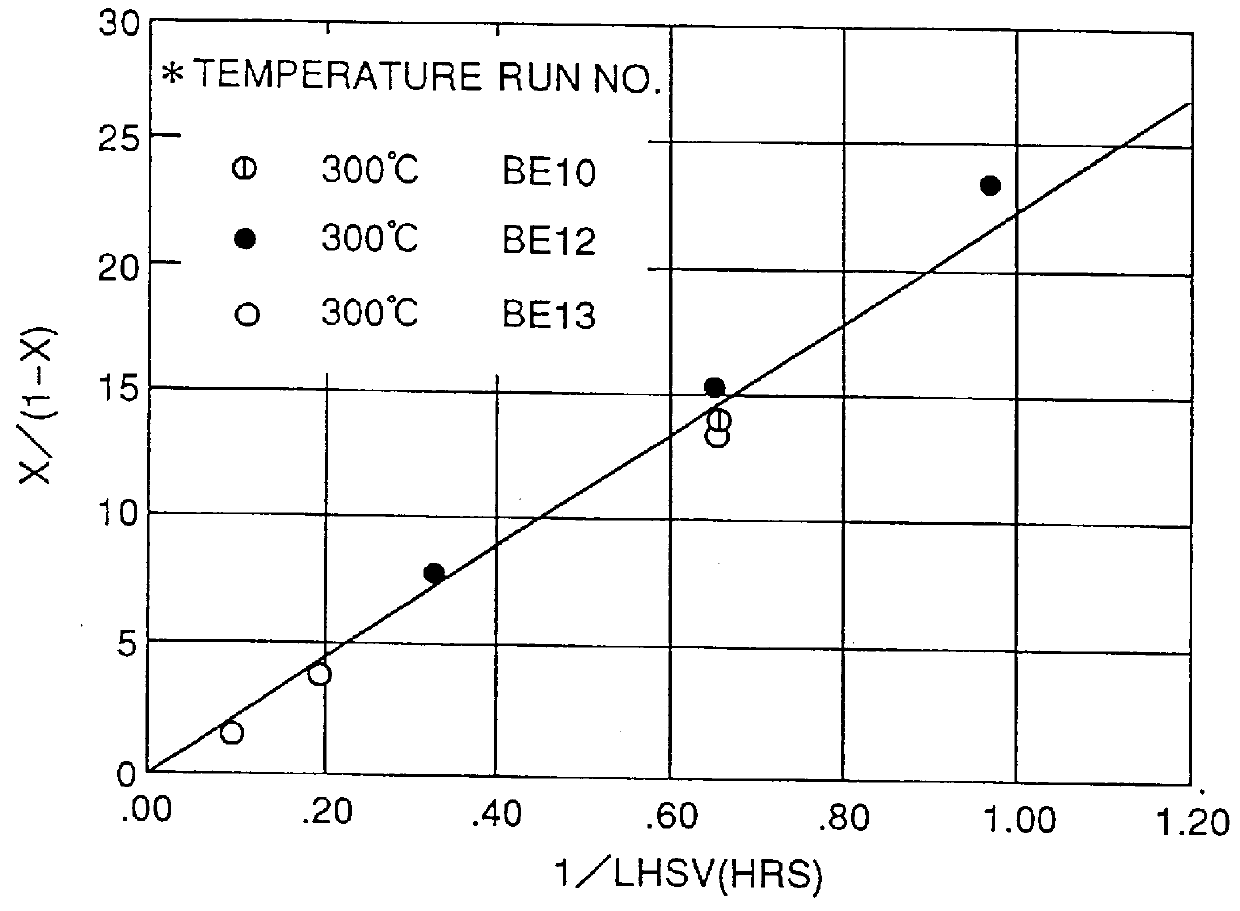

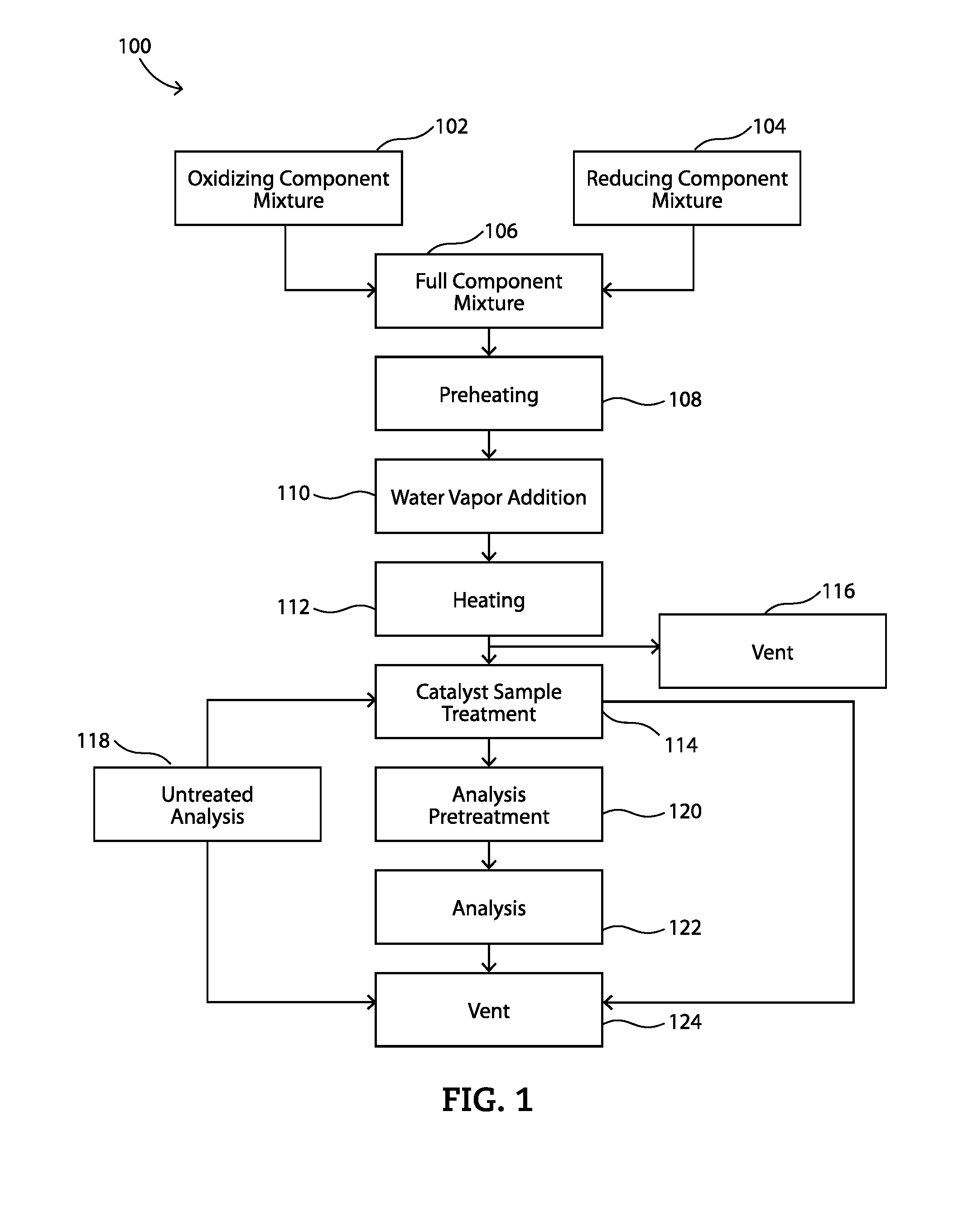

Apparatus for evaluating a solid catalyst and evaluation method using the apparatus

InactiveUS6086832AAccurate estimateIncrease rangeChemical analysis using catalysisPressurized chemical processLiquid productLaboratory scale

An apparatus for evaluating a solid catalyst which can enlarge a range of an applied fluid used for an evaluation of a performance of the solid catalyst and can accurately evaluate the performance of the solid catalyst on a laboratory scale and a method of evaluating a solid catalyst using the apparatus are provided. There are disclosed an apparatus of evaluating a solid catalyst, wherein a raw material feeding portion has a function capable of continuously feeding a liquid raw material or a mixed raw material consisting of a gas and a liquid, wherein a reactor in a reacting portion has an inlet for a fluid raw material and reaction product outlets for discharging a reaction product while separating it into a liquid product and a gaseous product, and wherein a recovering portion has reaction product inlets connected to each of the reaction product outlets of the reactor and has a liquid level control portion for keeping a liquid level within the reactor constant, and a method of evaluating a solid catalyst using the apparatus.

Owner:IDEMITSU KOSAN CO LTD

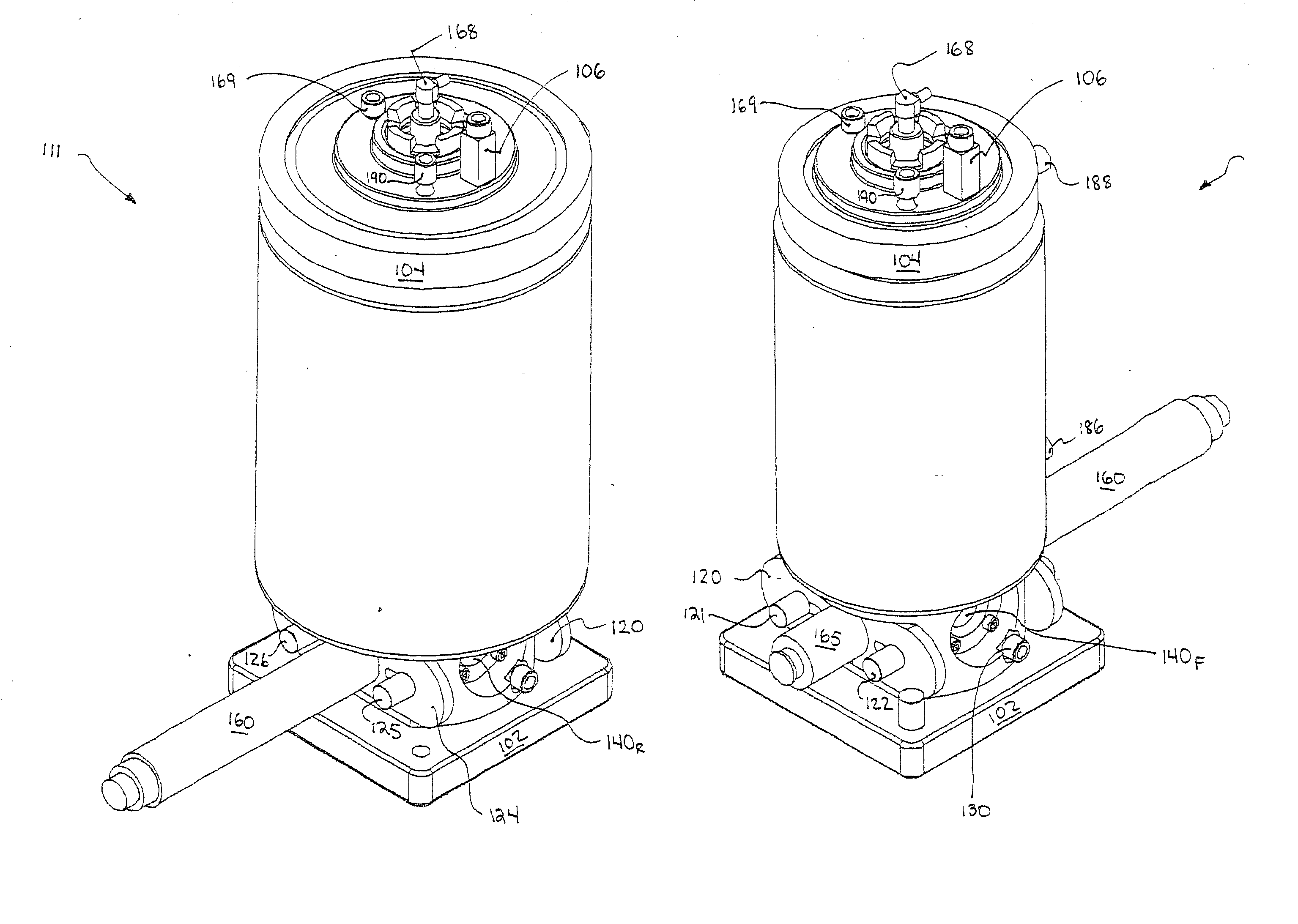

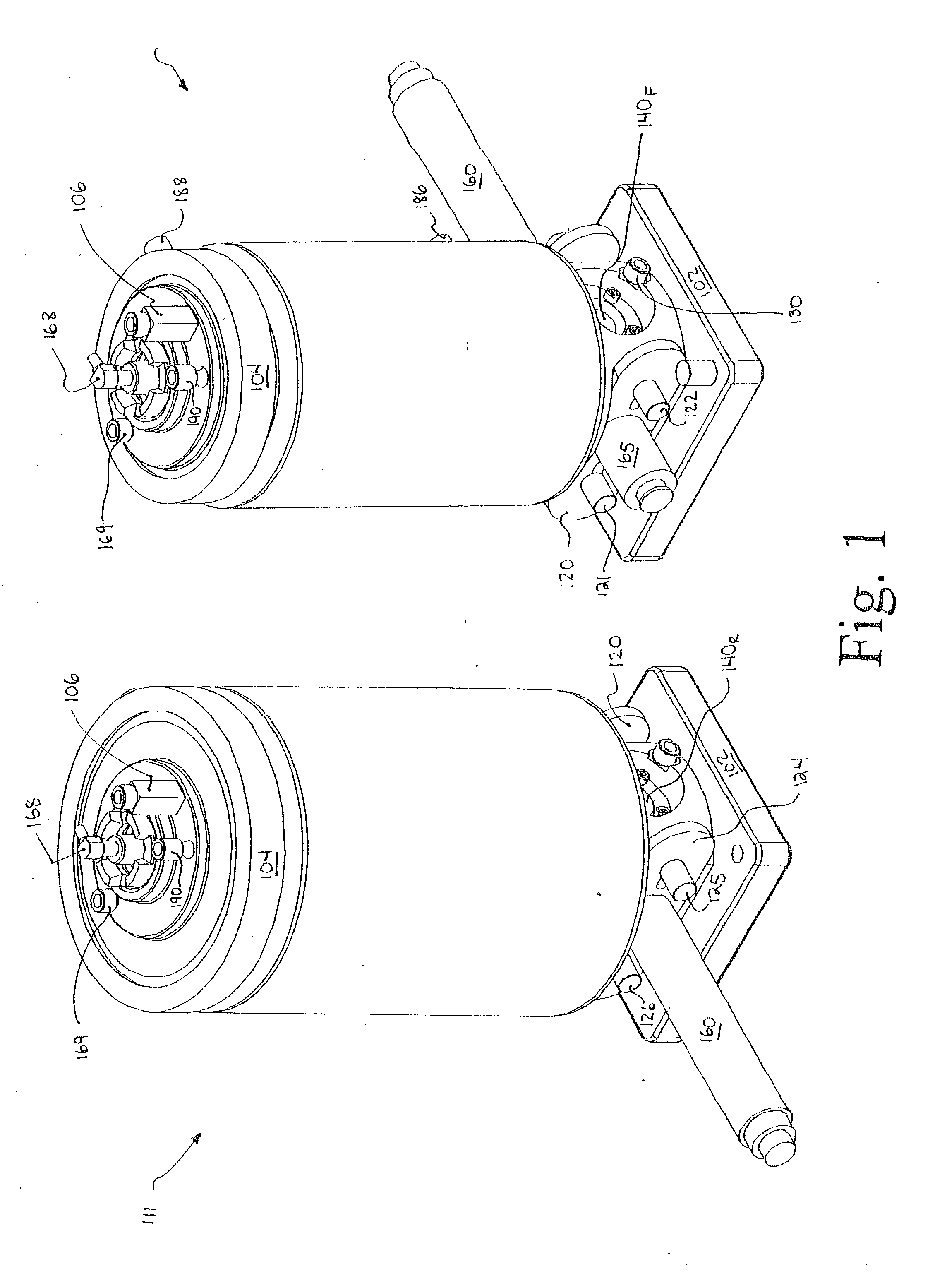

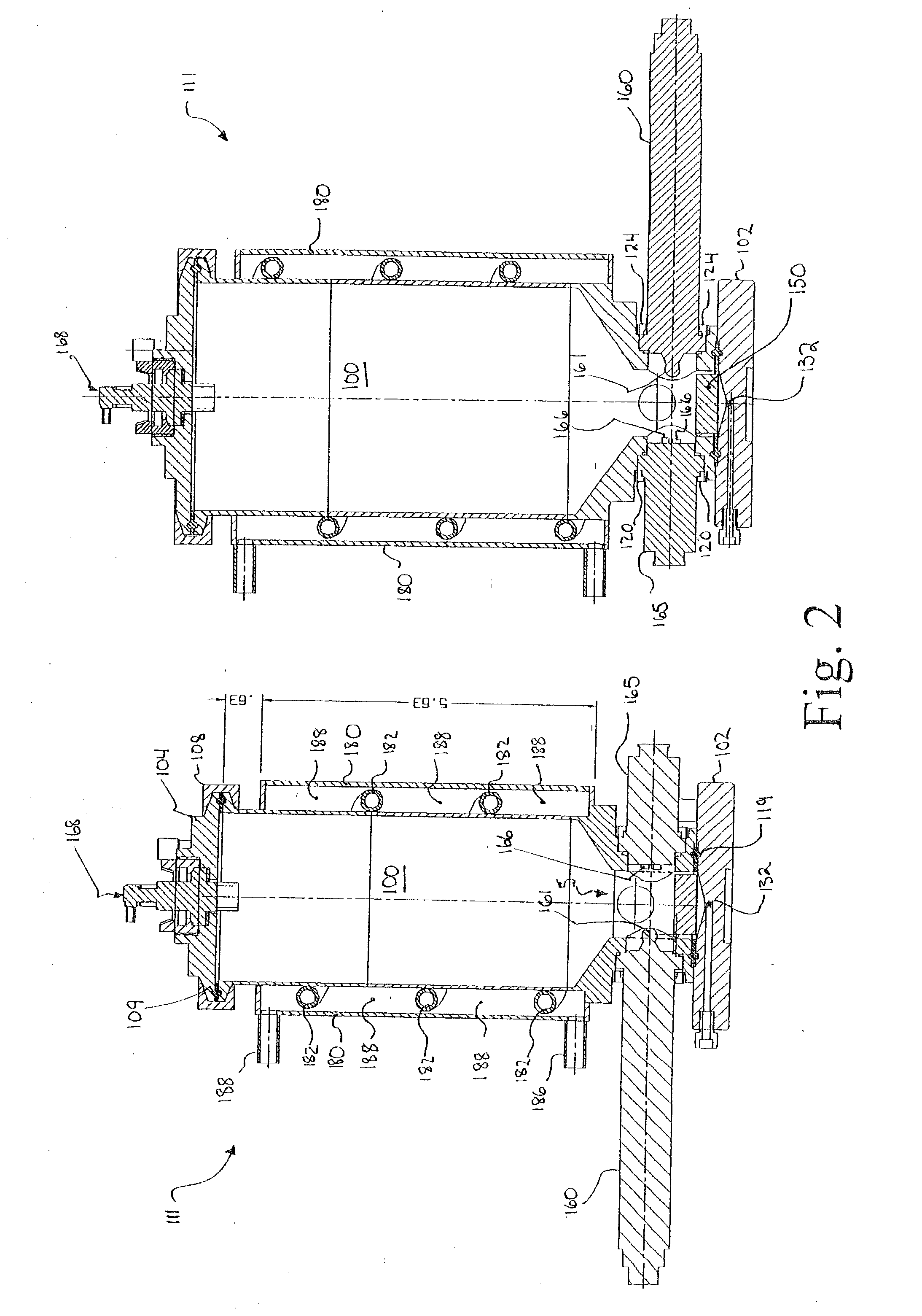

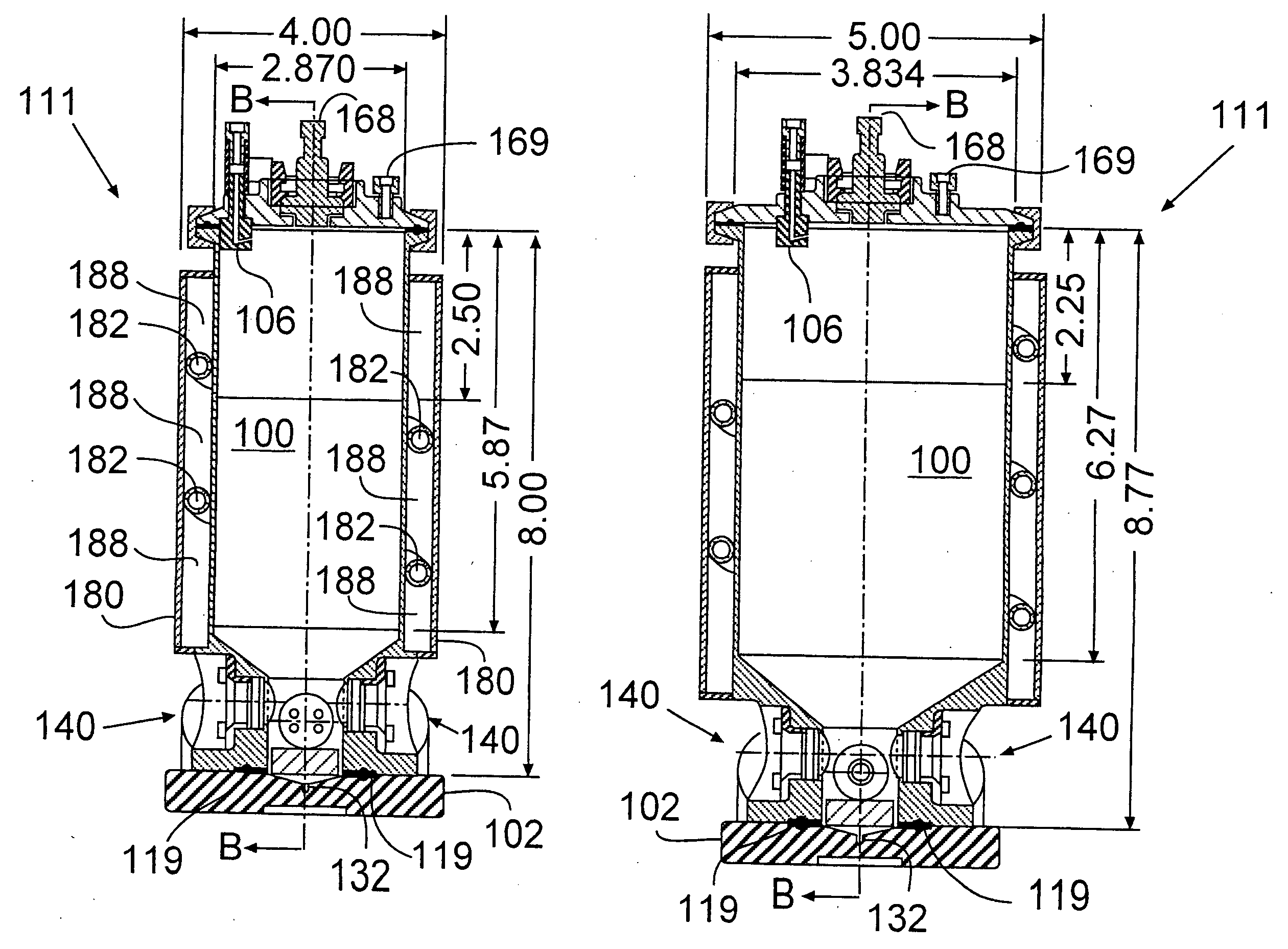

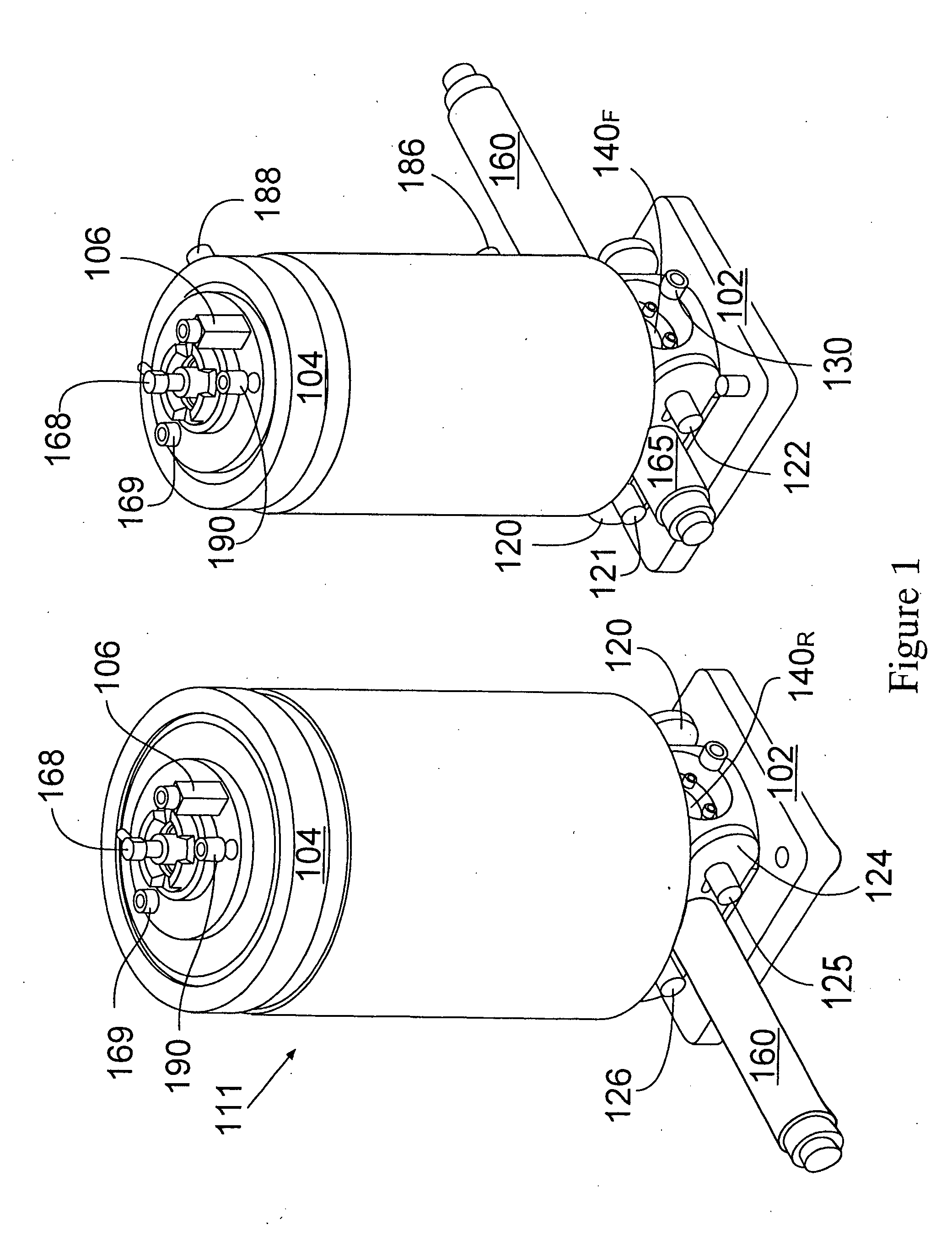

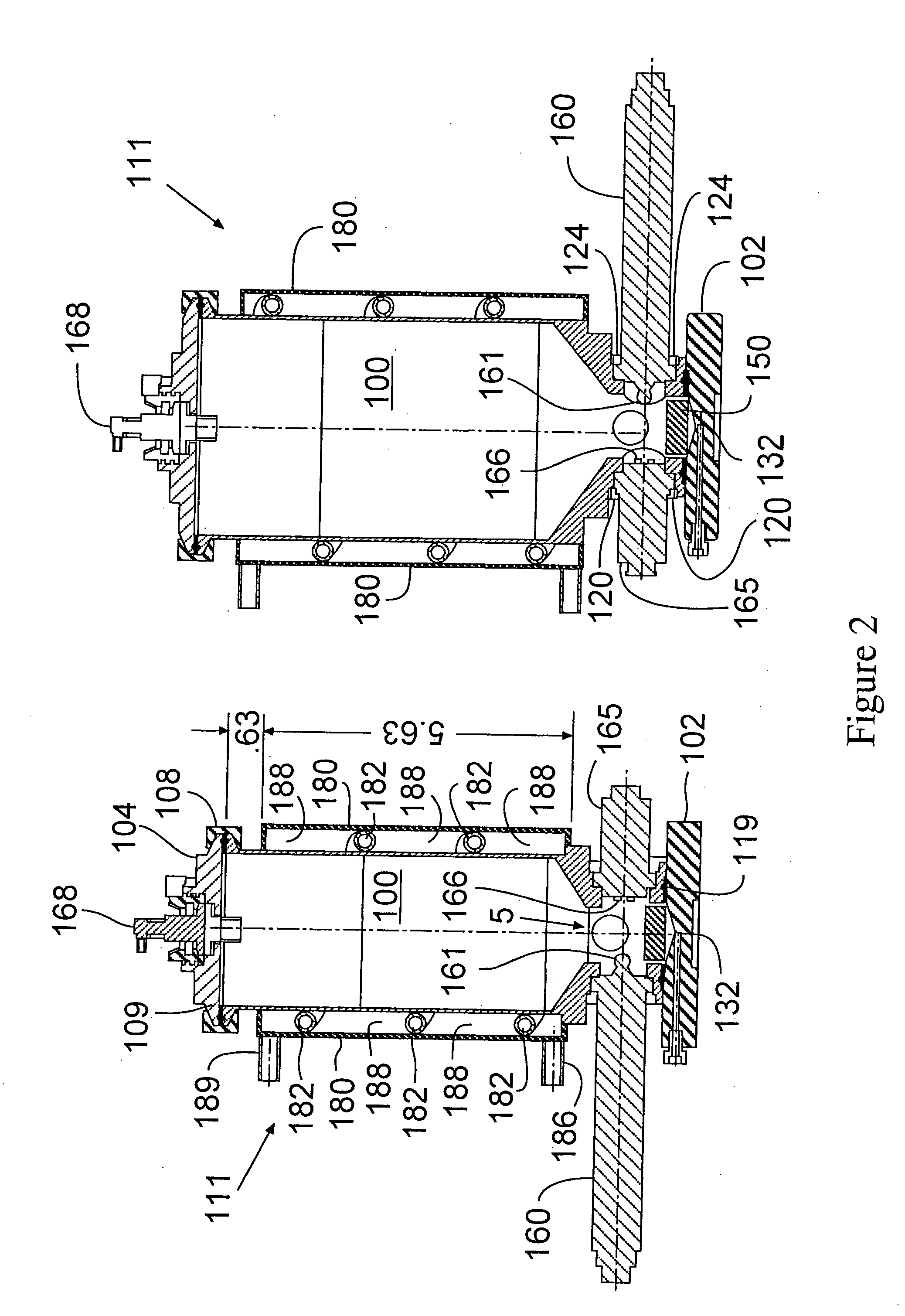

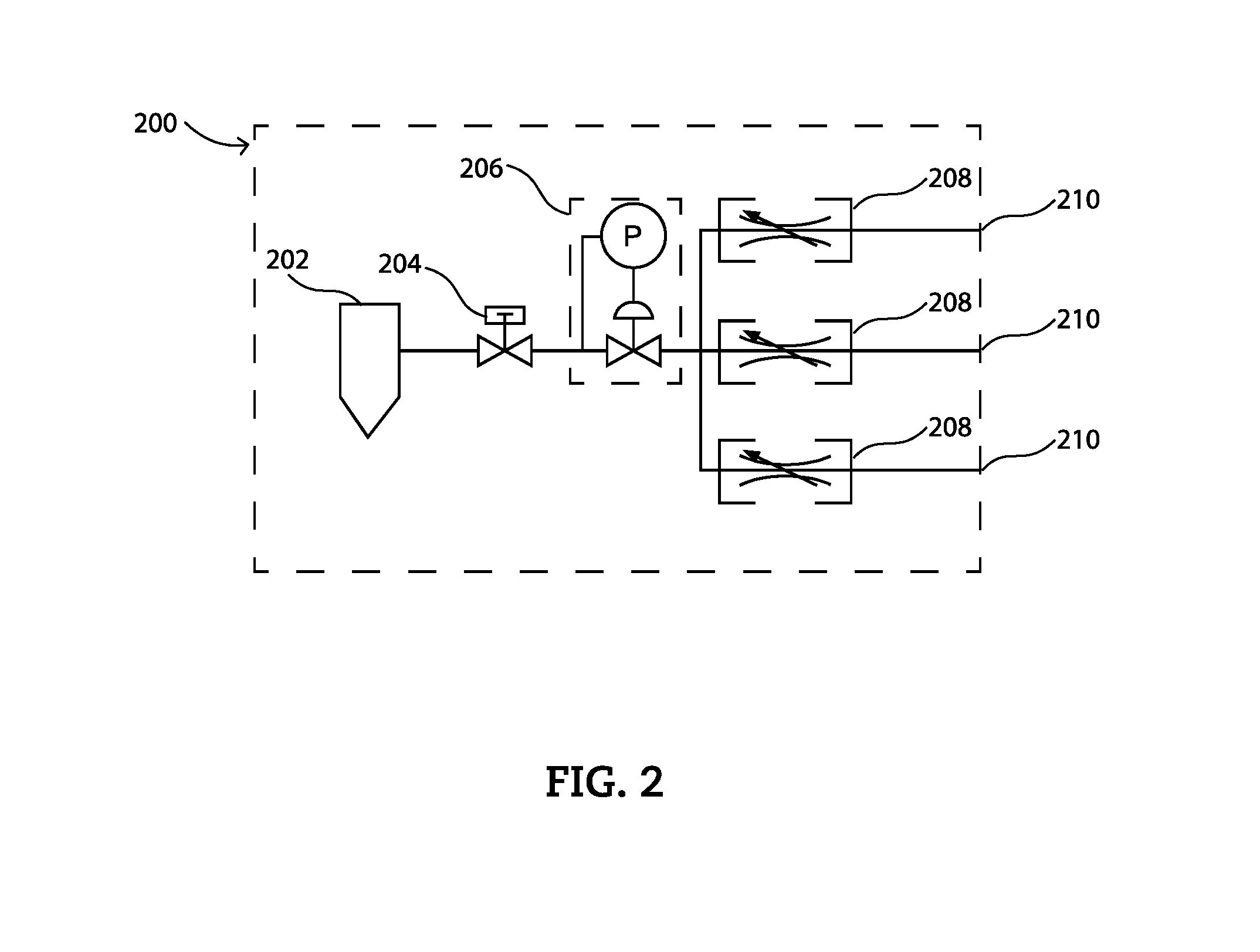

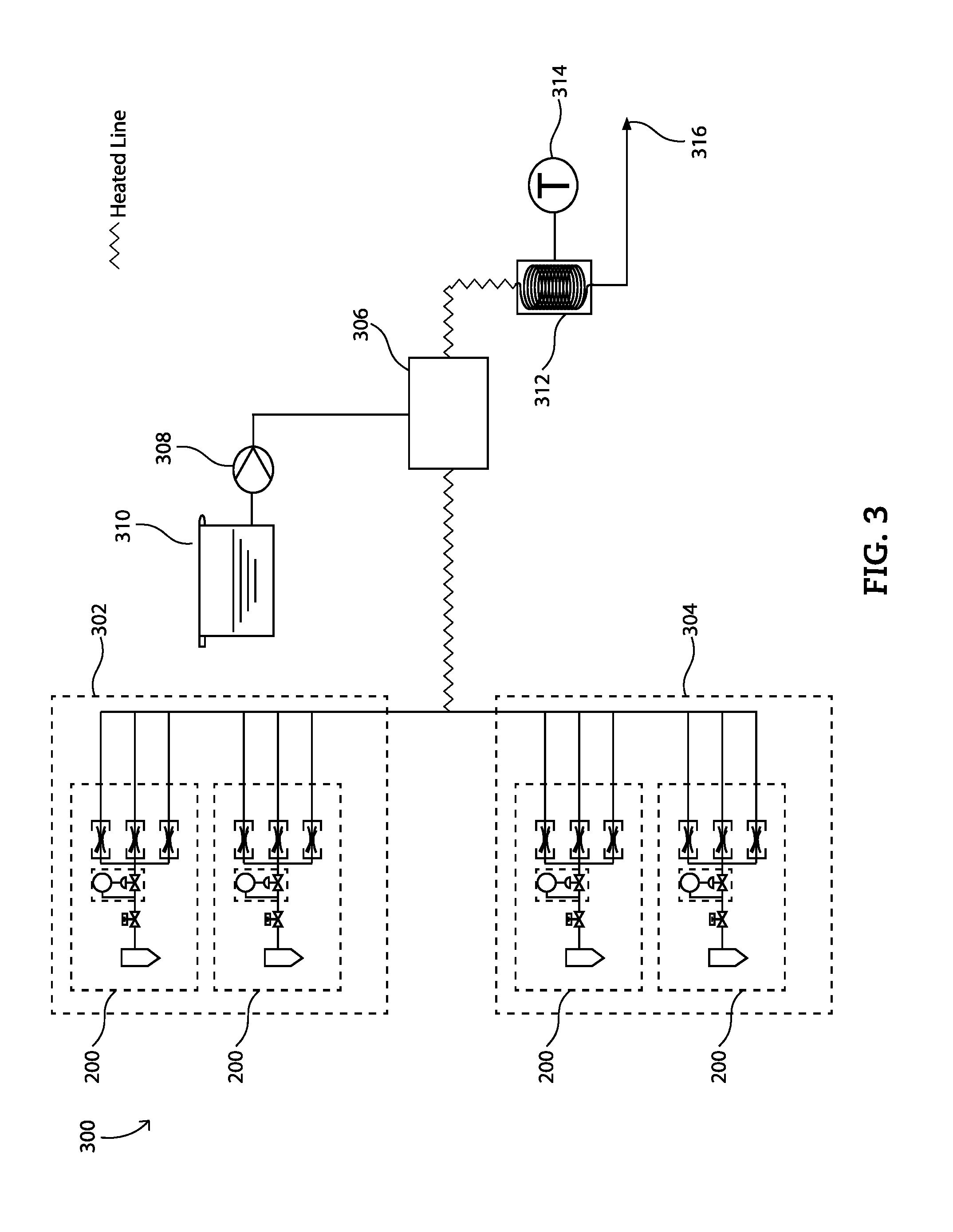

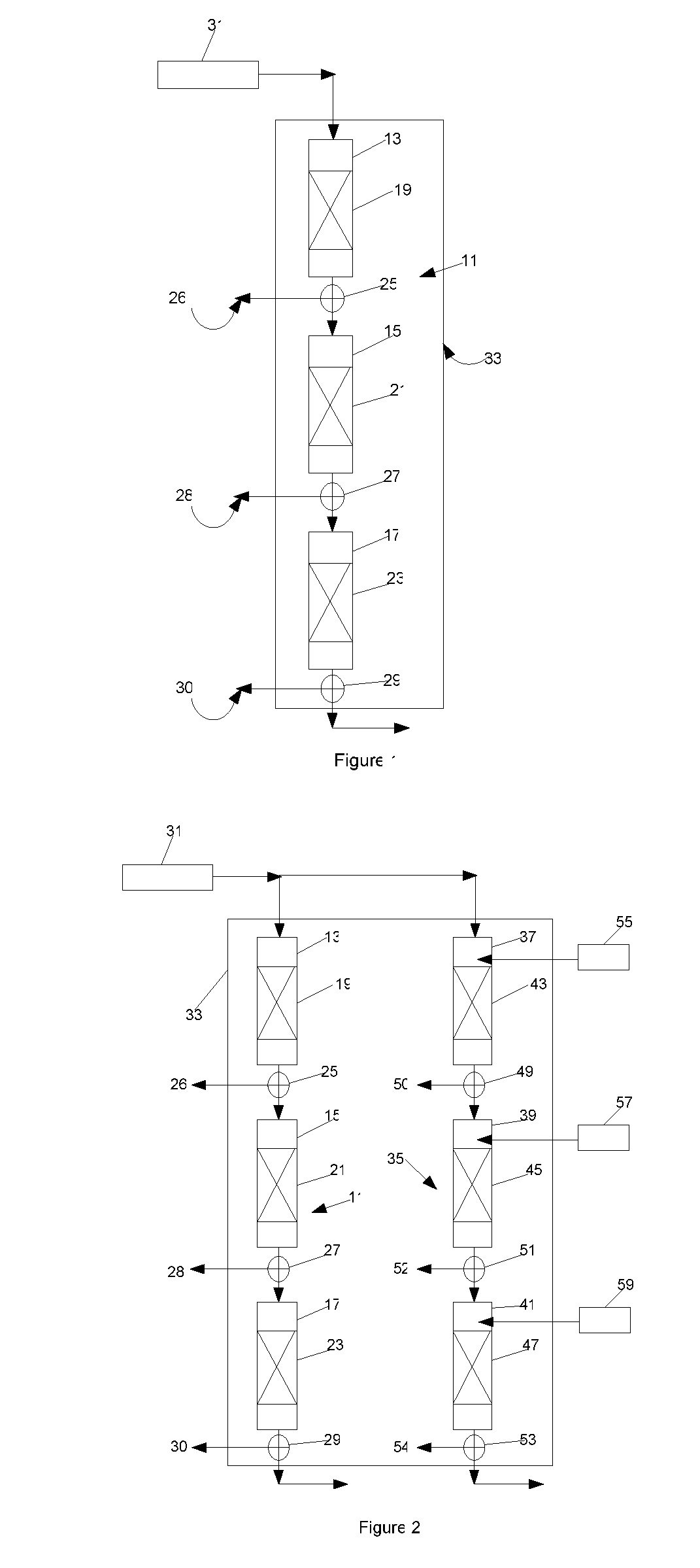

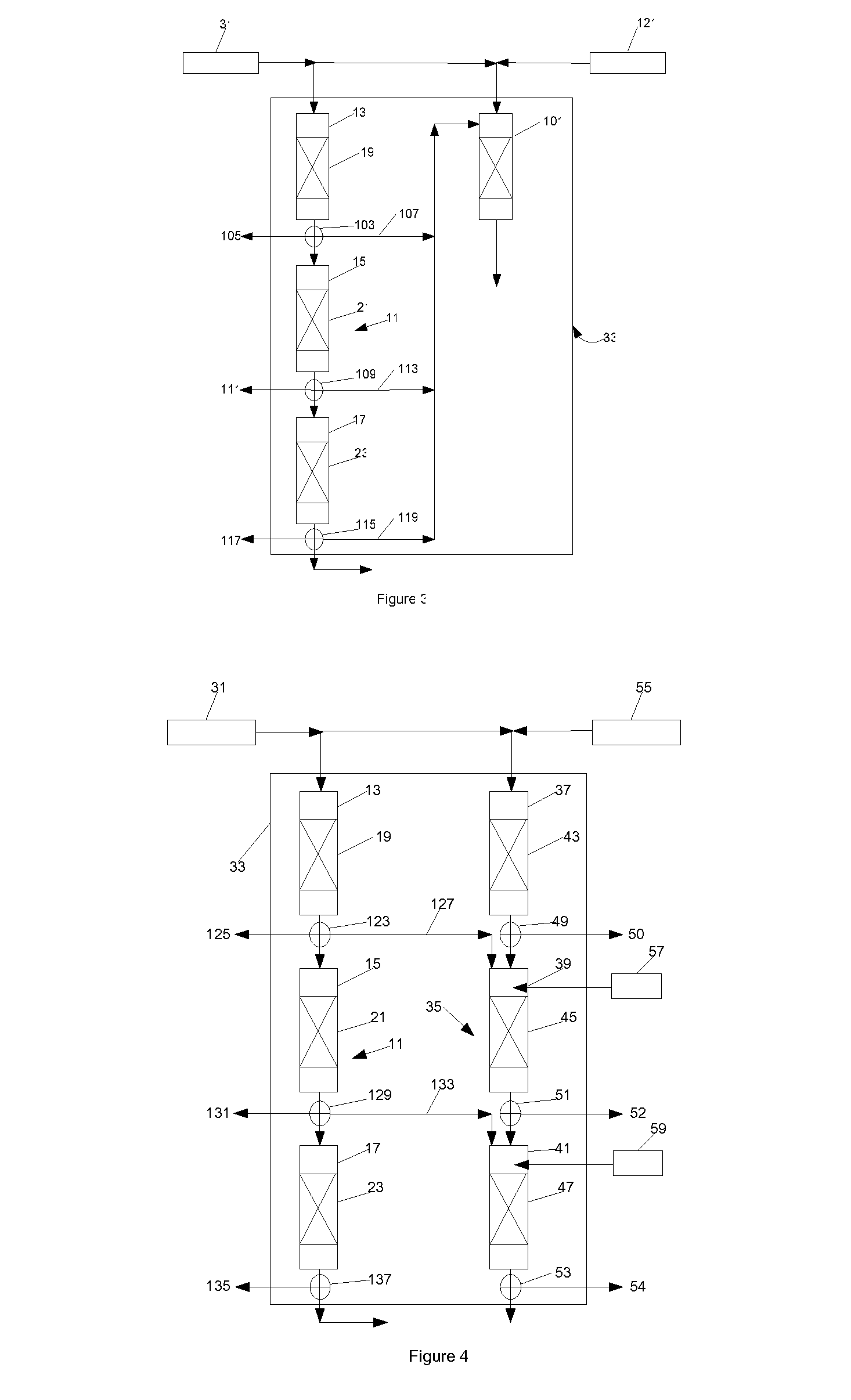

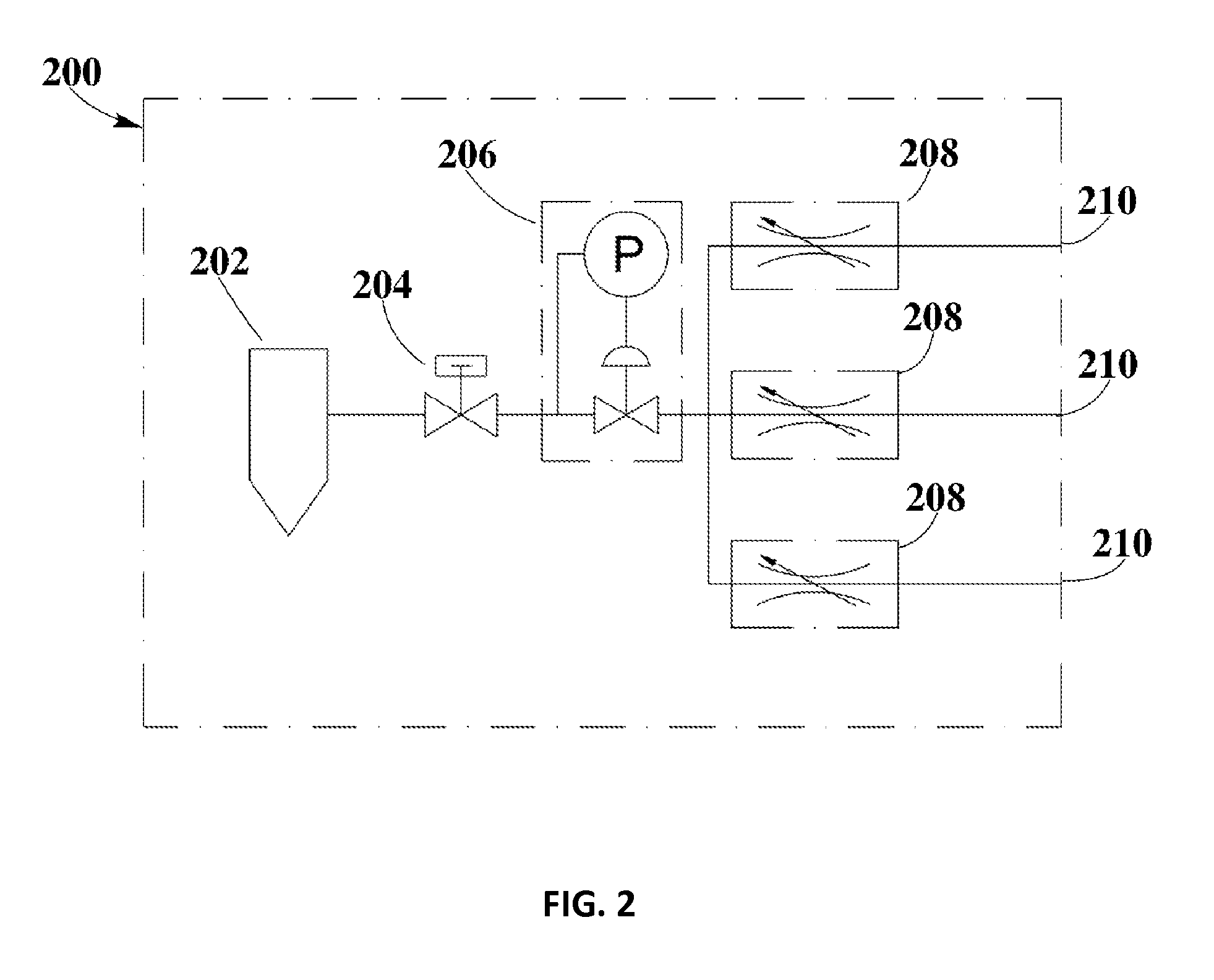

Automated low-volume tangential flow filtration process development device

InactiveUS20050023194A1Economical and fastEasy to disassembleIon-exchanger regenerationUltrafiltrationProcess developmentLaboratory scale

An automated process development device providing flexibility and accuracy for the investigative development of tangential flow filtration processes. The development device is used for evaluating the process parameters of a laboratory scale tangential flow filtration process with an eye towards developing a larger, commercial scale process. The process development device—operable to an unprecedented minimum reliable recirculation volume of less than approximately 20 milliliters—includes: (a) a reservoir having a distinct mixing zone; (b) a tangential flow filtration module; (c) conduits defining, together with the distinct mixing zone and the tangential flow filtration module, a fluid process stream through which a liquid sample is recirculated; (d) pumps for driving the flow of the liquid sample through the fluid process stream; (e) valves for regulating the flow of the liquid sample through the fluid process stream; (f) sensors for acquiring data about the liquid sample as it flows through the fluid process stream; and (g) an electronic data processing network capable of receiving, transmitting, processing, and recording data associated with the operation of the pumps, valves, and sensors, the recorded data being sufficiently comprehensive to determine the conduct of the tangential flow filtration process at a substantially larger scale.

Owner:MILLIPORE CORP

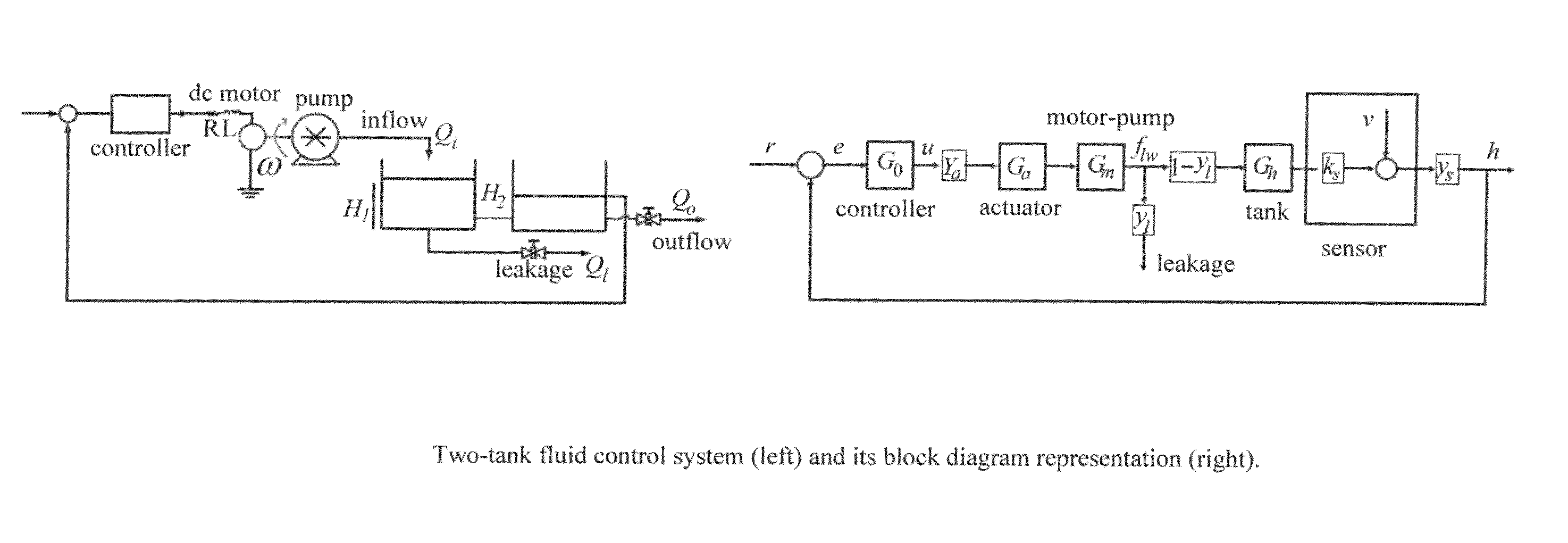

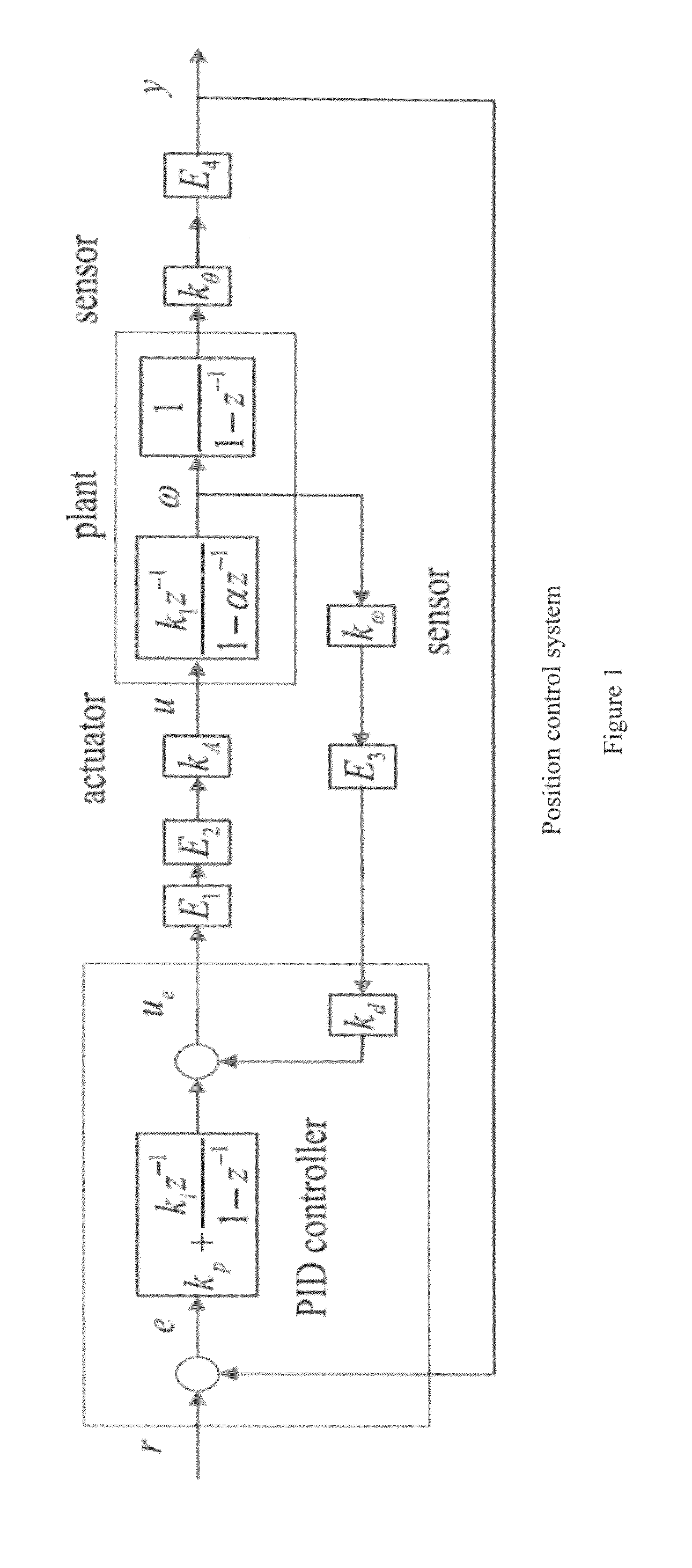

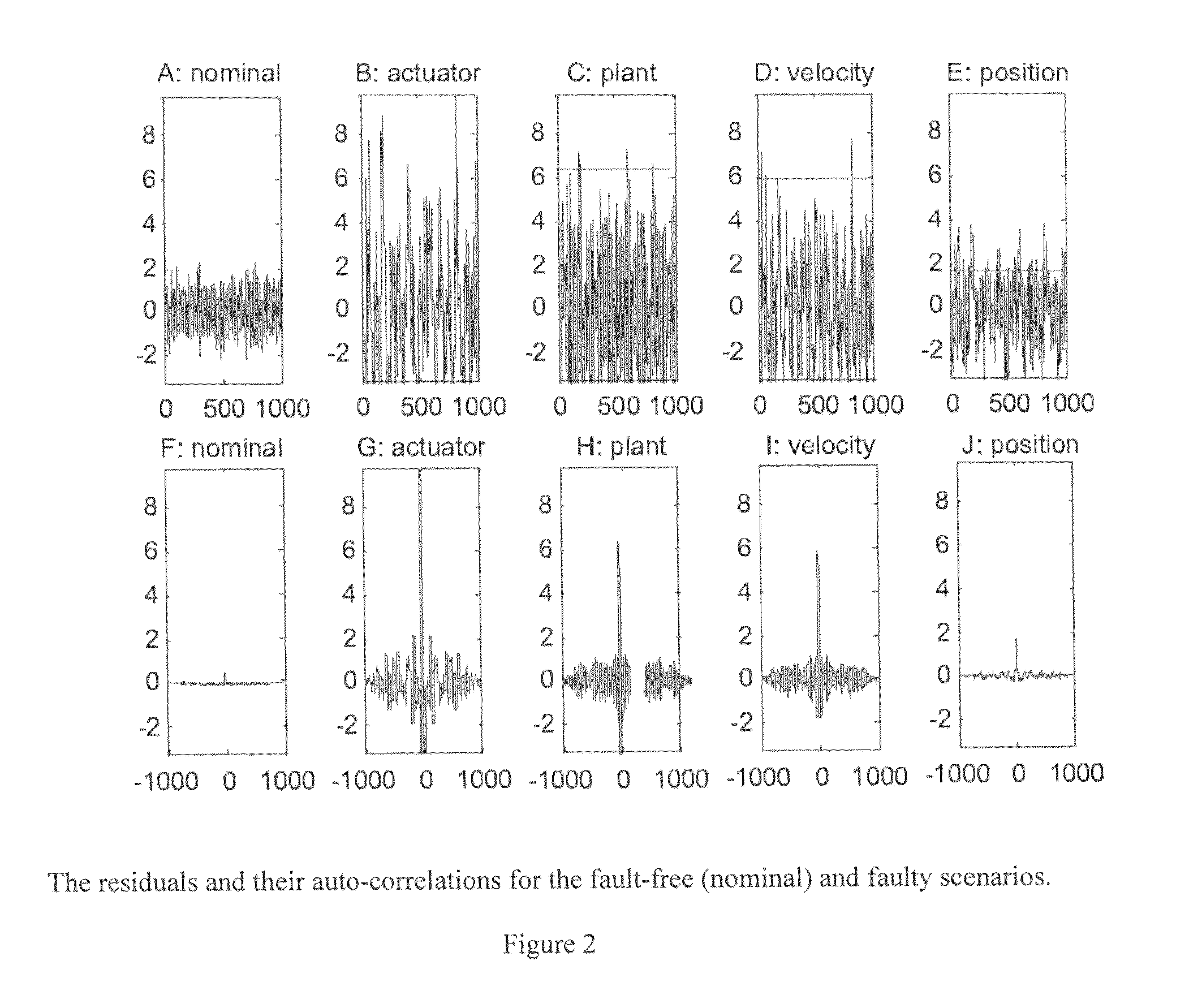

Unified approach to detection and isolation of parametric faults using a kalman filter residual-based approach

A unified method to detection and isolation of parametric faults in a physical system resulting from variations in the parameters of its constituting subsystems, termed herein as diagnostic parameters, uses Kalman filter residuals. Rather than using the feature vector made of the coefficients of the numerator and denominator of the system transfer function, which is known to be a non-linear function of the diagnostic parameter variations, the method first shows and then exploits, for fault detection purposes, the fact that the Kalman filter residual is a multi-linear function of the deviations in the diagnostic parameters, i.e. the residual is separately linear in each parameter. A fault is then isolated using a Bayesian multiple composite hypotheses testing approach. A reliable map relating the diagnostic parameters to the residual is obtained off-line using fault emulators. The unified fault detection and isolation method is successfully evaluated on both simulated data as well as on real data obtained from a benchmarked laboratory-scale coupled-tank system used to exemplify an industrial two-tank process.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

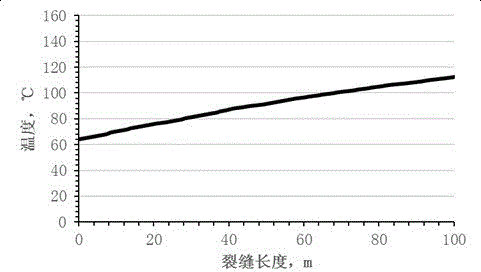

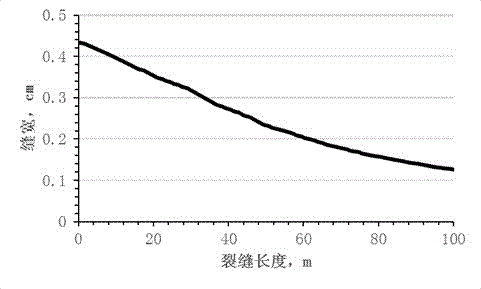

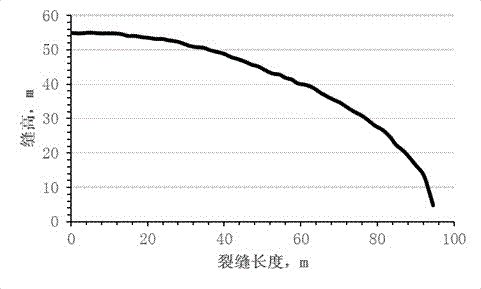

Method for experimentally determining carbonate rock oil and gas reservoir acid fracturing fracture conductivity distribution

ActiveCN106522935AImprove the transformation effectThe distribution of diversion capacity is conducive to real evaluationConstructionsFluid removalAcid fracturingAcid etching

The invention discloses a method for experimentally determining carbonate rock oil and gas reservoir acid fracturing fracture conductivity distribution. The method comprises the steps that an acid fracturing simulator FracproPT is adopted for simulating the down-hole acid fracturing fracture extending and acid etching process during acid fracturing, and fracture width distribution, fracture height distribution, temperature distribution and acid liquor mass concentration distribution data in the hydraulic fracture length direction are obtained; in the hydraulic fracture length direction, fracture width, fracture height and temperature data of total 10 feature points with the acid liquor mass concentration being 100%, 90%, 80%, 70%, 60%, 50%, 40%, 30%, 20%, 10% of the initial mass concentration are selected; acid injection displacement of the oil field site scale is converted into acid injection displacement of the laboratory scale; according to the acid liquor mass concentration data of the 10 feature points, acid liquor used for an experiment is prepared; and the acid etching process is simulated, the conductivity under the condition of reservoir closed pressure is tested experimentally, and a distribution diagram of the acid etching fracture conductivity in the fracture length direction under the reservoir condition is drawn. The method is reliable in principle and simple and convenient to operate and has wide market prospects.

Owner:SOUTHWEST PETROLEUM UNIV

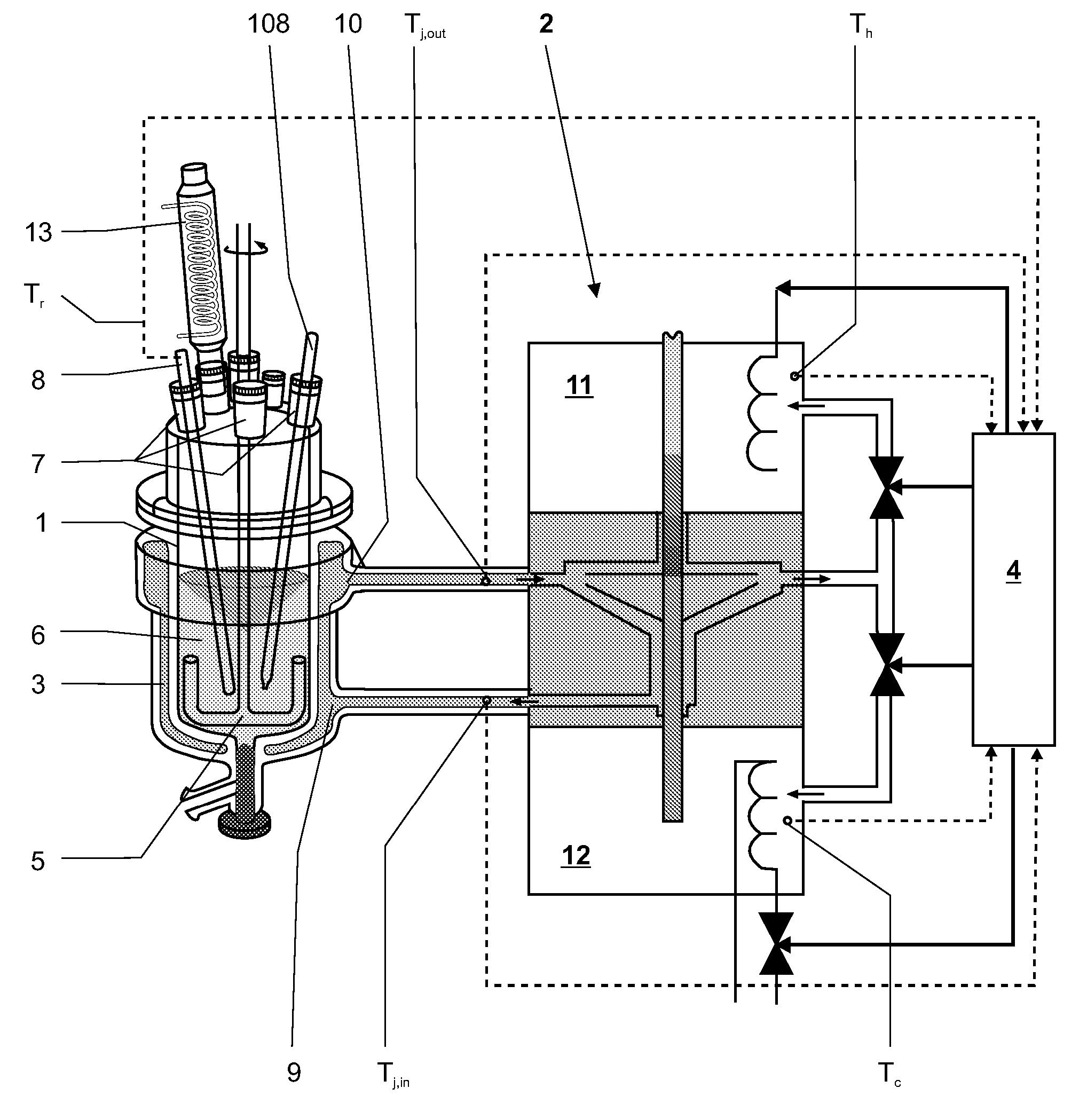

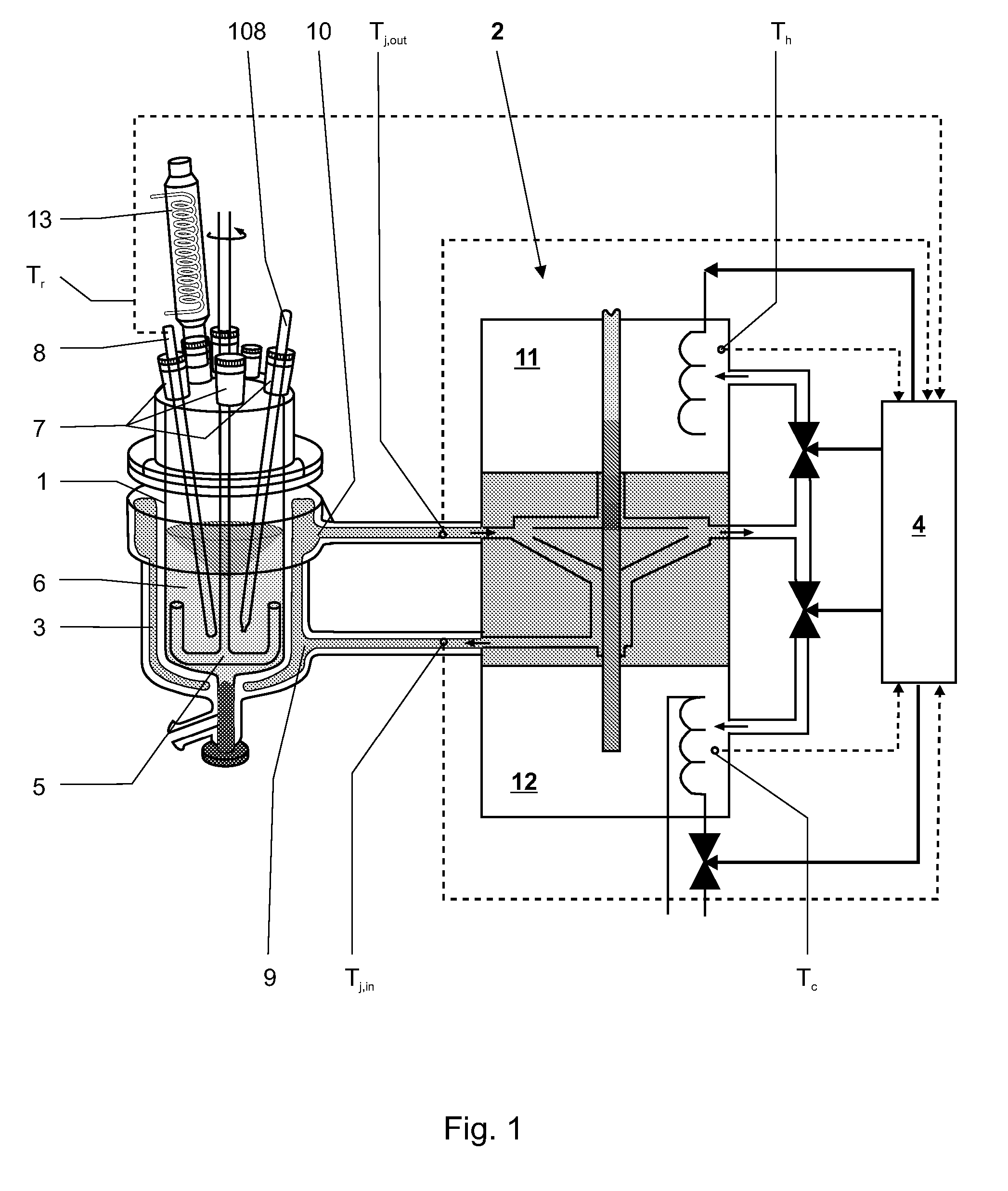

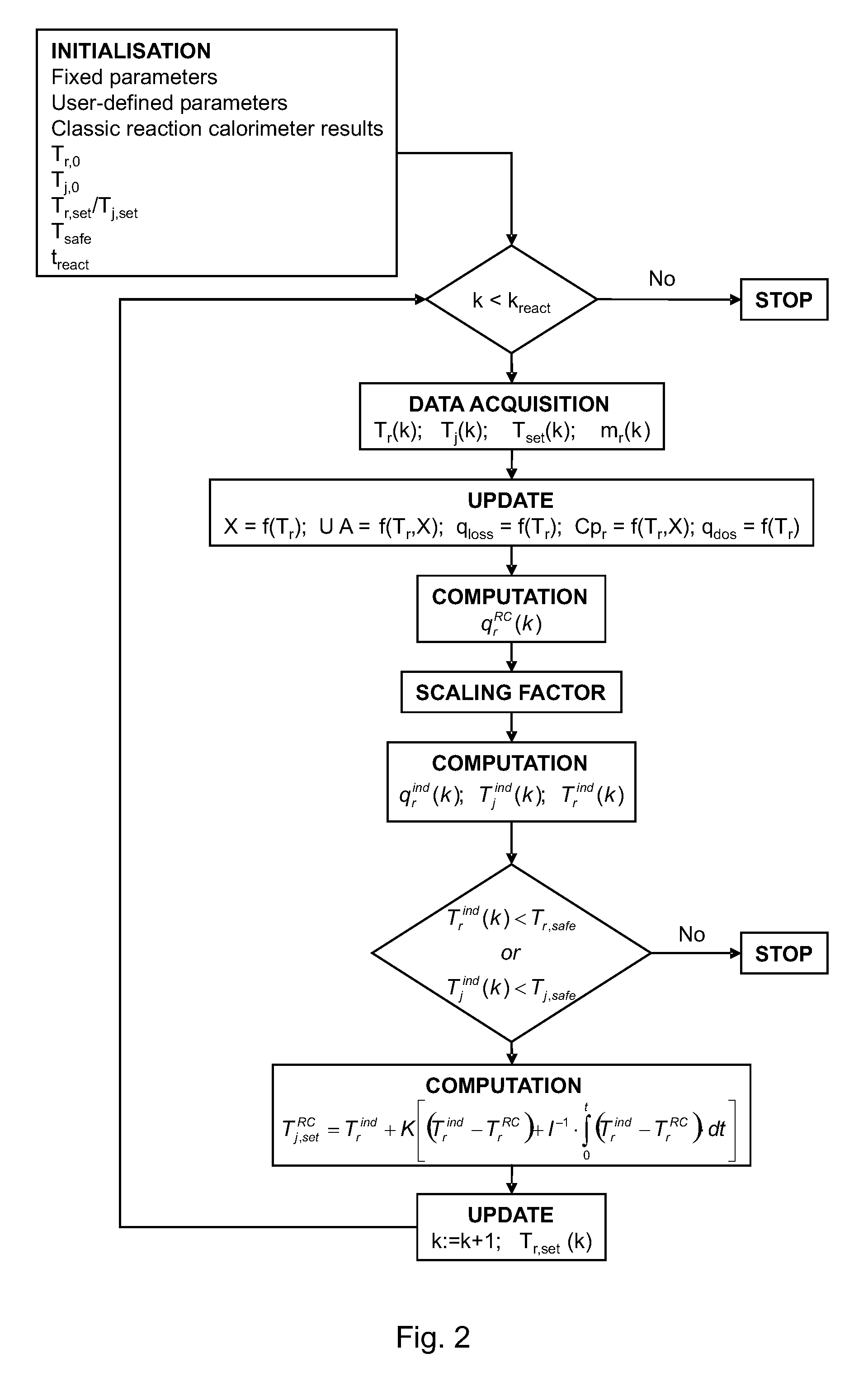

Method for simulating a process plant at laboratory scale

InactiveUS7476020B2Control the temperature of the reaction mixture fast and accuratelyRapid temperatureThermometer detailsSimulator controlIndustrial reactorLaboratory scale

A method, a laboratory device and the use of both are provided for simulating the dynamic temperature behavior of at least one part of a process plant, particularly an industrial reactor. The method provides a temperature profile and / or temperature setpoints at given time intervals for controlling the laboratory device. The temperature profile and / or temperature setpoints are derived from a mathematical model that describes the dynamic temperature behavior of at least one part of the process plant. The temperature profile and / or the temperature setpoints are used by a program for controlling the laboratory device.

Owner:METTLER TOLEDO GMBH

Automated low-volume tangential flow filtration process development device

An automated process development device providing flexibility and accuracy for the investigative development of tangential flow filtration processes. The development device is used for evaluating the process parameters of a laboratory scale tangential flow filtration process with an eye towards developing a larger, commercial scale process. The process development device - operable to an unprecedented minimum reliable recirculation volume of less than approximately 20 milliliters - includes: (a) a reservoir having a distinct mixing zone; (b) a tangential flow filtration module; (c) conduits defining, together with the distinct mixing zone and the tangential flow filtration module, a fluid process stream through which a liquid sample is recirculated; (d) pumps for driving the flow of the liquid sample through the fluid process stream; (e) valves for regulating the flow of the liquid sample through the fluid process stream; (f) sensors for acquiring data about the liquid sample as it flows through the fluid process stream; and (g) an electronic data processing network capable of receiving, transmitting, processing, and recording data associated with the operation of the pumps, valves, and sensors, the recorded data being sufficiently comprehensive to determine the conduct of the tangential flow filtration process at a substantially larger scale.

Owner:MILLIPORE CORP

Spray dried powdered detergents with perfume-containing capsules

The present invention relates to a process for the manufacture of a spray dried powder comprising:(a) forming a warm, stirred aqueous slurry comprising: inorganic salts, at least one binding agent and 0.001 to 20% by weight of capsules based on the weight of spray dried powder, said capsules containing benefit agents including at least perfume, and(b) spray drying the resultant slurry to form a spray dried powder, said capsules being such that:1) more than 40% of the benefit agents remain encapsulated 60 minutes after dispersion thereof at 70° C. in the slurry as defined in the “slurry survival test” in a sealed vessel without agitation; and2) more than 30% of the benefit agents added for 15 minutes to an ambient slurry as defined in the “spray dry test” survive spray drying through a laboratory scale spray drier.

Owner:TAKASAGO INTERNATIONAL CORPORATION

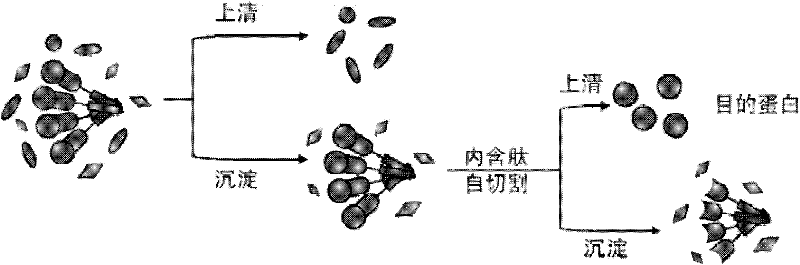

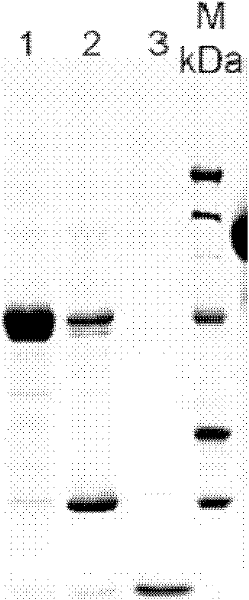

Method for purifying protein of enzyme aggregate based on self-aggregation short-peptide induction

ActiveCN102226172AHigh purityOvercoming Application BottlenecksHydrolasesMicroorganism based processesProtein targetIntein

The invention provides a method for purifying protein of enzyme aggregate based on self-aggregation short-peptide induction. The method comprises the following steps of: fusing and expressing a target protein, a peptide section (preferably intein) containing a cleavage site and a short peptide with self-aggregation function into a triplet in a sequence from left to right or from right to left, forming an enzyme aggregate in an expressing process, and separating from most soluble impurities in cell lysate by adopting a centrifuging or filtering method; and then releasing the target protein into solution by inducing cutting at a cleavage site so as to achieve the purpose of purification. The method has the characteristics of low cost and simple flow, can be used for laboratory-scale high-throughput protein purification and is also beneficial to industrial-scale protein production.

Owner:TSINGHUA UNIV

Spray drying

InactiveUS20070149423A1Organic detergent compounding agentsDrying soapInorganic saltsLaboratory scale

The present invention relates to a process for the manufacture of a spray dried powder comprising: (a) forming a warm, stirred aqueous slurry comprising: inorganic salts, at least one binding agent and 0.001 to 20% by weight of capsules based on the weight of spray dried powder, said capsules containing benefit agents including at least perfume, and (b) spray drying the resultant slurry to form a spray dried powder, said capsules being such that: 1) more than 40% of the benefit agents remain encapsulated 60 minutes after dispersion thereof at 70° C. in the slurry as defined in the “slurry survival test” in a sealed vessel without agitation; and 2) more than 30% of the benefit agents added for 15 minutes to an ambient slurry as defined in the “spray dry test” survive spray drying through a laboratory scale spray drier.

Owner:TAKASAGO INTERNATIONAL CORPORATION

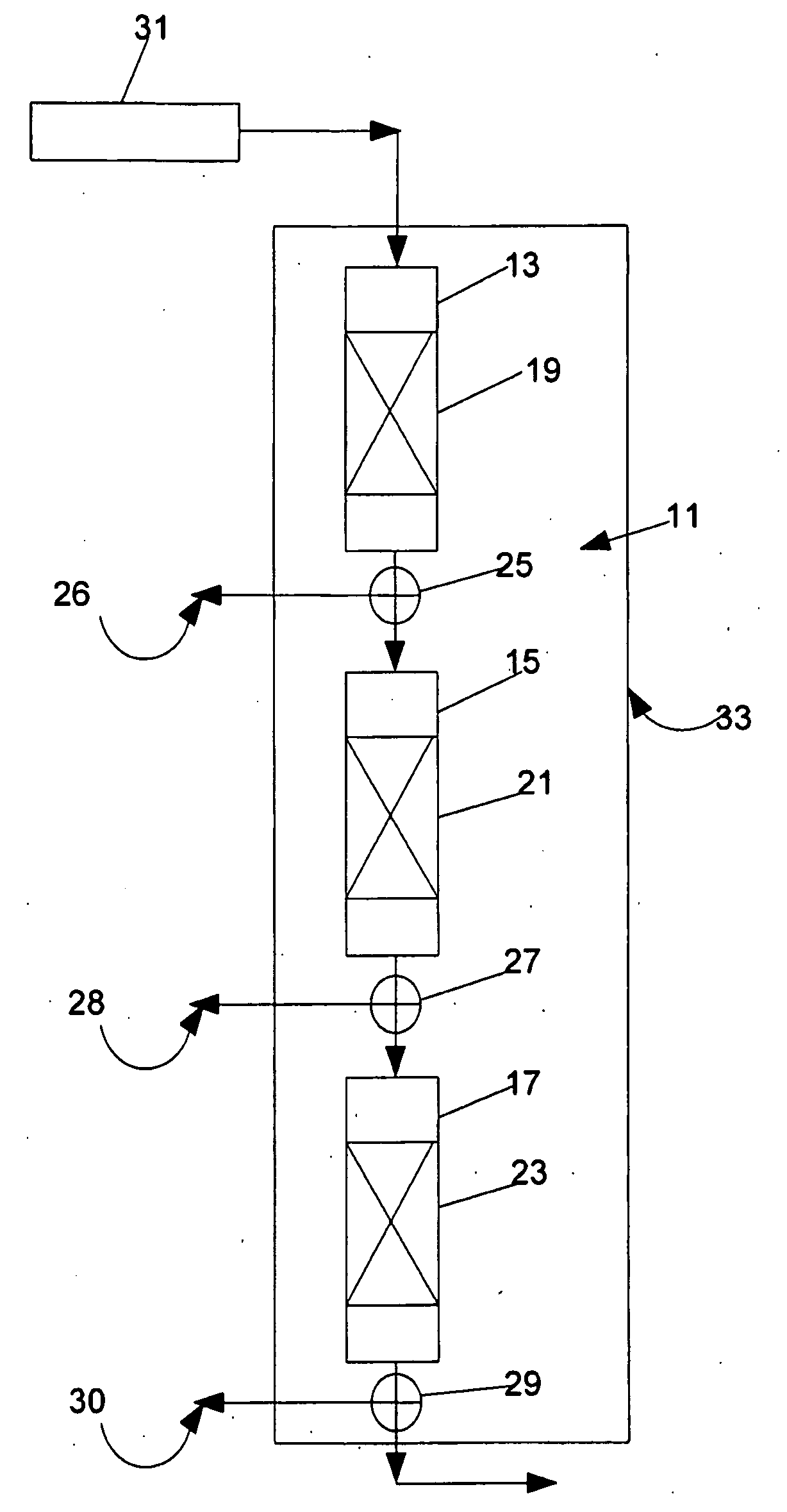

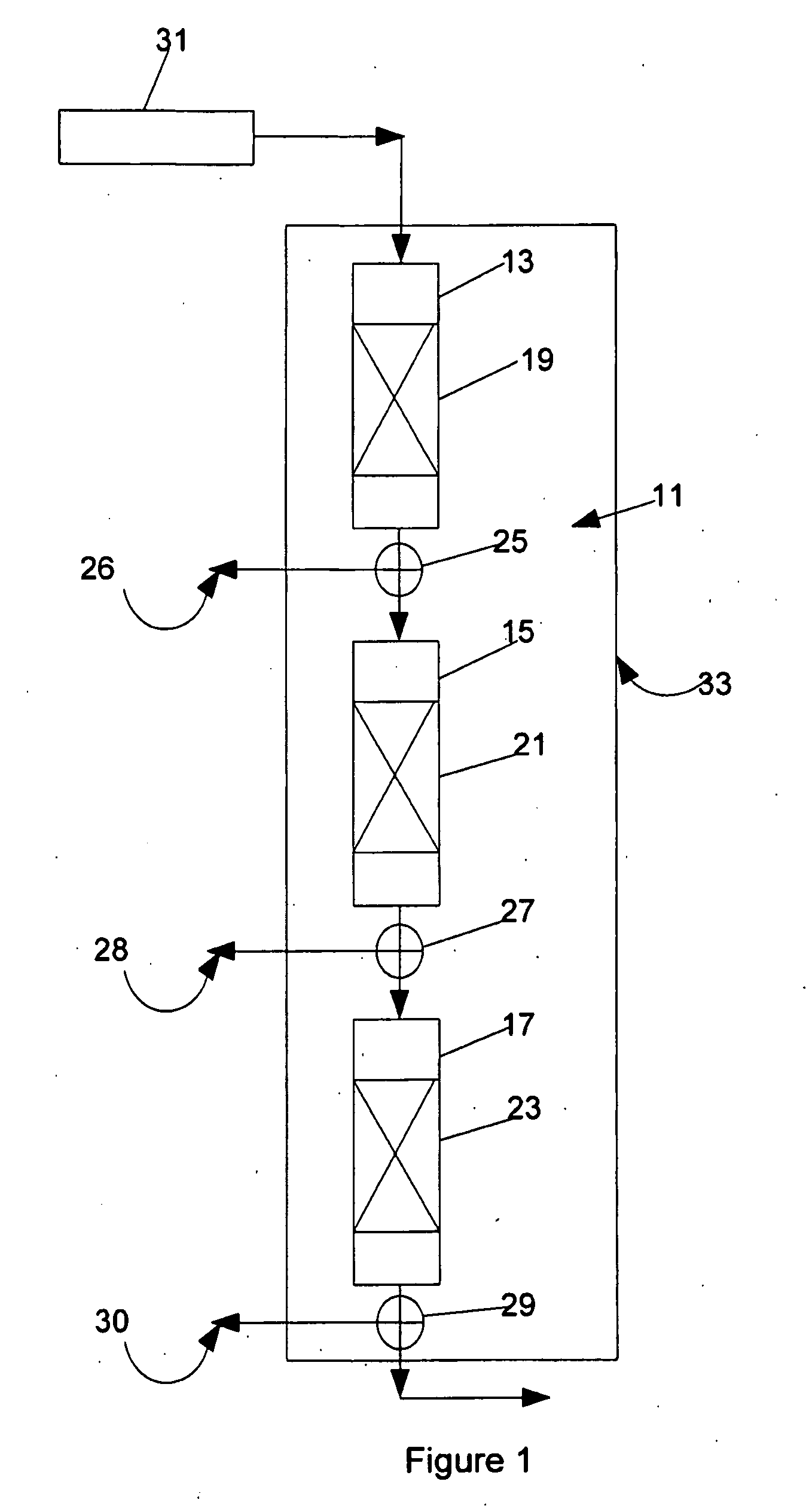

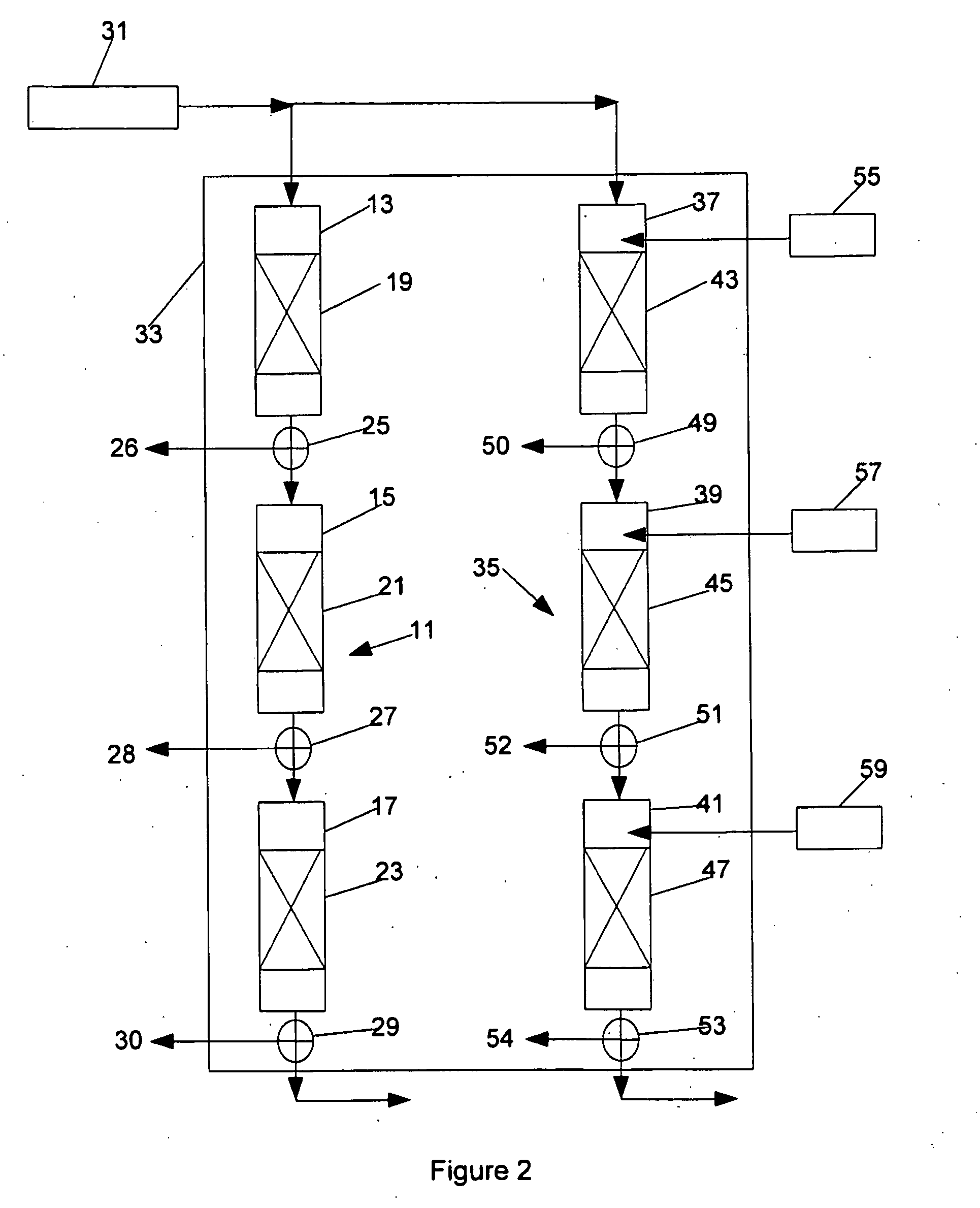

High throughput fischer-tropsch catalytic process development method

InactiveUS20100324157A1Low costSequential/parallel process reactionsHydrocarbon from carbon oxidesPtru catalystLaboratory scale

A method for determining a set of operating parameters for developing a commercial-scale Fischer-Tropsch catalytic plug flow process comprising the steps of: selectively feeding fresh feed gas to the inlet the first laboratory scale plug flow reactor stage of a composite multi-stage series-connected reactor, said reactant feed gas including CO and H2, said composite reactor having at least three series-connected reactor stages, the catalyst beds of the reactor stages of said composite reactor being laboratory scale and including crushed or powdered catalyst particles or commercial-size catalyst particles; and sampling and measuring the unreacted feed gas and reaction products and by products in the effluents of each of said reactor stages.

Owner:ACCELERGY CORP

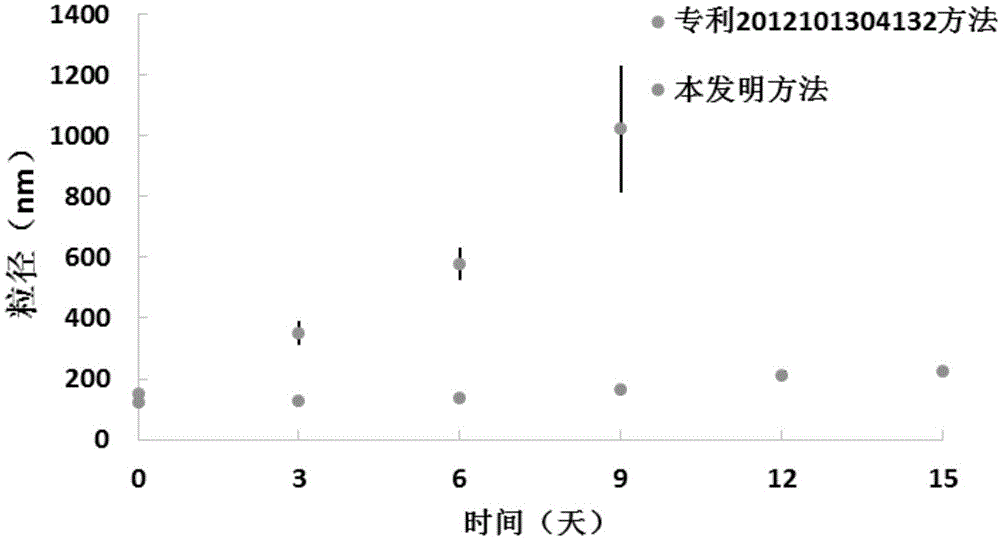

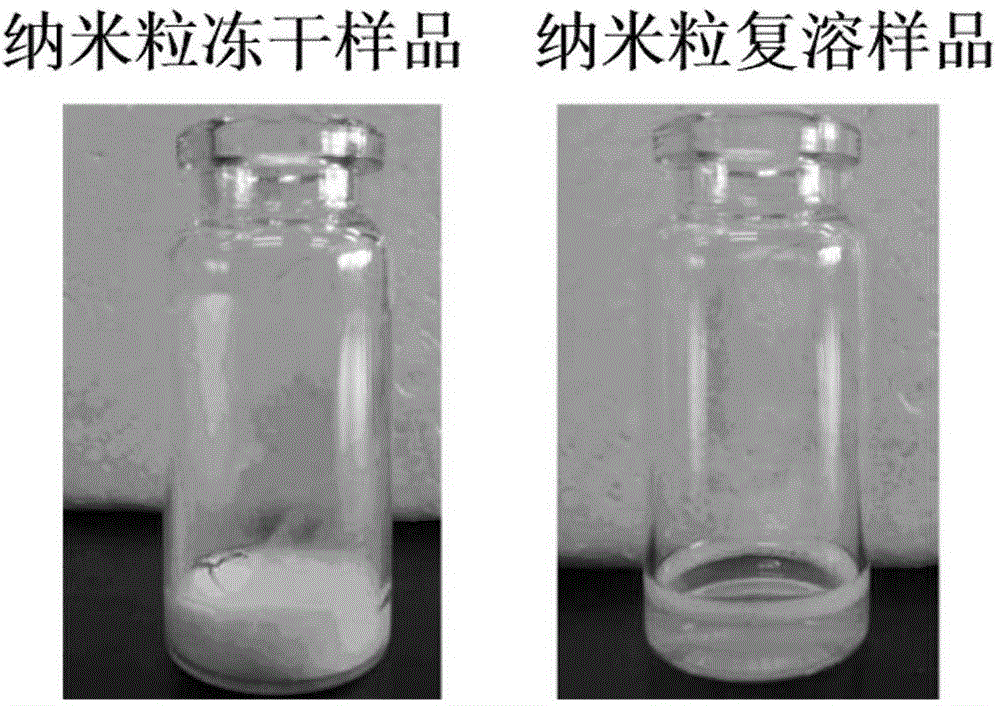

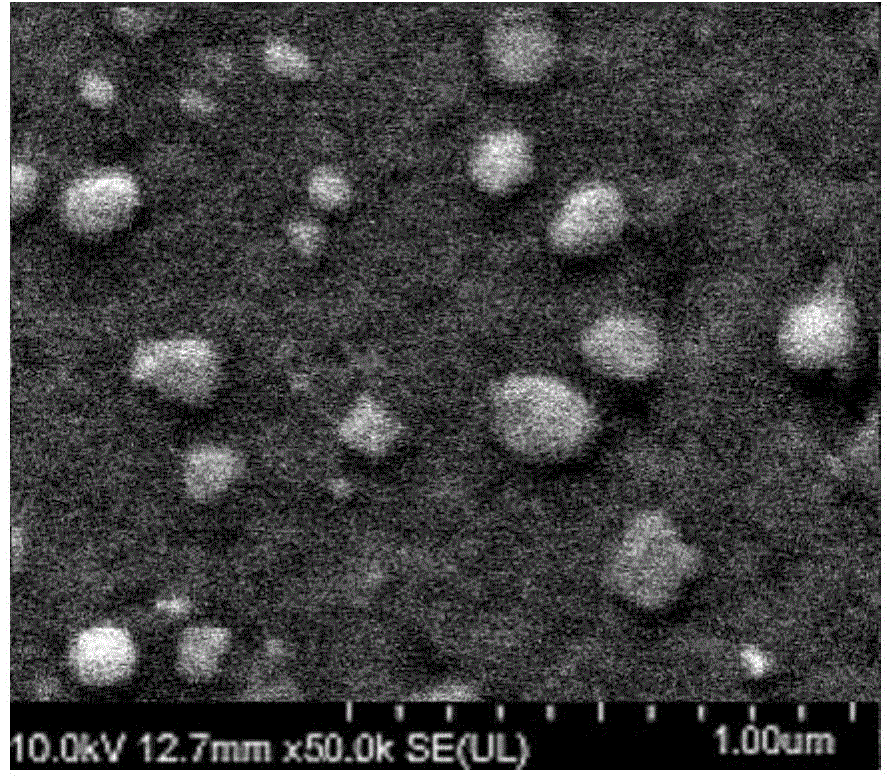

Preparation method of tinib drug alhumin nano preparation used for injection

InactiveCN105616361ASmall particle sizeEvenly distributedPowder deliveryOrganic active ingredientsLaboratory scaleFreeze-drying

The invention belongs to the field of medicinal preparation, and relates to a preparation method of a tinib drug alhumin nano preparation used for injection. According to the preparation method, a tinib drug is dissolved in an oil phase; a mixture is prepared from the oil phase and a human serum albumin water phase; the mixture is delivered into a high pressure homogenizer for high shearing so as to obtain a nano preparation; organic solvents are removed via thin film evaporation; and a finished product is obtained via freeze drying. A solubilizer, an oil stabilizing agent, and a pH adjusting agent are added so as to ensure the stability of the nano particles, relatively small particle size, and narrow particle size distribution. Reproducibility of the preparation method is excellent; content of the tinib drug in the nano particles can be increased; corresponding sets of apparatus from laboratory scale to large-scale production scale of the adopted technologies are available; and industrial production application prospect is promising.

Owner:FUDAN UNIV

Method of designing a low cost, high strength, high toughness, martensitic steel and an article made thereof

InactiveUS20090291013A1Low costImprove toughnessHeat treatment process controlMathematical modelLaboratory scale

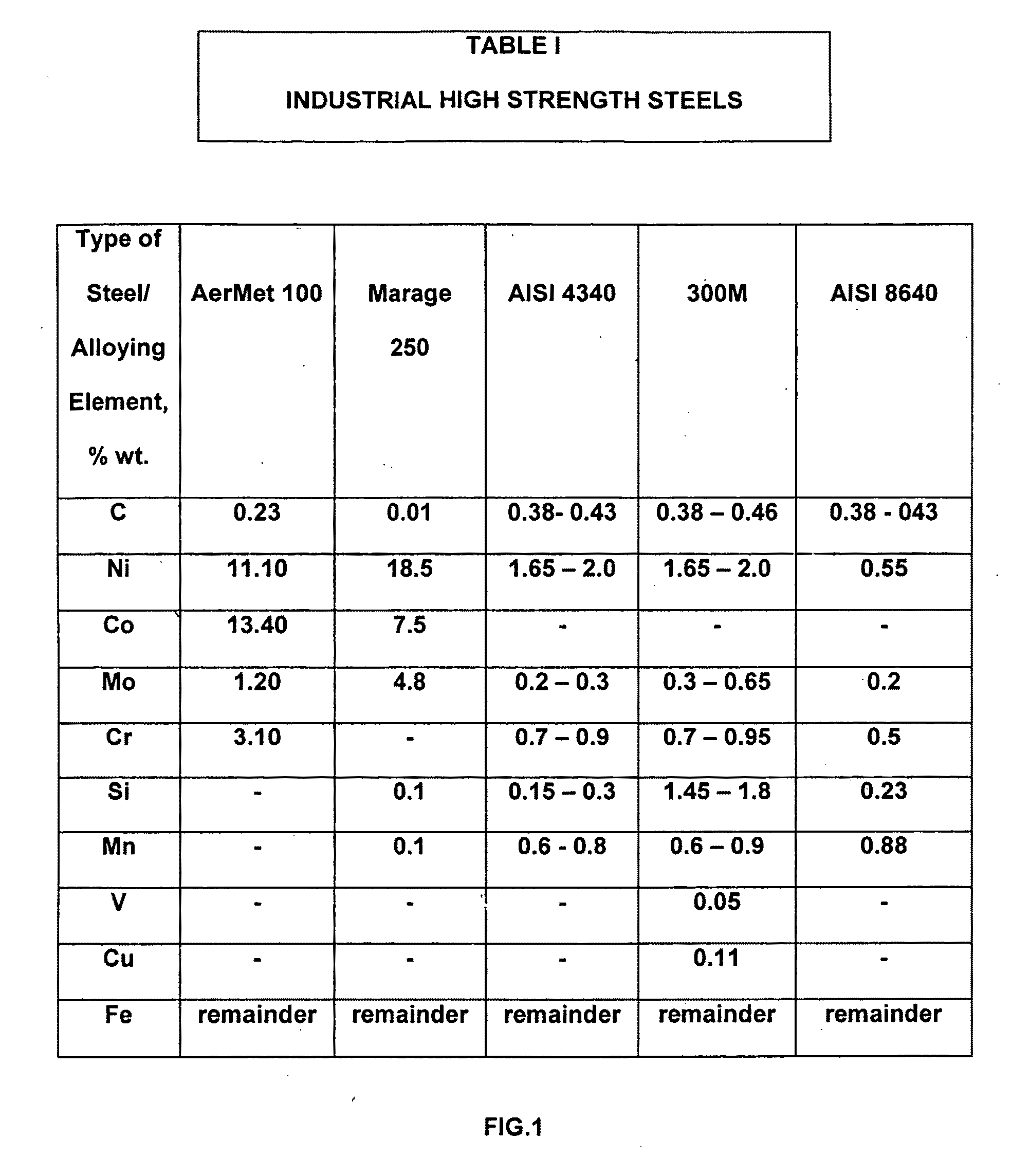

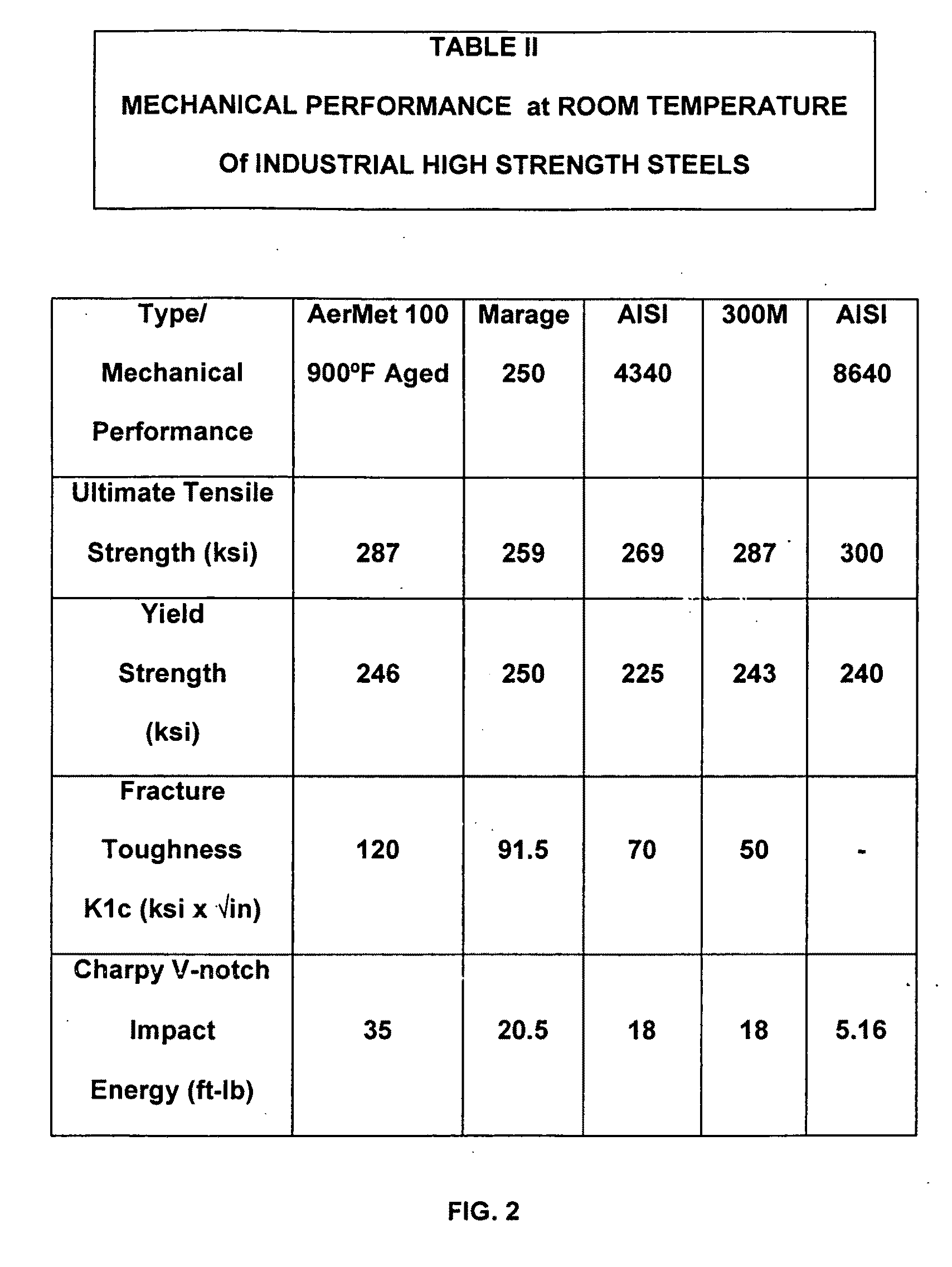

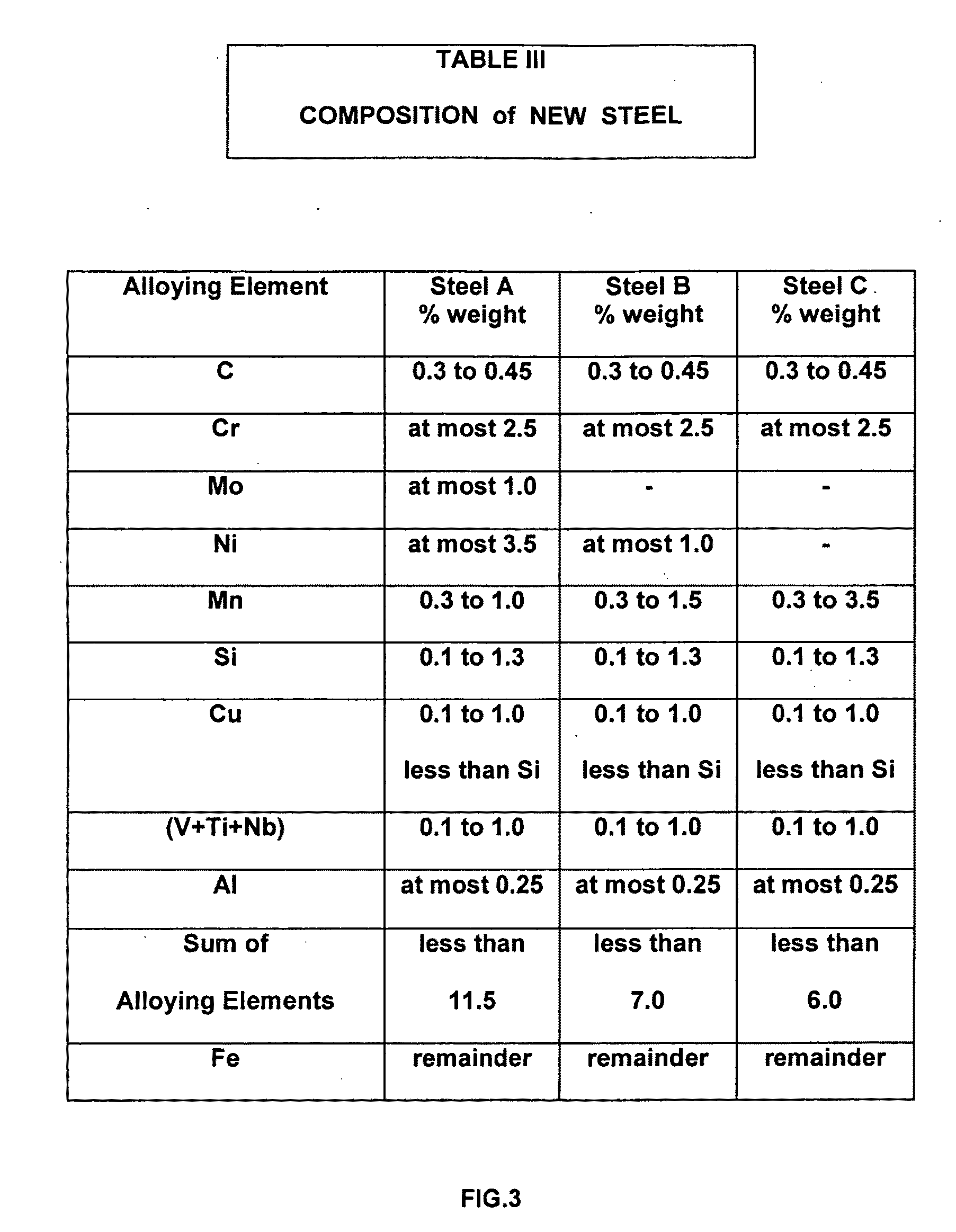

A method for designing a low cost, high strength, high toughness martensitic steel in which a mathematical model is used to establish an optimum low cost alloying concentration that provides specified levels of strength toughness. The model also predicts critical temperatures and the amount of retained austenite. Laboratory scale ingots of the optimum alloying composition were produced comprising by % wt. of about: 0.37 of C; 1.22 of Ni; 0.68 of Mn; 0.86 of Si; 0.51 of Cu; 1.77 of Cr; and 0.24 of V; and the balance Fe and incidental impurities were melted in an open induction furnace. After homogenized annealing, hot rolling, recrystallization annealing, and further oil quenching, refrigerating, and low tempering, a tempered martensite microstructure was produced consisting of small packets of martensitic laths, fine vanadium carbide, as centers of growth of the martensitic lathes, and retained austenite. Mechanical tests showed the following results: HRC of 52; UTS of 282 ksi; YS of 226 ksi; Charpy V-notch impact toughness energy of 31 ft-lbs. Energy consumption vacuum arc remelting (VAR) and electroslag remelting (ESR) were not required for improving strength and toughness.

Owner:FEDCHUN VLADIMIR A +1

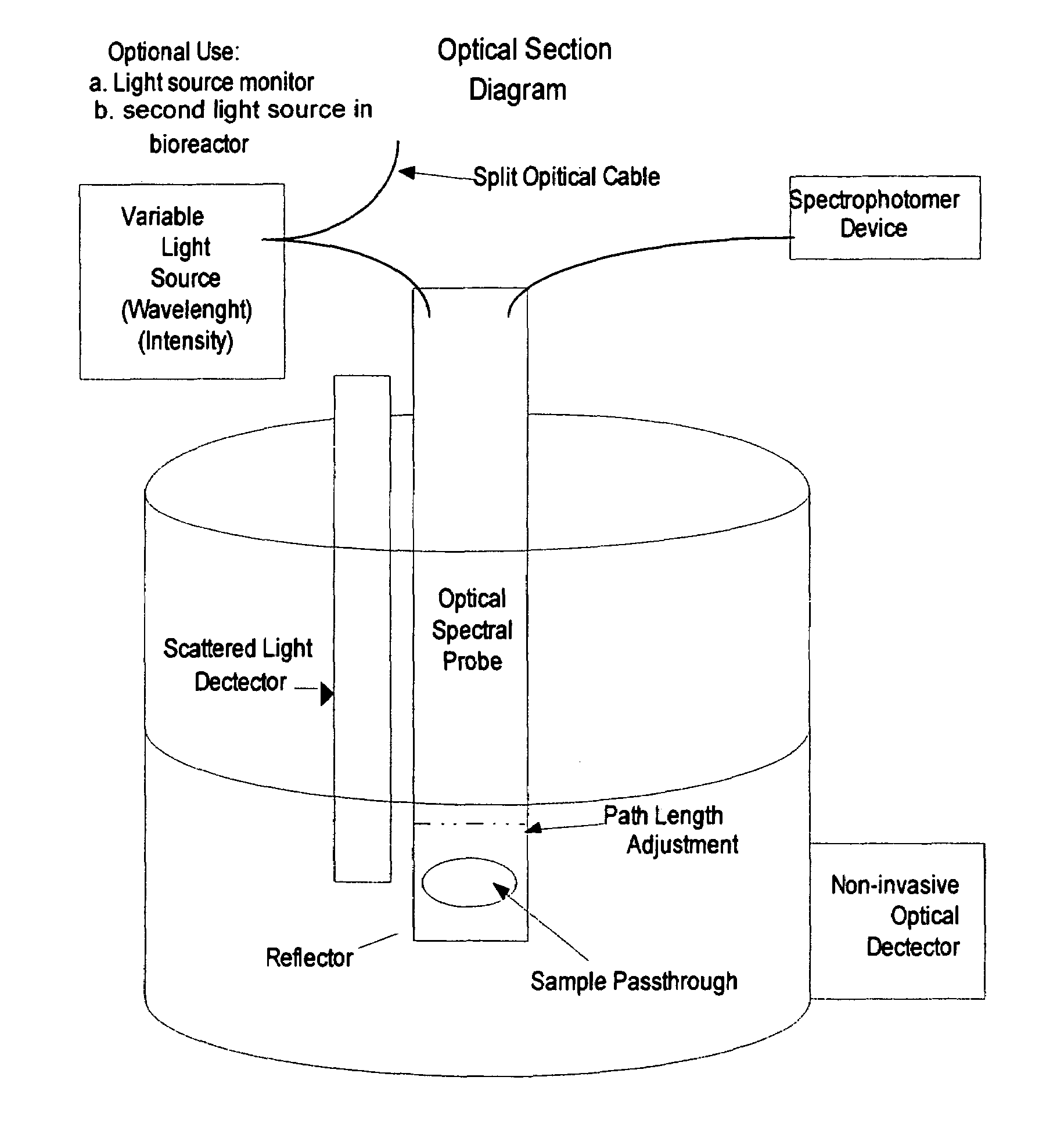

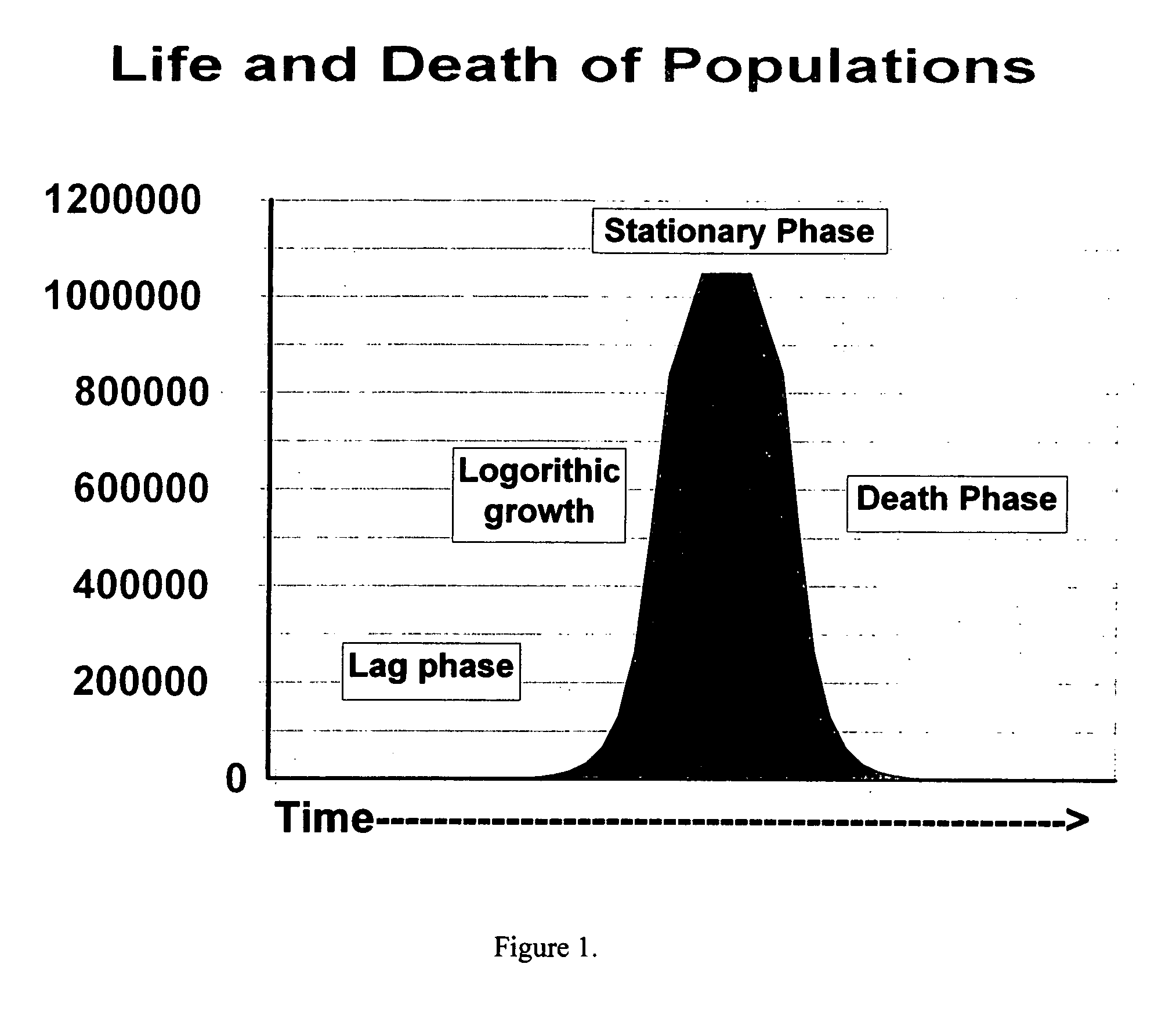

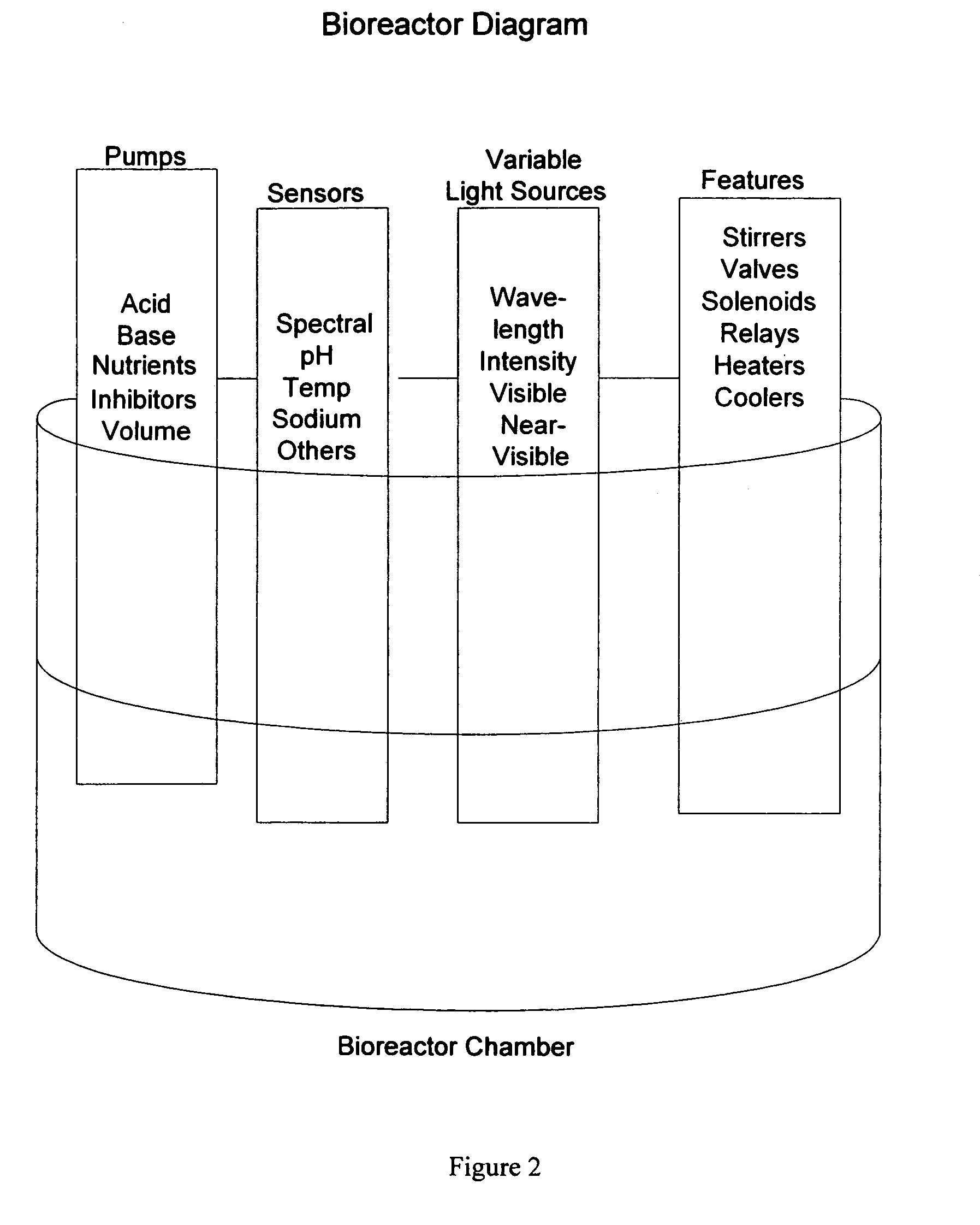

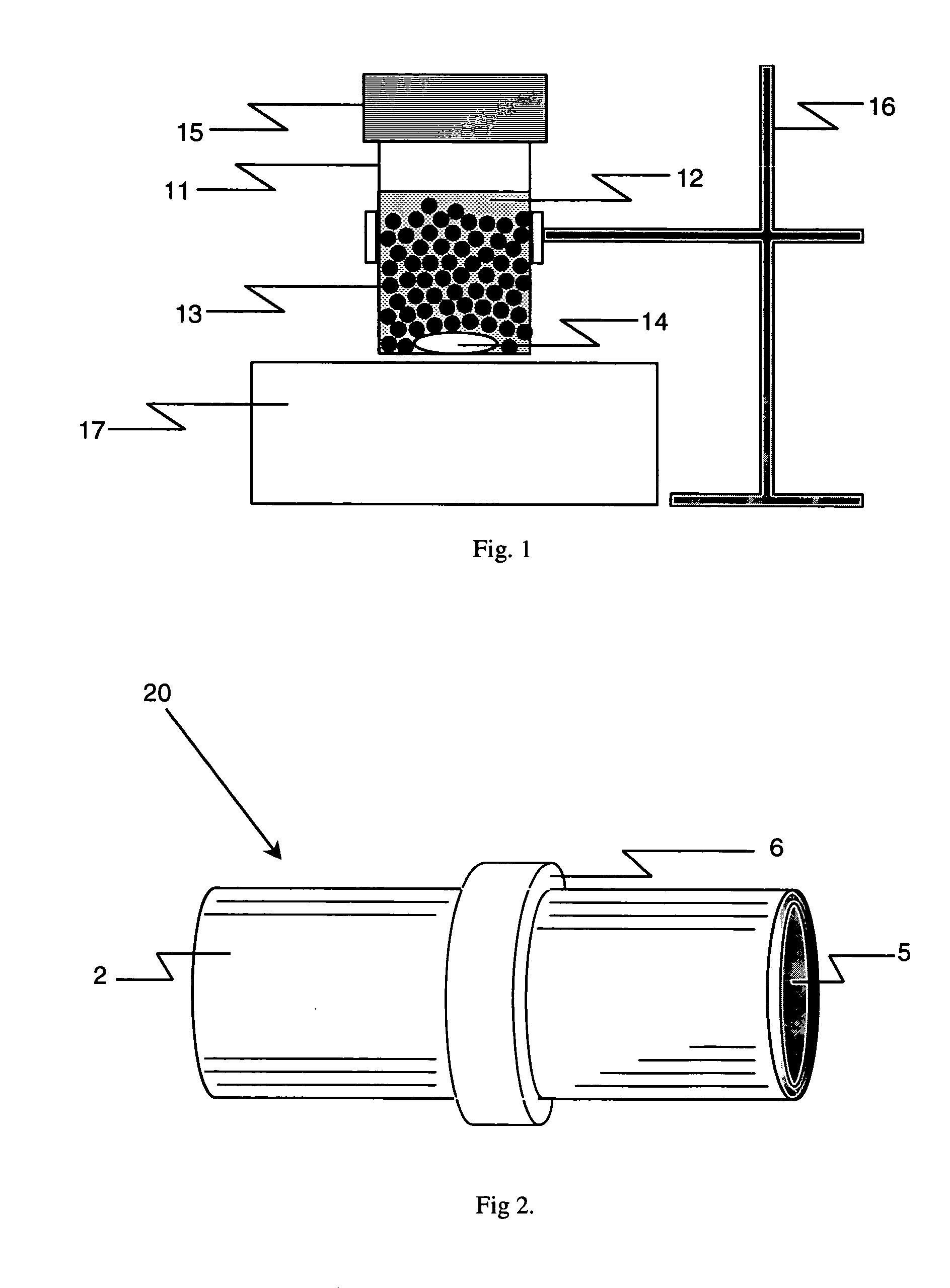

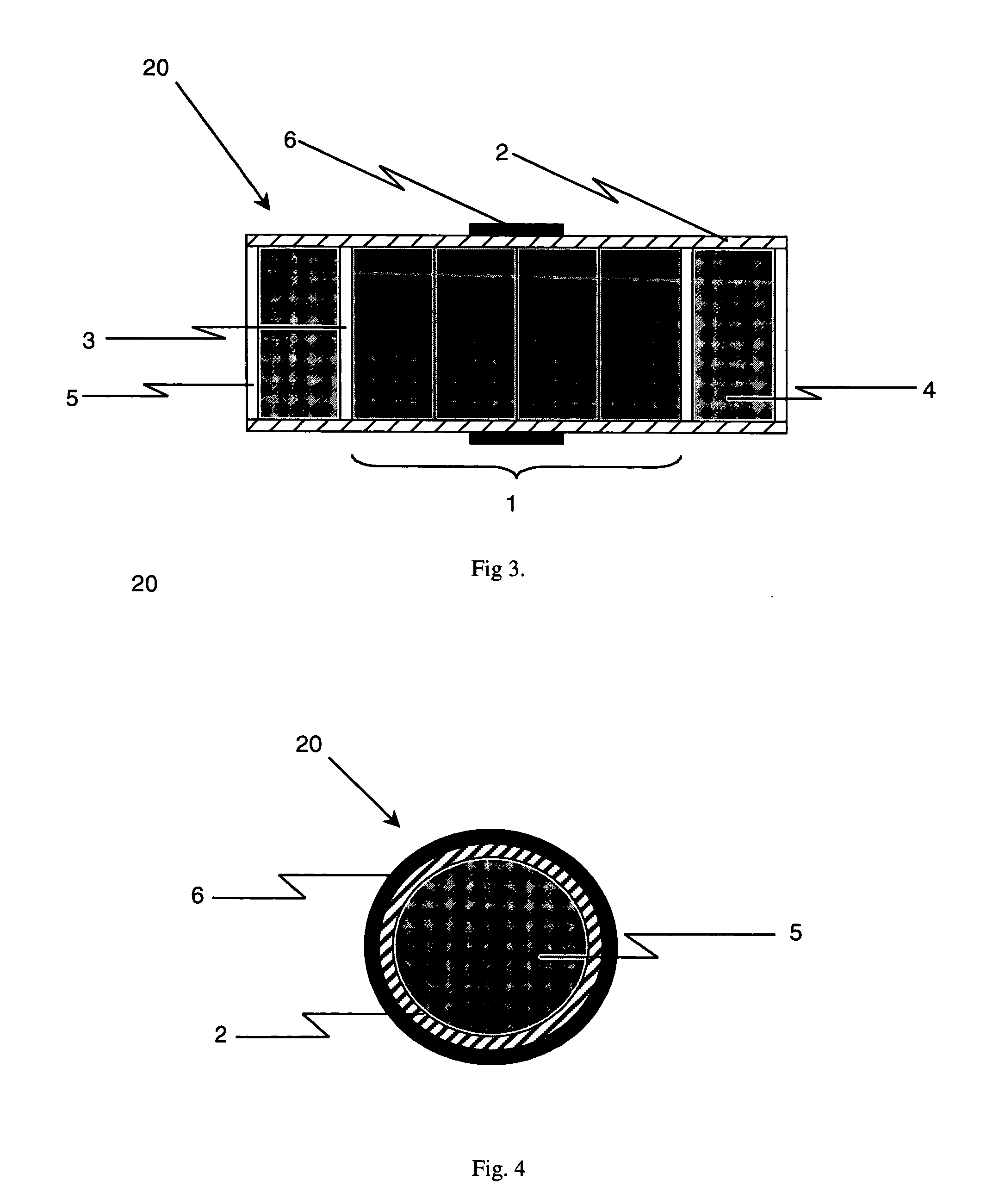

Decision-making spectral bioreactor

InactiveUS7510864B2Bioreactor/fermenter combinationsBiological substance pretreatmentsMetaboliteLaboratory scale

This invention fills several voids in bioreactor technology that allows efficient connection of aspects of physical science (optics, electronics, physical chemistry, sensors) to aspects of microbial and cell culture physiology in a uniquely interactive manner. This is accomplished mathematically through decision making software that utilizes detected changes in the course of fermentation. Decisions are aimed at determining the optima for cellular growth, optimizing for production or degradation of metabolites or substrates, or determining the limits of growth under various combinations of conditions. The invention determines optima or limits in a manner more quickly and at less cost than traditional methods. The basis for the computer generated decisions may be first or second derivative changes observed such as inflection points, limits on allowable rates of change, or the like. The most common measured parameter controlling the decision making process is the optically observed growth of the cells (e.g. microbial, animal, or plant cell cultures) under study. Any other measurable parameter (e.g. pH, temperature, pigment production) may be used to control the process (i.e., the independent variable). This process and variations of this process on a laboratory scale are valuable for research and development, education, pilot plant models, and bio-manufacturing optimization, including scale up to production volumes.

Owner:KRICHEVSKY MICAH I +4

Laboratory scale milling process

InactiveUS20050023386A1Small particle sizePowder deliveryCosmonautic condition simulationsLaboratory scaleEngineering

There is provided a process for reducing particle size of a drug, the process comprising (a) a step of dispersing about 10 g or less of the drug in a suitable volume of a liquid dispersion medium to form a suspension; (b) a step of bringing together in a vessel grinding media, magnetically activatable means for stirring and the suspension; (c) a step of magnetically activating the means for stirring to effect milling of the suspension to a weight average particle size not greater than about 1 μm; and (d) a step of separating the resulting milled suspension from the grinding media and the magnetically activatable means for stirring.

Owner:HASKELL ROYAL J

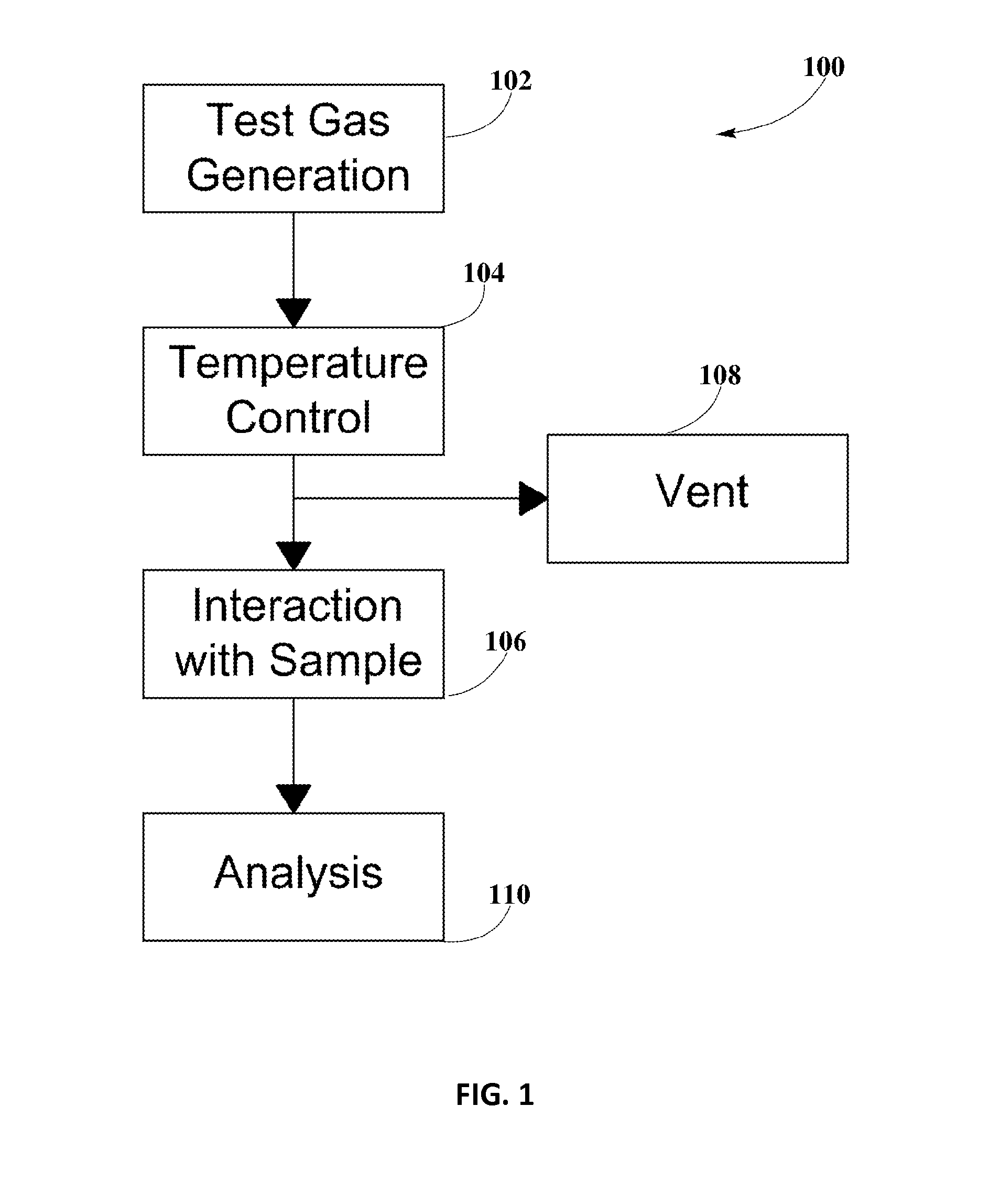

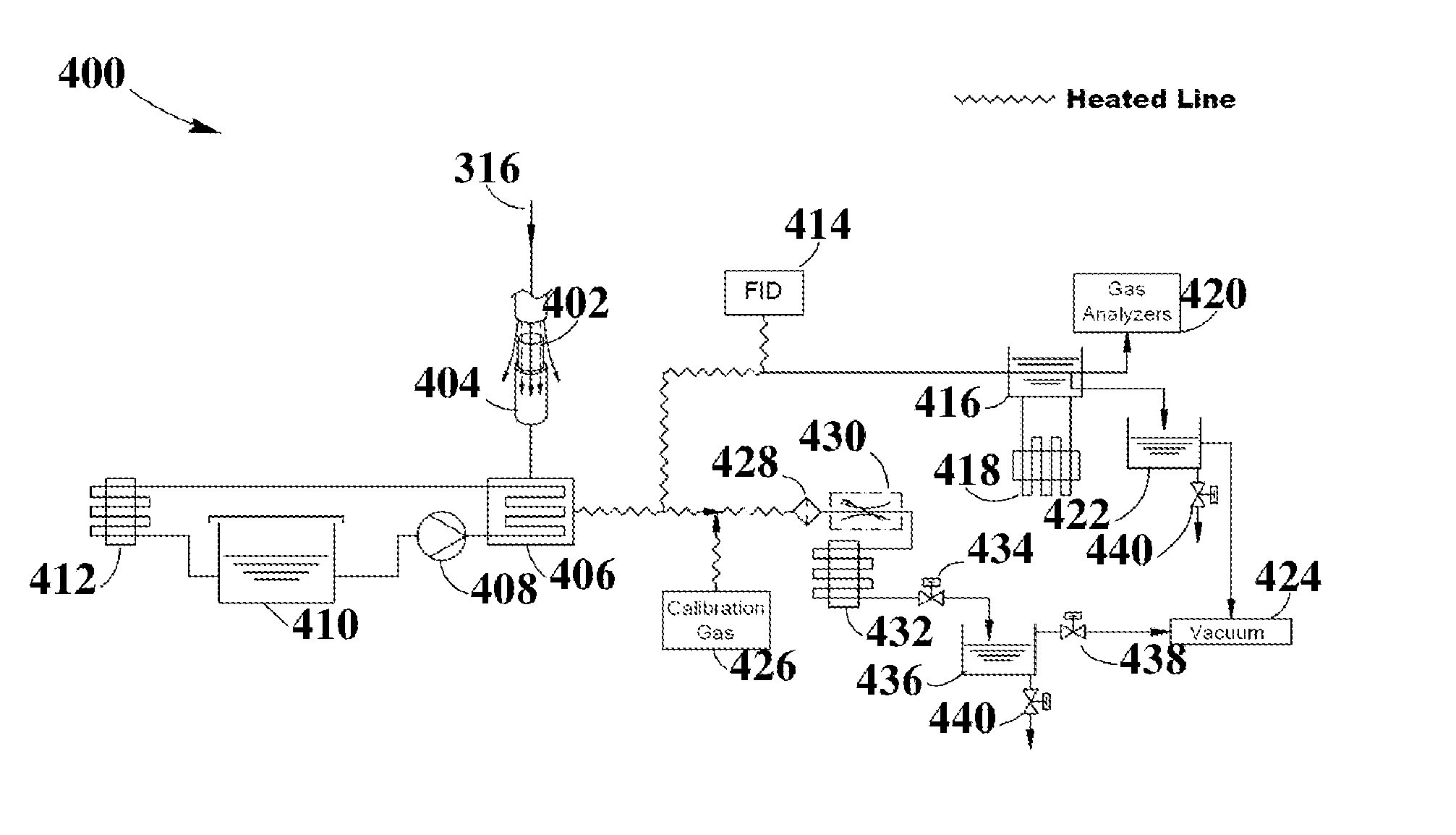

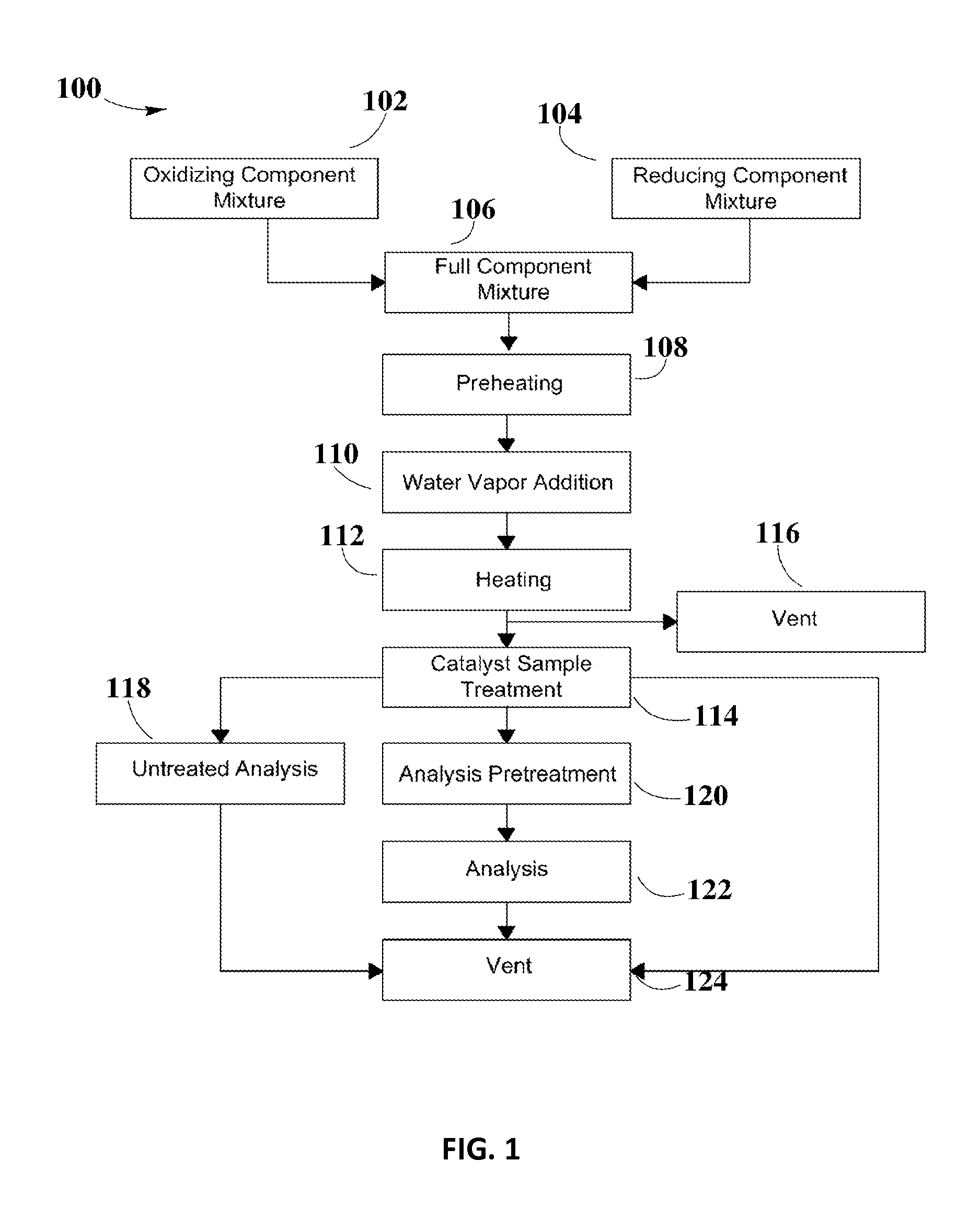

Temperature Control Method in a Laboratory Scale Reactor

InactiveUS20140335625A1Chemical analysis using catalysisMaterial analysis by electric/magnetic meansTemperature controlLaboratory scale

Disclosed herein is a method of separating variations in the mass flow of gas through a catalyst from the thermal load observed by the temperature control system in a test bench. The method may include separating the temperature control component from the mass flow control component.

Owner:CLEAN DIESEL TECHNOLOGIES

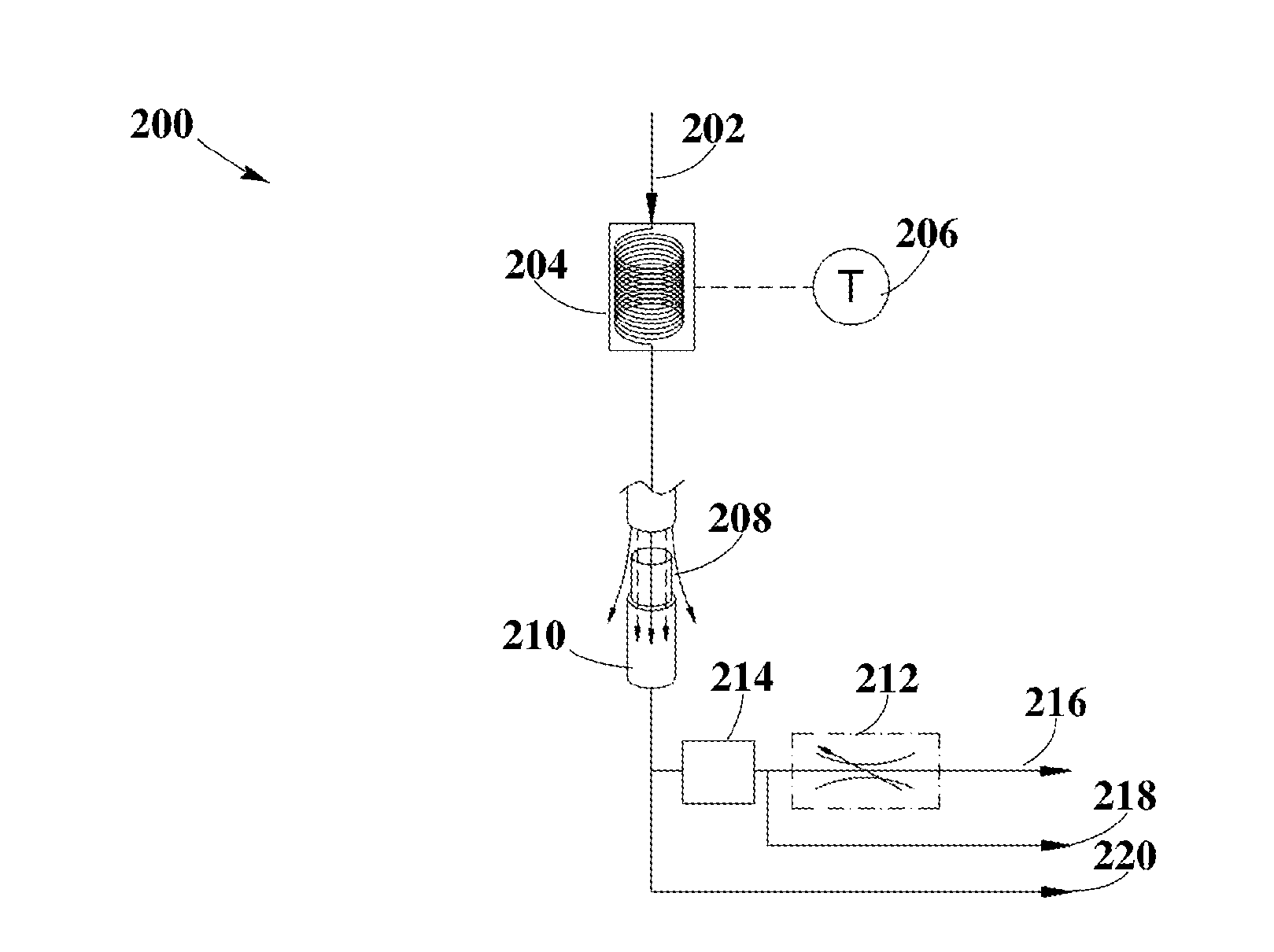

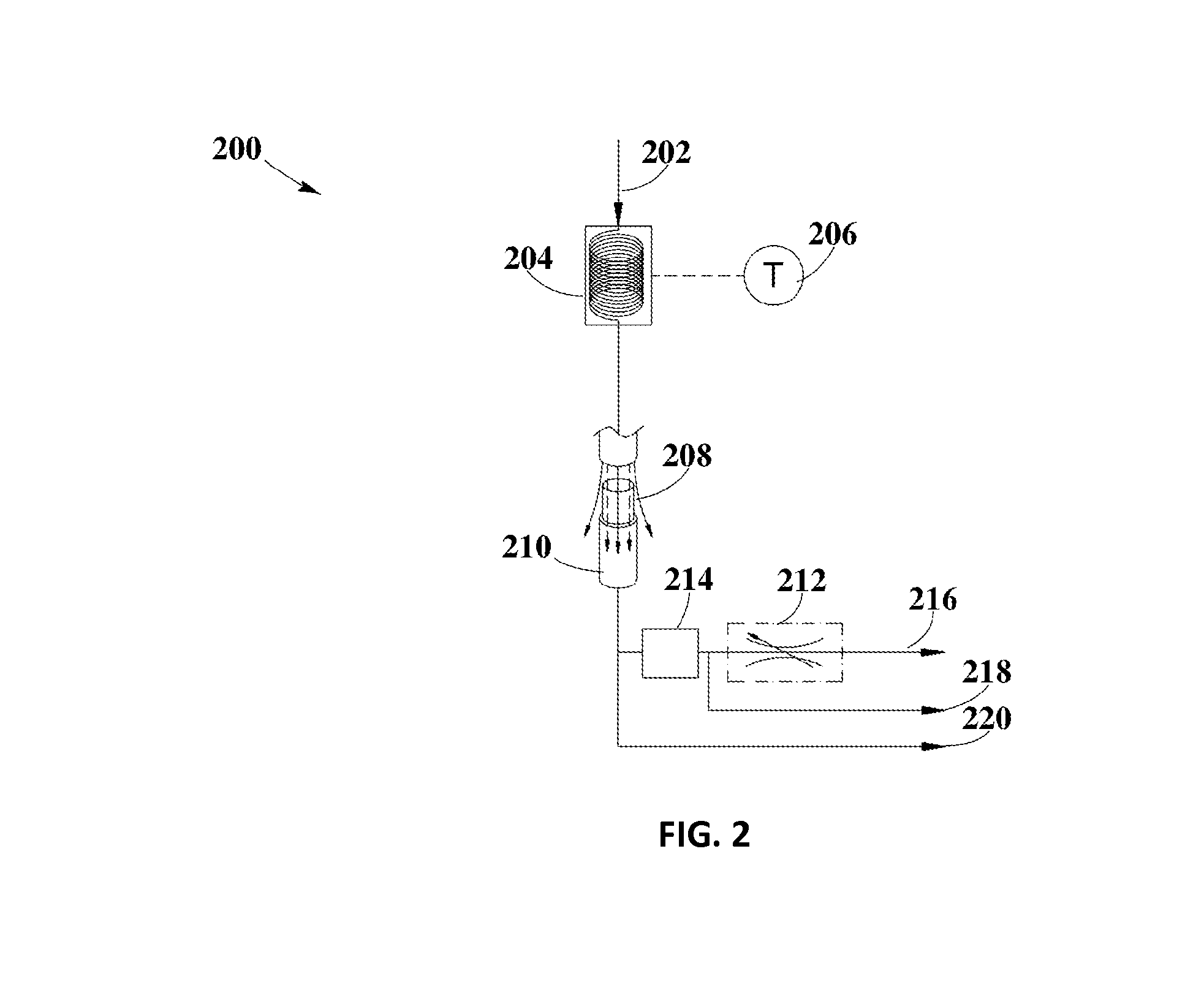

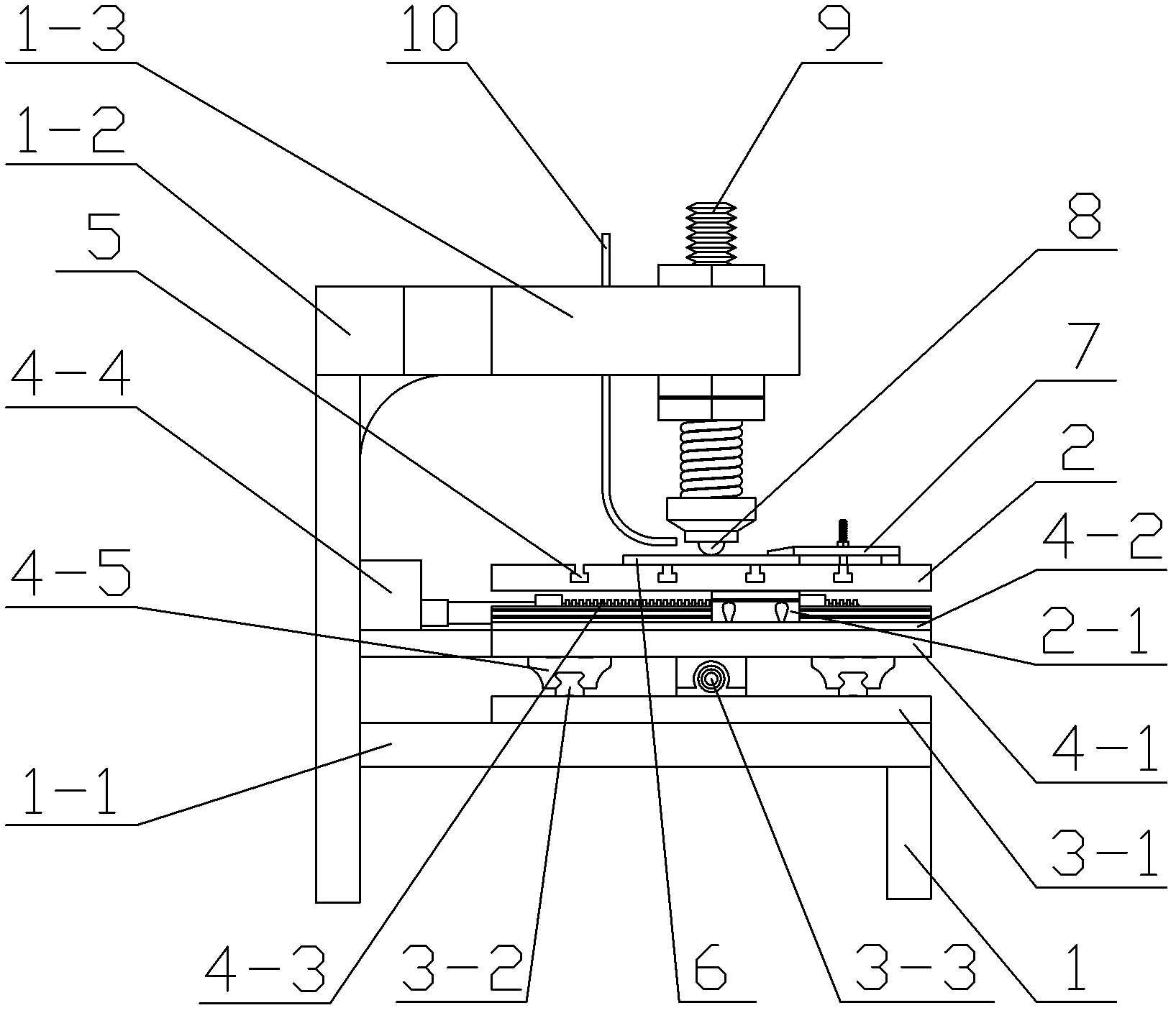

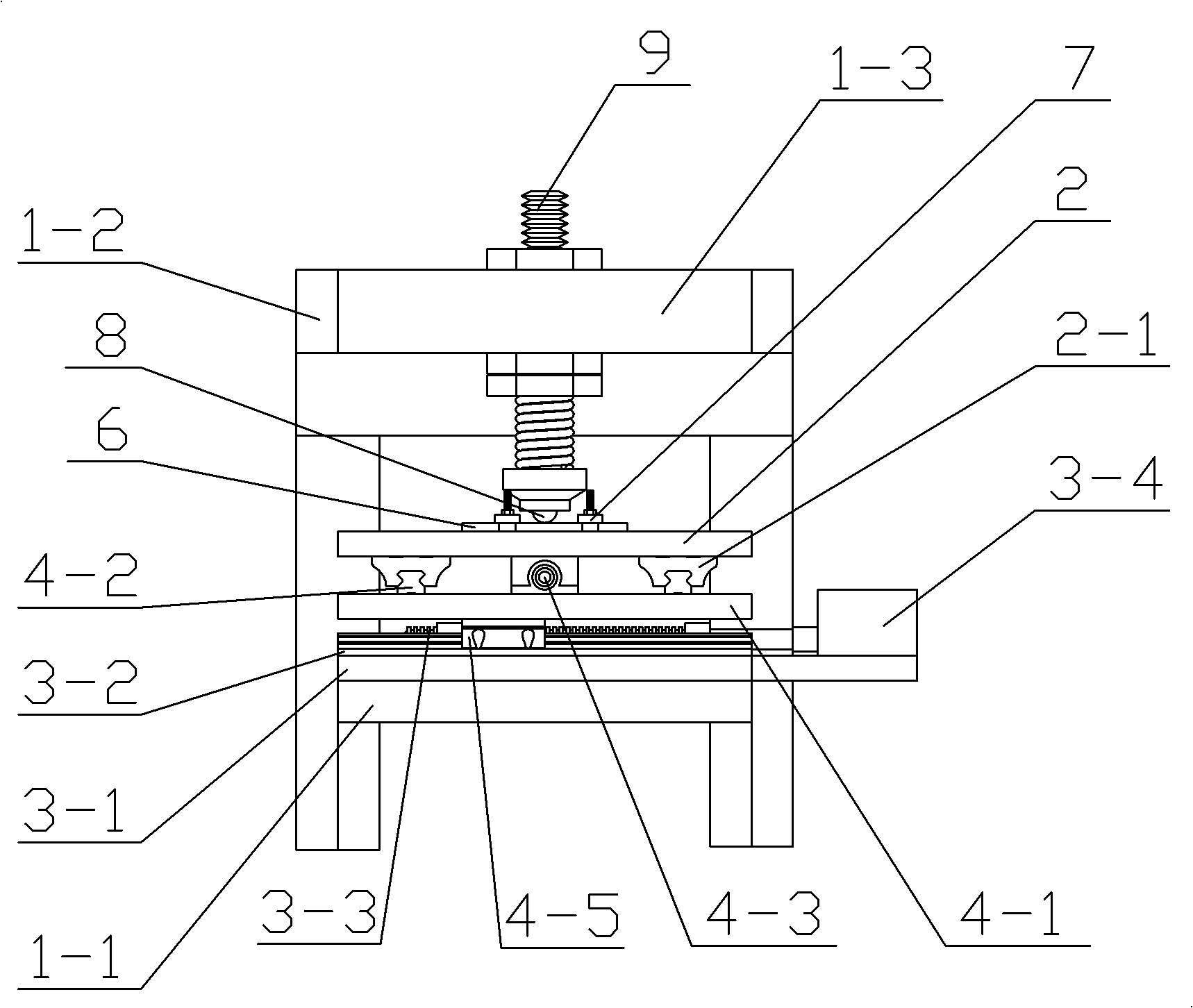

System and Apparatus for a Laboratory Scale Reactor

InactiveUS20140334978A1Chemical analysis using catalysisChemical analysis using combustionLaboratory scaleProcess engineering

The present disclosure may include a device for testing catalysts, and a method for controlling the flow rate and temperature parameters during the process. The device may separate mass flow control through heating elements from the mass flow through the sample, as well as separate banks for mixing oxidizing elements, carbon dioxide, and diluent gas as well as reducing agents, nitric oxide, and diluent gas. The device disclosed here may also use mass control units of a sufficiently high speed so as to allow the desired testing conditions.

Owner:CLEAN DIESEL TECHNOLOGIES

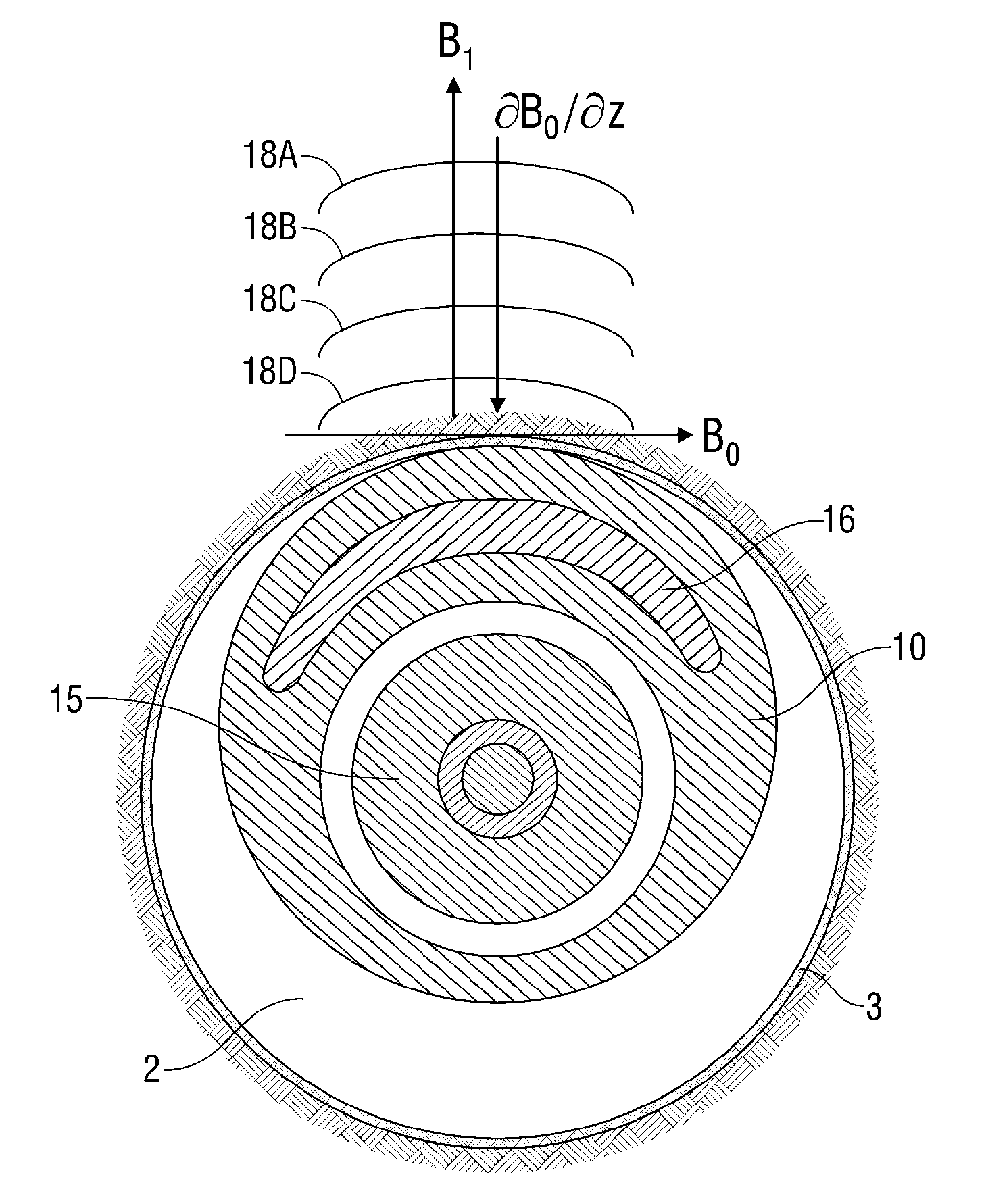

System and method for emulating nuclear magnetic resonance well logging tool diffusion editing measurements on a bench-top nuclear magnetic resonance spectrometer for laboratory-scale rock core analysis

InactiveUS8427145B2Spin dynamics are simplifiedImprove signal-to-noise ratioElectric/magnetic detection for well-loggingMeasurements using NMR imaging systemsWell loggingLaboratory scale

A laboratory NMR methodology (and corresponding laboratory apparatus) defines a sample volume. The method stores downhole tool data corresponding to a hydrocarbon-bearing sample collected from a given subsurface formation. The downhole tool data includes parameters pertaining to magnetic fields used by a downhole tool during a suite of NMR measurements of the given subsurface formation. The sample is positioned in the sample volume of the laboratory apparatus, which applies a static magnetic field in the sample volume. Furthermore, the laboratory apparatus applies a suite of NMR measurements to the sample volume to thereby determine a property of the sample. The NMR measurements of the suite each include a pulse sequence of oscillating magnetic field in conjunction with a pulsed-mode gradient field. The pulsed-mode gradient field is based on the stored downhole tool data corresponding to the sample. A laboratory NMR methodology for optimizing downhole NMR measurements is also described.

Owner:SCHLUMBERGER TECH CORP

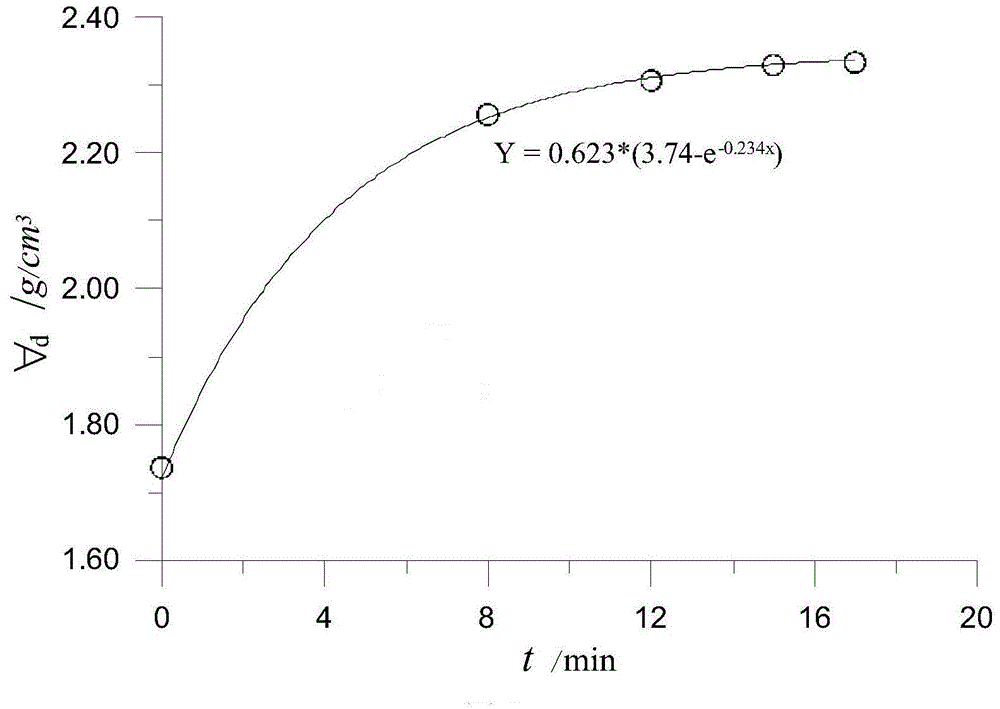

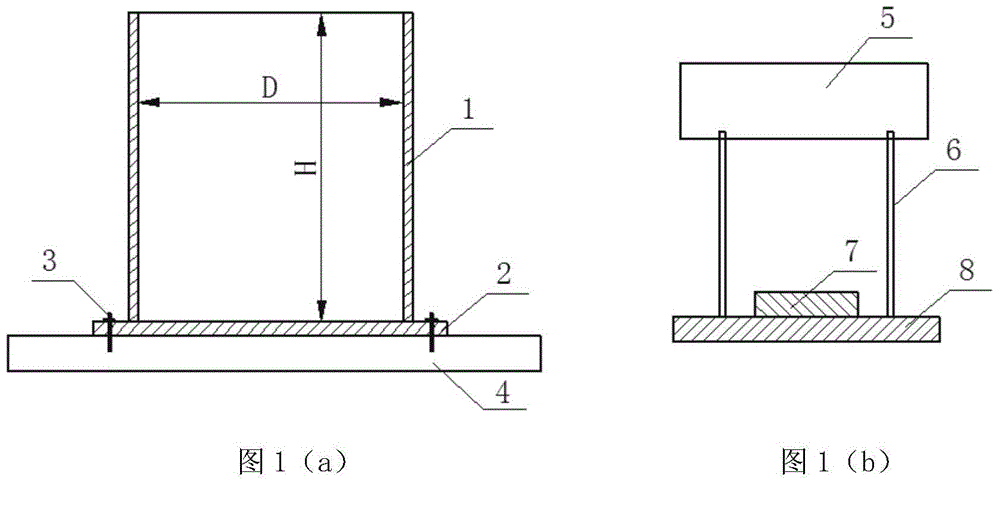

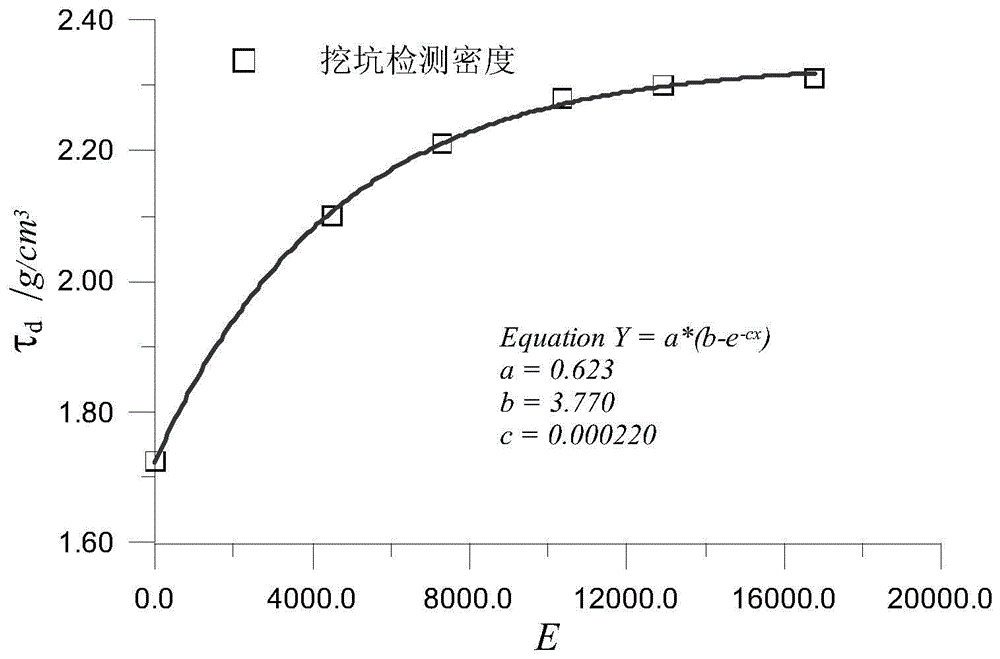

Method and tester for determining relative density sample preparation standard of laboratory scale test on coarse aggregate

InactiveCN104931305AReduce the impact of scale effectHigh precisionPreparing sample for investigationPorosityLaboratory scale

The invention relates to a method and a tester for determining a relative density sample preparation standard of a laboratory scale test on coarse aggregate, and belongs to the technical field of geotechnical testing. The method comprises the following steps: firstly, selecting graded coarse aggregate, and conducting a heavy vibrating roller extremum dry density test to obtain maximum dry density values of a field test; through a surface vibrator compaction manner, adjusting compaction parameters of the tester to obtain the maximum dry density values under different compaction manners and compaction parameters; then, determining selected equivalent compaction parameters under an indoor compaction manner to serve as a compaction standard of a laboratory maximum dry density test; finally, performing a laboratory relative density test on a scale material according to the compaction standard to obtain the extremum dry density of the scale material; according to a design index, to determining the sample preparation dry density or porosity of the laboratory scale test on the coarse aggregate through calculation. According to the method and the tester disclosed by the invention, by aiming at the scale problem of the original graded coarse aggregate, the influence of the scale effect of the coarse aggregate can be reduced, and the precision of the laboratory test on the coarse aggregate is effectively improved.

Owner:NANJING YIHAI WATER CONSERVANCY ENG TECH CO LTD

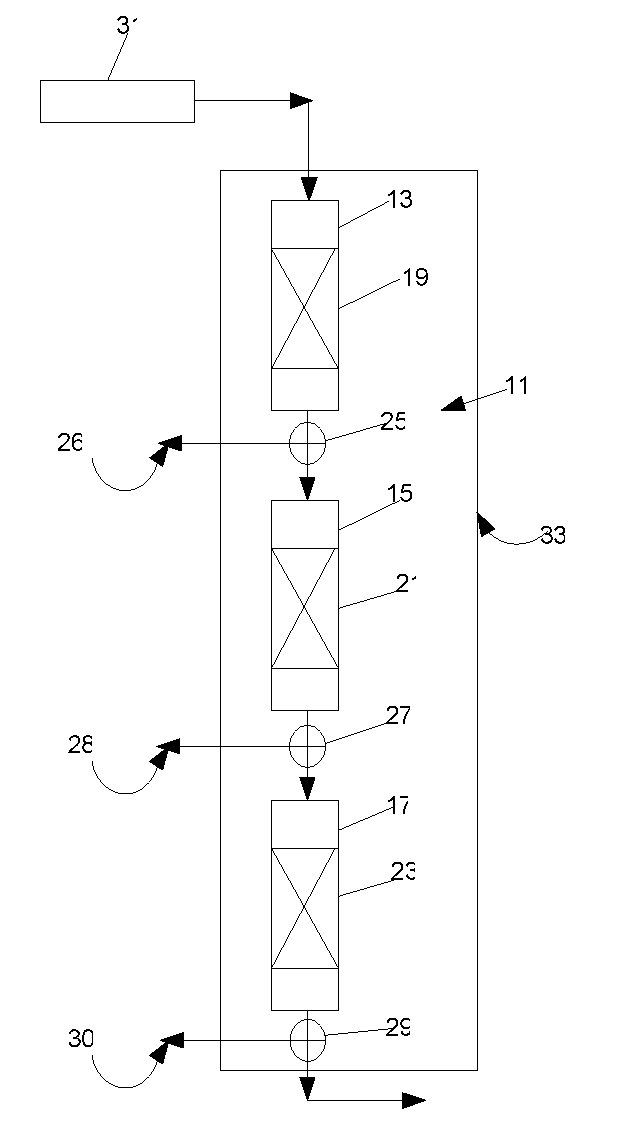

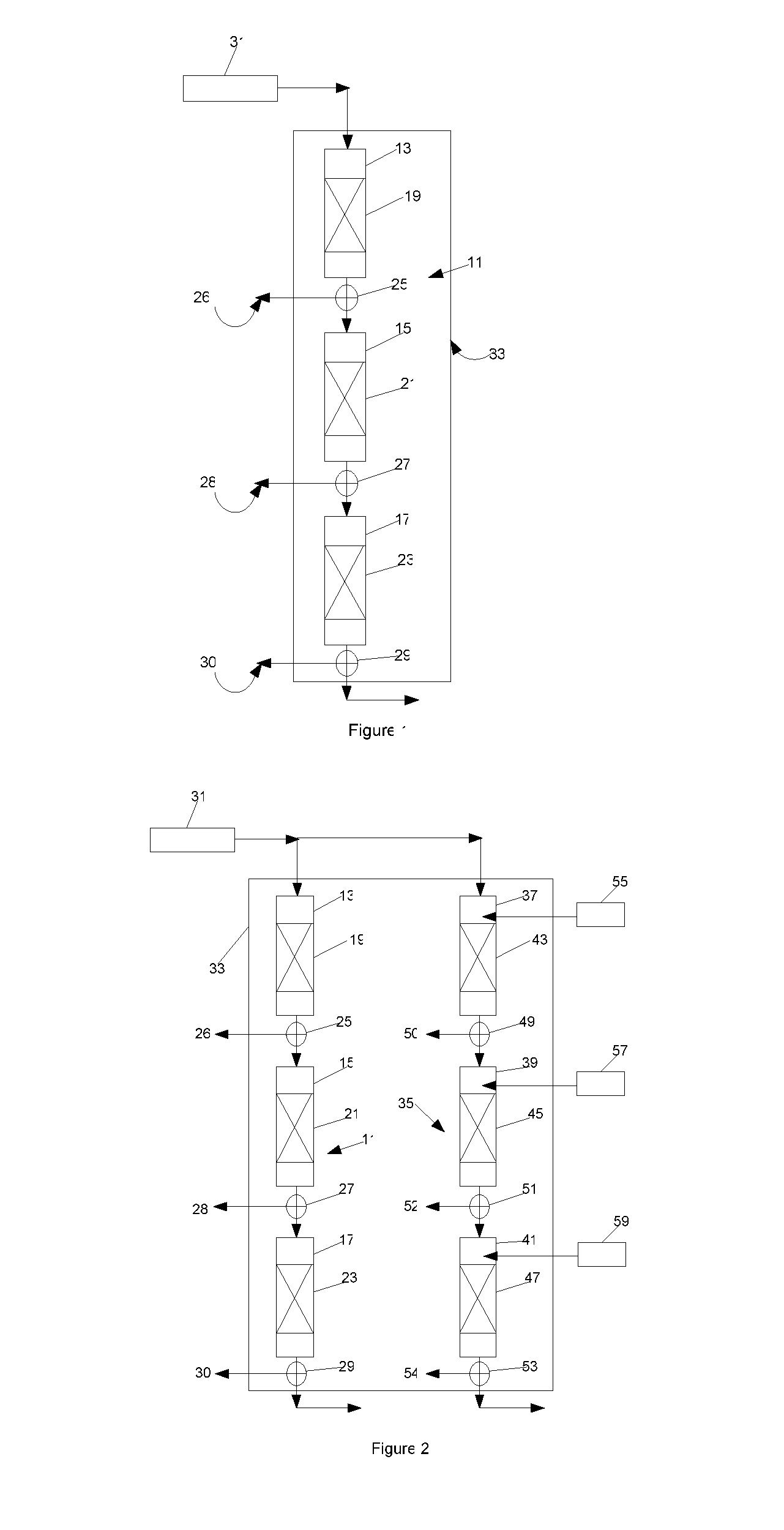

High throughput development method for catalytic hydroprocessing of dirty feedstocks

InactiveUS20100320121A1Low costIncrease productivitySequential/parallel process reactionsHydrocarbon oils treatment control/regulationHydrogenReactor system

A method for determining a set of operating parameters for a commercial scale plug flow catalytic process and reactor system for hydroprocessing dirty feedstocks, comprises the steps of: feeding selected partial pressures of said feedstock and hydrogen to the inlet the first reactor stage of a first composite multi-stage series-connected laboratory scale plug flow reactor including at least three reactor stages, the catalyst beds of each of said reactor stages including catalyst particles capable of catalyzing the removal by hydrogen of heteroatoms from said heterocyclic molecules; sampling the effluents of each of said reactor stages; measuring the concentration of heterocyclic molecules in said dirty feedstock in the concentrations of heterocyclic molecules and intermediate and final products and by products of the catalytic reaction in the effluents of each of said reactor stages.

Owner:ACCELERGY CORP

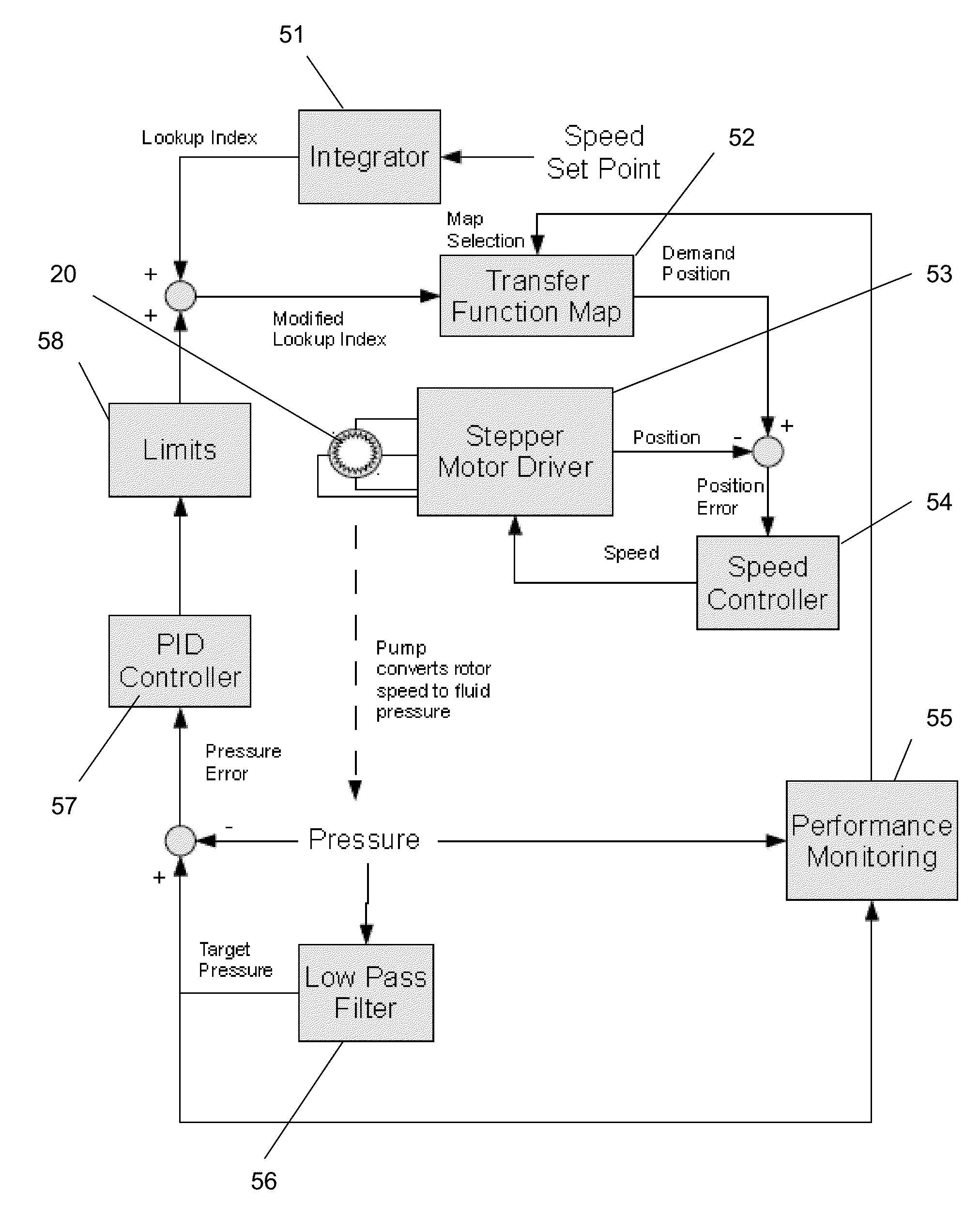

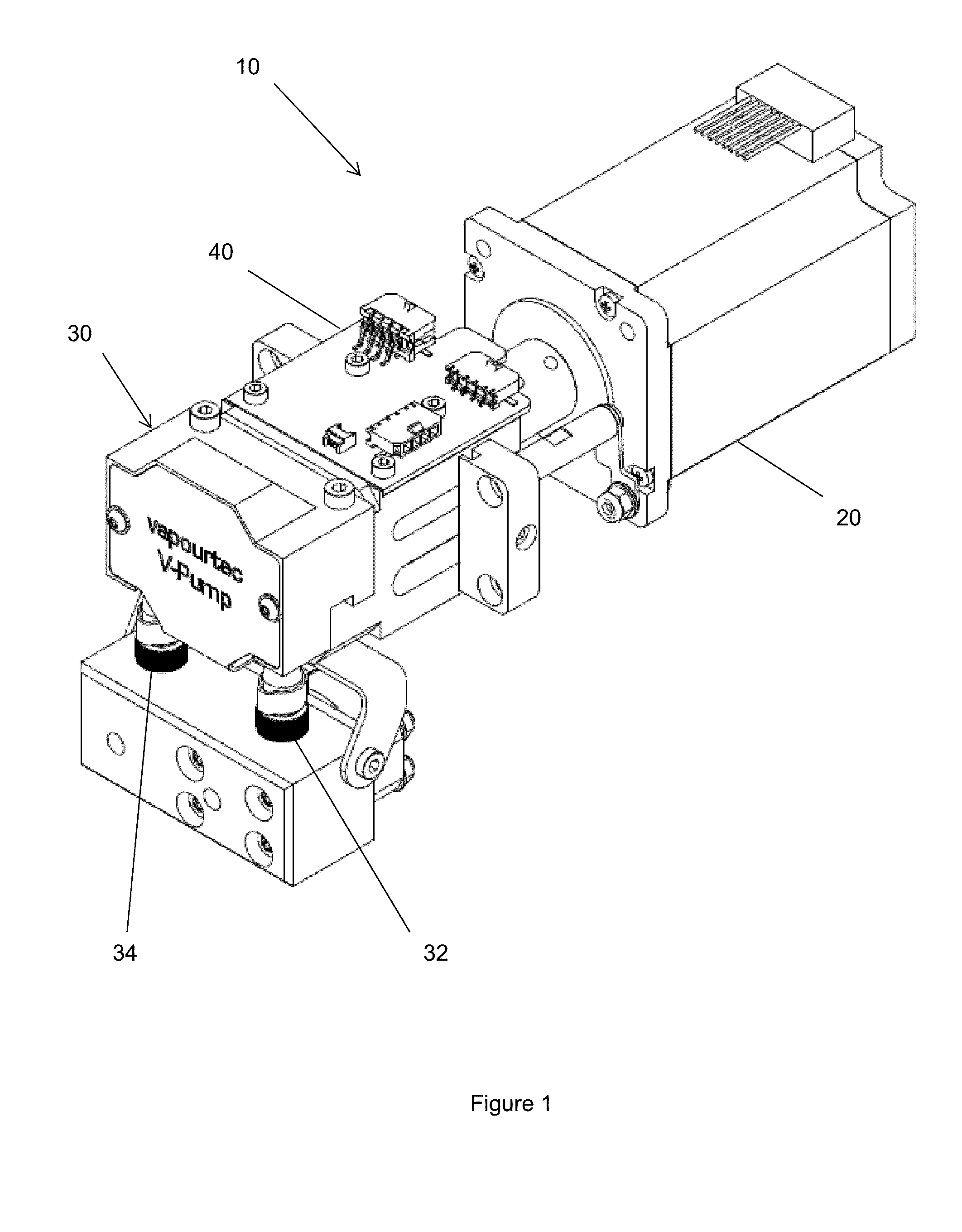

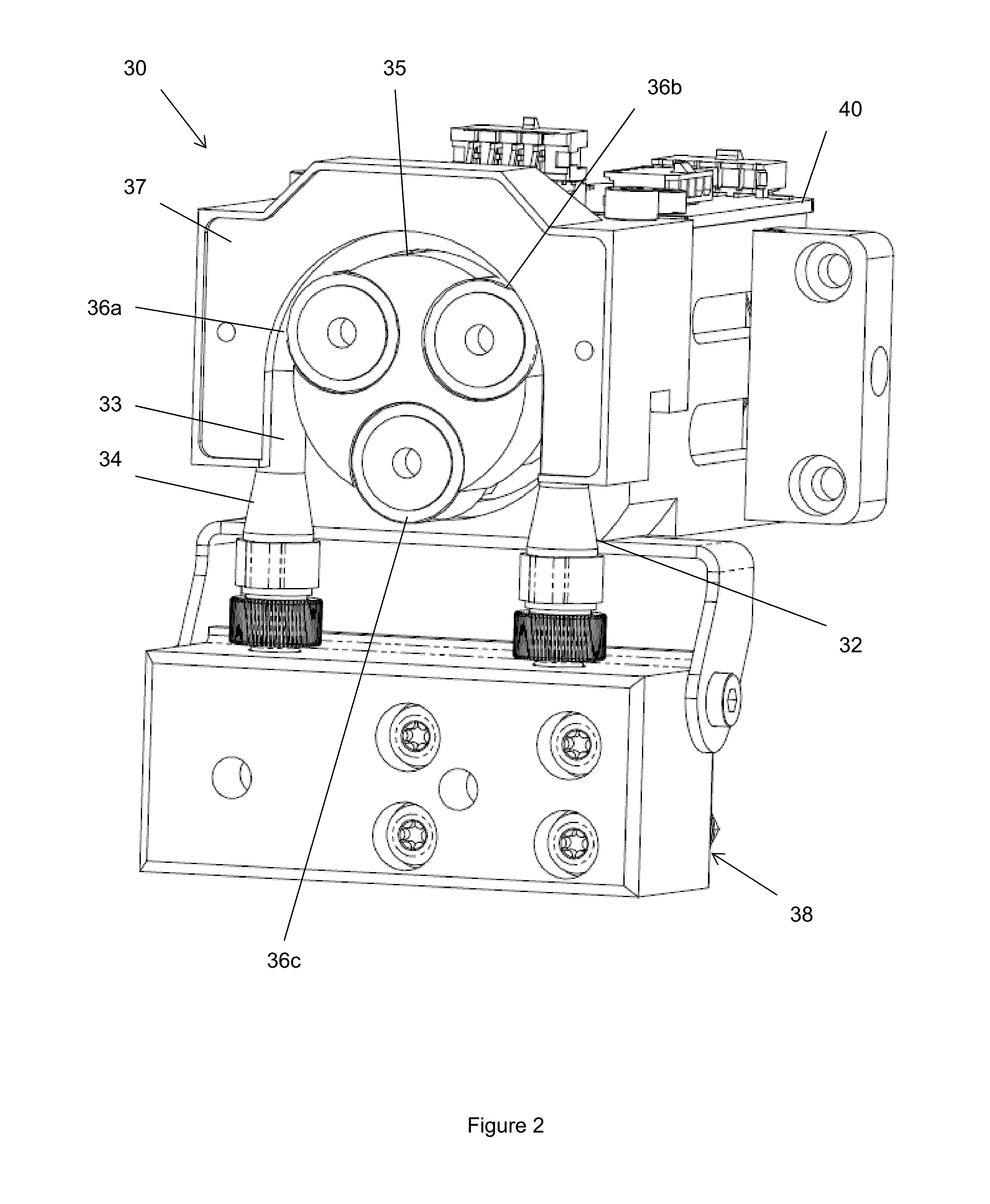

Pump

InactiveUS20150240802A1Accurate and rapid feedbackEliminate needFluid parameterFlexible member pumpsPeristaltic pumpEntry point

Provided is a pump and a method of controlling a pump. The pump and method are particularly for use in dispensing reagents, for example in flow chemistry, and more particularly on a laboratory scale. The pump aims to provide a substantially constant output flow of fluid. The pump comprises: a motor; a peristaltic pump having a rotor driven by the motor; a pressure sensor monitoring the pressure of the pumped fluid downstream of the pump; and a control unit which controls the motor by adjusting the standard operating speed of the motor according to the pressure detected by the pressure sensor, such that the pump operates continuously at a rate set by an operator. Embodiments of the pump make use of lookup tables to determine a desired position of the pump rotor at each point in the cycle with the entry point into the lookup table being determined by the feedback from the pressure sensor. Long term changes in the performance of the pump can also be accounted for by changing the entry in the lookup table which is consulted.

Owner:VAPORTEC

System for emulating nuclear magnetic resonance well logging tool diffusion editing measurements on a bench-top nuclear magnetic resonance spectrometer for laboratory-scale rock core analyis

InactiveUS20130265055A1Spin dynamics are simplifiedImprove signal-to-noise ratioElectric/magnetic detection for well-loggingMeasurements using NMR imaging systemsWell loggingLaboratory scale

A laboratory NMR methodology (and corresponding laboratory apparatus) defines a sample volume. The method stores downhole tool data corresponding to a hydrocarbon-bearing sample collected from a given subsurface formation. The downhole tool data includes parameters pertaining to magnetic fields used by a downhole tool during a suite of NMR measurements of the given subsurface formation. The sample is positioned in the sample volume of the laboratory apparatus, which applies a static magnetic field in the sample volume. Furthermore, the laboratory apparatus applies a suite of NMR measurements to the sample volume to thereby determine a property of the sample. The NMR measurements of the suite each include a pulse sequence of oscillating magnetic field in conjunction with a pulsed-mode gradient field. The pulsed-mode gradient field is based on the stored downhole tool data corresponding to the sample. A laboratory NMR methodology for optimizing downhole NMR measurements is also described.

Owner:SCHLUMBERGER TECH CORP

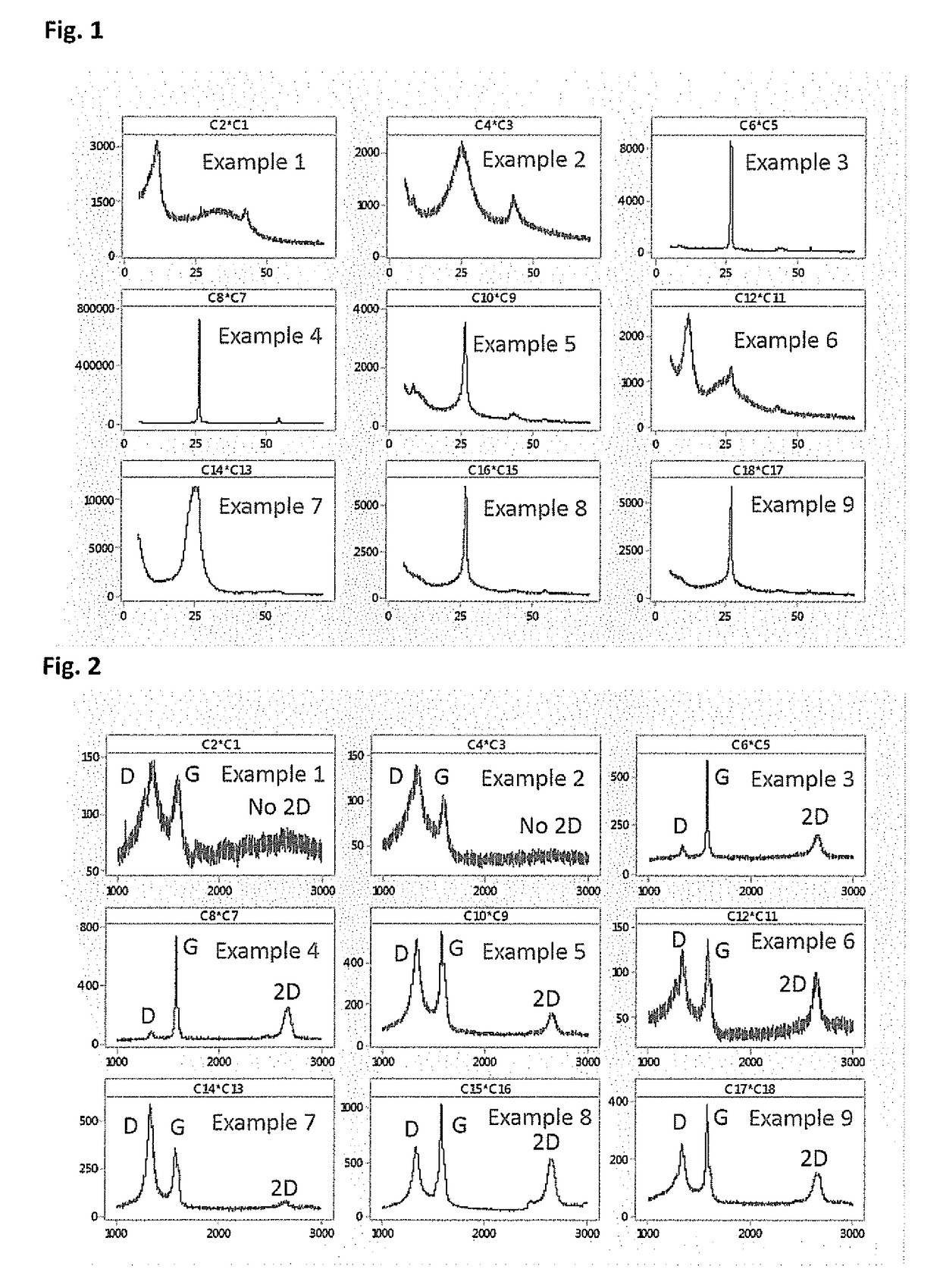

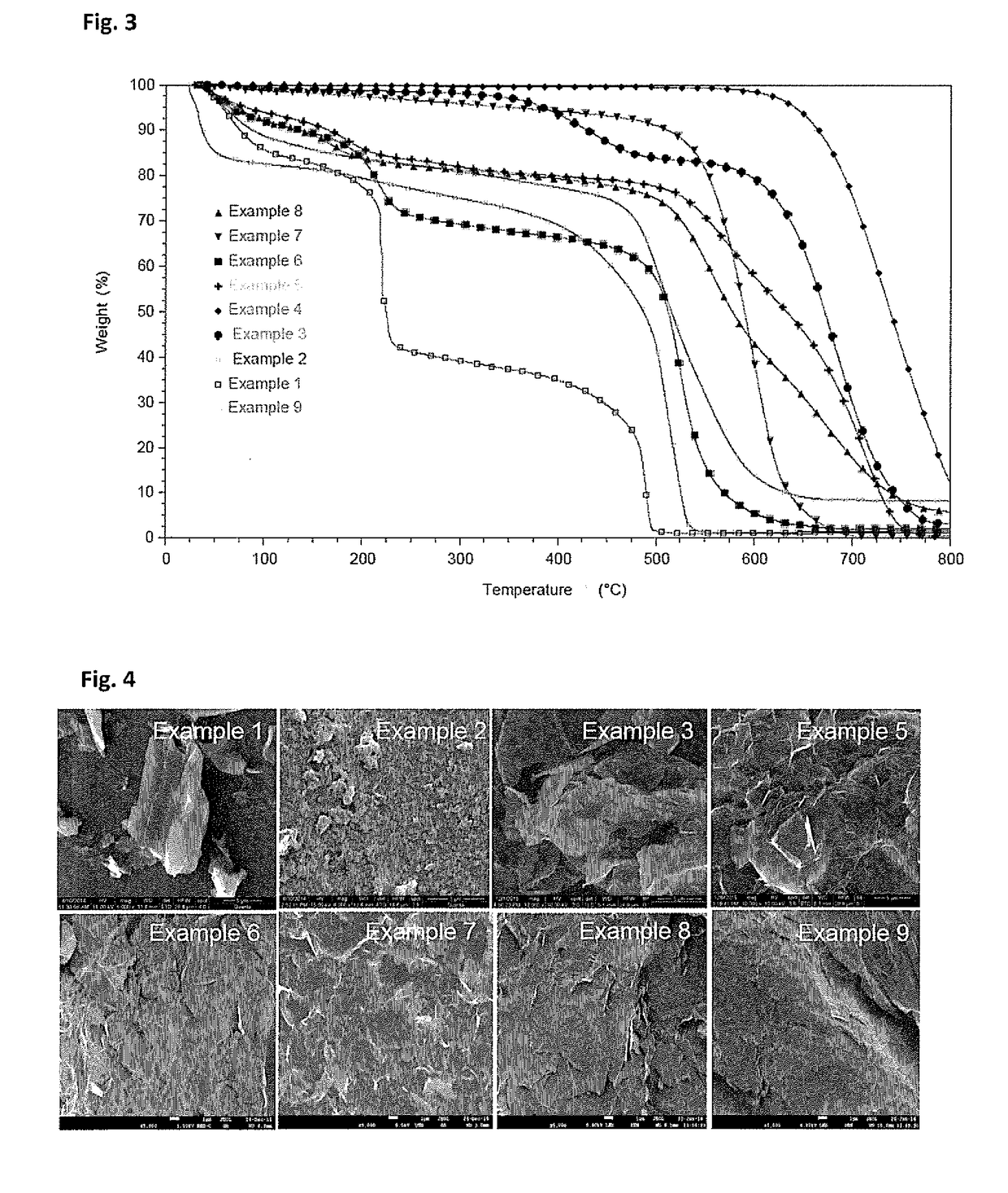

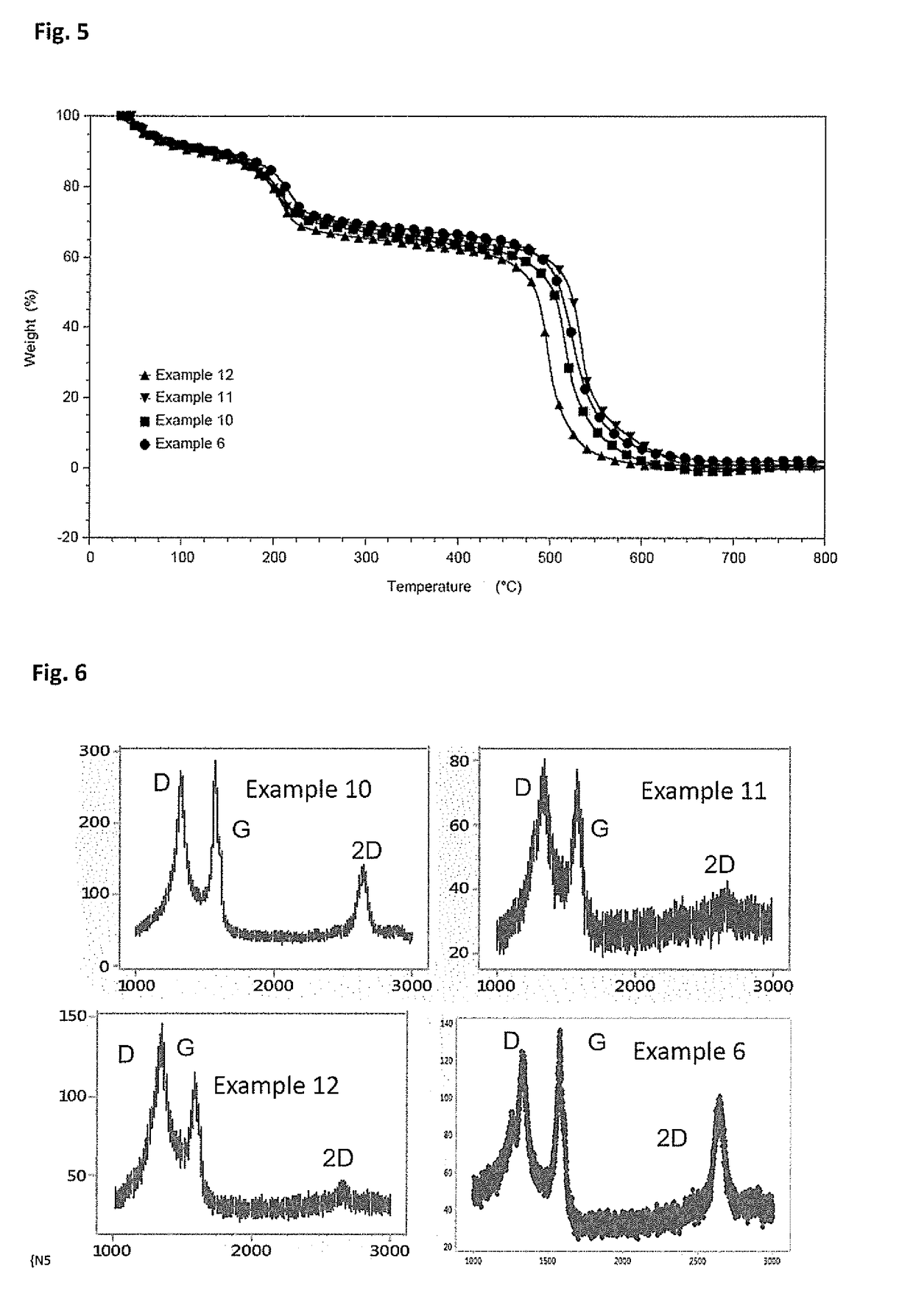

Production of Graphene

PendingUS20180072573A1High volume manufacturing capabilityLow costCellsGrapheneHigh volume manufacturingMetallurgy

A method of synthesizing high quality graphene for producing graphene particles and flakes is presented. The engineered qualities of the graphene include size, aspect ratio, edge definition, surface functionalization and controlling the number of layers. Fewer defects are found in the end graphene product in comparison to previous methods. The inventive method of producing graphene is less aggressive, lower cost and more environmentally friendly than previous methods. This method is applicable to both laboratory scale and high volume manufacturing for producing high quality graphene flakes.

Owner:FRY S METALS INC

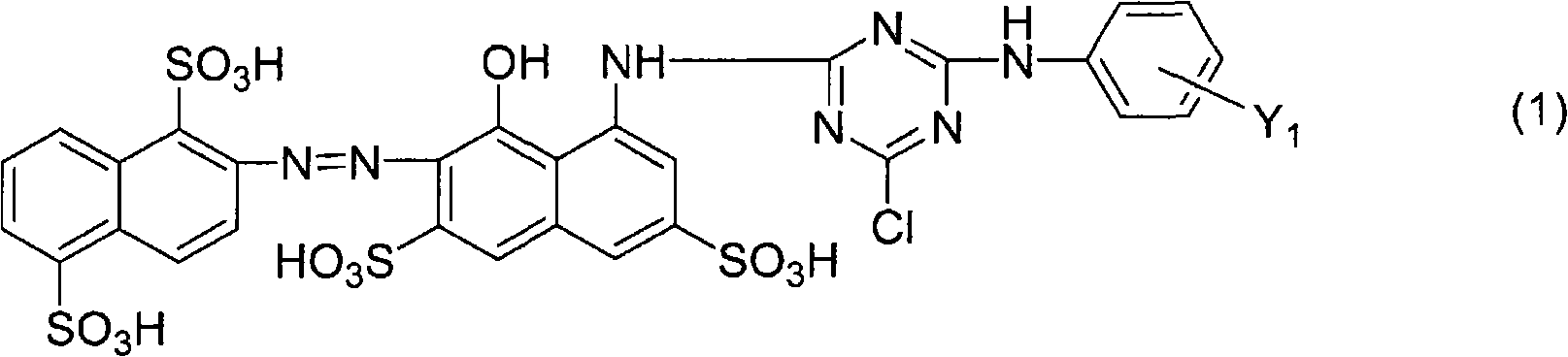

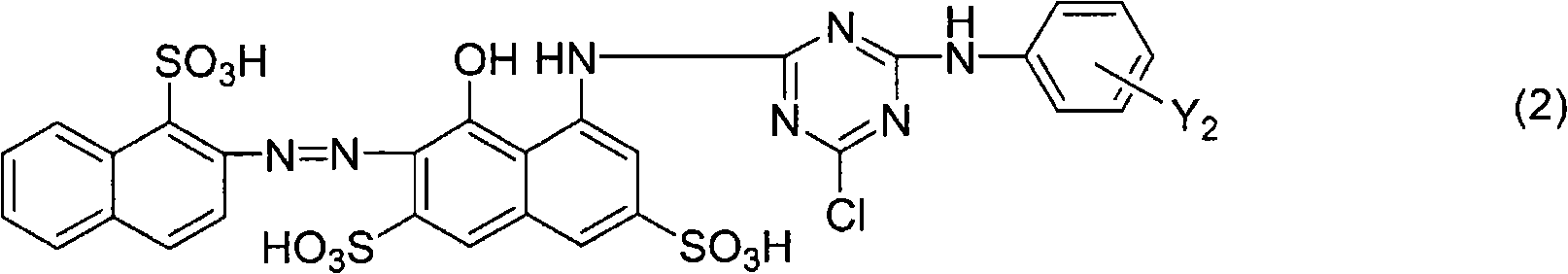

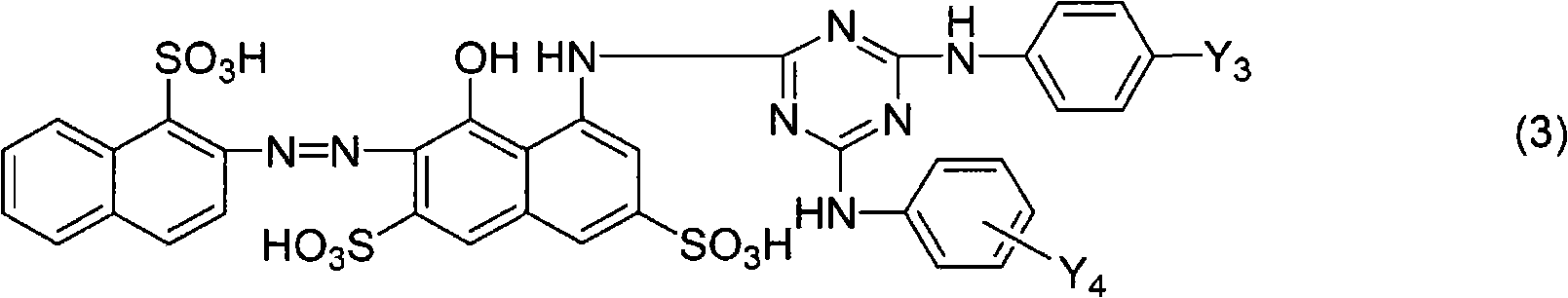

Reactive dye composition and dyeing method using the same

The existing dyes used as primitive colors different affinity to cellulose base fiber and different dyeing behaviors, such that there is a problem of difference colors due to concentration or color shade variation along with the variation of dye bath ratio, and coloration correction and decolouration correction must be performed frequently in a workshop. Therefore, primitive colors having an identical dye bath ratio variation behavior are required in a dyeing workshop. In addition, there is a problem of color difference due to alkalization temperature, and reproducibility badness is brought in laboratory scale and plant scale. The present invention provides a reactive dye composition and a dyeing method using the same, wherein a reactive dye composition combination contains red reactive dye composition containing special dyes represented by formula (1), formula (2) and formula (3), blue reactive dye composition containing more than one dyes represented by formula (4), formula (5) and formula (6), dark blue reactive dye composition containing dyes represented by formula (5), and formula (7), and yellow reactive dye represented by formula (8).

Owner:NIPPON KAYAKU CO LTD

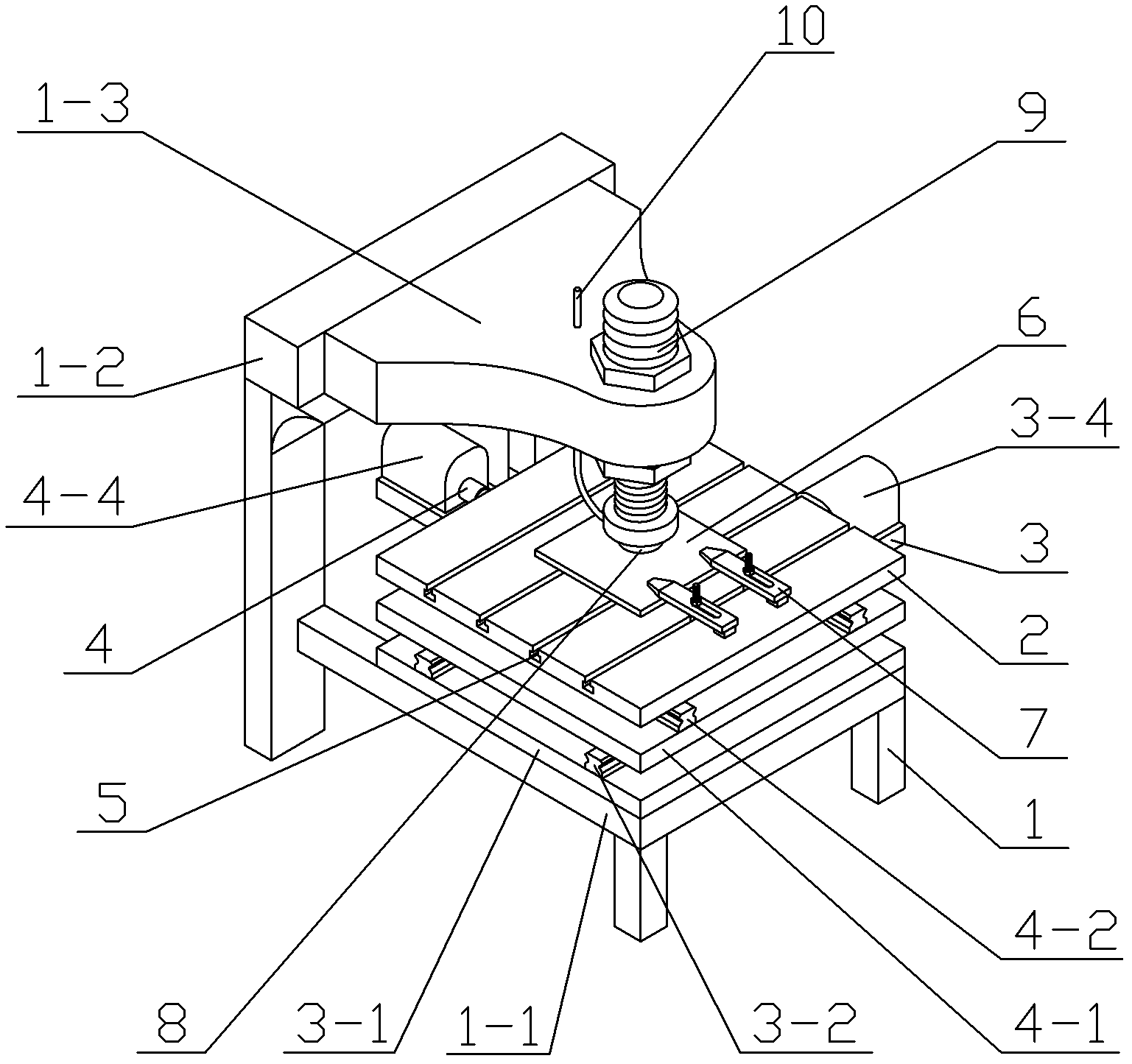

Nanometer modifying apparatus of metal material surface

The invention discloses a nanometer modifying apparatus of metal material surfaces. The apparatus comprises a frame and a working platform horizontally arranged above the frame. A Y-direction feeding system used for controlling the working platform to move along the Y direction and an X-direction feeding system used for controlling the working platform to move along the X direction are arranged between the frame and the working platform. The working platform is provided with grooves. Fixtures used for fixing a metal material on the working platform are installed on the working platform through the grooves. A rubbing mechanism used for rubbing the metal material is arranged above the working platform. A load system which is fixedly connected with the rubbing mechanism and is used for applying pressures to the rubbing mechanism is arranged on the frame at a place above the working platform. The apparatus provided by the invention is advantaged in simple structure, reasonable design, andhigh practicability. The apparatus can be used for processing planar metal materials with relatively large dimensions, and is not restricted in a laboratory scale. When processed by using the apparatus, the surface of the metal material is smooth, the roughness of the surface is small, and a surface nanometer layer is uniform.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

System and Apparatus for a Laboratory Scale Reactor

InactiveUS20150316524A1Chemical analysis using catalysisMaterial analysis by electric/magnetic meansLaboratory scaleProcess engineering

The present disclosure may include a device for testing catalysts, and a method for controlling the flow rate and temperature parameters during the process. The device may separate mass flow control through heating elements from the mass flow through the sample, as well as separate banks for mixing oxidizing elements, carbon dioxide, and diluent gas as well as reducing agents, nitric oxide, and diluent gas. The device disclosed here may also use mass control units of a sufficiently high speed so as to allow the desired testing conditions.

Owner:CLEAN DIESEL TECHNOLOGIES

High throughput propylene from methanol catalytic process development method

InactiveUS20100174129A1Low costHigh propylene productivitySequential/parallel process reactionsMolecular sieve catalystsProcess developmentLaboratory scale

A catalytic process development apparatus and method for simulating a commercial scale methanol and / or DME to propylene catalytic conversion system that includes a plurality of series-connected plug-flow reactors. The method involves simulating the operation of the series-connected plug-flow reactors by operating a series of multistage series-connected laboratory scale plug-flow reactors, the stages of which each containing a zeolite catalyst bed, each of the laboratory scale reactors corresponding to a separate one of the commercial scale series-connected reactors. Fresh feed, including methanol and / or DME, is supplied to the first of the laboratory scale reactor stages, and selected ones of steam, methanol and / or DME, contaminants and reaction products are supplied to selected ones of the laboratory scale reactor stages. The simulation is repeated at different sets of operating conditions and catalyst characteristics.

Owner:BAUMAN RICHARD F +1

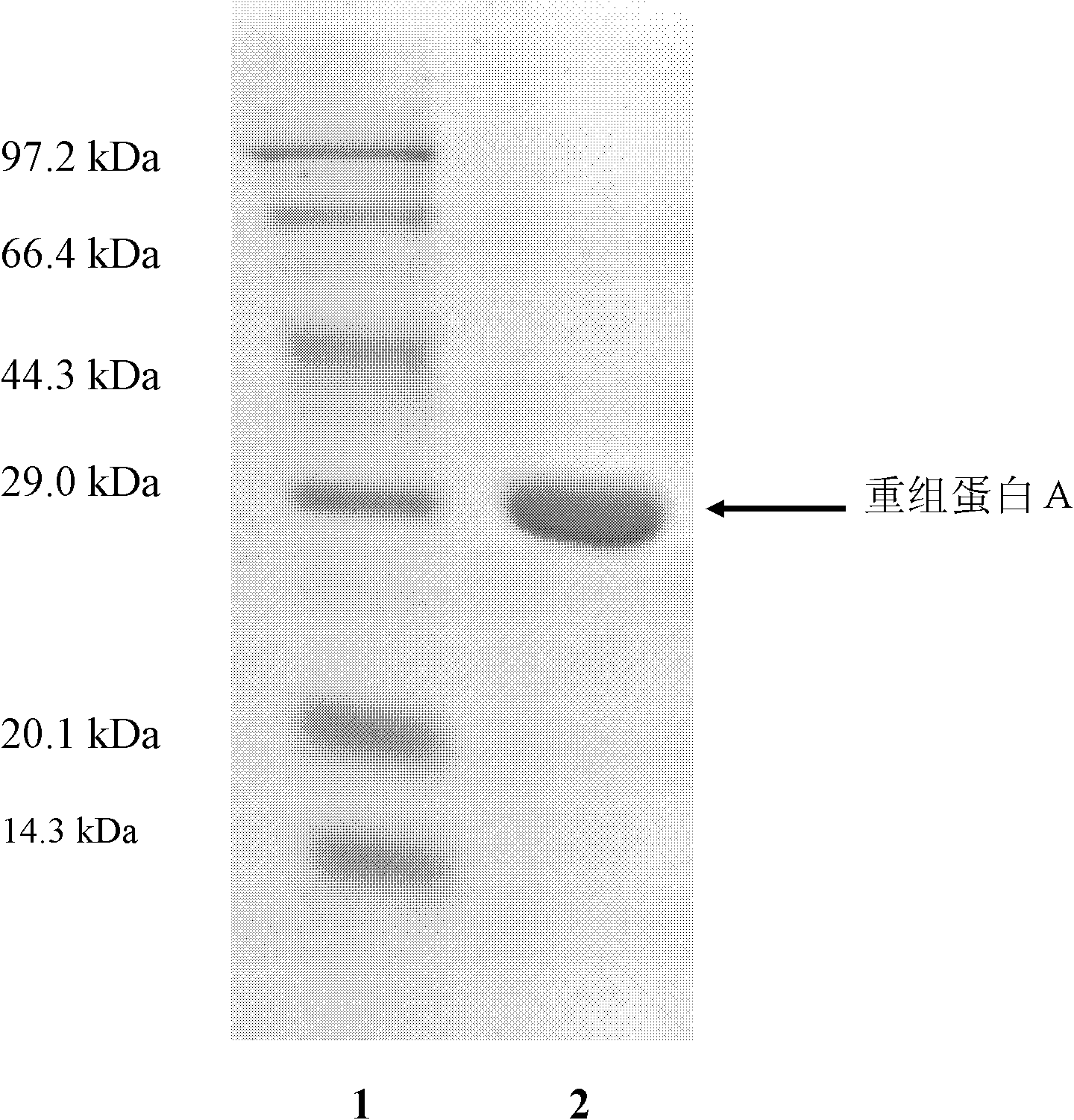

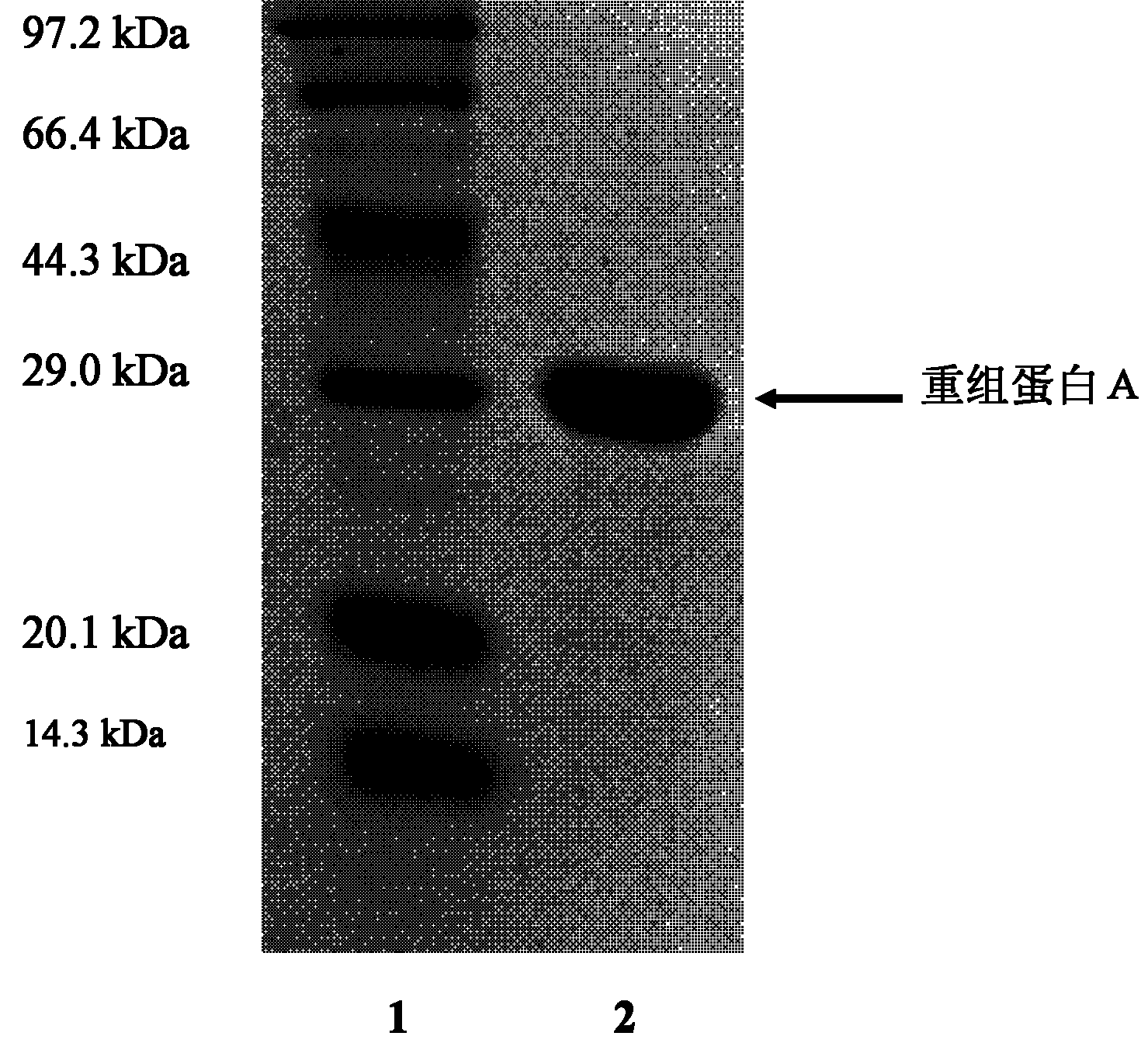

Separation and purification method of recombinant proteins A

InactiveCN101921320AHighly selective separation and purificationIncrease capacityDepsipeptidesPeptide preparation methodsPurification methodsLaboratory scale

The invention relates to a separation and purification method of recombinant proteins A, which comprises the steps of: preparing batch IgG Fc segments; directionally immobilizing the Fc segments; and separating and purifying the recombinant proteins A through an affinity chromatography technology by using the Fc segments as aglycones. The method belongs to the technical field of biological engineering. The purification of the proteins A finally obtained and detected by SAS-PAGE and HPLC is more than 95 percent. The method has the advantages of lower cost, high efficiency and simple and convenient operation, and not only can be used for purifying the proteins A in a laboratory scale way, but also can be used for producing industrialized proteins A.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com