Automated low-volume tangential flow filtration process development device

A tangential flow filtration and process technology, applied in filtration and separation, measuring devices, membrane filters, etc., can solve problems such as waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

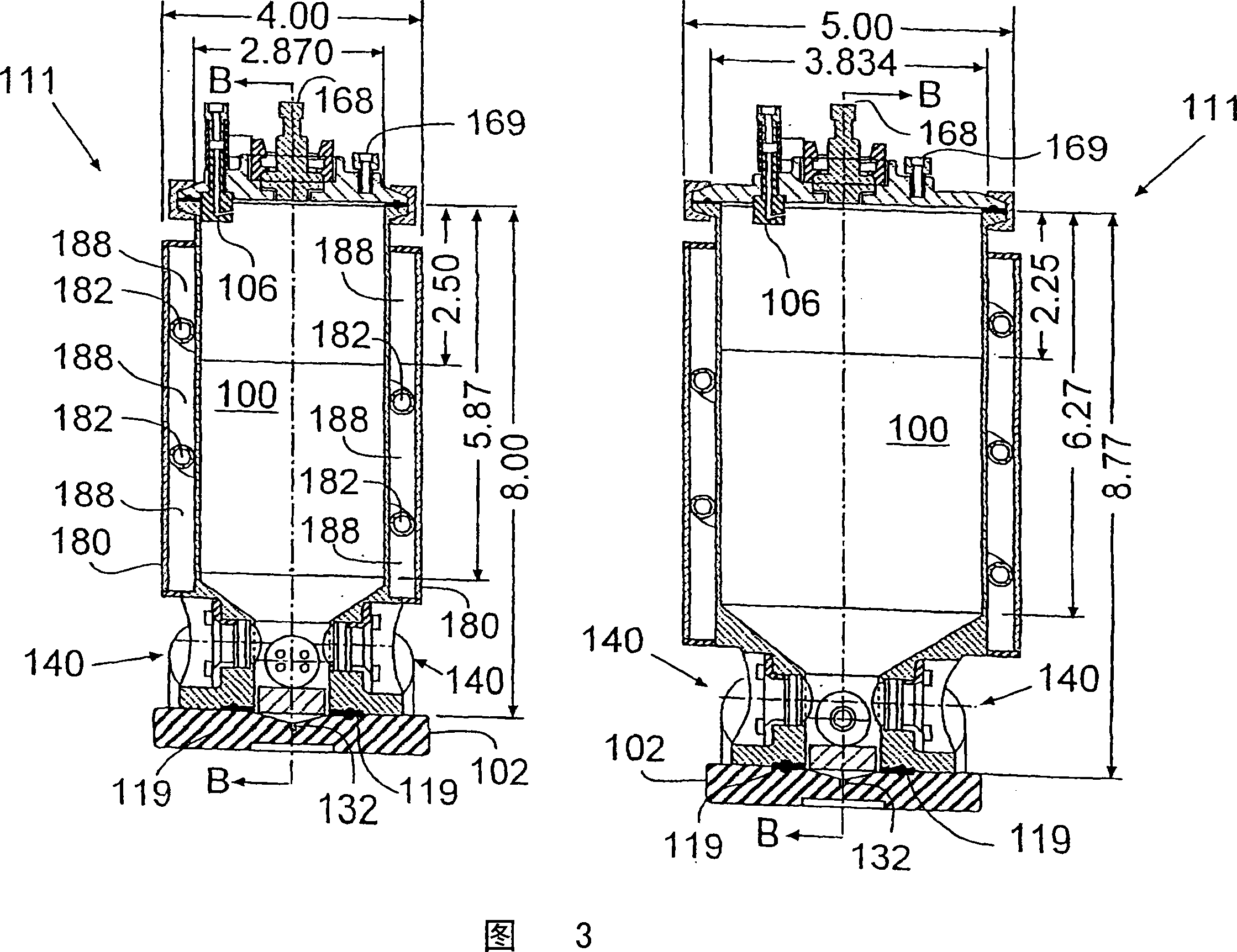

[0097] An automated TFF process development facility electronically configured with the previously described electronic data processing network is structurally configured as outlined in FIG. 7 and the table below:

[0098] parameters

value

Diaphragm area

50cm 2

Minimum recirculation volume

<20ml / PXL 50

2

starting volume

200ml to 1 liter

6 bar (86psi)

Feed flow rate

Up to 100ml / min

Processing temperature

4 to 55°C

pH

1 to 14

Can

1000ml recovery

device holder

PXL standard

Pump:

[0099] -feed(range)

0 to 100ml / min at 80psi

-filter(range)

0 to 50ml / min at 10psi

-coflow(range)

0 to 100ml / min at 80psi

-transfer(range)

0 to 100ml / min at 10psi

valve

Open close

- retain back pressure

-8 port selector

pressure indicator

-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com