Patents

Literature

486 results about "Feed pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

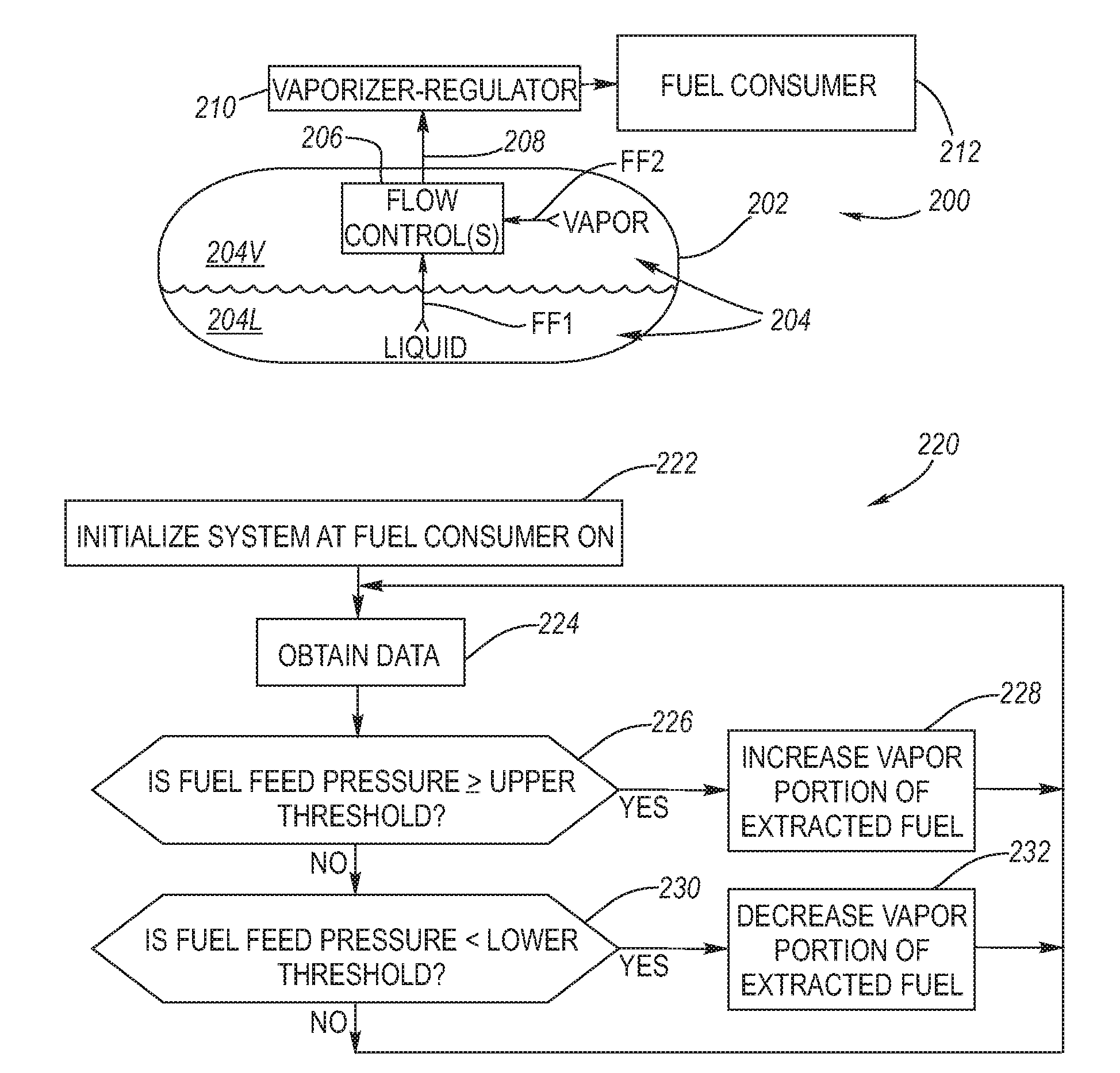

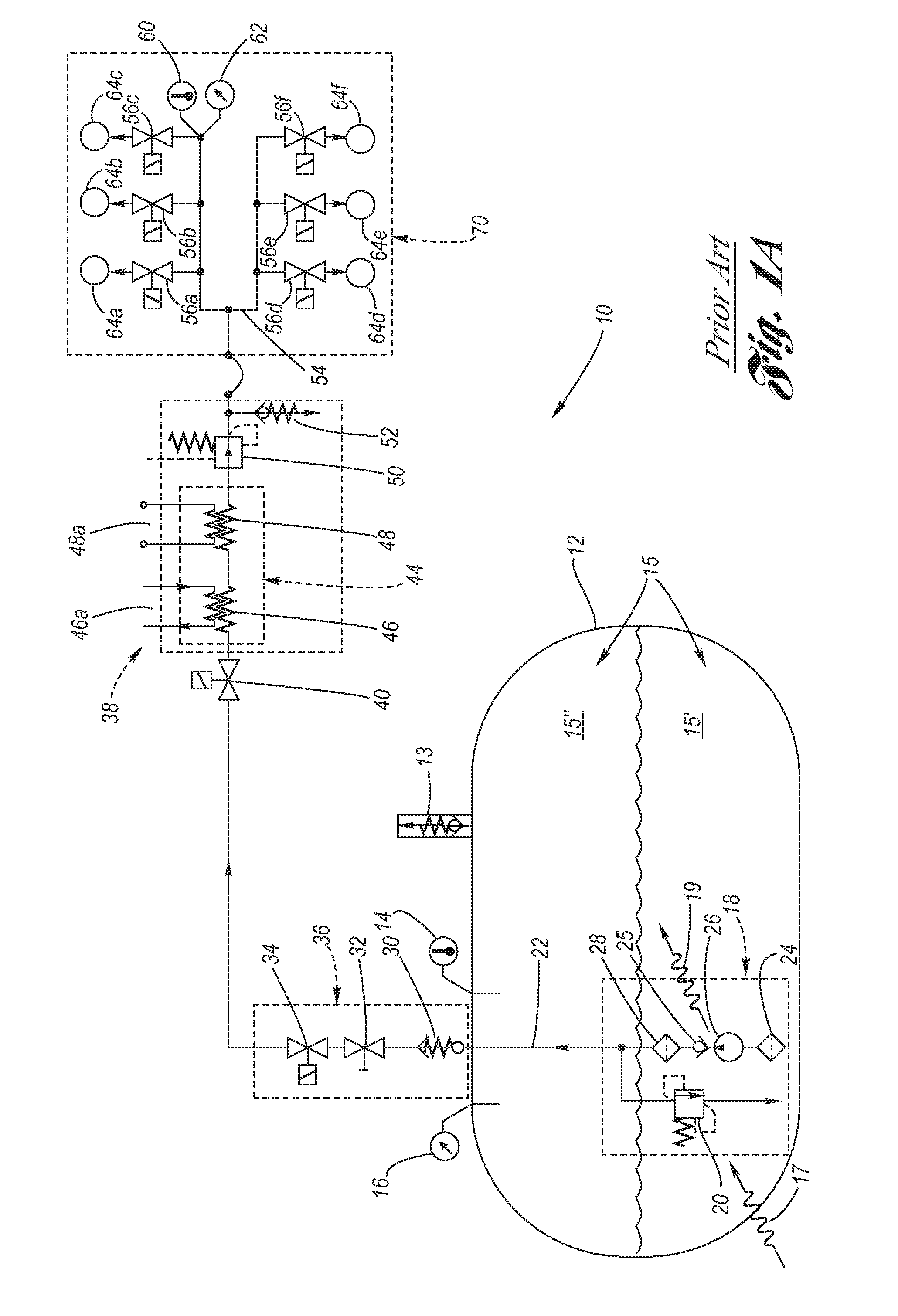

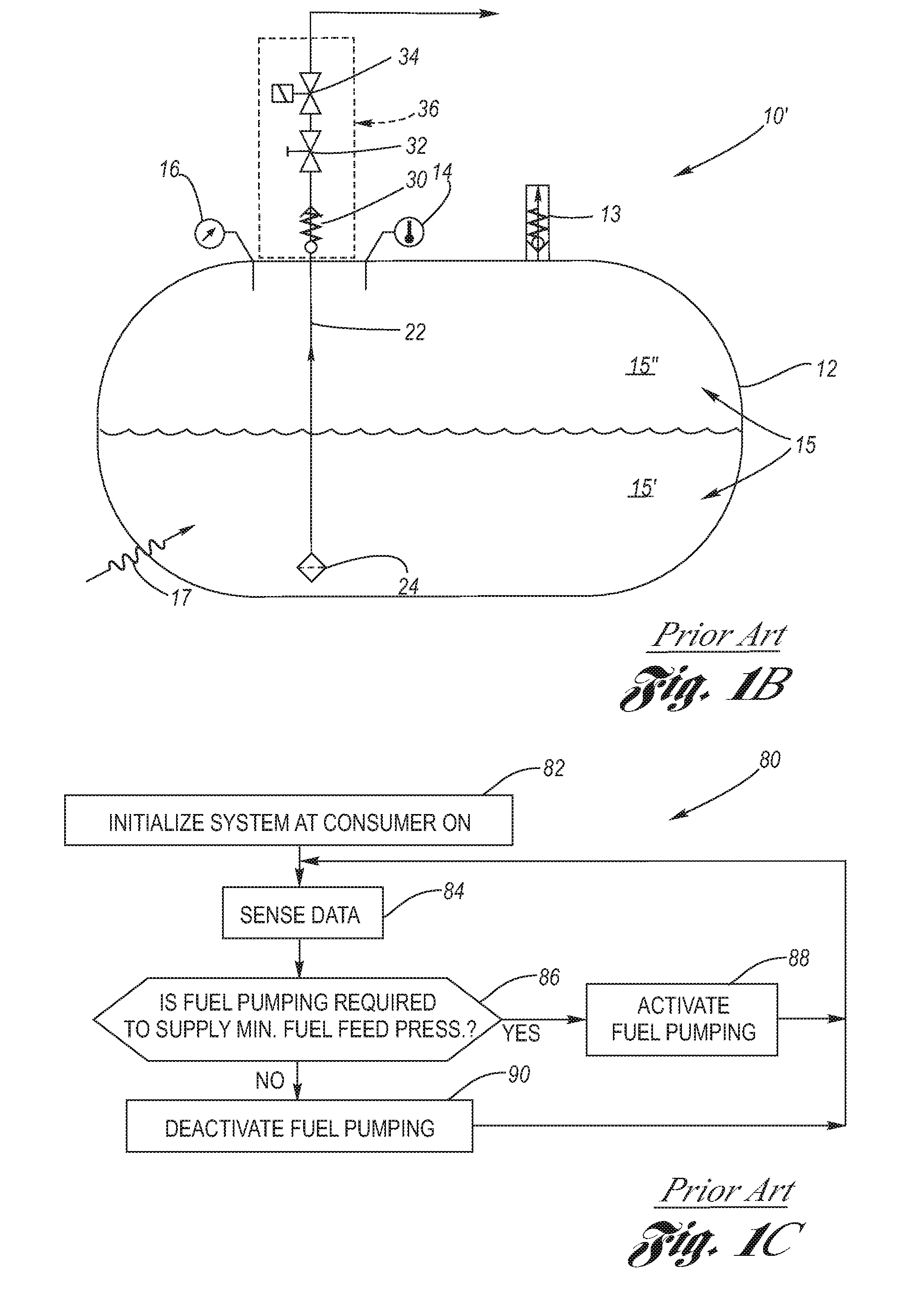

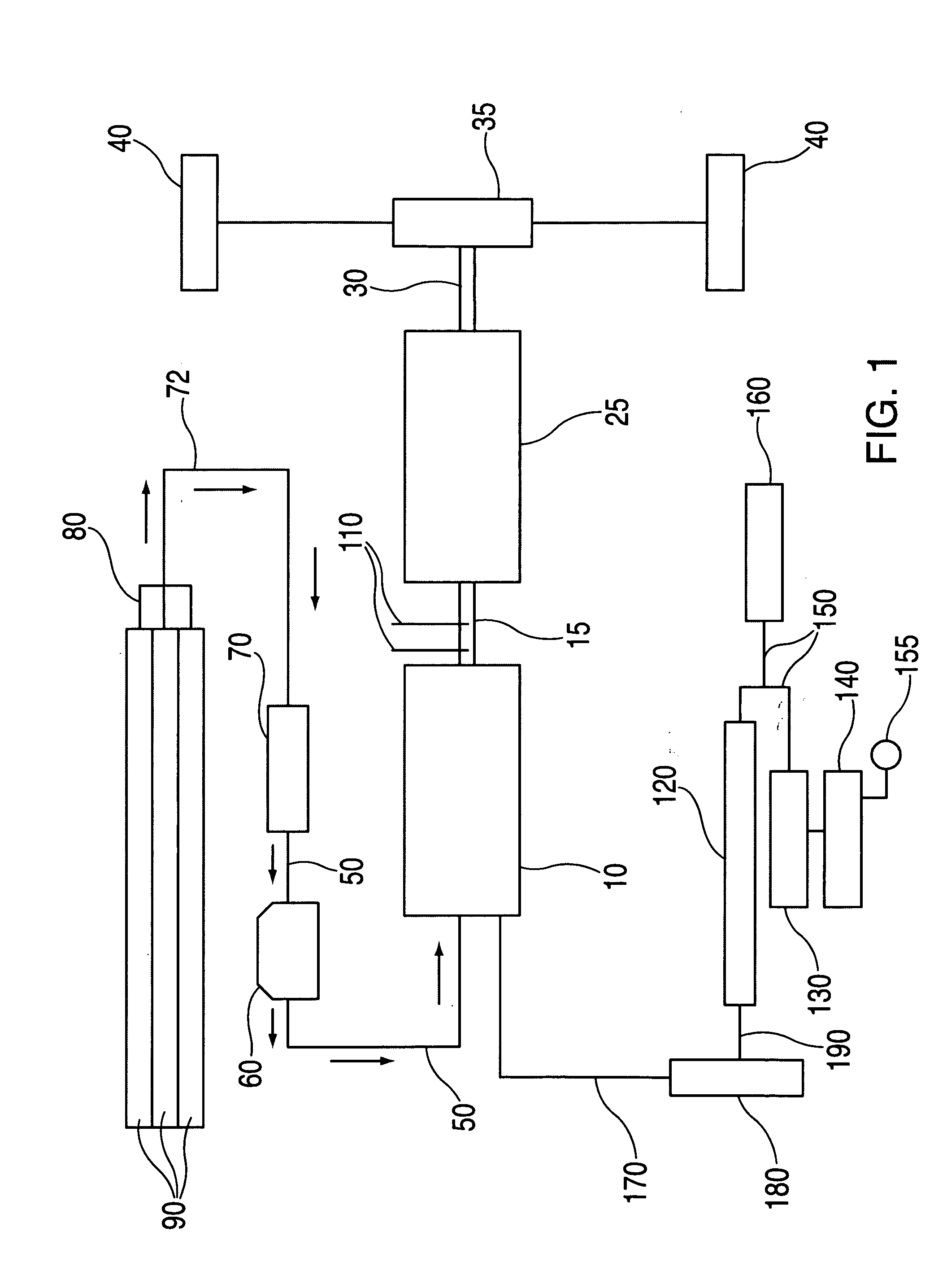

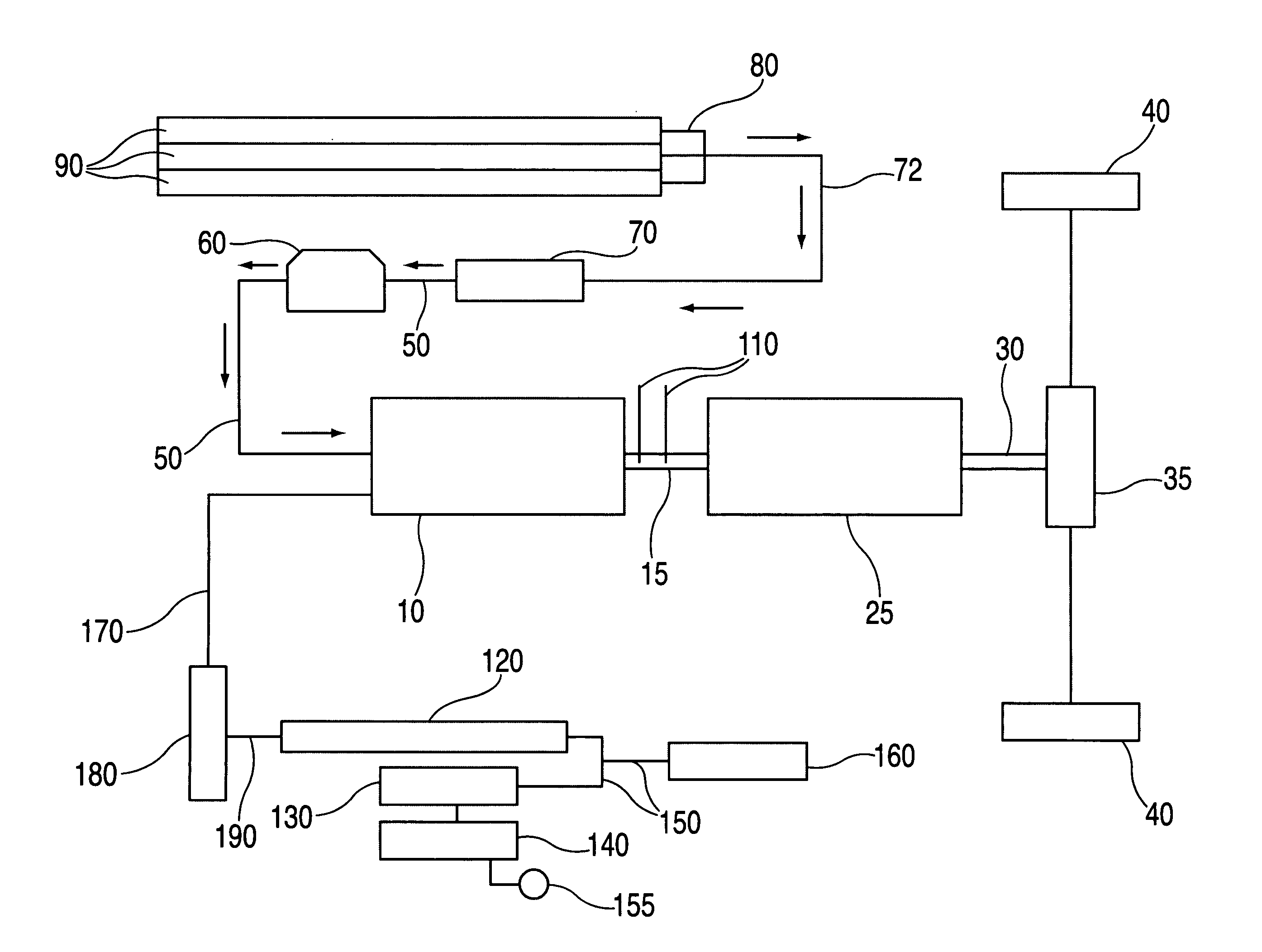

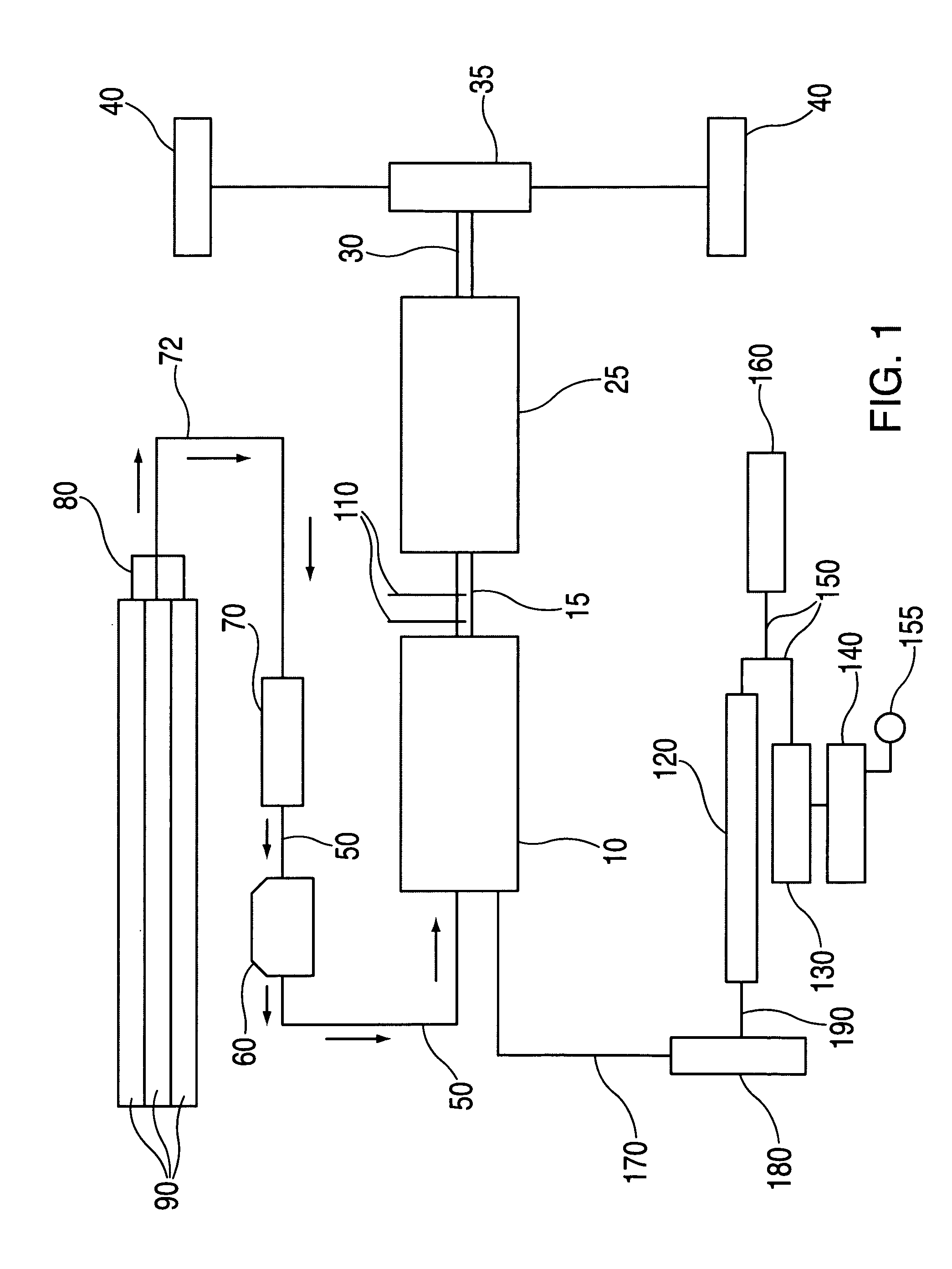

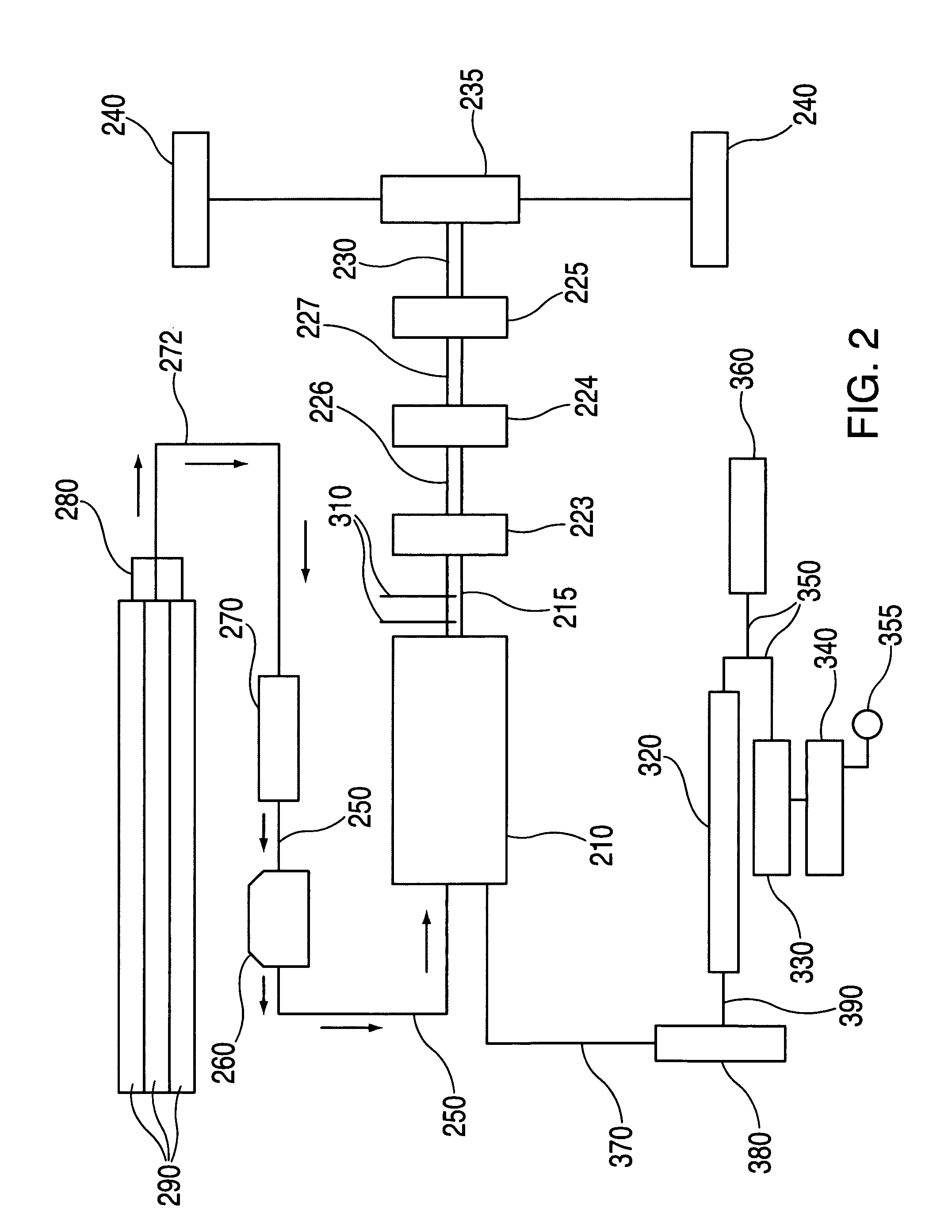

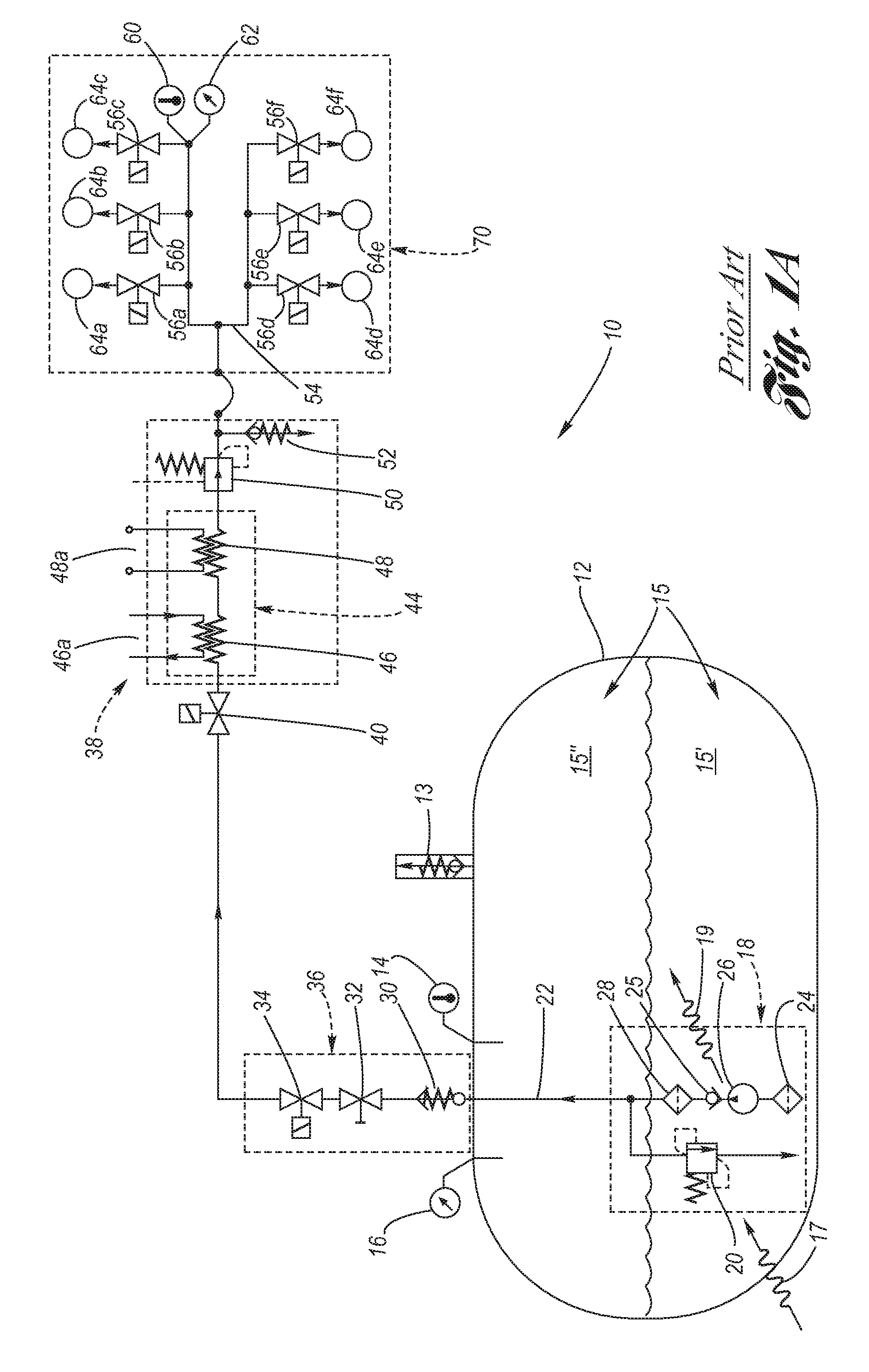

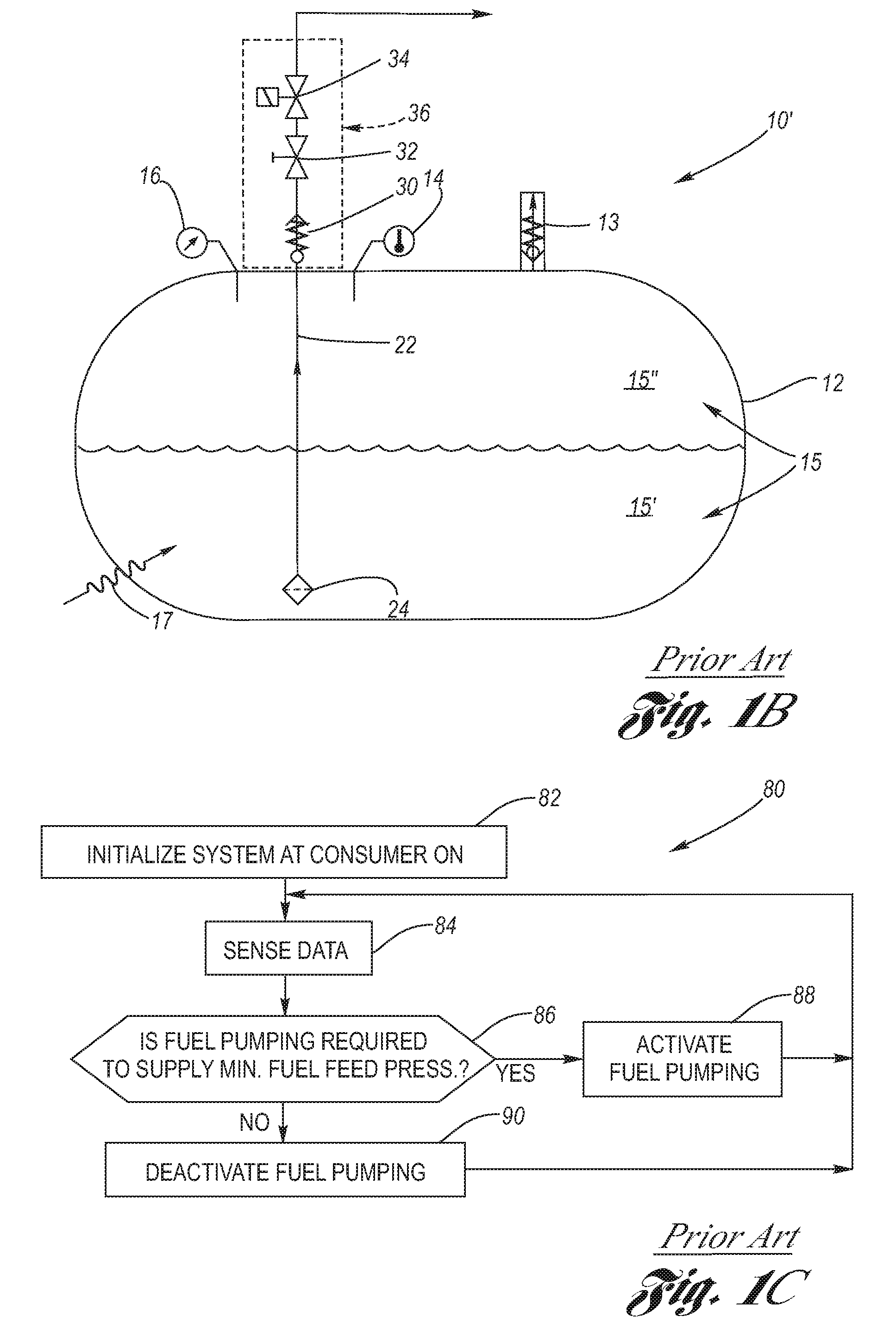

Fuel Tank Temperature and Pressure Management Via Selective Extraction of Liquid Fuel and Fuel Vapor

InactiveUS20120060935A1Low vapor pressureImproved vaporizationElectrical controlInternal combustion piston enginesLiquid fuelFuel vapor

A method and apparatus for managing temperature and pressure of fuel in a fuel tank stored at or near its vapor pressure. In response to fuel feed pressure, a variable ratio of liquid fuel to fuel vapor is extracted from the fuel tank in order to regulate temperature and pressure of the fuel for the purpose of keeping the pressure lower in anticipation of refilling or to assist a vaporizer of the fuel system which is incompletely vaporizing the fuel.

Owner:GM GLOBAL TECH OPERATIONS LLC

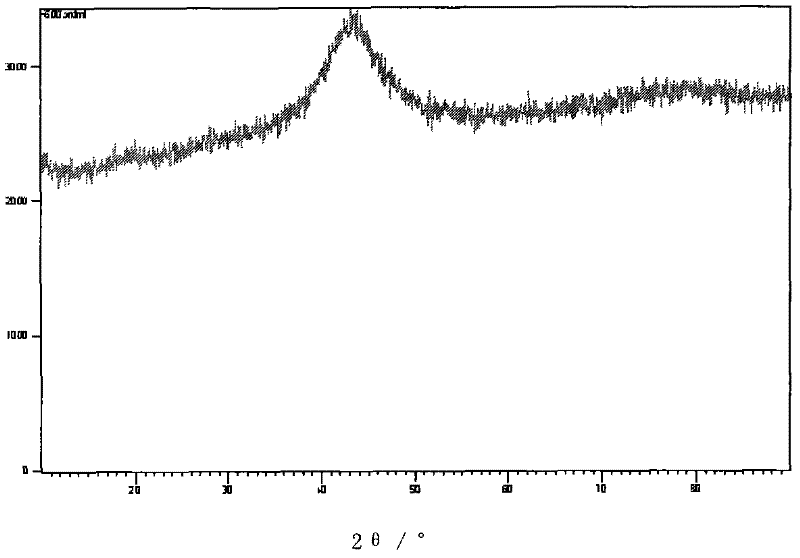

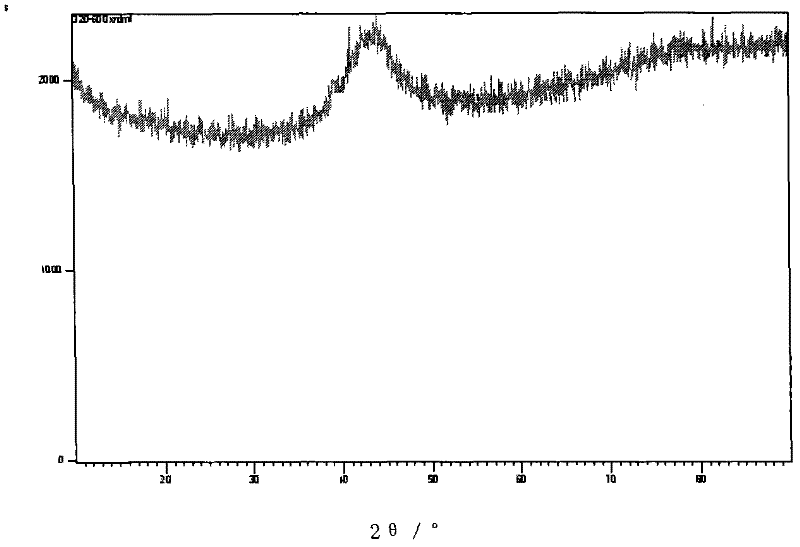

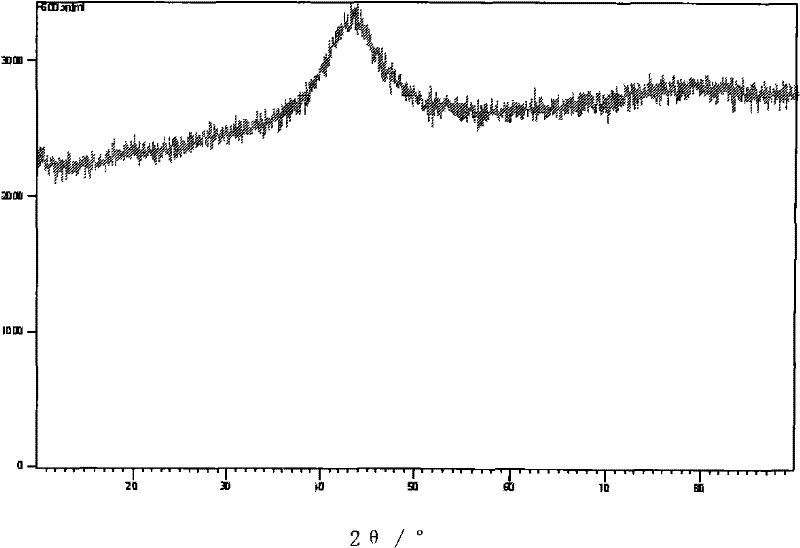

Iron-based amorphous alloy powder, iron-based amorphous alloy coating and preparation method thereof

InactiveCN102534435AAmorphous retentionImprove wear resistancePressure inorganic powder coatingFeed pressureRadiation protection

The invention discloses iron-based amorphous alloy powder capable of forming an amorphous alloy coating, and a method for preparing an amorphous coating. The amorphous alloy powder is taken as a raw material, and a complete amorphous coating is prepared by a cold spray method. The alloy powder mainly comprises Fe, Cr and Mo, can contain one or more of Ni, Co, Mn, Si, Re, Al, Cu, Nb, Zr, Ti, C, B and other elements, wherein Fe, Cr and Mo account for over 70 atomic percent of the alloy. The component has a wide supercooled liquid region and high amorphous forming capacity, amorphous powder can be obtained by an atomization powdering technology. In the process of preparing the amorphous alloy coating by the cold spray method, an inert gas such as nitrogen, helium and the like or a mixed gas of the nitrogen and helium is taken as a powder feeding gas and a powder accelerating gas, the temperature T of the inert gas is less than 700DEG C, and the powder feeding pressure P is 1-6MPa. The coating has a great application prospect in the fields such as wear resistance, corrosion resistance, radiation protection and the like.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

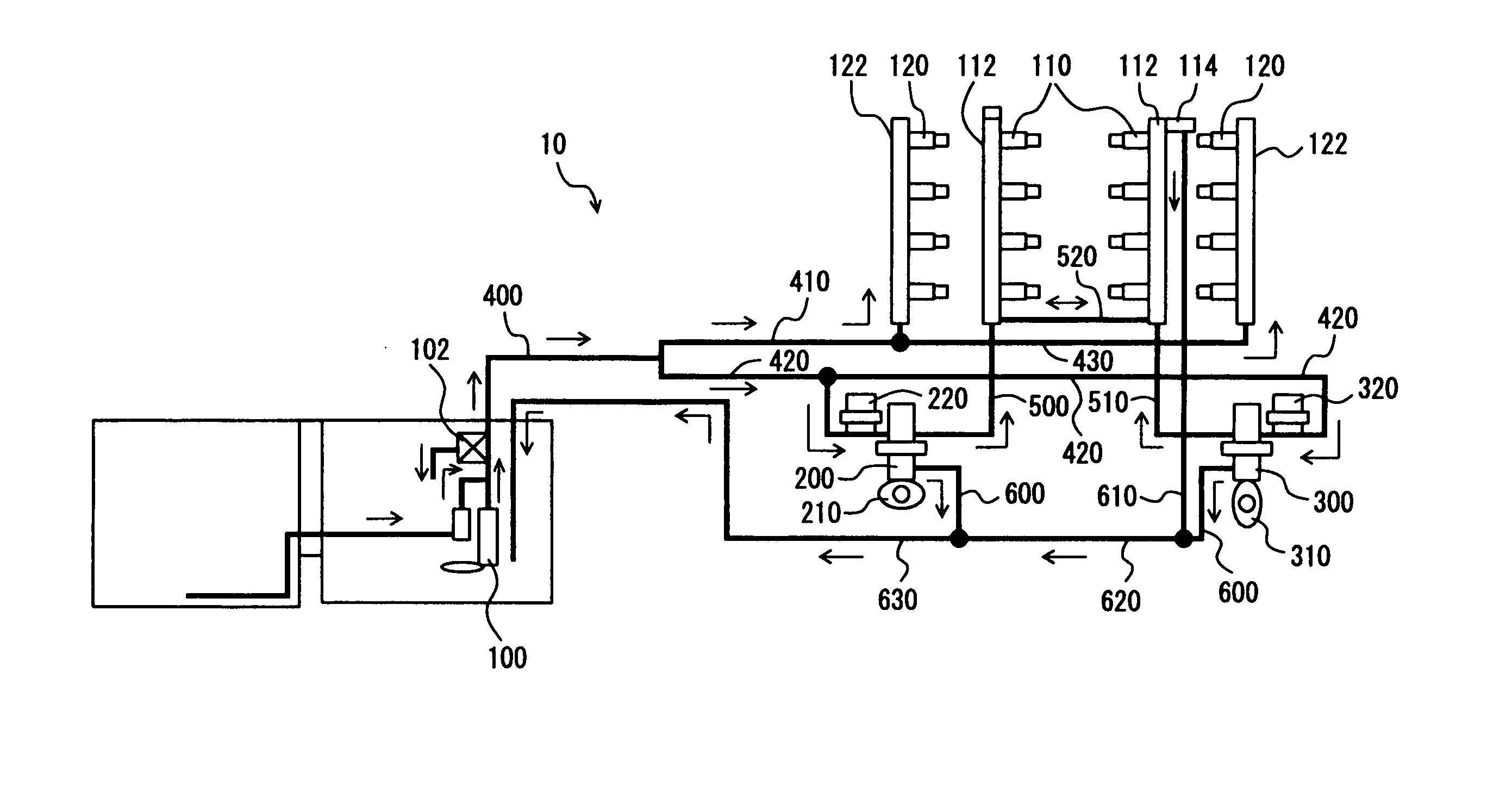

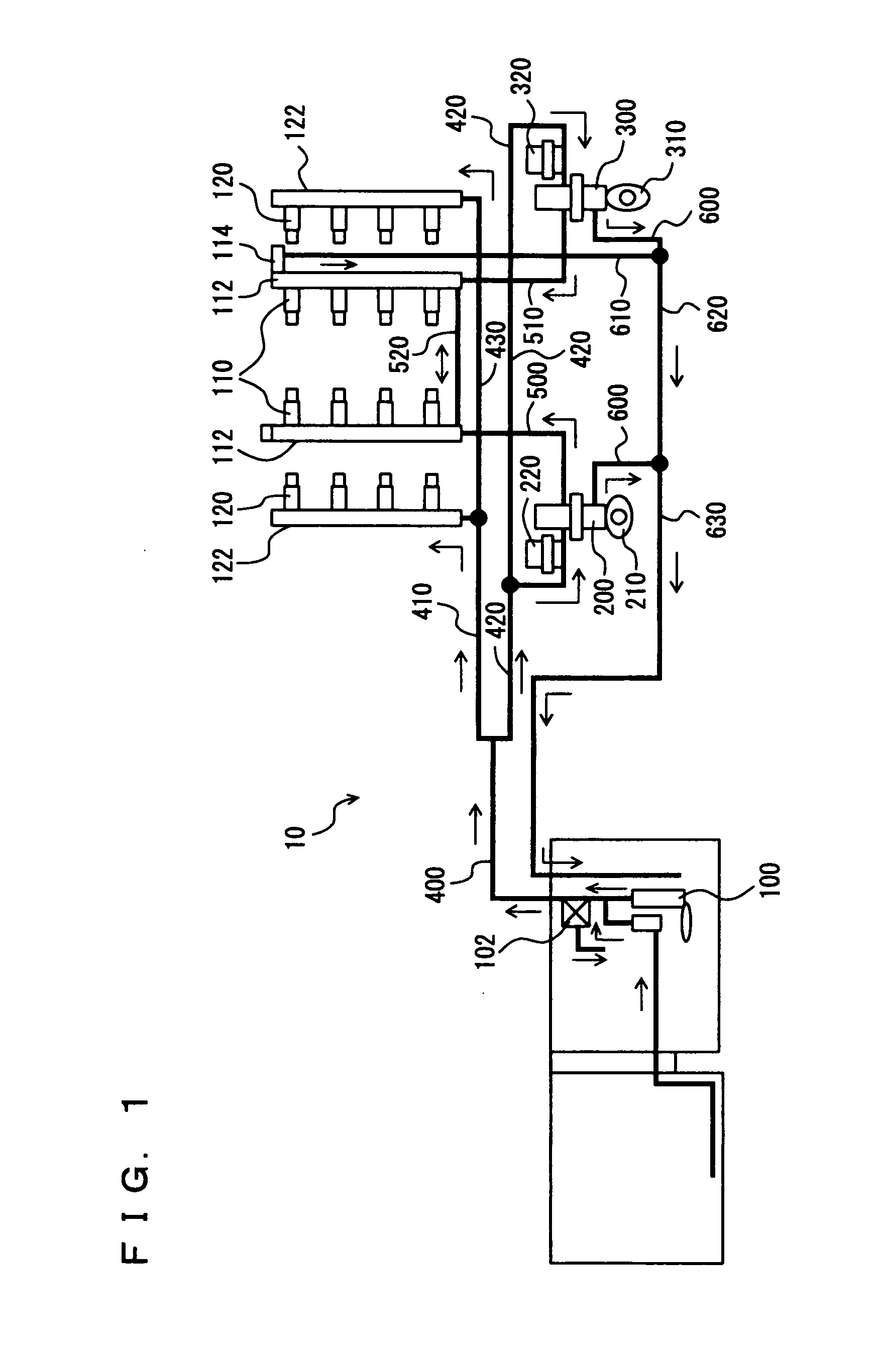

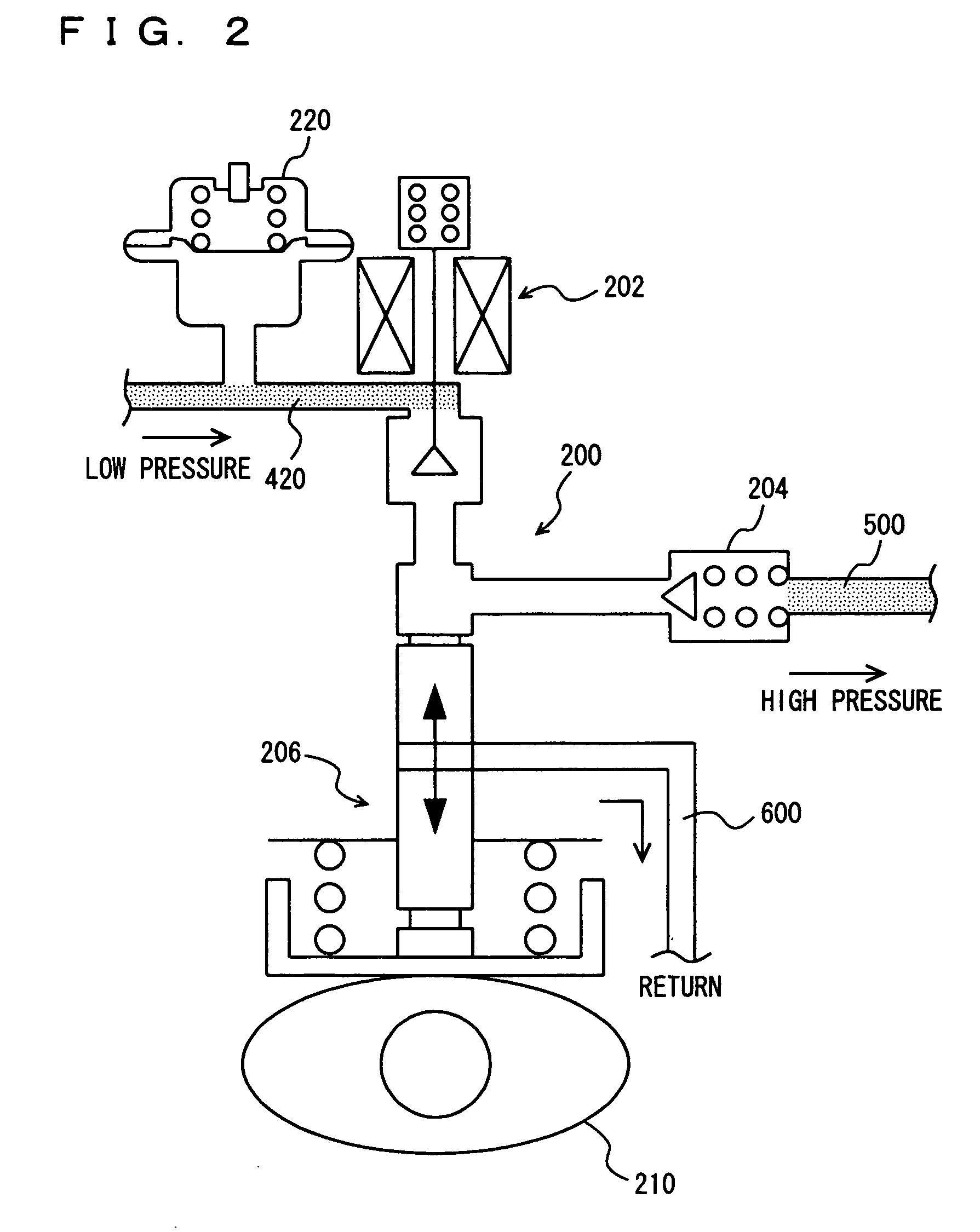

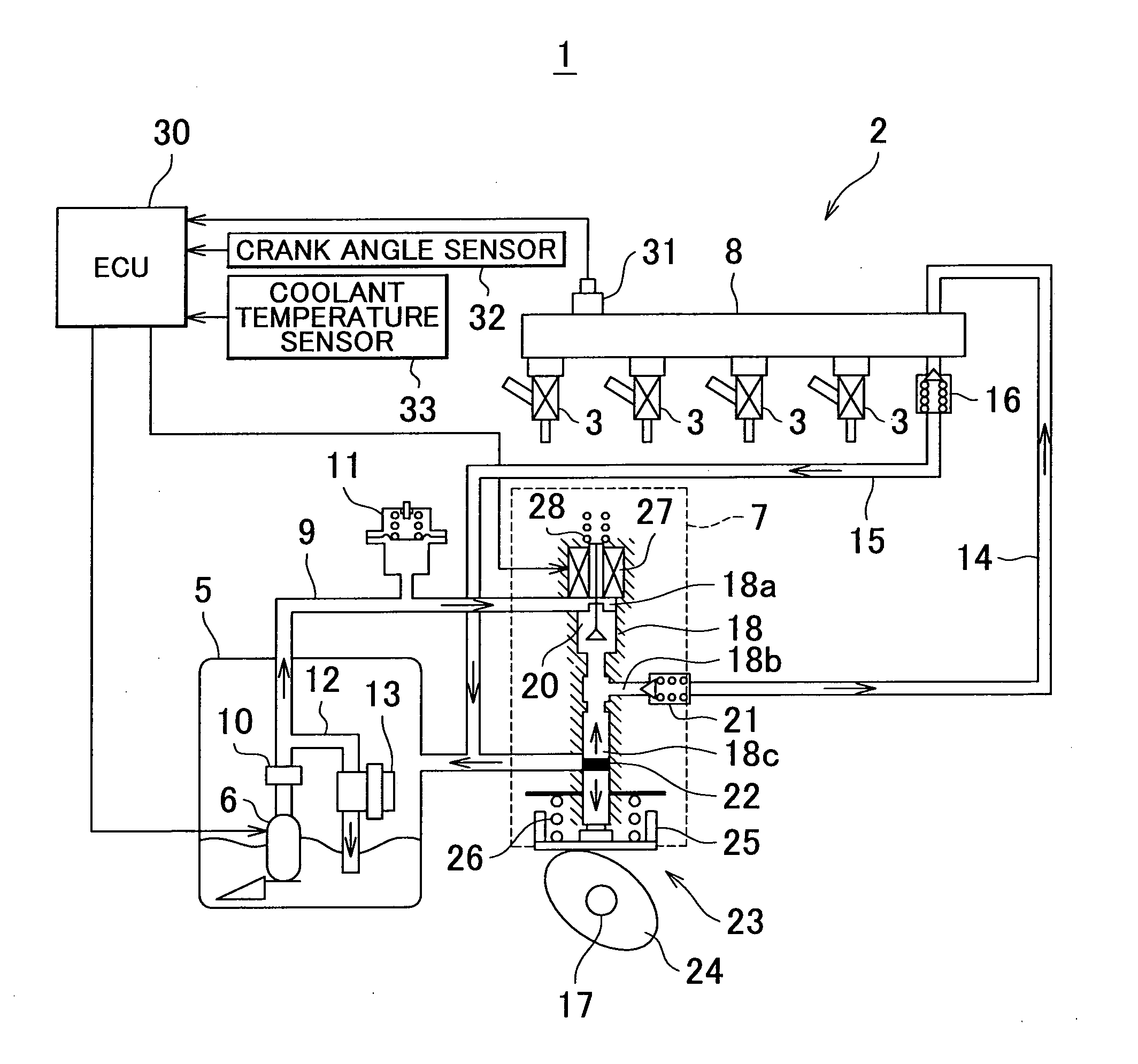

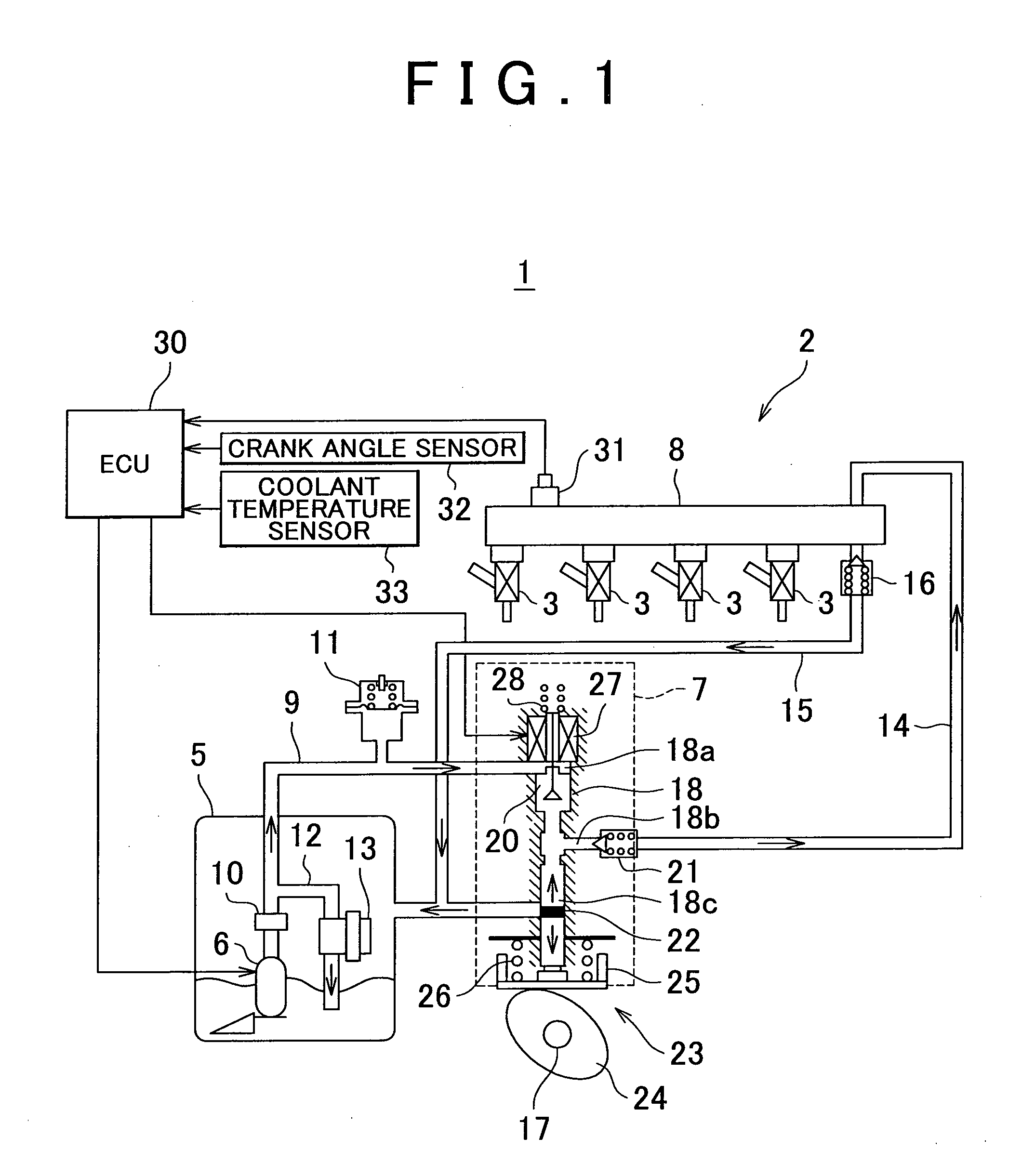

Control device of fuel system of internal combustion engine

InactiveUS20070006849A1Suppressing actuation soundGuaranteed uptimeElectrical controlInternal combustion piston enginesHigh pressureInternal combustion engine

An engine ECU executes a program including the step of detecting an engine speed NE and an engine load, the step of determining whether fuel can be injected at normal feed pressure from an in-cylinder injector during idling, the step of detecting or estimating a fuel temperature T in a high-pressure delivery pipe, the step of stopping the high-pressure fuel pump and injecting fuel from the in-cylinder injector at the normal feed pressure when the fuel temperature T is not greater than T(0), the step of stopping the high-pressure fuel pump and injecting fuel at the pressure greater than the normal feed pressure when the fuel temperature T is greater than T(0) and not greater than T(1), and the step of driving the high-pressure fuel pump to inject the fuel at high pressure when the fuel temperature T is greater than T(1).

Owner:TOYOTA JIDOSHA KK

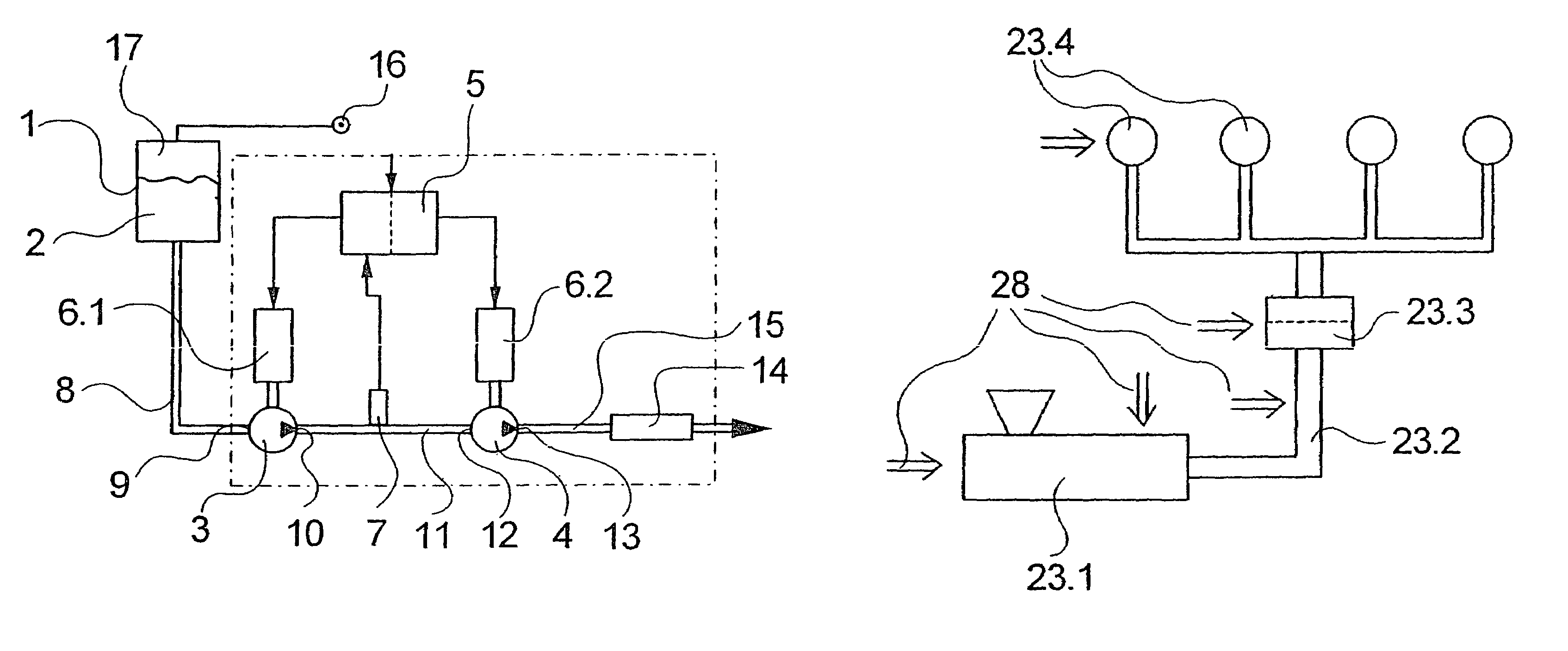

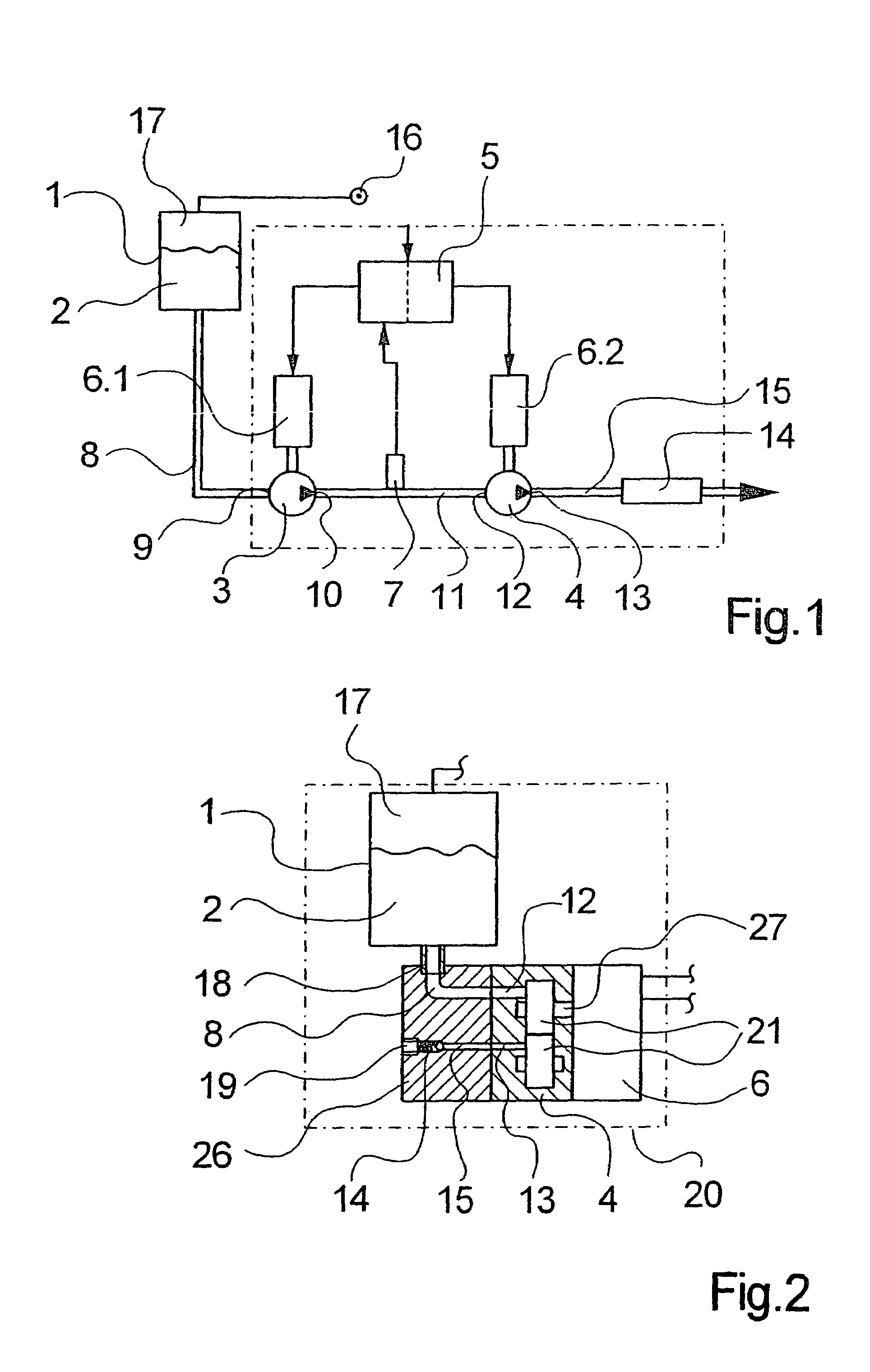

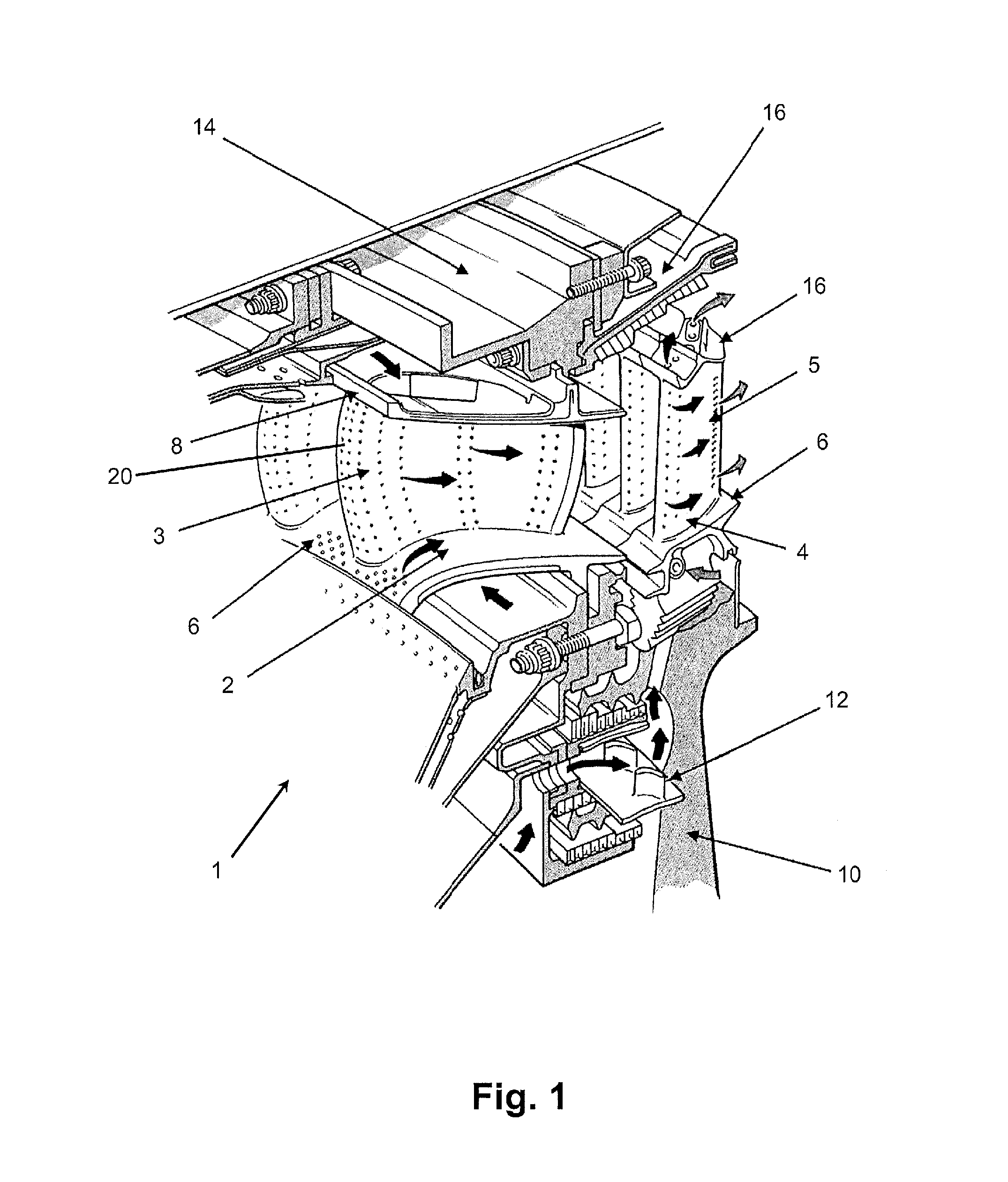

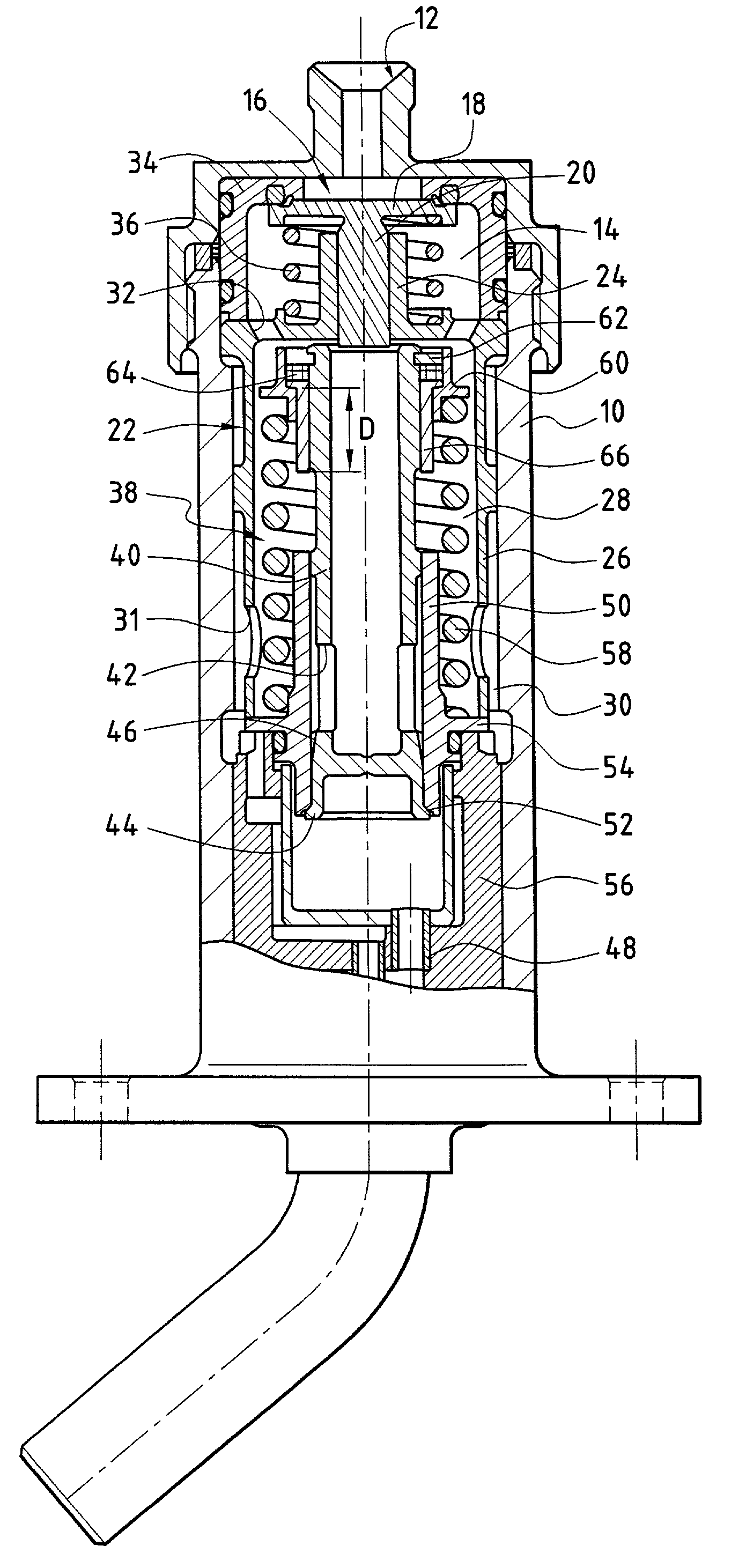

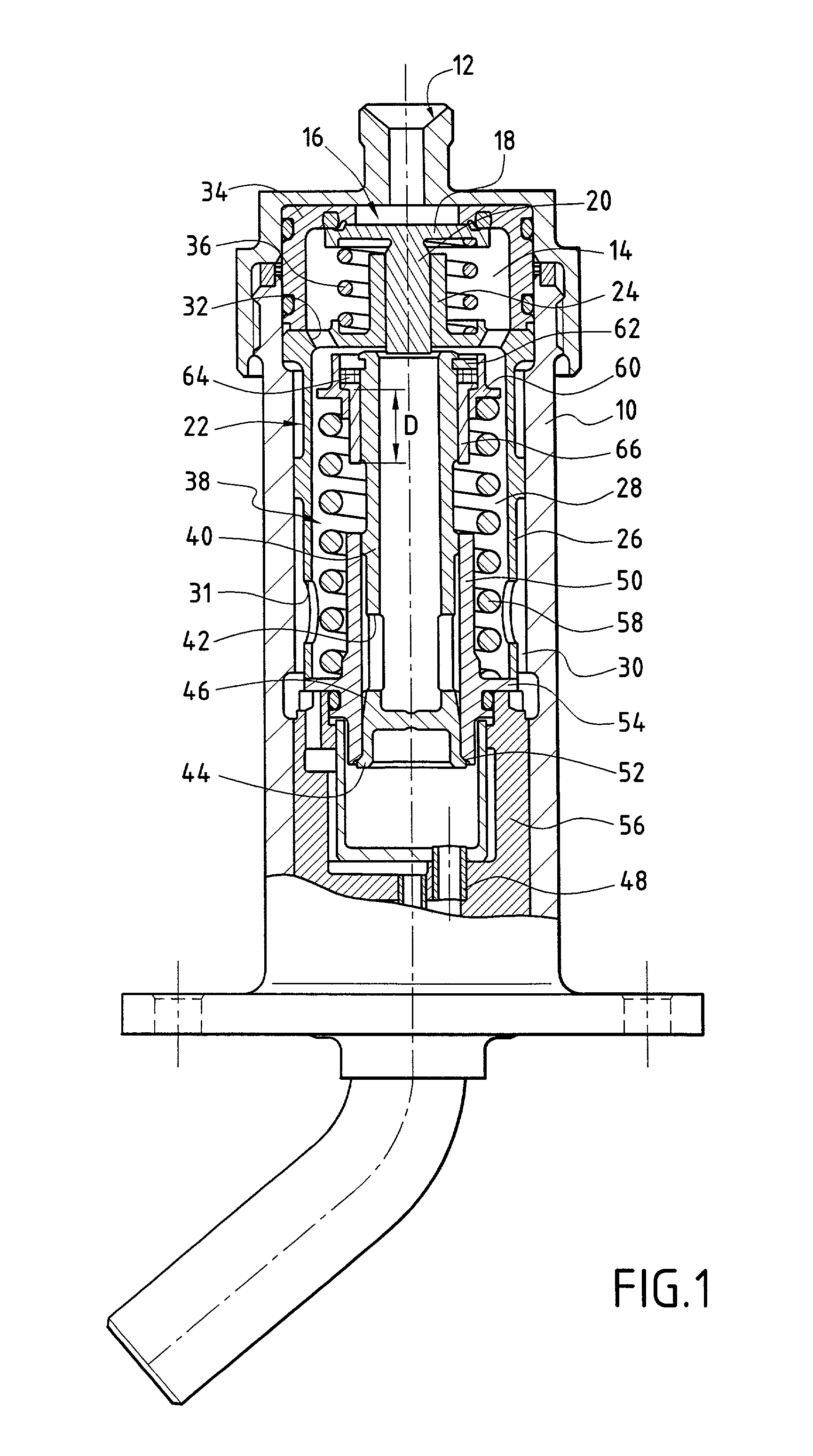

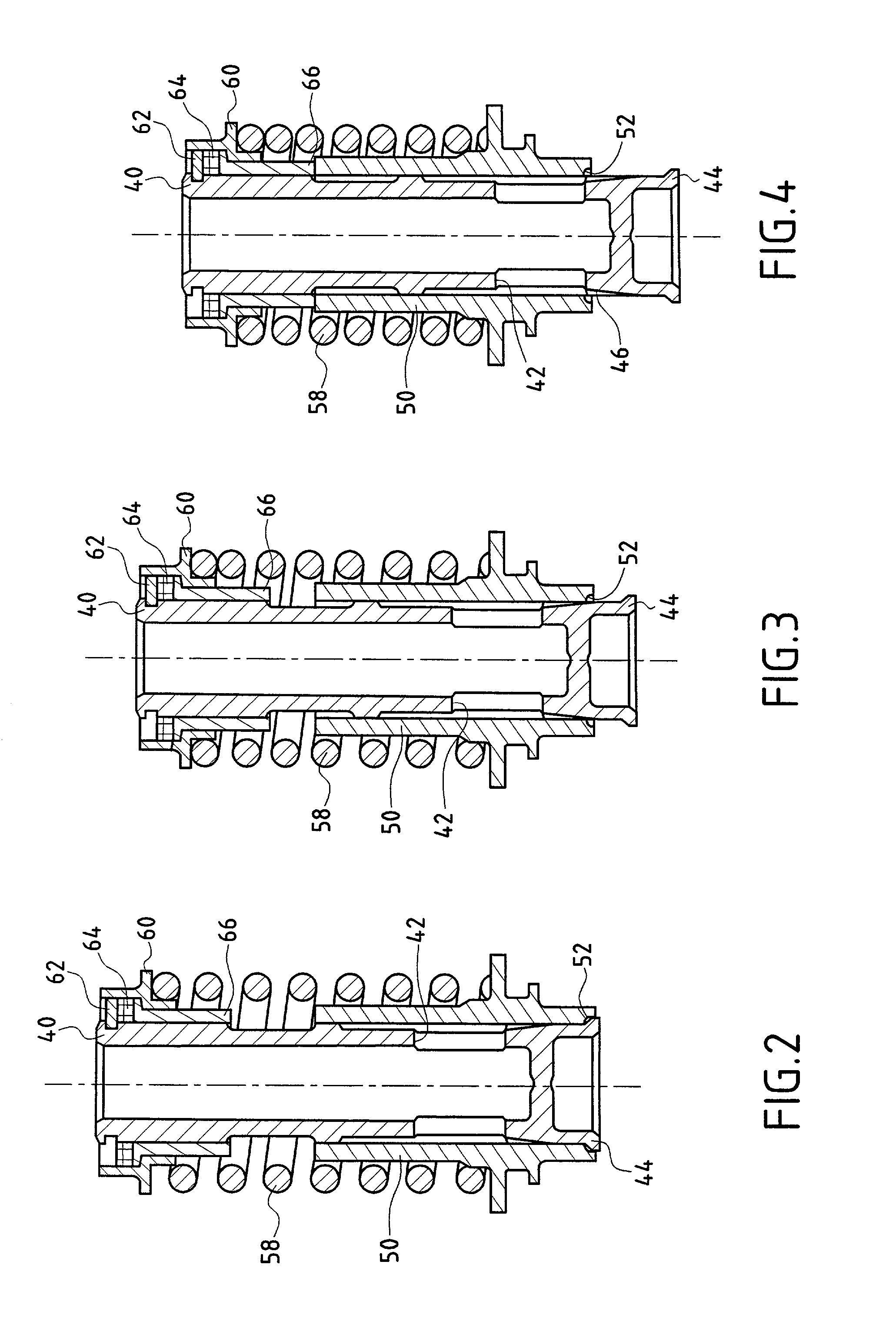

Apparatus and method for injecting a liquid dye into a polymer melt

InactiveUS7278776B2Easy to addImprove accuracyPump componentsSpinning head liquid feederInjection pressureFuel tank

An apparatus and a method for injecting a liquid dye into a polymer melt, which includes a metering pump with a metering inlet and a metering outlet. The metering inlet connects to a dye tank and the metering outlet connects to a polymer melt carrying component. To add the liquid dye to the polymer melt in the melt carrying component in a quantity that is as uniform and accurate as possible, the invention provides for connecting the metering inlet of the metering pump to a feed outlet of a feed pump, which connects with its feed inlet to the tank. With that, it is possible to generate a feed pressure at the metering inlet of the metering pump, which can be adapted to an injection pressure at the metering outlet of the metering pump.

Owner:SAURER GMBH & CO KG

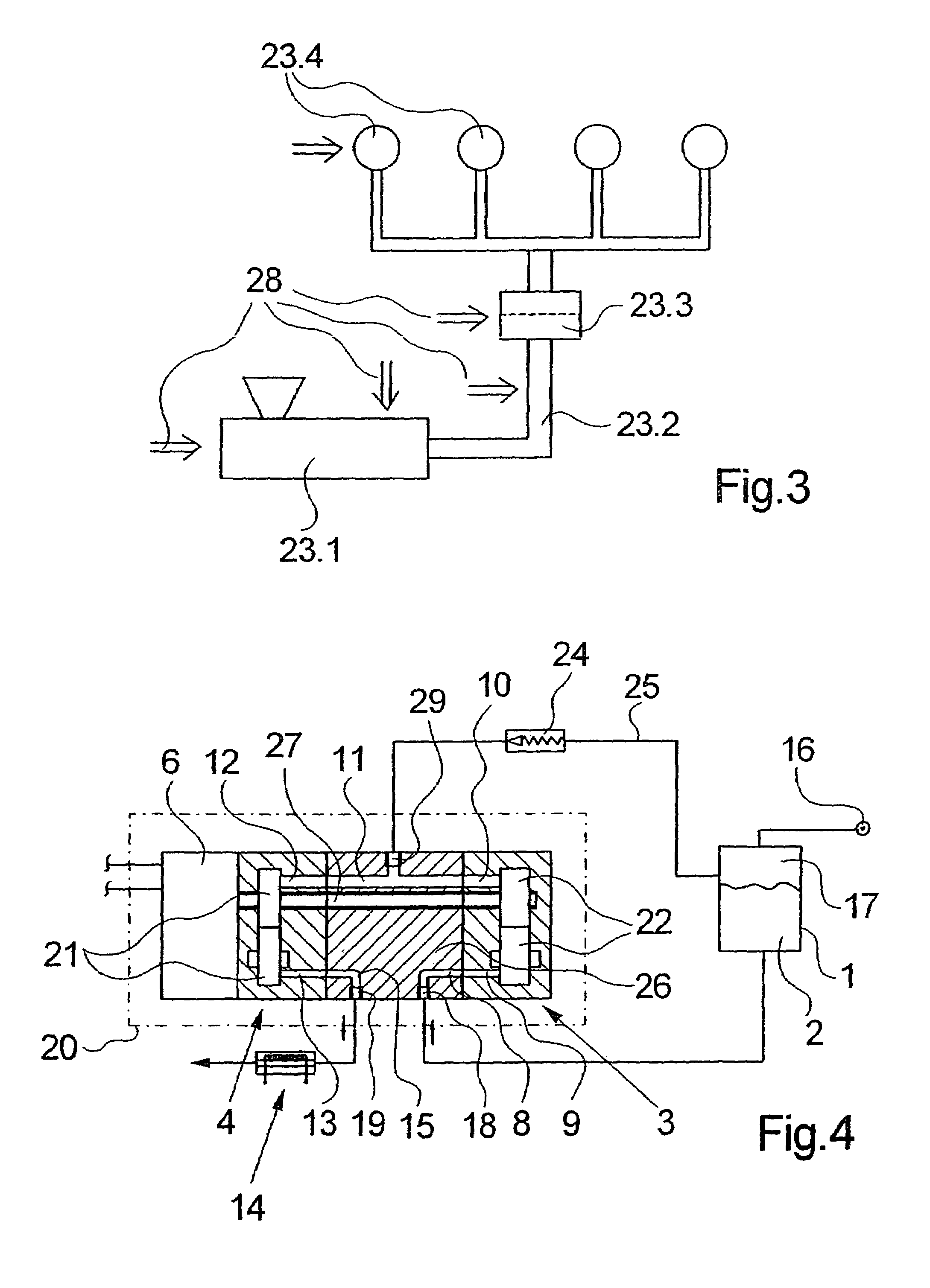

Fuel supply apparatus and fuel supply method for internal combustion engine

InactiveUS20110162622A1Suppress generation of vaporPromote gasificationElectrical controlLow-pressure fuel injectionExternal combustion engineInternal combustion engine

In a fuel supply apparatus for an internal combustion engine, fuel is delivered to a high pressure fuel pump driven by an internal combustion engine, using an electrically-operated low pressure fuel pump, and the fuel pressurized by the high pressure fuel pump is supplied to the internal combustion engine. The fuel supply apparatus includes a low pressure pump control portion that controls the low pressure fuel pump to avoid a discharge failure in the high pressure fuel pump due to insufficiency of a feed pressure at which the low pressure fuel pump delivers the fuel to the high pressure fuel pump. The low pressure pump control portion stops the low pressure fuel pump in a case where the discharge failure in the high pressure fuel pump is avoided even when the feed pressure is equal to a gauge pressure of 0.

Owner:TOYOTA JIDOSHA KK

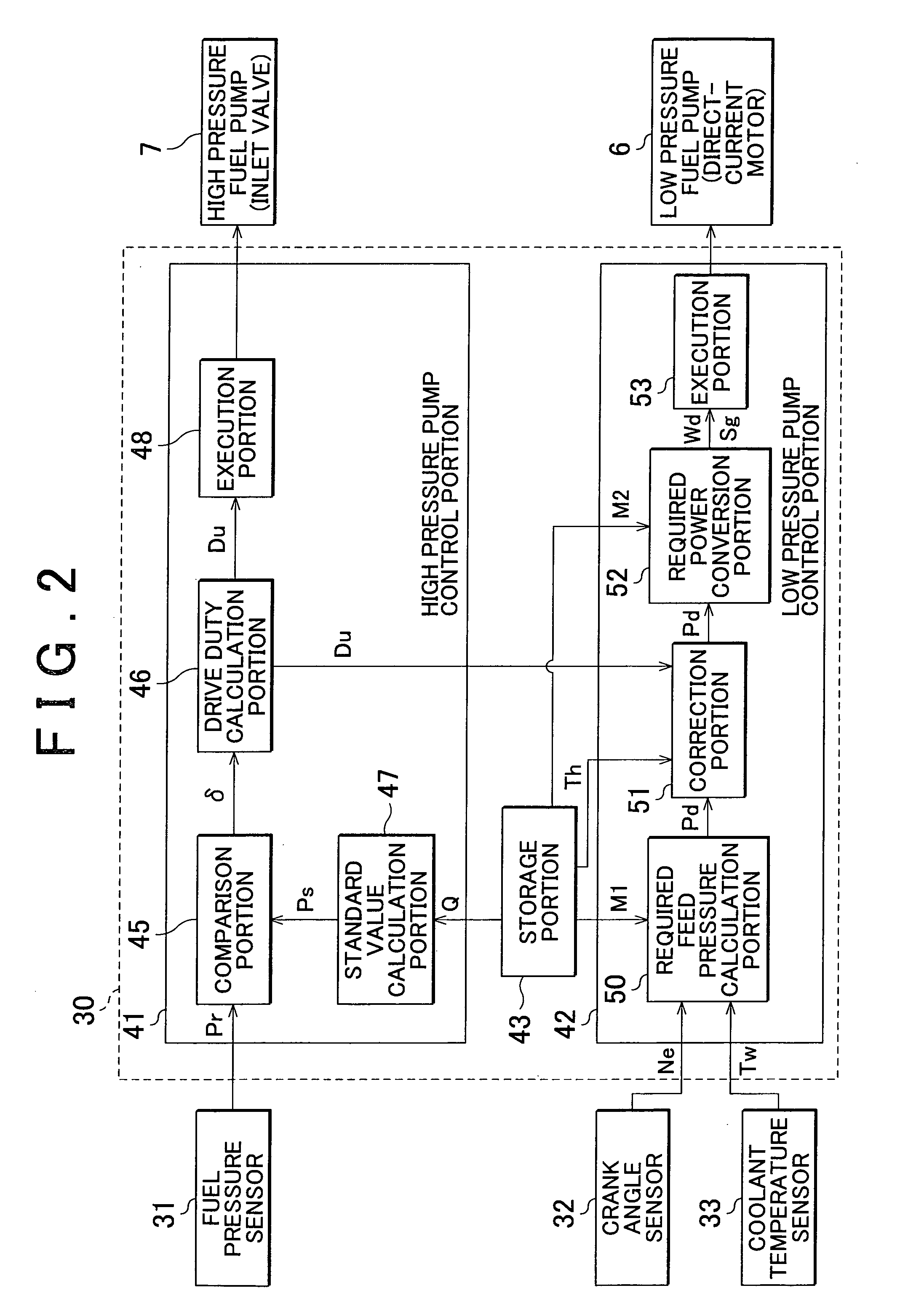

Hand held postage stamp applicator

A hand held stamp dispenser and applicator that feeds pressure sensitive stamps (self-sticking stamps on a backing tape) from a roll. The hand held stamp dispenser and applicator incrementally indexes each stamp by depressing and releasing a manually operated lever press pad. When the lever press pad is depressed three things occur with each press or squeeze that has effect on the dispensing and the application. First, a gear is rotated turning a mandrel to draw the stamp string through a feed channel, thereby, incrementally dispensing a stamp and automatically pealing off the backing tape and exposing the pressure sensitive adhesive. Second, prior to reaching the bottom of the press pad stop point, a latching pawl drops into a gear cog to prevent reversing of the gear and mandrel. Third, a brake pad coupled to the lever press pad bottoms out and presses on the stamp and backing tape in a feed channel locking the stamp string in place so that the stamp can be applied or taken without pulling on the roll of stamps.

Owner:RANDAZZO ANTHONY J

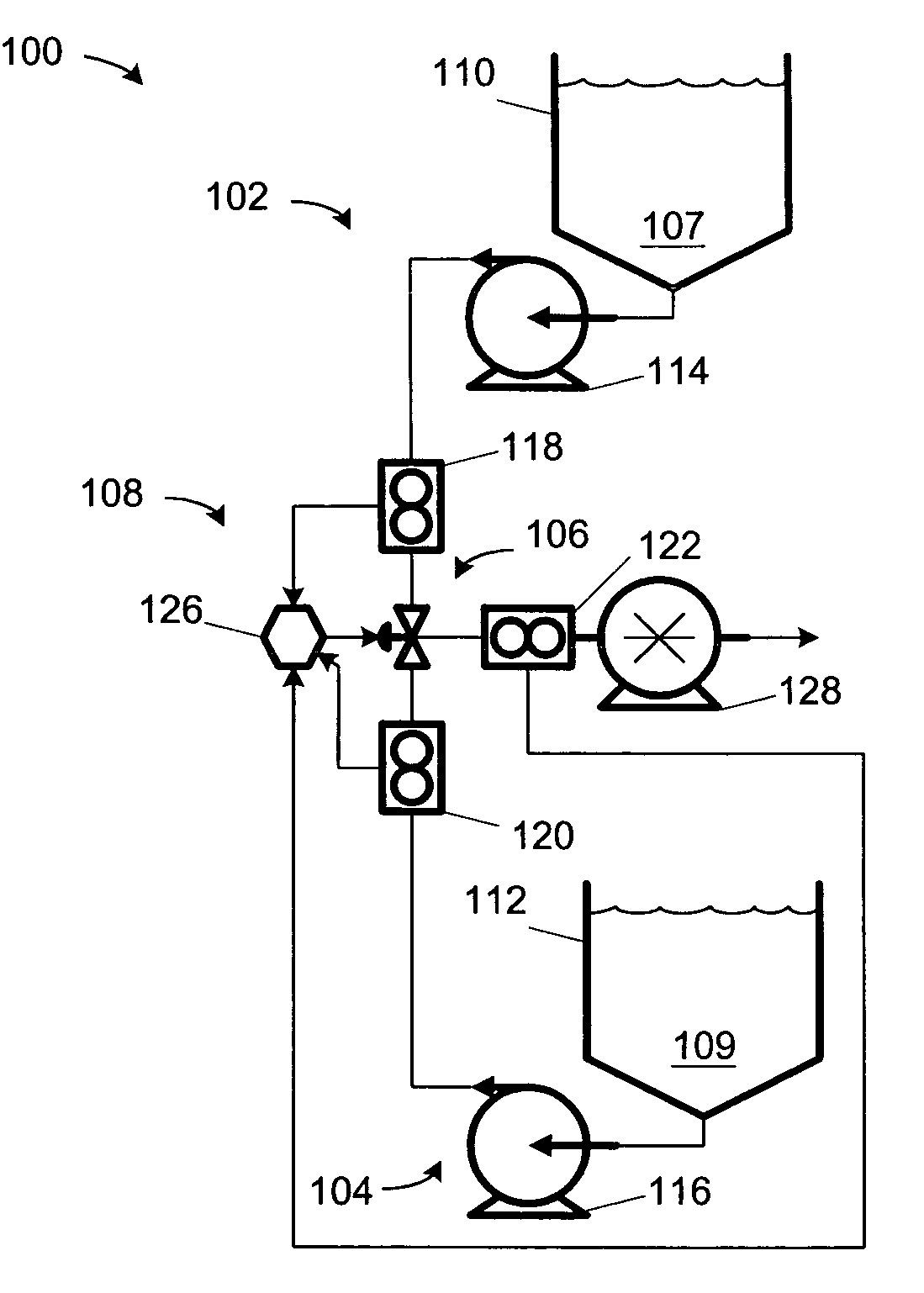

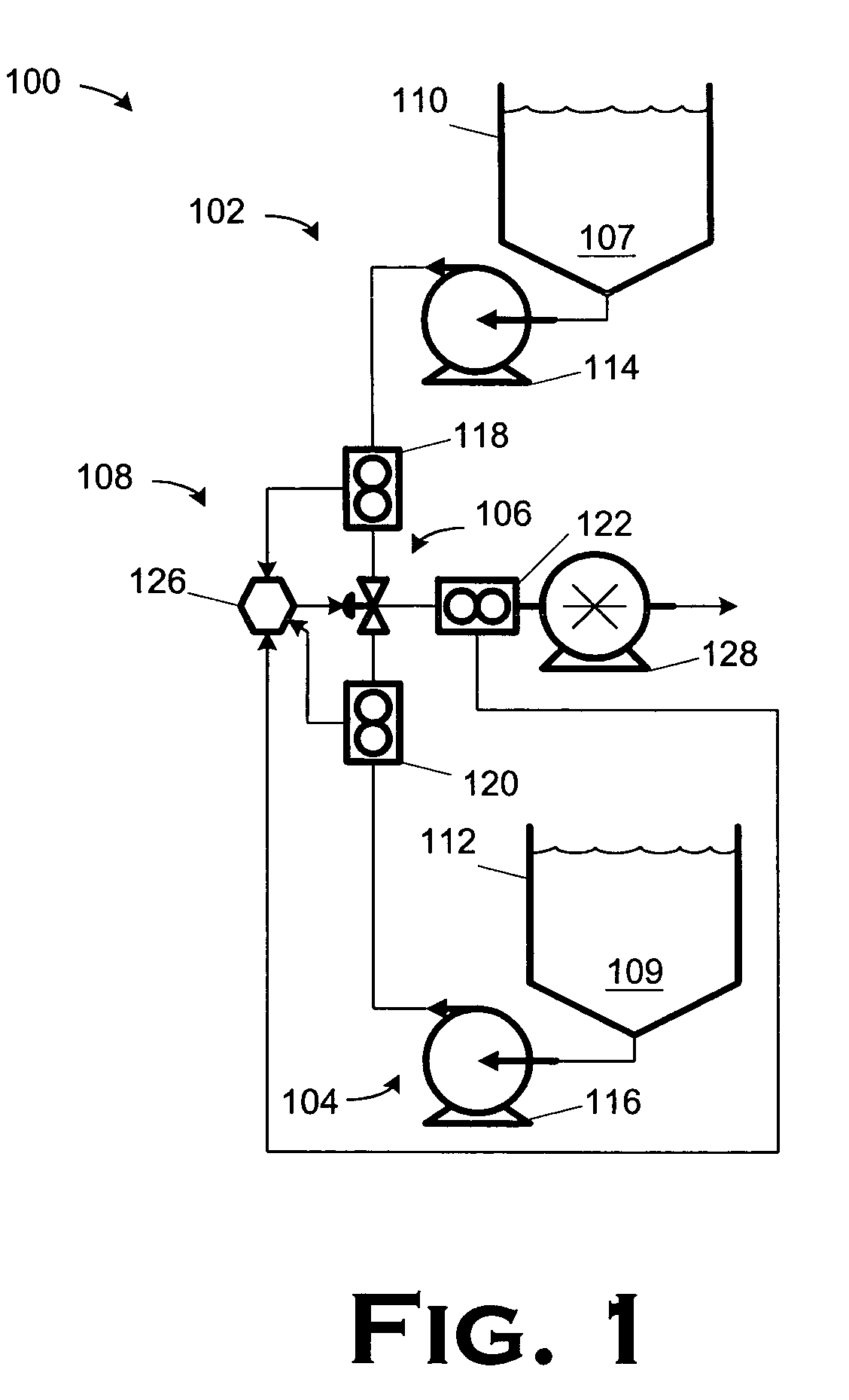

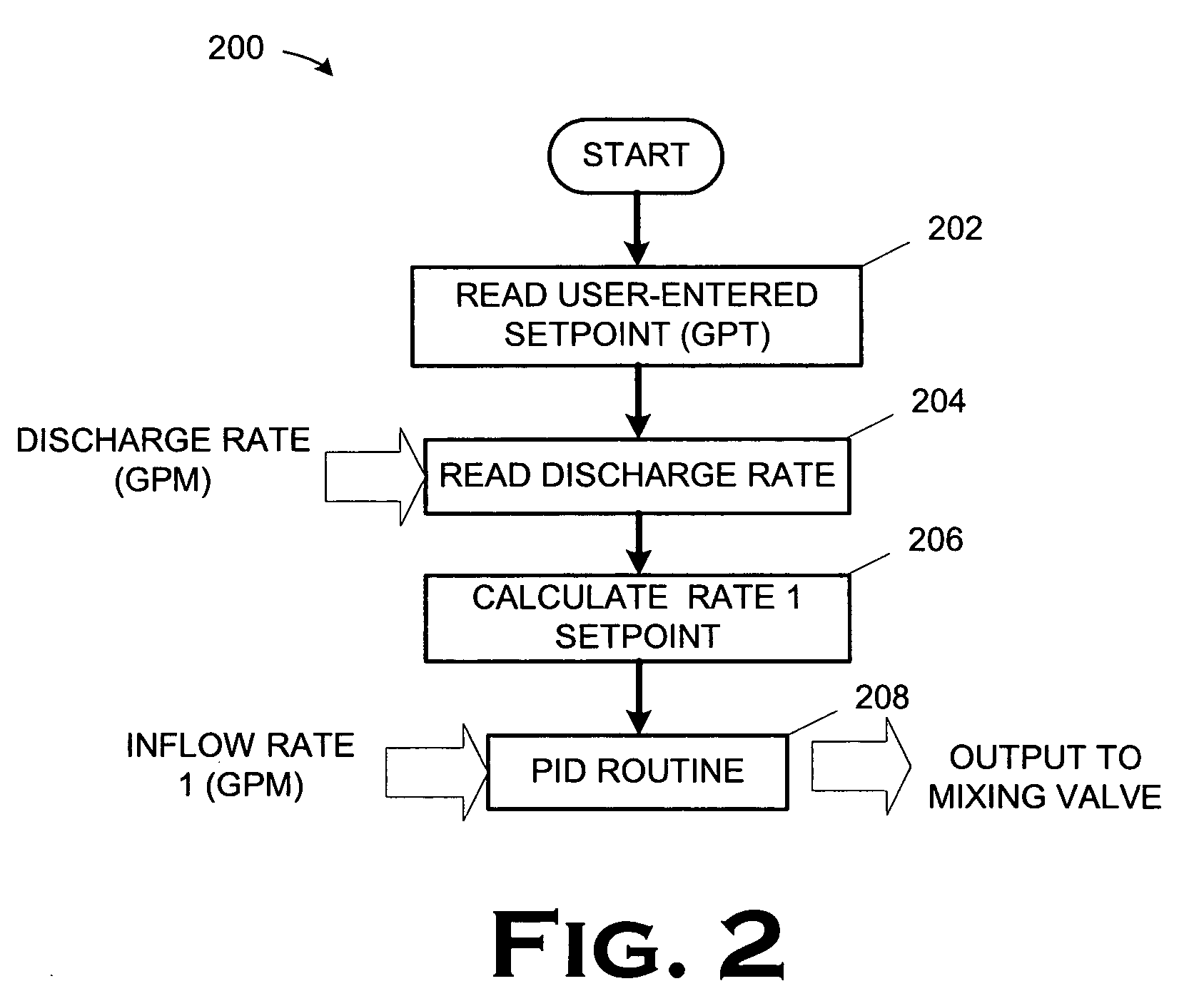

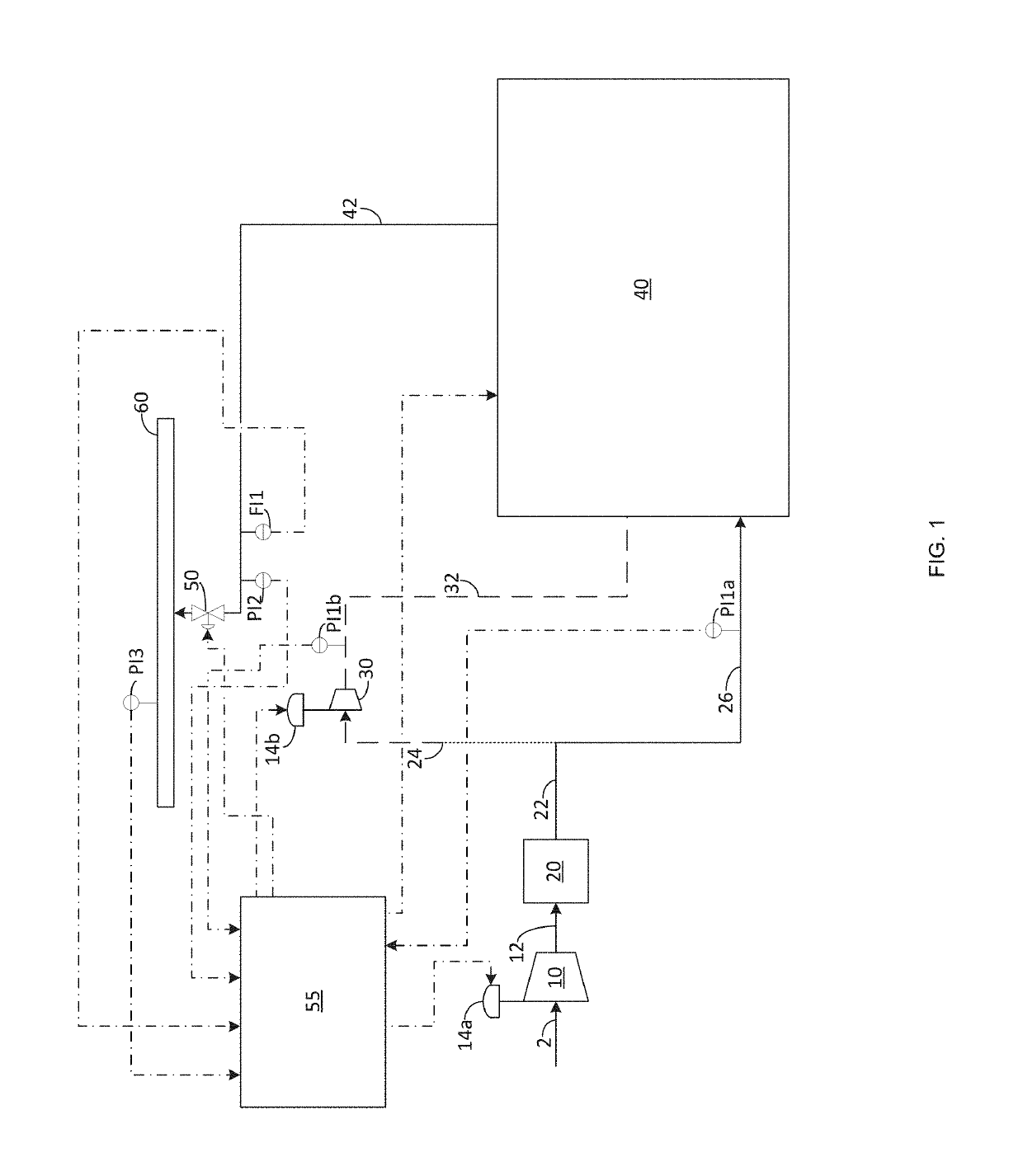

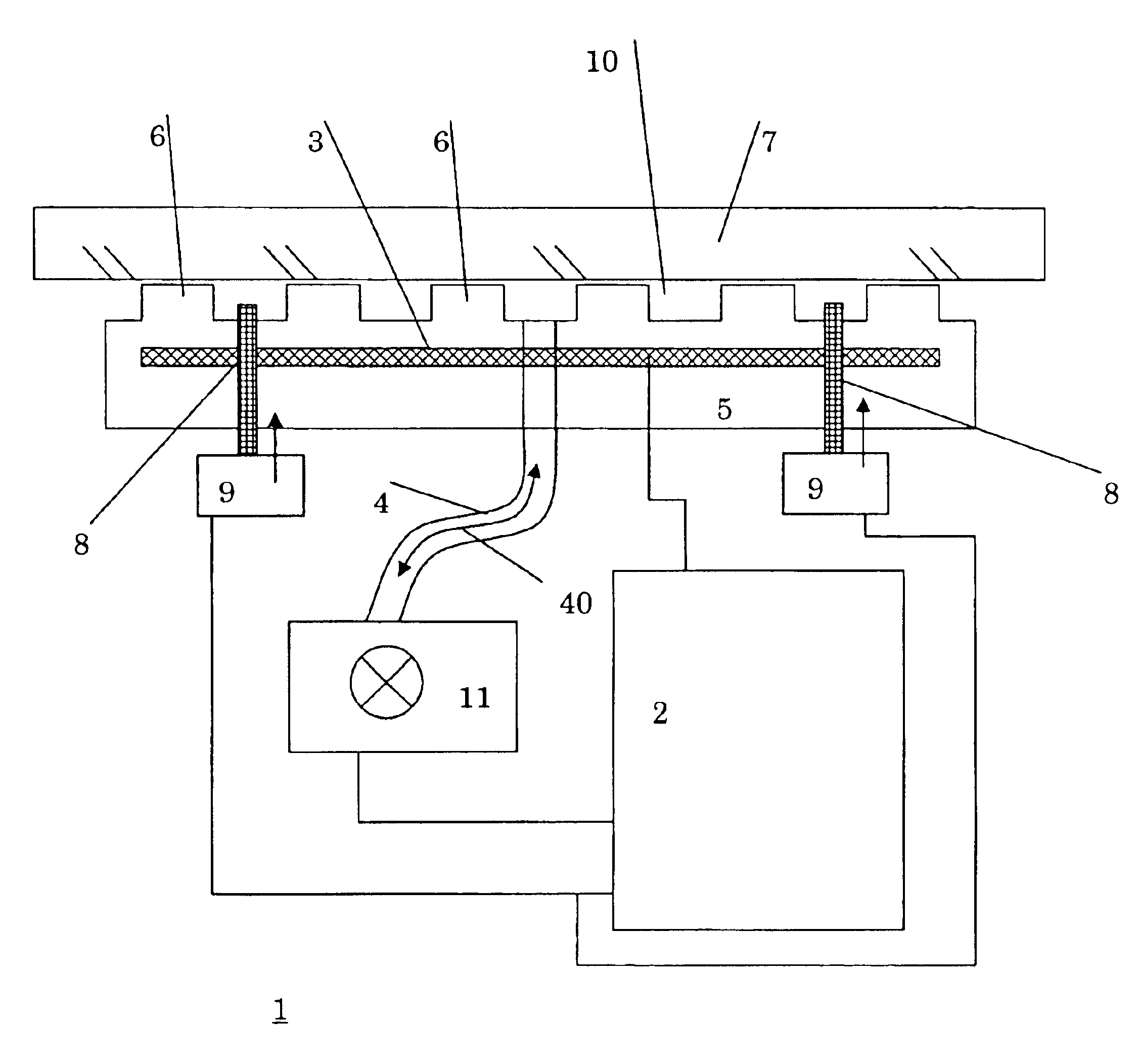

Closed automatic fluid mixing system

InactiveUS20050219945A1Keep the pressureControlling ratio of multiple fluid flowsFlow mixersHybrid systemControl system

A closed automatic fluid mixing apparatus and method for mixing two fluids while maintaining a feed pressure of the mixed fluid at a predetermined level are disclosed. The apparatus comprises a first fluid feed, a second fluid feed, a mixing valve, and a closed control system. The mixing valve is capable of mixing a first fluid received from the first fluid feed and a second fluid received from the second fluid feed to produce a mixed fluid. The closed control system is capable of controlling the mixing valve to determine the ratio of the first and second fluids in the mixed fluid while maintaining the pressure of the mixed fluid at a predetermined level. The method comprises feeding a first fluid and a second fluid to a mixing valve; mixing the first and second fluids therein; and controlling the mixing valve's actuation of to determine the ratio of the first and second fluids in a resultant mixed fluid while maintaining the pressure of the mixed fluid at a predetermined level.

Owner:BJ SERVICES CO

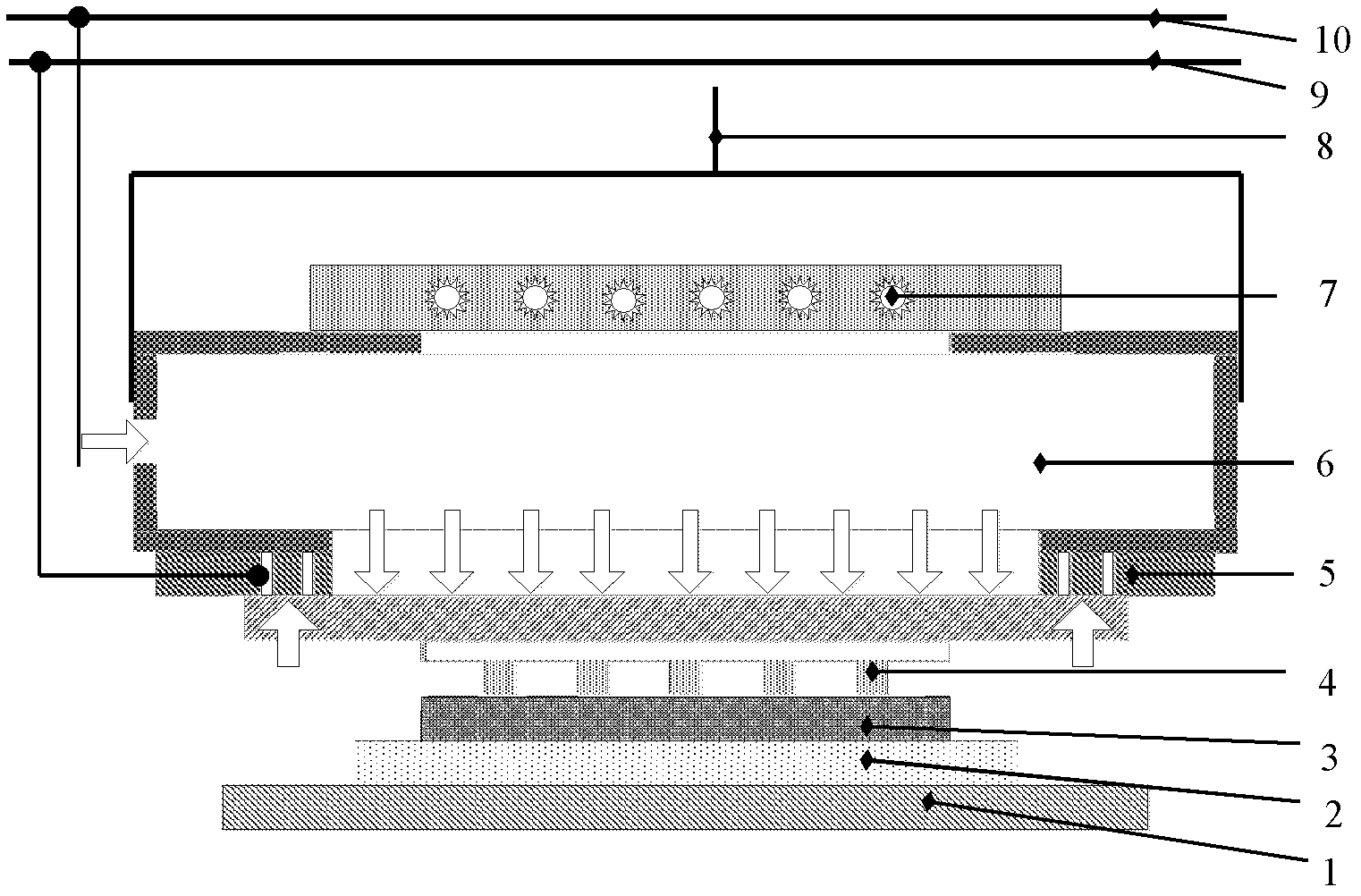

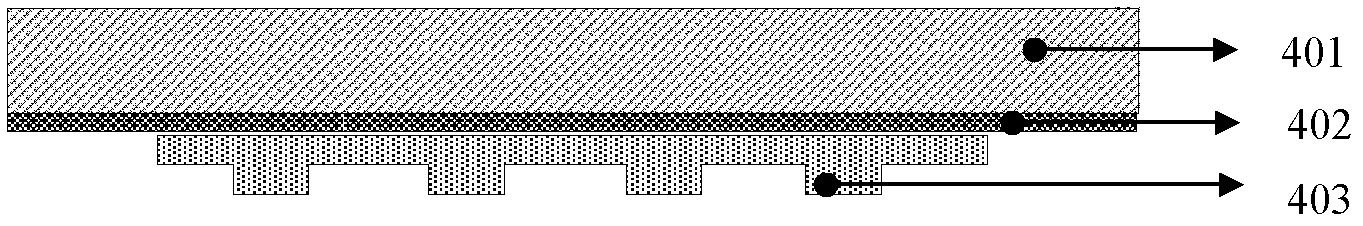

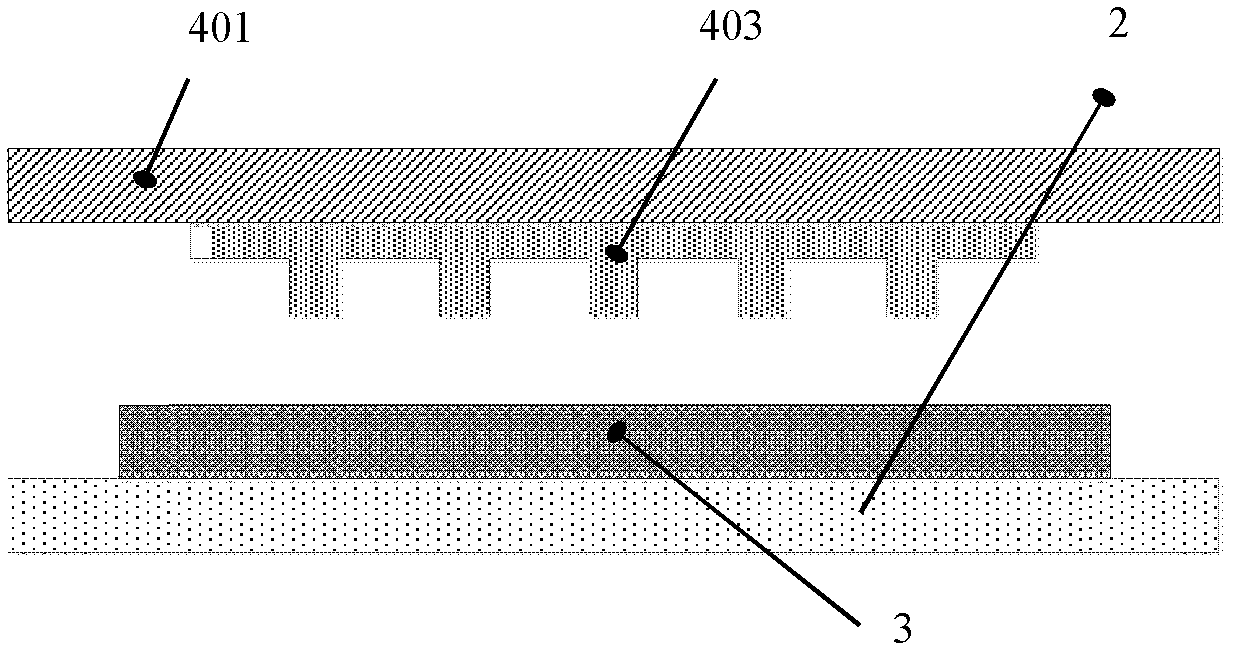

Device and method for large-area nano imprinting photoetching

ActiveCN102591143AHigh elastic modulusHigh complex precisionPhotomechanical apparatusNano structuringFluid control

The invention discloses a device and a method for large-area nano imprinting photoetching. A fluoropolymer-based thin film structure composite soft mould is introduced, and a gas assisting pressing mode and a mould micro-feed pressure pressing mode are adopted in the imprint process. The demoulding is carried out on the basis of low surface energy of a fluoropolymer base by a two-time solidifying and revealing type demoulding method, and thus the large area demoulding can be realized by small demoulding power. The device and the method for the large-area nano imprinting photoetching, disclosed by the invention, realize that a large-area nano-structure can be manufactured on various kinds of substrates, such as uneven (bent, cocked or stepped) substrates, curved substrates, or fragile substrates, and have the obvious advantages of high complex precision, large imprinting area, high efficiency, and low cost and a mould is long in service life. The device and the method for the large-area nano imprinting photoetching are suitable for LED (light emitting diode) nano-imaging technology and manufacturing of optical devices (such as optical lenses), butterfly solar condensers, micro-fluid control devices and the like.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

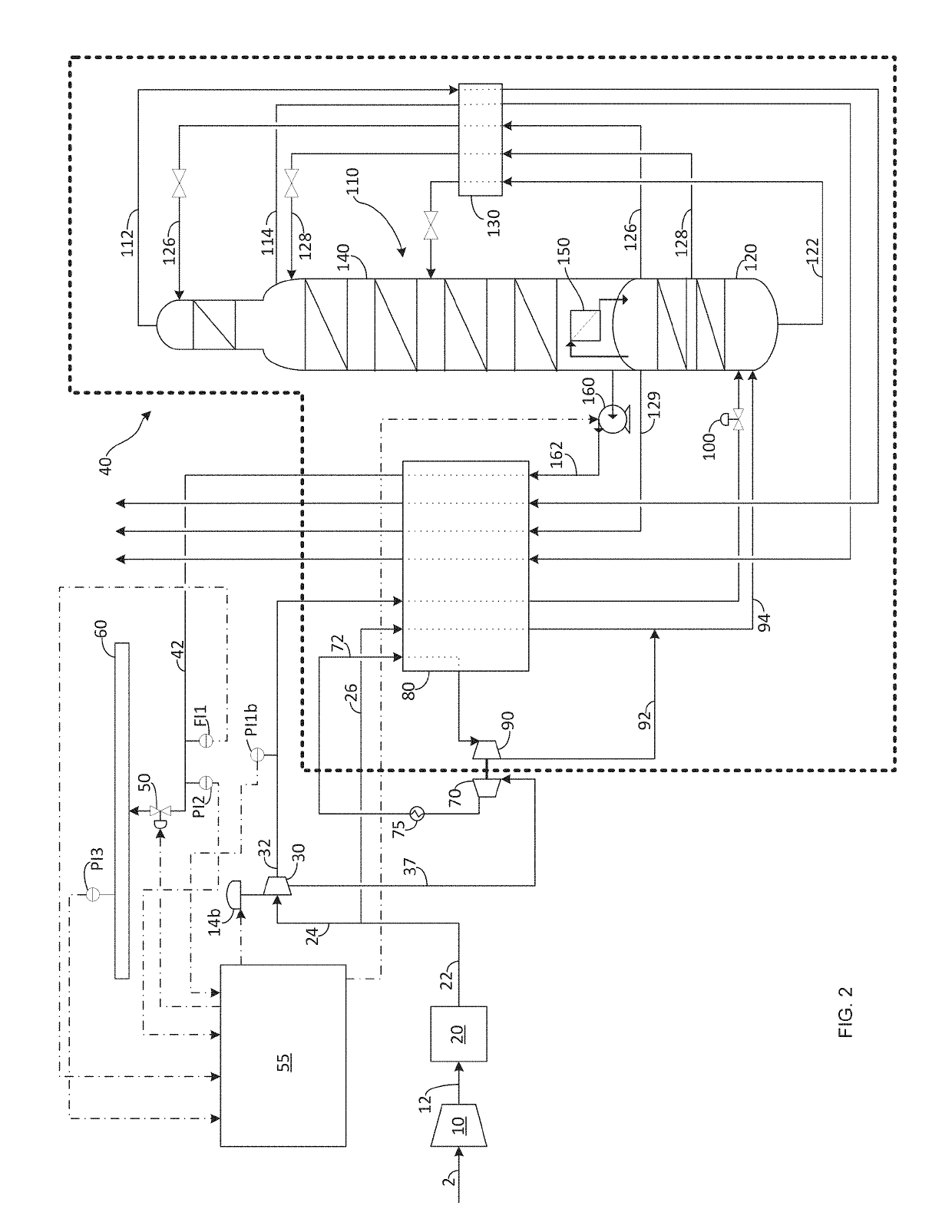

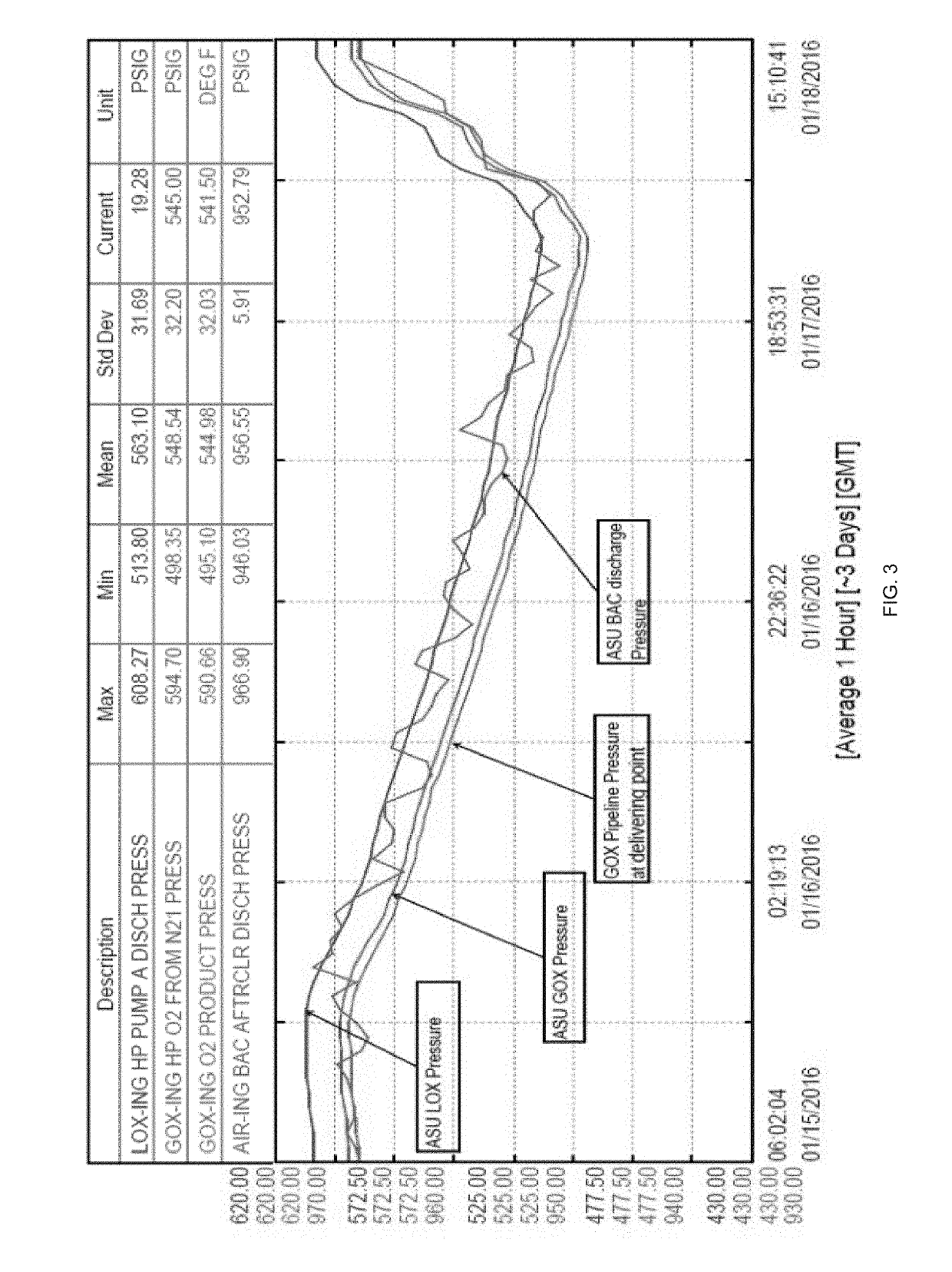

Method for the production of air gases by the cryogenic separation of air

A method for the production of air gases by the cryogenic separation of air can include the steps of sending a purified and compressed air stream to a cold box under conditions effective for cryogenically separating the air stream into an oxygen product and nitrogen using a system of columns, wherein the purified and compressed air stream is at a feed pressure when entering the system of columns; withdrawing the oxygen product at a product pressure; delivering the oxygen product at a delivery pressure to an oxygen pipeline, wherein the oxygen pipeline has a pipeline pressure; wherein during the second mode of operation, the method can include monitoring the pipeline pressure; and reducing the difference between the pipeline pressure and the delivery pressure. By operating the method in a dynamic fashion, a power savings can be realized in instances in which the pipeline pressure deviates from its highest value.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

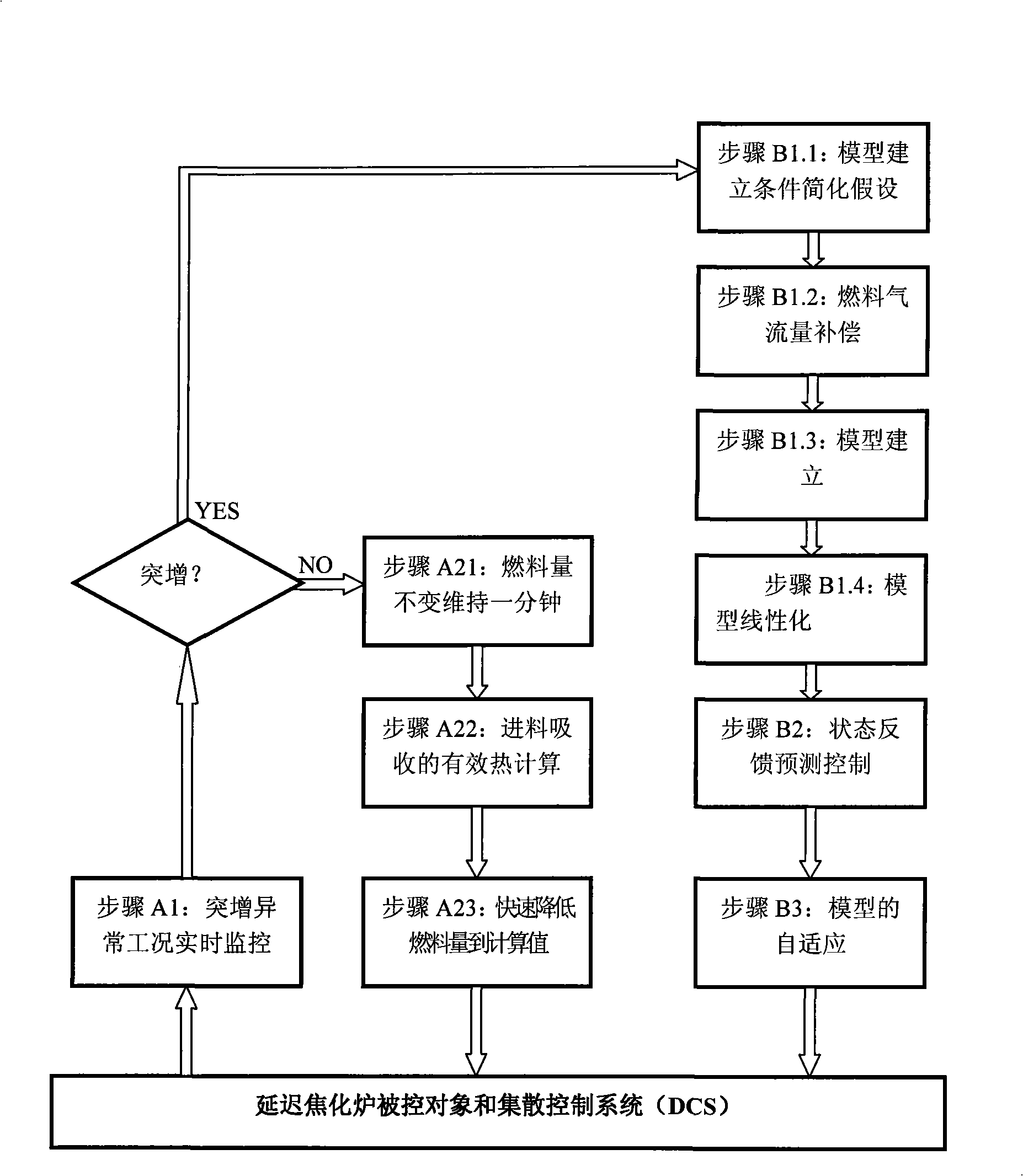

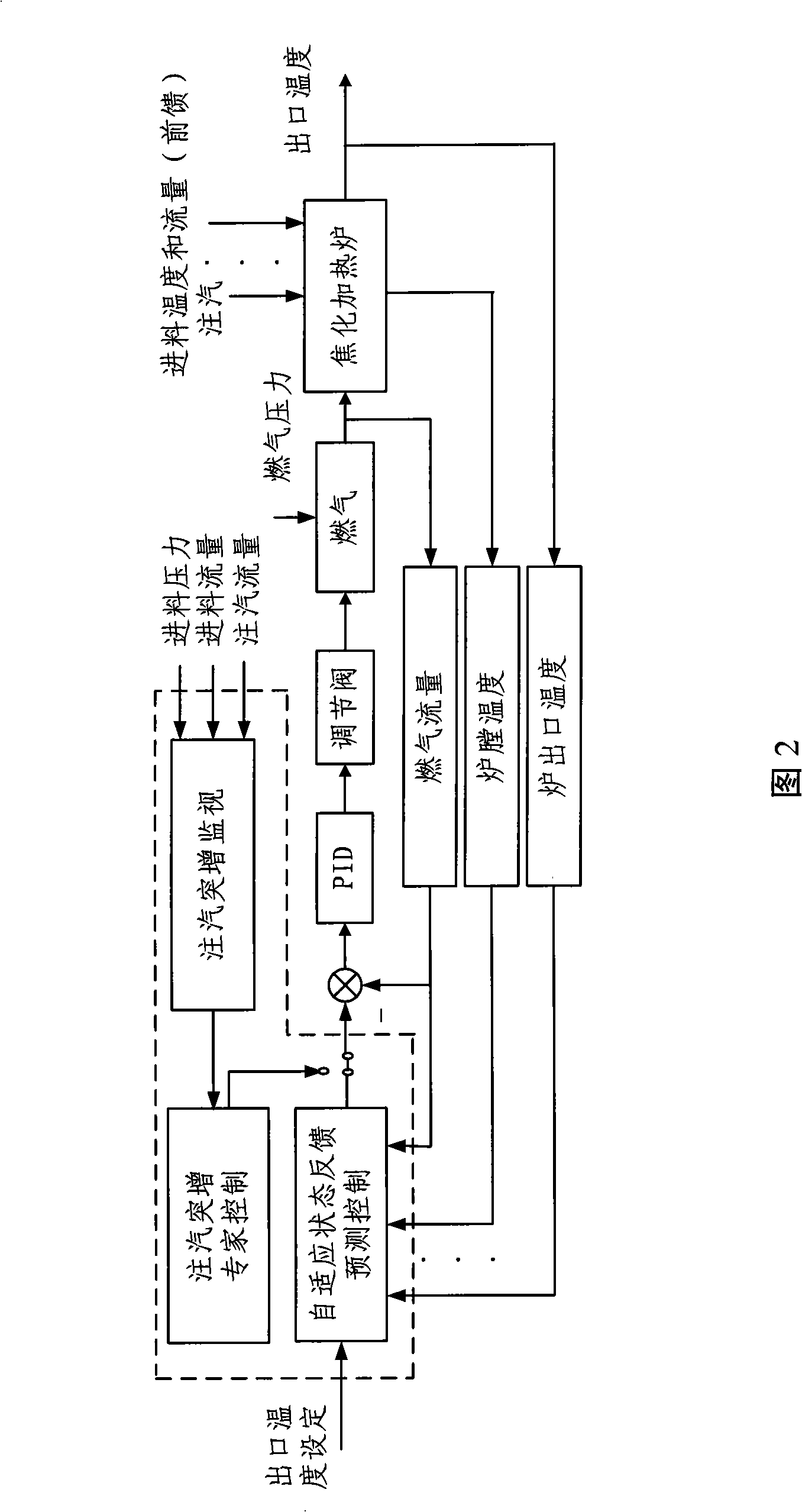

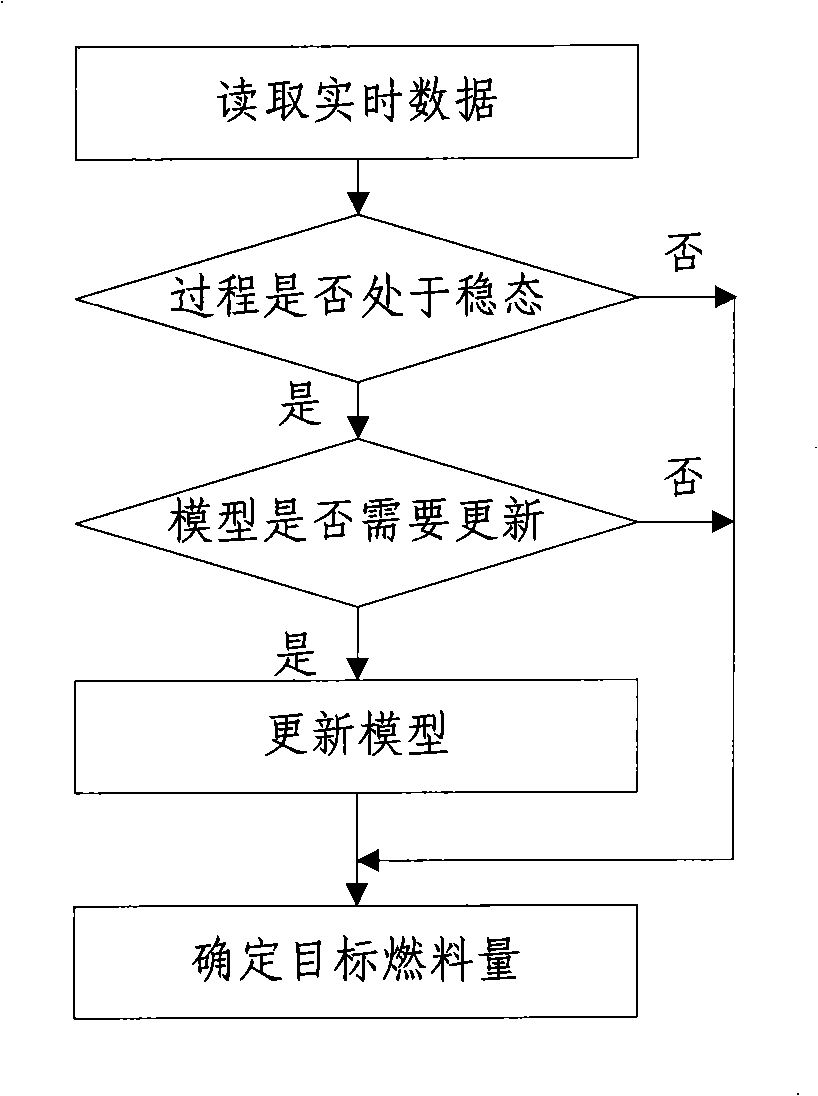

Control method for delay coking stove

InactiveCN101256400AAvoid overheatingImprove anti-interference abilityThermal non-catalytic crackingProgramme controlEngineeringHeat balance

The invention discloses a control method for a delayed coking furnace, comprising: measuring a steam injection quantity, a feeding quantity and a feeding pressure; judging whether the injection quantity has sudden increase abnormal working condition, according to the measured steam injection quantity, feeding quantity and feeding pressure; measuring the temperatures of a hearth and a tube wall, if the sudden increase abnormal working condition occurs; determining an objective fuel quantity, according to the hearth temperature, the feeding quantity and the tube wall temperature; and adjusting the fuel quantity of the delayed coking furnace to the objective fuel quantity. By a state feedback prediction control scheme of real states, the anti-interference ability is effectively improved. Directed at the process characteristic change caused by load change and coking, the variation of a working point is judged on line, model self-adaptation is carried out, and the rate of putting into operation is increased. Directed at great inverse response of an outlet temperature caused by sudden increase of steam injection quantity, expert control is performed based on heat balance calculation, which can effectively prevent the outlet temperature from exceeding, and improving the operation cycle of devices.

Owner:TSINGHUA UNIV

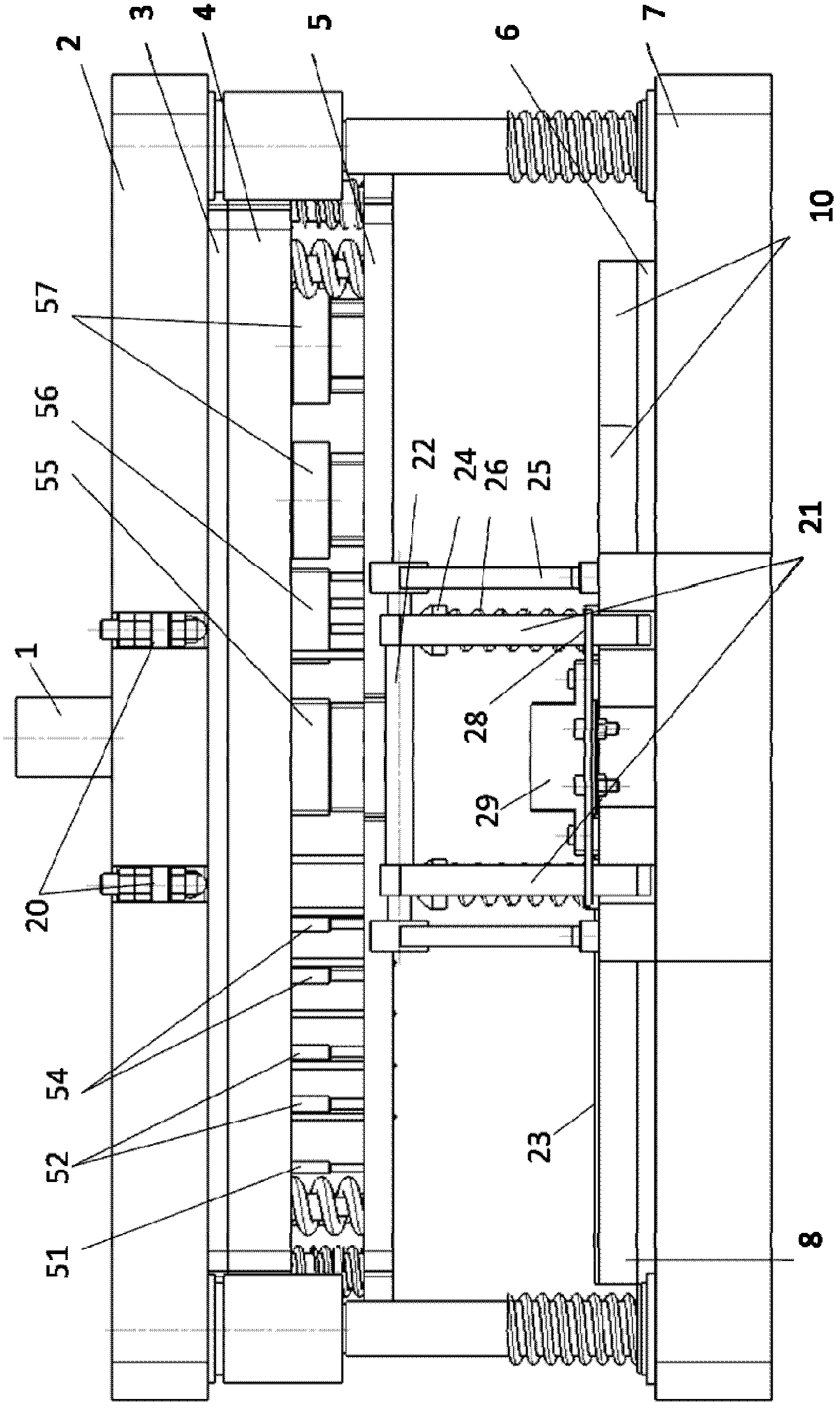

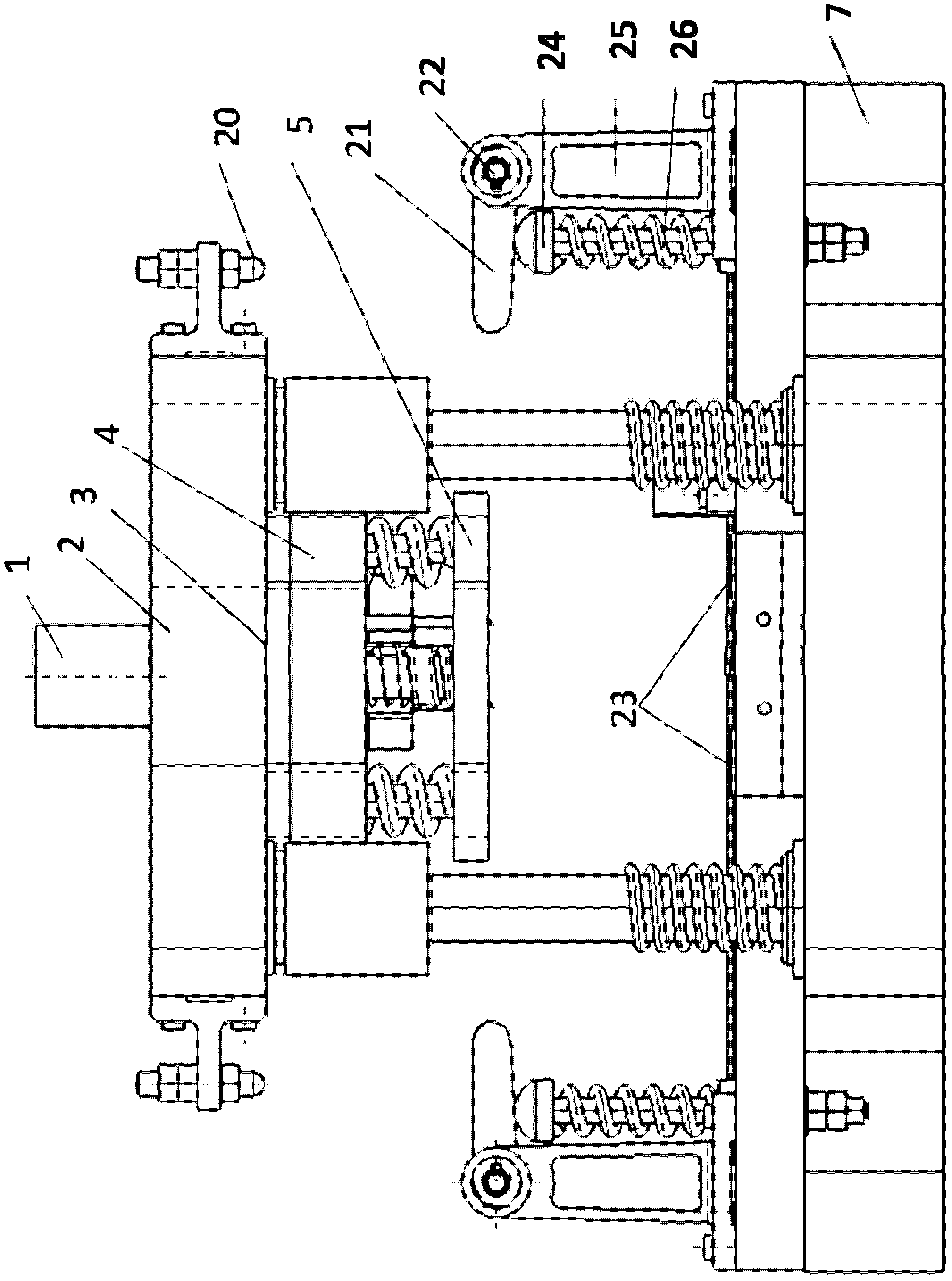

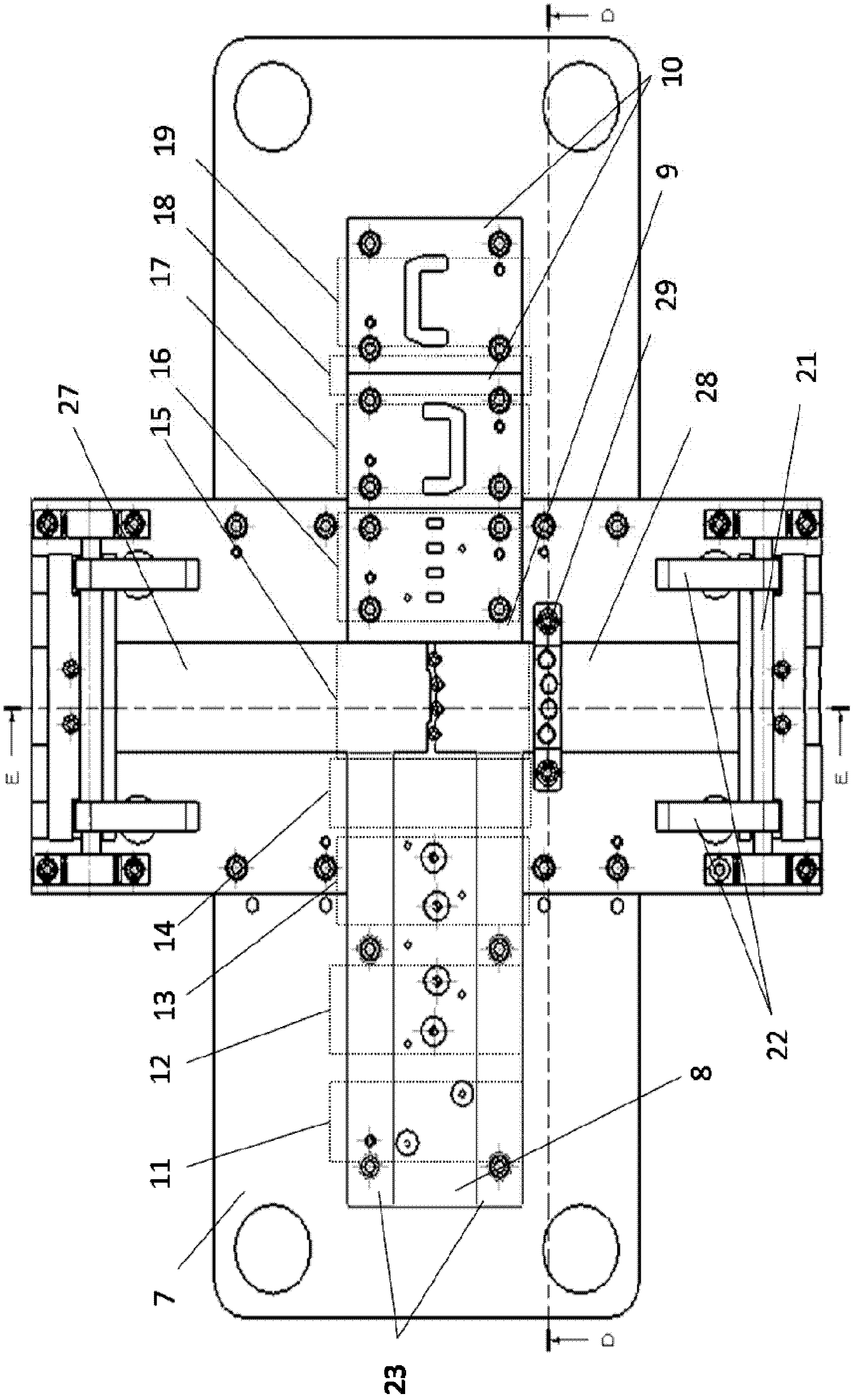

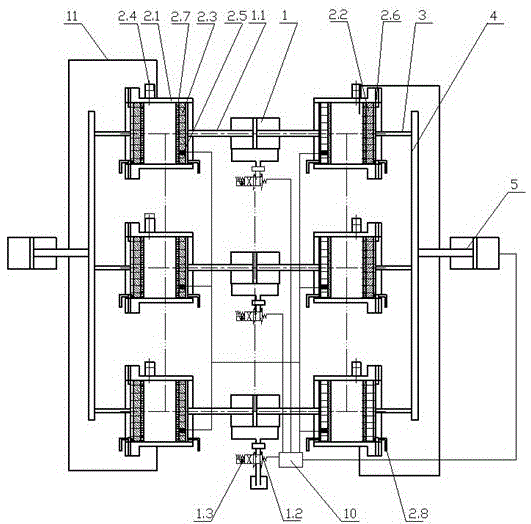

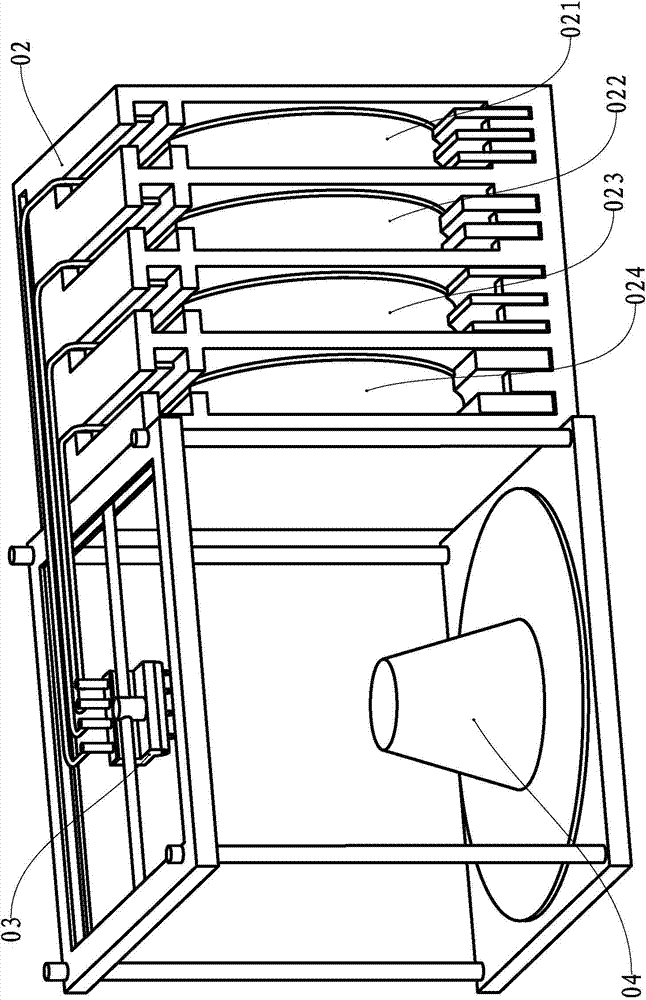

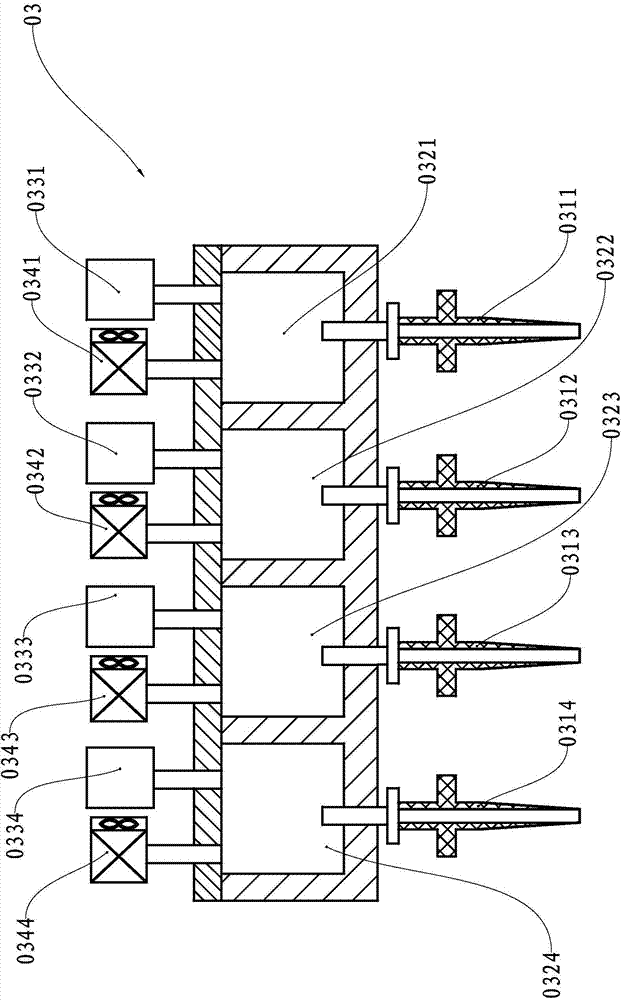

Multi-station stamping assembly composite mold

The invention discloses a multi-station punching / assembling composite die. A punching positioning hole, a first punching assembly hole, a second punching assembly hole, a landing edge waste cut-off station, a first blanking station, an idle station and a second blanking station are provided in this order between upper and lower die holders with a progressive punching die as a base body. A furtheridle station and a press riveting assembly station are orderly added between the punching assembly hole and the landing edge waste cut-off station. A press riveting assembly terrace die is arranged on the upper die holder of the progressive punching die at the position of the press riveting assembly station, while a press riveting assembly female die module is arranged on the lower die holder. Two pressure heads are mounted on the two side faces of the upper die holder in a direction parallel to a tape feeding direction, respectively. The structure of the lower die holder of the progressive punching die is changed into a cross-shaped structure from a rectangular structure and the centre of symmetry of the cross-shaped structure is coincident with the centre of the press riveting assembly station. Besides, a gate type automatic feeding mechanism for automatically feeding pressure riveting nuts is mounted on the cross-shaped structure of the lower die holder right under the pressure heads which are disposed on the two side faces of the upper die holder of the progressive punching die. The composite die realizes the continuity and complete automation of production.

Owner:ZHEJIANG SCI-TECH UNIV

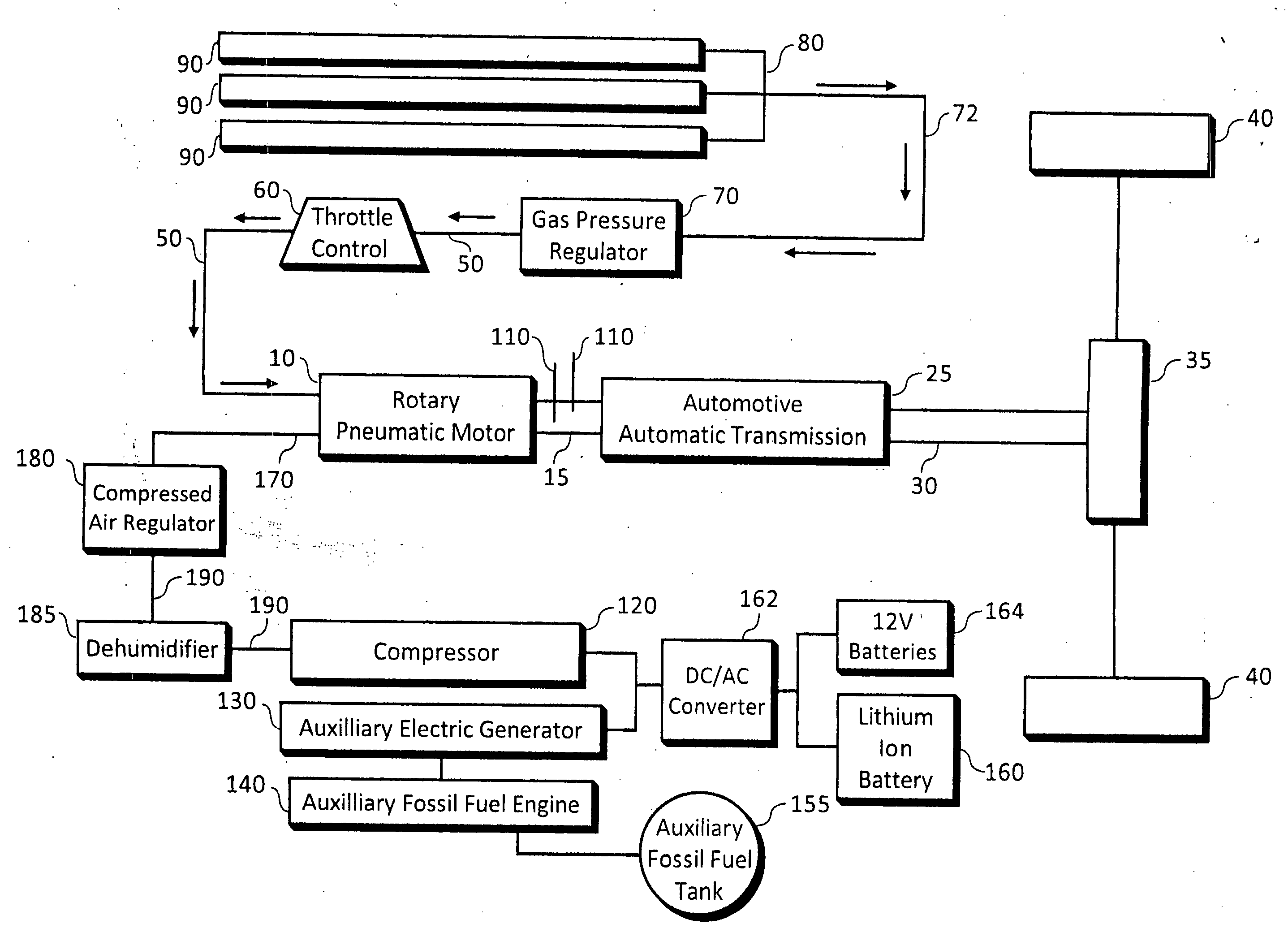

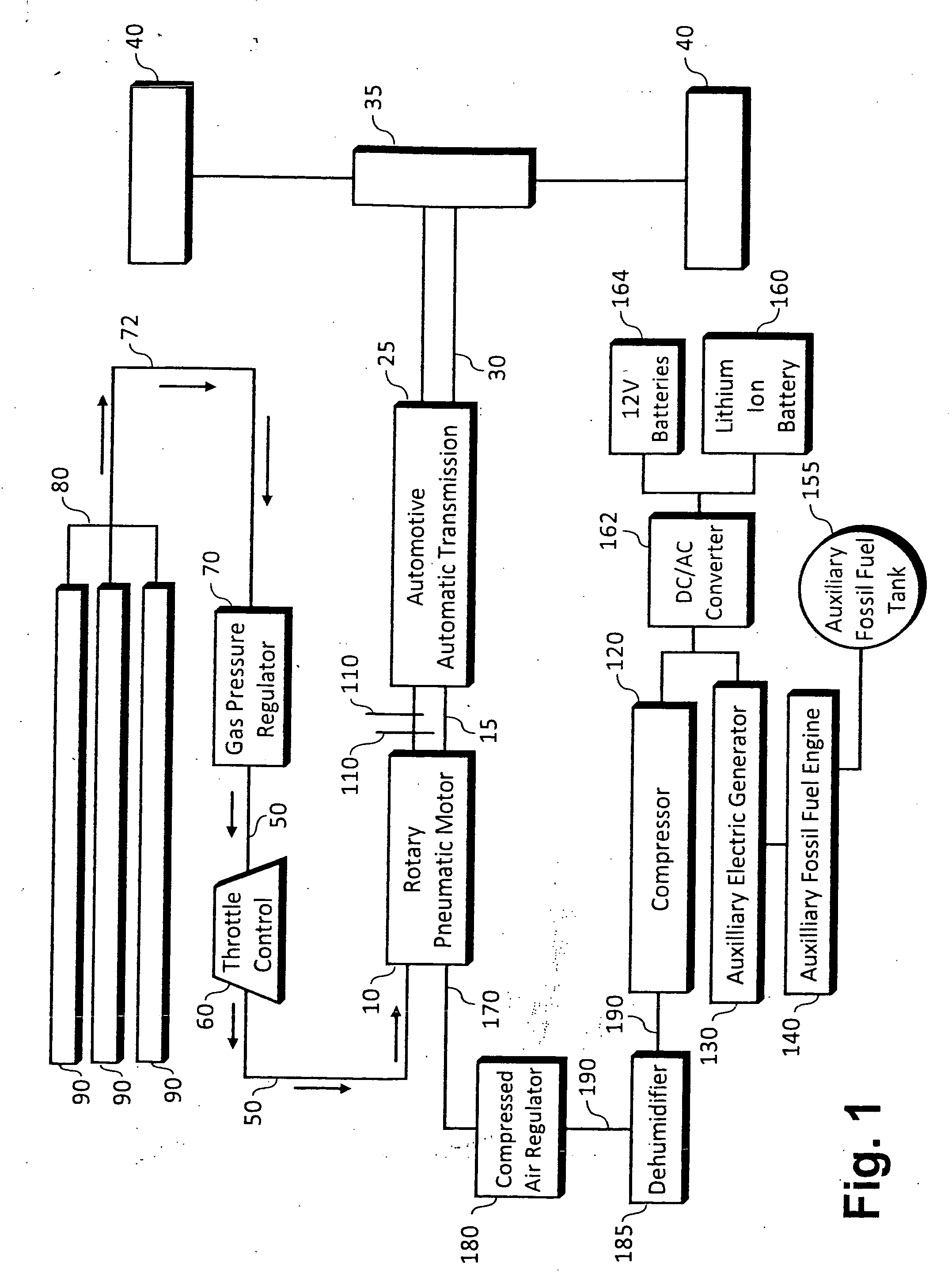

Pneumatic mechanical power source

ActiveUS20090266069A1Eliminate consumptionEliminate the problemAuxillary drivesRailway vehiclesAviationNitrogen

An mechanical power system is provided for providing torque without using a heat engine in virtually any non-aviation application where fossil-fuel engines have conventionally been used, by simply replacing the fossil-fuel burning engine with a rotary pneumatic motor of appropriate size for the application and feeding pressure-regulated compressed gas to the rotary pneumatic motor. The rotary pneumatic motor can be used virtually anywhere, and requires merely a supply of compressed gas to run it, preferably compressed nitrogen. Automotive, marine and electrical generating applications are easily adaptable, and auxiliary fossil-fuel engines can be added for emergencies where a supply of compressed gas has been exhausted. A screw-type compressor can be electrically powered to supply compressed gas to the pneumatic motor where tanks of compressed gas have been exhausted. Tanks of compressed gas are to be conveniently user replaceable.

Owner:DOMES TIMOTHY J

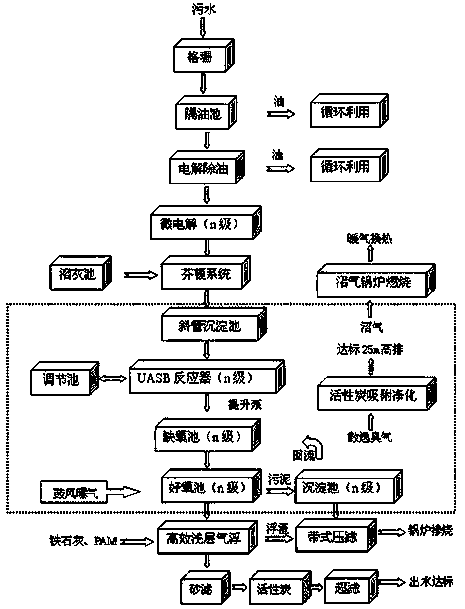

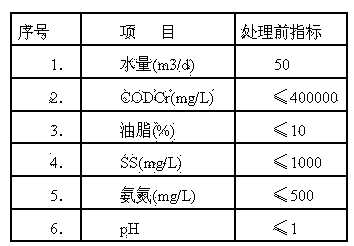

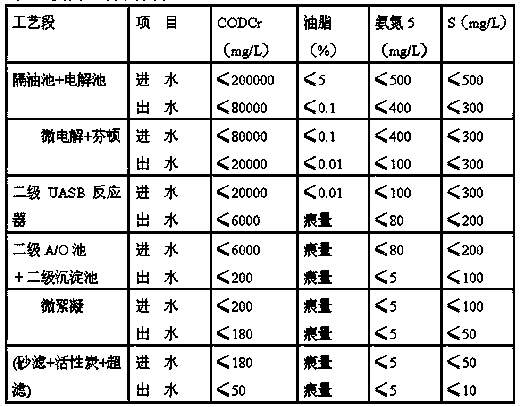

Treatment method for biodiesel waste water

ActiveCN104310715ALow toxicityEliminate ChromaFatty/oily/floating substances removal devicesWater treatment compoundsElectrolysisBiodiesel

A treatment method for biodiesel waste water is carried out by the following steps: arranging self-clearing gratings at water pipe network end points under production equipment, and pumping waste water flowing across the gratings into a multi-stage oil separator; pumping the waste water in the water layer of the oil separator into an electrolytic tank; pumping the waste water from which oil is separated and removed through electrolysis into a micro-electrolysis reaction tank to carry out micro-electrolysis treatment; pumping the micro-electrolyzed waste water into a Fenton system to carry out reaction; feeding the waste water treated by multiple steps into a biochemical system; removing SS from discharged water by efficient shallow gas flotation micro-flocculation; sequentially filtering the waste water purified by micro-flocculation by a sand filter, active carbon and an ultra-filtration system; pumping various sludge produced in the waste water treatment process into a sludge concentration tank. The method has the advantages that oil is fully separated from the waste water, and no impurities are left; massive COD and PH are removed, the water feeding pressure of the biochemical system is reduced, waste water toxicity is reduced, biodegradability is improved, waste water color and smell are removed, and the quality of finally discharged clear water reaches domestic first-grade emission standards.

Owner:TANGSHAN JINLIHAI BIODIESEL

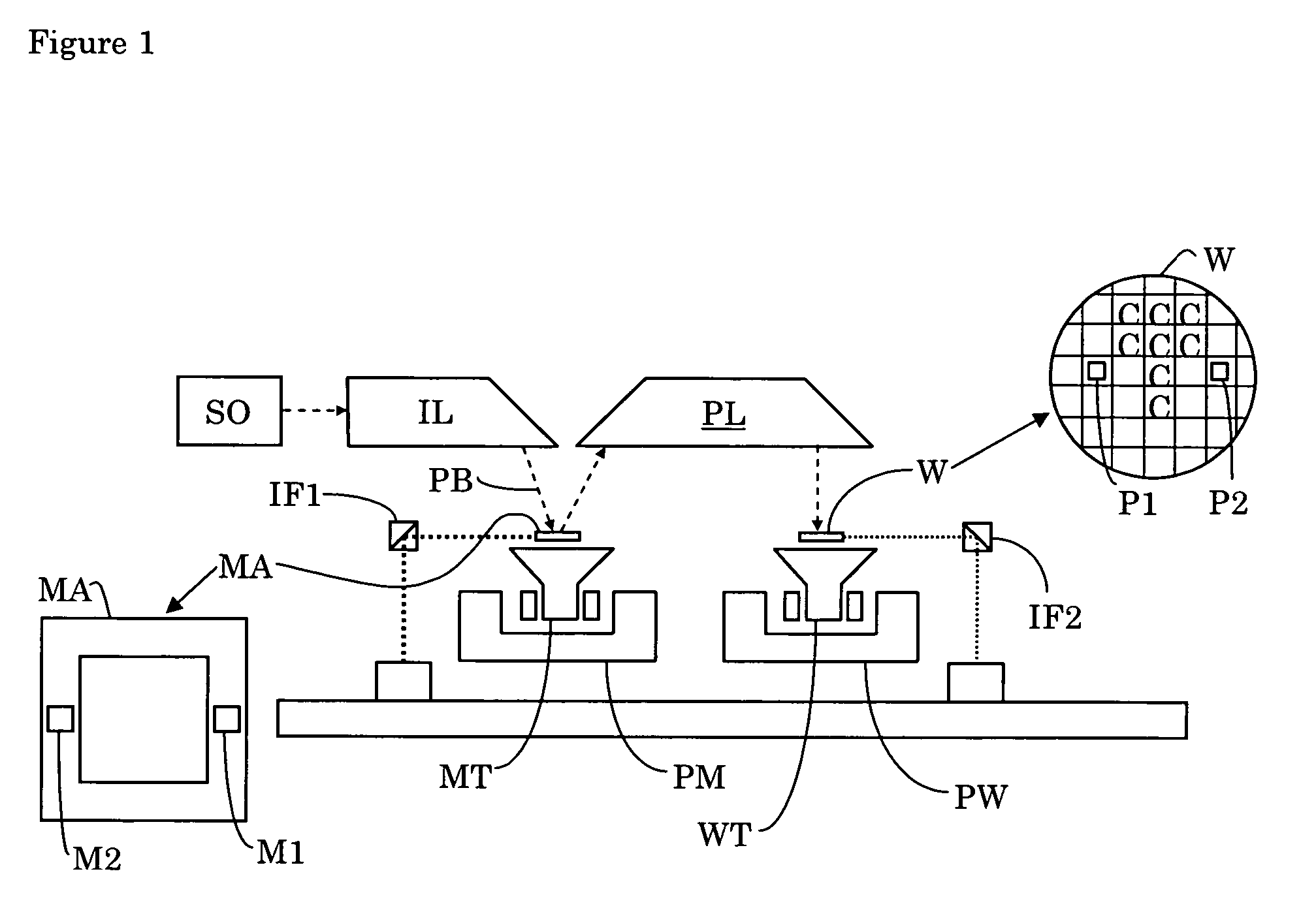

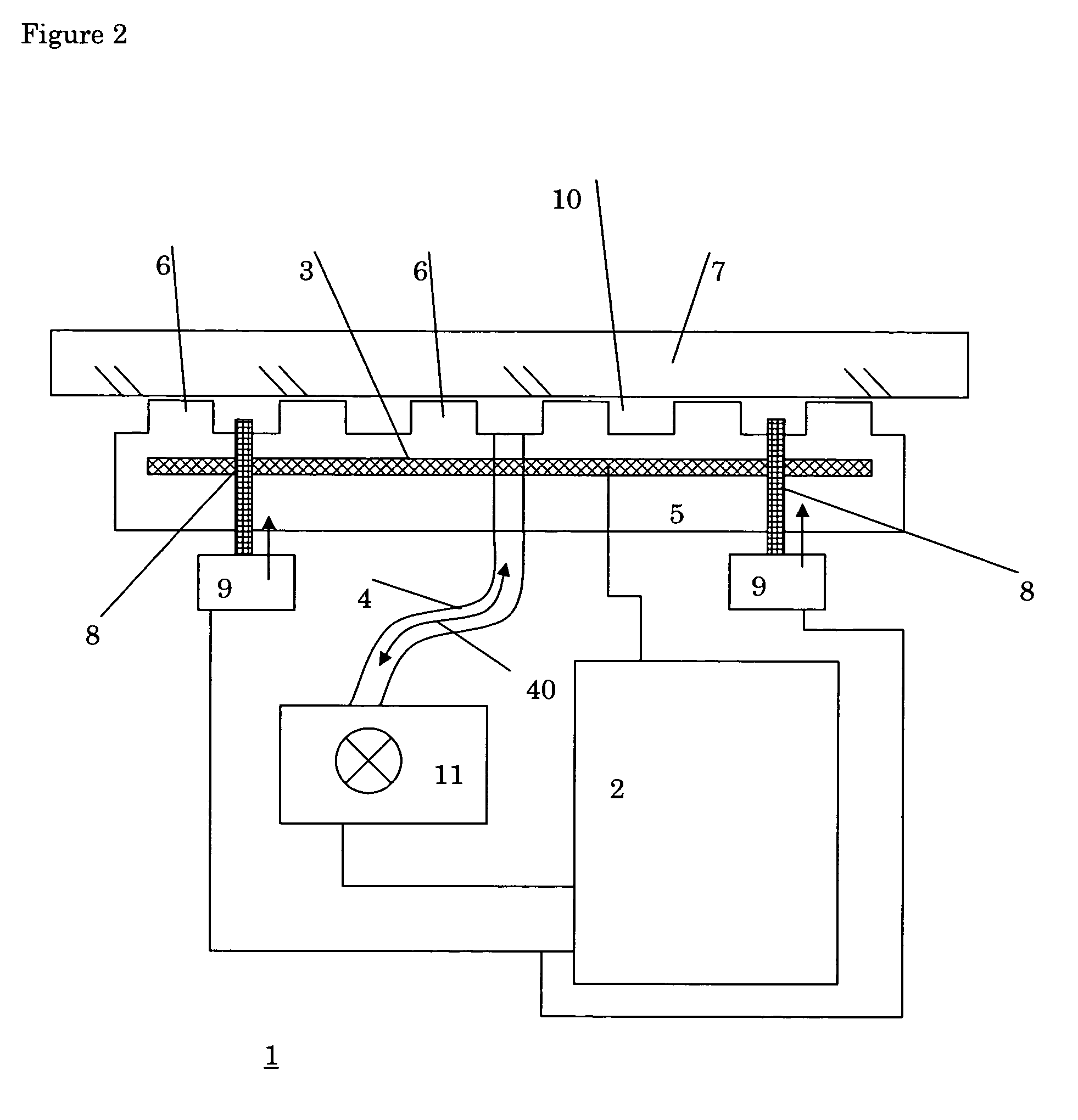

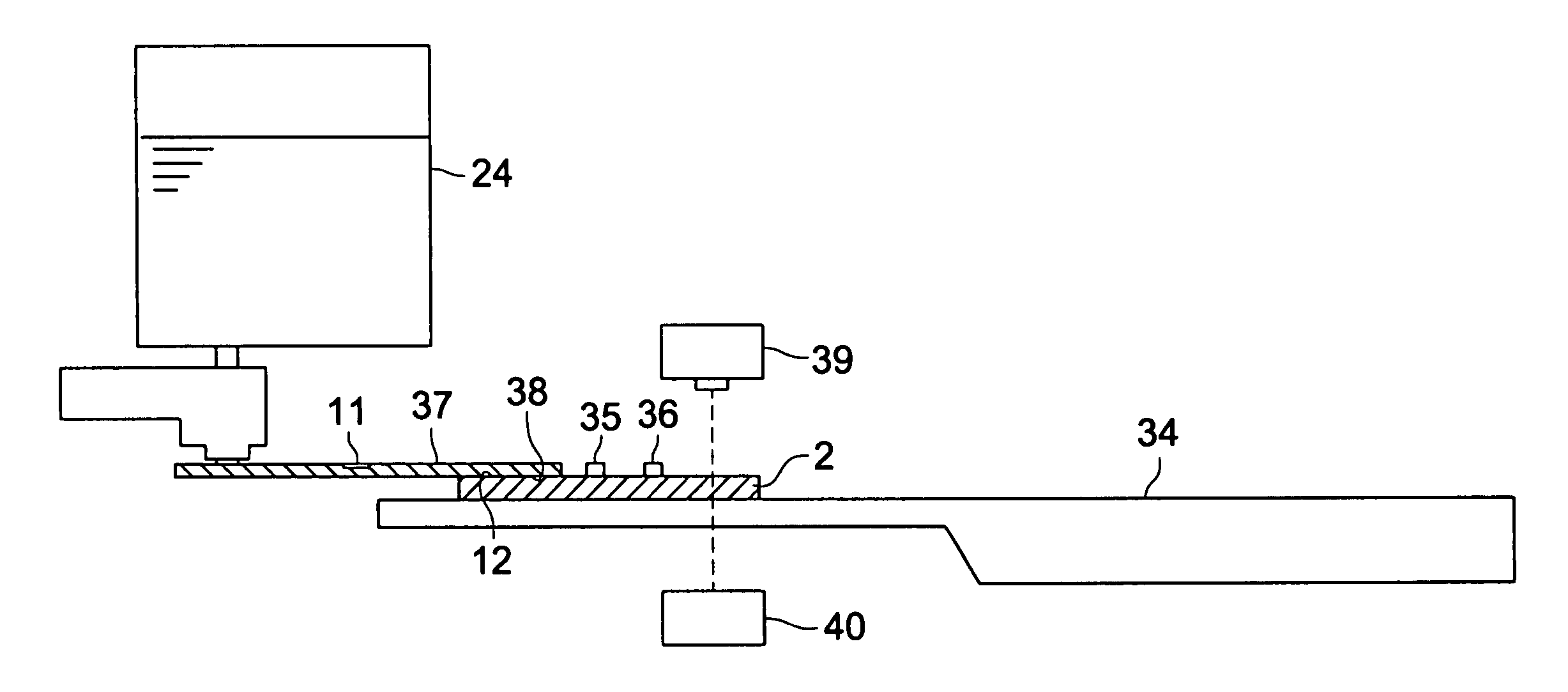

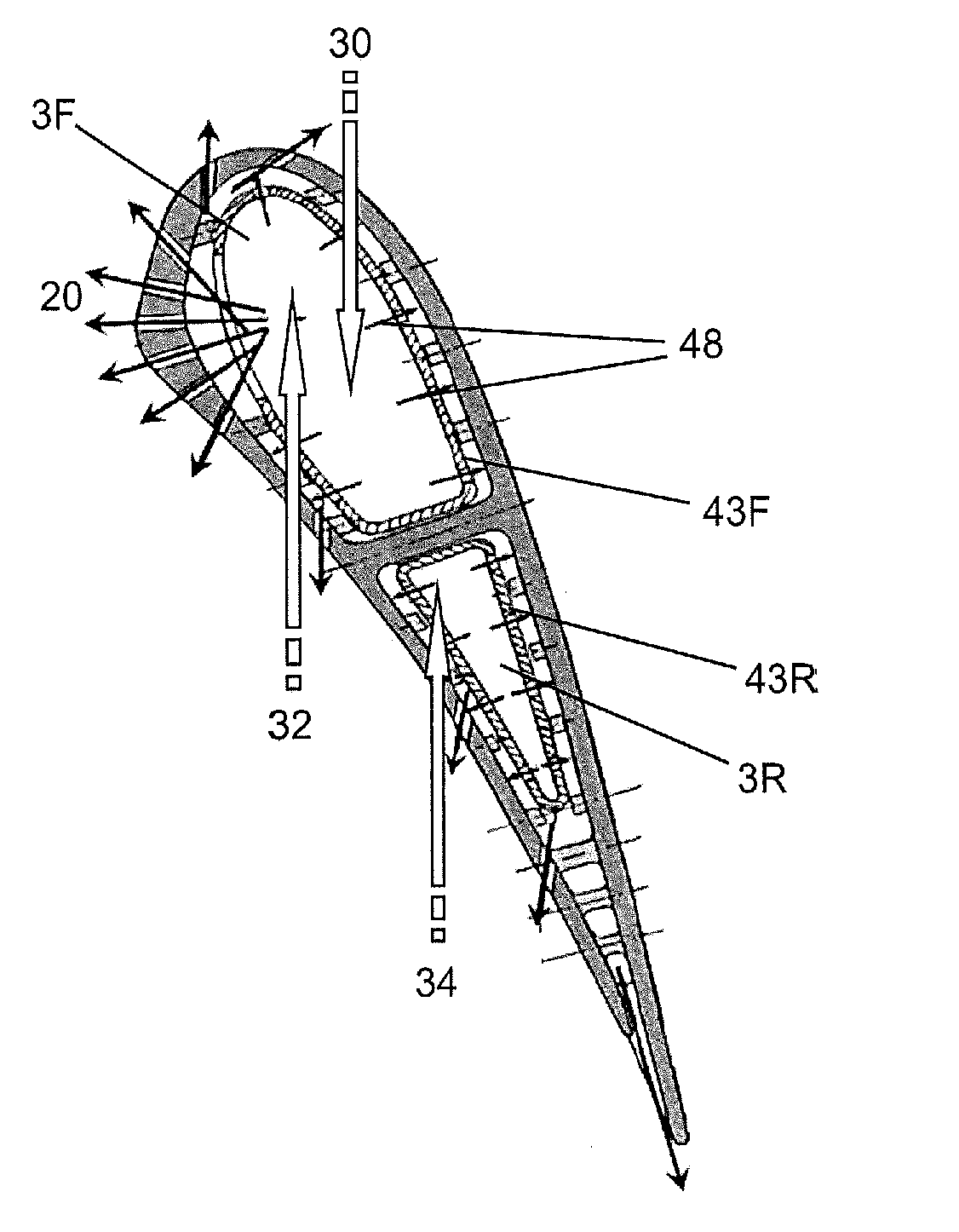

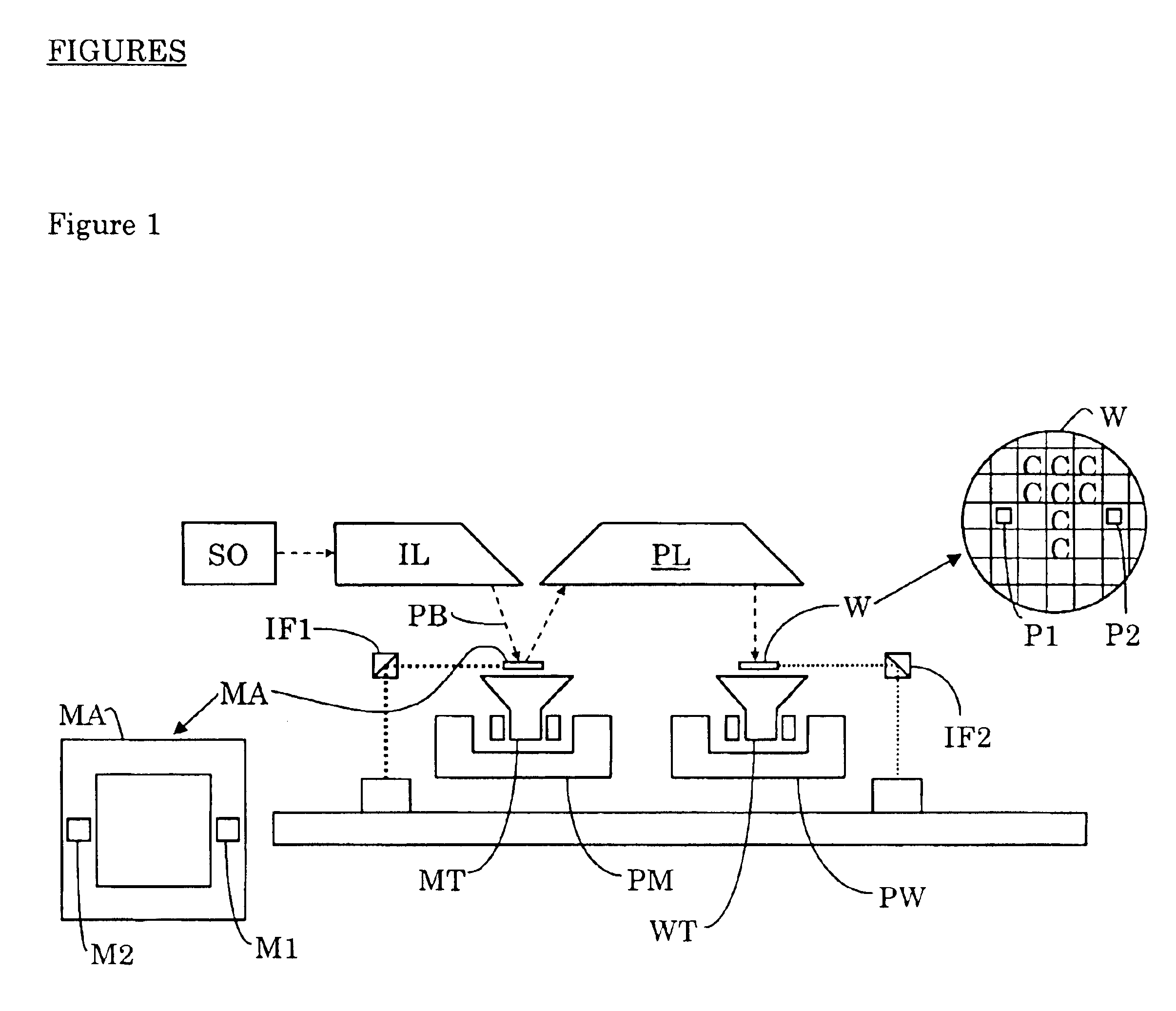

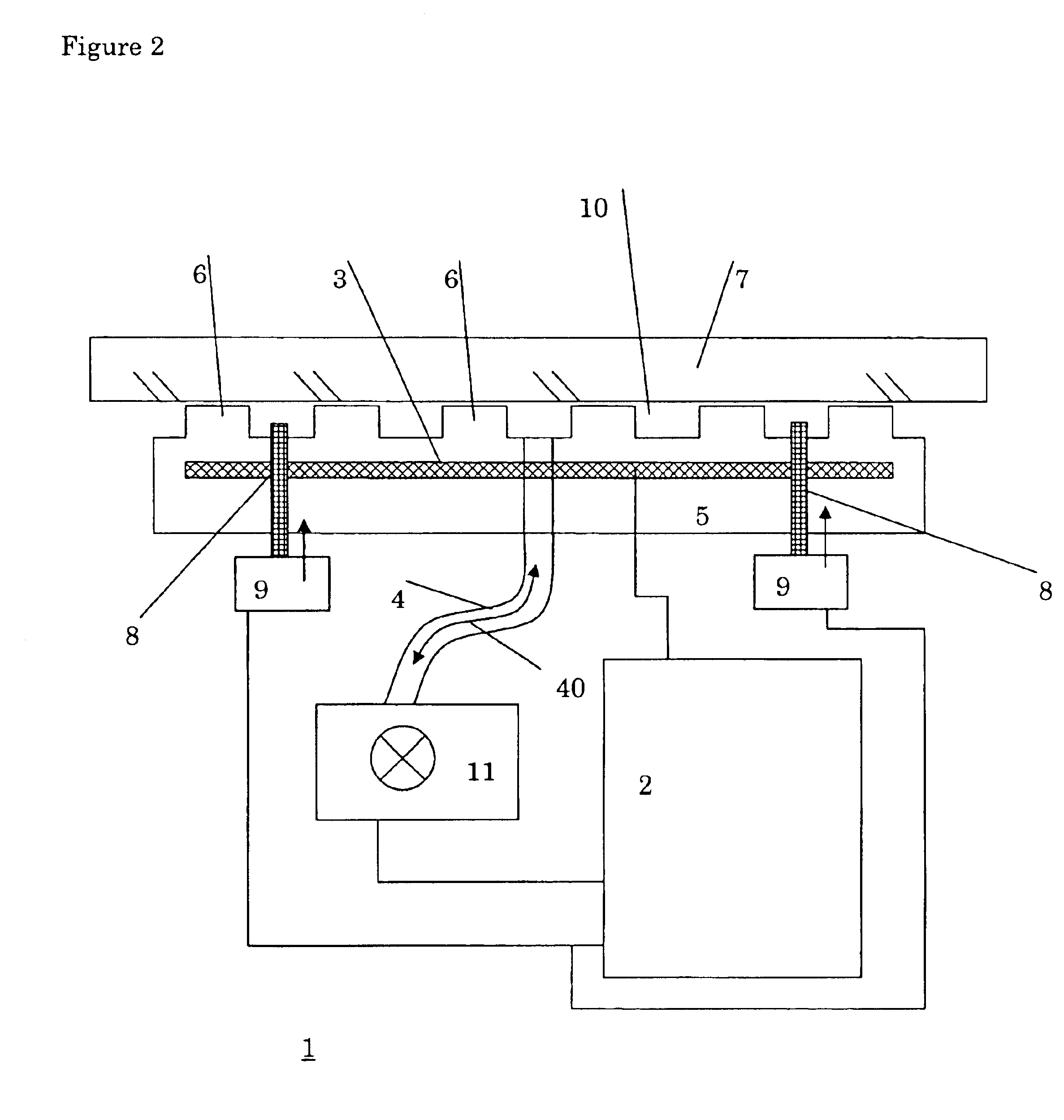

Lithographic apparatus and device manufacturing method

ActiveUS20050128463A1Fast heat conductionCapsCapping machinery safety/controlLighting systemFeed pressure

A lithographic apparatus includes an illumination system for providing a beam of radiation, an article support for supporting a flat article to be placed in a beam path of the beam of radiation on the article support, a backfill gas feed arranged in the article support for feeding backfill gas to a backside of the article when supported by the article support, and a clamp for clamping the article against the article support during projection. According to one aspect of the invention, the apparatus includes a controller for controlling the clamp and / or the backfill gas feed pressure so as to release the clamp prior to reducing the backfill gas feed pressure.

Owner:ASML NETHERLANDS BV

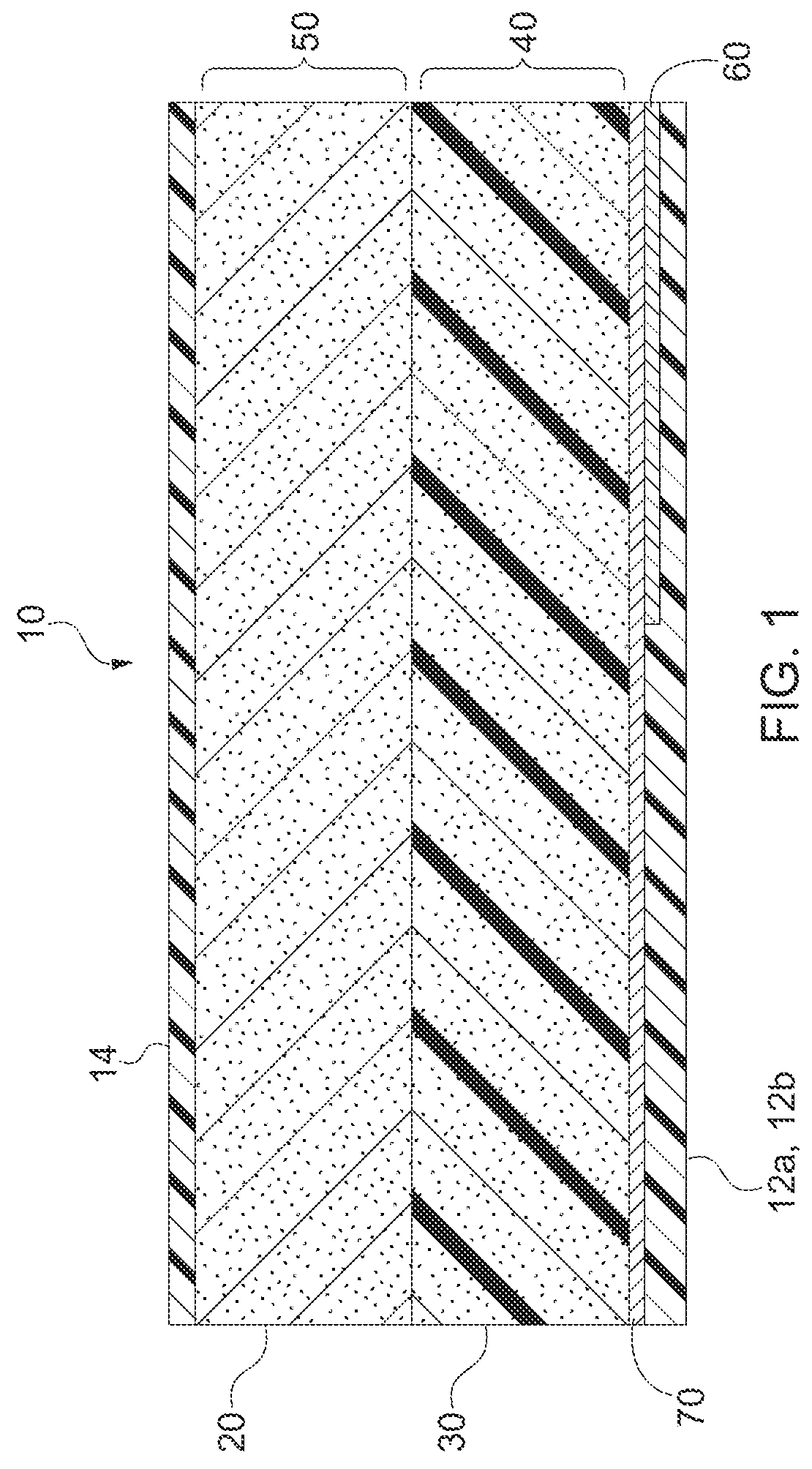

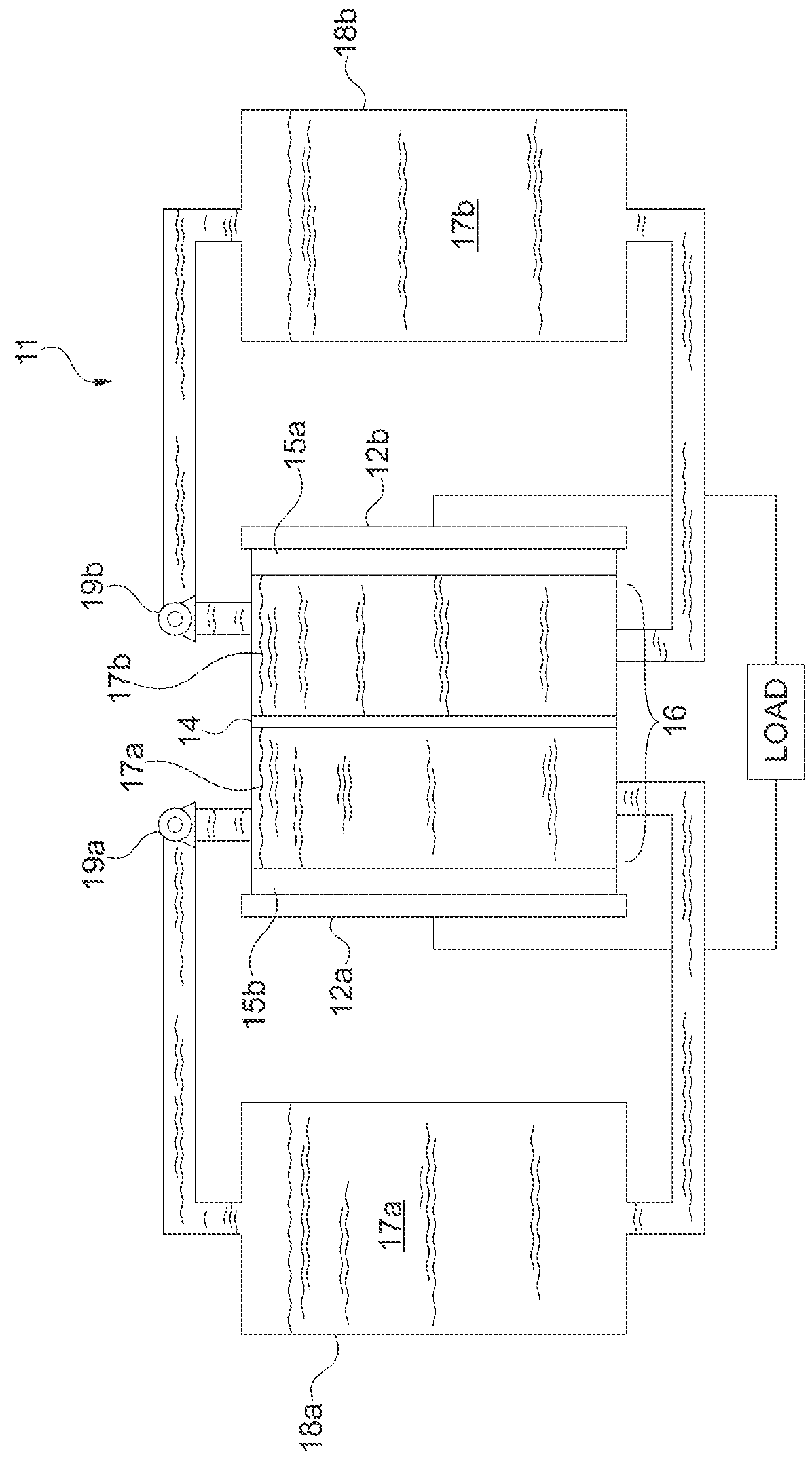

Composite electrode for flow battery

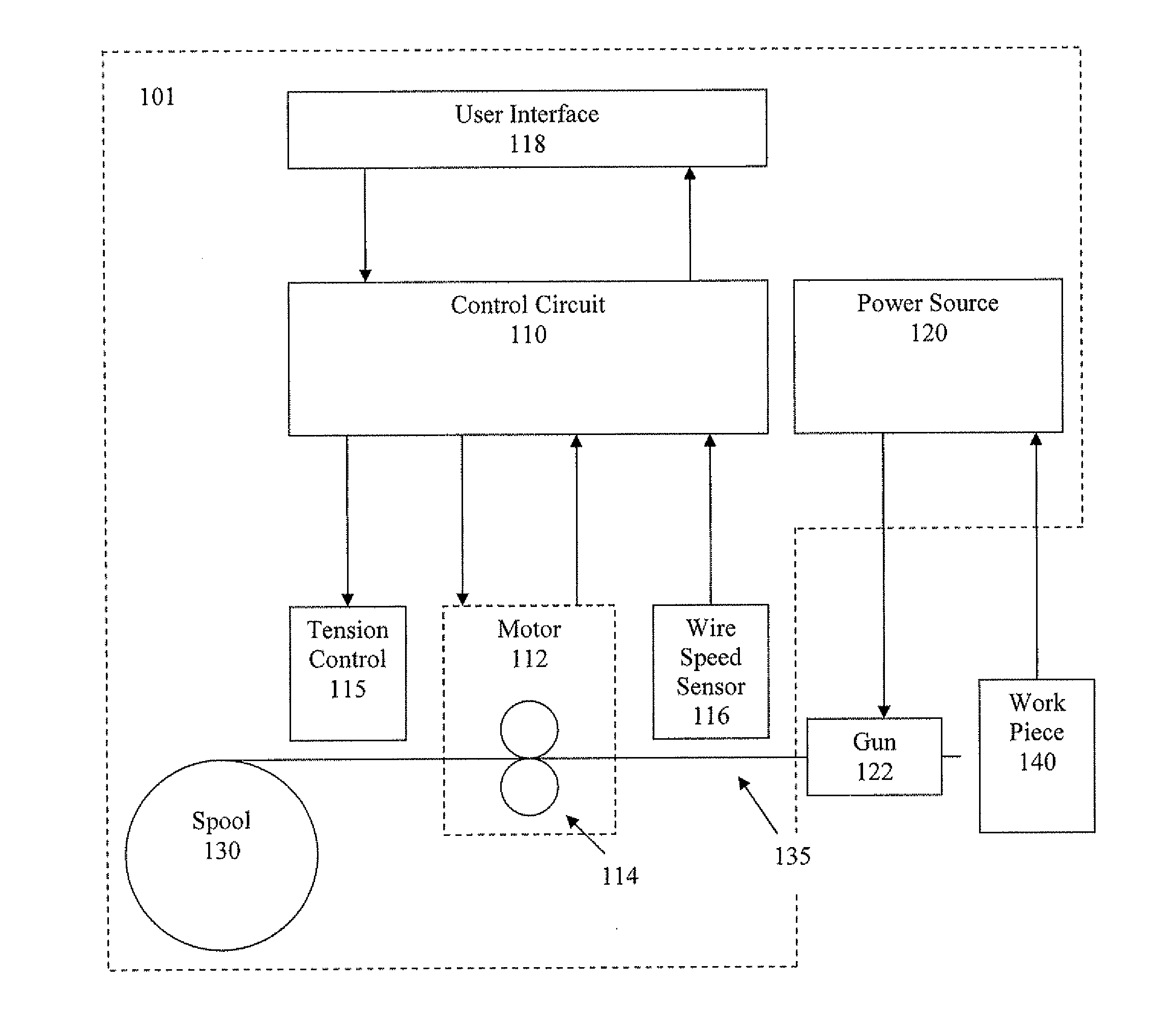

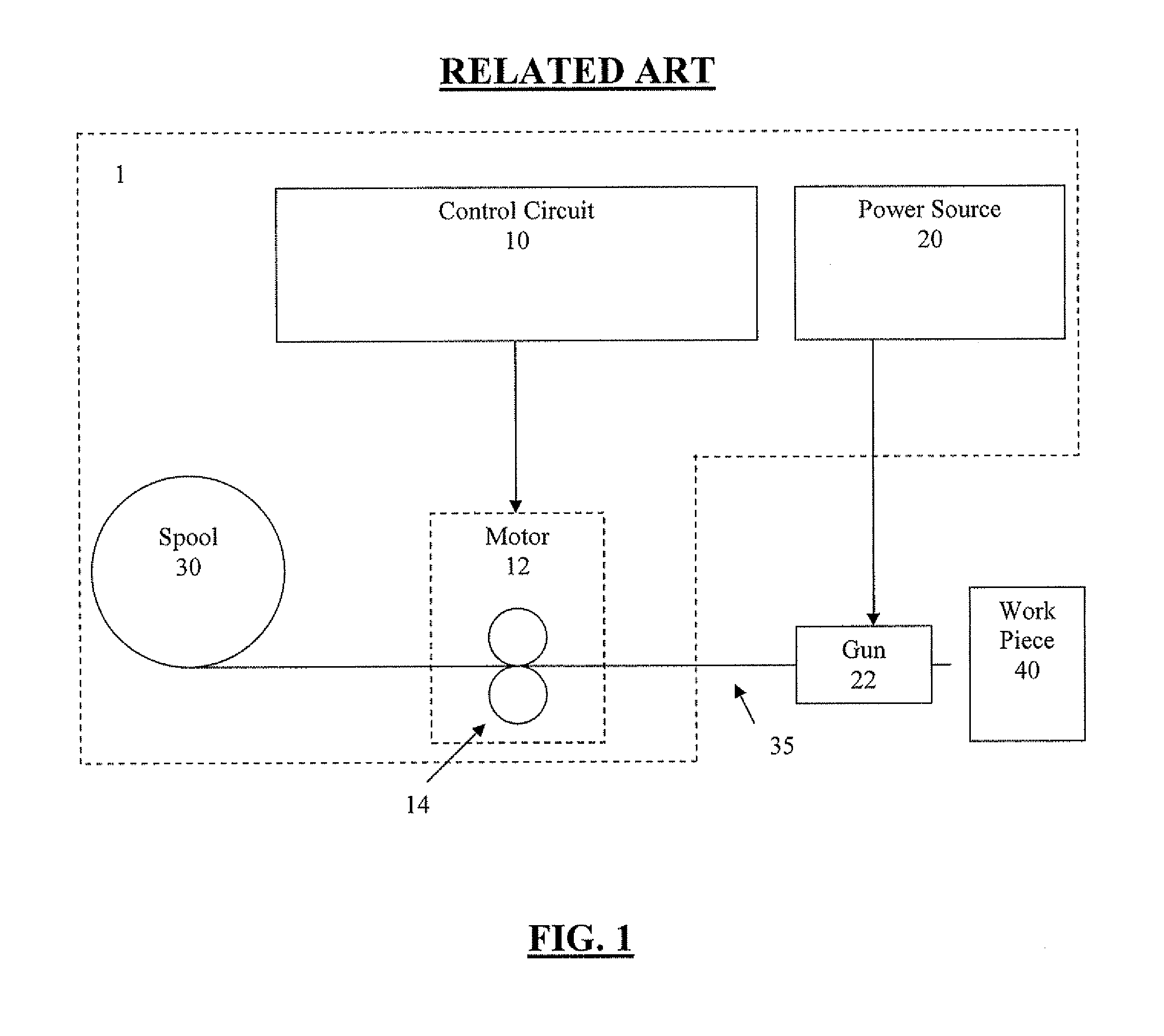

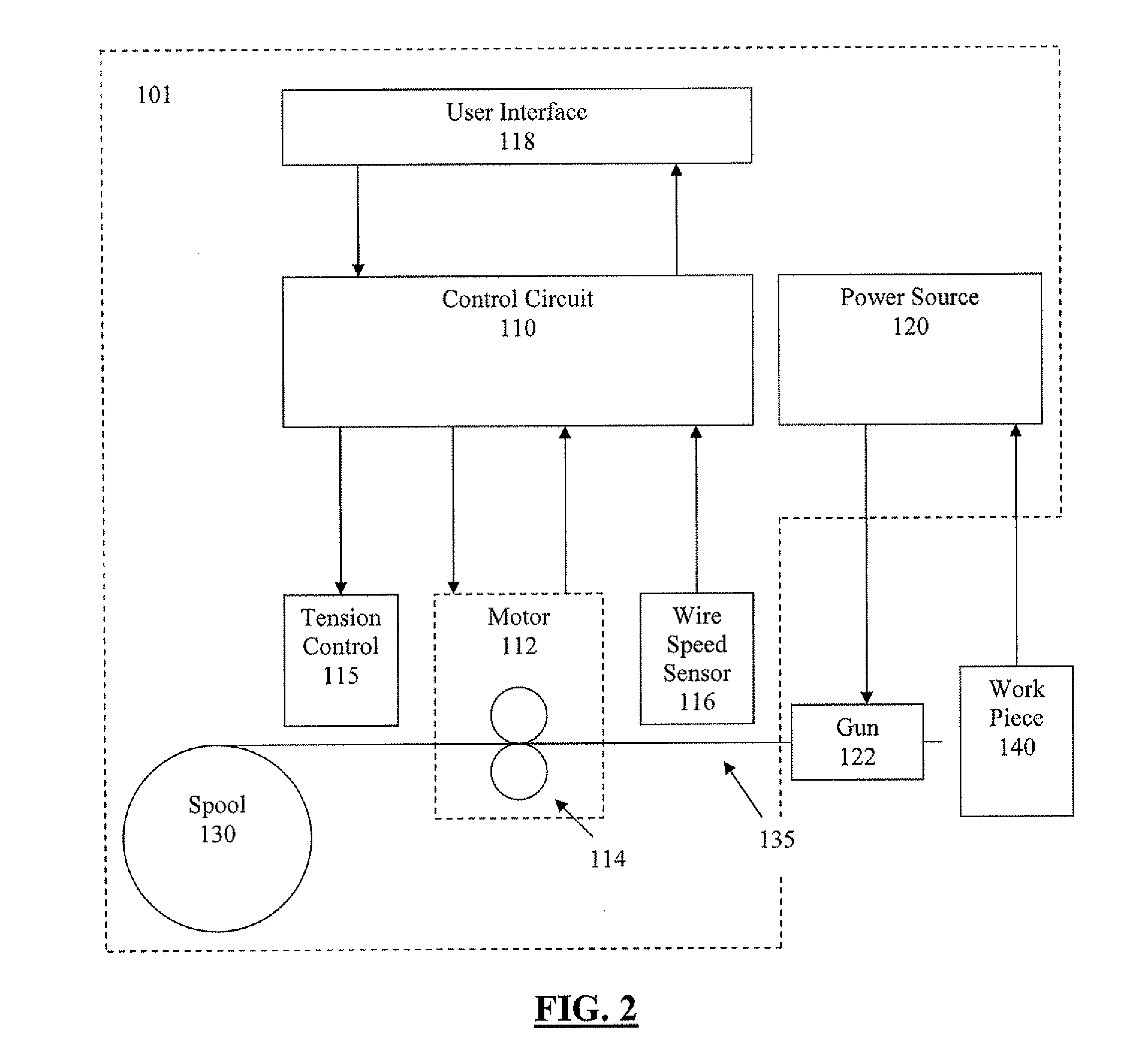

InactiveUS20160036060A1Less compressibleReduce feeding pressureCell electrodesRegenerative fuel cellsState of artComposite electrode

A composite electrode adapted for use in a flow battery stack system has a carbon felt stratum forming a semi-porous reaction zone and a carbon foam stratum forming a porous flow path zone. The composite electrode is less compressible than prior art electrodes having similar conductivity and specific surface areas. Flow battery stack systems employing the composite electrode operate with lower feed pressures, experiences a lower pressure drops across the electrodes, and realize improved electrical resistivity. Alternative embodiments provide electrical conductive elements and a current collector disposed on a surface of the composite electrode.

Owner:CONCURRENT TECH

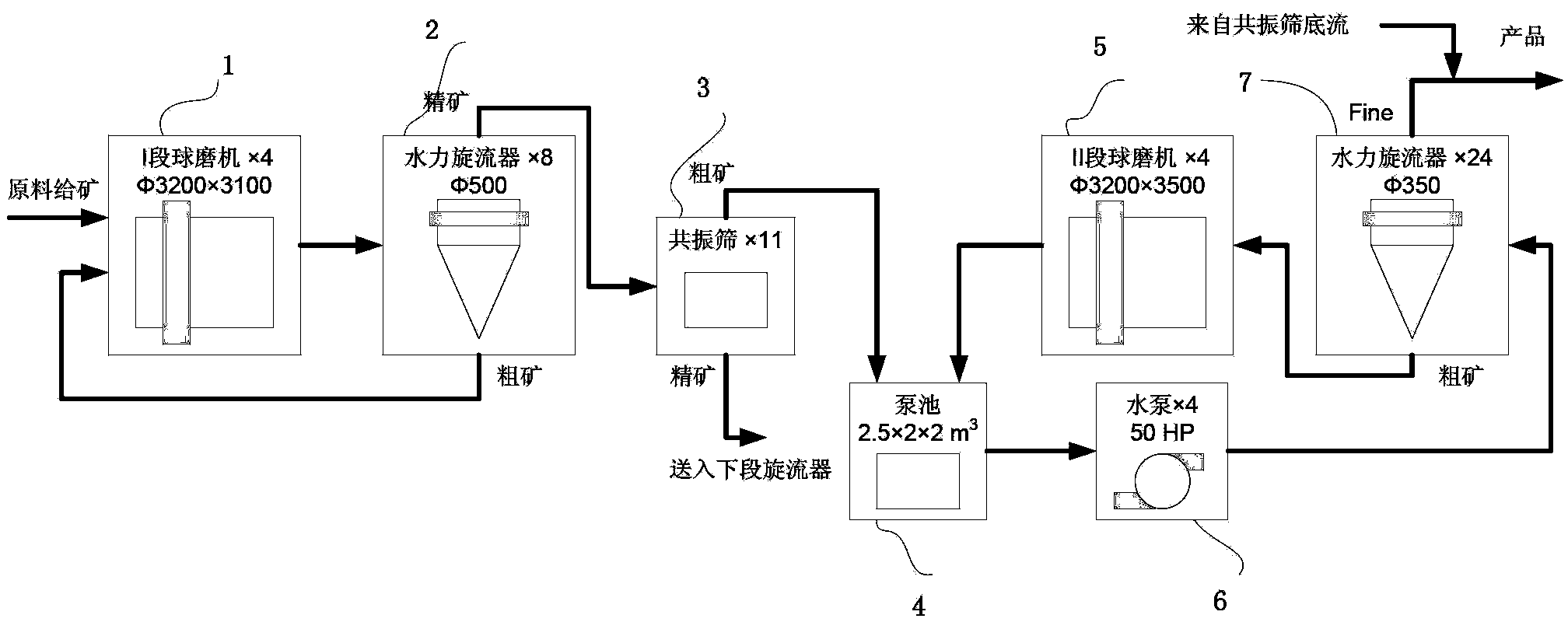

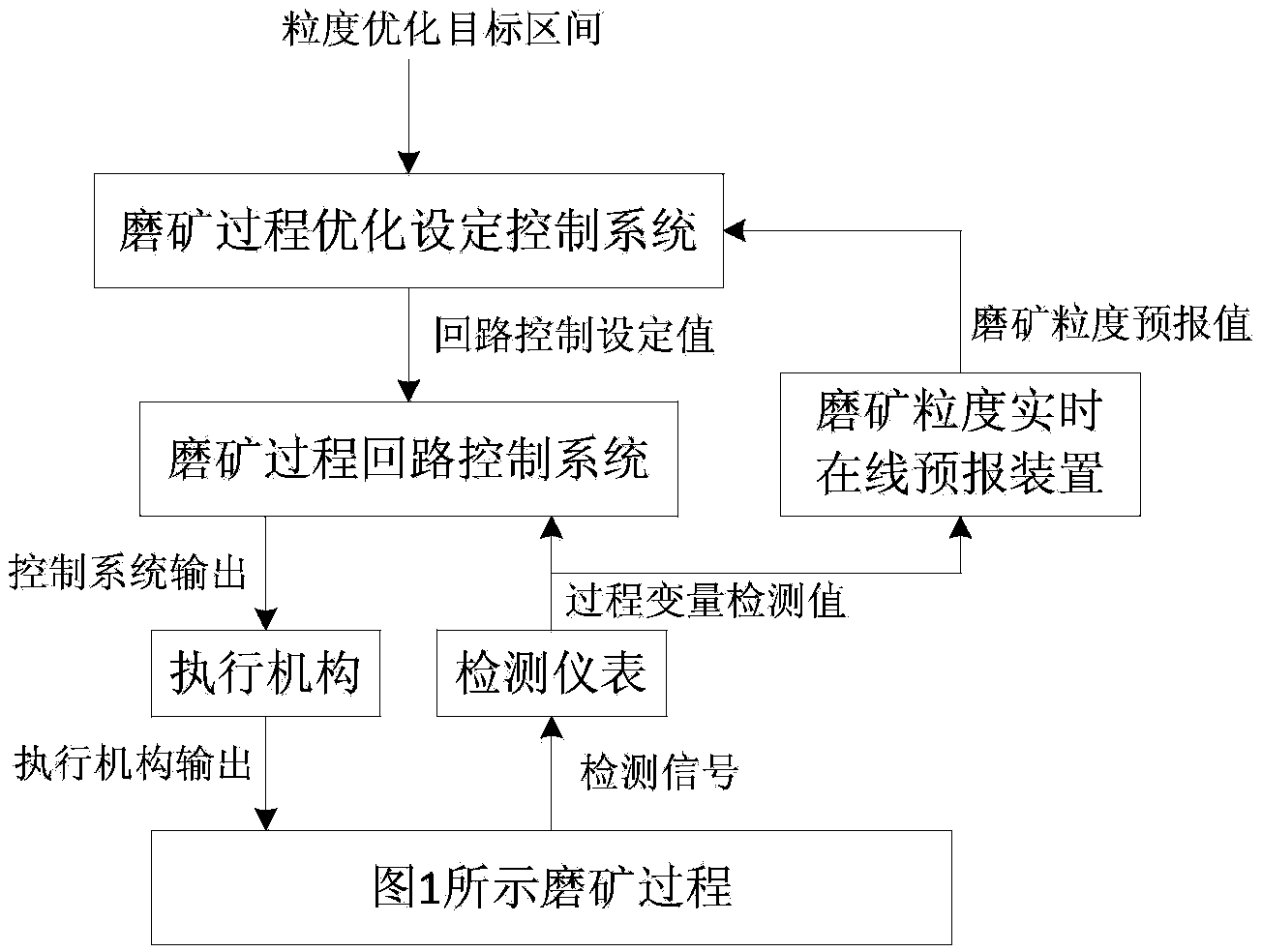

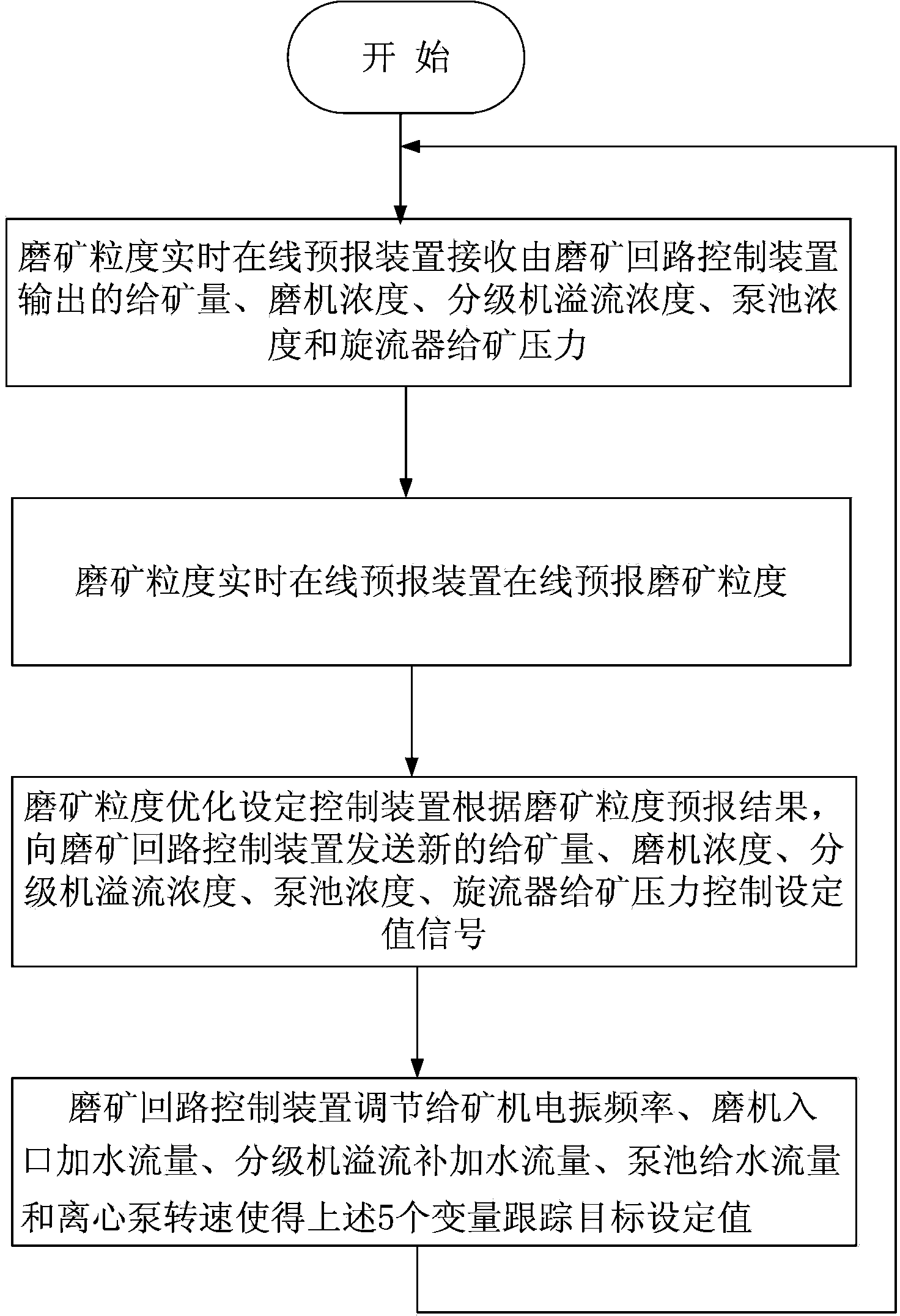

Ore grinding granularity online prediction system and method

ActiveCN103412489ARealize closed-loop controlAchieve real-time optimizationAdaptive controlLoop controlGranularity

The invention provides an ore grinding granularity online prediction system and method, and relates to the technical field of ore grinding. The ore grinding granularity real-time online prediction system receives ore feeding amount, grinder concentration, classifier overflow concentration, pump pool concentration and swirler ore feeding pressure which are output by an ore grinding loop control device; ore grinding granularity is online predicted; an ore grinding granularity optimal setting control device receives an ore grinding granularity prediction result and sends control signals of the new ore feeding amount, the new grinder concentration, the new classifier overflow concentration, the new pump pool concentration and the new swirler ore feeding pressure; the ore grinding loop control device conducts closed-loop control. Through the solution of an online ore grinding granularity prediction mechanism model, response speed of ore grinding granularity prediction is improved on the premise that calculation accuracy of the model is not reduced, and the real-time performance of prediction is improved. The ore grinding granularity online prediction system and method are used for online estimating ore grinding granularity indexes, and closed-loop control of the ore grinding granularity is achieved. The change of the ore grinding granularity in a period in future can be predicted according to fluctuation change of other production factors, and therefore real-time optimization of the ore grinding granularity is achieved.

Owner:NORTHEASTERN UNIV

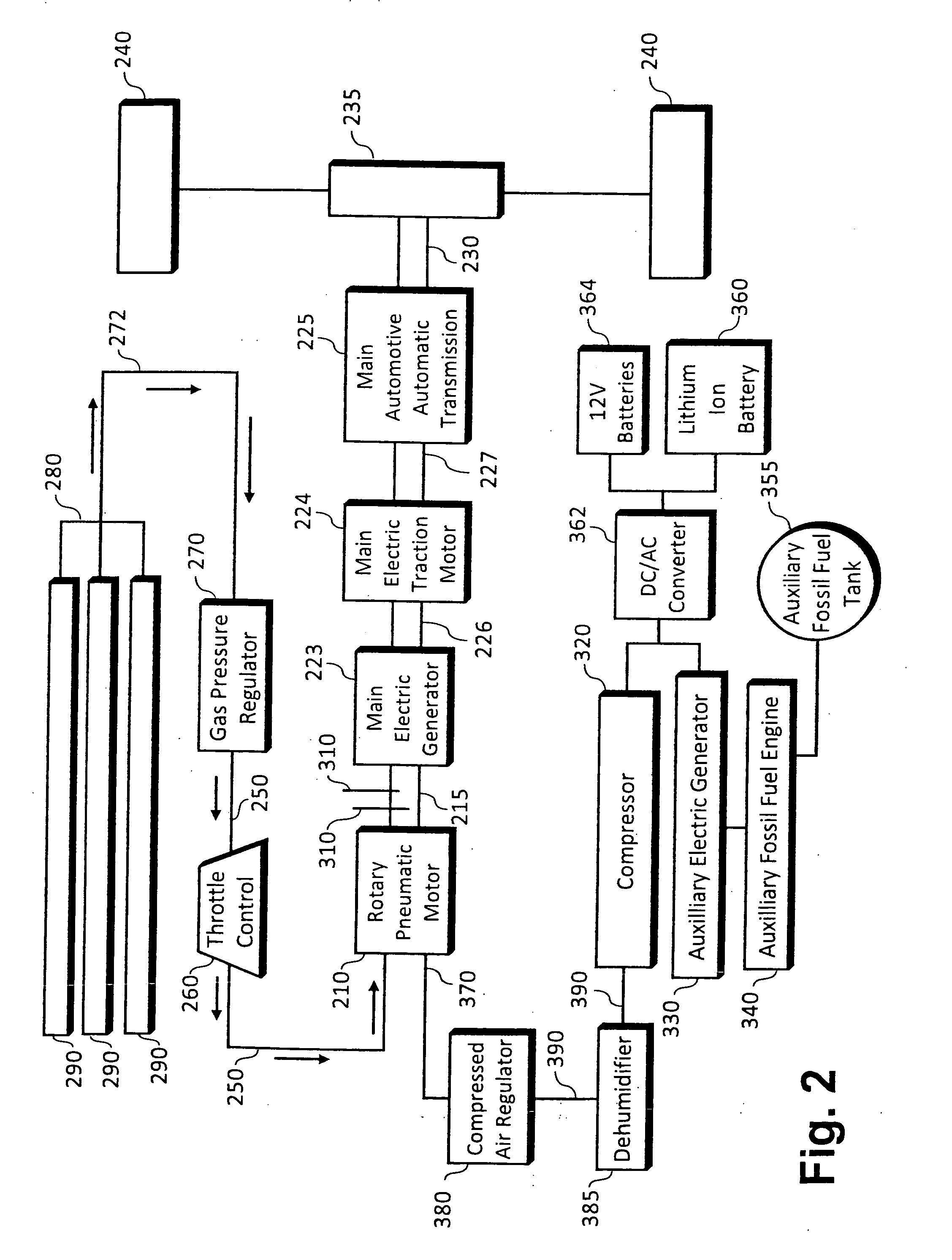

Pneumatic mechanical power source

ActiveUS20110049909A1Eliminate consumptionEliminate the problemServomotor componentsPlural diverse prime-mover propulsion mountingPower stationLiquid state

An mechanical power system provides torque without using a heat engine where fossil-fuel engines have conventionally been used, by replacing the fossil-fuel burning engine with a rotary pneumatic motor and feeding pressure-regulated compressed gas to the rotary pneumatic motor. The rotary pneumatic motor can be used anywhere, and requires preferably compressed nitrogen in a non-liquid state. Automotive, marine and electrical generating applications are adaptable, and auxiliary power is available for emergencies where a supply of compressed gas has been exhausted. A screw-type compressor can be electrically powered to supply compressed gas to the pneumatic motor where tanks of compressed gas have been exhausted. An electrical generating power plant includes an array of solar panels for generating direct current (DC) and a DC / AC converter for converting the DC to alternating current (AC) and outputting a portion of the AC via a power plant output port to supply an AC load.

Owner:DOMES TIMOTHY

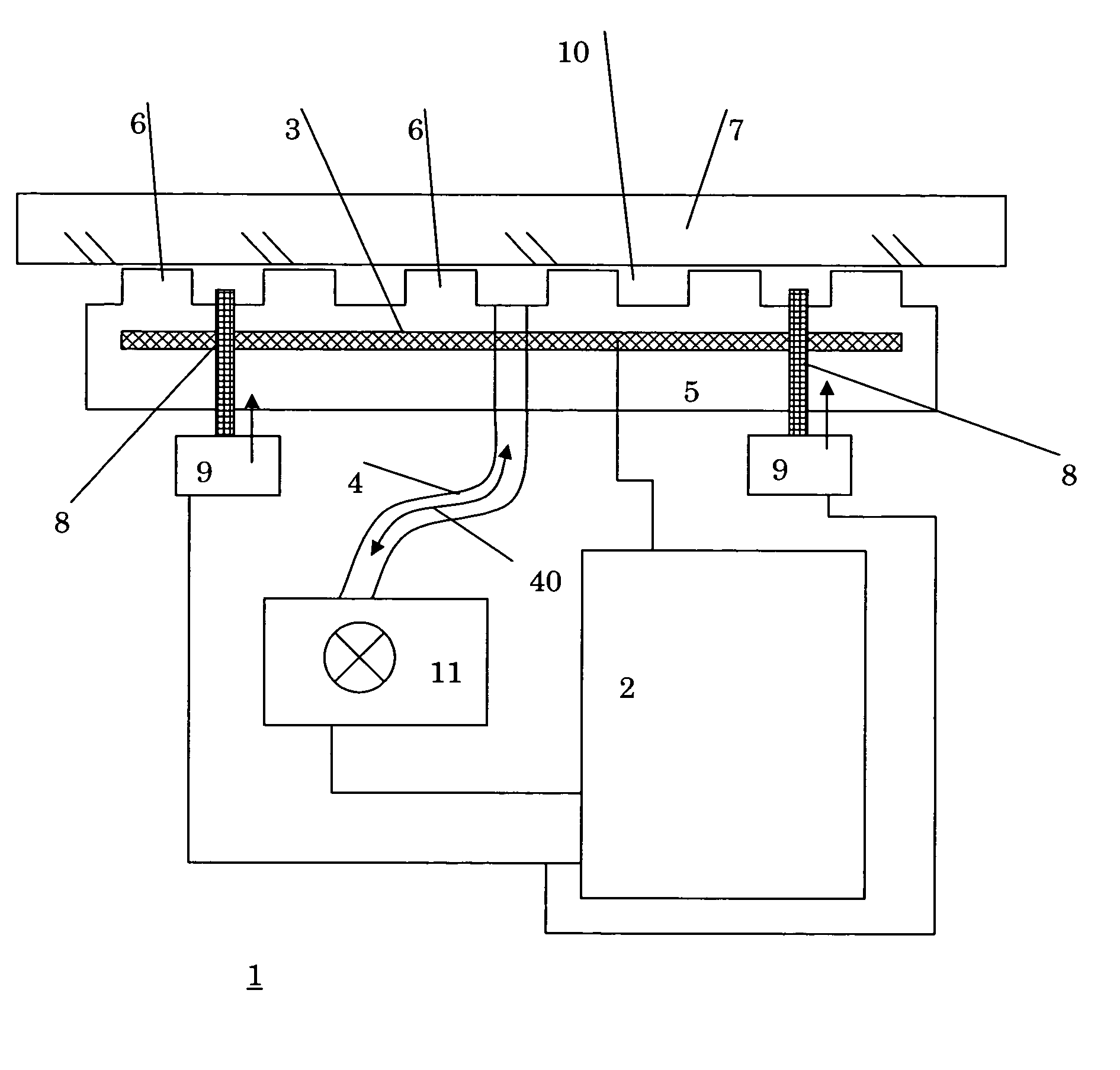

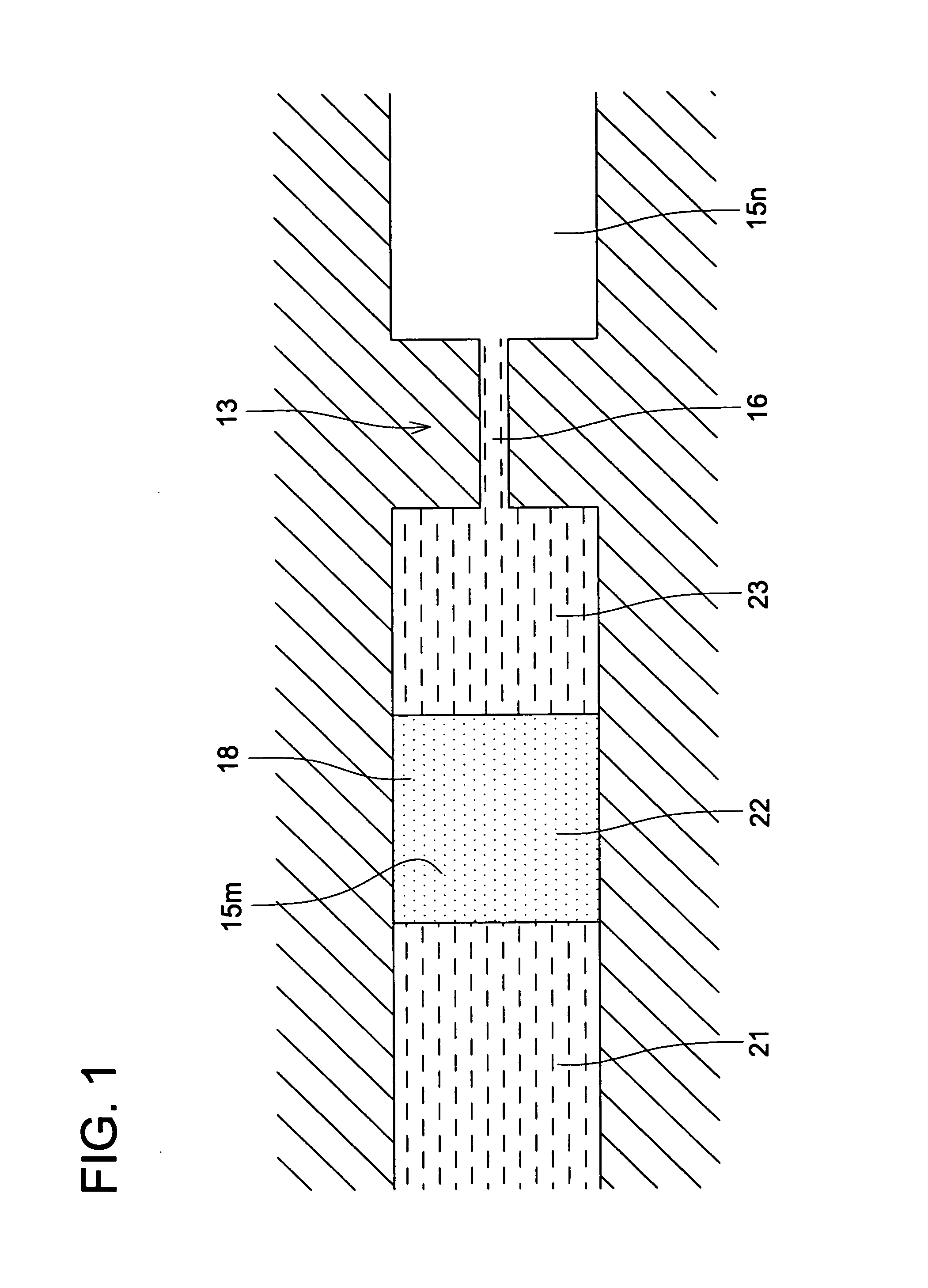

Testing chip and micro analysis system

InactiveUS20060239862A1Reduce feeding pressureSpeed up the flowBioreactor/fermenter combinationsSludge treatmentAnalysis sampleReagent

A testing chip that analyzes a specimen includes: a reagent storage section; a mixing and reaction flow channel to perform a series of operations to mix a specimen and aqueous reagent, make the specimen and reagent react with each other, and detect the reaction; and a liquid feed control section provided between an outlet flow channel of the reagent storage section and the inlet of the mixing and reaction flow channel. Herein, aqueous reagent, lipophilic liquid, and aqueous liquid having greater surface tension than that of the aqueous reagent are disposed in the reagent storage section in this order toward the outlet flow channel, the aqueous liquid being stored in contact with the liquid feed control section; and aqueous liquid passes the micro flow path of the liquid feed control section by applying a liquid feed pressure higher than or equal to a predetermined pressure to the reagent storage section.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

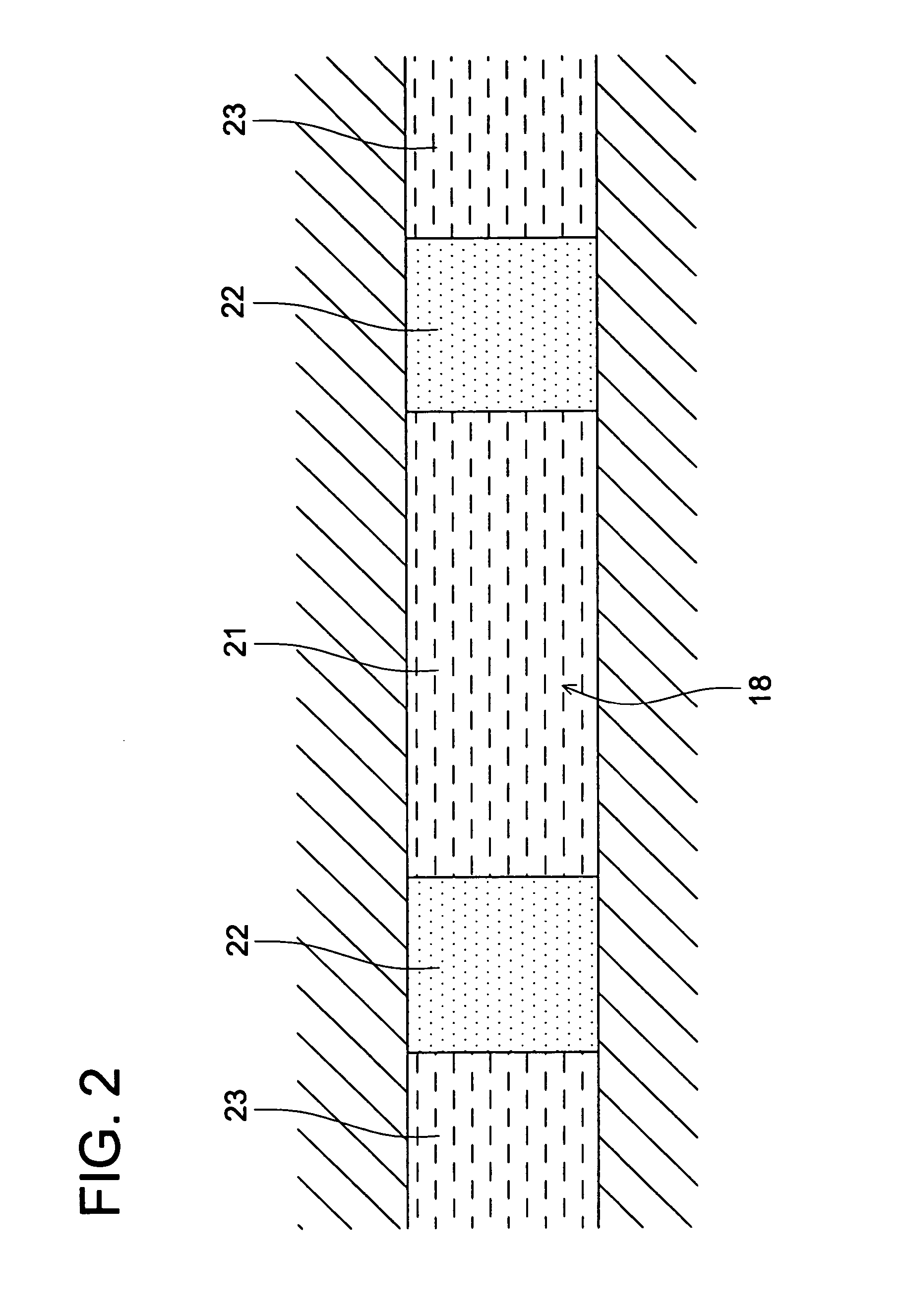

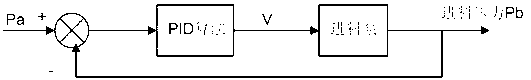

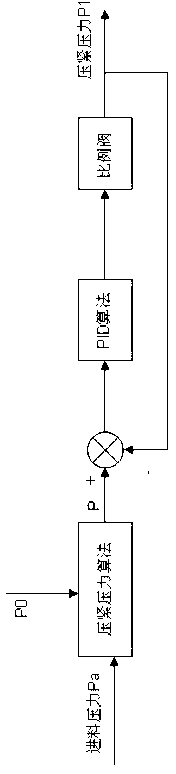

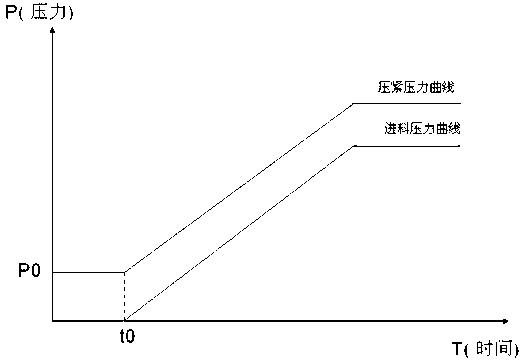

Feeding pressure and pressing pressure linkage type pressure filter control method and high-pressure pressure filter

ActiveCN103007628AIncrease feed pressureImprove the ability to separate filtrateFiltration separationEngineeringFilter press

Owner:ZHEJIANG HUAZHANG TECH

Sewage sludge reduction dewatering method

InactiveCN105601080ARealize unloadingAchieving deep reductionSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeSewage

The invention discloses a sewage sludge reduction dewatering method which is based on a reduction dewaterer. The reduction dewaterer comprises at least one dewatering module, wherein each dewatering module comprises a two-way cylinder (1) and two symmetrically arranged dewatering units (2); each dewatering unit (2) comprises a dewatering shell (2.1), a supporting plate (2.2) and an extrusion plate (2.3); the supporting plate (2.2) is positioned on the outer side of the dewatering shell (2.1); the extrusion plate (2.3) is positioned on the inner side of the dewatering shell (2.1); the dewatering shell (2.1) is provided with a feed port (2.4); the two-way cylinder (1) is provided with two piston rods (1.1); and the two piston rods (1.1) are respectively connected with the extrusion plates (2.3) of the two dewatering units (2). The feed dewatering and extrusion dewatering are carried out at the same time, thereby enhancing the work efficiency. Meanwhile, the feed pressure is ingeniously used for dewatering in the extrusion dewatering process, thereby enhancing the power use effect.

Owner:CHINA JILIANG UNIV

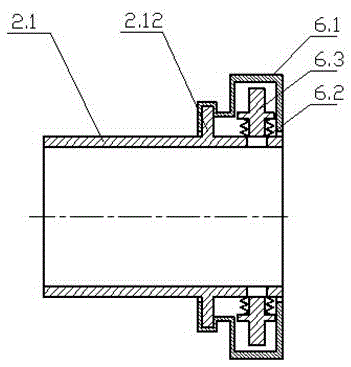

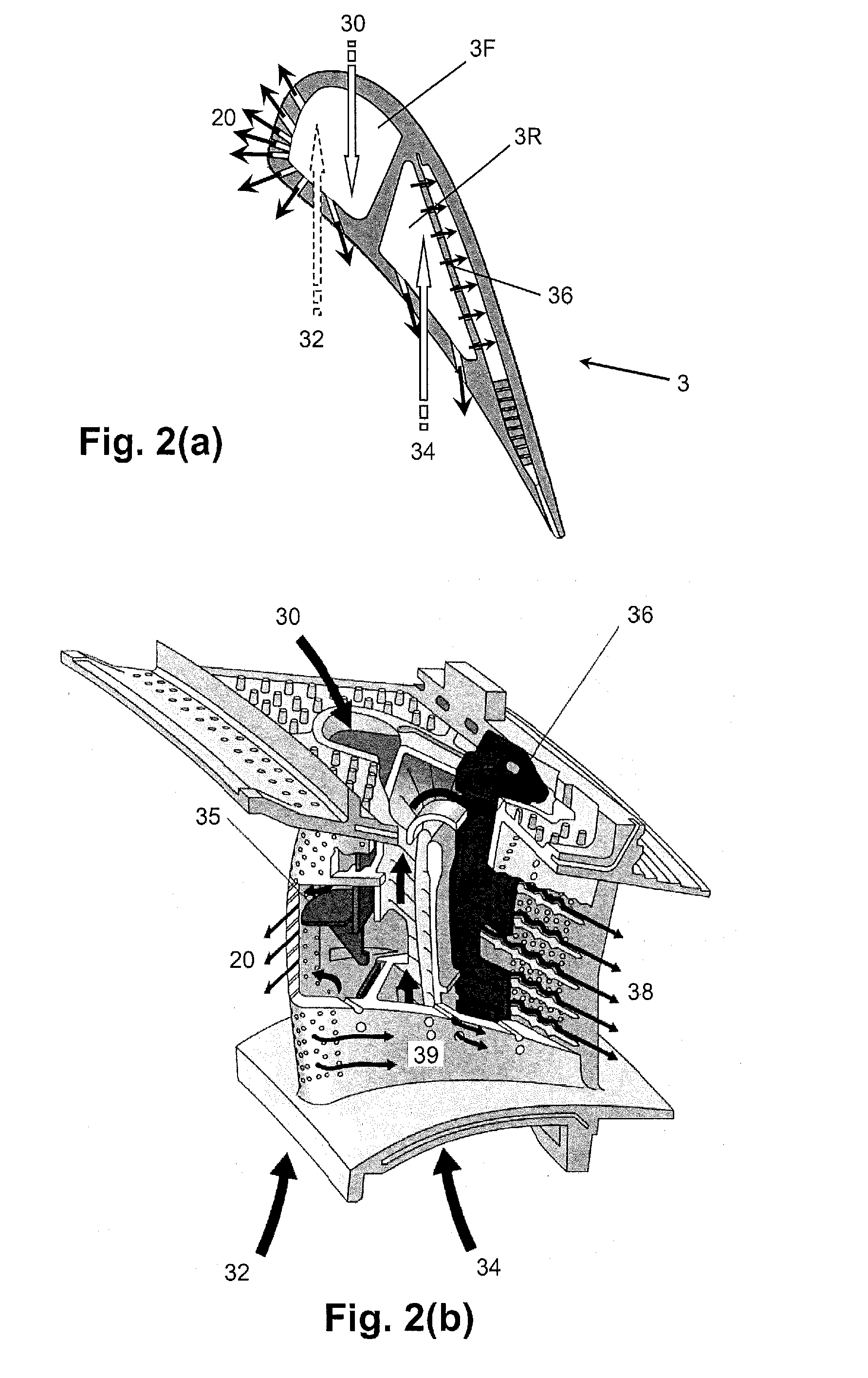

Internal cooling of engine components

InactiveUS20160097286A1Readily and assuredly maintainableBoost effective feed pressure of airflowPump componentsEngine fuctionsLeading edgeAir velocity

A gas turbine engine component, especially an aerofoil-sectioned nozzle guide vane (NGV), having at least one internal cooling chamber for passage of cooling air, the chamber including leading edge portion and one inlet portion via which cooling air may enter the chamber from feed source, wherein the component includes a partitioning element, e.g. curved or scoop-shaped partitioning plate or wall, provided in the chamber inlet portion and defining within the inlet portion a sub-chamber adjacent the leading edge portion, and wherein partitioning element is configured so the cooling air velocity in the sub-chamber is less than the cooling air velocity in the remainder of inlet portion. The reduced velocity of the cooling air in the sub-chamber adjacent the leading edge serves to increase pressure therein, thereby maintaining desired backflow pressure margin between the feed pressure of the cooling air delivered to the showerhead holes and the gas-path from the combustor.

Owner:ROLLS ROYCE PLC

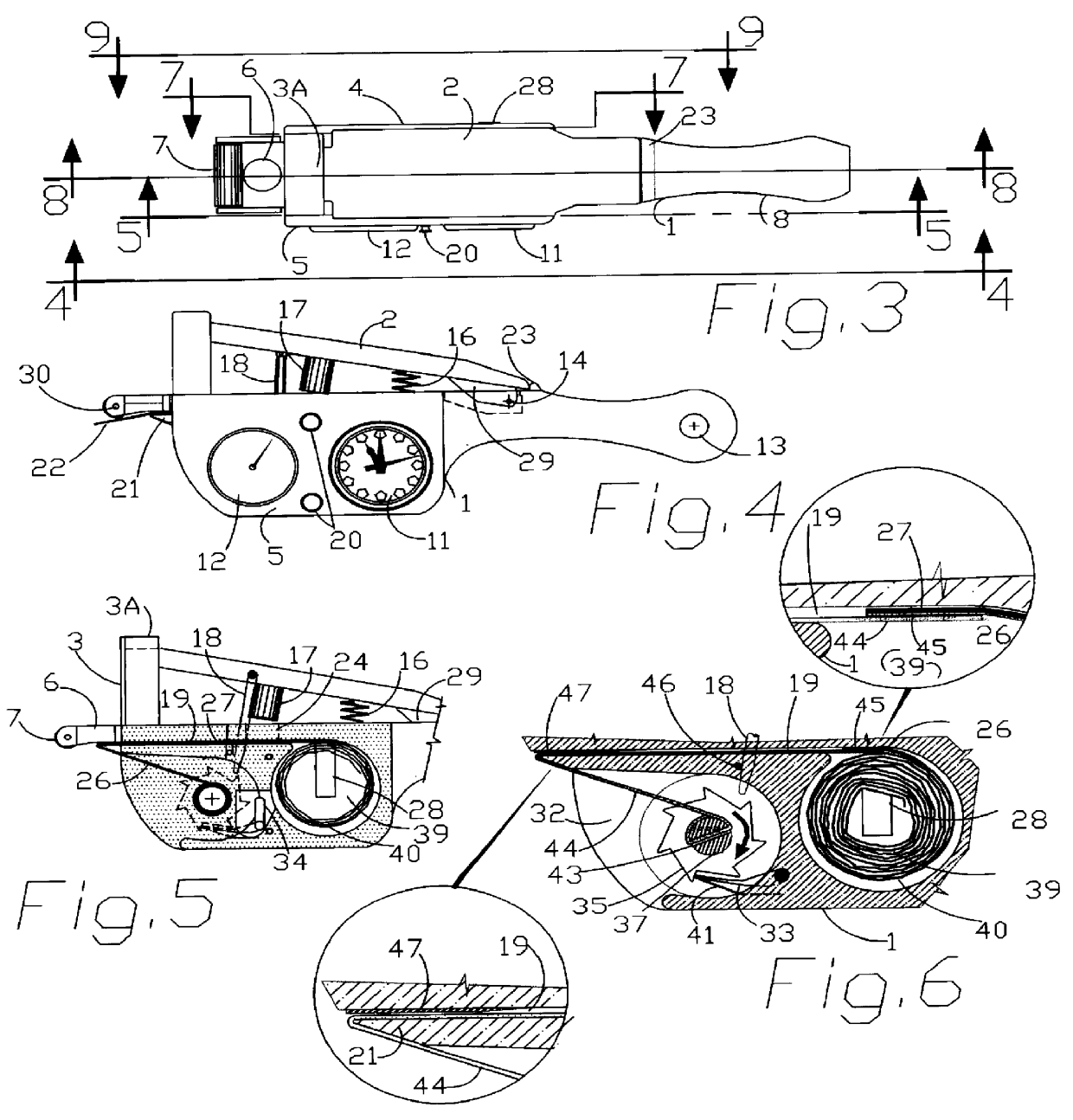

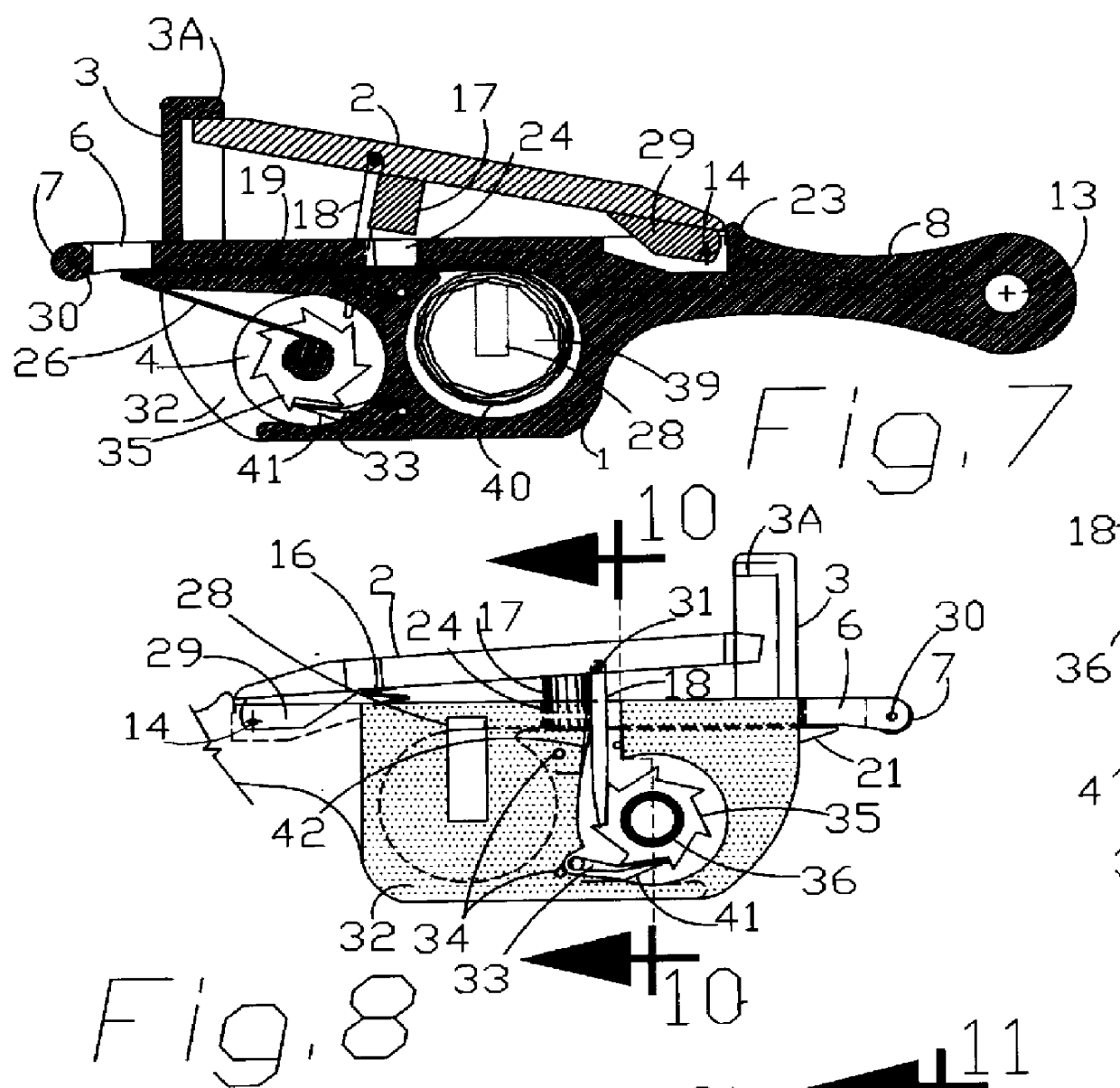

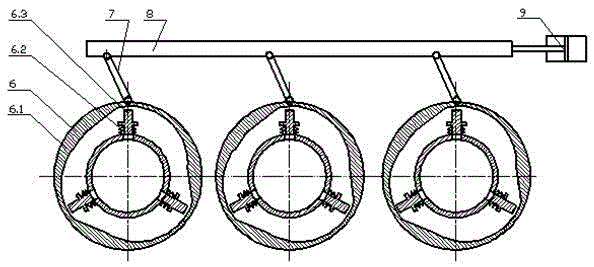

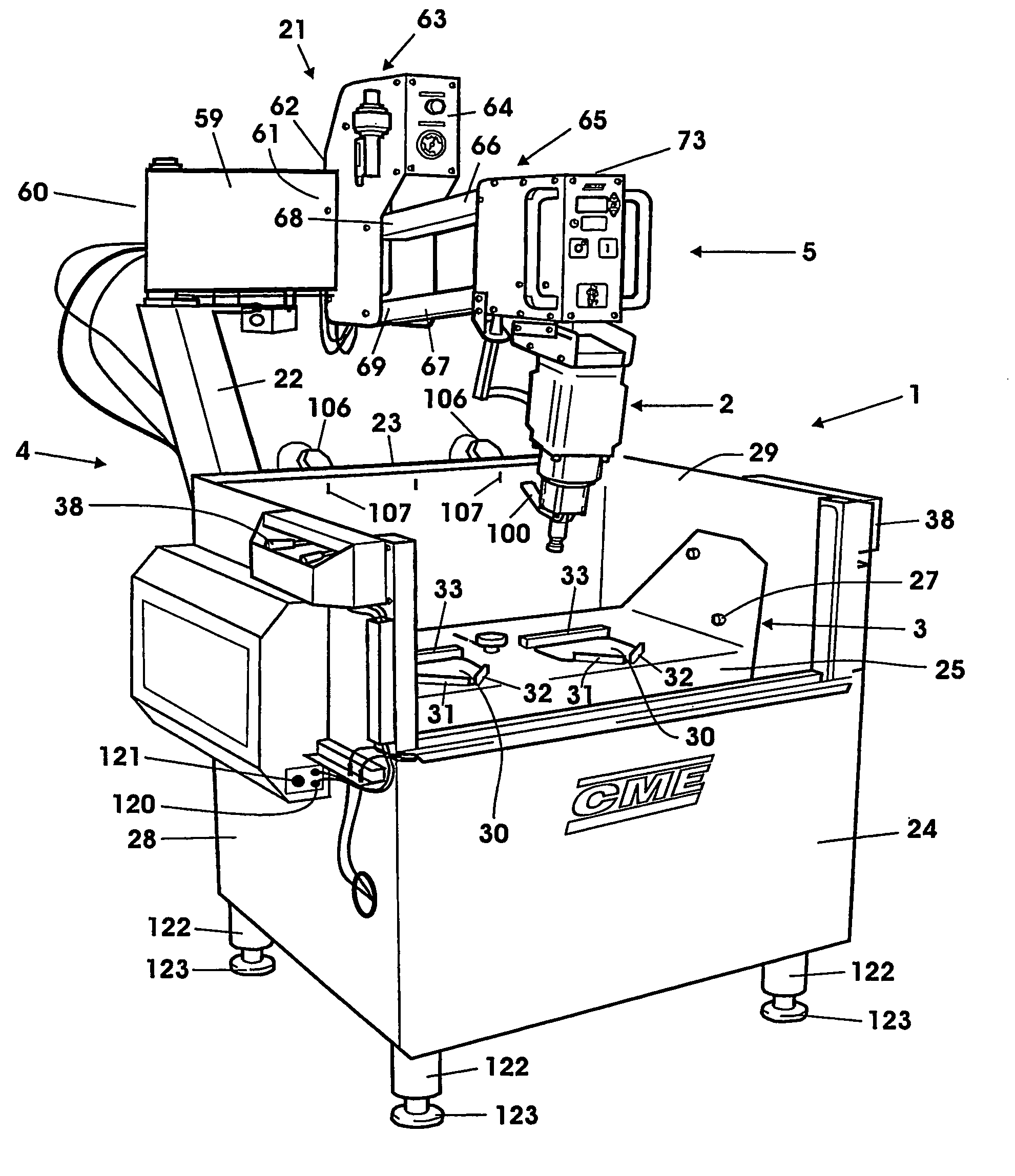

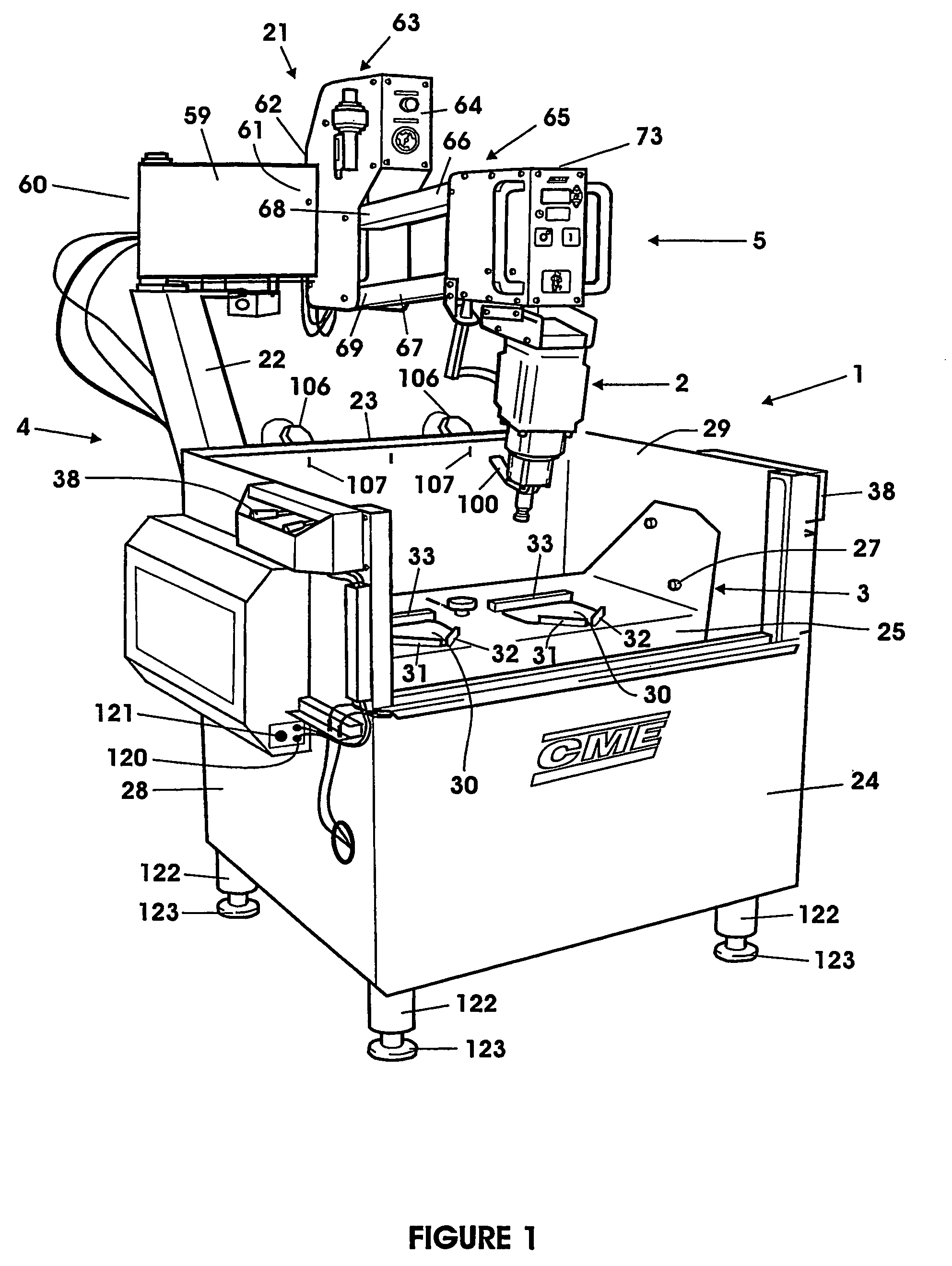

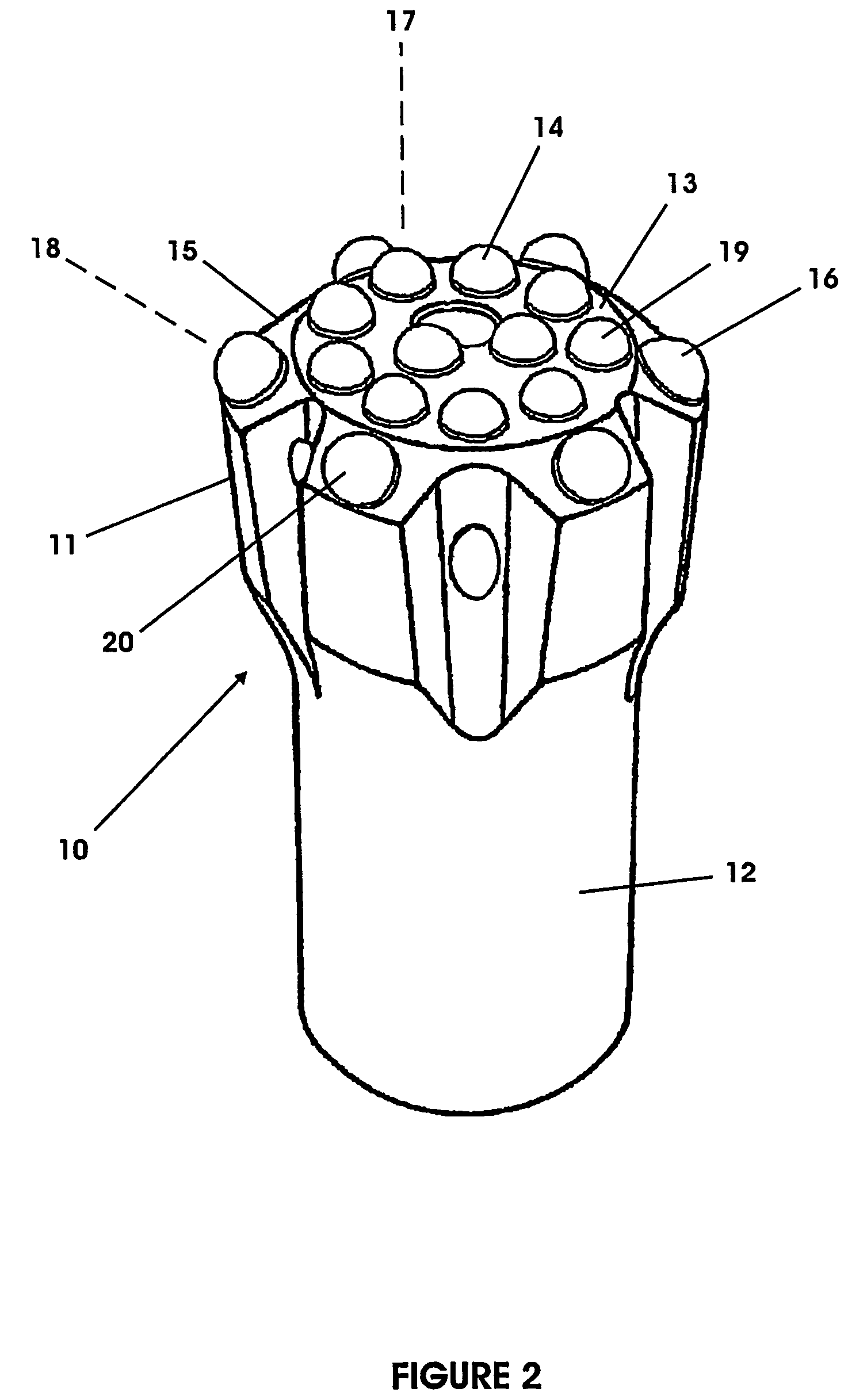

Grinding apparatus for buttons on rock drill bit

ActiveUS7402093B2Increase torqueCompact size and weightRevolution surface grinding machinesGrinding feed controlSupporting systemHard metal

The present invention relates to grinding apparatus for grinding the hard metal inserts of rock drill bits, said grinding apparatus having a grinding machine carried on an support system that provides a feed pressure for said grinding machine during grinding, said grinding machine equipped with a grinding pin driven by motor to rotate about its longitudinal axis wherein the grinding cup is rotated at variable speeds and the support system provides a variable feed pressure.

Owner:C M E BLASTING & MINING EQUIP

Pneumatic mechanical power source

An mechanical power system is provided for providing torque without using a heat engine in virtually any non-aviation application where fossil-fuel engines have conventionally been used, by simply replacing the fossil-fuel burning engine with a rotary pneumatic motor of appropriate size for the application and feeding pressure-regulated compressed gas to the rotary pneumatic motor. The rotary pneumatic motor can be used virtually anywhere, and requires merely a supply of compressed gas to run it, preferably compressed nitrogen. Automotive, marine and electrical generating applications are easily adaptable, and auxiliary fossil-fuel engines can be added for emergencies where a supply of compressed gas has been exhausted. A screw-type compressor can be electrically powered to supply compressed gas to the pneumatic motor where tanks of compressed gas have been exhausted. Tanks of compressed gas are to be conveniently user replaceable.

Owner:DOMES TIMOTHY J

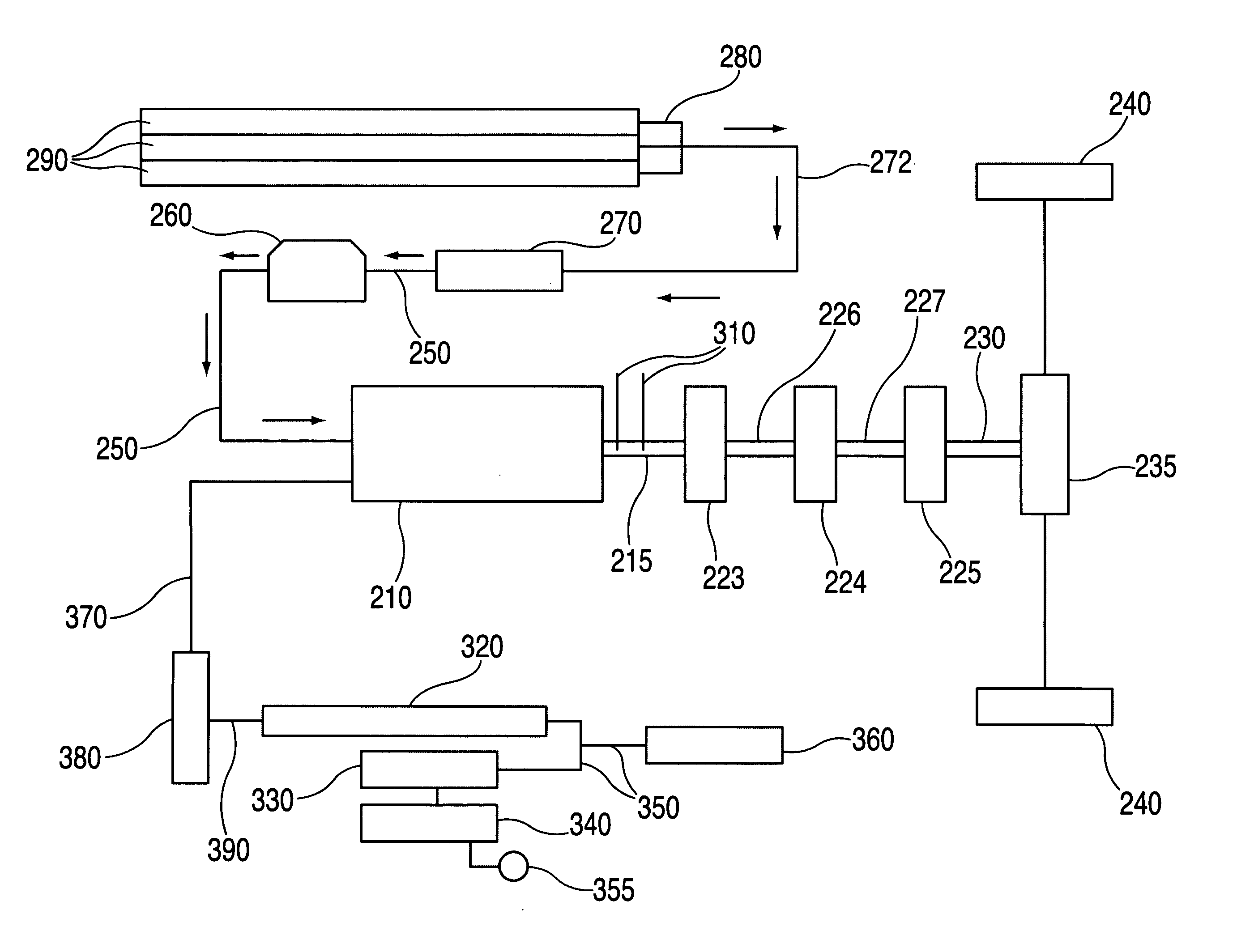

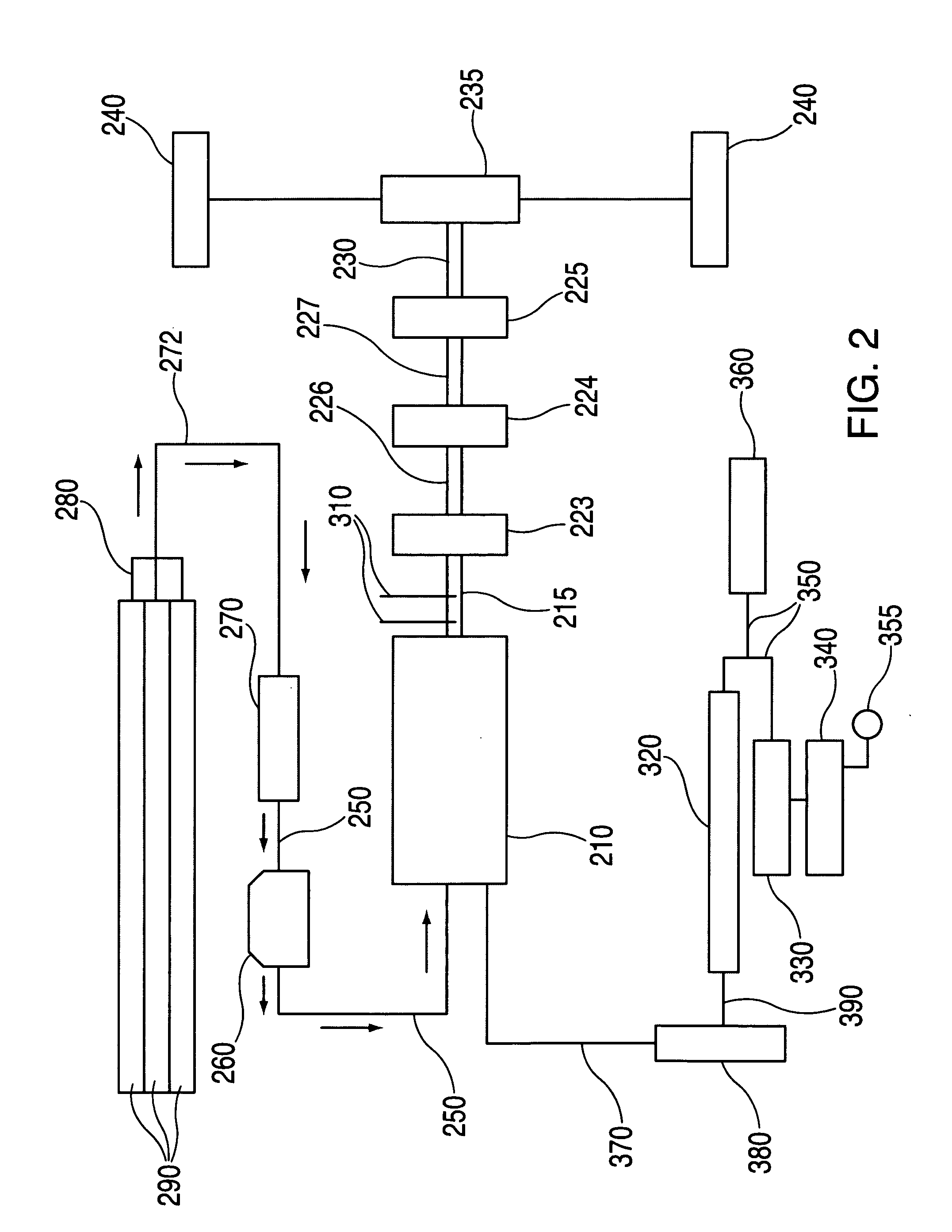

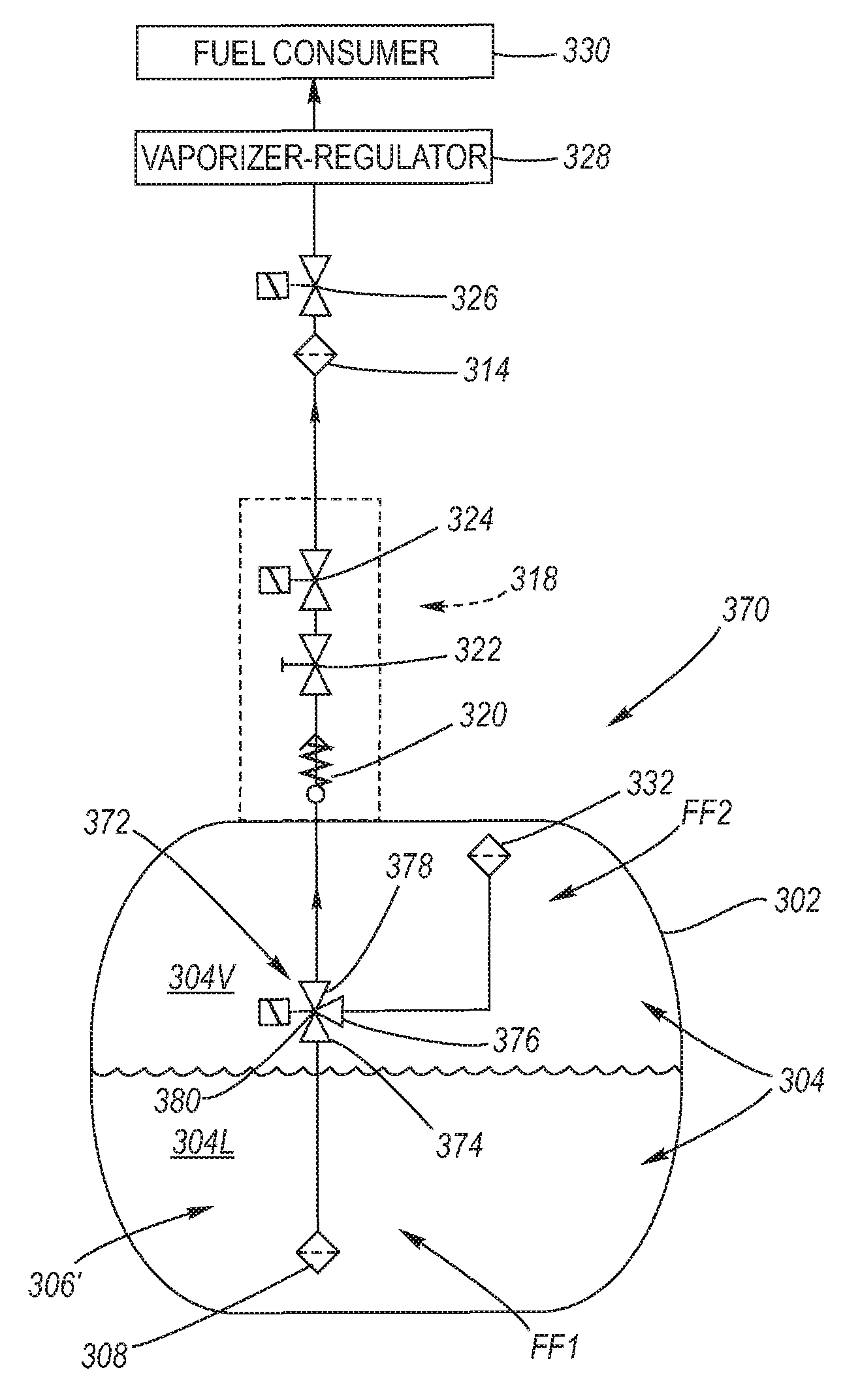

Fuel tank temperature and pressure management via selective extraction of liquid fuel and fuel vapor

InactiveUS8783281B2Raise the ratioReduce the possibilityFunctional valve typesInternal combustion piston enginesLiquid fuelFuel vapor

A method and apparatus for managing temperature and pressure of fuel in a fuel tank stored at or near its vapor pressure. In response to fuel feed pressure, a variable ratio of liquid fuel to fuel vapor is extracted from the fuel tank in order to regulate temperature and pressure of the fuel for the purpose of keeping the pressure lower in anticipation of refilling or to assist a vaporizer of the fuel system which is incompletely vaporizing the fuel.

Owner:GM GLOBAL TECH OPERATIONS LLC

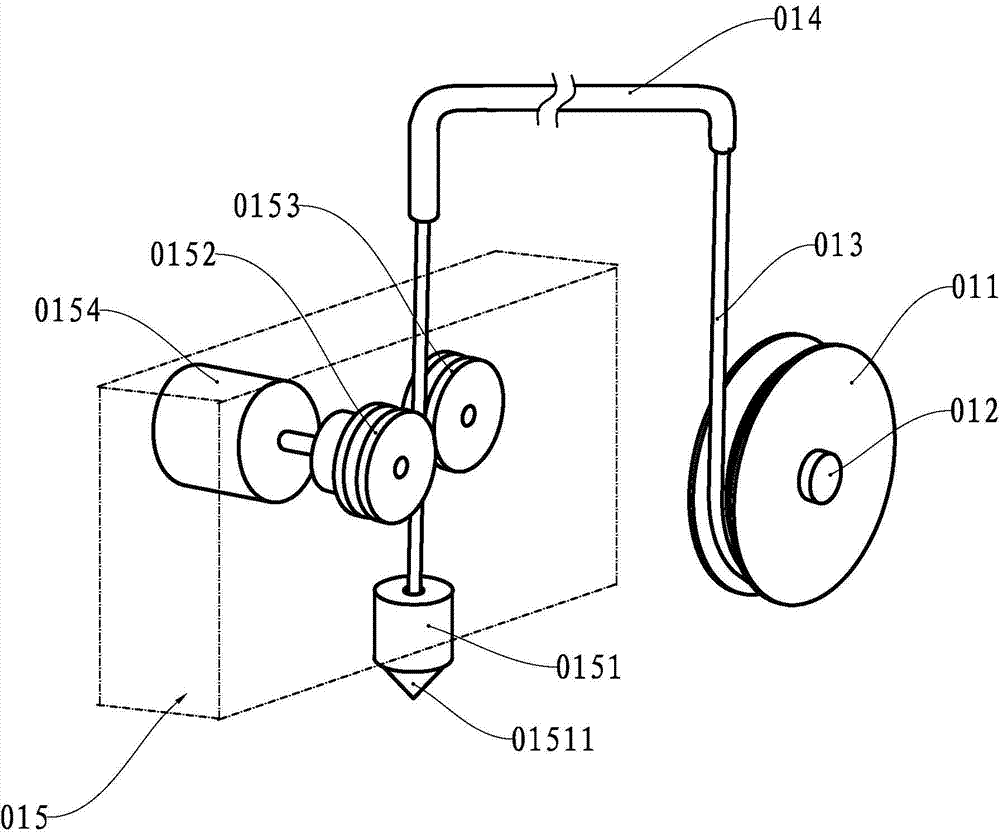

Printing head and three-dimensional printing machine

ActiveCN103895223AIsolation impactImprove printing qualityAdditive manufacturing with liquids3D object support structuresMolten stateRapid prototyping

The invention relates to a printing head for melting a sedimentation-type rapid molding device. The printing head comprises a printing nozzle, a heater and a feeding device, wherein a discharge hole of the feeding device is communicated with a feed hole of the heater; the printing nozzle is mounted on a printing vehicle of a three-dimensional printing machine; the heater is mounted on a stander of the three-dimensional printing machine; the discharge hole of the heater is communicated with the feed hole of the printing nozzle through a hose, so that molding materials in a molten state in a heating melting chamber of the heater are conveyed into the printing nozzle through the high-temperature-resistant hose; a feeding pressure device is used for supplying feeding pressure to the heating melting chamber of the heater. By adopting the printing head, vibration of the printing nozzle of the printing head during printing is reduced and the quality of the printer is improved. Besides, the invention also provides the three-dimensional printing machine comprising the printing head.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

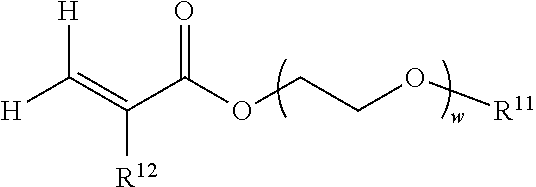

Composite membranes

A composite membrane comprising a discriminating layer and a porous support layer for the discriminating layer, CHARACTERISED IN THAT the discriminating layer comprises at least 60 wt % of oxyethylene groups and the porous support layer has a CO2 gas flux of 5 to 150×10−5 m3 (STP) / m2·s·kPa at a feed pressure of 2.07 kPa. The membranes are particularly useful for purifying waste gas streams e.g. by removing greenhouse gases.

Owner:FUJIFILM MFG EURO

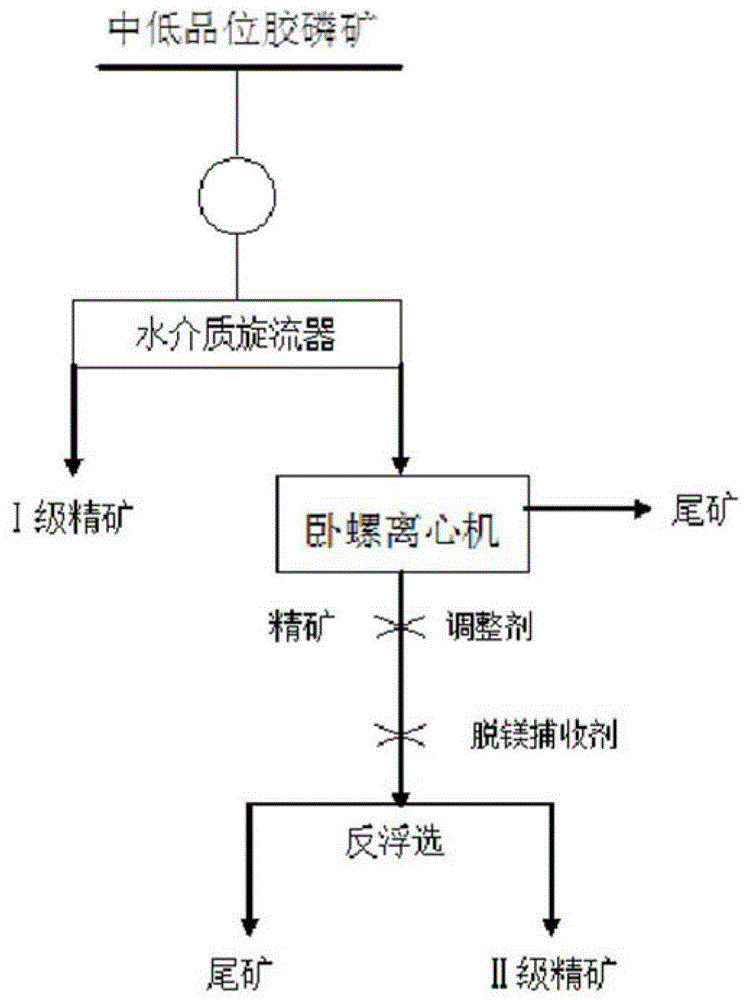

Process method for removing phosphate impurities by combining gravity, centrifugal force and flotation

The invention relates to a process method for removing phosphate impurities by combining gravity, centrifugal force and flotation. By the aid of the mineral processing flow sheet of a water-only cyclone, a horizontal screw decanter centrifuge and reverse flotation, the process method includes the steps: (1) taking phosphate ore which is colloid phosphate and setting the content of P2O5 to range from 22% to 27%; (2) grinding the phosphate ore to have -200 meshes larger than 75% by a wet method and setting the solid content of ore pulp to range from 20% to 45%; (3) throwing the ore pulp into the water-only cyclone and setting feed pressure to range from 1.5kg / cm<2> to 2.5kg / cm<2> to obtain first-grade concentrate; (4) feeding tailings in the water-only cyclone into the horizontal screw decanter centrifuge at the speed of 50-100m<3> / h, setting the speed of a rotary drum of the horizontal screw decanter centrifuge to range from 1500r / min to 2500r / min and setting the differential speed of the rotary drum and a screw to range from 10r / min to 50r / min; (5) adding regulators into the concentrate in the horizontal screw decanter centrifuge and regulating the pH (potential of hydrogen) value of the ore pulp to range from 4 to 5; and (6) feeding the regulated ore pulp into a flotation machine, adding 400g / T-600g / T of magnesium removing collectors into the regulated ore pulp, and performing inflation and defoaming to obtain second-grade concentrate. The process method has the advantages that agent consumption in a flotation process is reduced by the process method, other impurities can be removed, the grade of the phosphate is greatly improved, and the recovery rate is also increased.

Owner:KUNMING CHUAN JINNUO CHEM IND

Fuel injector with an optimized metering device

InactiveUS20020059799A1Reduce flow rateShorten the timeTurbine/propulsion fuel valvesGas turbine plantsCombustion chamberEngineering

A fuel injector has a metering valve arranged to open under a predetermined feed pressure which constitutes a first threshold pressure, and to remain open in response to said feed pressure increasing so as to deliver fuel to fuel utilization means. The flow rate of fuel passing through the injector is metered to feed said utilization means so long as the feed pressure remains below a second threshold pressure greater than the first threshold pressure. Above the second threshold pressure, the metering valve behaves like a fixed diaphragm as a function of the fluid flow sections formed therethrough. Individual adjustment means are provided so as to enable said second threshold pressure to be adjusted for each injector to ensure that fuel is injected at a uniform flow rate by all of the injectors in a combustion chamber.

Owner:HISPANO SUIZA SA

Lithographic apparatus and device manufacturing method

A lithographic apparatus includes an illumination system for providing a beam of radiation, an article support for supporting a flat article to be placed in a beam path of the beam of radiation on the article support, a backfill gas feed arranged in the article support for feeding backfill gas to a backside of the article when supported by the article support, and a clamp for clamping the article against the article support during projection. According to one aspect of the invention, the apparatus includes a controller for controlling the clamp and / or the backfill gas feed pressure so as to release the clamp prior to reducing the backfill gas feed pressure.

Owner:ASML NETHERLANDS BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com