Patents

Literature

236results about How to "Eliminate consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fill material for direct-contact heat/mass exchangers

InactiveUS20150048528A1Reduced dysfunctionSmall sizeAdditive manufacturing apparatusUsing liquid separation agentFilling materialsLinear element

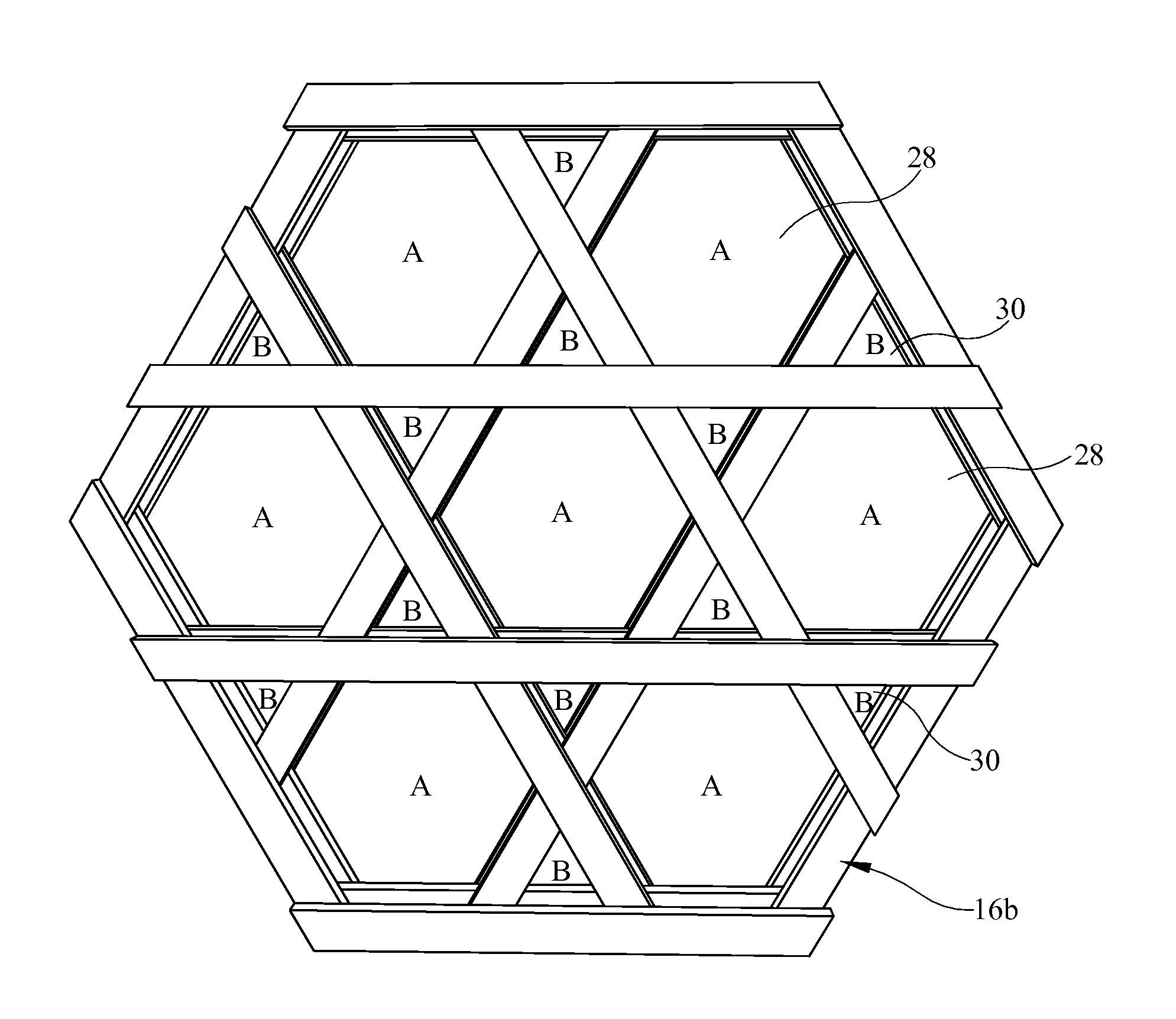

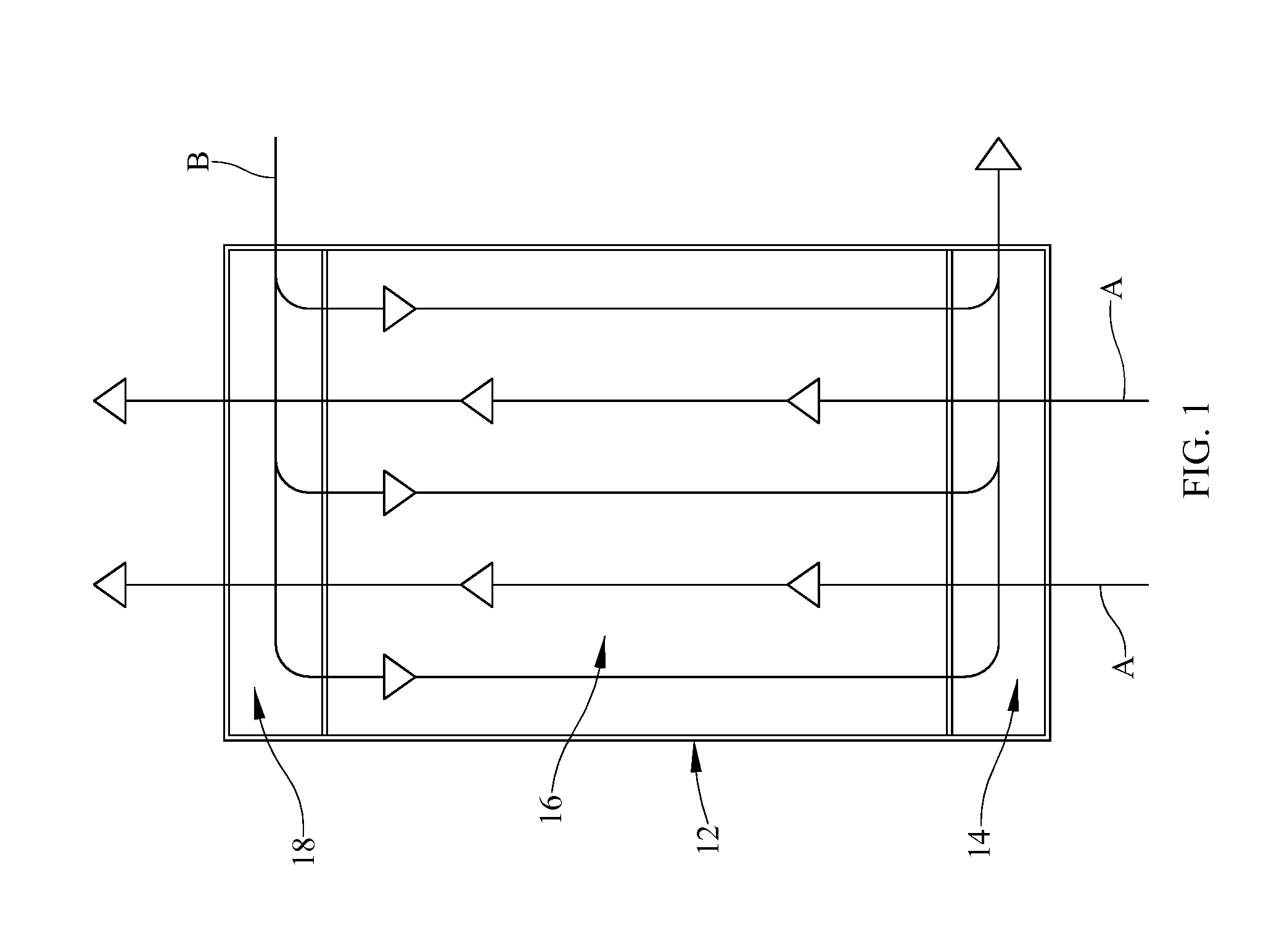

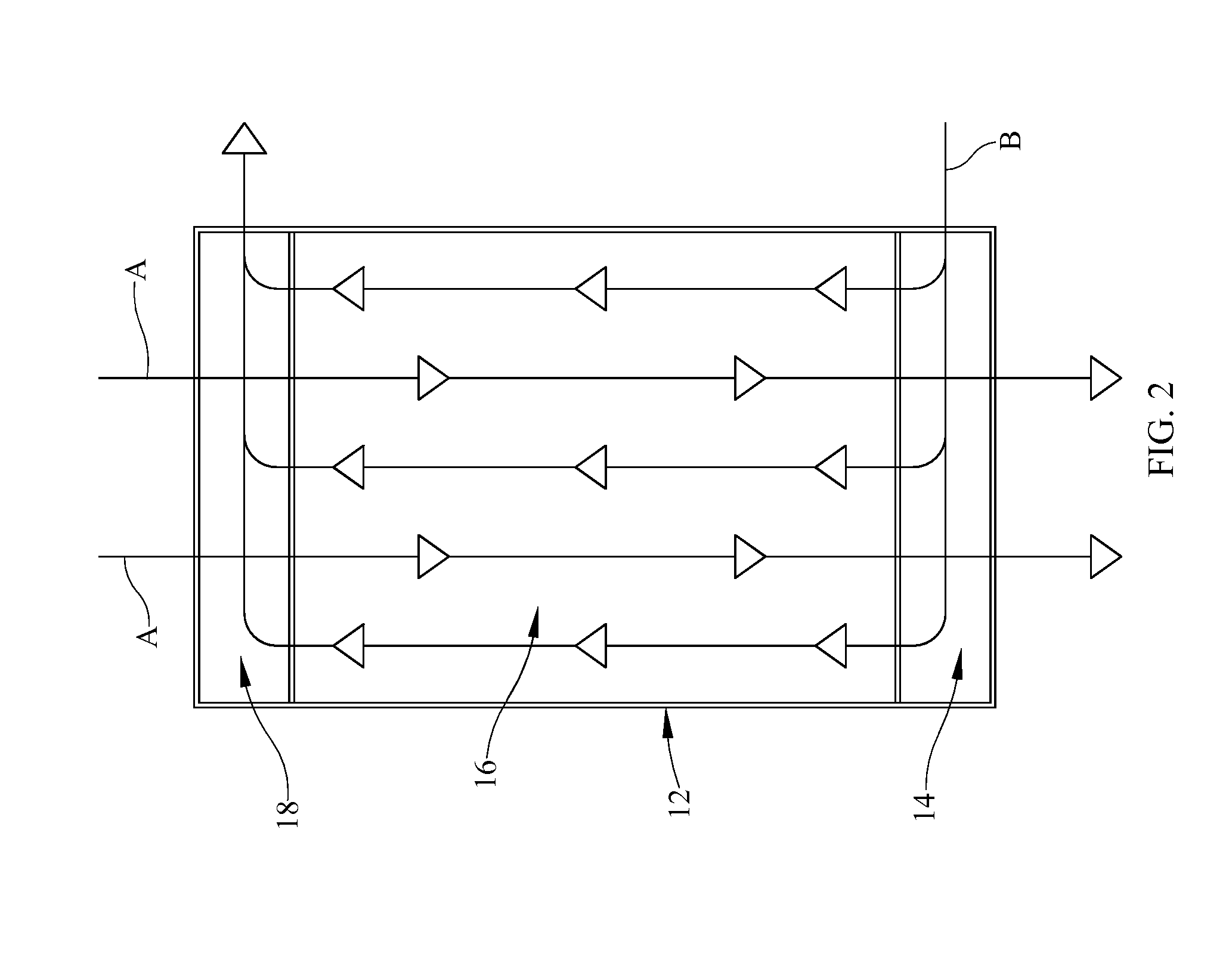

Fill material for a direct contact heat exchanger wherein the fill material has flow pathways bounded by an array of linear elements, namely a mesh. The invention intentionally uses surface tension and capillary action to anchor the fluid / fluid interface in a desired location. The heat exchanger is wick or collector in direct contact with the fill material (matrix) to extract fluid without formation of large droplets. The mesh is made from a neutrally wetting material.

Owner:BARTON SEAN ANDERSON

Method for manufacturing graphene-incorporated rechargeable li-ion battery

InactiveUS20150000118A1Enhanced power supply abilityFast deliveryFinal product manufacturePrimary cellsLithiumGraphene

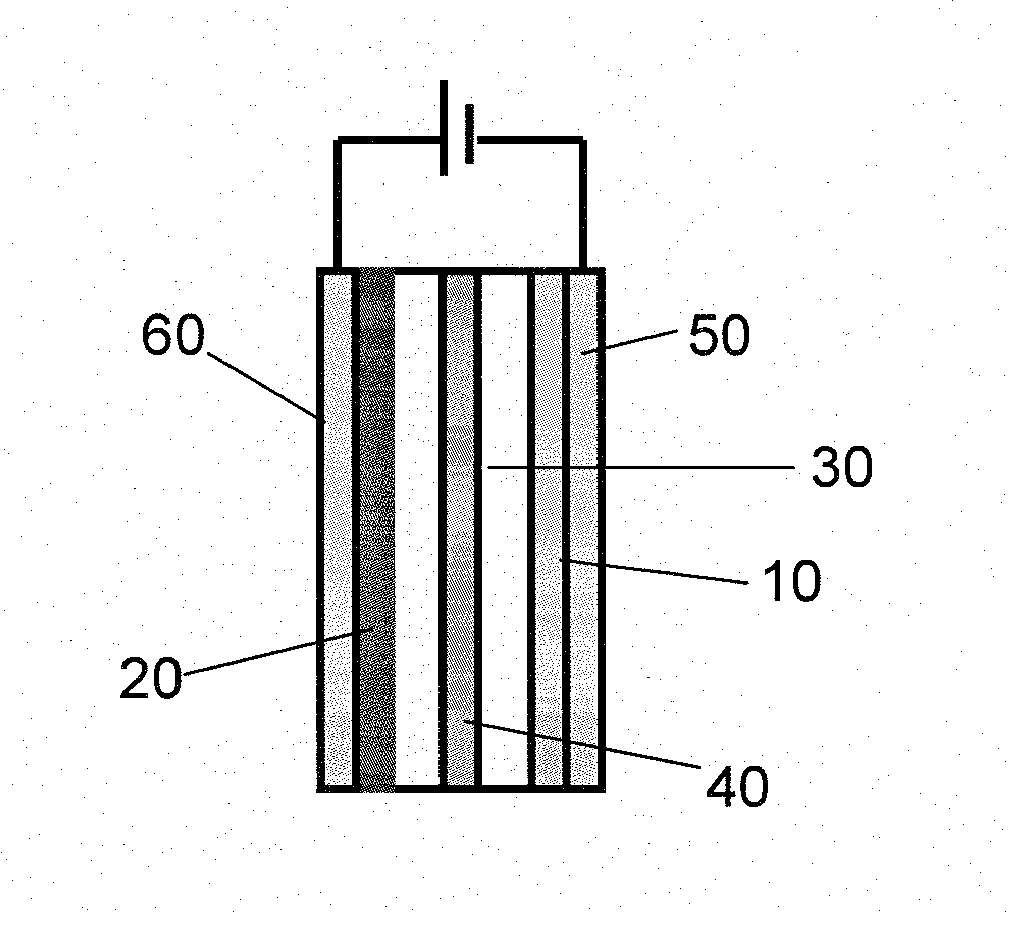

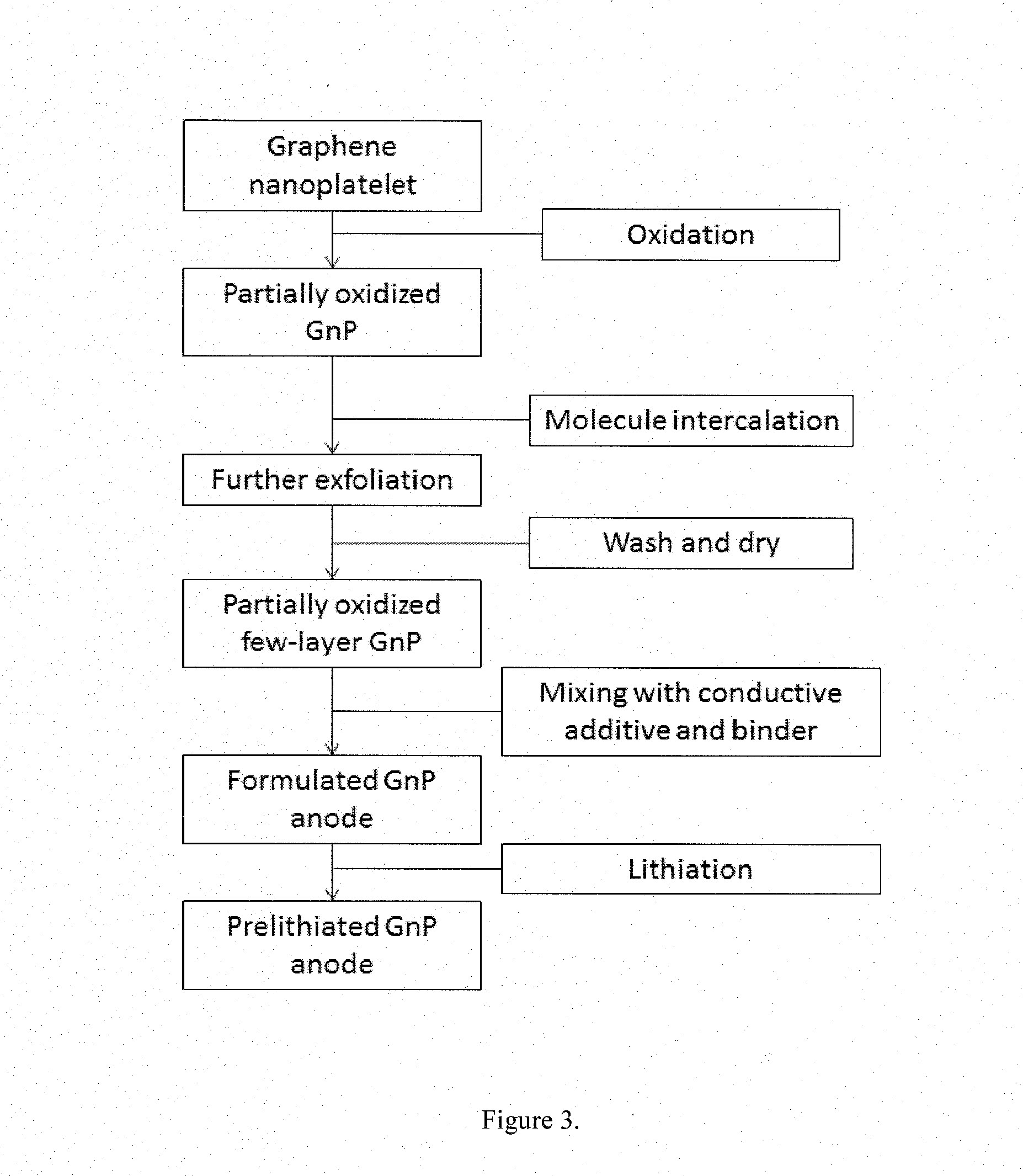

A method for manufacturing a graphene-incorporated rechargeable Li-ion battery discloses a graphene-incorporated rechargeable Li-ion battery with enhanced energy and power delivery abilities. The method comprises the steps (a) fabricating a high-performance anode film based on graphene or graphene hybrid; (b) introducing a desired amount of lithium into the anode material to produce a prelithiated graphene-based anode; (c) constructing a full cell utilizing a cathode film and the prelithiated anode film. The graphene-based anodes incorporating exfoliated graphene layers overcome the large irreversible capacity and initial lithium ion consumption upon pre-lithiation, and demonstrate remarkably enhanced specific capacity and rate capability over conventional anodes.

Owner:BLUESTONE TECH CAYMAN

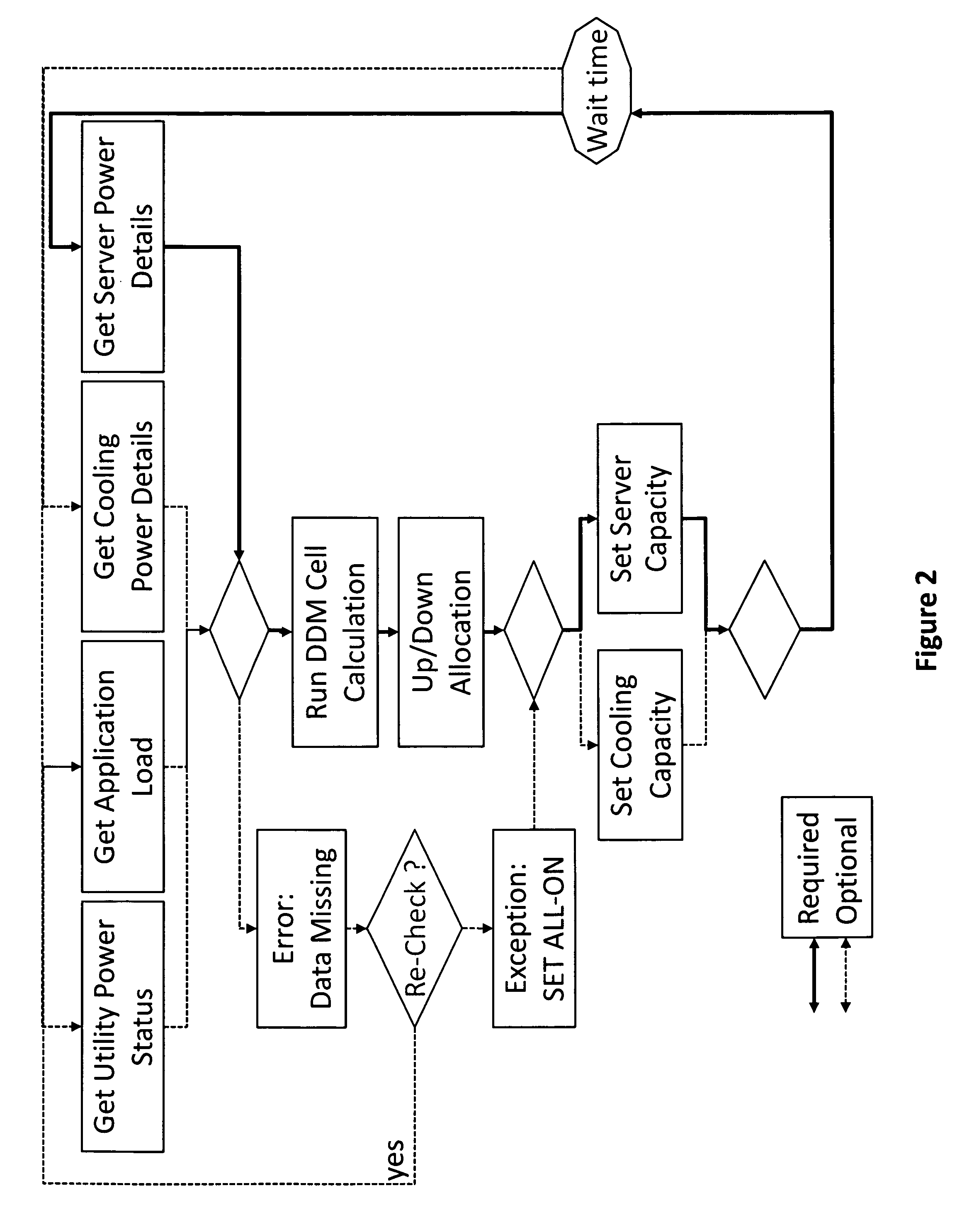

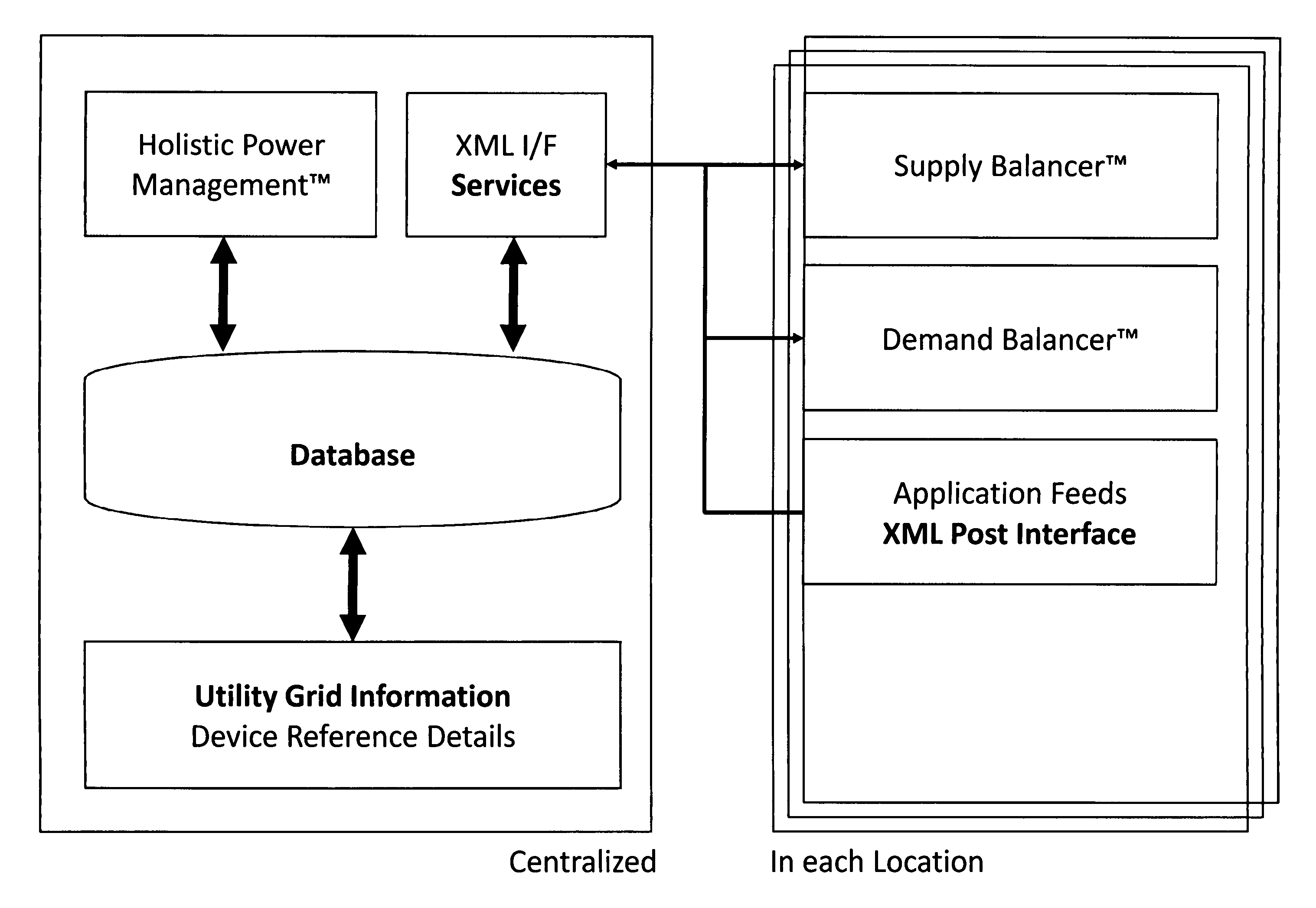

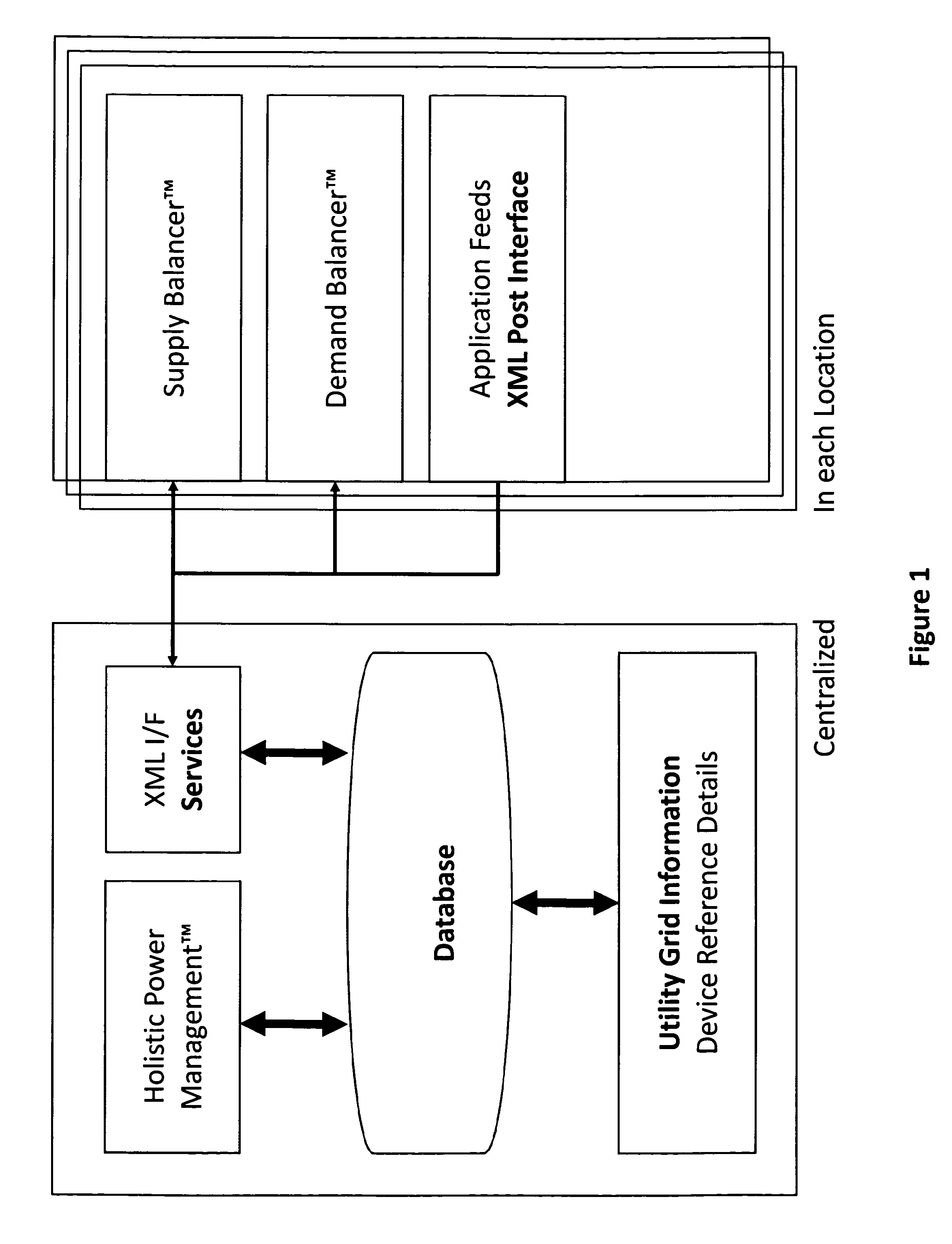

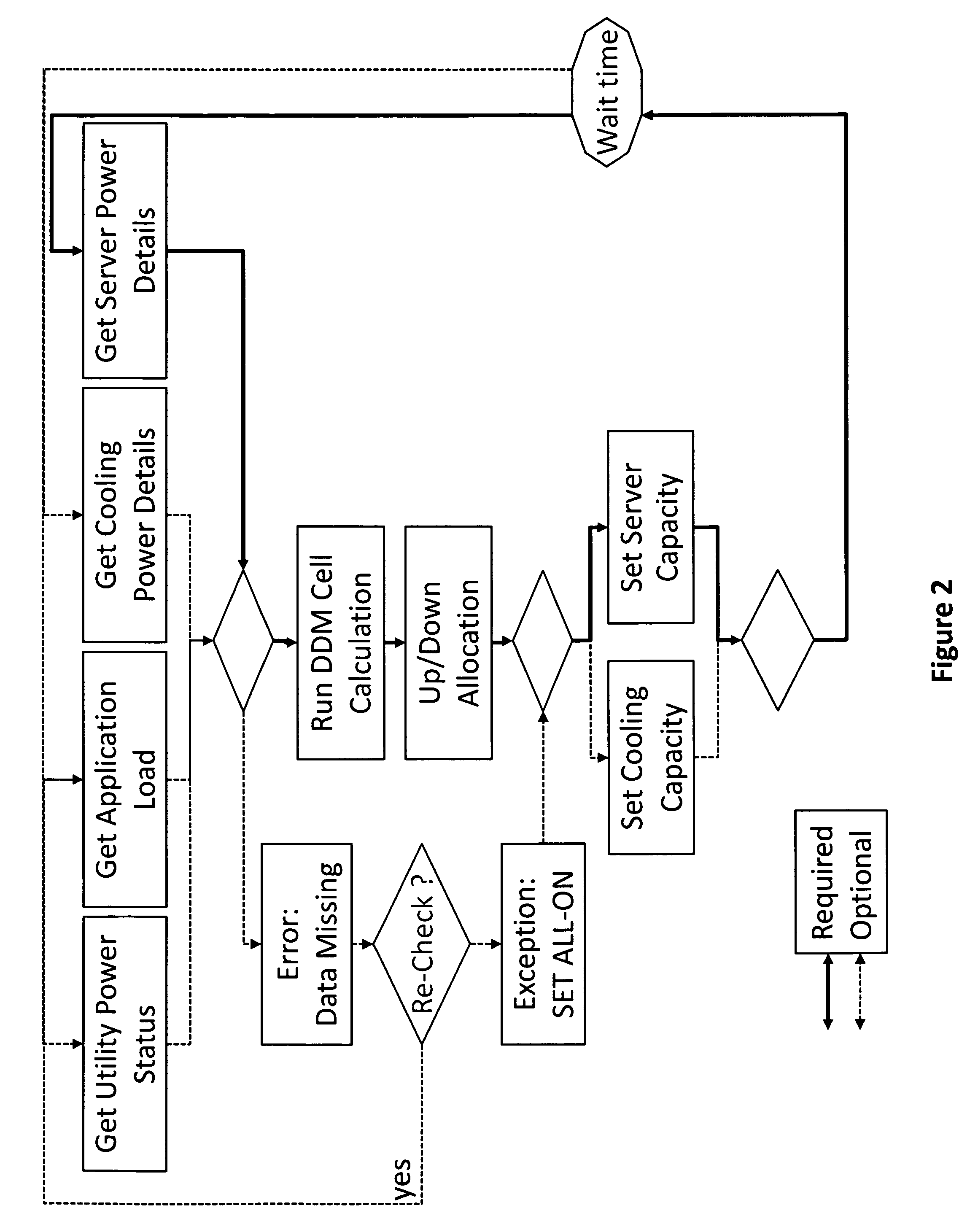

Method and apparatus for holistic power management to dynamically and automatically turn servers, network equipment and facility components on and off inside and across multiple data centers based on a variety of parameters without violating existing service levels

ActiveUS20090240964A1Improve overall utilizationEliminate consumptionVolume/mass flow measurementPower supply for data processingVirtualizationData center

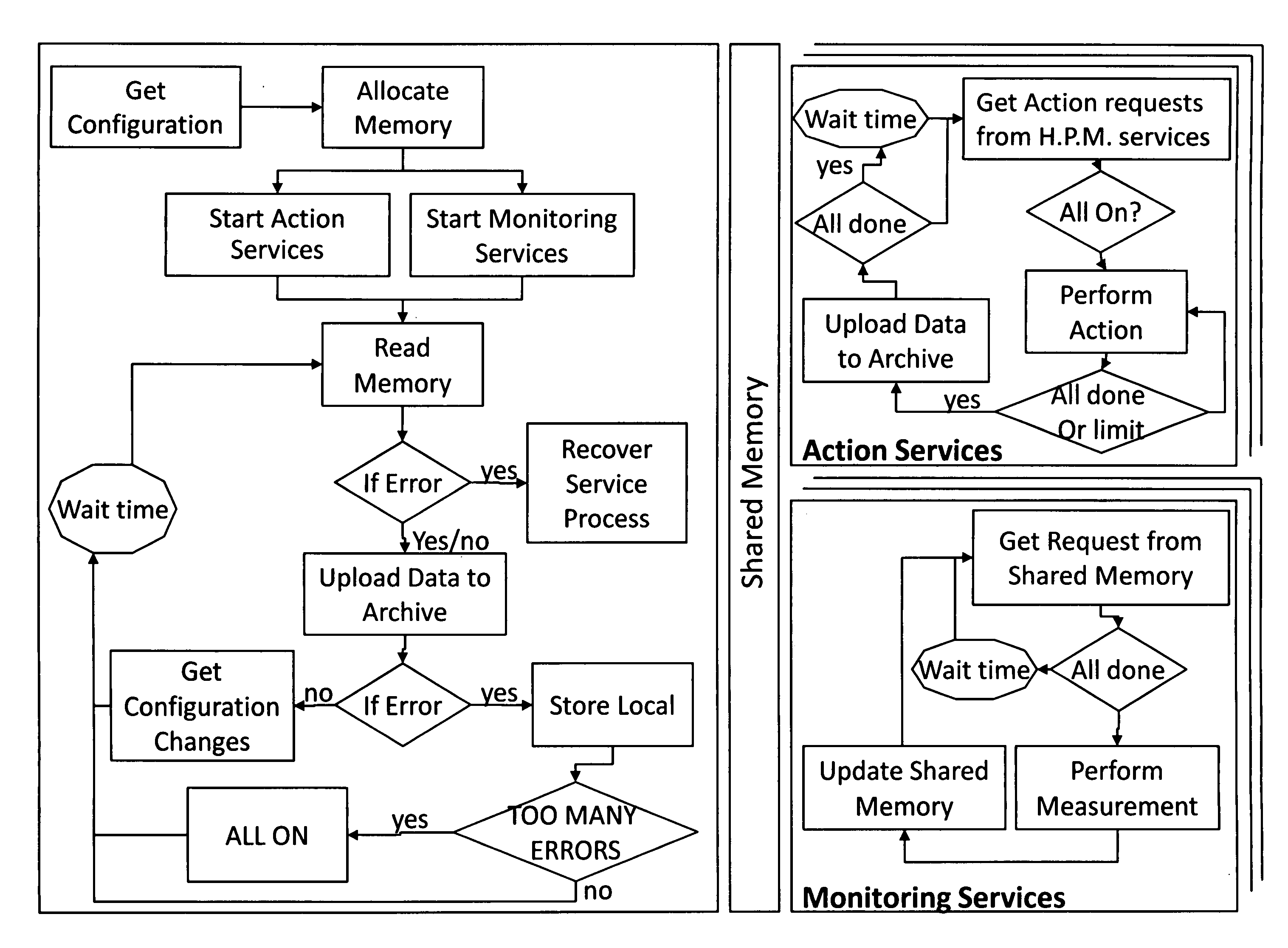

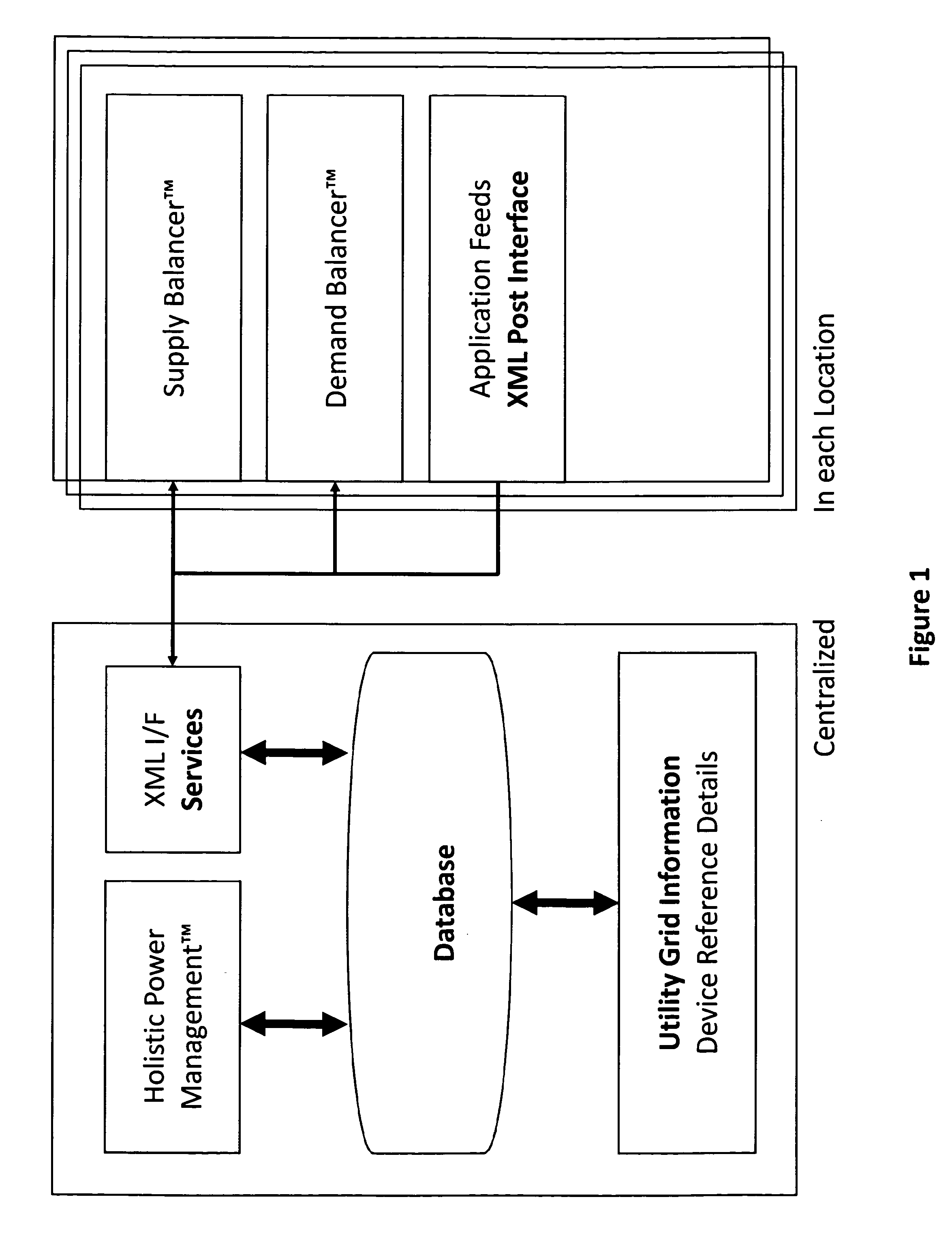

The present invention provides a METHOD AND APPARATUS FOR HOLISTIC POWER MANAGEMENT TO DYNAMICALLY AND AUTOMATICALLY TURN SERVERS, NETWORK EQUIPMENT AND FACILITY COMPONENTS ON AND OFF INSIDE AND ACROSS MULTIPLE DATA CENTERS BASED ON A VARIETY OF PARAMETERS WITHOUT VIOLATING EXISTING SERVICE LEVELS. This method and apparatus pertains specifically to a method and apparatus for power management in data centers and large server environments.Until today all servers running a specific application or virtualized environment are kept turned on to support various levels of application demand. With the invention of Holistic Power Management this invention completely automates the tasks required to shutdown and turn off servers not needed and to turn them on and start them up independent of their physical location. Furthermore this invention makes such changes dynamically based on application load, environmental conditions and energy pricing and availability and can adjust cooling services accordingly.

Owner:TIER44 TECH INC

Method and apparatus for holistic power management to dynamically and automatically turn servers, network equipment and facility components on and off inside and across multiple data centers based on a variety of parameters without violating existing service levels

ActiveUS9003211B2Eliminate consumptionVolume/mass flow measurementDigital computer detailsVirtualizationData center

The present invention provides a METHOD AND APPARATUS FOR HOLISTIC POWER MANAGEMENT TO DYNAMICALLY AND AUTOMATICALLY TURN SERVERS, NETWORK EQUIPMENT AND FACILITY COMPONENTS ON AND OFF INSIDE AND ACROSS MULTIPLE DATA CENTERS BASED ON A VARIETY OF PARAMETERS WITHOUT VIOLATING EXISTING SERVICE LEVELS. This method and apparatus pertains specifically to a method and apparatus for power management in data centers and large server environments.Until today all servers running a specific application or virtualized environment are kept turned on to support various levels of application demand. With the invention of Holistic Power Management this invention completely automates the tasks required to shutdown and turn off servers not needed and to turn them on and start them up independent of their physical location. Furthermore this invention makes such changes dynamically based on application load, environmental conditions and energy pricing and availability and can adjust cooling services accordingly.

Owner:TIER44 TECH INC

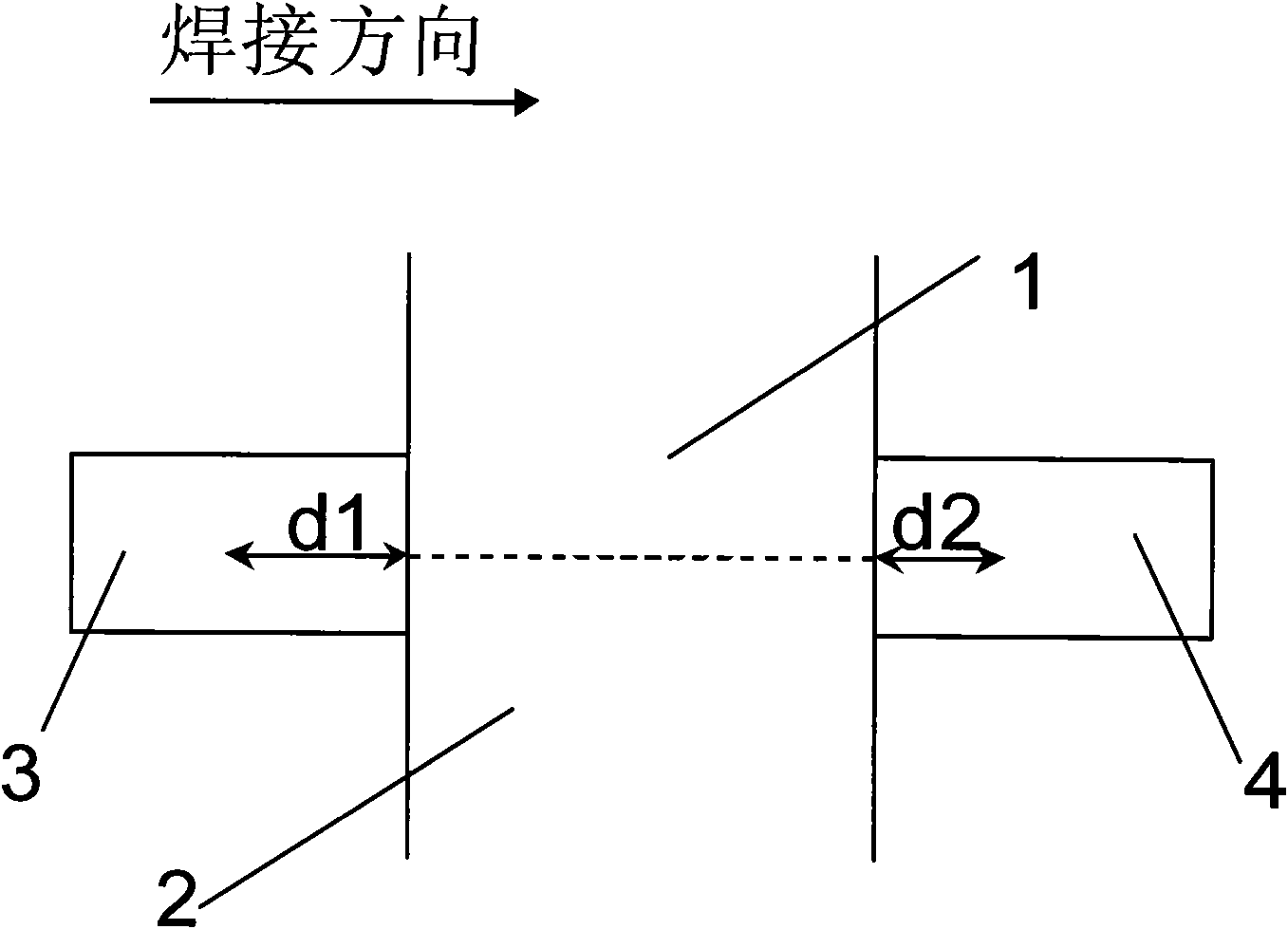

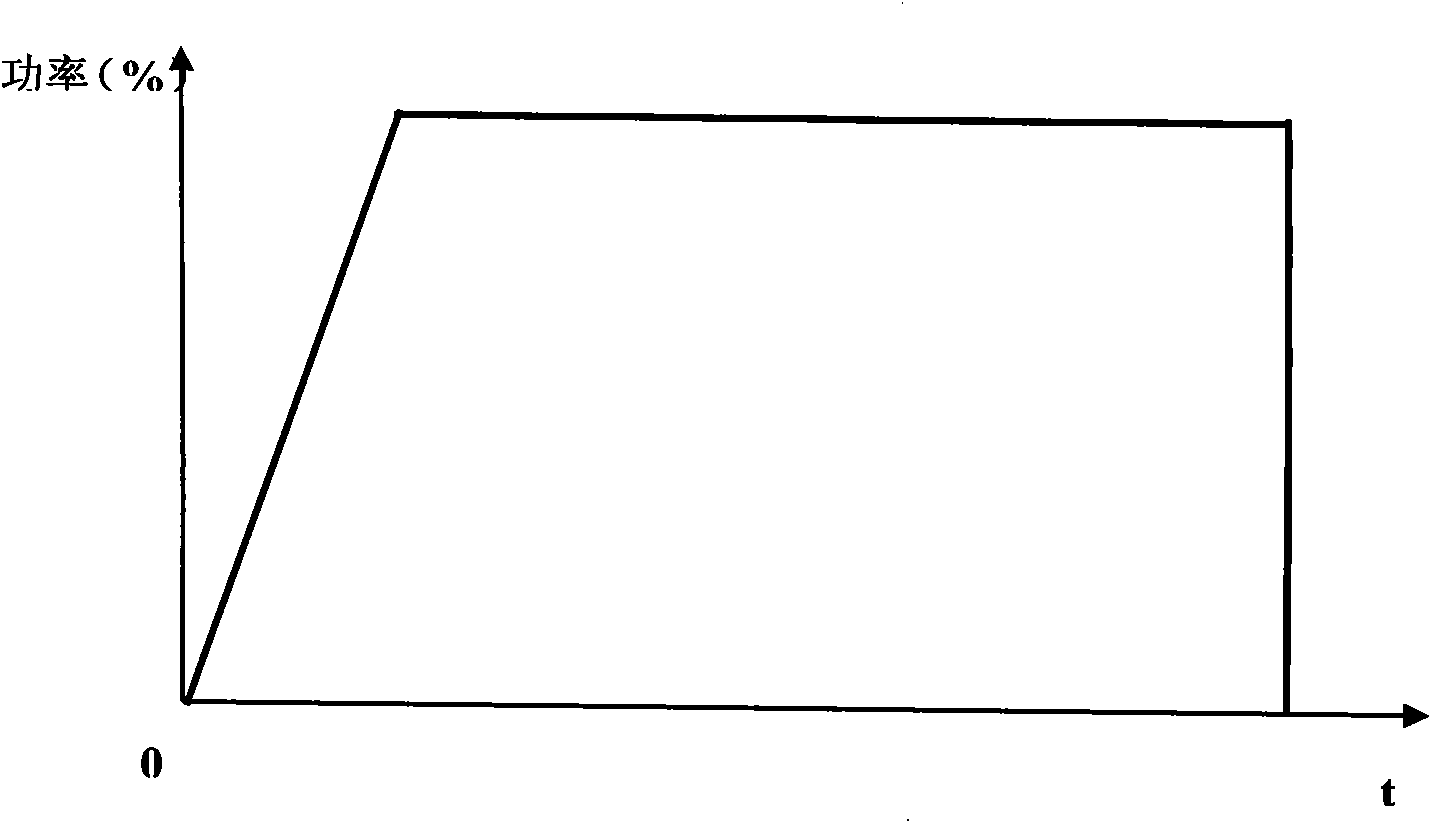

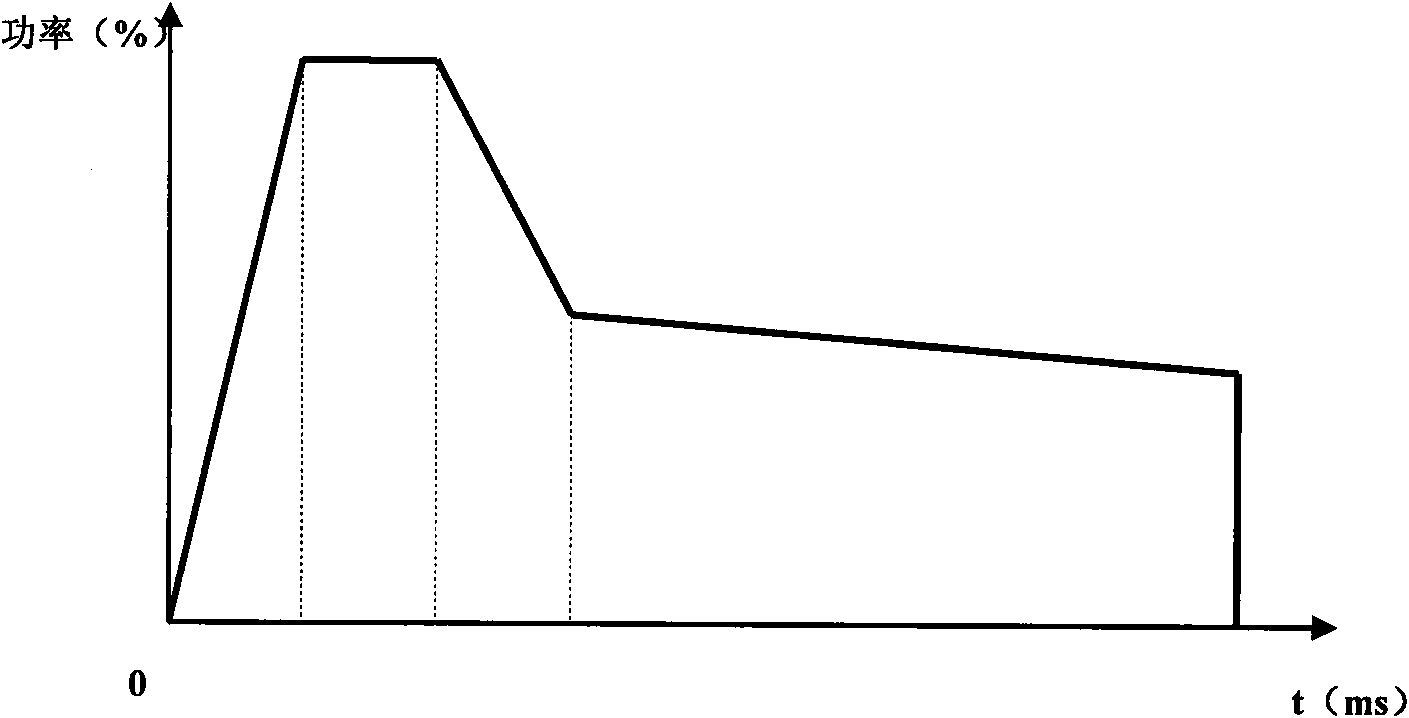

Laser welding method for butting two pieces of metal sheets

ActiveCN101569961AHigh strengthEliminate consumptionWelding/soldering/cutting articlesMetal working apparatusMetal sheetAbutment

The invention discloses a laser welding method for butting two pieces of metal sheets, comprising the following steps: determining the size of facula according to the metal sheets; selecting a corresponding laser welding device and determining welding height according to the size of the facula; closely arranging a first welding guide plate at the initiating end of an abutment joint of the two pieces of metal sheets and arranging a second welding guide plate at the tail end of the abutment joint; with certain welding frequency, single welding energy and certain welding movement speed, carrying out movement and laser release from the first welding position of the first welding guide plate to the second welding position of the second welding guide plate along the abutment joint. The method of the invention ensures the same welding strength at the initial end and other positions of the welding lines, improves welding quality and increases welding strength. The welding lines welded by the method of the invention maintain the same strength property as the parent metal after a plurality times of distortion and tearing, thus having no weak spots in terms of strength.

Owner:HANS LASER TECH IND GRP CO LTD

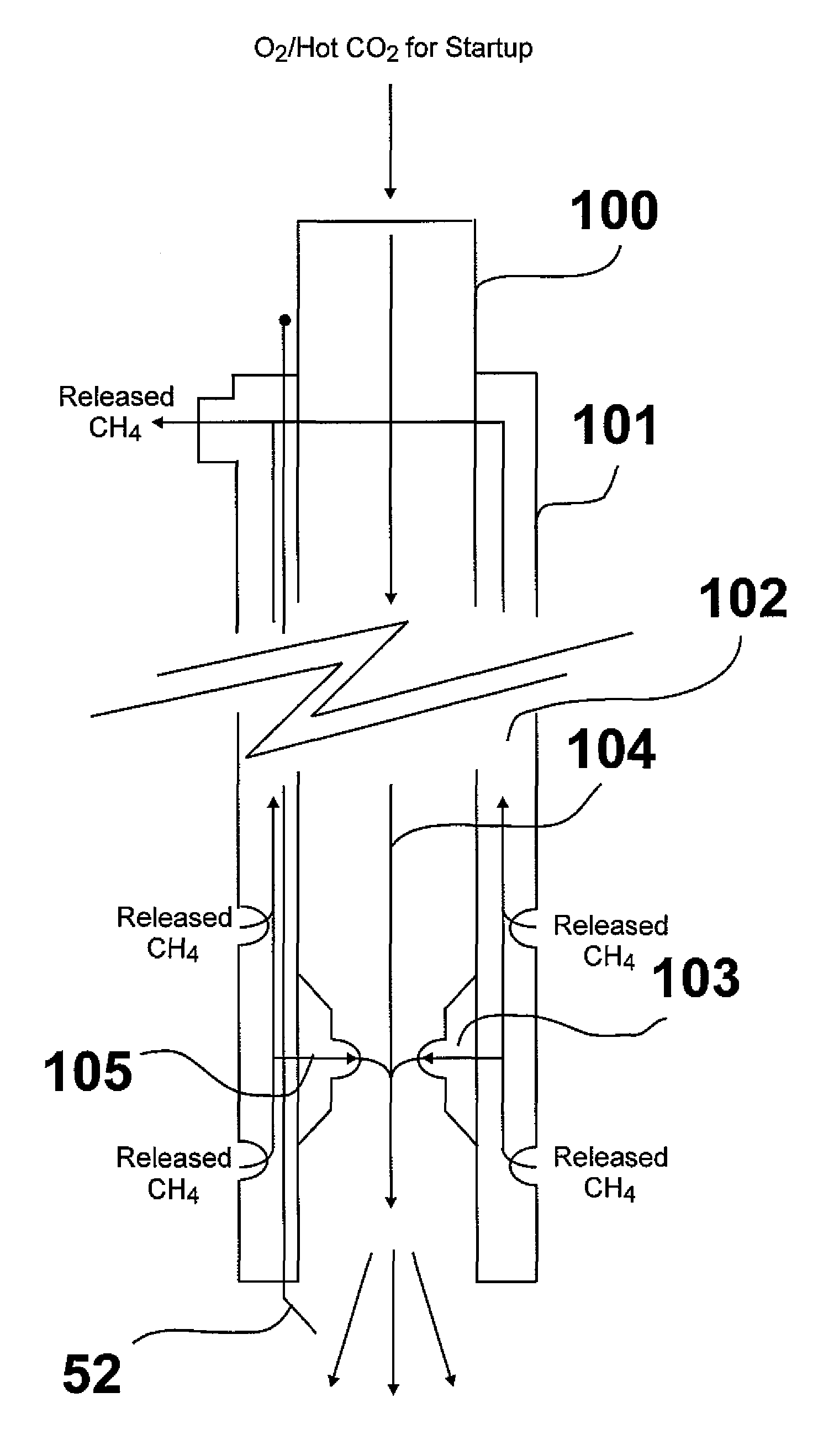

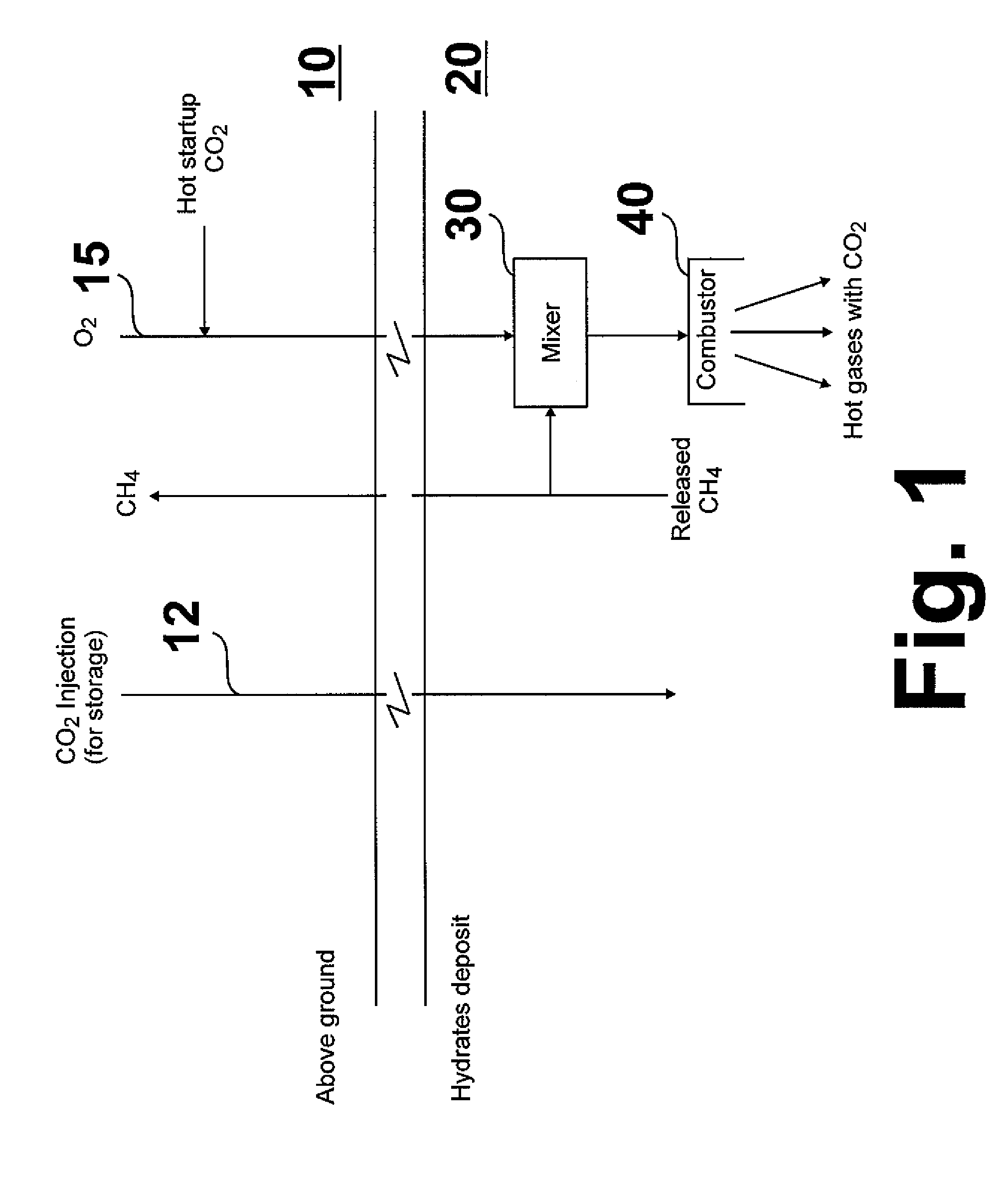

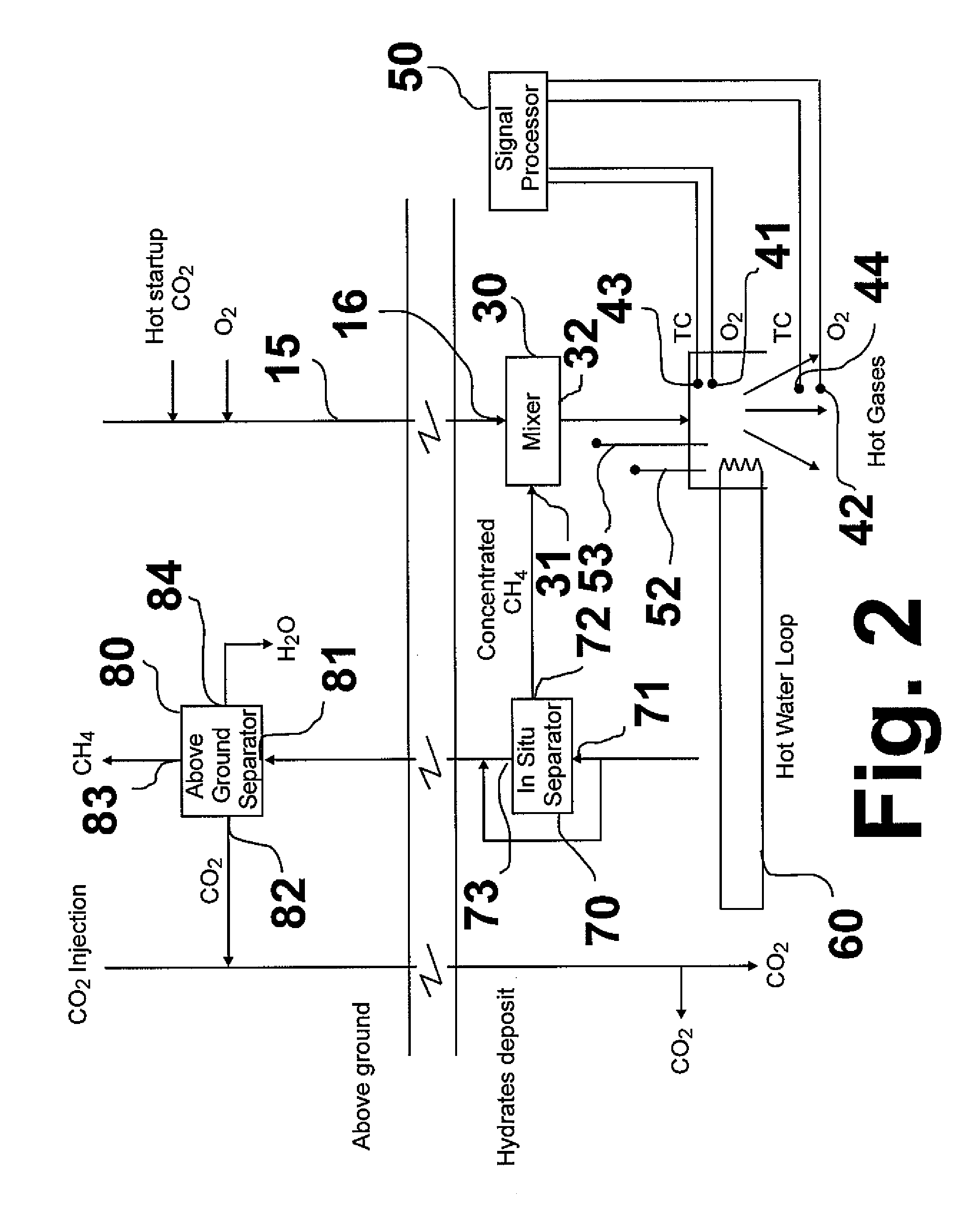

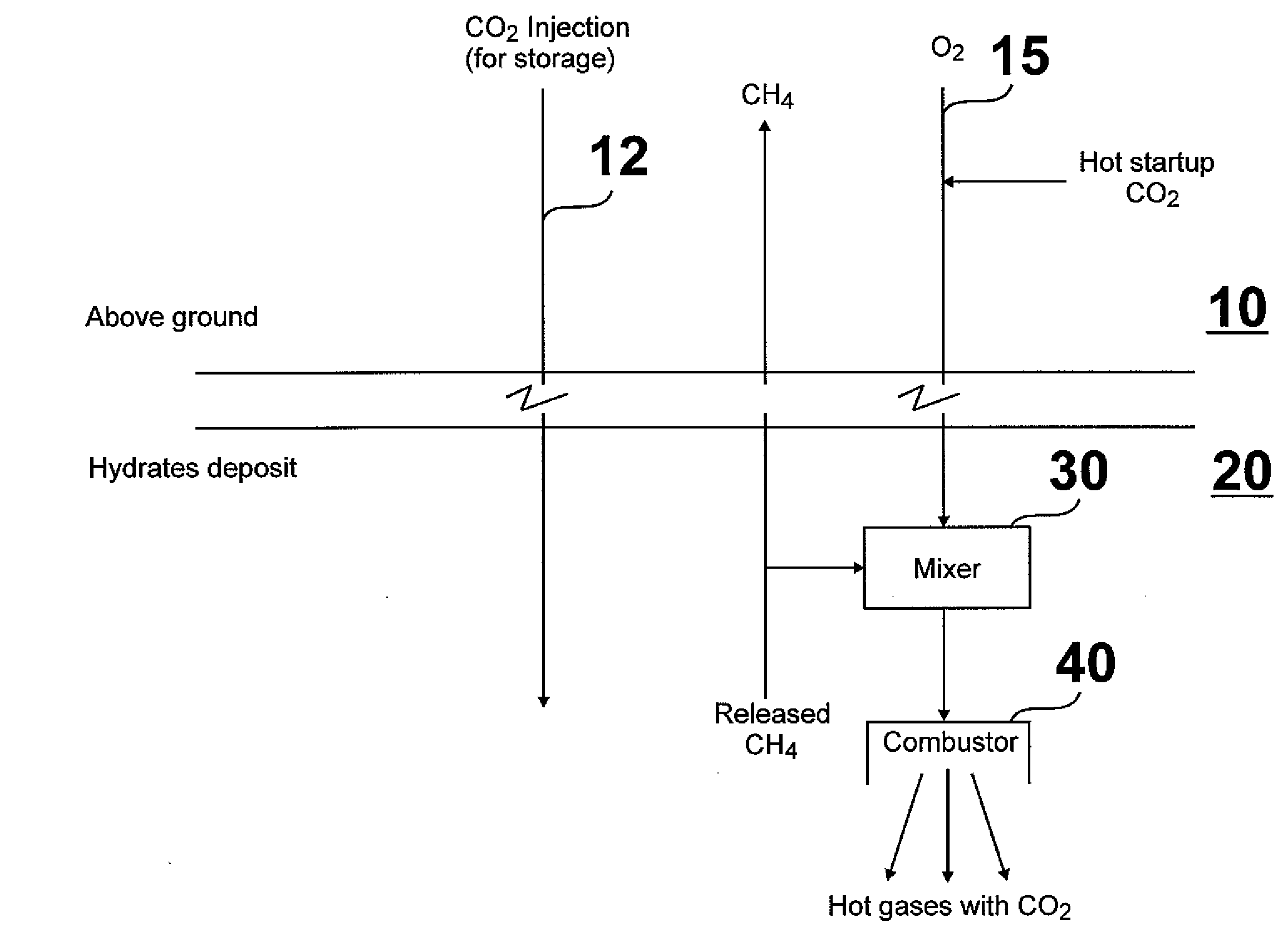

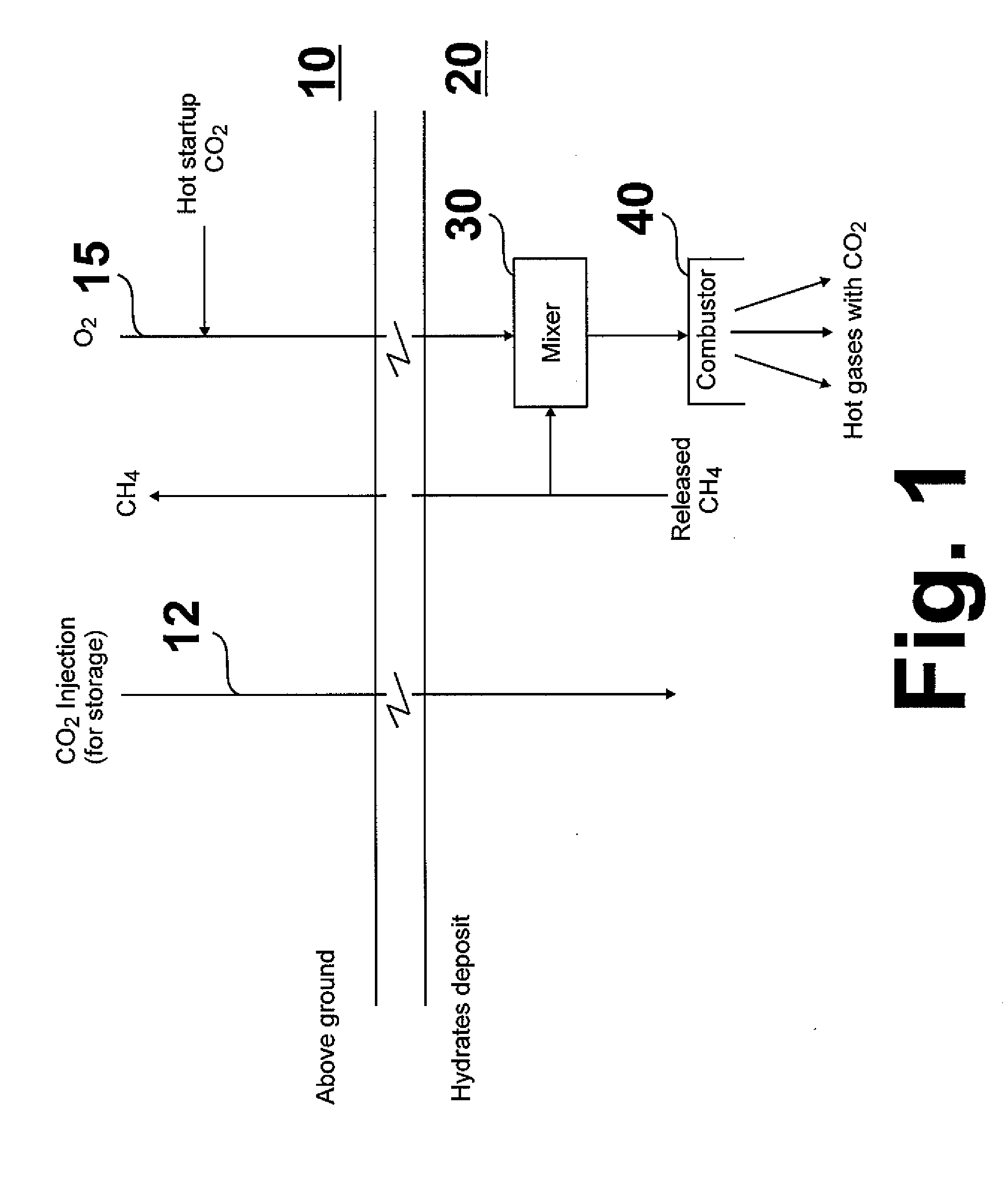

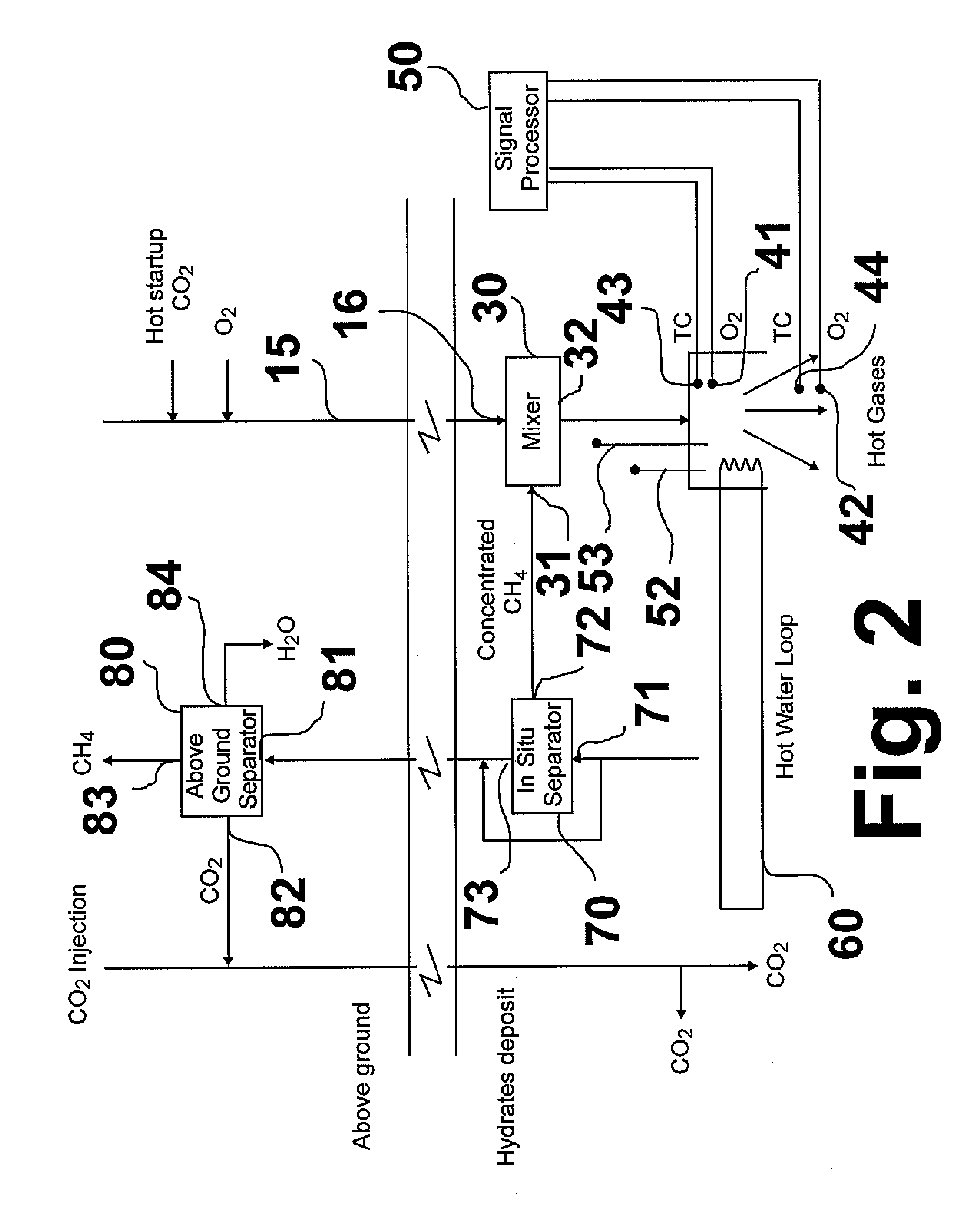

Process and apparatus for release and recovery of methane from methane hydrates

A process and system for release and recovery of methane from subterranean methane hydrate deposits in which heated CO2 is used to displace methane from the methane hydrate deposits and a portion of the displaced methane is routed to a combustion device proximate the deposit for combustion in-situ, generating heated CO2 which is introduced into the deposit, displacing additional methane, a portion of which is routed to the combustion device, thereby providing a substantially self-sustaining process. Portions of the displace methane not routed to the combustion device are captured for use elsewhere.

Owner:GAS TECH INST

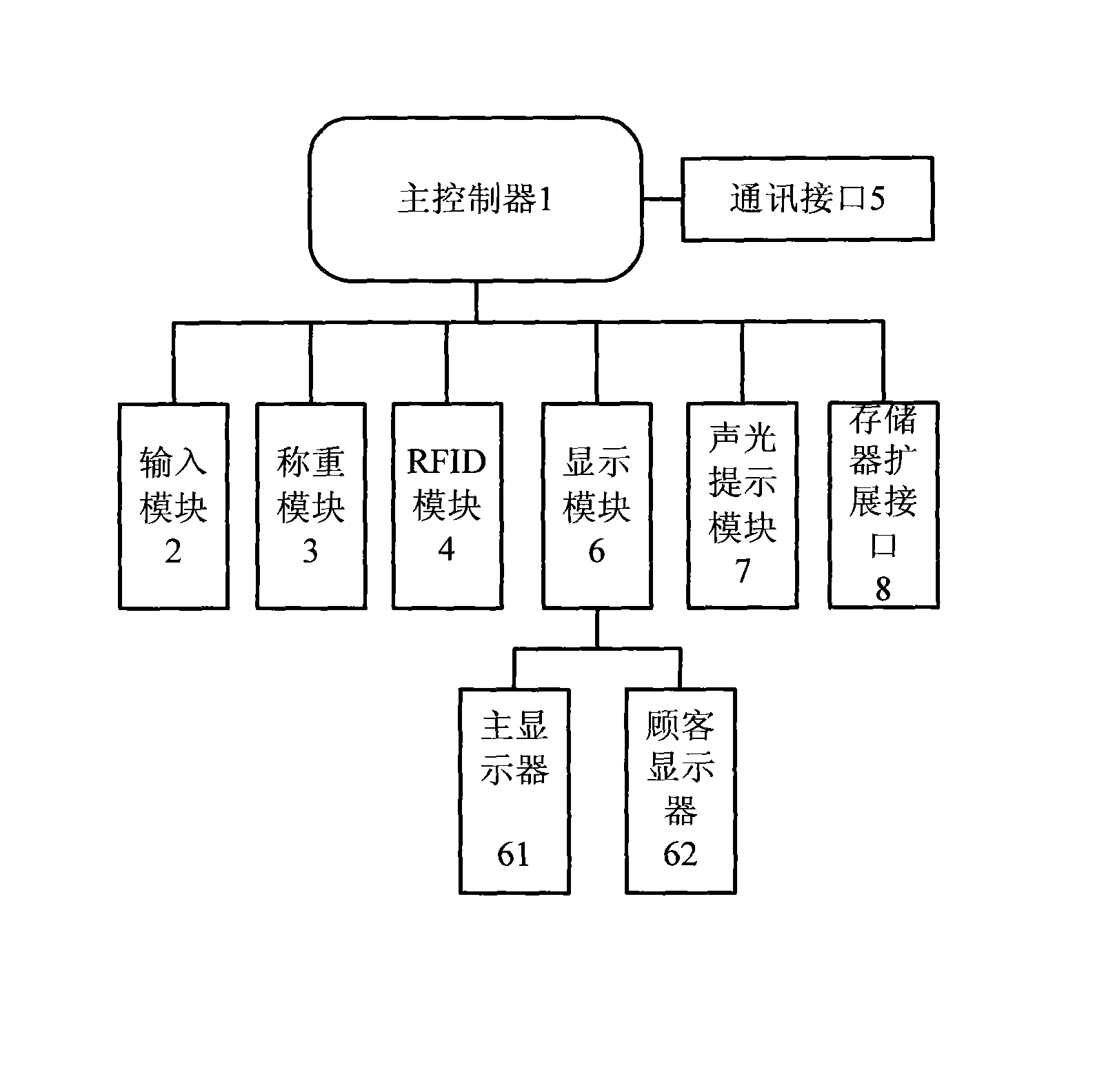

Electronic scale and working method thereof

InactiveCN101634585AEasy to operateOmit the procedure of printing and affixing barcode labelsCo-operative working arrangementsSensing record carriersData informationMaster controller

The invention discloses an electronic scale and a working method thereof. The electronic scale is used for weighing the articles with RFID tags through RFID (radio frequency identification devices) technology. The electronic scale comprises a main controller (1), an input module (2), a weighing module (3) and an RFID module (4). According to the situation that the RFID module (4) has read-only and read-write functions, the electronic scale can finish two charging modes of weighing in an online or an offline manner so that a settlement system can finish settlement quickly. The RFID electronic scale of the invention can simultaneously process a large amount of data information because the data transmitting rate of the RFID module (4) is quick; a settlement counter does not need to scan the tag of each article one by one; by using a non-contact mode, the reader-writer can quickly identify the article information in the RFID tag; so the speed of the follow-up settlement is greatly improved.

Owner:WEIHAI BEIYANG ELECTRIC GRP CO LTD BEIJING BRANCH

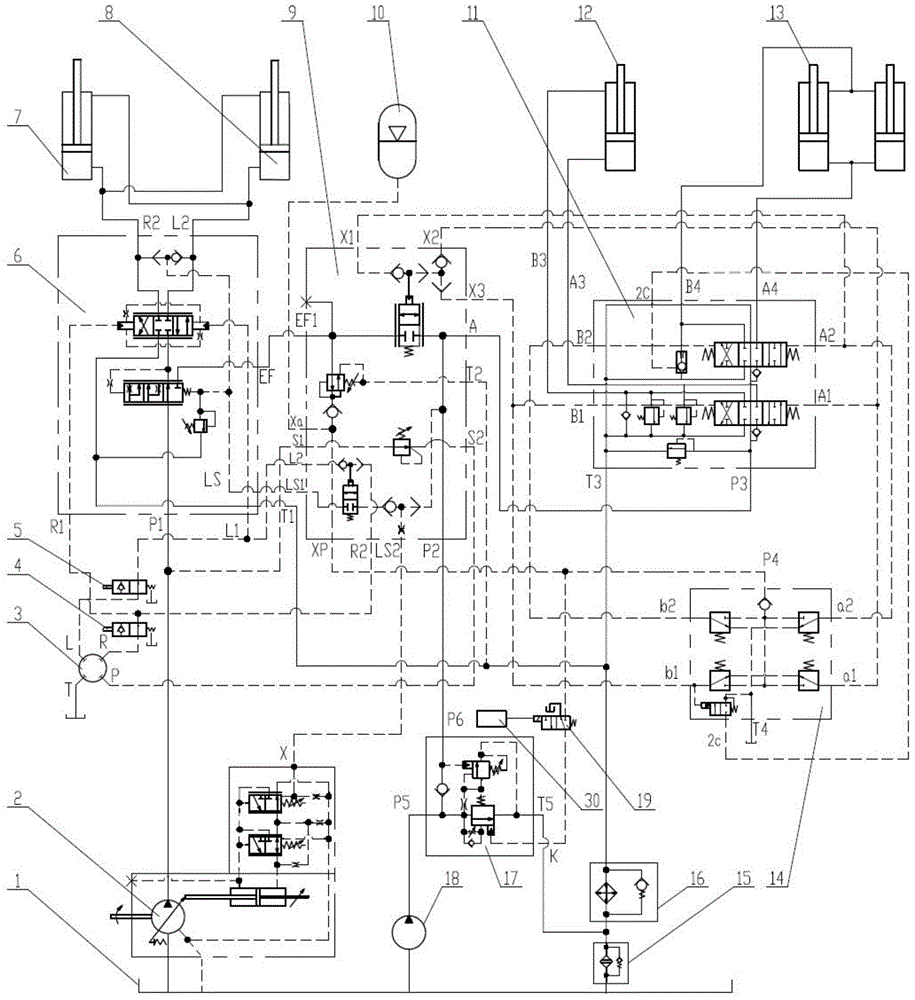

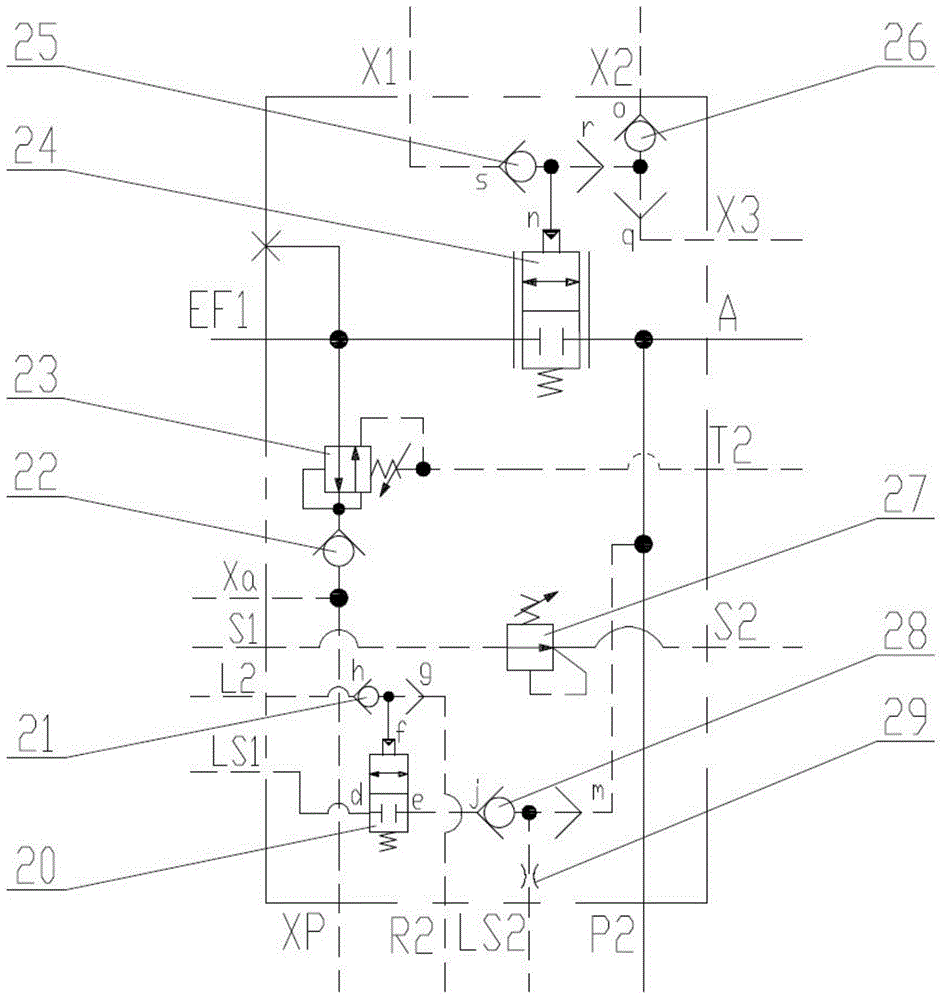

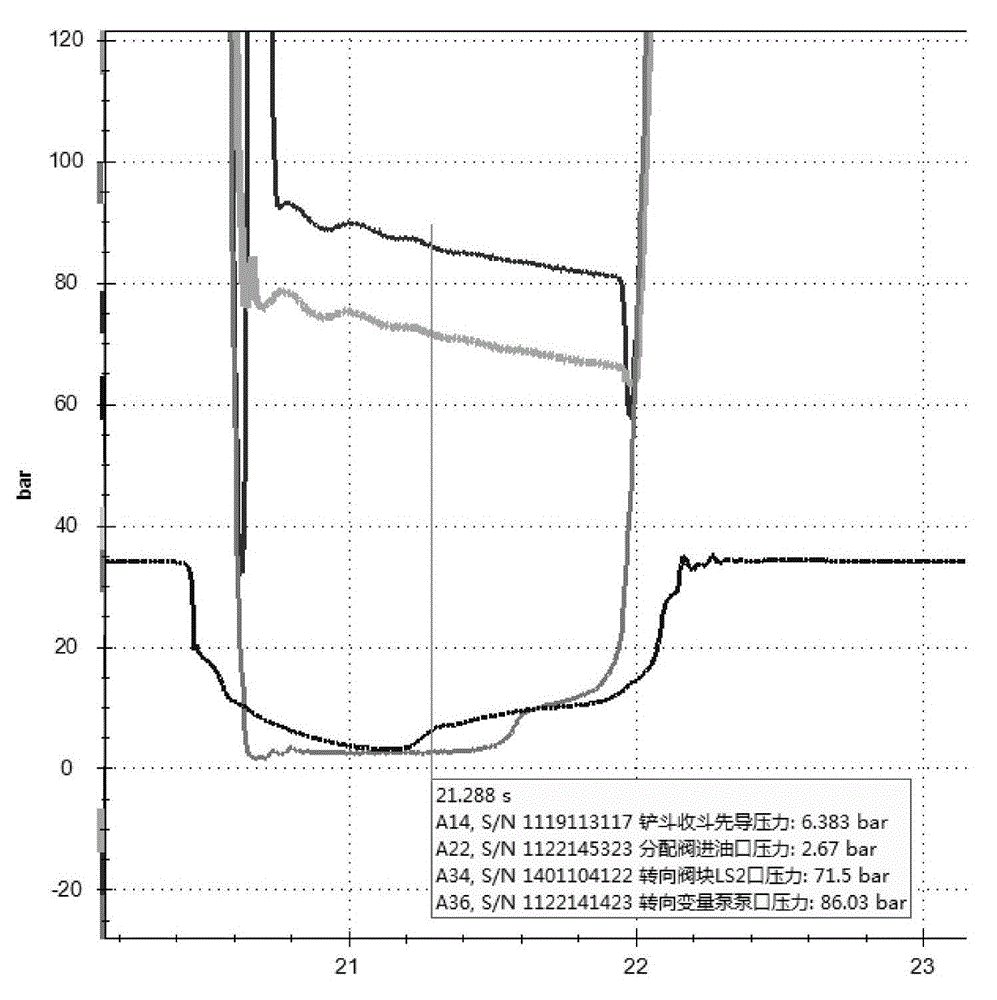

Loader constant and variable hydraulic system based on flow amplifying steering

ActiveCN104929183ALow powerProtect against high pressure shocksSoil-shifting machines/dredgersSolenoid valveEngineering

The invention discloses a loader constant and variable hydraulic system based on flow amplifying steering. The loader constant and variable hydraulic system comprises a hydraulic oil tank, a variable pump, a steering gear, a right limiting valve, a left limiting valve, a flow amplifying valve, a left steering cylinder, a right steering cylinder, a flow control valve block, an energy accumulator, a distribution valve, a tipping bucket cylinder, a movable arm cylinder, a pilot valve, an unloading valve block, a constant flow pump, a working mode switching electromagnetic valve and a working mode selector switch. The small-displacement steering gear is adopted to serve as a hydraulic pilot stage of the flow amplifying valve, throttling losses inside a coaxial flow amplifying steering gear in the rapid steering process can be removed, and fuel consumption is reduced; a low-cost home-made element is adopted to replace an inlet element, and steering stability of a variable system is achieved; a feedback signal of the flow amplifying valve is controlled in a time-shared manner, stability of a steering system is improved, and energy consumption is reduced; and meanwhile, the energy-saving effect and good control characteristics of the variable pump can be played out well, and the energy-saving effect and the control precision of a working system are improved.

Owner:XCMG CONSTR MACHINERY

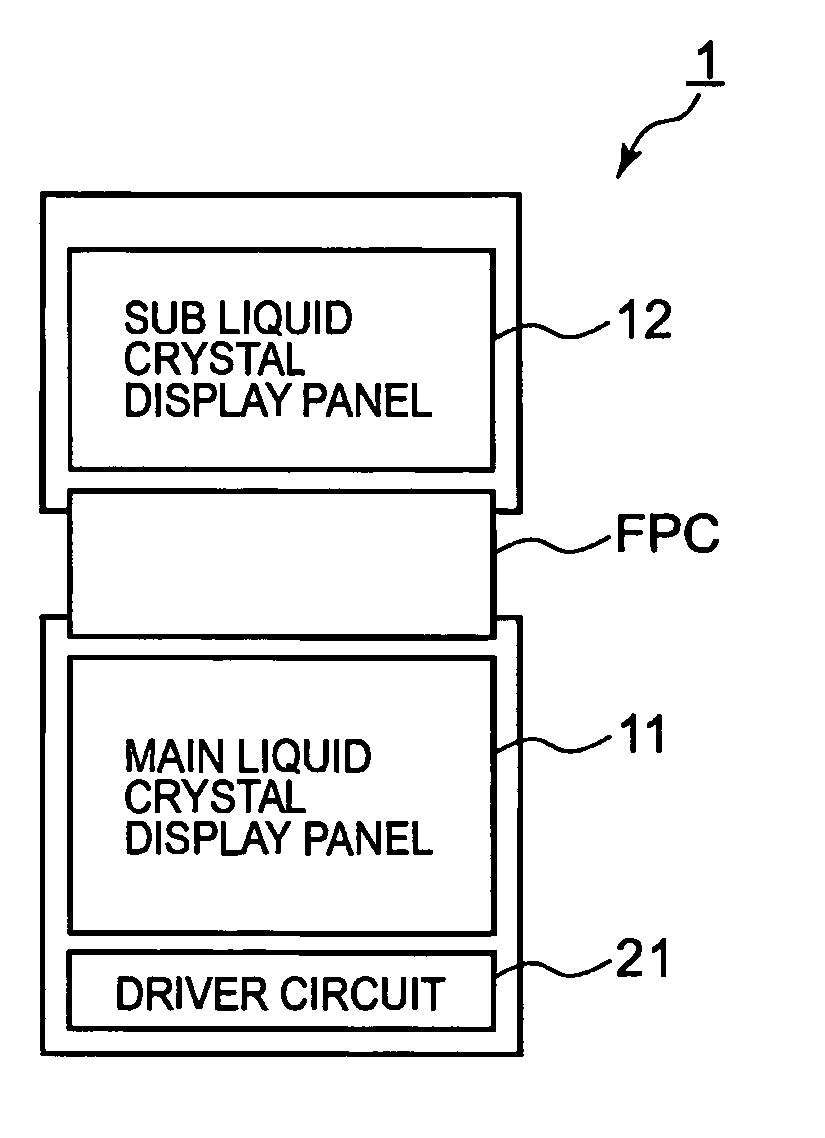

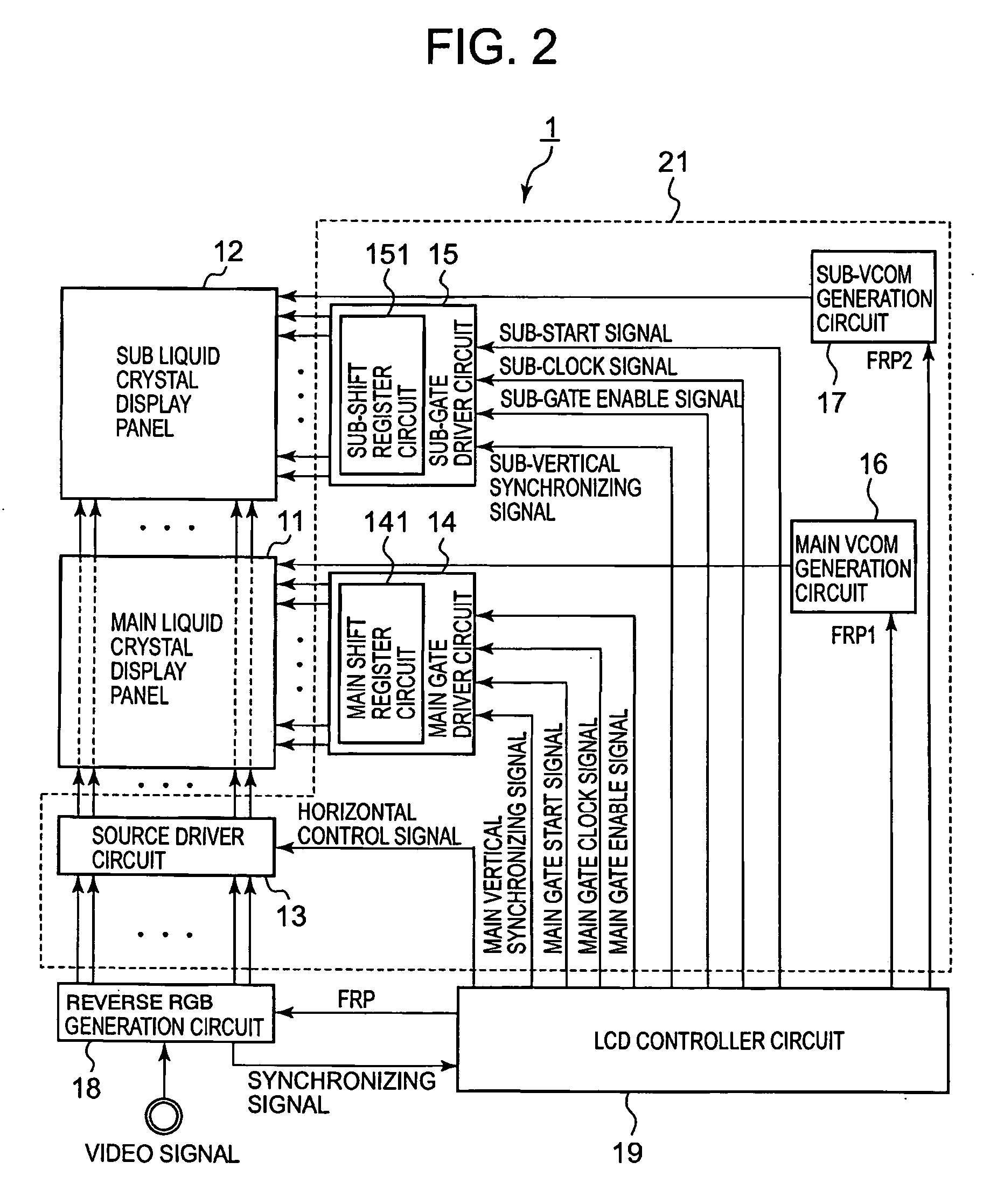

Display apparatus and drive control method thereof

InactiveUS20060050011A1Favorable reduction in power consumptionWasteful power consumption can be eliminatedCathode-ray tube indicatorsNon-linear opticsComputer science

A display apparatus which displays an image corresponding to a display signal comprising a plurality of display panels which have, respectively, a plurality of display pixels; and•• a control means which sets at least one display panel among the plurality of display panels in a display state and sets the plurality of display panels other than the at least one display panel in a non-display state, drives the display panel which has been set in the display state based on the display signal for each of a plurality of constant frame periods, and drives the display panel which has been set in the display state based on the display signal and performs a refresh operation of the display panel which has been set in the non-display state only in a specific frame period from the plurality of constant frame periods.

Owner:CASIO COMPUTER CO LTD

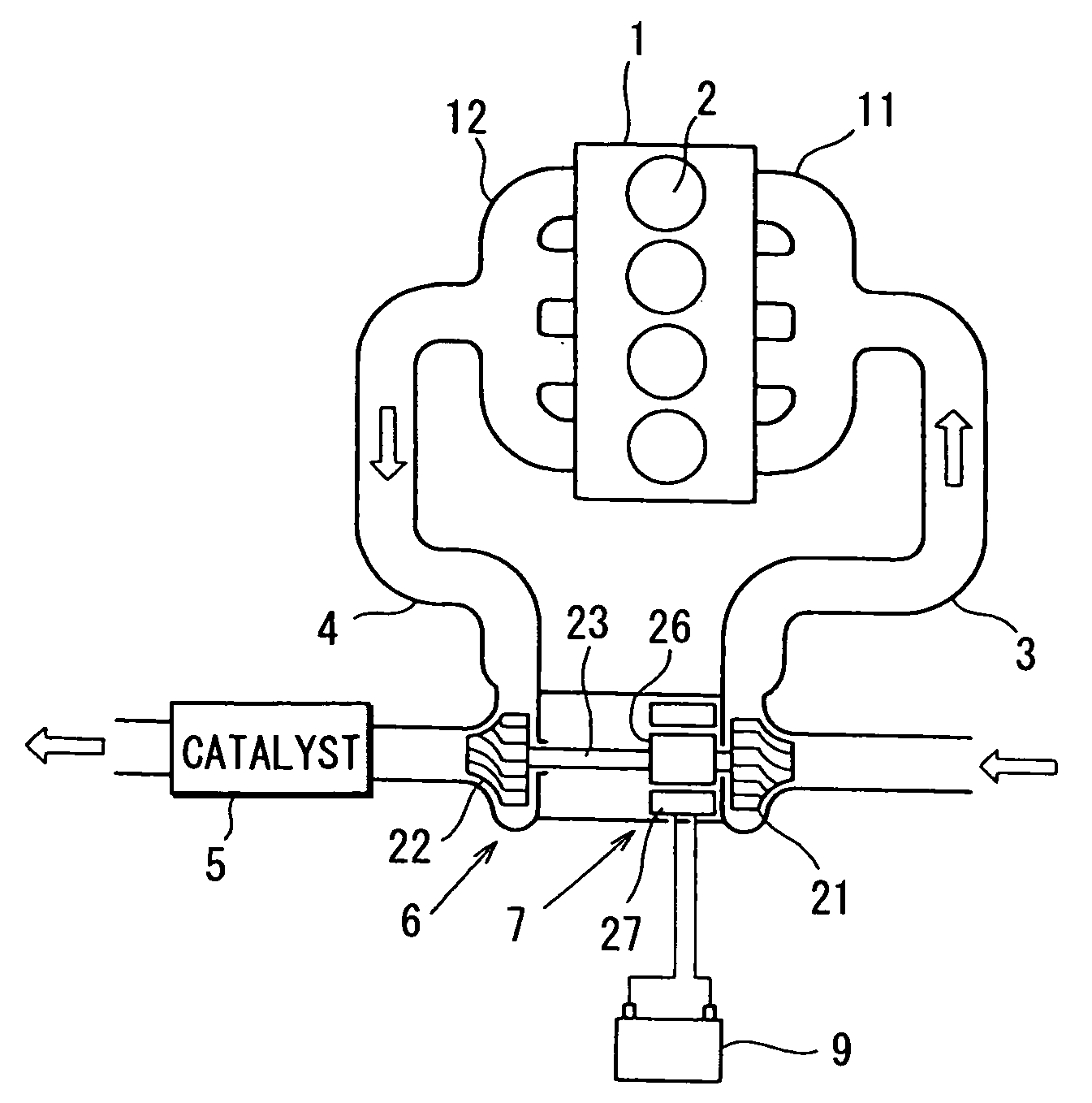

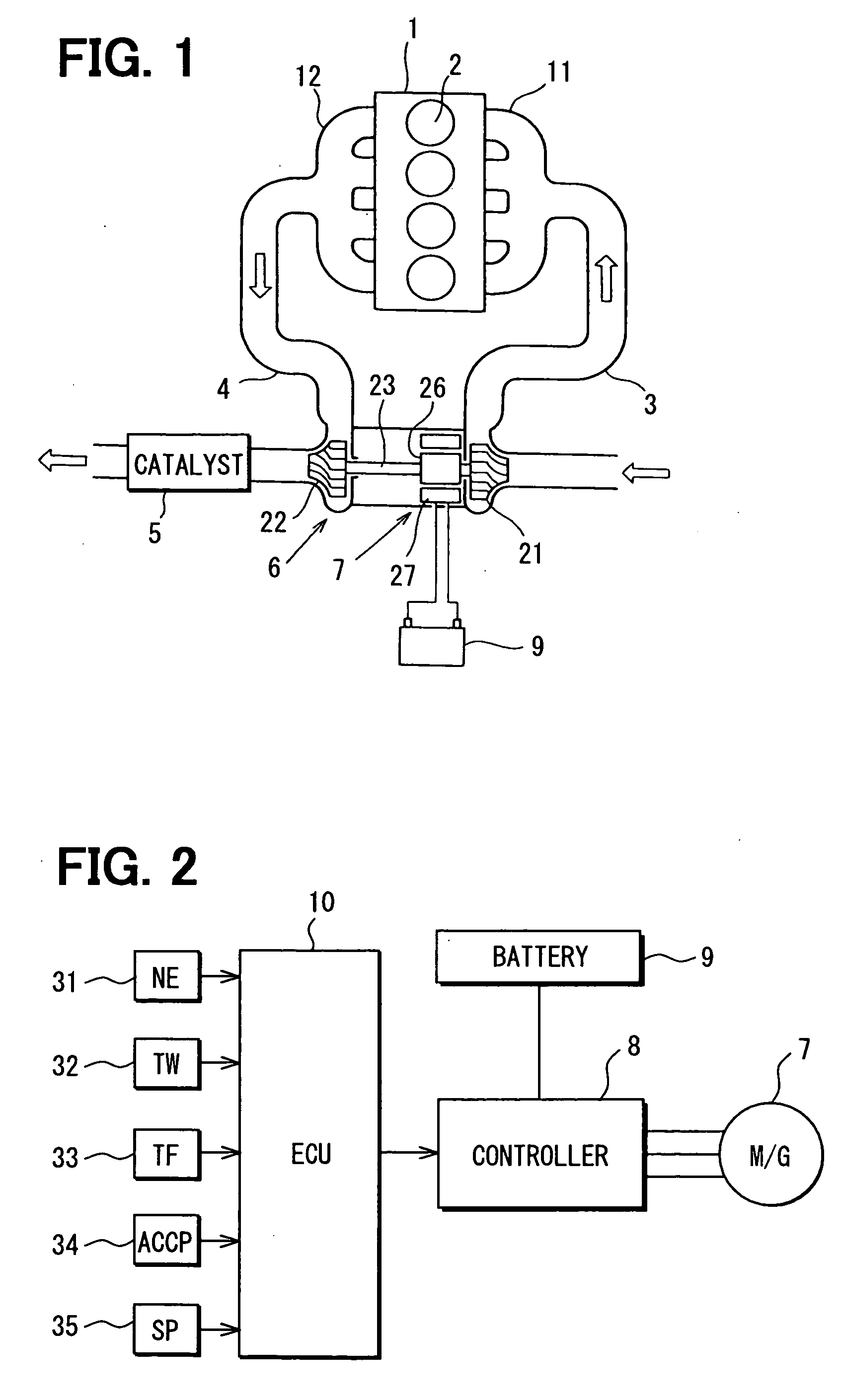

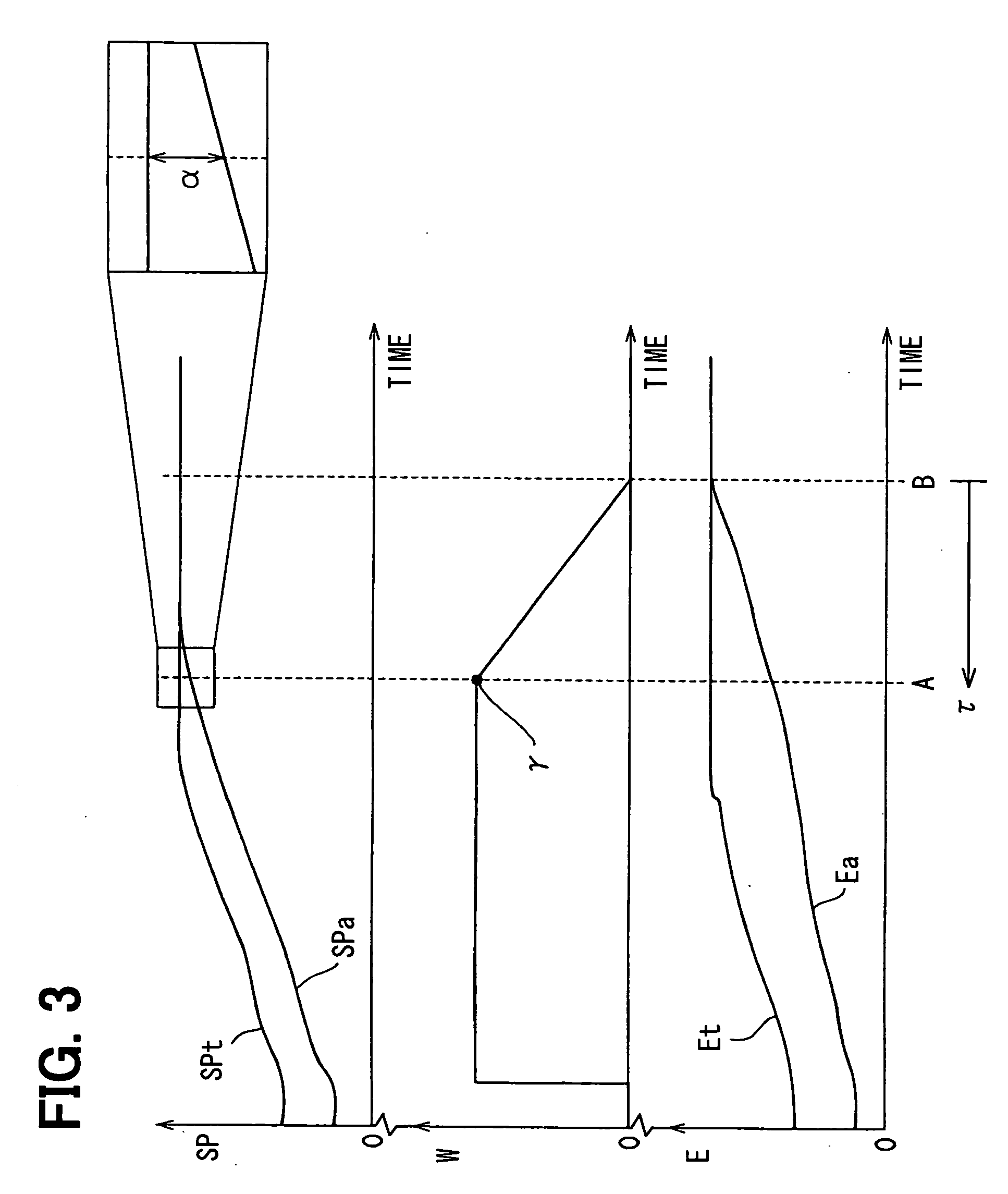

Supercharging pressure controller for engine

InactiveUS20060260305A1Avoid consumptionPoor fuel economyElectrical controlNon-fuel substance addition to fuelInternal combustion engineControl theory

A supercharging pressure controller of an internal combustion engine estimates time to execute a process of bringing power supplied to an assist motor to zero based on delay characteristics of actual emission energy immediately before actual supercharging pressure reaches target supercharging pressure. The supercharging pressure controller sets a gradient of a power gradual reduction waveform in a power gradual reduction control period at a gradient for bringing the power supplied to the assist motor to zero at the estimated time. Thus, the power supplied to the assist motor gradually reduces at the predetermined gradient over time finally to zero at the estimated time. The assist motor is turned off while the actual supercharging pressure follows the target supercharging pressure, without wastefully consuming electric energy.

Owner:DENSO CORP

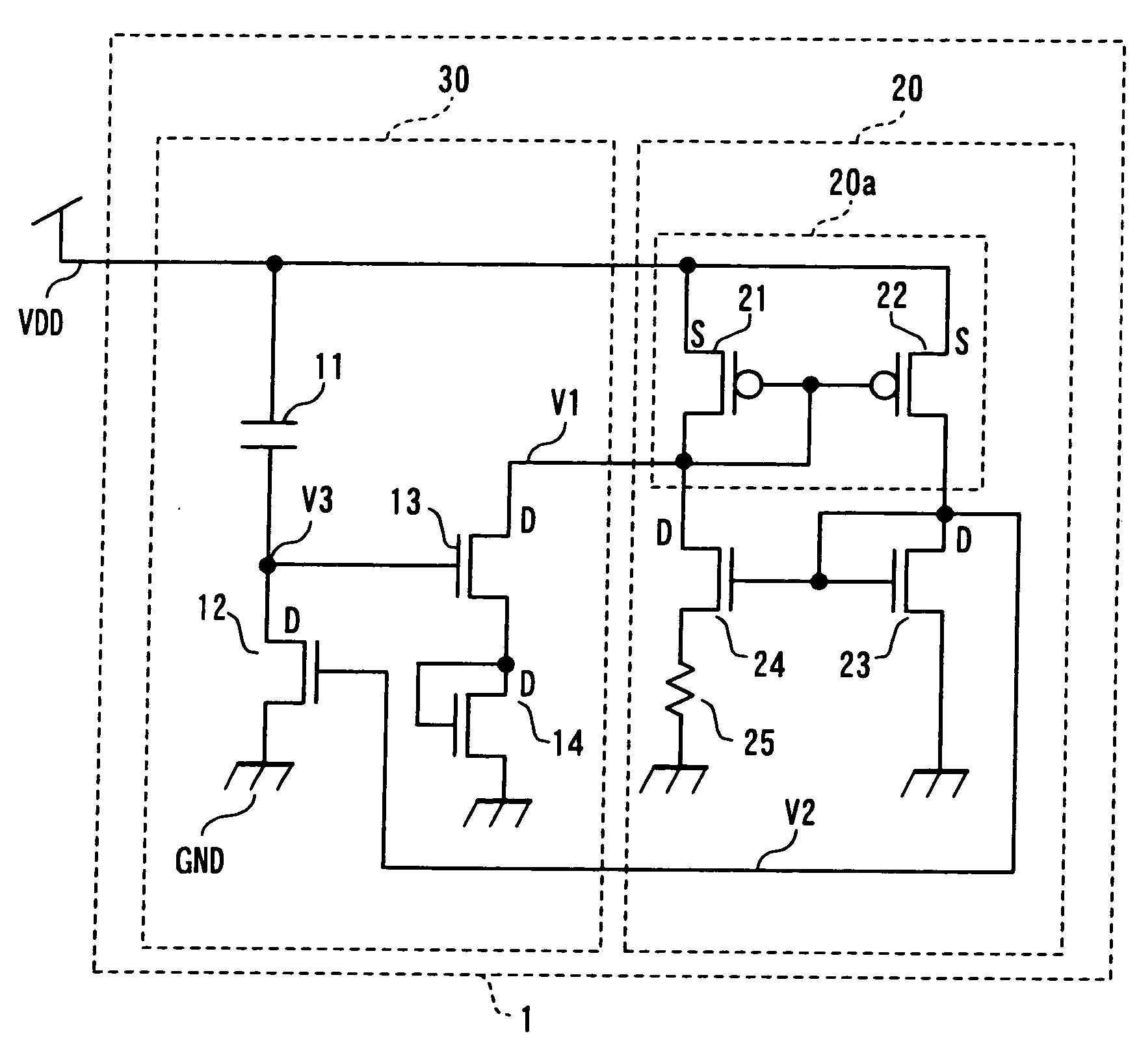

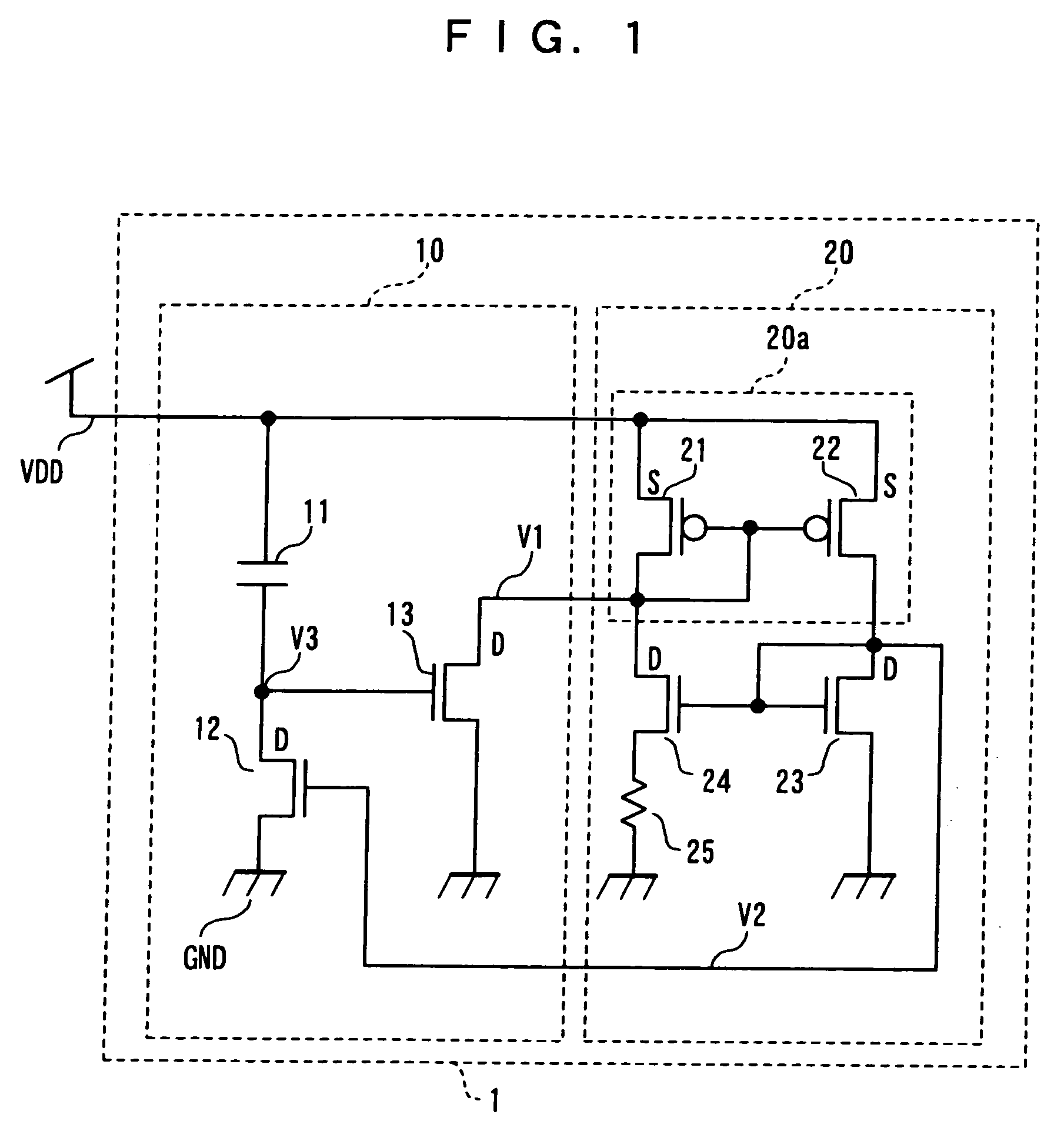

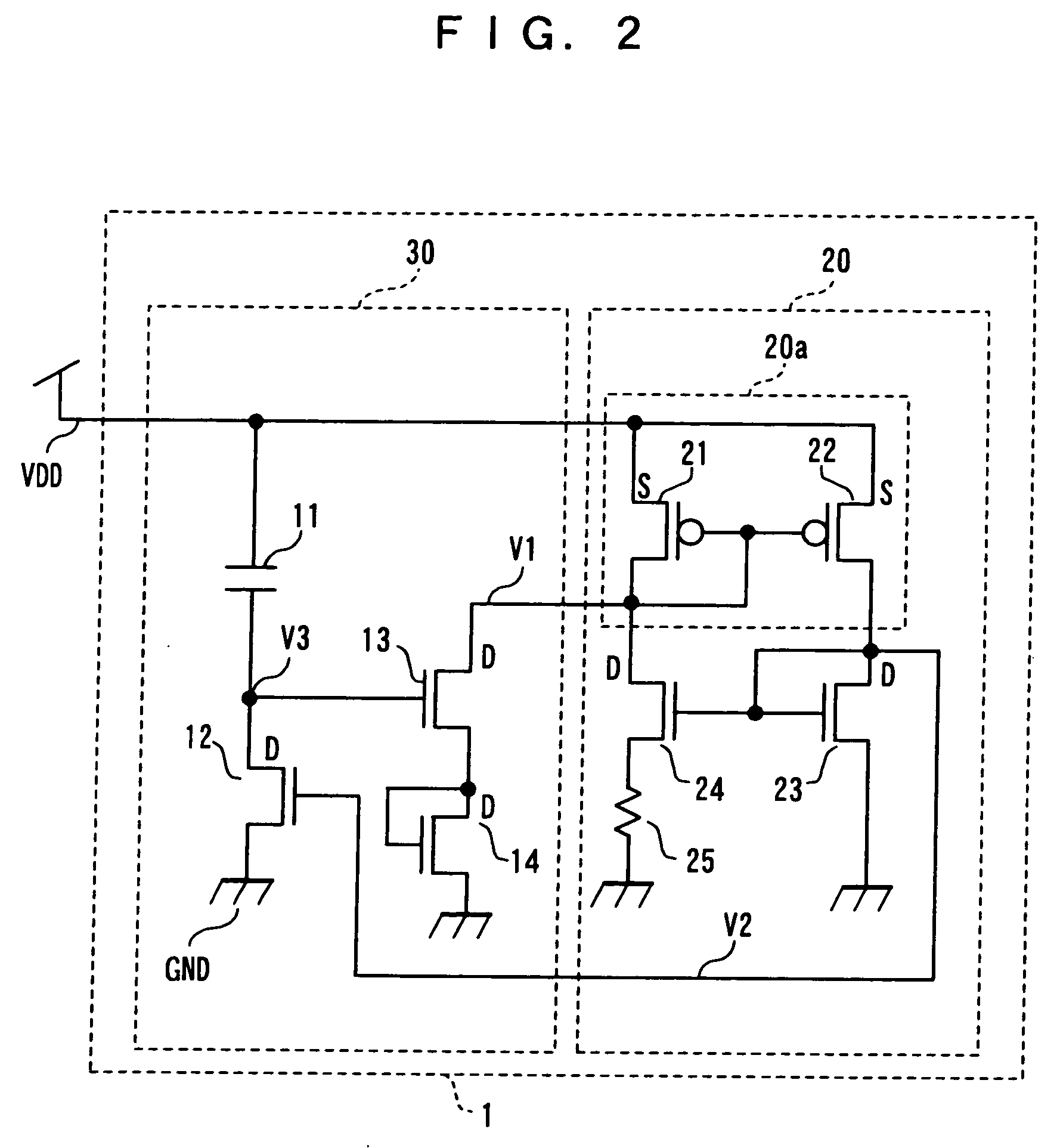

Current source circuit

InactiveUS20060087367A1Reduce power consumptionEliminate consumptionPulse automatic controlElectric variable regulationEngineeringCurrent consumption

According to the present invention, after a bias circuit (20) starts, a startup circuit (10) is isolated from the bias circuit (20) according to a bias voltage generated on an isolating voltage node (V2) from the bias circuit (20) to the startup circuit (10), and steady current consumption can be prevented in the startup circuit (10).

Owner:PANASONIC CORP

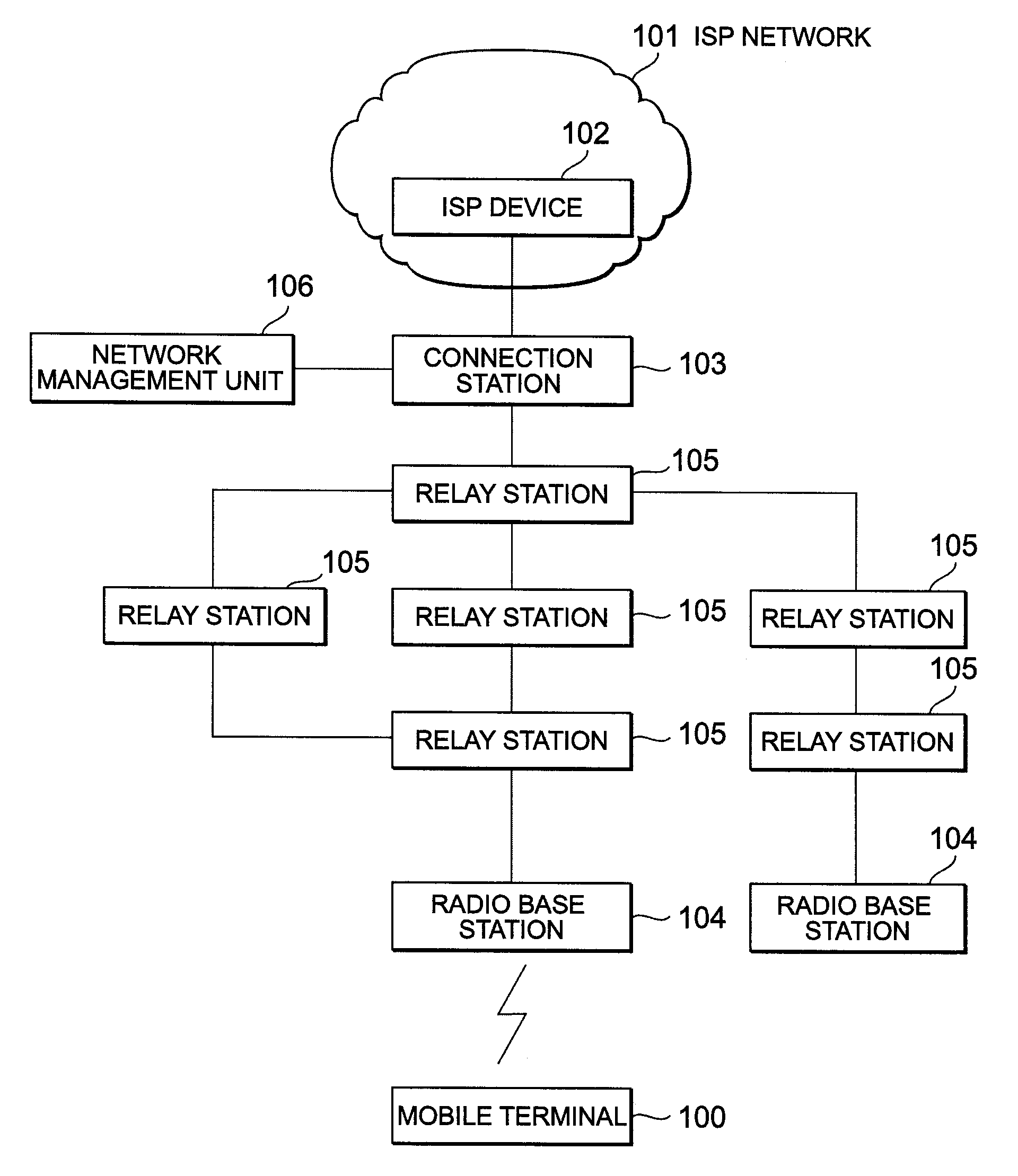

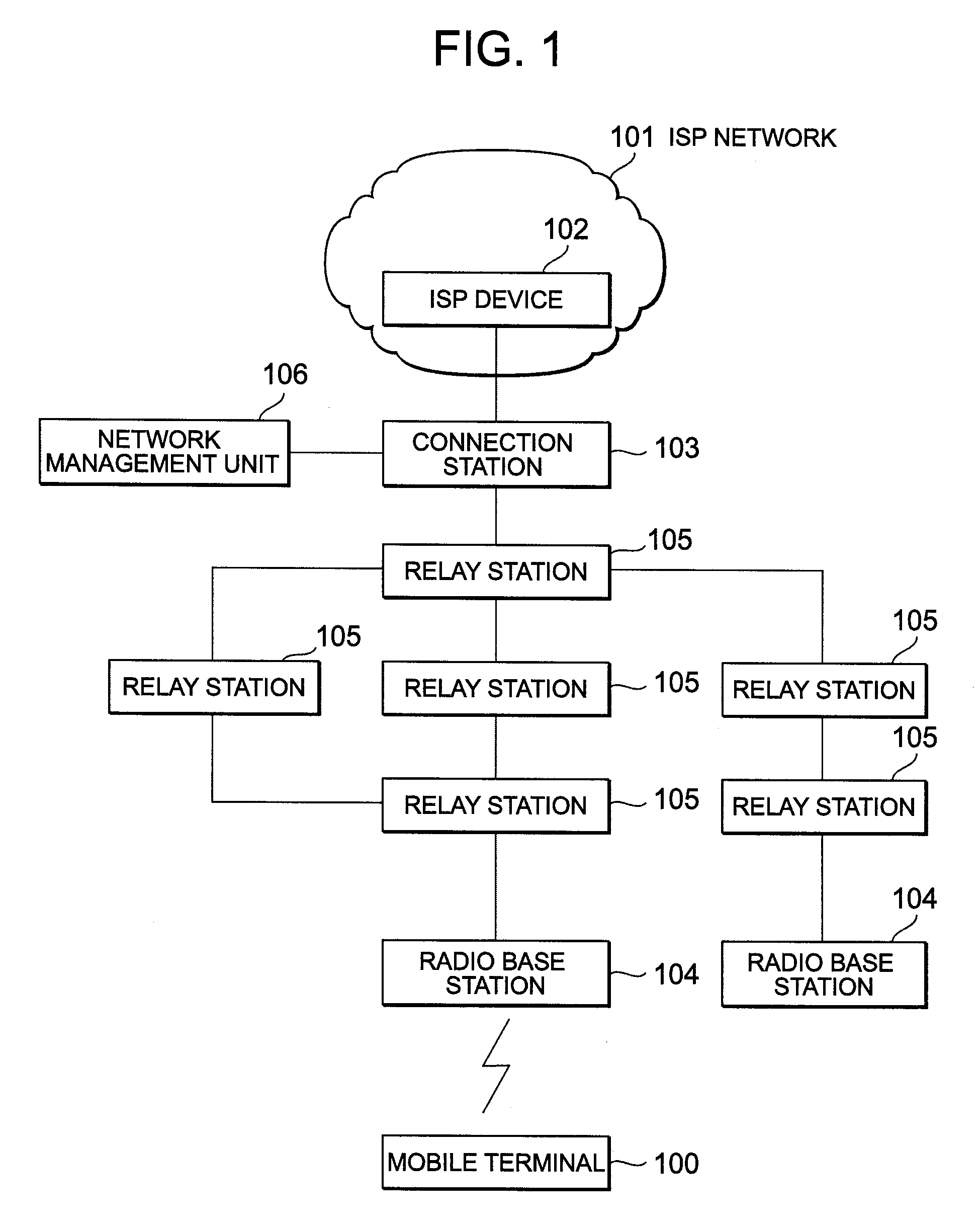

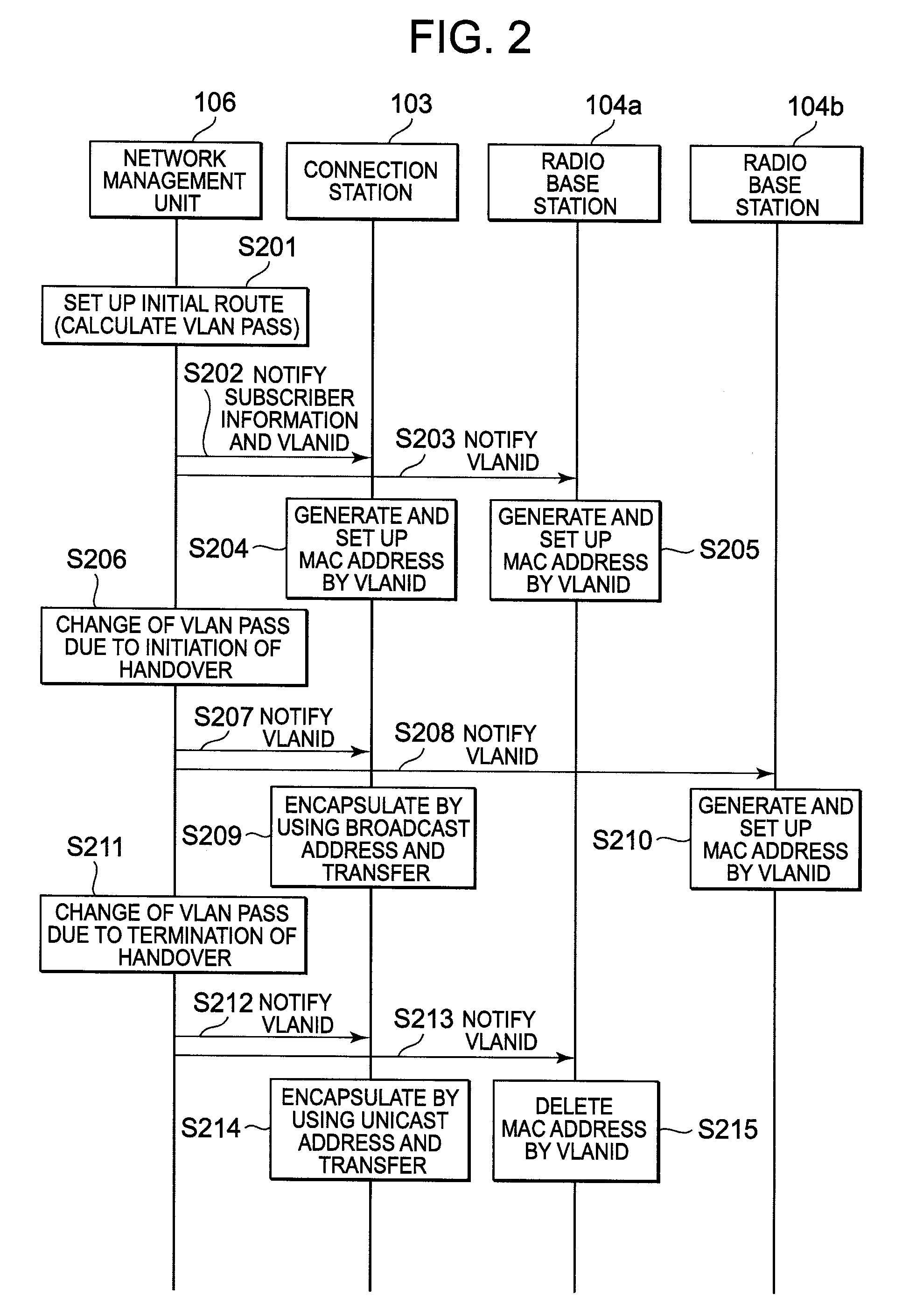

Access Network System, Connection Station Device, Radio Base Station Device, and Packet Loss Reducing Method

InactiveUS20070217364A1Packet lossReduce loadNetwork traffic/resource managementNetwork topologiesAccess networkPacket loss

The present invention discloses a technique to reduce packet loss during the handover of a mobile terminal and to eliminate wasteful consumption of band. According to this technique, a connection station 103 and a radio base station 104 where a mobile terminal 100 is connected generate a plurality of own MAC addresses based on identification information of the mobile terminal, and when the handover is started, a network management unit 106 makes up a point-to-multipoint VLAN path where VLAN path between new radio base station device and the connection station device is added to the VLAN path between previous radio base station device and the connection station device, and the connection station device adds a broadcast address, a MAC address of the connection station device, and an identification information of the mobile terminal to a packet received from the external IP network 101, and the packet is transferred via the point-to-multipoint VLAN path.

Owner:PANASONIC CORP

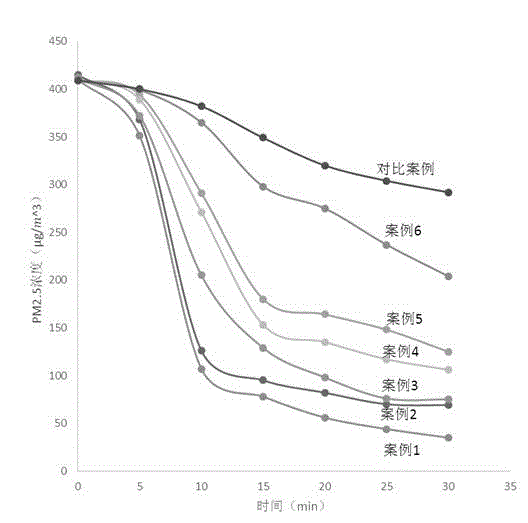

Novel spraying agent for reducing indoor haze, and application thereof

InactiveCN104910866AExtensive sources of materialsGood effectOther chemical processesUsing liquid separation agentAir cleaningChemistry

The invention relates to a novel spraying agent for reducing indoor haze, and an application thereof, and belongs to the technical field of air cleaning. The novel spraying agent for reducing indoor haze adopts a nitrogen-containing alkaloid plant extract product as a main active component, the main active component is compounded with polyvinylpyrrolidone and glycosaminoglycan, and a polyvinylpyrrolidone, glycosaminoglycan and deionized water mixture is wrapped into a respirable particle through the adsorption of the nitrogen-containing alkaloid, so the indoor haze concentration is effectively reduced. The spraying agent can be directly added into a sprayer and is used for indoor sprinkling to remove suspension particle dusts in air and reduce haze; and the spraying agent can be matched with an air conditioner to reduce indoor haze in order to reduce the indoor haze concentration and make indoor environment reach below third level in Technical Regulation on Ambient Air Quality Index HJ633-2012.

Owner:GUANGDONG UNIV OF TECH

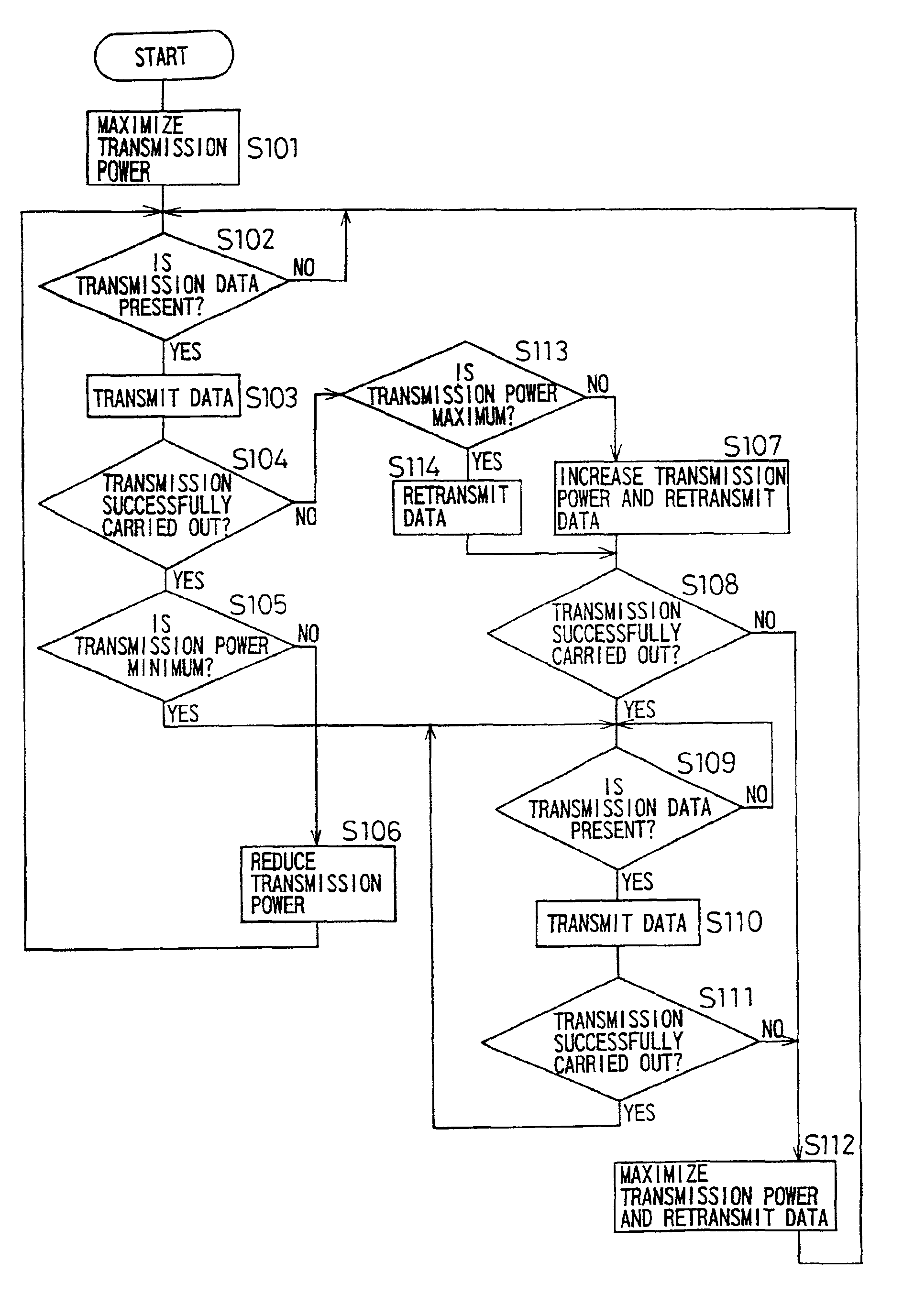

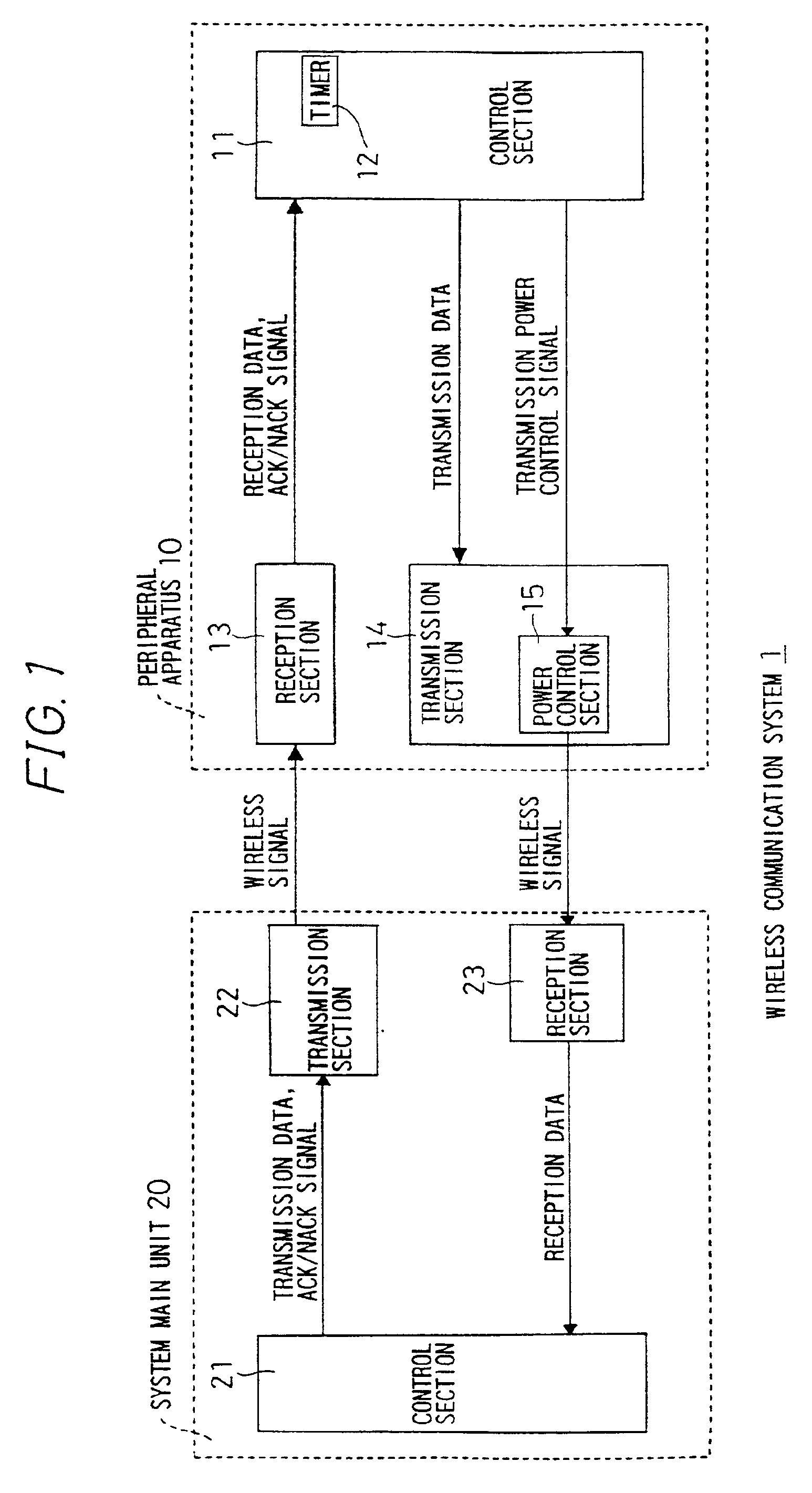

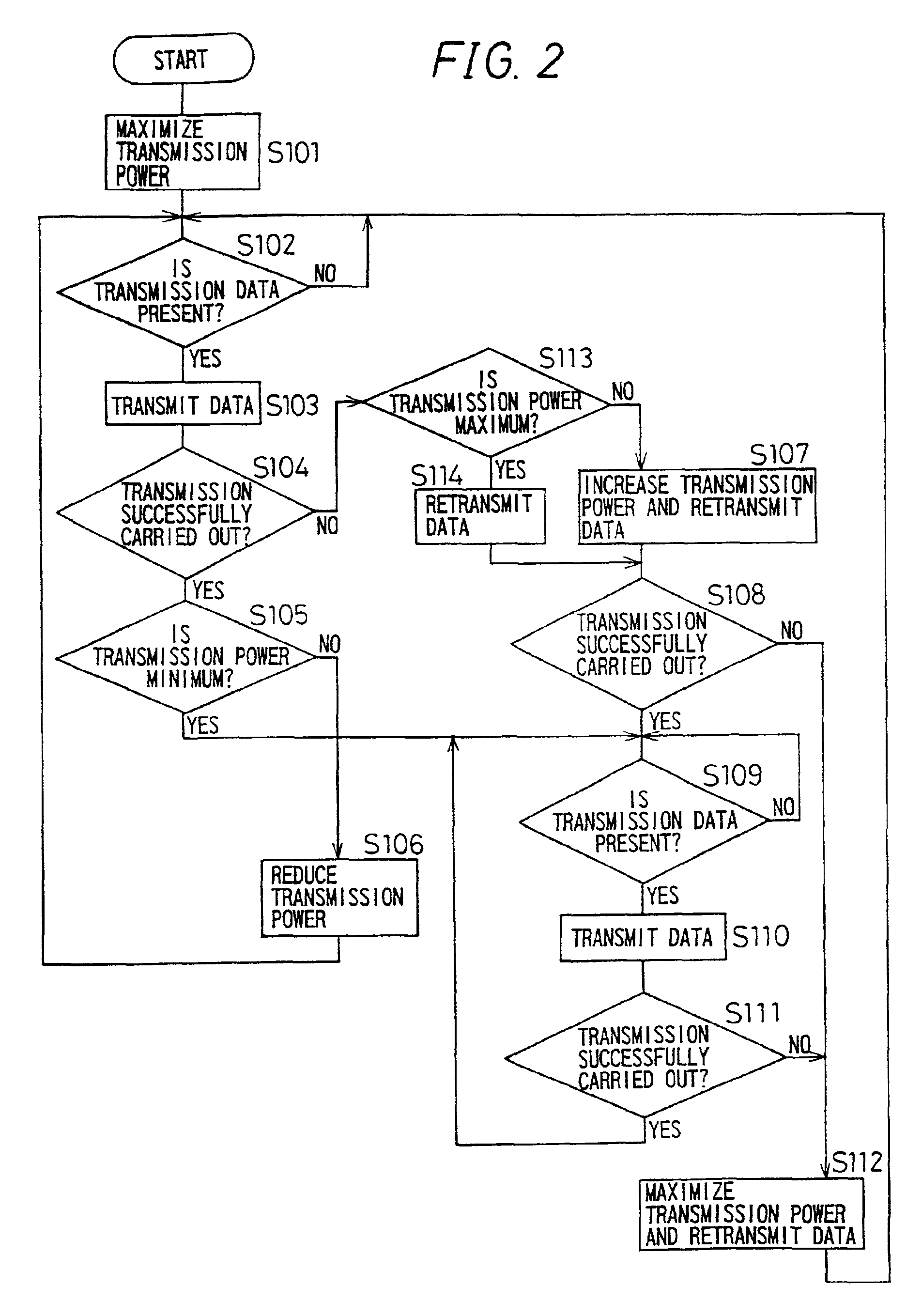

Method of automatically controlling transmission power of wireless communication apparatus, and storage medium on which the same is stored

InactiveUS6983164B2Eliminate consumptionEnergy efficient ICTPower managementAutomatic controlEngineering

A method of automatically controlling a transmission power of a wireless communication apparatus that reduces power consumption and adjusts the transmission power to enable communication to be carried out at an optimum transmission power, and a storage medium which stores the method are provided. At a start of communication, a wireless communication apparatus performs communication while setting the transmission power to the maximum value. Each time when transmission succeeds, the transmission power is reduced by a predetermined amount. When transmission fails as a result of the reduction by the predetermined amount, retransmission is carried out with increasing the transmission power by the predetermined amount. The increased power is set as an optimum transmission power. The power is maintained until transmission fails. When transmission fails after the optimum transmission power is set, transmission power is raised to the maximum value and setting of optimum transmission power is again carried out.

Owner:SHARP KK

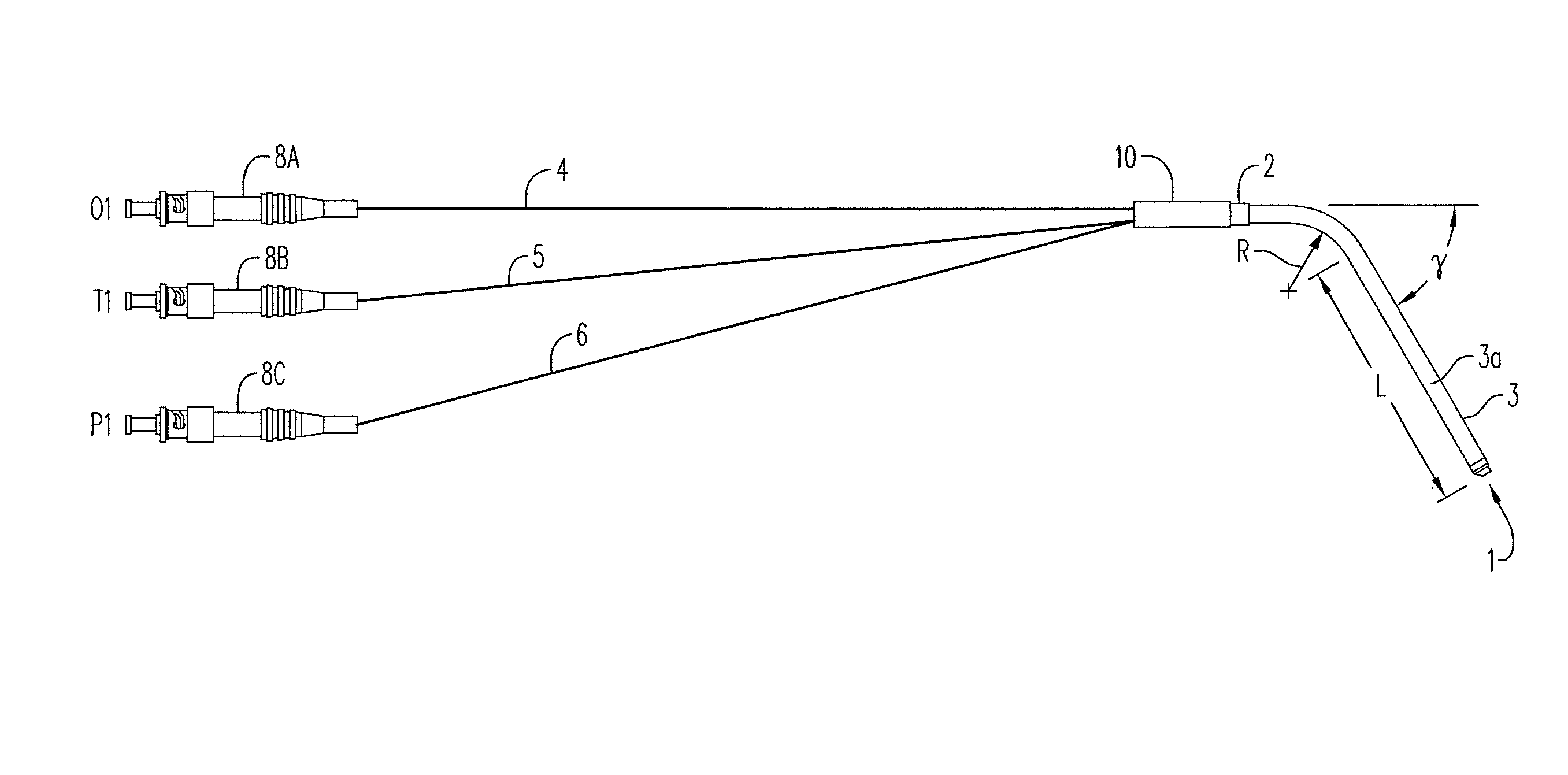

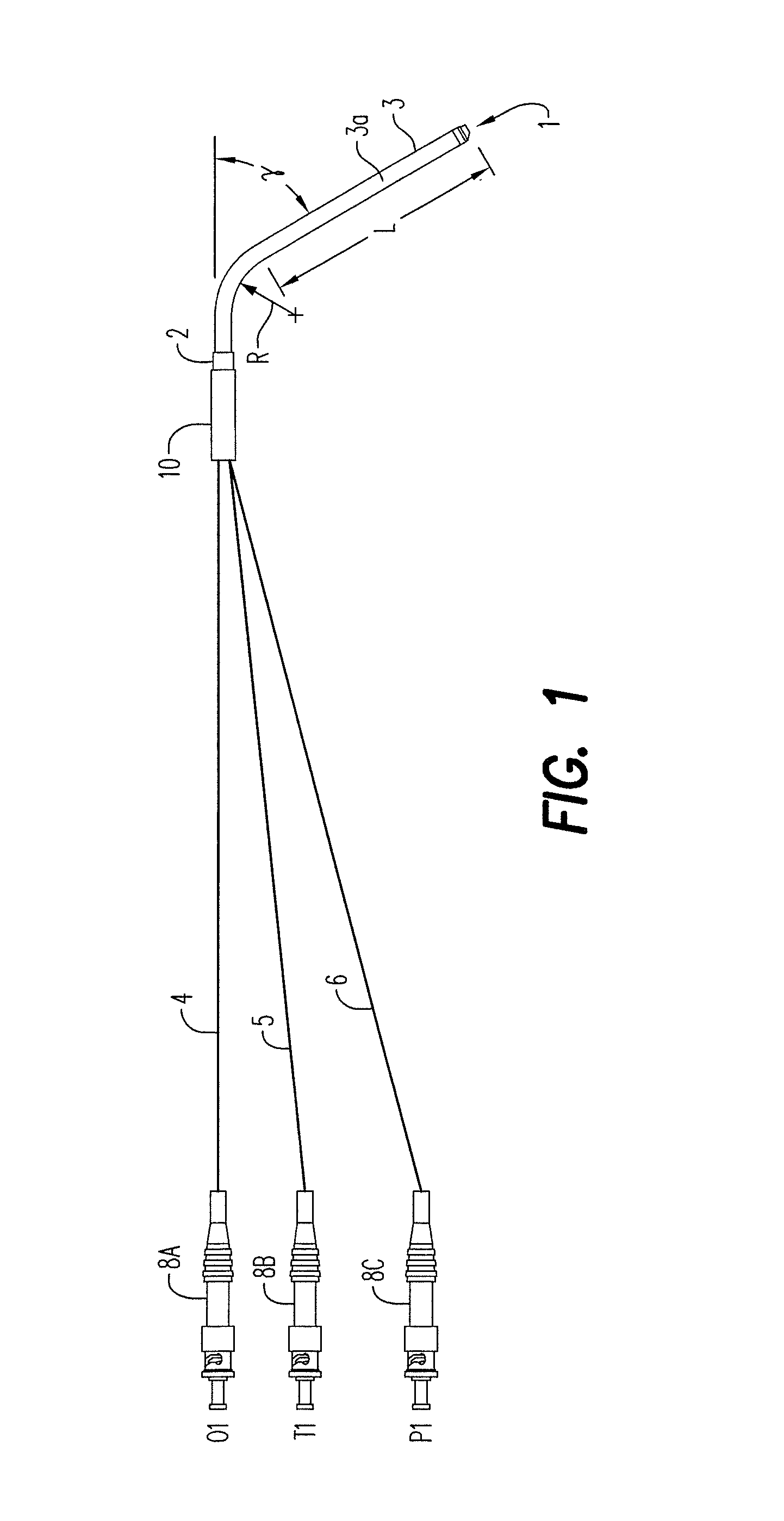

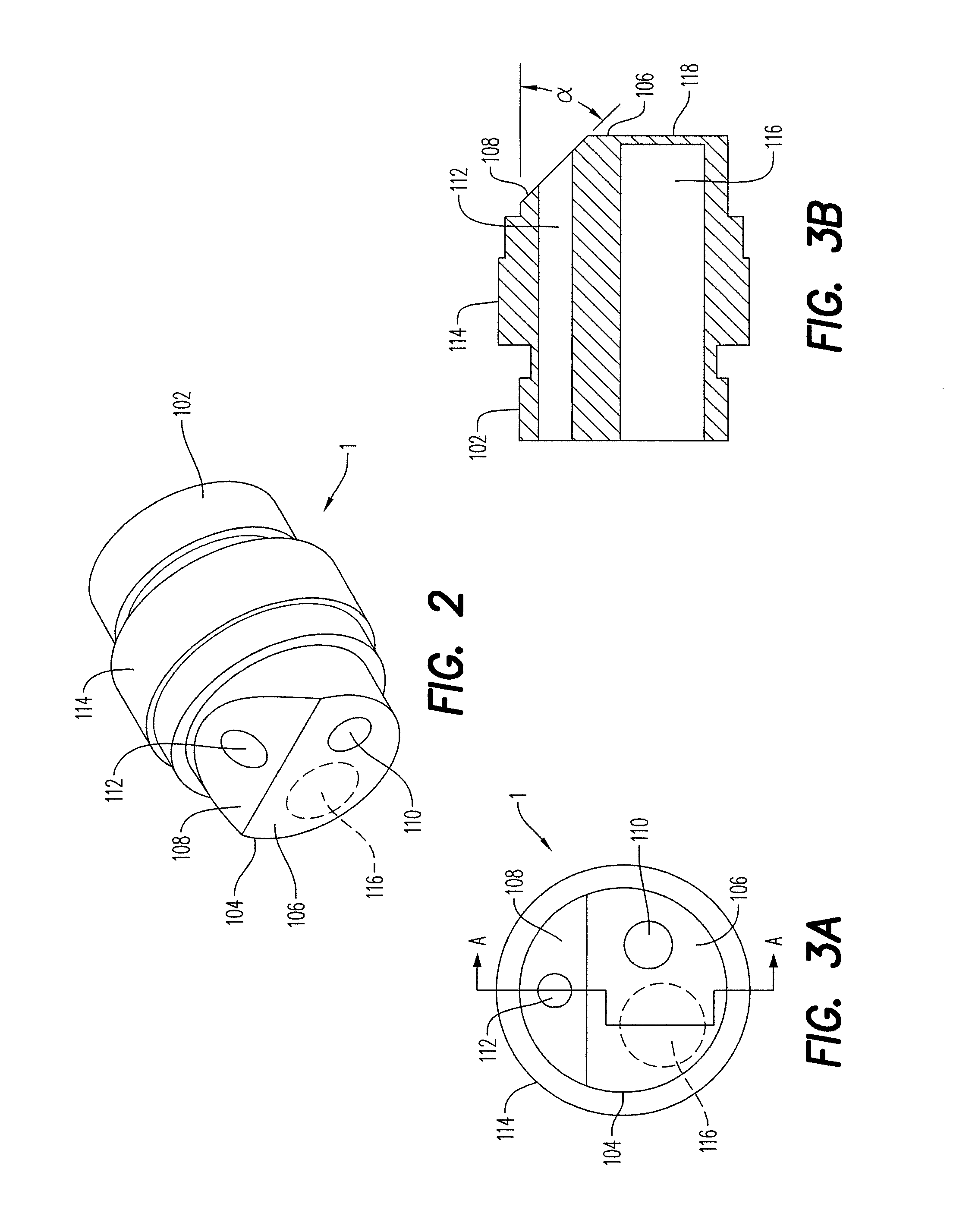

Optical probe containing oxygen, temperature, and pressure sensors and monitoring and control systems containing the same

InactiveUS20130206760A1Accurate calculationAccurate in determinationThermometer detailsMeasurement apparatus componentsSemiconductor materialsGrating

A probe for measuring oxygen, temperature, and pressure in a space to be monitored, comprising: a housing, comprising a thermally conductive material; an oxygen sensor disposed within the housing, comprising: a first end having coated thereon a coating which fluoresces at a fluorescent frequency when exposed to light having an excitation frequency in the absence of associated oxygen, and which undergoes a dampening of said fluorescence in the presence of associated oxygen; and a second end operatively connected to an optical fiber that extends through the housing; wherein the first end extends through the housing and is adapted to be exposed to the space to be monitored; a temperature sensor disposed within the housing adjacent to the thermally conductive material, comprising a fiber Bragg grating, or a semiconductor material, such as a GaAS material, wherein the temperature sensor does not extend through the housing and is not exposed to the space to be monitored; a pressure sensor disposed within the housing, comprising a fiber Bragg grating or a Fabry-Pérot white light interferometry sensor having a first end which extends through the housing and is adapted to be exposed to the space to be monitored.

Owner:SUSKO KENNETH

Process and apparatus for release and recovery of methane from methane hydrates

InactiveUS20100243245A1Reduce expenditureIncreases net heating valueSurveyConstructionsCombustionMethane clathrate

A process and system for release and recovery of methane from subterranean methane hydrate deposits in which heated CO2 is used to displace methane from the methane hydrate deposits and a portion of the displaced methane is routed to a combustion device proximate the deposit for combustion in-situ, generating heated CO2 which is introduced into the deposit, displacing additional methane, a portion of which is routed to the combustion device, thereby providing a substantially self-sustaining process. Portions of the displace methane not routed to the combustion device are captured for use elsewhere.

Owner:GAS TECH INST

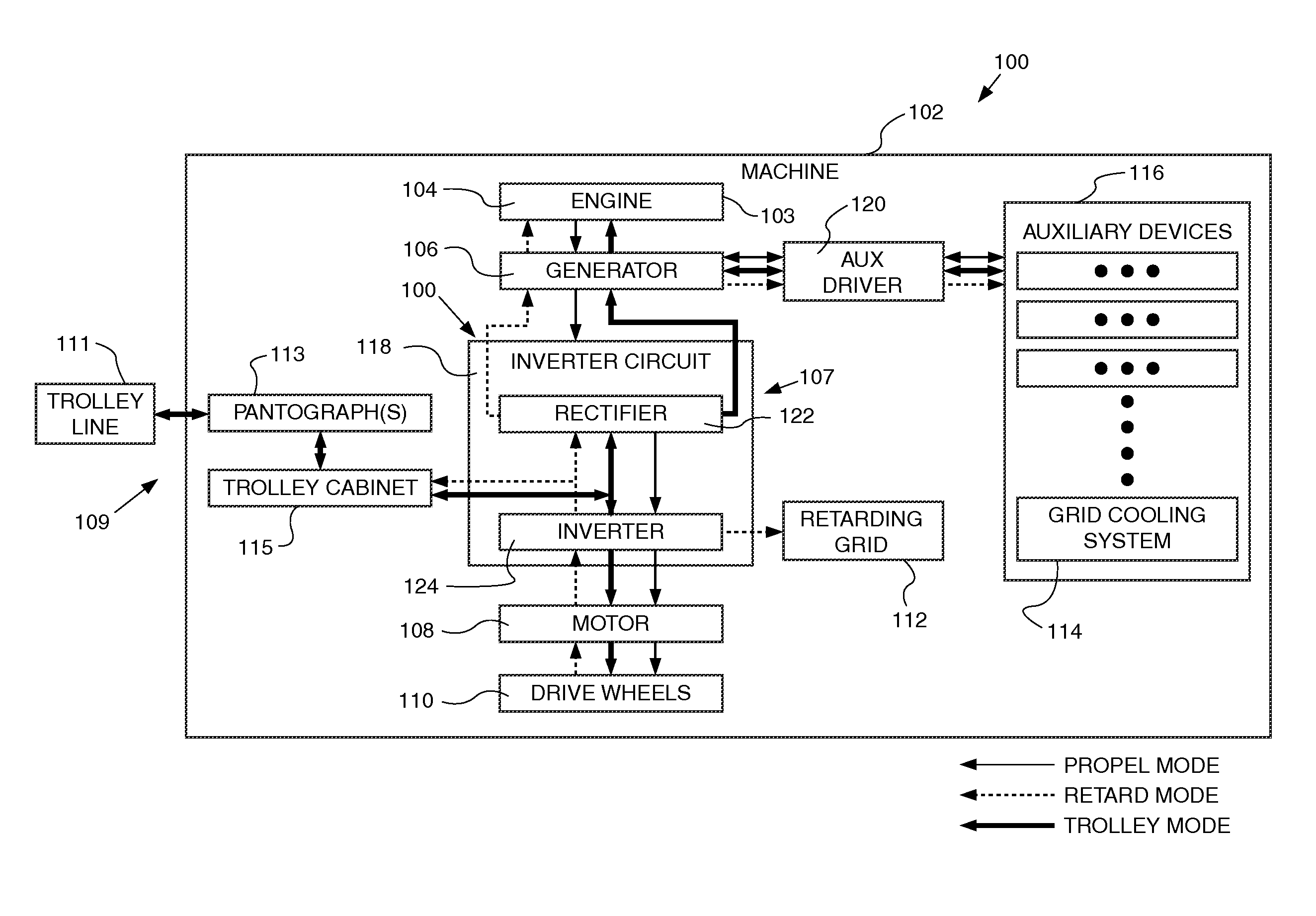

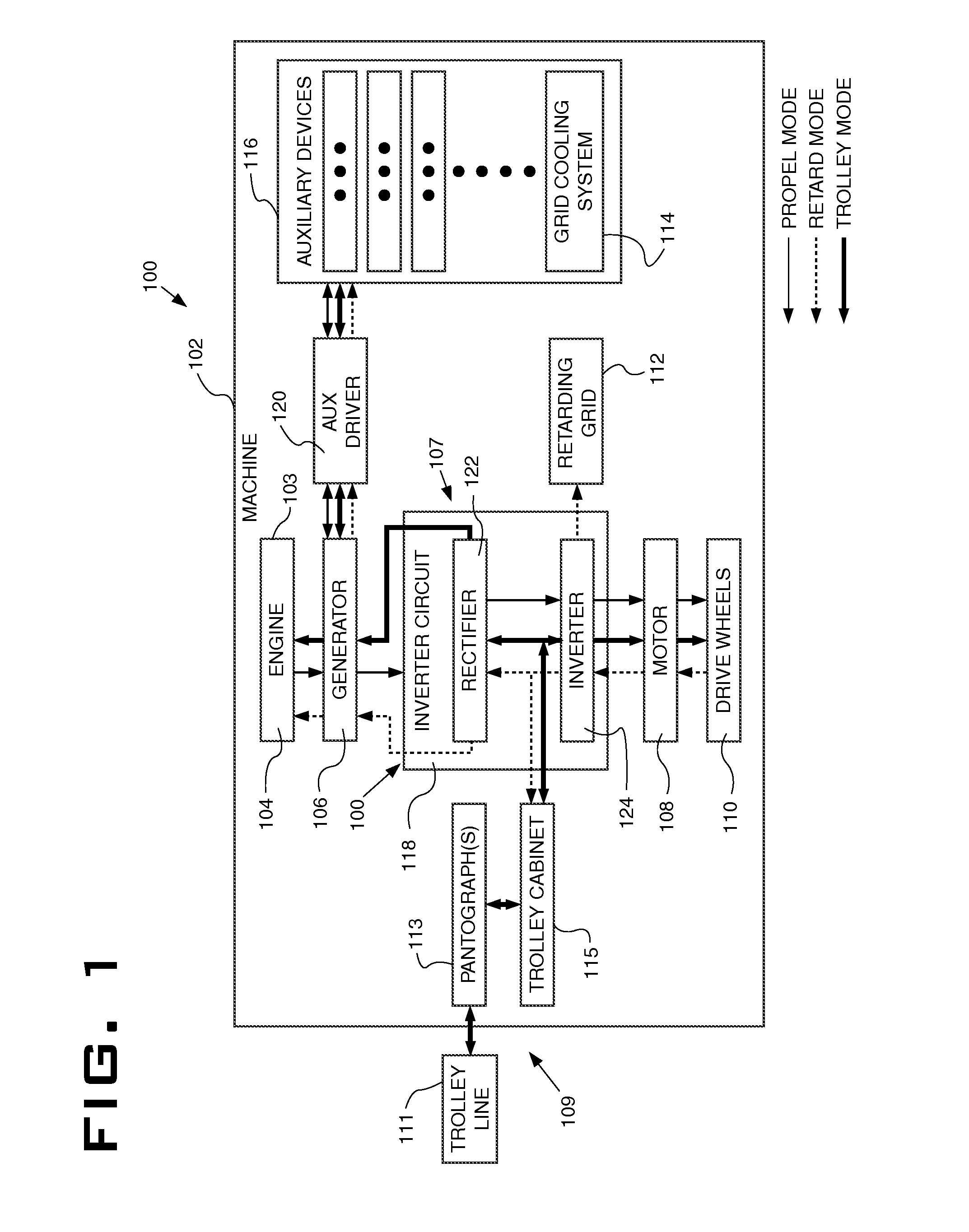

Method and apparatus to eliminate fuel use for electric drive machines during trolley operation

ActiveUS20130146411A1Eliminating fuel consumptionEliminate consumptionPropulsion using engine-driven generatorsPartially enclosed bus-bar installationsElectricityHybrid system

A drive system for a machine having an engine, a generator, a trolley drive arrangement, a motor, wheels and auxiliary devices is provided. The drive system includes an inverter circuit and an auxiliary driver both being operatively connected to the trolley drive arrangement. The inverter circuit may be coupled to each of the generator and the motor. The auxiliary driver may be coupled to each of the generator and the auxiliary devices. The inverter circuit and the auxiliary driver may be configured to automatically communicate power from the trolley drive arrangement and any power from the auxiliary devices to the motor in a trolley propel mode, and automatically communicate power from the motor to the engine, the trolley drive arrangement, and optionally to a hybrid system if applicable, in a dynamic braking mode, while attached to trolley lines so as to eliminate fuel consumption while attached to the trolley lines.

Owner:CATERPILLAR INC

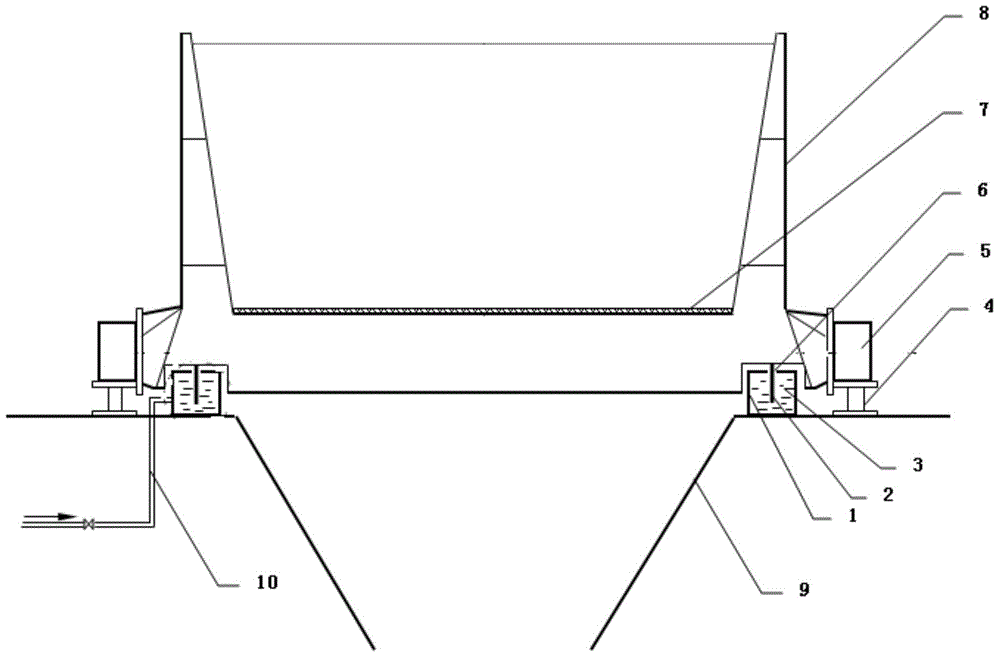

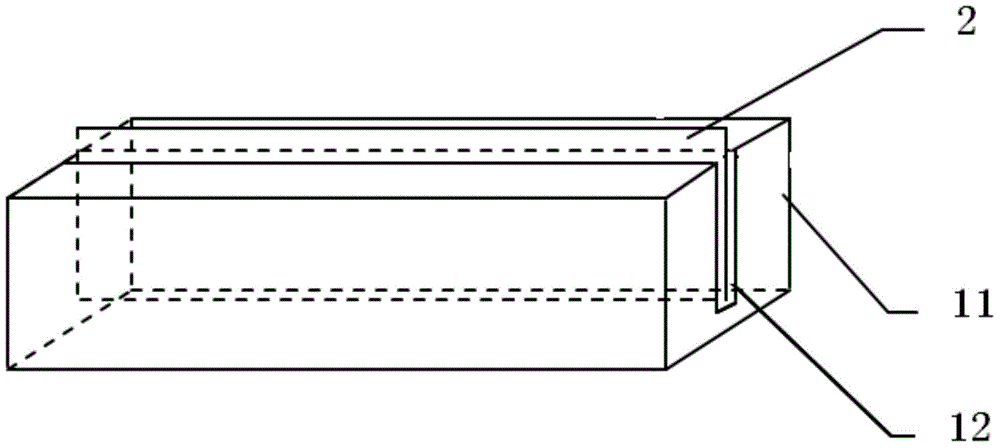

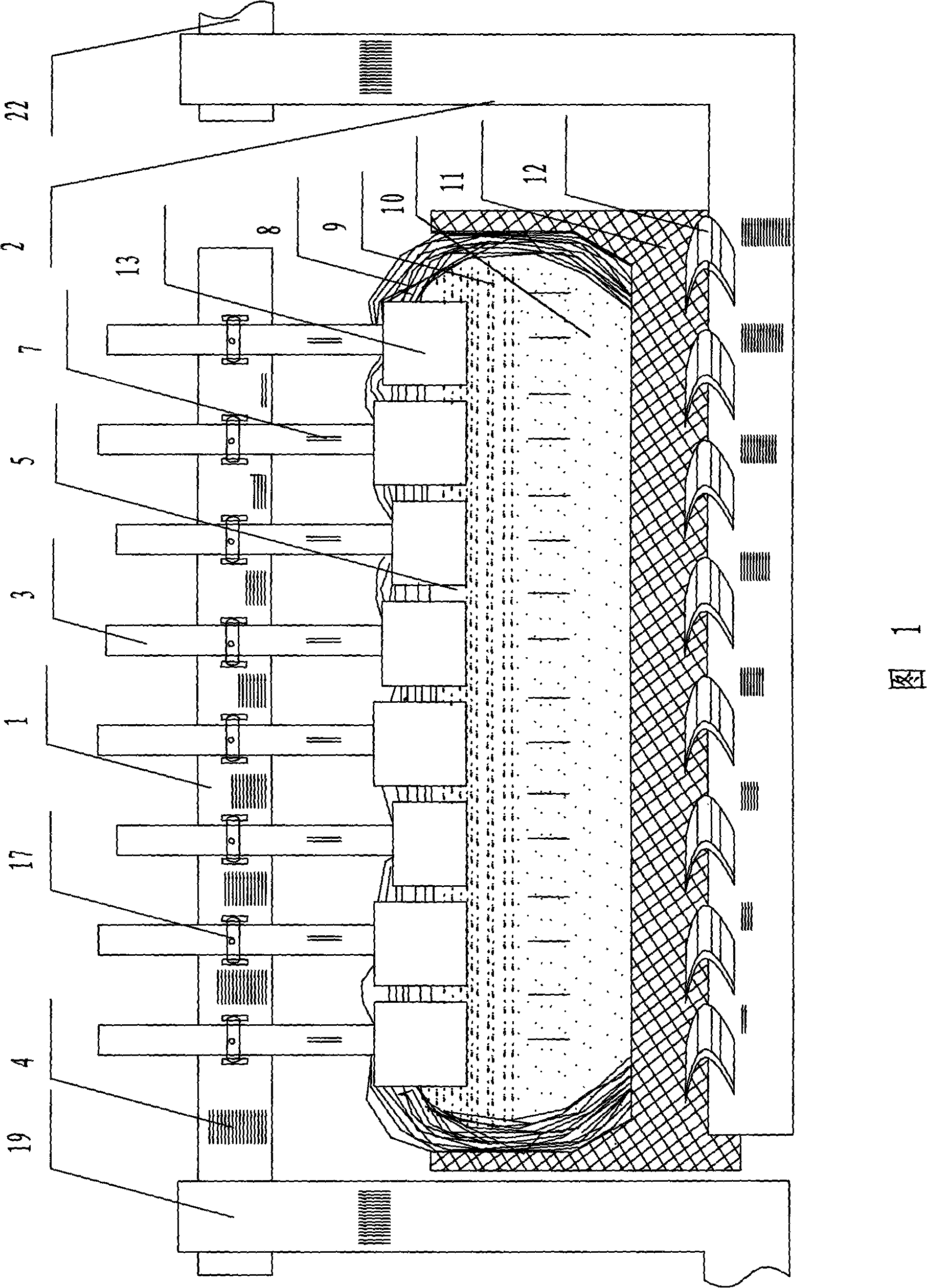

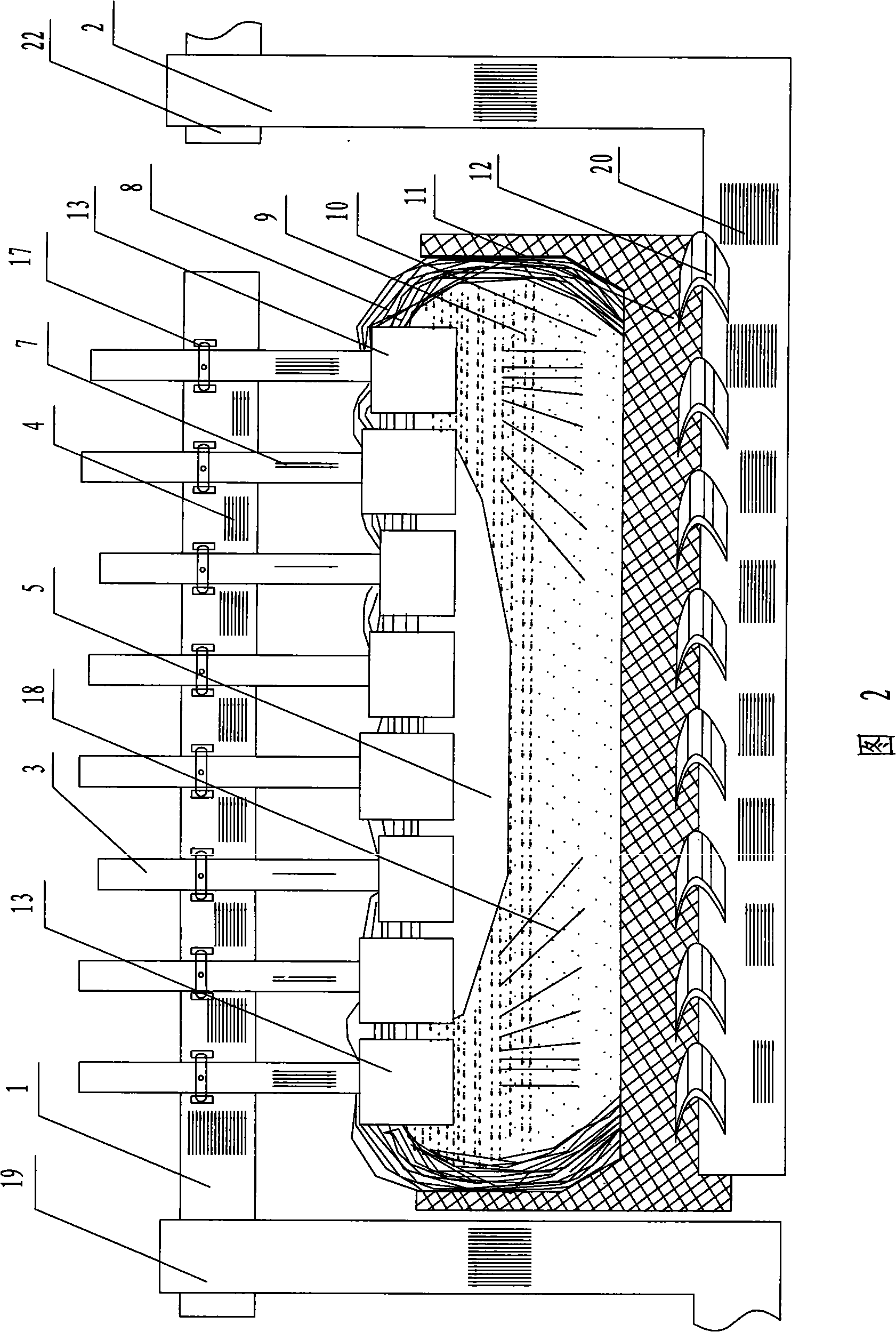

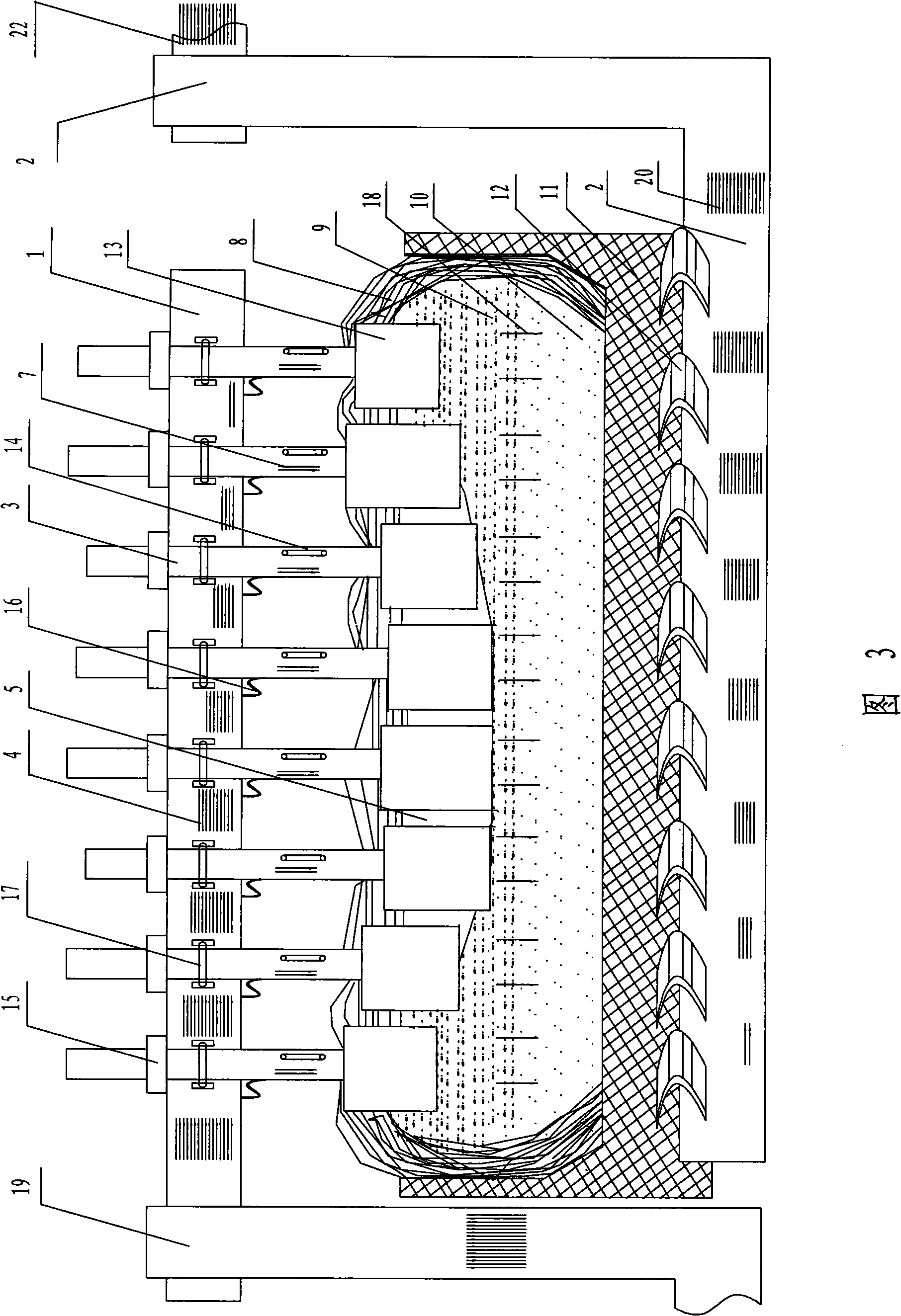

Sintering machine trolley bottom two-side sealing structure

ActiveCN104457257AReduce power consumptionReduce solid fuel consumptionEngine sealsFurnace typesMaterials scienceLeakage rate

The invention relates to the field of sintering machine flexible liquid sealing devices, in particular to a sintering machine trolley bottom two-side sealing structure. The sintering machine trolley bottom two-side sealing structure effectively achieves sealing of a sintering system through water seal formation. The sintering machine trolley bottom two-side sealing structure comprises a trolley and a sintering machine air box arranged below the trolley. Trolley wheels are arranged at the bottoms of the two sides of the trolley. The trolley wheels are arranged on trolley tracks in a slidable mode. The sintering machine trolley bottom two-side sealing structure further comprises sealing plates and sealing water tanks, wherein the sealing plates are fixedly arranged on the two sides of the bottom of the trolley in pairs and extend downwards in the vertical direction, and the sealing water tanks are arranged below the corresponding sealing plates. The sealing plates are inserted into the sealing water tanks through walking grooves in the upper portions of the sealing water tanks, and therefore the sintering machine air box is sealed. Due to the fact that the sealing plates are inserted into the sealing water tanks through the walking grooves in the upper portions of the sealing water tanks, the sintering machine air box is sealed relative to the exterior, the air leakage rate is lowered, and the sintering machine trolley bottom two-side sealing structure is particularly applicable to a sintering machine with the higher sealing requirement.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

Single anode shunt and regulation apparatus electrolyzed by multiple anodes cell and method

InactiveCN101358358ABalanced production currentEquilibrium heat incomeElectrolysis componentsPower flowElectrolysis

The invention relates to a single-anode shunting controller used for multi-anode electrobath electrolysis, and a method thereof; the device is an anode unit in an electrobath and comprises an anode bus and a plurality of anode sets which are vertically arranged on the anode bus; each anode set comprises an anode guide rod and an anode carbon block fixed on the anode guide rod; each anode set is independently and movably arranged on the anode but by the anode guide rod; the upper end of each anode guide rod is provided with an anode guide rod controller which is used for regulating the height of each anode guide rode appropriately; the anode bus and the anode guide rods are flexibly connected, and each anode guide rod is provided with an anode current measuring device. The invention changes the passive production process control, actively solves and prevents the current bias produced in electrobath and electrolysis production, automatically guides, controls and balances the production current of the electrobath, balances the heat income of the electrobath, can mostly improve the current efficiency of a single electrobath, protect the anode and the electrobath, make full use of the anode and is very good for promotion and implementation.

Owner:刘瑞杰

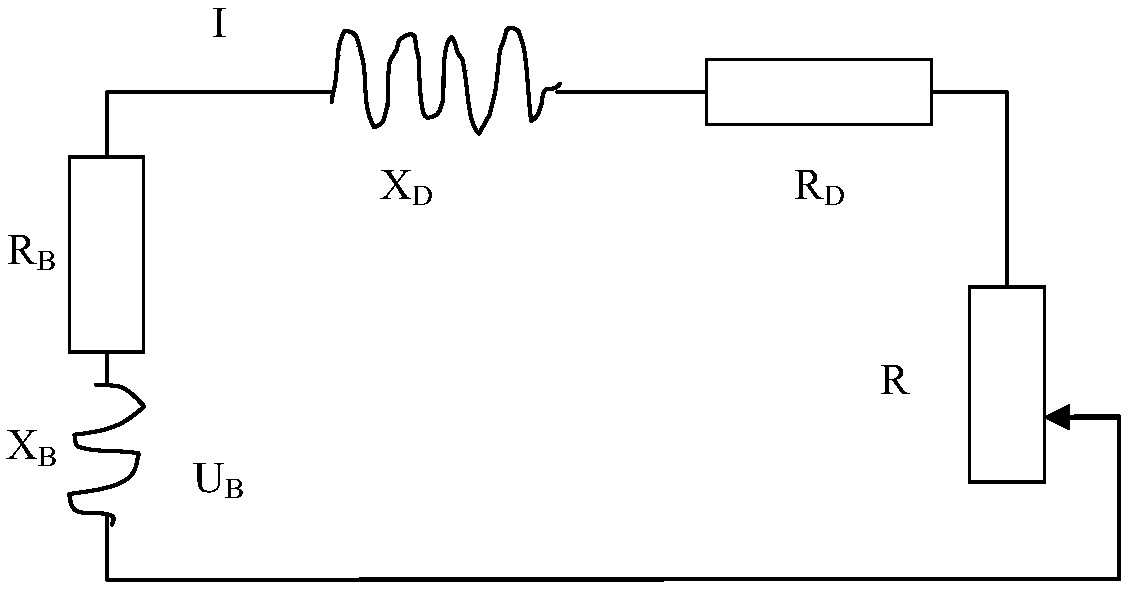

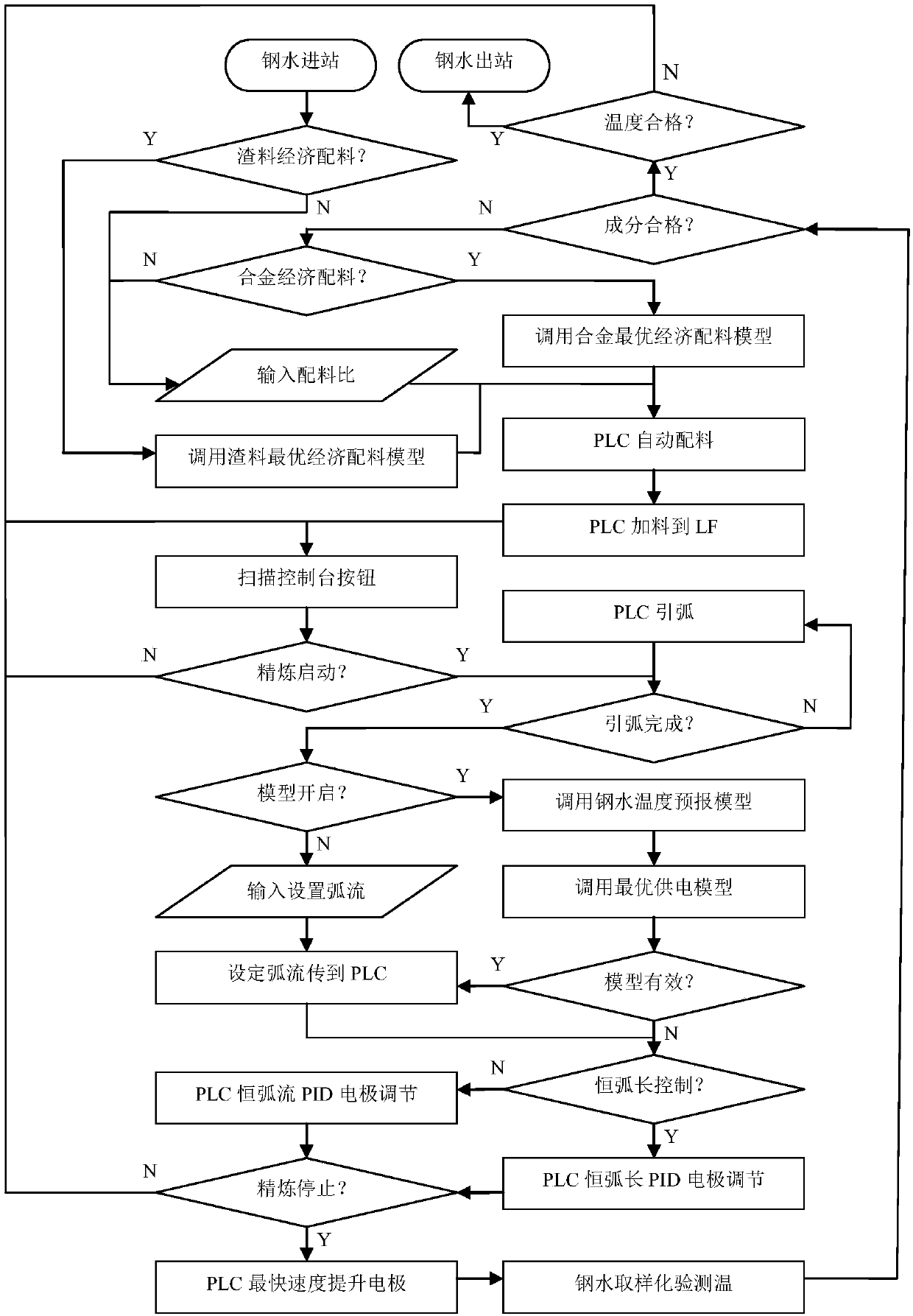

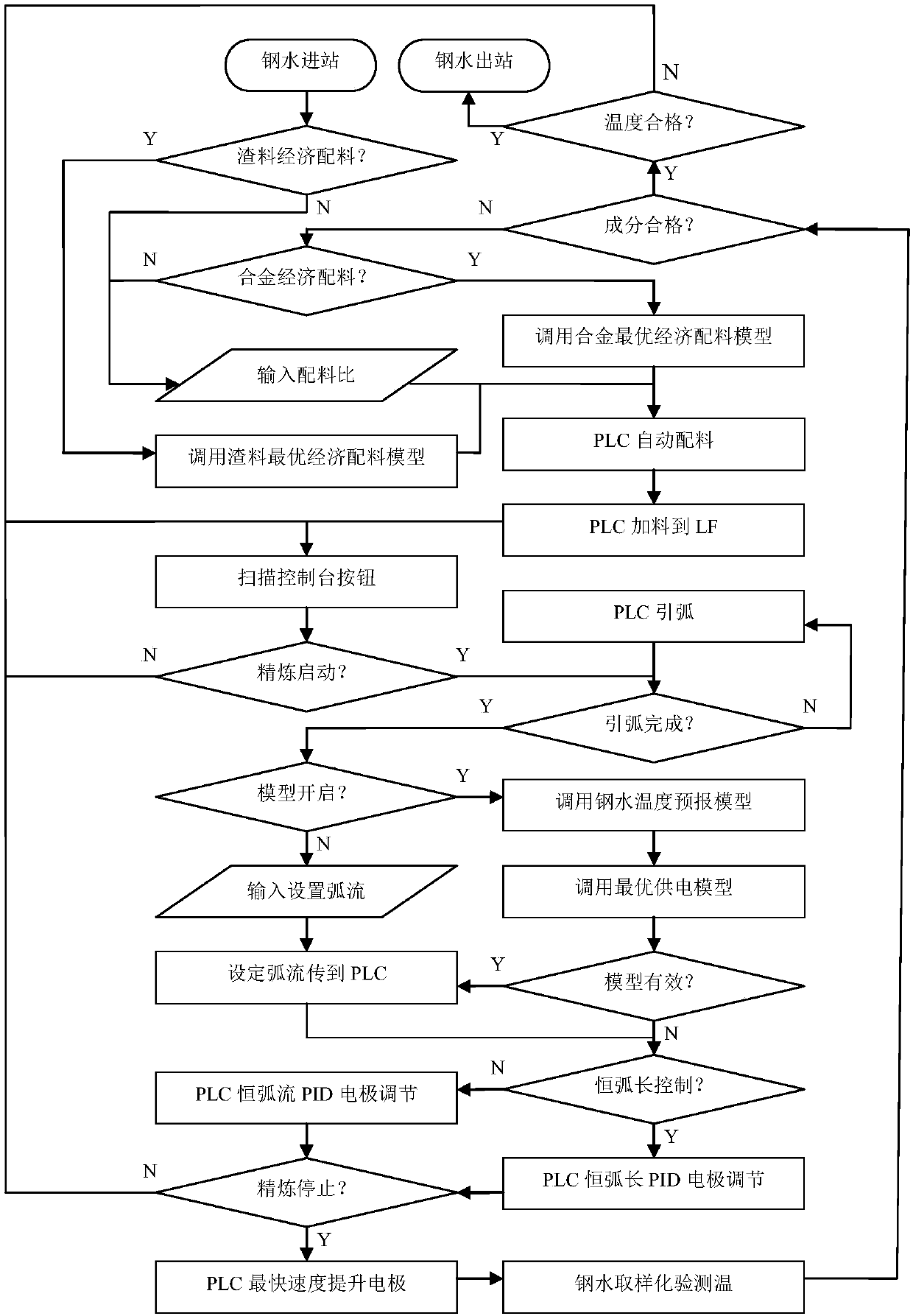

LF refining furnace optimal economical burdening and intelligent control model

ActiveCN107043842ARealize online temperature forecastEliminate consumptionIncreasing energy efficiencyDesign optimisation/simulationMathematical modelProcess engineering

The invention relates to an LF refining furnace optimal economical burdening and intelligent control model which comprises an LF furnace optimal economical burdening model and an LF furnace molten steel temperature prediction and optimal power supply model. Defects and shortcomings of an existing LF control technology are overcome, characteristics of an LF furnace are combined, the LF furnace optimal economical burdening mathematical model, the molten steel temperature prediction mathematical model, and an electrode intelligent adjusting mathematical model with the minimum power consumption as the target are elicited, and a VBS script program is written and embedded into WINCC, so that LF steel ladle refining furnace optimal economical burdening and intelligent control are achieved. The model is used for online prediction of the temperature of molten steel, automatic obtaining of the optimal economical burdening, and enabling the electric power consumption per ton steel to reach the minimum under the condition that process requirements are met.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

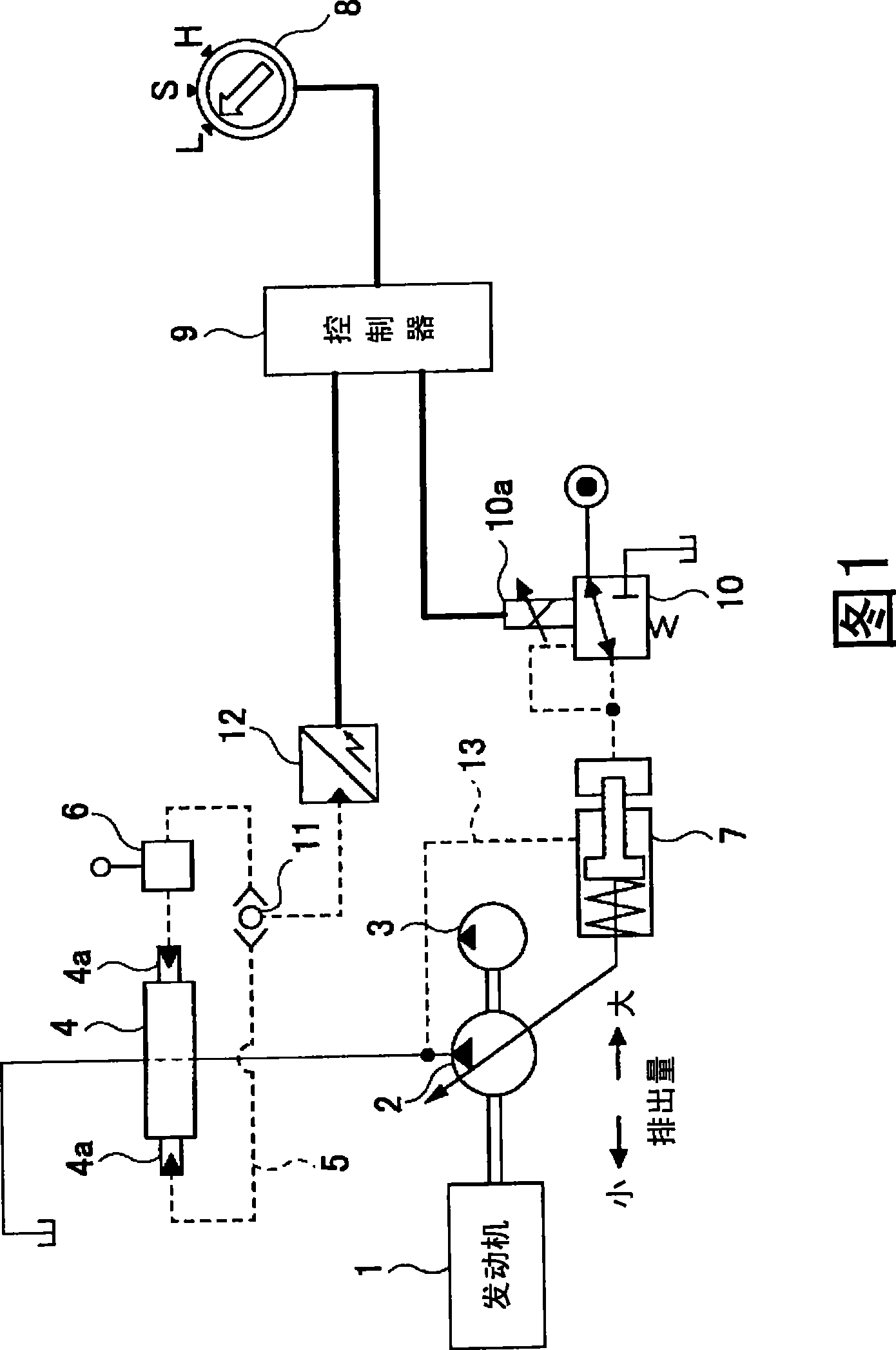

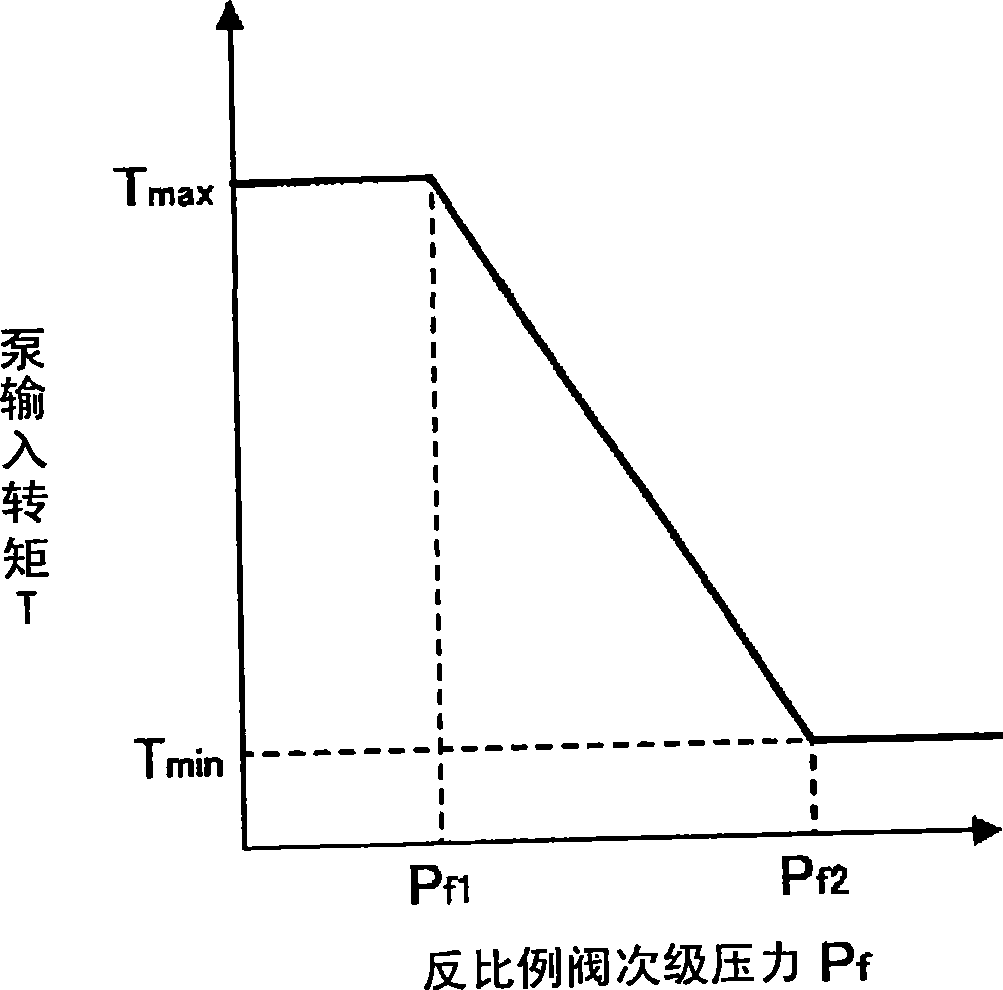

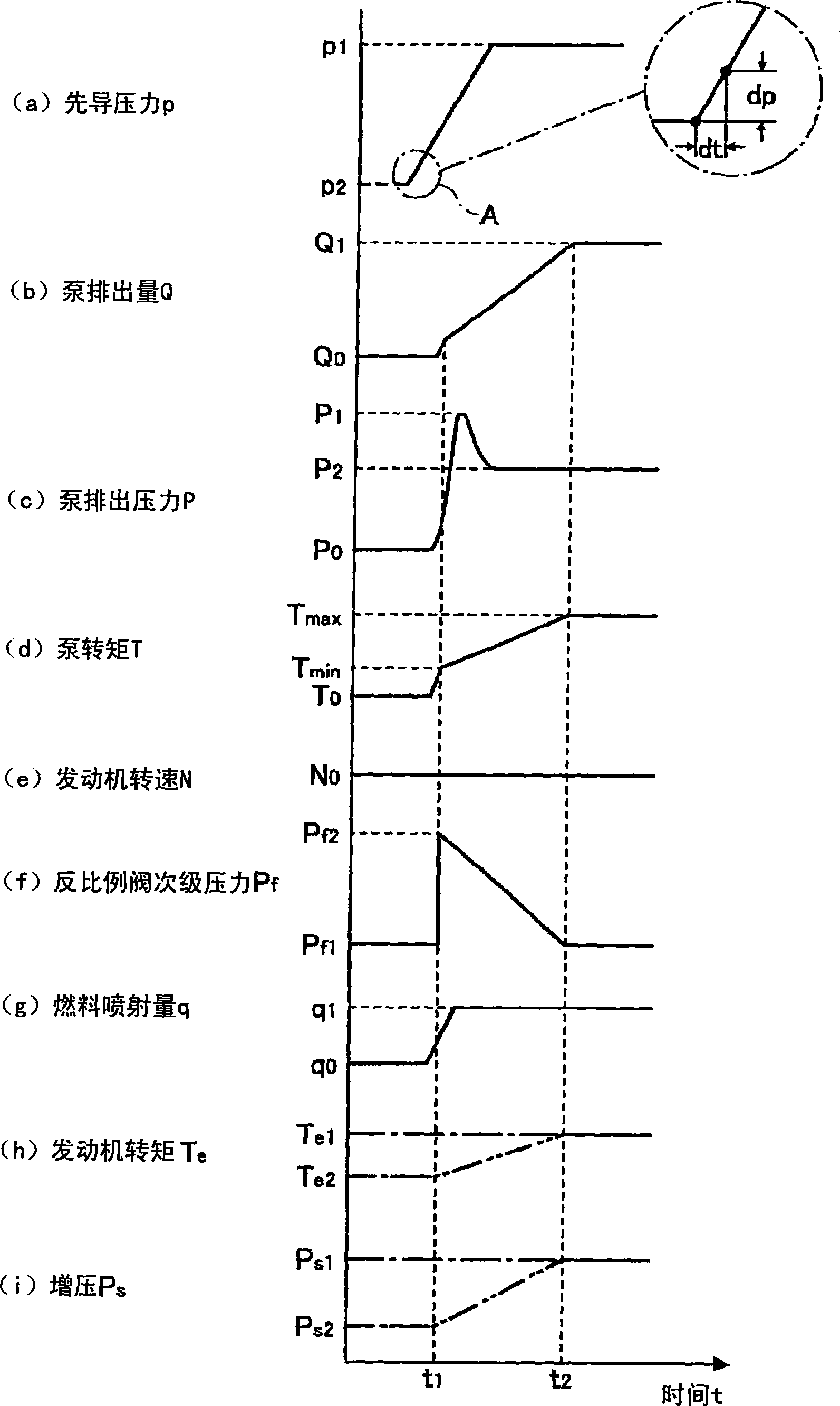

Overload prevention device for construction machine

ActiveCN101432529AEliminate loading slowdownsEliminate consumptionServomotorsServometer circuitsControl signalHydraulic pump

An overload prevention device for a construction machine, preventing occurrence of engine lag down in a sharp rise of discharge pressure of a hydraulic pump to prevent the amount of fuel injection of an internal combustion engine from increasing sharply, thereby reducing fuel consumption in the entire work of the construction machine and improving operability of a hydraulic actuator etc. The overload prevention device has operating condition detection means and control means. The operating condition detection means detects operating conditions of an operation lever. When the control means determines, based on the operating conditions detected by the operating condition detection means, that the lever is operated at a speed higher than a predetermined speed, the control means outputs to discharge amount control means a control signal for setting input torque of a hydraulic pump at a minimum torque value in constant-torque control, and after that, the control means changes the level of the control signal according to a predetermined control pattern to increase the input torque of the hydraulic pump to a maximum torque value in the constant-torque control.

Owner:SUMITOMO CONSTRUCTION MACHINERY

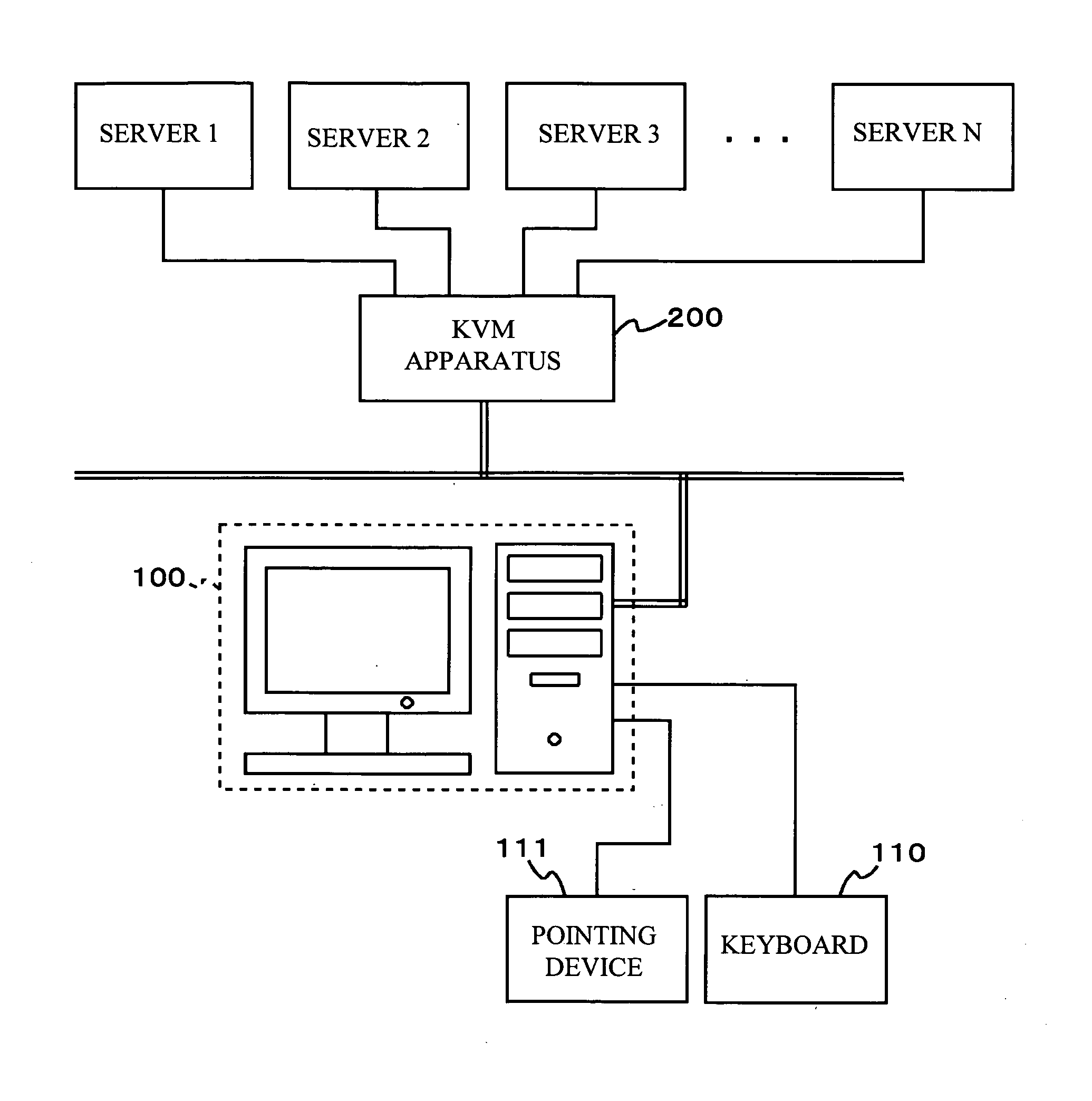

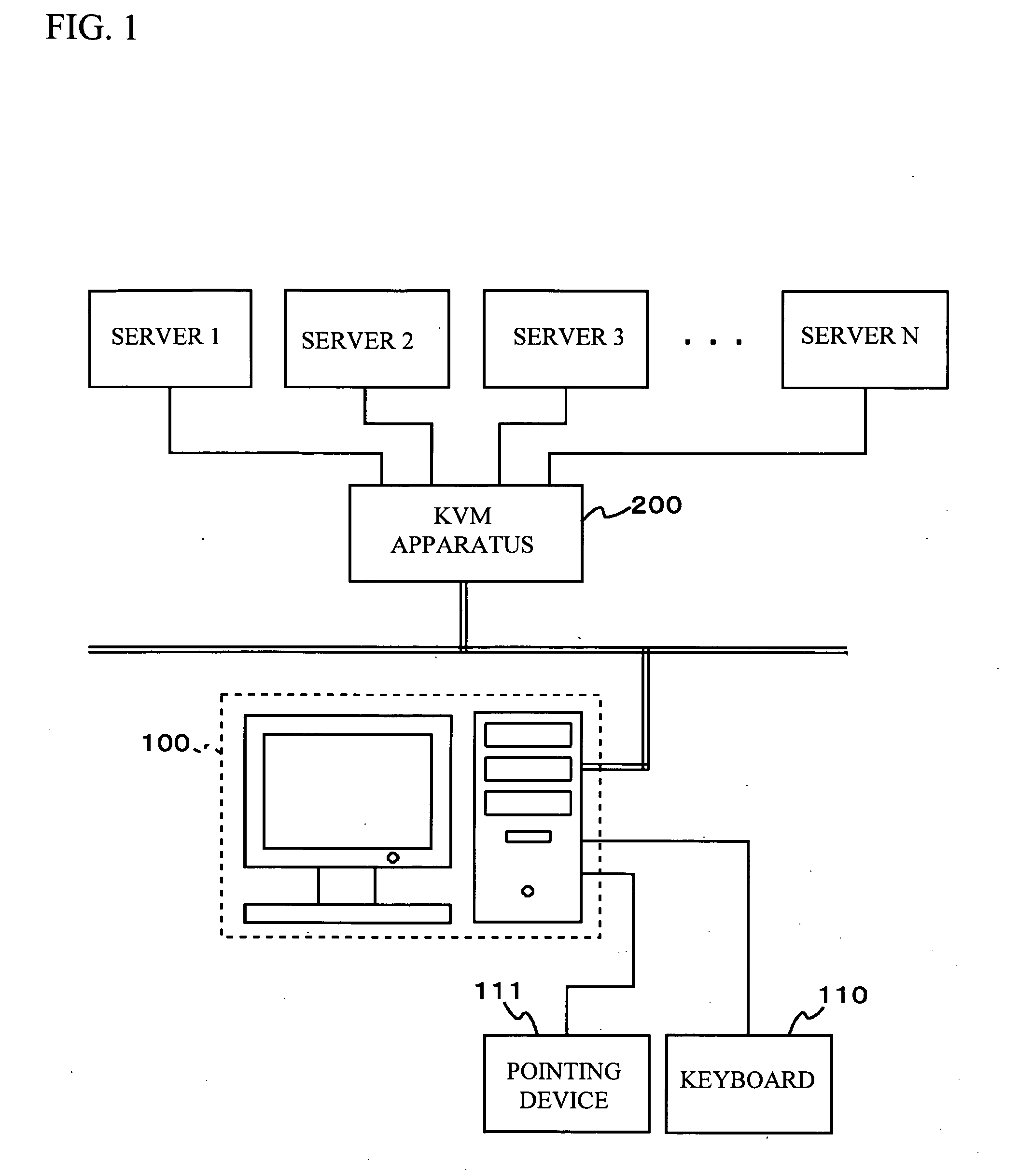

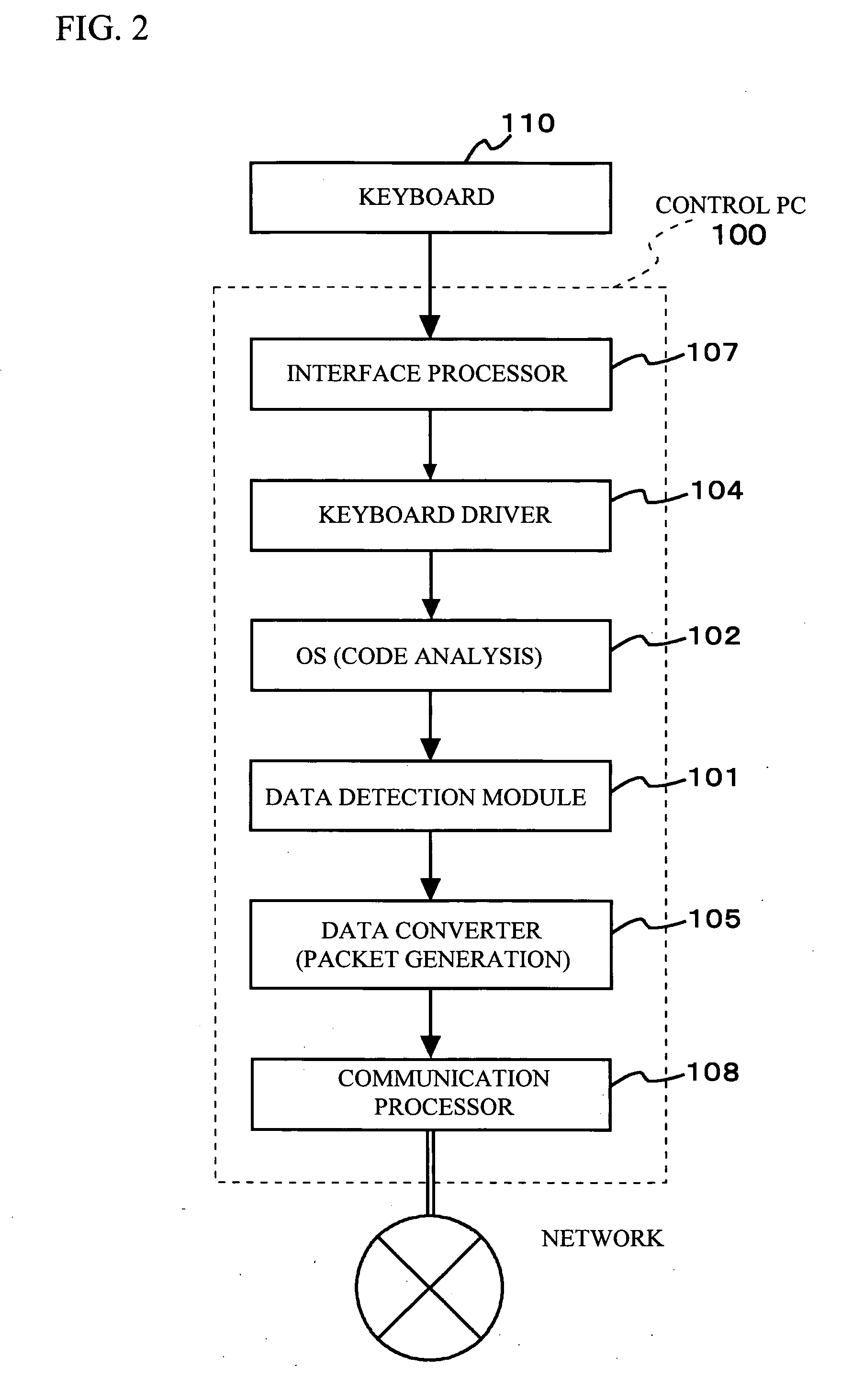

Information processing apparatus, selector, remote operation system, scan code transmission method, and program product therefor

InactiveUS20070038731A1Efficient identificationEliminate consumptionInput/output for user-computer interactionDigital computer detailsInformation processingData pack

An information processing apparatus includes a code converting portion that converts a scan code output from a keyboard into a corresponding key code, a data converting portion that converts the key code into packets, and a changing portion that changes an output destination of the scan code from the code converting portion to the data converting portion, when an application software to operate a server apparatus remotely located is activated in the information processing apparatus, which is in connection with the server apparatus over a network.

Owner:FUJITSU COMPONENENT LTD

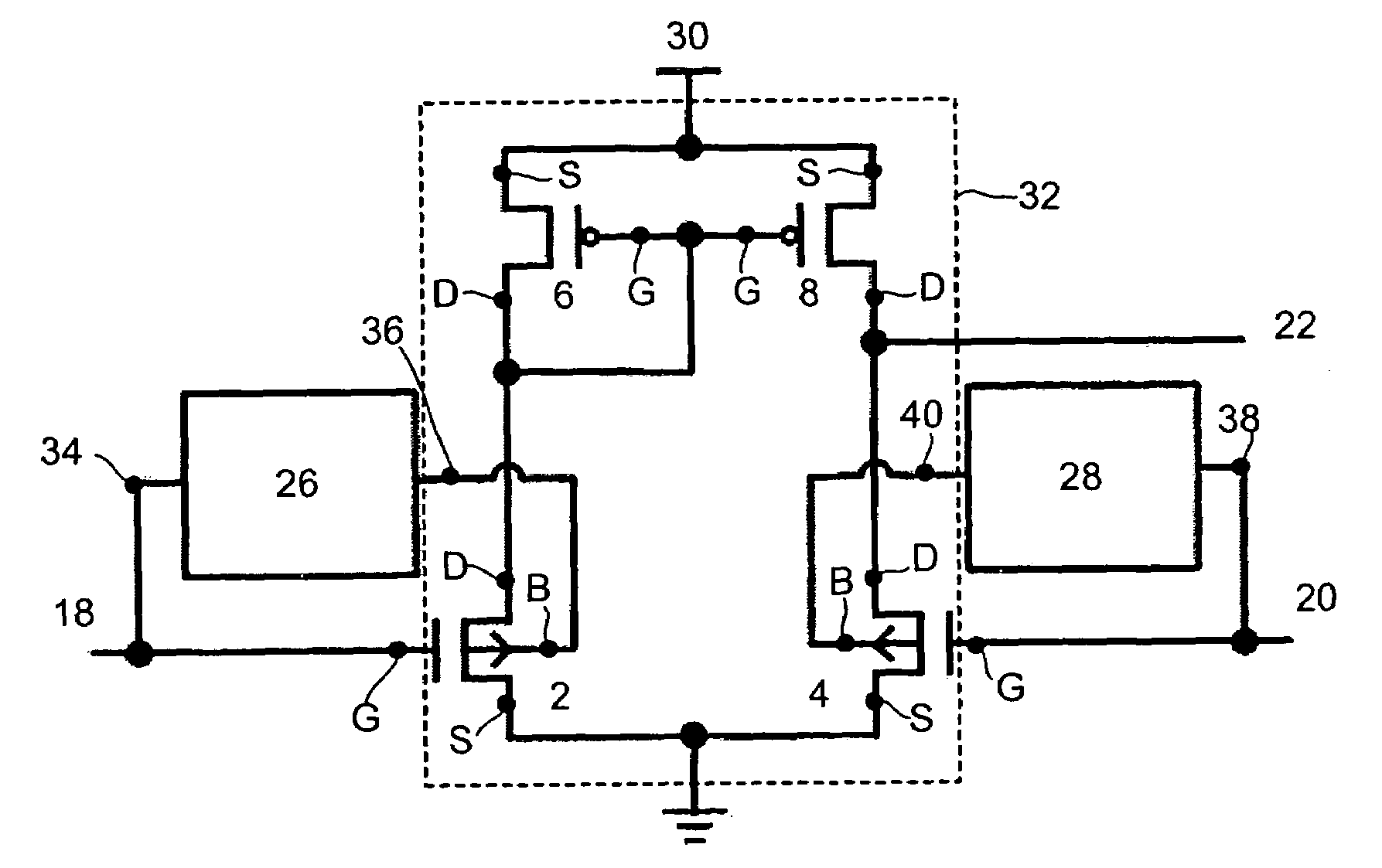

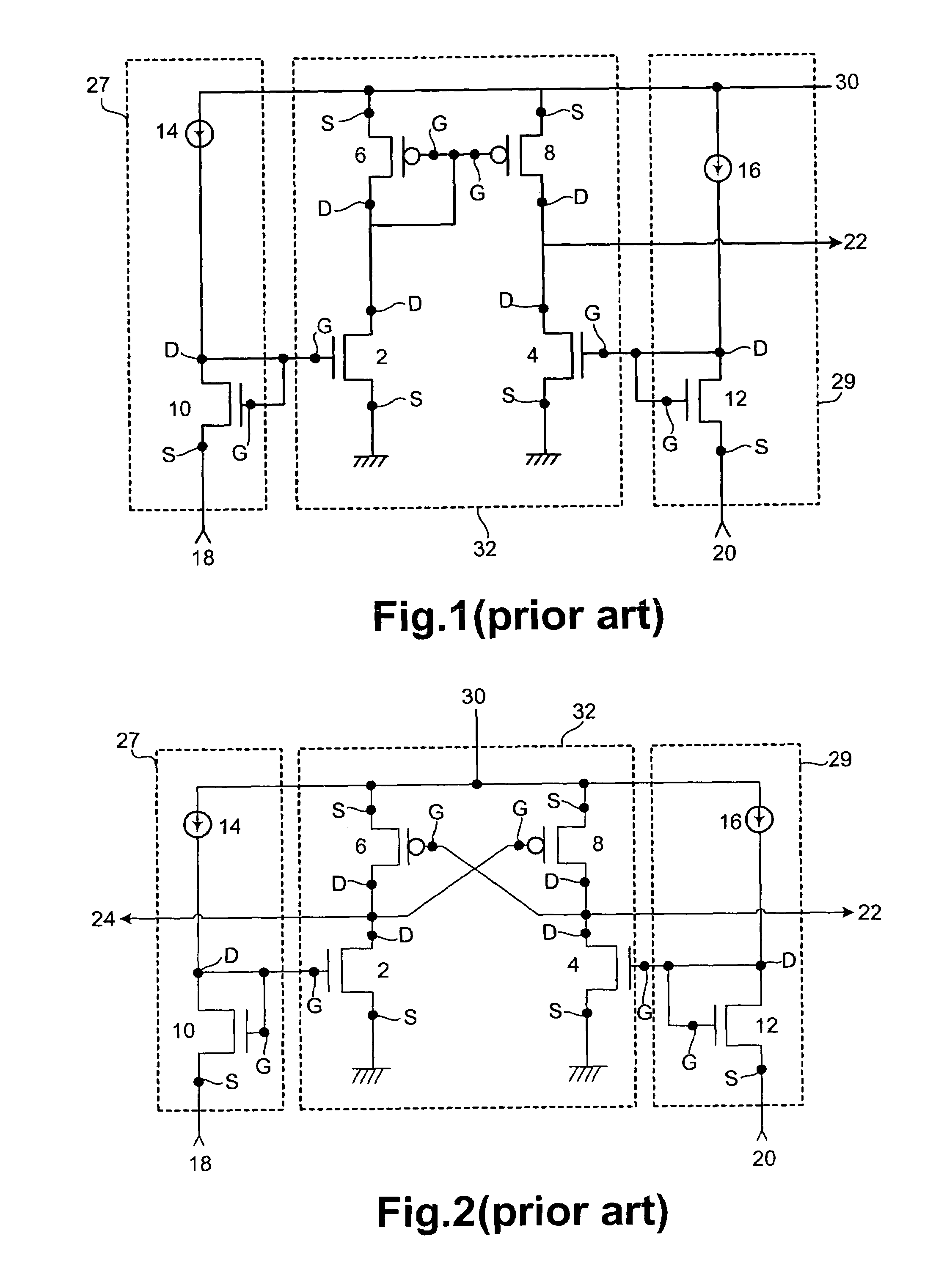

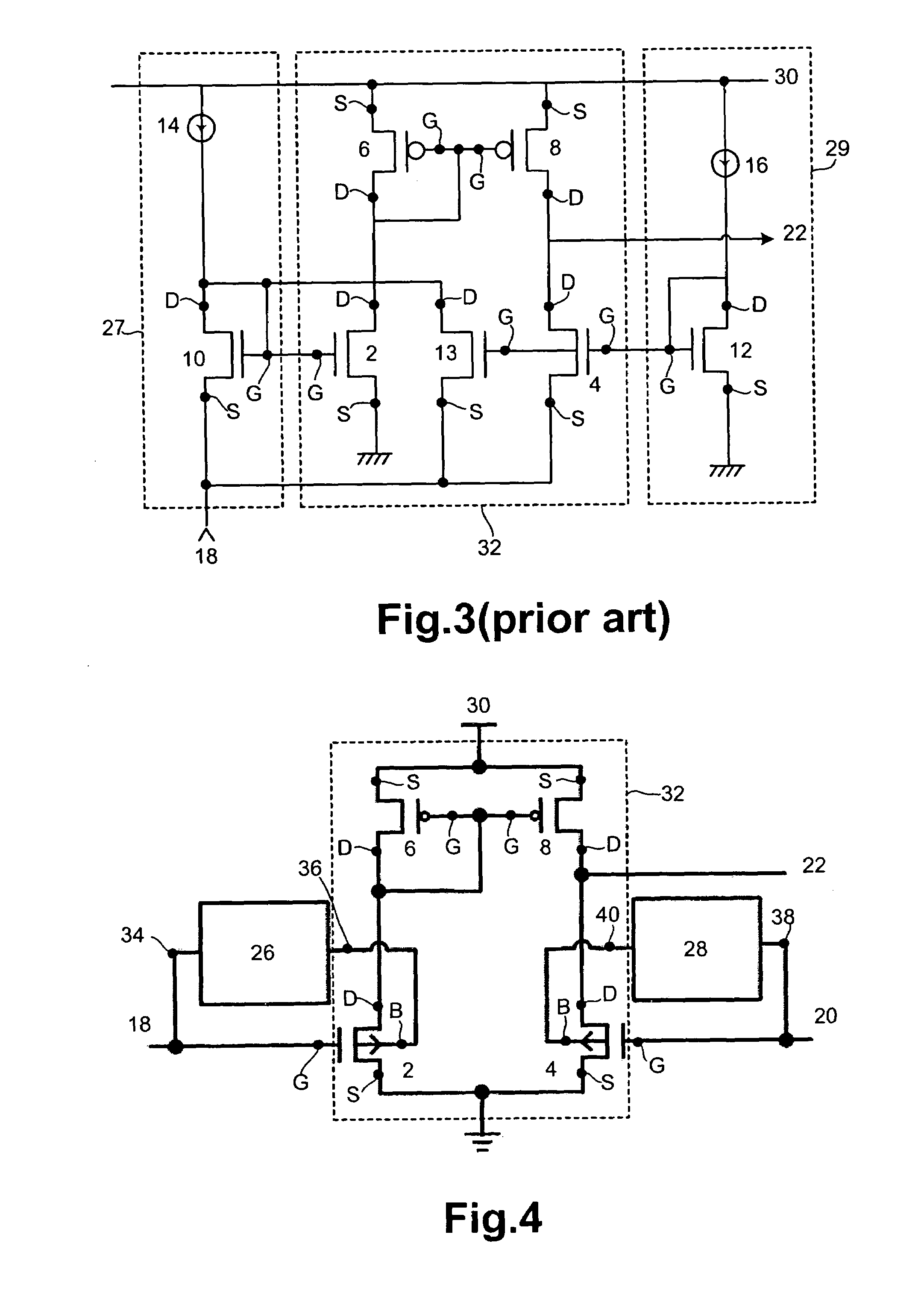

Level shifter with body-biased circuit

InactiveUS7123236B2Increase speedReduce power consumptionPower reduction in field effect transistorsStatic indicating devicesLiquid-crystal displayThin-film-transistor liquid-crystal display

A level shifter, with body-biased circuits, is provided for applying in a thin film transistor liquid crystal display (TFT-LCD). The body-biased circuits are configured to bias the bodies of the input terminal transistors of the level shifter so that the threshold voltages of the input terminal transistors are adjustable. This level shifter is capable of operating at a high frequency with low power consumption while a low-level signal is inputting.

Owner:INNOLUX CORP

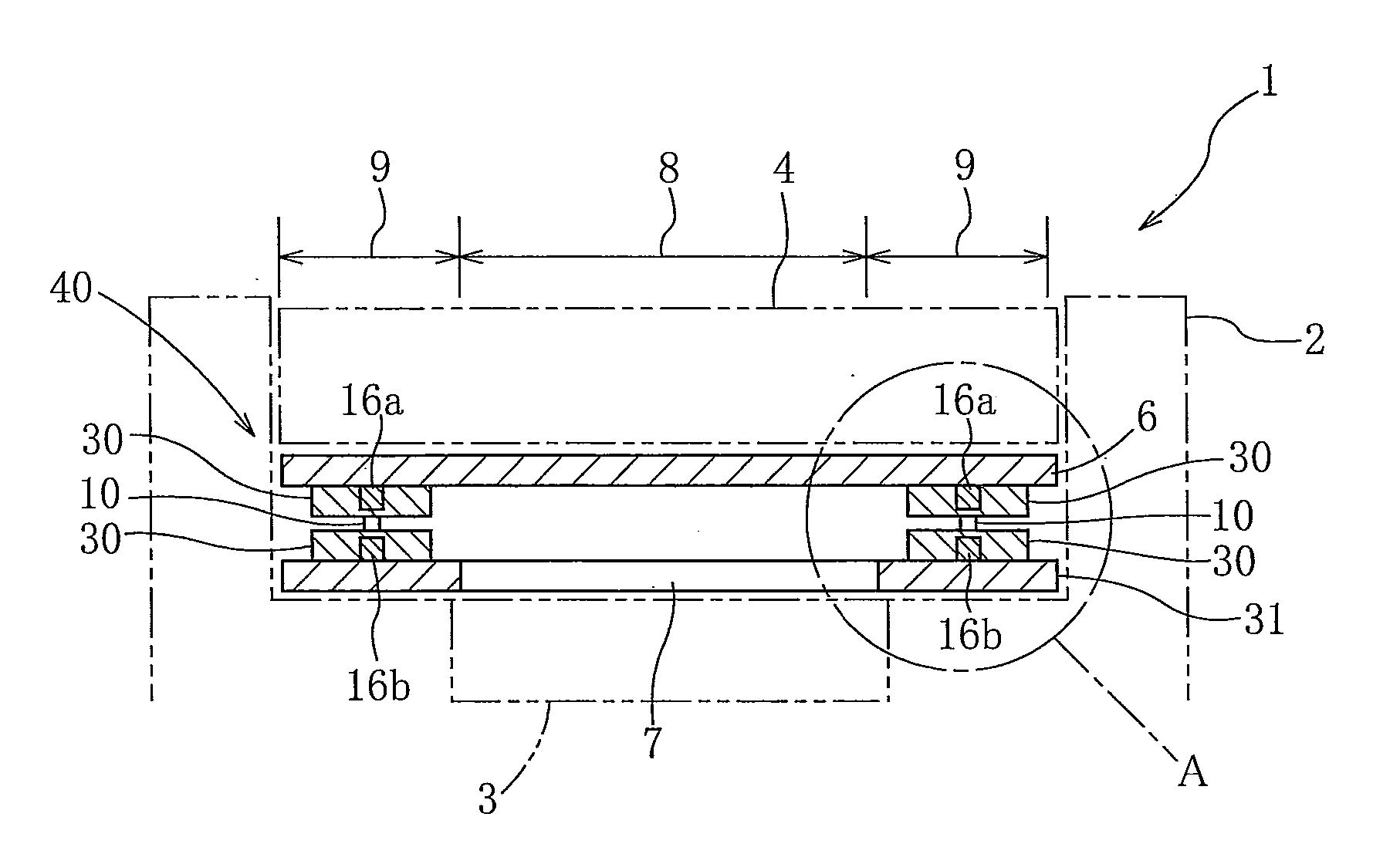

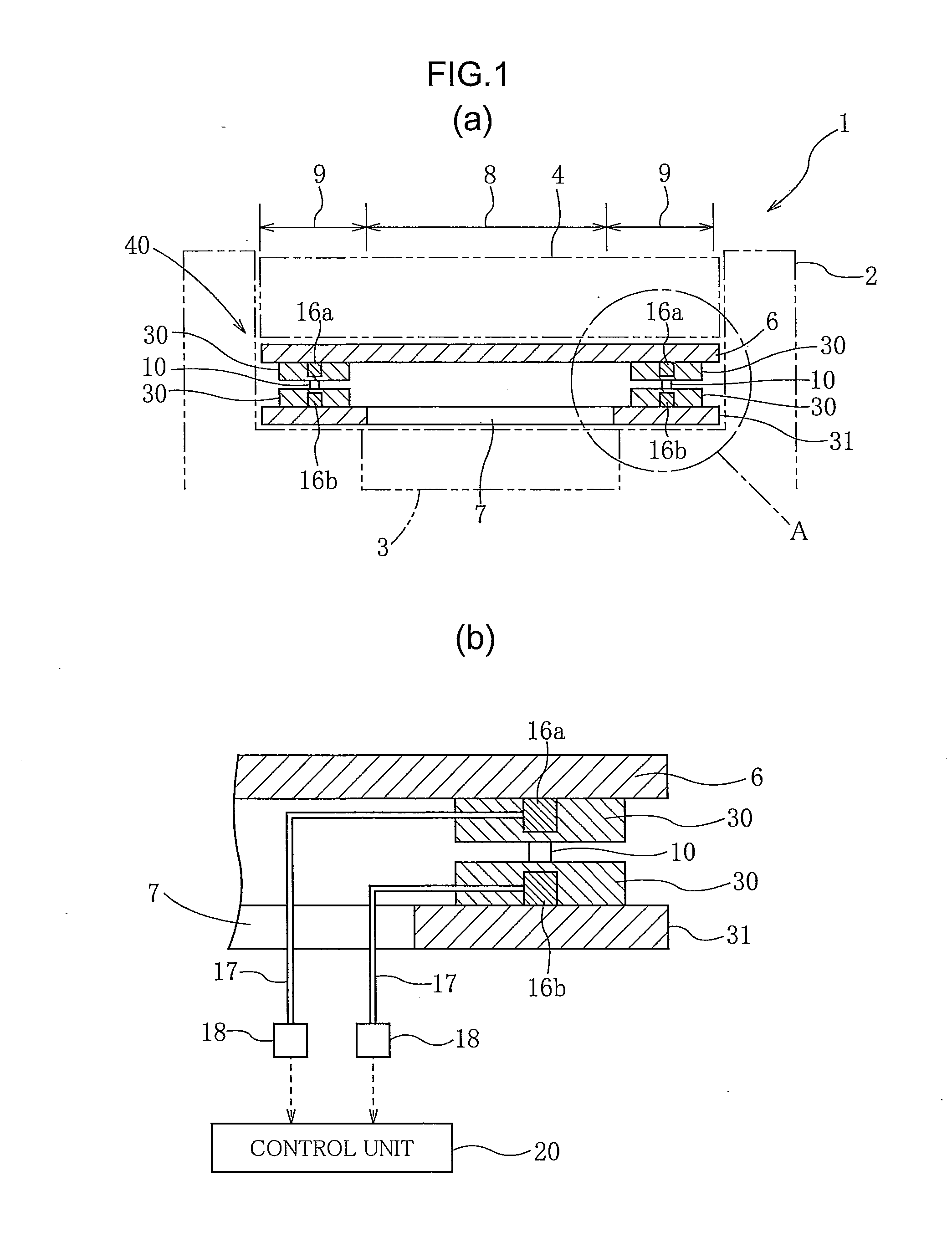

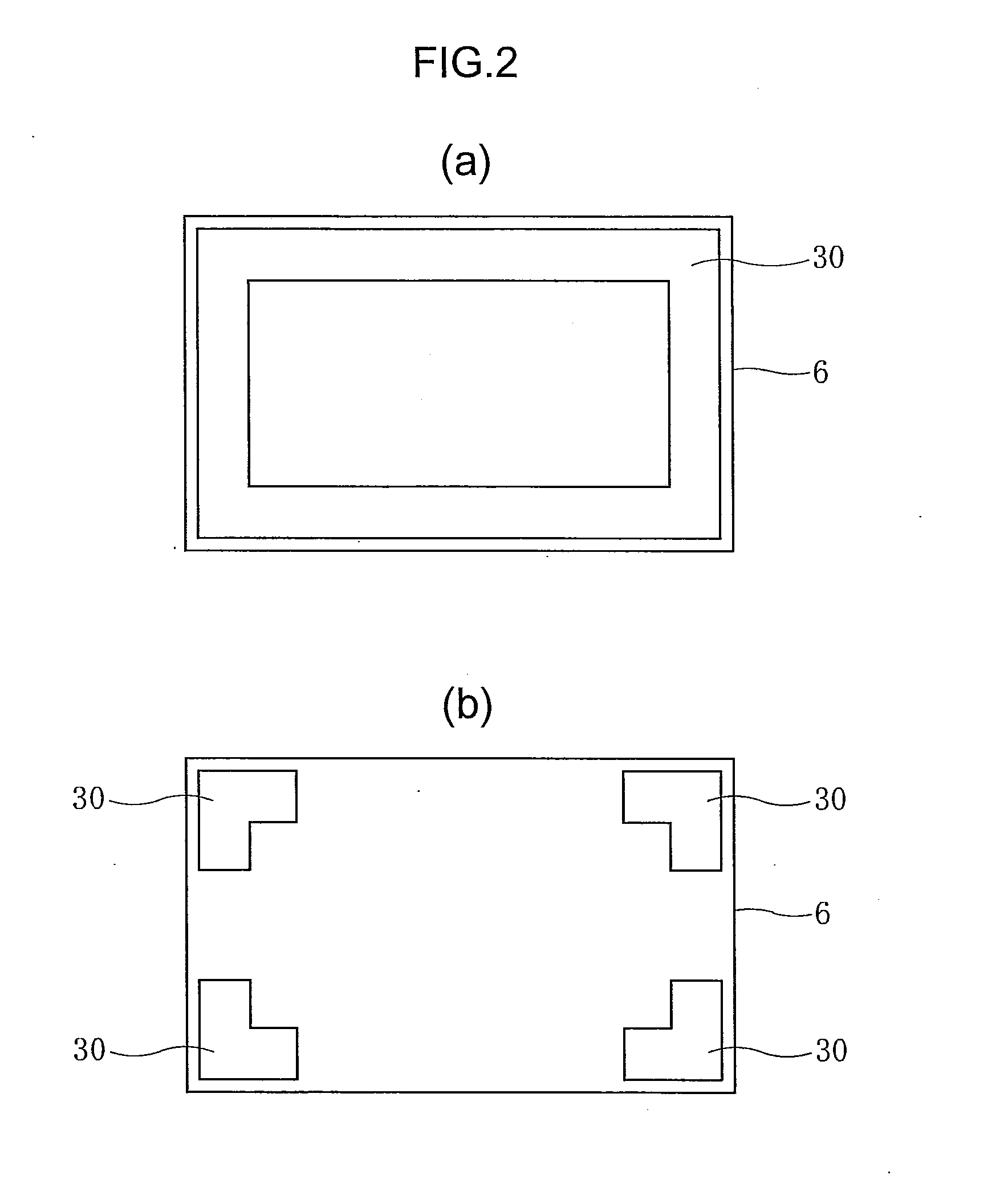

Pressure Sensor

InactiveUS20110198712A1Transmits pressing forceSufficiently elasticForce measurementApparatus for force/torque/work measurementEngineeringPressure sensor

A pressure sensor (40) comprises a pair of electrodes (16a), (16b), a base film (31) on which at least one electrode is disposed, an upper film (6) facing the base film (31), a pressure sensitive ink layer (30) disposed so as to be able to cover the pair of electrodes (16a, 16b) and having electrical characteristics changed by applied pressing force, and a spacer (10) having adhesive properties and interposed between the base film (31) and the upper film (6).

Owner:NISSHA PRINTING COMPANY

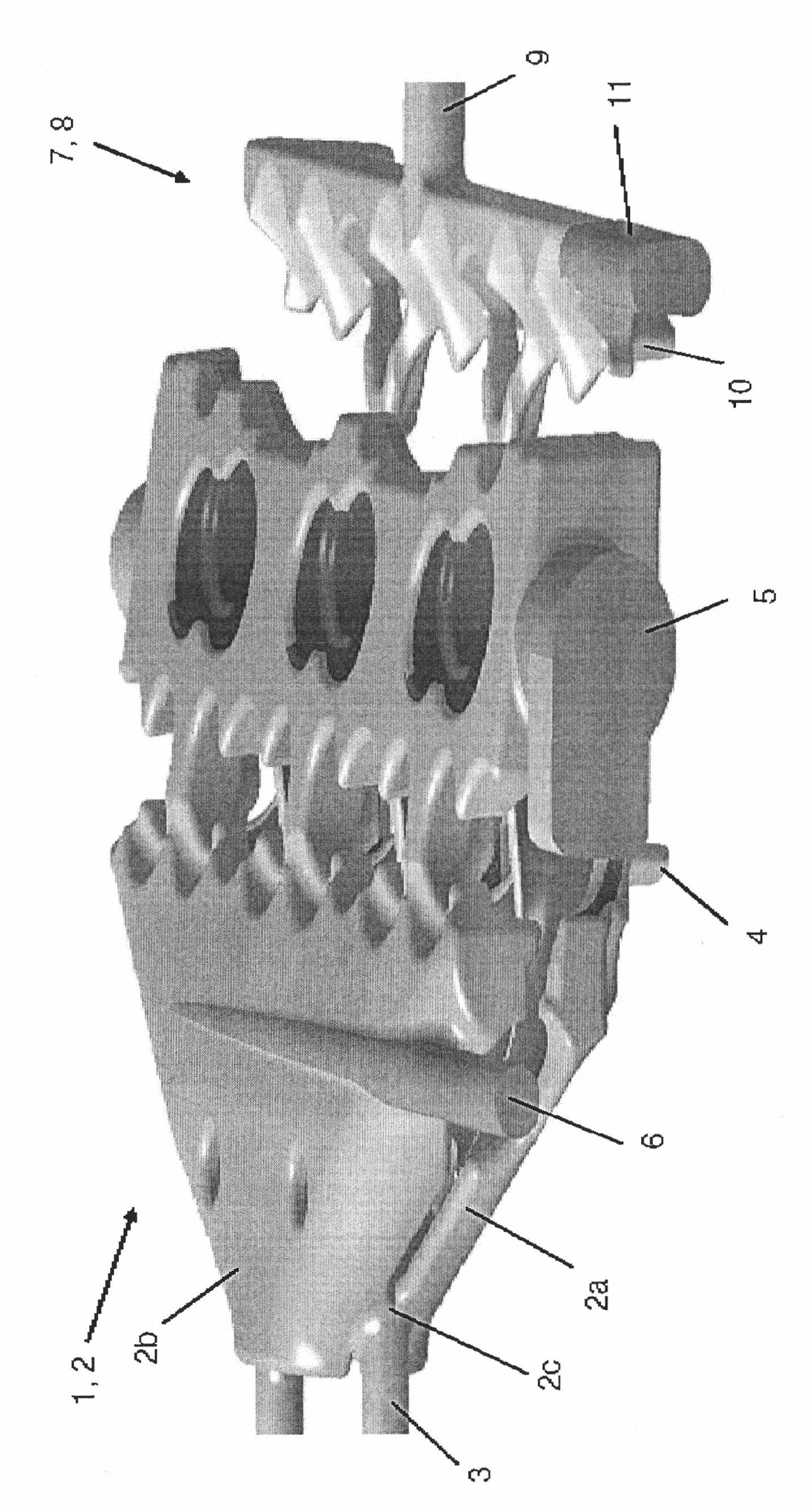

Internal combustion engine with liquid cooling

ActiveCN102235224AHeating fastEliminate consumptionLiquid coolingCoolant flow controlCylinder headExternal combustion engine

The invention relates to an internal combustion engine with at least a cylinder, the engine comprises: at least one cylinder cover, and a liquid cooling structure, the liquid cooling structure is provided with at least two coolant jackets (2, 8) integrated in the cylinder cover, wherein each cylinder is provided with at least one air outlet used for discharging exhaust at an outlet side, and at least an air inlet used for supplying fresh air at the inlet side. The invention aims at providing the internal combustion engine in the above type, and optimization is obtained in two aspects of cooling and wearing. In order to realize the purpose, the internal combustion engine is characterized in that, in the cylinder cover, at least a coolant jacket (2) is disposed at the outlet side and at least a coolant jacket (8) is disposed at the inlet side, wherein at least two coolant jackets (2, 8) are spaced part and belong to different independent coolant circuits.

Owner:FORD GLOBAL TECH LLC

Method for recovering zinc and manganese by waste dry batteries and directly preparing desulfurizer for industry

InactiveCN101532088AThe processing process is simpleReduce pollutionDispersed particle separationProcess efficiency improvementFiltrationManganese

The invention discloses a method for recovering zinc and manganese by waste dry batteries and directly preparing a desulfurizer for industry, which comprises the following steps that: manganese, zinc and iron of crushed waste zinc-manganese dry batteries are dissolved by dilute sulfuric acid, an undissolved substance is removed through the filtration, filtrate is neutralized by a sodium carbonate solution to produce precipitate, the precipitate is dried and then is baked to obtain a mixture of metal oxides, hydroxymethyl cellulose, No.425 cement, and attapulgite are added into the mixture to be mixed evenly, a proper amount of water is added for kneading, the band extrusion is performed on a banded extruder, and the obtained product is dried at a temperature of between 95 and 110 DEG C and is baked at a temperature of 300 DEG C to obtain the desulfurizer for industry. Compared with similar products at home and abroad, the performance index of iron-manganese-zinc series desulfurizers produced by adopting a reclaimed material of waste zinc-manganese batteries has the characteristics of high component content, high breakthrough sulfur capacity, moderate side pressure strength and low abrasion wear, various technical indexes all reach the technical indexes of the similar products at home and abroad, and the main index is better than that of the similar products at home and abroad. The method can meet the need of industrial use, and can be popularized and applied as industrially practical novel purifying agents.

Owner:南京强实精细化工技术有限公司 +1

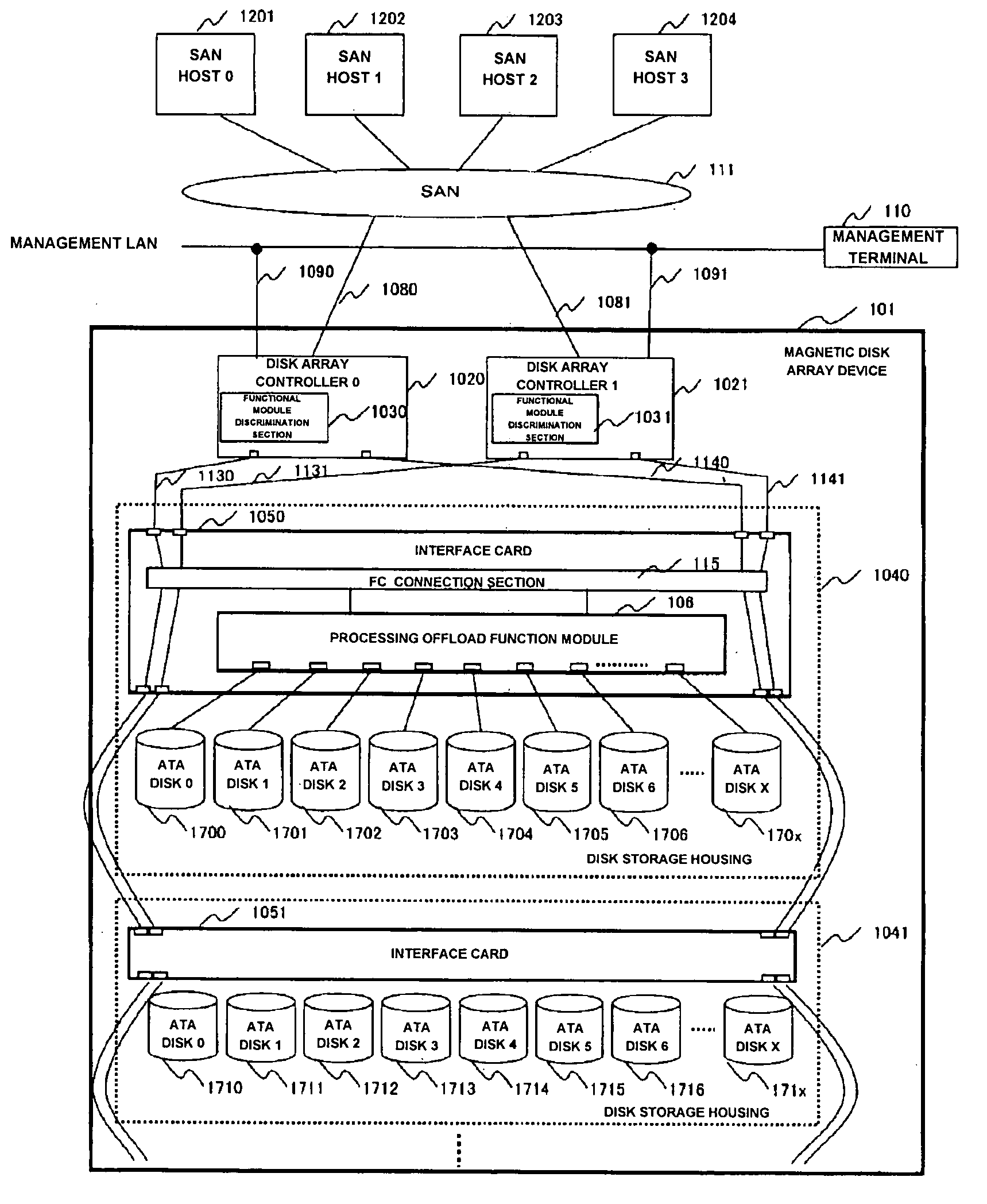

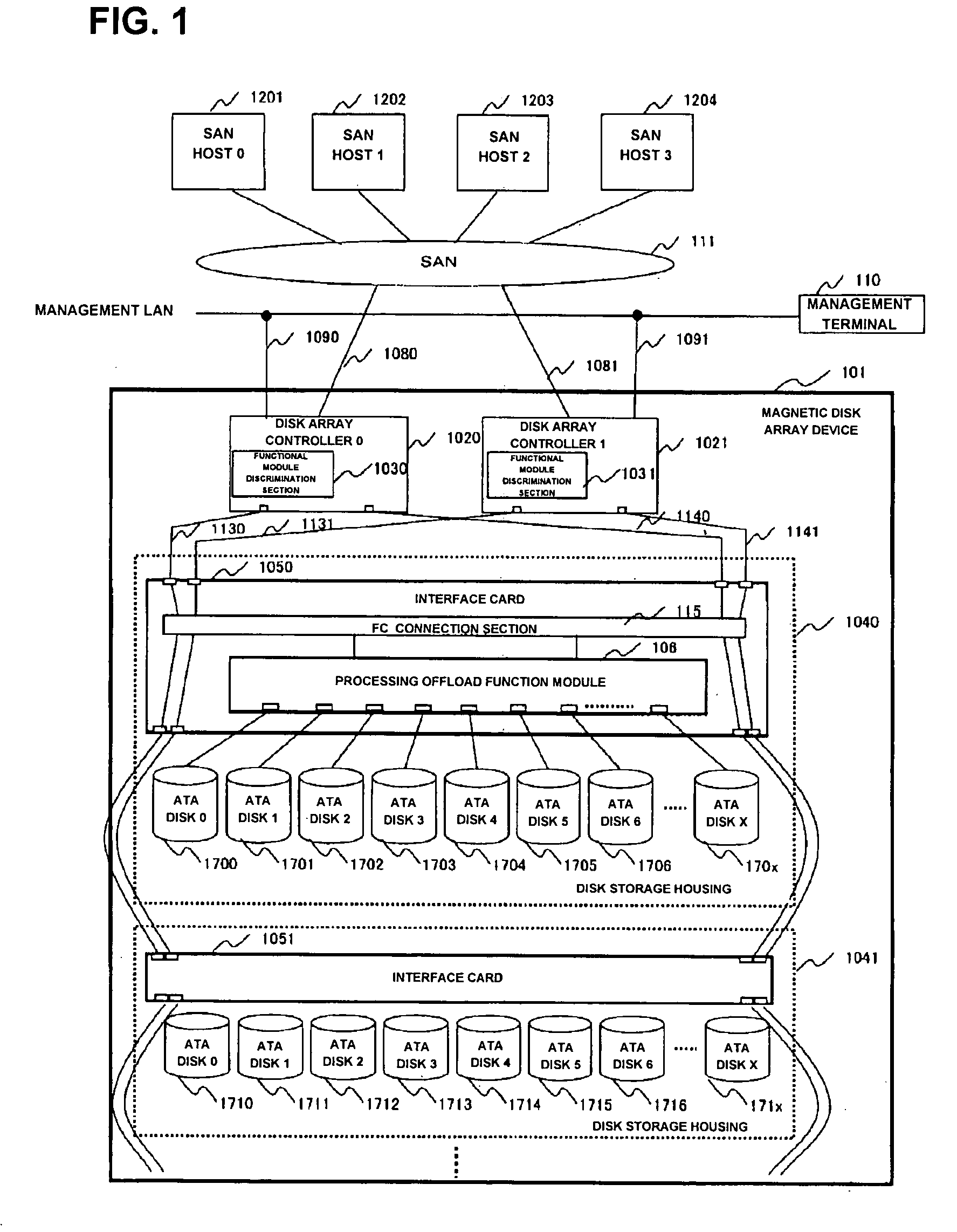

Magnetic disk array device with processing offload function module

InactiveUS7120705B2Reduce manufacturing costReduce in quantityInput/output to record carriersMultiple digital computer combinationsATA protocolDisk controller

A magnetic disk array device is equipped with ATA magnetic disks, at least one disk array controller for controlling the ATA magnetic disks, and at least one processing offload function module provided between the disk array controller and the ATA magnetic disk. The disk array controller outputs one of a standard processing FC command for performing a standard processing such as a read or write processing, and an offload processing FC command for performing a vendor-unique offload processing. The processing offload function module performs a command mapping for the standard processing FC command and issues to the ATA magnetic disk a corresponding ATA command, and prepares a group of ATA commands for the offload processing FC command for optimum processing in an ATA protocol.

Owner:GOOGLE LLC

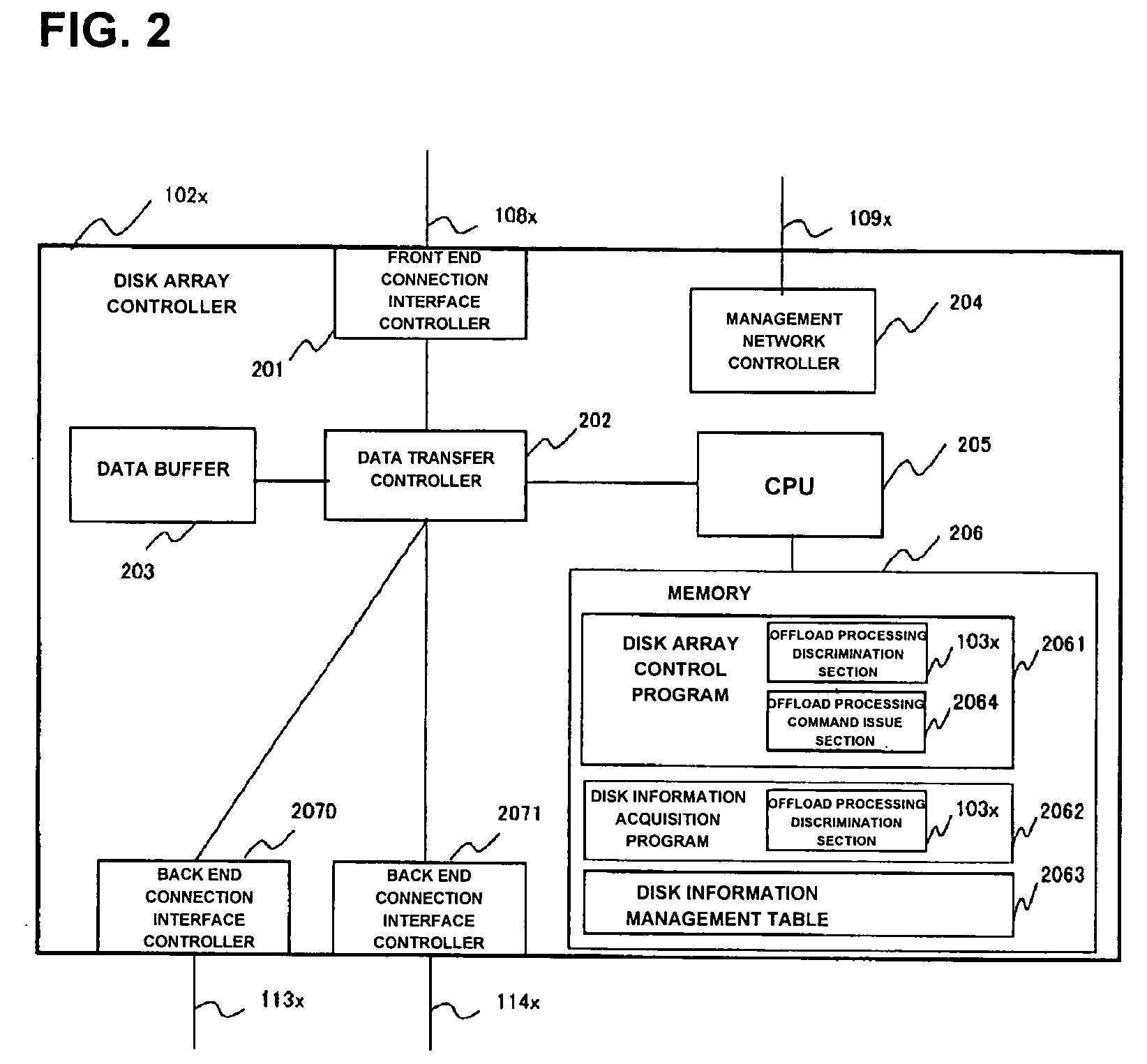

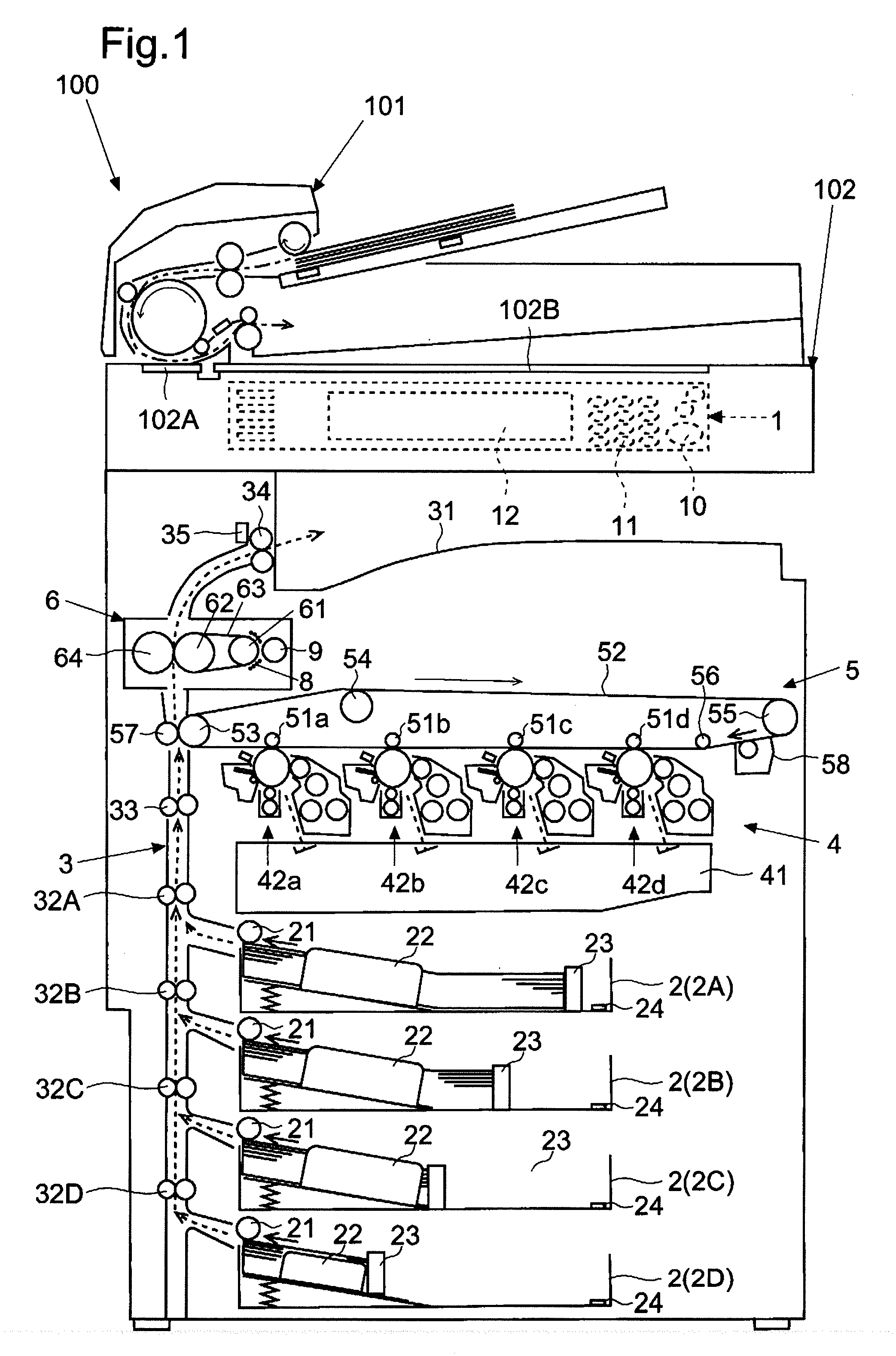

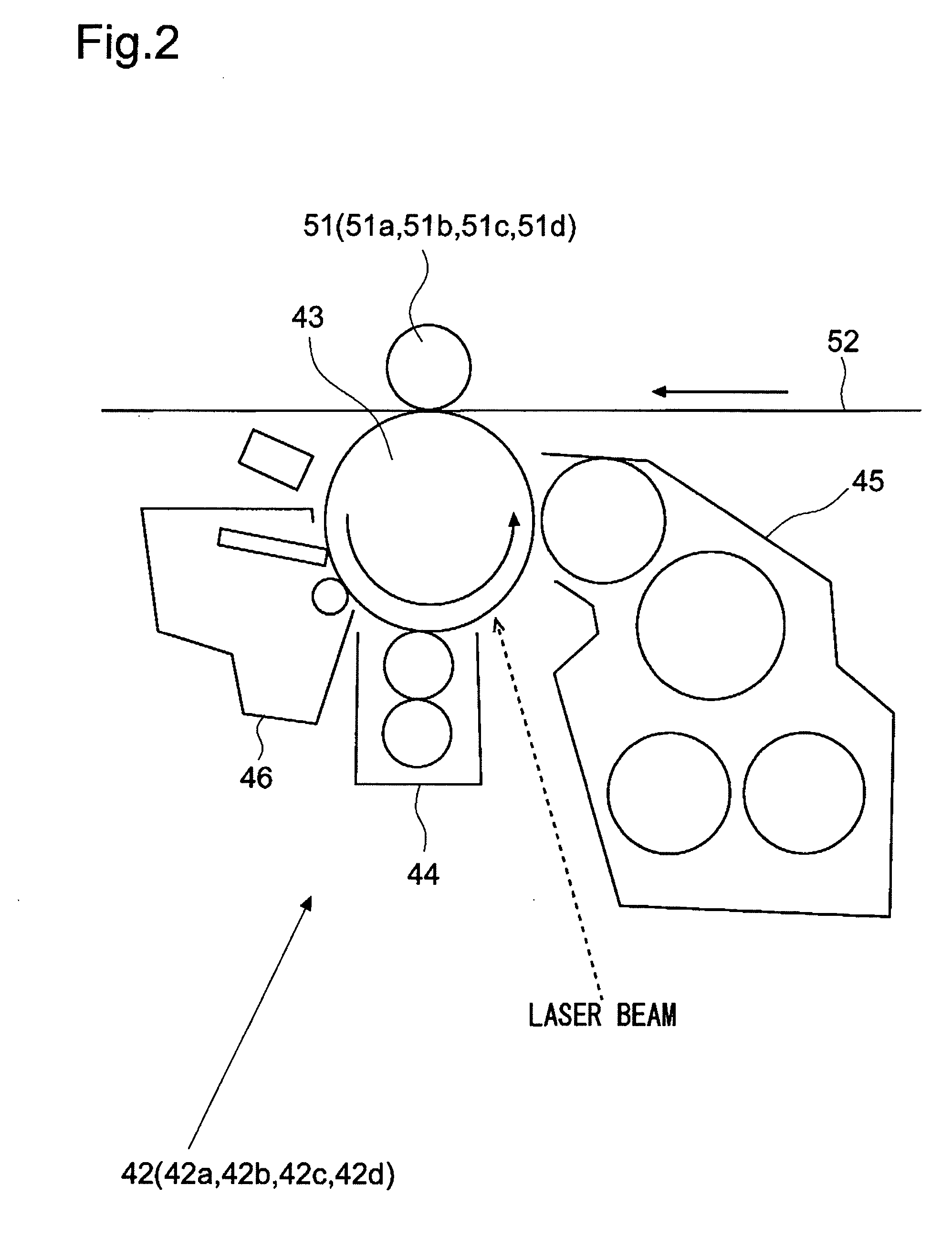

Image forming apparatus

ActiveUS20110123213A1Eliminate wasteful power consumptionEliminate consumptionOhmic-resistance heatingElectrographic process apparatusPaper sheetTemperature sense

Provided is an image forming apparatus, including: a heating section; a coil that is opposed to the heating section, for heating the heating section; a core that has a circumferential surface covered with a magnetic shielding plate having different lengths in an axis direction in a plurality of steps according to a position in a circumferential direction; a rotary section for causing the core to rotate; a plurality of temperature sensing elements for sensing temperatures of the heating section; and a control section for controlling a heating width by controlling the rotary section to control a rotation angle of the core, setting the heating width corresponding to a size of a paper sheet at a start of a print job, and setting the heating width wider than at the start of the print job midway through the print job.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

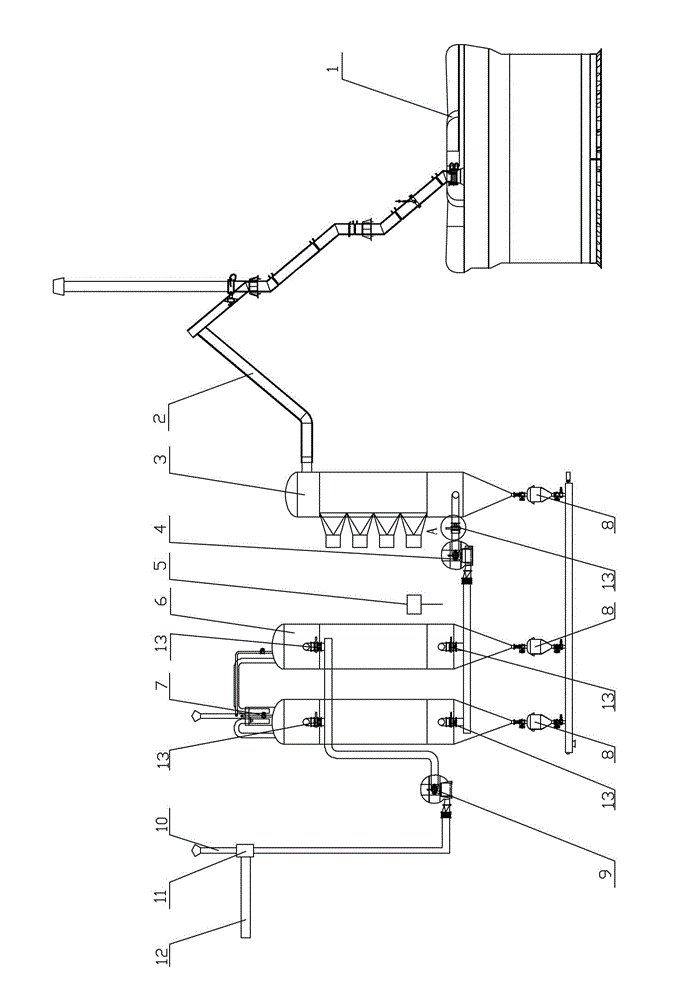

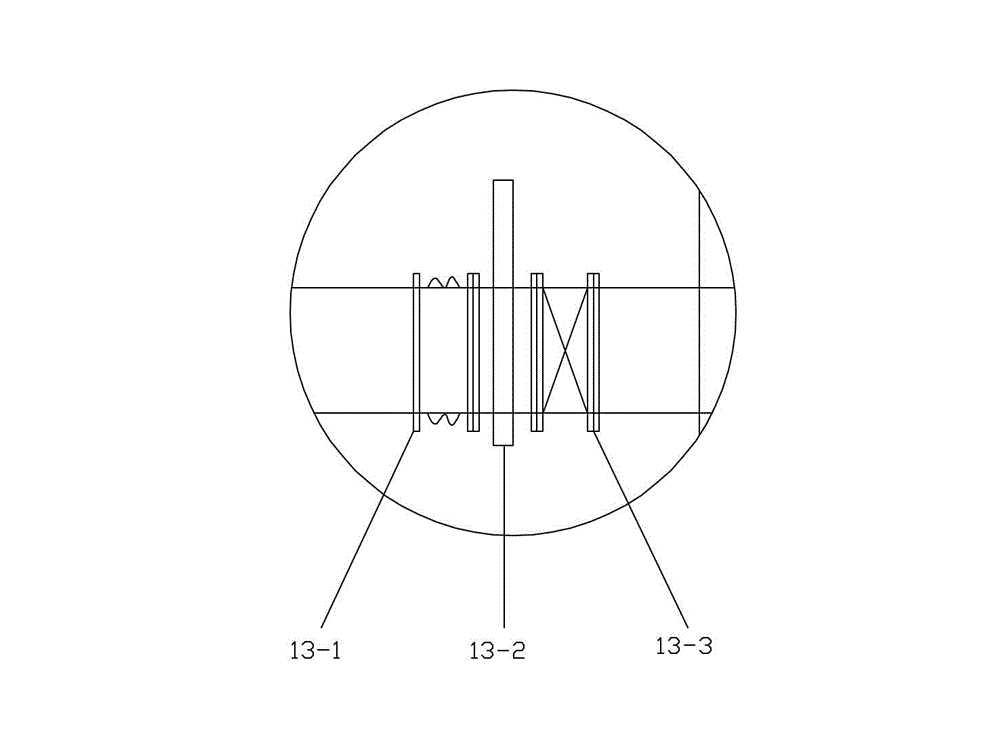

Device and method for purifying and recycling furnace gas of hermetic ore smelting furnace

ActiveCN102878822AEliminate consumptionAvoid secondary pollutionIncreasing energy efficiencyWaste heat treatmentBaghouseProcess engineering

The invention relates to a device and a method for purifying and recycling furnace gas of a hermetic ore smelting furnace. The technical scheme of the device for purifying and recycling furnace gas of the hermetic ore smelting furnace includes that the hermetic ore smelting furnace is connected with a cooler via a water-cooling flue, the cooler is connected with a waste furnace gas draught fan, an online gas detecting analyzer is mounted at an outlet of the waste furnace gas draught fan which is connected with bag-type dedusters via pipes, an explosion venting safety device is arranged on the bag-type dedusters, a gas outlet of the bag-type dedusters is connected with an inlet of a pure furnace gas pressurizing fan, the pure furnace gas pressurizing fan is connected with a three-way changeover valve, the online gas detecting analyzer is interlocked with the three-way changeover valve which is connected with a user pipe and a diffusing tower, and the lower ends of a mechanical air cooler and the pulse bag-type dedusters are respectively connected with dust removing devices. The device for purifying and recycling furnace gas of the hermetic ore smelting furnace is simple in systematic flow path and stable and reliable in running, dust content of furnace gas purified is less than 5mg / m<3>, dust recycled can be reutilized, and secondary pollution to water can be avoided.

Owner:HUANYU PURIFYING ENG EQUIP MFG DASHIQIAO CITY

Synthetic method of carbocisteine

ActiveCN105418471AReduce processEliminate consumptionOrganic compound preparationSulfide preparationCarbocisteinePhysical chemistry

The invention relates to a synthetic method of carbocisteine, wherein a two-pot reaction process in the prior art is changed into a one-pot reaction process, thereby simplifying the process and reducing devices. A low-temperature nitrogen protective process is changed into a normal-temperature nitrogen-free protective process, thereby reducing material and energy consumptions. A two-step crystallization process is changed into a one-step crystallization process, thereby reducing processes and devices and increasing the yield.

Owner:宜昌三峡普诺丁生物制药有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com