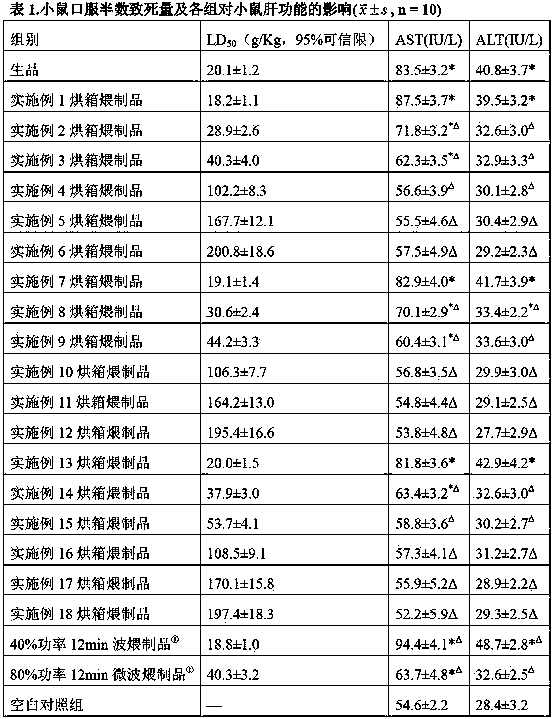

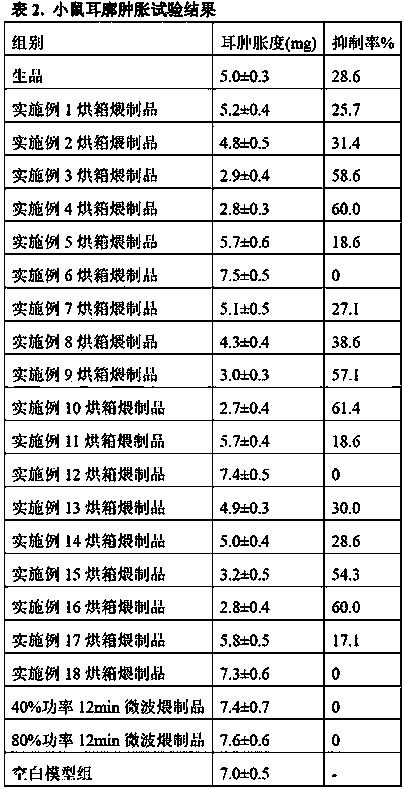

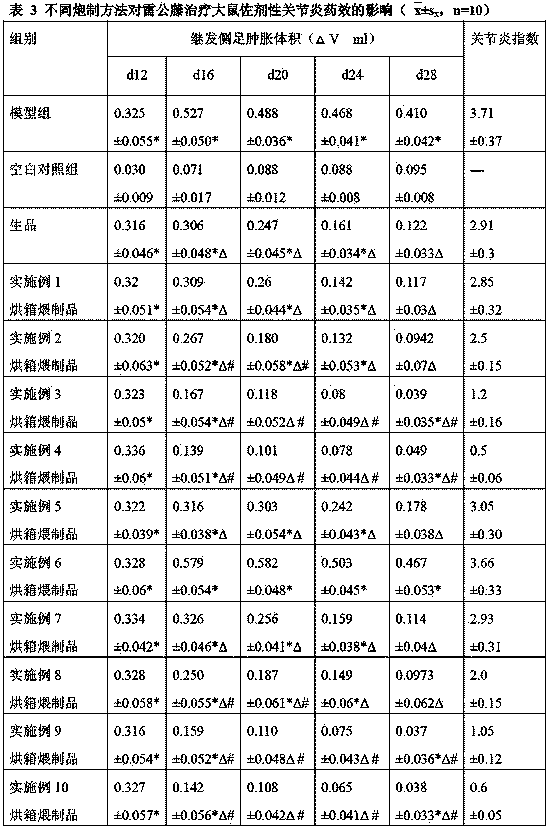

Patents

Literature

50results about How to "The processing process is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

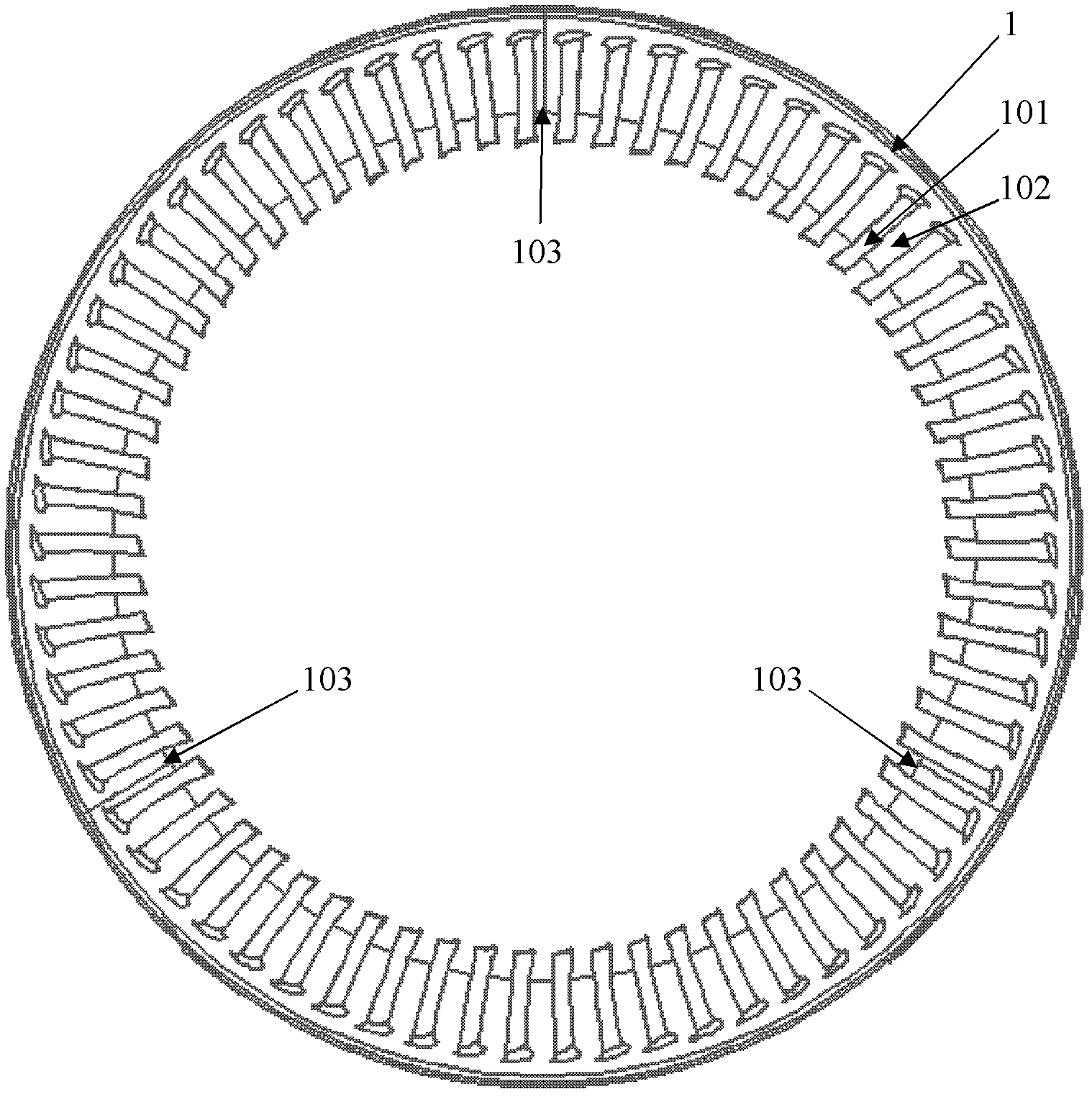

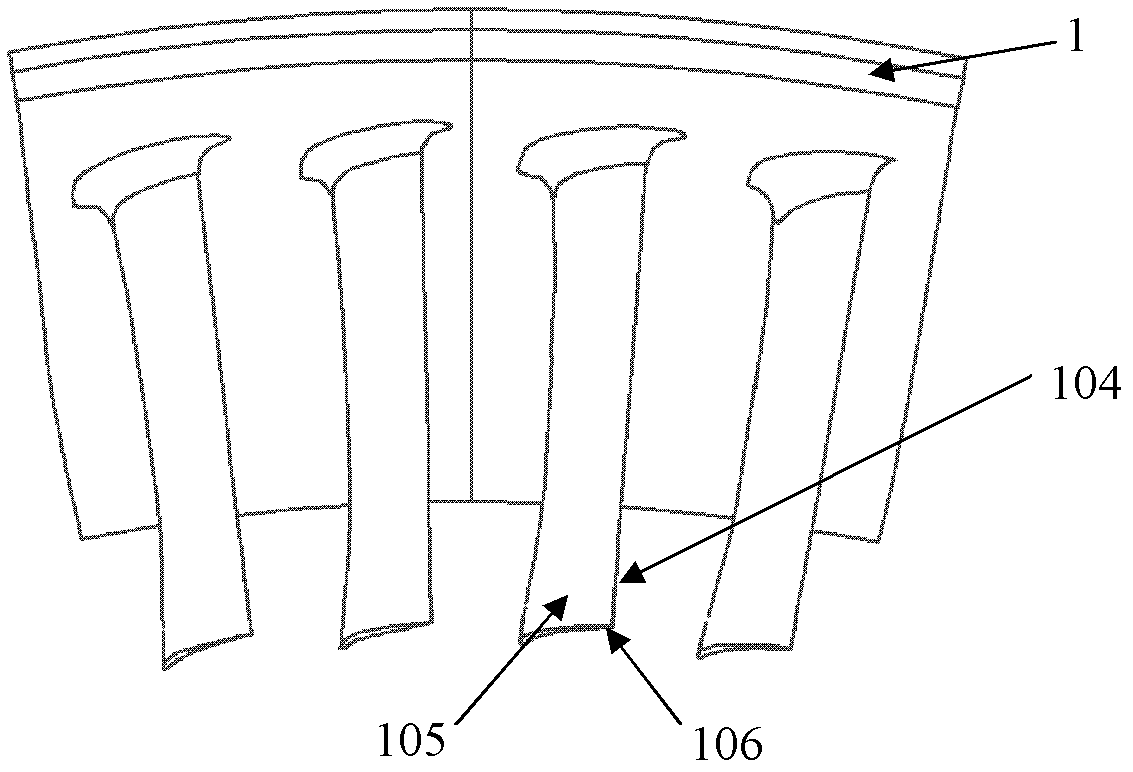

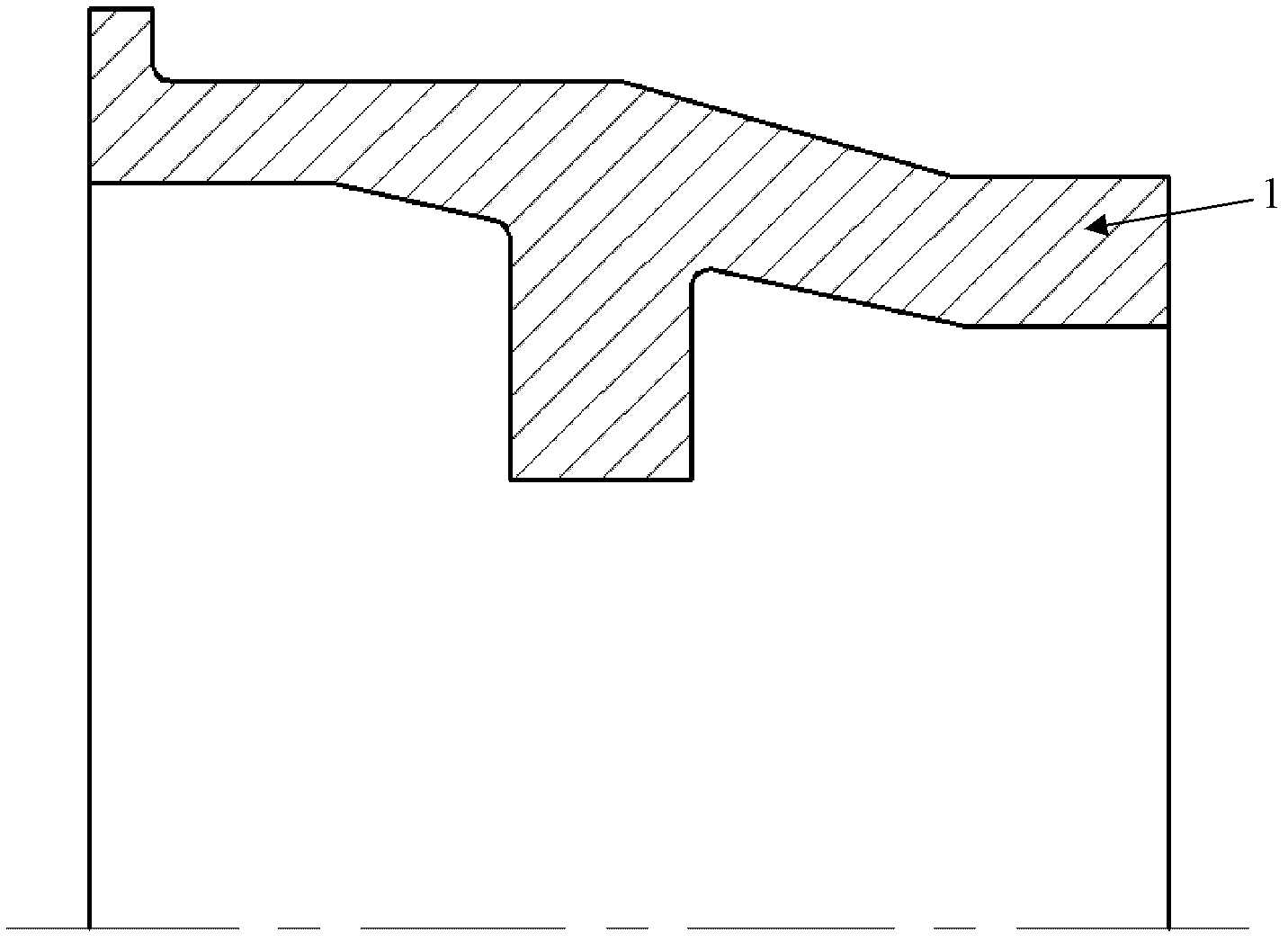

Method for processing integral casing of engine

The invention relates to a method for processing an integral casing of an engine, which is characterized by mainly comprising the steps of: inspecting blanks, carrying out rough turning on inner and outer shapes of the casing, carrying out numerical control milling on the outer shape of the casing and engraving lines for trisection, carrying out wire cutting and trisecting on the casing on the basis of the trisection lines, carrying out aging and stress-relieving treatments, grinding upper and lower end faces and processing two dowel holes in the lower end face, carrying out blade slot treatment and processing a faying surface and a flange hole, carrying out finish milling on the outer shape of the casing, carrying out the aging treatment again, assembling the trisected modules and establishing a benchmark again, carrying out finish turning on the inner surface of the casing, disassembling the modules of the casing, carrying out the finish milling on blades and assembling the modules of the casing, wherein a fillet variable-axis plunge milling method, a blade spacing processing method and a flexible supporting method are adopted in the blade finish milling process. The method provided by the invention has the advantages: the technical process is simple; the produced integral casing has higher precision; the advantages of good consistency, little deformation and high efficiencyare provided in the blade processing; the technical problem that the integral casing is difficult in numerical control is solved by means of the trisection processing method; and the process method can also be used for the development of multilevel integral casings.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Nickel-copper alloy with high strength and high corrosion resistance and manufacturing method thereof

The invention discloses a nickel-copper alloy with high strength and high corrosion resistance and a manufacturing method thereof. The method takes electrolytic copper and electrolytic nickel as major components, a small amount of manganese, iron, silicon, metal magnesium and metal titanium is added, and the impurity accounts for less than or equal to 0.5%. According to the invention, the components are sequentially put into a smelting furnace and subjected to the steps of smelting, stirring and slag extraction, refining, casting formation and the like to obtain a finished product of the nickel-copper alloy. Through the invention, the tensile strength is 670-720Rm / MPa, the elongation is 6-7.5, the strength is improved by 15% over the existing domestic nickel-copper alloy, and the corrosion resistance is improved by about twice. The nickel-copper alloy disclosed by the invention is widely applicable, has long service life and the like, can be used for producing plates, belts, pipes, rods, lines and forgings, and is applied to the industries such as shipbuilding, chemical industry, machinery manufacturing, aerospace, electronics and the like. The manufacturing method disclosed by the invention changes the original vacuum casting process, adopts a semi-continuous smelting method and reduces the production cost.

Owner:沈阳有色金属研究所有限公司

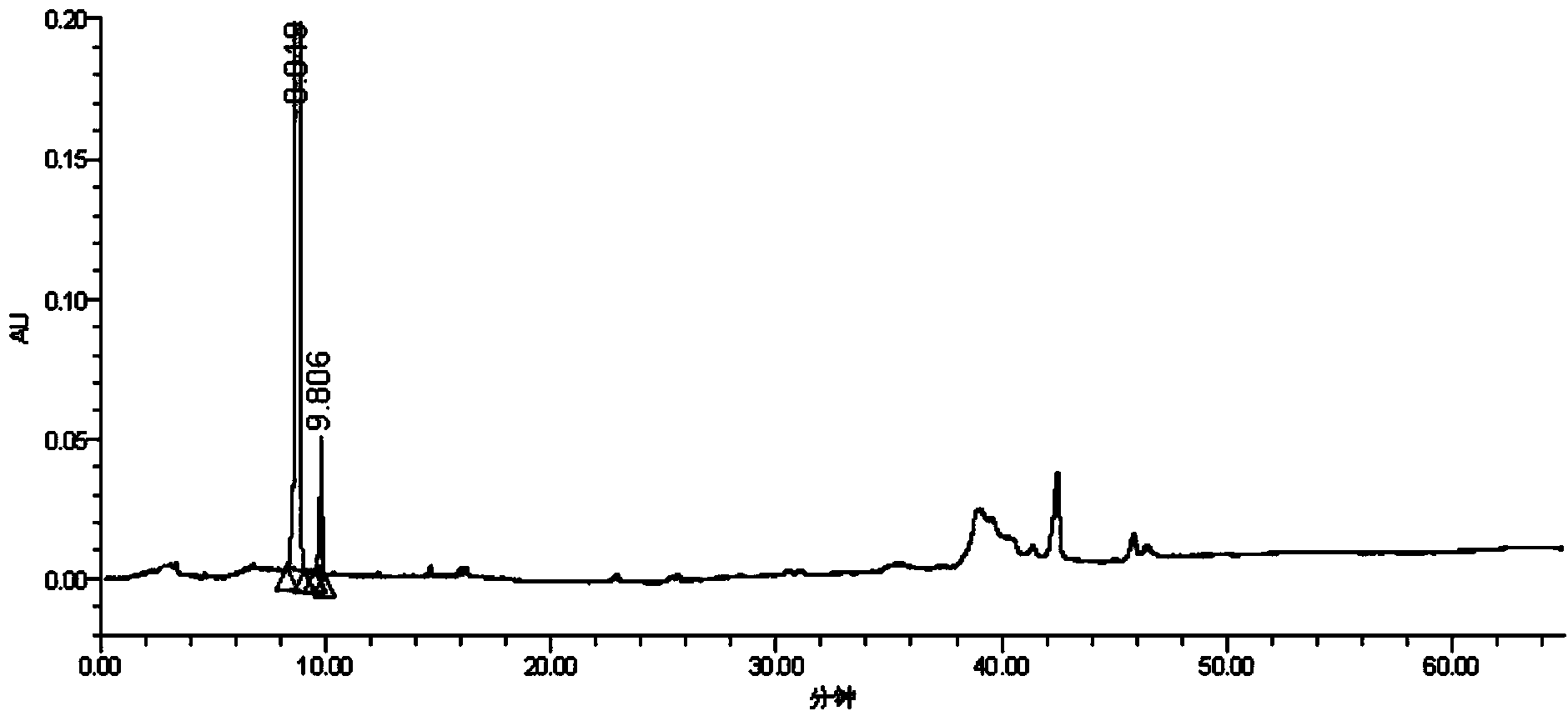

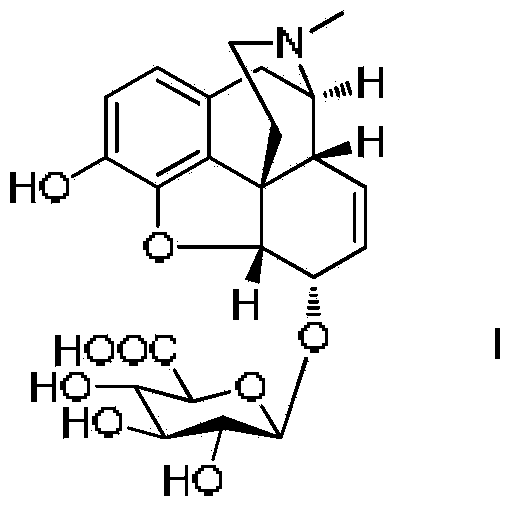

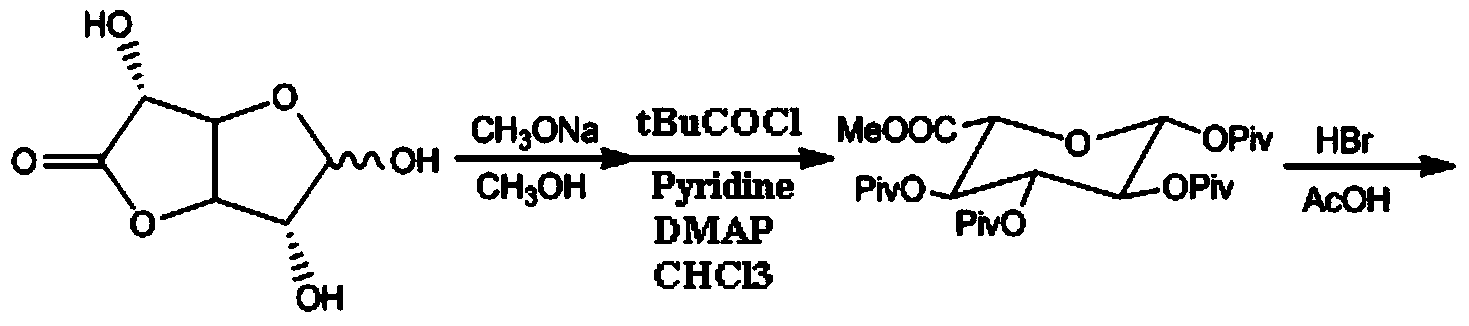

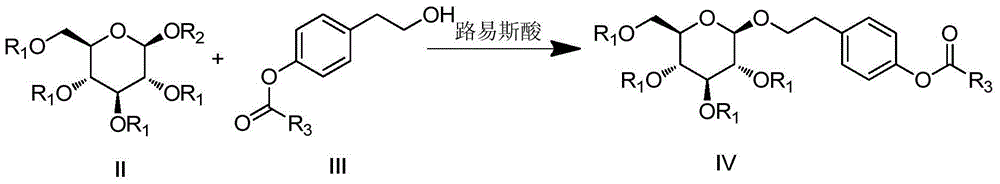

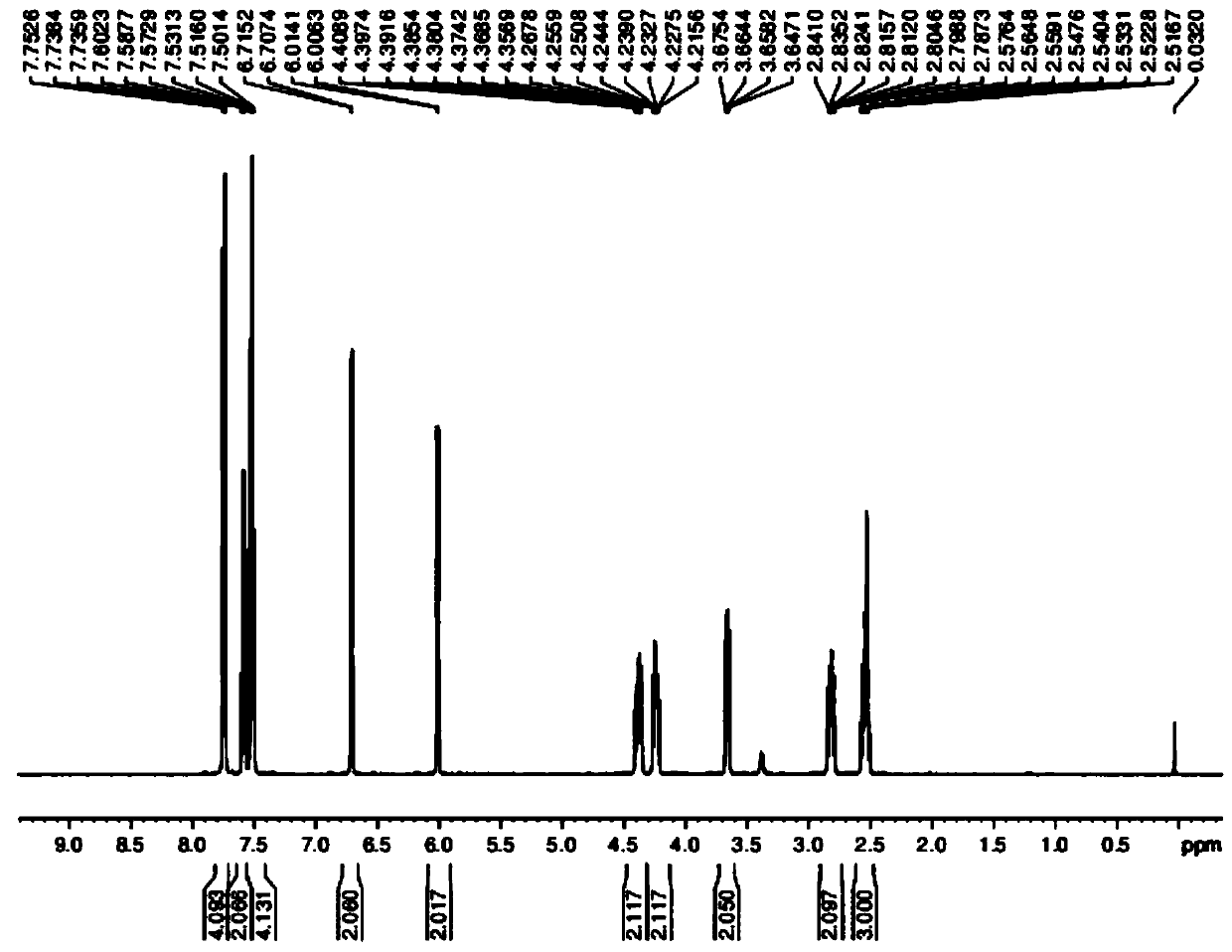

Synthesis method and intermediate compound of morphine-6-Beta-D-glucuronide

ActiveCN103864866AMedication safetyShort reaction pathEsterified saccharide compoundsSugar derivativesOrganic solventLithium hydroxide

The invention discloses a synthesis method and an intermediate compound of morphine-6-Beta-D-glucuronide. The synthesis method comprises the following steps: (1) carrying out a reaction on 3-acetyl morphine and acyl-protected glucuronate in an organic solvent 1 under the catalysis of lewis acid so as to obtain an intermediate shown as a formula (IV); (2) hydrolyzing the intermediate shown as the formula (IV) with lithium hydroxide and neutralizing the intermediate shown as the formula (IV) with hydrobromic acid in a mixture solvent of C1-C4 alkanol and water; and washing the intermediate with the C1-C4 alkanol and drying, thereby obtaining the intermediate compound of the morphine-6-Beta-D-glucuronide, wherein the definitions of substituent groups in the formula (III) and the formula (IV) are shown in the specification. The synthesis method has the advantages of moderate condition and high yield, and is simple to operate and easy to industrialize.

Owner:YICHANG HUMANWELL PHARMA

Method for recovering zinc and manganese by waste dry batteries and directly preparing desulfurizer for industry

InactiveCN101532088AThe processing process is simpleReduce pollutionDispersed particle separationProcess efficiency improvementFiltrationManganese

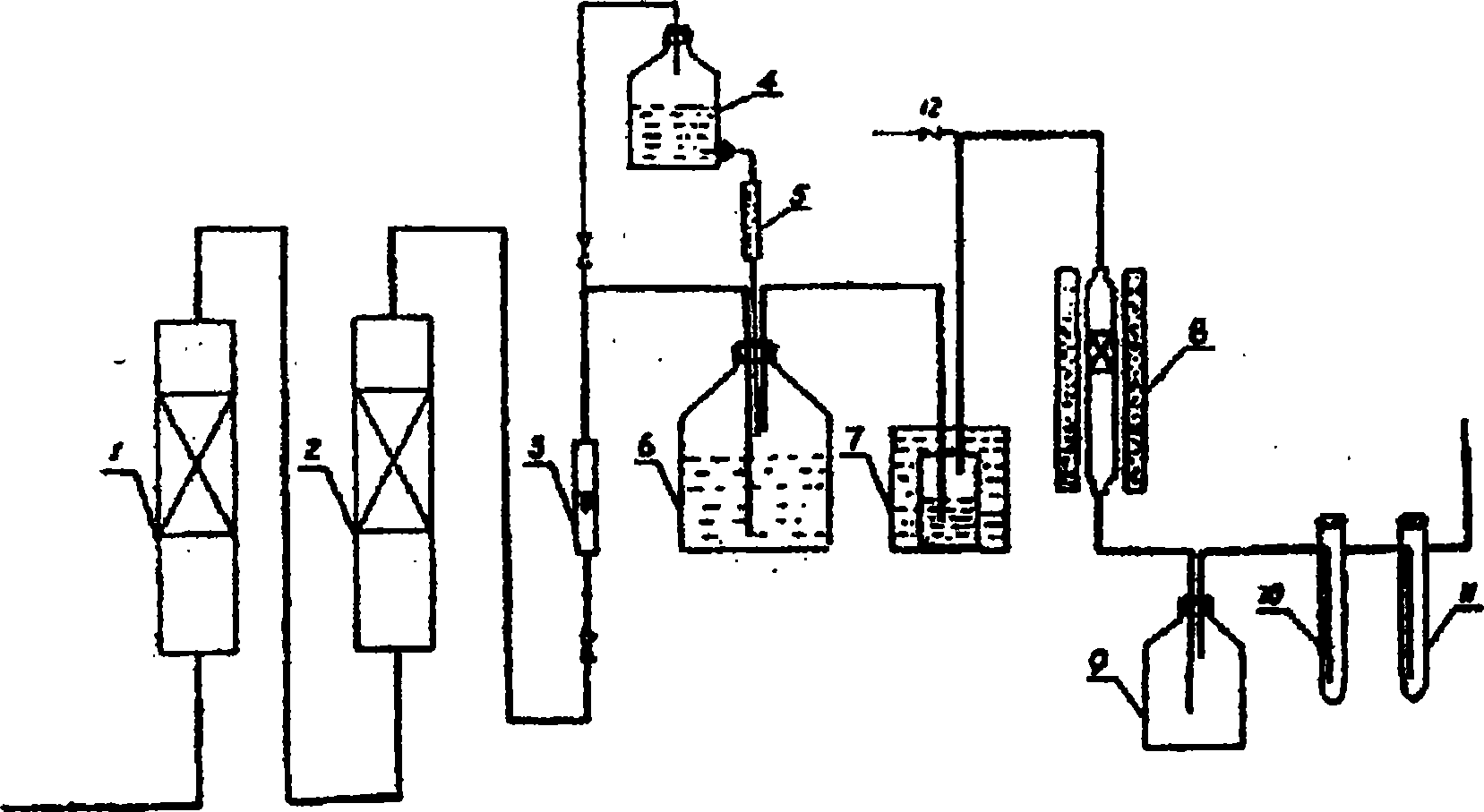

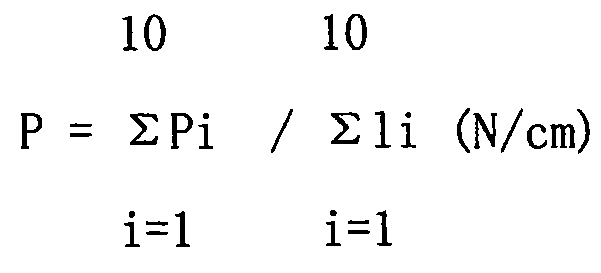

The invention discloses a method for recovering zinc and manganese by waste dry batteries and directly preparing a desulfurizer for industry, which comprises the following steps that: manganese, zinc and iron of crushed waste zinc-manganese dry batteries are dissolved by dilute sulfuric acid, an undissolved substance is removed through the filtration, filtrate is neutralized by a sodium carbonate solution to produce precipitate, the precipitate is dried and then is baked to obtain a mixture of metal oxides, hydroxymethyl cellulose, No.425 cement, and attapulgite are added into the mixture to be mixed evenly, a proper amount of water is added for kneading, the band extrusion is performed on a banded extruder, and the obtained product is dried at a temperature of between 95 and 110 DEG C and is baked at a temperature of 300 DEG C to obtain the desulfurizer for industry. Compared with similar products at home and abroad, the performance index of iron-manganese-zinc series desulfurizers produced by adopting a reclaimed material of waste zinc-manganese batteries has the characteristics of high component content, high breakthrough sulfur capacity, moderate side pressure strength and low abrasion wear, various technical indexes all reach the technical indexes of the similar products at home and abroad, and the main index is better than that of the similar products at home and abroad. The method can meet the need of industrial use, and can be popularized and applied as industrially practical novel purifying agents.

Owner:南京强实精细化工技术有限公司 +1

Preparation method of nutritional rhizoma dioscoreae soybean milk powder granules

InactiveCN103518853AThe processing process is simpleSimple processing technologyMilk substitutesFood scienceNutrientNutrition

The invention relates to a preparation method of nutritional rhizoma dioscoreae soybean milk powder granules, which comprises the following steps: selecting the soybeans with uniform and neat particles, cleaning and soaking in warm water, cooking and drying; removing the soybean peels; when the two leaves of the soybean are separated and slightly broken, heating the soybeans in warm water; grinding, filtering and emulsifying into a thick liquid; performing spray drying to obtain dried soybean milk powder; removing the odor of the soybean milk powder; selecting the in-season fresh rhizoma dioscoreae; cleaning to remove dust, peeling and slicing; baking in an oven; pulverizing the baked rhizoma dioscoreae slices in a pulverizing mill into powder; proportionally mixing the soybean powder, the rhizoma dioscoreae powder and soft sugar; and packaging in small bags for sale. The nutritional rhizoma dioscoreae soybean milk powder granules prepared by the method not only maintain the nutrient substances of the rhizoma dioscoreae and soybeans, but also can supplement multiple vitamins and proteins for the people eating the granules while realizing a function of reducing blood pressure and blood fat; and moreover, the processing process of the granules is simple, and the granules are suitable for large-scale production and sale.

Owner:刘烨

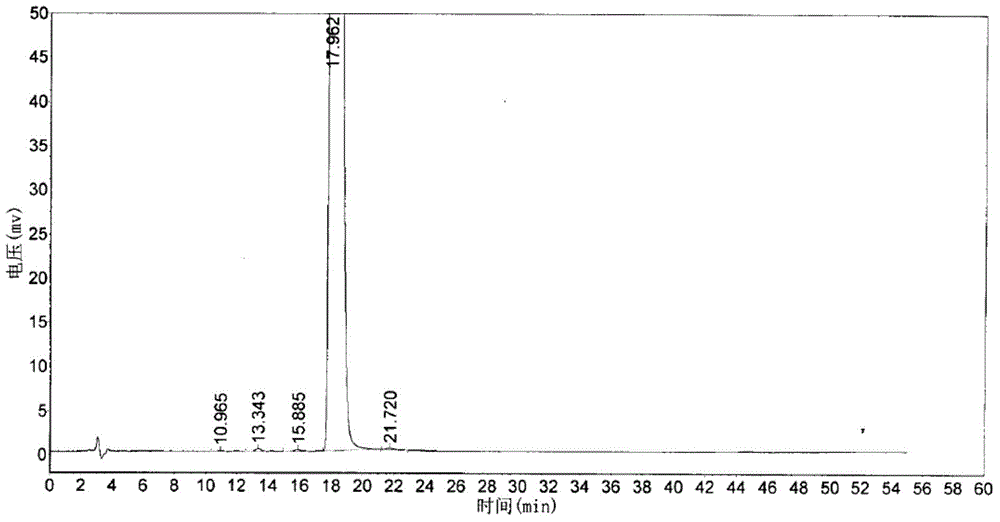

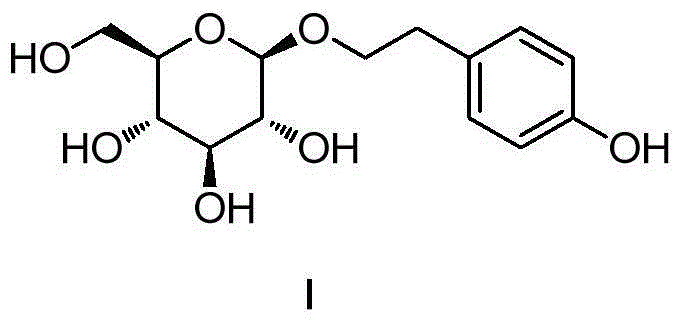

Synthesis method for salidroside and intermediate compound obtained in synthesis method

ActiveCN105294787AFast responseReduced transfer of acyl groupsEsterified saccharide compoundsSugar derivativesPhenethyl alcoholD-Glucose

The invention discloses a synthesis method for salidroside and an intermediate compound obtained in the synthesis method. The synthesis method comprises the following steps: (1) under the catalytic action of Lewis acid, carrying out a reaction between hydroxyl-protected benzyl carbinol and acyl-protected glucose ester to obtain the intermediate compound shown in formula (IV); (2) putting the intermediate compound shown in formula (IV) in C1-C4 alkanol, removing acyl protecting groups in the presence of alkali, and carrying out drying to obtain salidroside shown in the formula (I). The detailed definitions of substituent groups in formula (III) and formula (IV) are shown in the description. The synthesis method has the advantages of being simple to operate, mild in condition, high in yield and easy for industrialization.

Owner:YICHANG HUMANWELL PHARMA

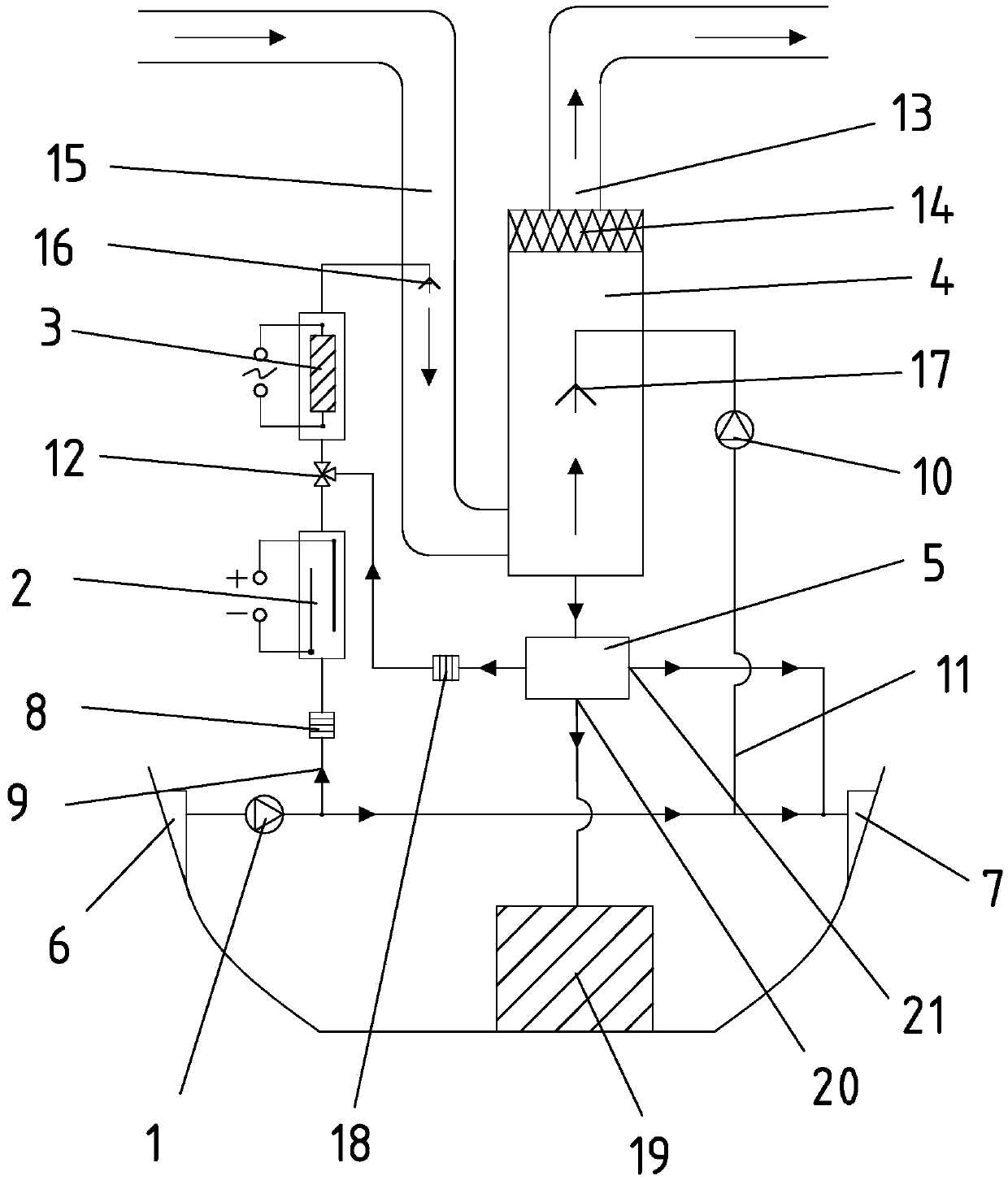

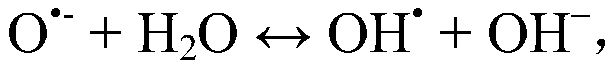

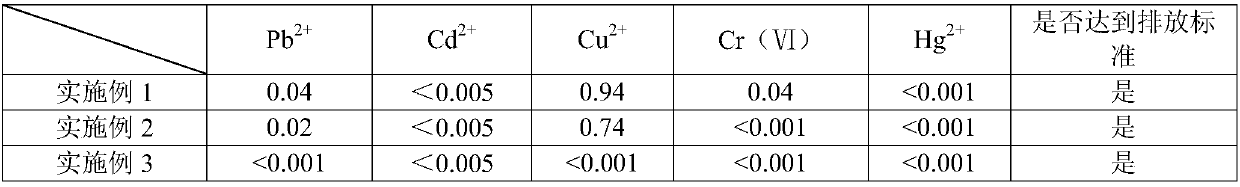

Seawater electrolysis and ultraviolet radiation integrated marine exhaust multi-pollutants comprehensive treatment method and device thereof

InactiveCN105498490AAvoid safety hazardsRapid and efficient liquid phase oxidation absorptionCombination devicesGas treatmentLiquid wasteElectrolysis

The invention discloses a seawater electrolysis and ultraviolet radiation integrated marine exhaust multi-pollutants comprehensive treatment method, which comprises the following steps: preparing a sodium hypochlorite solution by a diaphragm-free seawater electrolysis method, adjusting pH value of the sodium hypochlorite solution, carrying out ultraviolet radiation treatment to obtain a sodium hypochlorite solution containing strong oxidizing ROS, mixing the sodium hypochlorite solution containing strong oxidizing ROS and flue gas to be treated so as to obtain flue gas containing water-soluble high-valence acidic harmful pollutants and acid waste liquid, treating by a seawater wet processing, purifying the flue gas and directly discharging the purified flue gas into the atmosphere, and separating and purifying the waste liquid. The invention also discloses a seawater electrolysis and ultraviolet radiation integrated marine exhaust multi-pollutants comprehensive treatment device. By using seawater as a raw material, the strong oxidizing absorbent is prepared on line. Gas-liquid reaction and absorption effects are enhanced, power consumption of electrolysis is reduced, system economy is raised, and potential safety hazard of shipping business that is brought by transport and storage of chemicals is effectively avoided.

Owner:DALIAN MARITIME UNIVERSITY

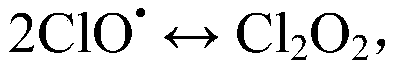

Spheroidal composite adsorbent for sewage treatment

ActiveCN109621921AHigh densityHigh mechanical strengthOther chemical processesWater contaminantsSorbentPolyacrylamide

The invention relates to the field of sewage treatment and aims to provide a spheroidal composite adsorbent for sewage treatment. The spheroidal composite adsorbent is prepared from 8-10 parts of lignin, 6-9 parts of sulfydryl modified polyacrylamide, 2-3 parts of sodium alginate, 30-40 parts of sulfydryl modified quartz sand and 20-30 parts of sepiolite. The spheroidal composite adsorbent has thefunctions of adsorbing and removing organic matter, suspended matter and heavy metals in sewage, and has the good removal effect on the heavy metals in the acidic sewage and has the integrated effectof adsorption, flocculation and sedimentation, the contents of COD, SS, lead, cadmium, copper and mercury in treated river channel sewage all reach the stipulations of national standard surface waterenvironmental quality standard GB3838-2002 of the People's Republic of China, and the removal rate of heavy metals in acid heavy-metal heavily polluted wastewater reaches 99% or above.

Owner:浙江省环境科技有限公司

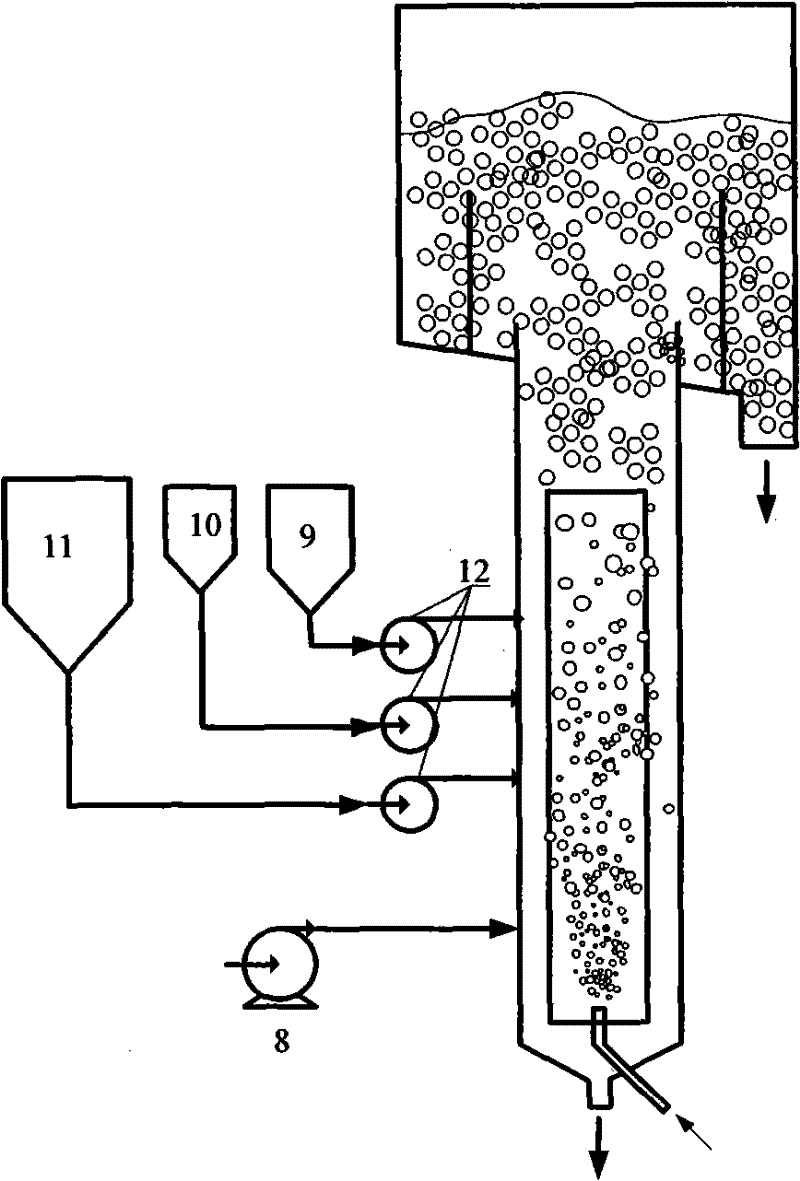

Degreasing method of super heavy oil wastewater

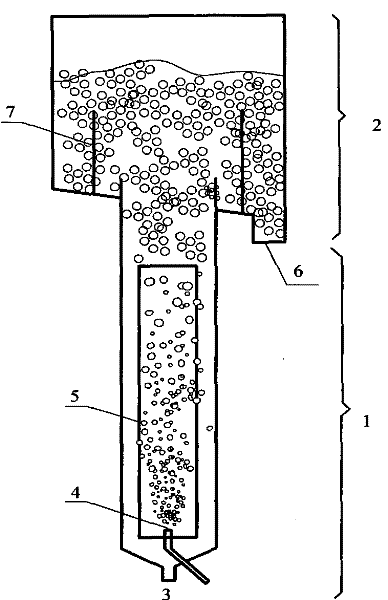

ActiveCN103043746AImprove separation efficiencyThe processing process is simpleFatty/oily/floating substances removal devicesLiquid separationContinuous operationFoam fractionation

The invention relates to a degreasing method of super heavy oil wastewater. A circulation bubble separation tower composed of a bubbling section and a foam section is adopted in degreasing of the super heavy oil wastewater; and batch type operation or continuous operation is adopted in the degreasing method. The degreasing method comprises the steps of: pumping wastewater into the bubbling section of the circulation bubble separation tower; feeding sodium hydroxide with a mass concentration of 20 percent or 0.1M hydrochloric acid to regulating pH to 8-9, introducing air from an air distributor, wherein throughput superficial vapor velocity is 0.5-1.5cm / s; feeding a demulsifier water solution, wherein the preparation volume concentration of the demulsifier water solution is the saturation concentration being 5-15 percent, and the feeding quantity is 0.1-0.5 percent of the volume of the bubbling section per hour; starting an oil scraper, collecting floating oil from an oil residue discharging hole at the bottom of the foam section, discharging wastewater without emulsified oil from a discharging hole at the bottom of the bubbling section, and when the removal rate of the emulsified oil is more than 90 percent, ending the operation of one batch. According to the degreasing method, once separation rate of the heavy emulsified oil is more than 90 percent.

Owner:PETROCHINA CO LTD

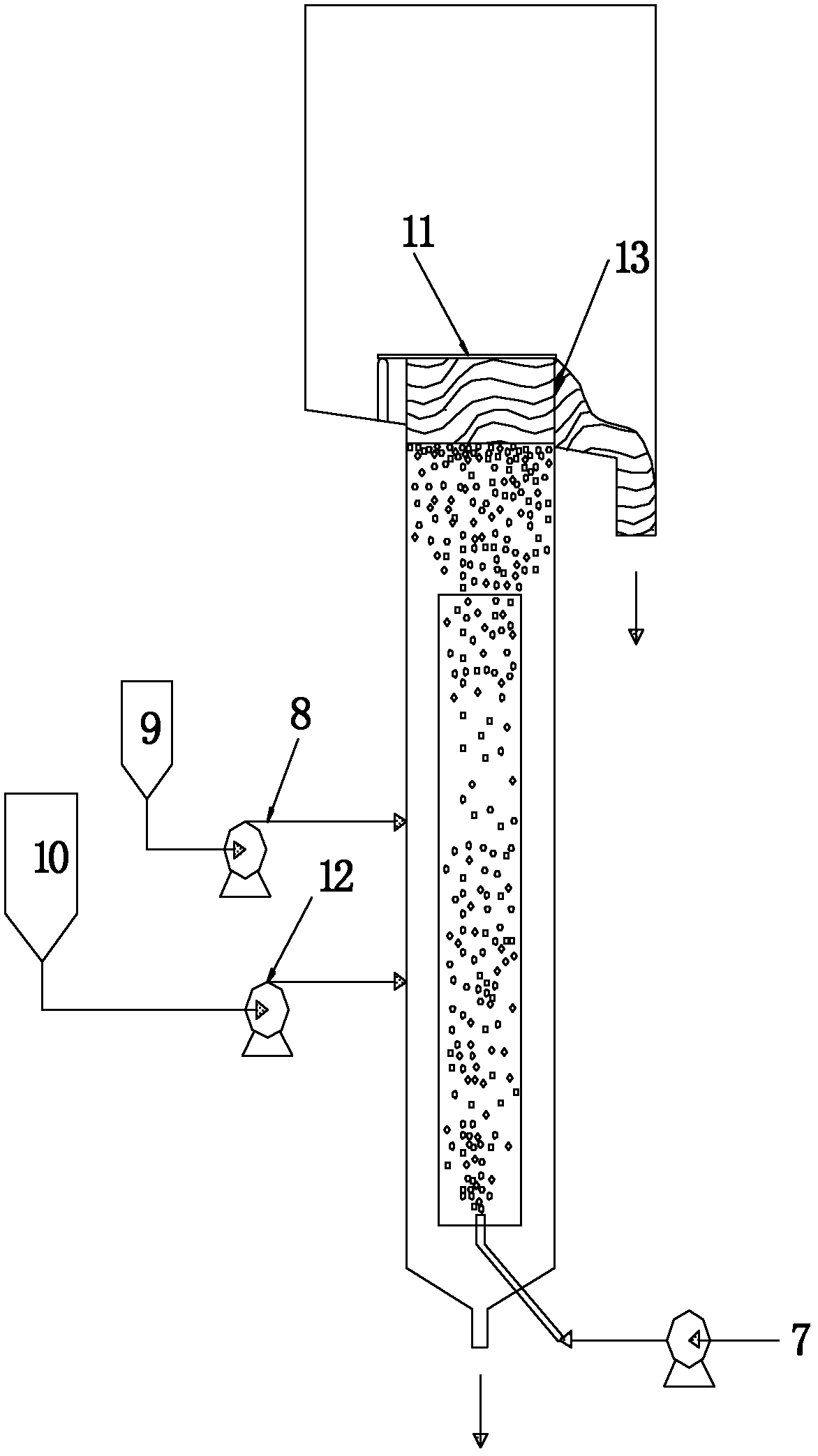

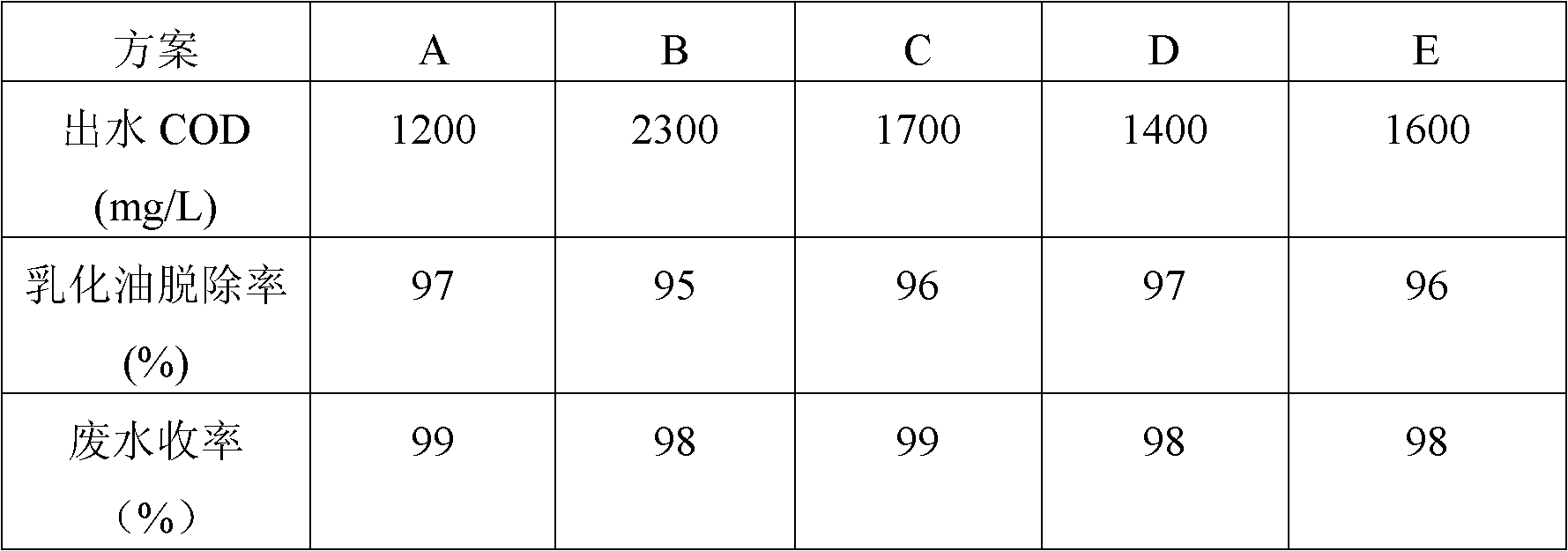

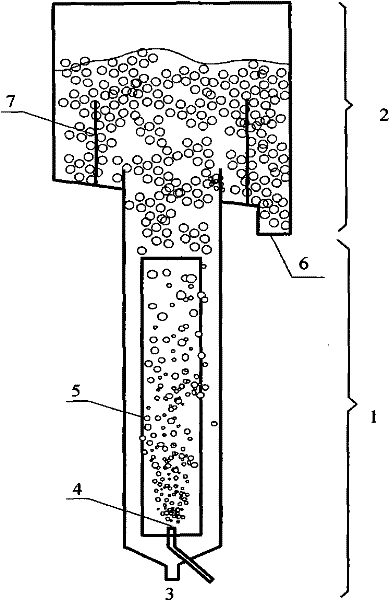

Method for treating heavy emulsified oil in waste water

ActiveCN102295320AAchieve removalThe processing process is simpleFatty/oily/floating substances removal devicesLiquid separationChemical oxygen demandVapor–liquid separator

The invention relates to a method for treating heavy emulsified oil in wastewater. The method is characterized in that a treatment device is formed by a lower bubble section and an upper foam section, wherein the lower bubble section of the treatment device is an airlift inner-circulation reactor, and the upper foam section of the treatment device is an overflow box type gas-liquid separator; thepH value of the wastewater is regulated to 8-9, and the wastewater is introduced into the bubble section; air is introduced to a tower bottom, and flocculating agents and a surface active agent are added, wherein the amount of an inorganic flocculating agent is 0.02-0.1mmol / g COD (chemical oxygen demand), the amount of a polymer flocculating agent is 10-50mg / m<3> wastewater, and the amount of an anion surface active agent is 5-20mg / g COD and is not less than 15-20mg / m<3> wastewater; the emulsified oil is separated from the wastewater through collecting foam; the gas speed of an empty tower ismaintained at 0.5-1.5cm / s; the separation efficiency is high: the primary separation rate can reach above 90%; the process is simple: solid suspended matters in the wastewater are removed once; the energy consumption and the reagent consumption are low: the amount of the flocculating agents is low; and the process flow is short.

Owner:PETROCHINA CO LTD

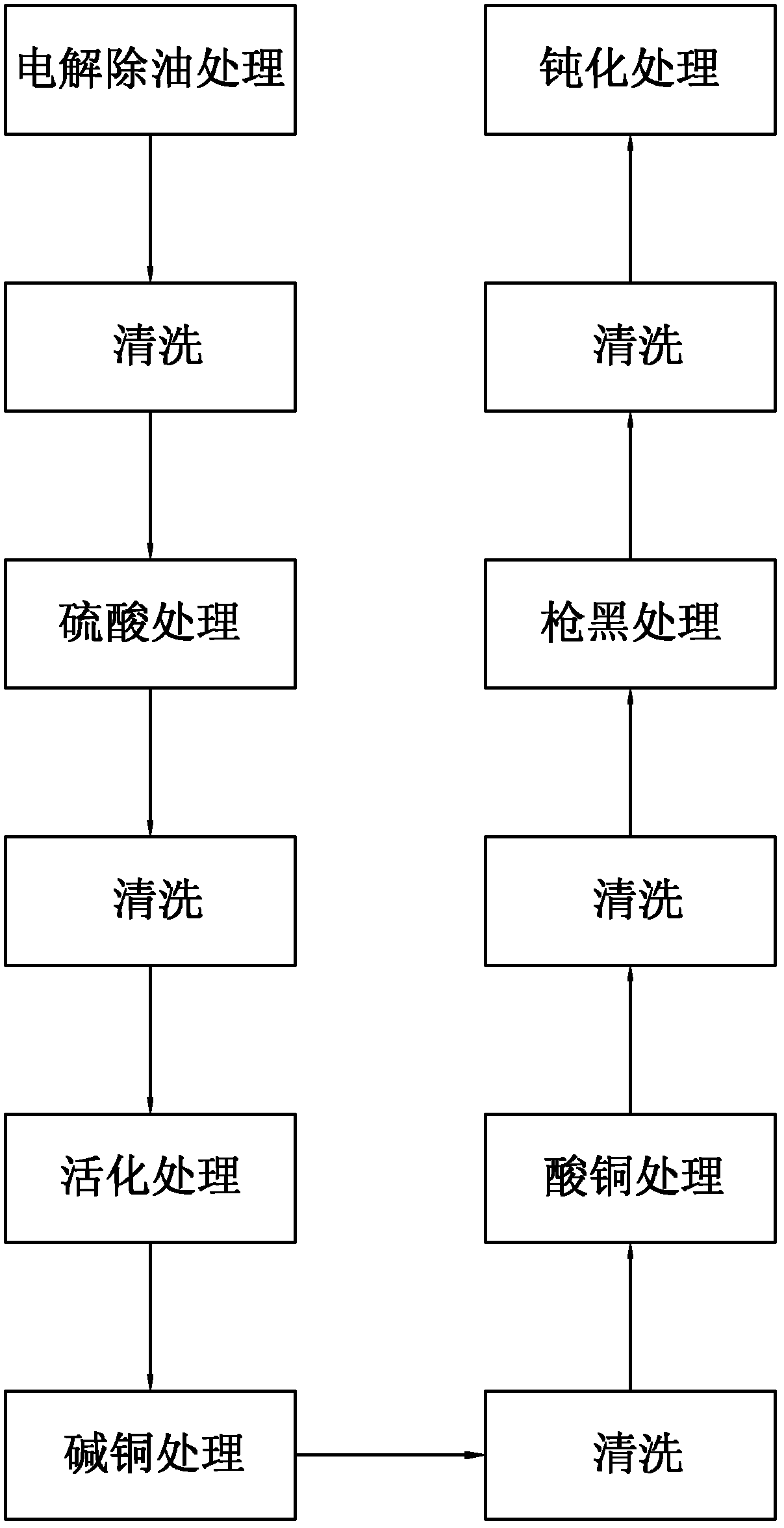

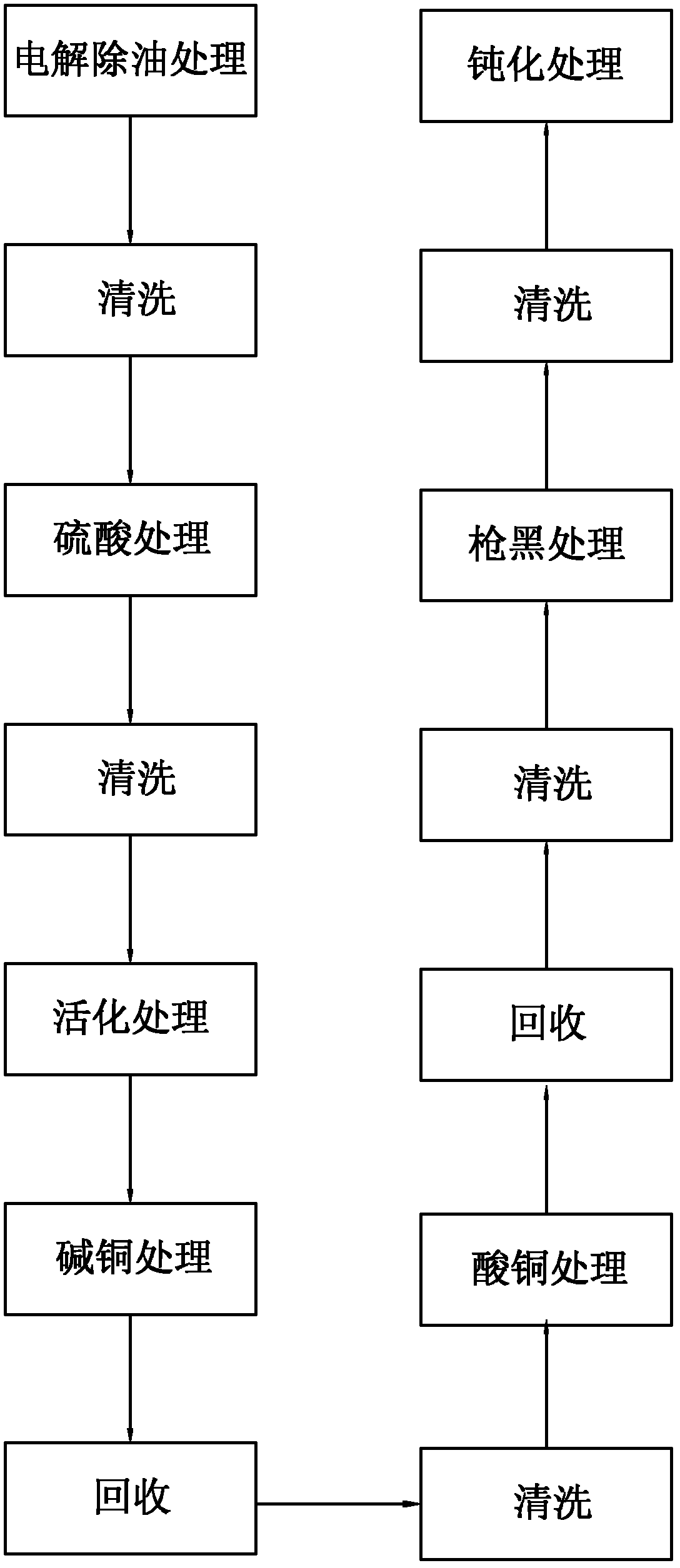

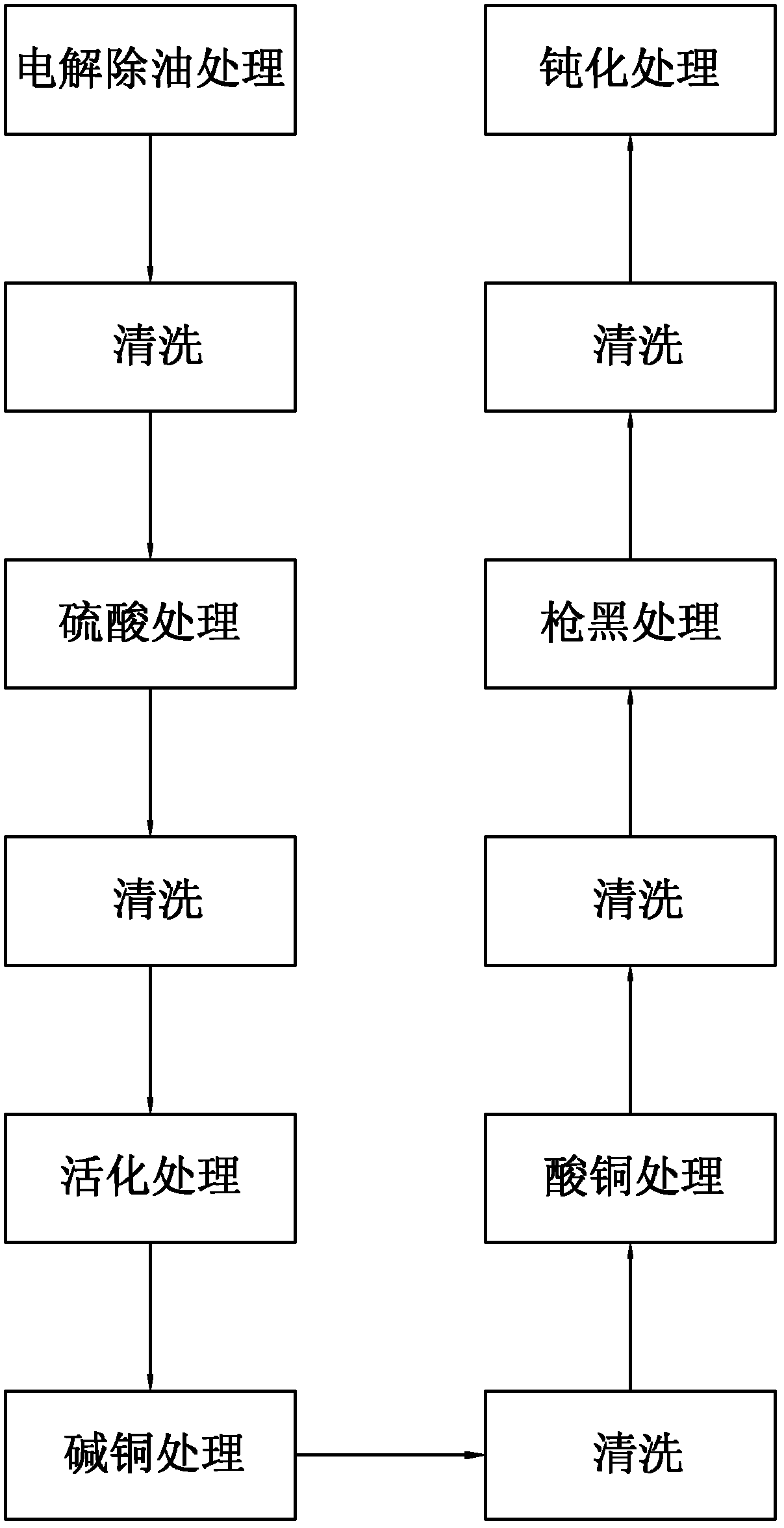

A method for surface treatment of electroplated copper door

InactiveCN102277600AOptimize process flowHigh precisionMetallic material coating processesSurface finishingCorrosion

The invention relates to a method for surface treatment of an electroplated copper door. The copper door treated by the existing electrochemical method has good corrosion resistance, but the accuracy of the existing electrochemical treatment process is poor, and the quality is not high, which is difficult to meet the current high-quality requirements. The present invention relates to a method for surface treatment of an electroplated copper door, wherein the method includes performing electrolytic degreasing treatment on the copper door; cleaning the copper door after electrolytic degreasing; performing degreasing on the cleaned copper door Activation treatment: performing alkali copper treatment on the copper gate after activation treatment; cleaning the copper gate after alkali copper treatment; performing acid copper treatment on the cleaned copper gate; Clean the copper door after cleaning; Carry out gun black treatment to the copper door after the cleaning; Clean the copper door after gun black; Carry out passivation treatment to the copper door after cleaning. Optimize the copper door surface treatment process, improve the accuracy of the copper door surface treatment process, and improve product quality.

Owner:朱国军

Cu-Ti-Cr-Zr high-performance copper-based elastic alloy and manufacturing method thereof

The invention relates to a Cu-Ti-Cr-Zr-V high-performance copper-based elastic alloy and a manufacturing method thereof. According to the technical points of the Cu-Ti-Cr-Zr-V high-performance copper-based elastic alloy, electrolytic copper serves as a matrix, chromium, zirconium, vanadium, cerium and titanium serve as main components, and the content of other impurities is smaller than or equal to 0.5%. In a product, the strength of extension ranges from 1,100 Rm / MPa to 1,300 Rm / MPa, the elongation ranges from 8 to 10, the yield strength ranges from 950 to 1,000, and the Vickers hardness ranges from 360 to 380. Compared with beryllium bronze (Be2.0 / CY4S) at present, the strength and hardness of the alloy can replace those of the beryllium bronze, and the elongation of the alloy is 4-5 times that of the beryllium bronze. Use of the element Be is avoided through the alloy at the same time, and greater environment friendliness is achieved when a material is prepared and used. The alloy is wide in application, is mainly used as various high-strength and high-elasticity elements such as elastic elements of electric switches and relays, and is widely applied to the fields such as instruments and meters, machine manufacturing, electronics, automobile household appliances, petrochemical engineering, aerospace and ships.

Owner:沈阳有色金属研究所有限公司

Burdock-common yam rhizome composite body building tea

InactiveCN102972588AThe processing process is simpleRetain nutrientsTea substituesBiotechnologyRhizome

The present invention relates to a burdock-common yam rhizome composite body building tea. The preparation method for the burdock-common yam rhizome composite body building tea comprises: selecting fresh infesting-free burdock and fresh infesting-free common yam rhizome, and cleaning in clear water; peeling the burdock and the common yam rhizome, and respectively carrying out slicing on the burdock and the common yam rhizome; rinsing the burdock slices and the common yam rhizome slices by using water, and placing the burdock slices and the common yam rhizome slices in a sterilized container to provide a spare use; placing the burdock slices and the common yam rhizome slices in a baking furnace to bake; taking the baked slices, and naturally cooling at a room temperature; respectively grinding the cooled burdock slices and the cooled common yam rhizome slices into powder by using a powder grinding machine; uniformly mixing 50-70% of the burdock powder and 30-50% of the common yam rhizome powder; carrying out small bag packaging on the mixed powder; and carrying out packing sale on the packaged tea powder. According to the burdock-common yam rhizome composite body building tea, nutrient substances of burdock and common yam rhizome are retained, a plurality of vitamins can be supplied after taking the burdock-common yam rhizome composite body building tea, effects of beautifying, body building, blood pressure lowering and blood fat lowering are provided, and the burdock-common yam rhizome composite body building tea has a simple processing process, and is suitable for large-scale production sale.

Owner:徐州康汇百年食品有限公司

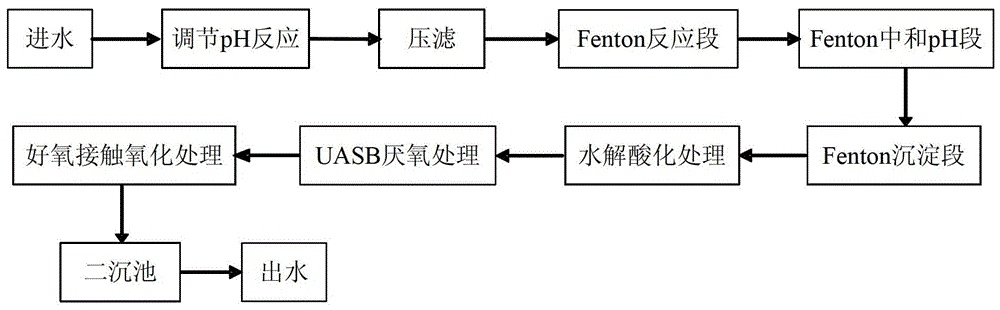

Treatment process for polycrystalline silicon cutting mortar recovered wastewater

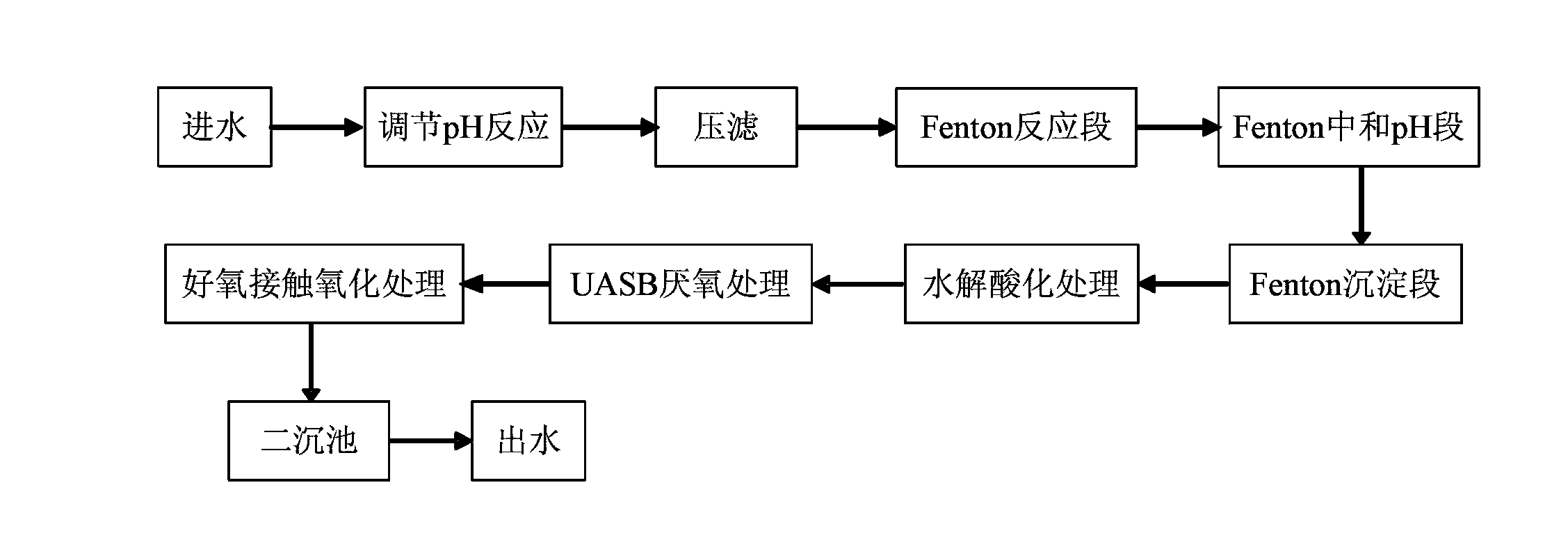

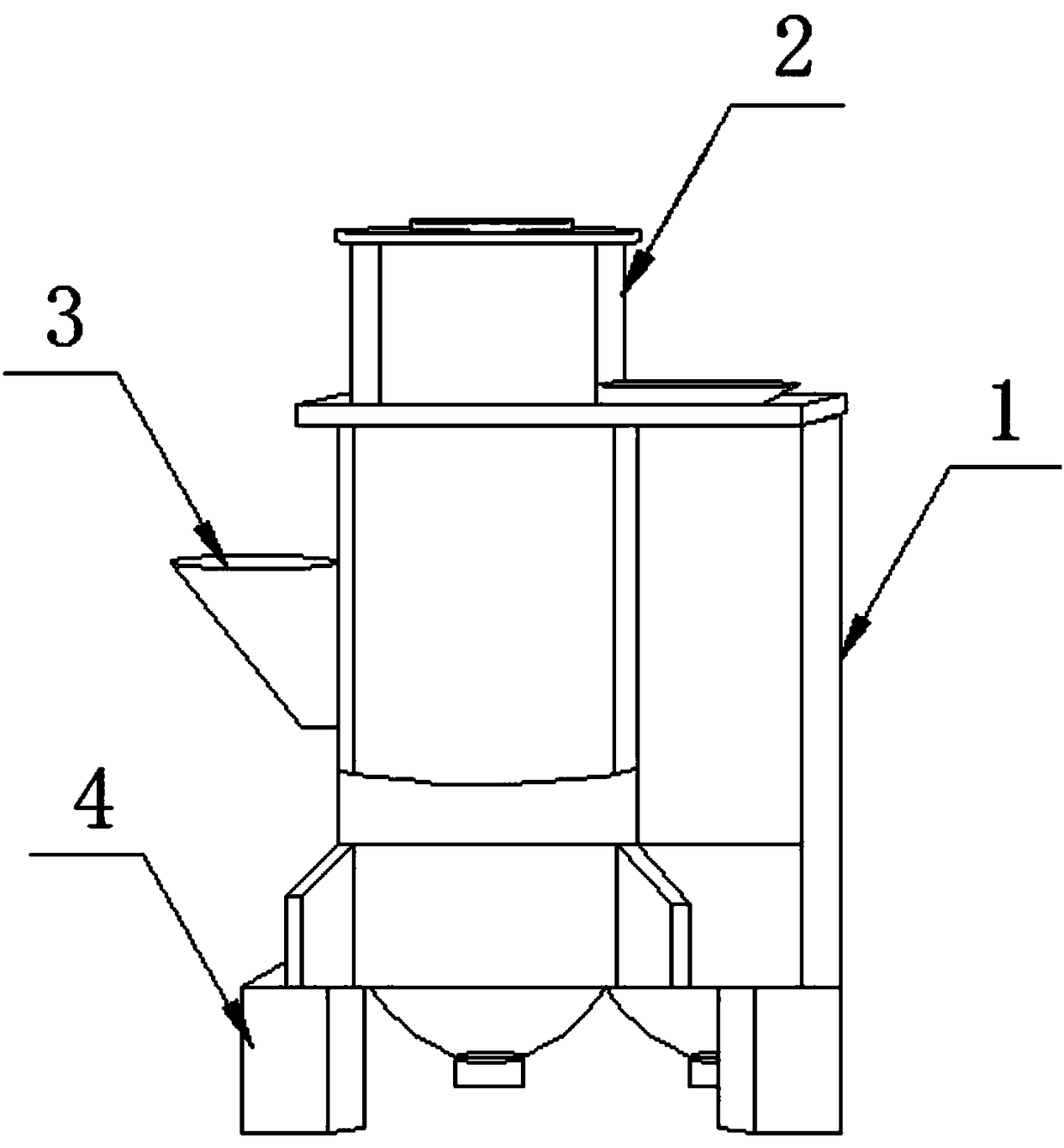

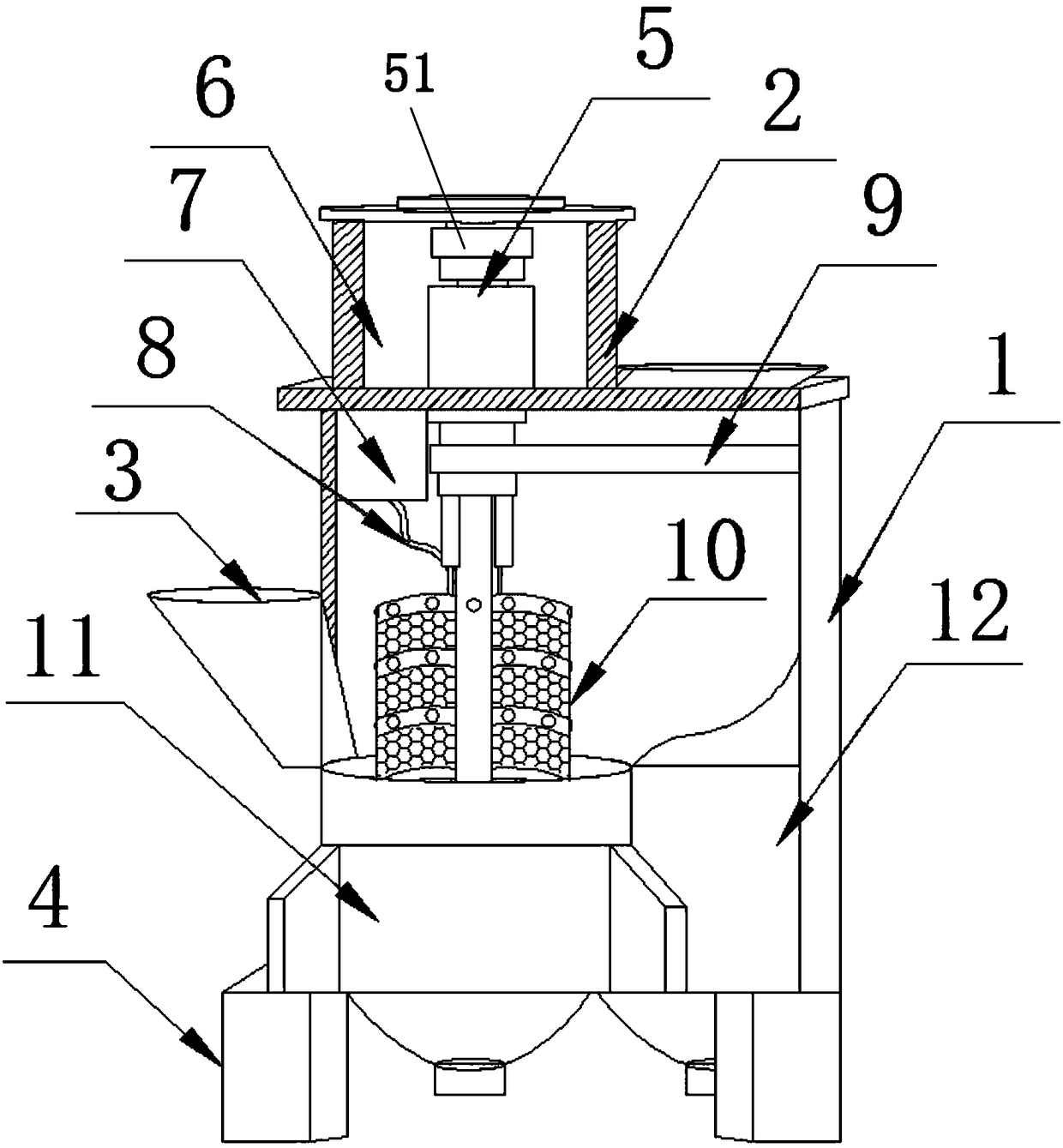

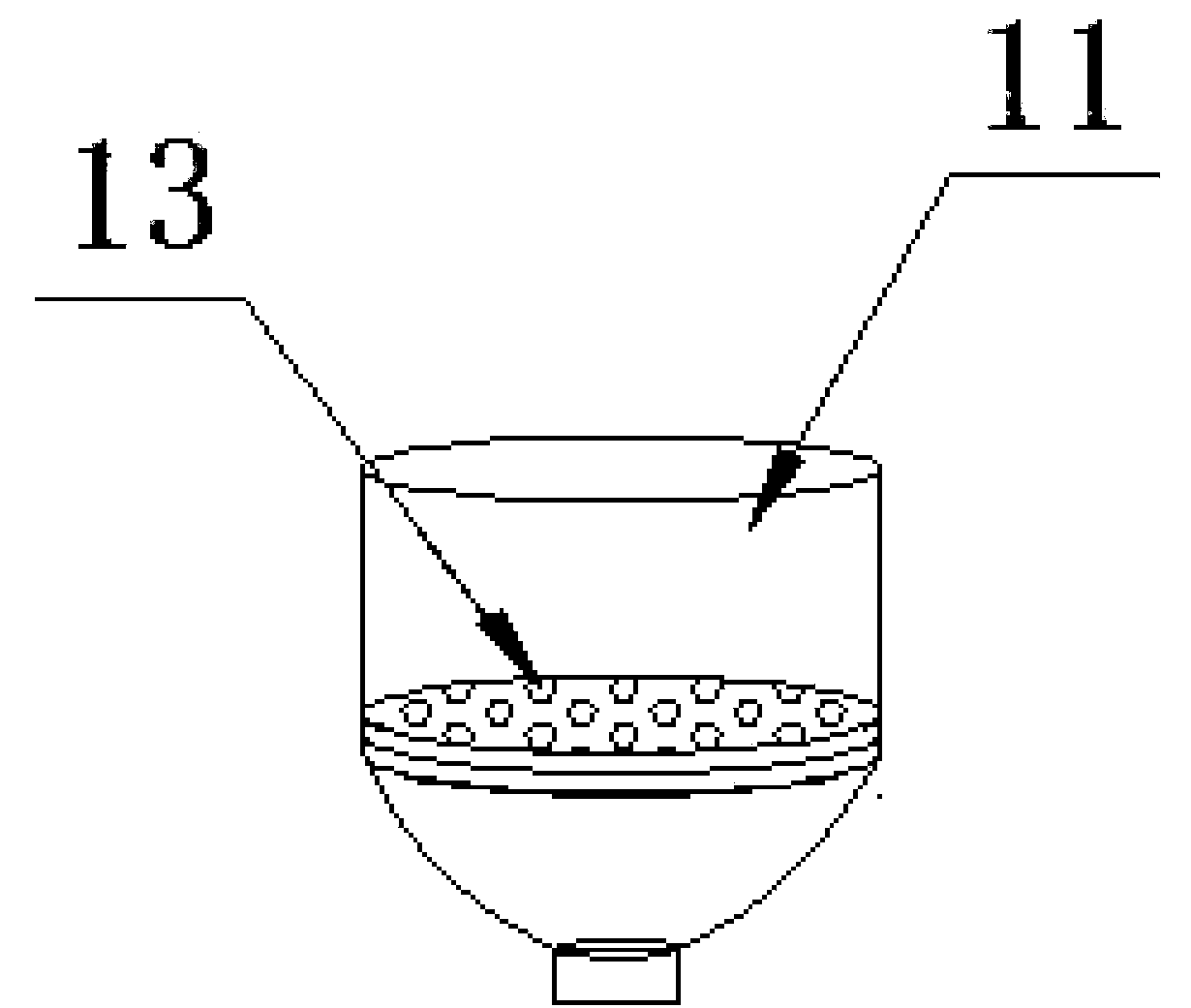

ActiveCN103803758AThe processing process is simpleLow construction and operation costsMultistage water/sewage treatmentAnaerobic treatmentPolycrystalline silicon

The invention discloses a treatment process for polycrystalline silicon cutting mortar recovered wastewater. The treatment process comprises the following steps: regulating pH of polycrystalline silicon cutting mortar recovered wastewater to 9.5-9.9, reacting and filter-pressing; carrying out Fenton oxidation treatment; implementing hydrolytic acidification treatment, upflow anaerobic sludge blanket (UASB) anaerobic treatment and aerobiotic contact oxidation treatment, and carrying out solid-liquid separation through settling by a secondary sedimentation tank. The treatment process is simple and convenient in flow, relatively low in construction and operation cost, simple in management, and capable of effectively treating the polycrystalline silicon cutting mortar recovered wastewater.

Owner:SHANGHAI EMPEROR OF CLEANING HI TECH

Pulp sewage treatment method for paper-making factory

ActiveCN108409043ARealize harmless treatmentThe processing process is simpleTreatment using aerobic processesTreatment involving filtrationFiberYarn

The invention discloses a pulp sewage treatment method for a paper-making factory. The pulp sewage treatment method includes the steps: leading pulp sewage into a primary filter tank, adding flocculating agents into the primary filter tank and reducing the concentration of the pulp sewage; guiding the sewage into a sewage filtering device, filtering the sewage and filtering and separating the pulpsewage again; fishing deposited pulp from the sewage by a spoon net; guiding the separated sewage into an aeration tank, performing aeration, adding hemp threads or artificial fiber yarns into the aeration tank and manually fishing floating agglomerated hemp threads or artificial fiber yarns from the sewage; sequentially leading the aerated sewage into an aerobic biological reaction tank and an anaerobic biological reaction tank and performing aerobic and anaerobic treatment; leading the sewage subjected to anaerobic treatment into an open-air drying tank and performing evaporation drying. Bythe aid of multistage filtering, aerobic and anaerobic treatment and evaporative treatment, the treatment technology process of the sewage is greatly simplified, and the pulp sewage treatment methodhas good application effects.

Owner:YUNNAN YUNJING FORESTRY & PULP MILL

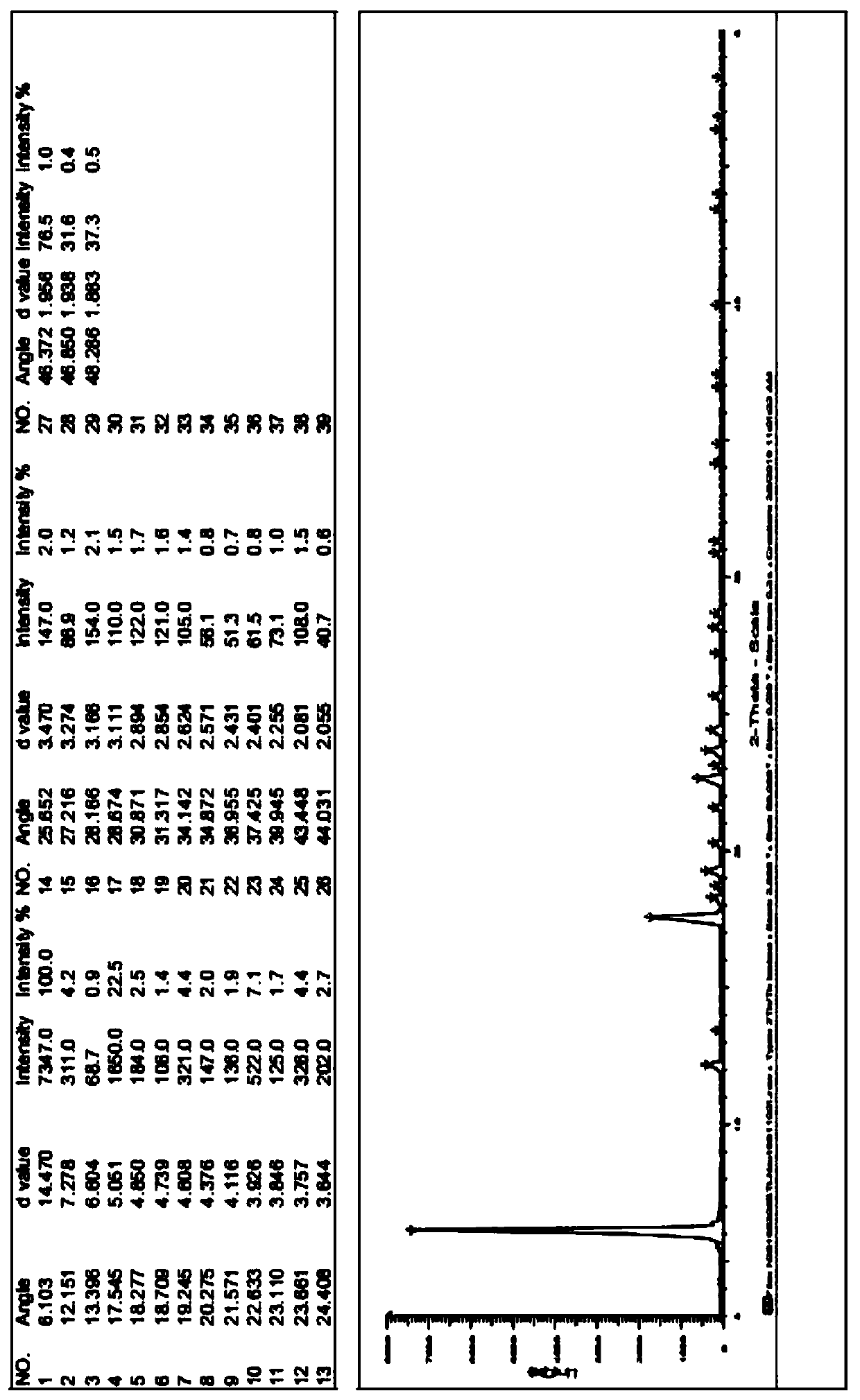

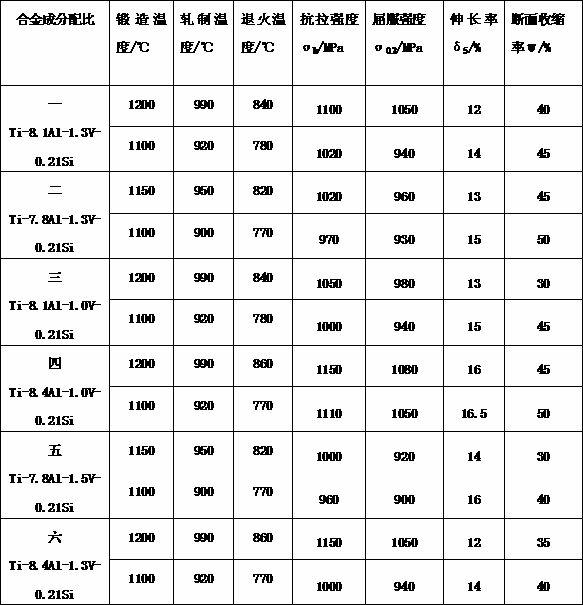

High-strength and high-plasticity titanium alloy

The invention discloses a high-strength and high-plasticity titanium alloy, which has the technical points that: the alloy comprises metal titanium serving as a main component, a small amount of metal aluminum, metal iron, metal zirconium and silicon elements and inevitable impurities. Since a small amount of Zr with refined grain structure is added, alpha and beta complete solid solutions can be formed with titanium. The alloy has higher plasticity under the condition of guaranteeing high strength; since noble metal V is replaced by Fe, the cost is greatly reduced in comparison with that of Ti-6Al-4V alloy; strength and oxidation resistance are improved through a small amount of Si elements; the alloy has high processability; a processing technique has simple procedures; the processing cost is low; and the alloy is easy to produce and meets the requirements for low-cost, high-strength and high-plasticity titanium alloy in each application field.

Owner:辽宁峰阁钛业集团有限公司

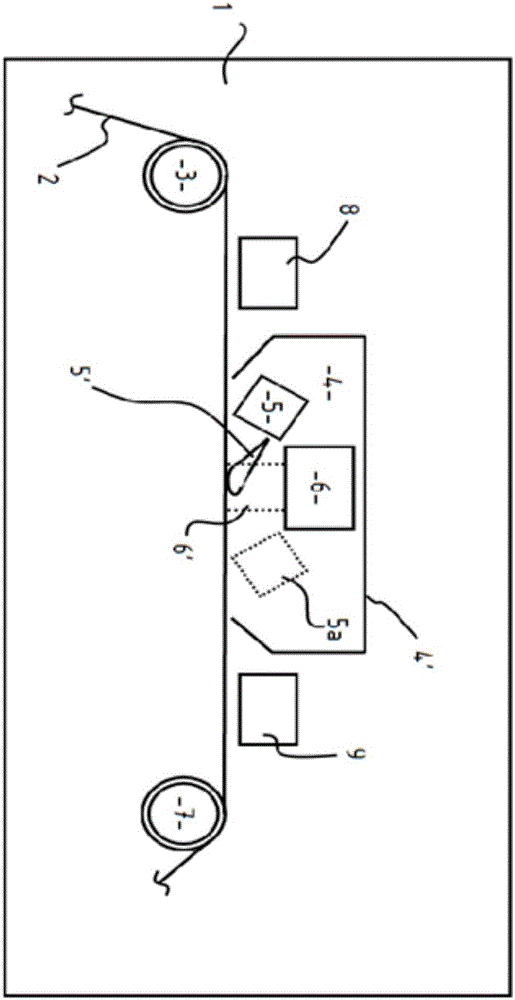

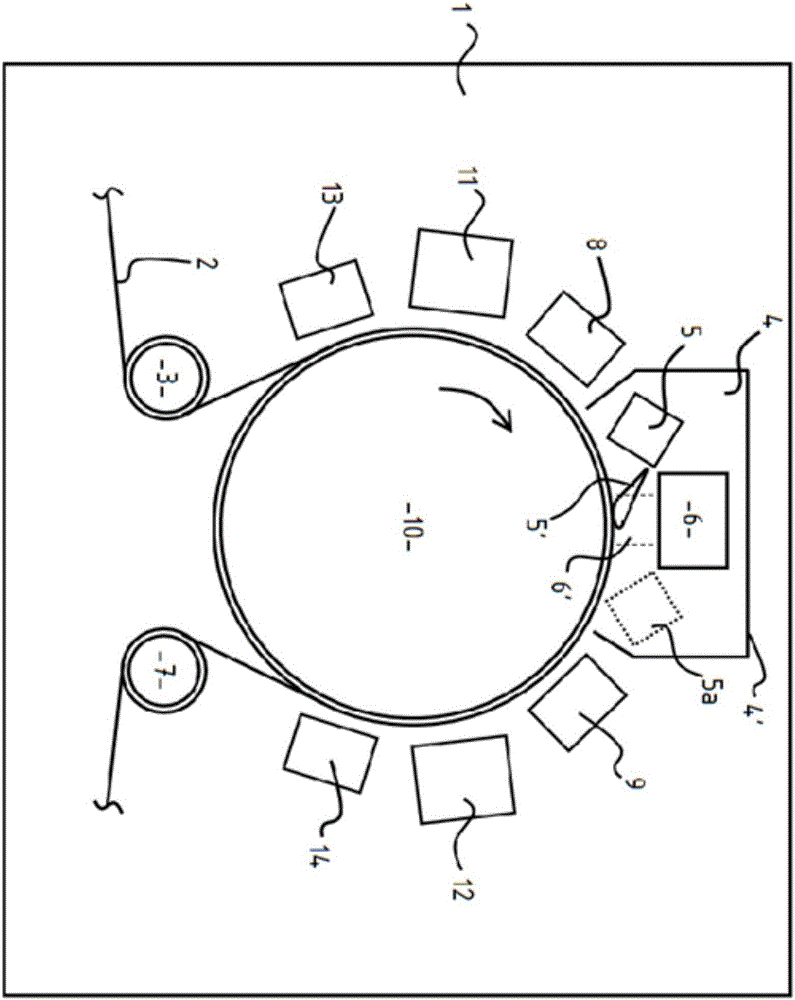

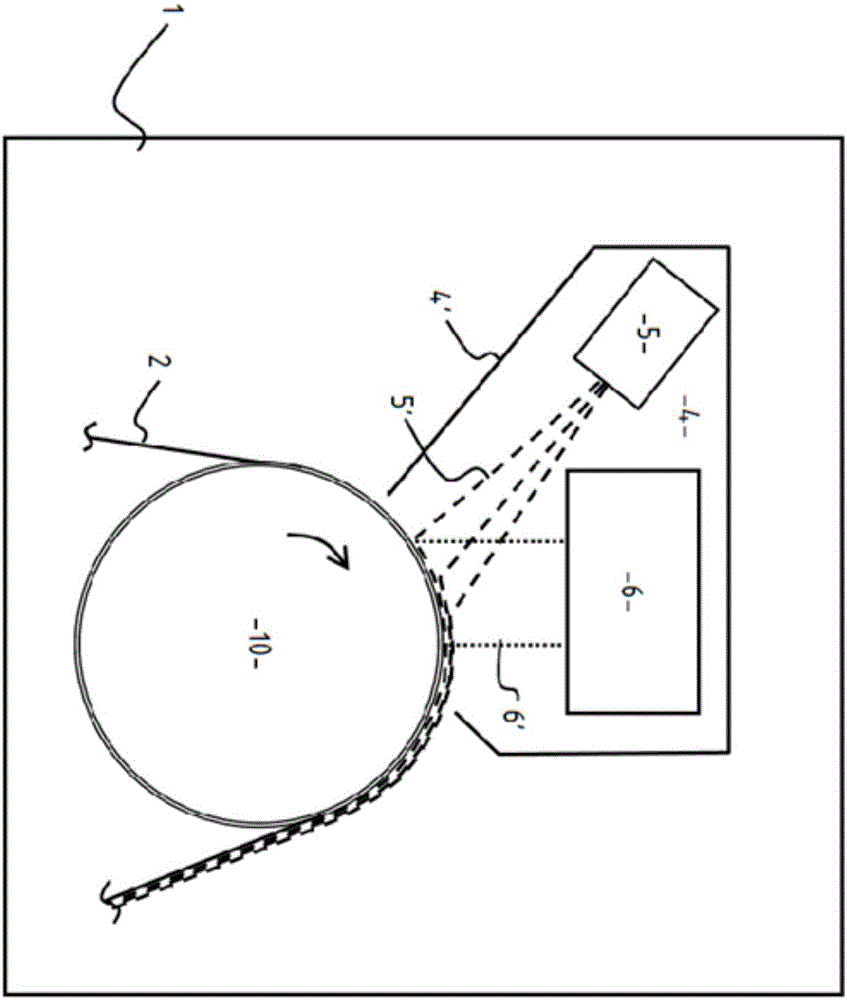

Apparatus and methods for defining a plasma

ActiveCN105074866AJamming tendency suppressionReduce riskElectric discharge tubesPretreated surfacesIonRace track

Apparatus comprising: a support 3, 7 arranged to transport a moving substrate 2, a plasma generator 6 arranged to generate plasma 6 and an electrode arranged to bias ions within the plasma towards the moving substrate 2 to form an ion flux. The ion flux has an energy level between 3.6eV and 250eV. The ion flux is used to cure radiation curable material on the moving substrate 2. Apparatus for defining plasma having a plurality of spaced race track portions using magnetic arrays is also disclosed (Fig. 9).

Owner:CAMVAC

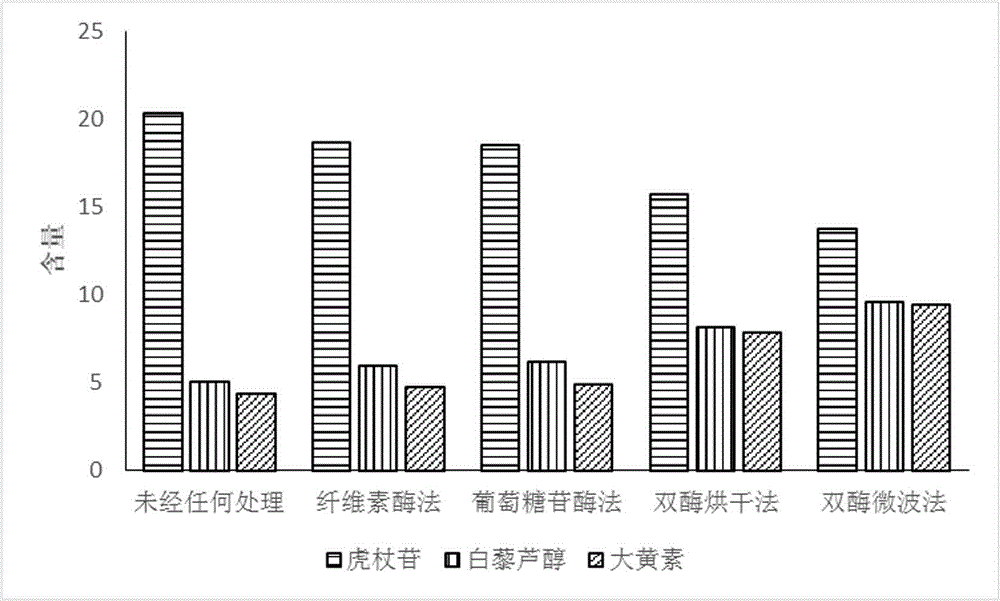

Processing method of giant knotweed rhizome

A processing method of giant knotweed rhizome comprises steps as follows: a medicinal material giant knotweed rhizome is immersed in a pretreatment mixed solution of cellulose and beta-glucosidase and processed under different power in a microwave oven, and a microwave processed product of giant knotweed rhizome is obtained; a preparation method of the pretreatment mixed solution is as follows: cellulose and beta-glucosidase are weighed respectively and dissolved with distilled water, and the pretreatment mixed solution is obtained; the weight ratio of cellulose to beta-glucosidase is (1:5)-(5:1). According to the provided processing method of giant knotweed rhizome, content of two effective ingredients of resveratrol and rheum emodin can be remarkably increased simultaneously, the content of polydatin is reduced, and conversion between polydatin and resveratrol in giant knotweed rhizome is accelerated effectively; compared with a conventional processing technology of giant knotweed rhizome, the processing method has no special requirements for temperature, environment and the like, the production conditions are easy to control, the product quality controllability is good, and an effective way applicable to industrial production is provided for application of giant knotweed rhizome, and the processing method has important practical value.

Owner:LIAONING UNIV OF TRADITIONAL CHINESE MEDICINE

Processing method of thunder god vine

The invention belongs to the processing field of Chinese herbal medicine, and discloses a processing method of thunder god vine. The method comprises the following processing steps: uniformly wrapping the medicinal material of thunder god vine with skins and roots with yellow mud, wherein the wrapping thickness is 0.2-0.5 cm, and the yellow mud is prepared by uniformly mixing yellow earth and 10% salt solution according to the proportion that 1 ml of salt solution is added to every 4 grams of yellow earth; after naturally airing, heating in a baking oven at 120-500 DEG C for 30-90 min; peeling the yellow mud to obtain a thunder god vine product stewed in a baking oven.

Owner:JIANGXI UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

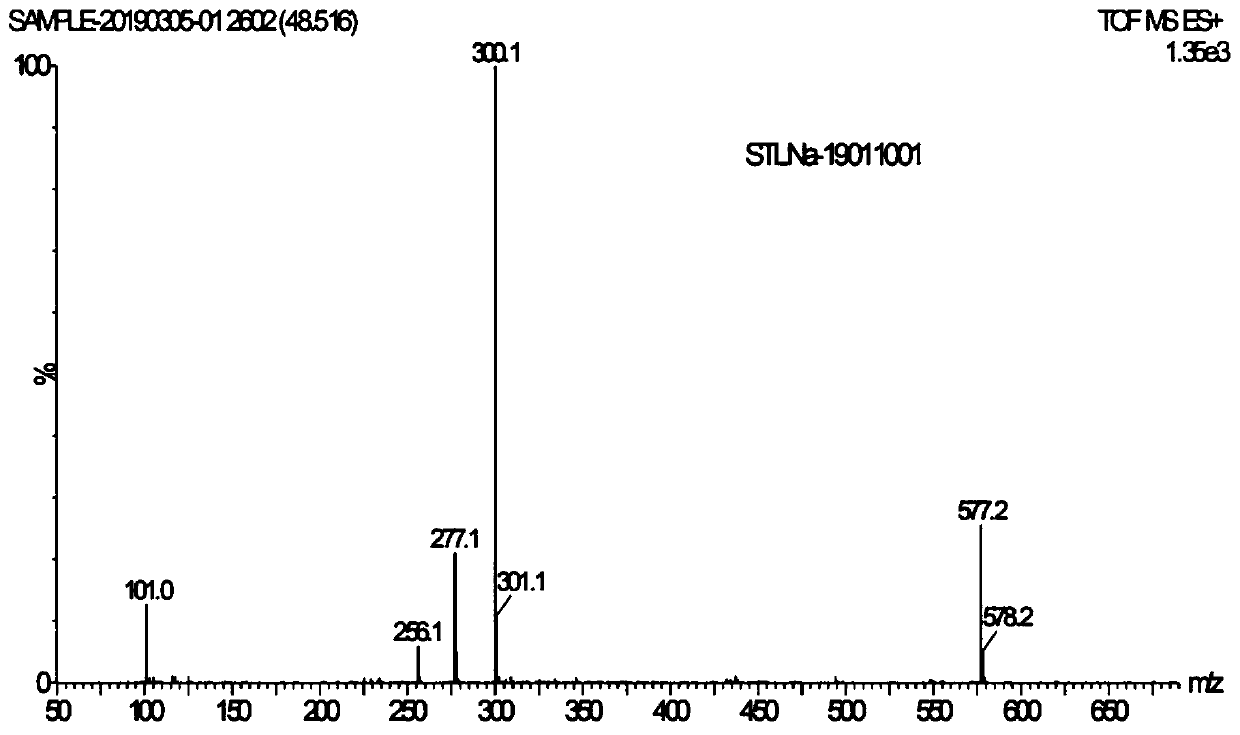

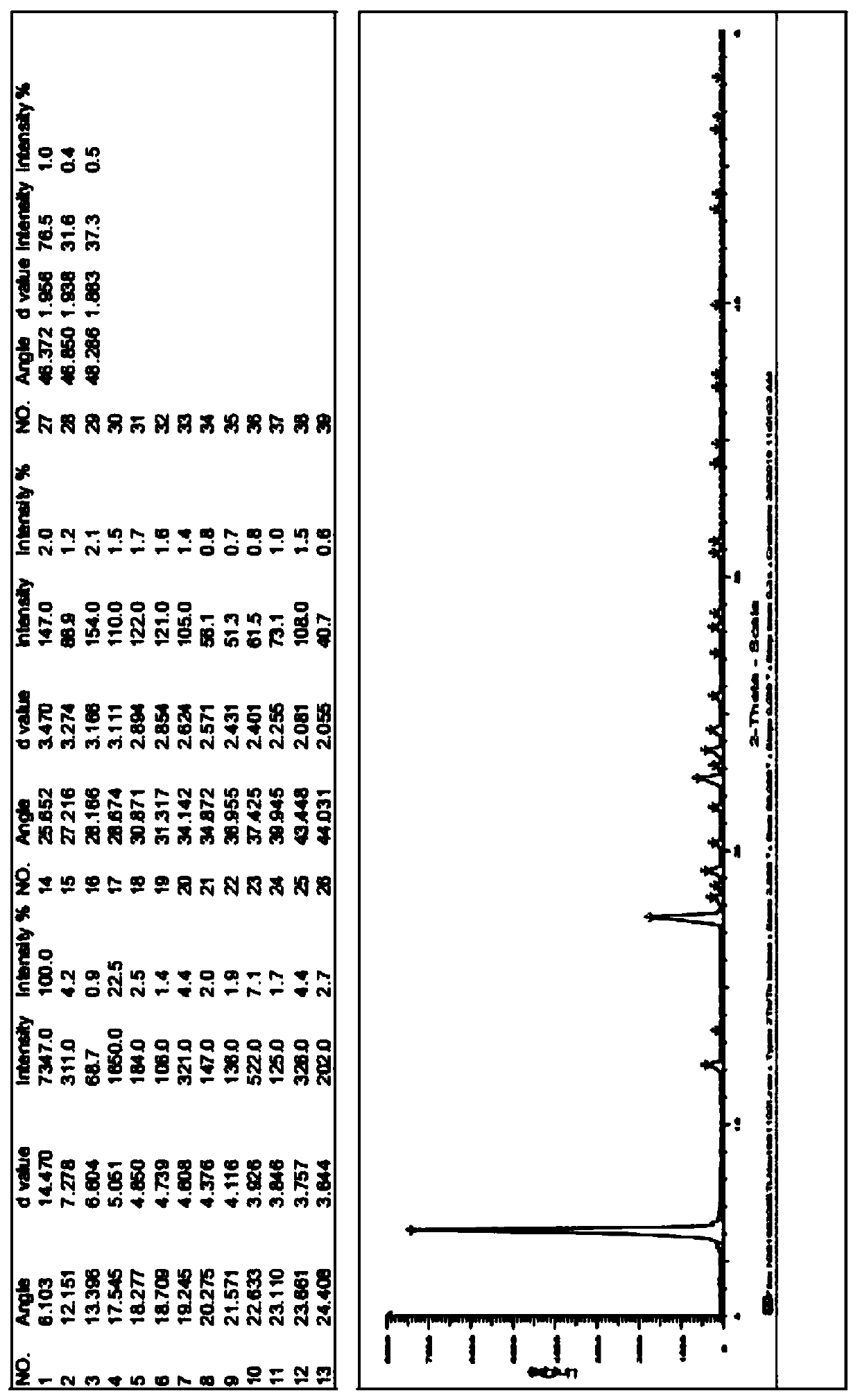

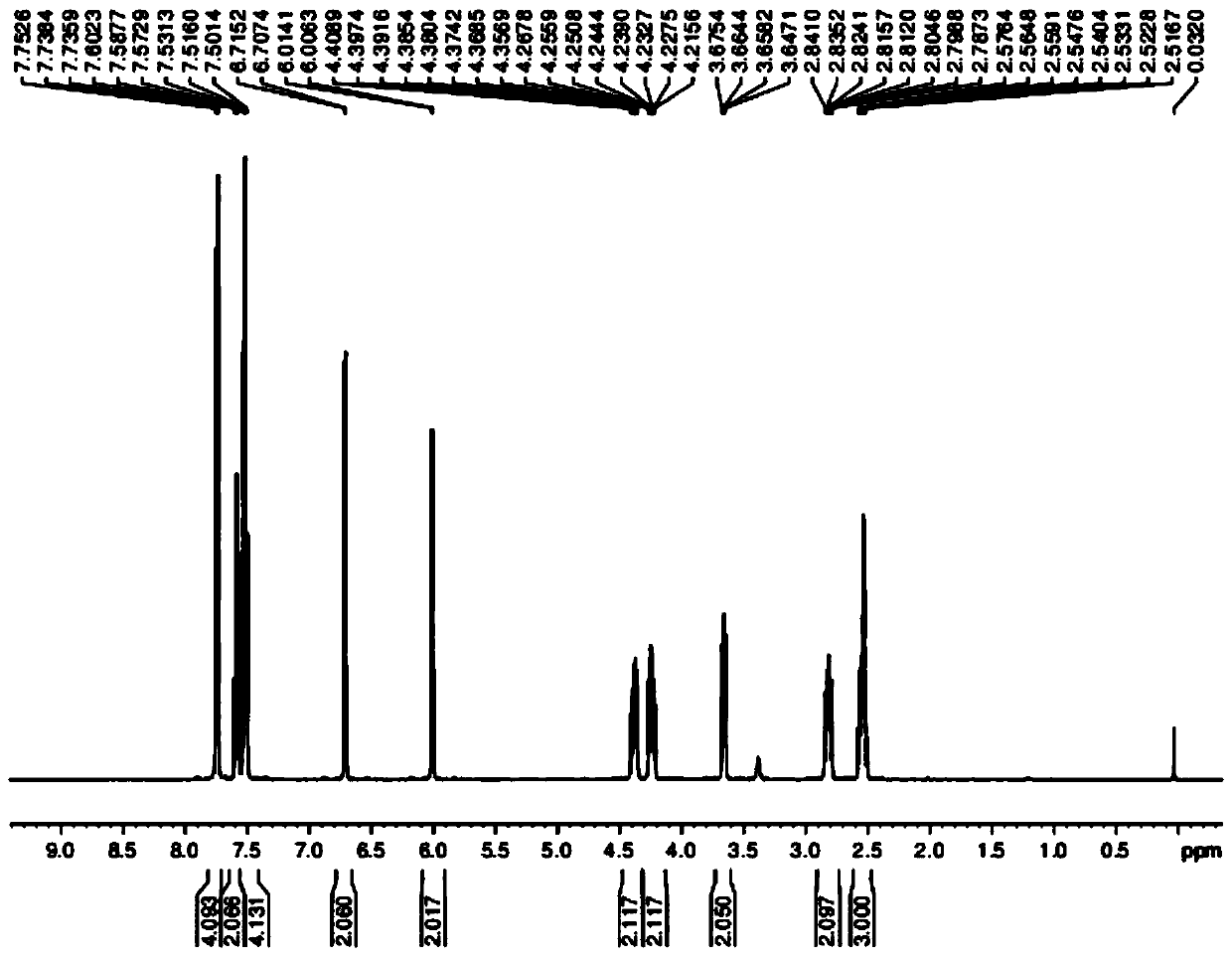

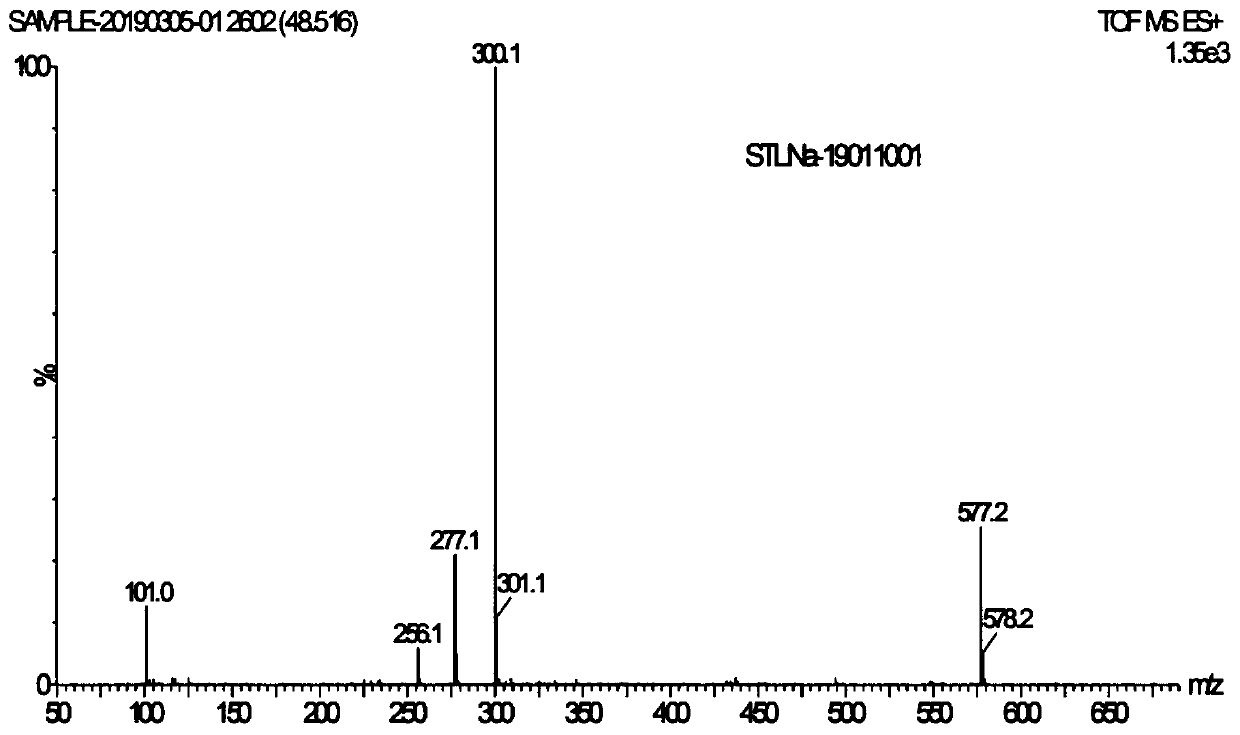

Sodium salt, crystal form and preparation method of pyrrolidine carboxylic acid compound

ActiveCN111454271AExcellent physical and chemical propertiesEasy to manufactureOrganic active ingredientsAntipyreticSide effectCombinatorial chemistry

Owner:NANJING HERON PHARMA SCI & TECH CO LTD

Sodium salt of phenylacetic acid compound as well as crystalline form and preparation method of sodium salt

InactiveCN110540542AImprove stabilityHalf the doseOrganic active ingredientsAntipyreticSolubilityBenzene

The invention provides a sodium salt of a phenylacetic acid compound as well as a crystalline form and preparation method of the sodium salt, a pharmaceutical composition containing the sodium salt, and a preparation form and a pharmaceutical application of the pharmaceutical composition. The compound represented by a formula I shown in the specification is a pharmaceutically active substance belonging to phenylacetic acid compounds. The sodium salt or crystalline form of the compound represented by the formula I has higher water solubility and physical and chemical stability, and has the advantages of a small dosage, a fast medicine effect and small toxic and side effects, and the pharmaceutical composition containing the sodium salt of the compound represented by the formula I obtained by alkali addition is widely used in the preparation of analgesic, antipyretic and anti-inflammatory drugs.

Owner:NANJING HERON PHARMA SCI & TECH CO LTD

Low density, high strength and high plasticity titanium alloy

The invention relates to a low density, high strength and high plasticity titanium alloy. The technological key points are as follows: the titanium alloy comprises metal titanium as the main component, a small amount of metal aluminum, metal iron, metal vanadium, silicon element, and inevitable impurities. Because of adding the small amount of noble metal V with same crystal structure with the titanium and capable of playing the role in suppressing the crystal nucleation and refining the crystal grains, the alloy has relatively high plasticity in the situation of ensuring the high intensity. The added Al replaces the noble metal V and the titanium sponge, thus the cost of the alloy is reduced, the addition of the small amount of the Si element increases the strength and the oxidation resistance of the alloy, the processability of the alloy is good, the process steps are simple, the process cost is low, and the alloy is easily produced. The alloy meets the requirements of various application fields for the low cost, high strength and high plasticity titanium alloy.

Owner:辽宁峰阁钛业集团有限公司

Treatment process of recycled waste water from polysilicon cutting waste mortar

ActiveCN103803758BThe processing process is simpleEasy to handleMultistage water/sewage treatmentOxygenFenton oxidation

Owner:SHANGHAI EMPEROR OF CLEANING HI TECH

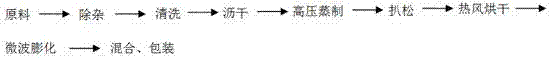

A kind of pretreatment method of black beans co-cooked with rice

InactiveCN104621485BGood for rehydrationImprove water absorptionFood scienceFlavorPretreatment method

The invention relates to a method for pretreatment of black soybeans, which belongs to the technical field of miscellaneous grain processing. It is characterized in that black soybeans are used as raw materials, and the corresponding black soybean products are obtained through the steps of impurity removal, cleaning, high-pressure steaming, hot air drying, microwave puffing, packaging and the like. The invention has the advantage that the treated black beans and rice can be cooked together when cooking, which solves the problem of pre-soaking or steaming black beans when consumers mix them with rice, improves the degree of ripening of black beans, and basically The complete particle shape and nutritious flavor of the black beans are maintained, and it is convenient for consumers to eat, and is convenient for retailing, storage and transportation.

Owner:JILIN AGRICULTURAL UNIV

Burdock and medlar composite fit-keeping dissolved medicine

InactiveCN103385467AThe processing process is simpleWith beauty and fitnessFood preparationNutrientMucus

The invention relates to a burdock and medlar composite fit-keeping dissolved medicine which is prepared through the steps of selecting fresh burdock without worm damage, and dedusting, desquamating and slicing the burdock; washing burdock slices with water to remove mucus on the burdock slices; putting the burdock slices into a baking furnace for baking; naturally cooling baked slices at normal temperature; selecting dried medlar with good color and without worm damage, and removing the dust on the surface of the dried medlar; respectively grinding the cooled burdock slices and the air-dried medlars into powder by utilizing a powder grinder; uniformly mixing the burdock and the medlar in proportion; packaging mixed powder into small bags, and encasing for sale. The burdock and medlar composite fit-keeping dissolved medicine disclosed by the invention not only retains the self nutrient substances of the burdock and the medlar, but also can be drunk instantly with boiling water, can supplement multiple vitamins for people after being drunk and has the effects of beautifying, keeping fit, reducing blood pressure and blood fat and replenishing vital essence to improve eyesight; in addition, the burdock and medlar composite fit-keeping dissolved medicine disclosed by the invention is simple in processing process flow and suitable for larger-scale production and sale.

Owner:陈家振

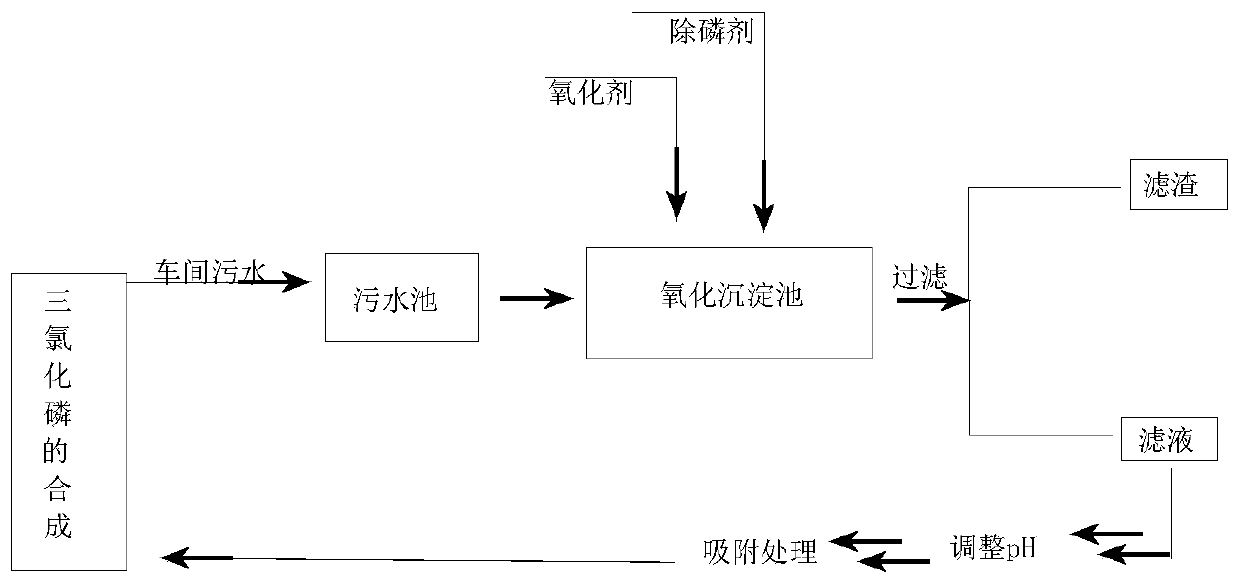

Treatment method for phosphorus trichloride production wastewater

InactiveCN111217477AConvenient sourceThe processing process is simplePhosphorus halides/oxyhalidesWater contaminantsPhosphoric acidWater chlorination

The invention discloses a treatment method for phosphorus trichloride production wastewater, and belongs to the technical field of chemical production. The method comprises the following steps: oxidizing phosphorus-containing sewage from a sewage tank into phosphate radicals in an oxidation settling tank by using an oxidant, making the phosphate radicals and a phosphorus removal agent react to generate precipitates, and carrying out aftertreatment on the filtered filtrate so as to be reused in phosphorus trichloride production, wherein the precipitates are used as phosphate fertilizer, and thephosphorus removal agent comprises one of ferric salt or aluminum salt.

Owner:安道麦股份有限公司

Oil sludge cleaning and recycling method based on kitchen waste oil

InactiveCN109987806AHarm reductionAchieve recyclingSludge treatmentLiquid hydrocarbon mixture productionRecovery methodOil and grease

The invention provides an oil sludge cleaning and recycling method based on kitchen waste oil. The method is characterized by comprising the following steps: by taking the kitchen waste oil as a raw material, carrying out high-temperature sterilization and then taking the sterilized kitchen waste oil as a carbon source, preparing a nutrient solution, and inoculating a proper amount of strains intothe nutrient solution of a fermentation tank to conduct fermentation for 3-5 days; and by taking the fermentation liquor as washing liquor and controlling the parameters (liquid-solid ratio, temperature, rotating speed, pH and time) of cleaning operation, cleaning oil-containing components in the oil sludge into the washing liquor, and finally separating and recycling oil in the washing liquor through high-speed centrifugal demulsification. On one hand, the harm of kitchen waste oil and oily sludge to the environment can be reduced, and on the other hand, the recycling of oil can be realized.The process is simple, the operation condition is mild, waste is treated with waste in the whole process, waste is turned into wealth, cost is saved, and environment friendliness is achieved.

Owner:SOUTHWEST PETROLEUM UNIV

Processing technology of blueberry beverage

InactiveCN112970986AThe processing process is simpleFull of nutritionNatural extract food ingredientsFood ingredient functionsBiotechnologyNutrition

The invention belongs to the technical field of food processing, and particularly relates to a processing technology of a blueberry beverage. The processing technology of the blueberry beverage according to the invention is simple in technological process, and avoids losses of nutrient substances, and the prepared blueberry beverage is rich in nutrition, unique in taste and rich in fruity flavor. By optimizing the process, the blueberry beverage has the effects of regulating the function of a human body, regulating blood pressure, softening blood capillaries, eliminating eye fatigue, improving vision, slowing down aging and the like.

Owner:麻江县瑞泽蓝莓发展农民专业合作社

Processing Technology of Engine Metal Piston Ring

The invention relates to the technical field of processing metal piston rings, and discloses a processing technology for metal piston rings of an engine, comprising the following steps: manufacturing an inlay groove on the outside of the gas ring of the engine piston ring, snapping and installing a piston ring assembly inside the piston ring assembly, the piston ring A wear-resistant rubber sealing ring needs to be installed on the outside of the component, and finally the outside of the installed sealing ring is sprayed with a coating of reinforcement material. The processing technology of the metal piston ring of the engine uses high-carbon steel as the raw material, which can be better installed inside the inlay groove. Compared with the traditional metal piston ring, the piston ring can better interact with the inner wall of the piston. It fits well and maintains a good sealing effect, which improves the flexibility of the piston ring's up and down movement. At the same time, the piston ring assembly can be cleaned after grinding. The metal ring after cleaning in metal cleaning agent can avoid oil pollution Rust occurs after long-term immersion, resulting in a decrease in service life.

Owner:武汉天海密封科技有限公司

A kind of biological leaching method of purified terephthalic acid sludge

ActiveCN105439406BImprove dehydration effectImprove efficiencySludge processingBiological sludge treatmentSludgeMicrobiology

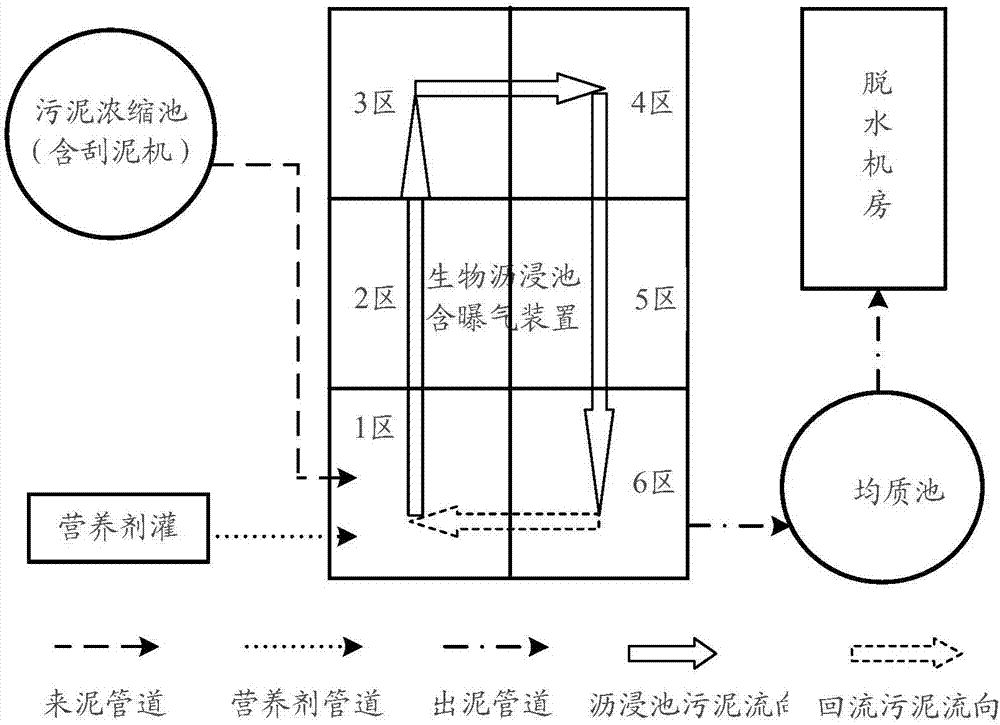

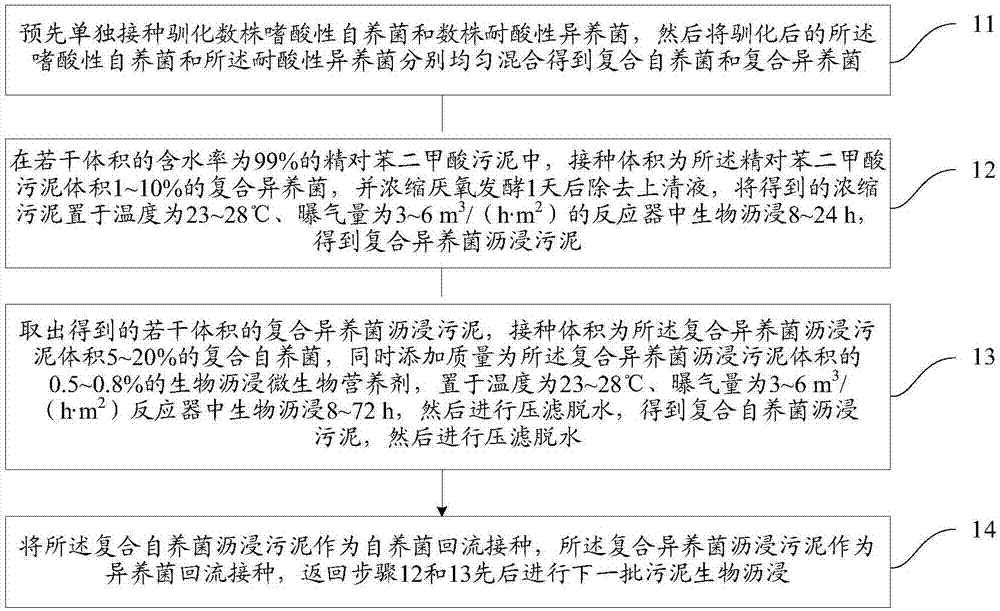

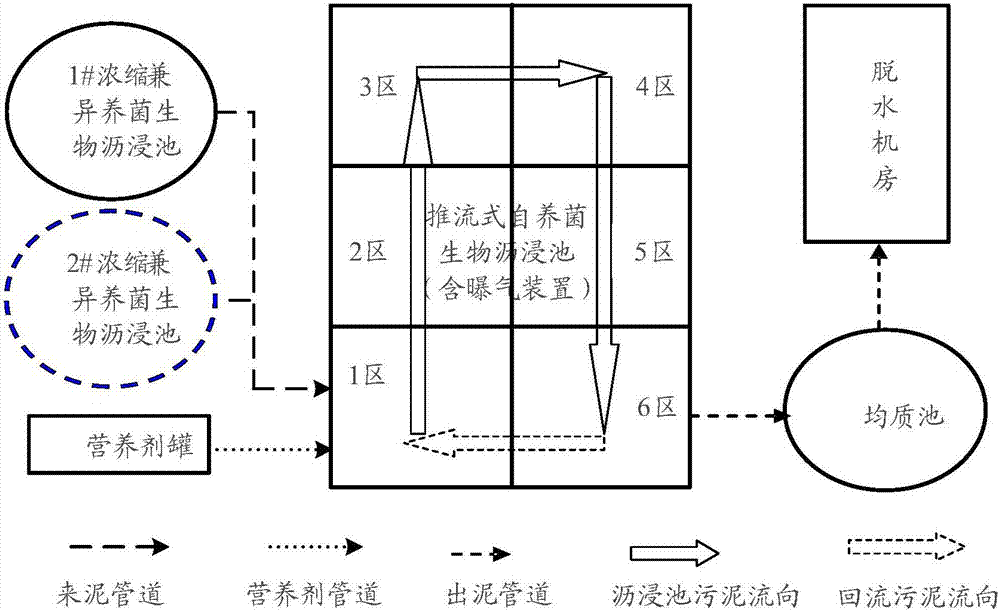

The present invention provides a purified terephthalic acid sludge bioleaching method comprising the following steps: 11, in advance separately inoculating and domesticating a plurality of strains of acidophilic autotrophic bacteria and a plurality of strains of acid-resistant heterotrophic bacteria, and then respectively uniformly mixing the acidophilic autotrophic bacteria and the acid-resistant heterotrophic bacteria to obtain composite autotrophic bacteria and composite heterotrophic bacteria; step 12, in purified terephthalic acid sludge, inoculating the composite heterotrophic bacteria for concentrated anaerobic fermentation for 1d, then removing supernatant, and putting the obtained concentrated sludge into a reactor for bioleaching for 8-24h to obtain composite heterotrophic bacteria leaching sludge; step 13, taking a number of volumes of the composite heterotrophic bacteria leaching sludge, inoculating the composite autotrophic bacteria, meanwhile adding a bioleaching microbial nutrient, placing in a reactor for bioleaching, and filtering by pressing for dewatering; and step 14, taking composite autotrophic bacteria leaching sludge as autotrophic bacteria for re-inoculation, taking the composite heterotrophic bacteria leaching sludge as heterotrophic bacteria for re-inoculation, and returning to the step 12 and 13 for bioleaching of next batch of sludge.

Owner:GENERAL TREATMENT ENVIRONMENT BEIJING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com