Patents

Literature

38 results about "Benzyl Carbinol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

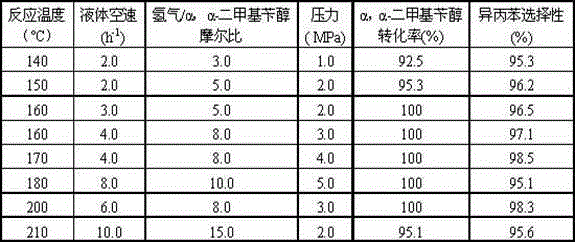

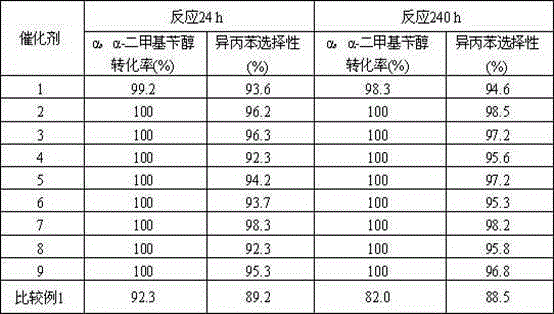

Alpha, alpha-dimethylbenzyl alcohol hydrogenolysis method for preparing isopropyl benzene

InactiveCN104230640AImprove technical effectHydrocarbon from oxygen organic compoundsMetal/metal-oxides/metal-hydroxide catalystsHydrogenAlcohol

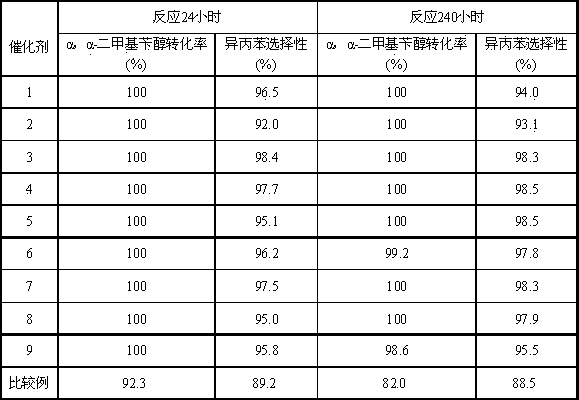

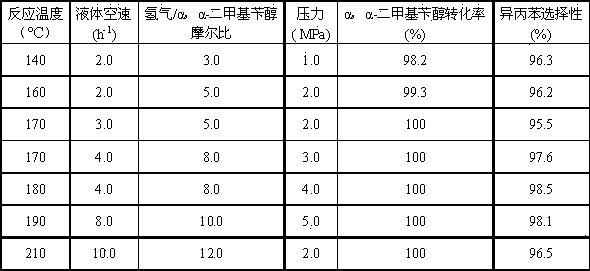

The invention relates to an alpha, alpha-dimethyl-benzyl carbinol hydrogenolysis method for preparing isopropyl benzene, and mainly solves the problems of poor stability of catalyst and serious environmental pollution in the isopropyl benzene production process. A technical scheme for solving the problem is as below: introducing raw materials of hydrocarbons containing alpha, alpha-dimethylbenzyl alcohol and hydrogen into a hydrogenolysis reaction zone, and reacting the raw materials with a catalyst by contact to produce isopropyl benzene. The catalyst comprises the following components by weight: a) 0.1-2.0 parts of Pd metal or oxide; b) 85.0 to 97.0 parts of SiO2; c) 1.0-10.0 parts of at least one selected from Ni or oxide thereof, Co or oxide thereof, and Cu or oxide thereof; and d) 1.0 to 5.0 parts of at least one selected from Mg or oxide thereof, Ca or oxide thereof and Ba or oxide thereof. The method can be used in industrial production of isopropyl benzene by alpha, alpha-dimethyl-benzyl carbinol hydrogenolysis.

Owner:CHINA PETROLEUM & CHEM CORP +1

Alpha, alpha-dimethyl-benzyl carbinol direct hydrogenolysis method for preparing isopropyl benzene

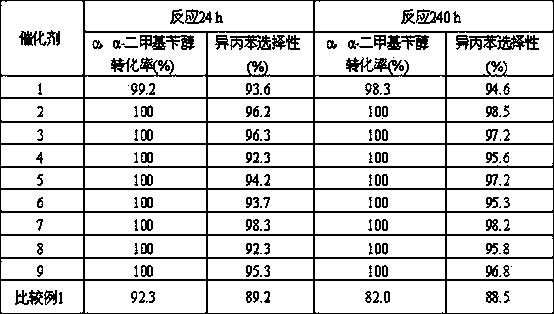

The invention relates to an alpha, alpha-dimethyl-benzyl carbinol direct hydrogenolysis method for preparing isopropyl benzene, and mainly solves the problem of poor stability of catalyst in the prior art for isopropyl benzene production by alpha, alpha-dimethyl-benzyl carbinol hydrogenolysis. A technical scheme for solving the problem is as below: introducing raw materials of hydrocarbons containing alpha, alpha-dimethyl-benzyl alcohol and hydrogen into a hydrogenolysis reaction zone, and reacting the raw materials with a catalyst by contact to produce isopropyl benzene. The catalyst comprises the following components by weight: a) 0.2-2.0 parts of Pd; b) 91.0-98.0 parts of active carbon; and c) 1.0-10.0 parts of at least one selected from Ni or oxide thereof, Co or oxide thereof, Cu or oxide thereof and Sn or oxide thereof. The method can be used for industrial production of isopropyl benzene by alpha, alpha-dimethyl-benzyl carbinol hydrogenolysis.

Owner:CHINA PETROLEUM & CHEM CORP +1

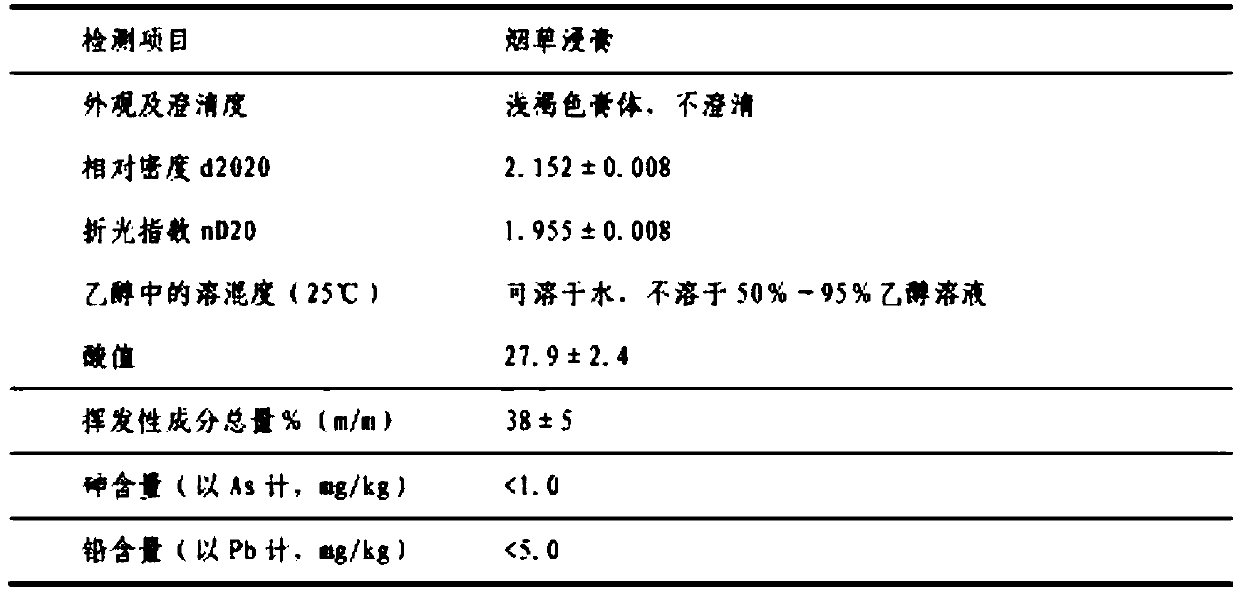

Producing raw material containing benzyl carbinol glycosides from Cistanche deserticola by using membrane separation technique and preparation method thereof

InactiveCN101041677AHigh retention rateRemove invalid ingredientsSugar derivativesPlant ingredientsGlycoside formationBenzyl Carbinol

The invention discloses a manufacturing method of raw material with phenethylol from Cistanche deserticola through film separating technique, which comprises the following steps: selecting material; extracting; micro-filtering; hyperfiltering; nano-filtering; drying; obtaining the product with effective enriching; improving the extracting rate of effective component; saving manufacturing cost; shortening technical period.

Owner:HETIAN DCM MEDICINE BIOLOGICAL TECH

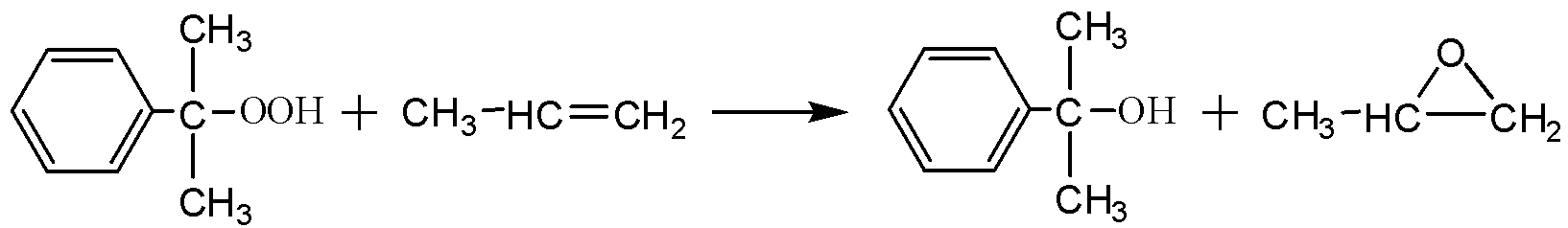

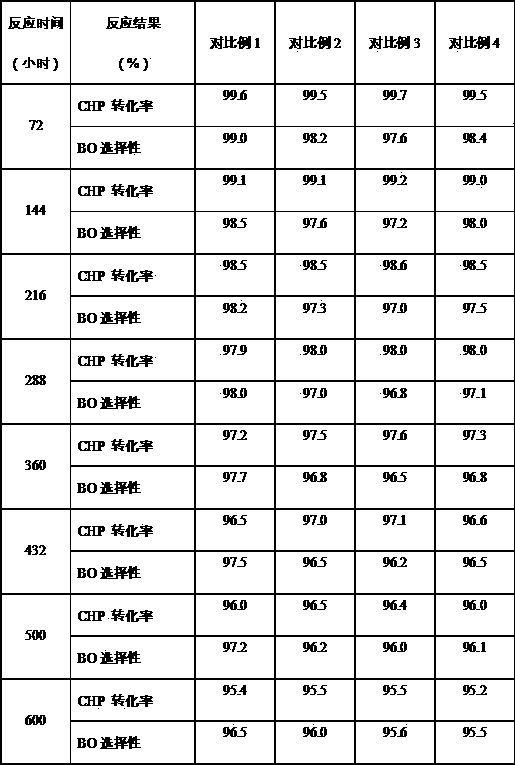

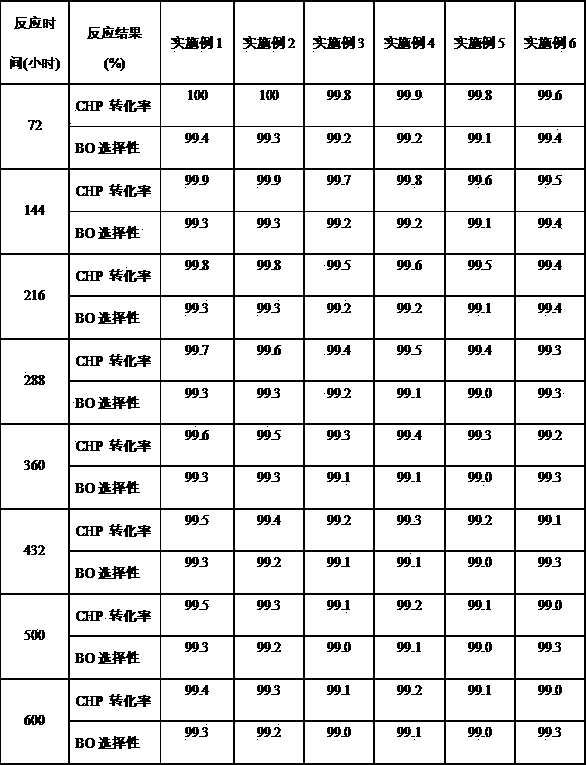

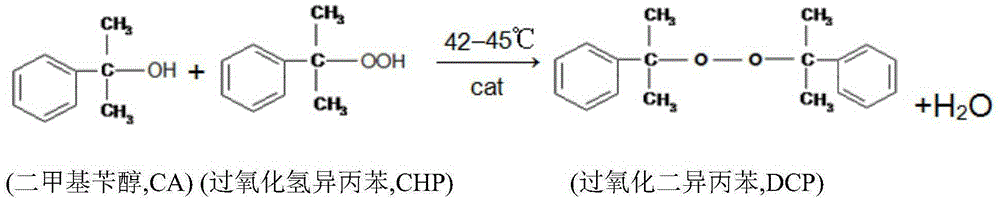

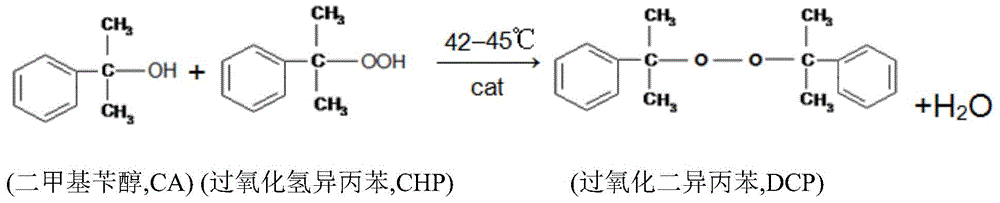

Method for preparing titanium-based catalyst and synthesizing epoxypropane and dicumyl peroxide

InactiveCN103212437AOvercoming multiple and environmental pollution problemsSolve pollutionMolecular sieve catalystsOrganic compound preparationCorrosionHydrogen peroxide

The invention discloses a method for preparing a titanium-based catalyst and synthesizing epoxypropane and dicumyl peroxide. According to the method, when the epoxypropane is synthesized on the basis of the titanium-based molecular sieve based catalyst, a byproduct, namely dimethyl-benzyl carbinol is continuously recycled to synthesize and prepare dicumyl peroxide; the problems of equipment corrosion, large quantity of byproducts and environmental pollution caused by the traditional chlorohydrins method and an indirect oxidation method are solved; the problem of environmental pollution caused by inorganic-salt-containing wastewater produced in a process of preparing the dicumyl peroxide by reducing cumyl hydroperoxide by using inorganic matters, such as water-soluble sulfur compounds is solved; and therefore the method is a synthesis process with high atom economy and has a favorable industrial application prospect.

Owner:DALIAN UNIV OF TECH

Method for preparing epoxybutane

The invention relates to a method for preparing epoxybutane so as to mainly solve problems of low selectivity of epoxybutane and short service life of a catalyst in the prior art The method provided by the invention comprises the following steps: a) an oxidation reaction between isopropyl benzene and molecular oxygen is carried out to obtain a cumyl hydroperoxide oxidation liquid; b) content of organic acid in the cumyl hydroperoxide oxidation liquid is controlled to be not more than 0.3 wt%, content of alkali metal or alkaline earth metal ions is controlled to be not more than 0.1 wt%, and content of water is controlled to be not more than 0.5 wt%; c) the cumyl hydroperoxide oxidation liquid and butylene react under the liquid-phase condition in the presence of a catalyst so as to generate epoxybutane and alpha, alpha-dimethyl-benzyl carbinol; d) alpha, alpha-dimethyl-benzyl carbinol undergoes dehydration to generate alpha-methyl styrene; and e) alpha-methyl styrene undergoes hydrogenation to generate isopropyl benzene. By the technical scheme, the above problems are solved well. The method provided by the invention can be used in industrial production of preparing epoxybutane.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for abstracting active compound rich in echinacoside and feltwort glycoside

The invention provides a system integration technology through cell disruption, slurry extraction, membrane separation and macroporous resin adsorption and chromatography separation and purification, high temperature enzyme deactivation and spray drying and the like, which achieves a technical process that from the time fresh cistanche raw materials are fed until obtaining active matters such as monomeric compounds which are rich in echinacoside and verbascoside and the like in 30 to 80 minutes, and the invention effectively overcomes a technical defect that active components such as benzyl carbinol glycosides compounds are normally seriously degraded and lost, which are caused by an enzymatic reaction which is initiated by an imperfect dry treatment method of cistanche, and the invention obviously improves the medical value of cistanche. In the active maters of cistanche which are obtained ( calculating by dry matter), the productivity of echinacoside monomeric compound reaches to 9.8% to 19.6%, and the yield of verbascoside monomeric compound reaches to 2.0% to 7.5%. The content of echinacoside monomeric compound in active matters of cistanche which are obtained reaches to 15% to 49.6%, and the content of verbascoside monomeric compound reaches to 5% to 26.7%.

Owner:广州绿色盈康生物工程有限公司 +1

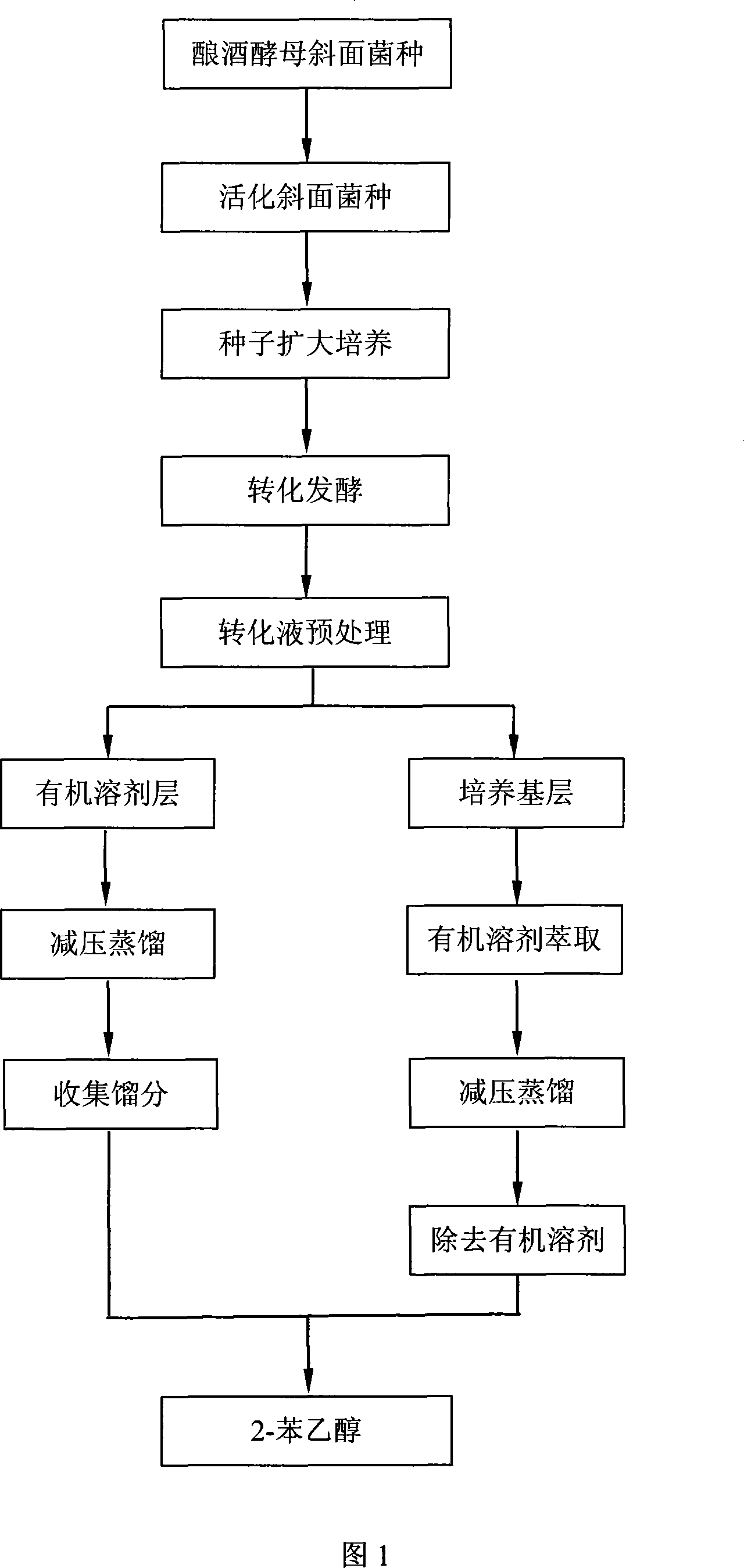

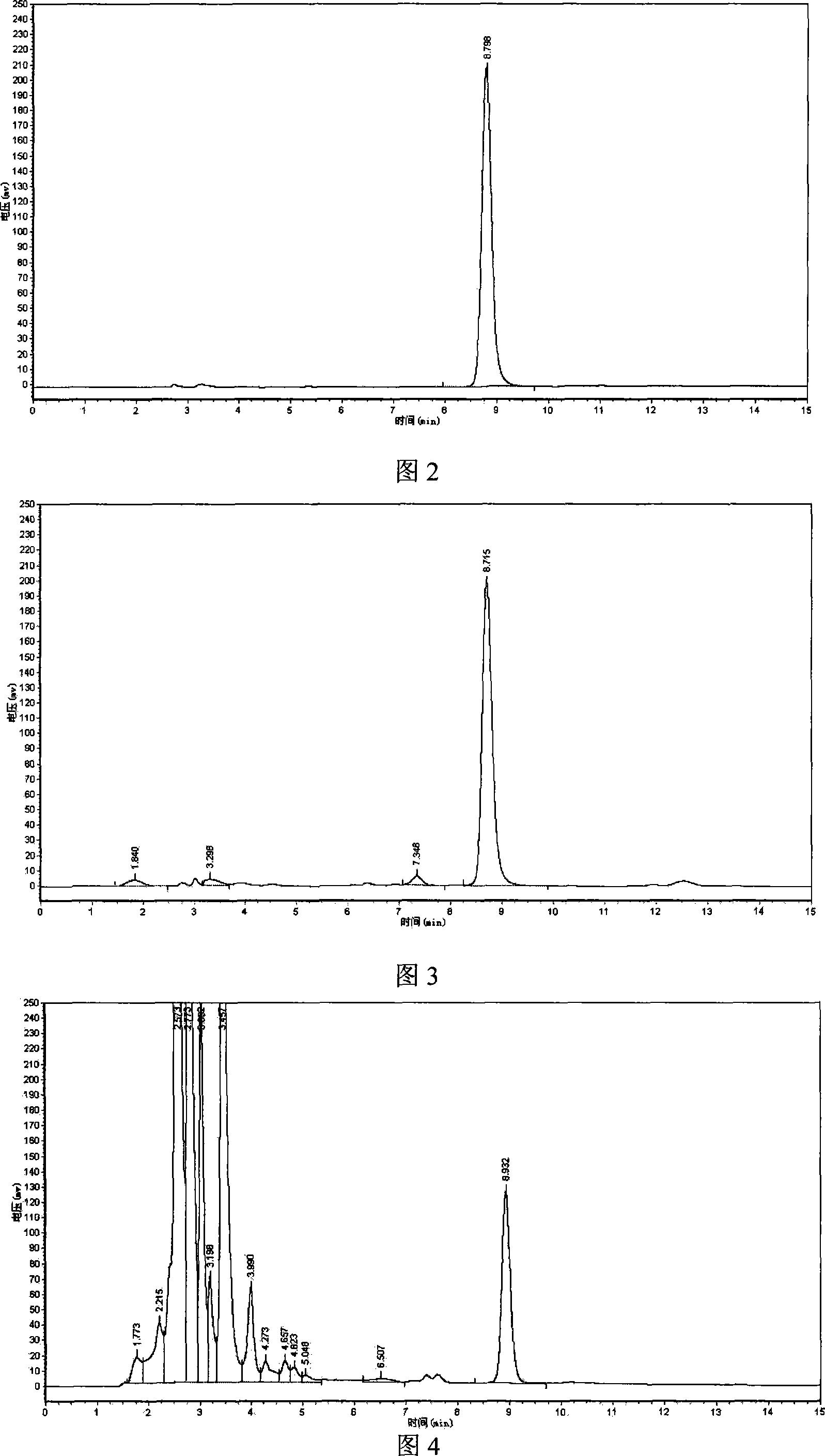

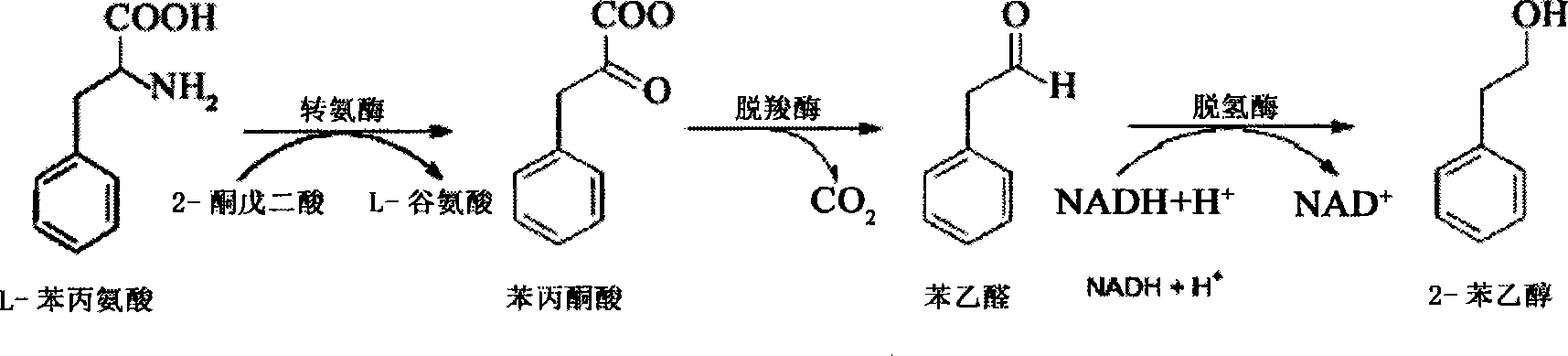

Method for preparing natural 2-benzyl carbinol

InactiveCN101157940AGrowth inhibitionEasy to chooseFungiMicroorganism based processesTransformation efficiencyPolypropylene

The invention relates to a method for producing natural 2-benzene alcohol. The method takes saccharomyces cerevisiae as biocatalyst, inoculates in a converting medium, uses L-phe-phenylalanine gained by an enzyme catalysis method or a microorganism fermentation method as substrate, vibrates by a swing bed or aeration-agitates under the condition of organic solvent and 25 to 30 DEG C for 18 to 24h, the output of converting liquid aftertreatment is natural 2-benzene alcohol. The concentration of L-phe-phenylalanine is 10 to 20g / L in aqueous phase and the organic solvent is oleinic acid or polypropylene. The invention catenates converting, synthesis and extract, abstraction of 2-benzene alcohol, thus being suitable for large scale industrialized application. The product 2-benzene alcohol has pure smell and belongs to natural product. The process of production has the advantages of short cycle, high transformation efficiency and low environmental pollution, etc.

Owner:ZHEJIANG UNIV OF TECH

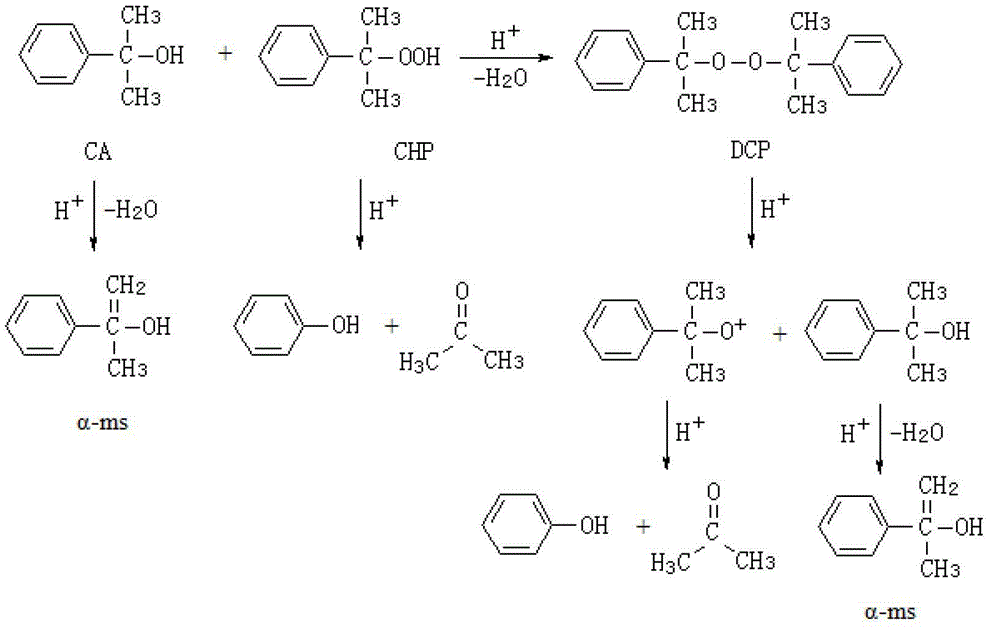

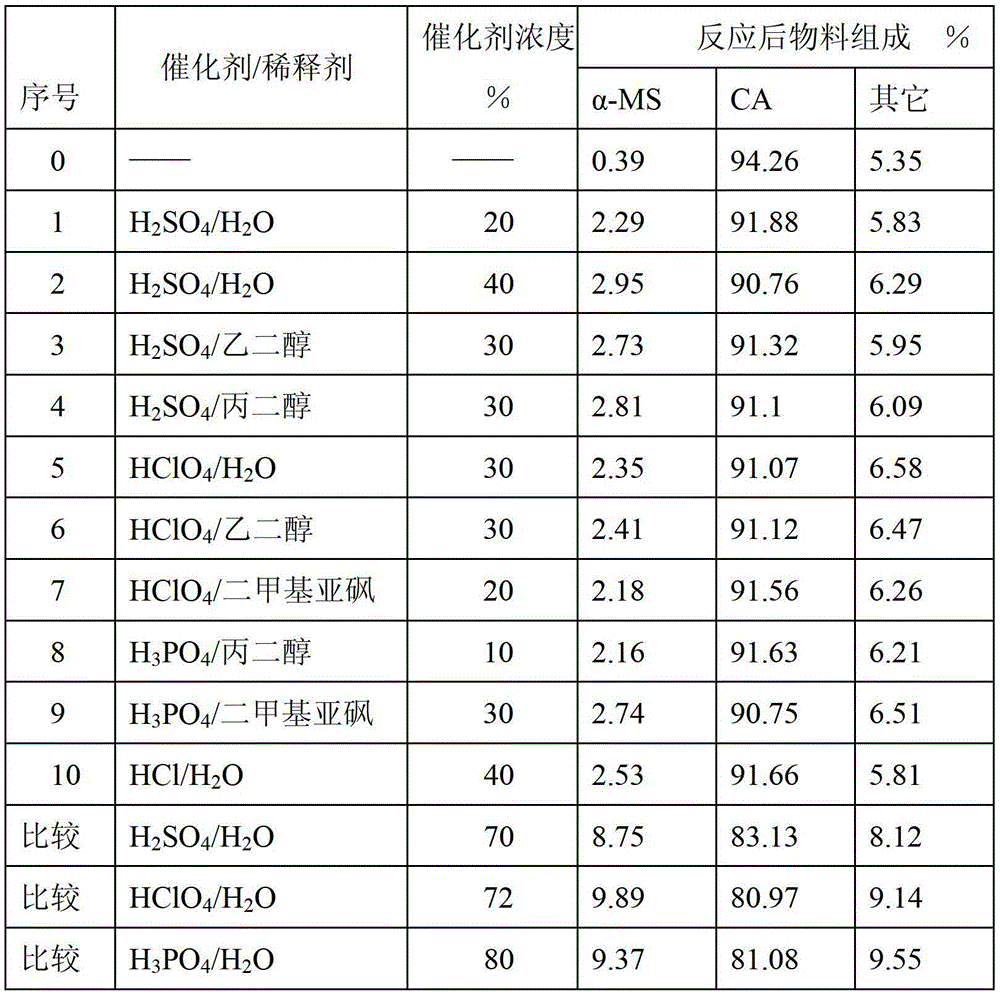

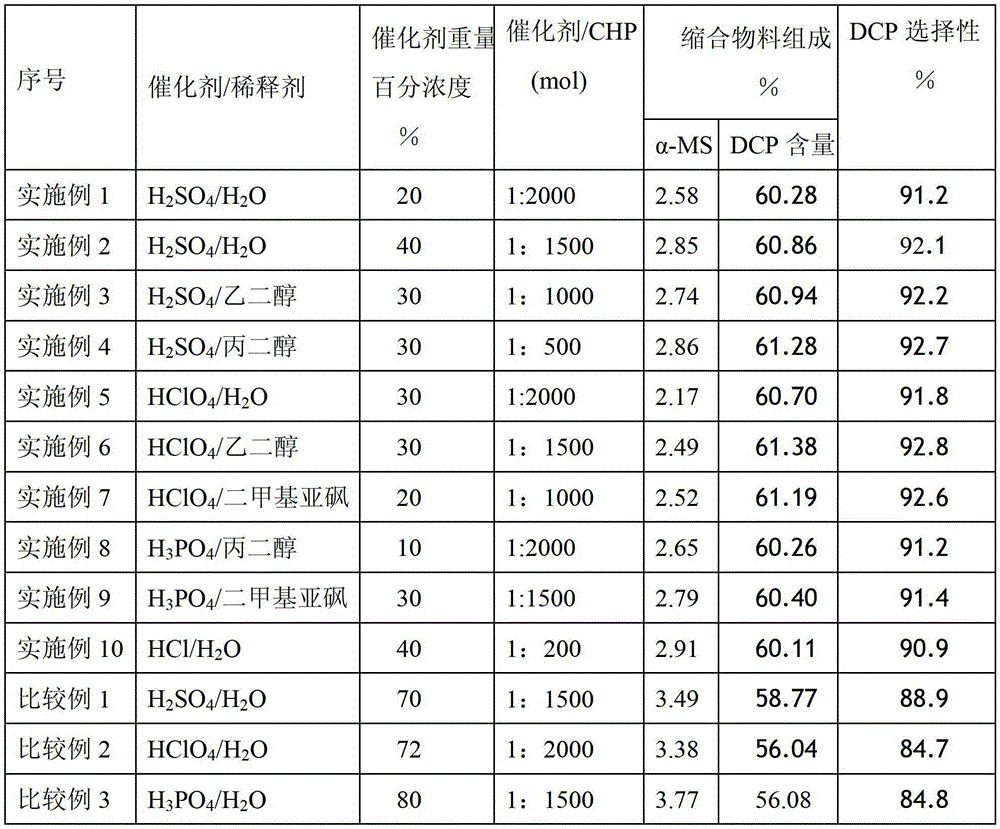

Method for producing dicumyl peroxide

ActiveCN103145597AReduce unit consumptionReduce α-MSOrganic compound preparationPeroxy compound preparationPhosphateReaction temperature

The invention relates to a method for producing dicumyl peroxide, and particularly relates to a production method for reducing a dicumyl peroxide condensation byproduct. The problem of high alpha-vinyltoluene content of the byproduct in condensation production is mainly solved. The method taking cumin as a solvent and dimethyl-benzyl carbinol and cumyl hydroperoxide as materials comprises the steps of carrying out reaction on the materials and a strong proton acid catalyst for 0.5-1 hour and carrying out condensation dehydration to generate the dicumyl peroxide under the conditions that the reaction temperature is 30-60 DEG C and the reaction manometer pressure is -0.1MPa. By adopting the production method disclosed by the invention, the condensation side effect of the dicumyl peroxide is reduced; the alpha-vinyltoluene content in condensation solution is reduced; the reaction selectivity is improved; and DCP (dicalcium phosphate) yield and quality are improved, so as to reduce isopropyl benzene consumption and reduce the production cost. On the other hand, the acid catalyst recommended to use is low in concentration, and safer in the production process.

Owner:CHINA PETROCHEMICAL CORP

Method for promoting the growth of plant succulent stem of Cistanche tutulosa

InactiveCN101449647APromote continuous growthSeed and root treatmentHarvestersTamarix chinensisLoment

The invention provides a method of advancing a succulent stem of Cistanche tubulosa to generate, through thick planting host Chinese tamarisk ecological forest in wide and narrow lines on hungriness and desert, a drip sprinkle system is built, a hole is drilled between wide lines of the planted host Chinese tamarisk ecological forest, seeds of Cistanche tubulosa are planted in single layer or in delamination or / and seed inoculating paper of is put in Cistanche tubulosa. 'Foliage fertilizer' is sprayed, system technology integration is adopted combining biological integrated control and the like, reaching succulent stems of Cistanche tubulosa 350-1380 kg / per mu yield in one year lasted for many years. Through detection, success ratio of inoculating the autoeciousness Cistanche tubulosa reaches 90.7-97.7%, effective components-benzyl carbinol glycoside compound in the Cistanche tubulosa reach 12.9-36.9%wt (dry product s).

Owner:SUN YAT SEN UNIV

Edge gluing cleaning agent used in processing procedure of colored filter

InactiveCN101544929AQuick washSimple methodSurface-active detergent compositionsDetergent solventsResistCleansing Agents

The invention provides an edge gluing cleaning agent used in processing procedure of colored filters, which has the prescription by the weight percent of 1-60 of water soluble organic amine compound, 1-60 of benzene aromatic alcohol organic solvent and 3-80 of water, wherein the water soluble organic amine compound is neovaricaine, trolamine, diethanolameine or the mixture of two or three of neovaricaine, trolamine, diethanolameine; the benzene aromatic alcohol organic solvent is phenylcarbinol, benzyl carbinol, phenylpropanol, phenaglycodol, fenipentol or benzyl hexanol or the derivatives of the six substances; and the water is pure water with the resistance higher than or equal to 18 mega ohms. The edge gluing cleaning agent obtained by compounding can remove superfluous colored photosensitive resist at the edges or backs of glass substrates very easily under normal temperature and in shorter time and has very excellent environmental-friendly performance of production and use, thereby having wide application prospect.

Owner:SUZHOU RUIHONG ELECTRONIC CHEM CO LTD +1

Vintage yeast CWY132 and application of the same in preparation of 2-phenethylol by microorganism fermentation

The invention discloses a saccharomyces cerevisiae mutagenesis strain--saccharomyces cerevisiae CWY132 and application to prepare 2-benzyl carbinol, which is characterized by the following: the CWY132 (Saccharomyces cerevisiae CWY132) is kept in Chinese typical culture preservation center; the preservation date is 12.15 2006; the keeping number is CCTCC NO: M206136; the ferment circle is short; the ferment temperature range is wider. This invention does not possess special demand to device, which can be used to general ferment plant.

Owner:ZHEJIANG UNIV OF TECH

Method for preparing isopropylbenzene through catalytic hydrogenolysis of alpha,alpha-dimethyl-benzyl carbinol

InactiveCN108947757AImprove technical effectOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon from oxygen organic compoundsHydrogenNitrogen

The invention discloses a method for preparing isopropylbenzene through catalytic hydrogenolysis of alpha,alpha-dimethyl-benzyl carbinol. According to the method, an NiB-Zn / ZIF-8 catalyst is adopted,alpha,alpha-dimethyl-benzyl carbinol and hydrogen are taken as the raw materials, the molar ratio of raw material gas / nitrogen is 1 to 15, the molar ratio of hydrogen / alpha,alpha-dimethyl-benzyl carbinol is 5 to 1, and under the condition that the reaction temperature is 120 DEG C, the reaction pressure is 0.5MPa and the volume velocity of inert carrier gas is 3.0h<-1>, the conversion rate of alpha,alpha-dimethyl-benzyl carbinol is 100%, and the selectivity of isopropylbenzene is over 96.8%, so that a relatively technical effect is achieved, the product is easy to separate, the after-treatmentis simple, and the catalyst can be recycled for repeated use.

Owner:崔九香

Method used for combined production of dimethyl-benzyl carbinol and 1,2-pentanediol

ActiveCN107445796ANothing producedSimple processOrganic compound preparationPreparation by hydrolysisCyclopenteneIsopropyl benzene hydroperoxide

The invention provides a method used for combined production of dimethyl-benzyl carbinol and 1,2-pentanediol. The method comprises following steps: 1-pentene and isopropyl benzene hydroperoxide are subjected to epoxidation reaction under the action of an epoxidation catalyst so as to obtain a reaction solution containing 1,2-cyclopentene oxide and dimethyl-benzyl carbinol; the reaction solution is subjected to separation so as to obtain 1,2-cyclopentene oxide and dimethyl-benzyl carbinol; 1,2-cyclopentene oxide and water are subjected to hydrolysis reaction under the action of a hydrolysis catalyst, and rectification is carried out so as to obtain 1,2-pentanediol. According to the method, 1-pentene and isopropyl benzene hydroperoxide are taken as the raw materials in combined production of dimethyl-benzyl carbinol and 1,2-pentanediol, operation is simple, synthesis cost is low, no waste water is generated in synthesis process, dimethyl-benzyl carbinol selectivity is 90% or higher, and 1,2-pentanediol selectivity is 80% or higher.

Owner:昌德新材科技股份有限公司 +1

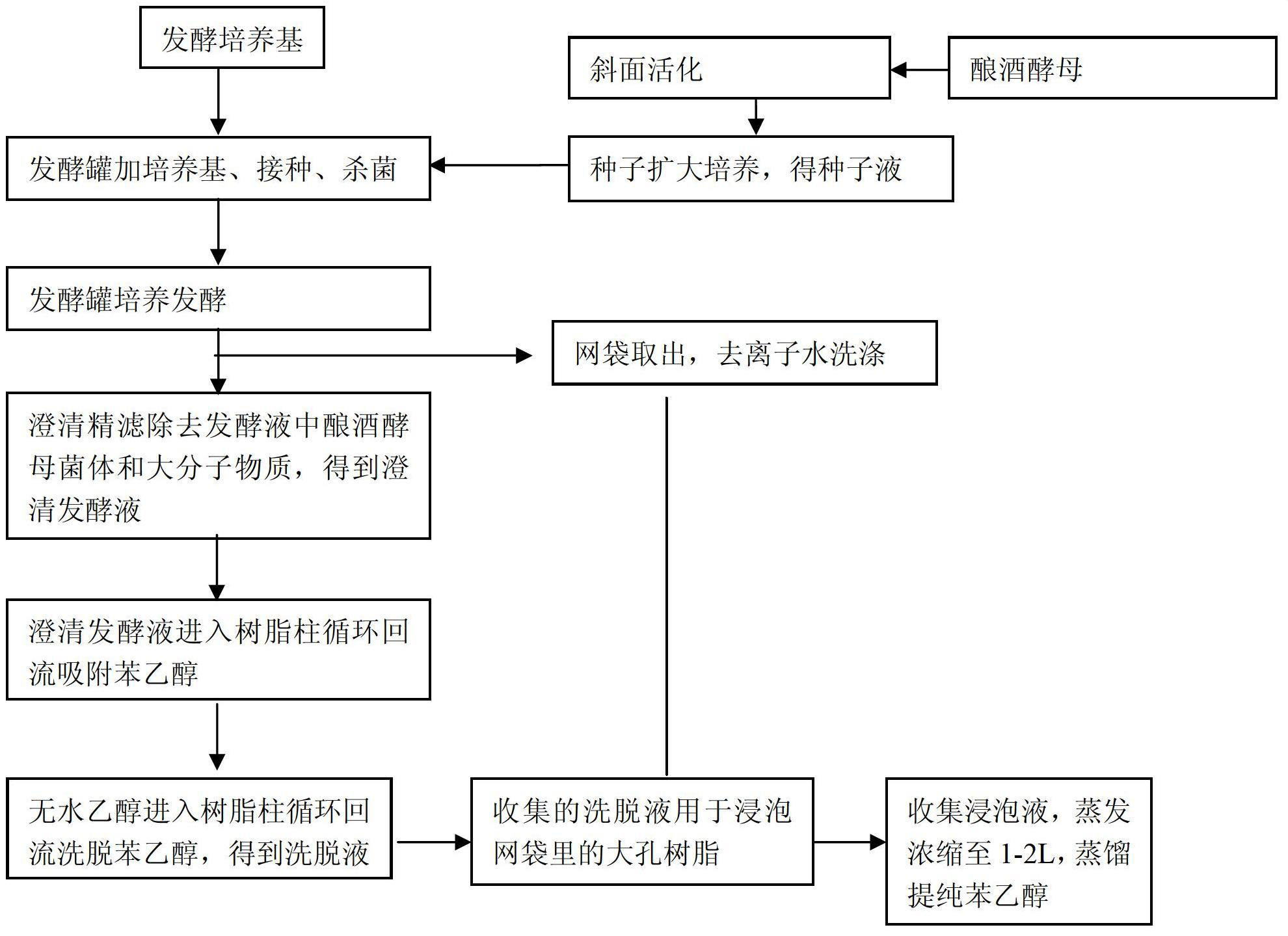

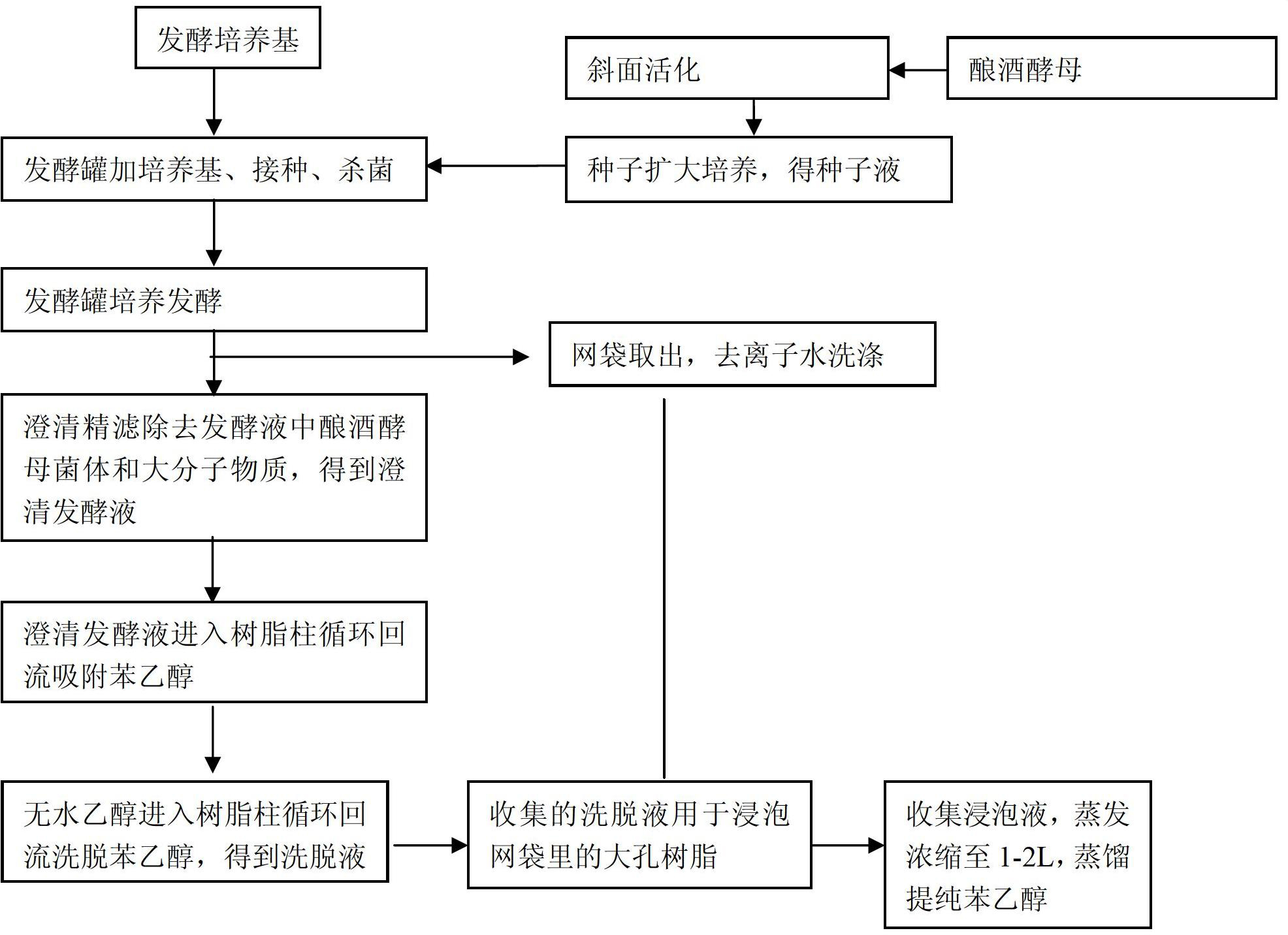

Method for producing beta-phenethyl alcohol by using biotransformation method

InactiveCN102660591AIncrease contentEasy extractionIon-exchange process apparatusIon-exchanger regenerationRotary evaporatorBeta-Phenylethanol

The invention relates to a method for producing beta-phenethyl alcohol by using a biotransformation method. The method comprises the following steps of: inoculating a seed solution subjected to amplification culture of sccharomyces cerevisiae as a biological catalyst into a fermentation tank filled with a fermentation medium with L-phenyl alanine as a reaction substrate; suspending a mesh bag filled with macroporous resin in the fermentation tank; after fermenting, taking out the mesh bag; clarifying and finely filtering fermentation broth and circularly reflowing the obtained fermentation broth in a resin column; then draining a residual adsorption liquid; eluting the resin column with absolute ethyl alcohol to obtain an eluant containing benzyl carbinol; soaking the mesh bag with the eluant first and then introducing the mesh bag into a rotary evaporator for concentrating and recovering the ethanol; and distilling the obtained concentrate to obtain high-purity beta-phenethyl alcohol. According to the method disclosed by the invention, the beta-phenethyl alcohol generated in the fermentation tank is adsorbed by the mesh bag filled with the macroporous resin suspended in the fermentation tank, so that the content of the beta-phenethyl alcohol in the fermentation broth adsorbed by the macroporous resin is increased, the extraction content of the beta-phenethyl alcohol is increased and high yield and purity of products are obtained.

Owner:CITYFLOWER GUANGZHOU

α, the method for preparing cumene by direct hydrogenolysis of α-dimethylbenzyl alcohol

Owner:CHINA PETROLEUM & CHEM CORP +1

Essence

The invention discloses essence, which aims at providing the essence with a reasonable recipe and a unique flavor. The invention has the technical scheme that the essence is characterized in that the essence comprises the following ingredients in percentage by weight: 5 percent of benzyl carbinol, 2 percent of benzaldehyde, 3 percent of glycerin, 80 percent of propanediol, 2 percent of butanedione and 8 percent of mango juice. The essence disclosed by the invention has the beneficial effects of reasonable recipe, unique flavor, good use effect and low production cost.

Owner:孟庆云

Heat insulating plastic bottle cap masterbatch

The invention discloses a heat insulating plastic bottle cap masterbatch. The heat insulating plastic bottle cap masterbatch is prepared from the following raw materials in parts by weight: 100-105 parts of a ABS (acrylonitrile-butadiene-styrene) copolymer, 0.6-1 part of basic bismuth chloride, 0.5-1 parts of dimethyl benzyl carbinol, 1-2 parts of difenoconazole, 3-4 parts of hollow glass beads, 0.5-1 part of tributyl tin trichloride, 1-2 parts of polybrominated styrene, 0.3-1 part of hexamethylphosphoramide, 0.6-1 part of 2-bromo-4-methylphenol, 0.8-1 part of ammonium metaborate, 0.8-2 parts of chromium carbonate, 2-3 parts of bisphenol A polycarbonate, 0.7-1 part of nano diatomite, 1-2 parts of glyceryl tristearate, 0.7-1 part of a silane coupling agent KH560 and 3-4 parts of a toughening packing. The added hollow glass beads and nano diatomite for preparing the heat insulating plastic bottle cap masterbatch have good heat insulating properties and have the effects of well protecting bottled items so that the service life of some bottled items stored in a high-temperature environment for a long time can be prolonged and the security of the bottled items can be improved, and the added toughening packing can further improve the toughness of the ABS copolymer and improve the wear resistance and the fracture resistance of plastic bottle caps so that the plastic bottle caps have good sealing and protecting effects.

Owner:HEFEI AOPAI METAL PROD

Compound closantel sodium-ivermectin injection for animal and preparation method thereof

InactiveCN1875923AEasy to makeLow priceOrganic non-active ingredientsPharmaceutical delivery mechanismCLOSANTEL SODIUMAvermectin

The invention relates to a Closantel sodium and avermectin compound injection for animals and process for preparation, wherein the injection is prepared from Closantel sodium, avermectin, glycerol formal, benzyl carbinol and methyl glycol as raw material through mixing homogeneously under predetermined conditions.

Owner:TIANJIN SHENGJI GRP CO LTD

Agent for generating hair

The invention relates to a hair tonic and hair promotion agent for rubbing scalp and hairs to lead hairs to grow strong, preventing hairs from being lost, and promoting hairs to grow. The main compositions of the hair tonic and hair promotion agent comprise residual liquid of alfalfa deproteinising, quinine sulfate, rose water, ceraniol, benzyl carbinol, lauryl alcohol, linalool, eugenol, alcohol and water. The relative hair tonic and hair promotion agent can be made by the main compositions through special technique. The main composition of the invention is residual liquid of alfalfa deproteinising which has low cost and easy availability, and is beneficial for lowering cost. Alfalfa is a natural edible plant, and deproteinising residual liquid of alfalfa which is used as effective composition is safe to human bodies. The invention has excellent hair tonic and hair promotion effect, which has the effects of leading hairs to grow strong, preventing hairs from being lost, and promoting hairs to grow, and the invention has quick results.

Owner:天津雪赢世纪专利技术有限公司

Plant indoor disinfectant

InactiveCN106577896ALow toxicityReduce odorInorganic/elemental detergent compounding agentsBiocideAdditive ingredientDisinfectant

The invention discloses plant indoor disinfectant, which is prepared from the following formula ingredients in parts by mass: 1 to 3 parts of alkyl polyglucoside, 3 to 5 parts of absolute ethyl alcohol, 6 to 10 parts of tea saponin, 3 to 5 parts of dimethyl benzyl carbinol, 4 to 6 parts of quick lime, 7 to 9 parts of aliphatic polyoxyethylene ether, 10 to 20 parts of traditional Chinese medicine compositions, 2 to 4 parts of sodium gluconate, 80 to 100 parts of distilled water, 3 to 5 parts of camphor wood oil and 10 to 14 parts of ginger juice. The plant indoor disinfectant has the advantages of no toxicity, no pollution and good decontamination performance; the toxicity of traditional Chinese medicine extraction solution can be reduced; and the peculiar smell in the traditional Chinese medicine is reduced.

Owner:QINGDAO YUANZHILIN AGRI SCI & TECH DEV

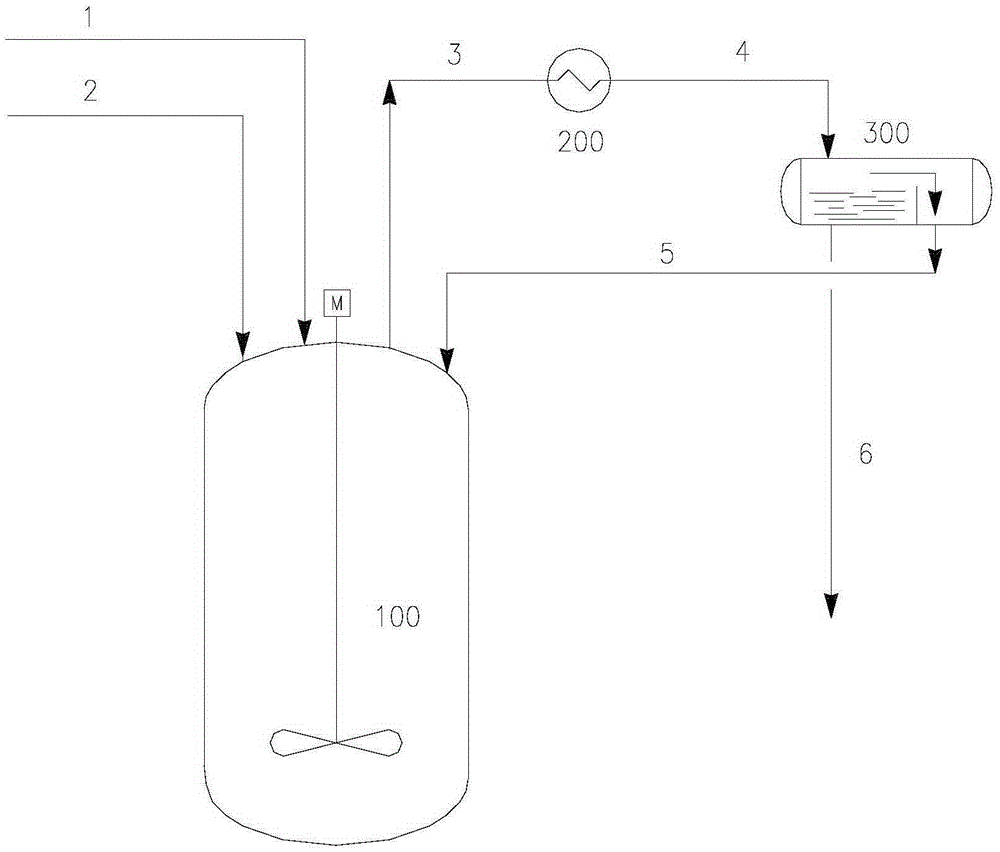

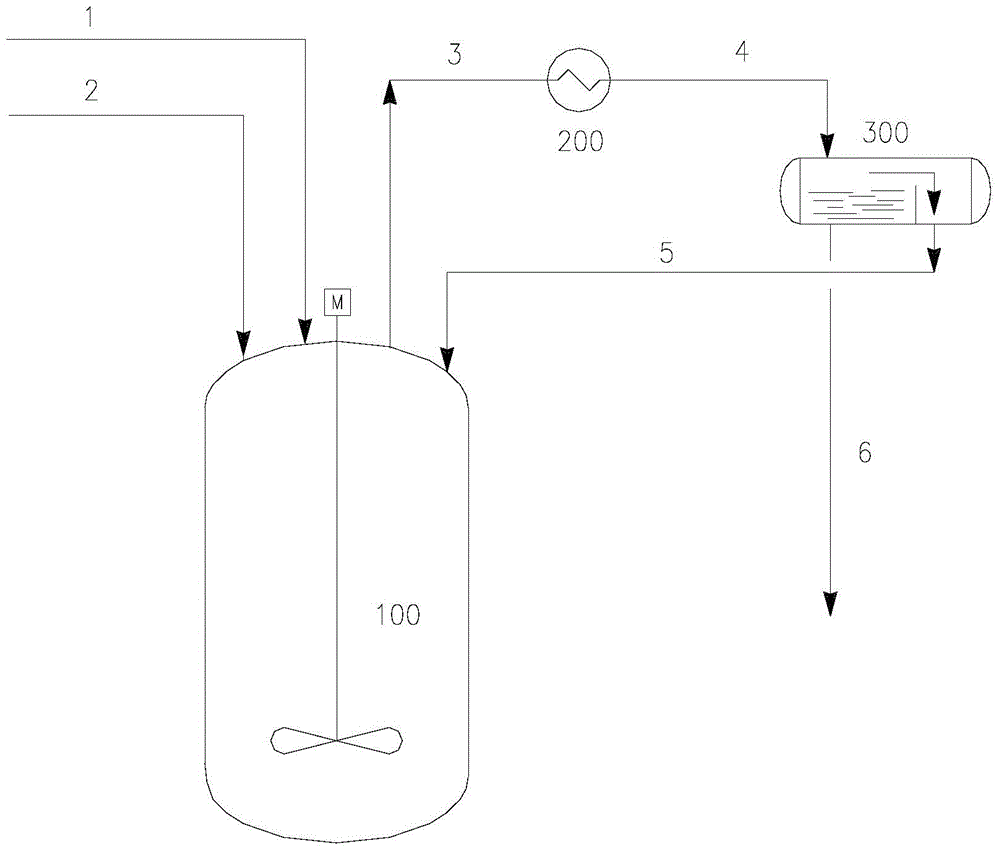

Energy-saving type dicumyl peroxide (DCP) device condensation reaction method

ActiveCN105294529AReduce energy consumptionAvoid outdated workmanshipOrganic compound preparationPeroxy compound preparationHigh energyOil phase

Owner:SINOPEC SHANGHAI ENG +1

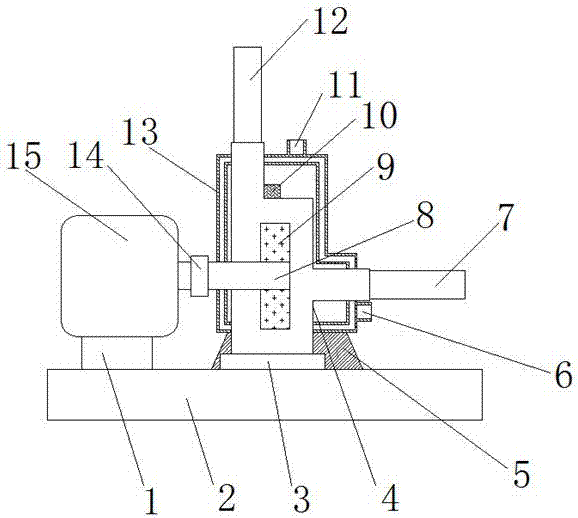

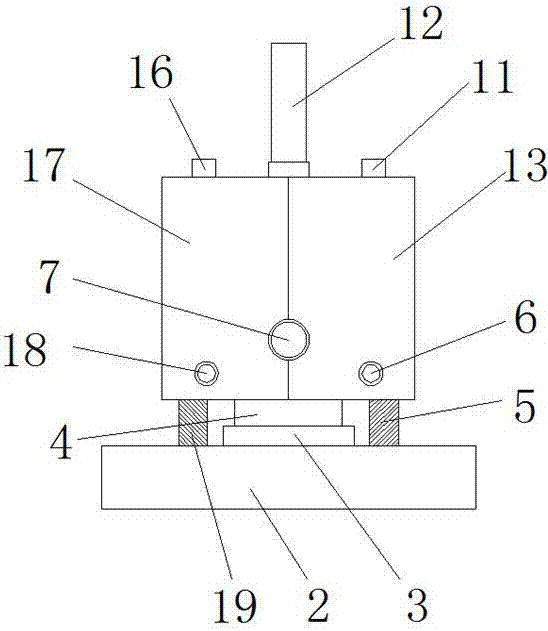

Centrifugal pump device for conveying dimethyl benzyl carbinol

The invention discloses a centrifugal pump device for conveying dimethyl benzyl carbinol. The device comprises a base, one side of the top of the base is provided with a motor base through a fastening bolt, the top of the motor base is provided with a motor through a fastening bolt, an output shaft of the motor is provided with a coupler through a bolt, the end, away from the motor, of the coupler is provided with a rotating shaft through a bolt, an impeller is clamped to the end, away from the coupler, of the rotating shaft, and a volute base is installed to the circle center position of the top of the base through a fastening bolt. The outer wall of a volute is wrapped by a first heating shell and a second heating shell, hot flows in the first heating shell and the second heating shell enable dimethyl benzyl carbinol conveyed in a pump body is in a liquid state, the outer wall of the pump body of the centrifugal pump is provided with a temperature gauge, and the temperature gauge is connected with an electric heater for heating water so as to keep the temperature of the volute at 40 DEG C always.

Owner:YANCHENG GUOZHONG CHEM CO LTD

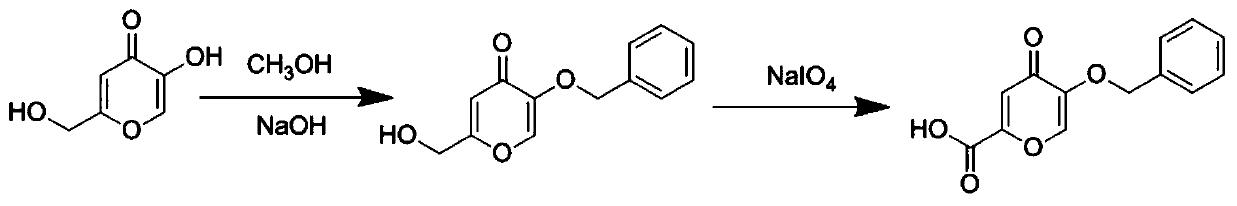

A kind of preparation method of 5-benzyloxy-4-oxo-4h-pyran-2-carboxylic acid

ActiveCN105481812BIncreased separation costIncrease production costOrganic chemistryKojic acidWastewater

The present invention discloses a 5-benzyloxy-4-oxo-4H-pyran-2-carboxylic acid preparation method comprising the following steps: adding kojic acid, benzyl chloride and methanol benzyl chloride into a reaction vessel, and heating for reflux reaction for 16 to 18 hours; distilling under reduced pressure, evaporating the solvent to dryness, and cooling to room temperature; adding methanol and water, stirring, washing, filtering and drying to obtain an intermediate; and adding the intermediate and water into the reaction vessel, reducing the temperature to 0 DEG C to -10 DEG C, adding sodium periodate, controlling the temperature to be not higher than 5 DEG C, then adding dropwise a proper amount of water, stirring for 5-15 minutes, heating to 12 DEG C-22 DEG C, stirring for reaction for 2.5 to 3.5 hours, extracting with ethyl acetate, layering, drying, filtering and drying to obtain white solid 5-benzyloxy-4-oxo-4H-pyran-2-carboxylic acid. The new 5-benzyloxy-4-oxo-4H-pyran-2-carboxylic acid preparation method is provided, does not produce large amounts of chromium-containing waste water, prevents severe environmental pollution, and can achieve industrial production.

Owner:CHONGQING TIANYI HENGHUA TECH CO LTD

Method for condensation reaction of energy-saving dicumyl peroxide dcp device

ActiveCN105294529BReduce energy consumptionAvoid outdated workmanshipOrganic compound preparationPeroxy compound preparationBenzeneHigh energy

The invention relates to an energy-saving type dicumyl peroxide (DCP) device condensation reaction method and mainly aims to solve the problem of high energy consumption of the device in the prior art. The energy-saving type dicumyl peroxide (DCP) device condensation reaction method comprises the following steps: firstly adding a certain amount of one or several mixed material of cyclohexane, hexane, benzene or methylbenzene into a condensation kettle, then adding dimethyl-benzyl carbinol and isopropylbenzene hydroperoxide into the condensation kettle to carry out condensation reaction, sucking heat released by the condensation reaction by one or several mixed material of the cyclohexane, the hexane, the benzene or the methylbenzene, vaporizing, introducing one or several mixed material of the cyclohexane, the hexane, the benzene or the methylbenzene into a condenser together with the steam generated by the reaction, condensing mixed gas into liquid, introducing the liquid into an oil-water separator for separating, returning oil phase of one or several mixed material of the cyclohexane, the hexane, the benzene or the methylbenzene to the condensation kettle to recycle. Through the technical scheme of discharging water phase which is process water generated by the reaction, the problem can be effectively solved; the method can be applied to the dicumyl peroxide (DCP) device condensation reaction.

Owner:SINOPEC SHANGHAI ENG +1

Catalyst and method for preparing chemical product 1,2-pentanediol by catalysis

InactiveCN108129259BReduce pollutionImprove industrial utilizationOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsLithium chloride2-Ethylhexanoic acid

The invention relates to a catalyst and a method for catalytic preparation ofthereof in preparing a chemical product 1,2-pentanediol in a catalytic modeusing same. The catalyst comprises a primary catalyst and a secondary catalyst, and is characterized in that the primary catalyst is salt of acetylacetonate salt or 2-ethylhexanoic acid salt 2-ethyl caproate, the secondary catalyst is lewis acid, and lewis acid is one or more of ferric trichloride, stannic chloride, tin trifluoromethanesulfonate, lithium chloride, lithium bromide or boron trifluoride. A process of preparing 1,2-pentanediol canbe simplified through catalysis of the catalyst, and 1,2-pentanediol and dimethyl-benzyl carbinol can be co-produced, and selectivity of the products 1,2-pentanediol and dimethyl-benzyl carbinol can be as high as 96% and 98% or more separately.

Owner:南京黛丽雅科技有限公司

Catalyst and method thereof in for catalytic preparing preparation of chemical product 1,2-pentanediol in catalytic modeusing same

InactiveCN108129259AReduce pollutionImprove industrial utilizationOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsLithium chloride2-Ethylhexanoic acid

The invention relates to a catalyst and a method for catalytic preparation ofthereof in preparing a chemical product 1,2-pentanediol in a catalytic modeusing same. The catalyst comprises a primary catalyst and a secondary catalyst, and is characterized in that the primary catalyst is salt of acetylacetonate salt or 2-ethylhexanoic acid salt 2-ethyl caproate, the secondary catalyst is lewis acid, and lewis acid is one or more of ferric trichloride, stannic chloride, tin trifluoromethanesulfonate, lithium chloride, lithium bromide or boron trifluoride. A process of preparing 1,2-pentanediol canbe simplified through catalysis of the catalyst, and 1,2-pentanediol and dimethyl-benzyl carbinol can be co-produced, and selectivity of the products 1,2-pentanediol and dimethyl-benzyl carbinol can be as high as 96% and 98% or more separately.

Owner:南京黛丽雅科技有限公司

Fermented extract of peaches as well as preparation method and application thereof

InactiveCN111100878AEasy to storeHigh activityTobacco preparationTobacco treatmentBenzaldehydeHexaldehyde

The invention discloses a fermented extract of peaches as well as preparation method and application thereof. The fermented extract of the peaches is prepared by fermenting peaches used as raw materials by using lodderomyces elongisporus, and extracting aromatic components in fermented solutions. The lodderomyces elongisporus is preserved in China Center for microbial culture collection managementcommittee general microbiology, the preservation number is CGMCC No.6645, and the preservation date is 08th, October, 2012. The fermented extract of the peaches contains a variety of aromatic substances, such as benzyl carbinol, hexaldehyde, benzaldehyde, ethyl acetate and 1-butanol. Aromatizing and smoking test result shows that the fragrance of the fermented extract can be harmonized with the fragrance of cigarettes, the fragrance of the cigarettes can be obviously improved, fumes are exquisite and mellow, the irritability is reduced, offensive odor is concealed, and smoking of cigarettes is improved, and a refreshing and special aromatic smell is produced.

Owner:李自力

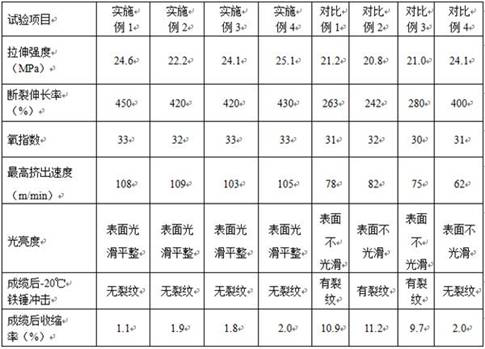

High-temperature-resistant low-shrinkage impact-resistant PVC cable material for 5G optical cables

The invention relates to a high-temperature-resistant low-shrinkage impact-resistant PVC cable material for 5G optical cables. The material is composed of the following components: SG3 type PVC resin,PVC resin with a polymerization degree of 2500, acrylonitrile-butadiene-styrene (ABS), nitrile rubber, 4-phenylethynyl phthalic anhydride, epoxy soybean oil, antimonous oxide, melamine phosphate, a filler, aluminum hydroxide, a calcium-zinc heat stabilizer, an antioxidant 1098, dimethyl benzyl carbinol, alpha-methyl styrene, 5-10 parts of an ethylene-vinyl acetate-maleic anhydride copolymer M506and glass beads. A cable prepared from the PVC cable material can be impacted by an iron hammer at -20 DEG C without cracking, the shrinkage rate is 2% or below, the extrusion speed of the product isincreased, and the lubricating effect and brightness of the PVC cable material are changed.

Owner:中广核三角洲(江苏)塑化有限公司

Producing raw material containing benzyl carbinol glycosides from Cistanche deserticola by using membrane separation technique and preparation method thereof

InactiveCN100503626CHigh retention rateRemove invalid ingredientsSugar derivativesPlant ingredientsSeparation technologyAdditive ingredient

Owner:HETIAN DCM MEDICINE BIOLOGICAL TECH

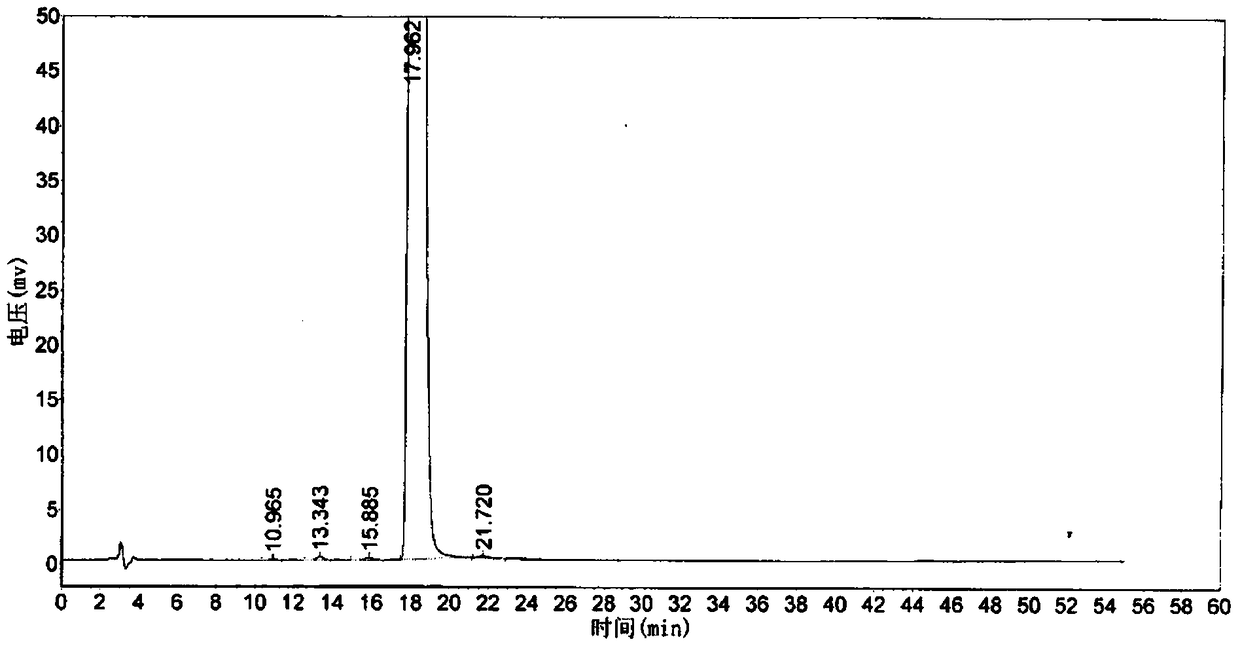

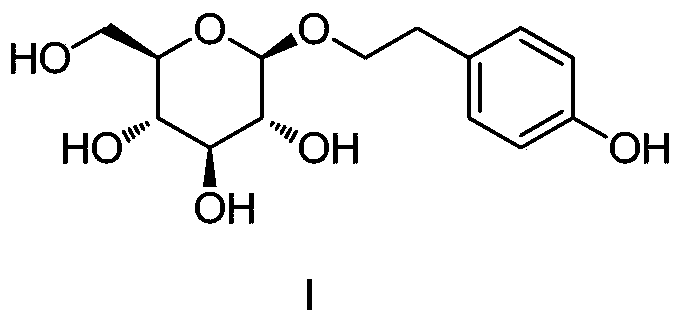

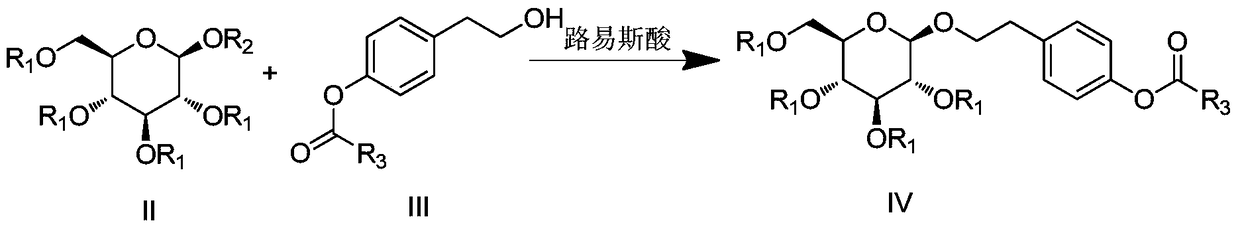

A kind of synthetic method of salidroside and intermediate compound thereof

ActiveCN105294787BReduce transferQuick responseEsterified saccharide compoundsSugar derivativesSalidrosideOrganic solvent

Owner:YICHANG HUMANWELL PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com