Method for producing beta-phenethyl alcohol by using biotransformation method

A biotransformation and phenylethyl alcohol technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of low productivity and low extraction and separation rate of 2-phenylethyl alcohol, and achieve short production cycle and high purity , pure smell effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

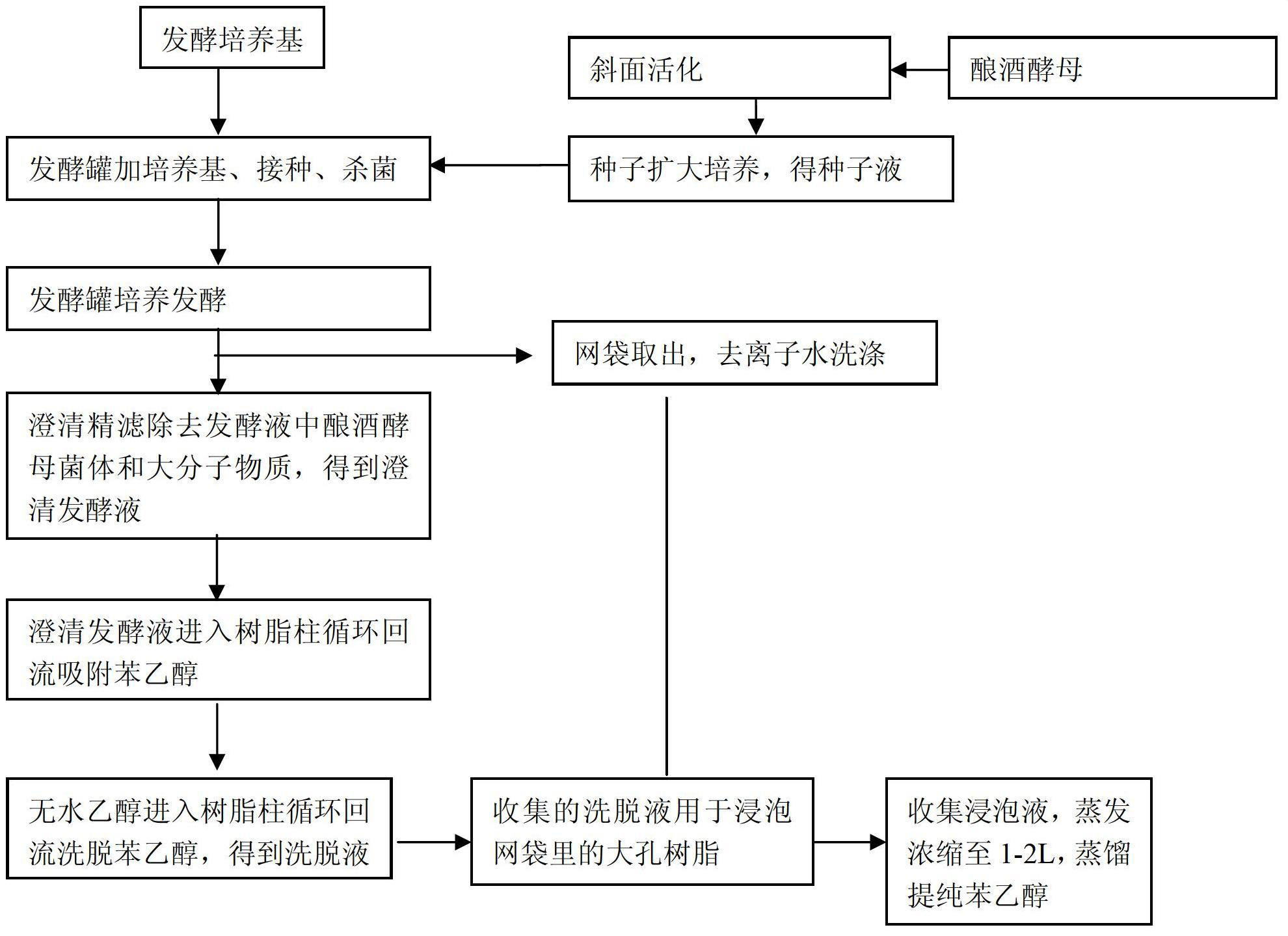

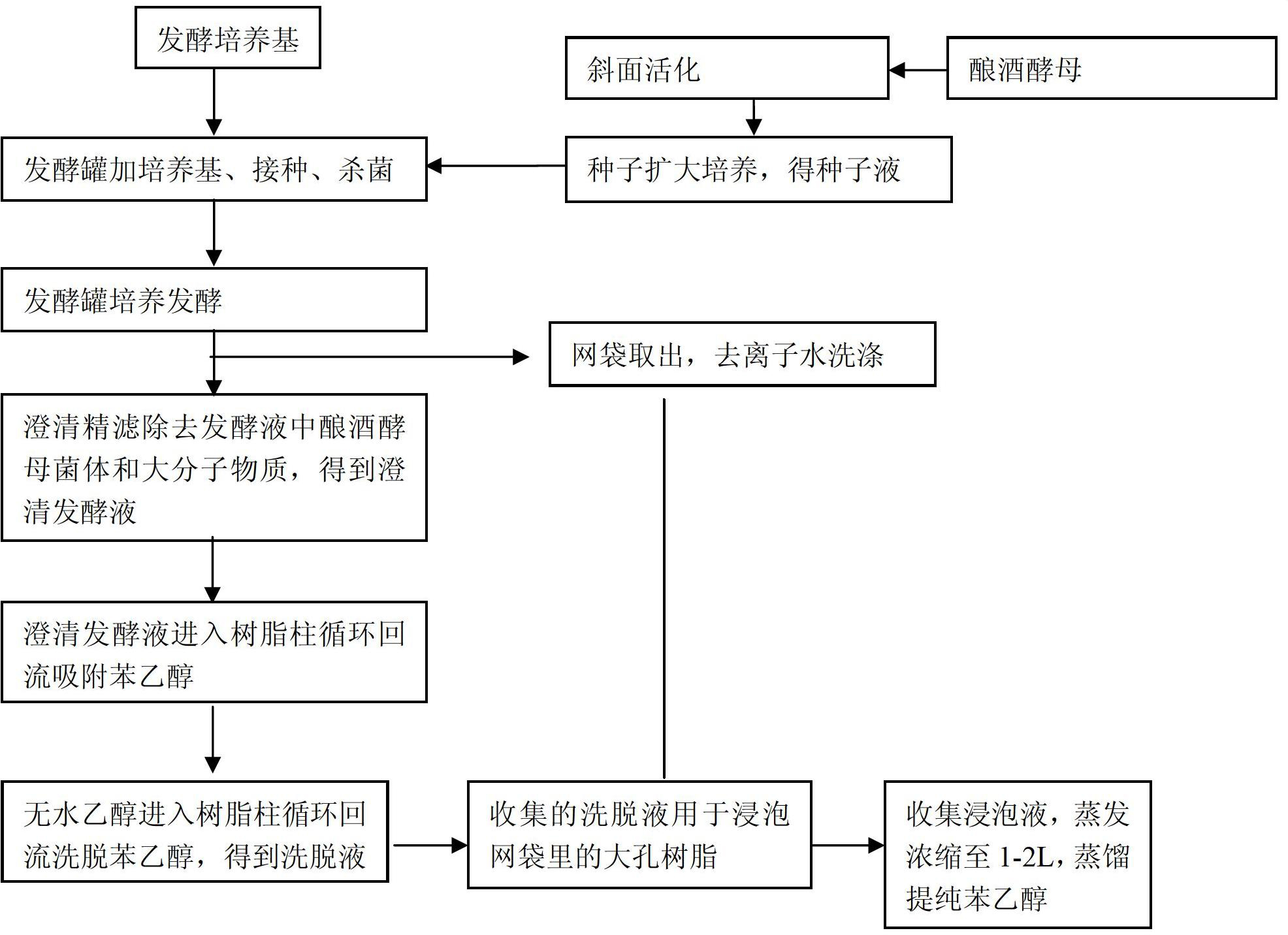

Method used

Image

Examples

Embodiment 1

[0029] 1. Preparation of culture medium

[0030] (1) Slant medium: 10°Bx malt juice agar medium, sterilized by high-pressure steam at 120°C for 20 minutes.

[0031] (2) Seed medium: glucose 10 g / L, 10°Bx wort 3 g / L, protein 5 g / L, yeast extract 3 g / L, solvent is water, and oxalic acid solution and oxalate solution Adjust the pH to 7.0, and sterilize with high pressure steam at 120°C for 20 minutes.

[0032] (3) Fermentation medium: glucose 30 g / L, L-phenylalanine 8 g / L, MgSO 4 ·7H 2 O 0.5 g / L, KH 2 PO 4 0.5 g / L, soybean meal powder 6 g / L, the solvent is water, and the pH is adjusted to 7.0 with oxalic acid solution and oxalate solution.

[0033] 2. Production process:

[0034] (1) Activation of strains on slopes: the temperature is 28°C, and the time is 4 days.

[0035] (2) Preparation of seed solution: Pick activated Saccharomyces cerevisiae cells into a conical flask containing seed medium, under the conditions of temperature of 28°C, stirring speed of 220r / min, an...

Embodiment 2

[0044] 1. Preparation of culture medium

[0045] (1) Slant medium: 10°Bx malt juice agar medium, sterilized by high-pressure steam at 120°C for 20 minutes.

[0046] (2) Seed medium: glucose 10 g / L, 10°Bx wort 3 g / L, protein 5 g / L, yeast extract 3 g / L, solvent is water, and oxalic acid solution and oxalate solution Adjust to pH 7.0.

[0047] (3) Fermentation medium: glucose 30 g / L, L-phenylalanine 8 g / L, MgSO 4 ·7H 2 O 0.5 g / L, KH 2 PO 4 0.5 g / L, soybean meal powder 6 g / L, solvent is water, and adjusted to pH 7.0 with oxalic acid solution and oxalate solution, and sterilized by high-pressure steam at 120°C for 20 minutes.

[0048] 2. Production process:

[0049] (1) Activation of strains on slopes: the temperature is 28°C, and the time is 4 days.

[0050](2) Preparation of seed solution: Pick activated Saccharomyces cerevisiae cells into a conical flask containing seed medium, under the conditions of temperature of 28°C, stirring speed of 220r / min, and ventilation rat...

Embodiment 3

[0058] 1. Preparation of culture medium

[0059] (1) Slant medium: 10°Bx malt juice agar medium, sterilized by high-pressure steam at 120°C for 20 minutes.

[0060] (2) Seed medium: glucose 10 g / L, 10°Bx wort 3 g / L, protein 5 g / L, yeast extract 3 g / L, solvent is water, and oxalic acid solution and oxalate solution Adjust the pH to 7.0, and sterilize with high pressure steam at 120°C for 20 minutes.

[0061] (3) Fermentation medium: glucose 30 g / L, L-phenylalanine 8 g / L, MgSO 4 ·7H 2 O 0.5 g / L, KH 2 PO 4 0.5 g / L, soybean meal powder 6 g / L, the solvent is water, and the pH is adjusted to 7.0 with oxalic acid solution and oxalate solution.

[0062] 2. Production process:

[0063] (1) Activation of strains on slopes: the temperature is 28°C, and the time is 4 days.

[0064] (2) Preparation of seed solution: Pick activated Saccharomyces cerevisiae cells into a conical flask containing seed medium, under the conditions of temperature of 28°C, stirring speed of 220r / min, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com