Patents

Literature

38 results about "Beta-Phenylethanol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

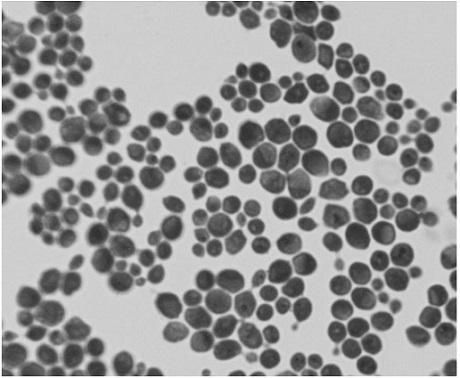

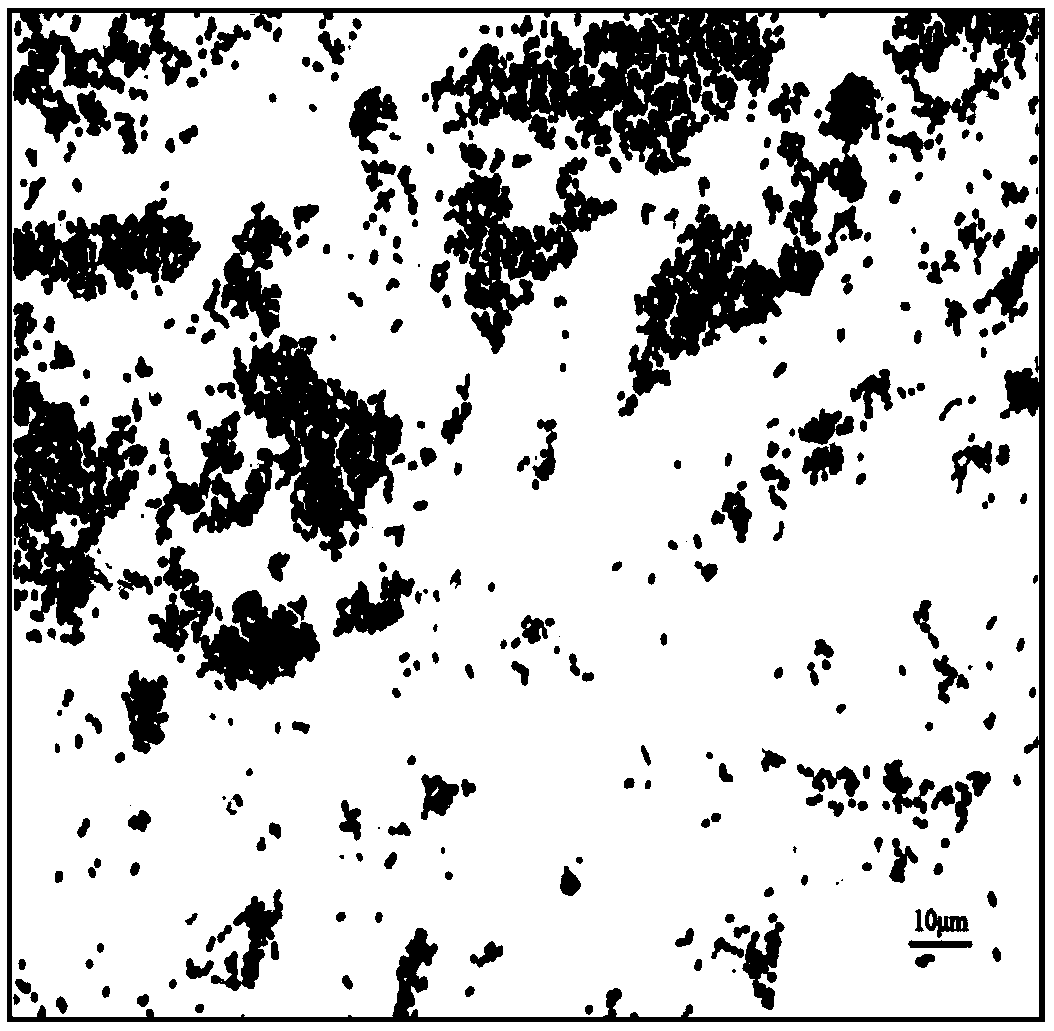

Saccharomyces Cerevisiae strain with high yield of beta-phenylethanol and application thereof

ActiveCN107177520AHigh-yield β-phenylethanol characteristicsGood alcoholic propertiesFungiMicroorganism based processesMicroorganismFlavor

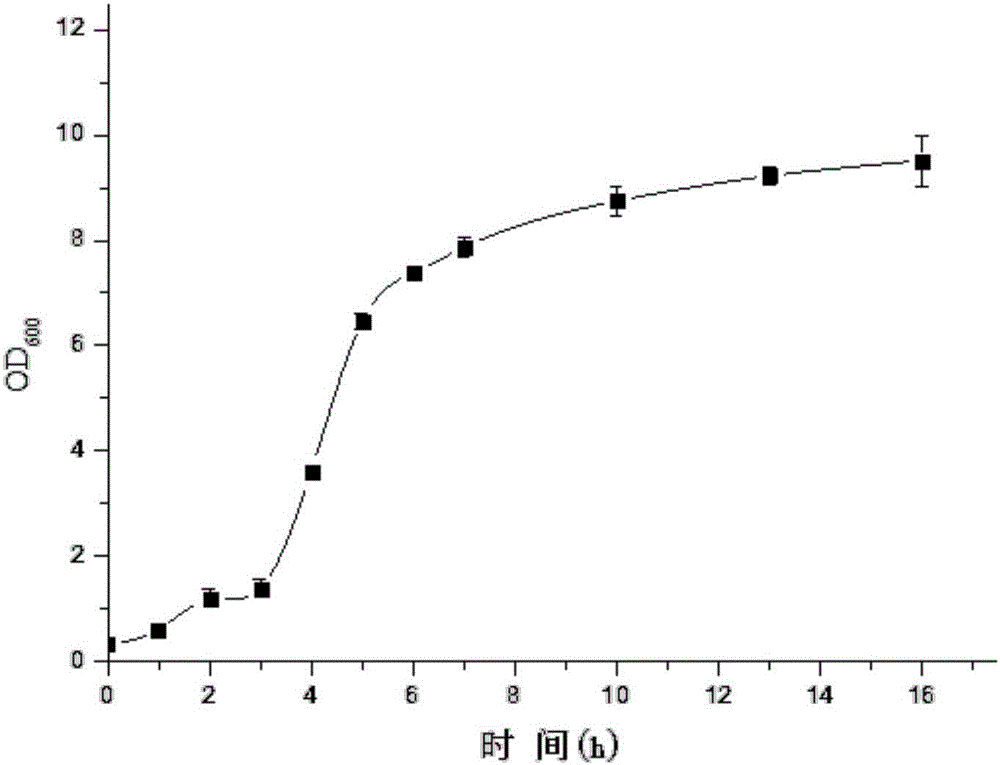

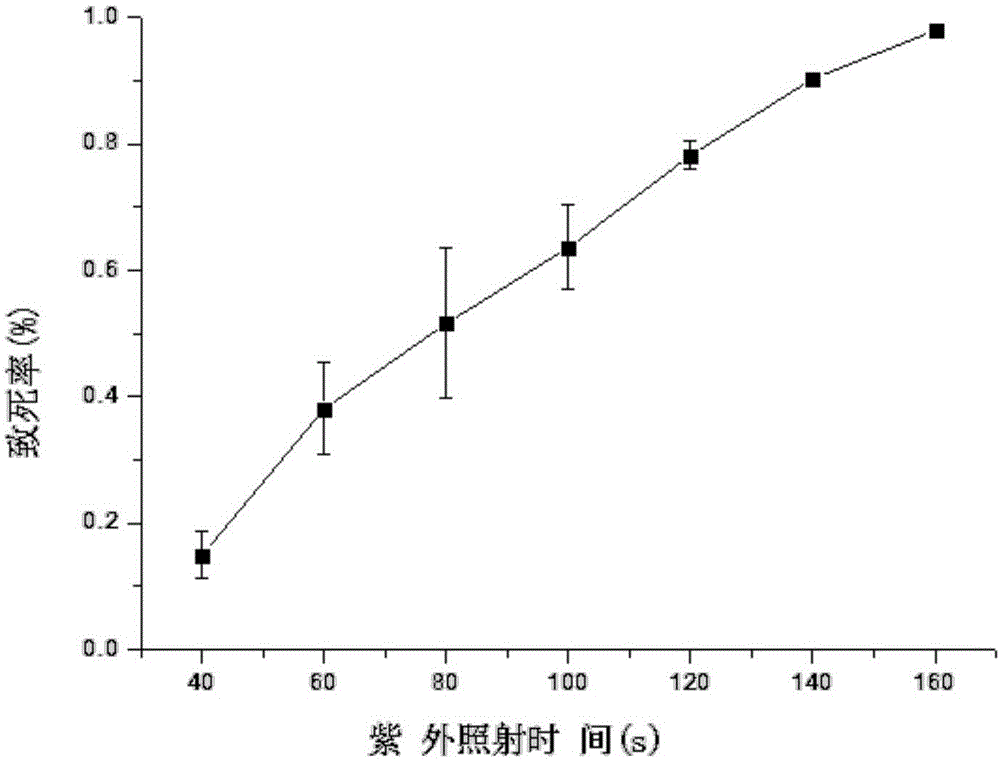

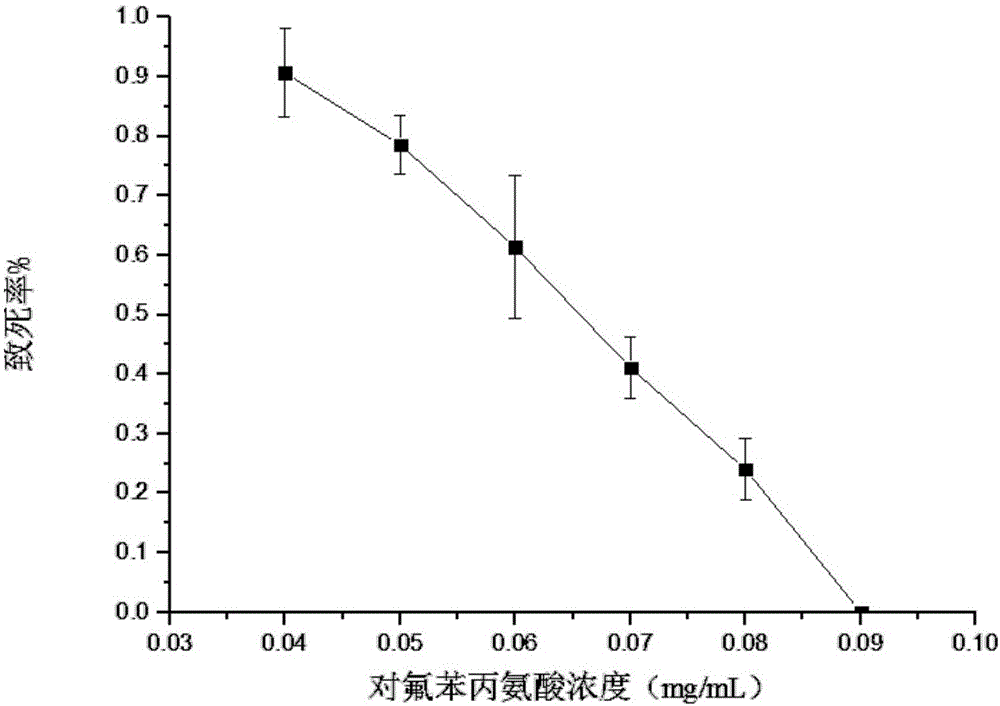

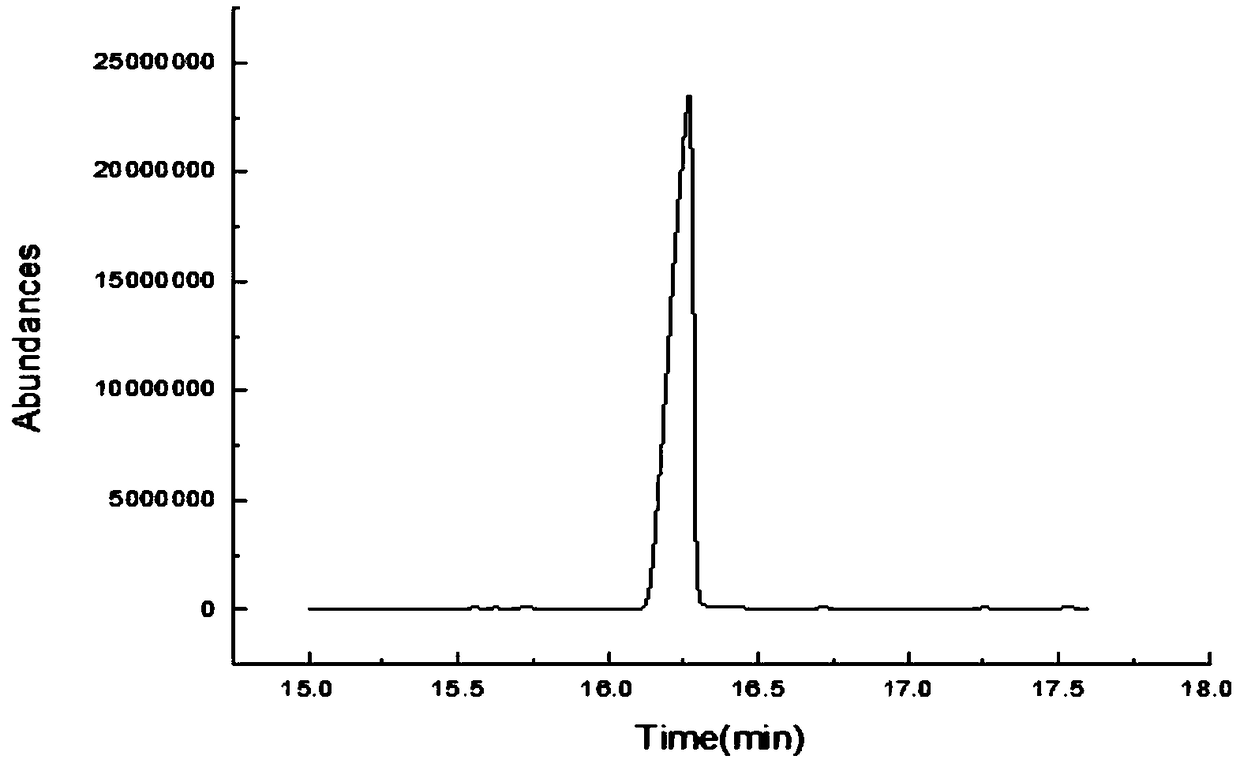

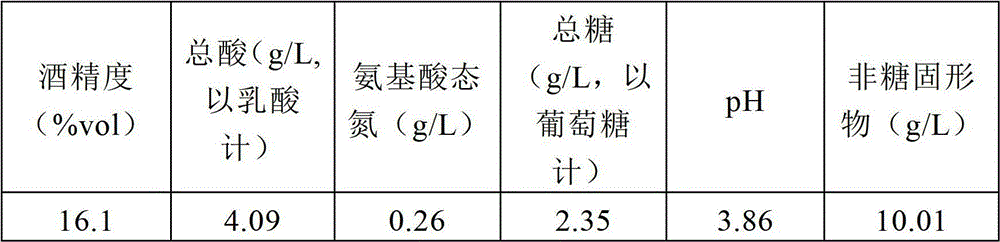

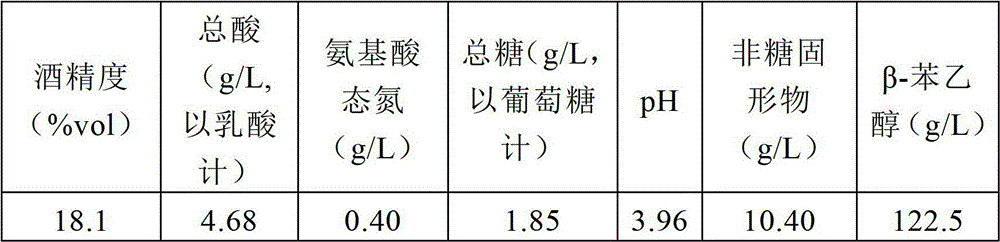

The invention discloses a Saccharomyces cerevisiae strain with high yield of beta-phenylethanol and application thereof, and belongs to the technical field of industrial microorganisms. The Saccharomyces cerevisiae strain with high yield of beta-phenylethanol is collected in China Center for Type Culture Collection on December 16, 2016, under CCTCC NO: M 2016785. The strain has capacity of high yield of beta-phenylethanol and is applied to yellow rice wine fermentation, cooking wine fermentation, vinegar brewing, soy sauce fermentation and baijiu fermentation, with beta-phenylethanol contents being 410mg / L, 450mg / L, 300mg / L, 200mg / L and 110mg / L respectively. Besides, flavor substances such as acetic acid-2-phenethyl ester are highly yielded. The Saccharomyces cerevisiae strain is good in fermentation performance, the content of beta-phenylethanol in fermented products is obviously increased, and fermented product quality is improved, so that the strain has a promising application prospect.

Owner:JIANGNAN UNIV +3

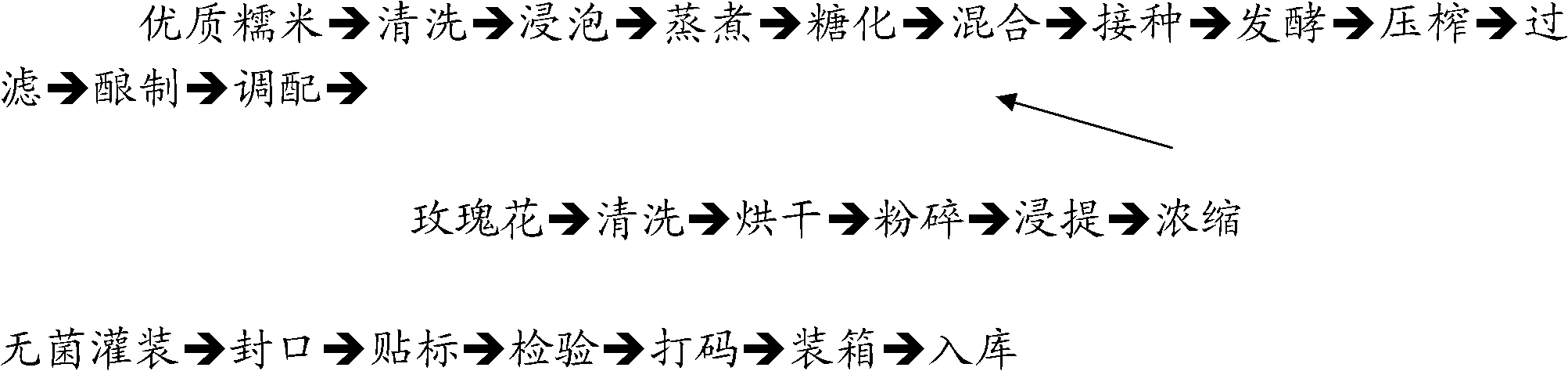

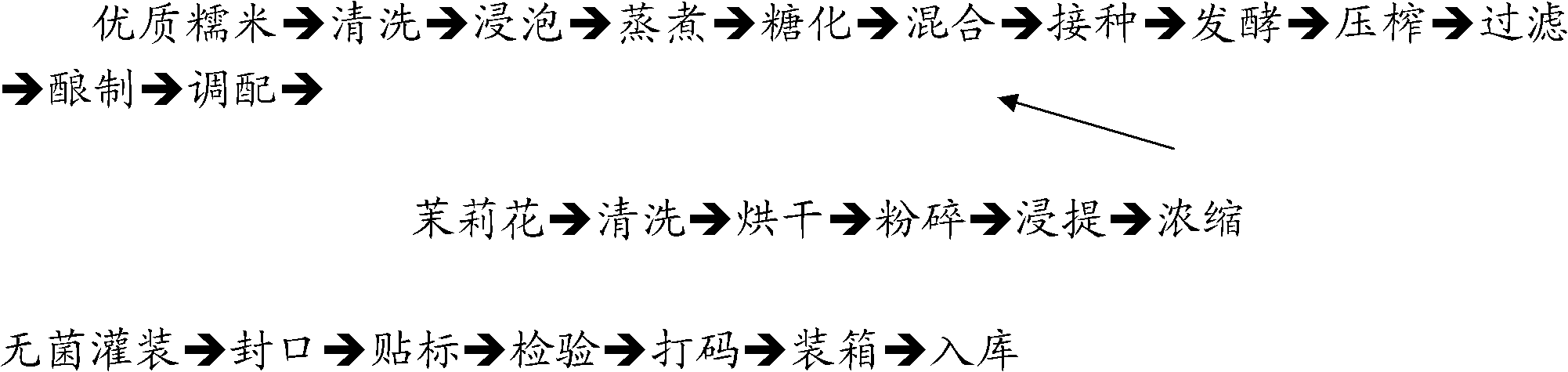

Preparation method of fermentation type plant flower rice wine

InactiveCN102604796ARich flavor ingredientsRich activityAlcoholic beverage preparationFlavorBeta-Phenylethanol

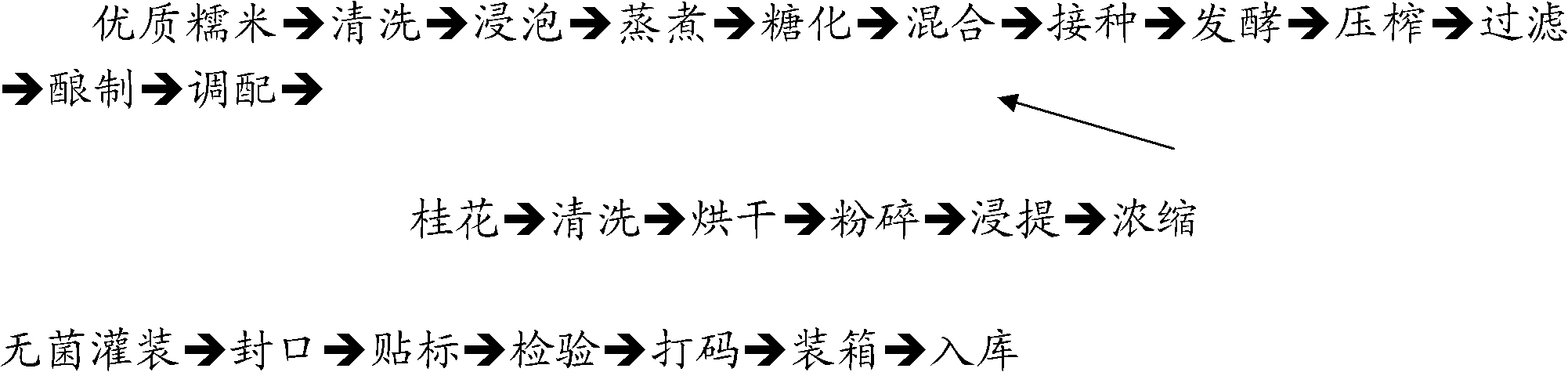

The invention discloses a preparation method of fermentation type plant flower rice wine, belonging to the technical field of food production. The preparation method comprises the following steps of: steaming sticky rice and adding saccharifying enzyme for saccharification; crushing sweet osmanthus, rose or jasmine and performing ultrasonic extraction and concentration; adding the concentrated solution into the saccharified sticky rice, and adding distiller yeast for fermentation, wherein the fermentation temperature is 28-32 DEG C, and the fermentation time is 24-48 hours; juicing the obtained product, collecting the juice and feeding the juice into a superfilter; filtering and collecting the juice, and brewing the juice in a storage tank at room temperature below 30 DEG C for 3-6 months; blending until the alcoholic strength is greater than or equal to 8.0 (vol), the total acid (based on lactic acid) is greater than or equal to 2.20g / L, the total sugar (based on glucose) is greater than or equal to 40.0g / L, the amino acid nitrogen is greater than or equal to 0.10g / L, and the beta-phenethyl alcohol is greater than or equal to 20.0mg / L; and filling. The preparation method disclosed by the invention has the beneficial effects that: the flavor components and physiological activators of the plant flower are richer than those in the product of the prior art.

Owner:YUNNAN ZHIWEIYUAN FOOD

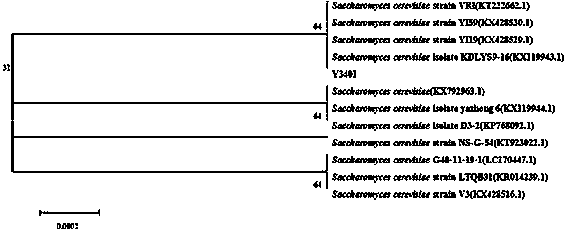

High-yielding ethanol yeast and method for improving quality of traditional fermented foods through symbiotic fermentation of high-yielding ethanol yeast and ester-producing yeast

ActiveCN109810910AIncreased ethanol productionOptimizing the Culture Conditions of Symbiotic FermentationFungiAlcoholic beverage preparationHydrolysateEthyl acetate

The invention relates to a saccharomyces cerevisiae Y3401 strain for high-yielding ethanol and a symbiotic fermentation culture method of the saccharomyces cerevisiae Y3401 strain and a Wickerhamomyces anomalus Y3604 strain for high-yielding ethyl acetate as well as application of the saccharomyces cerevisiae Y3401 strain. The saccharomyces cerevisiae Y3401 was preserved in China General Microbiological Culture Collection Center on October 20th, 2017, with a preservation number of CGMCC No.14828; the similarity of 26S rDNA D1 / D2 sequence of the saccharomyces cerevisiae Y3401 strain to 26S rDNA D1 / D2 sequence of other saccharomyces cerevisiae strains; symbiotic fermentation of two yeast strains in a sorghum enzymatic hydrolysate culture medium by a standing or shaking mode has the advantages that the content of the ethyl acetate is favorably improved and the contents of flavor substances such as total ester, beta-phenylethanol and isoamyl alcohol also can be improved. In a solid brewing system, the symbiotic fermentation of the two strains can enhance the characteristics of ester-improving and flavor-enhancing of yeast. The symbiotic fermentation method of the two strains, disclosed by the invention, can be applied to the brewing industries, having demands on the ethyl acetate, such as Baijiu, yellow rice wine and soy sauce.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Rice wine grain stillage refilling fermentation method

InactiveCN104212682AIncrease rice flavorImprove qualityAlcoholic beverage preparationYeastBeta-Phenylethanol

The invention relates to a rice wine grain stillage refilling fermentation method. The rice wine grain stillage refilling fermentation method comprises the steps of soaking of raw material rice, rice steaming, distiller yeast mixing, saccharification, fermentation, wine distillation and the like. The rice wine grain stillage refilling fermentation method greatly improves the content of flavor and fragrance components such as of total acid, total ester, ethyl lactate and beta-phenethyl alcohol.

Owner:GUILIN YINQUAN LIQUOR IND

Low-yield isoamylol and high-yield beta-phenylethanol yeast, isolated culture method thereof and application of yeast

ActiveCN110205253AImprove featuresExcellent sugar toleranceFungiAlcoholic beverage preparationBiotechnologyPhenethyl alcohol

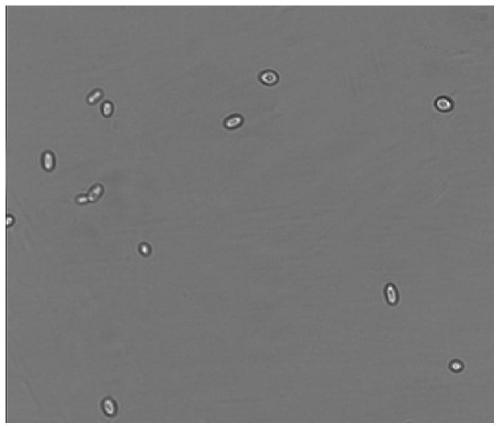

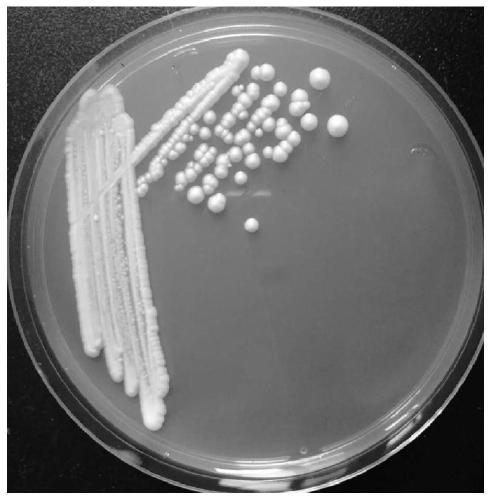

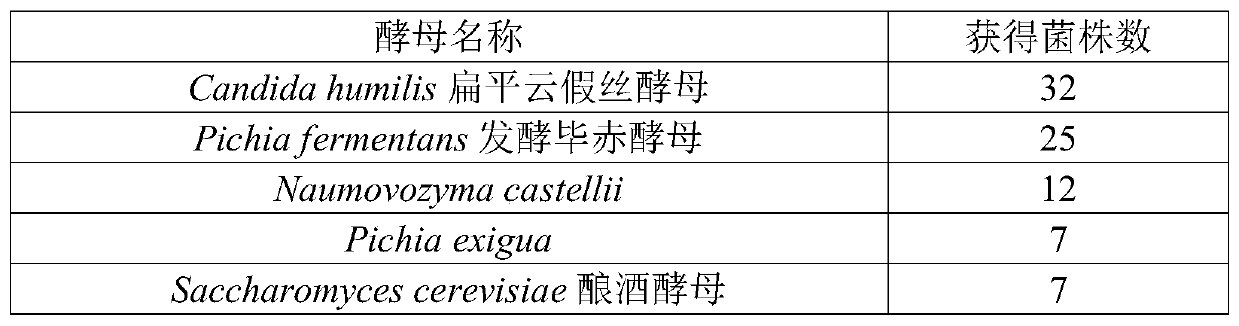

The invention relates to low-yield isoamylol and high-yield beta-phenylethanol yeast, an isolated culture method thereof and an application of the yeast. The low-yield isoamylol and high-yield beta-phenylethanol yeast is named as a Candida humilis YS023A strain, the strain is collected in a general microorganism center of a China Committee for Culture Collection of Microorganisms on No. 3, No. 1 courtyard Beichen West Road, Chaoyang District, Beijing on February 25, 2019, and the collection number of the strain is CGMCC NO:17257. The yeast has excellent characteristics of low-yield isoamylol and high-yield beta-phenylethanol and excellent sugar, alcohol and acid resistance, and the sugar utilization rate, the fermentation capacity and the ethanol production capacity of the yeast are good.The yeast is used for production of strong-flavor and rice-flavor Baijiu and has great significance for increasing of high-quality product rate and wine outlet rate of raw wine.

Owner:JIANGSU KINGS LUCK BREWERY

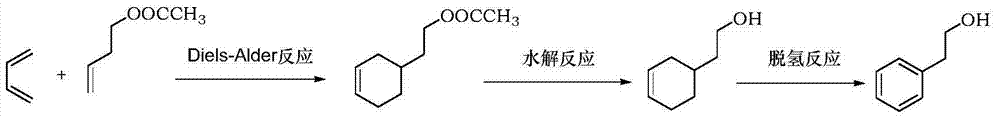

Method for preparing beta-phenethyl alcohol

ActiveCN104744216AGuaranteed water solubilityGood water solubilityOrganic compound preparationHydroxy compound preparationDehydrogenationPhenethyl alcohol

The invention discloses a method for preparing beta-phenethyl alcohol. According to the method, acetic acid-3-butene-1-alcohol ester and 1,3-butadiene are adopted as raw materials, and the preparation of beta-phenethyl is finished by adopting Diels-Alder, hydrolysis and dehydrogenation reactions. lewis acid supported by fullerol as a carrier is adopted as the catalyst for the Diels-Alder reaction, the atom utilization rate is high, the total yield can reach 87%-95%, the purity of products can reach 99.92wt%-99.98wt%, and an oxidation reaction process and a high-pressure hydrotreatment reaction process are not adopted, so that the production process is safe and environmentally friendly.

Owner:WANHUA CHEM GRP CO LTD

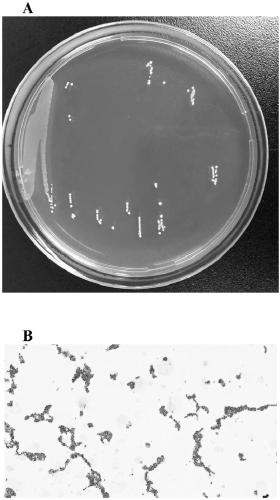

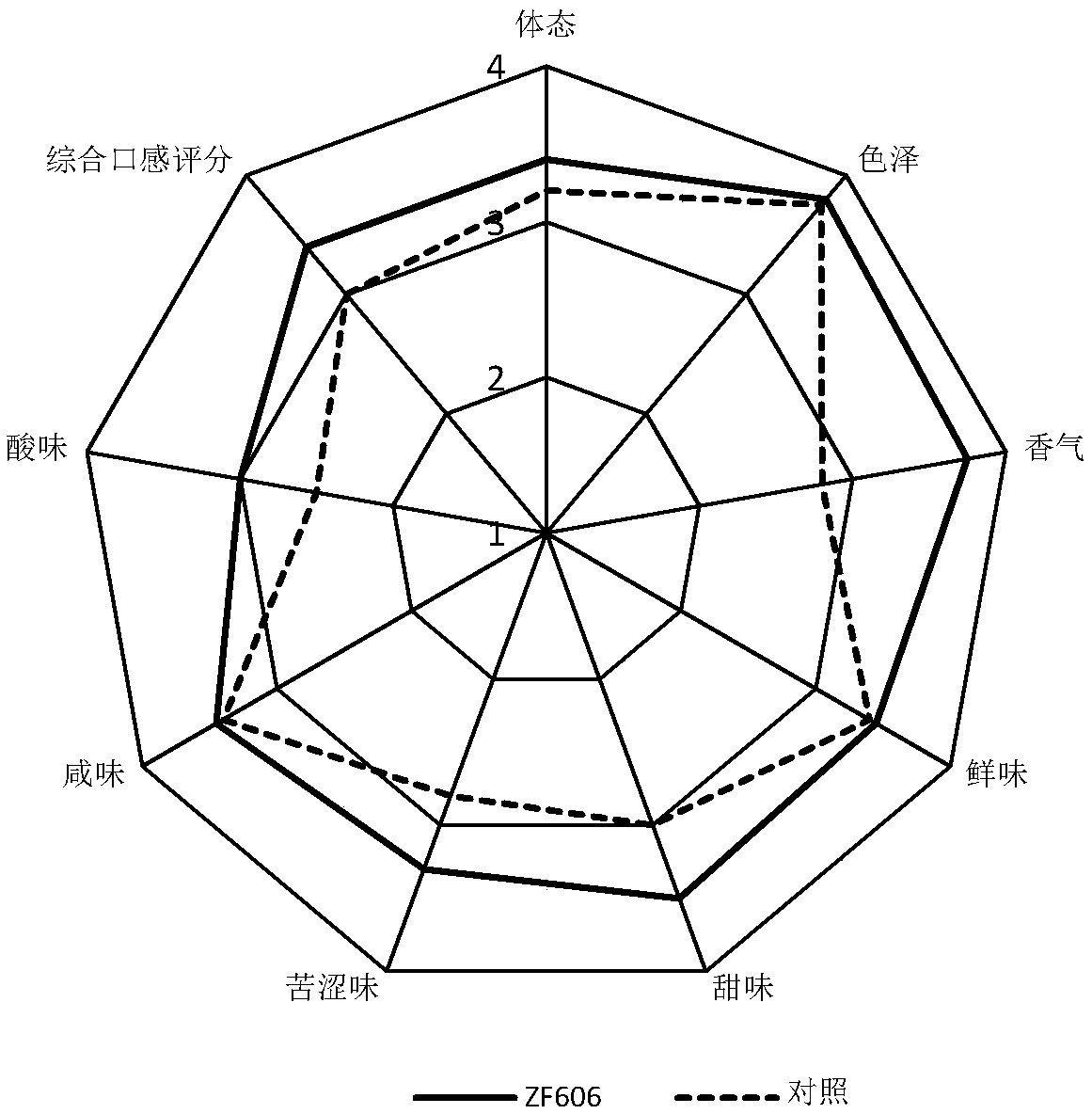

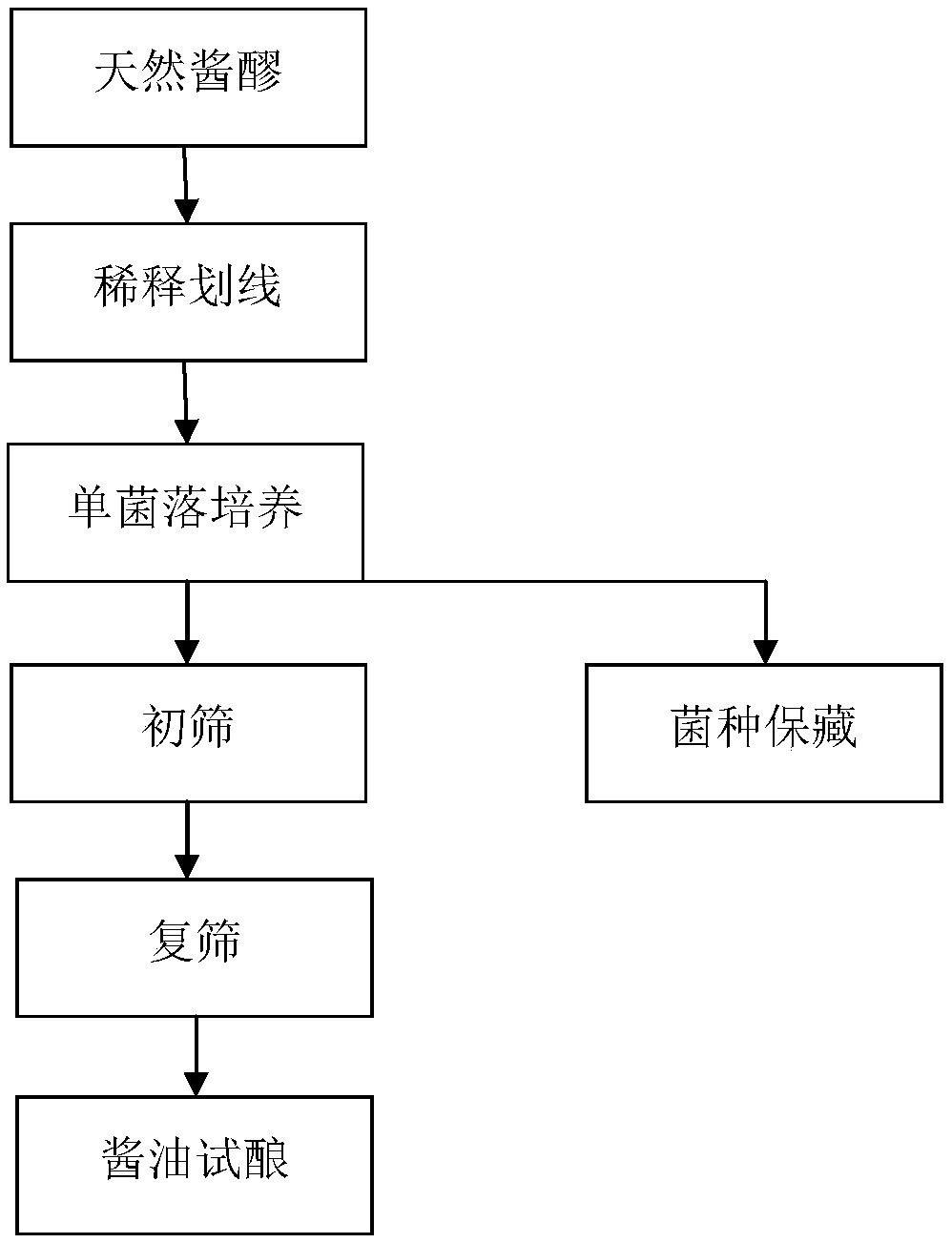

Weissella confusa for increasing content of beta-phenethyl alcohol in soybean sauce and application of weissella confusa

InactiveCN109370951ADoes not affect nutritional valueDoes not affect propertiesBacteriaMicroorganism based processesFlavorBeta-Phenylethanol

The invention relates to a weissella confusa ZF606 bacterial strain. After the weissella confusa ZF606 bacterial strain is inoculated at the fermentation stage of the soybean sauce, the content of beta-phenylethanol in the soybean sauce can be increased significantly, thus the fermented soybean sauce has light floral fragrance on the basis of not changing a flavor system of crude sauce, and the flavor quality of the soybean sauce is improved. Weissella confusa ZF606 provided by the invention has the characteristics that the content of the beta-phenylethanol can be increased, and other nutritional components in the soybean sauce system are not affected, the Weissella confusa ZF606 is originated from natural soy sauce mash, the safety risk is avoided, the crude soybean sauce with the harmonious fragrance, fresh, sweet and outstanding flavor, mellow taste, rich sauce flavor and durable taste can be fermented, the flavor does not need to be blended in the later period, and the soybean sauce is natural and healthy.

Owner:FOSHAN HAITIAN GAOMING FLAVORING & FOOD +2

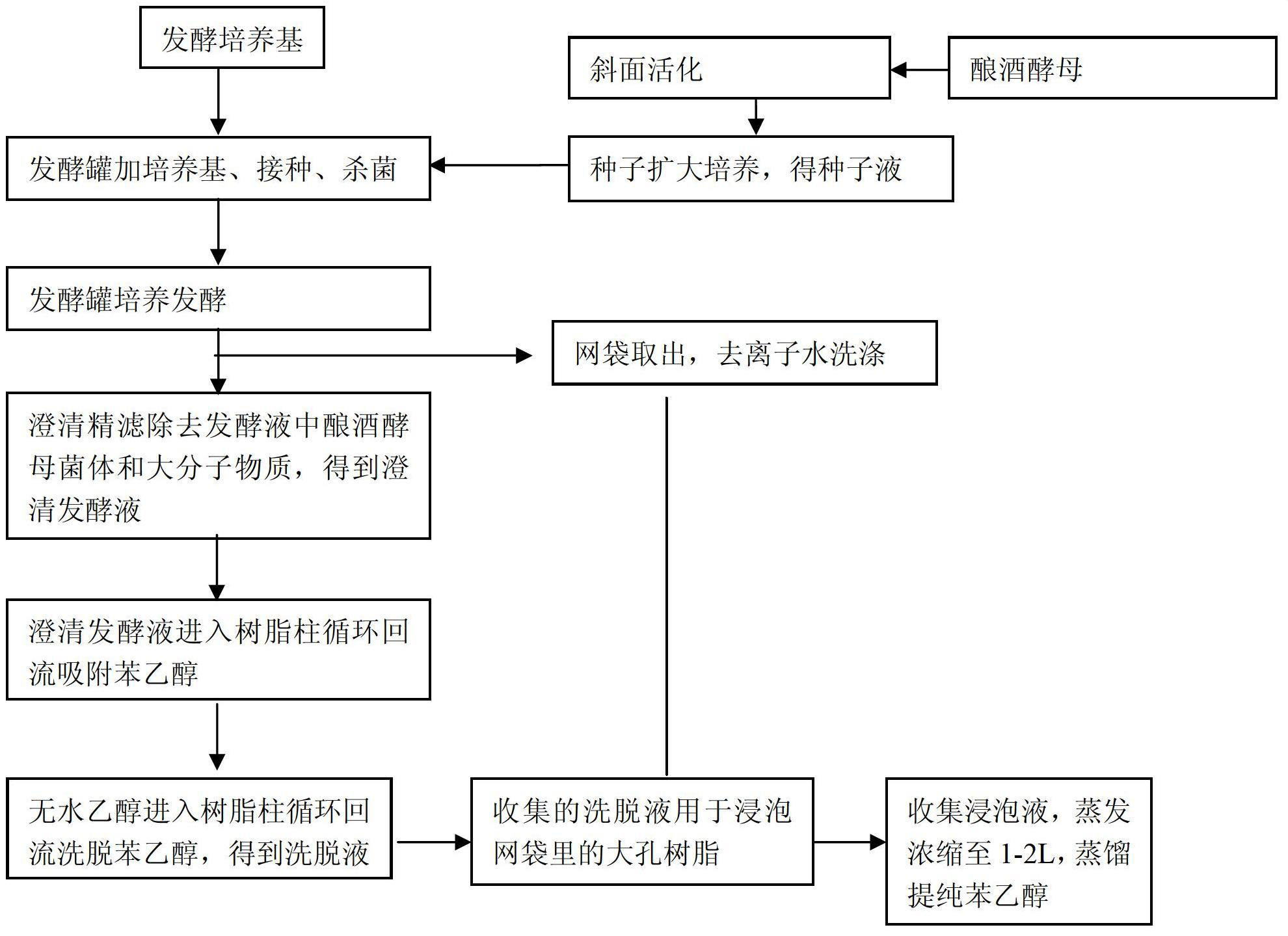

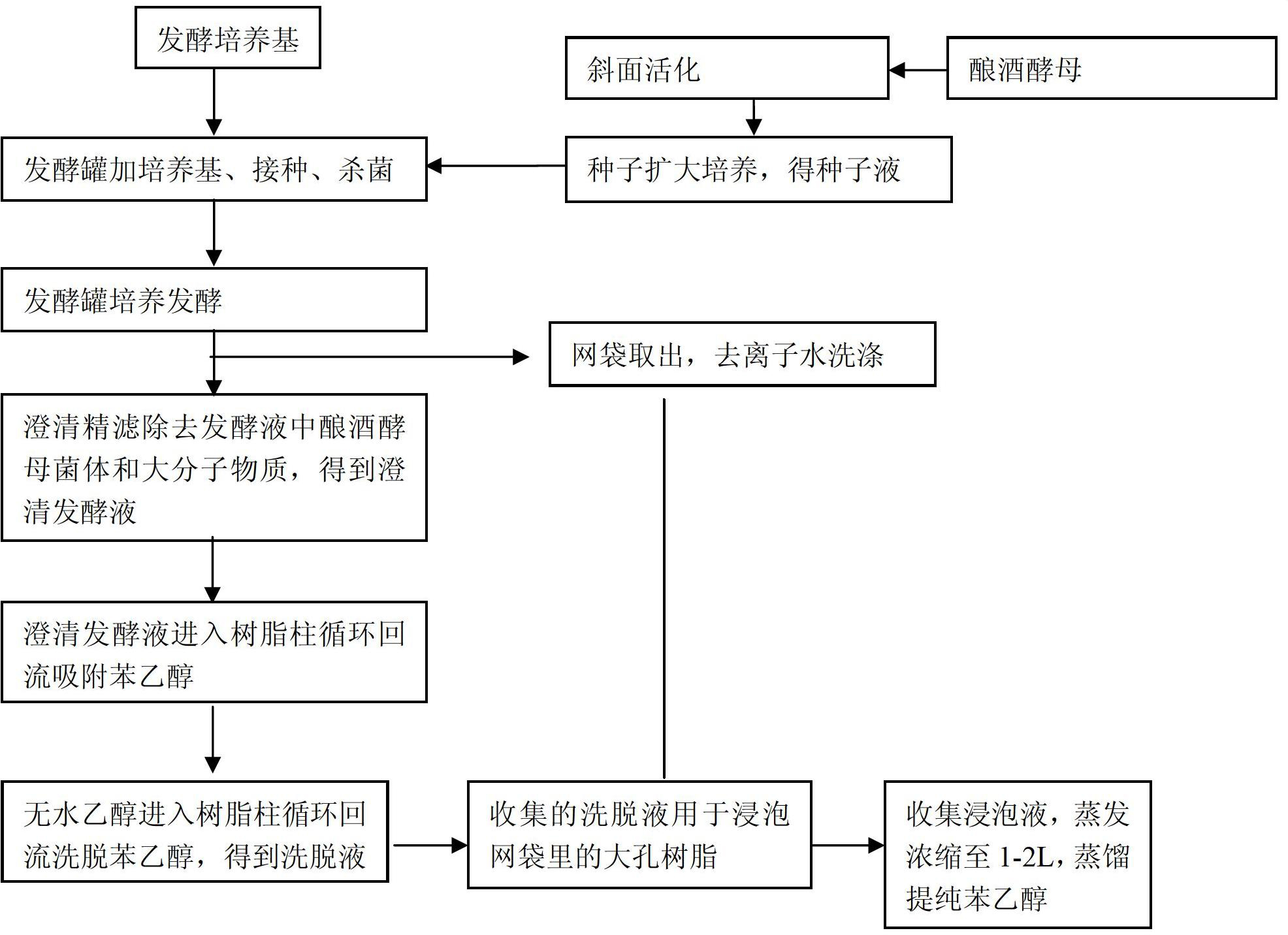

Method for producing beta-phenethyl alcohol by using biotransformation method

InactiveCN102660591AIncrease contentEasy extractionIon-exchange process apparatusIon-exchanger regenerationRotary evaporatorBeta-Phenylethanol

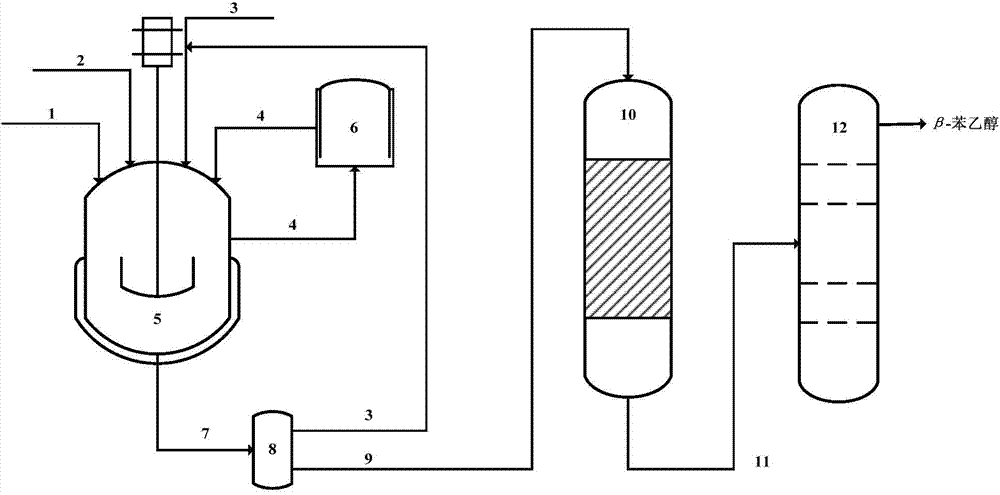

The invention relates to a method for producing beta-phenethyl alcohol by using a biotransformation method. The method comprises the following steps of: inoculating a seed solution subjected to amplification culture of sccharomyces cerevisiae as a biological catalyst into a fermentation tank filled with a fermentation medium with L-phenyl alanine as a reaction substrate; suspending a mesh bag filled with macroporous resin in the fermentation tank; after fermenting, taking out the mesh bag; clarifying and finely filtering fermentation broth and circularly reflowing the obtained fermentation broth in a resin column; then draining a residual adsorption liquid; eluting the resin column with absolute ethyl alcohol to obtain an eluant containing benzyl carbinol; soaking the mesh bag with the eluant first and then introducing the mesh bag into a rotary evaporator for concentrating and recovering the ethanol; and distilling the obtained concentrate to obtain high-purity beta-phenethyl alcohol. According to the method disclosed by the invention, the beta-phenethyl alcohol generated in the fermentation tank is adsorbed by the mesh bag filled with the macroporous resin suspended in the fermentation tank, so that the content of the beta-phenethyl alcohol in the fermentation broth adsorbed by the macroporous resin is increased, the extraction content of the beta-phenethyl alcohol is increased and high yield and purity of products are obtained.

Owner:CITYFLOWER GUANGZHOU

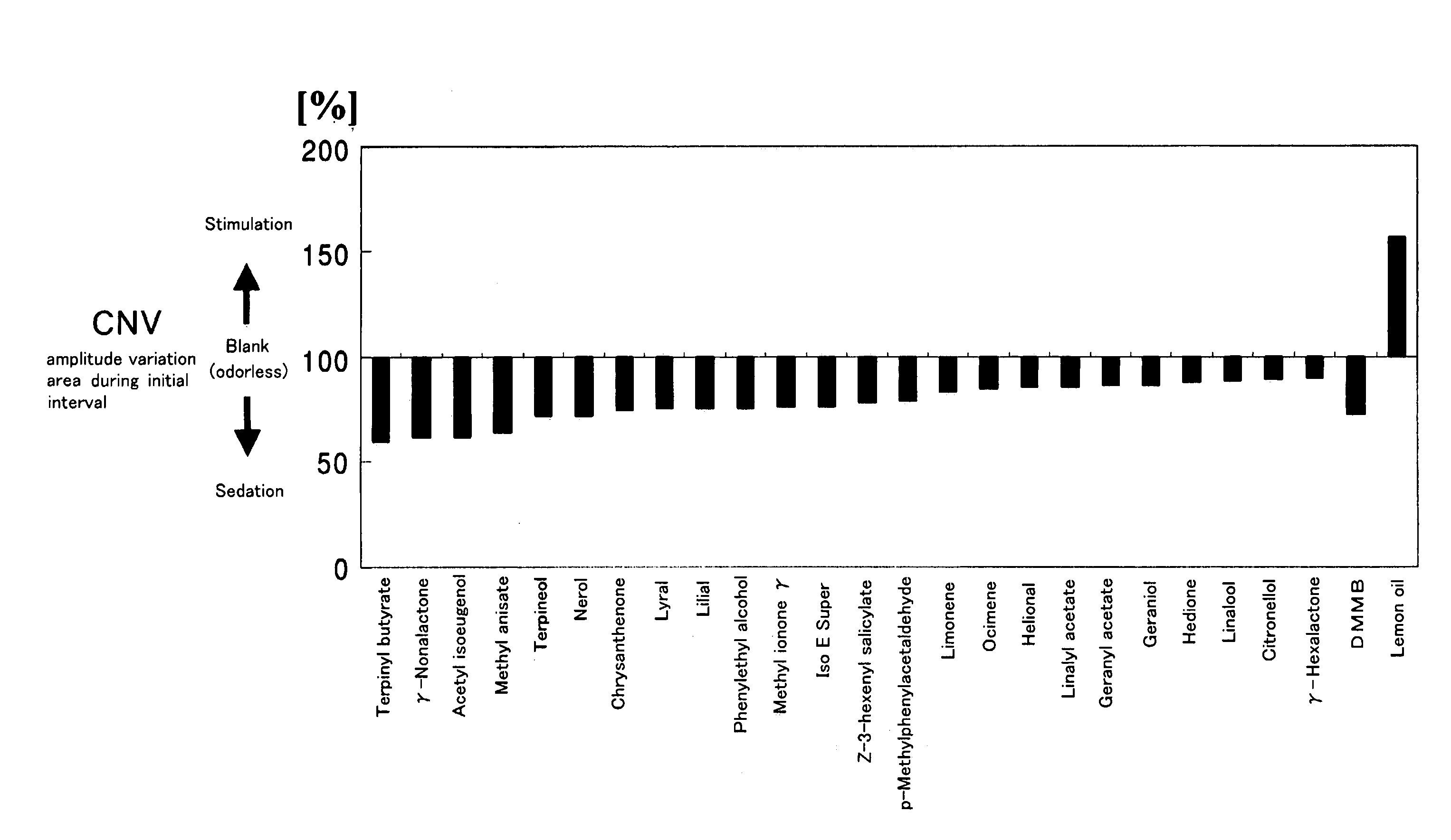

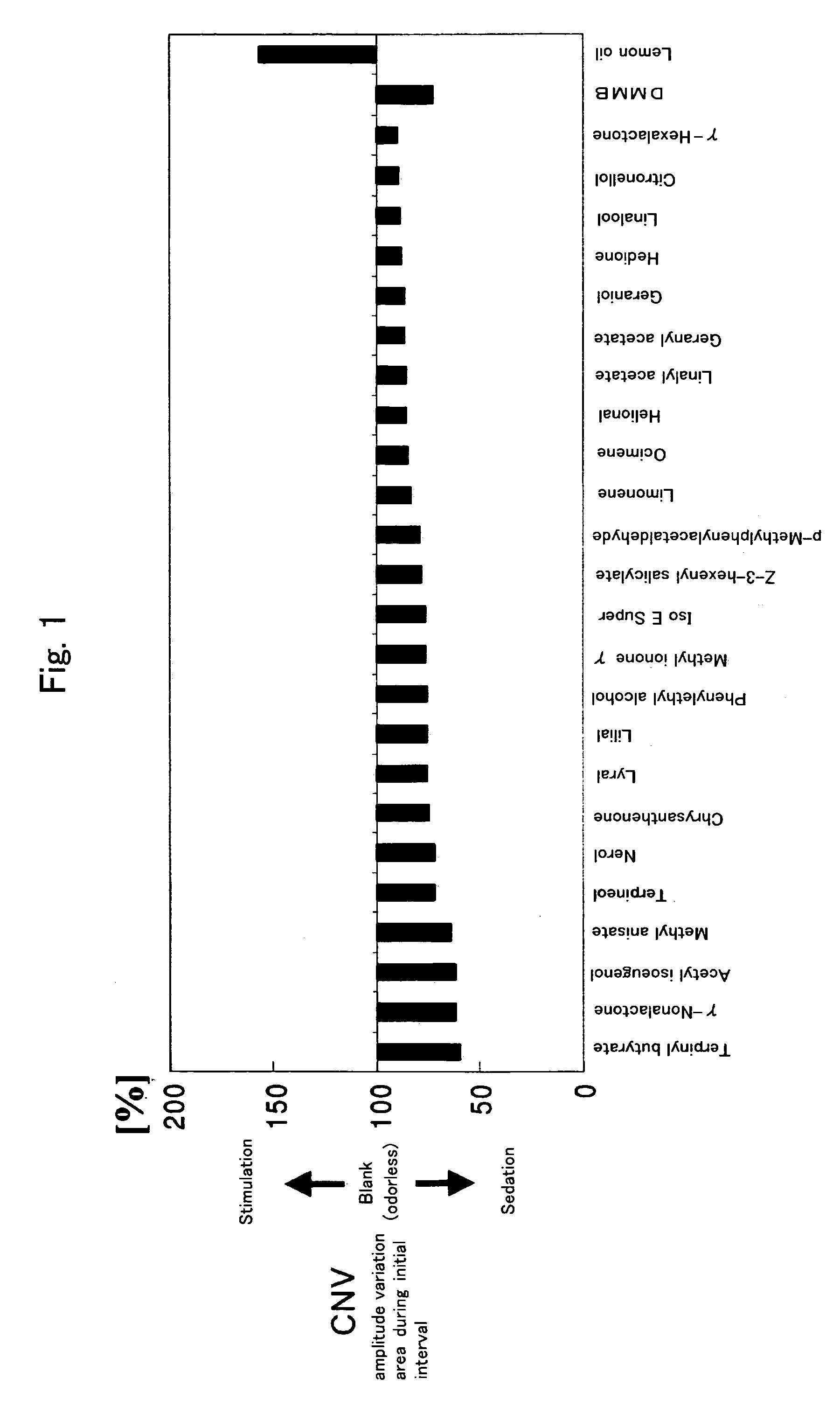

Perfume composition

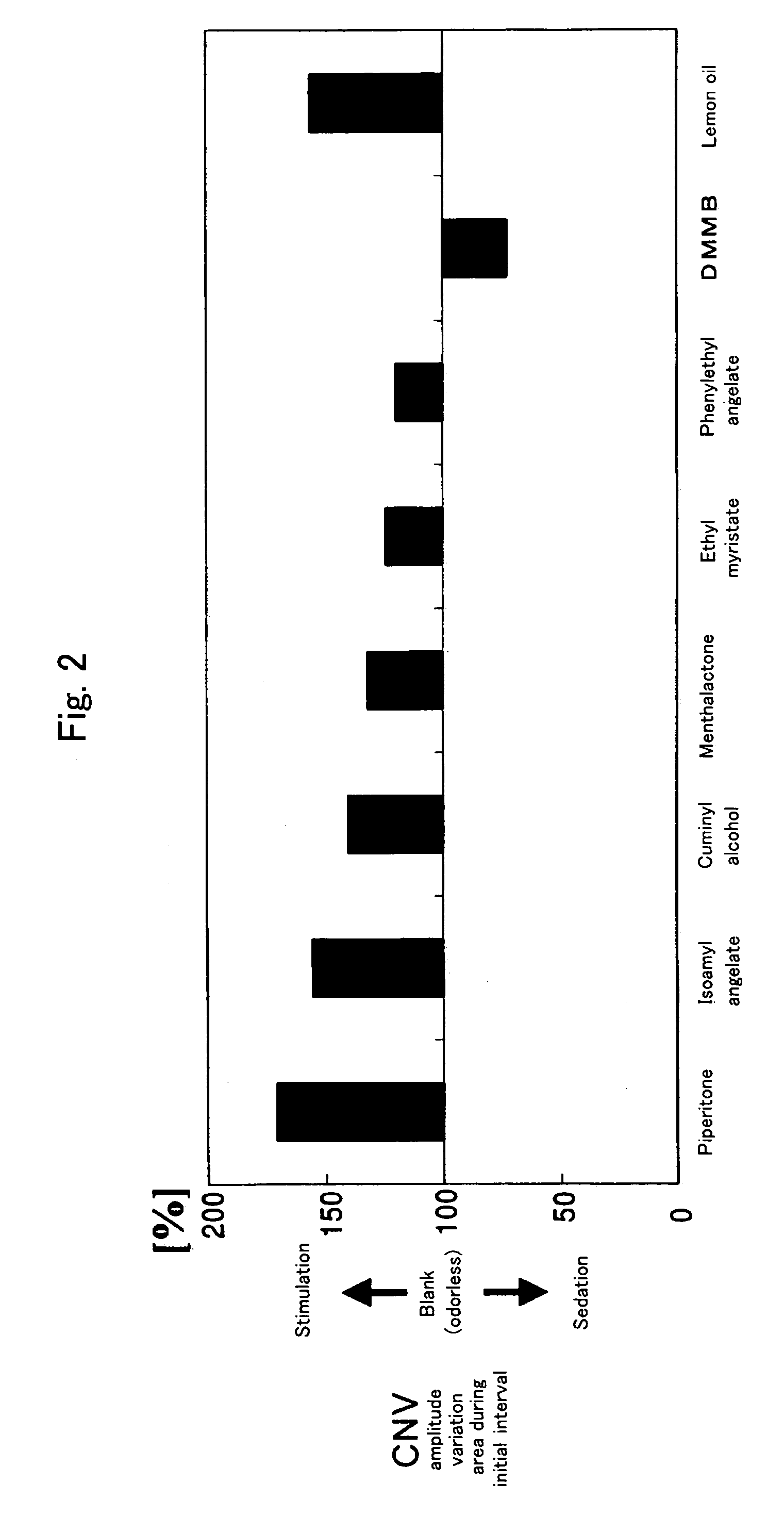

InactiveUS7169746B2Relaxed feeling to the userCosmetic preparationsSalicyclic acid active ingredientsPerillaldehydeIsoeugenol

The present invention provides a perfume composition for mental control, the composition containing one or more components acknowledged as having a psycho-sedative effect selected from the group consisting of terpinyl butyrate, γ-nonalactone, acetyl isoeugenol, methyl anisate, terpineol, nerol, chrysanthenone, lyral, lilial, β-phenylethyl alcohol, γ-methyl ionone, Iso E Super, Z-3-hexenyl salicylate, p-methylphenylacetaldehyde, limonene, ocimene, helional, linalyl acetate, geranyl acetate, geraniol, hedione, linalool, citronellol, and γ-hexalactone and / or one or more components acknowledged as having a psycho-stimulative effect selected from the group consisting of piperitone, isoamyl angelate, phenylethyl angelate, cuminyl alcohol, menthalactone, ethyl myristate, and perilla aldehyde. The invention also provides an external composition and daily-use goods, containing the perfume composition for mental control.

Owner:SHISEIDO CO LTD

Method of using trichoderma reesei to produce aromatic substance

The invention provides a method for producing beta-phenethyl alcohol and / or phenylacetaldehyde. The method is to provide a cheap carbon source (such as bran and degreased rice bran) to ferment trichoderma reesei to produce a natural aromatic substance, for example beta-phenethyl alcohol and phenylacetaldehyde. The method for producing the beta-phenethyl alcohol, disclosed by the invention, can reduce the production cost, and utilizes the agricultural byproducts such as the bran and the degreased rice bran, so as to reduce the waste treatment cost.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

Method for increasing content of beta-phenethyl alcohol in yellow rice wine

ActiveCN109825403AIncrease contentIncrease the sugar contentMicroorganism based processesAlcoholic beverage preparationBeta-PhenylethanolAspergillus

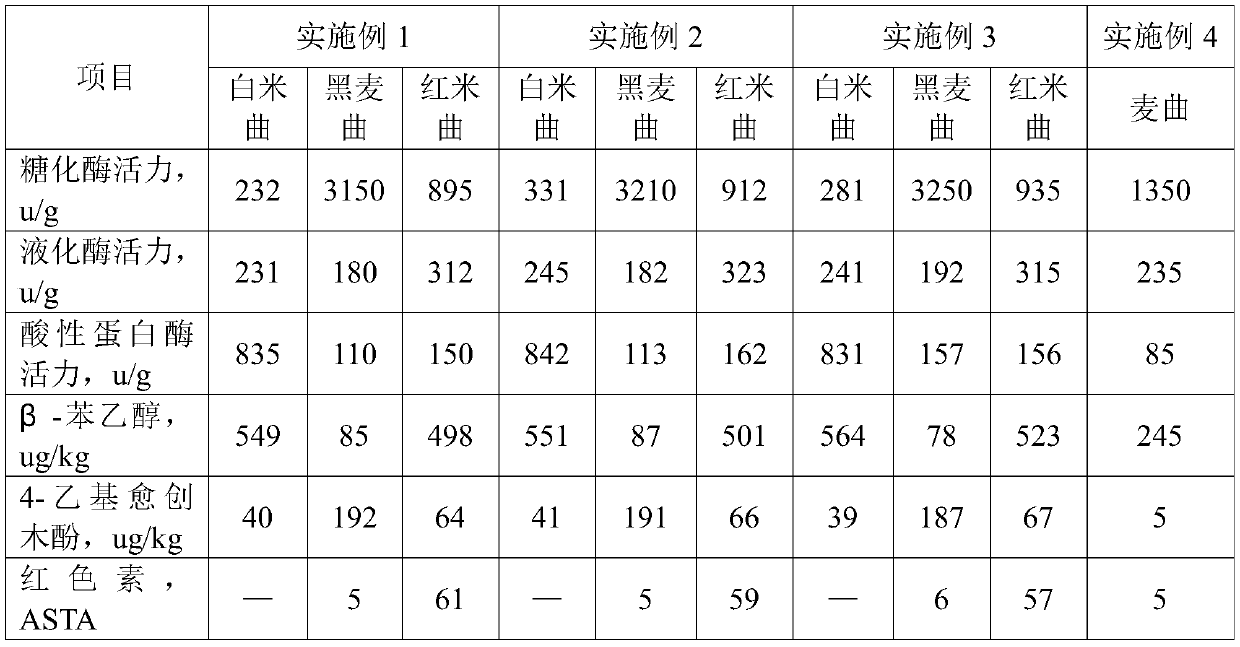

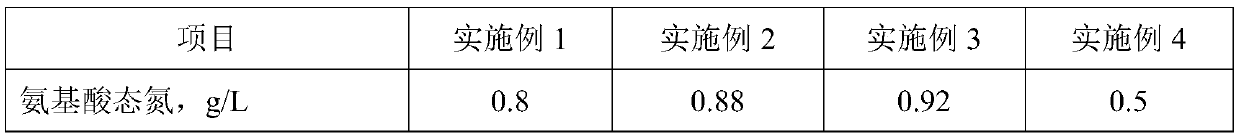

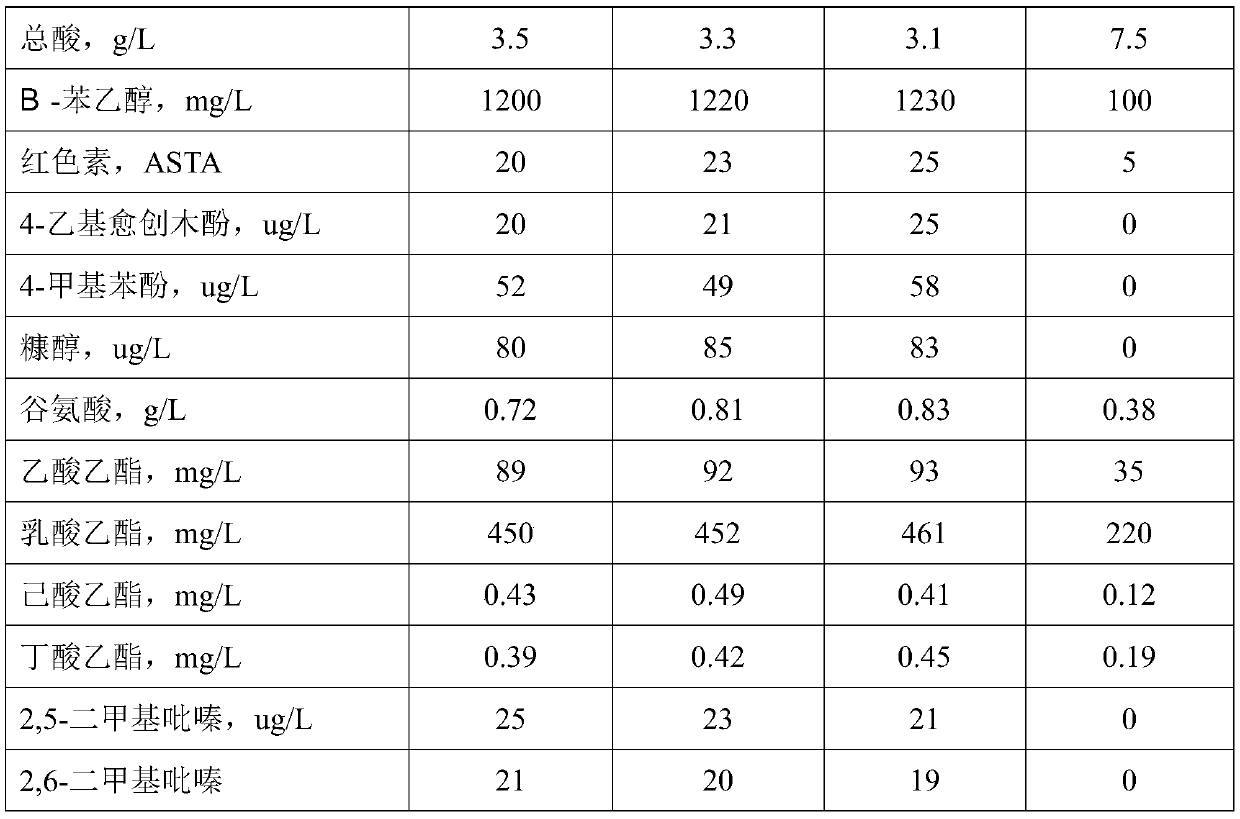

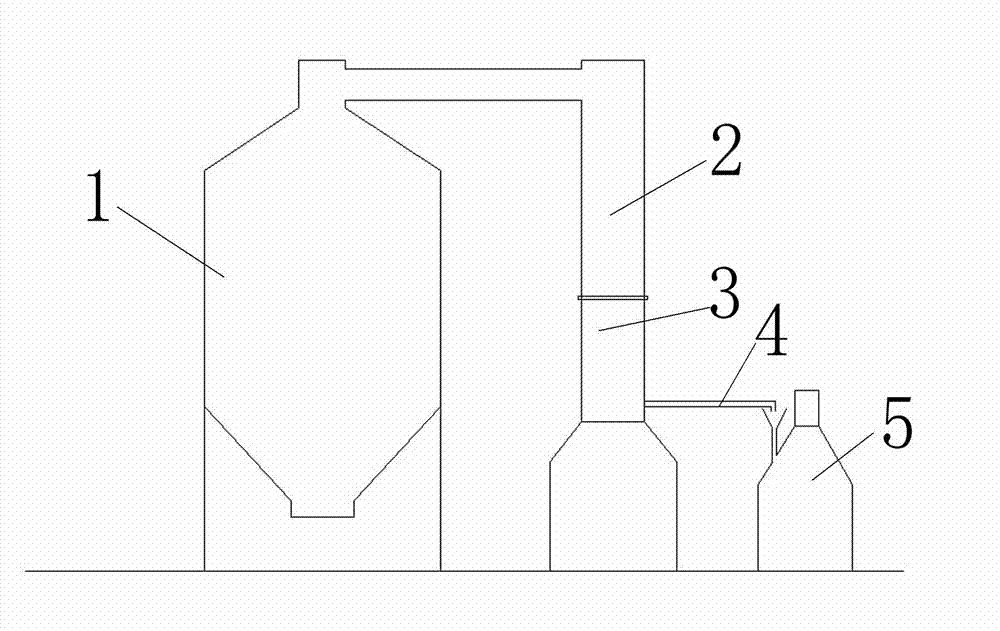

The invention discloses a method for increasing the content of beta-phenethyl alcohol in yellow rice wine. After being stir-fried, wheat is crushed into cloves for use; treated rice and stir-fried wheat are uniformly mixed, then aspergillus albicans is inoculated, the mixture is put into an aspergillus box for aspergillus treading, the temperature of a culture chamber is controlled to be 15-20 DEGC for 60-90 days of low-temperature culture, and then after-ripening is conducted for 60-90 days; the treated wheat and stir-fried wheat are uniformly mixed, then aspergillus niger is inoculated, themixture is put into an aspergillus box for aspergillus treading, the temperature of the culture chamber is controlled to be 65-70 DEG C for 60-90 days of high-temperature culture, and after-ripeningis conducted for 30-60 days; treated glutinous rice and stir-fried wheat are uniformly mixed, then monascus purpureus is inoculated, the mixture is put into an aspergillus box for aspergillus treading, the temperature of the culture chamber is controlled to be 30-35 DEG C for 30-60 days of middle-temperature culture, and after-ripening is conducted for 60-90 days. Three kinds of aspergillus are mixed for use, the respective advantages are taken, the vigor of saccharifying enzyme, the vigor of liquifying enzyme, the vigor of acid proteinase, the content of the beta-phenethyl alcohol, the content of 4-ethyl guaiacol and the content of haematochrome of the yellow rice wine are greatly increased, and the content of the beta-phenethyl alcohol is effectively increased.

Owner:QIANHE CONDIMENT & FOOD CO LTD

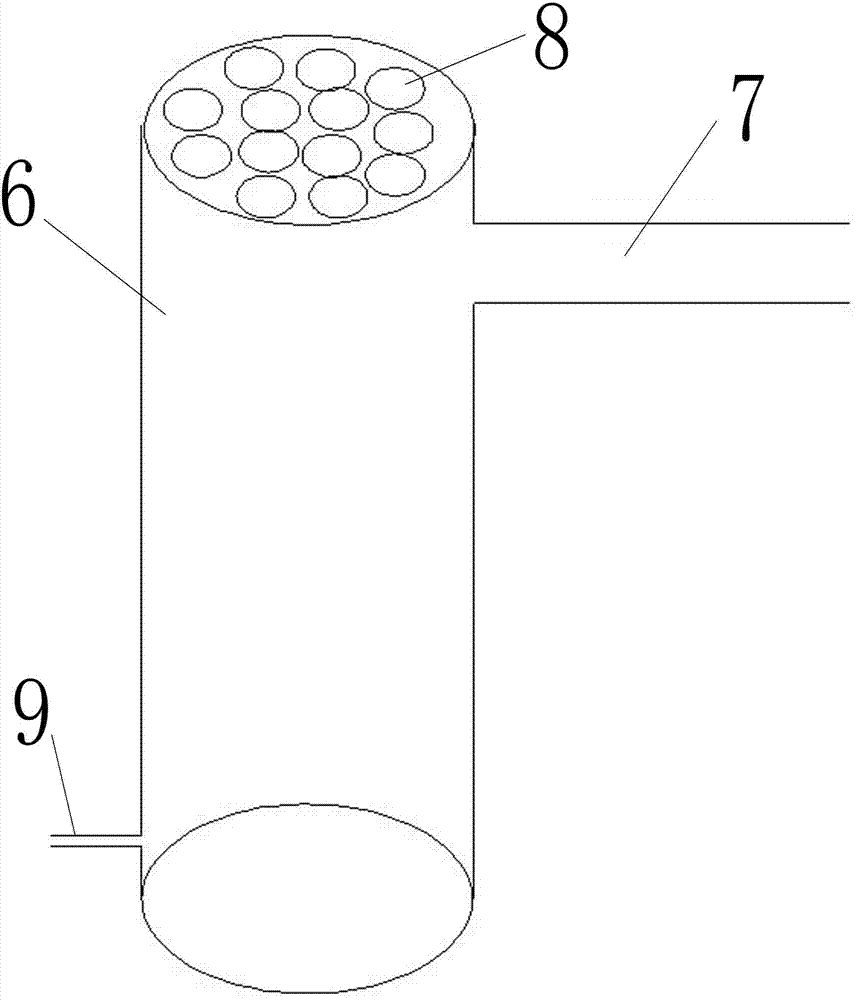

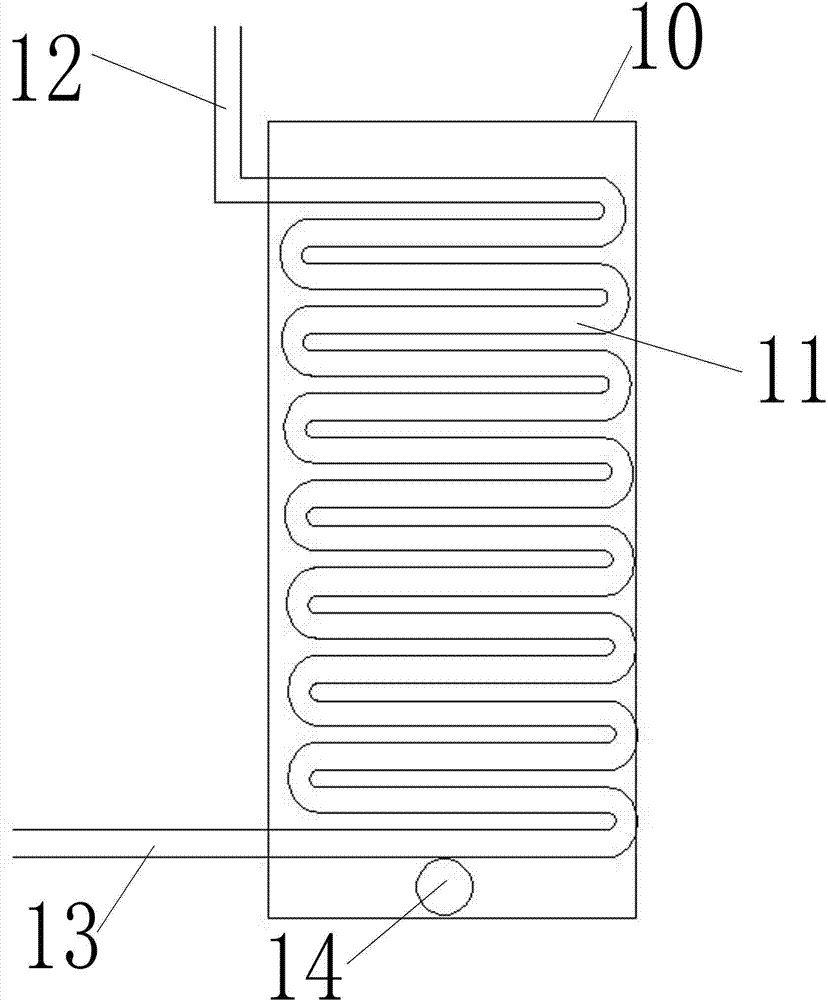

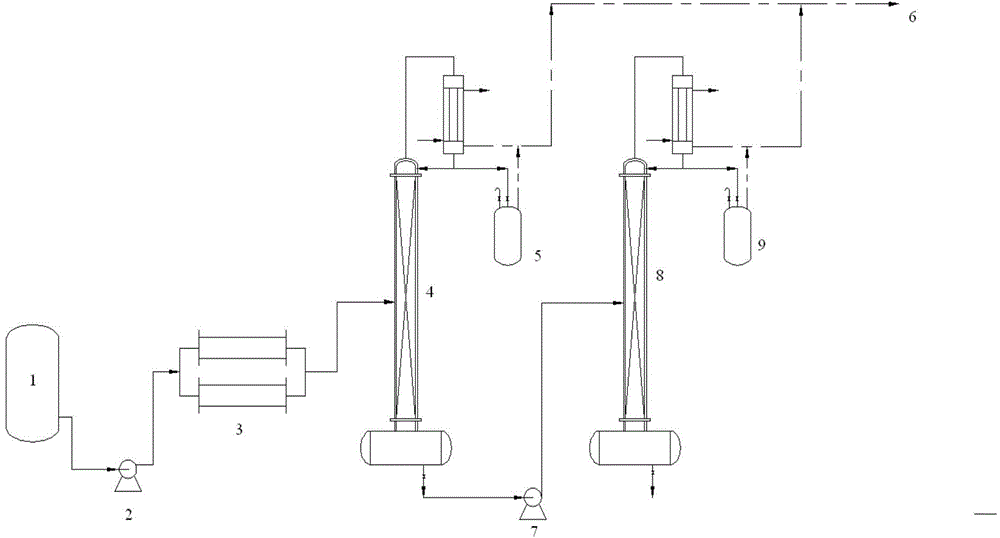

Secondary condensation extraction process and condensation equipment for rose essential oil

ActiveCN103484255AImprove oil yieldIncrease productivityVapor condensationEssential-oils/perfumesBeta-PhenylethanolGeraniol

The invention relates to a secondary condensation extraction process and condensation equipment for rose essential oil. The secondary condensation extraction process comprises the steps as follows: formed oil-water mixed vapor firstly enters the inner chamber of a closed primary condenser for condensation so as to form distillate with the temperature of 55-70 DEG C; then the distillate with the temperature of 55-70 DEG C is transported to a secondary condenser for secondary condensation through a spiral pipe spirally distributed inside the secondary condenser, so as to form distillate with the temperature of 25-35 DEG C; the distillate with the temperature of 25-35 DEG C is finally transported to an oil-water separator, so that the rose essential oil is obtained finally. According to the invention, through two-time condensation, the oil yield of the rose essential oil is increased to 0.028% from 0.024%, which is obtained by using a horizontal type straight tube condenser for condensation, the output rate of the rose essential oil is improved, ingredients such as trans-oxidation rose, cis-oxidation rose, alpha-terpilenol, beta-phenethyl alcohol, 2,7-dimethyl-1-octanol and geraniol formate in fresh roses are separated out effectively, so that the quality of the rose essential oil is improved, and the ingredient range of the rose essential oil conforms to international rose essential oil standards.

Owner:山东惠农玫瑰股份有限公司

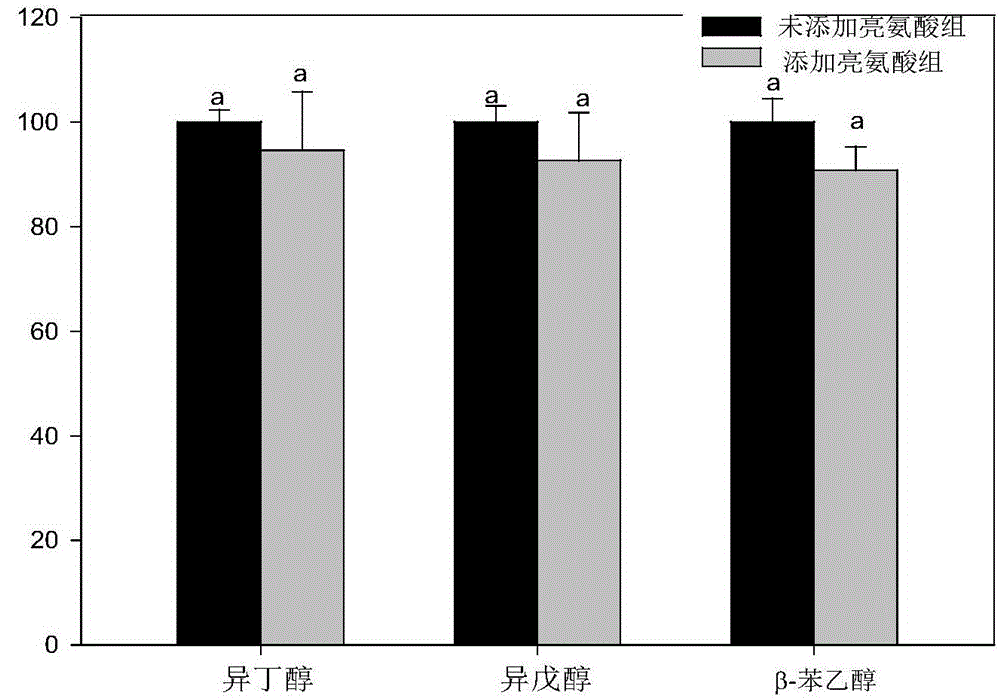

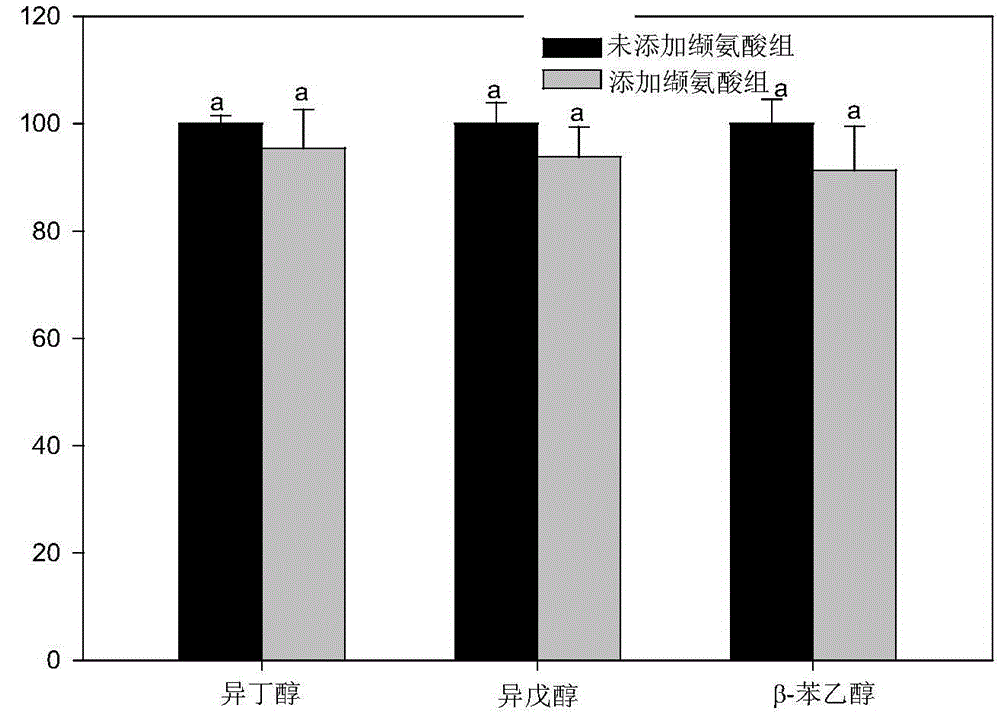

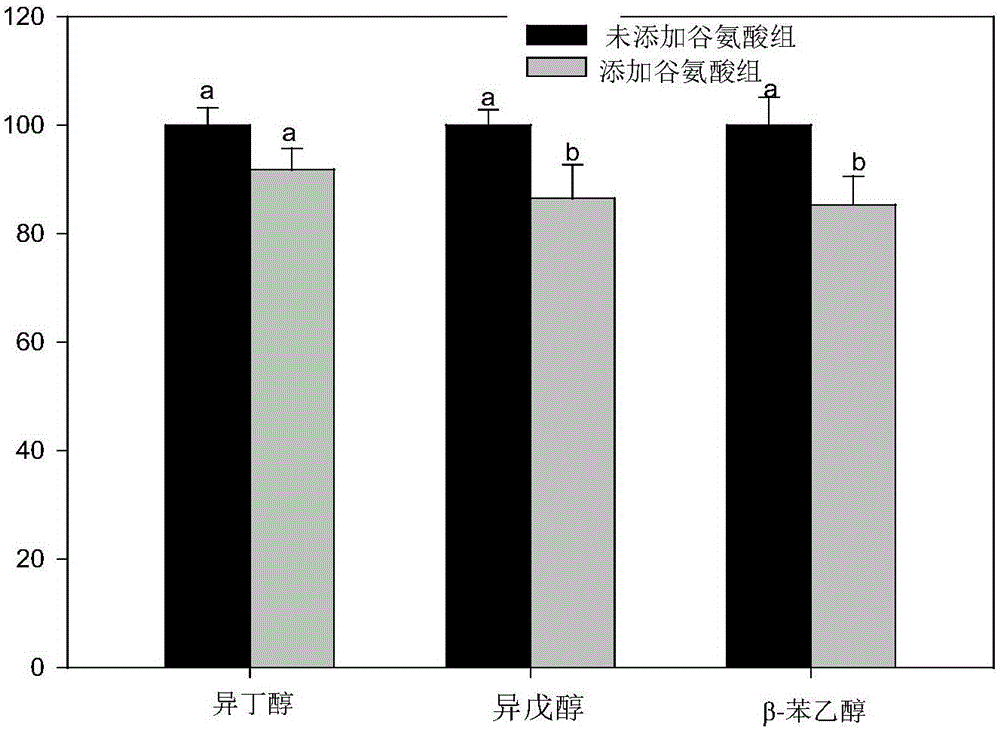

Nitrogen source compensation method for reducing major higher alcohol content of yellow wine

InactiveCN105062768AReduce contentLow costAlcoholic beverage preparationAlcohol contentBeta-Phenylethanol

The invention discloses a nitrogen source compensation method for reducing the major higher alcohol content of yellow wine, and belongs to the technical field of wine brewing. By starting from the aspects of assimilation amino acid type selection, addition control and the like, the invention provides the nitrogen source compensation method for reducing the major higher alcohol content of the yellow wine and an optimum addition amount on the basis of a conventional yellow wine brewing process. When the addition of glutamic acid is 200mg / L, the content of isobutyl alcohol in the yellow wine obtained by the method is reduced by 9.8 percent; the content of isoamylol in the yellow wine obtained by the method is reduced by 15.4 percent; and the content of beta-phenethyl alcohol in the yellow wine obtained by the method is reduced by 16.7 percent. The method provides the scientific basis for the high-quality yellow wine brewing.

Owner:JIANGNAN UNIV +1

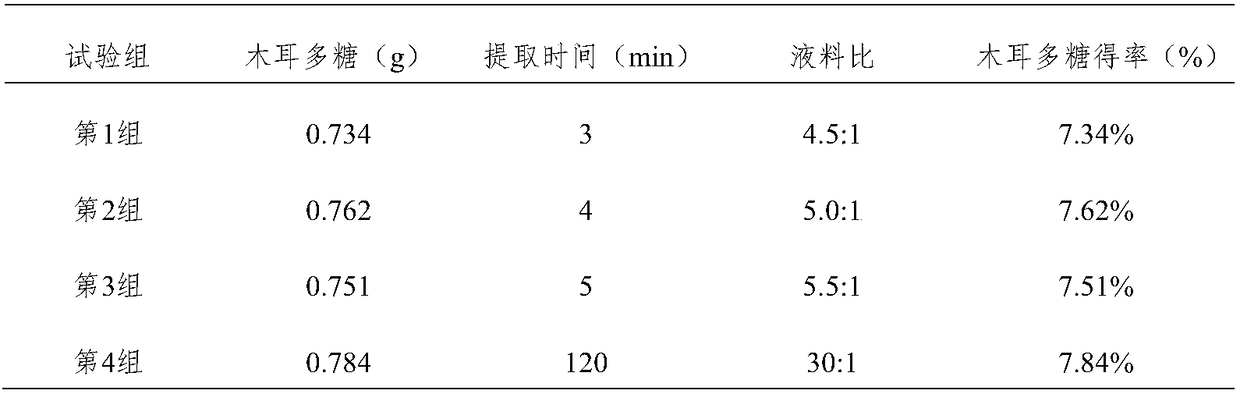

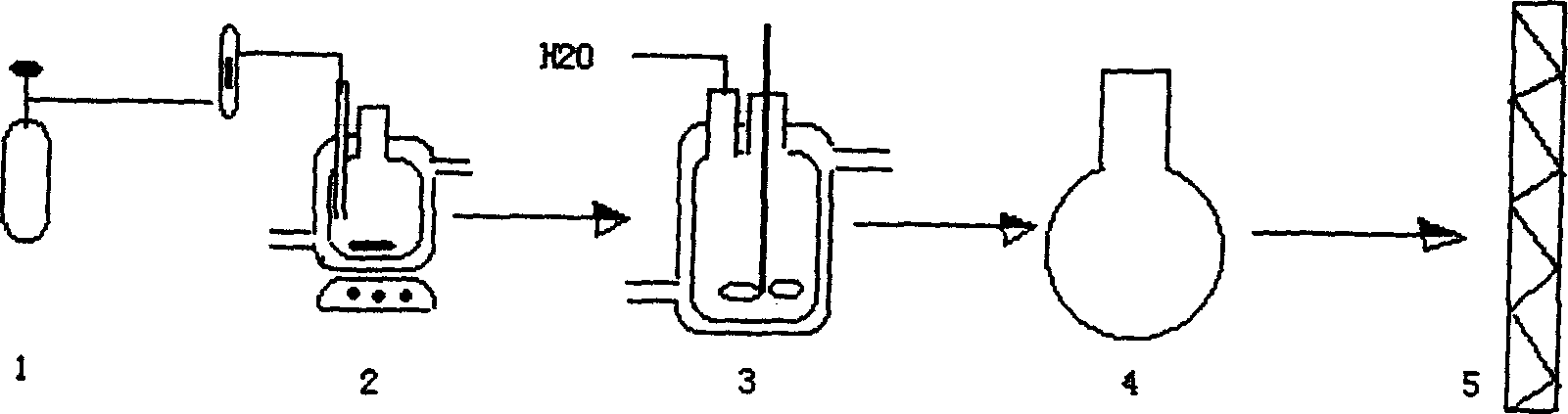

Method for extracting agaric polysaccharides

The invention relates to the technical field of bio-extraction and in particular relates to a method for extracting agaric polysaccharides. The method comprises the following steps: performing freezedrying, superfine grinding, zymolytic wall breaking, pre-extract preparation, microwave extraction and concentrated drying, breaking structures between agaric cells and cell walls thereof, grinding tissue structures of the agaric, enlarging an enzymolysis contact surface, performing microwave extraction through rose cell sap and agaric freeze-dried powder, and rapidly separating out polysaccharideactive substances in agaric by virtue of beta-phenylethanol in the rose cell sap and volatile matters thereof. The used liquid-to-solid ratio is reduced, and the efficiency of extracting the agaric polysaccharides is increased.

Owner:镇远县苗岭山珍有限公司

Process for preparing beta-phenylethanol

InactiveCN1465557AReduce water consumptionAvoid pollutionPreparation by hydrolysisBenzeneAluminium chlorohydrate

The present invention discloses a method for preparing beta-phenylethanol from benzene and epoxyethane under the catalytic action of anhydrous alchlor, in the course of preparation it adopts the quantitative hydrolysis method so as to obtain the invented beta-phenylethanol.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Catalyst and method for preparing beta-phenylethanol by using same

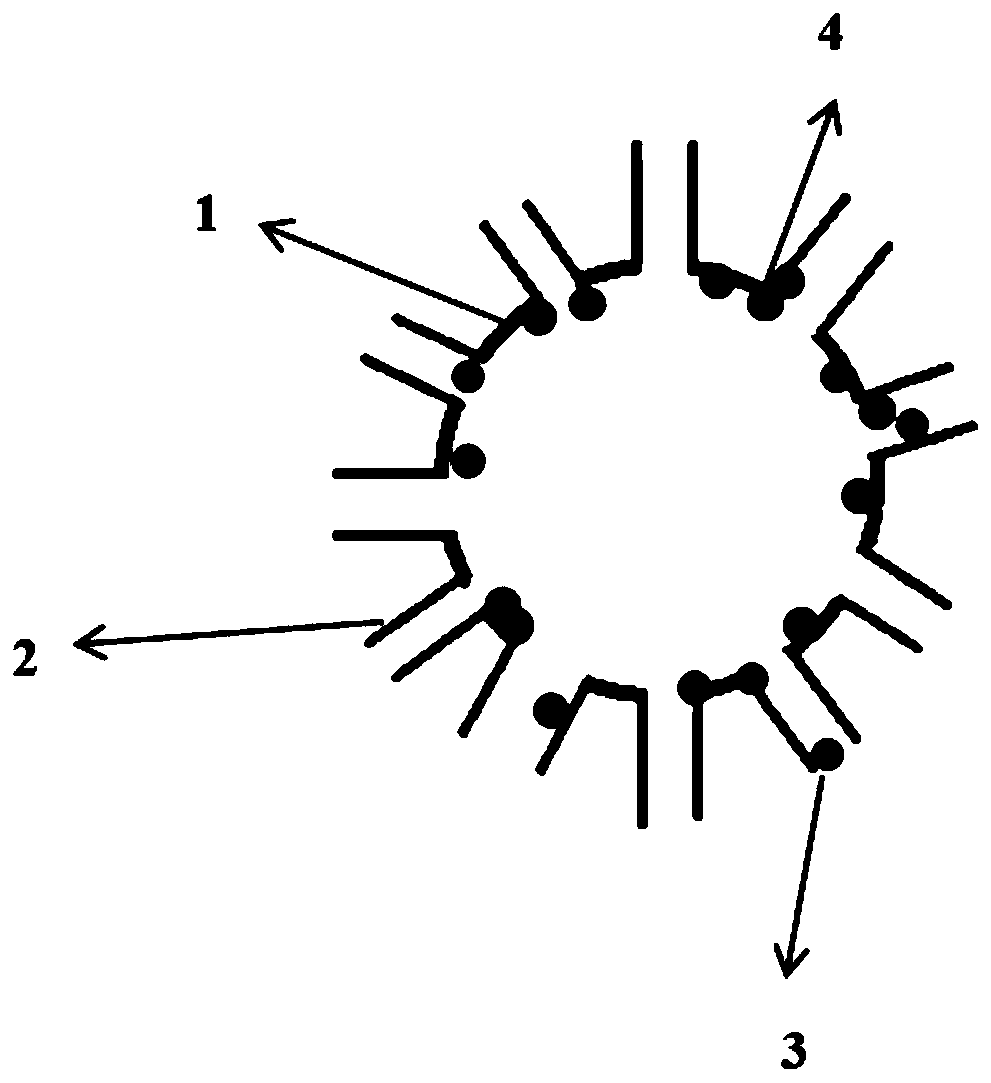

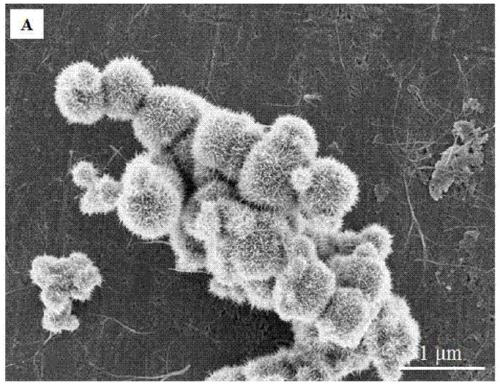

ActiveCN109847754ARealize continuous productionHigh selectivityMetal/metal-oxides/metal-hydroxide catalystsPreparation by hydrolysisStyrene oxideNanoreactor

The invention discloses a catalyst and a method for preparing beta-phenylethanol by the catalyst. The catalyst is a nickel-copper silicate composite echinus-shaped reactor type nanocatalyst. Accordingto the catalyst, the problem that the content of a byproduct, i.e., ethylbenzene is high due to the fact that a hydrogenation reaction speed of styrene oxide is too high and the supply of hydrogen isinsufficient is solved, the beta-phenylethanol can be prepared from the styrene oxide under mild conditions through high-selectivity and high-yield hydrogenation, the conversion ratio of the styreneoxide is higher than 99%, the selectivity of the beta-phenylethanol is not lower than 99.5%; and due to sufficient hydrogen supply, the high selectivity of the product can also be guaranteed under thecondition that hydrogenation of the styrene oxide is carried out in the absence of auxiliaries, the procedure of removing the auxiliaries is avoided, and product separating flows are simplified. Themethod for preparing the beta-phenylethanol can achieve continuous production of the beta-phenylethanol, and the production efficiency is increased greatly.

Owner:WANHUA CHEM GRP CO LTD

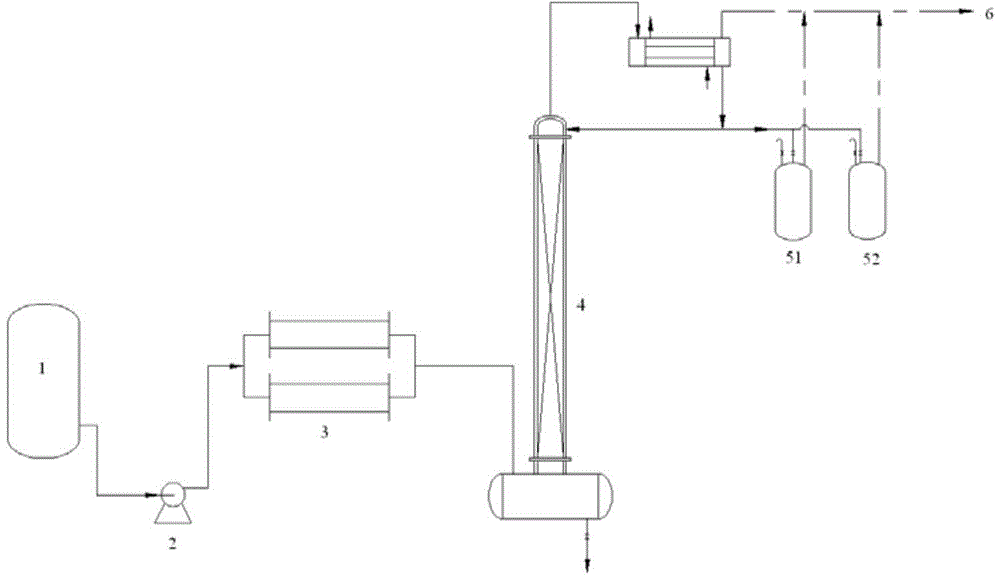

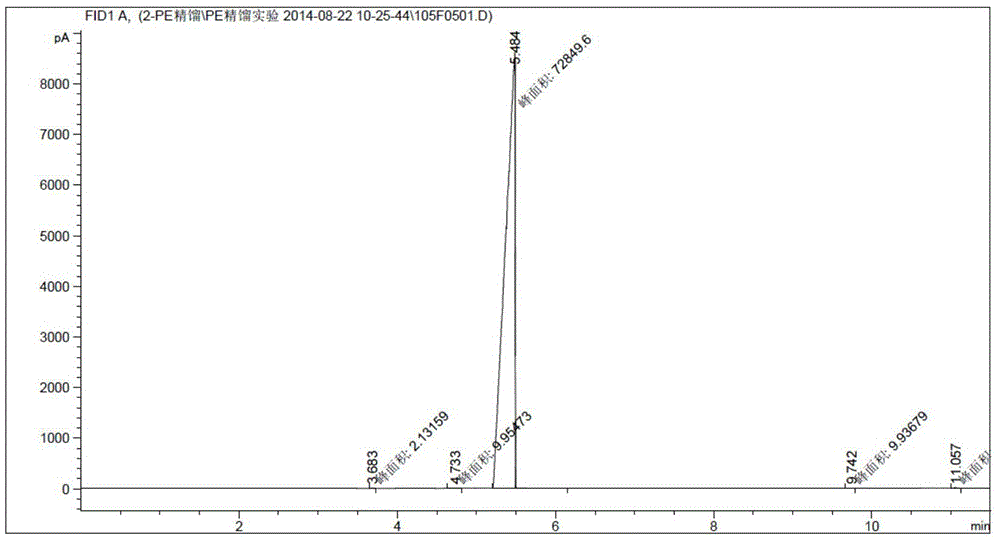

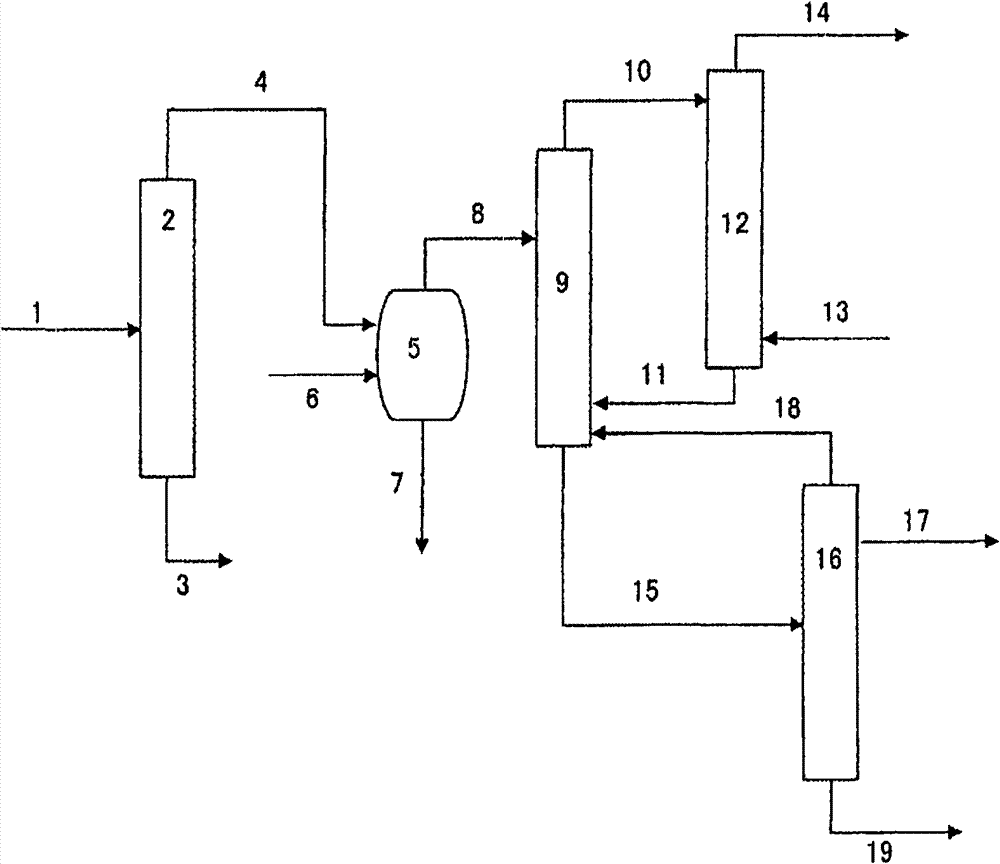

Purification method for beta-phenylethyl alcohol prepared by bio-fermentation

InactiveCN104529700AHigh purityOrganic compound preparationHydroxy compound separation/purificationBeta-PhenylethanolPurification methods

The invention relates to a purification method for beta-phenylethyl alcohol prepared by bio-fermentation. The method comprises the steps of: 1) pretreatment of a beta-phenylethyl alcohol crude product: taking the beta-phenylethyl alcohol crude product prepared by bio-fermentation as the raw material, removing macromolecular impurities remaining in beta-phenylethyl alcohol through an ultrafiltration device, and collecting permeate liquid; and 2) vacuum precise rectification purification: adding the permeate liquid into a precise rectification tower, conducting vacuum precise rectification to remove low-boiling point impurities and high-boiling point impurities respectively, thus finally obtaining the beta-phenylethyl alcohol product with purity higher than 99.9%. Compared with the prior art, the method provided by the invention adopts the way of filtering the crude product by an ultrafiltration assembly and then performing rectification, is especially suitable for purification of the beta-phenylethyl alcohol product prepared by bio-fermentation, and the obtained product has high purity, which reaches more than 99.9%.

Owner:SHANGHAI RES INST OF CHEM IND

Method for purification of ss-phenylethyl alcohol

InactiveCN101583584BOrganic compound preparationHydroxy compound preparationBeta-PhenylethanolDistillation

Disclosed is a method for the purification of ß-phenylethyl alcohol, which comprises supplying ß-phenylethyl alcohol to be purified to a distillation column to produce ß-phenylethyl alcohol in a purified form as a side-cut fraction. In the method, it is preferred to recycle a fraction collected from the top section of the distillation column into the light boiling substance separation step, from the view point of preventing the loss of ß-phenylethyl alcohol in the components present in the top section of the distillation column.

Owner:SUMITOMO CHEM CO LTD

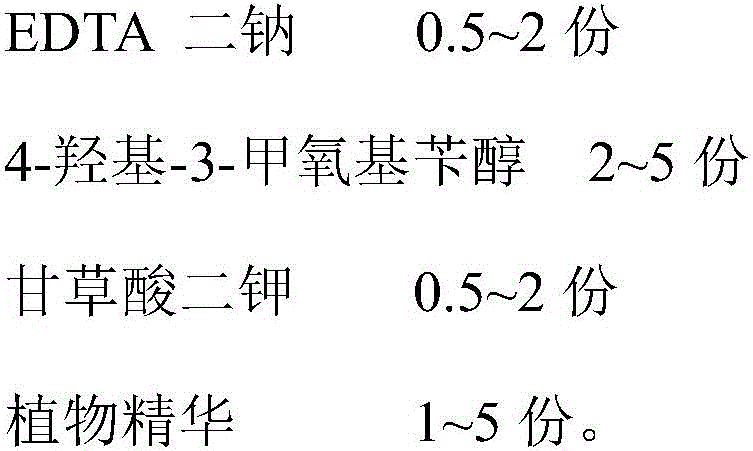

Biology coating agent, preparation and application in control of flue-cured tobacco axillary bud thereof

InactiveCN101313676BImprove qualityGood bud suppression effectBiocidePlant growth regulatorsAxillary budWHEAT SPROUT

The invention provides a biological coating agent containing active composition beta-phenylethyl alcohol. The biological coating agent is made through the following steps that: plant strains with strong biological activity and high yield are selected from plants through collection, separation and purifying cultivation; wheat sprout-inhibiting quick detection is carried out and then high-yield strains are screened out through repeated comparison; and the biological coating agent is made through cultivation, solvent extraction, concentration and drying. When the biological coating agent is usedin the control of flue-cured tobacco axillary bud, the available rate can reach to 92 to 98 percent, and the entire manufacturing process is safe and nontoxic; moreover, the biological coating agent does not contain toxic compositions, thereby causing no environmental pollution and no residual toxicity along with low production cost and low price; in addition, the biological coating agent can also be used in flower and vegetable preserving, crop growing regulation and control so as to improve quality and increase output, and so on.

Owner:重庆迎龙化工有限公司

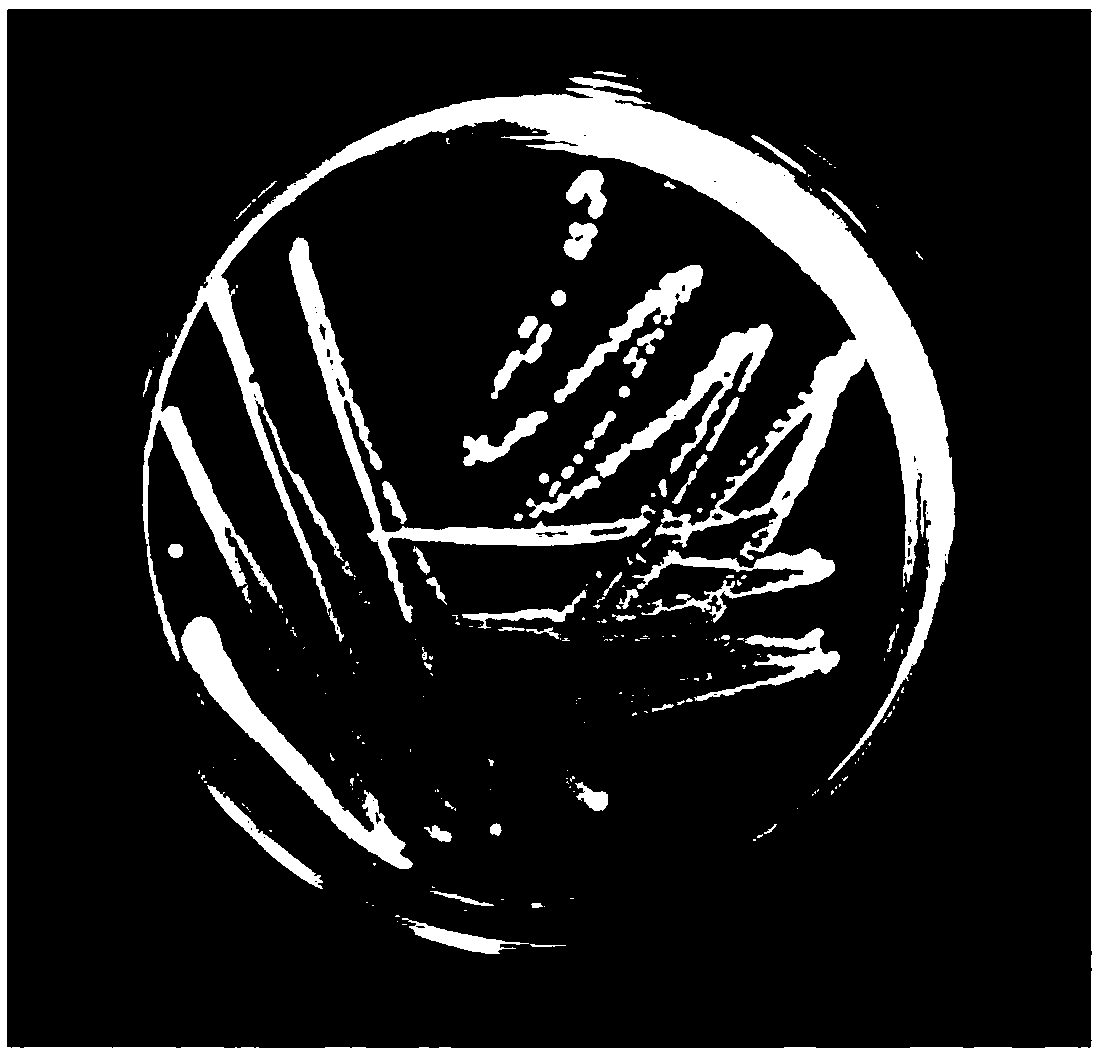

Strain and method for producing beta-phenethyl alcohol

ActiveCN108624626APromote growth rateFast growthBacteriaMicroorganism based processesBeta-PhenylethanolEnterobacter sp

The invention provides a strain for producing beta-phenethyl alcohol. The classification name of the strain is Enterobacter sp., and the preservation number of the strain is CGMCC No. 15641. The invention further provides a method using the strain to produce beta-phenethyl alcohol. The method includes: activating the Enterobacter, performing liquid fermentation, and performing tank fermentation; performing concentration extraction on the beta-phenethyl alcohol. Detection shows that beta-phenethyl alcohol yield can reach up to 0.5g / L. The Enterobacter MF024 is good in genetic stability, low inculture cost and the like. The fermentation and extraction method is mild in reaction condition, low in cost, environmentally friendly and the like. The obtained beta-phenethyl alcohol is green and natural and has great industrial application advantages.

Owner:SHANGHAI INST OF TECH

Yellow liquor from white granulated sugar and making method thereof

ActiveCN102876542AFragrant and elegantRefreshing and mellow tasteAlcoholic beverage preparationBeta-PhenylethanolAlcohol

The invention relates to a method for making yellow liquor from white granulated sugar. The method includes: adding 1.0 part of white granulated sugar, 0.15-0.25 part of wheat koji, rice koji or mixture of both, 0.45-0.65 part of distiller's yeast, and 6.0-8.0 parts of water into a fermenter, mixing well for fermentation, and controlling after-entry temperature at 20-30 DEG C; introducing compressed air and performing initial harrow after 10-14 hours of fermentation, and controlling the fermentation temperature at 27-33 DEG C; adding 0.85-1.15 parts of white granulated sugar after 20-25 hours of fermentation, and allowing for continual fermentation; adding 0.35-0.45 part of white granulated sugar again 20-25 hours after primary feed supplement; and post-fermenting. The made yellow liquor is light yellow with light aroma, tastes fresh, cool and mellow, and has typical style of the yellow liquor. The content of beta-phenylethano1 (featured ingredient in yellow liquor) is in the normal range, and the high bitterness style of the traditional yellow liquor is improved.

Owner:SHANGHAI JINFENG WINE IND

Preparation method for novel suckercide

ActiveCN103783087AImprove productivityIncrease concentrationBiocidePlant growth regulatorsBeta-PhenylethanolMetabolite

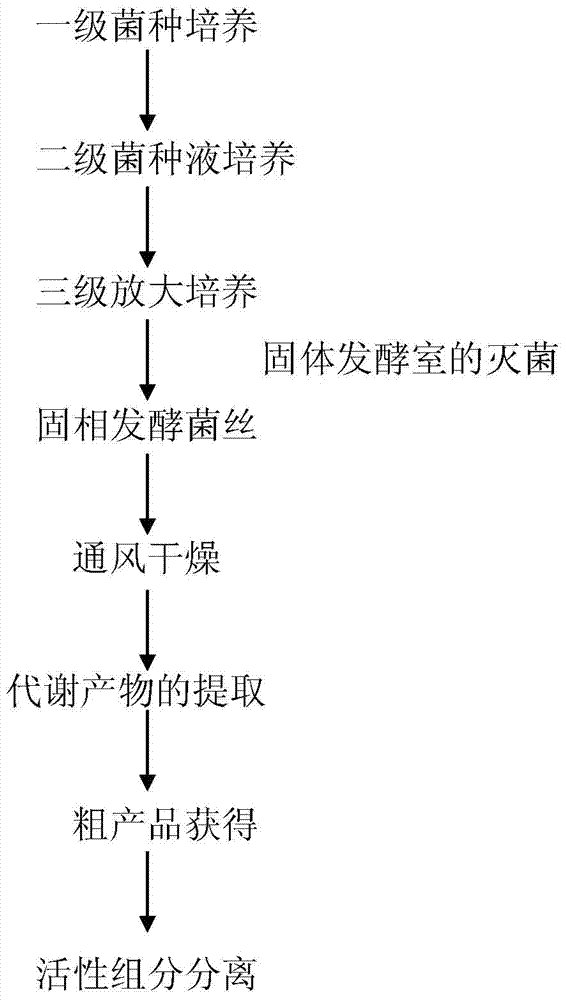

The invention provides a preparation method for a novel suckercide which takes beta-phenethyl alcohol as an active component. The preparation method comprises sample collection, medium culturing and solid fermentation. The solid fermentation comprises first-level strain culture, second-level strain liquid culture, third-level amplification culture, sterilization in a solid fermentation chamber, hyphe solid fermentation, aeration drying, metabolite extraction, crude product obtaining and active component separation. The suckercide prepared by the preparation method has the effective rate up to 92-98%, the whole production process is safe and non-toxic, and by the solid fermentation method, the fermentation process is simple, the production equipment investment is little, the product concentration is high, and risk of contaminating microorganism pollution is small.

Owner:CHONGQING YINGLONG CHEM PLANT

Environment-friendly mosquito control preparation and mosquito control liquid and bags prepared from environment-friendly mosquito control preparation

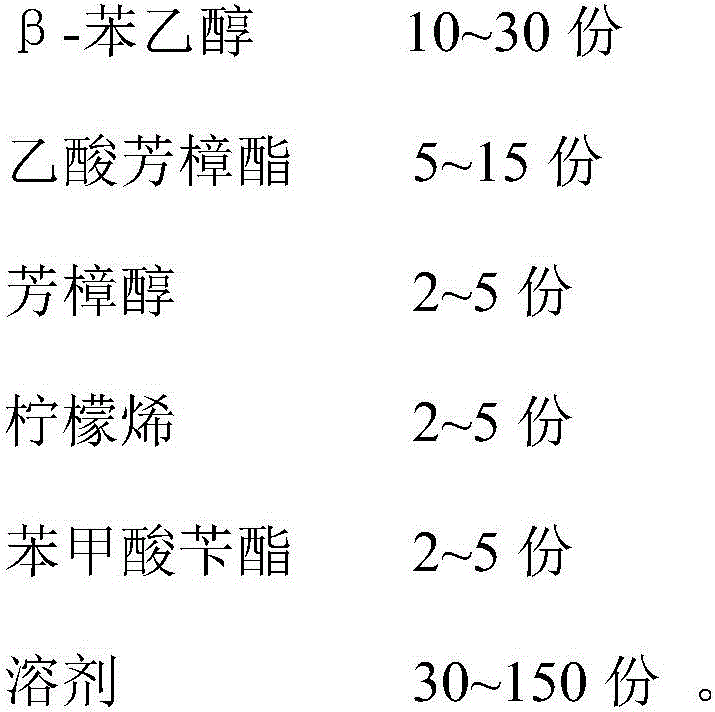

The invention discloses an environment-friendly mosquito control preparation and mosquito control liquid and bags prepared from the environment-friendly mosquito control preparation. The environment-friendly mosquito control preparation contains the following ingredients in parts by weight: 10-30 parts of beta-phenylethanol, 5-15 parts of linalyl acetate, 2-5 parts of linalool, 2-5 parts of limonene, 2-5 parts of benzyl benzoate and 30-150 parts of solvent. The mosquito control liquid disclosed by the invention is prepared from non-toxic and pollution-free raw materials, is free of any injury to human and is natural and pollution-free. In addition, the mosquito control preparation disclosed by the invention further has relatively good stability and still has relatively good mosquito control effect during long-time storage and use.

Owner:平阳县小鸽工艺品厂

Chinese wolfberry yellow rice wine and brewing process thereof

InactiveCN109628255AFull of nutritionRefreshing tasteAlcoholic beverage preparationAlcoholBeta-Phenylethanol

The invention relates to a Chinese wolfberry yellow rice wine and a brewing process thereof. The Chinese wolfberry yellow rice wine contains ethyl alcohol, saccharides, non-sugar solids, Chinese wolfberry, acid, amino acid liquid nitrogen, calcium oxide and beta-phenylethanol substances. The production process of the Chinese wolfberry yellow rice wine comprises the steps: firstly, obtaining a Chinese wolfberry soaking liquid, and fermenting the Chinese wolfberry soaking liquid with yellow rice wine together; secondly, choosing rice, elutriating, and soaking in ordinary cold water for standby application; preparing a yeast wine medicine, pouring into a jar and stirring with steamed rice evenly, covering a grass cover, and making the cooked rice become softer and sweeter; then adding purified drinking water and the Chinese wolfberry soaking liquid to a fermentation vat, and stirring; and after wine with dregs is fermented, pumping the wine with dregs into a large tank, carrying out low temperature fermentation, and carrying out solid-liquid separation by a vacuum solid-liquid separator. The Chinese wolfberry yellow rice wine has the advantages of nutrition of traditional yellow ricewine and advantages of mechanization yellow rice wine. The medicinal ingredients of Chinese wolfberry are fully fused into the yellow rice wine, and the Chinese wolfberry yellow rice wine is nutritious, can promote the human body to be healthy and has refreshing mouthfeel.

Owner:李庆山

Preparation method of beta-phenethyl alcohol for pharmaceutical and chemical industry

ActiveCN108164394AHigh selectivityImprove conversion rateOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsChemical industryBeta-Phenylethanol

The invention provides a preparation method of beta-phenethyl alcohol for the pharmaceutical and chemical industry. Benzyl alcohol and a catalyst are added into a reaction solvent, a synthesis gas isintroduced to react to obtain beta-phenethyl alcohol, the catalyst comprises a metal salt and a ligand of the metal salt, the metal salt is iridium metal salt or rhodium metal salt or ruthenium metalsalt or a mixture, the ligand is a non-water-soluble nitrogen-containing ligand, the conversion rate of the benzyl alcohol, the raw material of the reaction, in the method is up to 91.7%, and the selectivity of the product beta-phenethyl alcohol is up to 94.6%.

Owner:SHANGHAI LINKCHEM TECH CO LTD

Mosquito eradication aerosol

The invention discloses mosquito eradication aerosol. The mosquito eradication aerosol comprises beta-phenylethyl alcohol, aromatic alcohol, litsea cubeba fruit powder, ethanol and butane. The mosquito eradication aerosol has the advantages of reasonable formula, good use effects and low production cost.

Owner:徐长斌

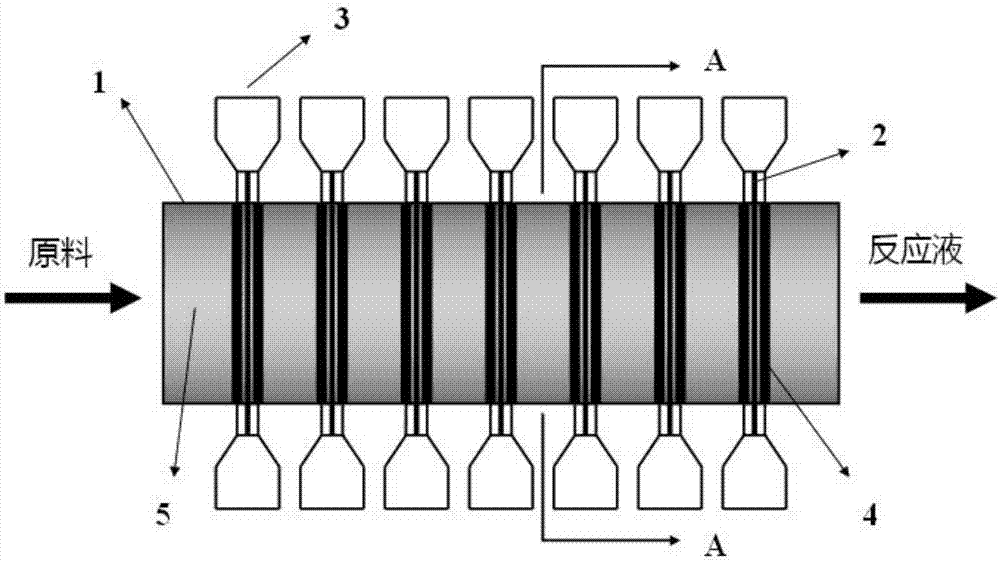

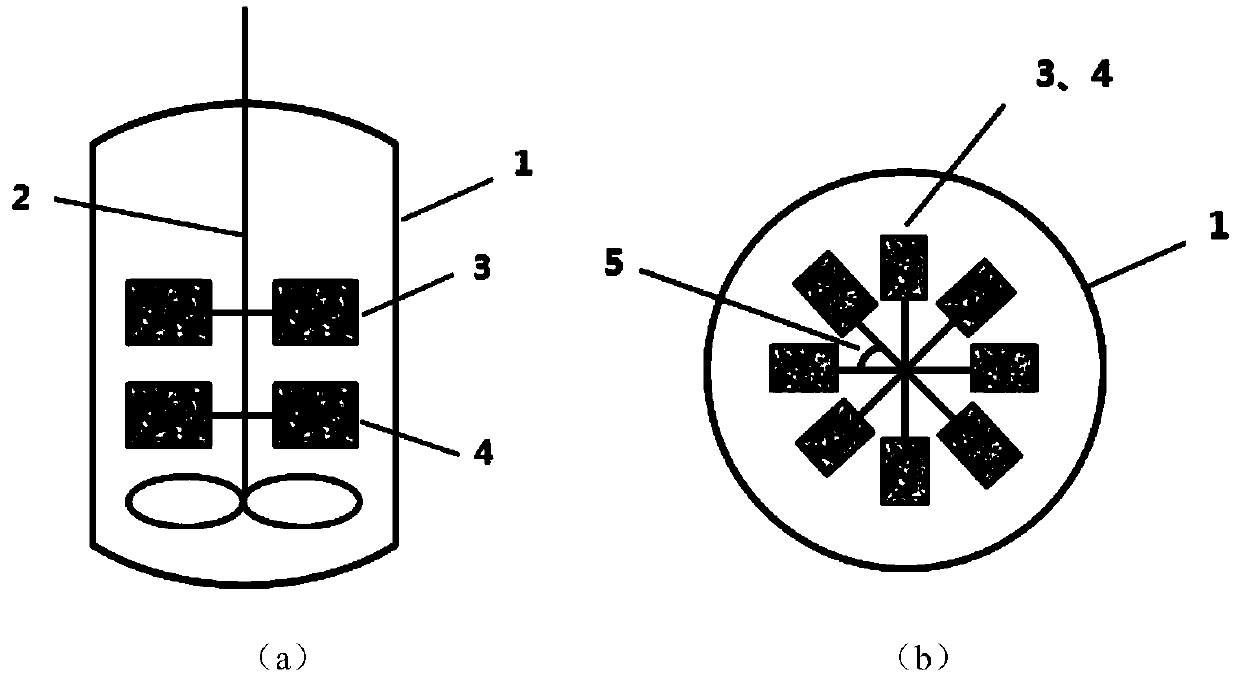

Catalyst, reactor using same and method for preparing beta-phenethyl alcohol

ActiveCN107952483ARealize continuous productionReduce processOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsStyrene oxidePhenethyl alcohol

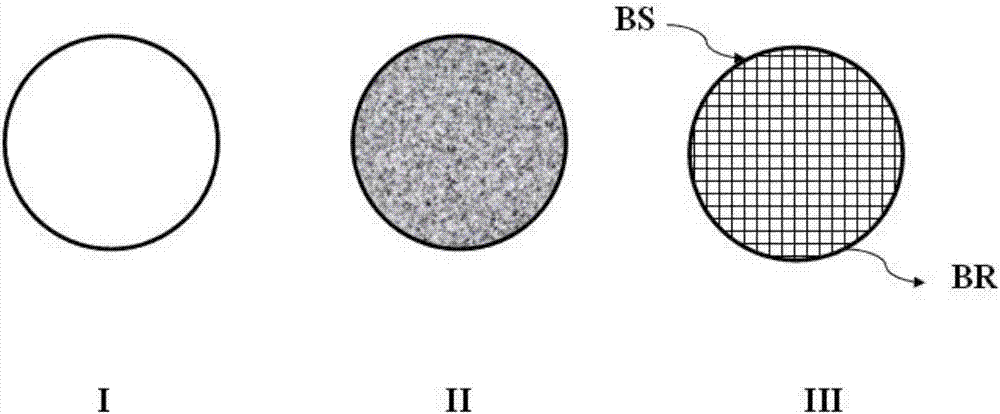

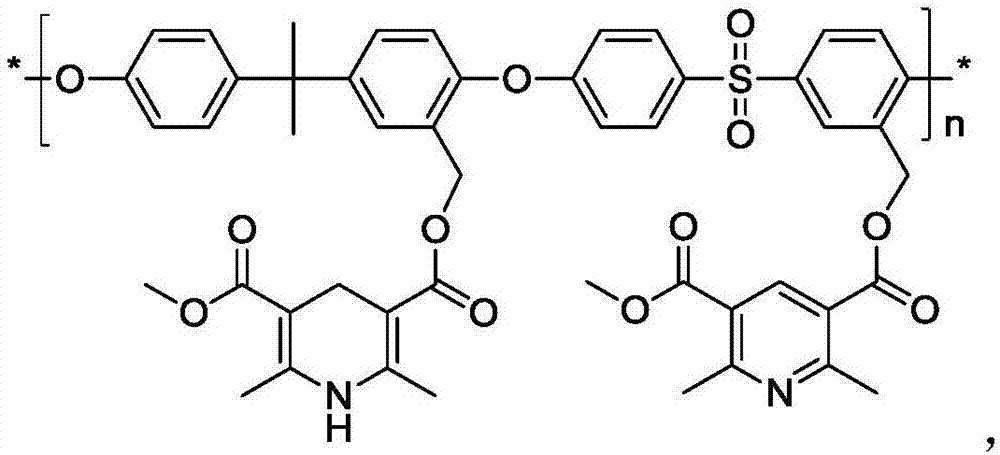

The invention discloses a catalyst, a reactor using the same and a method for preparing beta-phenethyl alcohol. The catalyst is a polysulfone microporous membrane supported 1, 4-dihydropyridine Hantzsch nicotinamide coenzyme model compound molecule catalyst. The tubular membrane reactor comprises a tubular shell, a reaction cavity, a catalyst clamp and heat transfer grid tubes, the tubular shell is equally divided into a plurality of cavities, the catalyst clamp fixes the catalyst, and the heat transfer grid tubes cling to the catalyst and are mounted on two surfaces of the catalyst. The catalyst can hydrogenate styrene oxide in a high-selectivity and high-yield manner under the condition of room temperature to obtain the beta-phenethyl alcohol. The reactor can timely remove reaction heat,hydrogenation of styrene oxide can be performed without solvents, and desolvent energy consumption and production cost are reduced.

Owner:WANHUA CHEM GRP CO LTD

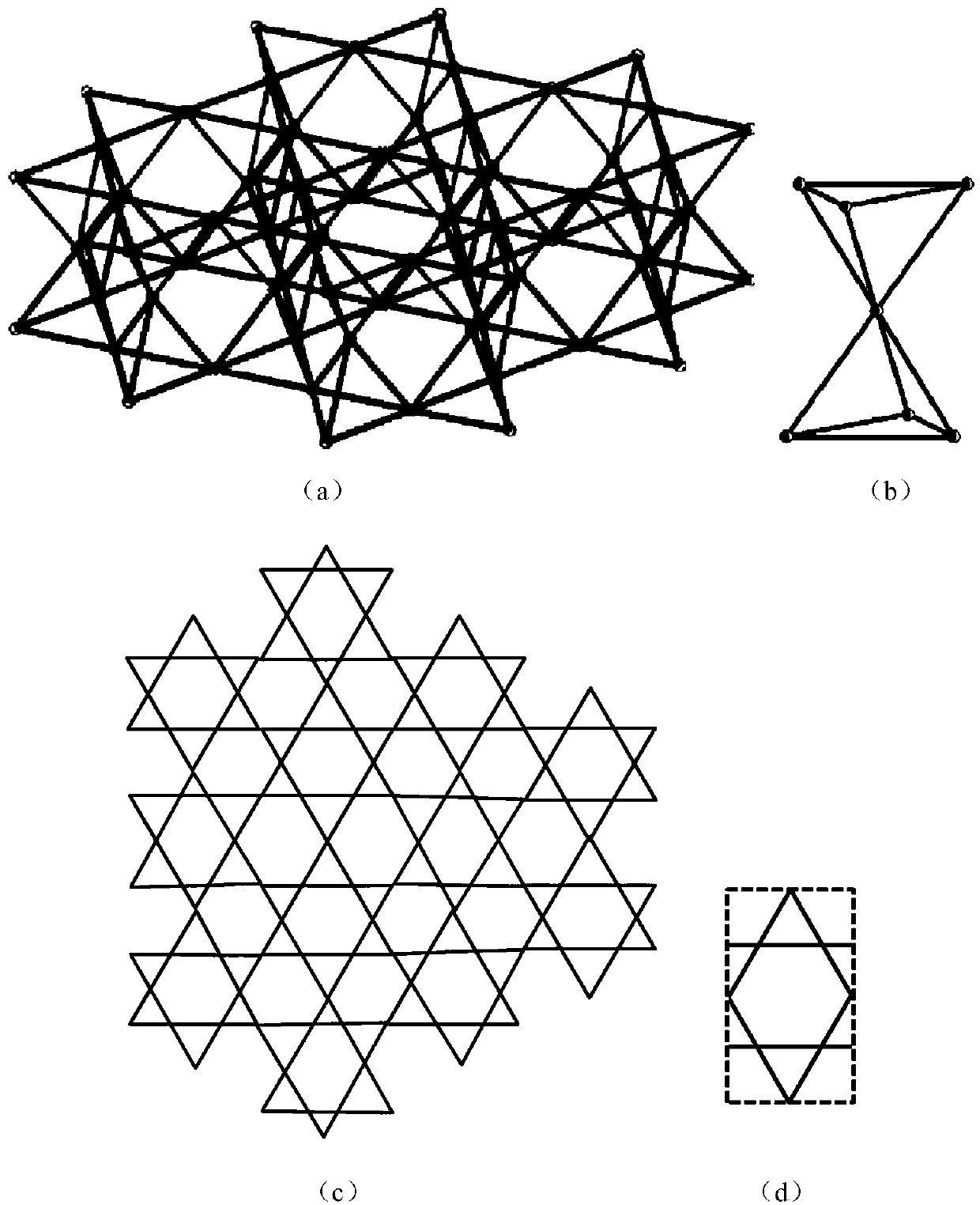

Three-dimensional hollow tube microarray framework catalyst and method of using same to prepare beta-phenylethanol

ActiveCN109569633ARealize continuous productionLarge specific surface areaPreparation by oxidation reactionsMetal/metal-oxides/metal-hydroxide catalystsPolymer scienceBeta-Phenylethanol

The invention discloses a three-dimensional hollow tube microarray framework catalyst and a method of using the same to prepare beta-phenylethanol. The three-dimensional hollow tube microarray framework catalyst is fixed to a stirring shaft to allow online activation. The three-dimensional hollow tube microarray framework catalyst is prepared by means of selective laser fusion. The three-dimensional hollow tube microarray framework catalyst is suitable for preparing beta-phenylethanol by styrene hydrogenation-oxidation under high selectivity and high yield under the conditions of zero solvent,zero aid and mildness; oxidized styrene conversion rate is >99.9%, beta-phenylethanol selectivity is > / =99%, desolvation energy consumption is lowered, and production cost is lowered. The preparationmethod of beta-phenylethanol herein is suitable for continuous production of beta-phenylethanol, and production efficiency is greatly improved.

Owner:WANHUA CHEM GRP CO LTD

A kind of fermenting method of continued grains of rice wine

InactiveCN104212682BIncrease rice flavorImprove qualityAlcoholic beverage preparationYeastBeta-Phenylethanol

The invention relates to a rice wine grain stillage refilling fermentation method. The rice wine grain stillage refilling fermentation method comprises the steps of soaking of raw material rice, rice steaming, distiller yeast mixing, saccharification, fermentation, wine distillation and the like. The rice wine grain stillage refilling fermentation method greatly improves the content of flavor and fragrance components such as of total acid, total ester, ethyl lactate and beta-phenethyl alcohol.

Owner:GUILIN YINQUAN LIQUOR IND

Method for preparing mosquitocide tablet

InactiveCN103843844AMosquito repellent effect is obviousNo smellBiocidePest repellentsBeta-PhenylethanolPhenethyl alcohol

The invention belongs to the field of daily necessities, and particularly relates to a method for preparing a mosquitocide tablet. The method concretely comprises the following steps: fully dissolving beta-phenethyl alcohol and garlic essential oil into a solvent; adding water to dilute, so as to obtain mosquitocide liquid; and fully soaking blank mosquitocide paper into the mosquitocide liquid in the step A, and then drying the soaked mosquitocide paper, so as to obtain the mosquitocide tablet. The method is simple in operation, and low in production cost, and the prepared mosquitocide tablet is significant in mosquito repelling and mosquito killing effects, free of a peculiar smell, free of poison and harm, and applicable to general people and pregnant women.

Owner:杨小宁

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com