Patents

Literature

167 results about "Harrow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In agriculture, a harrow (often called a set of harrows in a plurale tantum sense) is an implement for breaking up and smoothing out the surface of the soil. In this way it is distinct in its effect from the plough, which is used for deeper tillage. Harrowing is often carried out on fields to follow the rough finish left by plowing operations. The purpose of this harrowing is generally to break up clods (lumps of soil) and to provide a finer finish, a good tilth or soil structure that is suitable for seedbed use. Coarser harrowing may also be used to remove weeds and to cover seed after sowing. Harrows differ from cultivators in that they disturb the whole surface of the soil, such as to prepare a seedbed, instead of disturbing only narrow trails that skirt crop rows (to kill weeds).

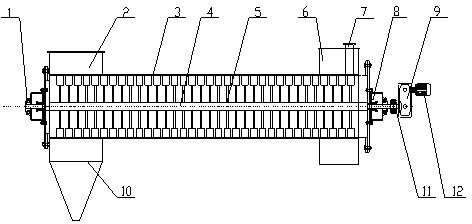

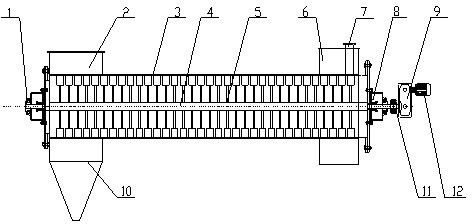

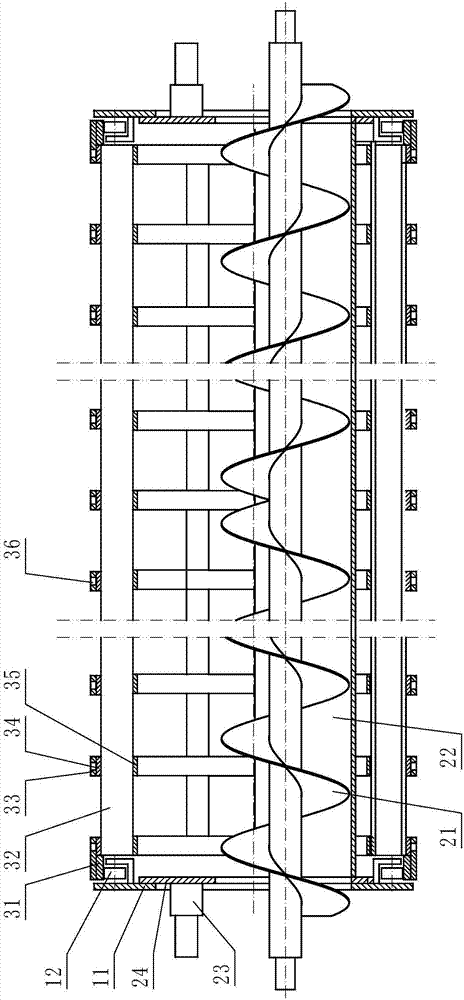

Sludge harrow type drying method and device

InactiveCN102674655AIncrease production capacityImprove work efficiencySludge treatment by de-watering/drying/thickeningGas solidSludge

The invention relates to a method for drying sludge and a drying device. A heat medium ( generally hot gas fume or hot air) for drying the sludge enters a sludge harrow type dryer from the tangential direction; wet sludge is added from one end of the harrow type dryer and is directly contacted with the heat medium in the drier to realize the drying process; the harrow type device can crush the block-shaped sludge and push the sludge from an inlet to an outlet; dry sludge is moved to the other end of the harrow type drier under the functions of the drying medium and the harrow type device and is separated from the drying medium through a function of an internal gas-solid separator and discharged out of the drier. The method has the characteristics that the drier can be securely and continuously operated, so that the obvious effects of high heat efficiency, low energy consumption and high yield are achieved.

Owner:SOUTHEAST UNIV

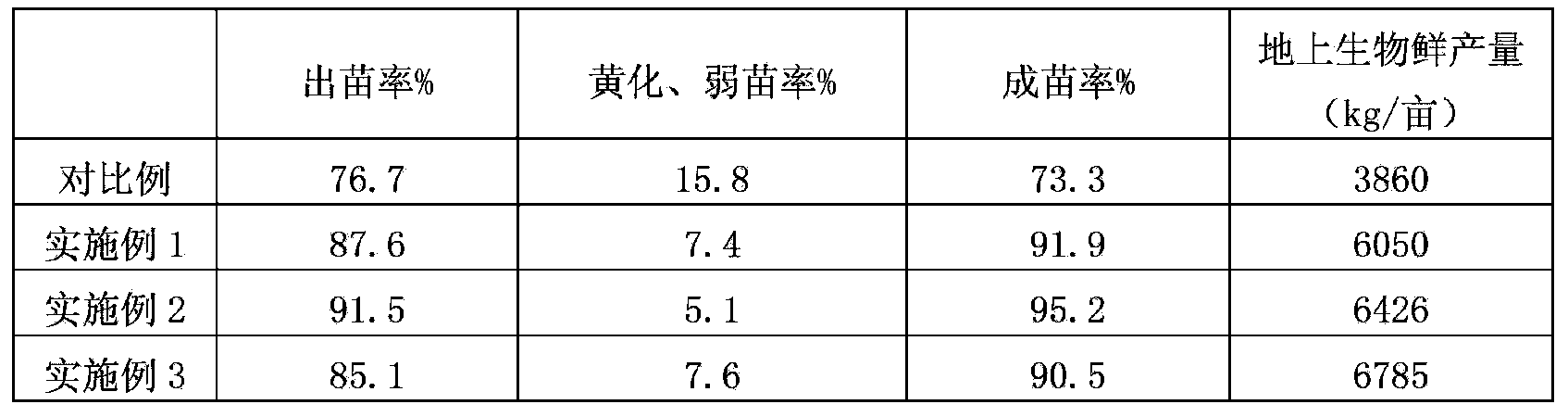

Cultivation method for improving corn yield in saline-alkali land

InactiveCN104396555AArea yield increaseIncrease incomeClimate change adaptationFertilising methodsAlkali soilMoisture

The invention discloses a cultivation method for improving corn yield in saline-alkali land. The method comprises the following steps: irrigating the saline-alkali land for flooding for once in the middle of March, wherein the irrigation volume for per mu is 60-100 m<3>, airing for 1-1.5 months until the surface of earth is dry enough to allow people to step on, applying 1000kg-1500kg of miscellaneous manure or 50kg-55kg of compound fertilizer per mu, then performing rotary tillage for 1-2 times to mix soil and the fertilizer, pressing by using a harrow and preserving soil moisture, and leveling the surface of earth; treating corn by using a seed coating agent before the corn is seeded, wherein the seed coating agent comprises actinomycin, bacillus mucilaginosus, azospirillum, diatomite, spicy powder, heteroauxin, potassium sulphate, magnesium sulfate, zinc sulfate, an alpha-pimacol growth regulator, an EDTA-2Na chelating agent, humic acid and turf; mixing bactericide and insecticide with seeds for treating the seeds, namely, firstly adding the insecticide, and then adding the bactericide after piling for 3-6 hours; and immediately seeding after the seed mixing treatment is finished.

Owner:王杨

Method of culturing of seedling and standardized planting protection of seeds of shinyleaf yellowhorn

InactiveCN101536656AGrow vigorouslyImprove qualityClimate change adaptationHarvestersDiseaseFarmyard manure

The invention relates to a method of culturing of seedling and standardized planting protection of seeds of shinyleaf yellowhorn, which is characterized by comprising the following steps of: (1) collecting seeds: collecting seeds which are fully mature and has full kernels; (2) seed treatment: soaking the seeds with clean water, carrying out sand burial and lamination and adopting a fast germinating method for seeds without being treated by sand burial; (3) soil preparation of nursery lands: turning over the soil while pressing with a harrow, leveling the nursery lands and applying the farmyard manure; (4) sowing: adopting sowing in strip in spring, or spot sowing; taking out the seeds for sowing after the fruit is mature in autumn; (5) building a tunnel, furrowing small grooves at the two sides of beds, inserting bamboo bows, coating films, tucking the edges at the periphery of the film and covering the film with soil and pressing the film; (6) management of seedling stage: watering in proper time and proper quantity, weeding, binding the supports of nursery plants and carrying out artificial capping in August; (7) digging pits for planting when planting in spring of next year, cultivating, weeding, cutting tiller at any time, applying fertilizers before flowering, in the stage of enlarging the fruit, after colleting seeds and in the stage of enlarging the fruit; and (8) controlling damage by disease and insect and preventing yellows, sooty mould and smaller velvety chafer.

Owner:北京金桐福绿色能源科技有限公司

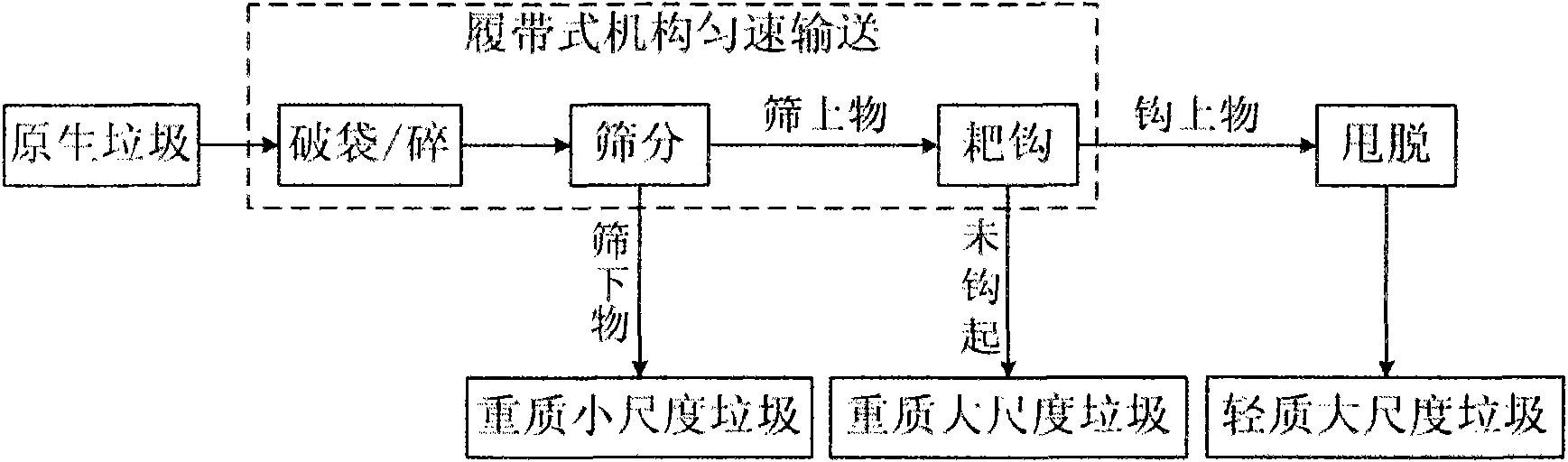

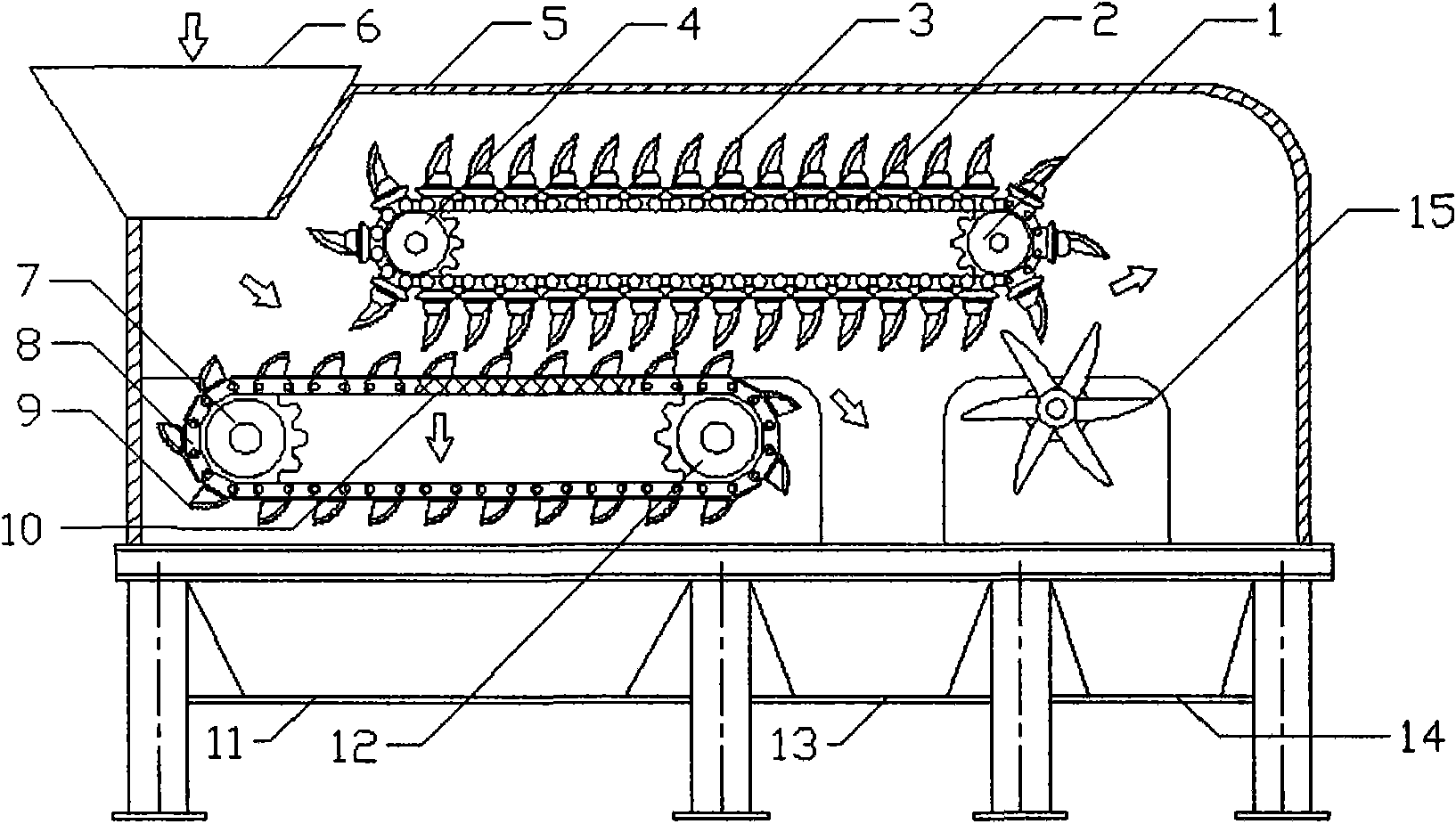

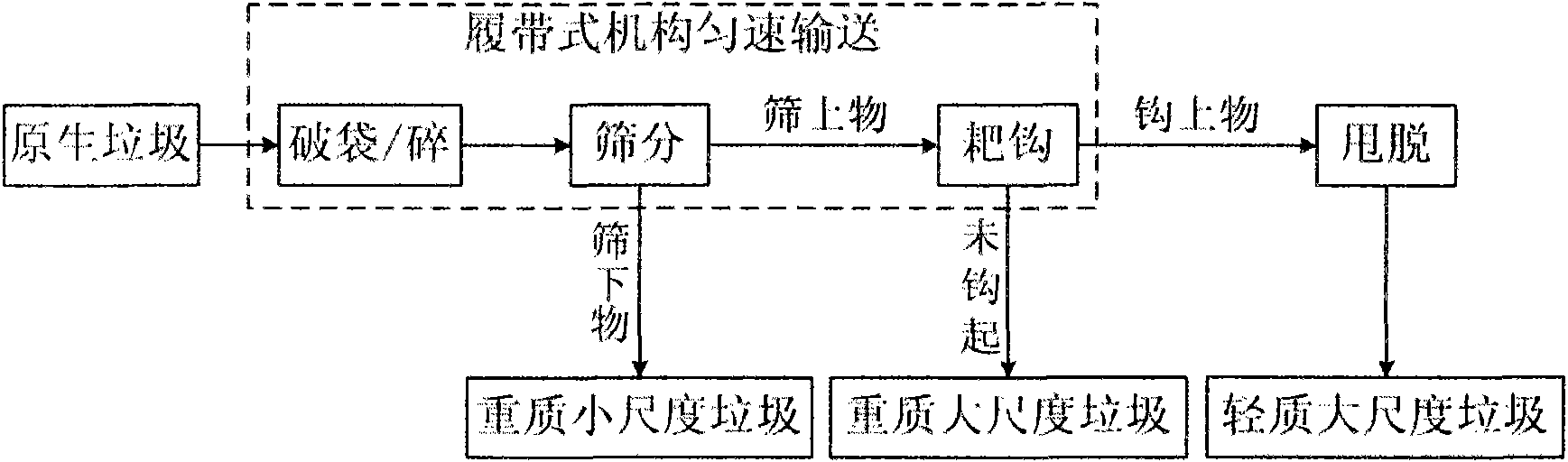

Automatic separating device and method for domestic garbage

ActiveCN101862748AImprove processing efficiencyImprove sorting effectSolid waste disposalSolid separationMotor driveSprocket

The invention discloses an automatic separating device and an automatic separating method for domestic garbage, and belongs to the technical field of garbage separation. The separating device has a differential crawler reciprocating structure, and comprises an upper crawler system consisting of an upper chain wheel, an upper chain wheel, an upper chain group and an upper harrow mechanism, a lowercrawler system consisting of a lower chain wheel, a lower chain group, a lower chain wheel and a lower harrow mechanism, a discharging system consisting of a strainer, a shaking-off mechanism, a first-level discharge hole, a second-level discharge hole and a third-level discharge hole, a feeding hole, a frame and a motor driving system. In the method, the continuous conveying of the materials is realized through the crawler harrow mechanism, the bag-breaking and crushing treatment on the materials is realized through the relative tearing force generated by the upper and lower harrow mechanisms, and the separation of the materials is realized through the sieving and shaking-off mechanisms, so three functions of conveying, bag-breaking / crushing and separating the materials are integrated and the domestic garbage is separated into three classes, namely heavy small-sized garbage, heavy large-sized garbage and light large-sized garbage. The device and the method have the advantages of highseparation efficiency, large treatment capacity, low energy consumption and environmental friendliness.

Owner:SHOUGANG ENVIRONMENTAL IND

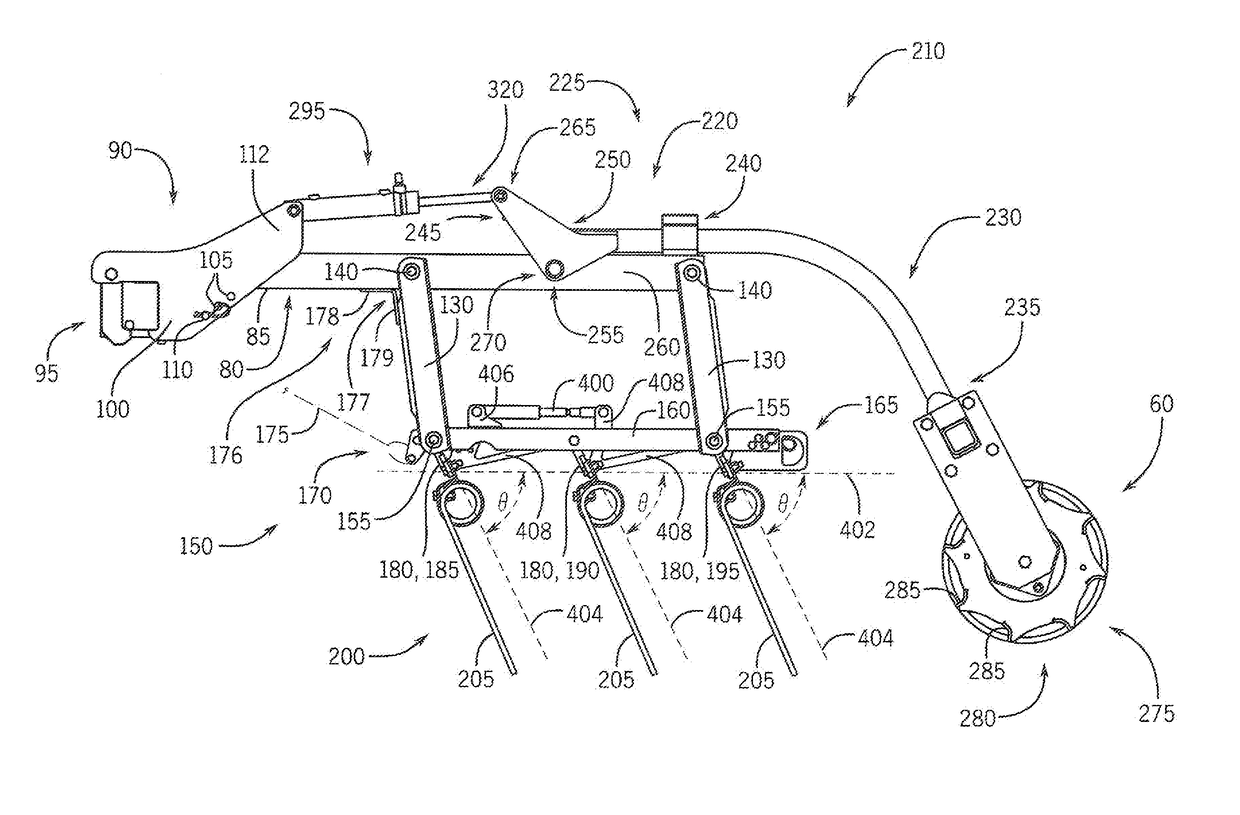

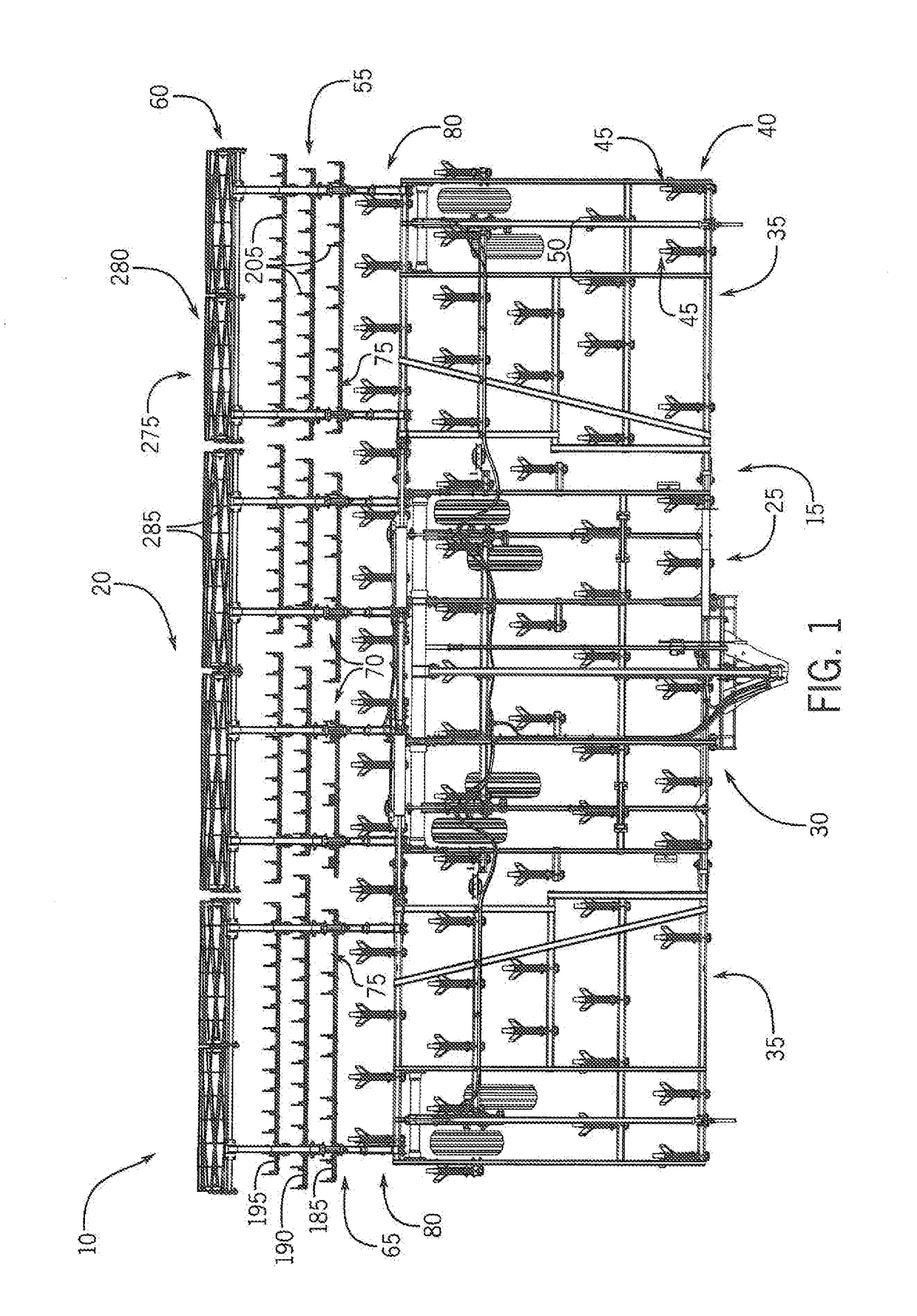

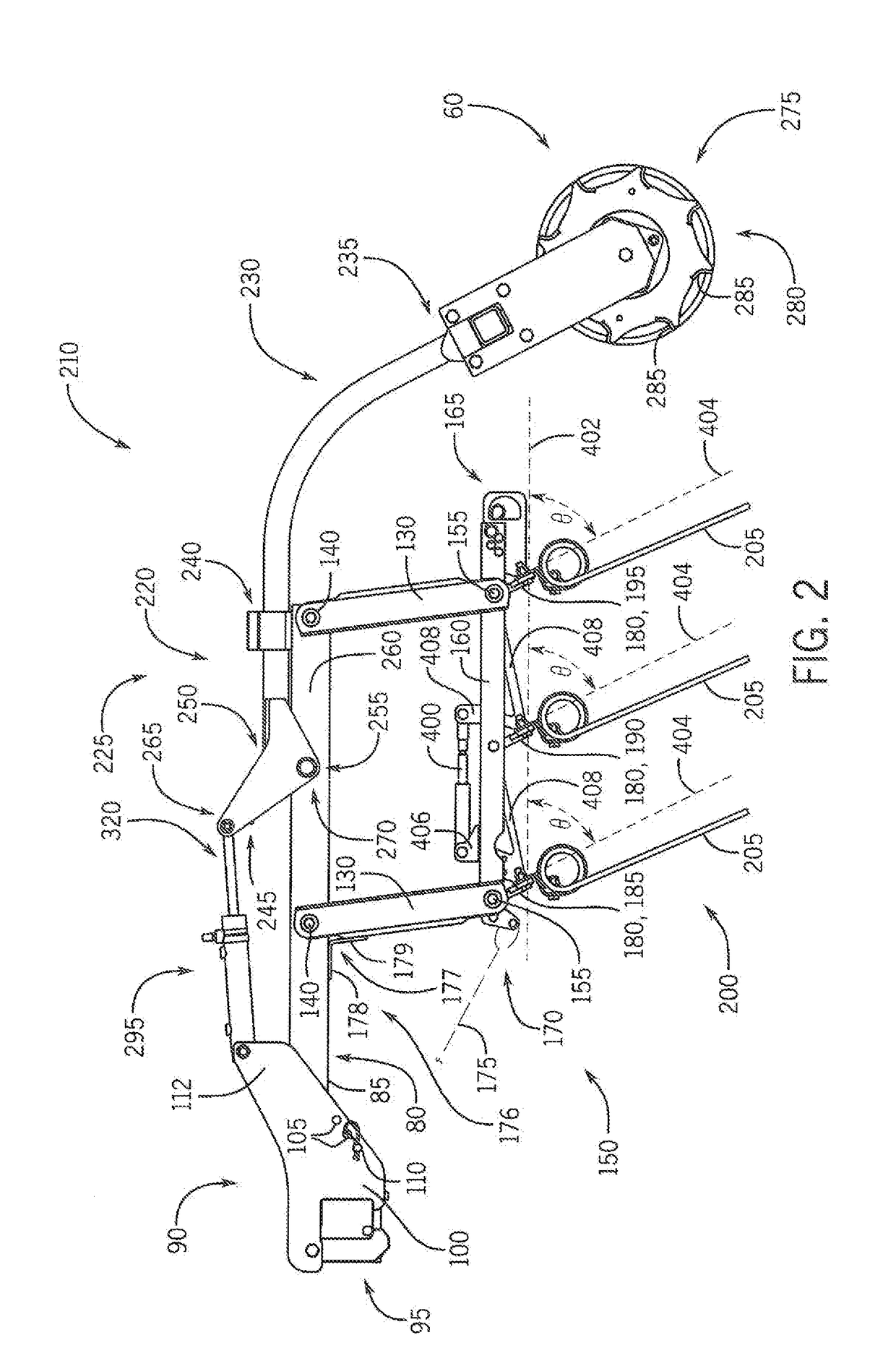

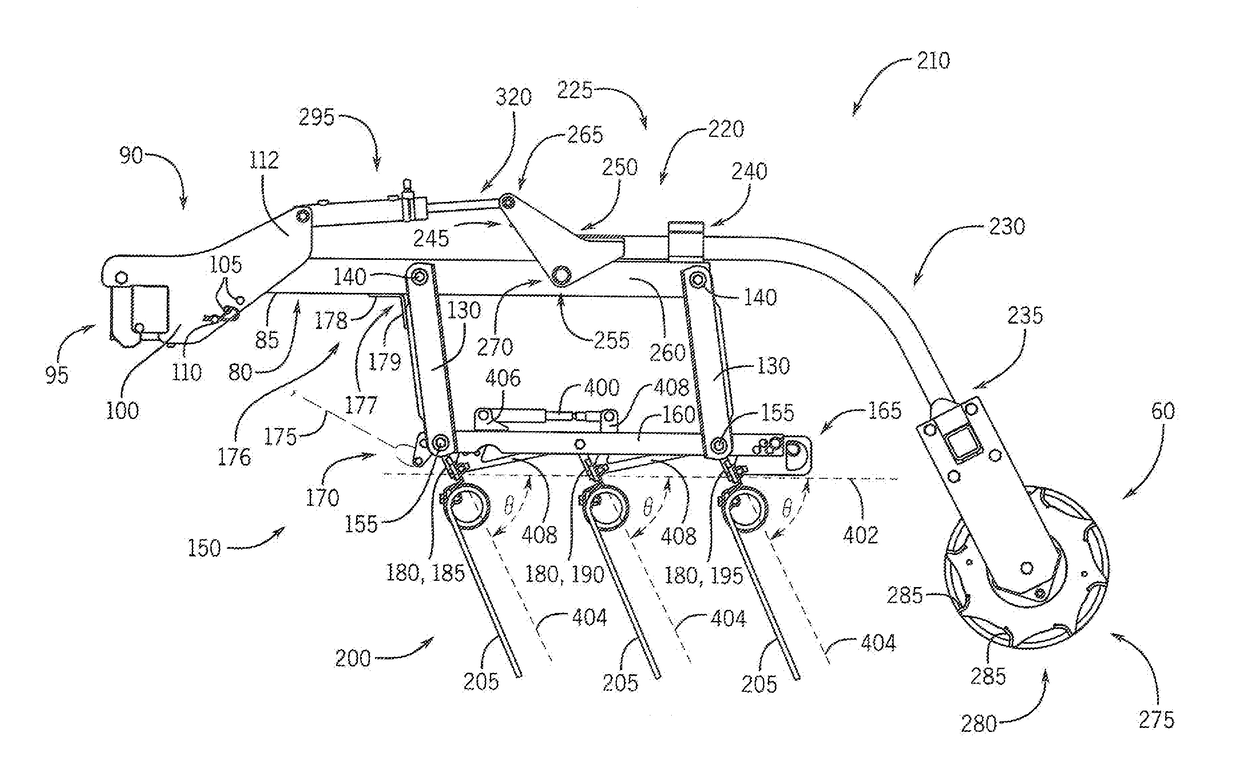

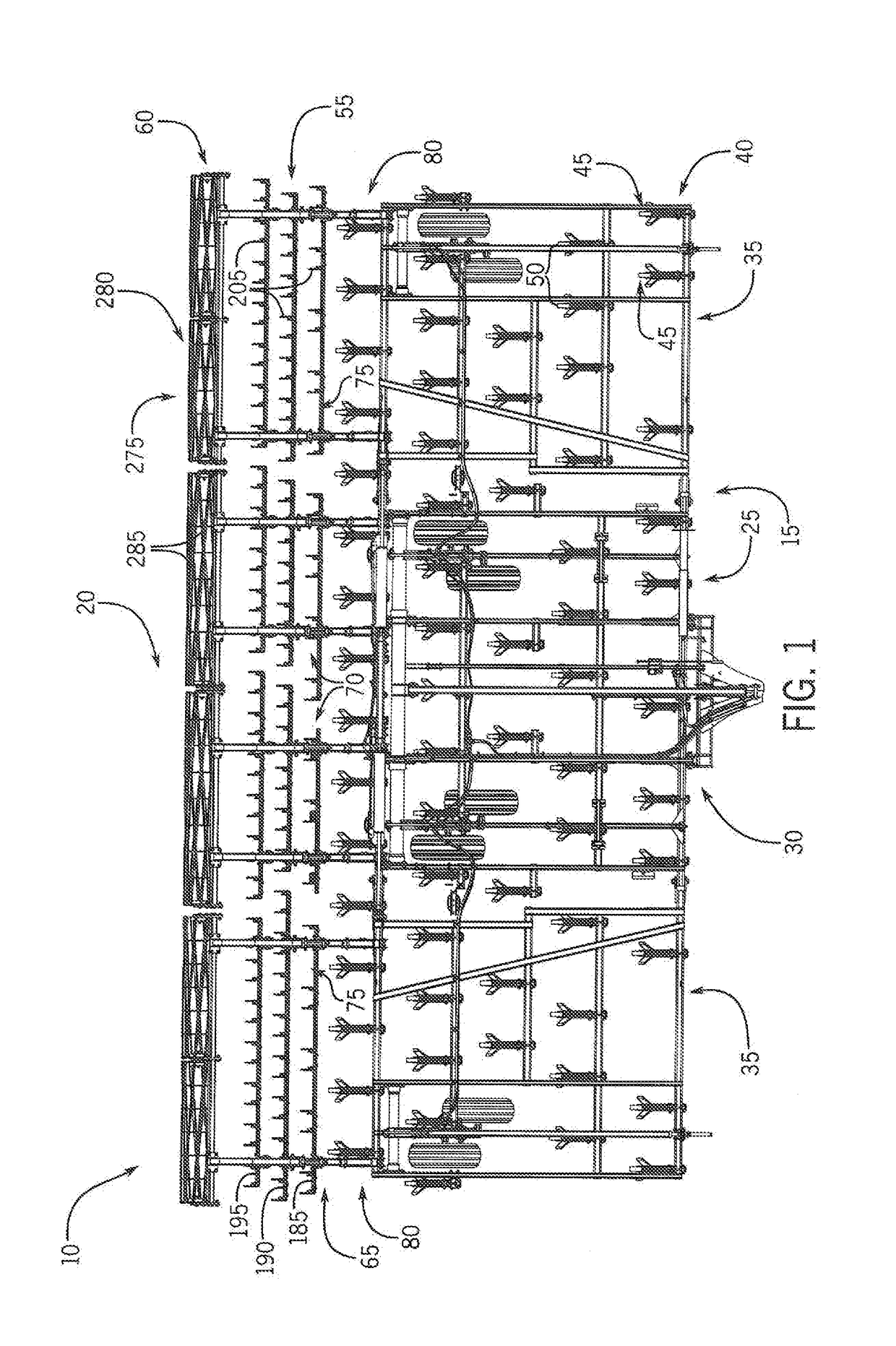

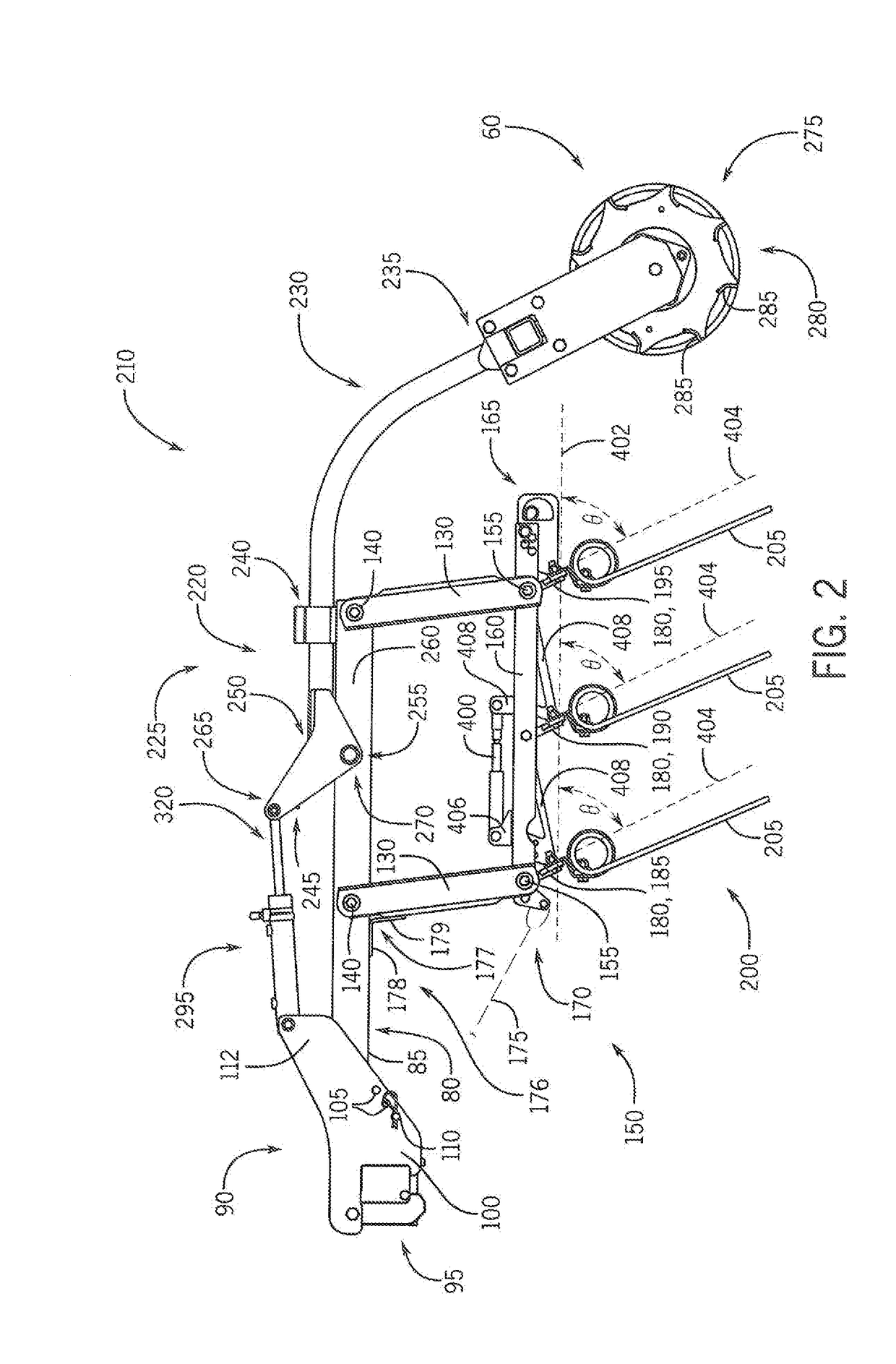

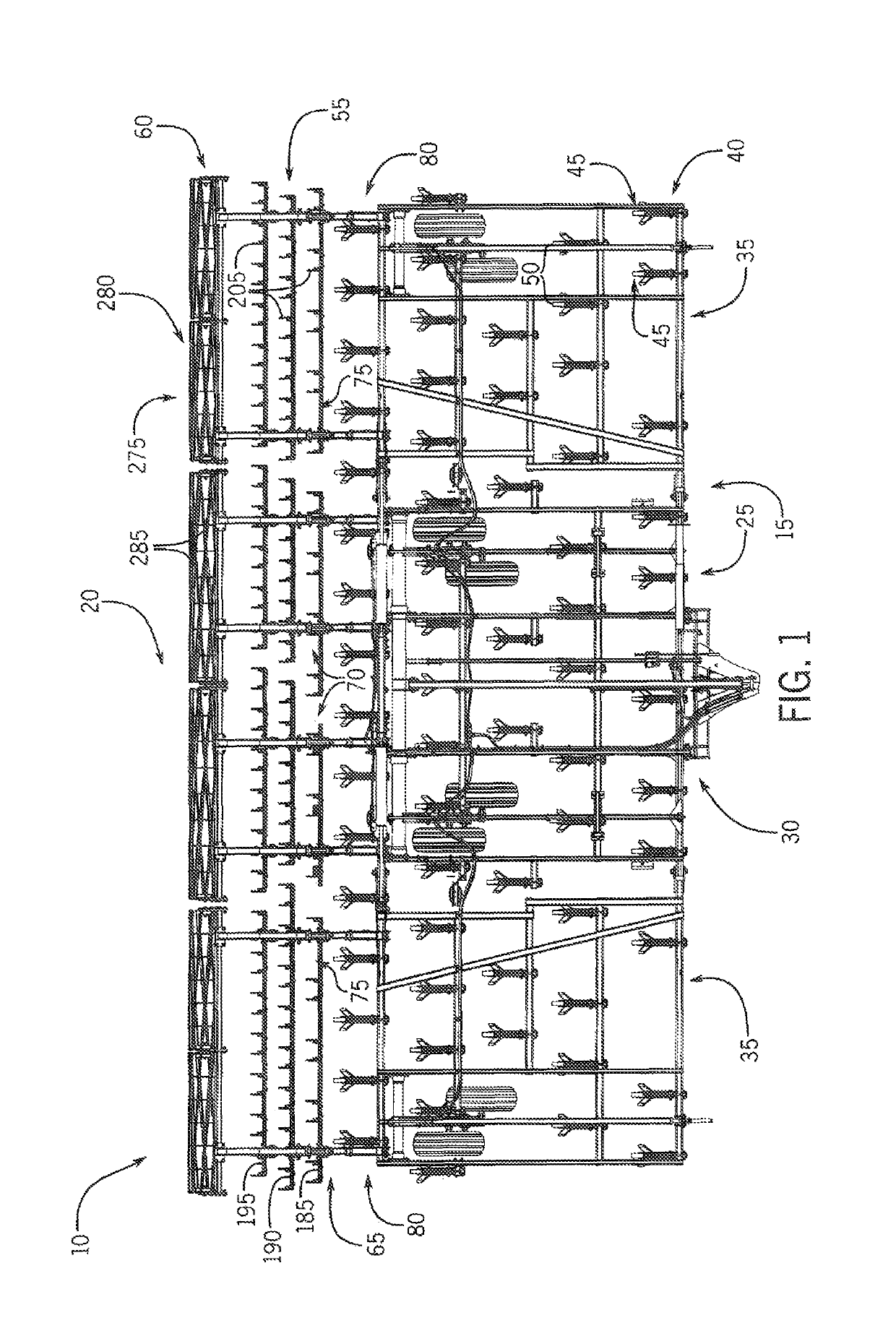

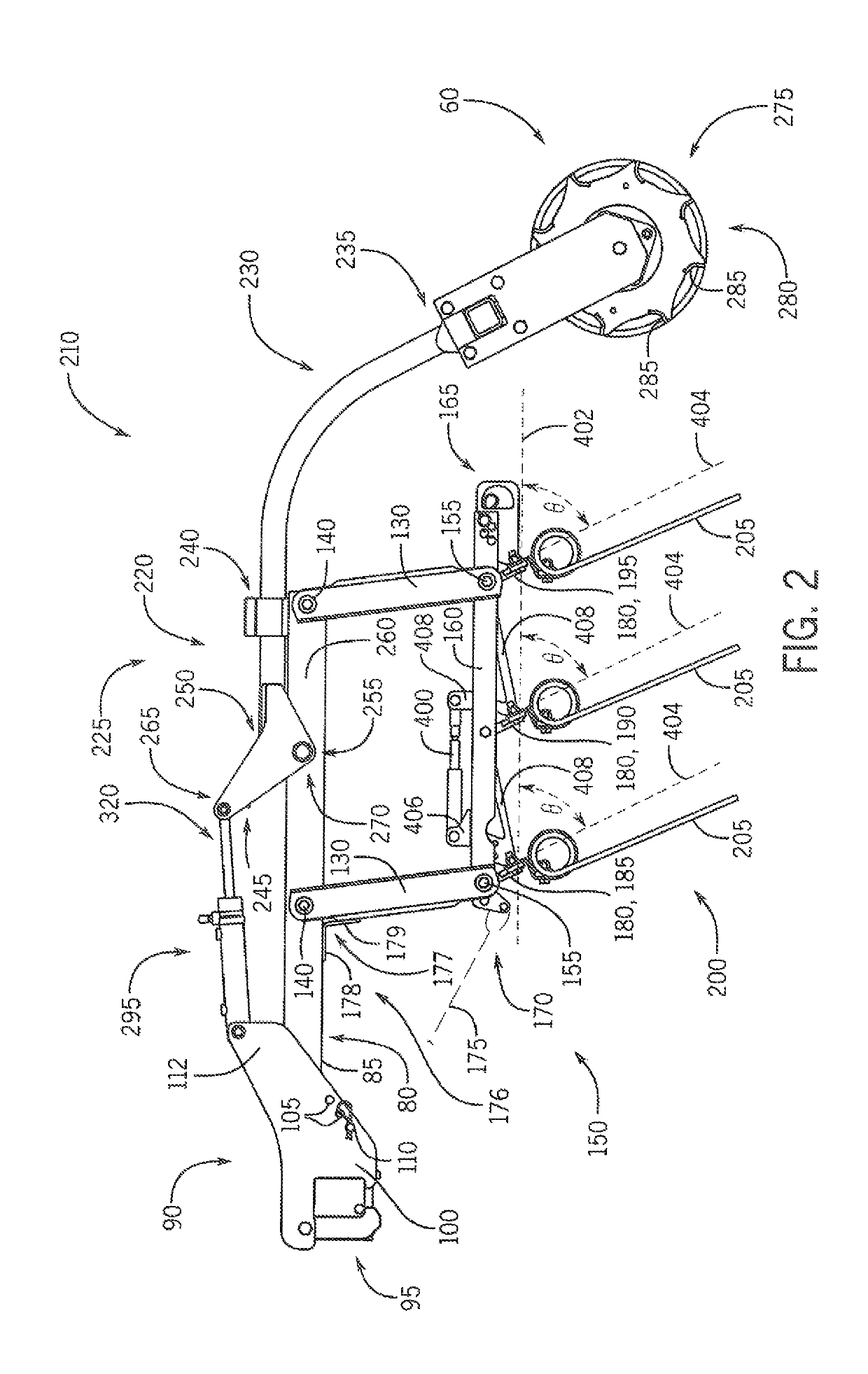

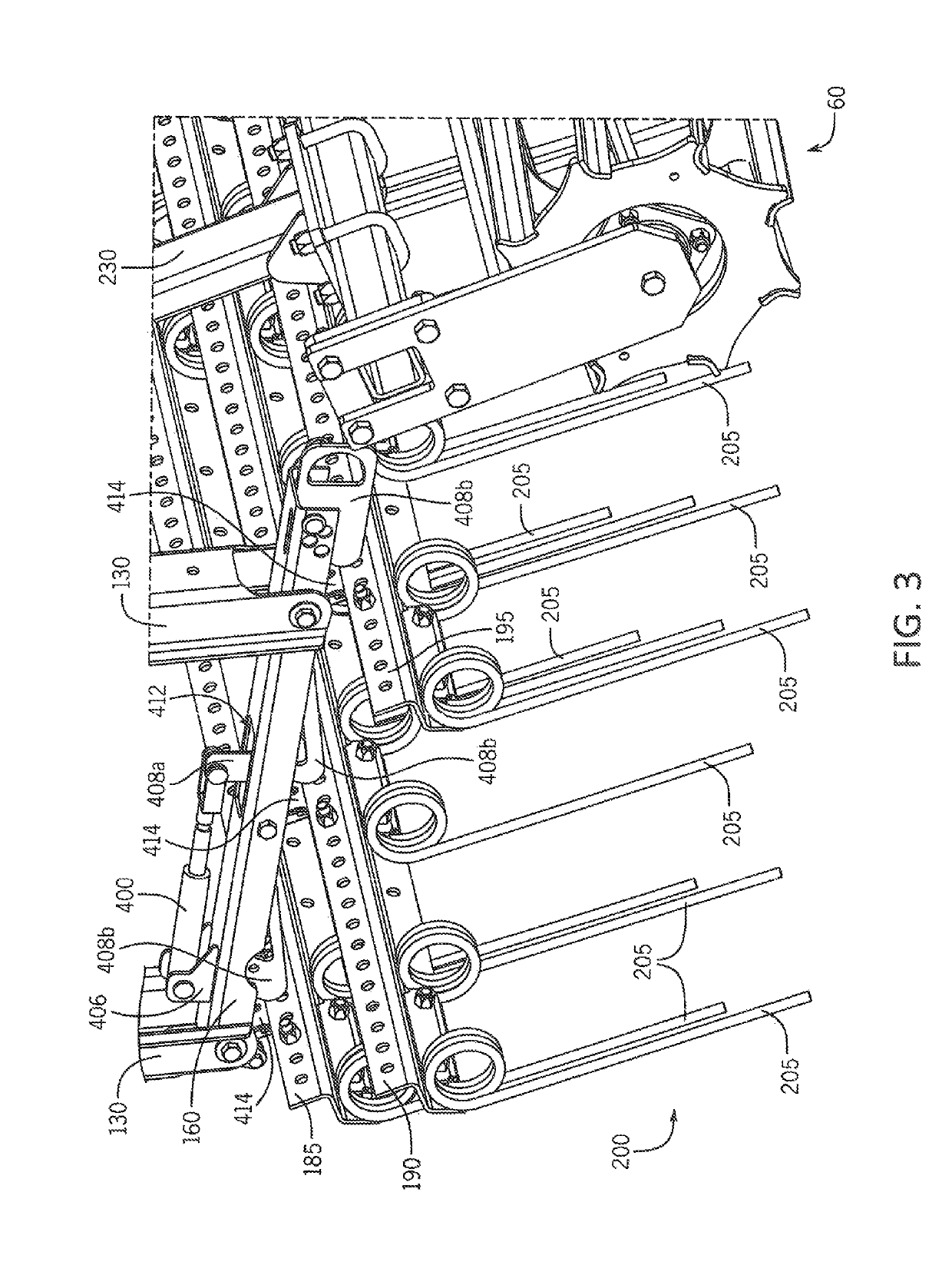

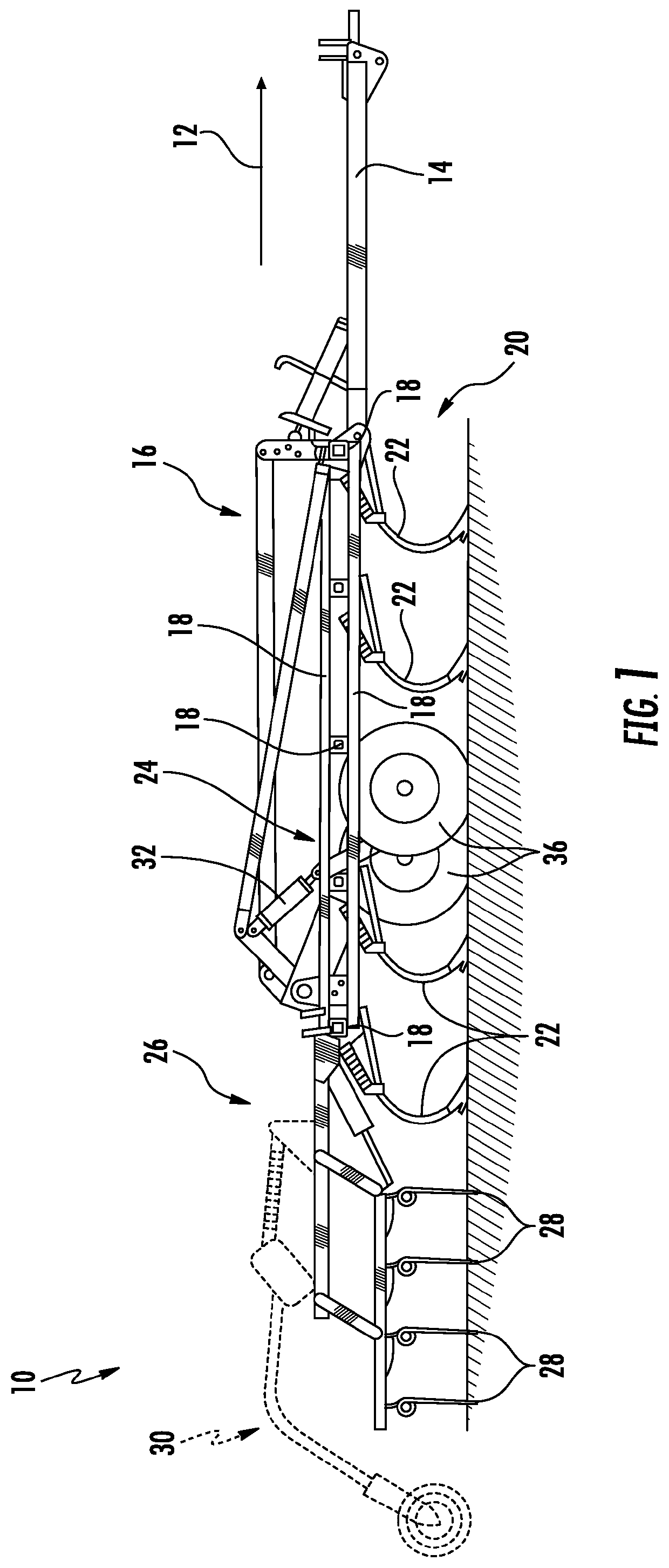

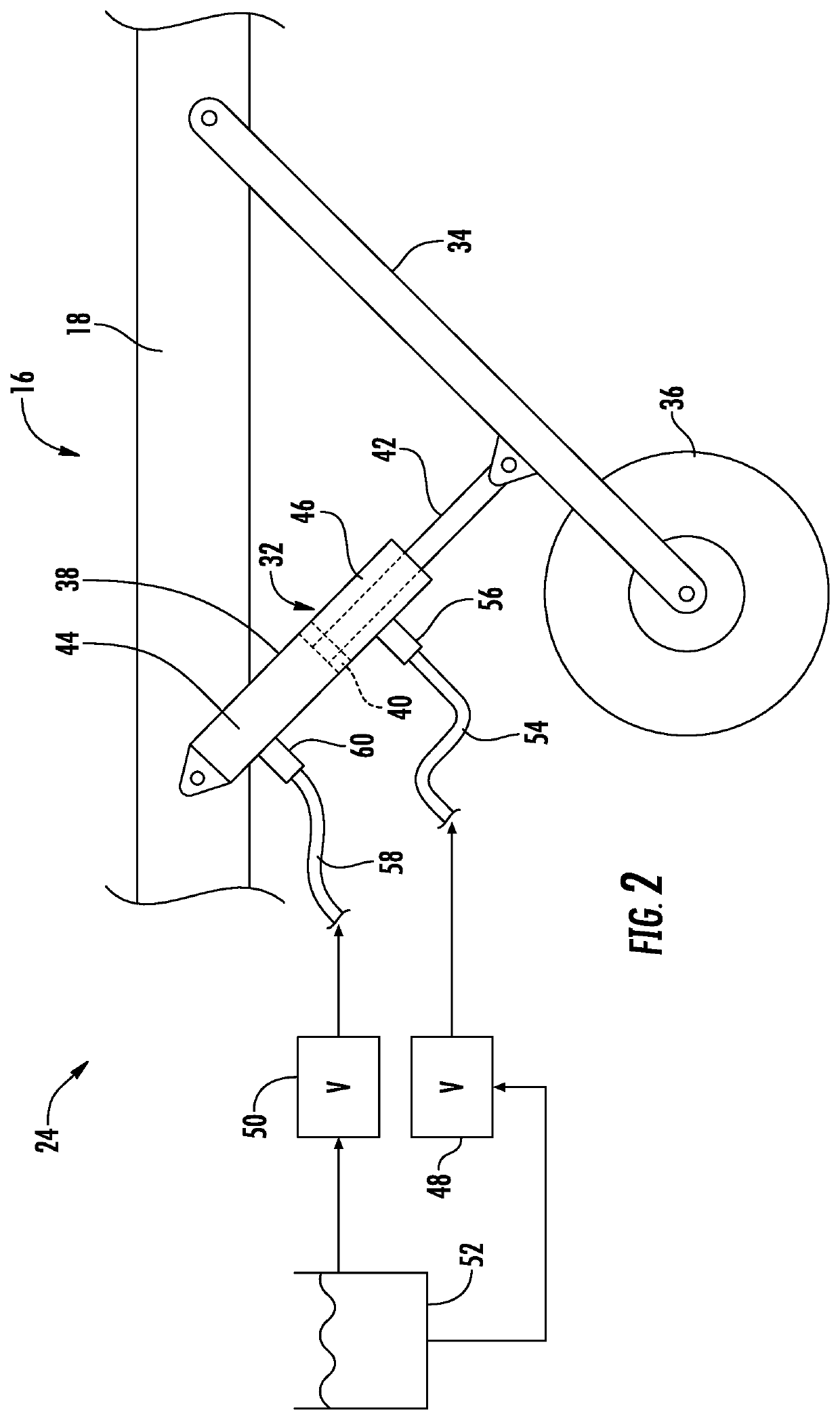

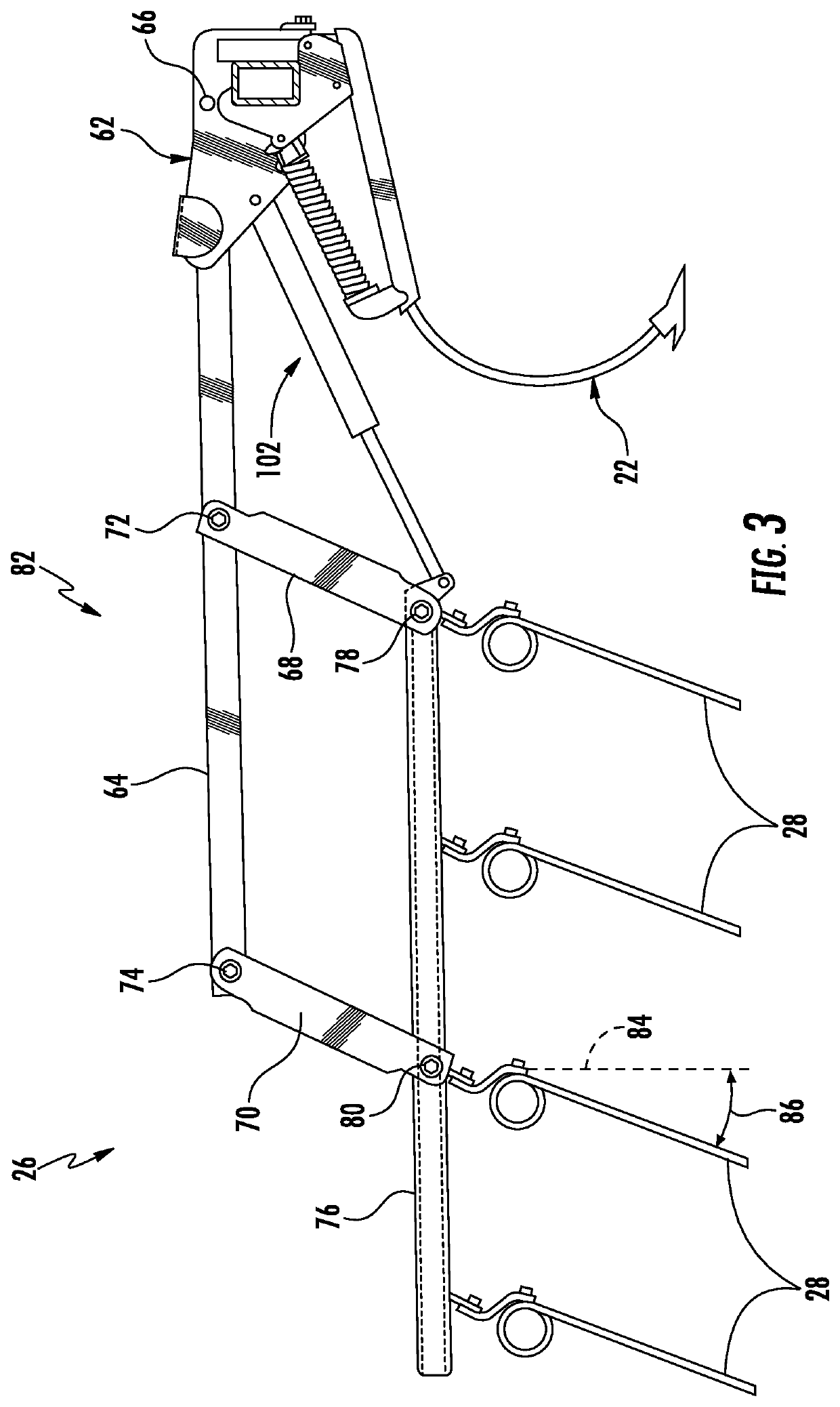

System For Adjusting Smoothing Tools Of A Harrow According To Location

ActiveUS20180139892A1Adjustable angleContinuous regulationSpadesAgricultural machinesField conditionsCommunications system

By providing a control system in communication with a hydraulic system for adjusting an angle of smoothing tools of a harrow, and a communications system for determining a present geographic location of the tillage implement in communication with the control system, the angle of the smoothing tools can be adjusted according to presently determined coordinate locations on a map which indicates amounts of plant residue. This may allow an automated process in which smoothing tools can be continuously adjusted during a tilling session in order to provide the most aggressive setting for optimum field leveling and residue flow based on field conditions.

Owner:BLUE LEAF I P

Bentonite reticular gel foam mud fire prevention and extinguishing agent

The invention discloses a bentonite reticular gel foam mud fire prevention and extinguishing agent, and the key point of the technical scheme is that the fire prevention and extinguishing agent is composed of a bentonite composite type flame-retardant foaming agent, an attapulgite clay powder with an air purifying function, inorganic fiber spraying cotton, a sodium-modified bentonite powder, a coal gangue powder, an expanded perlite powder, sodium alginate and water. The ingredients of the bentonite reticular gel foam mud fire prevention and extinguishing agent are inputted into a plow harrow type material mixing machine and are subjected to high speed mixing into the bentonite reticular gel foam mud fire prevention and extinguishing agent. Reticular gel foam mud is jetted to a burning coal layer by an inorganic fiber spraying machine, so as to be beneficial for generation of an integral reticular gel foam mud film in the fire prevention and extinguishing process, the integral reticular gel foam mud film covers and adheres to the surface of the ore layer all the time, contact of the burning coal layer with air is rapidly isolated, coal mines are prevented from continuing to burn, the coal layer is avoided from reburning, and the purposes of flame retardancy and fire prevention and extinguishing are reached; and the bentonite reticular gel foam mud fire prevention and extinguishing agent is applicable to coal mines, mine operating areas and forest fire prevention and extinguishing.

Owner:SHANDONG SHIDAFU IND CONTROL TECH CO LTD

Electronic Sensor Assembly For Monitoring Smoothing Tools Of A Harrow

ActiveUS20180139891A1Continuous monitoringEasy to moveSpadesAgricultural machinesTraffic capacityField conditions

By providing an electronic sensor in communication with a hydraulic system for adjusting an angle of smoothing tools of a harrow, the angle of the smoothing tools may be continuously monitored by a controller and / or an operator in the tractor cab. This may allow continuous adjustment of the smoothing tools during a tilling session in order to provide the most aggressive setting for optimum field leveling and residue flow based on field conditions.

Owner:BLUE LEAF I P INC

Asparagus high quality and high yield seedling raising method

InactiveCN103416186AImprove survival rateIncrease varietyHorticultureAsparagus adscendensEconomic benefits

The invention discloses an asparagus high quality and high yield seedling raising method. The method includes the following steps of step 1, nursery garden selection, specifically, selecting sandy soil, controlling the size of the nursery garden to be 40-50 square meters, and carrying out weeding on the nursery garden, step 2, fertilization, specifically, spreading 200-210 kilograms of compost in the nursery garden evenly, turning up the soil, carrying out transverse longitudinal treatment through a harrow, crashing soil blocks, leveling the land, making seeding ditches, and fully mixing and fertilizing 1.95-2.5 kilograms of ammonium sulfate and 1.0-1.2 kilograms of calcium superphosphate into the ditches, step 3, seed screening, specifically, screening seeds with diameters smaller than 3mm out through a sifter, step 4, seeding, specifically, carrying out seeding in a drilling method when daytime low temperatures of positions below the land by 2-3cm exceed 10 DEG C, and step 5, earthing, enabling the thickness of earthing to be 3-6cm, and compacting the soil after earthing. According to the asparagus high quality and high yield seedling raising method, survival rates of raised asparagus are improved by 35%, meanwhile, the raised asparagus is good in quality and plump and complete in shape, germinating time is shortened, therefore, growth cycles are shortened, raising cost is reduced, and economic benefits are greatly increased.

Owner:JURONG CHIHU FENGQING AGRI ECOLOGICAL PARK

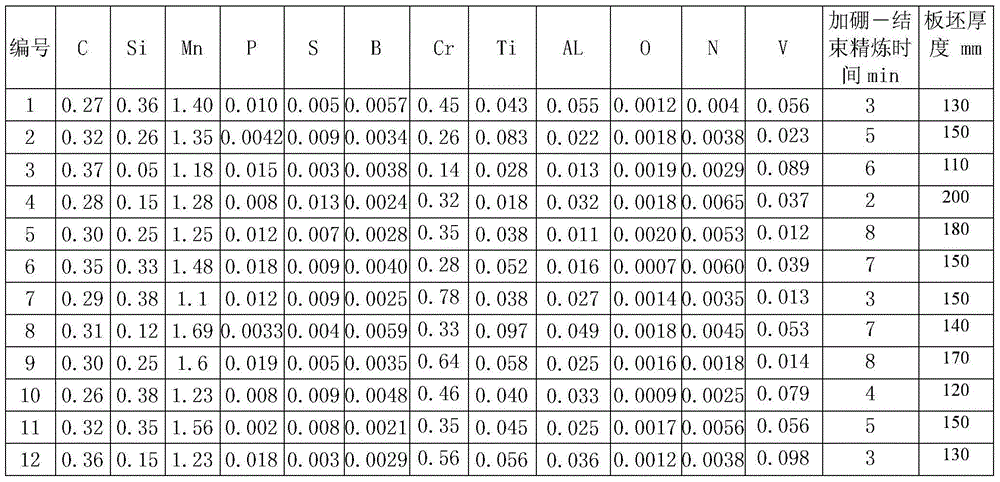

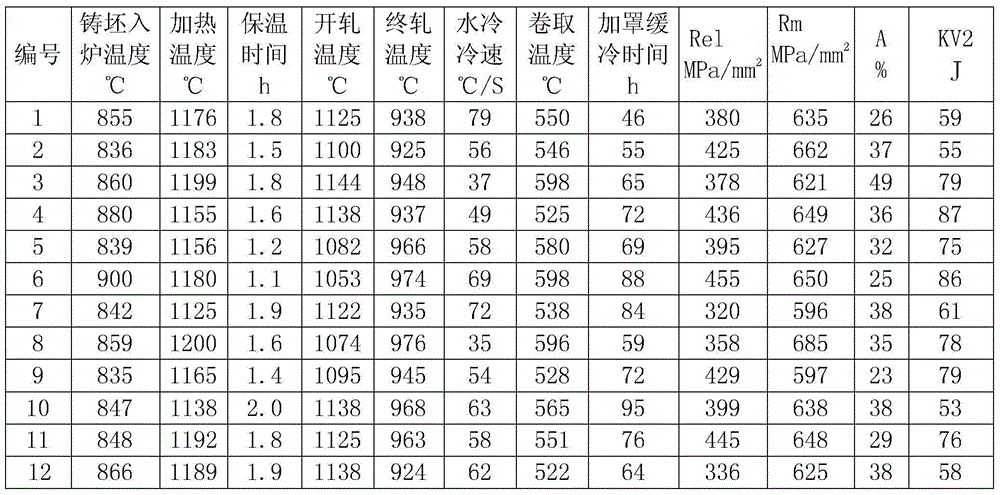

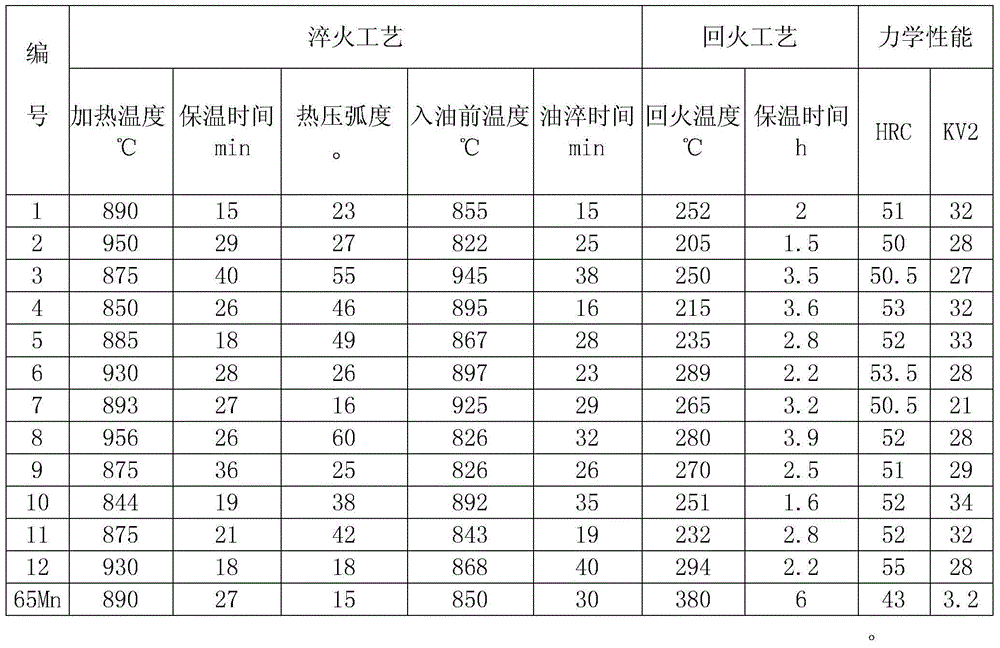

Harrow disc strip steel and production method and harrow disc heat treatment method

ActiveCN105132814AImprove toughness and plasticityExtended service lifeFurnace typesHeat treatment furnacesFurnace temperatureContinuous rolling

The present invention discloses harrow disc strip steel and a production method and a harrow disc heat treatment method, the harrow disc strip steel comprises the following chemical components: 0.27-0.37wt% of C, 0.1-0.40wt% of Si, 1.1-1.7wt% of Mn, 0.002-0.006wt% of B, 0.10-0.80wt% of Cr, 0.01-0.050wt% of Al, less than or equal to 0.1wt% of Ti, less than or equal to 0.1wt% of V, less than or equal to 0.0070wt% of N, less than or equal to 0.020wt% of P, less than or equal to 0.010wt% of S, and balance of Fe and impurities. Continuous casting and continuous rolling are used, the casting blank in-furnace temperature is greater than 830 DEG C, heating temperature is 1100-1200 DEG C, heat preservation is performed for 1-2h; and rough rolling finishing rolling temperature is 920-980 DEG C. After finishing rolling, the casting blank is cooled to 500-600 DEG C in the cooling rate of 30-80 DEG C / S, then winded, covered, and slowly cooled for more than 48h. Harrow blank heating temperature is 830-950 DEG C, heat preservation is performed for 15-40min; before-quenching temperature is greater than or equal to 820 DEG C, oil quenching is performed for 15-40min, the quenching oil discharge temperature is less than or equal to 200 DEG C; tempering temperature is 200 to 300 DEG C, and heat preservation is performed for 1-4h. The harrow disc hardness is greater than 50HRC, impact energy is greater than 27J, the harrow disc has good abrasion resistance and toughness and plasticity, the largest hot pressing radian is 60 degrees, and the service life is significantly higher than that of 65Mn harrow disc.

Owner:ANGANG STEEL CO LTD

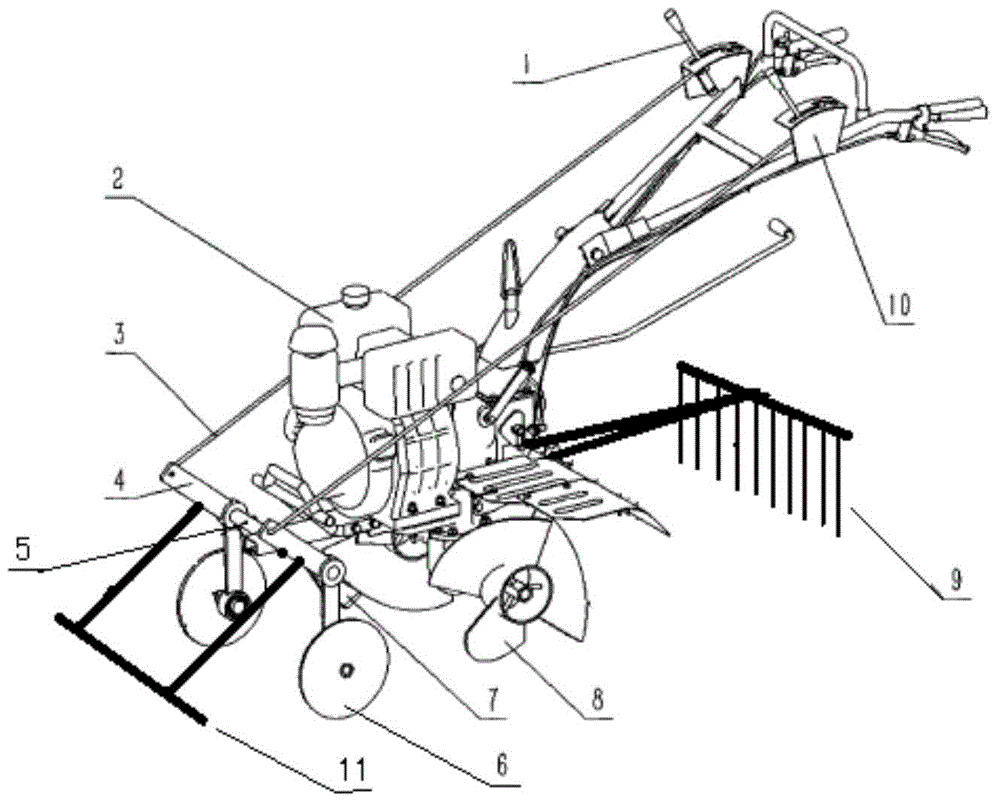

Weeding machine for cassava field

The invention discloses a weeding machine for a cassava field. The weeding machine for the cassava field mainly comprises a gasoline engine, a front pressing rod, lifting plates, pull wires, holders, a connecting welding frame, a blade rotation roller, a limiting sheet, lifting plate frames and a rear collecting harrow, wherein the gasoline engine is used for driving the rotary weeding and weed cutting of the blade rotation roller; the front pressing rod pre-presses weeds at the front part; the rear collecting harrow scrapes the buried weeds; two traveling wheels provide support for gravity and traveling. The weeding machine for the cassava field has the advantages that the weeding of the blade rotation roller is directly driven by the gasoline engine, and the weeding depth can be controlled; obstinate weeds with different properties can be handled; the special weeding machine for the cassava field is the best.

Owner:庞群

Electronic sensor assembly for monitoring smoothing tools of a harrow

An agricultural tillage implement is provided which includes an electronic sensor assembly supported by a harrow frame and in communication with a hydraulic system. The electronic sensor assembly includes a pivoting arm movable in conjunction with the movement of a first set of smoothing tools and is configured to generate an electrical signal corresponding to the angle of the first set of smoothing tools. The electrical signal is transmitted to a controller and / or an operator in the tractor cab for continuously monitoring the angle of the smoothing tools. The electrical signal is used to allow for the continuous adjustment of the smoothing tools during a tilling session.

Owner:BLUE LEAF I P INC

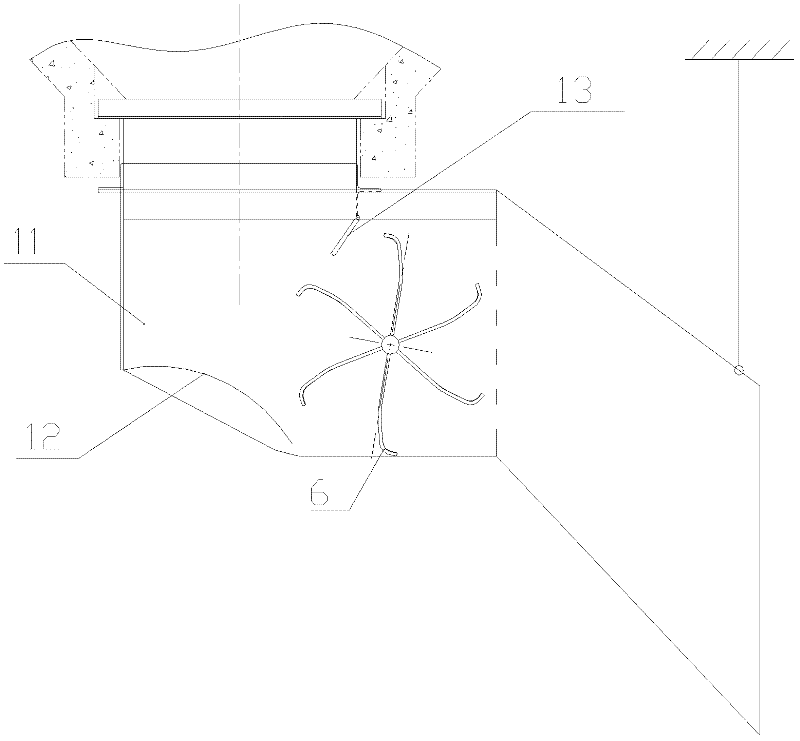

Simple trash remover for trash rack

The invention discloses a simple trash remover for a trash rack. The simple trash remover comprises a machine frame, the trash rack, a trash removing scraper shovel and a driving device, wherein the trash removing scraper shovel is a reverse trapezoidal box body with the open upper side; a hole is formed in the lower part; a turning plate capable of turning is arranged on the hole; an integrally formed harrow tooth part forming an included angle being 120 degrees with a right waist plate is arranged on the right waist plate at one side, near the trash rack, of the trash removing scraper shovel; a triangular cone is arranged on the harrow tooth part; the bottom end of the left waist plate of the trash removing scraper shovel is hinged onto a bottom plate of the trash removing scraper shovelthrough a hinge; the upper end of the left waist plate is tightly locked and fixed onto the adjacent front and back waist plates through a pin; a plurality of penetrating first insertion pin holes are formed in the front and back waist plates; a scraper shovel frame is arranged at the front side of the machine frame; a long groove in which a scraper shovel rolling wheel rolls is formed in the scraper shovel frame. The turning plate capable of turning is designed at the bottom of the trash removing scraper shovel, so that the entering of the trash in the next time after the former trash removal can be convenient; the structure is simple; the manufacturing cost is low; the trash removal efficiency is high; the use is convenient.

Owner:NEIJIANG DONGGONG HYDROPOWER EQUIP MFR

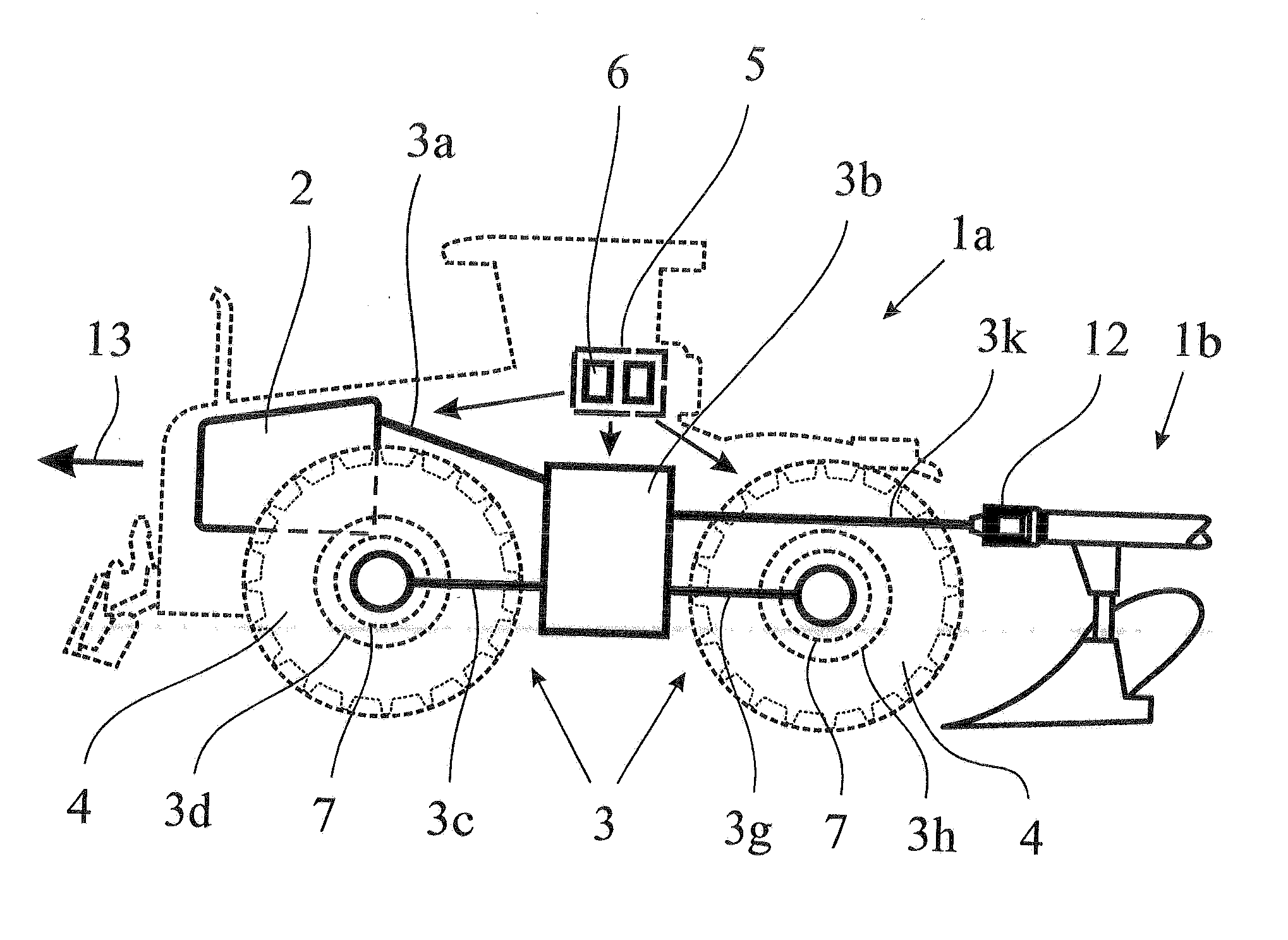

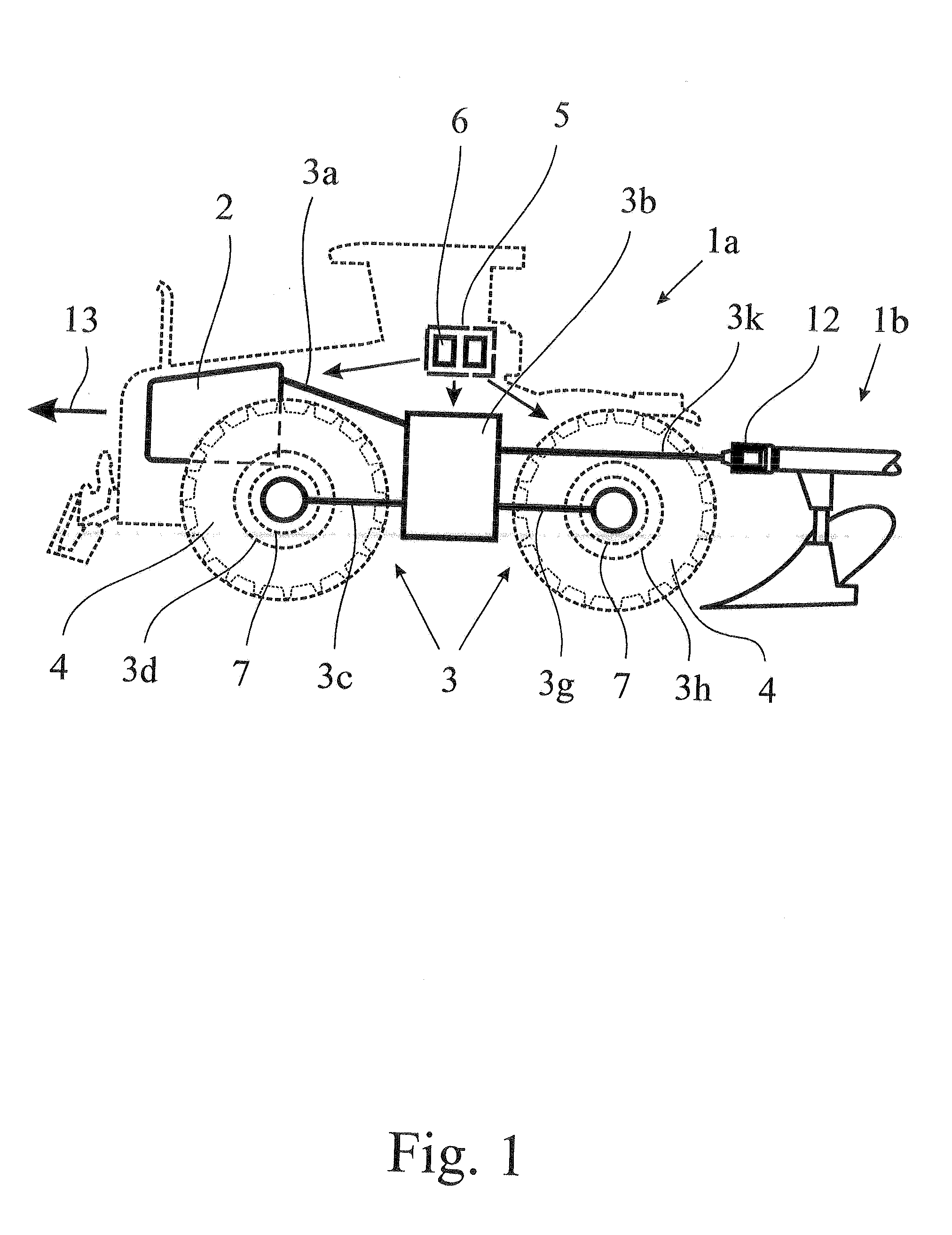

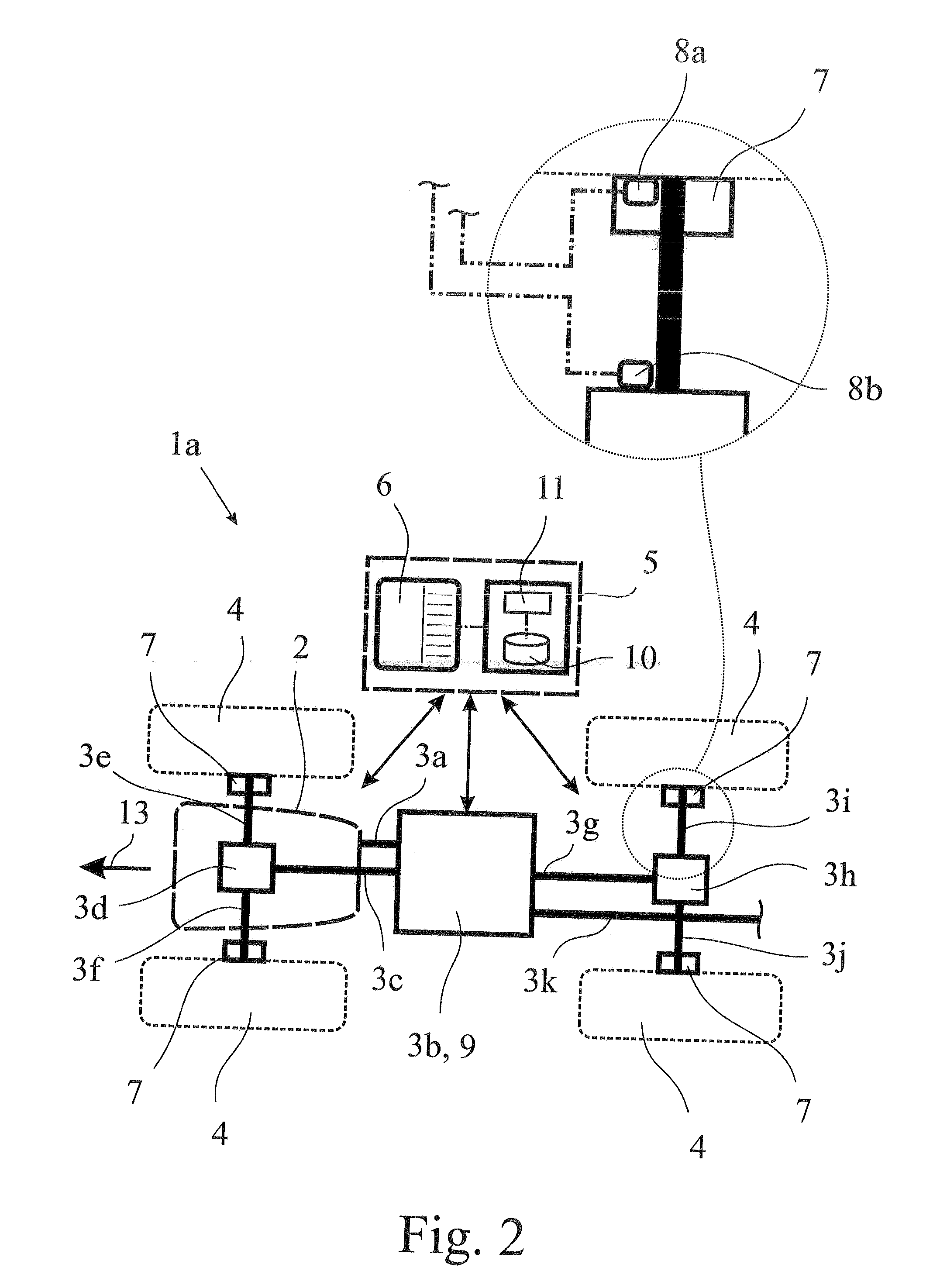

Agricultural working machine

ActiveUS20140081555A1Optimal working operationImprove operating conditionsAnalogue computers for vehiclesElectrical controlAgricultural scienceDrive shaft

An agricultural working system includes a self-propelled agricultural working machine equipped with an attachment in the form of a soil-management device such as a plow, a cultivator, or a harrow, a drive unit that acts as a drive train on land wheels, a control arrangement and a user interface and display unit associated with the control arrangement (5). The control arrangement ascertains the torque loads that occur during the working operation for at least one drive-train component, for example, drive shafts of the land wheels and provides at least one control function on the basis of the ascertained torque loads.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

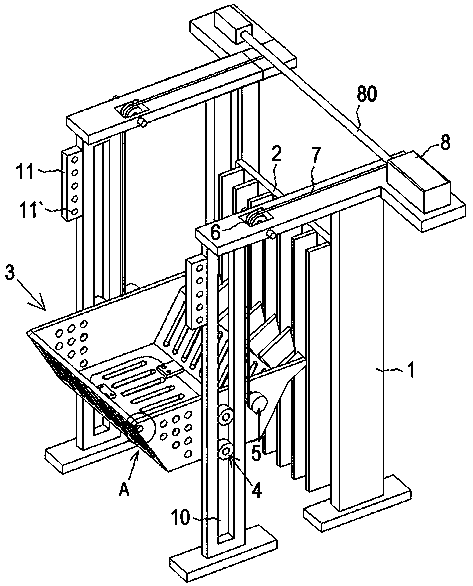

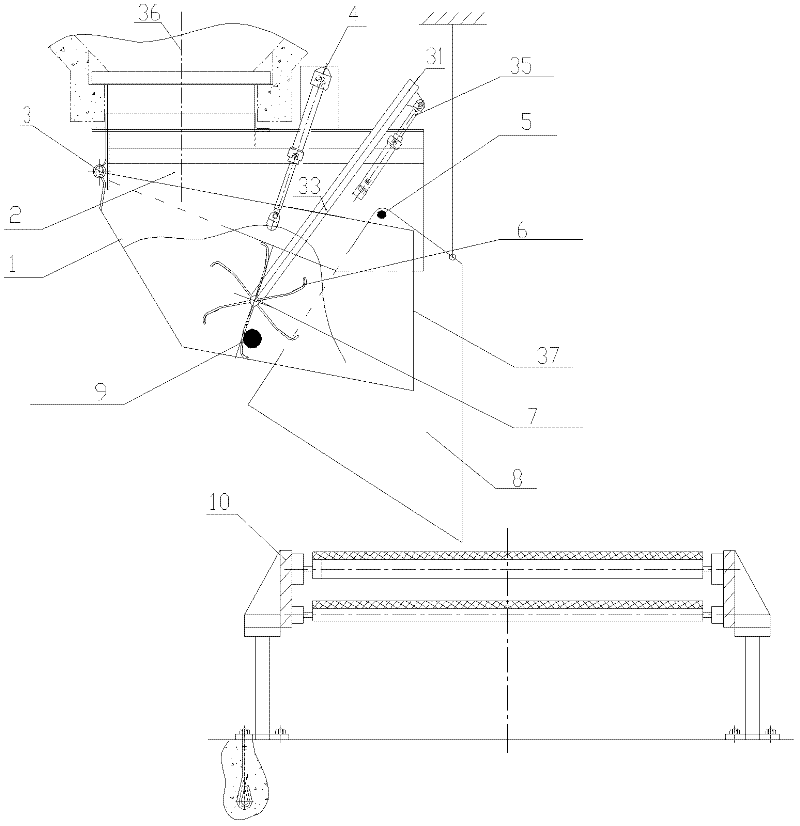

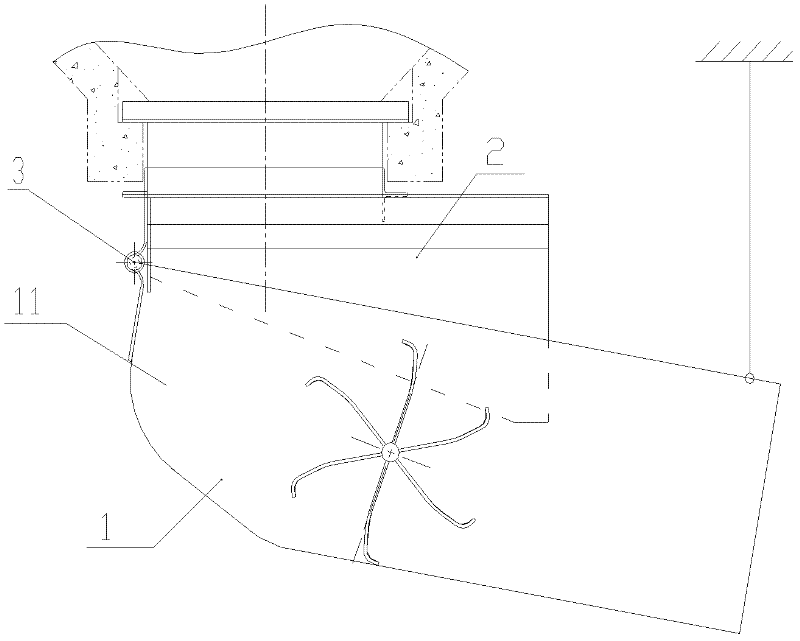

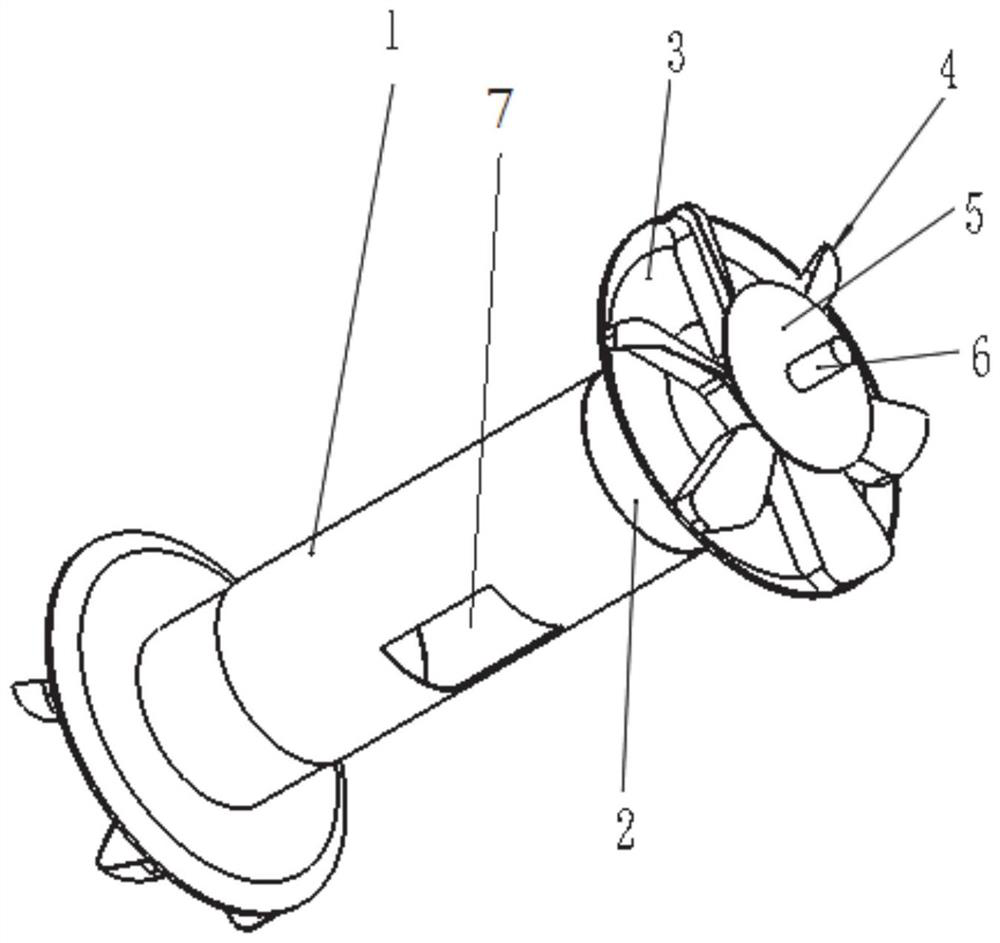

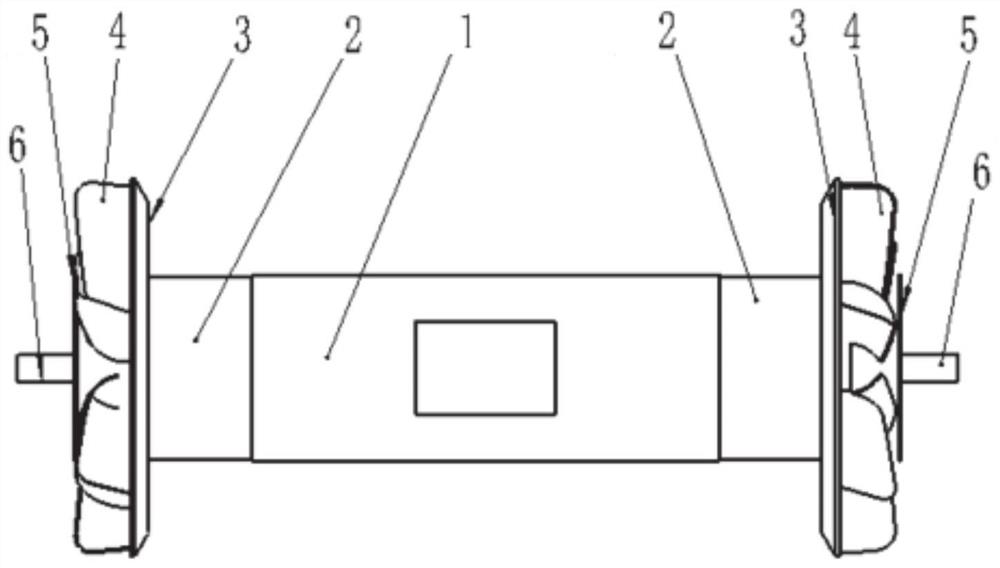

Feeding method and high-efficiency and energy-saving rolling-harrow feeding machine

ActiveCN102530579AImprove efficiencySave energyLoading/unloadingConveyor partsEnvironmental resistanceGrain weight

The invention belongs to the field of material conveying, and specifically discloses a feeding method and a high-efficiency and energy-saving rolling-harrow feeding machine, by which fed materials are different in grain size, unequal in grain weight, different in quality, and large and controllable in quantity. The high-efficiency and energy-saving rolling-harrow feeding machine comprises a material guide hopper and a rolling harrow, wherein the rolling harrow comprises a harrow shaft and / or harrow cylinder and the like, the harrow shaft and / or harrow cylinder and the like are arranged on the side part, upper part and / or side upper part of a material, and located between the feed end and discharge end of the material guide hopper or located outside the discharge end of the material guide hopper, and the harrow shaft and / or harrow cylinder are / is arranged perpendicular to the flow direction of the material. By using the method and machine disclosed by the invention, an effect that through setting a material-harrowing bearing and a shaft barrel outside materials, the materials are harrowed from positions beside and / or above the materials, thereby controlling the flow quantity of the materials such as coal and the like; and through real-time adjustment controlling, the purpose of improving efficiency, saving energy, and realizing the optimal feed reshipment is achieved.

Owner:刘素华

Sweet potato harvesting method and harvester

InactiveCN101911882AAvoid damageImprove tensile propertiesDigger harvestersAgricultural scienceWorking set

The invention relates to a sweet potato harvesting method and a sweet potato harvester. The sweet potato harvesting method comprises the following steps of: (1) pressing and loosening ridges and cutting potato vines; (2) gathering the cut potato vines at the middle parts of the ridges; (3) loosening the ridges and lifting upturned soil by using a digging shovel set; (4) clamping the potato vines and continuously lifting the potato vines; (5) picking off the potatoes by using a fruit picking plate when the potato vines and the potatoes are conveyed backwards; and (6) crushing the potato vines which are continuously conveyed backwards by using a crushing roll. The sweet potato harvester comprises a frame, wherein the rear end at the bottom of the frame is provided with supporting and conveying wheels; the bottom of the frame is provided with two working sets; each working set comprises a pressing wheel, a disc cutter, an offset rotary harrow, a vibrating digging shovel set, the fruit picking plate and the crushing roll; the top of the frame is provided with a gearbox which is connected with a truck tractor; and the gearbox is in transmission connection with a clamping and conveying chain controlled by an opening and closing control wheel. The method and the harvester can greatly reduce the power consumption for separating the potatoes from soil and can be widely applied to harvesting of various potato crops.

Owner:CHINA AGRI UNIV

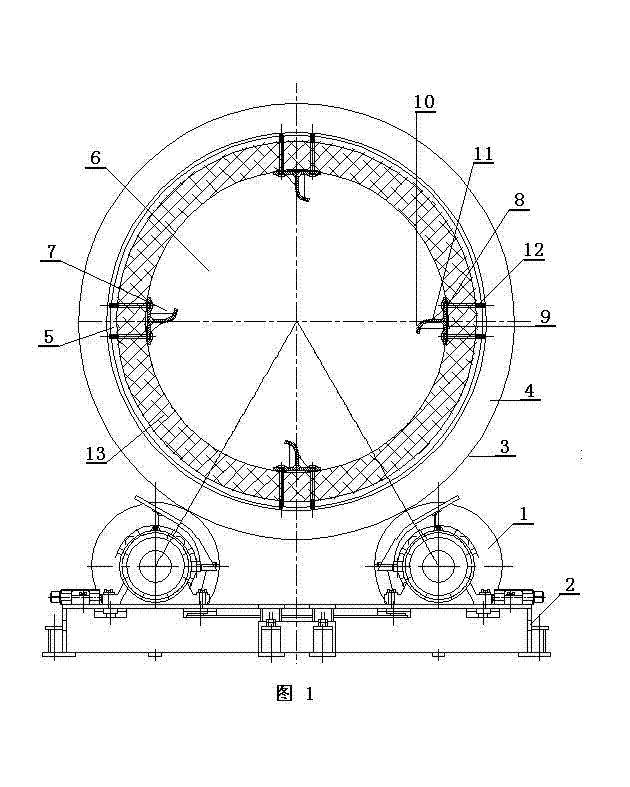

Rotary kiln type incinerator capable of improving sufficient burning of garbage materials

ActiveCN102901105AEasy to useQuality improvementIncinerator apparatusThermodynamicsMetallic materials

The invention relates to a rotary kiln type incinerator capable of improving sufficient burning of garbage materials. The rotary kiln type incinerator comprises a cylindrical kiln body and a plurality of harrow-shaped material throwing boards, wherein the cylindrical kiln body is arranged on a support with a power drive mechanism in an inclined lying mode and is driven to rotate, the harrow-shaped material throwing boards are arranged in the middle and on the rear portion of the inner wall of the kiln body, the harrow-shaped material throwing boards are cast by a refractory metal material and composed of harrow plates, the harrow plates are vertically arranged on a fixed installation bottom plate with limit assembling holes and provided with harrow teeth, and the top ends of the harrow teeth are in a buckling shape. During working, the harrow teeth on the material throwing boards are arranged in different matching angles such as middle, left avertence and right avertence, the garbage is prevented from sliding straightly downwards, turning over, being torn and loosened through shaking by force, the garbage slowly slides downwards and fully contacts with air and is continuously dried and burned in a loose state, during burning, slag is constantly grabbed and turned until the sufficient burning is achieved, ball-shaped, cake-shaped and shell-shaped insufficient burning wrappage can be effectively prevented, slag emission amount is reduced to the hilt, and effects of improving burning quality and efficiency, environmental protection and energy conservation are achieved.

Owner:上海博士高环保设备工程有限公司

Gypsum reticular gel foam mud fire prevention and extinguishing agent

The invention discloses a gypsum reticular gel foam mud fire prevention and extinguishing agent, and the key point of the technical scheme is that the fire prevention and extinguishing agent is composed of a gypsum composite flame-retardant foaming agent, an attapulgite clay powder with an air purifying function, inorganic fiber spraying cotton, a calcined gypsum powder, a coal gangue powder, an expanded perlite powder, sodium alginate and water. The ingredients of the gypsum reticular gel foam mud fire prevention and extinguishing agent are inputted into a plow-harrow type material mixing machine and are subjected to high speed stirring into the gypsum reticular gel foam mud fire prevention and extinguishing agent. Reticular gel foam mud is jetted to a burning coal layer by an inorganic fiber spraying machine, so as to be beneficial for generation of an integral reticular gel foam mud film in a fire prevention and extinguishing process, the integral reticular gel foam mud film always covers and adheres to the surface of the ore layer, contact of the burning coal layer with air is rapidly isolated, coal mines are prevented from continuing to burn, the coal layer is avoided from reburning, and the purposes of flame retardancy and fire prevention and extinguishing are reached; and the gypsum reticular gel foam mud fire prevention and extinguishing agent is applicable to coal mines, mine operating areas and forest fire prevention and extinguishing.

Owner:许庆华

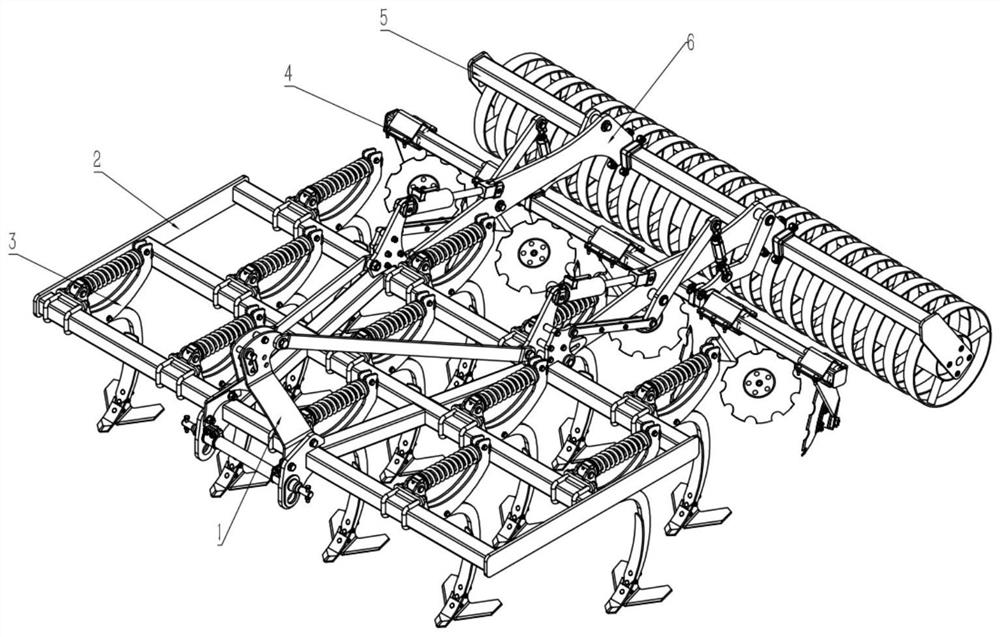

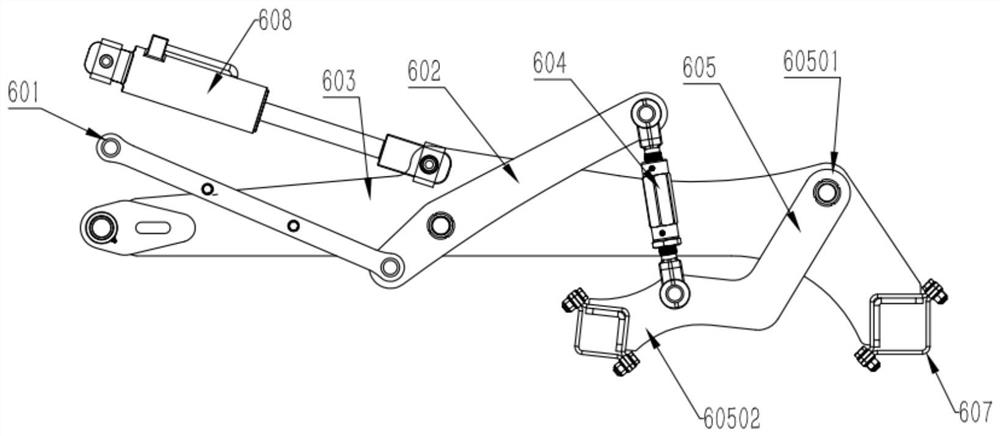

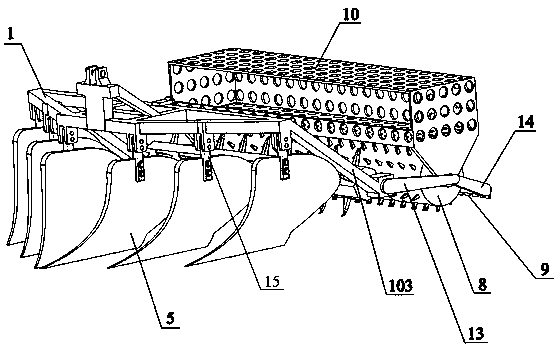

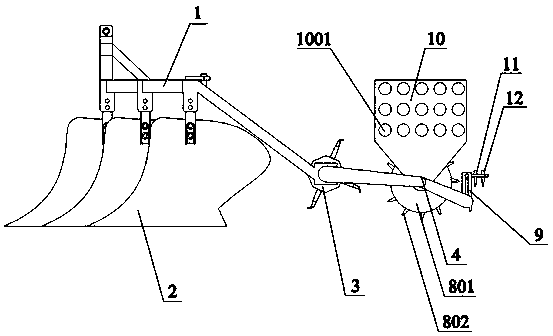

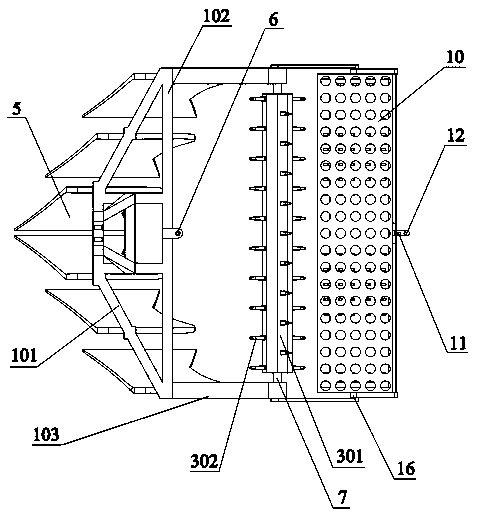

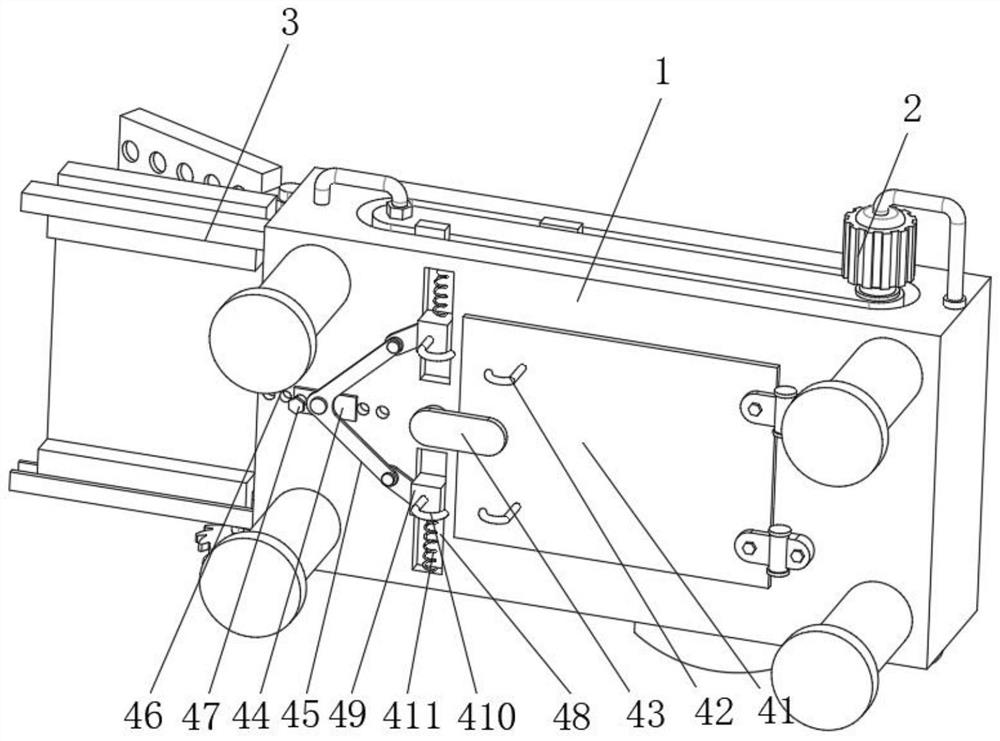

Deep scarification combined land preparation machine and operation method

PendingCN113711710AAdjust working depthSave secondary adjustment timeSpadesAgricultural machinesAgricultural engineeringTraction frame

The invention discloses a deep scarification combined land preparation machine and an operation method. The deep scarification combined land preparation machine comprises a traction frame, a tooth frame beam, a deep scarification tooth assembly, a harrow group and a pressing roller, wherein the traction frame is connected with the tooth frame beam, the deep scarification tooth assembly is hung at the lower end of the tooth frame beam, the harrow group comprises a harrow group cross beam and harrow pieces, the pressing roller comprises a pressing roller cross beam and a pressing roller body hung at the lower end of the pressing roller cross beam, the harrow group is located at the front end of the pressing roller body, and the harrow group cross beam and the pressing roller cross beam are connected with the tooth frame beam through the same depth-limiting leveling mechanism. The operation depth of the deep scarification tooth assembly and the operation depth of the harrow group can be synchronously adjusted, and on the basis that the operation depth of the deep scarification tooth assembly and the operation depth of the harrow group are synchronously adjusted, the operation depth of the harrow group can be further independently adjusted.

Owner:宜兴博登泰科工业装备有限公司

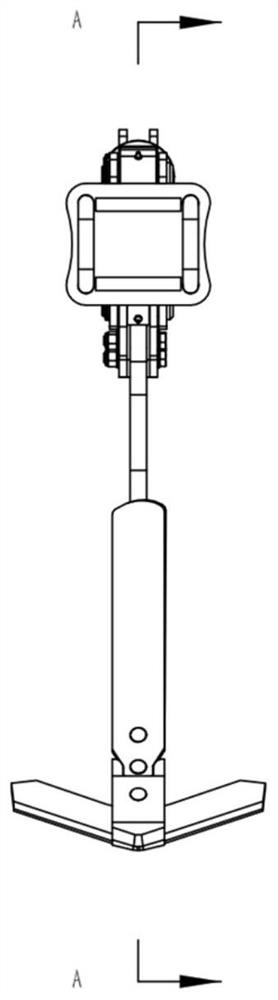

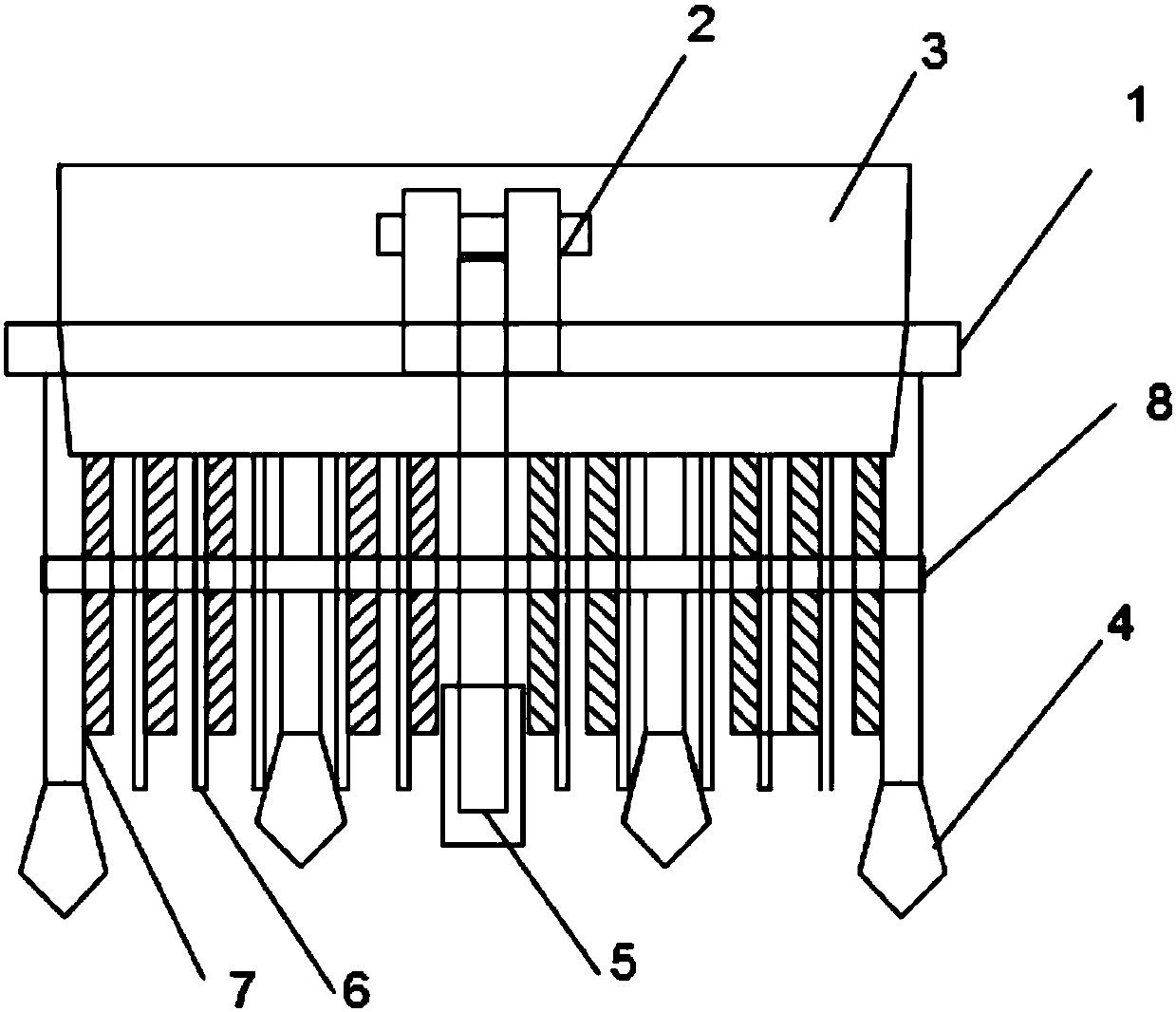

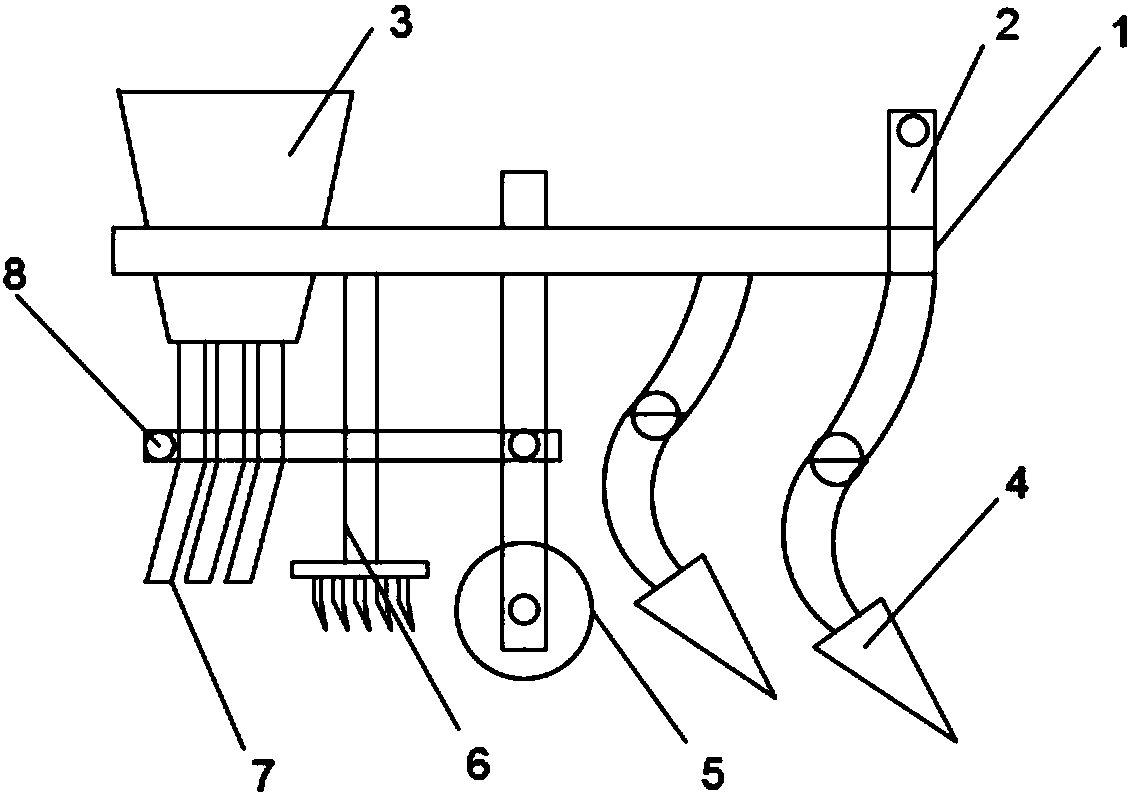

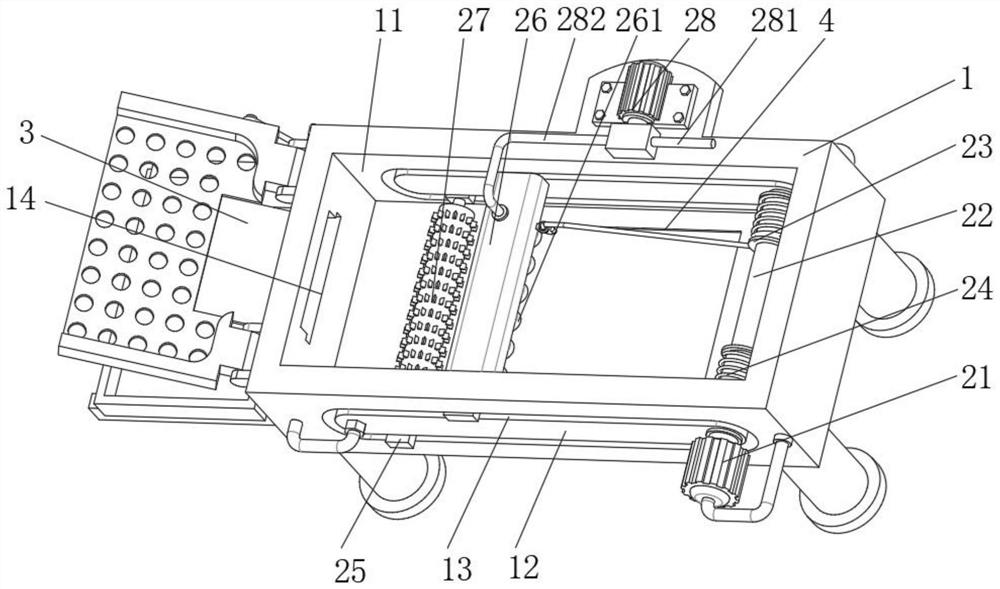

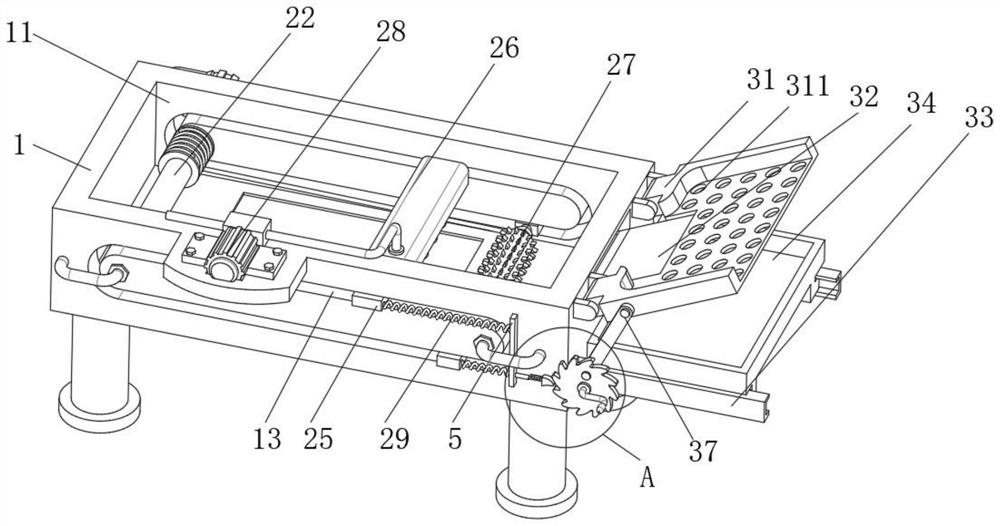

Plow harrow with adjustable grooving intervals

PendingCN107771462AAdjust spacingAdjustable slot spacingPlantingSoil-shifting machines/dredgersLinear motionRoller screw

The invention discloses a plow harrow with adjustable grooving intervals. The plow harrow comprises a mounting frame, wherein a pull rod is fixedly connected to the surface of the mounting frame, support seats are fixedly connected to two ends of the mounting frame, a threaded rod is fixedly connected between the two support seats, threaded sleeves are in threaded connection to the surface of thethreaded rod, ring grooves are formed in the surfaces of the threaded sleeves and are internally sleeved with fixed rings, and plow teeth are fixedly connected to the lower parts of the surfaces of the fixed rings. By arranging the threaded rod and the threaded sleeves, the threaded sleeves and the threaded rod can generate relative rotation when the threaded sleeves are rotated, the rotation of the threaded sleeves is changed into linear motion through the deviation of a roller screw rod, the threaded sleeves can transversely move on the threaded rod along the direction of the threaded rod, when the threaded sleeves rotate, the fixed rings cannot rotate due to the clamping between limiting teeth and a slide rail, and the plow teeth can face towards all the time, so that the intervals of the plow teeth can be regulated, and the grooving intervals can be regulated.

Owner:佛山宏发引力智能科技有限公司

Intelligent land ploughing and preparation equipment integrating land ploughing and impurity removal and use method

InactiveCN109121487AConvenient replenishmentEasy to handleSpadesPloughsMeasuring instrumentAgricultural engineering

The utility model relates to intelligent land ploughing and preparation equipment integrating land ploughing and impurity removal and a use method. The intelligent land ploughing and preparation equipment comprises a rack, a land ploughing mechanism, a stubble elimination mechanism and a land preparation mechanism, wherein the land ploughing mechanism comprises two groups of ploughs and a depth displacement sensor; the stubble elimination mechanism comprises a steel roller and a plurality of rows of barbs uniformly disposed on the surface of the steel roller in a radial direction, and the direction of rotation of the barbs is opposite to the advancing direction of the ploughs; and the land preparation mechanism comprises a roller-shaped soil-breaking harrow, a sawtooth-shaped land preparation harrow disposed on the rear side of the roller-shaped soil-breaking harrow, a storage box arranged above the roller-shaped soil-breaking harrow, a humidity sensor and a pH measuring instrument. The use method is as follows: first soil breaking and land preparation are carried out by the land ploughing mechanism, stubbles and weeds are eliminated by the stubble eliminating mechanism, and secondary soil breaking and land preparation are carried out by the land preparation mechanism. The land ploughing and preparation equipment is more mechanized and intelligent, reduces adhering of soil, andcan collect roots of previous-stubble crops and weed plants and acquire various soil information, thereby facilitating replenishment and treatment of soil before cultivation, and facilitating growthof crops.

Owner:HENAN UNIV OF SCI & TECH

Multifunctional fertilization device

PendingCN107852875AHeight adjustablePlay a role in stabilizing each otherSpadesPloughsAgricultural engineeringShovel

The invention relates to a multifunctional fertilization device. The device comprises a support, a fertilizer box is arranged at the rear end of the upper portion of the support, break shovels, a travelling land wheel, weeding harrows and fertilizer discharging pipes are arranged on the lower portion of the support from front to rear, the break shovels are installed on the support through telescopic rods with the heights capable of being adjusted in the vertical direction, and the upper ends of the fertilizer discharging pipes are communicated with the bottom of the fertilizer box. By means ofthe multifunctional fertilization device, the multiple operation steps for farm product planting of scarification, weeding, fertilization and the like can be achieved at once; the break shovels withthe adjustable heights are installed on the support, so that according to the farming soil condition and the growth stages of plants during fertilization, the heights of the break shovels can be adjusted, and then deep scarification or shallow scarification can be chosen.

Owner:荆州市俏佳人生物科技有限公司

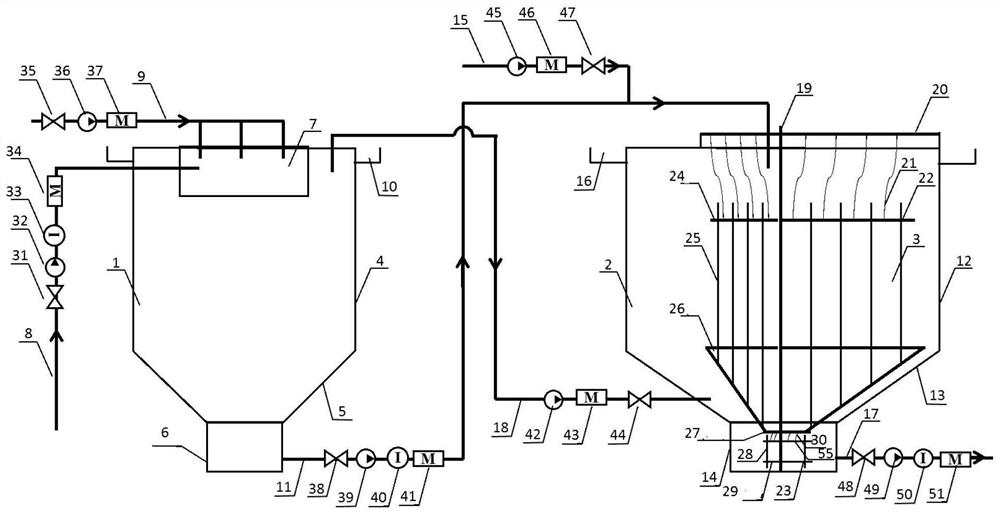

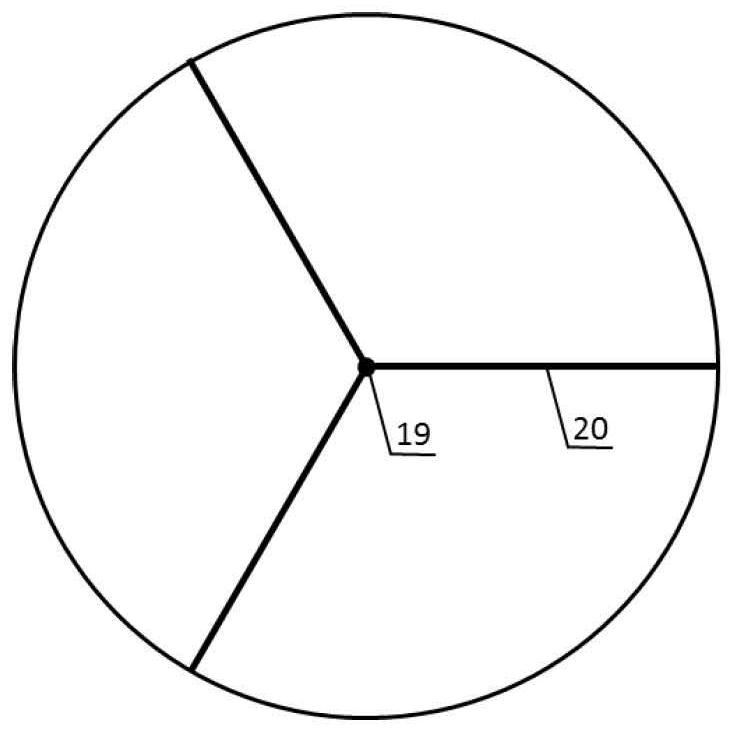

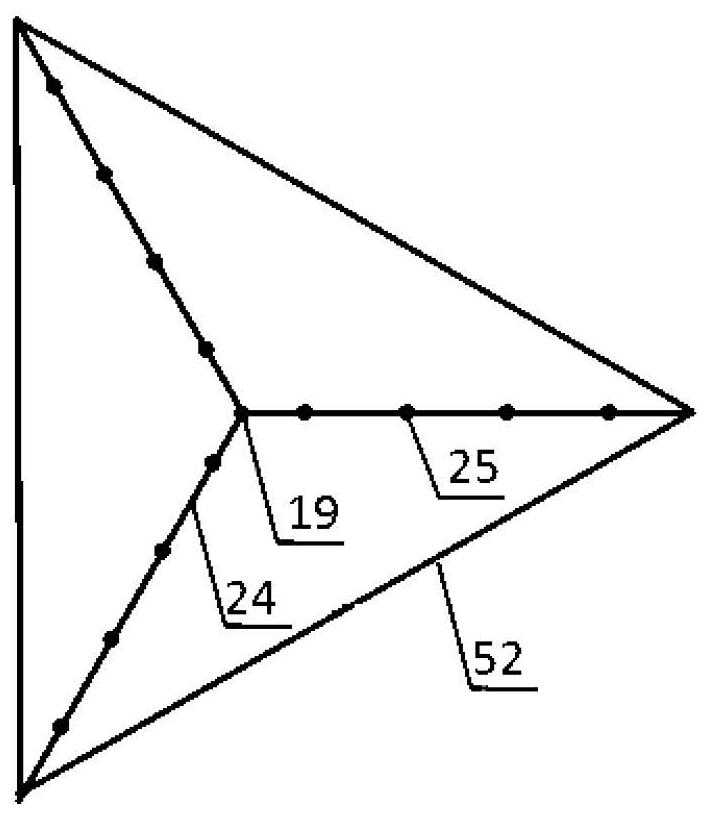

Two-section type continuous, rapid and deep dehydration system for full tailing slurry

InactiveCN113024080ADeep dehydration fastAvoid energy consumptionWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningFlocculationThermodynamics

The invention provides a two-section type continuous, rapid and deep dehydration system for full tailing slurry, and belongs to the technical field of mine tailing filling. The system comprises a tailing flocculation and sedimentation bin, a deep dehydration and activation storage bin and a deep dehydration and activation system. The deep dehydration and activation system is located in the deep dehydration and activation storage bin. The tailing flocculation and sedimentation bin and the deep dehydration and activation storage bin are connected through an underflow conveying pipe and a high-pressure water pipe. A driving rod of the deep dehydration and activation system is flexibly connected with a dehydration and activation harrow frame through a connecting device, the dehydration and activation harrow frame is flexibly connected with an underflow discharging harrow frame through a connecting device, and the circular motion of the driving rod drives the dehydration and activation harrow frame and the underflow discharging harrow frame to rotate. The dehydration system not only can realize rapid and deep dehydration of full tailing slurry and meet the requirement of tailing disposal on concentration, but also can perform storage for a long time, can ensure the continuity of the dehydration process and meets the requirement of continuous and stable production.

Owner:UNIV OF SCI & TECH BEIJING

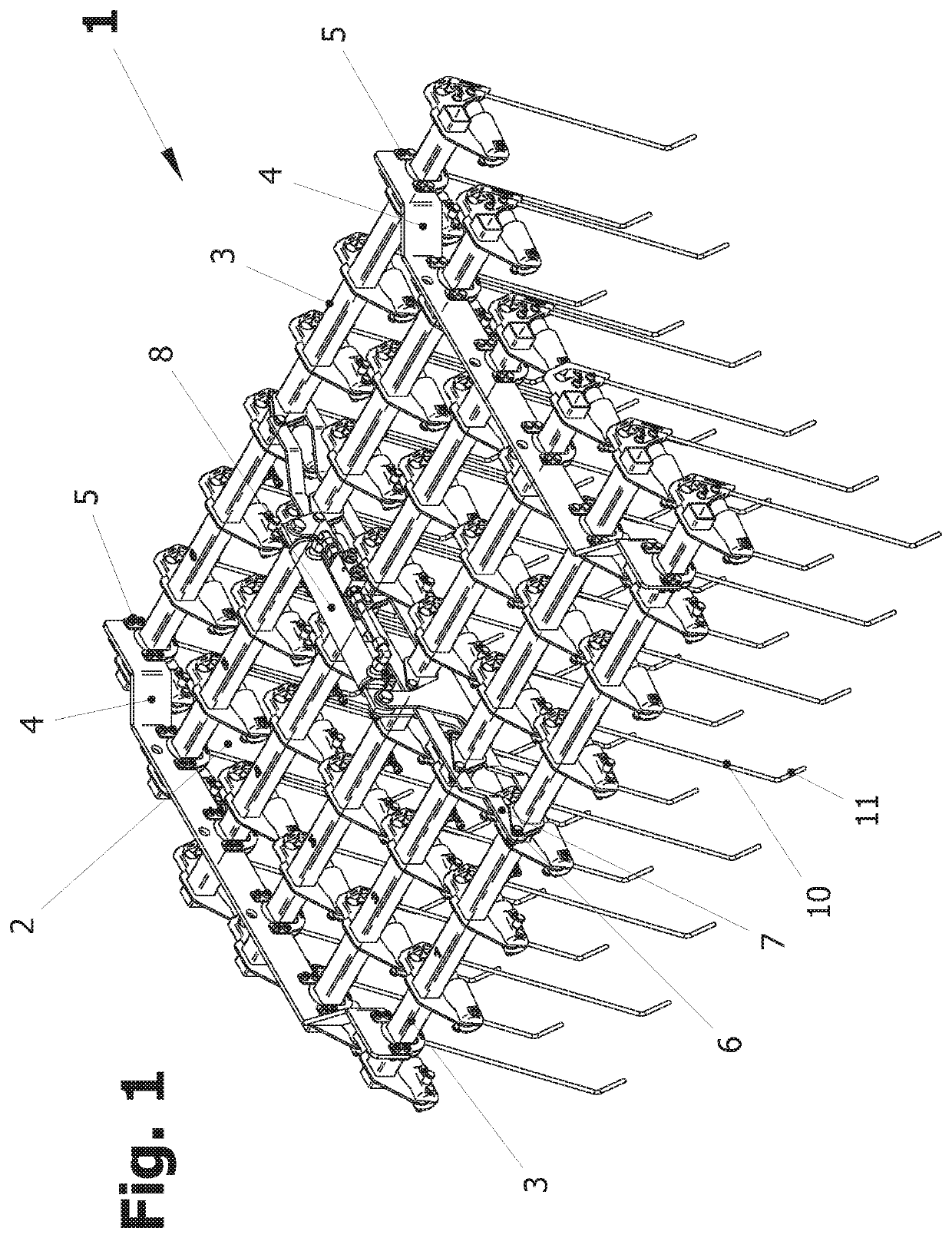

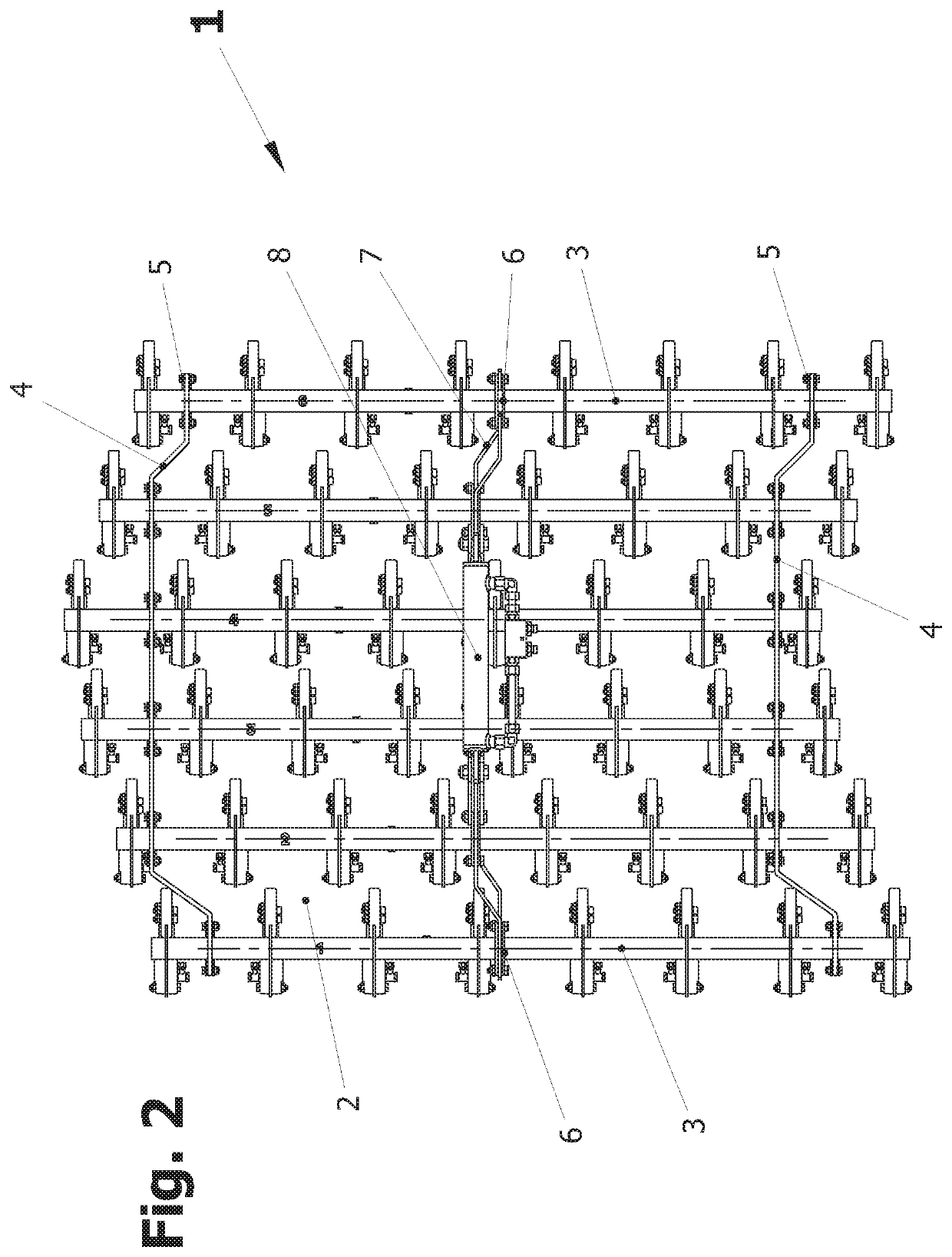

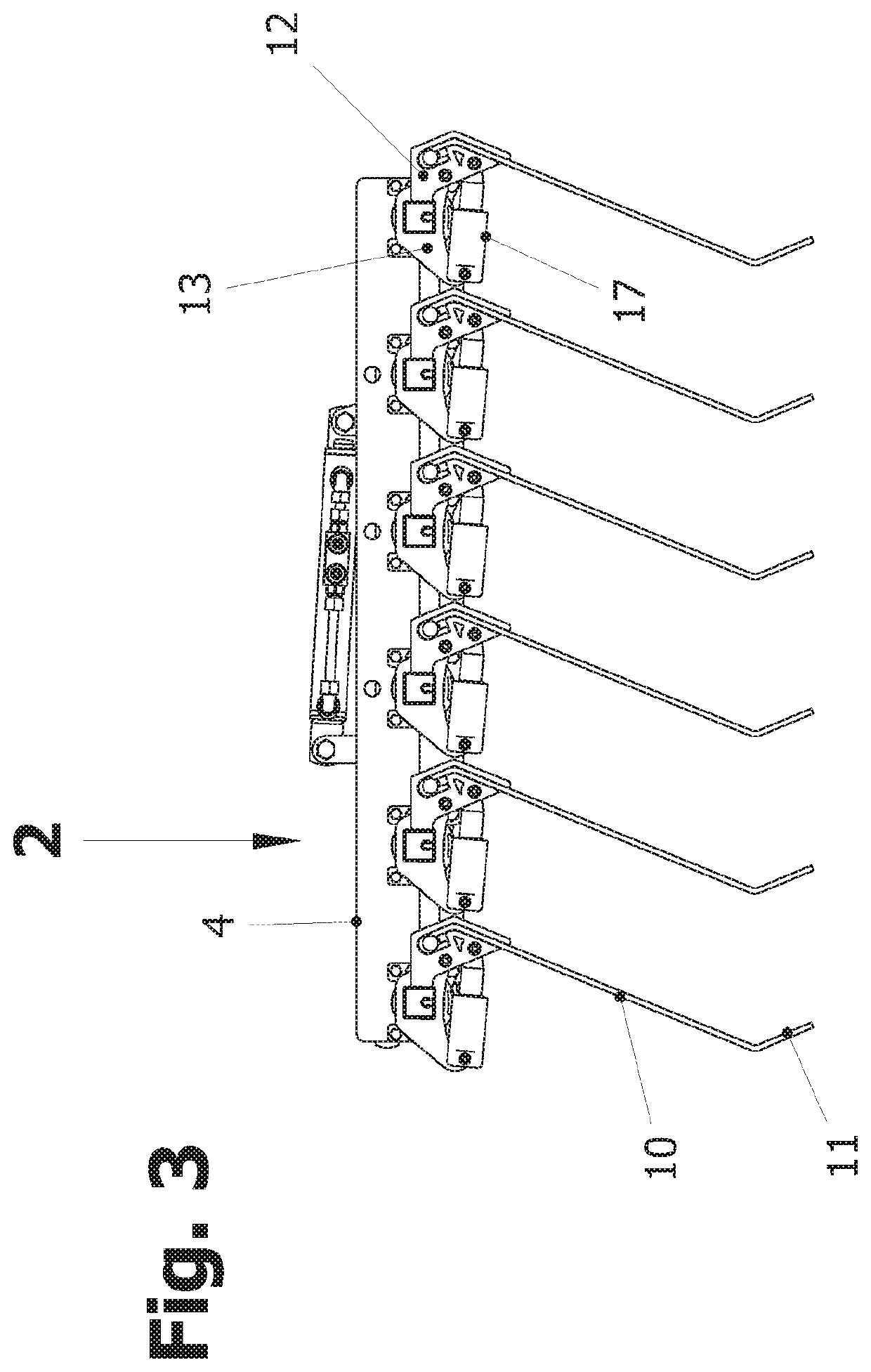

Soil cultivation device

PendingUS20200359540A1Smooth rotationAgricultural machinesSoil-working equipmentsAgricultural engineeringMechanical engineering

In the case of a soil cultivation device with multiple harrow tines, the harrow tines are fastened to levers, which are mounted to pivot on tie bars of the supporting frame via carriers. The operating position of the harrow tines is defined by the levers being adjacent to tie bars, and the harrow tines are prestressed into the operating position by springs assigned to them in the form of pneumatic cylinders.

Owner:THOMAS HATZENBICHLER AGRO TECHN

Seedling raising technique for okra

The invention provides a seedling raising technique for okra. The technique is characterized by comprising the following steps: 1, soil preparation and ridging: a step of preparing and irrigating a land according to a conventional process, carrying out ridging and ditching, applying fertilizer, and making ridges, wherein ridge distance is 80 to 90 cm; 2, sowing: a step of soaking seeds in a nutrient solution for 12 hours in advance, then dibbling 1 to 3 seeds in a hole by using a seeder according to plant spacing of 30 cm, then slightly carrying out raking with a hand harrow, then covering the seeds with the soil until a depth of the soil reaches 2 cm so as to prevent underground insects from drilling to eat the seeds and seedlings, after soil covering is completed, spraying a herbicide on all the soil, then covering a plastic film on seed holes by ridges, and compacting two sides of the film with the soil so as to prevent the film from being blown by wind; and 3, seedling protection: after 4 days and 5 nights, holing the film on the seed holes so as to help the seedlings to grow. The technique provided by the invention is applicable to seeding of the okra.

Owner:江志鑫

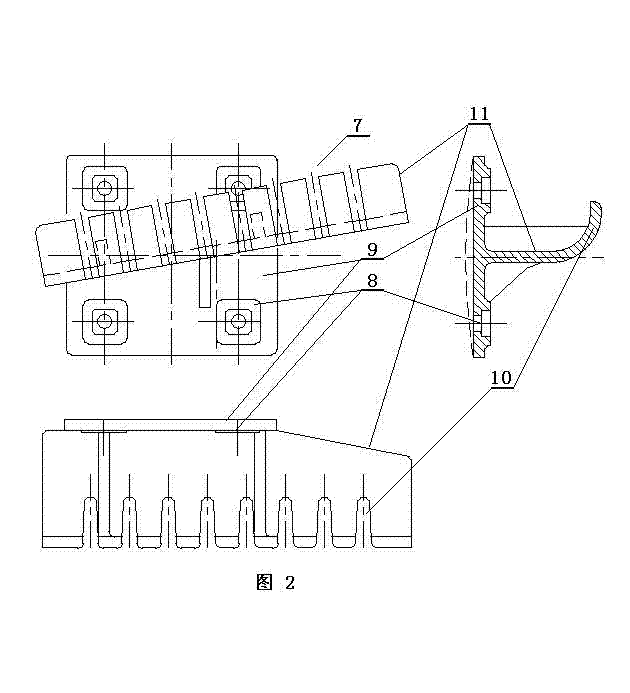

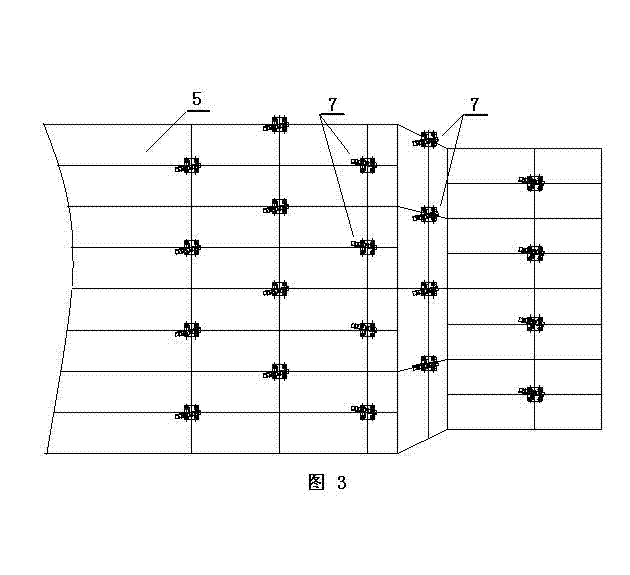

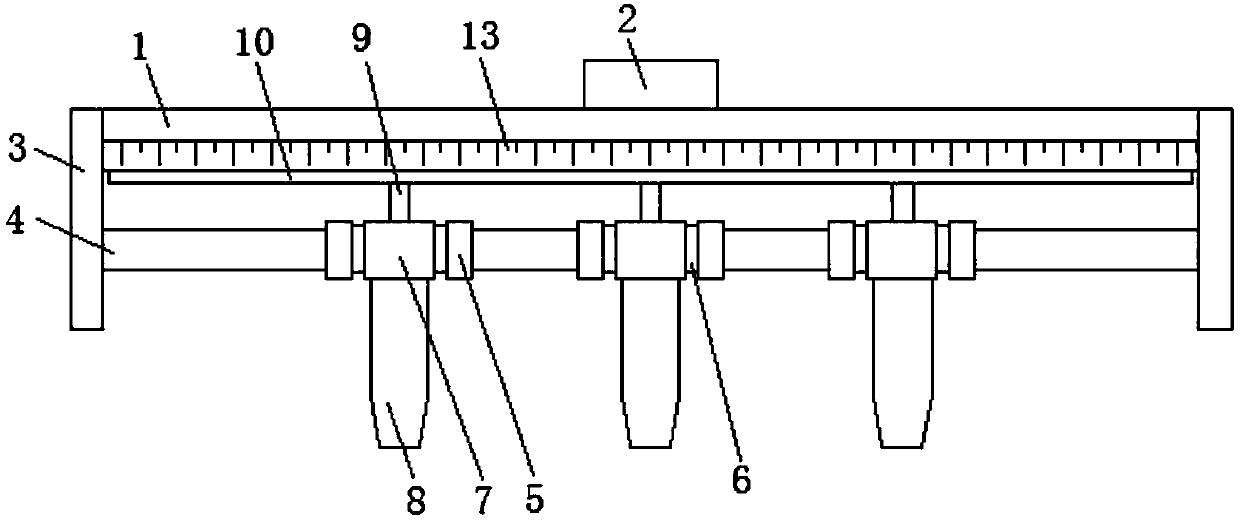

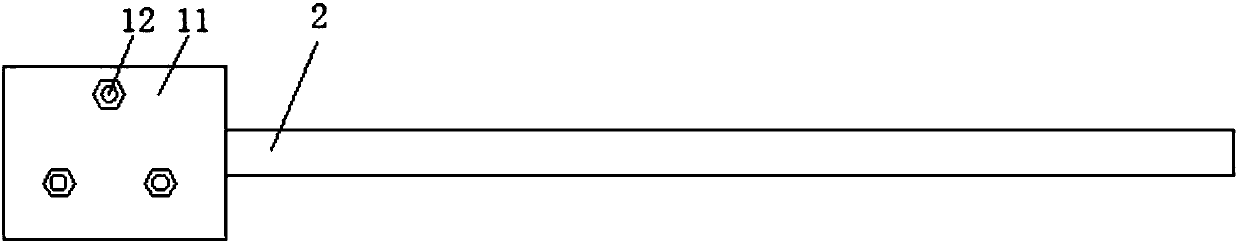

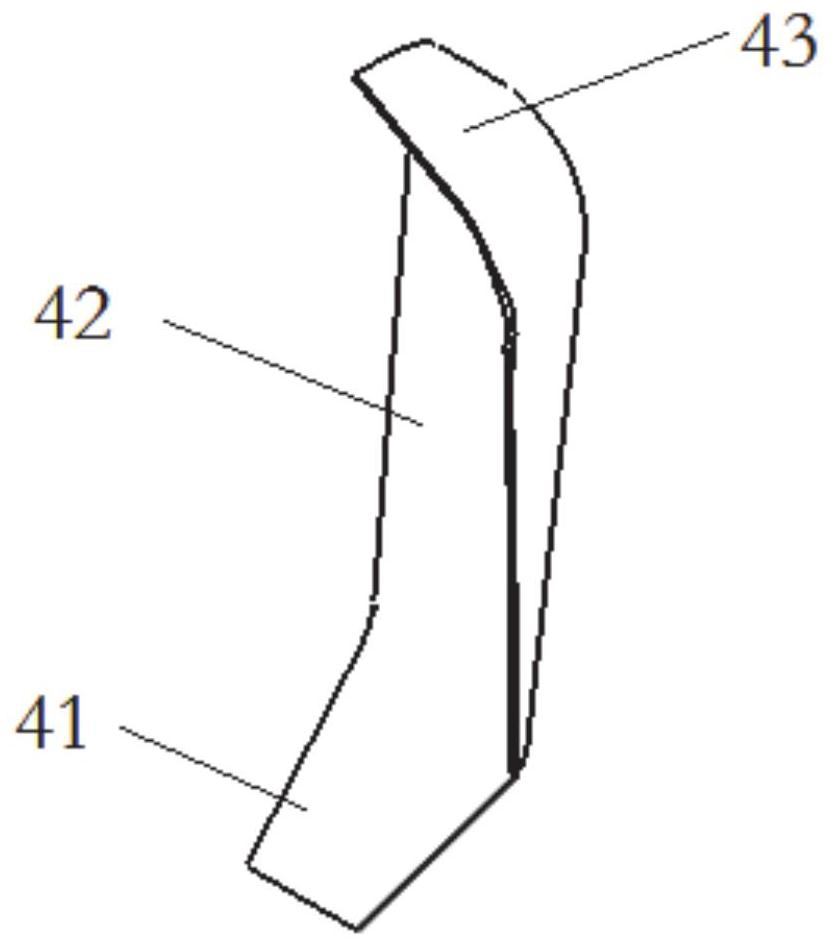

Asphalt pavement in-place hot recycling harrowing plow-shaped harrow tooth device and application of device in harrowing paving vehicle

PendingCN110792023AReduce impactReduce the chance of damageRoads maintainenceStructural engineeringRoad surface

The invention discloses an asphalt pavement in-place hot recycling harrowing plow-shaped harrow tooth device and the application of the device in a harrowing paving vehicle. The device comprises a harrowing frame I and a harrowing frame II which are correspondingly arranged, a corresponding horizontal driving device is arranged to adjust the horizontal distance between the harrowing frame I and the harrowing frame II, and a corresponding vertical driving device is arranged to adjust the vertical heights of the harrowing frame I and the harrowing frame II and the harrowing depth; and the harrowing frame I and the harrowing frame II comprise harrow tooth units used for harrowing, and the harrow tooth units are arranged on the harrowing frame I and the harrowing frame II through elastic adjusting mechanisms. According to the asphalt pavement in-place hot recycling harrowing plow-shaped harrow tooth device and the application of the device in the harrowing paving vehicle, through effectiveand reasonable adjustment of the degrees of freedom in different directions of the harrow tooth units, the harrowing requirements of different pavements can be adapted; and meanwhile, due to the elastic arrangement of harrow teeth, so that when obstacles or other harrowing resistance are encountered during construction, due to the existence of elastic springs and the like, most of the impact force on the harrow teeth caused by related factors can be buffered, so that the probability of damage of the harrow teeth is reduced, and the use cost of the harrow teeth is reduced.

Owner:JIANGSU AOXIN SCI & TECH +1

Feed dryer

The invention relates to the technical field of dryers and discloses a feed dryer which comprises a dryer body. An inner cavity is formed in the top of the dryer body, a drying device is arranged in the inner cavity, a screening device is arranged on the side wall of one side of the outer surface of the dryer body, and a packaging device is arranged at the bottom of the dryer body. A mounting plate is fixedly mounted on the outer surface of the dryer body, the drying device comprises a servo motor, the servo motor is fixedly mounted on the outer surface of the dryer body through a welding column, and the output end of the servo motor is movably connected with a rotating rod which penetrates through the dryer body and is rotatably connected with the inner wall of the inner cavity. By arranging the drying device, a plow harrow roller and spray heads are matched so that screened feed can be tiled, rolled and dried at the same time, a traditional manual drying mode is simulated, the feed is dried more uniformly, and the drying efficiency and quality of the feed are improved.

Owner:罗源县洪洋乡人民政府

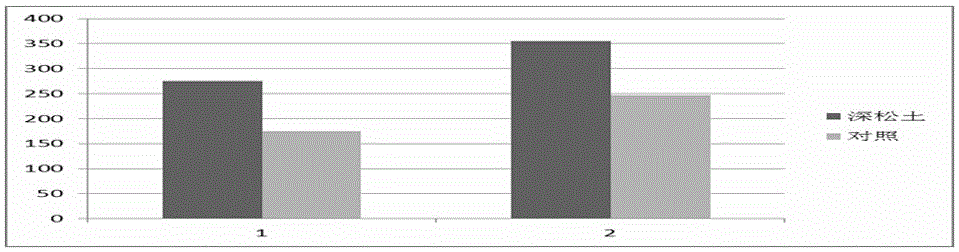

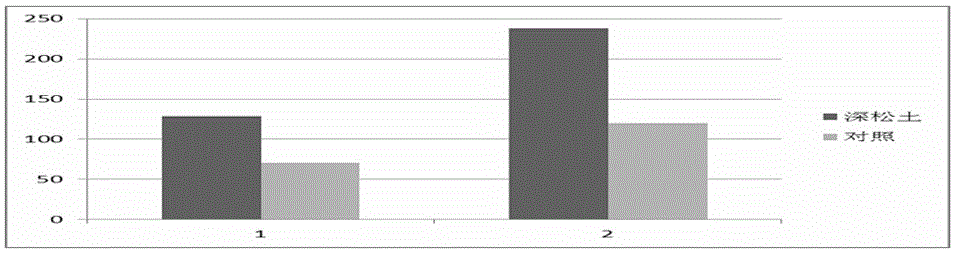

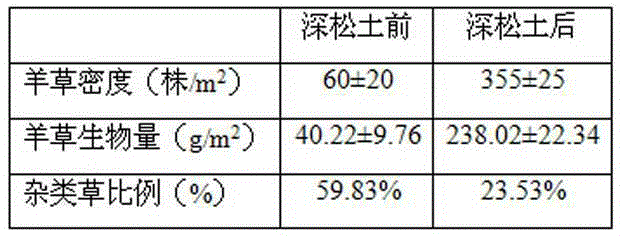

Improved method of deep digging of degenerated grazing leymus chinensis grassland at grassland area

The invention, which belongs to the technical field of soil improvement, discloses an improved method of deep digging of degenerated grazing leymus chinensis grassland at a grassland area. According to the improved method, one group of three-furrow ploughs and heavy harrows are dragged by a tractor to carry out smoothing improvement on manual soil loosening and clod crushing on the degenerated grazing leymus chinensis grassland. The improved method comprises: step 1, a tractor with the power larger than or equal to 80 horsepower drags one group of three-furrow ploughs to carry out soil loosening on the degenerated grazing leymus chinensis grassland at a rainy season at the first year, wherein the effective tillage depth is 18+ / -2cm; and step 2, reciprocating harrowing is carried out twice by using heavy harrows at the direction parallel to the tillage direction before the rainy season at the second year, wherein the effective depth is 12+ / -2cm. With the method, the soil can be loosened effectively; the soil porosity is increased and the soil bulk density is reduced. Meanwhile, the rootstocks of the chinese wildrye can be cut off to promote the sprout differentiation and growth, thereby accelerating the recovery and growth of the chinese wildrye.

Owner:INNER MONGOLIA UNIVERSITY

Spiral soil guide plate, on-film soil covering roller and soil covering planter

ActiveCN111919643AReduce weightReduce manufacturing costSowingPlant protective coveringsSeederSoil science

The disclosure relates to a spiral soil guide plate, an on-film soil covering roller and a soil covering planter. The spiral soil guide plate comprises a soil excavating part, a soil delivery part anda soil discharge part which are connected in sequence; the soil excavating part is provided with a soil excavating groove inside; the soil excavating groove can store soil and deliver the soil to thesoil delivery part in the process that the soil excavating part extends into the soil; the soil delivery part can deliver the soil to the soil discharge part and the soil is discharged; the spiral soil guide plate can be fixedly connected with an external rotation driving mechanism, so that the spiral soil guide plate revolves along a set axis; the conveying direction of the soil in the spiral soil guide plate is set towards the rotation axis direction of the spiral soil guide plate; the soil excavating part is provided with an arc-shaped panel inside; and the soil excavating groove is formedat one side of the arc-shaped panel in a defined manner. The spiral soil guide plate, the on-film soil covering roller and the soil covering planter can solve the problems that the weight of a planter is increased and frames of left and right adjacent ridges are different in length due to the fact that a soil covering disc and soil taking harrow disks are used in an existing soil covering device.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

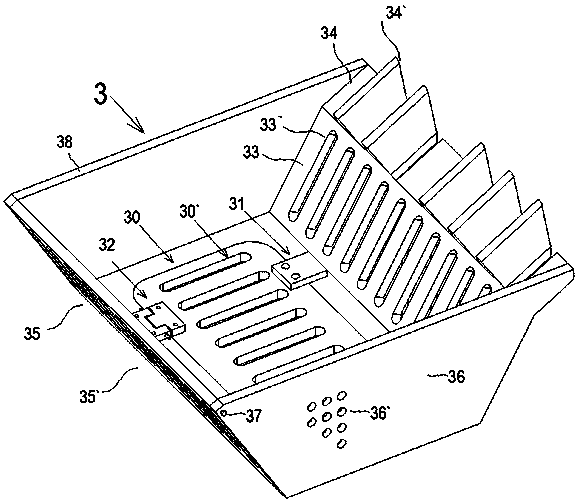

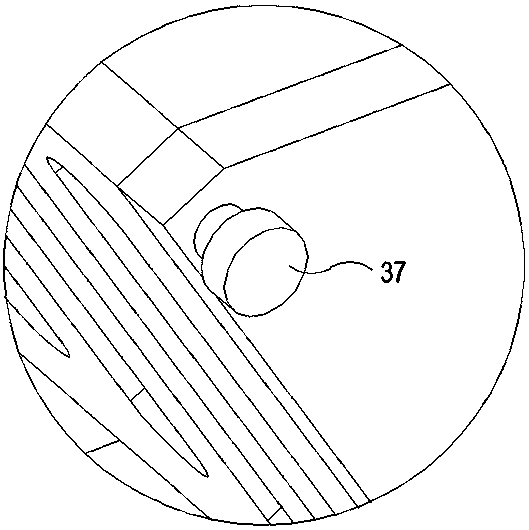

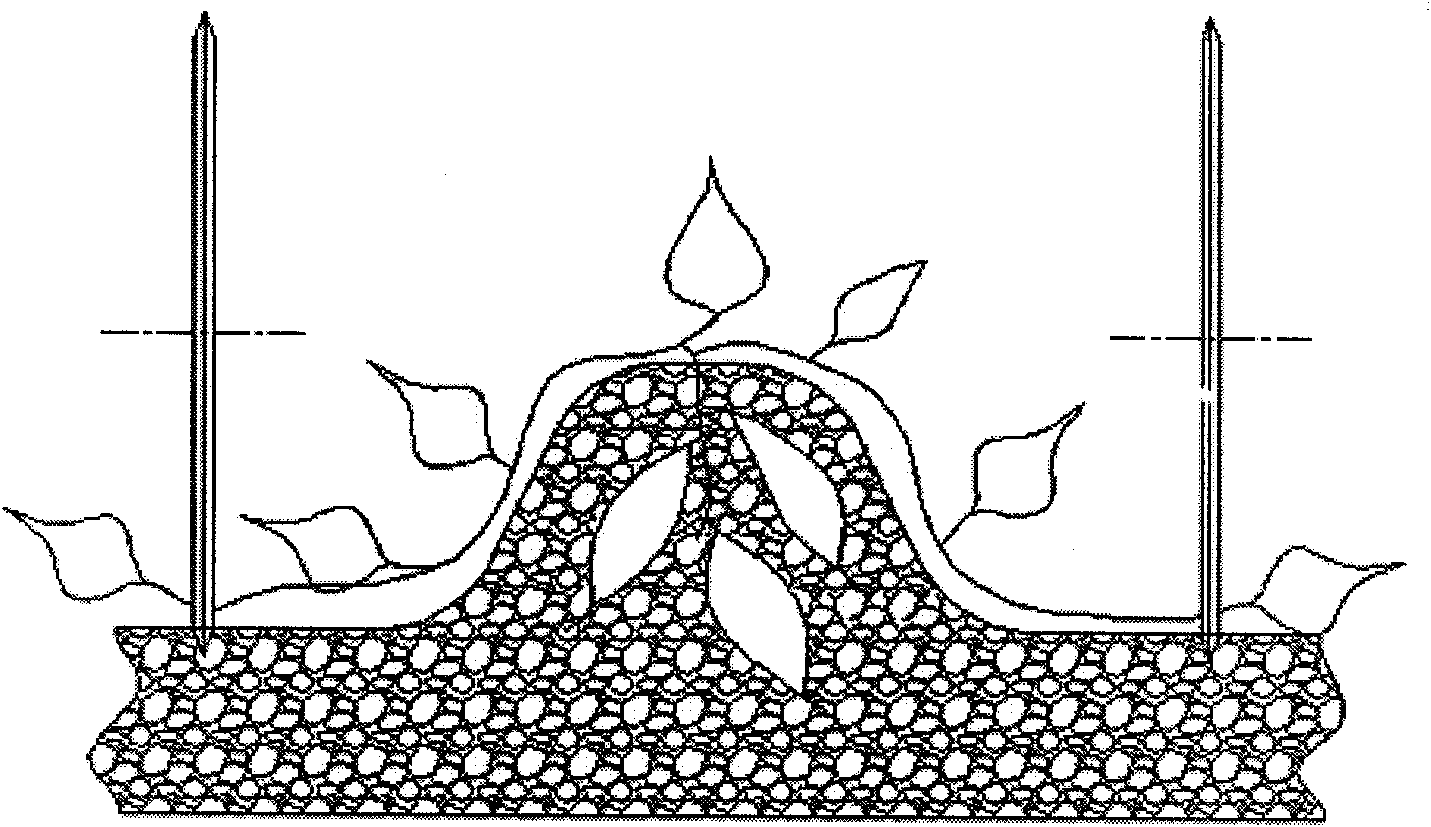

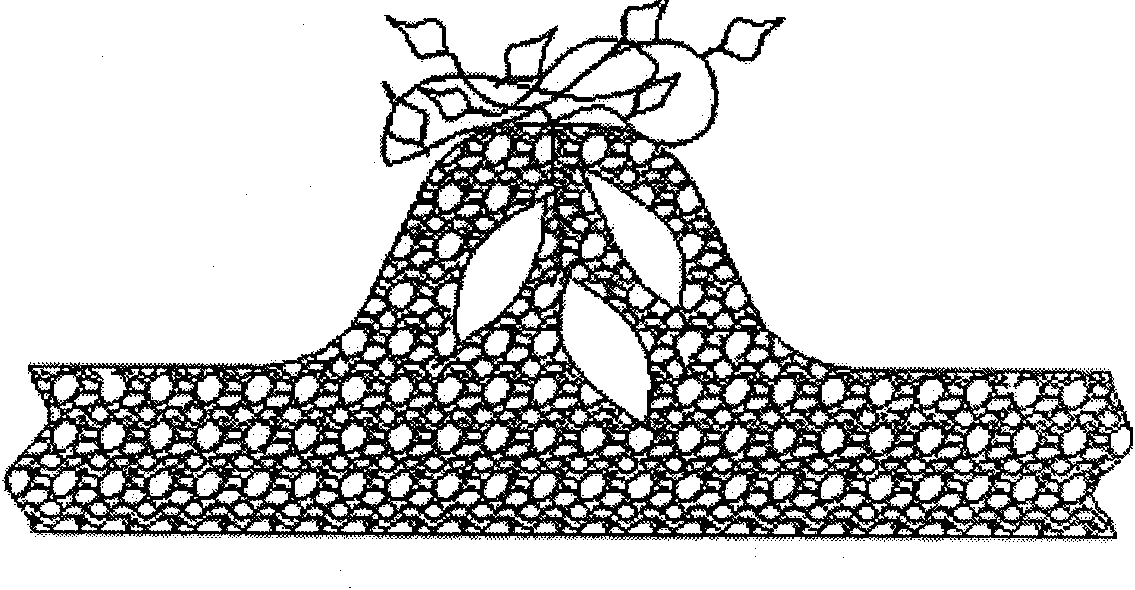

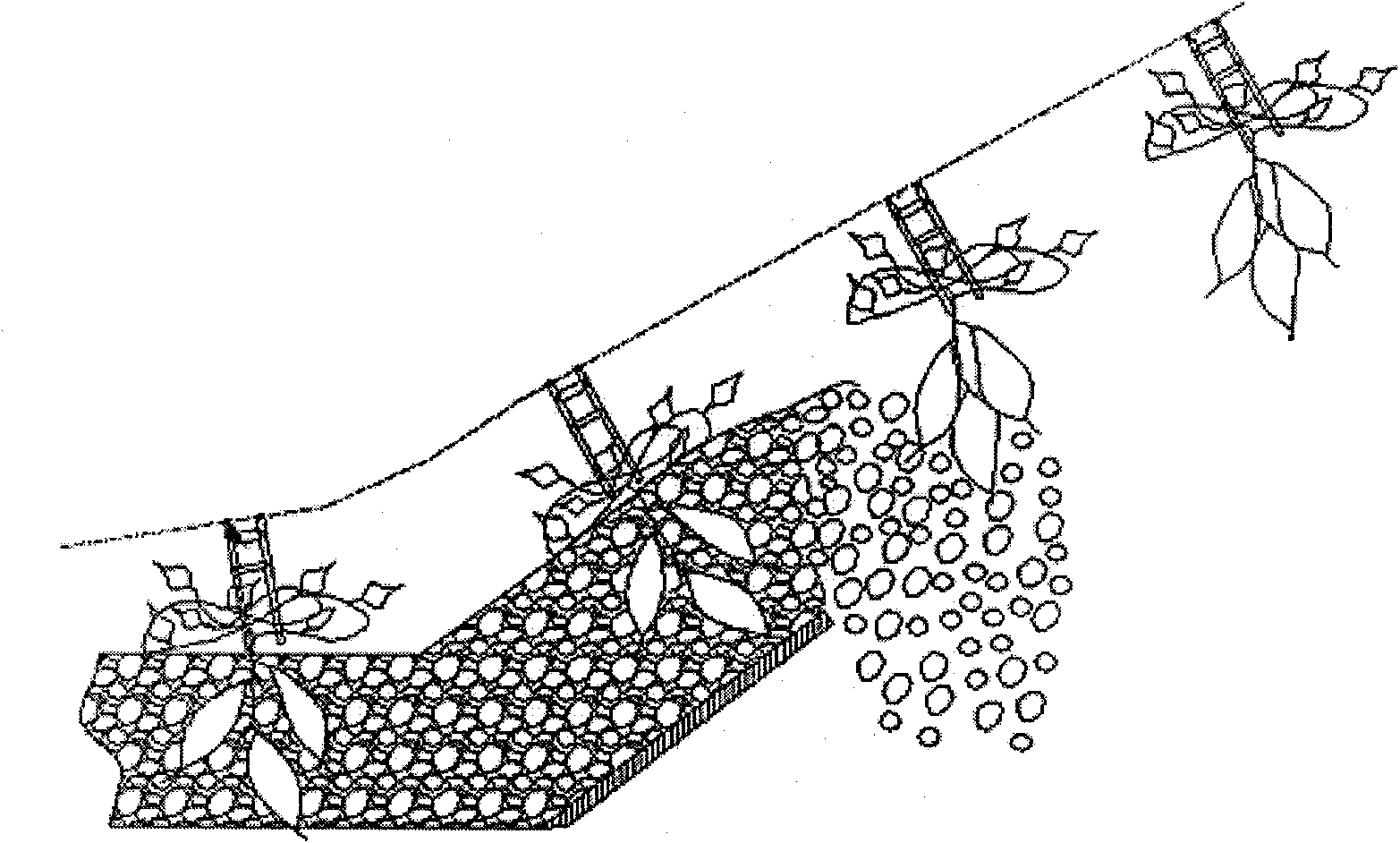

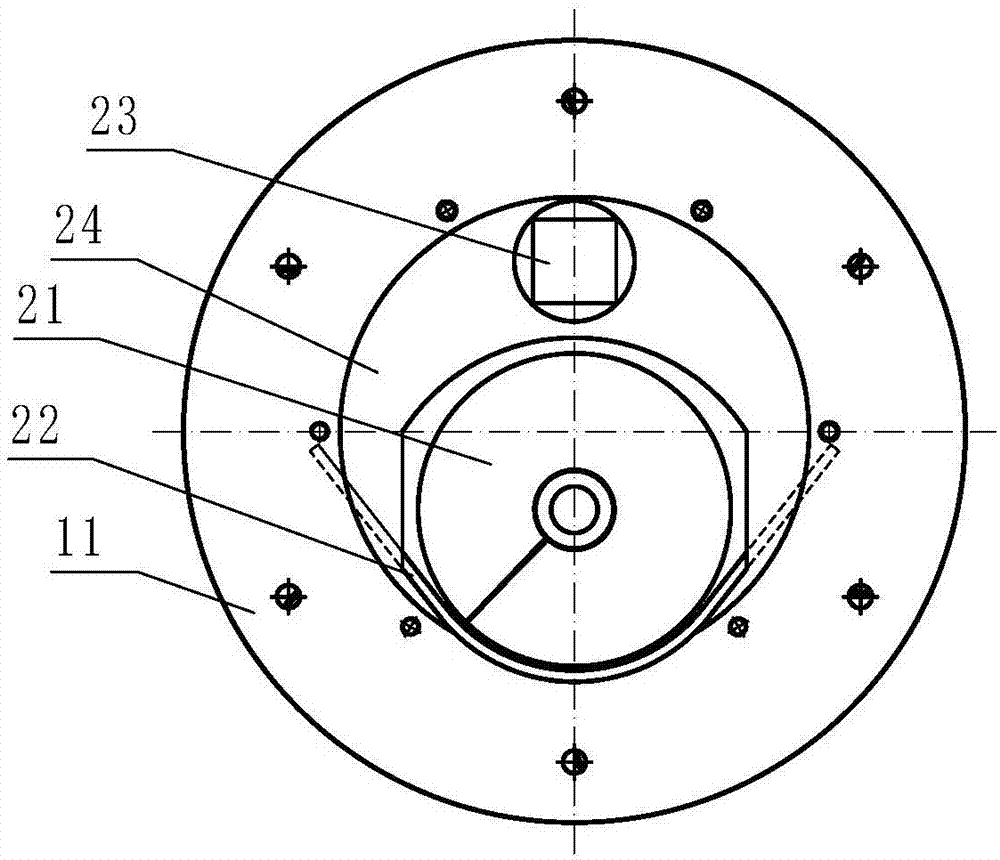

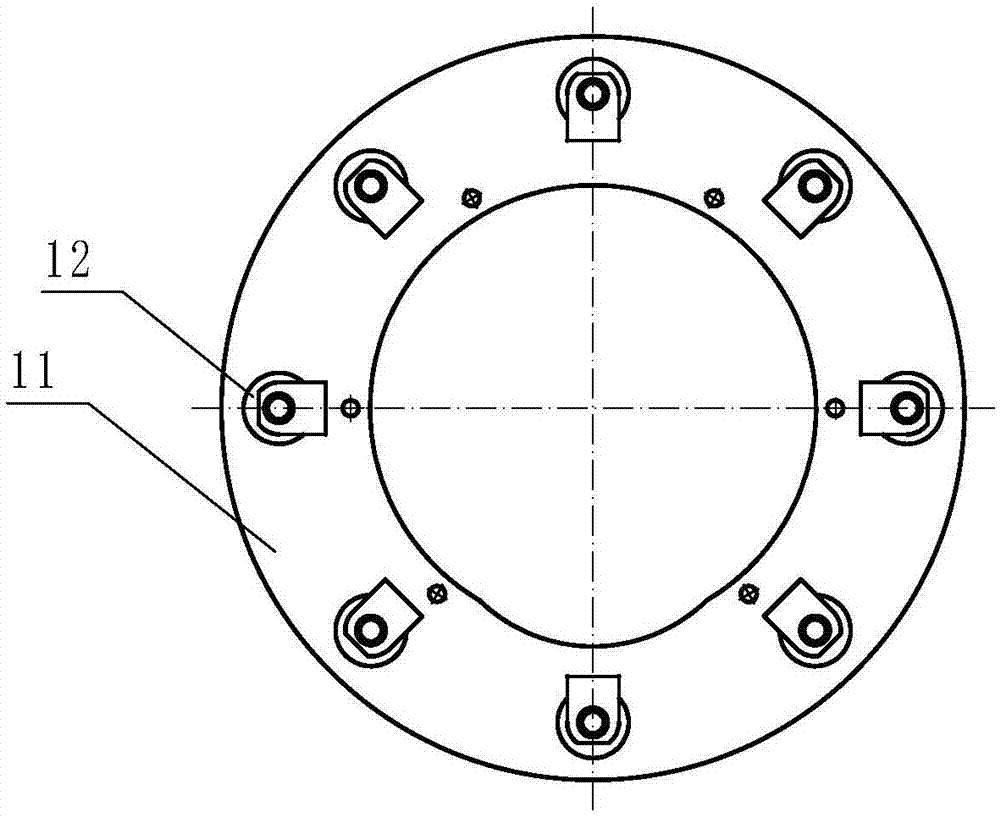

Non-core follow-up self-sundry-cleaning farmland residual film collecting roller and mulching film recovery machine composed of roller

ActiveCN107371409AEasy to cleanEffective attachmentGatherer machinesAgricultural engineeringPlastic mulch

The invention belongs to the technical field of agricultural machinery, and particularly relates to a non-core follow-up self-sundry-cleaning farmland residual film collecting roller and a mulching film recovery machine composed of the roller. The non-core follow-up self-cleaning farmland residual film collecting roller comprises two opposite fixation plates A (11) and a mouse-cage-shaped hollow frame between the two fixation plates A (11); a rolling wheel group (12) and an annular orbital body (31) are arranged between the fixation plates A (11) and a roller body (34), the roller body (34) is internally provided with a sundry connecting groove (32), and the roller body (34) between the two opposite fixation plates A (11) is internally provided with a sundry discharging mechanism. Film picking and collecting are conduced by the non-core follow-up self-sundry-cleaning farmland residual film collecting roller and the mulching film recovery machine composed of the roller, sundries can be effectively cleaned, sundries in mulching film is greatly reduced, especially the attachment of sundries to the surface of the roller body is greatly reduced, the sundries are effectively prevented from accumulating on the roller, and a chain harrow mechanism and the roller keeps clean, so that it is ensured that the operation is conducted normally, and the operation efficiency is improved.

Owner:XINJIANG ACADEMY OF AGRI & RECLAMATION SCI

System and method for controlling the orientation of ground engaging elements on an agricultural implement

ActiveUS10602653B2Reduce bias forceSpadesAgricultural machinesControl engineeringAgricultural engineering

A method for controlling an orientation of ground engaging elements of a harrow of an agricultural implement may include controlling an operation of an actuator such that the actuator applies an actuator force against a support arm when the harrow is disposed at an operating position. The method may also include receiving an input indicative of an instruction to move the harrow from the operating position to a raised position. Furthermore, after receiving the input, the method may include controlling the operation of the actuator such that the actuator force applied against the support arm is adjusted in a manner that reduces the biasing force being applied on the ground engaging elements. Additionally, the method may include initiating movement of the harrow from the operating position to the raised position to raise the ground engaging elements above the ground after reducing the biasing force.

Owner:CNH IND CANADA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com