Two-section type continuous, rapid and deep dehydration system for full tailing slurry

A deep dewatering, two-stage technology, used in dewatering/drying/concentrating sludge treatment, mining wastewater treatment, water/sludge/sewage treatment, etc. problems, to avoid air hazards, avoid high energy consumption, and achieve the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

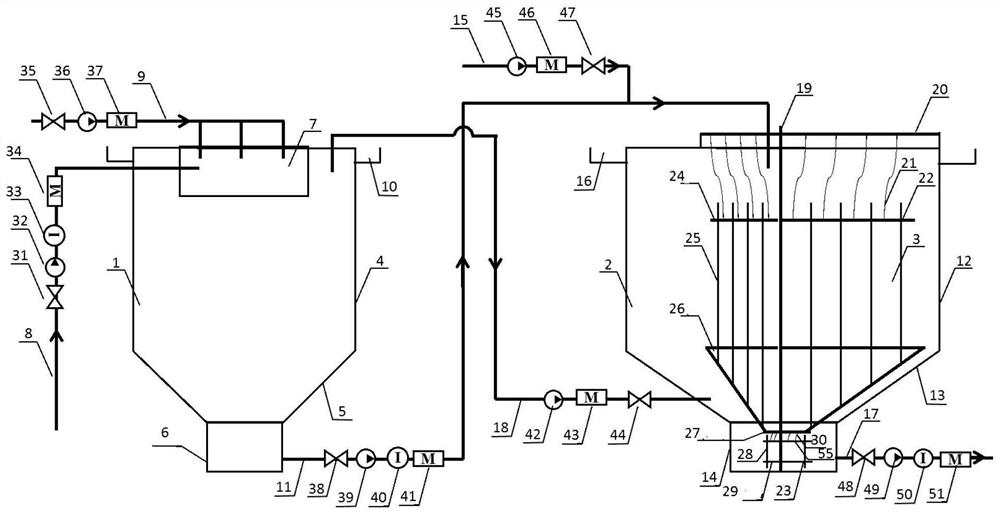

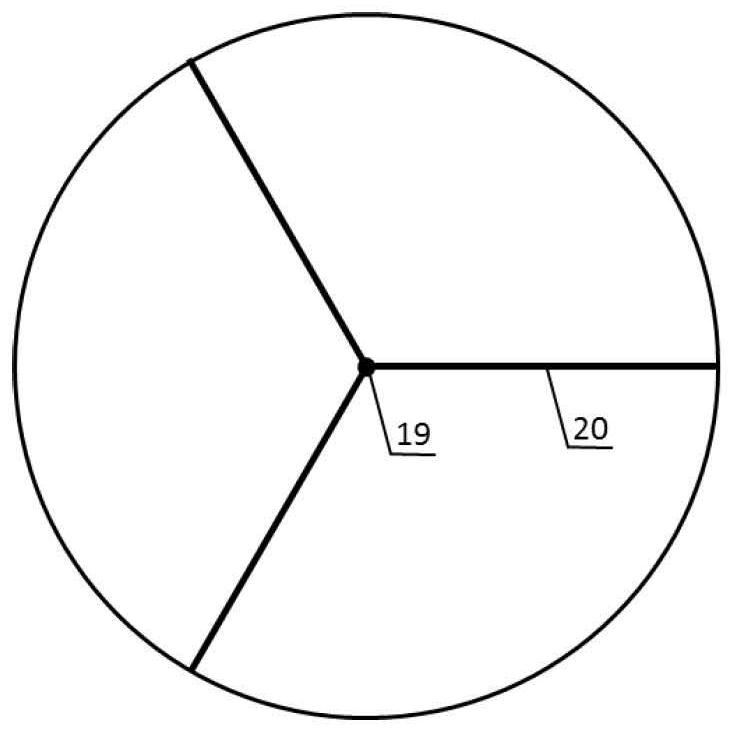

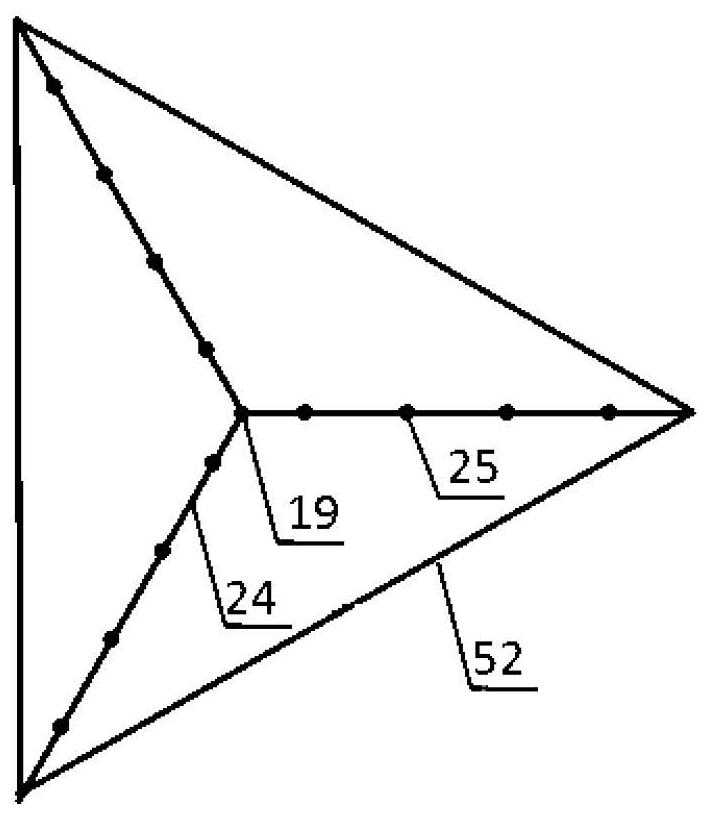

[0032] like figure 1 As shown, the structure of the two-stage continuous, rapid and deep dehydration system for full tailings slurry is as above, and the dimensions of the key structures are as follows: the diameter of the rapid settlement chamber of the flocculation settlement chamber 1 is 10 meters, the height is 10 meters, and the diversion The height of the warehouse is 2 meters, and the diameter of the collection bin is 1.5 meters and the height is 2 meters; the diameter of the depth dehydration bin 12 of the depth dehydration and activation storage bin 2 is 18 meters, and the height is 10 meters, and the height of the activation diversion bin 13 is 2 meters, the height of collecting bin 14 is 1.5 meters, and the diameter is 2 meters.

[0033] In the application process, the whole tailings slurry with a mass concentration of 20% to 25% in the dressing plant enters the central mixing well 7 of the tailings flocculation settlement bin 1 through the tailings feeding pipe 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com