Patents

Literature

10775 results about "Flocculation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flocculation, in the field of chemistry, is a process in which colloids come out of suspension in the form of floc or flake, either spontaneously or due to the addition of a clarifying agent. The action differs from precipitation in that, prior to flocculation, colloids are merely suspended in a liquid and not actually dissolved in a solution. In the flocculated system, there is no formation of a cake, since all the flocs are in the suspension.

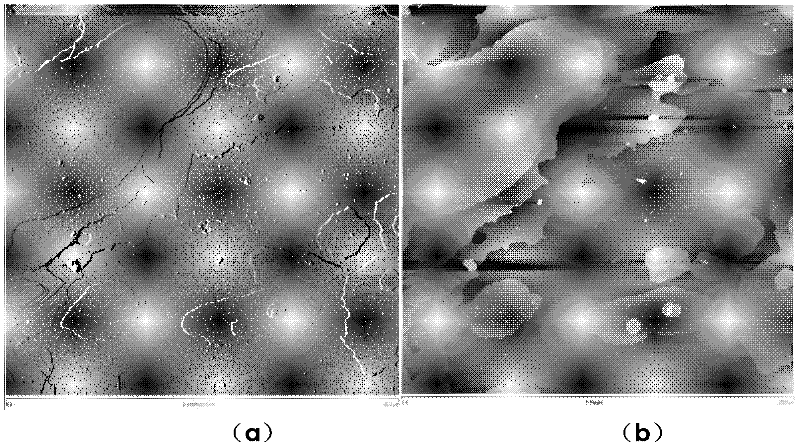

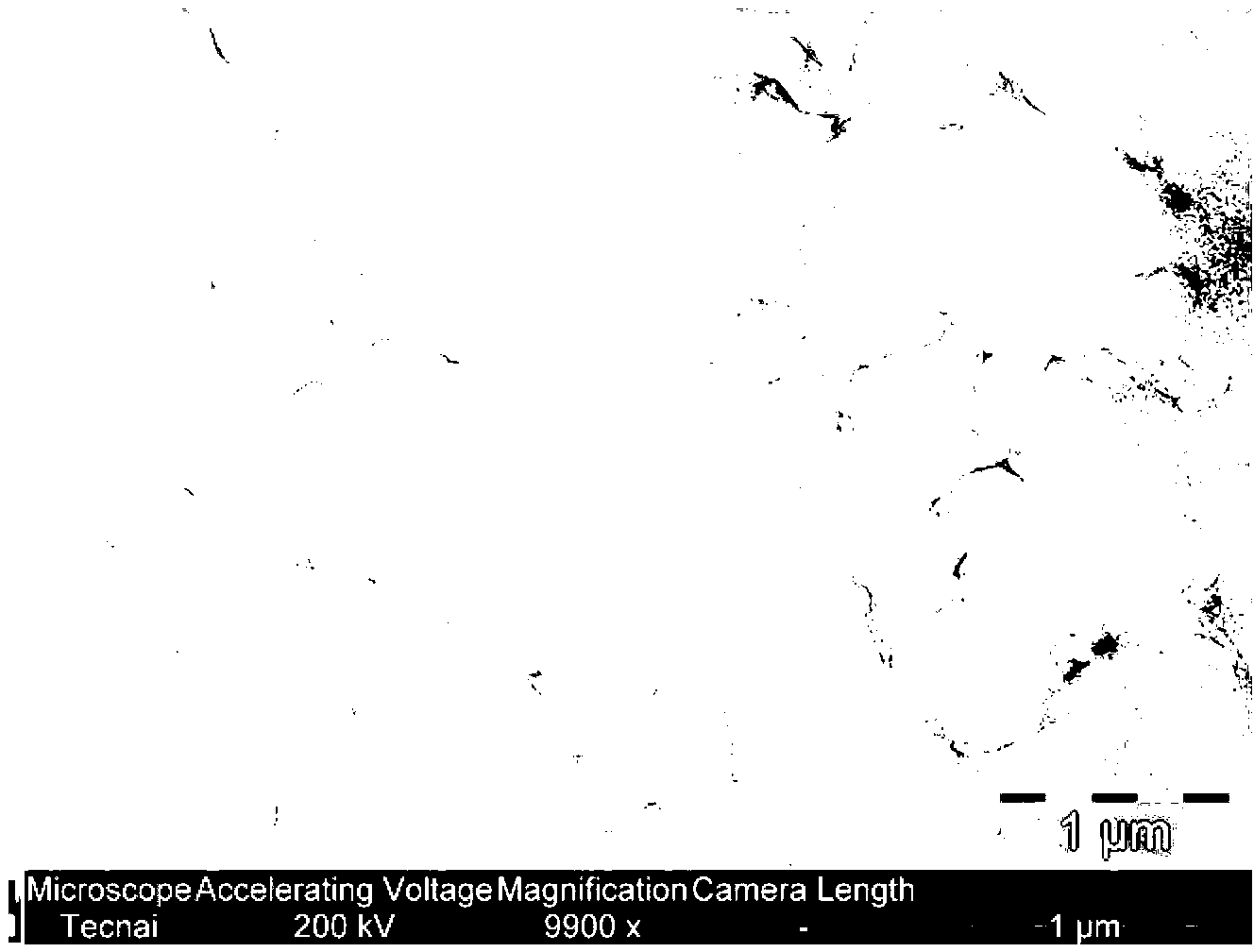

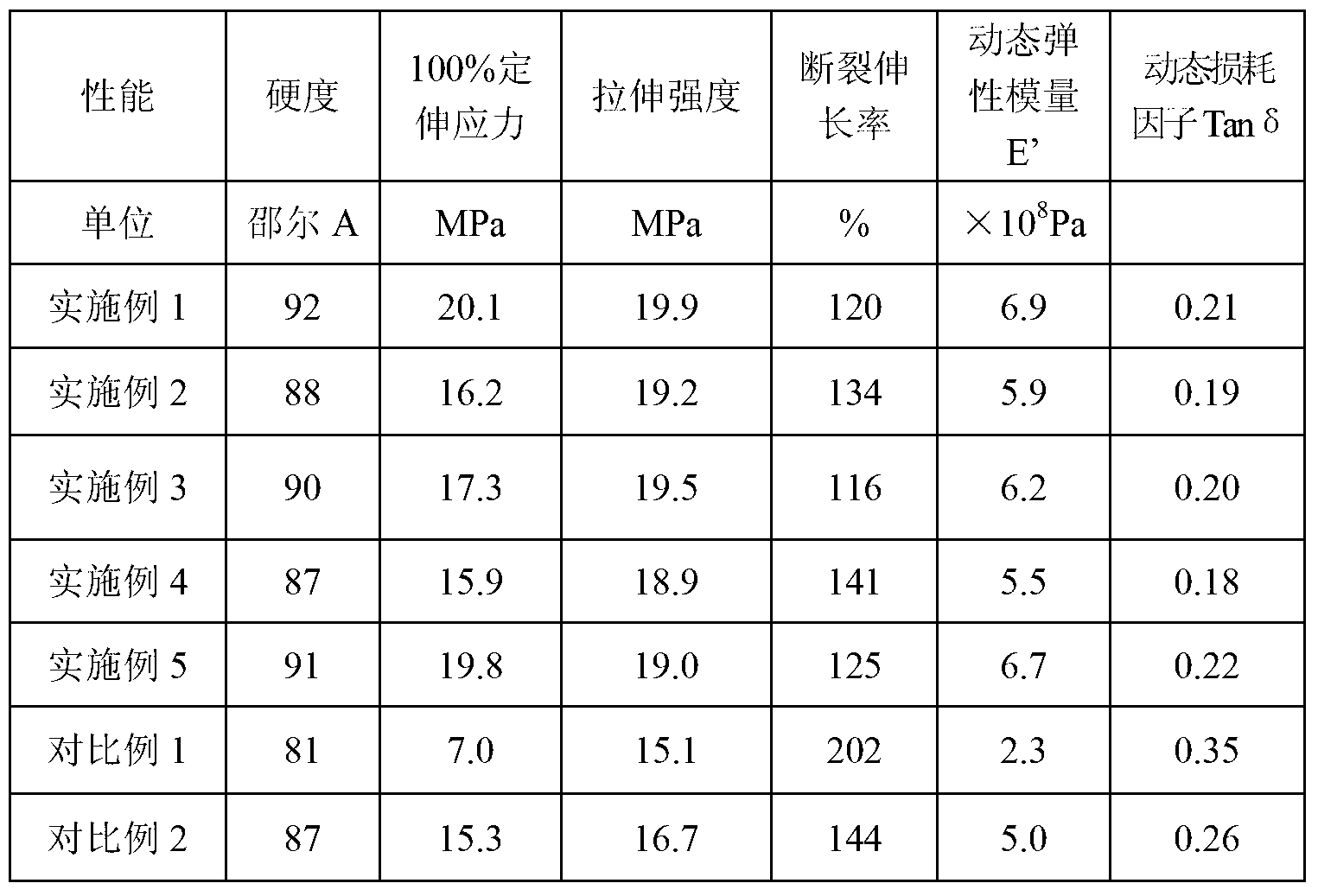

Preparation method of completely peeled oxidation graphene/ rubber nanometer composite material

A preparation method of completely peeled oxidation graphene / rubber nanometer composite material adopts combination of emulsion compounding and flocculation processes or combination of emulsion compounding and spraying drying processes. The preparation method retains the phase state structure of the oxidation grapheme / rubber composite emulation in the liquid state and obtains the phase-state structure which is highly dispersed, highly peeled and dispersed in nanometer scale dispersion. Simultaneously, substances capable of acting with generating ionic bond effect or chemical bond effect with an oxidation graphene surface functional group are added into the oxidation graphene / hydrosol to serve as an interface agent, thereby improving interface combination effect of oxidation graphene and rubber. Vulcanized rubber prepared by the composite material of the preparation method through follow-up mixing and vulcanizing has mechanical property such as high tensile strength, stretching stress and tearing strength and is capable of greatly improving abrasion resistance and gas separation performance of the vulcanized rubber. The preparation method is simple, easy, low in cost, apt to industrialization and wide in suitable aspect, saves energy and has better economical and social benefits.

Owner:JIANGSU LVYUAN RUBBER RESOURCE RECYCLING INNOVATION CENT CO LTD

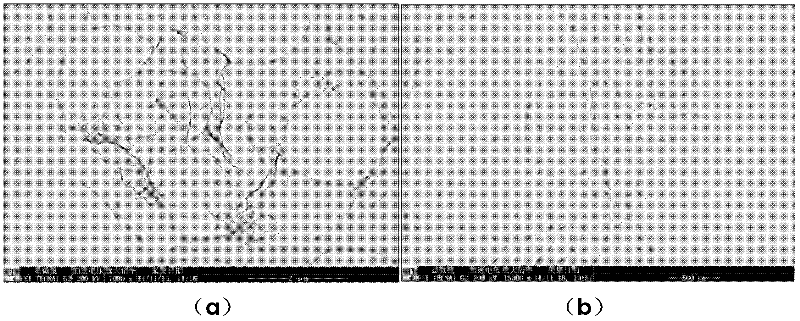

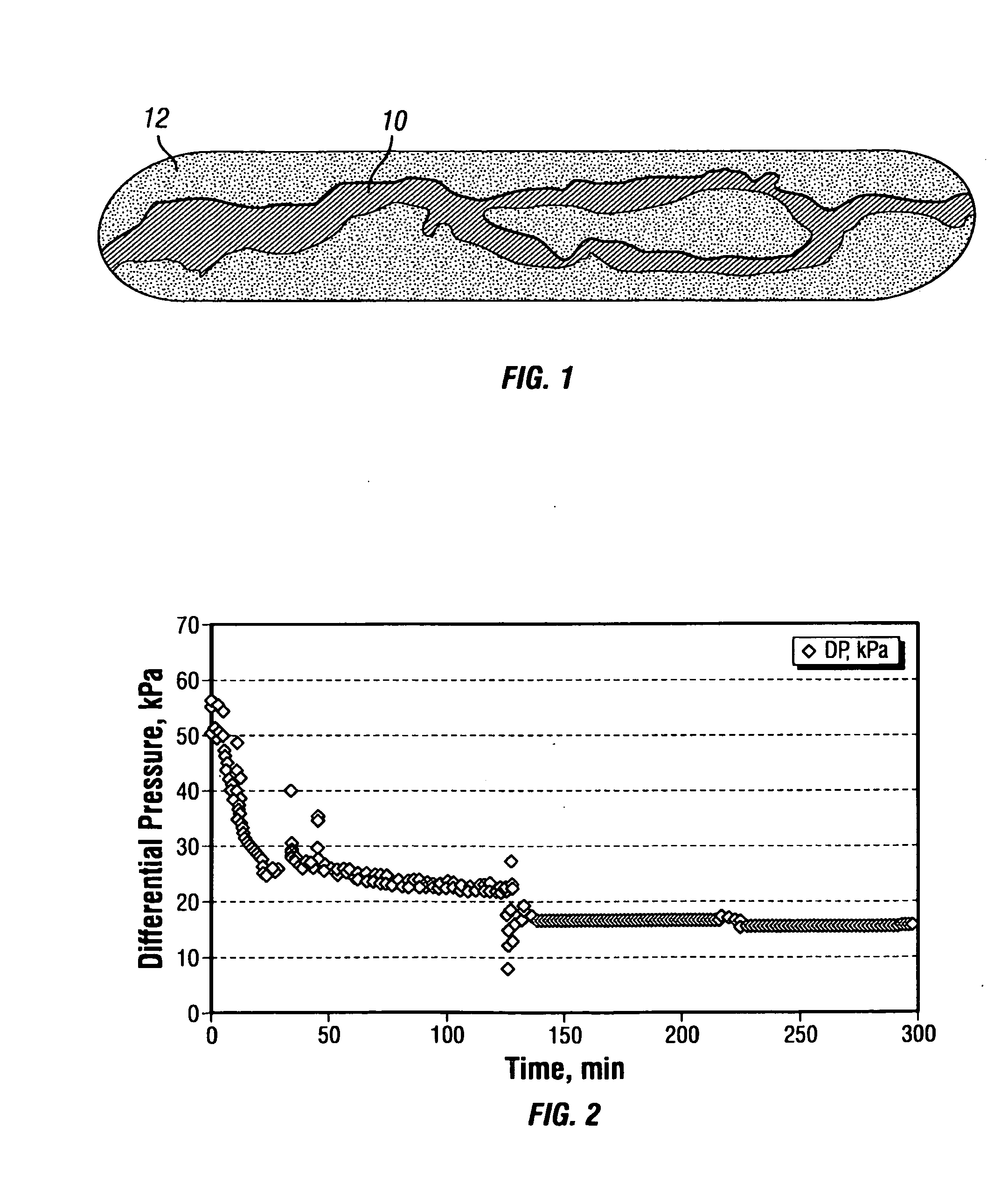

Proppant placement

InactiveUS20130161003A1Induce and enhance non-uniformityImprove conductivityFluid removalDrilling compositionFlocculationEngineering

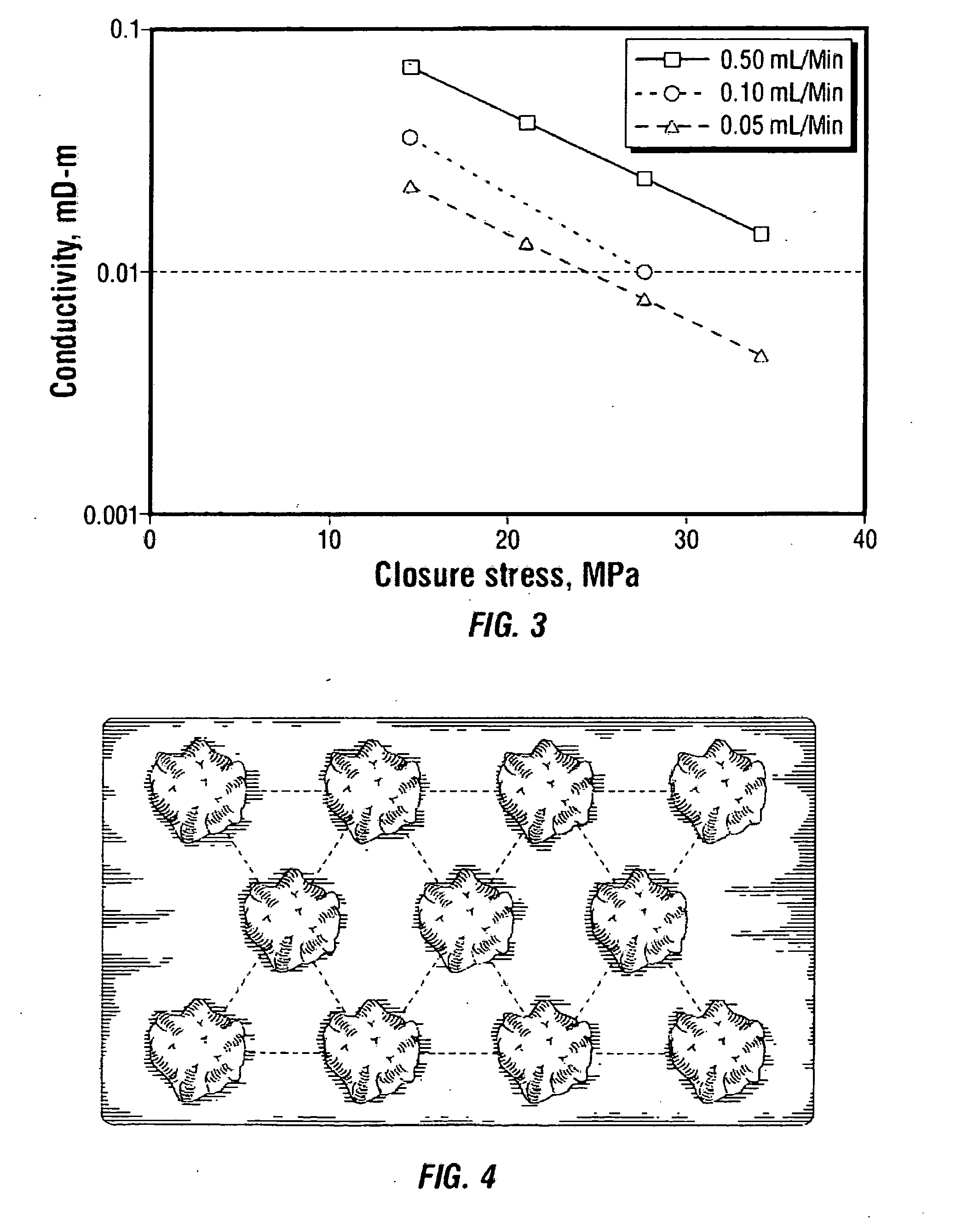

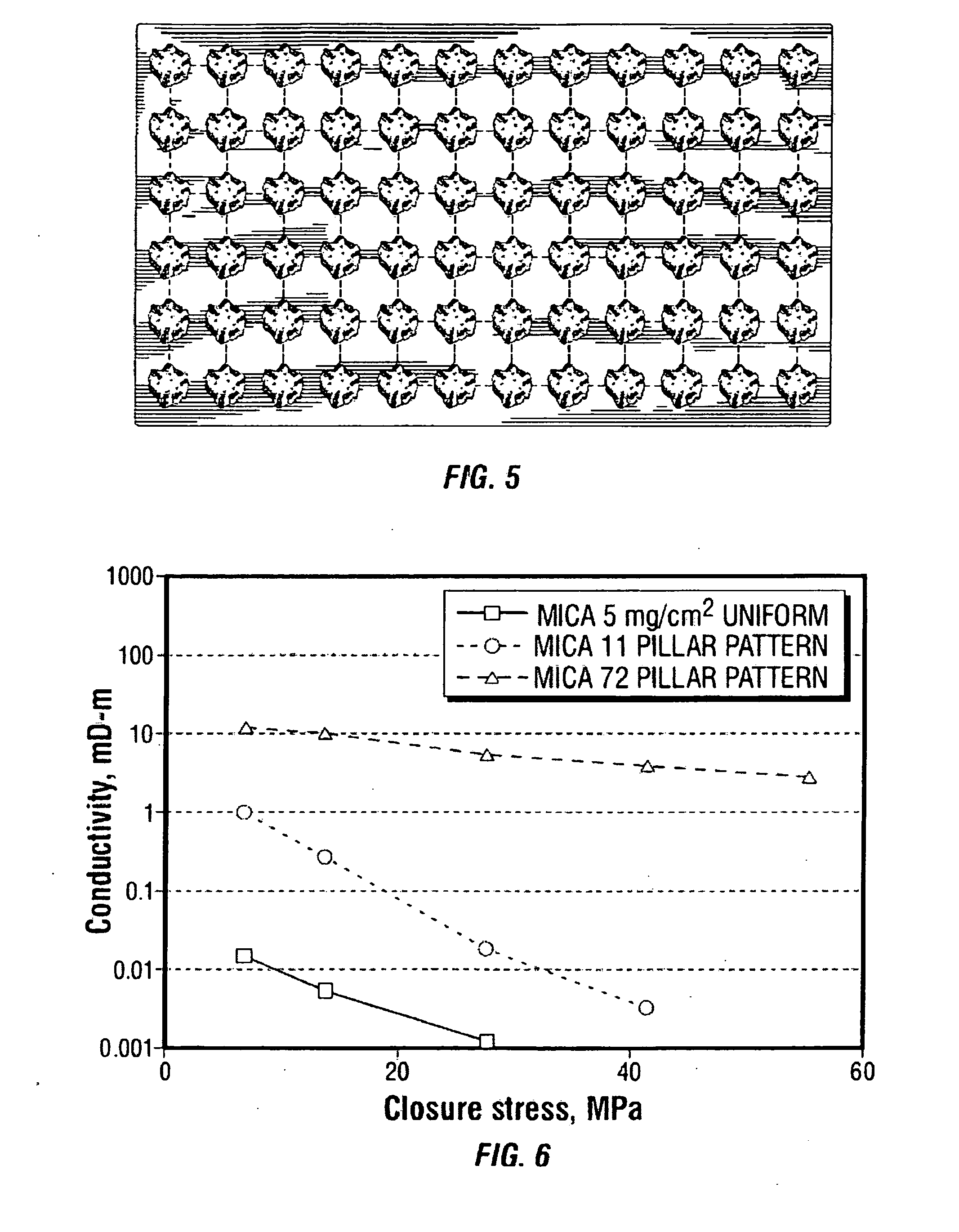

Embodiments of hydraulic fracturing methods disclosed herein use fine mesh proppant. In one embodiment the method is used to fracture a low permeability formation. In one embodiment the method uses flocculation to improve conductivity of a fracture. In one embodiment fluid flow through the fine mesh proppant in the fracture creates a network of connected channels to improve the fracture conductivity.

Owner:SCHLUMBERGER TECH CORP

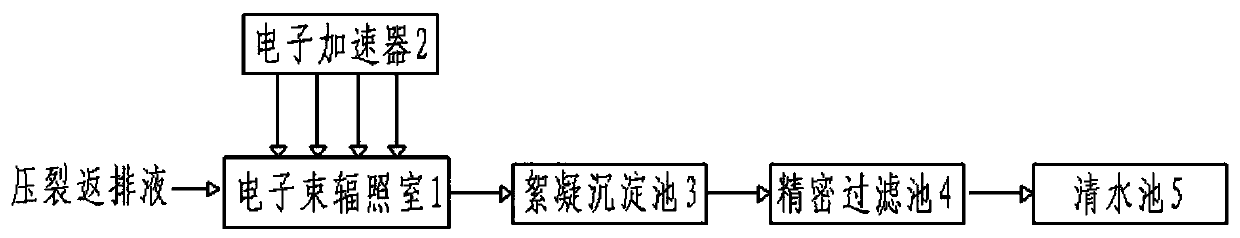

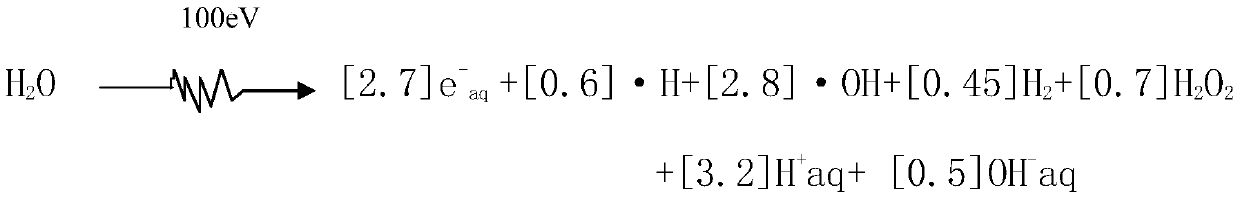

Rapid treatment method for fracturing flowback fluid

PendingCN110467298ARealize online processingLittle side effectsWaste water treatment from quariesTreatment involving filtrationFlocculationFiltration

Owner:RUIJIE ENVIRONMENTAL PROTECTION TECH CO LTD

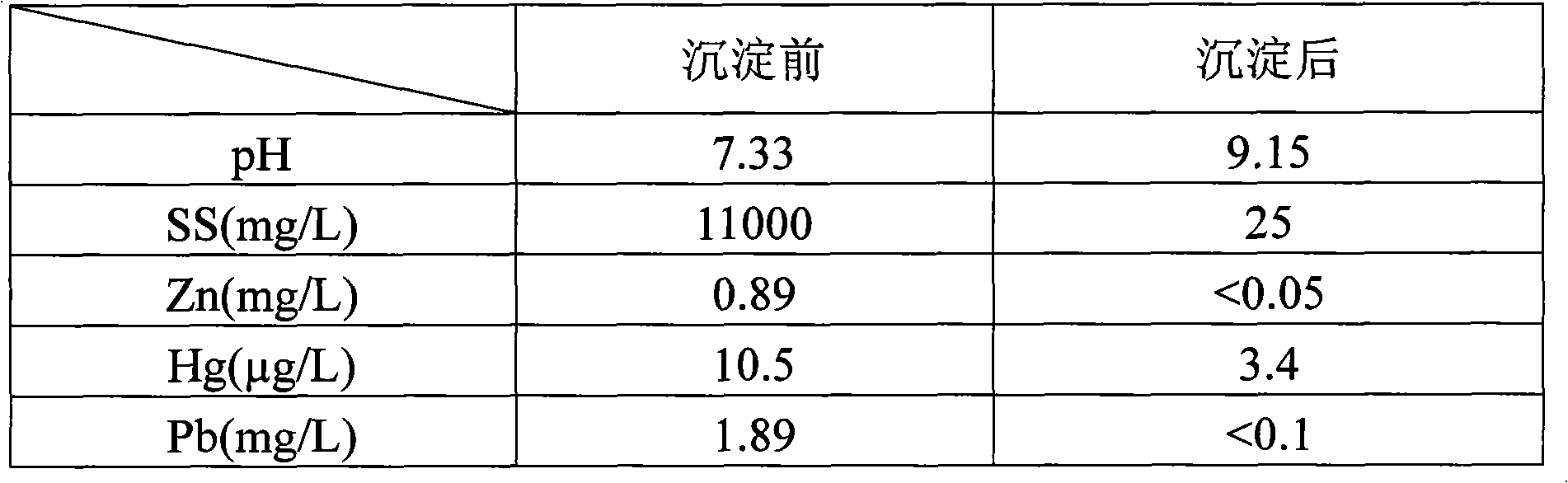

Method for producing feed additive from livestock and poultry breeding wastewater and purifying breeding wastewater to reclaimed water

InactiveCN102161550AReduce water consumptionAchieving zero emissionsWaste water treatment from animal husbandryAnimal feeding stuffUltrafiltrationSlurry

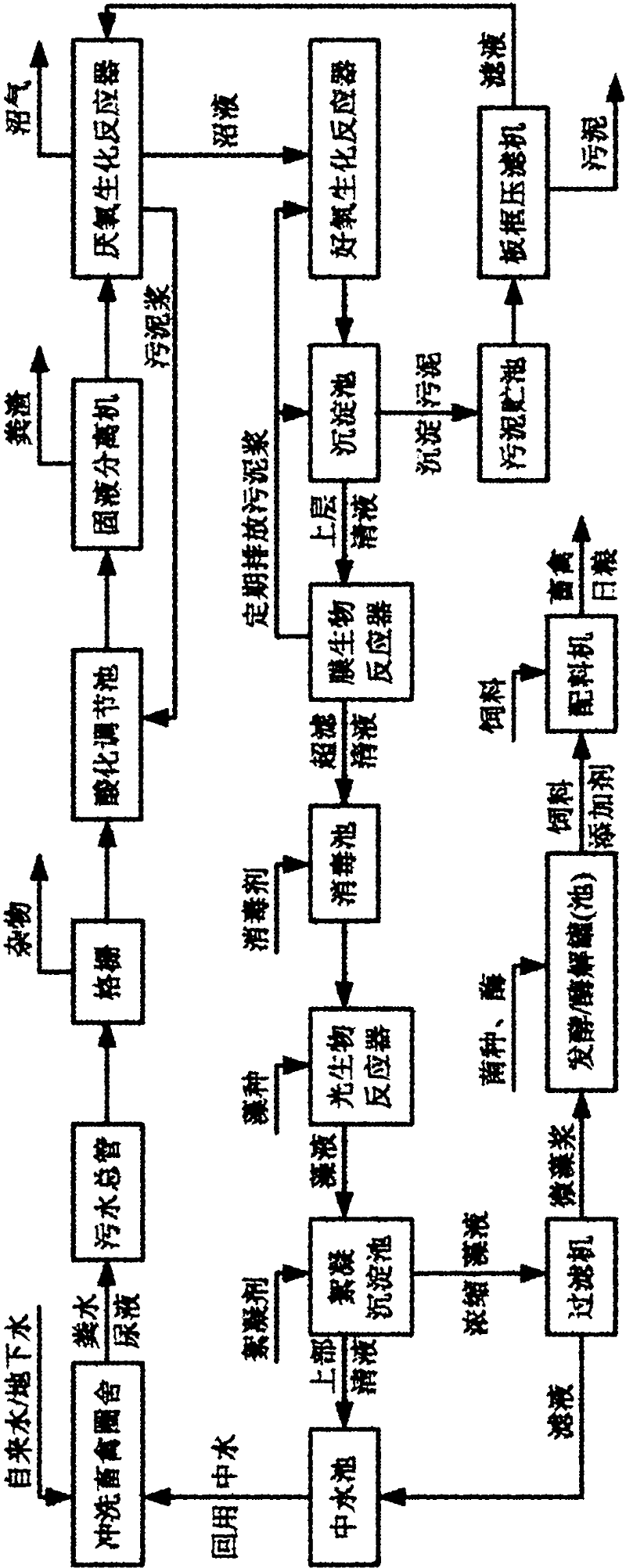

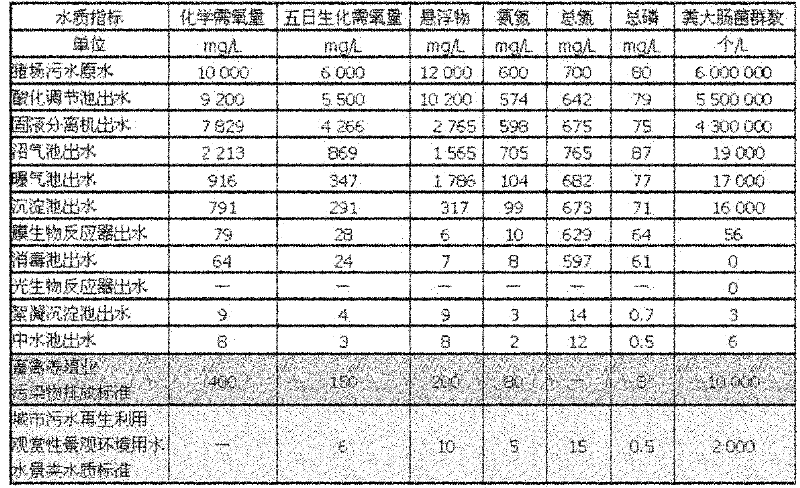

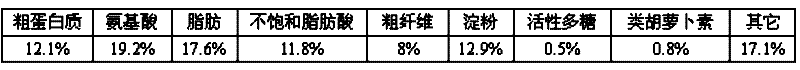

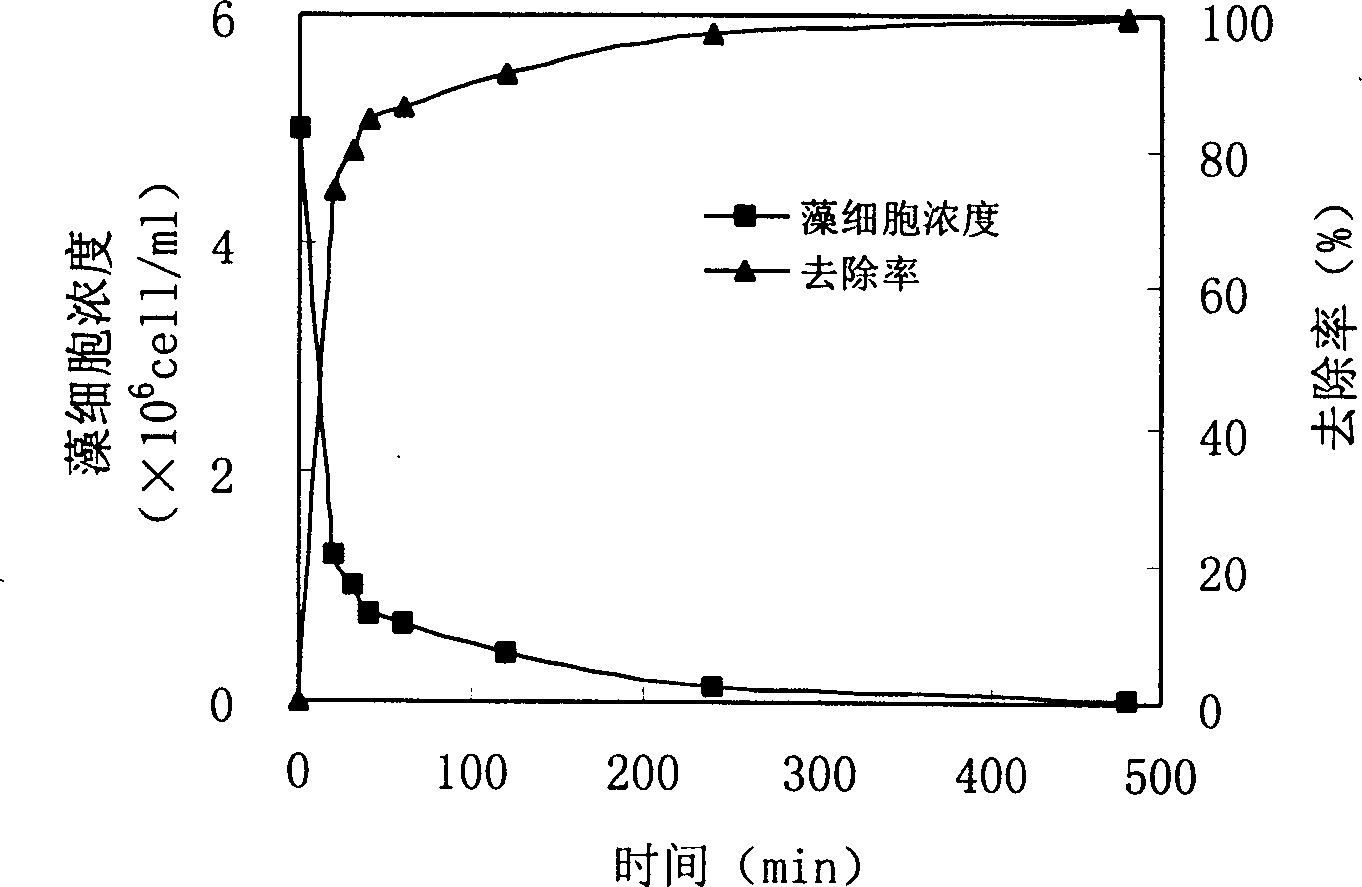

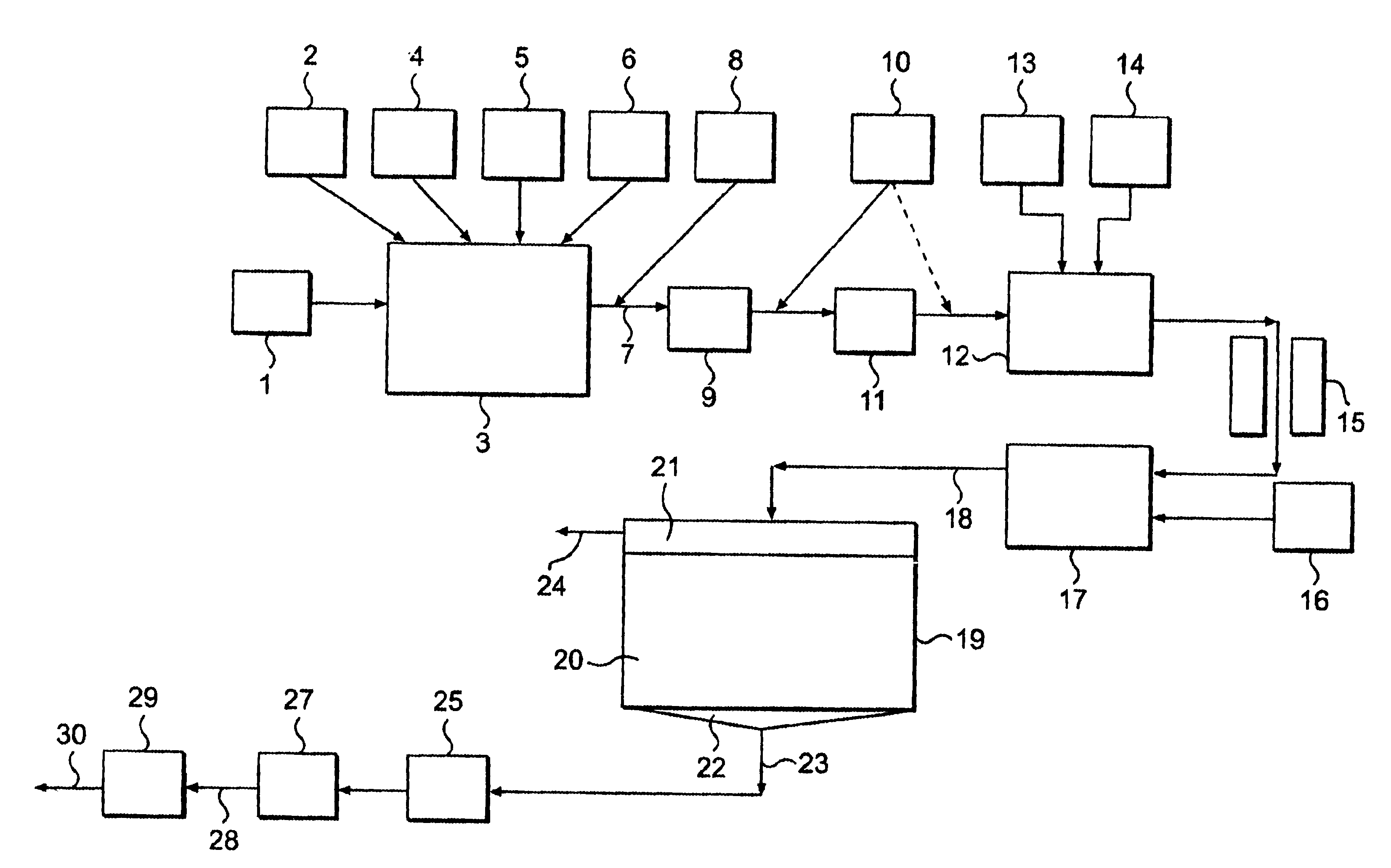

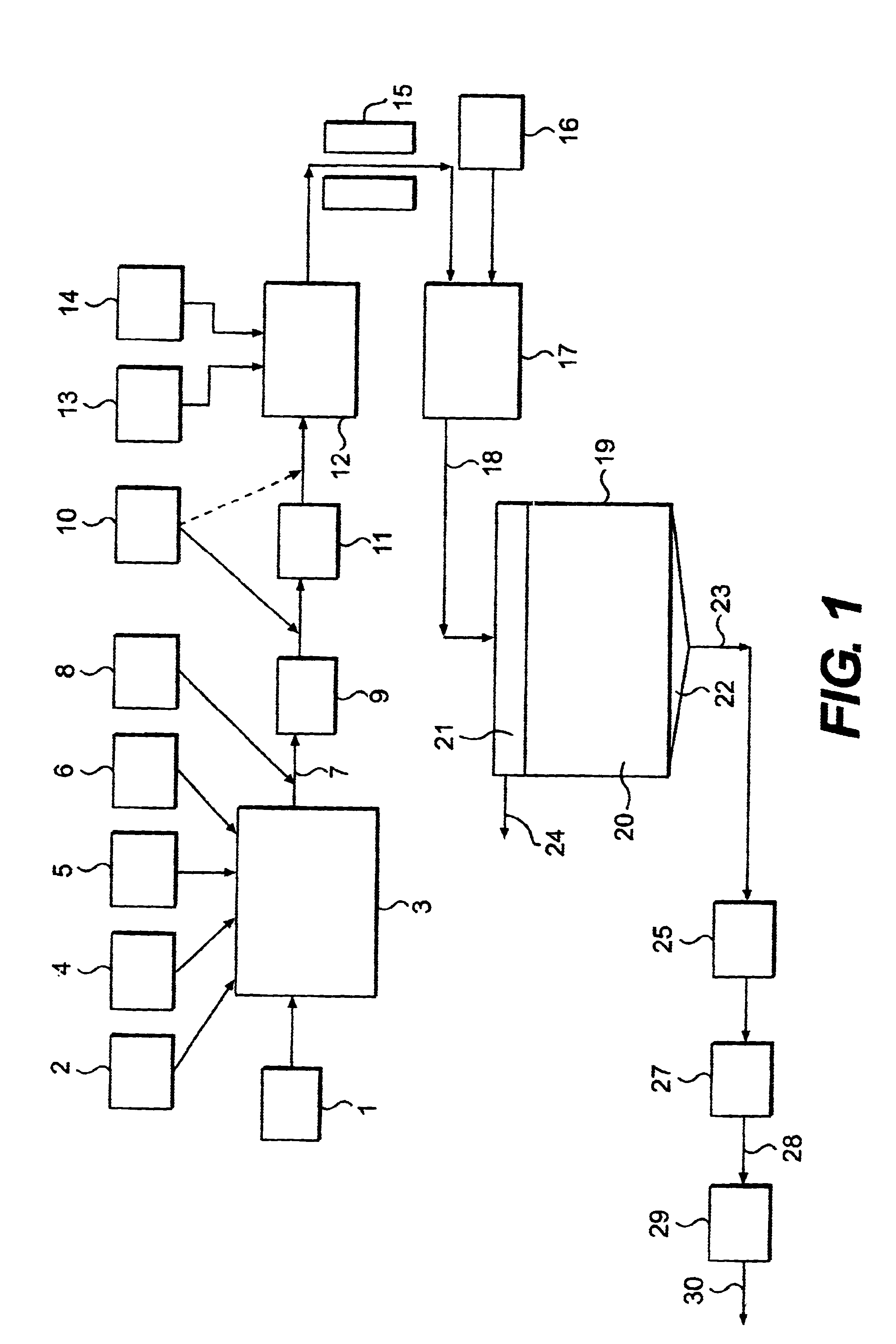

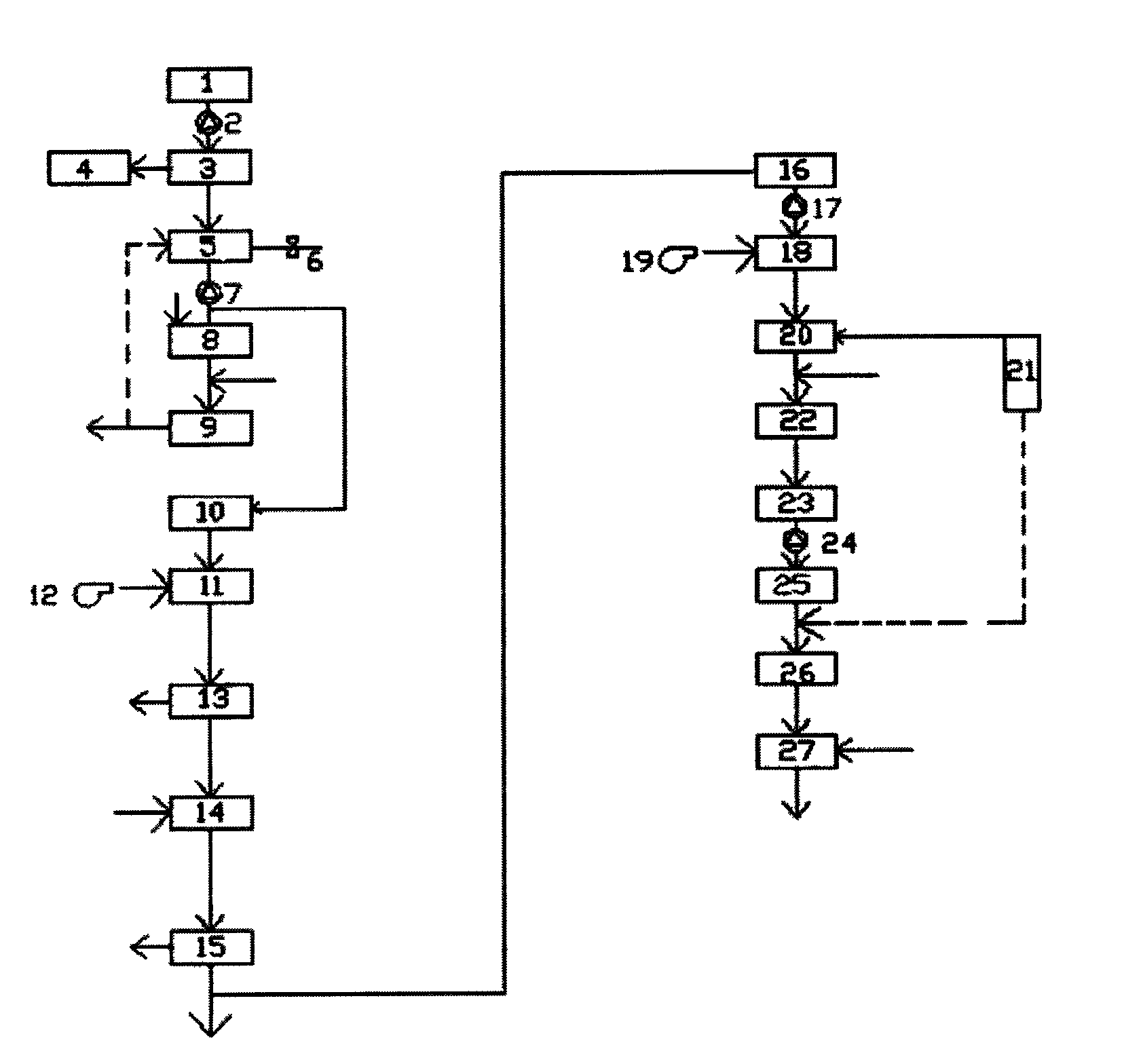

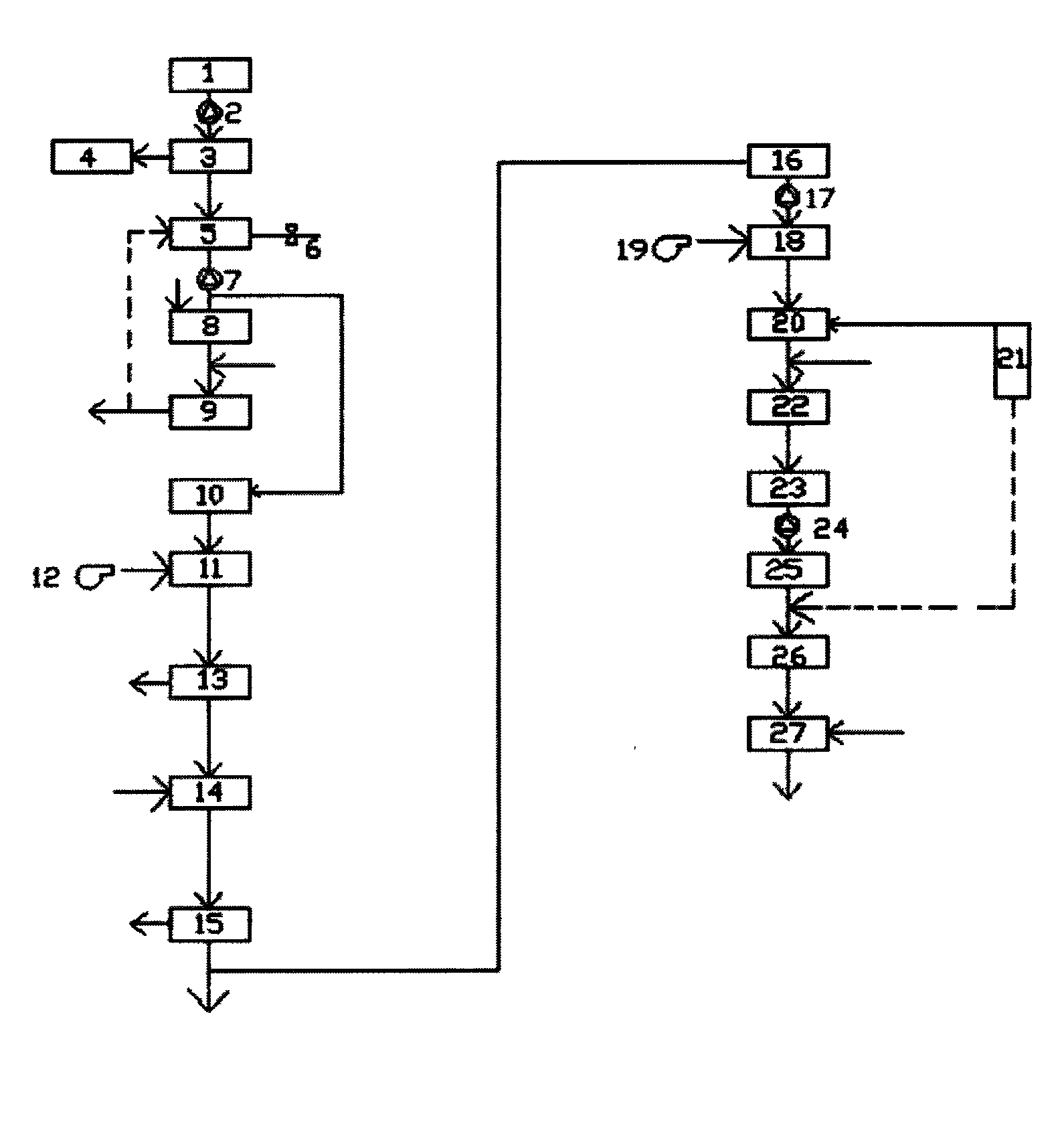

The invention relates to the fields of environmental technology and the breeding and processing of microalgae, in particular to a method for producing feed additive from livestock and poultry breeding wastewater and purifying breeding wastewater to reclaimed water. The method is characterized by comprising the following steps that: wastewater enters an acidification adjusting tank through a grille, and the acidified wastewater enters an anaerobic biochemical reactor for treatment and then enters an aerobic biochemical reactor; after the aerobic biochemical treatment, the obtained biogas slurry enters a settling tank for settling, the supernatant enters a membrane bioreactor for further aerobic treatment and is filtered by an ultrafiltration membrane, the generated ultrafiltration clear liquid is sterilized and neutralized and then enters a photobioreactor, algae are added into the photobioreactor to perform microalgae cultivation, and the algae liquid is discharged from the photobioreactor and then enters a flocculation and settling tank; and after flocculation and settling, the supernatant is used for water recycling, the concentrated algae liquid at the bottom enters a filter, and the separated microalgae slurry enters a fermentation / enzymolysis pot (tank) to perform fermentation / enzymolysis to be used as the feed additive. The invention has the advantages of high economic adaptability, zero discharge and the like.

Owner:蔡志武 +1

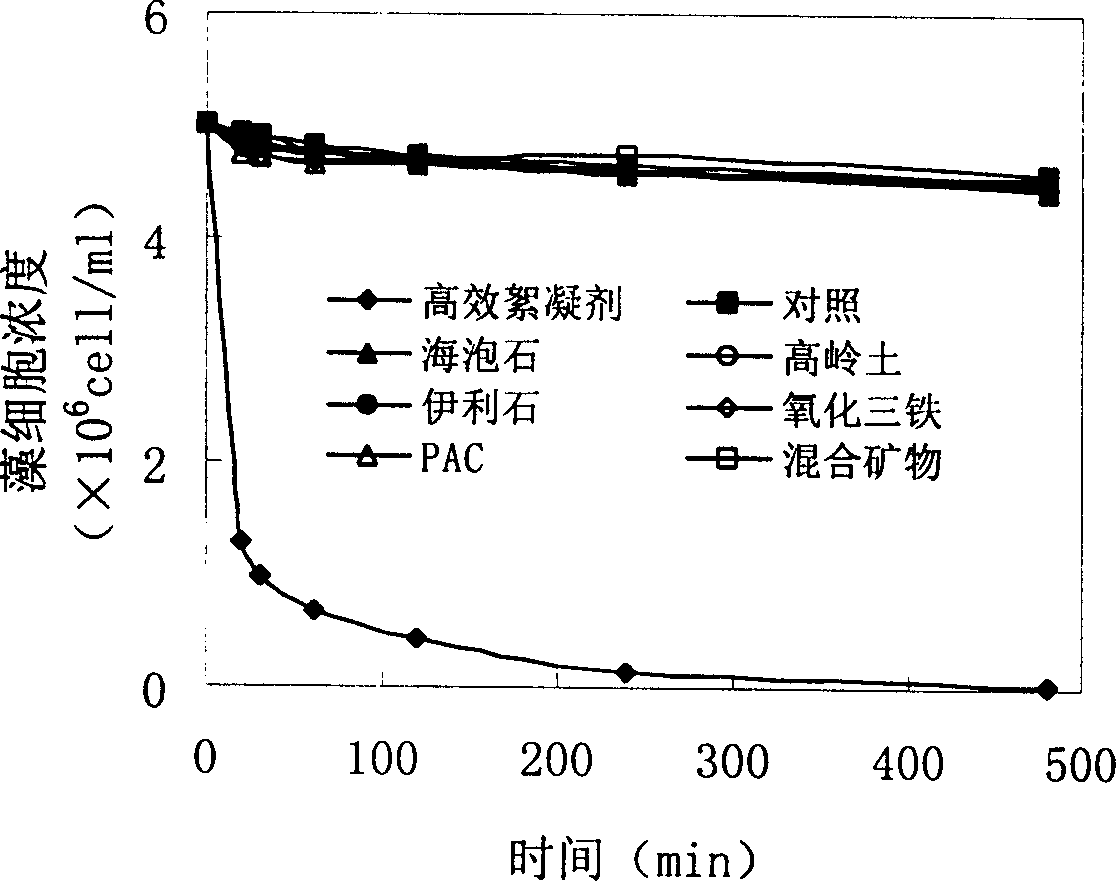

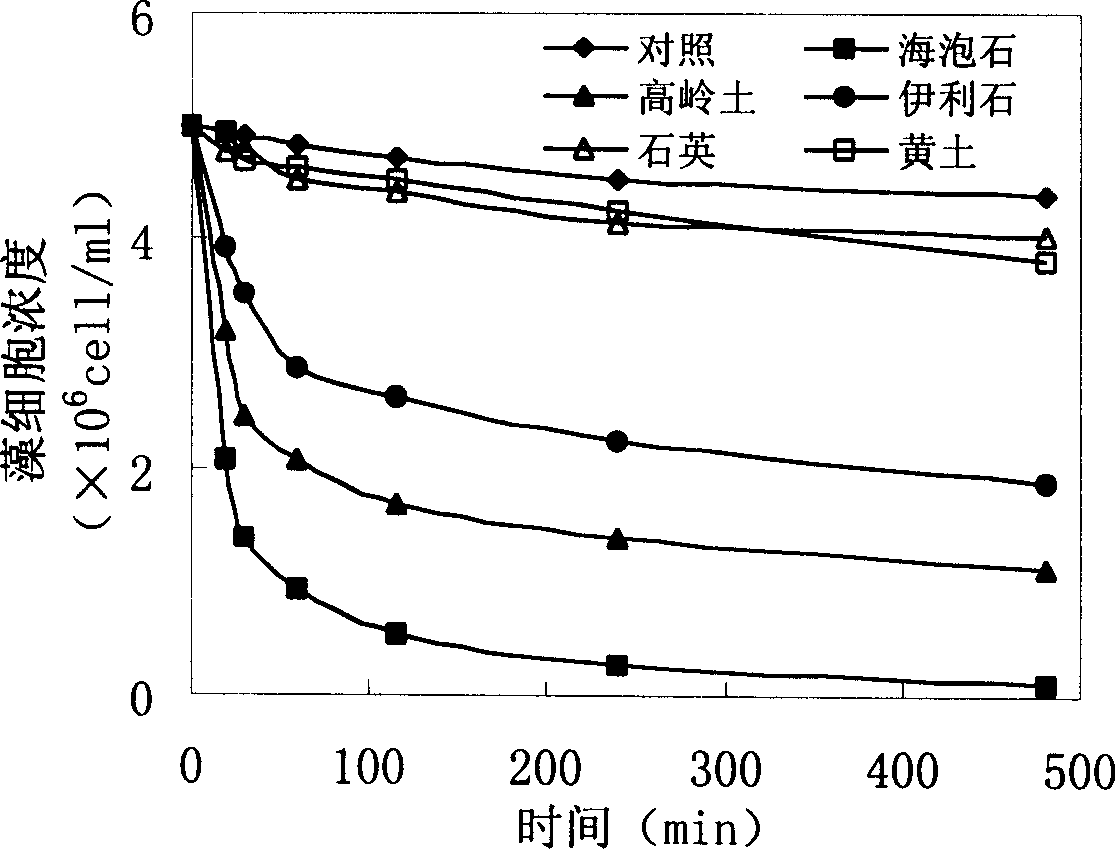

High efficiency algae flooculation agent, method for treating red tide and plakton bloom using same

InactiveCN1418825AReduce concentrationImprove the efficiency of flocculation and sedimentationWater/sewage treatment by flocculation/precipitationFlocculationPolymer modified

The present invention provides a method for preparing high-effective algae flocculant from non-toxic, easy-to-bio-degrade, cheap, natural macromolecular polymer modified clay. Said modification can obviously raise flocculation algae-removing capability of different clay, the algae-removing rate of various clays can be 20-95% Said high-effective algae flocculant can be used for controlling and treating large area red tide, fresh water algal bloom, and also can be used for removing harmful algae in river and drinking water plant.

Owner:BEIJING GREEN ECO ENVIRONMENTAL TECH

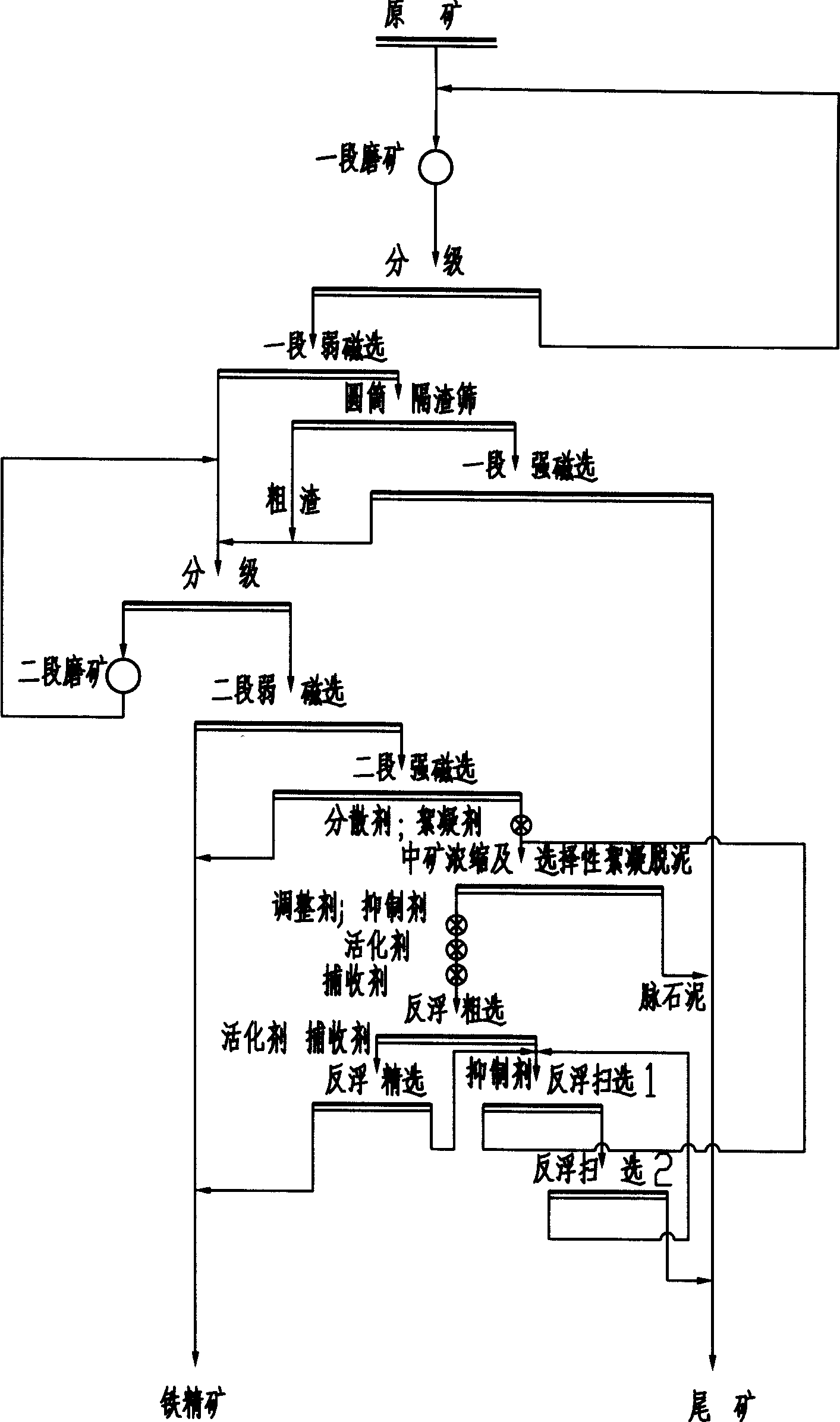

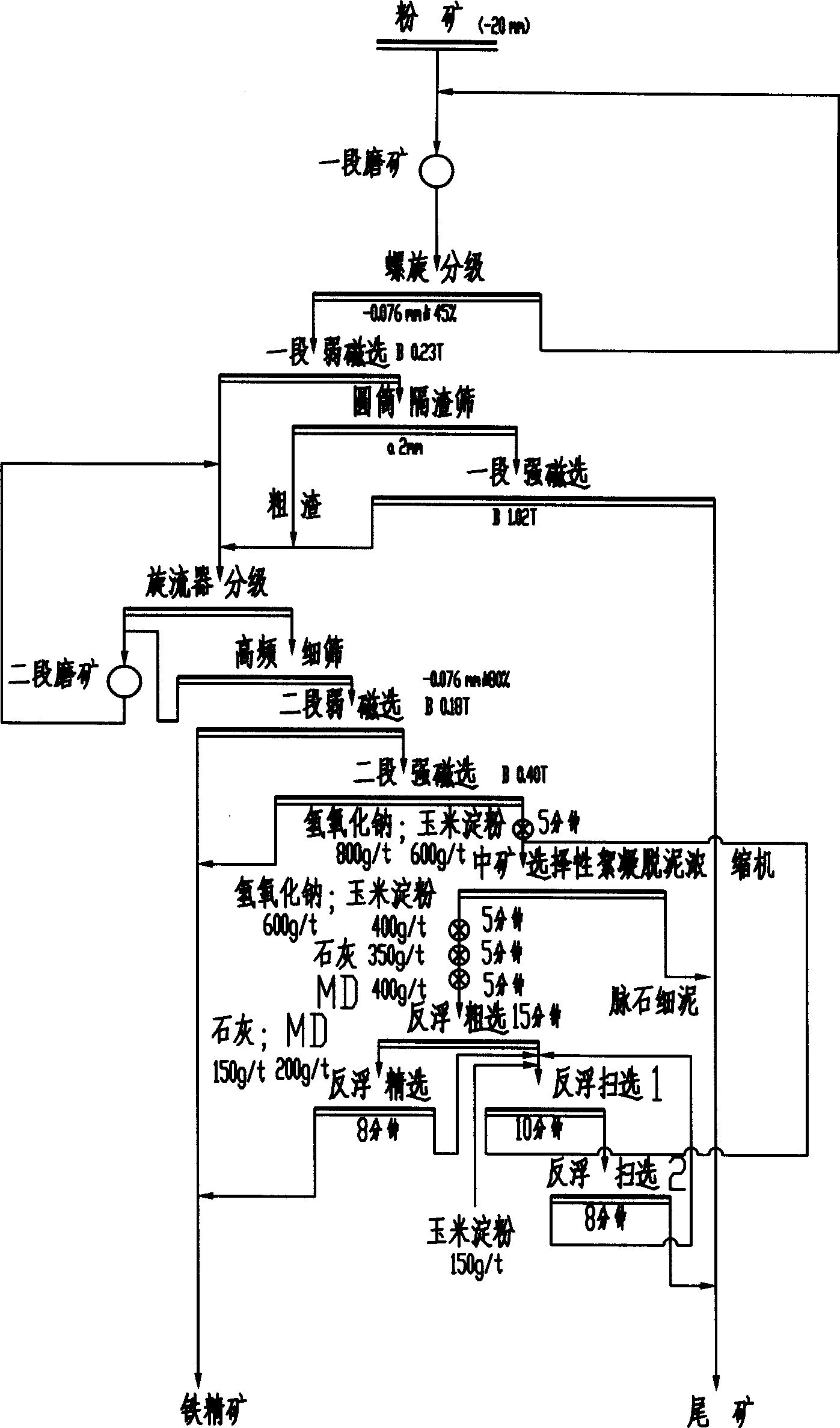

Beneficiation method for recycling specularite

InactiveCN101428248AReduce consumptionReduce the number of equipmentDifferential sedimentationFlotationIronstoneSlag

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Method of manufacturing a medical device having a porous coating thereon

Methods of manufacturing drug-coated medical devices having a porous coatings thereon. The pores are created by solid particle additives added to a mixture comprising a solvent, a drug, and a polymer to create a suspension, which is applied to the medical device. The method includes adding a surfactant to the mixture to prevent or decrease flocculation of the solid particle additives. Another method is provided that includes spraying a suspension on a medical device that comprises solid particle additives, a drug, and a polymer and analyzing the distribution of the solid particle additives in the suspension.

Owner:BOSTON SCI SCIMED INC

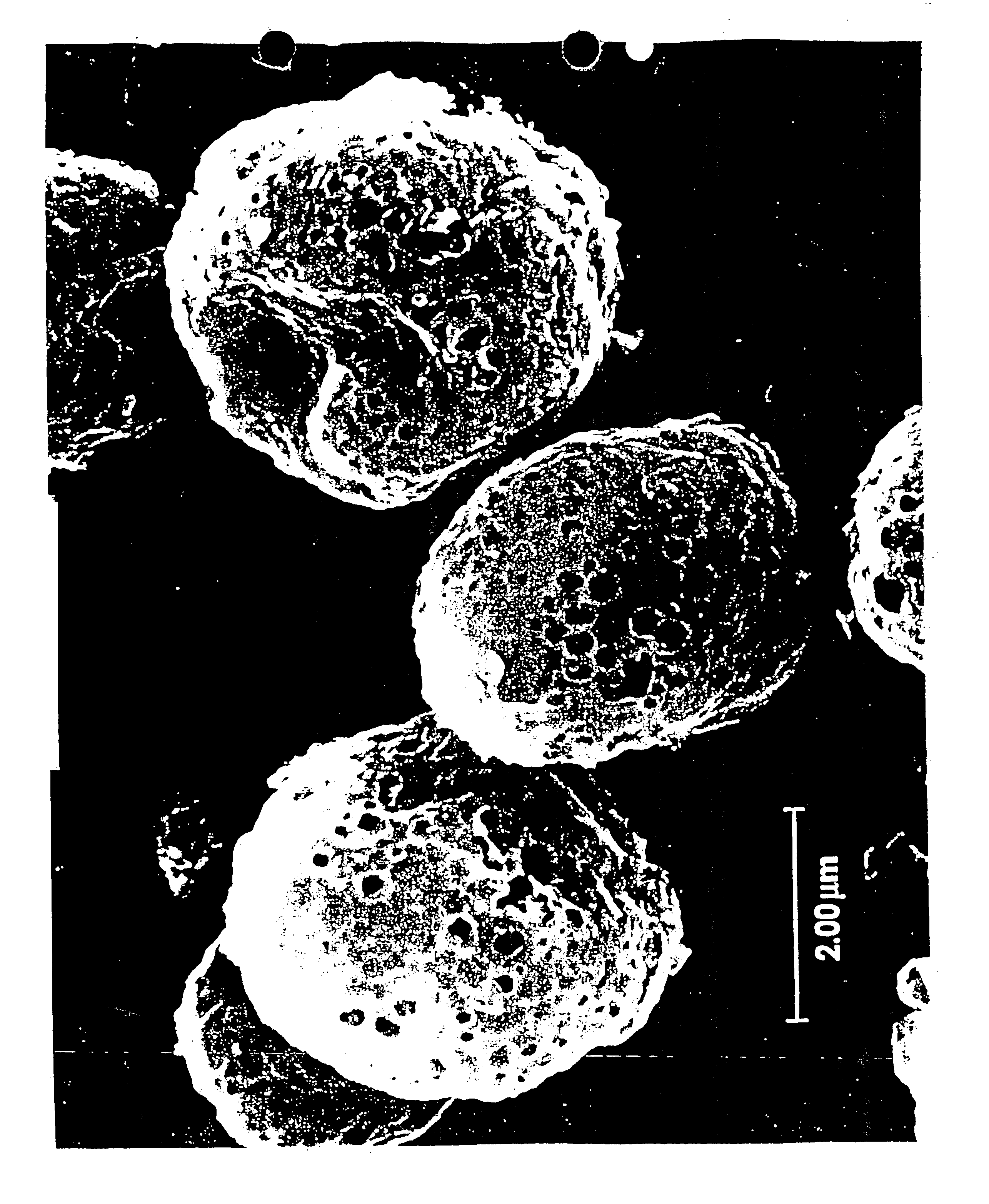

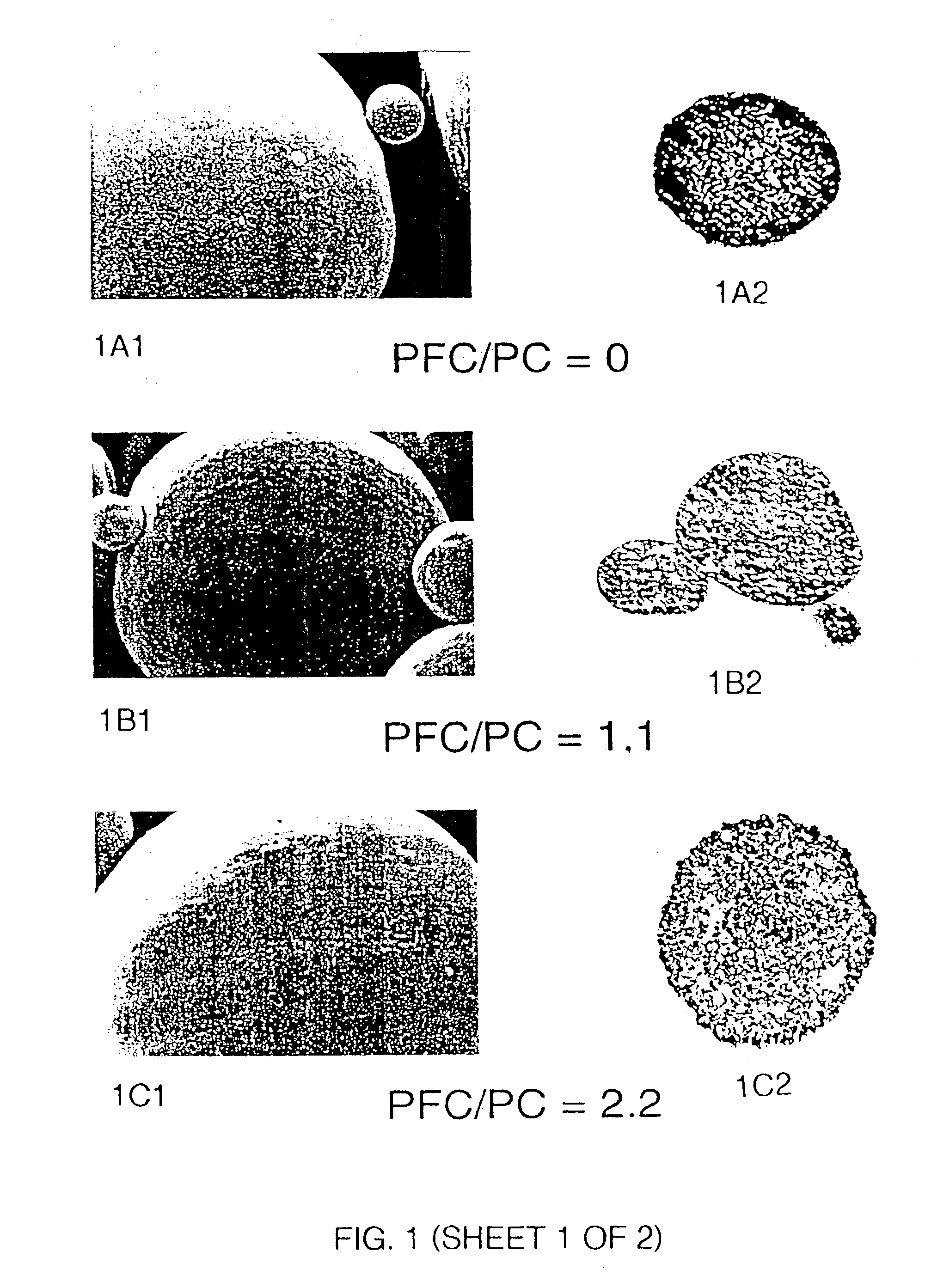

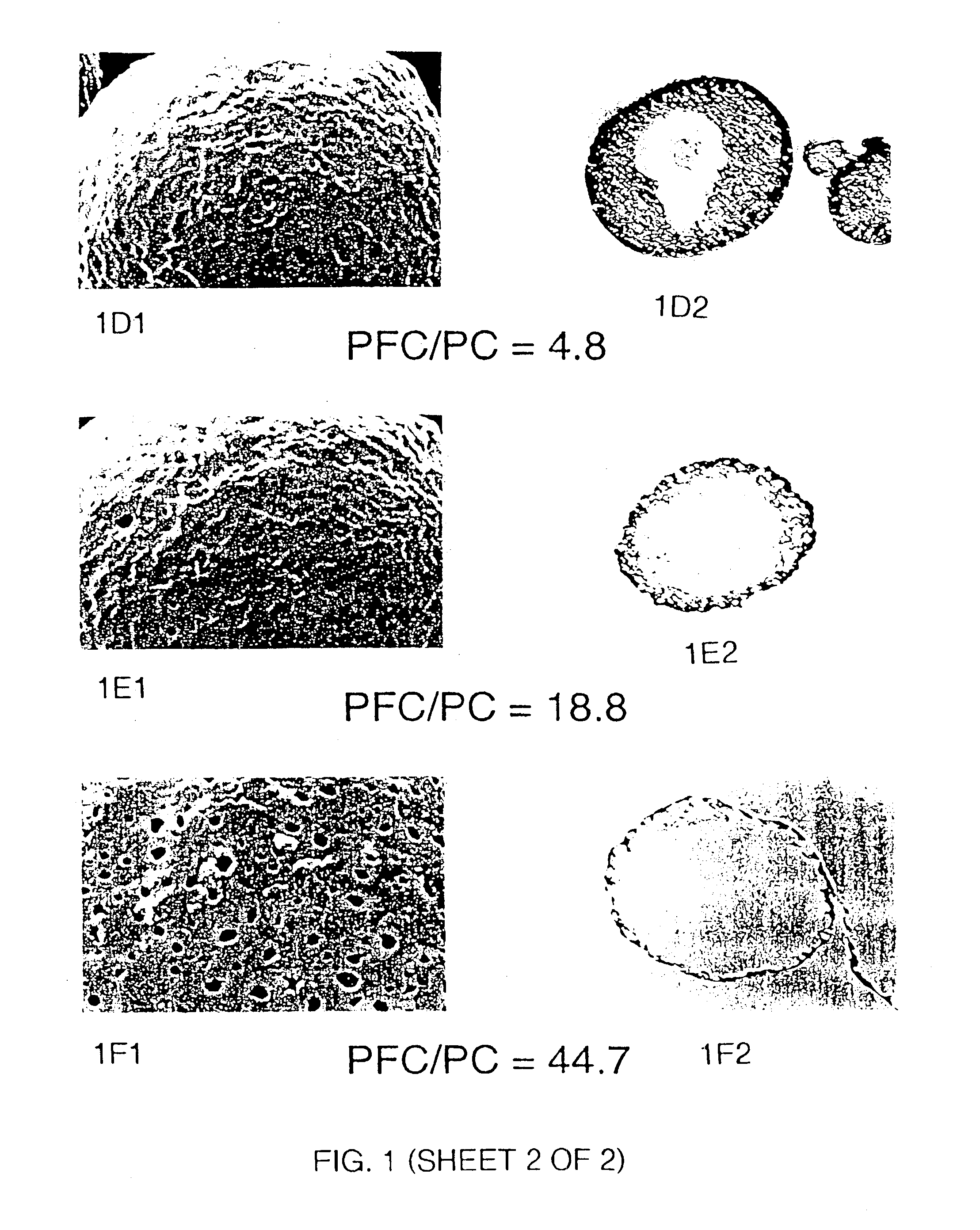

Stabilized preparations for use in nebulizers

InactiveUS6946117B1Effective pulmonary deliveryEfficient deliveryPowder deliveryDispersion deliverySuspended particlesFlocculation

Stabilized dispersions are provided for the delivery of a bioactive agent to the respiratory tract of a patient. The dispersions preferably comprise a stabilized colloidal system which may comprise a fluorochemical component. In particularly preferred embodiments, the stabilized dispersions comprise perforated microstructures dispersed in a fluorochemical suspension medium. As density variations between the suspended particles and suspension medium are minimized and attractive forces between microstructures are attenuated, the disclosed dispersions are particularly resistant to degradation, such as by settling or flocculation. In particularly preferred embodiments, the stabilized dispersions may be administered to the lung of a patient using a nebulizer.

Owner:NOVARTIS FARMA

Water-based cutting fluid used in slice machining of hard brittle crystal material and preparation method of water-based cutting fluid

InactiveCN102618374AGuaranteed lubrication effectGuaranteed anti-rust performanceAdditivesWater basedTool wear

The invention discloses a water-based cutting fluid used in slice machining of a hard brittle crystal material, comprising the following compositions: base oil, organic amine, organic acid, synthetic ester, emulsifier, rust and corrosion inhibitor, dispersion flocculation and hard-water resisting agent, antiseptic bactericide, antifoaming agent, coupling agent, adjuvant and a proper amount of water. Aiming at the machining techniques of inner circle slicing and outer circle slicing, the water-based cutting fluid has good generality, lubricity, strong antirust property and a long service life; when the cutting fluid is used, the machining situation can be observed easily, the cooling property is good, the cleaning and the permeability are strong, cuttings subside easily, and the machining problems of machining error, crack and the like caused by cutter blocking, abrasion and the like are solved; according to the invention, the problems that cuttings are easy to adhere and suspend, a cutter is seriously abraded, a machined product cracks easily, the accuracy is not high, the machining efficiency is low, the later period cleaning is complex and the like existing in the current slice machining of the hard brittle crystal material are solved, and further, a machine bed is protected, and the cost is reduced.

Owner:AMER TECH CO LTD

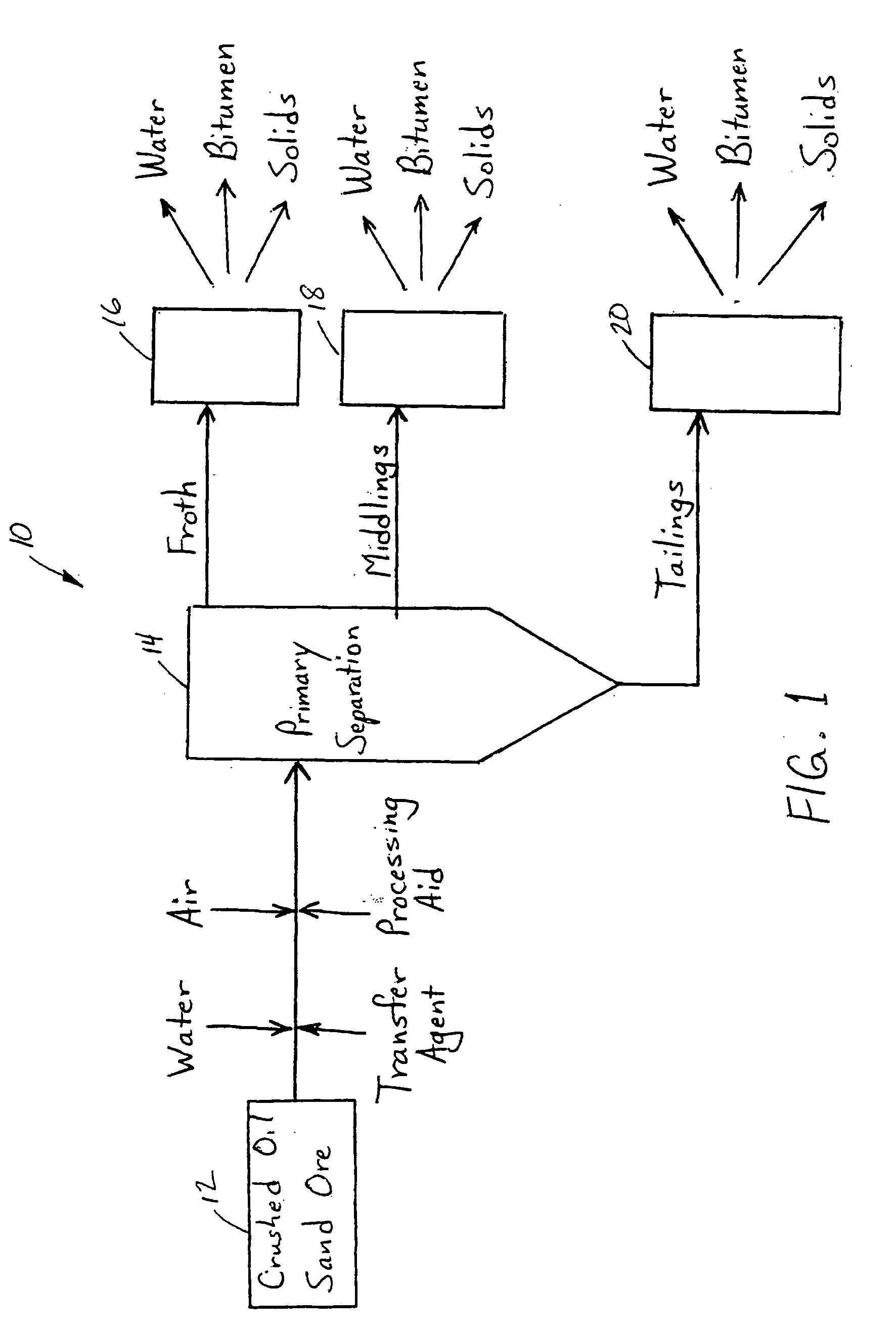

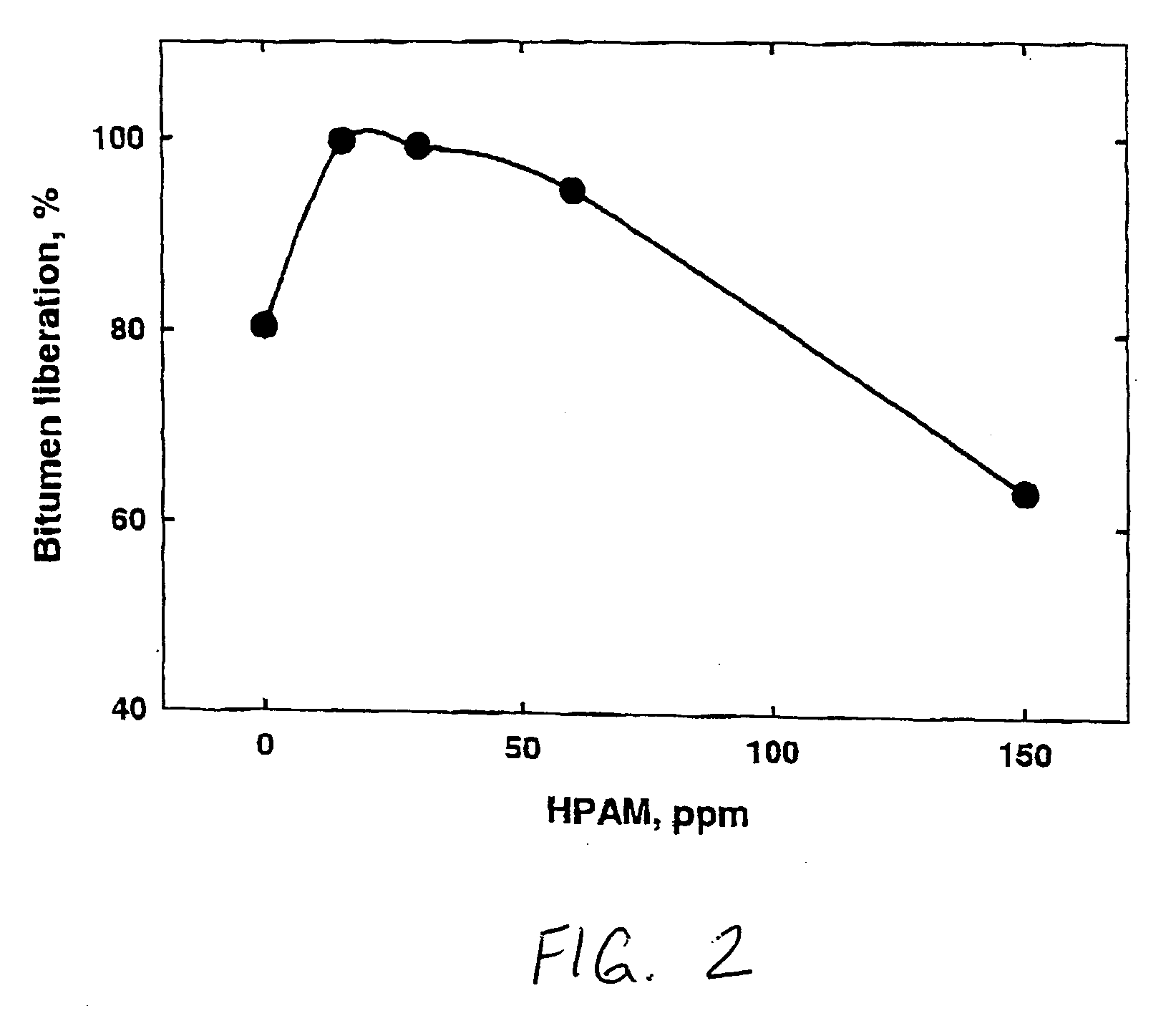

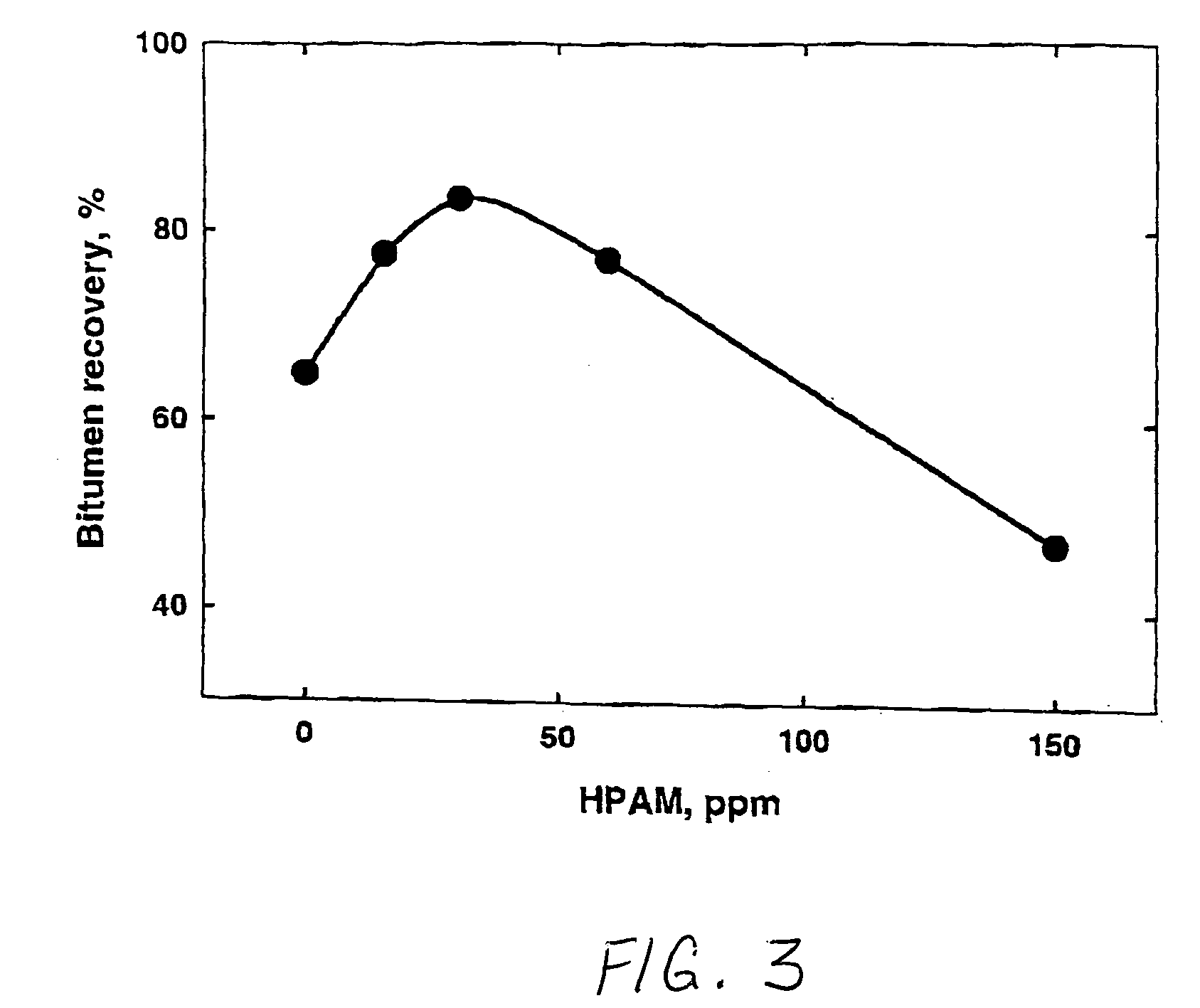

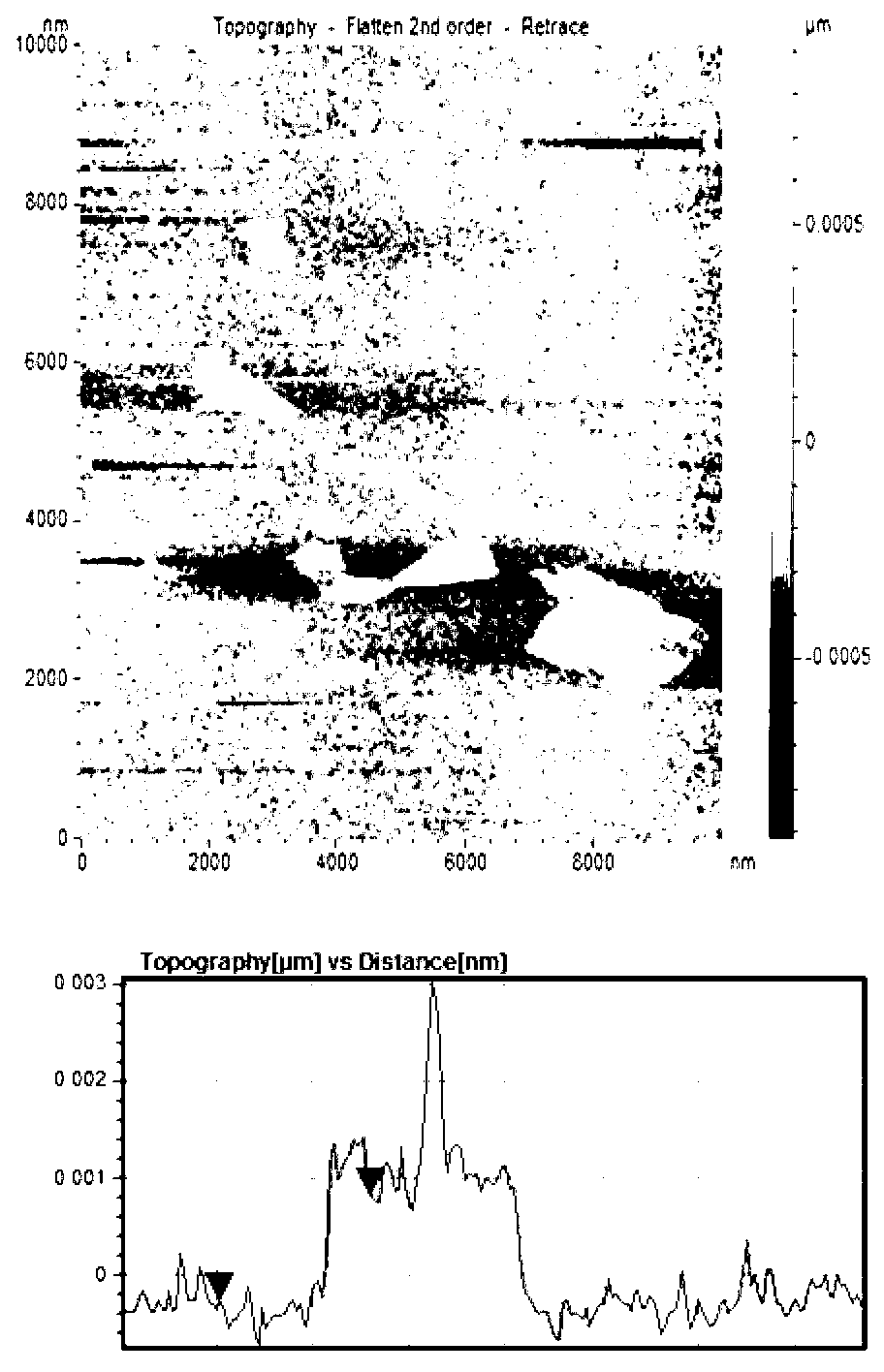

Processing aids for enhanced hydrocarbon recovery from oil sands, oil shale and other petroleum residues

InactiveUS20050194292A1Liberation of additionalPromote recoveryDewatering/demulsification with chemical meansLiquid hydrocarbon mixture productionHydrocotyle bowlesioidesSlurry

A method of improving hydrocarbon recovery from oil sands, oil shale, and petroleum residues includes adding a polymeric or nonpolymeric processing aid capable of sequestering cations, such as the multivalent calcium, magnesium and iron cations. The hydrocarbons are preferably contacted with the processing aid before a primary separation of the hydrocarbons in order to increase bitumen recovery. A processing aid is provided in an effective amount to increase the liberation of the hydrocarbons from inorganic solids, particularly when the source is a poor processing ore. Preferred processing aids include citric acid or a polymeric acid selected from polyacrylic acid, polymethacrylic acid, salts of these acids, partial salts of these acids, and combinations thereof. The processing aids significantly increase the hydrocarbon recovery typically with concentrations less than 50 ppm and the polymeric processing aids can also provide beneficial flocculation of solids in tailings slurry.

Owner:THE GOVERNORS OF THE UNIV OF ALBERTA

Oxidized grapheme/carbon black rubber nanocomposite and preparation method thereof

The invention provides an oxidized grapheme / carbon black rubber nanocomposite and preparation method thereof, which belongs to the field of rubber nanocomposite technology. The nanocomposite comprises the following basic compositions by mass: 100 parts of diene series rubber matrix, 0.5-5 parts of oxidized grapheme, 30-70 parts of hard carbon black of average particle size 11-30nm, 1-10 parts of plasticizer, 6-10 parts of activator, 0.5-4 parts of anti-aging agent, 1-4 parts of sulfuration promoter and 1-6 parts of insoluble sulphur; oxidized grapheme modifier. The oxidized grapheme powder is dispersed in deionized water for ultrasound, and a natural rubber emulsion is added, and masterbatch after flocculation, washing and drying is mixed uniformly with other additives, after sulfuration, the product is obtained. The oxidized grapheme / carbon black rubber nanocomposite has the advantages of excellent processing performance and obviously reduced dynamic themogenesis, thereby improving the usage life of tyre.

Owner:BEIJING UNIV OF CHEM TECH

Aqueous based surfactant compositions

InactiveUS6177396B1Low viscosityUnstable structureInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsFlocculationHydrophilic monomer

The use of a stabiliser comprising a hydrophilic polymeric chain of more than four hydrophilic monomer groups and / or having a mass greater than 300 amu, linked at one end to a hydrocarbon-soluble hydrophobic group to reduce or prevent the flocculation of systems comprising a flocculable surfactant and a liquid medium which is capable of flocculating the surfactant and in which the stabiliser is capable of existing as a micellar solution at a concentration of at least 1% by weight.

Owner:HUNTSMAN INT LLC

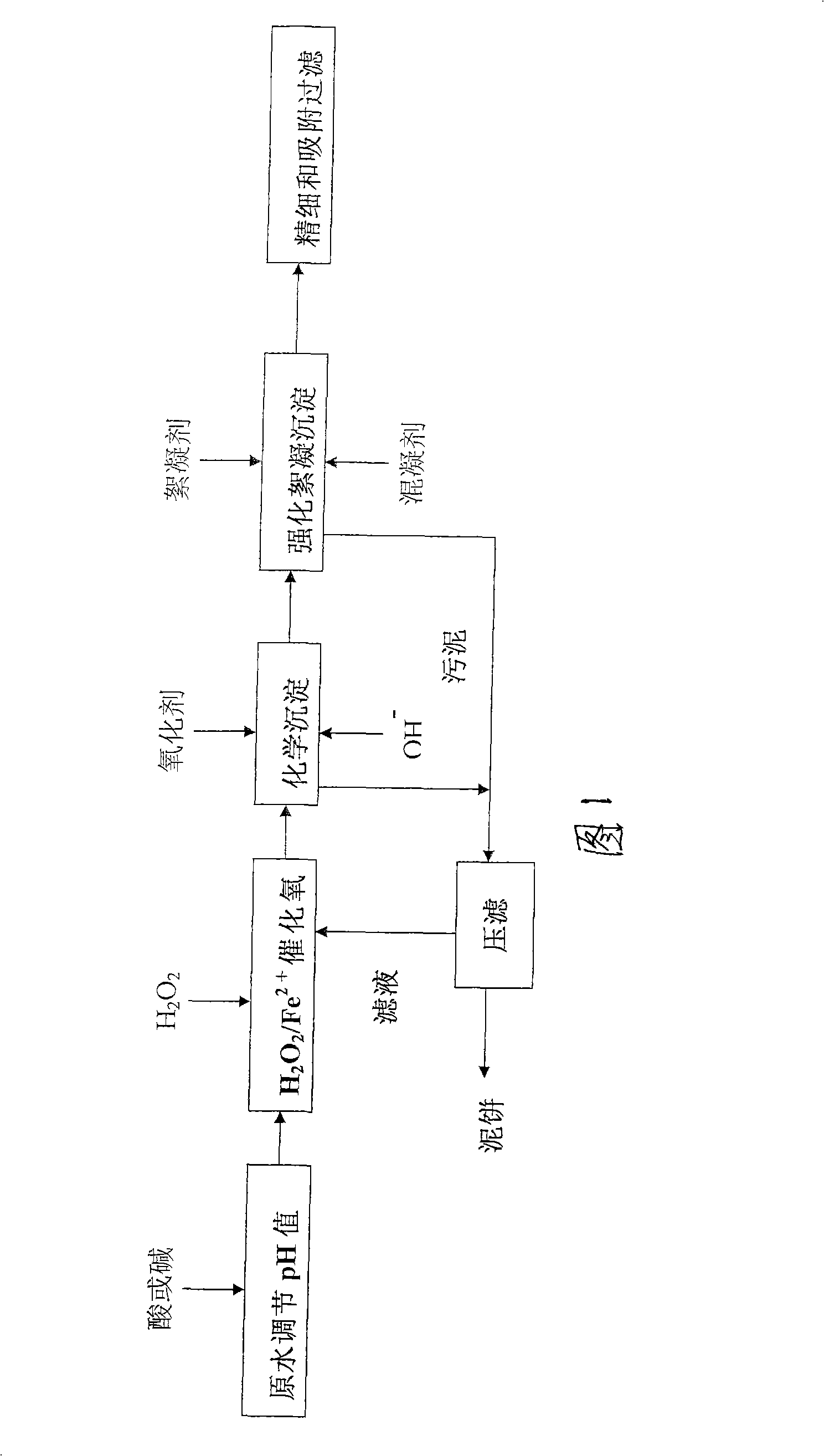

Method for processing oil-gas field fracturing waste liquor

ActiveCN101302065AMultistage water/sewage treatmentWater/sewage treatment by neutralisationLiquid wasteBrick

The invention provides a method for treating fracturing waste fluid in an oil-gas field, belonging to the oil-gas field waste fluid treatment technology, which overcomes the problems existed in other methods. The process steps of the method are as follows: the water quality achieves a recirculation standard or accords with the II grade discharge standard of the integrated sewage discharge standard GB8978-1996, through technical treatments of raw water (pH) adjustment, H2O2 / Fe<2+> catalytic oxidation, chemical precipitation, enhanced flocculation and sedimentation, fine filter and adsorption filtration, and system settling sludge, then the settled sludge is subject to filter pressing and dehydrating, press filtrate returns to the front end for after-treatment, and mud cake is desiccated and manufactured into bricks for application or is treated through using the incinerating treatment technology. The method is an effective method for treating the fracturing waste fluid in the oil-gas field.

Owner:PUYANG TIANDIREN ENVIRONMENTAL PROTECTION TECH CO LTD

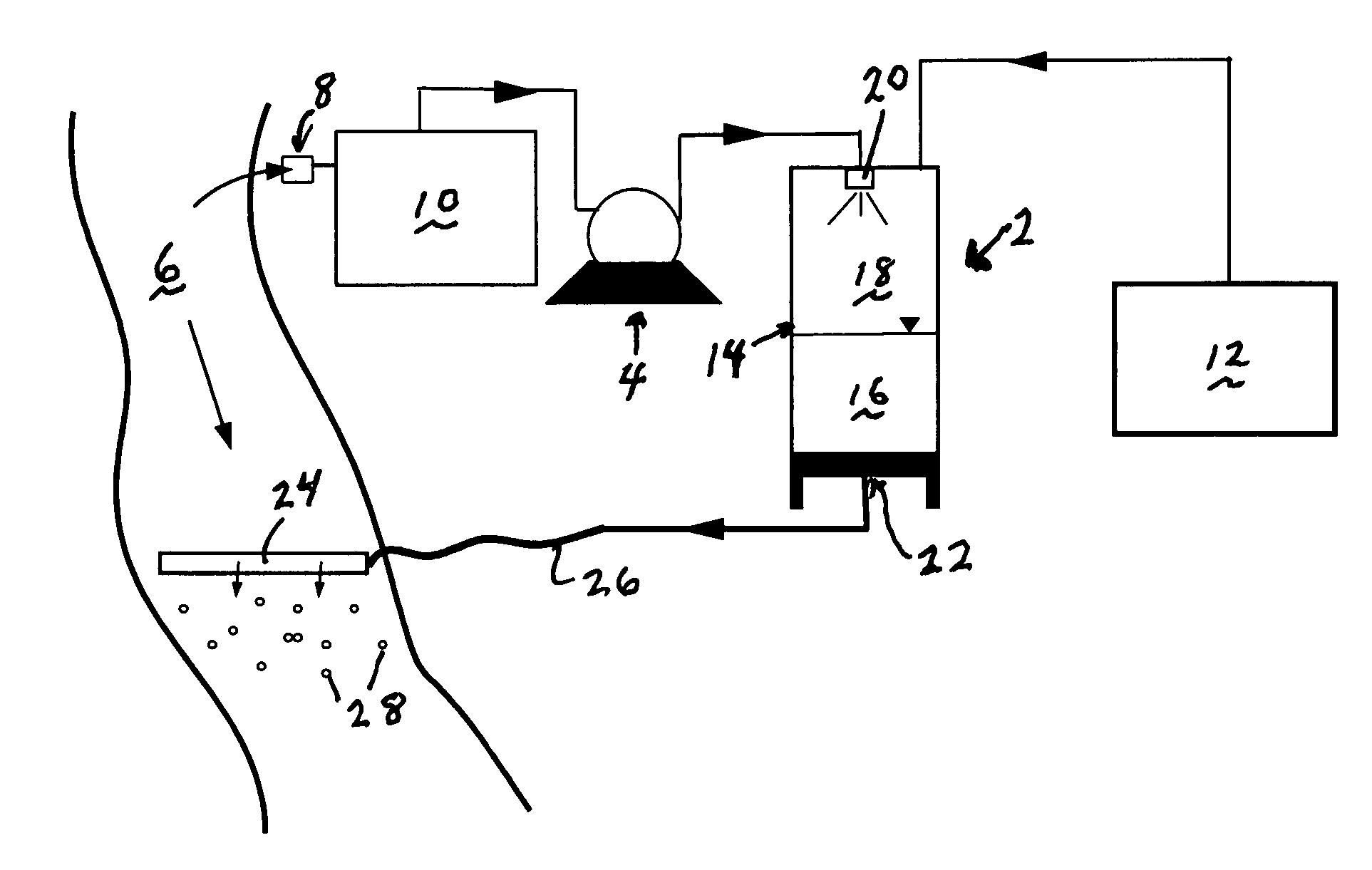

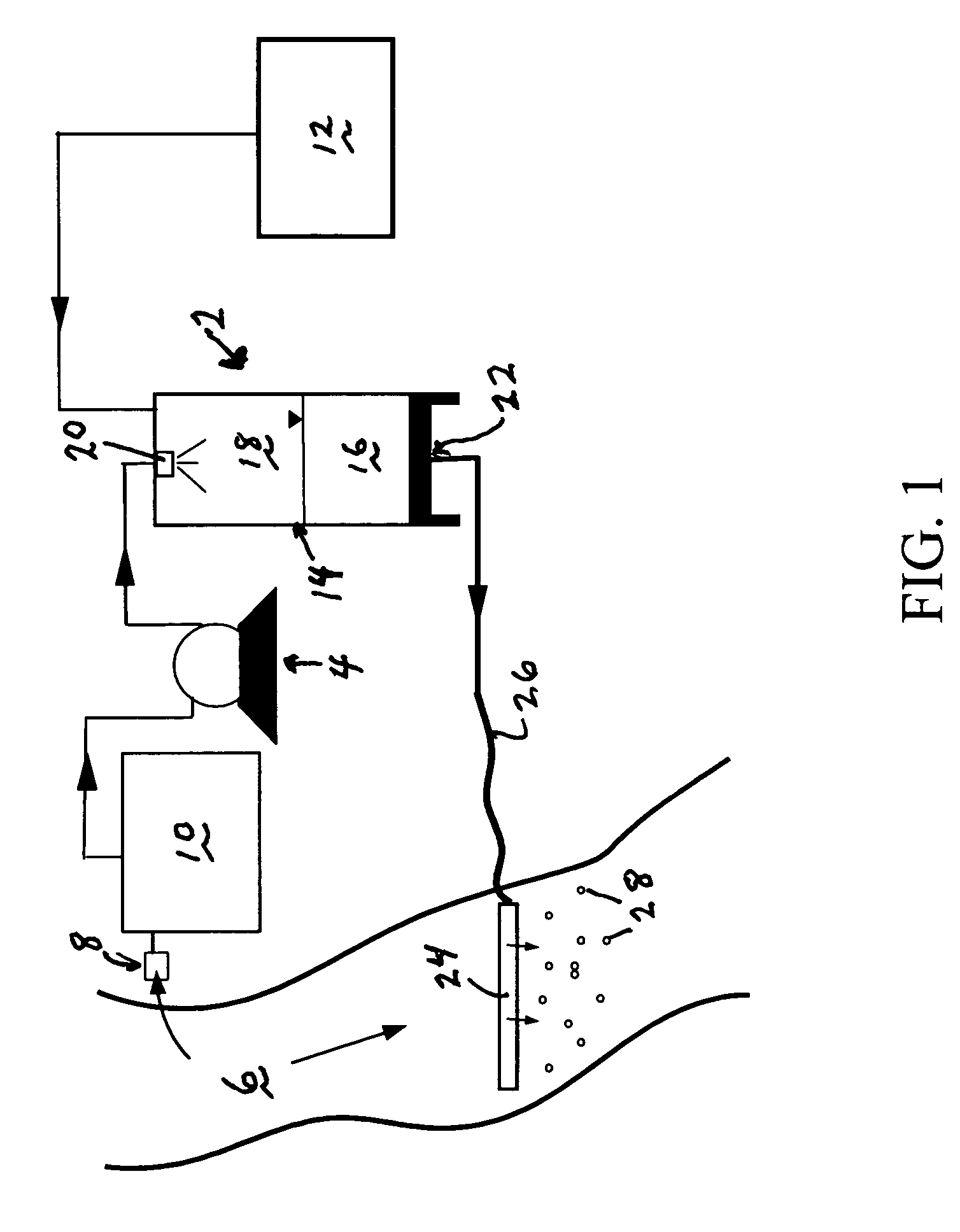

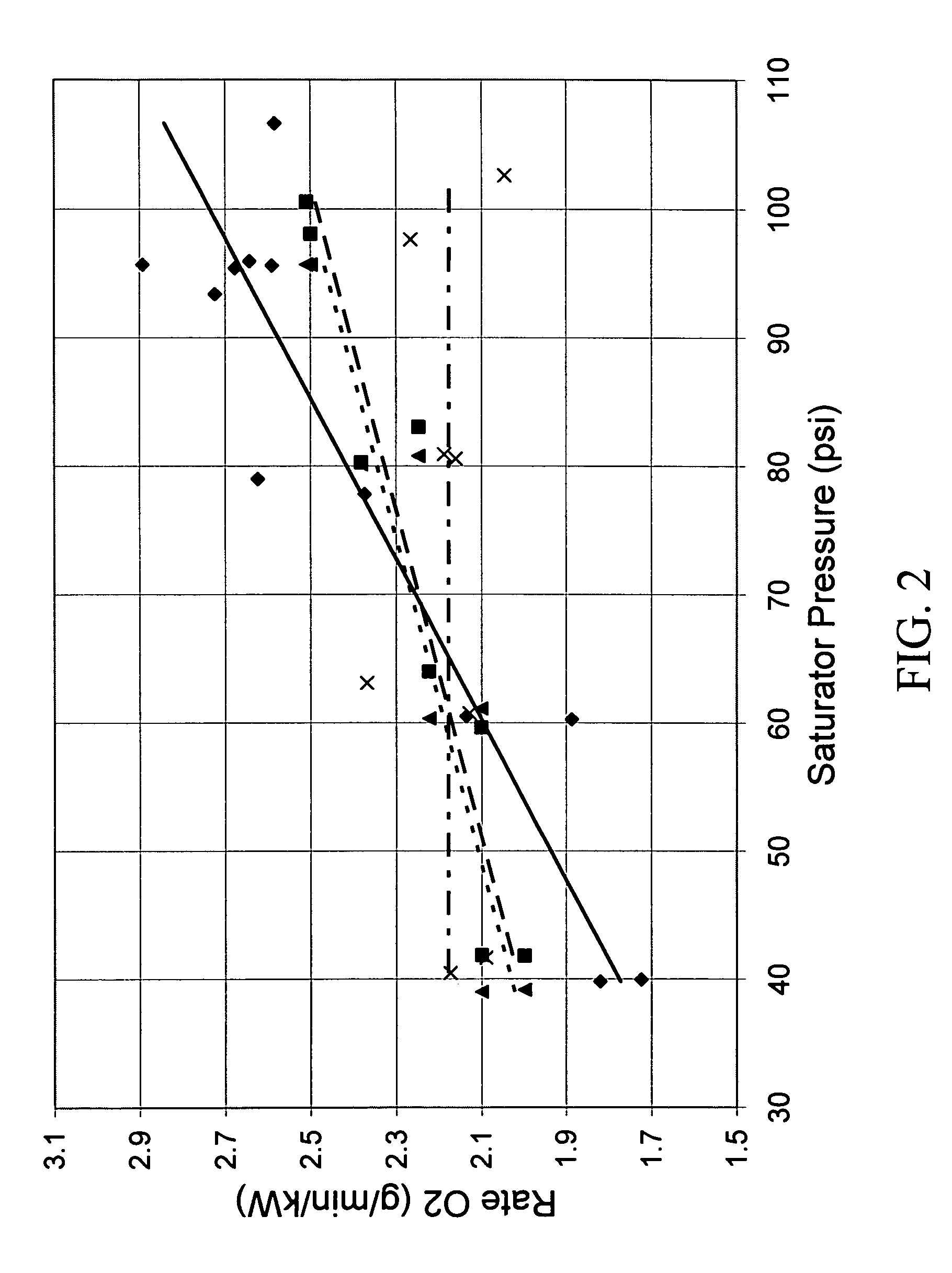

System and method for dissolving gases in liquids

ActiveUS7255332B2Improve solubilityFlow mixersTransportation and packagingSuspended particlesDissolution

Apparatus and methods for dissolving a gas into a liquid comprises a saturation tank, a high pressure liquid pump in fluid communication with the tank, and a pressurized gas source in communication with a regulated gas head space of the saturation tank. The saturation tank comprises a pressure vessel for containing the liquid and has a regulated gas head space above the liquid, contains at least one liquid spray nozzle that permits passage of liquid into the pressure vessel, and an outlet for the liquid containing dissolved gas. Upon passing the gas-containing liquid into a second fluid, the gas is released in the form of microbubbles. The microbubbles aid in flocculation of suspended particles and promote dissolution of the gas in the second fluid. Preferred gases for use with the apparatus are oxygen, air, and ozone. Anticipated uses include treatment of rivers, streams, and ponds in natural or industrial settings, as well as smaller scale applications.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

Ink jet ink

InactiveUS20050282928A1Readily re-dispersedReadily rejuvenatedDuplicating/marking methodsInksFlocculationSlurry

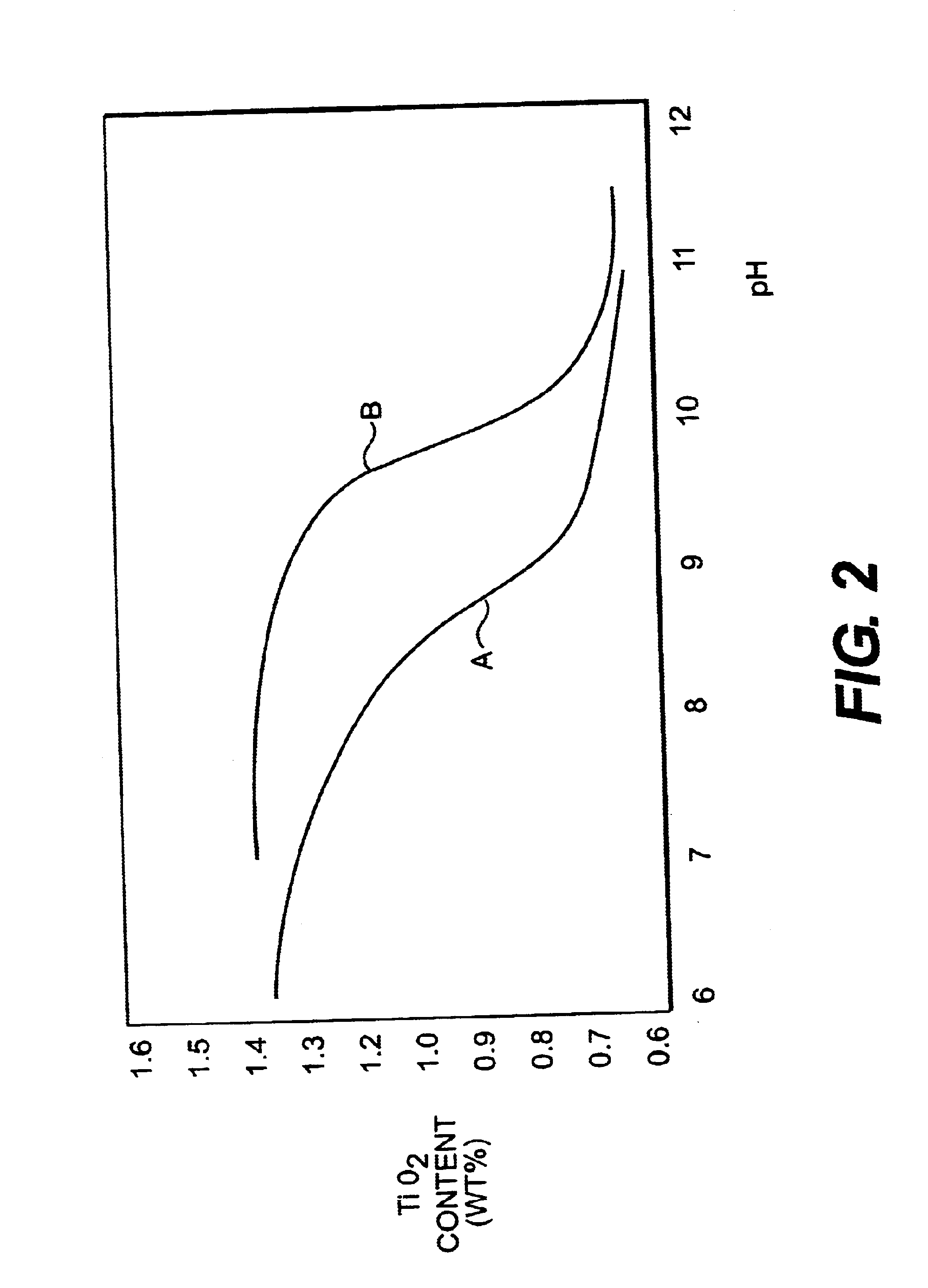

The present invention pertains to an aqueous inkjet ink made from certain aqueous titanium dioxide slurries, and an associated inkjet ink set for inkjet printing. The invention also pertains to a method of inkjet printing with the ink and ink set. The use of the specific titanium dioxide slurries described herein result in inkjet inks having improved stability and better anti-settling performance with less pigment agglomeration and flocculation over time.

Owner:EI DU PONT DE NEMOURS & CO

Method of treating an aqueous suspension of kaolin

InactiveUS6615987B1Improve effectivenessImproves floc formationPigmenting treatmentSedimentation separationFlocculationSolid particle

A method of treating a kaolin particulate material to improve its properties by removal of impurities which includes the steps of:(a) producing a dispersed aqueous suspension of a kaolin particulate material containing at least 0.1% by weight, based on the dry weight of the kaolin particulate material, of separable impurity by adding a dispersing agent to the kaolin particulate material to deflocculate solid particles of the material in the suspension;(b) conditioning the suspension prior to adding selective flocculation polymer thereto by allowing the suspension to age for a period of at least 30 minutes and optionally by adding one or more conditioning chemicals thereto;(c) adjusting the pH of the suspension to be at least about 9.5;(d) adding to the suspension at a pH of at least about 9.5 a selective flocculation polymer which facilitates separation of the separable impurity from the kaolin by flocculating the kaolin and allowing the separable impurity to be or remain deflocculated;(e) allowing the suspension at a pH of at least about 9.5 in a selective flocculation separator to separate into layers comprising a flocculated product layer and a deflocculated impurity layer containing the separable impurity; and(f) extracting the separated layers from the separator.

Owner:IMERYS USA INC

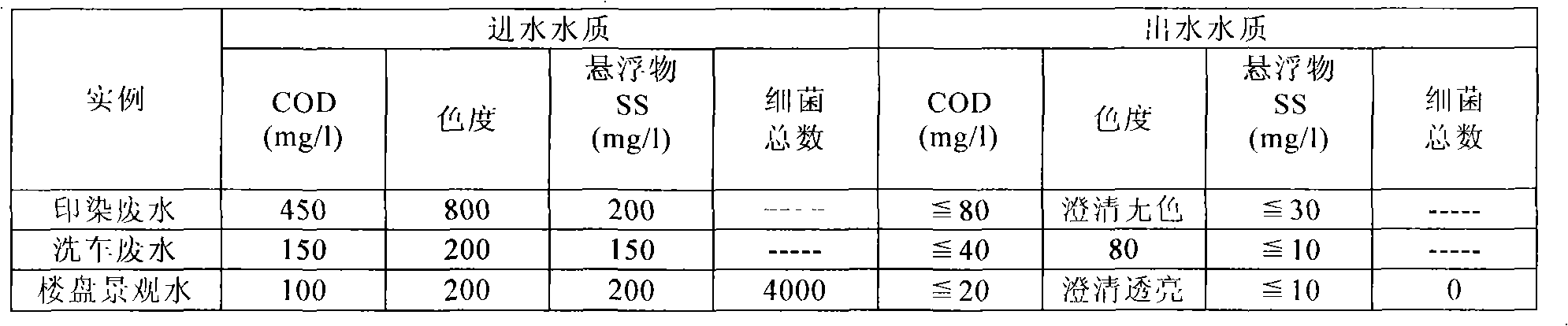

Textile dyeing wastewater advanced treatment recycling technology

InactiveCN102145965AReduce chromaImproved BioprocessingMultistage water/sewage treatmentWater/sewage treatment by neutralisationTextile fiberChemical treatment

The invention discloses a textile dyeing wastewater advanced treatment recycling technology. The technology comprises the following steps: filtering to remove textile fibers; cooling; neutralizing, degrading organic matters and decomposing, replacing or degrading (cracking) the chormophoric groups of the organic matters to reduce the chroma of the wastewater; performing biochemical treatment with the biomembrane; precipitating to ensure that the precipitated sludge enters a sludge treatment system and the supernatant enters a flocculation pool; performing chemical treatment, namely adding a medicament in the flocculation pool to remove the suspended matter (SS), CODcr (chemical oxygen demand), BOD (biochemical oxygen demand) and chroma of the water; performing secondary precipitation to ensure that the free SS is precipitated and the wastewater is decolored further; separating to remove and degrade the chloride ions of the reuse water; performing secondary biochemical treatment to further reduce the concentrations of the SS, CODcr and BOD in wastewater; performing ozone oxidation treatment, decoloring, degrading organic matters; performing chemical treatment to remove insoluble dye materials and SS and reduce the COD and chroma; and performing secondary filtration, and forming an ozone / activated carbon system to ensure that the hydroxyl radicals of activated carbon are used and the organic reaction in wastewater is adopted to decolor and degrade organic matters. The invention overcomes the defects of the existing physical method, chemical method and chemical method treatment technologies; and the technology has been used in many enterprises, and the good treatment effects are obtained.

Owner:李斌 +2

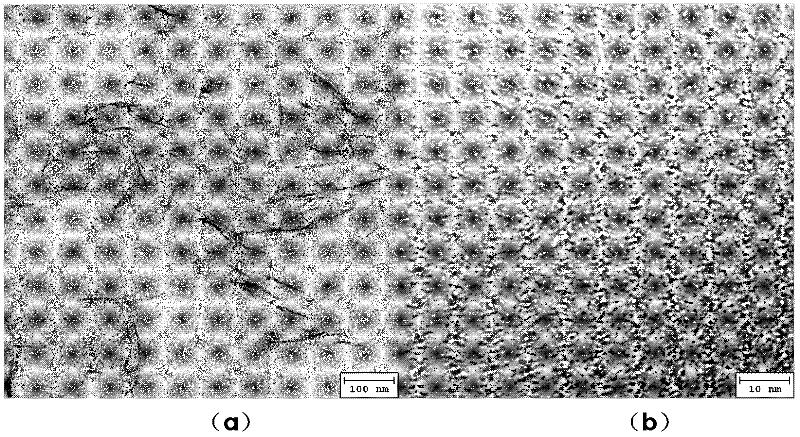

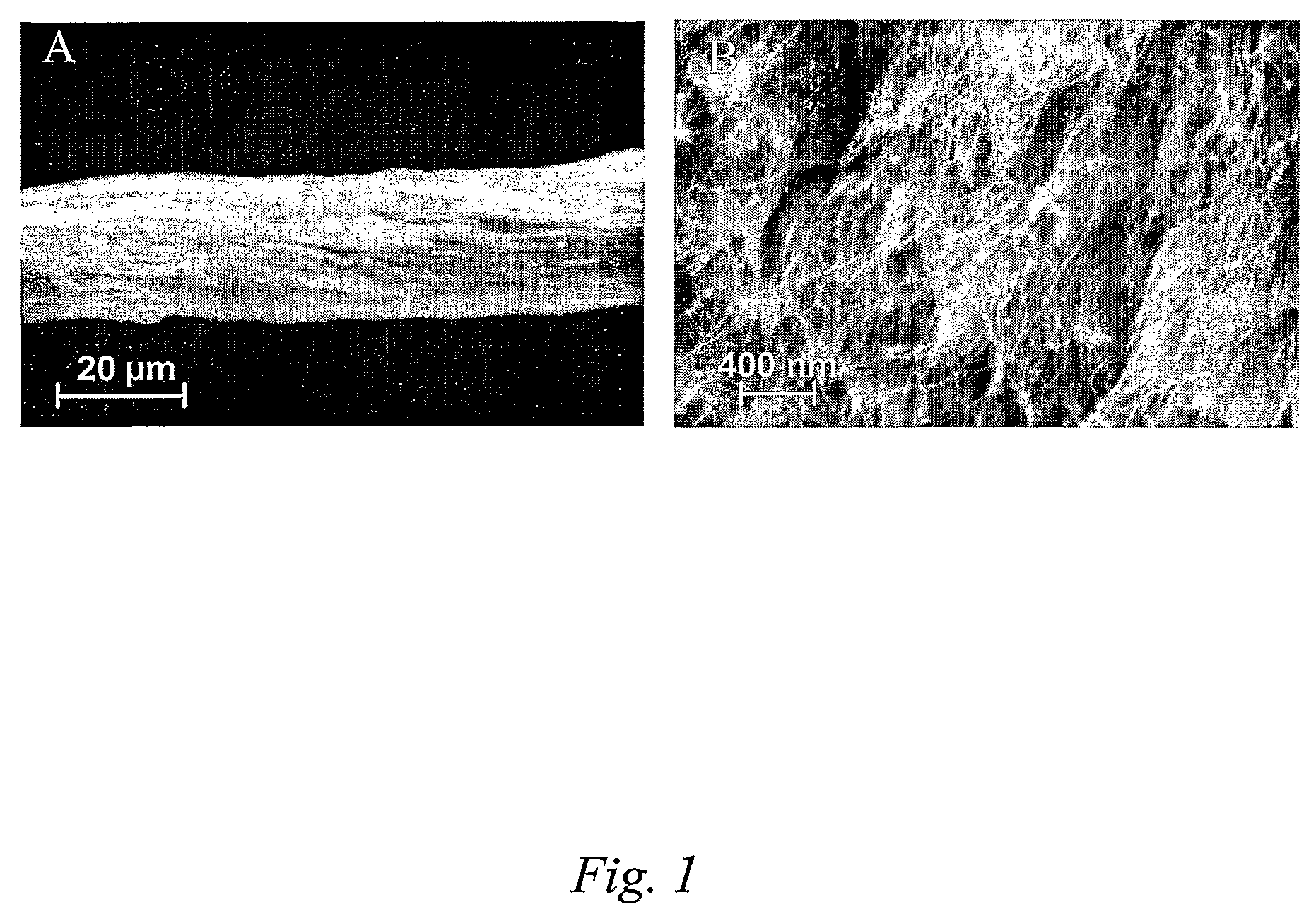

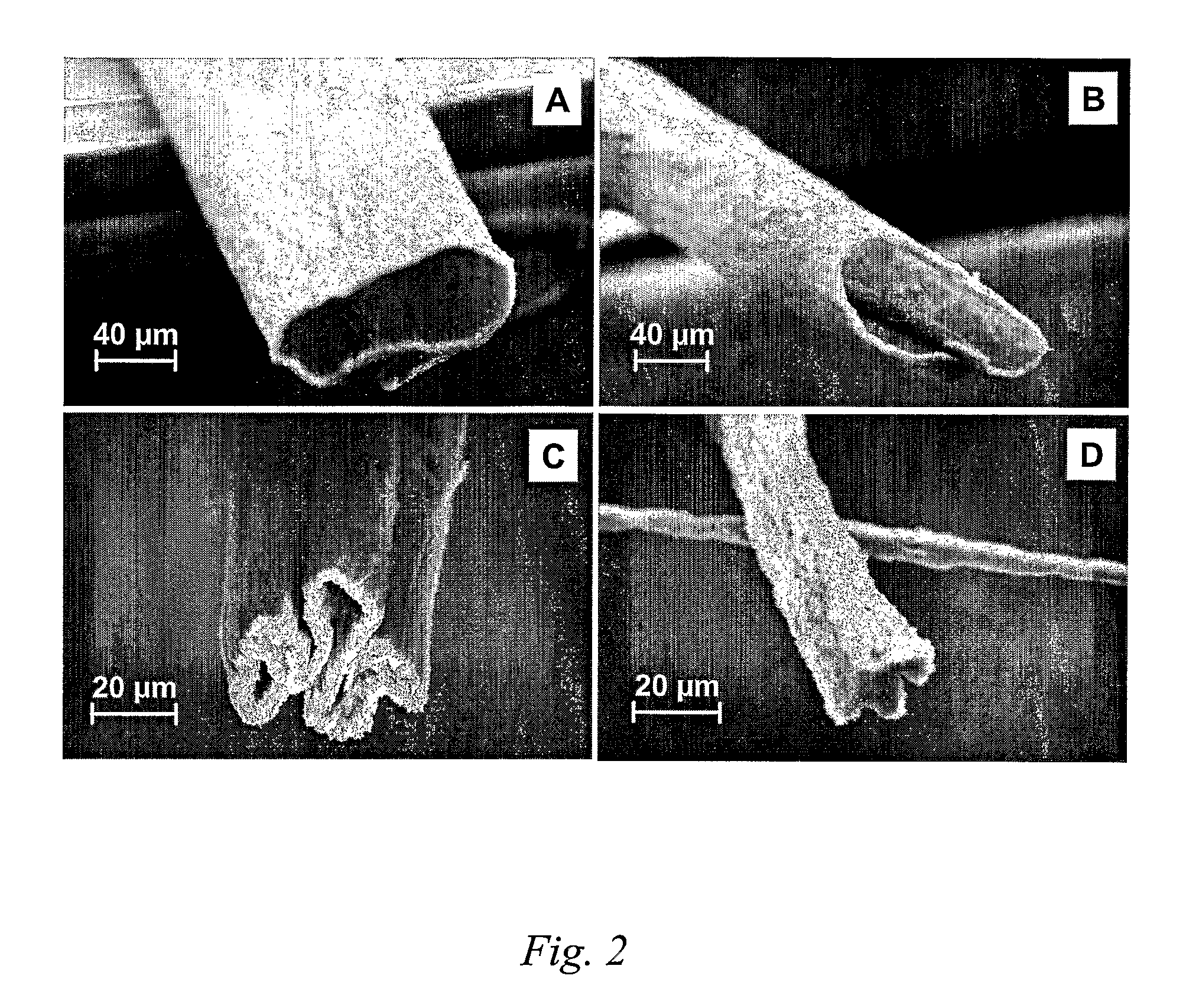

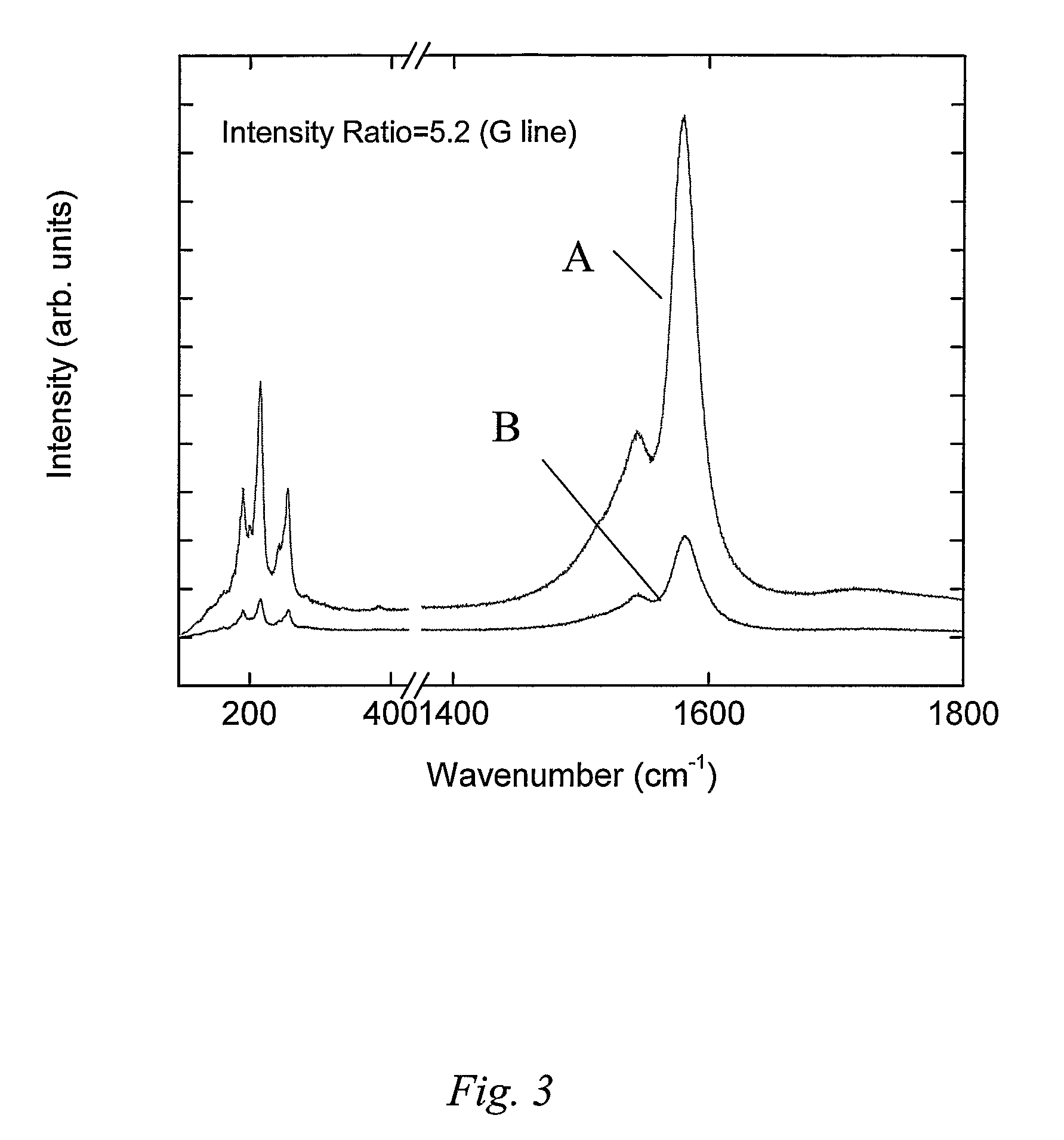

Polymer-free carbon nanotube assemblies (fibers, ropes, ribbons, films)

InactiveUS7938996B2Improve mechanical propertiesHigh mechanical strengthPigmenting treatmentRotating receptacle mixersFiberFlocculation

Process, apparatus, compositions and application modes are provided that relate to nanofiber spinning without the use of superacids in the spinning solution. The methods employ either acids or bases for a flocculation solution. The advances disclosed therein enable the use of nanofibers, including carbon nanotubes, for a variety of applications including, but not limited to, electromechanical actuators, supercapacitors, electronic textiles, and in devices for electrical energy harvesting.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Aqueous based surfactant compositions

InactiveUS6090762ALow viscosityUnstable structureInorganic/elemental detergent compounding agentsCosmetic preparationsFlocculationHydrophilic monomer

The use of a stabiliser comprising a hydrophilic polymeric chain of more than four hydrophilic monomer groups and / or having a mass greater than 300 amu, linked at one end to a hydrocarbon-soluble hydrophobic group to reduce or prevent the flocculation of systems comprising a flocculable surfactant and a liquid medium which is capable of flocculating the surfactant and in which the stabiliser is capable of existing as a micellar solution at a concentration of at least 1% by weight.

Owner:HUNTSMAN INT LLC

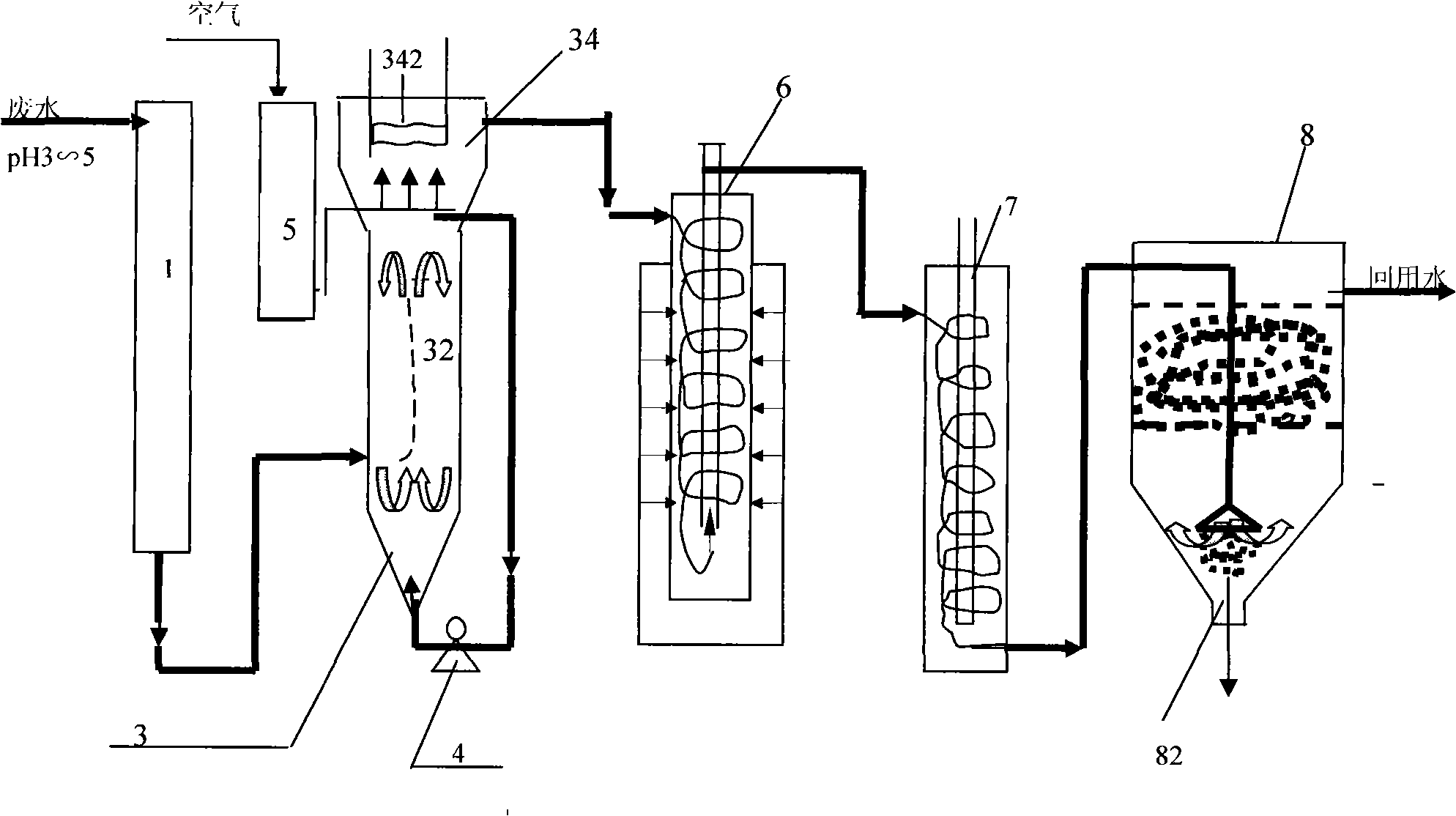

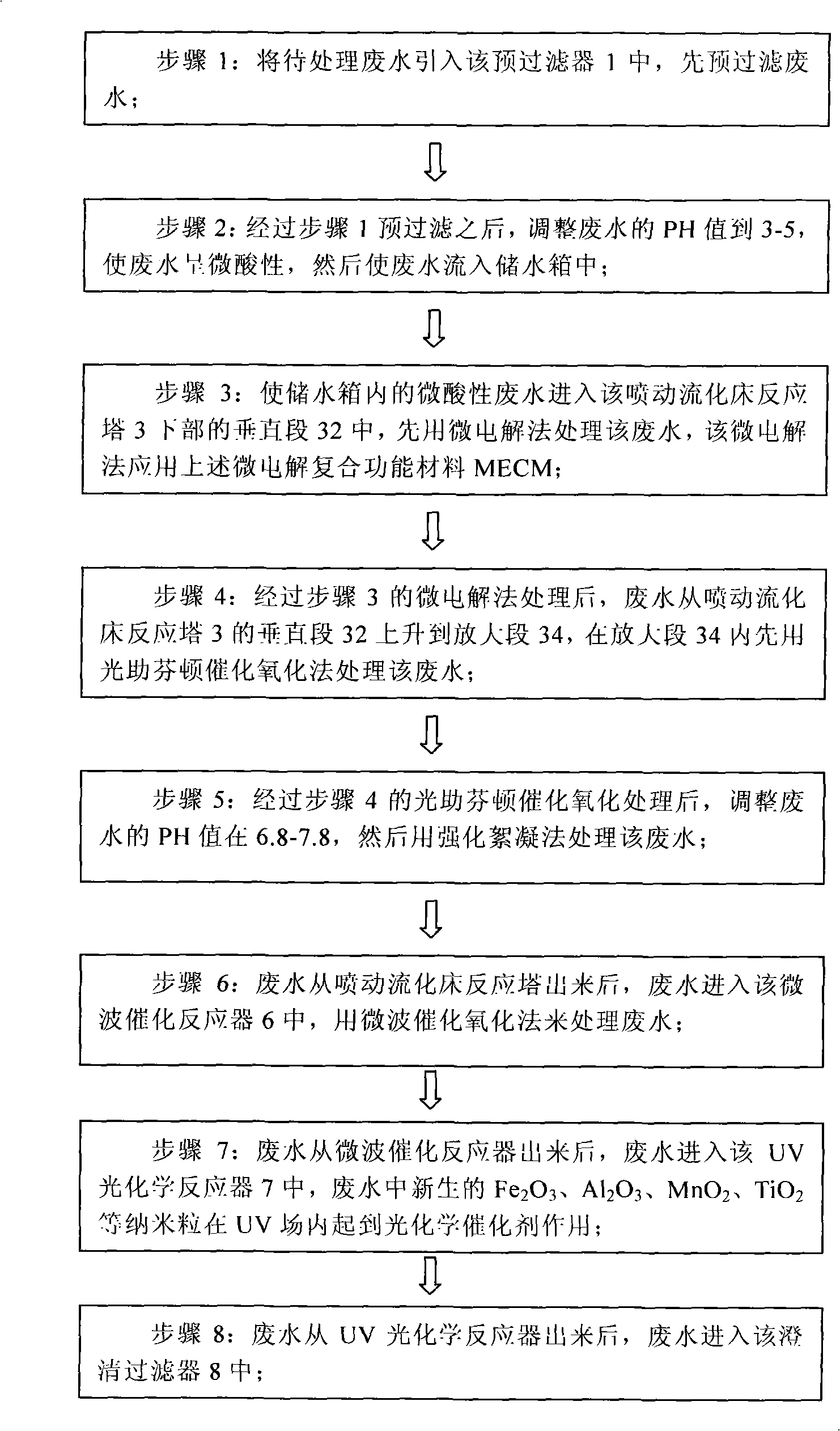

Handling method for advanced purification of little-volume refractory wastewater and operation equipment

InactiveCN101254987AHigh removal rateLow costWater/sewage treatment by irradiationMultistage water/sewage treatmentFlocculationElectrolysis

The invention relates to a treatment method for small water quantity refractory wastewater deep purifying and utilizing. The method comprises the following steps: step one, pre-filtrating wastewater is performed firstly; step two, the pH value of the wastewater is adjusted to 3-5 to ensure the wastewater to present subacidity; step three, the wastewater flows into a spout-fluid bed reaction tower, the wastewater is processed through a micro-electrolysis method, and micro-electrolysis composite functional material is utilized in the micro-electrolysis method; step four, the wastewater is processed through a photo-assisted fenton catalytic oxidation method; step five, the pH value of the wastewater is adjusted to 6.8-7.8, and then the wastewater is processed through strengthen flocculation method; step six, the wastewater flows to a microwave catalysis reactor, and is processed through a microwave catalytic oxidation method; step seven, the wastewater flows into a UV photochemical reactor, and is processed through the UV photocatalysis; step eight, the wastewater flows into a gravitation filter, and the wastewater can be clarified to meet the requirement of the reuse water quality. The invention also provides equipment for performing the treatment method.

Owner:东莞市英硫净水服务有限公司

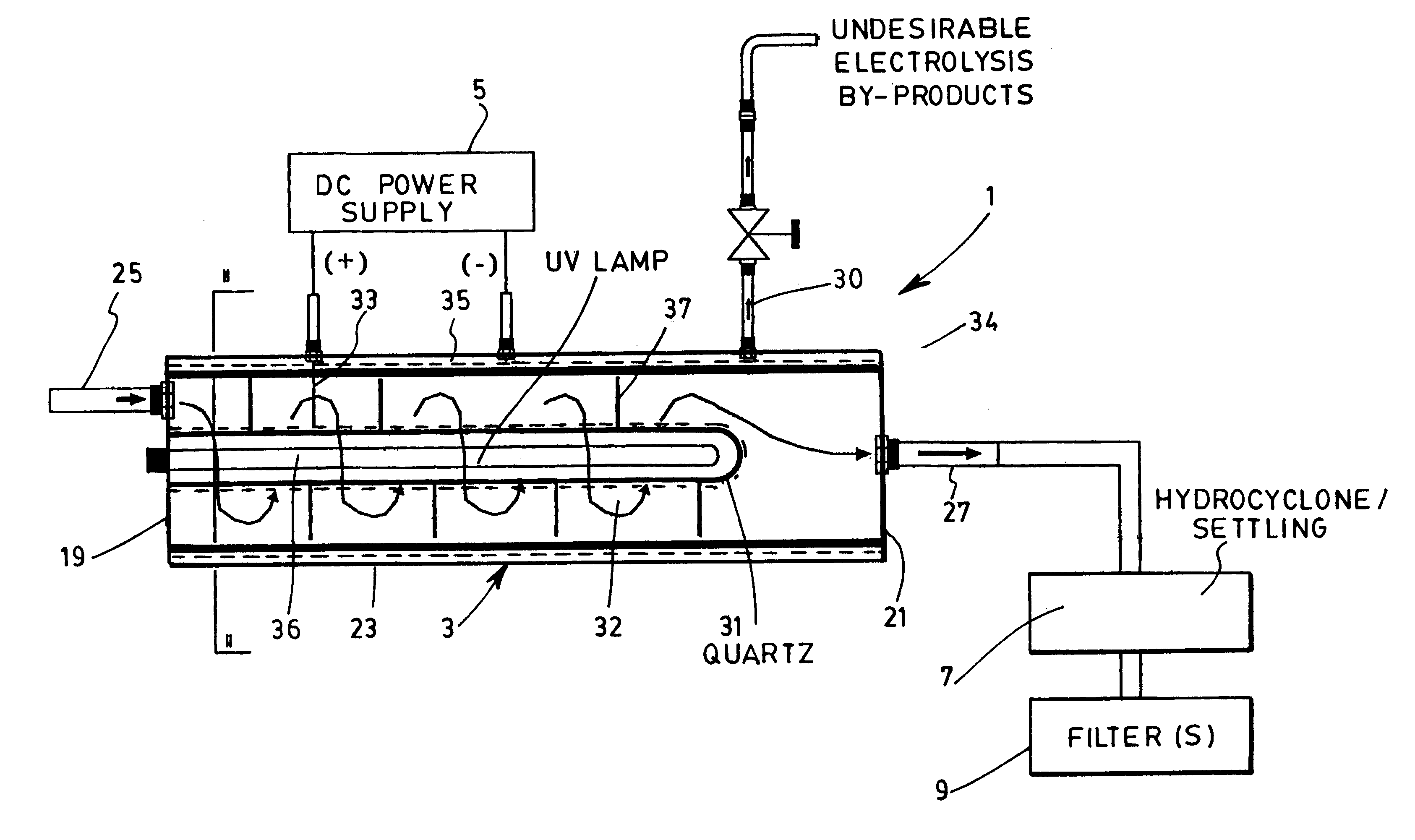

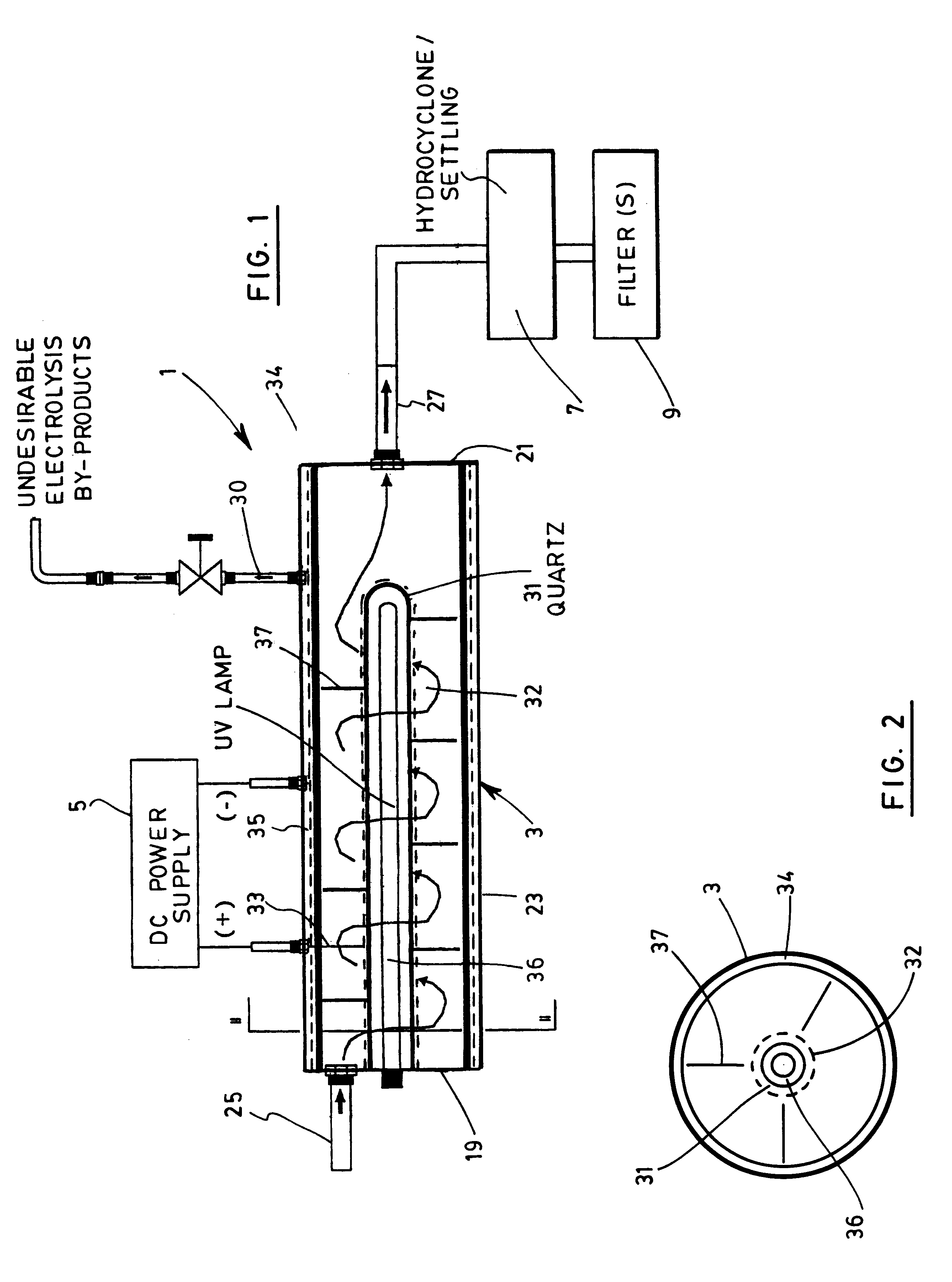

Device and method for treating water with ozone generated by water electrolysis

InactiveUS6180014B2Economical and efficient methodPhotography auxillary processesDisinfectionHigh concentrationElectrolysis

A process and a device for the treatment of water, especially for removing therefrom a large variety of pollutants, especially organic, inorganic and biological pollutants through in situ generation of ozone. Ozone is economically produced in situ at a high concentration through the interaction of electrolytically produced oxygen and UV light having a wavelength of 189 nm. The device has a set of anode and cathode for electrolytically producing nascent oxygen which reacts with UV light at a wavelength of 189 nm to produce ozone "in situ" within a vessel where the polluted water is submitted to the combinative action of ozone and other oxidation reactions. The device also has a hydrocyclone or retention tank of removing cationic pollutants such as heavy metals, free radicals as well as undesirable electrolysis byproducts such as nascent hydrogen through a secondary outlet. Oxidation by-products are subsequently removed from the exiting water stream by means of decantation, flocculation, coagulation or filtration.

Owner:SALAMA AMIR

Ink jet ink

InactiveUS20050215664A1Readily re-dispersedReadily rejuvenatedMeasurement apparatus componentsInksFlocculationSolubility

Disclosed is a non-aqueous inkjet ink containing certain titanium dioxide slurries, an associated inkjet ink set for inkjet printing, and a method of inkjet printing with the inkjet ink or ink set. The solvent and mixtures of solvents used for the dispersed titanium dioxide have a hydrogen bonding solubility parameter of greater than about 9. The inks have improved anti-settling properties with less pigment agglomeration and flocculation over time such that they can be utilized to prepare a stable inkjet ink. Also described is the use of this ink to print on colored or transparent surfaces.

Owner:EI DU PONT DE NEMOURS & CO

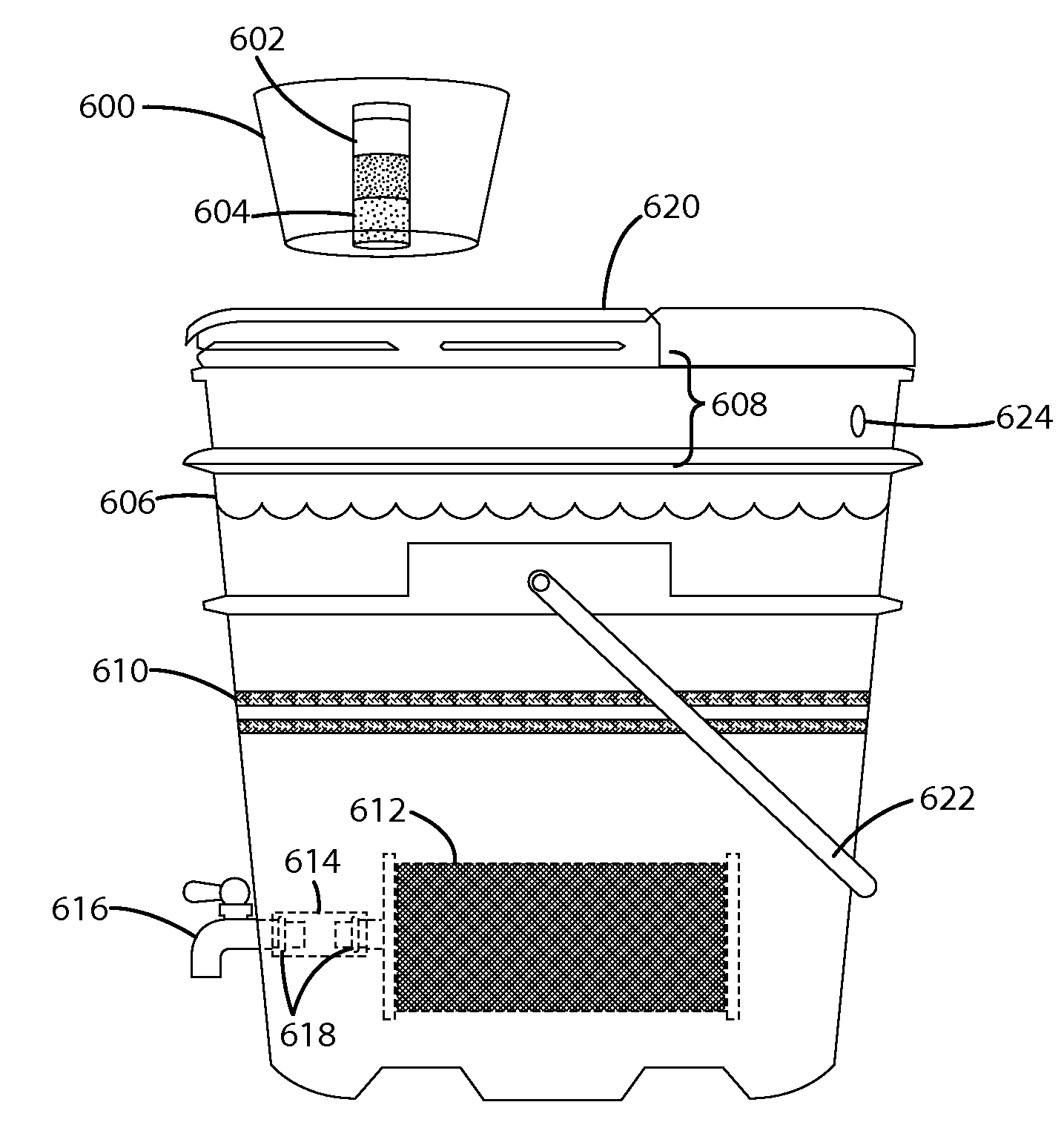

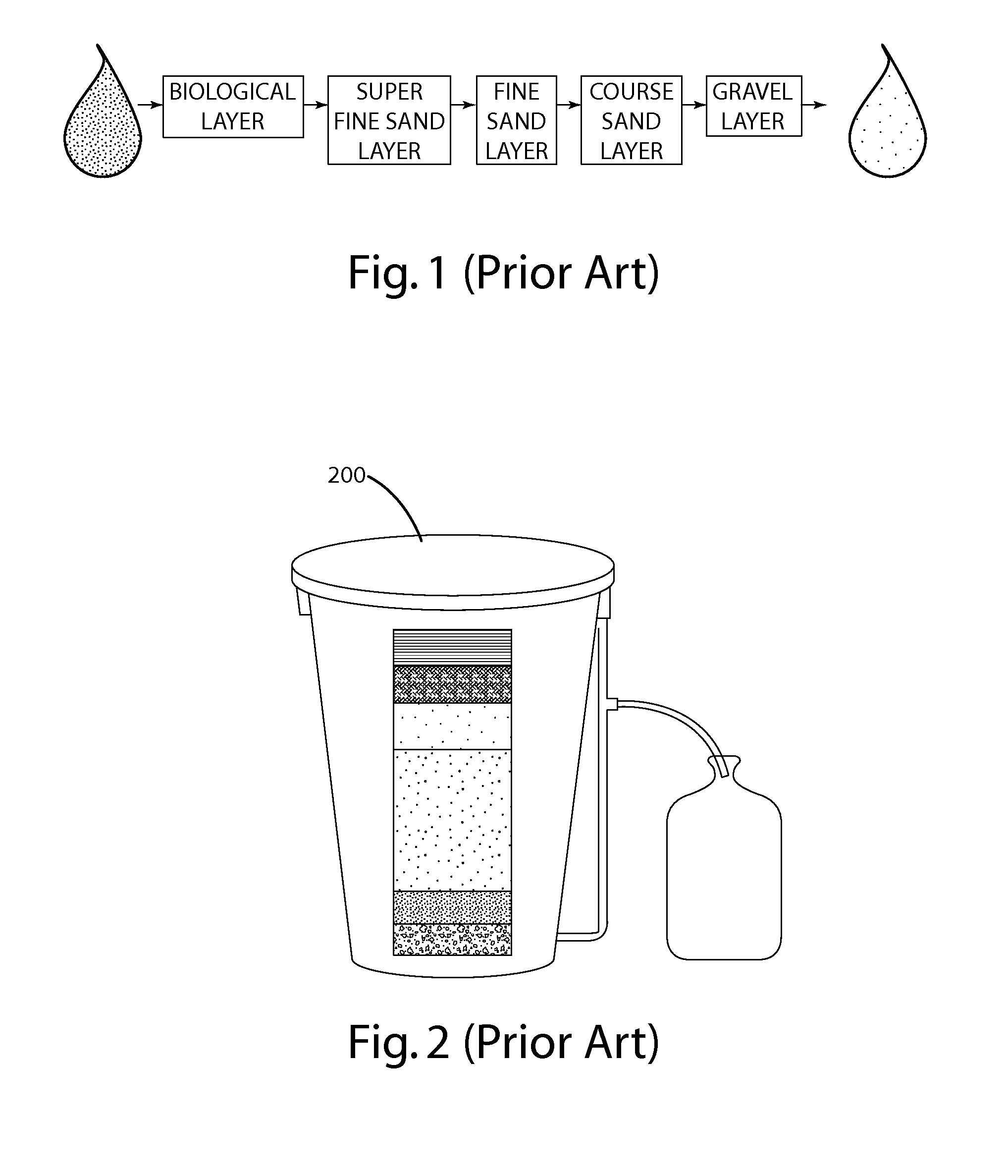

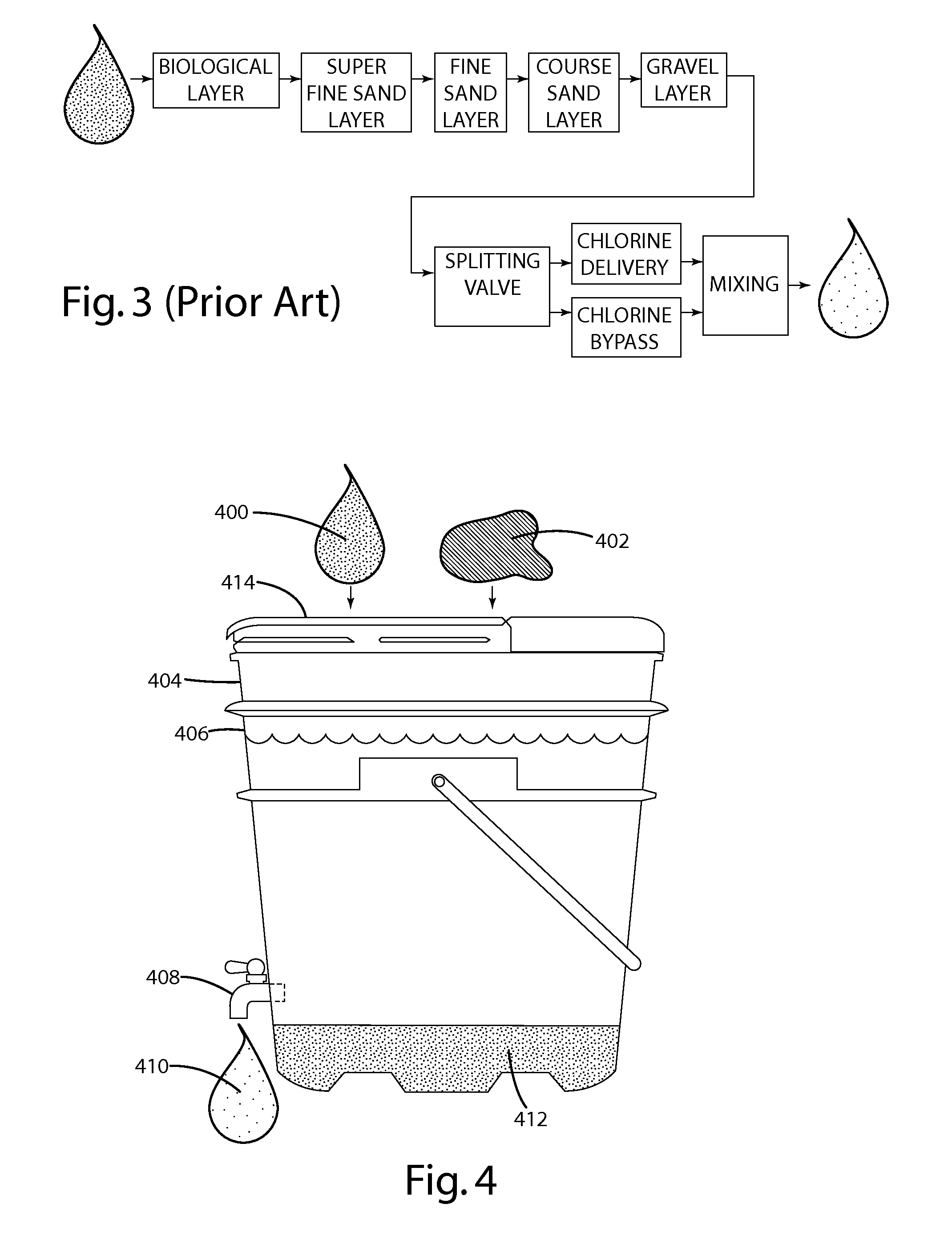

Gravity feed water treatment system

ActiveUS20110303589A1Increase flow rateHigh flow rateTreatment using aerobic processesTreatment involving filtrationFlocculationSiphon

A portable water treatment system includes at least one sub-system to treat water including a flocculation system, a chlorination system, and a bio-sand filter system. The water treatment system may include multiple sub-systems for treating water that feed into one another. The sand filter system may include a mini bio-sand filter, a foam filter, or a pressed block filter. The flocculation system may include a tank bottom that urges settling particles toward a sump and a ladle that removes settled particles. A manual pump or siphon may be included in the water treatment system.

Owner:ACCESS BUSINESS GRP INT LLC

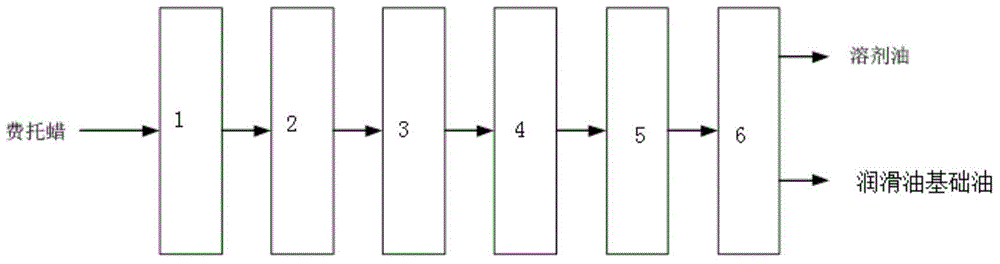

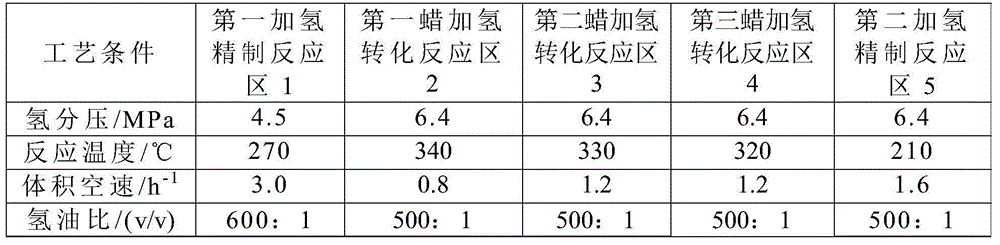

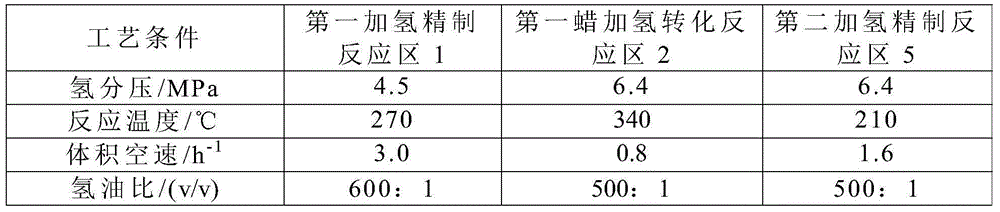

Method of treating Fischer-Tropsch wax, lubricant base oil and preparation method of same

ActiveCN105586083AHigh yieldNo flocculationTreatment with hydrotreatment processesLubricant compositionMolecular sieveWax

The invention discloses a method of treating Fischer-Tropsch wax, including the following steps: 1) successively contacting the Fischer-Tropsch wax with a hydrofining catalyst A, a hydroisomerization catalyst and a hydrofining catalyst B to obtain oil converted and generated from wax. A carrier of the hydroisomerization catalyst includes a molecular sieve. In the flowing direction of the Fischer-Tropsch wax, the hydroisomerization catalyst comprises a hydroisomerization catalyst A and a hydroisomerization catalyst B, wherein the pore diameter of the molecular sieve in the hydroisomerization catalyst B is larger than that in the hydroisomerization catalyst A. The invention also discloses a method of preparing lubricant base oil through the method of treating the Fischer-Tropsch wax and the lubricant base oil prepared through the method. The lubricant base oil is free of flocculation and is high in yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

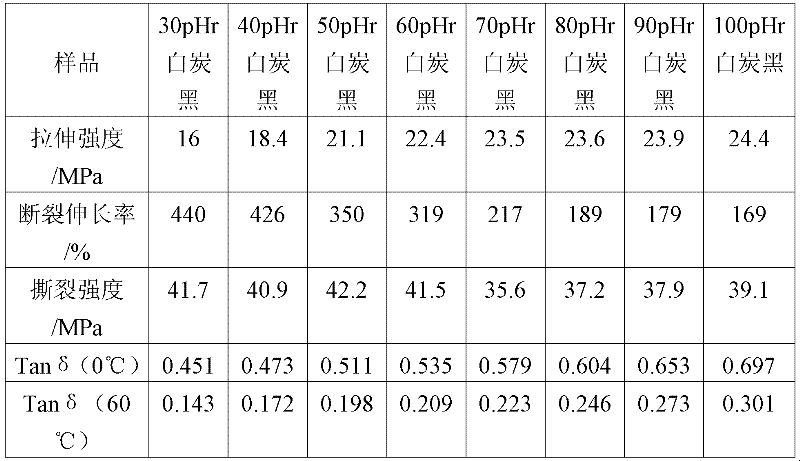

Preparation method of white carbon black modified styrene-butadiene rubber facing green tires and product thereof

ActiveCN102558627AEvenly dispersedImprove mechanical propertiesSpecial tyresRolling resistance optimizationFlocculationHydrogen

The invention provides a preparation method of white carbon black modified styrene-butadiene rubber facing green tires and a product thereof. White carbon black is used in the technical field of styrene-butadiene rubber modification, so as to provide guidance to the application of the white carbon black modified styrene-butadiene rubber in the tire industry. The styrene-butadiene rubber is characterized in that the styrene-butadiene rubber contains white carbon black of which the weight percentage to dry styrene-butadiene rubber latex is 30 percent to 100 percent. The preparation method comprises the steps that firstly, the white carbon black is mixed with water to obtain a white carbon black-water suspension; afterwards, the white carbon black-water suspension is subject to surface treatment, so as to enable the surface of the white carbon black to be organized; the pH (potential of hydrogen) value of the suspension is adjusted to be 9 to 12; and finally, the suspension is evenly mixed with the styrene-butadiene rubber latex to obtain liquid styrene-butadiene rubber sizing to which the white carbon black is added, and then the modified styrene-butadiene rubber containing the white carbon black is prepared by adopting an emulsion blending and flocculation process. The white carbon black modified styrene-butadiene rubber prepared by adopting the preparation method has the advantages that the white carbon black is evenly distributed in the styrene-butadiene rubber, and compared with pure styrene-butadiene rubber, the mechanical performance, the wet-skid resistant performanceand the rolling resistance of the white carbon black modified styrene-butadiene rubber are remarkably improved.

Owner:BEIJING UNIV OF CHEM TECH

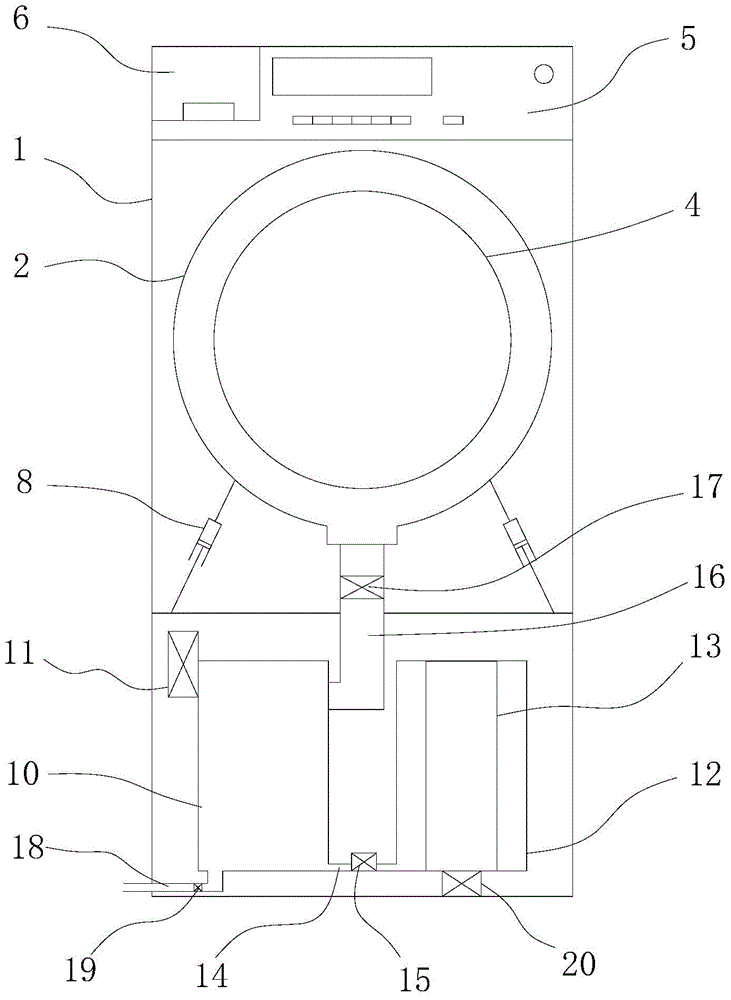

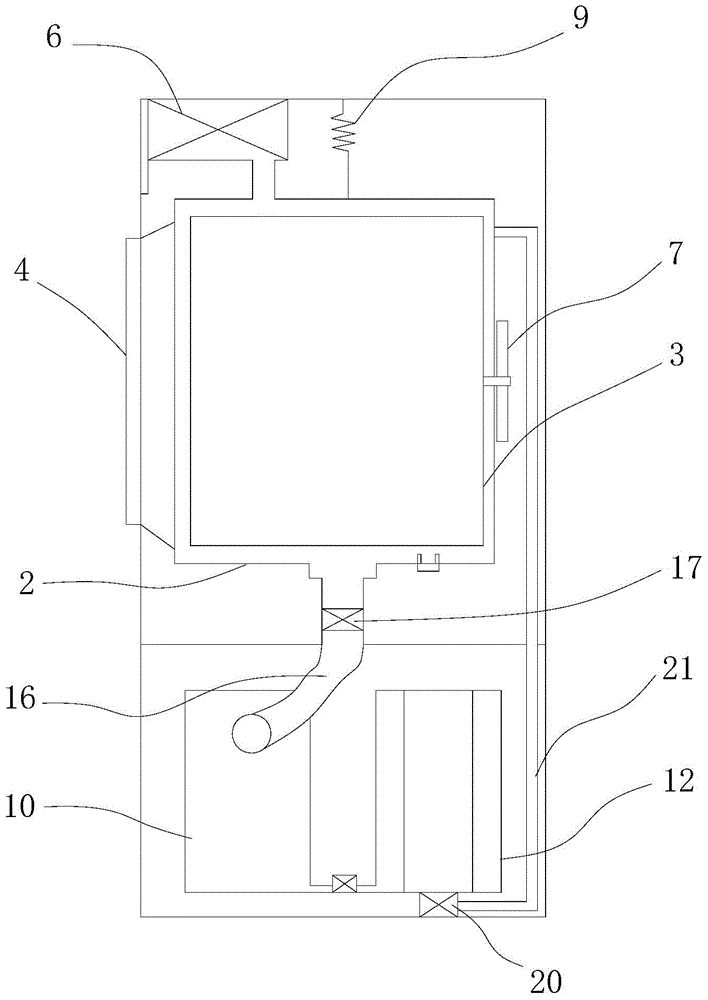

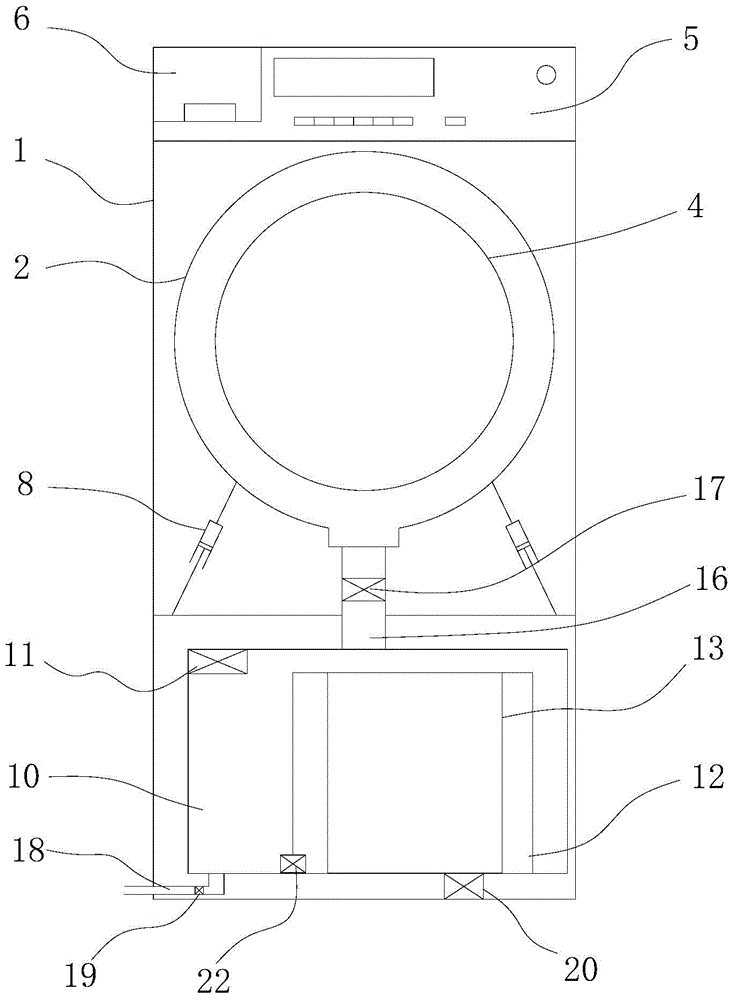

Washing machine with circulating water treatment function and control method thereof

ActiveCN104372574AGood for healthDoes not affect washing efficiencyOther washing machinesControl devices for washing apparatusFlocculationFiltration

A washing machine with a circulated water treatment function and a control method therefor. The washing machine comprises a water holding barrel (2), a washing structure arranged inside the water holding barrel (2) and a circulated water treatment device arranged under the water holding barrel (2), wherein the circulated water treatment device comprises a flocculation treatment unit and a filtering unit, the flocculation treatment unit comprises a flocculation container (10) connected to the water holding barrel (2) and a flocculation agent dosing device (11) for dosing a flocculation agent into the flocculation container (10), and water is discharged from the water holding barrel (2) to the flocculation container (10) for flocculation treatment; and the filtering unit comprises a filtering container (12) and a filter net (13) arranged inside the filtering container (12), the filtering container (12) is in communication with the flocculation container (10) and the water holding barrel (2), respectively, for filtering the water having been flocculation-treated in the flocculation container (10) and discharging same again into the water holding barrel (2) for reuse. The washing machine circularly treats water by flocculation and filtration till the end of washing, in which the water is discharged into the circulated water treatment device for purification in the flocculation treatment unit and the filtering unit and finally discharged outside. The washing machine has the advantages of saving water resources, reducing water pollution and protecting the environment.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

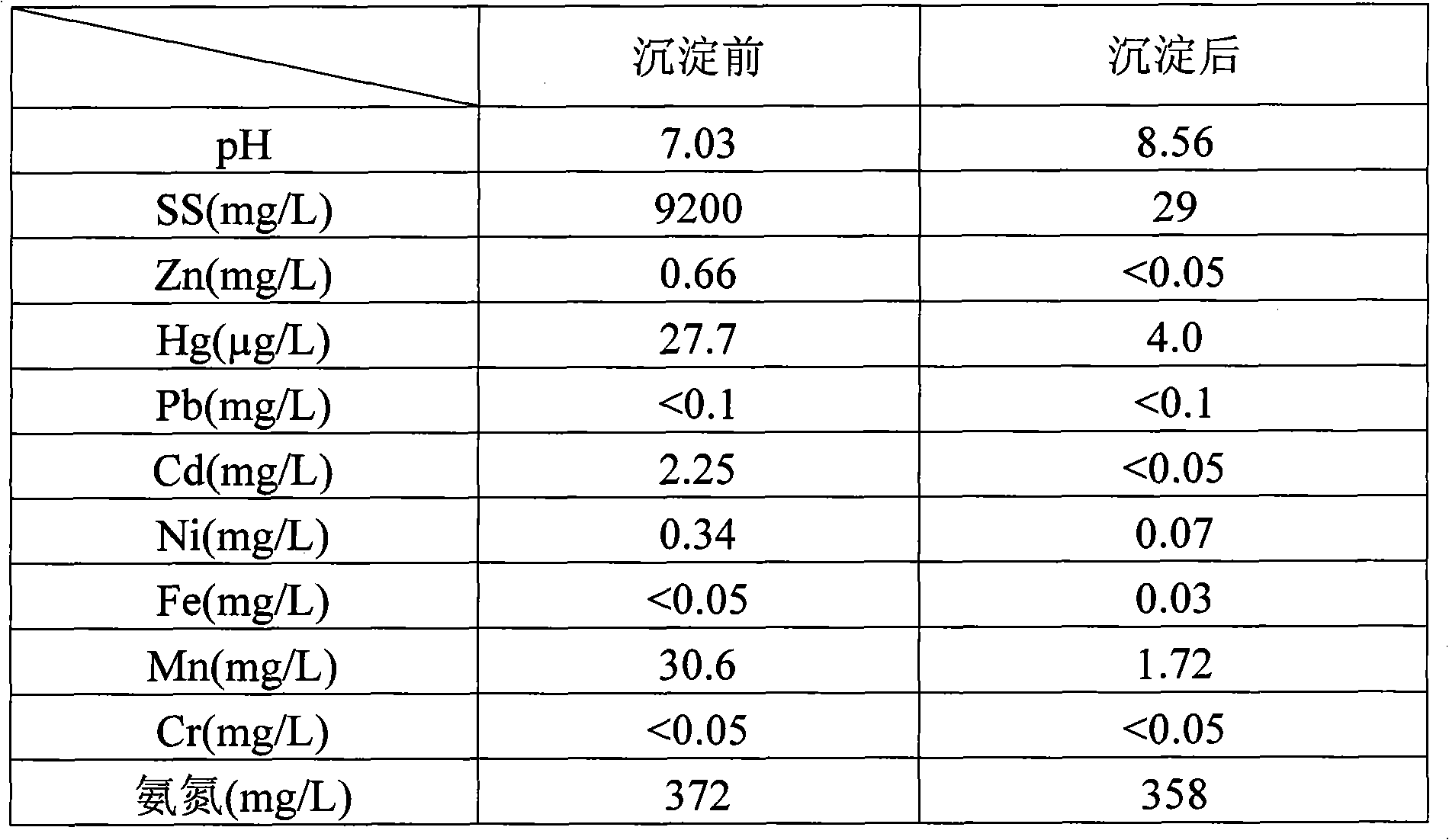

Treatment method of sintering flue gas desulphurization wastewater

ActiveCN101993169AReduce processing costsReduce the amount of waterTreatment with aerobic and anaerobic processesWater/sewage treatment bu osmosis/dialysisFlocculationFlue gas

The invention discloses a treatment method of sintering flue gas desulphurization wastewater, which completes the treatment on the sintering flue gas desulphurization wastewater through the following five steps of: 1. neutralization and coagulation: regulating the pH value of the sintering flue gas desulphurization wastewater to 8.5 to 9.5 by lye, and adding 0 to 200ppm of coagulating agents; 2. flocculation: adding 0 to 10ppm of coagulant aids for forming flocs; 3. precipitation and filter liquor separation; 4. biochemical treatment on filter liquor; and 5. deep treatment. The treatment method can be used for reducing the treatment cost of the desulphurization wastewater without generating influence on other treatment systems, thereby having good application and popularization prospects.

Owner:BAOSHAN IRON & STEEL CO LTD

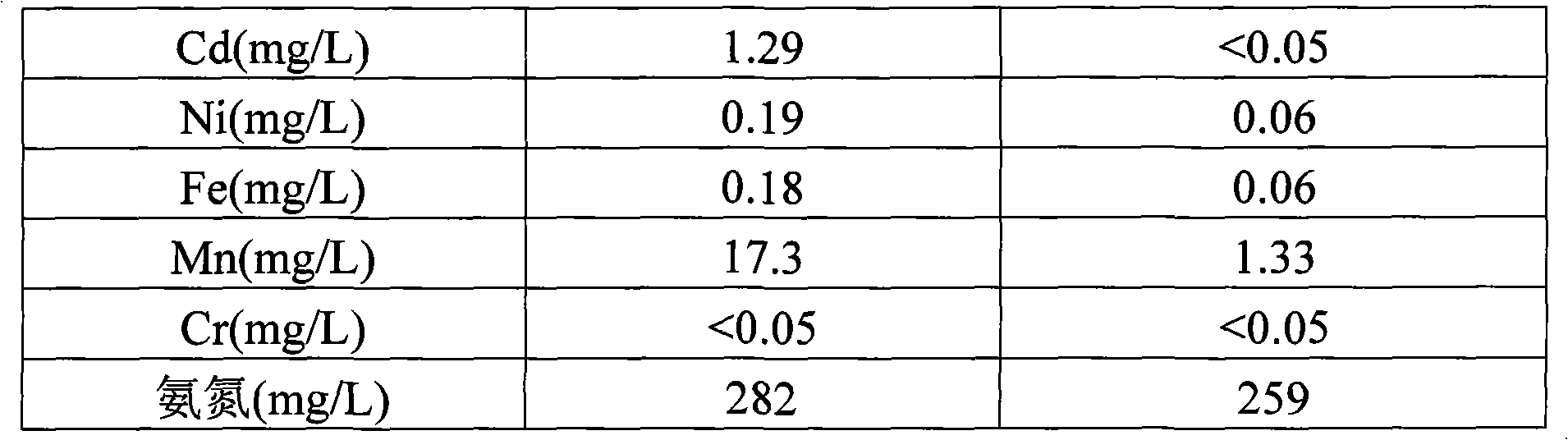

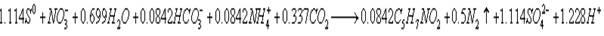

Excrement centralized processing method

ActiveCN101654318AAvoid cloggingCOD removalBio-organic fraction processingSludge treatment by de-watering/drying/thickeningFlocculationFeces

The invention relates to an excrement centralized processing method, comprising the steps of solid-liquid separation, flocculation water removing, aerobic compost treatment, anaerobic sewage treatment, facultative anaerobic sewage treatment, aerobic sewage treatment, membrane anaerobic reacting sewage treatment and odor treatment. Treated with the processing method of the invention, the urban night soil is 100% decontaminated, is 99.7% minimized and the excrement sludge is completely changed into resource.

Owner:北京昊业怡生科技有限公司

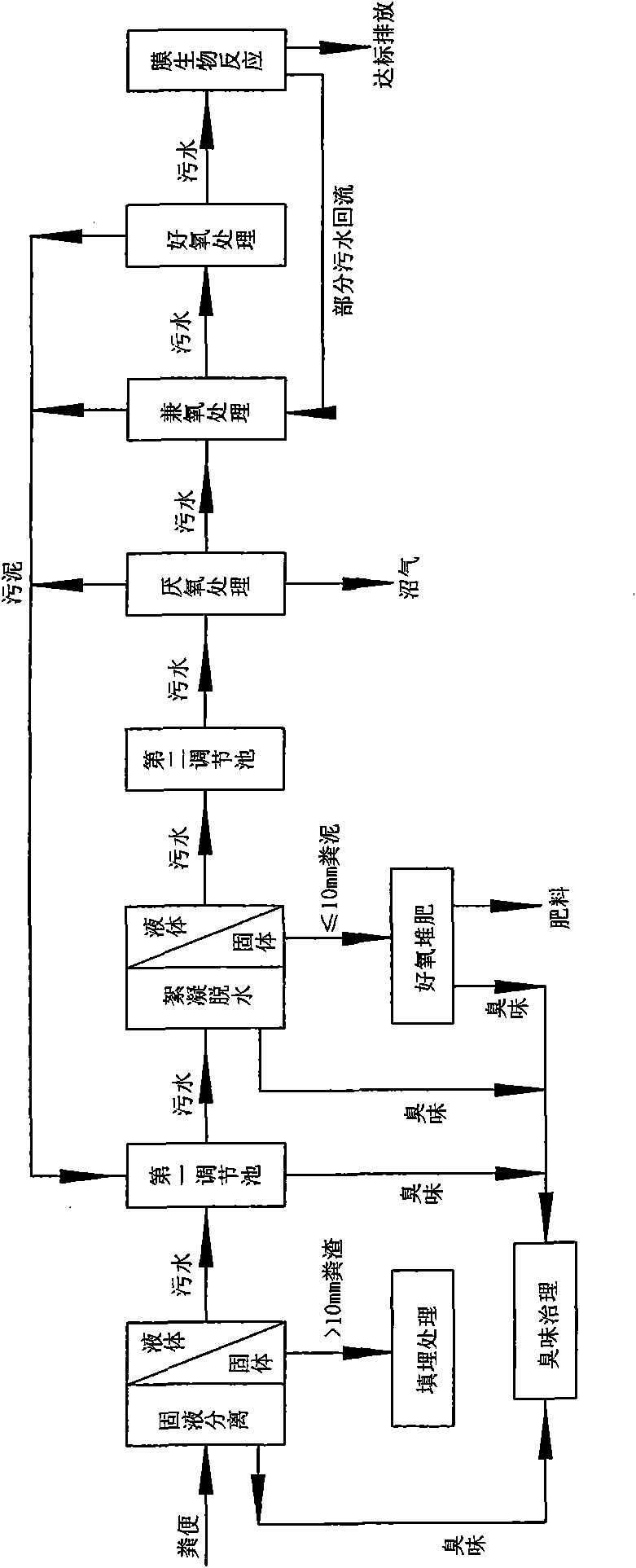

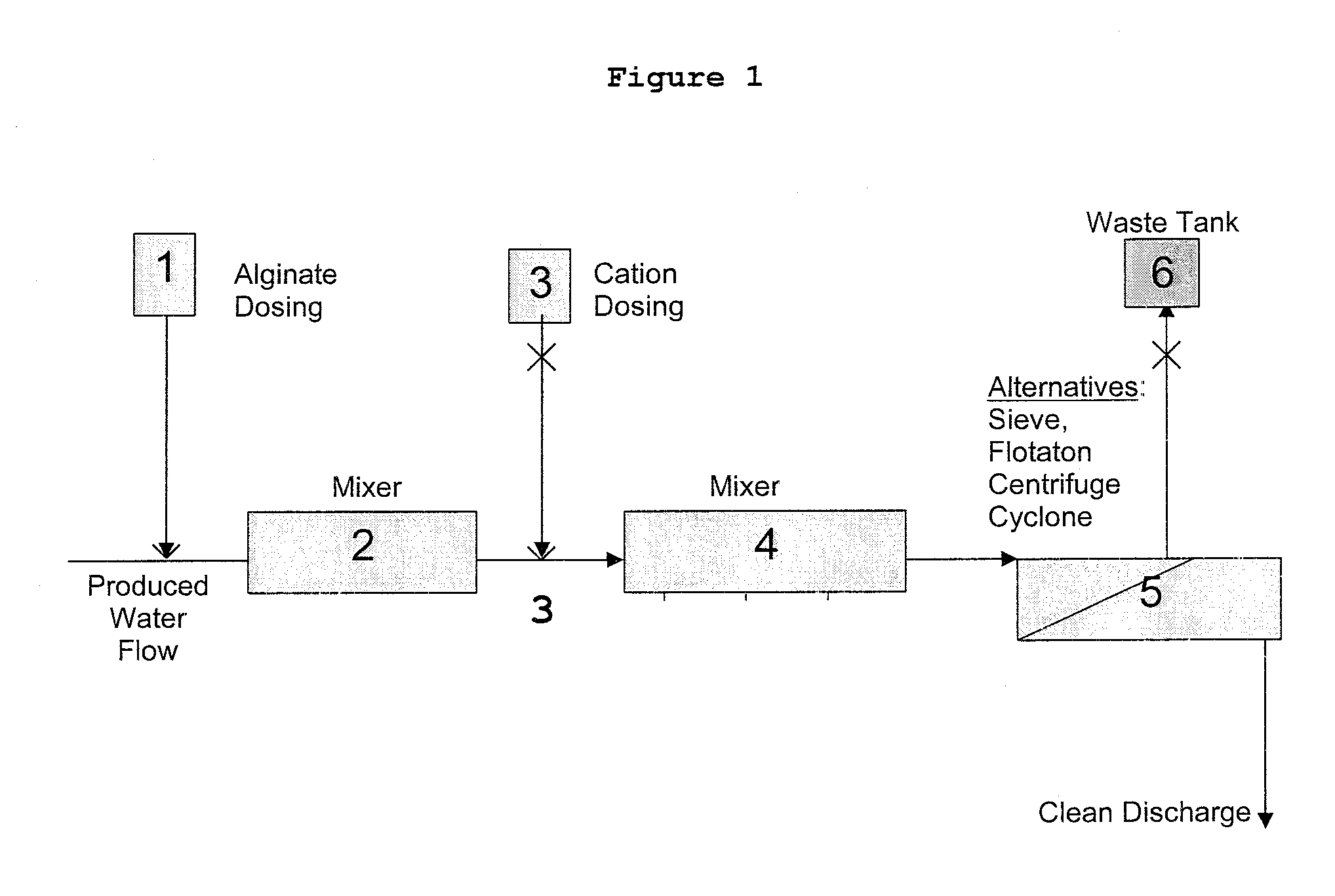

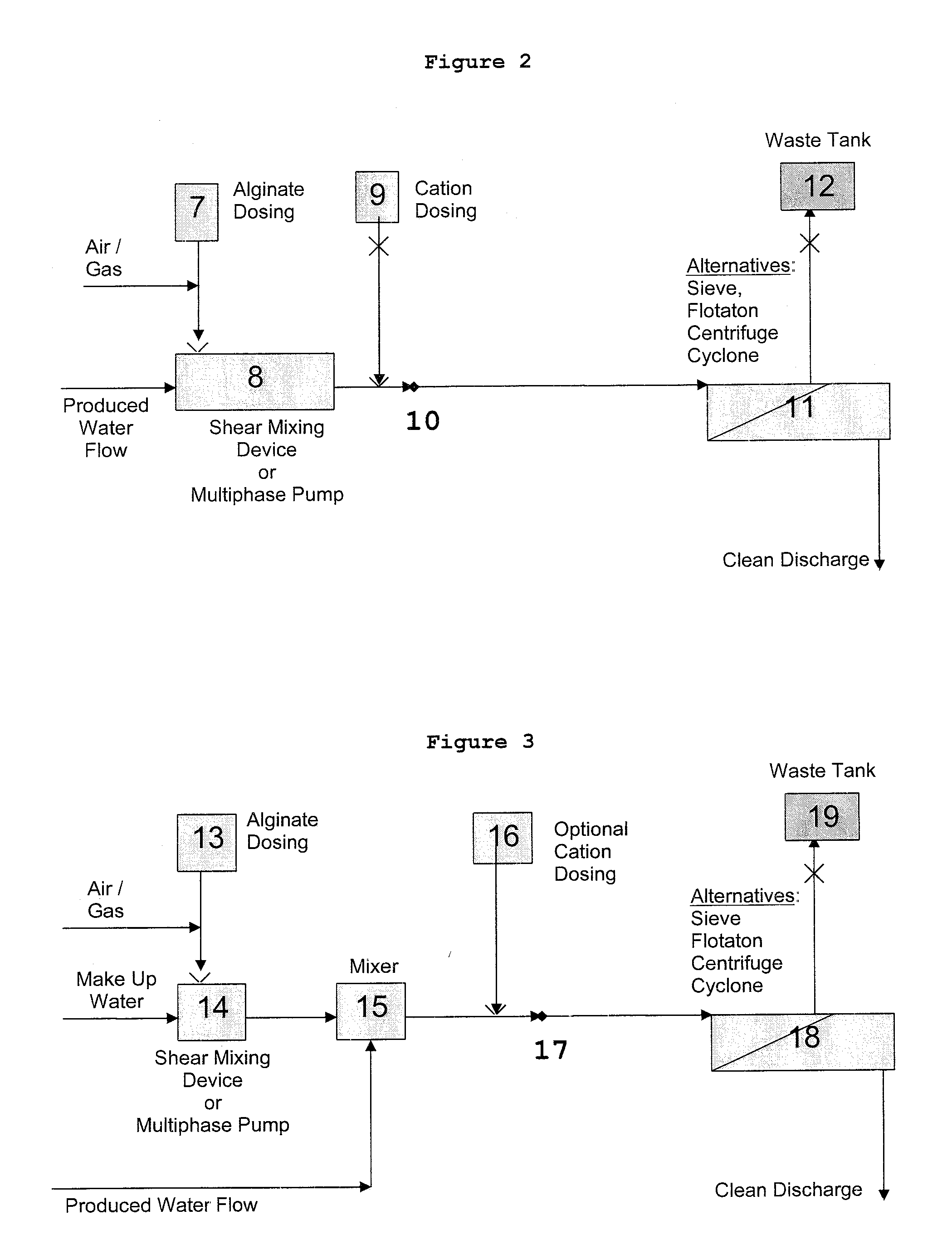

Method for removal of materials from a liquid stream

ActiveUS20070235391A1Avoid premature gellingHigh puritySolid sorbent liquid separationWater/sewage treatment by ion-exchangeCycloneMicroparticle

A method for removal of dissolved materials and / or particles from a liquid stream comprising flocculation by vigorously mixing polysaccharides or hydrocolloids into the liquid stream and subsequent gelation of the polysaccharides or hydrocolloids with cations capable of gelling same. Large, strong gelled agglomerates of pollutant and polysaccharide or hydrocolloid are formed with the help of suitable cations. The gelled agglomerates are well suited to separation from a liquid stream by flotation, in a sieve, in a centrifuge, in a cyclone or via other conventional separation processes. Also described is a method for mixing of un-dissolved polysaccharide or hydrocolloid with a polluted aqueous stream by shearing the polysaccharide or hydrocolloid into the aqueous stream to improve logistics and provide economic savings in treatment of large volumes of water. Also described is the use of dilute solutions of polysaccharides for treatment of a variety of effluent streams. An application of the invention is provided for removal of hydrocarbons within the oil industry, but also for other kinds of oil-containing water and also water with organic or particulate pollution.

Owner:SORBWATER TECH AS

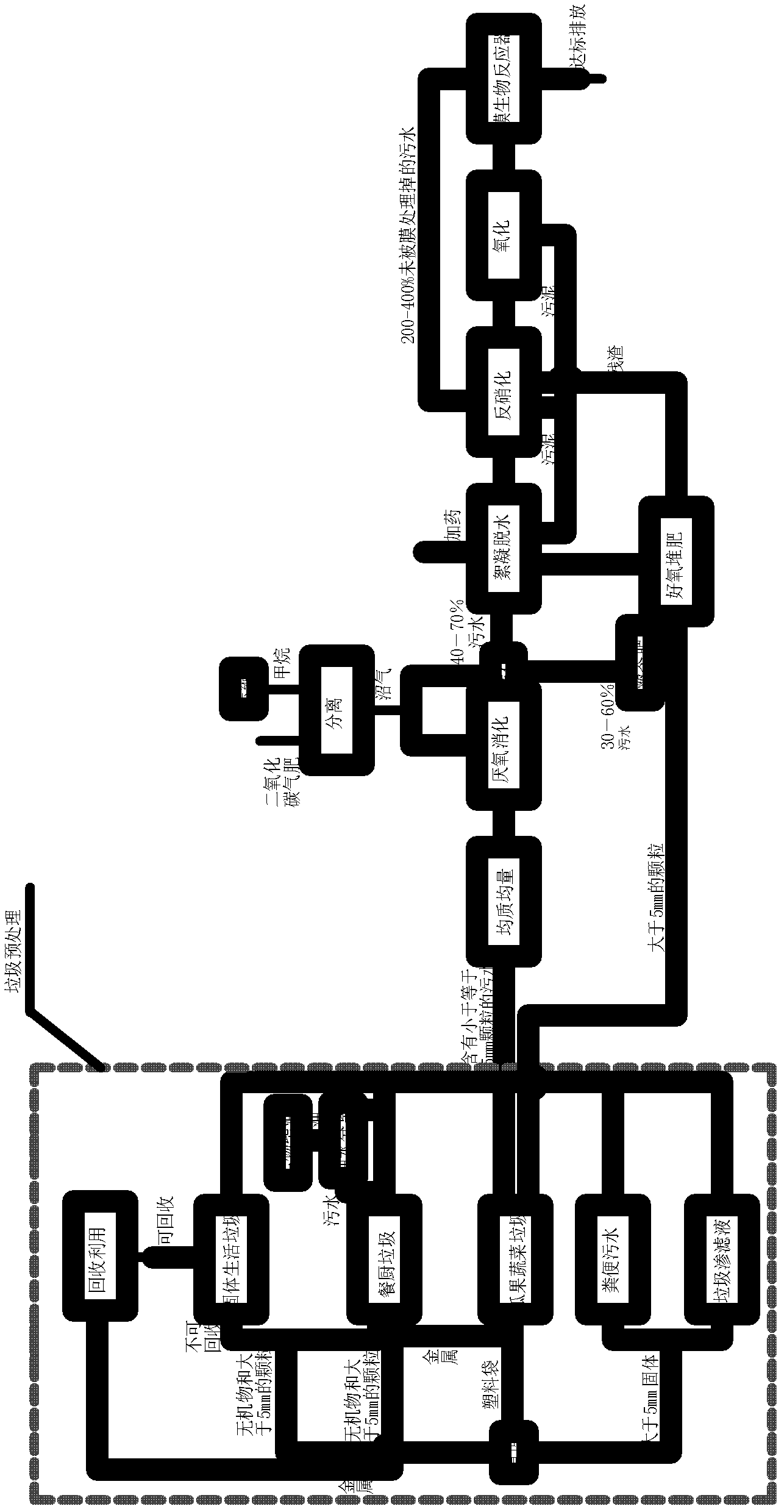

Method for jointly treating different garbage

ActiveCN102531295ASave processing powerProportional balanceBio-organic fraction processingWaste processingFlocculationBiodiesel

The invention discloses a method for jointly treating different garbage. In the implementation process, different garbage is subjected to pretreatment, homogenization, anaerobic digestion, flocculation dewatering, denitrification, oxidation treatment, membrane bioreactor treatment, aerobic composting and biodiesel production, treated sewage can reach the third grade Standard of Water Pollutants Discharge of DB11 / 307-2005, the process flow is greatly shortened, the cost is reduced, and methane generated in the treatment process and the recovered waste oil are subjected to deep processing to beutilized as green energy.

Owner:北京昊业怡生科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com