Handling method for advanced purification of little-volume refractory wastewater and operation equipment

A technology of deep purification and treatment method, applied in water/sewage treatment, light water/sewage treatment, neutralized water/sewage treatment, etc. High removal rate, easy engineering scale-up, high COD removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

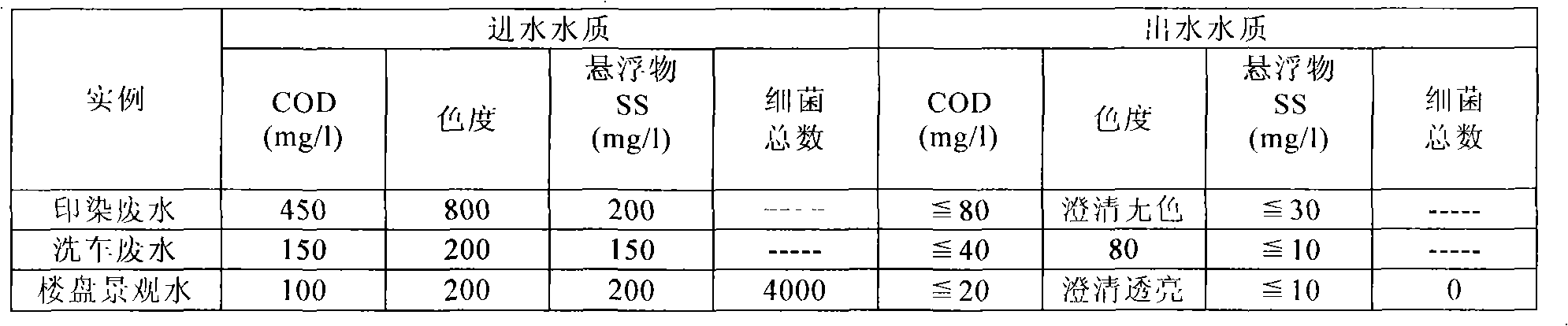

Examples

Embodiment Construction

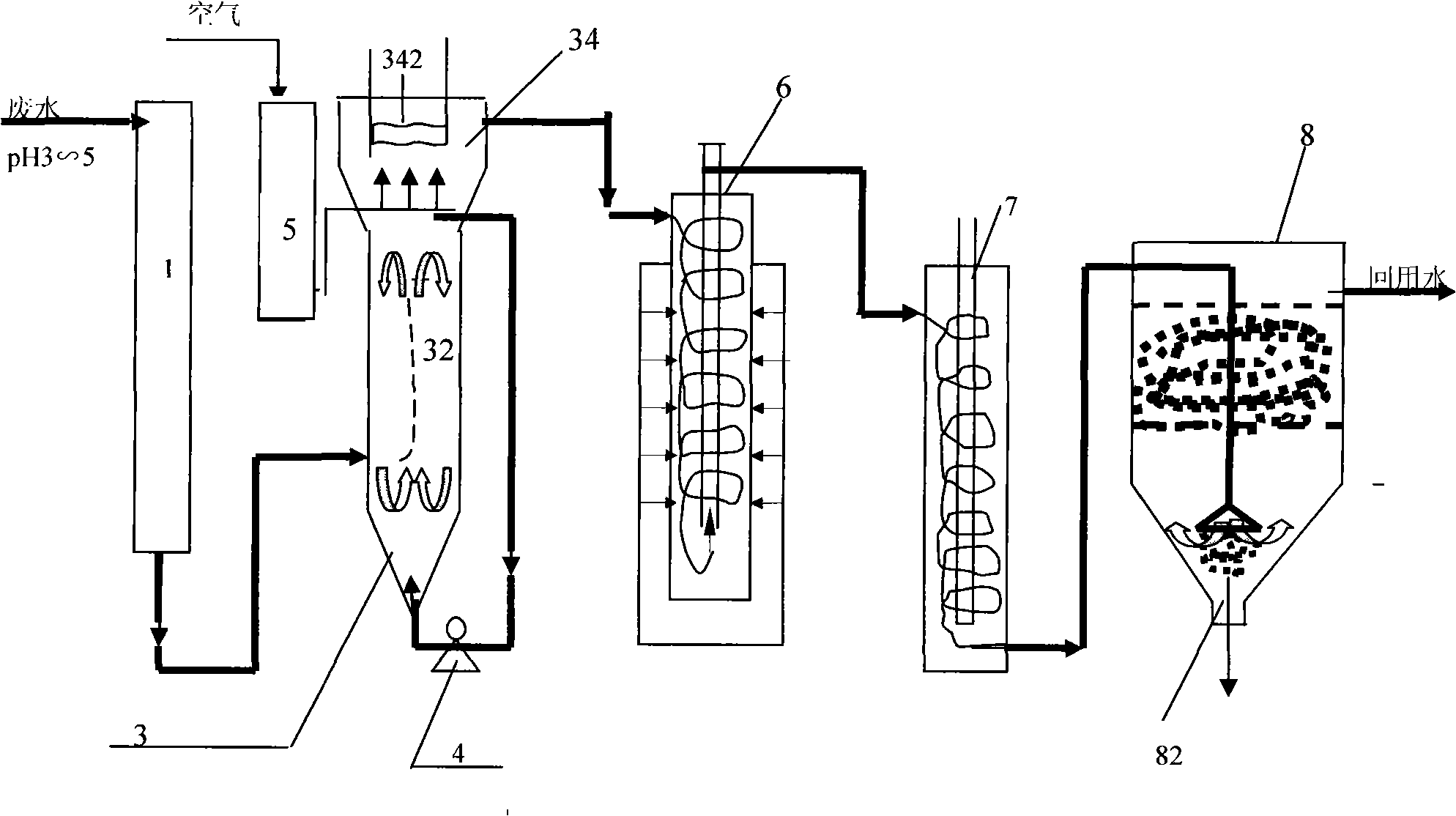

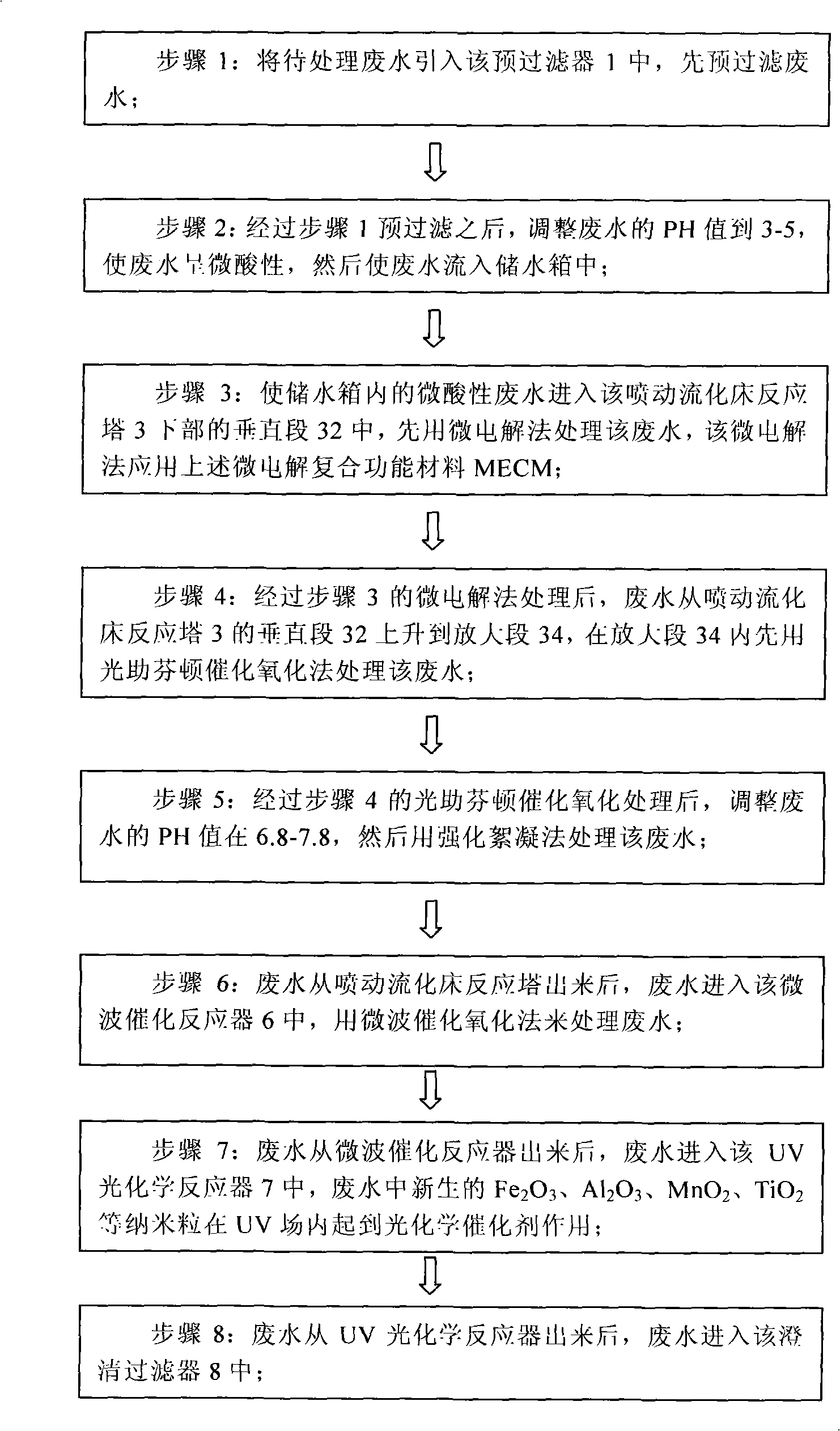

[0039] see figure 1 , the present invention proposes a kind of equipment used in the treatment method of deep purification and reuse of refractory wastewater with small amount of water, the equipment includes a pre-filter 1, a water storage tank (not shown in the figure), a spray fluidized bed reaction tower 3 , a circulation pump 4, an ozone (O 3 ) generator 5, a microwave catalytic reactor 6, a UV photochemical reactor 7, and a clarification filter 8.

[0040] Waste water to be treated enters from the top of the pre-filter 1 , and the bottom of the pre-filter 1 is connected to the water storage tank, and the water storage tank is connected to the spouted fluidized bed reaction tower 3 . The pre-filtered waste water flows into the spouted fluidized bed reaction tower 3 after passing through the water storage tank.

[0041] The spouted fluidized bed reaction tower 3 includes a vertical section 32 with a cone in the lower part and an enlarged section 34 in the upper part.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com