Patents

Literature

51results about How to "High chroma removal rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite flocculant and preparation method and application thereof

InactiveCN101734774AGood effectLow costWater/sewage treatment by flocculation/precipitationIron sulphateRare earth

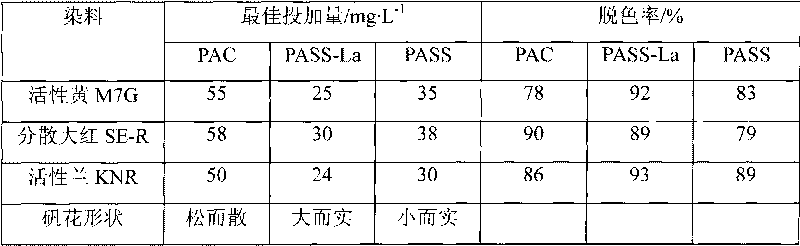

The invention discloses a composite flocculant and a preparation method and application thereof. The flocculant is prepared from rare-earth carbonate, sodium silicate and ferric sulfate / aluminum sulfate serving as raw materials by a composite copolymerization method. The effect of the composite flocculant of the invention is superior to that of the conventional polymeric ferric / aluminum silicate sulfate; the chroma removal rate of wastewater reaches over 90 percent; the COD Cr removal rate reaches over 65 percent; the removal rate of total phosphorus reaches over 88 percent; and the expense of a wastewater treatment medicament is reduced by 10 to 20 percent compared with PASS. The composite flocculant has rapid, large and solid alumen ustum, reduces the use amount of a single dye wastewater coagulating agent by over one half compared with PAC and by over 20 percent compared with PASS, improves the chroma removal rate of the wastewater by about 10 percent, has low processing cost, and improves the processing effect.

Owner:GUANGDONG UNIV OF TECH

Catalytic particle electrode used for removing refractory organics and ammonia nitrogen from wastewater and preparation method and application thereof

ActiveCN104925913AEasy to prepareFast adsorption rateWater/sewage treatment using germicide/oligodynamic-processChemistryActivated carbon

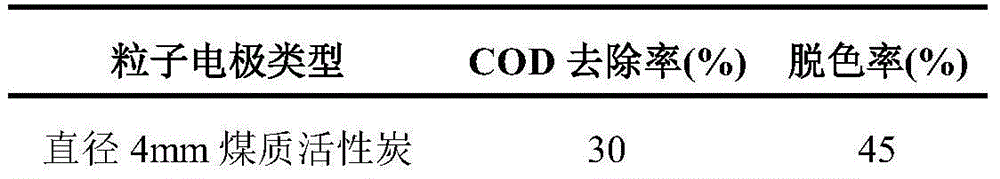

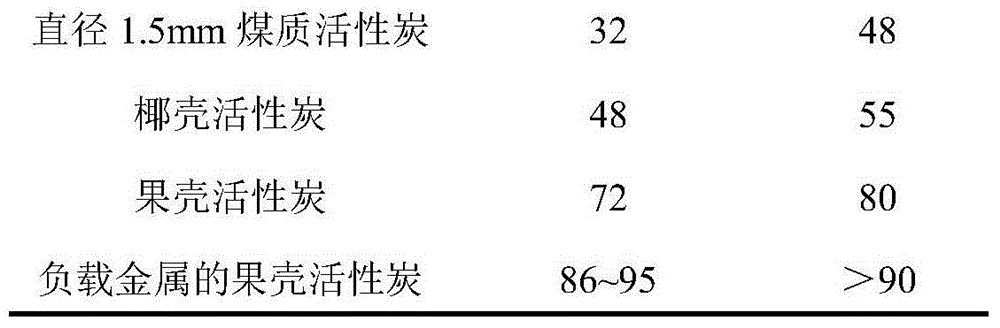

The invention relates to the field of wastewater treatment, in particular to a catalytic particle electrode used for synchronously removing refractory organics and ammonia nitrogen from wastewater and a preparation method and application thereof. The electrode comprises shell activated carbon and metal components loaded on the shell activated carbon, wherein the particle size of the shell activated carbon is 1mm-5 mm, and the content of the metal components is 0.8wt%-2.5wt% the total mass of the activated carbon. Packing of the catalytic particle electrode has the advantages of being high in catalytic activity, low in price, easy to obtain, simple in preparation, high in COD and ammonia nitrogen degradation and removal efficiency, high in produced water mineralization degree, low in unit COD energy consumption and capable of being used continuously. Accordingly, the electrode is suitable for treatment of wastewater which is difficult to degrade biologically and contains high-concentration organic pollutants and high ammonia nitrogen.

Owner:BEIJING FORESTRY UNIVERSITY

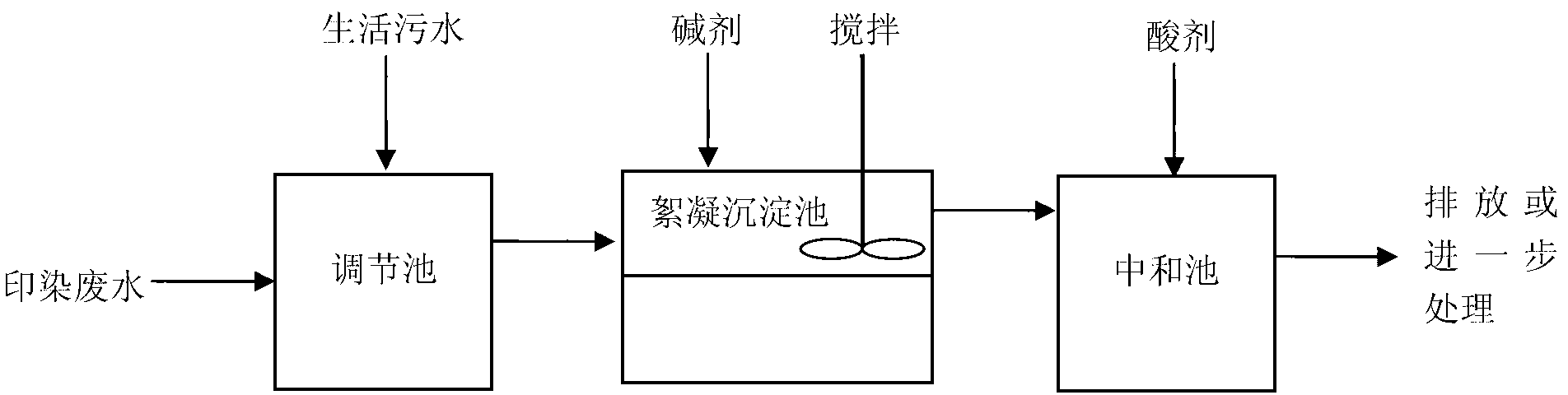

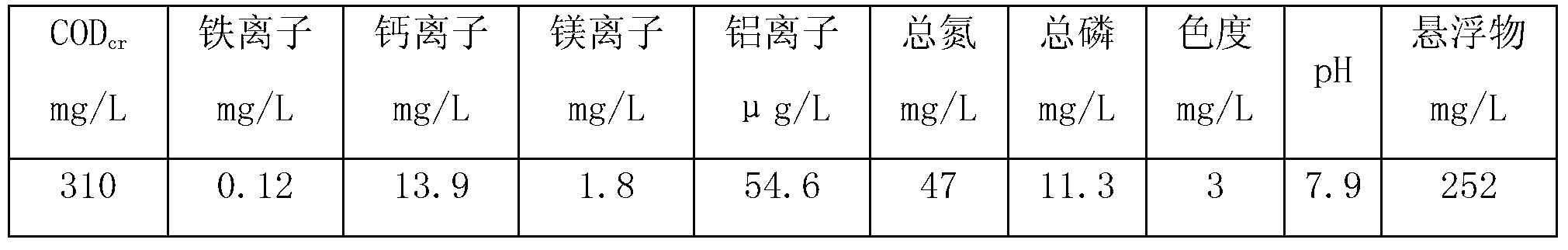

Printing and dyeing wastewater treatment method

InactiveCN103304054AWide applicabilityGood processing effectEnergy based wastewater treatmentMultistage water/sewage treatmentSuspended particlesChemical oxygen demand

The invention discloses a printing and dyeing wastewater treatment method which comprises the following steps of: firstly mixing the printing and dyeing wastewater with domestic sewage; stirring at a certain pH value; and mixing intrinsic iron irons, magnesium ions, calcium ions and hydroxides of magnesium ions in the wastewater and the components such as suspended particles and the like in the domestic sewage to form a composite flocculating body with a synergistic effect. The composite flocculating body removes chromaticity in the printing and dyeing wastewater through the effects such as electrostatic adsorption, adhesion, bridging, sweeping and the like, and the domestic sewage is purified at the same time. The method disclosed by the invention is applicable to water-soluble and non-water soluble single kind or more kinds of mixed wastewater, and can be matched with a biological method or other physical and chemical methods for further treatment. The method has the characteristics of high decoloration degree, remarkable reduction of COD (chemical oxygen demand), suspended solids and total phosphorus and nitrogen, short treatment flow, simplicity in operation and management, only need for acid-base agents, low equipment investment and operation cost, no need of changing the original treatment facilities, wide application range, convenience in popularization and application and the like.

Owner:DEZHOU UNIV

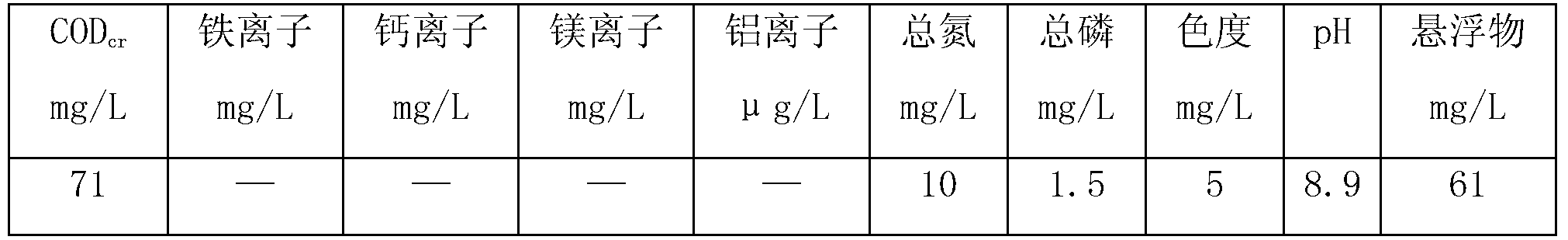

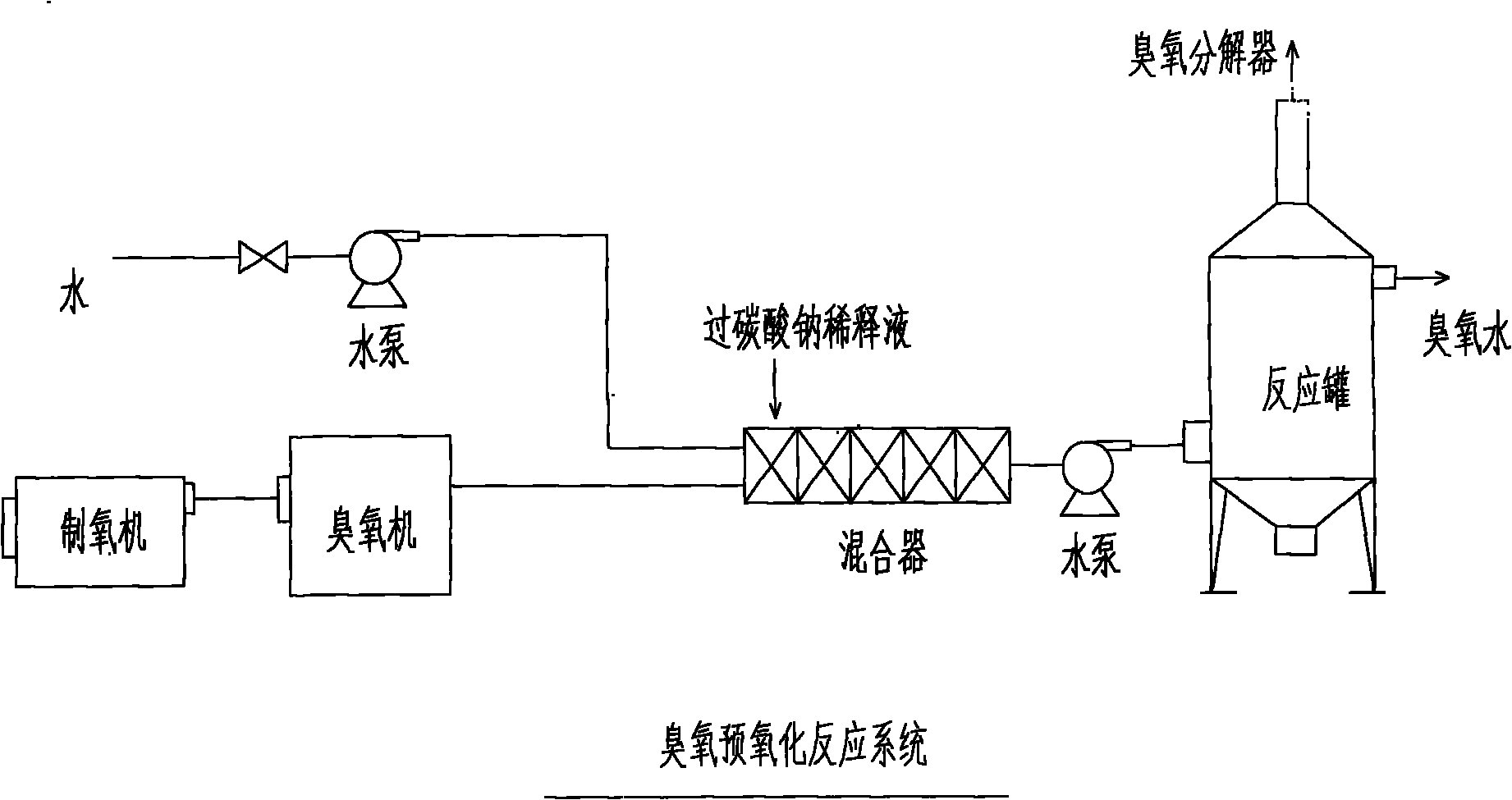

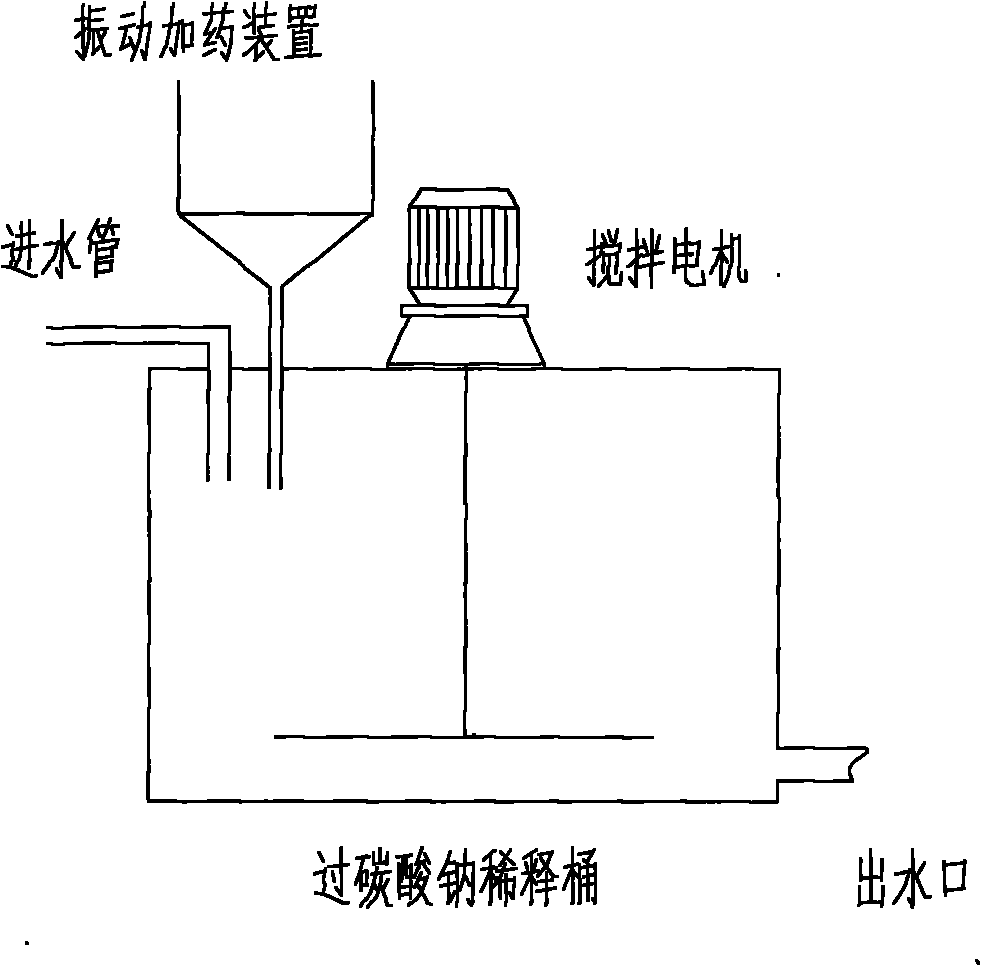

Ozone pre-oxidation and laccase advanced water treatment method

ActiveCN101817622AReduce chromaImprove biodegradabilityMultistage water/sewage treatmentDecompositionTherapeutic effect

The invention relates to an ozone pre-oxidation and laccase advanced water treatment method, which comprises the following steps of: mixing waste water, ozone and sodium percarbonate in a mixer; adding the mixture in an ozone reactor device for stirred reaction; making the mixture enter a tertiary sedimentation basin for solid-liquid separation; adding the separated supernate and laccase into a laccase reaction tank, and fully mixing the laccase with the waste water for reaction; mixing the diluted mediator and the effluent from the laccase reaction tank, and performing flocculent settling solid-liquid separation on the mixture in a final sedimentation basin; and performing anaerobic and aerobic biochemical treatment on the effluent. The method overcomes the defects of over-high cost, low efficiency of enzyme treatment, high enzyme consumption, difficult sedimentation and separation of enzyme per se, and the like. The method only makes two processing units of ozone pre-oxidation and laccase-mediator catalytic polymerization achieve good mutual acceleration and gradient treatment effects, accelerates decomposition of O3 to make micro-flocculation effect of the ozone pre-oxidation in the optimized pH value range, is favorable for reducing the coagulant consumption, can recycle the waste water, and has scale application.

Owner:NANJING SHENKELONG ENVIRONMENTAL PROTECTION

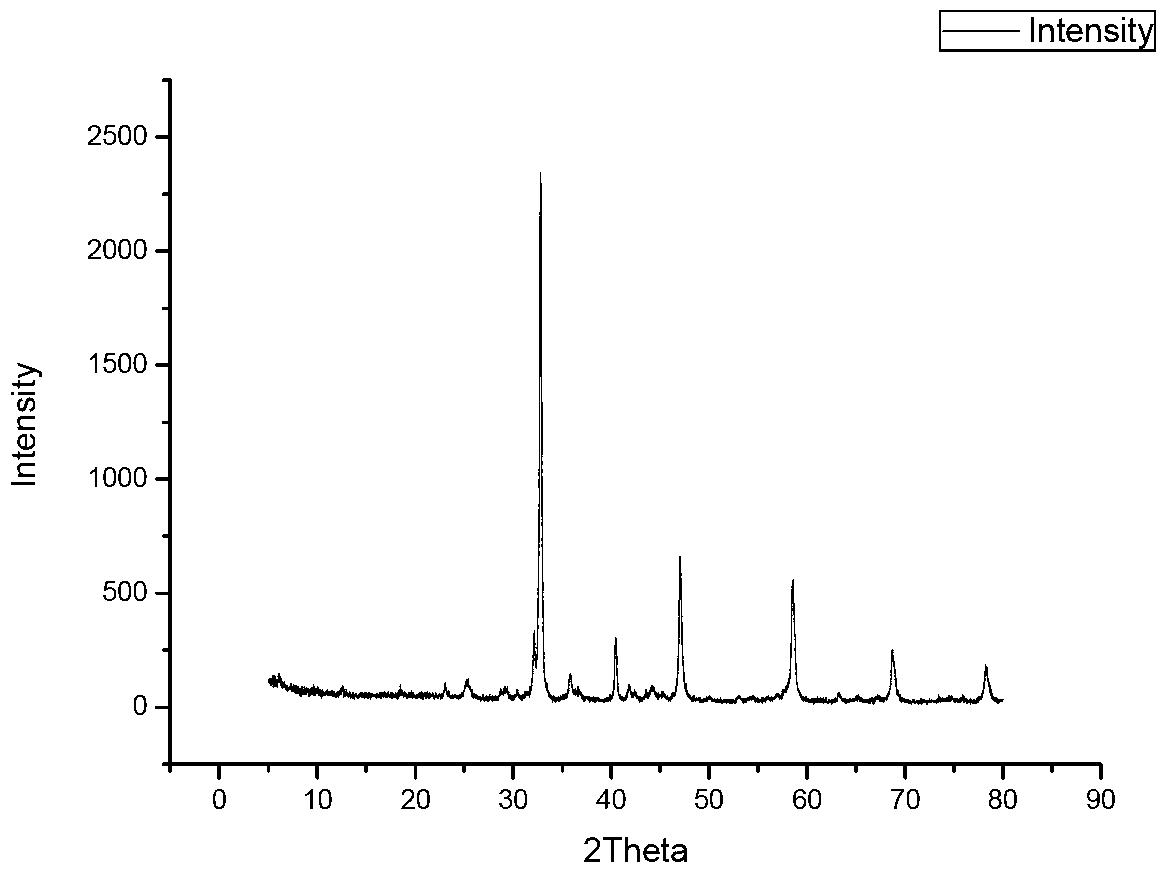

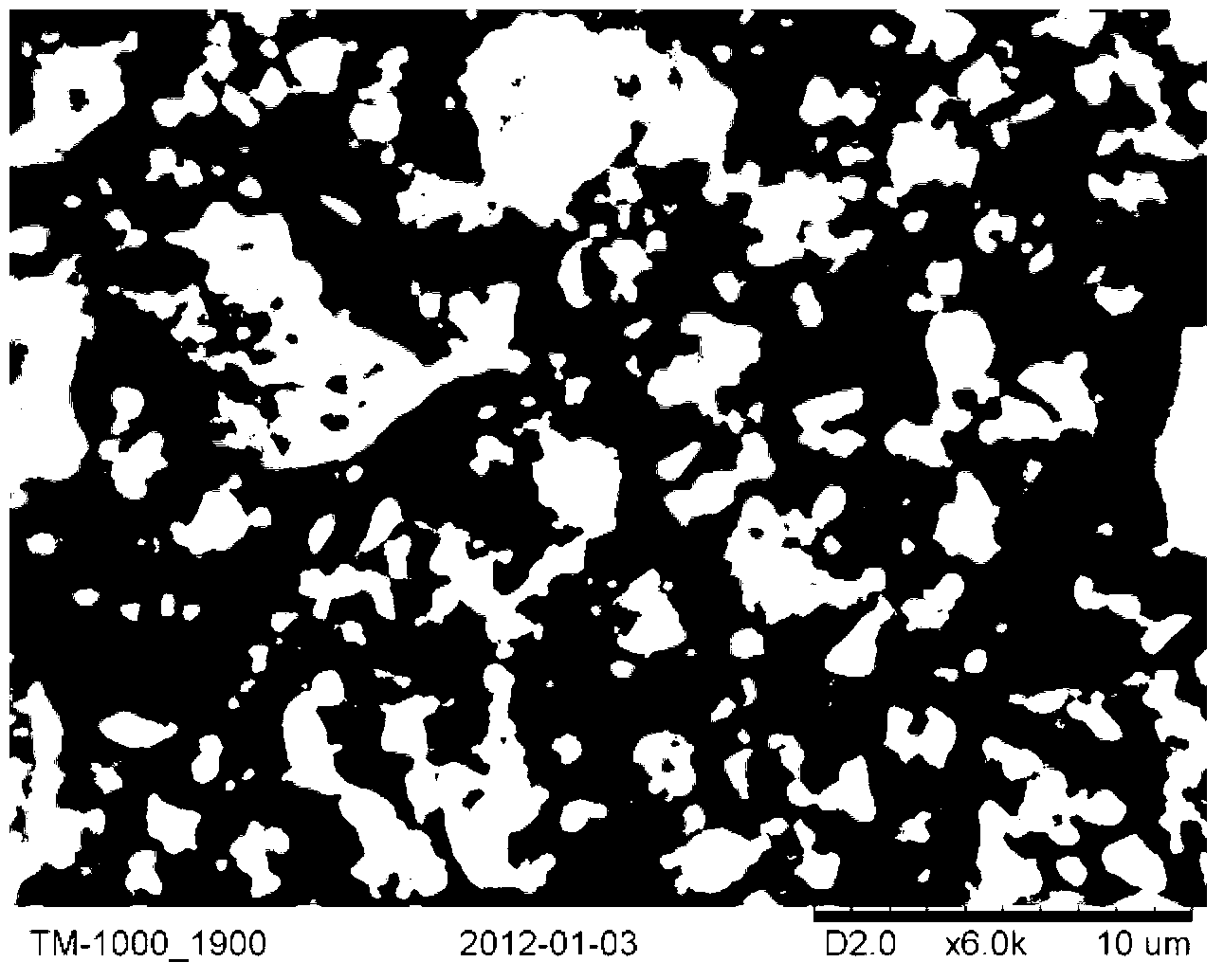

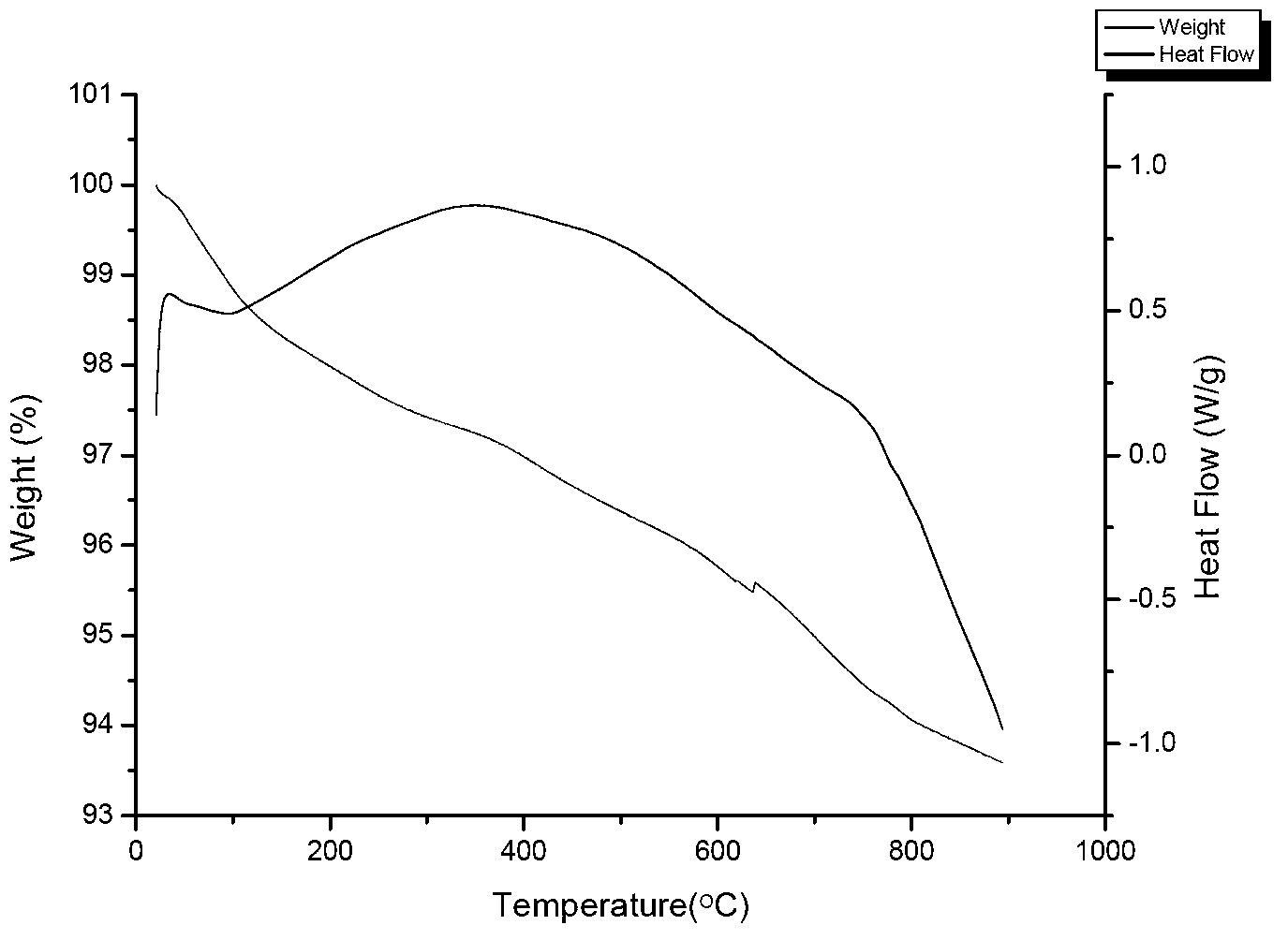

Preparation method of perovskite type photocatalyst and product thereof

InactiveCN102836719AGood photocatalytic degradation activityHigh chroma removal rateMetal/metal-oxides/metal-hydroxide catalystsPhotocatalytic degradationMethyl orange

The invention discloses a preparation method of a perovskite type photocatalyst. The method comprises the following steps of: (1) taking barium salt, strontium salt, cobalt salt, ferric salt and citric acid, adding distilled water to mix and dissolve, sealing and heating to be at 90-100 DEG C, stirring at a constant temperature for 3-4h, releasing the sealing and heating continuously until the water is evaporated to form colloid, drying the colloid for 18-22h, holding the temperature at 110-130 DEG C; and (2) taking out a dried sample for calcination and grinding the calcined sample to obtain the black powder-shaped BaxSSr1-xFe0.5Co0.5O3-delta photocatalyst. The invention also discloses a perovskite type photocatalyst product prepared according to the preparation method; the value range of the x in the prepared BaxSSr1-xFe0.5Co0.5O3-delta photocatalyst is 0-1. Perovskite type oxides prepared through using the preparation method have excellent photocatalytic degradation activity, the chroma removal rate after the reaction is high, the degradation rate for methyl orange with appointed concentration is above 95% and the introduction rate for appointed Congo red dyes is up to 93%.

Owner:ZHEJIANG SHUREN UNIV

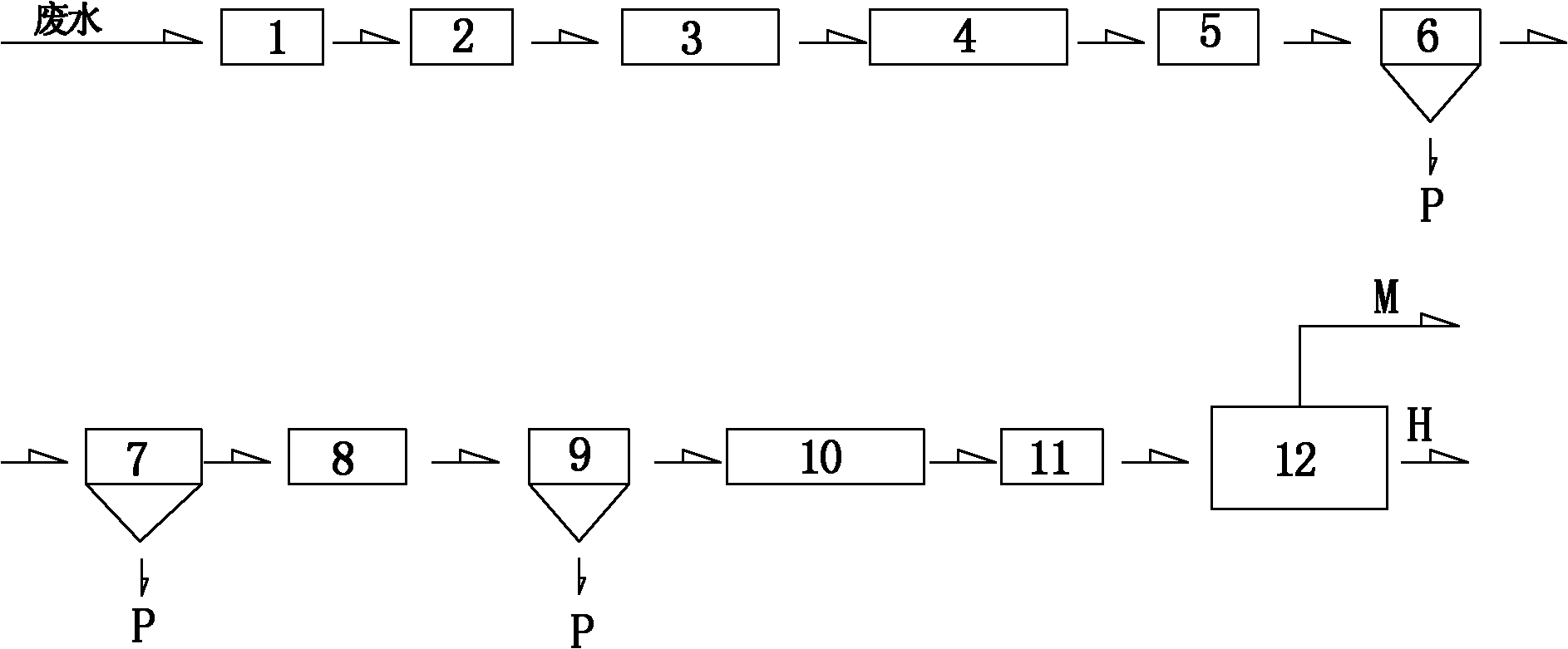

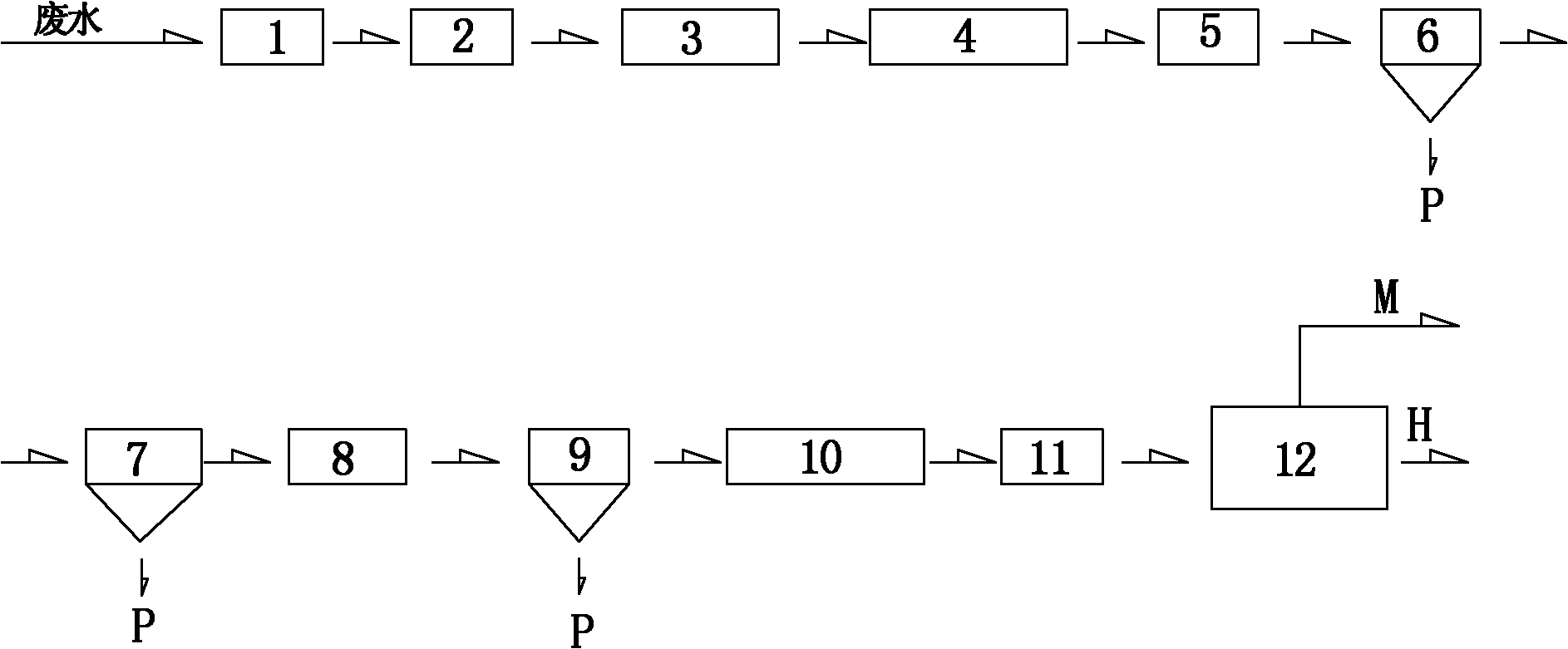

Tanning wastewater recycling device and method based on electrochemistry and ultrafiltration

InactiveCN102145961AReduce dosageReduce consumptionWaste water treatment from animal processingMultistage water/sewage treatmentChemical oxygen demandElectrolysis

A tanning wastewater recycling device and method based on electrochemistry and ultrafiltration relate to the treatment of one kind of wastewater. The invention provides a tanning wastewater recycling device and method based on electrochemistry and ultrafiltration, wherein the device and method have high CODCr removal rate (chemical oxygen demand), low chemical agent consumption, low sludge yield, thorough treatment and high water reuse rate. The device is provided with a grid filter, an adjusting pool, a hydraulic sizer, a nanocatalysis electrolysis flocculating machine, a sedimentation tank, an air floatation device, a biochemical tank, a secondary sedimentation tank, a secondary nanocatalysis electrolysis flocculating machine, a filter and a filter press. The method comprises the steps of flocculation and filtration, nanocatalysis electrolysis, sedimentation, air floatation, biochemical treatment, secondary catalysis electrolysis, filtration and ultrafiltration.

Owner:BOYING XIAMEN SCI & TECH

Treatment method for recycling potato starch production factory wastewater

InactiveCN102690031AImprove water qualityHigh chroma removal rateSludge treatment by de-watering/drying/thickeningTreatment with aerobic and anaerobic processesChemical oxygen demandPotato starch

The invention discloses a treatment method for recycling potato starch production factory wastewater, relating to the technical field of starch wastewater treatment. The method comprises the following steps: precipitating, regulating the pH value of the precipitate with acid, regulating the pH value of the precipitate with alkali, exchanging and recycling heat, carrying out anaerobic treatment, aerobic biochemical treatment and ultrafiltration membrane treatment, and detecting emissions. The COD (chemical oxygen demand) of the wastewater treated by the method is less than 50 mg / L, the chroma removal rate of the wastewater is not lower than 99%, and the water quality chroma index is lower than 10 times. The invention has the advantages of low treatment cost, high operation stability and high treatment efficiency, can generate additional economic benefits, and is suitable for wide popularization.

Owner:山东博洋环境资源有限公司

Technique for processing anionic dye printing and dyeing wastewater

InactiveCN101172673ALess investmentReduce energy consumptionNature of treatment waterWater/sewage treatment by flotationDyeing wastewaterChrominance

The invention provides a treatment process of anionic dye dyeing waste water, which belongs to the field of waste water treatment, and disposes the anionic dye dyeing waste water by use of the foam separation technology. The invention has the exact steps as follows: 1. the anionic dye dyeing waste water is collected and detected; 2. the anionic dye dyeing waste water is pretreated; 3. the process of foam separation circular decoloring means adding cationic surfactant hexadecyl trimethyl ammonium bromide into the anionic dye dyeing waste water and decoloring for four times in a bubble column; and 4. vaporizing and crystallizing. The invention has advantages of simple device, small investment, few energy consumption and convenient operation, not only has high chrominance removal rate and small treating effect fluctuation, but also obtains the dye coarse product used for the dyeing process again.

Owner:HEBEI UNIV OF TECH

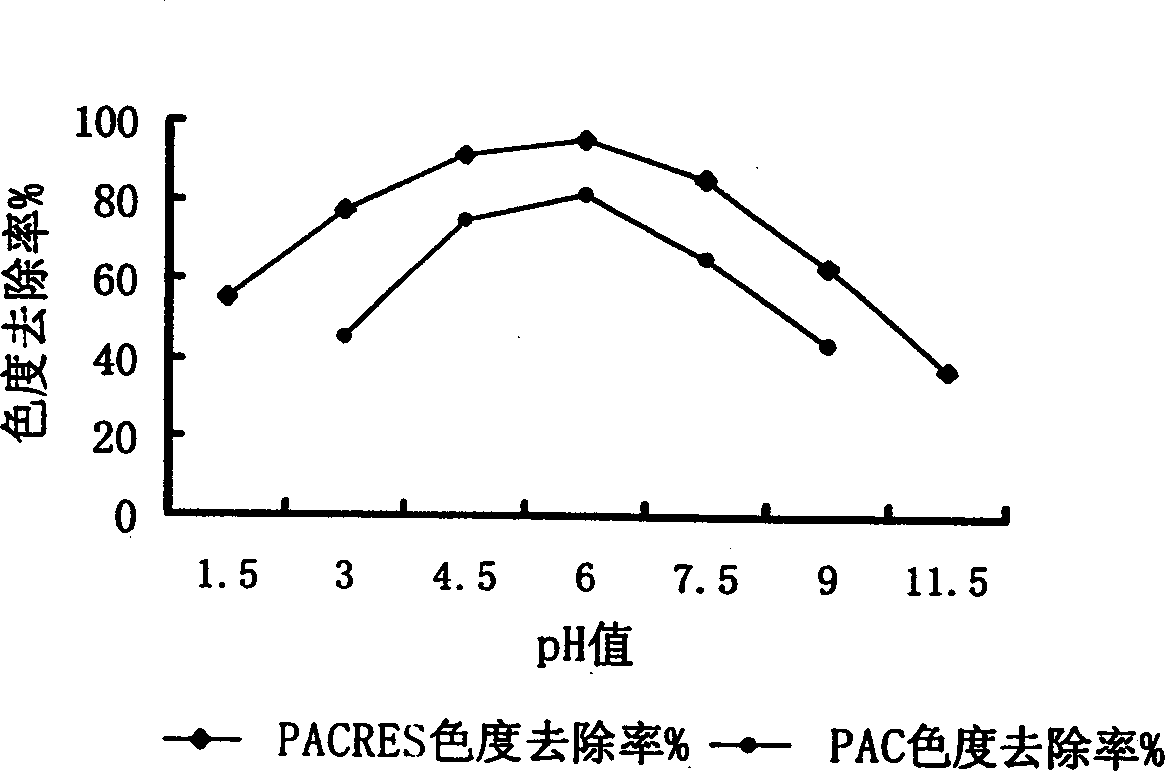

Rare earth compounded coagulating agent for treating waste water and its preparation method

InactiveCN1394815AThe effect of treating printing and dyeing wastewater is goodReduce dosageSedimentation separationWater/sewage treatment by flocculation/precipitationAluminium chlorohydrateSulfur

The present invention relates to a rare earth compounded coagulating agent for treating waste water, and the effective components of its solid product are Al2O3 27%-29%, Ln2O3 0.5%-6.0% and SO4(2-) 0.5%-6.5%, and its basic degree is 55%-68%. It is made up by using aluminium polychloride as main component and adding the elements of rare earth and sulfur, etc. through a certain compounding process, in which the introduction quantity of the rare earth compound can be controlled in that the mole ratio o f Ln / Al is 0.0055:1 to 0.06624:1. Said ivnention also provides the preparation method of said coagualting agent.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for producing high-efficiency purifying agent magnesium ferrous sulfate from titanium dioxide waste acid by using sulphuric acid method

InactiveCN101774650AIncrease the amount of controlSimple processMagnesium sulfatesIron sulfatesHydrometerFiltration

The invention discloses a method for producing a high-efficiency purifying agent magnesium ferrous sulfate from titanium dioxide waste acid by using a sulphuric acid method, aims to overcome the defect of the commonly used purifying agent at present, solves the problem of waste acid pollution in a titanium dioxide plant and provides a method for producing the purifying agent. The method comprises the following steps: putting mother liquor into a reaction pool; adding magnesia with the MgO content of more than or equal to 85 percent into the mother liquor; mixing with a stirrer; controlling the adding amount of the magnesia by using a method of measuring the specific gravity of mixed liquor with a Baume hydrometer; controlling the adding amount of waste sulphuric acid by using a method of detecting the pH value of the mixed liquor; controlling the reaction temperature not to exceed 95 DEG C; performing pressure filtration on a reacted mixed liquor with a pressure filter after the reaction is performed for 1.5 to 2.5 hours; delivering filtrate to a cooling bath for initial cooling and then delivering the filtrate to a cooling tank with a pump; further cooling the filtrate through stirring; discharging when the temperature is reduced to 10 to 30 DEG C; putting the cooled filtrate to a crystallizing pool to crystallize and precipitate naturally; and drying a precipitated product to obtain a granular product.

Owner:孙宝钦 +1

Method for simultaneously removing insoluble organic matter, total cyanogen and total nitrogen in wastewater of industrial park

InactiveCN107010782ASimple processSmall footprintWater treatment parameter controlTreatment using aerobic processesCyanideCatalytic oxidation

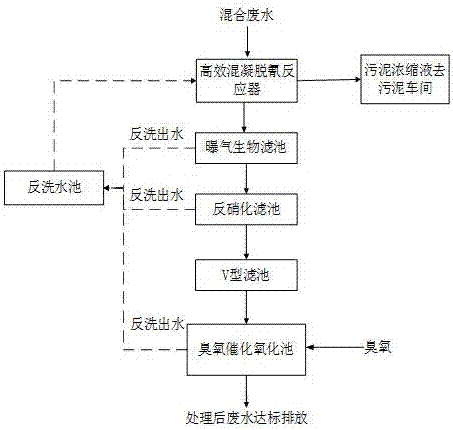

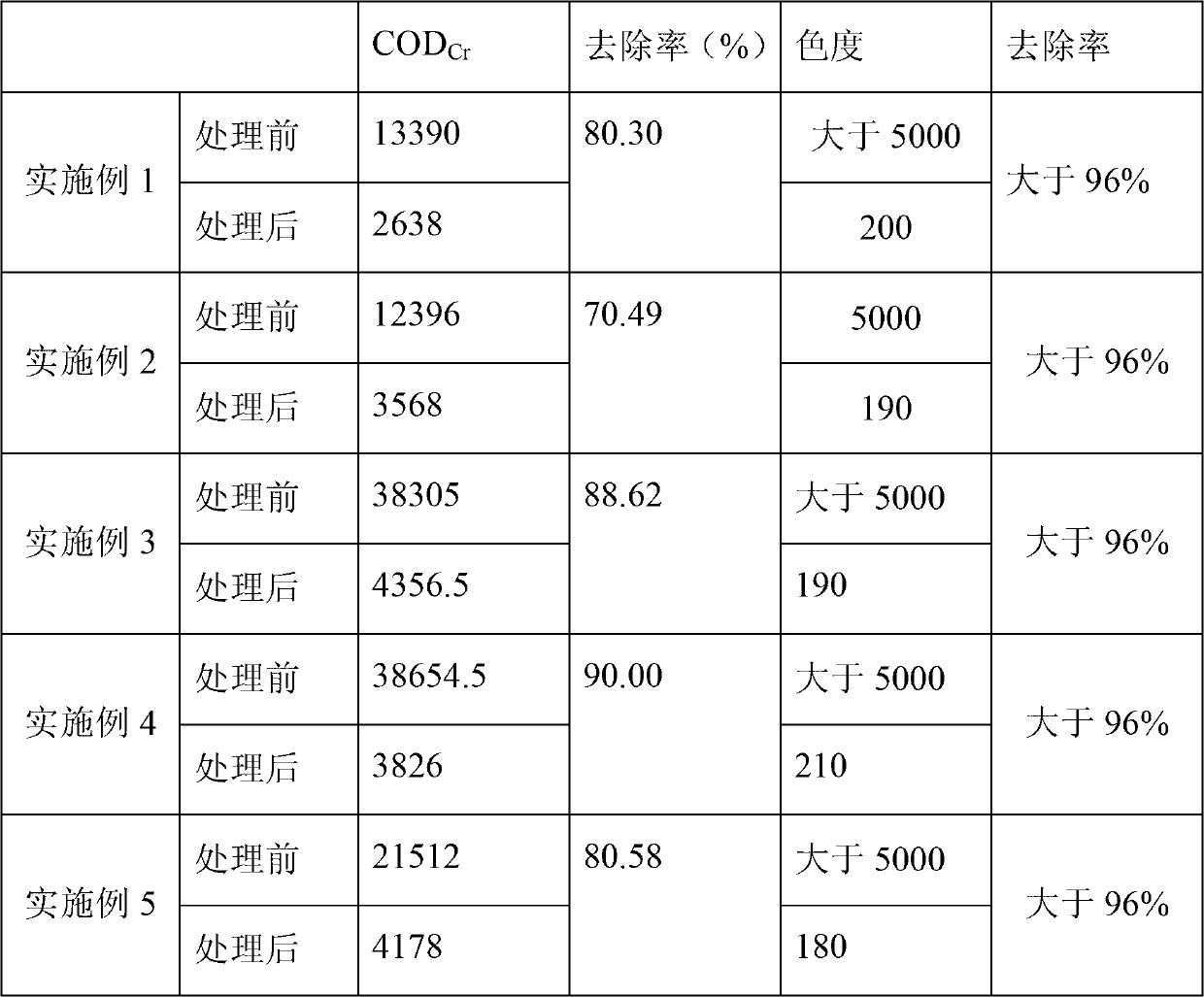

The invention relates to a method for simultaneously removing insoluble organic matter, total cyanogen and total nitrogen in wastewater of an industrial park. The method comprises the following steps: wastewater enters a high-efficiency coagulated decyanation reactor to remove total cyanogen in the wastewater removed from the coagulated decyanation reaction; effluent from the coagulating reaction enters an aeration biofilter, ammonia and nitrogen in the wastewater is oxidized into nitrate nitrogen or nitrite nitrogen, and partial organic matters are oxidized and removed; effluent from the aeration biofilter flows into a denitrification filter tank, and nitrate nitrogen and nitrite nitrogen in the wastewater are denitrified into nitrogen and removed; effluent from the denitrification filter tank is filtered in a V-shaped filter tank and then enters an ozone catalytic oxidation tank, and insoluble organic matters are oxidized into small-molecular organic matters or mineralized in the presence of a catalyst. The method can be used for oxidizing and degrading organic matters while removing total cyanogen and total nitrogen in the wastewater to ensure that treated effluent can be emitted in standard, thus having an excellent market prospect.

Owner:BEIJING CYCLE COLUMBUS ENVIRONMENTAL TECH RES INST CO LTD

Coagulant for treating polysulfonate slurry sewage

InactiveCN102786127AEffective flocculationPromote flocculationWater/sewage treatment by flocculation/precipitationCalcium hydroxideChemical oxygen demand

The invention discloses a coagulant for treating polysulfonate slurry sewage. The coagulant for treating the polysulfonate slurry sewage provided by the invention comprises calcium hydroxide or calcium oxide, and ferric sulfate or ferrous sulfate. The coagulant for treating the polysulfonate slurry sewage provided by the invention is used for treating the sewage containing polysulfonate slurry; the CODCr (Chemical Oxygen Demand) of the treated sewage is reduced by 70-85 percent; the chrominance is determined by using a dilution multiple method and can be reduced to 180-220; the subsequent physicochemical treatment and biochemical treatment can more easily reach standards; and the treatment cost is low.

Owner:成都凯迈环保技术有限公司

Preparation method of novel inorganic polymeric flocculant

InactiveCN104310545AHigh chroma removal rateHigh removal rateWaste water treatment from textile industryWater/sewage treatment by flocculation/precipitationIron sulfateSilicic acid

The invention discloses a preparation method of a novel inorganic polymeric flocculant, and belongs to the environmental protection field. The preparation method comprises the following steps: 1, transferring a certain amount of a sulfuric acid solution into a beaker at normal temperature under normal pressure, titrating by using 0.5mol / L of a sodium silicate solution, measuring the pH value of the solution by using pH meter while titrating, and stopping the dropwise addition when the pH value is 3.5-4.5; 2, continuously carrying out stirring polymerization for 1.0-2.0h, and allowing the polymerized solution to stand for ageing until the solution is pale blue; 3, sequentially adding a certain amount of 0.5mol / L of aluminum sulfate, 0.5mol / L of iron sulfate and 0.1mol / L of sodium pyroborate into the obtained aged polysilicic acid; and 4, adjusting the pH value to 2-3, fully stirring by using a magnetic stirrer for 1.5h, and allowing the fully stirred solution to stand in a refrigerating chamber with the temperature of 0-4DEG C for slaking for 24-28h to obtain the boron-containing polyaluminum ferric silicate flocculant.

Owner:QINGDAO WINCHANCE TECH

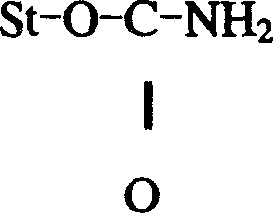

Coagulate method of water treatment purifying technology

InactiveCN1524801AHigh strengthImprove stabilityWater/sewage treatment by flocculation/precipitationAqueous solutionWater temperature

The invention relates to a coagulation process in water treatment purification technology, wherein metal salt flocculating agent and aquadrate starch are mixed in the form of water solution, and are charged into the water to be processed, the aquadrate, dried maize starch and water solution are mixed for mixing reaction for 3-4 hours under the temperature condition of 90-100 deg. C. The invention realizes fine water purification effect and less influence from water temperature.

Owner:WUHAN UNIV OF TECH

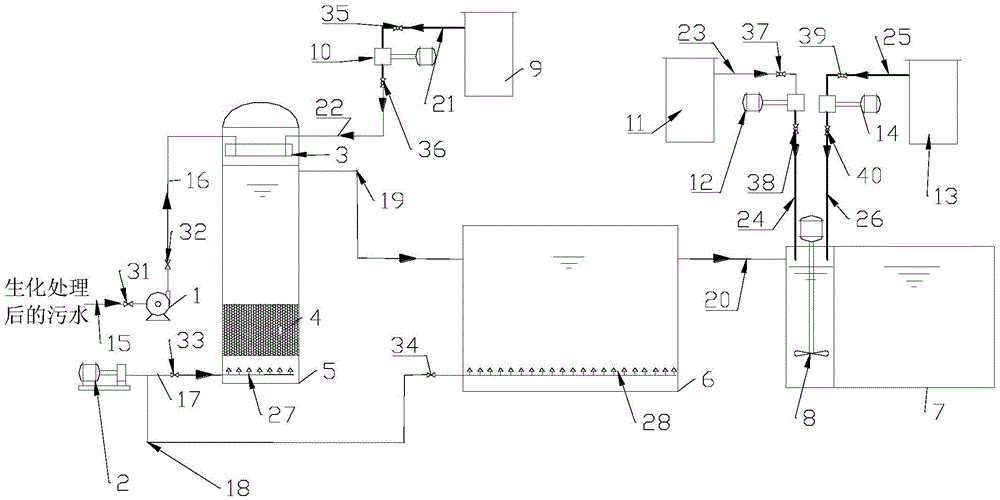

Process and device for efficiently treating wheat straw pulp intermediate wastewater by alkaline method

ActiveCN102329050ASimple structureRun smoothlyMultistage water/sewage treatmentWaste water treatment from plant processingPulp (paper)Pre treatment

The invention discloses a process and equipment for efficiently treating wheat straw pulp intermediate wastewater by an alkaline method. The process comprises the following four steps: carrying out pretreatment, pre-oxidation, aerobic biological treatment and coagulating sedimentation on wastewater so that effluent reaching standard is discharged. According to the invention, a combined process comprising pretreatment, Fenton pre-oxidation, aerobic biological treatment and coagulating sedimentation is adopted, the treatment equipment has simple structure, high efficiency and good treatment effect, and is stable to operate; total CODCr (chemical oxygen demand Cr) removal rate is up to 95-97%, and total chroma removal rate reaches 95-99%; cost is low, thus energy is saved by above 40%; and the yield of sludge is less, thereby saving sludge treatment cost. By the treatment with the process and equipment, the final effluent can stably reach the requirement of 'water pollutant emission standard in pulp-producing paper-making industry (GB3544-2008)'.

Owner:山东绿泉环保科技股份有限公司

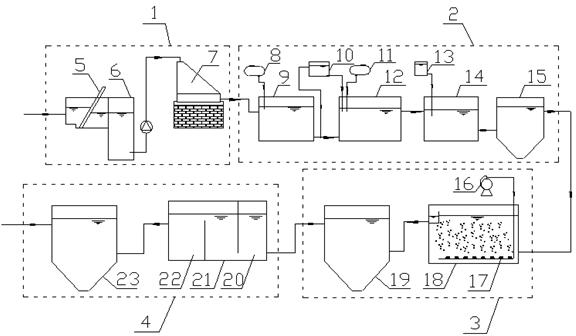

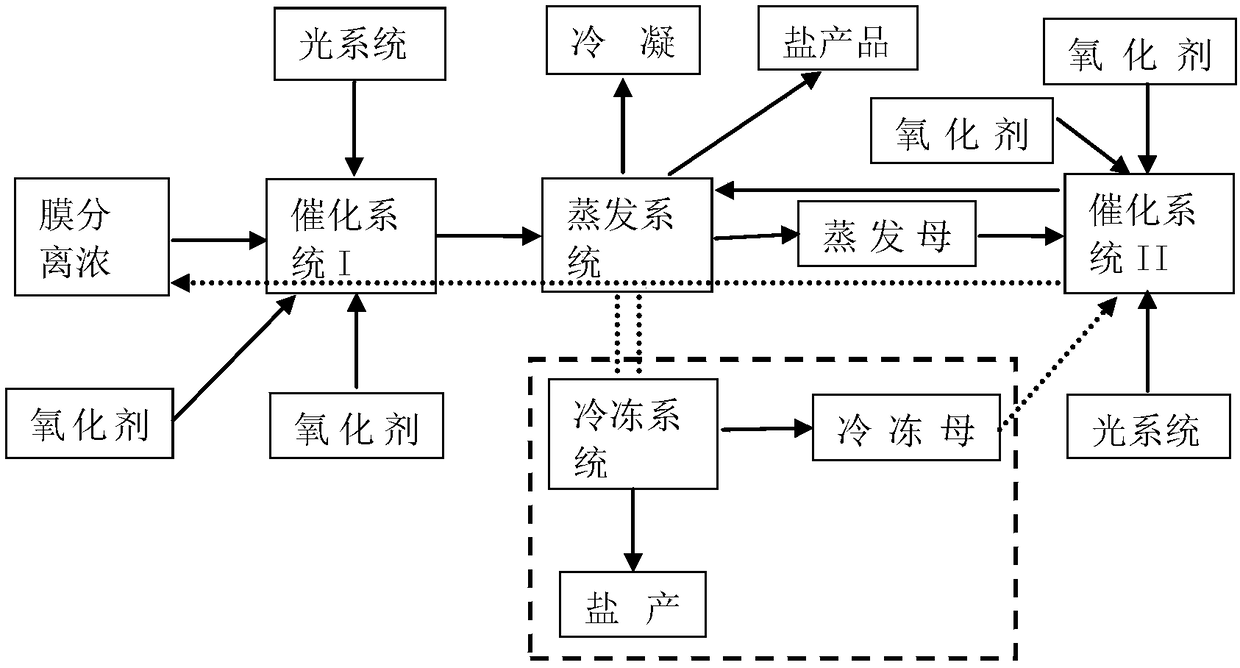

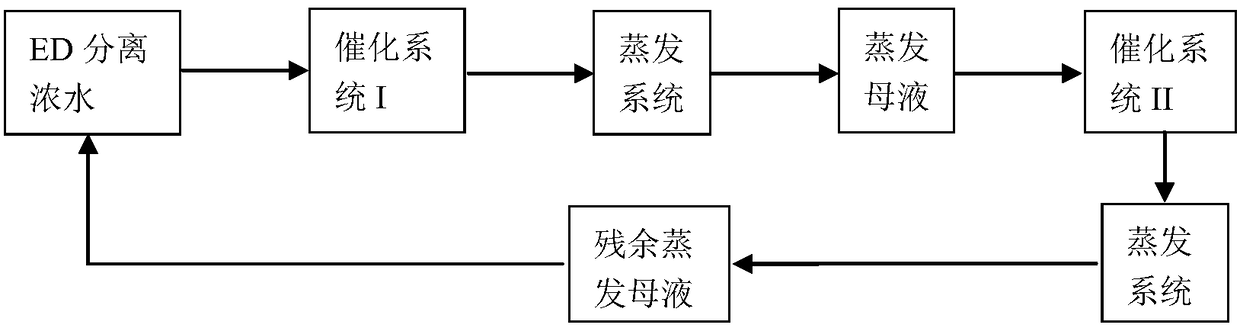

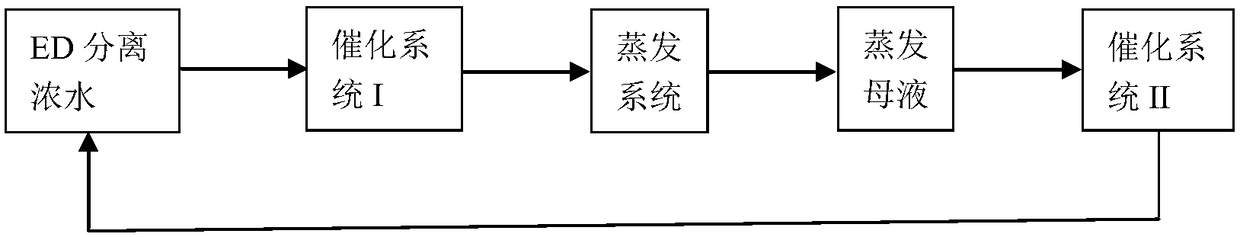

Method for separating high-salt-containing concentrated water by light-assisted catalytic membrane for decoloration

InactiveCN108383306ADifficult Problems Without RecyclingGuaranteed chromaticityWater/sewage treatment by irradiationWater treatment compoundsCatalytic oxidationEvaporation

The invention discloses a membrane separation concentrated-brine utilization technology, and in particular relates to a method for separating high-salt-containing concentrated water by a light-assisted catalytic membrane for decoloration and improving salt quality. The method adopts a fixed-bed catalyst, a plurality of oxidants are added, a processing membrane is used to separate the high-salt-containing concentrated water under light source excitation conditions, organic matter with a larger molecular structure is catalyzed the oxidized, and organic matter with a smaller molecular structure and no color or weak coloring ability is generated, so that chromaticity of the brine is reduced, and a part of COD is removed; and a mother liquor produced after the brine is separated is treated by adopting an enhancing catalytic system, so that quality of produced salt and stability of an evaporation system are improved, and zero emission is realized. The method provided by the invention has theadvantages that no new impurity oxidant is introduced, the problem of difficulty in catalyst recovery does not exist, the chromaticity of the obtained salt and the stability of the evaporation systemare ensured, and wastewater recycling and zero emission are truly realized.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

Preparing method for dyeing waste water treating agent

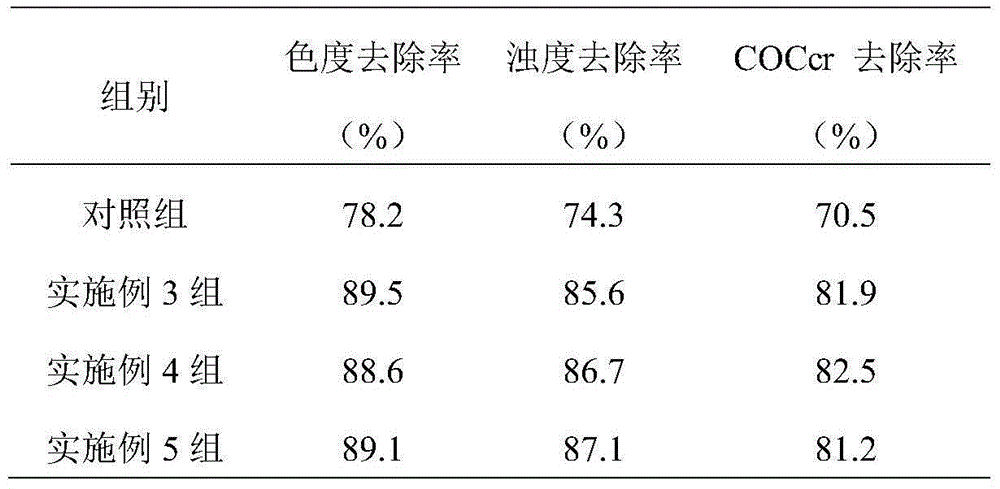

ActiveCN105198015AHigh chroma removal rateHigh turbidity removal rateWater/sewage treatmentSodium BentoniteTurbidity

The invention discloses a preparing method for a dyeing waste water treating agent. The preparing method includes the following steps that bentonite, ferric sulfate, alums, aluminum sulfate, activated carbon, basic aluminum chloride, ferrous sulfate and nickel nitrate are taken, mixed and smashed into fine powder; chitosan is added into certain amount of pure water and dissolved through heating, sodium polyacrylate and starch are added and stirred, and an intermediate material is obtained after heat preservation; the fine powder and the intermediate material are mixed, and polysorbate is added and stirred to obtain the dyeing waste water treating agent. Compared with the prior art, the preparing method is simple in technology and low in cost, the chroma removing rate, the turbidity removing rate and the COCcr removing rate of dyeing waste water treated by the obtained dyeing waste water treating agent can be substantially increased, and the dyeing waste water treating agent is excellent in performance.

Owner:SUZHOU XINENG ENVIRONMENTAL SCI & TECH CO LTD

Poly(ferric aluminum chloride silicate), and preparation thereof and method for treating sewerage by using same

InactiveCN101412554AHigh chroma removal rateWater/sewage treatment by flocculation/precipitationSulfateSilicic acid

The invention discloses polyaluminum ferric silicate chloride, a preparation method thereof and a method for using the polyaluminum ferric silicate chloride to treat sewage. The invention aims to provide polyaluminum ferric silicate chloride which has high removal rate to the colority of the sewage, a preparation method thereof and a method for using the polyaluminum ferric silicate chloride to treat the sewage. The technical proposal of the invention is as follows: a polyaluminum ferric silicate chloride liquid is a mixed liquid of the polyaluminum silicate chloride and polyferric silicate chloride. A method for preparing the polyaluminum ferric silicate chloride liquid comprises the following steps: (1) 1 portion of hydrochloric acid with a concentration of between 10 and 30 percent reacts for 1 to 4 hours in a reaction kettle, and then 0.1 to 0.3 portion of ferrous sulfate is added to react for 1 to 4 hours, and (2) 0.05 to 0.1 portion of silicic acid is dripped to react for 2 to 5 hours at constant temperature to obtain the polyaluminum ferric silicate chloride liquid. The invention is used for sewage treatment.

Owner:乔占印

Montmorillonite modified sodium polyacrylate printing and dyeing sewage treatment agent and preparation method thereof

InactiveCN108658148AImprove intrinsic viscosityEfficient processing effectWater contaminantsWater/sewage treatment by flocculation/precipitationMontmorilloniteSewage

The invention belongs to the technical field of sewage treatment, and particularly relates to a montmorillonite modified sodium polyacrylate printing and dyeing sewage treatment agent and a preparation method thereof. Montmorillonite modified sodium polyacrylate is adopted to replace a traditional coagulating agent (sodium polyacrylate), and because the characteristic viscosity of the sodium polyacrylate is increased by virtue of montmorillonite modification, the printing and dyeing sewage treatment agent compounded by the montmorillonite modified sodium polyacrylate has a more efficient printing and dyeing sewage treatment effect, can obviously improve the chroma removing rate, the turbidity removing rate and the COCcr removing rate of the printing and dyeing sewage, and has excellent properties.

Owner:肇庆市创业帮信息技术有限公司

A printing and dyeing sewage treatment agent

ActiveCN105084441BHigh chroma removal rateHigh turbidity removal rateWater/sewage treatmentWaste water treatment from textile industryTurbidityDyeing wastewater

Owner:太仓市业洪净水新材料有限公司

Sewage treating agent

InactiveCN108217783ASimple processLow costWater/sewage treatmentWaste water treatment from textile industryTurbidityChromia

The invention discloses a sewage treating agent, which is prepared from the following ingredients in parts by weight: 10 parts of sodium polyacrylate, 5-25 parts of starch, 30-50 parts of bentonite, 5-15 parts of ferric sulfate, 5-15 parts of white alum, 0.5-1.5 parts of aluminum sulfate, 1-9 parts of activated carbon, 1-7 parts of basic aluminium oxide, 0.5-1.5 parts of ferrous sulfate, 0.2-0.8 part of nickel nitrate, 10-20 parts of chitosan and 0.02-0.08 parts of polysorbate. Compared with the prior art, the sewage treating agent has the advantages of simple technology and low cost, the chroma removing rate, the turbidity removal rate and the COCrr removal rate of printing and dyeing sewage can be obviously improved, and performance is excellent.

Owner:安庆市龙珠包装有限公司

Cationic dye printing and dyeing wastewater treatment process

InactiveCN101381173BRealize industrial productionCost efficientMultistage water/sewage treatmentAfter treatmentEvaporation

The invention provides a cationic dye printing-dyeing wastewater treatment process, which belongs to the technical field of wastewater treatment. The treatment process uses a foam separation technique to treat cationic dye printing-dyeing wastewater, and concretely comprises the following: step 1, cationic dye printing-dyeing wastewater is collected and detected; step 2, the cationic dye printing-dyeing wastewater is pretreated; step 3, foam separation cyclic decolorization is carried out, which comprises a step of discoloring four times, wherein a device is a bubbling tower with the diameterof 32 mm; the decolorization needs sodium dodecyl benzene sulfonate as anionic surfactant every time; the cationic dye printing-dyeing wastewater after treatment meets the GB8978-1996 secondary discharge standard every time and is directly discharged; and a cationic dye crude product obtained by filtering anti-foam liquid is applied to a printing-dyeing procedure again; and step 4, evaporation and crystallization are carried out, and the collected cationic dye crude product is applied to the printing-dyeing procedure. The process has the advantages that the process can realize the industrial production of cationic dye printing-dyeing wastewater treatment, is convenient to operate and low in cost, and can greatly reduce secondary pollution.

Owner:HEBEI UNIV OF TECH

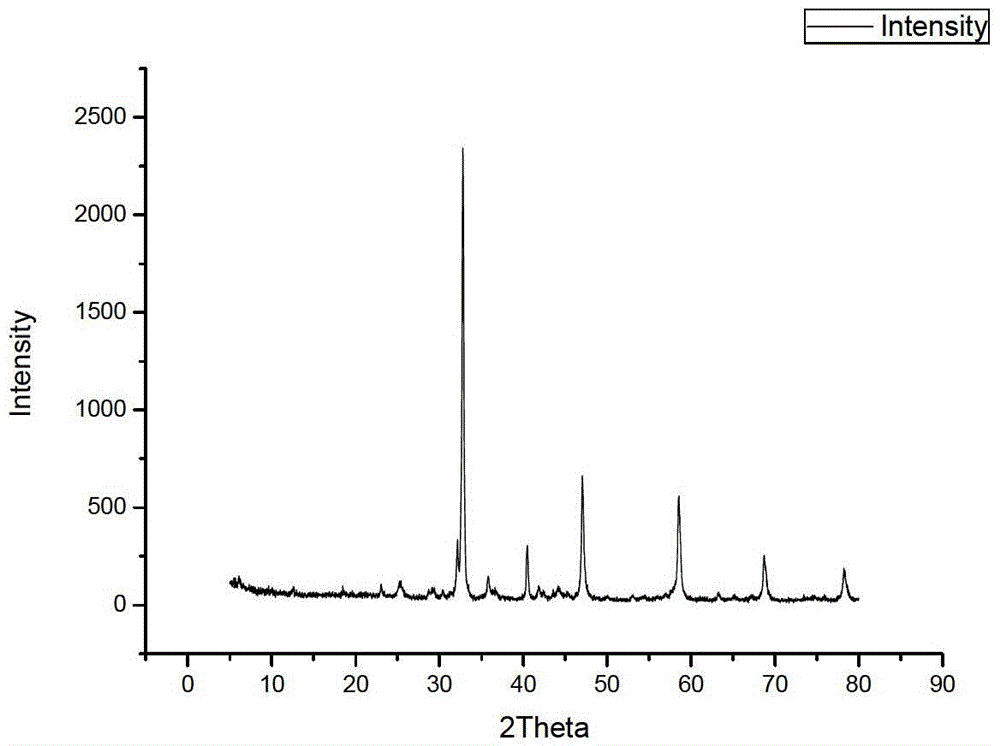

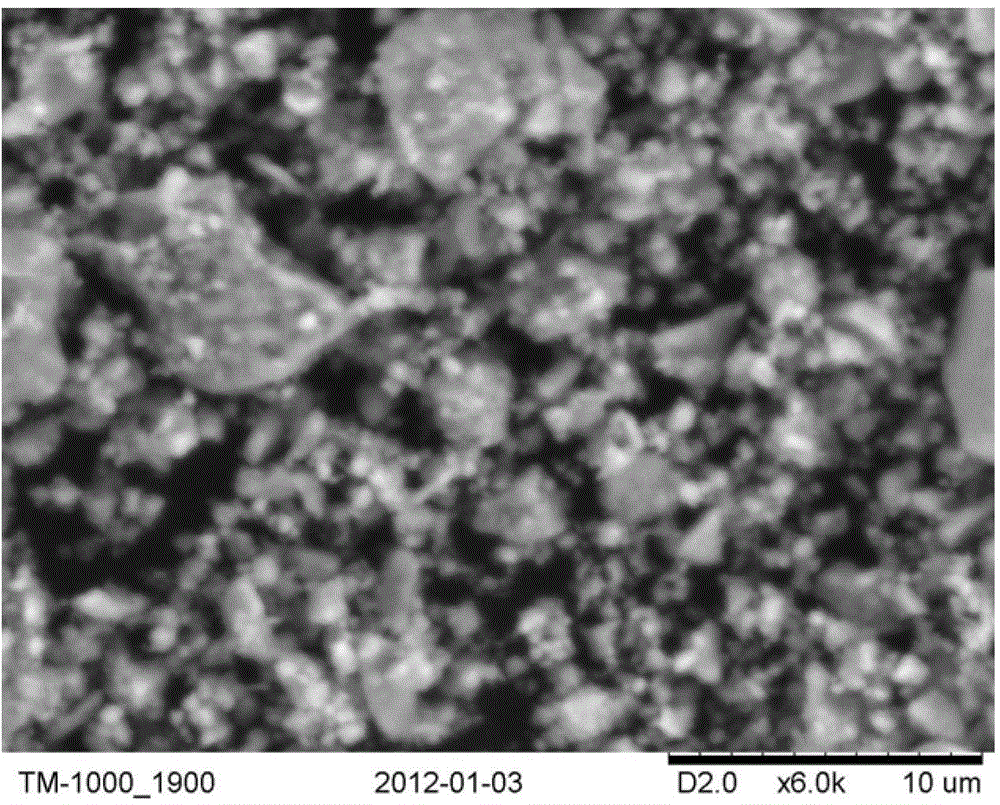

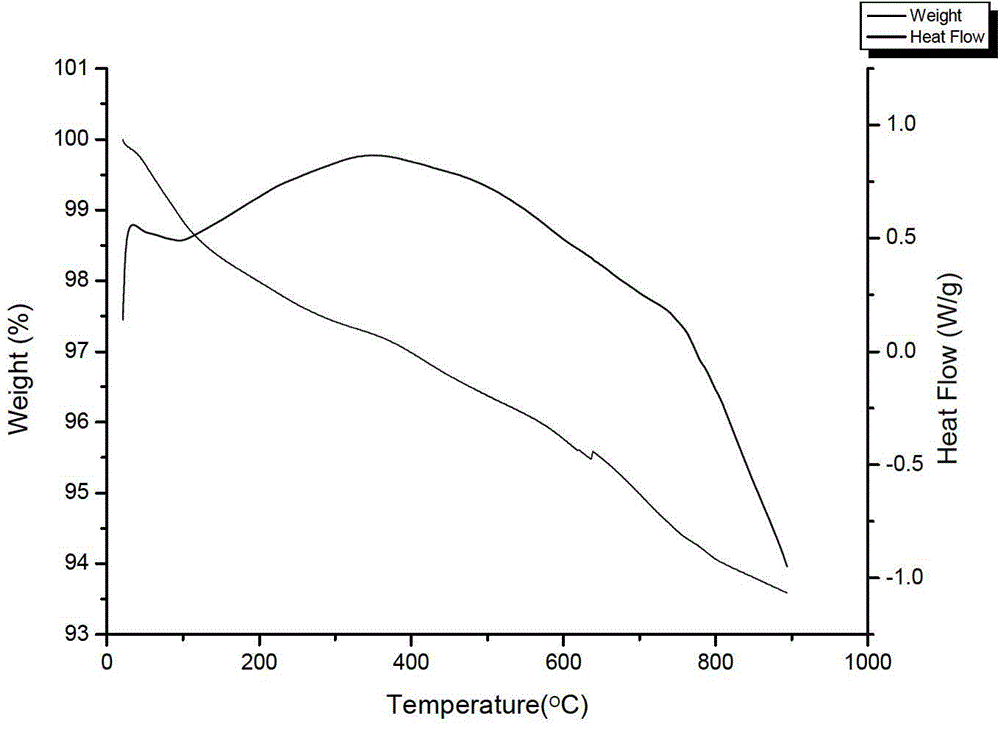

A kind of preparation method of perovskite type photocatalyst and its products

InactiveCN102836719BGood photocatalytic degradation activityHigh chroma removal rateMetal/metal-oxides/metal-hydroxide catalystsCongo redBarium salt

The invention discloses a preparation method of a perovskite type photocatalyst. The method comprises the following steps of: (1) taking barium salt, strontium salt, cobalt salt, ferric salt and citric acid, adding distilled water to mix and dissolve, sealing and heating to be at 90-100 DEG C, stirring at a constant temperature for 3-4h, releasing the sealing and heating continuously until the water is evaporated to form colloid, drying the colloid for 18-22h, holding the temperature at 110-130 DEG C; and (2) taking out a dried sample for calcination and grinding the calcined sample to obtain the black powder-shaped BaxSSr1-xFe0.5Co0.5O3-delta photocatalyst. The invention also discloses a perovskite type photocatalyst product prepared according to the preparation method; the value range of the x in the prepared BaxSSr1-xFe0.5Co0.5O3-delta photocatalyst is 0-1. Perovskite type oxides prepared through using the preparation method have excellent photocatalytic degradation activity, the chroma removal rate after the reaction is high, the degradation rate for methyl orange with appointed concentration is above 95% and the introduction rate for appointed Congo red dyes is up to 93%.

Owner:ZHEJIANG SHUREN UNIV

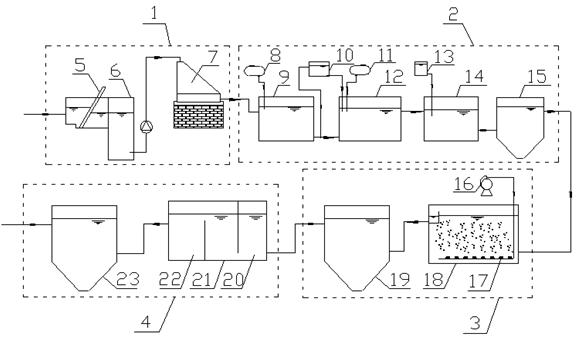

Handling method for advanced purification of little-volume refractory wastewater and operation equipment

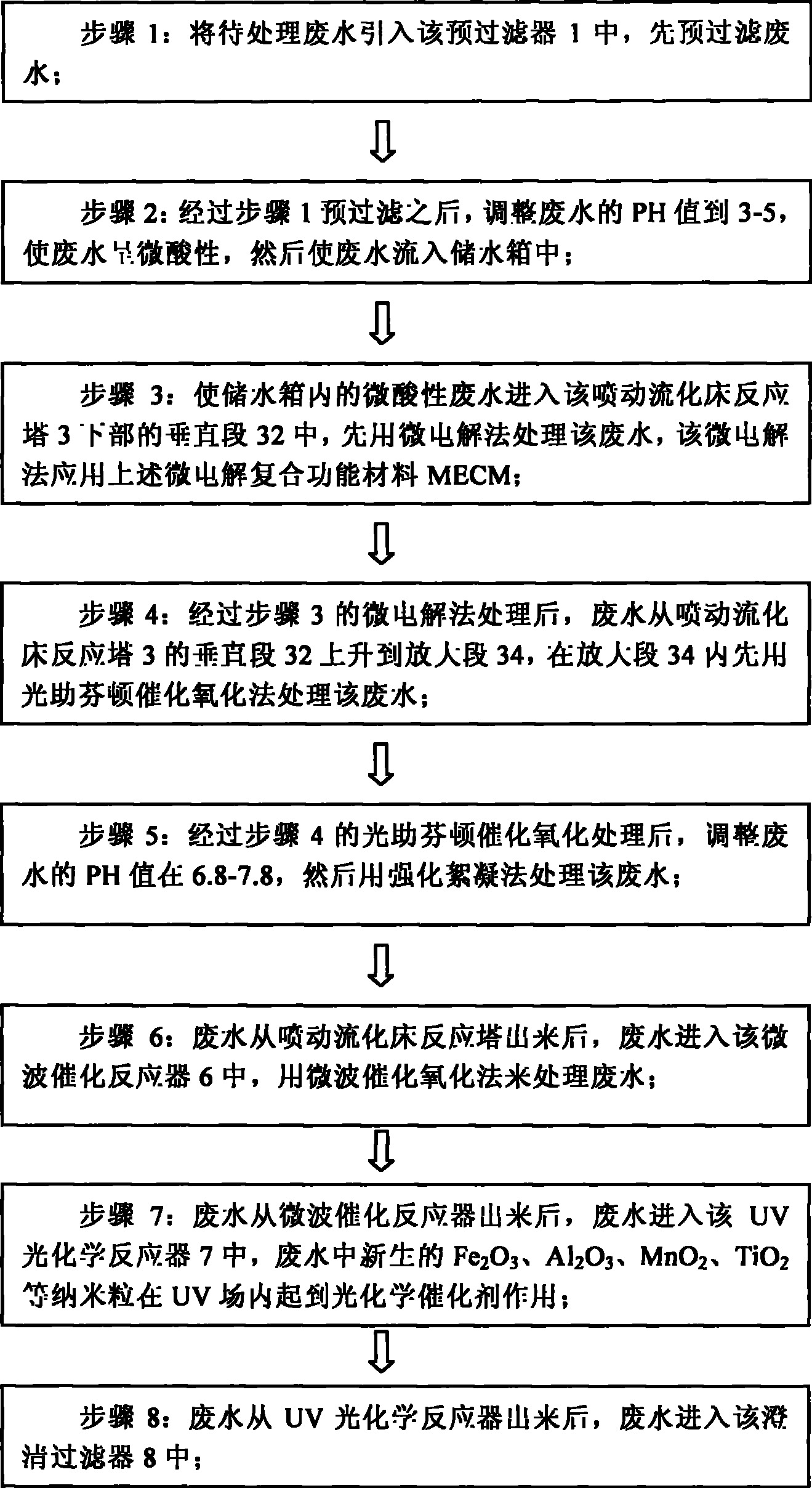

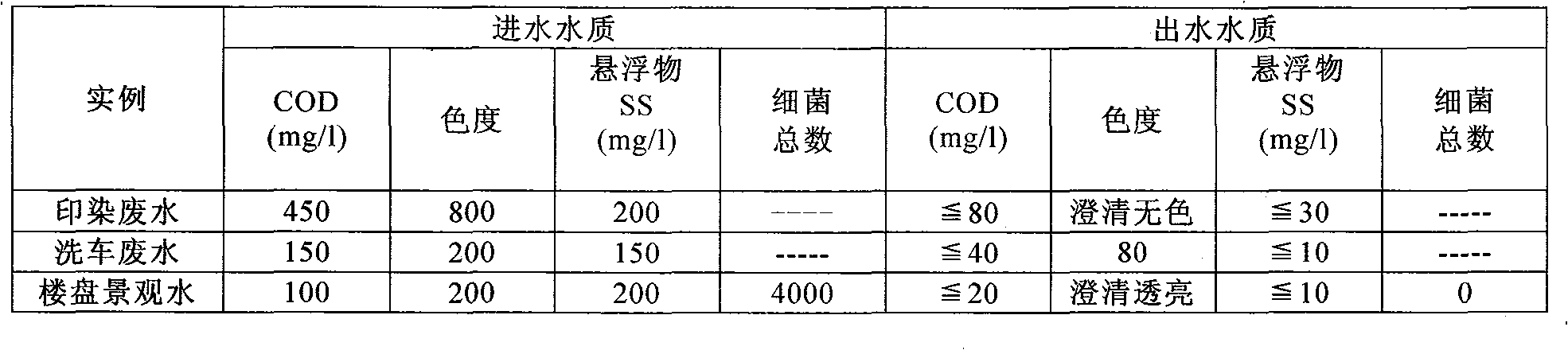

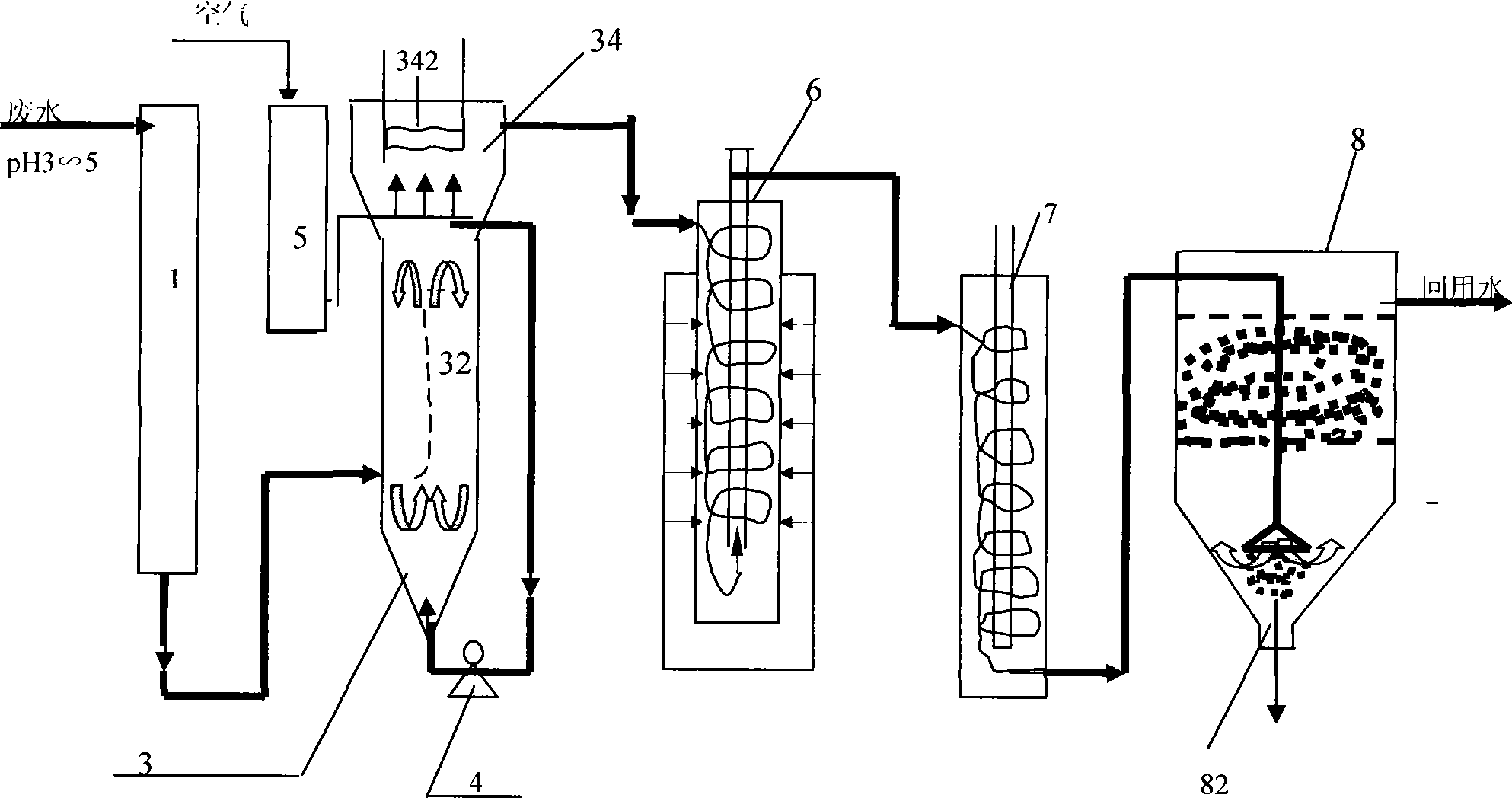

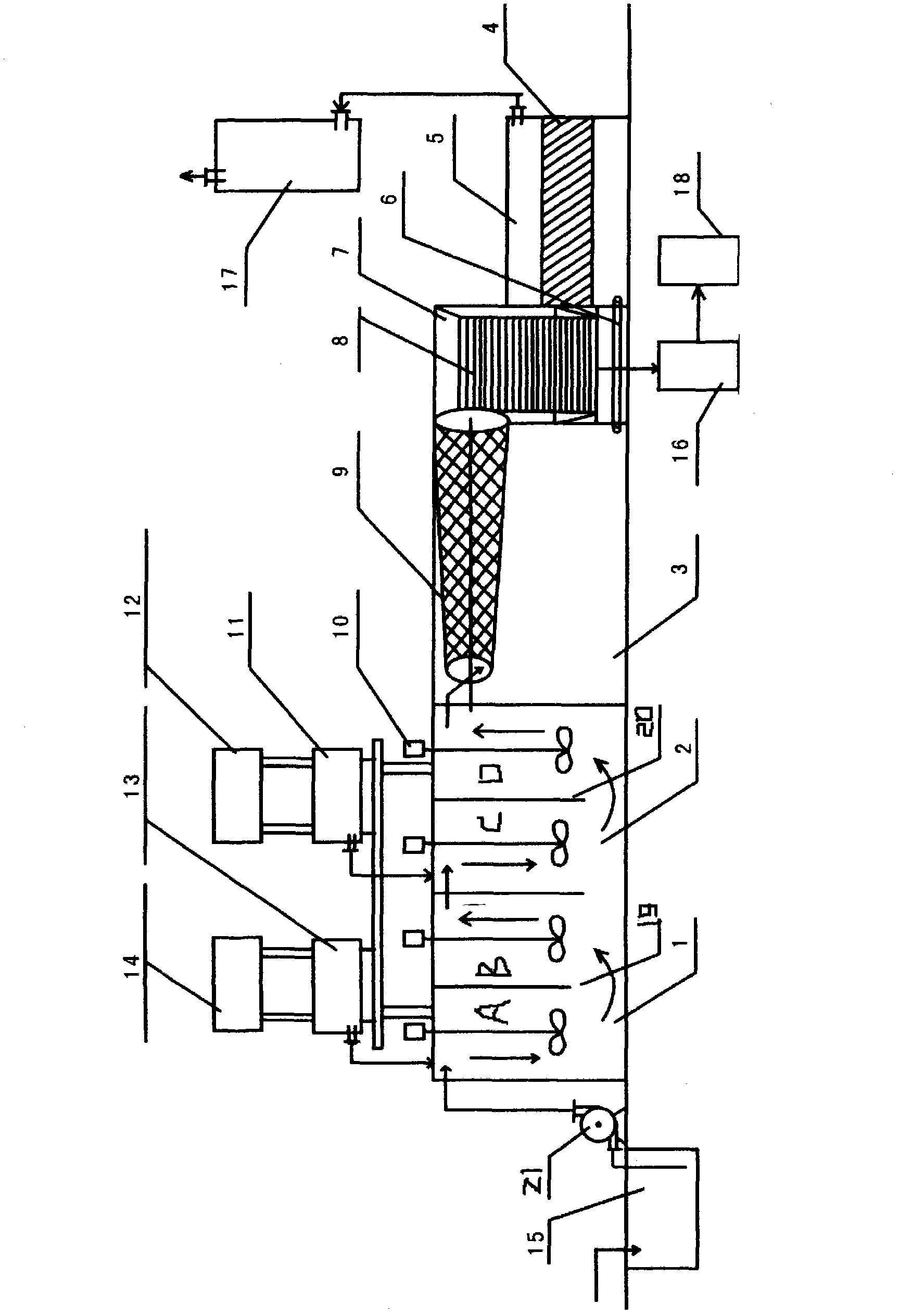

InactiveCN101254987BHigh removal rateLow costWater/sewage treatment by irradiationMultistage water/sewage treatmentElectrolysisFluidized bed

The invention relates to a treatment method for small water quantity refractory wastewater deep purifying and utilizing. The method comprises the following steps: step one, pre-filtrating wastewater is performed firstly; step two, the pH value of the wastewater is adjusted to 3-5 to ensure the wastewater to present subacidity; step three, the wastewater flows into a spout-fluid bed reaction tower, the wastewater is processed through a micro-electrolysis method, and micro-electrolysis composite functional material is utilized in the micro-electrolysis method; step four, the wastewater is processed through a photo-assisted fenton catalytic oxidation method; step five, the pH value of the wastewater is adjusted to 6.8-7.8, and then the wastewater is processed through strengthen flocculation method; step six, the wastewater flows to a microwave catalysis reactor, and is processed through a microwave catalytic oxidation method; step seven, the wastewater flows into a UV photochemical reactor, and is processed through the UV photocatalysis; step eight, the wastewater flows into a gravitation filter, and the wastewater can be clarified to meet the requirement of the reuse water quality. The invention also provides equipment for performing the treatment method.

Owner:东莞市英硫净水服务有限公司

Integrated combination device for physicochemical treatment of black liquid

The invention discloses a combination device for physicochemical treatment of black liquid. The combination device comprises chemical storage tanks, chemical feed tanks, an oxygenolysis bin, a coagulation polycondensation bin, a dehydration separator bin, a turning slag extractor bin and a clear water recycle bin all integrated. The oxygenolysis bin is connected with the coagulation polycondensation bin, a set of chemical storage tank and chemical feed tank are arranged at upper part, the oxygenolysis bin and coagulation polycondensation bin are be provided with a separating plates, with the lower parts being communicated, each bin is divided into two chambers, each chamber is provided with a set of stirring device, and the liquid is fed and discharged at the upper part. The coagulation polycondensation bin is connected with the dehydration separator bin, which is provided with a micro-filtering dehydrator at the upper part and with a water tank water pipe communicating with the clear water recycle bin at the lower part, the upper dehydrator communicates with the turning slag extractor bin, which is provided with a moving board for sludge discharge and connected with the clear water recycle bin, and a clear water bin is provided with a sloped tube sediment layer for sedimentation to obtain clear water and discharge into a water storage tank. The combination device adopts a black liquid lifting pump and chemical liquid, to rapidly decompose nano-lignin and perform polycondensation to obtain bulk-shaped solid substance with no viscosity, high dehydration speed and efficiency, chemical oxygen consumption removal up to 95% and chroma removal up to 98%. The combination device has reasonable design, high device integration level, small floor area, energy saving and environment friendliness, and can be matched with alkali recovery process to trap diluted black liquid for physicochemical treatment, and realize zero discharge of black liquid.

Owner:王新德

Composite material for printing and dyeing wastewater treatment and preparation method thereof

InactiveCN109331806AHigh catalytic efficiencyImprove mechanical propertiesWater/sewage treatment by irradiationWater treatment compoundsCeriumDyeing wastewater

The invention discloses a composite material for printing and dyeing wastewater treatment. An active component of the composite material is nanometer titanium oxide doped with zinc oxide and cerium oxide; a carrier of the composite material comprises surface-modified fly ash and aluminum oxide; the molar ratio of the zinc oxide to the titanium oxide is (1-10):1; the molar ratio of the cerium oxideto the titanium oxide is (0.2-5):1; the mass ratio of the surface-modified fly ash to the aluminum oxide is (1-10):1; in the composite material, the molar ratio of the active component to the carrieris (0.1-5):1. The composite material significantly improves the catalytic efficiency of a photooxidation catalyst and has relatively strong organic matter adsorbing capacity; the prepared composite material has good mechanical properties, can be repeatedly recycled for use, and has the service life being much longer than that of the composite material in the prior art.

Owner:青岛亿天环保科技有限公司

Cotton pulp wastewater treatment integration technology

InactiveCN105540927AImprove comprehensivenessSimple equipmentWater contaminantsWater aerationSewageOxidizing agent

The invention discloses a cotton pulp wastewater treatment integration technology. Cotton pulp wastewater subjected to biochemical treatment is placed in a catalytic oxidation tower, and meanwhile an oxidizing agent is pumped into the catalytic oxidation tower through an oxidizing agent adding box; a catalyst is arranged at the inner bottom of the catalyst oxidation tower; air is blown in through an air blower while the wastewater enters the tower; the sewage treated by the catalytic oxidation tower enters a contact pond, and an efficient air diffusion system is arranged in the contact pond; water flowing out of the contact pond enters a flocculation and sedimentation pond; a flocculating agent is pumped into a flocculation pond body of the flocculation and sedimentation pond through a flocculating agent adding box, meanwhile a coagulant aid is pumped into the flocculation pond body of the flocculation and sedimentation pond through a coagulant aid adding box, a stirrer and a water pump in the flocculation pond body of the flocculation and sedimentation pond are linked, and water flowing out of the flocculation and sedimentation pond can meet standards and be discharged. The COD and the chromaticity removal rate are high, the operation process is stable and reliable, operation is easy, the treated sewage can be reused, and economic benefits are considerable.

Owner:XINJIANG ENVIRONMENTAL ENG TECH

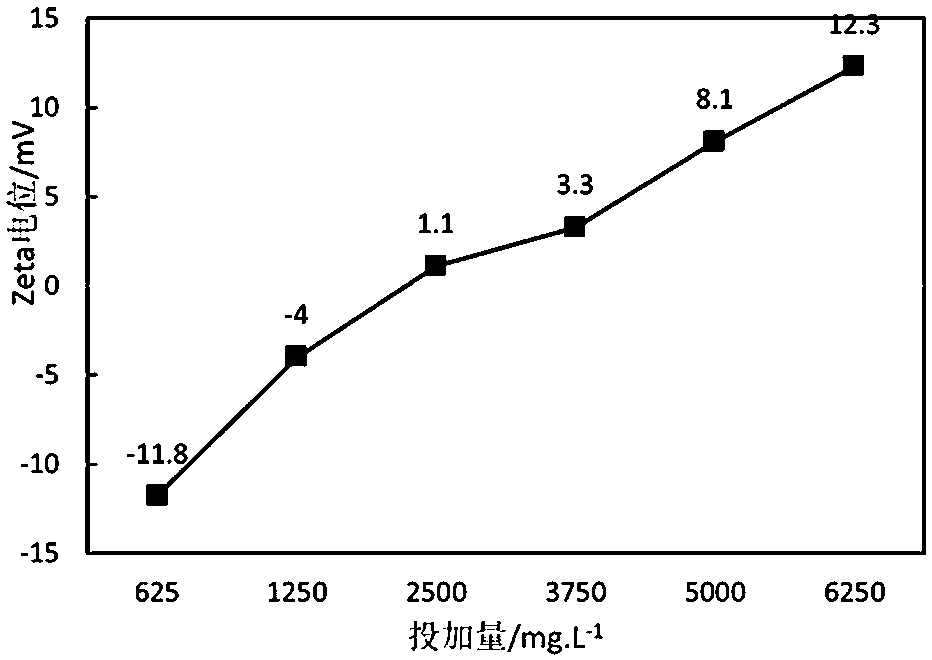

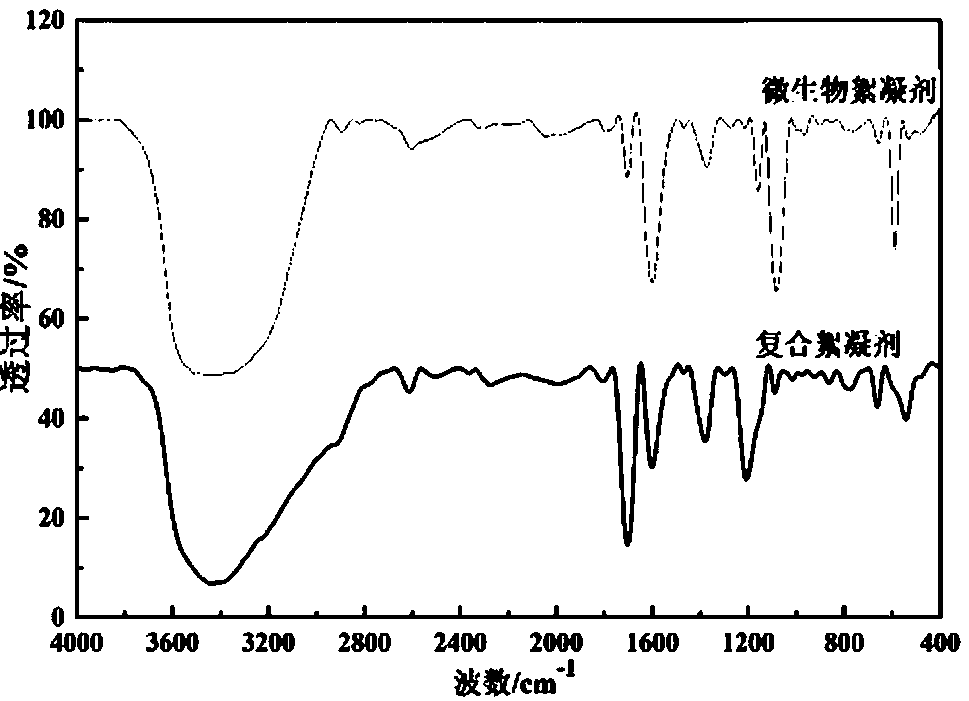

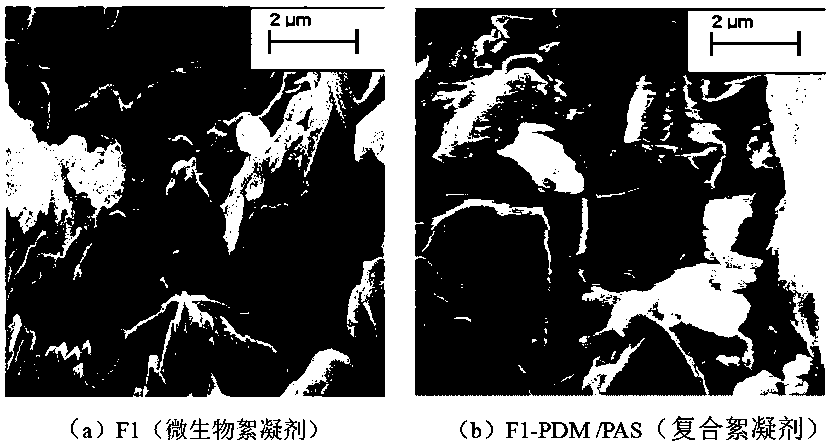

Aluminum salt type microbial composite flocculant for treating shale gas drilling wastewater

ActiveCN110615514AMultiple adsorption potentialEasy to compressWaste water treatment from quariesWater/sewage treatment by flocculation/precipitationAluminium sulfateWastewater

The invention discloses an aluminum salt type microbial composite flocculant for treating shale gas drilling wastewater, and belongs to the field of environmental wastewater treatment. A preparation process of the composite flocculant comprises the following specific steps: adding PDMDAAC (dimethyl diallyl ammonium chloride homopolymer) into an aluminum sulfate solution according to a mass ratio of (30:1)-(35:1) to obtain a PAS-PDM solution; then adding polysaccharide extracted from mycobacteria into the mixed solution, with the dosage being 1%; and stirring the mixture to obtain the stable aluminum salt microbial composite flocculant. In the wastewater treatment process, the coagulation effect of the prepared aluminum salt microbial flocculant is better than that of a conventional coagulant under the condition that the addition amounts are similar, and the COD removal rate of the aluminum salt microbial flocculant is increased by 24.10%-12.60%; and the chroma removal rate is increasedby 50%-10%.

Owner:SOUTHWEST PETROLEUM UNIV

Advanced treatment process for degumming wastewater of ramie

InactiveCN110015817AHigh removal rateHigh chroma removal rateWater/sewage treatmentTreatment with aerobic and anaerobic processesPectinaseFerrous salts

The invention belongs to the technical field of wastewater treatment, and provides an advanced treatment process for degumming wastewater of ramie. The method comprises the following steps: (1) adjusting a pH value of scouring wastewater, then adding biological enzymes into the scouring wastewater, carrying out a reaction, wherein the biological enzymes comprise pectinase, hemicellulase and xylanase, and carrying out filtering so as to obtain a first treated solution; (2) adding ferrous salt and hydrogen peroxide into the first treated solution for treatment, and carrying out filtering so as to obtain a second treated solution; (3) adding quicklime into the second treated solution, and carrying out stirring and standing so as to obtain a supernatant; and (4) mixing the supernatant with filtered wastewater, adding a flocculating agent, carrying out flocculation, then carrying out filtering, successively allowing obtained filtrate to enter a hydrolysis acidification pool, an anaerobic pool and an aerobic pool for treatment, then carrying out adsorption with an adsorbent, and carrying out filtering so as to obtain treated water. The process provided by the invention can significantlyreduce the content of pollutants in the degumming wastewater of the ramie, especially the scouring wastewater, so the degumming wastewater of the ramie can reach national first-level discharge standards after treatment.

Owner:SICHUAN JB RAMIE

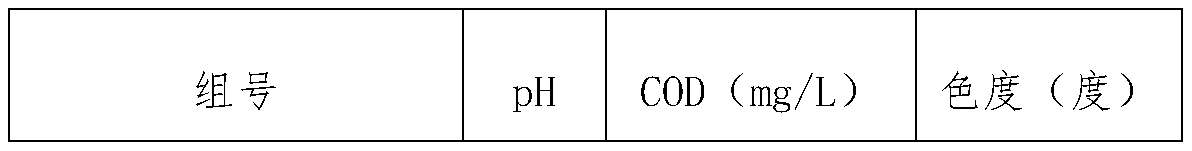

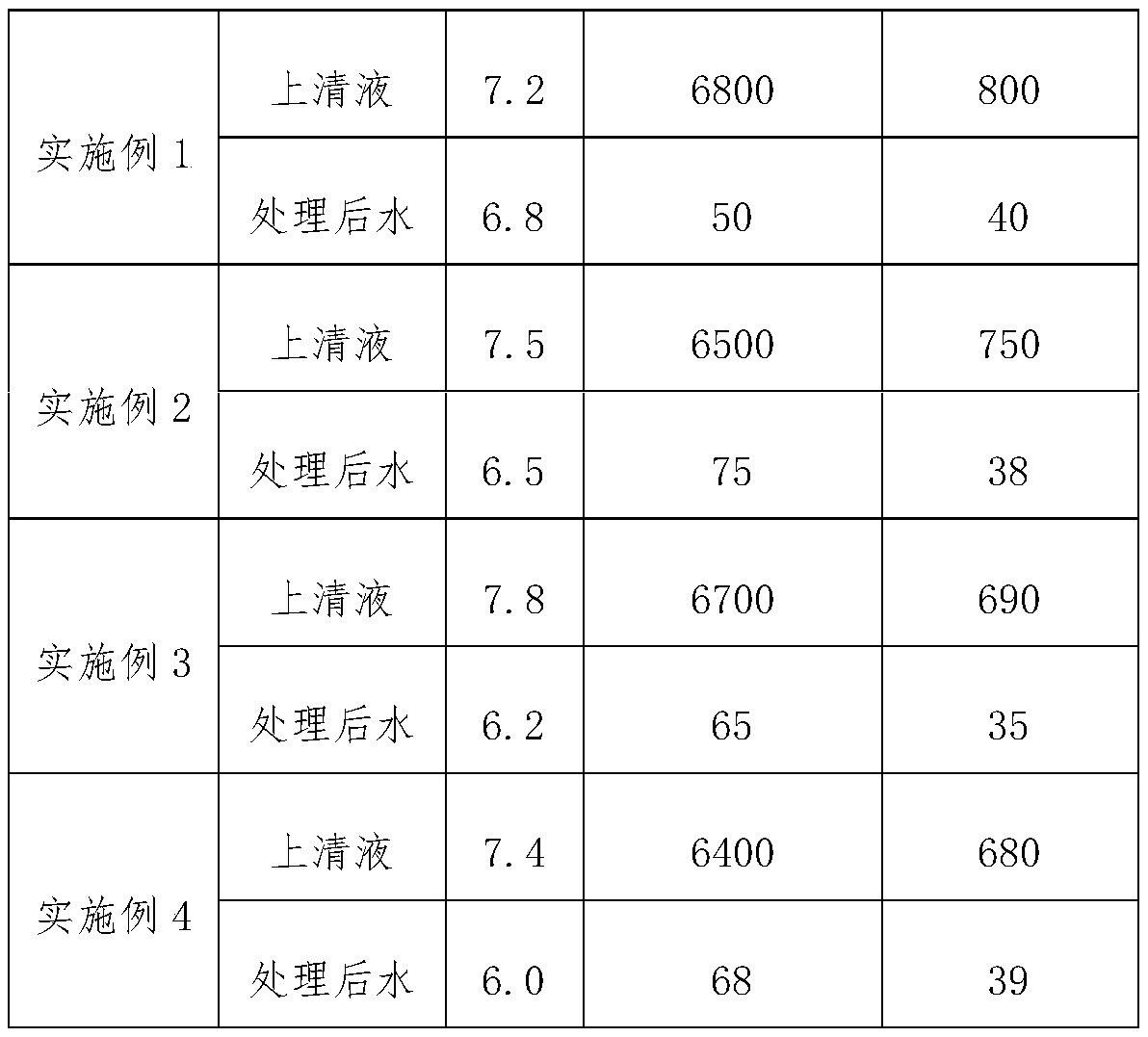

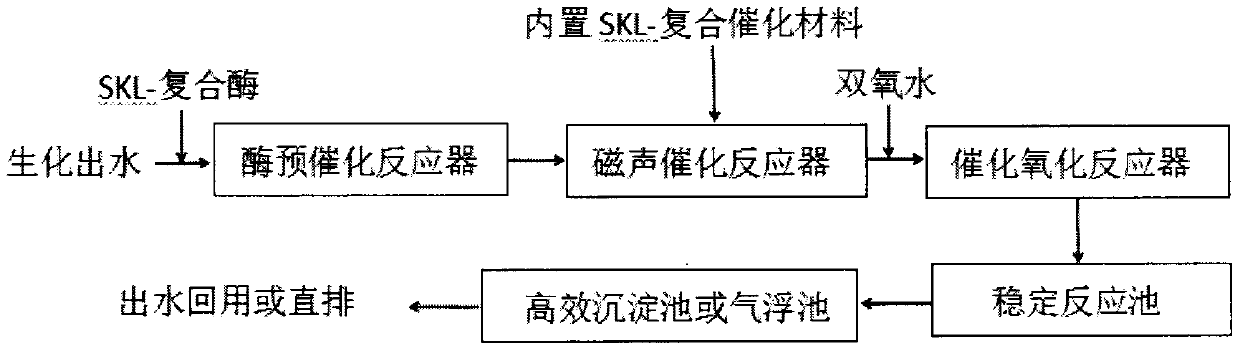

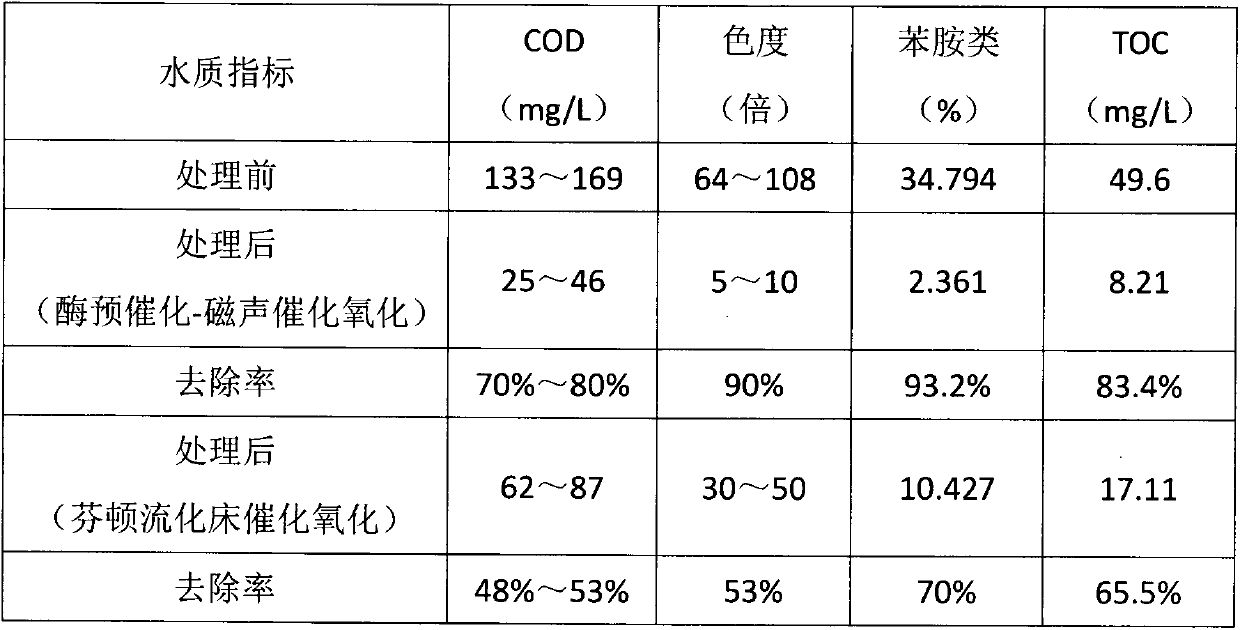

A kind of enzyme precatalysis-magnetoacoustic catalytic oxidation advanced water treatment method

ActiveCN106630390BReduce surface tensionFast catalytic speedWater/sewage treatment by magnetic/electric fieldsMultistage water/sewage treatmentFenton reactionCatalytic oxidation

The invention relates to an enzyme pre-catalysis-magnetosonic catalytic oxidation deep treatment method for water. According to the method, waste water subjected to physicochemical and biochemical twp-grade treatment is fed into an enzyme pre-catalysis reactor, and an SKL-composite enzyme is added to catalyze reactions; then the waste water is subjected to a multiple-potential-difference multi-metal chemical catalysis reaction; hydrogen peroxide is added to perform a strong oxidation reaction; generated hydroxy free radicals (.OH) and organic pollutants are subjected to a rapid chain type reaction, and harmful compounds are oxidized into CO2, H2O or mineral salts; objectives of degrading pollutants and fully utilizing agents are achieved; solid liquid separation is performed to remove SS; and PAM is added. The method overcomes the defects that emission standards cannot be stably met, and treating costs are at an all-time high. The method overcomes the problem that a large amount of iron sludge is generated in a traditional homogeneous Fenton reaction process, reduces secondary pollution, reduces the treating cost, and achieves catalytic pollutant degradation in a condition near a neutral condition.

Owner:南京神克隆环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com