Patents

Literature

379 results about "Catalytic membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A catalytic membrane reactor ( CMR) has a membrane that has either been coated with or is made of a material that contains catalyst, which means that the membrane itself participates in the reaction. Some of the reaction products (those that are small enough) pass through...

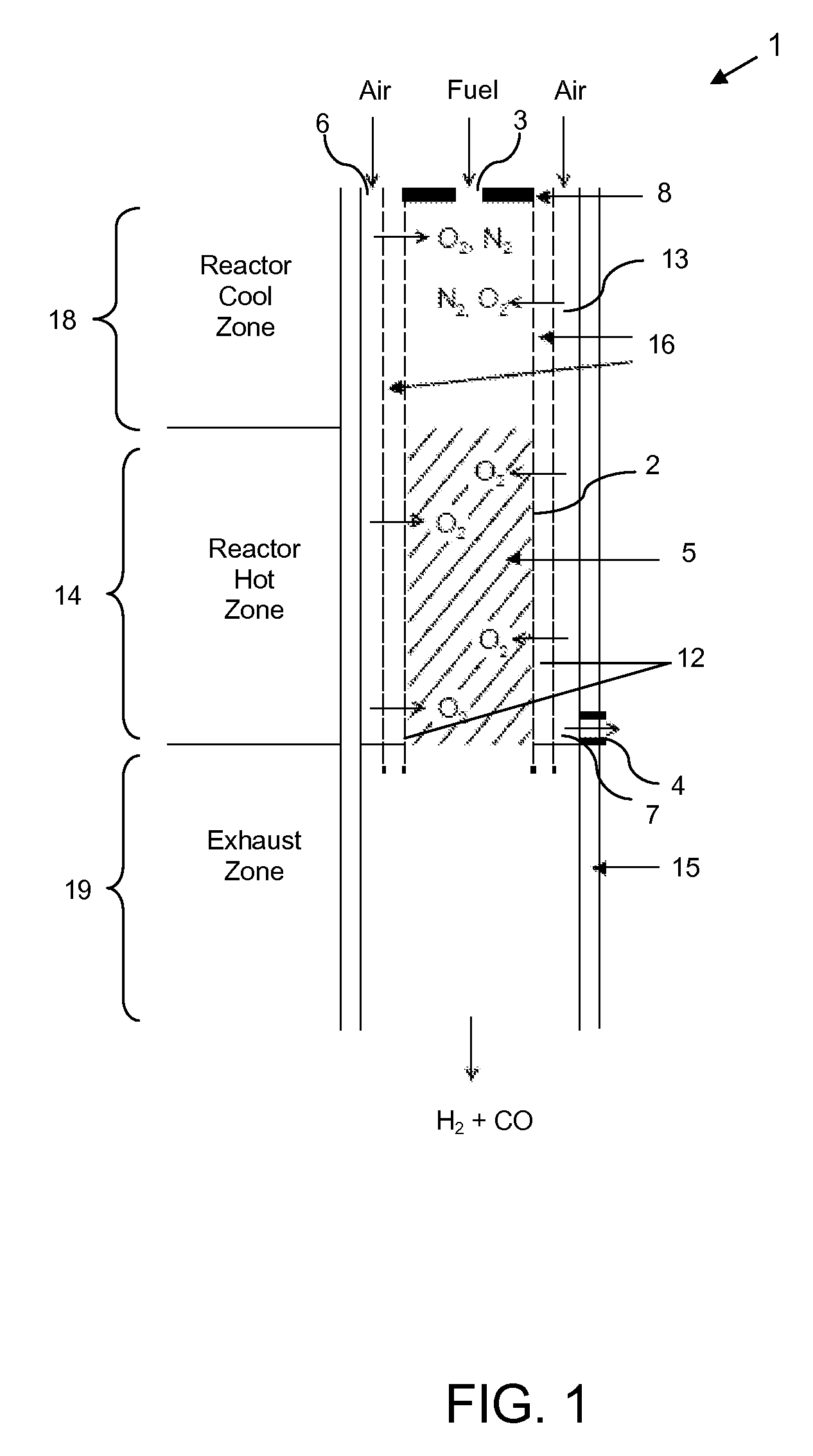

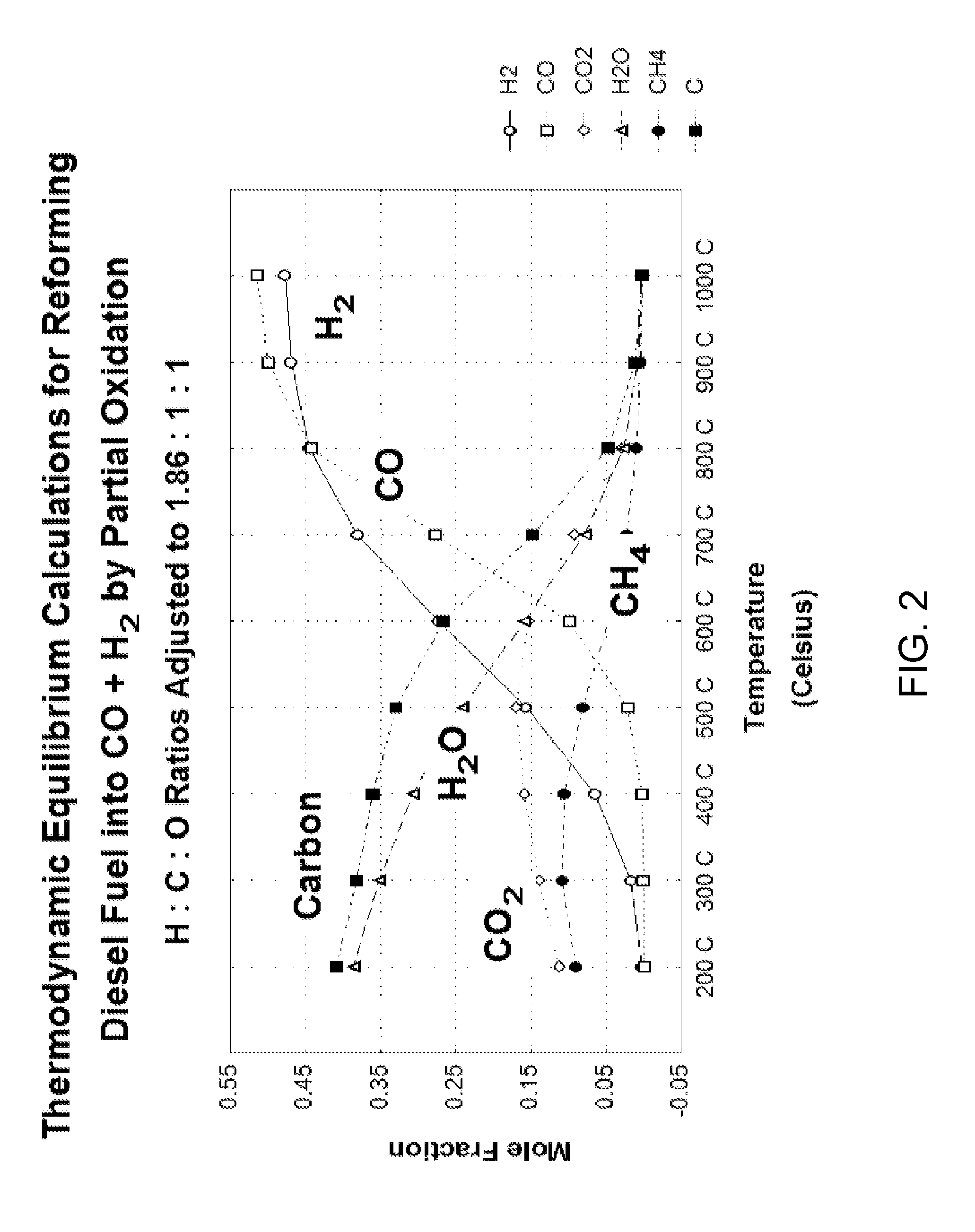

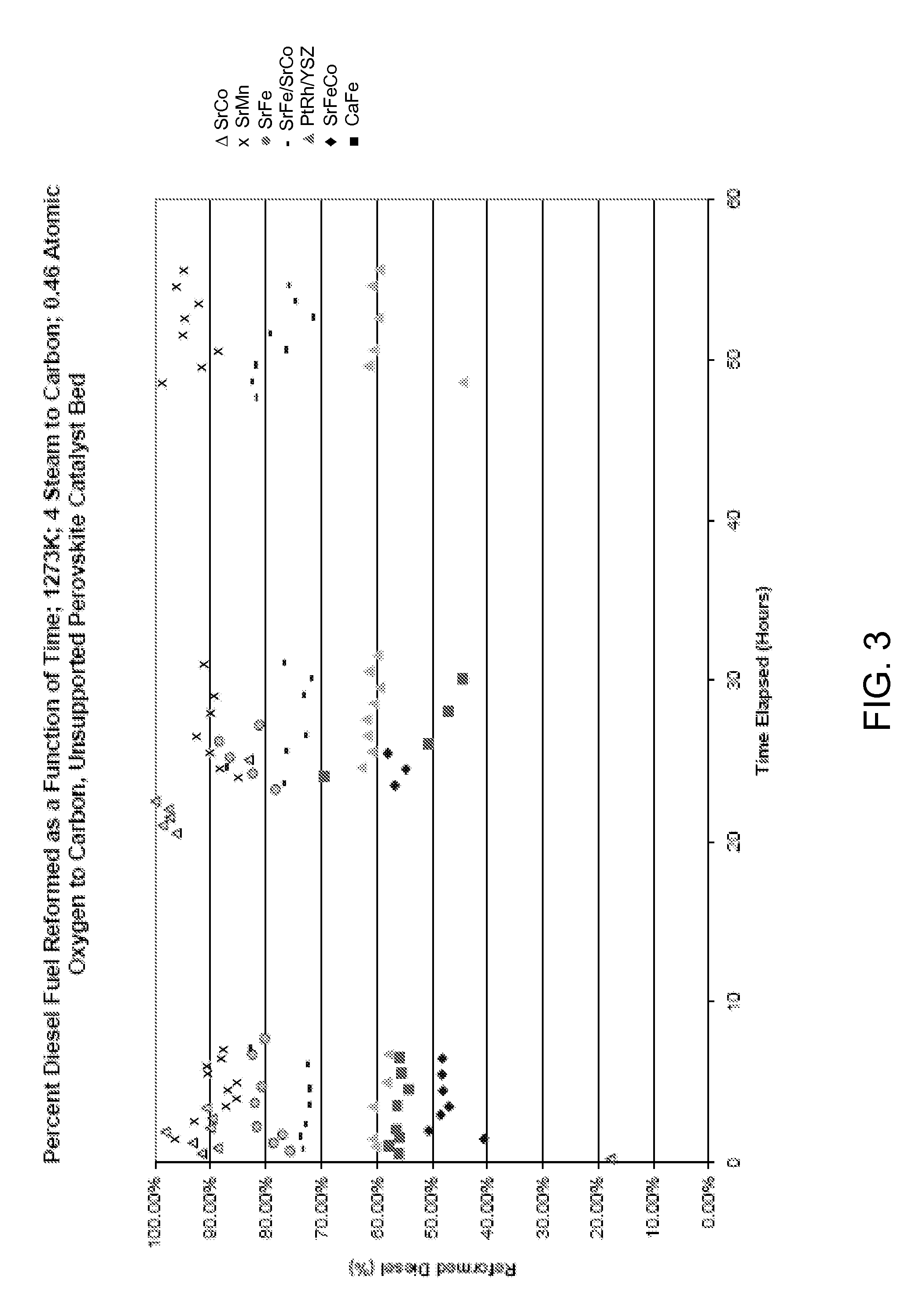

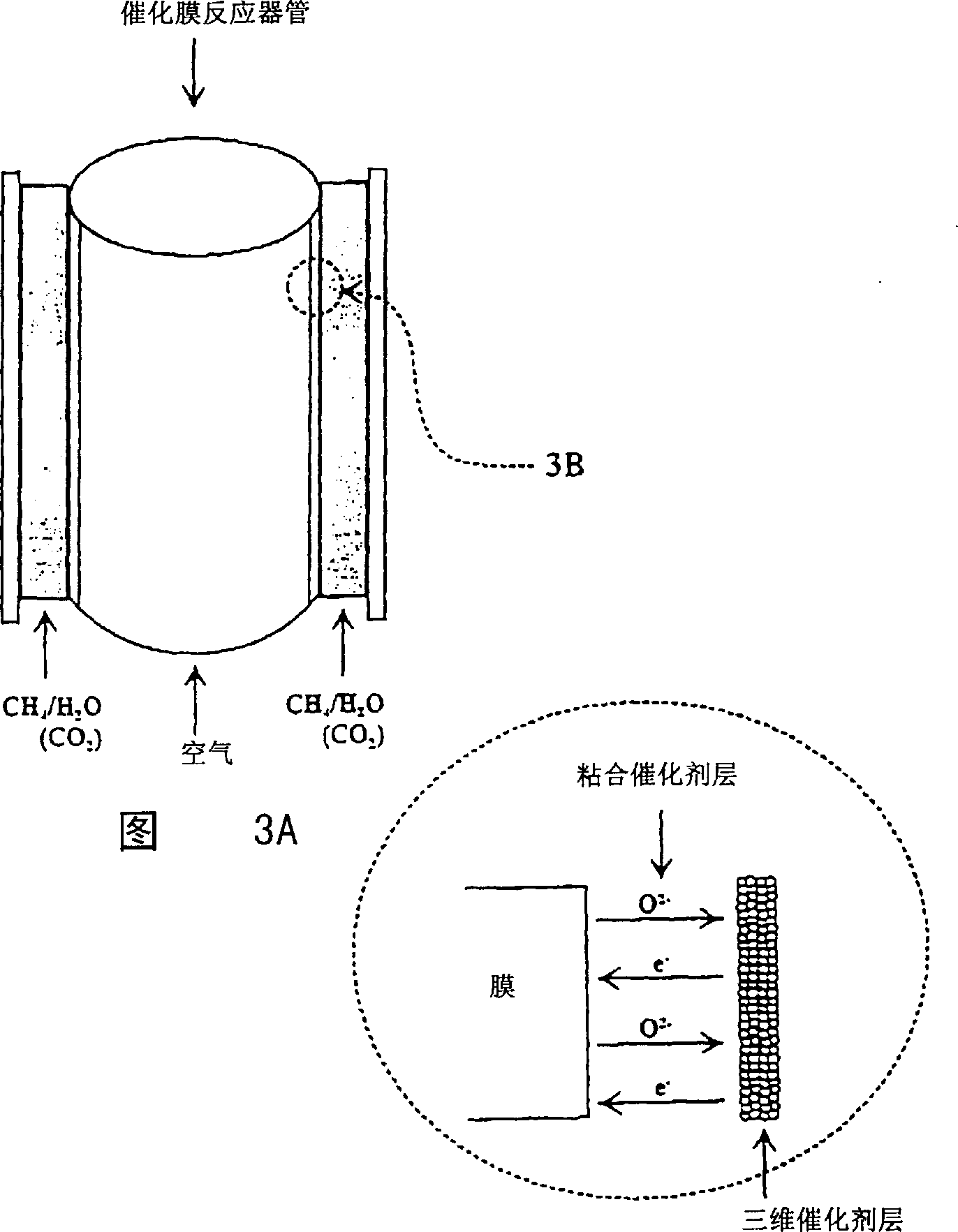

Catalytic membrane reactor and method for production of synthesis gas

InactiveUS20080169449A1High oxygen fluxHydrogenSemi-permeable membranesSulfur containingPhotochemistry

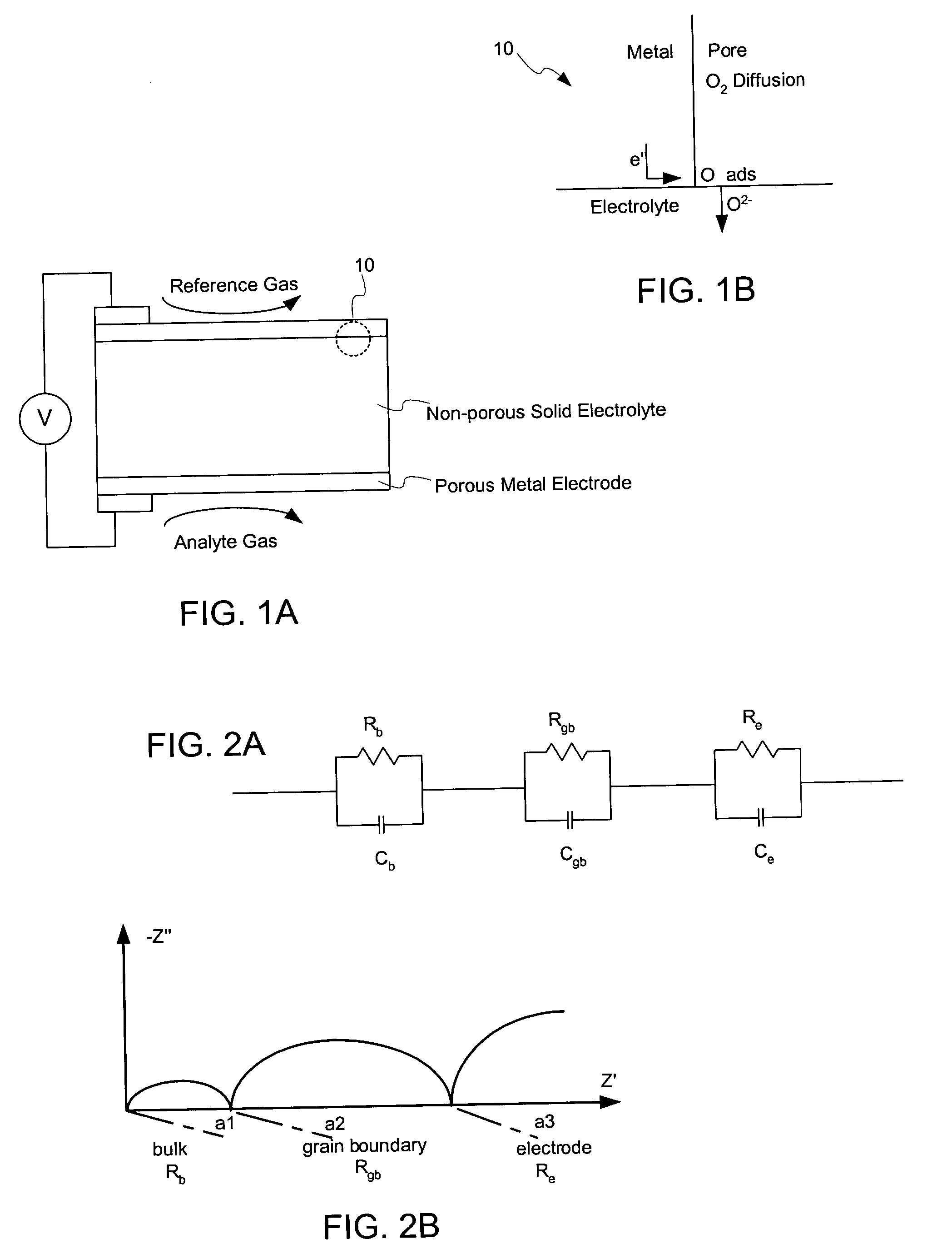

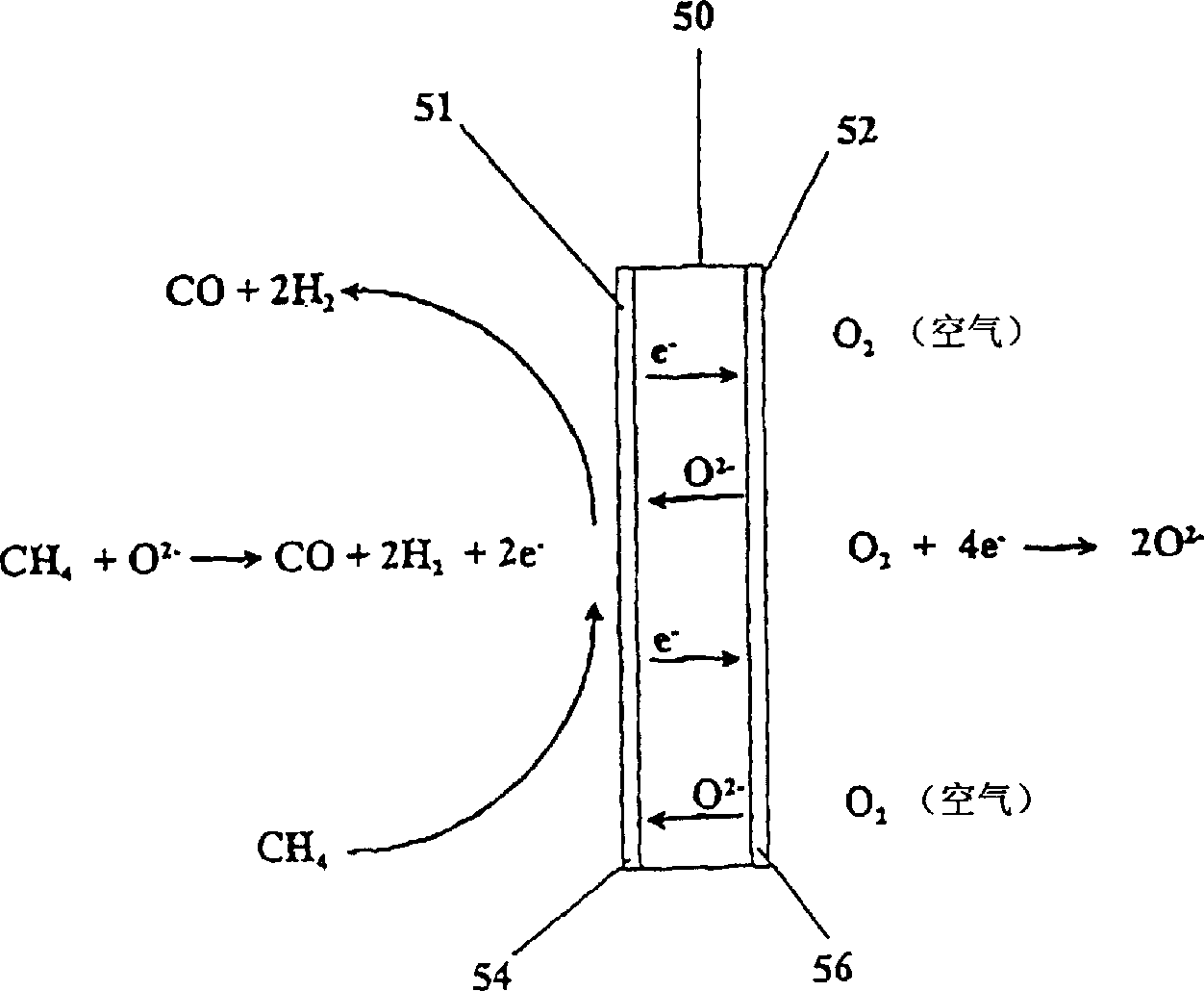

A solid state membrane for a reforming reactor is disclosed which comprises at least one oxygen anion-conducting oxide selected from the group consisting of hexaaluminates, cerates, perovskites, and other mixed metal oxides that are able to adsorb and dissociate molecular oxygen. The membrane adsorbs and dissociates molecular oxygen into highly active atomic oxygen and allows oxygen anions to diffuse through the membrane, to provide high local concentration of oxygen to deter formation and deposition of carbon on reformer walls. Embodiments of the membrane also have catalytic activity for reforming a hydrocarbon fuel to synthesis gas. Also disclosed are a reformer having an inner wall containing the new membrane, and a process of reforming a hydrocarbon feed, such as a high sulfur-containing diesel fuel, to produce synthesis gas, suitable for use in fuel cells.

Owner:ELTRON RES

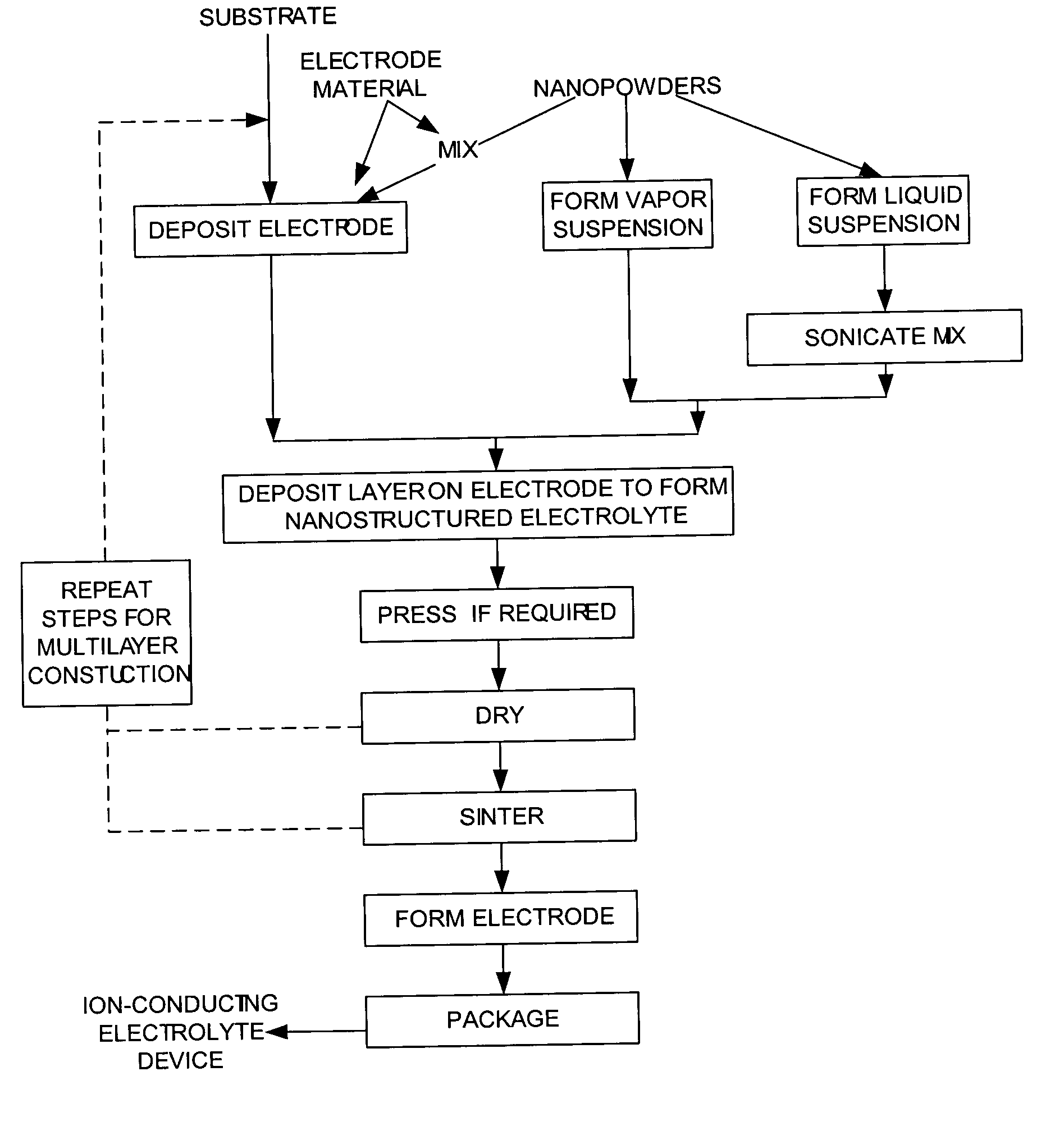

Nanostructured powders and related nanotechnology

InactiveUS7081267B2Low costReduce operating costsNitrogen compoundsSelenium/tellurium compundsThermal energyOxygen

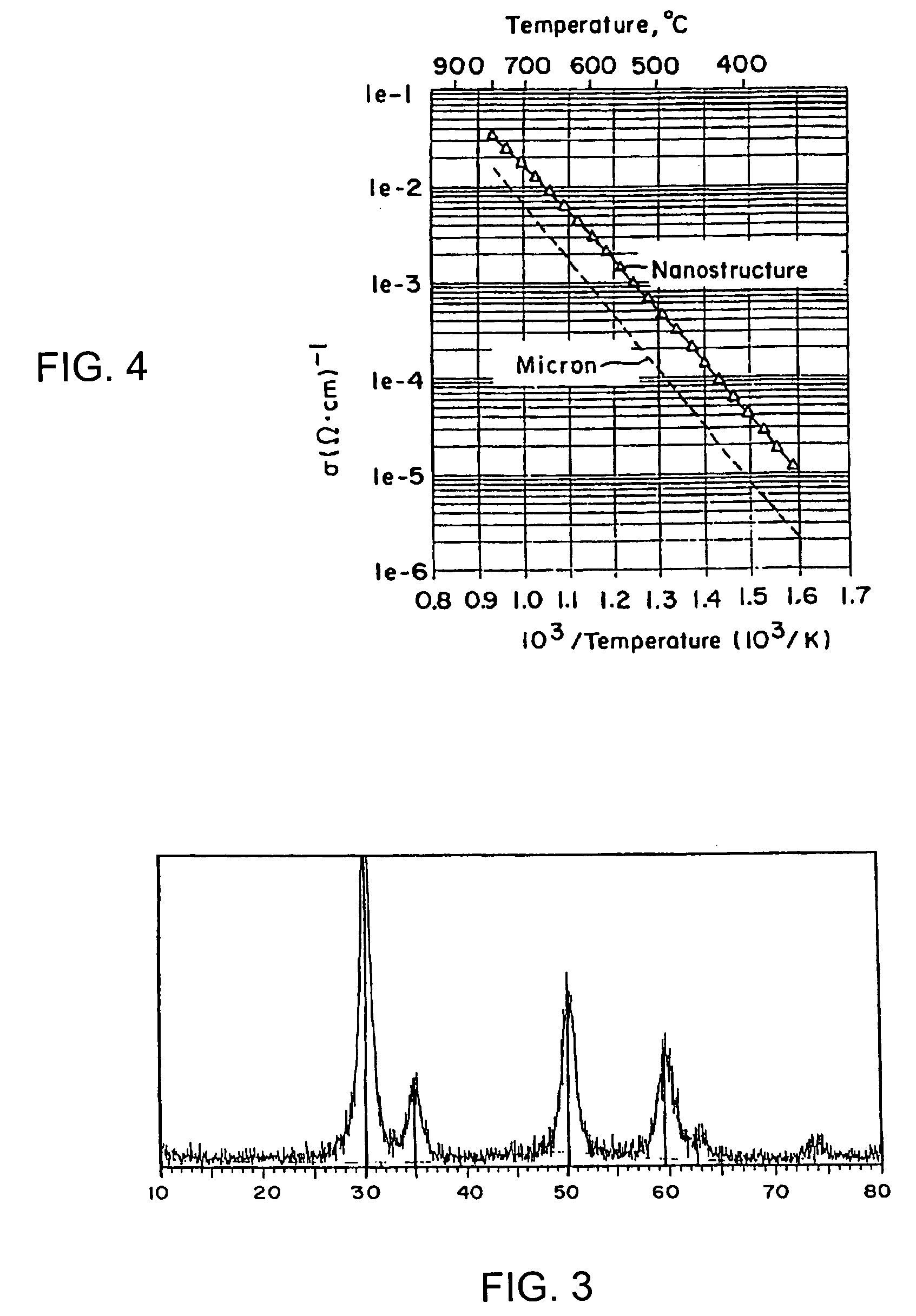

Methods to manufacture nanoscale particles comprising metals, alloys, intermetallics, ceramics are disclosed. The thermal energy is provided by plasma, internal energy, heat of reaction, microwave, electromagnetic, direct electric arc, pulsed electric arc and / or nuclear. The process is operated at some stage above 3000K and at high velocities. The invention can be utilized to prepare nanopowders for nanostructured products and devices such as ion conducting solid electrolytes for a wide range of applications, including sensors, oxygen pumps, fuel cells, batteries, electrosynthesis reactors and catalytic membranes.

Owner:PPG IND OHIO INC

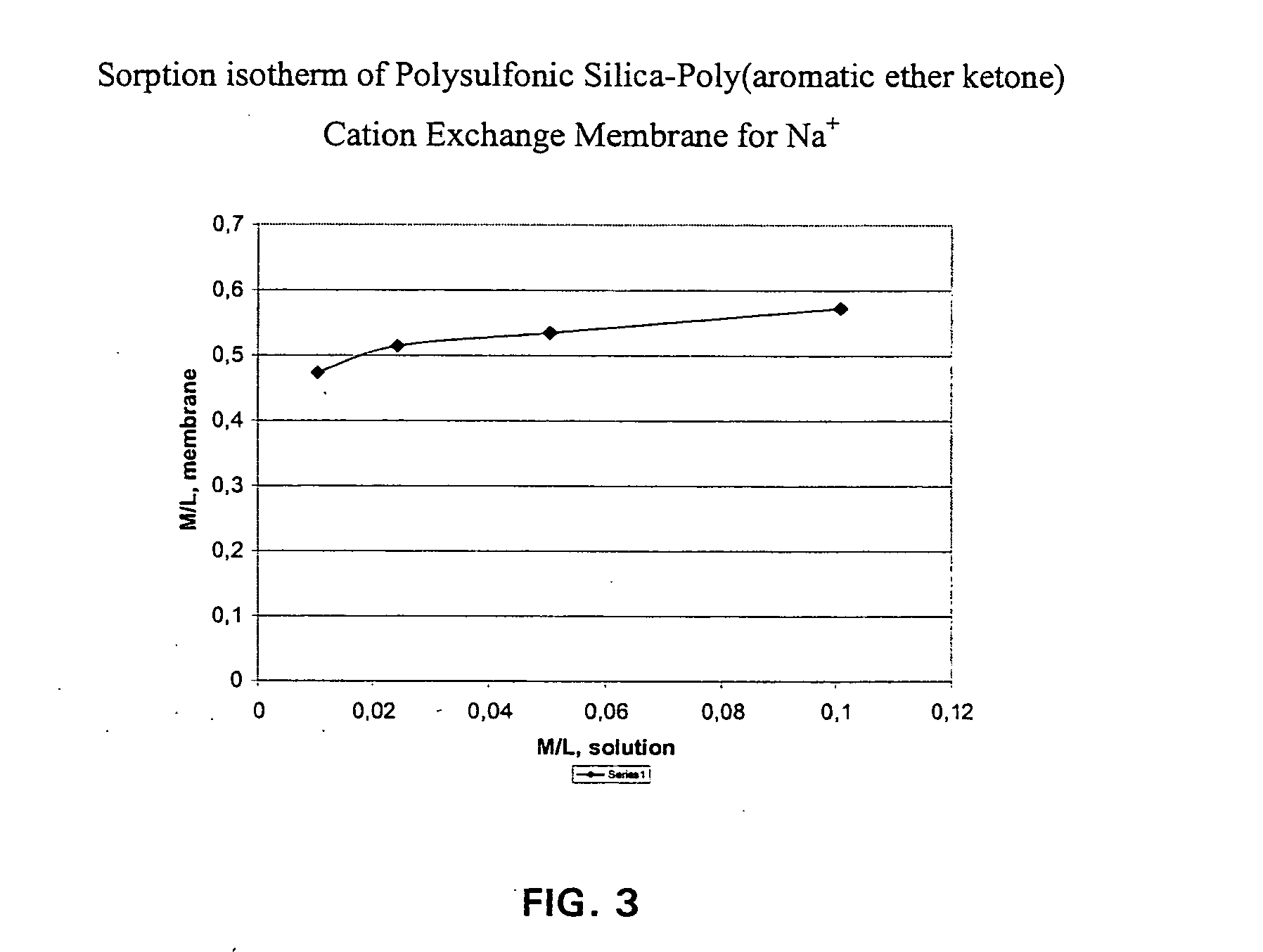

Ion exchange composite material based on proton conductive functionalized inorganic support compounds in a polymer matrix

InactiveUS20050053818A1Improve mechanical propertiesImprove impermeabilitySemi-permeable membranesSolid electrolytesIon exchangeLiquid fuel

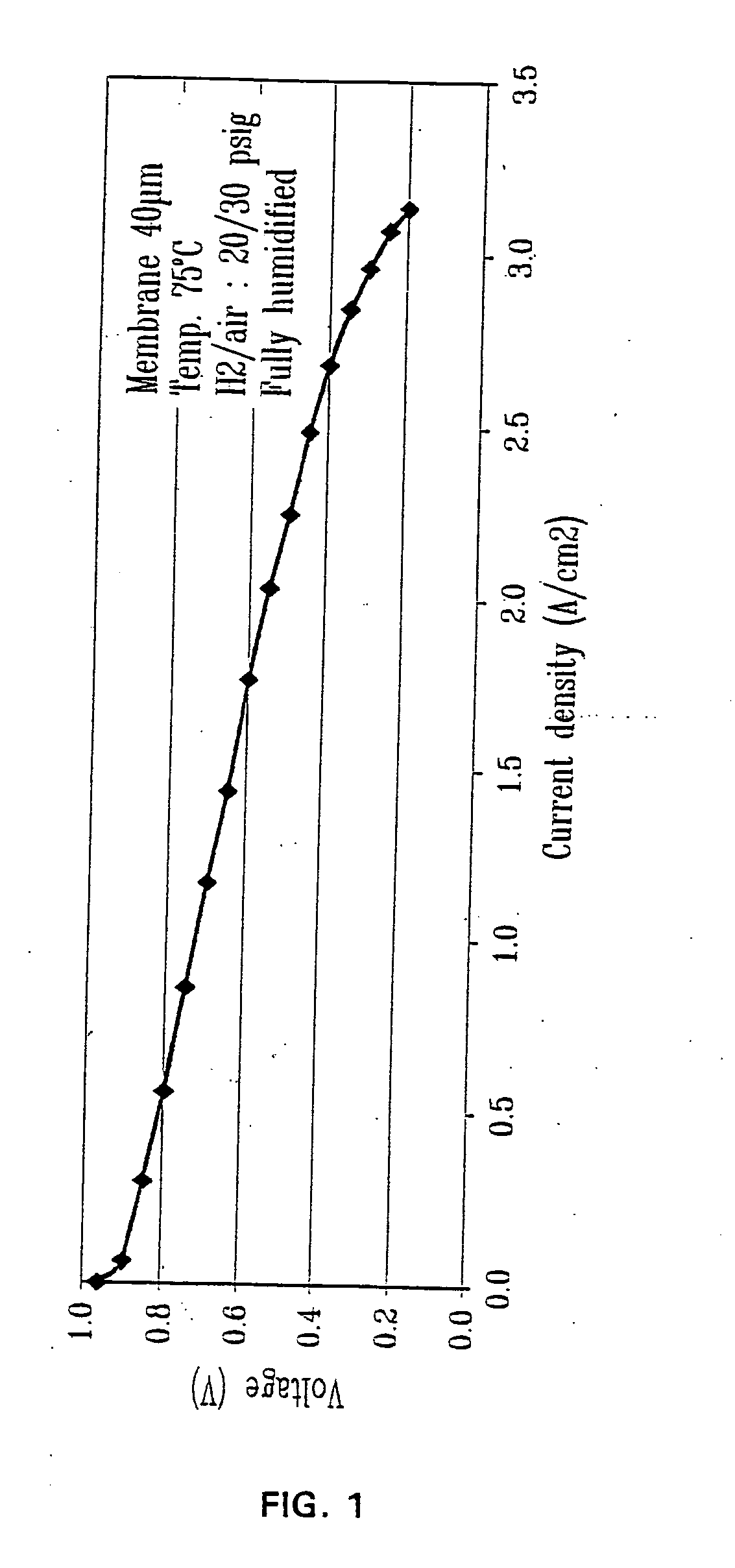

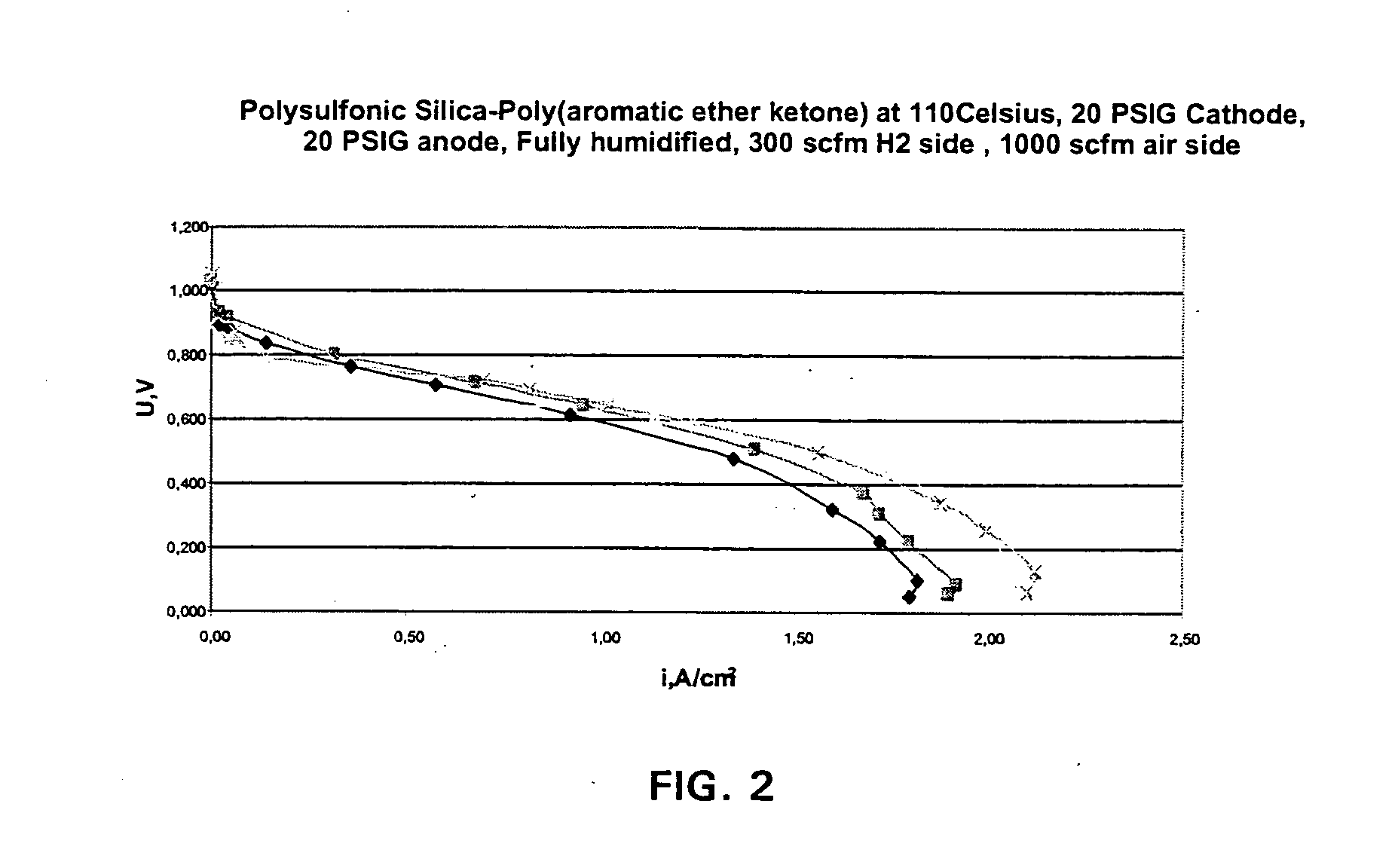

The composite material comprise acid functionalized inorganic supports such as silica dispersed in a functionalized and / or non-functionalized polymer matrix that is based on numerous polymers such as poly(aromatic ether ketones), or poly(benzoyl phenylene), or derivatives thereof. The composite material is characterized by good water retention capabilities due to the acidic functions and the hydrophilicity of the silica particles. Moreover, a good impermeability to gas and liquid fuels commonly used in fuel cell technology, like hydrogen gas or methanol solution, is also obtained due to the presence of silica particles. Good mechanical properties of the composite material let the material to be formed easily in thin film or membrane form. In that form, the composite material is usable for proton exchange membrane for fuel cells, for drying or humidifying membrane for gas or solvent conditioning, or as acid catalytic membrane.

Owner:SIM COMPOSITES INC

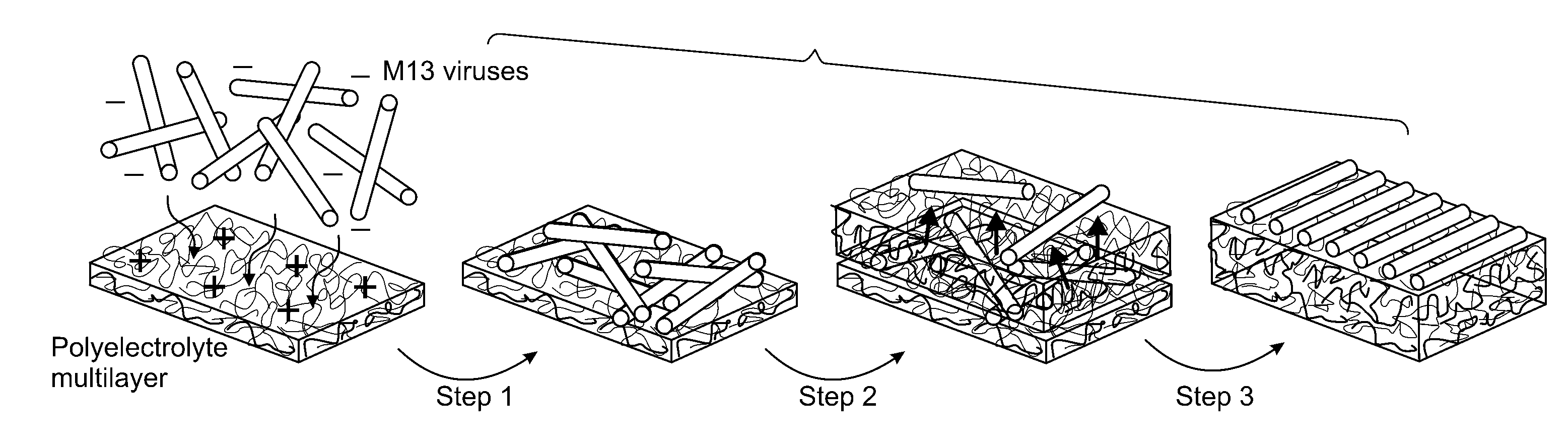

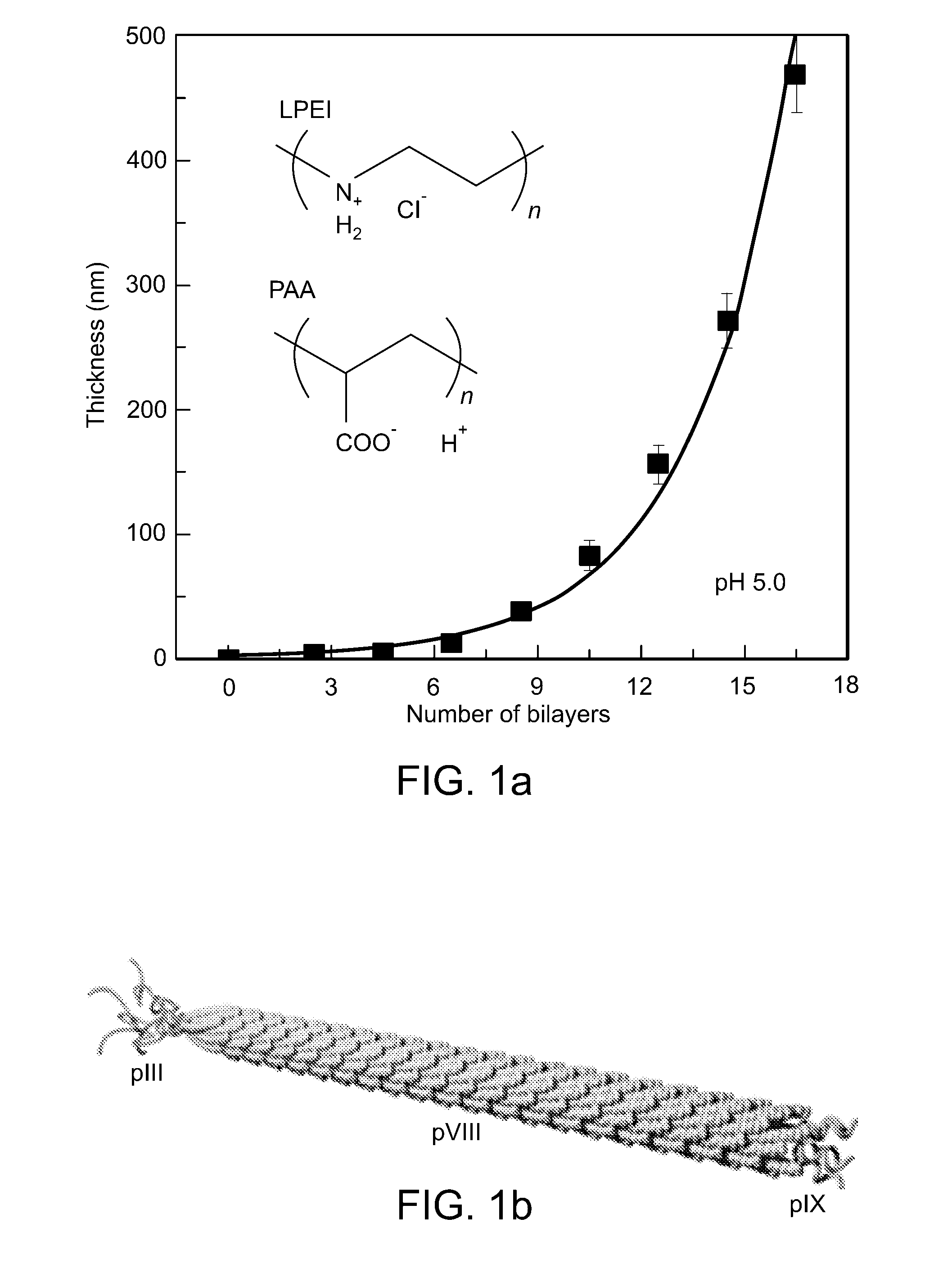

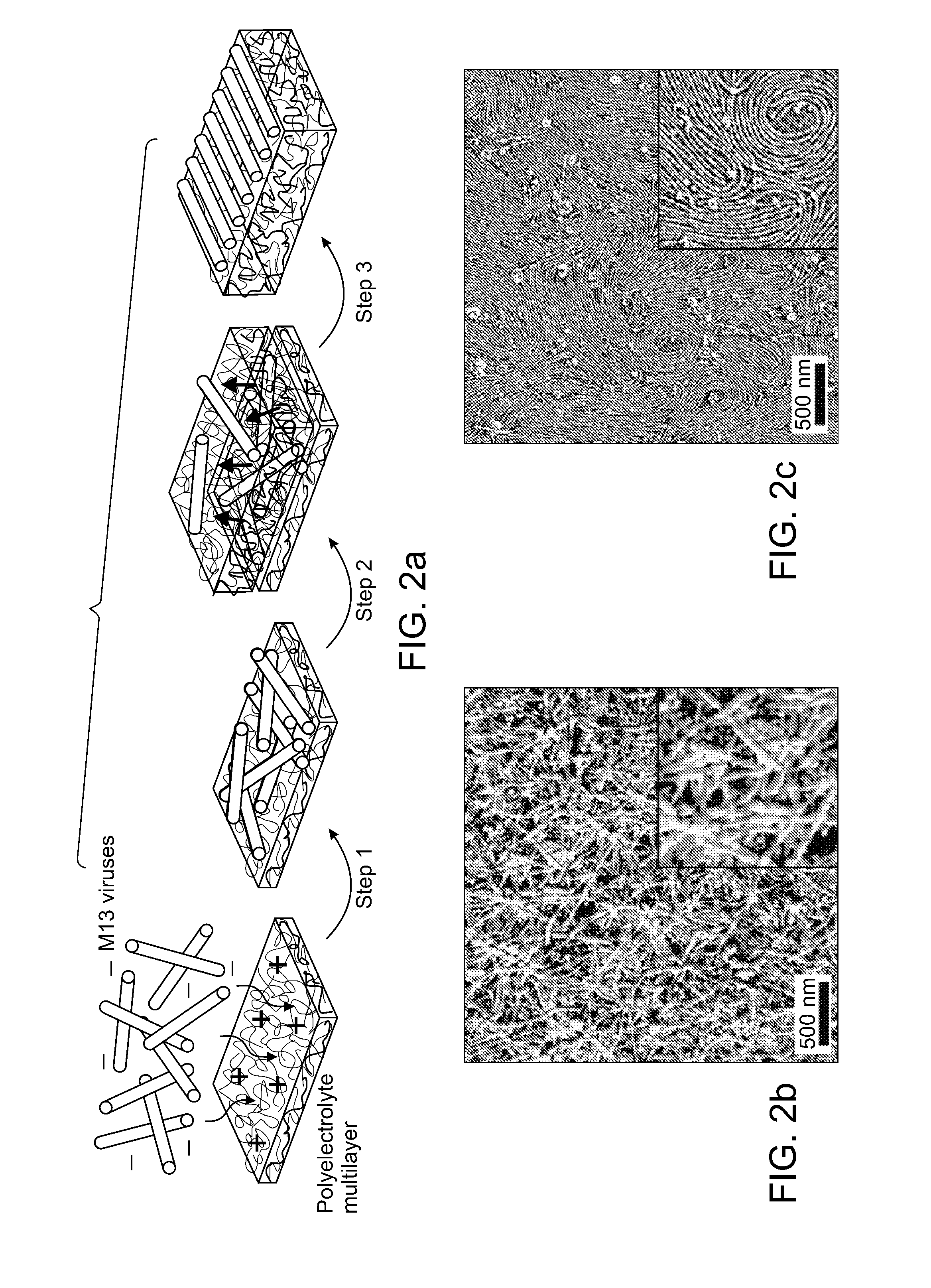

Self-assembly of macromolecules on multilayered polymer surfaces

ActiveUS20110114244A1Low costImprove functionalityMicrobiological testing/measurementSynthetic resin layered productsPolyelectrolyteEngineering

The invention is directed toward systems and methods for the formation of two dimensional monolayer structures of ordered biomacromolecules, such as viruses, atop cohesive polyelectrolyte multilayers to create functional thin films. Methods for the formation of such thin films are disclosed that involve an interdiffusion-induced assembly process of the biomacromolecules. The inventive systems provide a general platform for the systematic incorporation and assembly of organic, biological and inorganic materials and will enable many potential technological applications such as, for example, chemical and biological sensors, power devices and catalytic membranes.

Owner:MASSACHUSETTS INST OF TECH

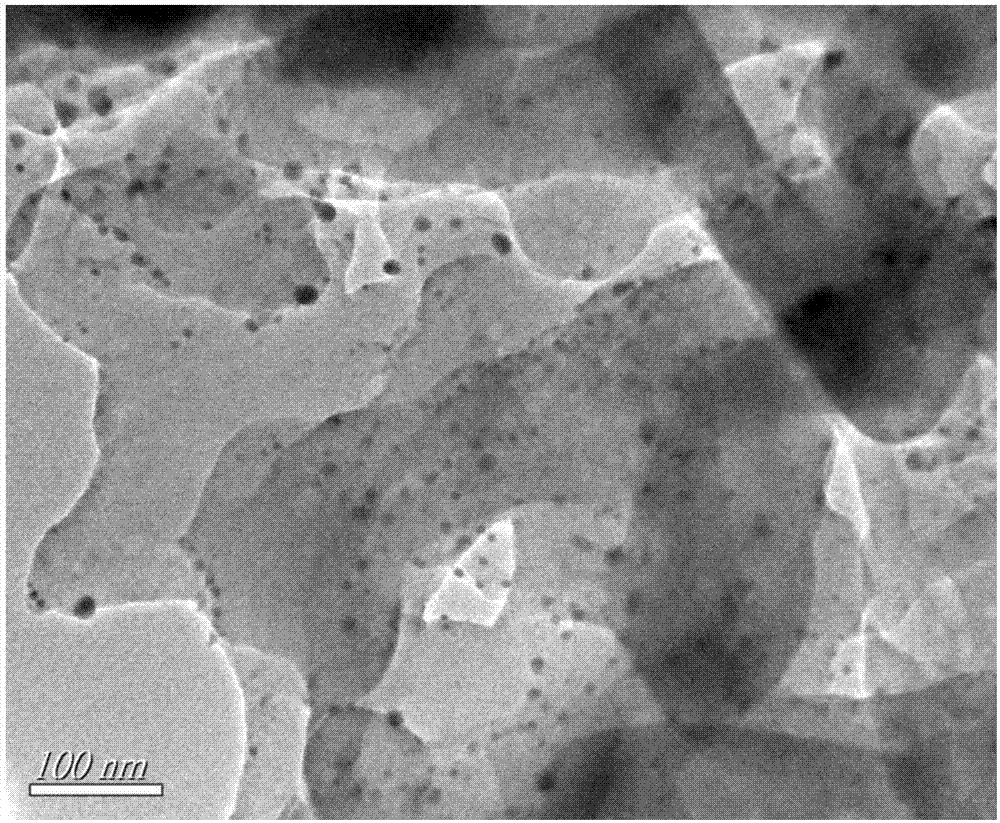

Catalyst for catalytic hydrogenation of p-nitrophenol and preparation method thereof

ActiveCN102091626AEasy to separateSimple production processCatalyst carriersOrganic compound preparationSilanesP-Aminophenol

The invention relates to a catalyst for preparing p-aminophenol through catalytic hydrogenation of p-nitrophenol, and a preparation method thereof, and belongs to the technical field of catalysis. The carrier of the catalyst is a ceramic membrane, and the preparation method comprises the following steps of: modifying the membrane surface by using aminosilane; immersing in salt solution of an active ingredient; and performing hydrazine hydrate reduction to prepare a catalytic membrane. The invention has the advantages that: nano-scale catalyst particles are supported on the surface of the ceramic membrane modified by silane, and the activity and stability of the catalyst are improved; moreover, a problem that the catalyst is hardly separated from the product subsequently is avoided. The catalyst is simple in preparation process and high in activity and stability and can be widely applied to preparing the p-aminophenol through catalytic hydrogenation of the p-nitrophenol.

Owner:NANJING UNIV OF TECH

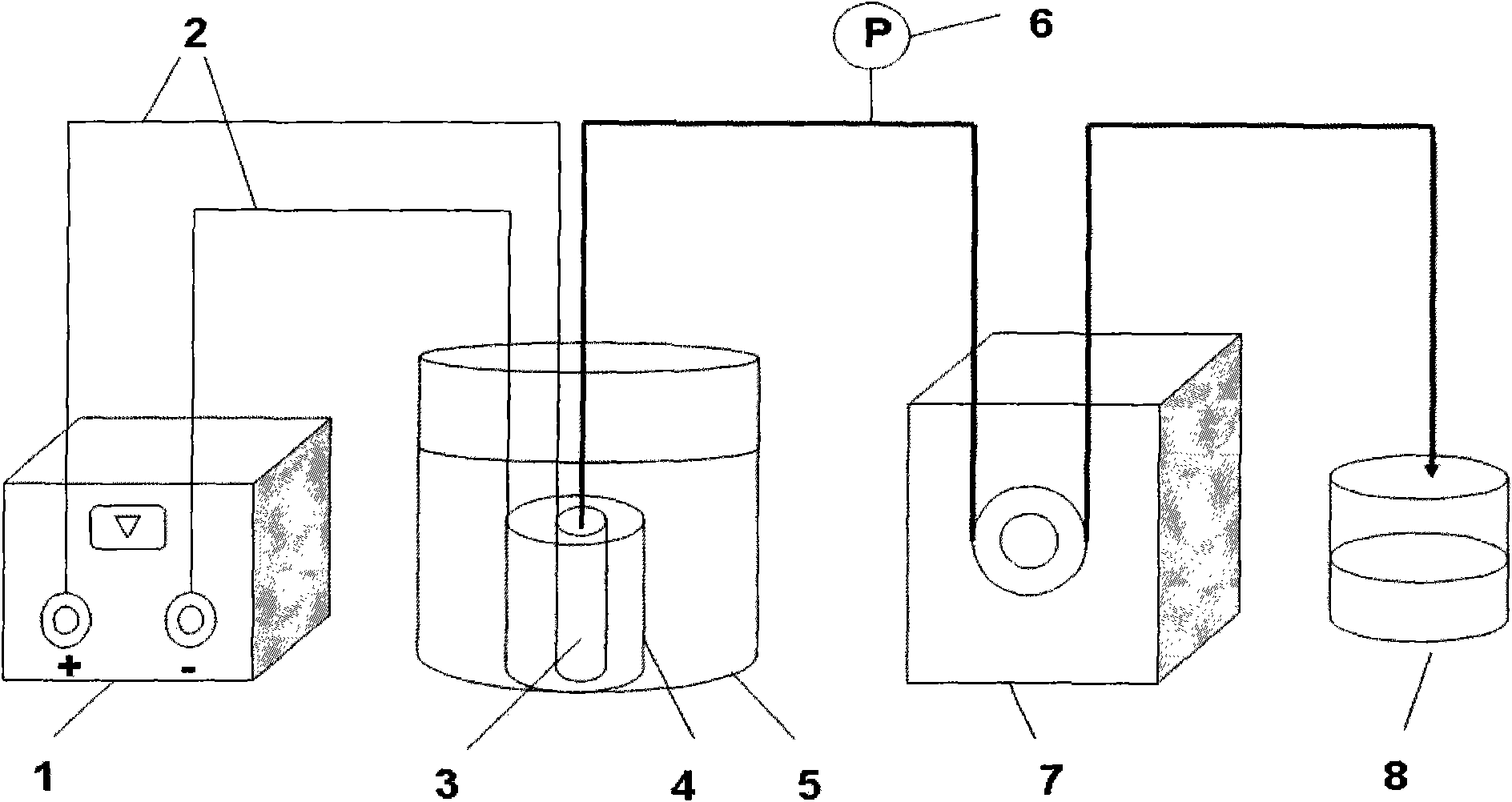

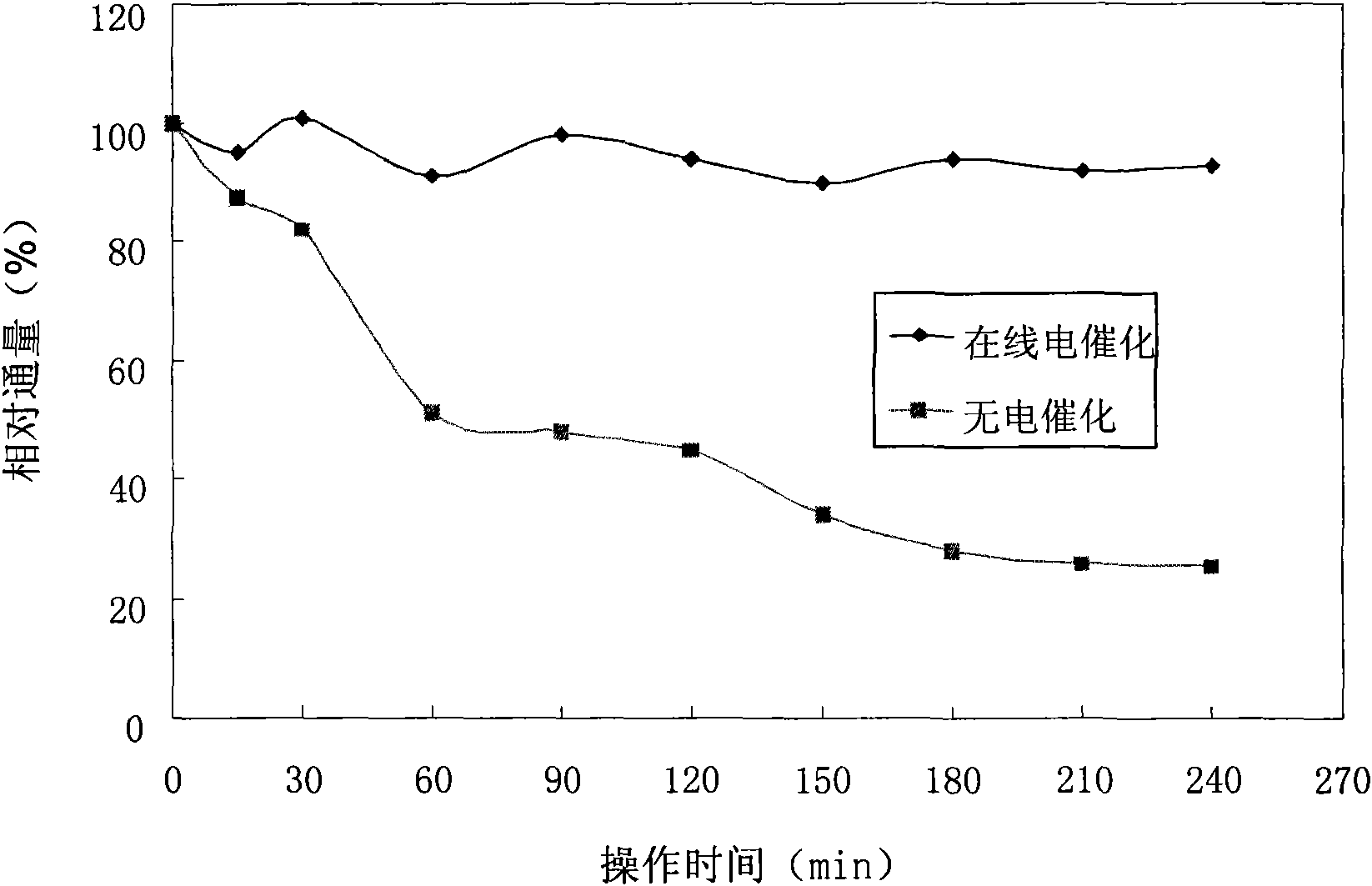

Electro-catalytic membrane reactor device

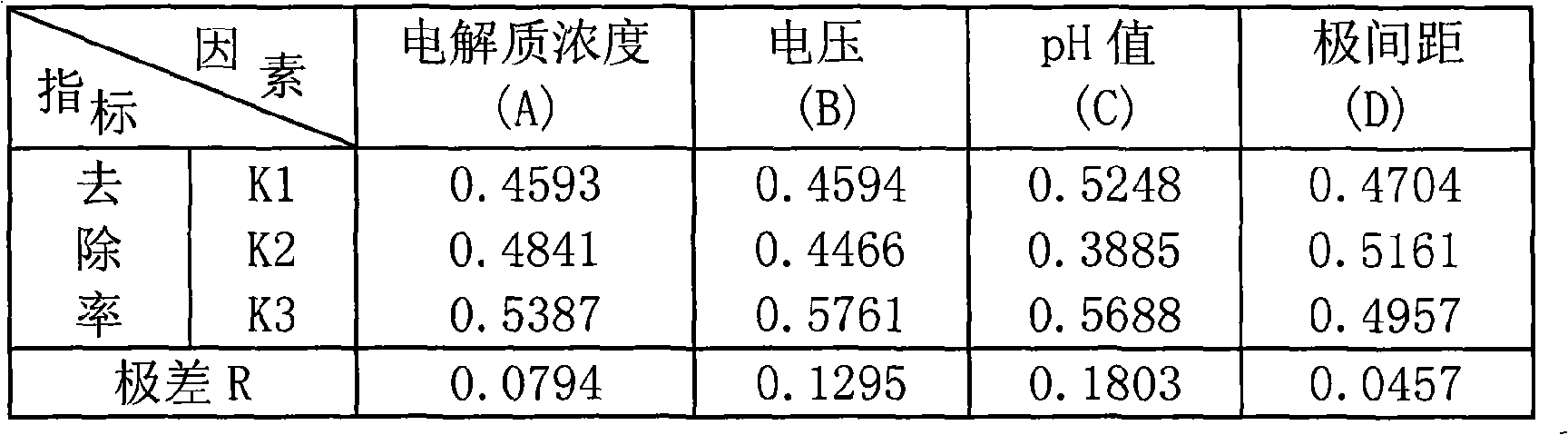

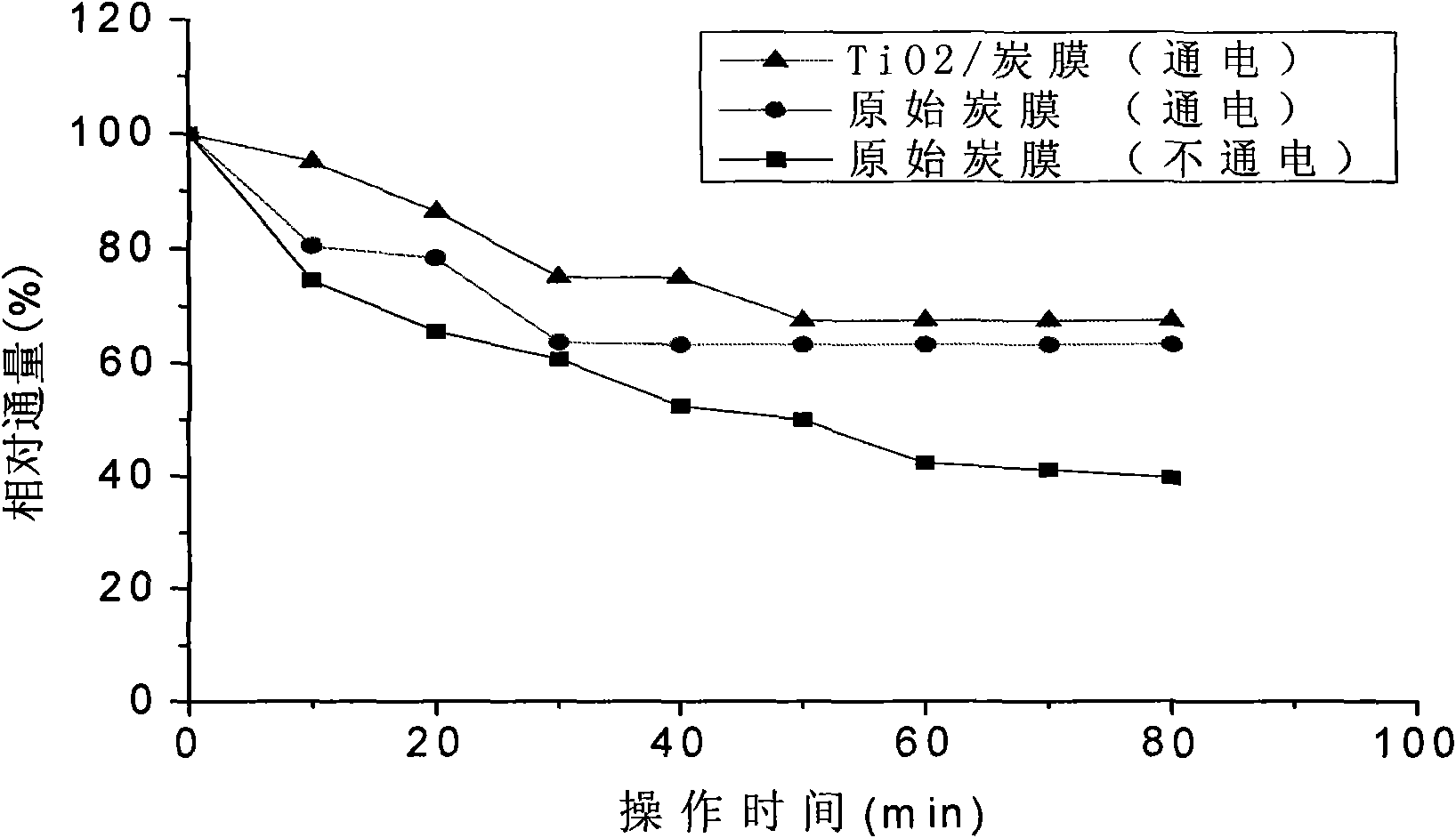

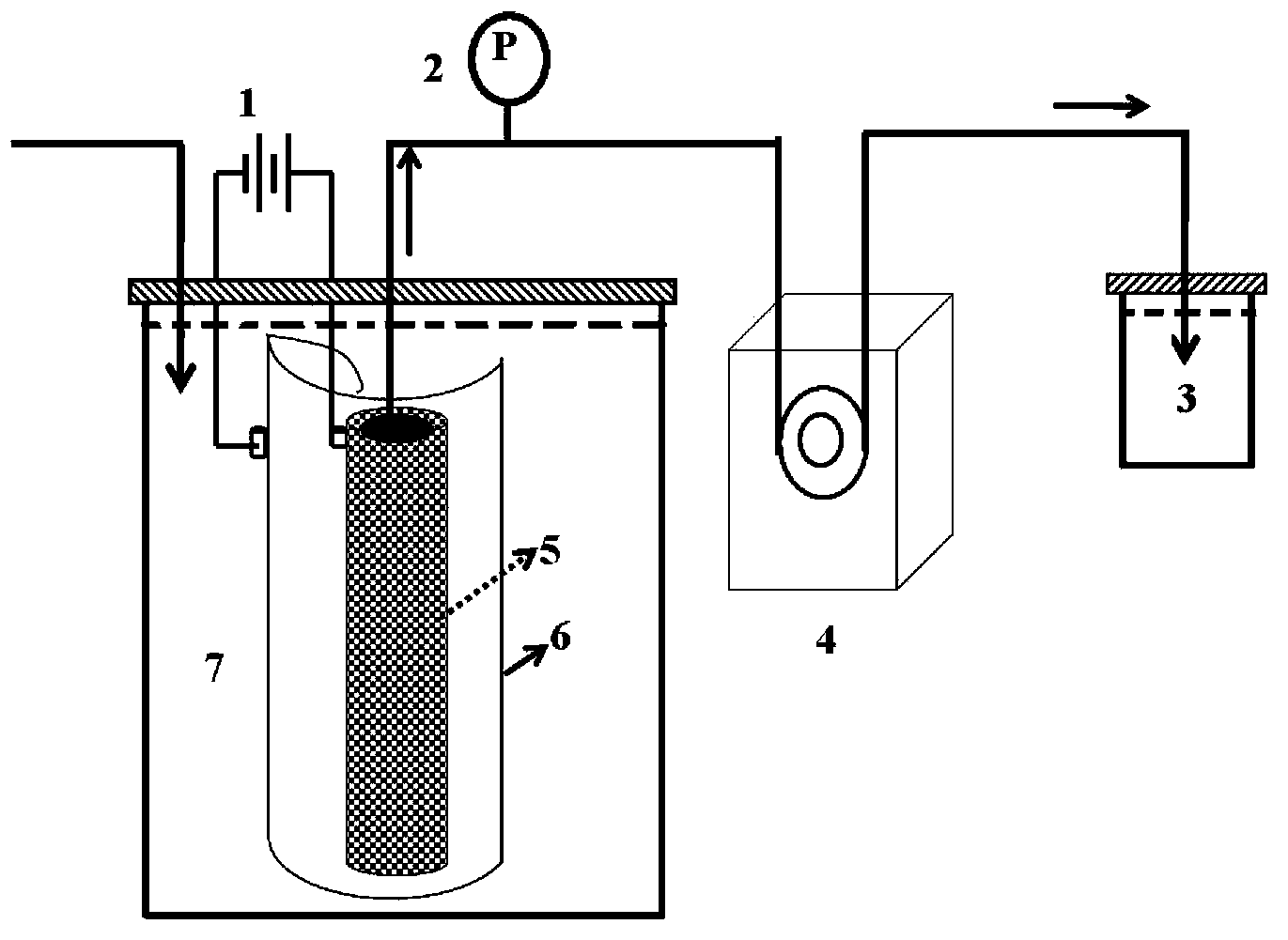

InactiveCN101597096AImprove electrocatalytic activitySimple processSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPeristaltic pumpElectrolysis

The invention describes an electro-catalytic membrane reactor device, which is characterized in that the device can couple the membrane separation technology and electro-catalysis technology for wastewater treatment, thereby solving the problem of membrane pollution and realizing self-cleaning function of the membrane. The reactor device comprises a feed liquid tank, an electro-catalytic composite membrane, an auxiliary electrode, a regulated power supply, a vacuum gauge, a peristaltic pump and the like; wherein, the electro-catalytic composite membrane is a novel membrane material prepared by taking a microporous carbon membrane as a matrix and a metal or metallic oxide as a catalytic coating layer; one end of the electro-catalytic membrane is closed and the other end thereof is connected with the peristaltic pump through a pipeline; the pump continuously supplies negative pressure so that the feed liquid permeates a separation membrane and seeps from outside to inside along the pipeline; meanwhile, the electro-catalytic composite membrane is taken as the anode and the auxiliary electrode is taken as the cathode; the electro-catalytic composite membrane and the auxiliary electrode are respectively connected with the regulated power supply by leads to form an electrolysis device. By applying voltage to the composite membrane in the process of membrane separation, the organic pollutants deposited on and adhered to the surface and holes of the membrane are electrolytically oxidized to realize antipollution of the membrane. The reactor device has the advantages of simple device, convenient operation, high efficiency, small energy consumption and the like, and can be widely used for treatment and reuse of such industrial wastewater as oily wastewater, dye wastewater, papermaking wastewater and the like.

Owner:大连华鑫源科技发展有限公司

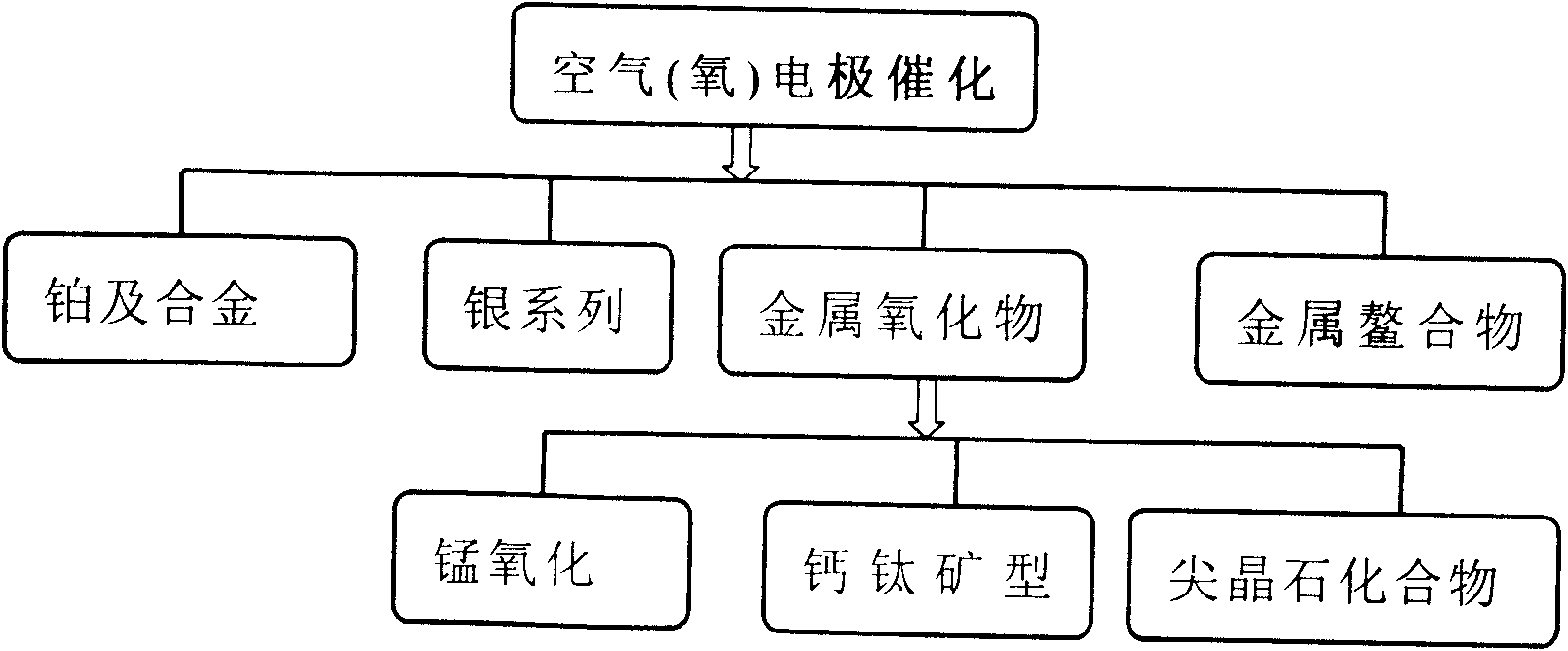

Catalytic agent for air electrode and novel air electrode manufactured by catalytic agent and manufacturing method of air electrode

InactiveCN101683613ALow costImprove catalytic abilityCell electrodesMetal/metal-oxides/metal-hydroxide catalystsCompound aOrganic solvent

The invention discloses a catalytic agent for an air electrode and a novel air electrode manufactured by the catalytic agent and a manufacturing method of the air electrode; the catalytic agent for the air electrode is formed by compounding a main catalytic agent and at least one auxiliary catalytic agent; the main catalytic agent is metal salts containing manganese, and the auxiliary catalytic agent is rare earth compound or rare metal compound; the weight of the main catalytic agent accounts for 60-85 percent of total weight of the catalytic agent, and the remaining is the auxiliary catalytic agent. The novel air electrode is formed by pressing a catalytic membrane, a current collector and a water-proofing breathable film sequentially. In order to manufacture the novel air electrode, thecatalytic membrane and the water-proofing breathable film are firstly manufactured, and then are pressed together or pressed together with a meshed current collector, and then the air electrode is prepared after removing organic solvents.

Owner:BEIJING CHANGLI UNION ENERGY TECH CO

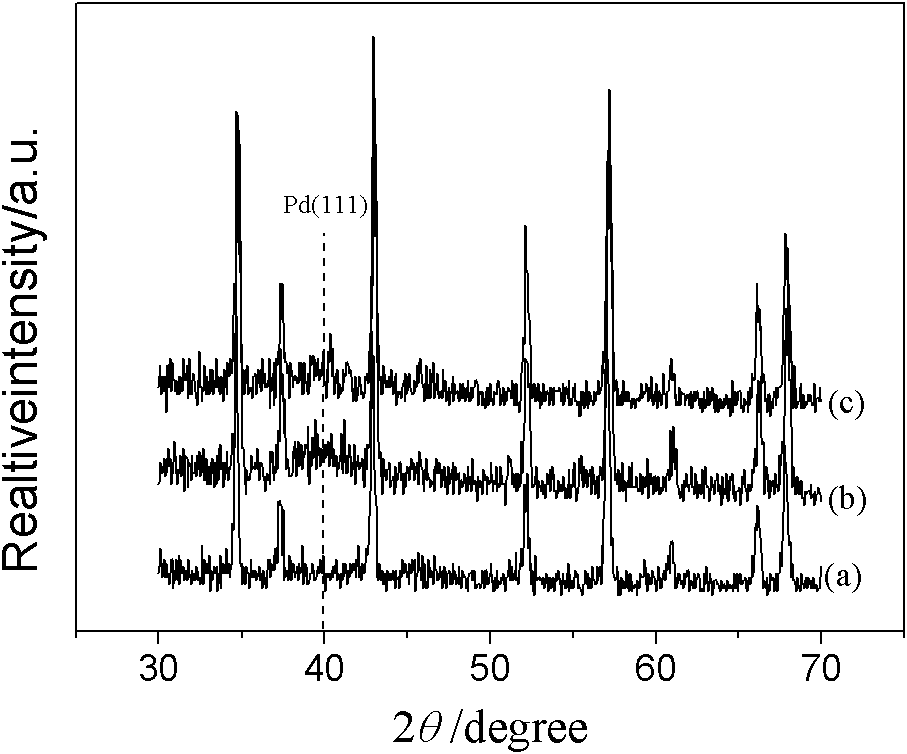

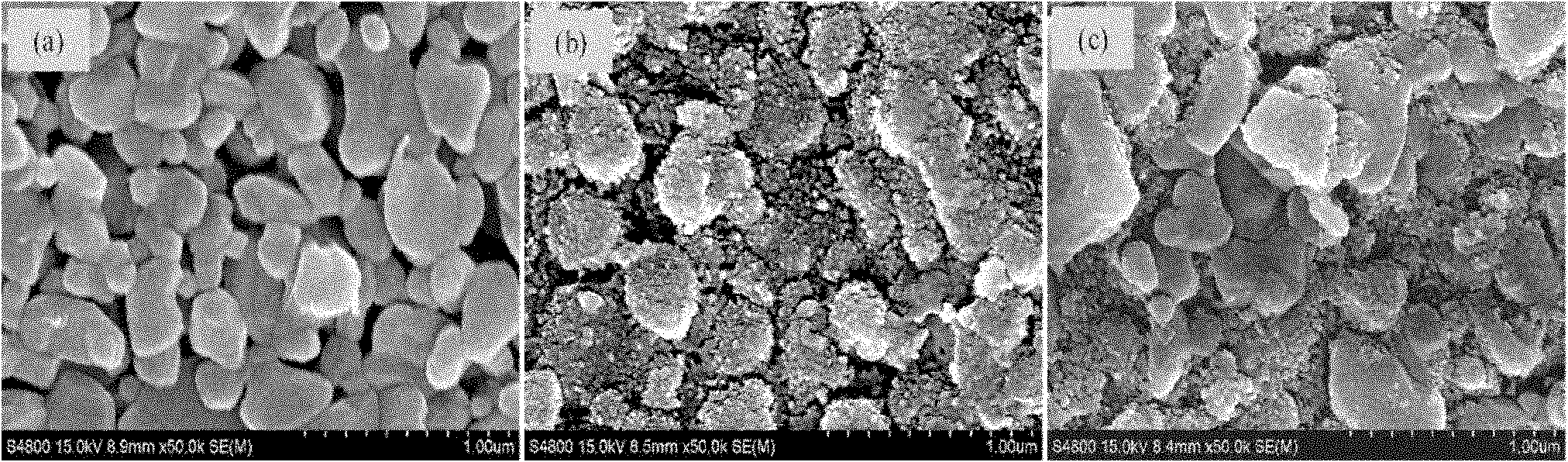

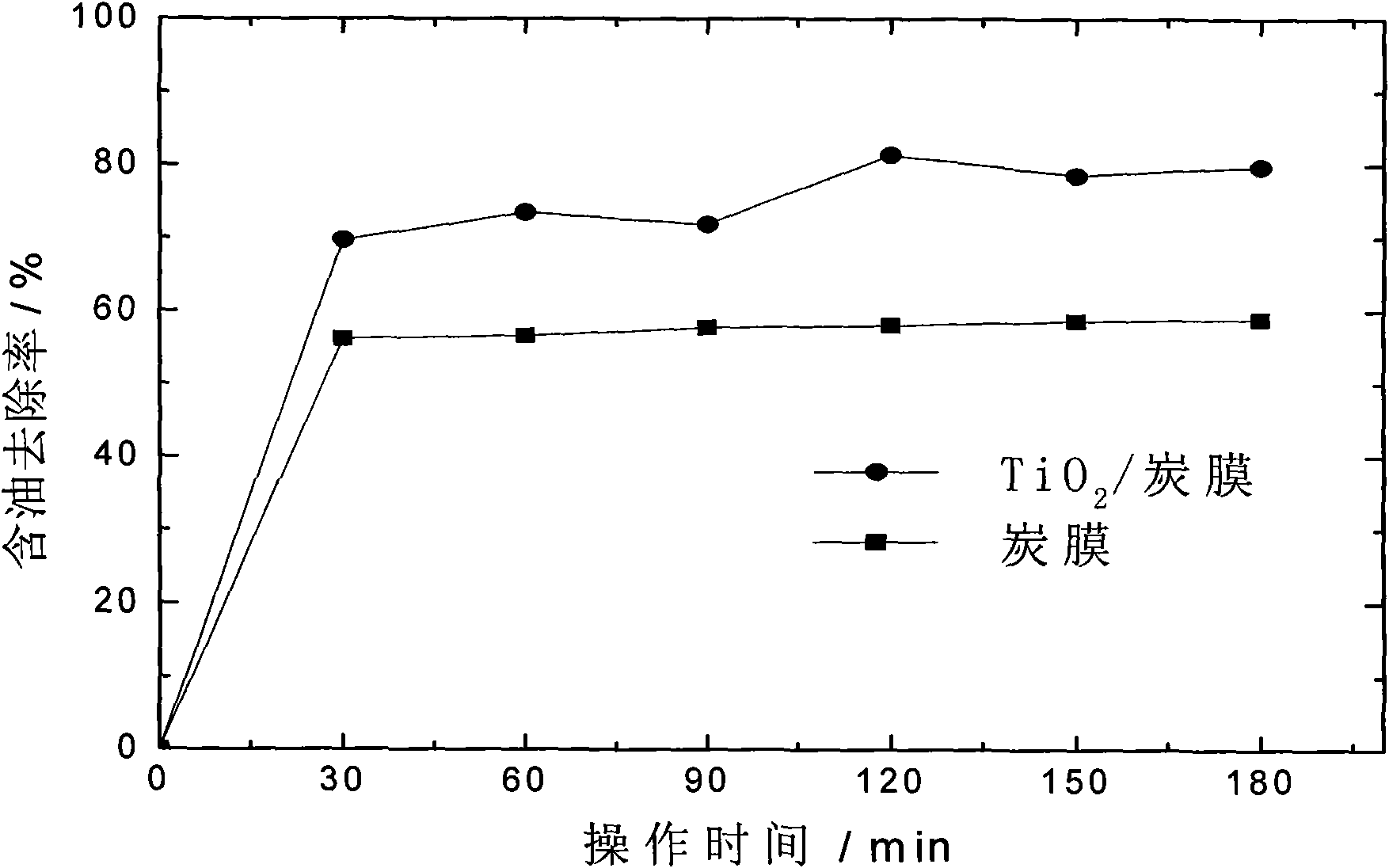

Novel electro-catalytic composite membrane material and preparation method thereof

InactiveCN101559332ATo achieve reinforcementRealize self-cleaningSemi-permeable membranesWater/sewage treatment by electrochemical methodsLow voltageSeparation technology

The invention relates to a novel electro-catalytic composite membrane material and a preparation method thereof. The novel electro-catalytic composite membrane material is characterized in that the material can couple electro-catalytic technology and membrane separation technology. The preparation method comprises the following steps: taking a microporous separation membrane with electric conductivity, namely a carbon membrane, as a substrate, adopting a sol-gel method, mixing a metallic compound, water, a solvent, a catalyst, other additives and the like to be configured into a precursor solution, and obtaining an electro-catalytic composite membrane by sol ageing, film coating, drying and heat treatment; and preparing the composite membrane with superior performances by pretreating a substrate and controlling the mixture ratio of raw materials, the soakage time, the pulling speed, the sintering temperature and the like. The novel electro-catalytic composite membrane material takes the electro-catalytic composite membrane as an anode and a metallic material as a cathode to treat wastewater and realizes the reinforcement of the membrane separation process and the self-cleaning function under the action of a low-voltage electric field. The electro-catalytic membrane material has the advantages of low energy consumption, high separation efficiency, strong antifouling property and the like, and can be widely used for treating and recycling heavily polluted wastewater such as oily wastewater, dye wastewater, paper-making wastewater and the like. The preparation method has the advantages of simple preparation process, cheap equipment, easily-obtained raw materials, convenient operation and suitability for industrialized implementation.

Owner:DALIAN HUAXINYUAN TECHNOLOGY DEVELOPMENT LIMITED COMPANY

Catalytic nanoporous membranes

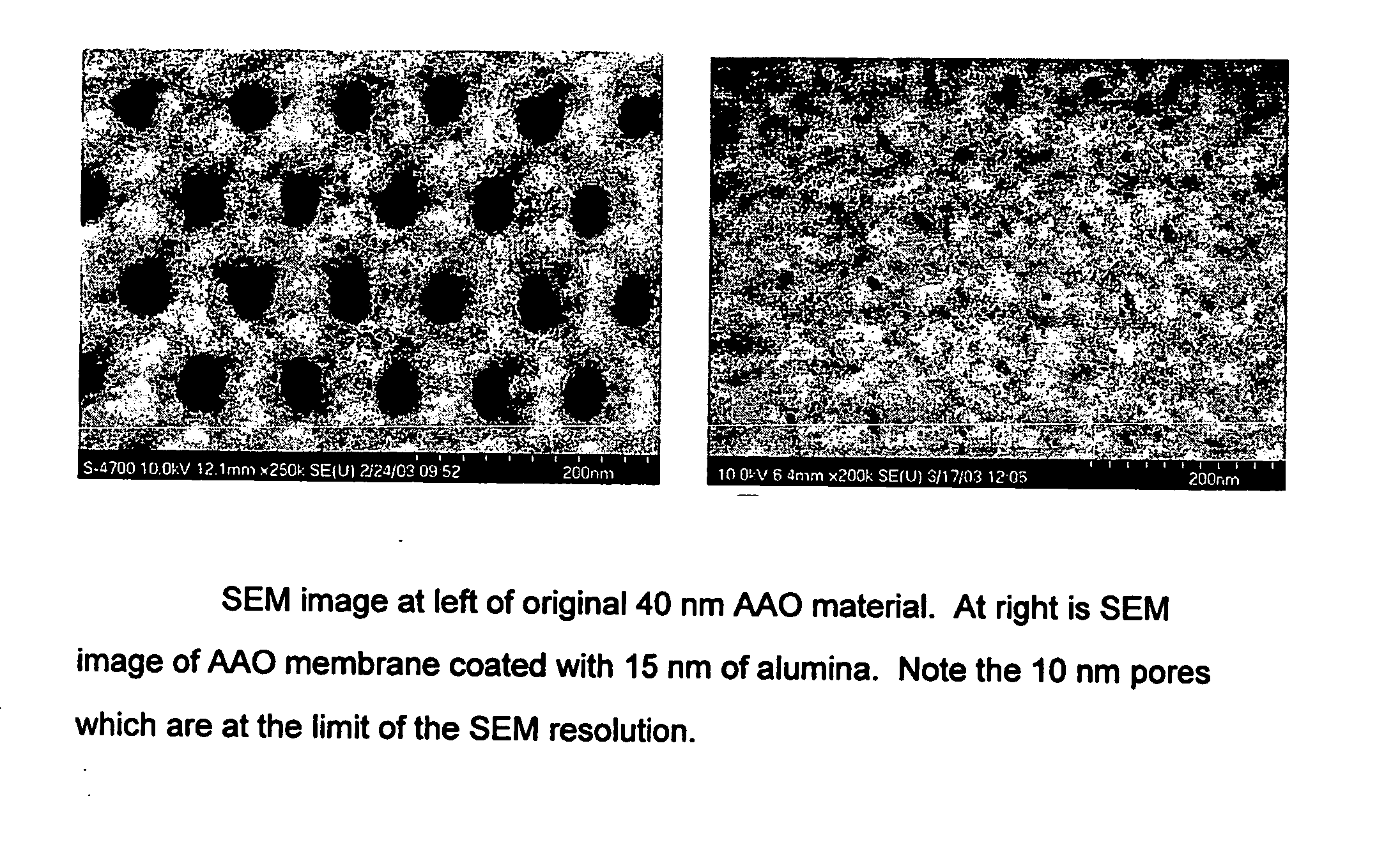

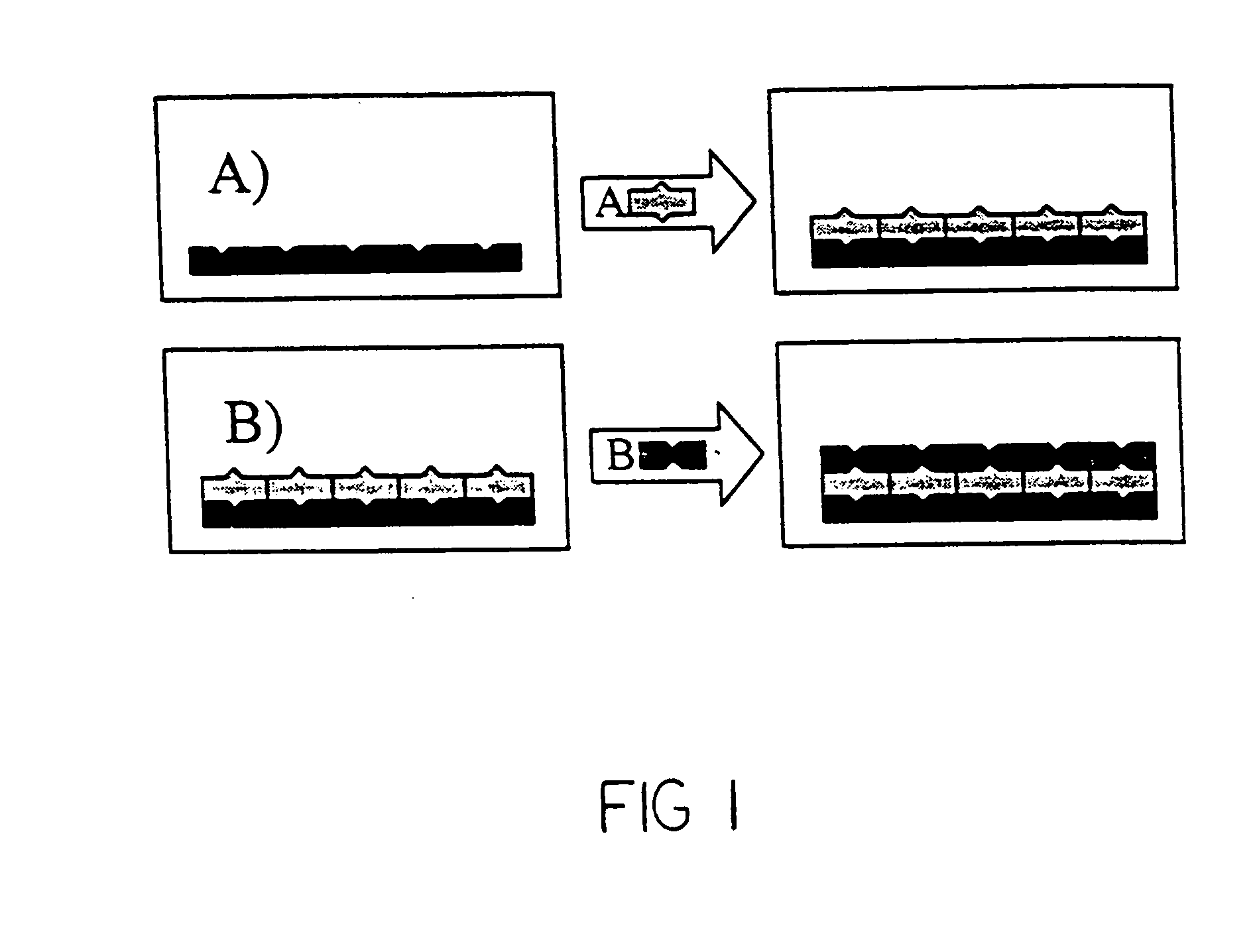

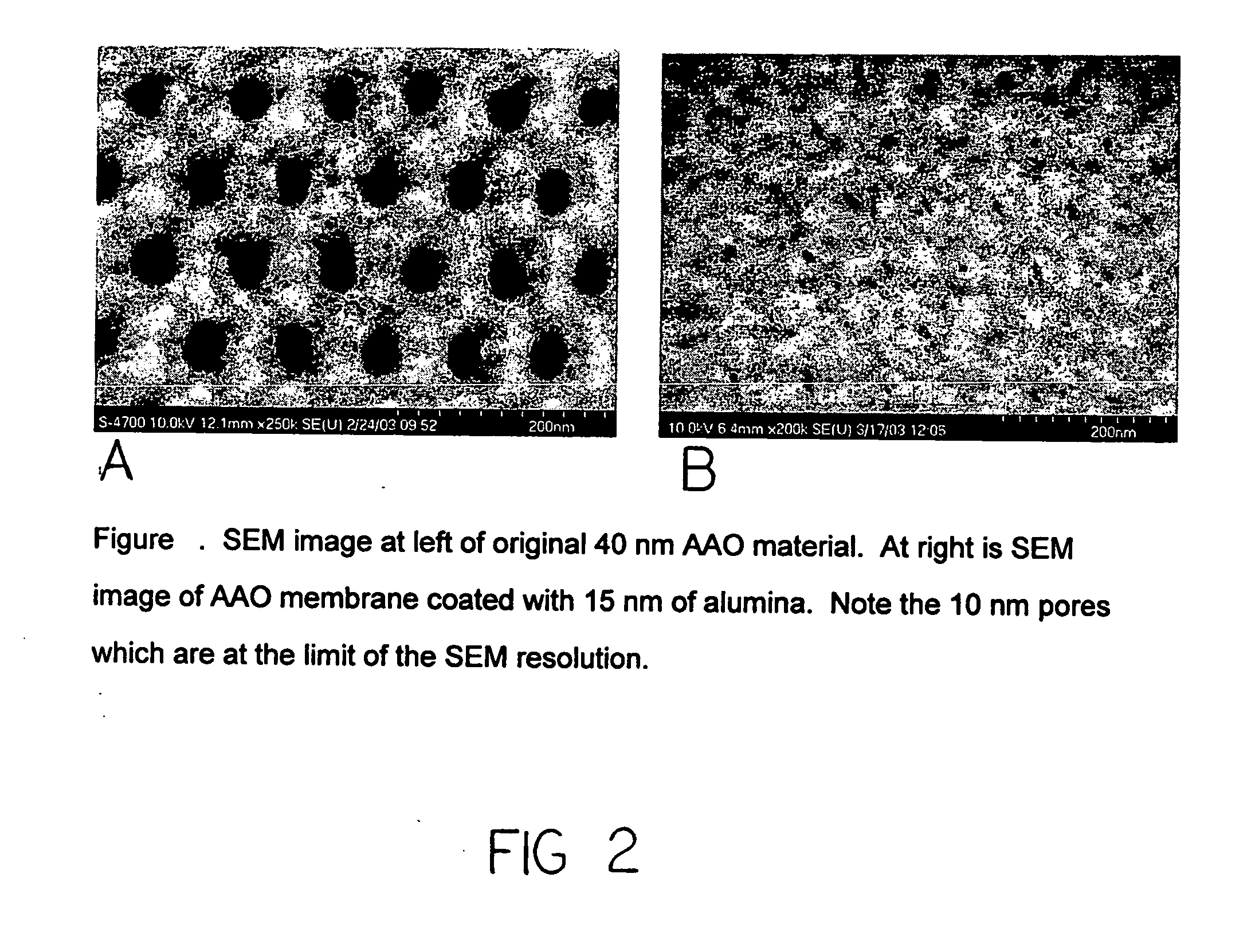

InactiveUS20050065028A1Unique catalyst environmentUniform coatingNanotechOther chemical processesPartial oxidationNanoporous membrane

A nanoporous catalytic membrane which displays several unique features including pores which can go through the entire thickness of the membrane. The membrane has a higher catalytic and product selectivity than conventional catalysts. Anodic aluminum oxide (AAO) membranes serve as the catalyst substrate. This substrate is then subjected to Atomic Layer Deposition (ALD), which allows the controlled narrowing of the pores from 40 nm to 10 nm in the substrate by deposition of a preparatory material. Subsequent deposition of a catalytic layer on the inner surfaces of the pores reduces pore sizes to less than 10 nm and allows for a higher degree of reaction selectivity. The small pore sizes allow control over which molecules enter the pores, and the flow-through feature can allow for partial oxidation of reactant species as opposed to complete oxidation. A nanoporous separation membrane, produced by ALD is also provided for use in gaseous and liquid separations. The membrane has a high flow rate of material with 100% selectivity.

Owner:UCHICAGO ARGONNE LLC

Porous inorganic membrane containing carbon; a process for its preparation; and use thereof

InactiveUS20040251201A1Improve permeabilityHigh selectivityIsotope separationHydrogen/synthetic gas productionHydrogenPorous carbon

A porous inorganic membrane comprises at least one inorganic phase having separating properties. Said membrane has a carbon content representing 0.05% to 25% by weight with respect to the mass of said inorganic phase and is selective to non-condensable gases. It is obtained by means of a selectivation treatment of a porous carbon-free inorganic membrane using a hydrocarbon feed. It is used in processes for separating non-condensable molecules such as hydrogen, and in association with a catalyst in a catalytic membrane reactor.

Owner:INST FR DU PETROLE

Alginate-based composite hydrogel catalytic membrane of renewable catalyst and preparation method thereof

InactiveCN103464217ASimple preparation processLow costWater/sewage treatment by irradiationOrganic-compounds/hydrides/coordination-complexes catalystsCross-linkGlass sheet

The invention discloses an alginate-based composite hydrogel catalytic membrane of a renewable catalyst and a preparation method thereof. According to the invention, a photo-catalyst / alginate composite membrane is prepared by mixing a photo-catalyst and sodium alginate fully to prepare a membrane casting solution, scraping the membrane on a glass plate by using a membrane scrapping rod and performing metal ion cross-linking. By selecting the type of the photo-catalyst, the content and the particle diameter of the photo-catalyst are changed, so that a catalytic degradation of toxic and harmful organic matters of the membrane is adjusted. The reusability of the membrane is greatly improved by applying the characteristics that an ion cross-linking agent in the alginate hydrogel is not degraded during radiating, and although the macromolecules of the alginate are degraded, a hydrogel with a similar strength of the hydrogel before degrading can be formed. The preparation method of the composite hydrogel catalytic membrane is simple and low in cost; the preparation process is free of pollution, green and environmental-friendly; the composite hydrogel catalytic membrane is immersed by a strong metal ion complexing agent; the expensive photo-catalyst can be recycled through simple precipitation separation.

Owner:YINGKOU KELIN MEMBRANE TECH ENG SERVICE

Metal supported silica based catalytic membrane reactor assembly

InactiveCN103596671AMaterial nanotechnologySemi-permeable membranesPhysical chemistryLiquid hydrocarbons

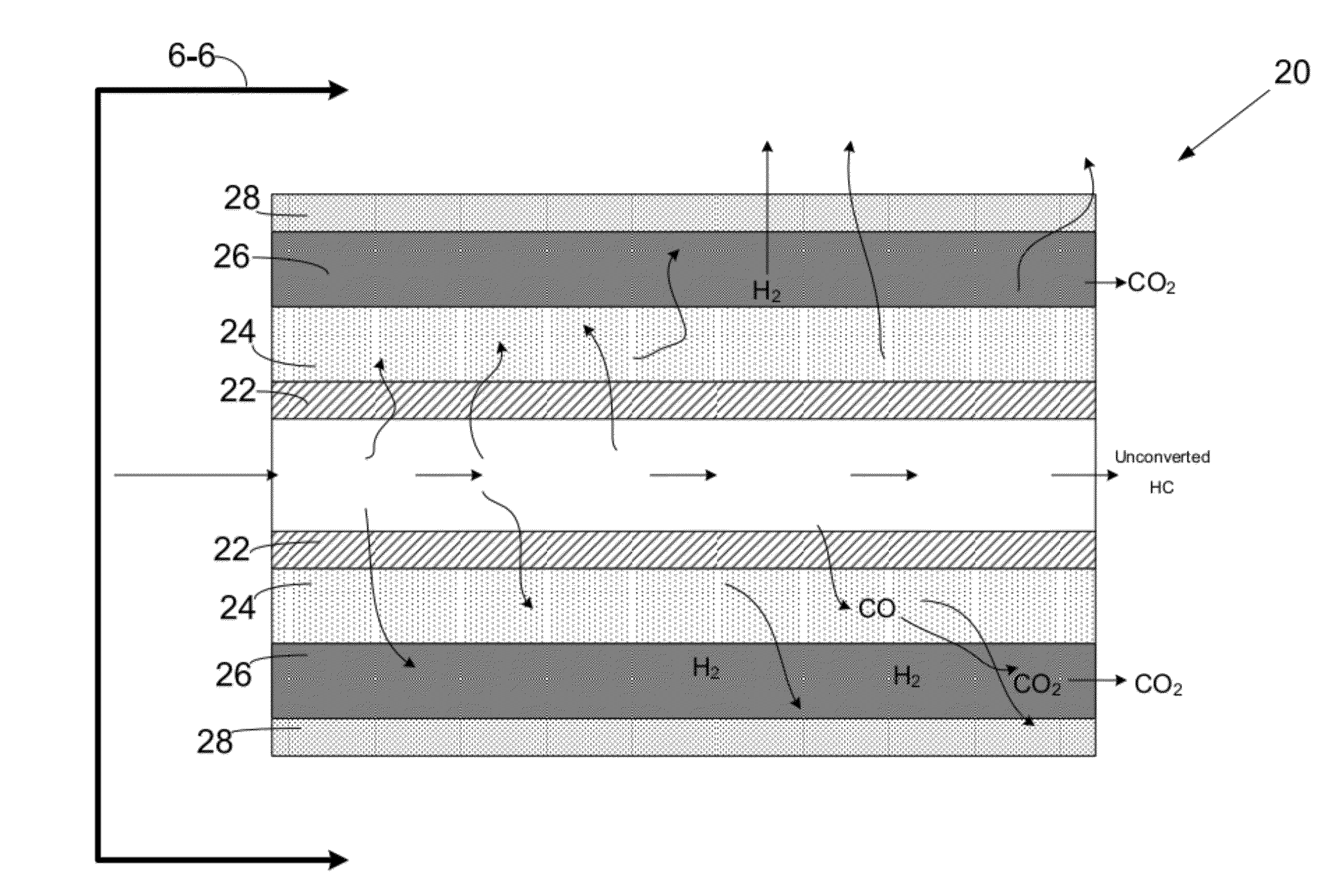

A catalytic membrane reactor assembly for producing a hydrogen stream from a feed stream having liquid hydrocarbons, steam, and an oxygen source through the use of an autothermal reforming reaction, a water-gas-shift reaction, and a hydrogen permeable membrane.

Owner:SAUDI ARABIAN OIL CO +1

Preparation method of gluconic acid and glucaric acid

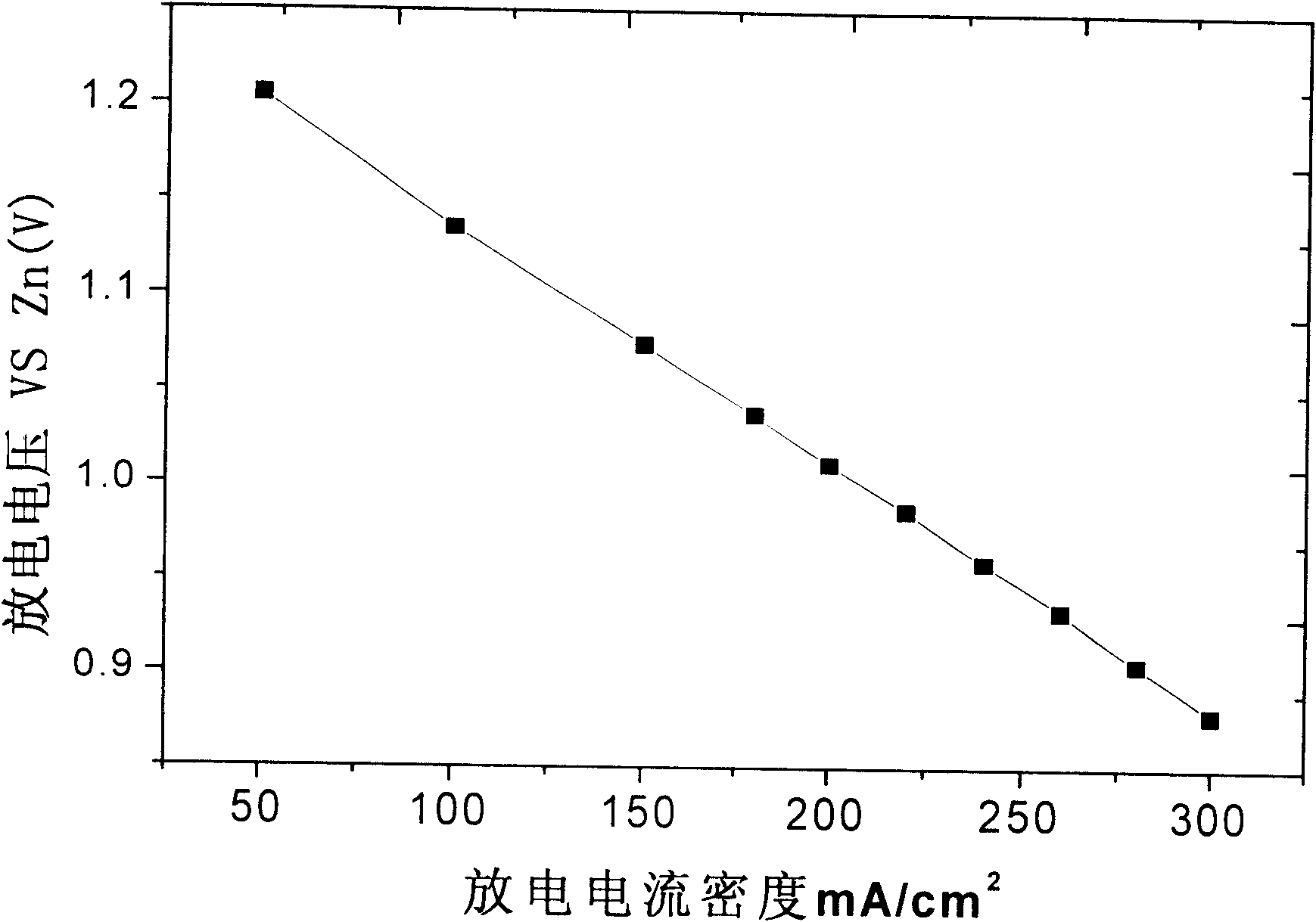

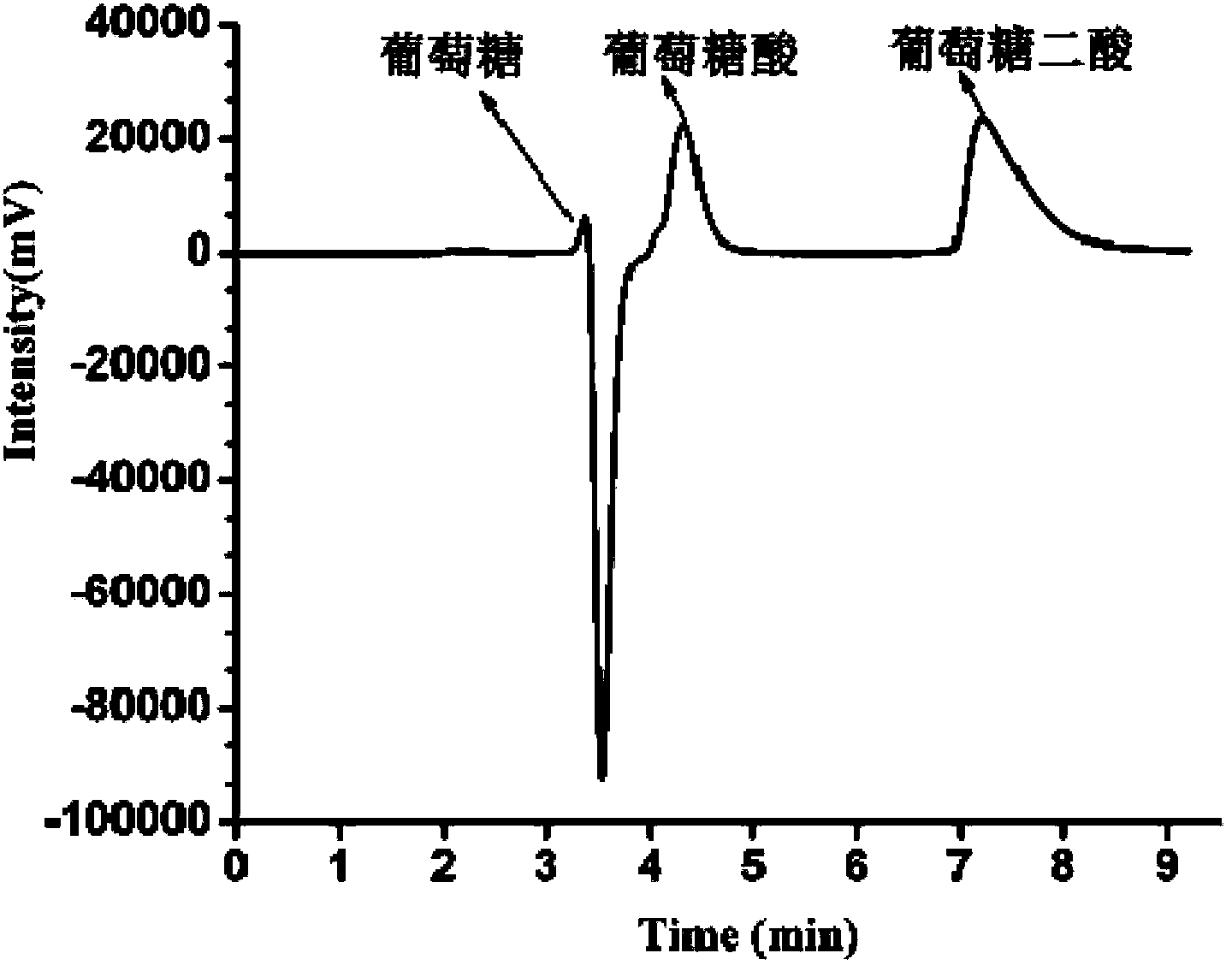

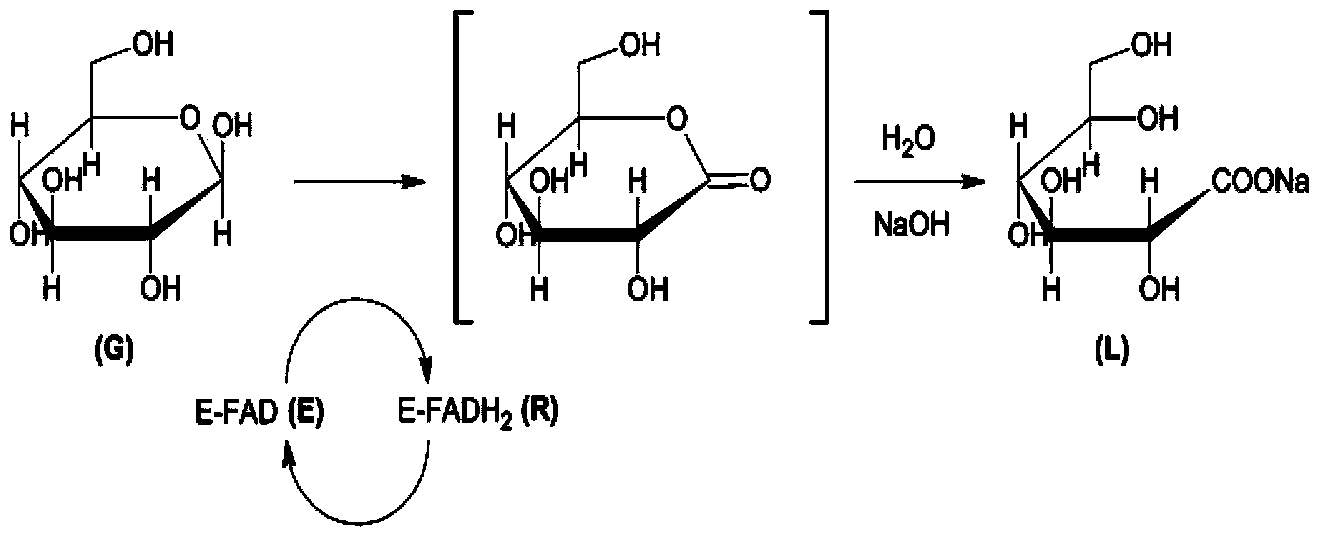

InactiveCN103436910AMaintain continuous efficiencySeparation in timeElectrolysis componentsElectrolytic organic productionPeristaltic pumpCatalytic oxidation

The invention discloses a preparation method of gluconic acid and glucaric acid in the technical field of organic electrochemistry synthesis. The preparation method comprises the steps that an electro-catalytic membrane serving as an anode and an auxiliary electrode serving as a cathode are connected with a voltage-stabilized source by wires to form an electro-catalytic membrane reactor; by taking a glucose aqueous solution as a reactant, and an inorganic substance as an electrolyte, gluconic acid and glucaric acid are prepared by catalytic oxidation of glucose with the electro-catalytic membrane under the action of an electric field; membrane penetration liquid is collected by suction of a peristaltic pump; obtained target products are separated from reaction liquid in real time by permeation of the membrane; the membrane penetration liquid is separated and purified to form gluconic acid and glucaric acid products; and yields of gluconic acid and glucaric acid are adjusted and controlled by adjusting and controlling current density and membrane flux. The preparation method integrates catalytic oxidation and separation functions, and can separate the obtained target products from the reaction liquid timely, so that the continuous high efficiency of the electro-catalytic membrane is maintained effectively; a side reaction is avoided; and the selectivity of the target products is improved.

Owner:TIANJIN POLYTECHNIC UNIV

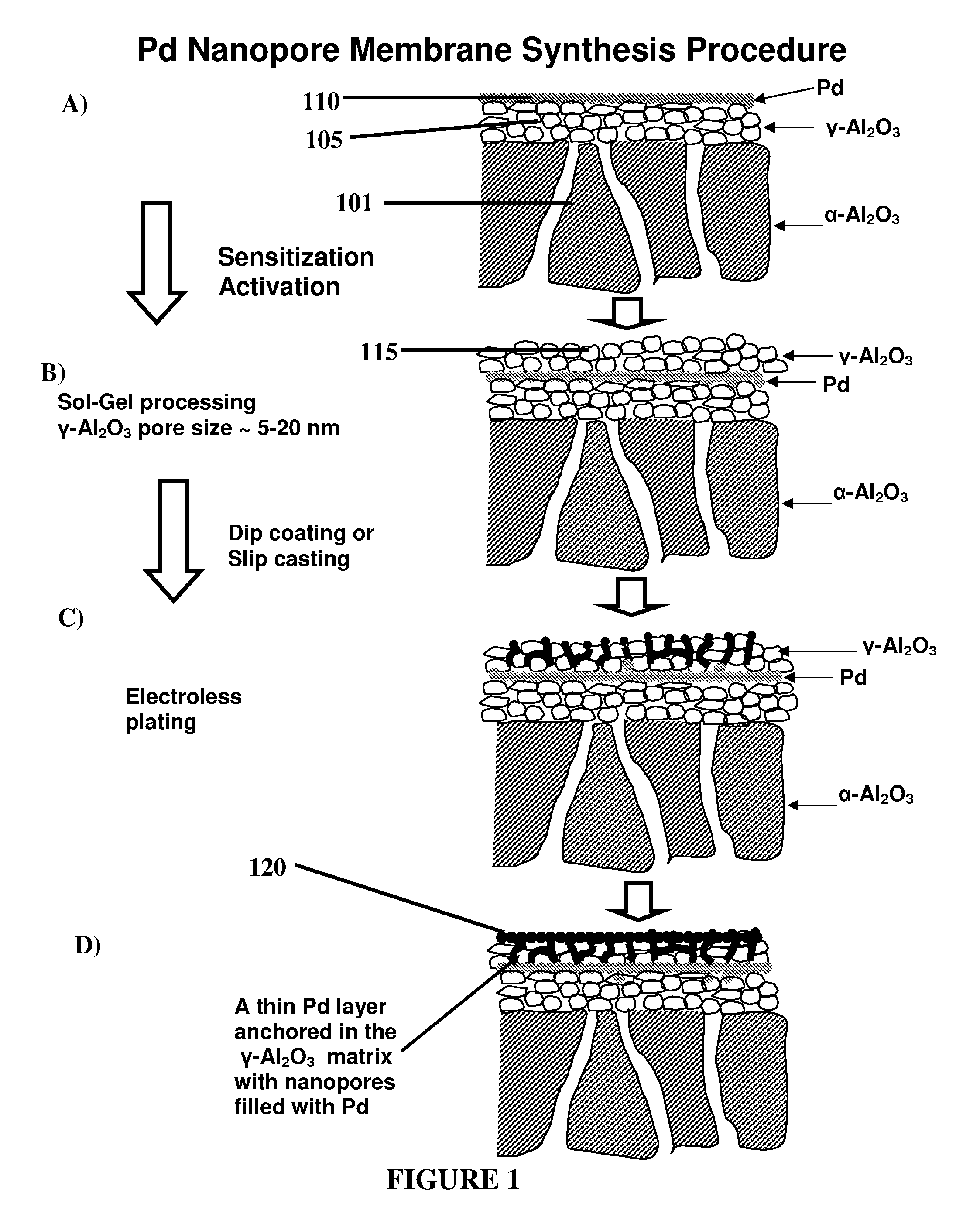

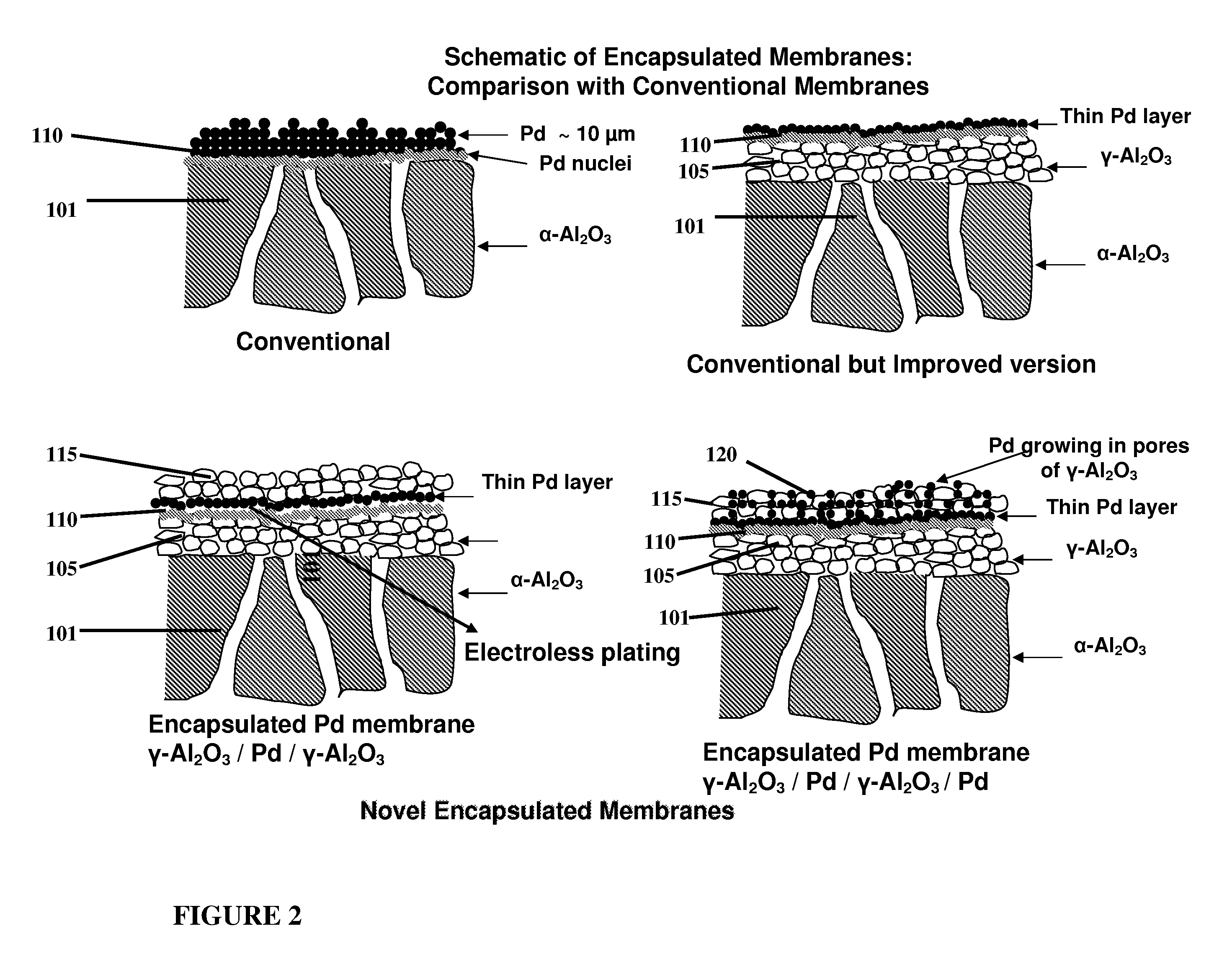

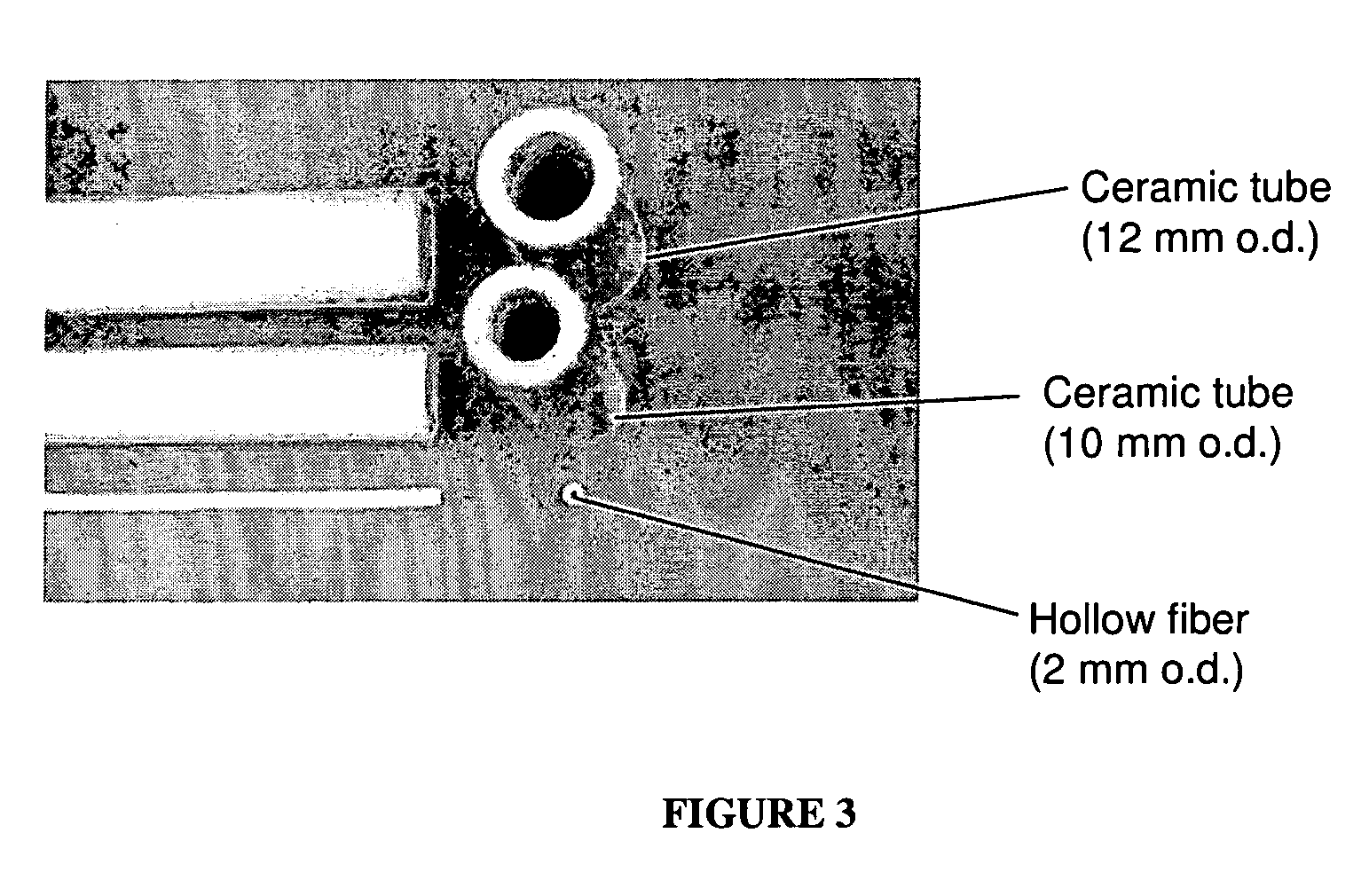

Pd NANOPORE AND PALLADIUM ENCAPSULATED MEMBRANES

InactiveUS20080176060A1Vacuum evaporation coatingSputtering coatingElectroless platingCatalytic membrane

Novel catalytic membranes and methods of synthesizing the membranes are disclosed herein. The technology involves the synthesis of a new type of permselective membrane that combines a hollow porous support with strategically positioned catalytic and selective transport functions to overcome thermodynamic, kinetic, and thermal obstacles, such as in the production of hydrogen. Sub-micron, dense metallic catalysts and films may be deposited within porous hollow substrates to create the membranes using the techniques of sol slip casting, film coating and electroless plating.

Owner:UNIV HOUSTON SYST

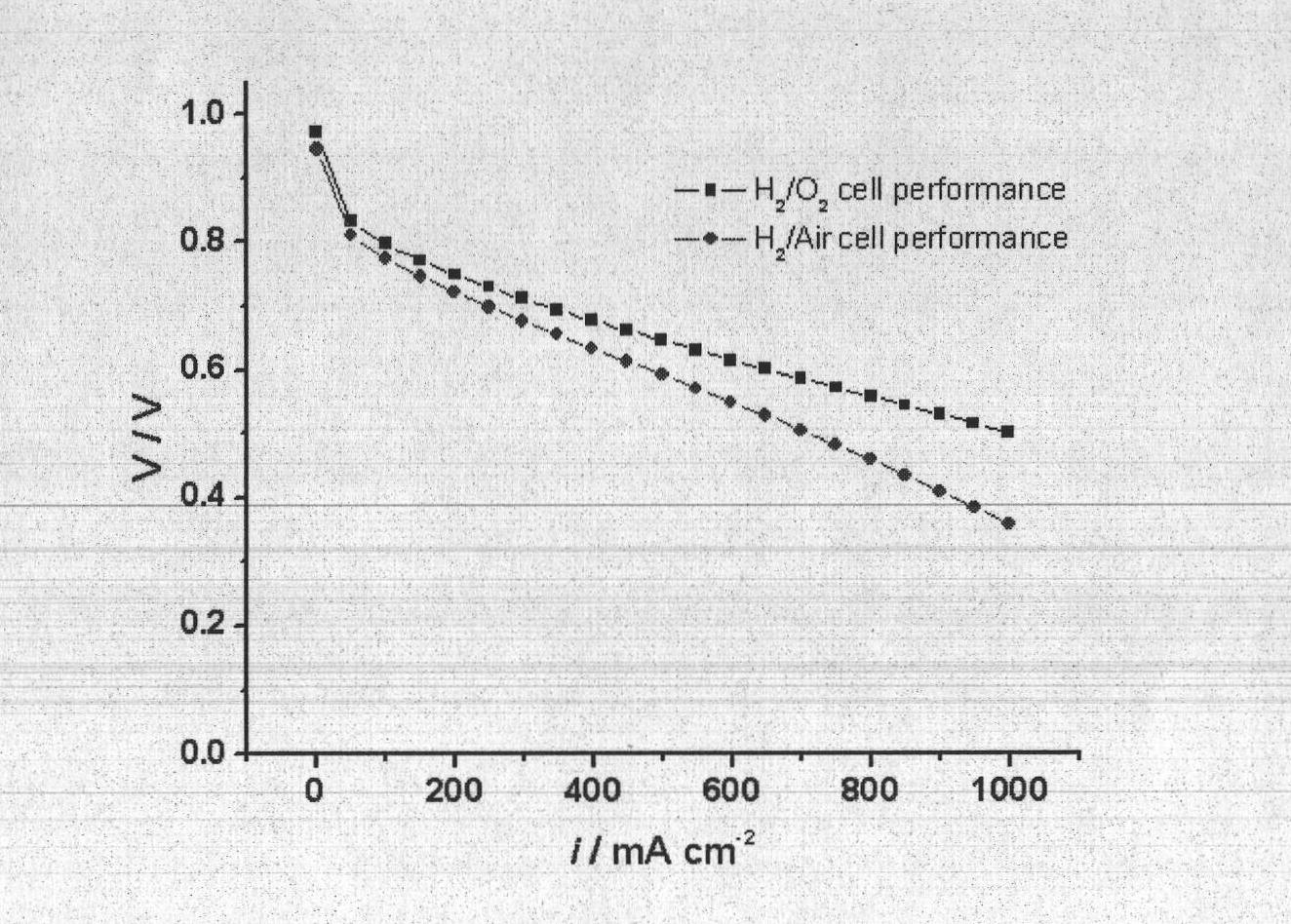

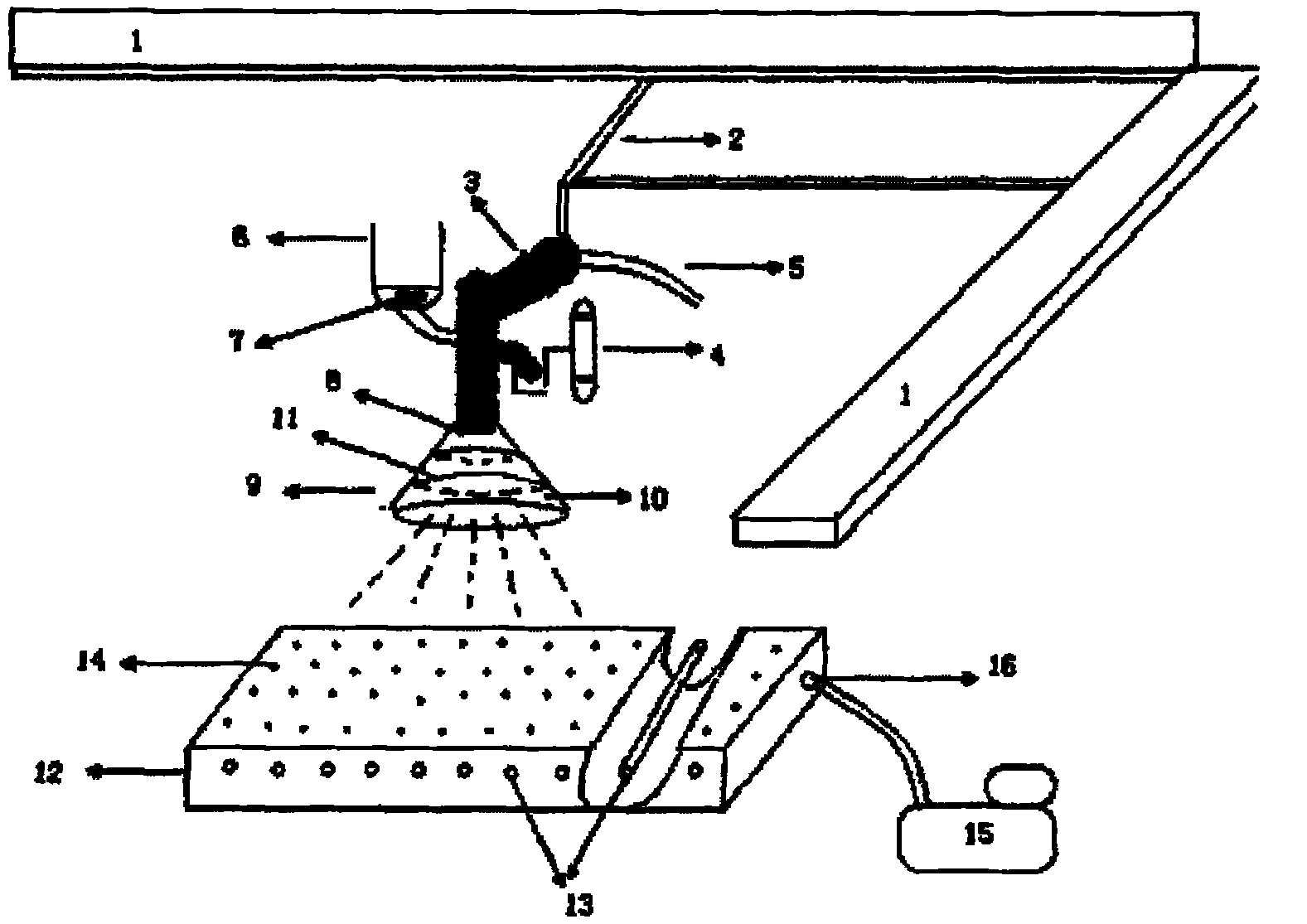

Automatic spraying device for preparing fuel cell membrane electrode

ActiveCN102101085APrevent swelling and deformationAccelerated settlementShaking/oscillating/vibrating mixersSpraying apparatusFuel cellsSlurry

The invention relates to an automatic spraying device for preparing a fuel cell catalytic membrane electrode, which comprises a workbench and a spray gun, wherein the workbench is a vacuumized heating bench which is a hollow box body internally provided with an electric heating element, the box body is connected with a vacuumizing system through a pipeline, and the upper surface of the box body is shaped as a flat plate and is provided with a hole capable of leading to an cavity of the box body; the spray gun is connected with a spraying machine liquid storage hopper through a pipeline, and an ultrasonic oscillator is arranged on the bottom or side wall of the hopper; and a nozzle of the spray gun is provided with an umbrella-shaped heating cover. The vacuumized heating bench for carryinga membrane material can be used for accelerating the solvent volatilization and avoiding the membrane swelling and deformation. A catalyst feed solution is in an ultrasonic oscillating environment during the spraying so as to ensure the uniformity. Through heating a fan-shaped environment between the gun opening of the spray gun and the membrane material, the volatilization of the solvent during the spraying of the feed solution can be improved. The spraying thickness can be determined through controlling the concentration, the spraying flow and the spraying times of the feed solution. Compared with the traditional manual spraying device for preparing the membrane electrode, the automatic spraying device has the advantages of improving the spraying efficiency, ensuring the spraying uniformity and the experimental repeatability, and correspondingly solving the problems of membrane swelling, slurry settlement due to long-time placement and the like in the direct spraying method for preparing the membrane electrode by introducing elements, such as the vacuumized heating bench, the ultrasonic oscillator and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Metal supported silica based catalytic membrane reactor assembly

ActiveUS20120258037A1Increased hydrogen productionMaterial nanotechnologyIsotope separationWater-gas shift reactionLiquid hydrocarbons

A catalytic membrane reactor assembly for producing a hydrogen stream from a feed stream having liquid hydrocarbons, steam, and an oxygen source through the use of an autothermal reforming reaction, a water-gas-shift reaction, and a hydrogen permeable membrane.

Owner:SAUDI ARABIAN OIL CO +1

Porous inorganic membrane containing carbon; a process for its preparation; and use thereof

A porous inorganic membrane comprises at least one inorganic phase having separating properties. Said membrane has a carbon content representing 0.05% to 25% by weight with respect to the mass of said inorganic phase and is selective to non-condensable gases. It is obtained by means of a selectivation treatment of a porous carbon-free inorganic membrane using a hydrocarbon feed. It is used in processes for separating non-condensable molecules such as hydrogen, and in association with a catalyst in a catalytic membrane reactor.

Owner:INST FR DU PETROLE

Method for preparing polymer heterogeneous Fenton-like catalyst-polyvinylidene fluoride (PVDF) catalytic membrane

InactiveCN102000608ALarge specific surface areaSimple methodOrganic-compounds/hydrides/coordination-complexes catalystsWater bathsSolvent

The invention relates to a method for preparing a polymer heterogeneous Fenton-like catalyst-polyvinylidene fluoride (PVDF) catalytic membrane, in particular to a preparation method of a Fenton-like catalytic membrane. By using the preparation method, the problems that iron ions are difficult to recover, and H2O2 has low utilization rate and small application range are solved. The method comprises the following steps: firstly, mixing PVDF powder, a solvent and an additive, stirring, and keeping stand, and carrying out knifing on a clean glass sheet; secondly, carrying out pretreatment on an ethanol solution, and cleaning with deionized water; thirdly, carrying out alkali treatment, and cleaning with the deionized water until neutrality; fourthly, grafting; fifthly, swelling and sulfonating; and finally, putting a solution containing Fe<3+>, vibrating in a water bath to obtain the PVDF catalytic membrane. In the invention, the catalyst has high oxidation resistance and large specific surface area, and can not only purify difficultly degradable macromolecular dye substances but also effectively catalyze organic pollutants in H2O2 degradable water through using the interception function of the membrane, and the method is simple and convenient to operate; and simultaneously, wastewater comes up to the reuse standard, thereby having significance for the development of environmental sustainability.

Owner:HARBIN INST OF TECH

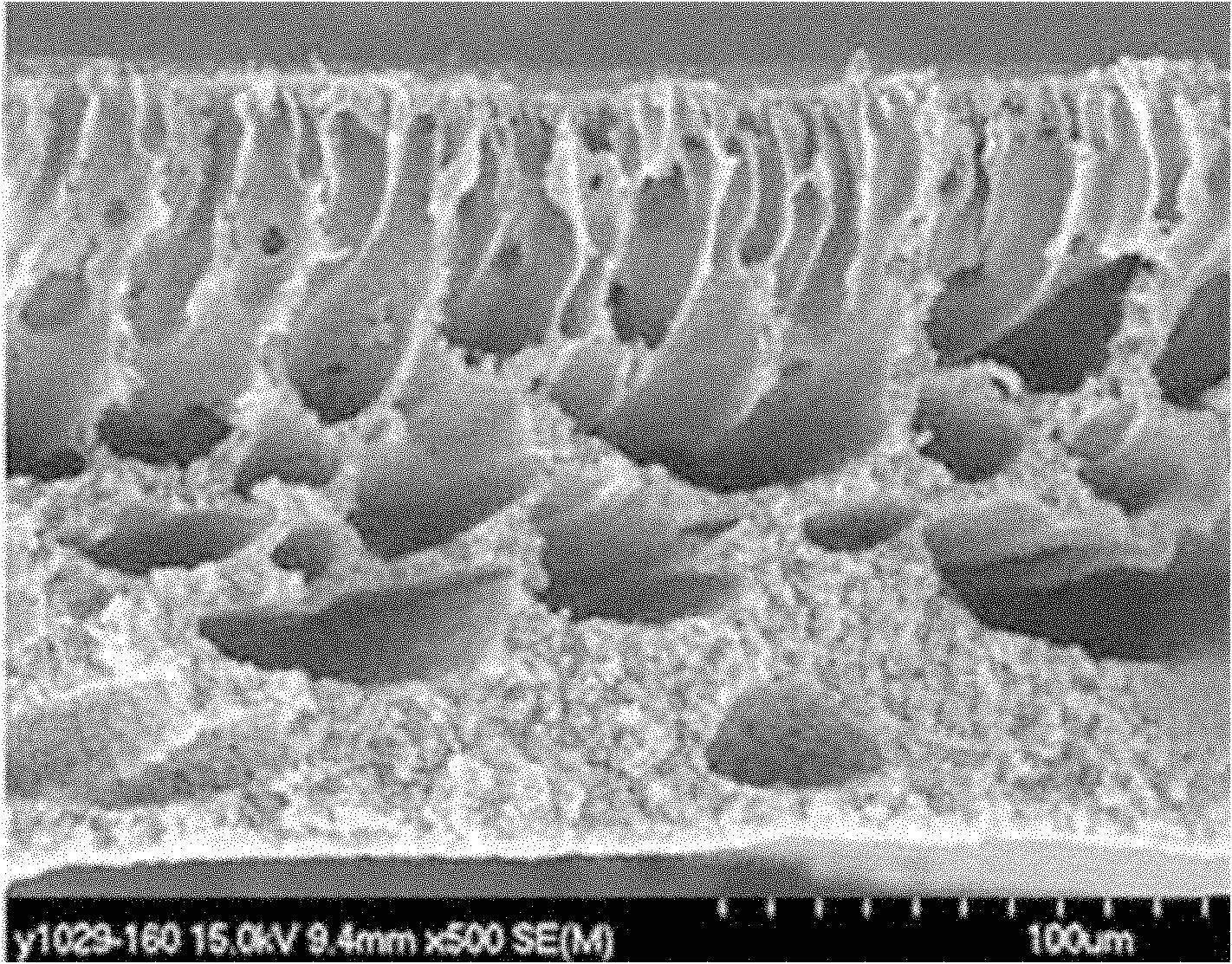

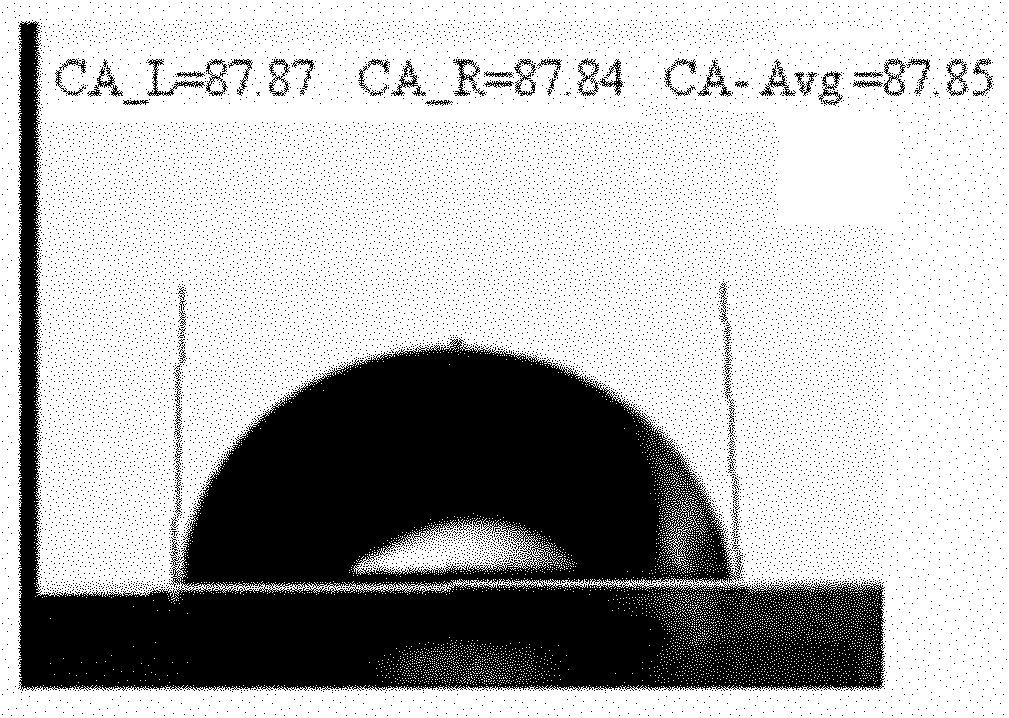

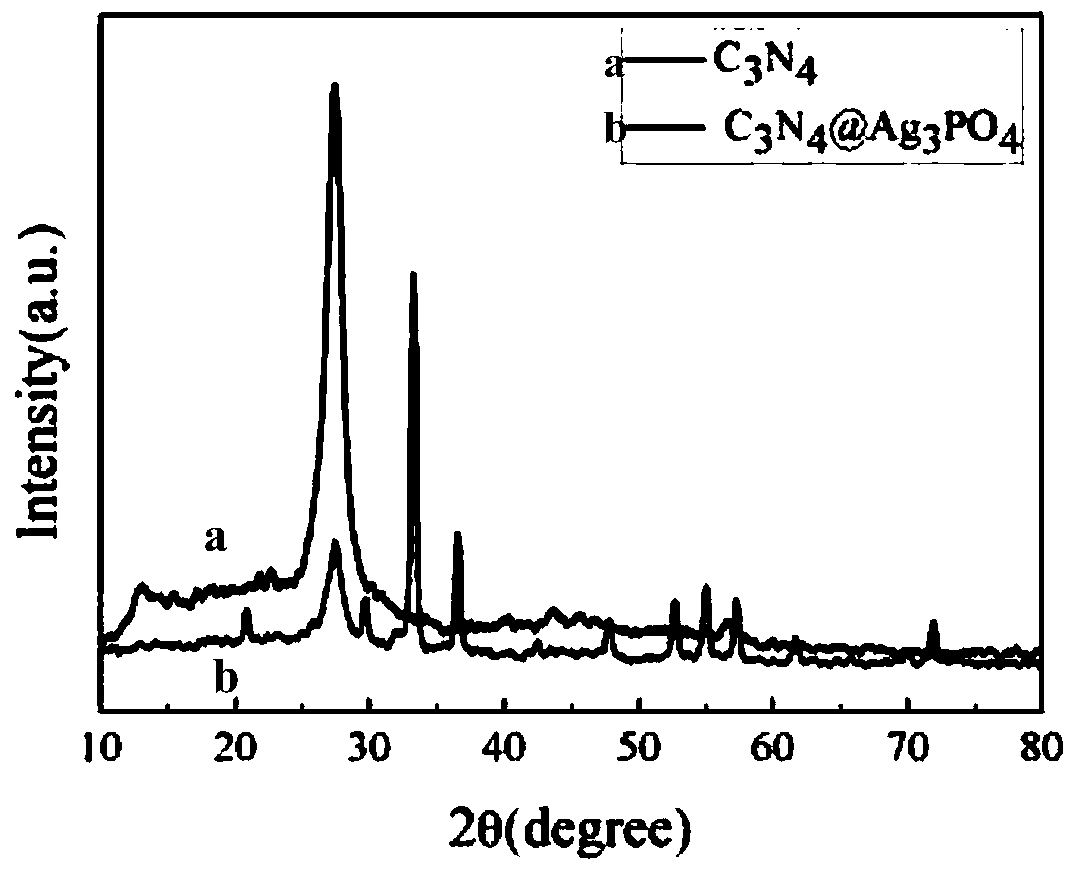

Preparation method and application of C3N4@Ag3PO4/PDA@PVDF bionic composite catalytic membrane

ActiveCN108283932AGood separation stabilityEfficient removalWater/sewage treatment by irradiationWater treatment compoundsSemiconductor materialsFiltration

The invention belongs to the technical field of environment functional materials and relates to a preparation method and application of a C3N4 composite catalytic membrane. The preparation method comprises the following steps: firstly, dissolving AgNO3 and g-C3N4 into water to obtain a solution A; dropwise adding a Na3PO4 solution into the solution A, stirring, washing, centrifugally separating and drying to obtain a binary composite semiconductor material C3N4@Ag3PO4; secondly, dissolving dopamine into a Tris-HCl solution, putting a PVDF membrane into the solution, modifying the dopamine, depositing a polydopamine layer on the surface of the PVDF membrane, and carrying out room temperature drying on the obtained polydopamine modification membrane (PDA@PVDF); dissolving the C3N4@Ag3PO4 into the water, and carrying out ultrasonic dispersion to obtain C3N4@Ag3PO4 suspension; taking PDA@PVDF as a base membrane, and carrying out vacuum filtration and room temperature drying. A silver phosphate nanomaterial is loaded with a graphite nitrogen carbide nano-sheet to form point-surface contact, so that compounding of C3N4 photo-induced electron hole pairs is inhibited, the stability of Ag3PO4 is improved and further the photocatalytic activity is improved; the C3N4@Ag3PO4 is loaded on the PVDF membrane, so that the problems that catalyst powder is difficult to recover and easy to waste,and membrane holes are blocked because of membrane pollution are solved; the removal rate of pollutants is improved.

Owner:JIANGSU UNIV

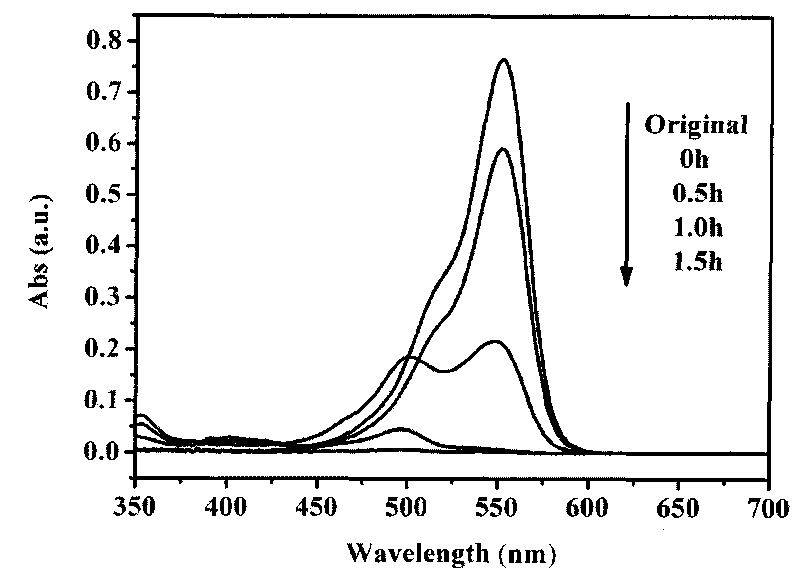

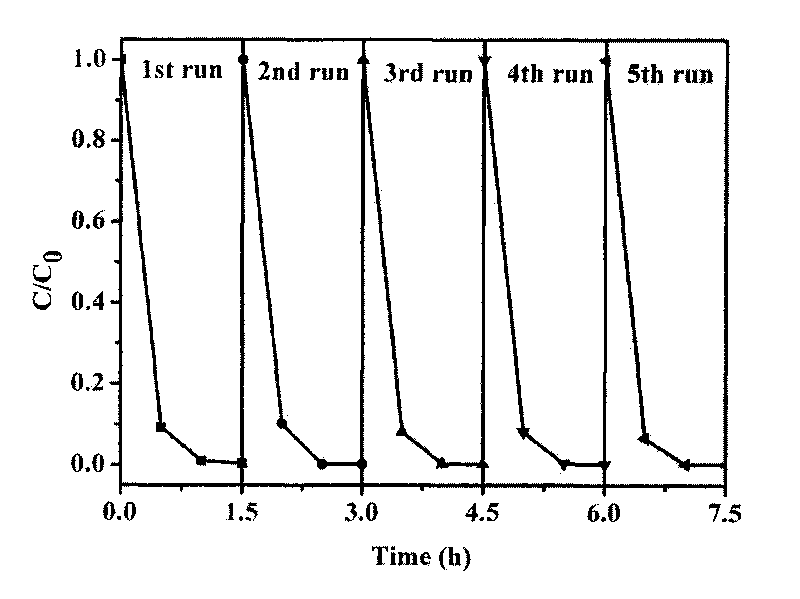

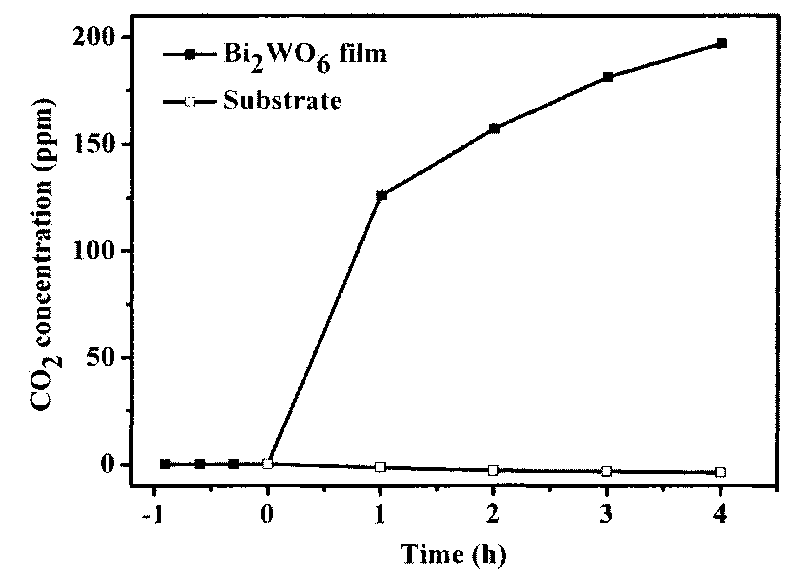

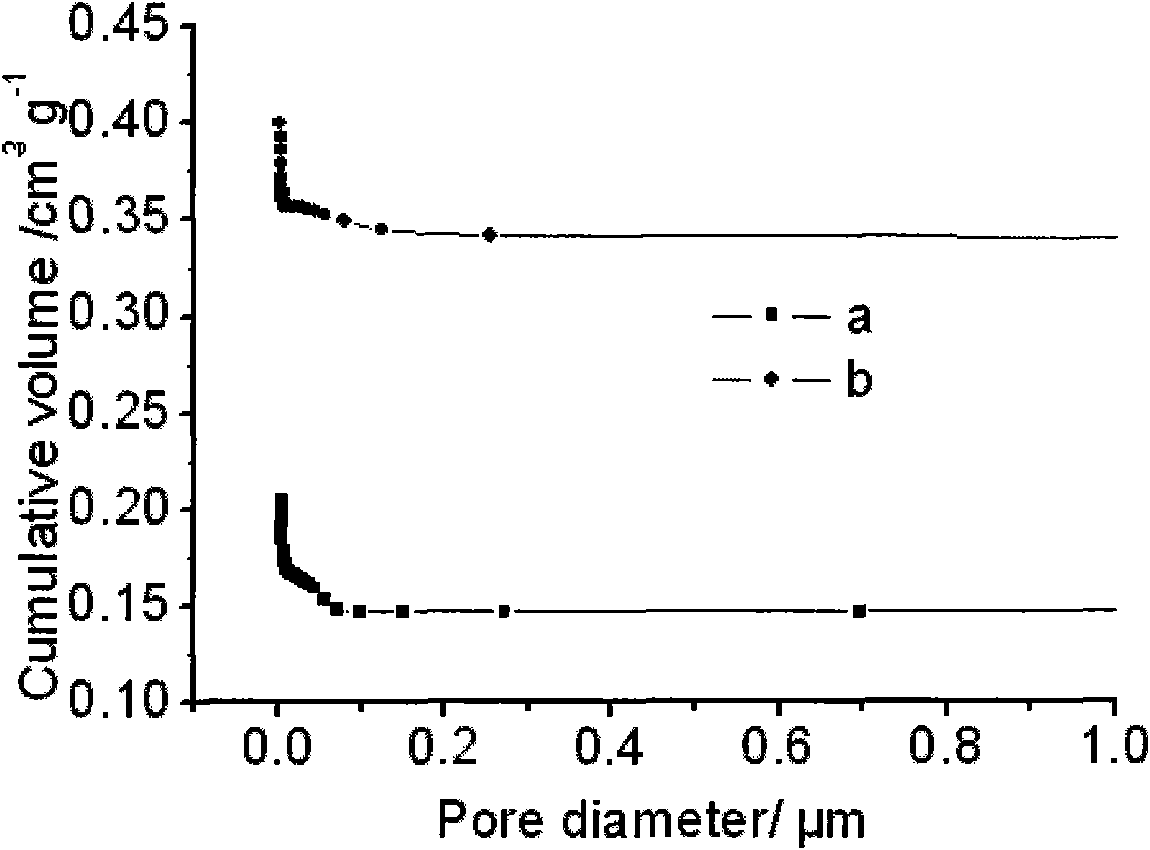

Bi2WO6 photocatalysis membrane loaded by base with high specific surface, method and application thereof

InactiveCN101745402AEasy to separate and recycleImprove photocatalytic activityBiocideWater/sewage treatment by irradiationAir purificationPorous ceramics

The invention relates to a Bi2WO6 photocatalysis membrane loaded by a base with a high specific surface, a method and application thereof. The preparation method comprises the following steps: firstly, Bi2WO6 nano-powder is prepared at the temperature of 60-300 DEG C, the clean base with the high specific surface is dipped into Bi2WO6 suspension to prepare a Bi2WO6 membrane, and finally the Bi2WO6 photocatalysis membrane loaded by the base with the high specific surface is prepared by heat treatment at the temperature of 100-950 DEG C. The bases with the high specific surface are a metal net,foam metal or porous ceramics; and the prepared Bi2WO6 membrane has the characteristics of small Bi2WO6 particle size, high photocatalysis activity, favourable cycle performance, simple preparation technology, low production cost and the like. Meanwhile, the photocatalysis membrane can be conveniently recycled and reused, thus solving the problem of difficult recovery in the practical applicationof a nanometer photochemical catalyst. The invention can be used for RhB degradation, air purification and photocatalysis antibacterial activity under visible light.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

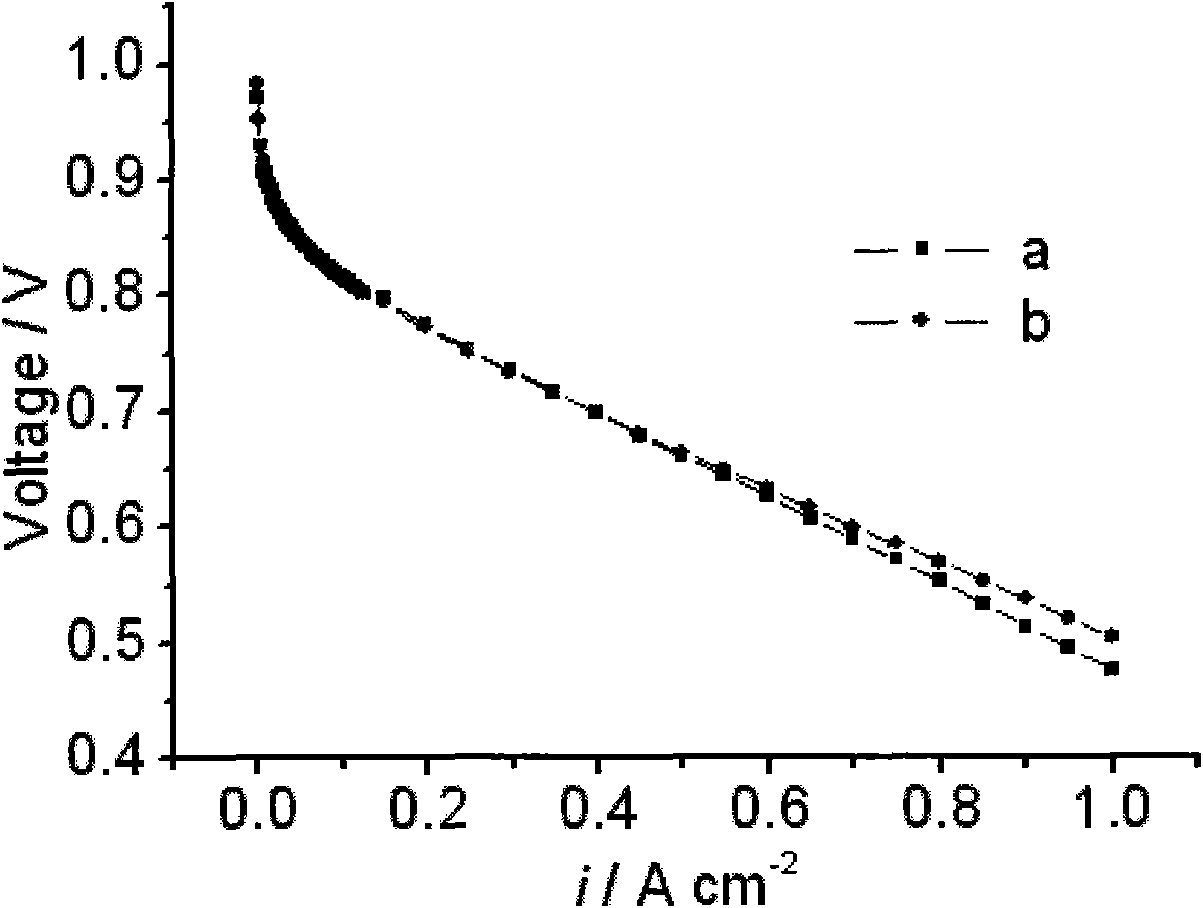

Catalyst sizing agent for preparing catalytic membrane electrode of fuel cell and preparation thereof

ActiveCN102255085ASimple methodIncrease profitCell electrodesMetal/metal-oxides/metal-hydroxide catalystsPorosityElectrical conductor

The invention relates to a catalyst sizing agent for preparing a catalytic membrane electrode of a proton exchange membrane fuel cell. The catalyst sizing agent consists of an electric catalyst, proton conductor polymer distilled water and an organic solvent. The catalyst sizing agent is controlled in a colloid state, so that the pore structure of a prepared catalytic layer of a catalytic membrane electrode is improved, and the cell performance is enhanced. The conventional sizing agent for preparing the catalytic membrane electrode is in a solution state, so that the utilization ratio of a prepared electrode catalyst is not high, the porosity of a catalytic layer is very low, and the gas diffusion process is suppressed. In the invention, the composition and adding sequence of organic solvents in the sizing agent are changed. A preparation method of the catalyst sizing agent comprises the following steps of: conditioning a solution-state catalyst sizing agent with isopropanol, ethanol, ethanediol and the like; and dropwise adding the formed sizing agent into butyl acetate under ultrasonic oscillation condition to form a colloid-state catalyst sizing agent.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

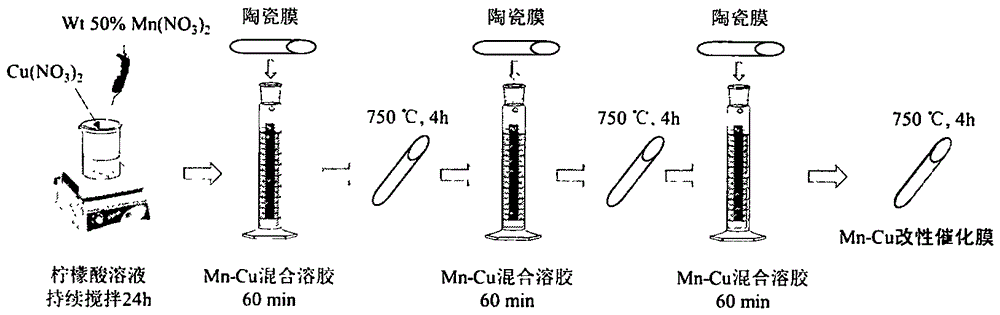

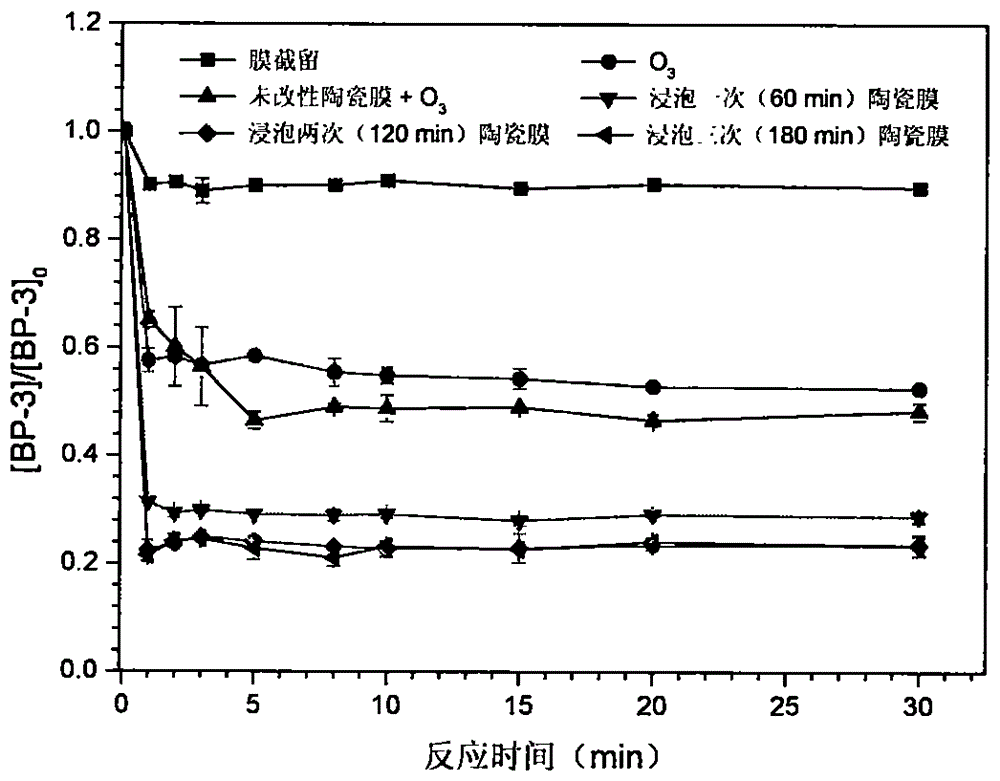

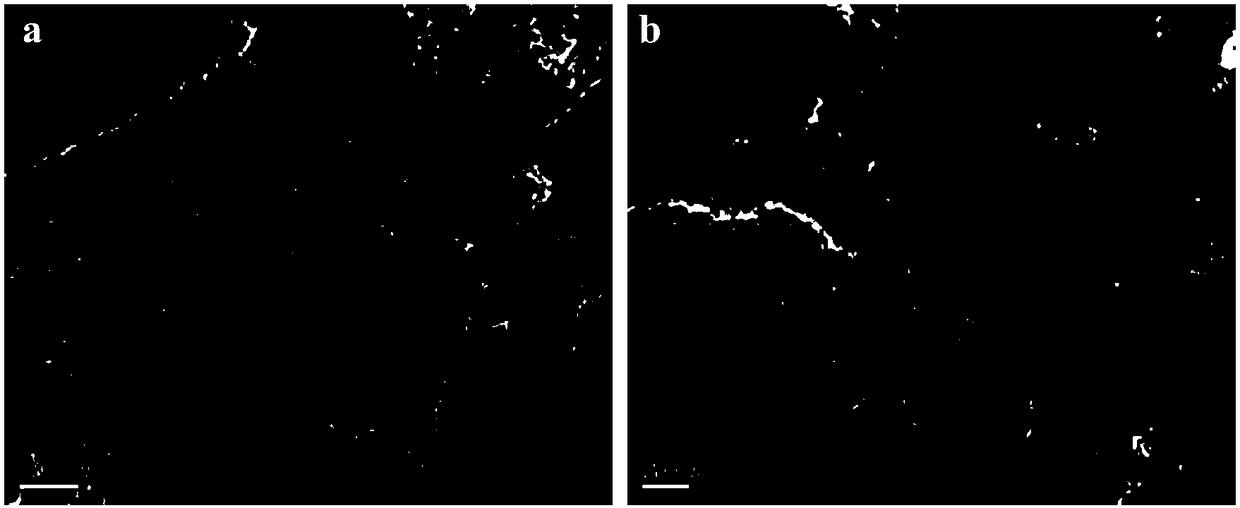

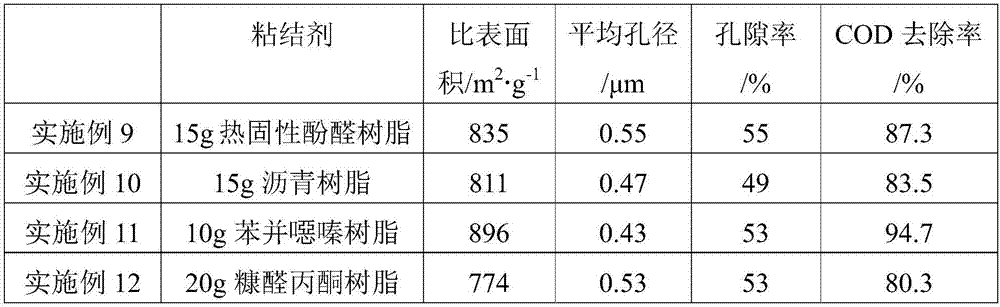

Nanometer copper manganate spinel catalytic membrane reactor, and construction and application method thereof in water treatment.

ActiveCN105800767APrevent contamination from formingWater/sewage treatment bu osmosis/dialysisWater/sewage treatment by oxidationNatural organic matterPtru catalyst

The invention relates to an advanced water treatment technique for pollution removal through heterogeneous catalytic ozonation. Directed at the disadvantage that a conventional powdery catalyst is unfavorable for separation and easy to inactivate in a water phase, a construction method for a novel nanometer copper manganate spinel catalytic membrane reactor is provided. The construction method aims to combine heterogeneous ozonation with a ceramic membrane filtration technique, and utilizes active components (CuMn2O4) on a ceramic membrane catalytic layer to catalyze ozone so as to generate -OH with high oxidation capacity, wherein organic compounds can directly react with molecular ozone or react with -OH generated by ozone decomposition; meanwhile, an interception function of the ceramic membrane can assist to reinforce removal of 2-hydroxyl-4-methoxybenzophenone in water. In addition, ozone can react with humic acid and natural organic matters (NOMs) in the water, so the formation of membrane pollution is effectively controlled. A nanometer copper manganate spinel catalytic membrane provided by the invention has the following advantages: preparation process is simple; operation is convenient; a catalyst on membrane surface is uniformly distributed, so mass transfer efficiency is improved; and the membrane has potential application prospects in treatment of drinking water or wastewater containing pharmaceutical and personal care products (PPCPs).

Owner:BEIJING FORESTRY UNIVERSITY

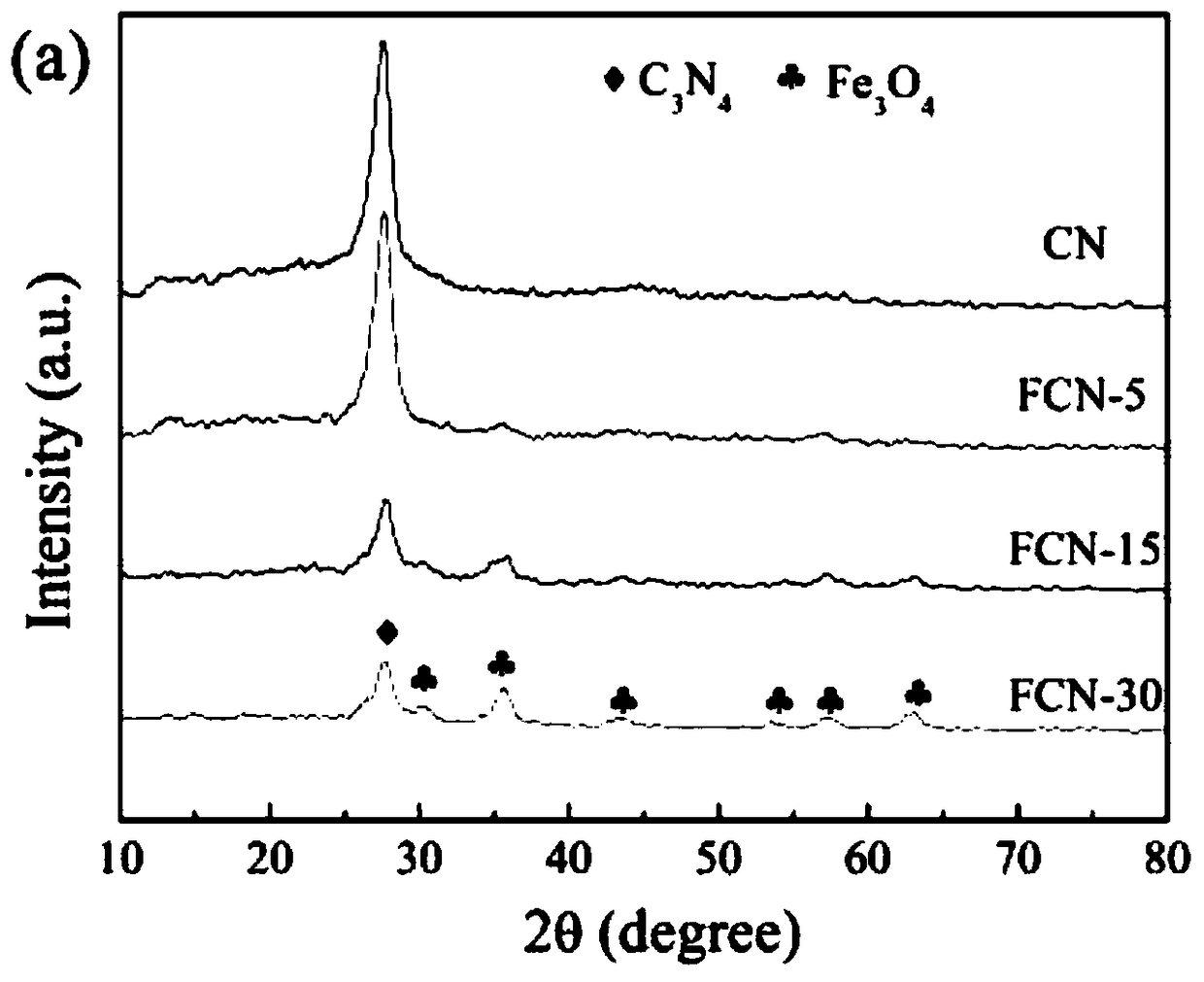

Preparation method for novel magnetic induction C3N4/Fe3O4 composite film and application of composite film

InactiveCN108187715AInhibitory complexImprove degradation ratePhysical/chemical process catalystsWater/sewage treatment by irradiationMaterials preparationComposite film

The invention belongs to the technical fields of material preparation and environmental pollution improvement, and provides a preparation method for a novel magnetic induction C3N4 / Fe3O4 composite film. The preparation method comprises the following steps: step 1, preparing a C3N4 / Fe3O4 composite photocatalyst; and step 2, performing magnetic induction on a C3N4 / Fe3O4 composite material to preparethe photocatalytic film. The catalytic film prepared by utilizing the magnetic induction method provided by the invention can effectively overcome the shortcoming that a catalyst is easy to imbed ina traditional blend film, achieves high-efficiency catalytic degradation of target pollutants, and has the advantages of simple synthesis, high degradation efficiency and the like.

Owner:JIANGSU UNIV

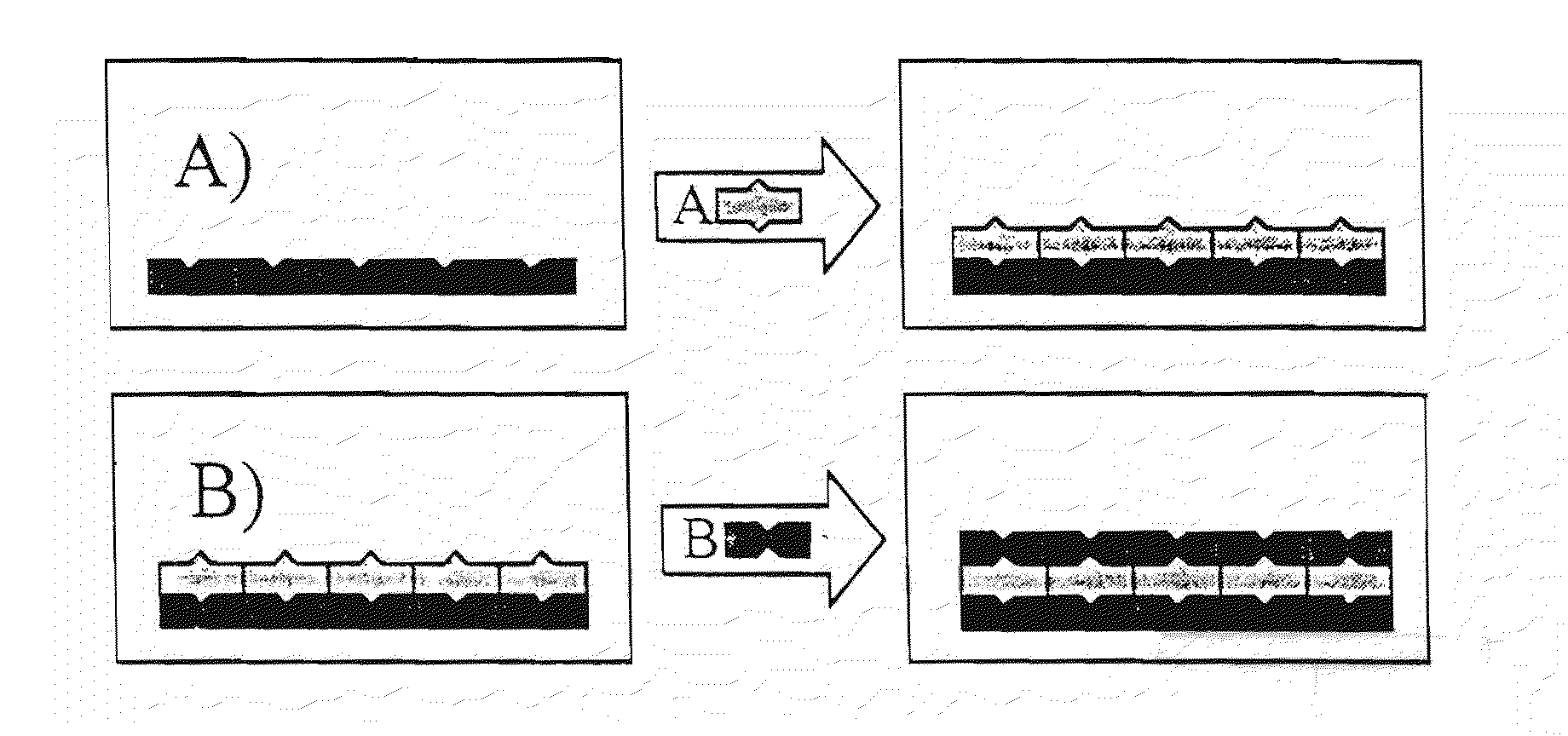

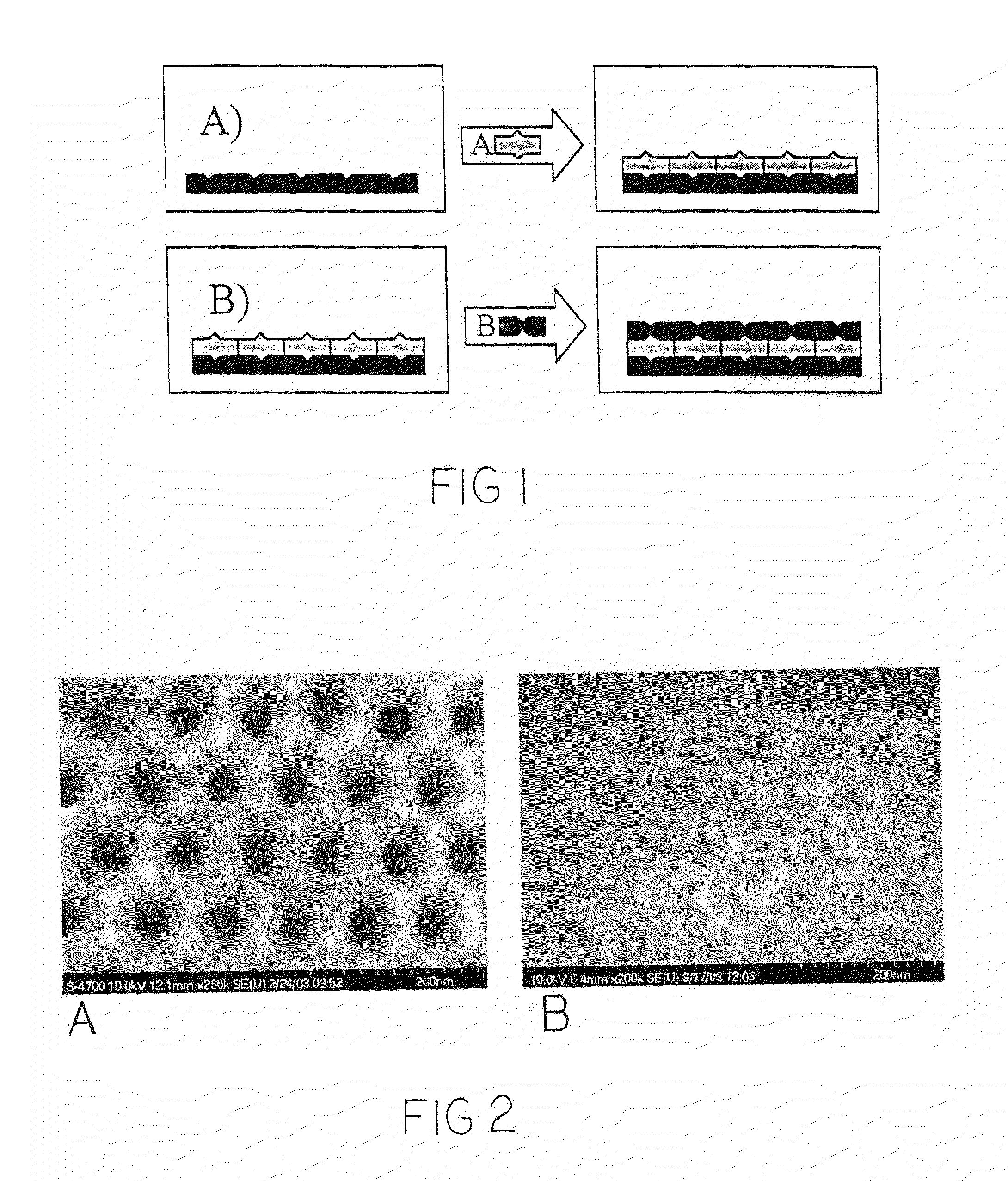

Catalytic nanoporous membranes

InactiveUS20100075827A1Unique catalyst environmentUniform coatingOther chemical processesCatalyst activation/preparationPartial oxidationGas phase

A nanoporous catalytic membrane which displays several unique features Including pores which can go through the entire thickness of the membrane. The membrane has a higher catalytic and product selectivity than conventional catalysts. Anodic aluminum oxide (AAO) membranes serve as the catalyst substrate. This substrate is then subjected to Atomic Layer Deposition (ALD), which allows the controlled narrowing of the pores from 40 nm to 10 nm in the substrate by deposition of a preparatory material. Subsequent deposition of a catalytic layer on the inner surfaces of the pores reduces pore sizes to less than 10 nm and allows for a higher degree of reaction selectivity. The small pore sizes allow control over which molecules enter the pores, and the flow-through feature can allow for partial oxidation of reactant species as opposed to complete oxidation. A nanoporous separation membrane, produced by ALD is also provided for use in gaseous and liquid separations. The membrane has a high flow rate of material with 100% selectivity. Also provided is a method for producing a catalytic membrane having flow-through pores and discreet catalytic clusters adhering to the inside surfaces of the pores.

Owner:UCHICAGO ARGONNE LLC

Molecular imprinting catalytic membrane capable of selectively degrading ciprofloxacin and preparation method

ActiveCN106955726AHighly selective degradation effectEasy to separatePhysical/chemical process catalystsWater/sewage treatment by irradiationSelective degradationCarbonate

The invention provides a molecular imprinting catalytic membrane capable of selectively degrading ciprofloxacin and a preparation method. The preparation method comprises the following steps: step 1, preparing graphite-like nitrogen carbonate g-C3N4; step 2, preparing a noble metal loaded semiconductor composite material; and step 3, preparing the molecular imprinting catalytic membrane capable of selectively degrading the ciprofloxacin. The material prepared by the preparation method can effectively realize the aims of preferably selectively adsorbing and degrading target pollutants in a mixed sewage system; post-treatment is simple, a photocatalyst is conveniently recycled for a plurality of times and secondary pollution is effectively avoided; and the molecular imprinting catalytic membrane has the advantage of selectively treating antibiotic wastewater very well.

Owner:JIANGSU UNIV

Polymer catalytic membrane containing palladium metal activity functional layer and preparation method thereof

InactiveCN102512991AEasy to prepareNo need for external power conditionsSemi-permeable membranesOrganic compound preparationPotassium borohydridePolyethylene glycol

The invention relates to a polymer catalytic membrane containing a palladium metal activity functional layer prepared based on the technology of layer-by-layer self assembly and a preparation method thereof, which belongs to the field of catalytic membranes. According to the invention, polyacrylonitrile (PAN) powder, polyethylene glycol (PEG) and polyvinylpyrrolidone (PVP) are dissolved in N,N-dimethyl formamide (DMF), and a PAN flat base membrane is prepared by using a phase inversion process; then the PAN membrane is soaked in a NaOH solution for treatment, which allows surface of the membrane to hydrolyze so as to produce carboxyl groups, thereby enabling the surface of the membrane to carry negative electric charges; a polyethyleneimine (PEI) solution and a potassium chloropalladate K2PdCl4 solution are fully mixed and react for a certain period of time so as to obtain a coordination compound of polyethyleneimine-palladium (PEI-Pd(II)); the treated flat base membrane is alternatively soaked in a solution containing the PEI-Pd(II) coordination compound and a polystyrene sulfonate (PSS) solution for self-assembly of functional layers on the surface of the membrane, and the amount of the assembled layers is controlled; and finally, the membrane obtained after assembly is soaked in a potassium borohydride KBH4 solution, Pd(II) is reduced to be Pd0, and the PAN catalytic membrane containing the palladium metal particle active layer is prepared.

Owner:TIANJIN POLYTECHNIC UNIV

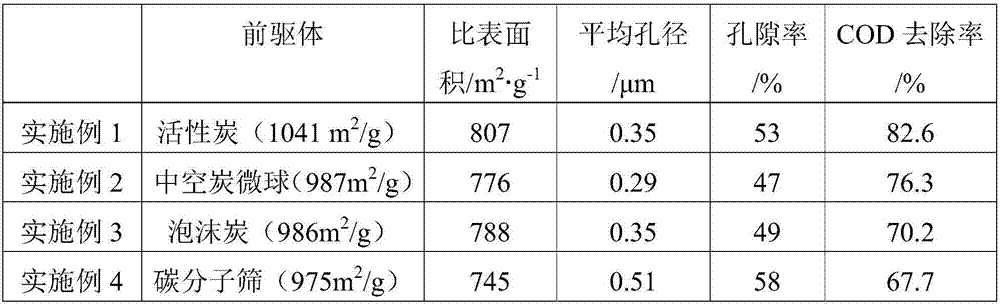

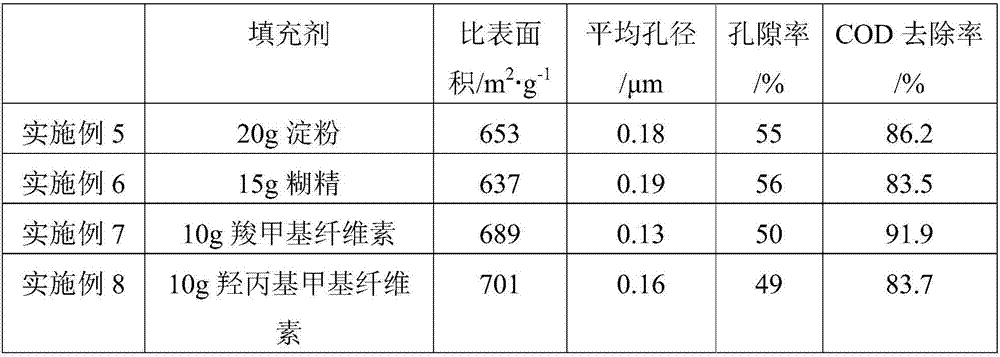

Carbon membrane having triple functions of adsorption/electrocatalysis/membrane separation, and preparation method of carbon membrane

ActiveCN107051218ASimplify the advanced processing processTo achieve the effect of deep purificationSemi-permeable membranesOther chemical processesPorous carbonWastewater

The invention relates to a carbon membrane having triple functions of adsorption / electrocatalysis / membrane separation, and a preparation method of the carbon membrane, and belongs to the technical field of novel membrane materials. In the invention, a porous carbon material having an adsorption function is adopted as a precursor to prepare the carbon membrane on the basis of an electrocatalytic carbon membrane, a multi-stage pore structure is adjusted, adsorption and membrane separation performances are adjusted and controlled, at the same, a catalyst is loaded on the carbon membrane substrate, so that the integration of triple functions of adsorption / electrocatalysis / membrane separation is realized and the carbon membrane base material having the triple functions of adsorption / electrocatalysis / membrane separation can be designed and prepared. The carbon membrane material having the triple functions of adsorption / electrocatalysis / membrane separation can be used for performing deep purification on source water and deep treatment on waste water; the developed porous structure of the membrane can effectively adsorb pollutants, such as organic molecules, microorganisms and heavy metals, in the water, to enable the pollutants to be gathered onto the surface and pores of the membrane; and at the same time, combined with membrane separation and electrocatalytic oxidation, the membrane can be used for achieving pollutant separation and degradation to obtain an effect of deep purification.

Owner:DALIAN UNIV OF TECH

Application method of MnxCe(1-x)O2 nanoparticles

ActiveCN103346334AImprove electrocatalytic performanceImprove electrocatalytic activityCell electrodesMetal/metal-oxides/metal-hydroxide catalystsPtru catalystElectrical battery

The invention discloses an application method of MnxCe(l-x)O2 nanoparticles. The MnxCe(l-x)O2 nanoparticles are used as a catalyst for manufacturing a catalytic film of an air electrode of an aluminum air battery, wherein x is greater than 0 but less than 1. The particles are superfine nanoparticles about 5nm, and have the advantages of large specific surface area, high electric catalytic activity, good chemical stability and the like. The air electrode is compressed by the catalytic film, a waterproof ventilating film and a current collector. The polarization current of the air electrode prepared by using the catalyst at -0.55V (the reference electrode is Hg / HgO) is 469Ma / cm<2>. The voltage platform of the air electrode forming the aluminum air battery under full current constant-current discharge of 200Ma / cm<2> is 1.24V.

Owner:CENT SOUTH UNIV

Preparation method and application of fiber composite membrane catalyst

InactiveCN108940374AAvoid reunionImprove conversion rate onceOrganic-compounds/hydrides/coordination-complexes catalystsWater contaminantsMicrowaveFiltration

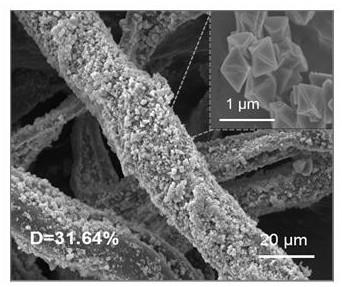

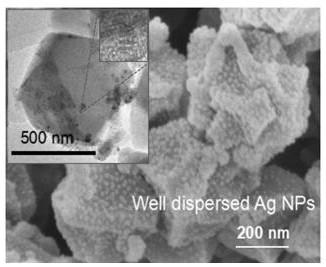

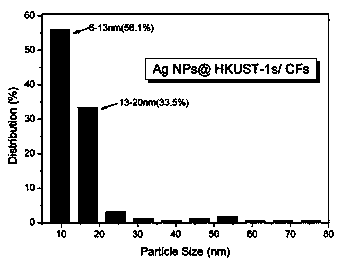

A preparation method of a fiber composite membrane catalyst is as follows: firstly, cellulose fiber is subjected to carboxymethylation treatment, a large amount of carboxyl groups are introduced, metal organic framework MOFs are synthesized in situ on the fiber by immersion stirring, nano-Ag (Ag NPs) is loaded and dispersed on the MOFs by microwave reduction, and a nano-paper-based composite filmcatalytic material is finally obtained by washing, suction filtration, and paper making and forming; the practical size of the Ag nano-particles is between 6 and 20 nm, and rapid catalytic degradationand conversion of p-nitrophenol in wastewater to p-aminophenol can be realized by synergistic effects of the MOFs and the Ag nano-particles. The primary conversion rate is over 99%. Compared with a traditional granular catalyst, and the problems of difficult recovery, short catalytic time and high efficiency can be solved. The fiber composite membrane catalyst can be used as a filler to prepare acatalytic membrane material by mixing for paper making with other plant fibers. The catalytic membrane material has broad application prospects in the field of treating industrial wastewater.

Owner:SHAANXI UNIV OF SCI & TECH

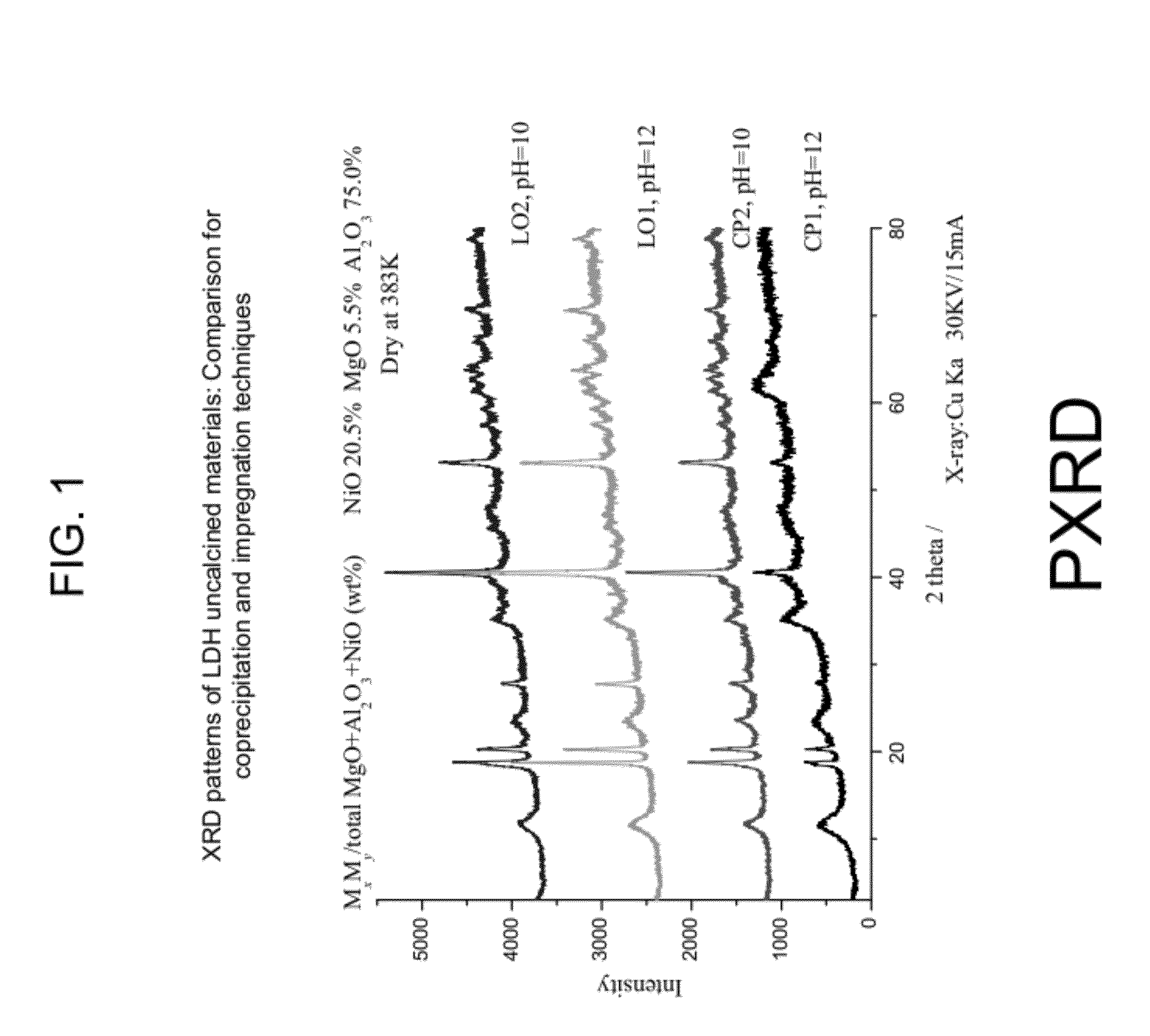

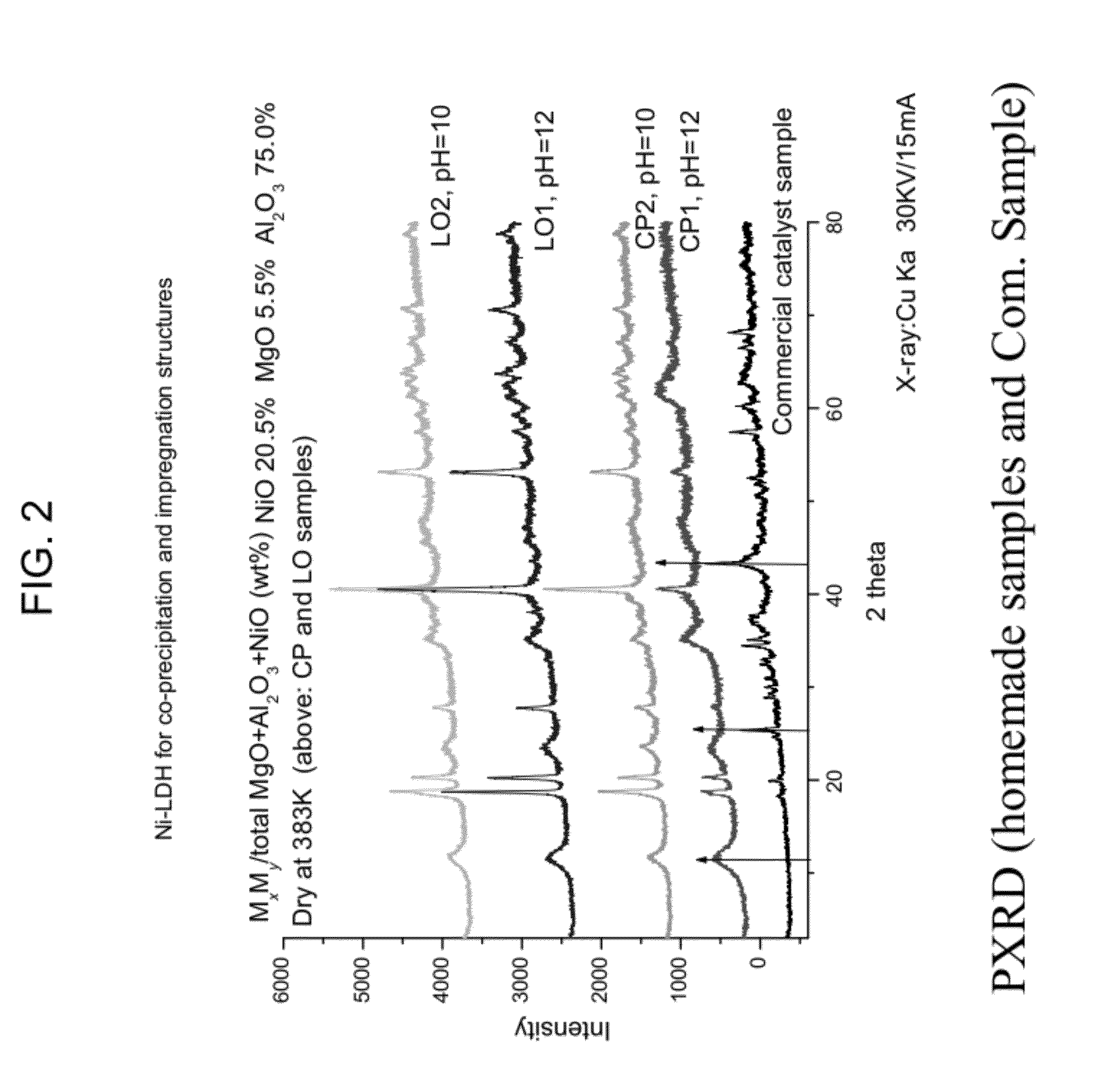

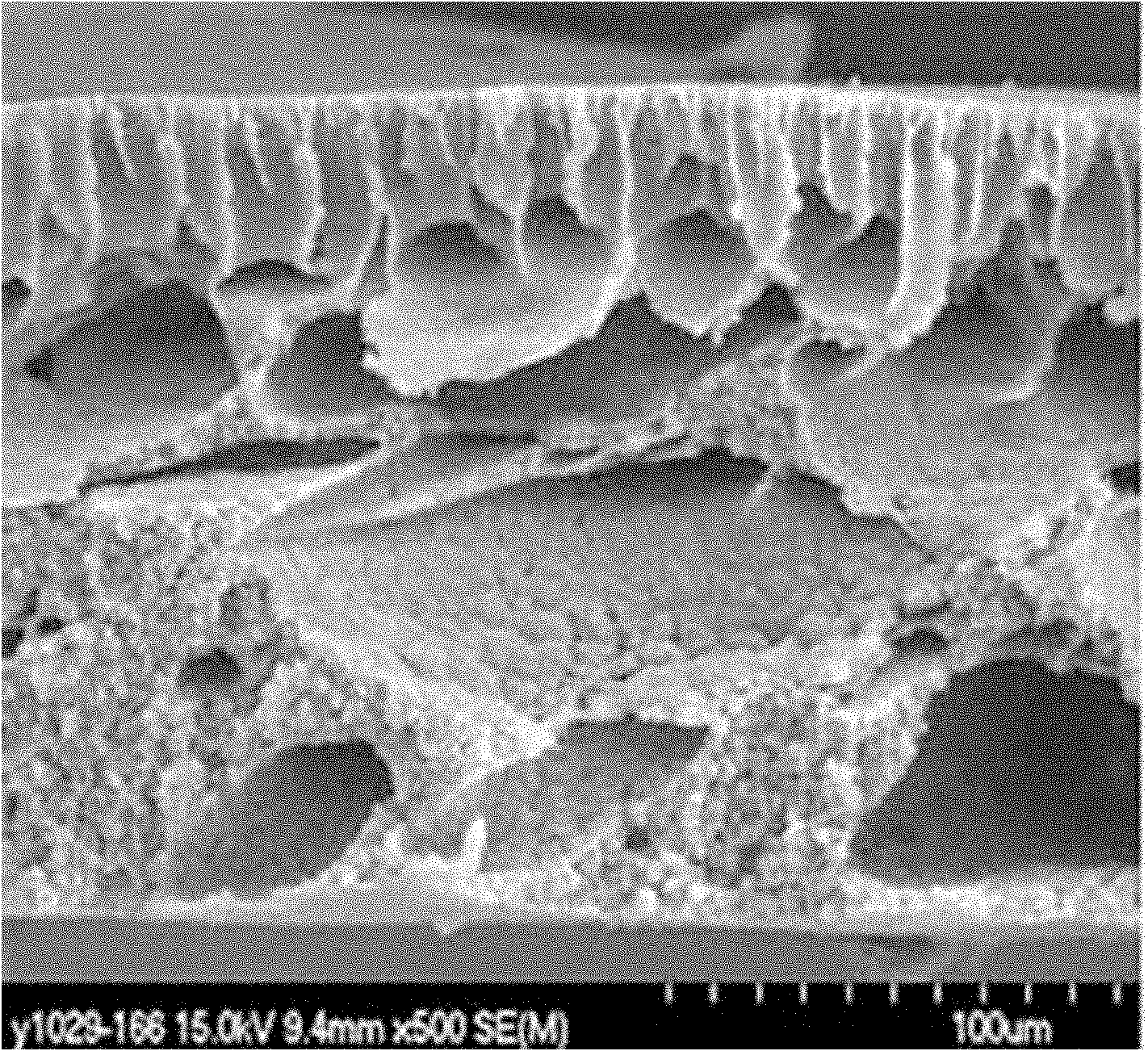

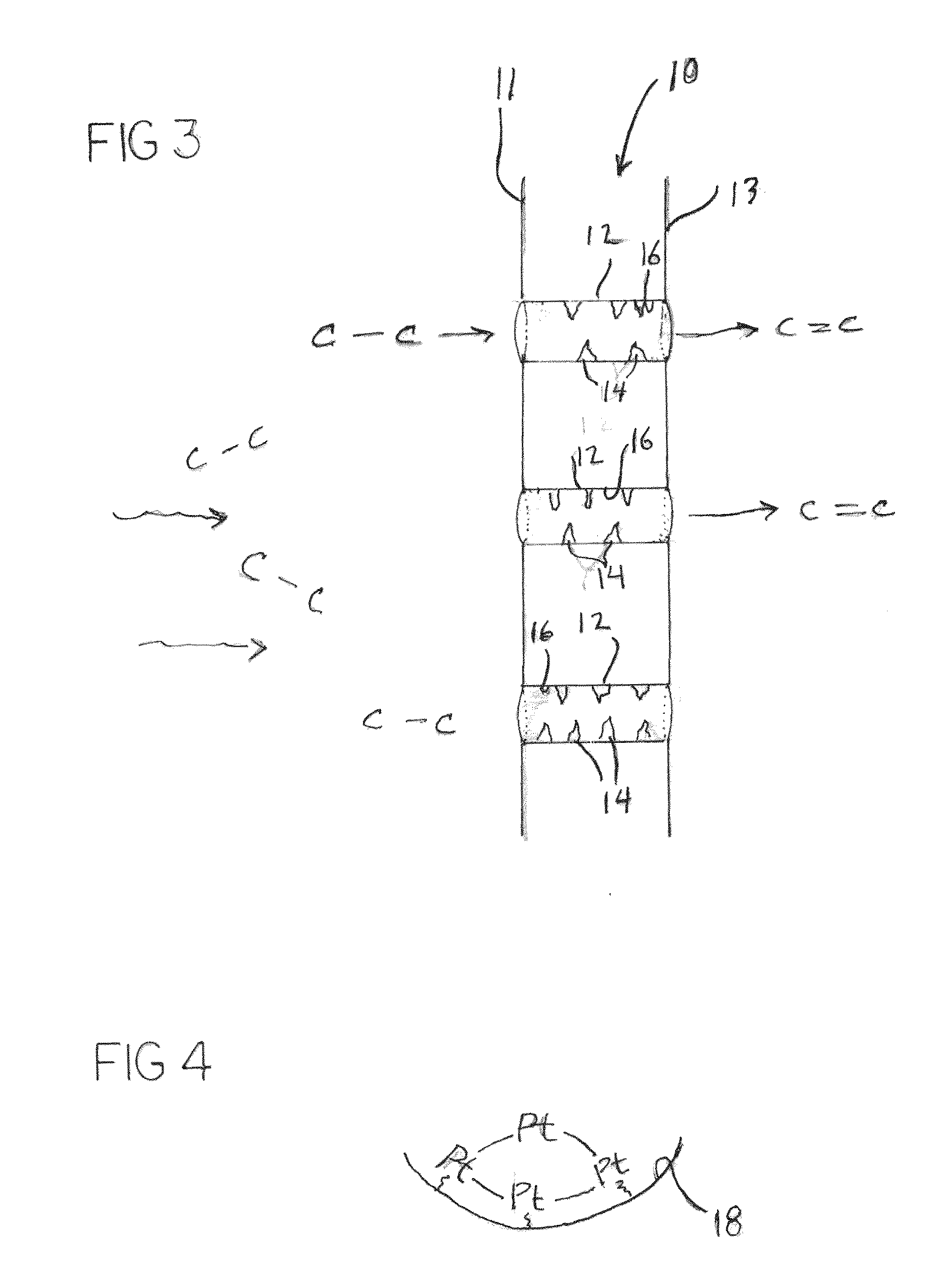

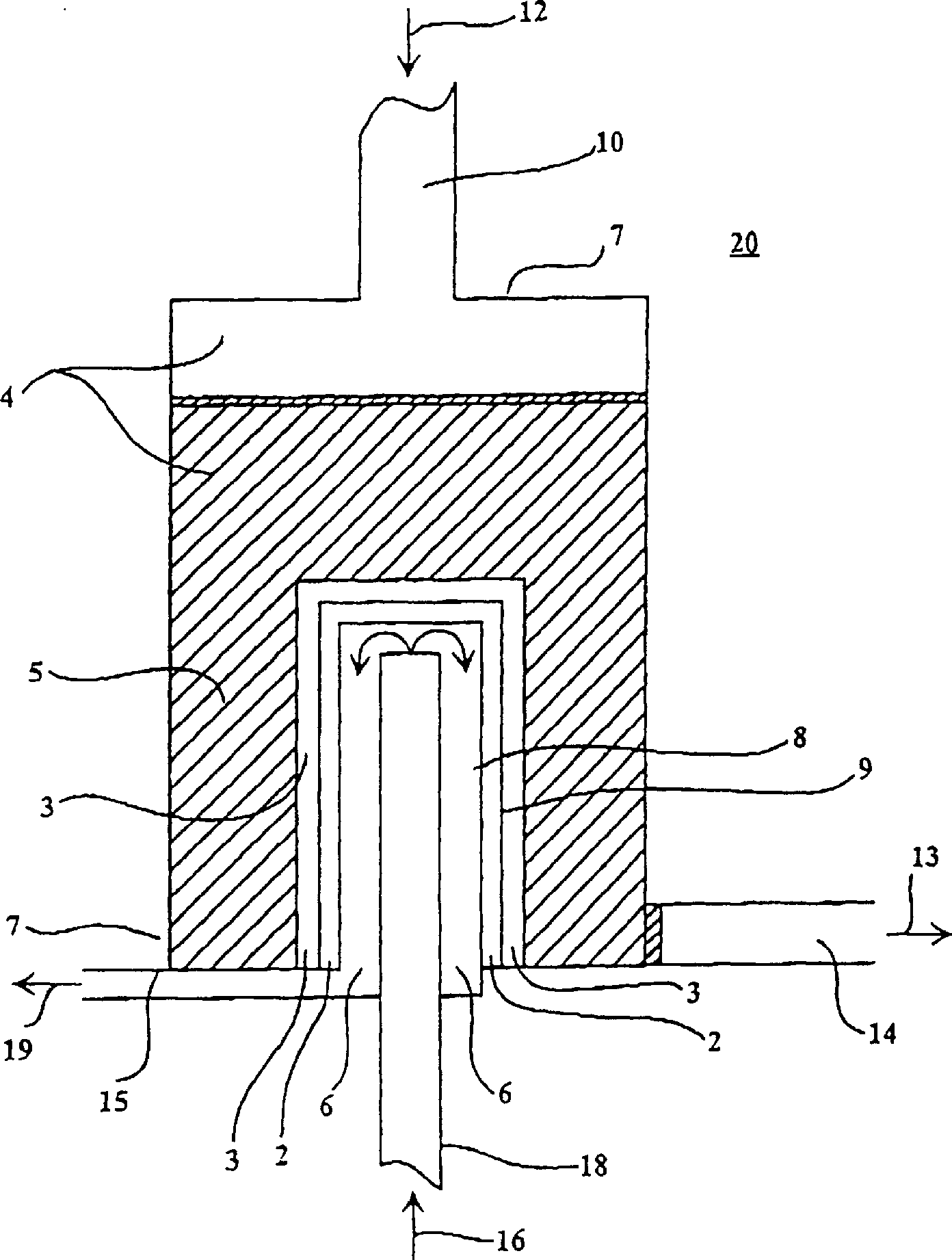

Catalytic membrane reactor with two component three dimensional catalysis

This invention relates to catalytic reactor membranes having a gas-impermeable membrane (2) for transport of oxygen anions. The membrane (2) has an oxidation surface and a reduction surface. The membrane (2) is coated on its oxidation surface with an adherent catalyst layer and is optionally coated on its reduction surface with a catalyst that promotes reduction of an oxygen-containing species (e.g., O2, NO2, SO2, etc.) to generate oxygen anions on the membrane. The reactor (20) has an oxidation zone (4) and a reduction zone (6) separated by the membrane (2). A component of an oxygen-containing gas in the reduction zone (6) is reduced at the membrane (2) and a reduced species in a reactant gas in the oxidation zone (4) of the reactor is oxidized. The reactor (20) optionally contains a three-dimensional catalyst (5) in the oxidation zone (4). The adherent catalyst layer and the three-dimensional catalyst (5) are selected to promote a desired oxidation reaction, particularly a partial oxidation of a hydrocarbon. Preferred membrane materials of this invention are mixed metal oxides which are derived from brownmillerite and can, themselves, have brownmillerite structure. In a preferred embodiment, the oxygen reduction catalyst is Pd (5% by weight) on La0.8Sr0.2CoO3-x. The adherent catalyst layer is Ni (20% by weight) on La0.8Sr0.2MnO3 and the three-dimensional catalyst is Ni (5% by weight) on alumina.

Owner:ELTRON RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com