Patents

Literature

285results about How to "Separation in time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

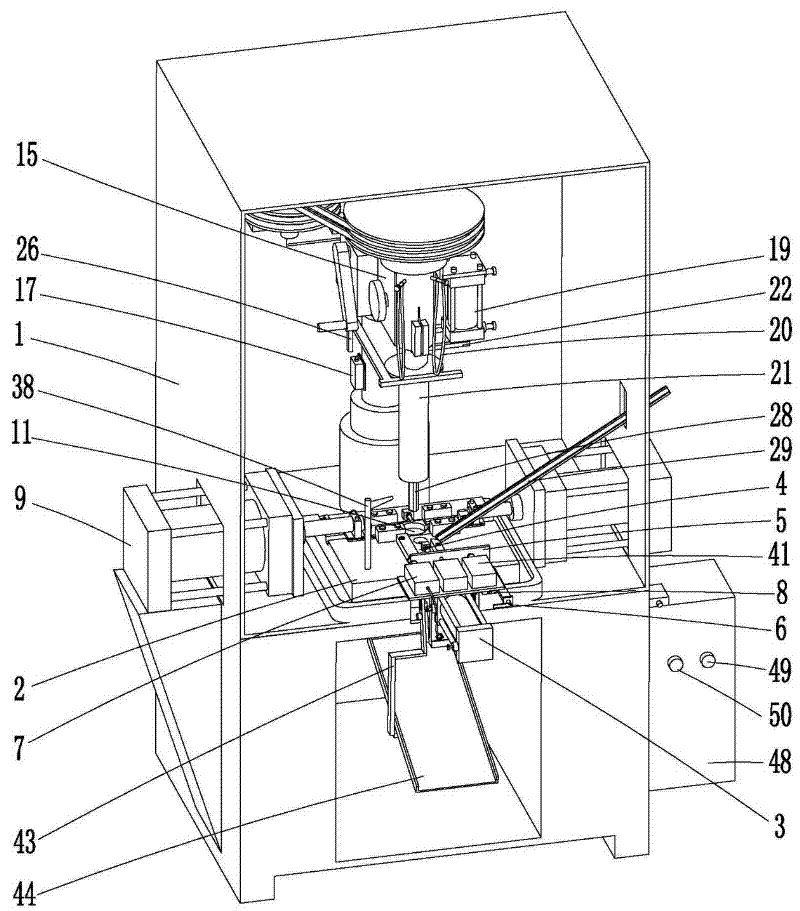

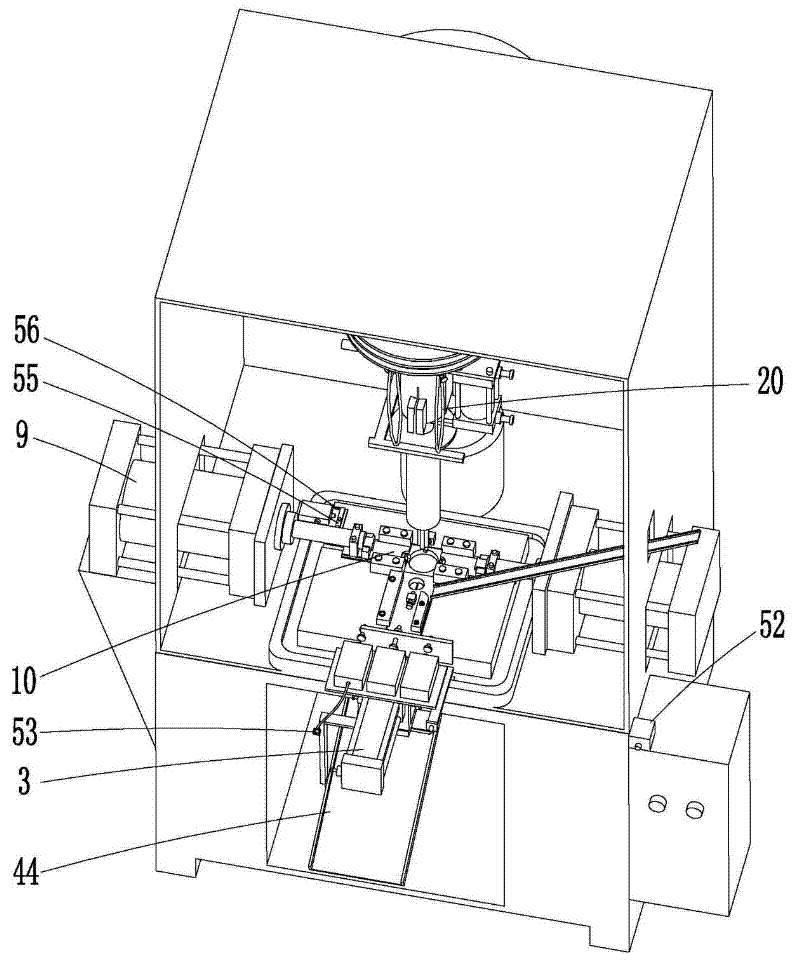

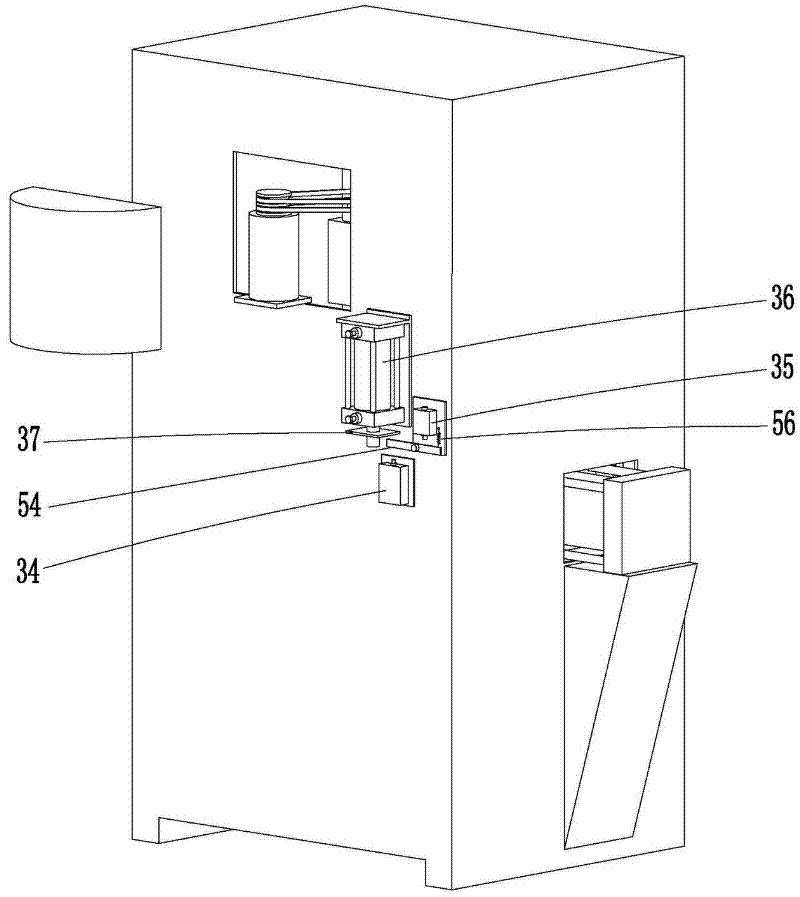

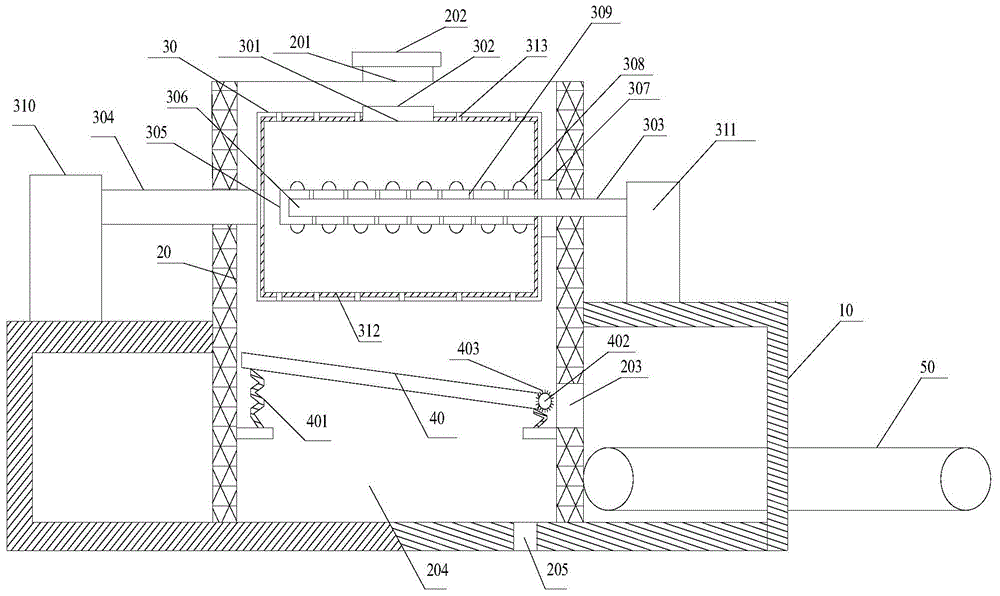

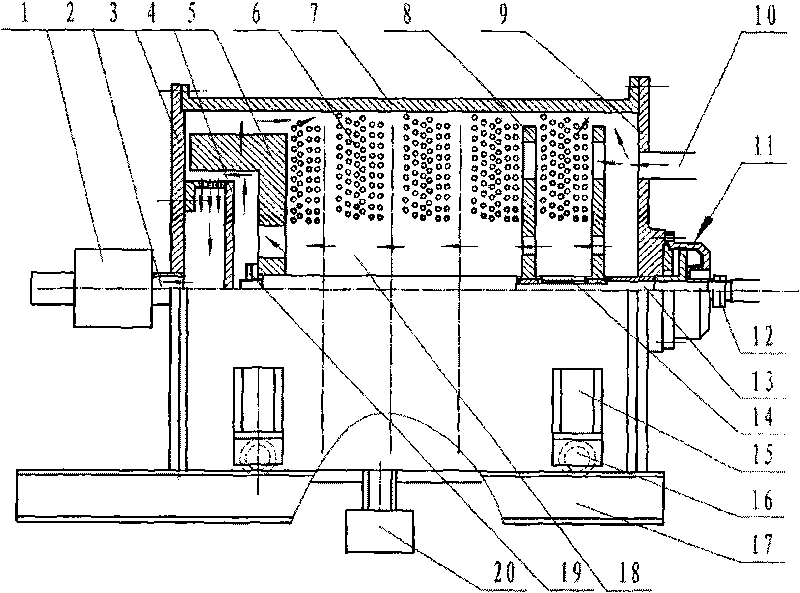

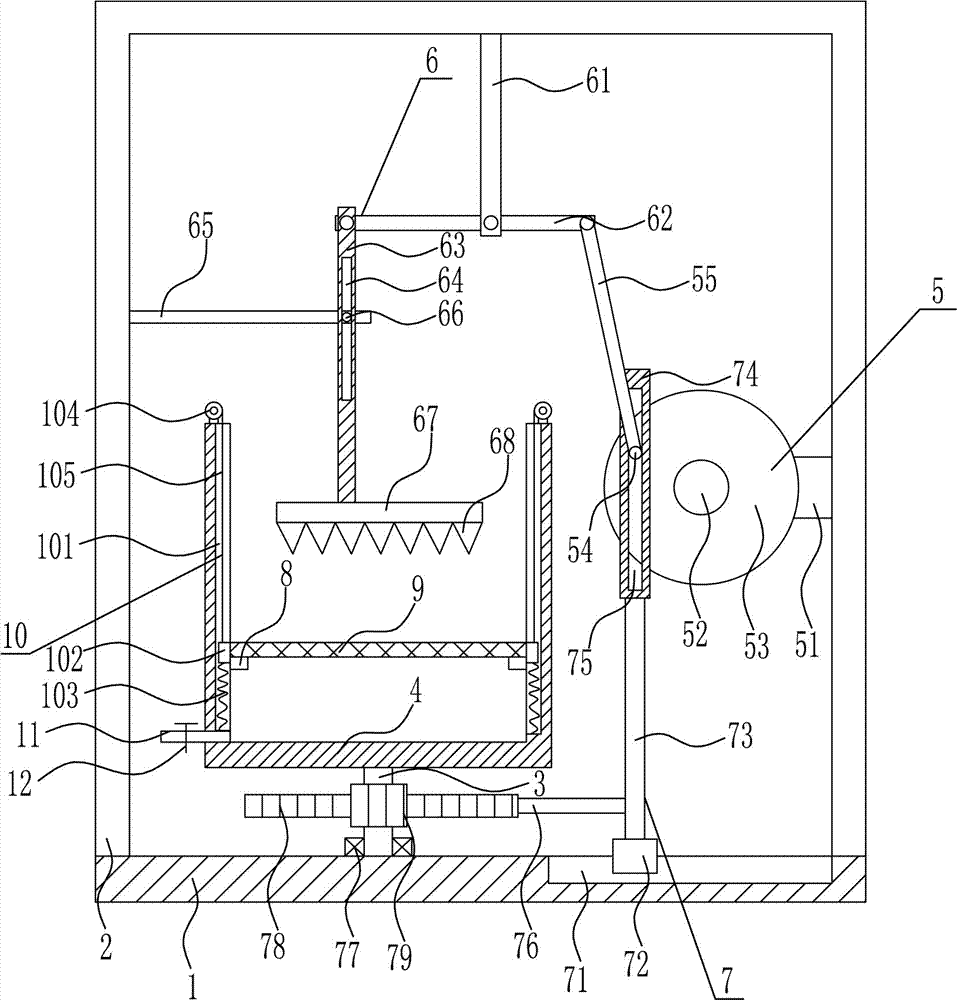

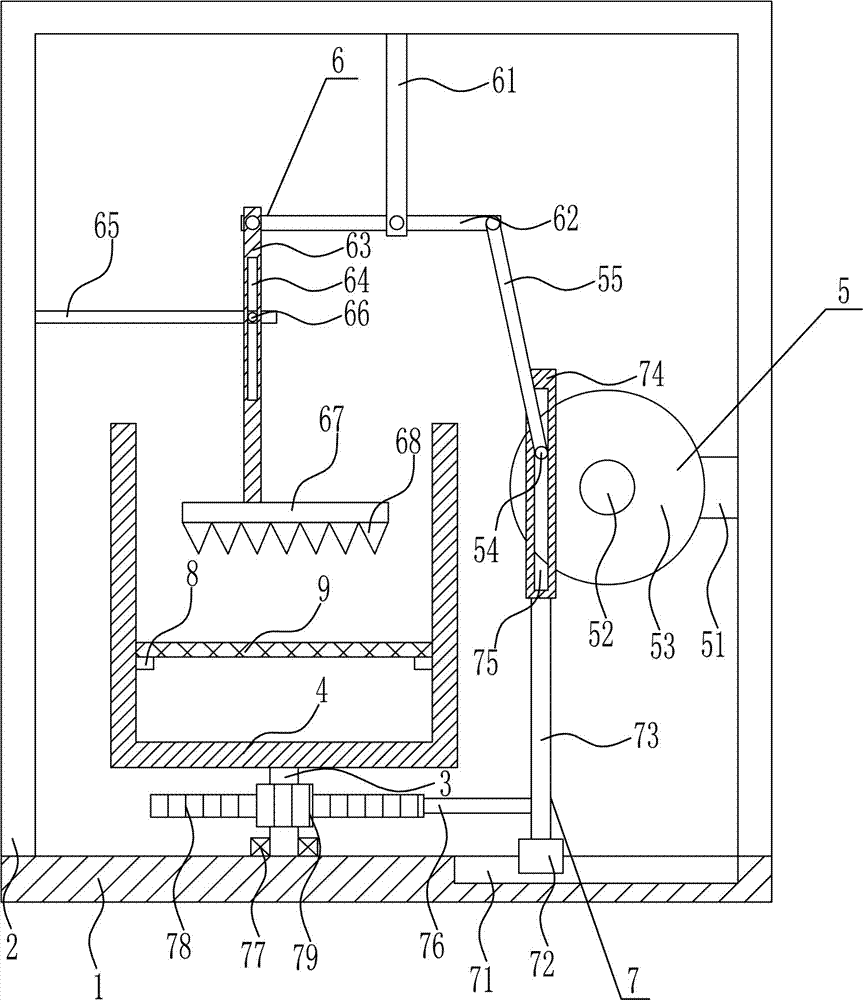

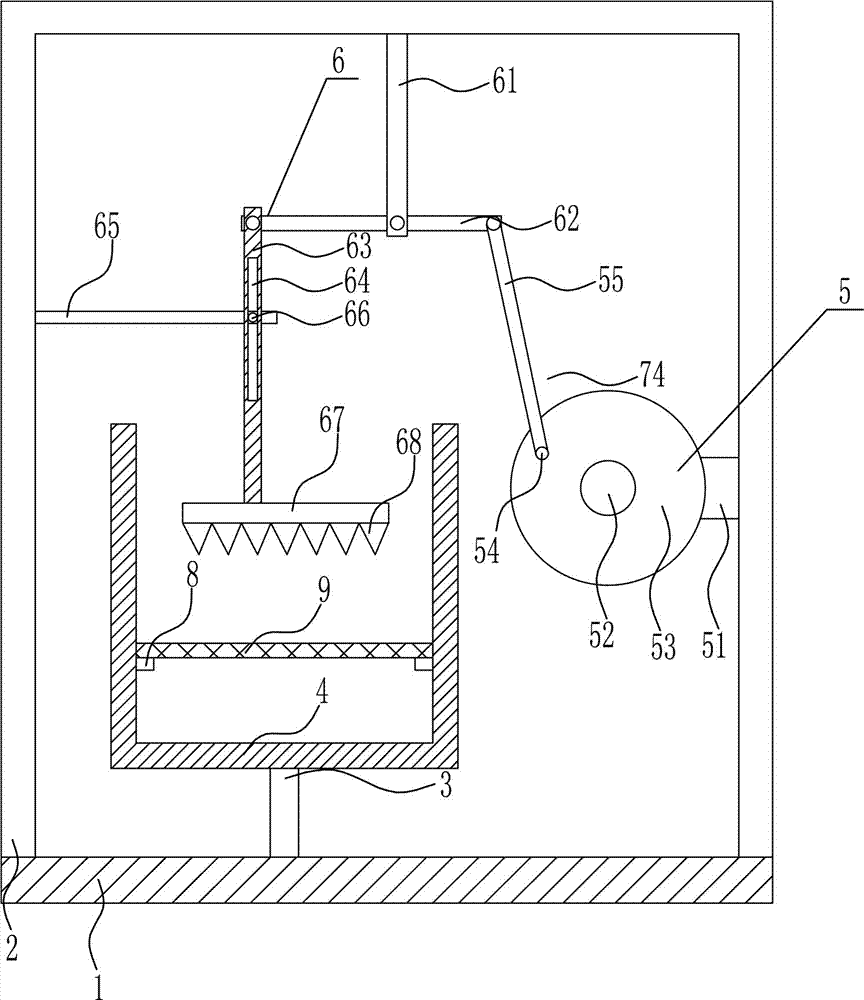

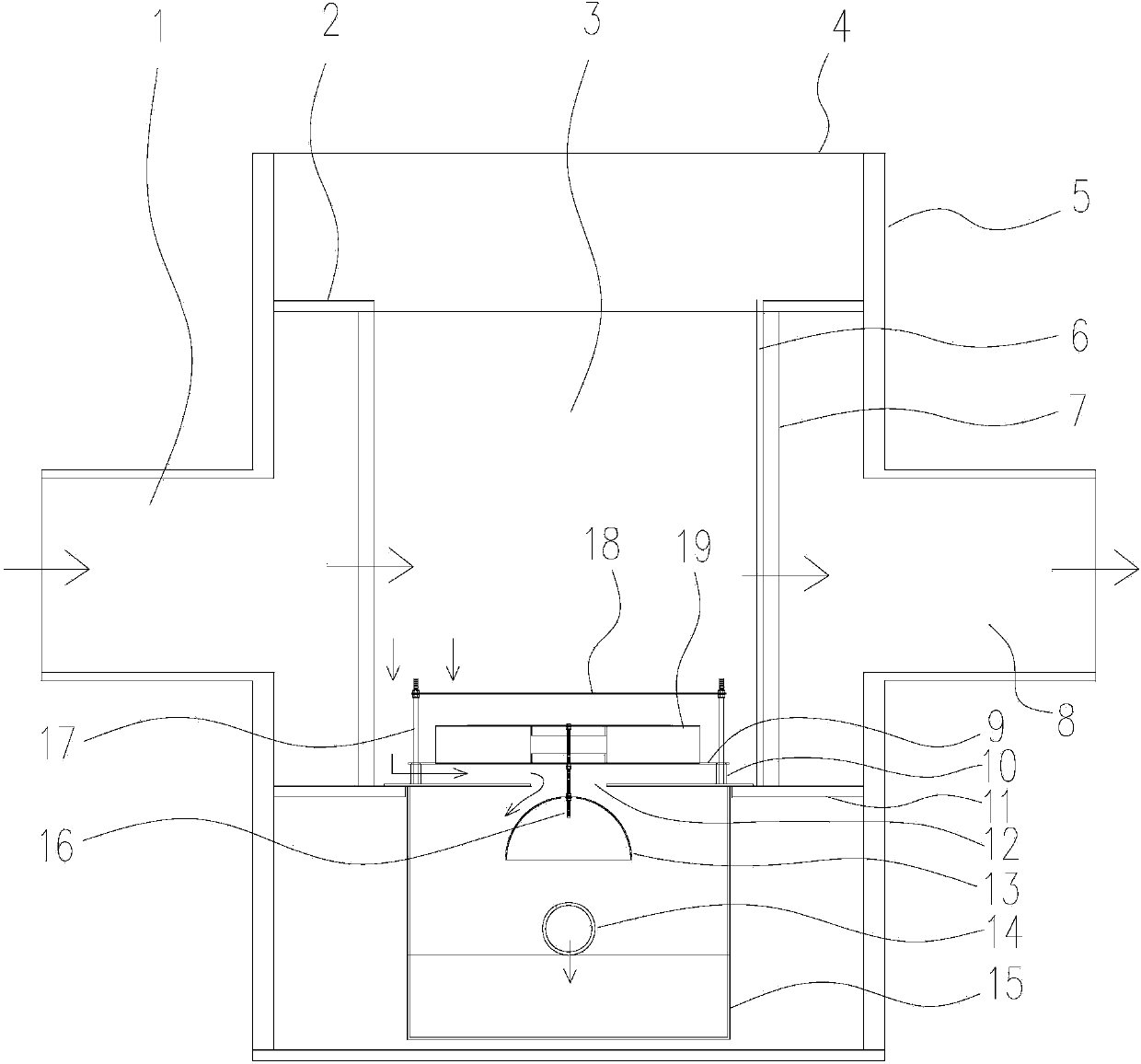

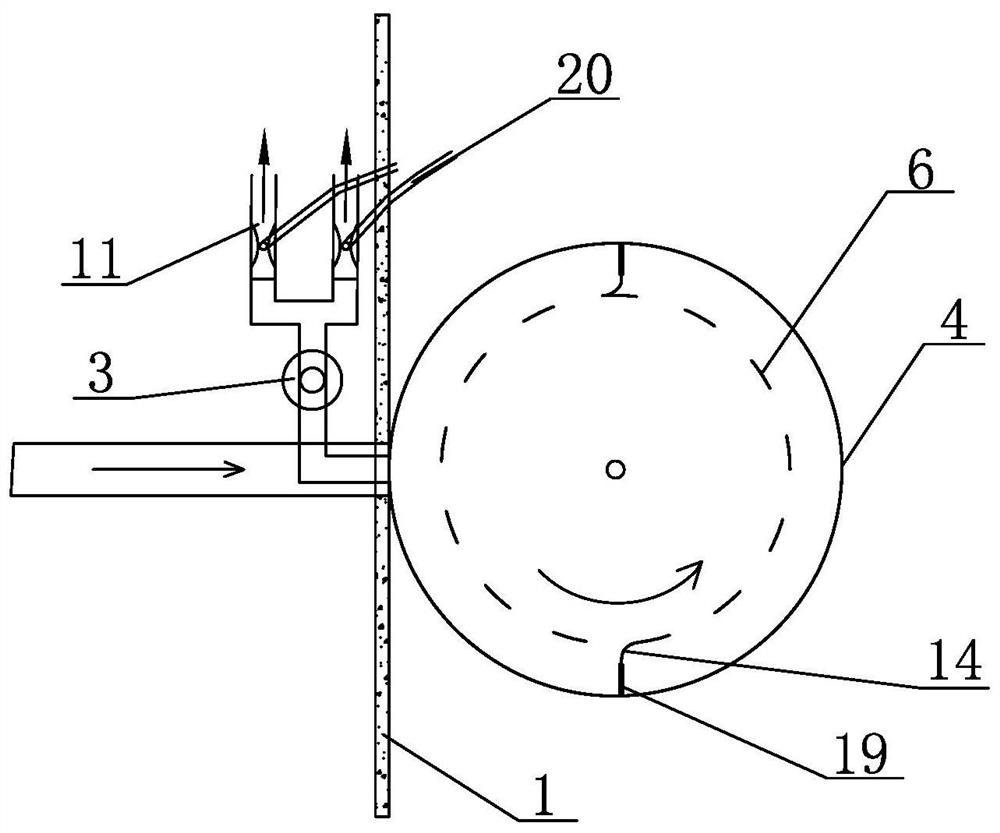

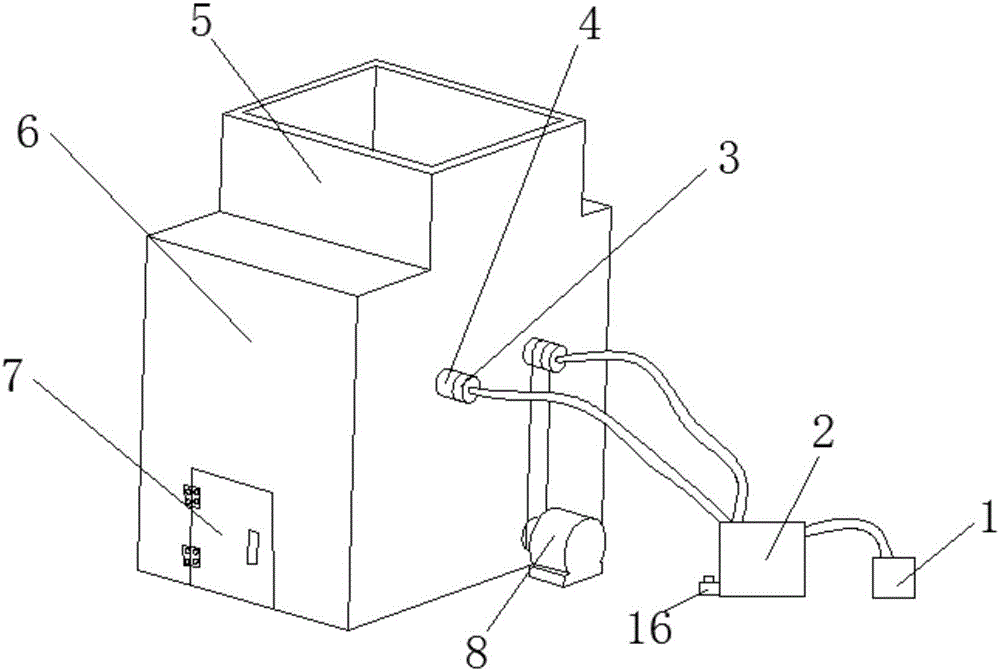

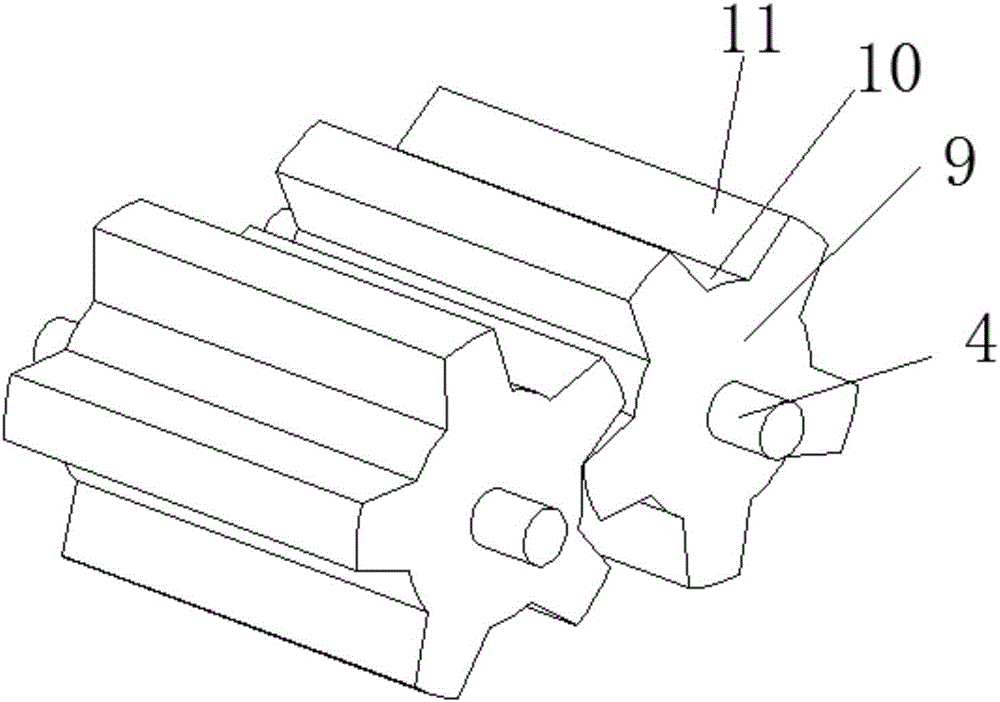

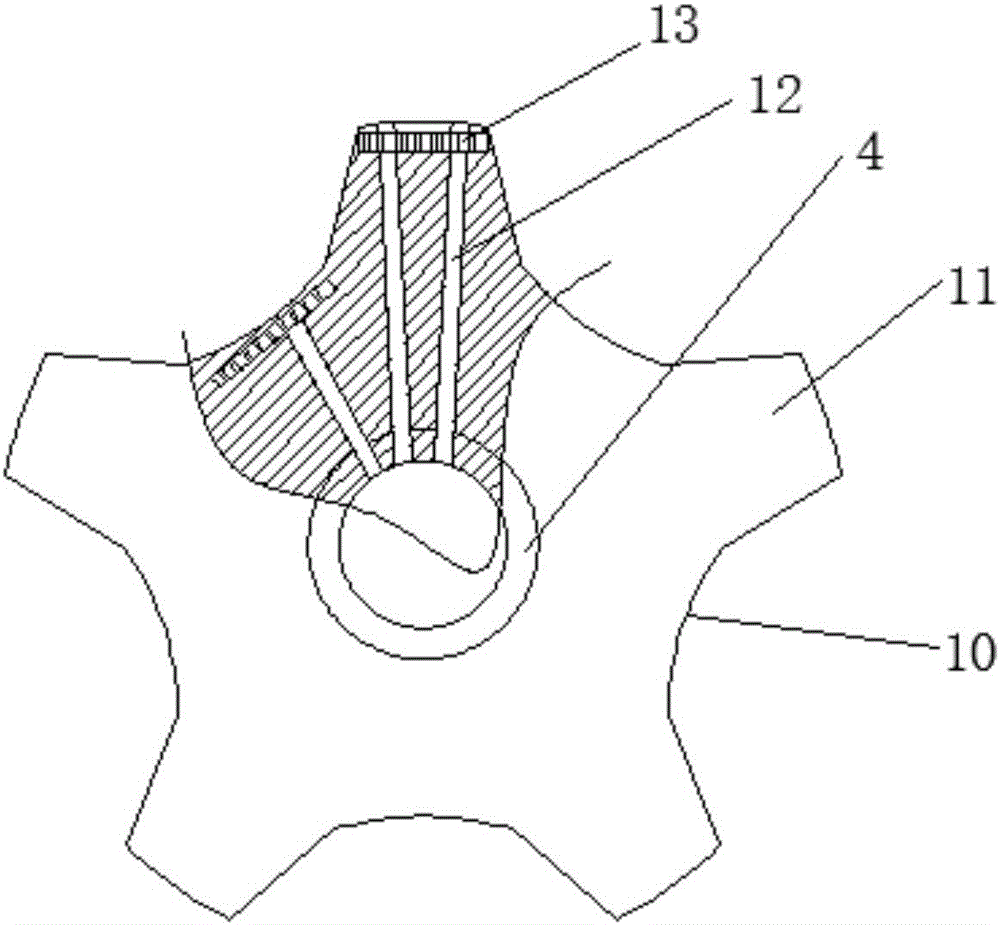

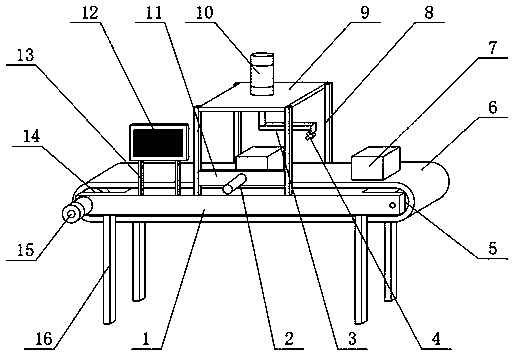

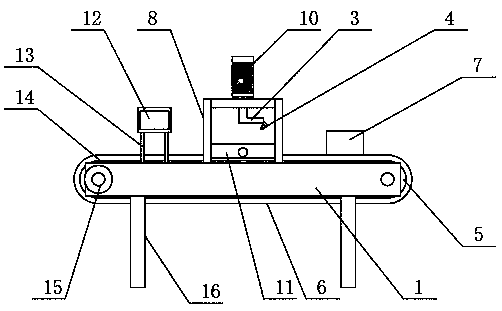

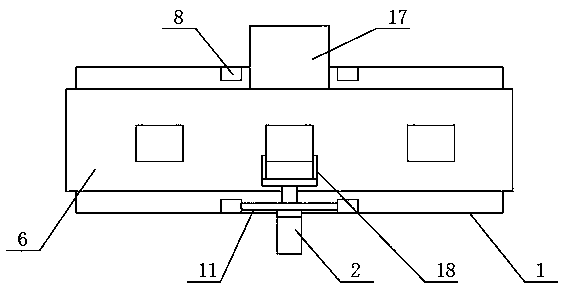

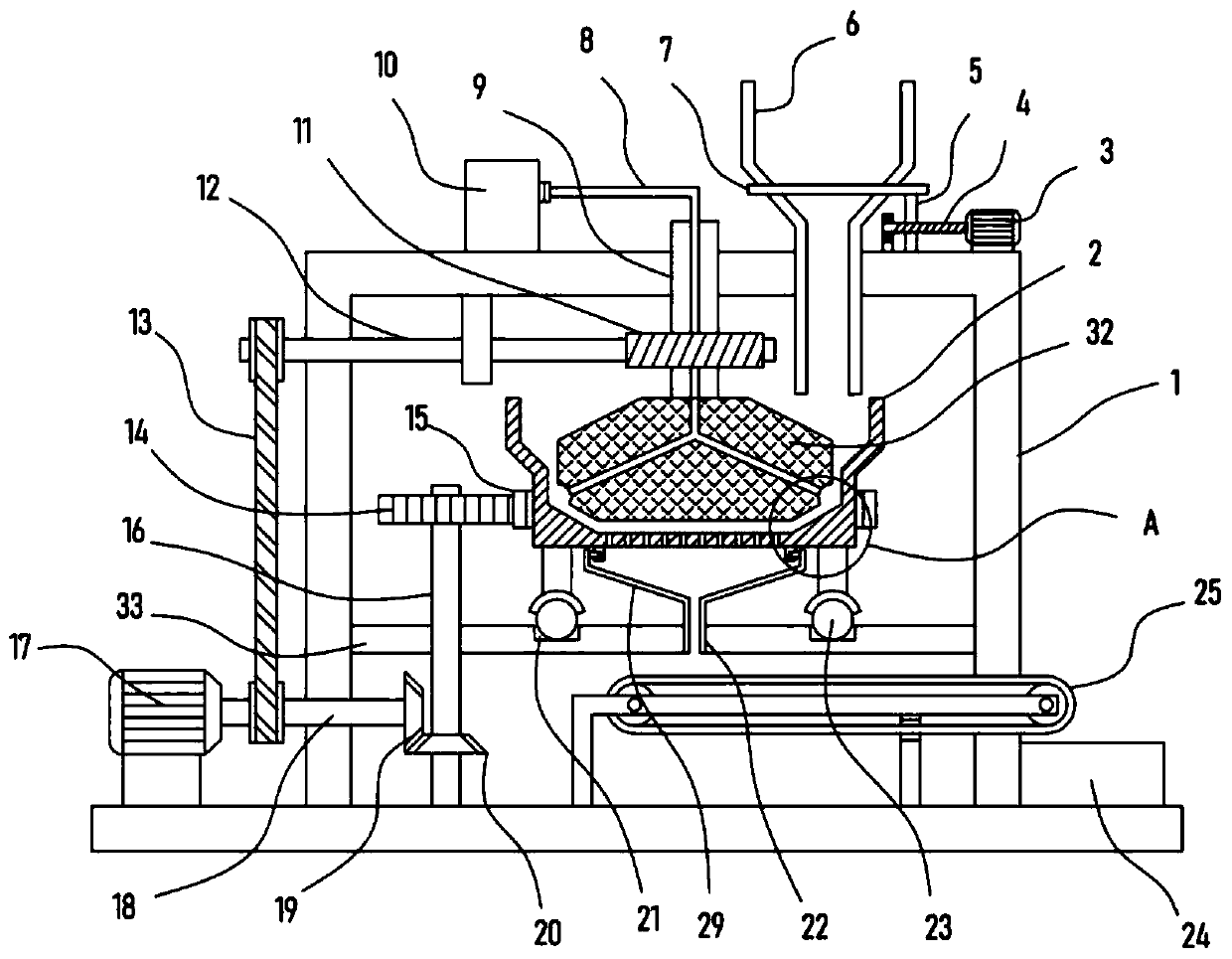

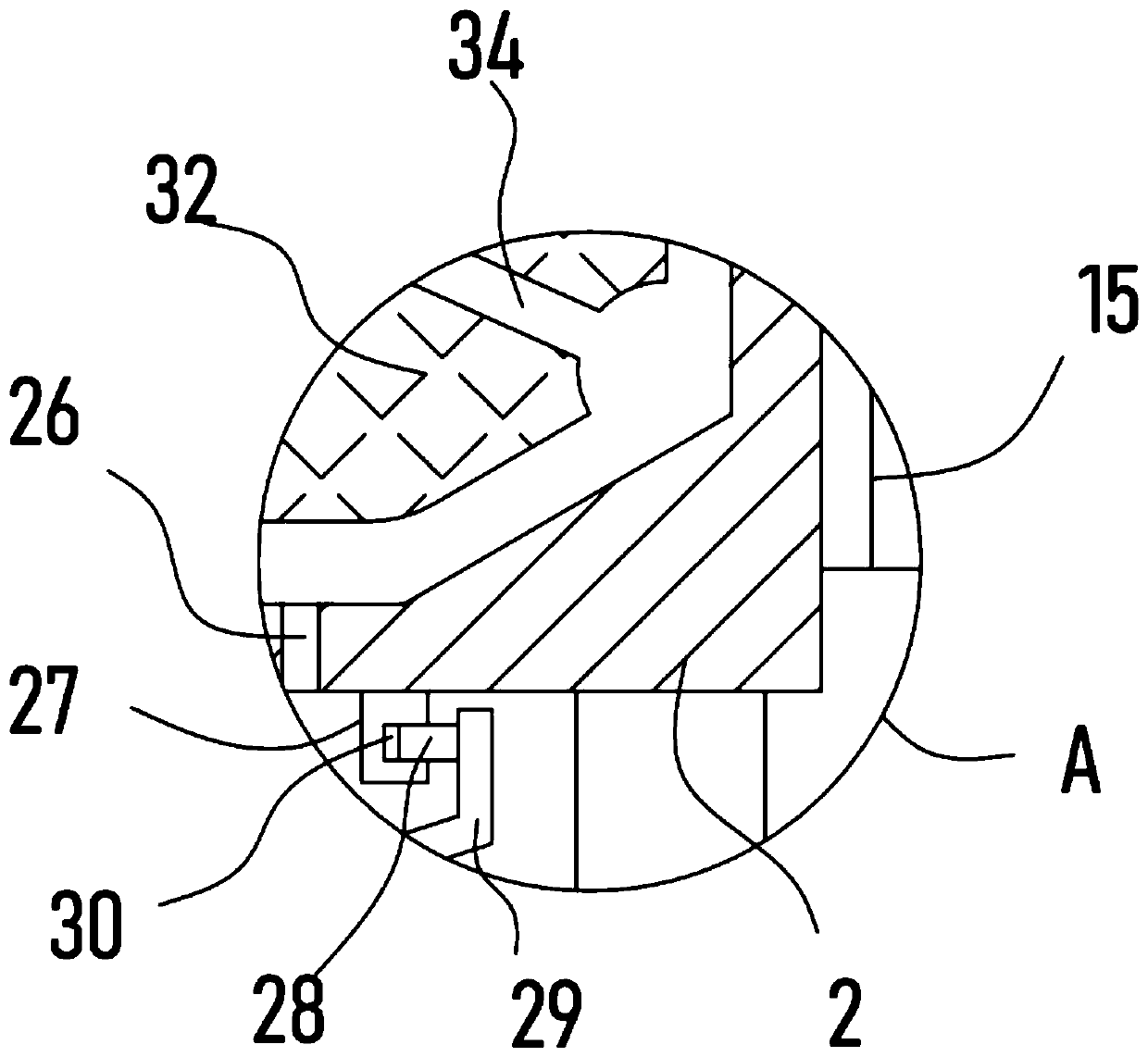

Fully-automatic tapping machine

ActiveCN102642055APrecise feedingEfficient separationThread cutting feeding devicesThread cutting machinesEngineeringFully automatic

The invention relates to a fully-automatic tapping machine which comprises a machine frame, wherein the machine frame is provided with an operating platform, and the operating platform is provided with an automatic feeding mechanism, an automatic clamping mechanism and an automatic tapping mechanism. According to the fully-automatic tapping machine, the operating platform, the automatic feeding mechanism, the automatic clamping mechanism, the automatic tapping mechanism, a material receiving plate and the like are reasonably arranged on the machine frame, so that the whole machine integrates the functions of automatic feeding, feed-linkage clamping, automatic tapping, automatic cutter retracting, automatic blanking, automatic material and residue separation, automatic cycle and the like, many problems of the traditional equipment and currently-emerging equipment are solved, the tapping accuracy is effectively improved, the production cost is reduced, and the production and machining efficiency is increased. The fully-automatic tapping machine has a compact and reasonable structure and is convenient to operate and control, a plurality of fully-automatic tapping machines can be simultaneously managed by one person during use, and the machining efficiency is several times higher than that of the traditional tapping machine; and the machining accuracy is high, and the service effect is good, thus the fully-automatic tapping machine is worthy of popularization and application.

Owner:景宁畲族自治县通用机械配件厂(普通合伙)

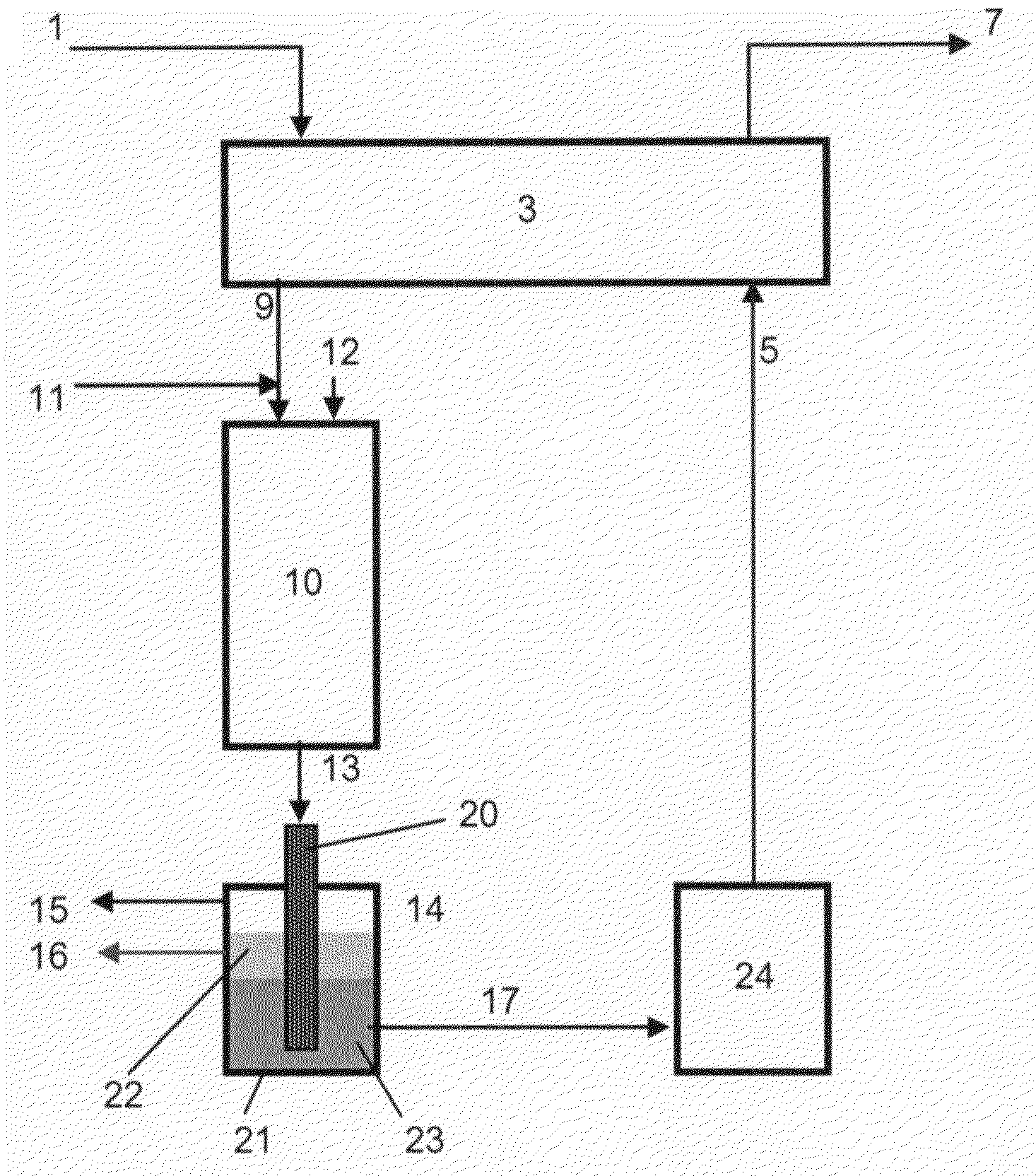

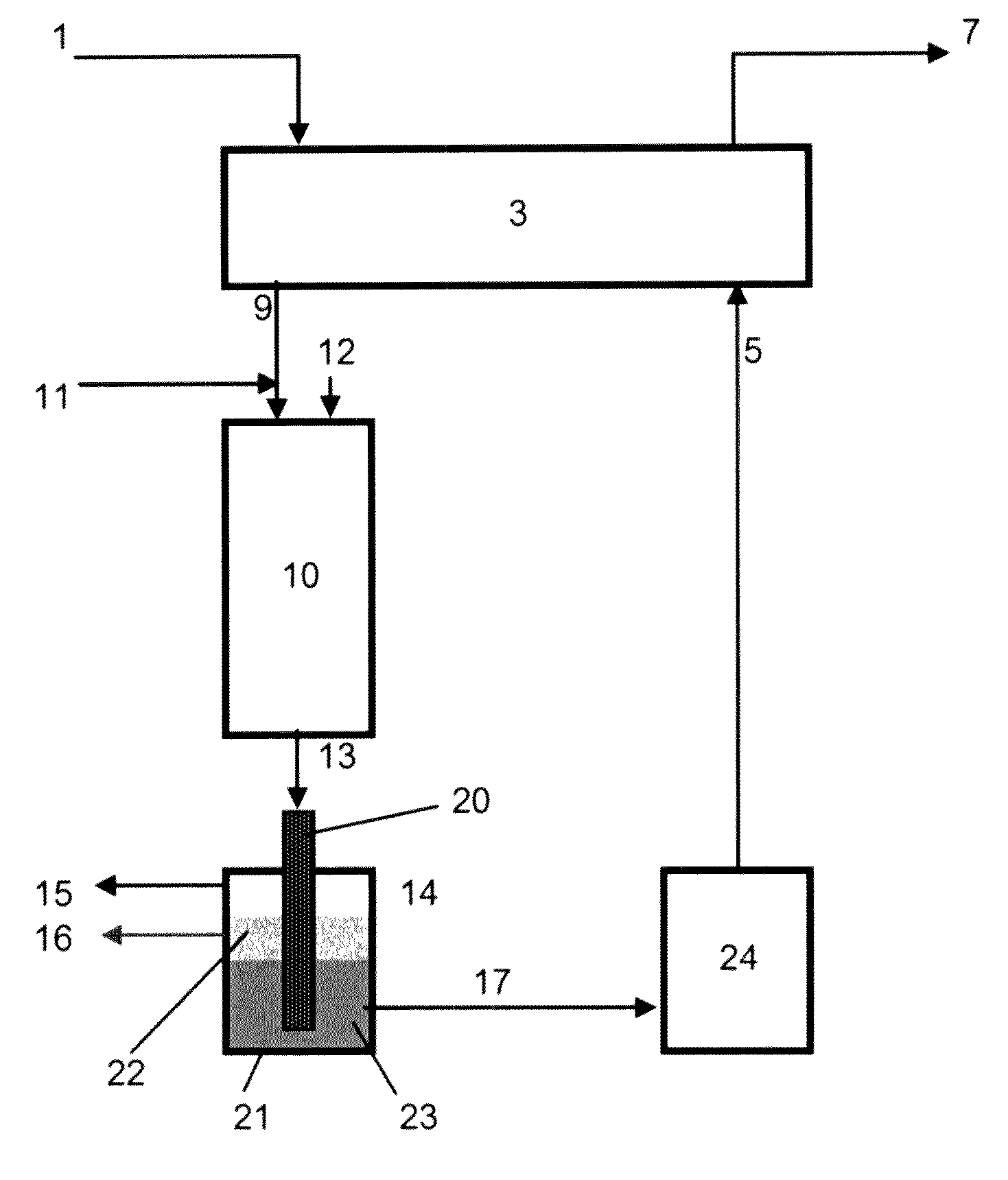

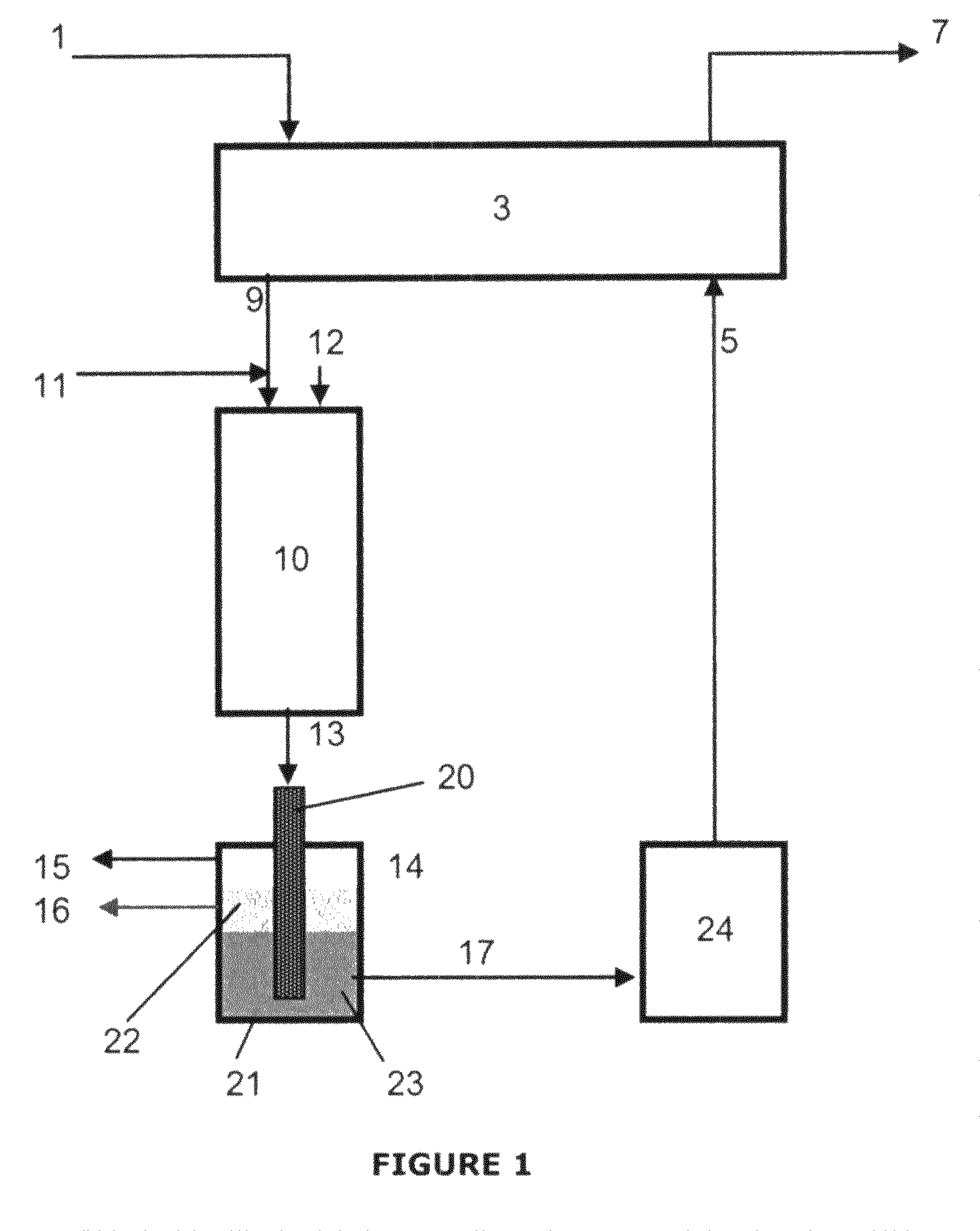

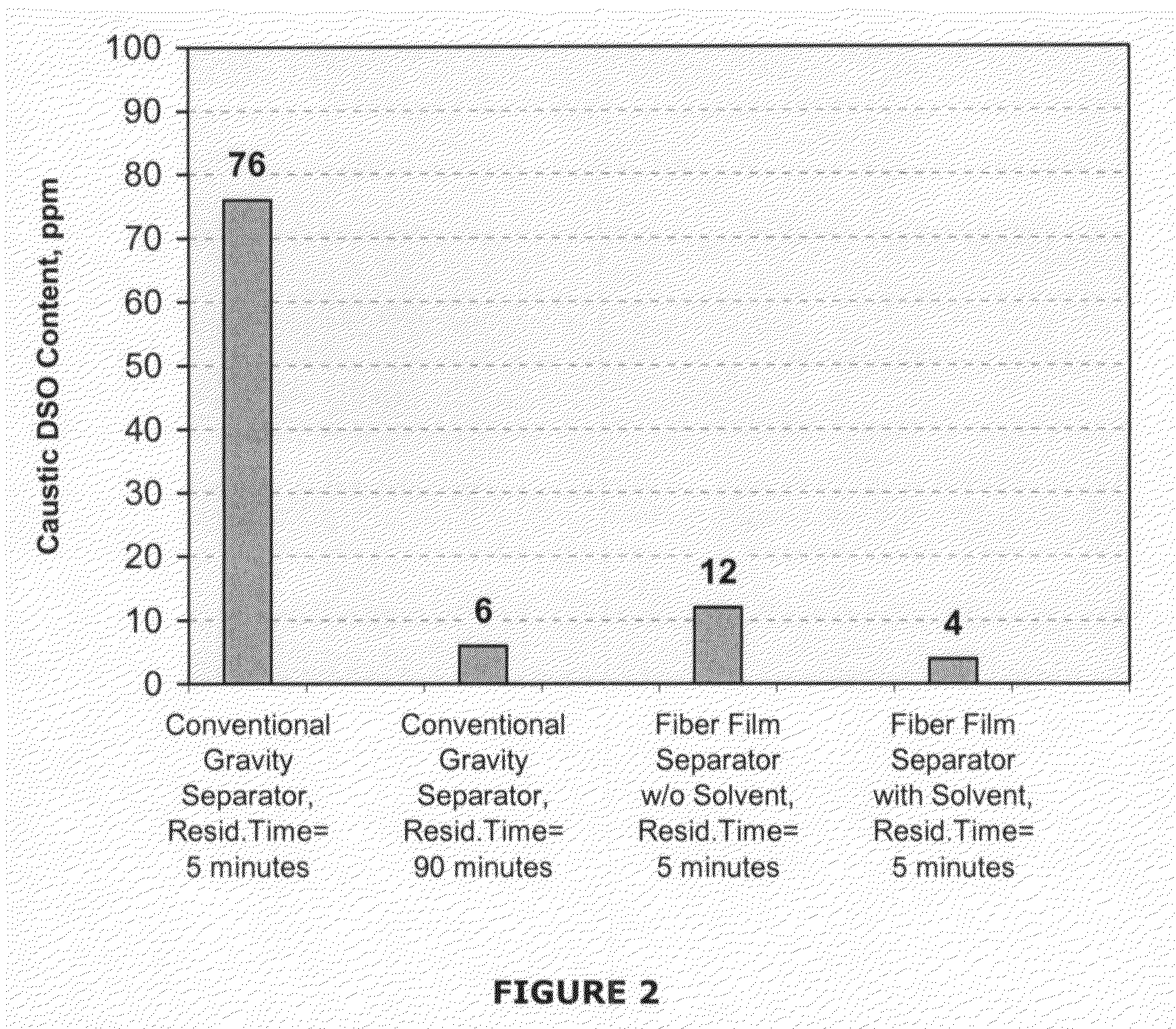

Separation process

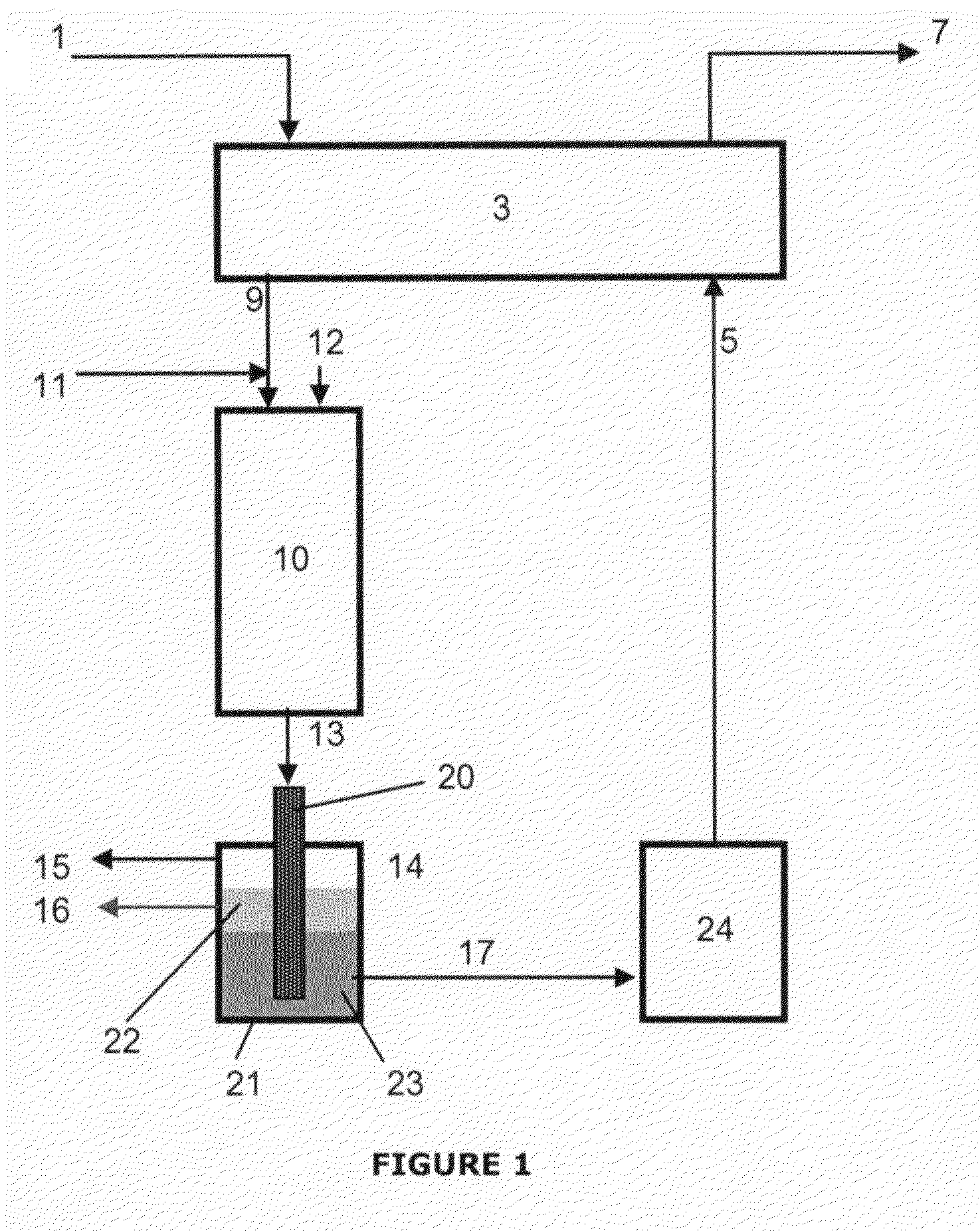

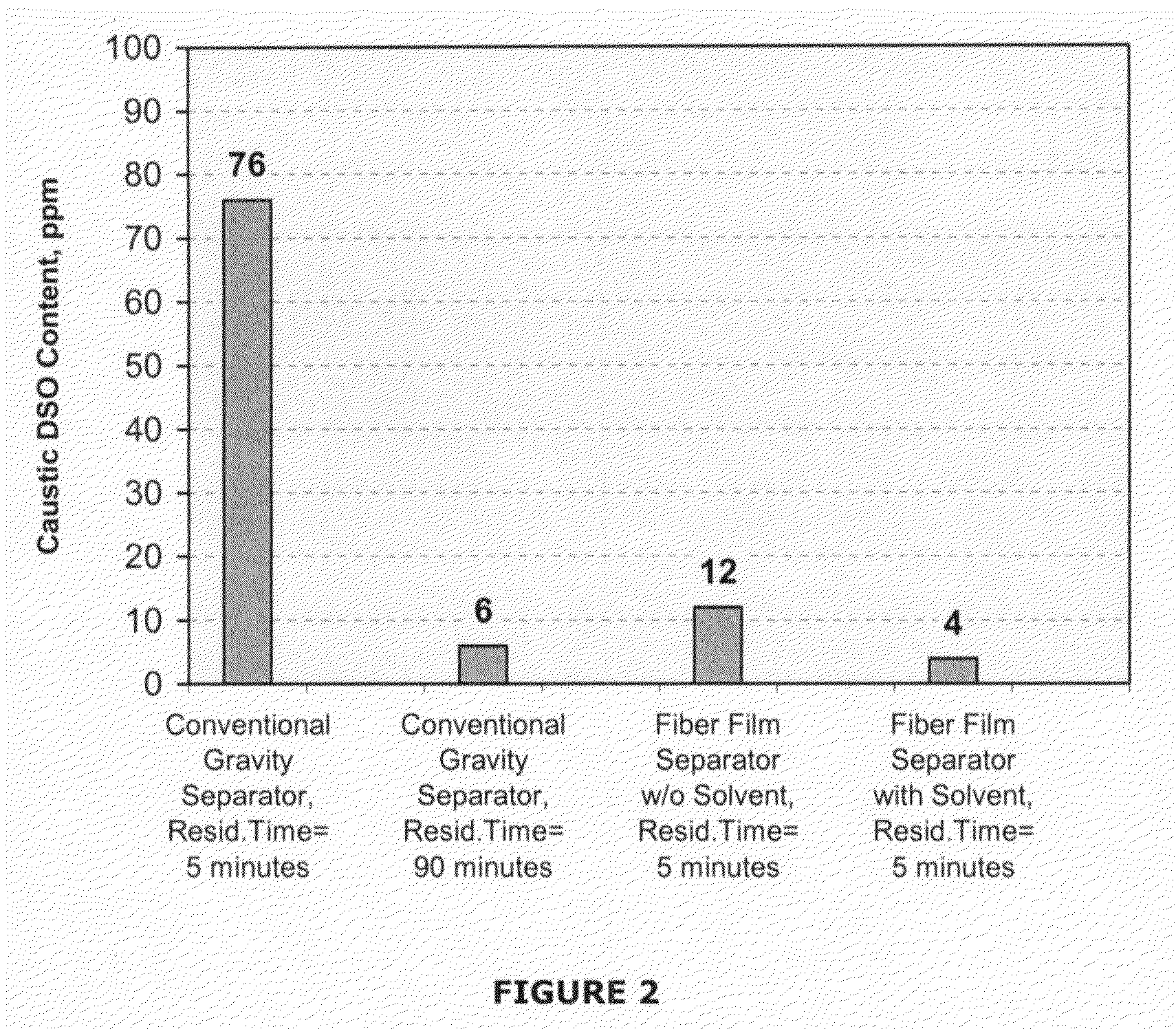

ActiveUS20080308503A1Separation in timeEasy to separateDewatering/demulsification with mechanical meansLiquid suspension thickening by filtrationFiberSulfur

A separation process for separating two or more immiscible liquids using fiber-film technology is disclosed. This separation process is especially useful in the separation of disulfide oil formed during the oxidation of spent caustic solution that was used to remove sulfur contaminates from light hydrocarbons.

Owner:MERICHEM CO

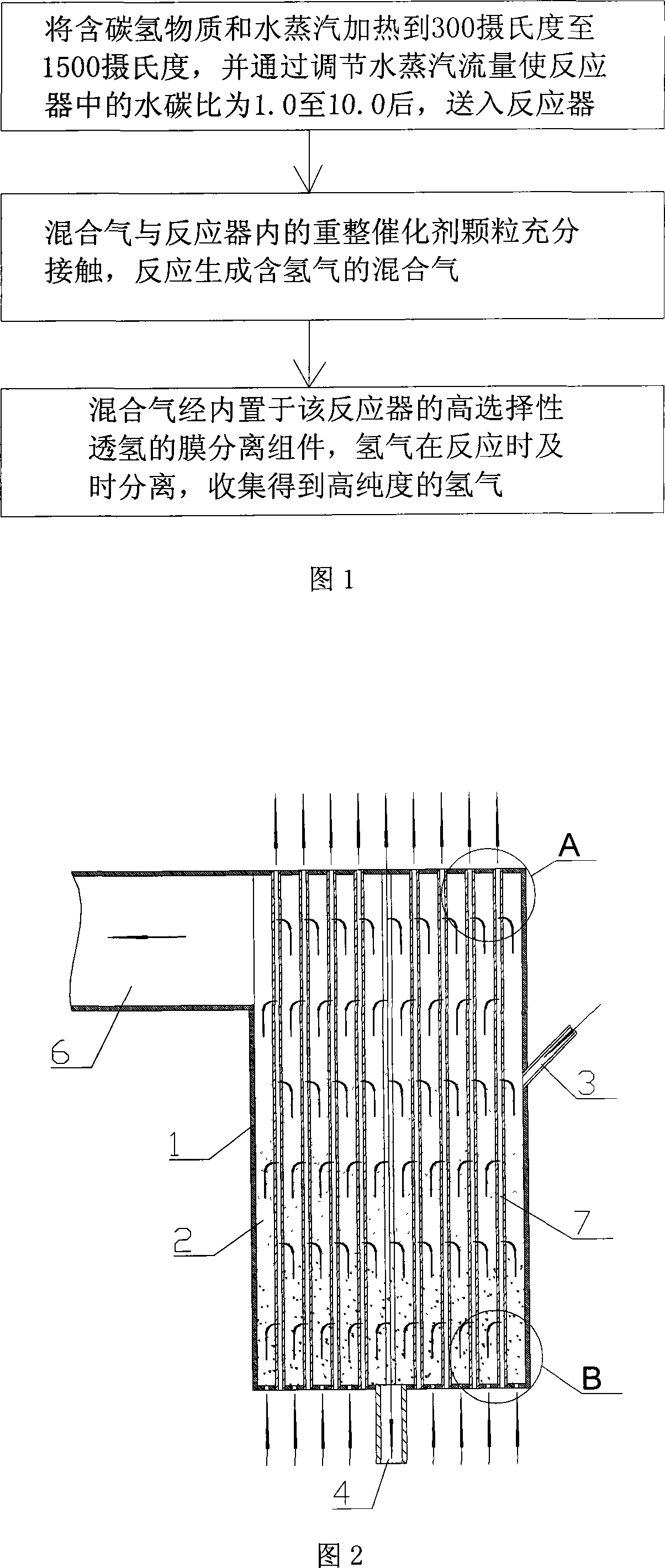

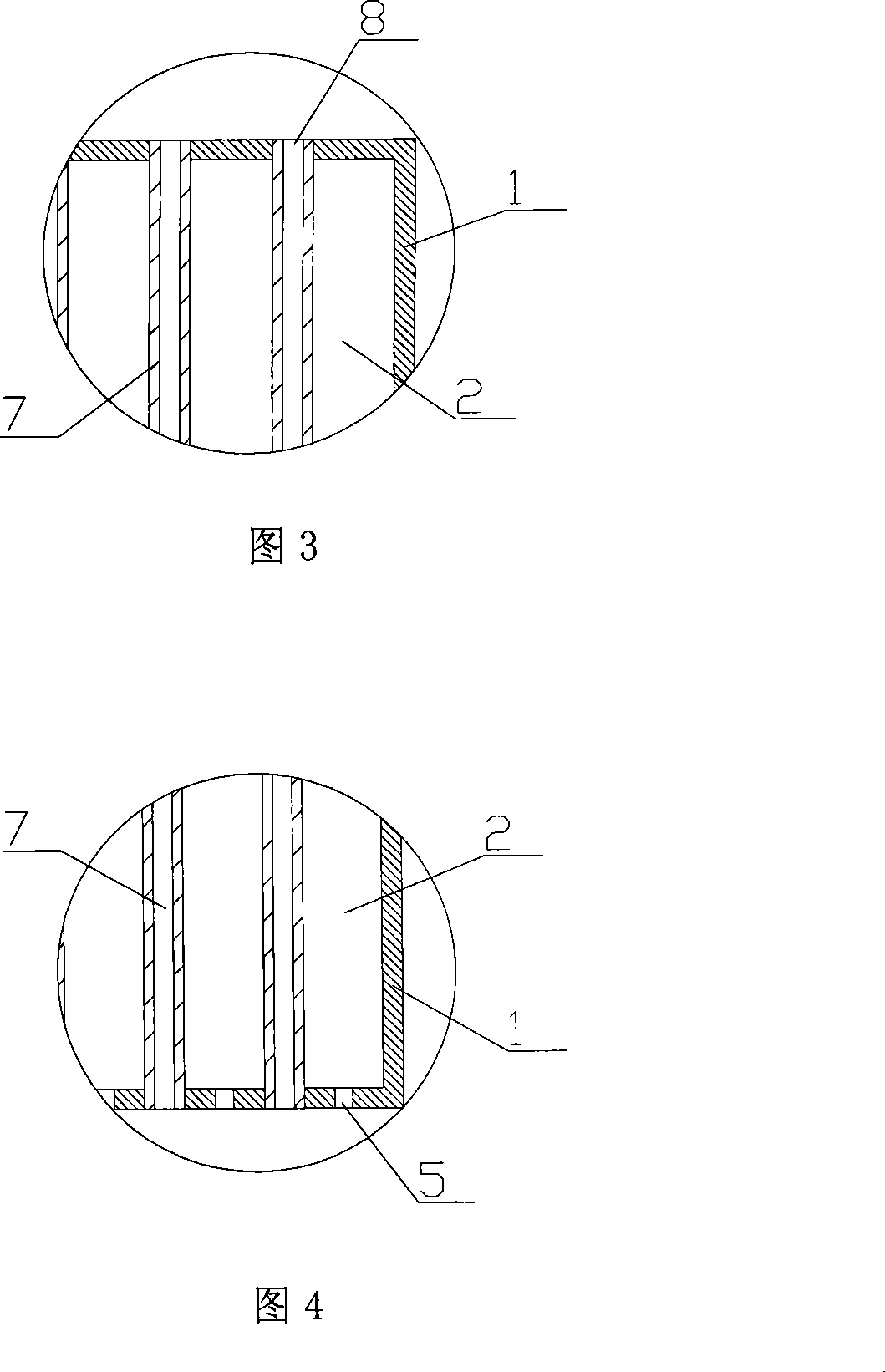

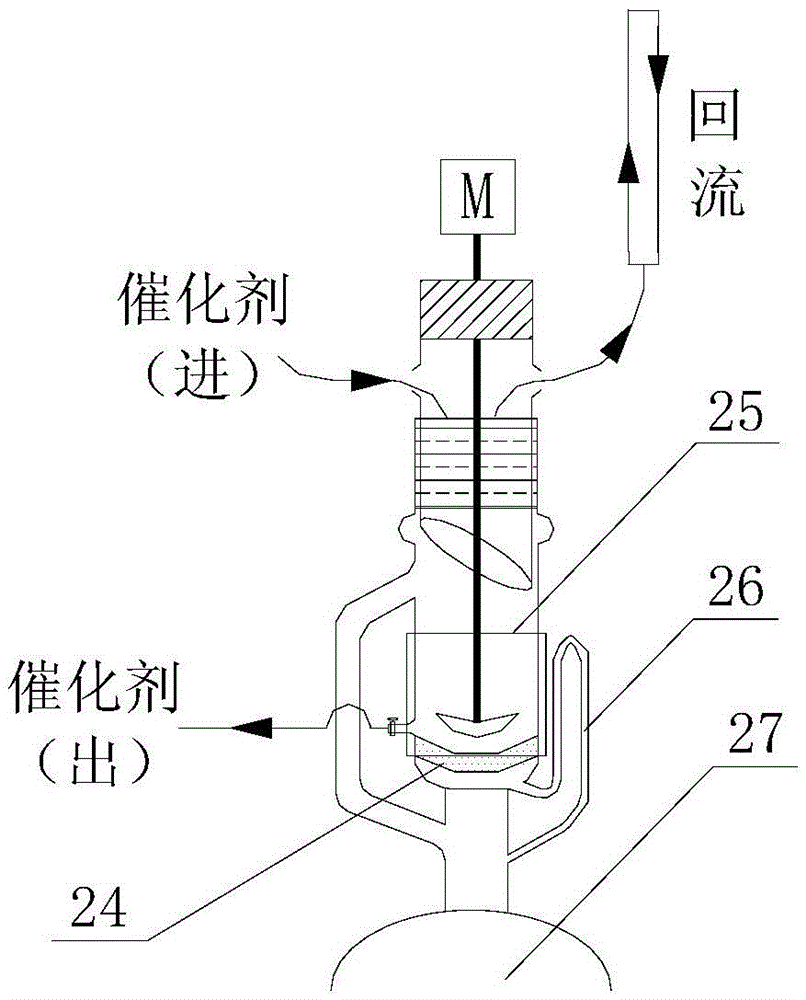

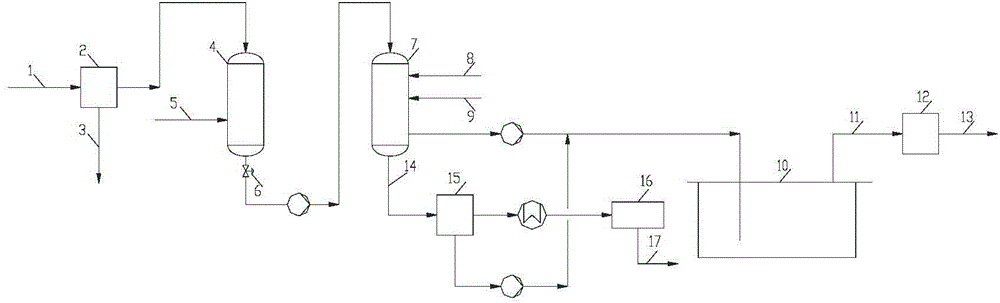

Coupling catalytic reforming-method and device for film separation reaction

InactiveCN101214921AHigh puritySeparation in timeHydrogen separationBulk chemical productionCatalytic reformingReactor system

The invention discloses a method of preparing high-purity hydrogen with a coupled catalyst reformation-film separation reactor device and a device thereof. The method includes the following steps: a. substance with carbon-hydrogen and water vapor are heated to 300 DEG C to 1500 DEG C; the water vapor is fed into a reactor after the water-carbon ratio in the reactor is 1.0 to 10.0 through regulating the flow of the water vapor; b. the mixed gas and the reformed catalyst particles in the reactor fully contact, react and produce mixed gas with hydrogen; c. the mixed gas goes through high-selective hydrogen permeable film separation components arranged in the reactor; the hydrogen is timely separated in the reaction, high-purity hydrogen is collected. With the invention, the high-selective hydrogen permeable film separation components are directly arranged in the reactor, so that the hydrogen produced by catalyst reformation is timely separated from the mixed gas produced by the reaction of carbon-hydrogen raw material and the vapor, which can prevent methanation and other side effects and improve the hydrogen making efficiency; the reactor system coupled with film separation components has simple structure.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

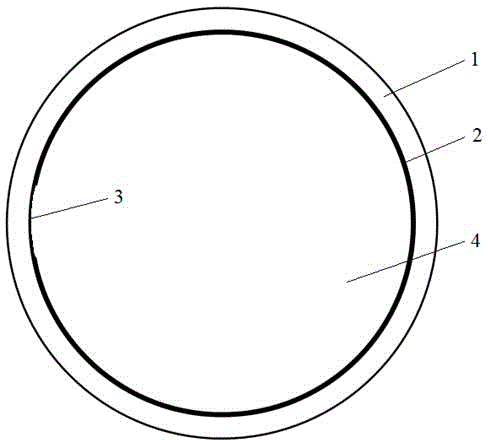

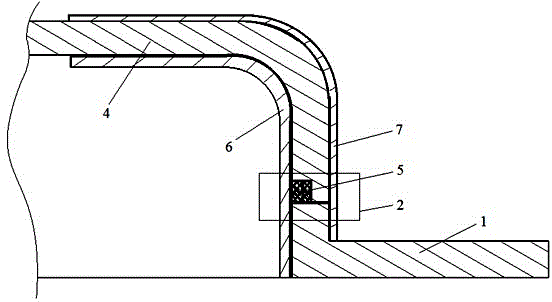

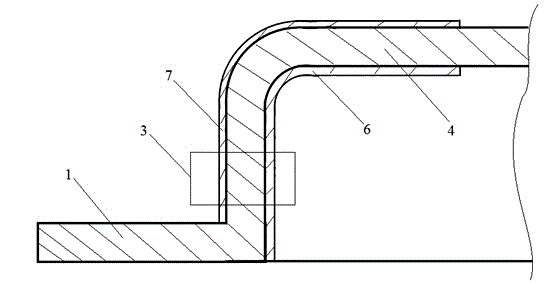

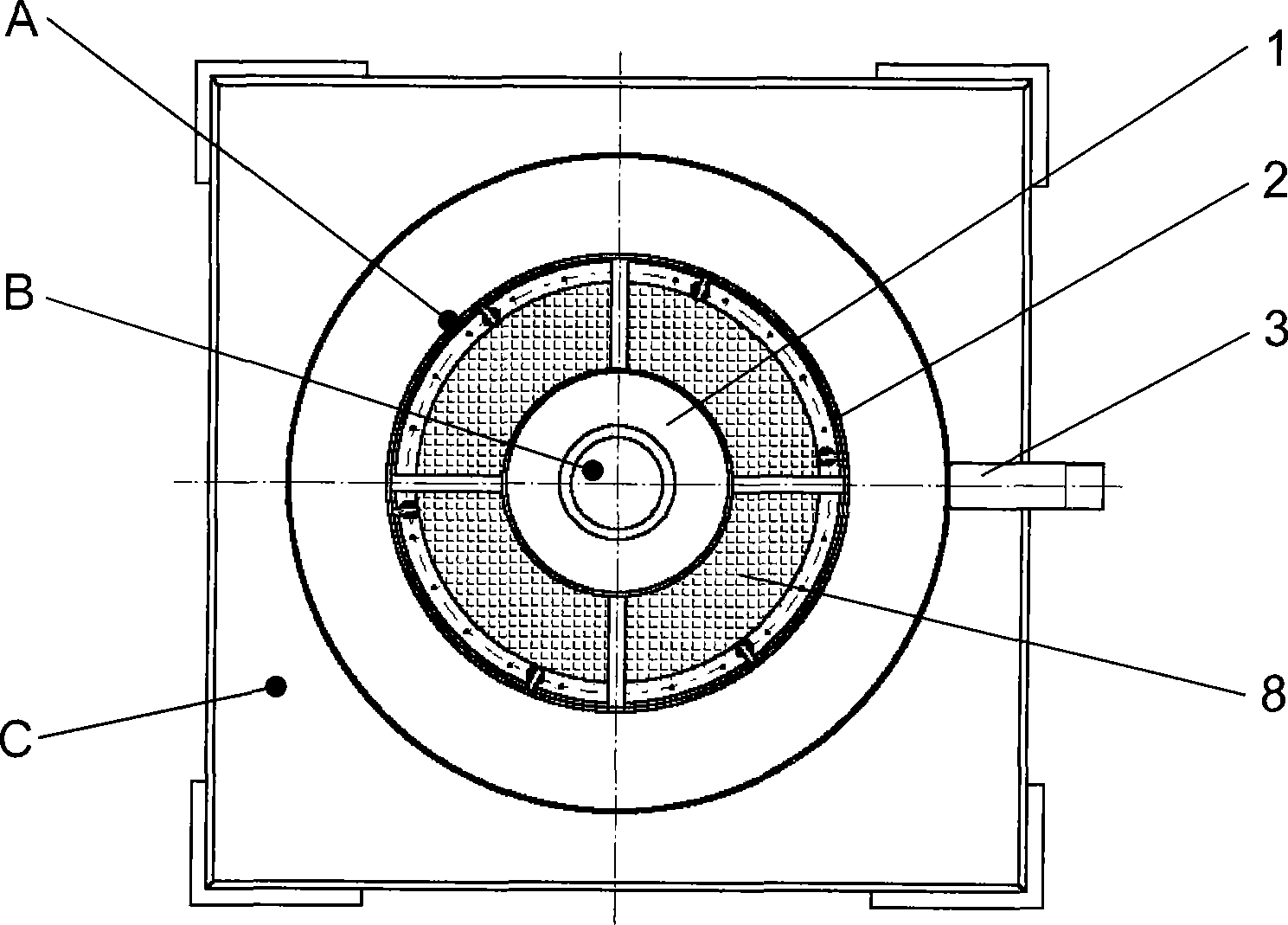

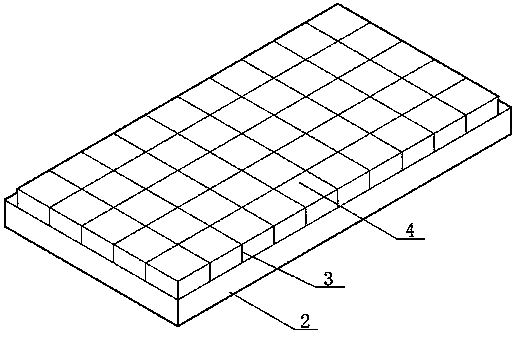

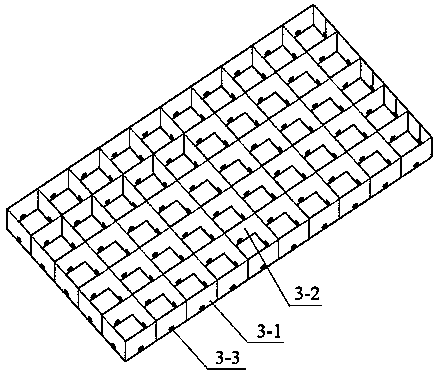

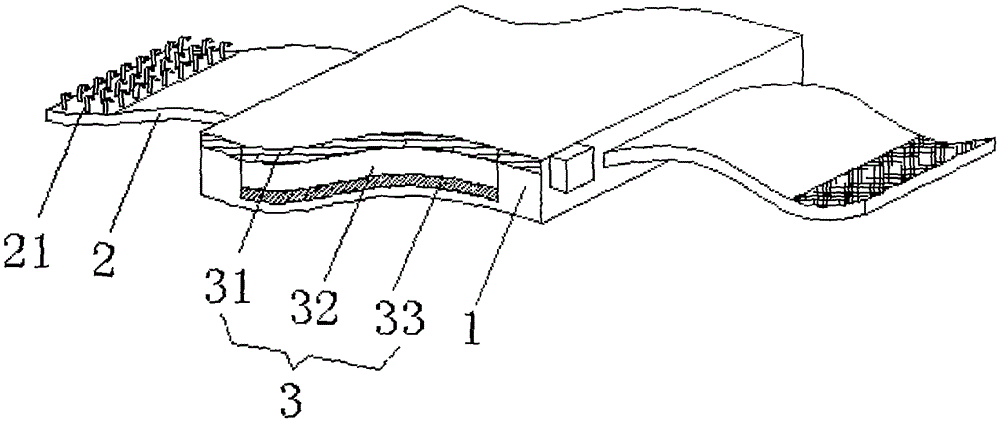

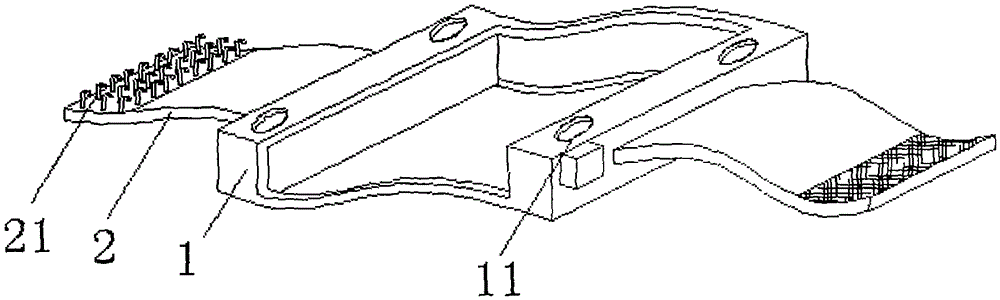

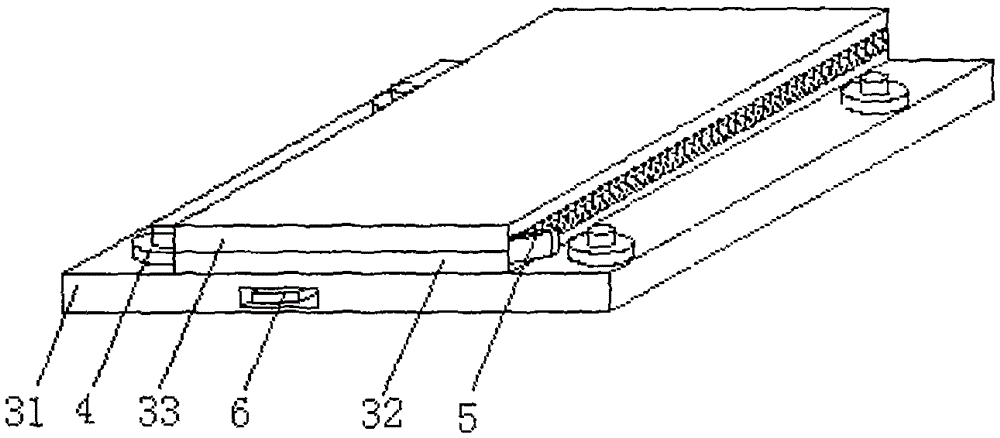

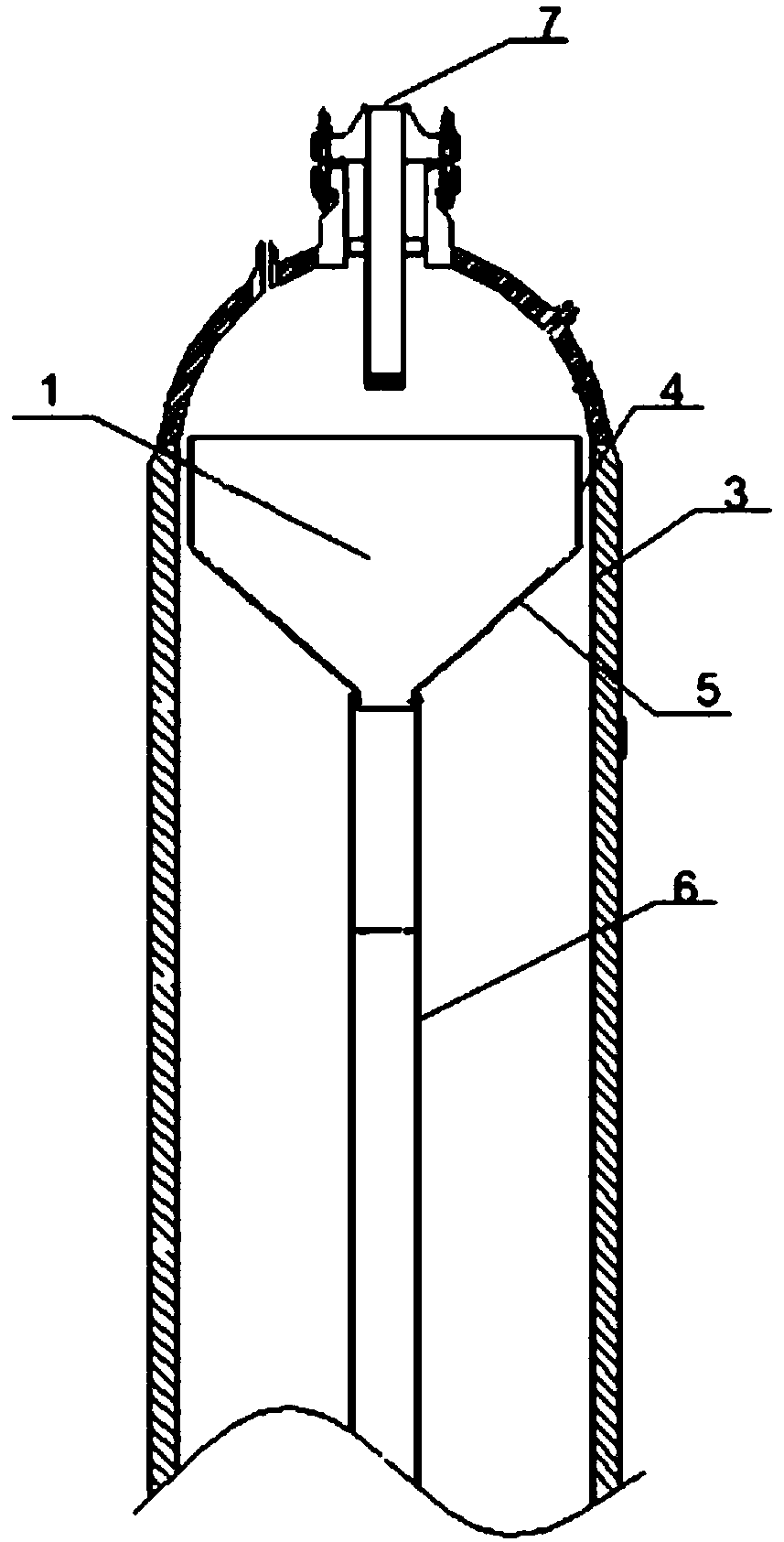

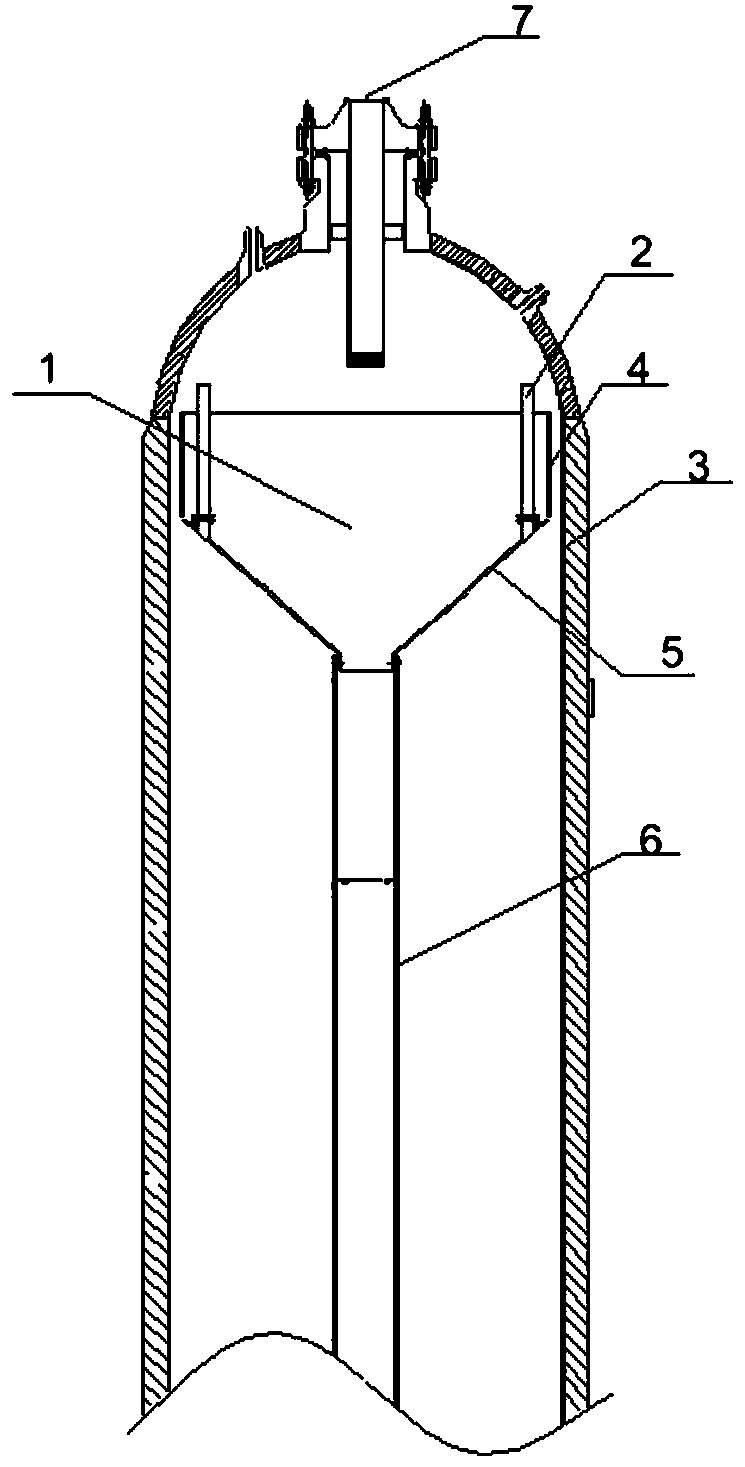

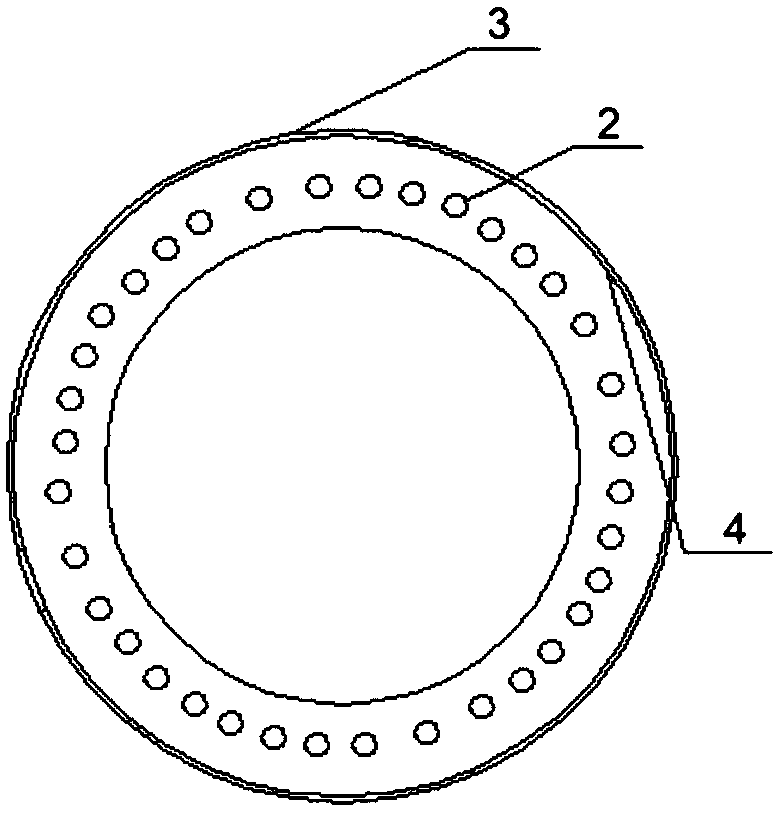

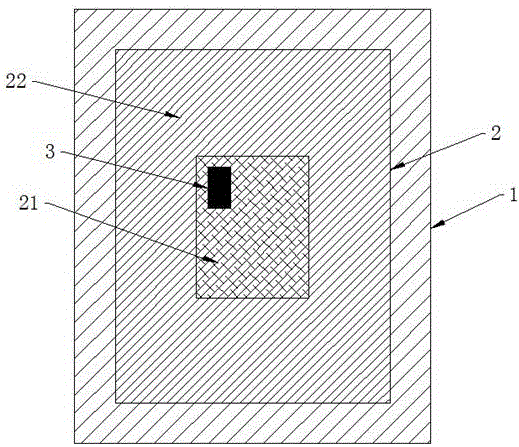

Composite material frangible cover enabling direction-pinpointed ejection and manufacturing method thereof

The present invention relates to a composite material frangible cover enabling a direction-pinpointed ejection and a manufacturing method thereof, belonging to the technical field of missile ejection and protection. The frangible cover herein comprises: a frame (1) and an ejection body (4), wherein the binding places of the frame (1) and the ejection body (4) are respectively a separation area (2) and a connection area (3), the separation area (2) being an area for glue treatment after segmentation between the frame (1) and the ejection body (4), on the internal side of the edge of the ejection body (4) within the separation area (2) being provided with a rectangular groove (5) which is filled with a AB glue therein, the ejection body (4) and the frame (1) being glued together on edges thereof with the AB glue, both the ejection body (4) and the frame (1) being adhered with an internal side fabric strip (6) and an external side fabric strip (7) via an epoxy resin glue on the internal and external sides thereof. The product of the present invention has the characteristics of simple structure, light weight and easy handling. The composite material frangible cover of the present invention has the characteristics of simple structure, light weight and easy operation, realizes a direction-pinpointed ejection of missiles under application of missile gas flow, and overcomes potential hazards of uncertain separation direction of the ejection body of the composite material frangible cover.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Device for polishing and impurity removal of steel balls

ActiveCN104858763AIncrease contact areaAchieve separationEdge grinding machinesPolishing machinesSteel ballEngineering

The invention discloses a device for polishing and impurity removal of steel balls. The device comprises a bracket, an external box body, an internal barrel body and a sieve plate, wherein the external box body is arranged on the bracket; the internal barrel body and the sieve plate are arranged in the external box body; a polishing rod is arranged in the inner axial direction of the internal barrel body; bulges are distributed on the polishing rod; through holes are distributed in the side walls of the internal barrel body; an elastic connecting piece is arranged at the lower end of the sieve plate; a material outlet is formed in the part, near the lower end of the sieve plate, of the external box body. Steel balls to be polished are added into the internal barrel body; the internal barrel body is driven to rotate through a driving device; the steel balls collide and rub with the bulges on the polishing rod; powdered scrap generated during the steel ball polishing process drops from the through holes; when the steel balls are polished, the internal barrel body is rotated to enable a material inlet-outlet to face down; a material inlet-outlet door is opened and the sieve plate vibrates up and down through the elastic connecting piece, so that the powdered scrap on the surfaces of the steel balls drops under collision. According to the device, the powdered scrap generated during the steel ball polishing can be timely separated from the steel balls and the impurity on the surfaces of the steel balls can be immediately removed after steel ball polishing is finished.

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

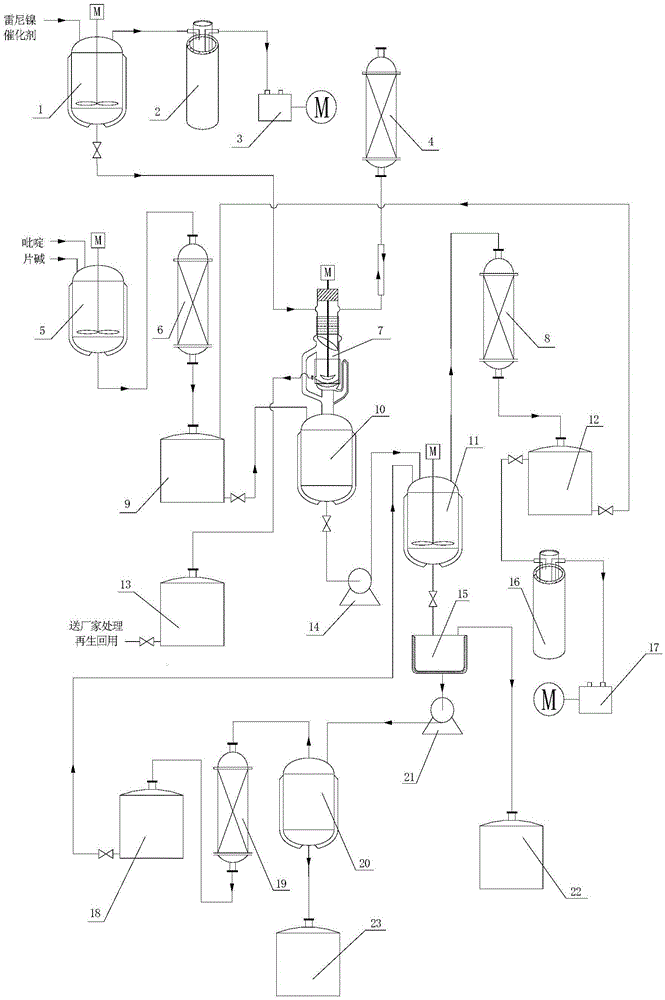

Raney nickel catalytic preparation method of 2,2'-bipyridine

The invention discloses a Raney nickel catalytic preparation method of 2,2'-bipyridine and belongs to the technical field of organic synthesis. The method comprises the following steps: pretreating raw materials to make purity of pyridine reach 99.8 wt% and above, carrying out dehydrogenation activation on a Raney nickel catalyst, and carrying out catalytic dehydrogenation coupled reaction, extraction separation and distillation purification so as to obtain 2,2'-bipyridine. Purity content is below 3 wt%. By reasonably combining soxhlet extraction principle and fluidized-bed process, timely separation of the product and the catalyst can be effectively guaranteed, service life of the catalyst is prolonged, side reaction can be reduced, and product purity is ensured. The method is clean and environmentally friendly. All solvents, including pyridine which hasn't participated in the reaction, can be recycled. The method is pollution-free to the environment. Waste of raw materials is avoided. The method has remarkably economic and social benefits.

Owner:安徽千和新材料科技发展有限公司

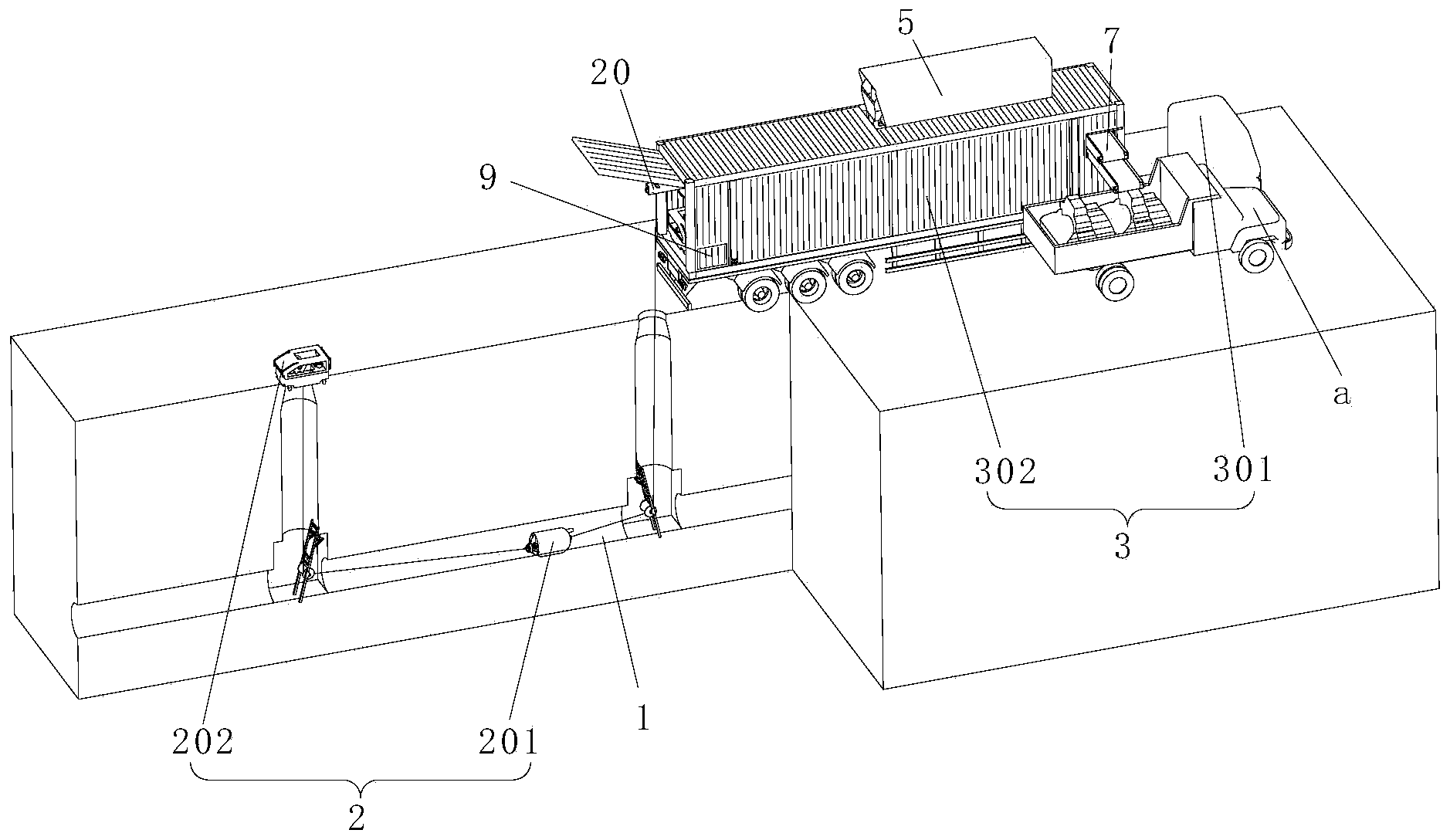

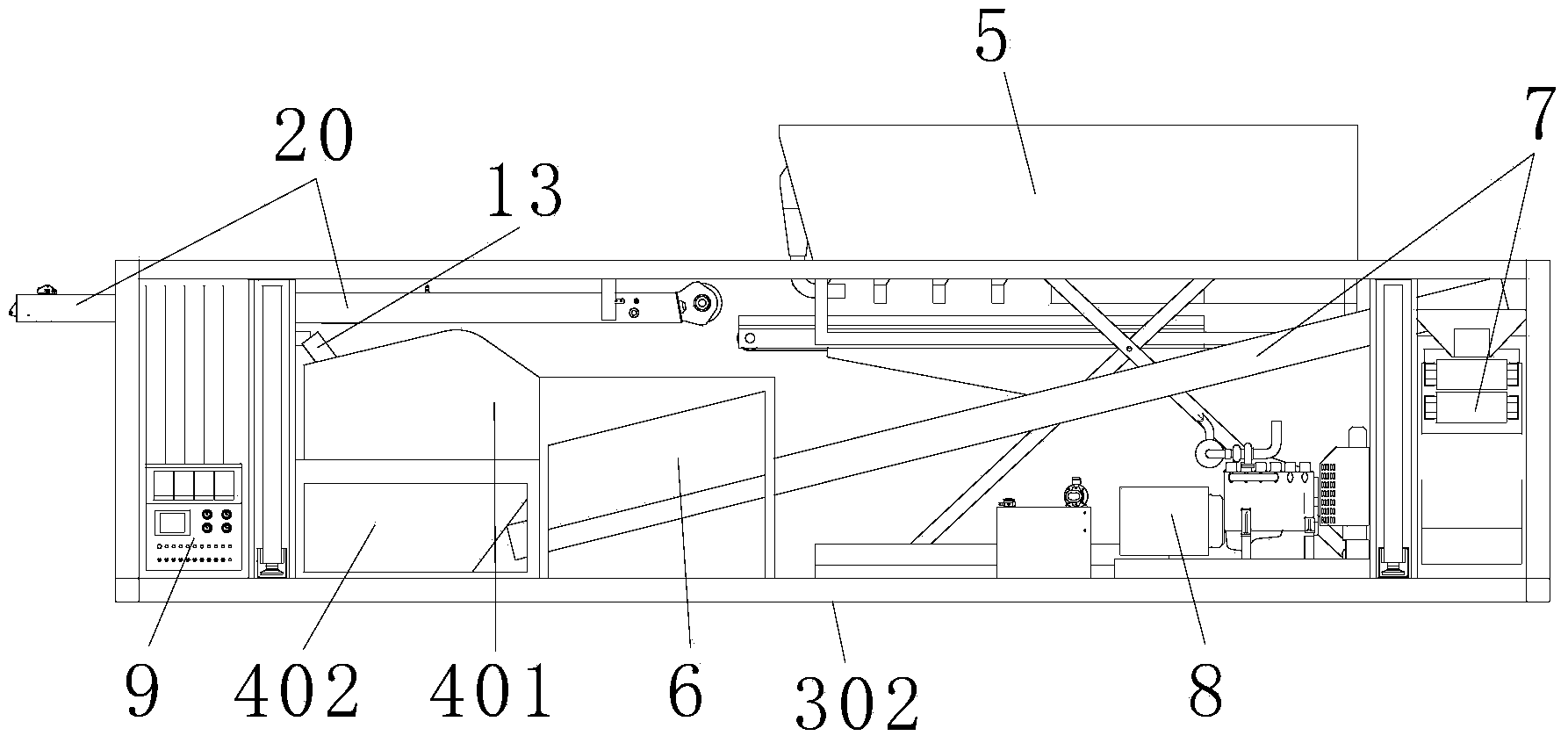

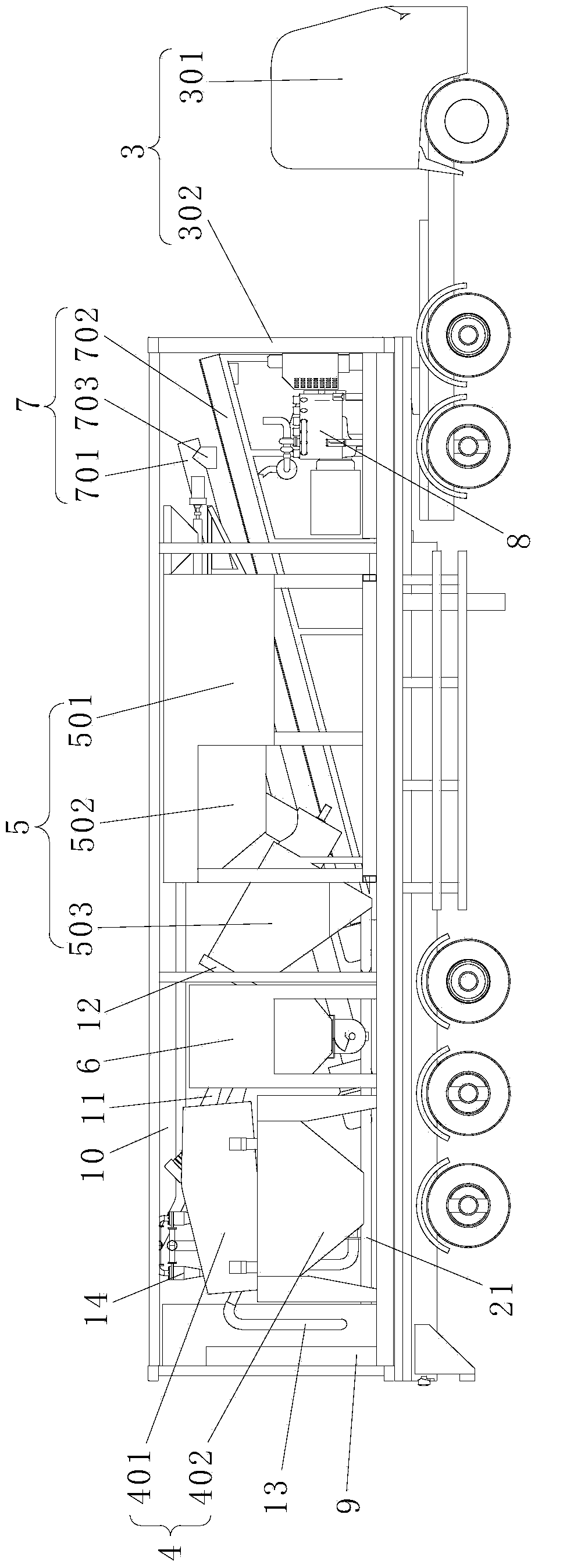

Sludge and sewage treatment system of drainage facility

ActiveCN103739185ATimely processingSeparation in timeSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentWater treatment systemSewage

The invention discloses a sludge and sewage treatment system of drainage facility. The system comprises drainage facility, a dredging mechanism and moving sludge and sewage treatment equipment, wherein the moving sludge and sewage treatment equipment comprises a moving handcart and a moving carriage; a filtering component, a sludge and sewage treatment component, a silt temporary storage device, silt output equipment, a generating set and control equipment are arranged in the moving carriage; the filtering component, the sludge and sewage treatment component and the silt temporary storage device are all connected with the generating set and the control equipment; the sludge and sewage treatment component is communicated with the filtering component through a pipeline; the filtering component is provided with a filtered granular impurity outlet; the sludge and sewage treatment component is provided with a sludge and sewage granular impurity outlet; both the filtered granular impurity outlet and the sludge and sewage granular impurity outlet are arranged towards the interior of the silt temporary storage device; a sludge and sewage accessing pipe is connected with the filtering device; a drainage pipe is connected with the bottom of the sludge and sewage treatment component; the dredging mechanism is connected with the sludge and sewage accessing pipe of the moving sludge and sewage treatment equipment through a discharge pipe. The sludge and sewage treatment efficiency are improved through filtering, treatment and separation.

Owner:中机恒通环境科技有限公司

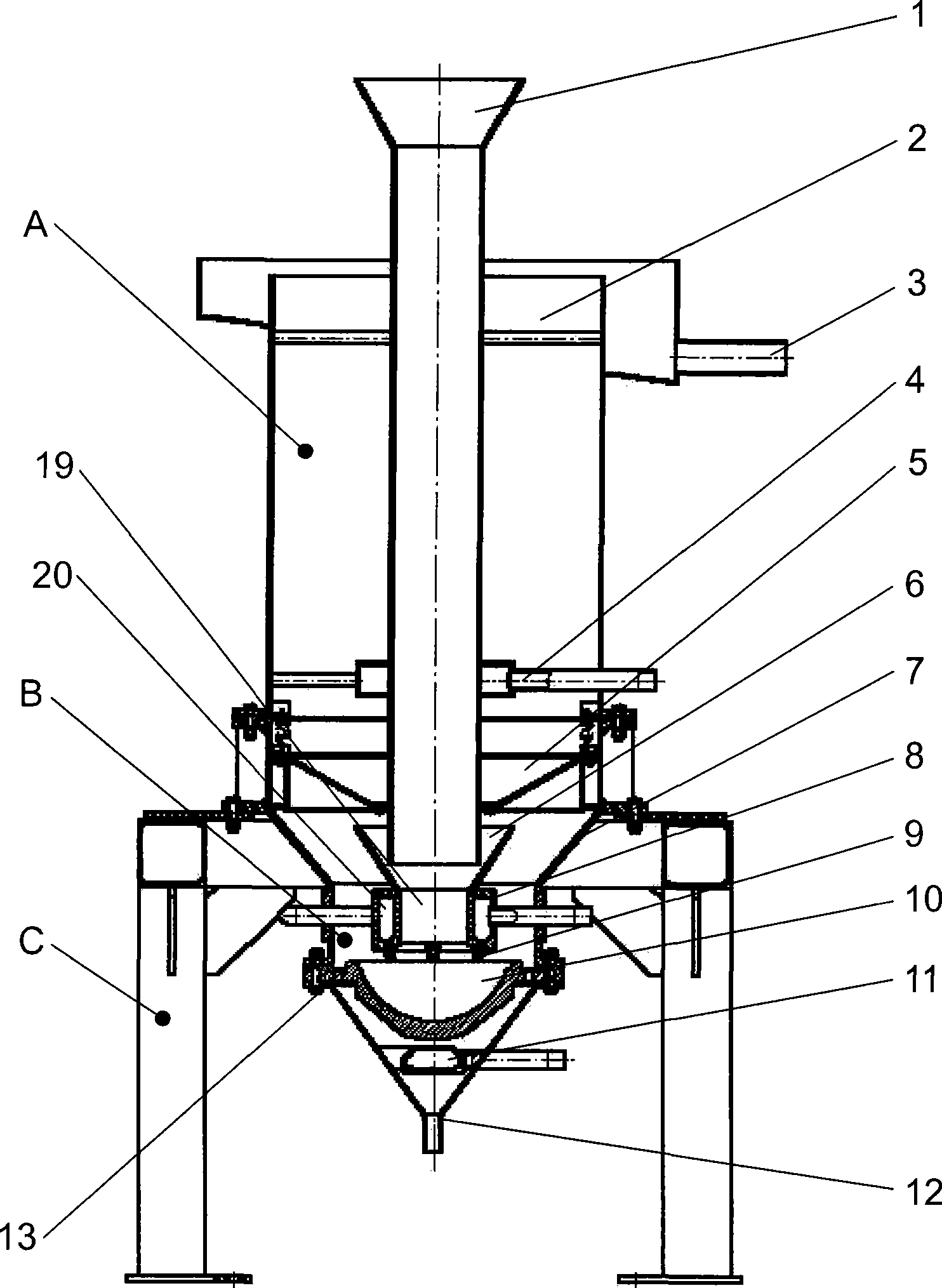

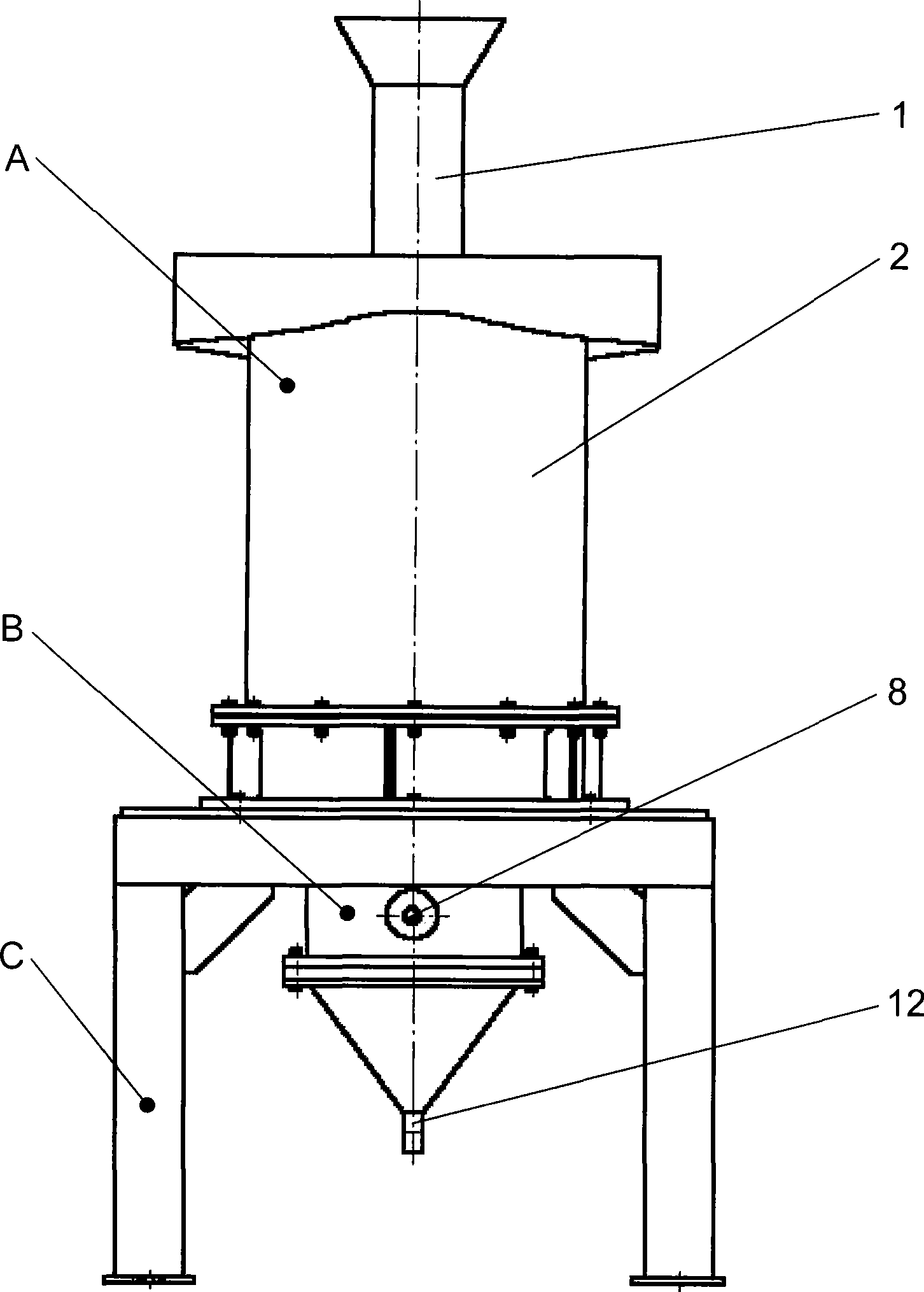

Cohesive target type water fluid jet grind

InactiveCN101367061AReduce consumptionImprove energy utilizationGrain treatmentsWet separationWater flowEngineering

The invention relates to a solid material crushing device, in particular to a cohesion target type water-jet mill which is characterized by comprising a material grading part, a material crushing part and a stand, wherein the material grading part comprises a central feed pipe, an overflow suspension assorting cylinder, an overflow groove, an annular water uniform distributor, and a water shock conical vibration sieve; the upper part of the overflow suspension assorting cylinder is welded with the overflow groove which is provided with a discharge hole; the lower end of the overflow suspension assorting cylinder is connected with the upper end of a cylinder body of a crushing part of the material crushing part through a flange; a feed hole of the central feed pipe is higher than the discharge hole of the overflow groove; the material crushing part comprises a material guide cone, the cylinder body of the crushing part, an annular nozzle holder, a nozzle, a cohesion target body, a conical water injector, a grading hopper and a separating grate sieve; and the cylinder body of the crushing part is fixedly connected with the stand. The cohesion target type water-jet mill has the characteristics of high utilization rate of energy and good effects of cleavage and crushing.

Owner:WUHAN UNIV OF TECH

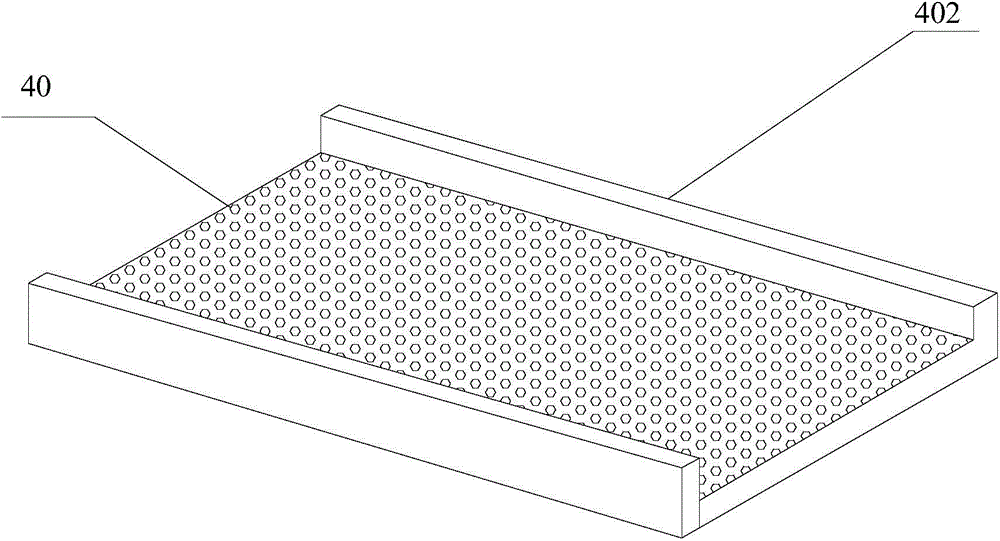

Lining band type filter press with press rolls for fixing mud

InactiveCN101376073ARestore elasticityImprove working conditionsPressesMoving filtering element filtersPulp and paper industryFilter press

The invention discloses a lining belt type pressure filter with a solid mud press roller. The press filter comprises a stander, a driving device, a feeding device, a press area and an auxiliary device, and has the structure that the press area comprises the solid mud press roll, a carrier roller, a guide roller, a filtering stripe and a compression lining belt; the solid mud press roller is a press roller with a solid mud layer covering the surface of the roller, and the solid mud layer adopts the material which has high elasticity, high recoverability, and high fraction coefficient, and is easy to separate from dehydrate material; the solid mud press roller is provided with a maintenance device, which is arranged behind the press position of the solid mud press roller, and the elasticity and the fraction coefficient of the solid mud layer can be recovered in time through the maintenance to the solid mud press roller by the maintenance device; the filtering stripe wraps the solid mud press roller, the carrier roller and the guide roller in sequence; the compression lining belt and the filtering stripe are stacked in parallel in the press segment of the press area; the driving device drives filtering stripe and the compression lining belt; and the feeding device and the auxiliary device are arranged in the corresponding positions of the filtering stripe. The pressure filter of the invention has solid mud structure, thereby effectively solving the problem of mud leaking and achieving better press filter effect.

Owner:ZHEJIANG HUAZHANG TECH

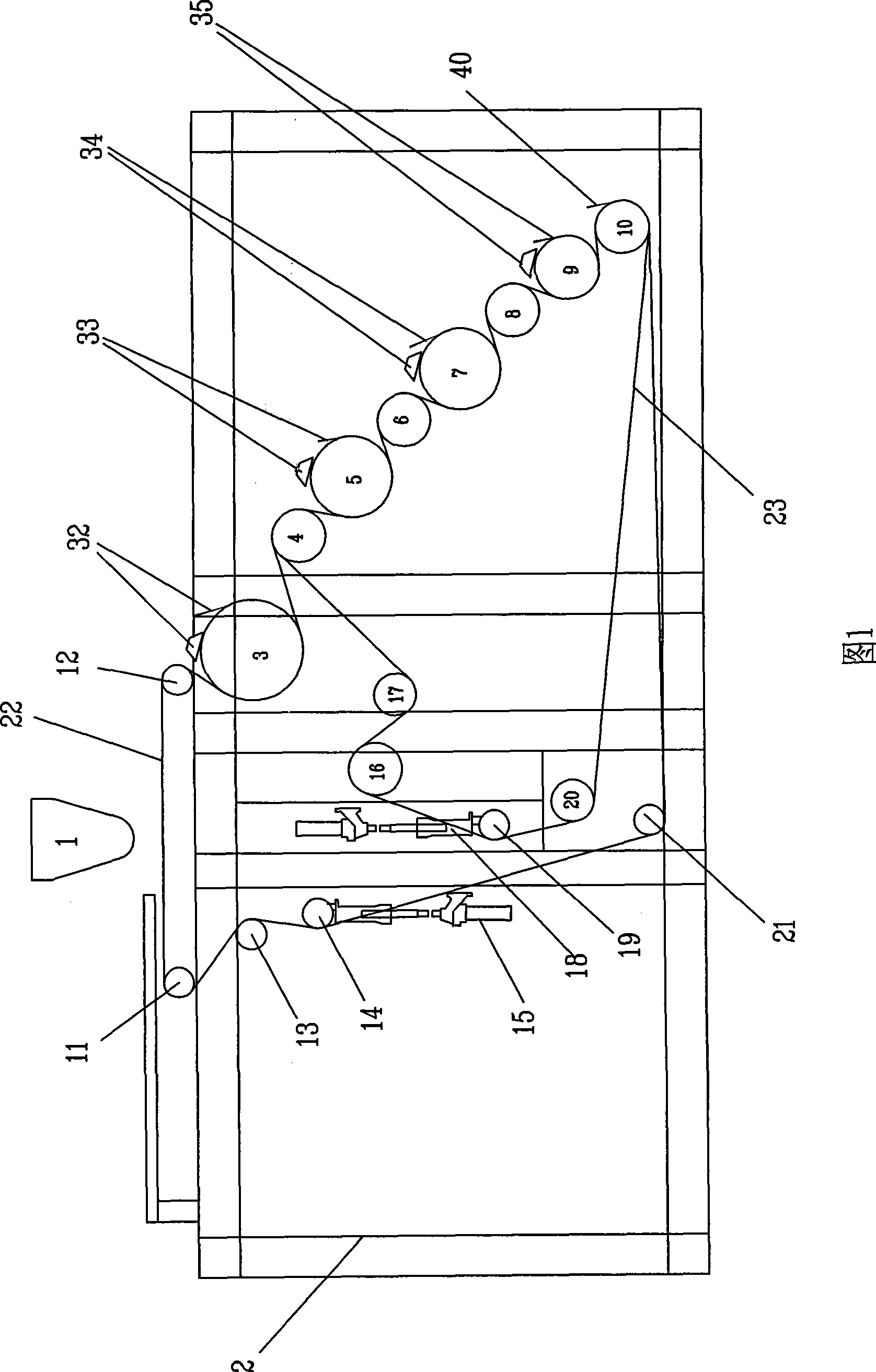

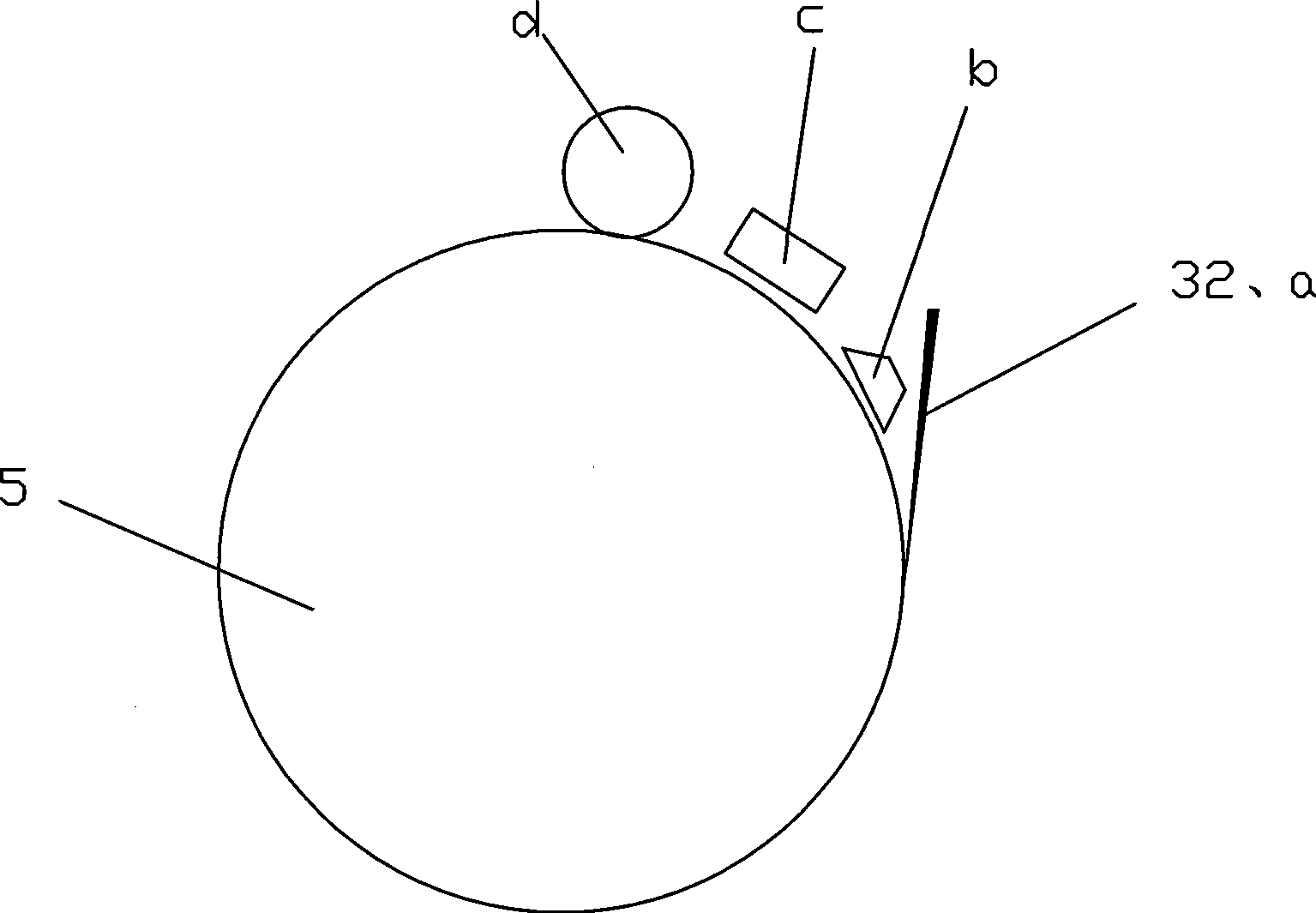

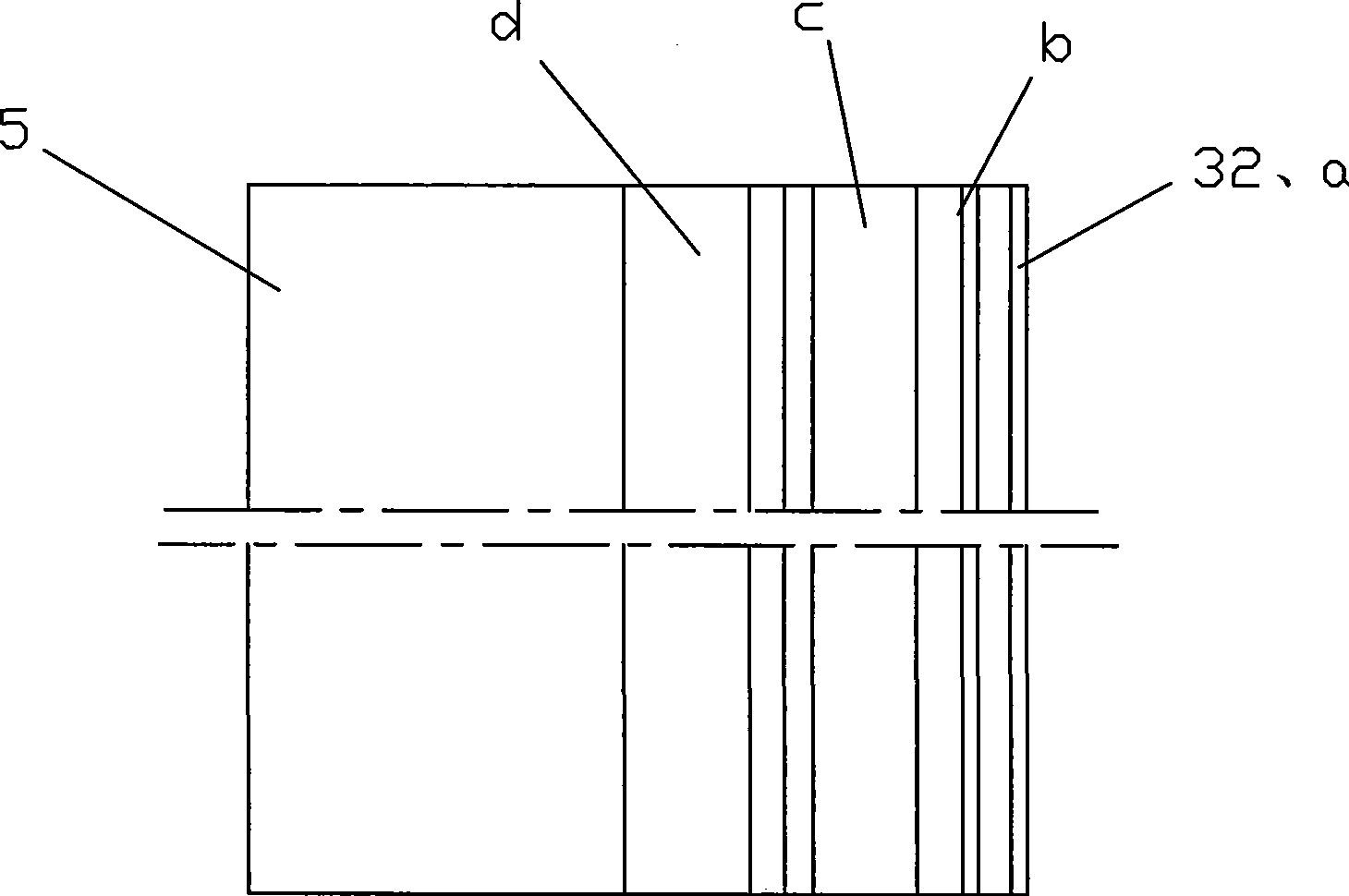

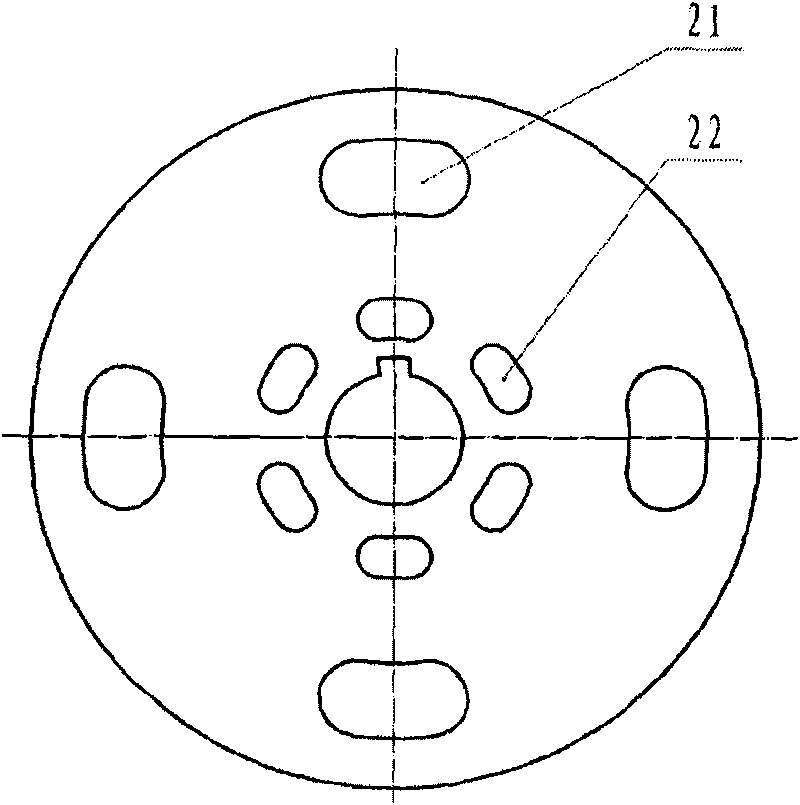

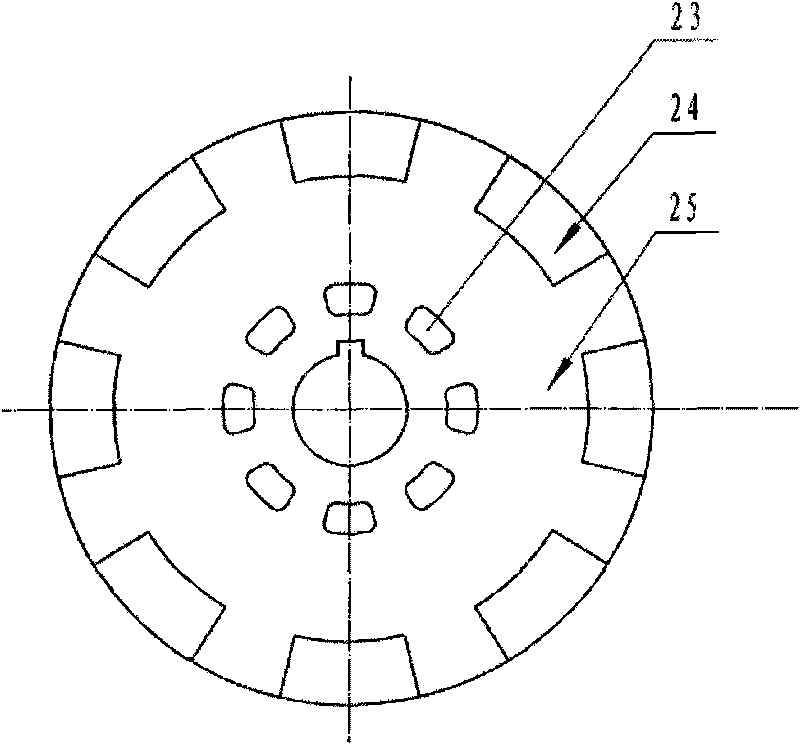

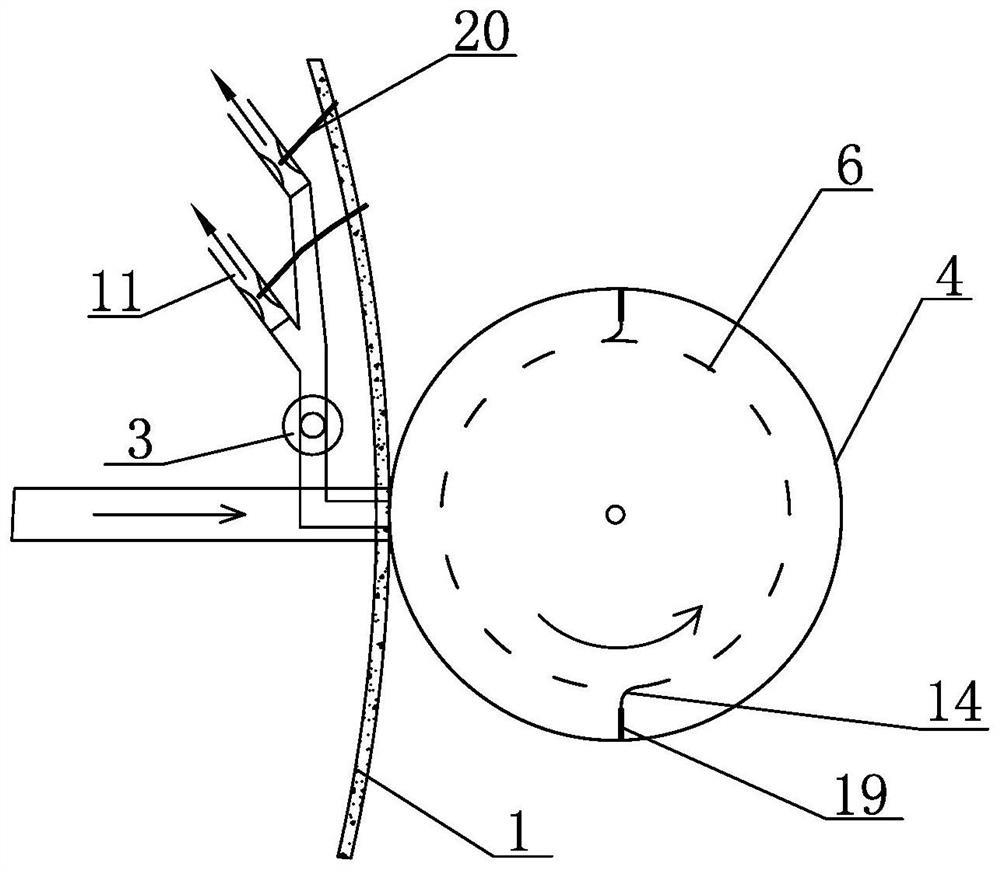

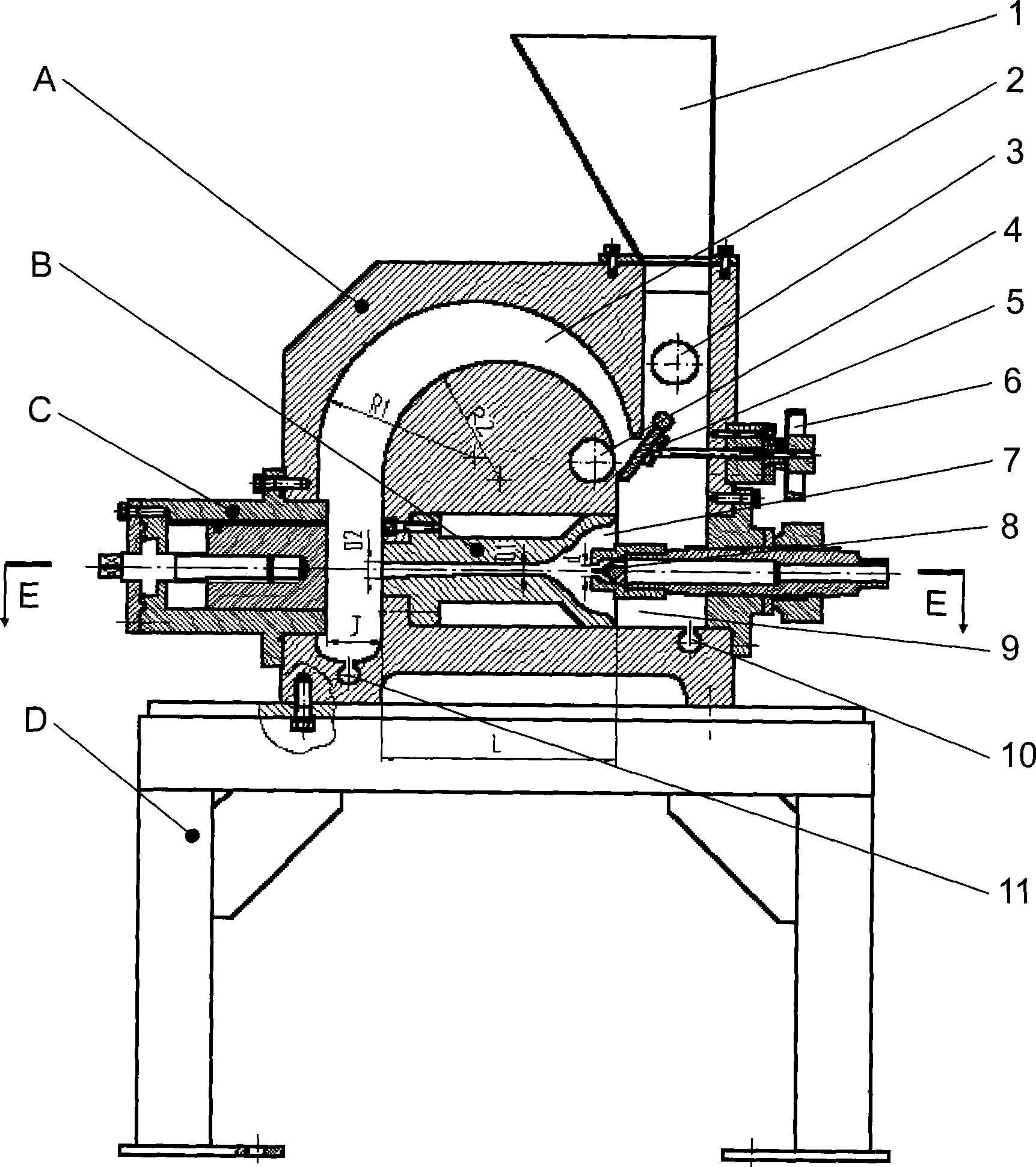

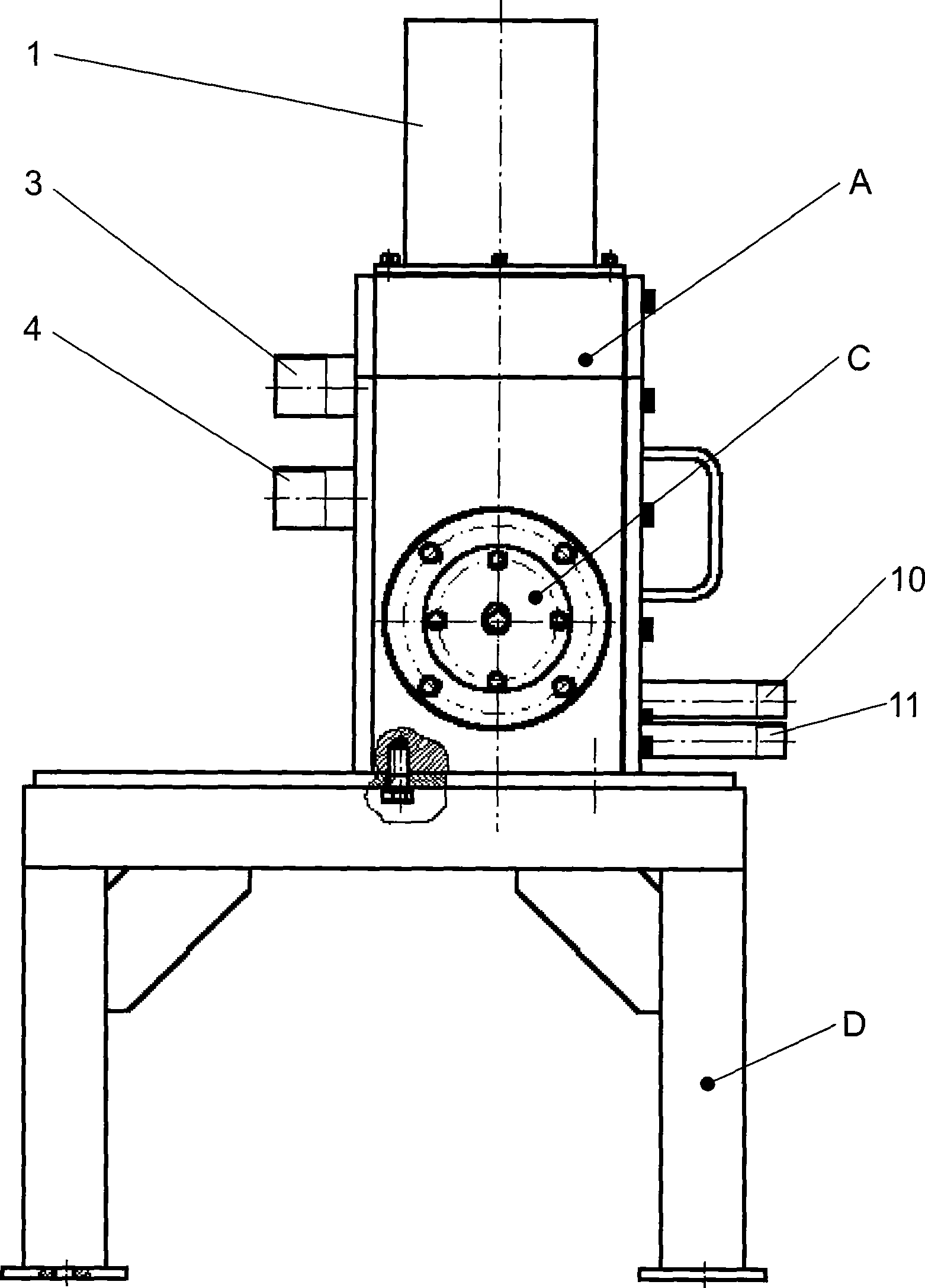

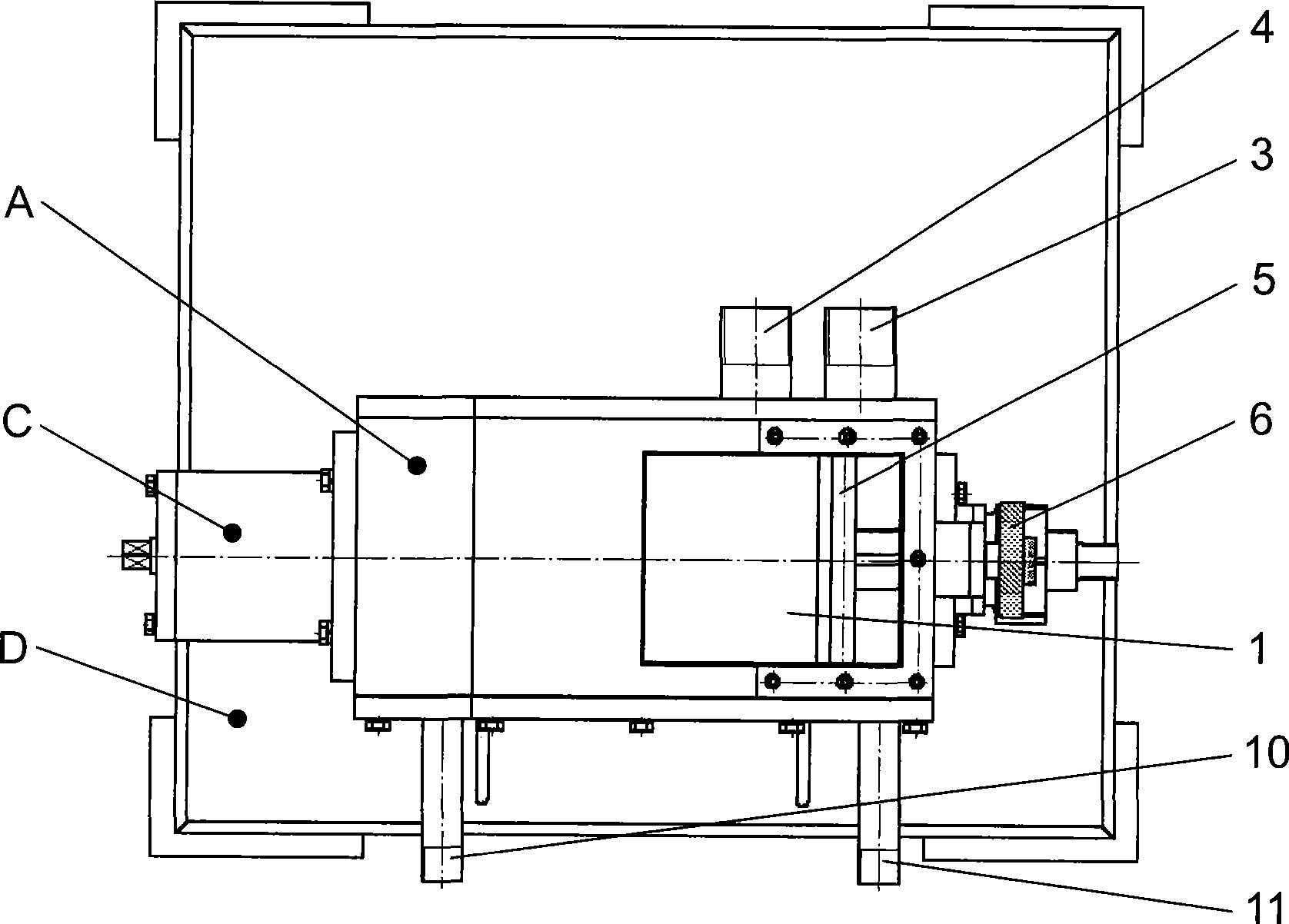

Horizontal grinding mill with built-in classifying turbine

InactiveCN101700504AOvercoming frictional resistanceReduce starting powerEngine sealsGrain treatmentsImpellerTurbine

The invention relates to a horizontal grinding mill with built-in classifying turbine, the technical solution of which is that a grinding chamber [18] is filled with grinding medium [6], a medium discharging valve [20] is installed on the middle of the bottom of a cylinder [7], a feeding pipe [10] is above a right end cover [9] of the grinding chamber [18] and a medium discharging pipe [2] is concentrically communicated with the grinding chamber [18] by a left end cover [3]. The length of the cylinder [7] is 1.5 to 2.5 times of the diameter thereof. A fairing [4] is fixedly installed on the left end cover [3] of the grinding chamber [18]. A classifying turbine [5] is vertically installed on the left end of a spindle [13]. A clearance between the classifying turbine [5] and the left end cover [3] is 5mm to 10mm. Five to eight mixing turbines [8] are vertically installed on the spindle [13]. The distance between the mixing turbines [8] decreases gradually from left to right and the right distance is 0.9 to 0.95 times of the left distance. The right end of the spindle [13] is connected with a driving mechanism by the right end cover [9] and a sealing device [11]. The invention has low starting power and can grind and classify with a function of selectively grinding.

Owner:WUHAN UNIV OF SCI & TECH +1

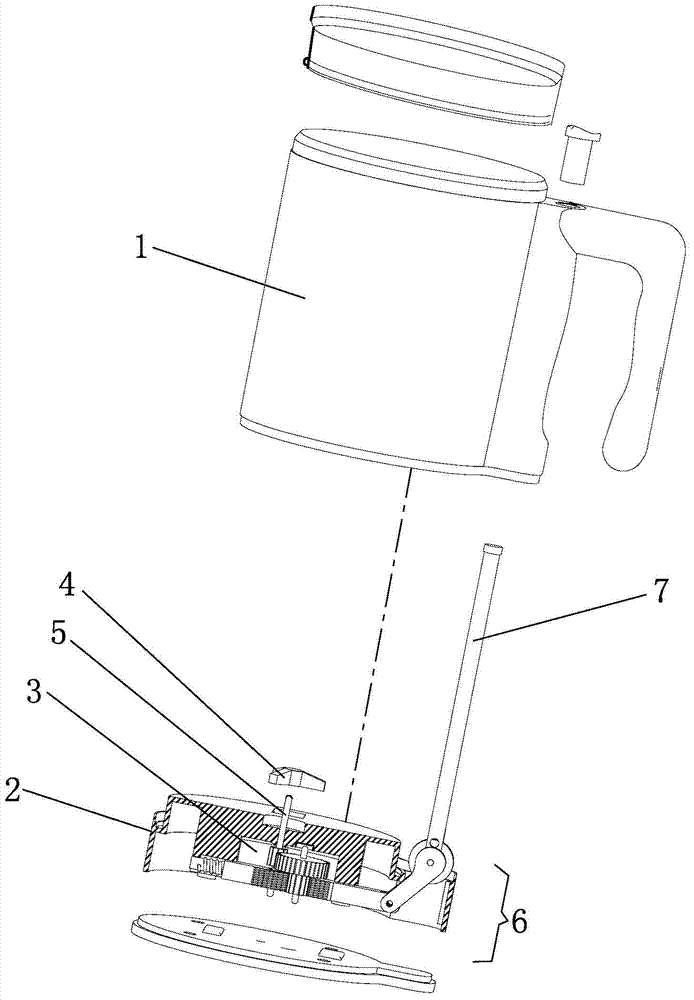

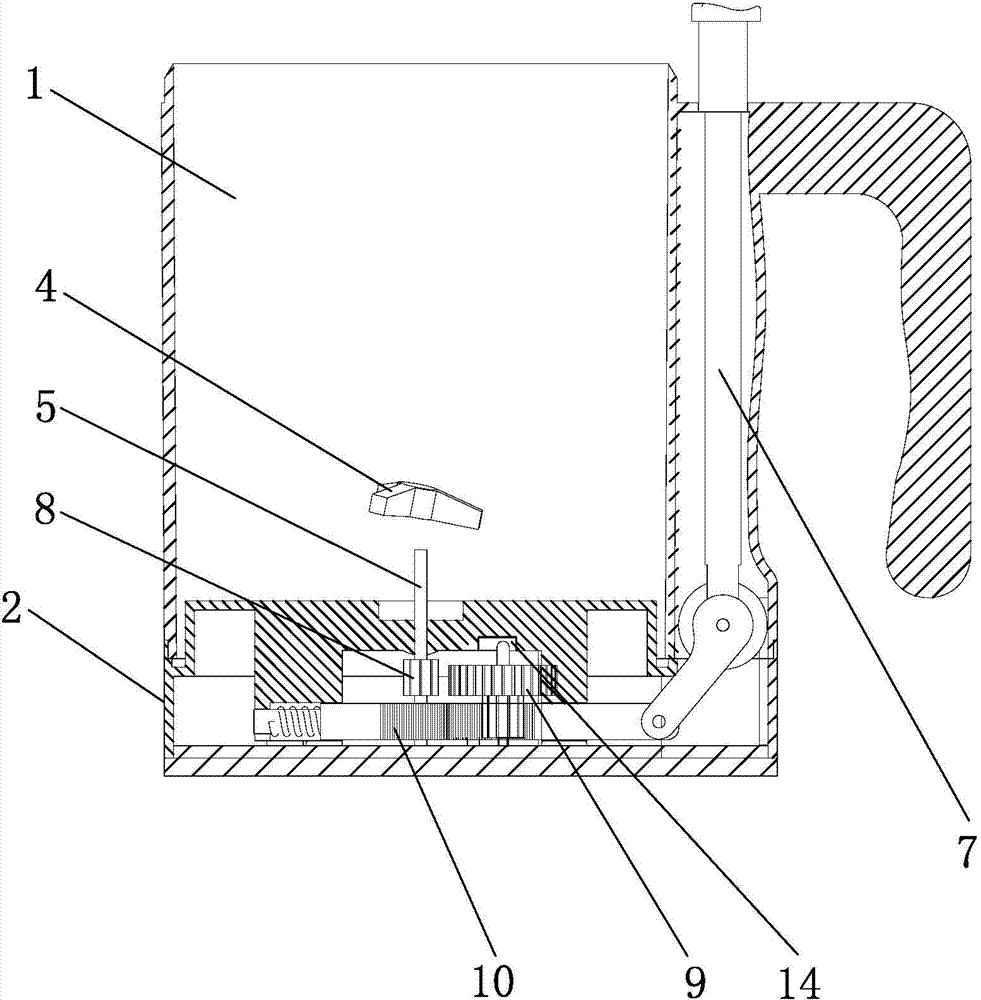

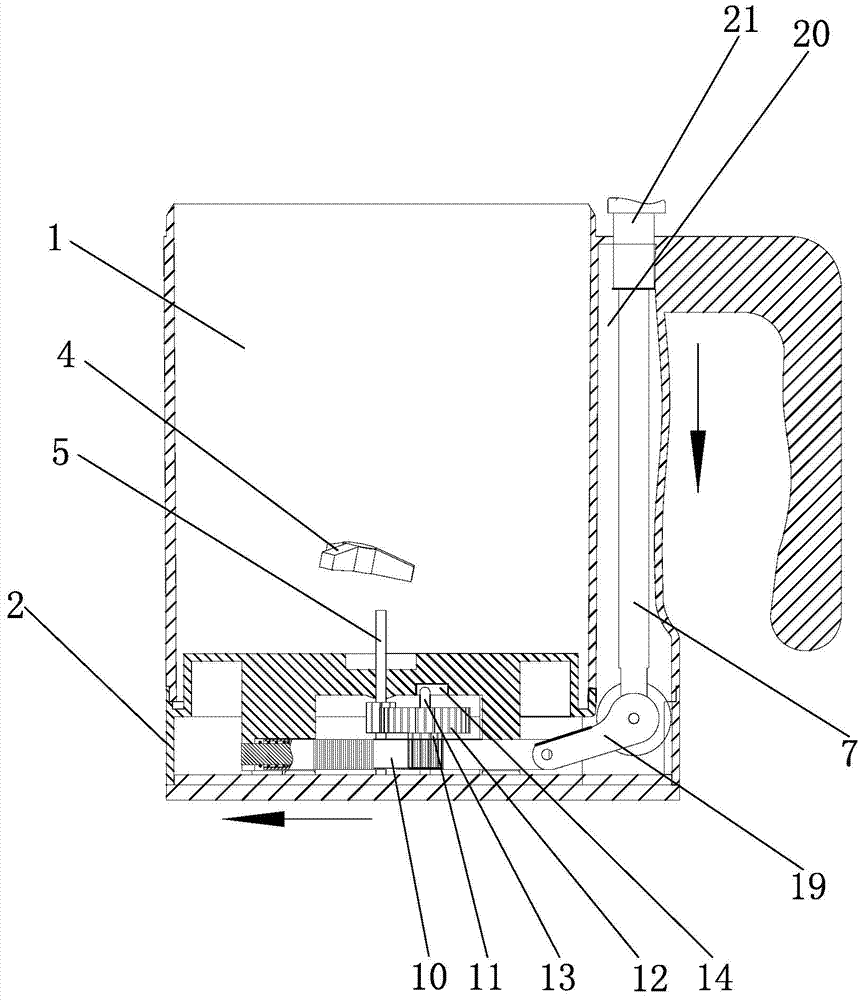

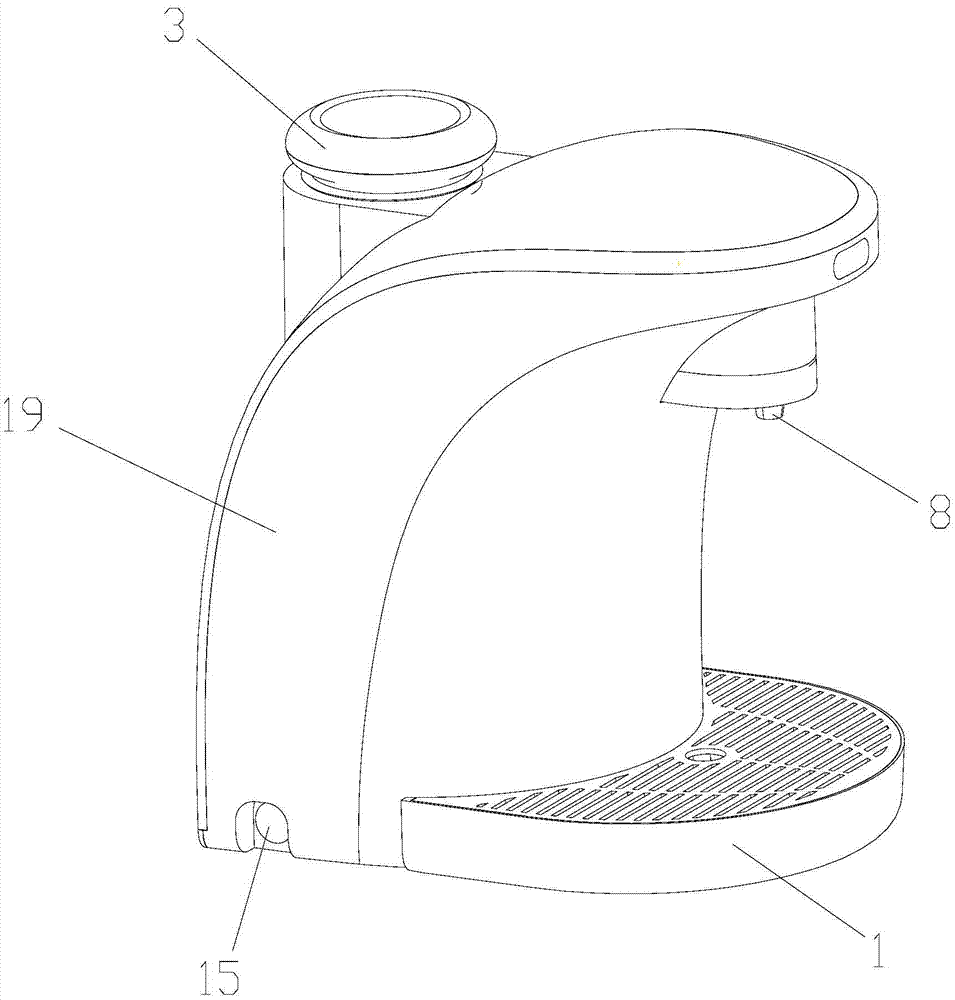

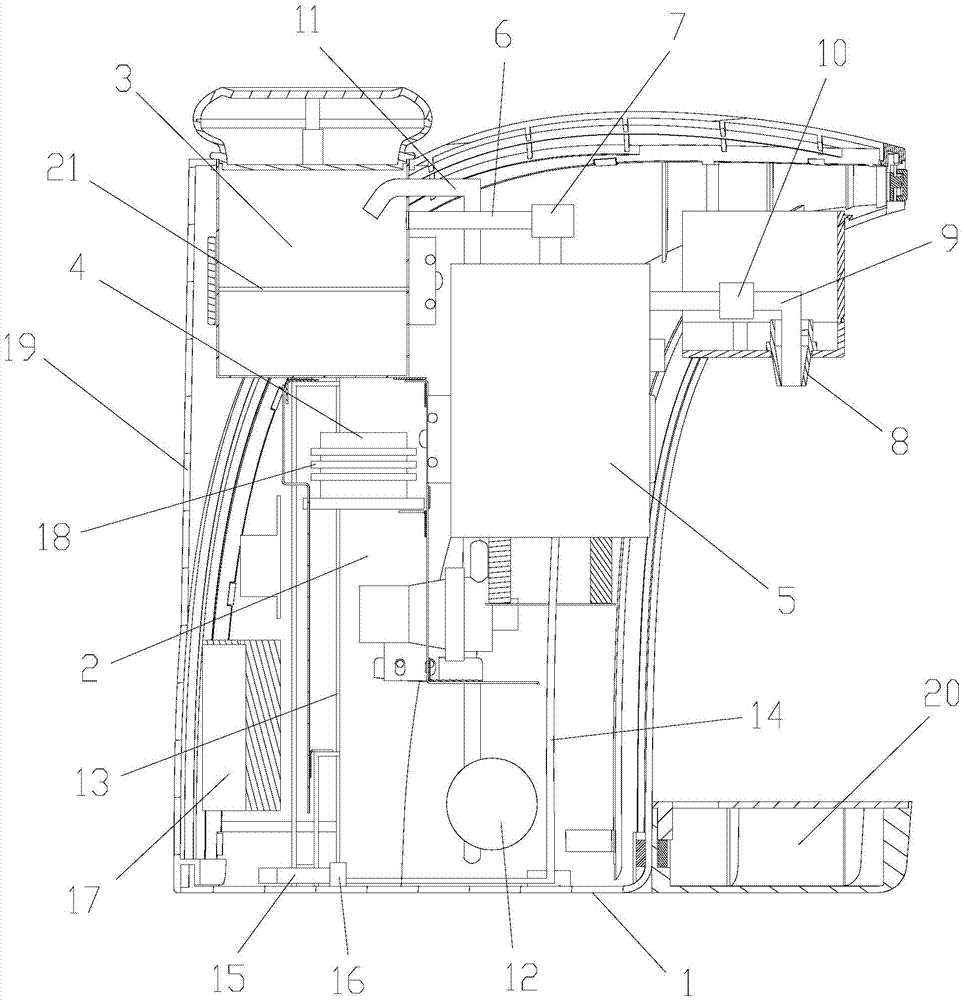

Mechanical transmission stirring cup

The invention provides a mechanical transmission stirring cup and belongs to the technical field of cups. The problems that manual stirring is troublesome, and a cup with a stirring function itself is complex in structure, large in size and inconvenient to carry are solved. The mechanical transmission stirring cup comprises a cylindrical cup body, the lower end of the cup body is fixedly connected with a base in a clamped mode, a cavity is formed in the base, a stirring impeller is arranged in the cup body, a rotating shaft is arranged in the center of the stirring impeller, and one end of the rotating shaft penetrates to the cavity of the base; a transmission mechanism is arranged in the base and drives the rotating shaft to rotate so that the stirring impeller can rotate for stirring, and the transmission mechanism is driven by a driving rod which can be pushed, or pulled or poked. The mechanical transmission stirring cup has the advantages of being compact in overall structure, convenient to carry, rapid and convenient to use, simple and effective and meeting requirements of fast-paced life at present.

Owner:孙正标

Multifunctional intelligent tea-making water dispenser and tea-making process

InactiveCN105433794AQuality improvementImprove the quality of family lifeBeverage vesselsWater storageEngineering

A multifunctional intelligent tea-making water dispenser comprises a base, wherein a supporting seat is installed on the base, a tea-making bucket, a heating tank and a tea storage canister is arranged on the supporting seat, the tea-making bucket is connected with a water inlet pipe, a small water pump is connected to the water inlet pipe, a controller is installed on the base, and tea making is performed through complete cold water discharge, automatic flushing and automatic brewing. The multifunctional intelligent tea-making water dispenser has the advantages that the water dispenser can perform precise tea making according to a required tea-making formula, accordingly high-quality tea water is obtained, heating and fragment enhancing can be conducted on tea before tea making, the problem of water deterioration caused by water storage of the tea-making bucket can be avoided, made tea water and tea can be timely separated, the taste, quality and temperate of the tea water can be ensured, and the multifunctional intelligent tea-making water dispenser has an independent water dispensing function, can output water at constant temperature, is diversified in function, can clean internal pipes and the tea-making bucket to prevent stain from being left and is good in using effect.

Owner:遂昌睿丰科技有限公司

Rapid extraction equipment for plant coloring agent for textile

The invention relates to rapid extraction equipment for a plant coloring agent, in particular to the rapid extraction equipment for the plant coloring agent for the textile. The invention aims to provide the rapid extraction equipment for the plant coloring agent for the textile which is high in extraction efficiency, is sufficiently uniform in rolling compacting, and is capable of timely separating a liquid from plant residues during extraction. The rapid extraction equipment for the plant coloring agent for the textile comprises a bottom plate and the like; the top of the bottom plate is provided with an n-shaped frame, a driving mechanism is arranged on the right side in the n-shaped frame, a rolling compacting mechanism is arranged at the inner top of the n-shaped frame, a first supporting rod is arranged in the middle of the top of the bottom plate, and a box body is connected to the top end of the first supporting rod. According to the equipment, the effects that the extraction efficiency is high, rolling compacting is sufficiently uniform, and the liquid can be separated from the plant residues timely during extraction are achieved; and the driving mechanism works to drive the rolling compacting mechanism to roll and compact the plant to extrude out the juice, and a lifting mechanism enables the plant residues and the extraction liquid to be separated timely, so that theextraction speed is accelerated.

Owner:邱有萍

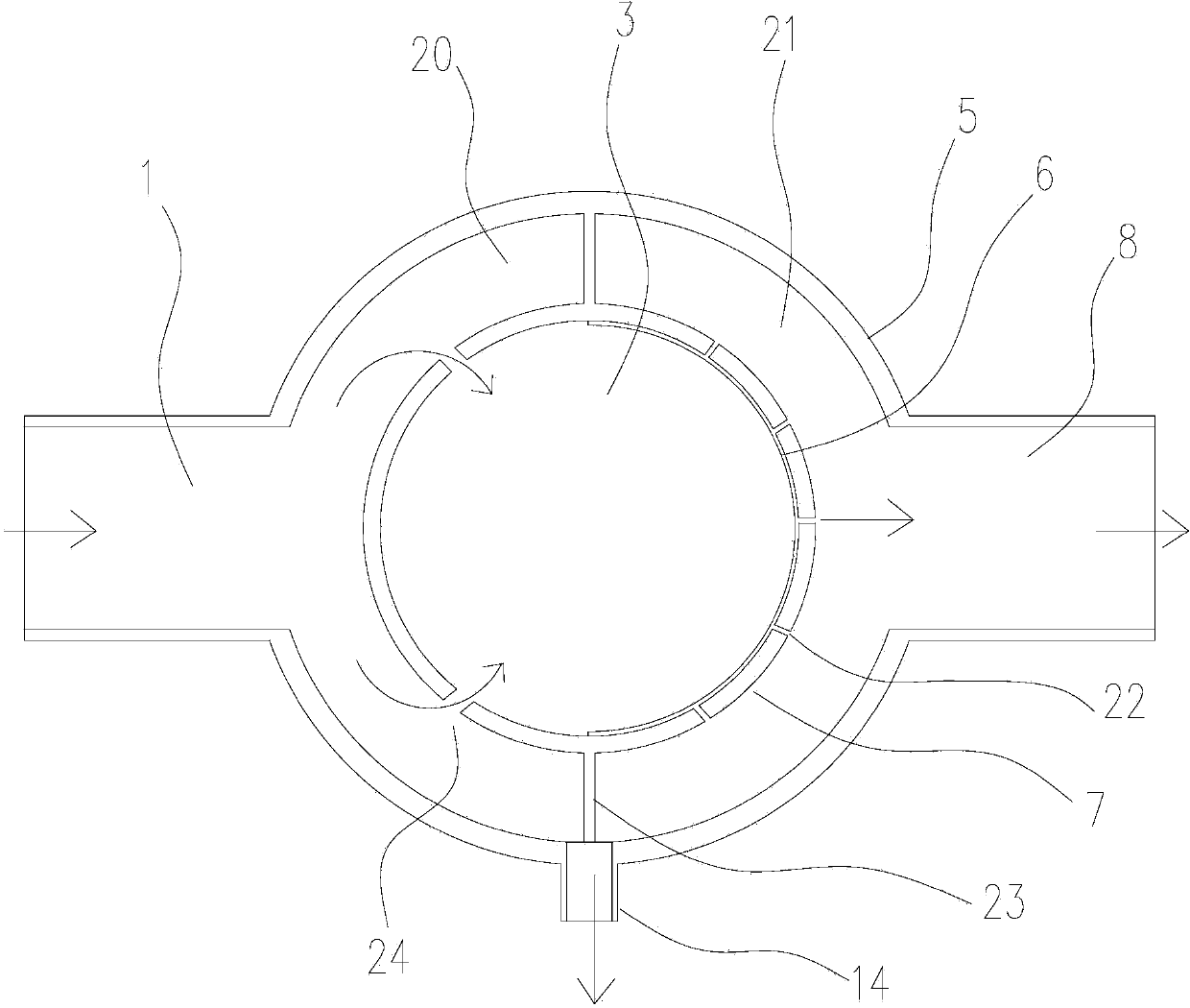

Shunting type discarding flow filter device

InactiveCN104179246ARealize automatic managementGuaranteed overtreatment efficiencyFatty/oily/floating substances removal devicesSewer pipelinesShunt typesFilter system

The invention relates to a shunting type discarding flow filter device which comprises an outer cylinder, an inner cylinder, a hanging cylinder and a float valve, wherein the inner cylinder is fixed on the inner wall of the outer cylinder through an upper partition board and a lower partition board; a water inlet and a water outlet are formed in two sides of the outer cylinder; stabilizer bars are arranged on two sides of the top end of the hanging cylinder; the float valve is nested on the stabilizer bars through a stainless steel board in a penetrating manner; a center hole and a discarding flow port are formed in the hanging cylinder; the float valve is connected with a half-ball valve through a connecting rod; a medium partition board for dividing space between the outer cylinder and the inner cylinder into a front outer cavity and a rear outer cavity is arranged between the outer cylinder and the inner cylinder; and shunting holes and water permeating holes are formed in two sides of the inner cylinder respectively. According to the shunting type discarding flow filter device, pollutants can be separated in time, a filter system is prevented from being blocked by impurities and suspended matters in rainwater, the filter efficiency at the later period when the rain is heavier is guaranteed, besides, the device is simple in structural design, low in cost, high in stability and simple to operate, and the pollutants are convenient to clean.

Owner:SHANGHAI BIAONENG BUILDING TECH

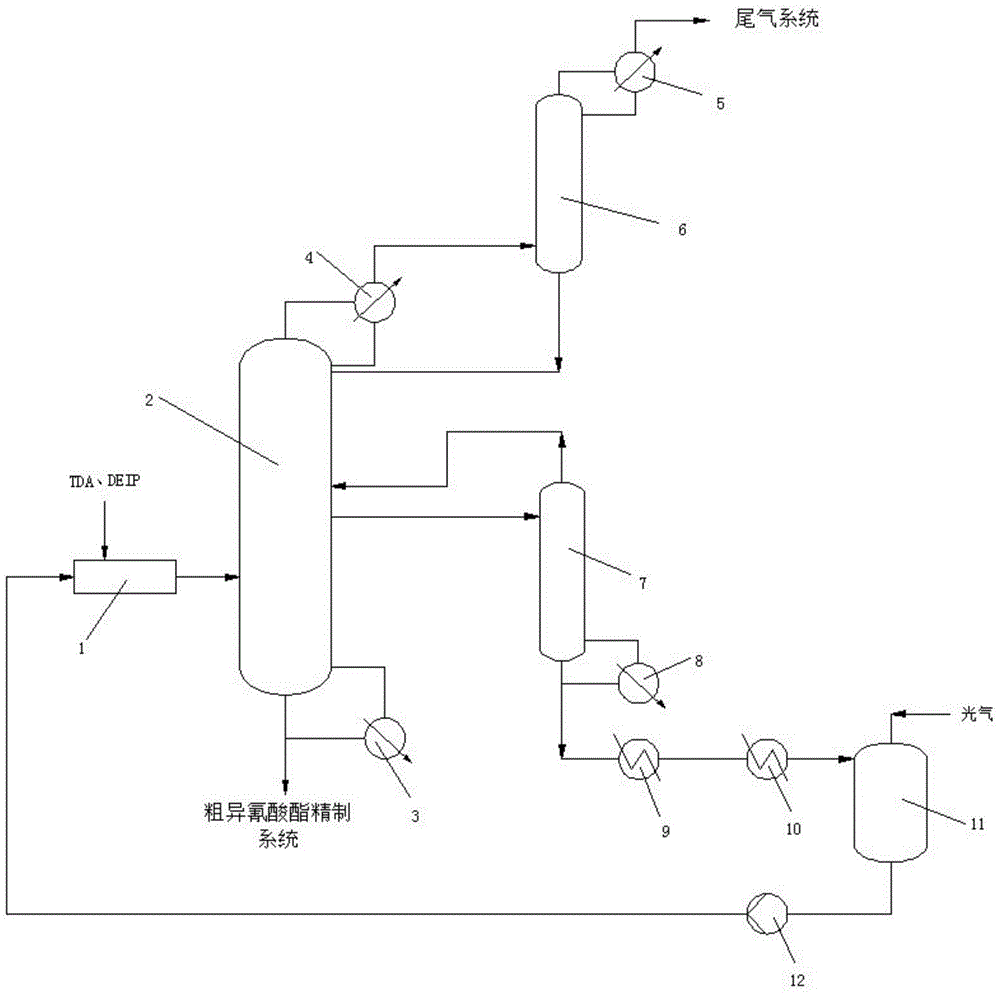

Method for preparing isocyanate via reaction distillation method

InactiveCN104892458ALower side discharge temperatureIncrease operating loadChlorine/hydrogen-chloride purificationOrganic compound preparationReactive distillationPhysical chemistry

The invention belongs to the technical field of isocyanate preparation and relates to a method for preparing isocyanate via a reaction distillation method. The method includes that amine reacts with liquid phosgene to prepare the isocyanate, the amine and the liquid phosgene are in cold reaction in a jet reactor firstly prior to entering a reactive distillation column to be subjected to thermal reaction for preparing crude isocyanate, meanwhile excessive phosgene and a by-product HCL (hydrogen chloride) gas are separated by distillation, and the phosgene and the HCL gas are refined prior to recycling. The method is simple in technique, convenient to operate, capable of separating the by-product in time, energy saving, low in cost, high in efficiency and environment friendly.

Owner:QINGDAO UNIV OF SCI & TECH +1

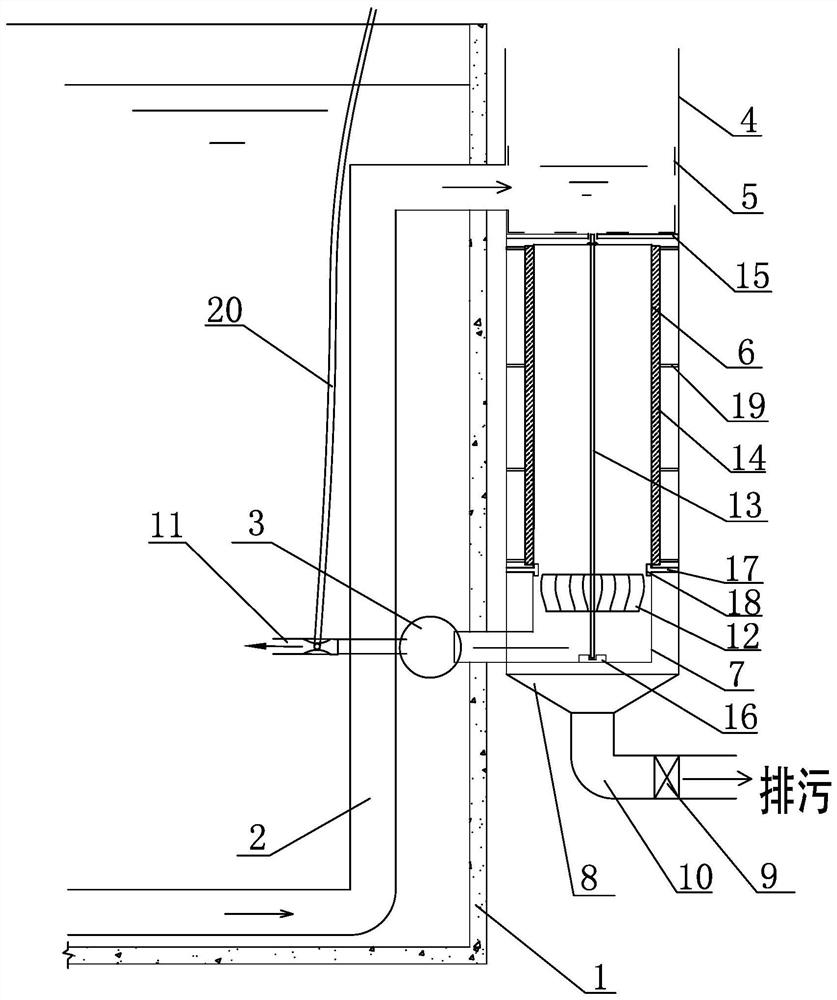

Rotary filtration, concentration and sewage discharge device and method for shrimp pond

ActiveCN112772538ARealize self-cleaningImprove filtering effectClimate change adaptationPisciculture and aquariaFiltrationMechanical engineering

The invention discloses a rotary filtration, concentration and pollution discharge device and method for a shrimp pond. The device is characterized by comprising a sewage suction pipe and a water pump which are arranged in a culture pond, and an outer cylinder which is arranged inside / outside the culture pond and is through up and down, a filter screen lifting basket, a filter cylinder and a filtered water pipe are sequentially arranged in the outer cylinder from top to bottom, and a sewage collection bin is arranged at the bottom of the outer cylinder; a blow-off pipe with a blow-off valve is arranged at the bottom of the sewage collection bin; a top outlet of the sewage suction pipe penetrates through the outer cylinder wall to be communicated with the filter screen lifting basket, the top of the filter cylinder is closed, an opening is formed at the bottom of the filter cylinder, the filter cylinder is in butt joint communication with the filtered water pipe, the filtered water pipe is connected with the water pump, and a water outlet pipe of the water pump is connected with a plurality of water ejectors; and an impeller is arranged at a top inlet of the filtered water pipe, a rotating shaft fixedly connected with the filter cylinder is fixedly arranged in the center of the impeller, and a plurality of mud scraping plates are arranged between the outer cylinder and the filter cylinder, the device has the advantages that shrimp shells, dead shrimps and sick shrimps with poor vigor can be separated in time, residual feed and excrement are concentrated and then discharged, and the water consumption of sewage discharge is low.

Owner:NINGBO UNIV

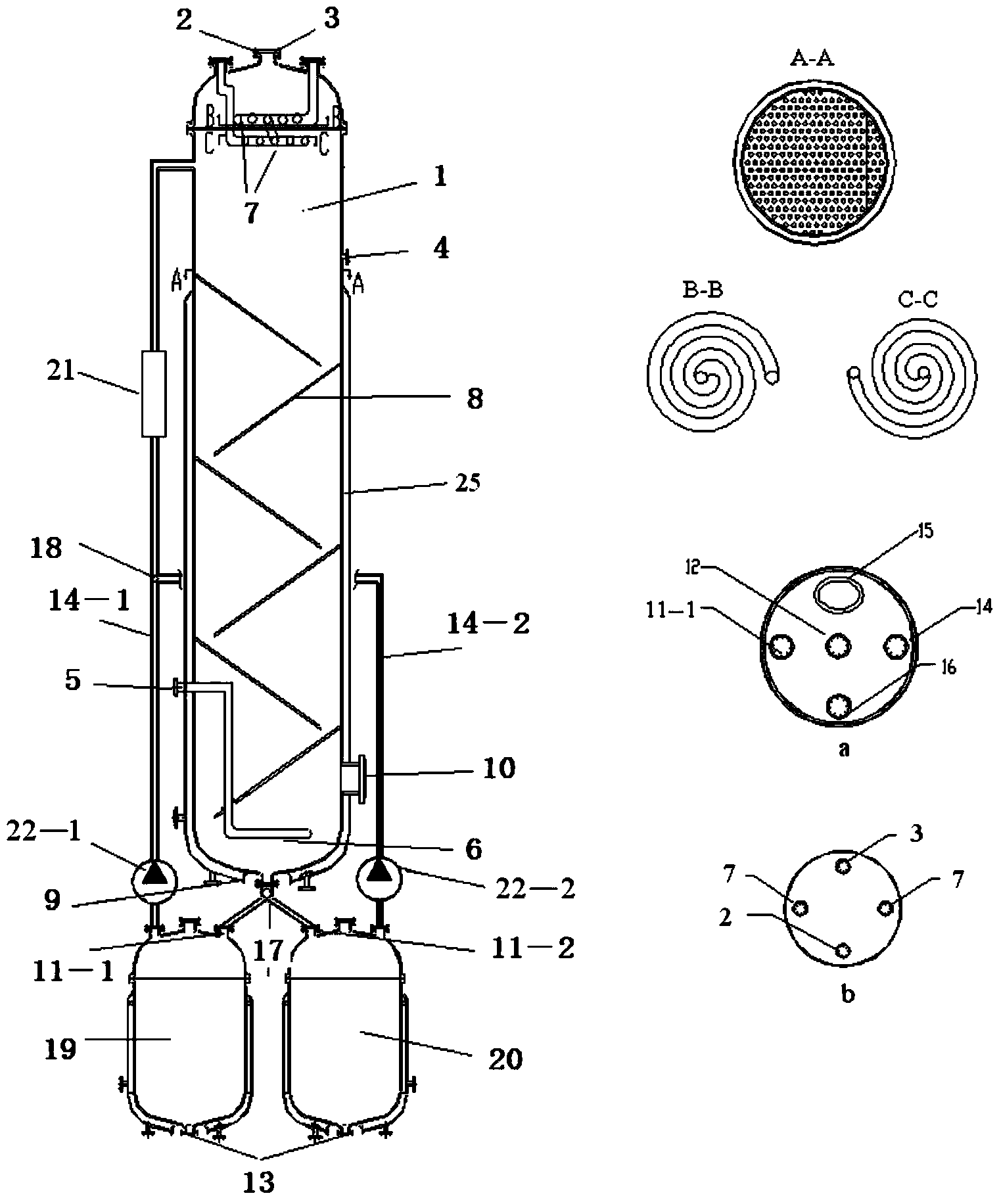

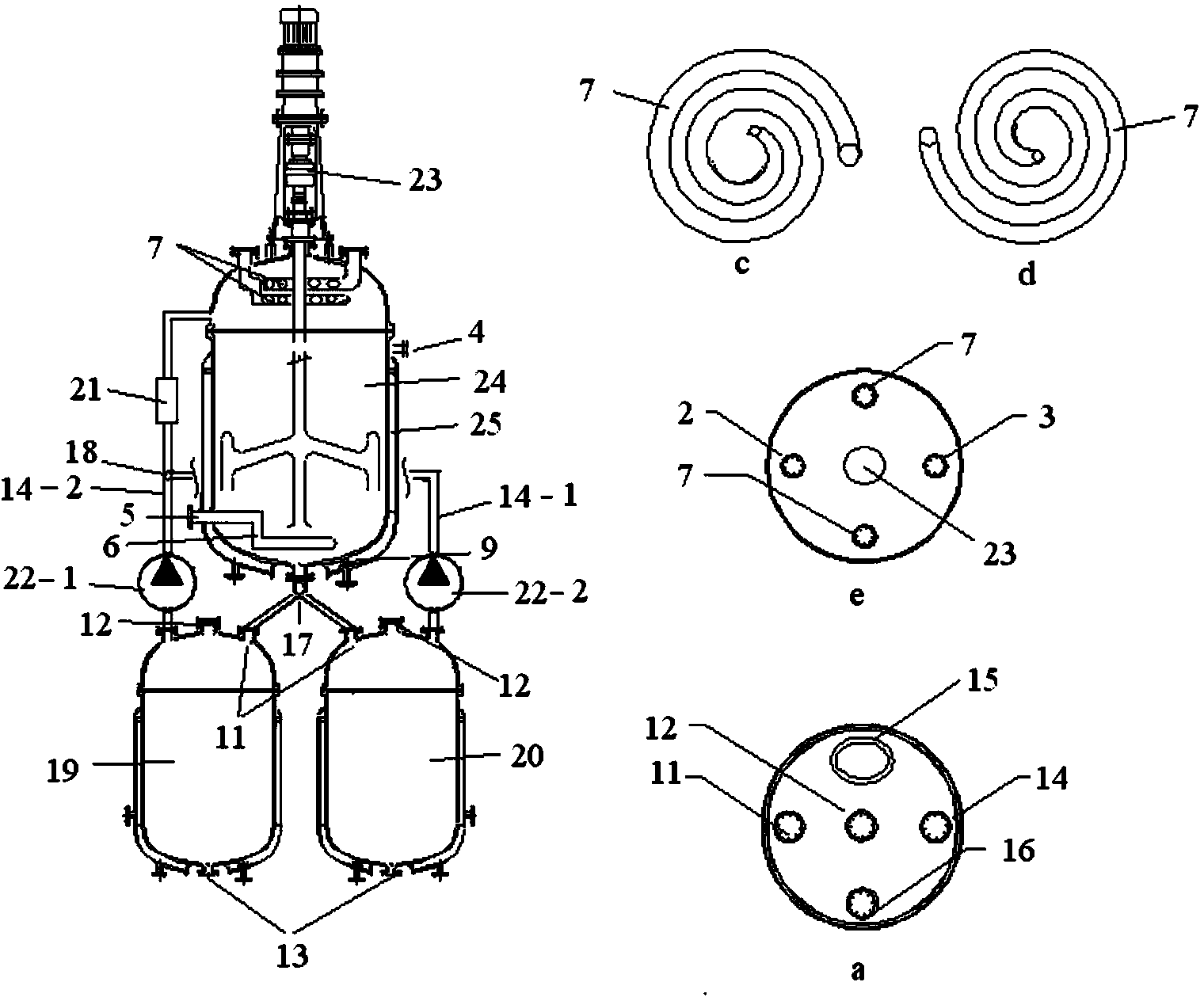

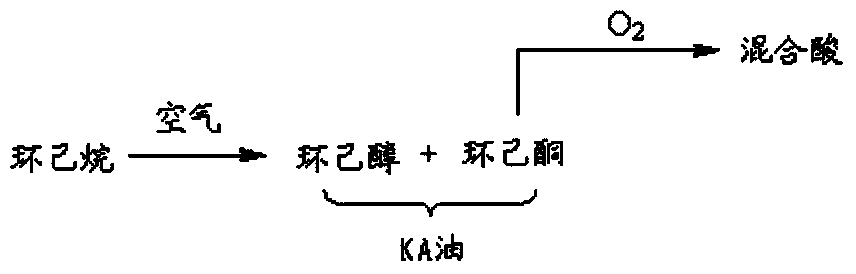

Method for producing KA oil through oxidizing cyclohexane by using air on basis of gas-liquid-solid heterogeneous reaction separation synchronization reactor

ActiveCN103755521AHigh yieldReduce the effect of settling velocityPreparation by oxidation reactionsOrganic compound preparationGas phaseOil phase

The invention discloses a method for producing KA oil through oxidizing cyclohexane by using air on the basis of a gas-liquid-solid heterogeneous reaction separation synchronization reactor, wherein the water-containing cyclohexane is added into the reactor, the reactor comprises a reaction tower and at least two constant temperature settlement towers communicated with the bottom of the reaction tower, and the reaction tower is internally provided with a gas phase area, an oxidization area and a gas outlet; the oxidization area and the constant temperature settlement towers are filled with the cyclohexane in the reaction, the air is introduced continuously from the bottom of the oxidization area and is in contact with the cyclohexane to carry out the oxidization reaction, meanwhile, the produced KA oil is blended with water to form a KA oil phase, the KA oil phase is settled into the constant temperature settlement tower, the cyclohexane in the constant temperature settlement tower at the moment enters the oxidization area through an external circulation system, so that the reaction is conducted continuously, the KA oil phase continues to settle in the constant temperature settlement tower until the constant temperature settlement tower is fully filled the KA oil phase, then the reaction tower is switched to be communicated with the other constant temperature settlement tower filled with the cyclohexane, the operation is conducted on the constant temperature settlement towers alternatively to continuously produce the KA oil. The method is used to continuously produce the KA oil with high percent of conversion and high selectivity, the production efficiency is improved, and the production cost is lowered.

Owner:新疆普禾粟新型环保材料有限公司

Bitter herb juice extracting device

The invention relates to the technical field of extracting devices, in particular to a bitter herb juice extracting device which comprises transmission shafts. The transmission shafts penetrate through a rolling shaft, a guide hole is formed in each transmission shaft, one end of each transmission shaft is blocked through a sealing door, and the other ends of the transmission shafts penetrate through the side wall of a box and are communicated with a guide pipe through rotary joints. The other end of the guide pipe is connected into the top of a juice storage device, the top end of the juice storage device is communicated with a gas producing device through a guide pipe, and a switching valve is arranged at the bottom of the juice storage device. One transmission shaft is connected with an output shaft of a gear motor through a belt, and the gear motor is fixed to the ground through a motor base. According to the device, juice of bitter herb can be extracted on a large scale, liquid and residues are separated in time, a blocked through hole can be dredged easily, and juice extraction is greatly convenient.

Owner:徐亮

Method and device for producing methane gas and lignin from straws

InactiveCN104818298AImprove enzymatic hydrolysis efficiencyReduce inhibitionApparatus sterilizationGas production bioreactorsFiltrationHydrolysate

The invention discloses a method and device for producing methane gas and lignin from straws. The method comprises the following steps of removing impurities of straws, crushing the straws into straw powder, feeding the straw powder into a hydrolysis device, controlling a hydrolysis degree until all hemicelluloses is hydrolyzed and 20-100% of cellulose is hydrolyzed, feeding an upper hydrolysate into an anaerobic fermentation pool, carrying out fermentation to obtain crude methane gas, discharging lower lignin slurry, and carrying out filtration and drying to obtain lignin powder. Straw hydrolase comprises excision beta glucanase, incision beta glucanase, beta glucosidase and xylanase according to a mass ratio of 1: 1.2-10: 0.8-5: 1.5-8. The culture contains an inducer activator, and in use, the culture is added with a starter. The method and device used by the method fully utilize straws, produce methane gas and lignin, adjust a straw hydrolysis degree, produce marketable products and are suitable for different raw materials.

Owner:CATECH TECH

Integrated inspection bench for control system

InactiveCN111112126AAvoid blind spotsImprove inspection efficiencyMaterial analysis by optical meansSortingMotor driveControl system

The invention discloses an integrated inspection bench for a control system. The integrated inspection bench for the control system comprises an inspection bench body; two sides of the inspection bench body are respectively and rotatably connected with a driving roller and a driven roller; the driving roller is in transmission connection with the driven roller through a conveying belt; a second motor is mounted on the front surface of the inspection bench body; and an output shaft of the second motor is in transmission connection with the driving roller. When the integrated inspection bench for the control system performs inspection, a system integration is placed at the right end of the conveying belt, at the moment, the conveying belt drives the system integration to move to the positionbelow a supporting seat, and at the moment, a first motor drives a camera to rotate through the bracket; four side surfaces of the system integration are photographed after the camera surrounds the system integration for a circle; images are displayed through a display screen, so that a blind area is avoided; meanwhile, the inspection efficiency is improved; at the moment, the system integrationis pushed to the supporting plate by an air cylinder through a pushing plate, so that unqualified products are separated from qualified products; and the qualified products are conveyed to the left side through the conveying belt.

Owner:XIAN HUIFU RONGTONG INFORMATION TECH CO LTD

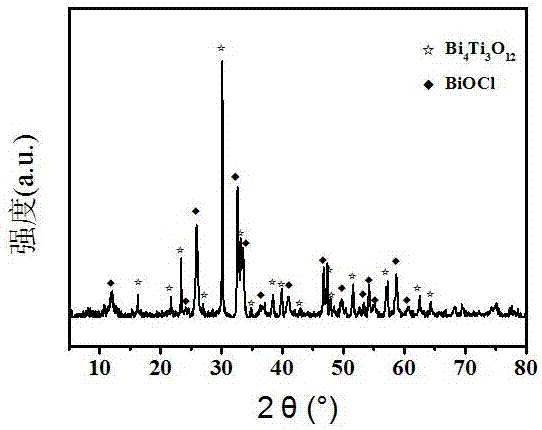

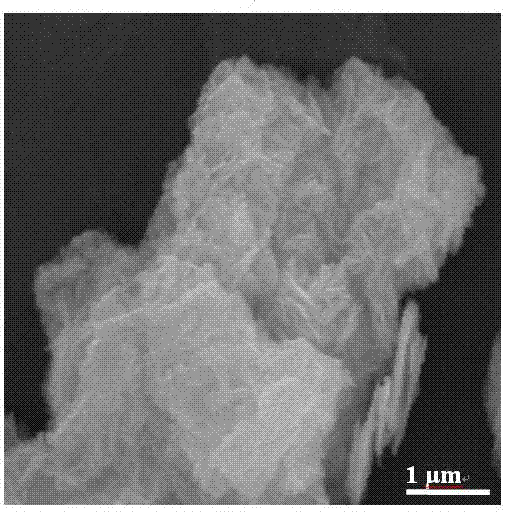

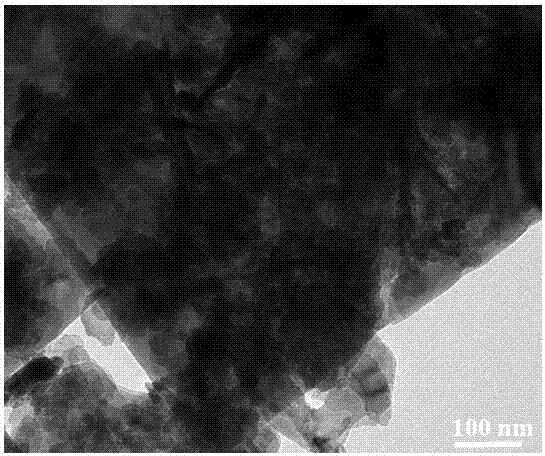

Bismuth titanate nanosheet/bismuth oxide chloride nanosheet composite photocatalyst in three-dimensional structure and preparation method of composite photocatalyst

InactiveCN107008473AEasy to operateReaction conditions are easy to controlPhysical/chemical process catalystsWater/sewage treatment by irradiationMolten saltPhotocatalytic degradation

The invention belongs to the technical field of photocatalysis and relates to a bismuth titanate nanosheet / bismuth oxide chloride nanosheet composite photocatalyst in a three-dimensional structure and a preparation method of the composite photocatalyst. The bismuth titanate nanosheet / bismuth oxide chloride nanosheet composite photocatalyst in the three-dimensional structure is prepared by preparing a bismuth titanate nanosheet by a molten salt method and vertically growing a bismuth oxide chloride nanosheet on the surface of the bismuth titanate nanosheet by taking bismuth nitrate and sodium chloride as raw materials by a hydrothermal method. A dye photocatalytic degradation experimental proves that the prepared three-dimensional composite photocatalyst has very good photocatalytic activity, and the performance of the composite photocatalyst is much better than that of the single bismuth titanate nanosheet and the single bismuth oxide chloride nanosheet; a reaction condition is easy to control; a technology and a flow are simple and convenient; the energy consumption is low; large-scale production is easy to realized; and the composite photocatalyst and the method have good economic and environmental beneficial effects.

Owner:JIANGSU UNIV

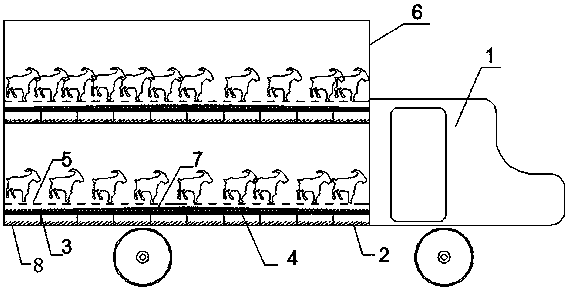

Environment-friendly livestock transport device

InactiveCN107856596AImprove hygiene and cleanlinessInhibitory activityAnimal housingAnimal transportationFecesSewage

The invention relates to an environment-friendly livestock transport device and belongs to the technical field of animal husbandry engineering equipment. A sewage tank is arranged at the bottom in a compartment of a transport wagon, a sewage damper is arranged in the sewage tank, a geotextile layer is paved on the sewage damper, and slatted floors are arranged above the geotextile layer. When livestock moves on the slatted floors, urine or sewage leaks into the sewage tank through the geotextile layer, and excrement or other solid waste is intercepted on the geotextile layer to realize timelyseparation of excrement and urine so as to effectively prevent the livestock from moving on the excrement and urine, so that the pollution is reduced, and the sanitation and cleanliness of the transport vehicle are improved; and the vibration of the sewage entering the sewage tank is relieved under the action of the sewage damper so as to avoid overflow pollution to the compartment and pavements.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

Lung protecting membrane for cardiothoracic surgery

InactiveCN105596086AEasy to installEasy to disassembleElectrotherapyDiagnosticsPhysical therapyCardiothoracic surgery

The invention discloses a lung protecting membrane for a cardiothoracic surgery. The lung protecting membrane comprises a shell and a lung protecting layer; the shell is of a hollow structure, the two side faces of the shell are each provided with a fastening belt, and the tail ends of the two fastening belts are provided with hook and loop fasteners which are used in a matched mode; the lung protecting layer is sequentially provided with an installing layer, a physical therapy layer and a gauze layer, the installing layer is connected with the shell through buckle heads and buckle holes which are arranged at the two ends of the surface and fixedly connected with the physical therapy layer, and the physical therapy layer and the gauze layer are connected through a zipper on the side. According to the lung protecting membrane for the cardiothoracic surgery, the lung protecting layer is connected with the shell through the buckle heads and the buckle holes, therefore, the lung protecting layer is convenient to assemble, disassemble and replace for a patient in time, and use is convenient; the shell is fastened on the body of the patient through the hook and loop fasteners and the fastening belts, so that use is convenient; the physical therapy layer and the gauze layer are connected through the zipper, so that the physical therapy layer and the gauze layer are convenient to separate; an electric heating wire and magnetic therapy blocks are arranged in the physical therapy layer, so that recovery of a patient is facilitated.

Owner:唐怀好

Ultra-fine cavitated target type water fluid jet grind

InactiveCN101367060AImprove energy utilizationEasy particle size controlGrain treatmentsCavitationGranularity

The invention relates to a solid material crushing device, in particular to a superfine cavitation target type water-jet mill which is characterized by comprising a hopper, a cavity of the mill, a granularity regulating plate, a jet mixing accelerating part, an impact regulating target body and a stand, wherein the hopper is fixed on the upper end of the cavity of the mill and is communicated with an injection cavity of the cavity of the mill; the bottom of the cavity of the mill is fixed on the stand; a diffusion mixing pipe of the jet mixing accelerating part is fixed in a cavity of a diffusion mixing pipe positioning seat in the cavity of the mill; a nozzle mouth of a cavitation nozzle is positioned in an input port of a diffusion mixing pore channel; the impact regulating target body is positioned on the left of an output port of the diffusion mixing pipe of the jet mixing accelerating part; the granularity regulating plate is arranged on the position of an output end of a gradually varied channel with an arc section and a grading discharge hole in the cavity of the mill; and the grading discharge hole of the cavity of the mill is communicated with the output end of the gradually varied channel. The superfine cavitation target type water-jet mill has the characteristics of high utilization rate of crushing energy and easy regulation of granularity.

Owner:WUHAN UNIV OF TECH

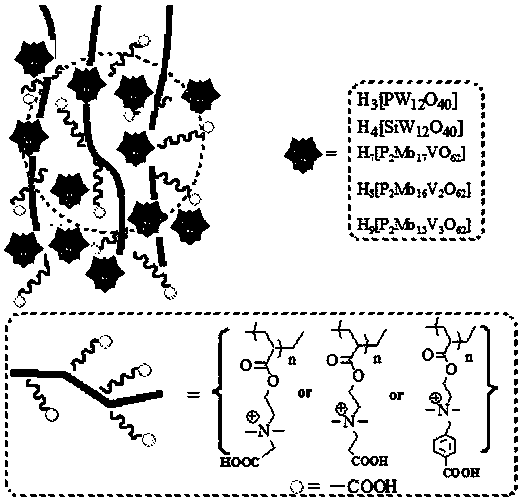

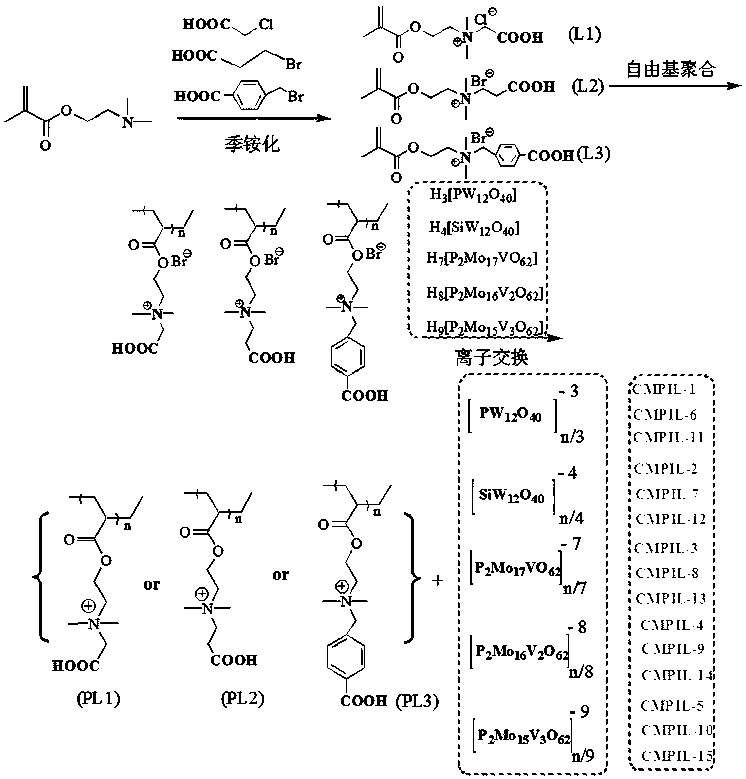

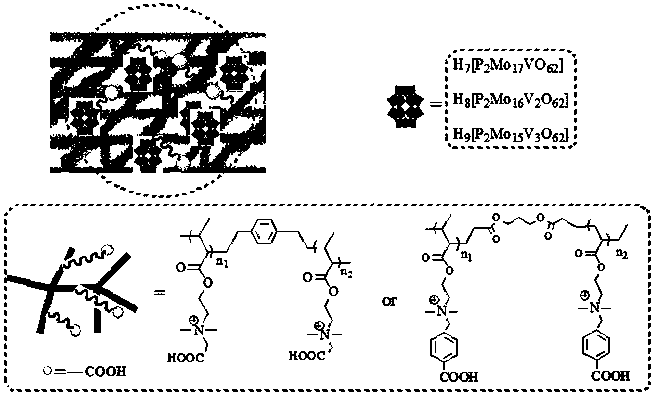

Carboxyl functionalized porous heteropoly acid polyionic liquid and use thereof

ActiveCN109289919AFacilitate the reaction between two phasesSeparation in timeOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsCross-linkVanadium doping

The invention discloses a carboxyl functionalized porous heteropoly acid polyionic liquid and a use thereof. A carboxyl functionalized polyquaternary ammonium salt with a long chain linear structure and a heteropoly acid as building units are self-assembled into a three-dimensional network porous structure under electrostatic interaction so that the polyionic liquid is obtained, or a carboxyl functionalized polyquaternary ammonium with a long chain cross-linked structure and a Dawson-type vanadium-doped heteropoly acid as building units are self-assembled into a three-dimensional network porous structure under electrostatic interaction. The carboxyl functionalized porous heteropoly acid polyionic liquid can be used as a heterogeneous catalyst. Industrial grade hydrogen peroxide is used asan oxidant. A cyclic ketone compound undergoes Baeyer-Villiger oxidation to produce a corresponding cyclic lactone under the solventless condition. The catalytic system has a novel structure, is usedfor a Baeyer-Villiger oxidation reaction, and has the characteristics of good selectivity, mild reaction condition, large operation flexibility and convenient recycling of the catalytic system.

Owner:MINJIANG UNIV

Novel internal structure of reactor and design method and application of novel internal structure

PendingCN107790073ASpeed up the mixingIncrease the degree of mixingLiquid hydrocarbon mixture productionHydrocarbon oil crackingEngineeringCirculating pump

The invention relates to a novel internal structure of a reactor and a design method and application of the novel internal structure. The internal structure comprises a reactor barrel, a feeding opening, a discharging opening, a circulating bubble cap, a flow guiding tube and a circulating pump, wherein the feeding opening is positioned in the lower part of the barrel; the discharging opening is positioned in the top of the barrel; the circulating bubble cap comprises a hollow cylindrical cup cap on the upper part, a hollow truncated cone shaped cup cap on the lower part and a plurality of bubble cap rising tubes; the top of the cylindrical cup cap is open and is positioned below the discharging opening; the diameter of the bottom surface of the truncated cone shaped cup cap is smaller than the diameter of the top surface of the truncated cone shaped cup cap; the bottom surface of the truncated cone shaped cup cap is connected with the flow guiding tube; the bubble cap rising tubes areuniformly distributed in the periphery of the circulating bubble cap; the tops of the bubble cap rising tubes are higher than the upper plane of the cylindrical cup cap; the bottoms of the bubble caprising tubes are parallel and level to the truncated cone shaped cup cap; the lower end of the flow guiding tube leads to the bottom of the reactor barrel and communicates with the circulating pump which is positioned on the outside of the reactor barrel; the other end of the circulating pump leads to the feeding opening; and a ring gap between the flow guiding tube and the inner wall of the reactor barrel is far greater than a ring gap between the outer wall of the cylindrical cup cap and the inner wall of the reactor barrel and the inner diameters of the bubble cap rising tubes.

Owner:CATECH TECH

Separation process

ActiveUS7833499B2Separation in timeEasy to separateDewatering/demulsification with mechanical meansLiquid suspension thickening by filtrationFiberSulfur

A separation process for separating two or more immiscible liquids using fiber-film technology is disclosed. This separation process is especially useful in the separation of disulfide oil formed during the oxidation of spent caustic solution that was used to remove sulfur contaminates from light hydrocarbons.

Owner:MERICHEM CO

Material chemical processing grinding device

InactiveCN109718922AReduce the amount of particlesAvoid accumulationGrain treatmentsEngineeringLarge size

The invention discloses a material chemical processing grinding device and relates to the technical field of chemical material grinding. The material chemical processing grinding device comprises a supporting frame. The supporting frame is horizontally and fixedly provided with a fixing plate. The fixing plate is provided with a grinding head matched with a grinding groove. The bottom of the grinding groove is evenly provided with a plurality of material falling mesh holes. A material falling hopper is arranged under the grinding groove. The rotation direction of a rotating shaft is opposite to that of the grinding groove. The supporting frame is provided with a discharging hopper with a lower end opening located above the grinding groove. According to the material chemical processing grinding device, rotary grinding is carried out on chemical materials in the grinding groove through rotation of the grinding head, the grinding groove rotates during the grinding period, the rotation direction of the grinding groove is opposite to that of the grinding head, and the grinding speed of chemical material particles is greatly increased; and during the grinding period, particles in a certain size fall through the material falling mesh holes, timely separation of the particles in a certain size from material particles in a relatively large size is achieved, ,the number of the material particles in the grinding groove is gradually reduced, accumulation of the material particles is avoided, and the grinding effect is greatly improved.

Owner:HEFEI NORMAL UNIV

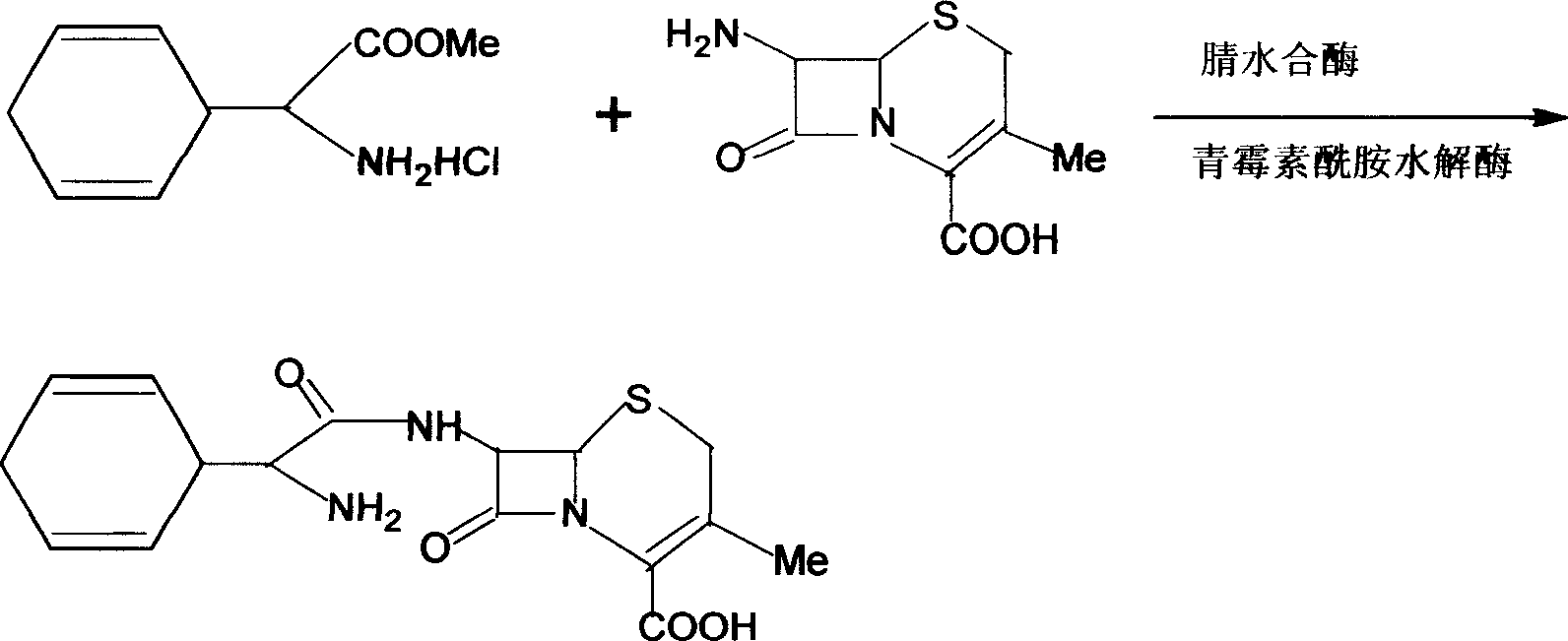

Cefradine preparing process

The present invention discloses cefradine preparing process. Under the catalysis of enzyme, 7-ADCA and methyl dihydrogen benzene glycinate are reacted in a double water phase system inside an enzyme catalyzed reactor to form cefradine. Cefradine is obtained through separating the upper phase and the lower phase and filtering, and the mother liquid is returned to the enzyme catalyzed reactor for circular reaction. The enzyme catalyzed cefradine synthesizing process has low solvent consumption, reduced environmental pollution, timely separation of the reaction product from side product and high reaction conversion rate.

Owner:ZHEJIANG ANGLIKANG PHARMA

Microcircuit module back side pre-soldering and pre-soldering heating device

The invention provides a microcircuit module back side pre-soldering method which comprises the steps of (A) making a tool: preparing an aluminum silicon plate, carrying out gold plating at the center area of the upper surface of the aluminum silicon plate, dividing the upper surface of the aluminum silicon plate into a plating area and a non-plating area, and making the tool, (B) carrying out tool and workpiece preheating: fixing the tool to a heating platform 1, starting the heating platform 1 to heat the tool to a preset temperature, placing a workpiece with the need of pre-soldering to a heating platform 2, and starting the heating platform 2 to carry out preheating of the workpiece, (C) adding a solder: placing the solder to the plating area of the tool and allowing the solder to melt, (D) tinning: moving the preheated workpiece to the plating area of the tool, wherein the back side of the took is in contact with the solder and rubs the plating area, and thus the solder is uniformly coated to the back side of the workpiece, and (E) examination: moving the workpiece to the non-plating area of the tool, checking whether the tinning of the back side of the workpiece is qualified or not, and repeating the step (D) if not until the tinning of the back side of the workpiece is qualified. The invention also provides a pre-soldering heating device.

Owner:ZHUZHOU TIANWEI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com