Rapid extraction equipment for plant coloring agent for textile

A technology for plant dyes and extraction equipment, which is applied in the field of rapid extraction equipment for plant dyes for textiles, can solve the problems of inability to timely remove liquid and plant residues, insufficiently uniform rolling, and low extraction efficiency, and achieve uniform rolling of plants, The effect of speeding up efficiency and speed of extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

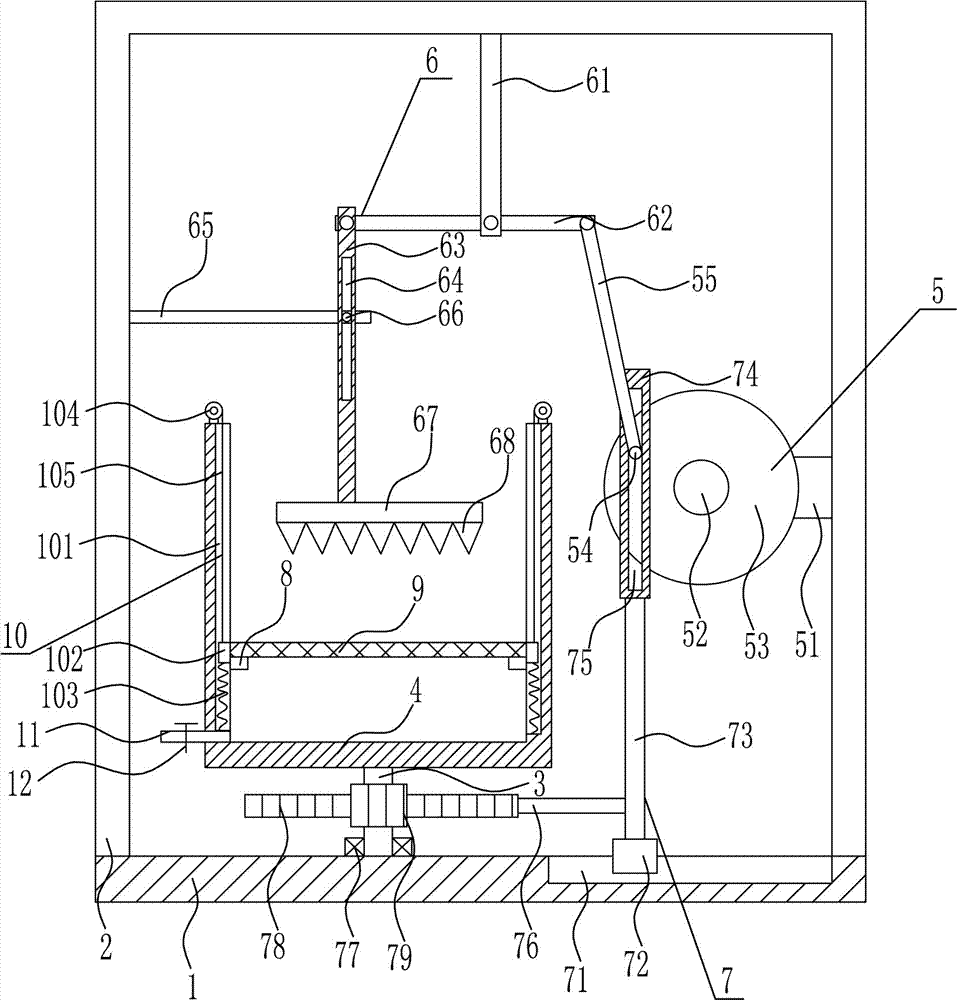

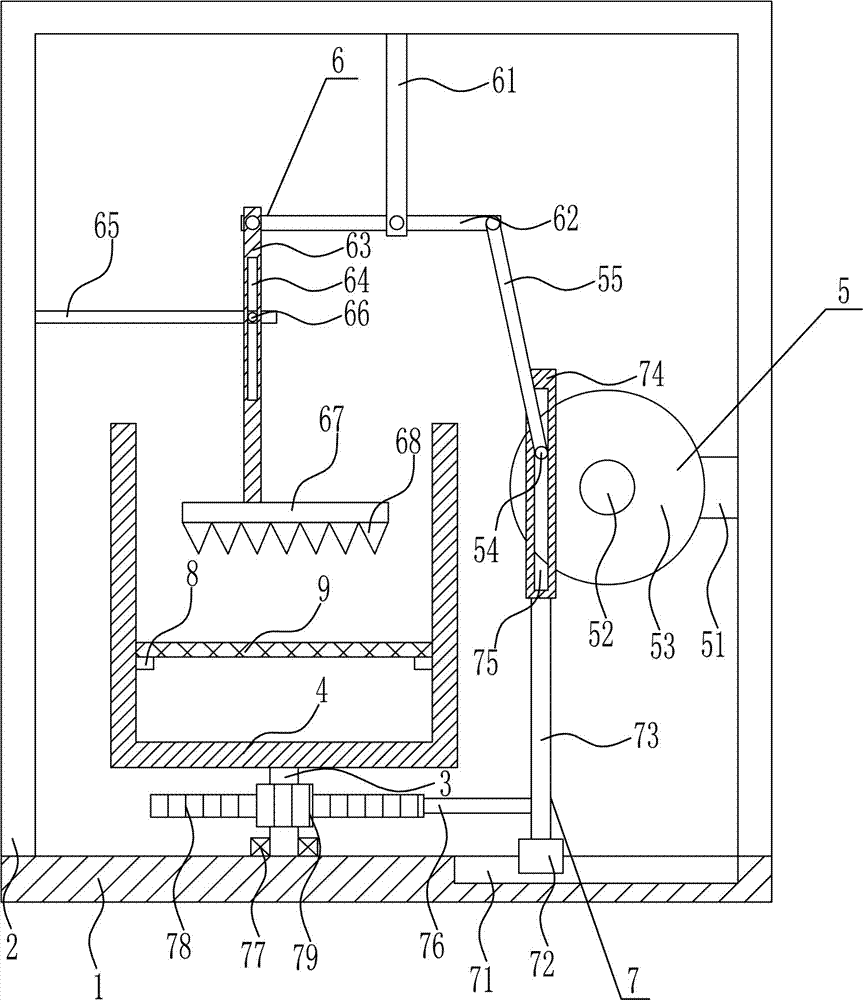

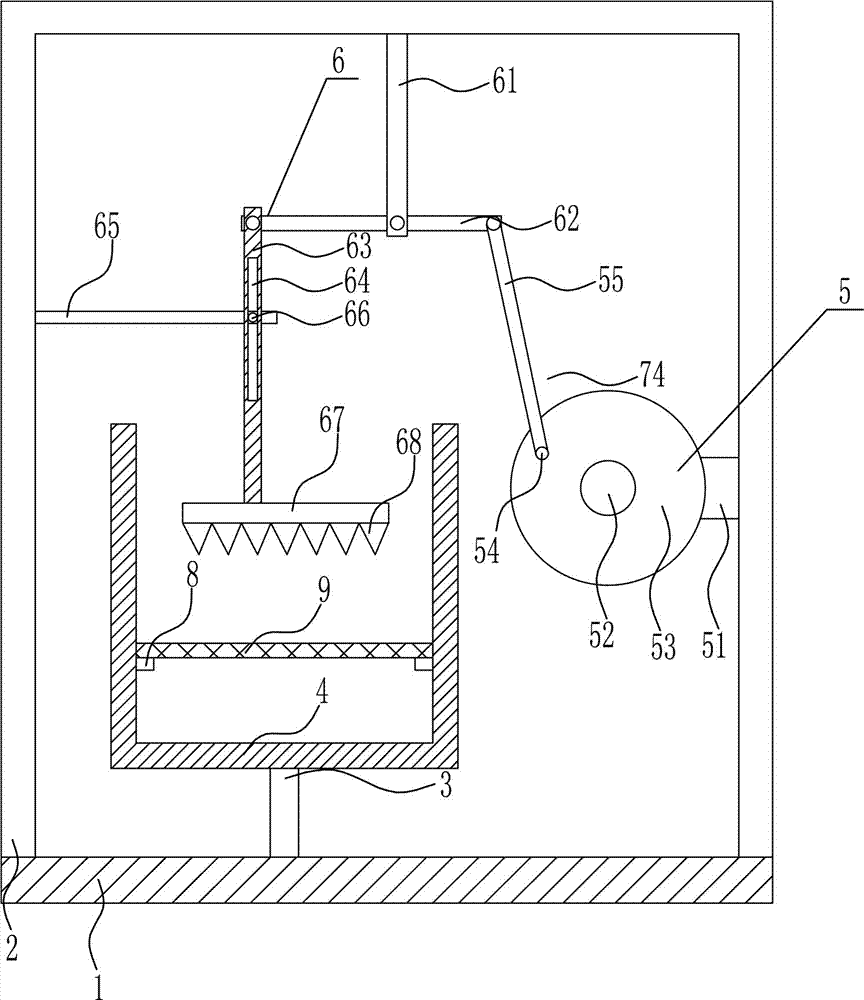

[0031] A rapid extraction equipment for plant dyes for textiles, such as Figure 1-4 As shown, it includes a bottom plate 1, an n-shaped frame 2, a first support rod 3, a box body 4, a driving mechanism 5, and a rolling mechanism 6. The top of the bottom plate 1 is provided with an n-shaped frame 2, and the right side of the n-shaped frame 2 is provided There is a driving mechanism 5, a rolling mechanism 6 is provided on the top of the n-shaped frame 2, a first support rod 3 is provided in the middle of the top of the bottom plate 1, and a box body 4 is connected to the top of the first support rod 3.

Embodiment 2

[0033] A rapid extraction equipment for plant dyes for textiles, such as Figure 1-4 As shown, it includes a bottom plate 1, an n-shaped frame 2, a first support rod 3, a box body 4, a driving mechanism 5, and a rolling mechanism 6. The top of the bottom plate 1 is provided with an n-shaped frame 2, and the right side of the n-shaped frame 2 is provided There is a driving mechanism 5, a rolling mechanism 6 is provided on the top of the n-shaped frame 2, a first supporting rod 3 is provided in the middle of the top of the bottom plate 1, and a box body 4 is connected to the top of the first supporting rod 3.

[0034] The driving mechanism 5 includes a second support rod 51, a motor 52, a disc 53, a first roller 54 and a connecting rod 55. A second support rod 51 is provided in the middle of the right side of the n-shaped frame 2, and the left end of the second support rod 51 A motor 52 is connected, the output shaft of the motor 52 is connected with raw materials, a first roller 5...

Embodiment 3

[0036] A rapid extraction equipment for plant dyes for textiles, such as Figure 1-4 As shown, it includes a bottom plate 1, an n-shaped frame 2, a first support rod 3, a box body 4, a driving mechanism 5, and a rolling mechanism 6. The top of the bottom plate 1 is provided with an n-shaped frame 2, and the right side of the n-shaped frame 2 is provided There is a driving mechanism 5, a rolling mechanism 6 is provided on the top of the n-shaped frame 2, a first supporting rod 3 is provided in the middle of the top of the bottom plate 1, and a box body 4 is connected to the top of the first supporting rod 3.

[0037] The driving mechanism 5 includes a second support rod 51, a motor 52, a disc 53, a first roller 54 and a connecting rod 55. A second support rod 51 is provided in the middle of the right side of the n-shaped frame 2, and the left end of the second support rod 51 A motor 52 is connected, the output shaft of the motor 52 is connected with raw materials, a first roller 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com