Patents

Literature

457results about How to "Smooth rolling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

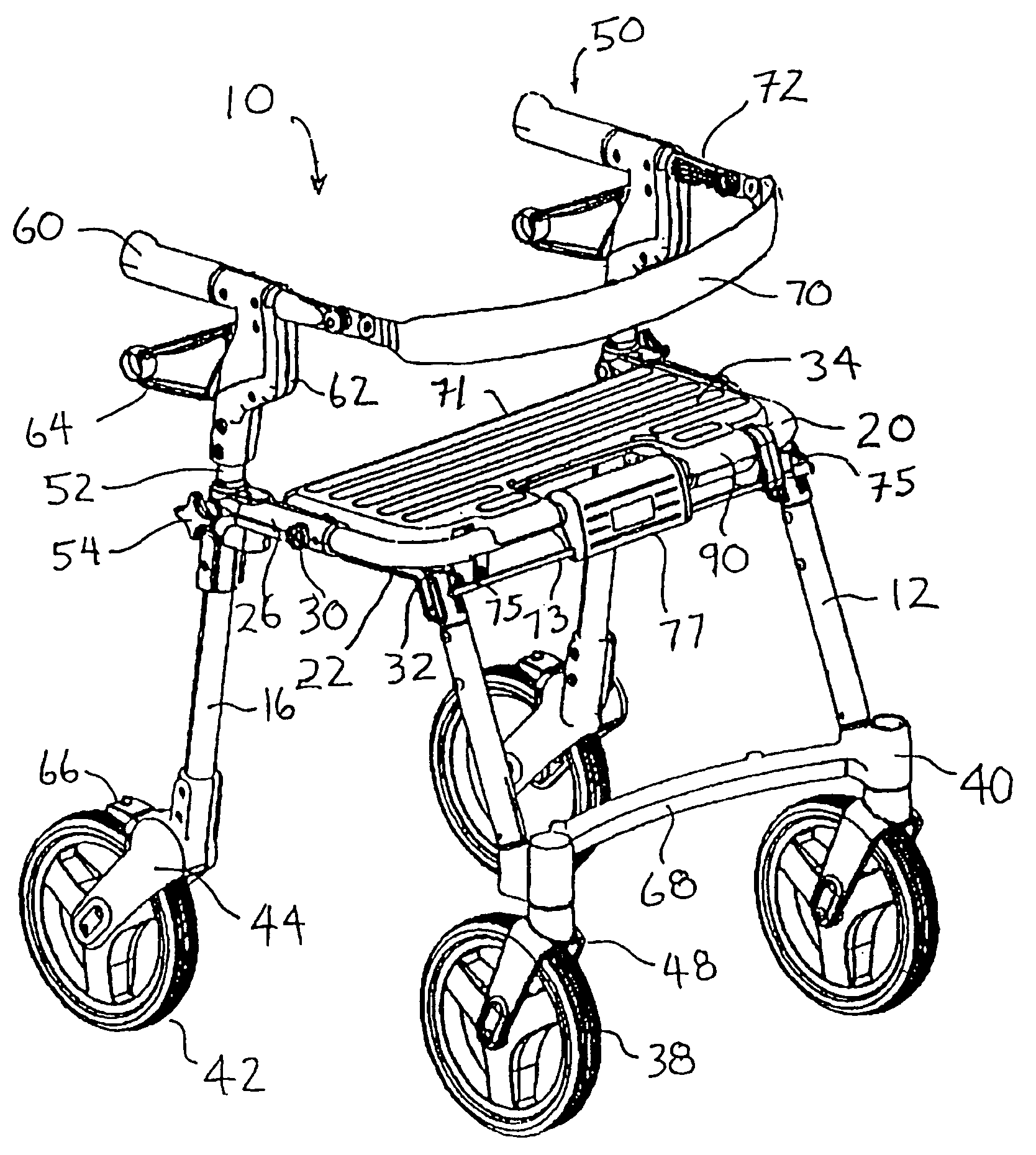

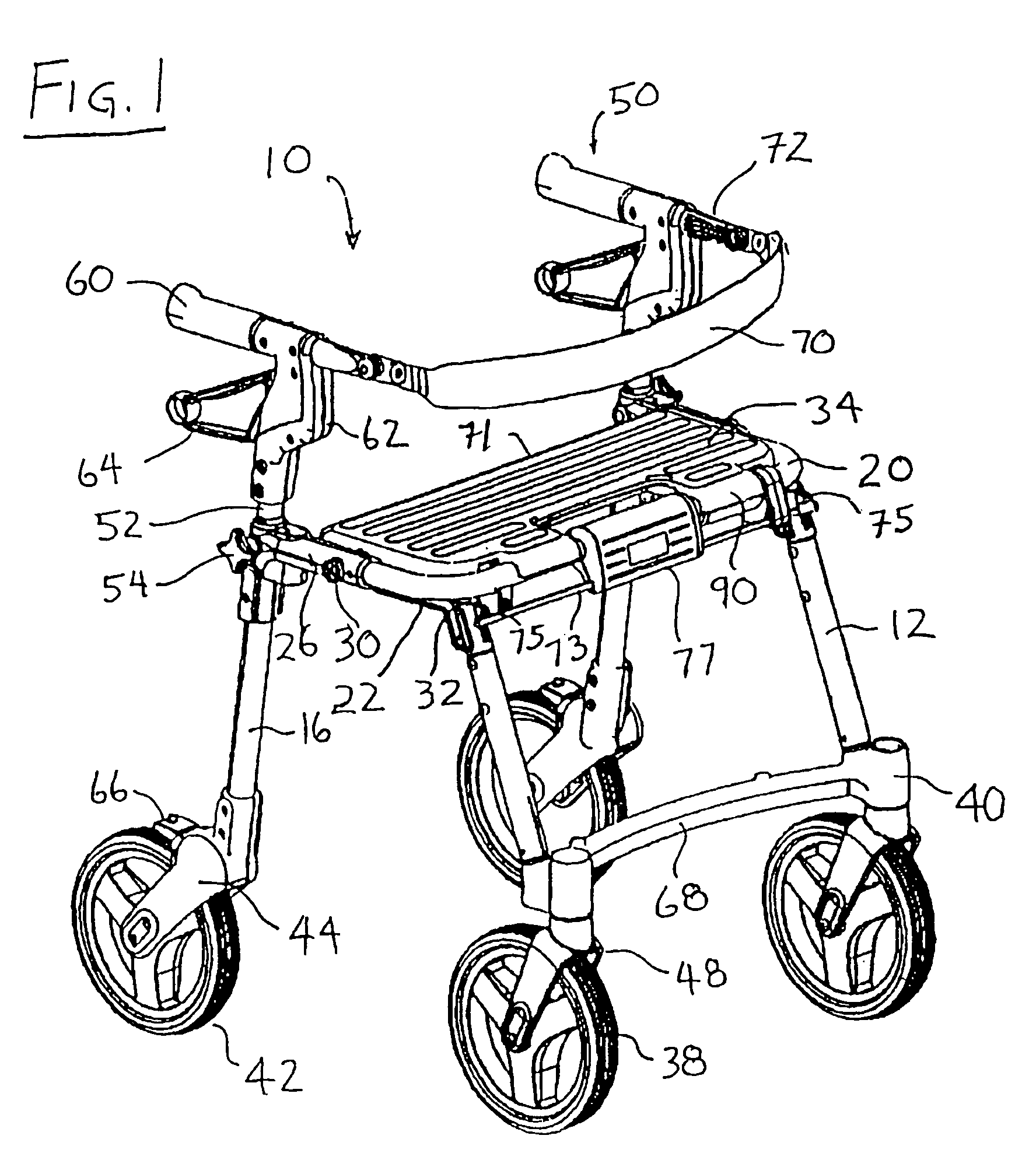

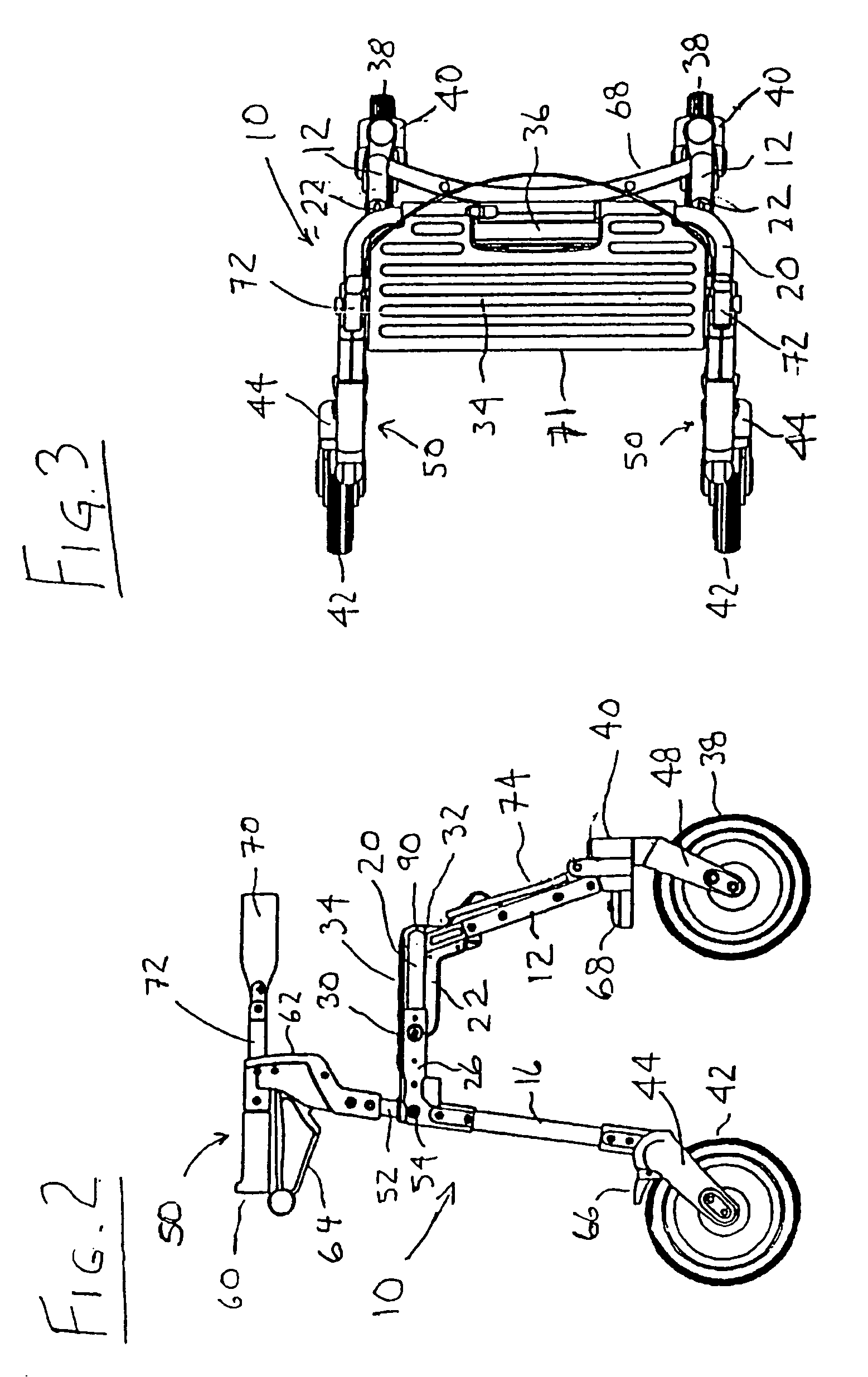

Height-adjustable cordless brake

InactiveUS7219906B2Avoid actionSmooth rollingBraking element arrangementsWheelchairs/patient conveyanceEngineeringAids walking

The present invention relates to a cordless braking system for a mobility-aiding device, such as a wheeled walker (a rollator) or a transport chair. The cordless braking system includes a brake actuating linkage, disposed inside the leg and handlebar members of the mobility-aiding device, which extends during height adjustment of the handlebars. The brake-actuating linkage and the leg / handlebar of the mobility-aiding device are designed to enable a locking pin or bolt to extend all the way therethrough to ensure that all of the height-adjustable members are secured together during use.

Owner:RANDOM PRODS TRUST +1

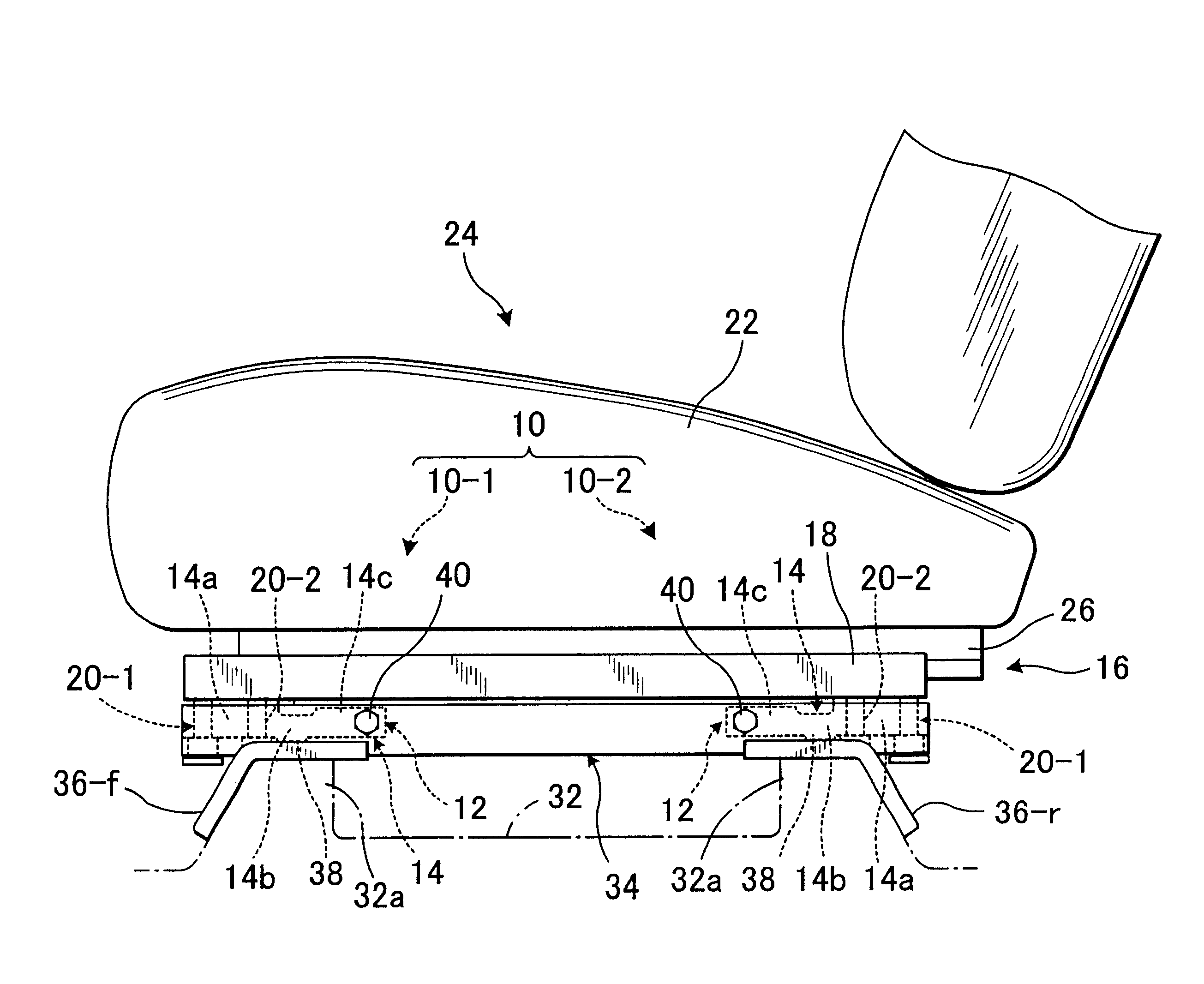

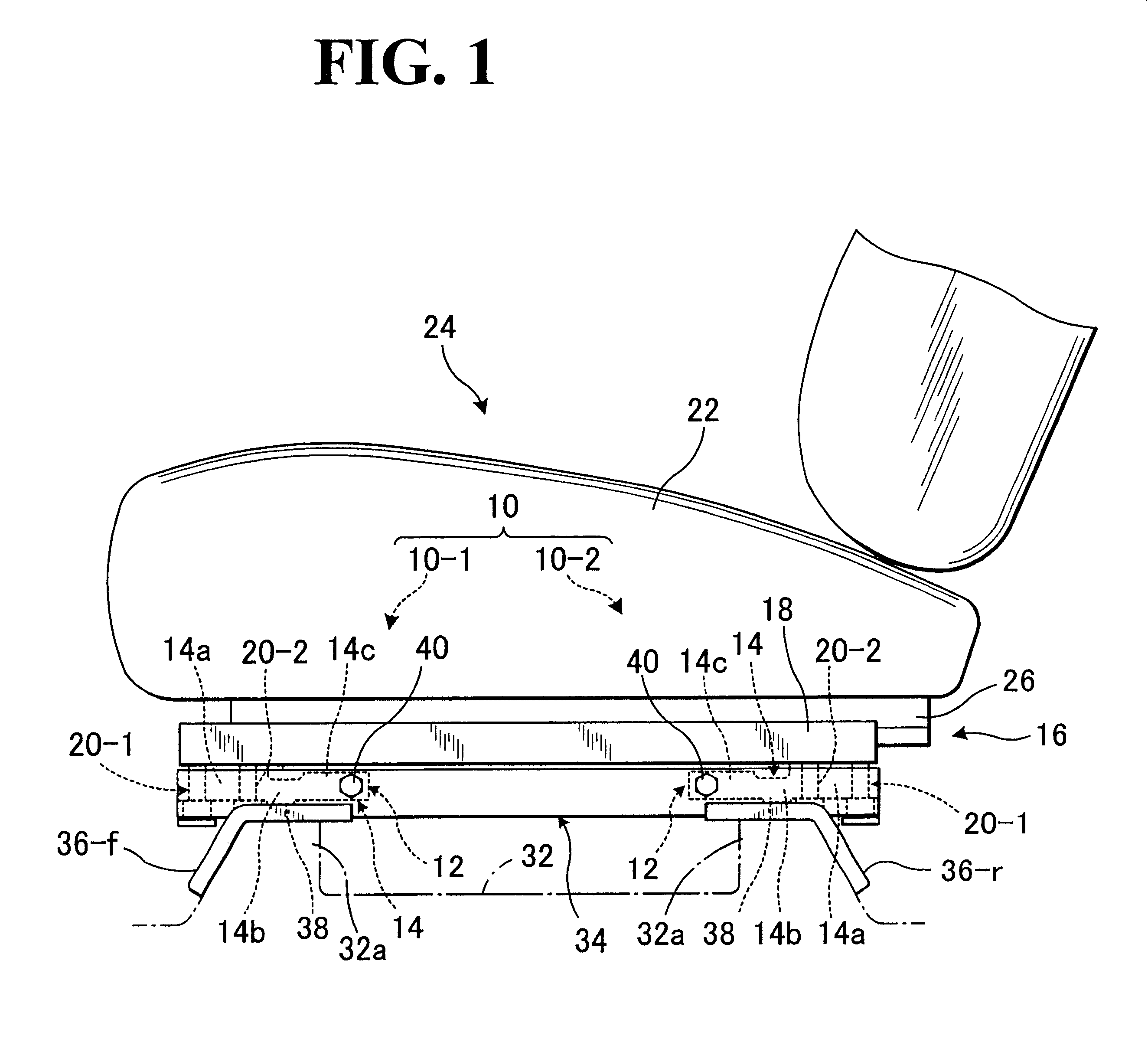

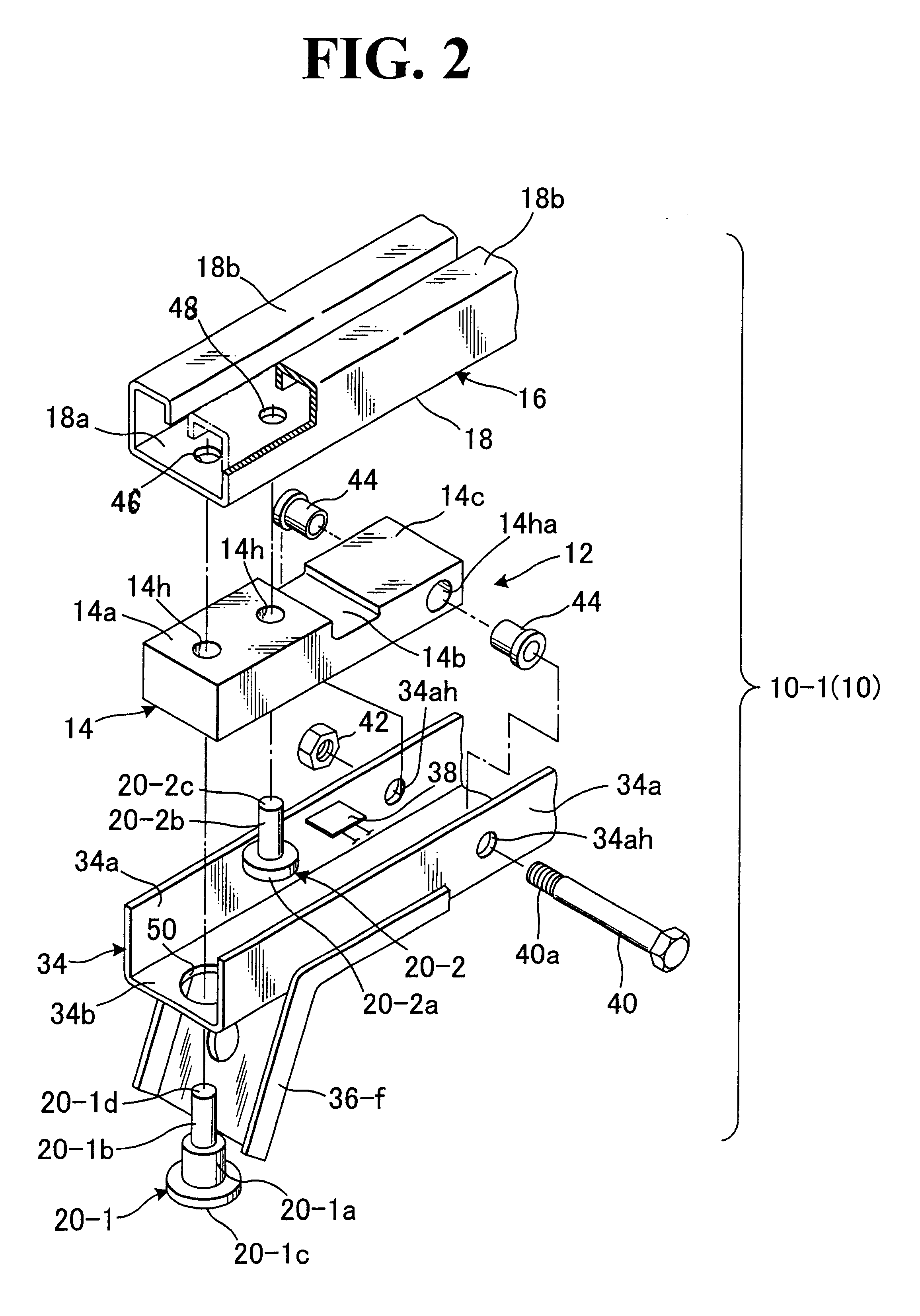

Structure for load detection element in vehicle seat

InactiveUS6695379B1Easy to moveSmooth rollingElectric devicesPedestrian/occupant safety arrangementIn vehicleEngineering

Structure for securing a load detection element under a vehicle seat in combination with a support leg element having a hole formed in one end portion thereof, wherein the load detection element is pivotally connected with the support leg element, while being fixedly secured by first and second securing pins to the vehicle seat. The first pin has an end riveted to a bottom side of the vehicle seat and an end portion extending through the hole of support leg element. Such another end portion has a head larger in diameter than that hole and is disposed outwardly under the support leg member, with one space given between the head and support leg member. The second pin has a end fused and fixed in the bottom side of vehicle seat and a head disposed beneath the load detection element, with another space given between the head and support leg member.

Owner:TACHI S CO LTD

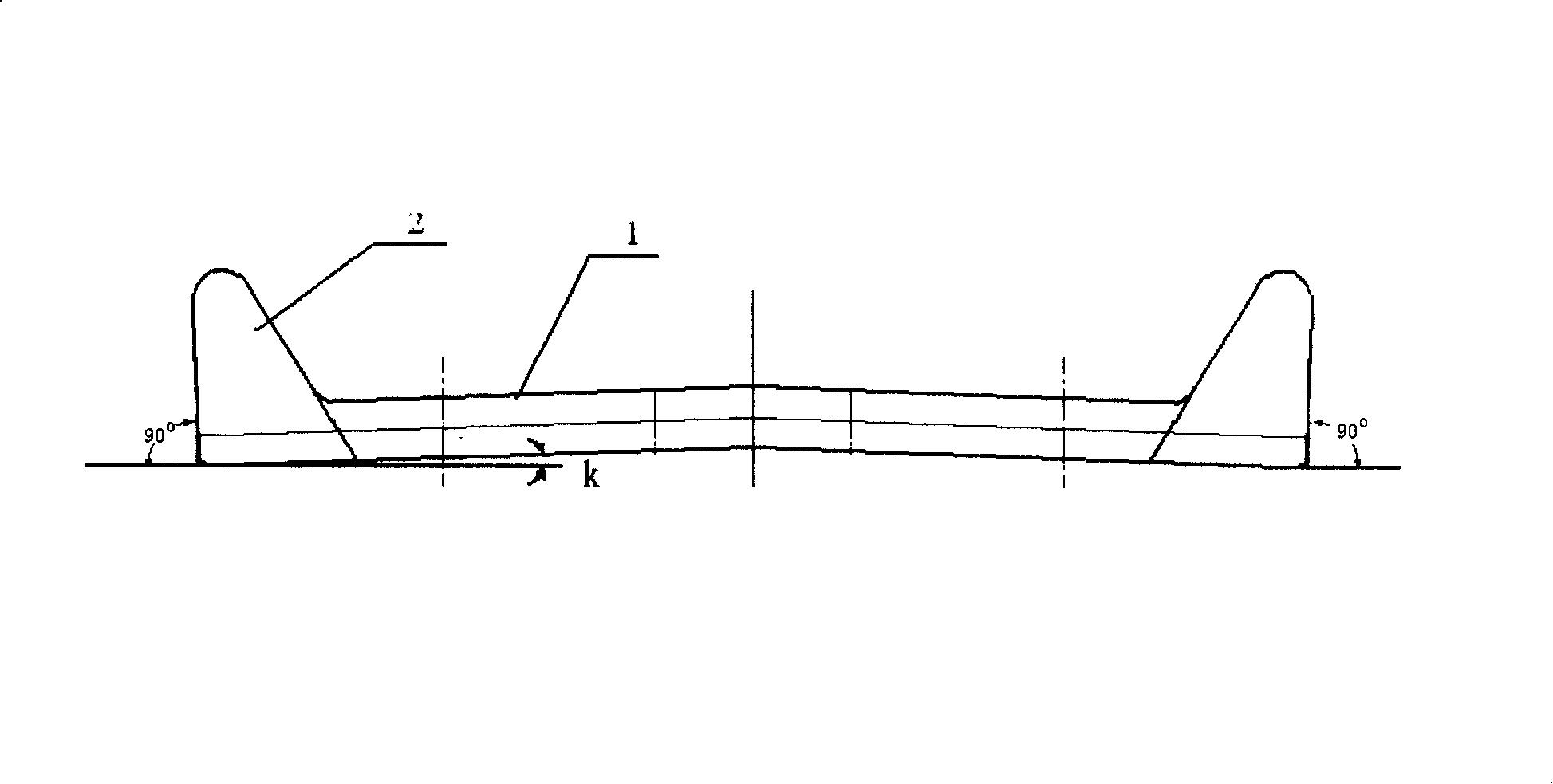

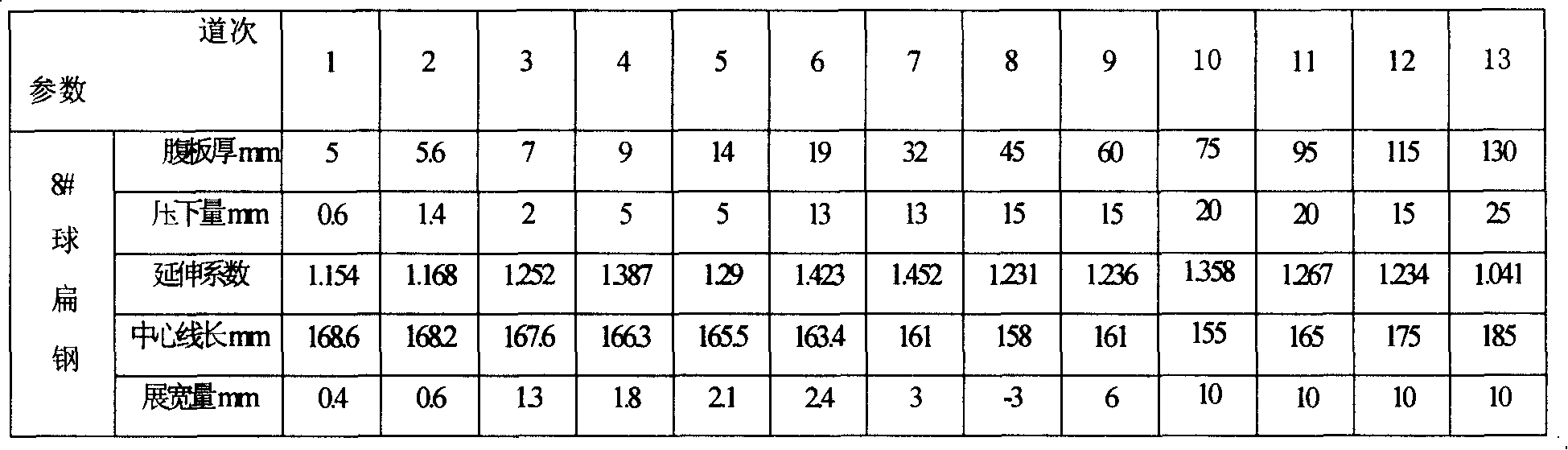

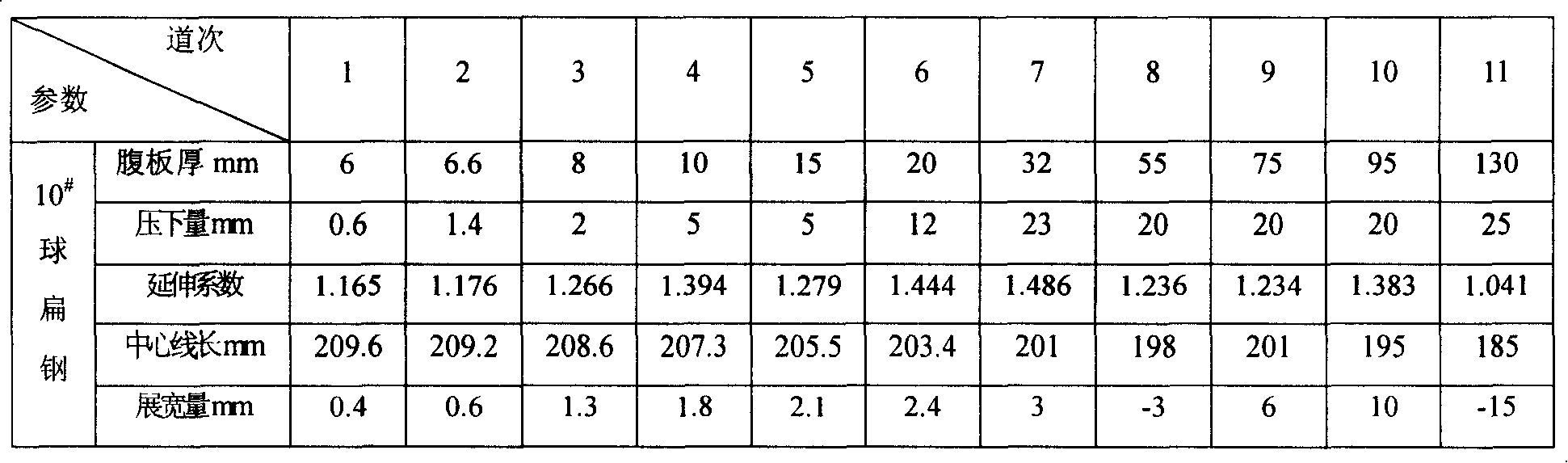

Bulb steel production technology

InactiveCN101190442ASmall fluctuations in section sizeSmall fluctuations in the size of the arcRollsMetal rolling arrangementsIron productionCompression ratio

The invention discloses a ball flat iron production technique, comprising steps of billet, heating, symmetrical rolling, straightening and dissection. The invention is characterized in that the dissection process is carried out after the processes of symmetric rolling and straightening; hole shapes in all the passages of a rolling mill are constituted by two ball flat iron hole shapes which are symmetrically identical. By adopting the technique of symmetric rolling, the invention solves the problems that existing large and medium rolling mills can not produce small ball flat irons with symmetrical rolling and dissection technology. The invention has the advantages of the small size fluctuation of profiles when producing, particularly the small size fluctuation of width, thickness, ball filling and the lower arc of the ball flat iron, rollers subject to uniform forces, easy control in rolling process, greatly reducing the scraping, the rolling mark and the waves of the product by 50% to 70%, improving the quality of the product, enlarging the types of rolled products, leading large profiled bar rolling mill to produce small ball flat iron, enlarging the profile of the billet, large corresponding compression ratio, improving the comprehensive performance of the products, etc.

Owner:ANGANG STEEL CO LTD

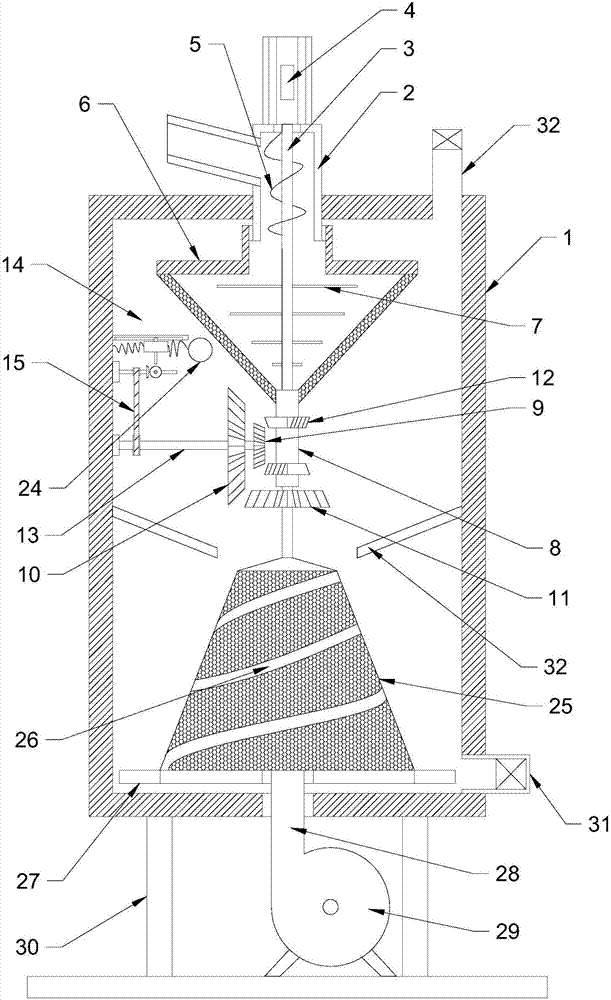

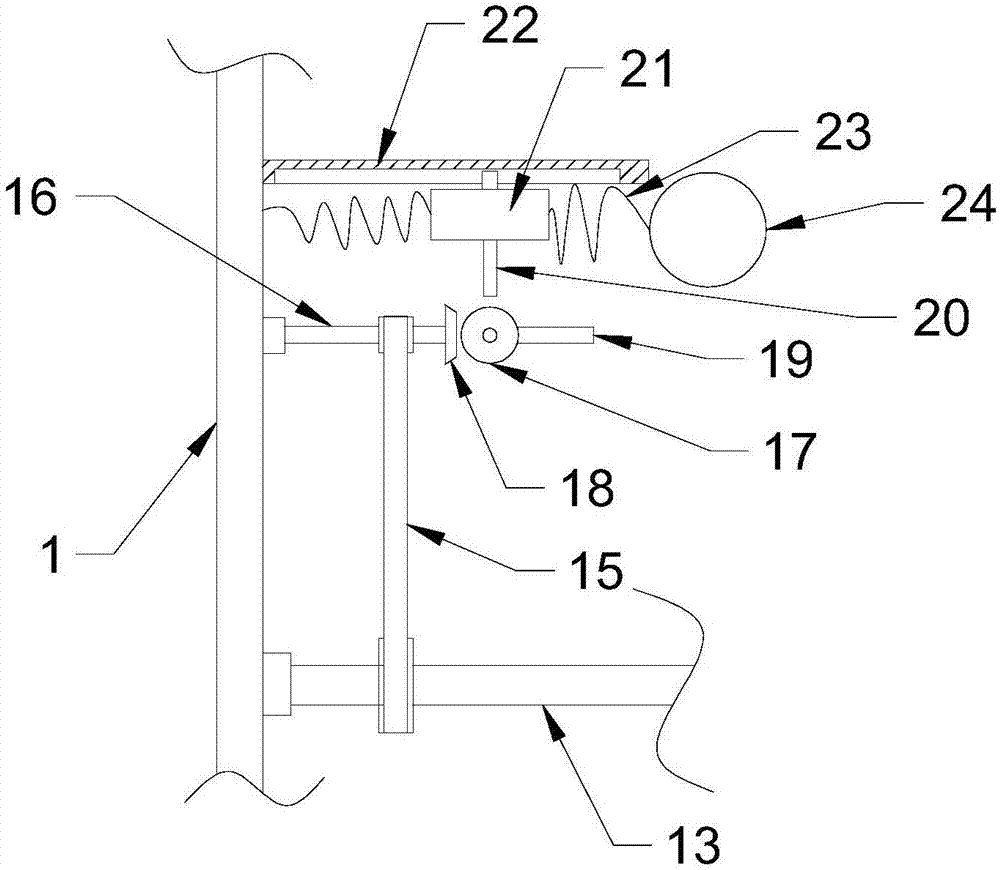

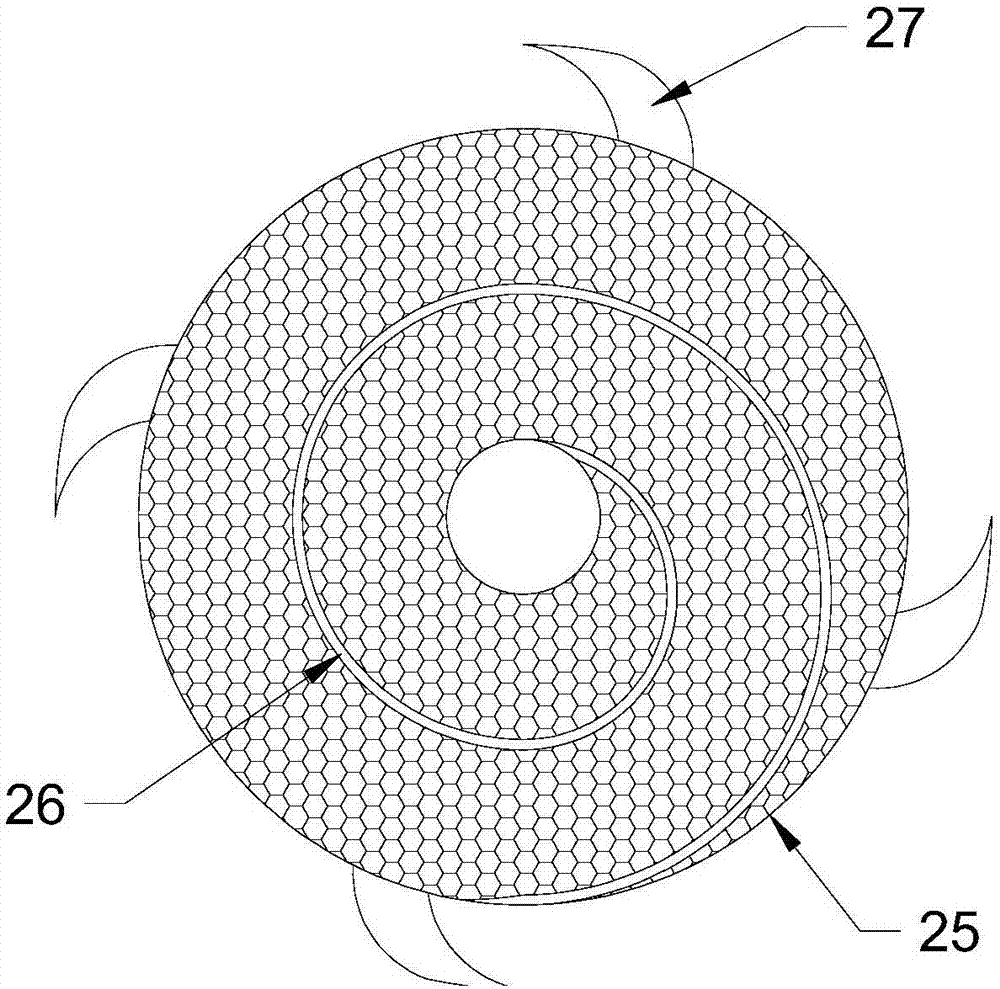

Rotary feed crushing and drying device

ActiveCN107952540ACrushed fullyFull and efficient screeningSievingFeeding-stuffDischarge efficiencyEngineering

The invention discloses a rotary feed crushing and drying device including a machine body; a crushing screen cylinder is arranged in the machine body, a knocking device is arranged on the left side ofthe crushing screen cylinder, and a drying conical cylinder is arranged below the crushing screen cylinder. According to the rotary feed crushing and drying device, a crushing knife and a crushing screen cylinder with a periodic square rotation are used to fully smash and screen feed, thereby improving the efficiency of smashing and screening. The knocking device linkaged with a rotary shaft canknock the outer wall of the crushing screen cylinder, and the clogging of screen holes and the feed residues can be avoided. The drying conical cylinder with a cone structure and an annular stock guide are used to enable the feed to roll down uniformly on the surface of a drying screen cylinder, the feed is evenly dried, a spiral raised line is provided to increase the falling time of the feed, and the drying effect is ensured. According to an arc-shaped feed discharging scraper and a feed discharging pipe which is in tangential communication with the machine body, the feed discharging efficiency is increased, so that the feed discharging is more thorough.

Owner:南宁扬翔农牧有限公司

Integrated infusion management system

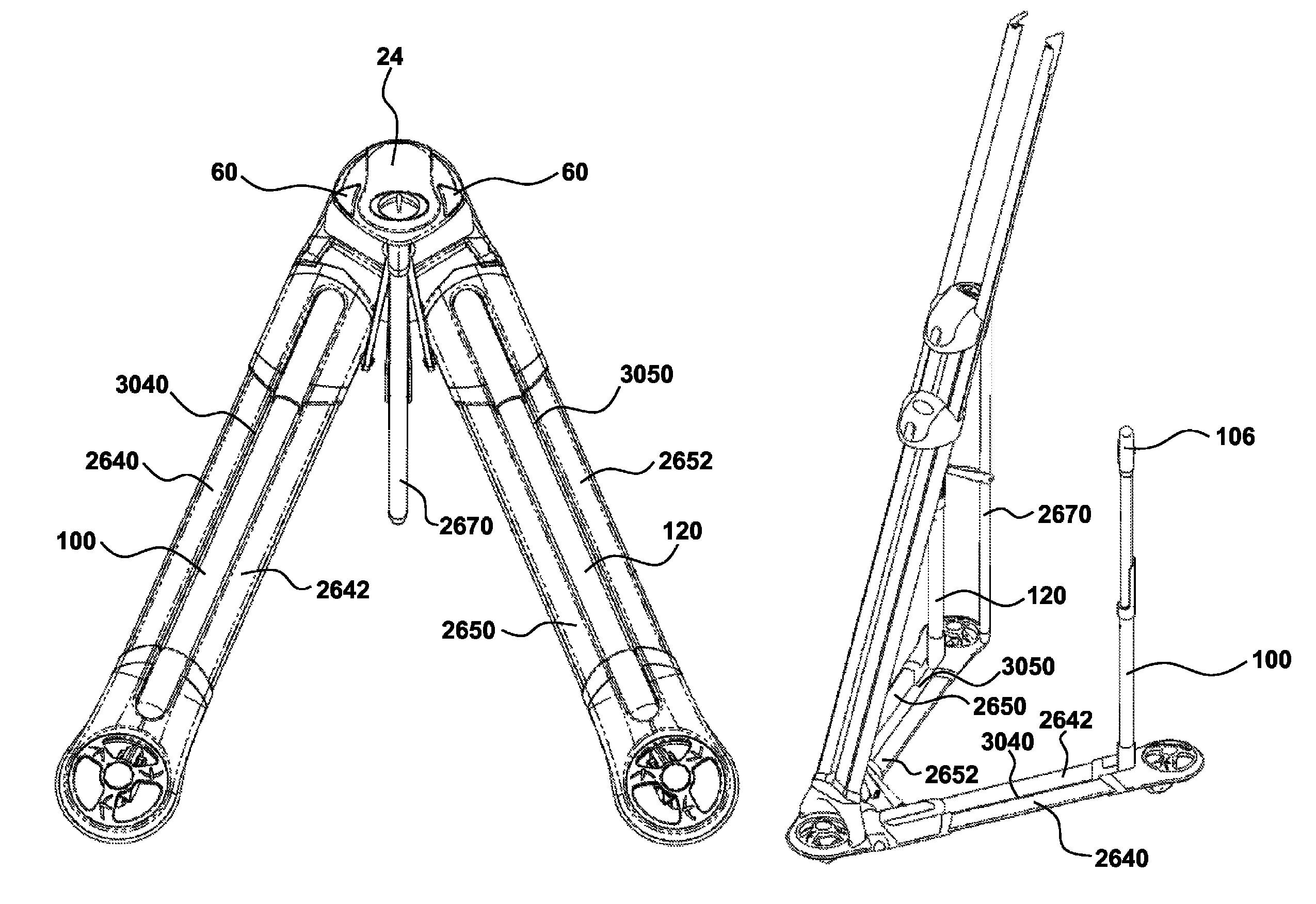

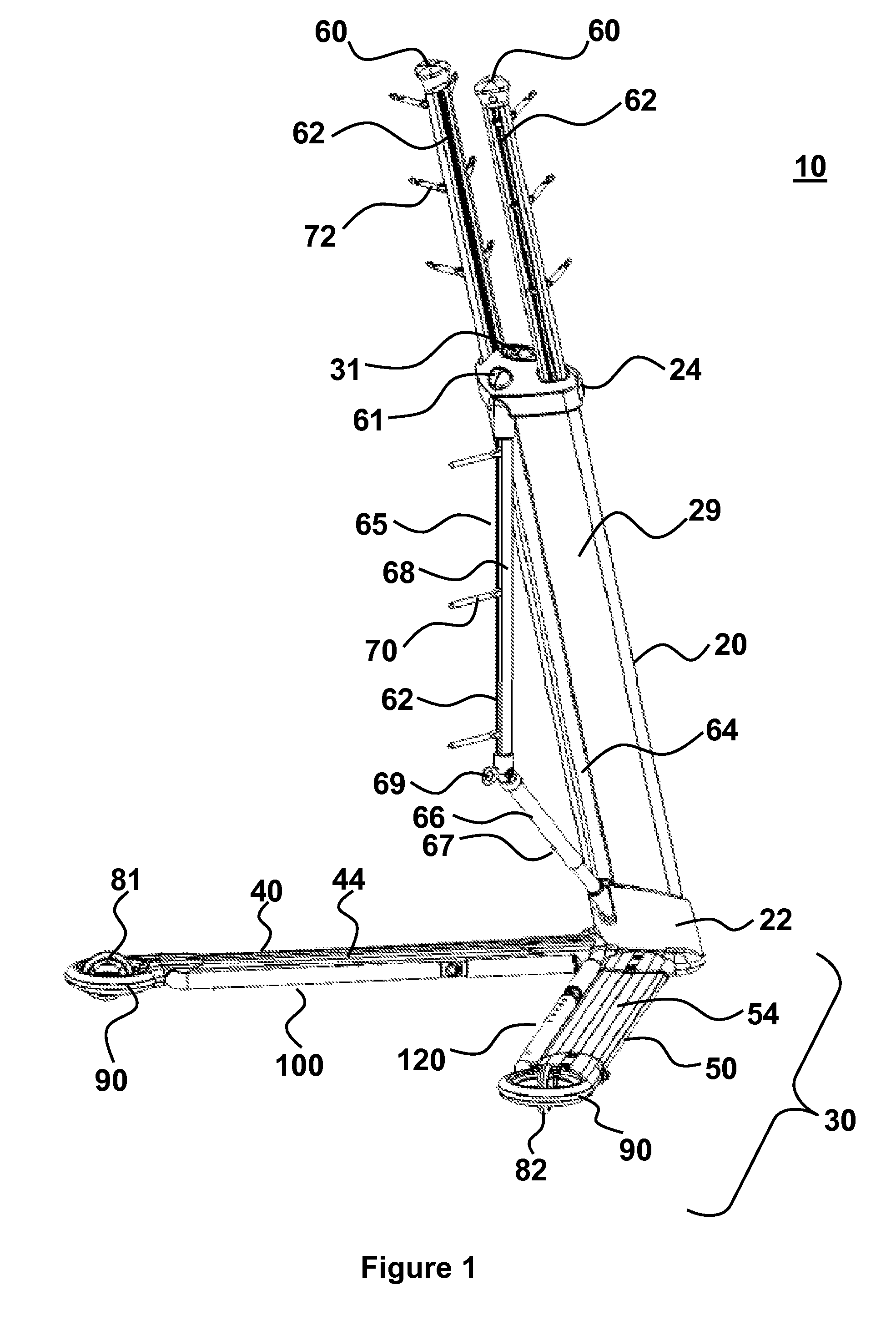

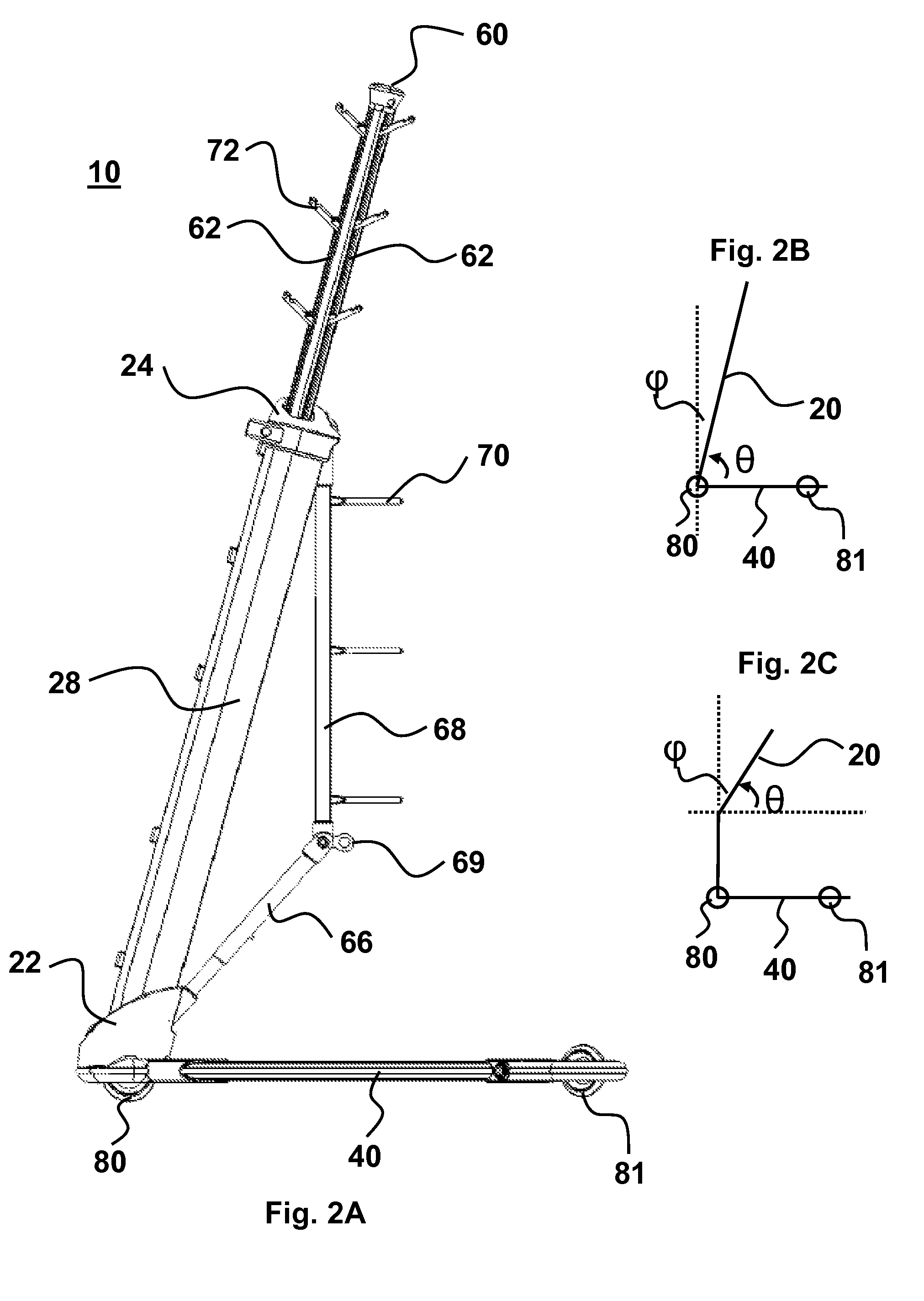

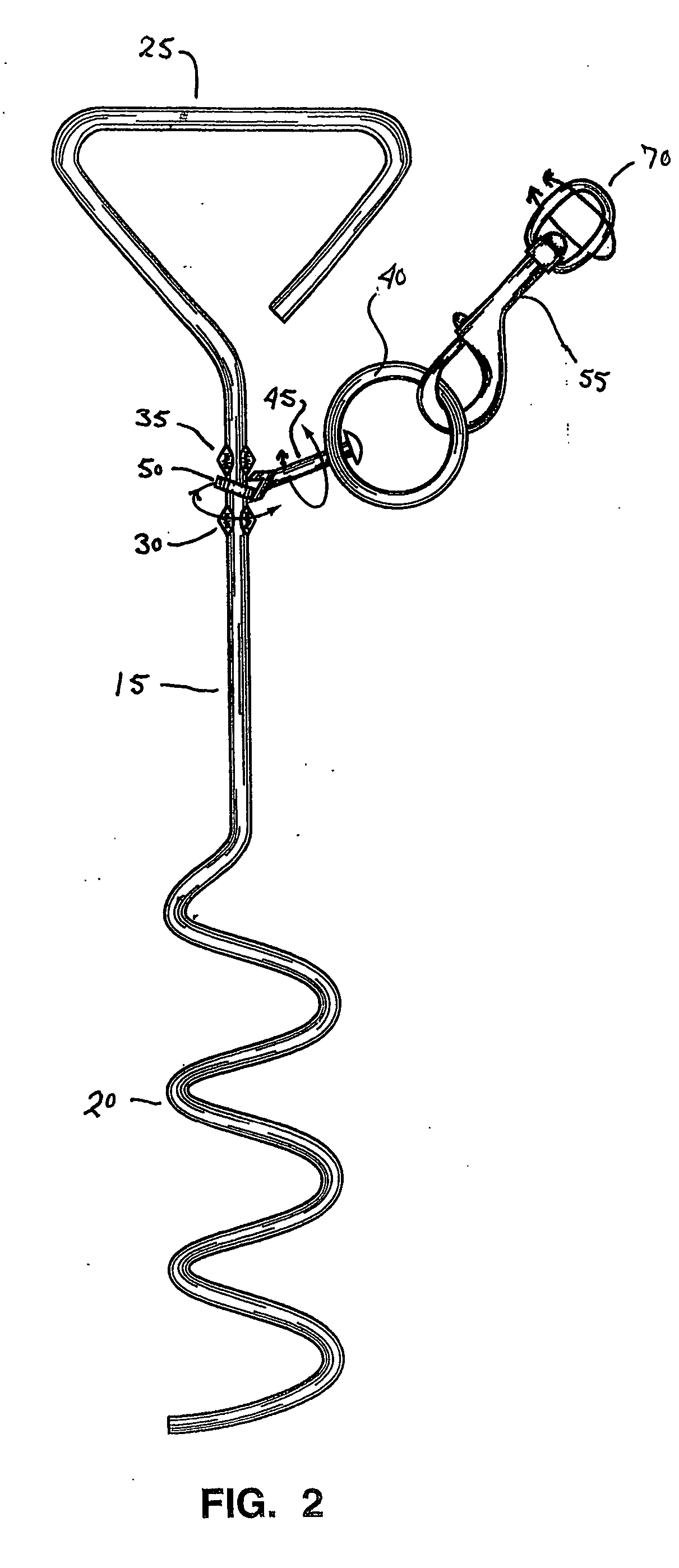

An integrated infusion management system provides for stable support of components attached to the system, even when the system is mobile. The system is optionally a mobility assist or walker for a patient who is attached to any number of medical components. A central trunk connects to a two-sided base that does not interfere with patient motion. The trunk may be angled with respect to vertical and oriented to support medical components in a configuration that is tip-resistant. The system is optionally deployable to facilitate conversion between a compact storage configuration and a stable deployed configuration. In an embodiment, additional deployable features include holding arms for holding various medical components, wheels, mobility arms and handles. Also provided is a novel wheel system with deployable wheels and methods associated with providing compact storage of any one or more of the systems presented herein.

Owner:FIREFLY MEDICAL

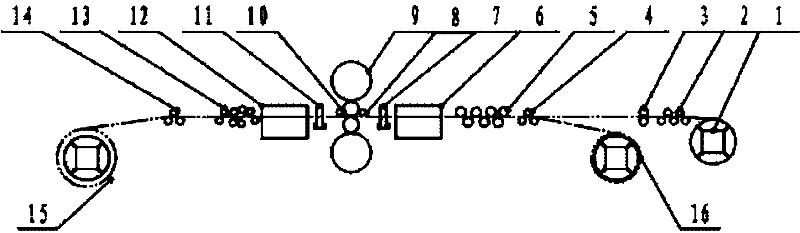

Rolling device for preparing high-toughness high-formability magnesium alloy sheet strip coil

ActiveCN102240676ARealize continuous temperature-controlled rollingImprove mechanical propertiesMeasuring devicesTension/compression control deviceMetallic materialsFeedback control

The invention relates to a rolling device for preparing a high-toughness high-formability magnesium alloy sheet strip coil and belongs to the field of metal material rolling. The rolling device provided by the invention comprises a rolling machine, an uncoiling machine, a left-right recoiling machine, a front online heating insulating device of the roll machine, a rear online heating insulating device of the roll machine, a straightening machine, a bending rectifying machine, a thickness measuring device, a steering tension roll, a guide roll, a roller heating and lubricating device and the like. In the invention, an online continuous heating device and an advanced PLC (programmable logic control) feedback control system are adopted, and continuous temperature control rolling on the magnesium alloy strip coil is realized. The rolling device provided by the invention has the advantages of uniform heating temperature, high heating efficiency and high temperature control accuracy, and high-quality thin wrought magnesium alloy strip coils are efficiently produced by virtue of a roller preheating insulating system, a technical lubricating system, a strip shape control system and a tension straightening device, thus the geometric quality and structure properties of rolled metal can meet operating requirements.

Owner:江苏永良镁业科技有限公司

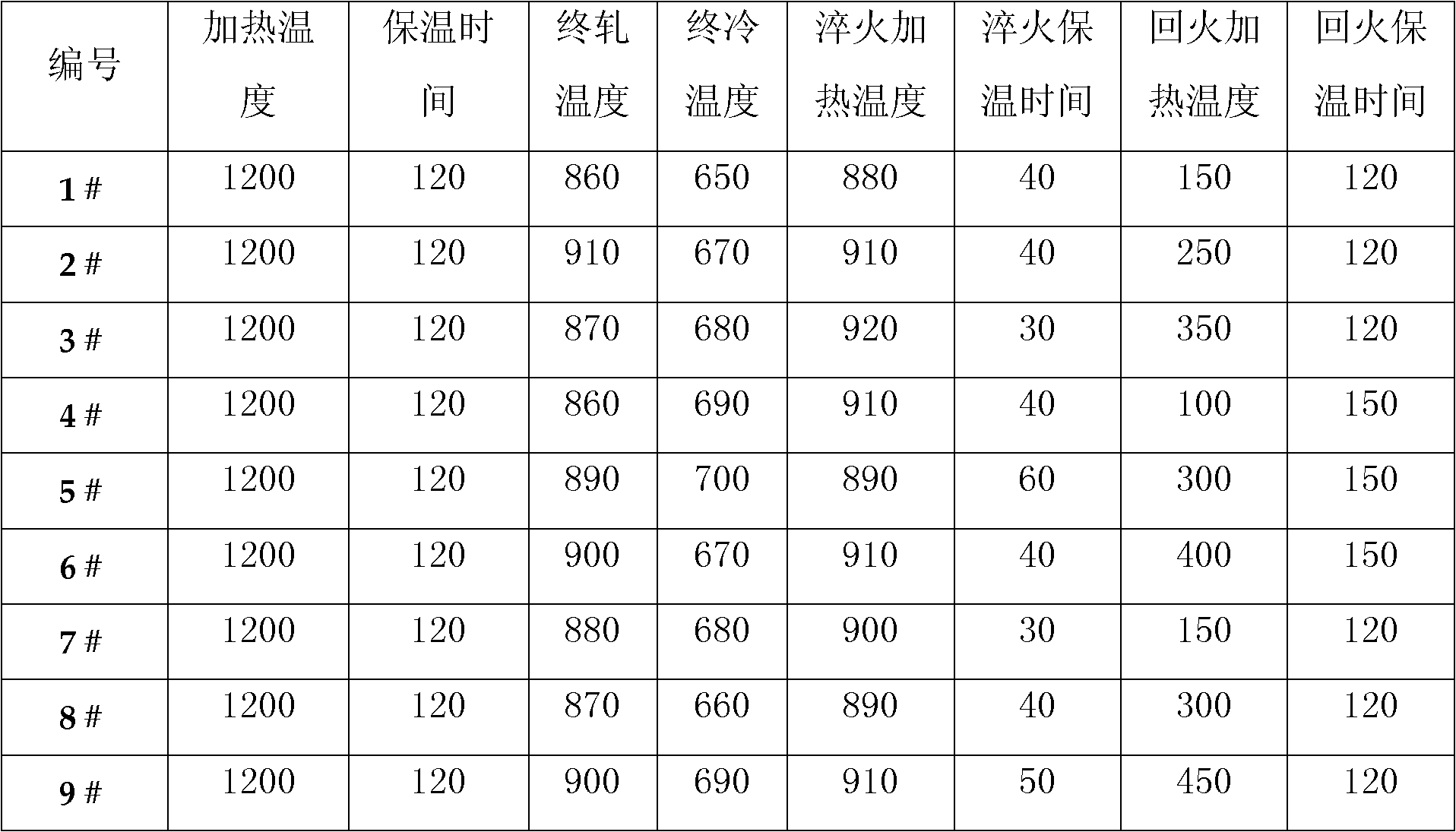

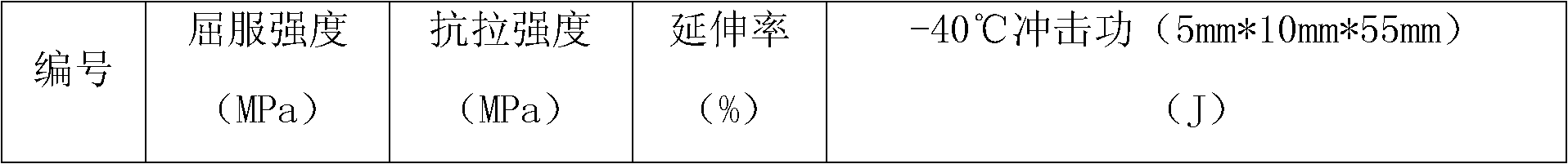

Ultra-high strength steel with yield strength level of 1100MPa-1200MPa and production method of steel

The invention provides ultra-high strength steel with yield strength level of 1100MPa-1200MPa and a production method of the steel. The chemical constituents (weight percentage) include: 0.15-0.18% of C, 0.20-0.25% of Si, 0.85-1.25% of Mn, 0.20-0.60% of Cr; and 0.45-0.65% of Mo, 0.035-0.060% of V, 0.015-0.020% of Nb, 0-0. 55% of Ni, 0-0.035% of Cu, 0.01-0.06% of Al, no more than 0.015% of P, no more than 0.01% of S, no more than 0.008% of N, the balance of Fe and unavoidable impurities. The production method includes: smelting and casting into casting blank; and heating the casting blank to 1150-1250 DEG C, wherein the final rolling temperature is 860-920 DEG C, the coiling temperature is 650-750 DEG C, the quenching heating temperature is 880-930 DEG C, the thermal insulation time is 20-90min, the tempering heating temperature is 100-450 DEG C, the thermal insulation time is over 90min. Slow cooling or air cooling is conducted to room temperature. For the steel plate produced with the constituents and the technology, the yield strength is 1150-1230MPa, the tensile strength is 1250-1340MPa, the elongation is 11-13.5%, and the impact power value at minus 40 DEG C is 21-34J.

Owner:SHOUGANG CORPORATION

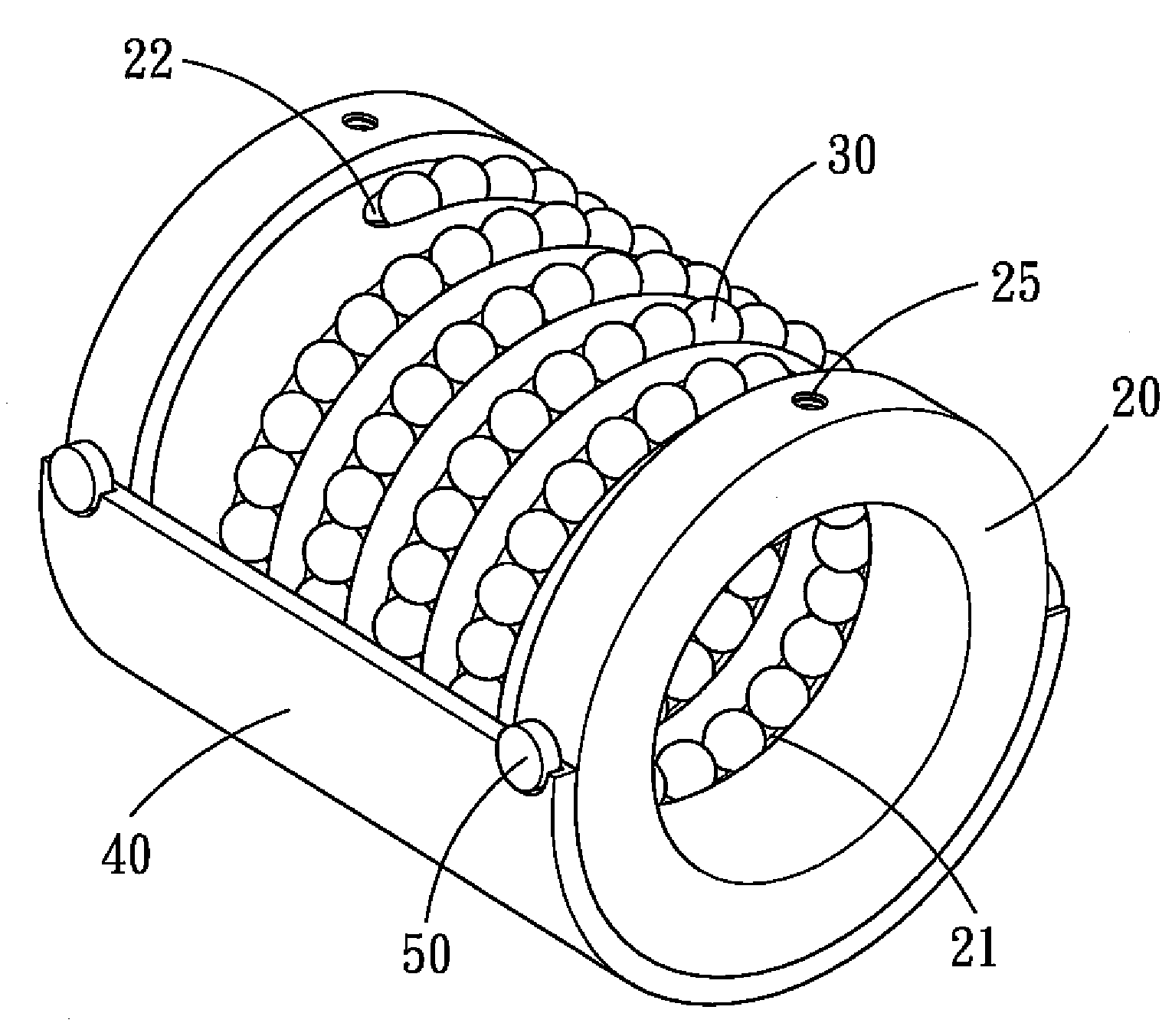

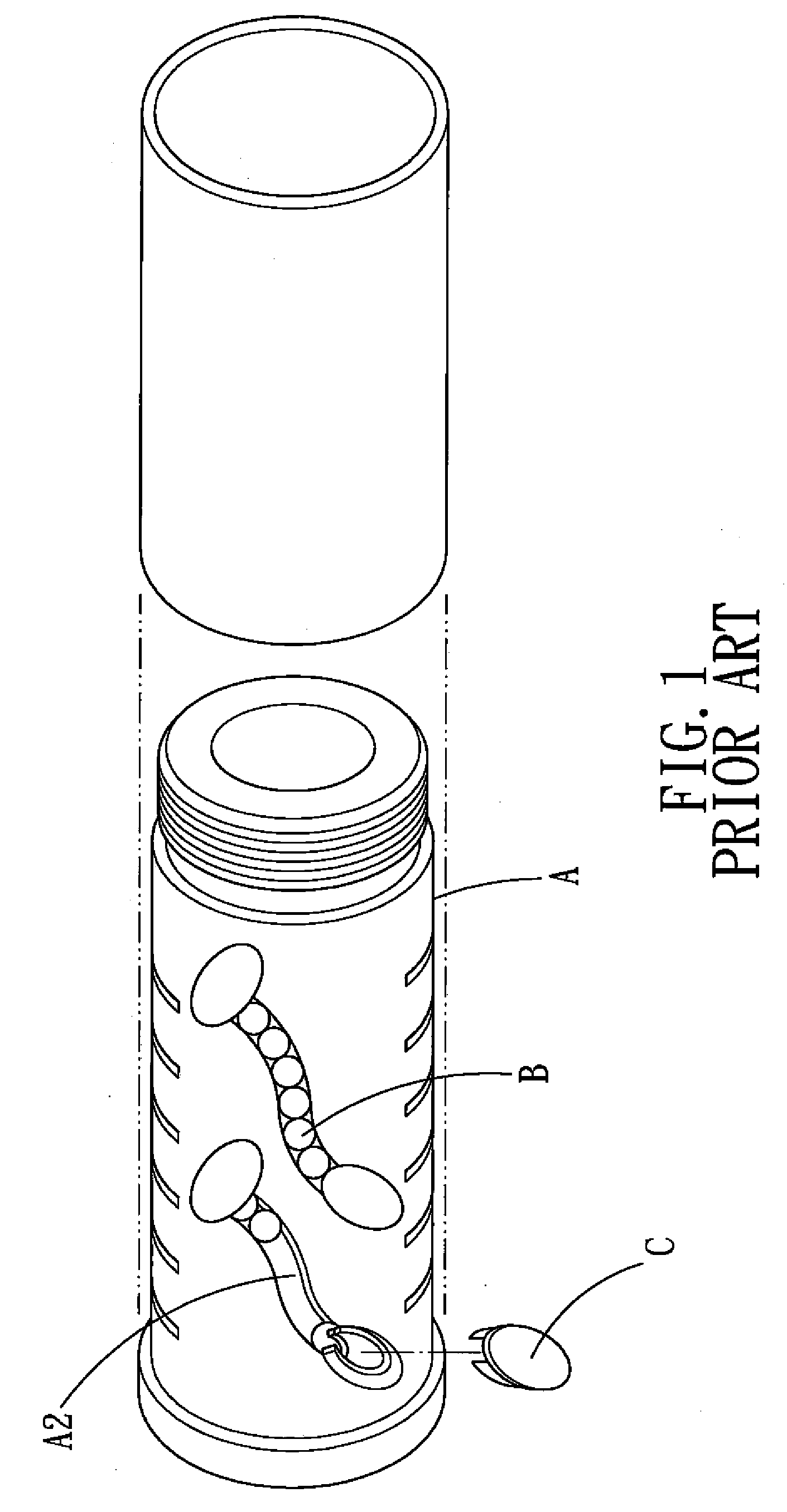

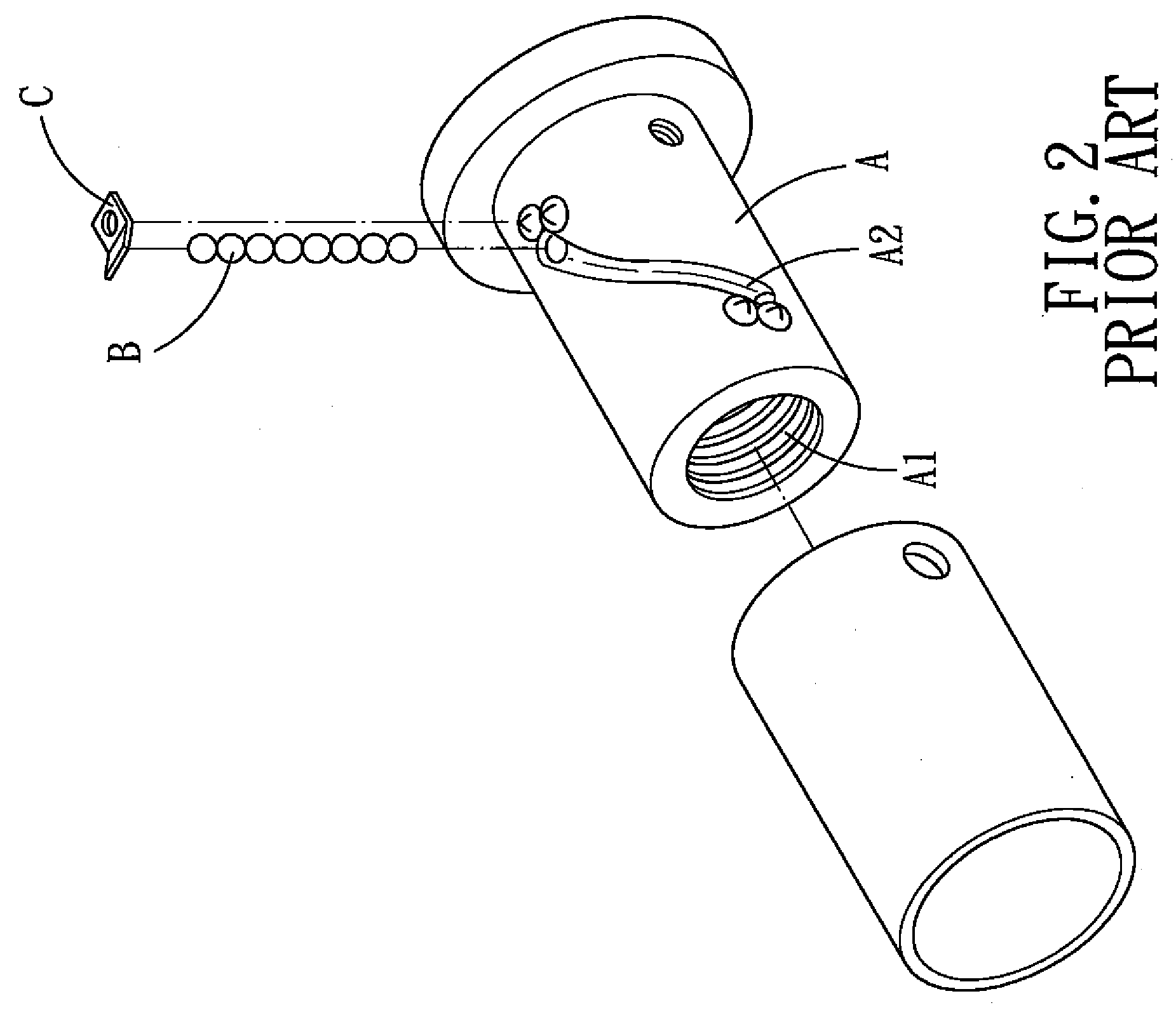

External Circulation Type Ball Screw

InactiveUS20090090207A1Reducing turning angleSmooth rollingToothed gearingsPortable liftingBall screwEngineering

An external circulation type ball screw is provided with a helical passage in the outer surface of the nut. The helical passage and the inner helical groove of the nut are opposite in winding direction to each other. The nut is defined with two through holes which are connected to both ends of the inner helical groove and the helical passage, respectively, so that the helical passage and the inner helical groove are connected to each other to form a circulating path for the circulation of the balls. Since the helical passage winds about the outer periphery of the nut, the balls can roll more smoothly.

Owner:HIWIN TECH

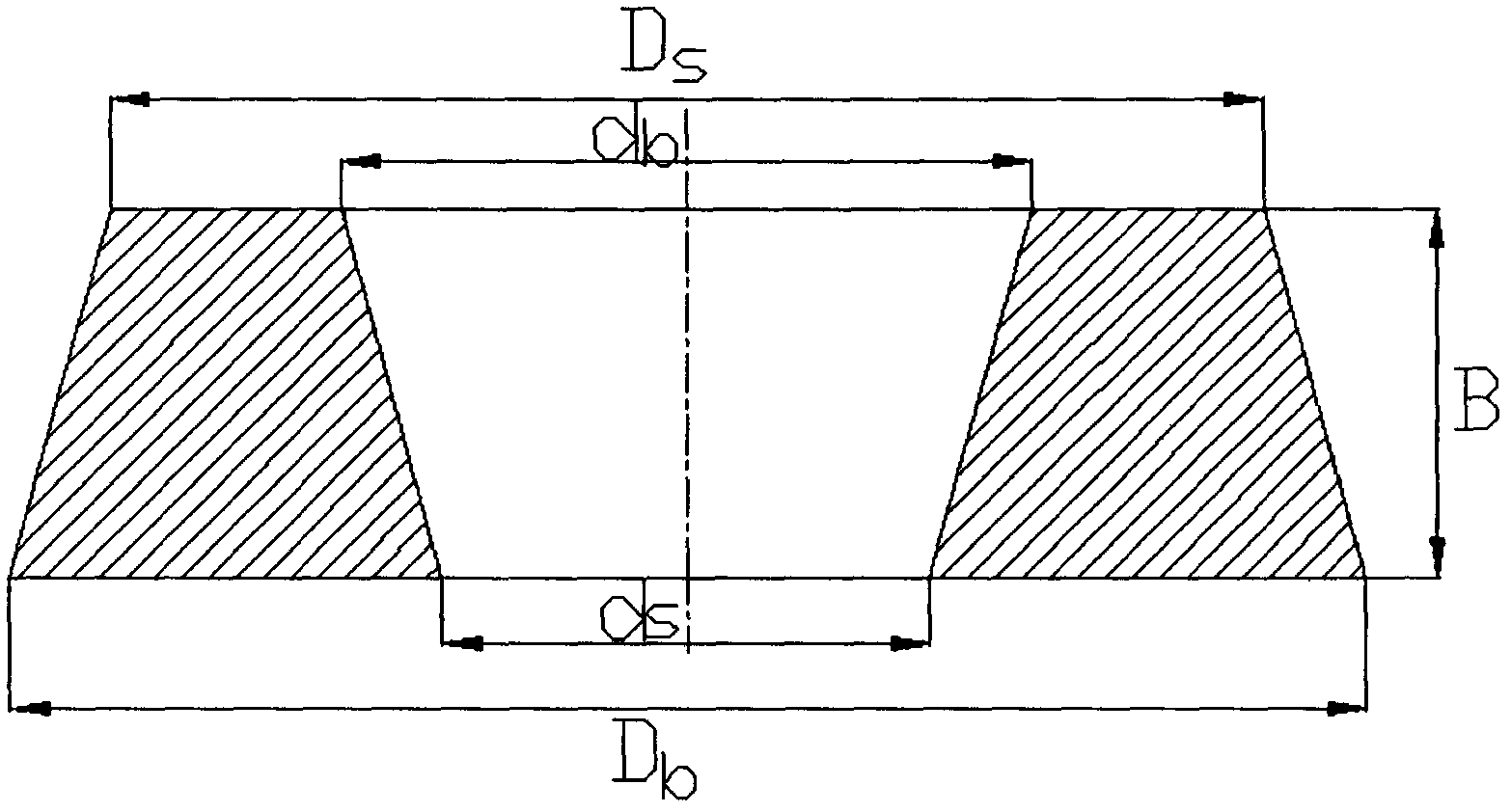

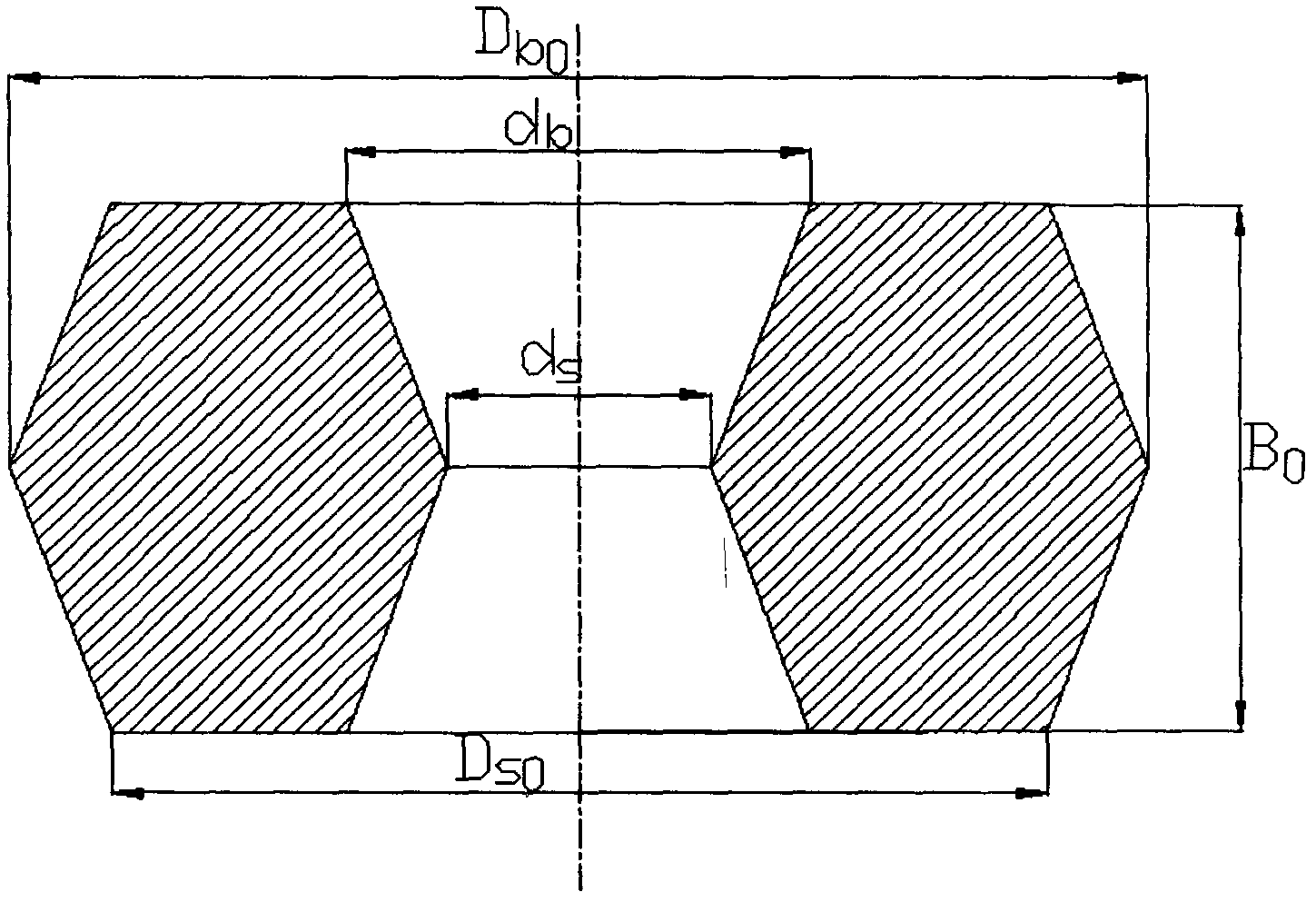

Method for simultaneously rolling and expanding two trapezoid-cross-section flange ring forge pieces

ActiveCN102615223AReduce heating timesImprove organizationGas flame welding apparatusMetal rollingRoom temperatureEngineering

The invention relates to a method for simultaneously rolling and expanding two trapezoid-cross-section flange ring forge pieces. The method comprises cutting a cylindrical billet into material sections; heating the material sections from room temperature to austenitizing temperature evenly and keeping warm; then heading, punching and chambering the material sections to be manufactured into ring piece blanks to be rolled and expanded; baking again and heating the obtained blanks to reach target temperature and keep warm; placing the obtained blanks into a hole mould of a ring rolling machine formed by an irregular-shaped driving roller and an irregular-shaped core roller to be rolled, expanded and formed; achieving the ring forge pieces which is narrow at two ends and wide in middle and with the axial height as twice as the height of a target trapezoid flange; cutting the ring forge pieces from the middle of the axial height, symmetrically dividing a work piece into two parts to obtain two trapezoid-cross-section flange ring forge pieces; and finally turning the forge pieces into end product flanges. The method for simultaneously rolling and expanding two trapezoid-cross-section flange ring forge pieces is high in production efficiency, energy-saving, environmental-friendly and capable of improving utilization rate of raw materials and quality of products.

Owner:SHANDONG JIANZHU UNIV

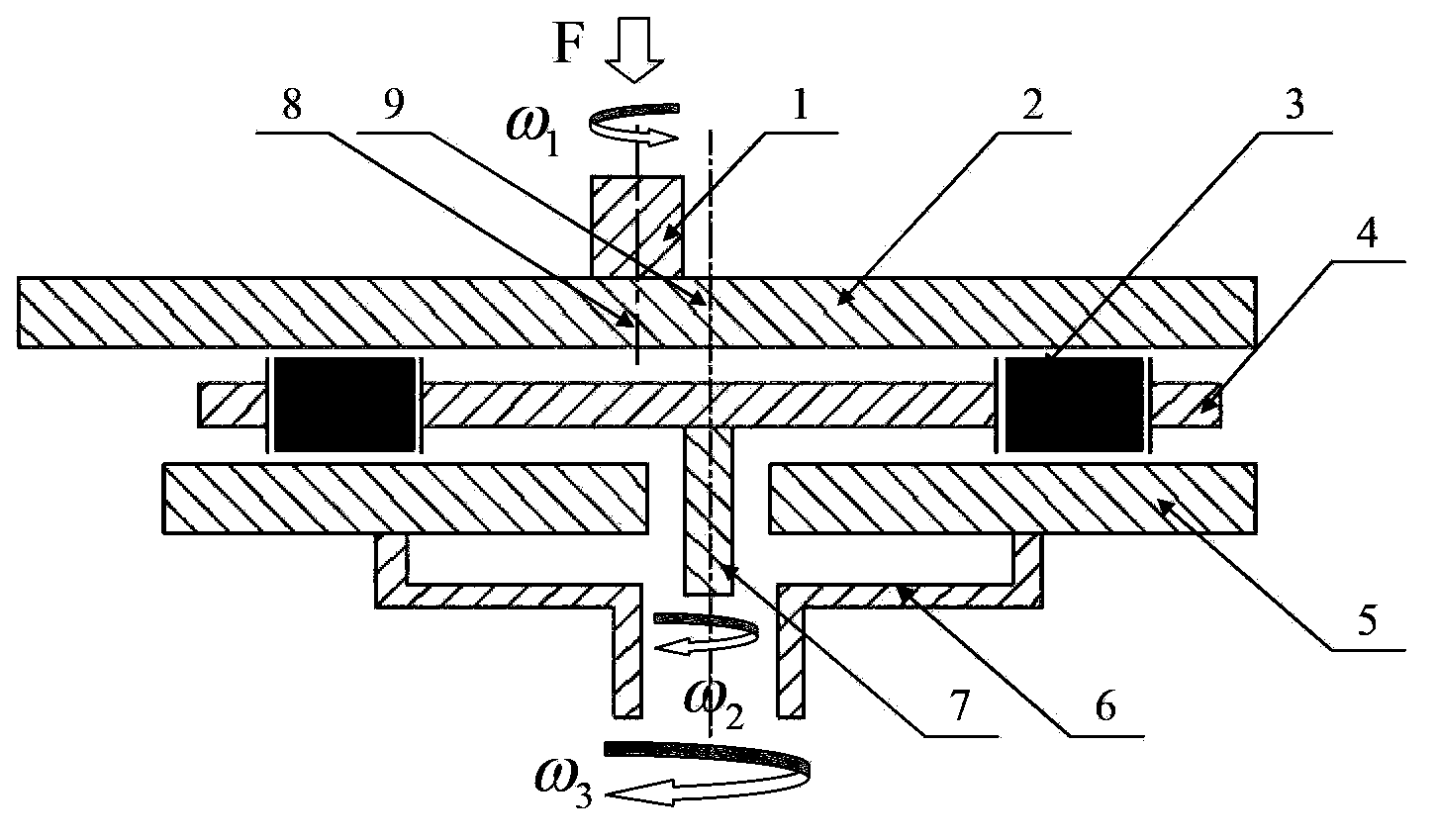

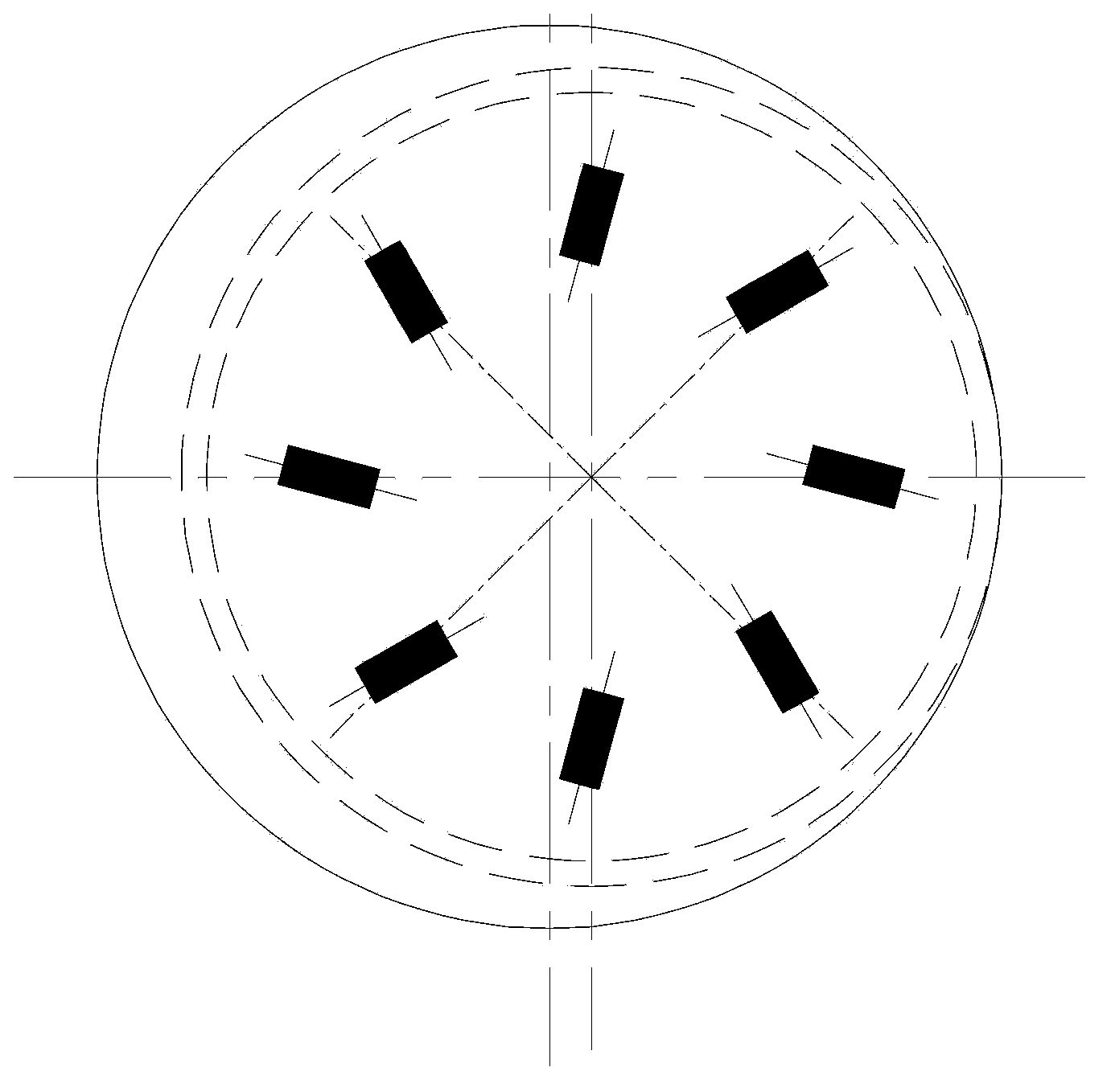

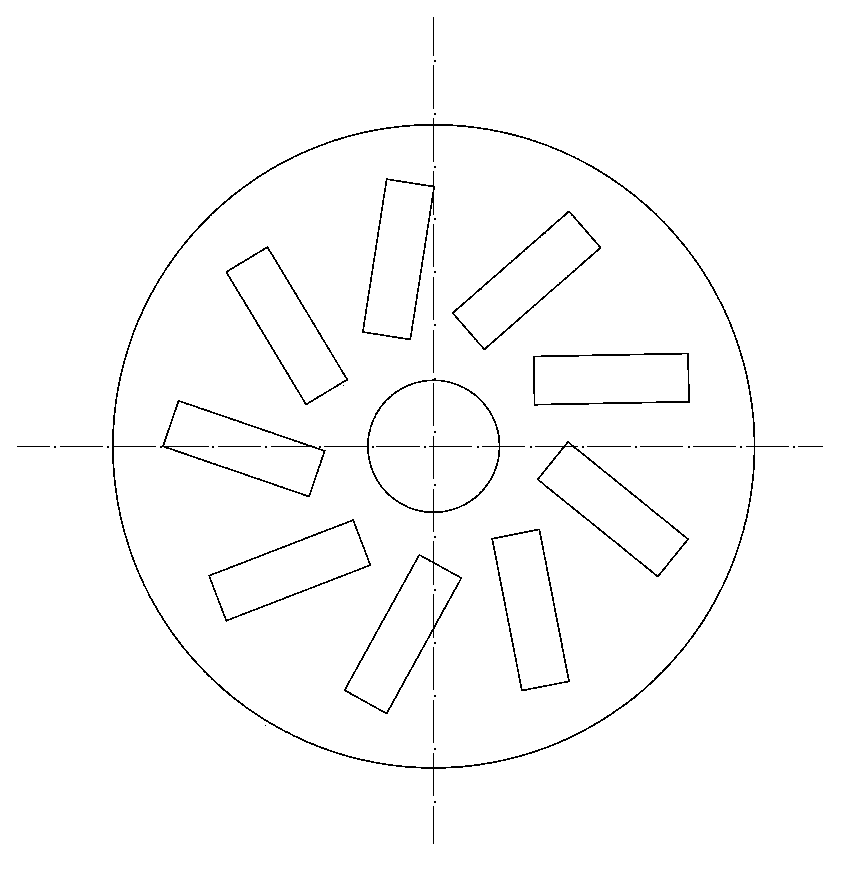

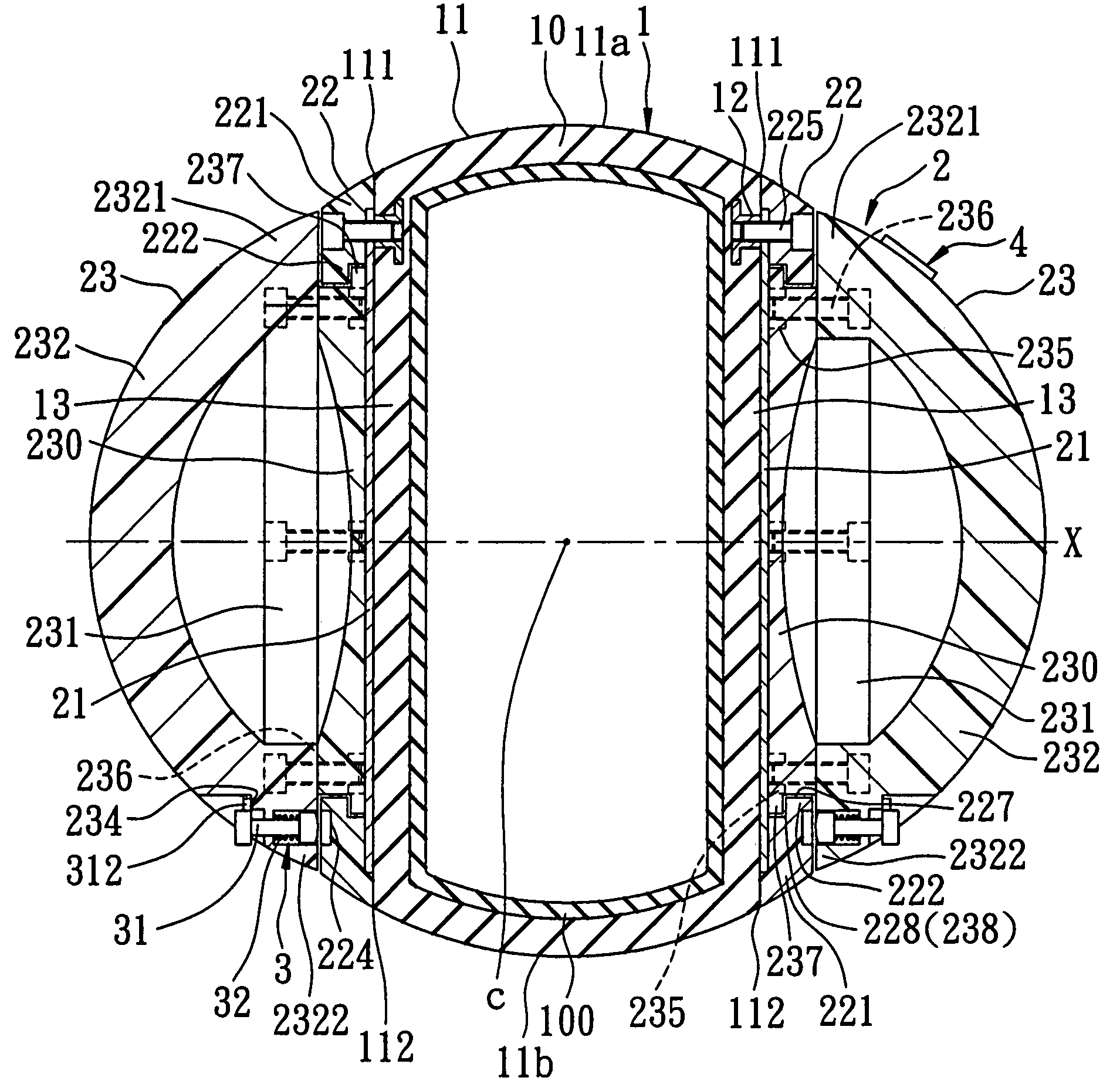

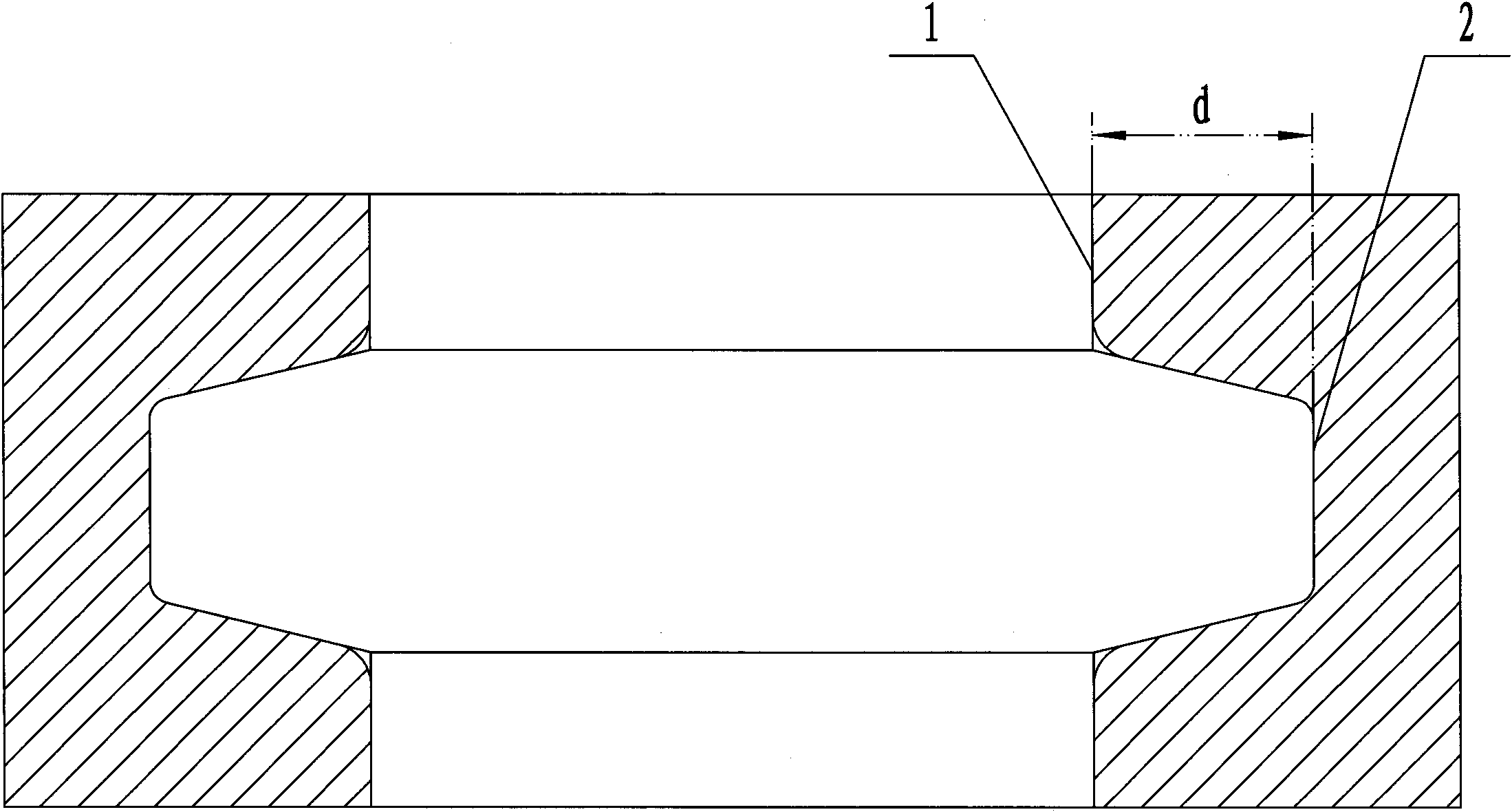

Method for processing outer circle of cylindrical part based on upper plate eccentric pressurizing

ActiveCN103522166AHigh precisionImprove consistencyLapping machinesWork carriersOffset distanceMechanical engineering

A method for processing an outer circle of a cylindrical part based on upper plate eccentric pressurizing. A processing device for achieving the processing method comprises an upper grinding plate, a holder and a lower grinding plate. The upper grinding plate is located above the lower grinding plate, the holder is located between the upper grinding plate and the lower grinding plate, a rotating shaft of the holder and a rotating shaft of the lower grinding plate are coaxial, and a definite offset distance exists between a rotating shaft of the upper grinding plate and the rotating shaft of the holder. In the process of processing, a loading device eccentrically acts on the cylindrical part through the upper grinding plate, and the outer circle of the cylindrical part is processed through the cooperation of a plane of the upper grinding plate, a plane of the lower grinding plate and matched abrasive materials. The method for processing the outer circle of the cylindrical part is high in precision and good in consistency.

Owner:ZHEJIANG UNIV OF TECH

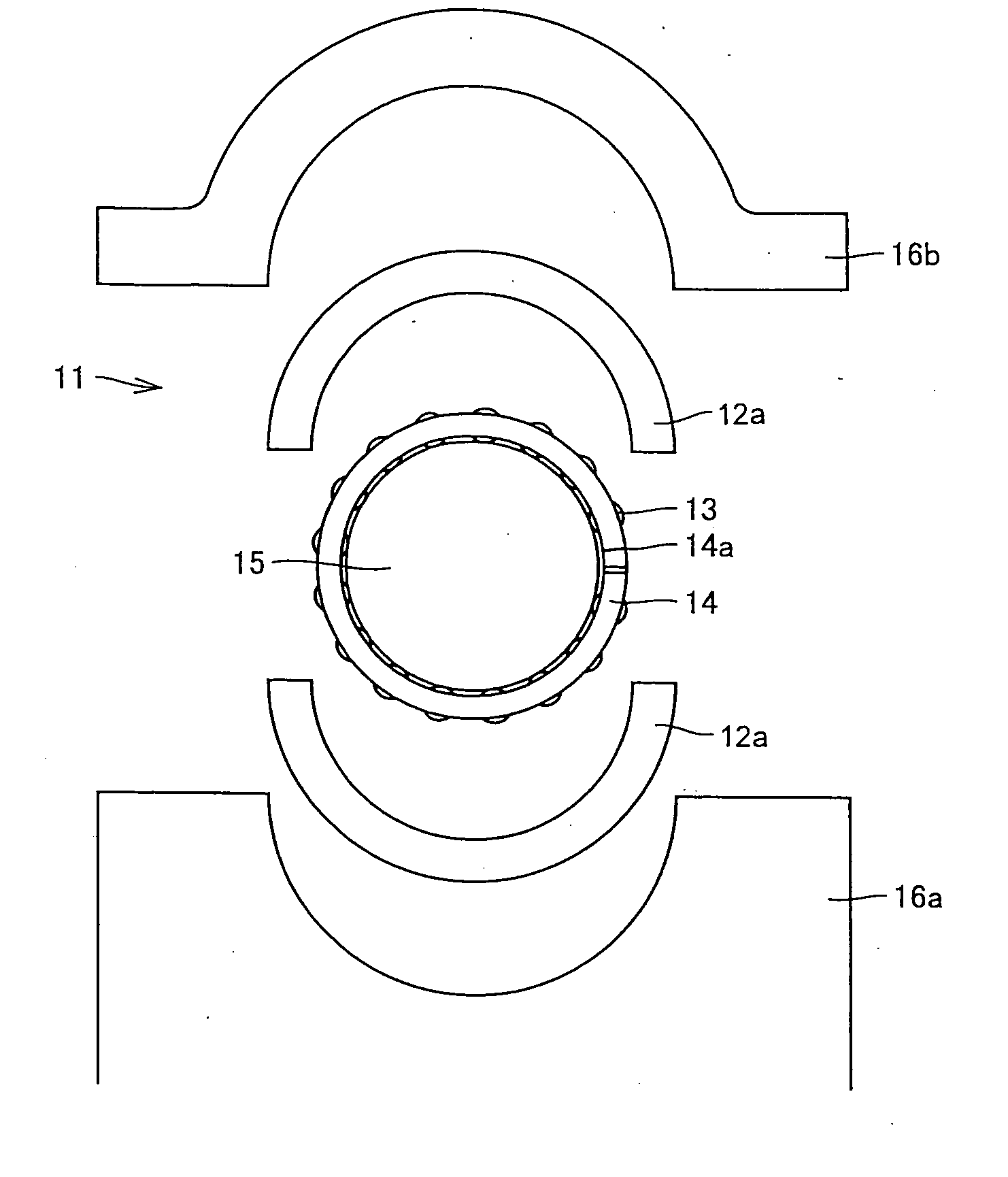

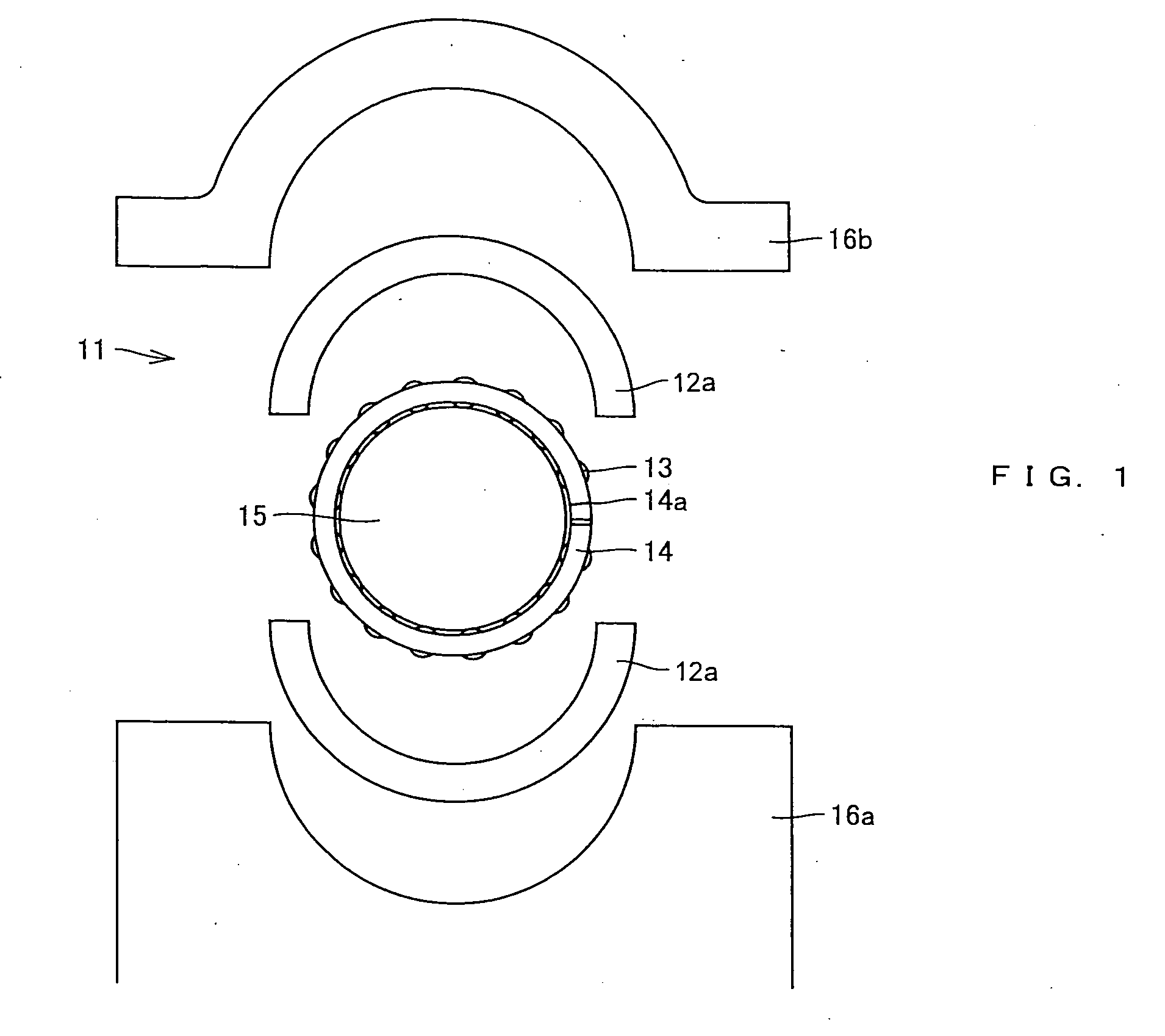

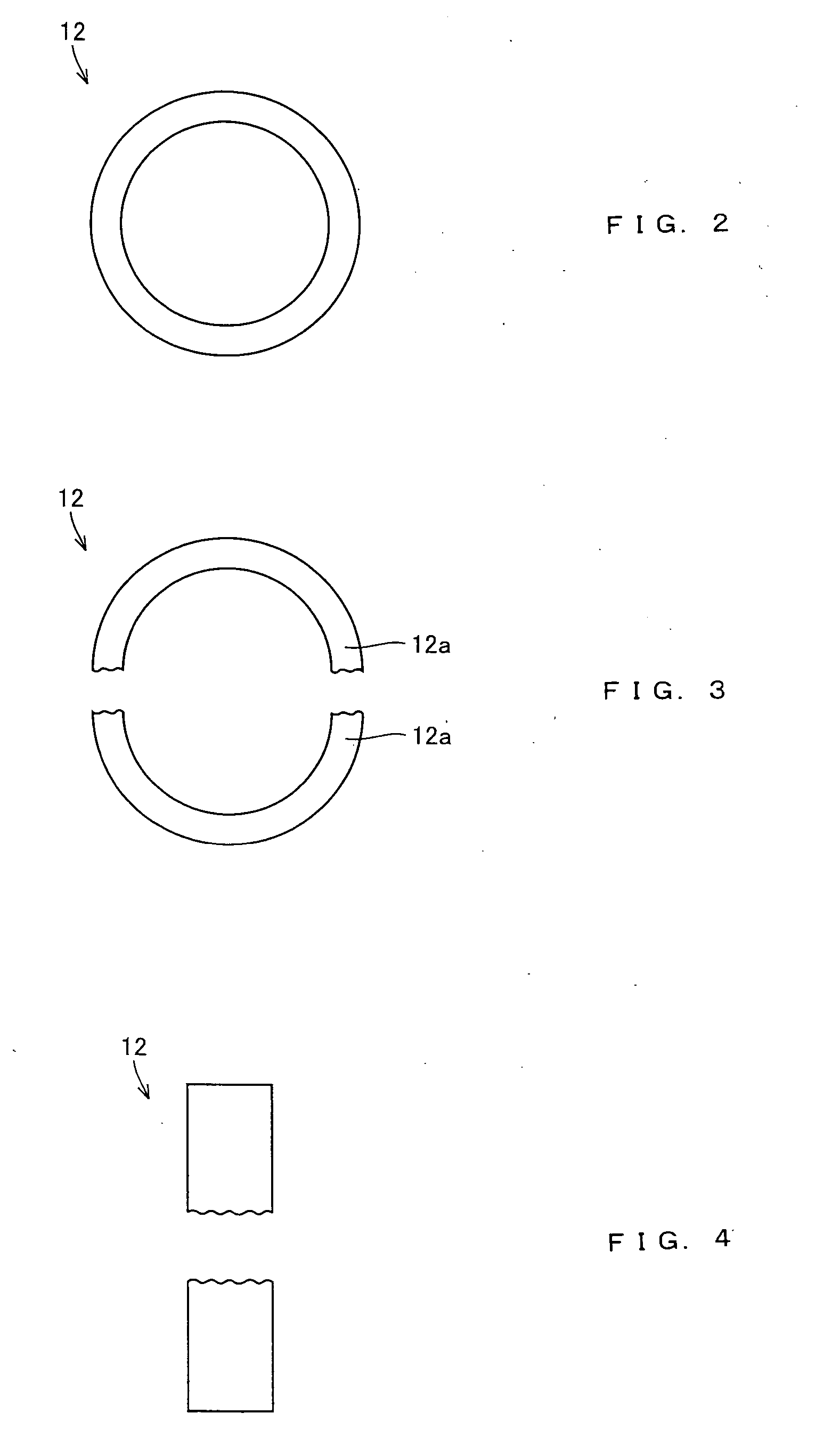

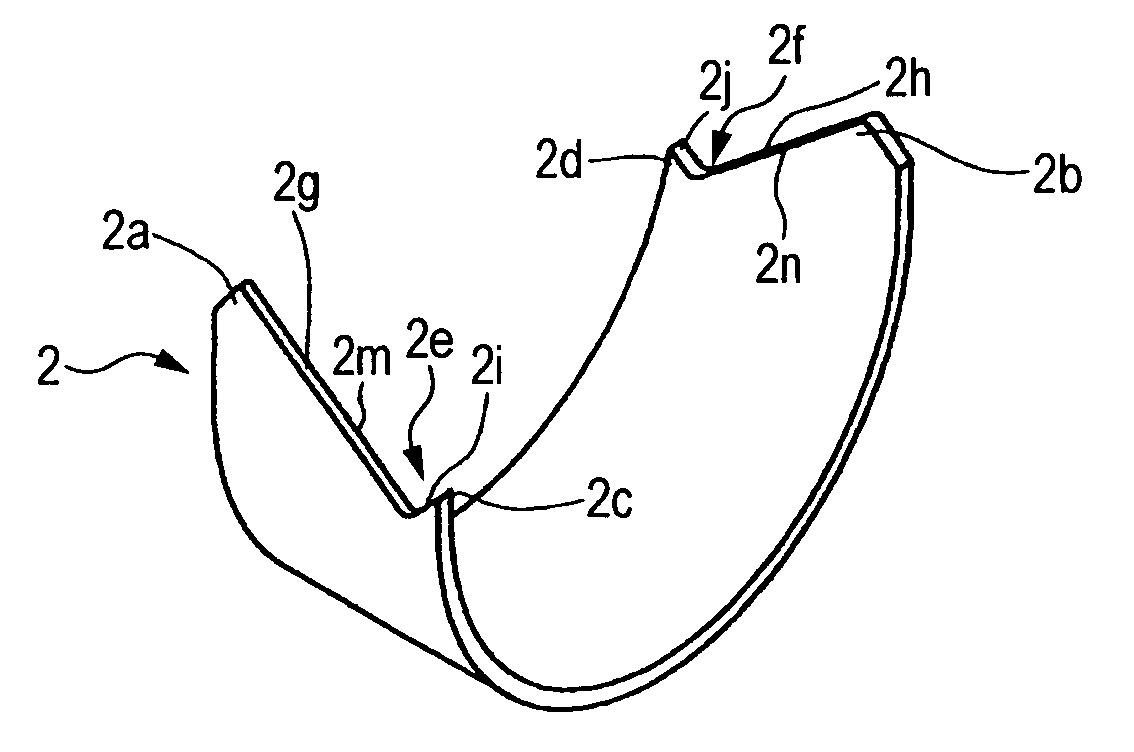

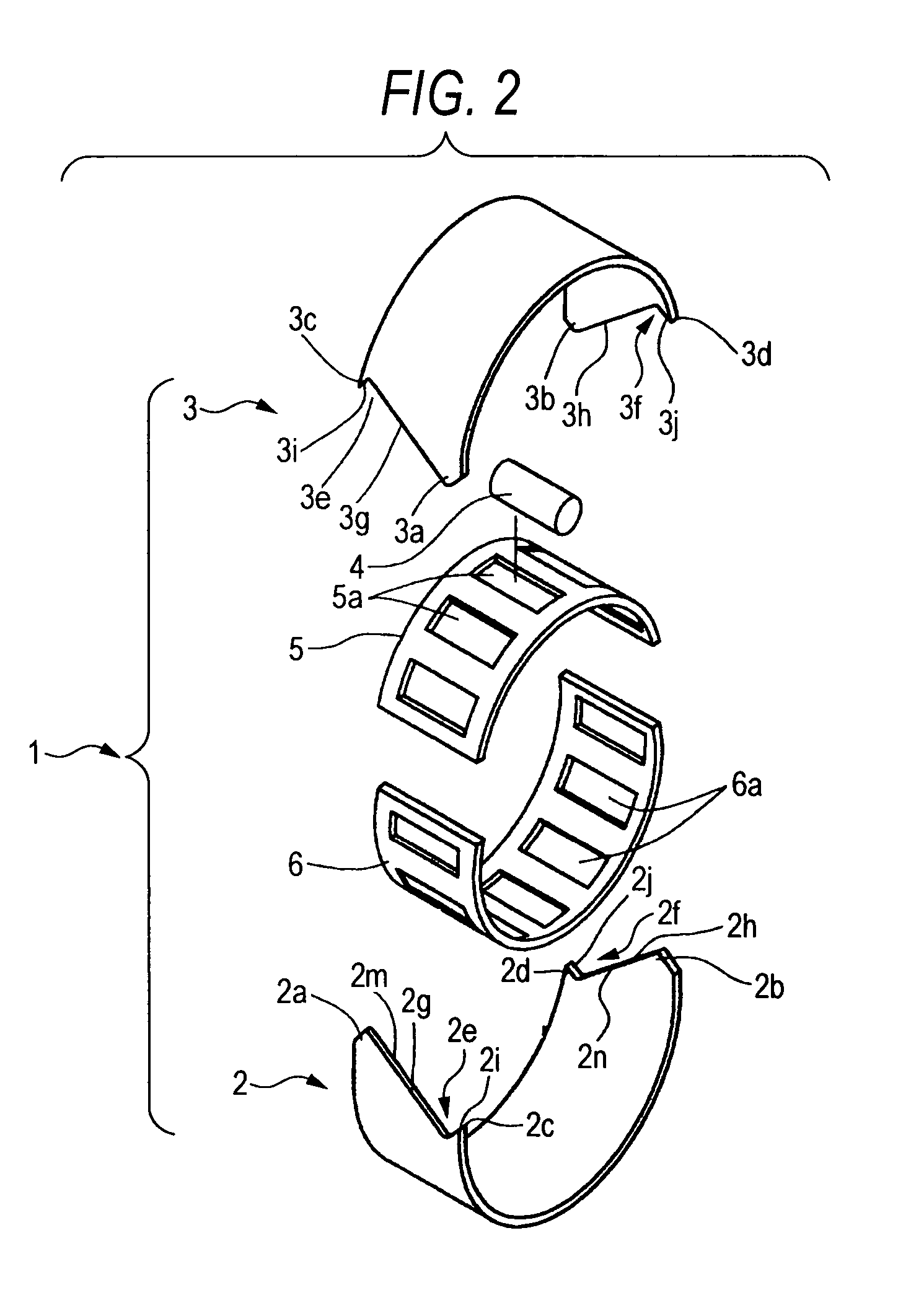

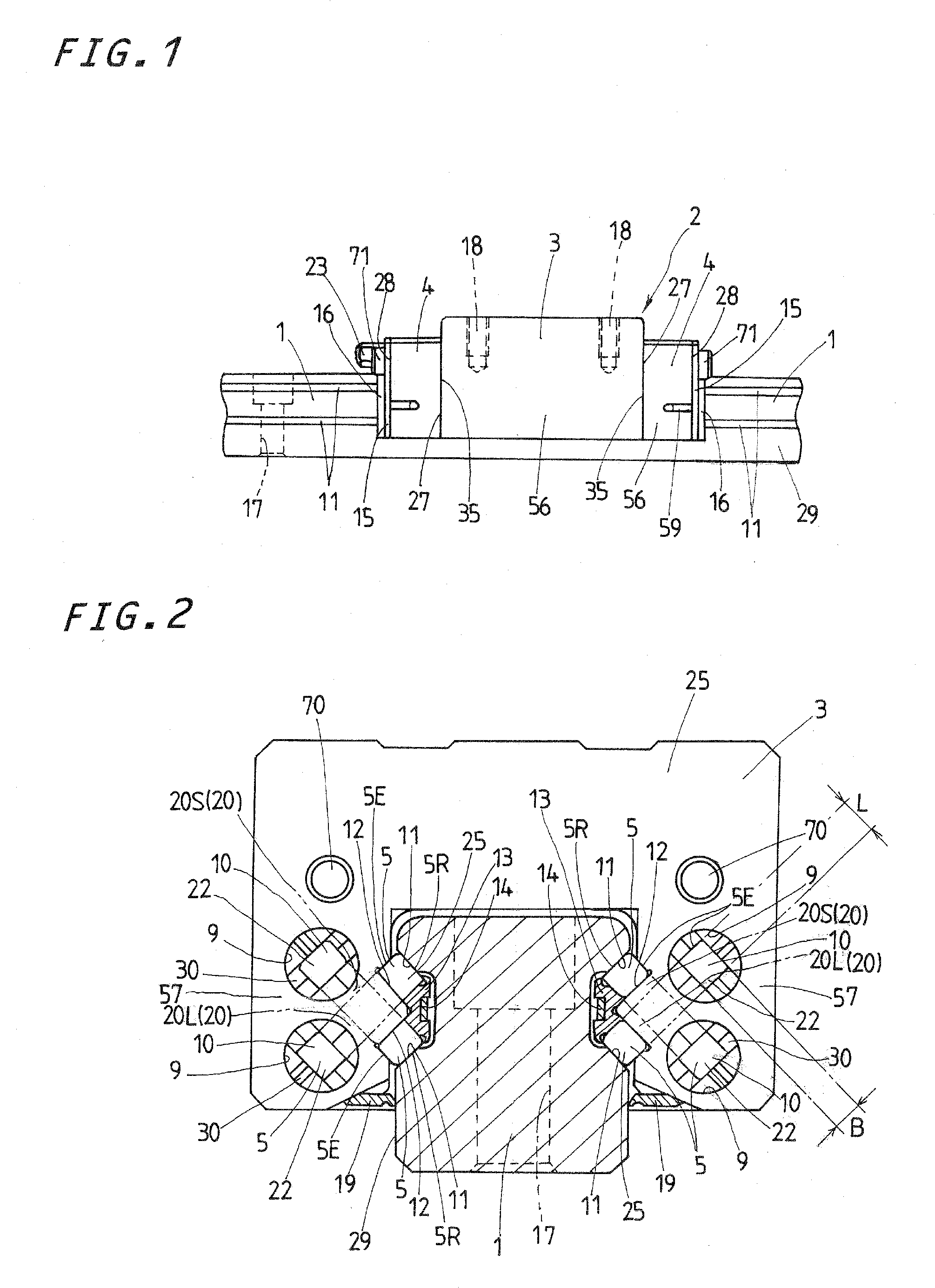

Needle roller bearing, crank shaft supporting structure, and split method of outer ring of needle roller bearing

InactiveUS20070116393A1Smooth rollingAvoid troubleCrankshaft bearingsShaftsNeedle roller bearingEngineering

A needle roller bearing comprises an outer ring having a plurality of outer ring members split by split lines extending in the axial direction of the bearing, and a plurality of needle rollers arranged on the track surface of the outer ring so that they can roll. The outer ring is split by a load applied to its end surface in the direction crossing the end surface.

Owner:NTN CORP

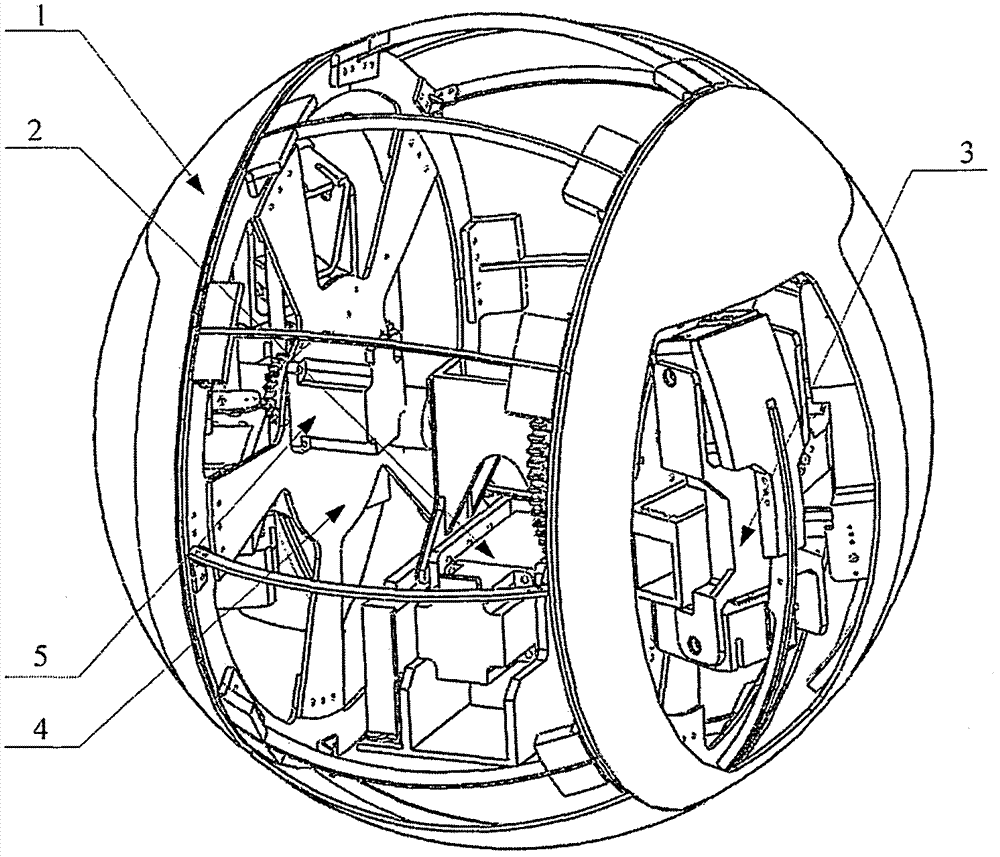

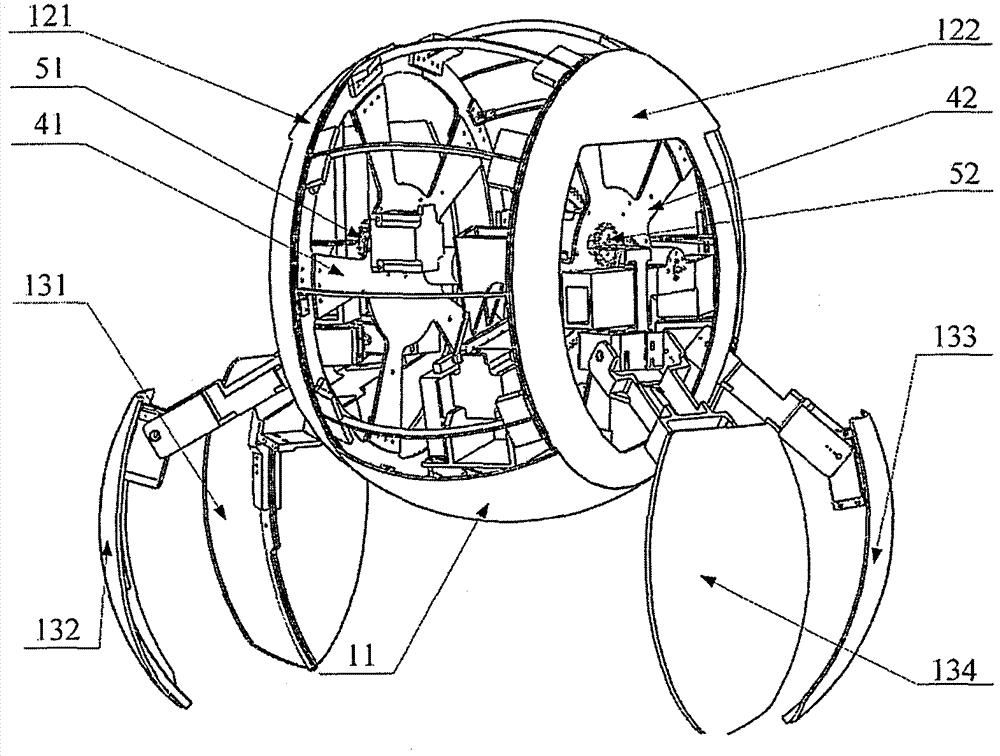

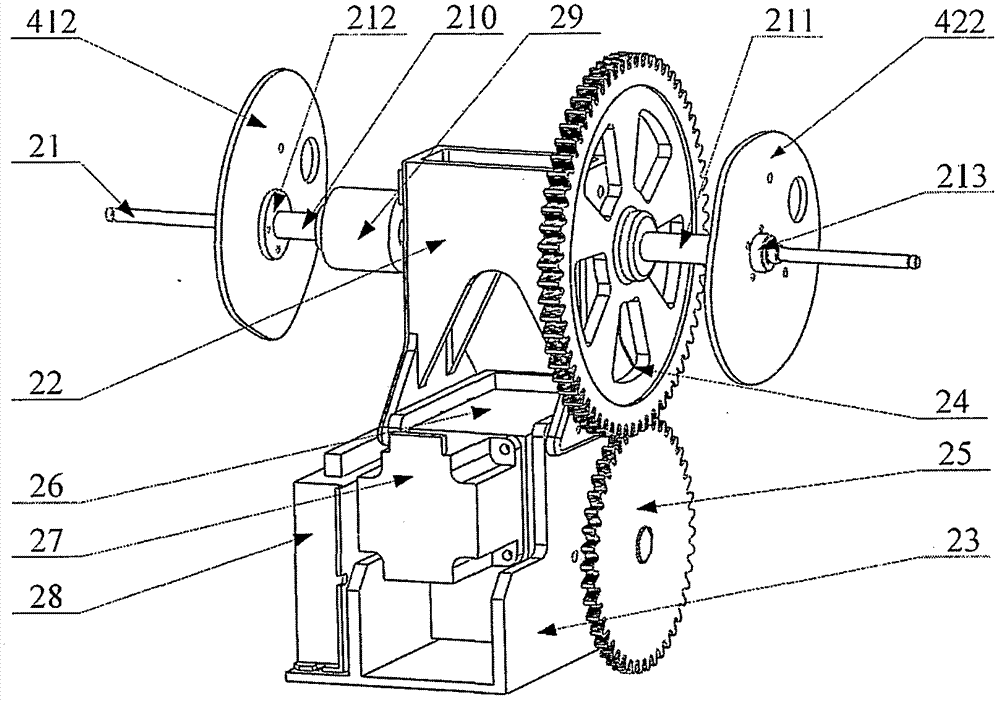

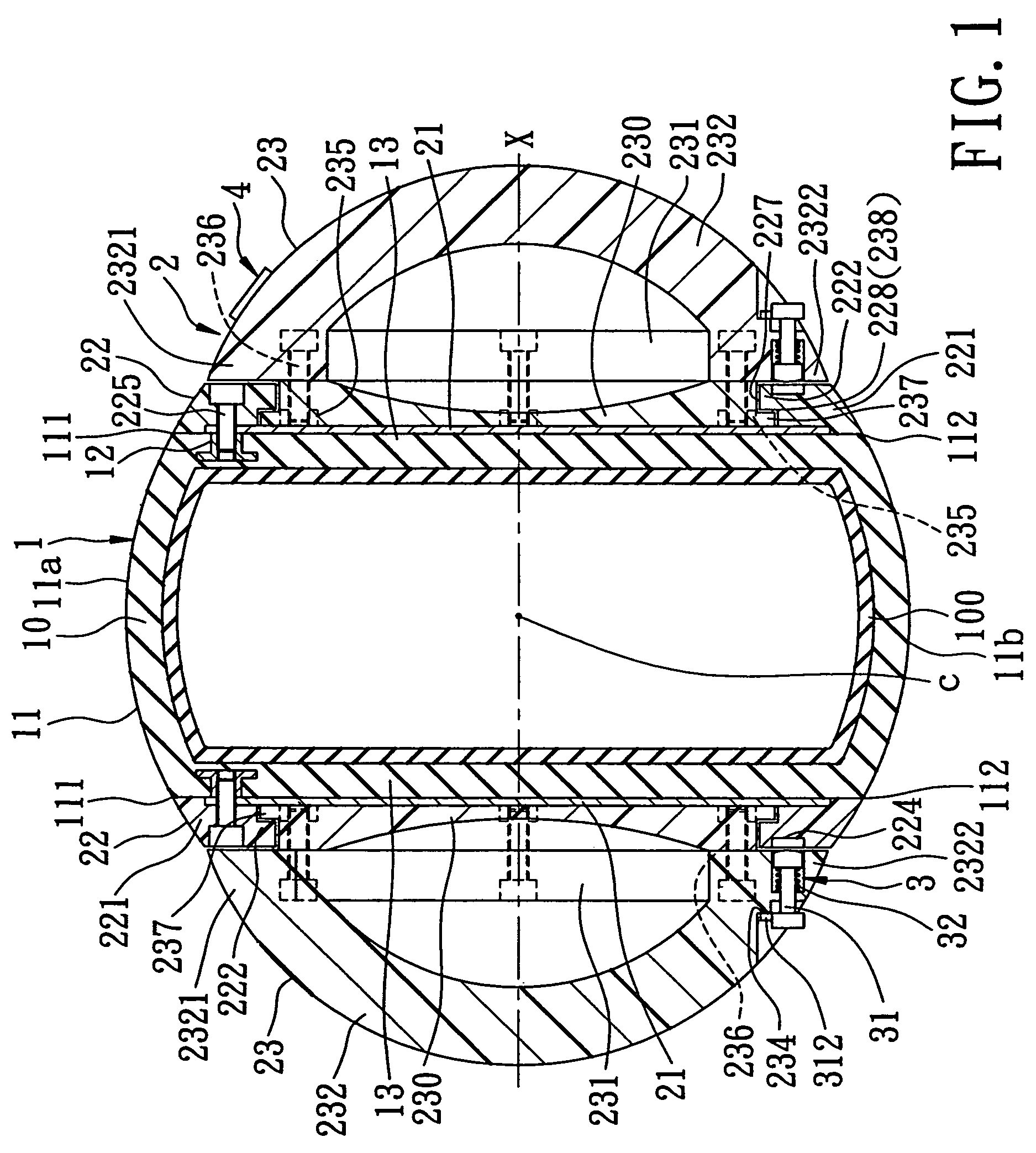

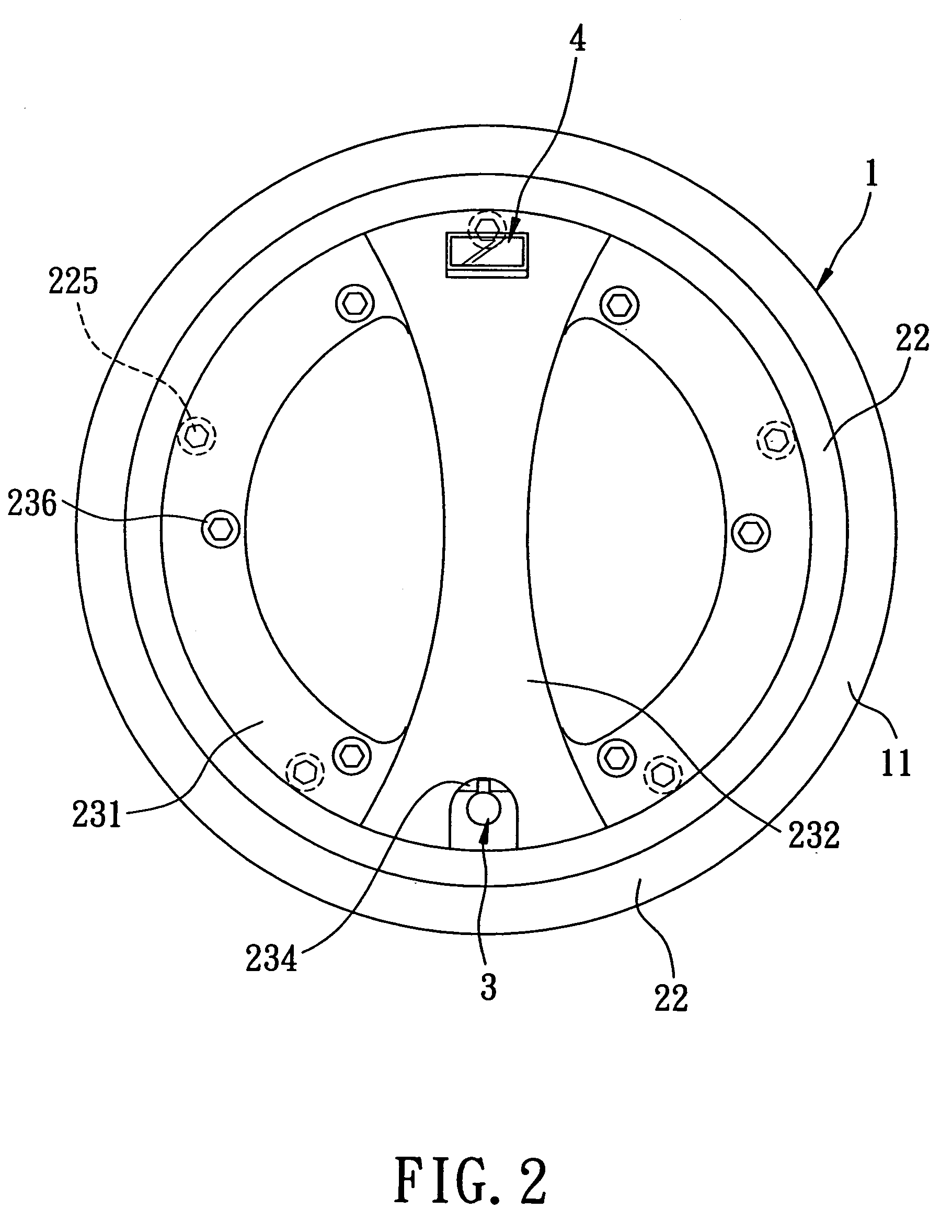

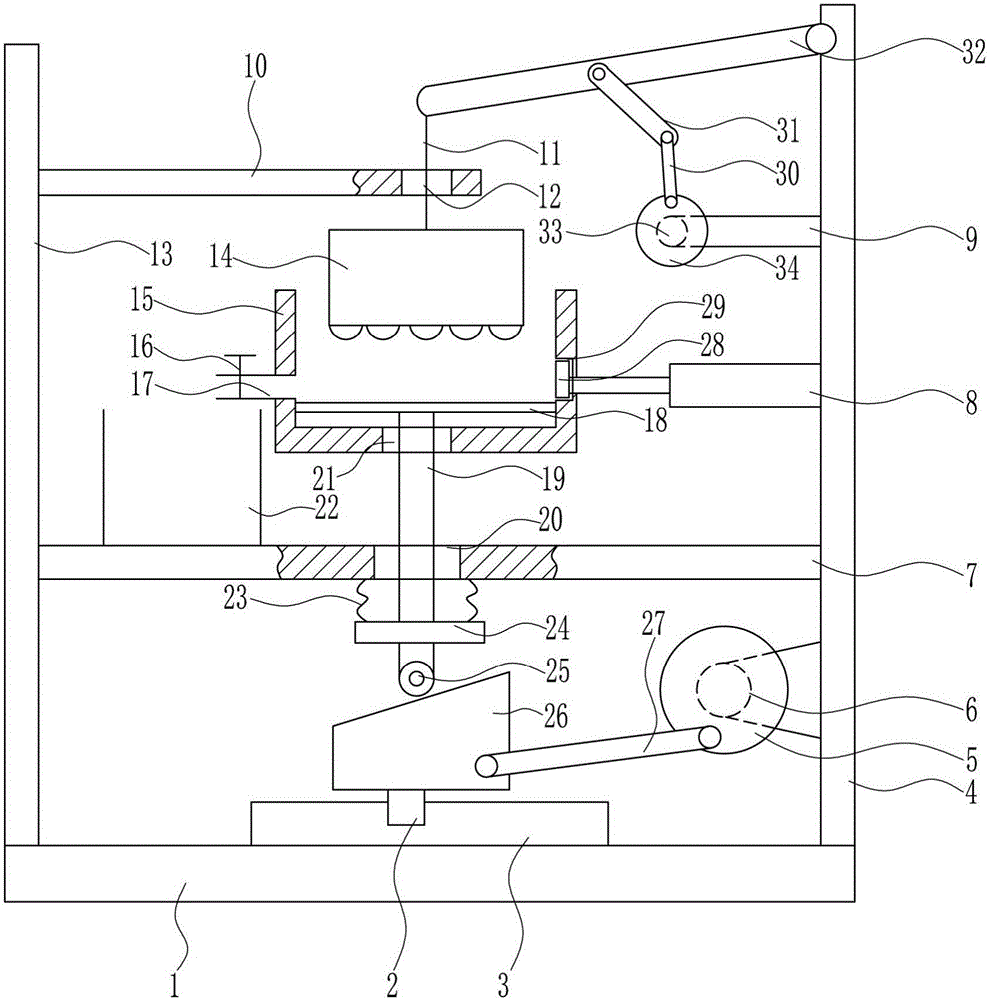

Spherical robot having walking function

The invention discloses a spherical robot having a bionic walking function. The spherical robot comprises a spherical shell module, a rolling driving module, a foot module, a supporting module and a foot balance module. The spherical robot disclosed by the invention has two basic movement modes of spherical rolling movement and foot type walking movement, so that the spherical robot has high movement efficiency of spherical rolling and good terrain adaptability of foot type walking, and can also enable the two movement modes to supplement each other, and the obstacle surmounting performance of the spherical rolling and the movement efficiency of the foot type walking are improved.

Owner:SHANGHAI UNIV

Ball exerciser

A ball exerciser includes a deformable rolling body having an outer surrounding wall surface and at least one lateral mount wall, a rigid stationary coupling member secured to the lateral mount wall and having a stationary coupling end distal from the lateral mount wall, a movable coupling member having a movable coupling end disposed to be swivelable and frictionally rotatable relative to the stationary coupling end about a rolling axis, a grip including a grip segment which is spaced apart from the lateral mount wall and which is coupled to the movable coupling end so as to permit the grip segment to swivel with the movable coupling member.

Owner:WANG WEN CHING

Split outer race, split rolling bearing using same, and manufacturing method for split outer race

ActiveUS7270484B2Suppress and prevent and noiseSuppress and prevent vibrationConnecting rod bearingsShaftsRolling-element bearingEngineering

Owner:JTEKT CORP

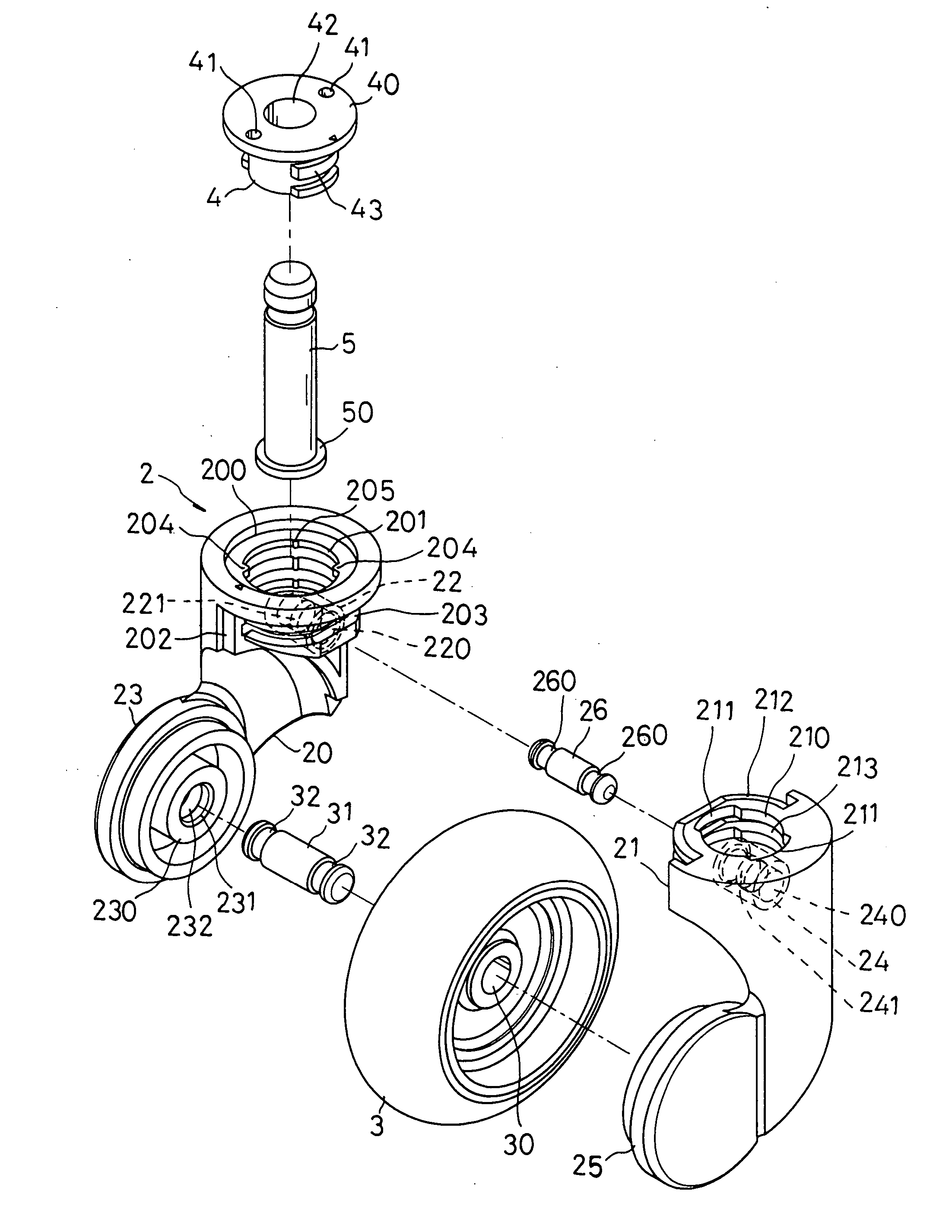

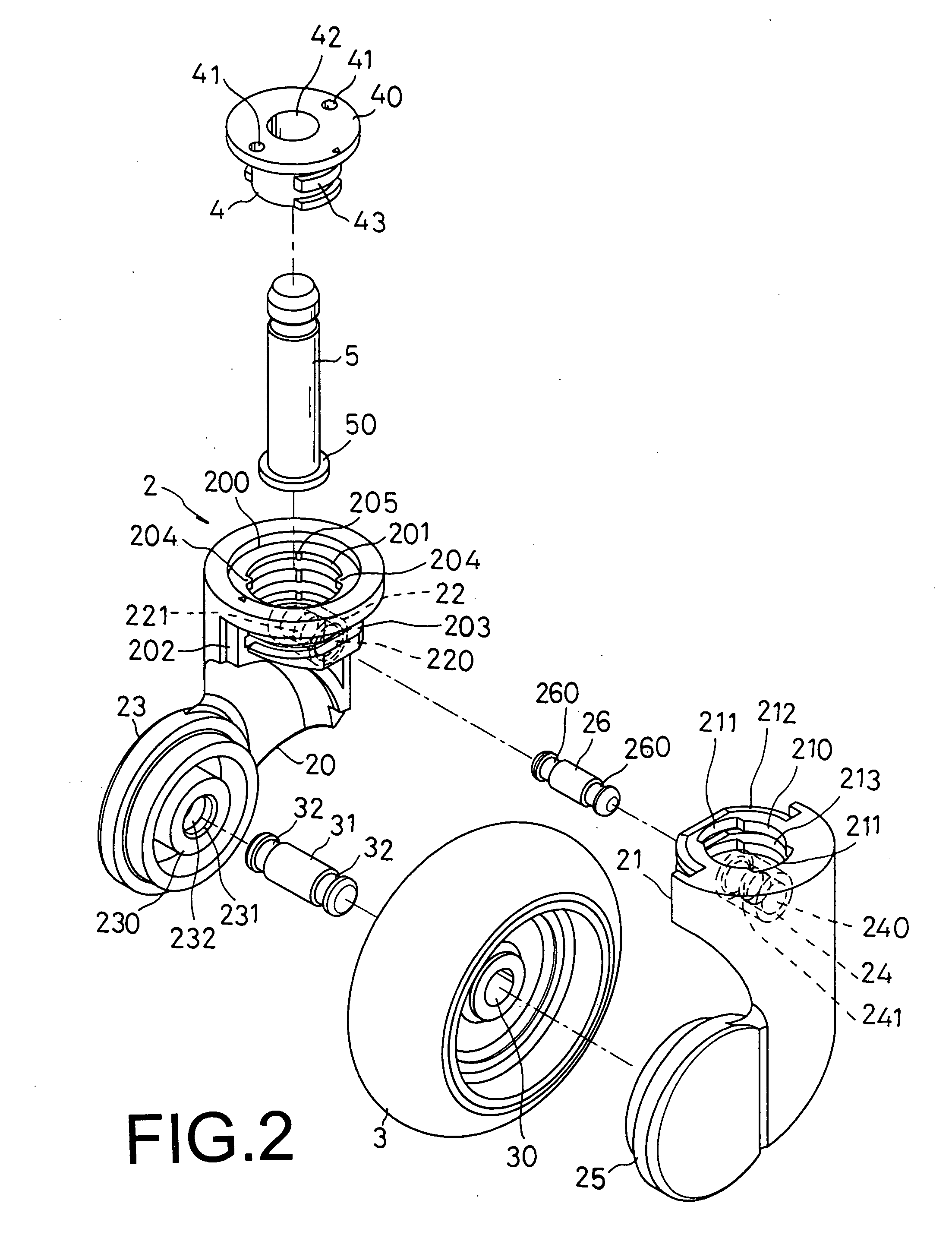

Office chair caster

An office chair caster has a wheel holder, a wheel body, a spindle seat and a spindle. Make a first base and a second base oppositely joined together to form the wheel holder with retaining pieces of the second base inserted into fitting slots of the first base, and make the spindle seat that is extended through by the spindle inserted into through holes of the first and second bases with engagement protuberances of the spindle seat aligned with engagement grooves of the second base. The spindle seat can be rotated at 90 degree to make the engagement protuberances impelled over projections of the first base, stopped by stop blocks of the first base, engaged in sliding slots of the second base, and limited between the projections and the stop blocks without moving, thereby the spindle seat can be firmly fixed in the wheel holder to hold the spindle securely.

Owner:TSAI PO CHUAN

Soybean pulverizing device for pre-production of soybean milk

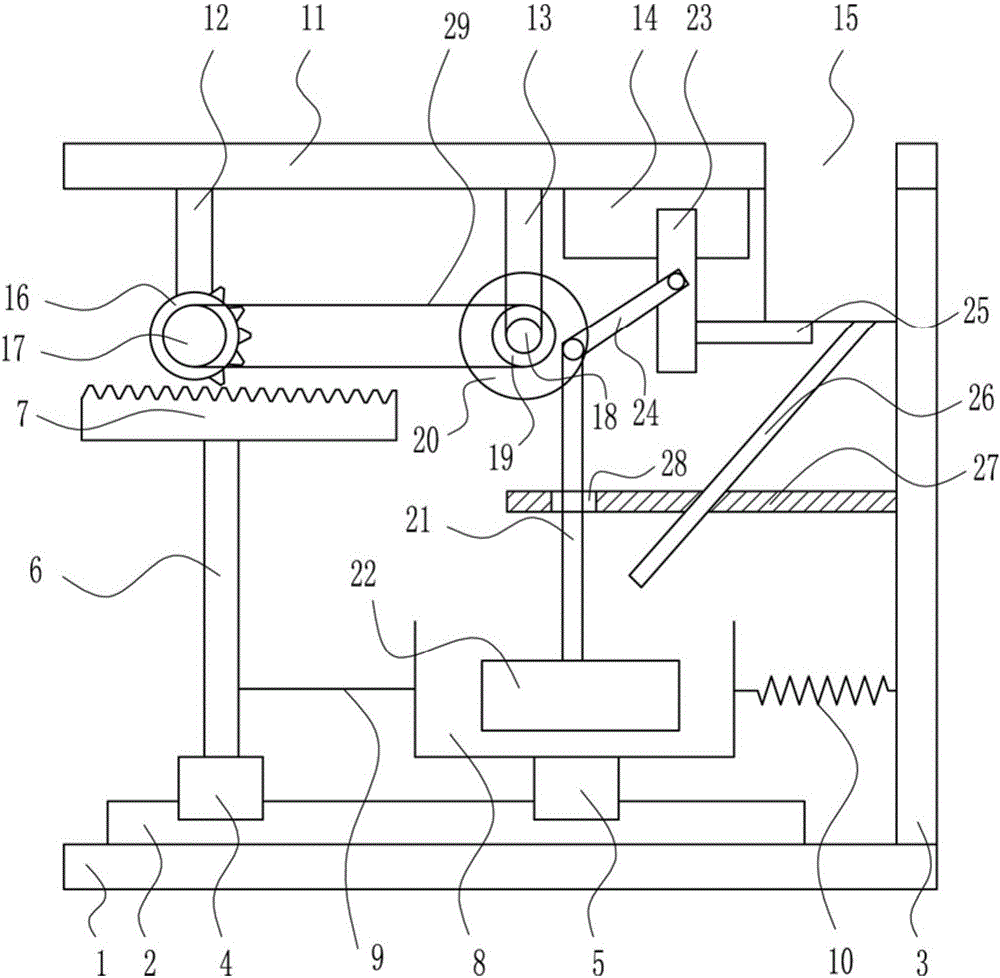

InactiveCN106622465AExtended service lifeHigh strengthGrain treatmentsMilk substitutesEngineeringSoybean meal

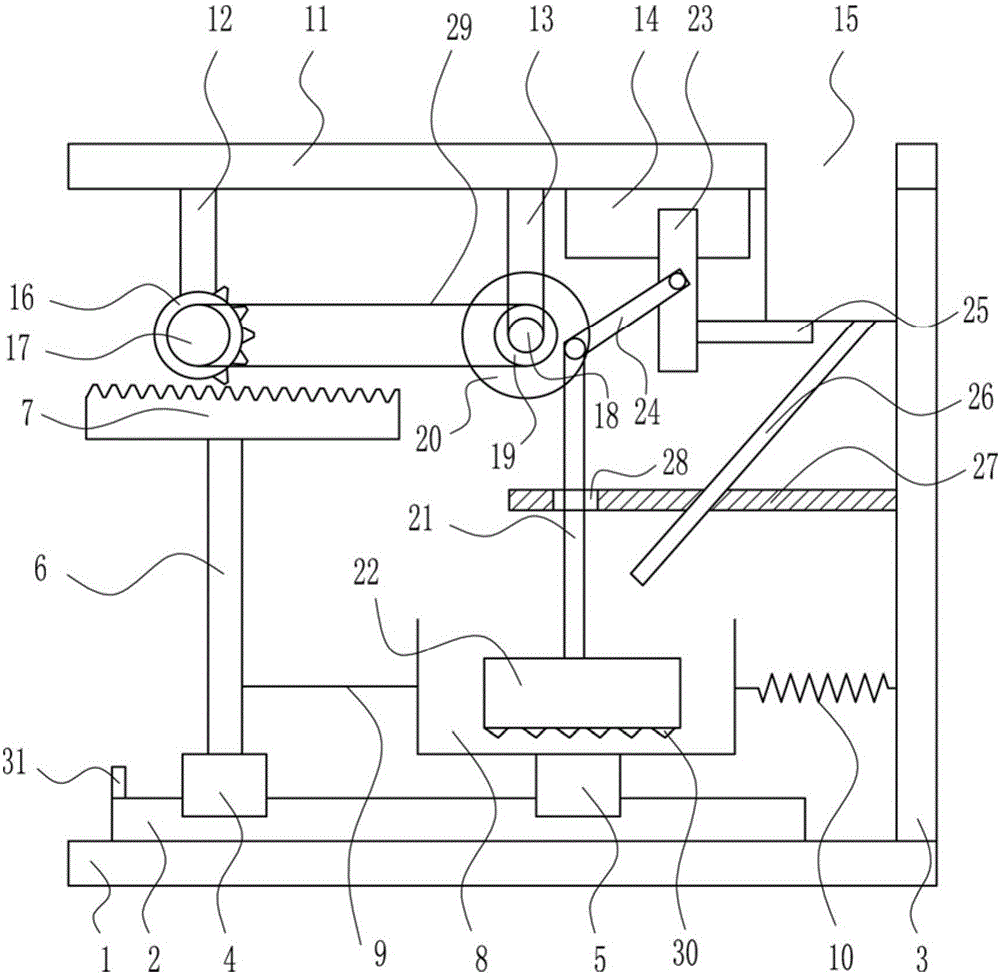

The invention relates to a soybean pulverizing device, in particular to a soybean pulverizing device for pre-production of soybean milk and aims at achieving the technical purpose of providing the soybean pulverizing device for pre-production of the soybean milk, wherein the soybean pulverizing device is easy to operate, uniform in grinding and high in work efficiency. To achieve the above technical purpose, the soybean pulverizing device for pre-production of the soybean milk is provided and comprises a bottom plate, a sliding block, a sliding rail, a right side plate, a first disc, a first motor, a fixed plate, an air cylinder, a supporting rod, a guiding plate, a pull wire, a left side plate, a weight block, a crushing box, a valve, a discharging pipe, a movable plate, a lifting rod, a spring, a fixing block, a contact wheel, a wedge block, a connecting rod, a push block, a first connecting rod, a second connecting rod, a third connecting rod, a second motor and a second disc, and the bottom plate is provided with the left side plate, the sliding rail and the right side plate from left to right. The soybean pulverizing device achieves the effects that operation is easy, grinding is uniform, and the work efficiency is high.

Owner:张巧芳

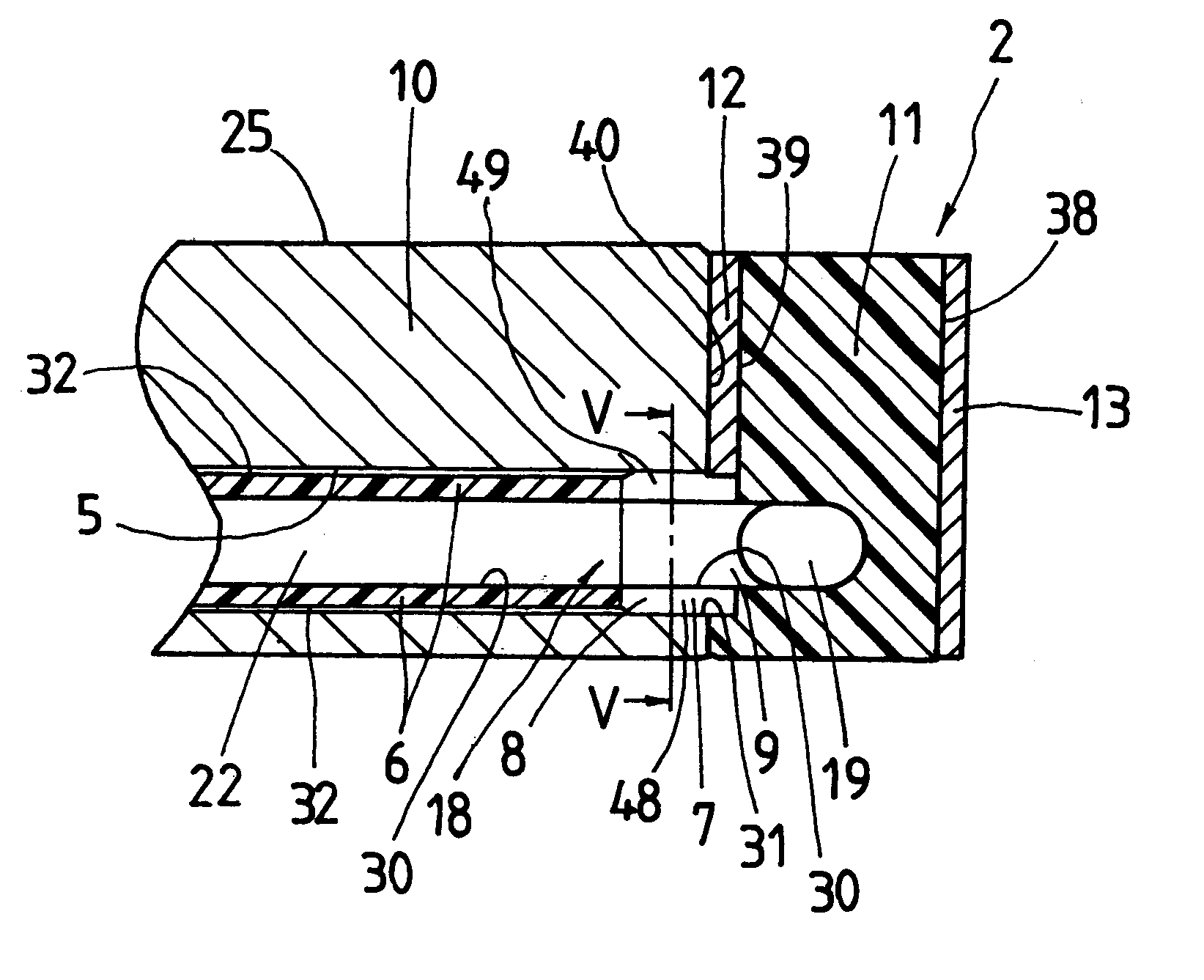

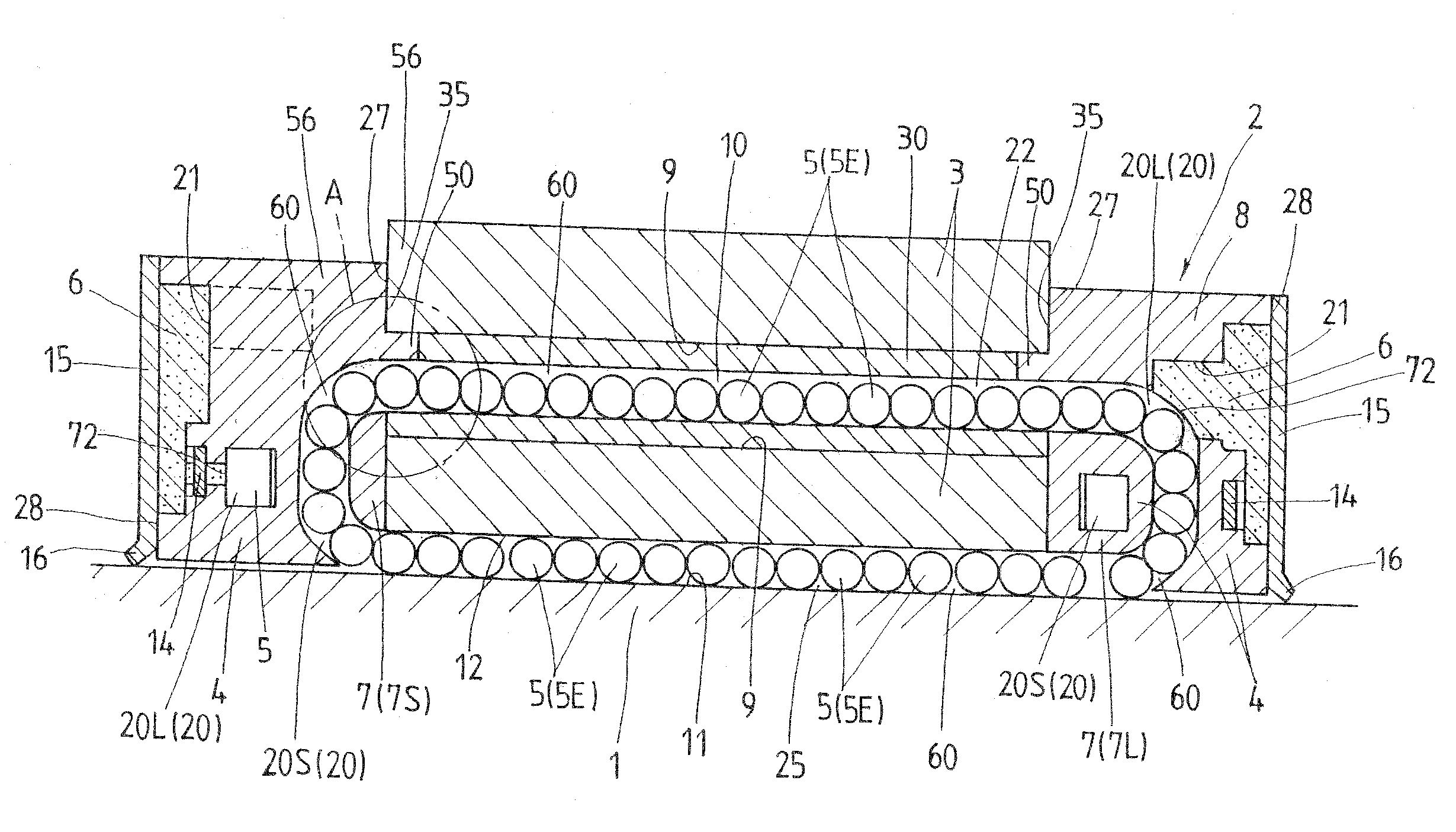

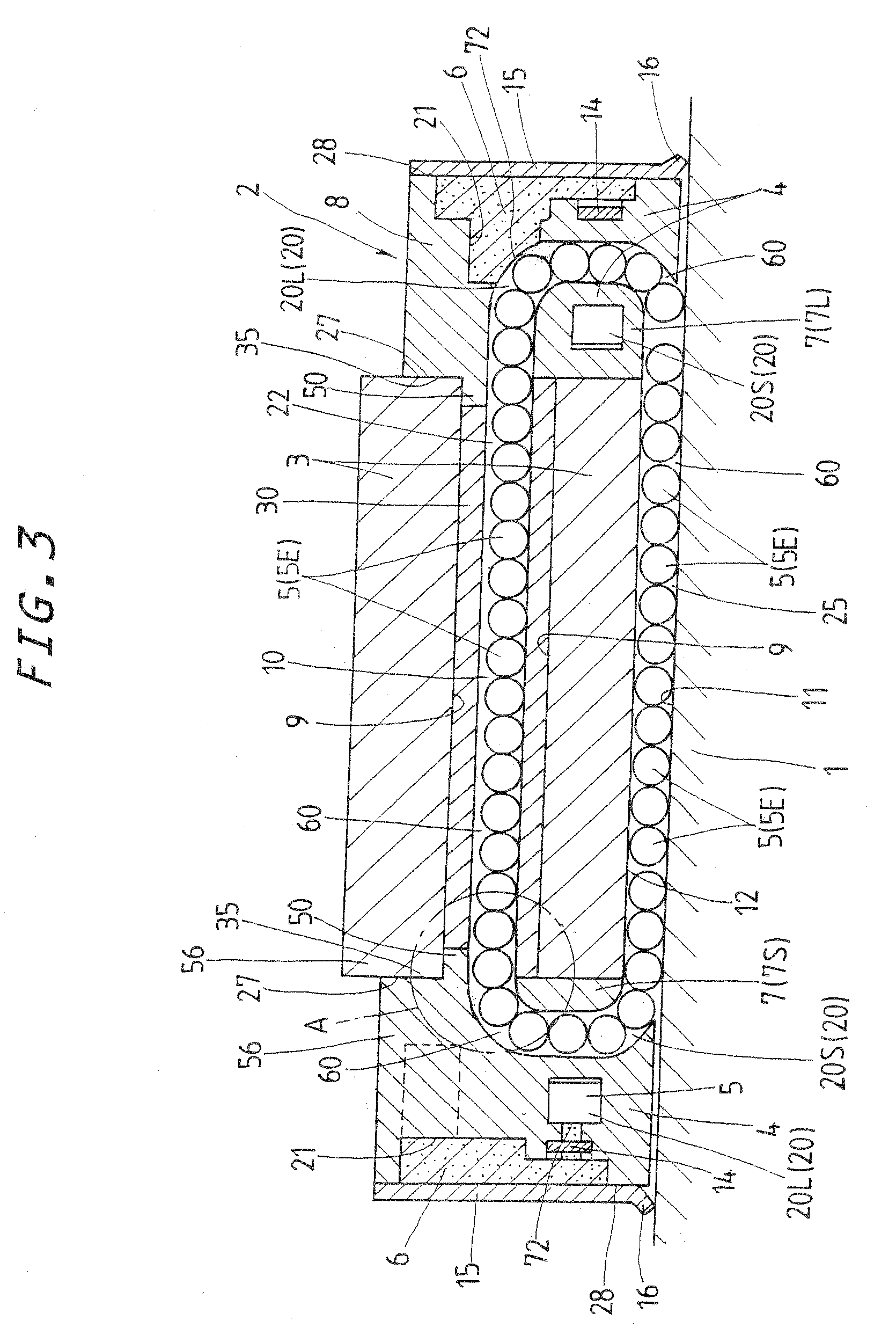

Linear motion guide unit with joint tube between return passage and turnaround

InactiveUS6729761B2Reduce resistanceInexpensive lubricationLinear bearingsBearing componentsLinear motionEngineering

A linear motion guide unit is disclosed in which a joint tube connects between a turnaround and a return passage of a sleeve made of sintered resinous material to ensure smooth turnabout of rolling elements and further in which lubricant can be supplied to the rolling elements for a prolonged period, thereby refining the durability. A slider is comprised of a sleeve for a return passage held with clearance fit in a through-hole of a carriage in a way lining major area of the through-hole with only forward and aft ends of the through-hole being left naked, a spacer with a lug having a radially inside curved half for a turnaround and an inside part for a joint tube to make up for any one end of the return passage joining with the radially inside curved half, and an end cap having a radially outside half for the turnaround and an outside part for the joint tube to make up for any one end of the return passage joining with the radially outside curved half.

Owner:NIPPON THOMPSON

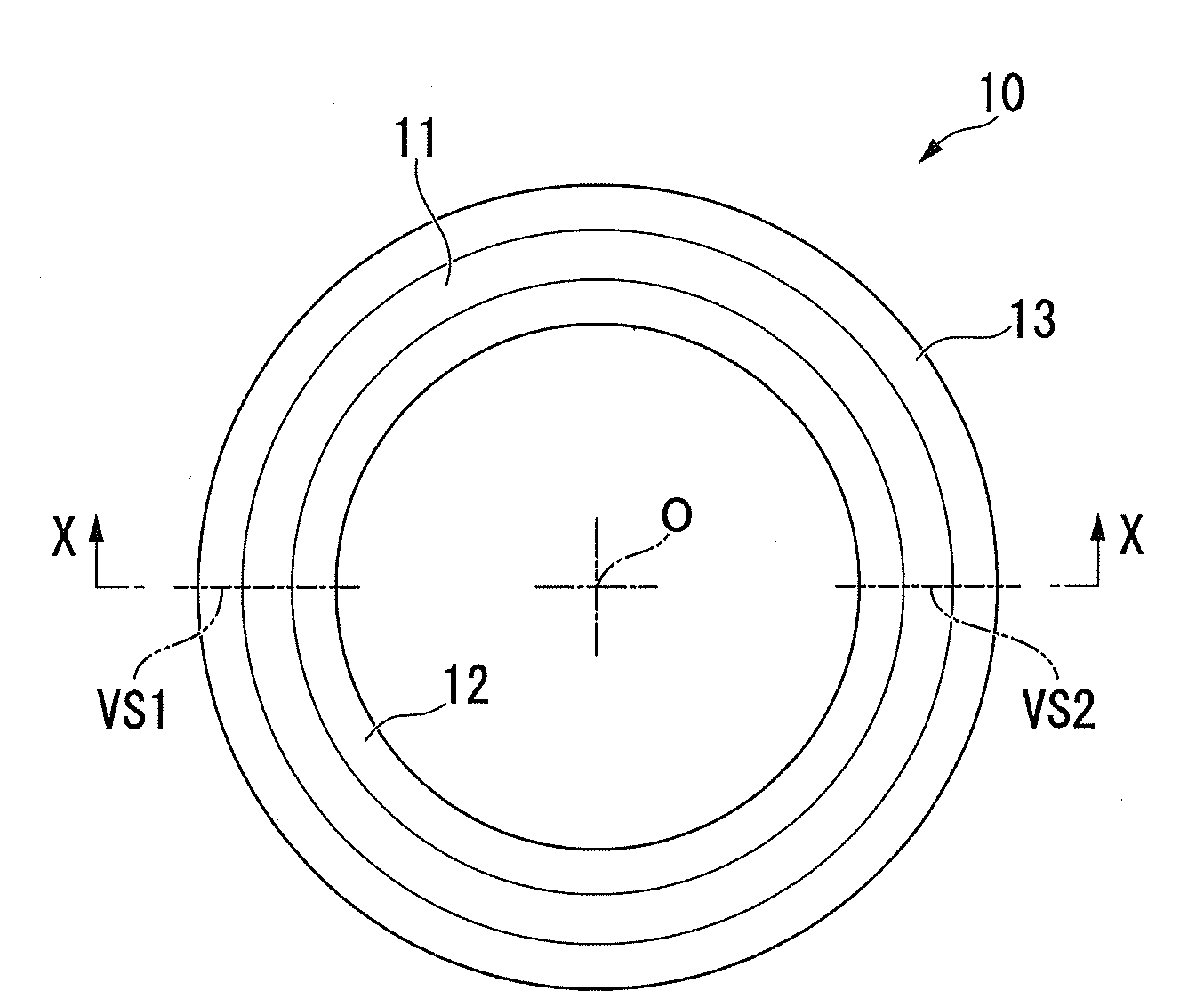

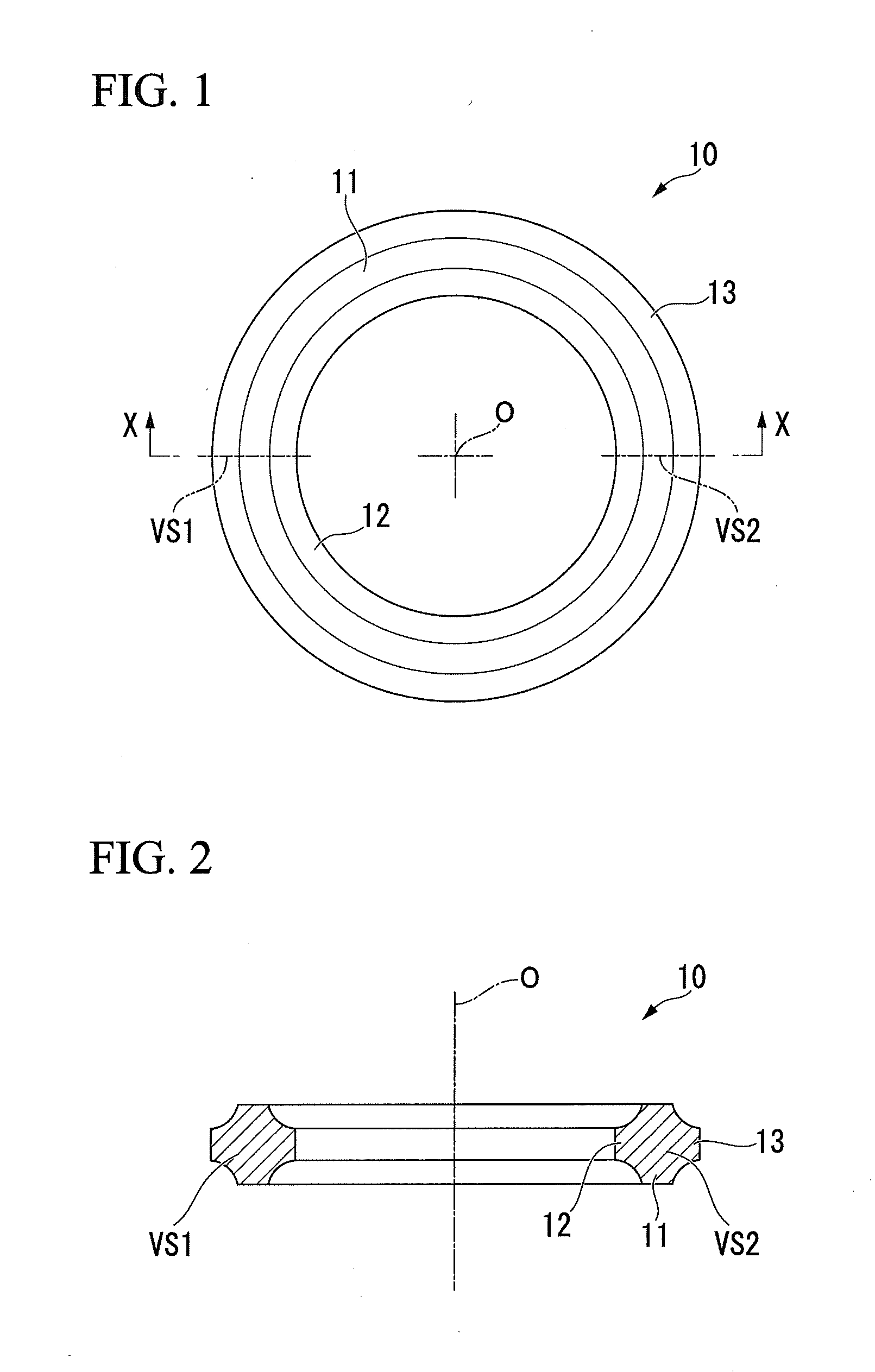

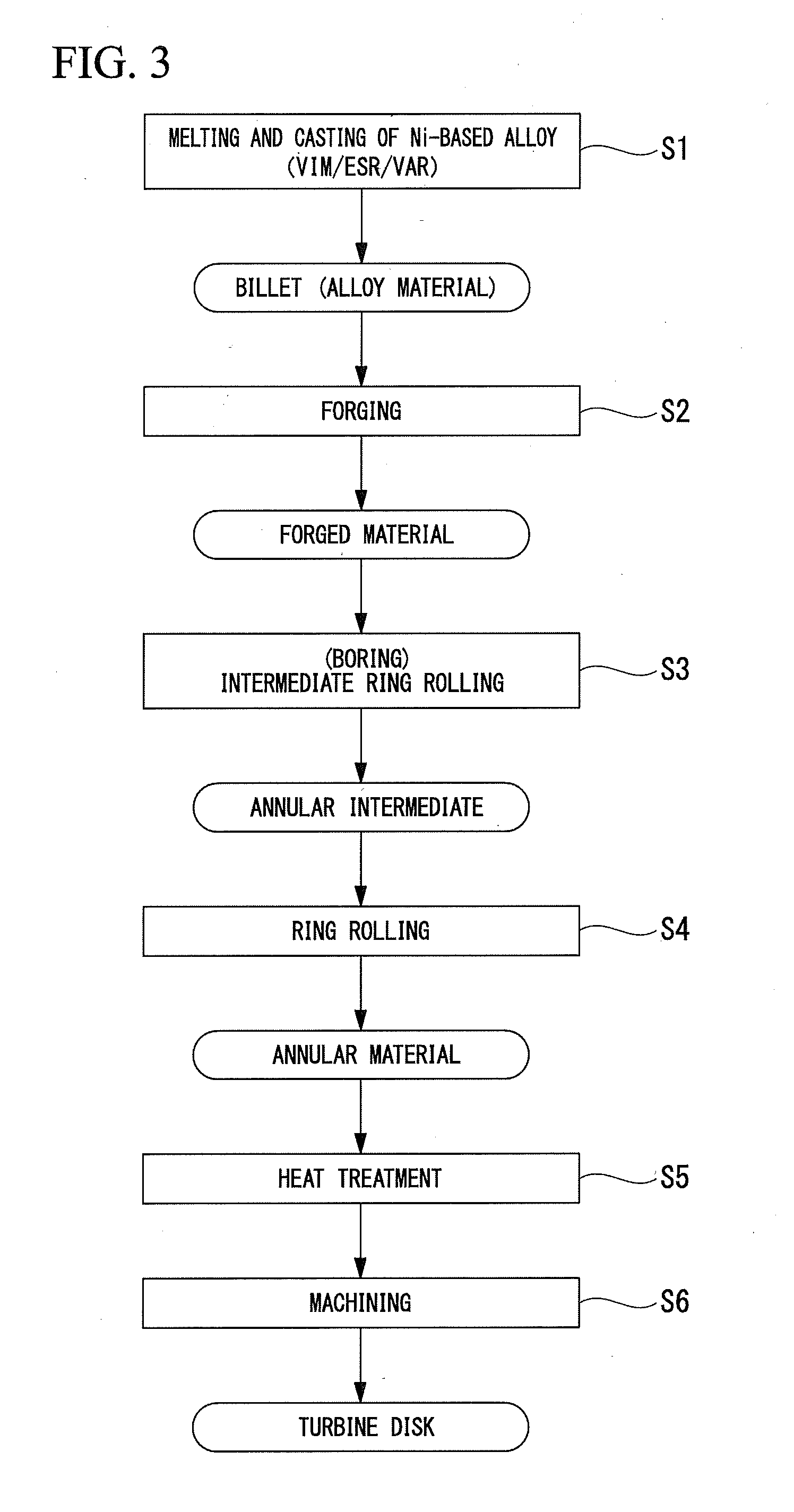

Method of manufacturing annular molding

A method of manufacturing an annular material includes: a forging process of making a discoid forged material by forging an alloy material; and a ring rolling process of making an annular material by performing ring rolling on an annular intermediate made by forming a through-hole in the forged material. In the forging process, hot forging which achieves an absolute value εθ1 of a strain in a circumferential direction of the forged material that is greater than or equal to 0.3, an absolute value εh of a strain in a height direction of the forged material that is greater than or equal to 0.3, and a ratio εh / εθ1 between the absolute values of the strains that is in a range of 0.4 to 2.5 is performed at least two or more times.

Owner:MITSUBISHI MATERIALS CORP

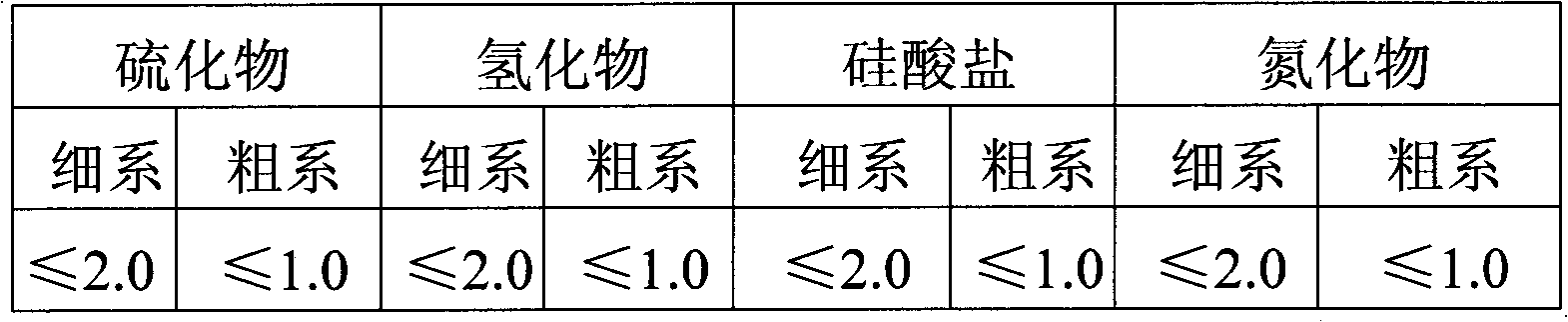

Stone material cutting saw blade steel and its manufacturing method

ActiveCN1904119AReduce the risk of continuous casting billet breakageReduce the technical problem of large deformation resistanceFurnace typesMetal rolling arrangementsChemical compositionImpurity

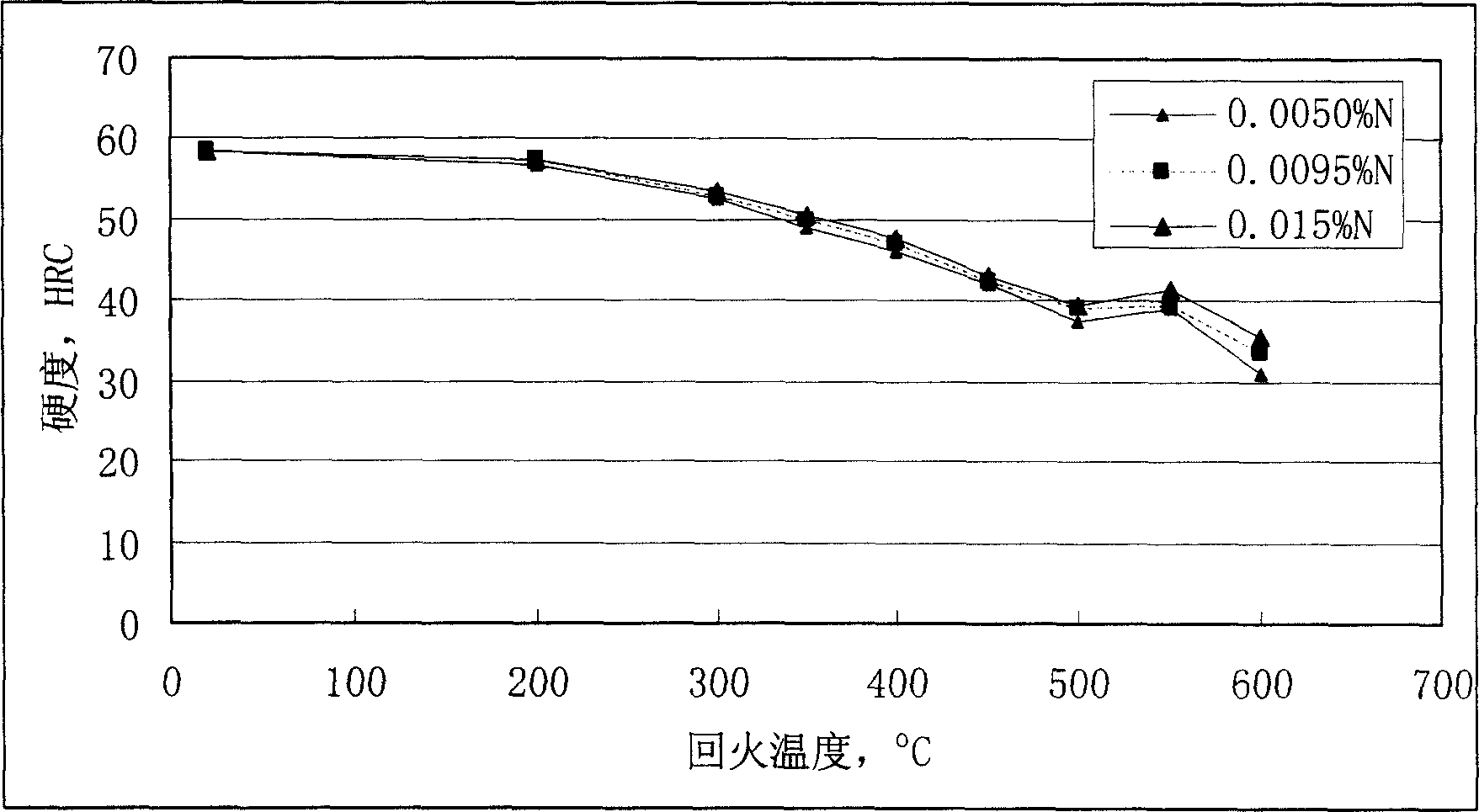

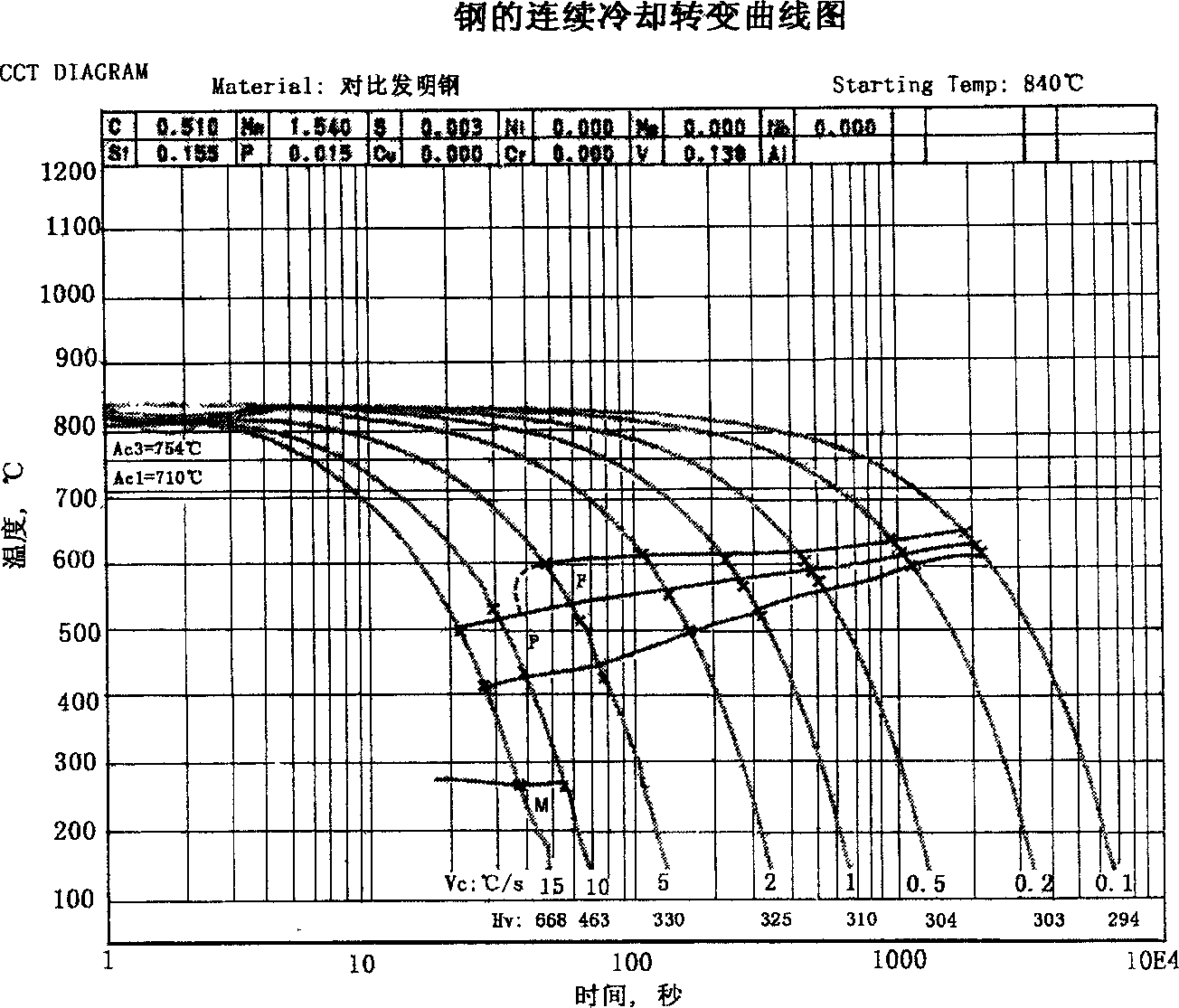

This invention relates to a type of steel used for saw blade for stone slotting. Account for weight the chemical composition is: C 0.45-0.60,Si 0.10- 0.60,Mn 1.30-1.80,P<=0.02,S<=0.01,V 0.05-0.20,Cr 0.15-0.30, N 0.005-0.020,Ca 0-0.0050,Al 0.005-0.040, and the rest is Fe and inevitable impurity. The process includes steps as follows: smelting, casting,; continuous casting billet use heat sending and heat packing , ensure the temperature keep above 300DEG C before it be send into plate body for heating; keep temperature for plate body heating above 1150DEG C,temperature for hot rolling above 900DEG C; cooling after rolling, then coiling, keep the coiling temperature above 700DEG C. This invention has higher hardenability then midst-carbon and low-alloy steel, especially refer to make large saw blade which diameter is above 1000mm.

Owner:BAOSHAN IRON & STEEL CO LTD

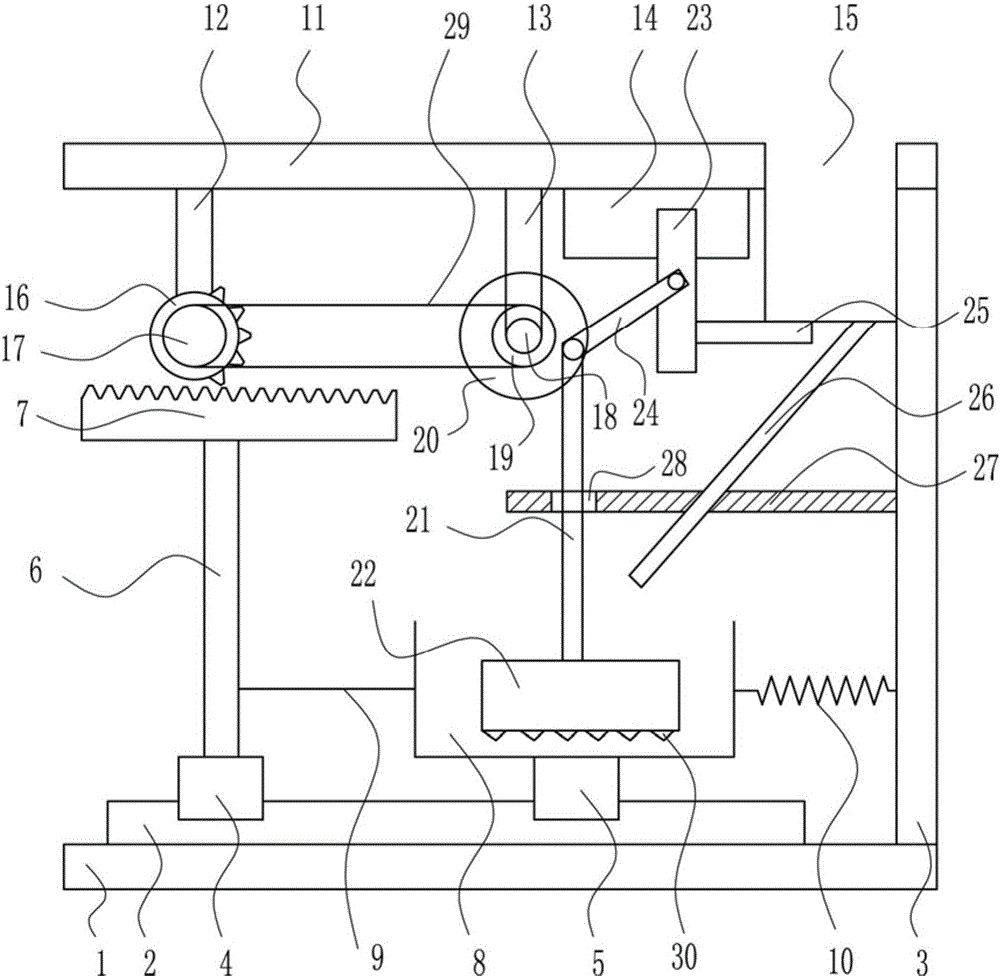

Fast crushing equipment used for herb medicine

This invention relates to a kind of herb medicine crusher, especially a kind of efficient crusher of herb medicine. The technical issue solved by this invention is to provide an efficient herb medicine crusher which can save manpower and time. To solve this issue, this invention provides such an efficient herb medicine crusher which includes bottom plate, first sliding rail, right side plate, first sliding block, second sliding block,first supportive rod, rack, treatment basket, pull wire, elastic element, roof plate, second supportive rod, on the bottom plate there is first sliding rail and right side plate, the first sliding rail is located on the left side of right side plate, the first and second sliding blocks are connect to first sliding rail, the first sliding block is located on the left side of second sliding block. This invention provides fast crushing equipment of herb medicine used for medical care, which adopts electric motor to drive the pressure block to move up and down to crush the herb inside treatment basket.

Owner:王彩云

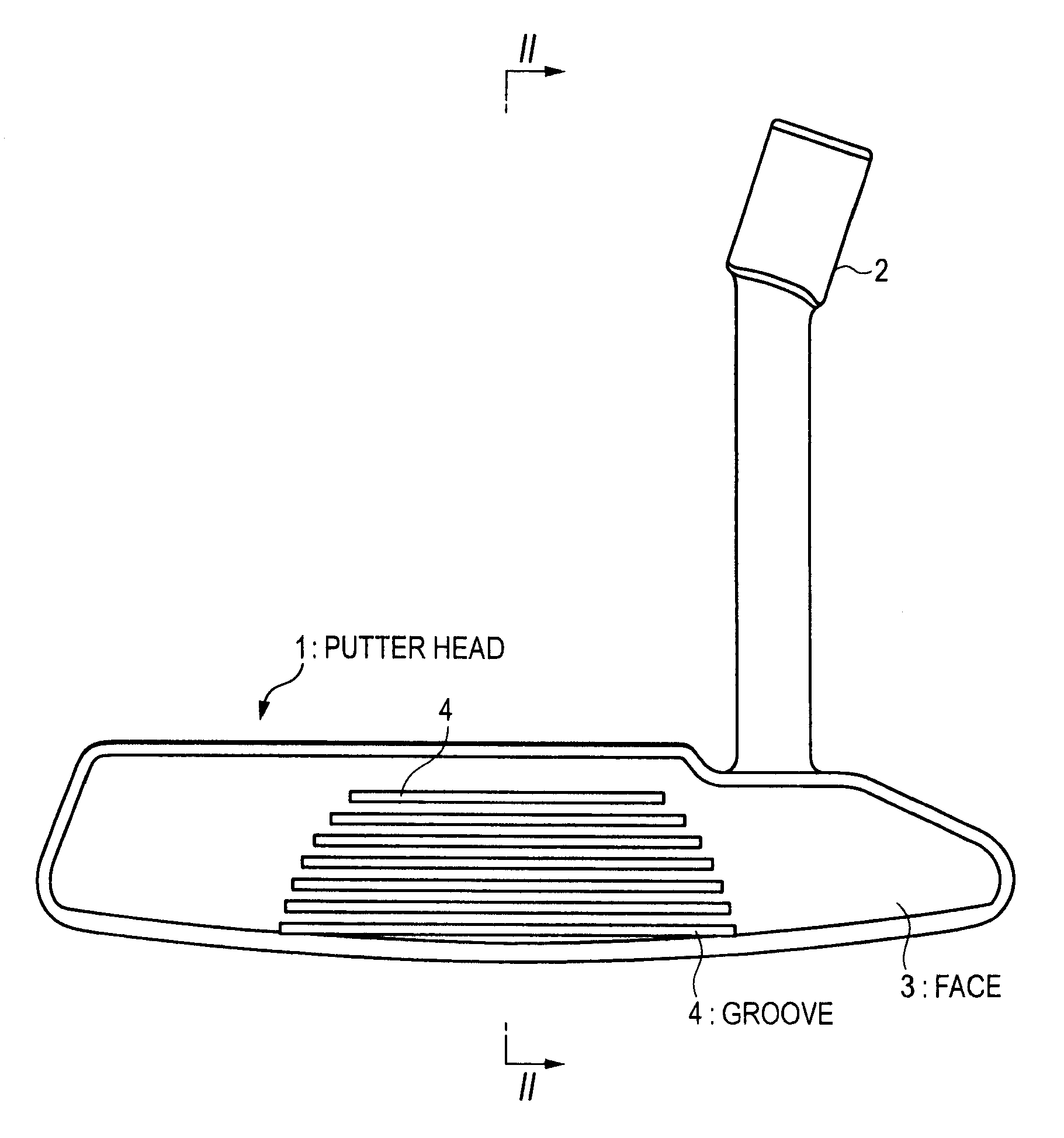

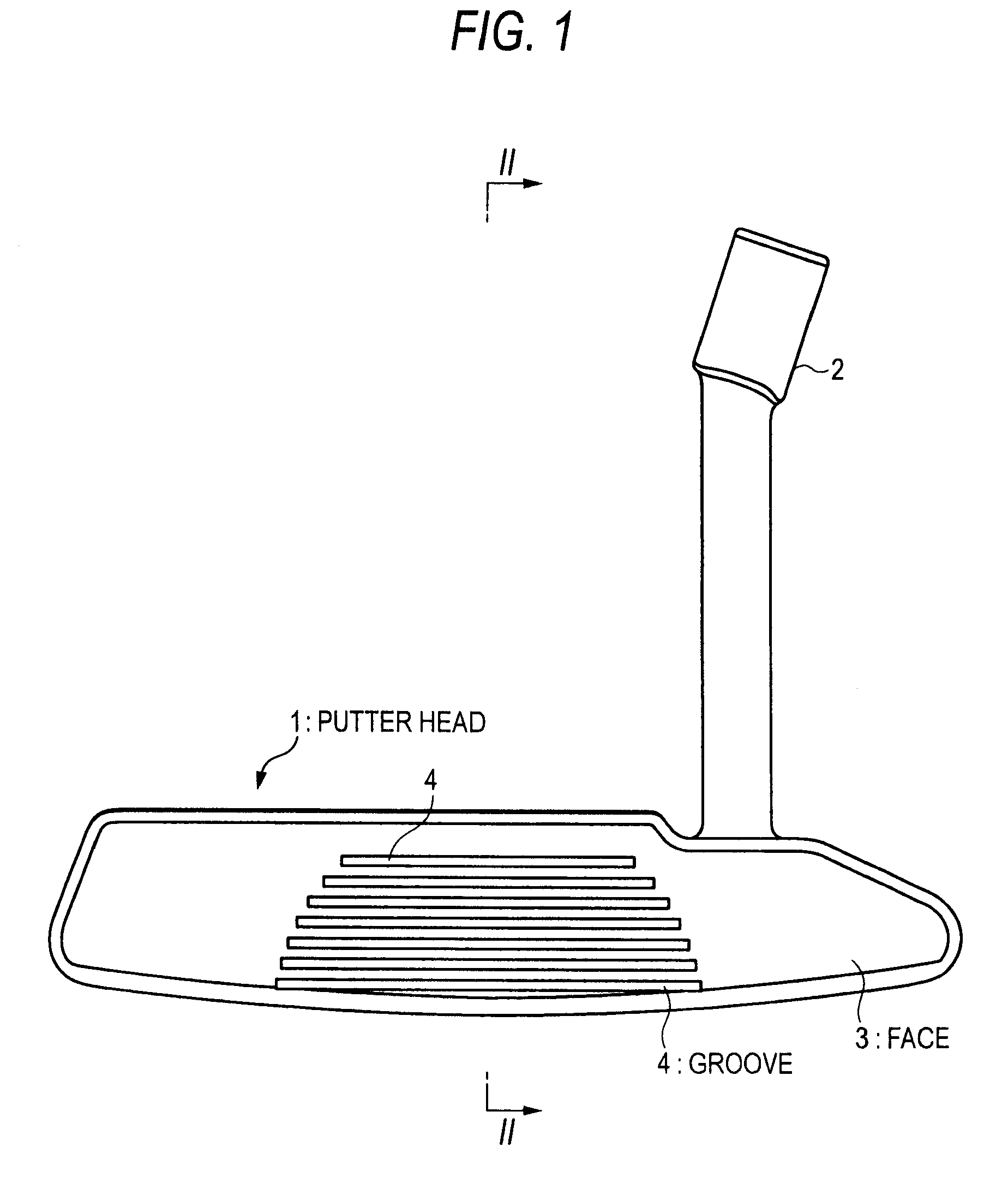

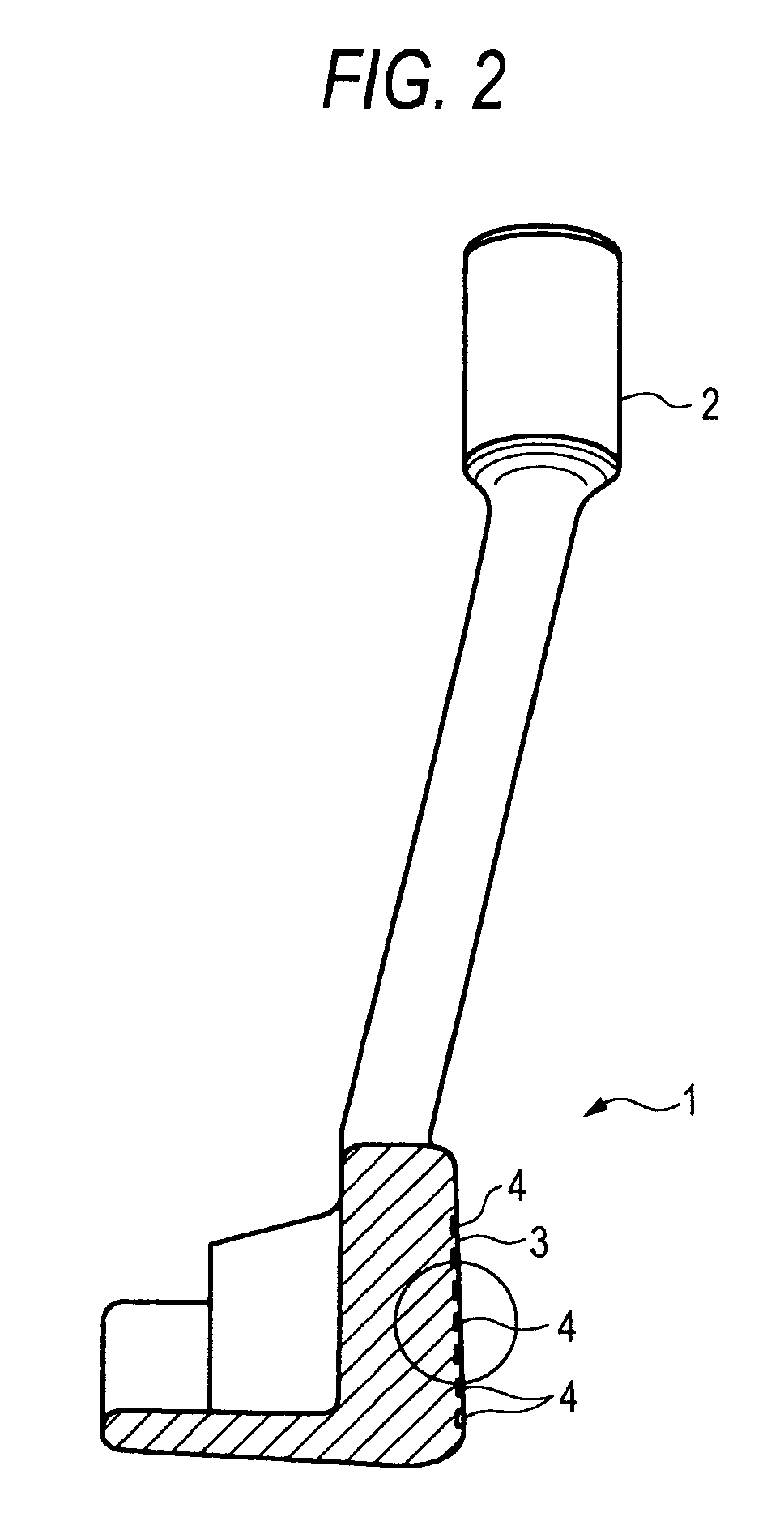

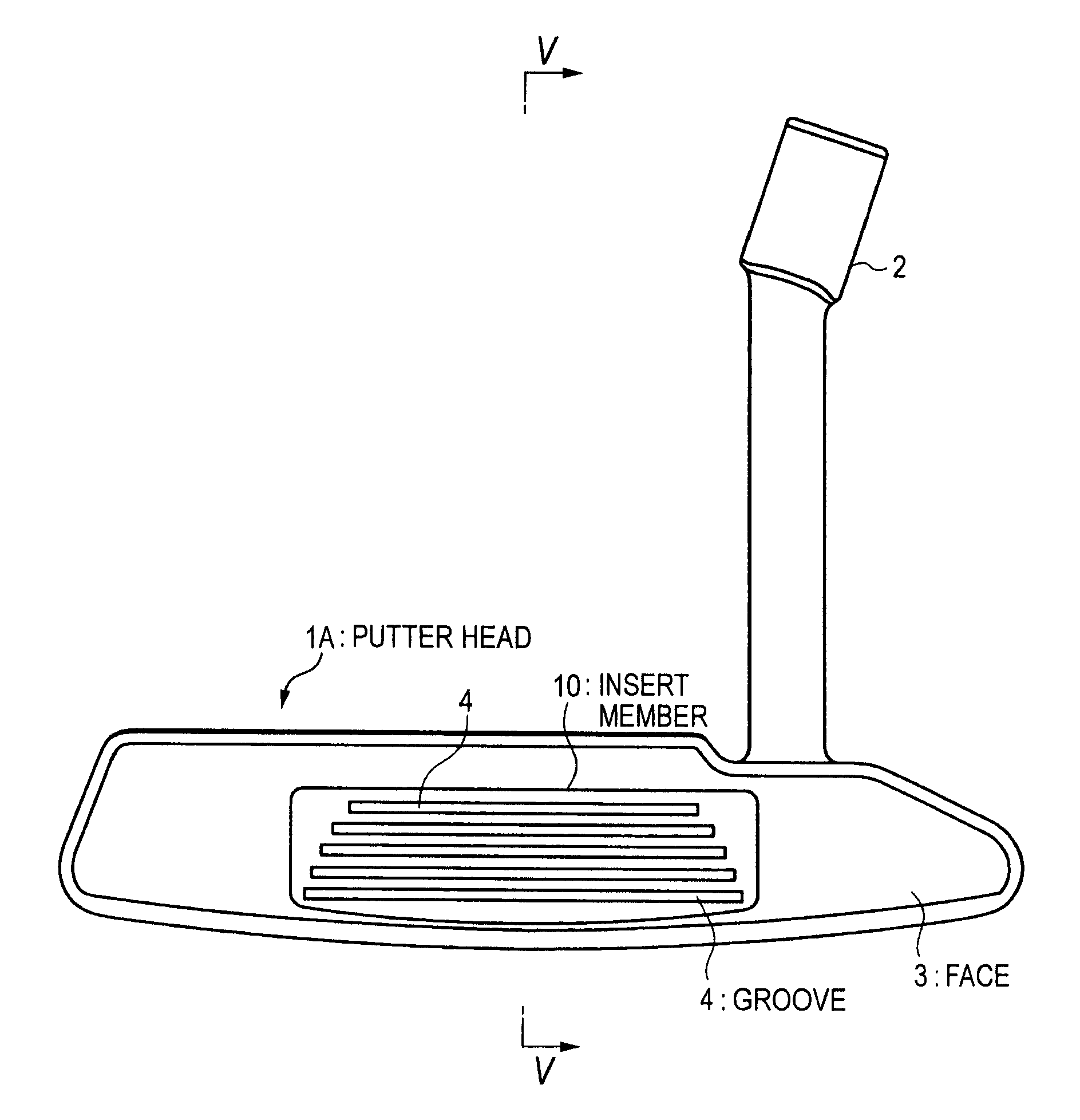

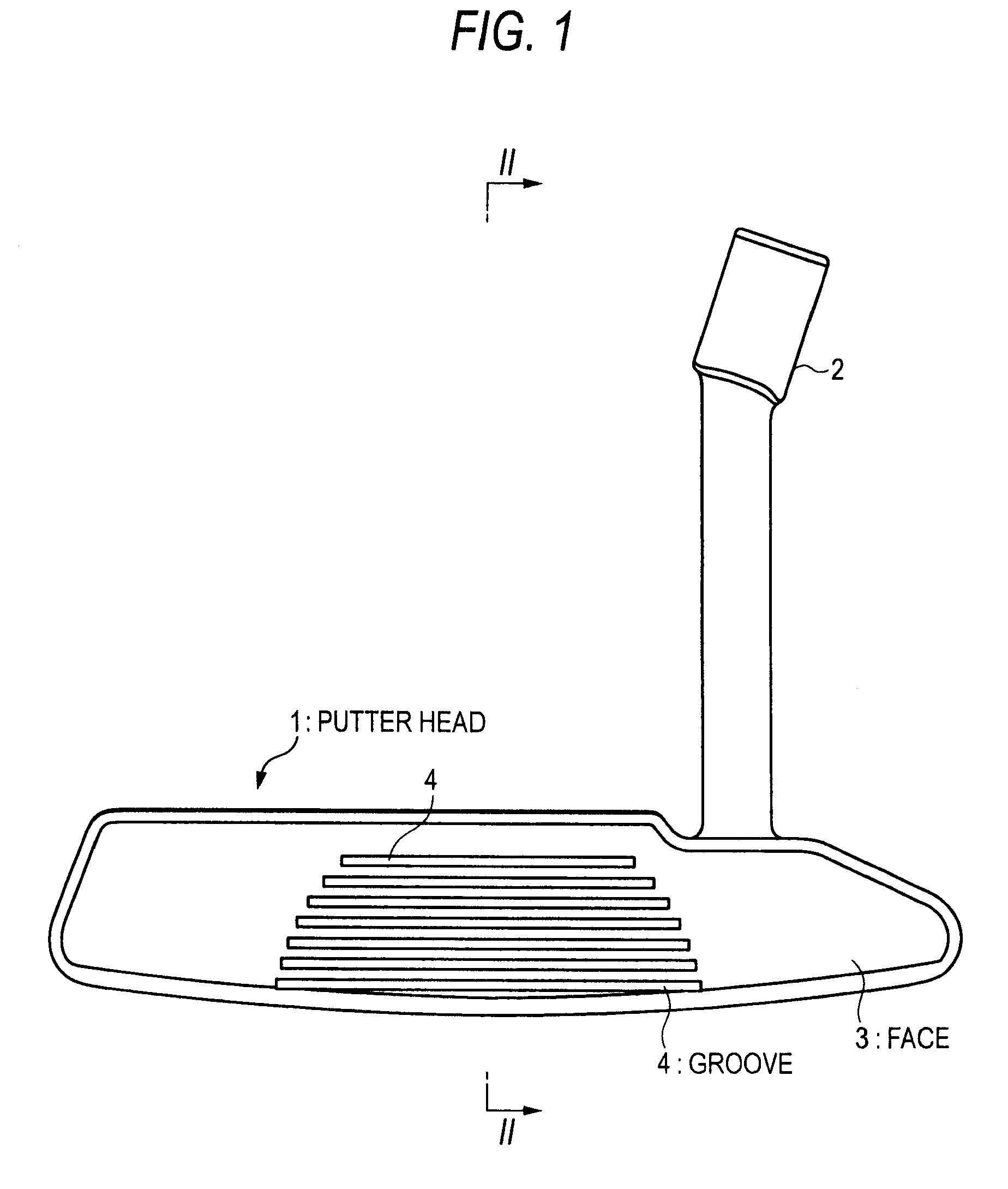

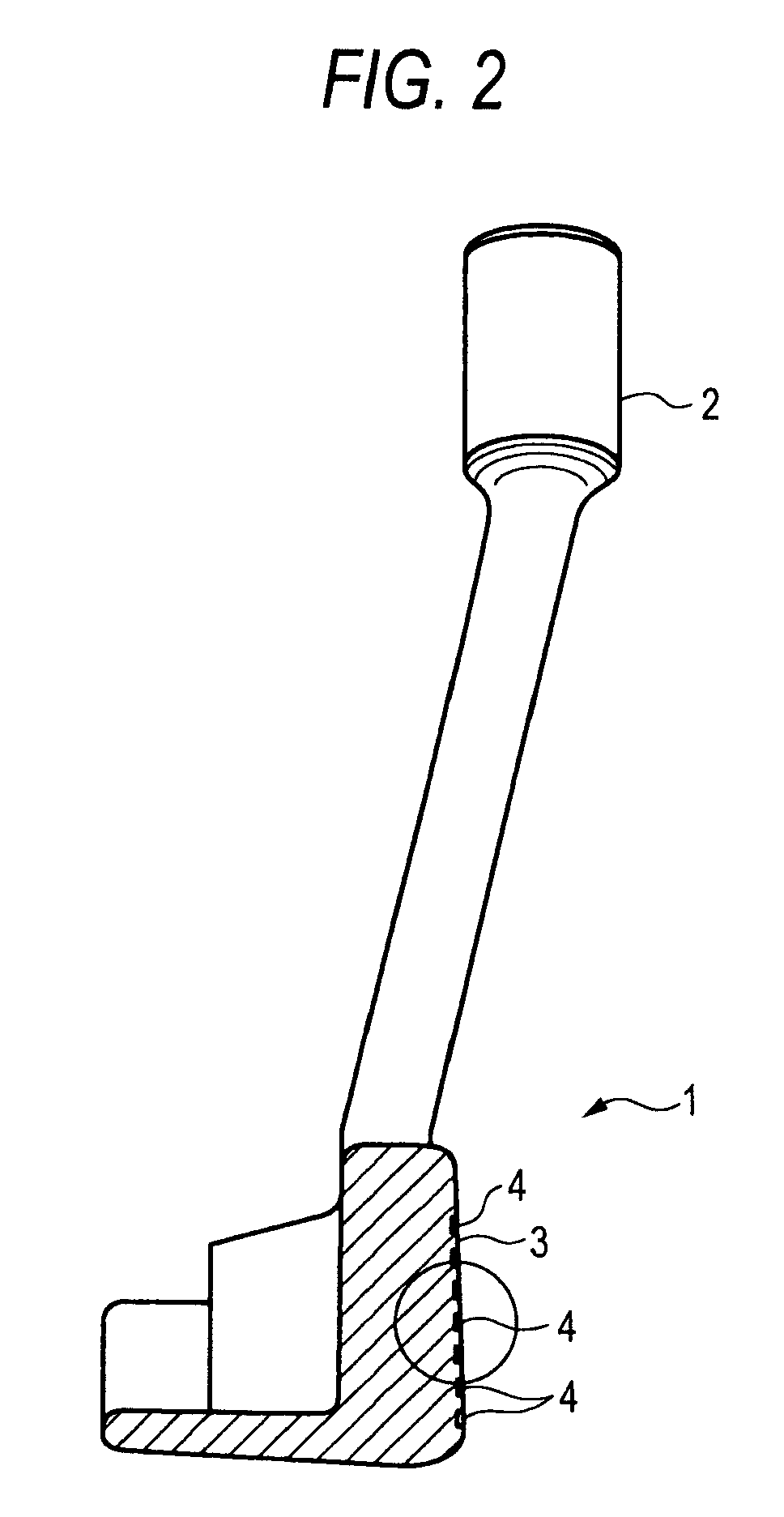

Putter head

InactiveUS20080125240A1Smooth rollingLow backspin amountGolf clubsRacket sportsGroove widthEngineering

A putter head includes substantially parallel plural grooves formed on a face thereof, wherein a ratio W / S of a groove width W (mm) and a space width S (mm) between the grooves is from 0.5 to 2.0.

Owner:BRIDGESTONE SPORTS

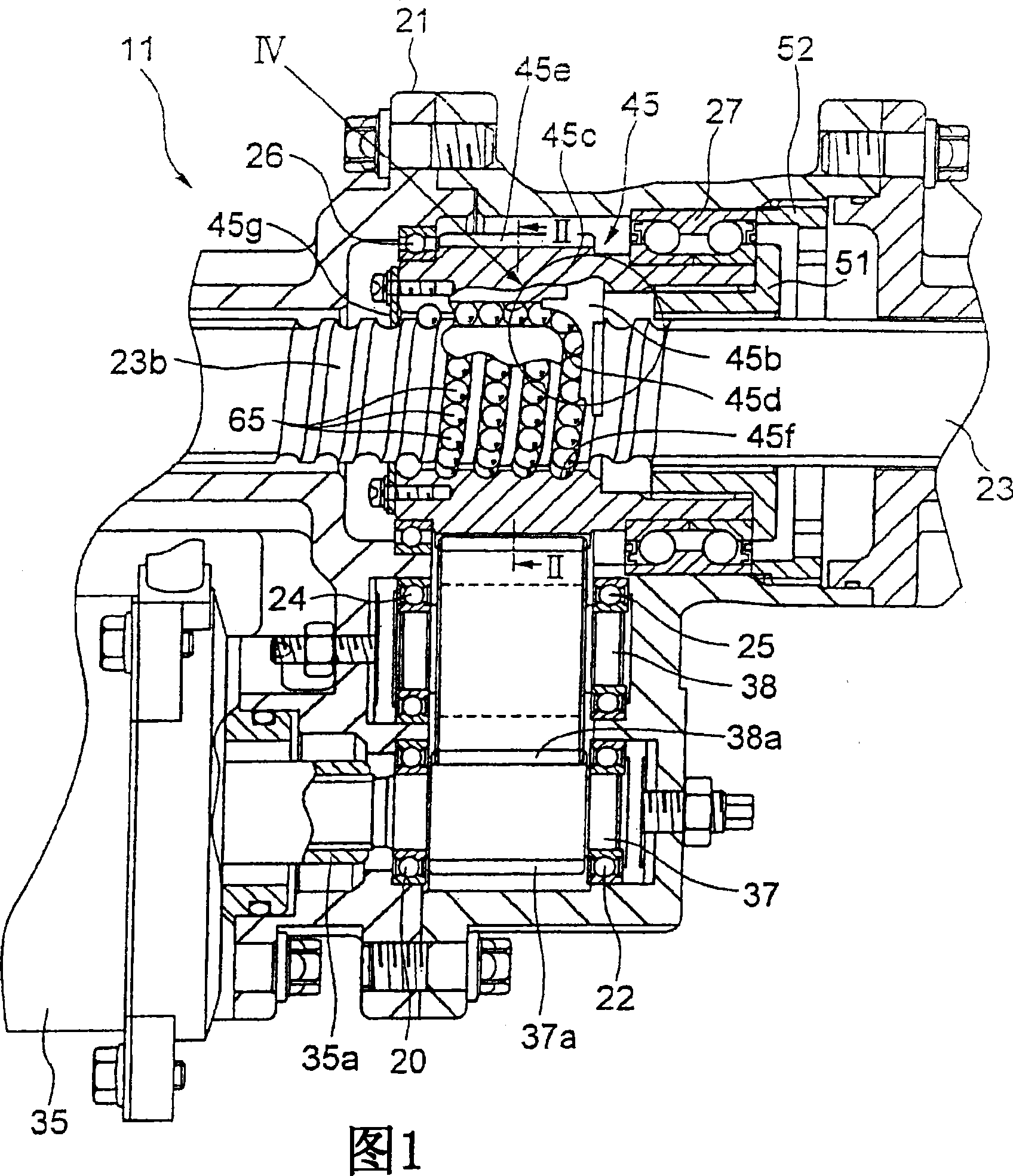

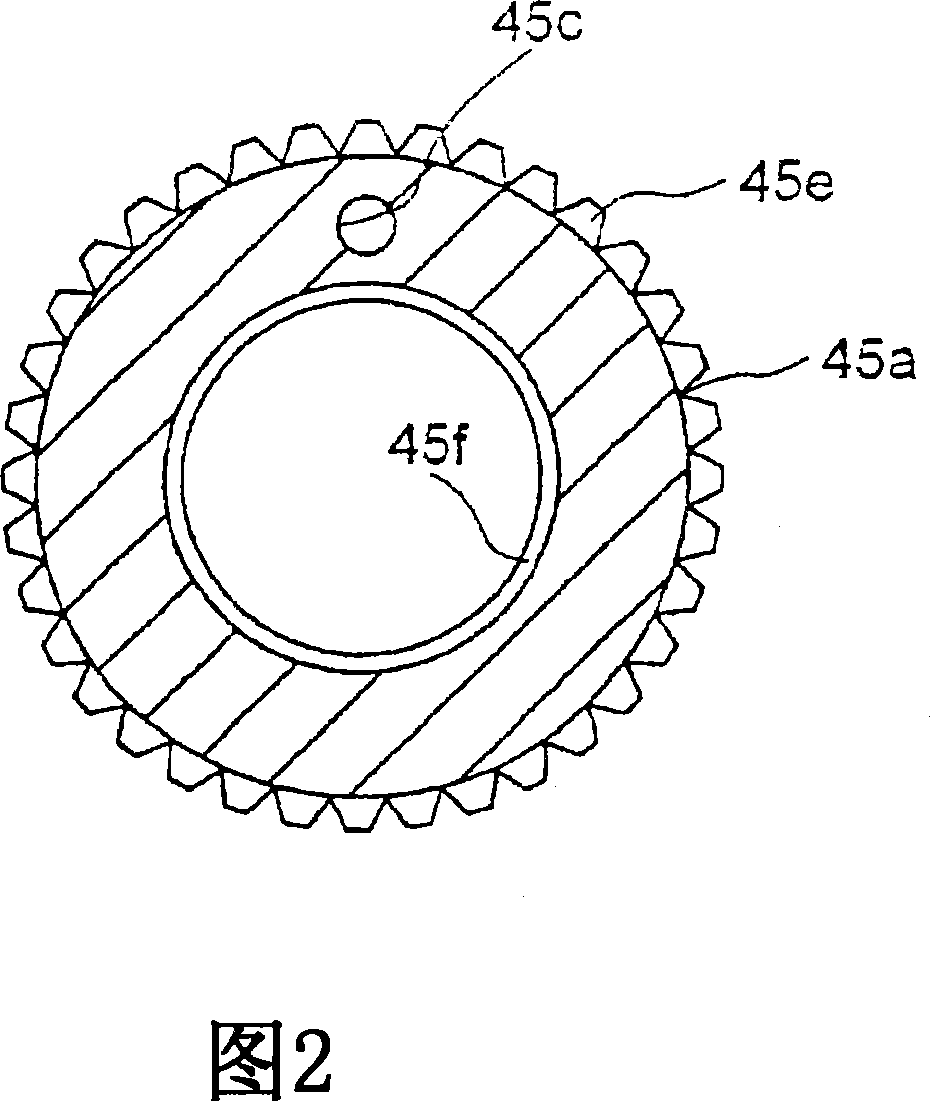

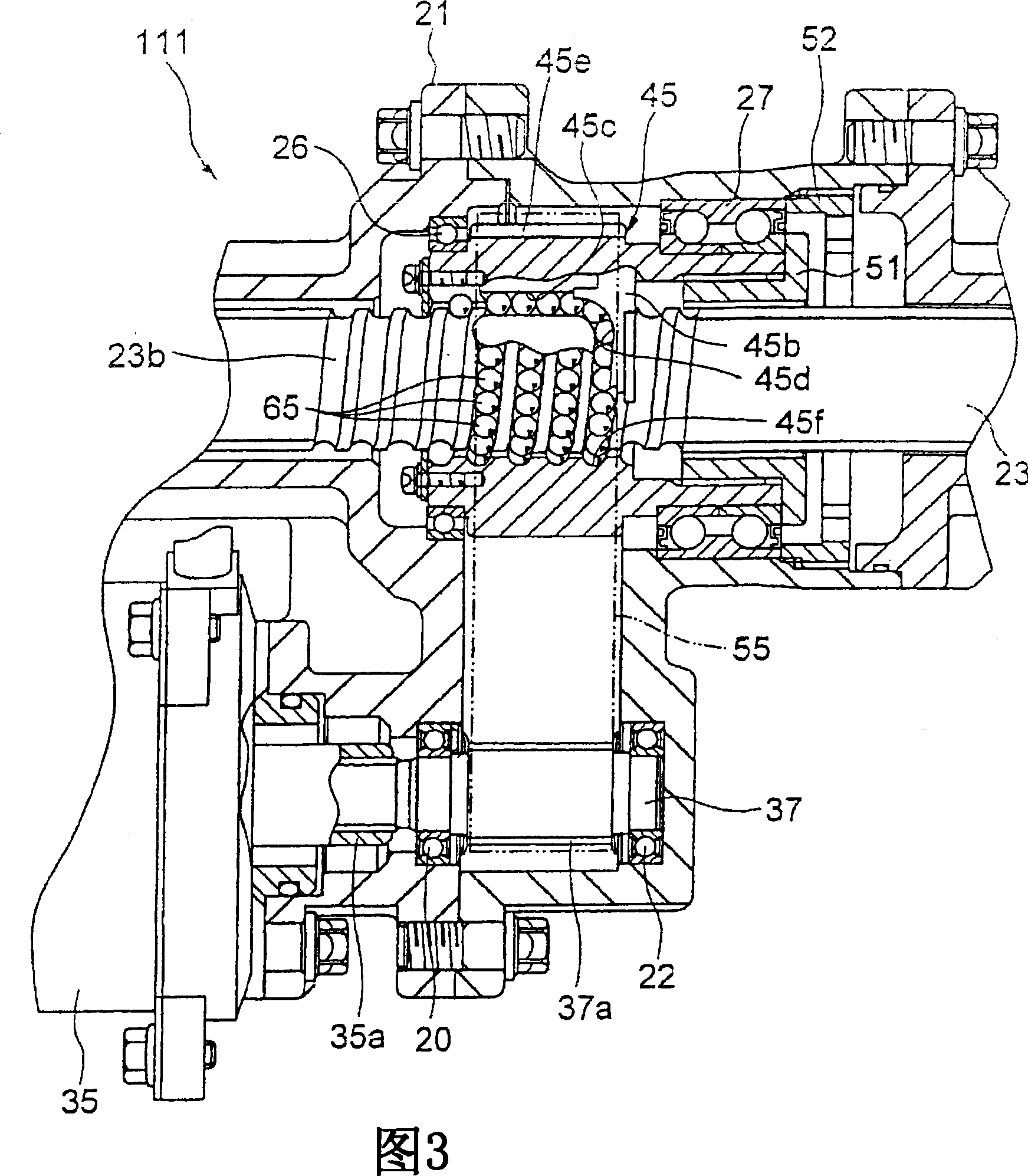

Electric power steering device

InactiveCN101001778ASmooth rollingSmall sizeGearingElectrical steeringElectric power steeringElectrical and Electronics engineering

A deflector (45b) of a nut (45) scoops up balls (65) from rolling raceways (23b, 45f) to a tangential direction of the rolling raceways, in the direction of a lead angle. As a result, the balls (65) are scooped up to a circulation path (45c) with their direction of rolling unchanged, so that smooth rolling can be achieved, and operation noise and vibration can be suppressed to low levels.

Owner:NSK LTD

Putter head

InactiveUS8066587B2Hinders the rolling of the golf ballReduce backspinGolf clubsRacket sportsGroove widthEngineering

A putter head includes substantially parallel plural grooves formed on a face thereof, wherein a ratio W / S of a groove width W (mm) and a space width S (mm) between the grooves is from 0.5 to 2.0.

Owner:BRIDGESTONE SPORTS

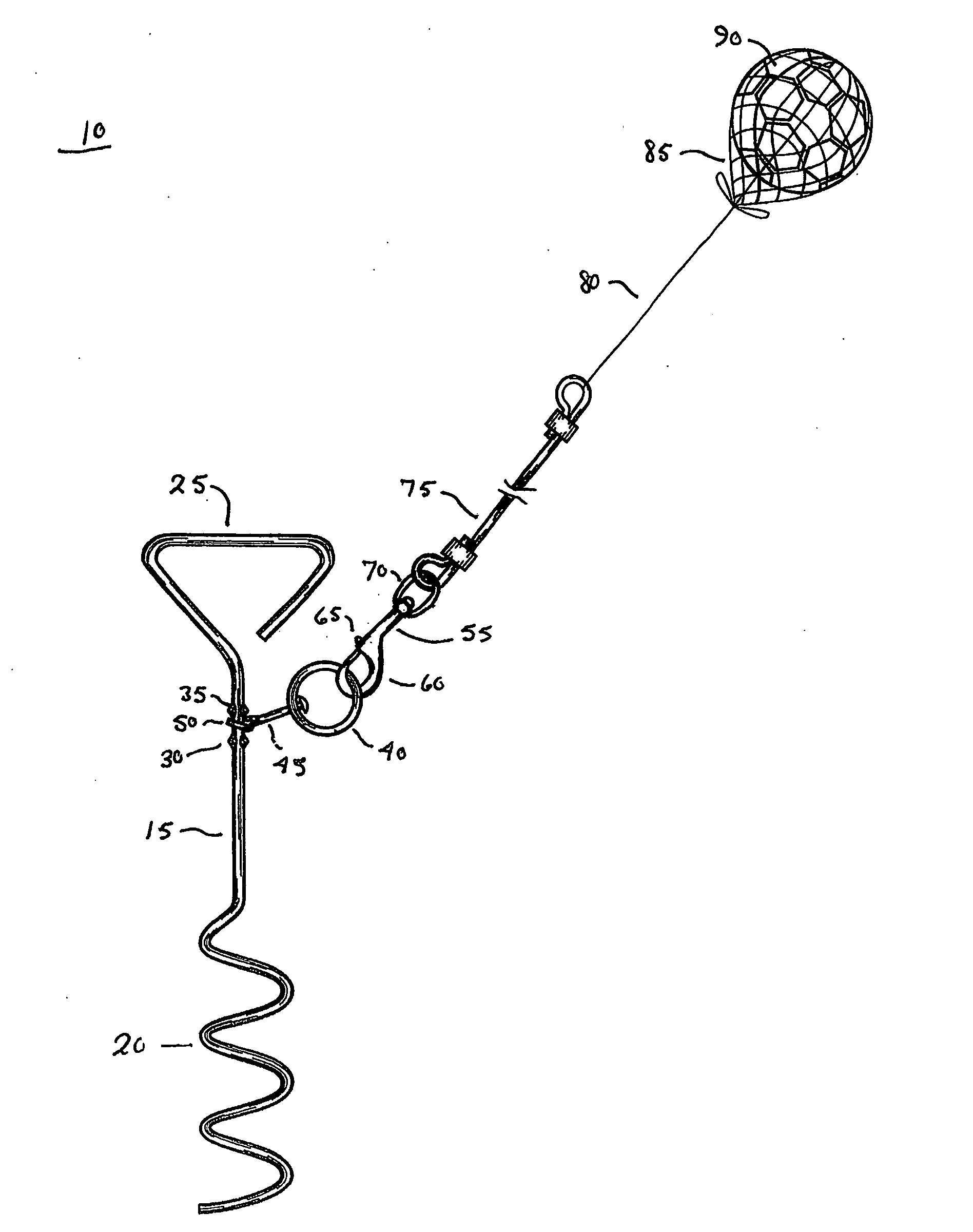

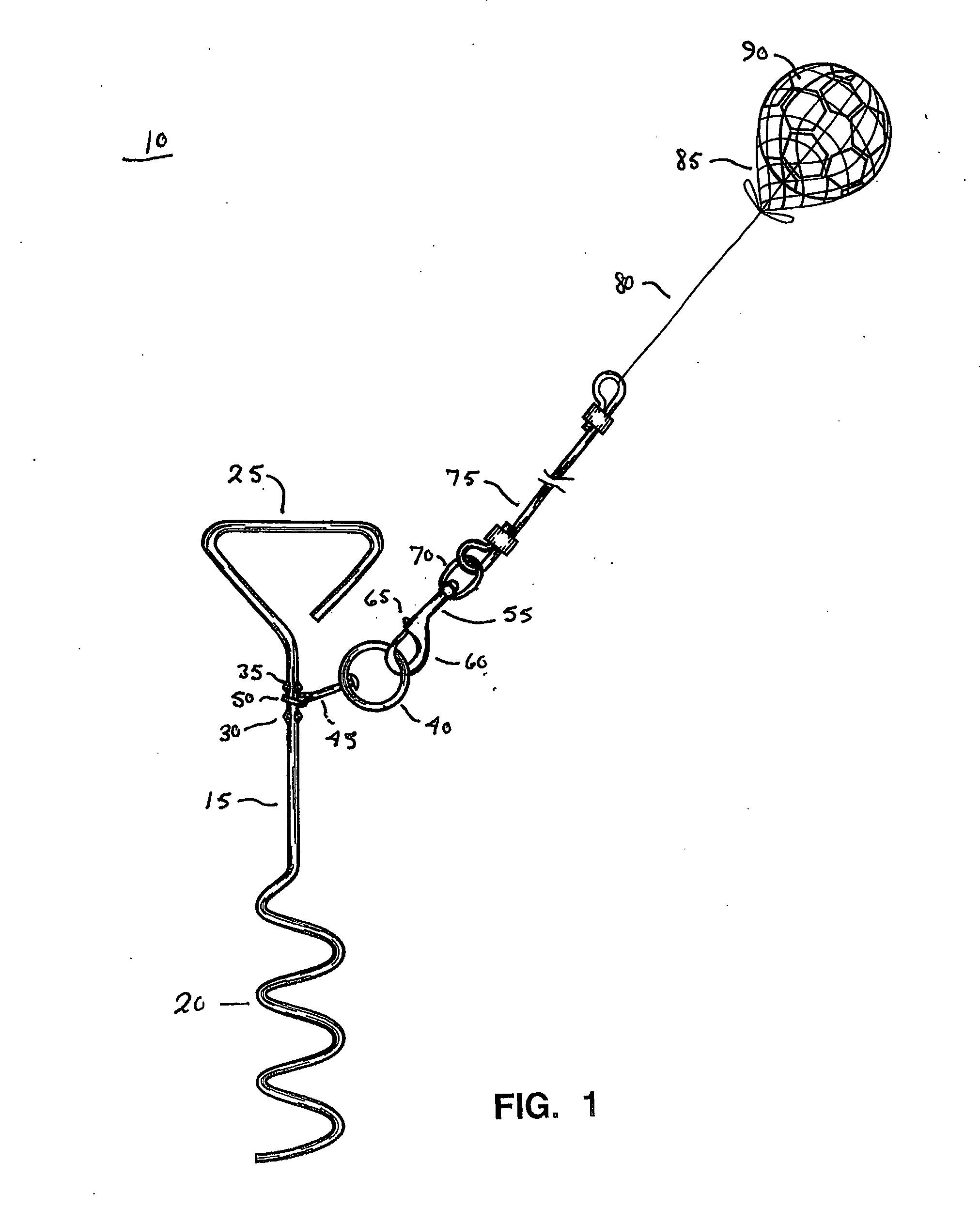

Interchangeable soccer training system

The present invention is a soccer training system for holding and retrieving a soccer ball including a detachable tether mechanism that is capable of easily switching between being ground-mounted, hand-held, and belt-mounted, depending on what practice skills are desired. The invention is an incorporated kicking, shooting, dribbling and juggling soccer training device that simulates real soccer play.

Owner:EVANS CHRISTOPHER +1

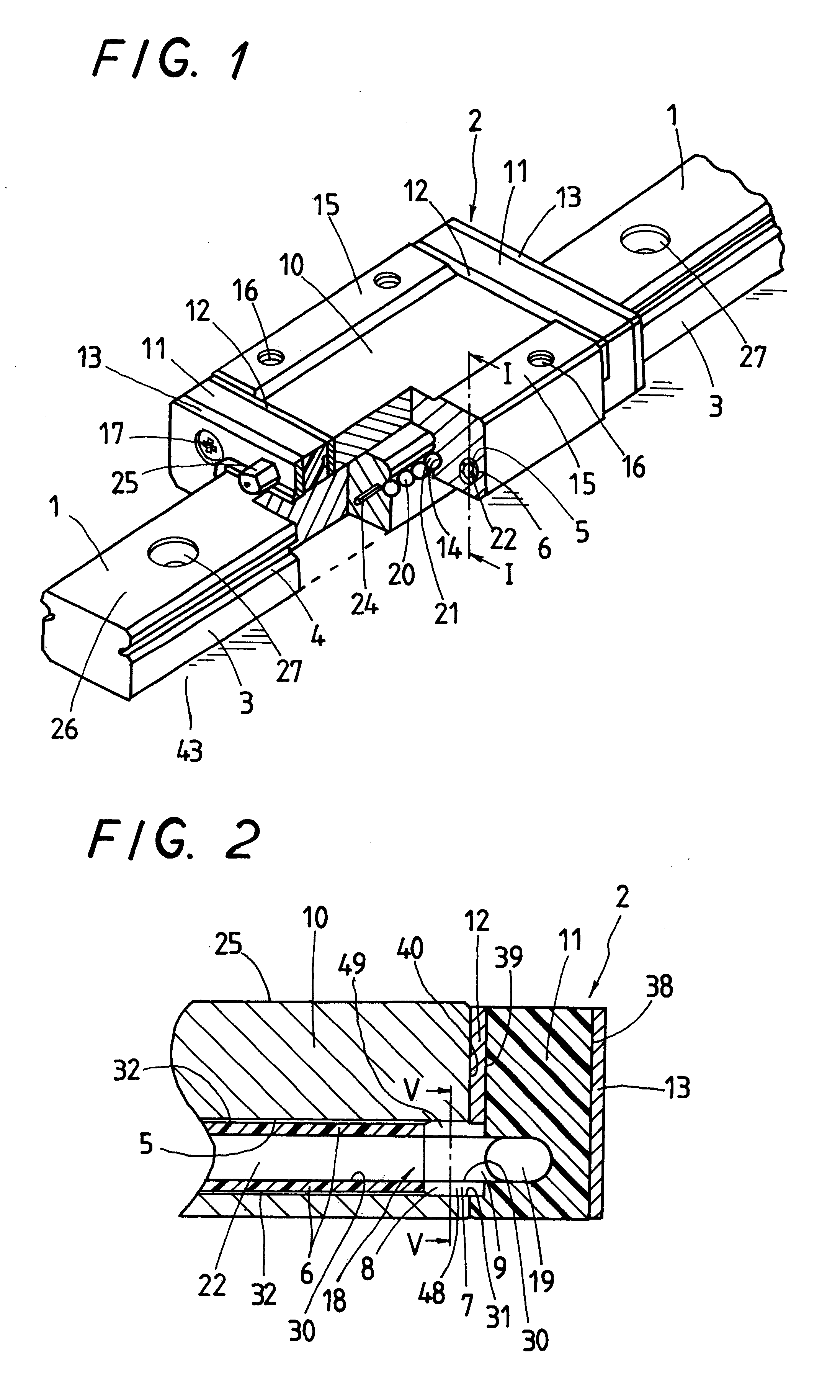

Linear motion guide unit with roller

ActiveUS20090016654A1High rigidity and accuracySmooth rollingLinear bearingsReturn channelEngineering

A linear motion guide unit is envisaged smooth transfer of a roller from a turnaround passage to a return passage and vice versa across a joint between the turnaround passage and the associated return passage. Protrusions extending stepwise from an end of the turnaround passage come into complementary fit joints with an associated end of a tubular member defining the return passage to make wall surfaces to guide axially opposite ends of the roller, in which the joints are staggered or different in their locations between wall surfaces. The return passage is defined with a fore-and-aft hole of rectangular shape in transverse section inside a tubular member that fits into a bore made in the carriage. The tubular member is joined at lengthwise opposite ends thereof together to the protrusions that are raised above end surfaces of the end caps to extend the turnaround passage into the bore. Edges of the protrusions come into complementary fit joints with the associated ends of the tubular member to provide wall surfaces to guide axially opposite ends of the roller.

Owner:NIPPON THOMPSON

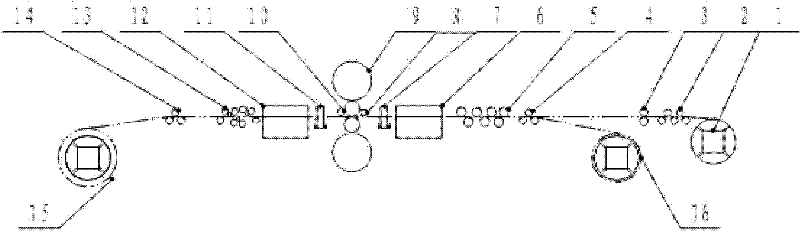

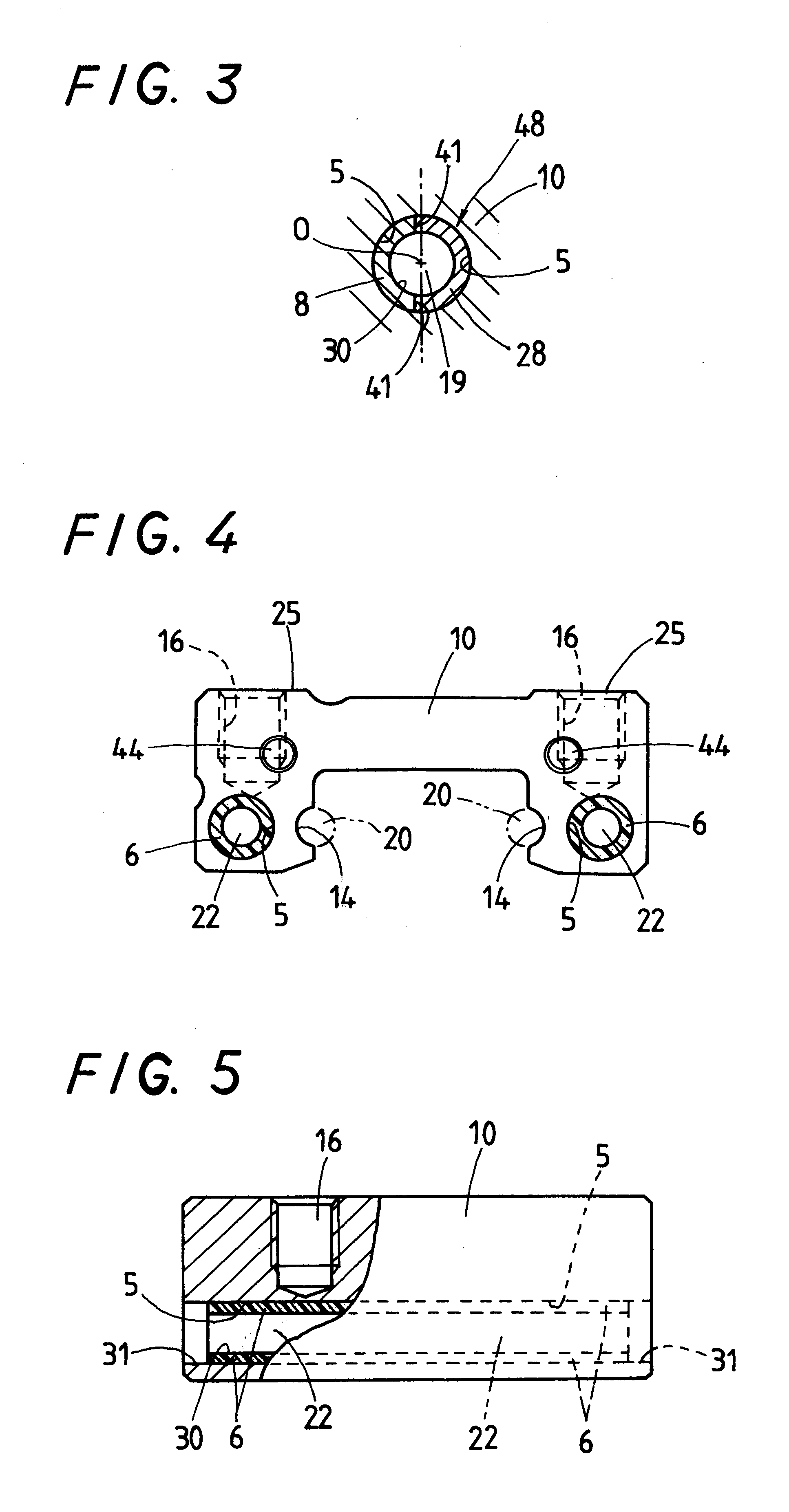

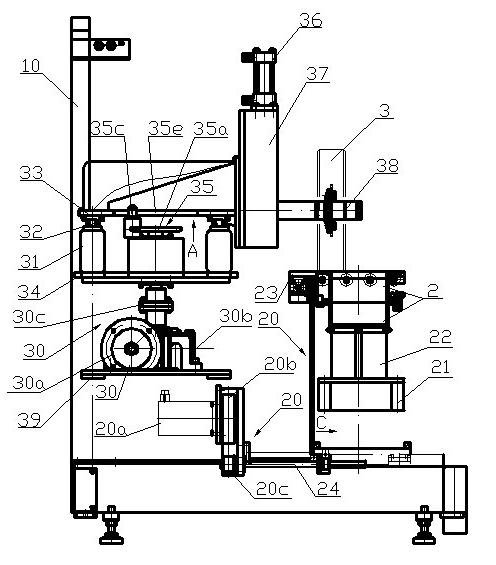

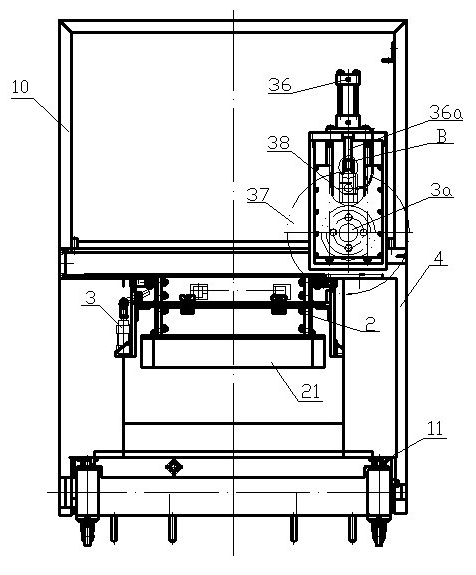

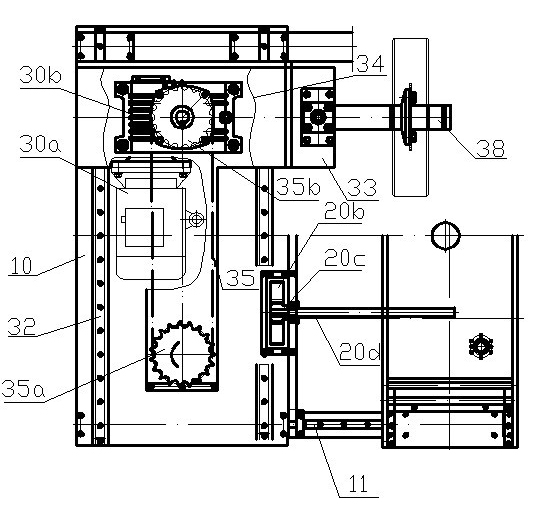

Indoor grinding and forming instrument of bituminous mixture test specimen and forming control method thereof

InactiveCN102042923ASmooth rollingUniform densityPreparing sample for investigationHydraulic ramGrinding wheel

The invention relates to an indoor grinding and forming instrument of a bituminous mixture test specimen and a forming control method thereof. The forming instrument comprises a rack, a grinding wheel, a mould and a mould drive device, and also comprises a grinding wheel drive device; the device mainly comprises a first reducing gear, a grinding wheel support, a hydraulic ram, a first guide rail and a driving chain; the mould drive device mainly comprises a mould driving support, a second guide rail, a second reducing gear, a speed reducing elevator mechanism, an elevating platform and a horizontal screw; the grinding wheel is arranged on the grinding wheel support, the grinding wheel support is connected with the first reducing gear, the mould drive support is connected with the second reducing gear through the horizontal screw, and the speed reducing elevator mechanism is fixed on the mould driving support and connected with the elevating platform. The method comprises the steps of:setting parameters, judging whether a starting position is reached or not, applying a grinding force, comparing a pressure value with a set value, grinding with the grinding wheel, judging whether one round of grinding is ended or not, and the like. The grinding and forming instrument has the advantages of high simulation degree, high automation degree and wide application range.

Owner:JIANGSU TRANSPORTATION RES INST CO LTD +1

Chromium-containing high silicon steel strip and preparation method thereof

InactiveCN103276174AImprove low temperature ductilityWide applicabilityElectric furnaceVacuum induction furnaceSilicon

The invention relates to a chromium-containing high silicon steel strip and a preparation method thereof. According to the technical scheme, the high silicon steel strip contains 5.5-7.0wt% of silicon and 0.05-10.0wt% of chromium, and the balance of iron and inevitable impurities. The preparation method comprises the following steps: preparing raw materials including technically pure iron, commercial silicon and pure chromium according to the chemical components of the chromium-containing high silicon steel strip; smelting the raw materials by employing an intermediate frequency vacuum induction furnace, casting into a casting blank under the condition of 1250-1650 DEG C, forging the casting blank into a plate blank with the thickness of 10-20mm under the condition of 800-1250 DEG C, and performing hot rolling on the plate blank to form a strip with the thickness of 0.6-0.8mm under the condition of 700-1250 DEG C; and finally, performing warm rolling till the thickness of the strip is 0.2-0.3mm under the condition of 1507-50 DEG C. The method has the characteristics of low cost, simple process and utilization of existing equipment, the brittleness of the prepared chromium-containing high silicon steel strip is obviously improved, the plasticity is obviously improved, and the plate shape is good.

Owner:WUHAN UNIV OF SCI & TECH

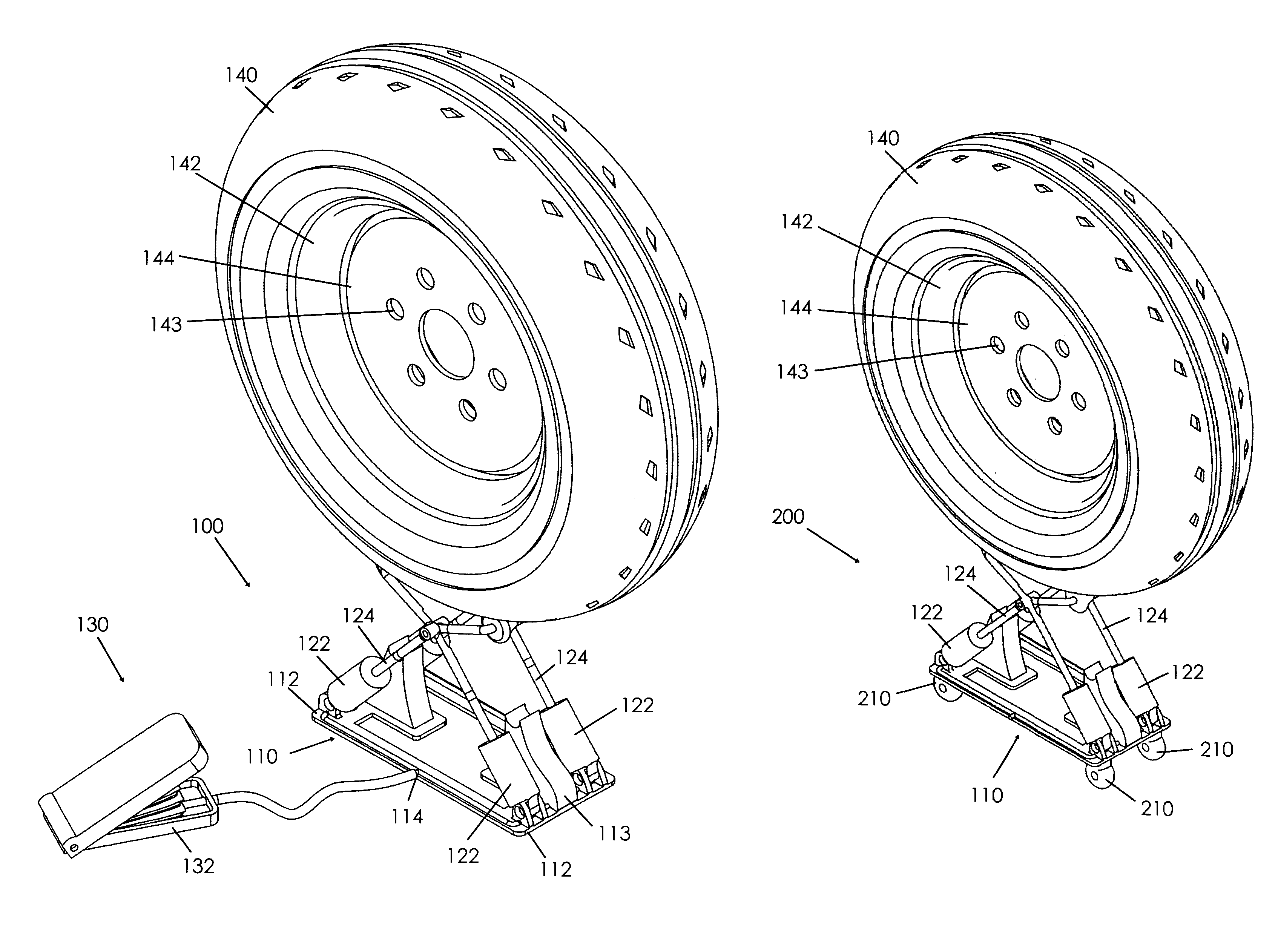

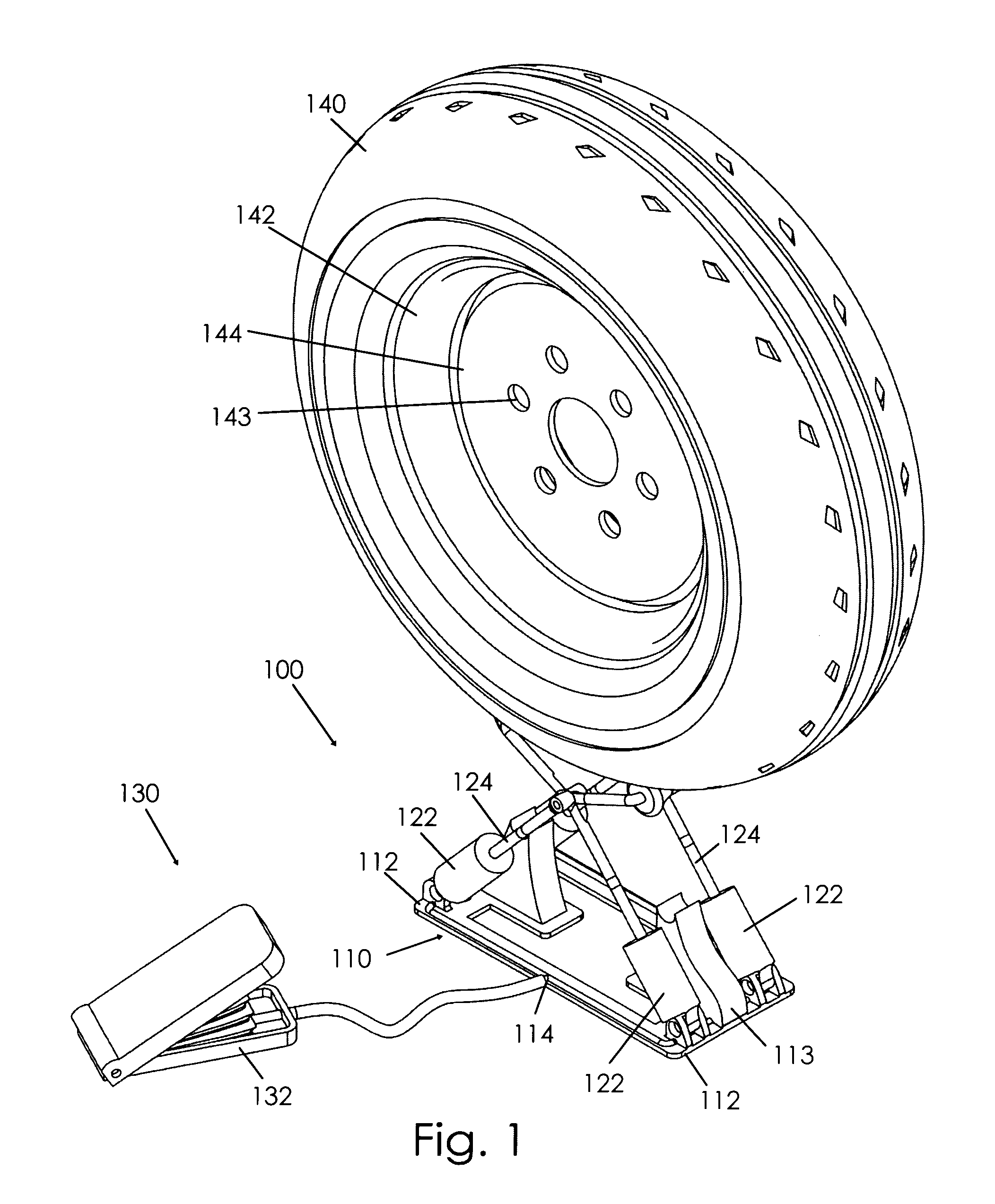

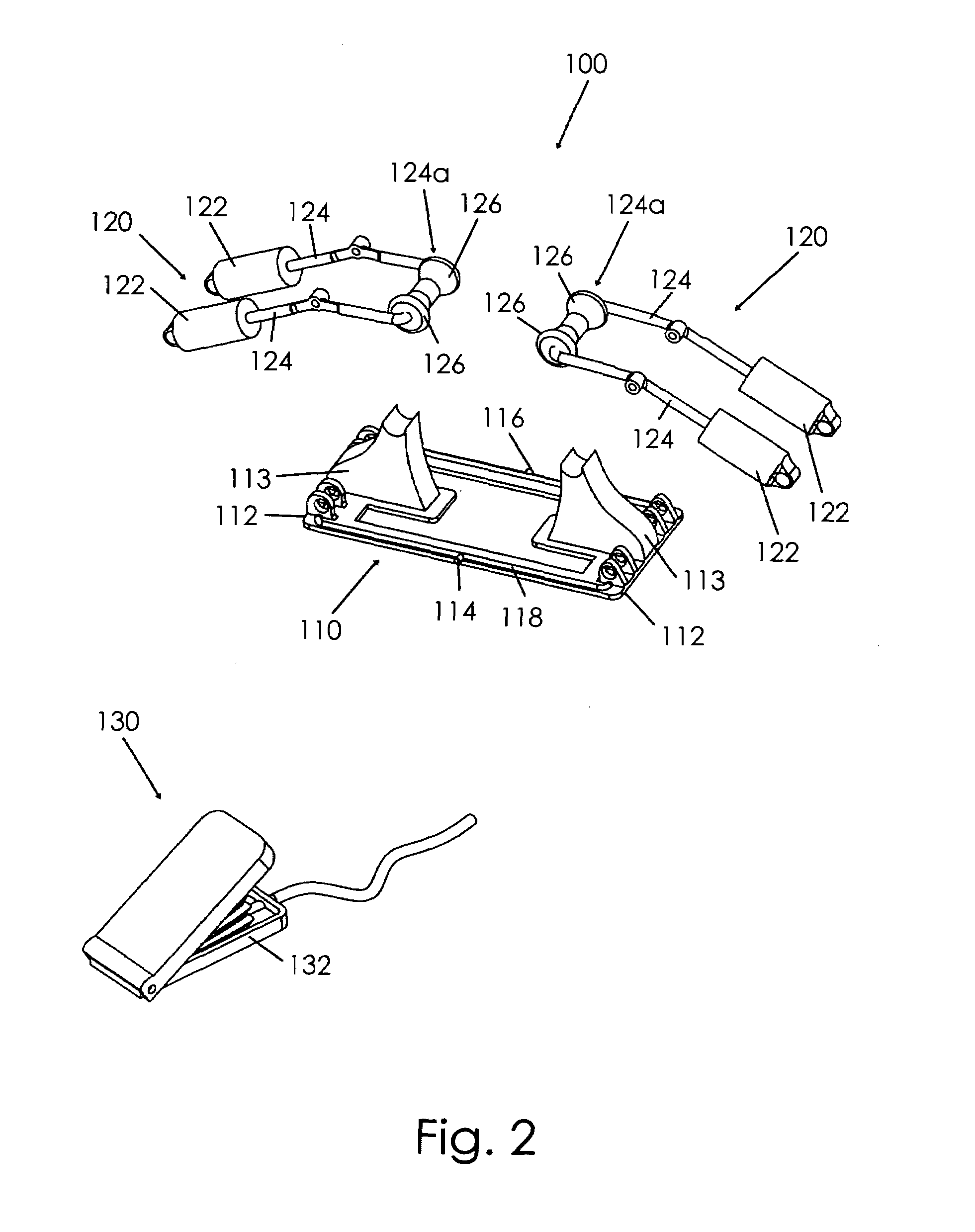

Portable tire and wheel lifting apparatus

ActiveUS7334804B2Minimal cargo areaSmooth rollingPassengers carsSupporting partsEngineeringSpare tire

A portable tire and wheel lifting apparatus includes a base, a pair of lifting arms pivotally coupled in a scissor configuration, pneumatic cylinders, an air input device, and an air outlet valve. In use, a tire and wheel are smoothly rolled from the ground to the lifting arms, which are in a retracted configuration. The air input device adds air to the pneumatic cylinders, causing the lifting arms to move from the retracted to an extended configuration, thus raising the tire and wheel. The tire and wheel are turned to line up the rim with the vehicle's hub and fastened to the vehicle. The air outlet valve selectively releases air from the pneumatic cylinders, allowing the lifting arms to move from the extended to the retracted configuration. The tire and wheel lifting apparatus is small enough to fit inside the cavern defined by a spare tire and wheel for storage.

Owner:MITCHELL KNECOLE A +1

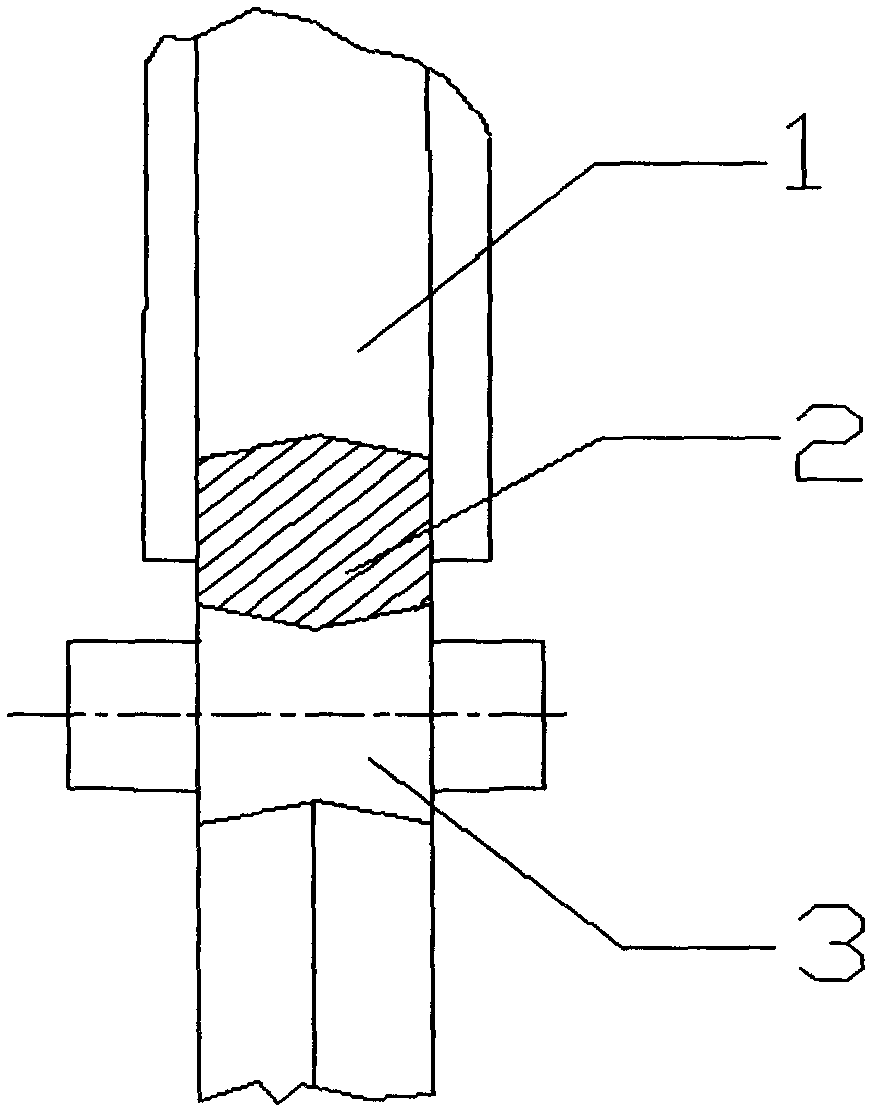

Production method of wind tower flange deformed ring forging

InactiveCN101811246ASmooth rollingImprove product qualityFurnace typesHeat treatment furnacesEngineeringTower

The invention discloses a production method of a wind tower flange deformed ring forging. The wind tower flange deformed ring forging is made of billet by the steps of blanking, blank forging and ring rolling, heating treatment and finish turning. The step of blank forging and ring rolling comprises the steps of: firstly rolling the billet into a ring by a plain barreled roll, wherein the inner wall of the ring is a smooth circumferential surface; and then heating in a furnace; rolling the ring into a workpiece with an annular concave cavity in the middle of the inner wall by a deformed core roll, wherein the deformed core roll is provided with a core roll boss, the core roll boss is twice wider than the connecting face of a tower cylinder of the wind tower flange deformed ring forging, and the height of the core roll boss is equal to the width of a flange connecting boss of the wind tower flange deformed ring forging; and sawing the workpiece from the middle of the side to separate the workpiece into tow parts symmetrically and equally to obtain tow blanks of the wind tower flange deformed ring forging. The invention is a production method of the wind tower flange deformed ring forging, which can improve product quality and has high production efficiency.

Owner:ZHANGJIAGANG HAILU ANNULAR FORGINGS

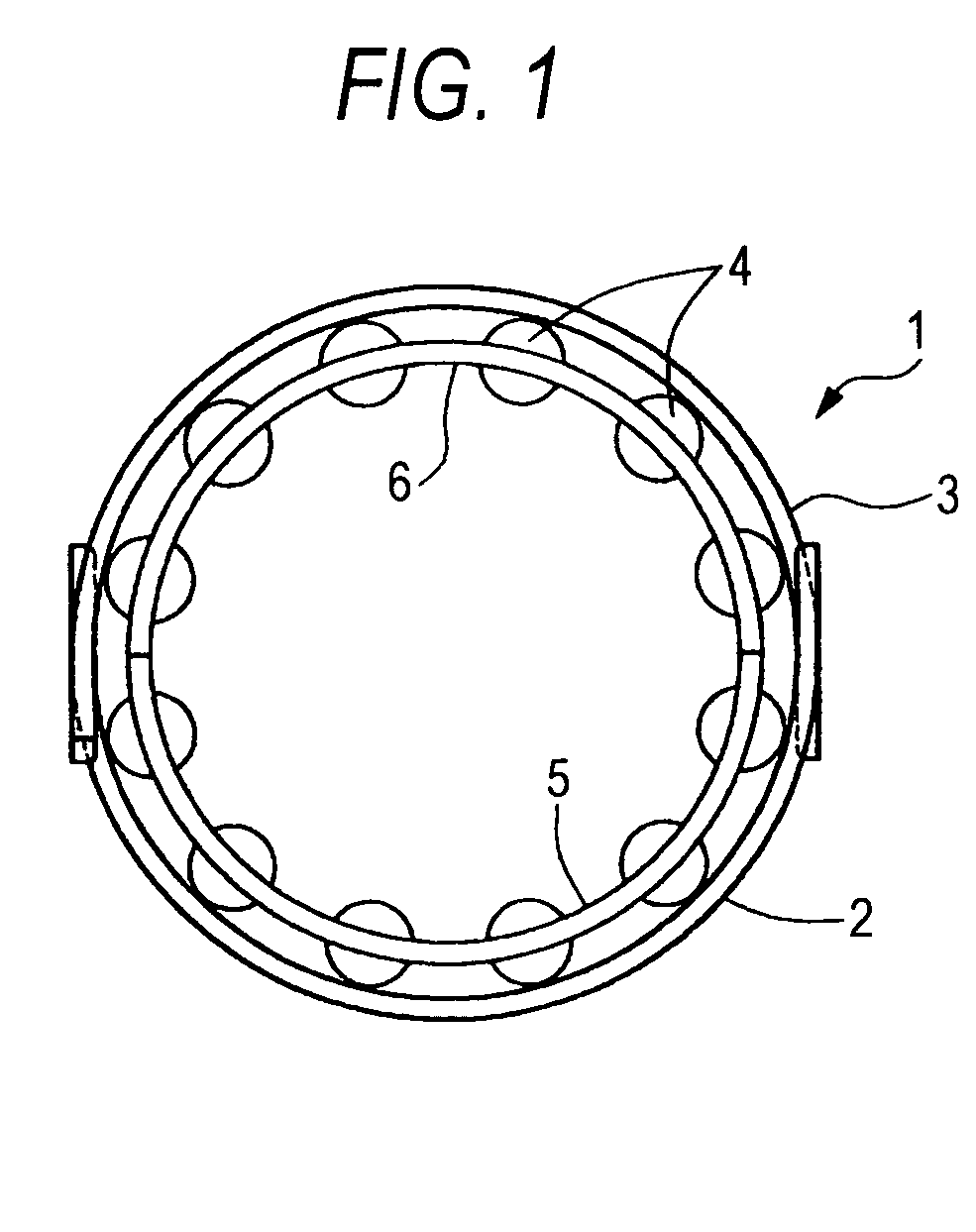

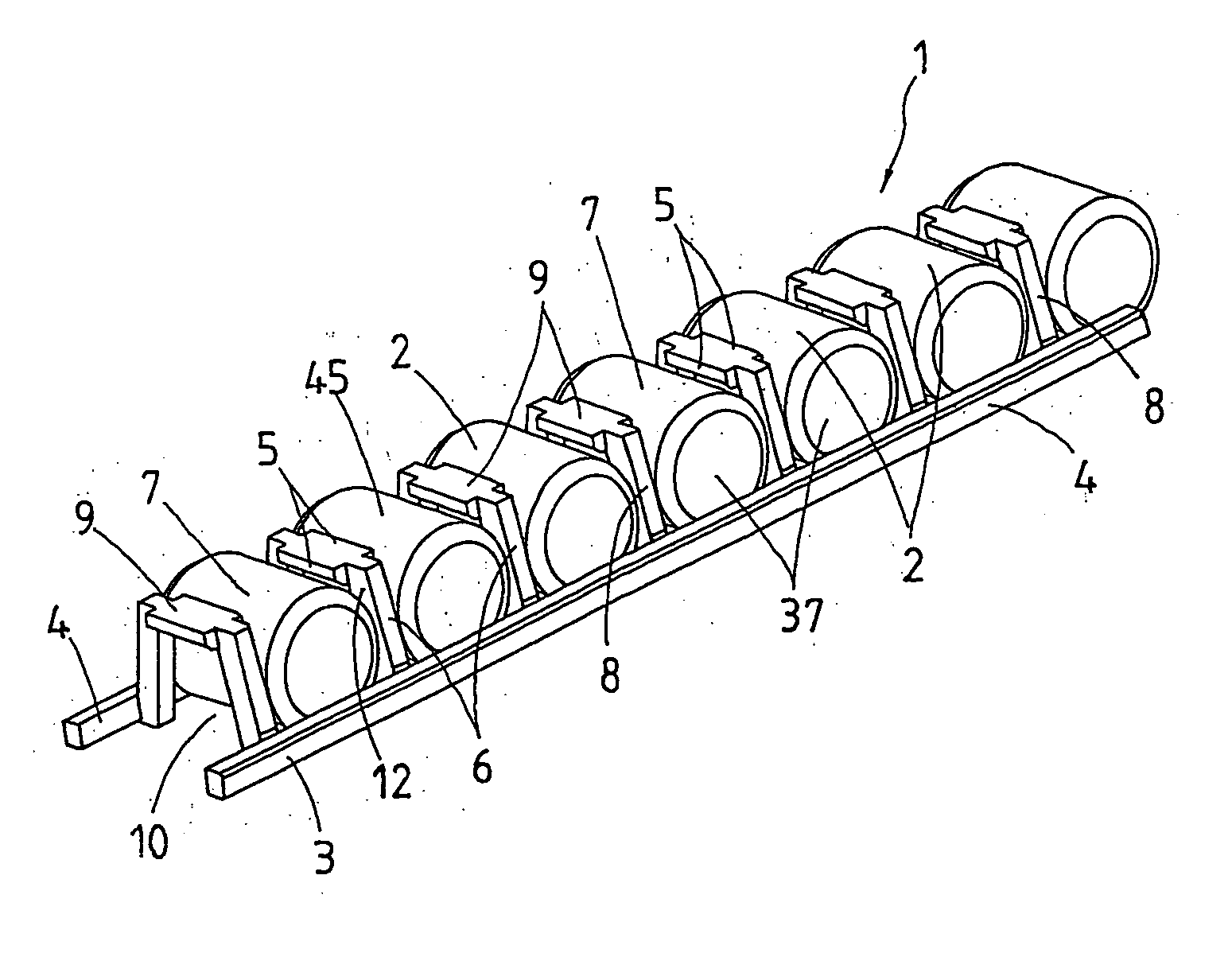

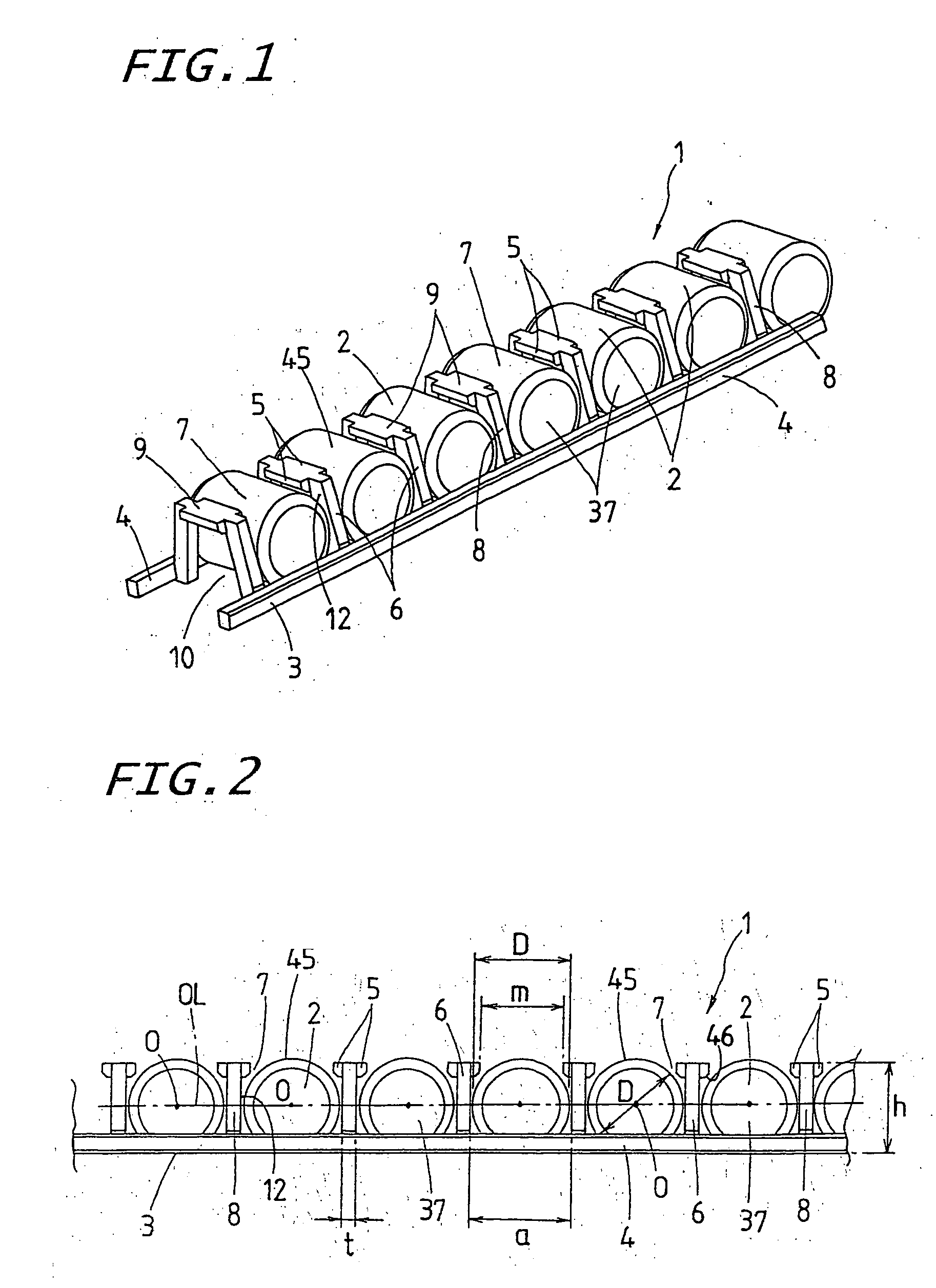

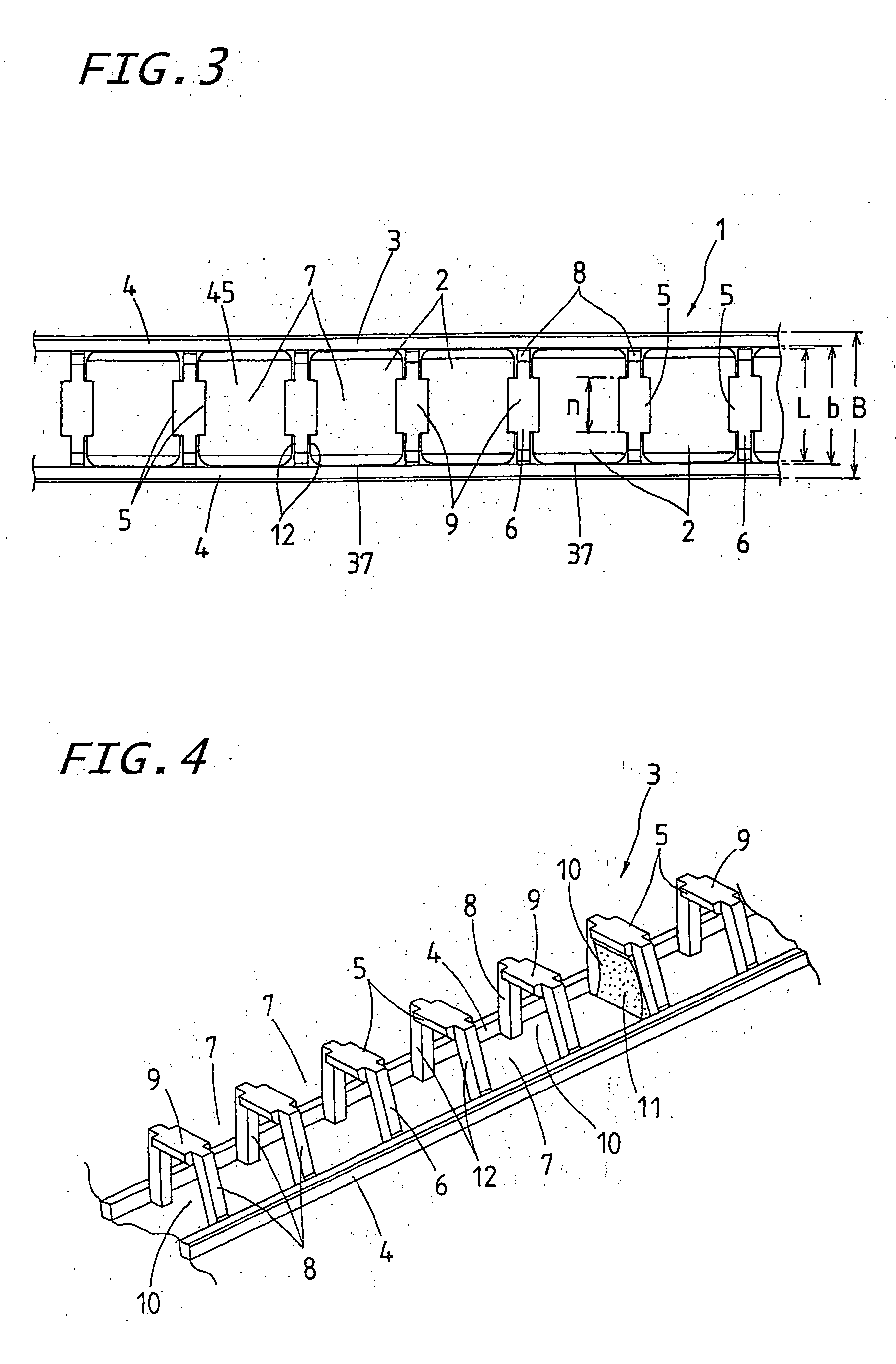

Roller chain and guide unit having the same therein

ActiveUS20050152625A1Improve accuracyHigh in mechanical strengthLinear bearingsBearing componentsEngineeringRoller chain

A roller chain is provided, which is composed of more than one roller and a carrier belt. The roller chain helps make sure of keeping the rollers against moving on the skew even under carrying high loads while the carrier belt is made to have a large space to reserve lubricant sufficient to ensure good lubrication. The carrier belt is comprised of a pair of continuous bands lying to carry or bear axially opposite ends of the roller across an area set off-centre from an axis of the roller, and more than one U-type separator to join the continuous bands together with one another. The U-type separators 6 are each composed of a pair of legs joined together with their associated continuous bands, and a horizontal bridge interconnecting the sidewise spaced leg with each other.

Owner:NIPPON THOMPSON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com