Patents

Literature

2952results about "Work carriers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flat sic semiconductor substrate

ActiveUS20140117380A1Efficient polishingImprove performanceEdge grinding machinesPolycrystalline material growthCrystallographyWafering

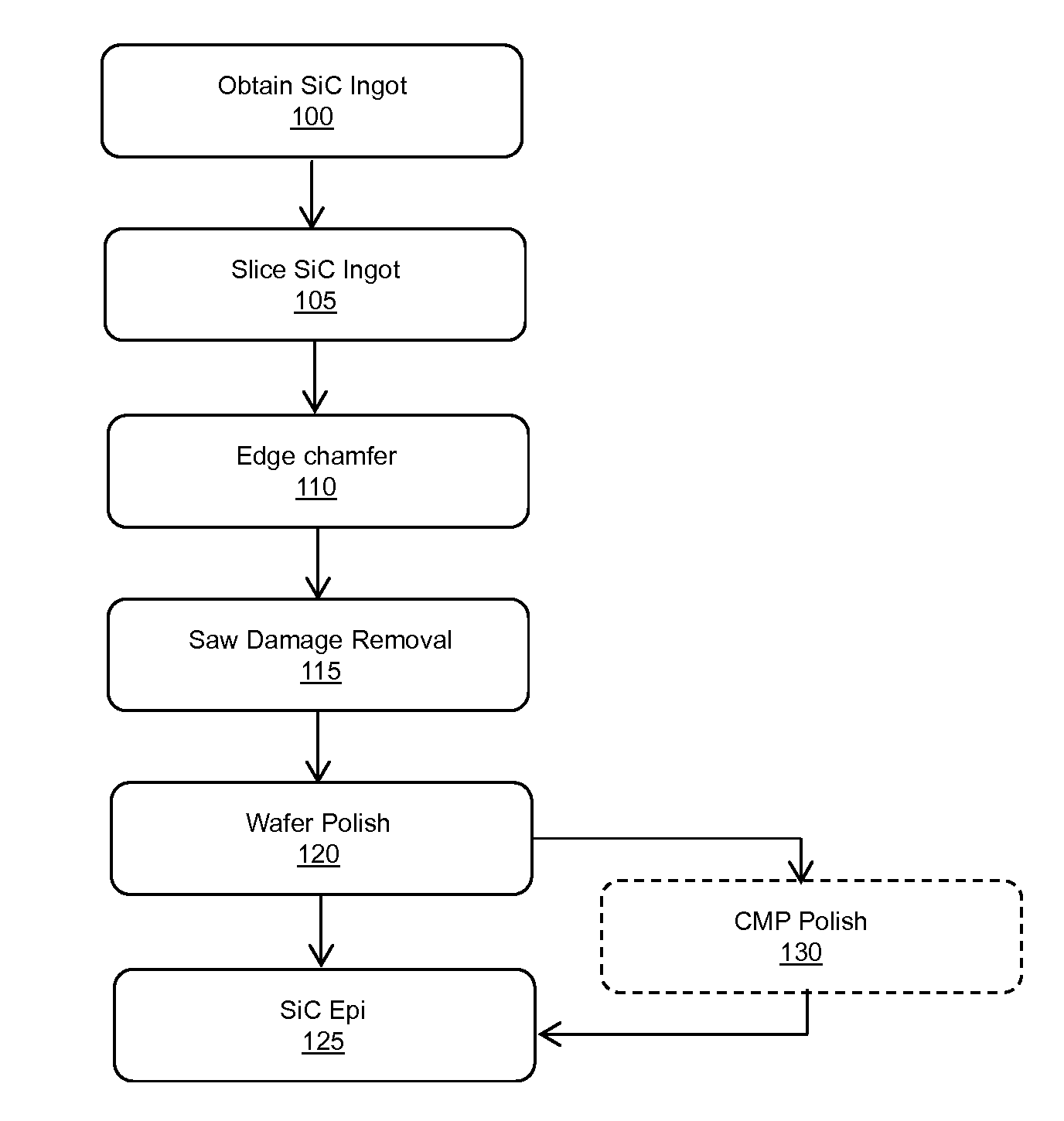

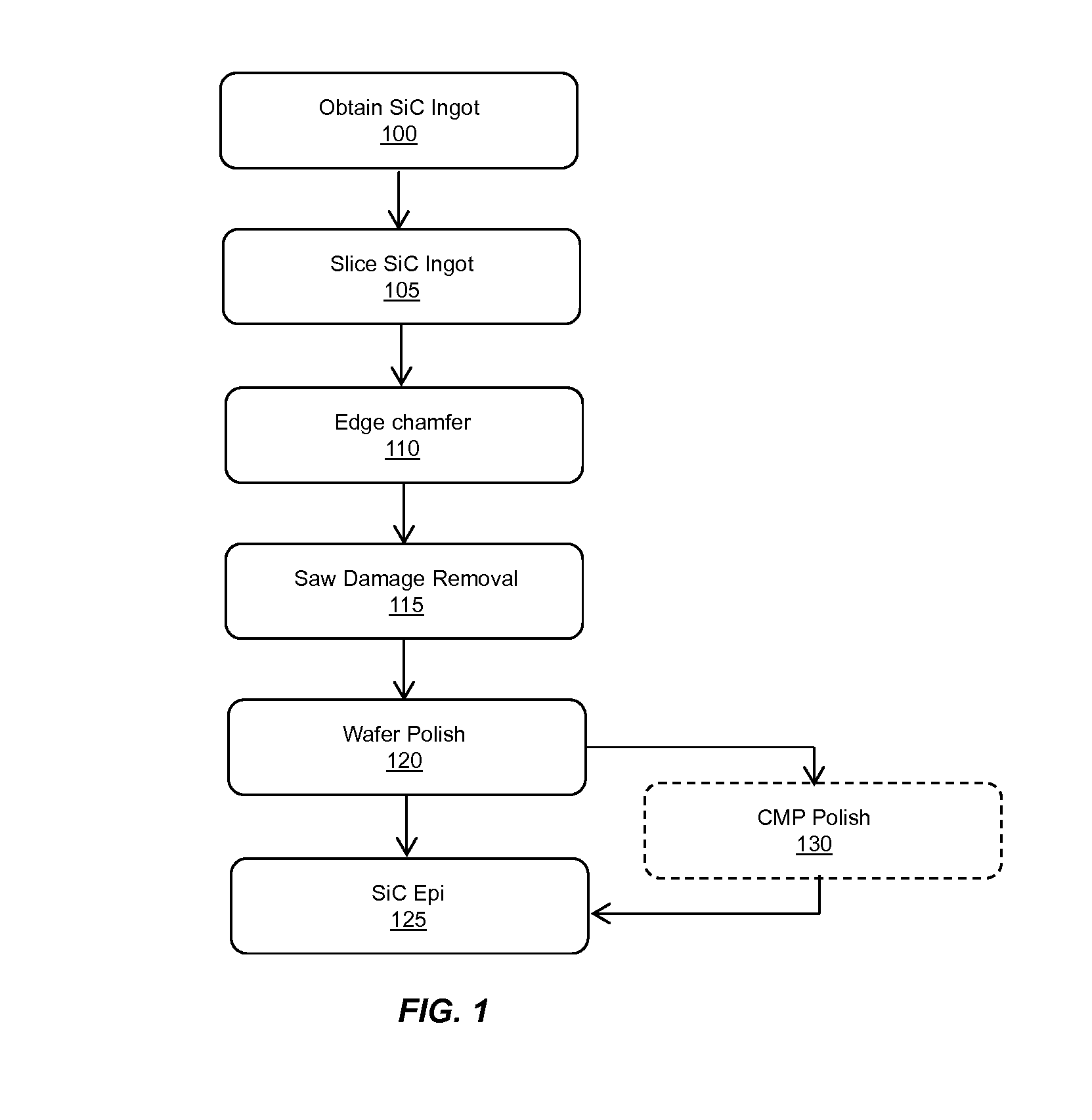

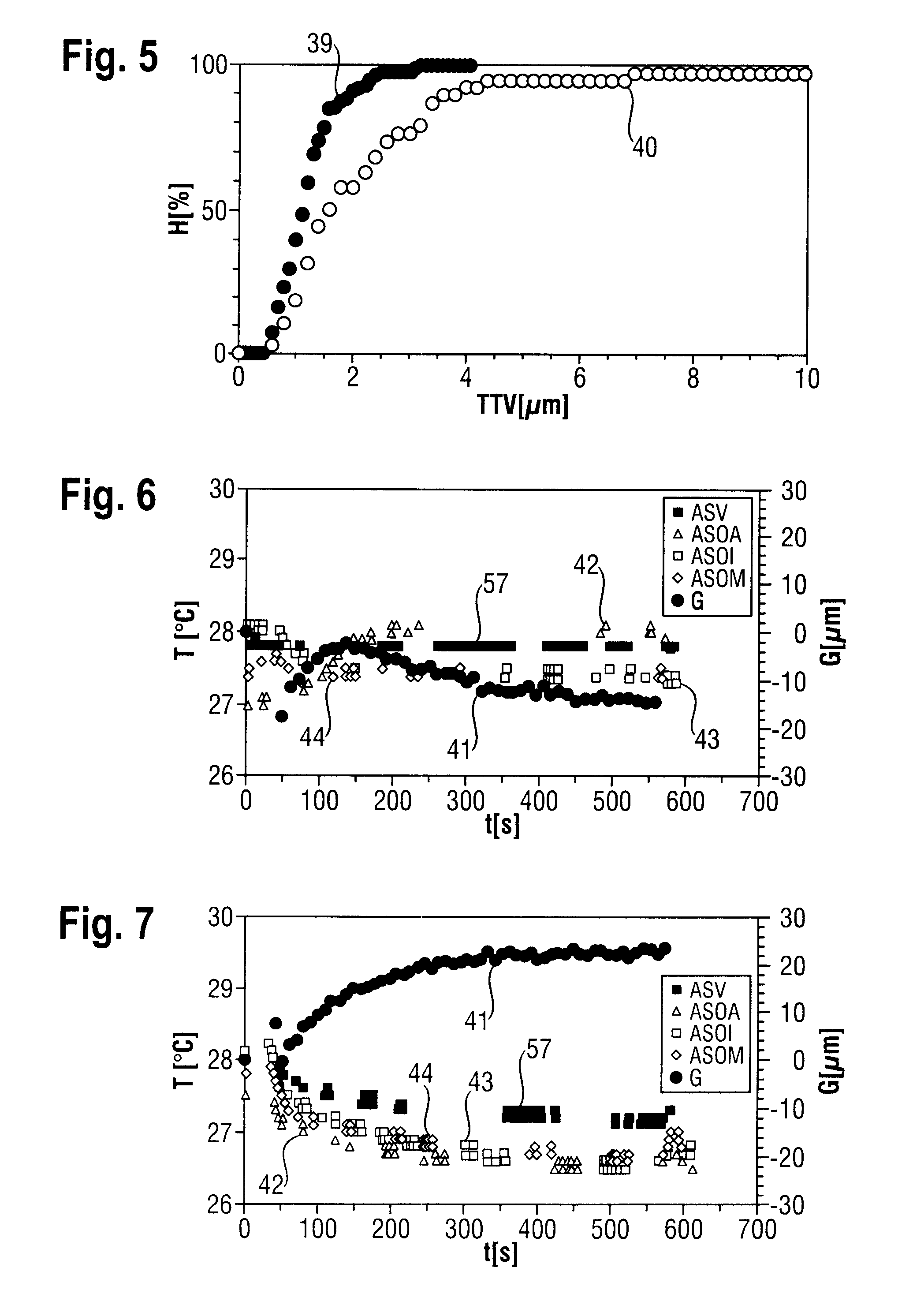

Methods for manufacturing silicon carbide wafers having superior specifications for bow, warp, total thickness variation (TTV), local thickness variation (LTV), and site front side least squares focal plane range (SFQR). The resulting SiC wafer has a mirror-like surface that is fit for epitaxial deposition of SiC. The specifications for bow, warp, total thickness variation (TTV), local thickness variation (LTV), and site front side least squares focal plane range (SFQR) of the wafer are preserved following the addition of the epitaxy layer.

Owner:SK SILTRON CSS LLC

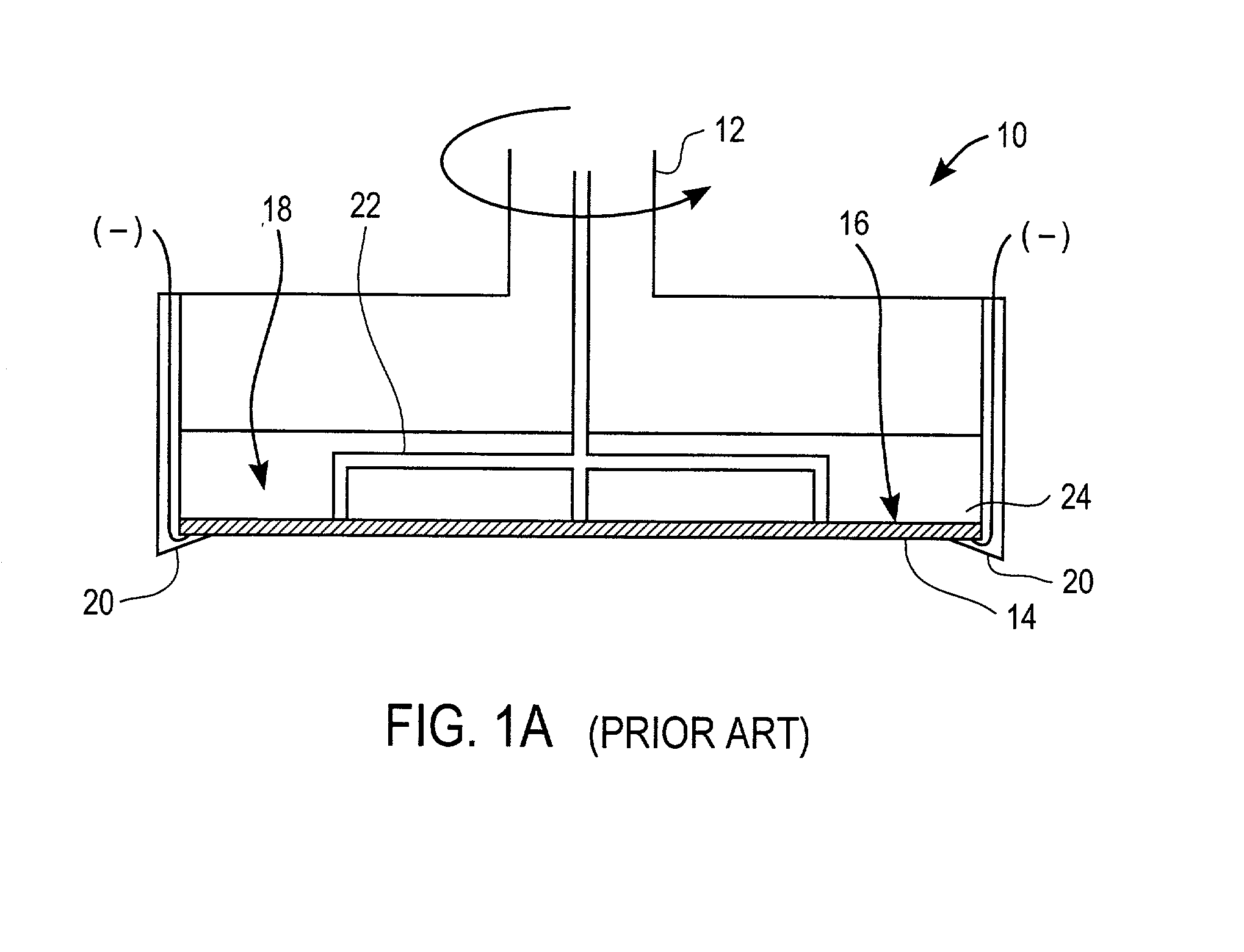

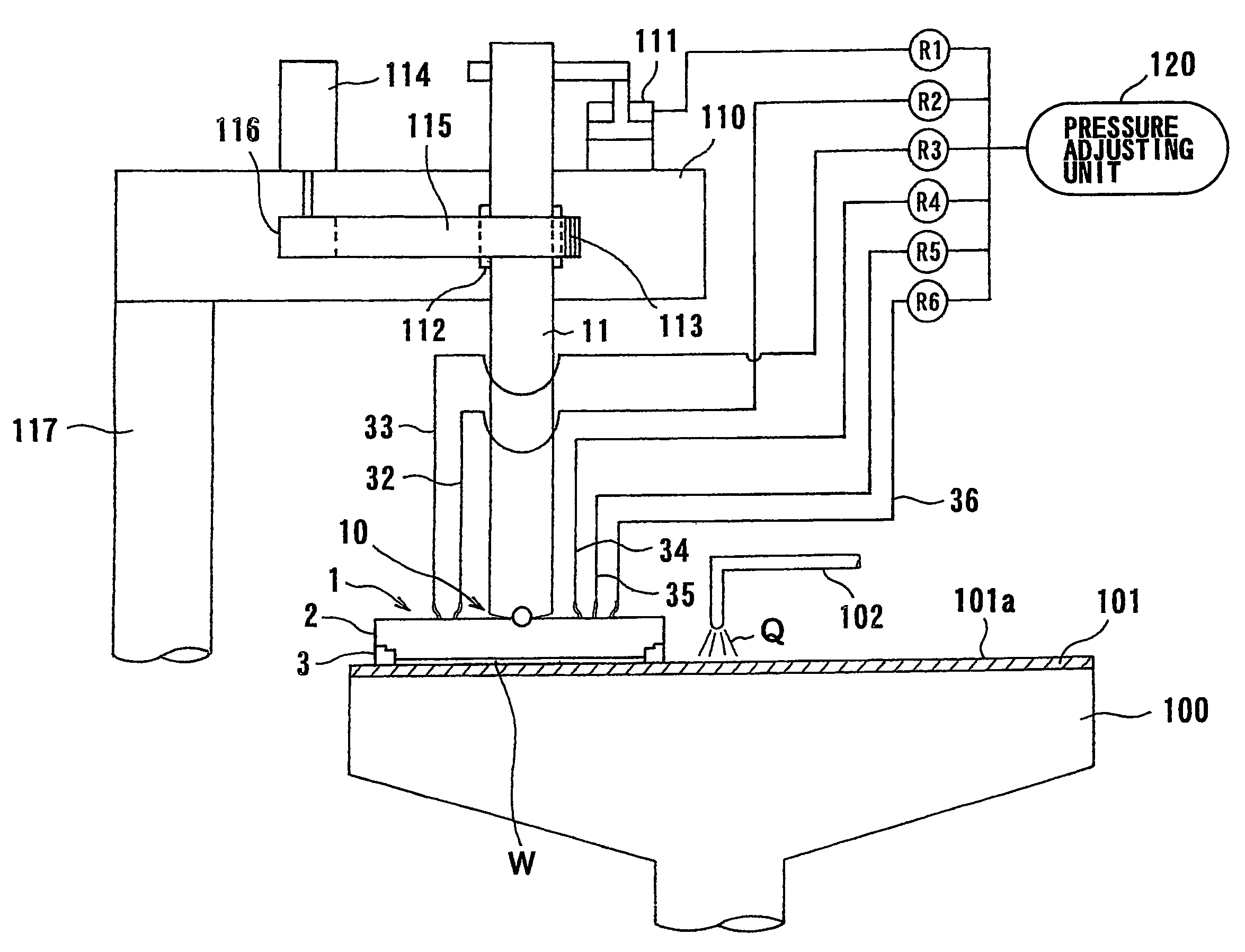

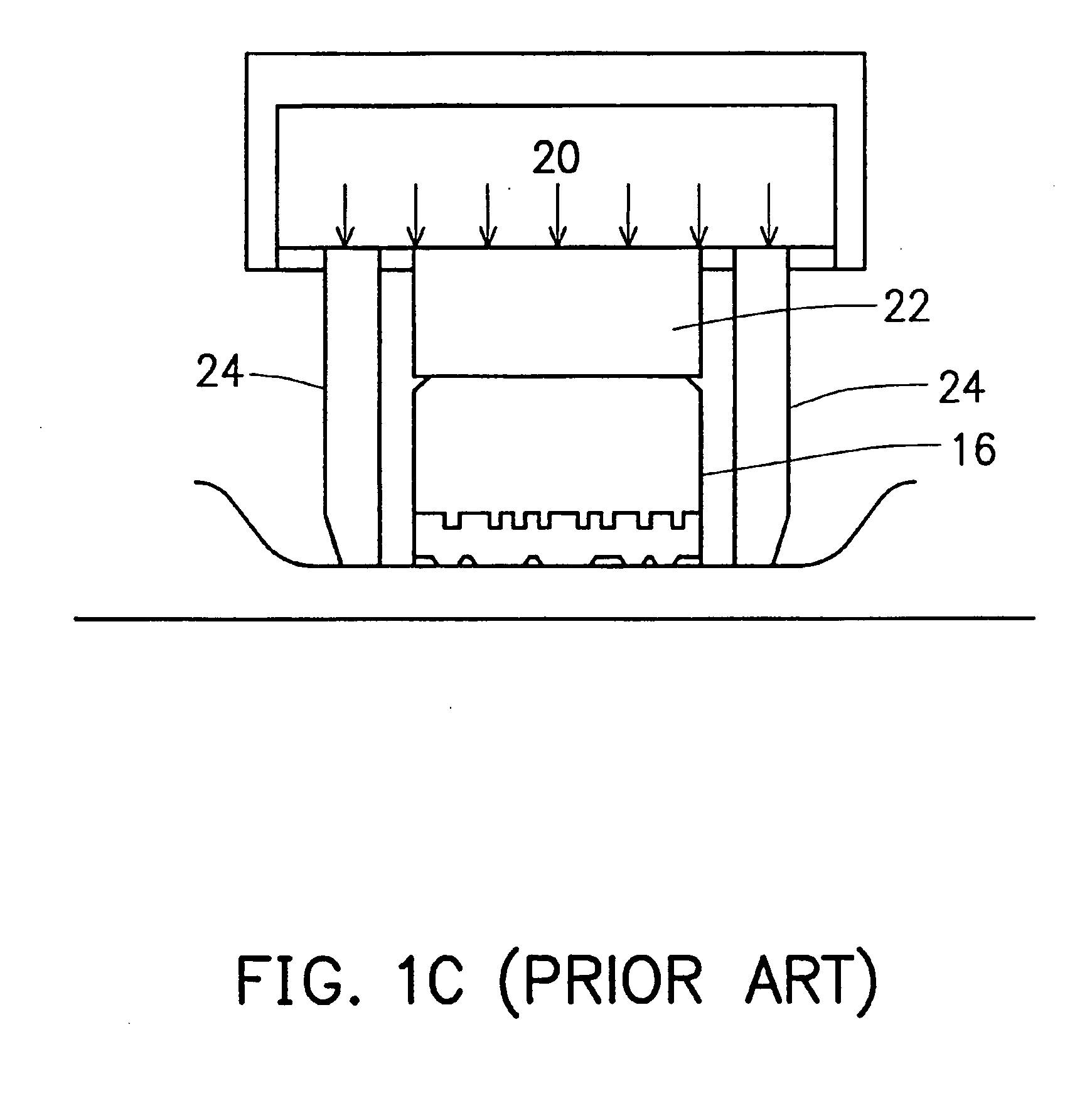

Methods for controlling the pressures of adjustable pressure zones of a work piece carrier during chemical mechanical planarization

ActiveUS7115017B1Polishing machinesRevolution surface grinding machinesEngineeringChemical-mechanical planarization

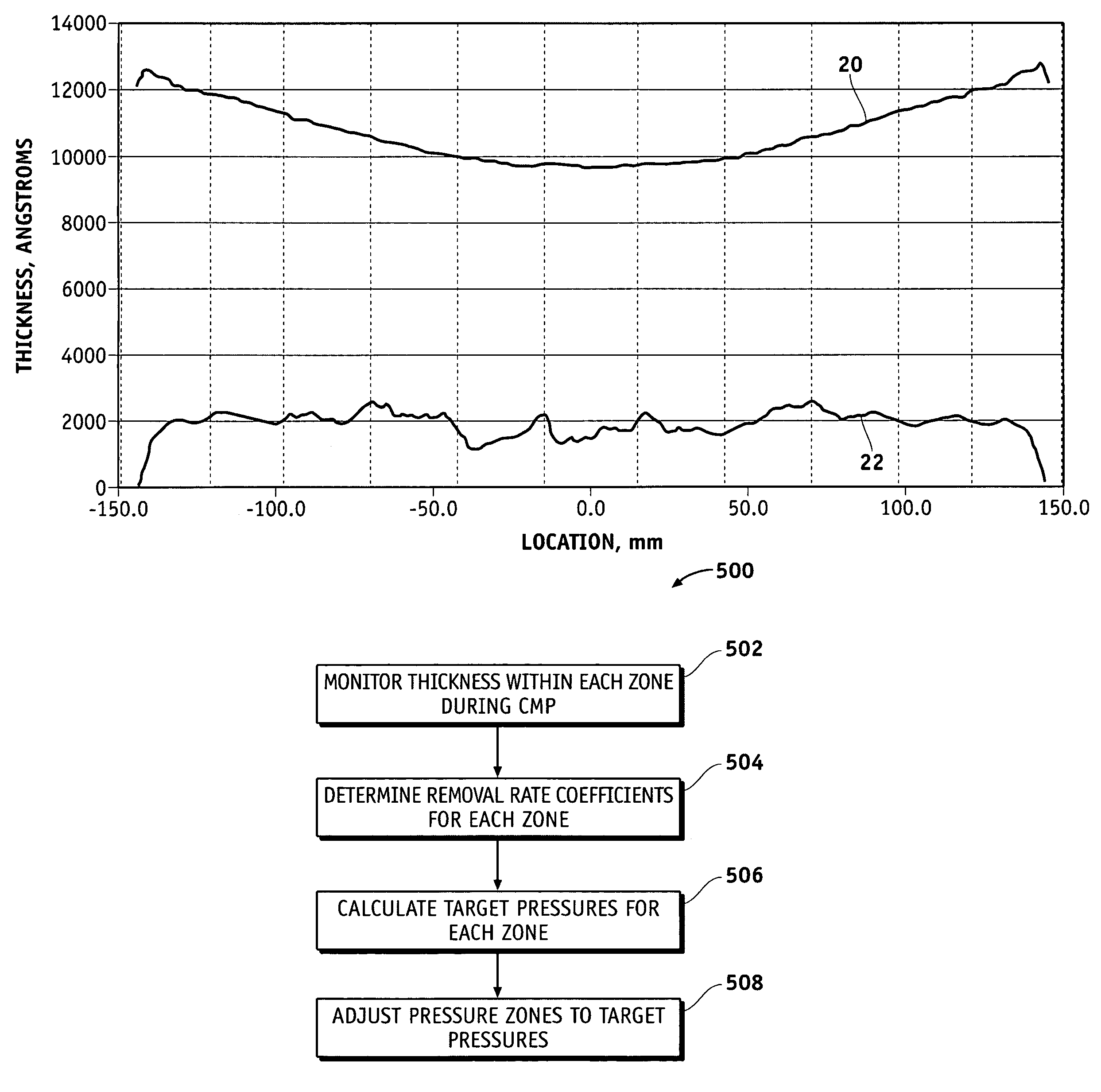

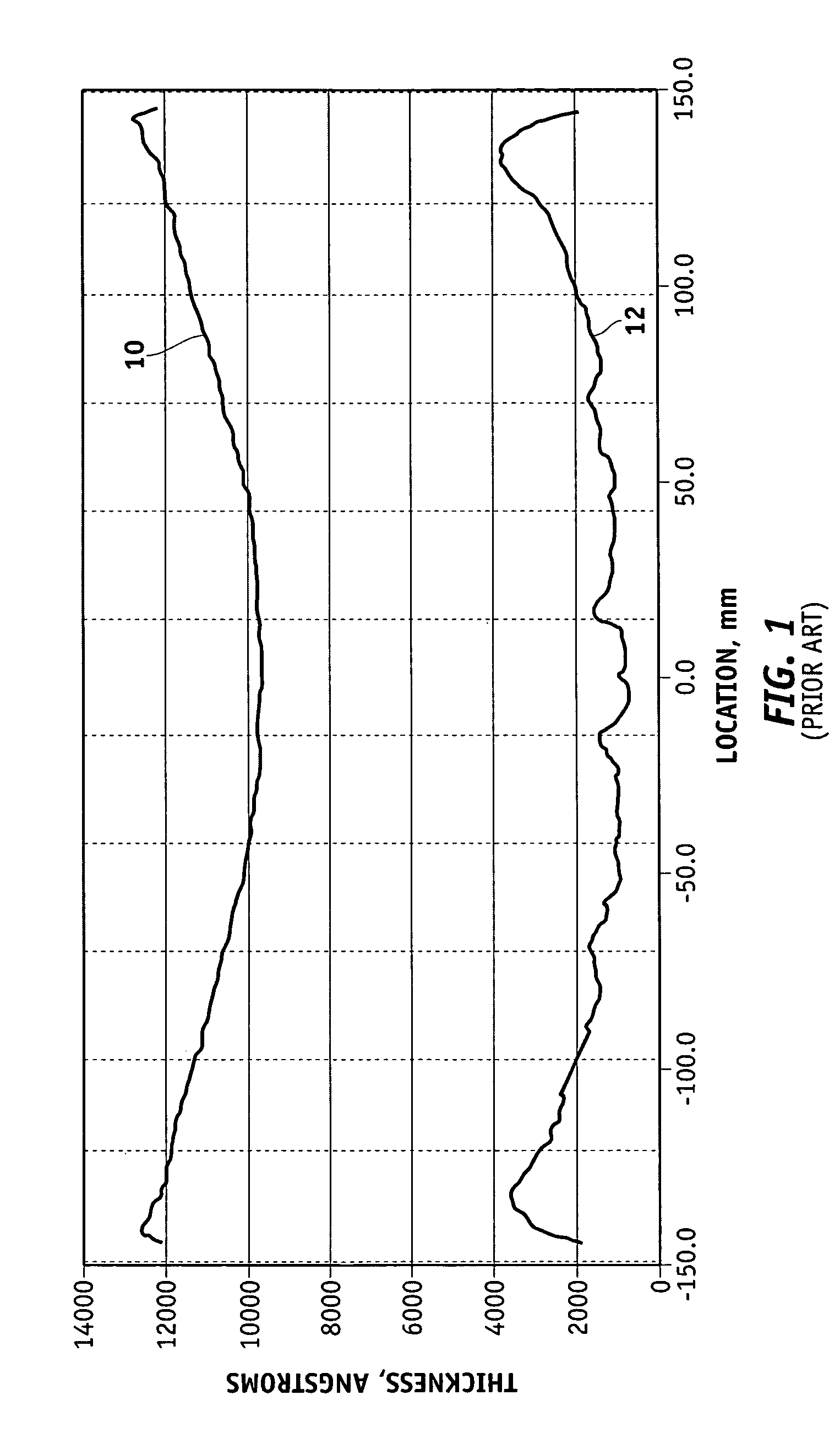

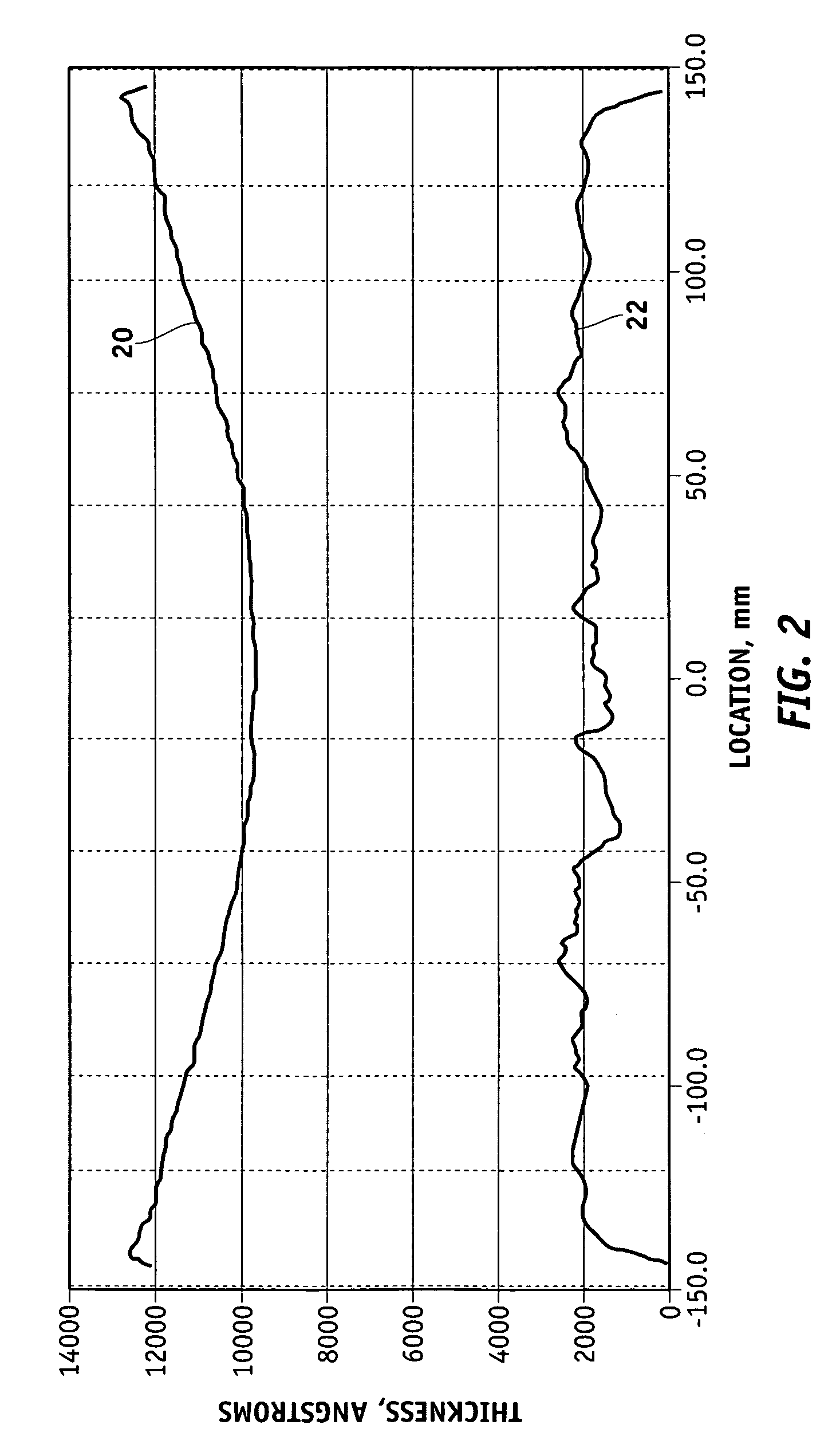

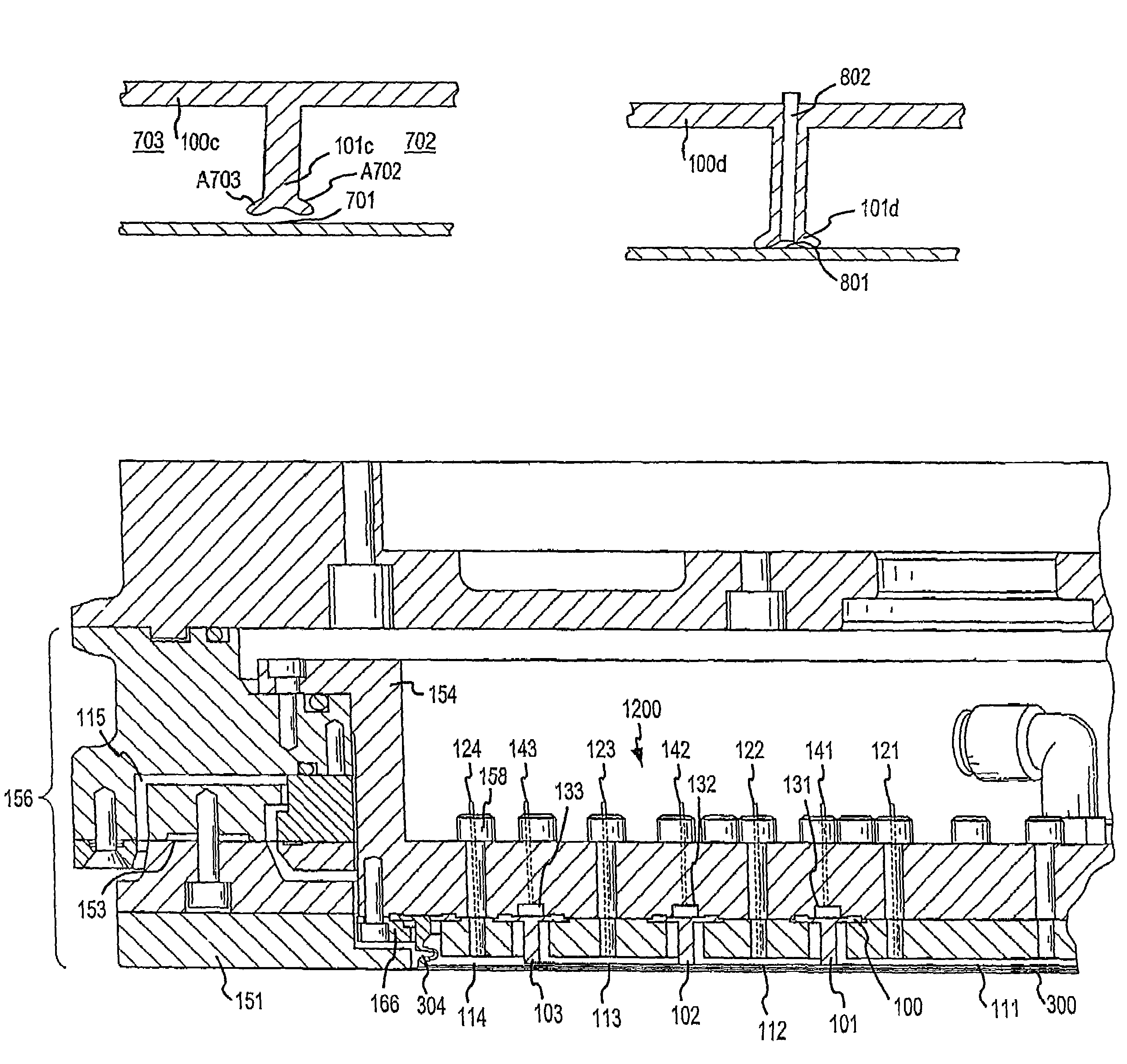

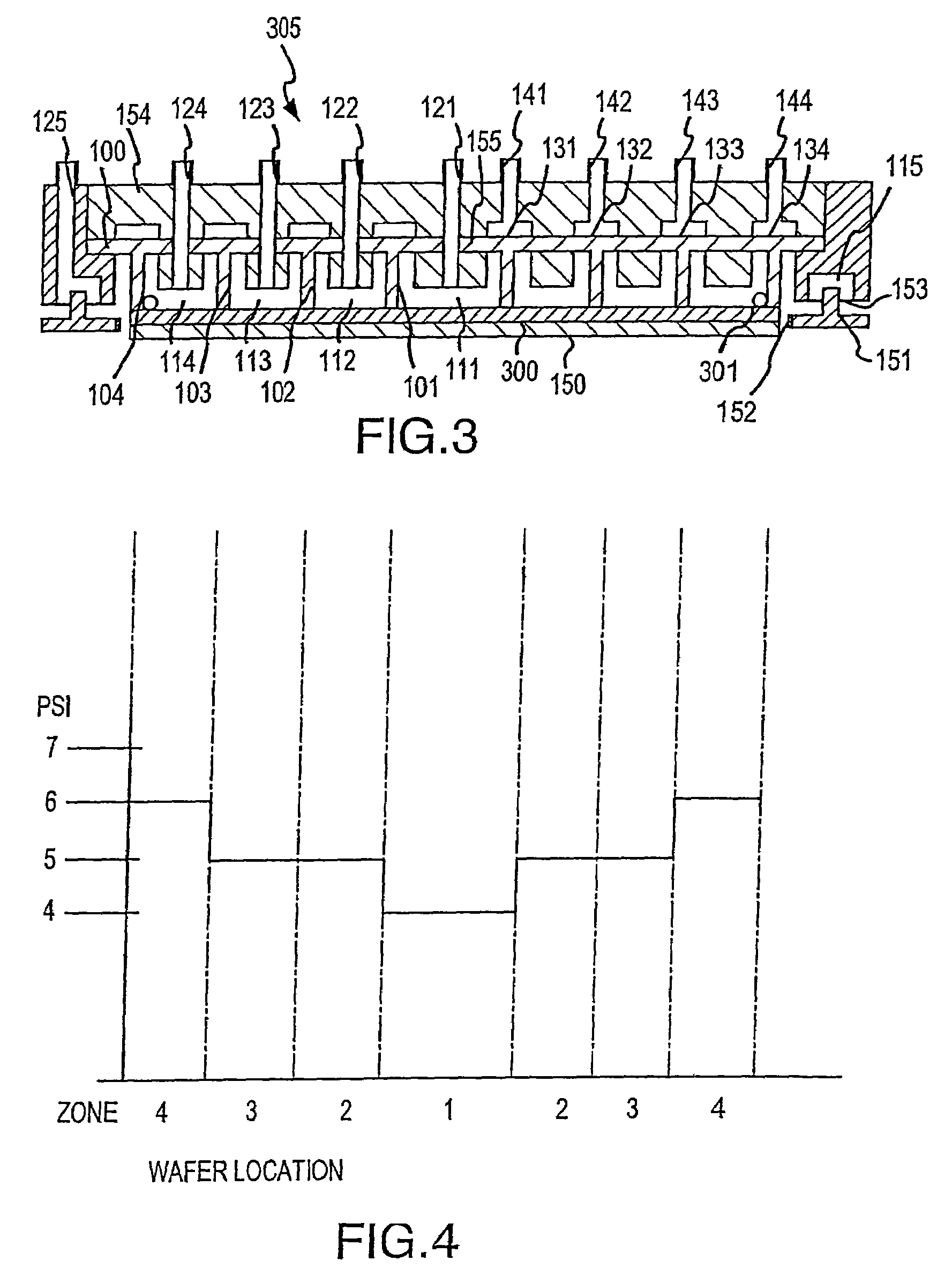

Methods are provided for controlling adjustable pressure zones of a CMP carrier. A method comprises determining a first thickness of a layer on a wafer underlying a first zone of the carrier. A first portion of the layer underlying the first zone is removed. The first zone is configured to exert a first pressure against the second surface of the wafer. A second thickness of the layer underlying the first zone is determined and a target thickness corresponding to a predetermined thickness profile is selected. A second pressure for the first zone is calculated using the first thickness, the second thickness, the first pressure, and the target thickness. The pressure exerted by the first zone against the second surface of the wafer is adjusted to the second pressure and the steps are repeated for a second zone.

Owner:NOVELLUS SYSTEMS

Polishing apparatus and related polishing methods

InactiveUS20060189259A1Uniform thicknessPolishing machinesRevolution surface grinding machinesEngineeringMagnetic field

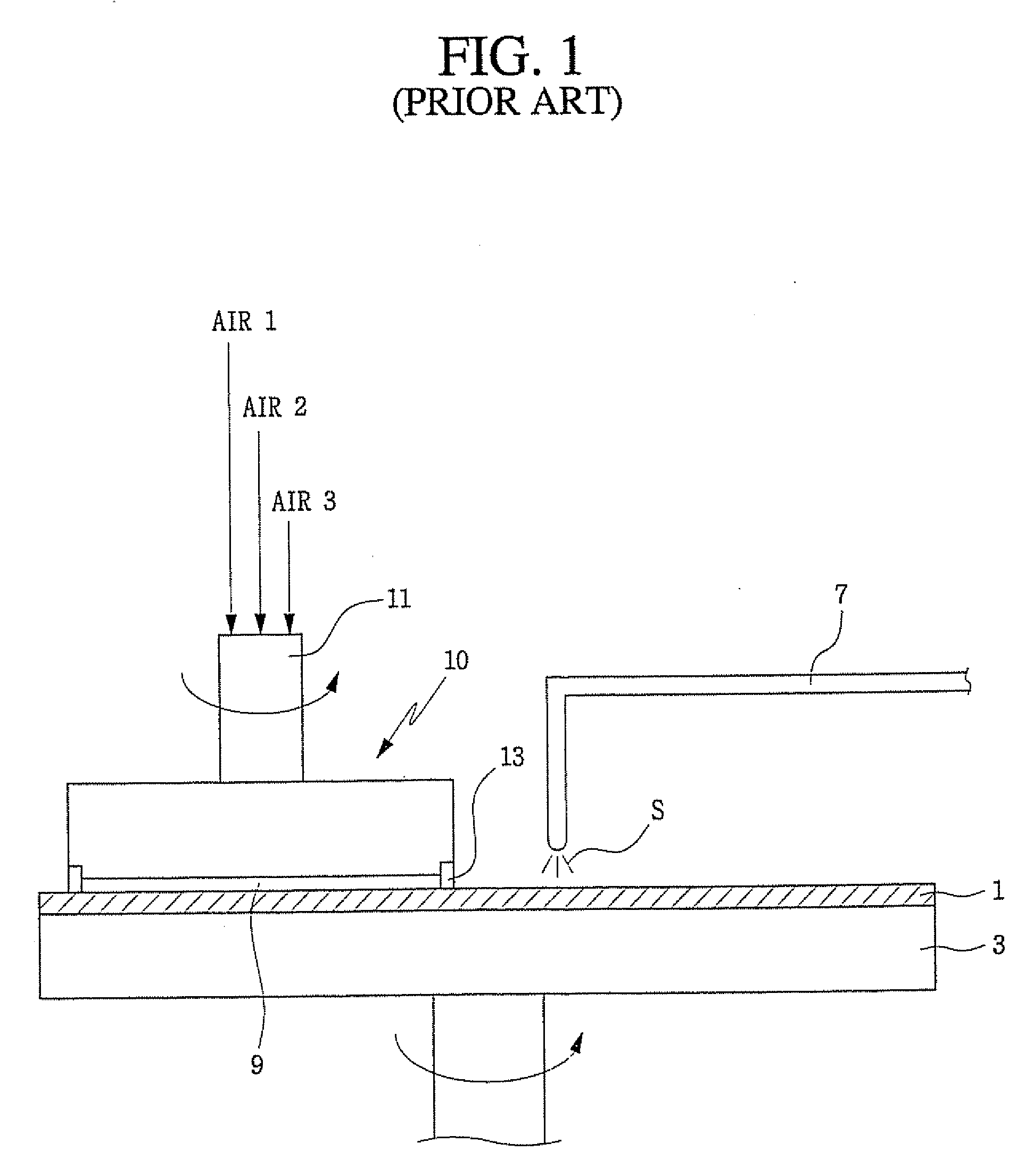

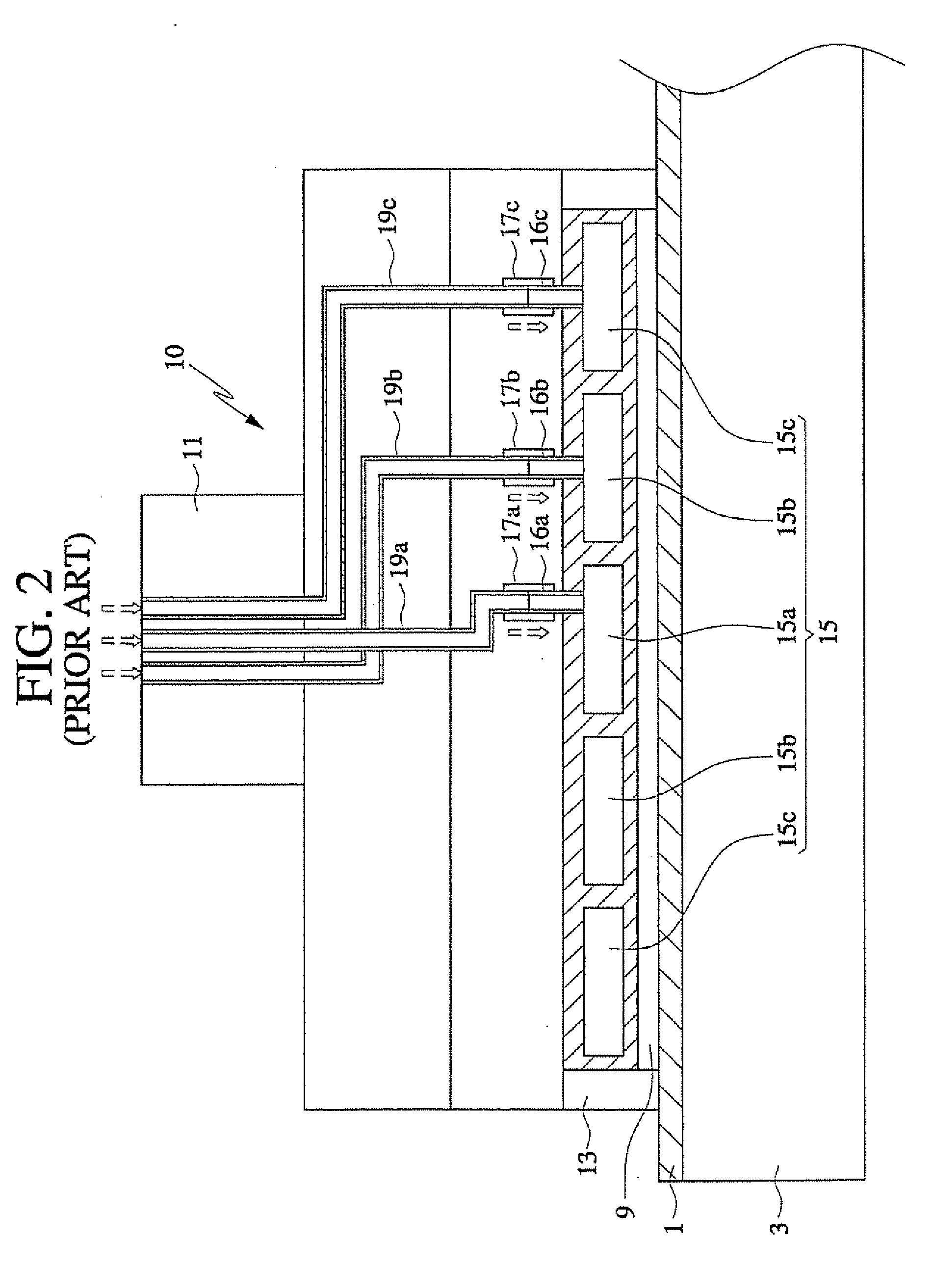

Polishing apparatus and related methods employ aligned first and second magnetic field sources to adjust the compressive force and / or pressure applied by a carrier head against a target workpiece (such as a wafer) by selectively and controllably generating a repellant or attractive force between the two magnetic field sources.

Owner:SAMSUNG ELECTRONICS CO LTD

Method and apparatus of sealing wafer backside for full-face electrochemical plating

InactiveUS20030008602A1Efficient configurationMinimize irregularityEdge grinding machinesPolishing machinesMechanical engineeringElectroplating

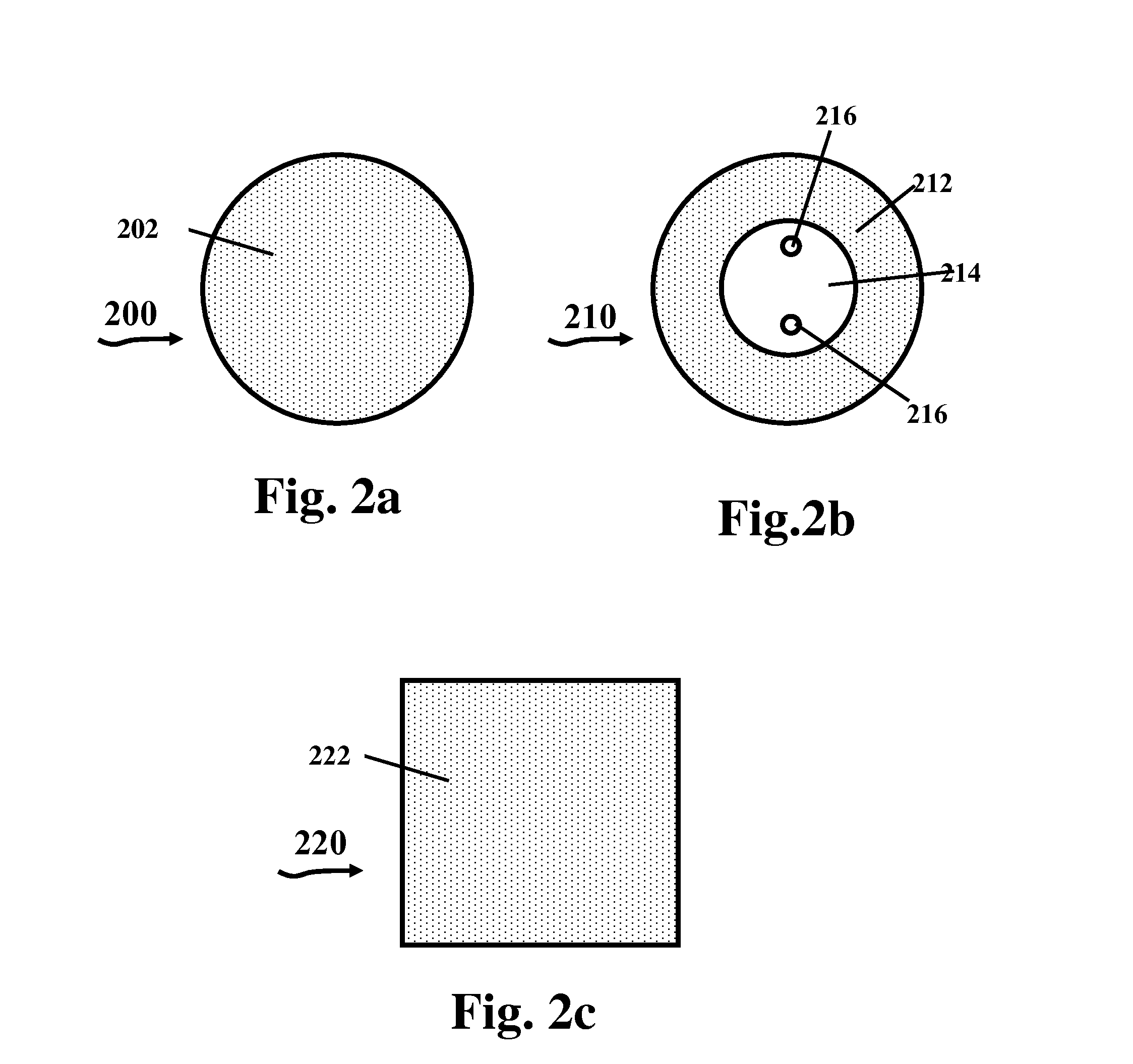

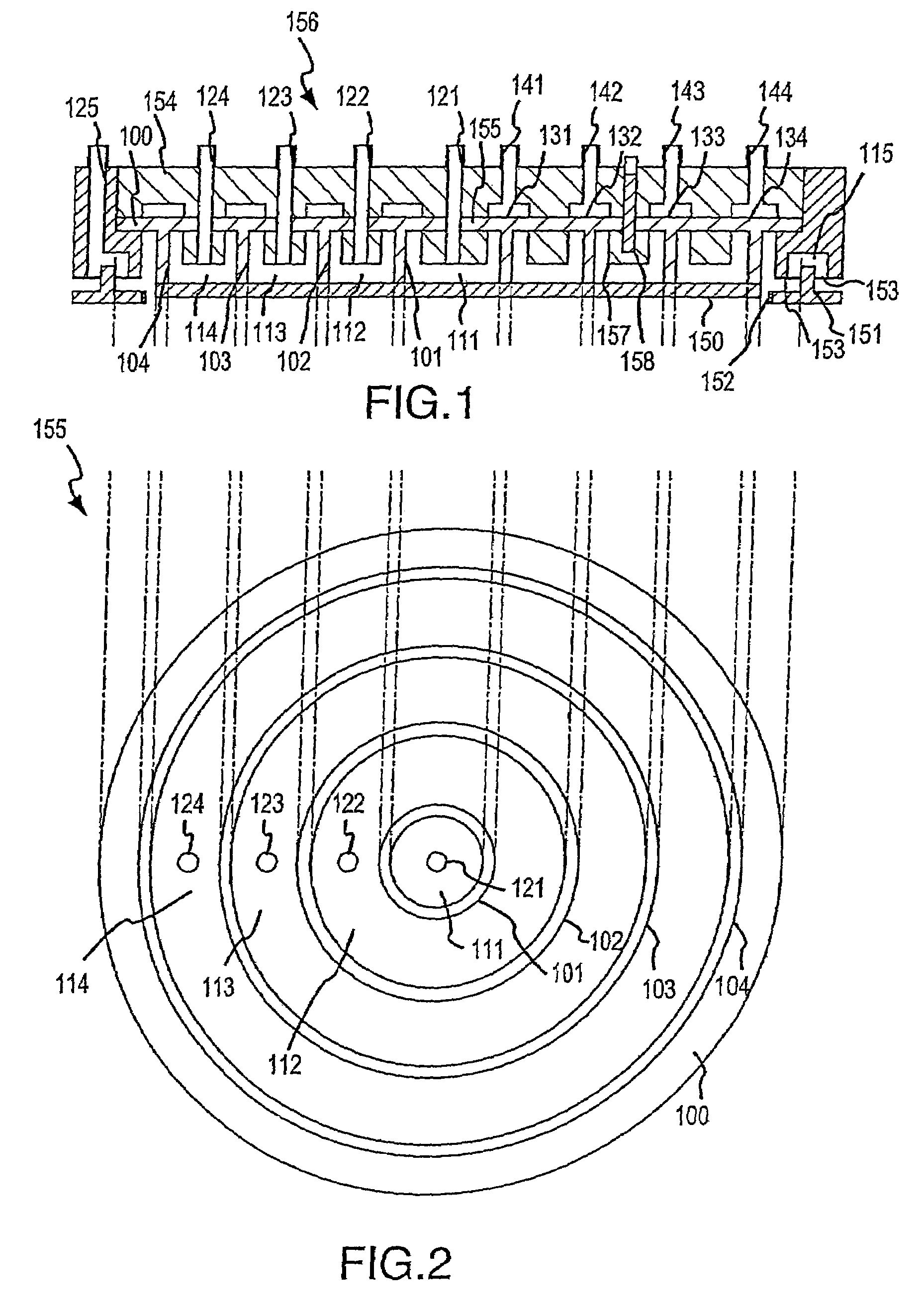

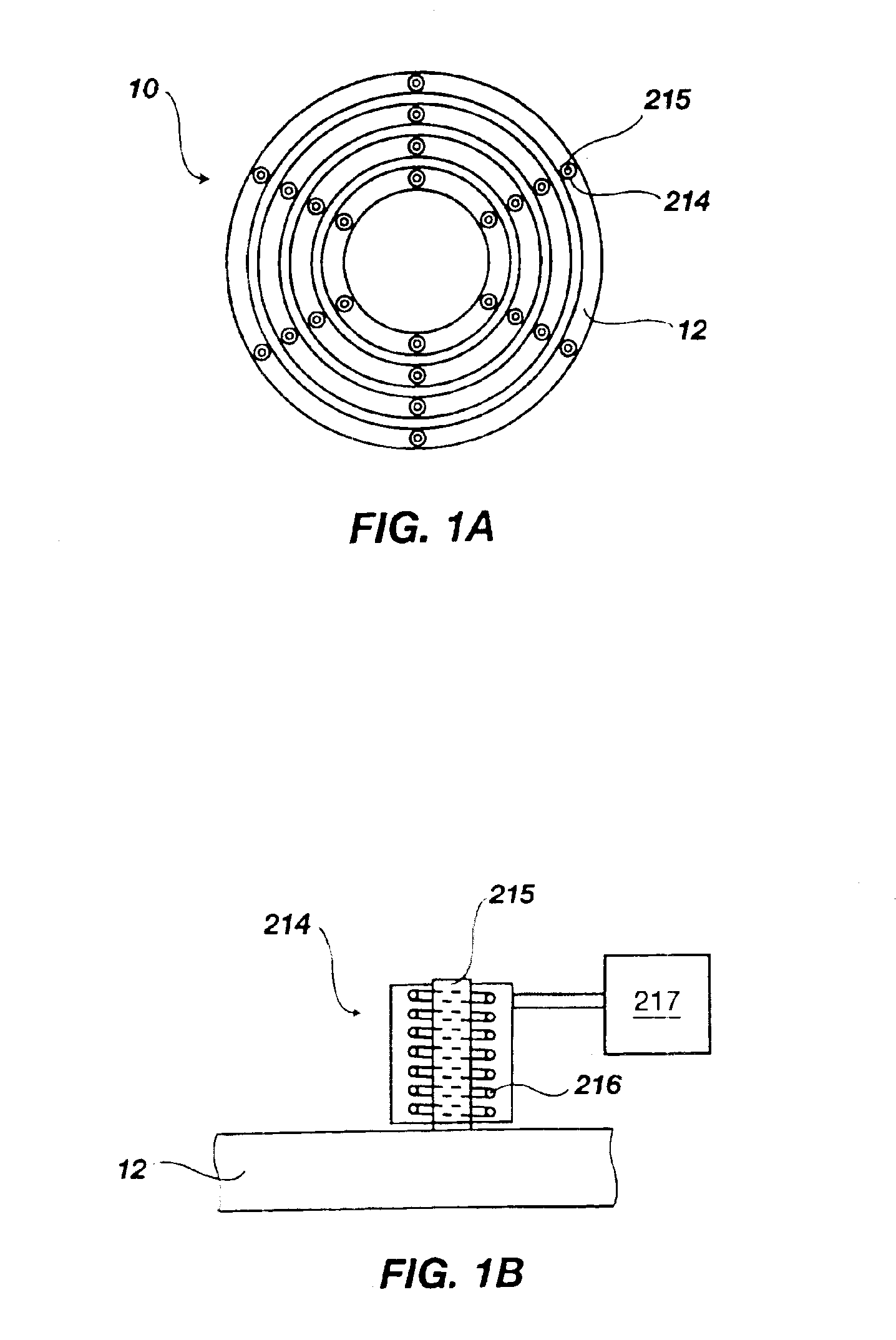

The present invention provides a wafer carrier that includes a plurality of concentric sealing members that provide a seal, with the outer seal independently movable to allow cleaning of a peripheral backside of the wafer to occur while the wafer is still attached to the wafer carrier, and a plurality of vacuum openings that a re disposed only adjacent to an inner side of the inner seal at a location corresponding to the backside periphery of the wafer.

Owner:NOVELLUS SYSTEMS

Non-contact support platforms for distance adjustment

An apparatus for supporting a stationary or moving substantially flat object without physical contact on an fluid-cushion. The object floats on a fluid cushion gap, the apparatus aimed for globally or locally adjusting the gap. The apparatus comprising: a first platform for supporting the object without contact, the platform having a substantially flat active surface comprised of one or more sectors, each sector comprising at least one of a plurality of basic cells, each basic cell having at least one of a plurality of pressure outlets fluidically connected through a pressure flow restrictors to a higher-pressure manifold associated with the sector in which the basic cell lies, the higher-pressure manifold is fluidically connected through main supply pipeline to pressurized fluid supply and at least one of a plurality of fluid-evacuation channels fluidically connected to a lower-pressure manifold associated with the sector in which the basic cell lies having main evacuation pipeline; wherein the flow restrictor characteristically exhibiting fluidic return spring behavior; and wherein at least one pressure control valve is interposed with at least one of the two main pipelines of at least one sector for controlling pressure levels of at least one of the two manifolds of that sector.

Owner:COREFLOW SCI SOLUTIONS

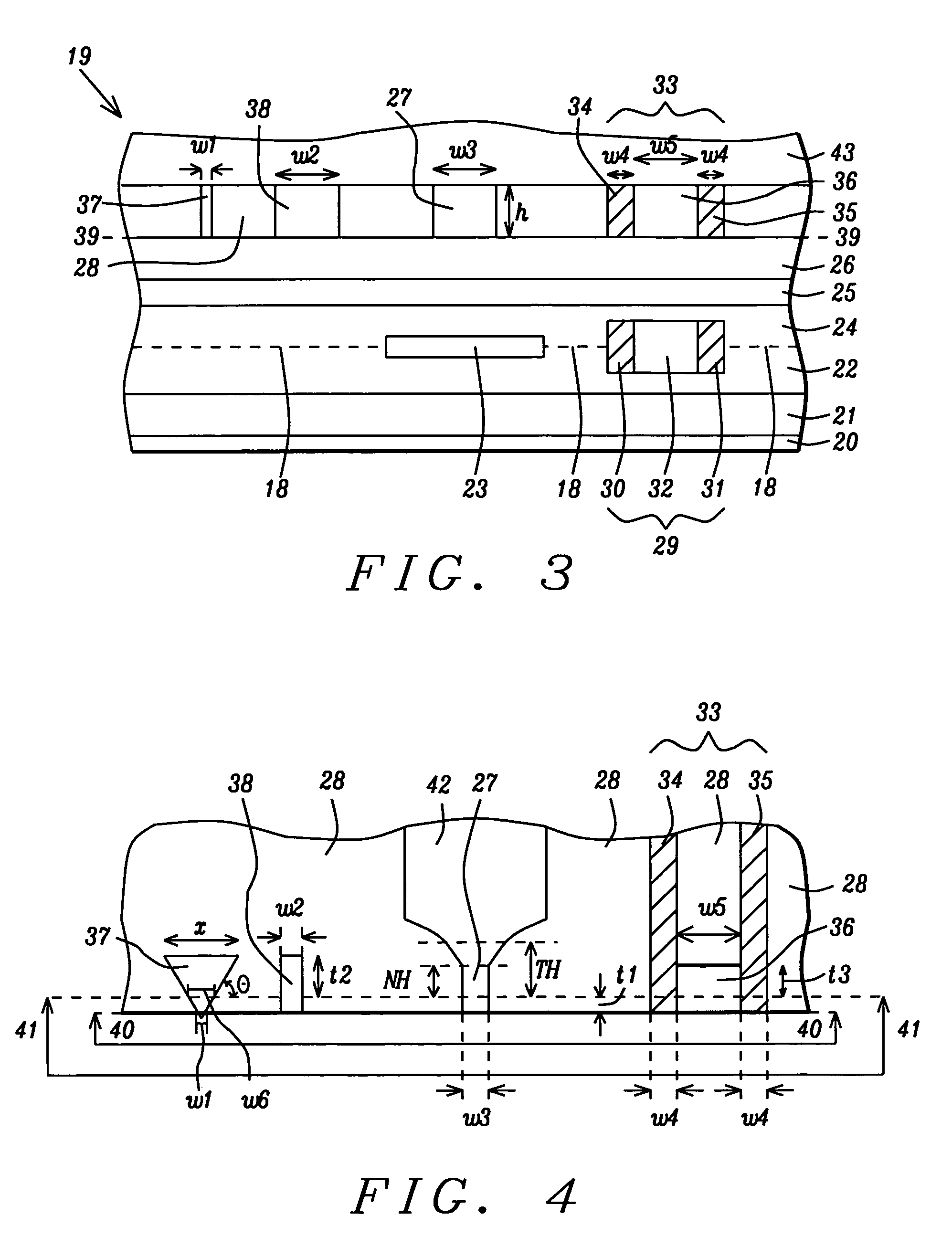

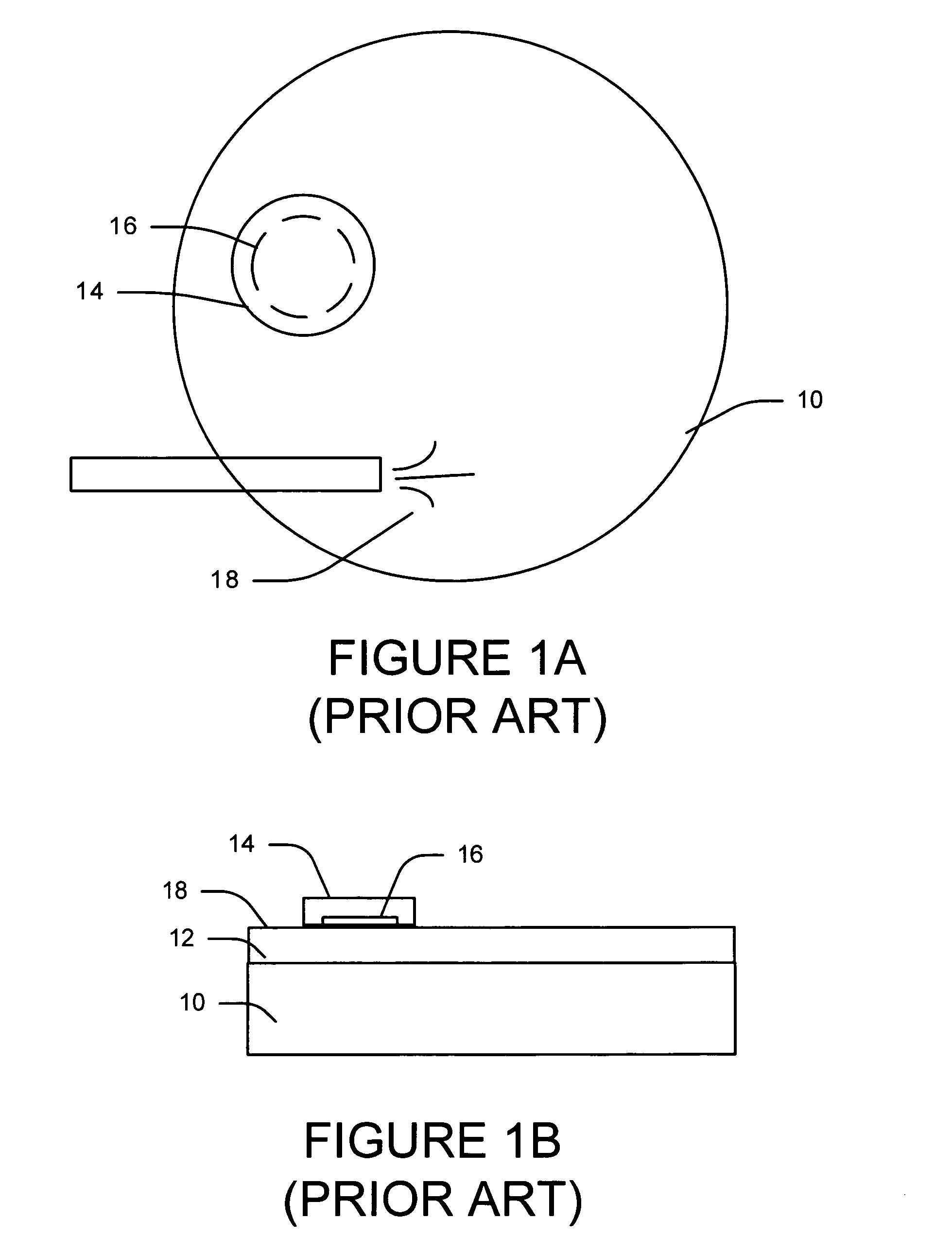

Independently controlled read and write head stripe height parameters in slider back end process

ActiveUS6884148B1Heads using thin filmsLapping machinesElectrical resistance and conductanceEngineering

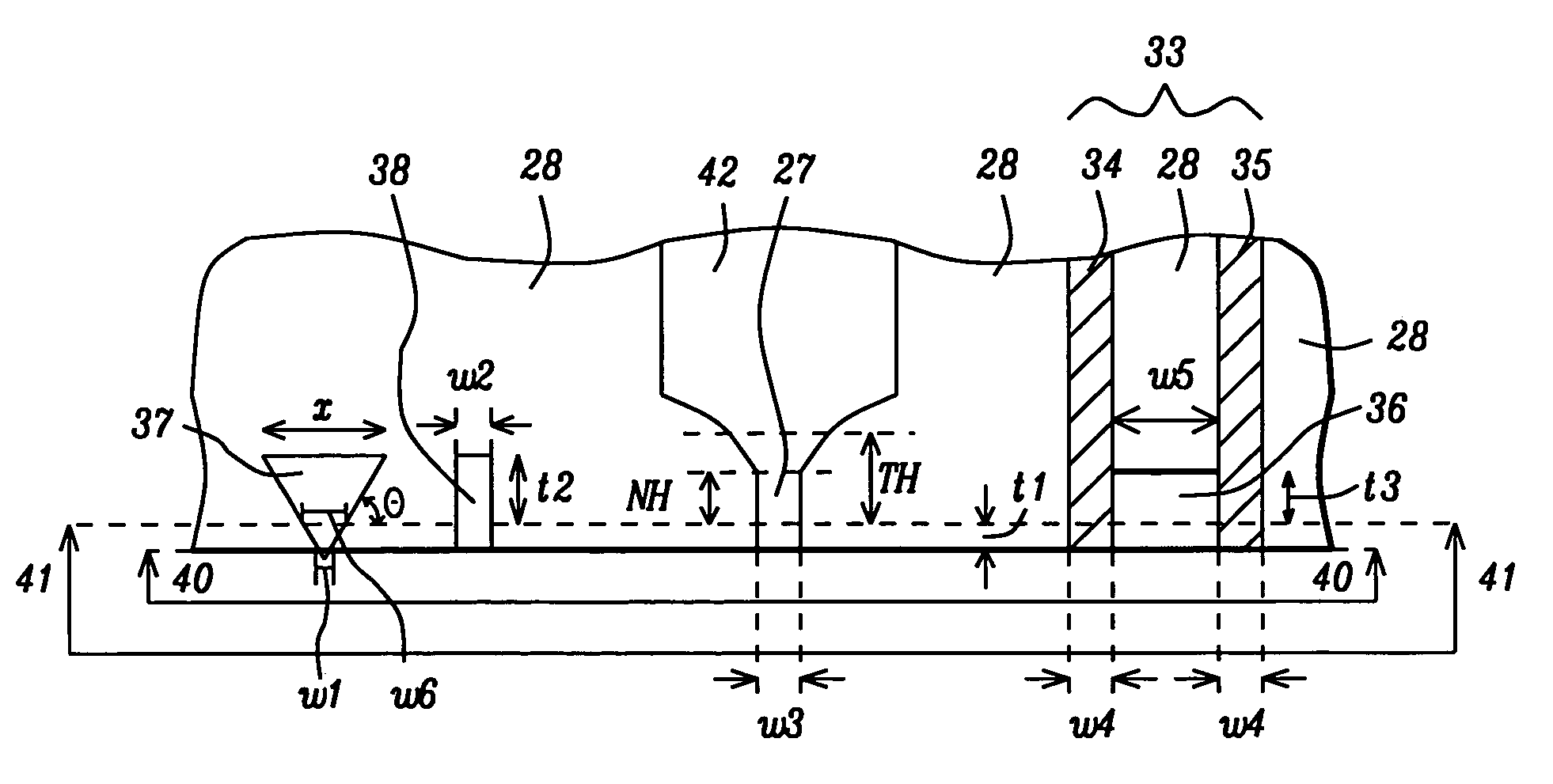

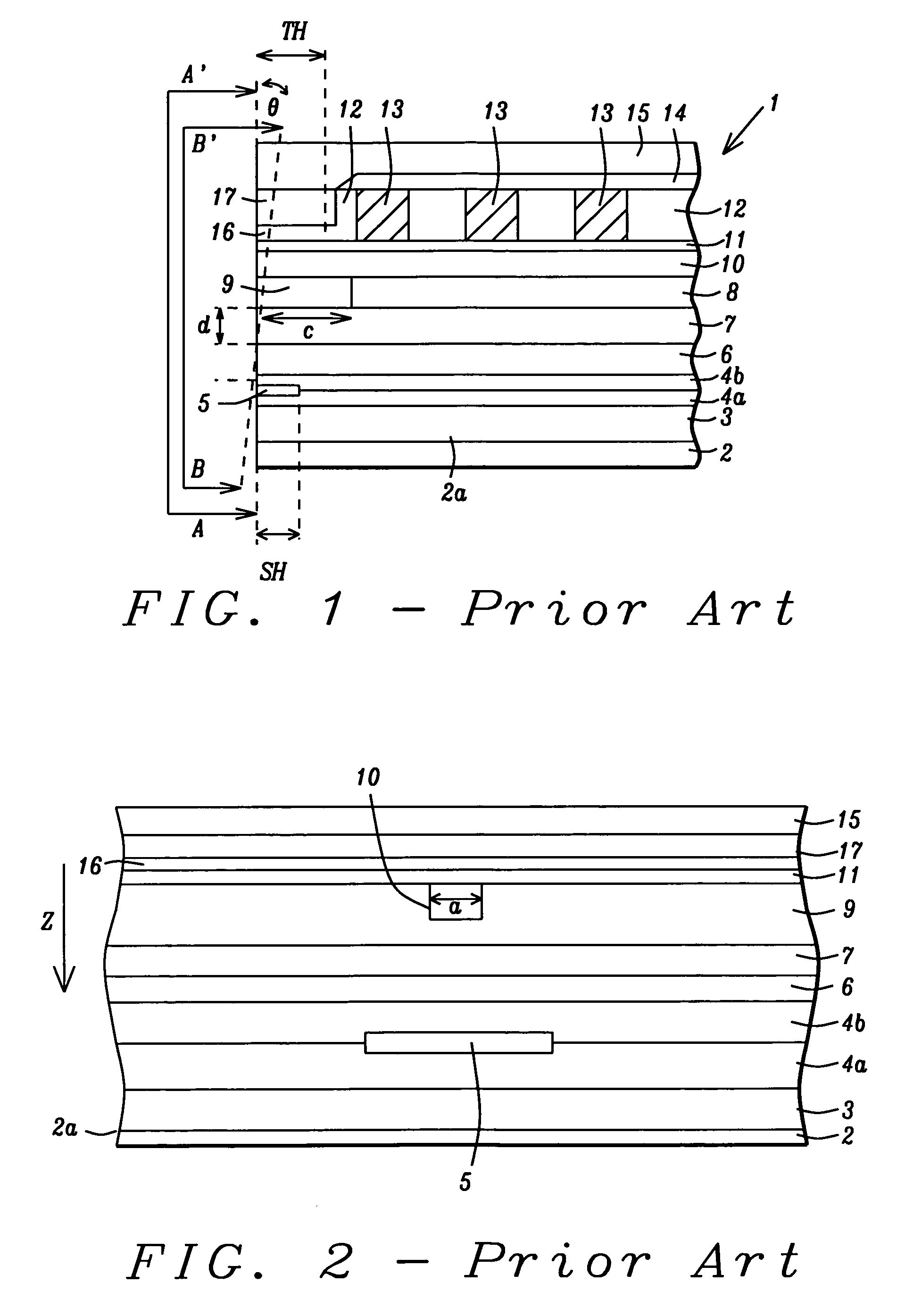

A lapping guide system and method for lapping a merged read / write head are disclosed. The resistance RRE of a first ELG near the sensor in the read head is correlated to the resistance RWE of a second ELG and to the width of a first optical lapping guide (OLG) near the neck region of the write head. As the lapping progresses, RWE and RRE increase and the OLG width along the lapping plane increases. Thus, an OLG width and a RWE corresponding to a target neck height or throat height and a RRE corresponding to a target stripe height are determined. A lapping plane is actively tilted to enable write head dimensions to be independently controlled on a per wafer or per row basis. The first OLG is a triangular feature with one side parallel to the lapping plane and the other two sides converging near the lapping plane.

Owner:HEADWAY TECH INC

Non-contact support platforms for distance adjustment

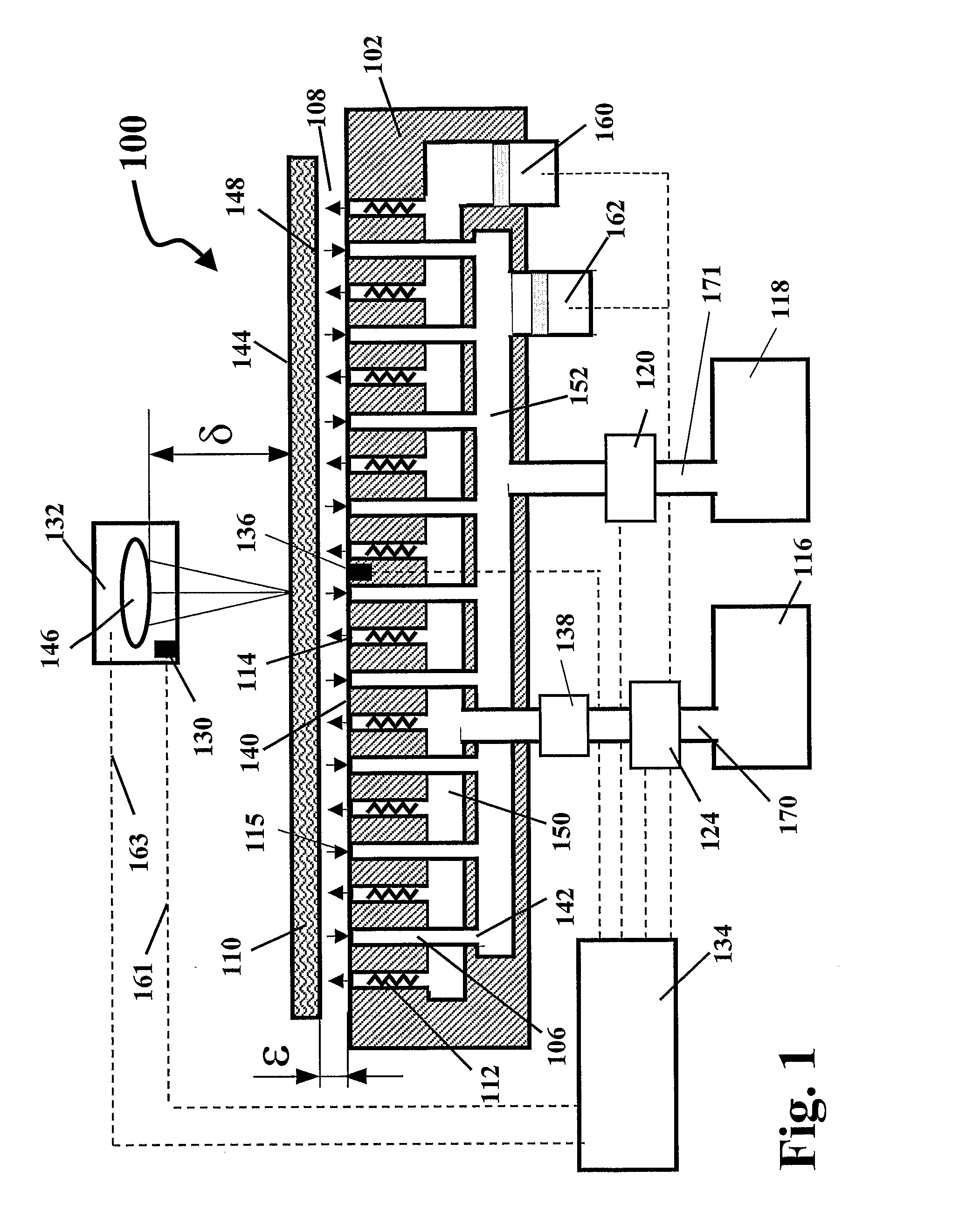

ActiveUS20070195653A1Effectively rigidCombination recordingLinear bearingsHigh pressurePressure control

An apparatus for supporting a stationary or moving substantially flat object without physical contact on an fluid-cushion. The object floats on a fluid cushion gap, the apparatus aimed for globally or locally adjusting the gap. The apparatus comprising: a first platform for supporting the object without contact, the platform having a substantially flat active surface comprised of one or more sectors, each sector comprising at least one of a plurality of basic cells, each basic cell having at least one of a plurality of pressure outlets fluidically connected through a pressure flow restrictors to a higher-pressure manifold associated with the sector in which the basic cell lies, the higher-pressure manifold is fluidically connected through main supply pipeline to pressurized fluid supply and at least one of a plurality of fluid-evacuation channels fluidically connected to a lower-pressure manifold associated with the sector in which the basic cell lies having main evacuation pipeline; wherein the flow restrictor characteristically exhibiting fluidic return spring behavior; and wherein at least one pressure control valve is interposed with at least one of the two main pipelines of at least one sector for controlling pressure levels of at least one of the two manifolds of that sector.

Owner:COREFLOW SCI SOLUTIONS

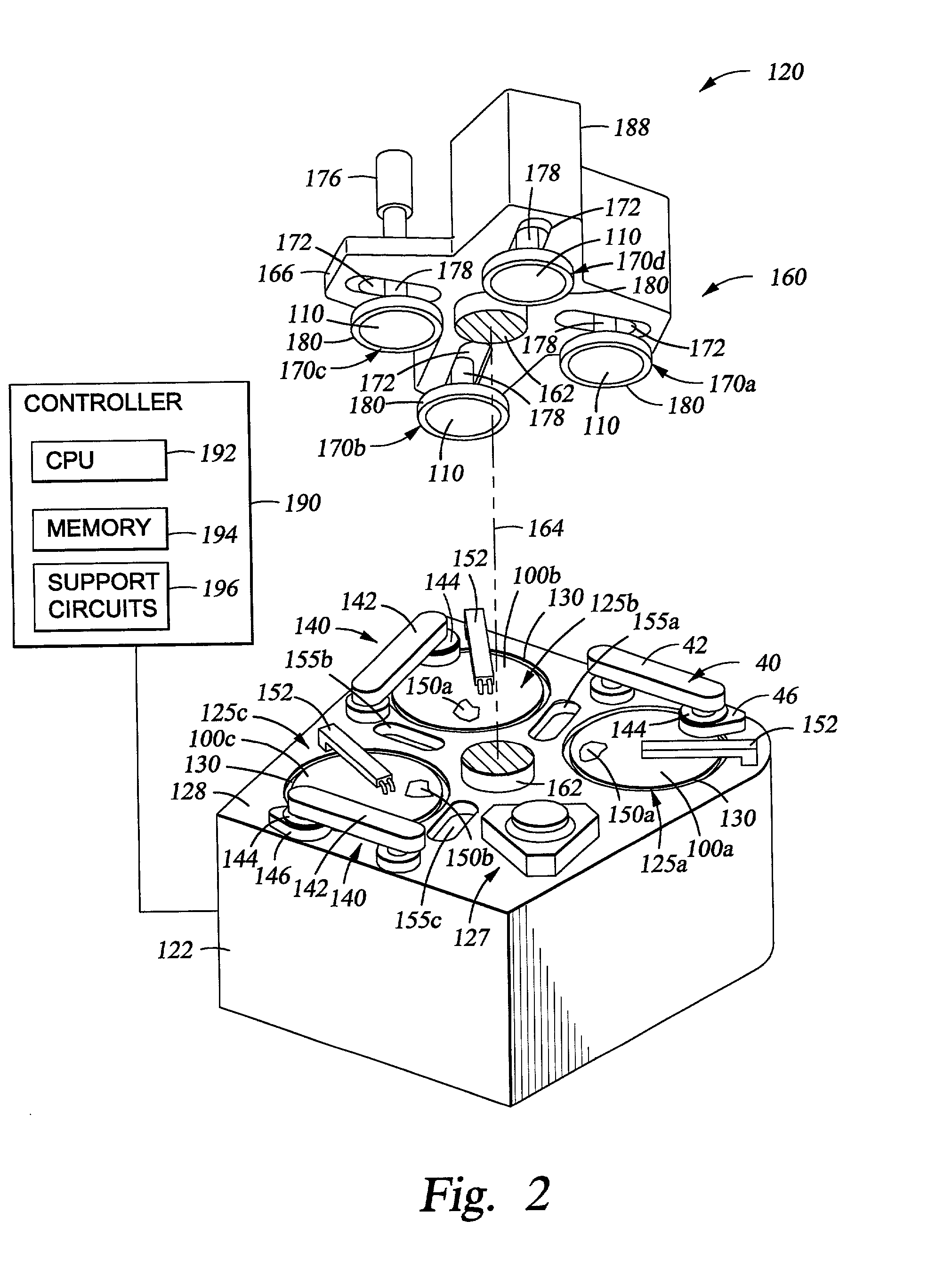

Planarization system with multiple polishing pads

InactiveUS6626744B1Edge grinding machinesPolishing machinesElectrical and Electronics engineeringHead position

An apparatus for simultaneously polishing wafers including at least a first and a second web of polishing media. At least two polishing heads are provided on a carrier coupled to a drive system such that one polishing head positions a wafer against the first web and a second polishing head positions a second wafer against the second web. The drive system imparts a programmed polishing motion or pattern to the polishing heads.

Owner:APPLIED MATERIALS INC

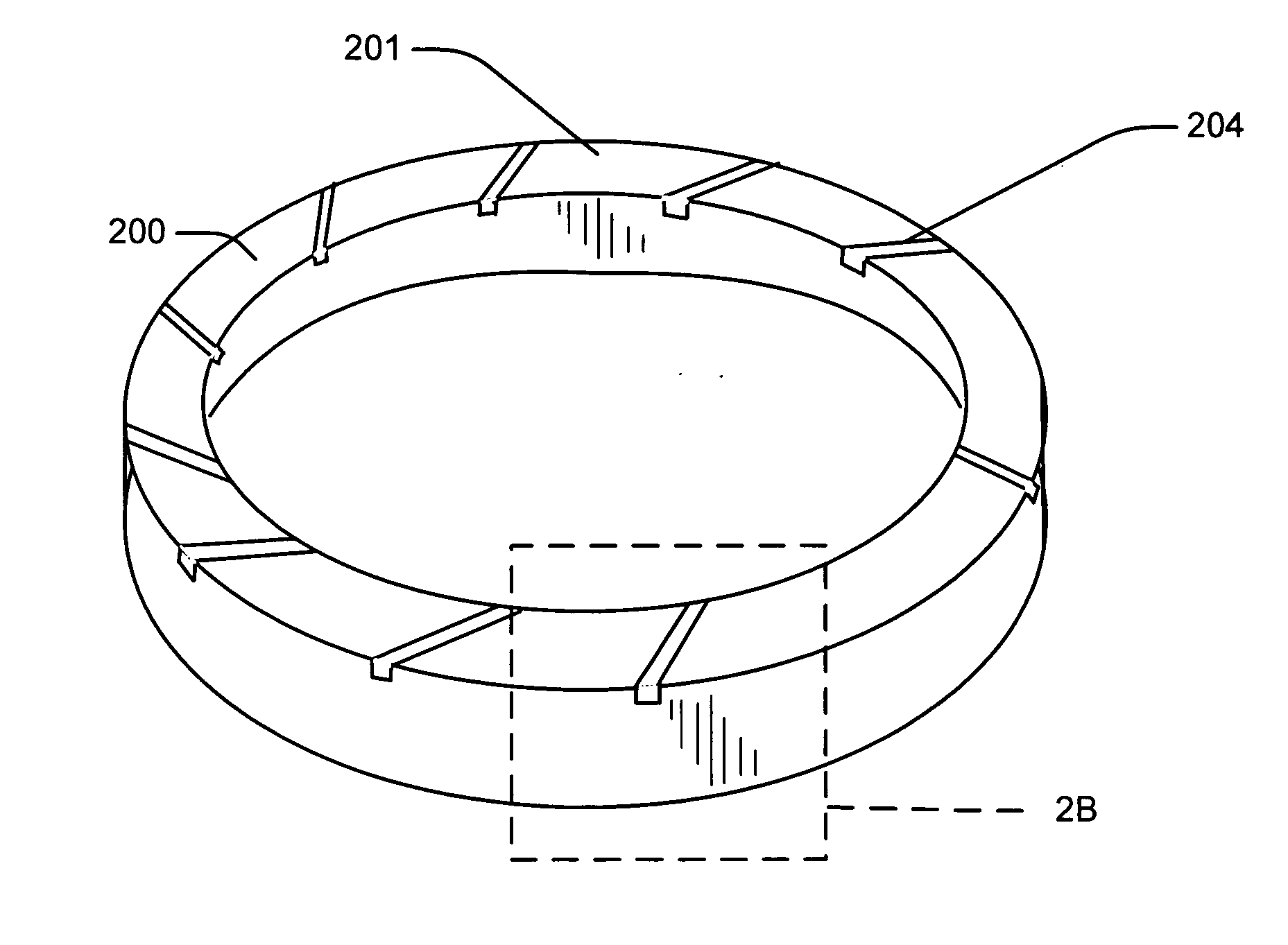

Carrier head with non-contact retainer

A carrier head for chemical mechanical polishing of a substrate has a base and a retaining ring positioned beneath the base. The retaining ring includes a main portion with a first surface to apply a load to a perimeter portion of the back surface of the substrate and an annular projection with a second surface to retain the substrate. A bottom surface of the projection is separated from a top surface of a polishing pad by a gap.

Owner:APPLIED MATERIALS INC

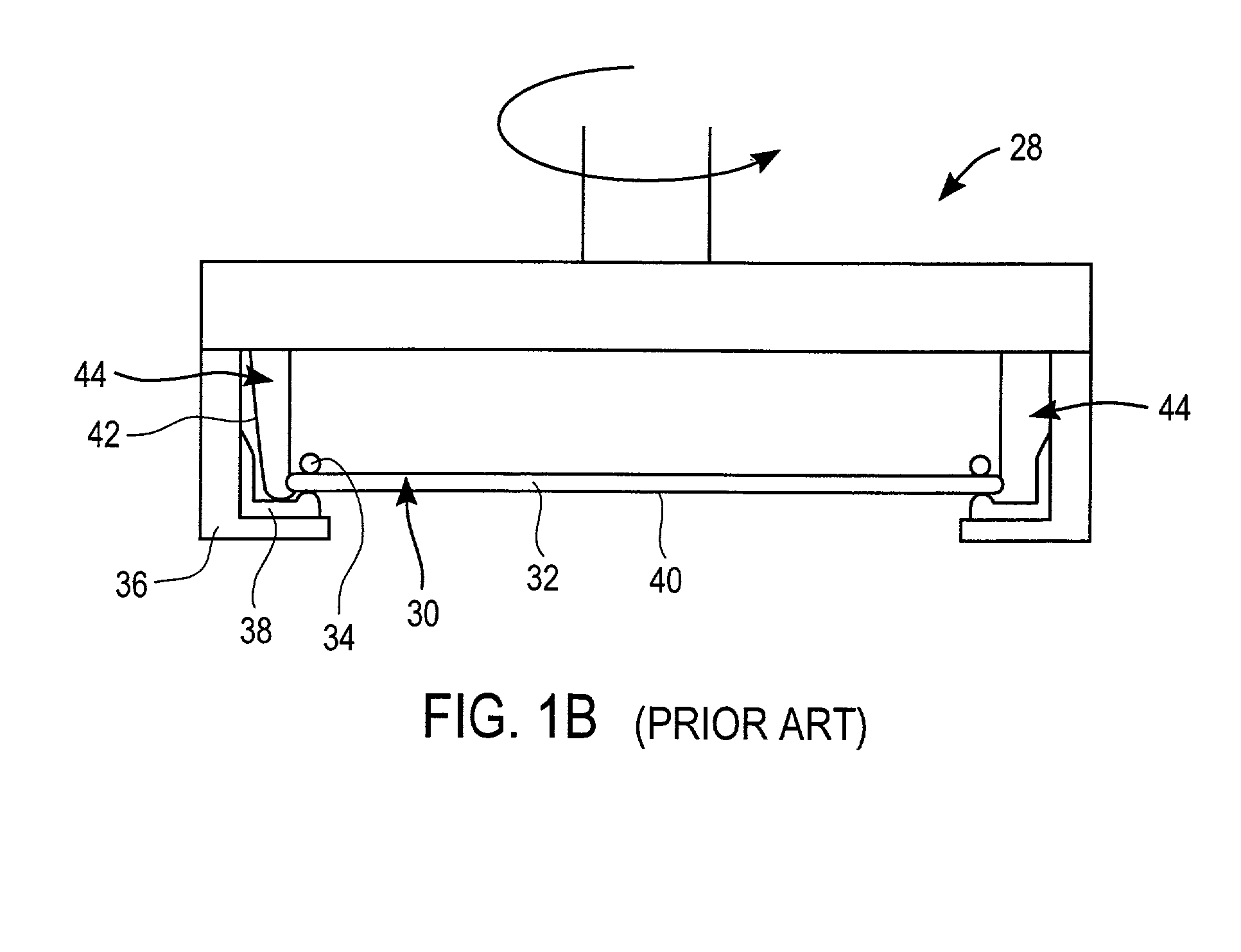

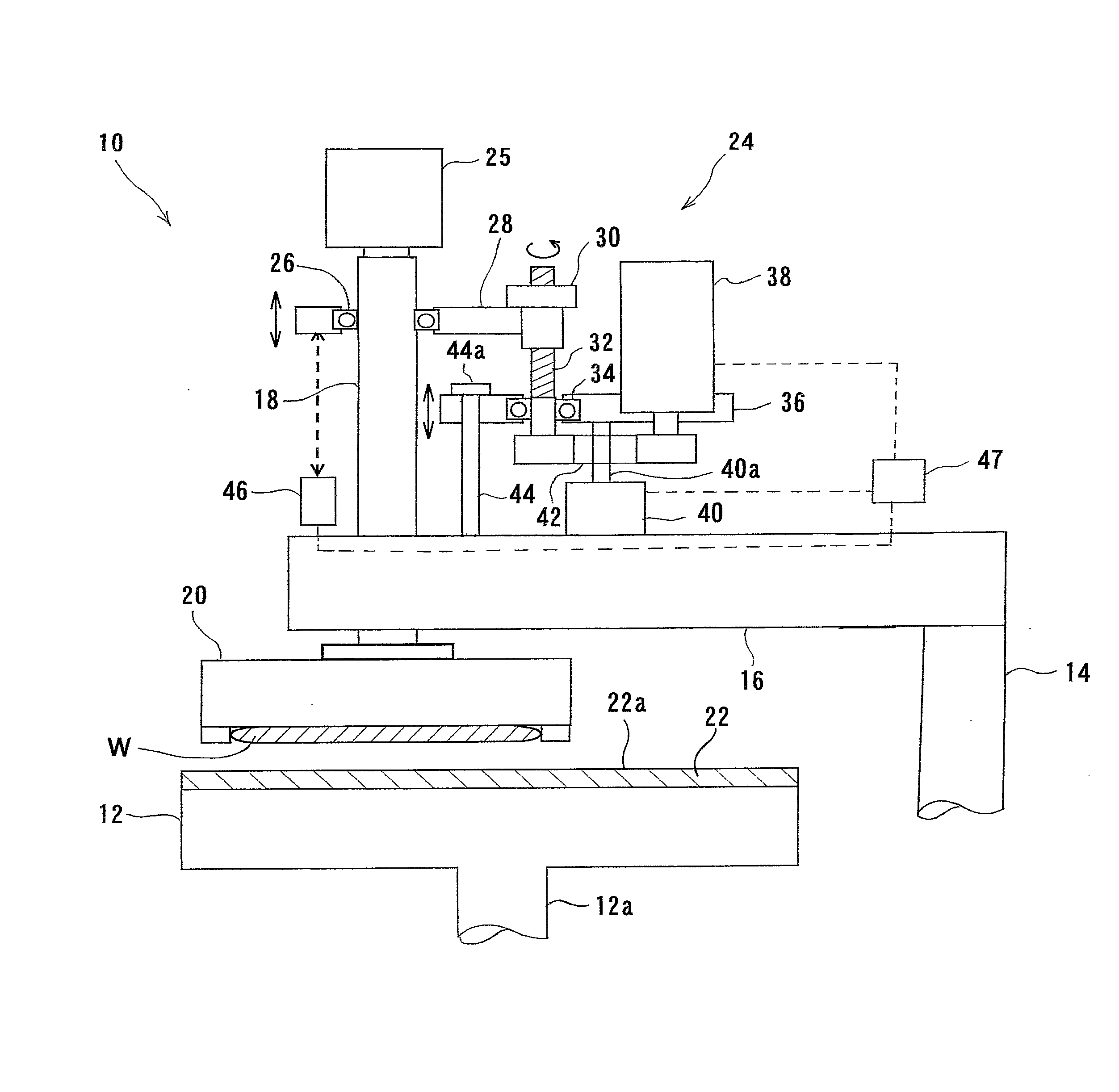

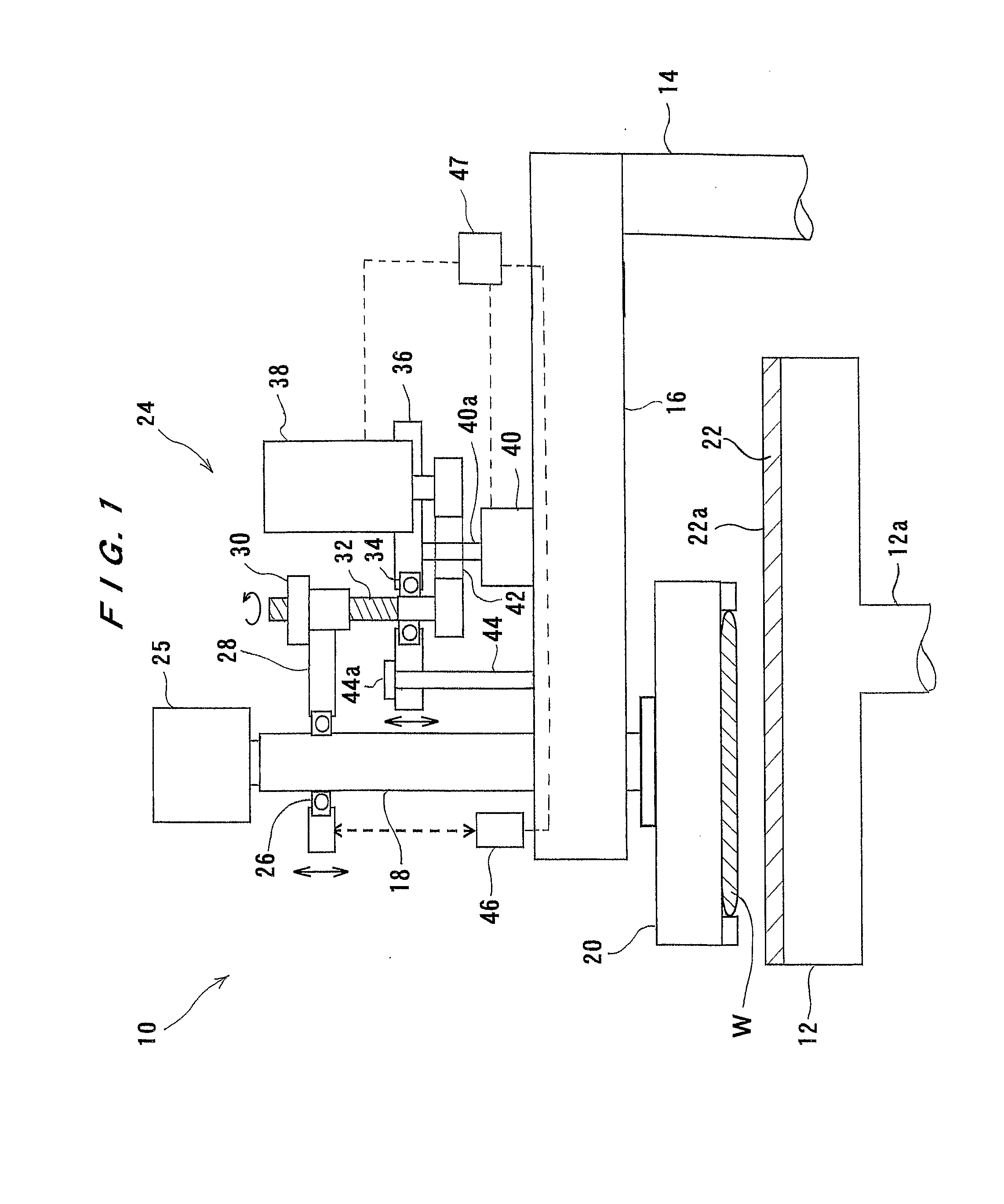

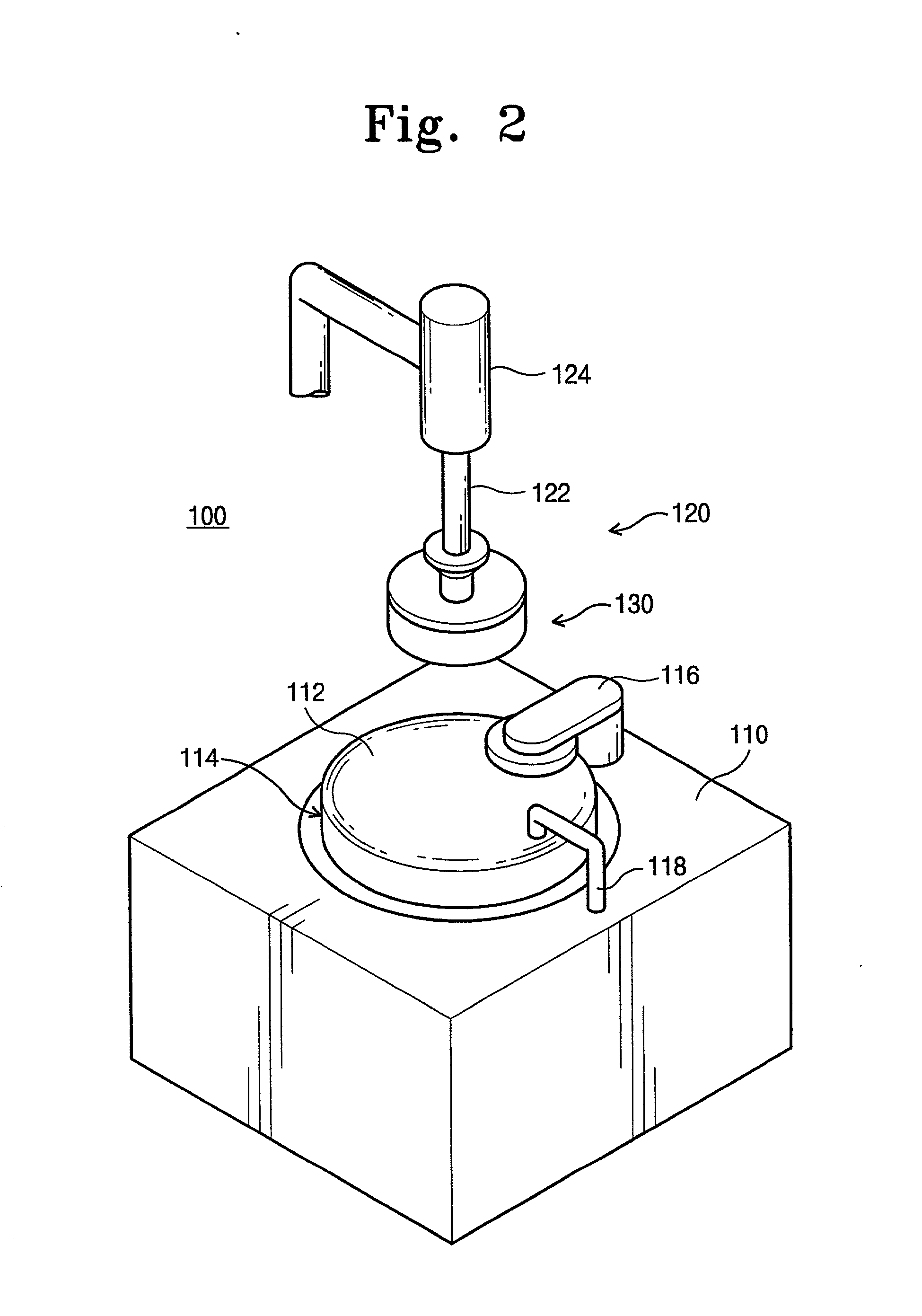

Polishing Apparatus

ActiveUS20080070479A1Easy to replacePolishing machinesRevolution surface grinding machinesEngineeringSemiconductor

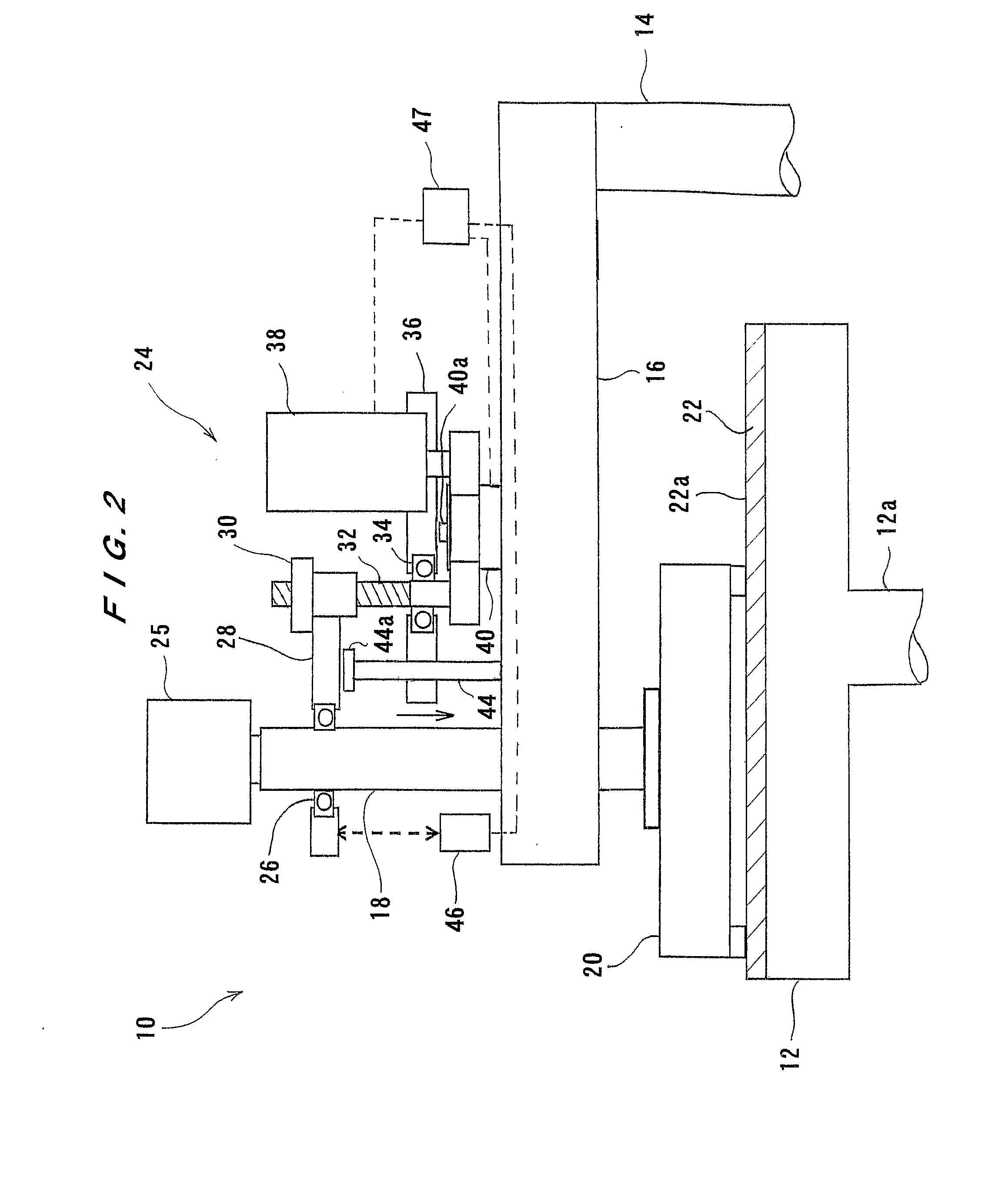

A polishing apparatus (1) has a polishing pad (22), a top ring (20) for holding a semiconductor wafer (W), a vertical movement mechanism (24) operable to move the top ring (20) in a vertical direction, a distance measuring sensor (46) operable to detect a position of the top ring (20) when a lower surface of the top ring (20) is brought into contact with the polishing pad (22), and a controller (47) operable to calculate an optimal position of the top ring (20) to polish the semiconductor wafer (W) based on the position detected by the distance measuring sensor (46). The vertical movement mechanism (24) includes a ball screw mechanism (30, 32, 38, 42) operable to move the top ring (20) to the optimal position.

Owner:EBARA CORP

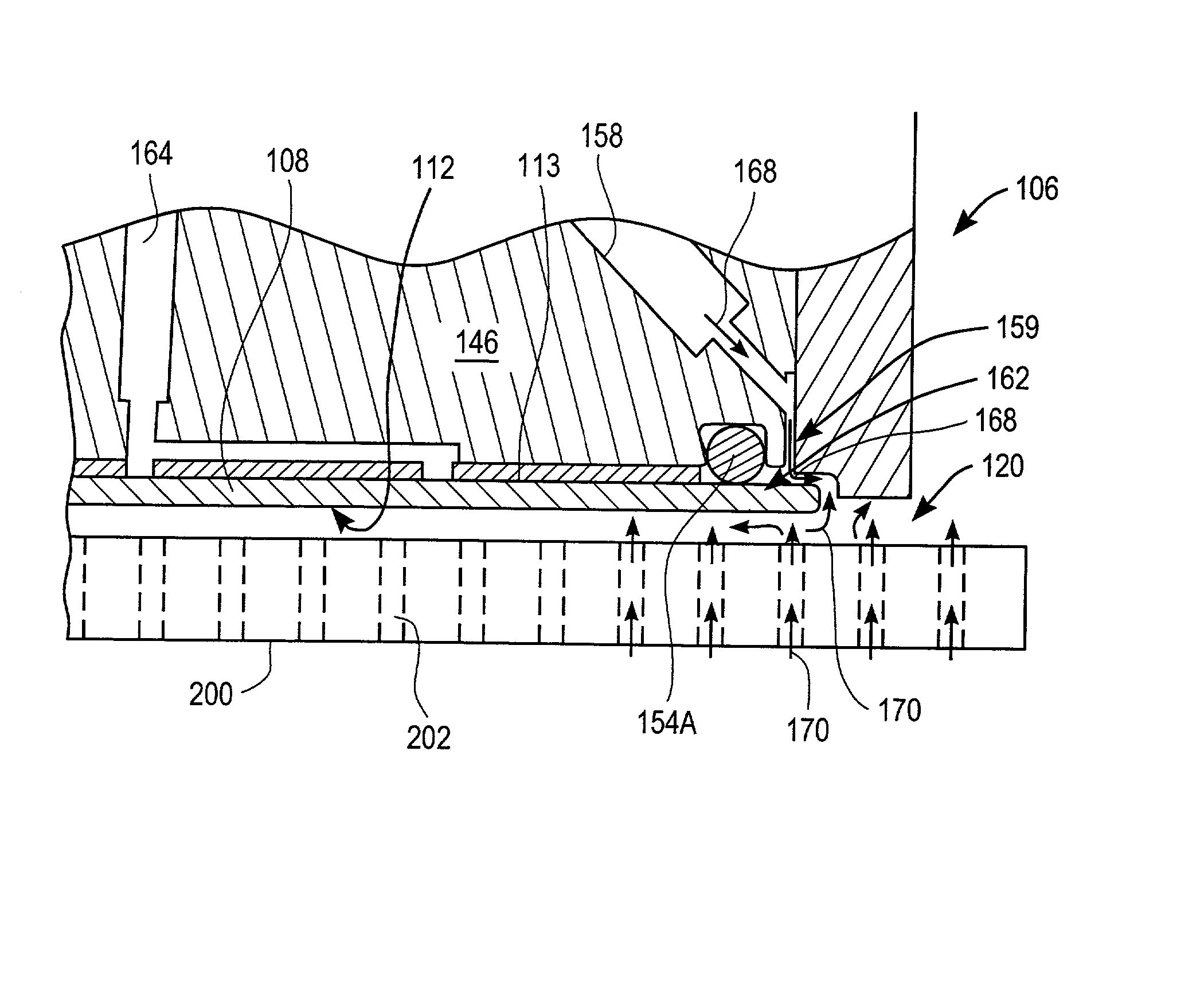

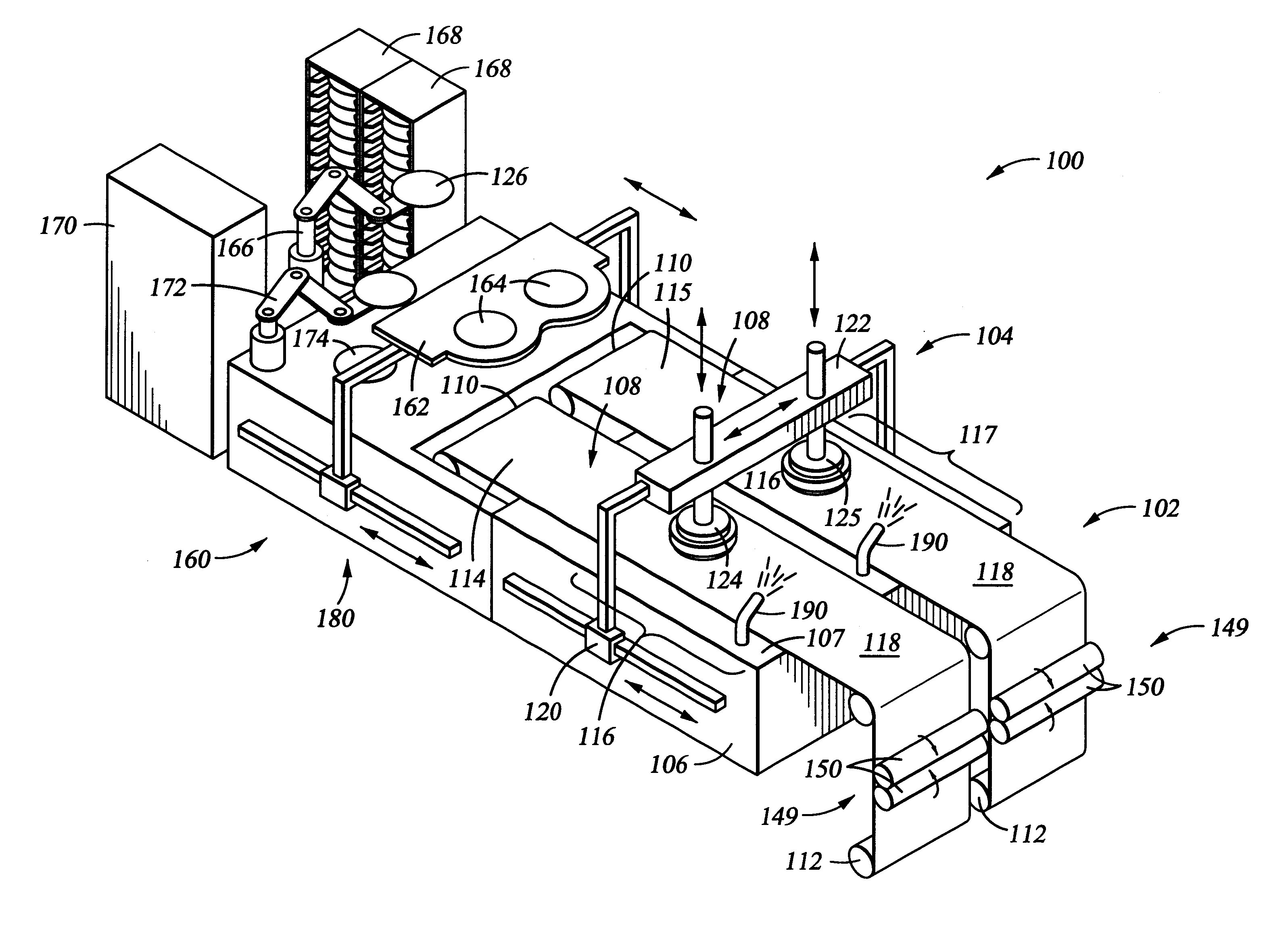

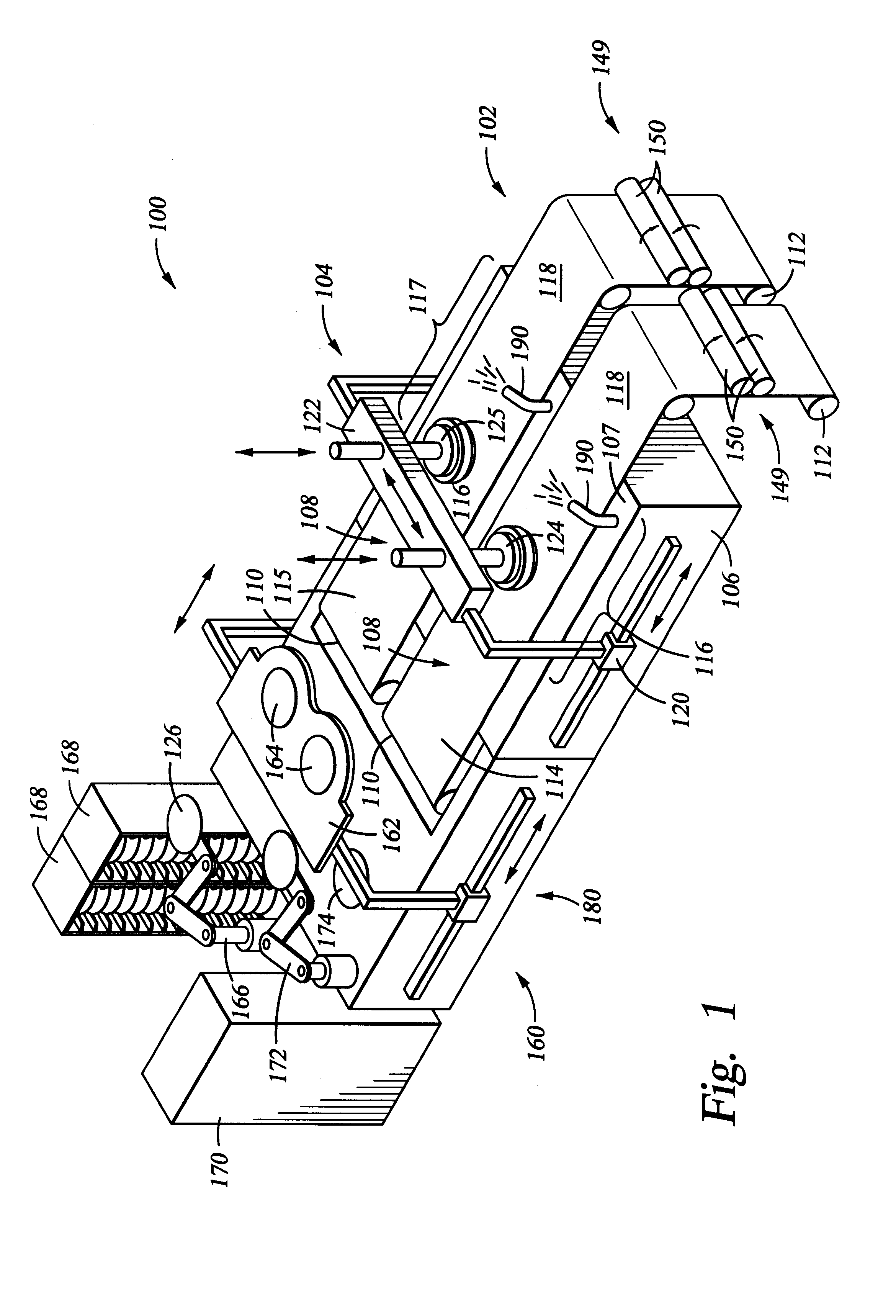

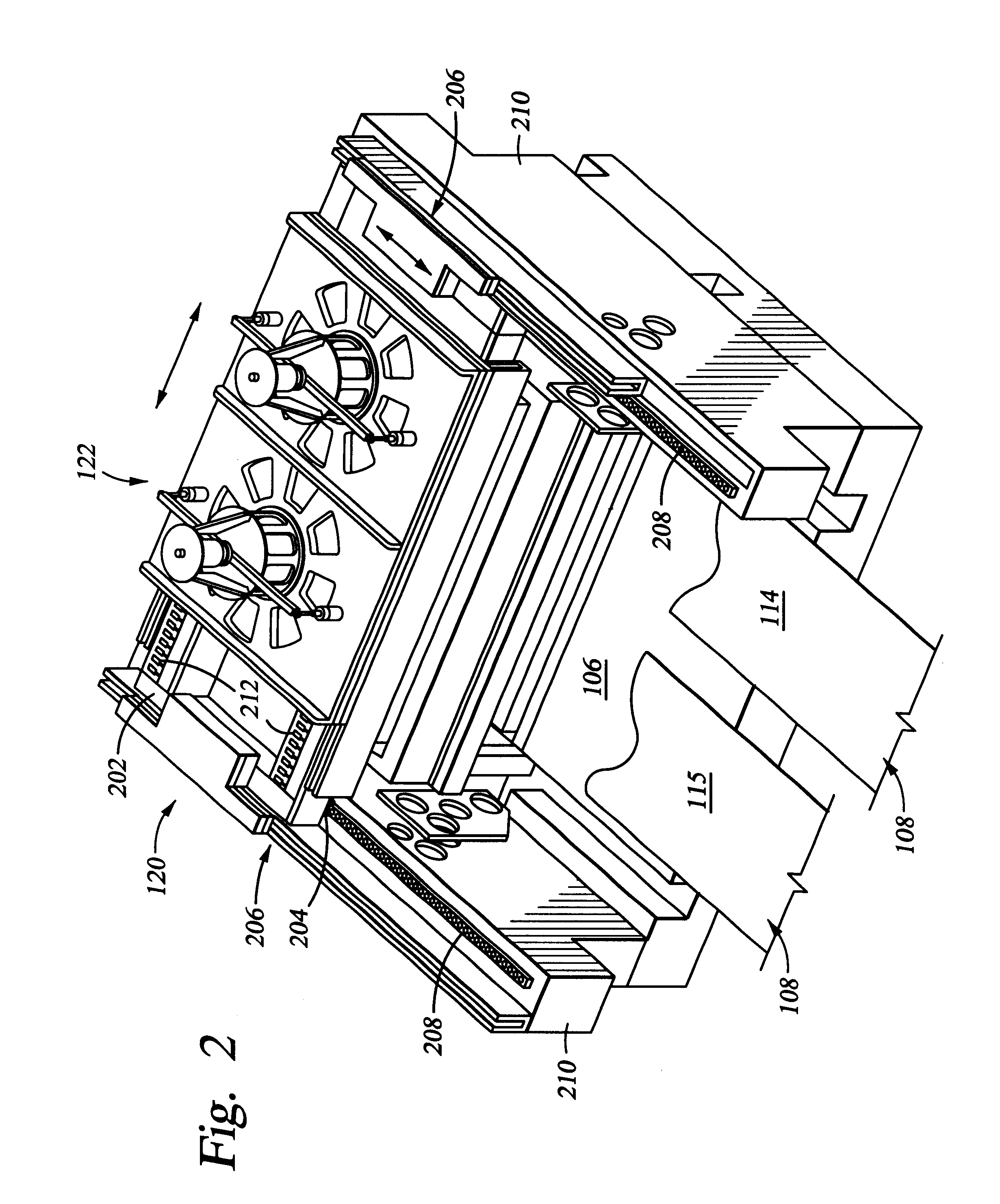

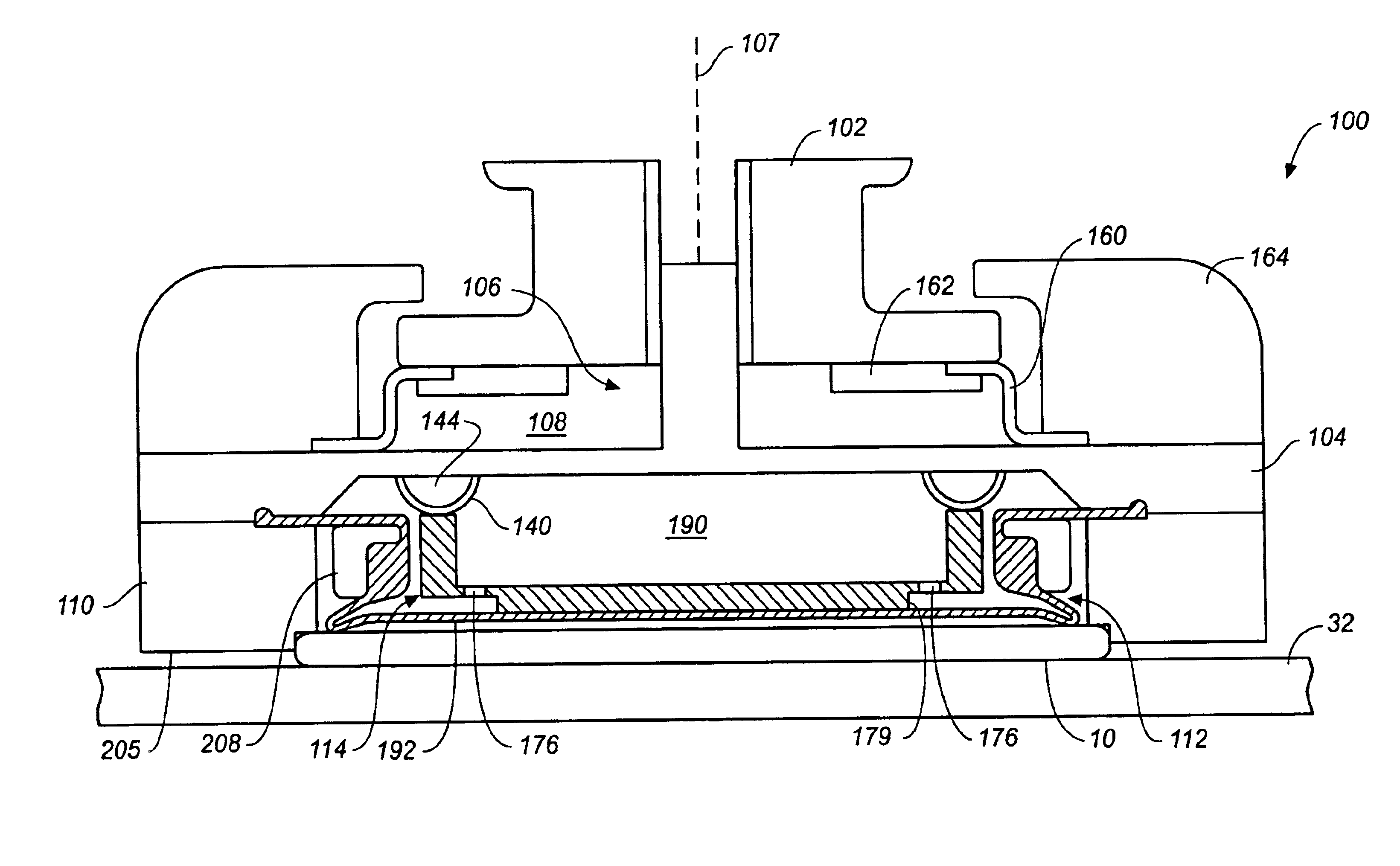

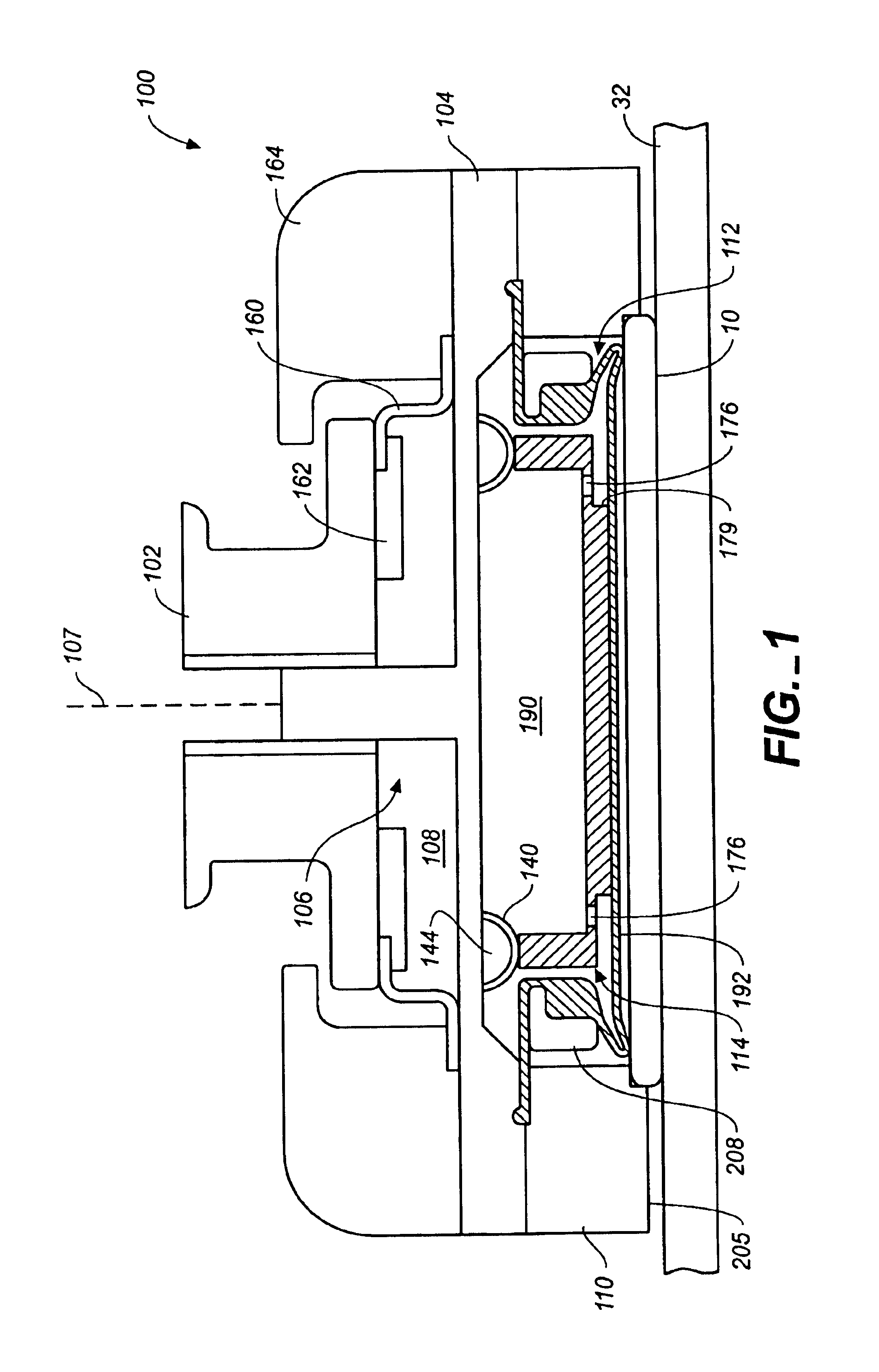

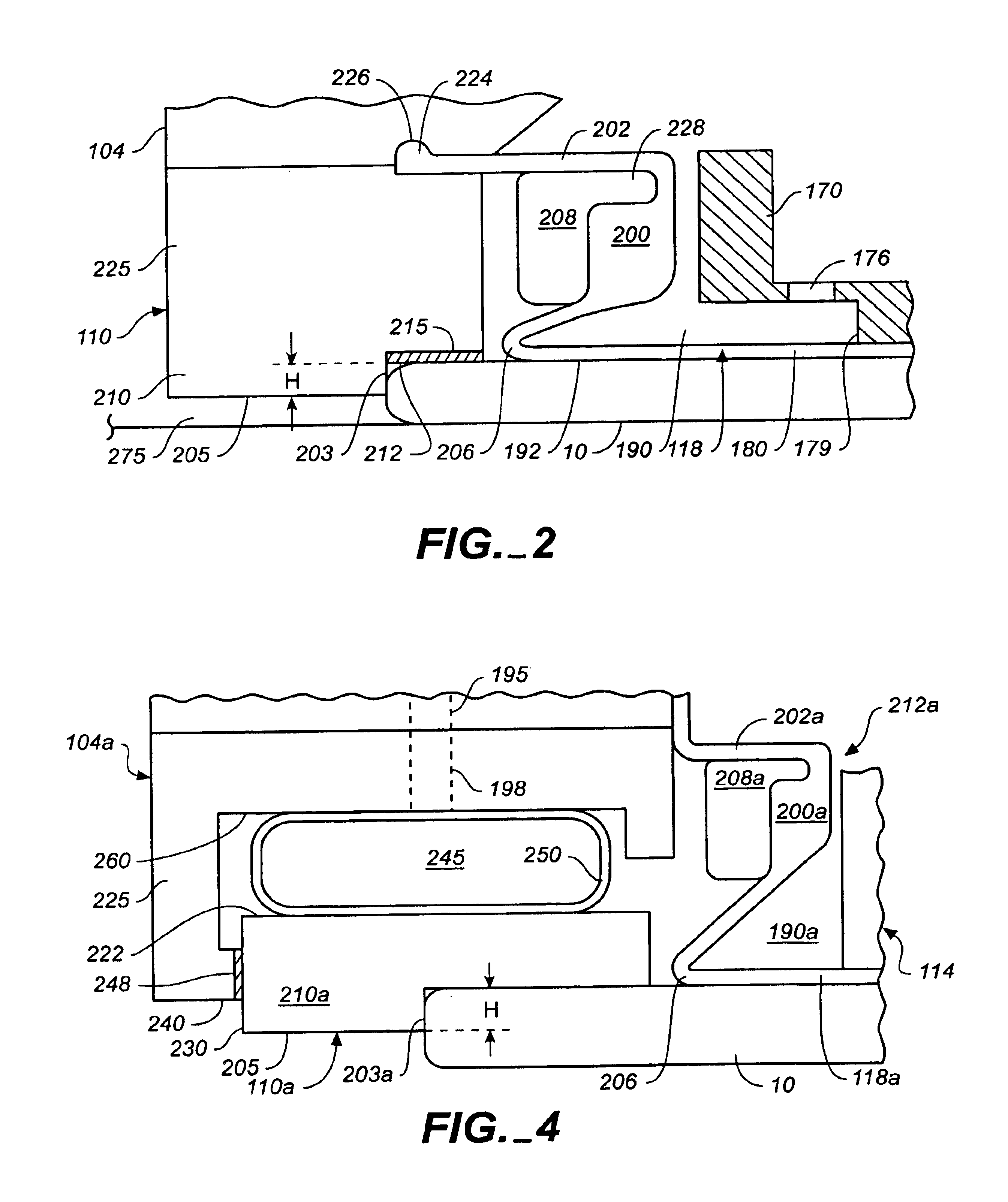

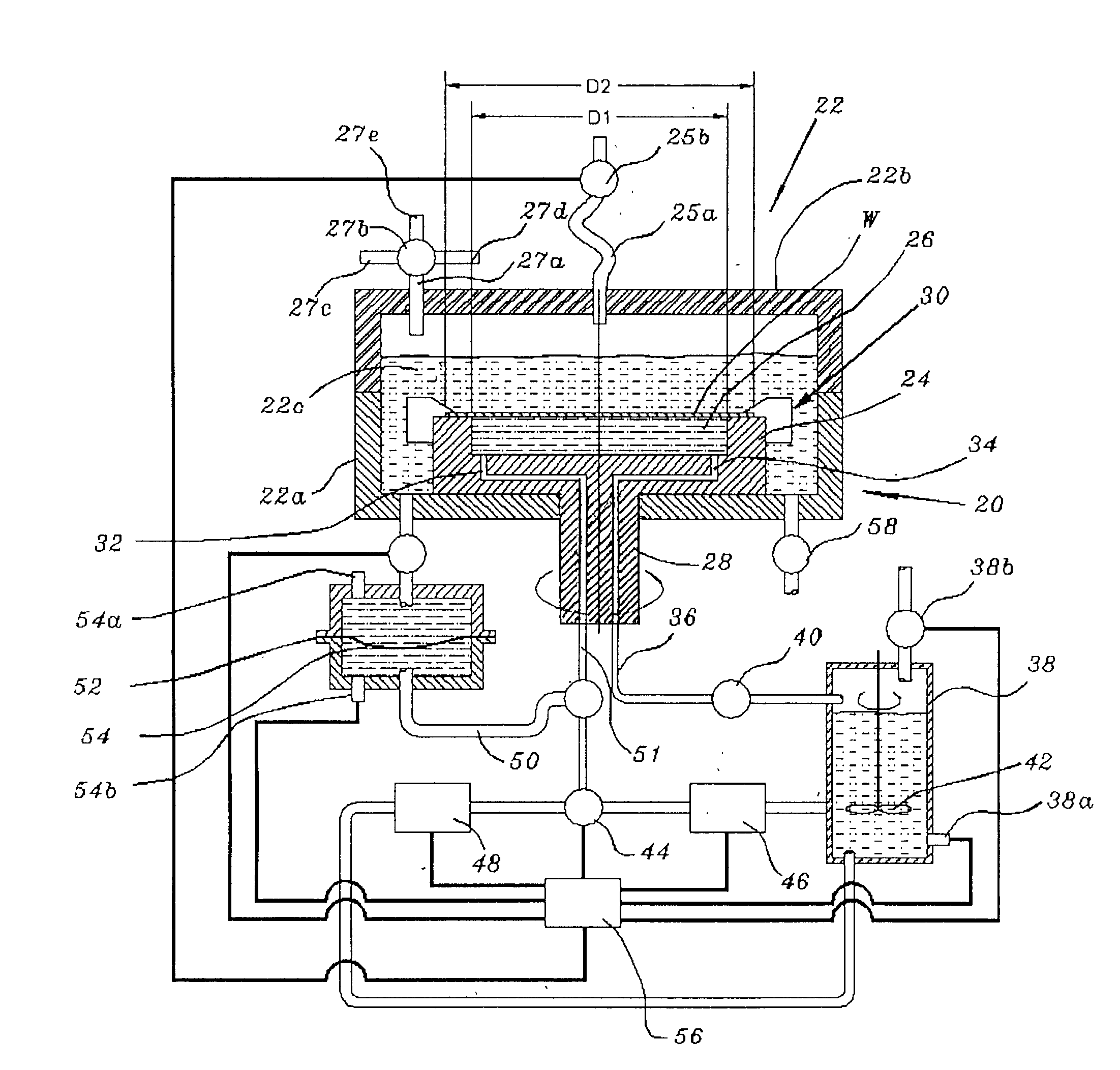

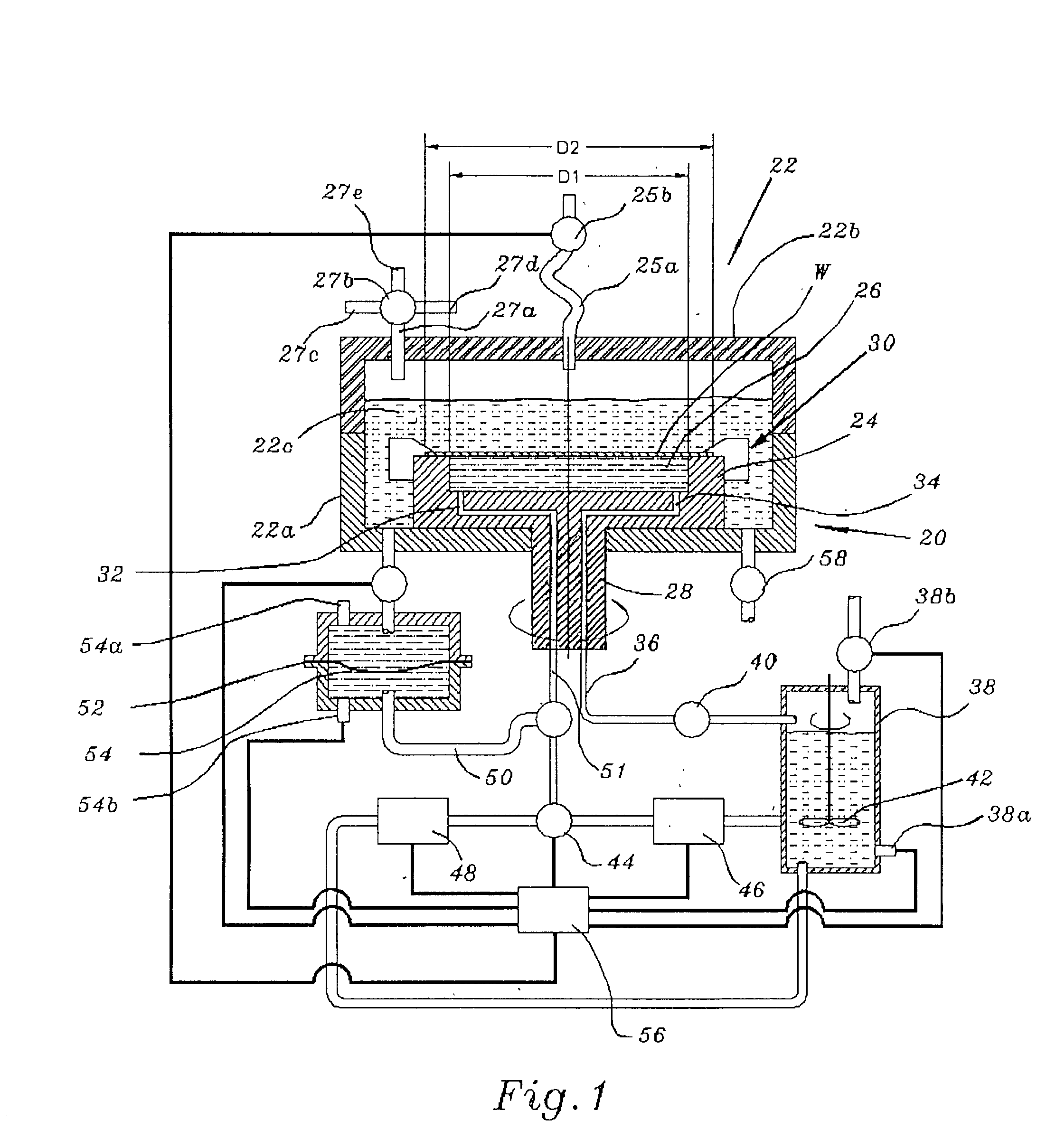

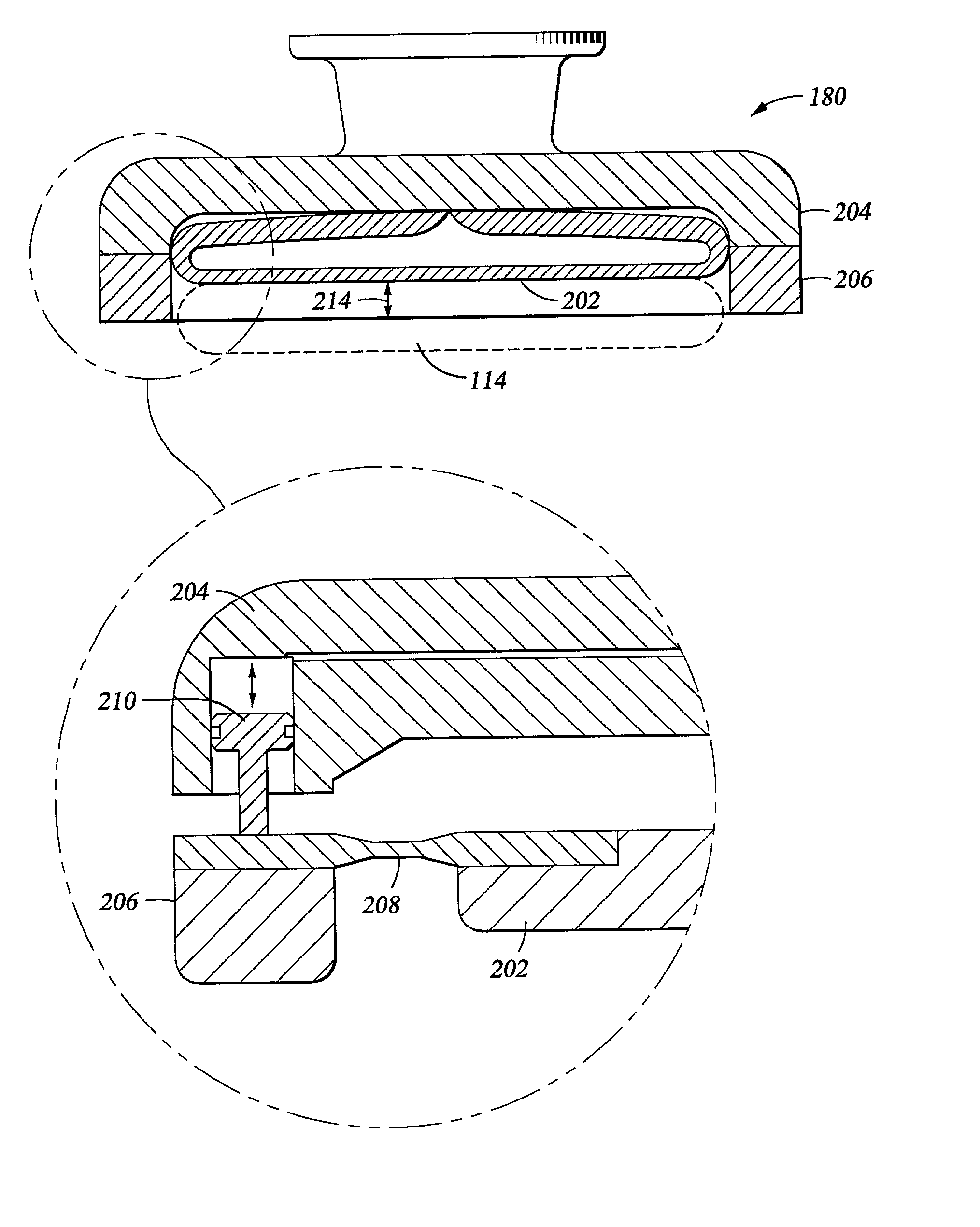

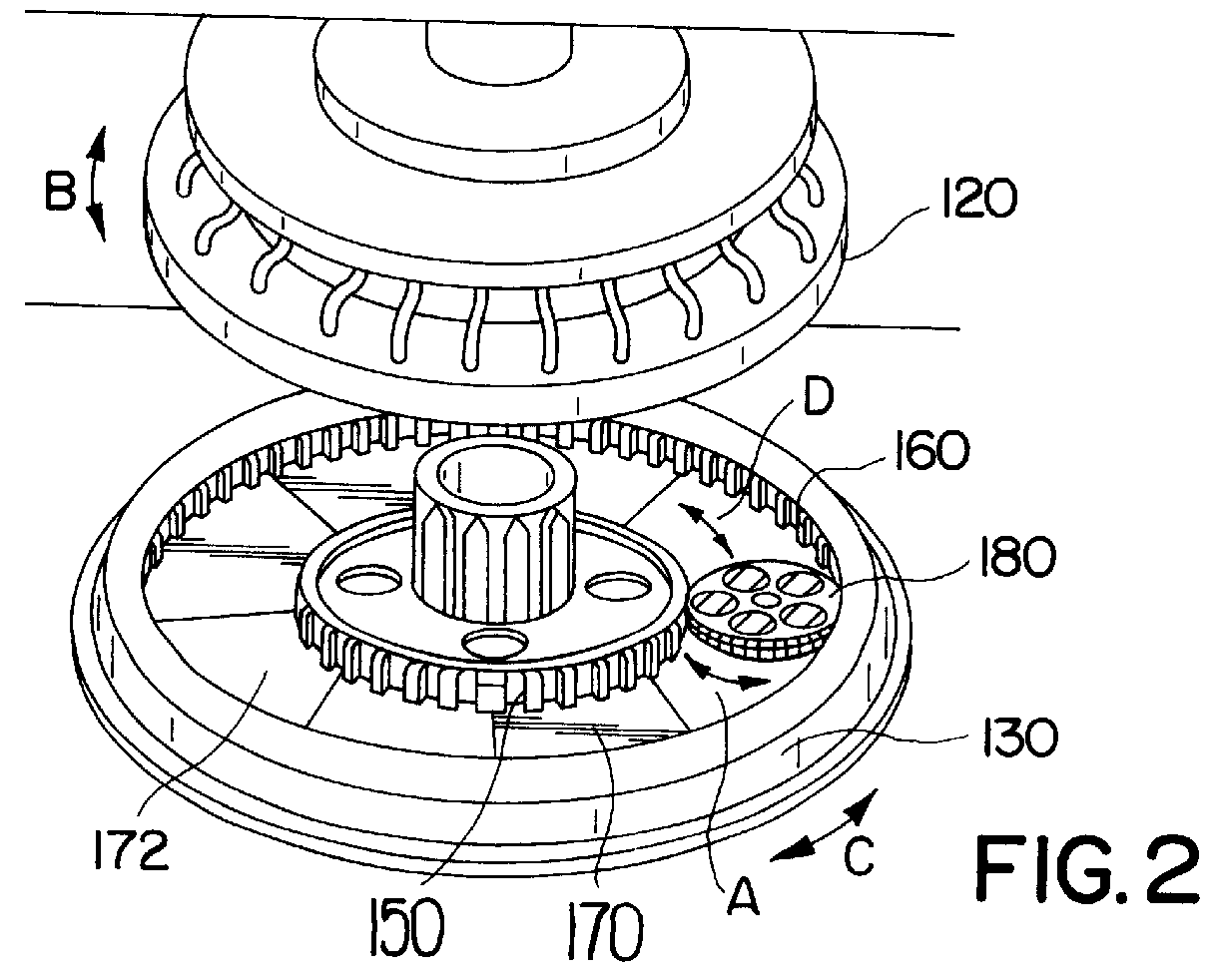

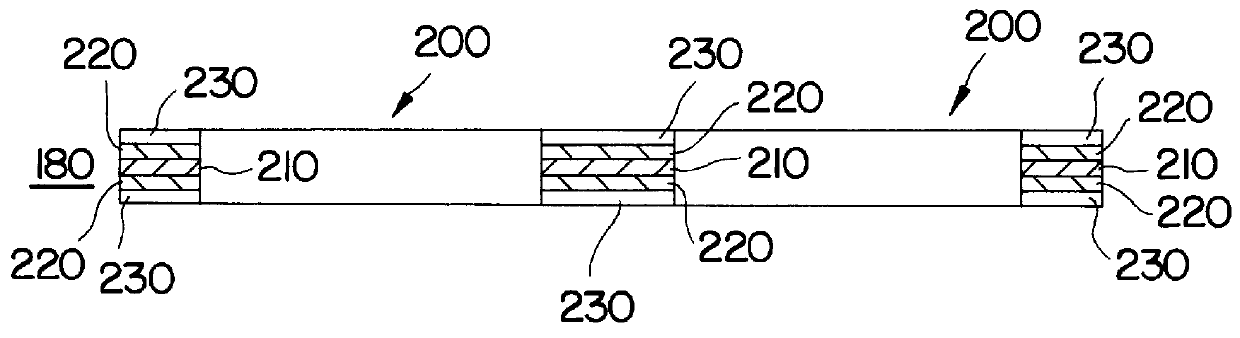

Work piece carrier with adjustable pressure zones and barriers and a method of planarizing a work piece

InactiveUS7140956B1Polishing machinesRevolution surface grinding machinesMaterial removalEngineering

An apparatus for planarizing a work piece includes an easily assembled work carrier. The carrier includes a carrier insert having a work piece bladder clamped to a carrier backing plate with a plurality of clamps to form a plurality of web plenums. The outer edge of the bladder is supported by a rib that is coupled to a carrier plenum. By adjusting the pressure in the carrier plenum, the pressure exerted on the edge of a work piece during a planarization operation can be adjusted. The carrier also includes a floating wear ring that surrounds the work piece bladder and a work piece mounted on that bladder. By adjusting the force exerted by the wear ring on a polishing pad, independently of the pressure exerted by the rib at the edge of the bladder, the material removal rate near the edge of the work piece can be controlled.

Owner:NOVELLUS SYSTEMS

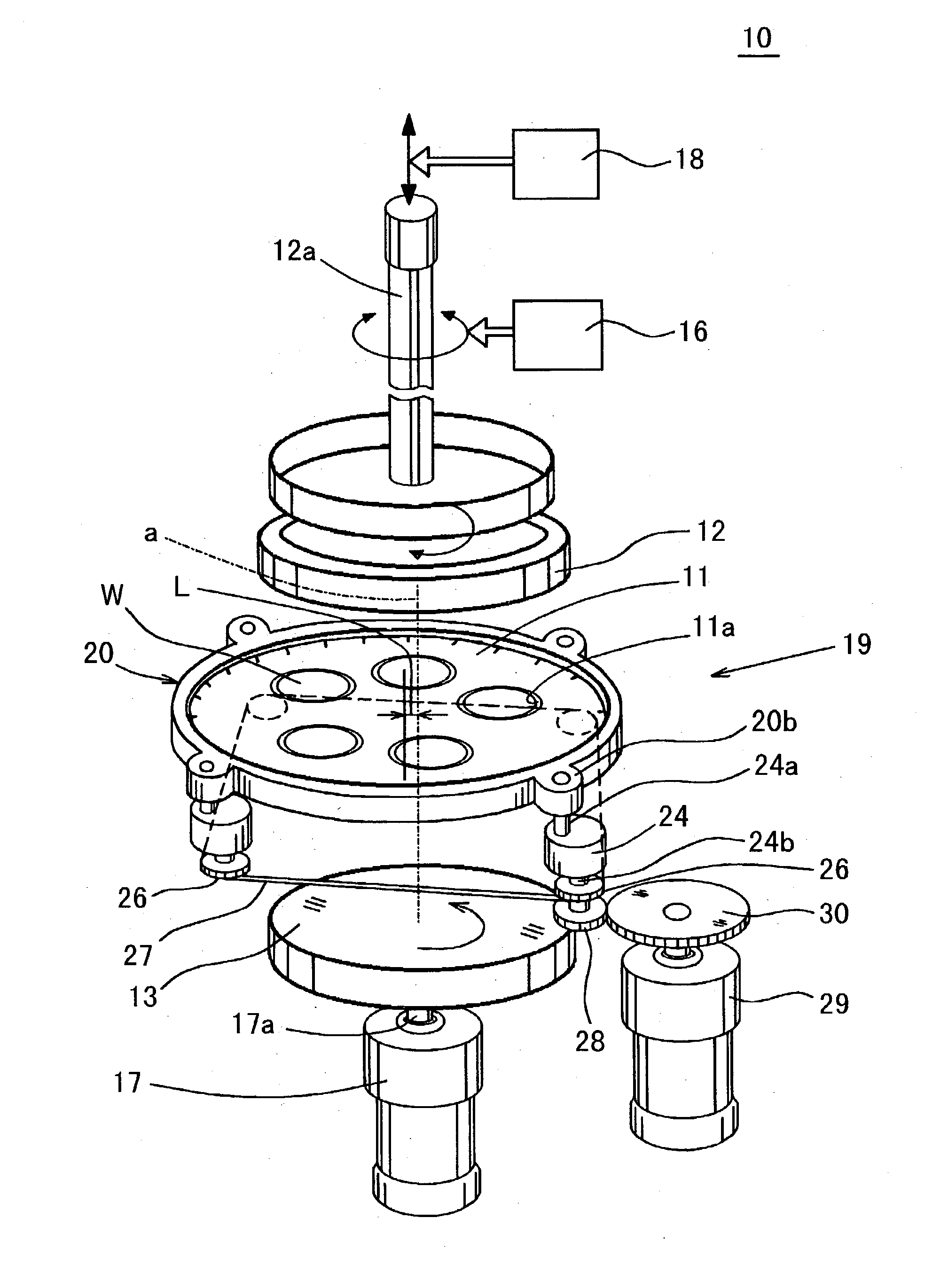

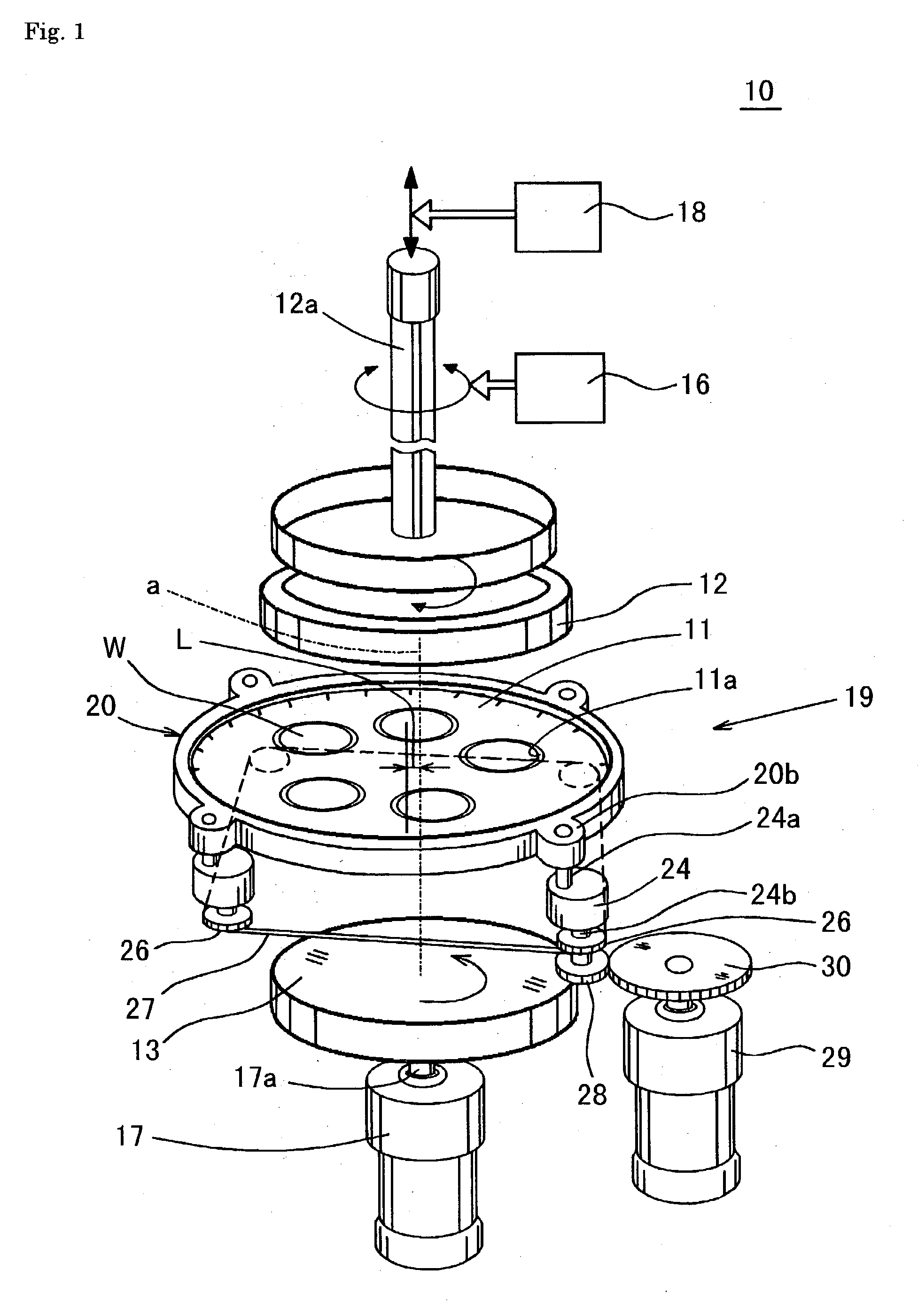

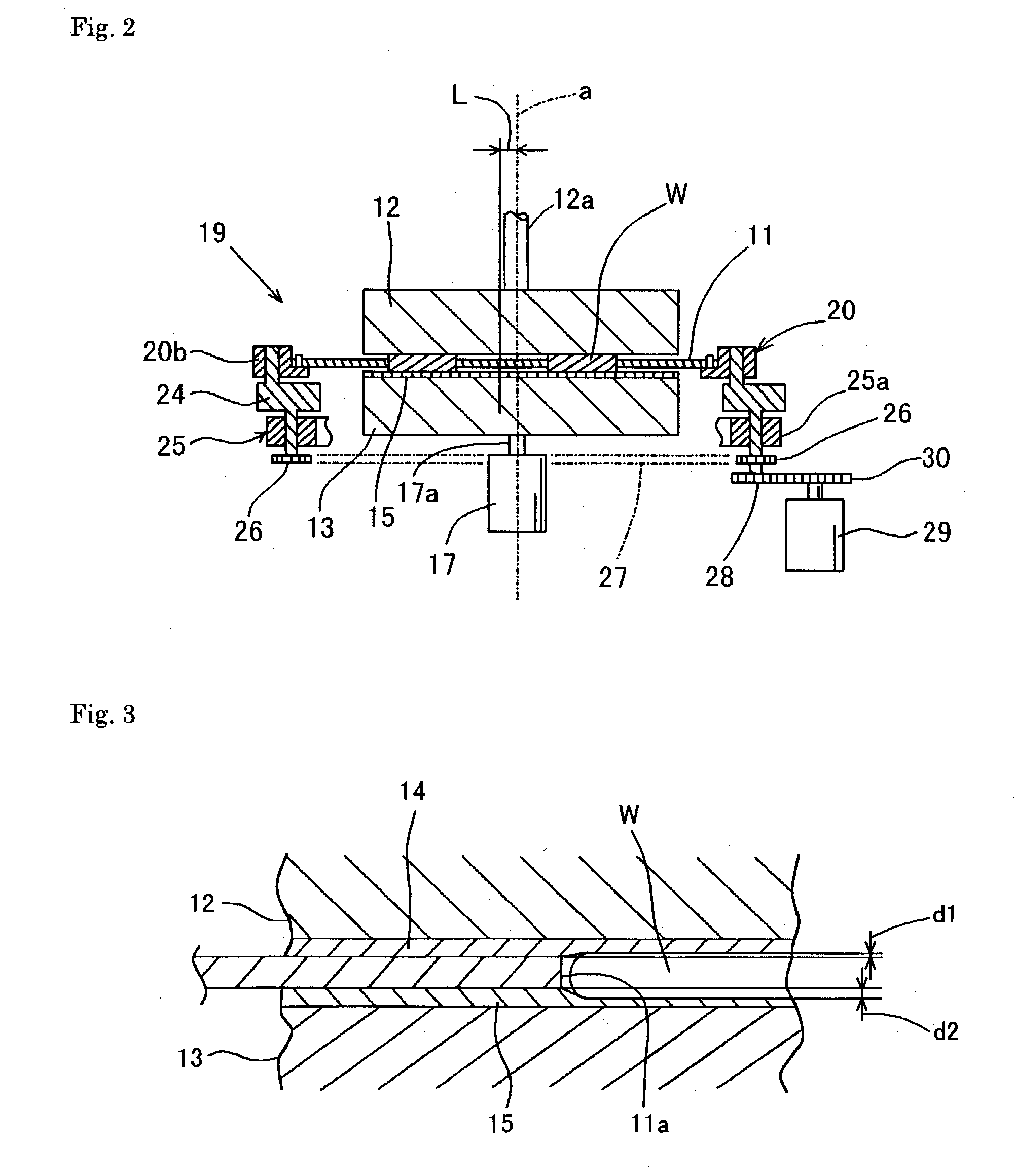

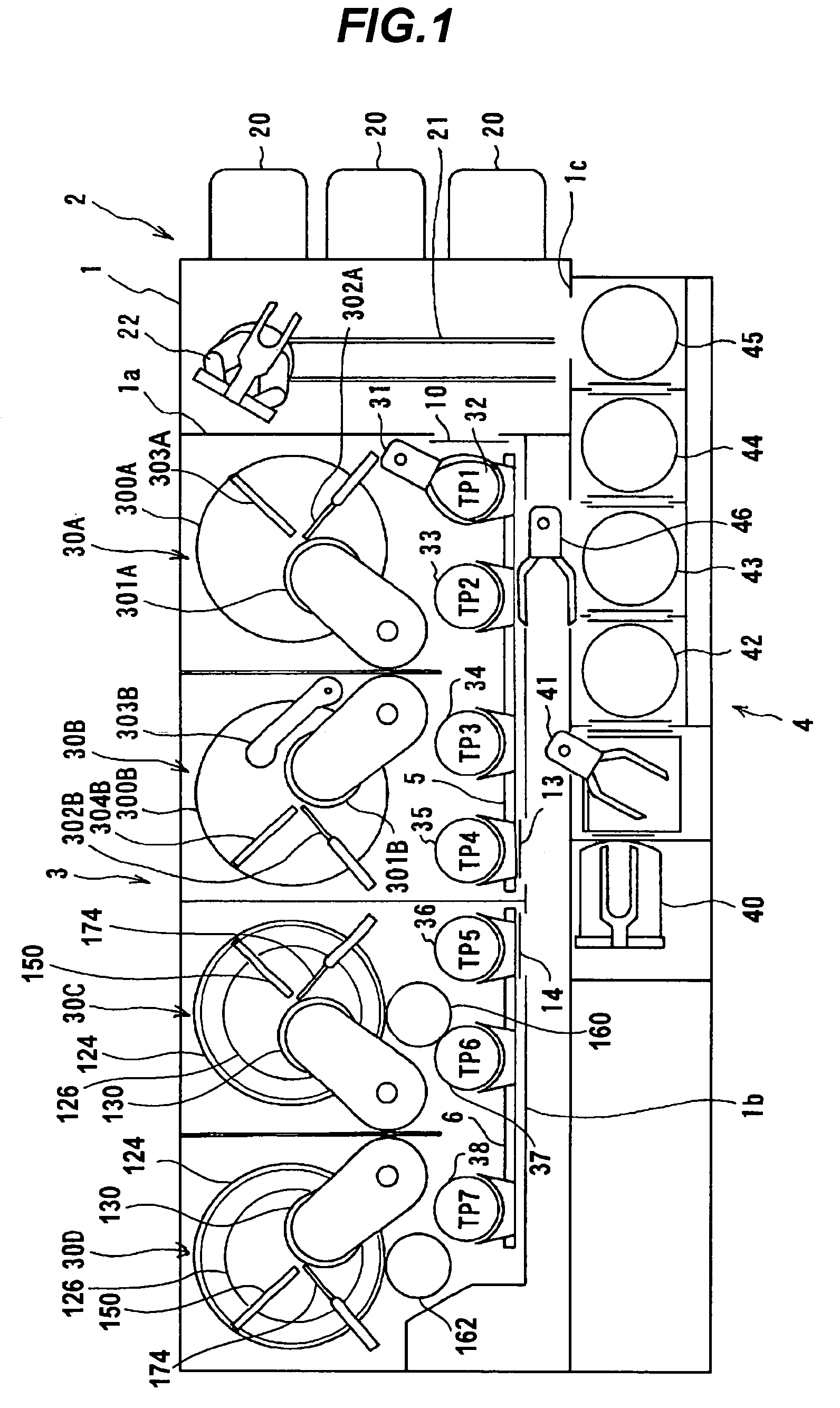

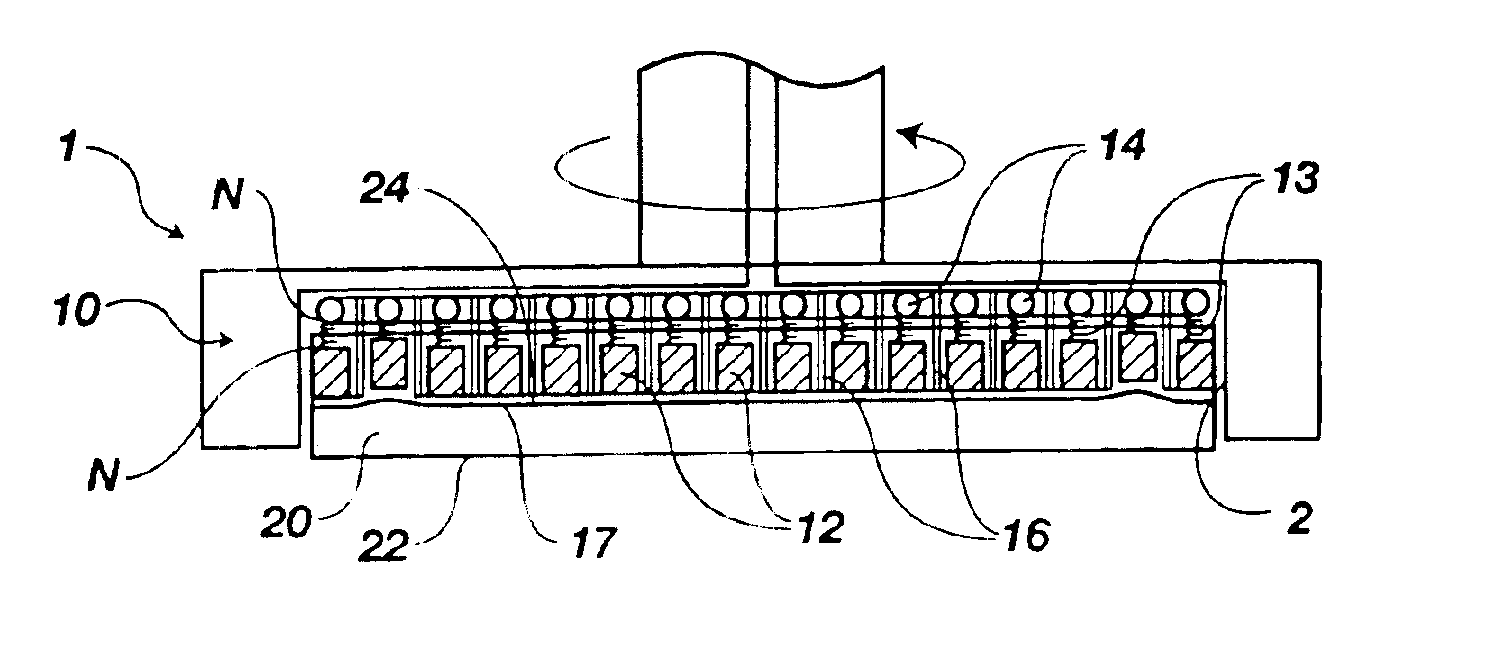

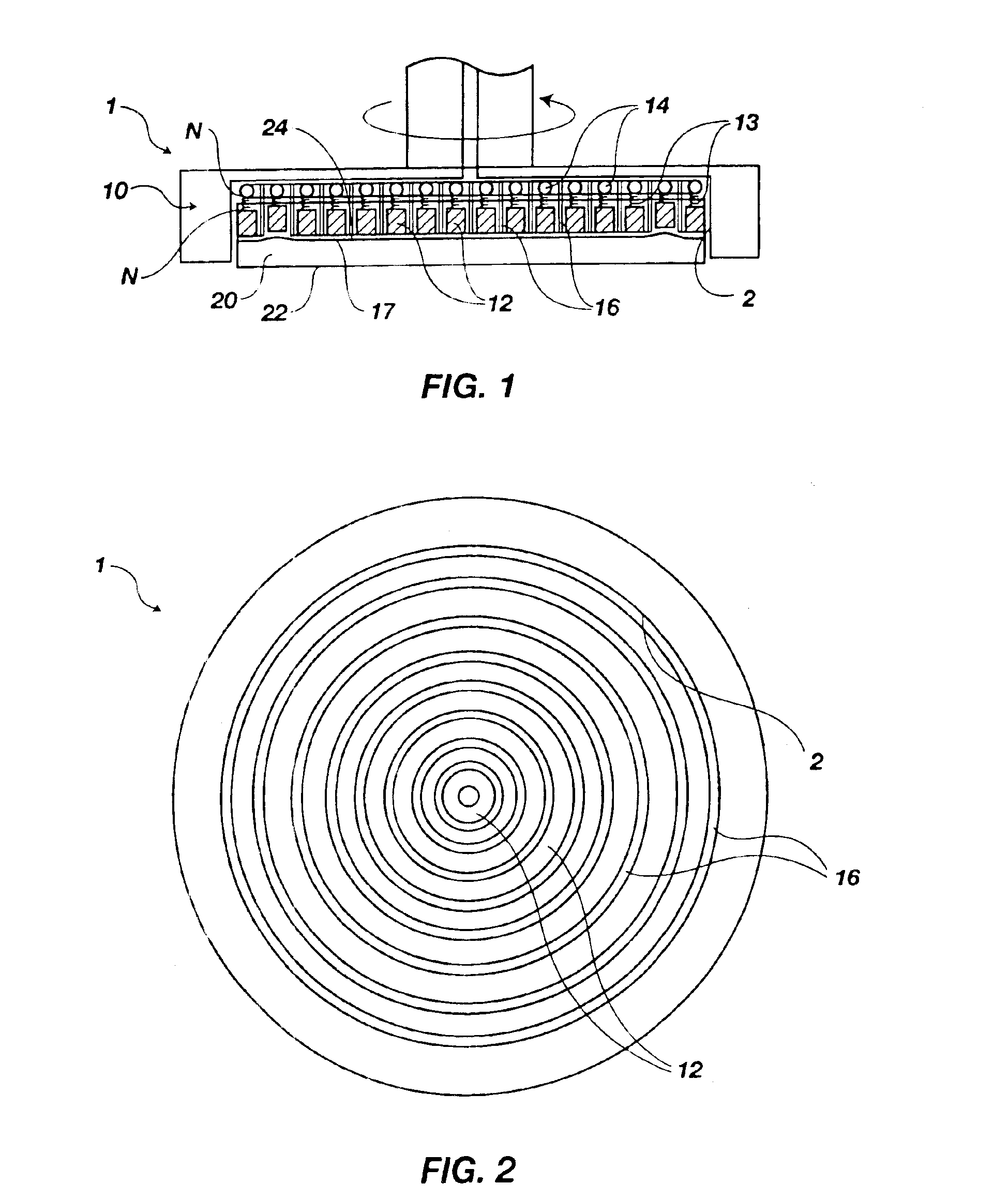

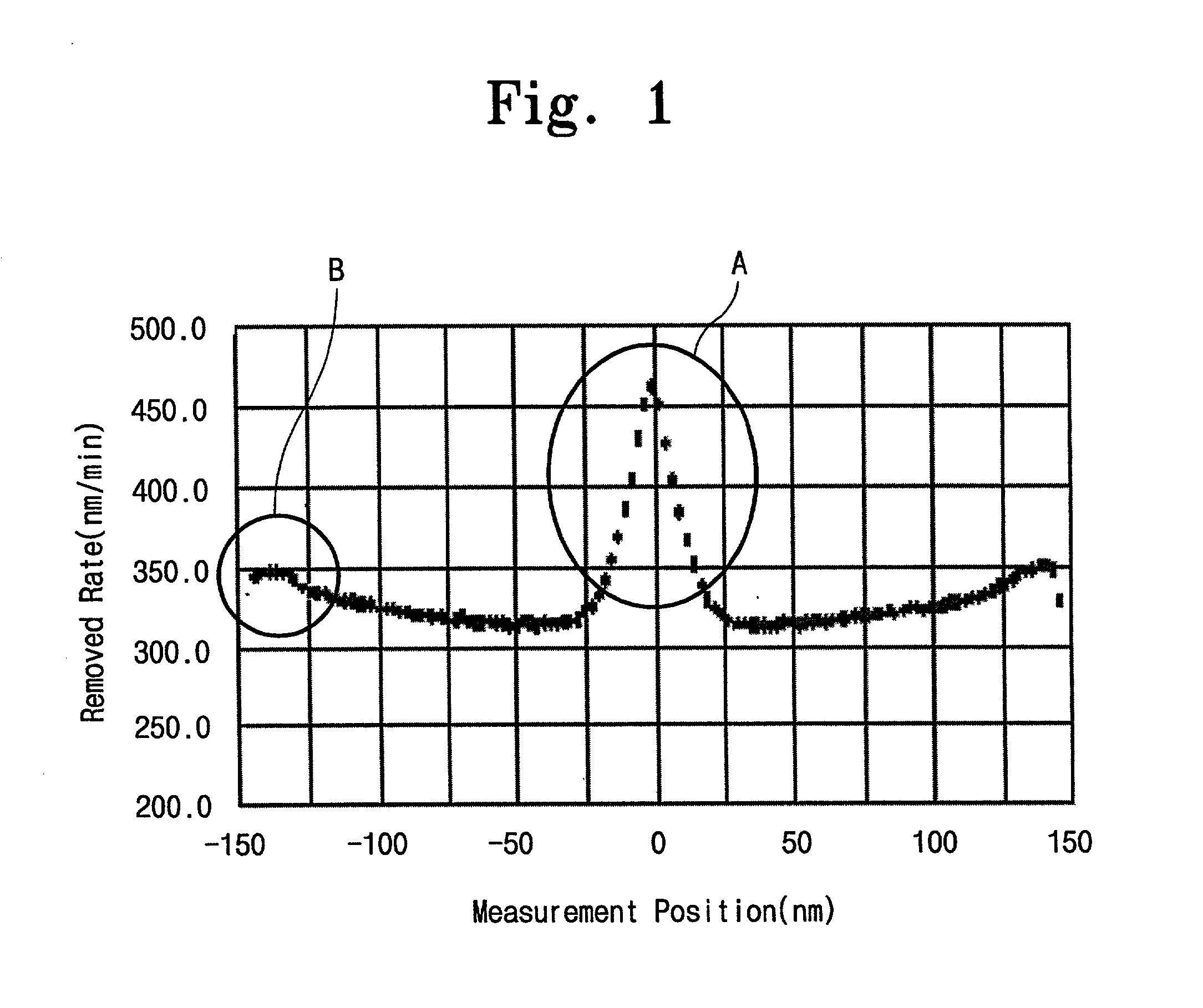

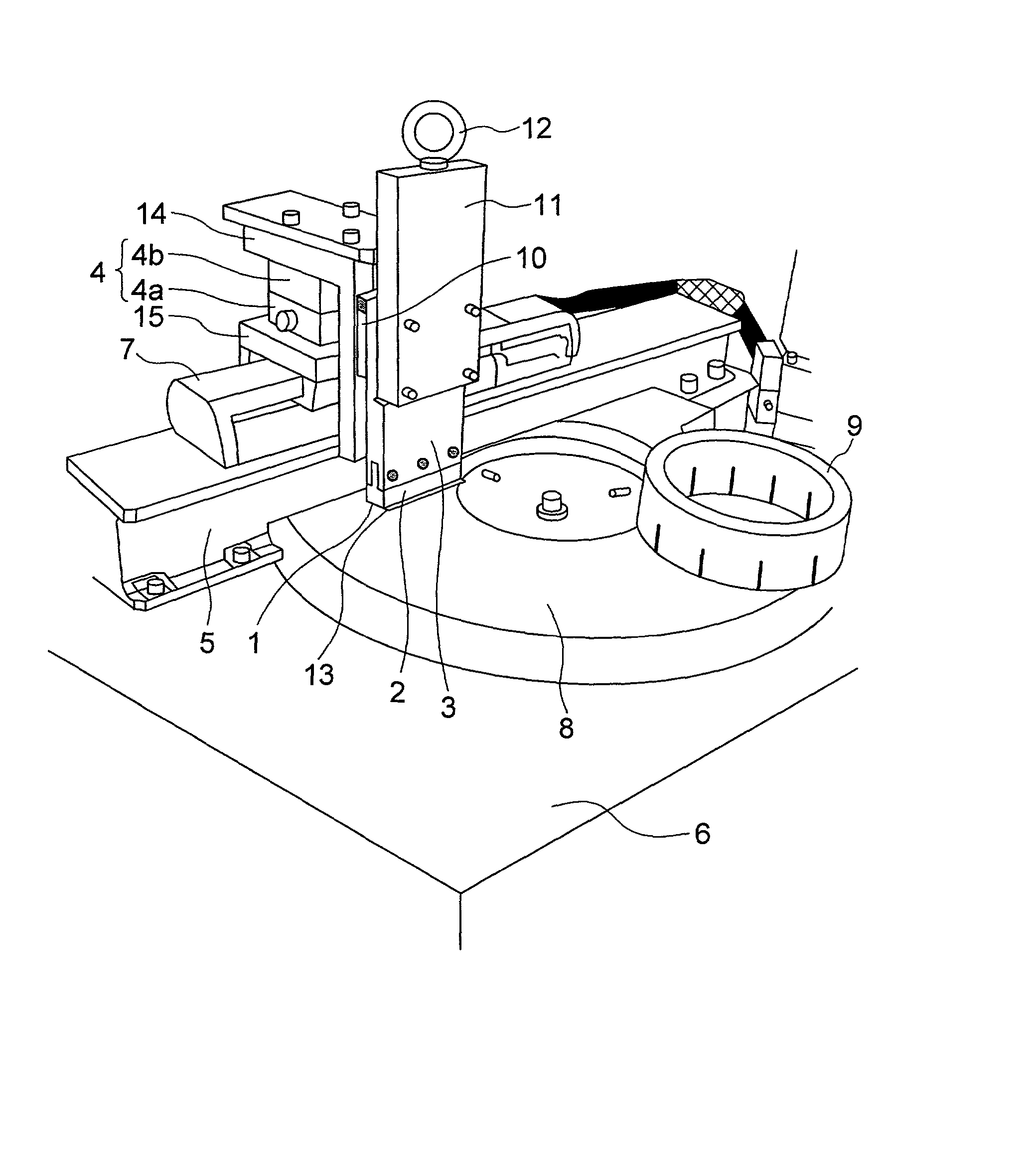

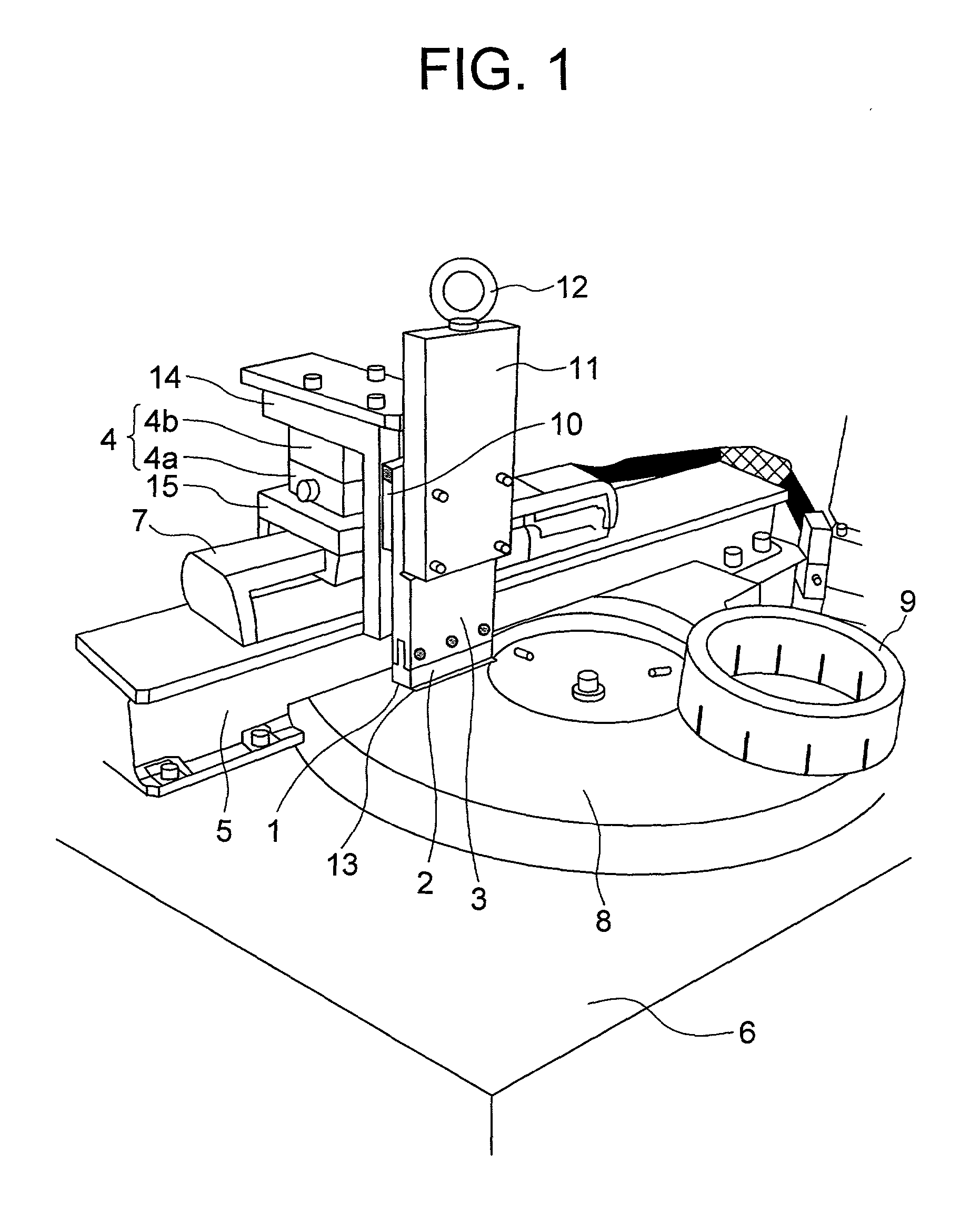

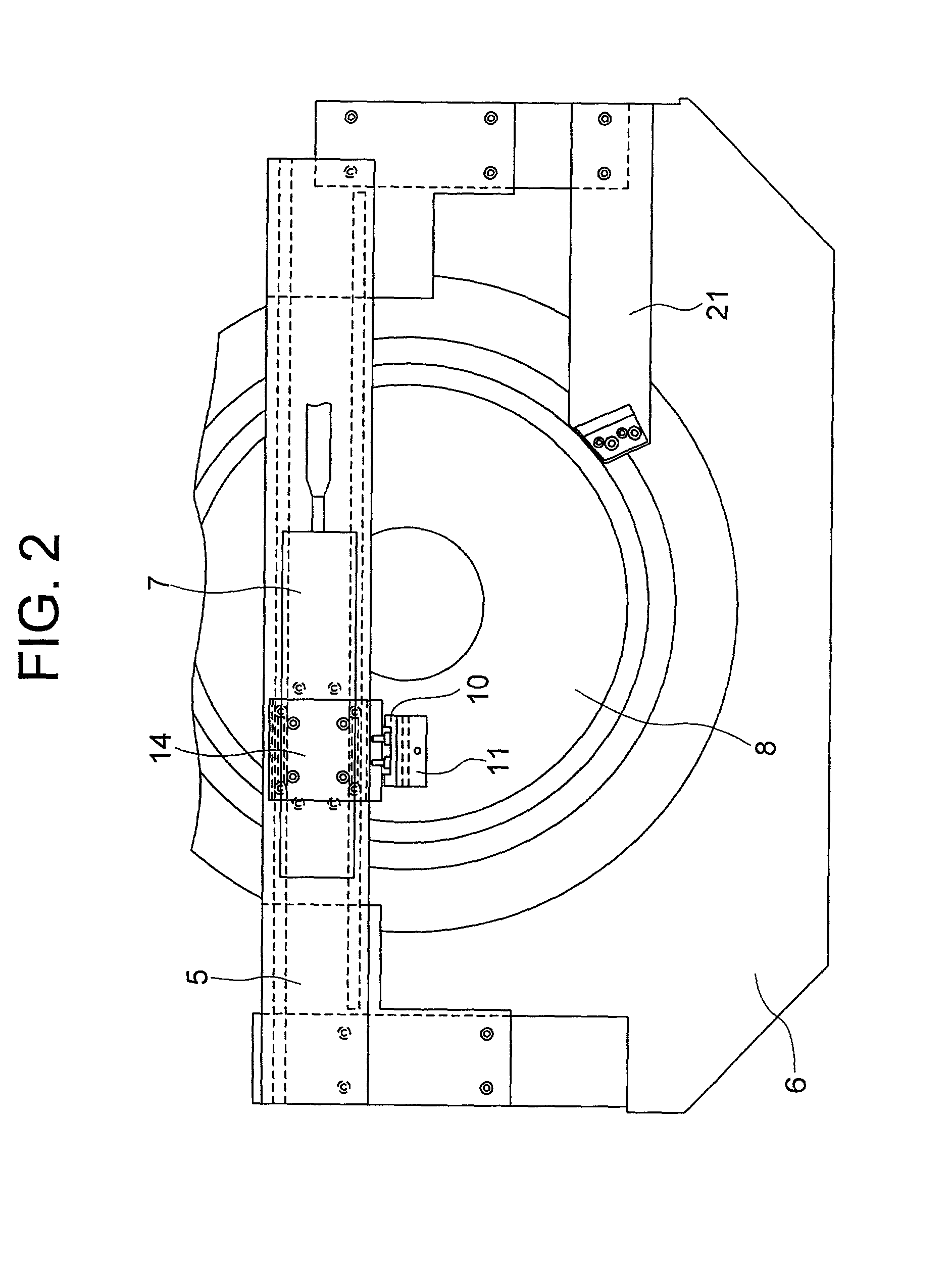

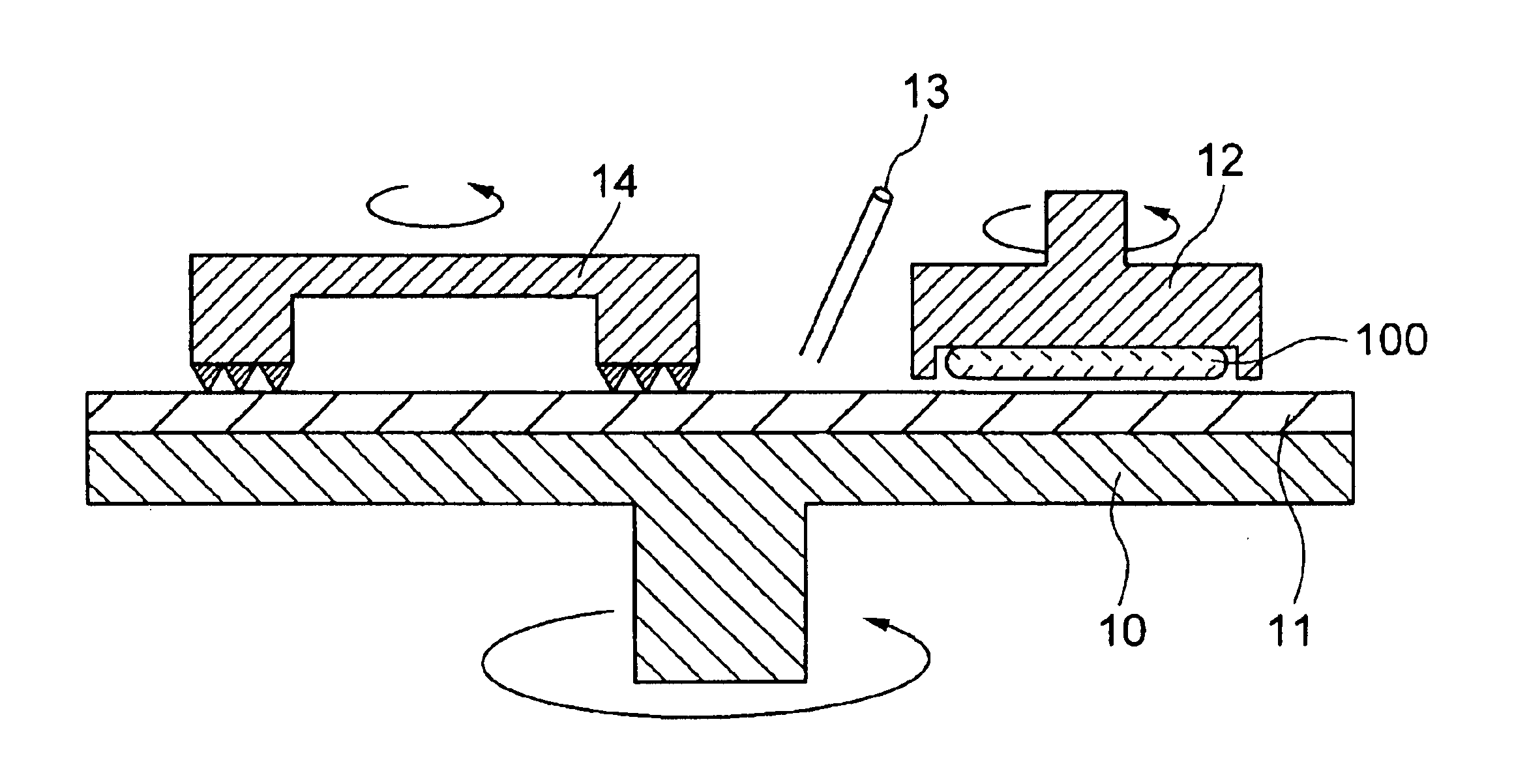

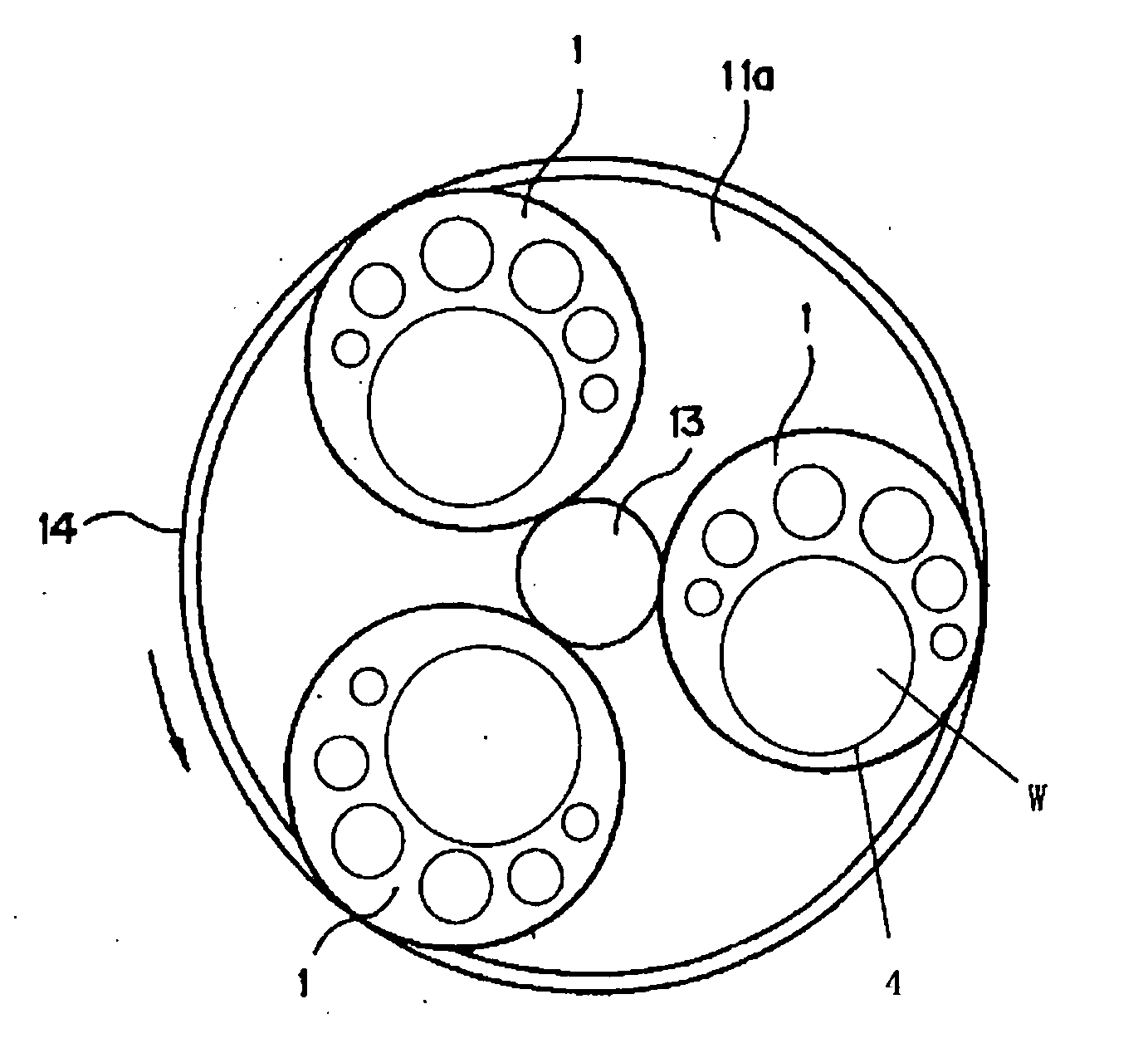

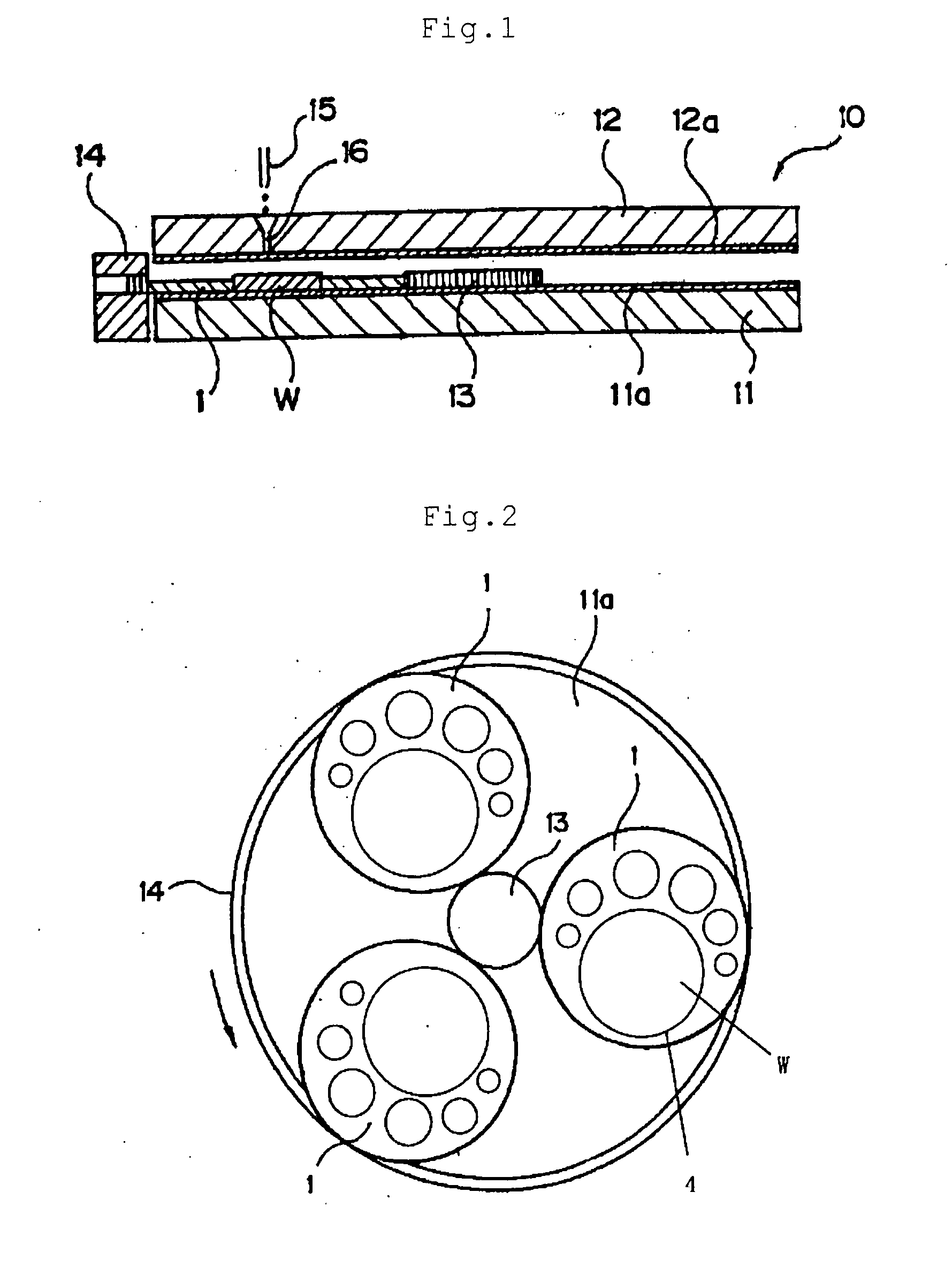

Method of manufacturing semiconductor wafer

ActiveUS20030104698A1Small polishing volumeShort polishing timePolishing machinesRevolution surface grinding machinesSlurryEngineering

An object of the present invention is to provide a semiconductor wafer having a front and a back surfaces polished so as to have different glossiness from each other, yet with a lower cost. The glossiness of the front surface and the back surface can be selected arbitrarily. In a double-sided polisher with no sun gear, silicon wafers W are inserted in respective holding holes 11a of a carrier plate 11. The wafers W are placed with their back surfaces facing up. An expanded urethane foam pad 14 is pressed against the back surfaces of the wafers W and a non-woven fabric pad 15 is pressed against the front surfaces of the wafers W. A carrier holder 20 and thus the carrier plate 11 are then driven to make a circular motion associated with no rotation on their own axes within a horizontal plane while supplying a slurry to the wafers W from an upper surface plate 12 side. As a result, each of the front and the back surfaces of respective silicon wafers W can be polished uniformly over entire area thereof respectively. At that time, the urethane pad 14 has a sink rate of the wafer lower than that of the non-woven fabric pad 15. Therefore, such a polished wafer having the back surface formed into a satin-finished surface and the front surface formed into a mirror-finished surface can be obtained. Alternatively, those polishing cloths having different sink rates from each other may be employed for the upper and the lower surface plates, respectively. Further, the upper surface plate and the lower surface plate may be rotated at different speeds from each other. Those methods are also advantageously used to manufacture the semiconductor wafer having different glossiness between the front surface and the back surface thereof.

Owner:SUMITOMO MITSUBISHI SILICON CORP

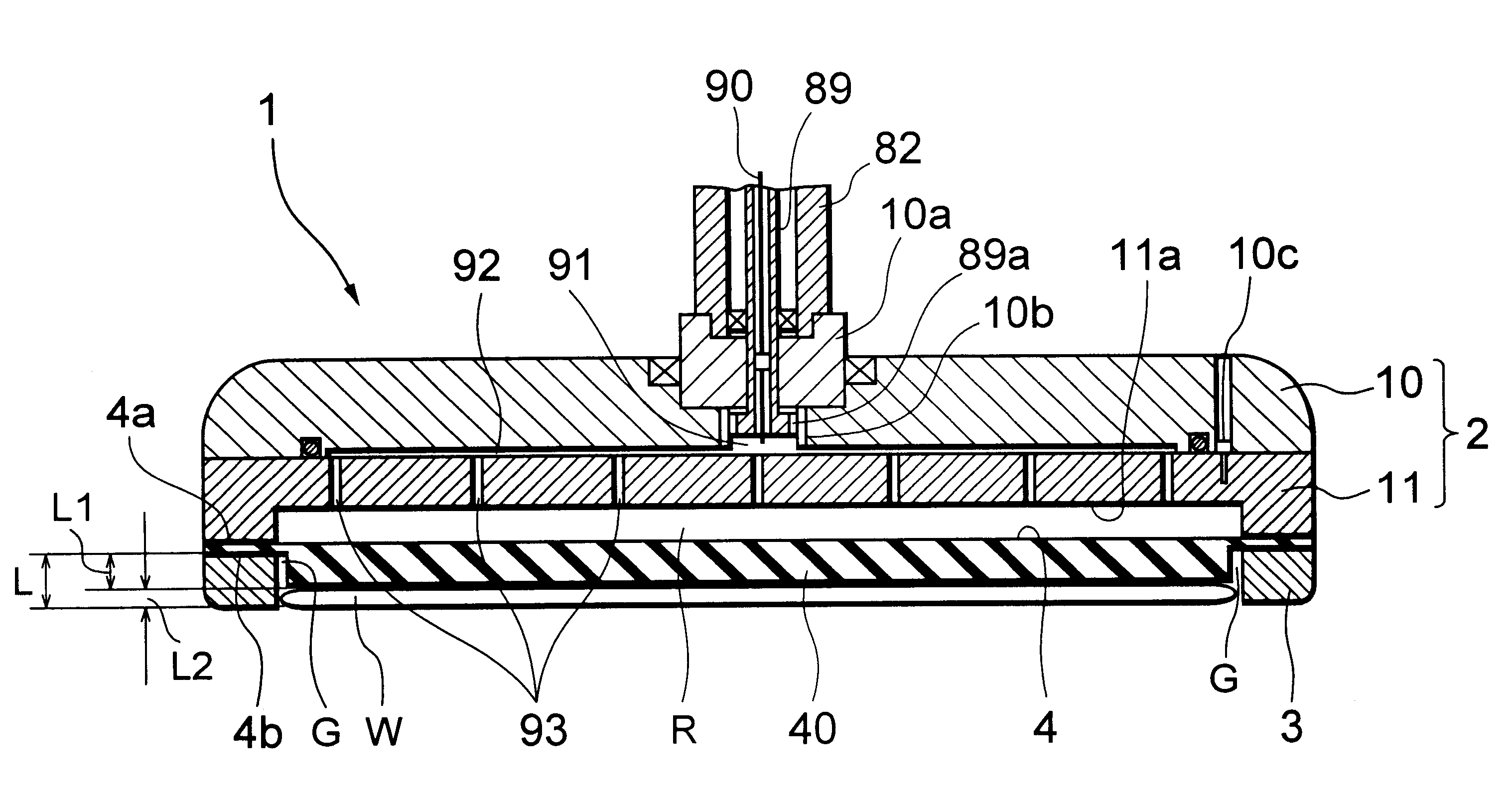

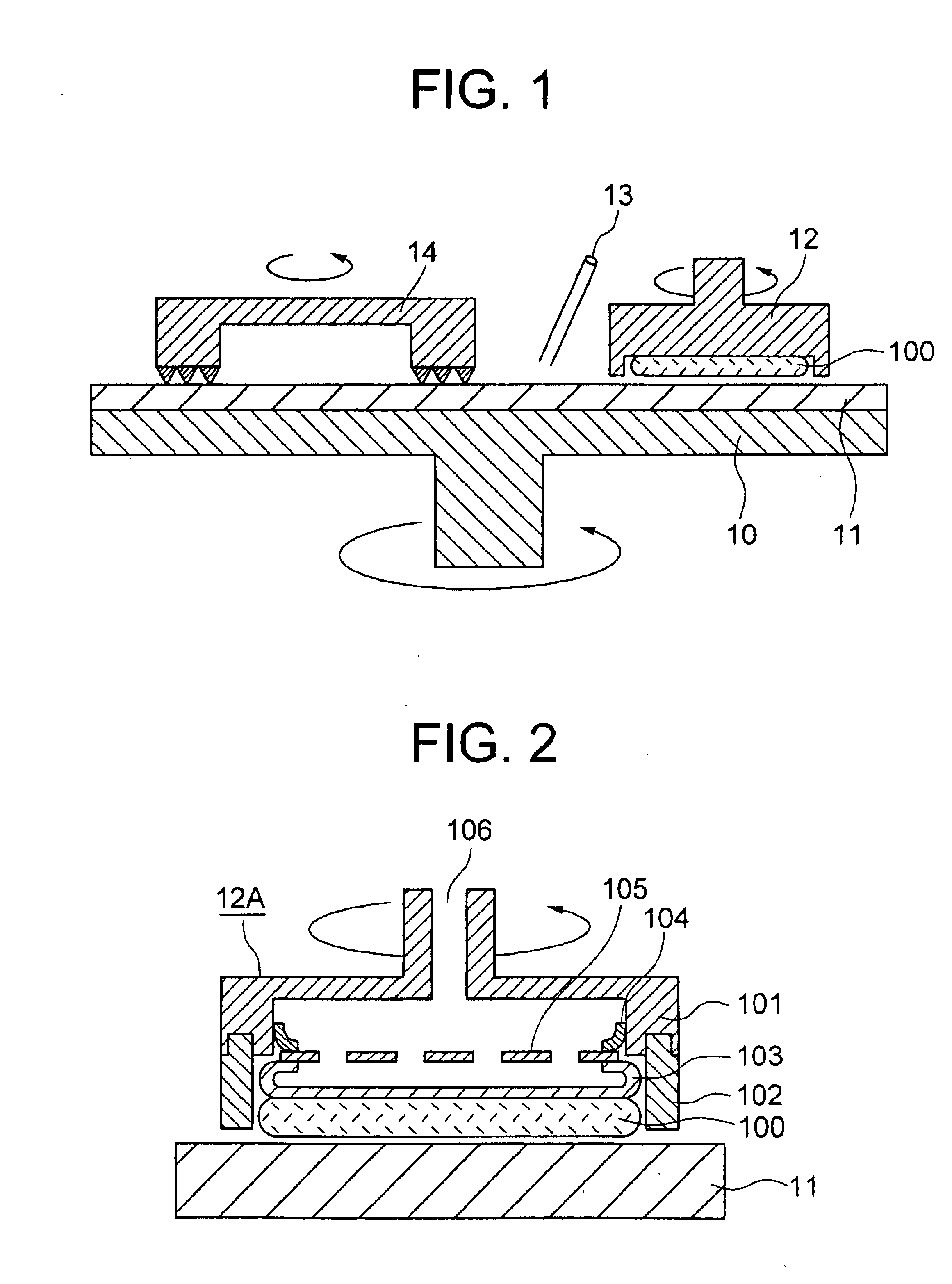

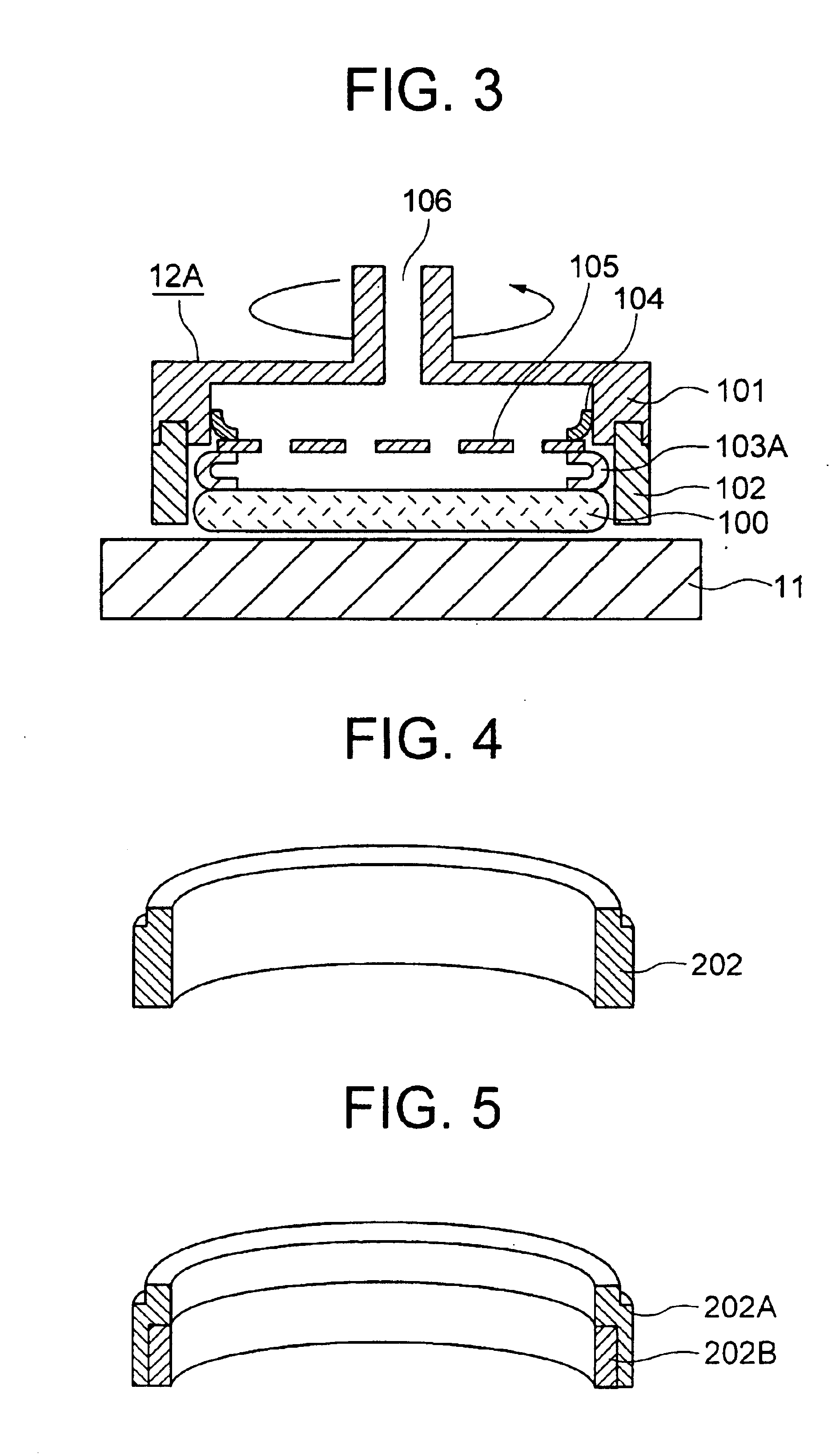

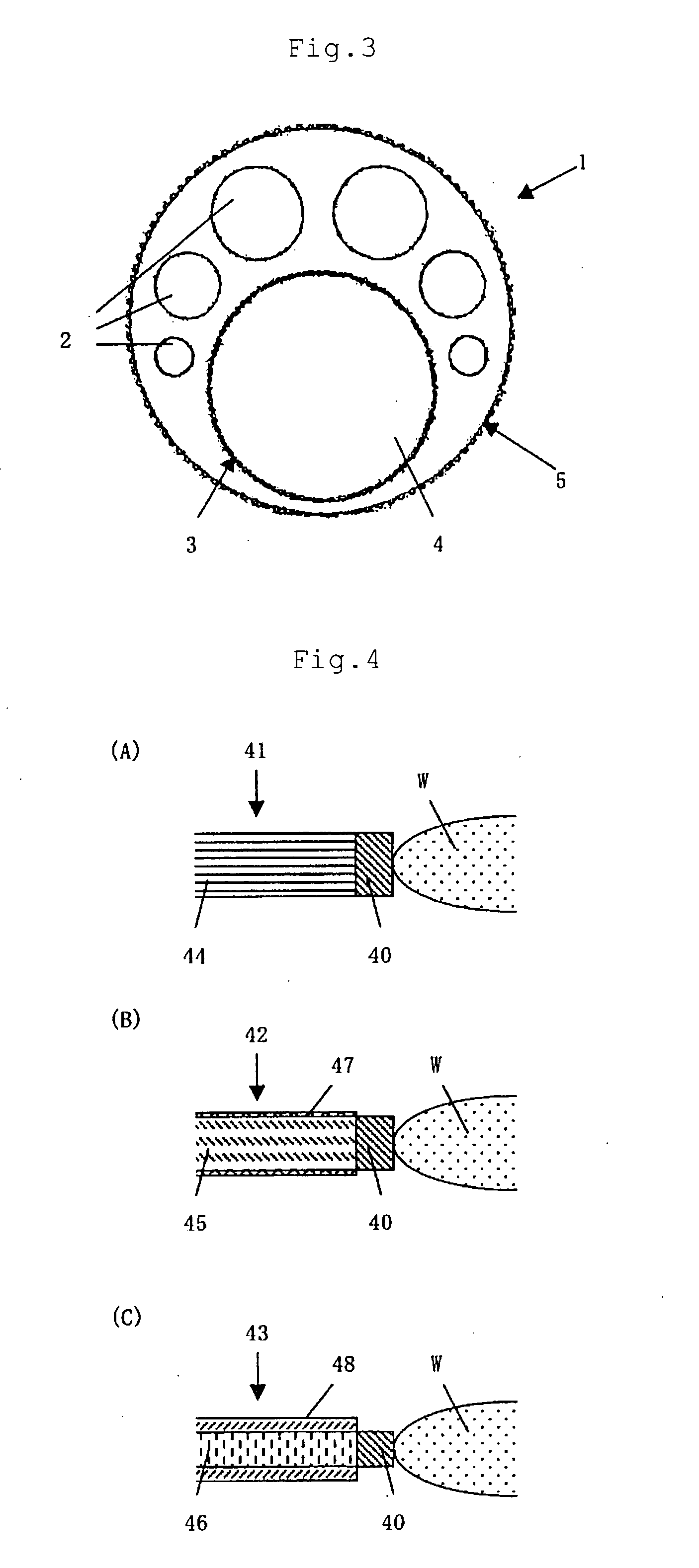

Carriers and polishing apparatus

A carrier and a polishing apparatus are designed to improve the mass producibility of wafers while using a retainer ring formed by a soft material. A rubber sheet 4 is bonded to the bottom surface of a carrier body 2 of the carrier 1 to define a pressure chamber R, a retainer ring 13 formed by a soft material such as EG is bonded to the bottom surface of the sheet 4. A margin block 40 is provided projecting out from the bottom side of the sheet 4, and the thickness of the retainer ring 13 is set to be substantially equal to the sum of the thickness L1 of the margin block 40 and the thickness L2 of the wafer W.

Owner:SPEEDFAM CO LTD

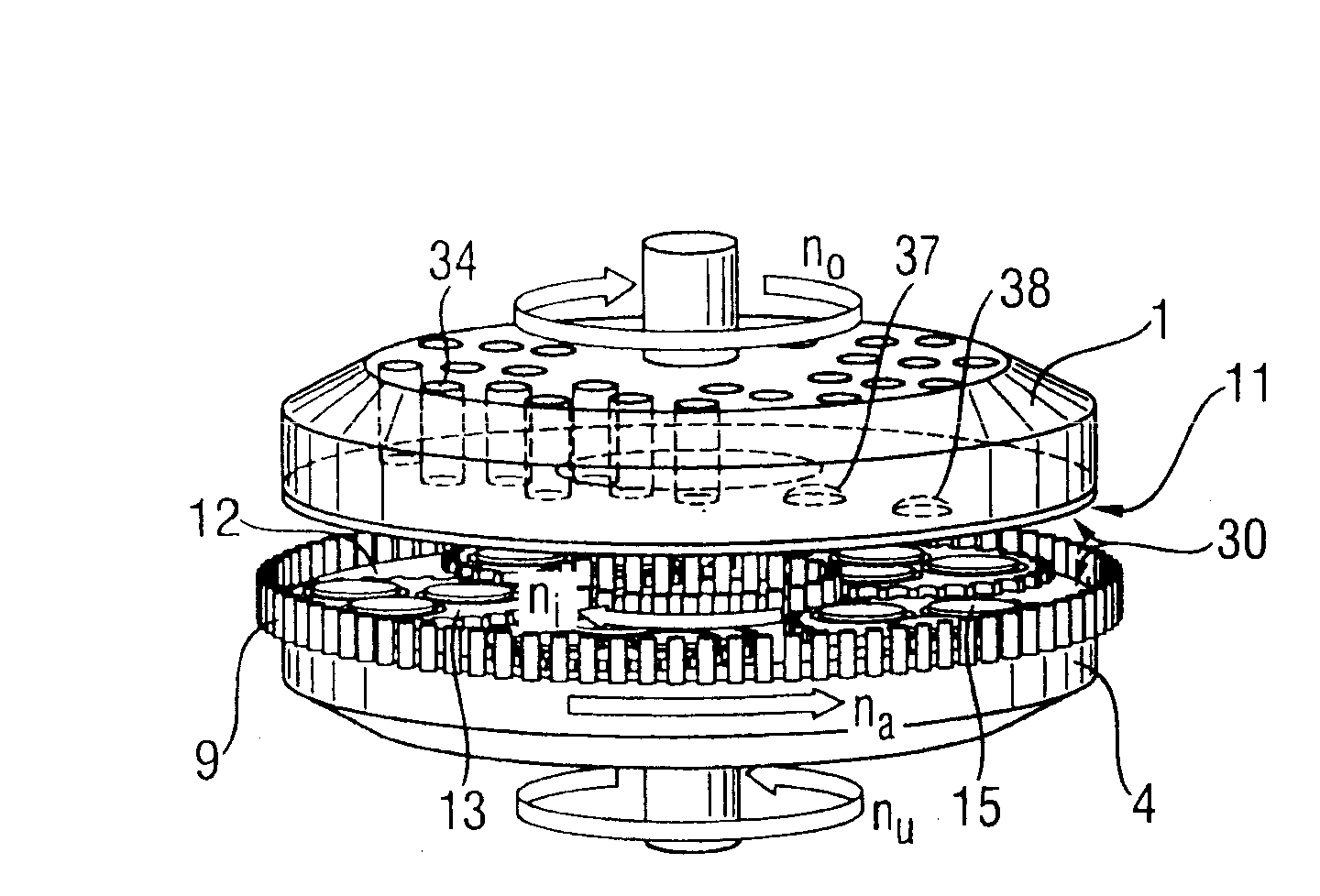

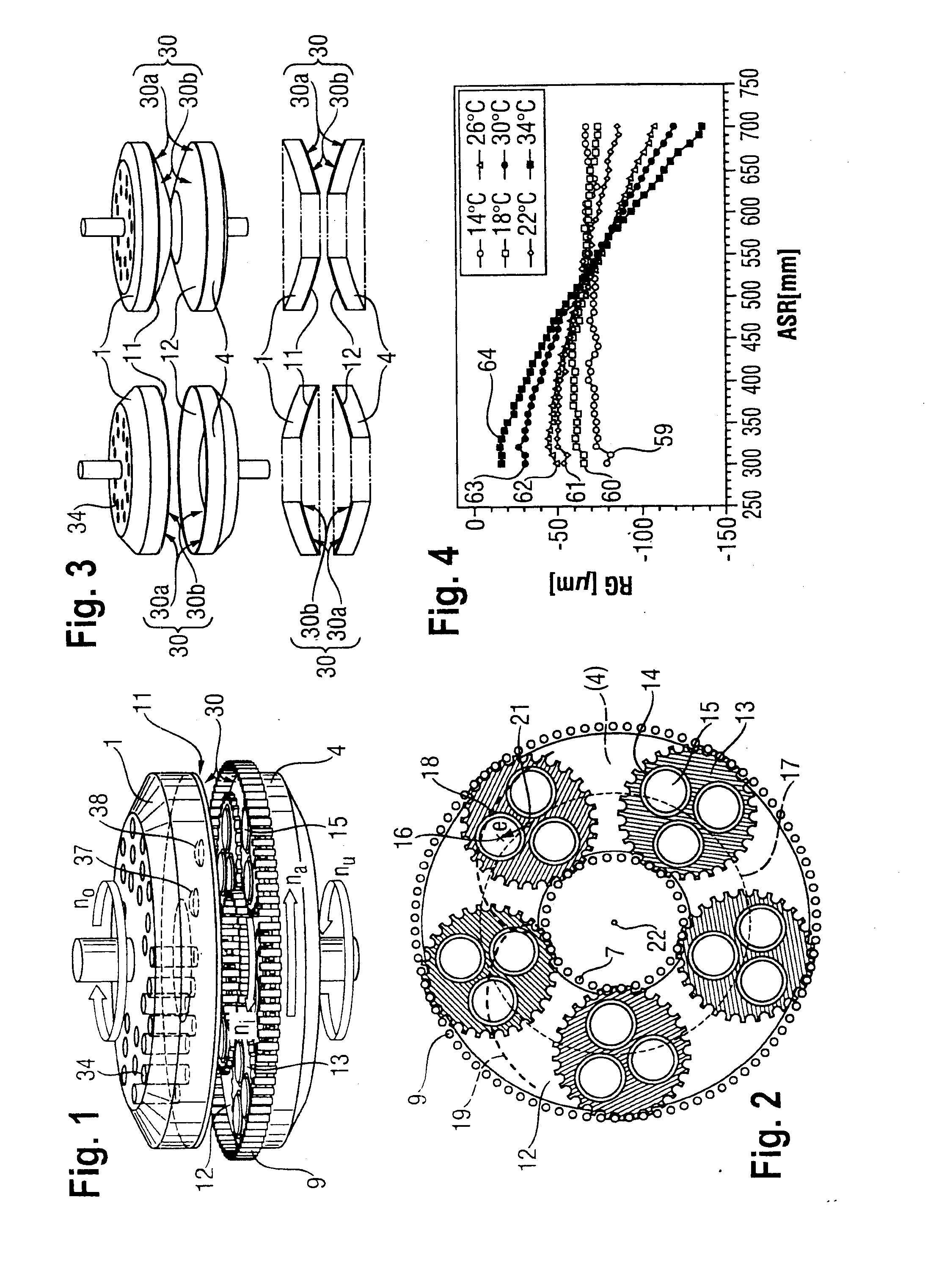

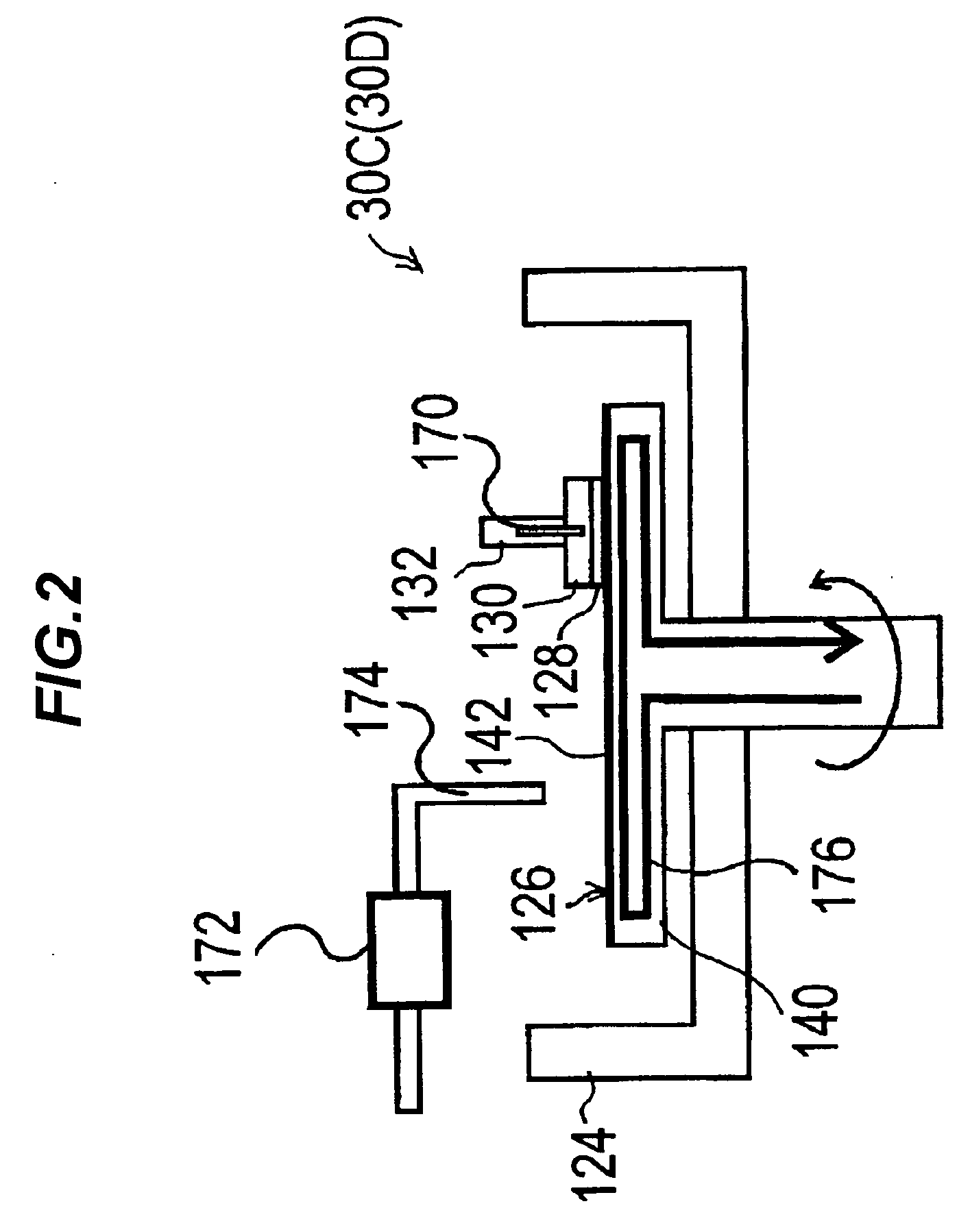

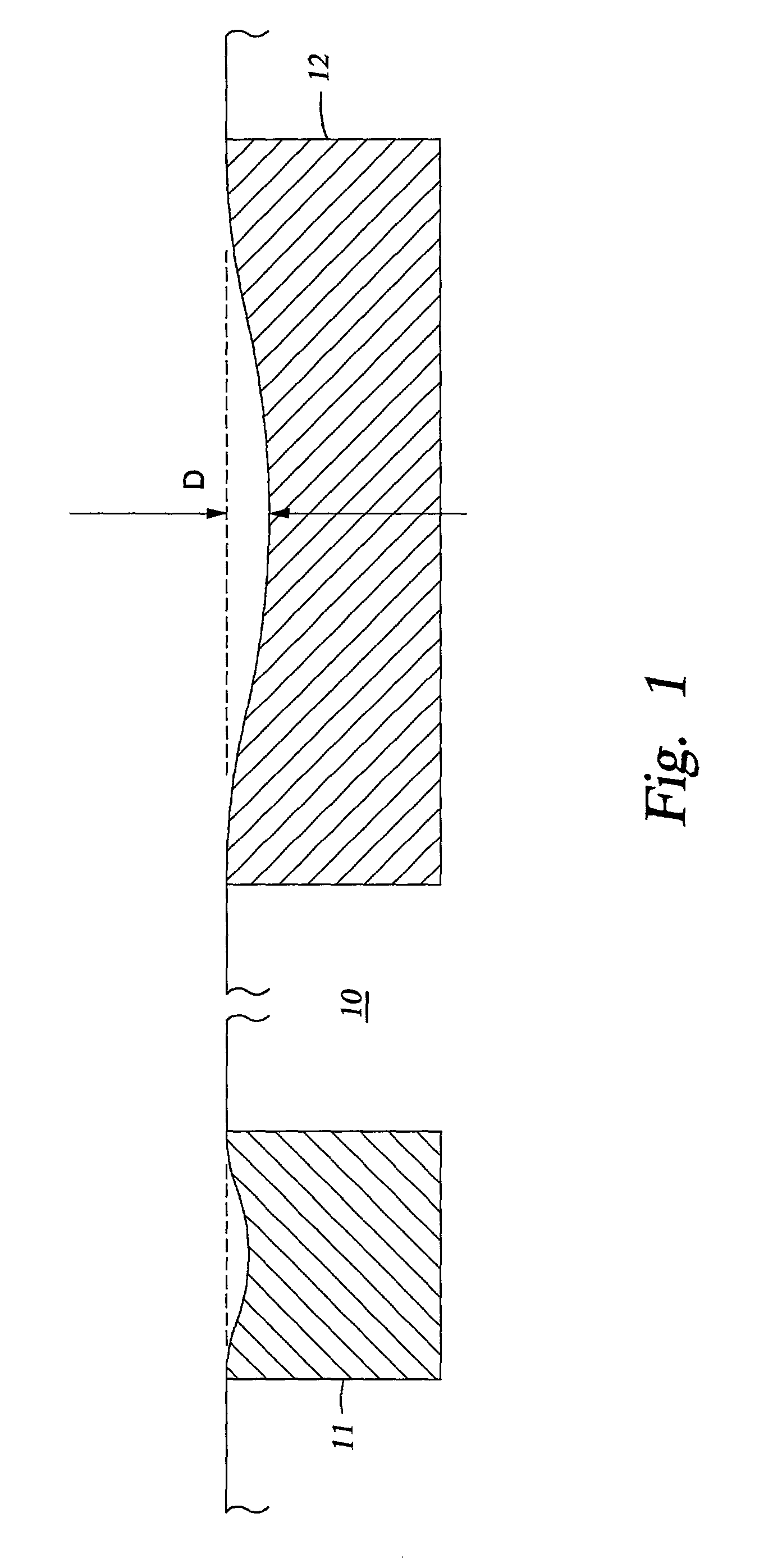

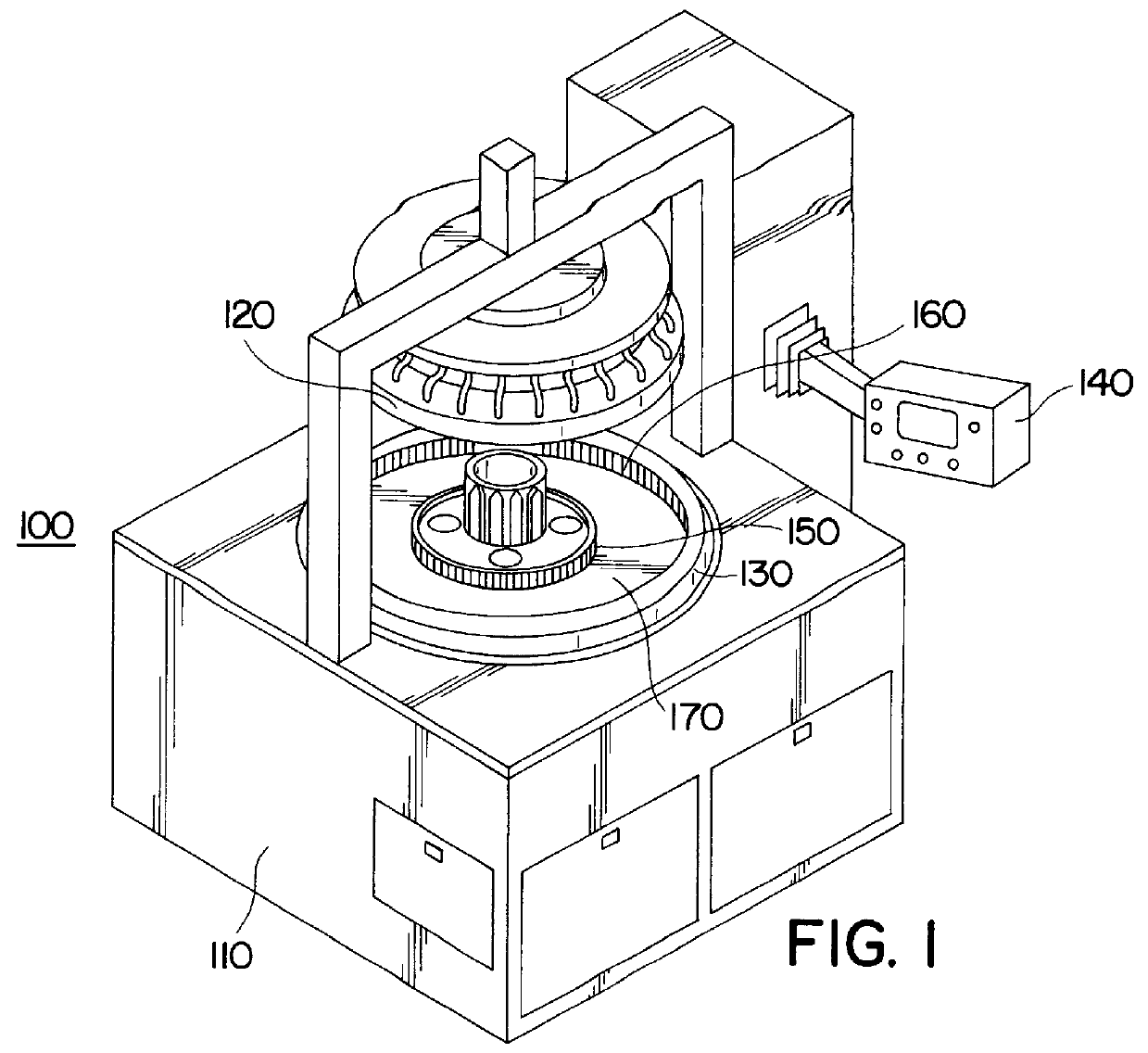

Method For The Simultaneous Grinding Of A Plurality Of Semiconductor Wafers

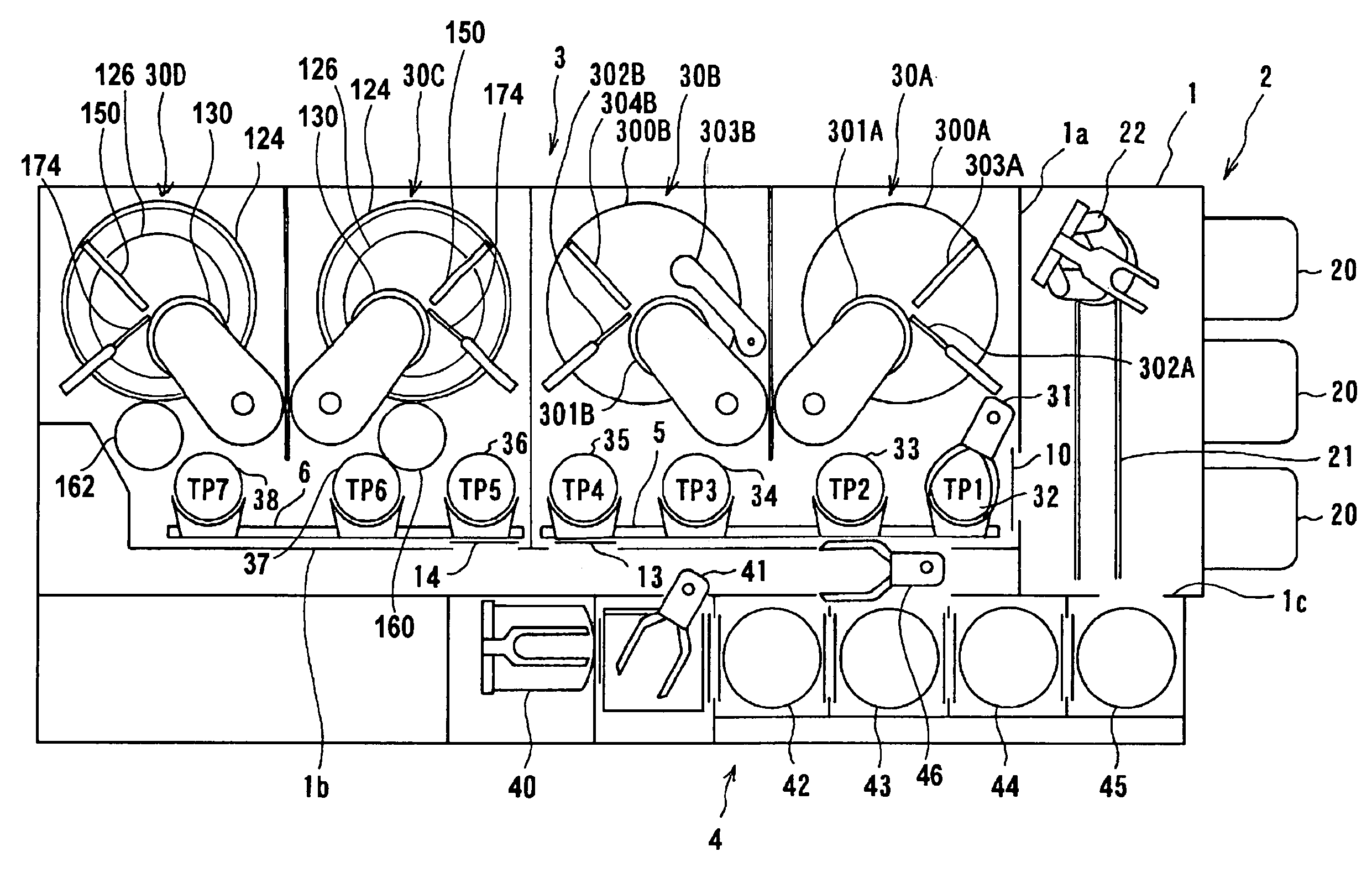

ActiveUS20080233840A1Low bowLow warpEdge grinding machinesPolishing machinesMachining processSemiconductor

Simultaneous double-side grinding of a plurality of semiconductor wafers involves positioning each wafer freely in a cutout of one of plural carriers which rotate on a cycloidal trajectory, wherein the wafers are machined between two rotating ring-shaped working disks, each disk having a working layer of bonded abrasive, wherein the form of the working gap between working layers is determined during grinding and the form of the working area of at least one disk is altered such that the gap has a predetermined form. The wafers, during machining, may temporarily overhang the gap. The carrier is optionally composed only of a first material, or is completely or partly coated with the first material such that during machining only the first material contacts the working layer, and the first material does not reduce the machining ability of the working layer.

Owner:PETER WOLTERS GMBH

Flattening method and flattening apparatus

ActiveUS20090095712A1Improve flatnessSufficient processing rateDecorative surface effectsSemiconductor/solid-state device manufacturingPlatinumMetal

A flattening method, by utilizing the advantages of the CARE method and making up for the disadvantages, can perform removal processing of a surface of a workpiece at a sufficient processing rate and can provide a processed surface having enhanced flatness without leaving damage in the processed surface. A flattening method comprises at least two surface removal steps and at least two cleaning steps, the final surface removal step being a catalyst-referred etching step comprising immersing a workpiece in a processing solution containing at least one of hydrohalic acid, hydrogen peroxide water and ozone water, and bringing a surface of a catalyst platen into contact with or close proximity to a surface to be processed of the workpiece to process the surface, said catalyst platen having in a surface a catalyst selected from the group consisting of platinum, gold, a ceramic solid catalyst, a transition metal, glass, and an acidic or basic solid catalyst.

Owner:EBARA CORP

Temperature-controlled substrate holder for processing in fluids

InactiveUS20040084143A1Quick changeLiquid surface applicatorsDrying gas arrangementsTemperature controlFirst Fill

A substrate holder has a disk-like body with a central recess having diameter smaller than the diameter of the substrate placed onto the upper surface of the holder. The substrate can be clamped in place by the clamps of the edge-grip mechanism or placed into a seat without the use of clamps. In both cases, the substrate forms a partial wall that confines the heating / cooling recess or chamber. The aforementioned recess is filled with a cooling or heating liquid (depending on the mode of metal deposition) selectively supplied from a liquid heating or cooling system. In order to ensure in the working chamber above the substrate a pressure slightly higher than the pressure in the cooling / heating recess, the working chamber is first filled with the working solution under the atmospheric pressure, and then the recess is filled with a heating or cooling liquid with simultaneous increase of pressure in the working chamber to a level slightly exceeding the pressure in the recess. The substrate holder of the invention provides direct heat / cool-exchange between the heating / cooling medium and the substrate and allows instantaneous change of temperature of the heating / cooling liquid.

Owner:LAM RES CORP

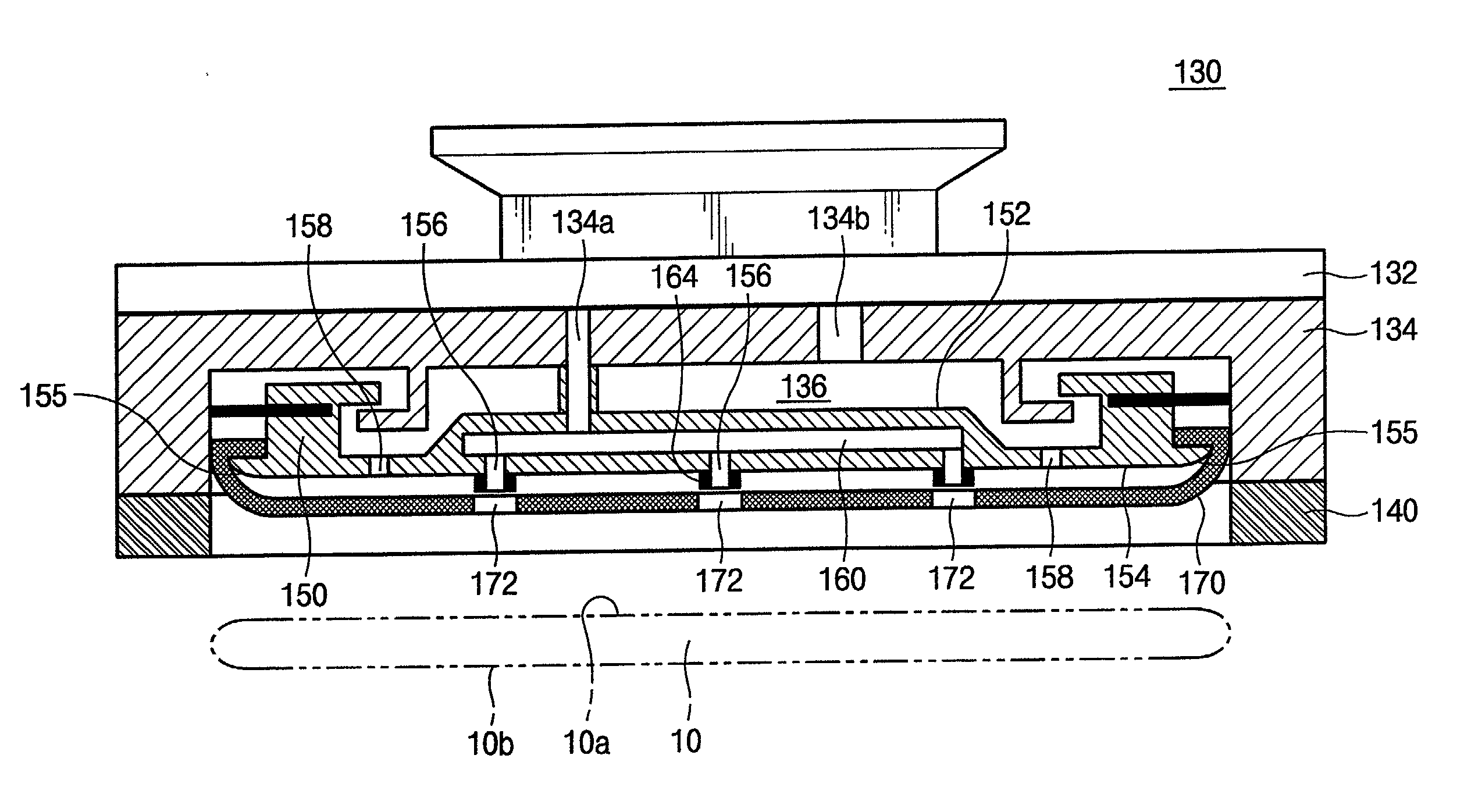

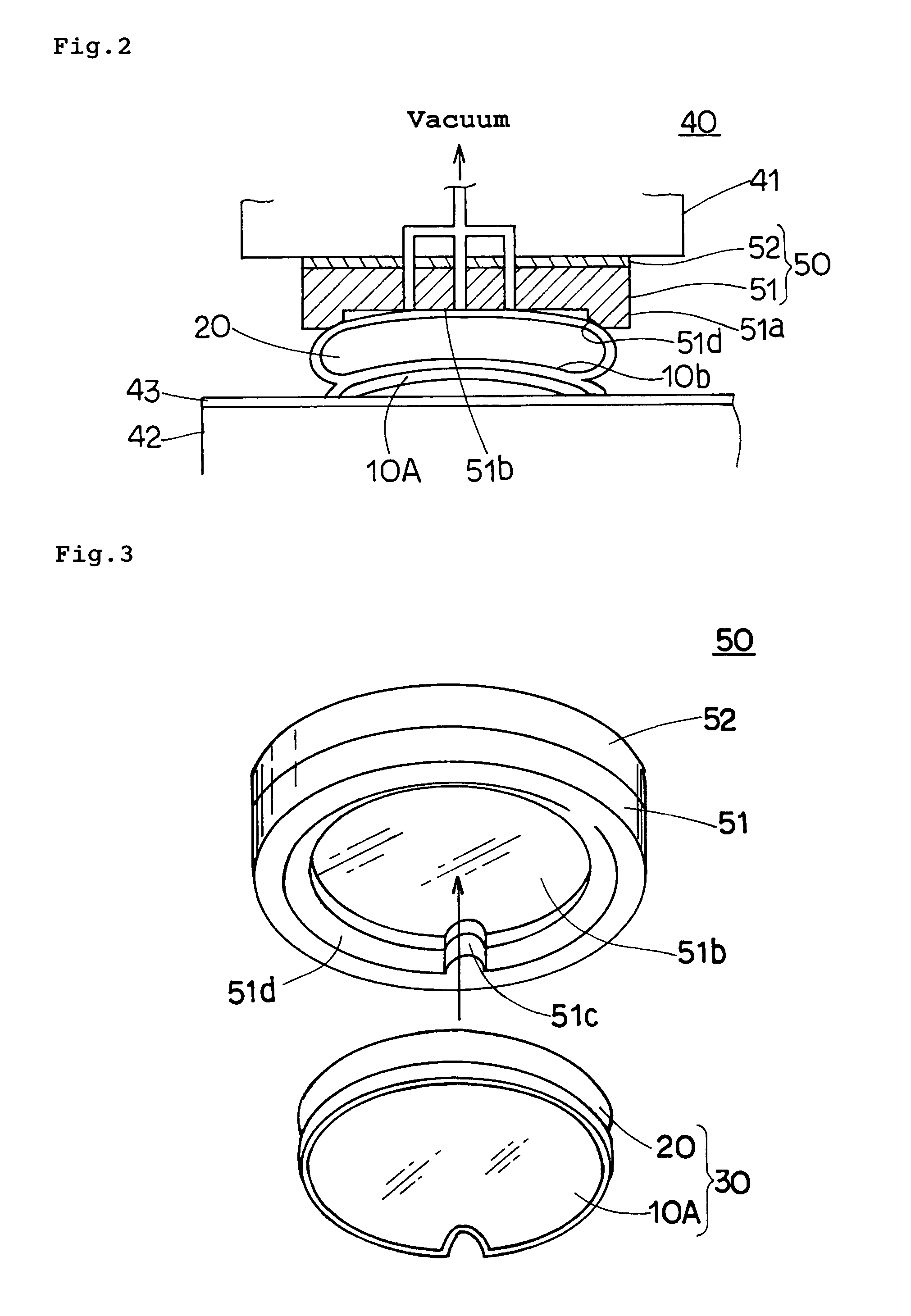

Substrate holding apparatus and polishing apparatus

ActiveUS7357699B2Uniform pressureStay in shapePolishing machinesRevolution surface grinding machinesEngineeringMechanical engineering

A substrate holding apparatus is for holding a substrate such as a semiconductor wafer in a polishing apparatus for polishing the substrate to a flat finish. The substrate holding apparatus comprises a vertically movable member, and an elastic member for defining a chamber. The elastic member comprises a contact portion which is brought into contact with the substrate, and a circumferential wall extending upwardly from the contact portion and connected to the vertically movable member. The circumferential wall has a stretchable and contractible portion which is stretchable and contractible vertically.

Owner:EBARA CORP

Polishing systems for use with semiconductor substrates including differential pressure application apparatus

InactiveUS6899607B2Reduce rateImprove material removal ratePolishing machinesRevolution surface grinding machinesDifferential pressureEngineering

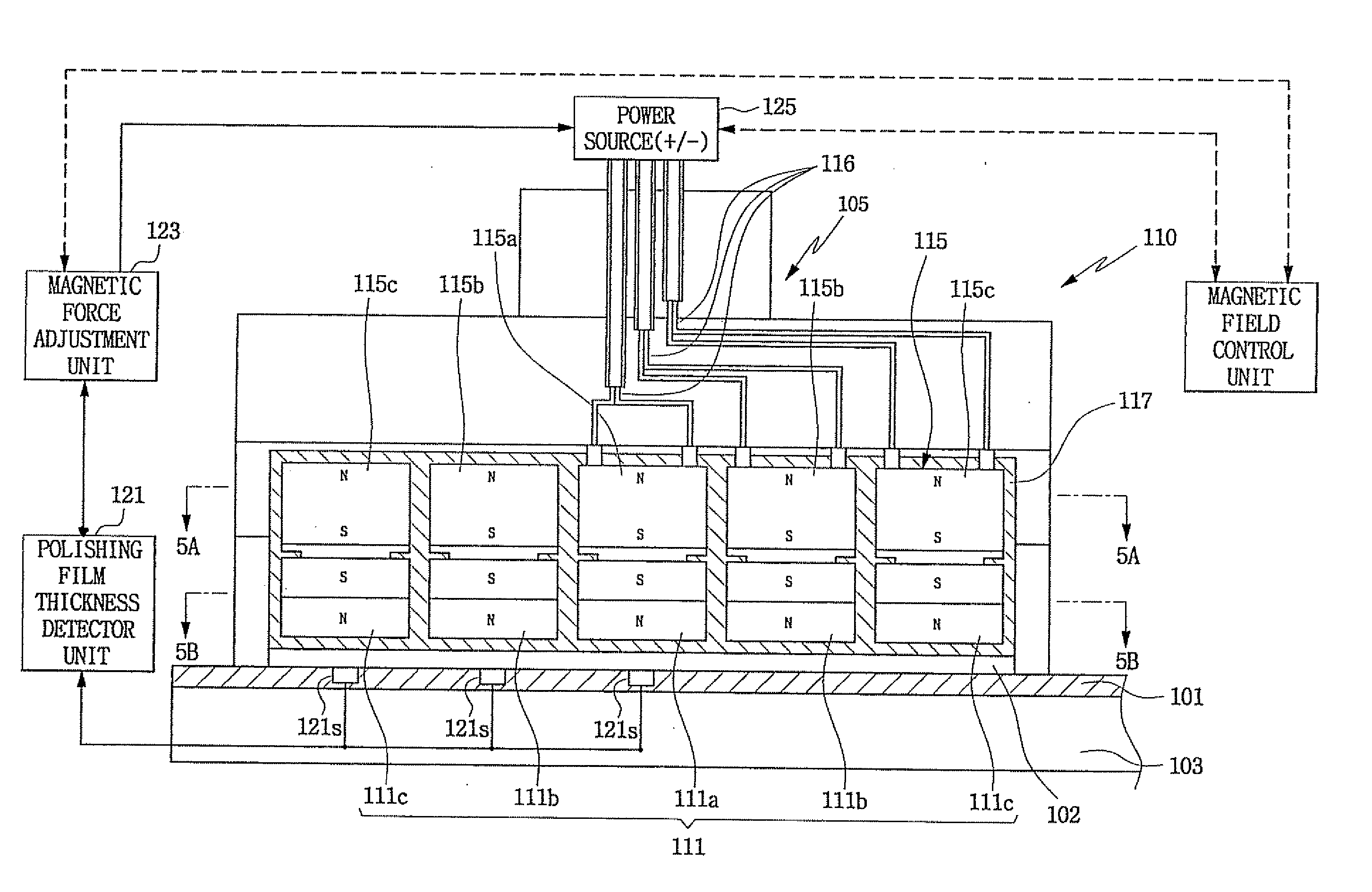

An apparatus for applying different amounts of pressure to different locations of a backside of a semiconductor device structure during polishing thereof. The apparatus is configured to be associated with a wafer carrier of a polishing apparatus and includes pressurization structures configured to be biased against the backside of the semiconductor device structure during polishing thereof. The pressurization structures are independently movable with respect to one another. The amount of force or pressure applied by each pressurization structure to the backside of the semiconductor device structure is controlled by at least one corresponding actuator. The actuator may magnetically facilitate movement of the corresponding pressurization structure toward or away from the backside of the semiconductor device structure. The actuator may alternatively comprise a positive or negative pressure source. Systems including the pressure application apparatus, as well as differential pressure application methods and polishing methods are also disclosed.

Owner:ROUND ROCK RES LLC

Substrate holding apparatus

InactiveUS6852019B2Uniform film thicknessSmooth movementPolishing machinesRevolution surface grinding machinesEngineeringMechanical engineering

The present invention relates to a substrate holding apparatus for holding a substrate to be polished and pressing the substrate against a polishing surface. The substrate holding apparatus comprises a top ring body for holding a substrate, an elastic pad for being brought into contact with the substrate, and a support member for supporting the elastic pad. The substrate holding apparatus further comprises a contact member mounted on a lower surface of the support member and disposed in a space formed by the elastic pad and the support member. The contact member has an elastic membrane for being brought into contact with the elastic pad. A first pressure chamber is defined in the contact member, and a second pressure chamber is defined outside of the contact member. The substrate holding apparatus further comprises a fluid source for independently supplying a fluid into, or creating a vacuum in, the first pressure chamber and the second pressure chamber.

Owner:EBARA CORP

Method and apparatus for polishing metal and dielectric substrates

InactiveUS20030029841A1Polishing machinesRevolution surface grinding machinesContact pressureDielectric substrate

Method and apparatus are provided for polishing substrates comprising conductive and low k dielectric materials with reduced or minimum substrate surface damage and delamination. In one aspect, a method is provided for processing a substrate including positioning a substrate having a conductive material formed thereon in a polishing apparatus having one or more rotational carrier heads and one or more rotatable platens, wherein the carrier head comprises a retaining ring and a membrane for securing a substrate and the platen has a polishing article disposed thereon, contacting the substrate surface and the polishing article to each other at a retaining ring contact pressure of about 0.4 psi or greater than a membrane pressure, and polishing the substrate to remove conductive material.

Owner:APPLIED MATERIALS INC

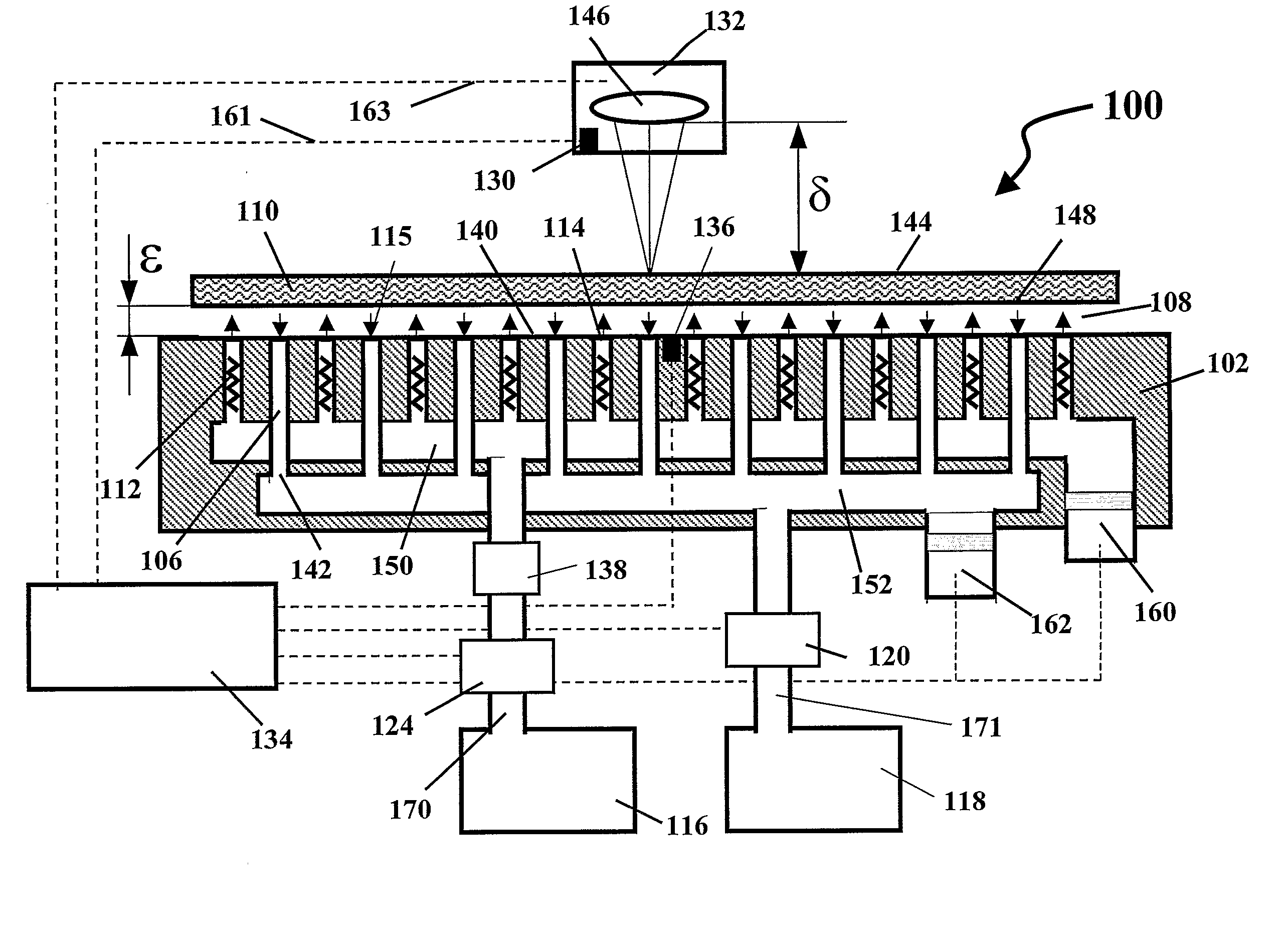

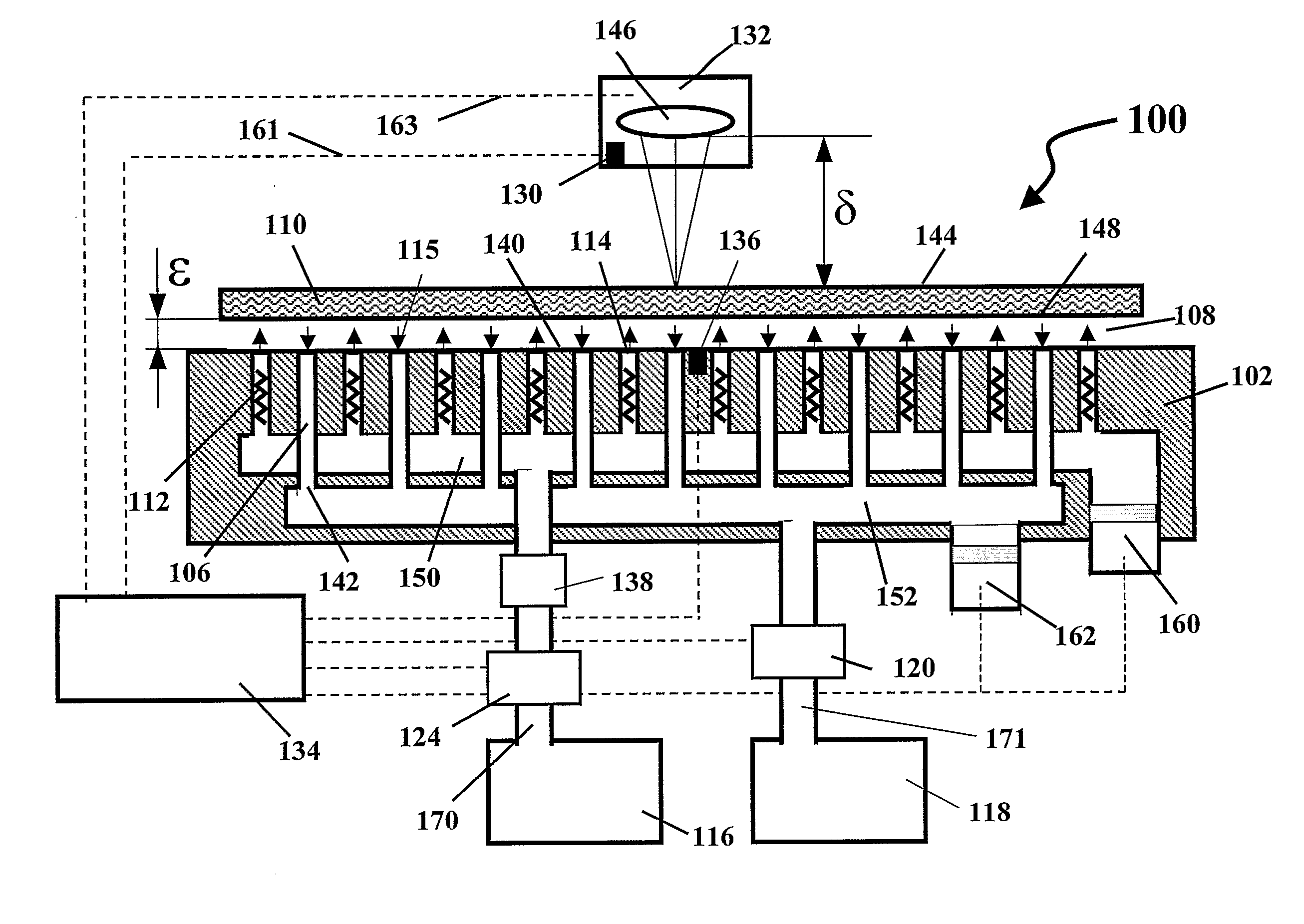

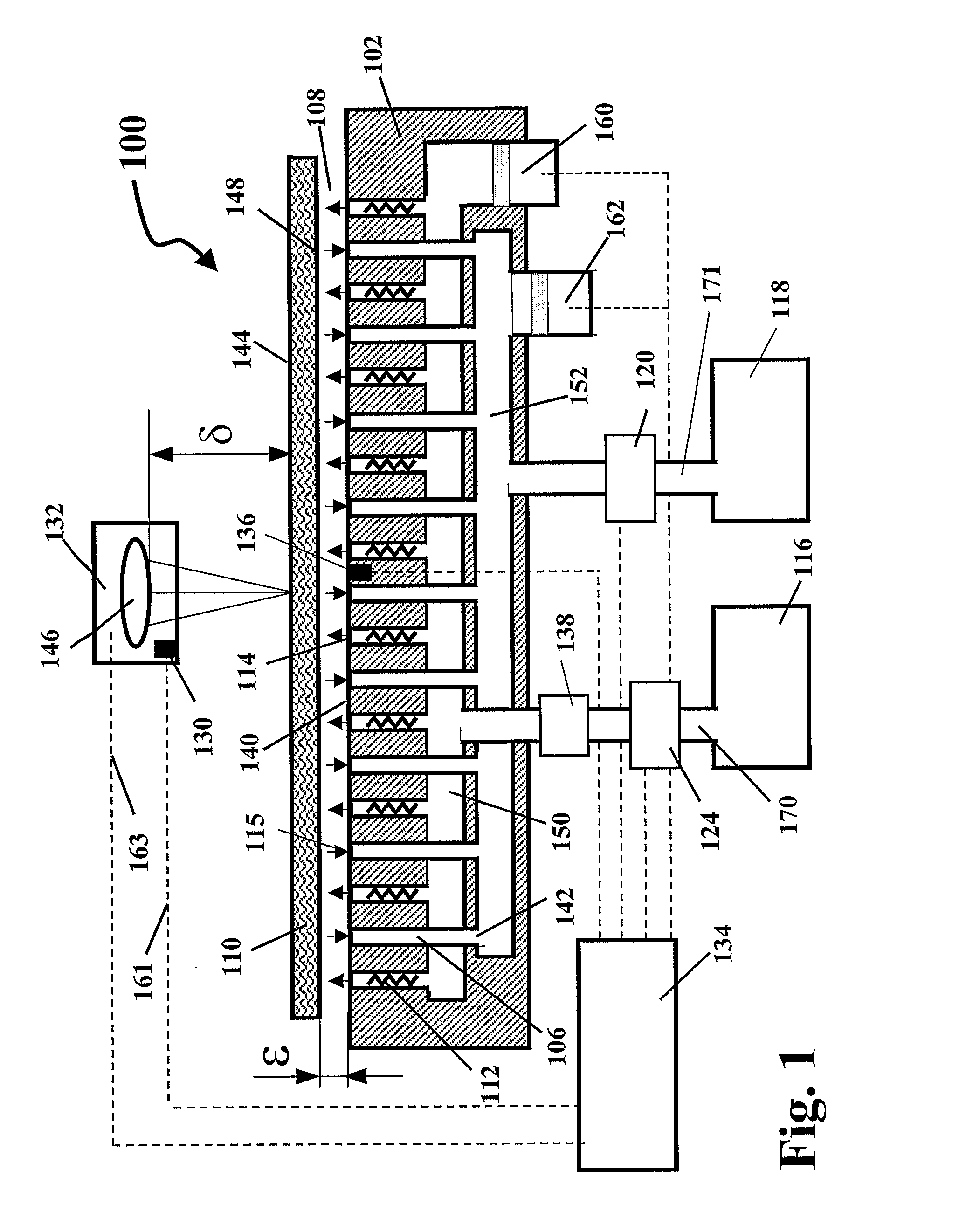

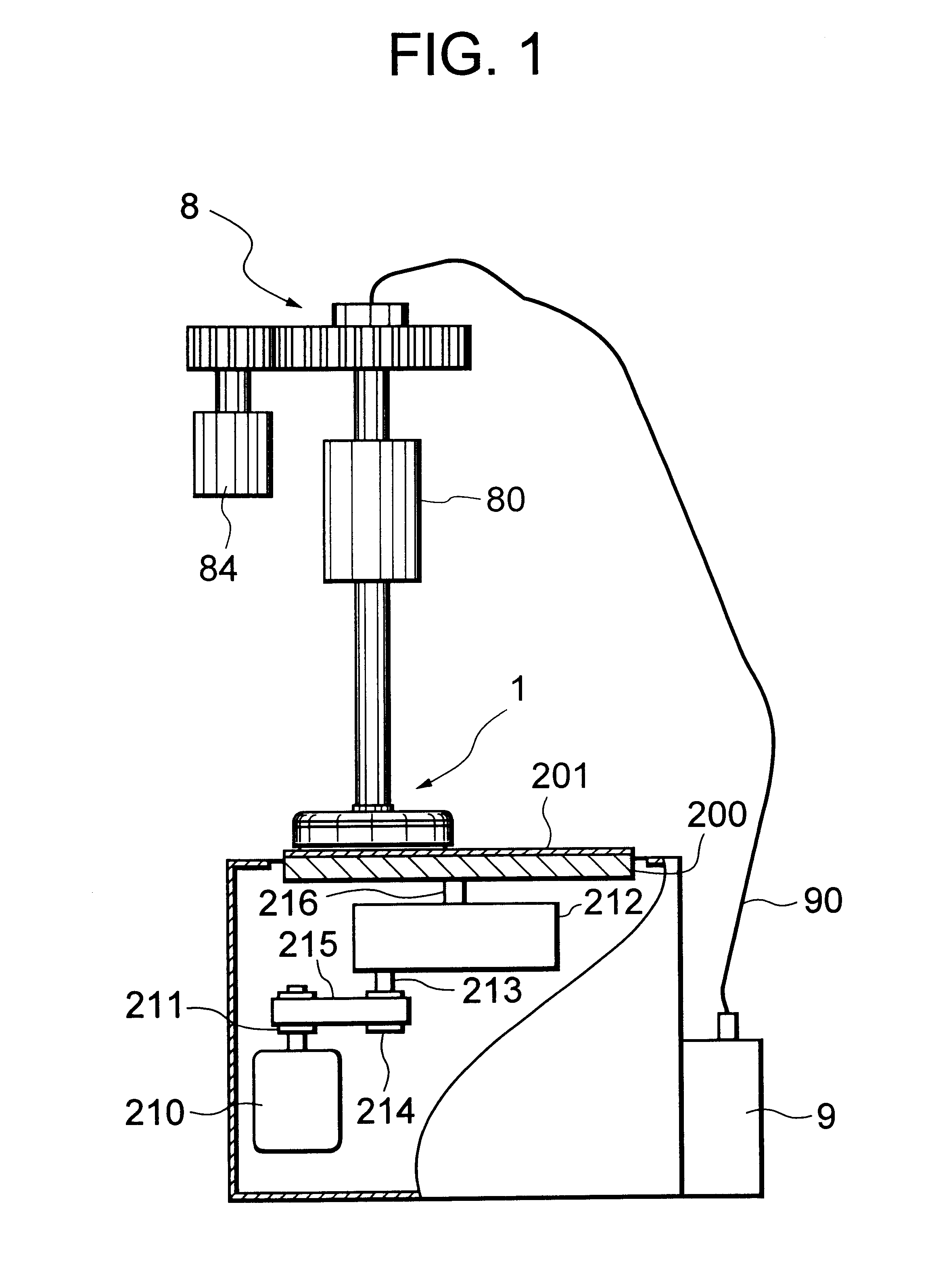

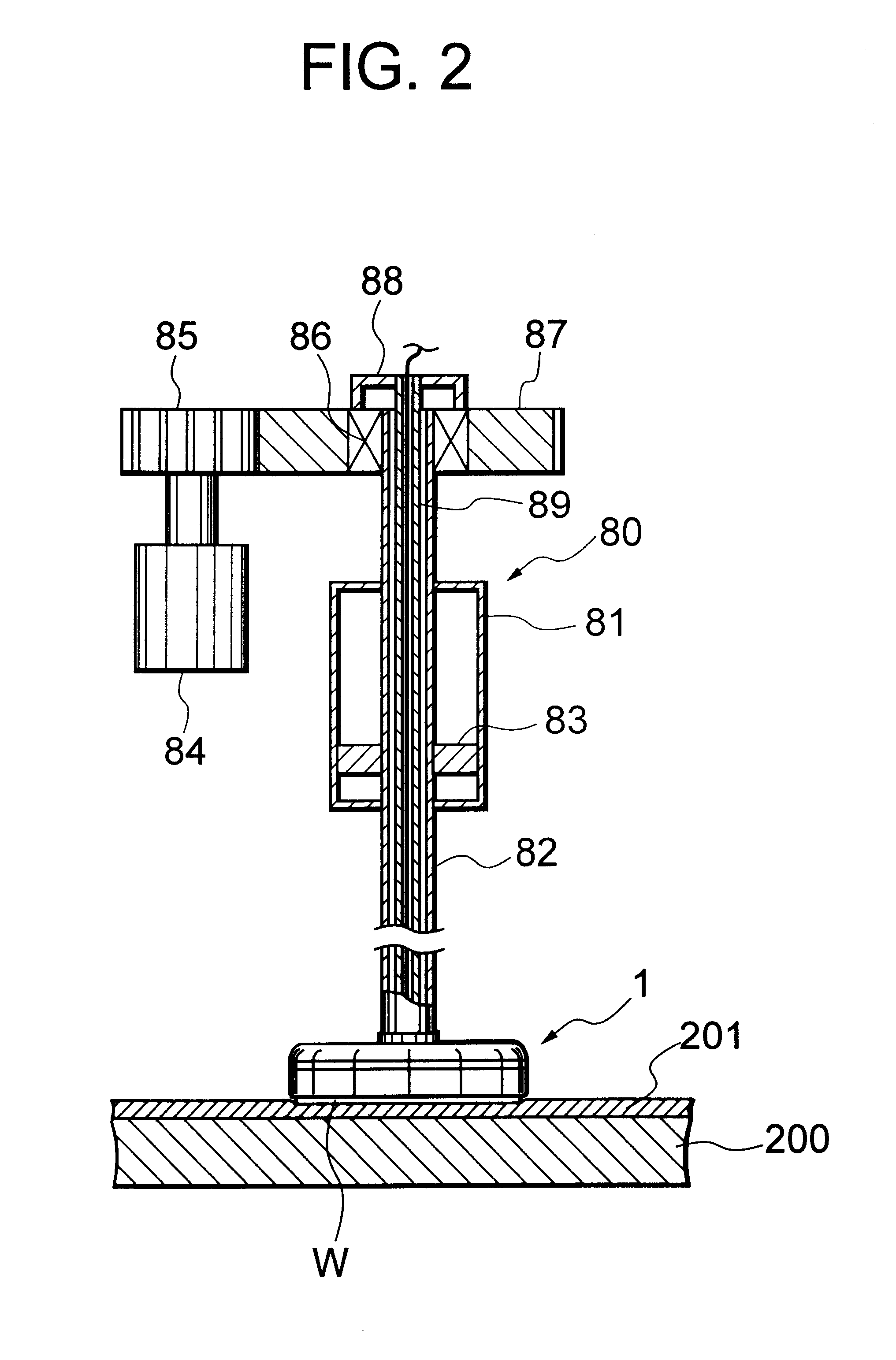

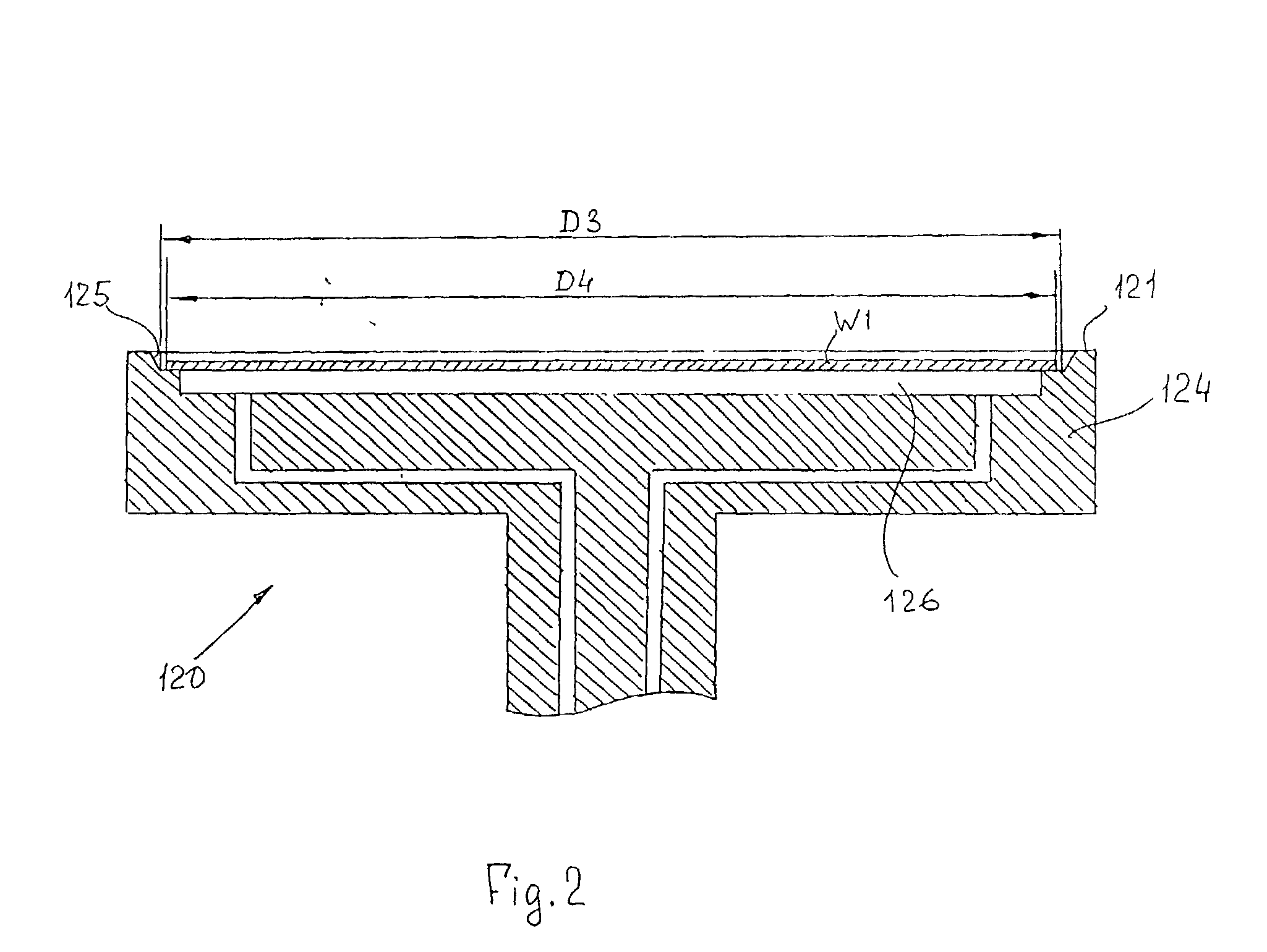

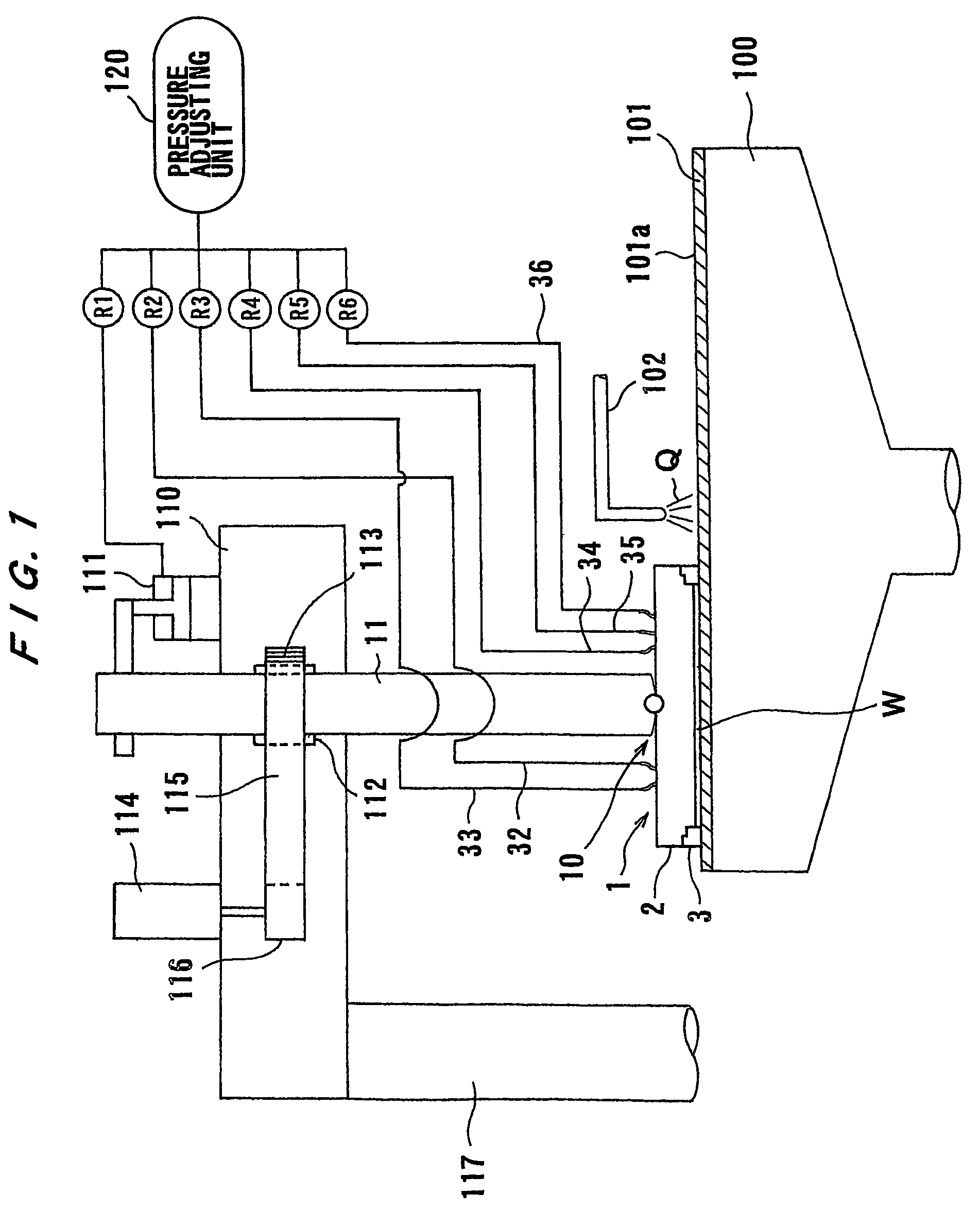

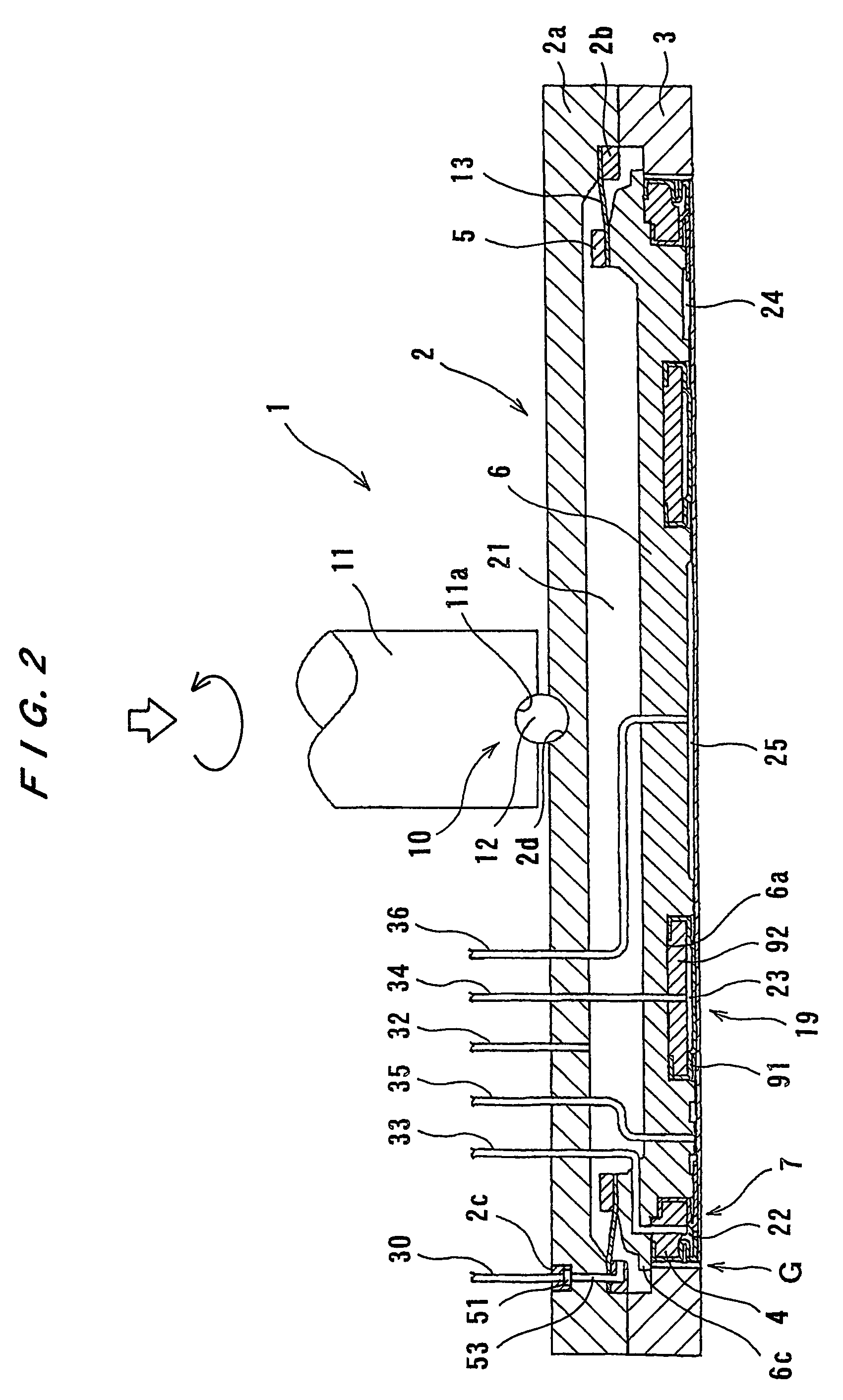

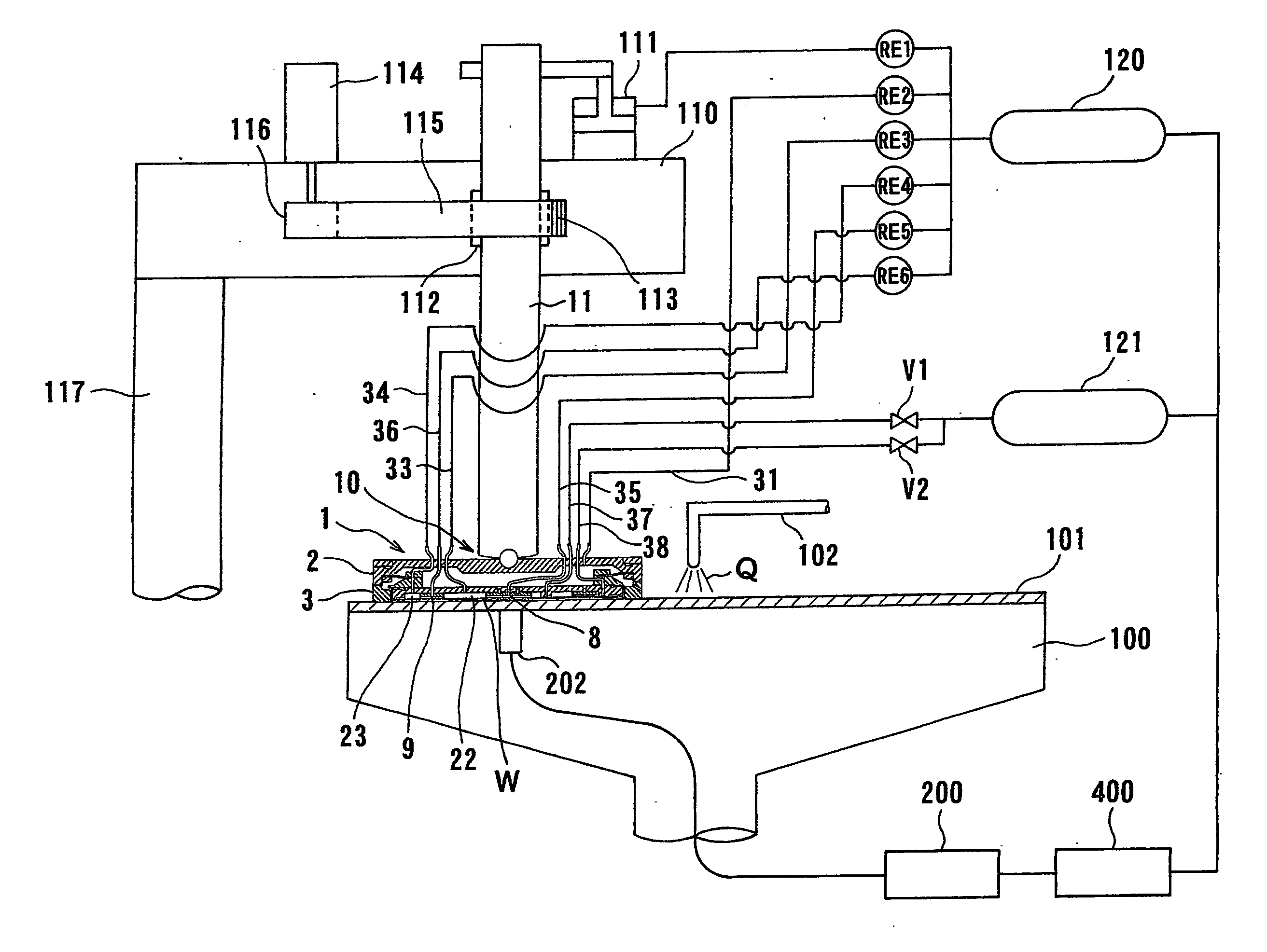

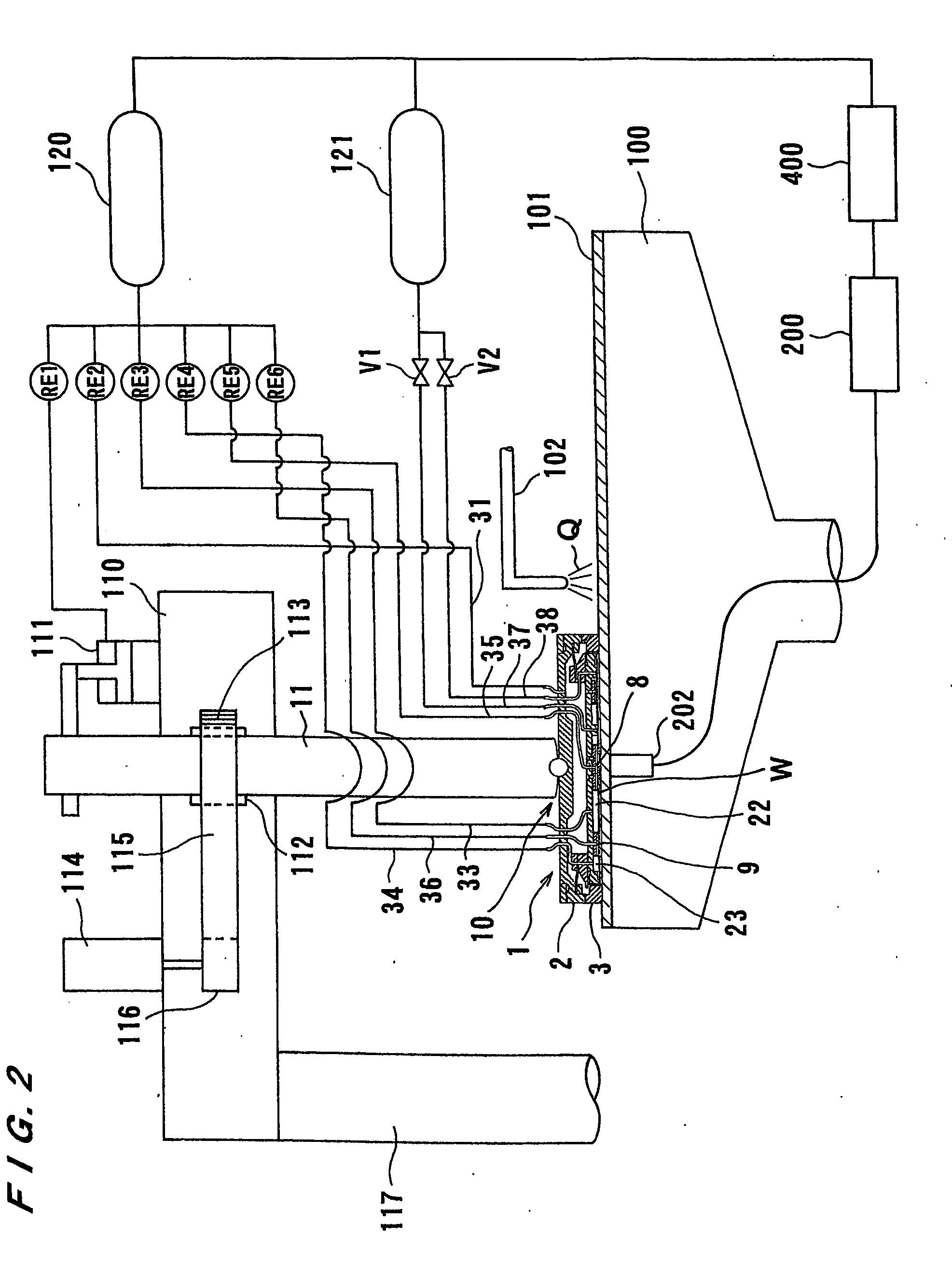

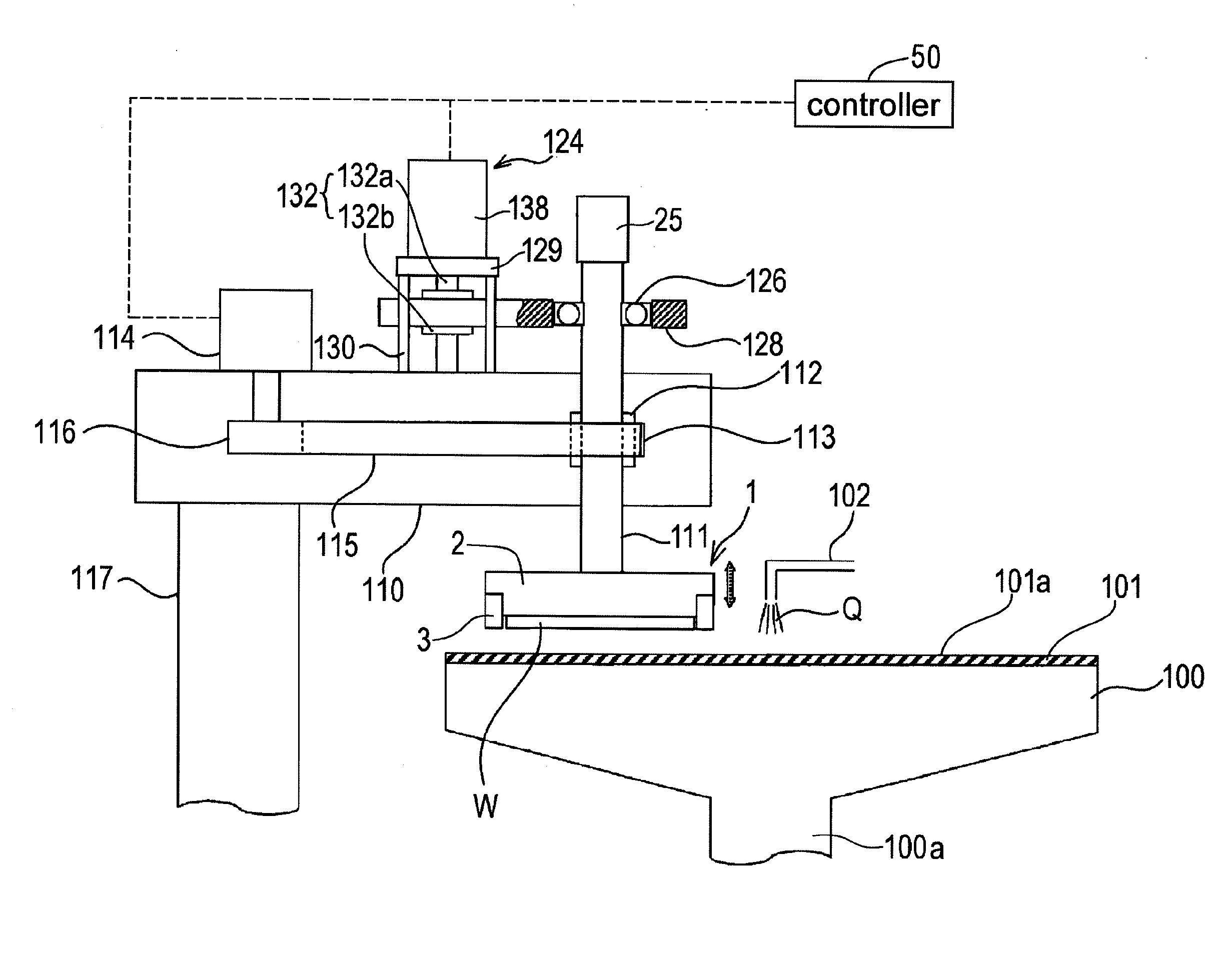

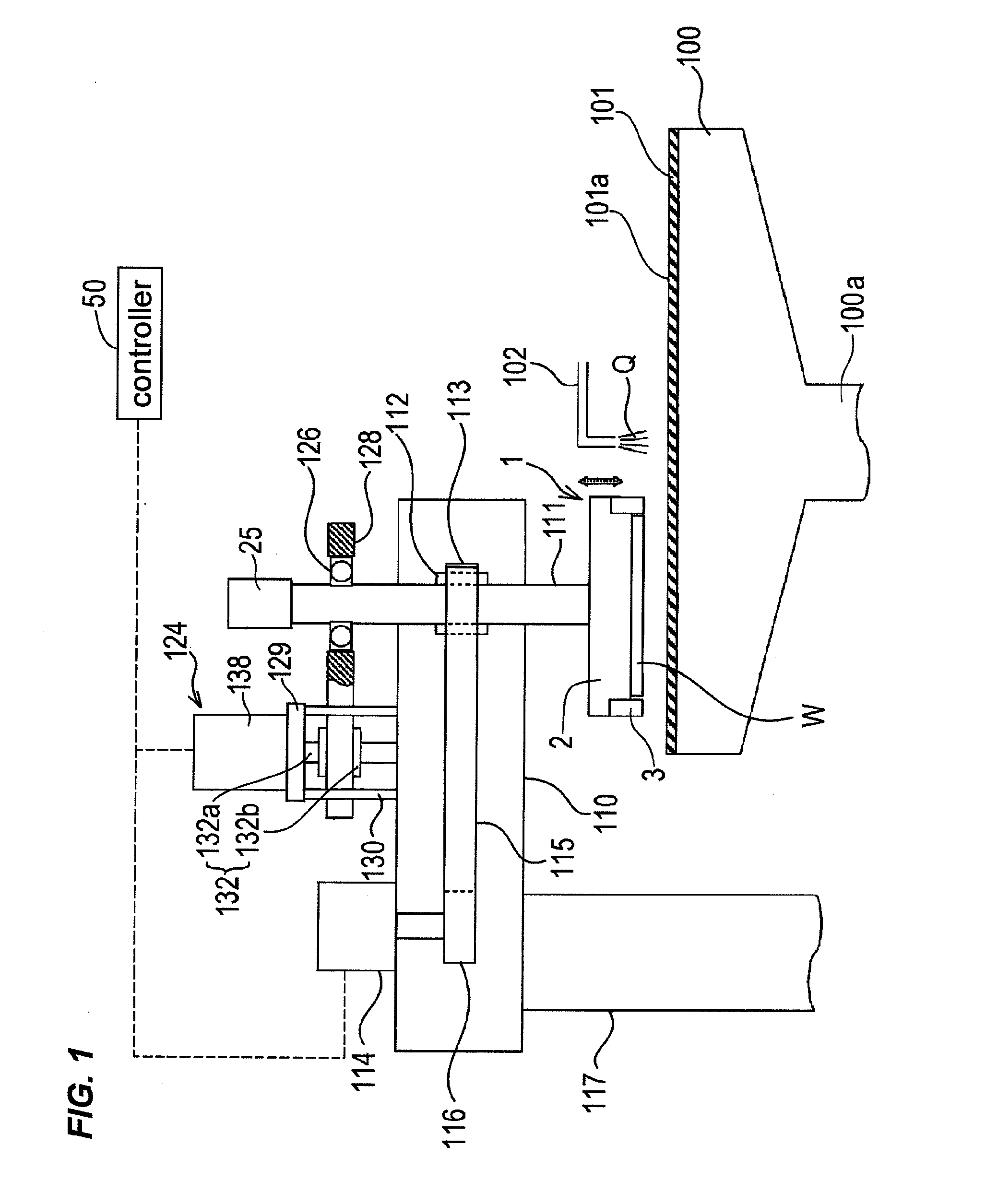

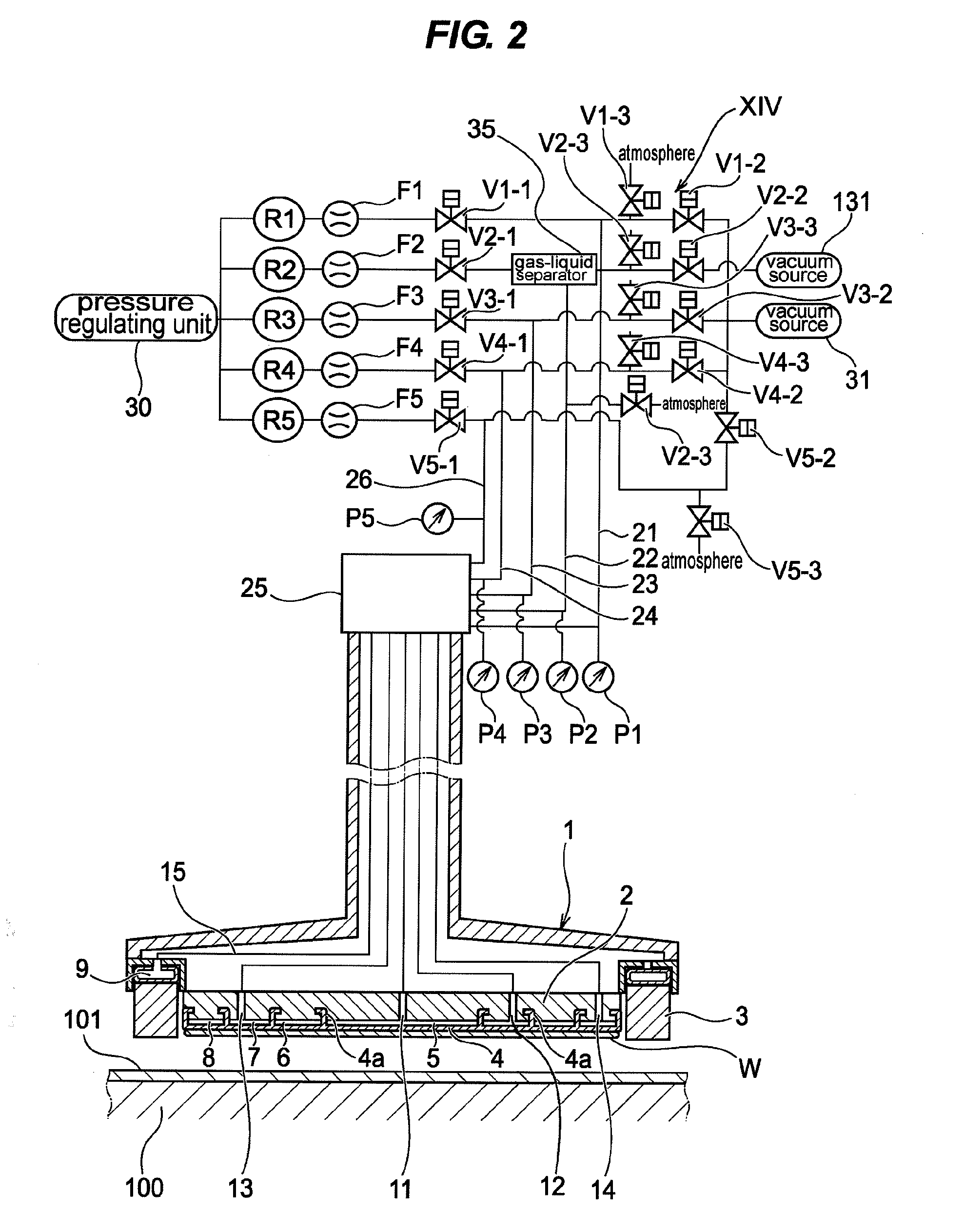

Substrate Polishing Apparatus And Substrate Polishing Method

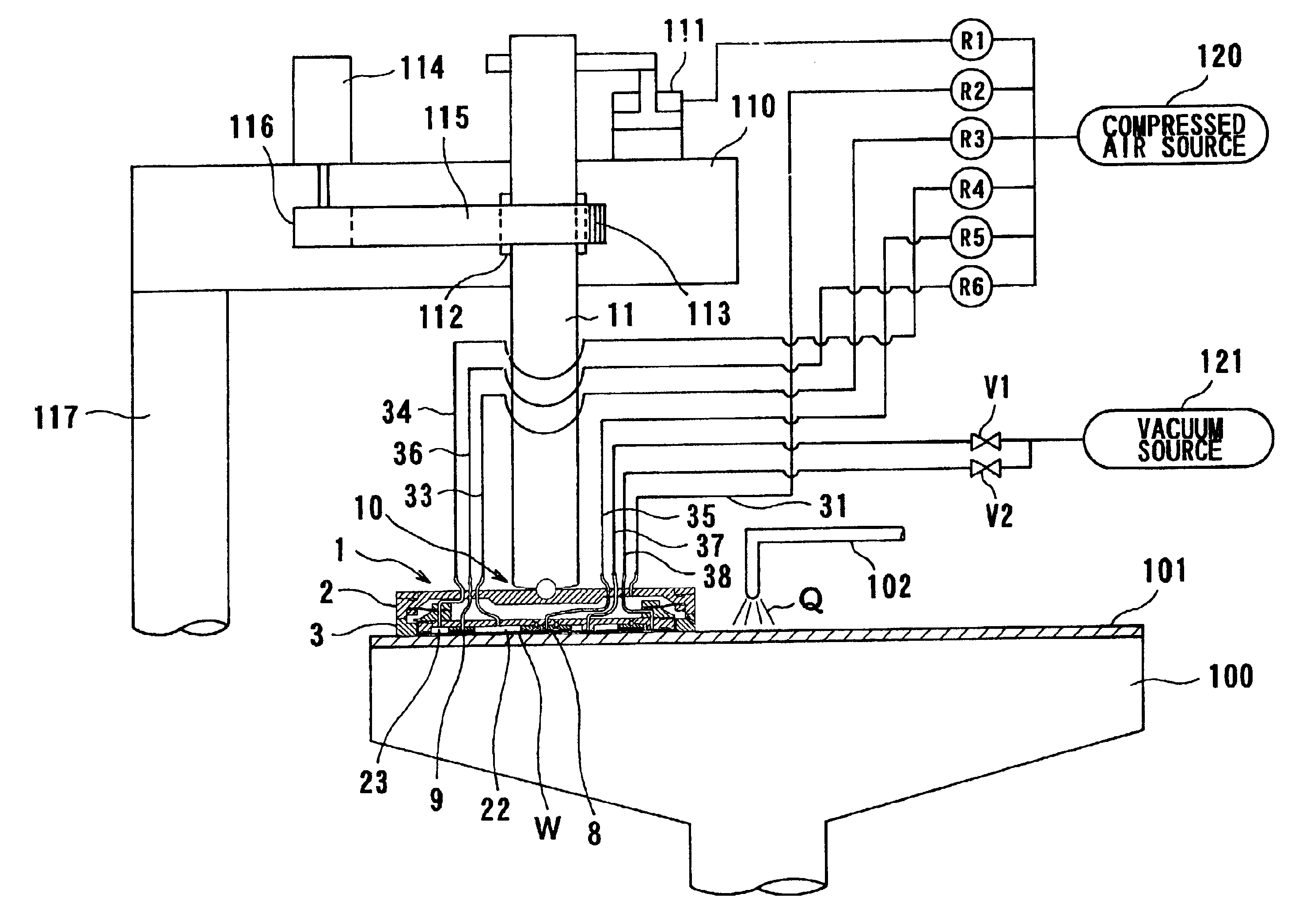

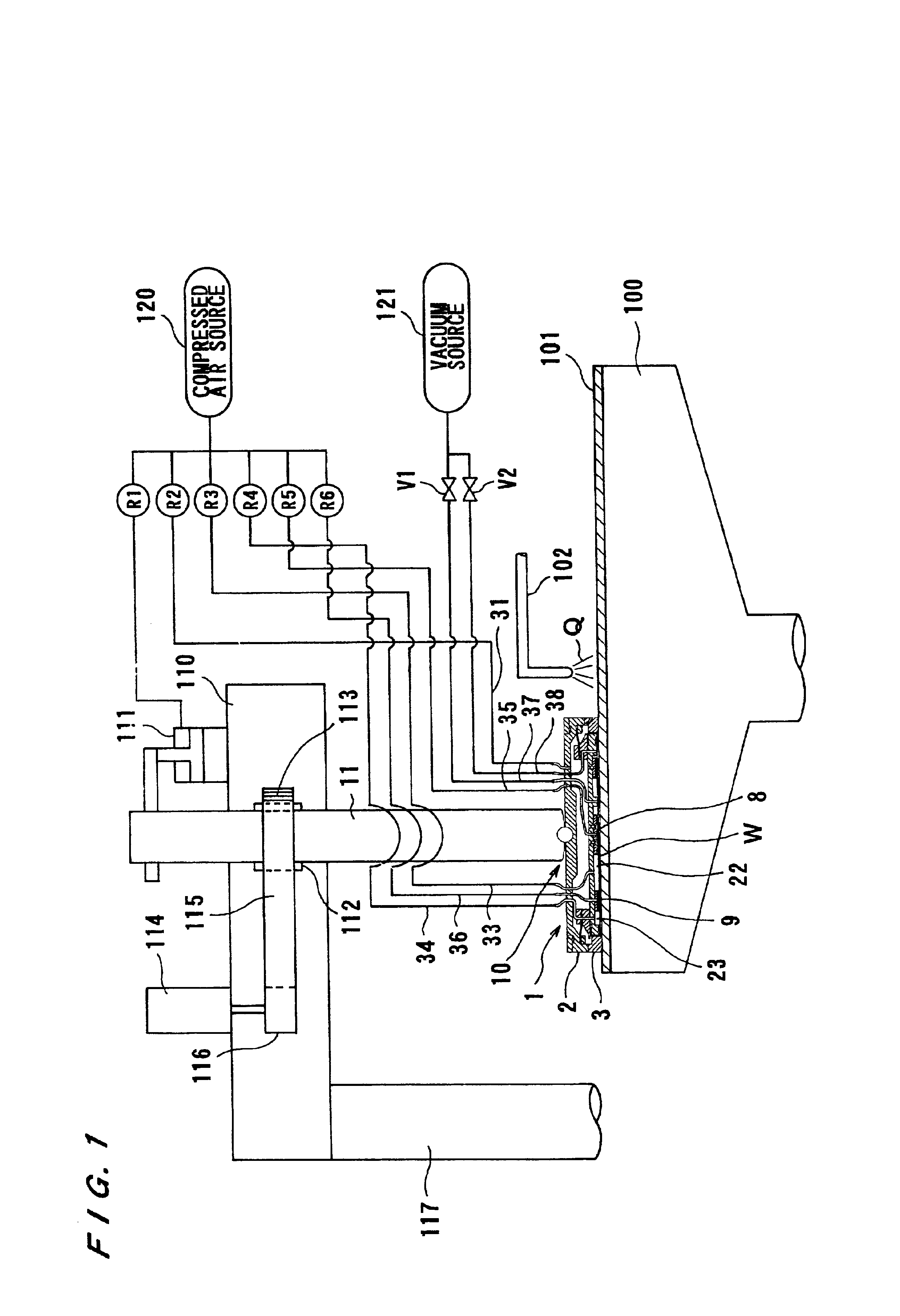

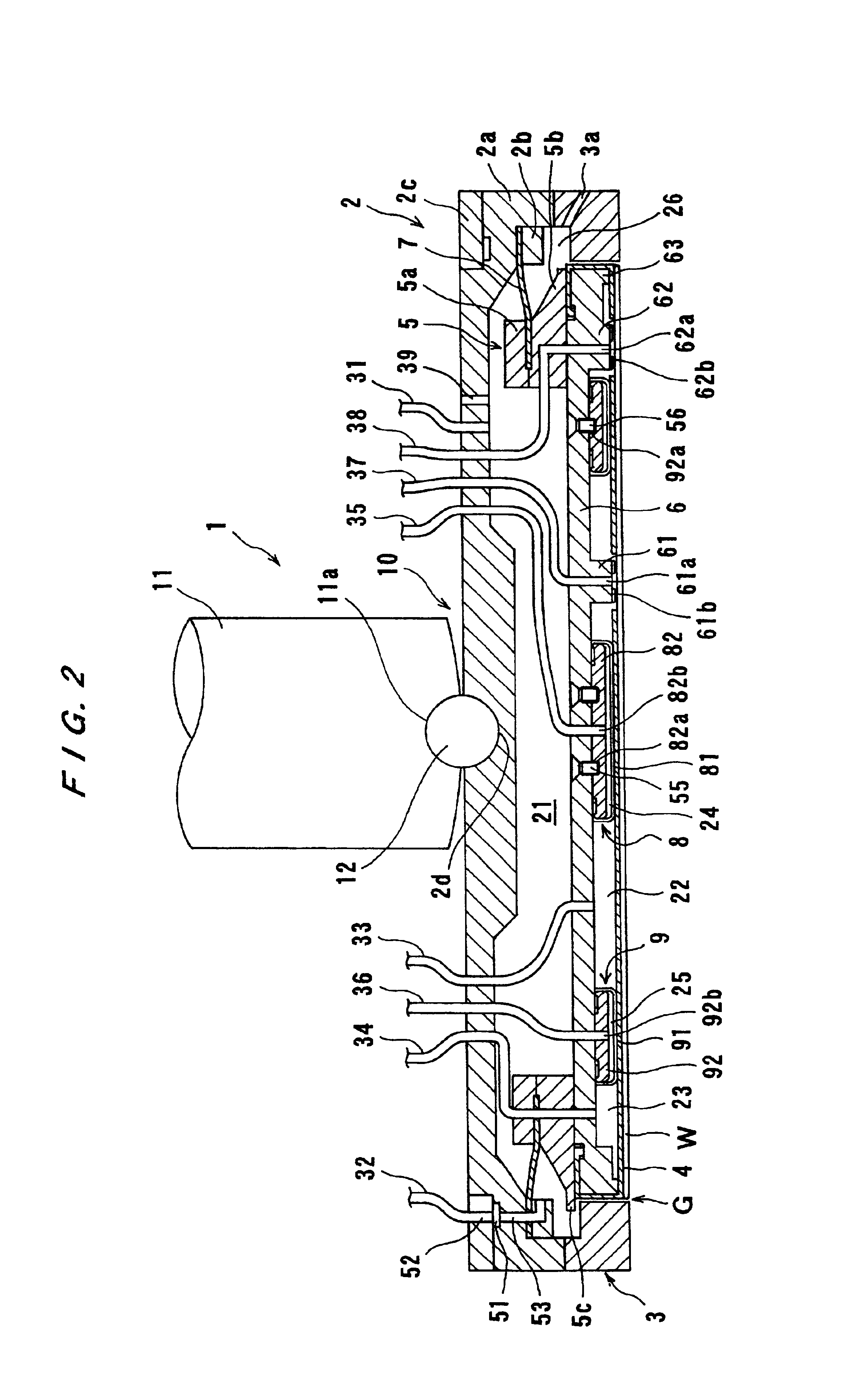

ActiveUS20080139087A1Uniform film thicknessUniform and stable resultPolishing machinesRevolution surface grinding machinesEngineeringSemiconductor

The present invention relates to a substrate polishing apparatus and a substrate polishing method for polishing a substrate such as a semiconductor wafer to a flat finish. The substrate polishing apparatus includes a polishing table (100) having a polishing surface (101), a substrate holder (1) for holding and pressing a substrate (W) against the polishing surface (101) of the polishing table (100), and a film thickness measuring device (200) for measuring a thickness of a film on the substrate (W). The substrate holder (1) has a plurality of pressure adjustable chambers (22 to 25), and pressures in the respective chambers (22 to 25) are adjusted based on the film thickness measured by the film thickness measuring device (200).

Owner:EBARA CORP

CMP polishing heads retaining ring groove design for microscratch reduction

InactiveUS20050113002A1Reduce duplicationLapping machinesWork carriersManufacturing technologyCompound (substance)

A chemical-mechanical polish (CMP) machine and fabrication process using the same. The CMP machine has a CMP retaining ring comprising: an inner peripheral surface; an outer peripheral surface; a lower surface adapted to contact and depress an upper surface of a polishing pad during chemical mechanical polishing of a lower surface of a substrate. The substrate is contained within the inner peripheral surface of the retaining ring during chemical mechanical polishing. At least a groove on the lower surface of the retaining ring. At least a portion of the groove has a rounded contour. In an aspect, the groove has a semicircle profile. In another aspect, the groove has a semicircle profile and a curved top corner profile at adjacent to the lower surface of the retaining ring. The retaining ring with a curved portion of groove reduces the accumulation of dried slurry in the groove and thus reduces micro-scratches.

Owner:CHARTERED SEMICONDUCTOR MANUFACTURING +1

Apparatus for polishing a semiconductor wafer and method therefor

InactiveUS20020098780A1Polishing machinesRevolution surface grinding machinesSemiconductorBiomedical engineering

An apparatus for polishing a wafer comprises a supporting portion having an abrasive pad disposed thereon, and a polishing head disposed over the abrasive pad. The polishing head comprises a carrier having at least two fluid passages, a retainer ring disposed on a lower edge of the carrier, forming a space for receiving the wafer, a supporter disposed in the carrier, and a flexible membrane disposed to be in contact with the wafer. The supporter has an upper surface portion, a lower surface portion, a plurality of first holes, a plurality of second holes, and a first chamber. The upper surface portion of the supporter forms a second chamber along with an inner surface of the carrier. The second chamber is in communication with one of the two fluid passages of the carrier and the second holes are formed in a lower surface portion of the supporter to communicate with the second chamber. The first chamber is in communication with the other one of the two fluid passages and the first holes are formed in the lower surface portion of the supporter to communicate with the first chamber. The lower surface portion of the supporter has a flat surface and a chamfered or rounded edge. The membrane disposed to enclose the lower surface portion of the supporter has a plurality of third holes formed at positions corresponding to the first holes to absorb and hold the wafer by vacuum.

Owner:SAMSUNG ELECTRONICS CO LTD

Polishing apparatus and method

ActiveUS20120058709A1Preventing pressurizationReduce lossesSemiconductor/solid-state device manufacturingLapping machinesThermal energyEngineering

A polishing is used for polishing a substrate such as a semiconductor wafer to a flat mirror finish. The polishing apparatus includes a polishing table having a polishing surface, a substrate holding apparatus configured to hold the substrate and to press the substrate against the polishing surface, and a controller. The substrate holding apparatus includes an elastic membrane configured to form a substrate holding surface which is brought into contact with the substrate, a carrier provided above the elastic membrane, at least one pressure chamber formed between the elastic membrane and the carrier, and an infrared light detector configured to measure thermal energy from the elastic membrane. The controller calculates an estimate value of a temperature of the elastic membrane using a measured value of the infrared light detector.

Owner:EBARA CORP

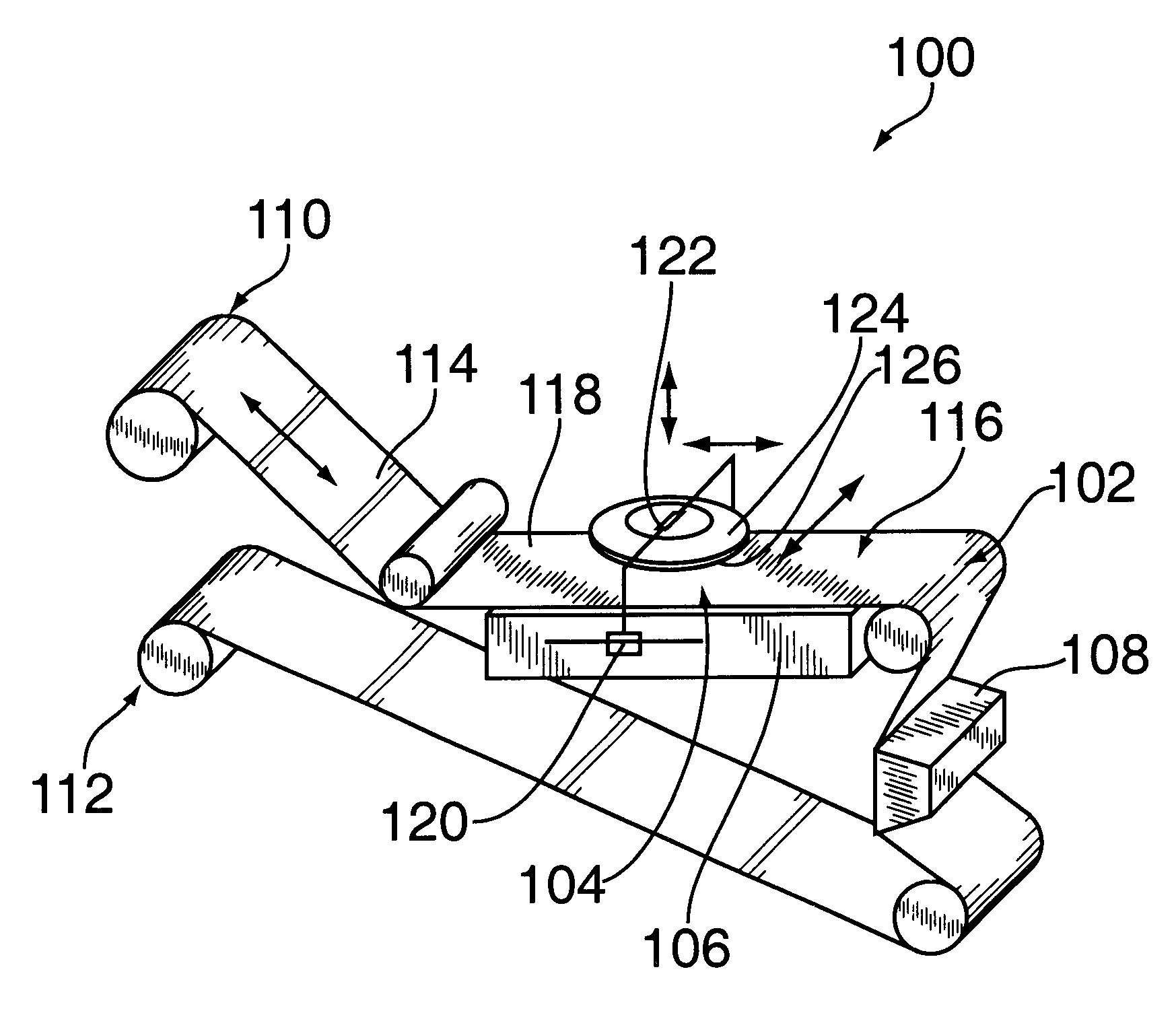

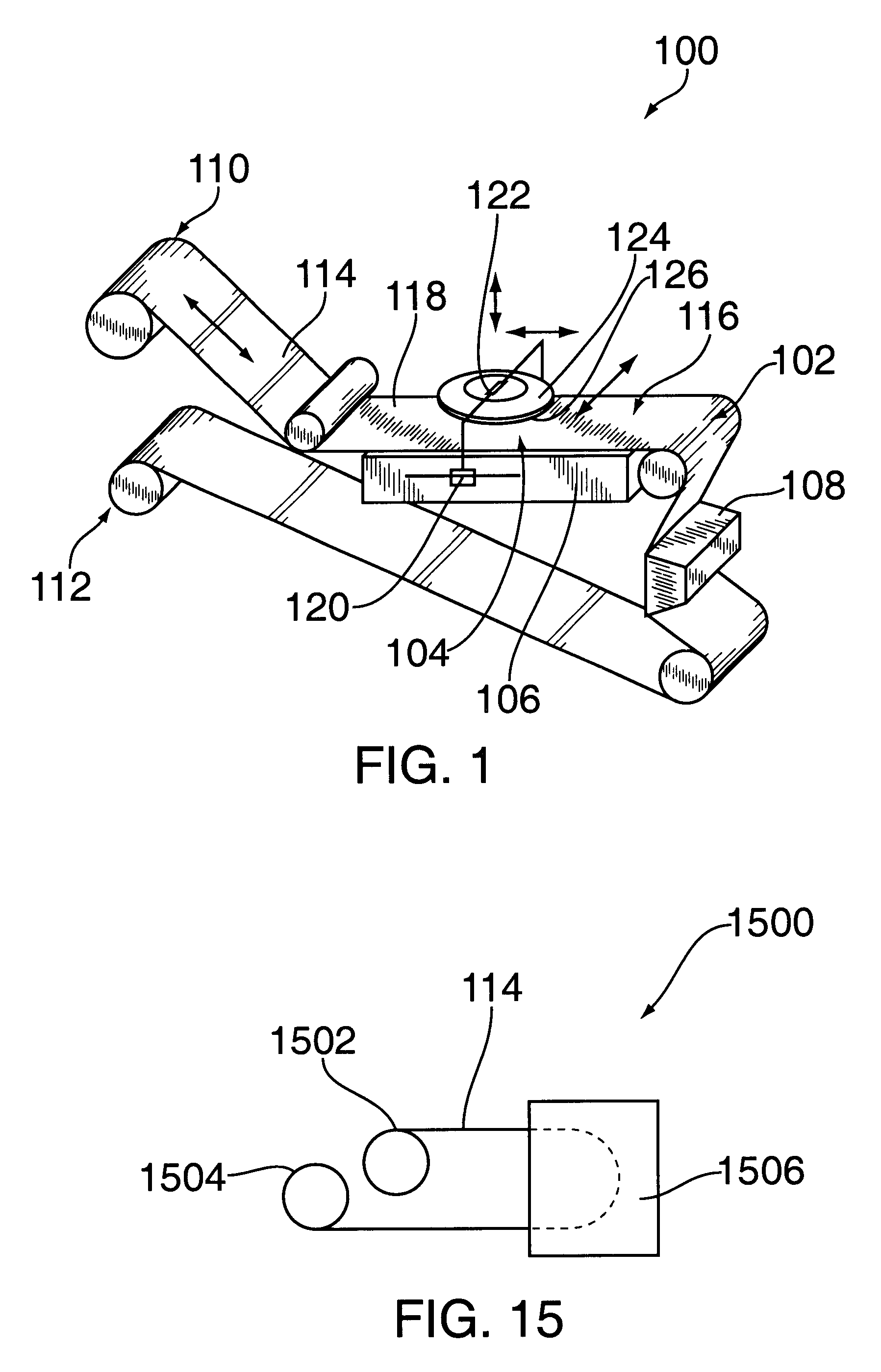

Lapping apparatus, magnetic head and method of manufacturing the same

InactiveUS20020126421A1Reduce formationDecrease in element recession is limitedDecorative surface effectsRecord information storageReciprocating motionSlide plate

An L-shaped slide plate mounted with a workpiece holding device on a slide guide is firmly attached to an angle adjustment mechanism, and a reciprocating motion drive unit mounted with the angle adjustment mechanism on a slider table is firmly attached to a bridge so that an angle between a surface of a workpiece to be lapped and a surface of a lapping plate is kept substantially constant, and also the bridge is disposed so as to stride the lapping plate. Thereby, in a state of row bar in which a plurality of magnetic head sliders run in a line, an air bearing surface of magnetic head can be lapped with high accuracy with an element recession being decreased and an occurrence of a scratch being restrained.

Owner:HITACHI GLOBAL STORAGE TECH JAPAN LTD

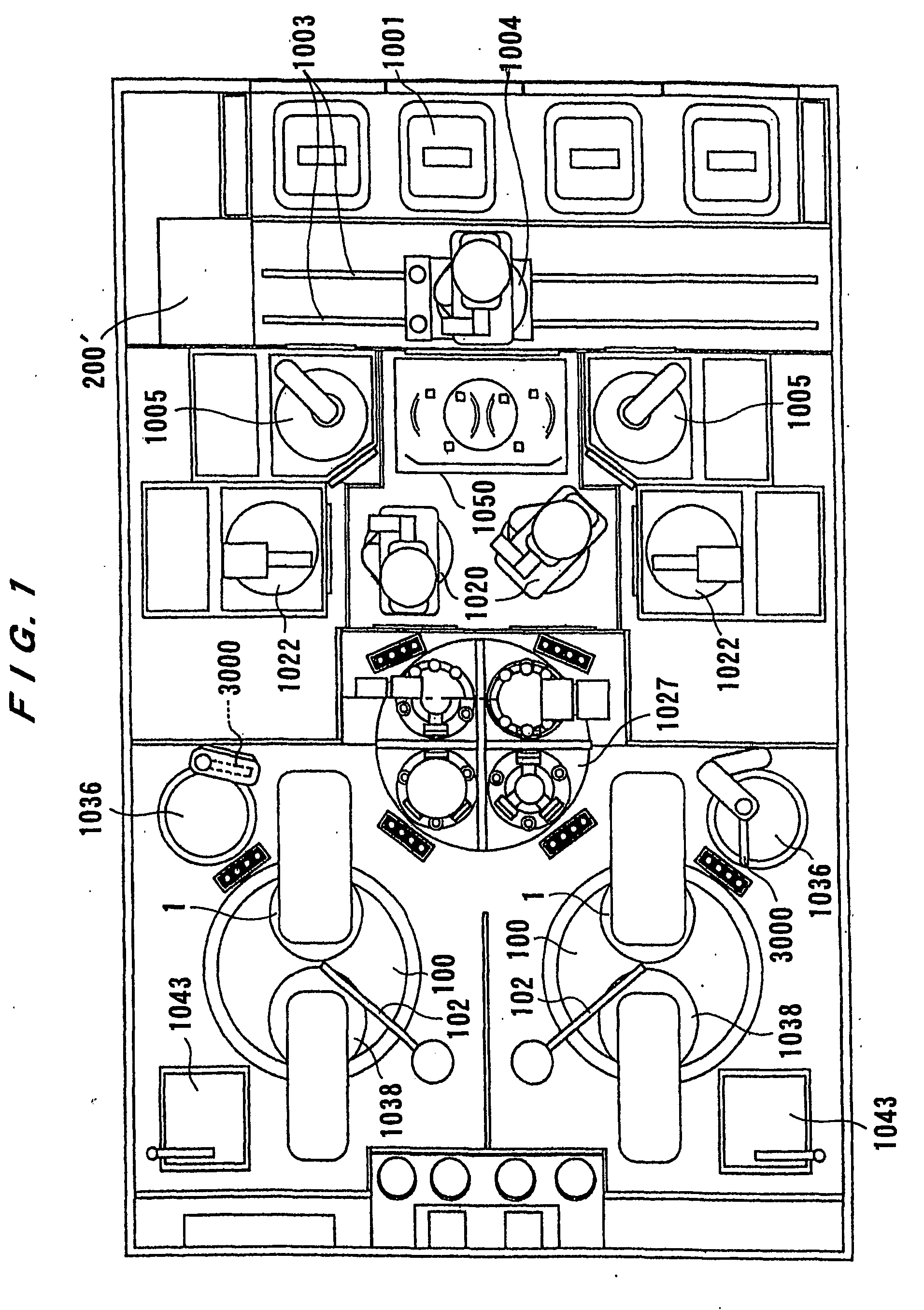

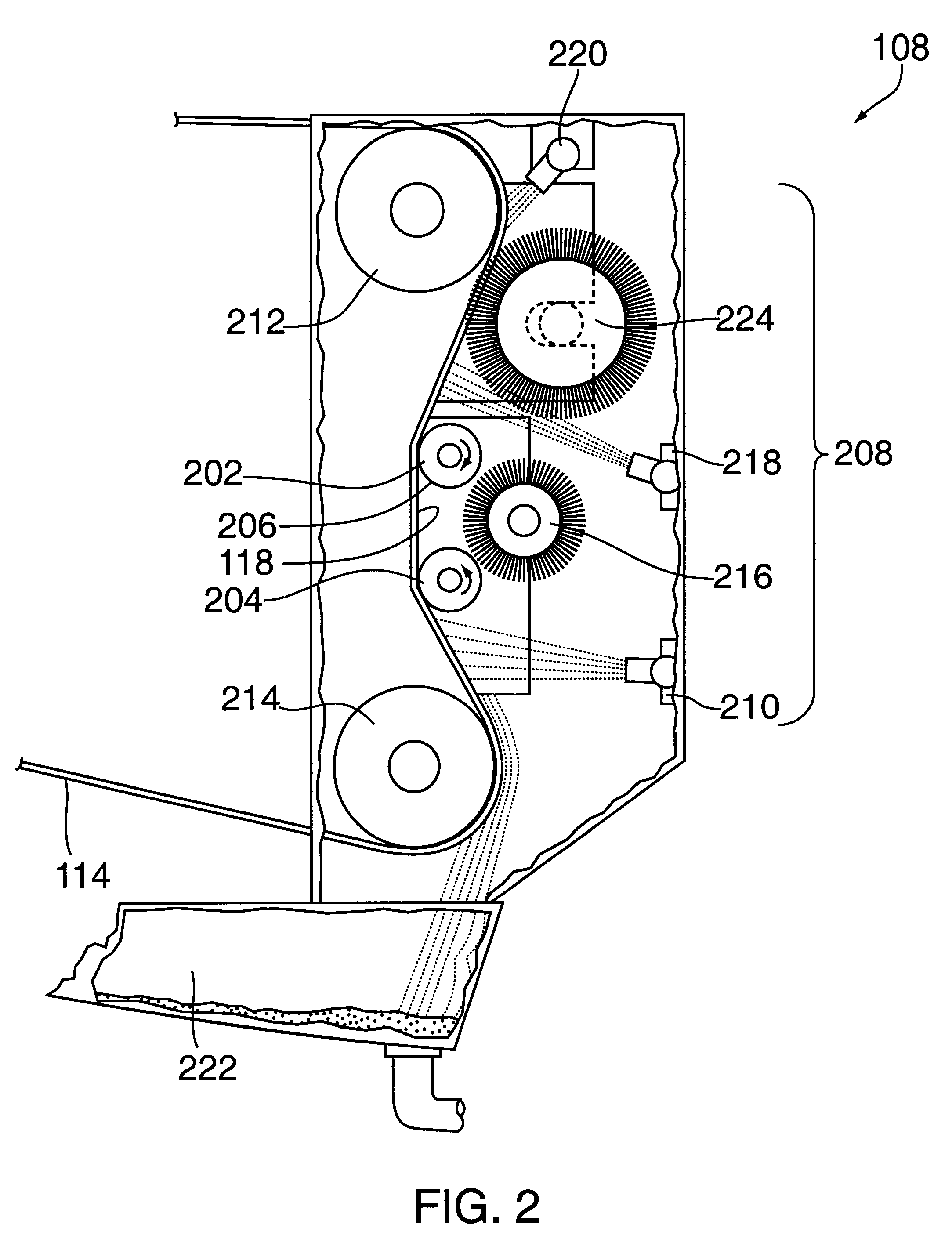

Chemical mechanical planarization system

A semiconductor wafer processing system, more specifically, a chemical mechanical planarization system including a polishing media reconditioning system. In one embodiment, the polishing media reconditioning system comprises at least a first and second conditioning roller that contact a working surface of a polishing media while rotating in opposite directions. Other embodiments include conditioning plates disposed on a carrier that includes the polishing head, a conditioning roller or disk that traverses the surface of the polishing media and a conditioning disk that conditions the polishing media while retained in the polishing head. Alternatively, the polishing media may be conditioned utilizing the devices embodied above remotely from the processing system.

Owner:APPLIED MATERIALS INC

Polishing apparatus

InactiveUS6899603B2Reduce the possibilityAvoid instabilityPolishing machinesRevolution surface grinding machinesEngineering

In a polishing apparatus having a cover body with fluid pressing mechanism, during polishing, vibration and migration of sticking portion between a retainer and a membrane generated in downstream of rotation of a polishing platen is prevented by reducing sticking force between the retainer and the membrane to less than force needed to wafer polishing with rotation of the cover body.

Owner:RENESAS TECH CORP

Carrier For Double-Side Polishing Apparatus, Double-Side Polishing Apparatus And Double-Side Polishing Method Using The Same

InactiveUS20080166952A1Improve carrier strengthHigh strengthEdge grinding machinesSemiconductor/solid-state device manufacturingTitaniumEngineering

The present invention is a carrier for a double-side polishing apparatus in which, in a double-side polishing apparatus, the carrier is set between upper and lower turn tables to which polishing pads are attached, and a holding hole to hold a wafer sandwiched between the upper and lower turn tables in polishing is formed in the carrier, wherein the carrier is made of titanium. Thereby, there is provided a carrier for a double-side polishing apparatus in which the strength of the carrier itself is high, and at the same time, contamination of a wafer such as a silicon wafer by impurities is suppressed, and sag in a peripheral portion of the wafer after being polished is suppressed.

Owner:SHIN-ETSU HANDOTAI CO LTD

Apparatus for holding workpieces during lapping, honing, and polishing

InactiveUS6030280AMinimizing scratchEasy to manufactureRevolution surface grinding machinesGrinding drivesFiberRigid core

The present invention relates generally to a device used to process workpieces. In particular, the invention relates to a carrier that is used to support a workpiece during workpiece honing, grinding, or polishing. The carrier includes a rigid core coated with a fiber-free, scratch-resistant material to prevent scratching of workpieces disposed in the carrier. An adhesive layer is typically used to attach the scratch-resistant layer to the rigid core. The adhesive film and the scratch-resistant films may be attached to the rigid core by hot pressing.

Owner:SPEEDFAM IPEC

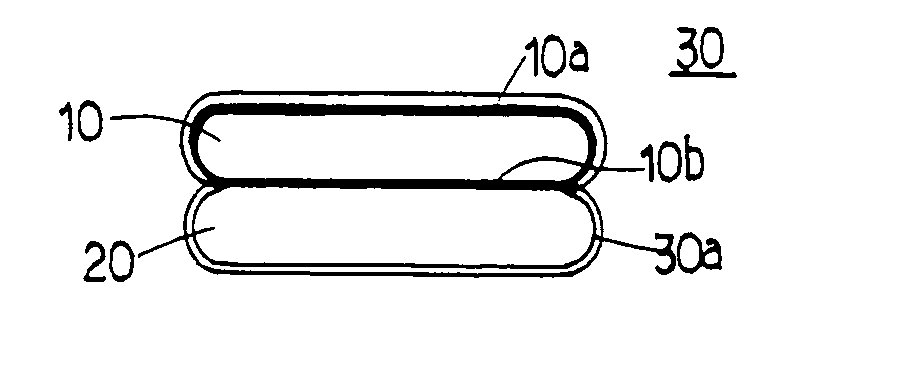

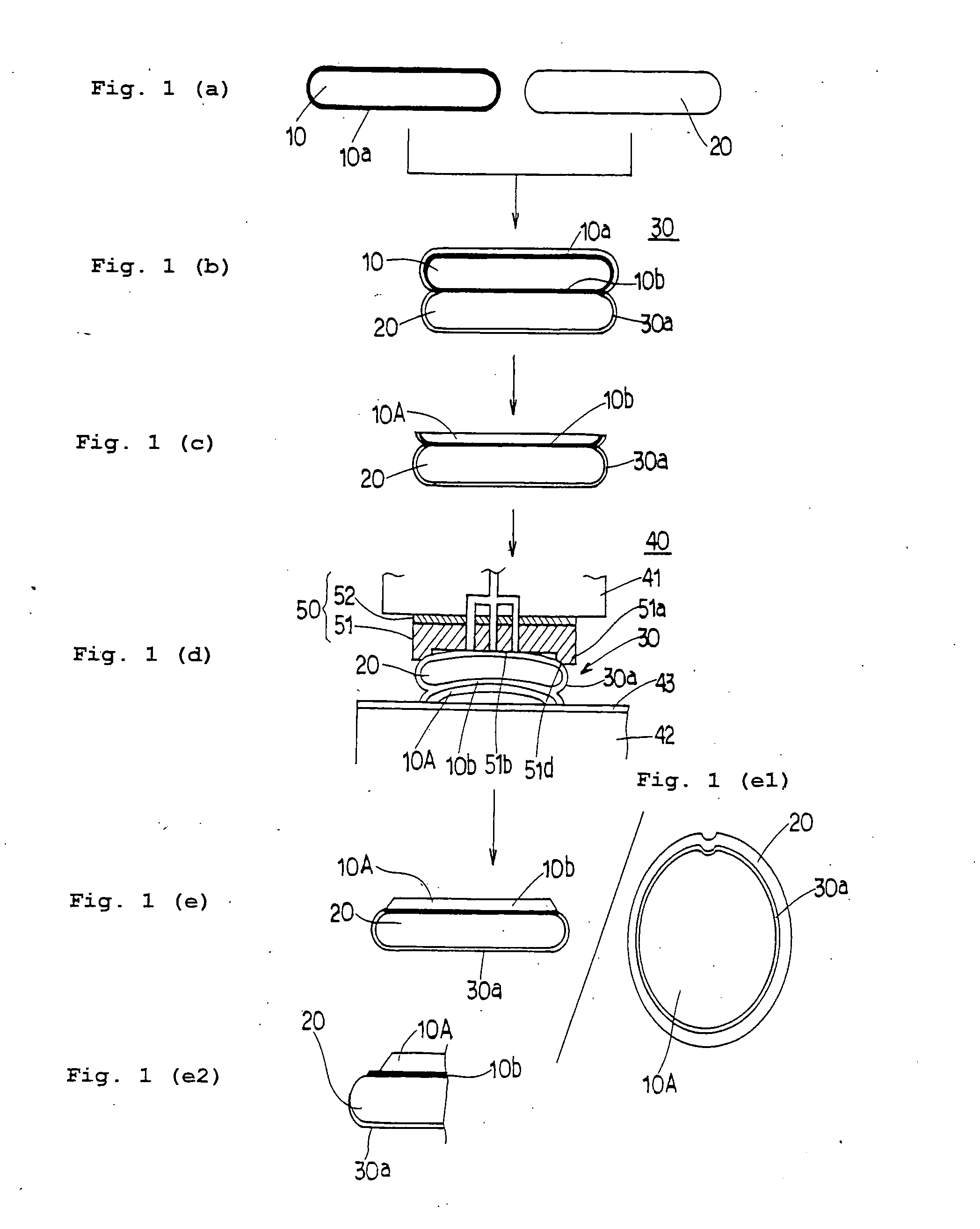

Laminated substrate, method of manufacturing the substrate, and wafer outer periphery pressing jigs used for the method

ActiveUS20050014347A1Reduce in quantityShorten production timeSemiconductor/solid-state device manufacturingWork carriersState of artEtching

Provided are a bonding substrate whose defective bonding portion in a peripheral region of an active layer has been removed by a polishing applied thereto after a surface grinding, a manufacturing method of the same substrate and wafer periphery pressing jigs. After the surface grinding, a periphery removing polishing is applied from an active layer wafer side of a bonding wafer so that a peripheral region of the active layer may be removed and a central region thereof may be left un-removed. Consequently, a periphery grinding and a periphery etching according to the prior art can be eliminated. Furthermore, an etch pit on a circumferential face of a wafer which could be caused by the periphery etching and a contamination or a scratching in an SOI layer which could be caused by a silicon oxide film left un-ground-off can be prevented, thereby achieving high yield and low cost.

Owner:SUMITOMO MITSUBISHI SILICON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com